Patents

Literature

269 results about "Spray foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spray foam is a chemical product created by two materials, isocyanate and polyol resin, which react when mixed with each other and expand up to 30-60 times its liquid volume after it is sprayed in place. This expansion makes it useful as a specialty packing material which forms to the shape of the product being packaged and produces a high thermal insulating value with virtually no air infiltration.

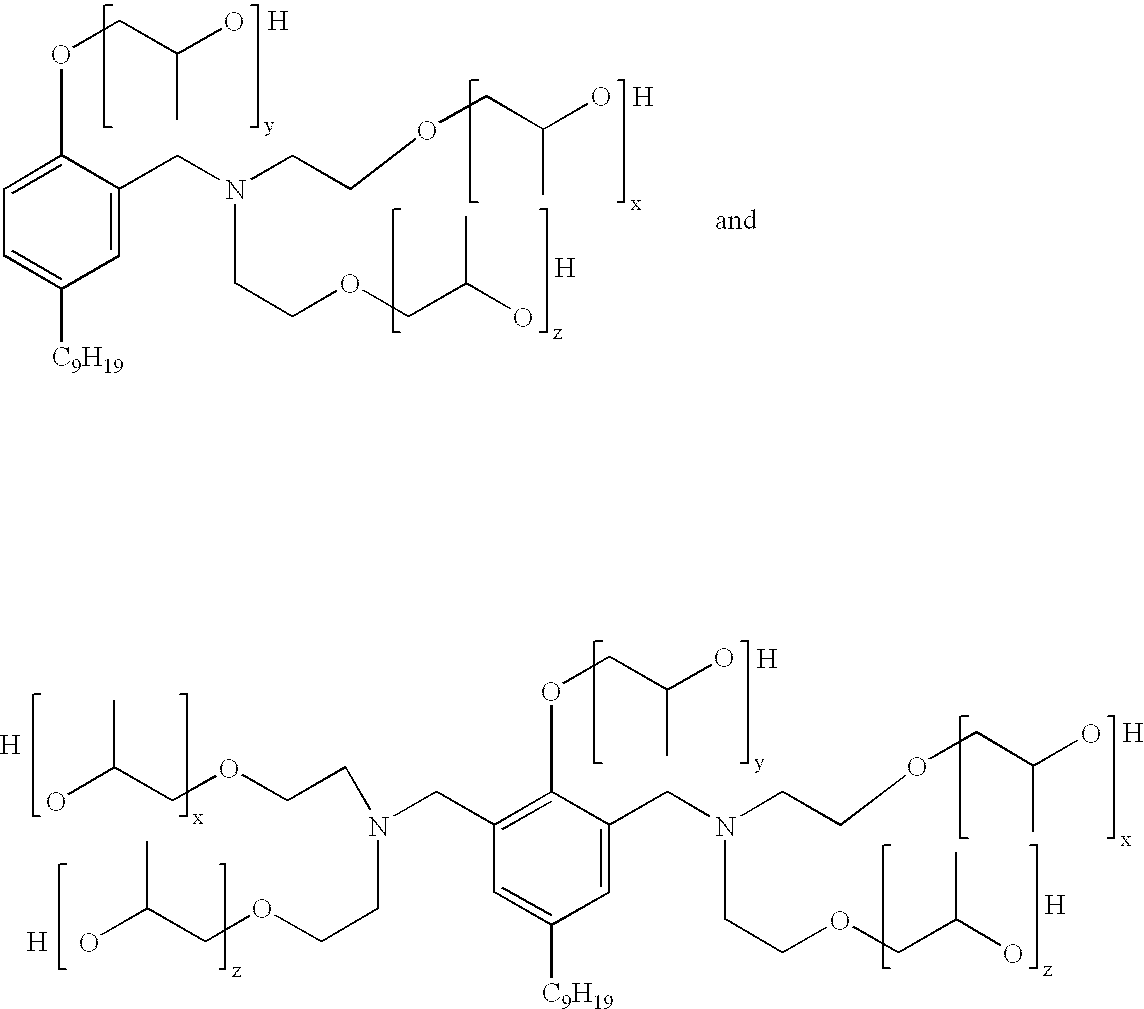

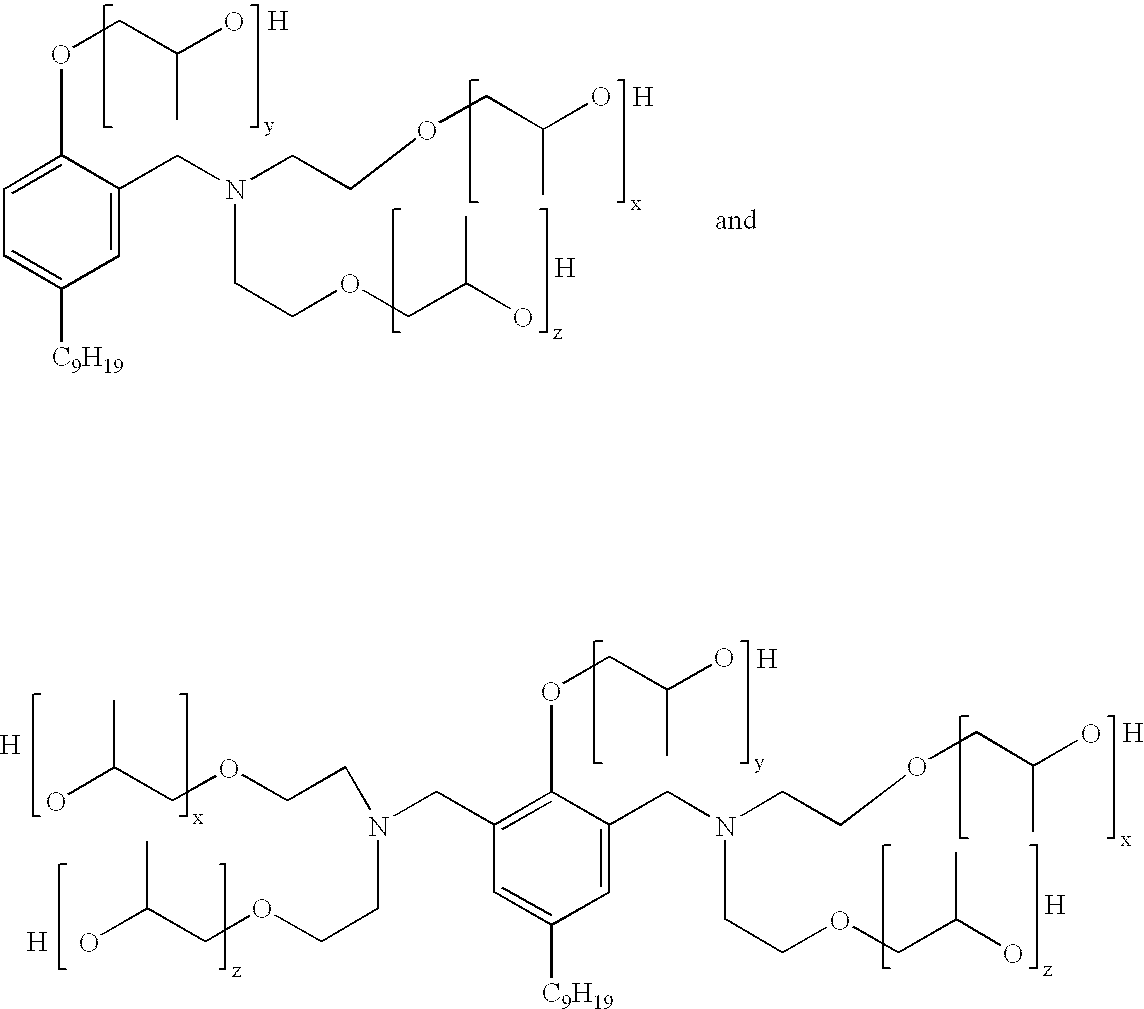

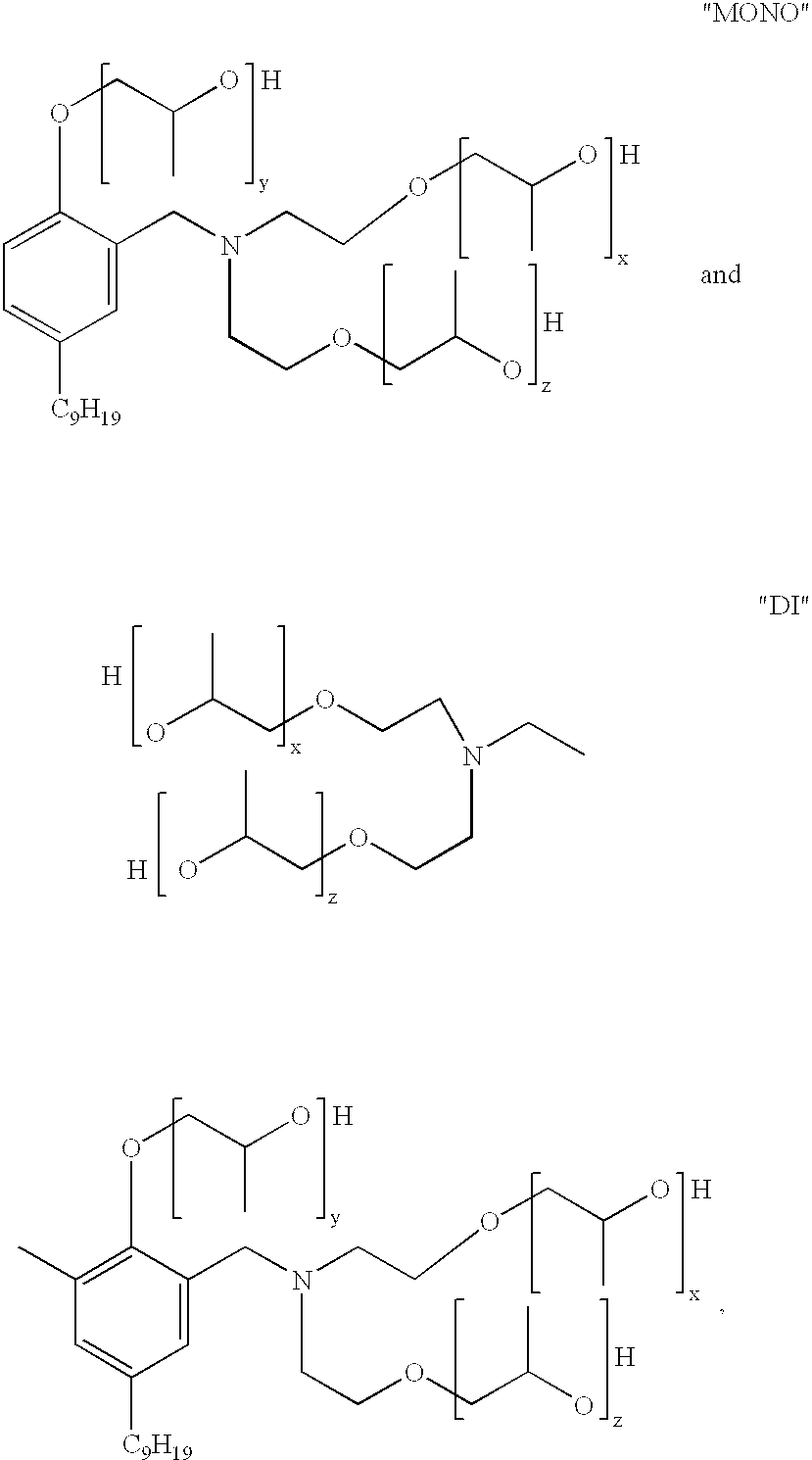

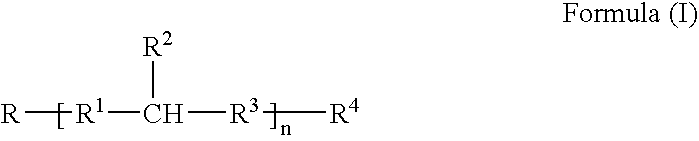

Mannich polyols for rigid spray foams

Provided herein are polyurethane foams which may be prepared by spray techniques. The foams of the invention are prepared using conventional isocyanates and a novel Mannich condensate polyol having a hydroxy number in the range of 250-340 and a viscosity of 3500 cps or less, and wherein the Mannich condensate polyol is derived from nonylphenol, formaldehyde, an alkanolamine, and propylene oxide as the sole alkoxylating agent. Polyurethane foams prepared according to the invention possess superior physical properties over sprayed polyurethane foams prepared using Mannich condensate polyols which are made using mixtures of propylene oxide and ethylene oxide.

Owner:HUNTSMAN PETROCHEMICAL LLC

One-part non-toxic spray foam

A one-part spray foam formed by Michael addition chemistry is provided. The foamable composition includes at least one electron donor, at least one electron acceptor, an encapsulated catalyst, and one or more blowing agents. The catalyst is a weak or strong base. The encapsulation of the catalyst controls the polymerization of the Michael addition compounds such that the catalyst can be added and / or activated at a desired time to begin the foaming reaction. The catalyst may be encapsulated in a high molecular weight inert polymer or wax. In some embodiments, the chemical blowing agent(s) are also encapsulated. To produce a foam according to the invention, a single stream of the foamable composition is fed into an application gun where the slurry is heated and mixed. The heat and / or mixing in the gun releases the catalyst, which initiates the reaction between the Michael donor and Michael acceptor to form the foam.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

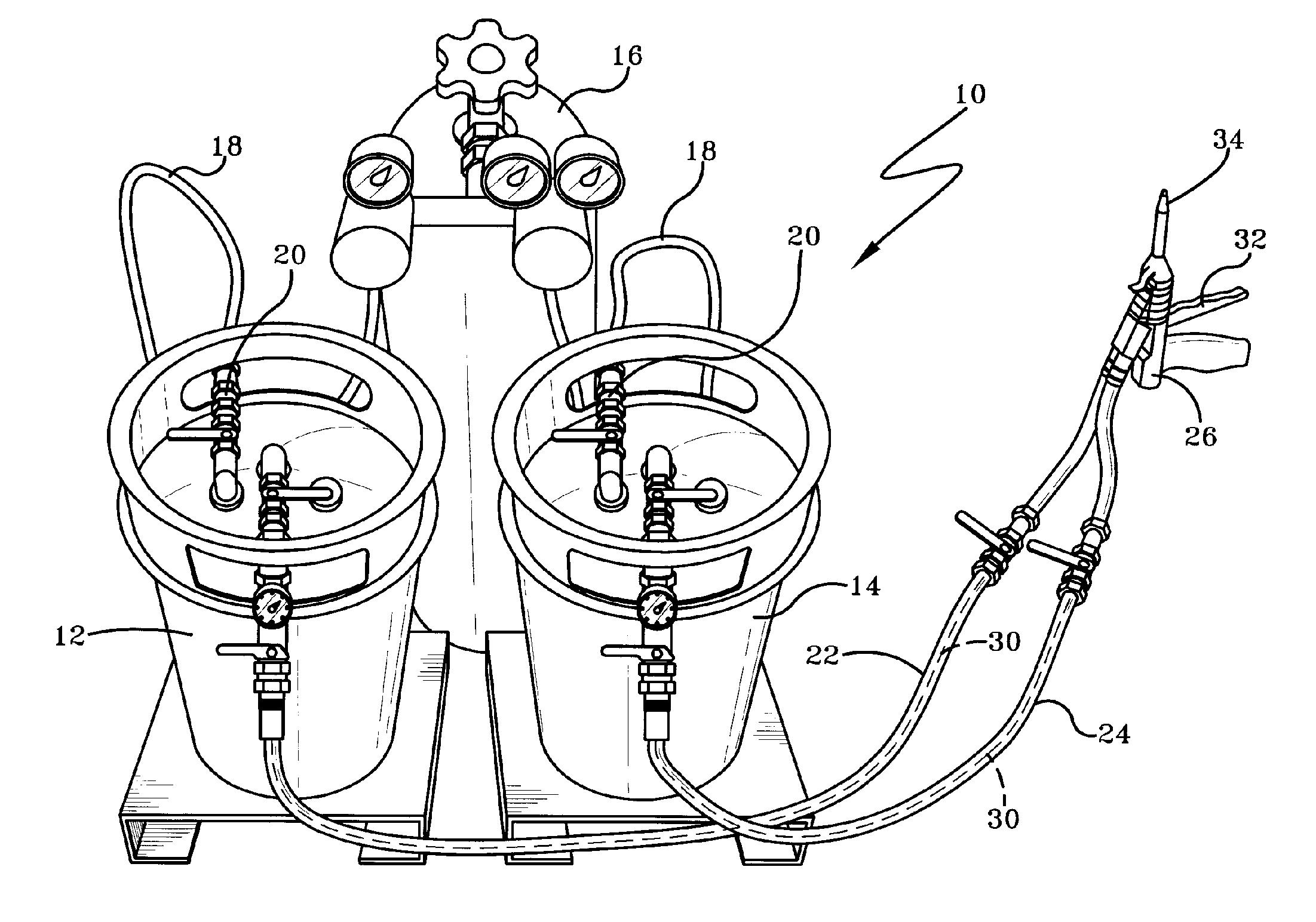

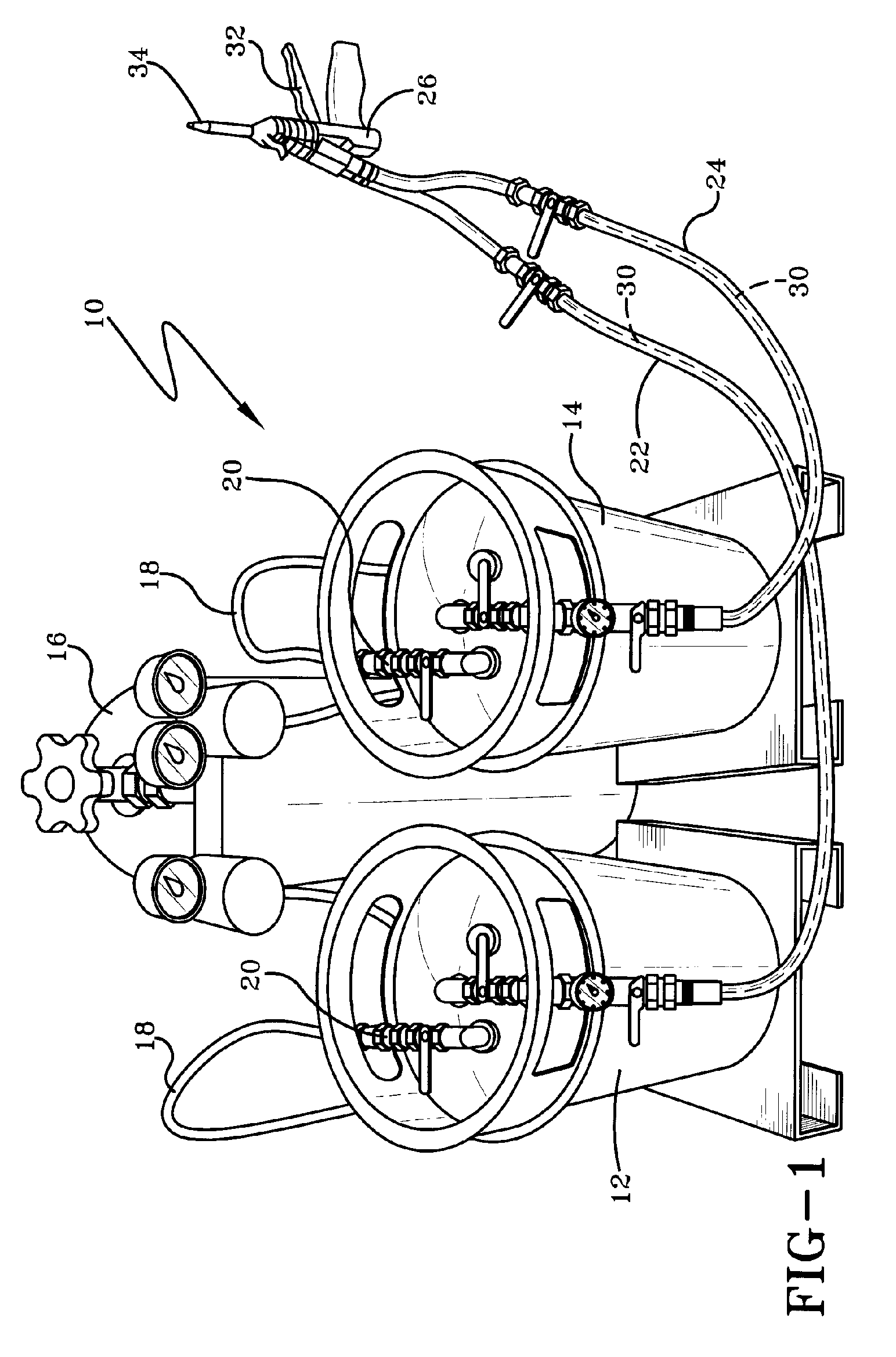

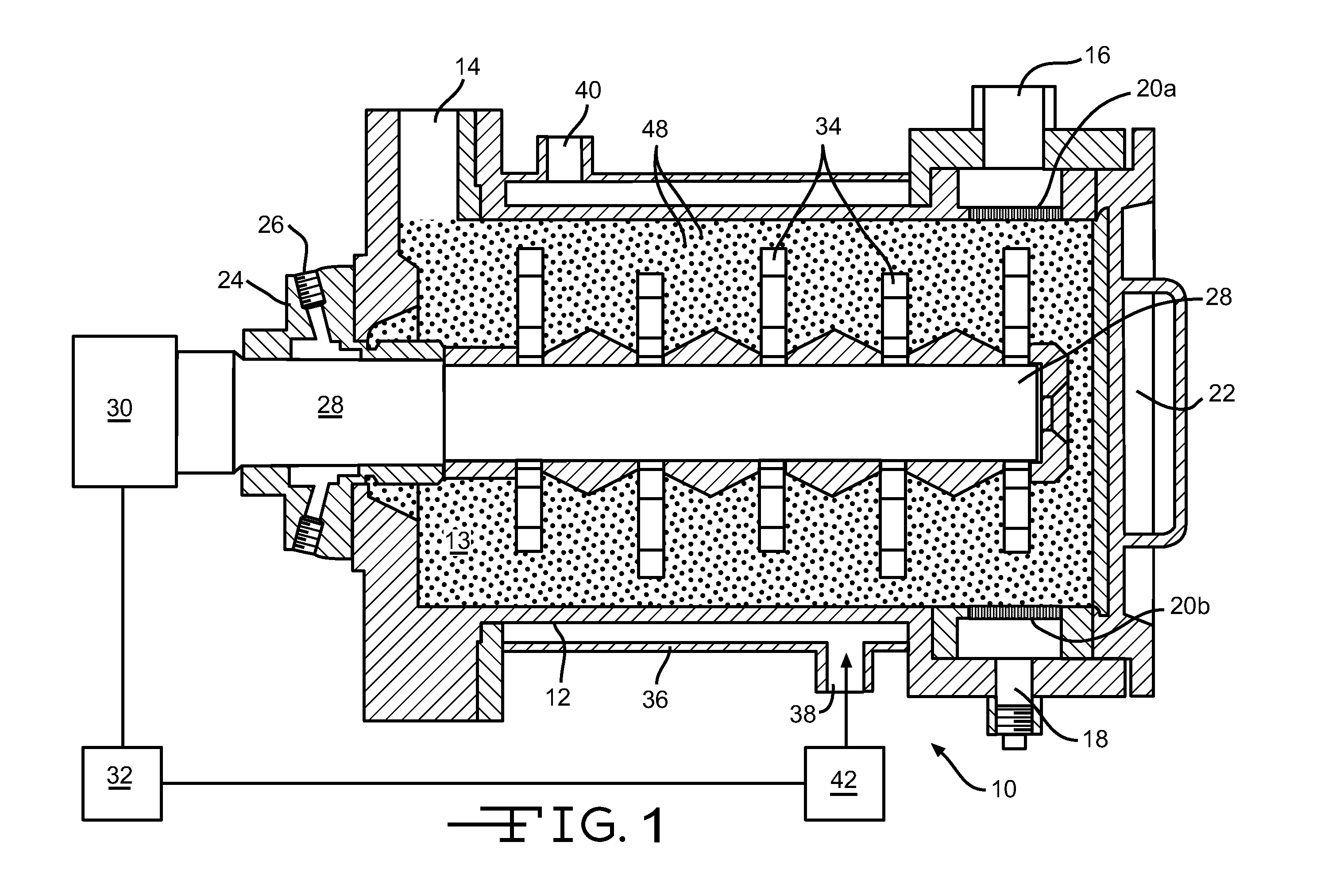

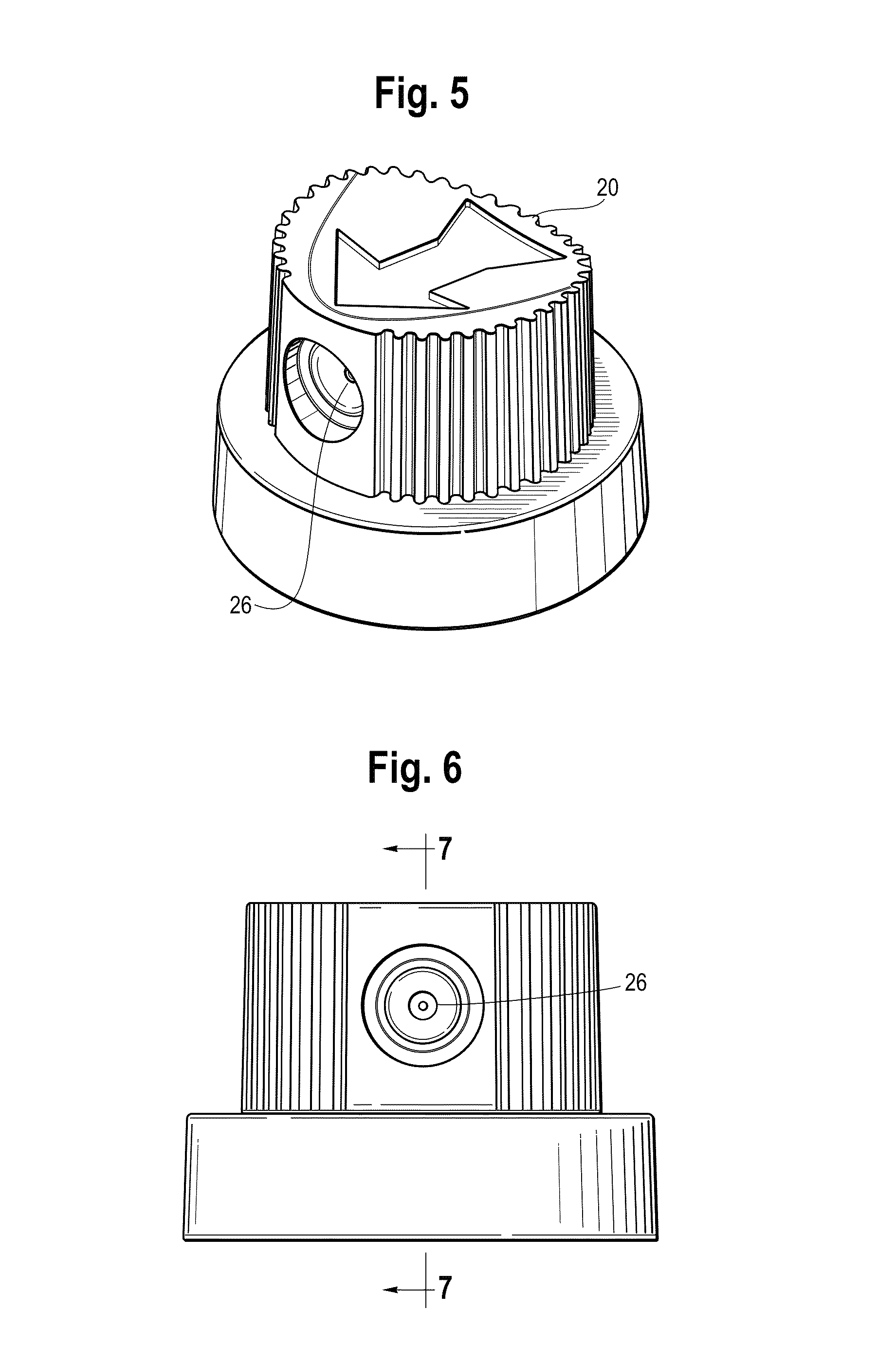

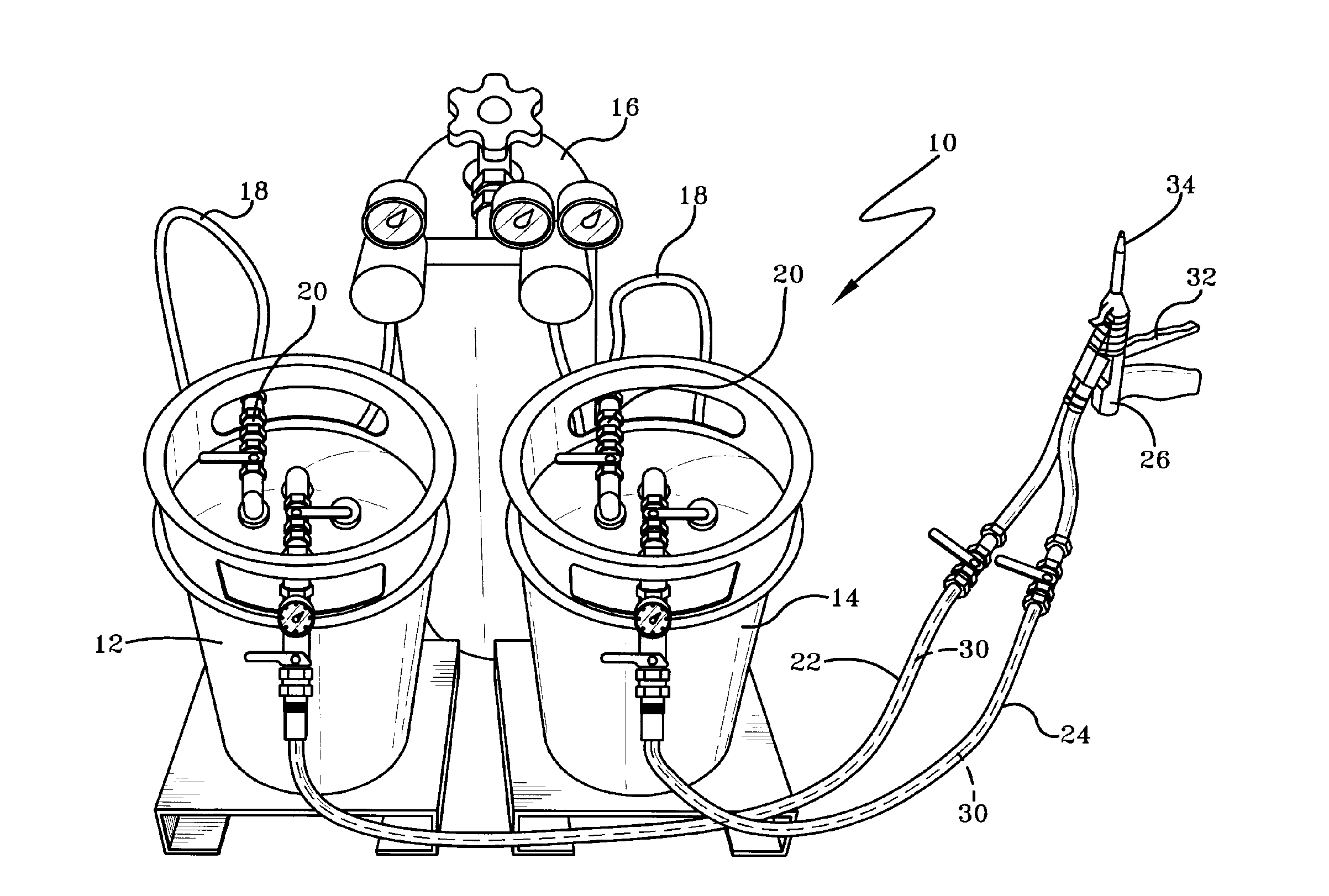

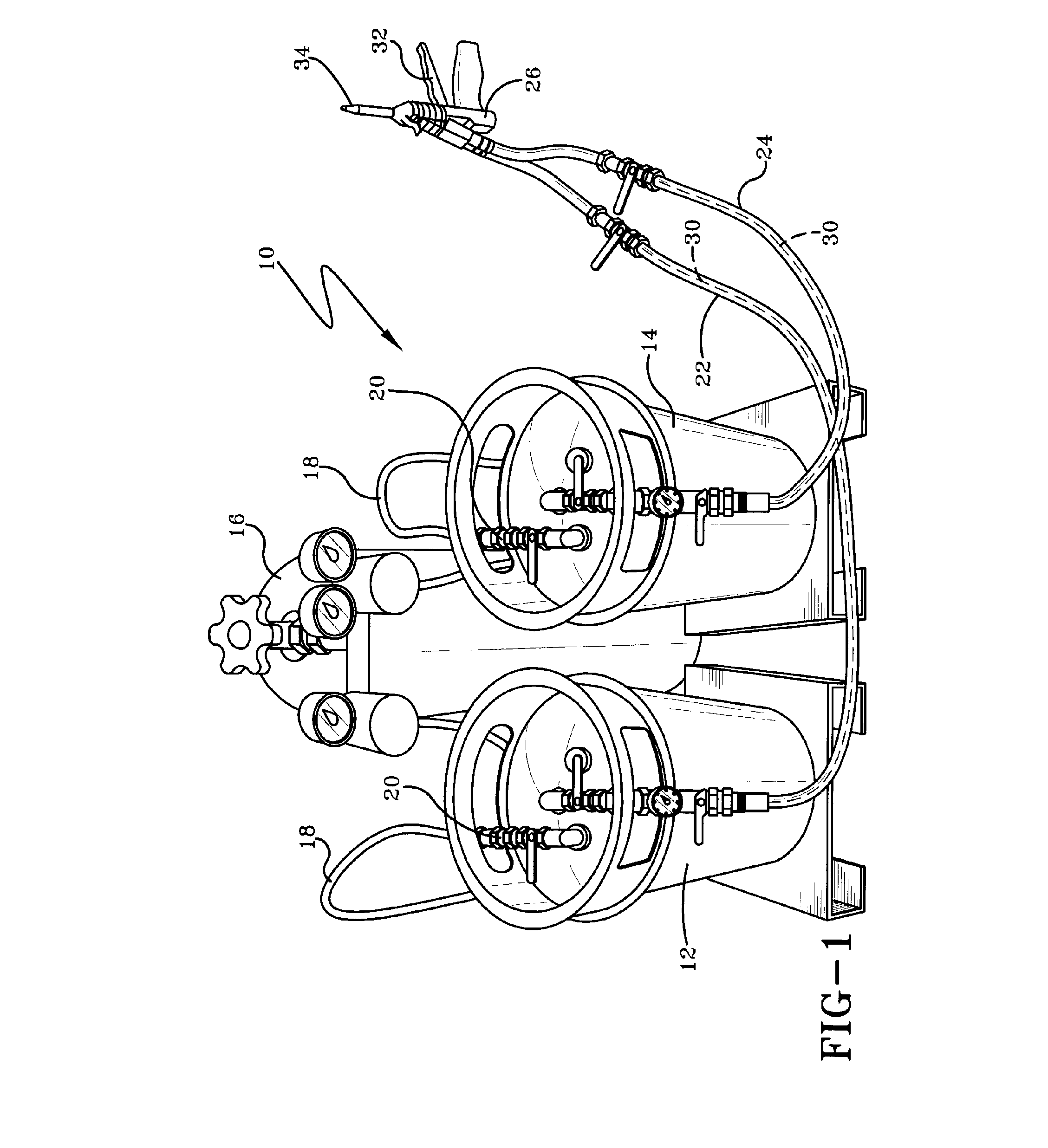

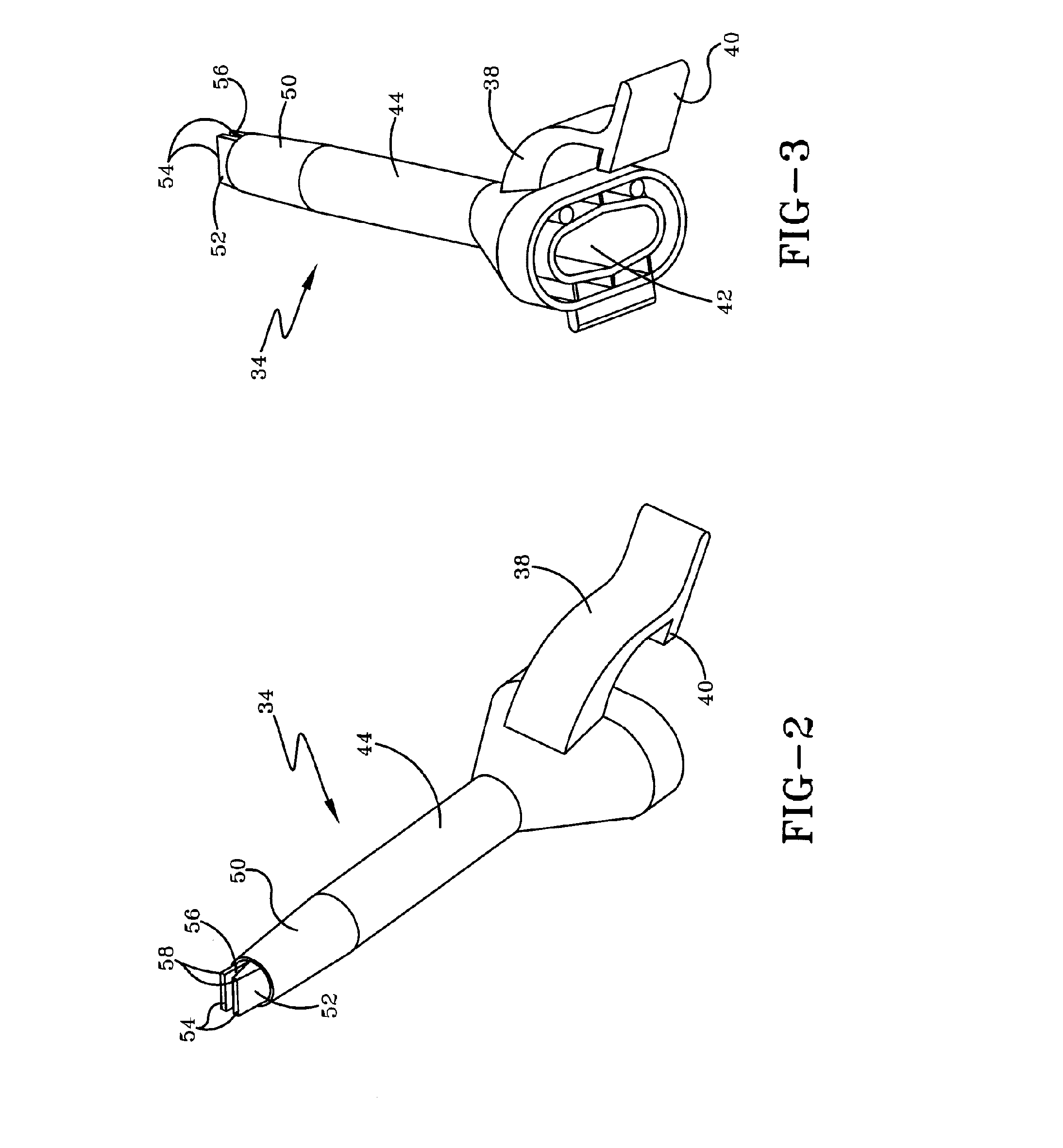

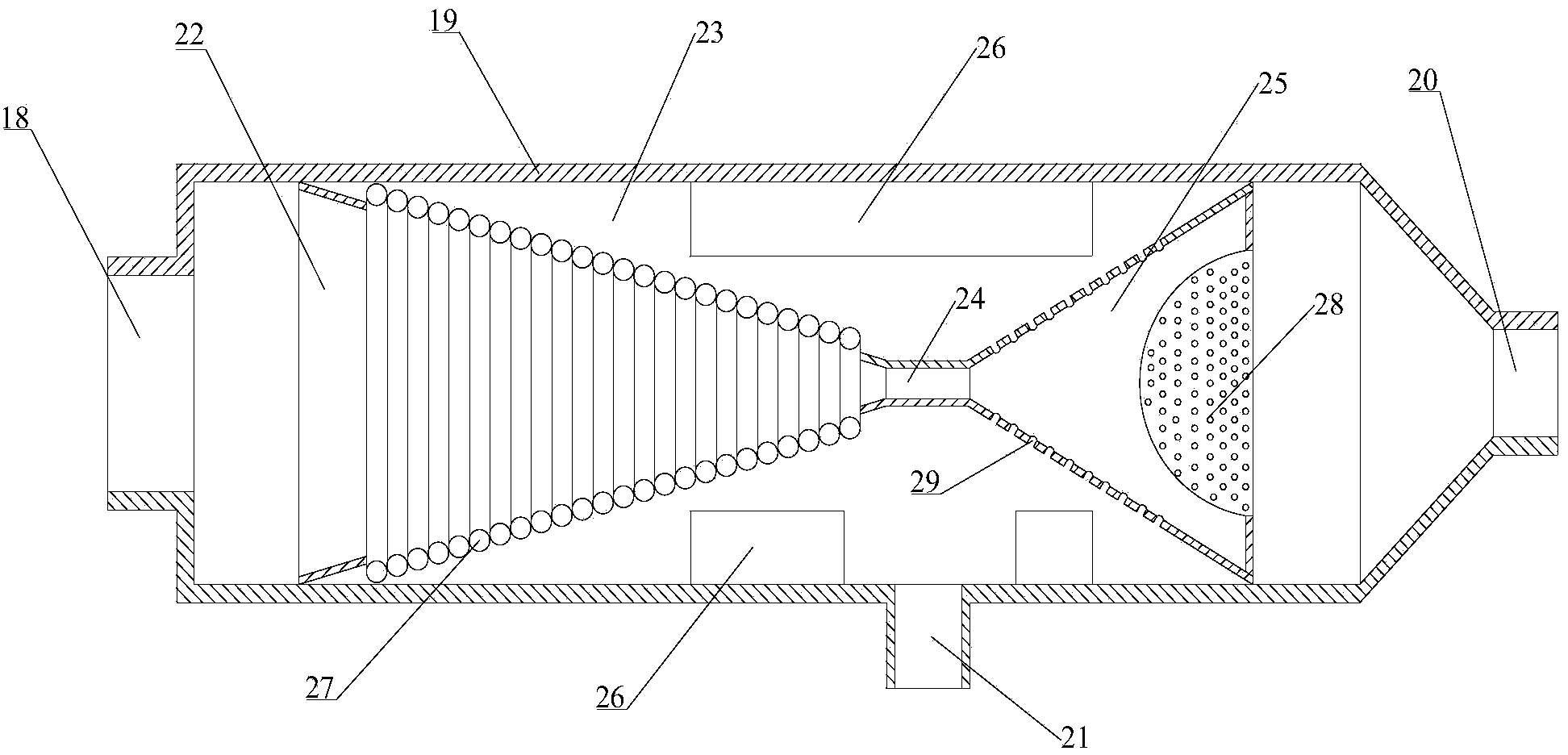

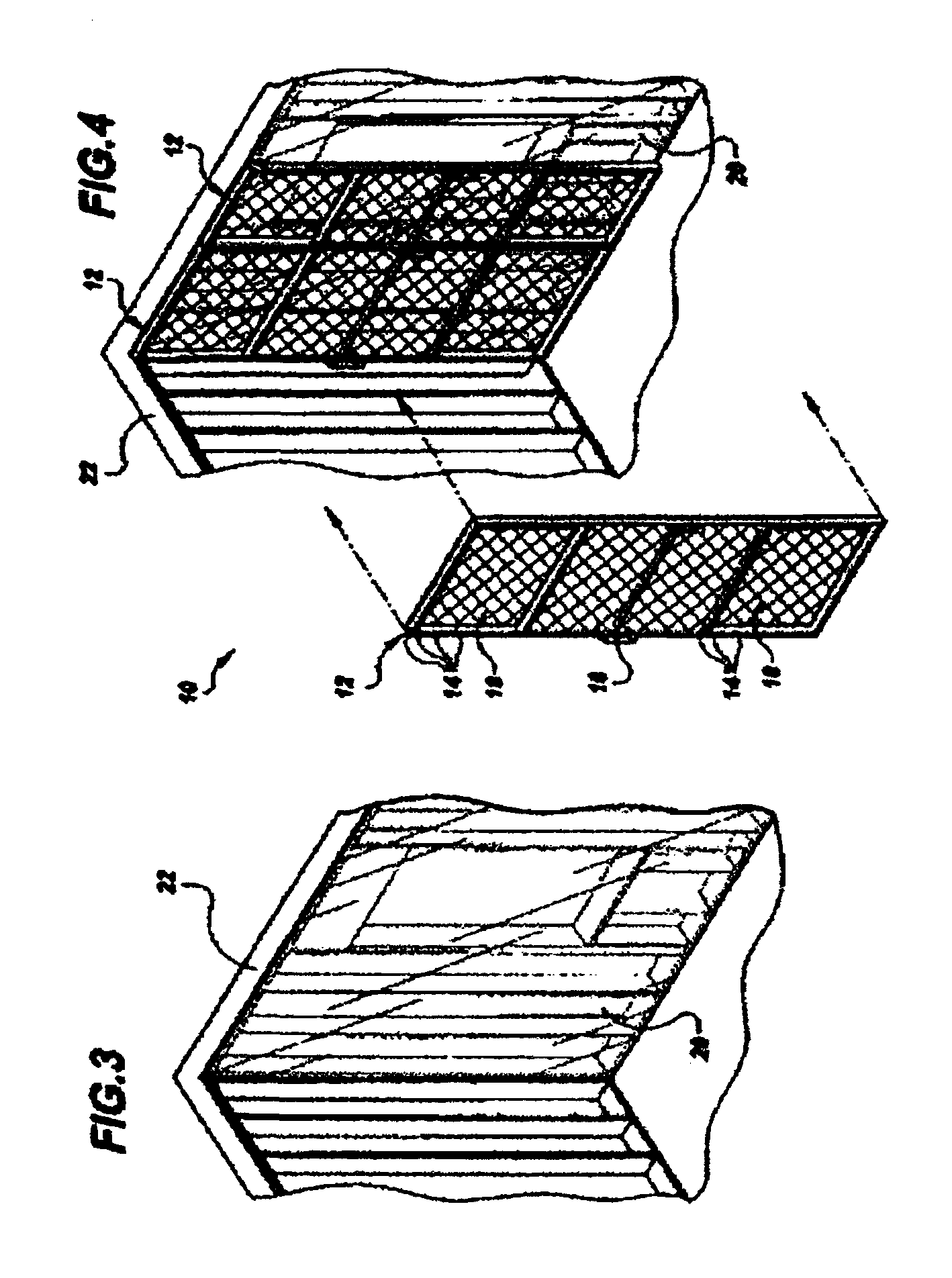

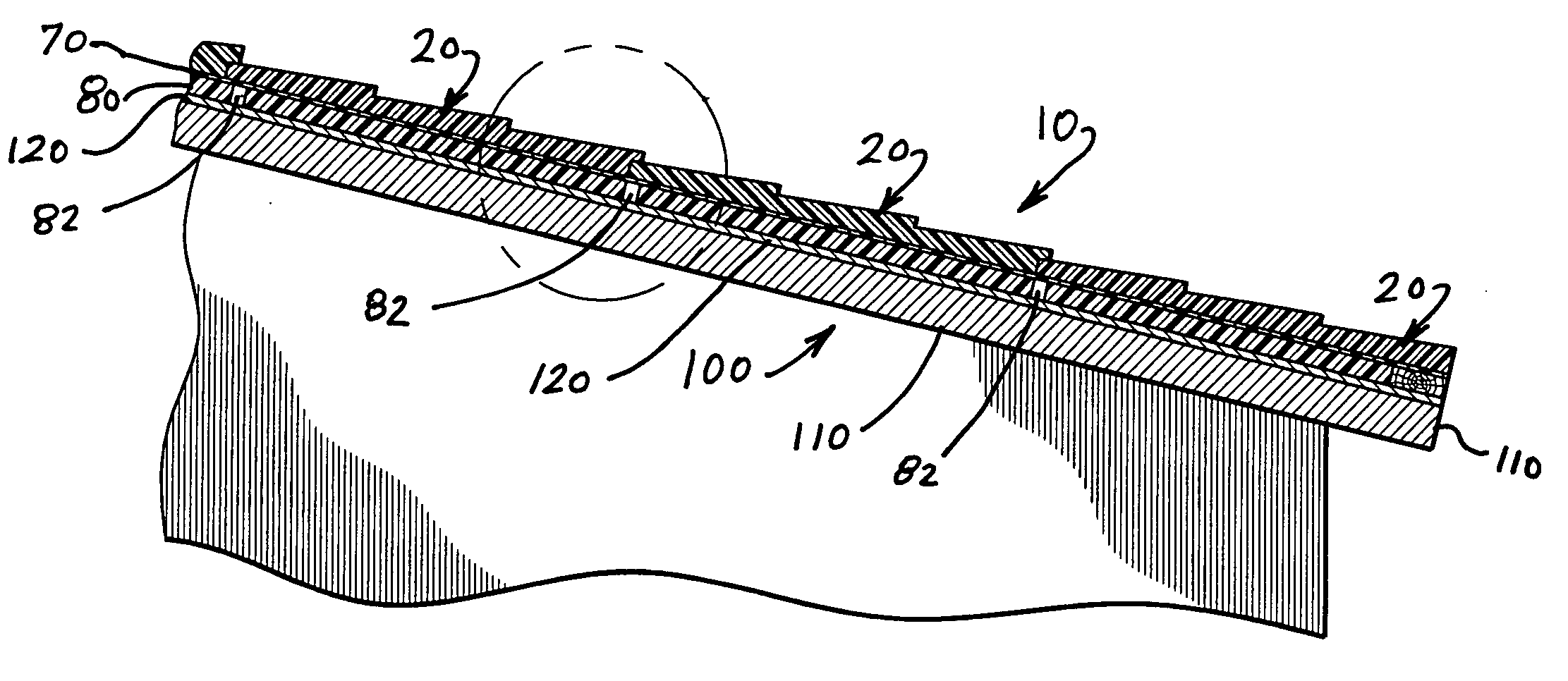

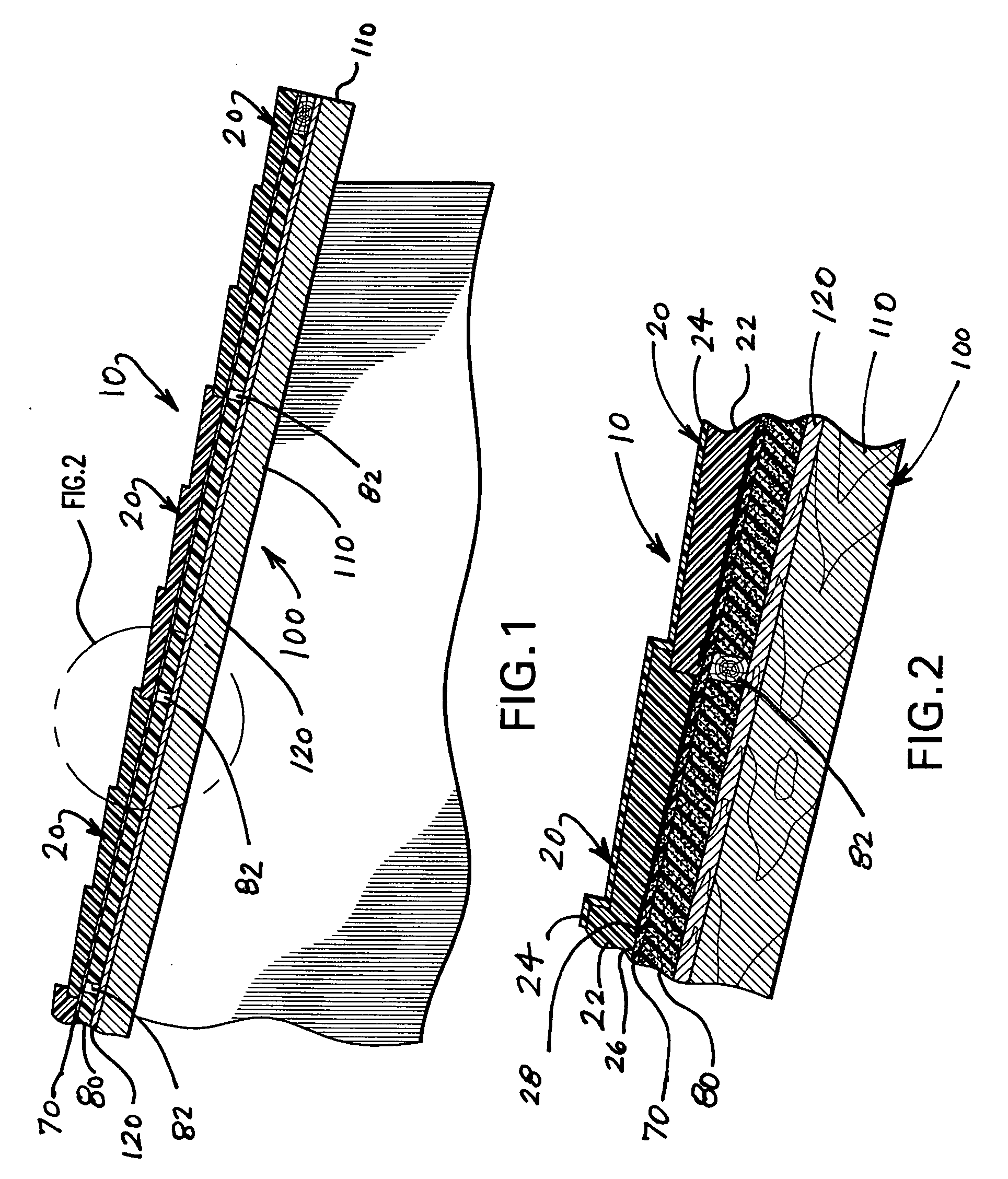

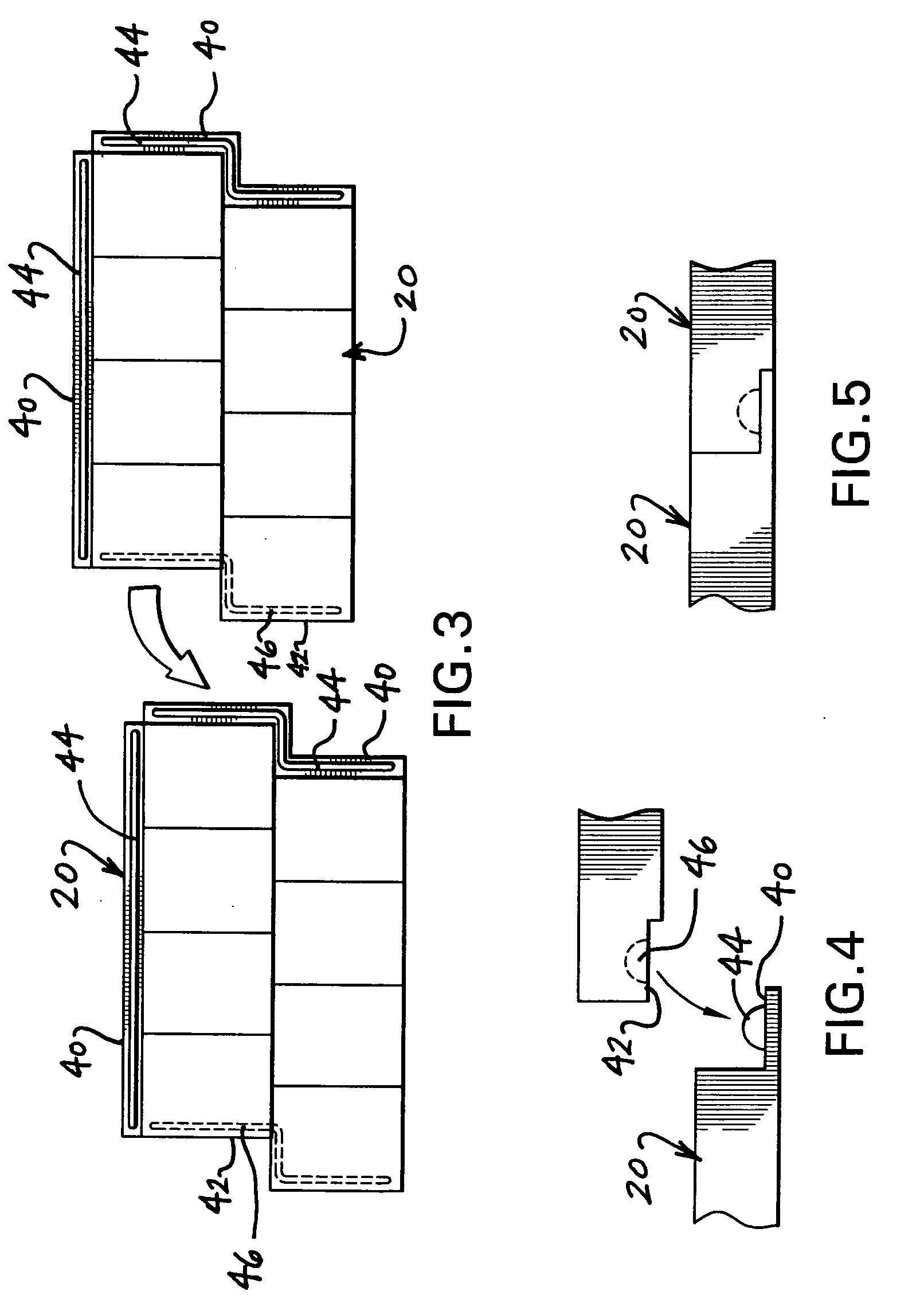

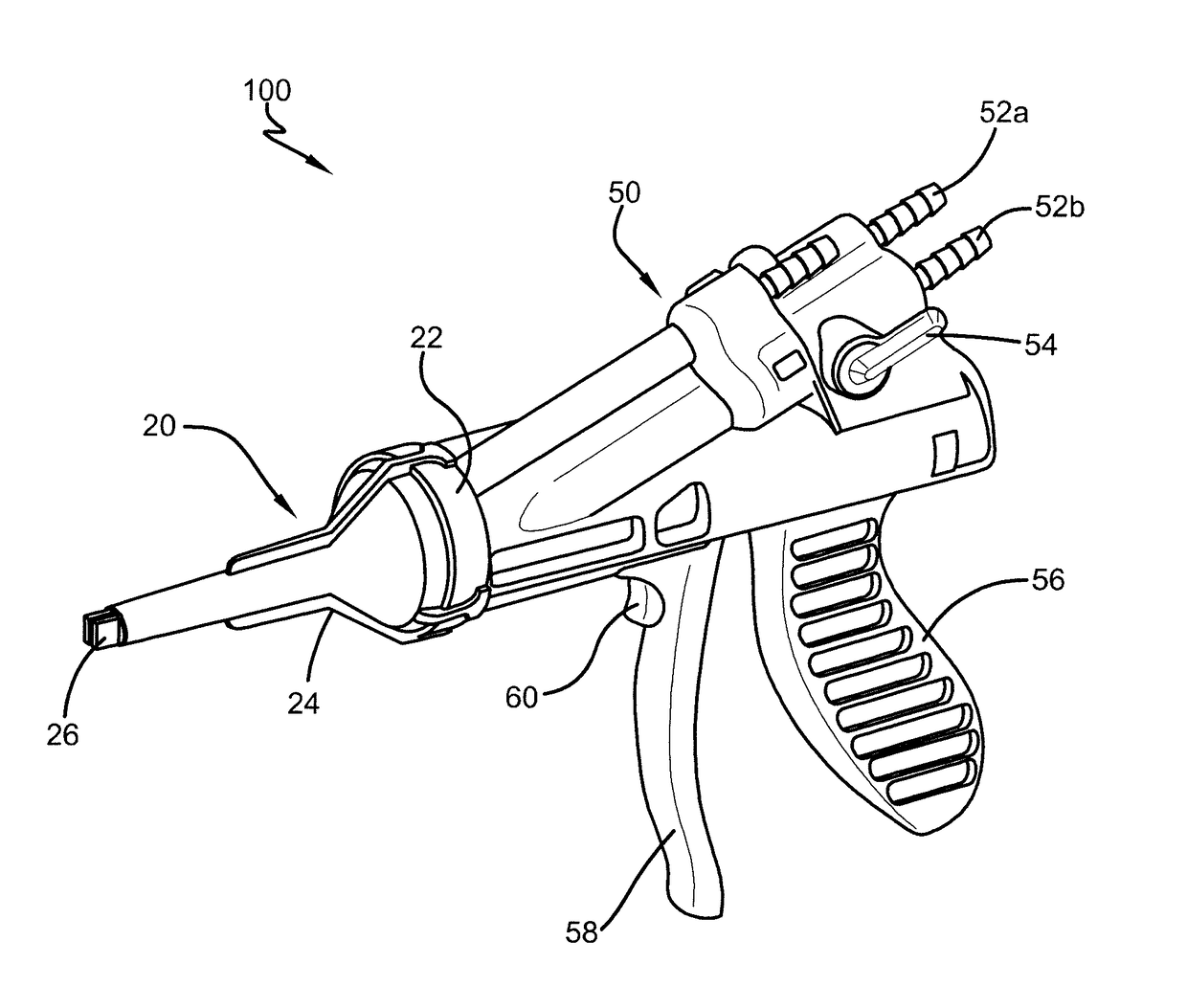

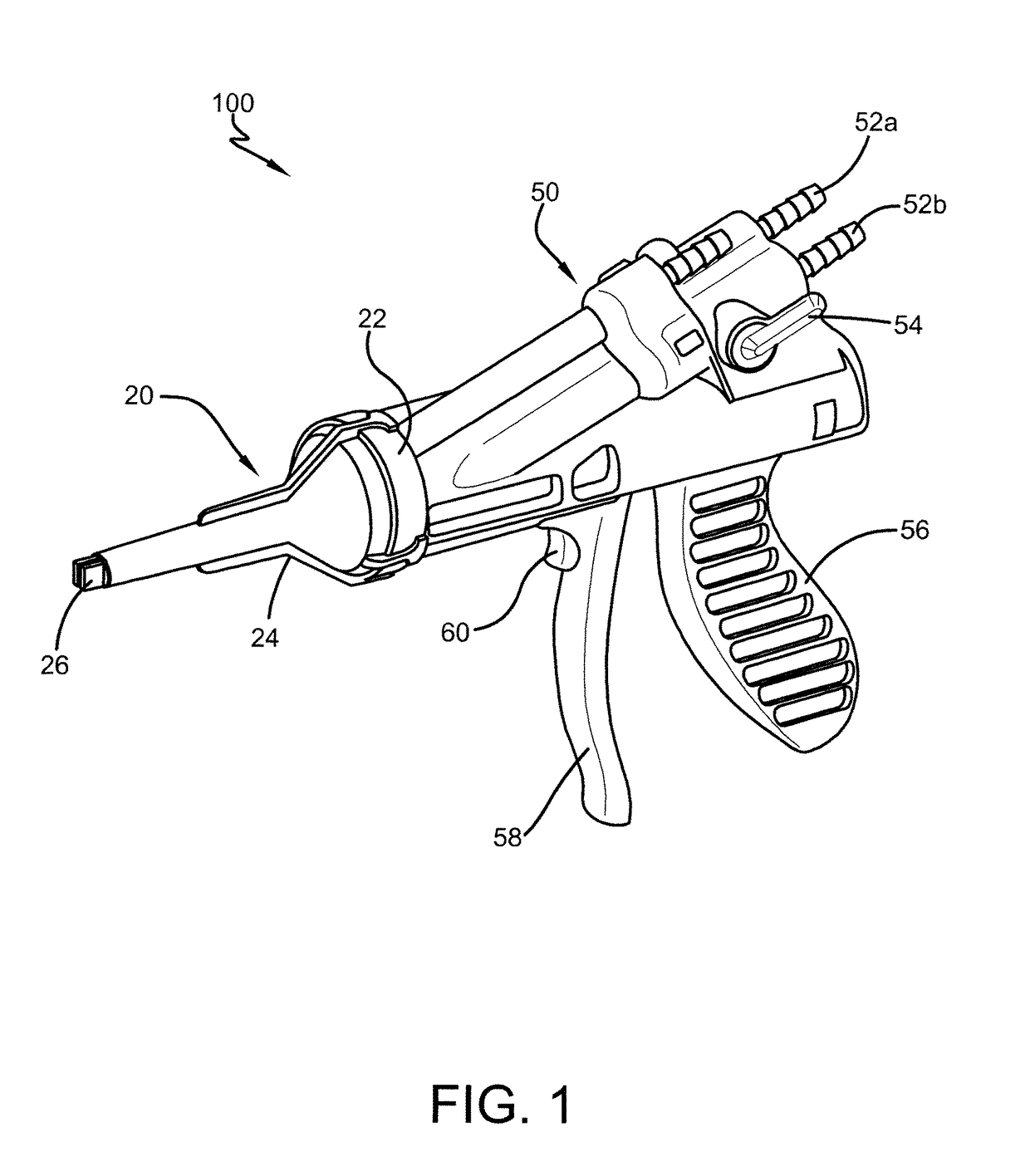

Method for Rapid Insulation of Expanses

ActiveUS20060192033A1Way fastIncrease the areaLiquid surface applicatorsFlow mixersEngineeringTriangular prism

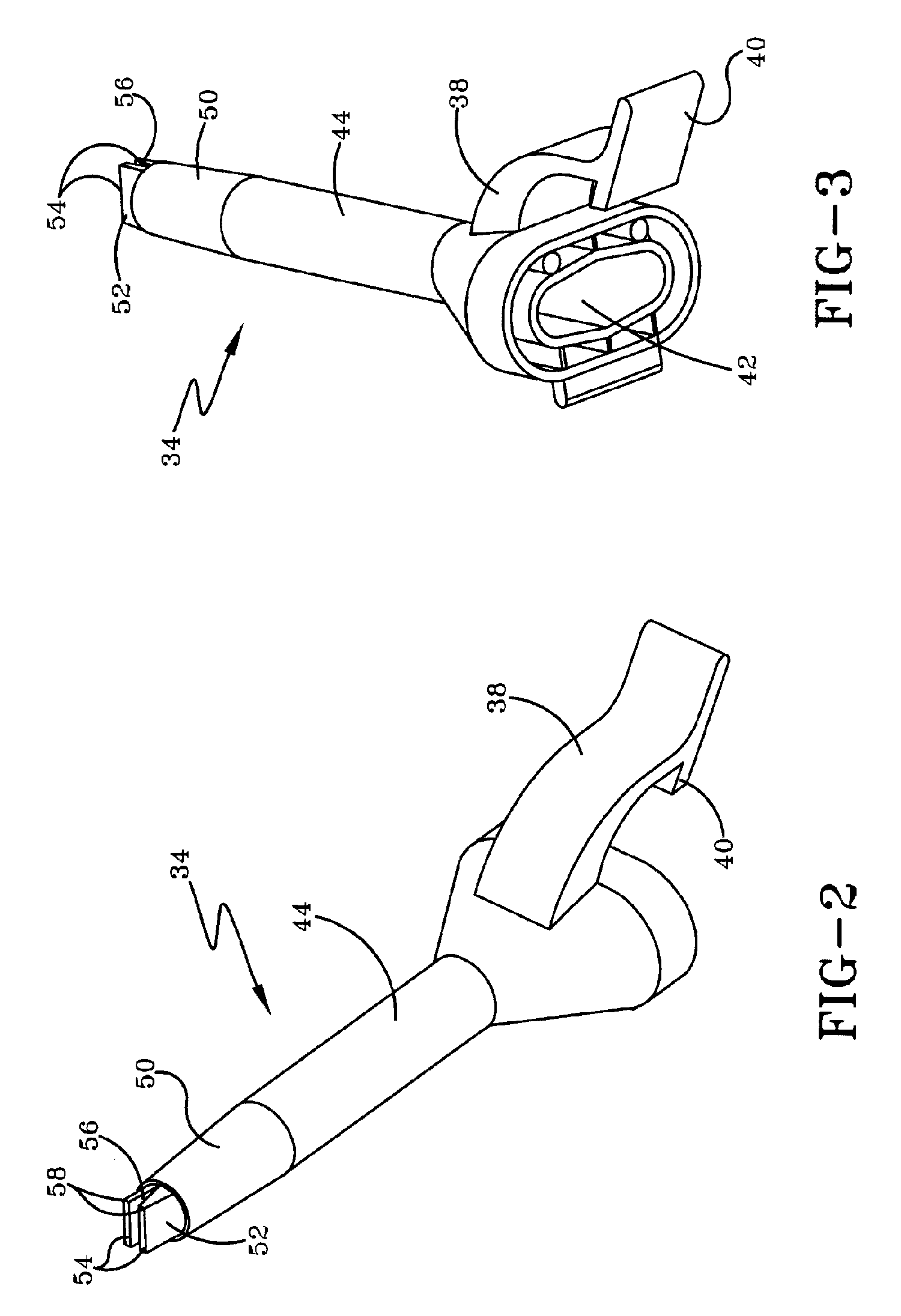

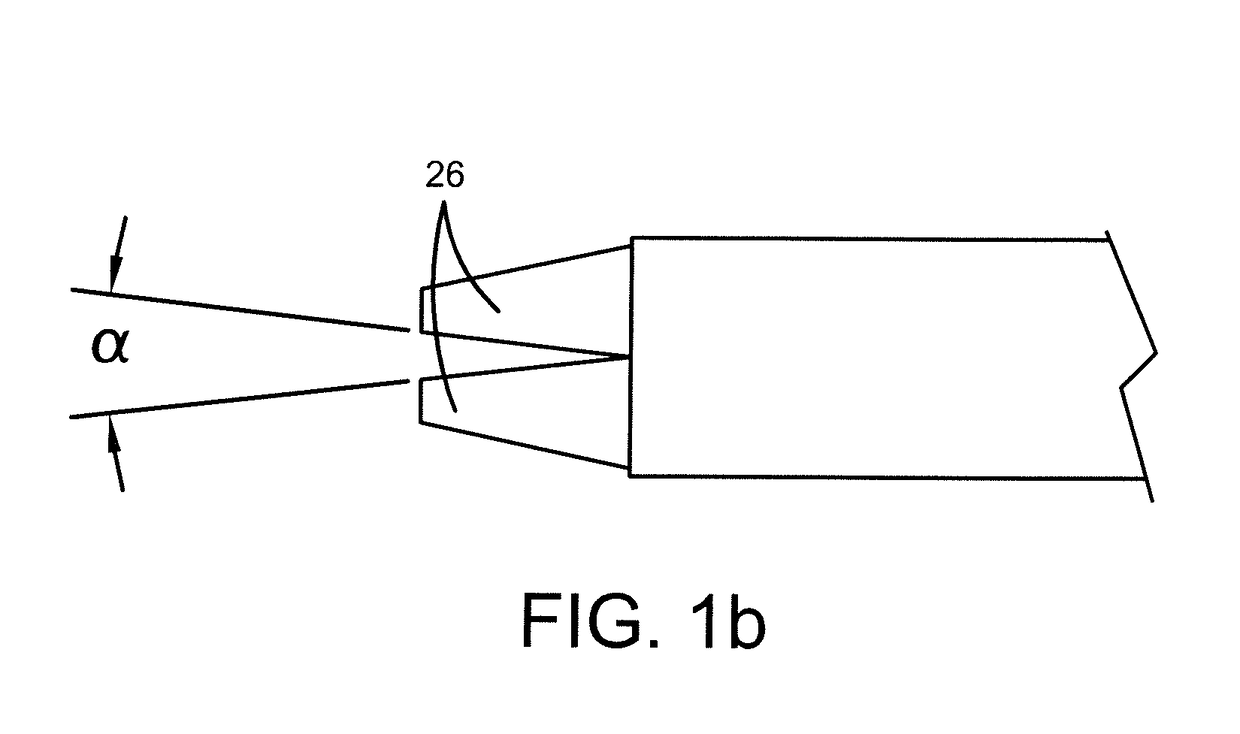

A process for cost-effectively and rapidly insulating a desired surface with spray foam insulation is described which includes the application of a polyurethane foam dispensed through heated conduits into a dispensing gun having a nozzle with essentially planar divergent lips having a triangular prism opening, the lips of the nozzle diverging at an angle of between about 5 and 35° inclusive, more preferably between 8 to 15° inclusive, most preferably 10 to 12° inclusive, thereby achieving application rates which are in excess of 70 Ft2 / min, and optimally in excess of 100 Ft2 / min.

Owner:ICP CONSTR INC

Formulated resin component for use in spray-in-place foam system to produce a low density polyurethane foam

The subject invention provides an open-celled polyurethane foam formed from a polyurethane spray foam system that mixes a formulated resin component with an isocyanate component. The resultant open-celled polyurethane spray foam has a density of about ½ pound per cubic foot. The resin component includes water as a blowing agent, a first aliphatic, amine-initiated polyol having a number-average molecular weight of from 150 to 500 and having tetra-functionality, and a second polyol having terminal hydroxyl groups and having a number-average molecular weight of from 3500 to 8000. A curing component having at least one primary amine group and having a number-average molecular weight of from 150 to 5000 is also included in the resin component. The spray foam system reacts a) the resin component and b) the isocyanate component in a volumetric ratio of a) to b) of from 1:1.2 to 1:5 and having an isocyanate index of from 15 to 70.

Owner:BASF CORP

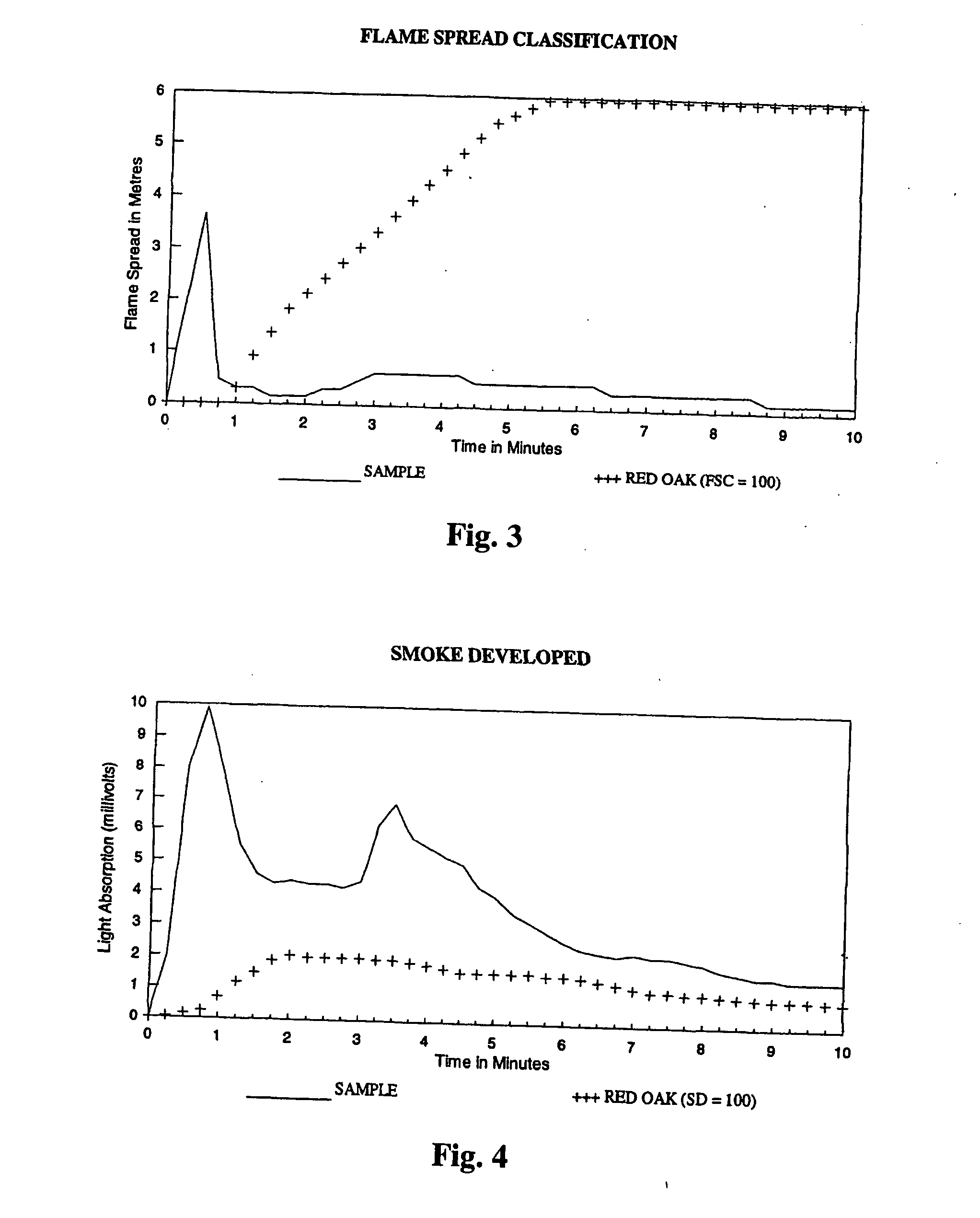

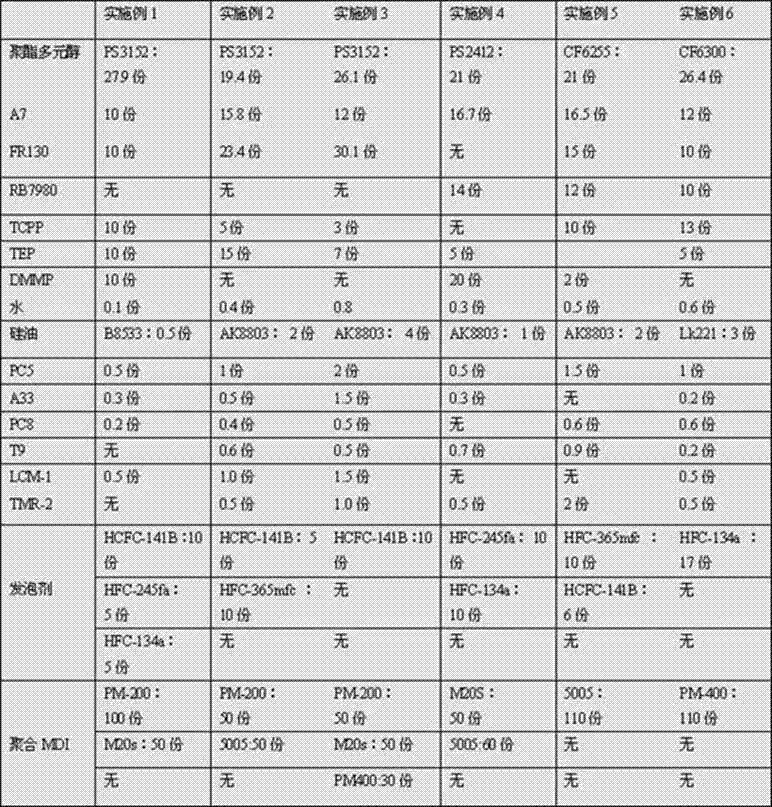

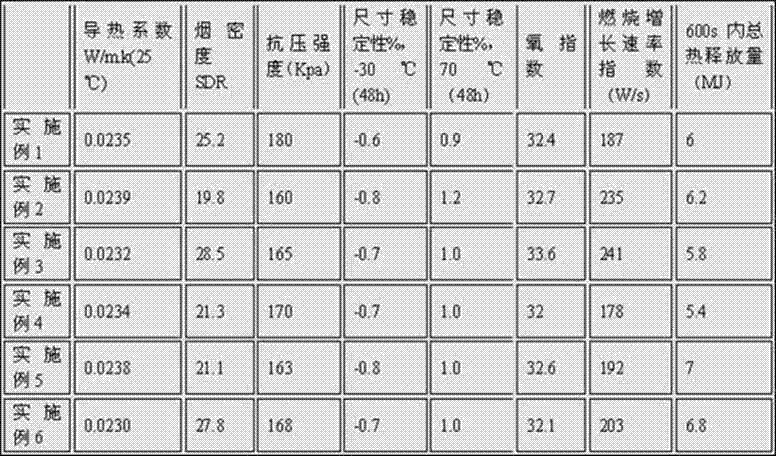

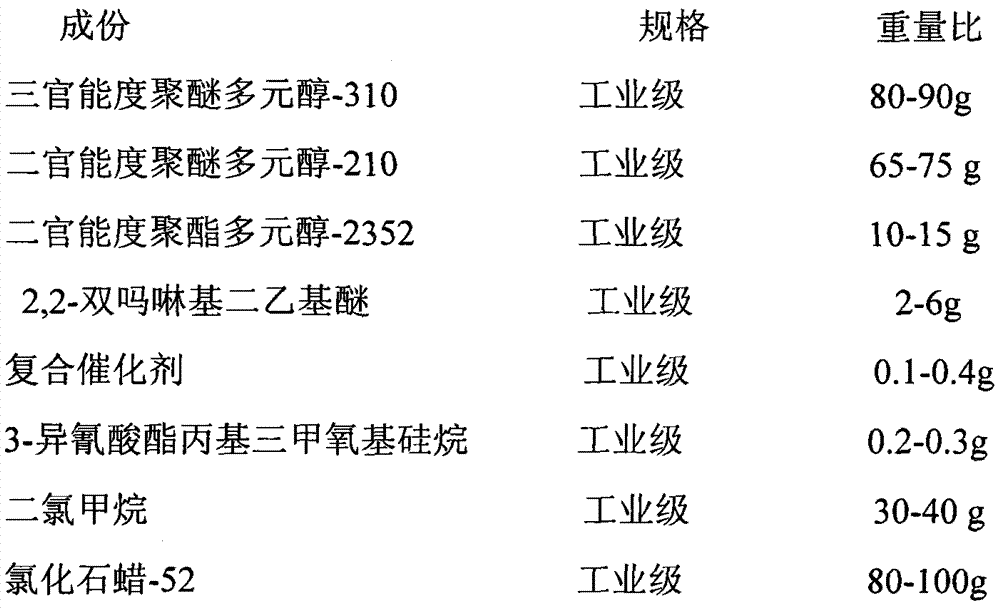

Advanced flame-retardant polyurethane spray foam material and preparation method thereof

ActiveCN103073986AImprove adhesionGood dimensional stabilityFireproof paintsPolyurea/polyurethane coatingsPolymer scienceCombustion

The invention relates to an advanced flame-retardant polyurethane spray foam material and a preparation method thereof. The advanced flame-retardant polyurethane spray foam material comprises an isocyanate component and a composite white material component. The advanced flame-retardant polyurethane spray foam material is mainly used for an external wall build thermal-insulation industry. The advanced flame-retardant polyurethane spray foam material has foam flame-retardant properties satisfying C-level flame-retardant requirements in the national standard GB8624-2006, a combustion increasing rate index less than 250W / s in a single burning experiment, a total heat release amount less than 10MJ in 600s in the single burning experiment, size stable shrinkage less than 1.5%, a smoke density SDR level of 10 to 30, a heat conductivity coefficient of 0.020 to 0.024W / m.K, and an oxygen index more than 32.

Owner:WANHUA CHEM NINGBO RONGWEI POLYURETHANE

Spray foams with fine particulate blowing agent

InactiveUS20110224317A1Safe disposalSafe installationBuilding constructionsPolymer scienceFoaming agent

Latex foams for filling cavities and crevices and for forming foamed products are provided. The latex foam includes a functionalized latex, a crosslinking agent and a blowing agent package, and optionally a non-functionalized latex. The foamable compositions may be two-part, having an A-side and a B-side to keep reactants separate until use. The blowing agent package may be the combination of two or more chemicals, such as acid and base, that when mixed together form a gas. In two-part compositions, the acid and base preferably are in separate sides to prevent premature gassing; in alternative one-part compositions, the spray latex foam may include a functionalized latex, a crosslinking agent, and an encapsulated dry acid and dry base. The encapsulating agent may be a protective, non-reactive shell that can be broken or melted at the time of application. The acid and / or base are preferably dry powder particulates, for example milled bicarbonate having a median particle diameter of from about 0.5 to about 40 microns, e.g. from about 2 to about 40 microns or from about 0.5 to about 5 microns.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

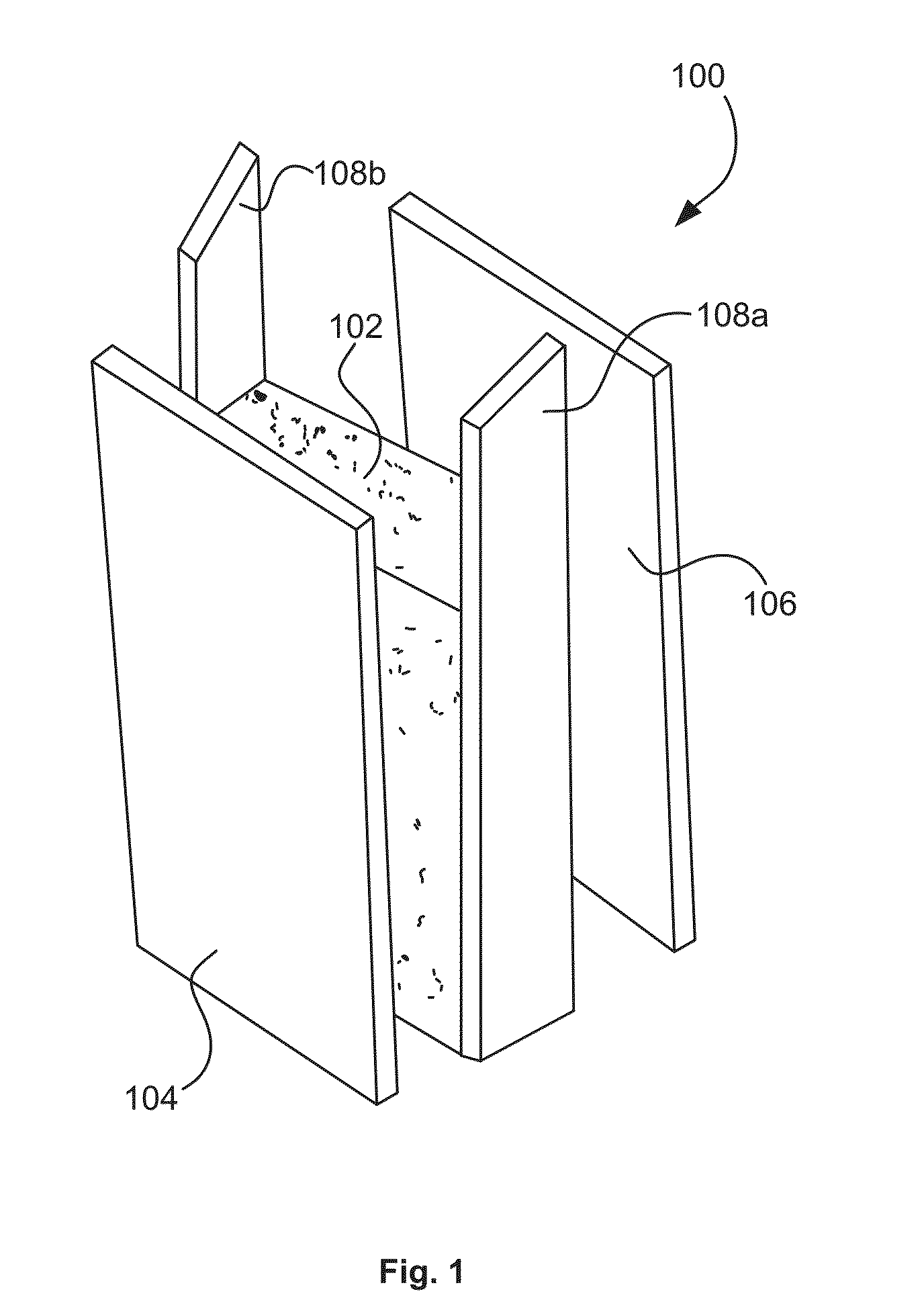

Spray-in latex foam for sealing and insulating

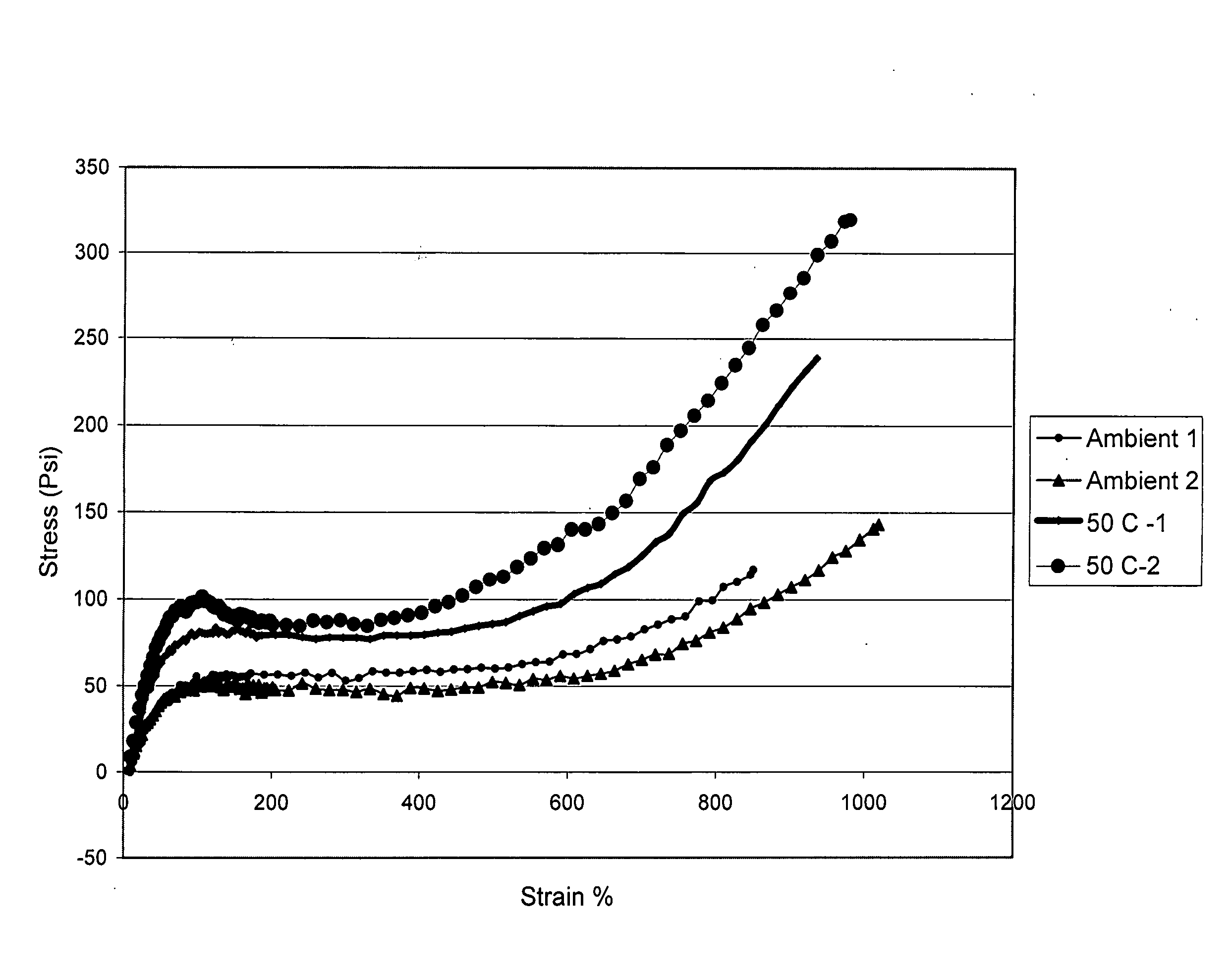

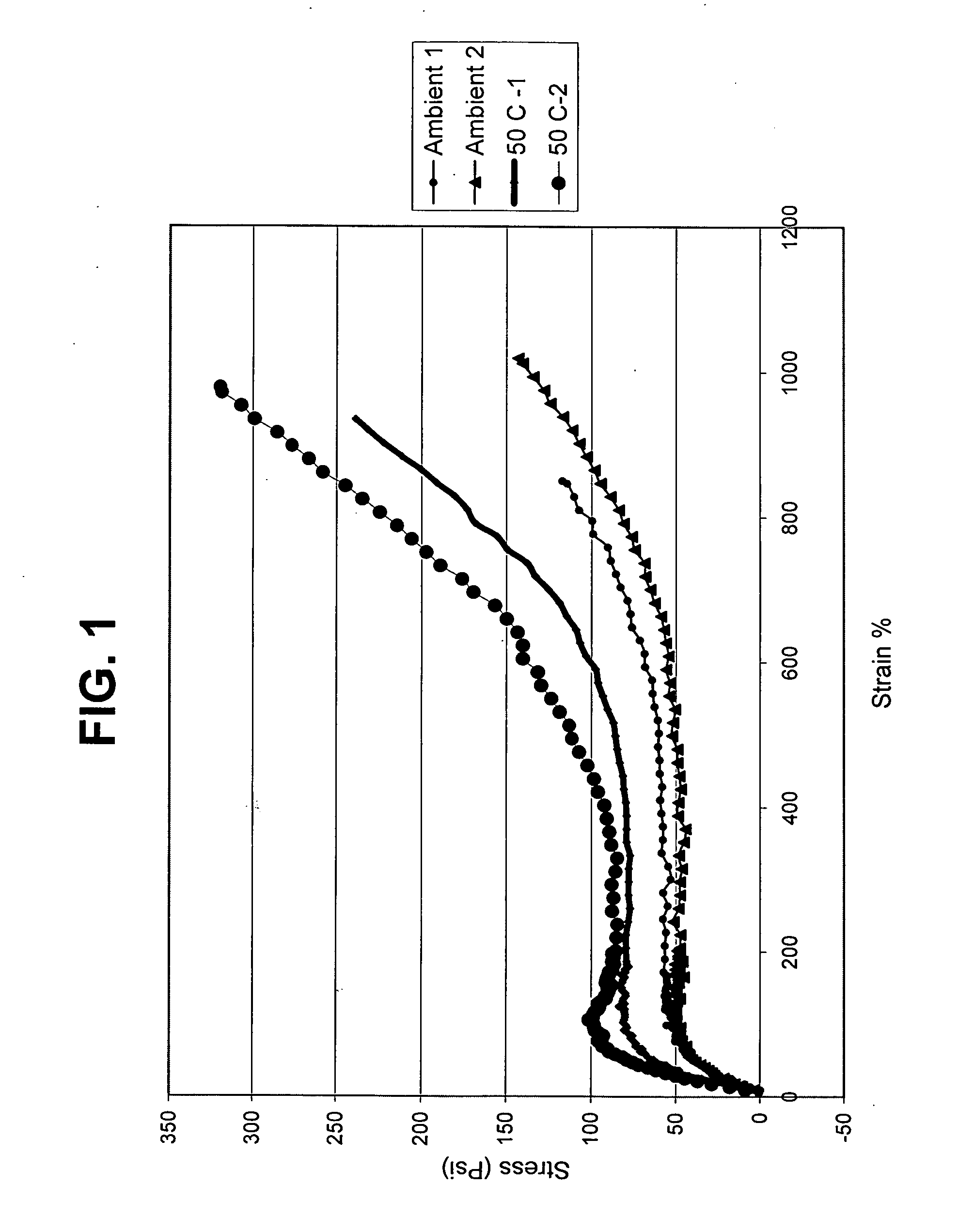

ActiveUS20080160203A1Broaden applicationIncrease shearOther chemical processesWallsSpray foamsButadiene-styrene rubber

A spray latex foam for filling wall cavities to enhance the sealing and insulating properties of a building is provided. The spray latex foam includes a latex system and a gaseous coagulating component. In at least one exemplary embodiment, carbon dioxide is included as a gaseous coagulating agent. One latex suitable for use in the spray foam is polyvinylidene chloride (PVDC), which possesses fire retardancy and environmental durability. However, a preferred latex is styrene-butadiene rubber (SBR). The latex system may also include a thixotropic agent, such as Laponite® RD synthetic clay. The spray latex foam is polyurethane-free. A method of preparing a spray latex foam that includes supplying a latex system and adding a gaseous coagulating component to the latex system is also provided.

Owner:OWENS CORNING FIBERGLAS TECH INC

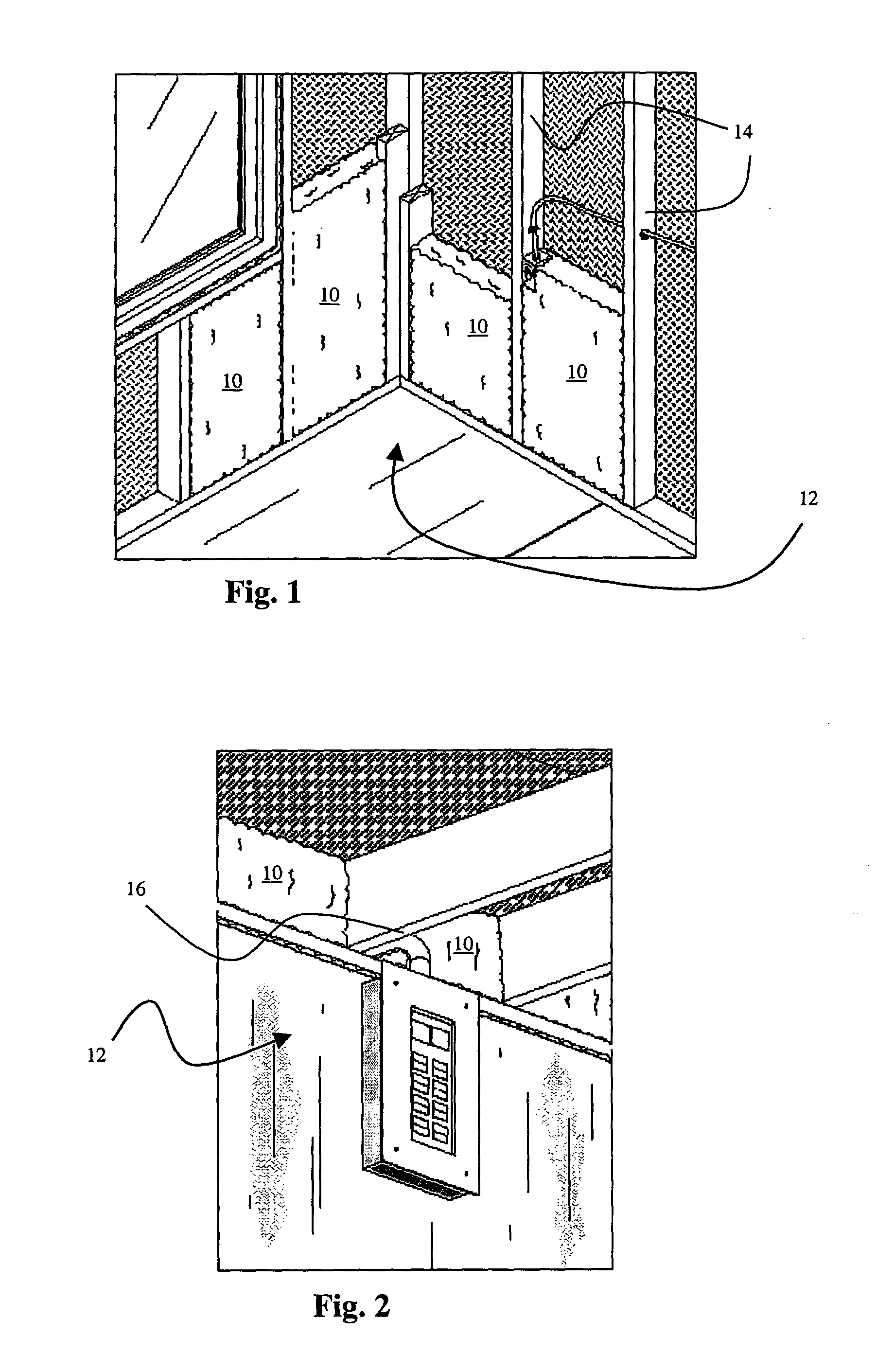

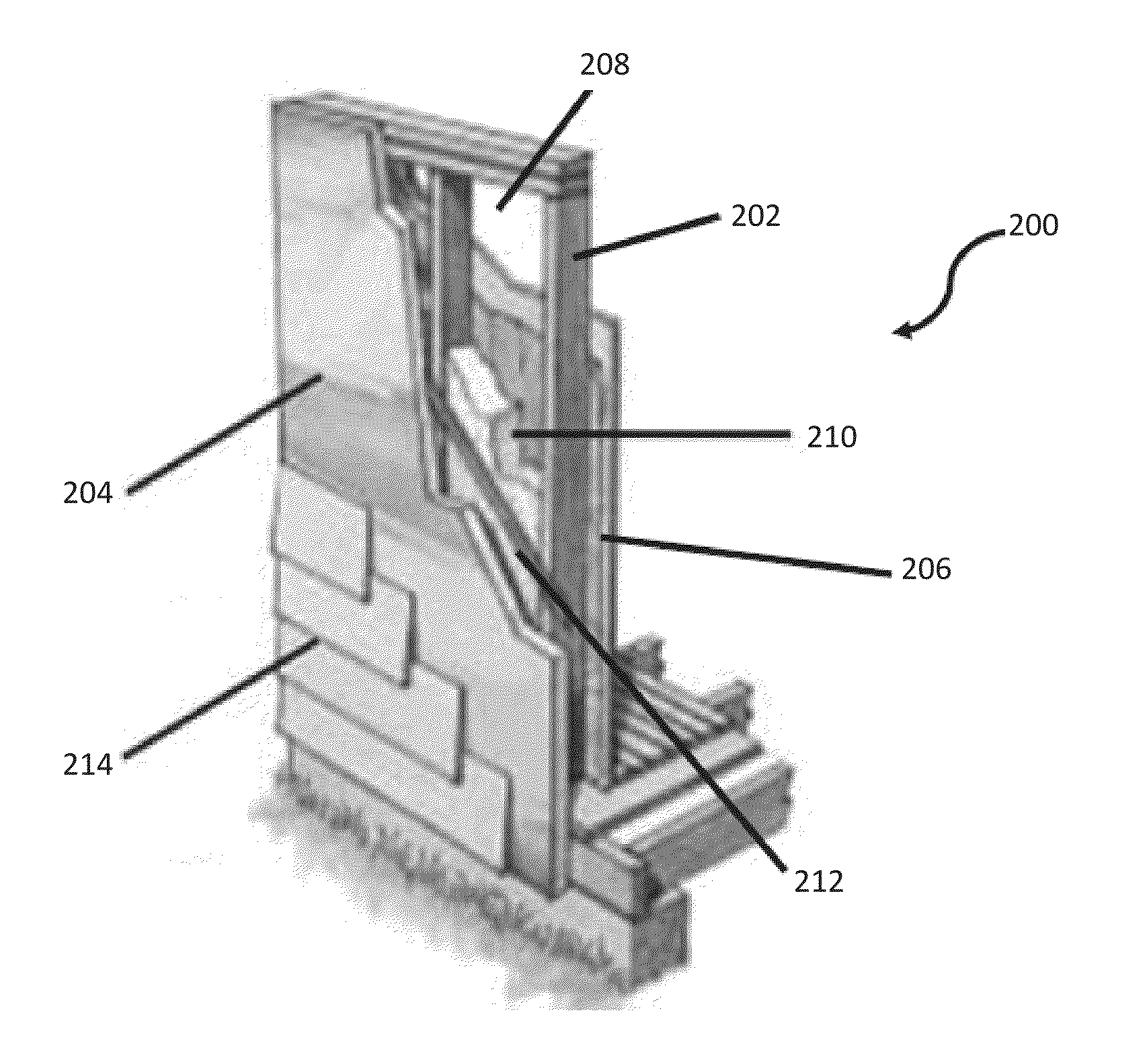

Spray foam and mineral wool hybrid insulation system

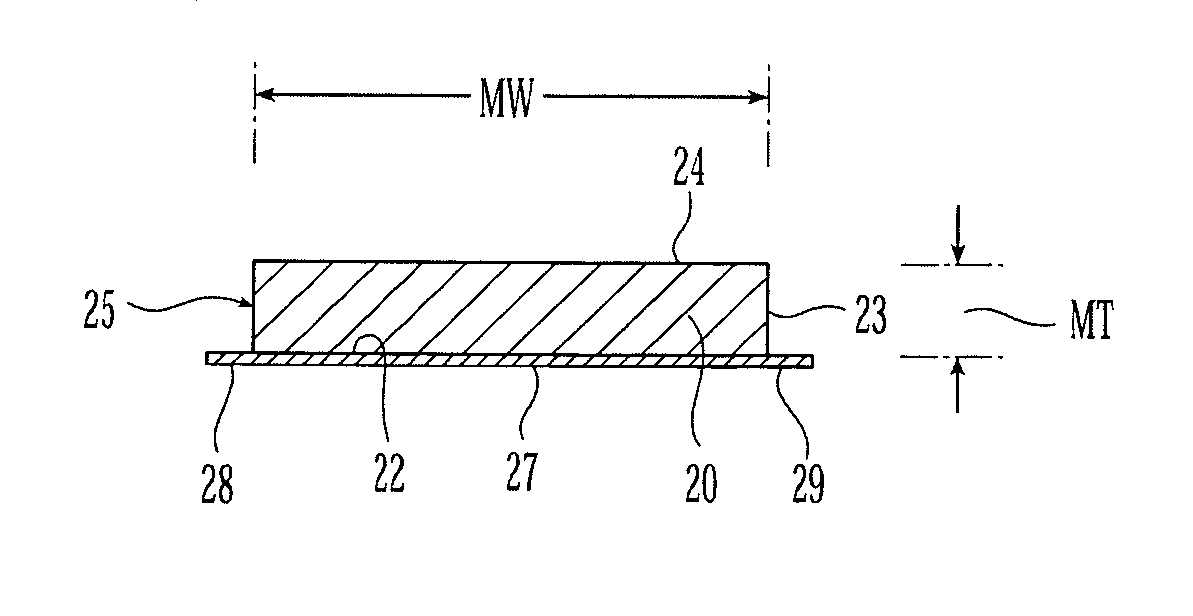

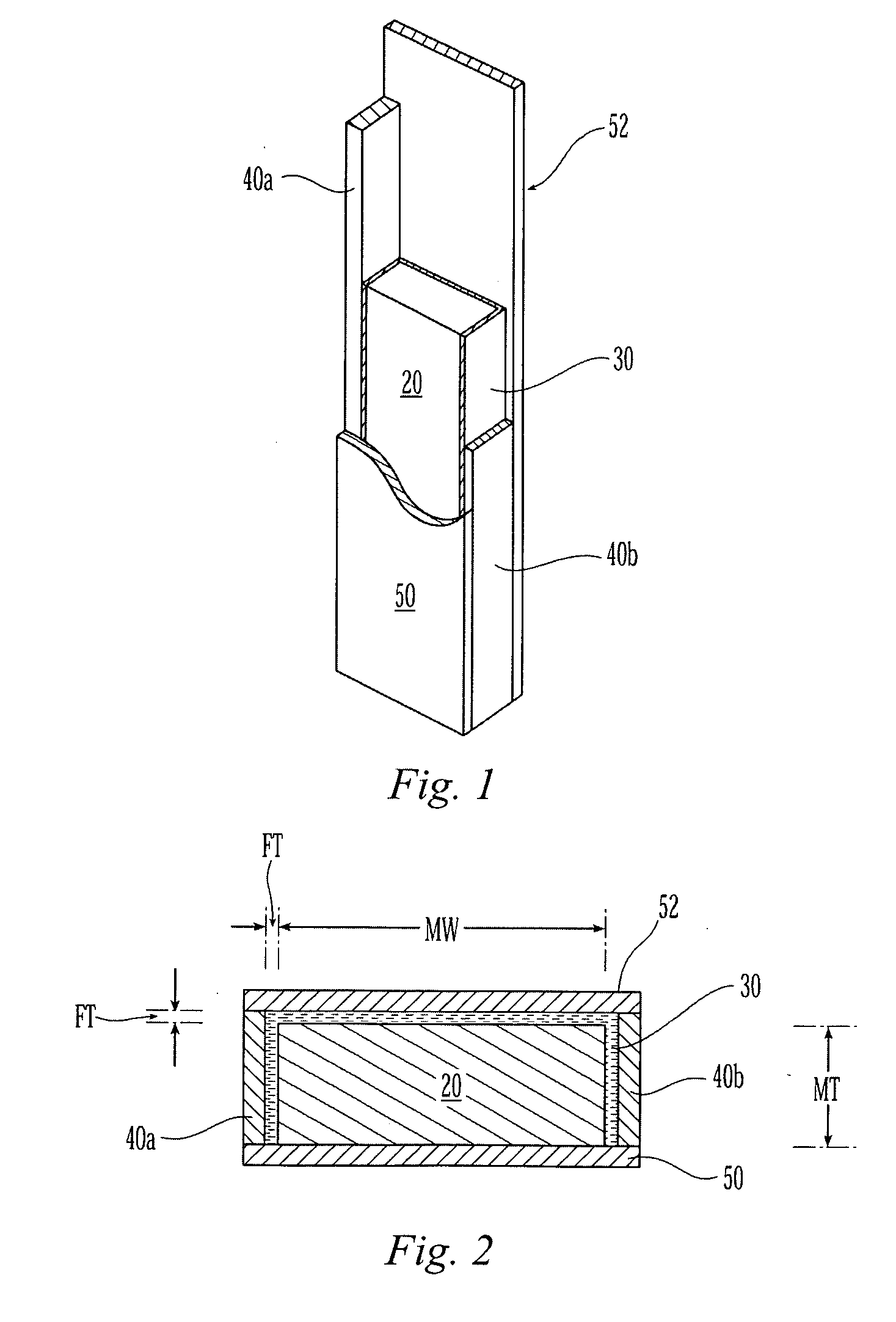

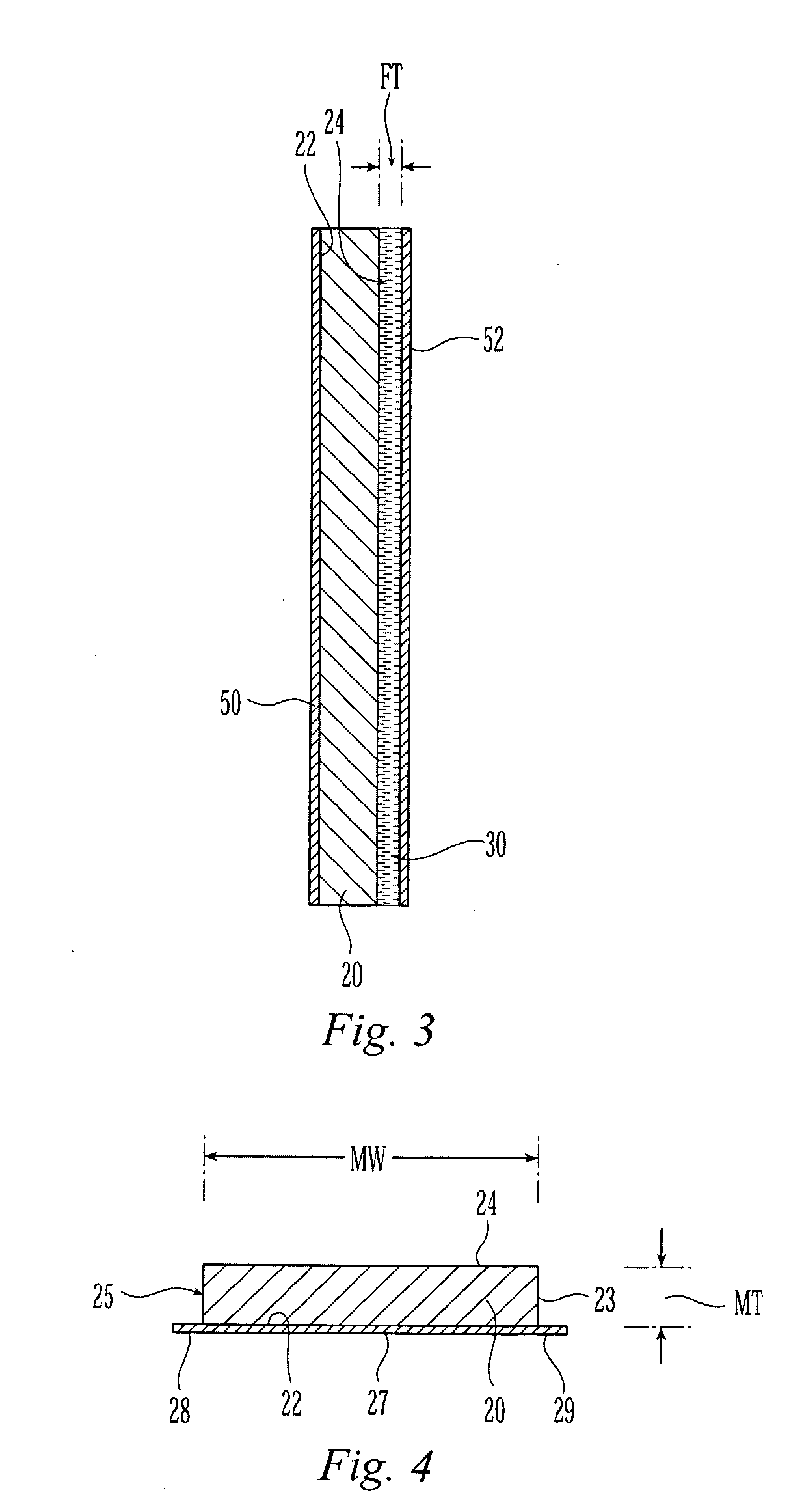

A reduced thickness and / or reduced width insulation product is provided for use in combination with spray-on foam insulation. The insulation product is configured to be inserted into standard-size spaces between adjacent wall studs to which a spray-on foam insulation has been applied. The reduced size of the insulation product is specifically designed so that the combined width and thickness of the insulation product and the spray-on foam insulation fill the entirety of the building space, but do not overfill the space.

Owner:CERTAINTEED CORP

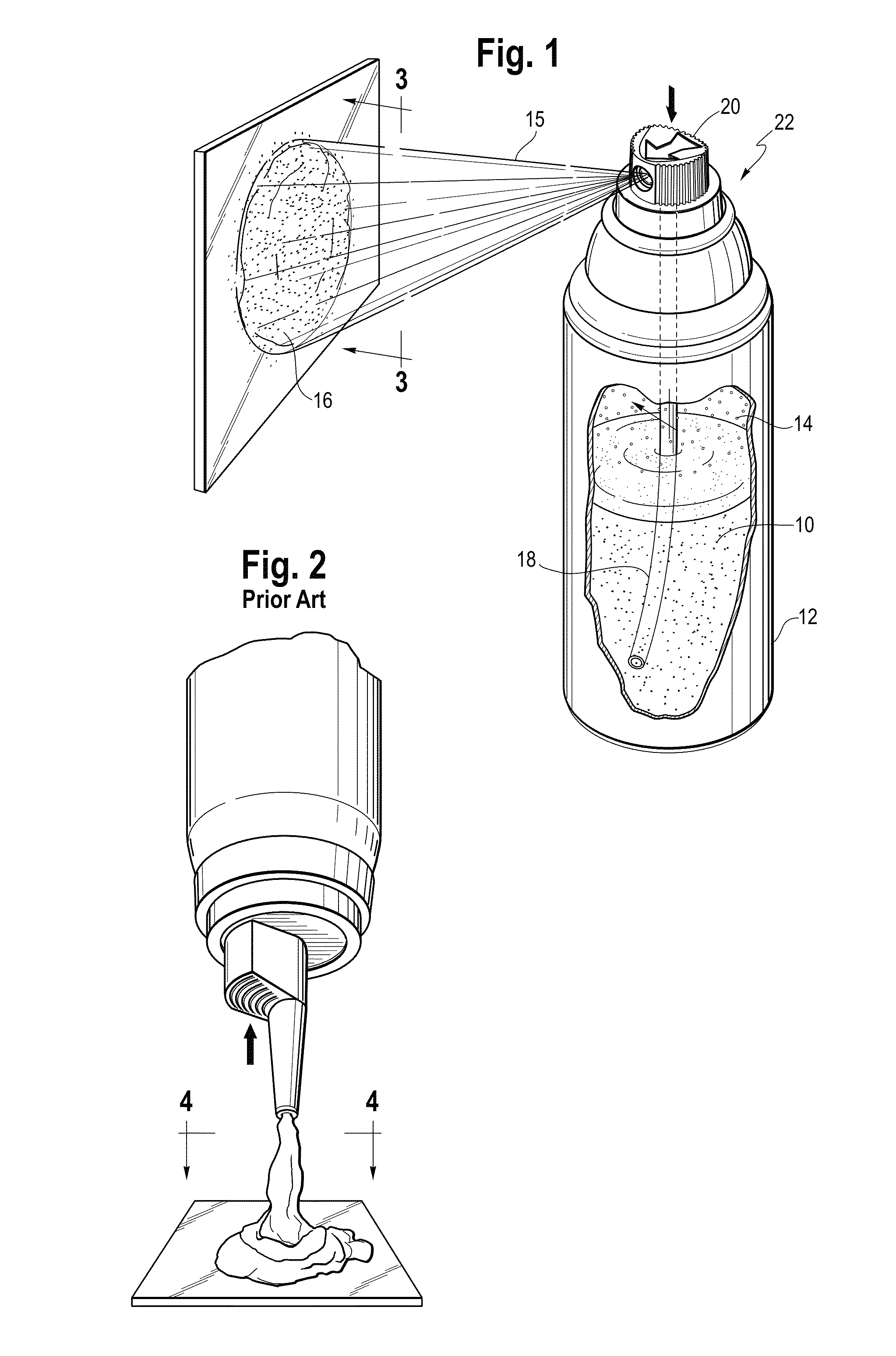

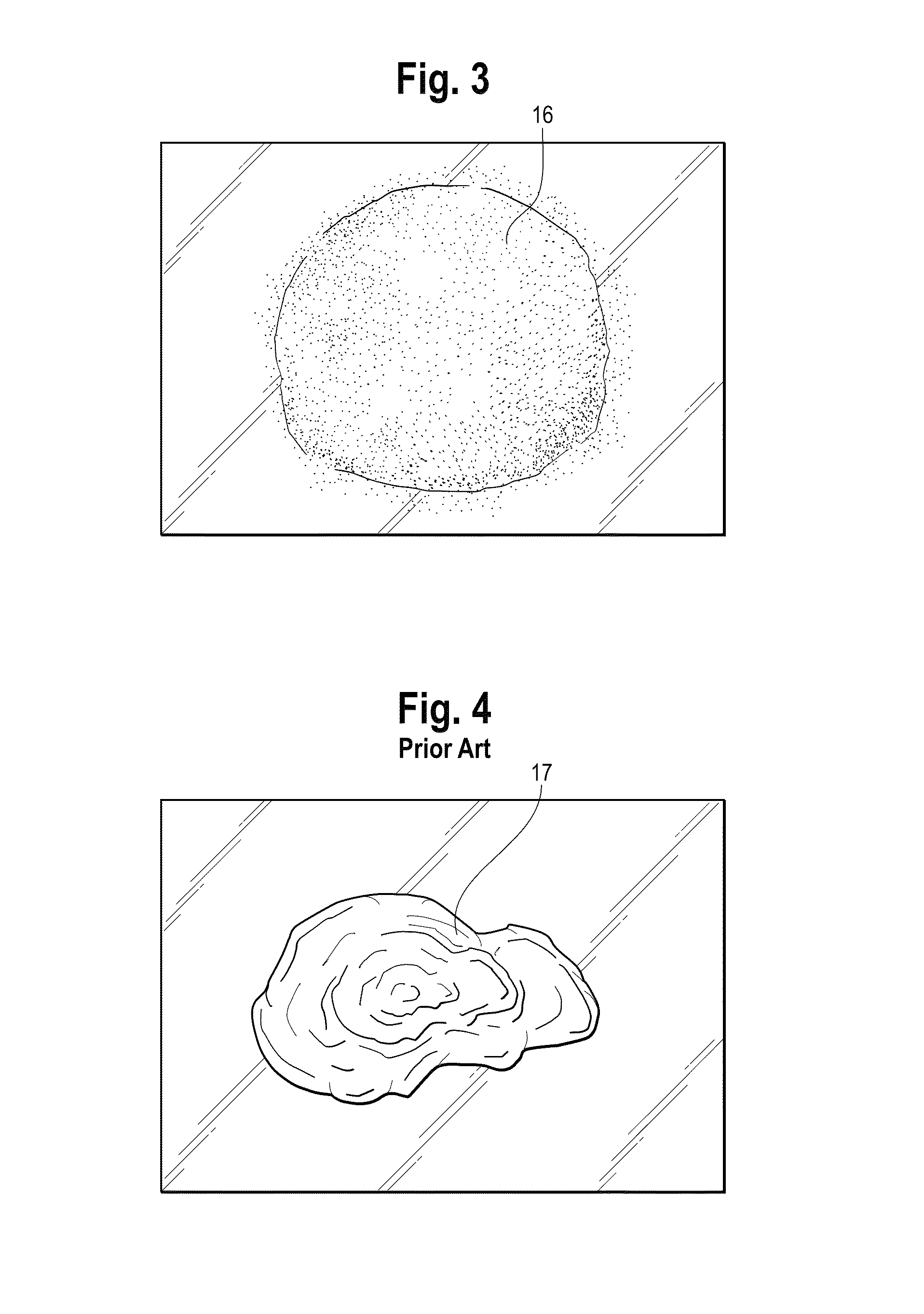

Spray foam corticosteroid product

ActiveUS9265727B1Less irritatingReduce product wasteOrganic active ingredientsAerosol deliverySurface-active agentsActuator

A foamable pharmaceutical composition and a method of treating corticosteroid-responsive dermatoses of the skin are disclosed. The foamable pharmaceutical composition comprises a corticosteroid compound as an active ingredient; a quick-break foaming agent including an aliphatic alcohol, water, a fatty alcohol and a surface active agent; a buffering agent; and a propellant. The foamable composition is disposed within a pressurizable container that comprises an aerosol valve assembly including a dip tube communicating with a valve orifice through which the foamable composition is dispensed and an actuator to start and stop dispensation. The valve assembly dispenses a conically-shaped spray at a rate of about 2 to about 0.3 g / sec and provides a foam having a density of about 0.12 to about 0.25 when sprayed at a distance of about 5 to about 10 cm from the valve orifice onto a glass surface that is at ambient room temperature.

Owner:DELCOR ASSET

Water blown polyurethane spray foam system

A composition and a method for producing primarily water blown polyurethane foams is provided. The composition uses isocyanate ratios greater than conventional foam system to provide a water blown polyurethane foam suitable for a wide variety of applications including spray roofing, insulation, etc. The preferred composition for preparing a polyurethane foam comprises an isocyanate component and a polyol component, wherein the polyol component preferably comprises a combination of Mannich polyol, polyester polyol, and polyether polyol. Preferably, the composition includes water to act as a blowing agent and a metal salt catalyst to assist in the reaction. Preferably, the isocyanate index is between about 1.2 and about 2.0. Additional catalysts, surfactants, flame retardants, and blowing agents may also be used depending upon the desired finished product.

Owner:ACCELLA POLYURETHANE SYST LLC

Open and closed cell polyurea foams

An open cell spray polyurea foam for use in an insulation layer in a wall structure may include a polyurea. The polyurea may be a reaction product of an isocyanate compound and water. The open spray polyurea foam may also include a filler. The majority of the filler may exist in the spray foam formulation as an unreacted first fire retardant. The spray foam formulation may further comprise a second fire retardant, and the insulation layer may exhibit a fire retardancy sufficient to pass Appendix X and / or ASTM E-84.

Owner:JOHNS MANVILLE CORP

Betamethasone spray

InactiveUS20080102039A1Organic active ingredientsAerosol deliveryBetamethasone valerateDimethyl isosorbide

A spray foaming dosage form comprising betamethasone valerate, dimethyl isosorbide, propylene glycol, non ionic surfactant, sodium dodecyl sulphate, a buffer, optional preservative, optional further excipients, and water.

Owner:NUPHARM LAB

Method for Rapid Insulation of Expanses

ActiveUS20070290074A9Way fastIncrease the areaLiquid surface applicatorsFlow mixersEngineeringTriangular prism

A process for cost-effectively and rapidly insulating a desired surface with spray foam insulation is described which includes the application of a polyurethane foam dispensed through heated conduits into a dispensing gun having a nozzle with essentially planar divergent lips having a triangular prism opening, the lips of the nozzle diverging at an angle of between about 5 and 35° inclusive, more preferably between 8 to 15° inclusive, most preferably 10 to 12° inclusive, thereby achieving application rates which are in excess of 70 Ft2 / min, and optimally in excess of 100 Ft2 / min.

Owner:ICP CONSTR INC

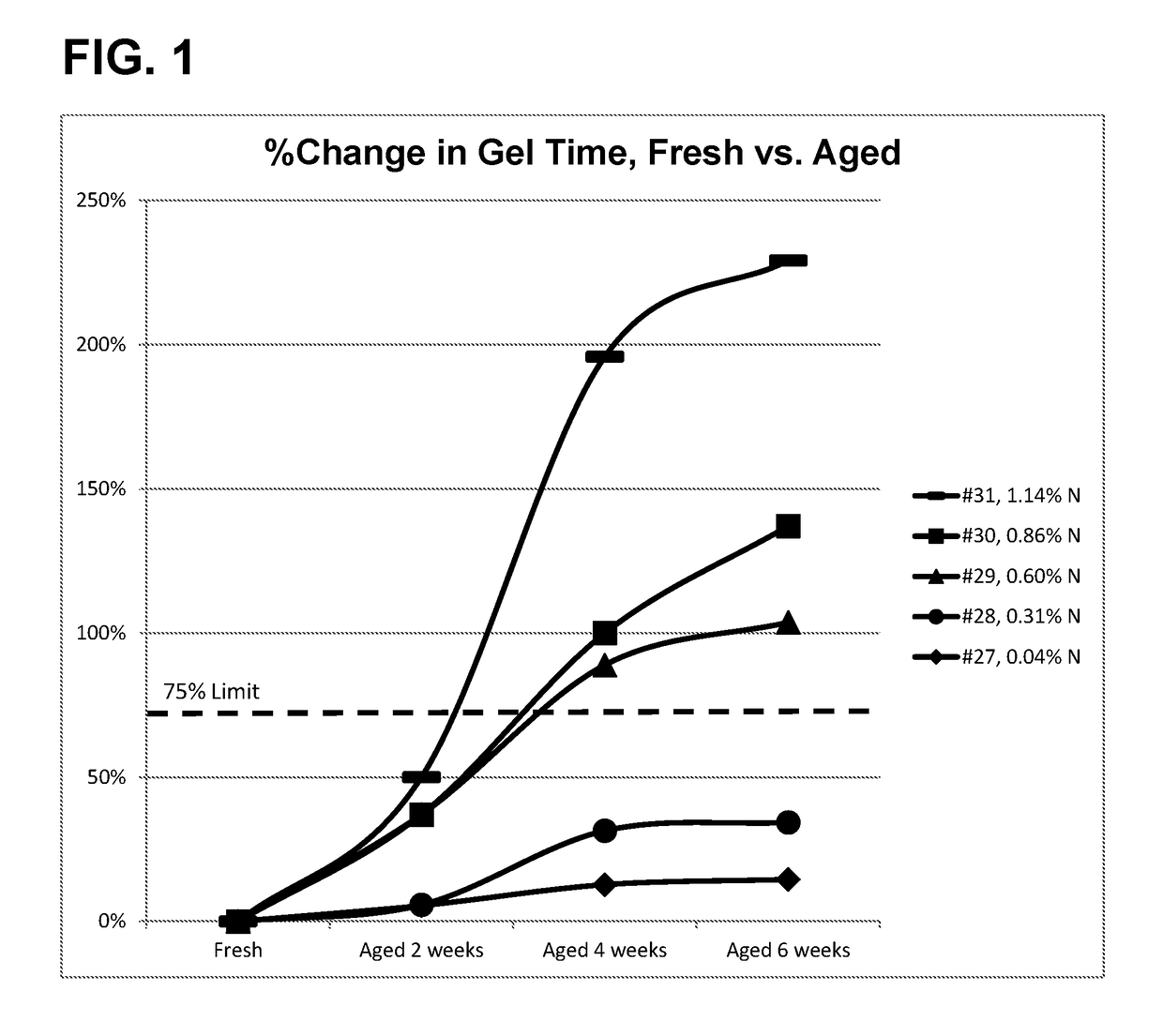

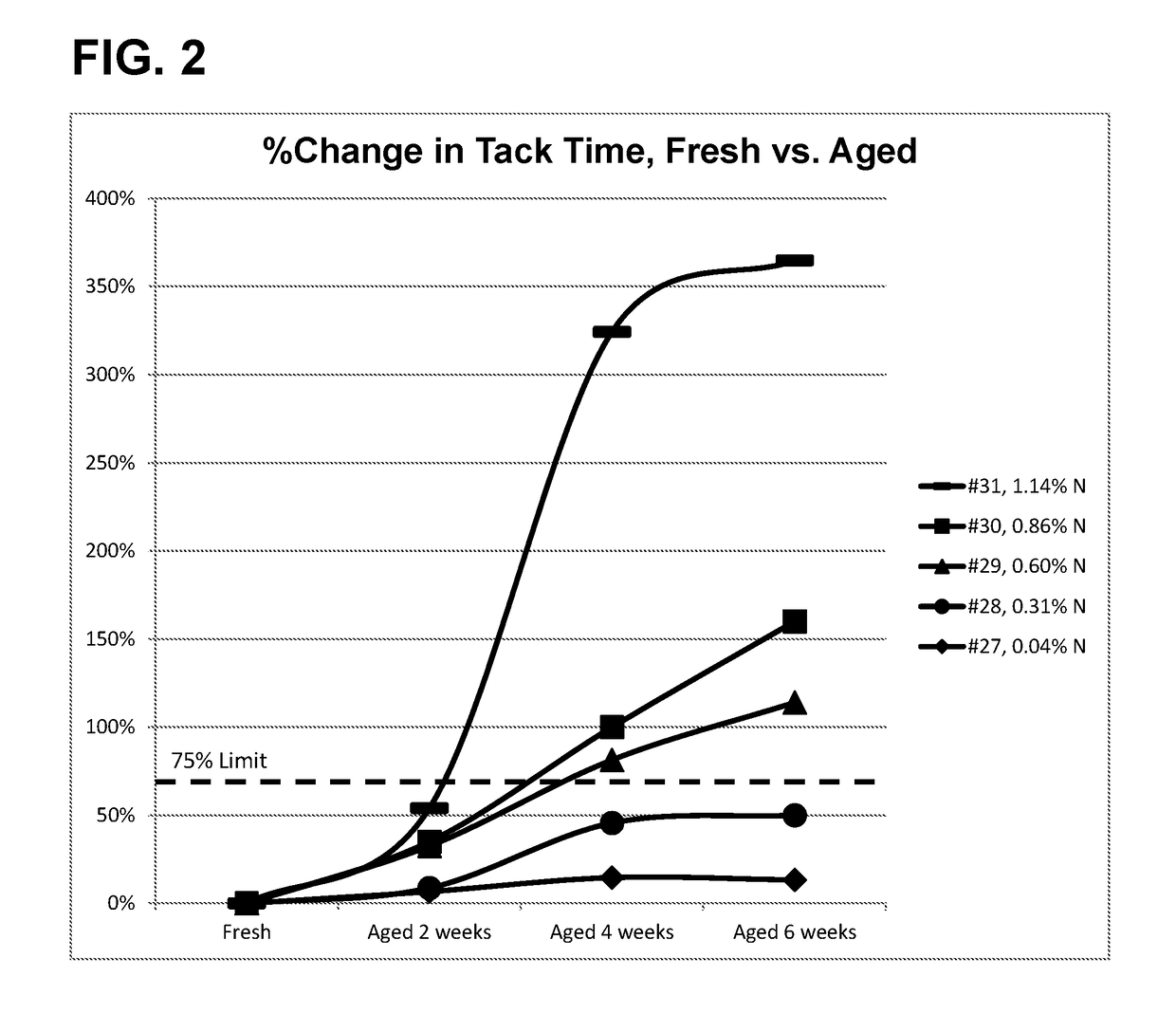

Stable two component spray foam compositions containing hydrohaloolefin propellant or blowing agent

A formulation technology for low pressure two component polyurethane foam-funning compositions containing gaseous hydrohaloolefin blowing agents is described with improved storage stability and extended shelf-life. The “B”-side component of the formulations contain a gaseous hydrohaloolefin blowing agent and a polyol pre-mix, the polyol pre-mix comprising liquid blowing agent, polyol, and a catalyst containing at least one catalytic metal compound.

Owner:DAP PRODUCTS

High-temperature rigid polyurethane spray foam for pipe insulation

The present invention provides a rigid polyurethane spray foam, which is made using cyclopentane as the blowing agent and which is useful for pipe insulation because of its ability to withstand high-temperatures (>250° F.). The inventive foams may be sprayed with existing foam spraying equipment because the foams are reacted at about a 1:1.25 polyol to isocyanate ratio.

Owner:BAYER MATERIALSCIENCE AG

Water blown polyurethane spray foam system

Owner:ACCELLA POLYURETHANE SYST LLC

Special environment-friendly combined polyether for sprayed pipeline and preparation method of special environment-friendly combined polyether

The invention discloses special environment-friendly combined polyether for a sprayed pipeline and a preparation method of the special environment-friendly combined polyether. The special environment-friendly combined polyether is composed of a component A and a component B, wherein the component A is composed of polyethylene-polypropylene glycol, polyester polyol, a crosslinking agent, a foam stabilizer, a catalyst and a foaming agent; the component B is polymethylene polyphenyl polyisocyanate. By using the special environment-friendly combined polyether, the problems of inside cracking, heart rot and surface roughness of sprayed foam are solved, the aim of completely protecting the environment is achieved, meanwhile, the bonding property of the foam and a base material is improved, and the production requirement of the process is met.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

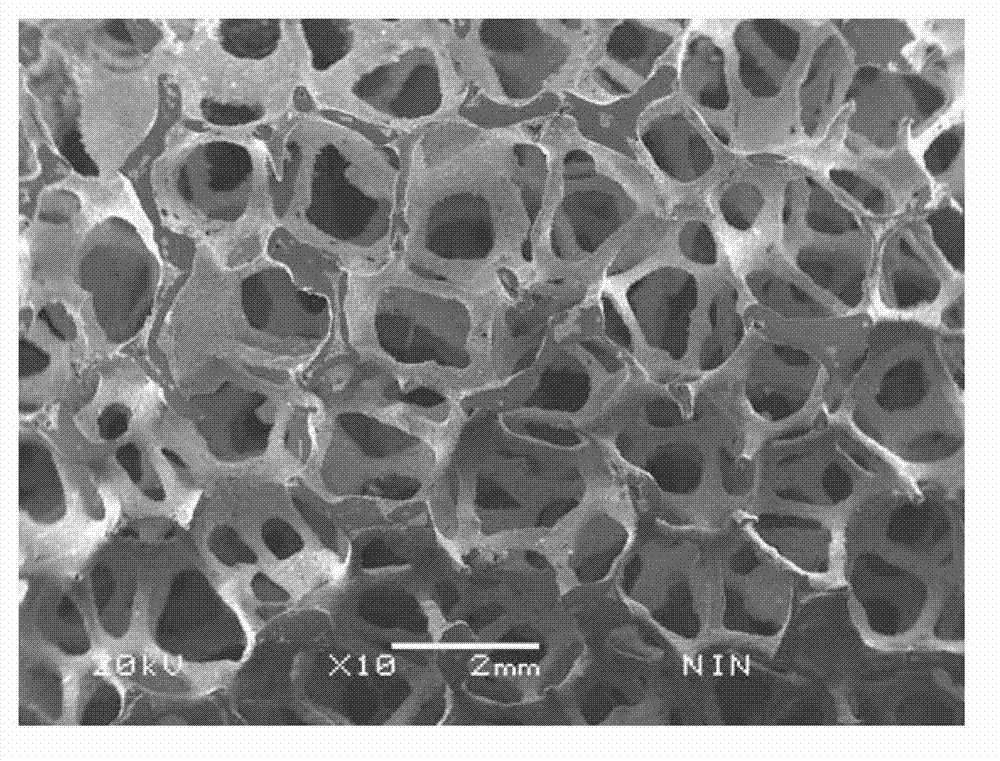

Method for preparing foam metal material with communication pore structure

The invention discloses a method for preparing a foam metal material with a communication pore structure. The method comprises the following steps of: immersing polyurethane foam plastic into slurry consisting of metal powder, anion surface active agent and deionized water; centrifuging the immersed polyurethane foam plastic in a centrifugal machine; drying the centrifuged polyurethane foam plastic; immersing the dried polyurethane foam plastic into slurry consisting of metal powder, an adhesive and deionized water; centrifuging the immersed polyurethane foam plastic in the centrifugating machine to obtain a foam billet; spraying the foam billet by adopting slurry consisting of the metal powder and a defoamer; drying the sprayed foam billet; and carrying out pyrolysis sintering on the dried foam billet in a sintering furnace to obtain the foam metal material with the communication pore structure. The method is resonable in design, simple in process and operation step and low in production cost; and the material prepared by the method has the characteristics of pore communication, no plugged pore, uniform structure, high porosity and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

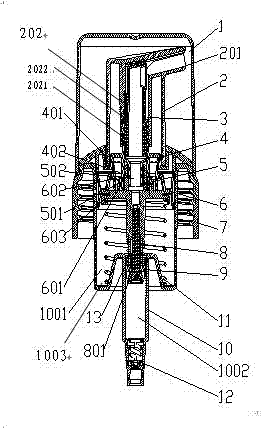

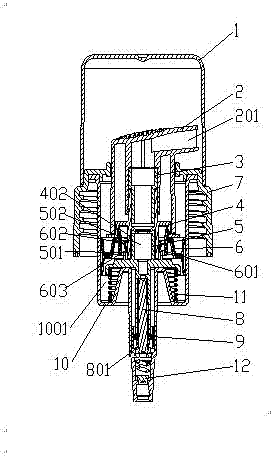

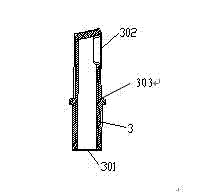

foam pump

The invention relates to a foam pump, which is used to absorb liquid in a container and make the liquid spray out foam from a nozzle. The shell is composed of a pressure head, a screw cap and a cylinder. The shell includes a pressure head, an air valve, a main column, Large piston, screw cap, connecting rod, small piston, cylinder, spring and valve. There is a network pipe between the pressure head and the air valve, and the spring is provided between the main column and the base of the cylinder. Among them: a network pipe extends into the pressure head sleeve from below Inside, the lower end of the network pipe communicates with the air valve, and at least a filter screen is provided at the entrance of the network pipe; the air valve is a tubular structure, and the middle part is provided with a circular ring with a downward peripheral edge and a convex edge, and the pressure head is against the top of the circular ring. An air inlet groove is arranged on the inner wall of the ring, and an exhaust groove is arranged on the inner wall of the tube below the air valve. Because the spring is placed in the air chamber of the cylinder, it prevents it from contacting with chemical materials and prevents the spring from rusting; and because the large and small pistons can be unlinked, it provides sealing, and the design of the network tube makes the sprayed foam more uniform.

Owner:DERXIN SHANGHAI COSMETICS

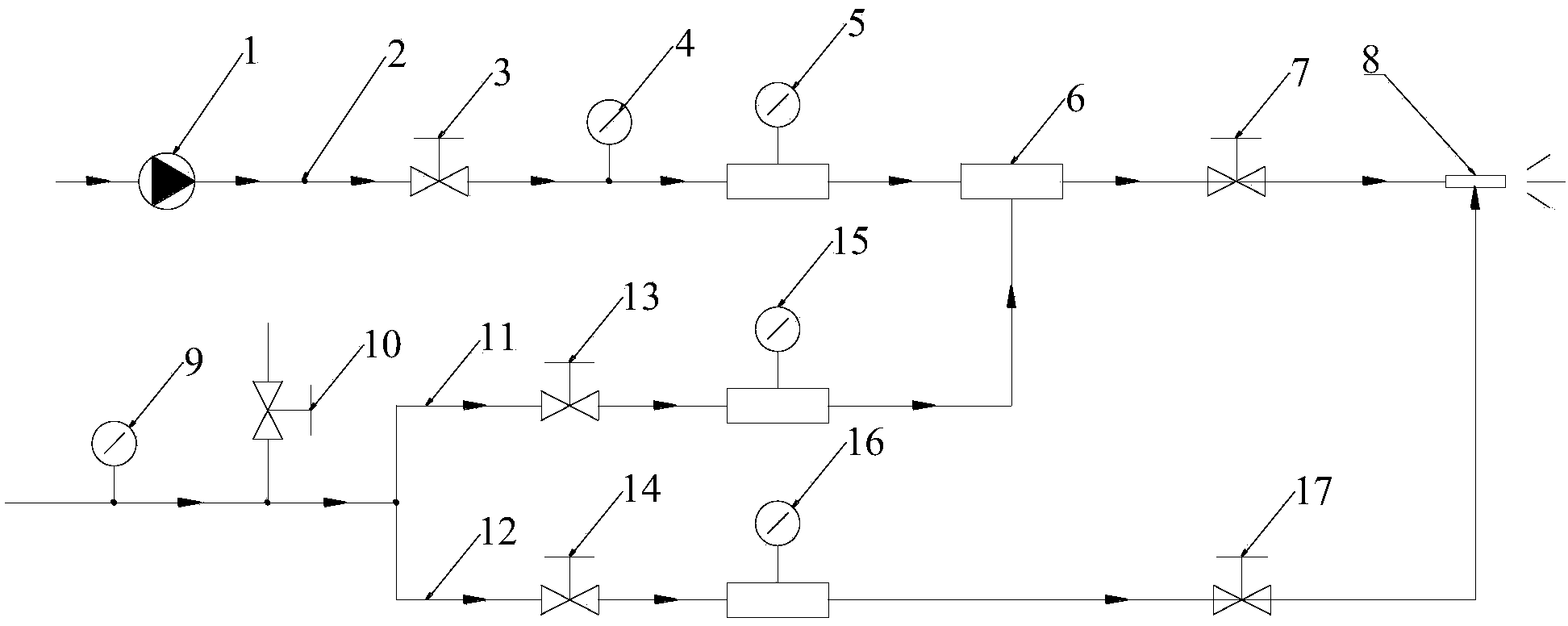

Dual-fluid magnetization foam dustfall system and method

ActiveCN103670492AEasy to captureImprove adsorption capacityUsing liquid separation agentDust removalSpray nozzleMagnetization

The invention relates to a dual-fluid magnetization foam dustfall system and method, and belongs to dustfall systems and methods for a coal mine. The dustfall system comprises a liquid pipeline and an air pipeline with certain pressure, wherein the liquid pipeline is composed of foaming liquid, and the air pipeline is composed of a pressure ventilation pipe under the shaft. The air pipeline is connected to a magnetization foaming device for foaming, the other pipeline is connected to a dual-fluid foam nozzle and used for spraying foam. The magnetization foaming device comprises a turbulent flow pipe and a shell. The turbulent flow pipe comprises a solution medium cavity, a medium mixing cavity and a communication hole in the flowing direction of a medium, and the solution medium cavity is communicated with the medium mixing cavity through the communication hole. The outer wall of the solution medium cavity of the turbulent flow pipe is wound by magnetic tubes or magnetized metal tubes, and a circle of magnets are arranged in the shell. Hemispheric spoilers provided with turbulent flow holes are evenly distributed in the outlet end of the medium mixing cavity. According to the dual-fluid magnetization foam dustfall method, the dustfall capacity of foam is improved through foam magnetization, and the jetting effect of the foam is improved by using the dual-fluid foam nozzle, so that dustfall efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

Environmentally-friendly energy-saving polyurethane spraying composite material with ultralow density

InactiveCN102391774ANo damageMeet the requirements of green environmental protectionFireproof paintsPolyurea/polyurethane coatingsPolyolFoaming agent

The invention discloses an environmentally-friendly energy-saving polyurethane spraying composite material with ultralow density, which comprises the following components in part by weight: 20-60 parts of polyether polyol which takes glycerol as an initiator, 3-10 parts of amine catalyst, 0.5-3.0 parts of foam stabilizer, 22-30 parts of water, 30-45 parts of fire retardant and 95-120 parts of isocyanate. In the environmentally-friendly energy-saving polyurethane spraying composite material, pure water is used for replacing the traditional hydro chlorofluorocarbon (HCFC)-141b foaming agent, and the environmentally-friendly energy-saving polyurethane spraying composite material is an environmentally-friendly energy-saving polyurethane spraying foam with the ultralow density. The polyurethane spraying composite material has the ultralow density which can reach 5-10kg / m3. Because the polyurethane spraying composite material has tapping performance, the sound absorption performance can reach 70%. Meanwhile, the oxygen index of the environmentally-friendly energy-saving polyurethane spraying composite material reaches 23 and can pass the Society of Tool and Manufacturing Engineers (ASTME)-84 authentication.

Owner:可利亚多元醇(南京)有限公司

High-temperature rigid polyurethane spray foam for pipe insulation

The present invention provides a rigid polyurethane spray foam, which is made using cyclopentane as the blowing agent and which is useful for pipe insulation because of its ability to withstand high-temperatures (>250 DEG F.). The inventive foams may be sprayed with existing foam spraying equipment because the foams are reacted at about a 1:1.25 polyol to isocyanate ratio.

Owner:BAYER MATERIALSCIENCE AG

Cooling regeneration method of asphalt added with foam asphalt

A method for the in-situ cold regeneration of asphalt on pavement by adding foam asphalt includes such steps as heating the old asphalt pavement to 160 deg.C by plate-type heater, loosening the asphalt pavement by a machine following said plate-type heater, recovering the mixture back into a stirring drum, adding cement, stirring, spraying foam asphalt, stirring, pumping the mixture onto road, spreading, and compacting.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

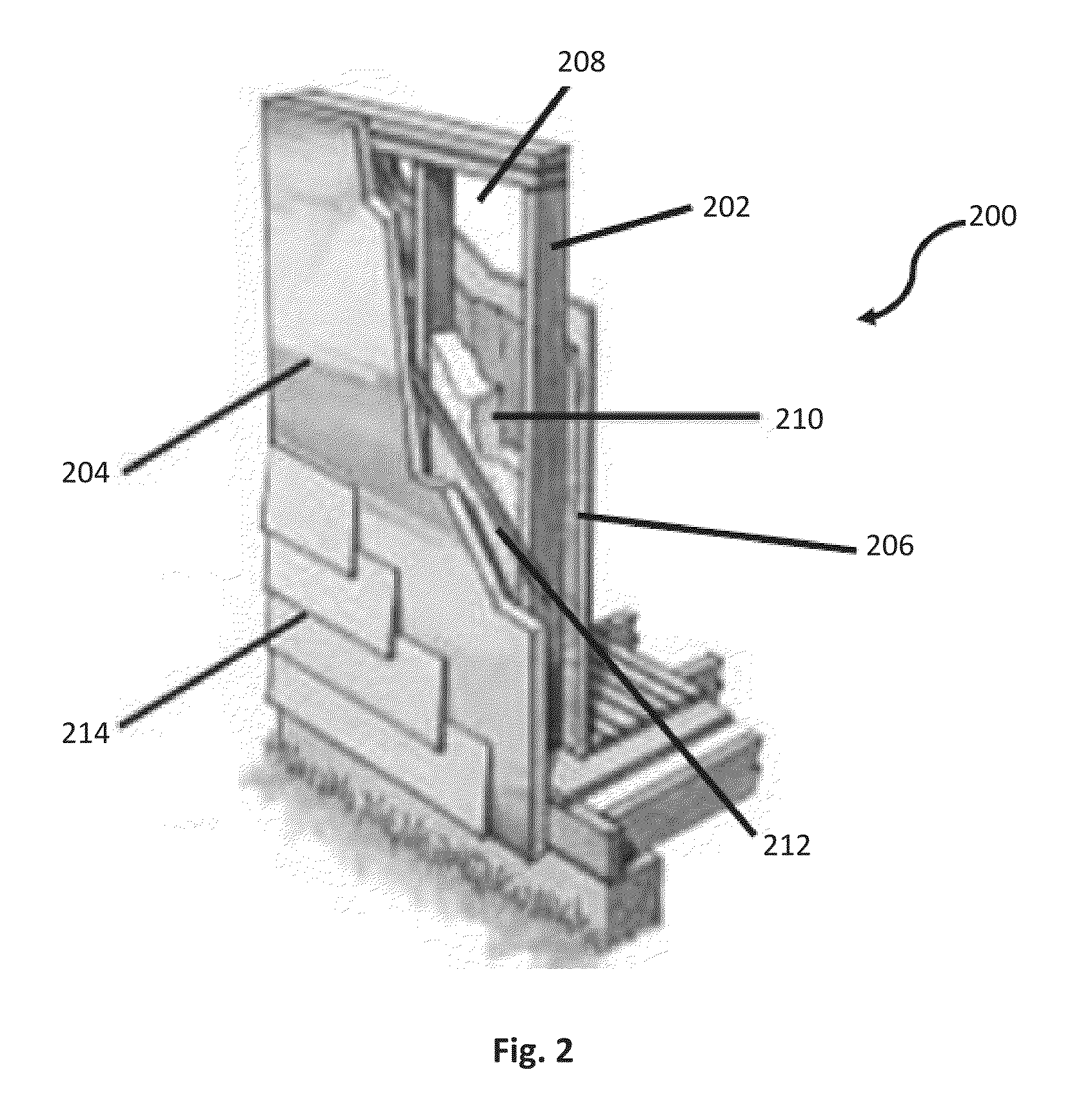

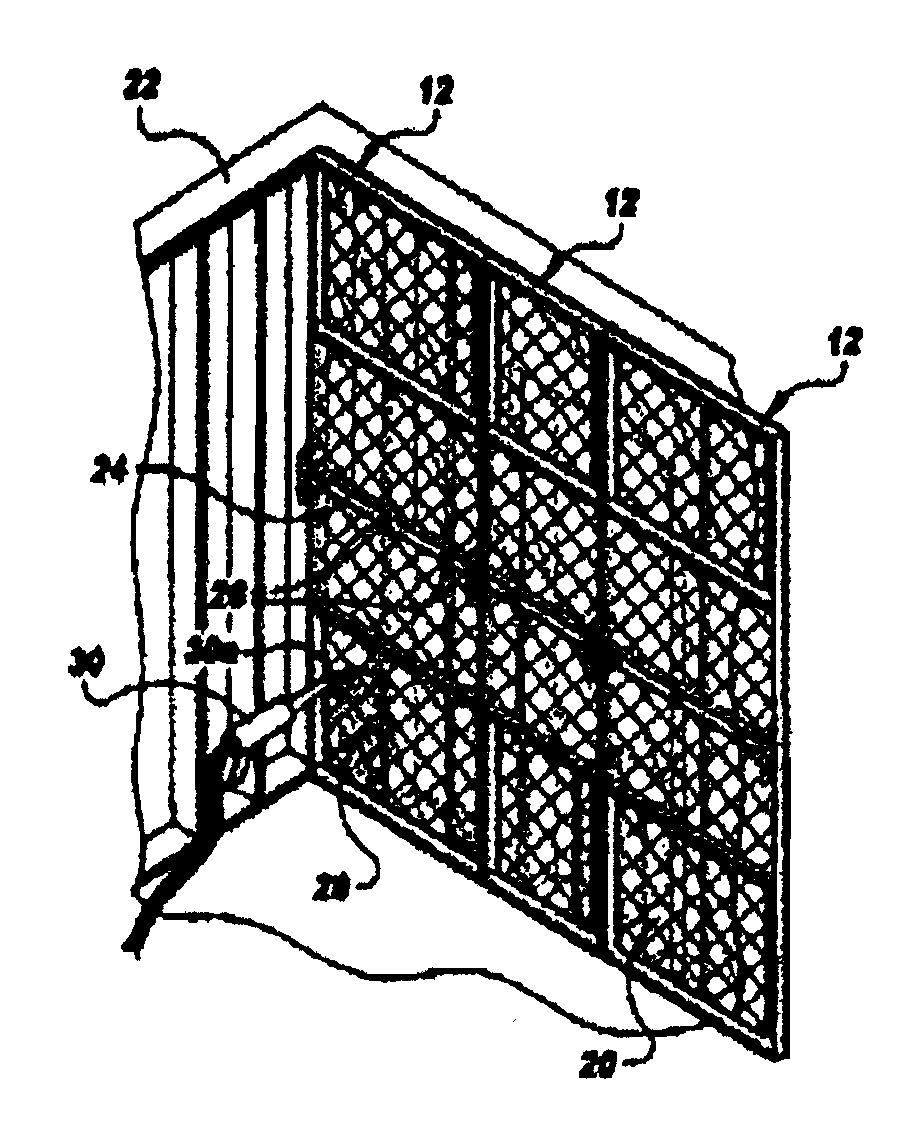

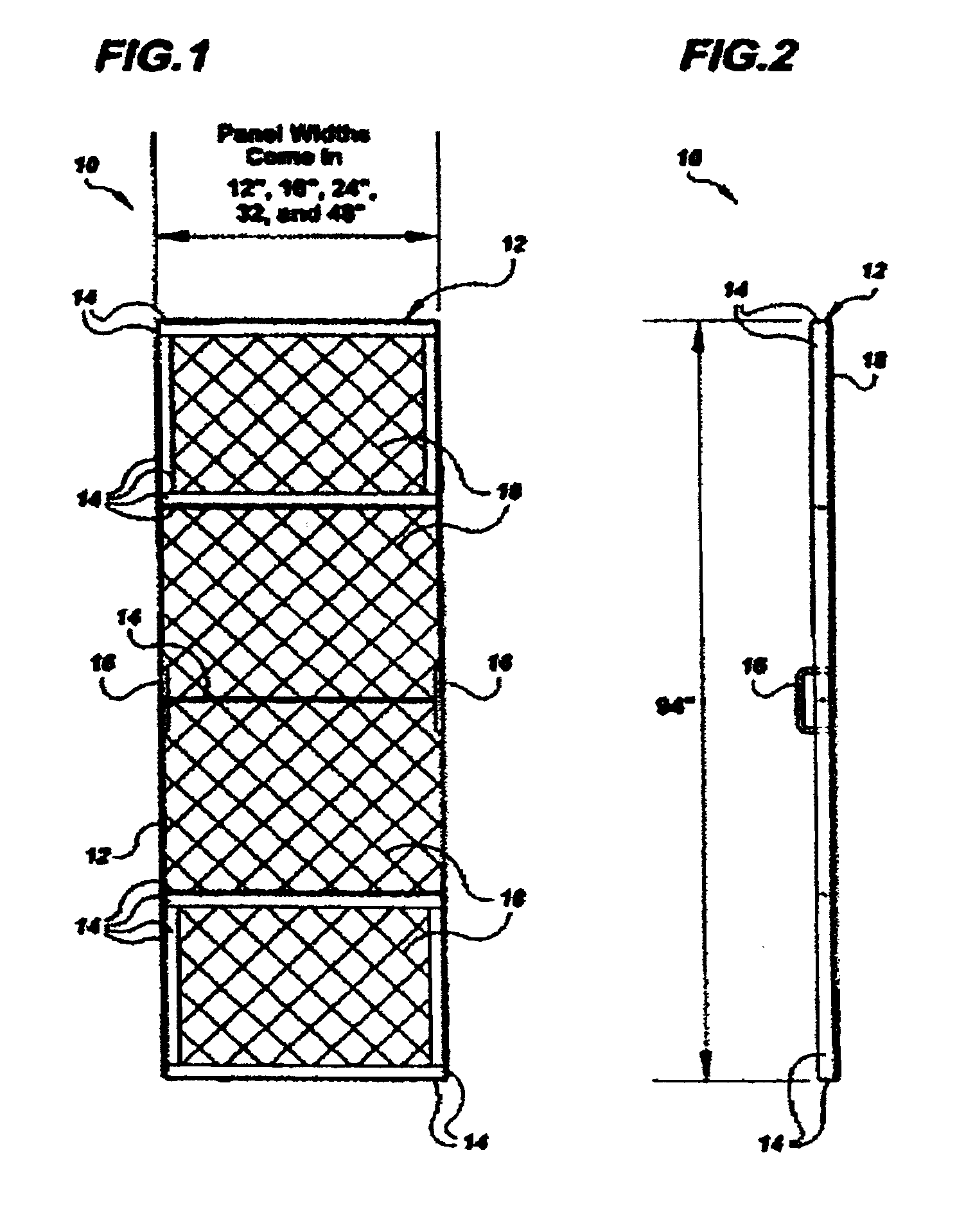

Wall Forms for Spraying Insulation

A panel system is provided to form a barrier and an enclosed cavity for spraying foam insulation. The panel system may use panel sections removably attached together to achieve a desired length. The panel sections are attached to wall studs and foam insulation is sprayed into the resulting cavity. After the foam has reacted, the panels may be removed and reused in another section. In one embodiment, a plastic sheet is used as a barrier between the panel and the foam insulation, which sheet can later be removed.

Owner:SHERNER JONATHAN

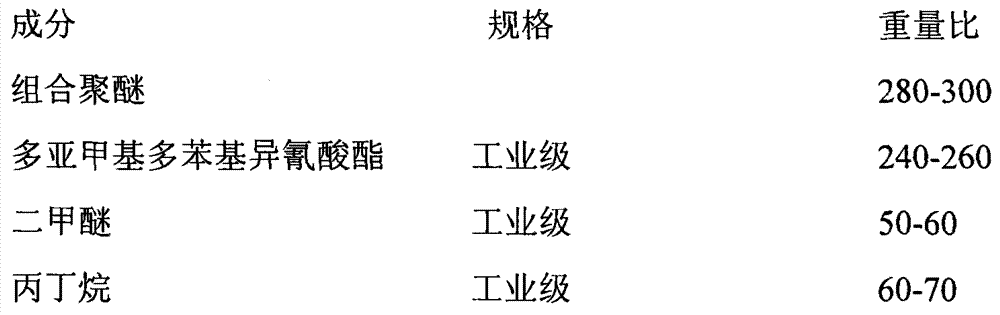

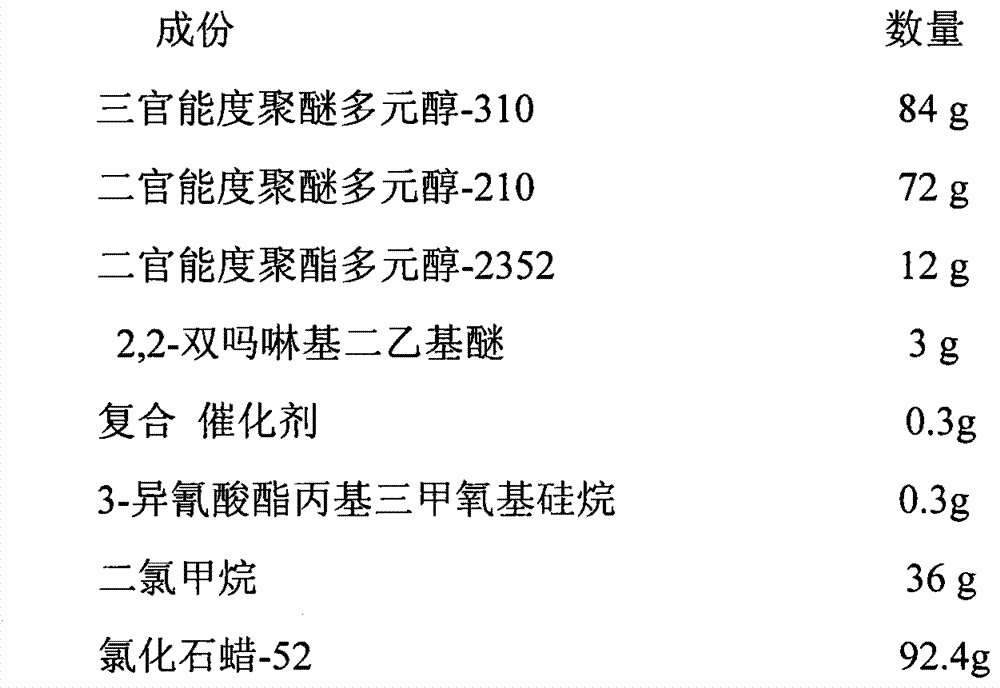

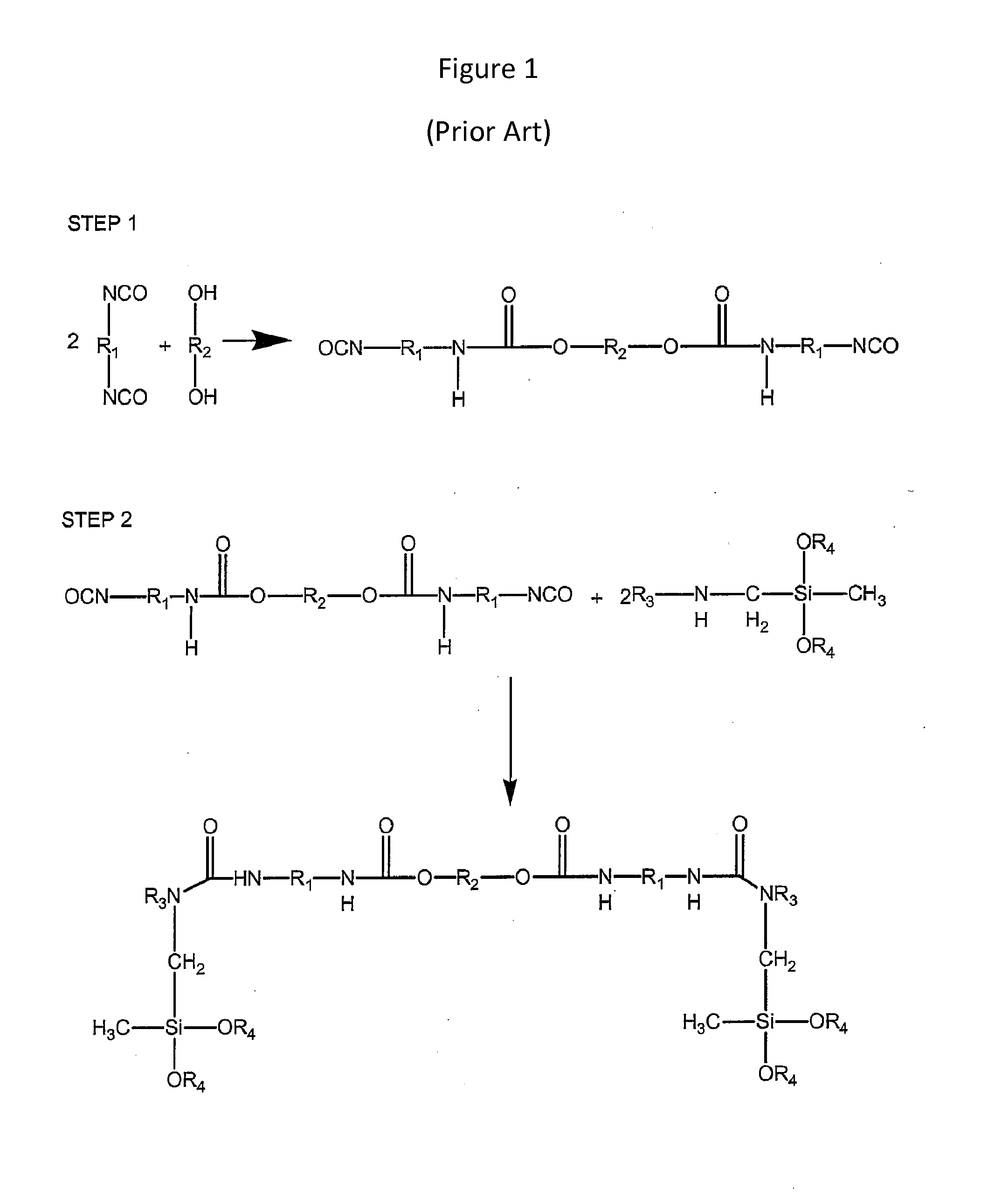

Preparation method of single-component polyurethane foam joint mixture

The invention relates to a preparation method of a single-component polyurethane foam joint mixture, and specifically provides a preparation method of a single-component polyurethane foam joint mixture capable of achieving one-time foaming and with super-long linear meter. The method comprises preparation of a composite catalyst and a combined polyether. The method is simple and easy to carry out. The invention adopts dual catalyst to strengthen gel catalytic effect, and can promote rapid curing and fixing of sprayed foam and realize one-time foaming and fixing. A coupling agent is added to react with polyol containing hydroxyl and amino and polymer to obtain silane groups with moisture curing crosslinking mechanism for accelerating foam curing. The added organic solvent reduces material viscosity and density of unit foam material; and under the effect of fast curing reaction of composite catalyst and coupling agent, the linear meter the foam is increased. The method has the realizes easy control of construction operation and spray amount, saves labor cost, increases foaming volume of the sprayed foam, increases construction area to 1.39-1.89 times that of the ordinary joint mixture, reduces the material cost, and solves the problems of the existing products.

Owner:天元(宜昌)新材料科技有限公司

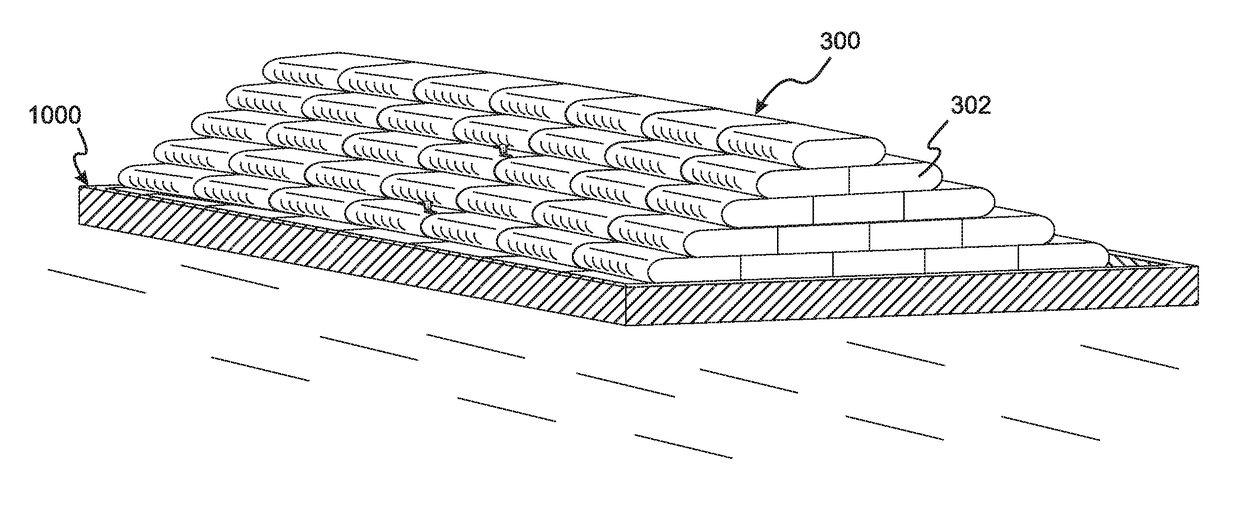

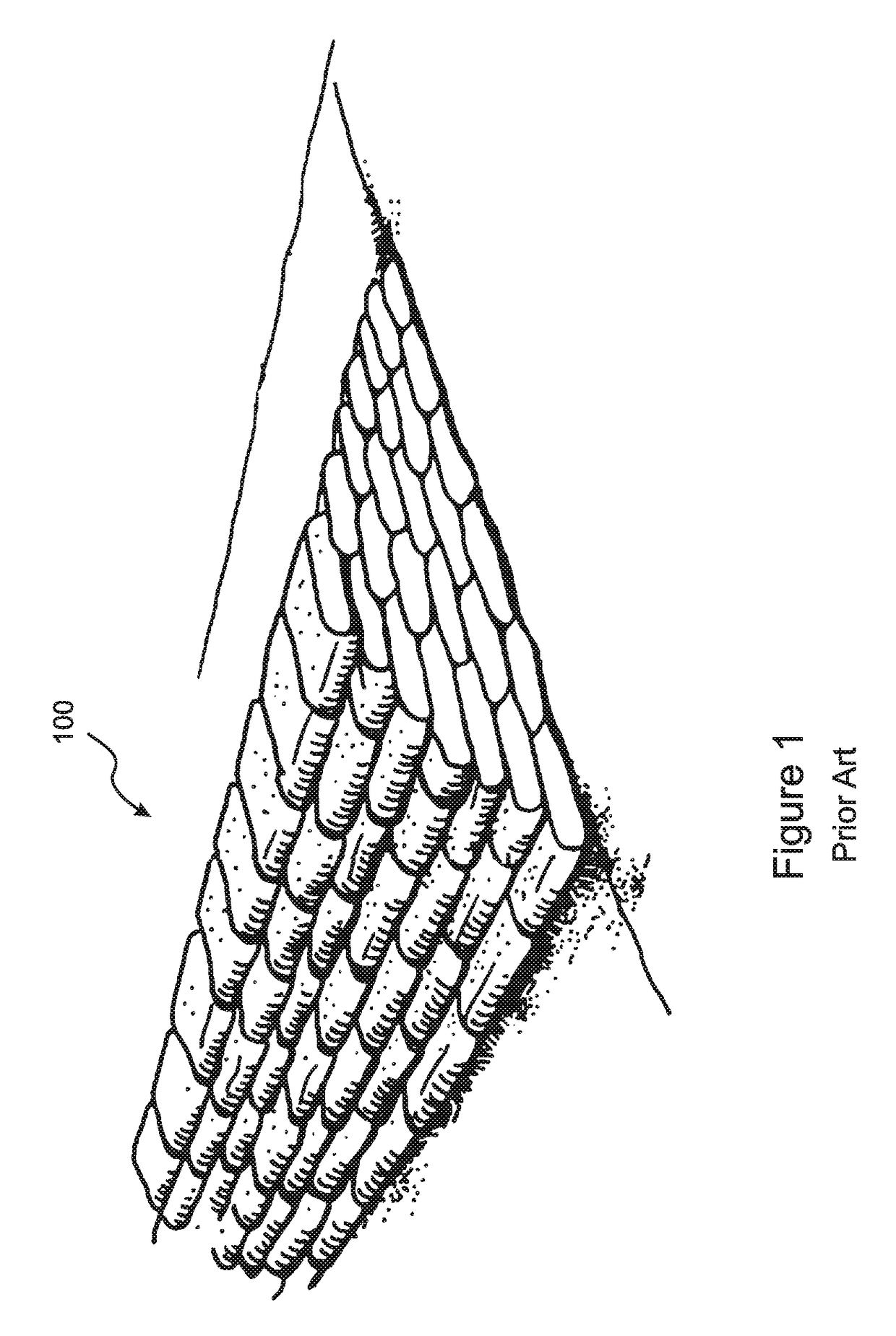

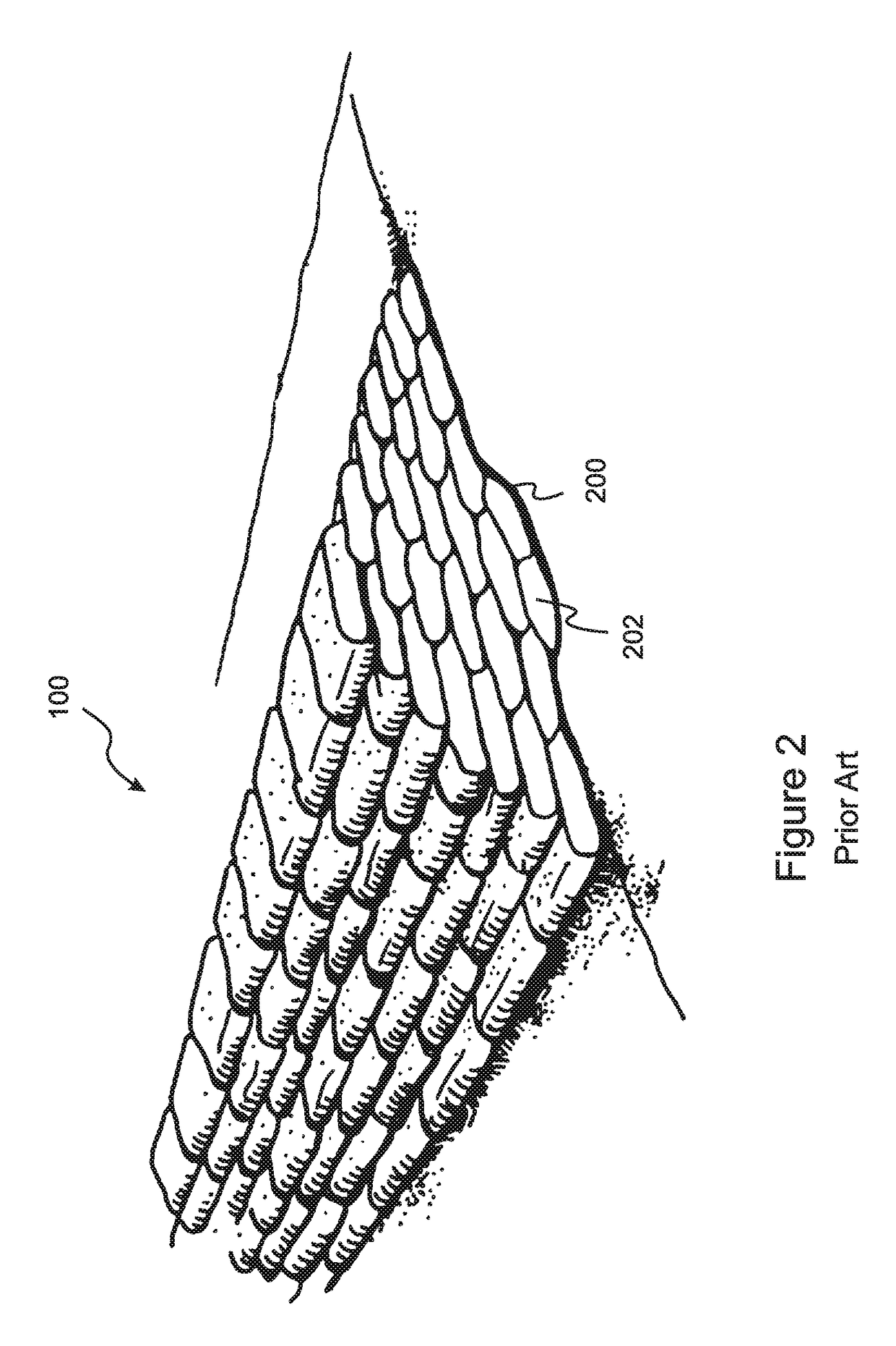

Roof system and method of fabrication and installation

In a roof system having exceptional insulating value, high density polyurethane foam or extruded polystyrene is used to form molded panels of predetermined size, shape and ornamental configuration. A non-skid primer coat is applied to the top surfaces and sides of the panels at the time of manufacture. A fabric layer or polyester mesh may be embedded in the bottom of the molded foam panels to enhance adhesion characteristics. During installation, the panels are set in a layer of low rise foam adhesive that is applied to the underlying roof deck or other surface (e.g., plywood, concrete, roofing felts, or spray foam), thereby avoiding the use of penetrating fasteners while enhancing wind uplift resistance. The panels may include interlocking structure for side-by-side and / or overlapping installation. Edges of the foam panels that need to be cut for fitting at valleys, hips, ridges, etc. are repaired in the field using factory supplied fabric and coating. After complete installation of the panels, a final topcoat composition such as, but not limited to, acrylic epoxy, silicon, or polyurea is applied to seal the roof system and provide a select roof color and desired grade.

Owner:ANAYA RICHARD J

Heat-insulating wall body based on jet type light and energy-saving material, and construction method thereof

ActiveCN102605875AReduce thermal bridgesImprove thermal insulation performanceCovering/liningsWallsThermal insulationSpray foams

The invention provides a heat-insulating wall body based on a jet type light and energy-saving material, comprising a base wall body and further comprising an interface transition layer, an insulating layer, a protecting layer and a facing layer which are attached on the surface of the base wall body from inside to outside in sequence, wherein the protecting layer is composed of an anti-crack mortar layer and an insulating closed layer; the thickness of the insulating closed layer is 0.5-1mm; the thickness of the anti-crack mortar layer is 2-5mm; the insulating closed layer is located between the insulating layer and the anti-crack mortar layer; and the insulating layer is obtained by spraying foam inorganic light and energy-saving material. The invention also provides a construction method of the heat-insulating wall body. The heat-insulating wall body based on the jet type light and energy-saving material provided by the invention is high in construction speed and low in manufacturing cost, and has good thermal insulation performance.

Owner:武汉沃尔浦科技有限公司

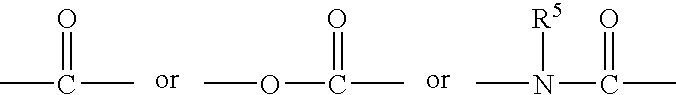

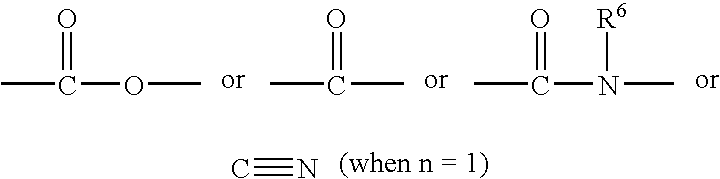

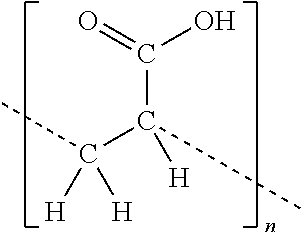

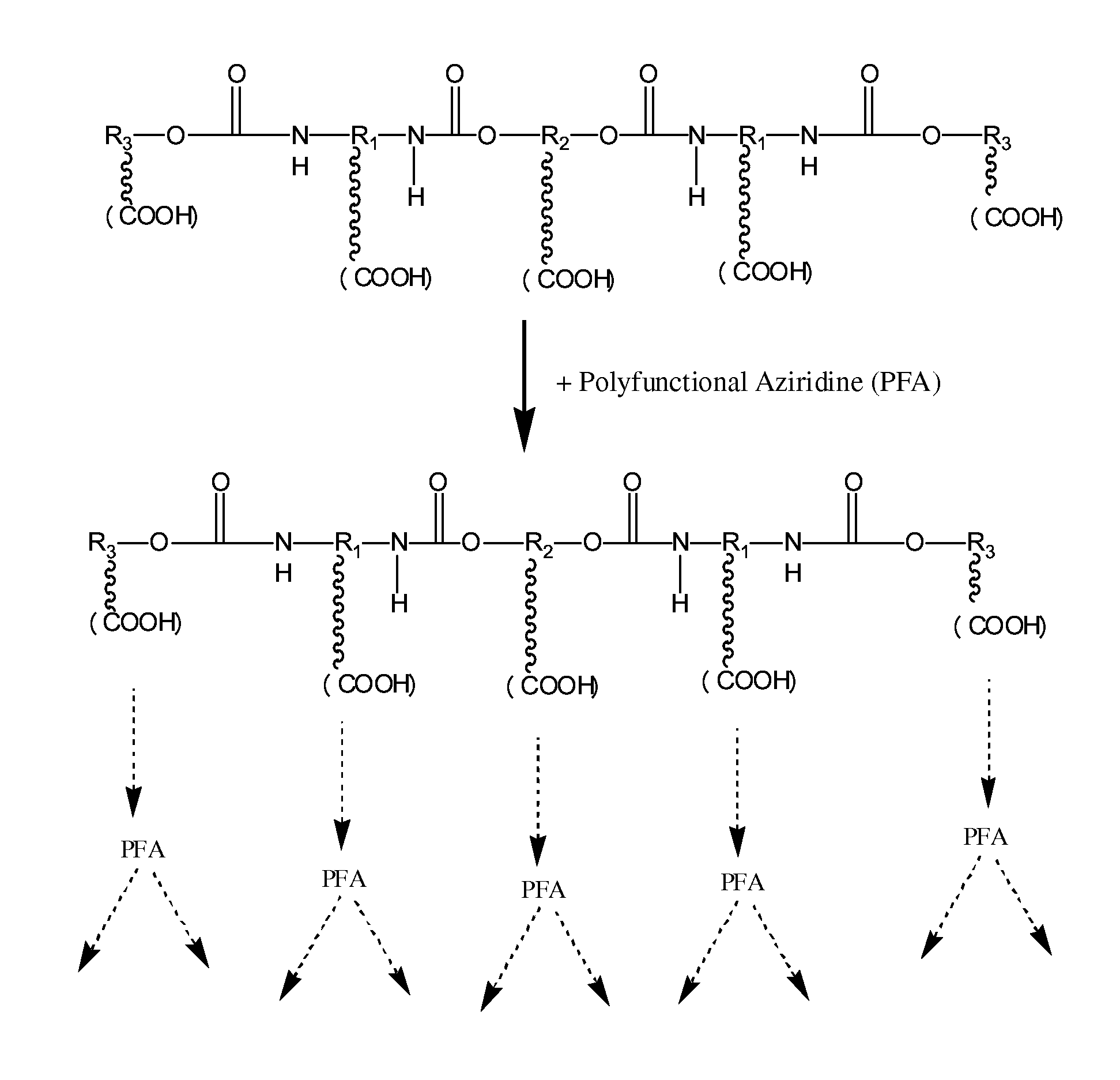

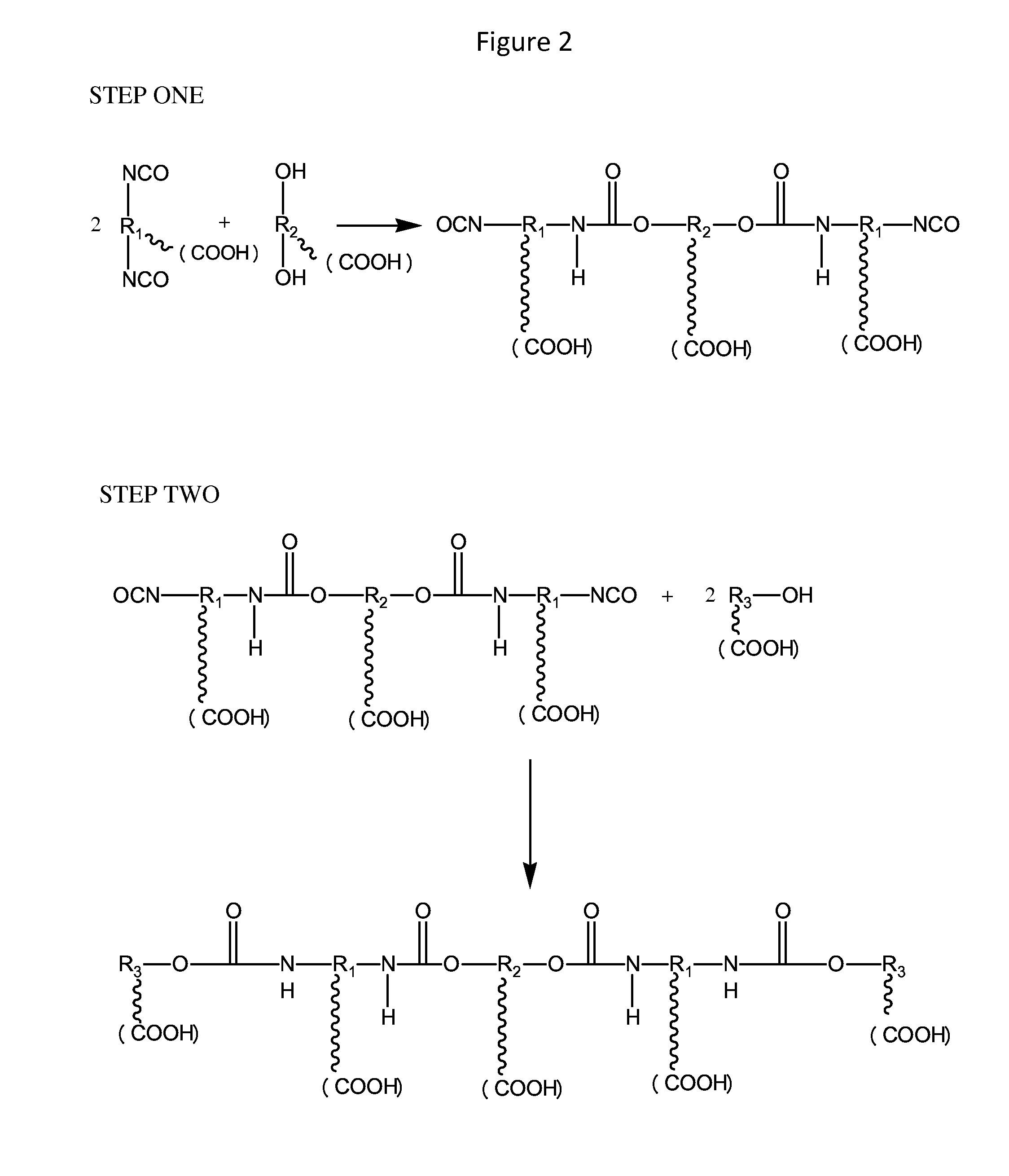

Non-isocyanate spray foam

One- and two-part spray non-isocyanate foams that include an amide-based oligomer containing pendant carboxylic acid and a polyfunctional aziridine crosslinking agent is provided. The amide oligomer typically contains urea links, urethane links or both groups. Additionally, the foams may include one or more plasticizer, a non-functionalized resin, a surfactant, and / or a thickening agent or rheology modifier. The amide oligomer does not contain any isocyanate groups, and, as a result, there are no free isocyanate moieties generated during formation of the foam that may be potentially hazardous to workers installing the foam. The presence of the urethane segments on the oligomer permits for the generation of a polyurethane foam without the drawbacks of conventional polyurethane foams. The foams may be used to fill cavities, cracks, gaps and crevices, such as around windows and doors, and may also be used in flash and batt systems.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Re-Orientable Spray Foam Gun Nozzles

InactiveUS20180043379A1Spray nozzlesThermometers using physical/chemical changesEngineeringSpray foams

Owner:ICP ADHESIVES & SEALANTS INC

Portable water inflatable barrier with water inflatable base

ActiveUS9719225B2Simple and inexpensive to removeResist punctureBarrages/weirsDamsEngineeringSpray foams

A portable, water-filled barrier system includes a barrier internally divided into cells that emulates a section of a sandbag dike or wall. Automatic valves can seal openings between the filled cells, so that a punctured cell will not cause cells below and behind to deflate. In embodiments the barrier can be initially filled with air, positioned, and then filled with water while the air escapes through a pressure valve. The system further includes a base with water inflatable front and back panels. The side panels and bottom panel of the base can be water inflatable or flat. The base can be used to increase friction with the ground, protect against stones, and / or to support a leveling wedge or leveling material such as sand or spray foam when located on a sloped surface. A plurality of adjacent bases and barriers can provide an extended barrier system.

Owner:ABELES GARY E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com