Patents

Literature

486 results about "Building insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Building insulation is any object in a building used as insulation for any purpose. While the majority of insulation in buildings is for thermal purposes, the term also applies to acoustic insulation, fire insulation, and impact insulation (e.g. for vibrations caused by industrial applications). Often an insulation material will be chosen for its ability to perform several of these functions at once.

Curable fiberglass binder comprising salt of inorganic acid

InactiveUS20110040010A1Good adhesion to glassLaminationLamination apparatusGlass fiberWater insoluble

A curable formaldehyde-free binding composition for use with fiberglass is provided. Such curable composition comprises an aldehyde or ketone and an amine salt of an inorganic acid. The composition when applied to fiberglass is cured to form a water-insoluble binder which exhibits good adhesion to glass. In a preferred embodiment the fiberglass is in the form of building insulation. In other embodiments the product is a microglass-based substrate for use in a printed circuit board, battery separator, filter stock, or reinforcement scrim.

Owner:JOHNS MANVILLE CORP

Curable fiberglass binder

ActiveUS20110039111A1Good adhesion to glassImprove adhesionNon-macromolecular organic additionPretreated surfacesGlass fiberWater insoluble

A curable formaldehyde-free binding composition for use with fiberglass is provided. Such curable composition comprises an addition product of an amine and a reactant to form an amino-amide intermediate. To the amino-amide is added an aldehyde or ketone to form the curable binder composition. The composition when applied to fiberglass is cured to form a water-insoluble binder which exhibits good adhesion to glass. In a preferred embodiment the fiberglass is in the form of building insulation. In other embodiments the product is a microglass-based substrate for use in a printed circuit board, battery separator, filter stock, or reinforcement scrim.

Owner:JOHNS MANVILLE CORP

Facing and faced insulation products

ActiveUS20080081138A1Less moistureLess expansionPipe protection by thermal insulationGlass/slag layered productsWood veneerFiber

A facing laminate for insulation products includes: a foil or metallized polymeric film sheet layer forming an inner layer of the laminate that is adapted be bonded directly to a surface of an insulation product; a paper composite sheet layer, which may include synthetic and / or inorganic fibers, forming an outer exposed layer of the laminate; and a scrim intermediate and bonded to the foil or metallized polymeric film sheet and paper composite sheet layers. The facing laminate may include a humectant and / or a water, oil, and / or grease repellant component. The paper composite sheet layer of the laminate exhibits greater dimensional stability and reduced wrinkling when the laminate is exposed to conditions of high humidity. Insulation products to be faced with this facing laminate include pipe insulation, duct board, duct wrap insulation, metal building insulation, and other building insulation products.

Owner:JOHNS MANVILLE CORP

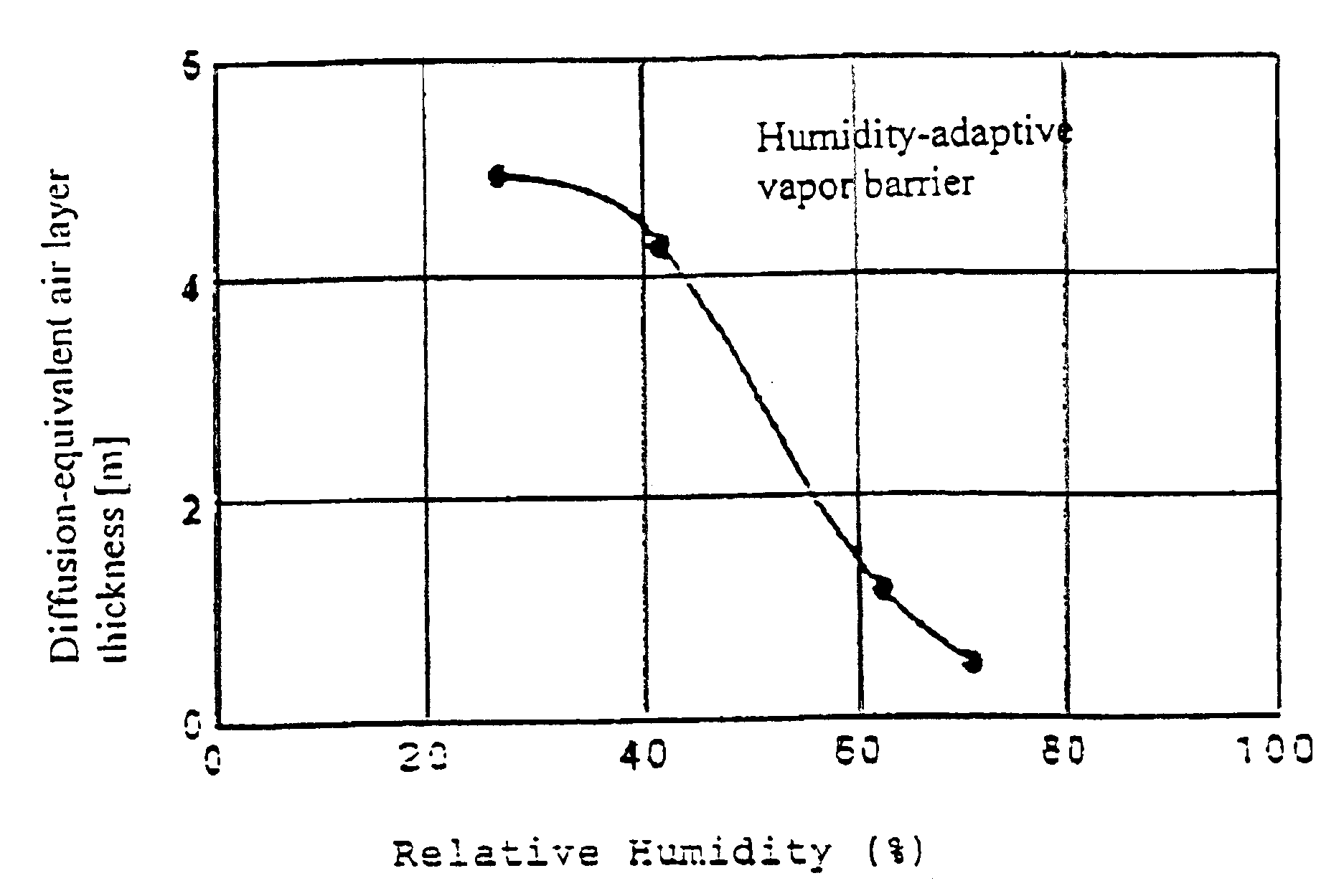

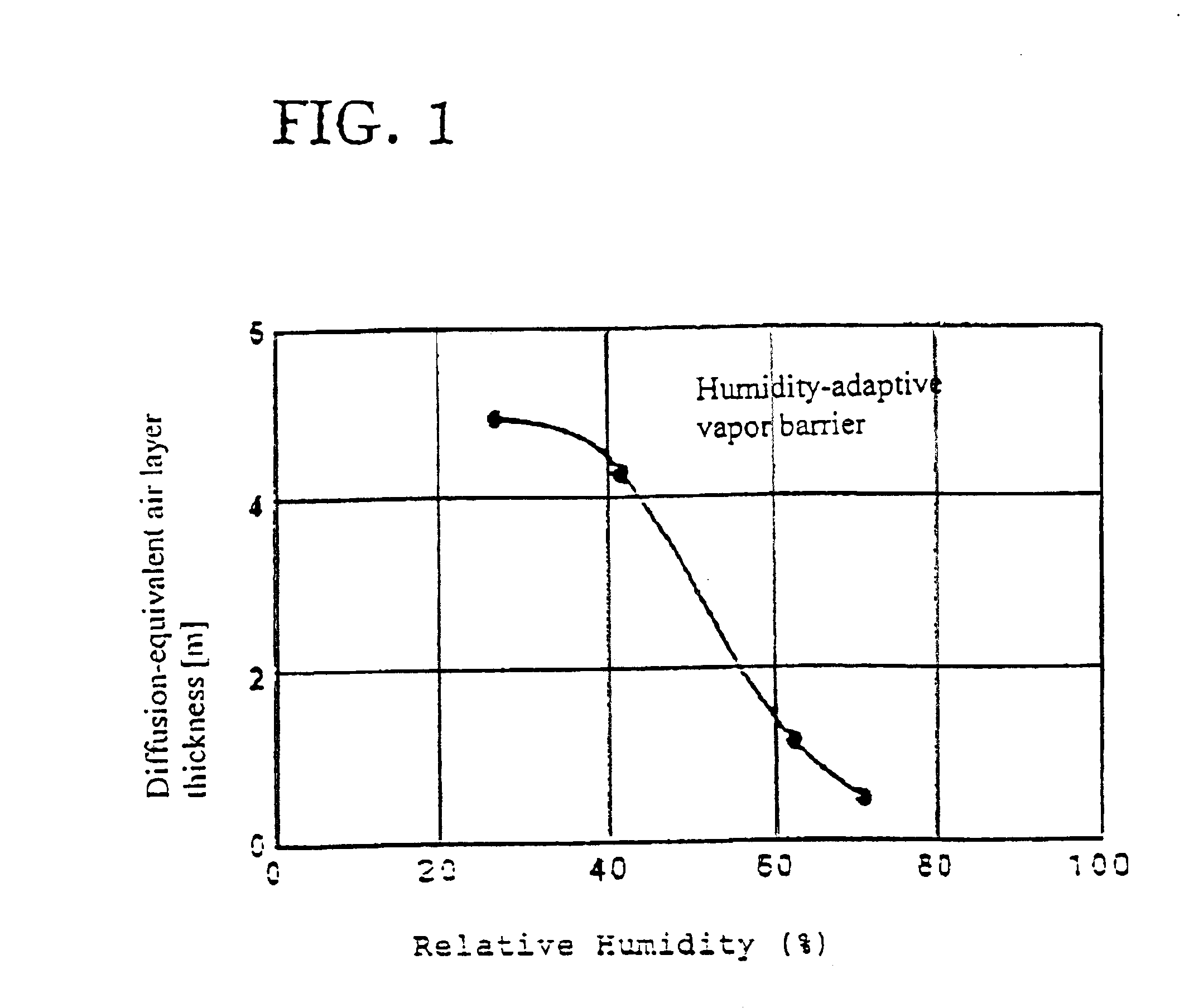

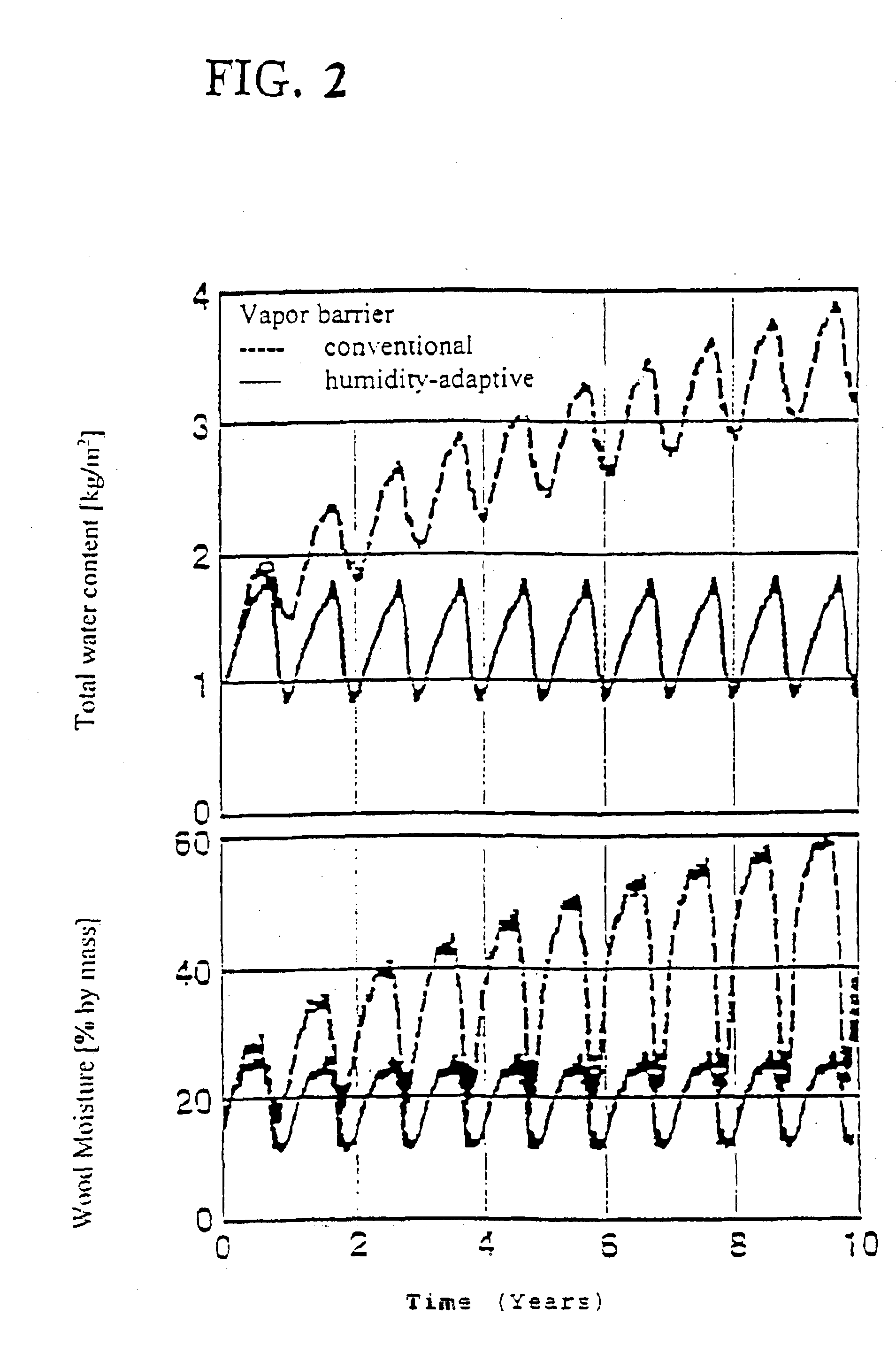

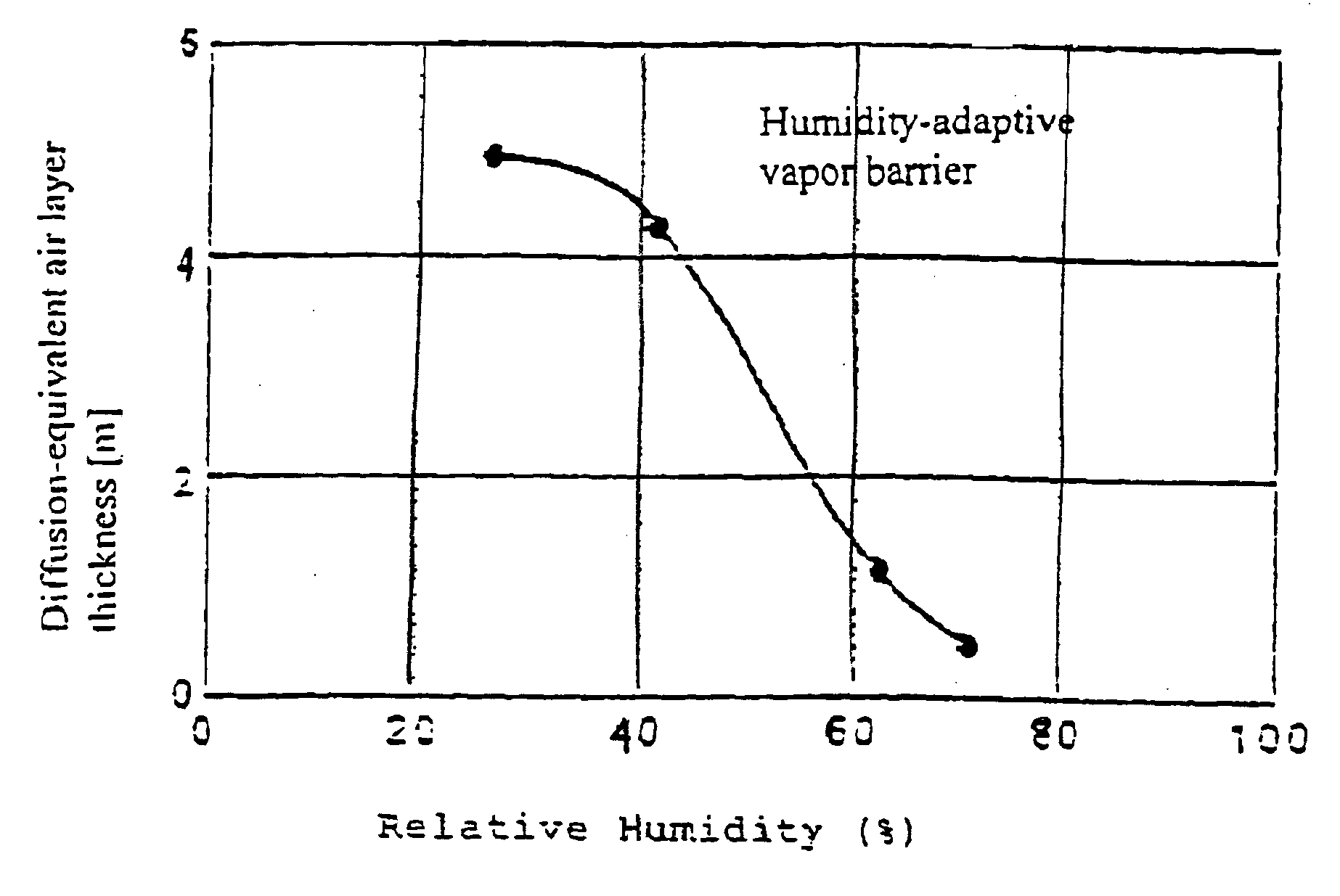

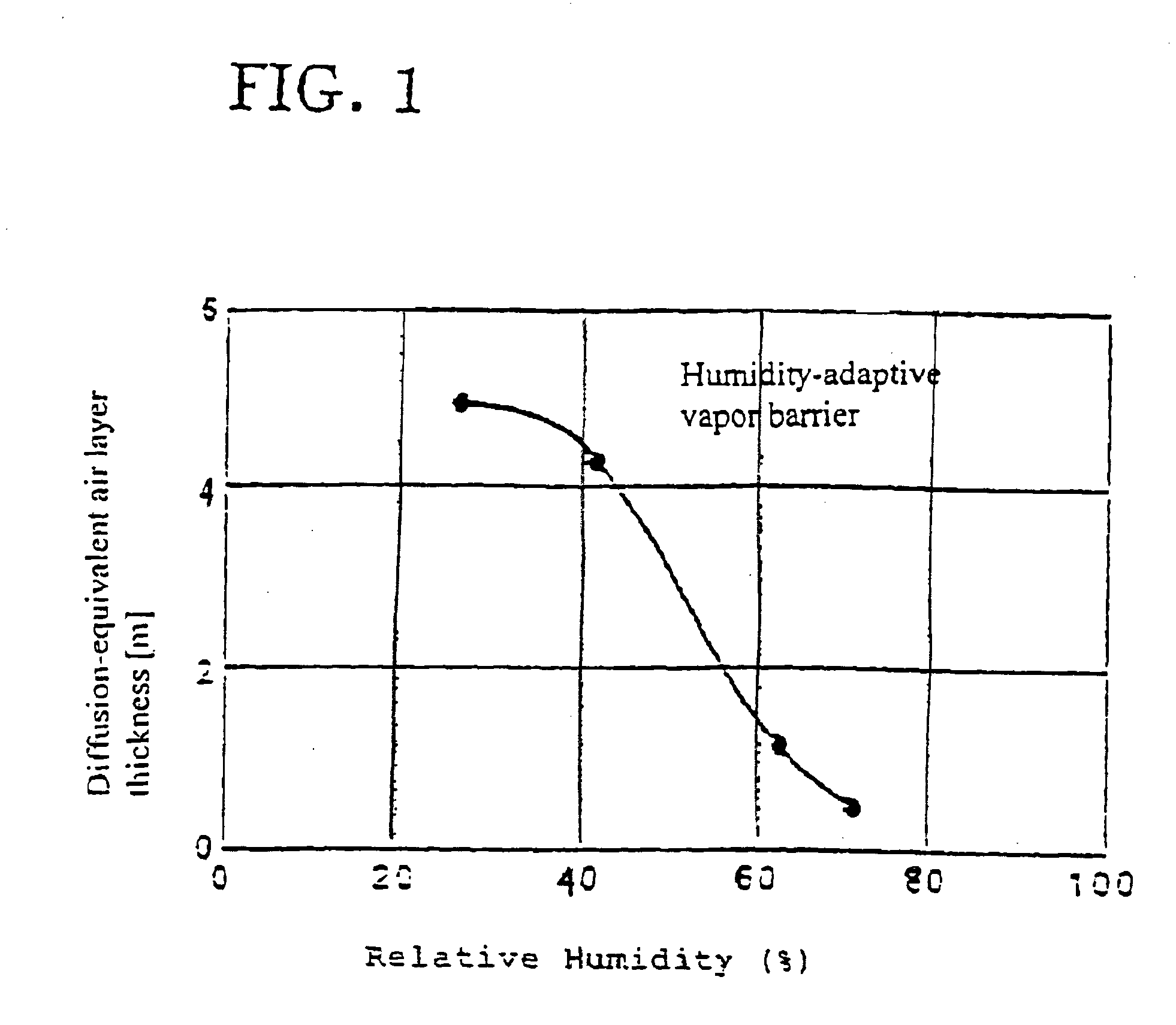

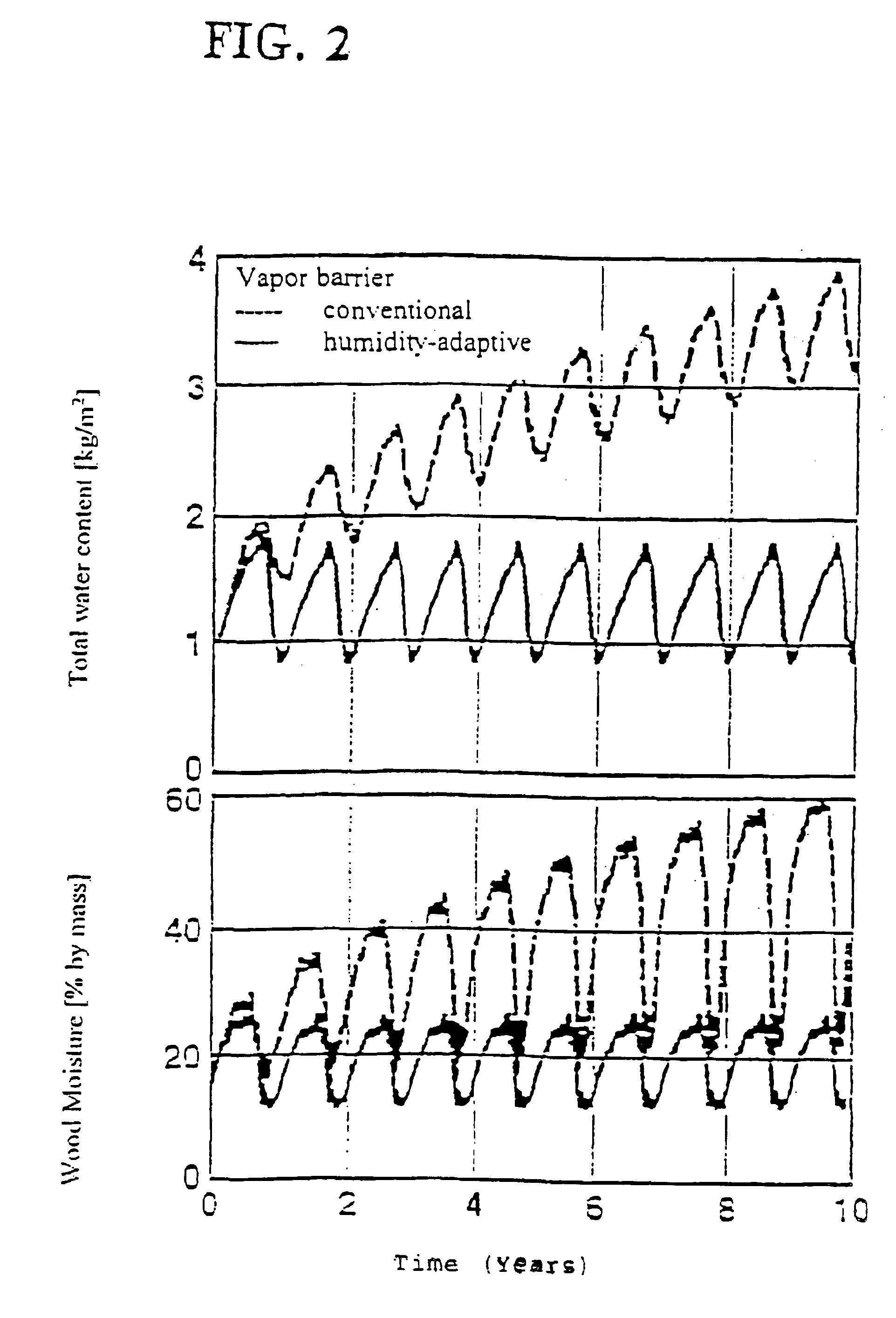

Vapor barrier for use in the heat insulation of buildings

InactiveUS6890666B2Synthetic resin layered productsCellulosic plastic layered productsVapor barrierAmbient humidity

The invention relates to a vapor barrier for use in cthe thermal insulation of buildings which can be used, in particular, for thermal insulation procedures in new buildings or in the renovation of old buildings. The vapor barrier in accordance with the invention is thereby capable of achieving water vapor exchange under different ambient conditions. This is achieved by using a material which has a water vapor diffusion resistance which is dependent on the ambient humidity and which also has adequate tensile strength and tear resistance.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Vapor barrier for use in the heat insulation of buildings

The invention relates to a vapor barrier for use in the thermal insulation of buildings which can be used in particular, for thermal insulation procedures in new buildings or in the renovation of old buildings. The vapor barrier in accordance with the invention is thereby capable of achieving water vapor exchange under different ambient conditions. This is achieved by using a material which has a water vapor diffusion resistance which is dependent on the ambient humidity and which also has adequate tensile strength and tear resistance.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

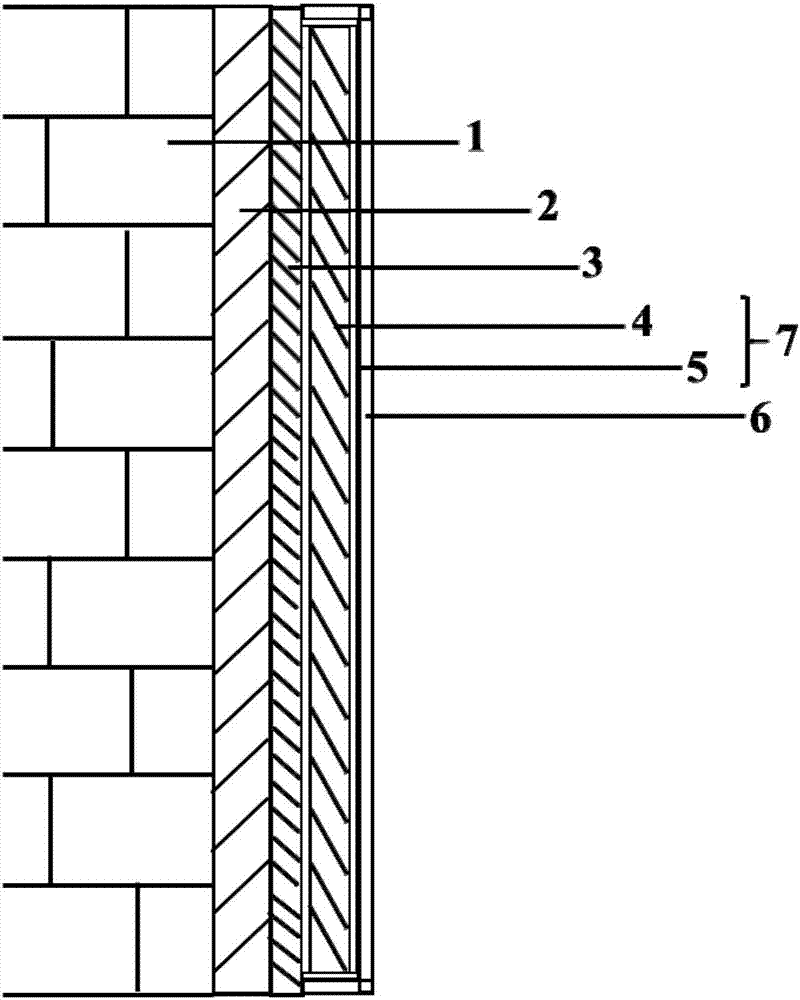

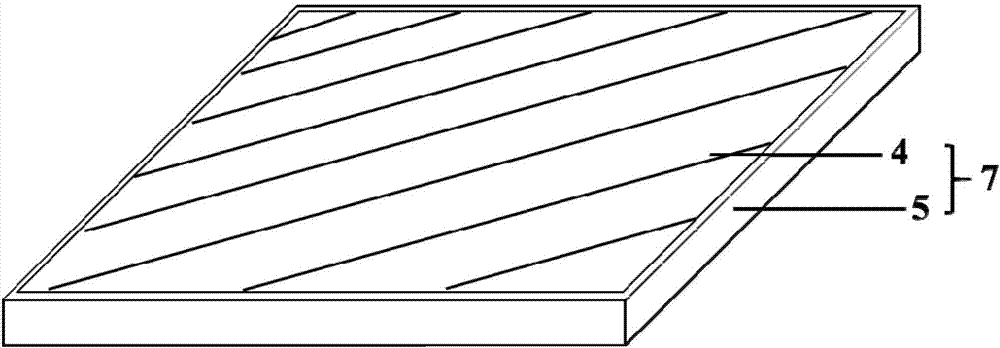

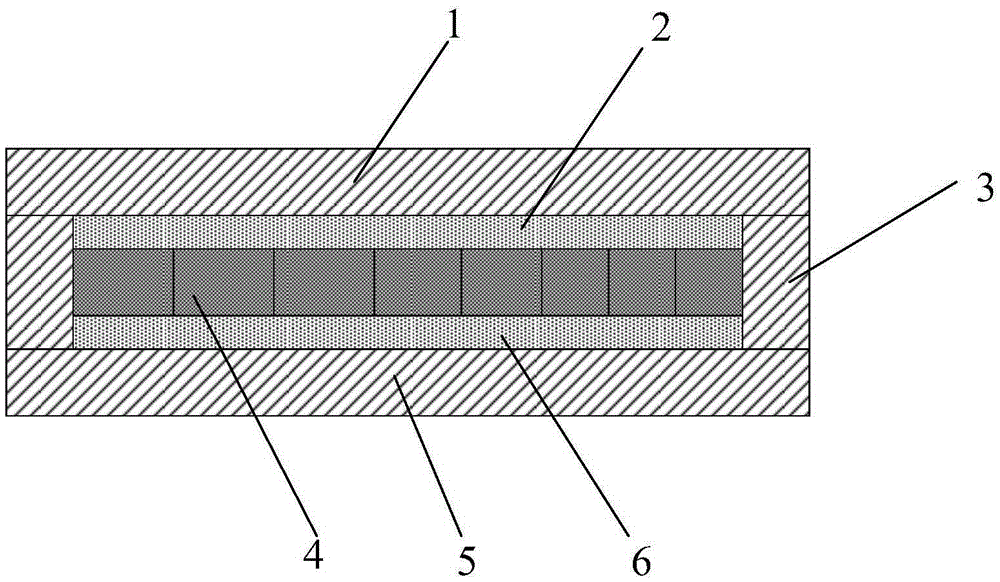

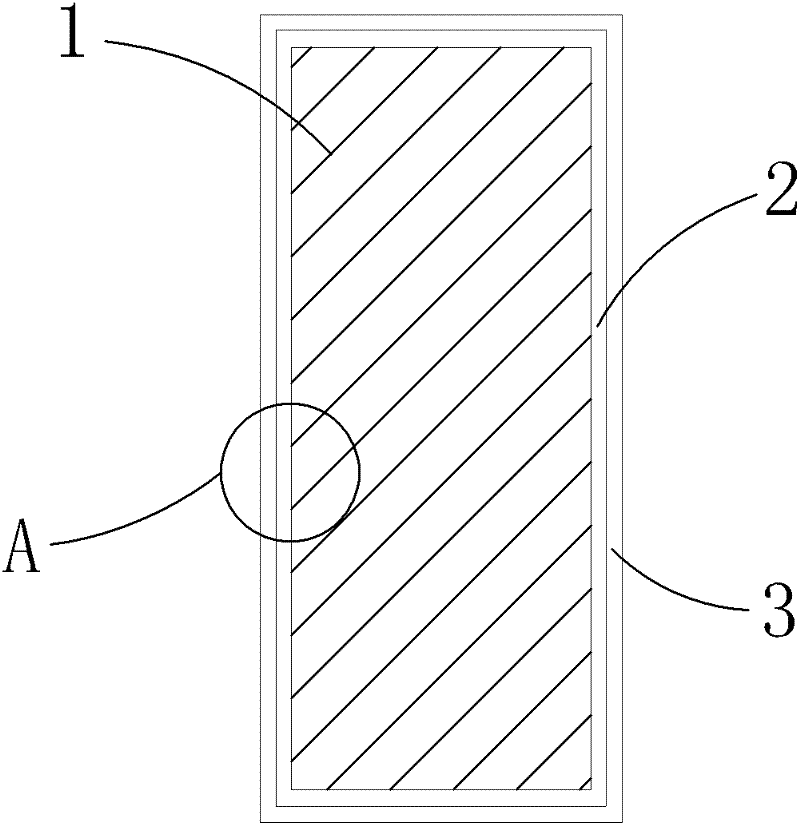

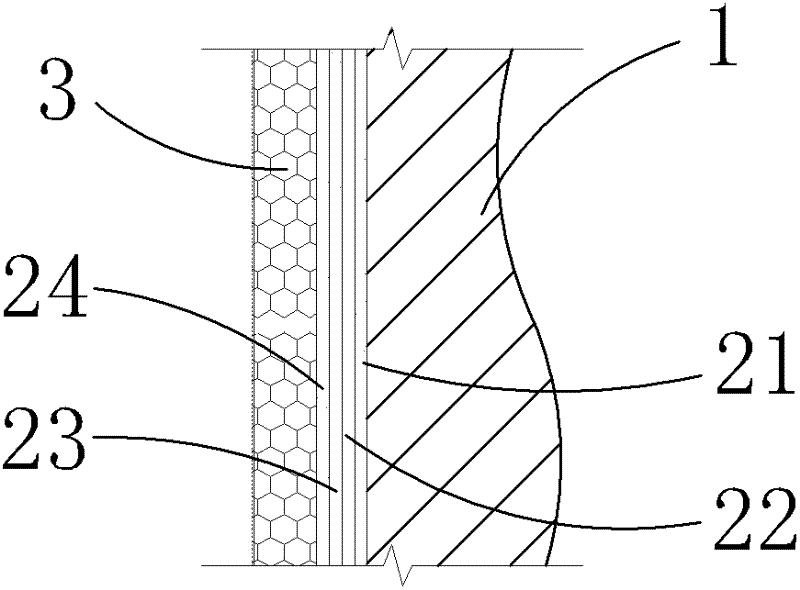

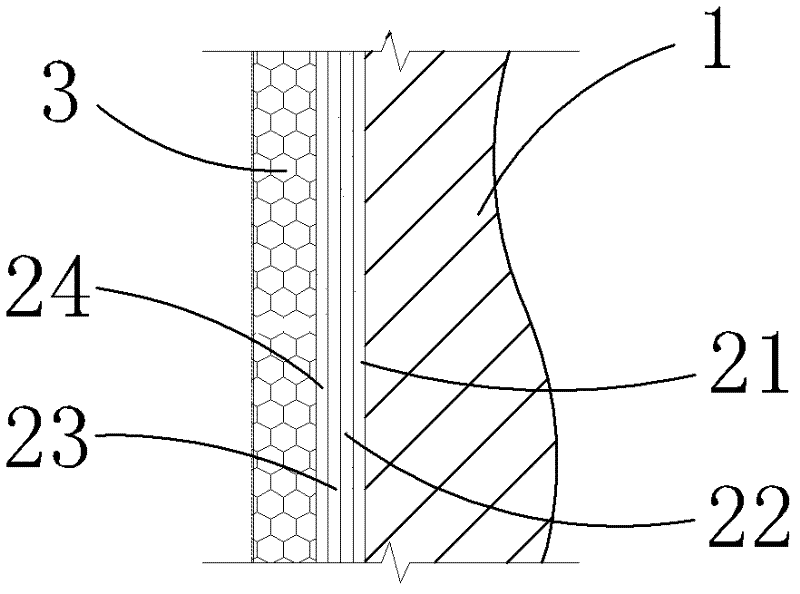

Phase-change energy-storage building insulation structure

InactiveCN107227807AResolve separabilitySolve the shortcomings of large supercoolingConstruction materialWallsInsulation layerPhase change

The invention discloses a phase-change energy-storage building insulation structure. A wall structure is successively provided with a wall substrate, an insulation layer, a directional structural plate, a fixed-form phase-change energy-storage insulation board and an exterior board in the direction from outdoor to indoor, and the fixed-form phase-change energy-storage insulation board comprises an inorganic composite phase change material and a packaging plate; the inorganic composite phase change material is composited from inorganic hydrated salt and a porous structure carrier, and the phase transition temperature of the phase change material is 10-40 DEG C; in inorganic composite phase change material, the weight percentage content of the inorganic hydrated salt is 40-95%, and the inorganic composite phase change material is coated with light-cured resin with fire resistance and corrosion resistance. The phase-change energy-storage building insulation structure has the good effects of heat preservation and thermal insulation, and can store cold quantity in outdoor air at summer night in the phase-change energy-storage insulation board; in the daytime, the stored cold quantity is released into indoor air so as to prolong the time of an indoor peak temperature, reduce the fluctuation of the indoor temperature, improve the environmental comfort and reduce the energy consumption of an air conditioner in summer.

Owner:SOUTH CHINA UNIV OF TECH

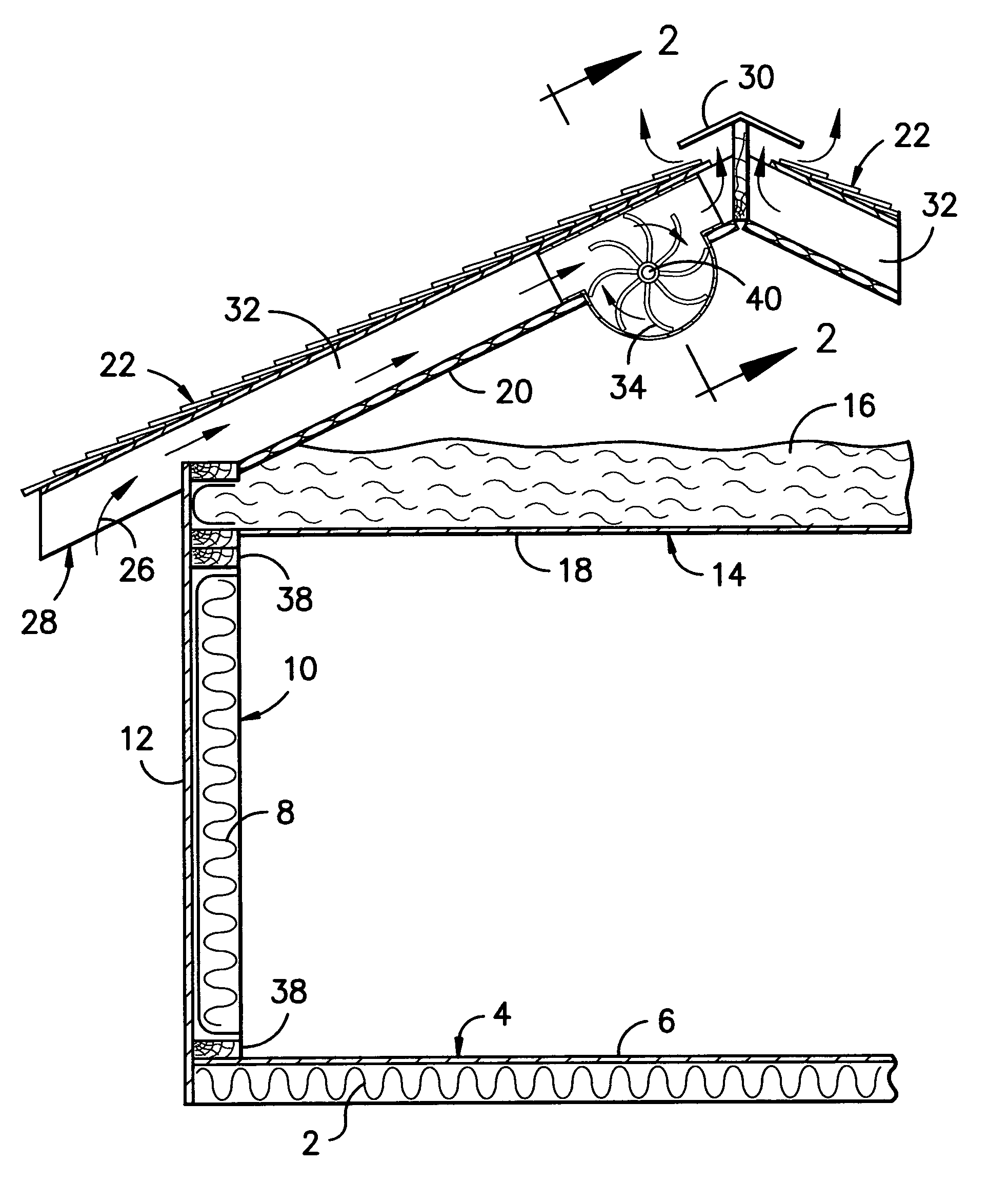

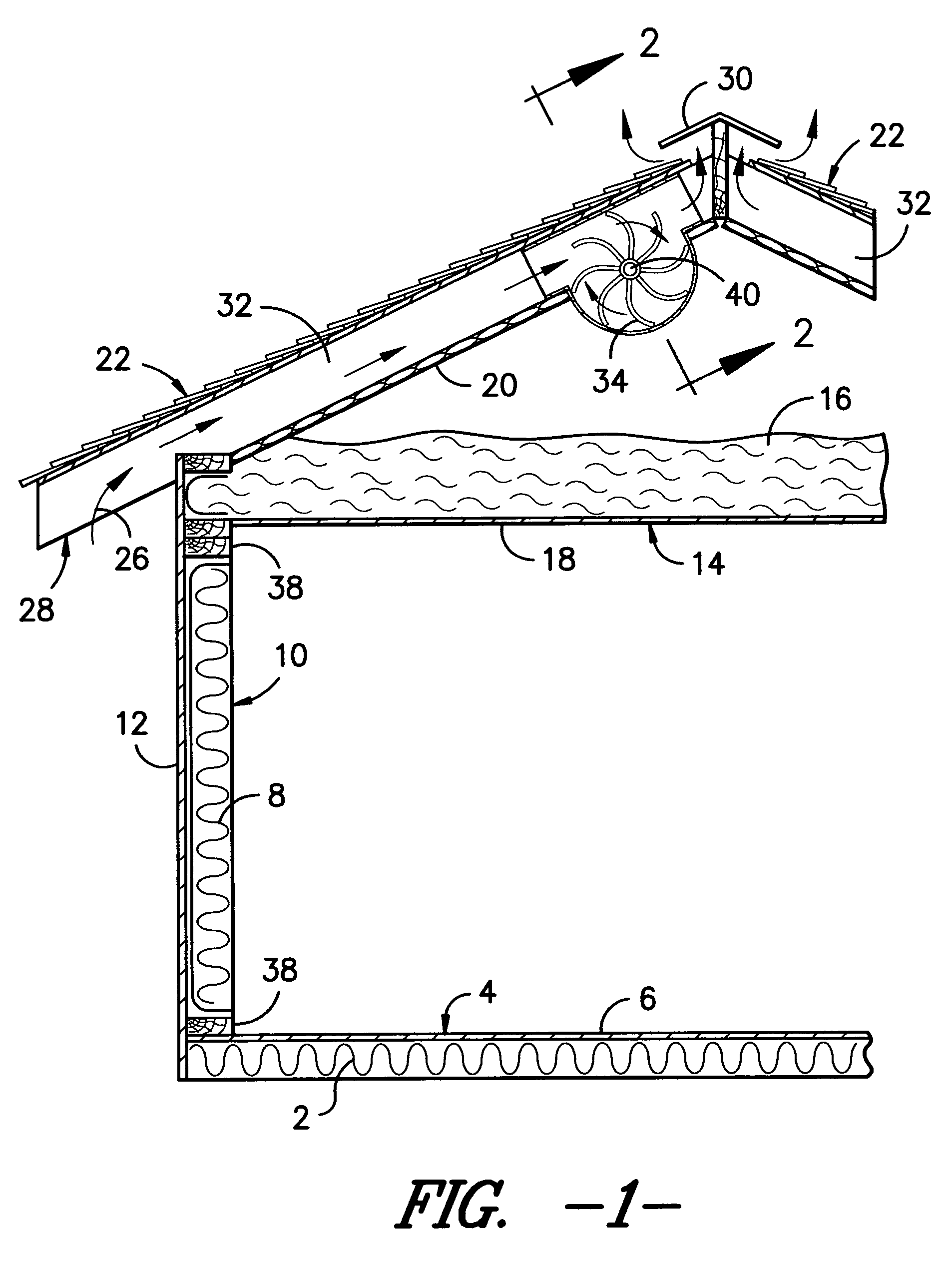

Insulation and power generation system for buildings

A system for insulating a building and generating electricity includes a method for providing insulation for a building that resists heat transfer through conduction, convection and radiation, creating a series of air channels to transfer heat away from the underside of a roof using air currents, and harnessing such air currents to generate electricity. A series of turbines are positioned within or adjacent to the air channels, and are rotated by the air currents. The turbines are connected to an electrical generator, which generates electricity when the turbines are rotated. The generator is then connected either to an electrical storage device, such as a battery or a series of batteries, or is alternatively connected to the local power grid to provide electrical power back into the power grid.

Owner:ALL IN ONE INSULATION LLC

Method for manufacturing composite mineral wool board for building insulation

ActiveCN102501300AEasy constructionHigh tensile strengthCeramic shaping apparatusHeat proofingAdhesiveVolumetric Mass Density

The invention discloses a method for manufacturing a composite mineral wool board for building insulation. The method uses special interface agents as adhesives, a fiberglass mesh fabric completely wraps the surface of the high-density mineral wool board for the building to improve defects of an inorganic mineral wool board, and the mineral wool board can meet the requirements of national or industrial relevant standards and becomes a level-A non-combustible, flexible, high-strength, waterproof, air-permeable, high-weatherability and heat-insulation mineral wool material for the building. Experiments prove that the composite mineral wool board for building insulation, manufactured by the method, meets the relevant requirements of the national or industrial standards of Rock wool products for exterior insulation and finish systems (GB / T25975-2011), External thermal insulation composite system based on expanded polystyrene (JG149-2003), fire prevention regulations for buildings (GB50016) and the like.

Owner:CHANGAN UNIV

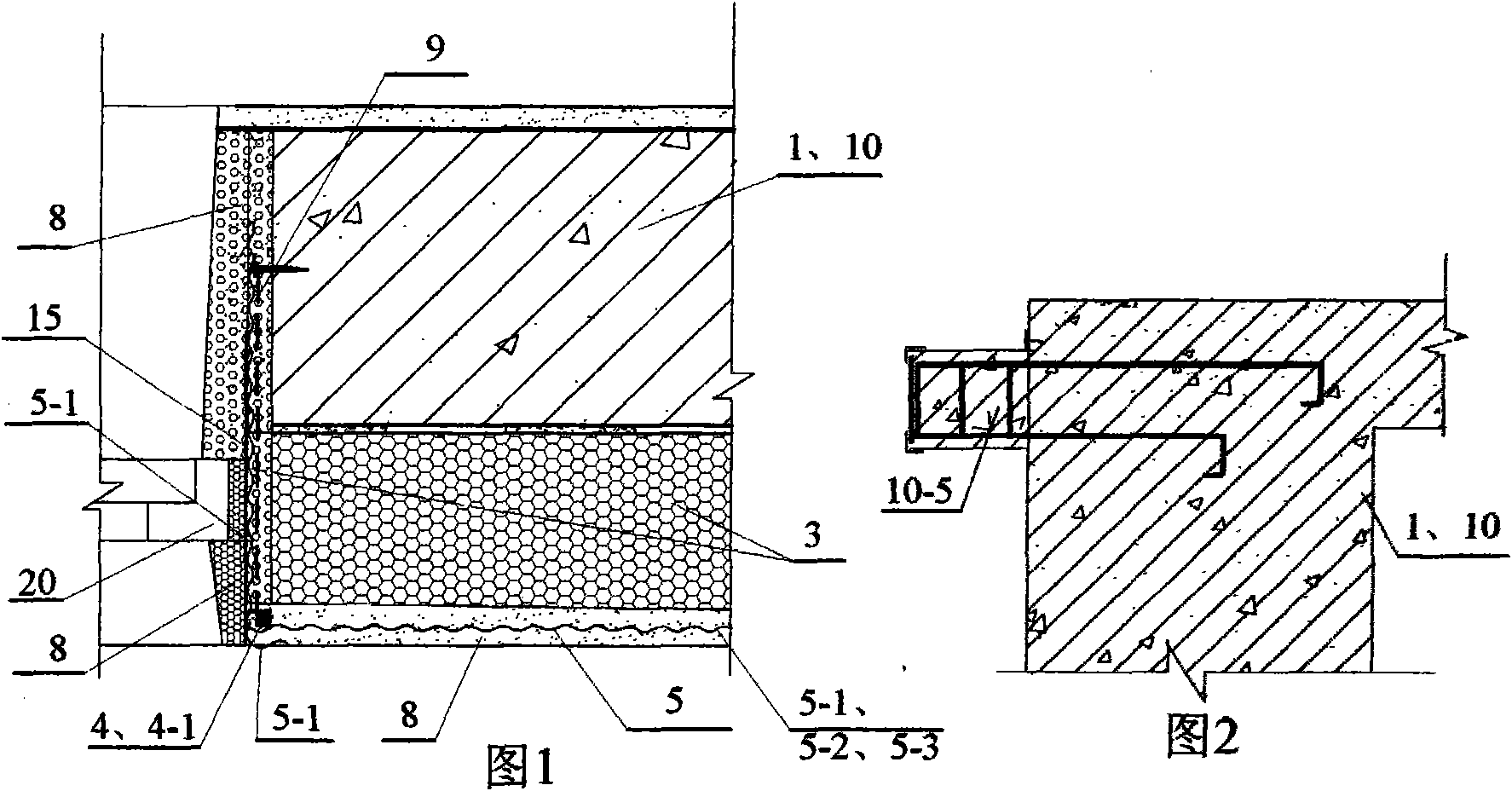

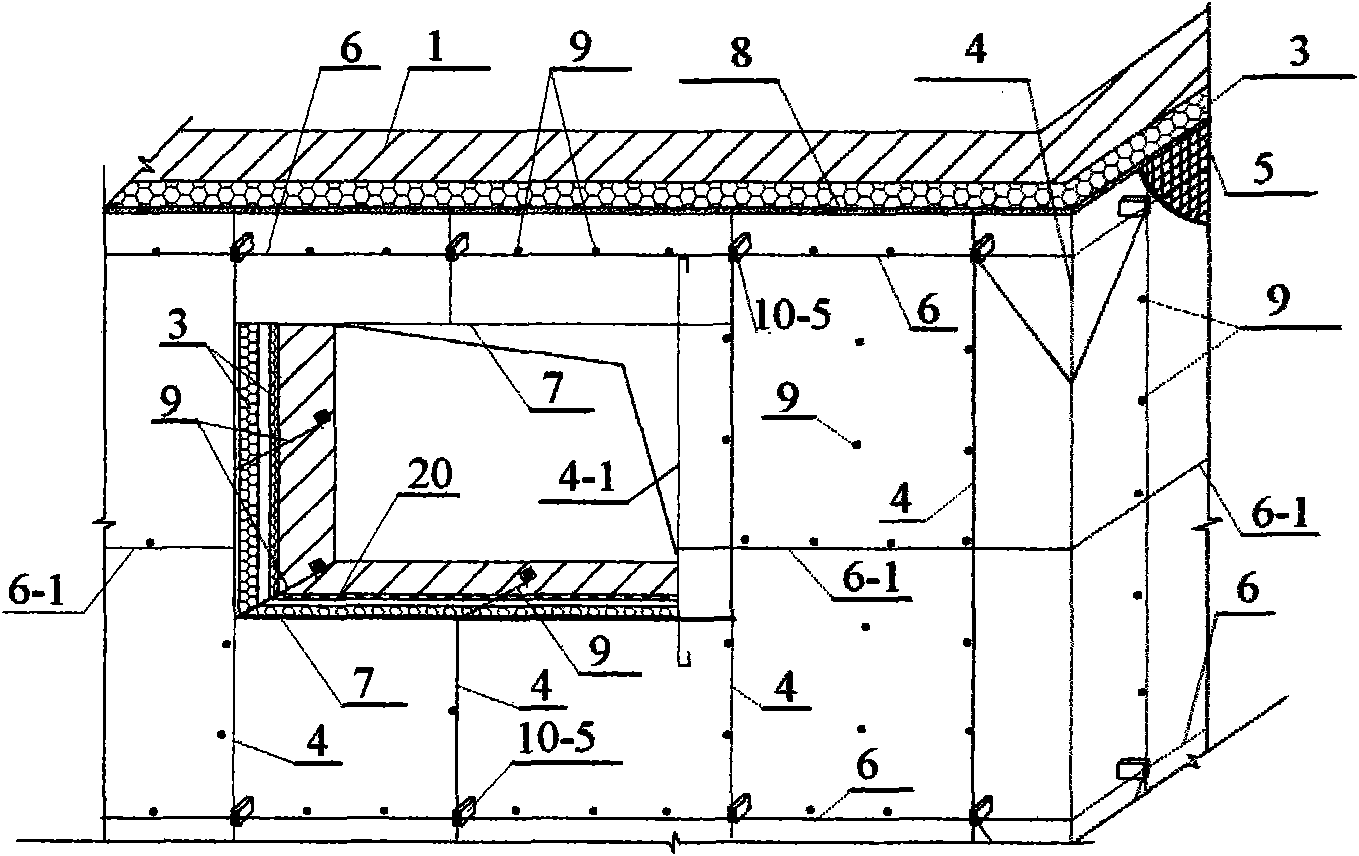

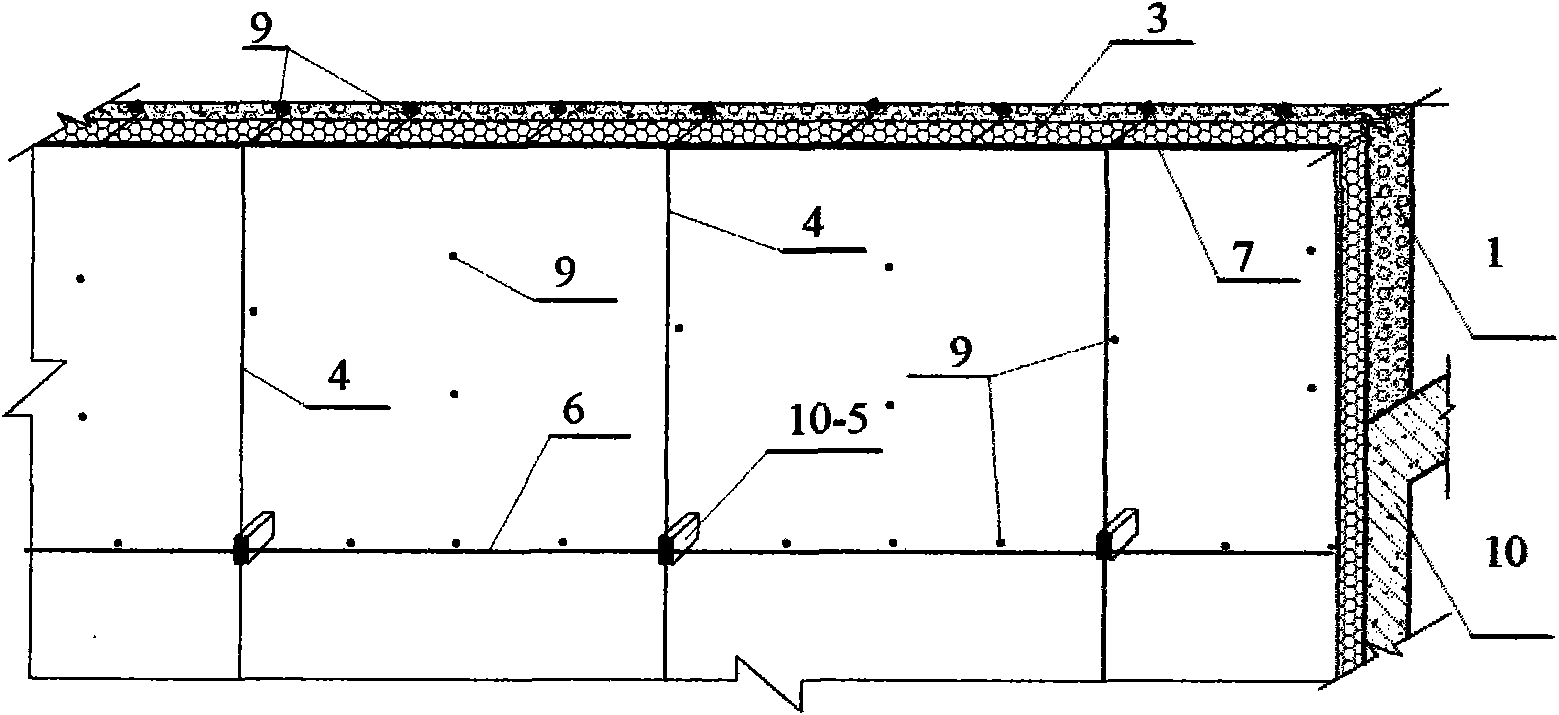

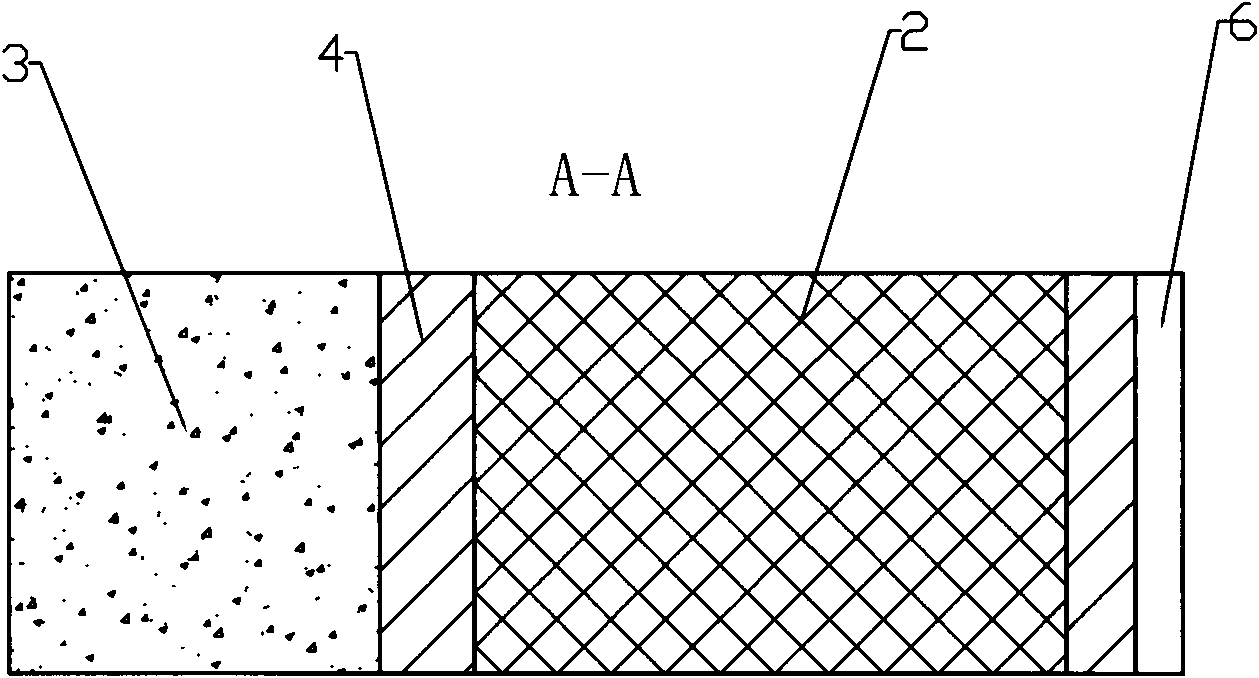

Exterior wall external insulation composite wall body with support

InactiveCN101914961AImprove insulation effectIncreased durabilityCovering/liningsWallsSurface layerThermal bridge

The invention discloses an exterior wall external insulation composite wall body with a support, relates to a building insulation composite wall body and aims to solve the problem of a large number of thermal bridges in the conventional insulation wall. A first structure of the composite wall body is that: a concrete cantilever beam supporting member is fixed in a main body structure of a building; an insulating layer is positioned outside a substrate wall body; a vertical reinforced steel bar is arranged outside the insulating layer and welded with an embedded steel plate of the concrete cantilever beam supporting member; a metal mesh is fixed with the vertical reinforced steel bar; a door and a window are arranged on insulating layers on openings; protective layers are formed outside the insulating layer and on the insulating layers on both sides of the door and the window; and the vertical reinforced steel bar and the metal mesh are positioned in the protective layers. A second structure of the composite wall body is that: the concrete cantilever beam supporting member is fixed in the main body structure of the building; profile steel is welded at the outer end of the concrete cantilever beam supporting member; a decorating large plate protective layer is fixed with the profile steel; and an insulating layer is formed between an external decorating large plate protective layer and a substrate wall body. The composite wall body has the advantages of capacity of reducing the thermal bridges in a large scale, best insulating effect, safe external protective layer and decorating surface layer, high fire resistance, high durability, simple structure and convenient construction.

Owner:吴淑环

Inorganic composite insulation board and preparation method thereof

InactiveCN103265262AImprove heat resistanceLow temperature shrinkageFiberBuilding insulation materials

The invention provides an inorganic composite insulation board and a preparation method thereof, belonging to the technical field of novel building insulation materials. The inorganic composite insulation board is characterized by comprising the following components by weight parts: 40-48 parts of expanded perlite, 5-15 parts of phenolic foam particles, 32-36 parts of an inorganic binder, 2-6 parts of an organic reinforcing agent, 2-3 parts of a waterproof agent, 2-3 parts of inorganic enhance fibers, 1-2 parts of a hardening agent, and 1-2 parts of a fire retardant. The above raw materials are fully stirred, compressed, molded, and dried under a constant temperature to prepare the inorganic composite insulation board, and the board has advantages of good thermal insulation performance, light weight, small thermal conductivity coefficient, good stability, high intensity, convenient construction, etc., and can be widely applied in roofs and walls of various industrial and civil buildings, waterproofing and insulation of cold storages, barns and basements, as well as various cold insulation engineering.

Owner:安徽百穗供应链有限公司

Building insulation system

InactiveUS20130094791A1Promotes reflectionWrappersDomestic cooling apparatusThermal energyThermal energy storage

The building insulation system includes a reflective, non-porous bag filled with thermal insulation material. The covering of the bag is made from reflective polymeric facer or plastic, which facilitates reflection of thermal energy radiation. The reflective non-porous bag provides a thermal barrier for conduction, convection and radiation aspects of thermal energy transfer.

Owner:ASPENSON MARK A

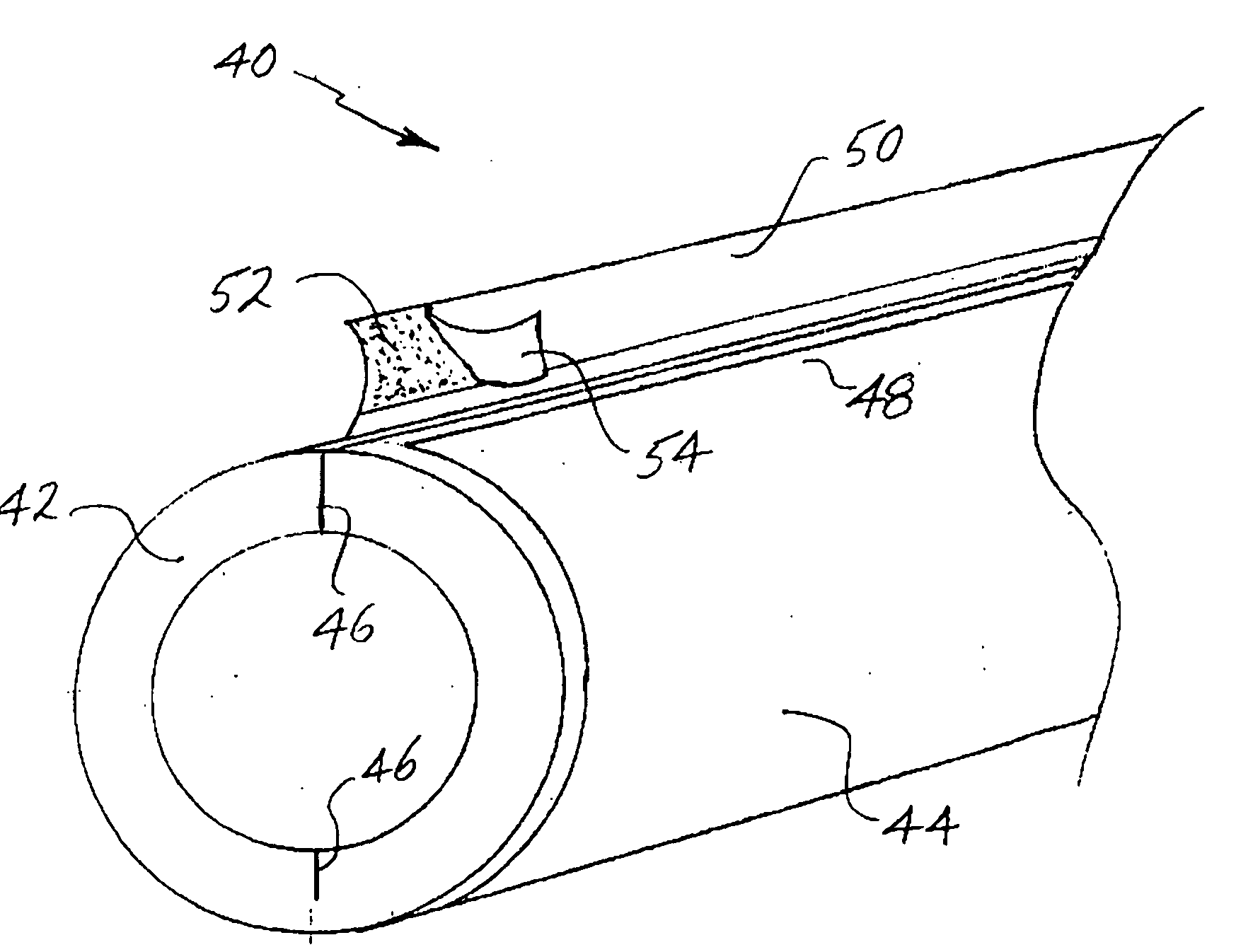

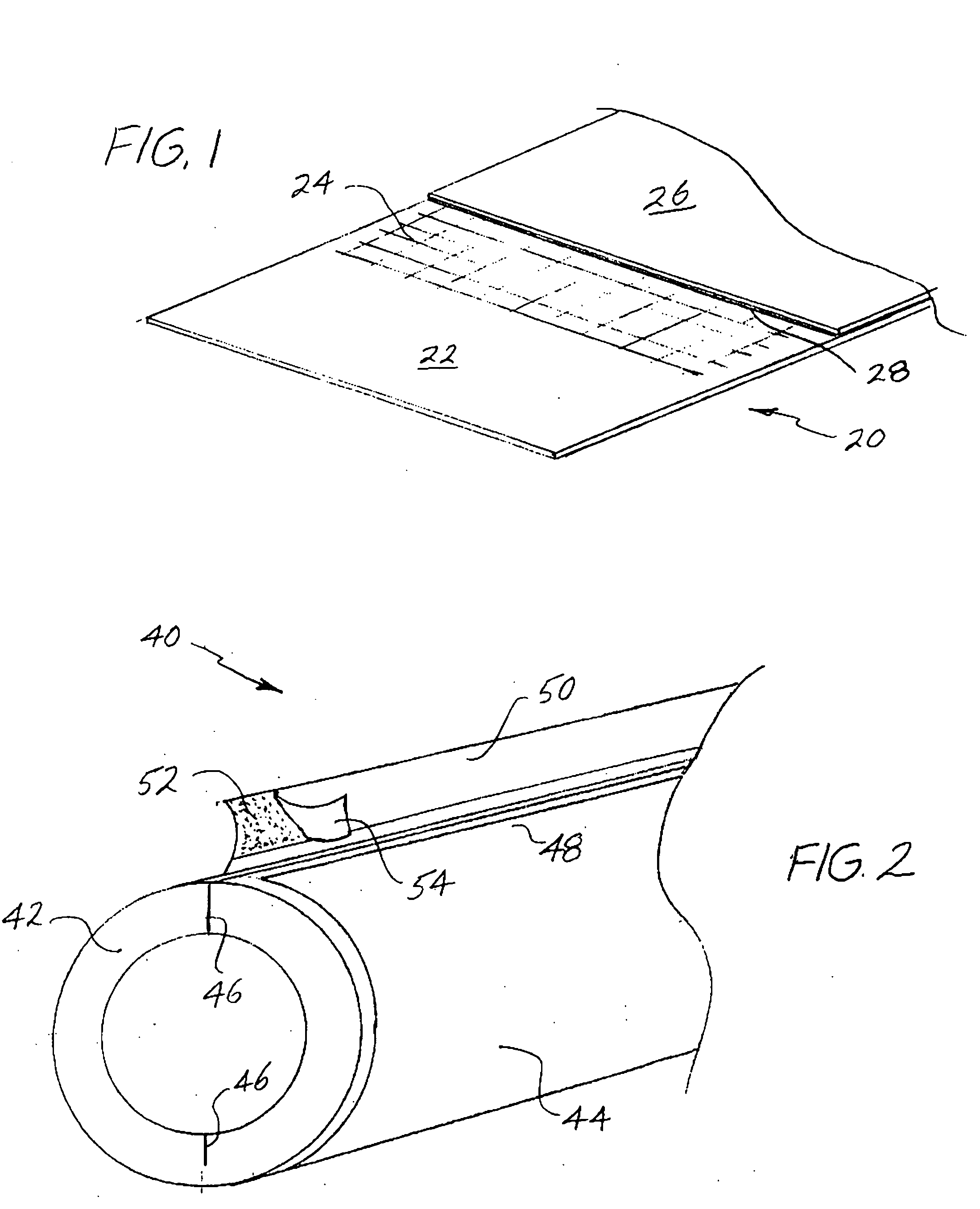

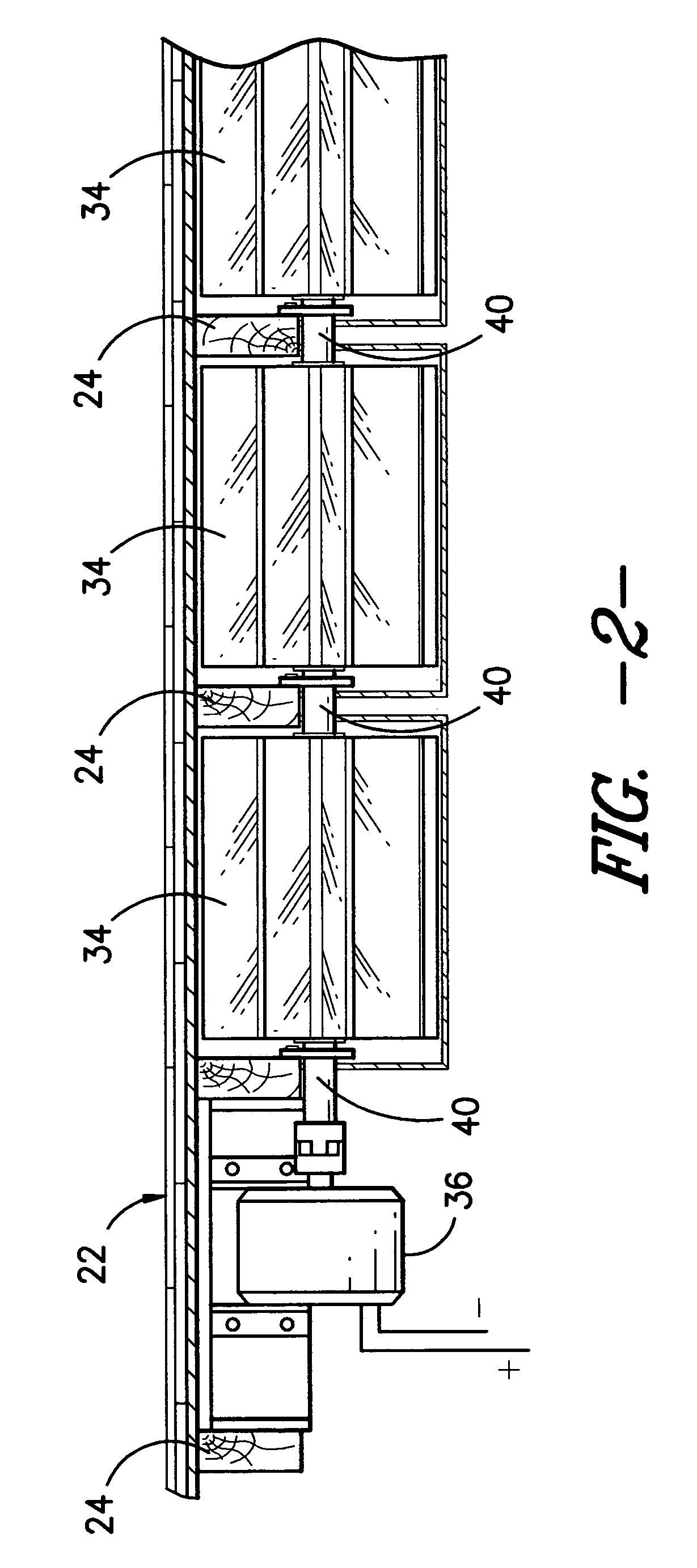

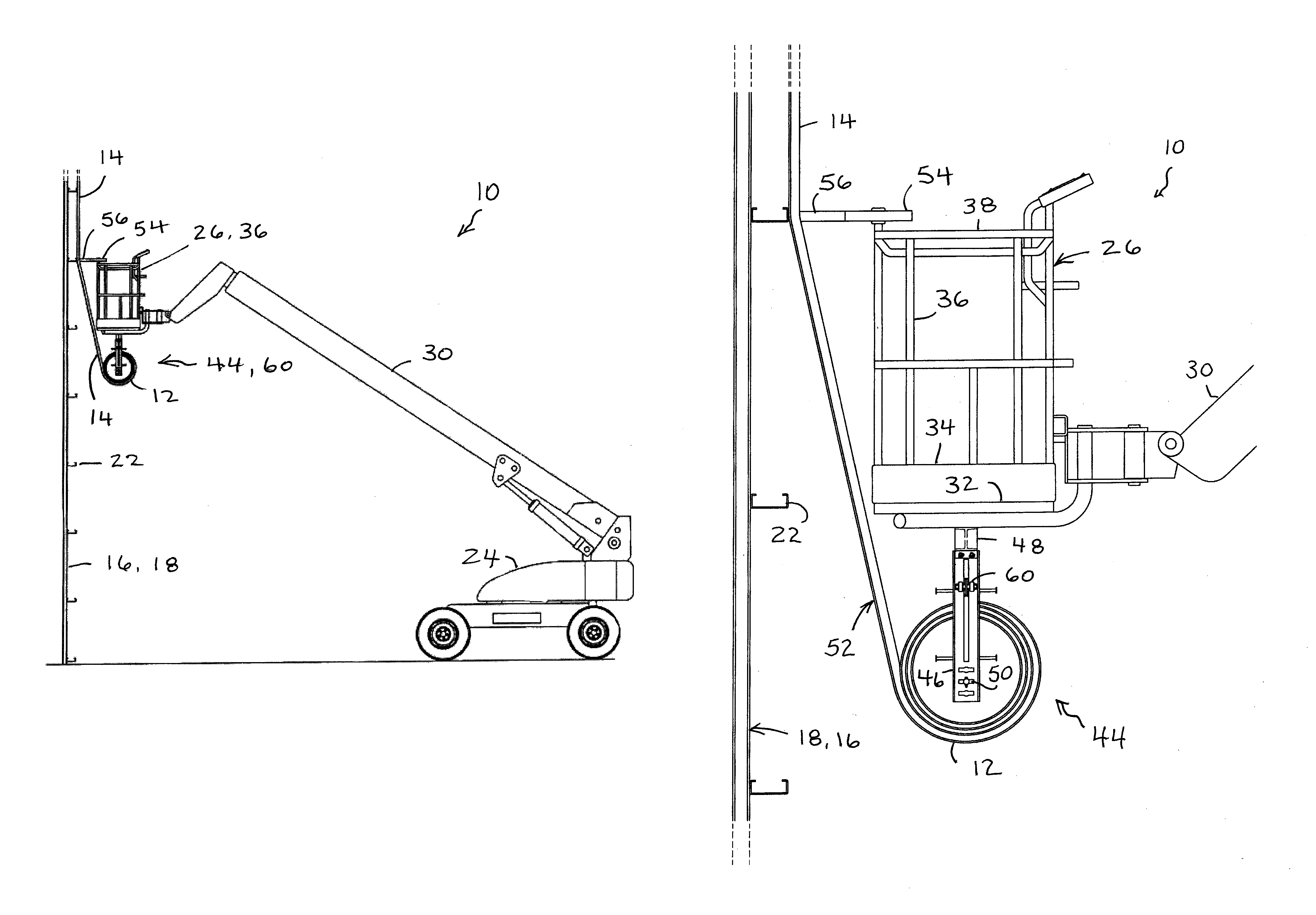

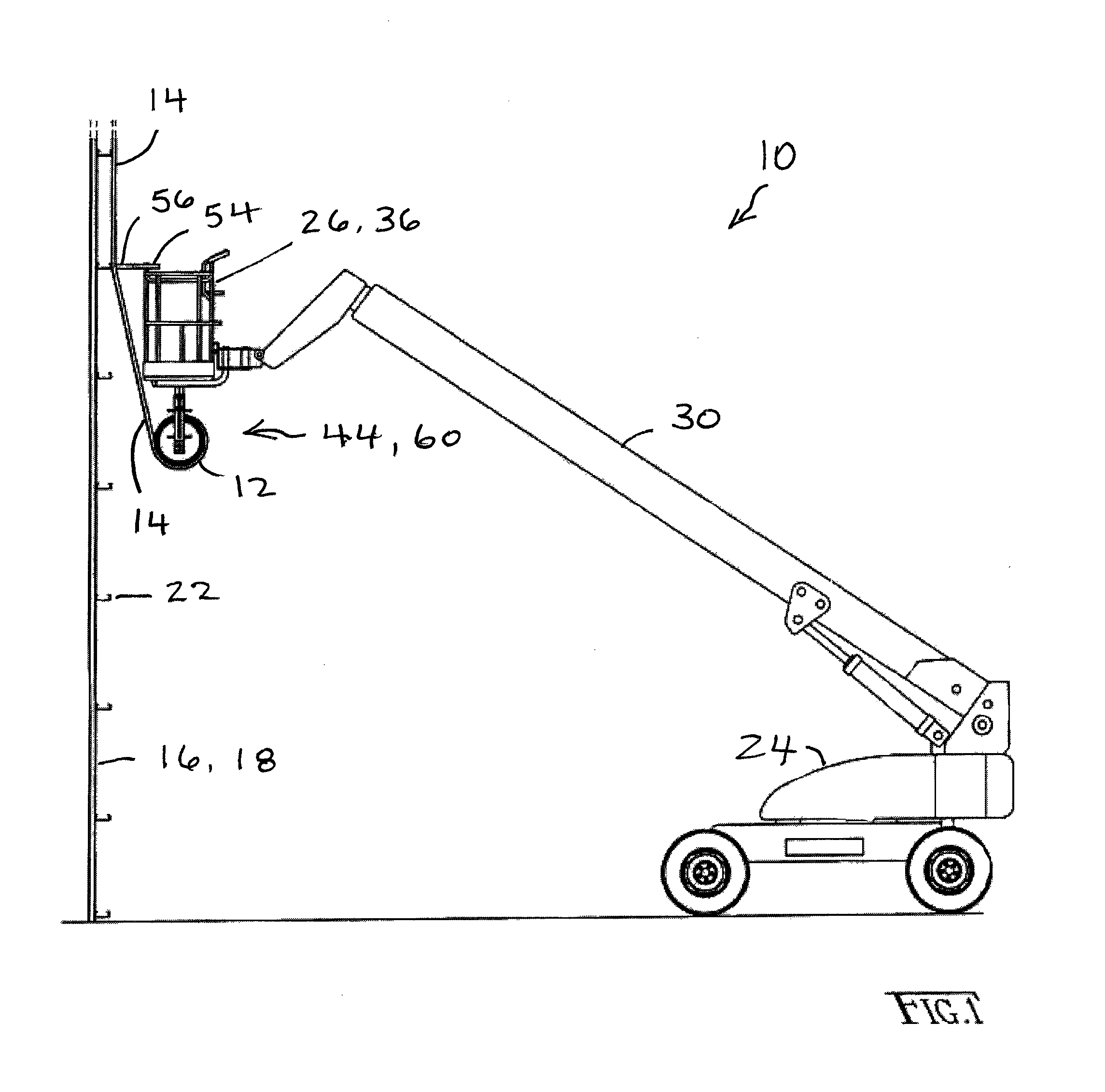

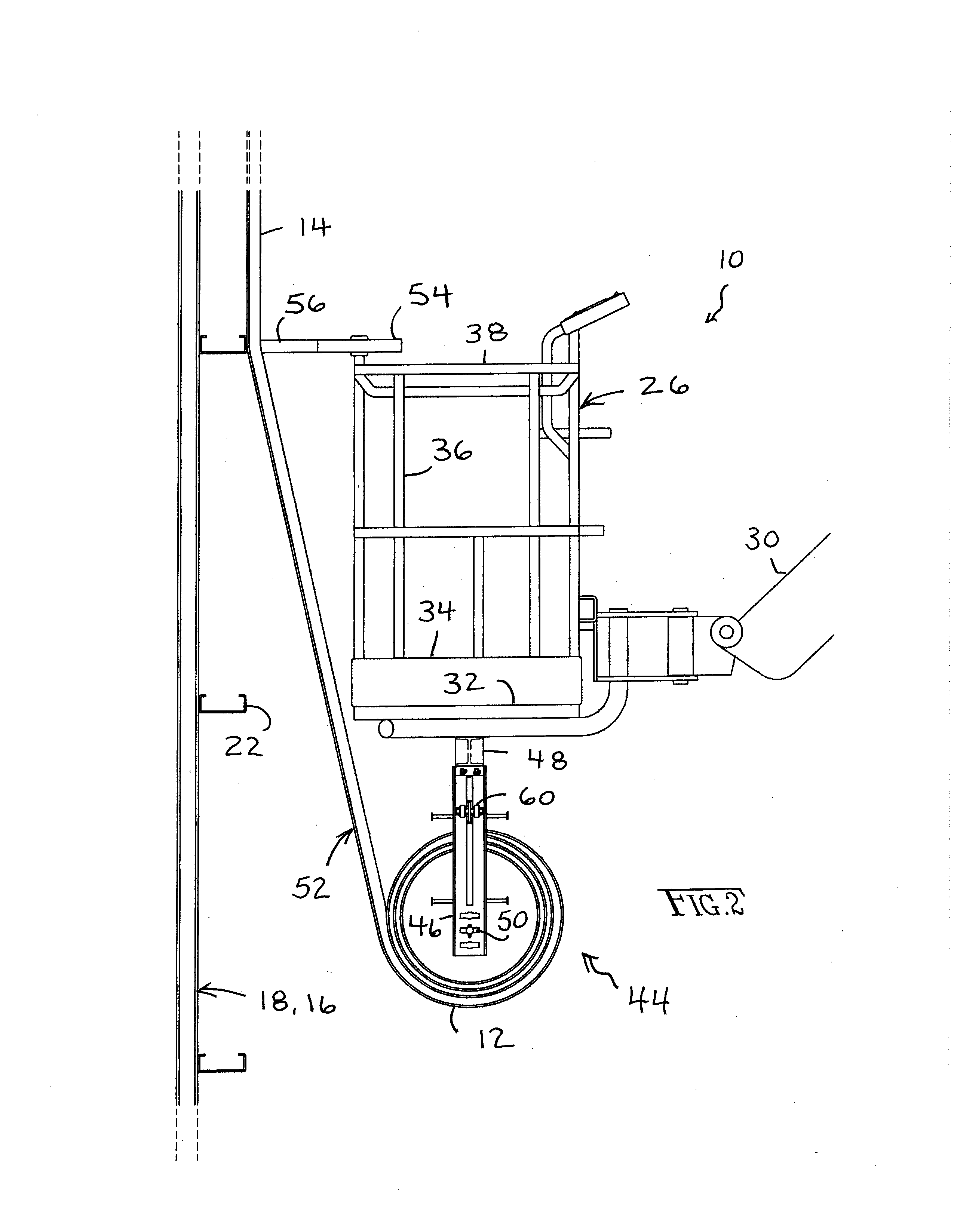

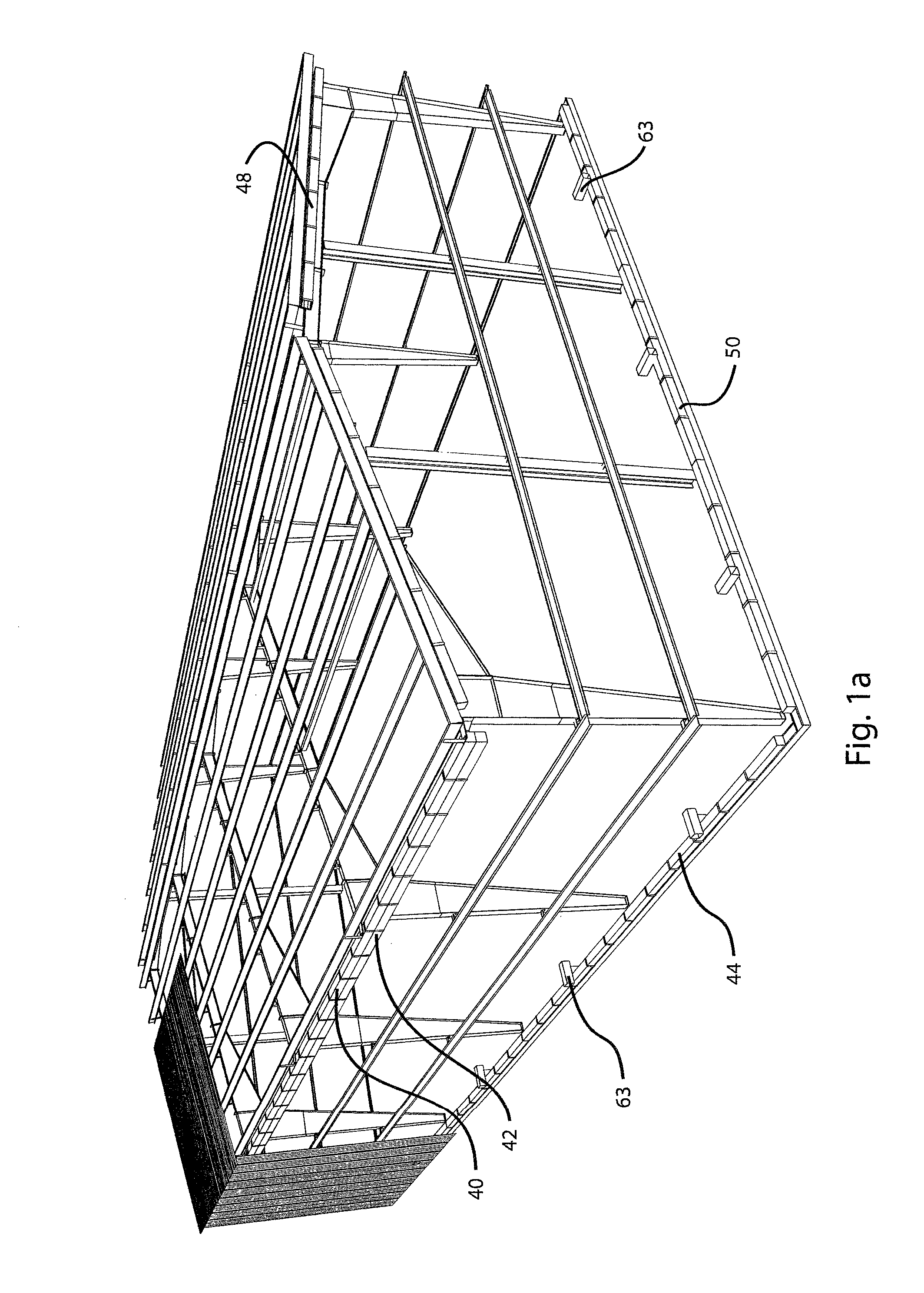

Apparatus for unrolling rolls of insulation in vertical strips from the top down

Apparatus for unrolling rolls of building insulation in vertical strips from the roof eave down, and adapted to be carried by an aerial work platform that in turn is carried by an elevator, has a pair of spars as well as an arbor and a tensioning control mechanism. The spars are spaced apart and are mounted to as well as project away from the aerial work platform. The arbor is carried between the spaced spars for inserting through the core of a role of insulation and allowing the insulation to be unrolled from the roll in the form of strips to be hung on the building. The tensioning control mechanism is provided for controlling the unrolling of the roll.

Owner:GALLETTE ERIC S +1

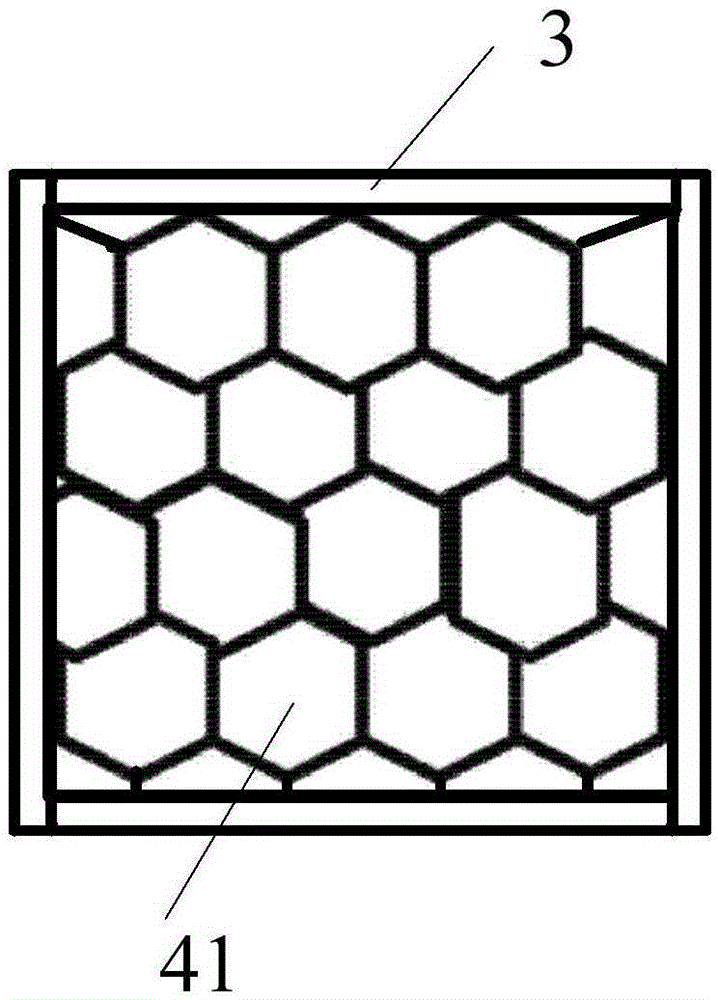

Aerogel composite insulation board

InactiveCN105328934AImprove insulation effectLess materialWater-setting substance layered productDomestic wallsMaterial consumptionEngineering

The invention discloses an aerogel composite insulation board which comprises a panel, a bottom board, an edge sealing board and an insulation core board. The panel and the bottom board are fixedly attached to the upper surface and the lower surface of the insulation core board respectively; the edge sealing board is arranged between the panel and the bottom board, the edge sealing board is arranged on the outer side of the periphery of the insulation core board in a wrapping mode, and the edge sealing board is bonded to the panel, the bottom board and the insulation core board; the insulation core board comprises a honeycomb structural body, and honeycomb pores in the honeycomb structural body are filled with aerogel particles or aerogel powder. The aerogel composite insulation board provides a novel building insulation board and is good in insulating effect, little in material consumption, capable of being widely applied to insulation of outer walls of high-rise buildings and capable of being applicable to different occasions by adopting different bottom board and panel materials according to different conditions, the cost is reduced, and the application range of the aerogel composite insulation board is wide.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Curable fiberglass binder comprising a polyacetal or polyketal

A curable formaldehyde-free binding composition for use with fiberglass is provided. Such curable composition comprises an acid-catalyzed reaction product of an aldehyde or ketone with a multihydric alcohol. When heated, the composition forms polyacetal or polyketal that undergoes curing to form a water-insoluble resin binder which exhibits good adhesion to glass. In a preferred embodiment, maleic anhydride initially serves as a catalyst and subsequently enters into a cross-linking reaction during curing to form a poly(ester-acetal). Also, in a preferred embodiment, the fiberglass is in the form of building insulation. In other embodiments the product can be a microglass-based substrate for use in a printed circuit board, battery separator, filter stock, or reinforcement scrim.

Owner:JOHNS MANVILLE CORP

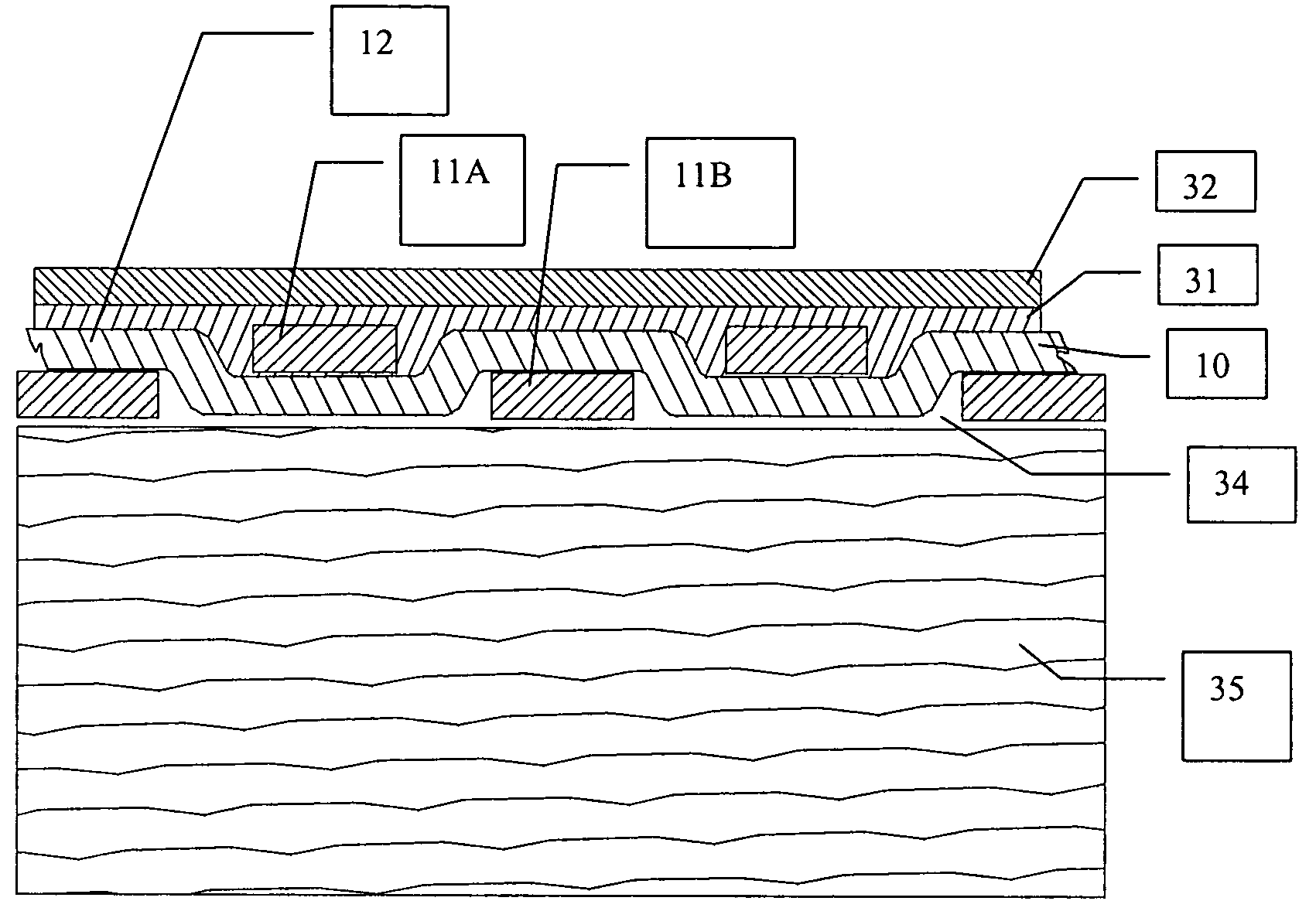

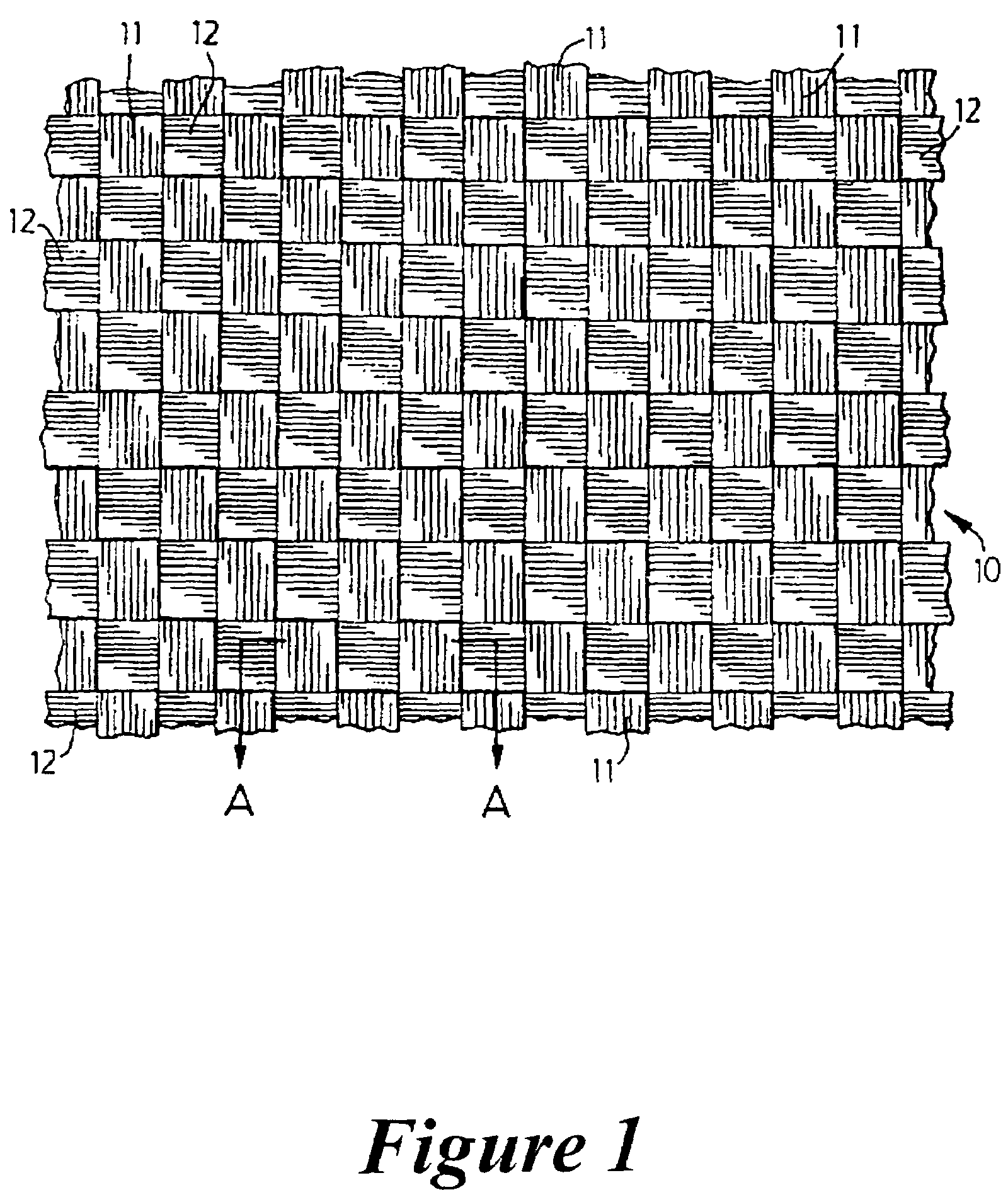

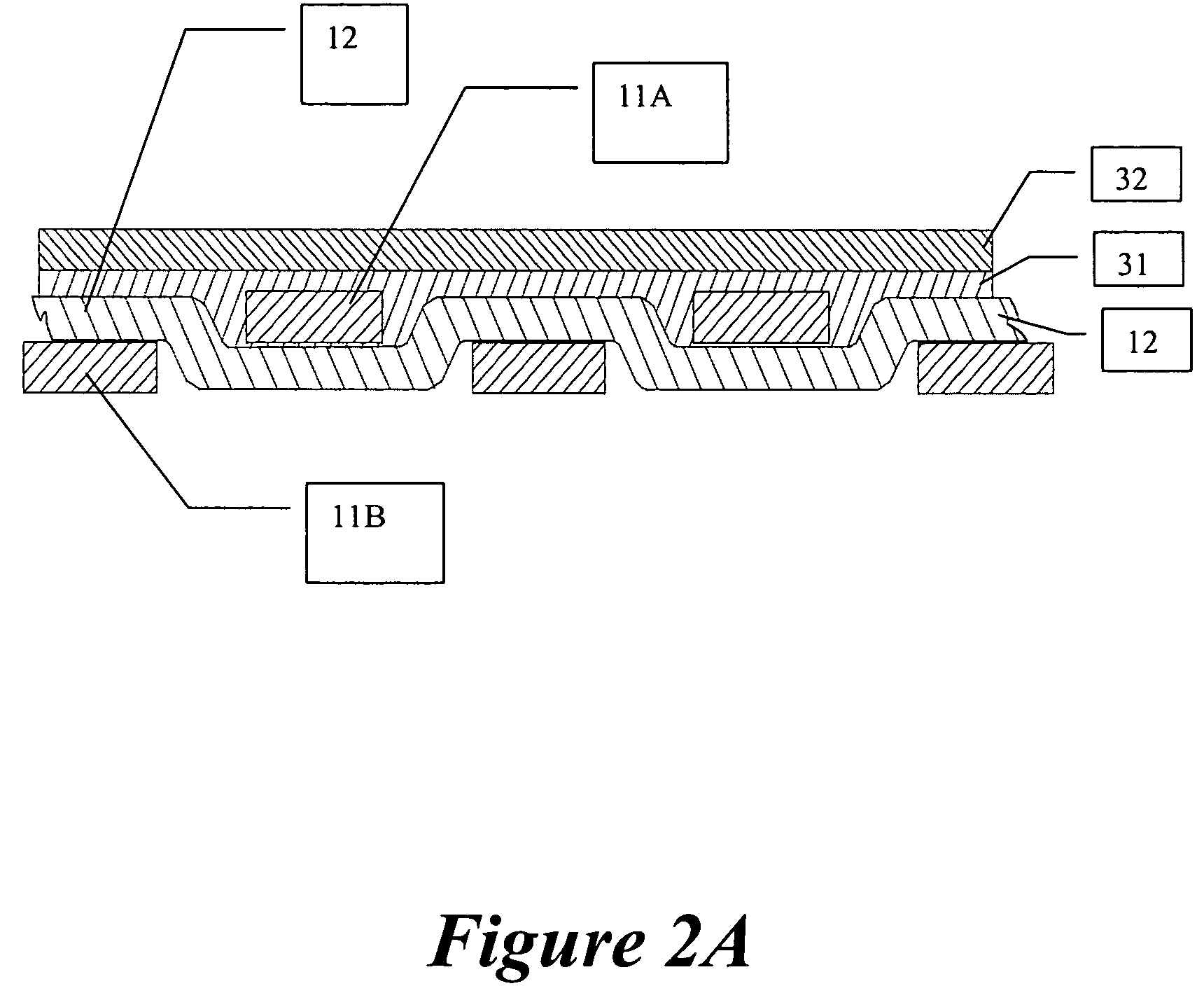

Failure resistant flame retardant vapor barrier insulation facing

ActiveUS7309665B2Improve puncture resistanceImprove tear resistanceLoomsSynthetic resin layered productsVapor barrierPolyolefin

A failure resistant, flame retardant vapor barrier facing for insulation is disclosed. The facing is comprised of a coating and a backing. The coating comprises a pair of coextruded composites each composite comprised of FR material, UV blocking material, pigment material and a polyolefin (e.g., LDPE). The backing is a woven substrate woven from flame retardant polyolefin (e.g., HDPE) tapes. The woven substrate is laminated to building insulation using an adhesive. The woven substrate lends strength, flexibility and form to the facing.

Owner:IRIS WOVEN U S LLC

Fiber-reinforced fireproof insulation board and preparation process thereof

InactiveCN103979918AOvercome defectsAvoid defectsSolid waste managementClimate change adaptationCalcium formateFire retardant

The invention discloses a fiber-reinforced fireproof insulation board. The fiber-reinforced fireproof insulation board is prepared from the raw materials in parts by weight: 80-100 parts of fly ash, 30-50 parts of expanded perlite, 10-20 parts of ceramsite, 10-20 parts of plant fiber, 5-10 parts of floating bead, 5-8 parts of meerschaum, 3-5 parts of sodium fluosilicate, 3-5 parts of calcium formate, 3-5 parts of flame retardant, 0.1-0.5 part of oleic triisopropanolamine and 0.1-0.3 part of glycol dimethyl ether. According to the fiber-reinforced fireproof insulation board, industrial production wastes are adopted as main raw materials, so that the production cost is reduced; through the organic combination and generated synergism of the fly ash, lightweight aggregate and additives, the defects in the existing building insulation boards can be effectively overcome.

Owner:秦菊霞

Curable fiberglass binder comprising a beta-amino-ester or beta-amino-amide conjugate addition product

InactiveUS20070082208A1Good adhesion to glassSynthetic resin layered productsCoatingsAmino estersWater insoluble

A curable formaldehyde-free binding composition for use with fiberglass is provided. Such curable composition comprises a conjugate addition product of an amine and an unsaturated reactant in the form of a β-amino-ester or β-amino-amide intermediate. The composition when coated on fiberglass is cured to form a water-insoluble polyamide or polyimide binder which exhibits good adhesion to glass. In a preferred embodiment the fiberglass is in the form of building insulation. In other embodiments the product is a microglass-based substrate for use in a printed circuit board, battery separator, filter stock, or reinforcement scrim.

Owner:JOHNS MANVILLE CORP

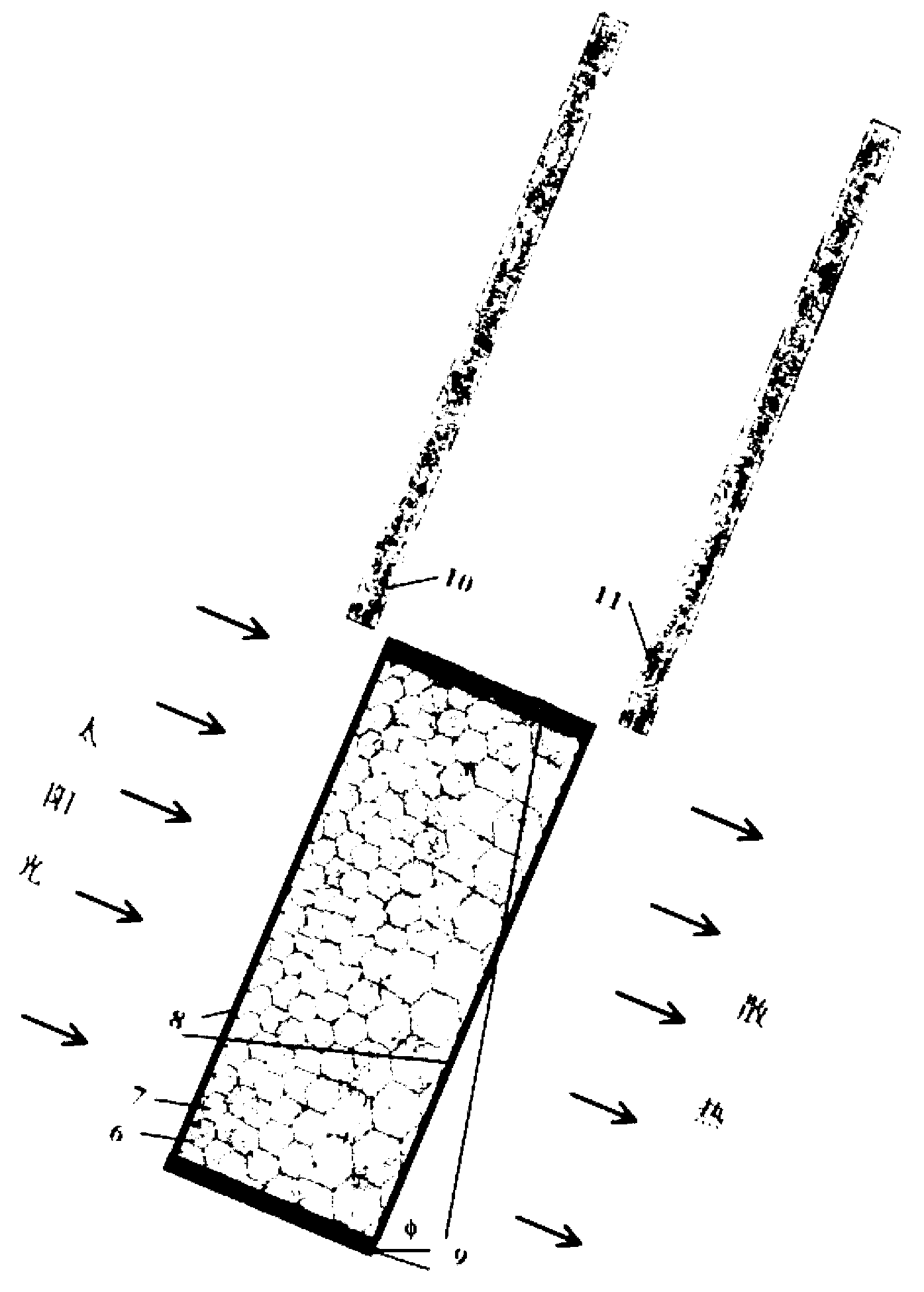

Phase change heat storage device based on gradient metal foam

InactiveCN103234377AImprove heat storage capacityIncrease the heat transfer specific surface areaHeat storage plantsHeat exchange apparatusMaterial consumptionRelease time

A phase change heat storage device based on gradient metal foam is used for building insulation and utilizes the technical field of the rigid heat transfer bodies. The phase change heat storage device based on the gradient metal foam comprises two insulation plates, two heat exchange wall surfaces, two adiabatic wall surfaces, gradient metal foam with the gradually-changed denseness of inner through holes and a phase change portion prepared of phase change materials. The gradient metal foam is sintered between the two heat exchange wall surfaces, the denseness of the gradient metal foam gradually decreases from left to right in the vertical direction of the heat exchange wall surfaces, the left side portion faces the outdoor, the right side portion faced the indoor, the upper side portion and the lower side portion are respectively provided with an adiabatic wall surface. The phase change portion is filled in the gradient metal foam. Two insulation plates are arranged on the outside of the two heat exchange wall surfaces respectively. According to the phase change heat storage device based on the gradient metal foam, the heat storage and release time can be controlled by adjusting gradient feature parameters, the phase change heat exchange performance can be enhanced through the gradient metal foam, and the problems of poor heat exchange efficiency, great material consumption, large size and the like in existing heat exchange time are solved.

Owner:SHANGHAI JIAO TONG UNIV

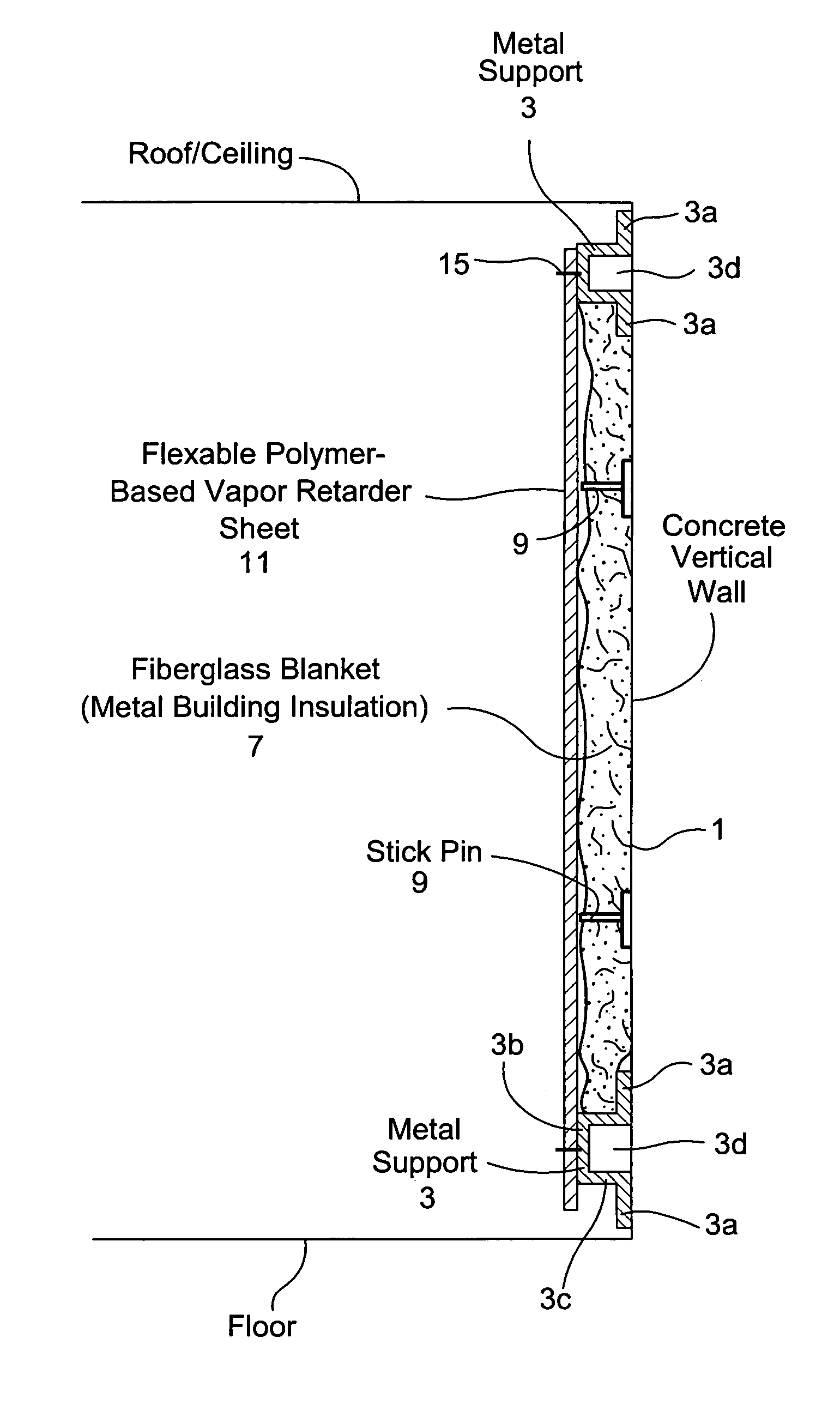

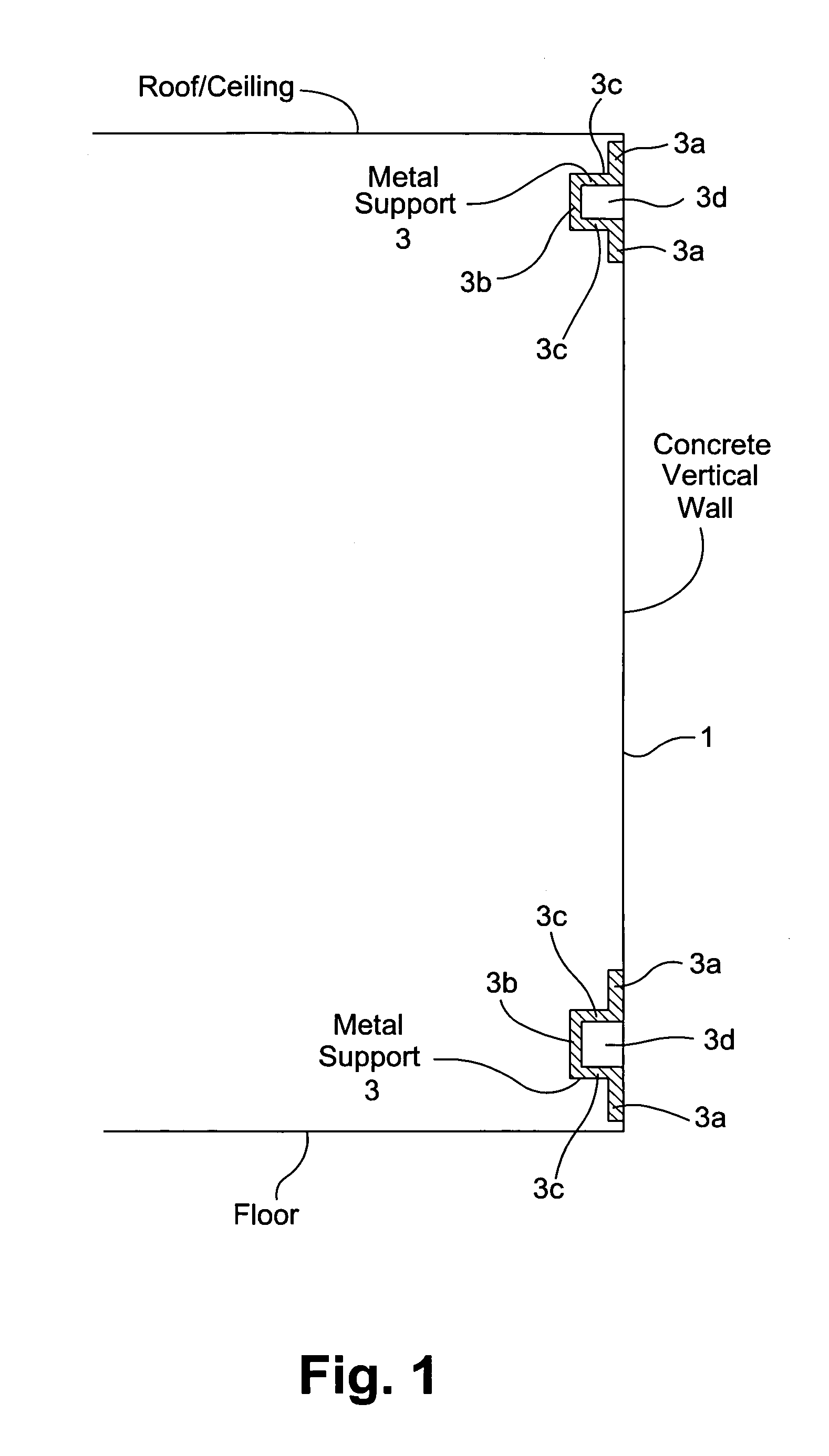

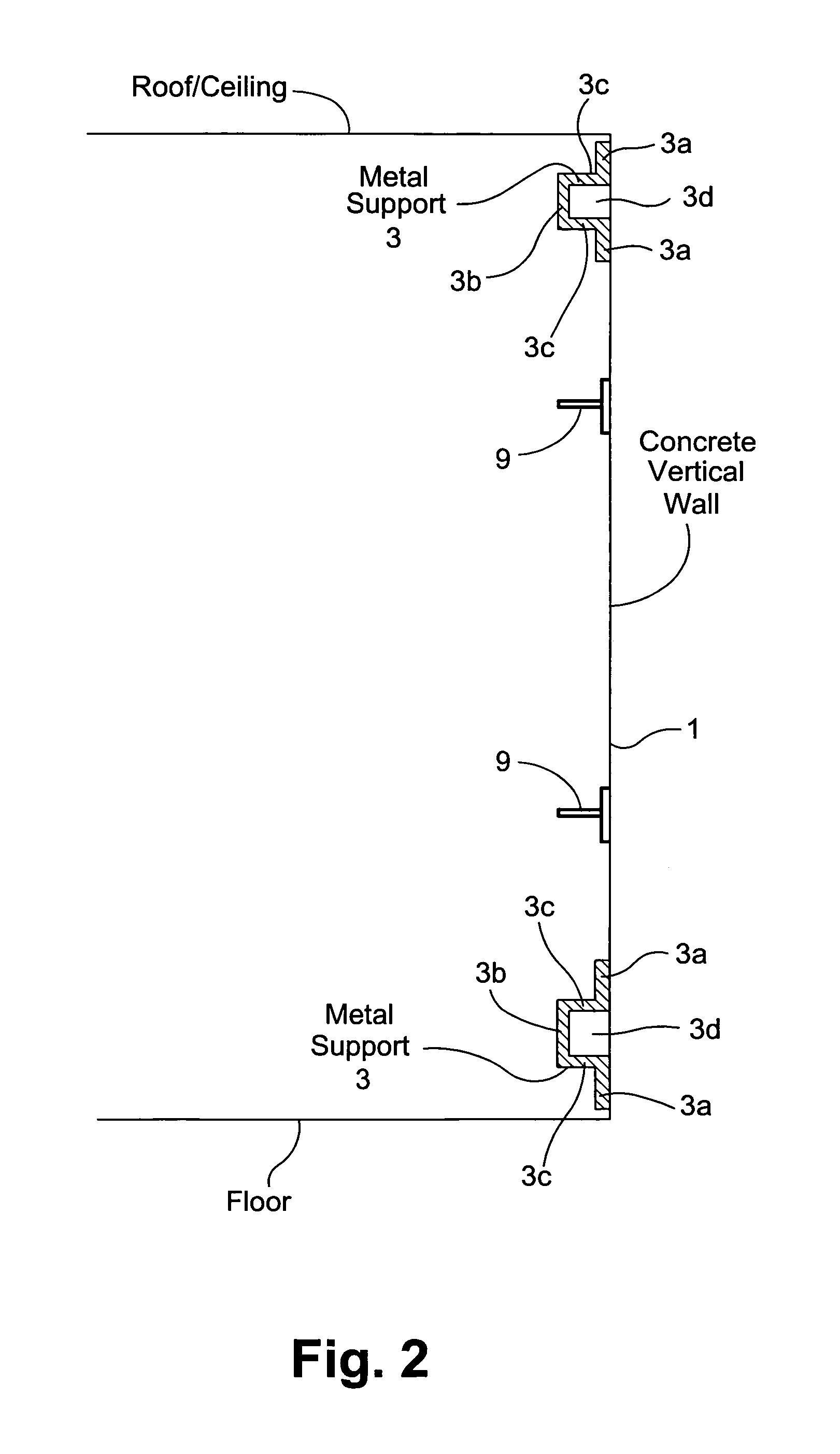

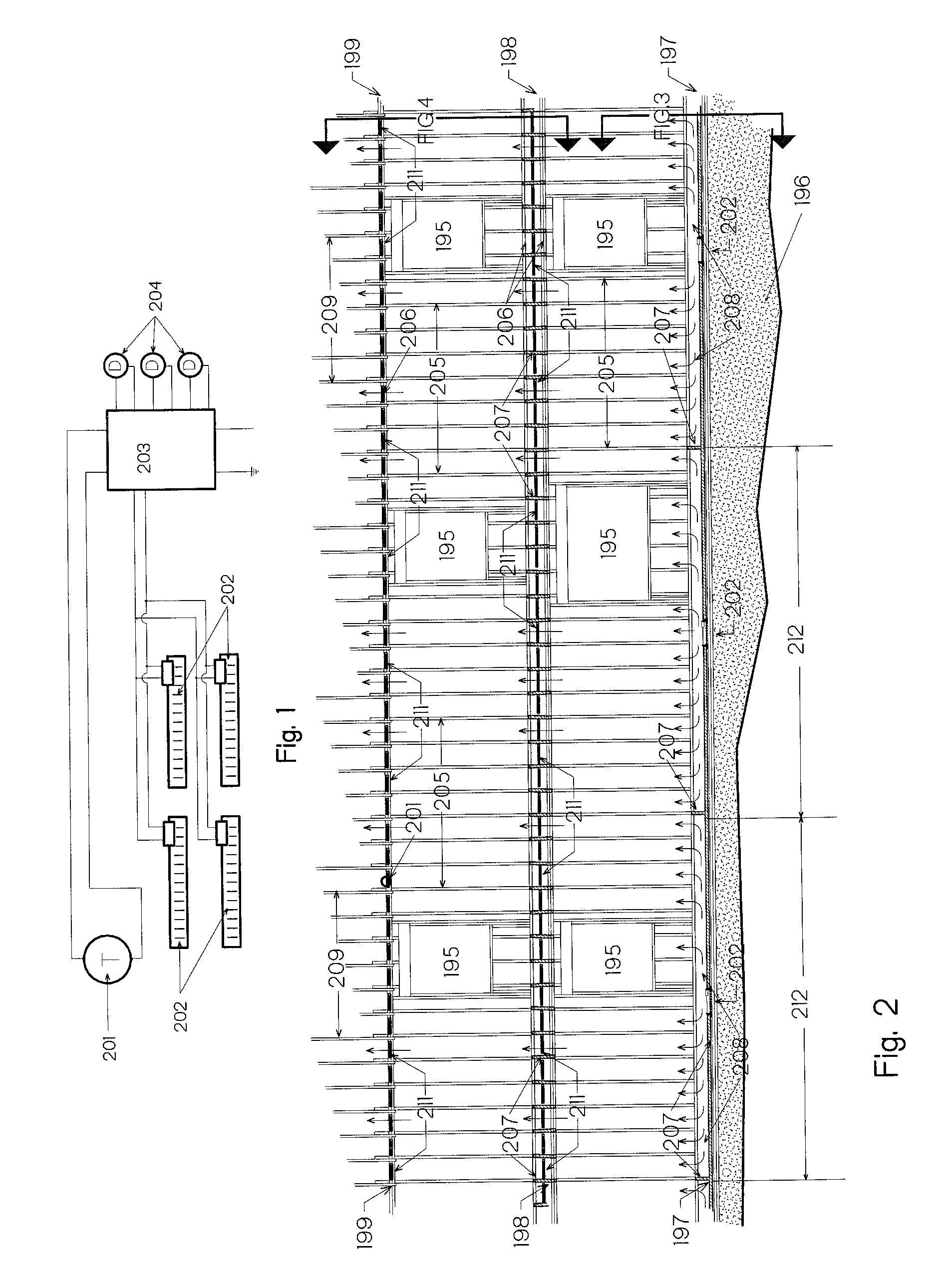

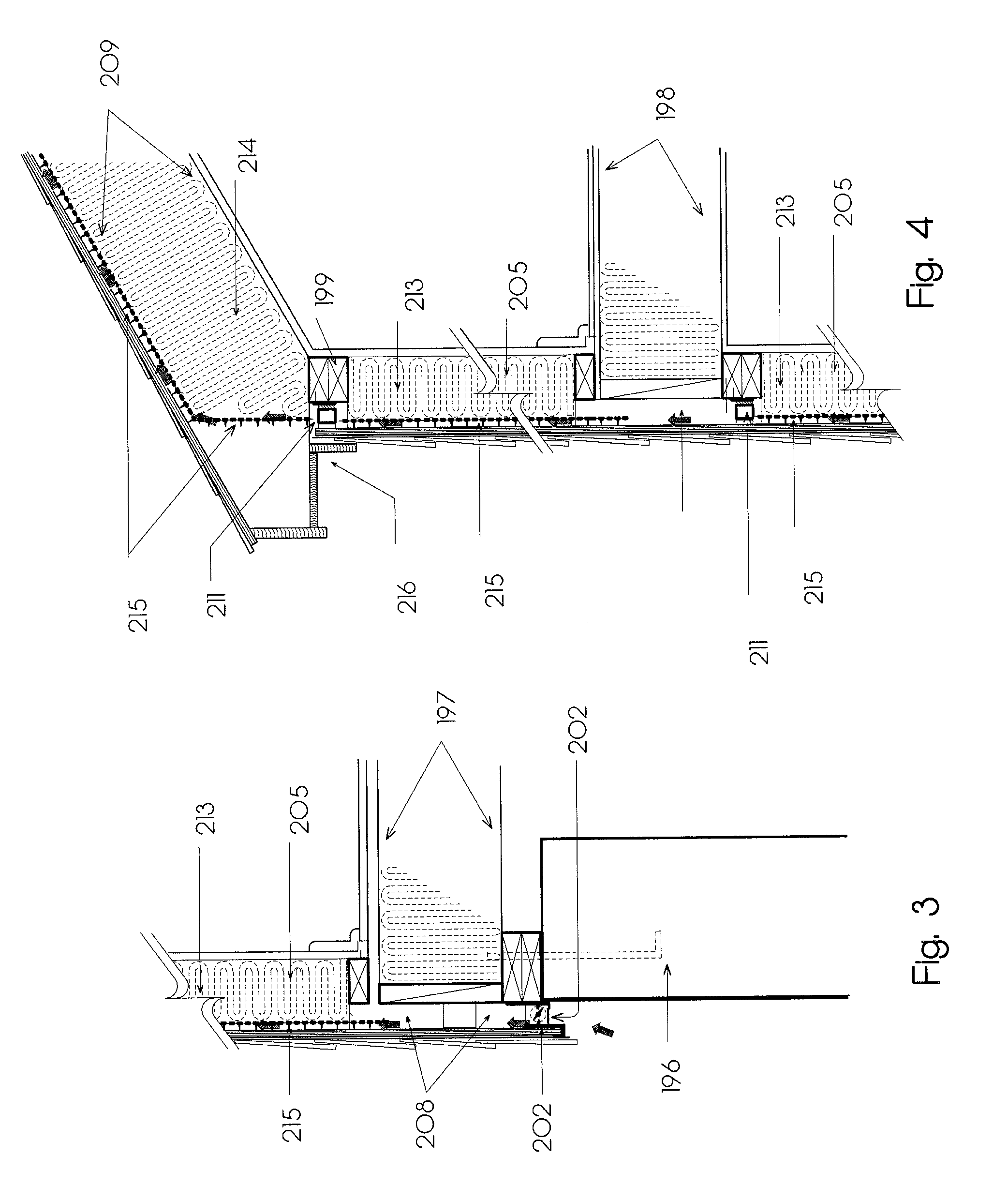

System for insulating vertical wall

A system and method are provided for insulating a vertically extending wall (e.g., concrete wall). First and second supports are first attached to the vertical wall at respective first and second vertically spaced locations (e.g., proximate the top and bottom of the wall). After the supports have been attached to the wall, a blanket(s) of rolled fiberglass insulation (e.g., metal building insulation) is attached to the wall between the first and second supports. Then, a flexible sheet of vapor retarder is attached to protruding portions of the first and second supports so as to cover the blanket(s) of fiberglass insulation thereby causing the blanket of fiberglass insulation to be partially or fully hidden from view and retained in the cavity defined between the vertical wall and the vapor retarder.

Owner:KNAUF INSULATION LLC

A-level fire-protection energy-saving rubber-plastic compound building insulation material and preparation method thereof

ActiveCN102786740AImprove insulation effectMeet Class A flame retardant requirementsLow-density polyethyleneStearic acid

A preparation method for A-level fire-protection energy-saving rubber-plastic thermal-insulating compound foam comprises the following steps: adding polypropylene powder resin, methyl vinyl base silicone rubber, ceramic powder, a fire retardant, glass fiber powder, an antioxidant, white carbon black and polyethylene wax in a high-speed mixer for kneading at a normal temperature, discharging the kneaded materials to an internal mixer so as to obtain material groups through internal mixing, discharging the material groups to a single-screw extrusion pelletizer so as to obtain a basic material A through melting, plasticizing and granulation; adding low-density polyethylene resin in a high mixing machine, then adding an AC blowing agent, talc powder, a lubricating agent and zinc stearate for kneading at the normal temperature, and then discharging the kneaded materials into a single-screw extruder so as to obtain a foaming masterbatch B through granulation; adding the basic material A, the foaming masterbatch B and the polyethylene wax into the high-speed mixer for kneading at the normal temperature, and then discharging the kneaded materials into the single-screw extruder so as to obtain sheets through extruding; carrying out irradiation crosslinking and foaming; grooving on the surface of the prepared foam; and embedding fire-protection filler in the grooves of the foam, immersing in a fire retardant solution and baking so as to obtain the compound building foam.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

Vacuum insulation panel suitable for field of building

InactiveCN102310603ALow thermal conductivitySolution to short lifeSynthetic resin layered productsMetal layered productsSilicic acidPolyethylene glycol

The invention relates to a vacuum insulation panel suitable for the field of building. The vacuum insulation board comprises a core material, a high performance barrier film and an inorganic protective layer. The high performance barrier film is coated on an external surface of the core material; the inorganic protective layer is coated on an external surface of the high performance barrier film. The core material includes main components of silica and oxide inorganic impurities; the high performance barrier film includes a polyethylene layer, a polyethylene glycol terephthalate layer, a nylon layer and an aluminium foil layer from inside to outside; and the inorganic protective layer includes silicic acid, mineral filler and inorganic pigment. The vacuum insulation panel of the invention has characteristics of resistance to physical and chemical destroy, insensitive powder to vacuum degree, long service life, hard rebound deformation, better flame resistance and more suitability for building insulation and energy saving.

Owner:FUZHOU STANLEY ENVIRONMENTAL MATERIALS TECHCO

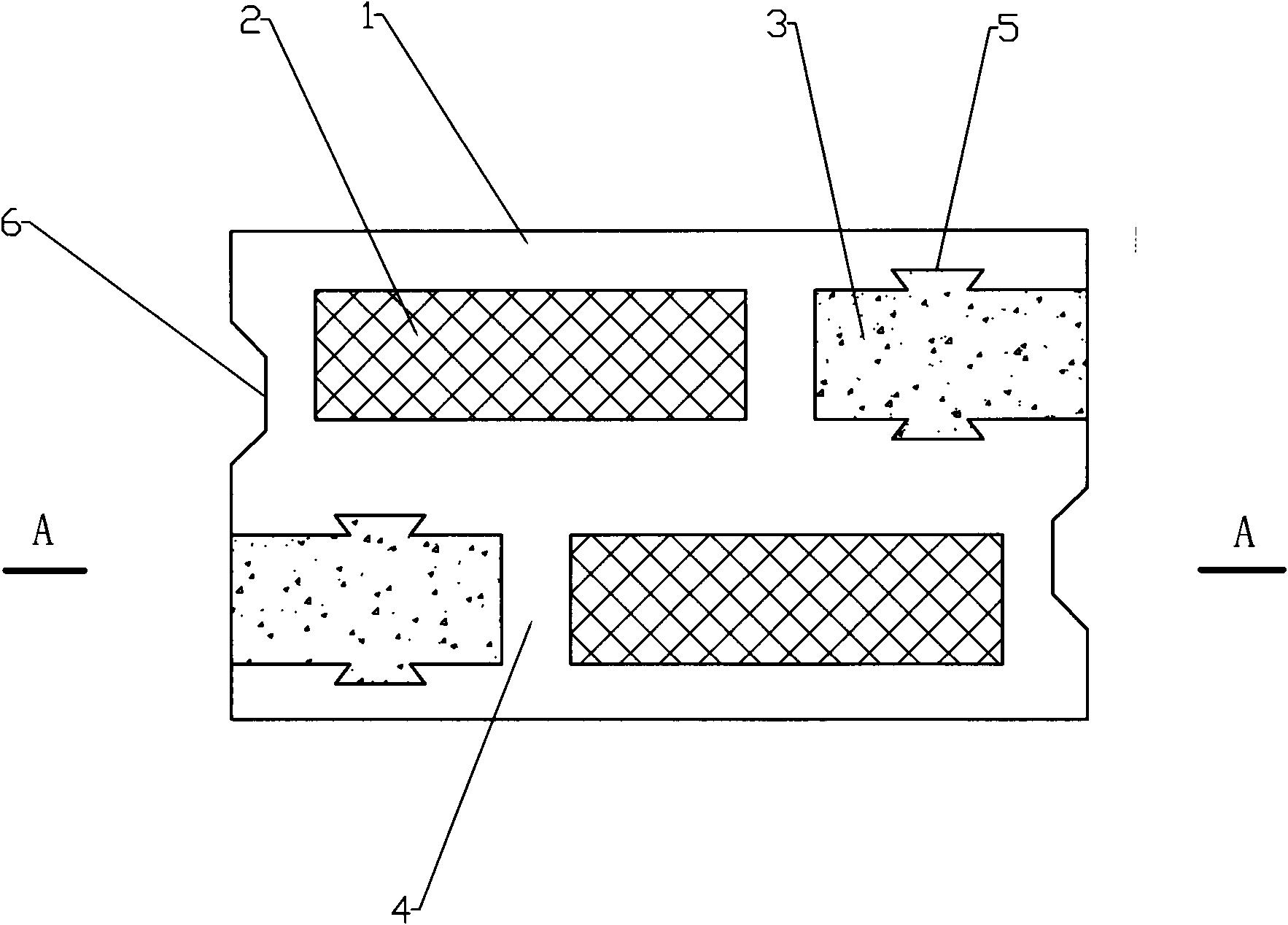

Novel composite building energy-saving building block and manufacturing method thereof

InactiveCN103161256AInhibit sheddingHigh strengthConstruction materialClimate change adaptationSpontaneous combustionFiber

The invention discloses a novel composite building energy-saving building block and a manufacturing method thereof. The building block is characterized in that two vertically staggered rows of hole grooves are provided on a microporous lightweight concrete block, wherein each row of hole groove is separated into 2 holes by a rib. Insulation molded polystyrene boards and vermiculite boards are arranged in the holes with a staggered manner. The manufacturing method comprises the point that: a microporous lightweight concrete slurry is composed of common Portland cement, fast-hardening sulphoaluminate cement, vermiculite powder, spontaneous-combustion coal gangue powder, alkali-resistant chopped crack-resistant reinforcing fiber, a high-efficiency dispersing agent, and a foaming agent. The vermiculite boards are prepared through the steps that: vermiculite powder, phenolic resin, and silicone emulsion are blended; and the obtained material is subjected to extrusion molding in a mold. The building block provided by the invention has the advantages of good thermal insulation effect, high strength, and no fire hazard risk. The building block can be widely applied as building insulation and energy-saving building blocks.

Owner:HAMI CITY TAOLUE NEW BUILDING MATERIAL CO LTD

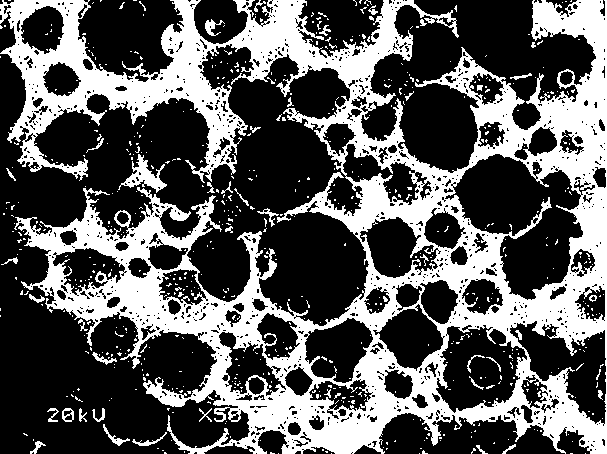

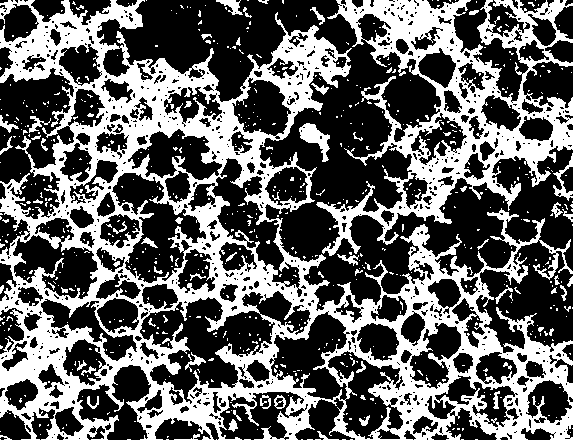

Lightweight foamed ceramics and preparation method thereof

The invention relates to lightweight foamed ceramics and a preparation method of the lightweight foamed ceramics. The lightweight foamed ceramics are prepared by the steps as follows: mechanically agitating raw material, curing agent and foam based on a certain ratio, so as to obtain uniform ceramic size; moulding the ceramic size by casting; and curing and drying same at a certain temperature; and finally sintering the dried blank body to obtain the lightweight foamed ceramics. The lightweight foamed ceramics are important for efficiently utilizing the solid waste, reducing the pollution of the industrial solid waste to the environment, and reducing the production cost; the produced lightweight ceramics have the advantages of being more in closed air pores, relatively low in heat conductivity, relatively high in strength, and relatively low in sintering temperature; and the lightweight foamed ceramics are suitable to be applied to the fields of lightweight decorative material, building insulation wall material, sound insulating material, fireproof material and sinking preventing material.

Owner:GANSU WANTE TECH DEV

Formula design of novel cement-based insulation dry powder

The invention discloses formula design of a novel cement-based insulation dry powder and belongs to the technical field of building energy-saving insulation materials. The formula design comprises the following components: (1) cement; (2) aggregates; (3) a calcification agent; (4) an insulation filling material and (5) a thickening agent. According to the invention, a special formula design is adopted, designed components are simple, the production process is simple, low-cost cement is used as a base material, diatomite and bentonite which have the advantages of rich yield, low cost and good insulation effect are used as the aggregates, and an inorganic insulation filling material is added in the formula, thus the novel cement-based insulation dry powder is environmentally-friendly, efficient and energy-efficient; and after being mixed with water, the formula product forms high-quality insulation mortar and exerts bonding, padding, protection and decoration effects in an insulation thin layer form in the building industry, and even can be used as inner and outer wall putty, colorful decorative dry powder, powder paint and the like, and the use of building insulation material can be reduced due to the excellent insulation property, thereby reducing the construction cost. The density of the dry powder is 1.7-1.8g / cm<3>, the impact strength of the dry powder after solidification reaches 12MPa, the low-temperature conductive coefficient of the dry powder is 0.035w / (m.k), and the high-temperature conductive coefficient of the dry powder is 0.075w / (m.k).

Owner:上海奇葩环境科技有限公司

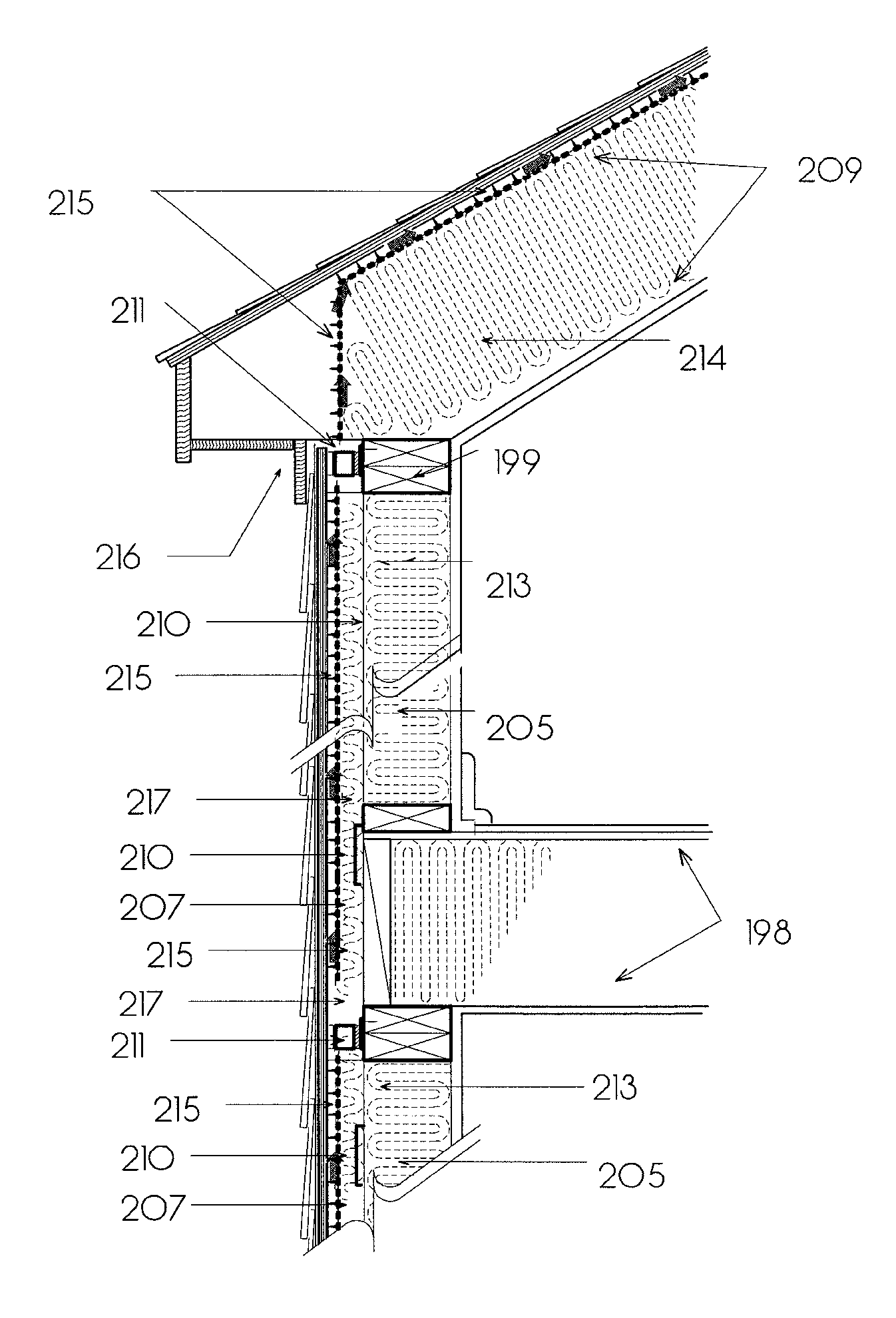

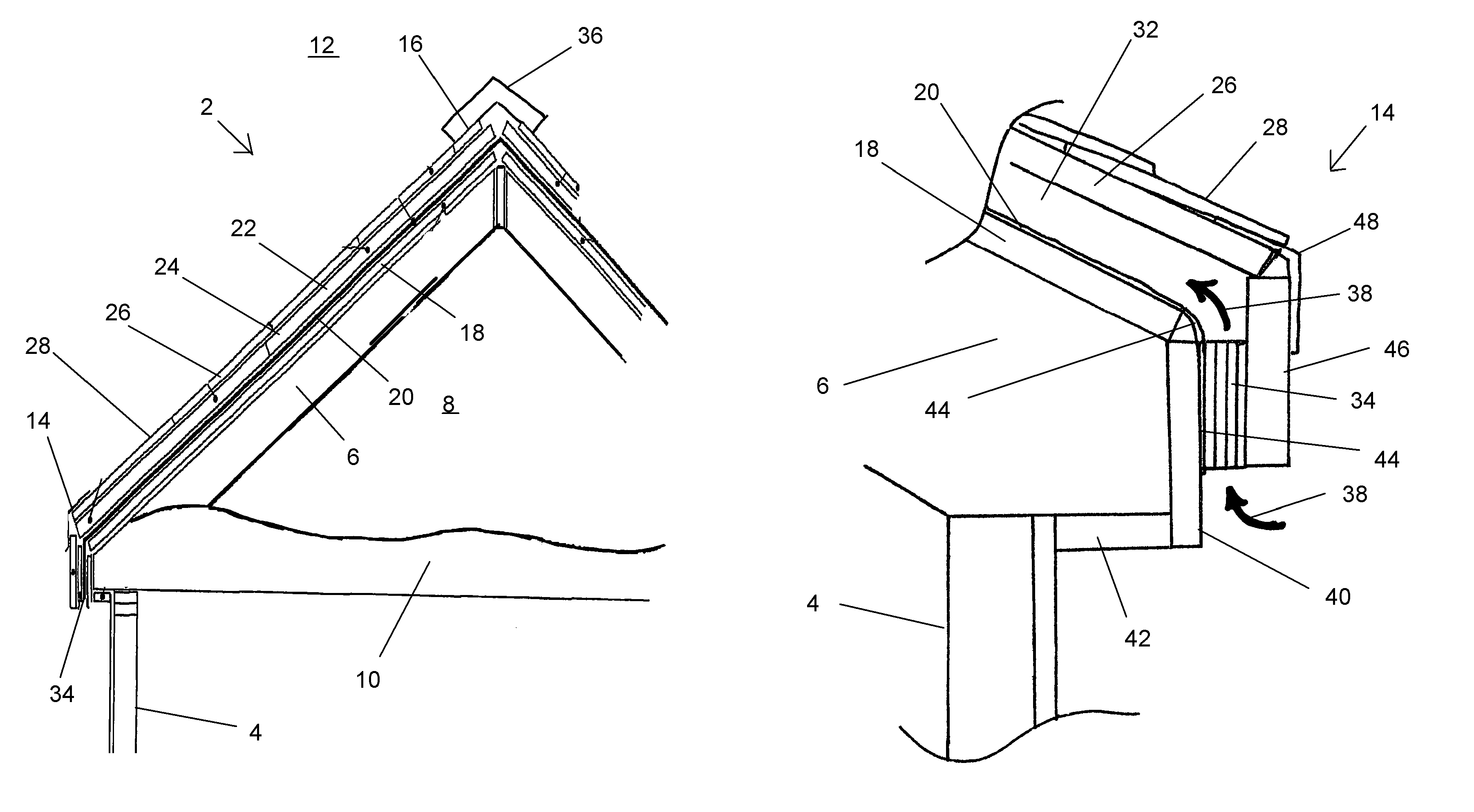

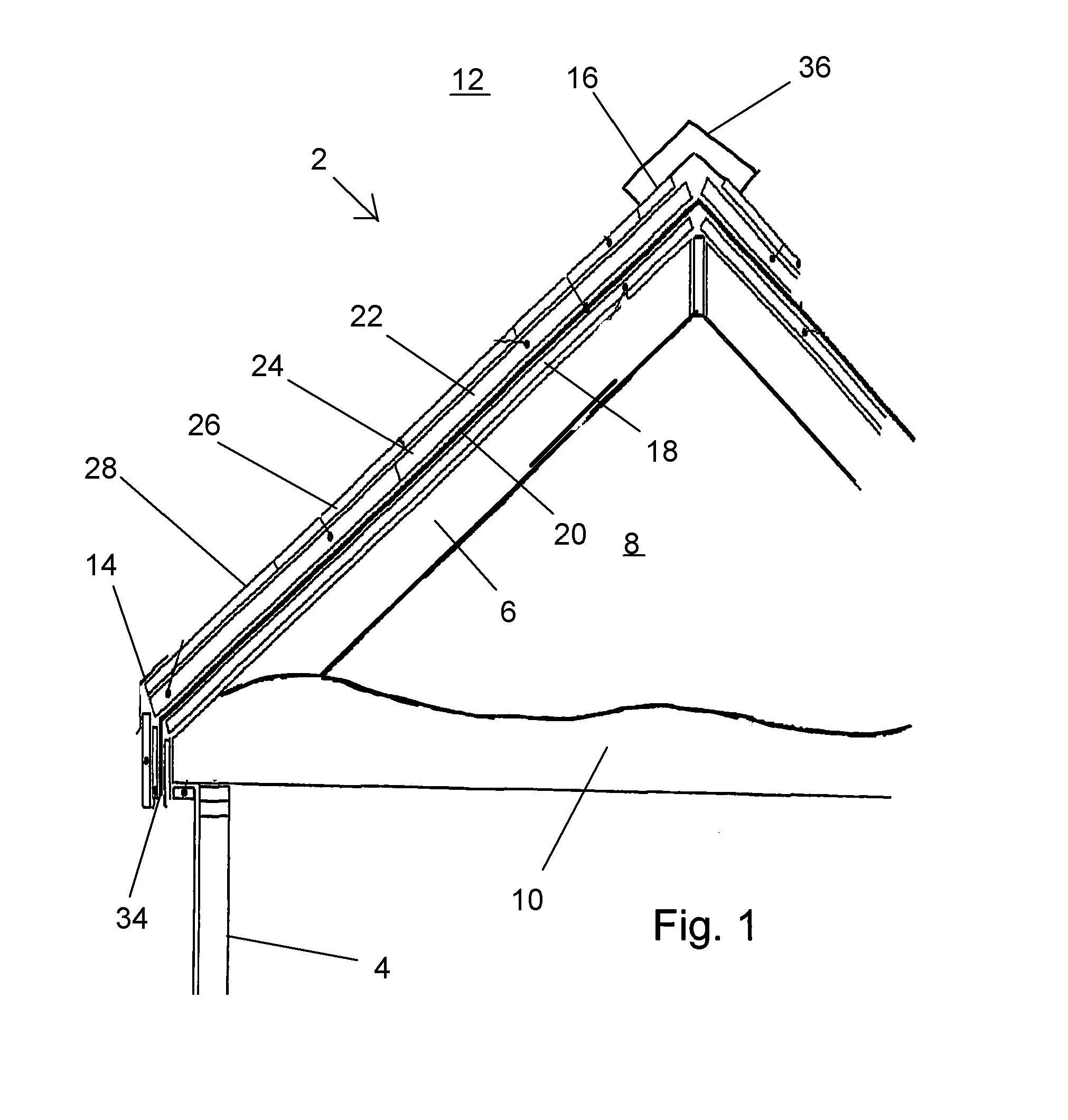

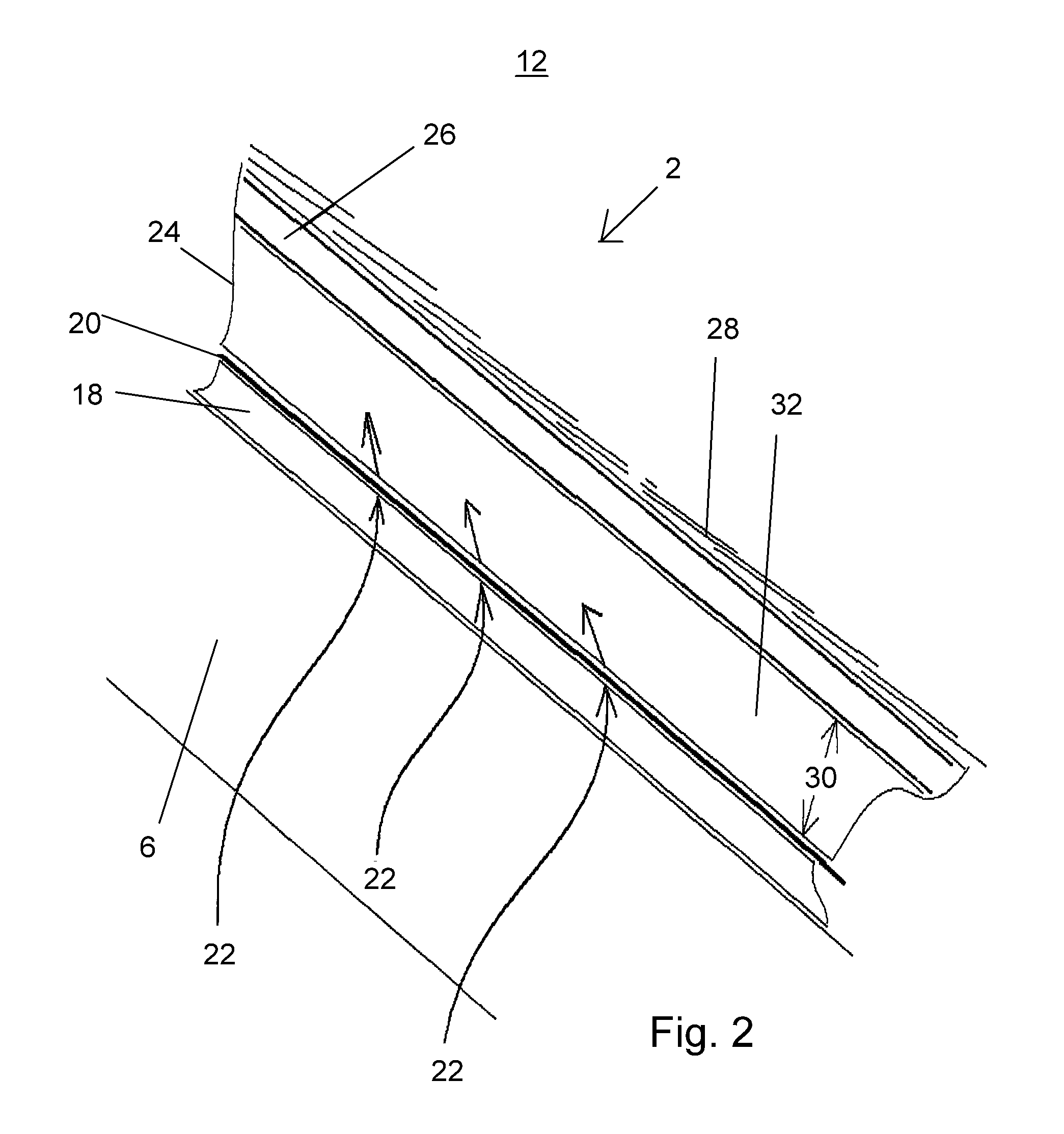

Devices and methods to provide air circulation space proximate building insulation

Devices and associated methods are provided for improving ventilation of insulation material and building construction and renovation. Specifically, the present disclosure includes devices and system(s) to achieve the ventilation of exterior walls and roofs. Components of the system(s) consider shut-down of the ventilation process when it is not necessary, such as in winter, and in the event of fire, where the prevention of vertical and horizontal fire spread is desired.

Owner:HETTRICH HANSL

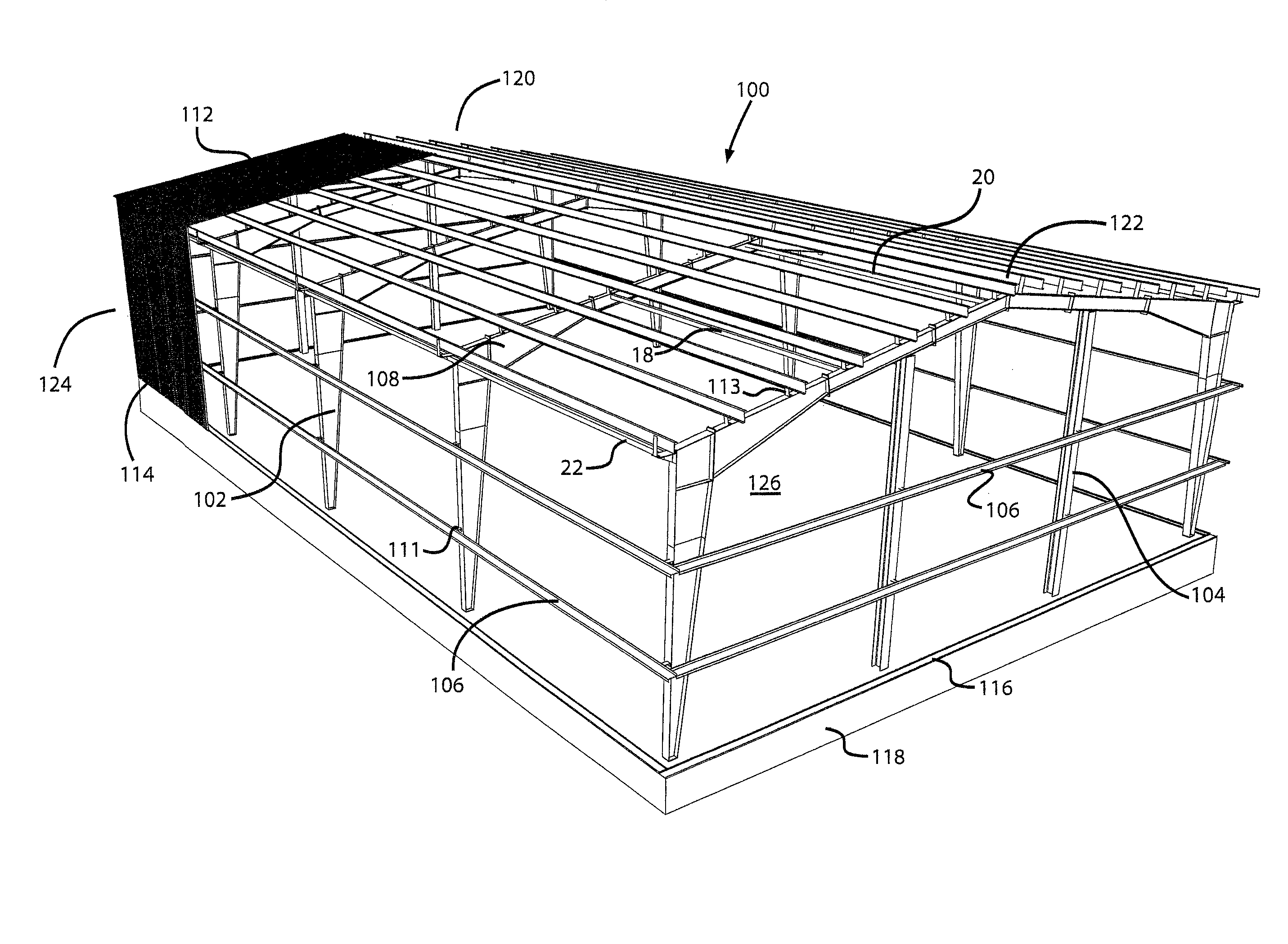

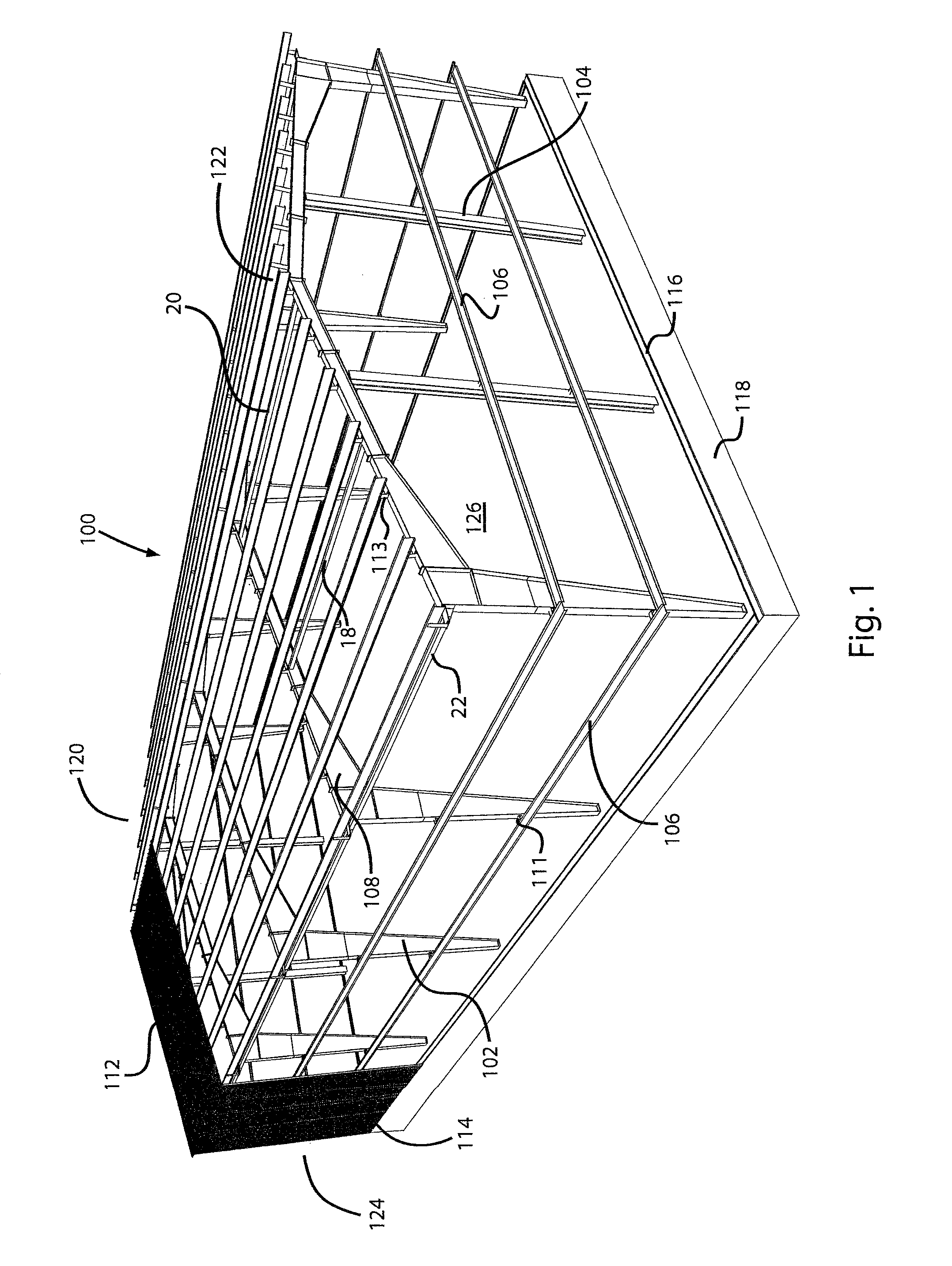

Building insulation system

A tensioned panel extended insulation system includes a support structure, a panel support structure and a pair of insulation panels. A telescoping tube extended insulation system includes a support structure and a ceiling sheet material. A rafter clip may be attached to a rafter for attachment of an end of the support structure. A cable arched telescoping tube extended insulation system includes an arched support structure, an adjustable spacer, a cable and the ceiling sheet material. A bar joist extended insulation system includes a support structure, an insulation support structure and an ceiling sheet material. A bar joist extended insulation system may be arched. A system for installing ceiling sheet material in buildings preferably includes either two roller supports or two sheave supports, a middle section, a first end section and a second end section. A rotary strut could also be used to replace an existing strut.

Owner:HARKINS DANIEL J

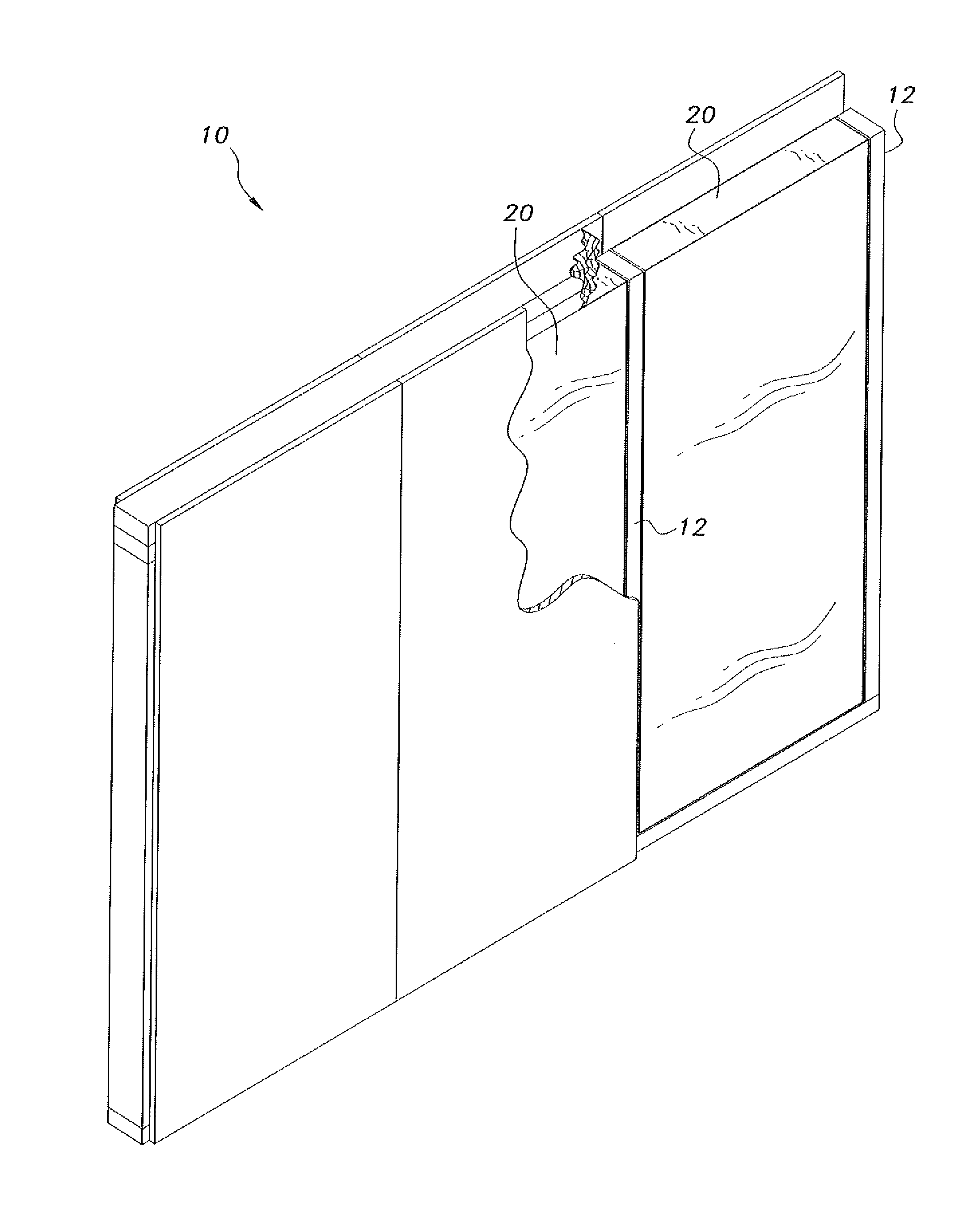

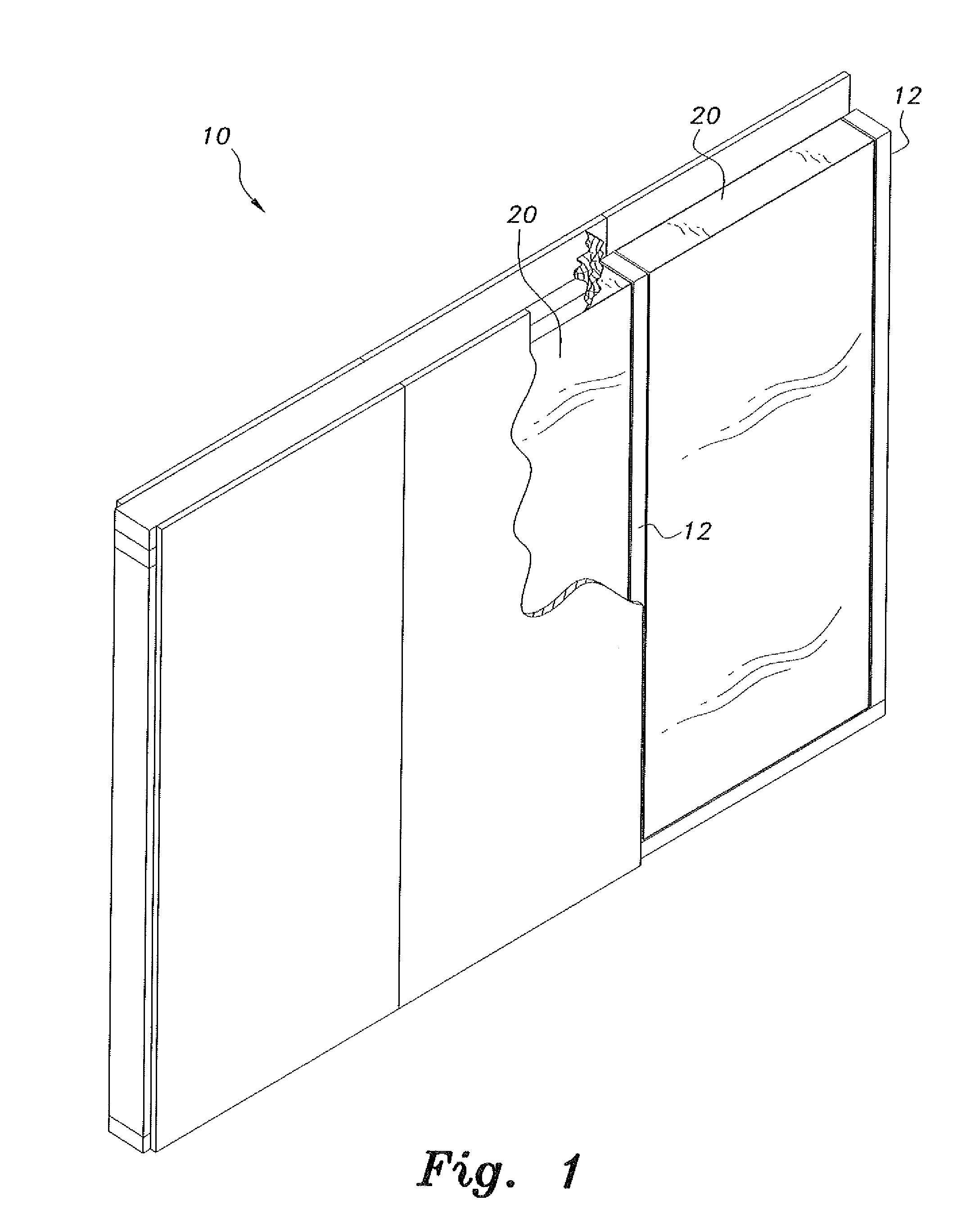

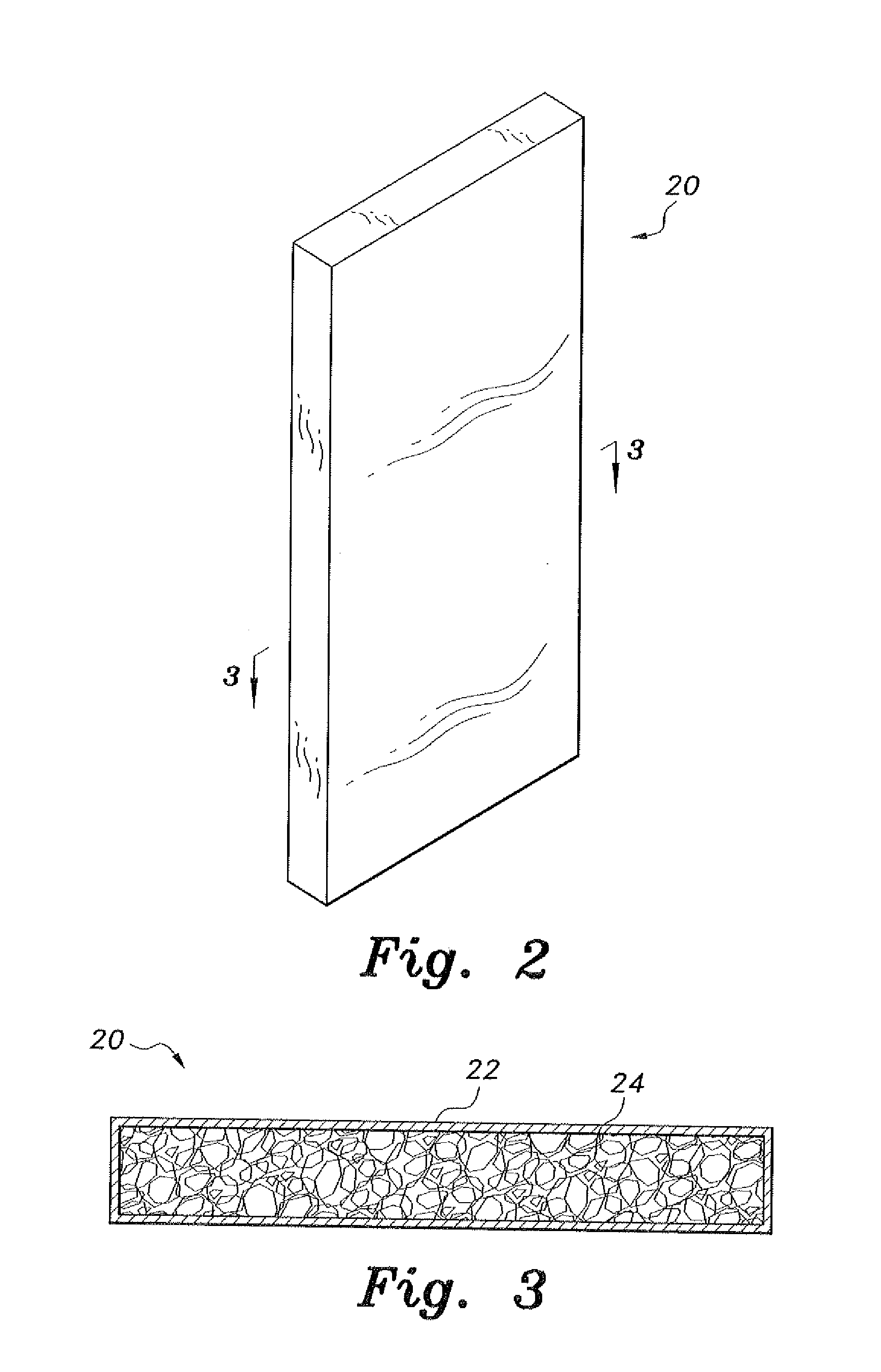

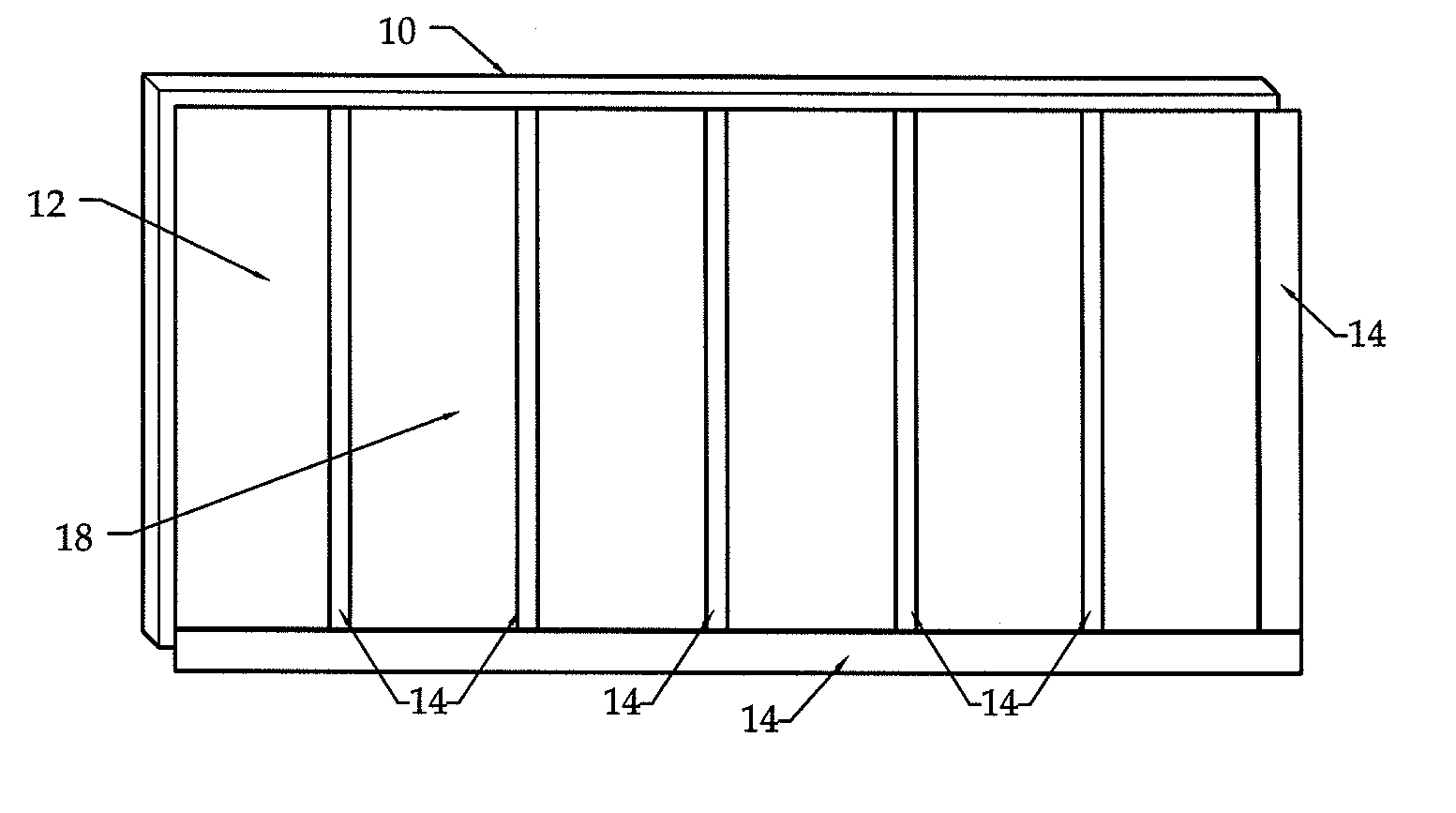

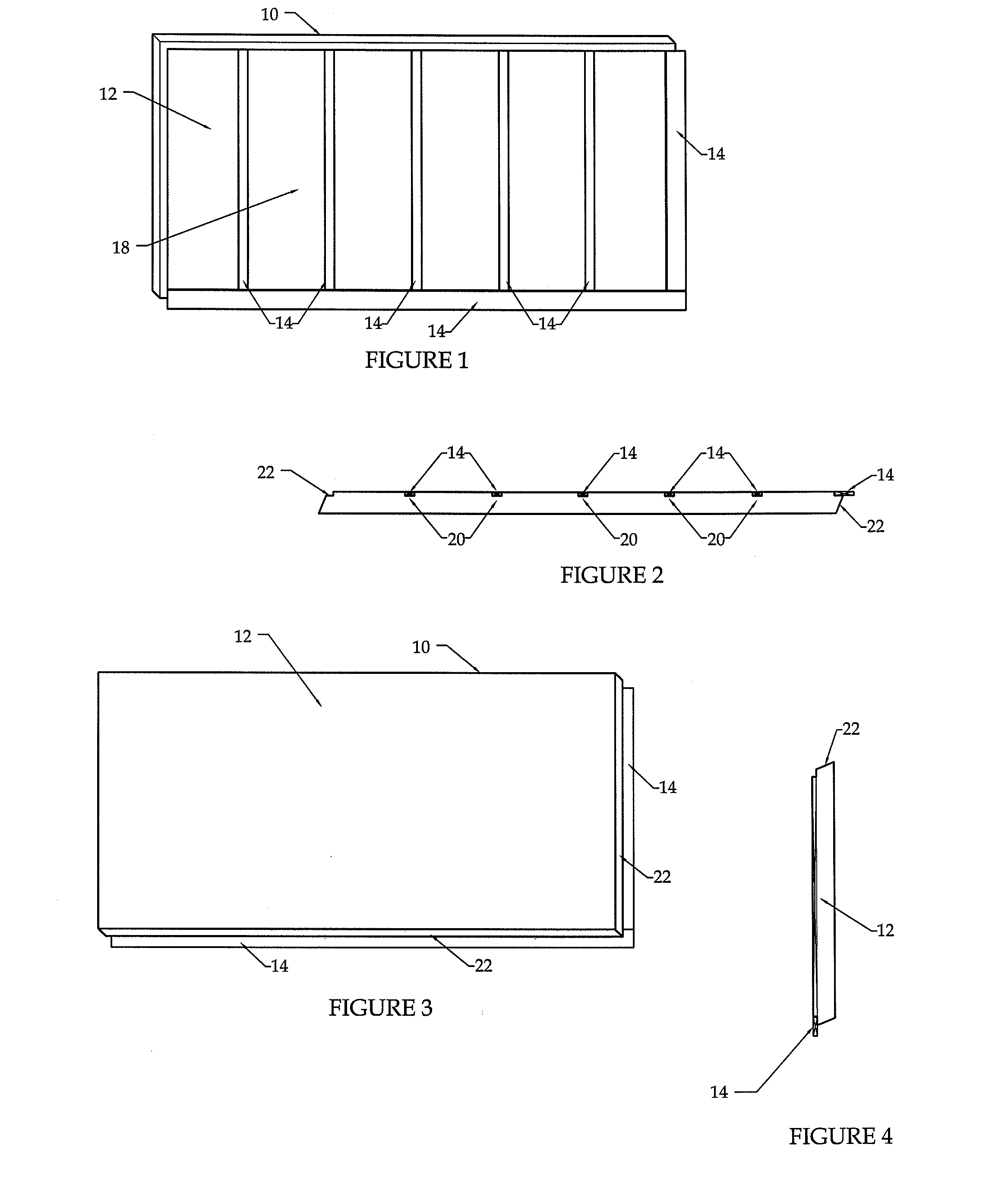

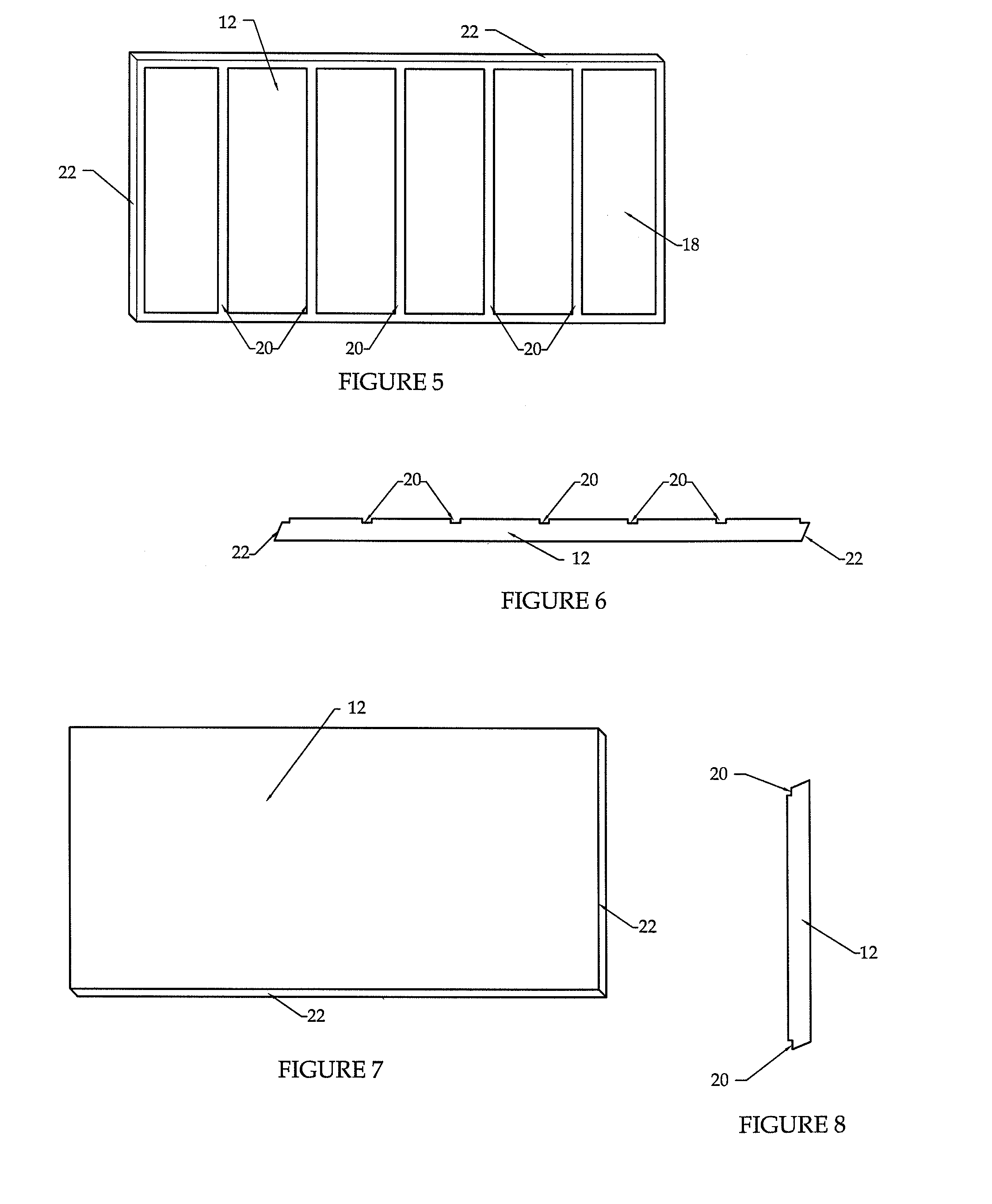

Building Insulation Sheathing Systems and Methods of Use Thereof

InactiveUS20110036030A1Effective installationAttached with easeCeilingsConstruction materialArchitectural engineeringBuilding insulation

The present invention relates to a building insulation sheathing system that provides for efficient installation of insulation, material and labor reduction during installation, as well as provides a stable structure for ease in attachment of protective and / or decorative cladding to a building. The present invention further includes a method for insulating a building using the sheathing system of the present invention.

Owner:SUPREME ENERGY PRODS

Ventilated roof system and method

ActiveUS8973310B1Avoid enteringAvoid structureRoof covering using slabs/sheetsBuilding roofsLiquid waterWater vapor

An energy-efficient ventilated roofing system and method provides a deck protected from the weather by shingles and a sub-deck in a spaced apart relationship below the deck. The sub-deck is covered by a barrier fabric that is permeable to water vapor but that is substantially impermeable to liquid water. The deck and sub-deck define ventilation channels. The barrier fabric allows water vapor to escape from the building while acting as a secondary barrier to liquid water that may penetrate the shingles and deck. The ventilation channels allows the flow of ventilation air under the deck, avoiding damage to the deck and preventing blinding of roof ventilation due to building insulation or structural members or building debris.

Owner:HENDERSON JOHN C

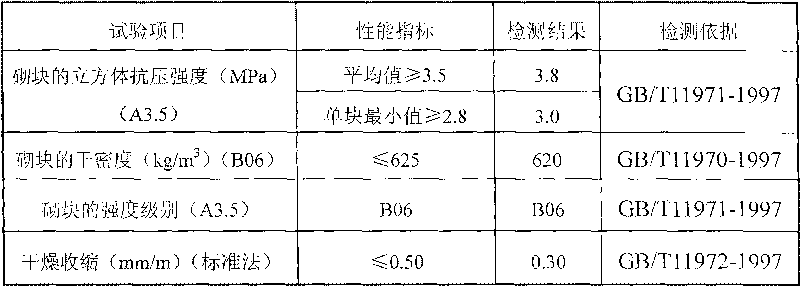

Natural volcanic ash autoclaved aerated concrete block and preparation method thereof

ActiveCN101696586ATake advantage ofAvoid the needMixing operation control apparatusCeramic shaping apparatusLow densityFly ash

The invention relates to a natural volcanic ash autoclaved aerated concrete block. The block consists of natural volcanic ash accounting for 50 to 60 percent of total weight, cement accounting for 4 to 6 percent of total weight, quick lime accounting for 15 to 20 percent of total weight, building gypsum accounting for 0 to 2.0 percent of total weight, aluminum powder paste accounting for 0.03 to 0.04 percent of total weight and water accounting for 20to 25 percent of total weight. Meanwhile, the invention also discloses a method for preparing the block. The block has good strength, low density, low thermal conductivity coefficient, low shrinkage and other performances. The method can fully utilize local resources in regions which are abundant in natural volcanic ash but short of sand and fly ash so as to solve the need of local building insulation markets.

Owner:甘肃土木工程科学研究院有限公司

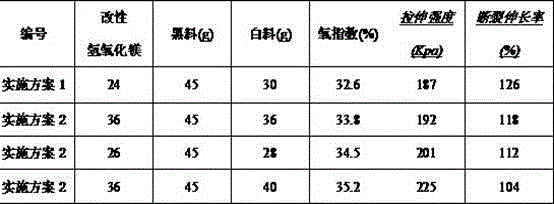

Preparation method of halogen-free flame retardant rigid polyurethane foam insulation material for exterior wall insulation

The present invention relates to a preparation method of halogen-free flame retardant rigid polyurethane foam insulation material for exterior wall insulation, and belongs to the field of energy-saving environment-friendly building insulation materials. The material is prepared by mixing a black material and a combined white material. The black material is isocyanate; the combined white material comprises 20-40 parts of polyol, 10-40 parts of a modified flame retardant, 1-10 parts of a synergistic flame retardant, 0.5-5 parts of a catalyst, 1-5 parts of a foaming agent and 0.5-3 parts of a stabilizer. The modified flame retardant employed by the present invention is magnesium hydroxide treated by a special coupling agent, has excellent flame retardation effect and fire rating of up to B1 grade; and the combined white material prepared from the flame retardant is not easy to produce stratification or precipitation, and can be placed for 30 days. The insulation material provided by the invention meets the needs of industrial production, plays a role in energy conservation and environmental protection, and is superior to the existing organic flame retardant insulation materials on the market.

Owner:大连亚泰科技新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com