Drilling fluid with synthesized substrate

A drilling fluid and synthetic-based technology, applied in drilling equipment and other directions, can solve the problems of unacceptable environment, biotoxicity, and difficult biodegradation, and achieve the effects of low environmental pollution, low solubility and high drilling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

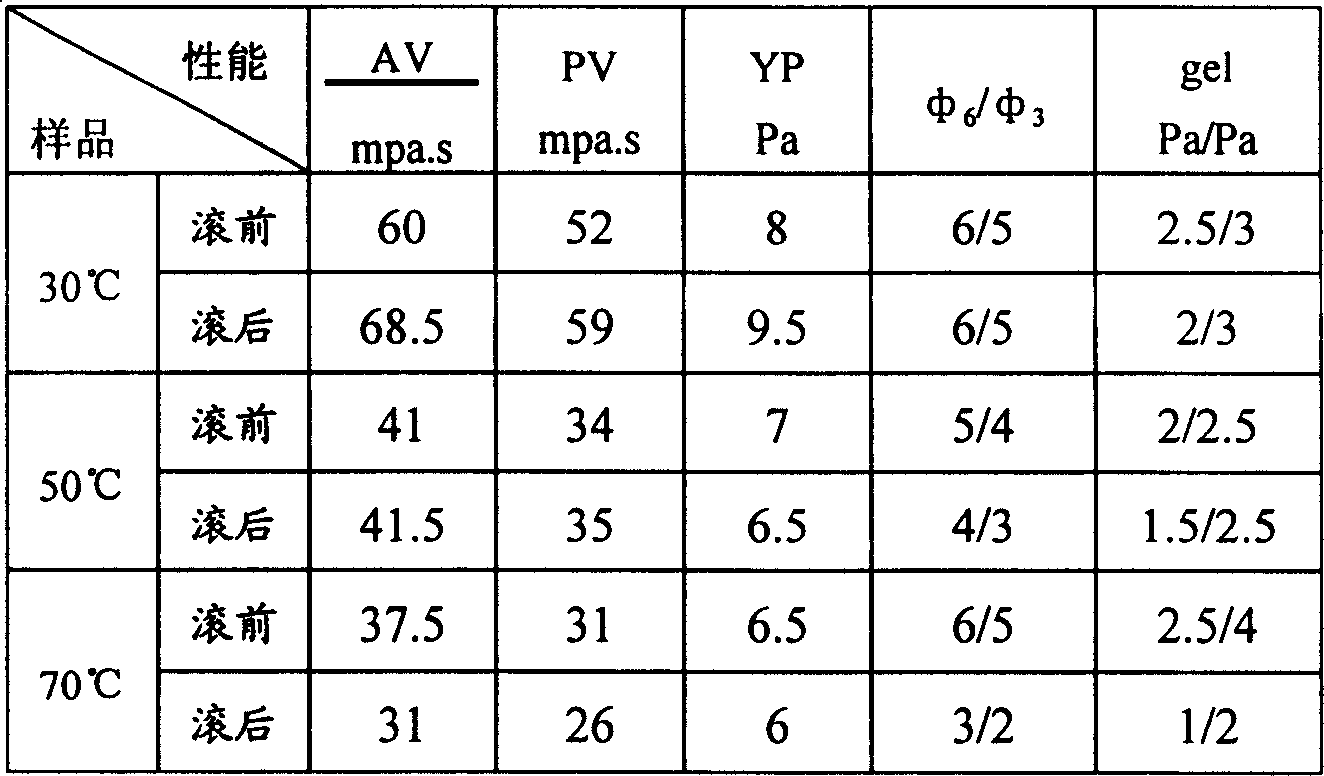

Embodiment 1

[0014] Embodiment one: at room temperature, to the 40M with high-speed stirring 3 Add 24T octyl 4,5,6 carbon dicarboxylate, 0.9T organic soil, 0.6T mixture of sulfonated lignite and sulfonated bitumen as fluid loss reducer, 0.9T fatty acid alcohol polyoxyethylene ether in the circulating pool A mixture of ammonium sulfate and nonylphenol polyoxyethylene ether as the main emulsifier, 0.9T of 2-oleyl-N-methyl-N-hydroxyethyl imidazoline quaternary ammonium salt, fatty amide polyvinyl ether and nonylphenol A mixture of polyoxyethylene ether as a co-emulsifier, a mixture of 600Kg of 2-alkyl-N-hydroxyethylimidazoline-2`-hydroxypropyl betaine and dodecyl dimethyl betaine As a wetting agent, 0.6T ethylene oxide-propylene oxide block copolymer is used as a flow regulator, after full stirring and shearing, then add 20% CaCl 2 Aqueous solutions of 6.0T and 10T limestone are used as weighting materials, and are fully circulated at room temperature for 6 hours to prepare synthetic-based d...

Embodiment 2

[0015] Embodiment two: at room temperature, to the 40M with high-speed stirring 3 Add 24T of octyl 4,5,6 carbon dicarboxylate, 0.8T of organic soil, 0.75T of a mixture of sulfonated lignite and sulfonated asphalt, 0.75T of fatty acid alcohol polyoxyethylene ether ammonium sulfate and nonylphenol into the circulating pool A mixture of polyoxyethylene ethers, 0.75T of 2-oleyl-N-methyl-N-hydroxyethyl imidazoline quaternary ammonium salt, a mixture of fatty amide polyvinyl ether and nonylphenol polyoxyethylene ether, 500Kg of 2 - A mixture of alkyl-N-hydroxyethylimidazoline-2`-hydroxypropanesulfonium salt and dodecyl dimethyl betaine salt, 0.8T ethylene oxide-propylene oxide block After the copolymer, after full stirring and shearing, add 20% CaCl 2 6.0T aqueous solution and 2T weighting material were fully circulated at room temperature for 6 hours to prepare synthetic-based drilling fluid. Adding ethylene oxide-propylene oxide block copolymer to the synthetic base drilling flu...

Embodiment 3

[0016] Embodiment three: at room temperature, to the 40M with high-speed stirring 3 Add 36T of octyl 4,5,6 carbon dicarboxylate, 0.9T of organic soil, 0.6T of a mixture of sulfonated lignite and sulfonated asphalt, 0.9T of fatty acid alcohol polyoxyethylene ether ammonium sulfate and nonylphenol into the circulating pool A mixture of polyoxyethylene ethers, 0.9T of 2-oleyl-N-methyl-N-hydroxyethyl imidazoline quaternary ammonium salts, a mixture of fatty amide polyvinyl ethers and nonylphenol polyoxyethylene ethers, 600Kg of 2 - A mixture of alkyl-N-hydroxyethylimidazoline-2`-hydroxypropanesulfonium salt and dodecyl dimethyl betaine salt, 0.6T ethylene oxide-propylene oxide block After the copolymer, after full stirring and shearing, add 20% CaCl 2 4.0T aqueous solution and 10T weighting material are fully circulated at room temperature for 6 hours to prepare synthetic base drilling fluid. Adding ethylene oxide-propylene oxide block copolymer to the synthetic base drilling fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com