Patents

Literature

1808 results about "Nonylphenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nonylphenols are a family of closely related organic compounds composed of phenol bearing a 9 carbon-tail. Nonylphenols can come in numerous structures, all of which may be considered alkylphenols. They are used in manufacturing antioxidants, lubricating oil additives, laundry and dish detergents, emulsifiers, and solubilizers. These compounds are also precursors to the commercially important non-ionic surfactants alkylphenol ethoxylates and nonylphenol ethoxylates, which are used in detergents, paints, pesticides, personal care products, and plastics. Nonylphenol has attracted attention due to its prevalence in the environment and its potential role as an endocrine disruptor and xenoestrogen, due to its ability to act with estrogen-like activity. The estrogenicity and biodegradation heavily depends on the branching of the nonyl sidechain. Nonylphenol has been found to act as an agonist of the GPER (GPR30).

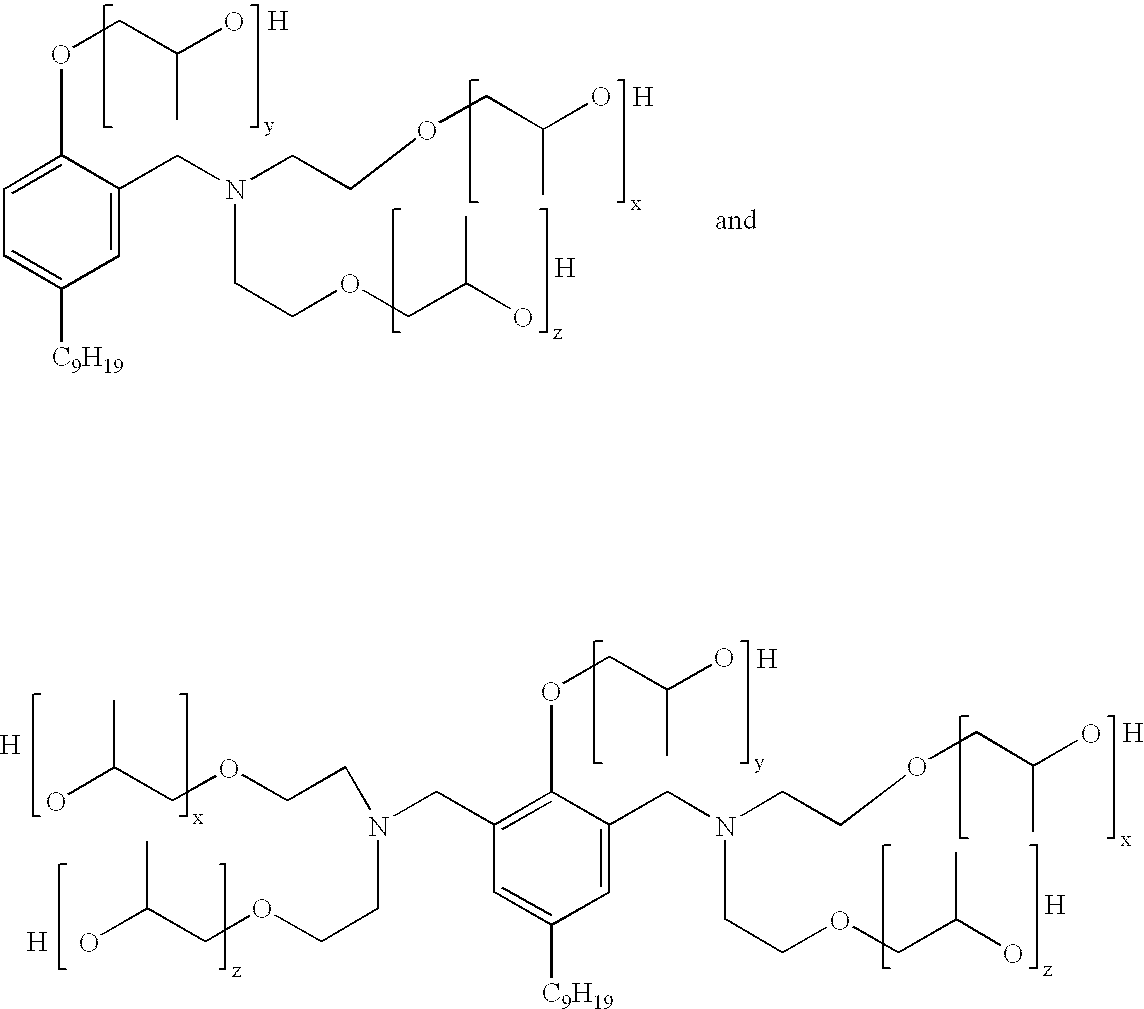

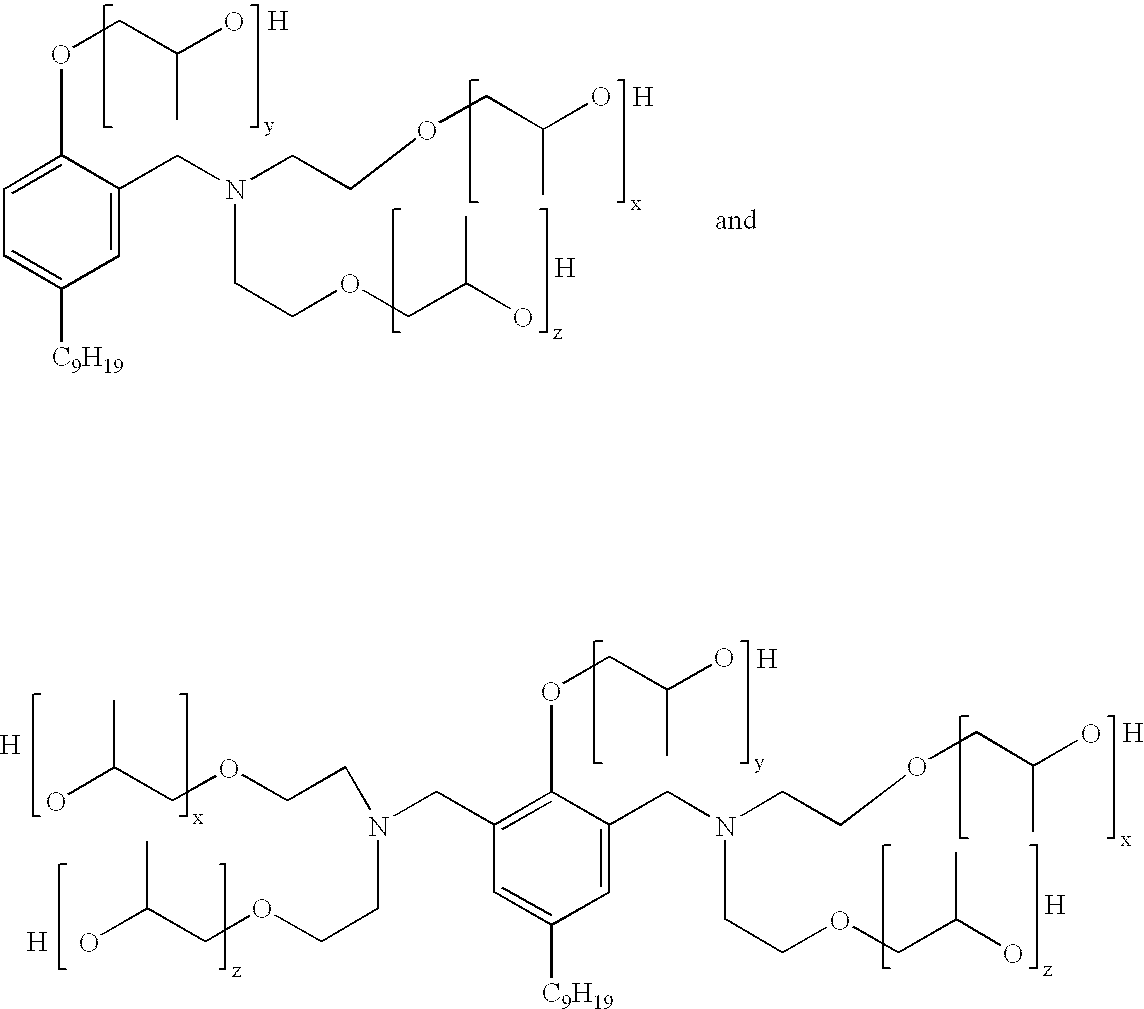

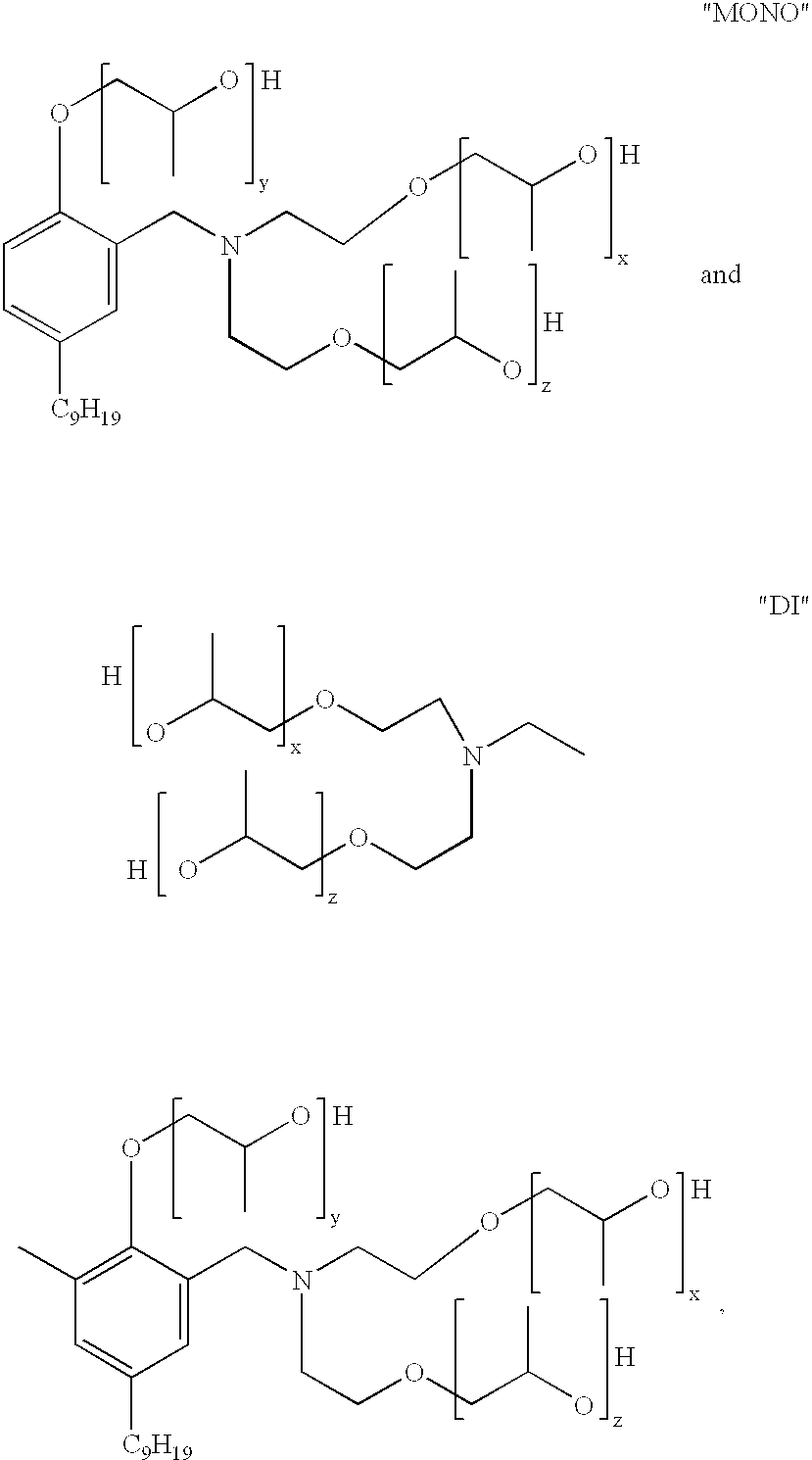

Mannich polyols for rigid spray foams

Provided herein are polyurethane foams which may be prepared by spray techniques. The foams of the invention are prepared using conventional isocyanates and a novel Mannich condensate polyol having a hydroxy number in the range of 250-340 and a viscosity of 3500 cps or less, and wherein the Mannich condensate polyol is derived from nonylphenol, formaldehyde, an alkanolamine, and propylene oxide as the sole alkoxylating agent. Polyurethane foams prepared according to the invention possess superior physical properties over sprayed polyurethane foams prepared using Mannich condensate polyols which are made using mixtures of propylene oxide and ethylene oxide.

Owner:HUNTSMAN PETROCHEMICAL LLC

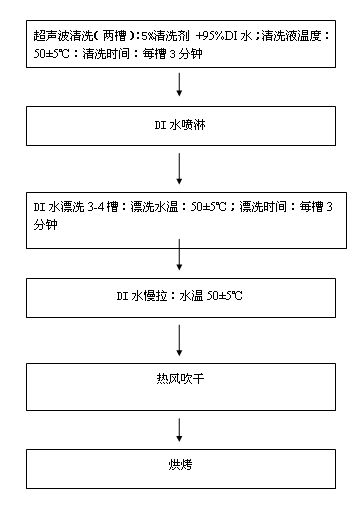

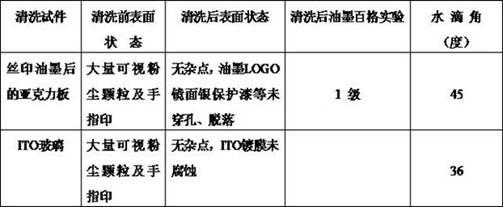

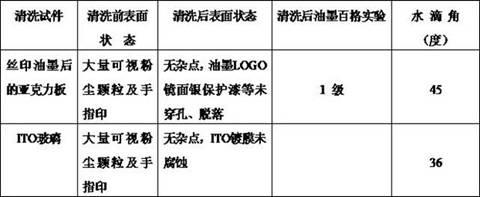

Cleaning agent for optical glass

ActiveCN102604751AEasy to cleanPromote wettingOrganic detergent compounding agentsNon-ionic surface-active compoundsOrganic baseCarbon chain

The invention discloses a cleaning agent for optical glass, which comprises the following components in weight percentage: 2-4% of long carbon chain dibasic acid; 6-10% of an anionic surfactant; 2-4% of an inorganic base; 2-6% of a nonionic surfactant; 2-4% of a special surfactant; 6-12% of a chelator; 10-20% of an organic base; and 40-70% of deionized water, wherein the long carbon chain dibasic acid is dicarboxylic acid with 21 carbon atoms, the anionic surfactant is dodecylbenzene sulfonic acid, the inorganic base is industrial NaOH, the nonionic surfactant is primary alcobol ethoxylate AEO9, the special surfactant is sodium POE nonylphenol ether sodiosulfosuccinate, the chelator is a mixture of Tetrasodium Ethylenediamine Tetraacetate and sodium gluconate, and the organic base is diethanol amine. The cleaning agent for optical glass provided by the invention has low corrosivity and good cleaning effect.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Making method and application of CdS sensitized TiO2 environmental estrogen photoelectrochemical sensor

ActiveCN104297305AImprove photoelectric conversion efficiencySave raw materialsMaterial electrochemical variablesAntigenAntigen capture

The invention relates to a making method and an application of a CdS sensitized TiO2 environmental estrogen photoelectrochemical sensor. The method uses TiO2 as an antigen capture substrate material, a CdS photoelectric active material is in situ generated on the surface of a Cd2<+> functional TiP nanomaterial maker modified electrode through a direct Na2S dropping technology, and CdS is irritated by an LED lamp of visible light wavelength to be converted to a photoelectric current signal. The substrate material TiO2 can be well matched with CdS energy band, so the photocurrent conversion signal of CdS is further improved, thereby the competitive photoelectrochemical immunosensor for ultra sensitive detection of estradiol, estriol, diethylstilbestrol, bisphenol A, nonylphenol, oestrone and other environmental pollutants is made.

Owner:UNIV OF JINAN

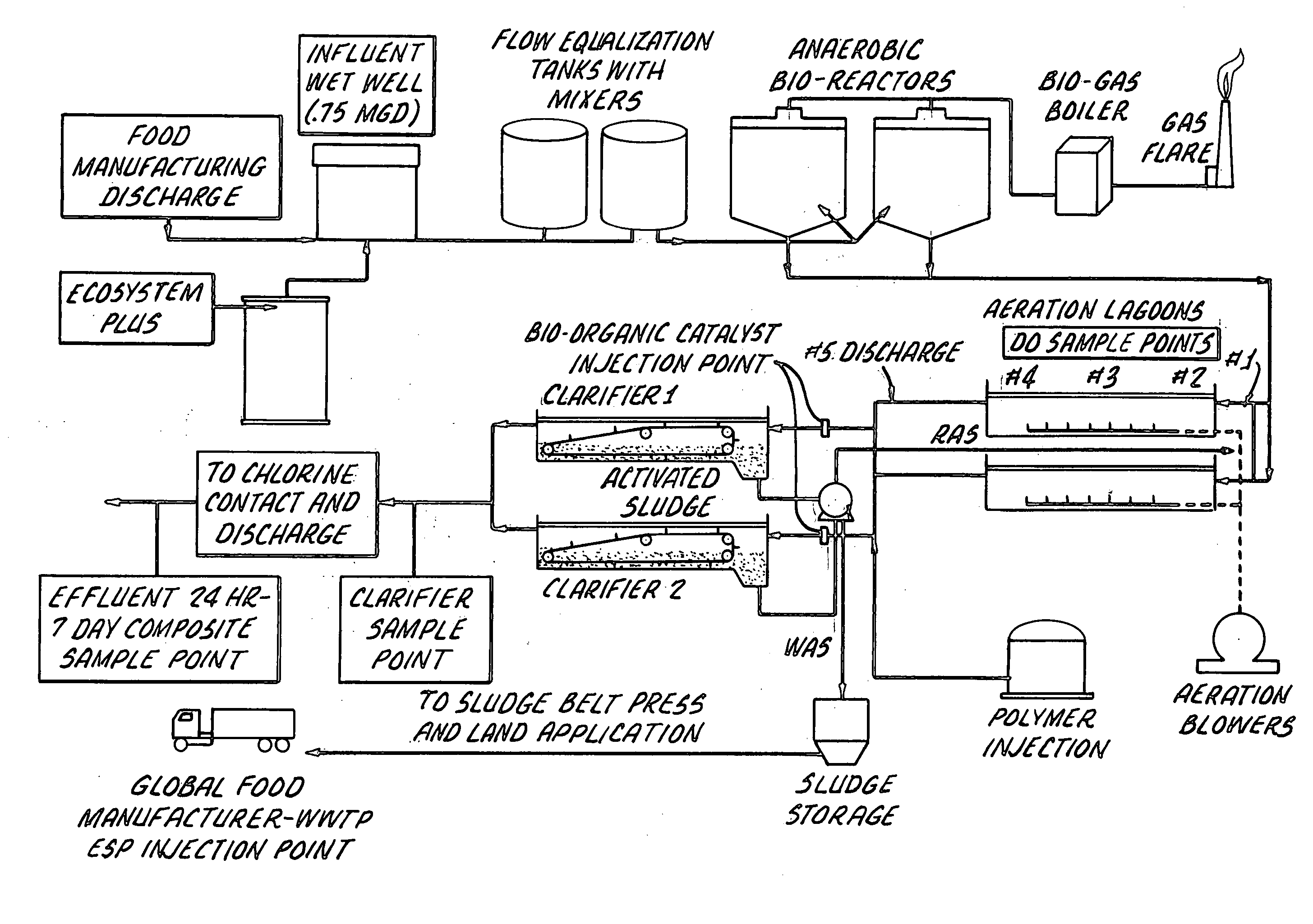

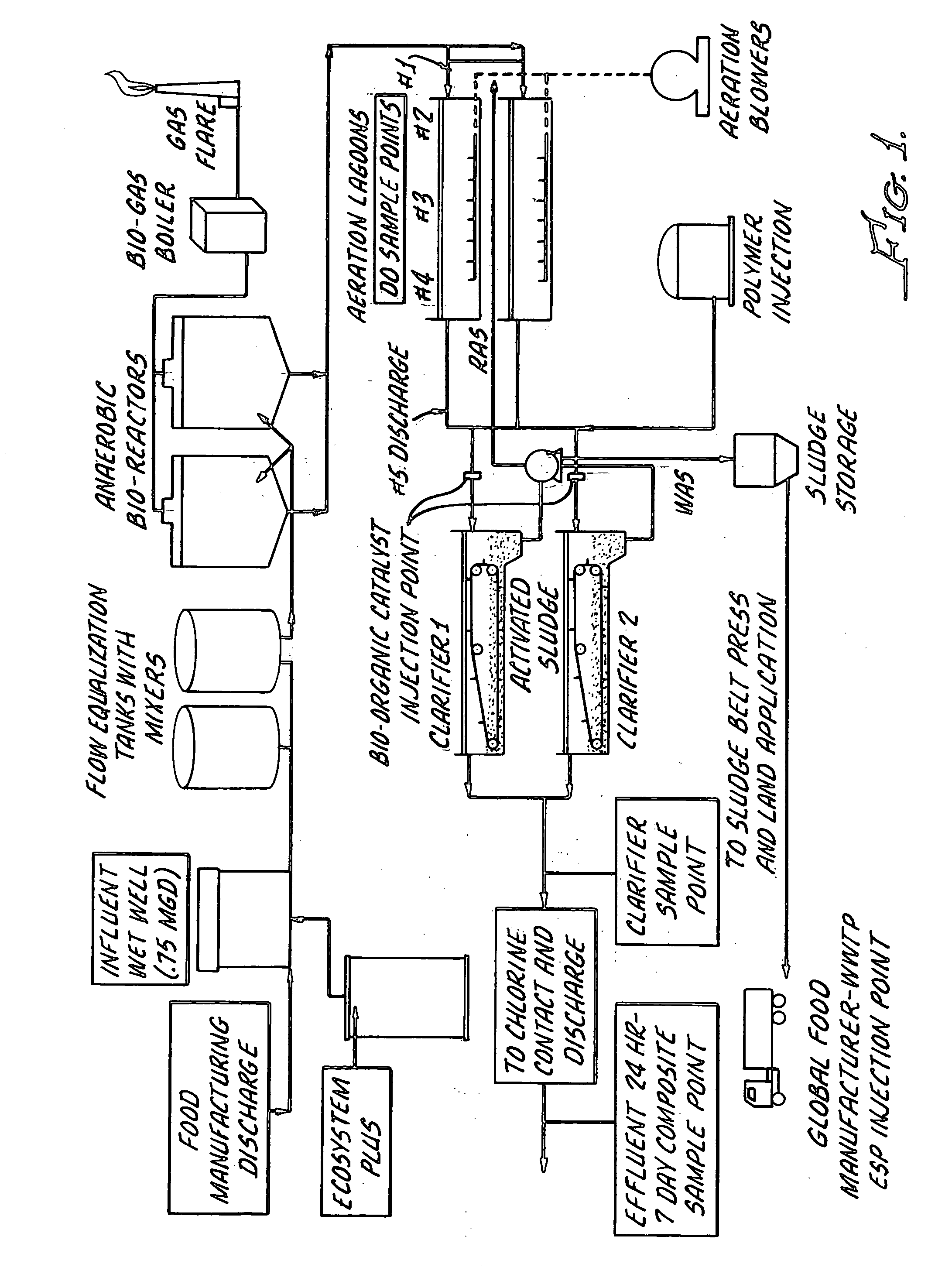

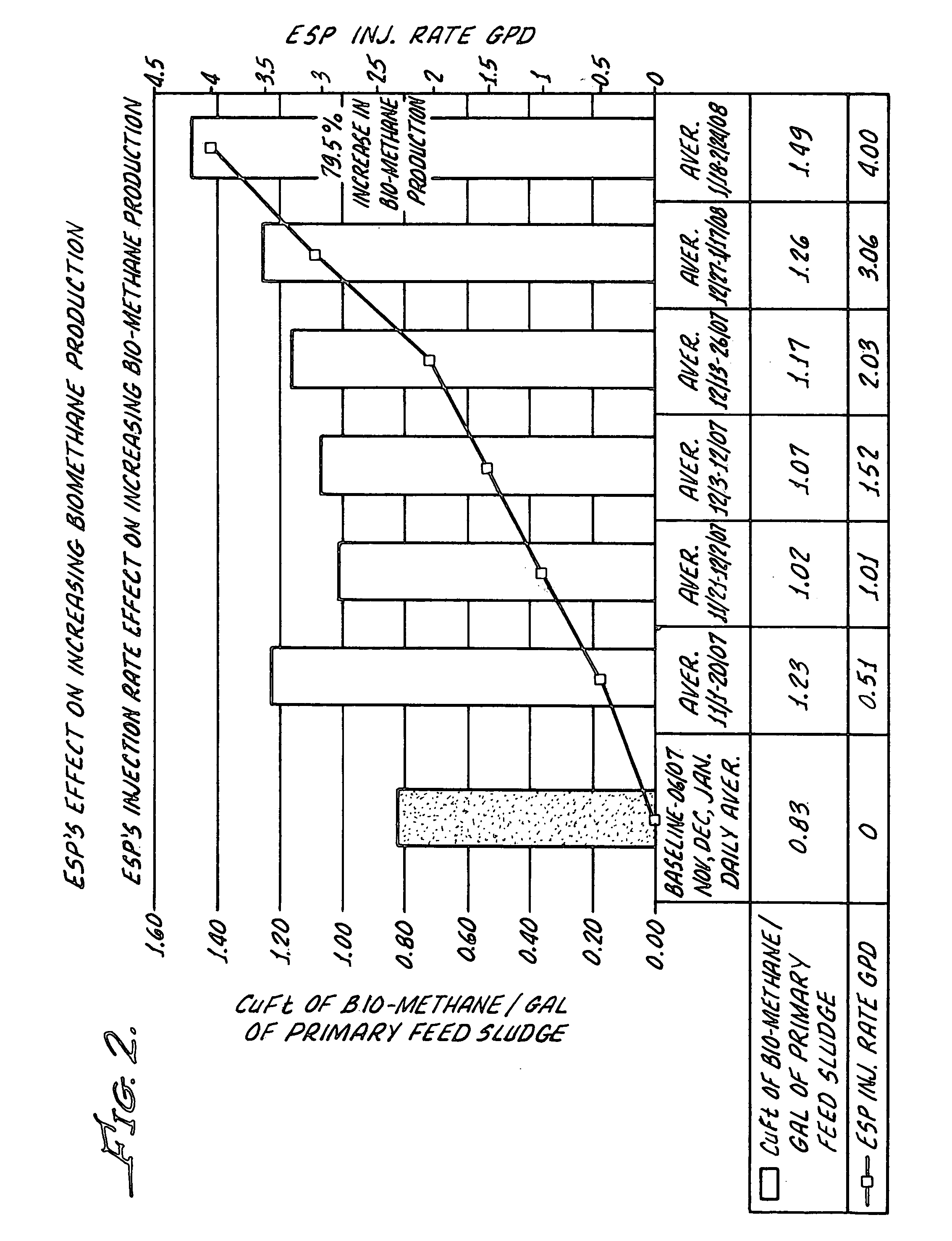

Anaerobic process for treating organic material to generate biogas

InactiveUS20100078307A1Reduce volatile organic solidWater treatment compoundsWater contaminantsActive enzymeDigestion

The present invention provides an anaerobic digestion process for the treatment of organic waste materials, which process comprises a bacterial process that is carried out in the absence of oxygen and wherein said process comprises digestion, in which said waste is fermented in tanks at an elevated temperature, and wherein said process results in the production of biogas, which can be used in generators for electricity production and / or in boilers for heating purposes, the comprises treating an organic waste with a composition comprising a fermentation supernatant containing active enzymes from a Saccharomyces cerevisiae culture; and a non-ionic surfactant, wherein said nonionic surfactant may be selected from the group consisting of ethoxylated nonylphenol and ethoxylated octyl phenol.

Owner:NEOZYME INT

Trivalent-chromium blue-white passivator for zinc-plated permanent magnetic material and passivation method thereof

InactiveCN102041497AAvoid pollutionAvoid damageMetallic material coating processesRare-earth elementNickel salt

The invention provides a trivalent-chromium blue-white passivator for a zinc-plated permanent magnetic material and a passivation method thereof. The trivalent-chromium blue-white passivator contains a main film-forming agent, an auxiliary film-forming agent, a stabilizer, an oxidant and a surfactant, wherein the main film-forming agent is a soluble salt of trivalent chromium, the stabilizer is selected from at least one of fluoride, citric acid and oxalic acid, the auxiliary film-forming agent is selected from at least one of soluble cobalt salt, soluble nickel salt or soluble salts of rare-earth elements, the oxidant is nitrate ions or hydrogen peroxide, and the surfactant is NPE (Nonylphenol Polyoxyethylene Ether) or sodium dodecyl benzene sulfonate. The trivalent-chromium blue-white passivator provided by the invention has a low cost, does not pollute the environment, and also does not cause damage to the health of operators.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

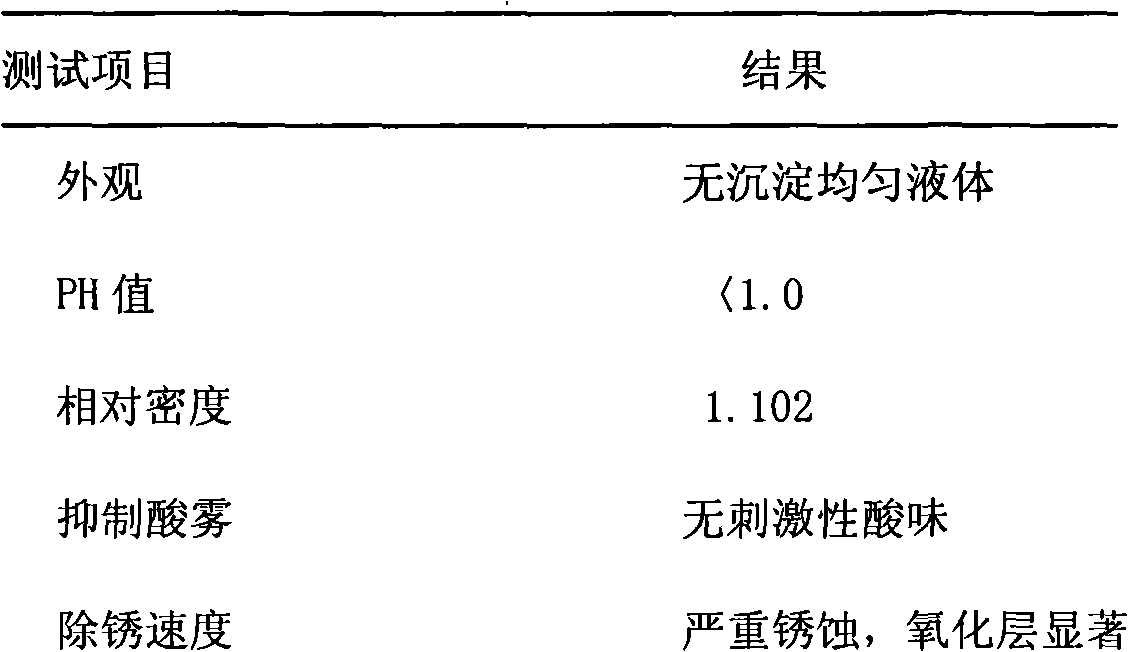

Acid-wash additive for iron and steel

The invention discloses an acid-wash additive for iron and steel. Every 4000g of the acid-wash additive is prepared from 200-250g of accelerator-oxalic acid or citric acid, 900-1000g of phosphoric acid, 200-250g of anionic surfactant-sodium lauryl sulfate, 150-200g of corrosion inhibitor-urotropine, 150-200g of mist inhibitor-nonylphenol polyethenoxy ether and the balance of water. The acid-wash additive is prepared by the following steps: evenly mixing phosphoric acid, anionic surfactant and water, adding the rest of components, and dissolving by stirring. The FSD-7001 acid-wash additive can further increase the derusting speed of hydrochloric acid, prevent iron and steel workpieces from generating over etching, reduce the acid consumption, inhibit acid mist, and enable the acid liquor to have certain oil removal function.

Owner:CHONGQING NORMAL UNIVERSITY

Brightening agent for vehicle without water washing, and preparation method

A type of anhydrous car washing polish agent is prepared from wax polish, emulsifier, solvent naphtha, oleic acid, additive and distilled water of which emulsified is made of nonylphenol polyethenoxy ether dehydrosorbito oleate polyethenoxy ether -80 or -60 and TA-20 emulsifier. The preparation method is included in operation manual.

Owner:王金环

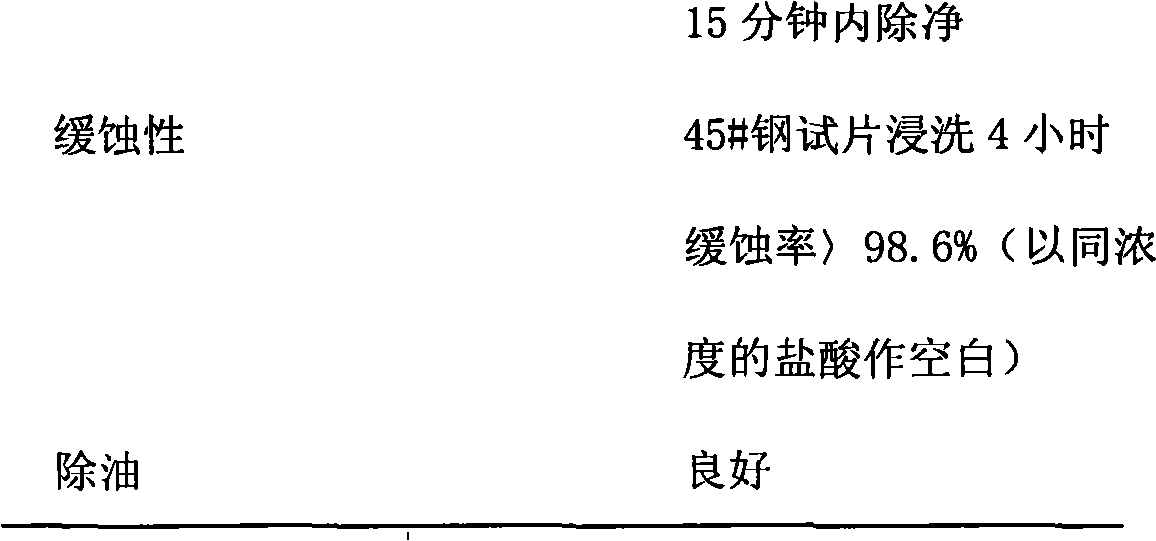

Compound lightyellow sophora root-selinum japenious seed bacteriostatic lotion and preparation method thereof

InactiveCN102526301ADefense against intrusionSuitable for useAntibacterial agentsOrganic active ingredientsChlorhexidine AcetateToxic material

The invention discloses a compound lightyellow sophora root-selinum japenious seed bacteriostatic lotion and a preparation method thereof. The lotion contains an extract of lightyellow sophora root, amur corktree bark and selinum japenious seed, chlorhexidine acetate, a surfactant, ethanol and water, wherein the surfactant is selected from lauryl dimethylamine oxide, Alcohol Ethoxylate (AEO-9), Lauric Acid Ethoxylate (LAE-9) and nonylphenol polyoxyethylene ether (NPE-10); the extract is prepared by performing reflux extraction on 10-25 percent of lightyellow sophora root, 35-45 percent of amur corktree bark and 35-45 percent of selinum japenious seed by taking 50-70 percent by volume of an ethanol aqueous solution as an extraction solvent for 1-3 times, every time for 1-1.5 hours, combining extracting solutions, filtering, recovering a filtrate under reduced pressure in vacuum, and concentrating with ethanol till the relative density is 1.08-1.12; and the using amount of the ethanol aqueous solution is 6-8 times of the total mass of the lightyellow sophora root, amur corktree bark and selinum japenious seed. The compound lotion consisting of Chinese native medicament and western medicament components has the effects of killing parasites to relieve itching, clearing heat, drying dampness and clearing away heat and toxic materials, can play a role in protecting private skin mucosa and preventing bacteria invasion, has low cost, and is suitable for young and middle-aged women.

Owner:上海豪源生物制品有限公司

Gemini quaternary-ammonium-salt water injection increasing agent

ActiveCN101705081AImprove seepage capacityReduce interfacial tensionDrilling compositionSodium acetatePotassium

The invention provides a gemini quaternary-ammonium-salt water injection increasing agent, which is an additive applied to injected water of oilfield injection wells. The parts by weight of the components are: 20 to 26 parts of N,N'-butylidene bislauroyl ammonium bromide, 5 to 8 parts of C12 fatty alcohol polyoxyethylene ether sodium acetate, 1.5 to 2.5 parts of ethylene glycol, 4.5 to 7.5 parts of polyoxyethylene (7) nonylphenol ether NPE-7, 4.5 to 8.5 parts of sorbitananhydride monostearate polyoxyethylene ether, 1 to 2.5 parts of ethyl ethylthio sulfonate, 12.5 to 16.5 parts of Monoethanolamine, 45 to 55 parts of distilled water, 0.5 to 1 part of sodium hydroxide, 2.5 to 4.5 parts of polyhydroxypropyl dimethyl ammonium chloride, and 0.05 to 0.1 part of perfluoroalkyl ether carboxylic acid potassium salt FC-5. The agent has the advantages that 0.05 to 0.2 percent of the agent added to the injected water can change the wettability of rock surfaces, enables oil reservoirs to be more hydrophilic, reduces blockage at well bottom and reservoirs, reduces damage to strata, and can drop the well-head pressure of the injection well by 5 to 15 percentage points.

Owner:PETROCHINA CO LTD

Water-borne permeable crystalline waterproofing material and preparation method thereof

Water-borne permeable crystalline waterproofing material and a preparation method thereof belong to the technical field of the building engineering; the waterproof material comprises components according to the mass percentage: 0.01-0.07% of alkyl benzene sulfonic acid solution, 0.05-0.3% of isopropanol, 0.005-0.075% of nonylphenol polyoxyethylene ether, 7.5-25.0% of sodium silicate, 0.75-3.5% oftartaric acid powder, 0.532-2.428% of anhydrous sodium carbonate, 1.65-7.5% of potassium methyl silicate solution and the rest of ionized water. The waterproofing material has simple production technique, low cost, outstanding waterproofing effect, is not-toxic and pollution-free, and belongs to the environmental friendly building material.

Owner:SHANGHAI JIAO TONG UNIV

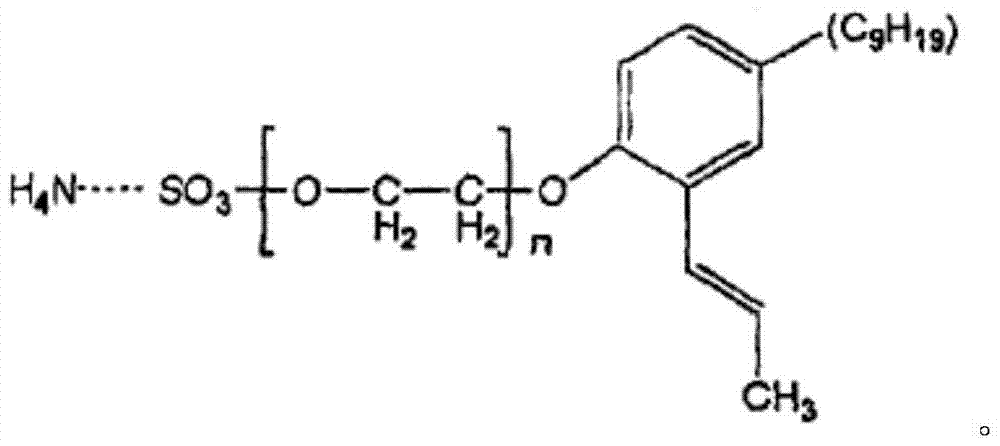

Water resistant whiting emulsion pressure sensitive adhesive synthesis method

The invention discloses a water resistant whiting emulsion pressure sensitive adhesive synthesis method, and a water resistant whiting emulsion pressure sensitive adhesive comprises the following components by weight: 20-60% of a soft monomer; 1-40% of a hard monomer; 1-5% of an emulsifier and the balance of water. The emulsifier is selected from allyloxy nonylphenol propanol polyoxyethylene ether ammonium sulfate, allyloxy nonylphenoxy propanol polyoxyethylene ether ammonium sulfate, allyloxy nonylphenoxy propanol polyoxyethylene ether, and a mixture of allyloxy nonylphenol propanol polyoxyethylene ether ammonium sulfate, allyloxy nonylphenoxy propanol polyoxyethylene ether ammonium sulfate and allyloxy nonylphenoxy propanol polyoxyethylene ether. The method comprises the following steps: (I) mixing the emulsifier and the monomer basically without stirring; (II) adding part of an initiator at 78 to 82 DEG C into a reaction kettle with water, adding dropwise the monomer mixture, after addition of the monomer mixture for 30 minutes, adding dropwise the remaining initiator solution for 2 to 5 hours, controlling the reaction temperature at 80-85 DEG C, and performing thermal insulation for 0.5 to 1 hour; and (III) after thermal insulation, reducing the temperature to 50 to 70 DEG C, adding tert-butyl hydroperoxide and methylsodium hydrosulfite aqueous solution, continuing to react for 0.2-1 hour, and adjusting the emulsion pH value to 6-8 when the temperature is reduced to 40 to 50 DEG C.

Owner:SHANGHAI HUAYI NEW MATERIAL

Wax polish and preparation method thereof

The process provides one kind of polishing wax and its preparation process. The polishing wax consists of silicone oil 3-8 wt%, vaseline 0.2-5 wt%, polyethylene 0.1-8 wt%, montan wax 0.1-0.5 wt%, coumarone-indene resin 0.1-5 wt%, carnauba wax 0.1-1 wt%, C12 fatty alcohol polyoxyethylene ether 0.5-3 wt%, nonylphenol polyoxyethylene ether 1-5 wt%, alkyl alcohol amide 2-5 wt%, ammonium hexadecyl trimethyl chloride or ammonium octadecyl trimethyl chloride 2-8 wt%, bentonite 1-5 wt%, glutaraldehyde 0.05-0.1 wt% and water 46.4-89.85 wt%. The polishing wax has no corrosion to the paint surface, and can eliminate dirt from paint surface, make paint surface clean and bright, and form protecting film with high heat resistance, less ageing and good luster.

Owner:李而淮

High solid phase drilling fluid filter cake removal treating fluid

ActiveCN101597488AGood lifting effectHigh corrosion rateCleaning apparatusDrilling compositionPotassiumDissolution

Owner:PETROCHINA CO LTD

Method for stripping cured paint from plastic, steel, aluminum, brass, magnesium and non-ferrous substrates with surfactants low in volatile organic compounds

InactiveUS20050079984A1Efficient removalLow in (VOCs) volatile organic compoundsSurface-active detergent compositionsNon-surface-active detergent compositionsO-Phosphoric AcidAlkylphenol

A method of stripping cured paint comprising: a) adding a stripping composition to a strip tank, said stripping composition consists of a mixture of, surfactants selected from the group consisting; surfactants, non-ionic surfactants, anionic surfactants, cationic surfactants, amphoteric surfactants, acetate based surfactants, fluorosurfactants, solvent based surfactants, phosphate ester surfactants, acid pH based surfactants, alkaline pH based surfactants, neutral pH surfactants, sulfonic acid surfactants, phosphoric acid surfactants, fatty acid based surfactants, inorganic acid based surfactants, carboxylate based surfactants, alkylate based surfactants, alcohol based surfactants, nonylphenol surfactants, alkylphenol surfactants, ethoxylated surfactants, sulphonate based surfactants, amine based surfactants, amide surfactants, glycol based surfactants and quaternary surfactants and surfactant blends thereof; b) immersing said cured painted substrate in said strip tank containing said stripping composition; c) heating said stripping composition from 150 F. to 350 F for approximately 1-3 hours , wherein cured paint is removed from said substrate.

Owner:MILES SAMUEL LEE

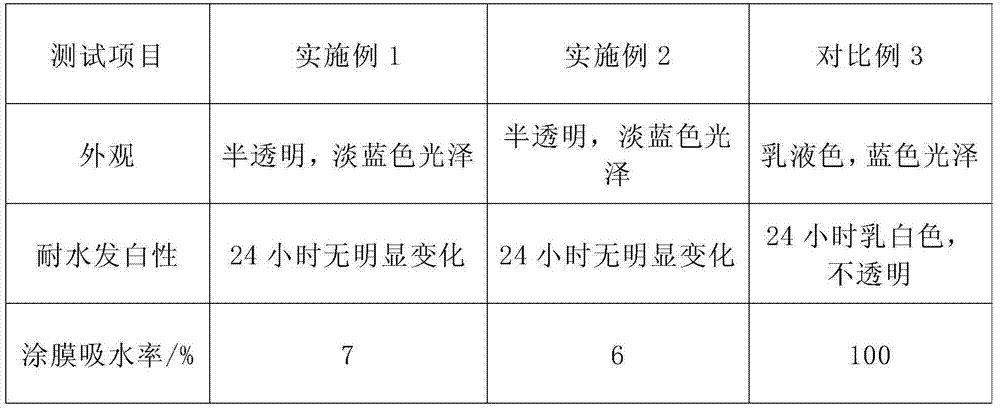

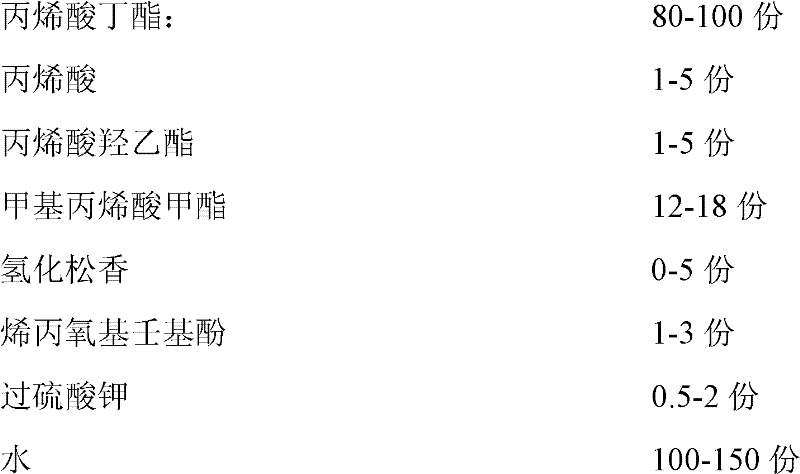

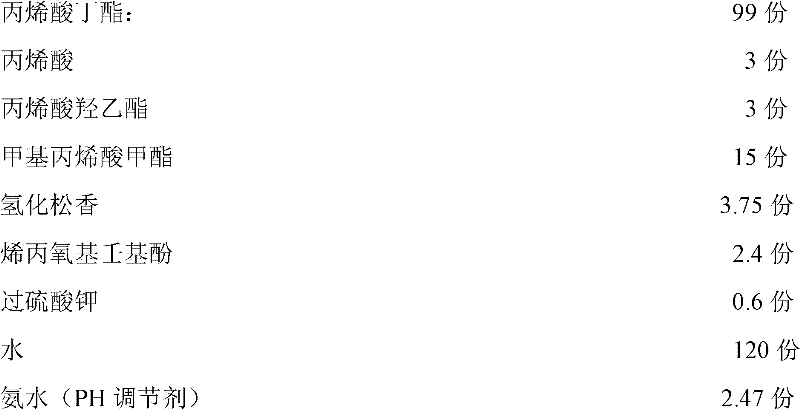

Emulsion type acrylate pressure sensitive adhesive and preparation method thereof

InactiveCN102533174AStrong weather resistanceReduced post-processingEster polymer adhesivesPotassium persulfateTemperature resistance

The invention relates to an emulsion type acrylate pressure sensitive adhesive and a preparation method thereof. The emulsion type acrylate pressure sensitive adhesive is obtained by polymerizing the following components in parts by weight through free radicals: 90-100 parts of butyl acrylate, 1-5 parts of acrylic acid, 1-5 parts of hydroxyethyl acrylate, 12-18 parts of methyl methacrylate, 0-5 parts of hydrogenated rosin, 1-3 parts of allyloxy nonylphenol, 0.5-2 parts of potassium persulfate and 100-150 parts of water. Through pre-emulsion semi-continuous seeding polymerization reaction, an emulsion type pressure sensitive adhesive with high viscosity, high temperature resistance and strong weather resistance is synthesized. According to the invention, polymerizable allyloxy nonylphenol is adopted as emulsifying agent; after the reaction is finished, an allyloxy nonylphenol unit directly enters the prepared polymer so that the post-treatment process of the emulsifying agent is saved.Because no organic solvent is used, the pollution caused by volatilization of the organic solvent to the environment is avoided and the cost is reduced.

Owner:新丰杰力电工材料有限公司

Polishing solution for precision polishing of LED sapphire substrate

InactiveCN103184010AImprove liquidityConsistent removal ratePolishing compositions with abrasivesOrganic baseActive agent

The invention relates to a preparation formula of a polishing solution for precision polishing of an LED sapphire substrate. The polishing solution comprises the following components in percentage by weight: 0.7-1.0% of organic base diethanol amine, 25-35% of silica solution with grain diameter of 50-70nm, 0.4-0.7% of dispersing agent ethanediamine, and 0.1-0.3% of activating agent nonylphenol polyoxyethylene ether. The removal rate of the polishing solution can be up to 28 nm / min; the surface roughness Ra is smaller than 0.5 nm, which can meet the main performance index requirements for sapphire substrate CMP (chemical mechanical polishing). The polishing solution has the advantages of high removal rate, low surface roughness and cost, non-pollution to the environment and non-corrosion to equipment.

Owner:铜陵市琨鹏光电科技有限公司

Acrylate emulsion pressure-sensitive adhesive with high solid content and low viscosity and preparation method thereof

ActiveCN104371607AHigh solid contentHigh viscosityEster polymer adhesivesAdhesive cementPolymer science

The invention provides an acrylate emulsion pressure-sensitive adhesive with a high solid content and low viscosity, and a preparation method thereof. The provided polyacrylate emulsion is prepared by synthesizing 2-ethylhexyl acrylate, butyl acrylate, vinyl acetate, methyl methacrylate, acrylic acid, 2-hydroxypropyl acrylate, vinyl acetate, carboxyl-containing functional monomers, and inter-crosslinked polyacrylate monomers through a pre-emulsifying semi-continuous polymerization technology. Compared to the prior, the provided adhesive has the characteristics of high solid content, which is not less than 65%, and low viscosity, which is less than 800 mPas at a temperature of 25 DEG C under a rotation speed of 60 rpm. The gel content of the adhesive is low, and the stability of the adhesive is good. The adhesive basically does not contain any nonyl phenol or contains very little nonyl phenol, is an environment-friendly acrylate emulsion pressure-sensitive adhesive, and can be used as a single-component pressure sensitive adhesive.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

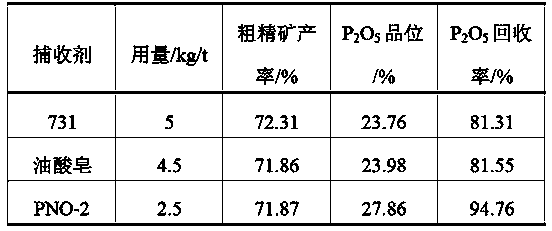

Collophanite direct flotation collector, and preparation method, purposes and application method thereof

The invention provides a cellophane direct flotation collector. The collophanite direct flotation collector comprises, by weight, 75 parts to 80 parts of fatty acid soap, 10 parts to 15 parts of fatty acid monoethanolamine and 3 parts to 8 parts of non-ionic surface active agents, and the non-ionic surface active agents are selected from one or more of octylphenol ethoxylate, nonylphenol polyeothoxylates and fatty alcohol polyoxyethylene ether. The invention further discloses a preparation method of the cellophane direct flotation collector, illegal cooking oil serves as raw materials, and the cellophane direct flotation collector is obtained after deodorization and decoloring. The collophanite direct flotation collector is good in selectivity and high in collecting capacity. According to the method, the illegal cooking oil harmful to the environment serves as the raw materials, waste is turned into wealth, the carboxylic acid derivative collector containing hydroxyl and amide polar groups is prepared, and the collector has great actual significance in development and utilization of medium and low grade collophanite.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Nursing traditional Chinese medicine disinfectant and preparation method

The invention provides a nursing traditional Chinese medicine disinfectant and a preparation method. The nursing traditional Chinese medicine disinfectant comprises, by weight, 10-20 grams of camphor bark, 5-10 grams of honeysuckle, 8-12 grams of light-yellow sophora root, 5-15 grams of glabrous greenbrier rhizome, 10-15 grams of common cnidium fruit, 4-6 grams of coptis, 3-5 grams of ginger, 4.2-6.5 grams of safflower, 10.5-12g grams of cortex dictamni, 12.4-13 grams of aloe and 7.8-12.8 grams of ginkgo seeds. The preparation method includes the steps: (1) weighting the raw materials by weight; (2) adding water into the raw materials for decocting twice, filtering, mixing filtrates and adding sterile water into the mixture to 1000ml; and (3) adding 5 grams of nonyl phenol polrvinyl chloride ether and 10 grams of glycerol into the mixture with uniformly stirring, and adding 2 grams of available iodine and 2 grams of metronidazole with uniformly stirring. The nursing traditional Chinese medicine disinfectant is good in disinfection effect, low in skin irritation, suitable for disinfecting the skin and capable of disinfecting clothes and tableware.

Owner:张吉玲

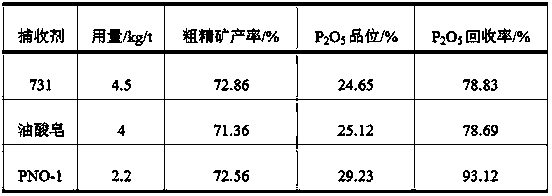

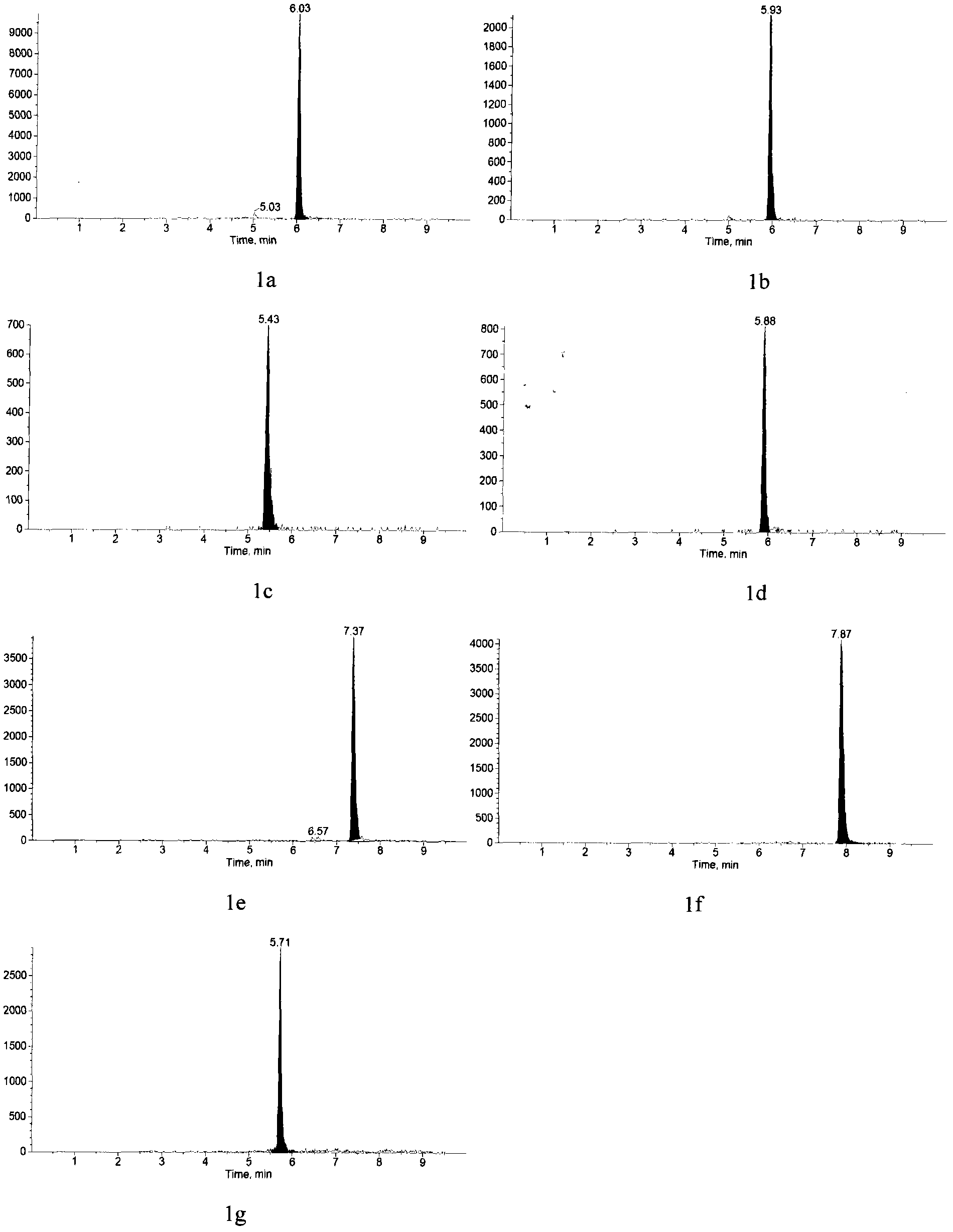

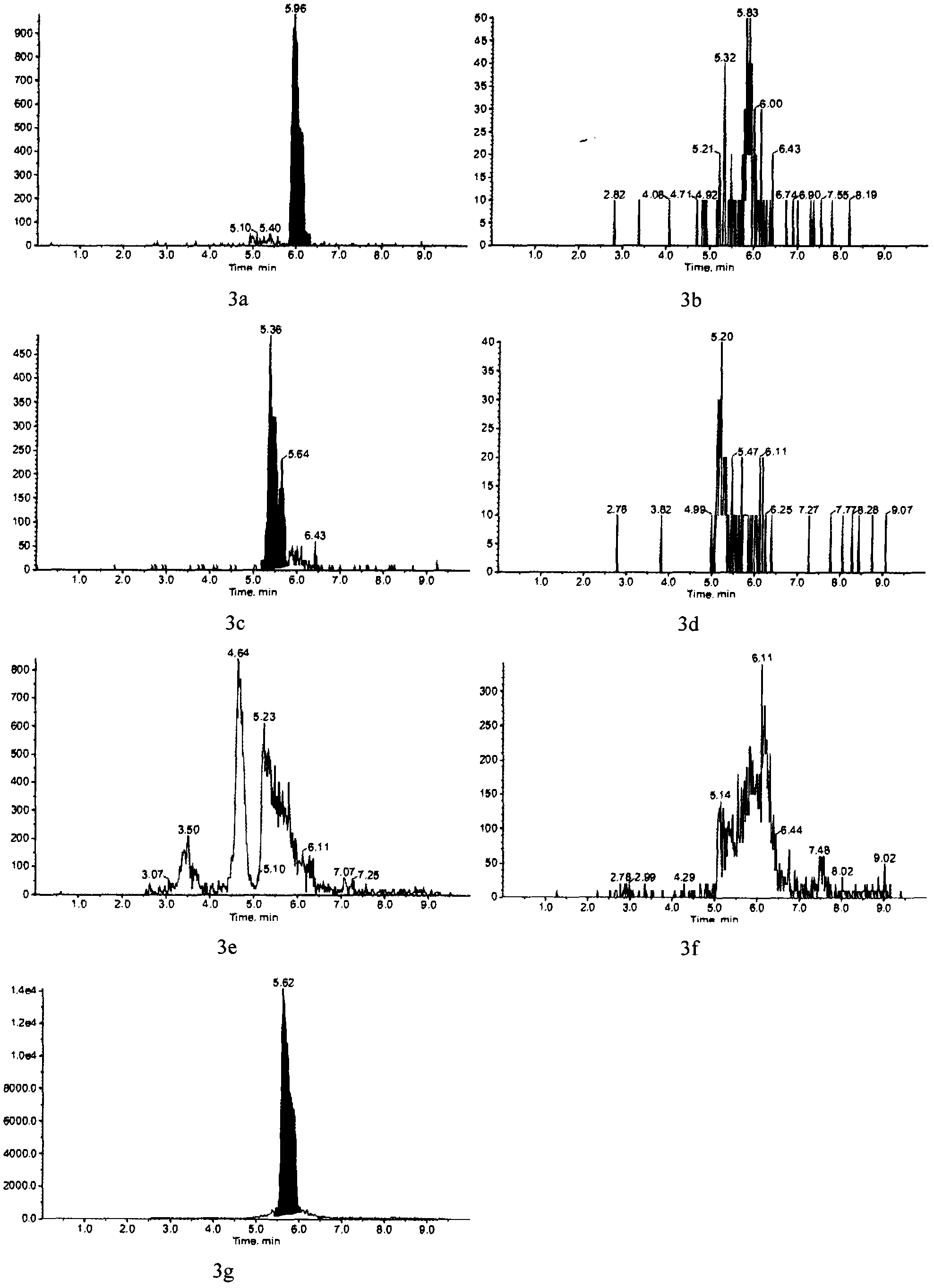

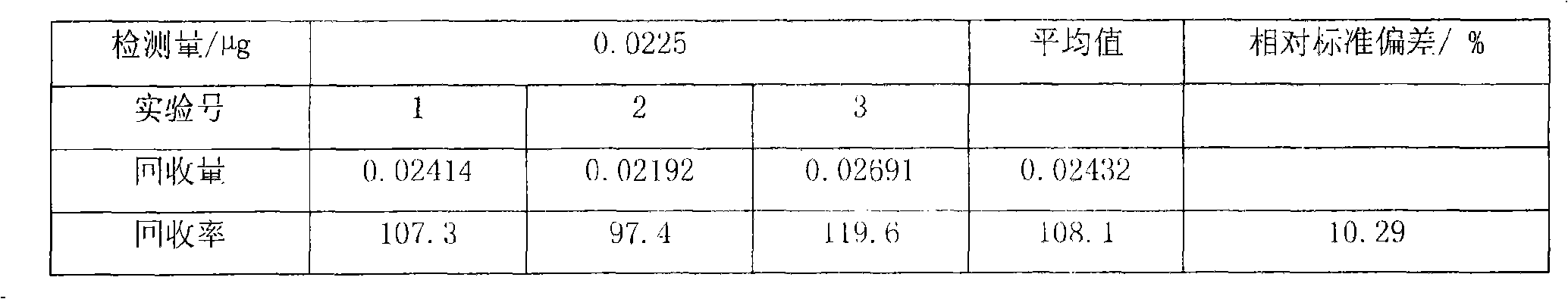

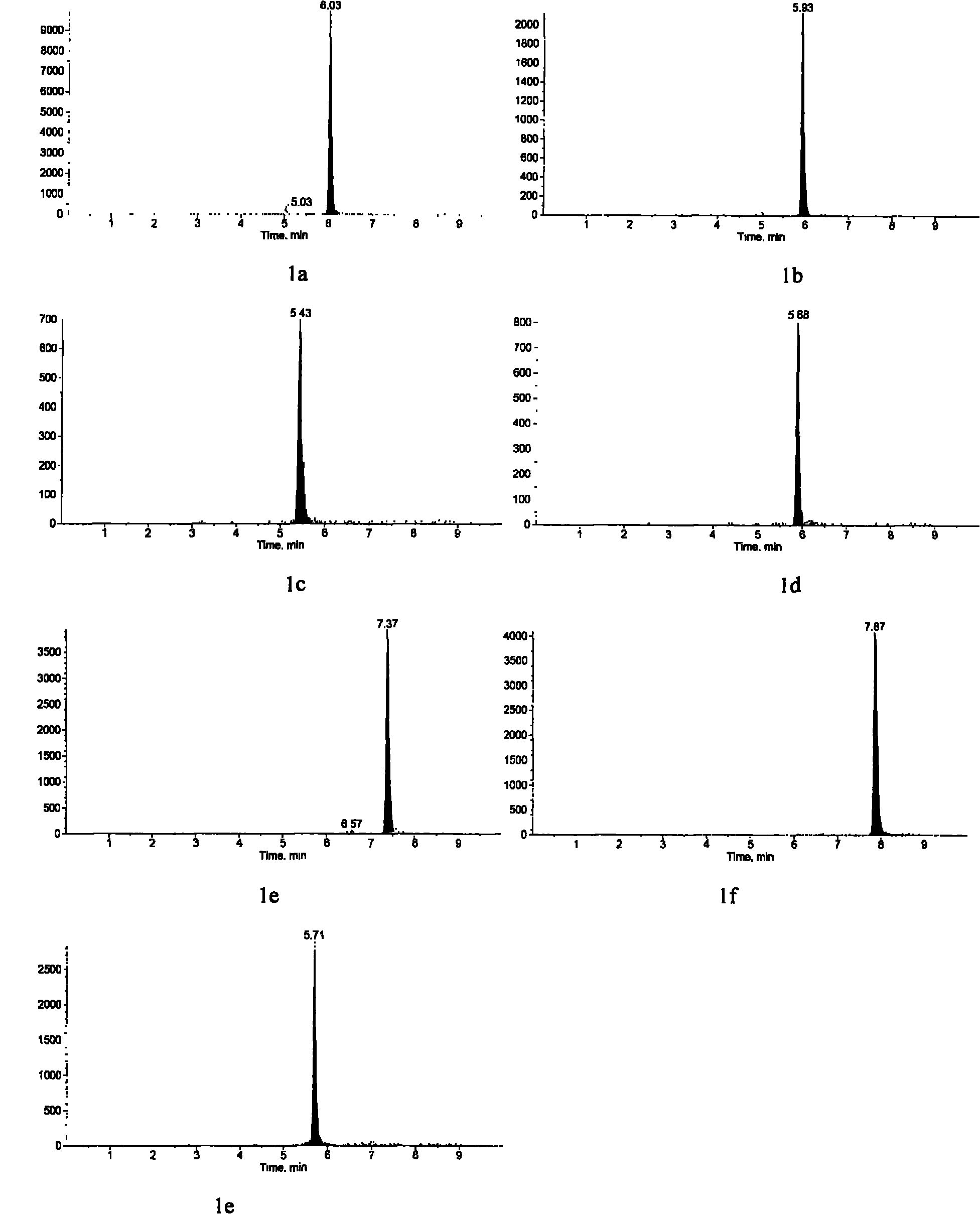

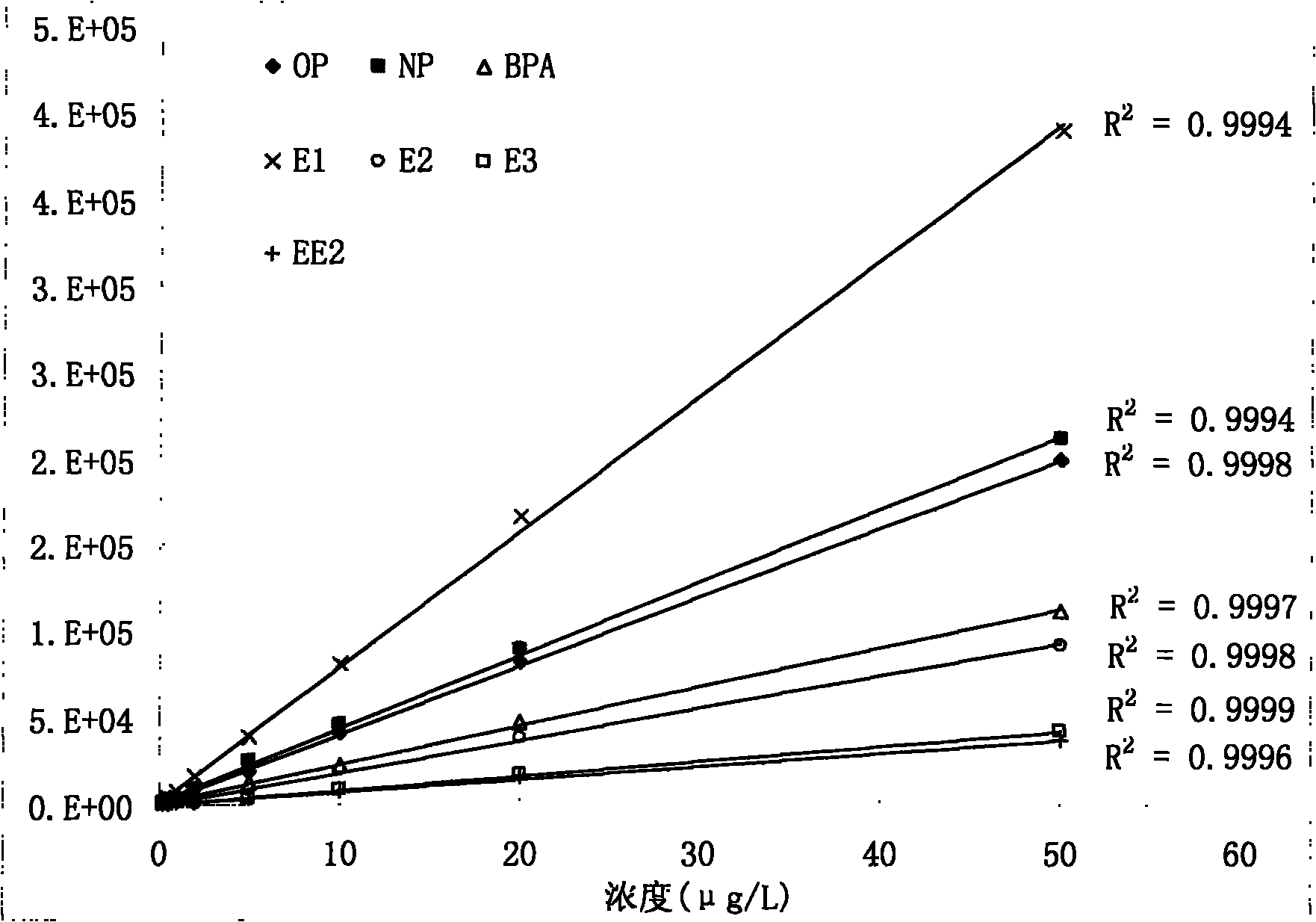

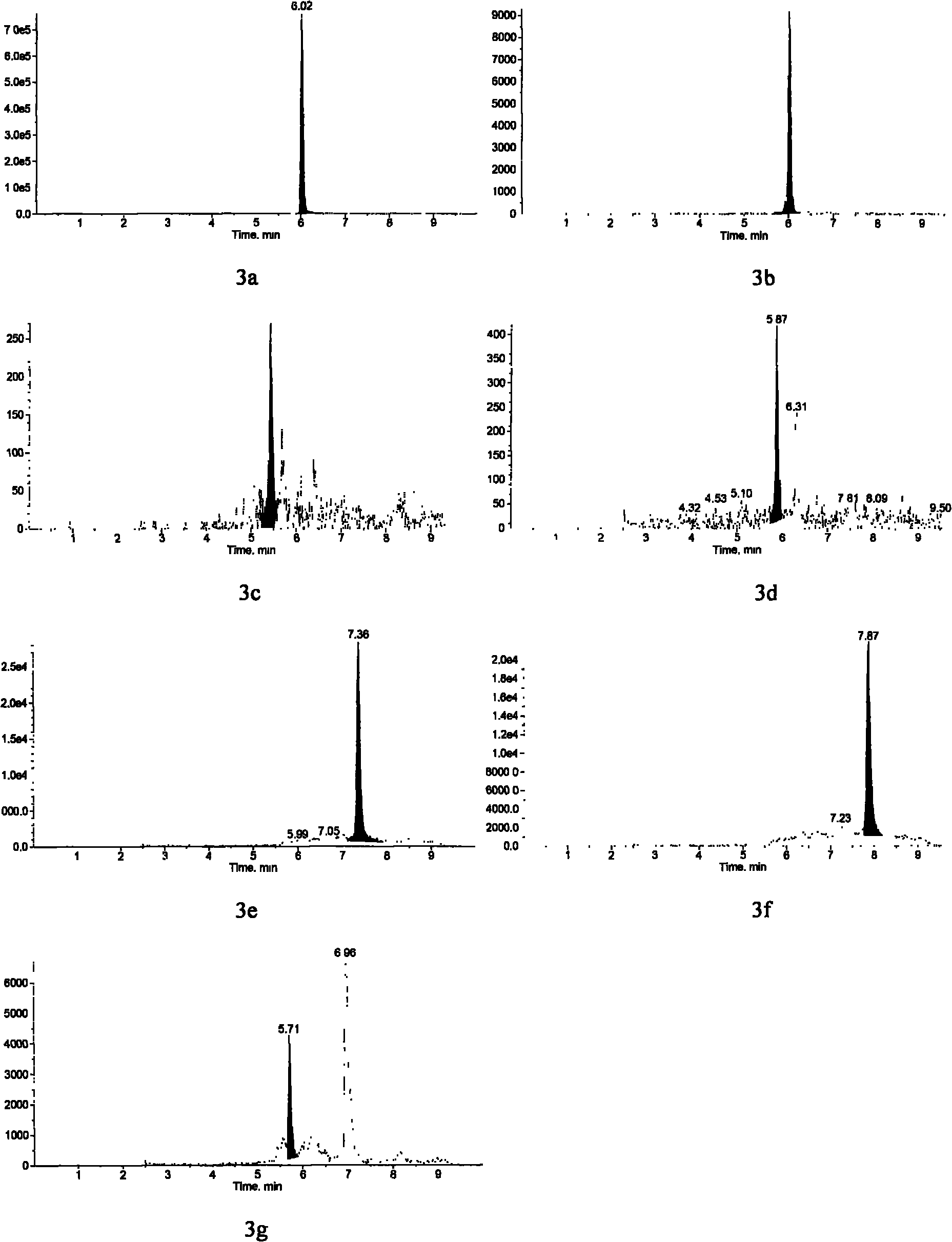

Method for jointly detecting estrogen, nonyl phenol, octylphenol and bisphenol A in complex substrate water sample

The invention relates to a detecting technique of endocrine disrupters in water environment and particularly relates to a technique for quantitative analysis on oestrone, 17beta-estradiol, estriol, 17alpha-ethinyl estradiol, nonyl phenol, octylphenol and bisphenol A in a complex substrate water sample by adopting a liquid chromatogram-tandem mass spectrum combined technique. The method comprises the following steps: enriching a collected water sample by using a HLB (Hydrophile-Lipophile Balance) solid-phase extraction column and washing with carbinol; drying elution liquid nitrogen and purifying by using Florisil; and finally, analyzing by utilizing the liquid chromatogram-tandem mass spectrum combined technique. The method is environment-friendly, easy to operate and high in recovery rate. The method can quickly analyze the trace amount of oestrone, 17beta-estradiol, estriol, 17alpha-ethinyl estradiol, nonyl phenol, octylphenol and bisphenol A in the complex substrate water sample.

Owner:BEIJING NORMAL UNIVERSITY

Carbon deposition cleaning agent for automobile engine

The invention provides manufacturing of a carbon deposition cleaning agent for an automobile engine, and is characterized in that the carbon deposition cleaning agent consists of anionic surfactant alkyl benzenesulfonic acid triethanolamine serving as the cleaning agent, anionic surfactant oleic acid triethanolamine serving as the cleaning agent, a nonionic surfactant nonylphenol polyoxyethylene ether serving as the cleaning agent, a nonionic surfactant lauryl amine polyoxyethylene ether serving as the cleaning agent, triethanolamine serving as a metal antirust agent, benzotriazole serving as a corrosion inhibitor, a propylene glycol monoethyl ether solvent, a butyl cellosolve solvent, a trichloromethane solvent and a 97# gasoline solvent. The carbon deposition cleaning agent is mainly suitable for performing rapid infiltration and powerful cleaning on deposited carbon on the automobile engines, the top of pistons, gasoline nozzles, air valves, air valve conduits and the inner walls of exhaustion pipe silencers. The carbon deposition cleaning agent is faint yellow and transparent liquid and has no corrosiveness against the metals, and a pH value is 7-9; and the cleaning agent can be directly used in the gasoline, and the using amount is 0.5-3 percent.

Owner:TAINJIN BOKNI TECH DEV

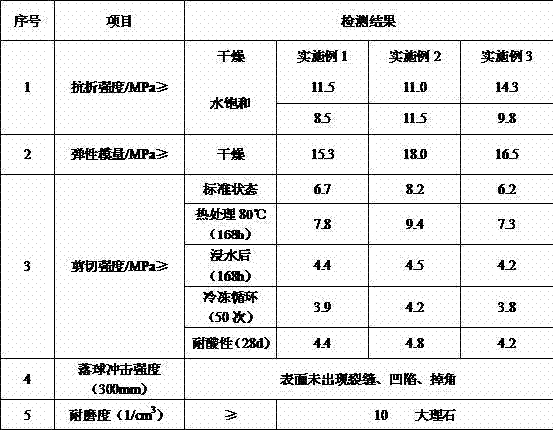

Modified epoxy adhesive for stone combination and preparation method thereof

ActiveCN102786903AHigh hardnessLow shrinkageNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFatty amine

The invention relates to a two-component modified epoxy adhesive for stone combination and a preparation method thereof, which is characterized in that an A component is prepared by bisphenol A epoxy resin, bisphenol F epoxy resin, an active diluent, a bisphenol A, an anti-yellowing additive, a wetting agent, and inorganic powder, and a B component is prepared by self-made ketoimine, nonyl phenolglycidyl ether modified aliphatic amine, alicyclic amine, a coupling agent, a wetting agent, and a curing accelerator; the A and B components are mixed and used according to a mass ratio of 10:2.5-5.In the ketoimine preparation, the mass ratio of butanone to diethylenetriamine is 70-90:100; in the modified aliphatic amine preparation, the mass ratio of nonyl phenol glycidyl ether to diethylenetriamine is 100:21-32; the two-component modified epoxy adhesive for stone combination has the characteristics of good curing performance, and low cost.

Owner:HUNAN KOSEN NEW MATERIAL

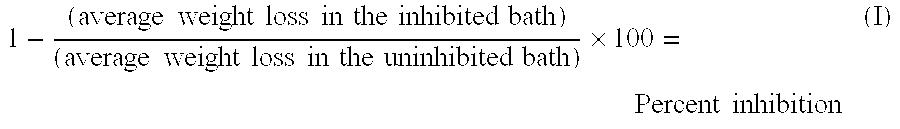

Stable acid inhibitor formulations with improved performance, lower toxicity and minimal environmental issues

InactiveUS20060180795A1Great metal corrosion protectionExtended shelf lifeOrganic detergent compounding agentsOther chemical processesNuclear chemistryIngested food

Aqueous concentrates of non-toxic corrosion inhibitors, preferably storage-stable, useful in acidic cleaning solutions for cleaning the surfaces of metal that contacts food or potable water, the concentrates comprising at least one polymer, which may be protein-derived or synthetic; at least one iodine ion providing compound; an acidifier; and optionally, at least one anionic, nonionic or amphoteric surfactant; at least one coupling agent; and a pH adjuster; the concentrates being substantially free of nonylphenol derivatives and compounds containing elemental iodine and providing an improved acid inhibition and less foaming than similar compositions comprising nonylphenol derivatives and elemental iodine when mixed with aqueous acidic cleaners; acidic solutions prepared therefrom; and methods of their use.

Owner:HENKEL KGAA

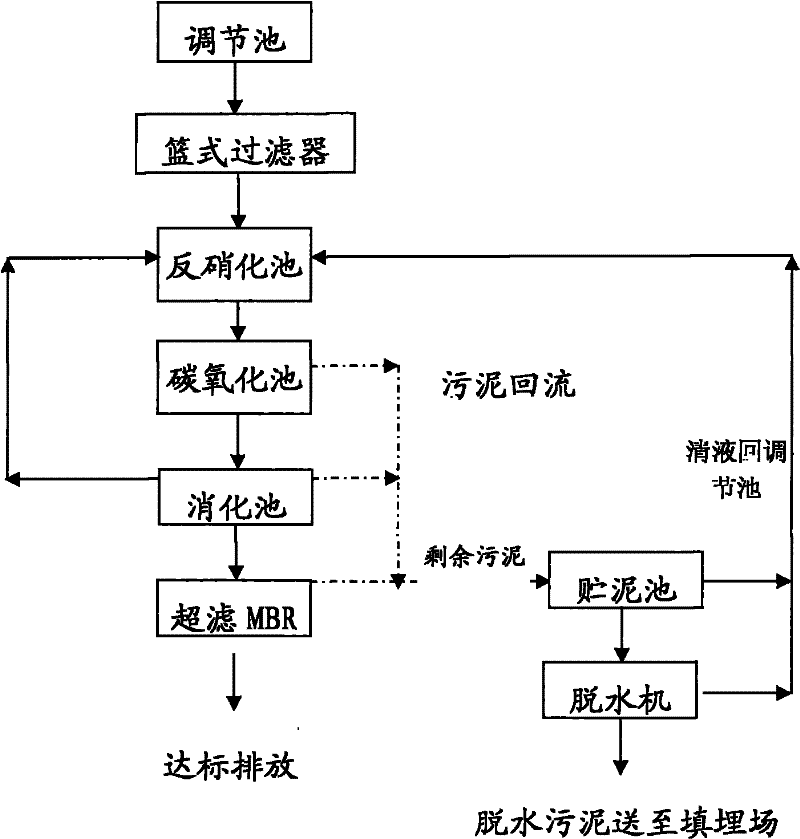

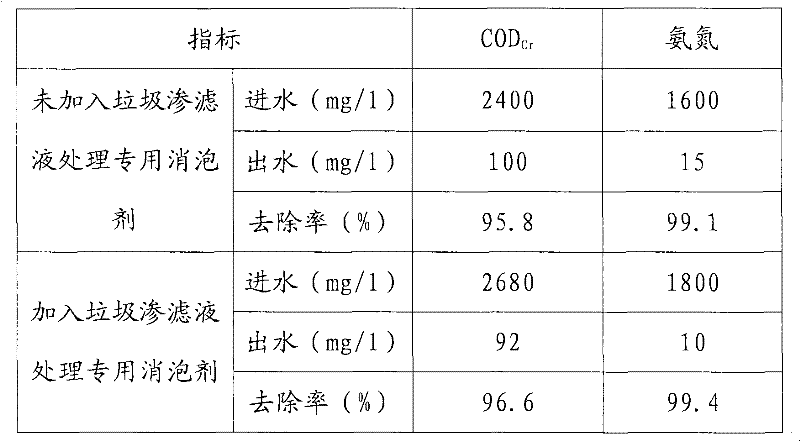

Deformer special for treating landfill leachate

InactiveCN102126763ARaw materials are cheap and easy to getThe process is simple and convenientWater/sewage treatment by flocculation/precipitationHigh concentrationAlcohol

The invention discloses a deformer special for treating landfill leachate, relates to the technical field of defoaming in the treatment process of high-concentration landfill leachate in environmental engineering, and belongs to the technical category of auxiliary medicaments for treating high-concentration organic waste water and preparation. The deformer comprises the following main components: nonylphenol ethoxylates, polyoxypropylene-polyoxyethylene glycerin ether, alkylphenol ethoxylates, low-carbon alcohol and microbial flocculant; the special deformer is used as an auxiliary process for treating the landfill leachate, so the problems of poor effluent water quality, high cost of production management, environmental pollution and the like are solved, and the deformer is easy and convenient to operate, efficient, energy-saving and low in operating cost, can be used in all main stream processes for treating the landfill leachate by a biochemical method, and has the wide applicationprospect.

Owner:SHANGHAI HUALIZHEN ENVIRONMENTAL PROTECTION TECH

Topical treatment for carpet and textiles and topically treated carpet and textile products

InactiveUS20050177957A1Lasting effectImpart propertyLiquid surface applicatorsPhysical treatmentO-Phosphoric AcidMicrobial agent

A composition to be used as a topical treatment for carpet and textiles, and a process for producing the composition are provided. The composition has desirable antibacterial, antimicrobial, and antifungal properties, and is made up of an effective amount of an antimicrobial agent having a blend of substituted ammonium salts of alkylated phosphoric acids admixed with free alkylated phosphoric acid, an effective amount of a pesticide containing Permethrin, a sufficient amount of an emulsifier in the form of an ammonium nonylphenol ether sulfate, and, optionally, an effective amount of a fragrance additive, all mixed with water. The process involves premixing with water the emulsifier, the antimicrobial agent, and, where used, the fragrance additive, adding this premix to a larger quantity of water, agitating the composition, slowly adding the pesticide while agitating, and continuing the agitation for a predetermined period of time.

Owner:TEXTILE RUBBER & CHEM CO INC

Degreasing agent for cold-rolled continuous annealing unit

The invention discloses a degreasing agent for a cold-rolled continuous annealing unit. The degreasing agent is prepared from an alkaline matter, an auxiliary cleaning agent, a chelating agent, a surfactant and desalted water, wherein the alkaline matter is prepared from the following ingredients in percentage by weight: 12-36 percent of sodium hydroxide and 0-6 percent of potassium hydroxide; the auxiliary cleaning agent is prepared from the following ingredients in percentage by weight: 1-5 percent of sodium carbonate and 1-5 percent of trisodium phosphate; the chelating agent is prepared from the following ingredients in percentage by weight: 1-6 percent of sodium gluconate and 0.5-2 percent of ethylenediamine tetraacetic acid; the surfactant is prepared from the following ingredients in percentage by weight: 0.5-2 percent of polyacrylic acid sodium salt, 0.5-2 percent of nonylphenol polyoxyethylene ether and 0.5-2 percent of an H-11type anionic surfactant. The degreasing agent is good in cleaning performance and low in cost. According to the degreasing agent, the cleaning rate of the cleaned band steel can be more than 98 percent, the oil residue on surface is smaller than or equal to 10 mg / m<2>, and the residual quantity of iron is smaller than or equal to 10 mg / m<2>. The degreasing agent can well adapt to the requirement on the cleaning quality of boards during high-speed production of the cold-rolled continuous annealing unit.

Owner:武汉钢铁有限公司

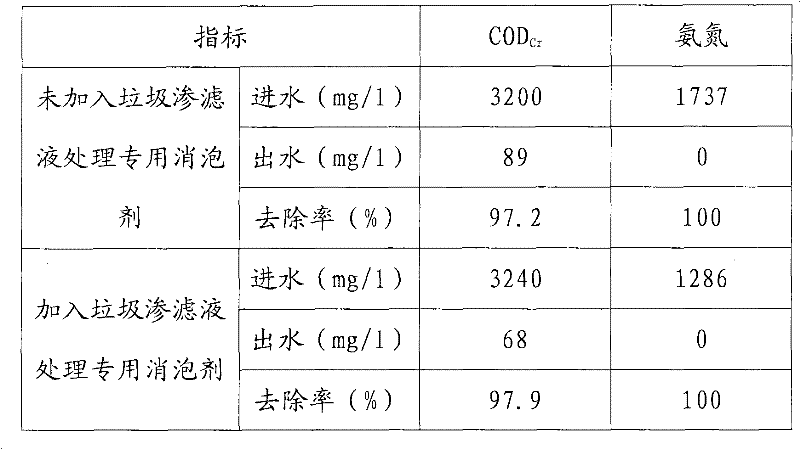

Method for detecting concentration of trace amount of bisphenol A in water environment

InactiveCN101315354AThe pre-processing process is simpleQuick analysisComponent separationChlorobenzeneSurface water

The invention belongs to the detection technology field of pollutants in an aquatic environment. The invention relates to a method for detecting the trace bisphenol A concentration of a water body, in particular to a detection method of the trace bisphenol A concentration of tap water, reclaimed water or surface water. The method comprises the steps as follows: processing a water sample with an extractant and a dispersant, taking and quantifying the underlayer organic phase, carrying out liquid chromatographic detection, comparing with a standard curve, and quantifying to obtain the trace bisphenol A concentration value. The water sample pretreatment is simple and environment-friendly, the operation is easy, the linear range is wide, the enrichment multiple is high, and the trace bisphenol A concentration in the water body can be rapidly analyzed with better reproducibility. The method can be applied to the detection of acetone, estriol, 17a-lynoral, estradiol, estrone, chlorobenzene and 4-nonylphenol.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for preparing polyacrylate/nanometer ZnO composite coating printing binder by using Pickering emulsion polymerization method

InactiveCN103613700AImprove \"hot sticky cold crisp\"High fastnessDyeing processAmmonium sulfateAqueous dispersion

The invention discloses a method for preparing a polyacrylate / nanometer ZnO composite coating printing binder by using a Pickering emulsion polymerization method. The method comprises the steps: mixing nanometer ZnO, allyloxy nonylphenol polyoxyethylene ether ammonium sulfate and water, and then, carrying out uniform ultrasonic treatment by using an ultrasonic pulverizer to obtain an aqueous dispersion of nanometer ZnO and allyloxy nonylphenol polyoxyethylene ether ammonium sulfate; then, adding butyl acrylate and methyl methacrylate into the aqueous dispersion and emulsifying to obtain a Pickering emulsion; carrying out free radical polymerization on the Pickering emulsion by taking ammonium persulfate as an initiator to obtain the polyacrylate / nanometer ZnO composite coating printing binder. By using the method, the defects of hot sticking and cold brittleness of polyacrylate binders can be overcome; after the prepared polyacrylate / nanometer ZnO composite coating printing binder is applied to a fabric coating printing process, the phenomena including mesh clogging and crazing cannot be caused, and a coating printed fabric has favorable color fastness.

Owner:河北汇彩永泰科技有限公司

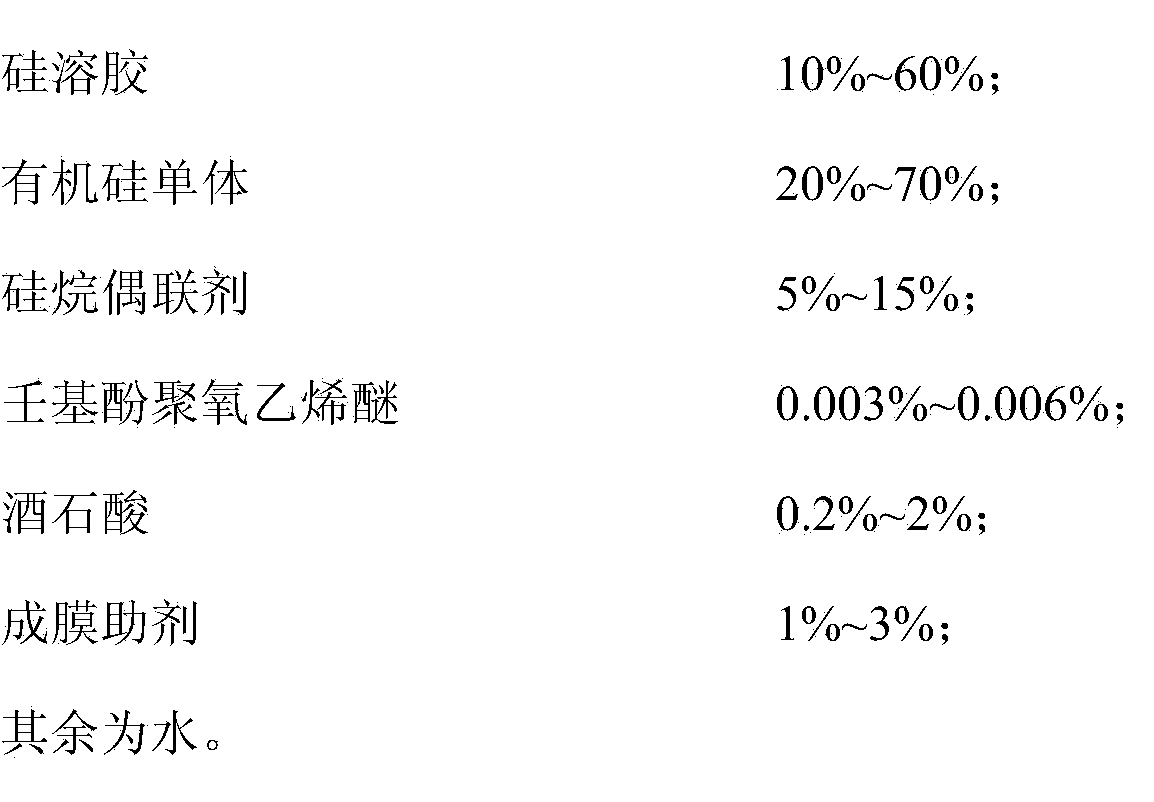

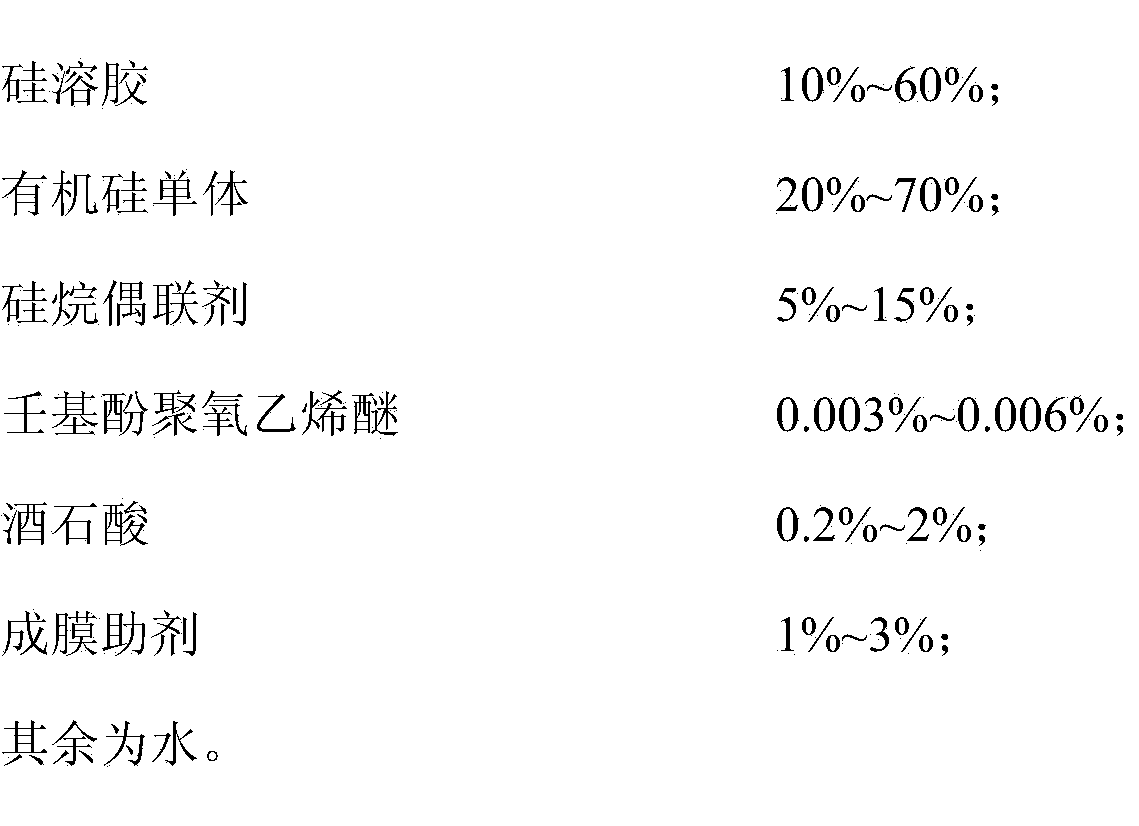

Silica sol-organosilicone monomer capillary crystalline waterproof material and preparation method thereof

The invention belongs to the technical field of building construction materials and preparation of the building construction materials, and relates to a silica sol-organosilicone monomer capillary crystalline waterproof material and a preparation method thereof. The preparation method comprises the following steps: at first, mixing silica sol, organosilicone monomers, silane coupling agents, nonylphenol polyoxyethylene ether, tartaric acid and coalescing agents in proportion, controlling the temperature to 40-60 DEG C, stirring all the time, and cooling after sufficiently reacting for 3-6 h, wherein the weight percentage of the silica sol, the organosilicone monomers, the silane coupling agents, the nonylphenol polyoxyethylene ether, the tartaric acid and the coalescing agents are respectively 10%-60%, 20%-70%, 5%-15%, 0.003%-0.006%, 0.2%-2% and 1%-3%; then regulating the pH value to 3.5-5.5 with phosphoric acid, and at last, adding water to enable the weight percentage to 100% to obtain the silica sol-organosilicone monomer capillary crystalline waterproof material. The preparation process is simple, the cost is low, the prepared waterproof material is excellent in waterproofness, strong in resistance to harmful ion penetration, and excellent in weather resistance and durability.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for detecting estrogen, nonyl phenol, octyl phenol and bisphenol A in water body sediment together

InactiveCN102183606AEasy to analyzeFast extractionComponent separationAutosamplerLiquid chromatography mass spectroscopy

The invention discloses a method for detecting estrogen, nonyl phenol, octyl phenol and bisphenol A in water body sediment based on an accelerated solvent extraction (ASE), liquid-liquid extraction (LLE) and liquid chromatography / tandem mass spectrum (LC / MS / MS) technology. The method comprises the following steps of: performing accelerated solvent extraction by using acetone as an extracting agent to extract the estrogen, the nonyl phenol, the octyl phenol and the bisphenol A in the water body sediment; dissolving residues generated after extract is blown by nitrogen by using 1mol / L sodium hydroxide solution, performing centrifugal collection on the supernate, and performing liquid-liquid extraction by using ethyl acetate under the condition that the pH is equal to 2; and performing concentration detection by using a 3200QTRAP type liquid chromatography / tandem mass spectrometer and an Agilent 1100 high performance liquid chromatography system of American Applied Biosystem Company and an automatic sample injector of American Agilent Company. The recovery rate is 59 to 94 percent, and the detection limit is 0.04ng / g.

Owner:BEIJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com