Patents

Literature

30results about How to "Increase the heat transfer specific surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

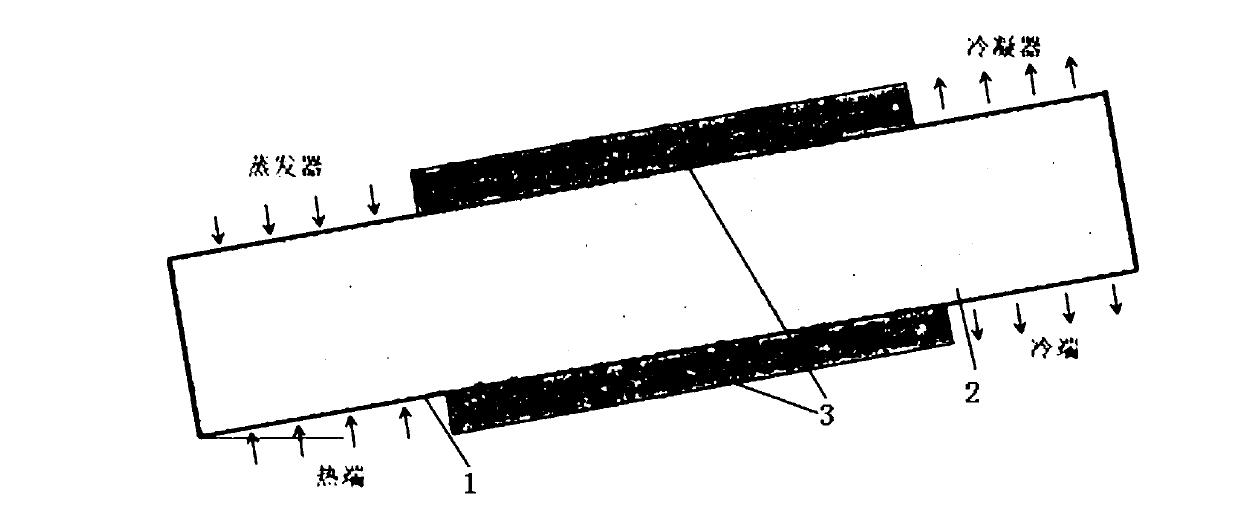

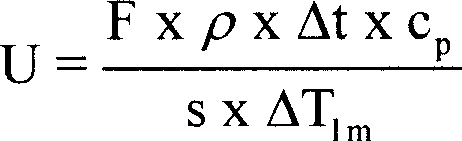

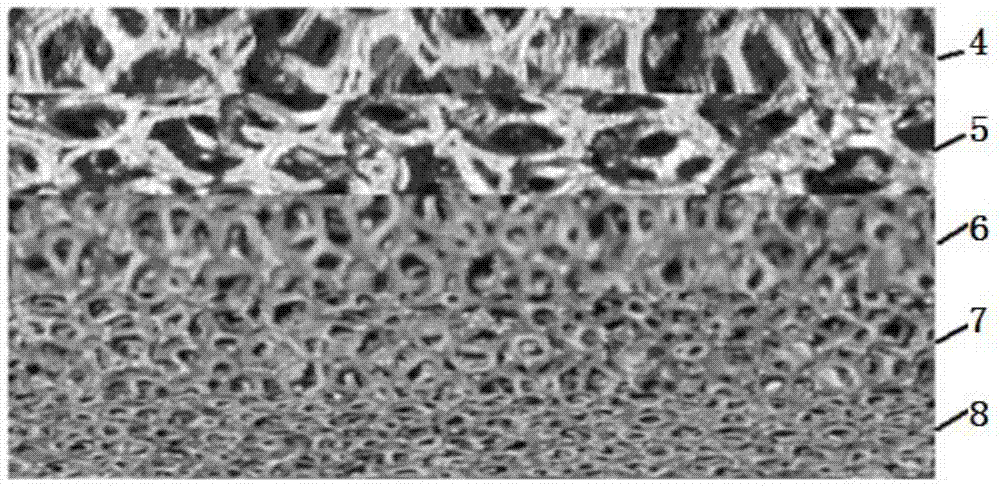

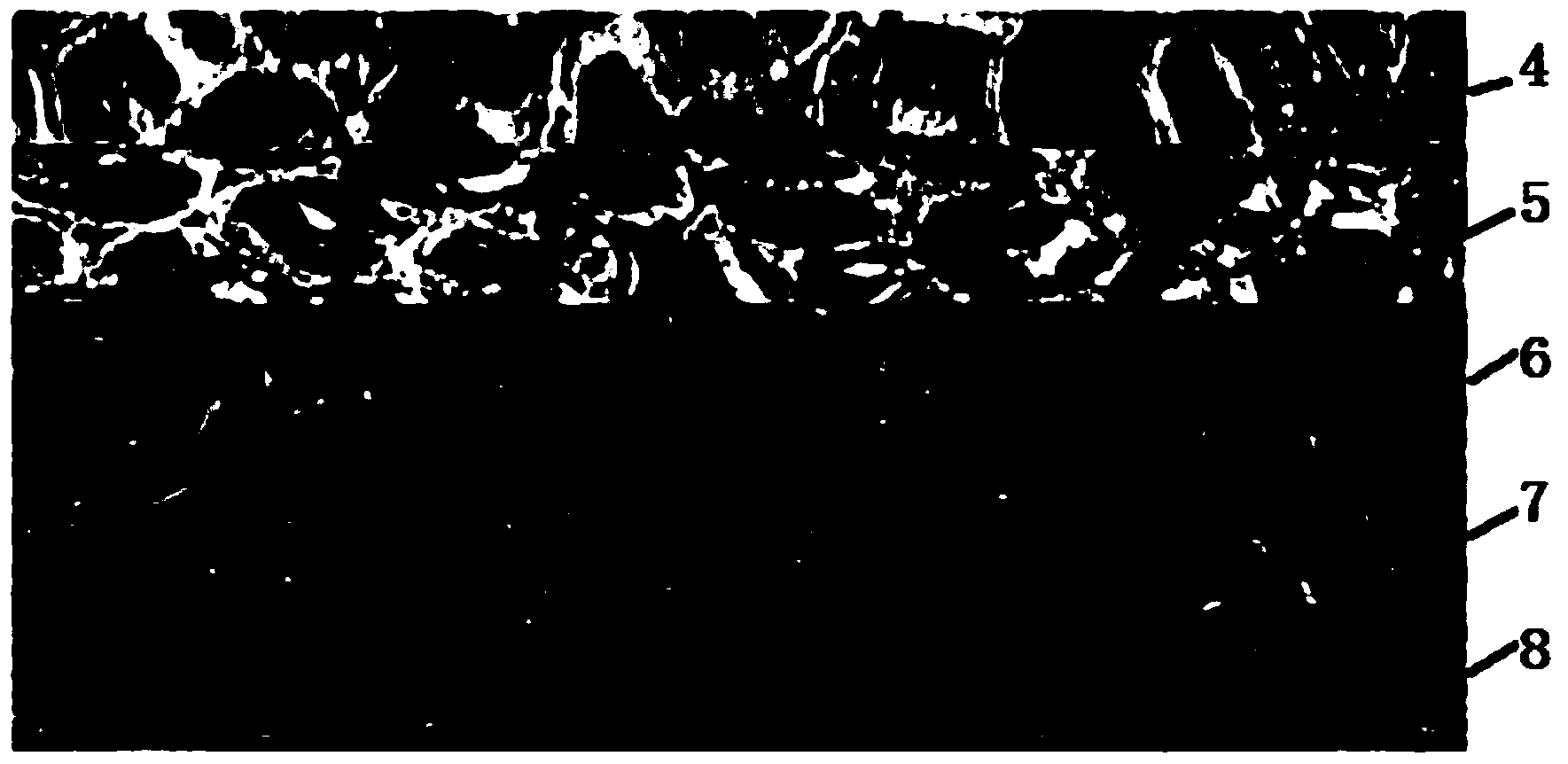

Through-hole metal foam with gradually varied morphologic characteristics, preparation method of through-hole metal foam, and heat exchange device

InactiveCN103060592AImprove heat transfer effectImprove heat transfer efficiencyFoundry mouldsFoundry coresMetal frameworkVolumetric Mass Density

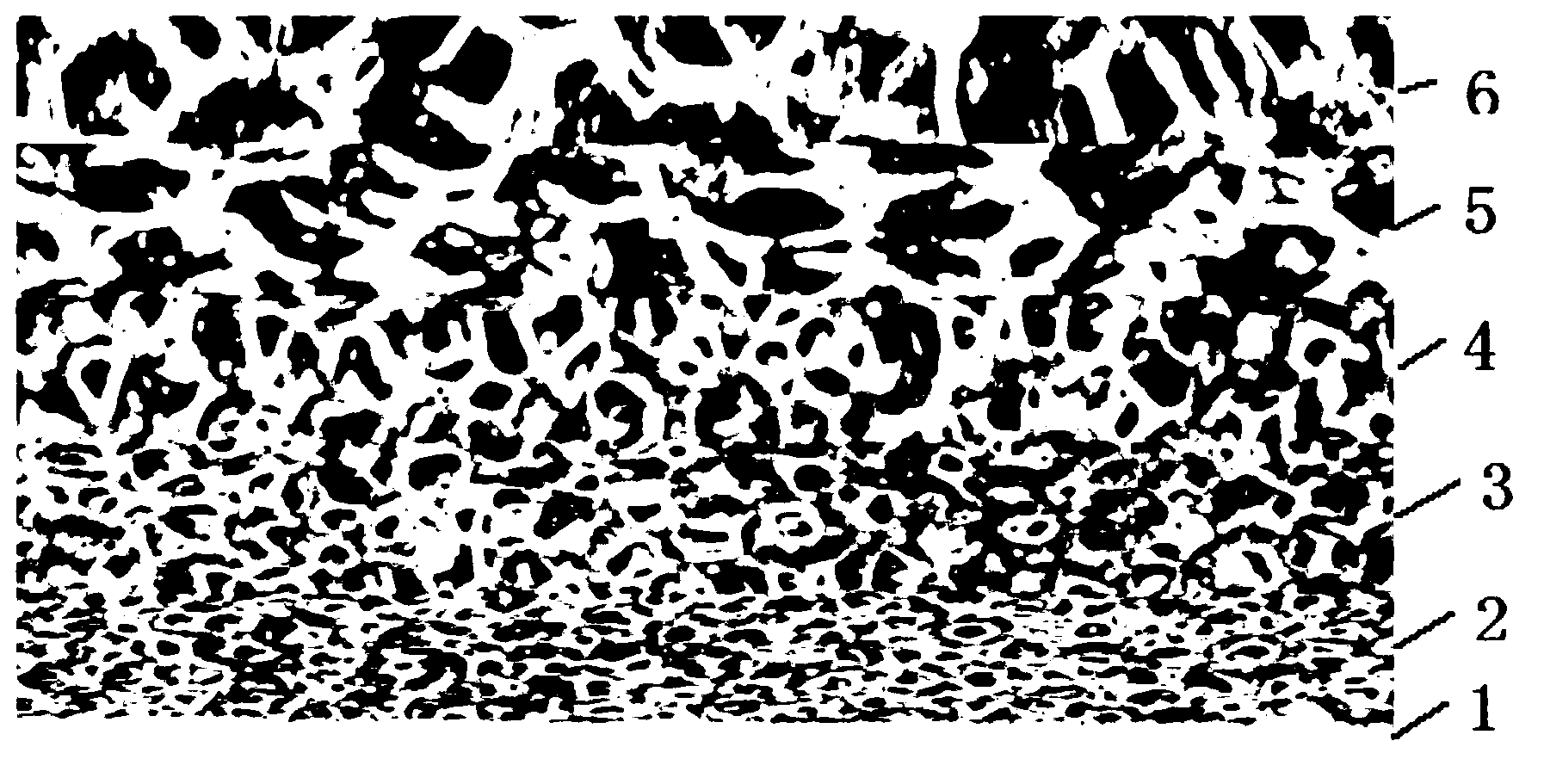

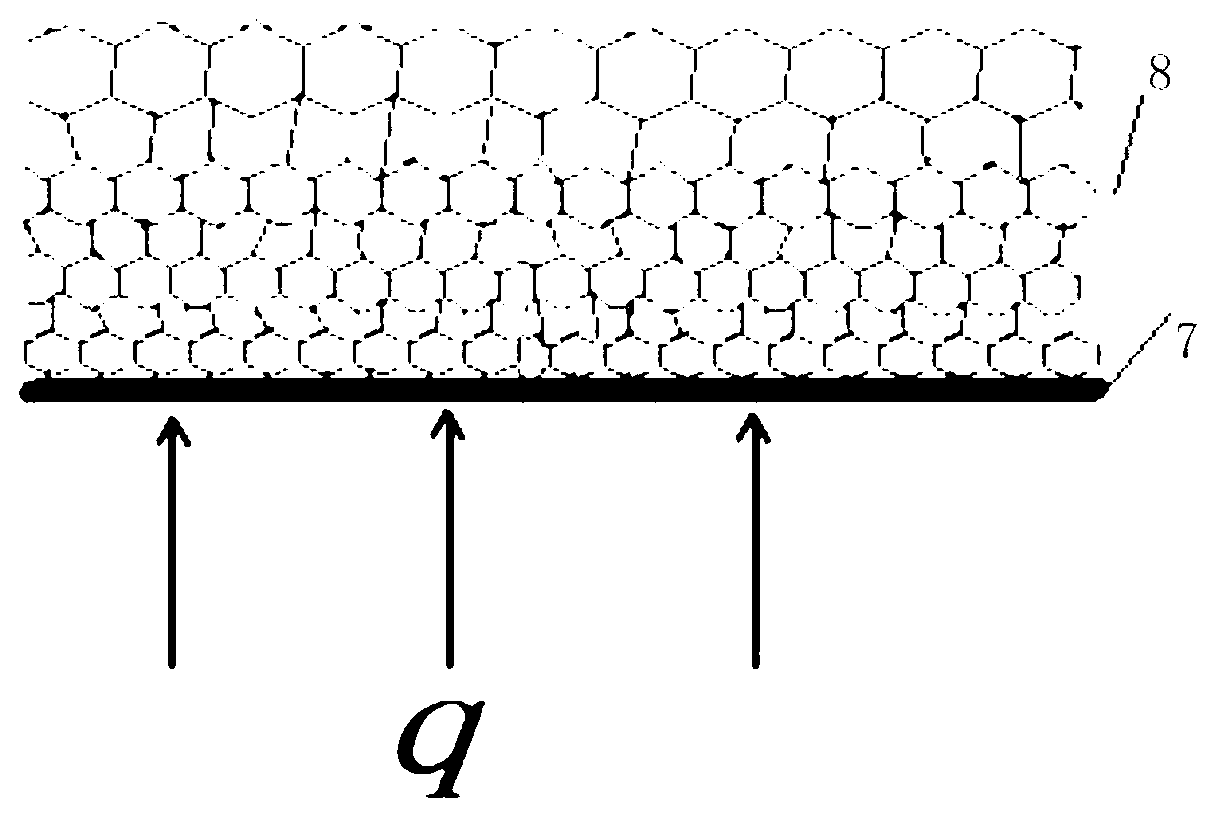

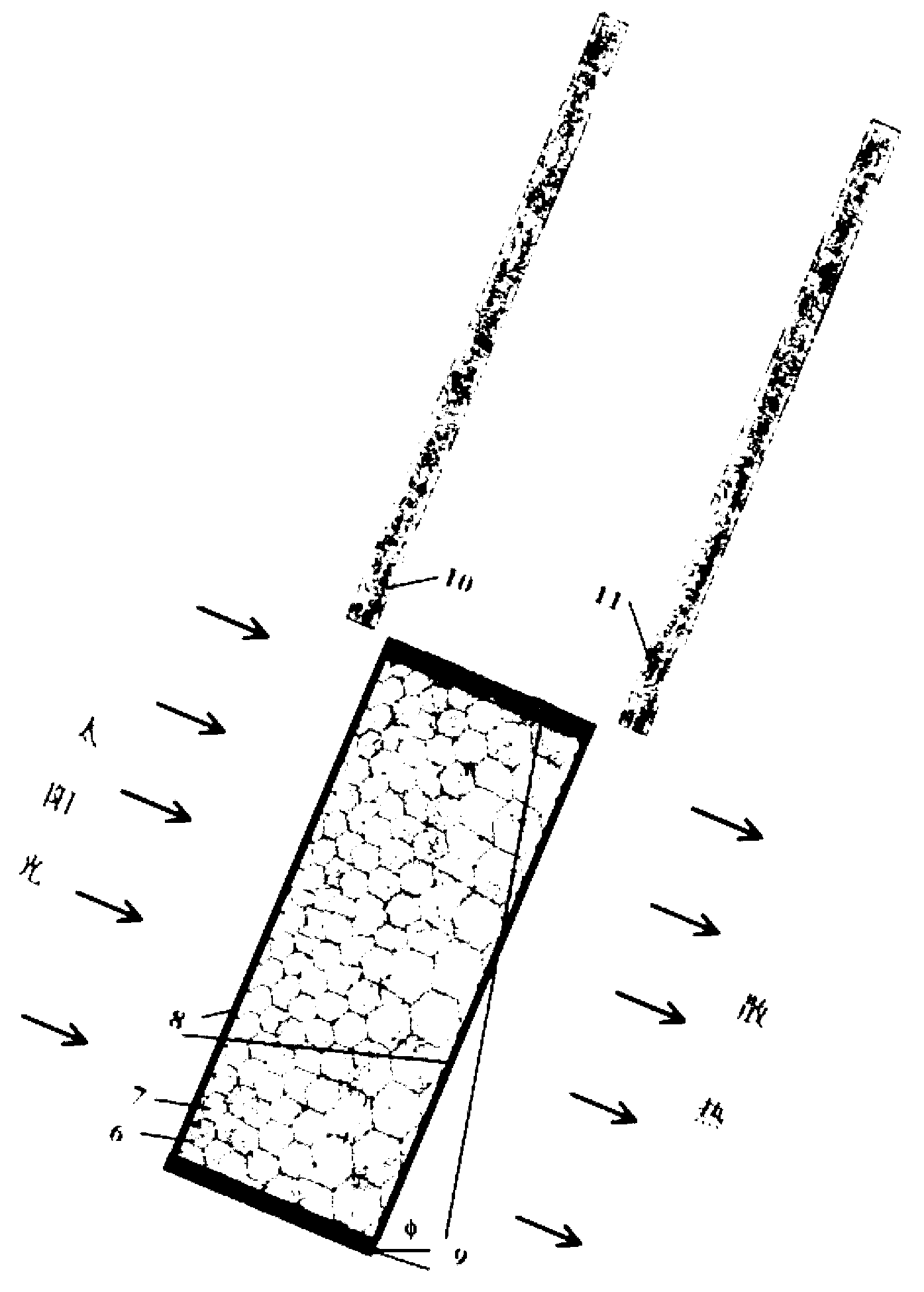

The invention provides a through-hole metal foam heat exchange device with gradually varied morphologic characteristics, which makes use of the technical field of a rigid heat transfer object. The through hole in the metal foam is of a structure with density being gradually varied; the gradually varied density means that the porosity is identical and the hole density is gradually increased or decreased in the vertical direction of the wall, or the hole density is identical and the porosity is gradually increased or decreased, or both the hole density and the porosity are identical to form the gradual change of the material of the through-hole metal foam. By adopting a metal framework with the density being gradually varied, which is fired on the heat exchange wall, the method has the advantages that the heat exchange performance of the heat exchanger is improved, a traditional heat exchange fin is replaced, the specific surface area of the heat exchange is enlarged, the fluidity and heat exchange of flows gradually expanded because of being heated are benefited, the heat exchange efficiency of the heat exchanger in the same heat exchange effect circumstance is higher, the metal consumption is lower, and the volume is smaller.

Owner:SHANGHAI JIAO TONG UNIV

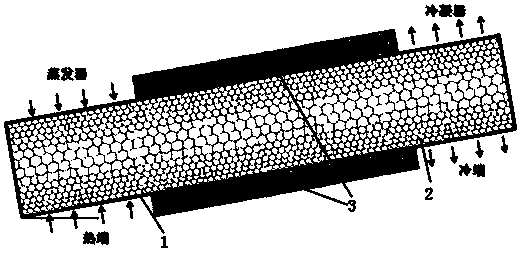

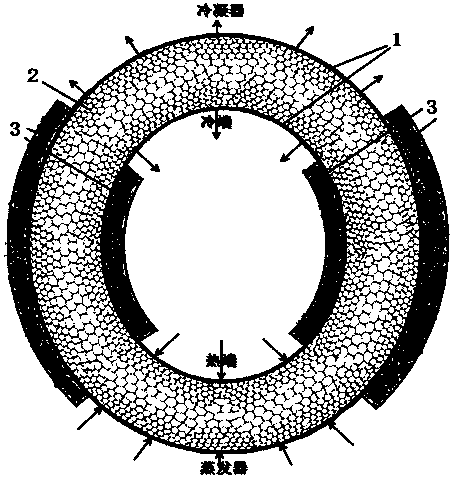

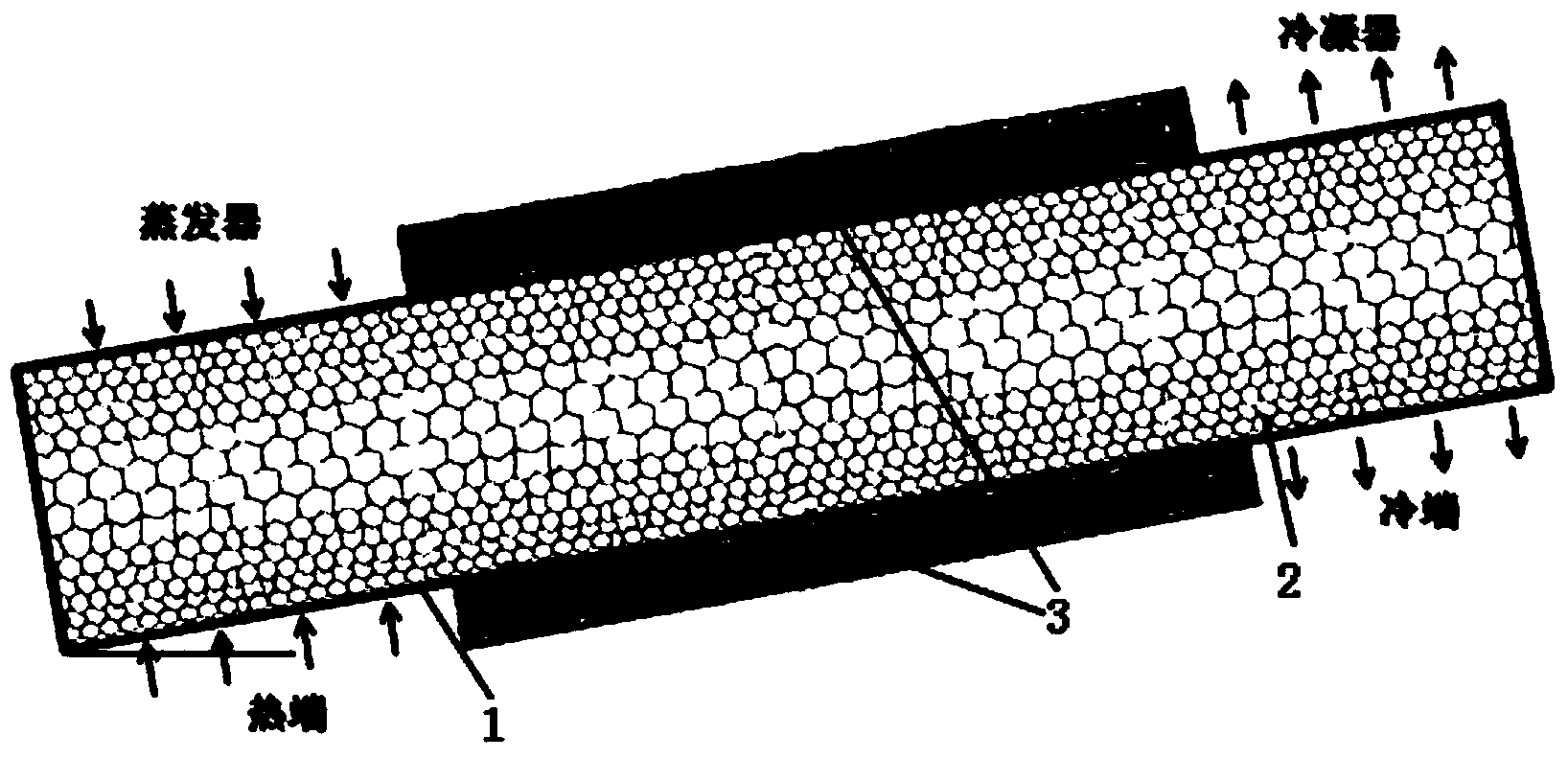

Phase change heat storage device based on gradient metal foam

InactiveCN103234377AImprove heat storage capacityIncrease the heat transfer specific surface areaHeat storage plantsHeat exchange apparatusMaterial consumptionRelease time

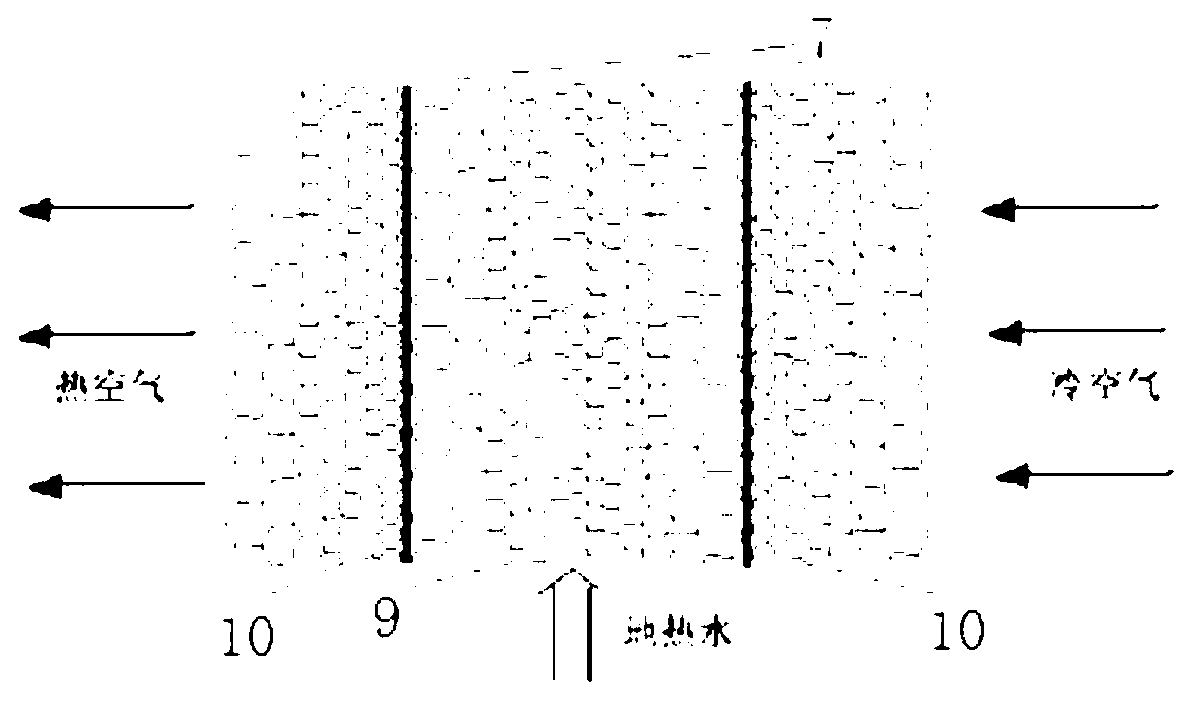

A phase change heat storage device based on gradient metal foam is used for building insulation and utilizes the technical field of the rigid heat transfer bodies. The phase change heat storage device based on the gradient metal foam comprises two insulation plates, two heat exchange wall surfaces, two adiabatic wall surfaces, gradient metal foam with the gradually-changed denseness of inner through holes and a phase change portion prepared of phase change materials. The gradient metal foam is sintered between the two heat exchange wall surfaces, the denseness of the gradient metal foam gradually decreases from left to right in the vertical direction of the heat exchange wall surfaces, the left side portion faces the outdoor, the right side portion faced the indoor, the upper side portion and the lower side portion are respectively provided with an adiabatic wall surface. The phase change portion is filled in the gradient metal foam. Two insulation plates are arranged on the outside of the two heat exchange wall surfaces respectively. According to the phase change heat storage device based on the gradient metal foam, the heat storage and release time can be controlled by adjusting gradient feature parameters, the phase change heat exchange performance can be enhanced through the gradient metal foam, and the problems of poor heat exchange efficiency, great material consumption, large size and the like in existing heat exchange time are solved.

Owner:SHANGHAI JIAO TONG UNIV

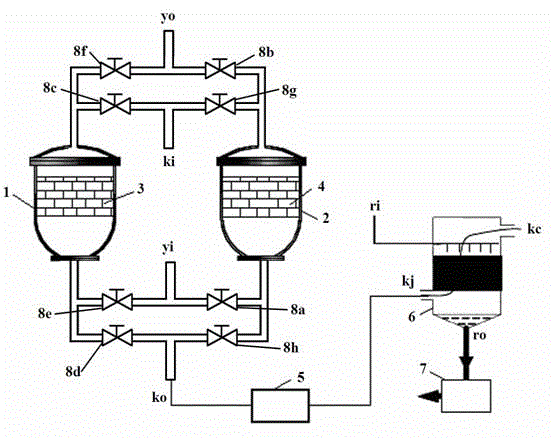

Continuous heat-storage type fume residual heat recovering device

InactiveCN101122446AImprove thermal conductivityIncrease the heat transfer specific surface areaStationary plate conduit assembliesFailure riskThermal transmittance

A continuous regenerative flue gas residual heat recycle device belongs to the industrial furnace energy saving field. The device is made from high heat resistance and conduction materials. A gas passage in the device is separated into mutually independent multistory spaces. Flue gas passages and air (gas) passages are arranged in a stratified and staggered way (that is a layer of flue gas passage is connected with a layer of air (gas) passage in the height direction, a staggered arranged sandwich structure). Every layer of gas flow passage is a honeycomb channel, which is made from high thermal conductivity materials. The hest recycle device has the advantages mentioned below. First, the heat exchange rate is fast. The thermal conductivity rate of a regenerator is high. And heat exchange between flue gas and air can be done rapidly. Second, the device can work continuously. Communication is not required in the wind supply and the smoke exhaust. And the system is simple. Third, utmost waste recovery is really realized. No heat and fuel loss caused by volume effect is made during the communication. Fourth, with a long service life, the device can be flexibly arranged. And the device has relative small relevance with the furnace, which makes the failure risk lowered and is convenient for the engineering management.

Owner:UNIV OF SCI & TECH BEIJING

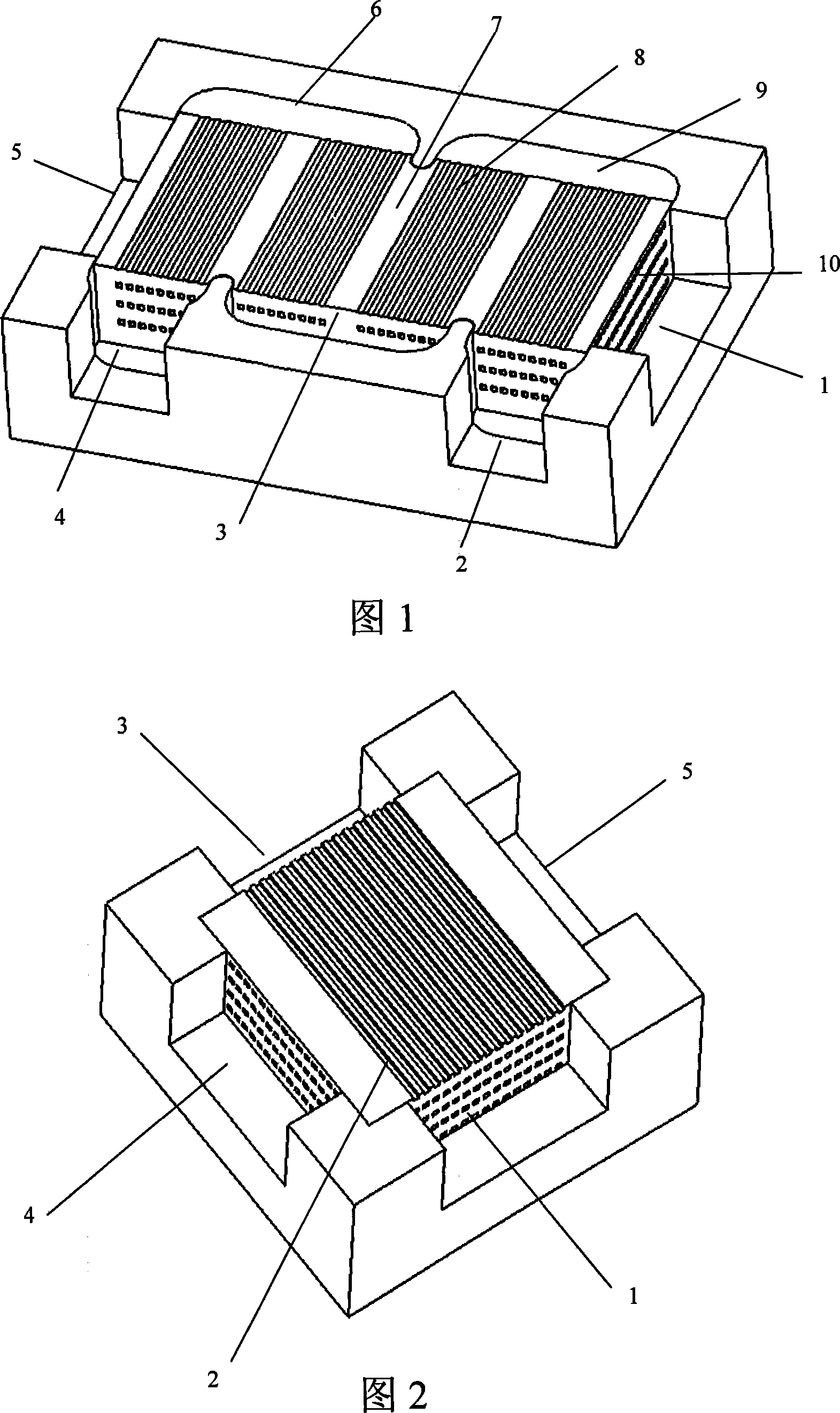

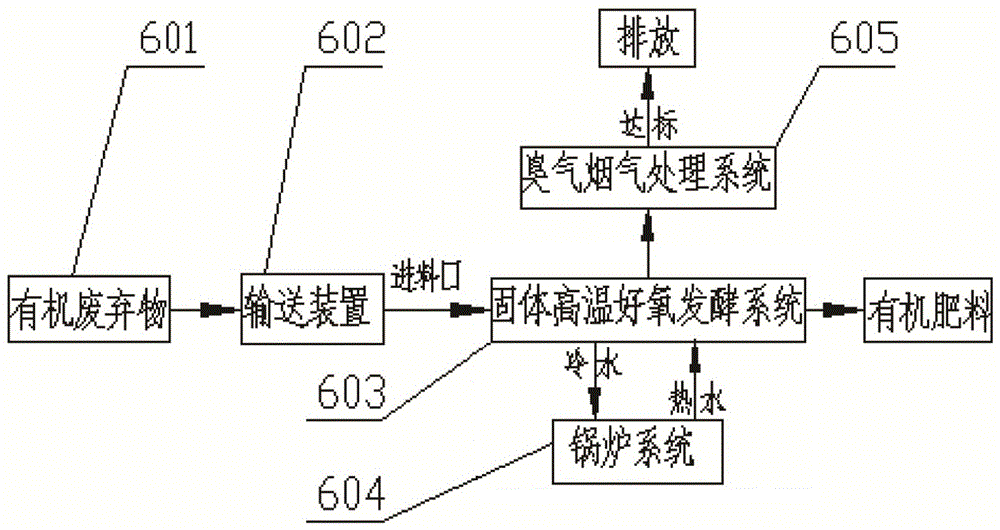

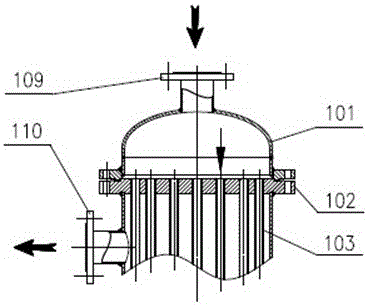

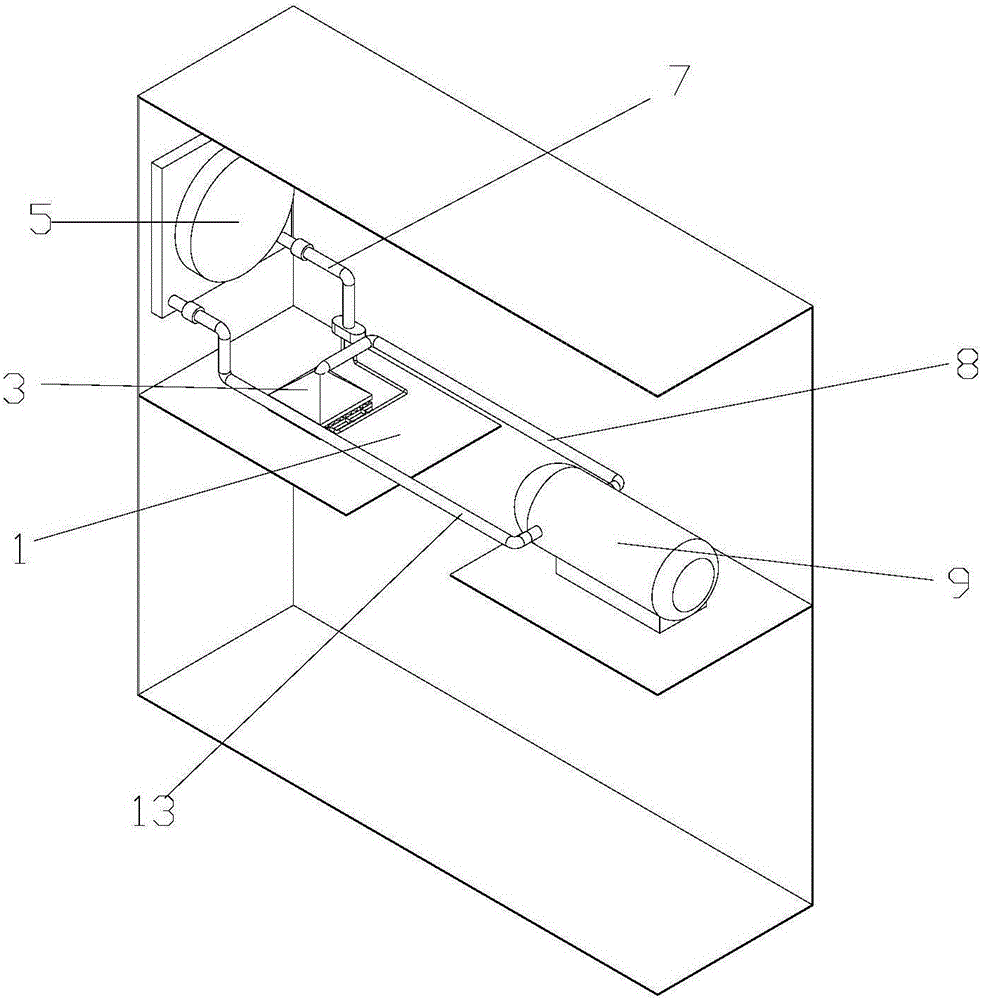

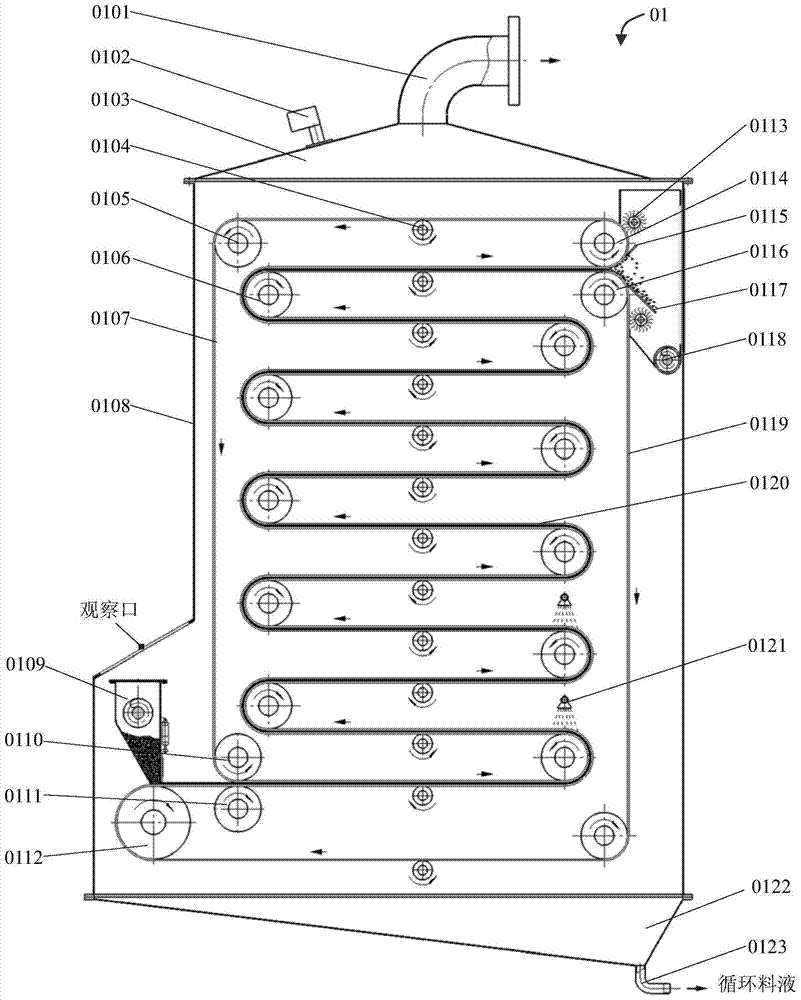

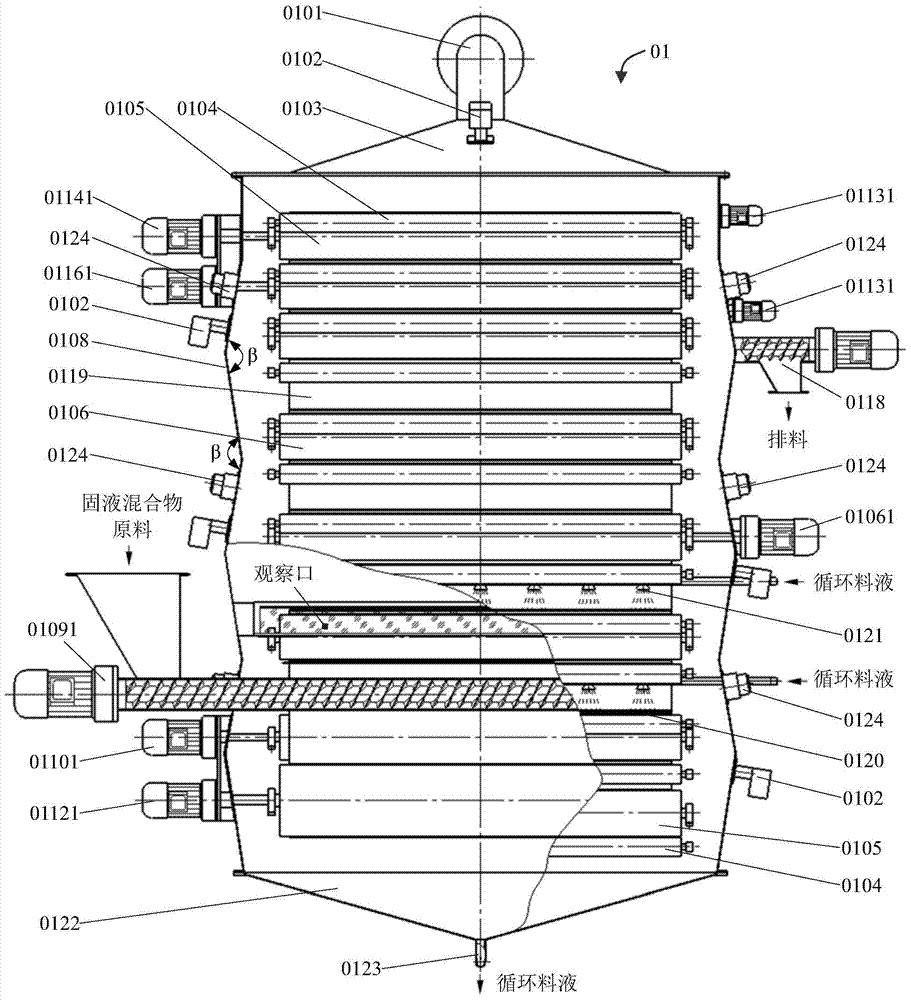

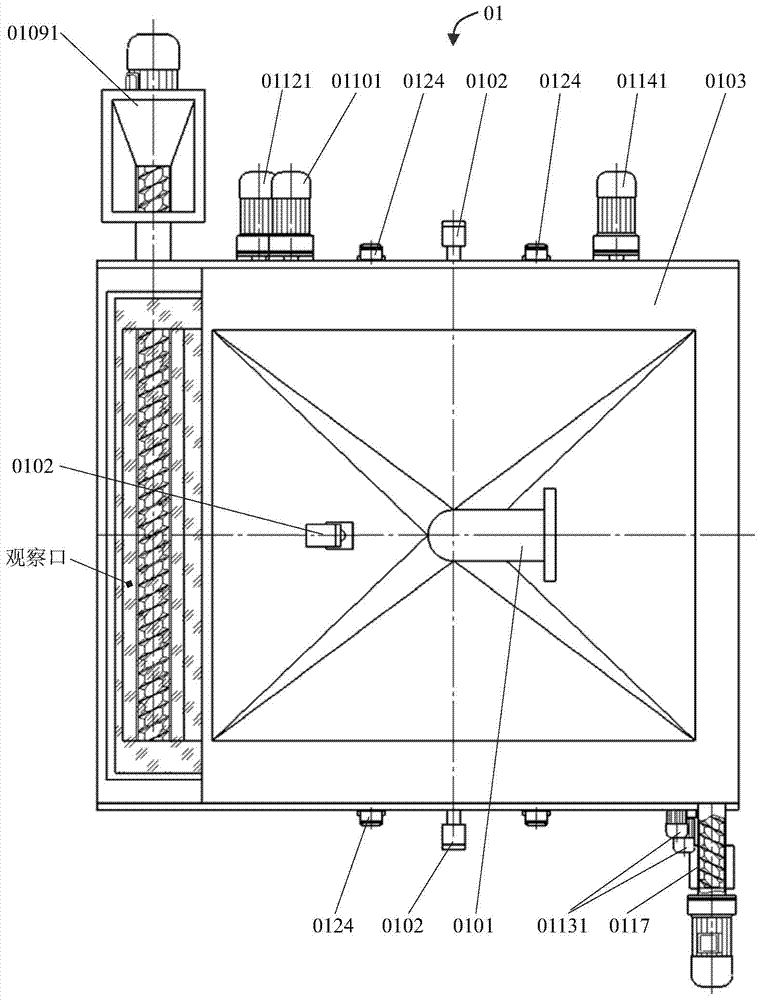

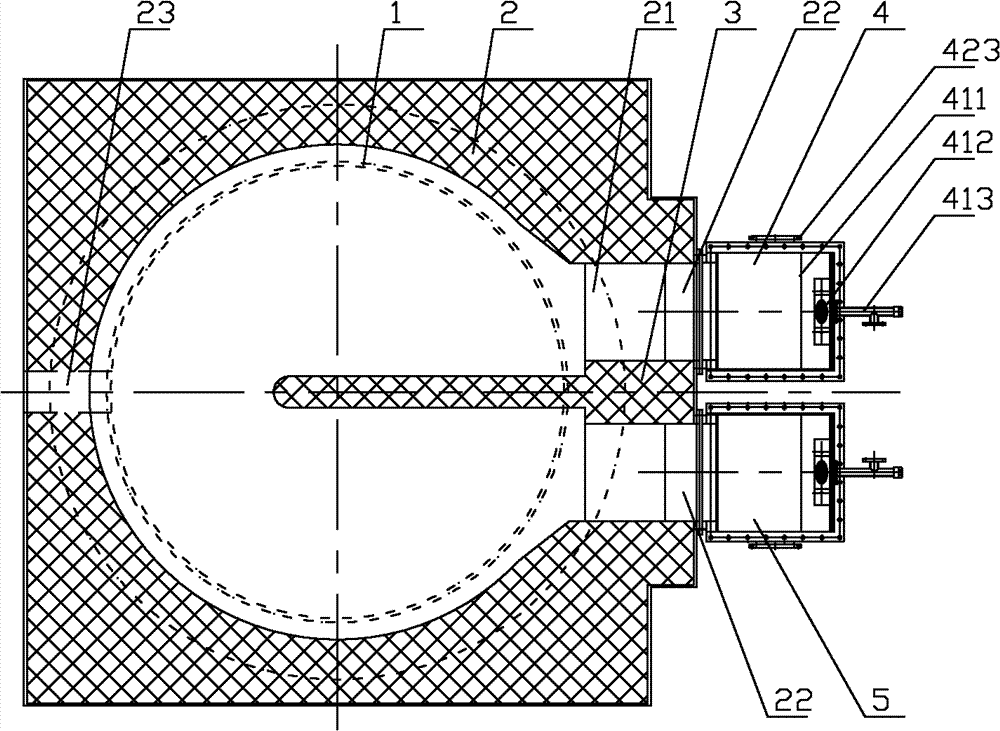

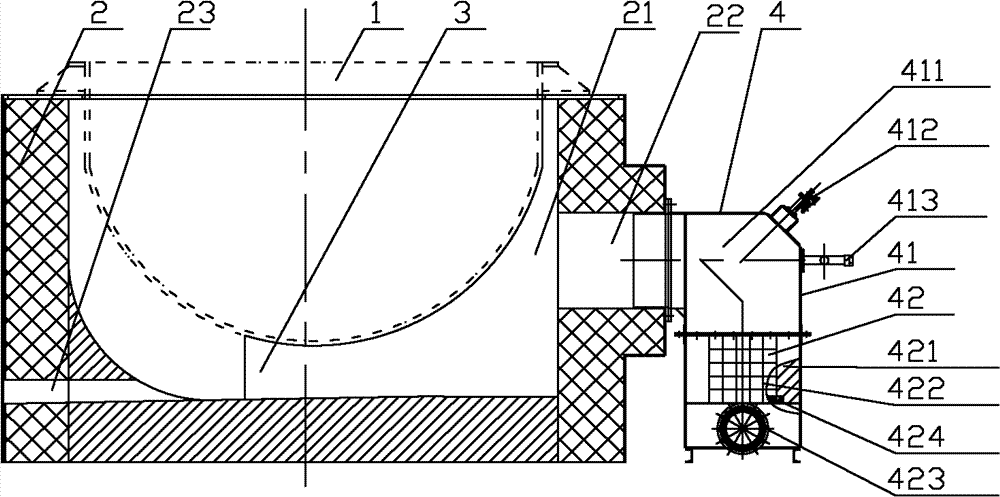

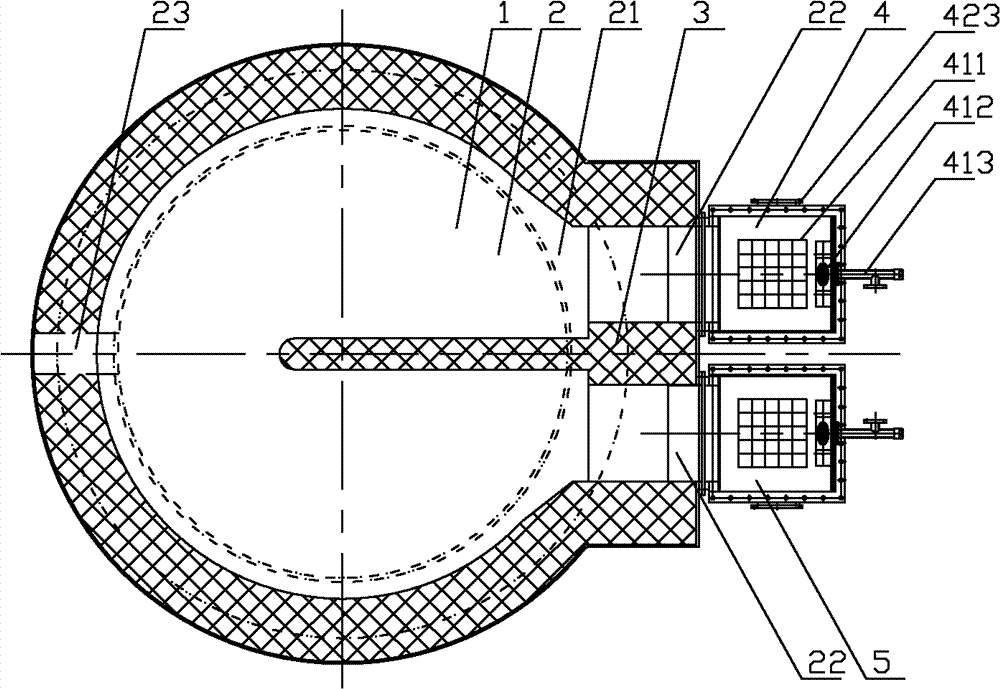

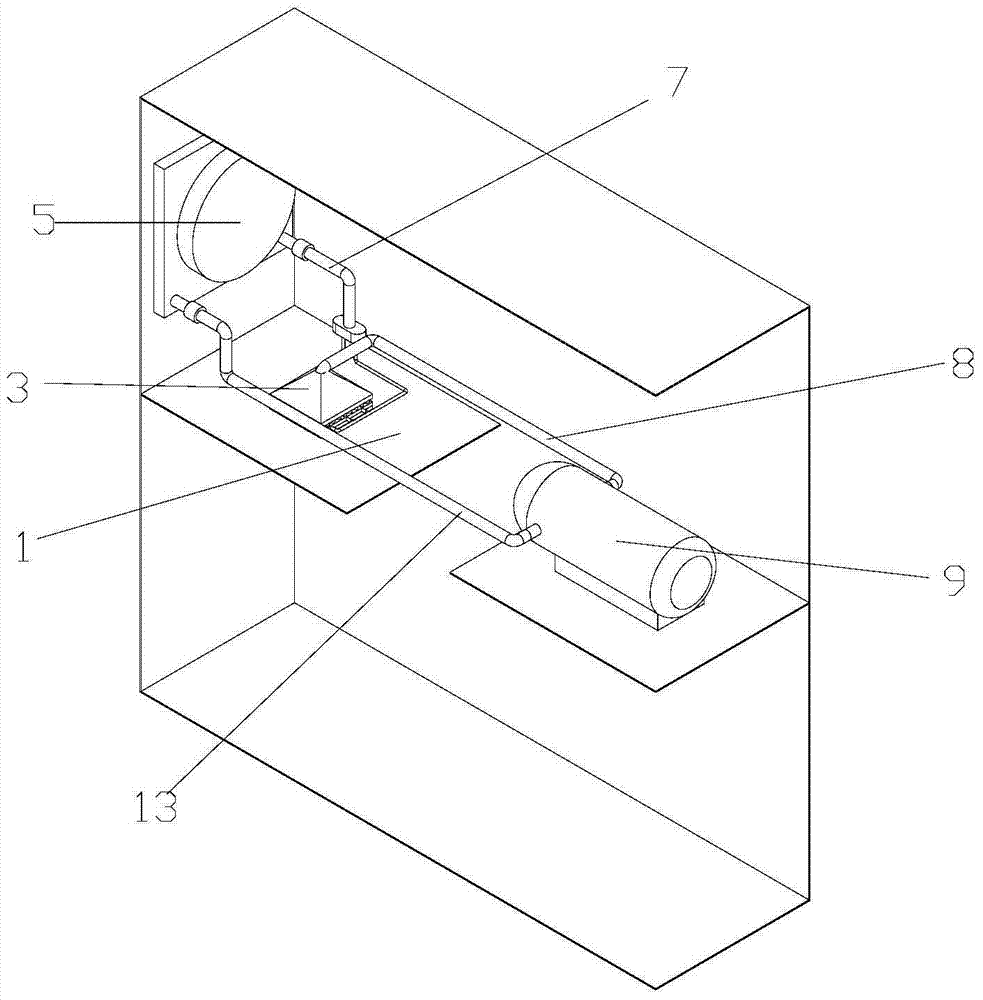

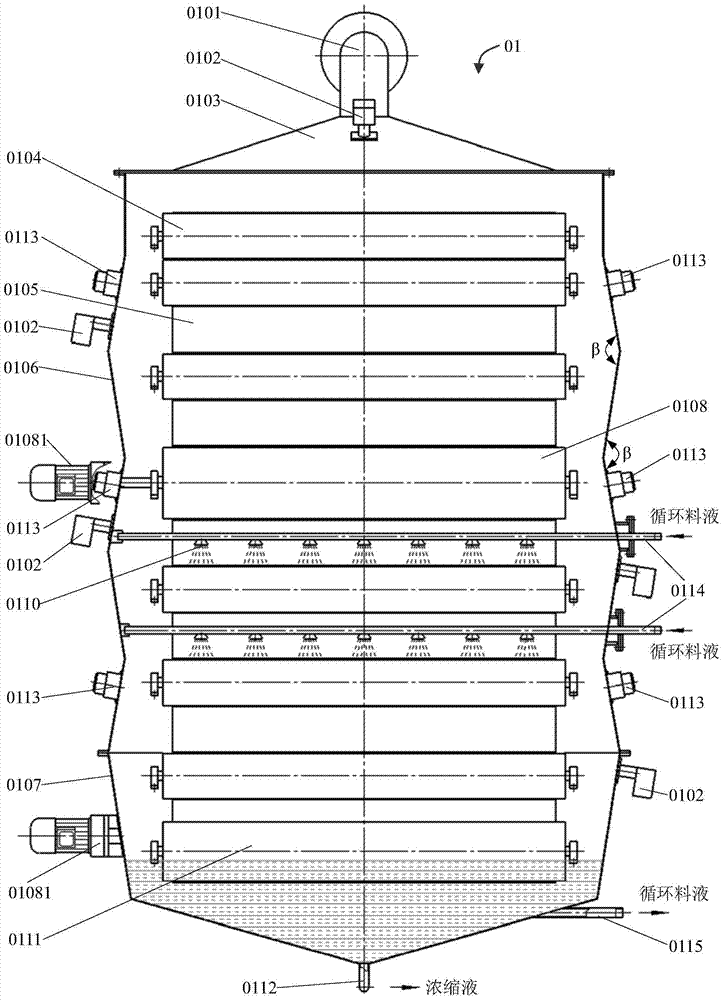

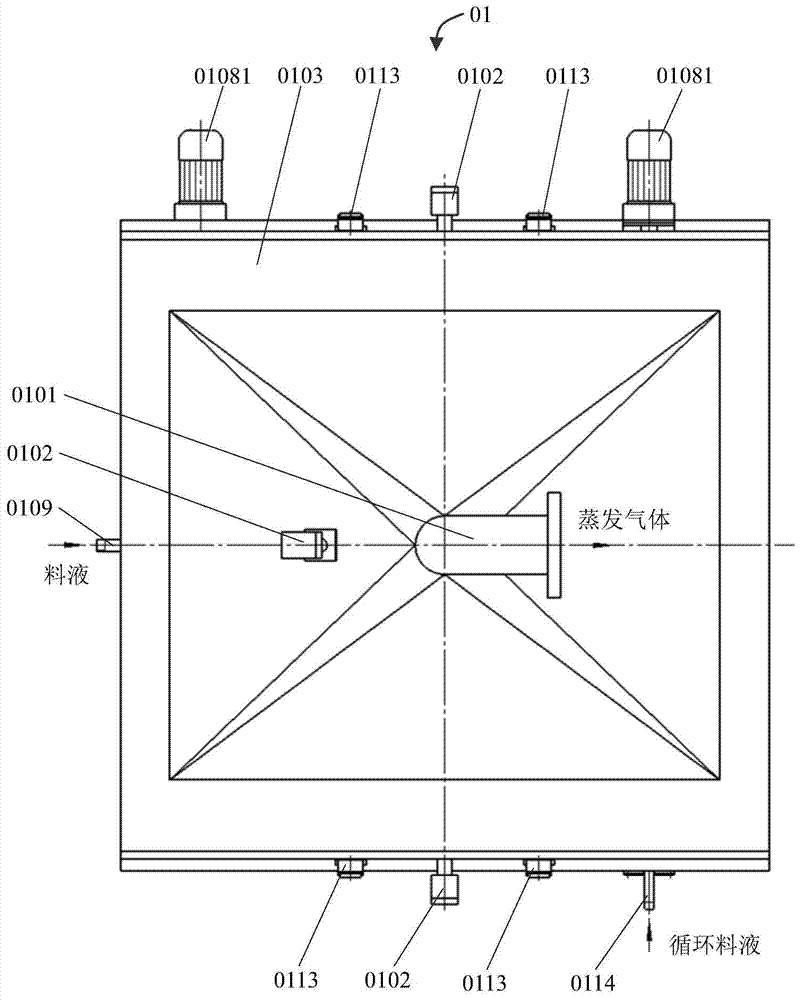

Solid high-temperature aerobic fermentation reaction system and method

ActiveCN106119105AAvoid stickingEasy to use and maintainBioreactor/fermenter combinationsBio-organic fraction processingEnvironmental resistanceSmall footprint

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

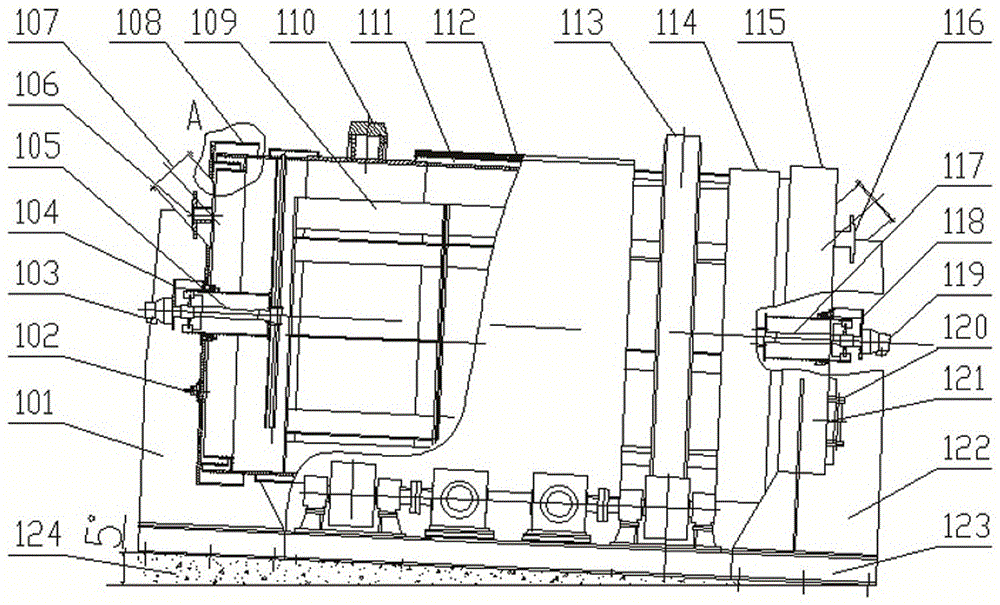

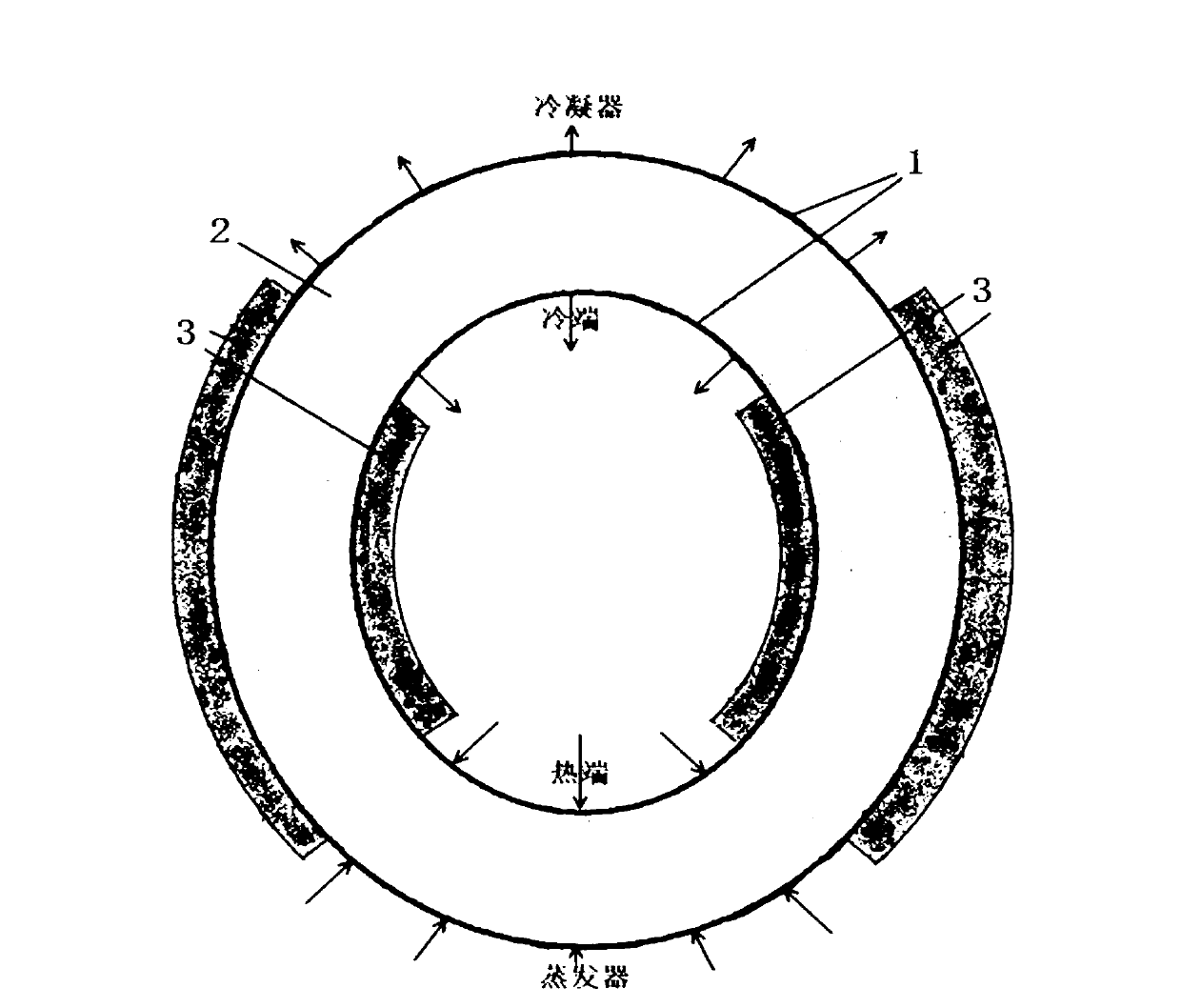

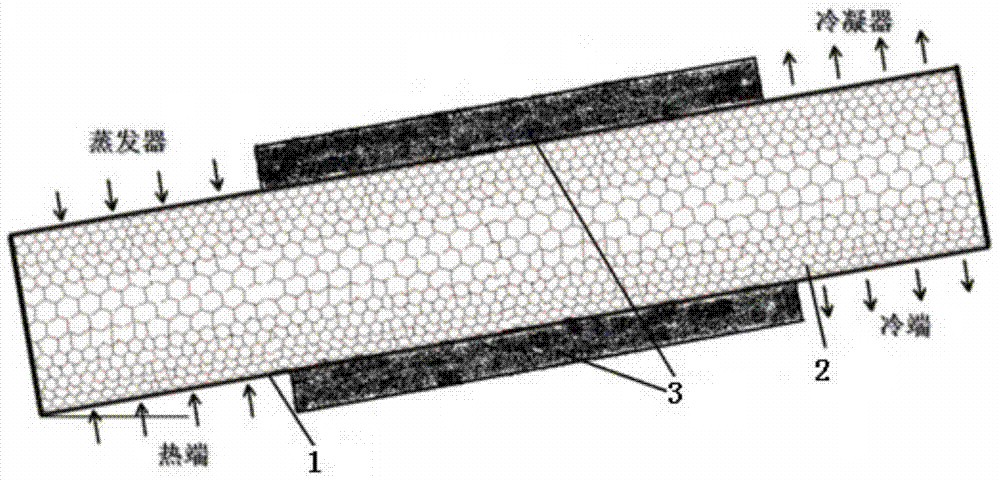

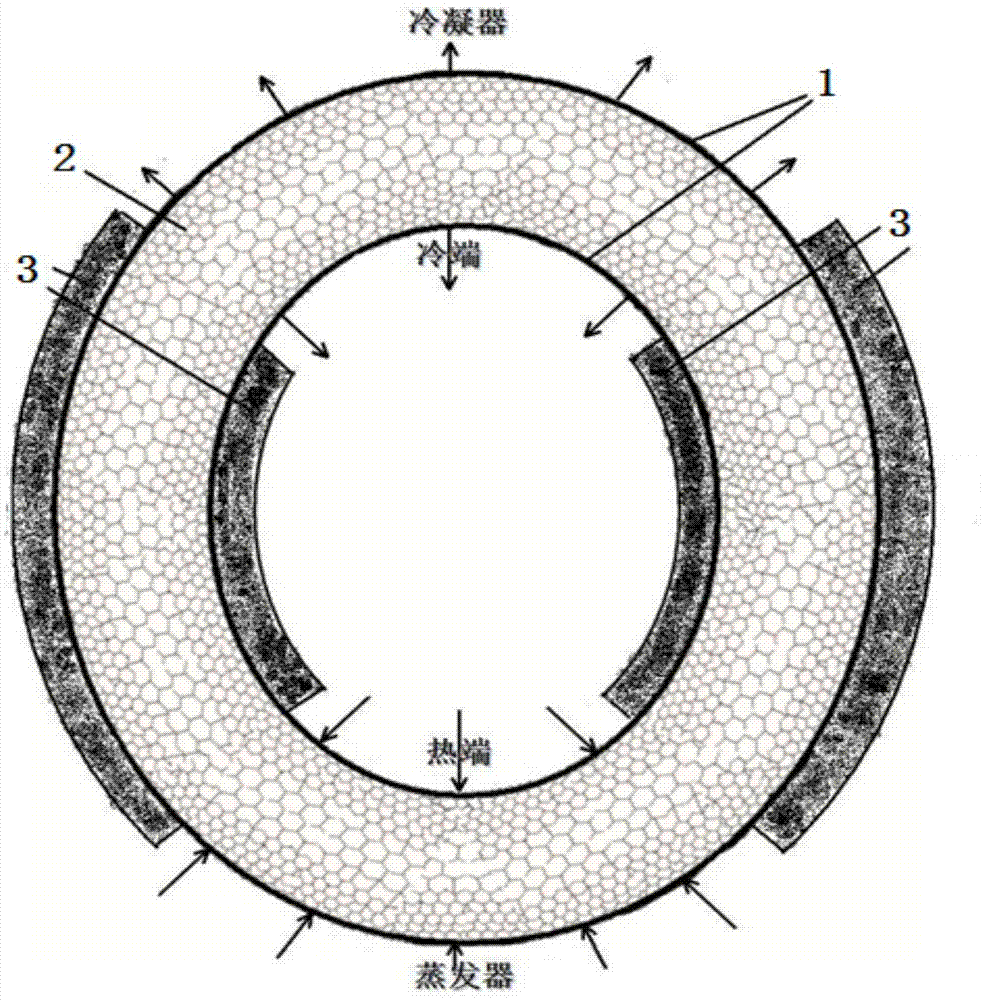

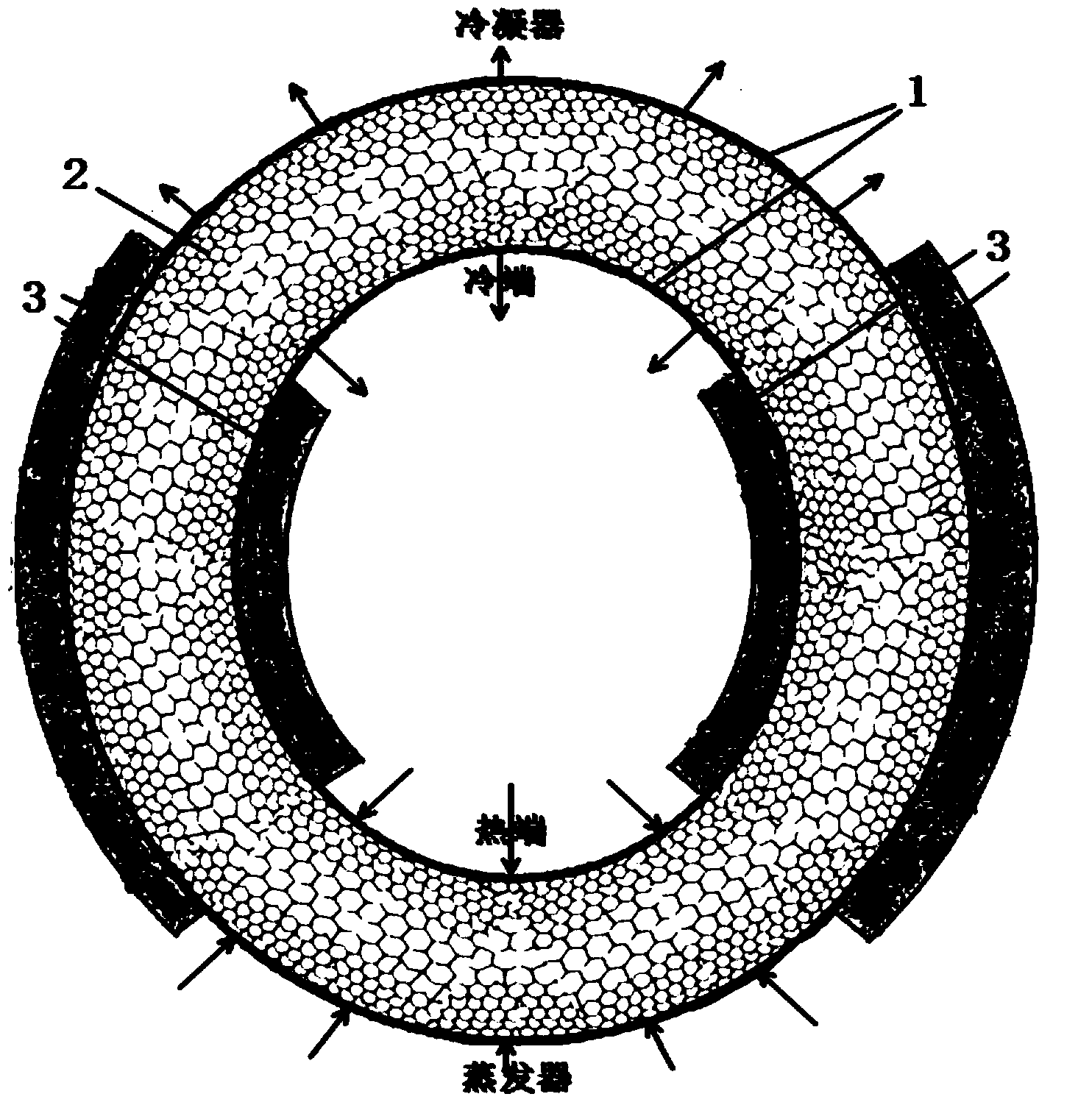

Through hole metal foam heat pipe heat exchange device with gradient topographic characteristics

InactiveCN103134365ALess consumablesReduce volumeFoundry mouldsIndirect heat exchangersThermal insulationPipe insulation

The invention provides a through hole metal foam heat pipe heat exchange device with gradient topographic characteristics and relates to the technical field of rigid heat conductors. The through hole metal foam heat pipe heat exchange device with gradient topographic characteristics comprises a heat pipe and through hole metal foams sintered on the inner wall of the heat pipe. A heat insulation section is arranged on the outer layer in the middle of the heat pipe, and two ends are respectively arranged at the cold end and the hot end of heat exchange environment. The structure of the through hole metal foams is that inner through holes are structures with gradient density, namely porosity factor is the same, and hole density is increased or reduced gradually along the perpendicular direction of the wall surface of the heat pipe; or hole density is the same, and the porosity factor is increased or reduced gradually along the perpendicular direction of the wall surface of the heat pipe; the hole density and the porosity factor are the same, and used materials are changed according to layers. The through hole metal foam heat pipe heat exchange device with gradient topographic characteristics increases heat exchange surface area, facilitates flow and heat exchange of fluid expanded gradually because of being heated, enhances capillary force, and enables the heat pipe to have high heat exchange efficiency under the condition of same heat exchange effect. Metal consumption is small, and volume is small.

Owner:SHANGHAI JIAO TONG UNIV

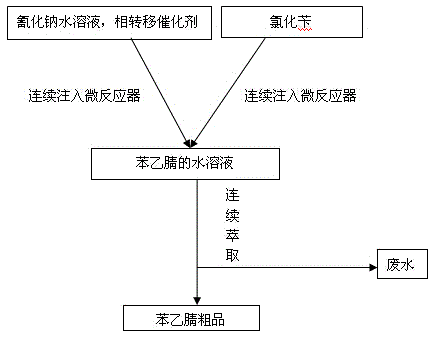

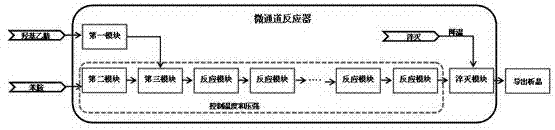

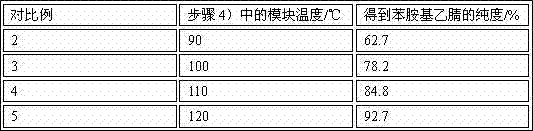

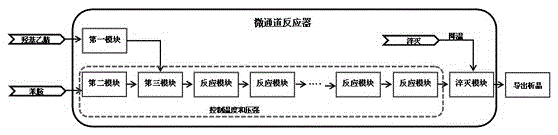

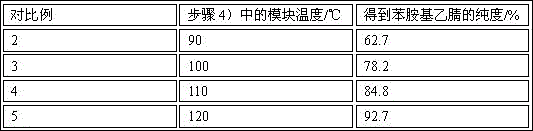

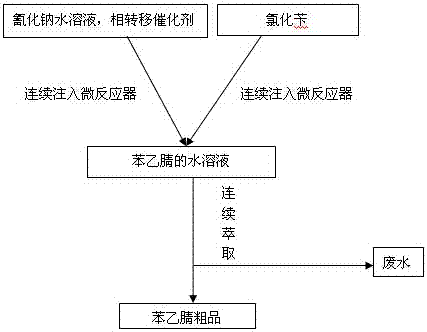

Method for synthesizing phenylacetonitrile by performing continuous reaction

ActiveCN105218401ARealize continuous productionIncrease productivityPreparation by cyanide reactionAutomatic controlBenzyl chloride

The invention discloses a method for synthesizing phenylacetonitrile by performing continuous reaction, and relates to the field of preparing a compound containing six-membered aromatic ring connected with cyano group by saturated carbon chain. The method comprises the following steps: adjusting the temperature of a micro-reactor to 80-400 DEG C; adding a mixture of a sodium cyanide aqueous solution and phase-transfer catalyst, and benzyl chloride in the micro-reactor continuously; reacting in the micro-reactor for 20-300 s to get a phenylacetonitrile aqueous solution. The method has rapid reaction speed, high production efficiency, low cost, good product quality, is easy to realize automatic control, is beneficial to subsequent post-treatment, and can raise the phenylacetonitrile yield, reduce the side reaction, and save labour.

Owner:HEBEI CHENGXIN

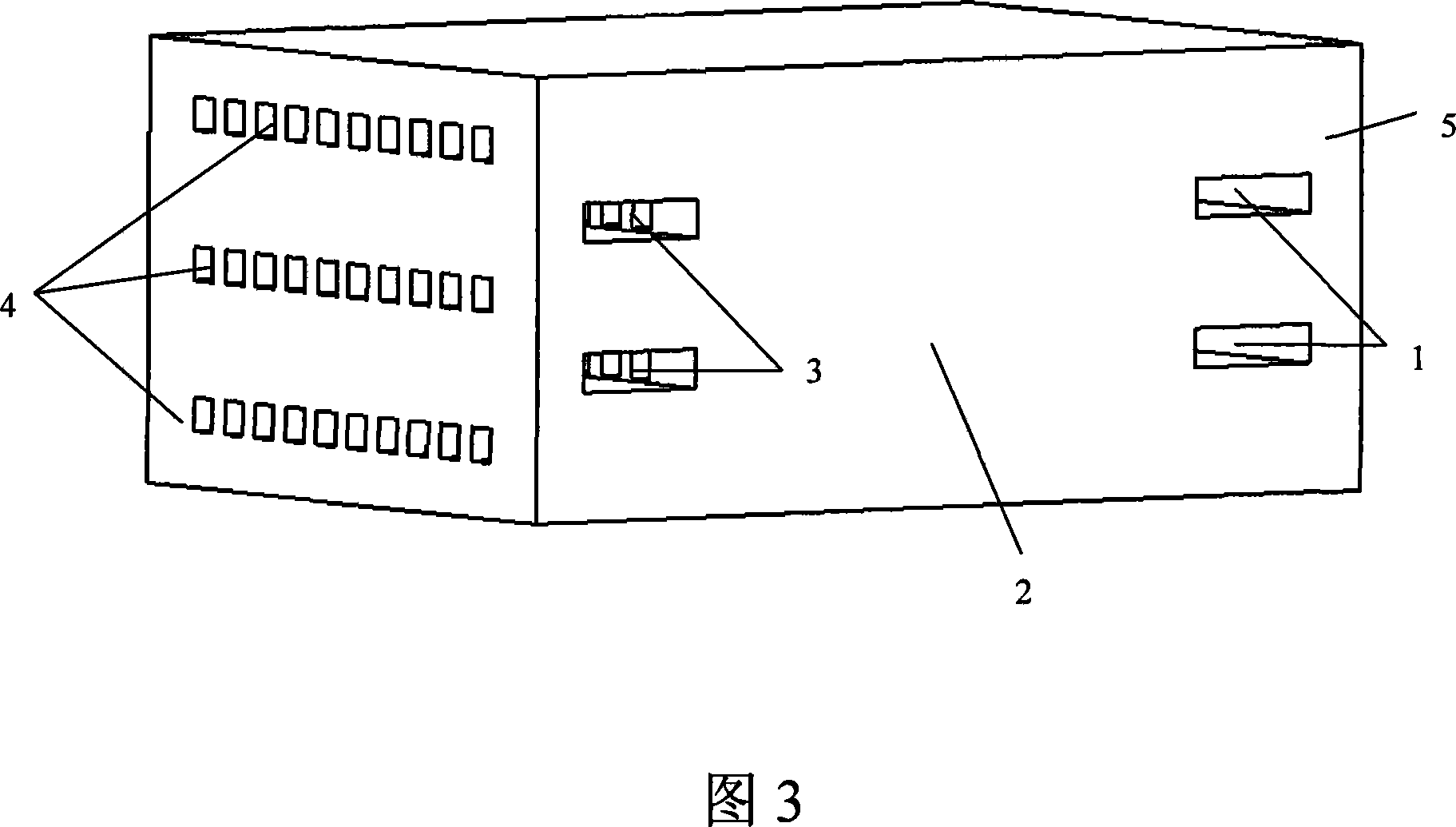

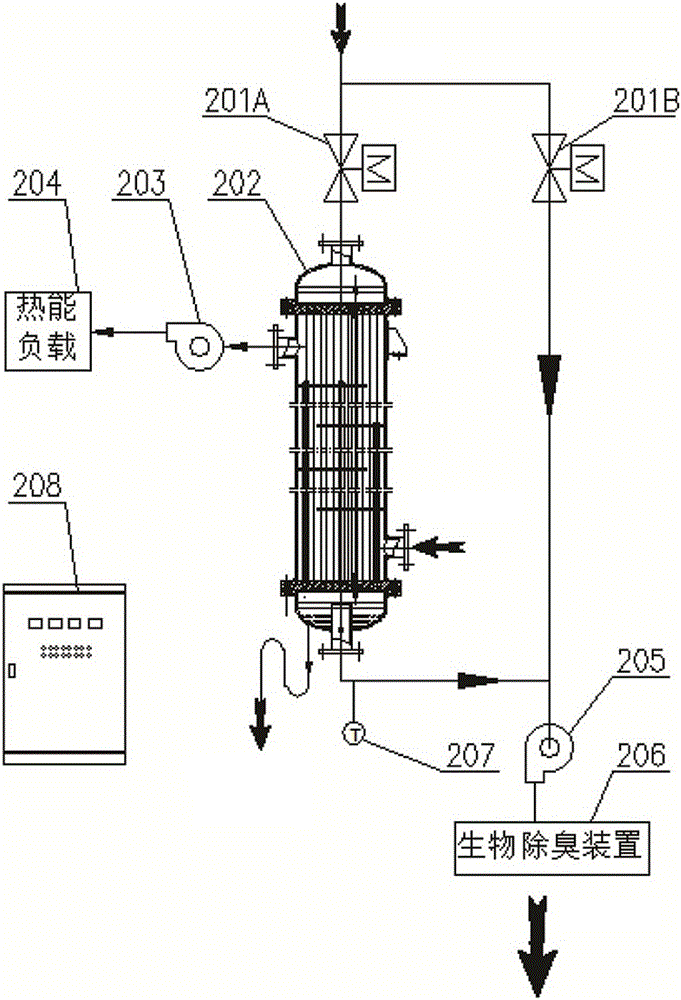

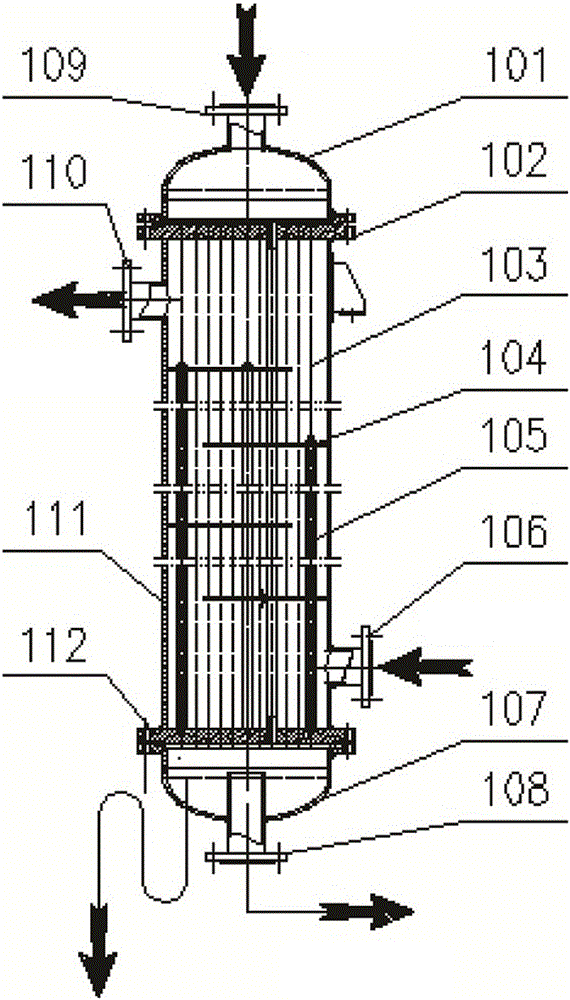

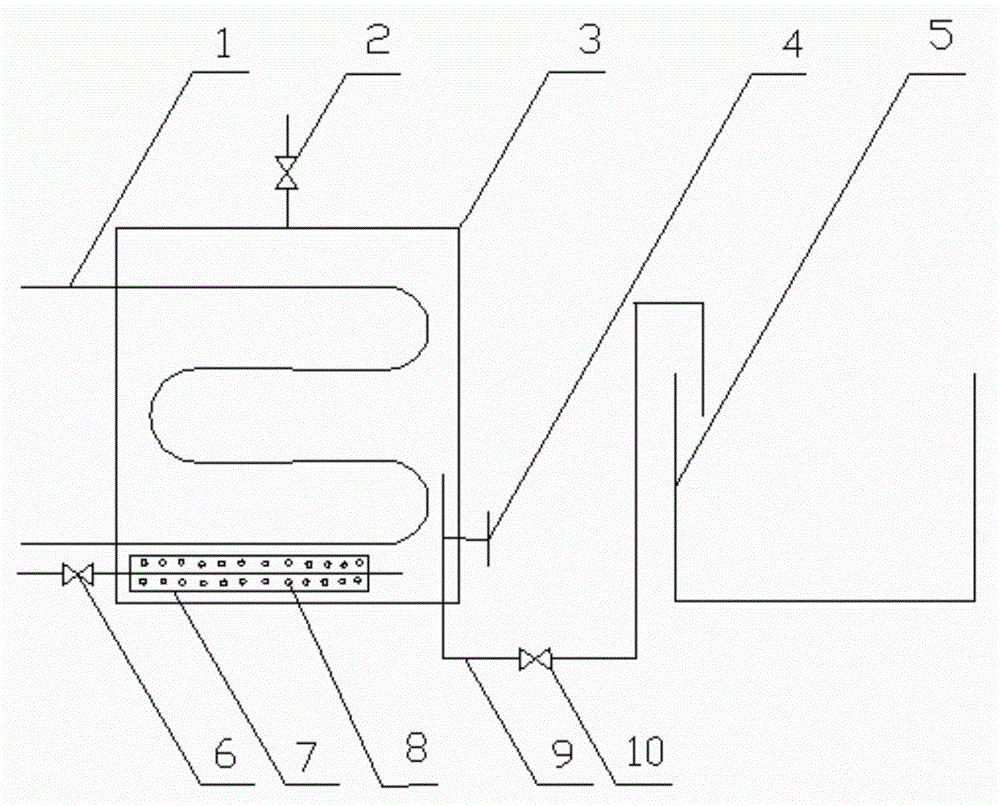

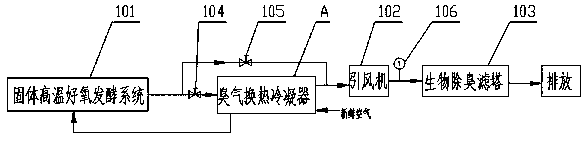

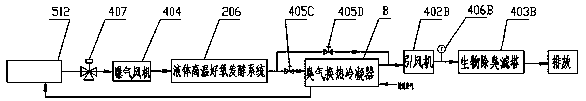

Odor heat exchange condensation system and method

InactiveCN106839796AGuaranteed deodorizing effectRecycling and HarmonyCompression machines with non-reversible cycleDispersed particle separationThermal energySolenoid valve

The invention discloses an odor heat exchange condensation system and method. The system comprises a heat exchange condenser, a temperature sensor, a biological deodorization device, a detection control device, an odor collection pipeline and an odor exhaust pipeline. The heat exchange condenser comprises an upper end cover, a tank body and a lower end cover. The odor collection pipeline is fixedly connected with the upper end cover. The lower end cover is fixedly connected with the odor exhaust pipeline. The odor exhaust pipeline is connected with the biological deodorization device through an induced draft fan. A bypass branch and a bypass branch solenoid valve are further connected between the odor collection pipeline and the induced draft fan. A fresh air inlet flange and a hot air exhaust flange are arranged on the side wall of the tank body, and hot air is connected with a heat energy load. An air heat exchanger is mounted in the tank body. The temperature sensor mounted at an odor exhaust opening of the heat exchange condenser is connected with the detection control device. The detection control device controls an odor inlet solenoid valve or the bypass branch solenoid valve. According to the odor heat exchange condensation system and method, microorganism dormancy and death are avoided, the deodorization effect is guaranteed, and heat energy can be provided.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

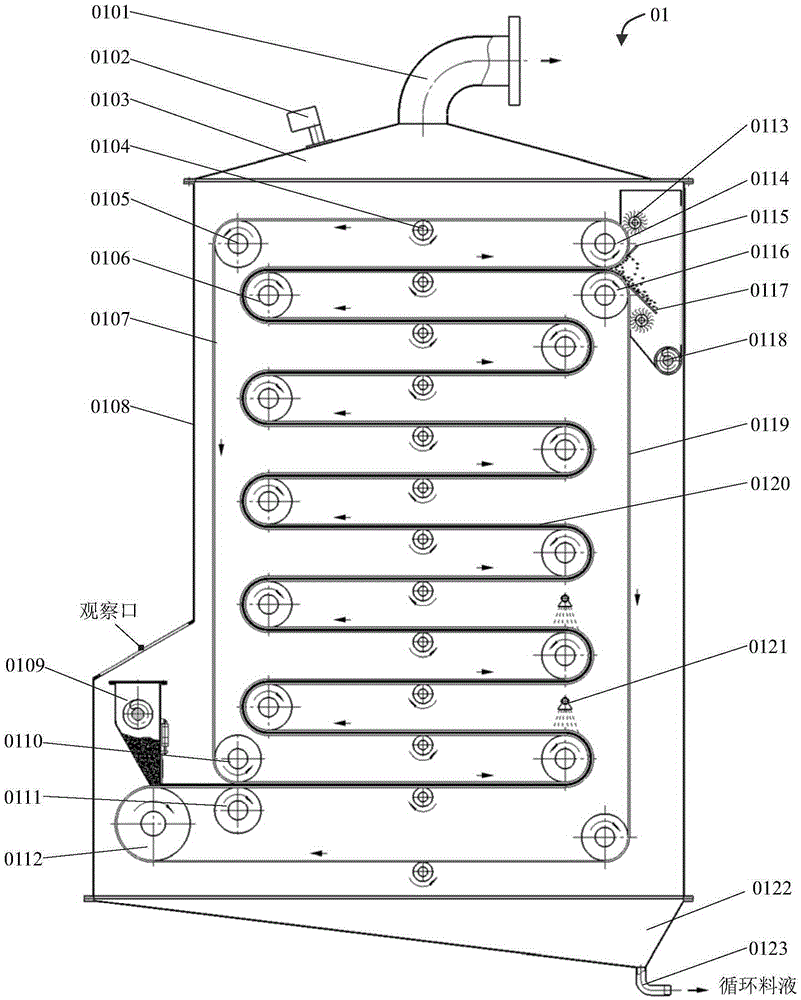

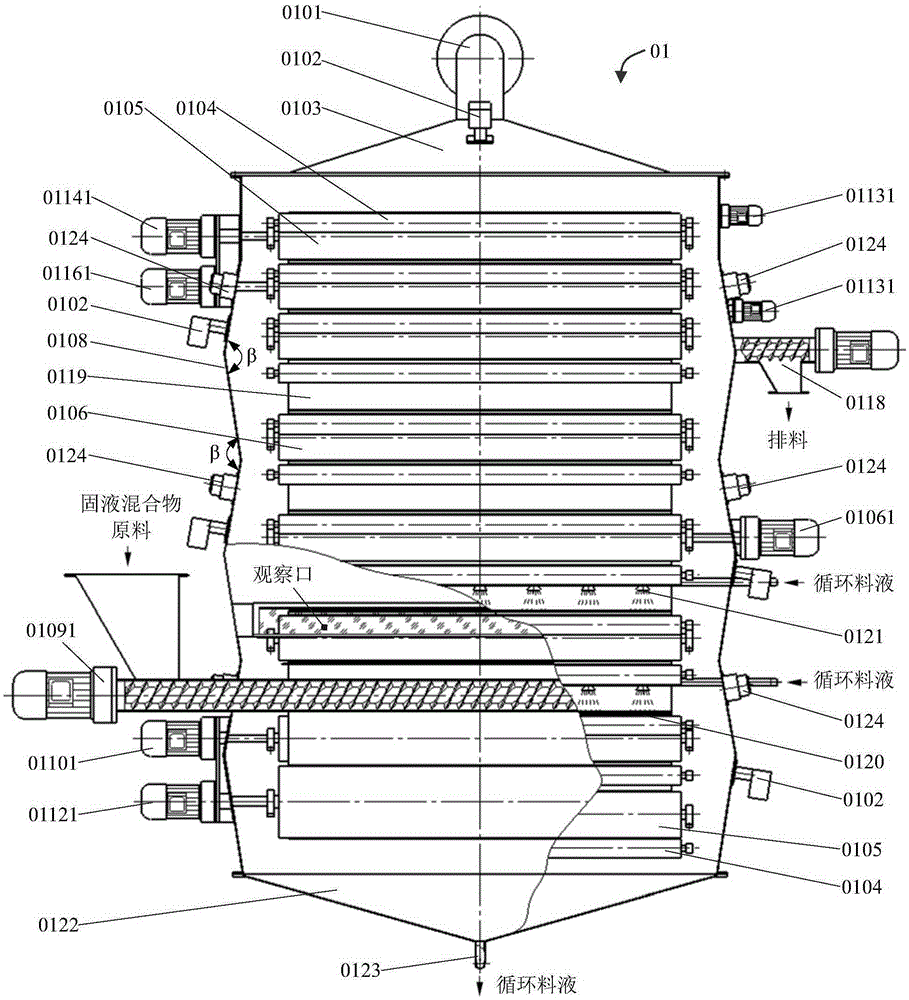

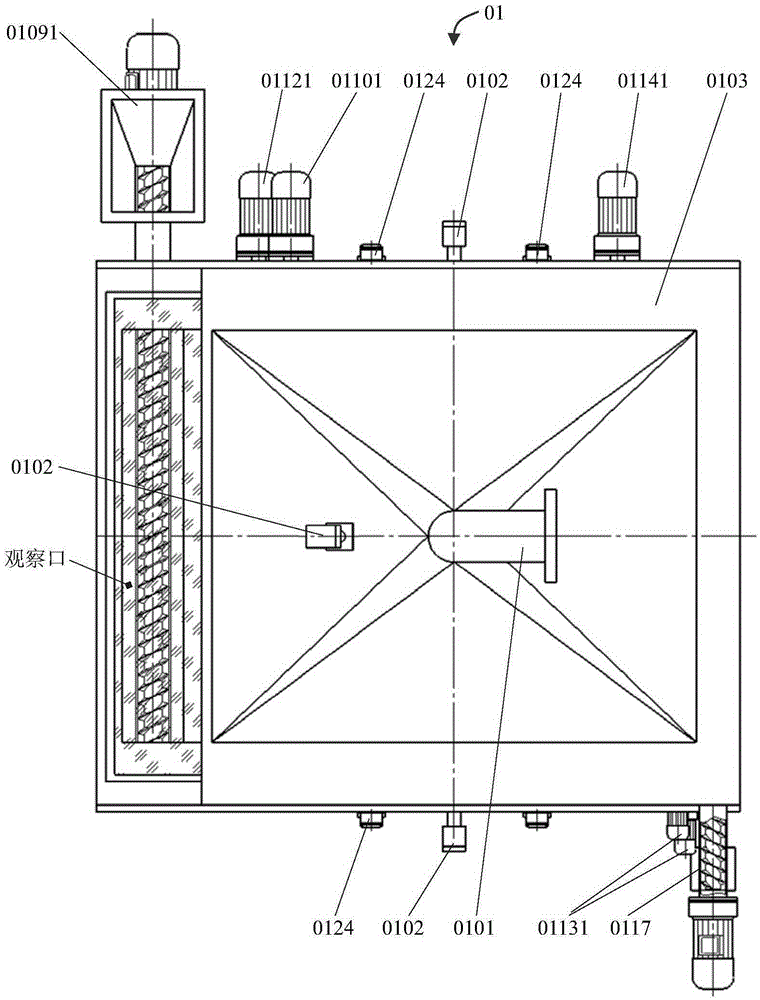

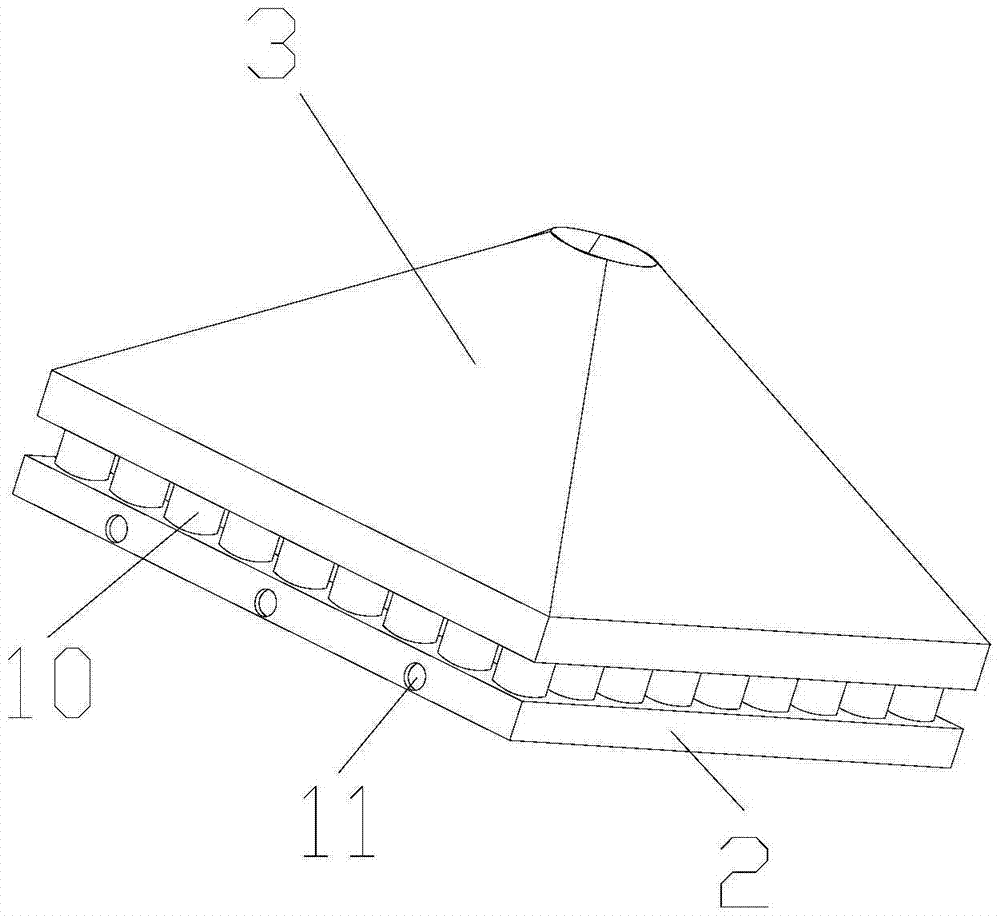

Continuous belt-clamping type thin material layer microwave evaporation method and device

InactiveCN105251224AEfficient conversionIncrease vacuumEvaporator accessoriesResonant cavityMicrowave

The invention provides a continuous belt-clamping type thin material layer microwave evaporation method and a continuous belt-clamping type thin material layer microwave evaporation device. A solid and liquid mixture is oppositely clamped between two endless filtering net belts by a pair of upper clamping roller and lower clamping roller which revolve to form an oppositely clamping material layer structure of the upper filtering net belt, a solid and liquid mixture layer and the lower filtering net belt; through a microwave resonant cavity in a horizontal reciprocating and layer-by-layer raising transportation way, the solid and liquid mixture material liquid in the oppositely clamped material layer absorbs microwave energy in a uniform thin layer state to be heated and evaporated; meanwhile, the evaporation capacity is improved by circularly loading a nozzle of isolation material liquid, the vacuum degree in an evaporator is improved by a feeding and discharging sealing structure, and the material liquid is effectively translated to gas phase at a relatively low temperature. Furthermore, due to the adoption of the oppositely clamping material layer in a multi-layer transportation state, the heat exchange specific surface area is increased; due to the fact that an evaporation device is compact, the area utilization rate is high; distillation operation and extraction operation can be realized by matching the evaporation device with a condensation and gas-liquid separation device.

Owner:WUHAN NEWWAY PHARMA MACHINERY

Method for preparing n-phenylglycinenitrile

ActiveCN104496848APost-processing saves time and effortReduce processCarboxylic acid nitrile preparationOrganic compound preparationAnilineOperation safety

The invention relates to a method for preparing n-phenylglycinenitrile. The method is characterized in that condensation reaction is continuously performed for aniline and glycolonitrile by a micro-channel reactor to obtain n-phenylglycinenitrile; the pH of glycolonitrile is pre-regulated to be 1.5 to 7 through a basic catalyst; the molar ratio of aniline to glycolonitrile is 1.00: 1.00-1.30. The method for preparing n-phenylglycinenitrile has the advantages that the process route is simple, and the reaction is fast, so that the working efficiency and production capacity can be ensured, and moreover, the production and operation safety of the process can also be ensured; with the adoption of the process method, the purity of a n-phenylglycinenitrile product exceeds 98.0% and the yield exceeds 99.9%.

Owner:内蒙古诚信永安化工有限公司

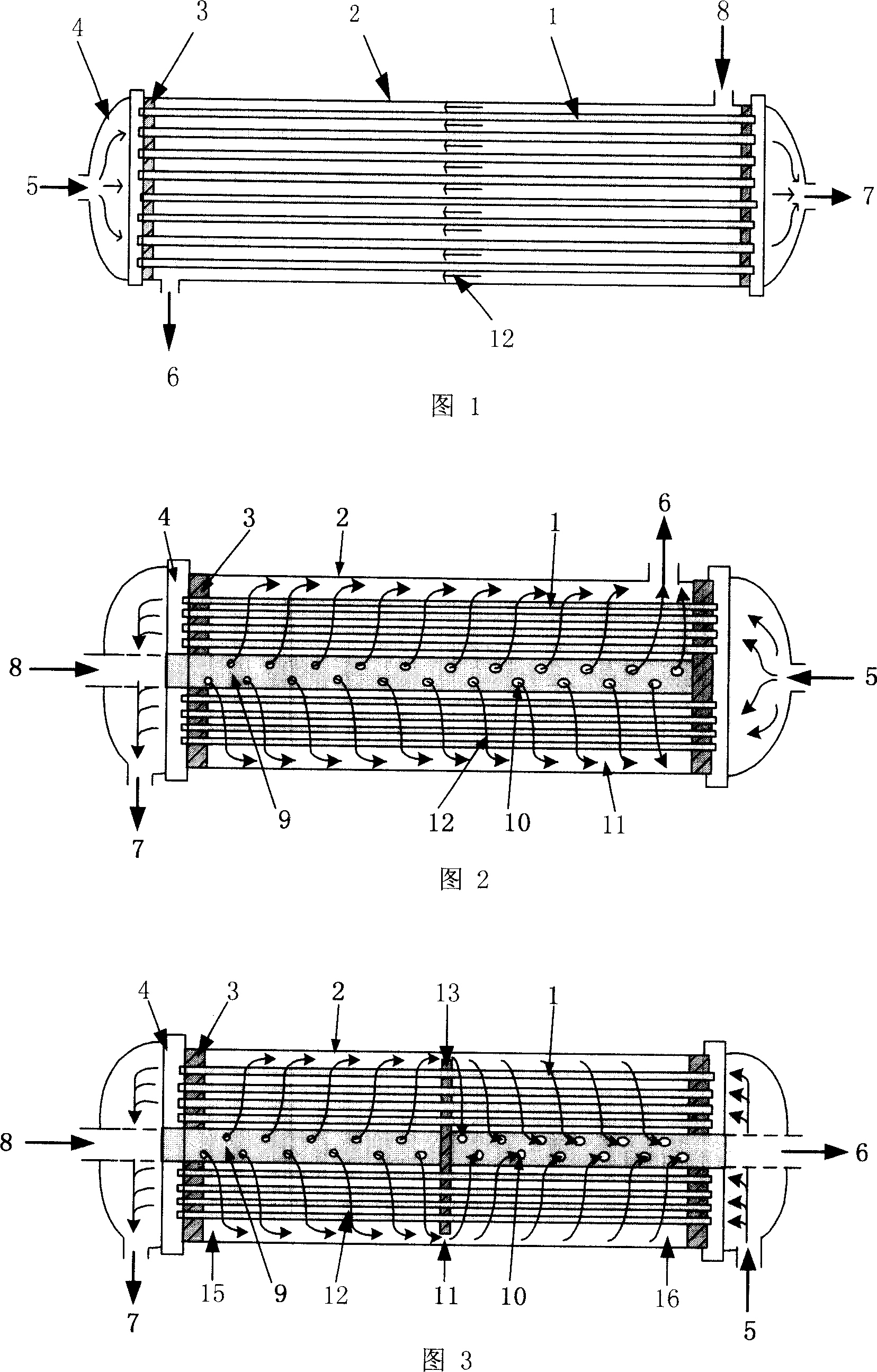

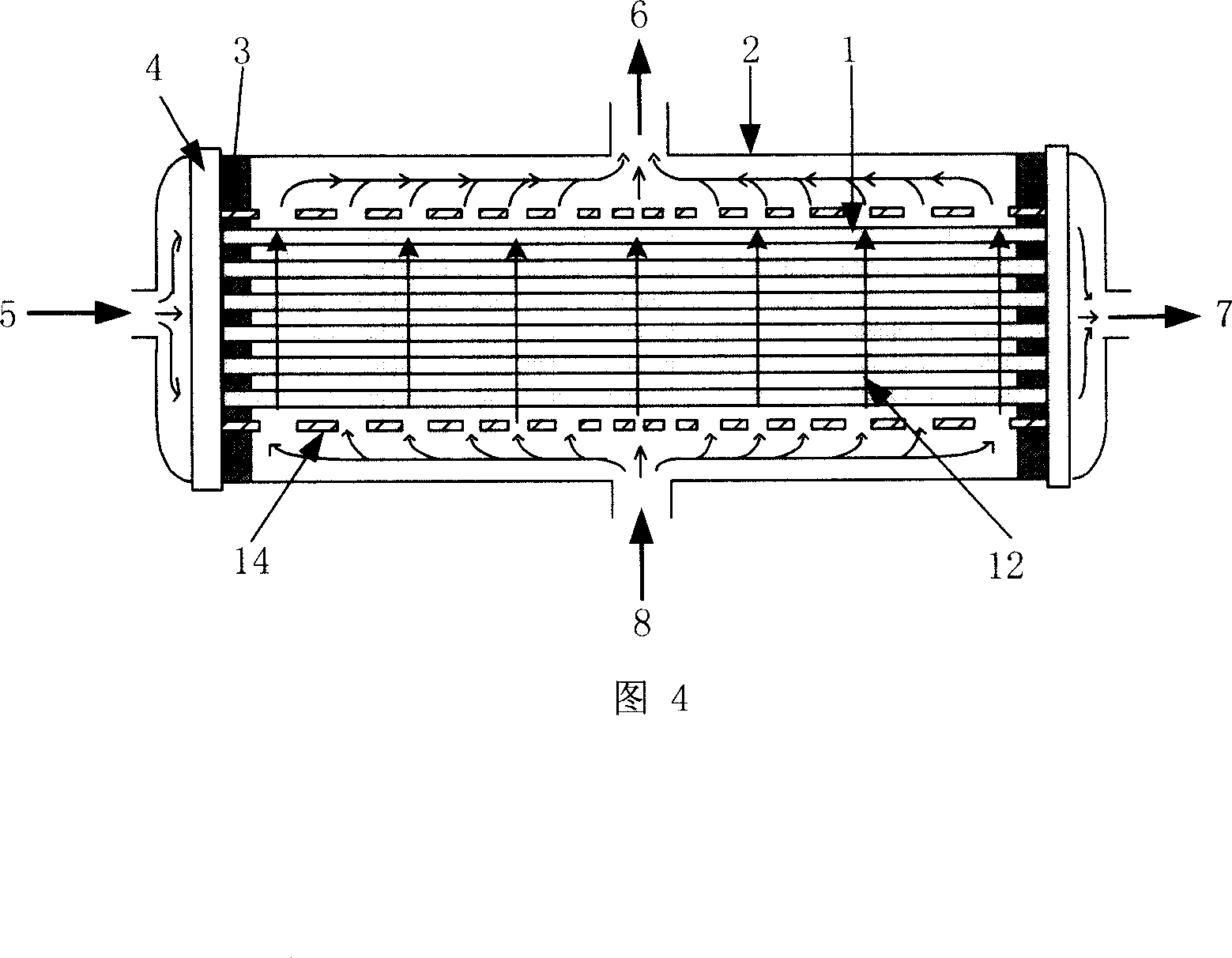

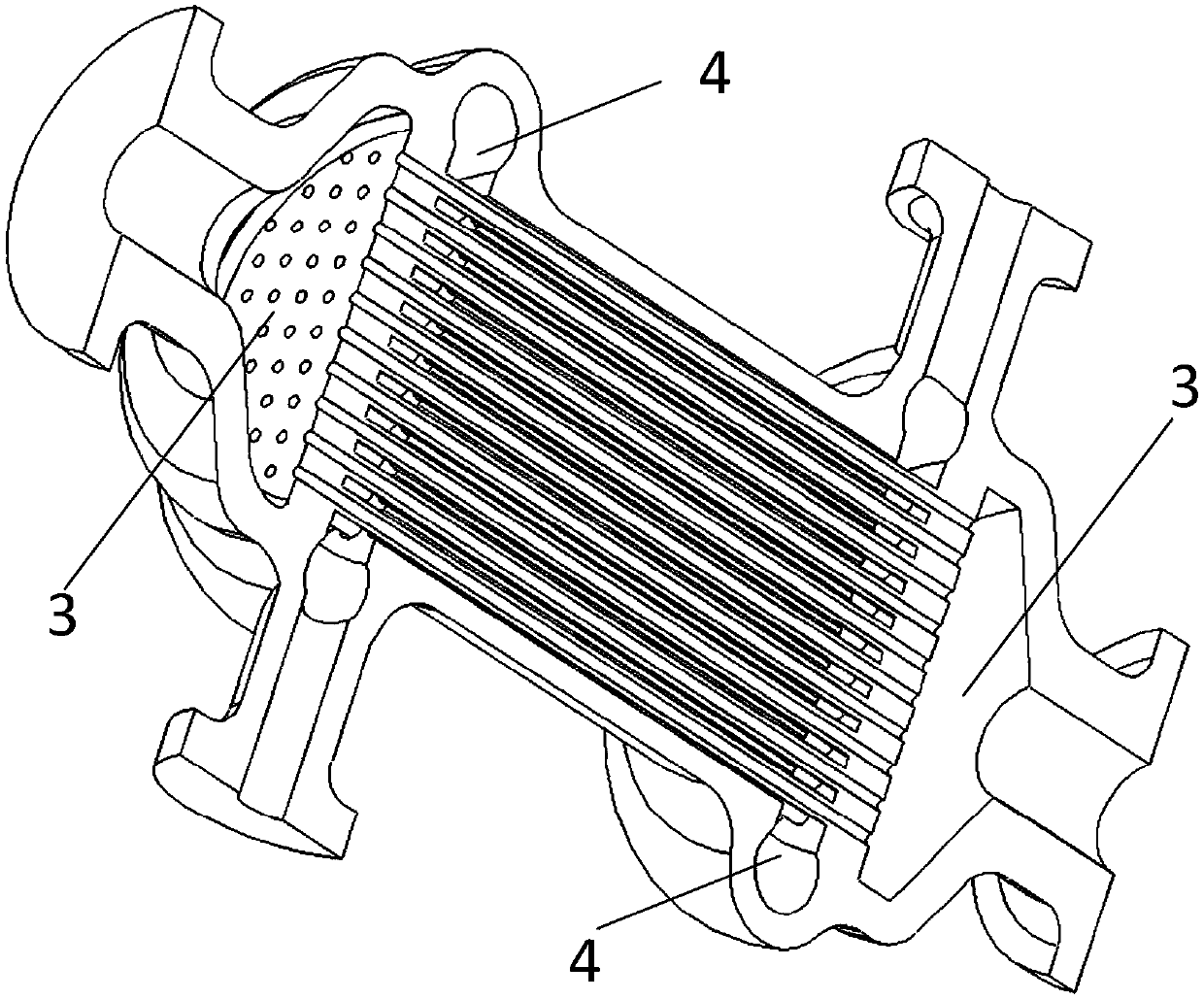

Hollow fibre heat-exchange device and method

ActiveCN101105380AImprove heat transfer efficiencyImprove overall heat transfer coefficientHeat exchange apparatusHollow fibreFiber

The invention relates to a hollow fiber heat exchanger, which comprises hollow fiber, a component enclosure, and a flow rate distribution system. Structurally, the hollow fiber heat exchanger has parallel counter current and cross current two basis modes. In the components of different modes of heat exchanger, the hollow fiber is parallelly and uniformly arranged in the enclosure of component, the two ends of the hollow fiber is fixed in the component enclosure by binder, and the two ends of the component enclosure are respectively connected with a tail cap with fluid inlet / outlet port. The inventive heat exchanger is suitable for heat exchange between gas, steam and liquid system, and has the advantages of high overall heat transfer coefficient, salinity tolerance, acid resistance, alkali resistance, low volume, light weight, easy production, low production cost, and broad application range.

Owner:TIANJIN MOKELI TECH

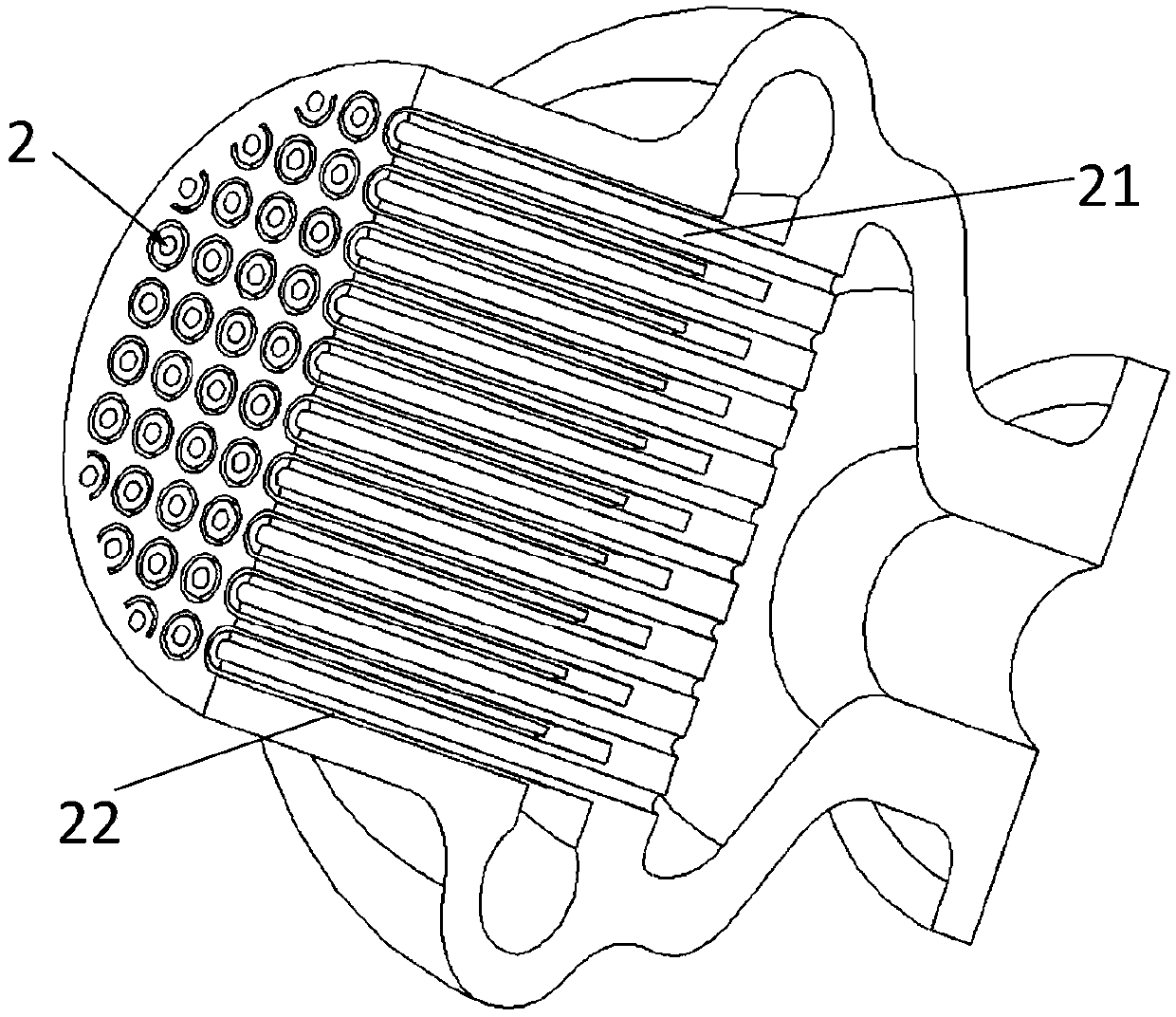

Heat exchange device of gradually-varied hole density of through hole metal foam heat pipe

ActiveCN104266519ALess consumablesReduce volumeFoundry mouldsIndirect heat exchangersVolumetric Mass DensityMetal foam

The invention provides a heat exchange device of a gradually-varied hole density of through hole metal foam heat pipe and relates to the technical field of rigid heat transfer bodies. The heat exchange device comprises the heat pipe and through hole metal foam which is sintered on the inner wall of the heat pipe; an outer layer of the middle of the heat pipe is provided with a heat insulation section; two ends of the heat pipe are arranged at a cold end and a hot end of a heat exchange environment respectively; every through hole which is formed inside the through hole metal foam is of a density gradually-varied structure and namely that the porosity of the through holes is equal to each other and the hole density is gradually increased or decreased along the vertical direction of the wall surface of the heat pipe, the hole density of the through holes is equal to each other and the porosity is gradually increased or decreased along the vertical direction of the wall surface of the heat pipe, or the porosity and the hole density of the through holes are equal to each other and materials change according to layers. According to the heat exchange device of the gradually-varied hole density of through hole metal foam heat pipe, the heat exchange rate surface area is increased and accordingly the flow and the heat exchange of the fluid which is gradually expanded due to the heat are facilitated, the capillary force is enhanced, the heat exchange efficiency of the heat pipe is high under the same heat exchange effect, metal materials are less, and the size is small.

Owner:SHANGHAI JIAOTONG UNIV

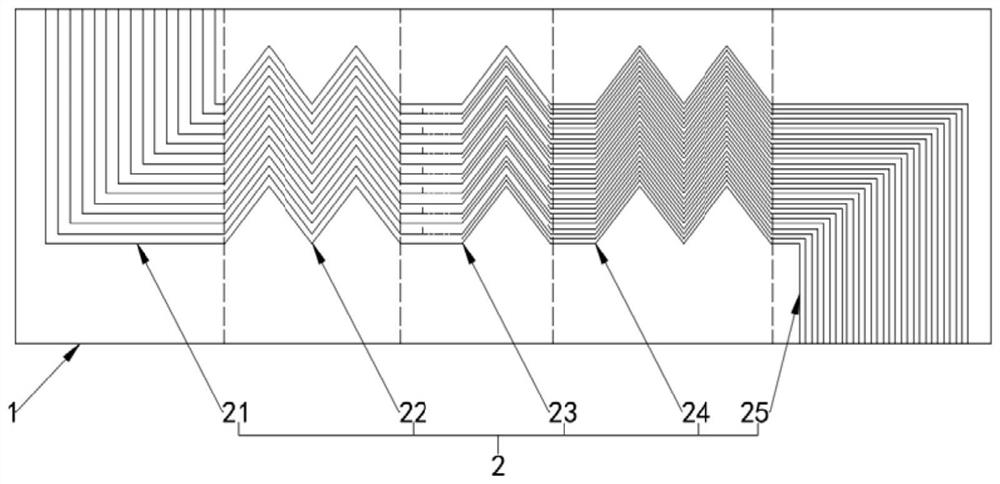

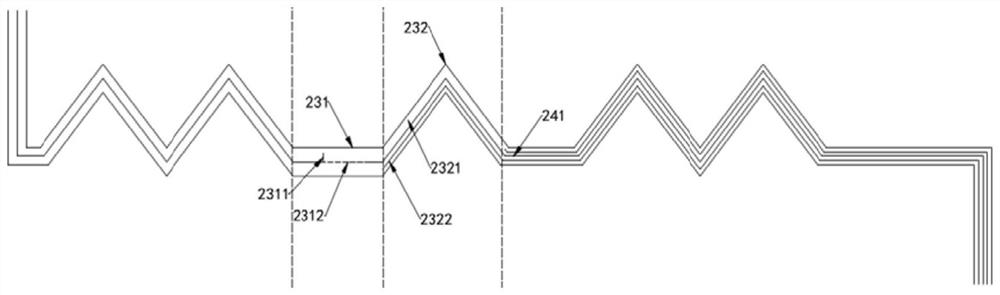

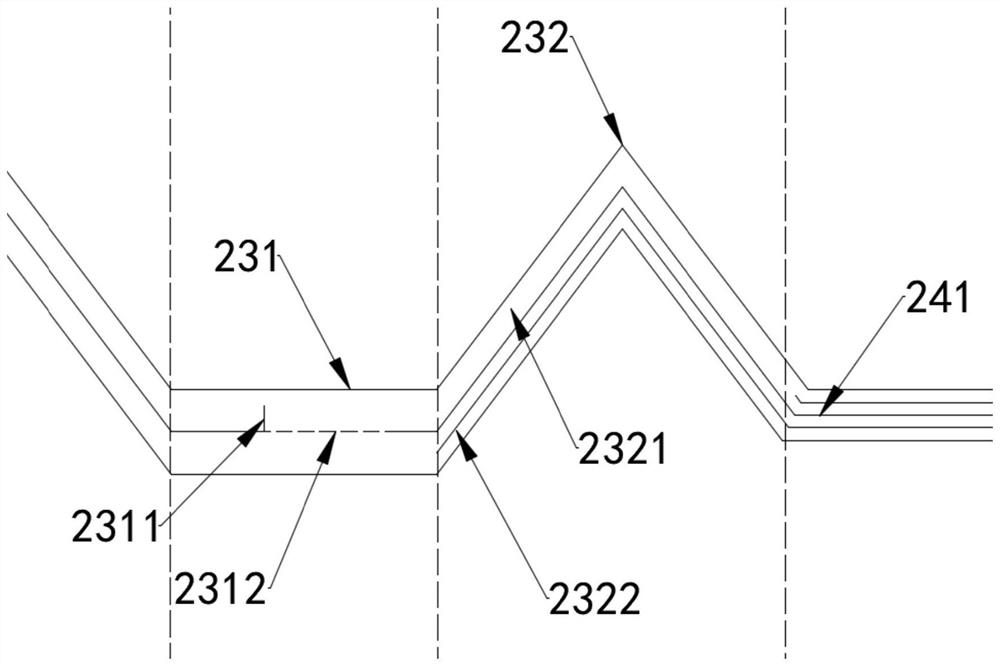

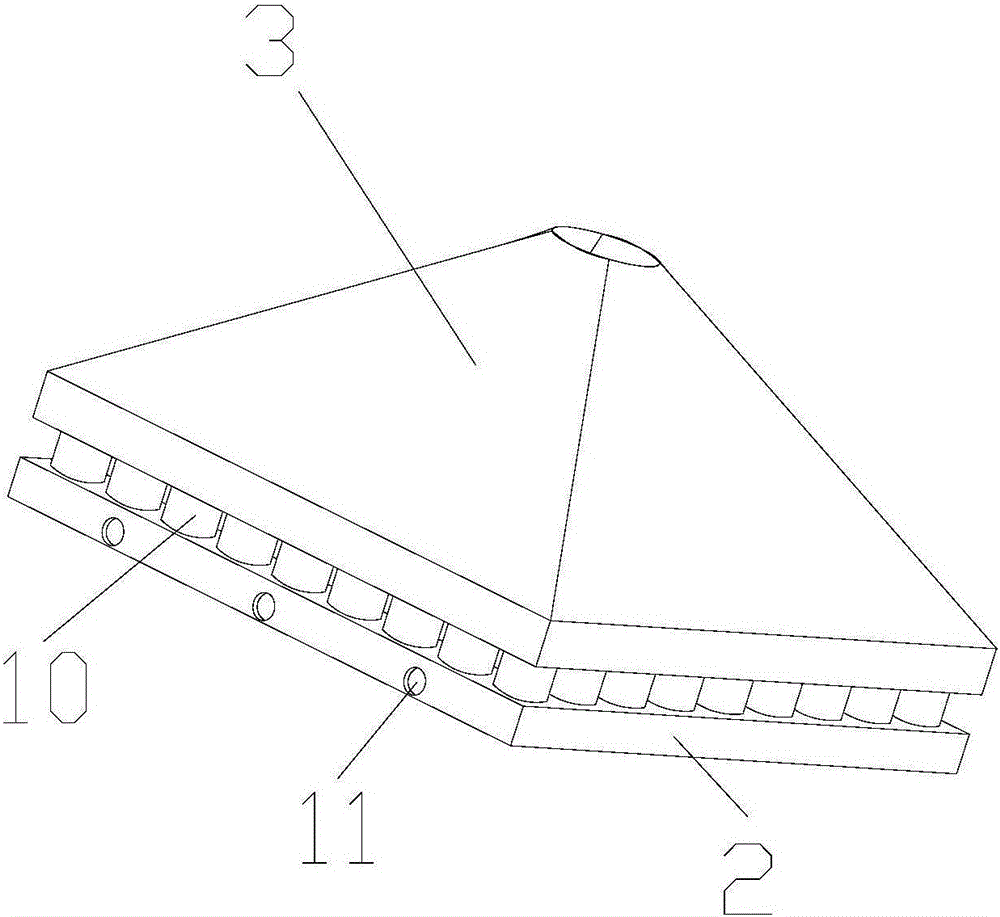

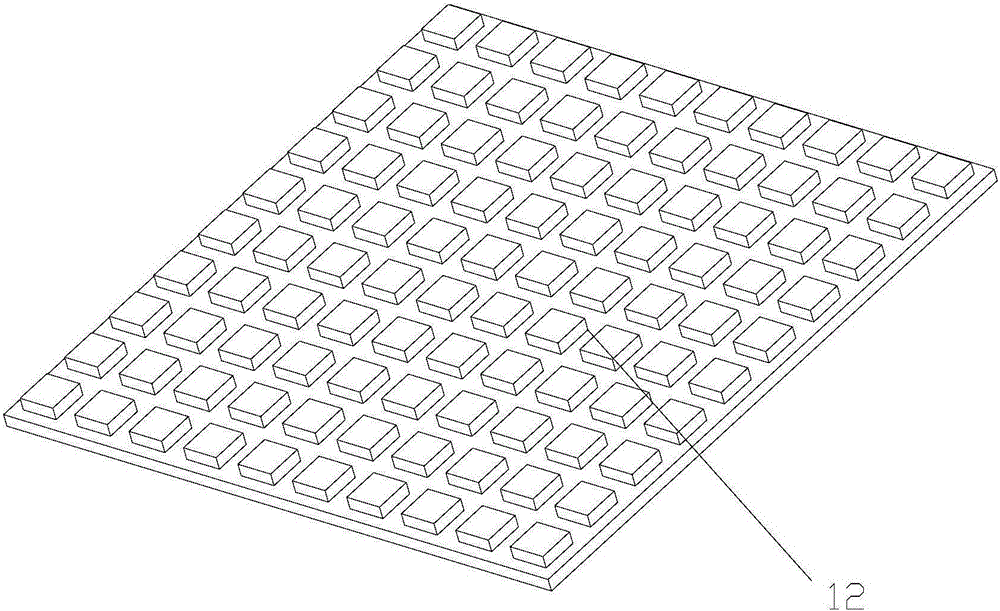

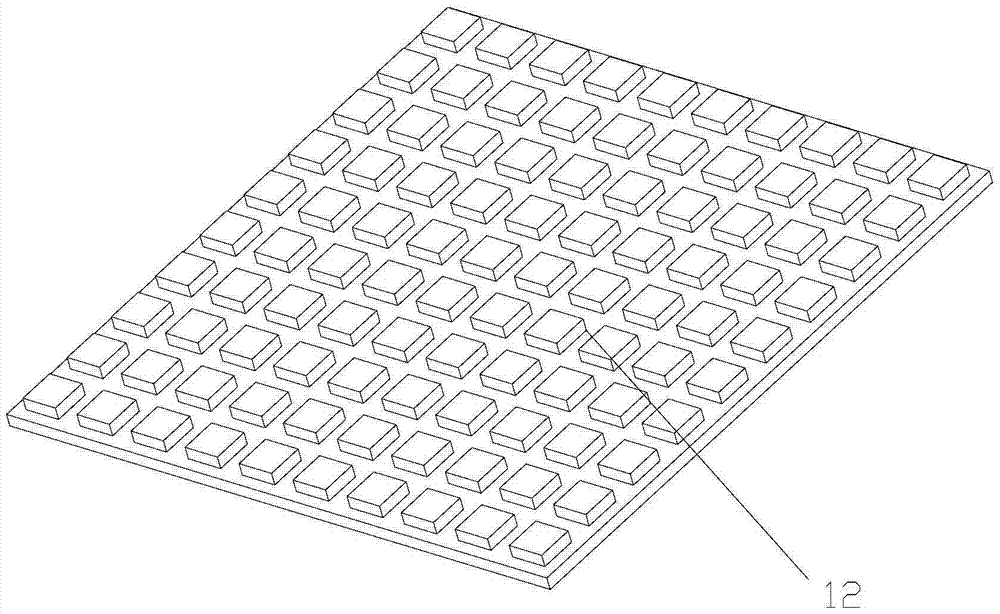

Micro-channel heat exchange panel suitable for phase-change heat exchange and heat exchanger

PendingCN112964102AIncrease the heat transfer specific surface areaImprove heat transfer effectIndirect heat exchangersHeat exchange apparatusFluid phaseEngineering

The invention provides a micro-channel heat exchange panel suitable for phase-change heat exchange and a heat exchanger. The micro-channel heat exchange panel suitable for phase-change heat exchange comprises a plate body and a plurality of heat exchange channels arranged on the plate body, each heat exchange channel comprises an inlet section, a preheating section, an evaporation section, an overheating section and an outlet section, the inlet section, the preheating section, the evaporation section, the overheating section and the outlet section of each heat exchange channel are connected in sequence, each evaporation section comprises a first separation section and a second evaporation section which are connected in sequence, each first separation section is used for performing gas-liquid separation on flowing fluid, and each second evaporation section is used for completely evaporating the liquid-phase fluid after gas-liquid separation. According to the micro-channel heat exchange panel, the advantages that an original micro-channel heat exchange panel is large in heat exchange specific surface area and high in heat exchange efficiency can be guaranteed, meanwhile, the micro-channel heat exchange panel can be suitable for fluid heat exchange with the phase change process, and automatic separation of gas and liquid phases is achieved in the evaporation process.

Owner:GATO OIL & GAS TECH (SHANGHAI) CO LTD

A kind of method for preparing anilinoacetonitrile

ActiveCN104496848BPost-processing saves time and effortReduce processCarboxylic acid nitrile preparationOrganic compound preparationAcetonitrileAniline

The invention relates to a method for preparing n-phenylglycinenitrile. The method is characterized in that condensation reaction is continuously performed for aniline and glycolonitrile by a micro-channel reactor to obtain n-phenylglycinenitrile; the pH of glycolonitrile is pre-regulated to be 1.5 to 7 through a basic catalyst; the molar ratio of aniline to glycolonitrile is 1.00: 1.00-1.30. The method for preparing n-phenylglycinenitrile has the advantages that the process route is simple, and the reaction is fast, so that the working efficiency and production capacity can be ensured, and moreover, the production and operation safety of the process can also be ensured; with the adoption of the process method, the purity of a n-phenylglycinenitrile product exceeds 98.0% and the yield exceeds 99.9%.

Owner:内蒙古诚信永安化工有限公司

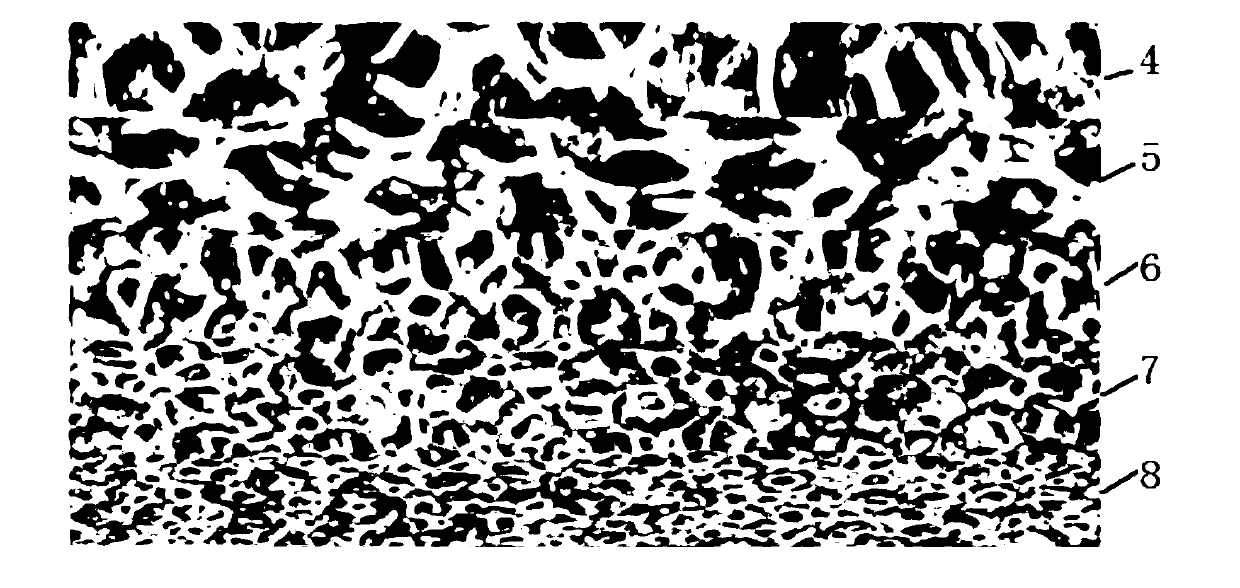

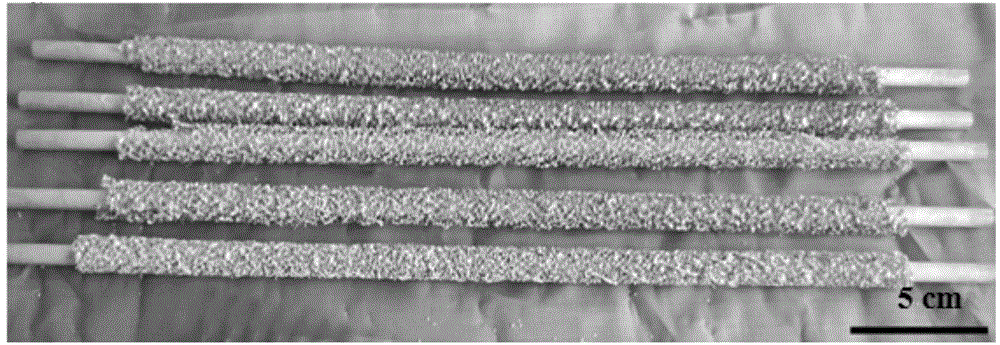

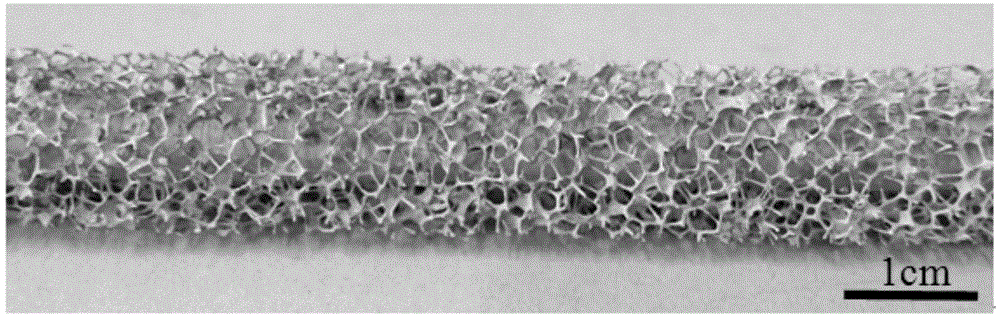

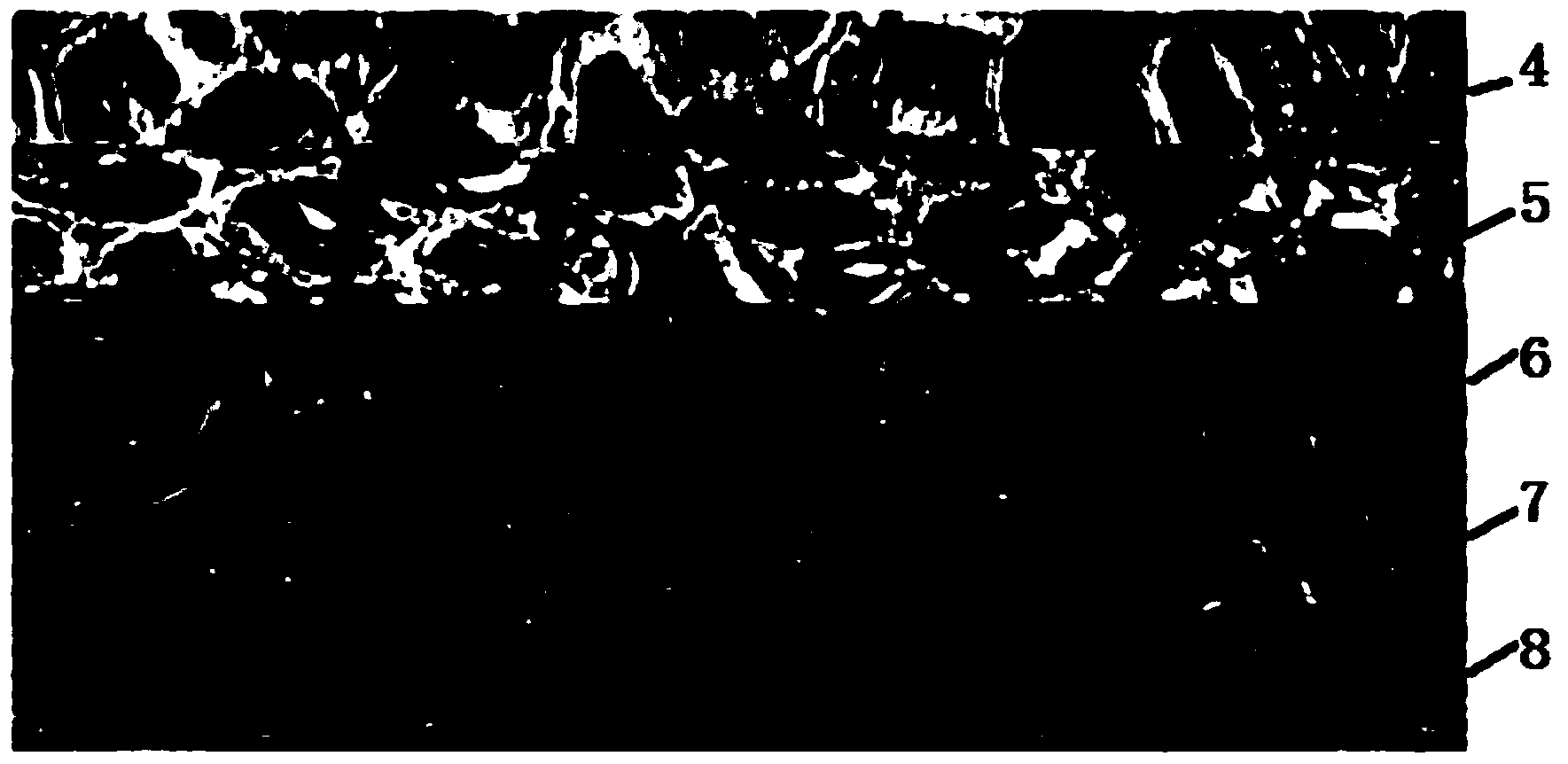

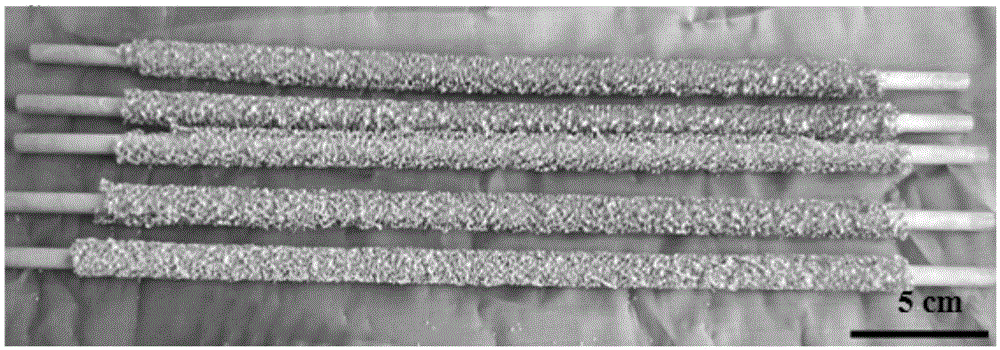

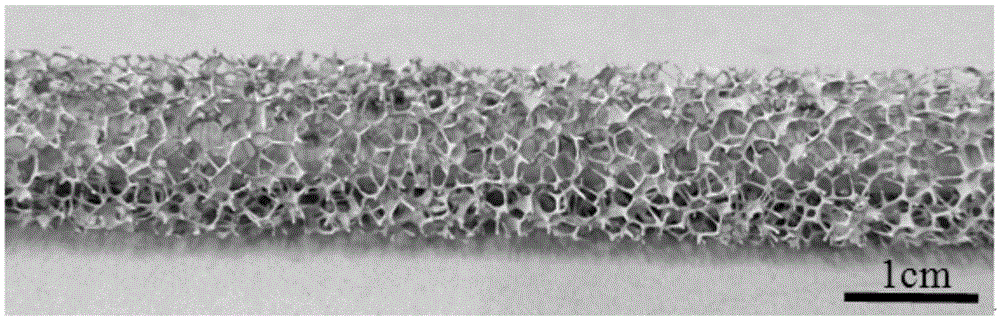

Method for manufacturing foam stainless steel composite tube

The invention discloses a method for manufacturing a foam stainless steel composite tube. The method includes the first step of preparing a dispersant, the second step of preparing stainless steel powder slurry, the third step of evenly coating the stainless steel powder slurry on the outer surface of a stainless steel tube, carrying out heat treatment after drying and obtaining a stainless steel powder sintered porous layer, the fourth step of covering the surface of the stainless steel powder sintered porous layer with a foam formwork, evenly applying the stainless steel powder slurry to the foam formwork, carrying out heat treatment after drying and obtaining a stainless steel foam layer, namely obtaining the foam stainless steel composite tube. According to the method, raw materials are wide in source range and easy to obtain, the manufacturing process is simple, the heat conductivity coefficient of the obtained foam stainless steel composite tube is reduced by more than 10 times compared with that of a stainless steel bare tube, critical heat flux density is improved more than twice, the specific area is large, and the foam stainless steel composite tube has the advantages of being good in machining performance, little in raw material consumption, large in heat exchange specific area and stable in repetitive use performance and can serve as a key part of a radiator.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Through-hole metal foam heat pipe heat exchanger with gradually-changed appearance characteristics

InactiveCN103925819ALess consumablesReduce volumeFoundry mouldsIndirect heat exchangersMetal foamHeat pipe heat exchanger

The invention discloses a through-hole metal foam heat pipe heat exchanger with gradually-changed appearance characteristics and belongs to the technical field of rigid heat transfer bodies. The heat exchanger comprises a heat pipe and through-hole metal foam, wherein the through-hole metal foam is arranged on the inner wall of the heat pipe in a sintering mode, a heat insulation segment is arranged on the outer layer of the middle of the heat pipe, the two ends of the heat pipe serve as a cold end and a hot end respectively, and the cold end and the hot end are arranged in a heat exchange environment. The through-hole metal foam is structurally characterized in that internal through holes are of a structure with the density gradually changed; namely, if the porosity is not changed, the hole density is gradually increased or decreased in the vertical direction of the wall of the heat pipe, or if the hole density is not changed, the porosity is gradually increased or decreased in the vertical direction of the wall of the heat pipe, or if neither the hole density nor the porosity is changed, adopted materials are gradually changed layer by layer. By means of the heat exchanger, the heat exchange specific area is enlarged, flow and heat exchange of liquid gradually expanded under heat are facilitated, capillary force is increased, the heat pipe has higher heat exchange efficiency under the condition that the heat exchange effect is not affected, the consumption of metal materials is smaller, and the size is smaller.

Owner:SHANGHAI JIAO TONG UNIV

Marine immersed type porous medium condenser

InactiveCN104154772ACompact structureStable and continuous quantitySteam/vapor condensersInterior spaceExhaust valve

The invention provides a marine immersed type porous medium condenser which comprises a tank body, a water tank, a cooling water guiding pipe, a condensate water draining pipe and a steam guiding pipe. The two wind-up ends of the cooling water guiding pipe are placed out of the tank body. The bent middle portion, shaped like a Chinese character 'ji', of the cooling water guiding pipe is arranged in the whole inner space of the tank body. A porous medium is wrapped on the steam guiding pipe which extends to the bottom of the tank body. Steam holes are formed in the steam guiding pipe. Holes of the porous medium correspond to the steam holes. One end of the condensate water draining pipe is arranged at the lower end portion of the tank body. The other end of the condensate water draining pipe is communicated with the water tank. A drain valve is arranged on the condensate water draining pipe. An exhaust valve is arranged at the top of the tank body. The weigh and the size of the condenser are lowered, meanwhile, the liquid level and the pressure of condensate water in the condenser are controlled, the condensate water is recycled, and application on a ship power device is convenient.

Owner:HARBIN ENG UNIV

Enhanced heat abstractor employing pulsating flow and foam metal plate

ActiveCN105097735ALittle flow resistance lossIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesCavitationHeat transfer efficiency

The invention discloses an enhanced heat abstractor employing pulsating flow and a foam metal plate. The enhanced heat abstractor comprises a pulsating pump, a heat sink chamber, an accumulated liquid cavity and a cooler, wherein the pulsating pump conveys a cooling liquid into the accumulated liquid cavity through a liquid inflow pipe; the accumulated liquid cavity sprays the cooling liquid into the heat sink chamber; the heat sink chamber conveys the liquid which is subjected to heat transfer into the cooler to cool through a liquid discharge pipe; the pulsating pump sucks in the cooled cooling liquid from the cooler through a connecting pipe; the heat sink chamber comprises the foam metal plate, a heat transfer support plate and a cover board; the heat transfer support plate is connected with a high-heating flux device; the foam metal plate is fixedly connected with the heat transfer support plate; and a dispenser is vertically connected with the top of the cover board. The pulsating flow of the enhanced heat abstractor is matched with a dual-layer foam metal structure, so that transverse and longitudinal disturbance and mixing of working mediums can be increased; a thermal boundary layer is continuously recombined; and meanwhile, cavitation and vortex formation are caused by pressure change in the disturbance process, therefore, the heat transfer efficiency can be greatly improved.

Owner:常州贺斯特科技股份有限公司

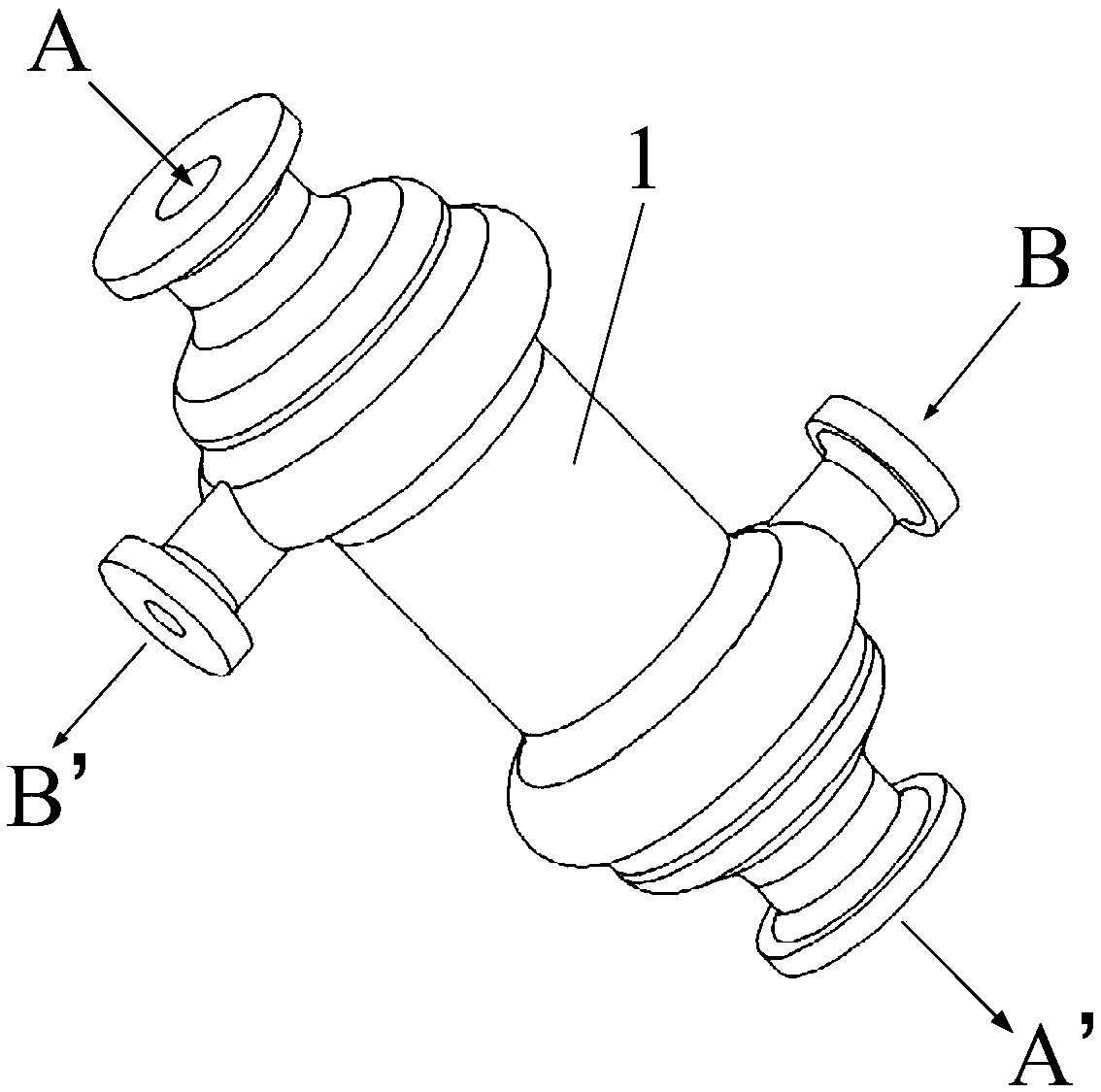

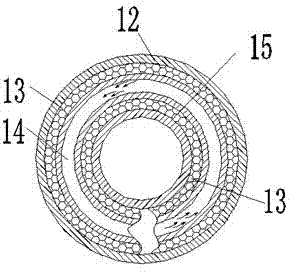

Micro-channel heat exchanger

InactiveCN109579570AIncrease the heat transfer specific surface areaImprove unityHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerEngineering

The invention relates to the field of heat exchangers, in particular to a micro-channel heat exchanger. The micro-channel heat exchanger comprises a body internally provided a plurality of heat exchange units, each heat exchange unit comprises a first flow channel and a second flow channel which are coaxially arranged in a sleeved manner and are independent of each other, the two ends of the firstflow channel in each of the multiple heat exchange units are connected to two first volume chambers, the two ends of the second flow channel in each of the multiple heat exchange units are connectedto two second volume chambers, the first volume chambers and the second volume chambers are arranged in the body and are independent of each other. The micro-channel heat exchanger is easy to processand has the better heat exchange effect.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

The method of continuous method synthetic benzyl nitrile

ActiveCN105218401BRealize continuous productionIncrease productivityPreparation by cyanide reactionAutomatic controlBenzyl chloride

The invention discloses a method for synthesizing phenylacetonitrile by performing continuous reaction, and relates to the field of preparing a compound containing six-membered aromatic ring connected with cyano group by saturated carbon chain. The method comprises the following steps: adjusting the temperature of a micro-reactor to 80-400 DEG C; adding a mixture of a sodium cyanide aqueous solution and phase-transfer catalyst, and benzyl chloride in the micro-reactor continuously; reacting in the micro-reactor for 20-300 s to get a phenylacetonitrile aqueous solution. The method has rapid reaction speed, high production efficiency, low cost, good product quality, is easy to realize automatic control, is beneficial to subsequent post-treatment, and can raise the phenylacetonitrile yield, reduce the side reaction, and save labour.

Owner:HEBEI CHENGXIN

Through-hole metal foam heat pipe heat exchange device with gradually-changed appearance characteristics

ActiveCN103900412ALess consumablesReduce volumeFoundry mouldsIndirect heat exchangersMetal foamMaterials science

The invention belongs to the technical field of rigid heat transfer bodies and discloses a through-hole metal foam heat pipe heat exchange device with gradually-changed appearance characteristics. The device comprises a heat pipe and through-hole metal foam which is arranged on the inner wall of the heat pipe in a sintered mode. The outer layer of the middle of the heat pipe is provided with a heat insulation segment, the two ends of the heat pipe serve as a cold end and a hot end respectively, and the cold end and the hot end are arranged in a heat exchange environment. The through-hole metal foam is structurally characterized in that the density of internal through holes is gradually changed; namely, if the porosity is the same, the hole density is gradually increased or decreased in the vertical direction of the wall of the heat pipe, or if the hole density is the same, the porosity is gradually increased or decreased in the vertical direction of the wall of the heat pipe, or if both the hole density and the porosity are the same, adopted materials are changed by layers. According to the device, the heat exchange specific area is enlarged, flow and heat exchange of fluid which expands gradually under heat are facilitated, capillary force is increased, the heat pipe has higher heat exchange efficiency with the same heat exchange effect, the consumption of metal materials is smaller, and the size is smaller.

Owner:SHANGHAI JIAO TONG UNIV

A kind of preparation method of foam stainless steel composite pipe

The invention discloses a method for manufacturing a foam stainless steel composite tube. The method includes the first step of preparing a dispersant, the second step of preparing stainless steel powder slurry, the third step of evenly coating the stainless steel powder slurry on the outer surface of a stainless steel tube, carrying out heat treatment after drying and obtaining a stainless steel powder sintered porous layer, the fourth step of covering the surface of the stainless steel powder sintered porous layer with a foam formwork, evenly applying the stainless steel powder slurry to the foam formwork, carrying out heat treatment after drying and obtaining a stainless steel foam layer, namely obtaining the foam stainless steel composite tube. According to the method, raw materials are wide in source range and easy to obtain, the manufacturing process is simple, the heat conductivity coefficient of the obtained foam stainless steel composite tube is reduced by more than 10 times compared with that of a stainless steel bare tube, critical heat flux density is improved more than twice, the specific area is large, and the foam stainless steel composite tube has the advantages of being good in machining performance, little in raw material consumption, large in heat exchange specific area and stable in repetitive use performance and can serve as a key part of a radiator.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

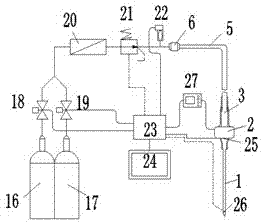

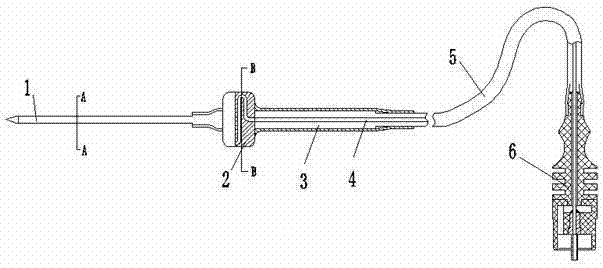

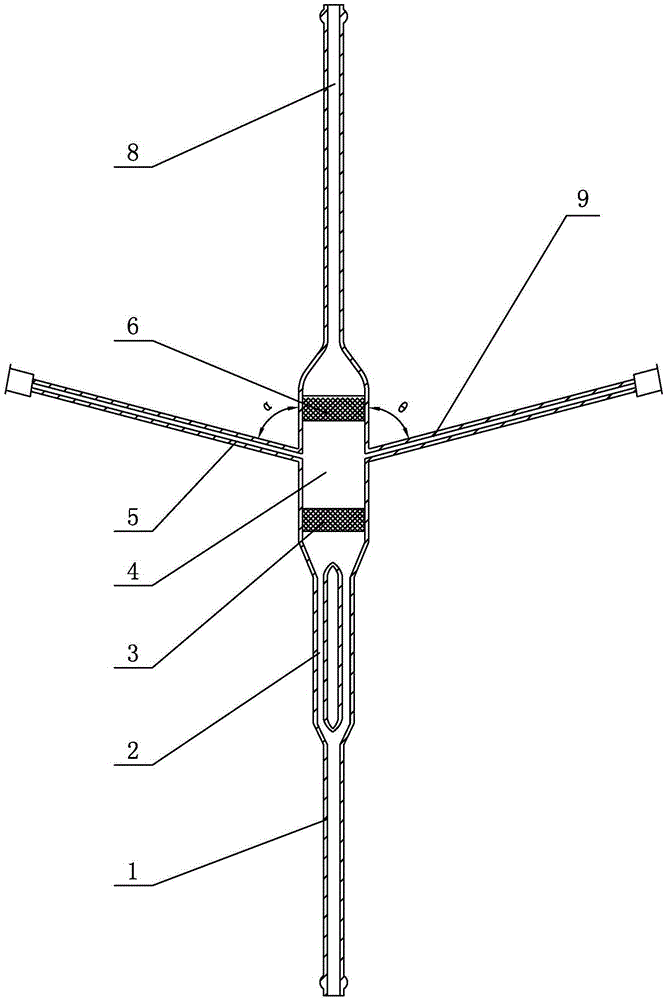

Low-temperature therapeutic apparatus for tumour

InactiveCN102488550BTake advantage ofIncrease the heat transfer specific surface areaSurgical instruments for coolingProgrammable logic controllerMagnetic valve

The invention discloses a low-temperature therapeutic apparatus for tumour, which comprises a low-temperature scalpel and a low-temperature control device. The low-temperature scalpel comprises a low-temperature probe, a thermoelectricity module, a handle, an air inlet pipe and an air source connector which are sequentially connected, wherein a transmission protection pipeline is arranged outsidethe air inlet pipe. The low-temperature control device comprises a high-pressure air tank, a high-pressure magnetic valve, a filter, a high-pressure regulation valve, a pressure sensor, a programmable logic controller, a touch screen, a thermoelectric module, a controllable direct-current power supply and a temperature sensor. Metal foams are arranged in the low-temperature probe, and the thermoelectric module can fully use returned air energy in freezing and rewarming stages. Consumption of high-pressure air can be effectively reduced by adjusting the thermoelectric module, the low-temperature probe is led to be capable of working when pressure of inlet air is low, and the defect that small-diameter probes are lack of cold energy is overcome to some degree. The low-temperature therapeutic apparatus is suitable for cryoablation surgeries of canceration tissues.

Owner:ZHEJIANG UNIV

A continuous entrainment thin material layer microwave evaporation method and device

InactiveCN105251224BEfficient conversionIncrease vacuumEvaporator accessoriesVapor liquidDistillation

The invention provides a continuous entrainment thin material layer microwave evaporation method and device, using a pair of rotating upper and lower nip rollers, through two endless filter belts, the solid-liquid mixture is sandwiched between the filter belts Between them, the structure of the upper filter belt, the solid-liquid mixture material layer and the lower filter belt is formed, and the microwave resonator is passed through the microwave resonant cavity in a horizontal back-and-forth layer-by-layer transport mode, so that the material in the pair of sandwich layers The solid-liquid mixture material liquid absorbs microwave energy in a uniform thin layer state and is heated and evaporated. At the same time, the evaporation rate is increased by circulating loading on the nozzle of the separated material liquid, and the sealing structure of the material inlet and outlet is used to improve the evaporation rate. The vacuum degree in the evaporator makes the feed liquid efficiently transform into gas phase at a lower temperature. In addition, due to the use of multi-layer transport state, the specific surface area of heat exchange is increased, the evaporation device is compact, and the area utilization rate is high. With the condensation and gas-liquid separation device, distillation and extraction operations can be realized.

Owner:WUHAN NEWWAY PHARMA MACHINERY

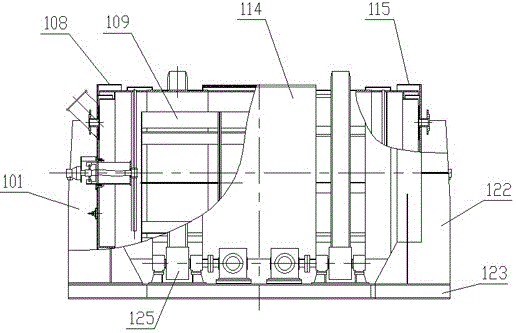

Heat-storage lead-melting furnace

ActiveCN101871727BSimple structureAvoid local high temperatureCrucible furnacesIndirect carbon-dioxide mitigationCombustionFlue gas

The invention discloses a heat-storage lead-melting furnace ,which comprises a pot body, a furnace body and two heat-storage combustion components, wherein the pot body is arranged on the furnace body which is internally divided into two independent heating cavities by a partition; each heating cavity is communicated with one heat-storage combustion component by a flue gas pipeline arranged on the furnace body; the heat-storage combustion components are arranged at the outer side of the furnace body; each heat-storage combustion component comprises a combustion section used for generating high-temperature gas for heating, and a heat-storage section used for providing high-temperature air for the combustion section; and the combustion sections are communicated with the heating cavities by the flue gas pipeline. The heat-storage lead-melting furnace has the advantages of simple and compact structure, small volume, convenient installation and maintenance, good heating effect, long service life and the like.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

A heat dissipation device that adopts pulsating flow and foam metal plate to strengthen

ActiveCN105097735BIncrease disturbanceEnhanced blendingSemiconductor/solid-state device detailsSolid-state devicesCavitationWorking fluid

The invention discloses a device for strengthening heat dissipation by adopting pulsating flow and foamed metal plates, which comprises a pulsating pump, a heat sink chamber, a liquid accumulation chamber and a cooler. The liquid accumulation chamber sprays the cooling liquid into the heat sink chamber through the liquid separator, and the heat sink chamber sends the heat-exchanged liquid into the cooler through the liquid discharge pipe for cooling, and the pulsation pump sucks the cooled cooling liquid from the cooler through the connecting pipe. liquid; the heat sink chamber includes a foamed metal plate, a heat exchange carrier plate and a cover plate, the heat exchange carrier plate is connected to a high heat flux device, the foam metal plate is fixedly connected to the heat exchange carrier plate, and the liquid separator is connected to the heat exchange carrier plate The top of the cover plate is connected vertically. The pulsating flow in the present invention combined with the double-layer metal foam structure can increase the horizontal and vertical disturbance and mixing of the working fluid, and the thermal boundary layer is continuously reorganized. At the same time, the pressure change will lead to the formation of cavitation and vortex during the disturbance process. , can greatly improve the heat transfer efficiency.

Owner:常州贺斯特科技股份有限公司

A continuous traction type omentum microwave evaporation method and device

InactiveCN105251223BAchieving selective evaporative separationAchieve distillationEvaporator accessoriesMicrowave cavityDistillation

The invention provides a continuous traction type omentum microwave evaporation method and device, using an endless mesh belt, driven by a group of rotary traction rollers, positioned by dipping rollers, and when immersed in the material liquid, the continuously moving mesh The material liquid mesh is formed by pulling the material liquid, and it passes through the microwave resonant cavity in a horizontal reciprocating and layer-by-layer transport mode, so that the material liquid mesh absorbs microwave energy in a uniform thin layer state and is heated and evaporated, and the The evaporating material-liquid mesh is sprayed and loaded with material-liquid, and evaporated in parallel circulation. In addition, selective evaporation and separation can be realized by modifying the surface of the mesh belt with hydrophilic or lipophilic properties. Due to the adoption of the circulation transport structure of multi-layer material-liquid mesh, the specific surface area of heat exchange is improved, the evaporation device is compact, and the area utilization rate is significantly improved. It can perform fast and efficient low-temperature evaporation under high vacuum, and cooperate with condensation. And gas-liquid separation device, can realize distillation and extraction operations.

Owner:WUHAN NEWWAY PHARMA MACHINERY

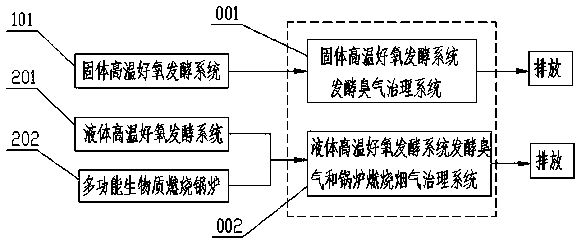

System and method for controlling odor and smoke in livestock and poultry farms

ActiveCN106178929BShorten the fermentation heating timeIncrease the heat transfer specific surface areaGas treatmentDispersed particle separationControl systemFlue gas

Provided are a system and a method for livestock and poultry farm odor and flue gas treatment, comprising a solid high temperature aerobic fermentation system, a liquid high temperature aerobic fermentation system fermentation odor and boiler combustion flue gas treatment system (002), and a detection control system. The solid high temperature aerobic fermentation system fermentation odor treatment system (001) comprises an odor heat exchange condenser A, a draft fan (102) and a biological deodorization filter (103). The liquid high temperature aerobic fermentation system fermentation odor and boiler combustion flue gas treatment system (002) comprises a multi-functional biomass combustion boiler (202), a three-way electrical regulating valve (203), an aeration fan (204), an odor heat exchange condenser B, a draft fan (205) and a biological deodorizing filter (206). Sensors of the detection control system are provided in each of the systems to detect key parameters, and to detect the control system's connection to and control of the described systems.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

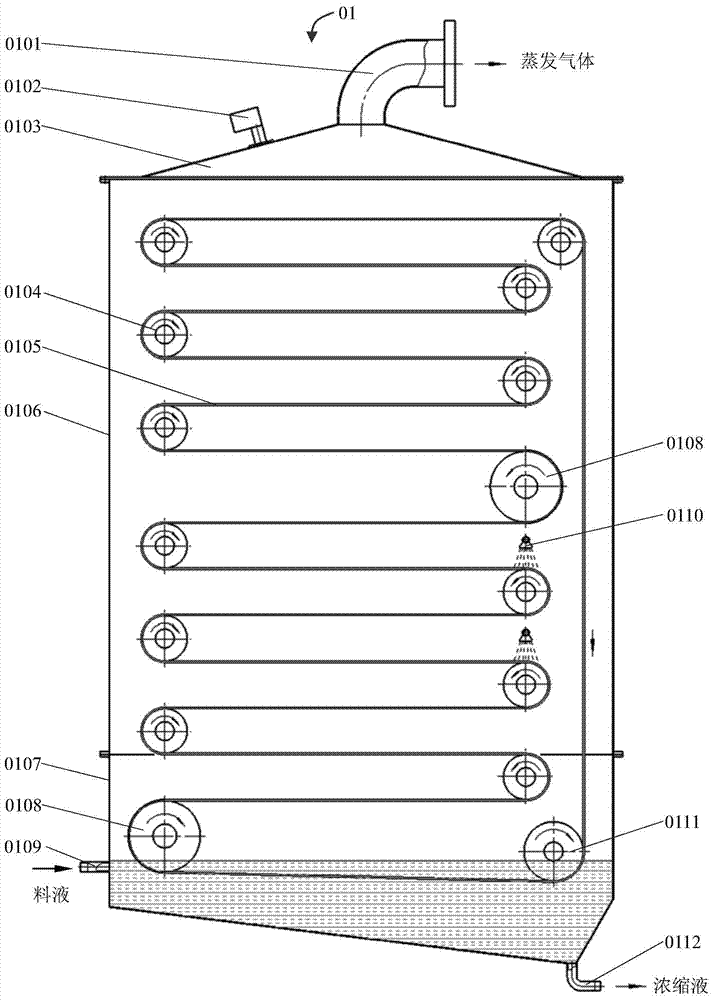

Solution regeneration device based on heat accumulating chamber low-temperature flue gas residual heat utilization

InactiveCN103007699BLow operation and maintenance costsRich waste heat recovery technologyDispersed particle separationEnergy industryFlue gasFresh air

The invention discloses a solution regeneration device based on heat accumulation chamber low-temperature flue gas residual heat utilization, and belongs to the technical field of residual heat recycling. The device comprises a solution regenerator, a heat accumulating chamber, a concentrated solution groove, a heat accumulating body, a filter and a valve. The device recycles low-temperature flue gas residual heat emitted during industrial production process by utilizing a heat accumulating and heat transfer technology, and utilizes the low-temperature flue gas residual heat for heating air; air after temperature rising is in direct contact with the solution for transferring heat and media, so that the solution is regenerated; and the regenerated solution can be used for air blowing and dehumidification for an industrial kiln or fresh air dehumidification of an air conditioner. According to the invention, the heat accumulating chamber is adopted for recycling low-temperature flue gas residual heat, energy sources are saved, and the heat recovery efficiency is high, so that hot air is in direct contact with the solution for transferring heat and media, and the aims of intensifying the media transfer effect and improving heat transfer and media transfer efficiency can be realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

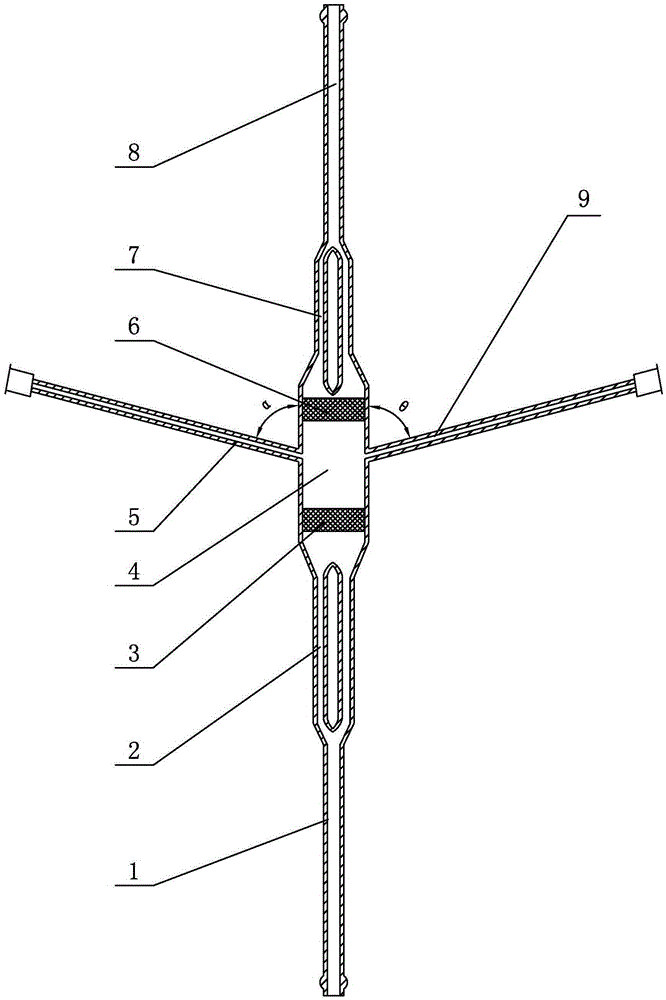

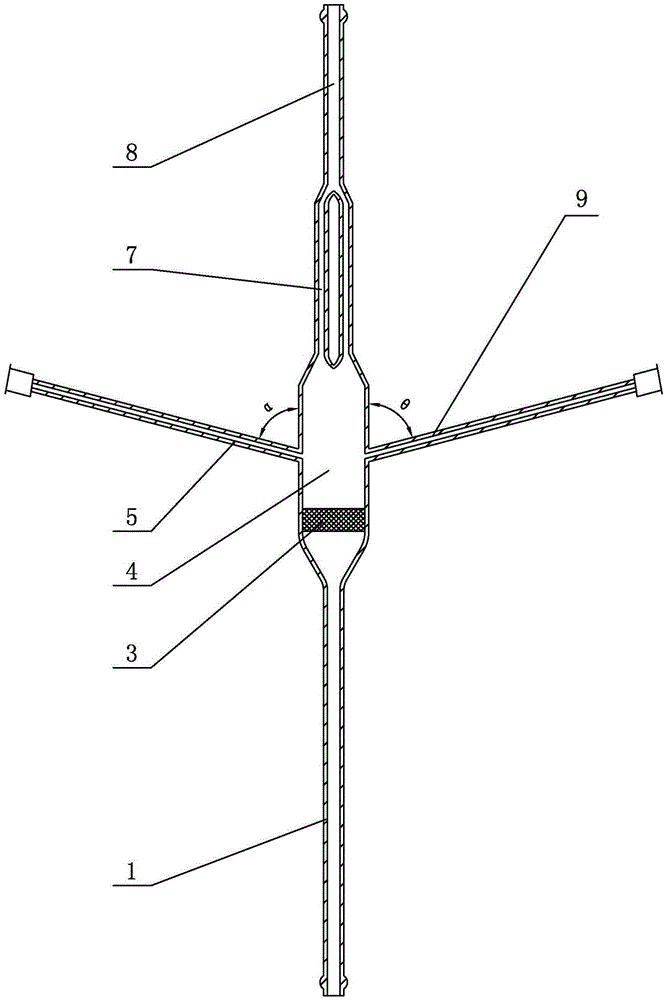

A Decoupled Reactor Based on Atmosphere Switching

ActiveCN103908928BImprove convective heat transfer efficiencyFully warmed upChemical methods analysisSolid carbonChemical reaction

The invention relates to a reactor, and particularly relates to a decoupling reactor based on atmosphere switching. The decoupling reactor solves the problem that an existing high-temperature chemical reactor can not be well used for analyzing a multistage in-situ decoupling reaction of a solid carbon-based fuel. The decoupling reactor comprises a reaction pipe main body, a thermocouple side pipe and an instant feeding side pipe, wherein the reaction pipe main body sequentially comprises a lower pipe section, a lower annular space section, a lower porous plate, a reaction section, and an upper pipe section from bottom to top, the thermocouple side pipe and the instant feeding side pipe are arranged at two sides of the reaction section, one end of the thermocouple side pipe is connected with the outer side wall of the reaction section, and one end of the instant feeding side pipe is connected with the outer side wall of the reaction section. The decoupling reactor is used in the field of analysis and testing of a high-temperature chemical reaction.

Owner:HARBIN INST OF TECH

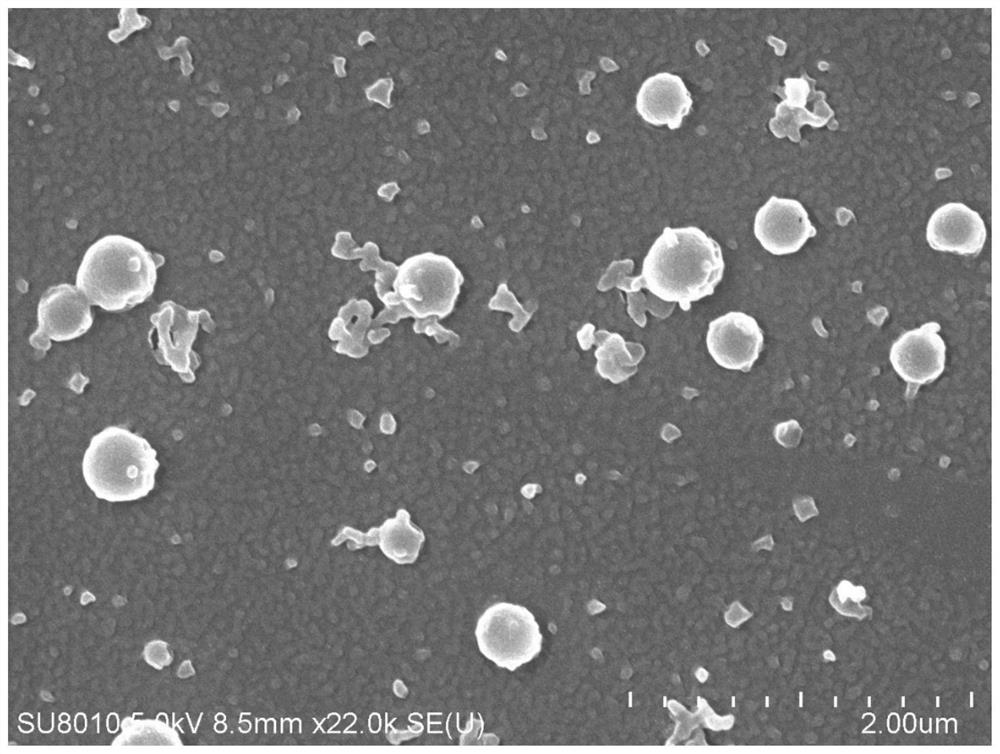

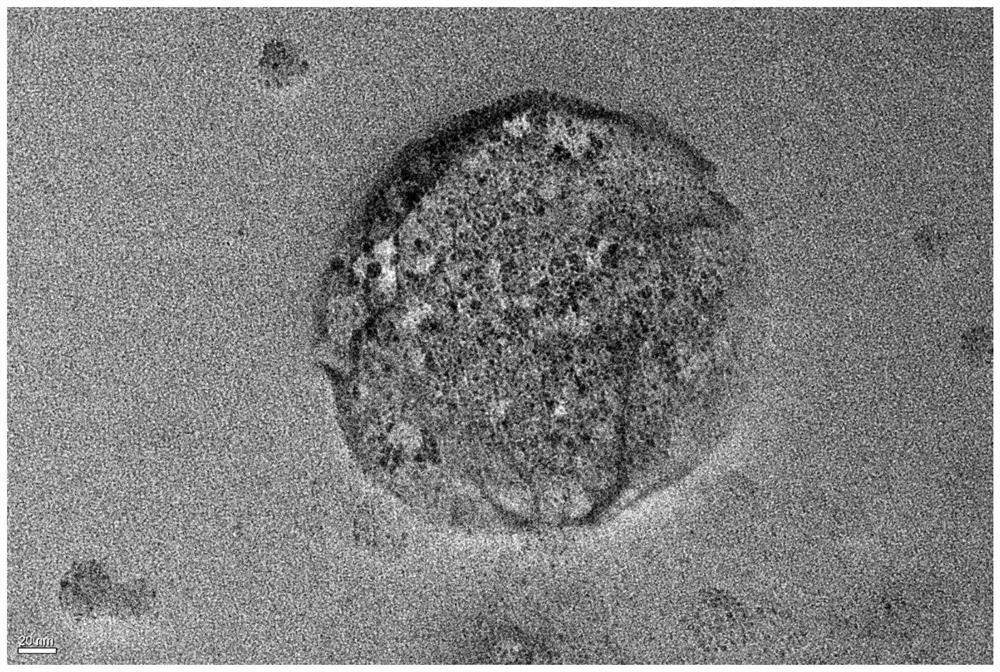

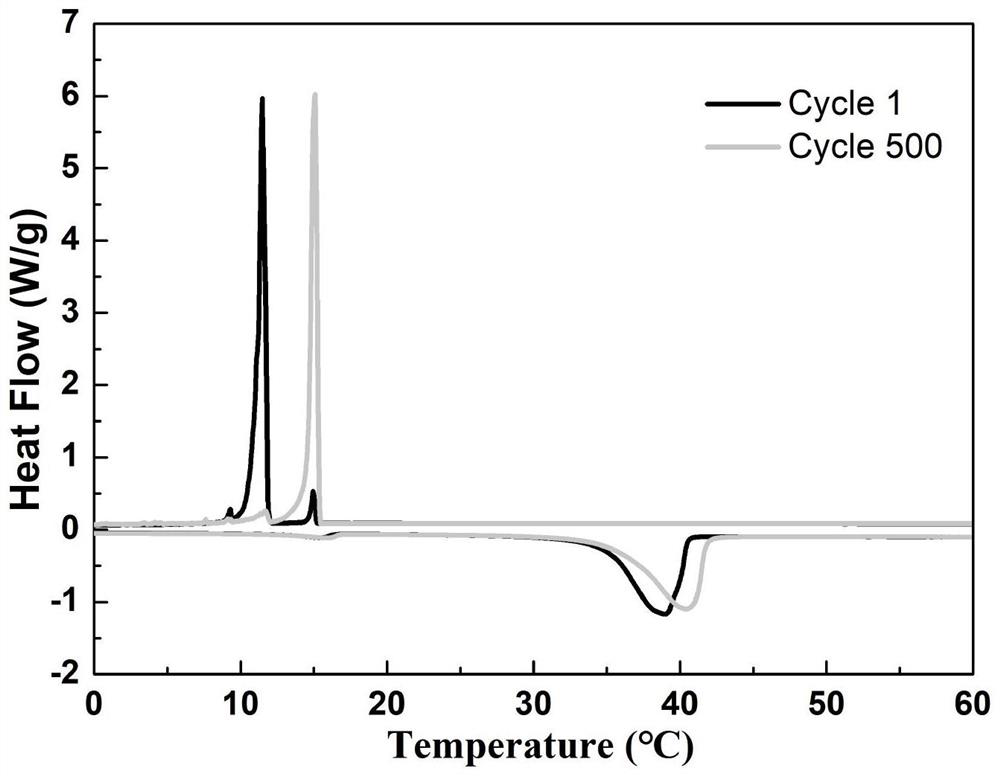

Monodisperse high-stability inorganic hydrated salt phase change nanocapsule as well as preparation method and application thereof

PendingCN114250063AGood dispersionDense shellHeat-exchange elementsMicroballoon preparationAlkaneEmulsion

The invention belongs to the technical field of phase-change materials and preparation thereof, and discloses a monodisperse high-stability inorganic hydrated salt phase-change nanocapsule as well as a preparation method and application thereof. A wall material of the nanocapsule is an organic polymer material such as polymethyl methacrylate and polystyrene, a core material is an inorganic hydrated salt phase change material, and the mass ratio of the core material in the capsule is 20-95%. According to the invention, an in-situ polymerization preparation technology is adopted, a water-based inorganic hydrated salt core material is dispersed in an alkane solvent for emulsification to form a W / O type emulsion with good dispersion stability, and an oil-soluble nanocapsule shell material is added, so that a polymer is enriched on an oil-water interface and is polymerized to form a compact shell which completely coats the core material; and finally obtaining the hydrated salt nano phase change capsule material with the hydrated salt wrapped by the polymer. The hydrated salt nanocapsule disclosed by the invention is high in coating rate, good in dispersion system and stable in performance, and has a good market application prospect.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com