Spray foam and mineral wool hybrid insulation system

a hybrid insulation and foam technology, applied in building components, construction, building construction, etc., can solve the problems of reducing the total space available for fitting not reaching the optimal thermal performance of the insulation technique, and reducing the overall r-value of the insulation blanket or ba

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

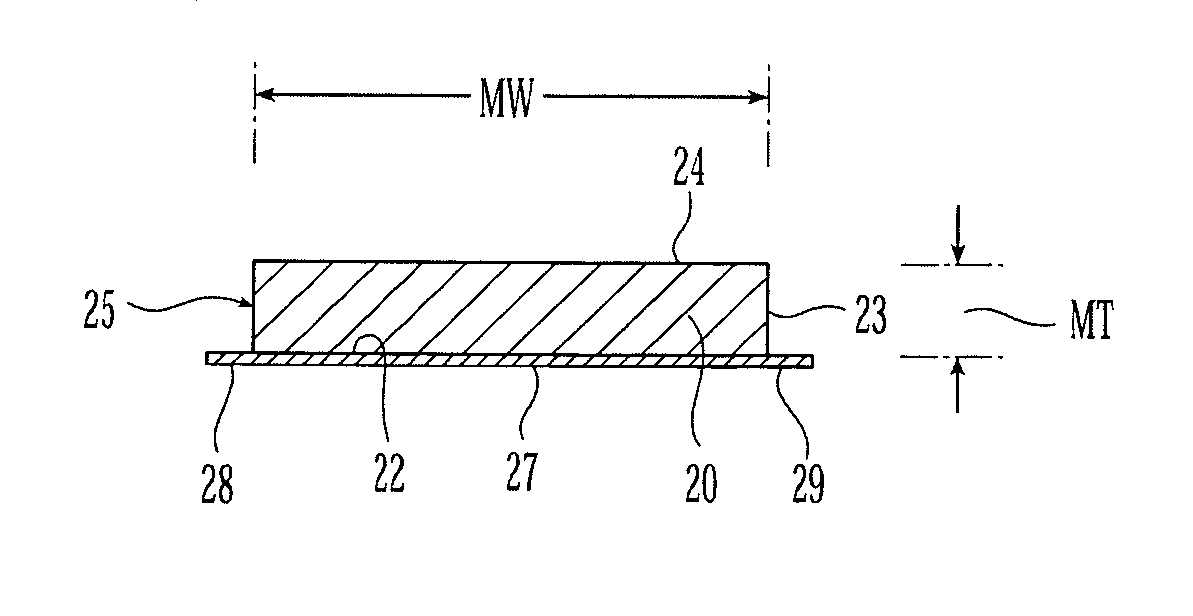

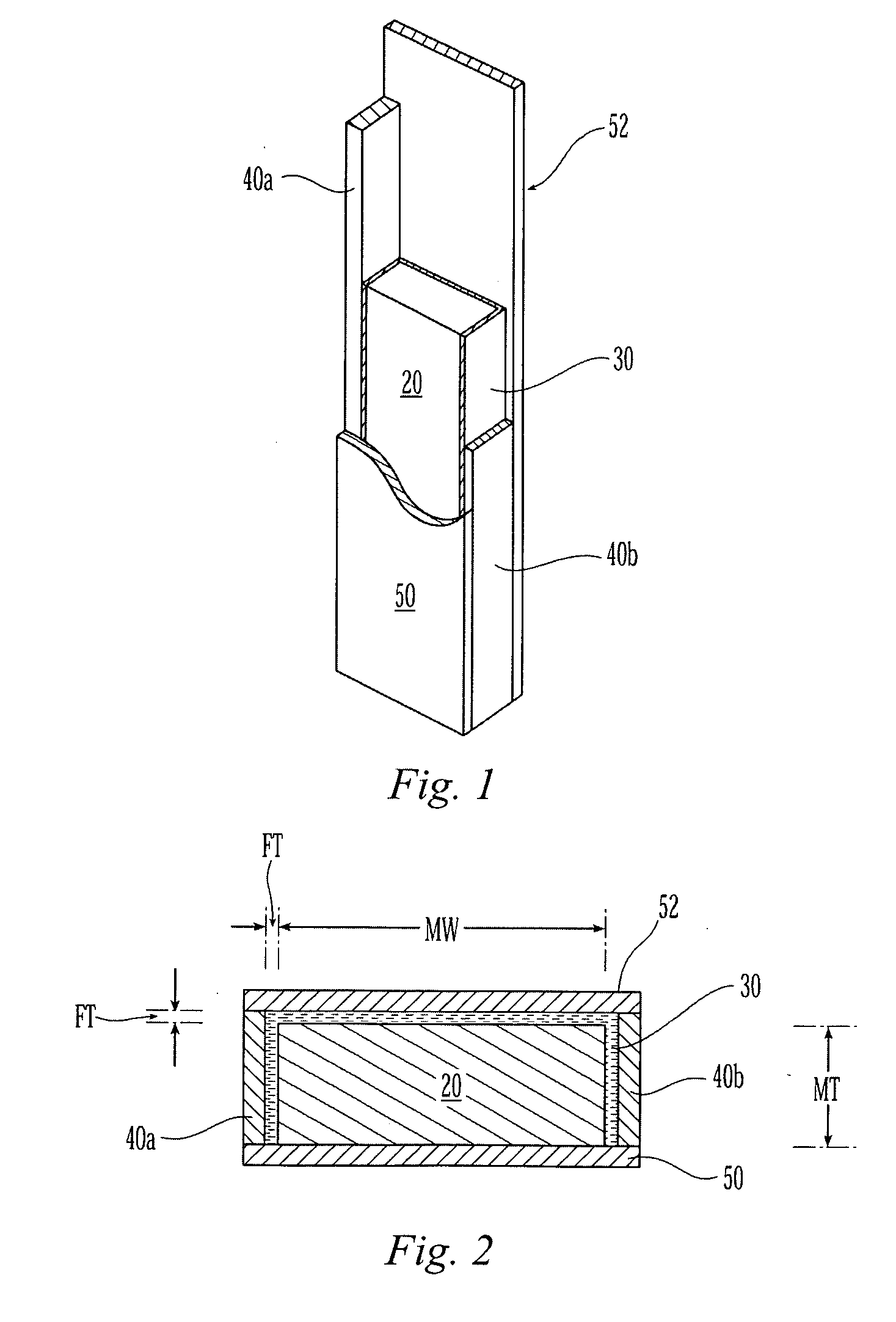

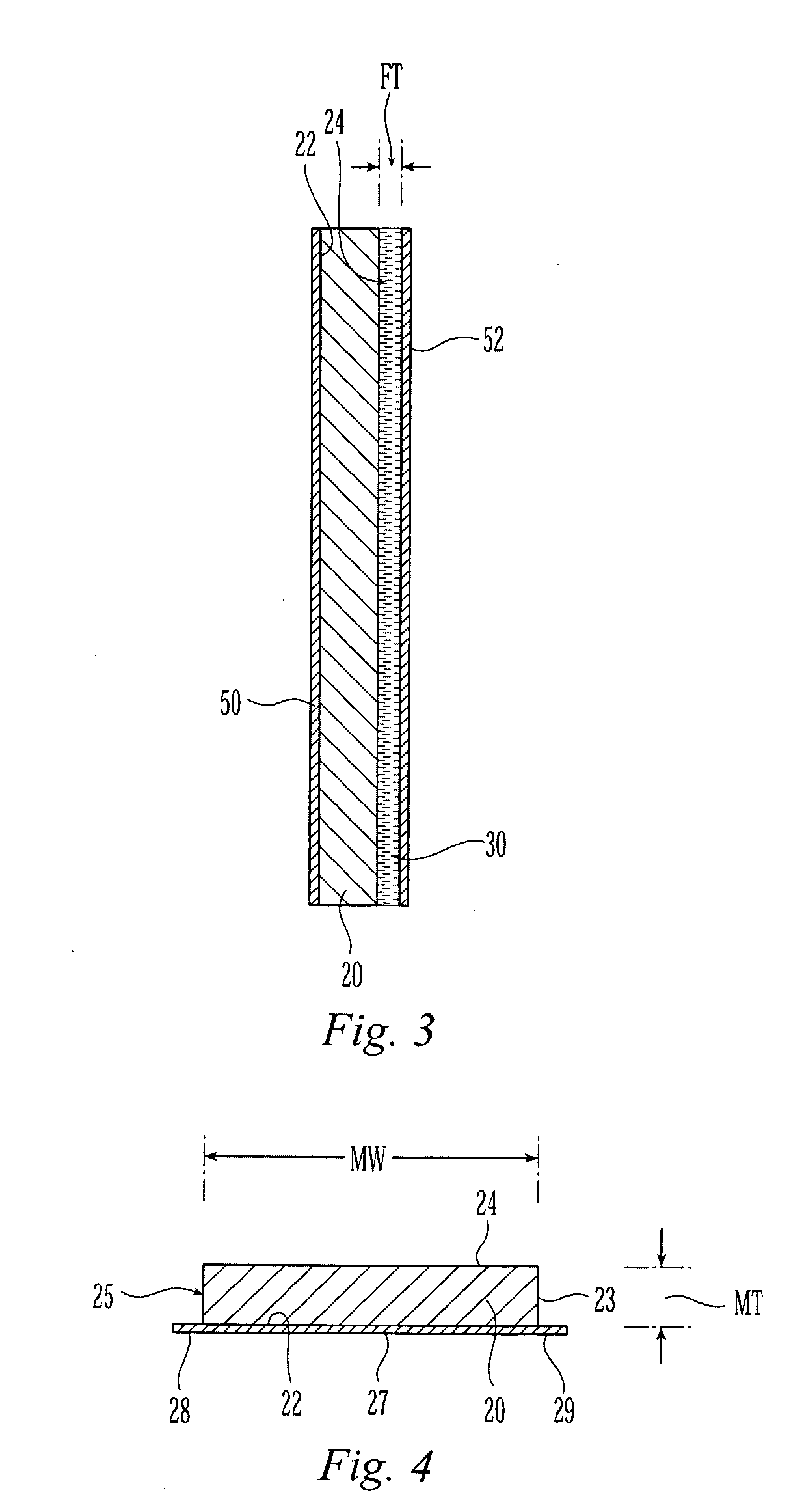

[0015] This invention is directed to insulation materials for use in insulating wall spaces of residential and commercial buildings. Insulation systems for use within the walls of buildings typically comprises a blanket or batt of thermal insulation material disposed between adjacent wall studs and between the inner and outer wall sheathing. Often, to improve insulative properties of the wall, a “house wrap” such as Tyvek® housewrap is installed on the outer surfaces of the outer wall sheathing to provide a barrier to wind entering the house through joints, seams or gaps in the house structure, as well as through permeable building materials used to construct the walls. Similar wind-resistance can be provided by a spray-on foam applied internal to the inner surface of the outer wall sheathing, and to the adjacent studs. This foam can provide multiple benefits, including increased insulative properties (inherent in the foam itself), decreased air permeability, and increased wall rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com