Phase change heat storage device based on gradient metal foam

A technology of metal foam and phase change heat storage, applied in heat storage equipment, heat exchange equipment, heat exchanger types, etc., can solve the problems of large amount of consumables, large volume, low heat exchange efficiency, etc., and prolong the heat release time , Increase the specific surface area of heat transfer and improve the effect of heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

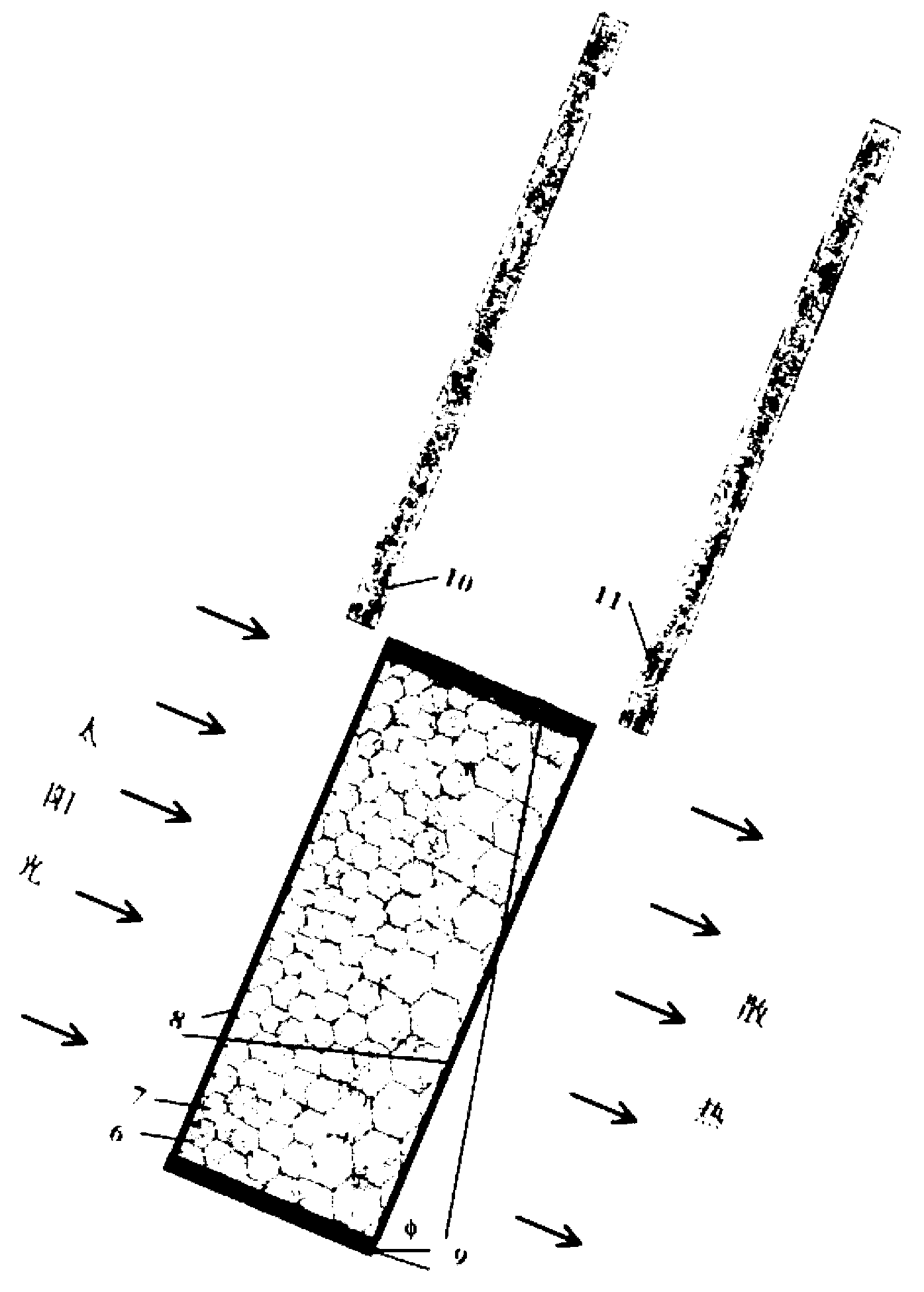

[0024] Such as figure 1 As shown, this embodiment includes: two heat insulation panels 10, 11, two heat exchange wall surfaces 8, two heat insulation wall surfaces 9, a gradient metal foam 6 in which the density of internal through holes gradually changes, and phase change materials. Transformation part 7, wherein: the gradient metal foam 6 is sintered in the middle of the two heat exchange walls 8, and the density gradually decreases from left to right along the vertical direction of the heat exchange walls 8, the left side is facing the outdoor side, and the right side is facing the outside. On the side of the house, a heat insulating wall 9 is arranged on the upper and lower sides; the phase change part 7 is filled in the inside of the gradient metal foam 6; the outer sides of the two heat exchange walls 8 are respectively provided with a heat insulating board 10, 11.

[0025] The material of the gradient metal foam 6 can be copper, nickel, aluminum and their alloys; the ph...

Embodiment 2

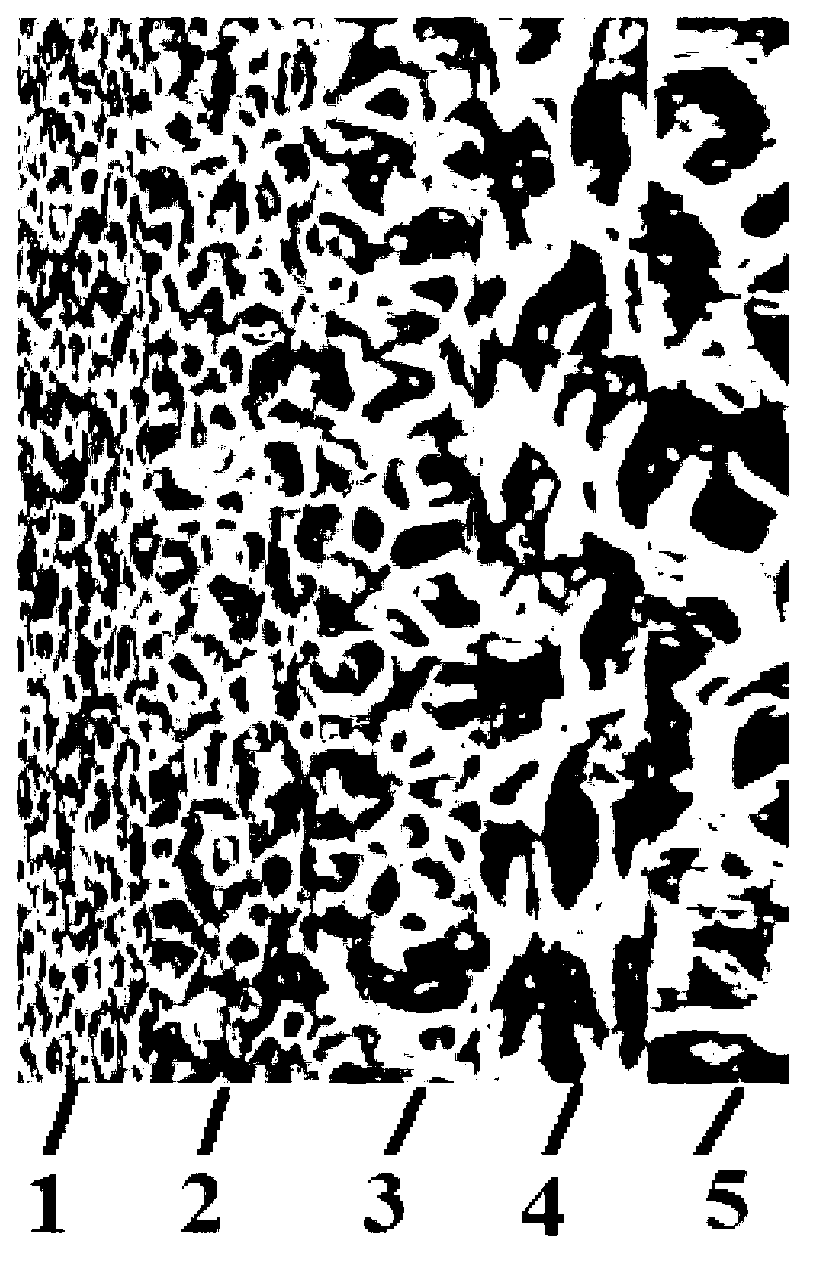

[0030] Such as figure 2 As shown, this embodiment is an example of the graded metal foam 6 filled with the phase change portion 7 in Embodiment 1, and the graded metal foam 6 includes: a first through-hole copper foam layer 1, a second through-hole copper foam layer 2 , the third through-hole copper foam layer 3 , the fourth through-hole copper foam layer 4 and the fifth through-hole copper foam layer 5 , each layer of foam is filled with phase change parts 7 . After the through-hole copper foam layers are prepared by investment casting method, silver-copper alloy sheets with high thermal conductivity are added between the layers, placed in a high-temperature electric furnace and heated until the silver-copper alloy is melted, and then cooled, and finally each metal The foam layers are sintered together.

[0031] The density of 2 holes in the first through-hole copper foam layer is 40PPI; the density of 3 holes in the second through-hole copper foam layer is 30PPI; the densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com