Patents

Literature

1534results about How to "Increase disturbance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

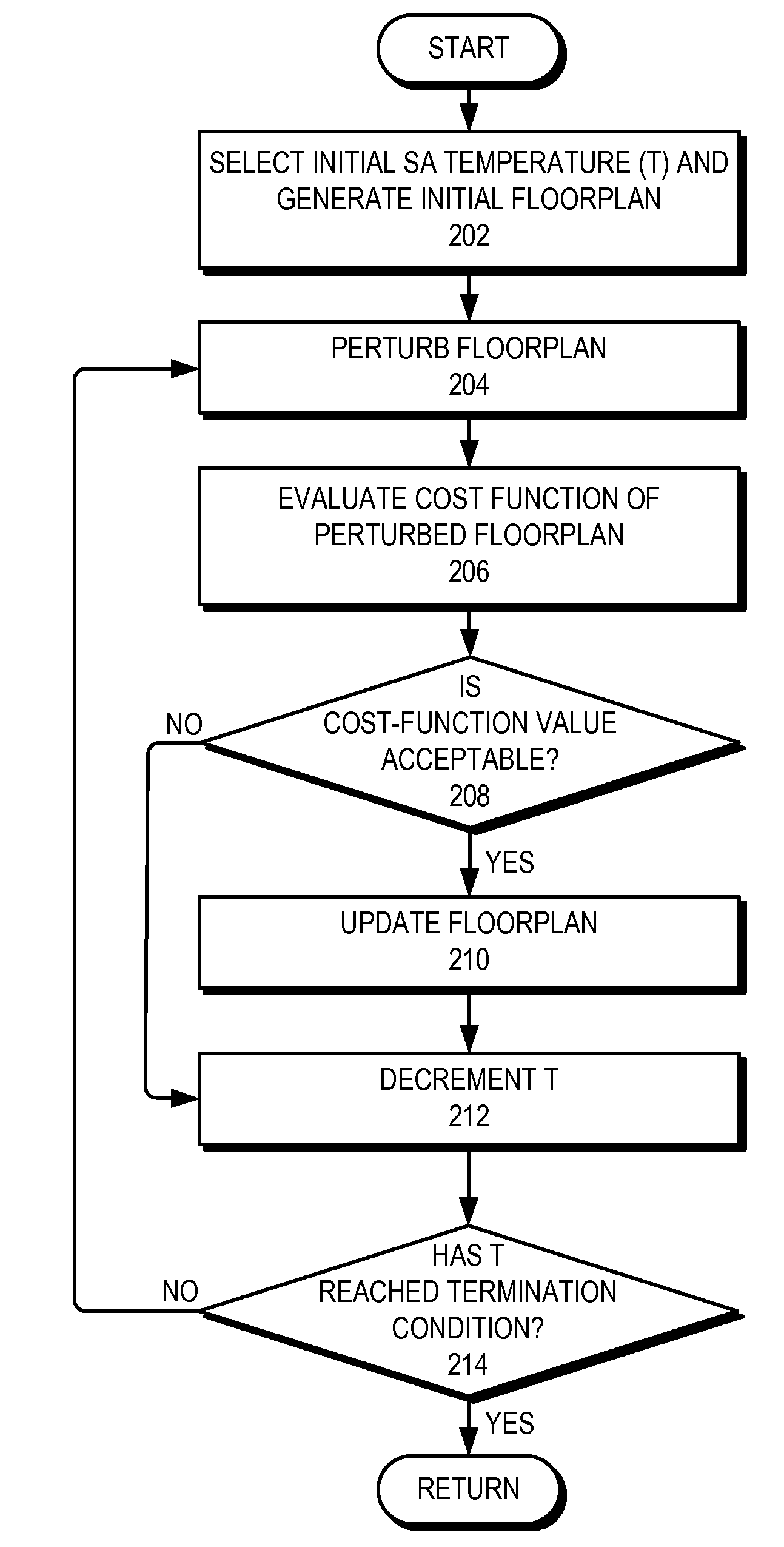

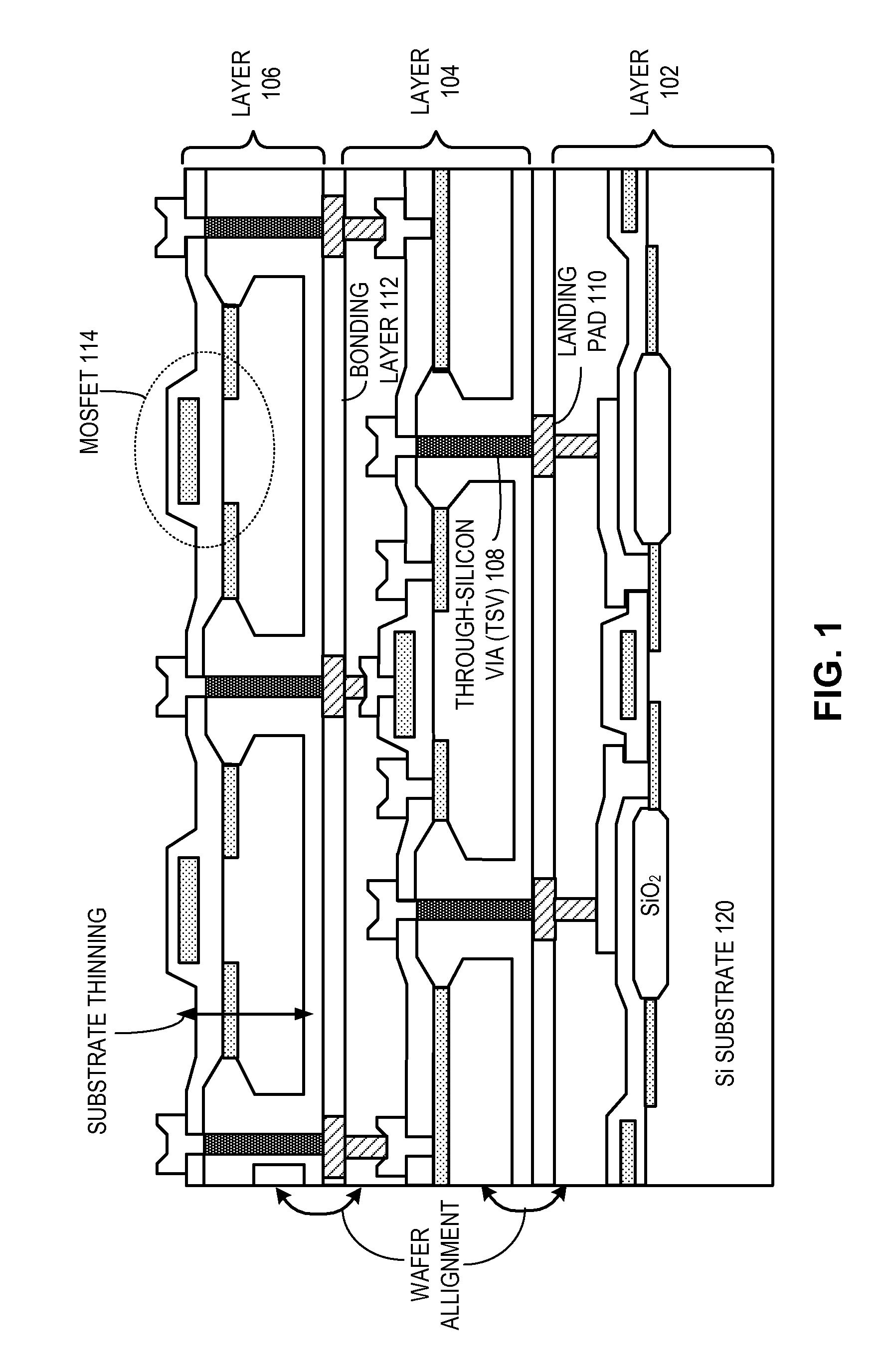

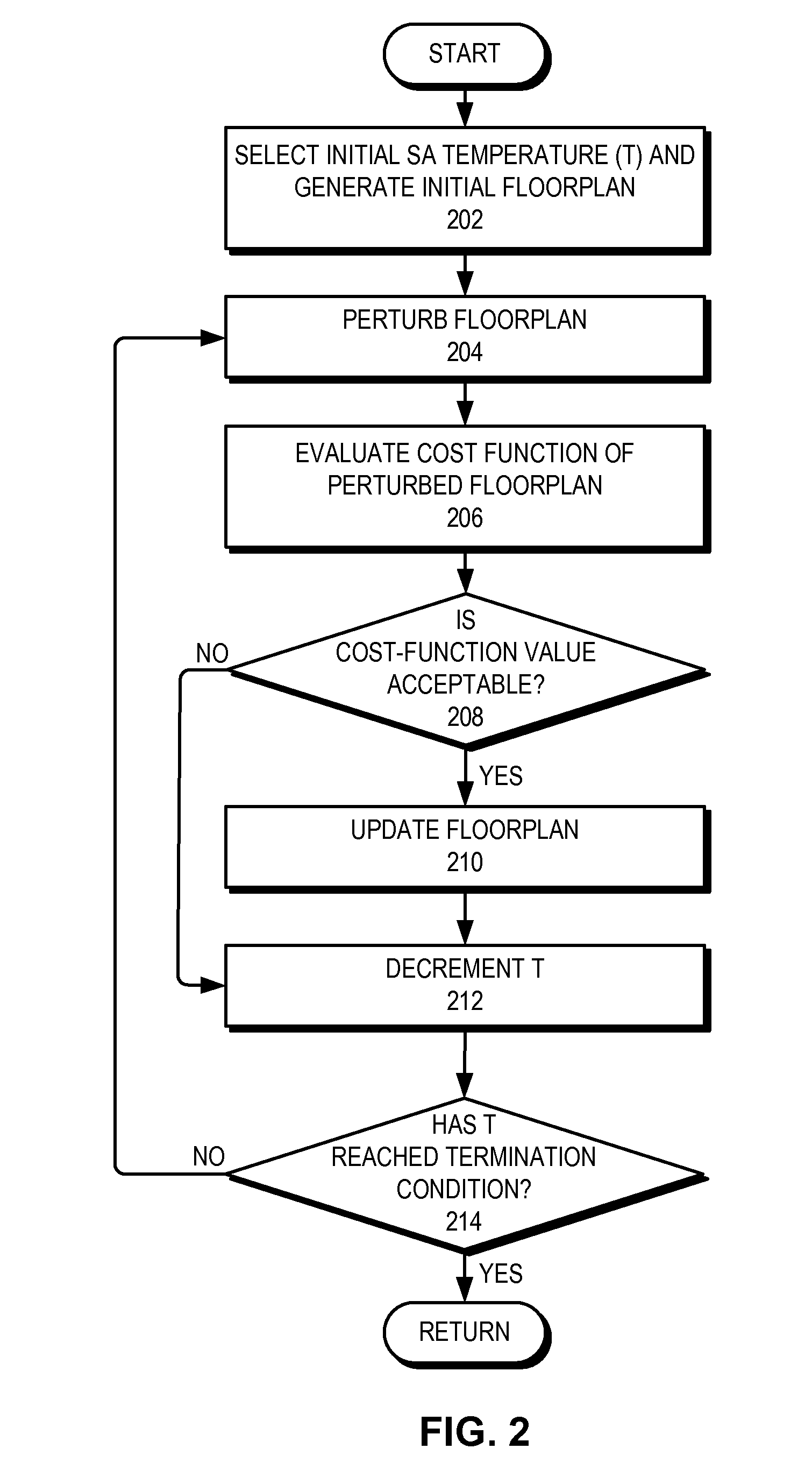

Method and system for facilitating floorplanning for 3D IC

ActiveUS20100031217A1Increase disturbanceMulti-objective optimisationSoftware simulation/interpretation/emulationComputer scienceIntegrated circuit

One embodiment of the present invention provides a system for facilitating floorplanning for three-dimensional integrated circuits (3D ICs). During operation, the system receives a number of circuit blocks. The system places the blocks in at least one layer of a multi-layer die structure and sets an initial value of a time-varying parameter. The system then iteratively perturbs the block arrangement until the time-varying parameter reaches a pre-determined value.

Owner:SYNOPSYS INC

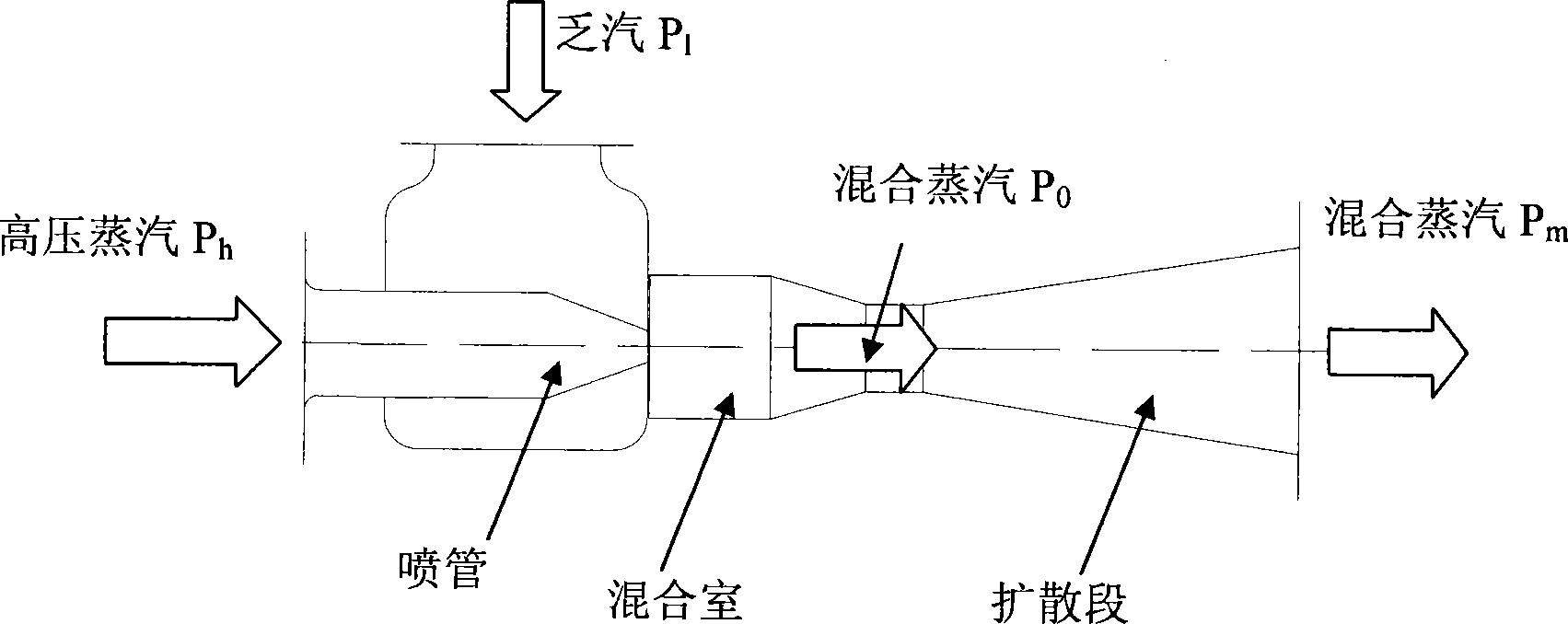

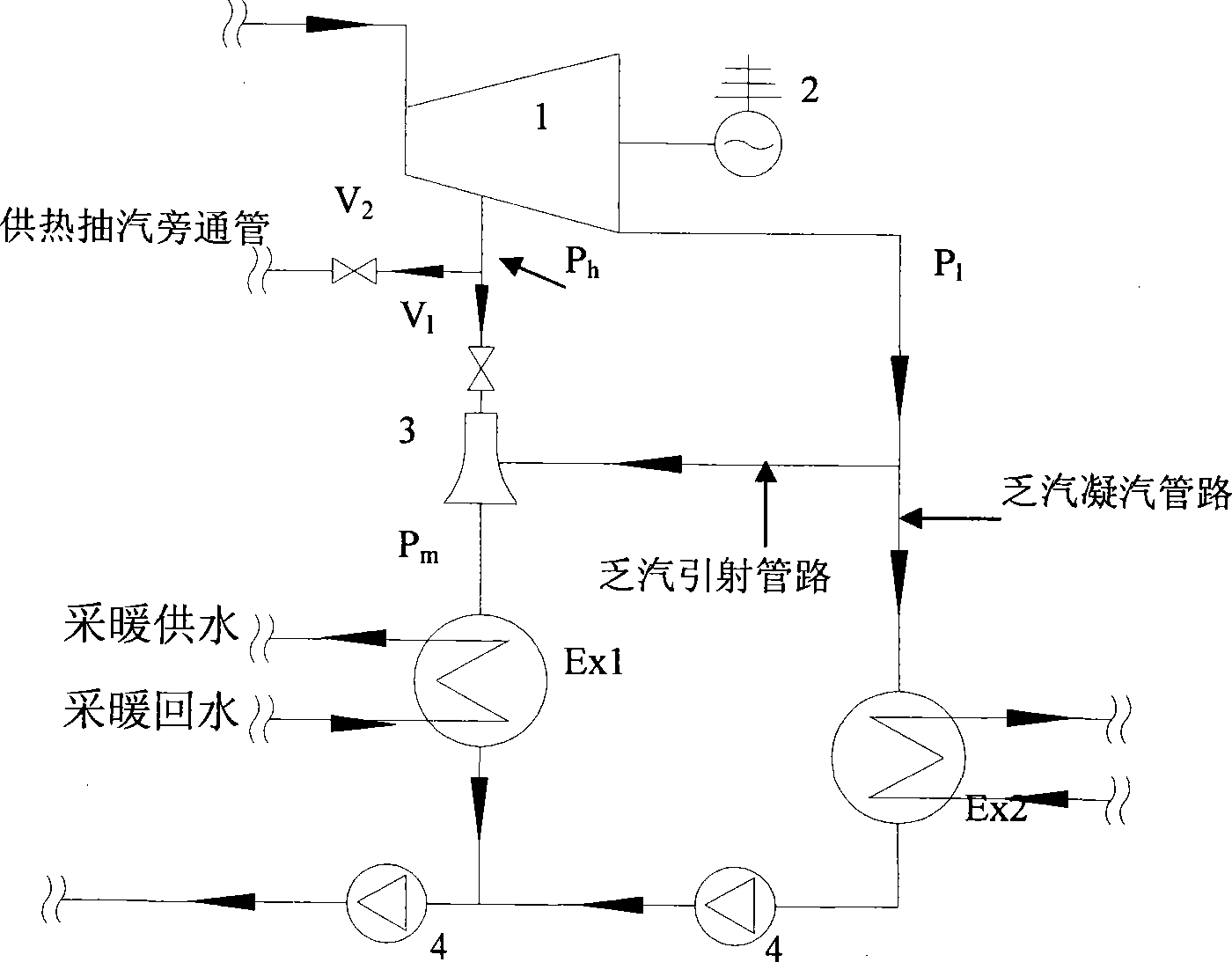

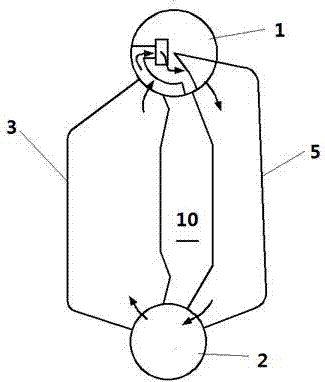

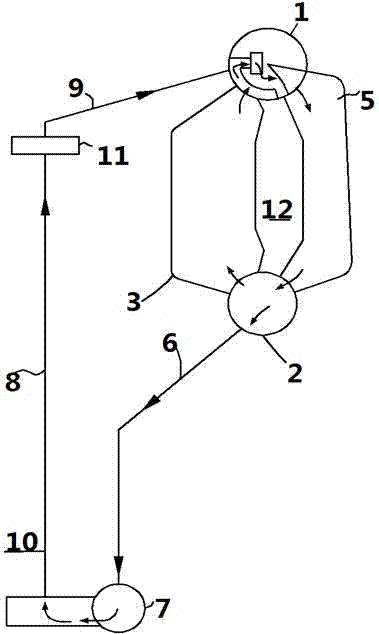

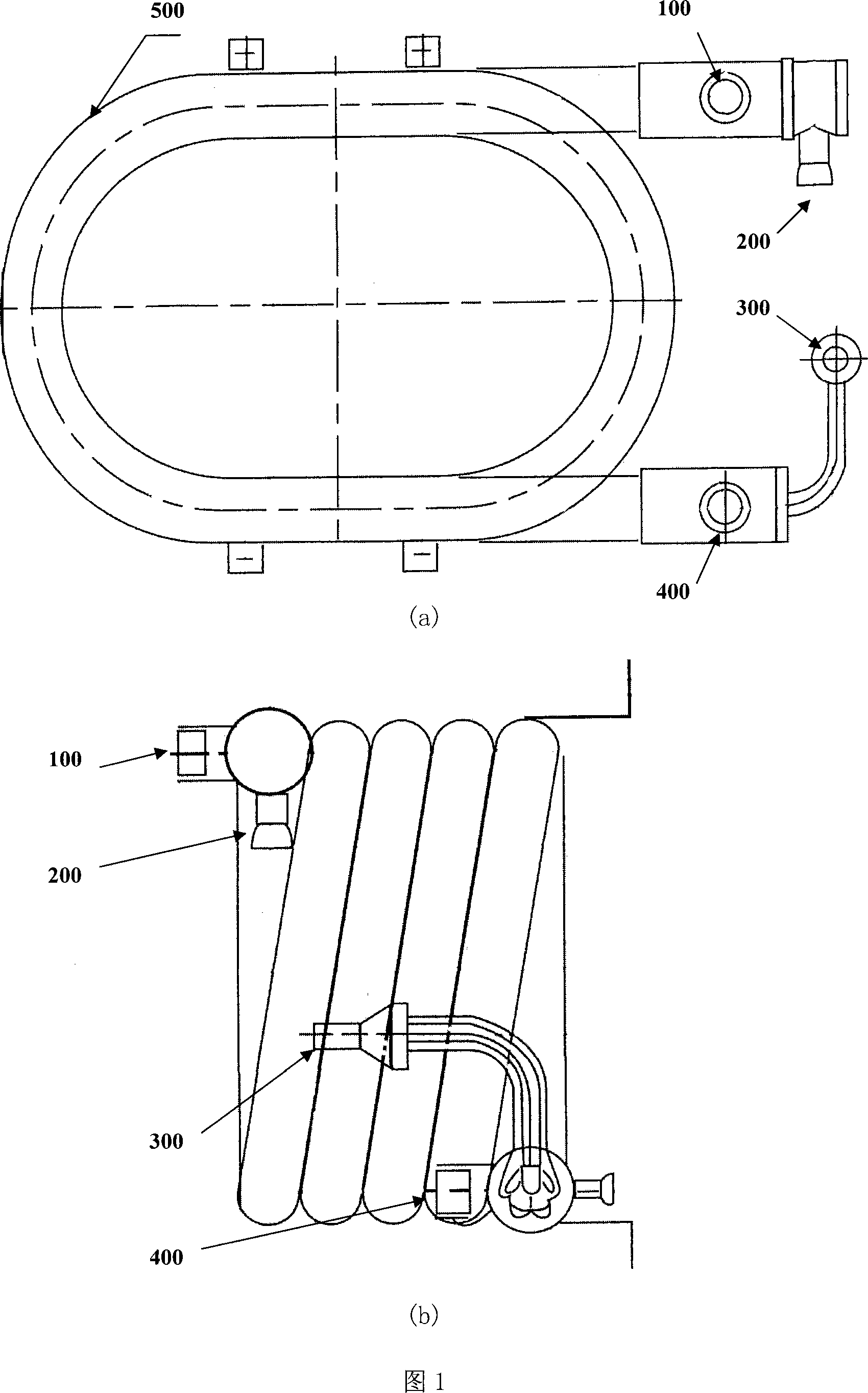

Steam jet type heat pump heat distribution system for recovering thermal power plant condensing residual heat

InactiveCN101240909AEasy to manufactureImprove heat transfer effectFeed water supplyEnergy efficient heating/coolingLow voltageCore component

The present invention provides a steam injection heatpump heating system. The technical solution is that the system is composed of a steam injector, a high voltage steam pipeline, a low voltage steam pipeline, a throttling gear and a bypass connecting pipe. The high voltage steam enters in the heat exchanger heaing backwater after injecting lower steam turbine voltage condensing in low temperature, this realises waste heat recovery in low temperature condensing steam of the steam turbine. The core component is the steam injector, the high voltage heat supplying pumping is used as high-velocity jet acceleratively formed in the injecting tube of the working steam, and lower voltage steam turbine is rolled in the mixing room as injected flow, mixing steam in the expanding section of the steam injector is decelerately compressed in a certain back pressure, then sending to the heat interchanger for heating backwater, a certian back pressure mixing steam condenses to water after heat releasing in the exchanger, returning to the backwater system of electrical factory, completing thermal circuit of the combined heat and power generation set.

Owner:TSINGHUA UNIV

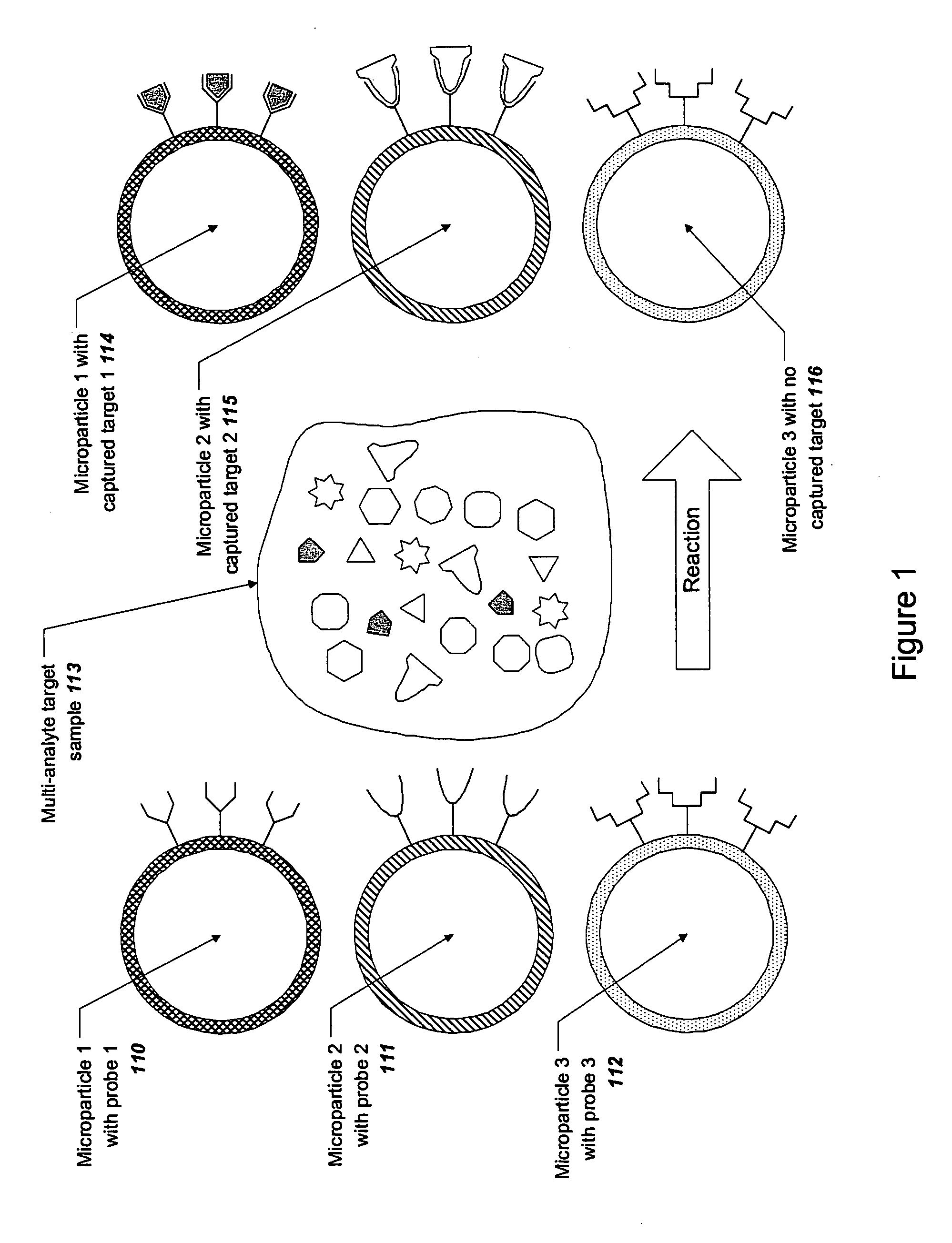

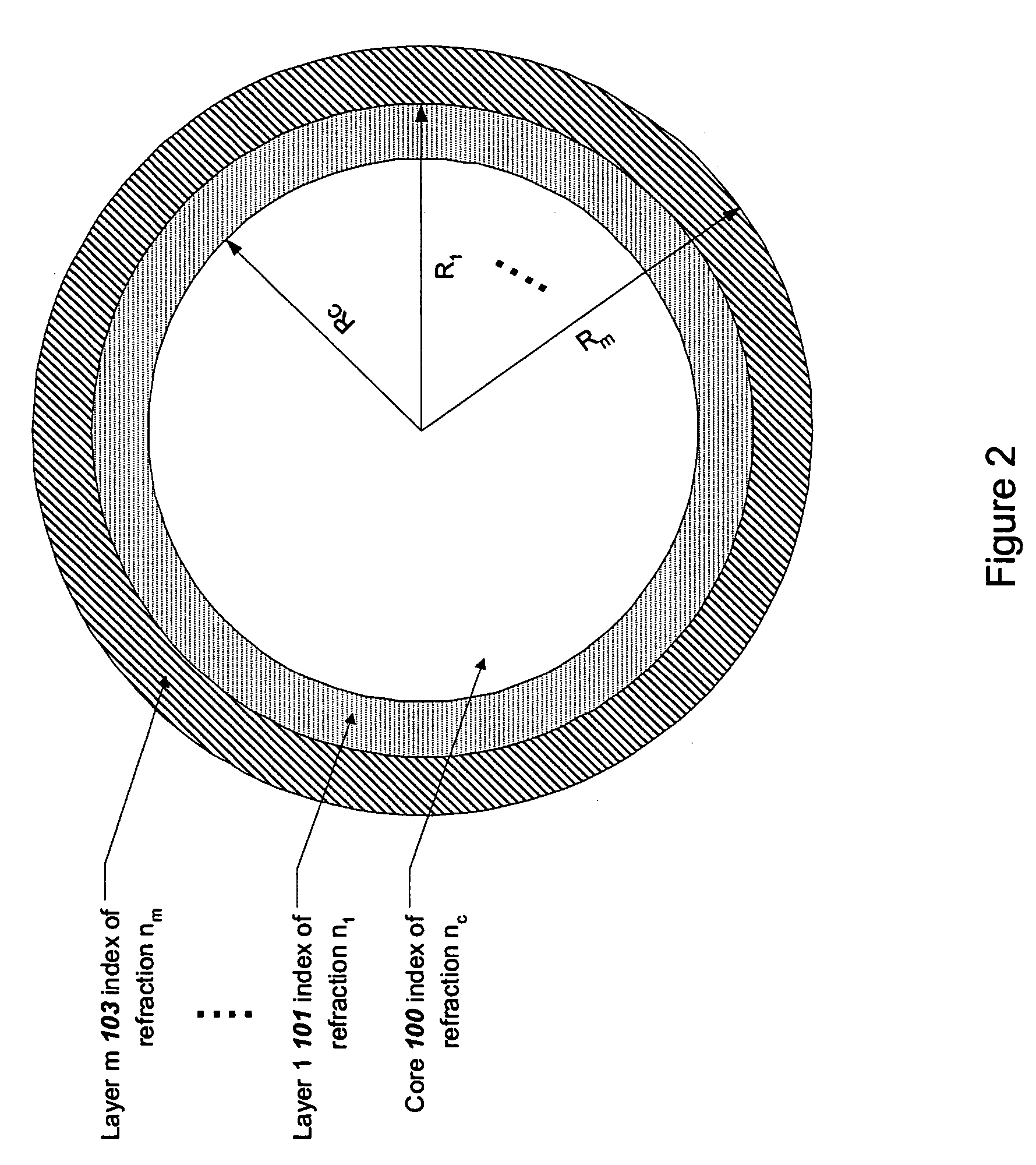

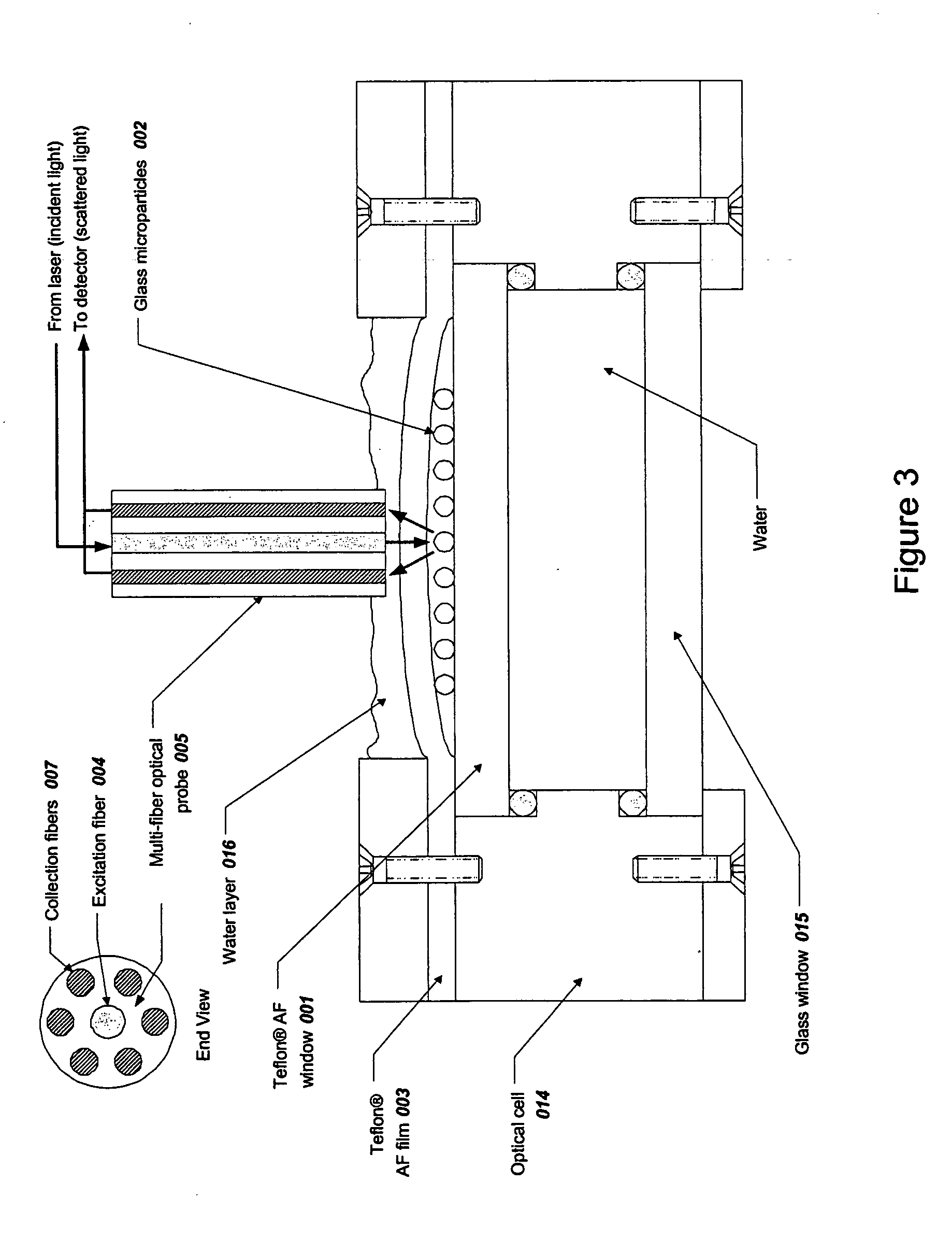

Microparticle-based methods and systems and applications thereof

InactiveUS20050282220A1Eliminates opportunityElimination of potentialMicrobiological testing/measurementNanoinformaticsTarget analysisAnalyte

Microparticle-based analytical methods, systems and applications are provided. Specifically, the use of resonant resonant light scattering as an analytical method for determining either or both a particle's identity and the presence and optionally, the concentration of one or more particular target analytes is described. Applications of these microparticle-based methods in biological and chemical assays are also disclosed.

Owner:PROBER JAMES +6

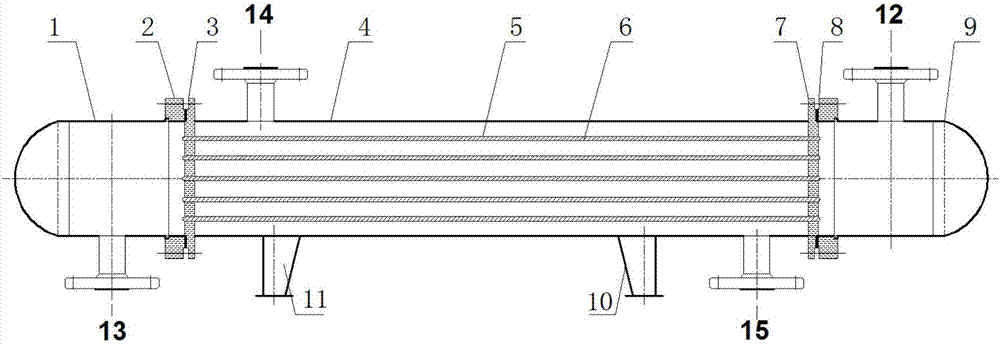

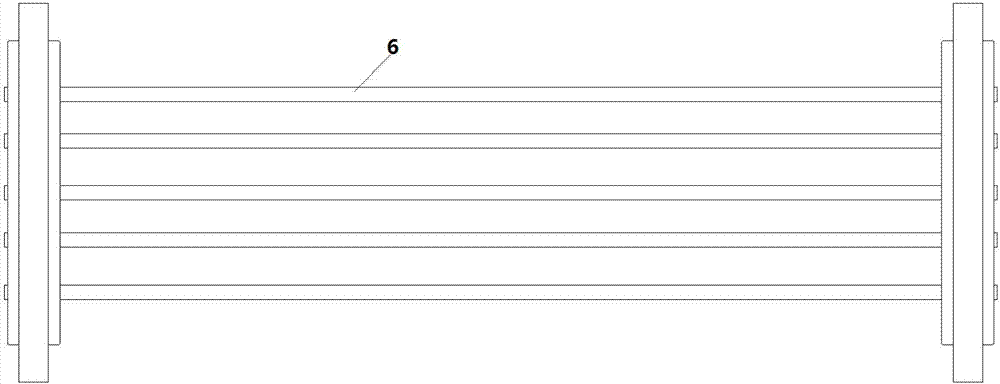

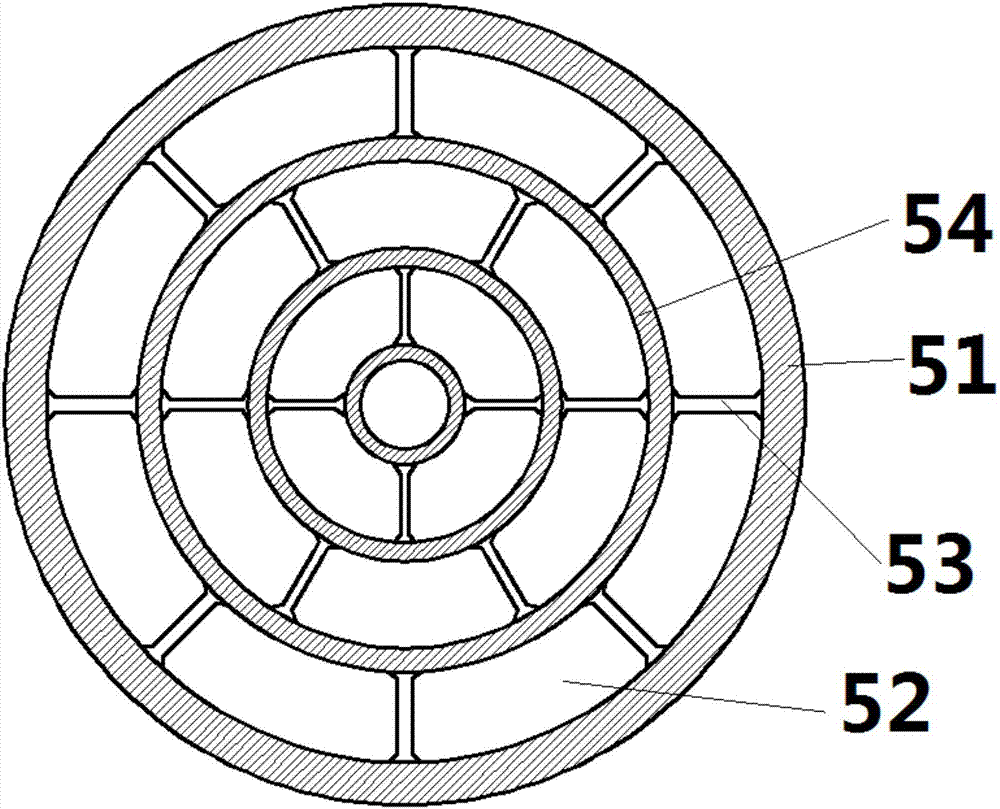

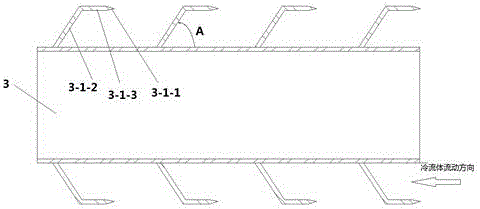

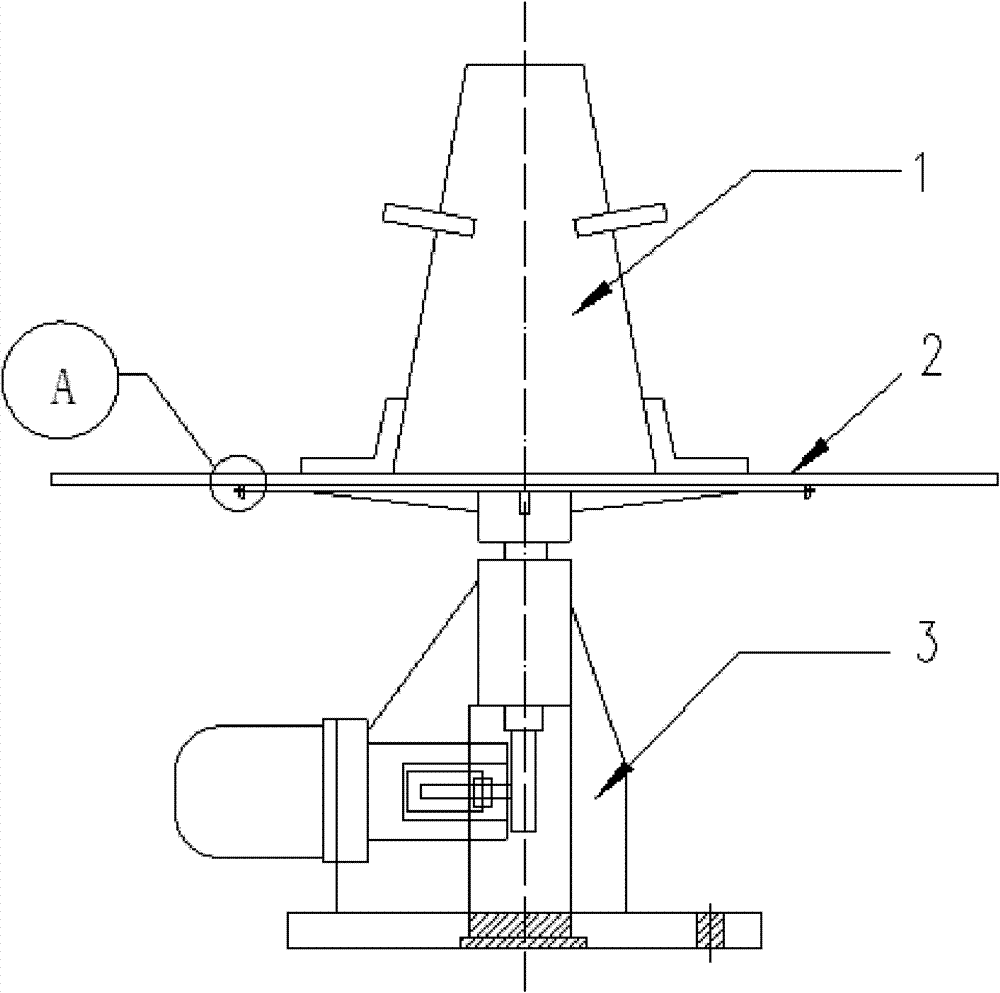

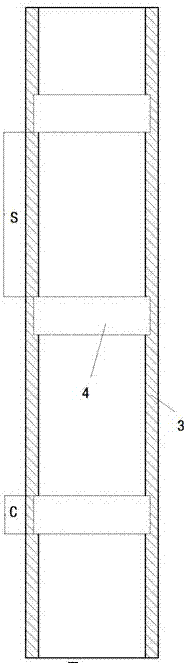

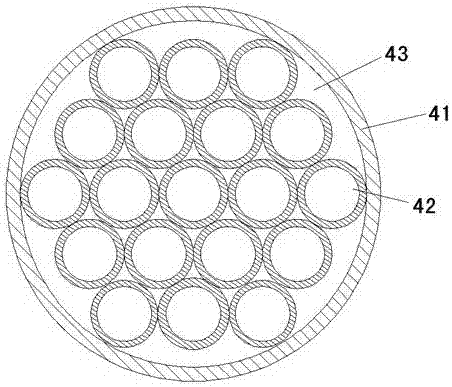

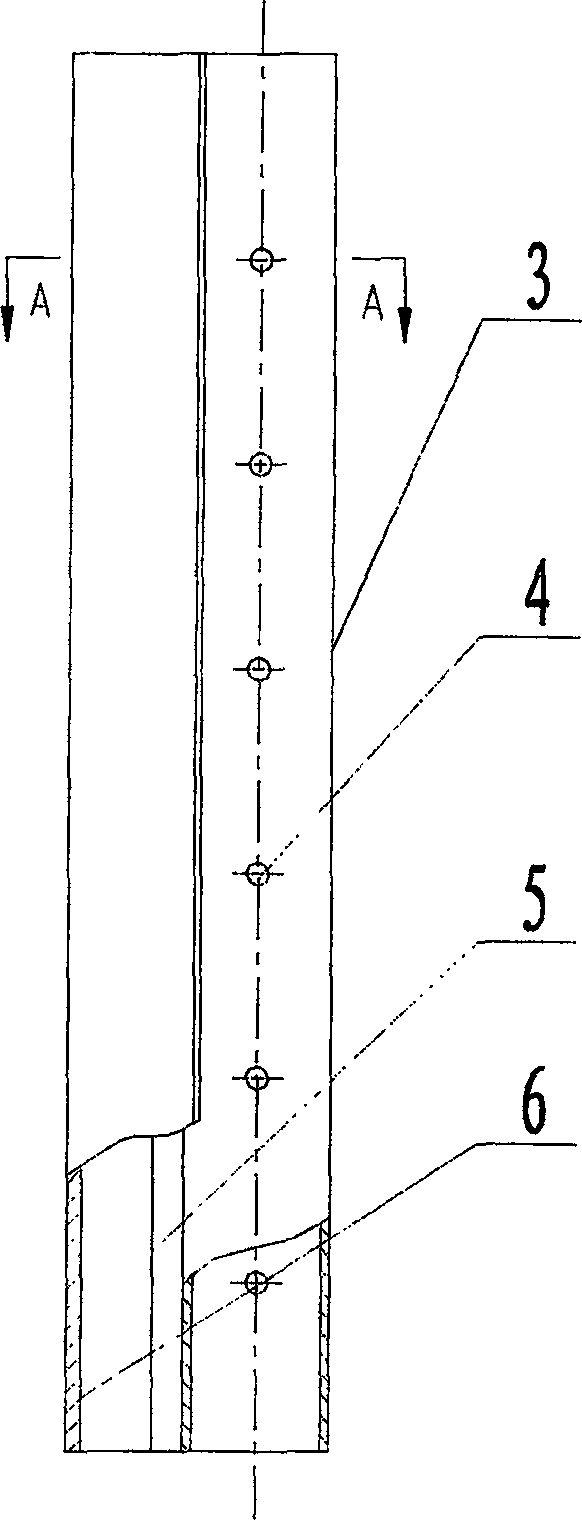

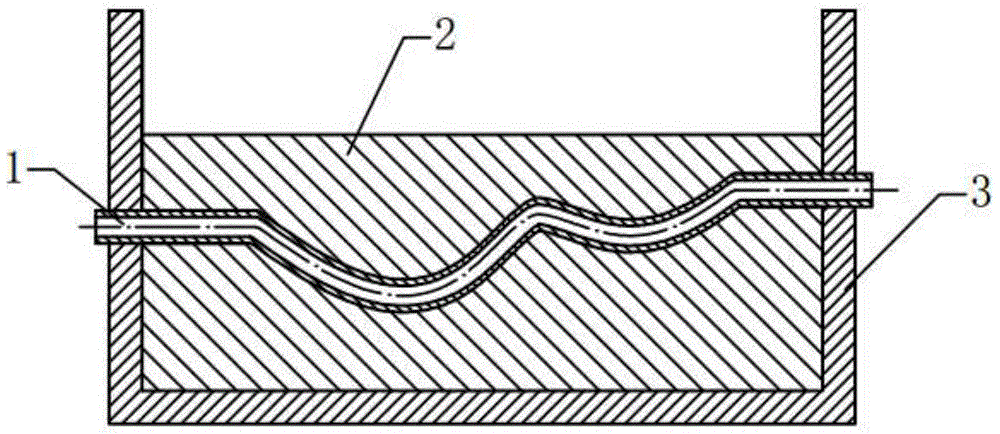

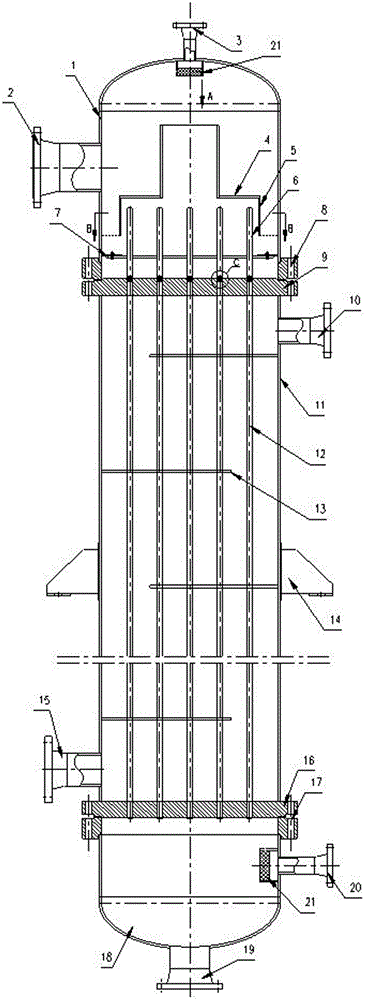

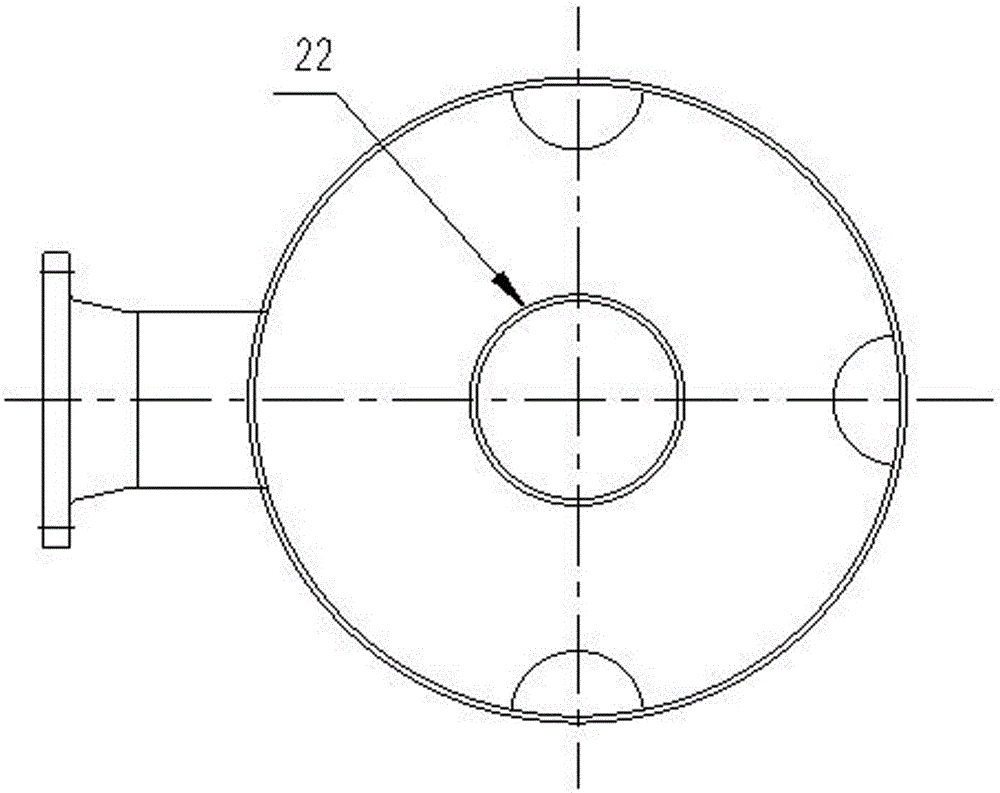

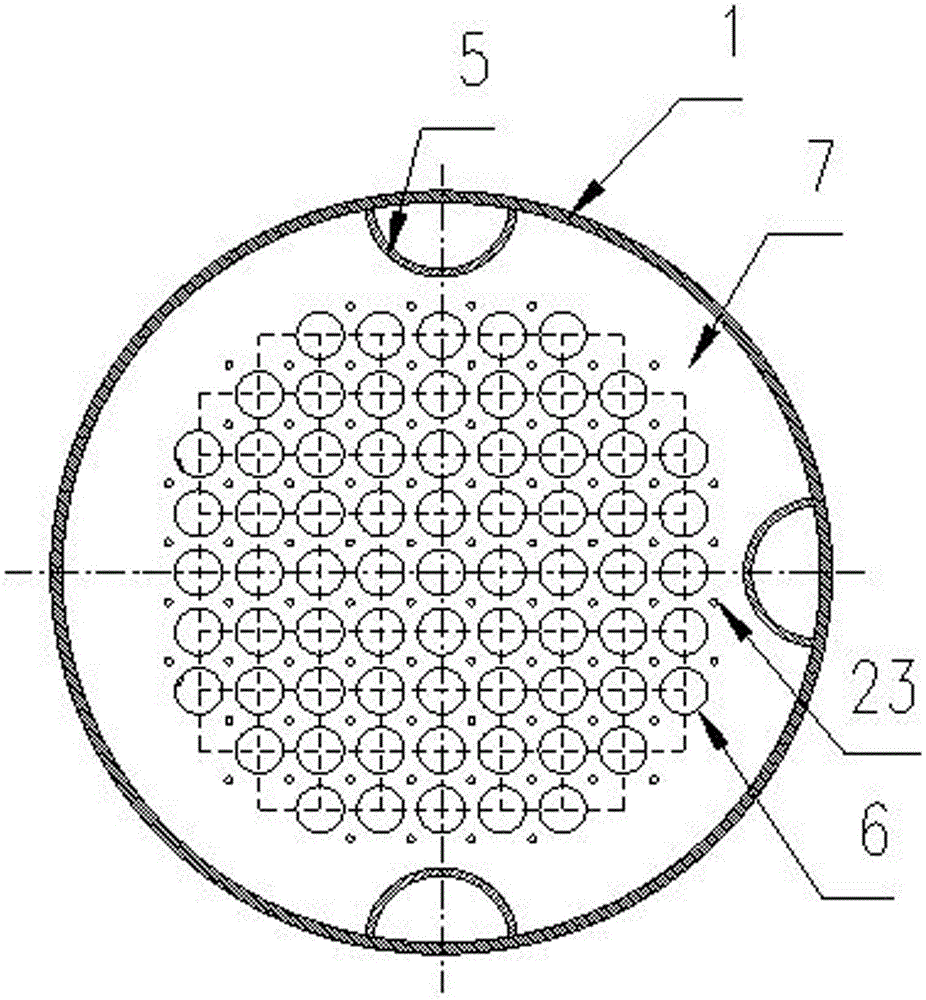

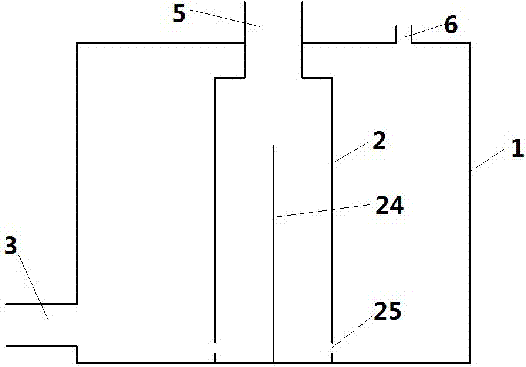

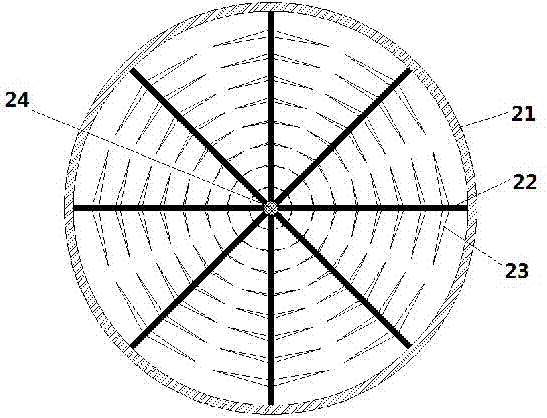

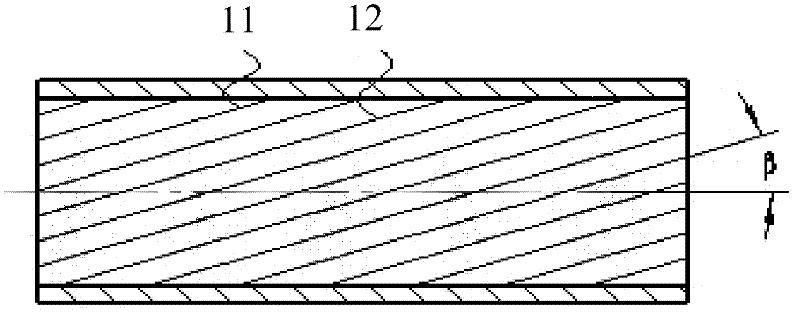

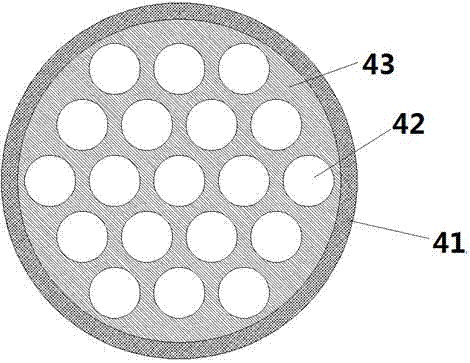

Length-variable condensable annular separation device heat exchanger

ActiveCN106969652AShorten the lengthReduce vibrationStationary tubular conduit assembliesHeat transfer modificationVapor liquidNoise level

The invention provides a vapor-liquid two-phase flow tube shell type heat exchanger. The heat exchanger comprises a shell, wherein sealing heads are arranged at two ends of the shell respectively; tube plates are arranged in connection positions between the sealing heads and the shell; heat exchange tubes are connected with the tube plates at two ends; vapor phase in vapor-liquid two-phase flow can be condensed into liquid phase in the heat exchange process; the vapor-liquid two-phase flow flows in a tube process; separation devices used for decreasing vibration and reducing noise are arranged in the heat exchange tubes; a plurality of separation devices are arranged in the same heat exchange tube; the length of the separation devices is gradually reduced along the flowing direction of flow in the heat exchange tubes. According to the vapor-liquid two-phase flow tube shell type heat exchanger, the vibration of the tubes can be decreased to a maximum extent due to the length change of the separation devices when the vapor-liquid two-phase flow flows in the tubes; the noise level is reduced; meanwhile, the flowing resistance is reduced; the heat exchange uniformity is improved.

Owner:SHANDONG UNIV

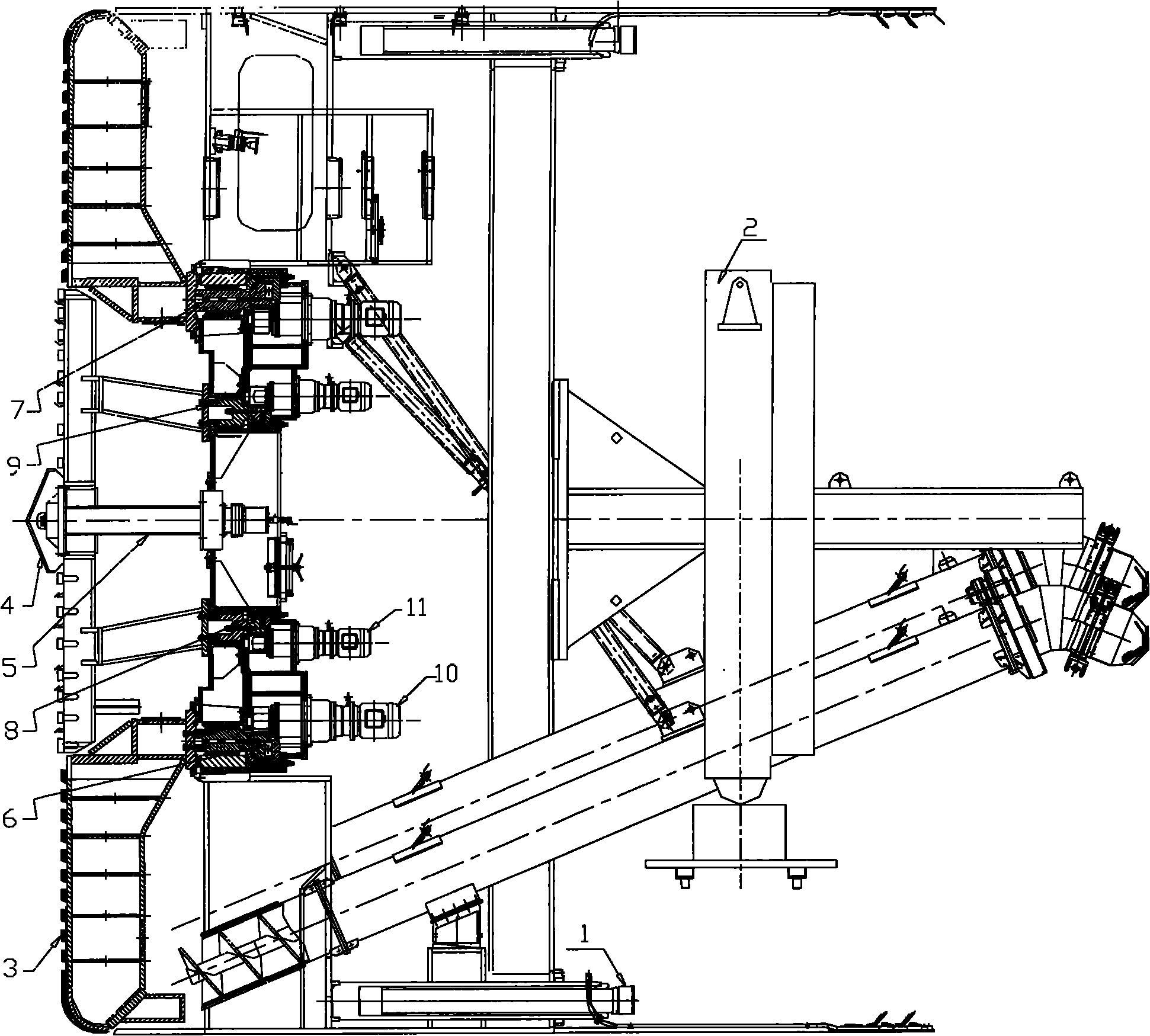

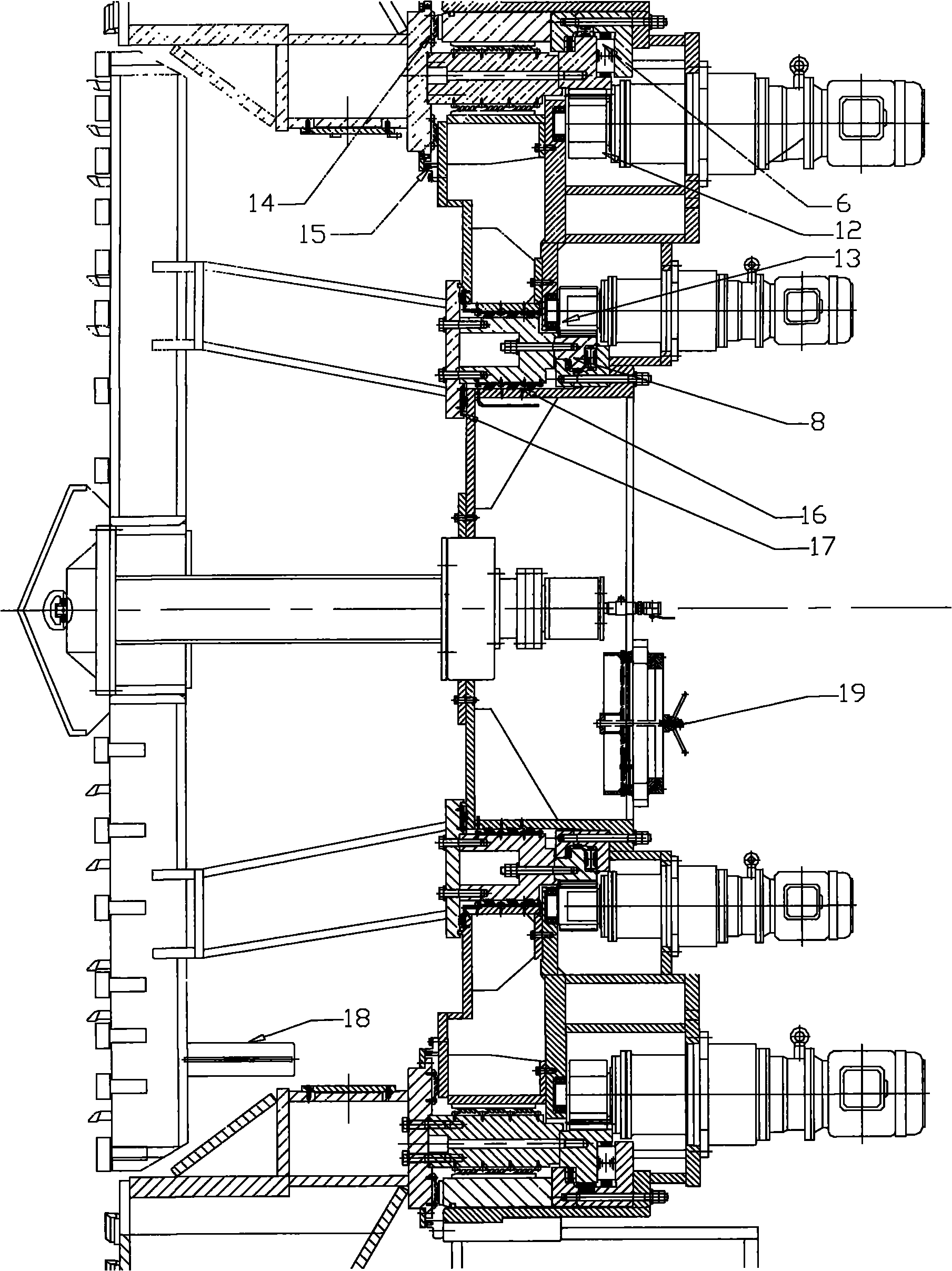

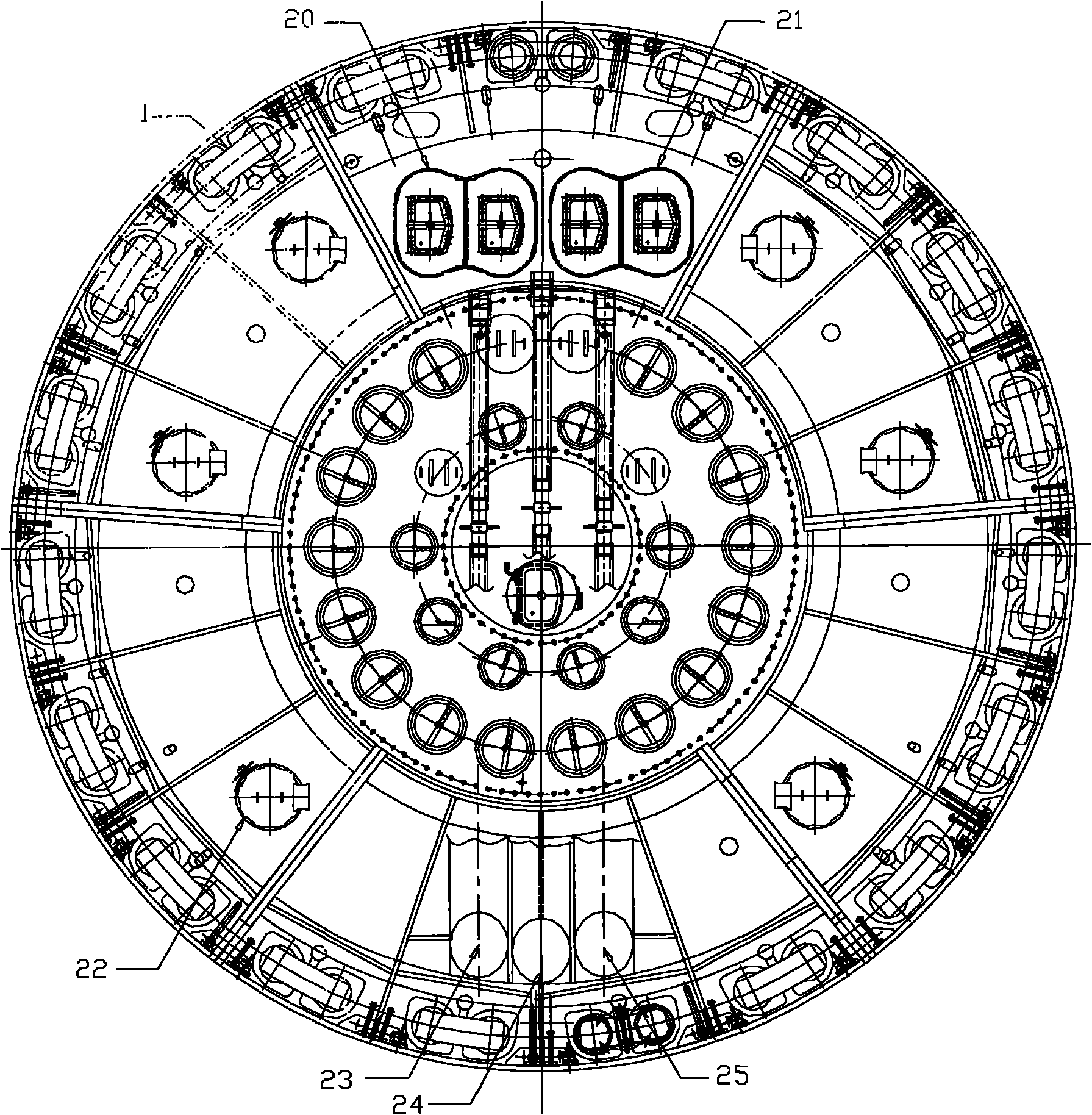

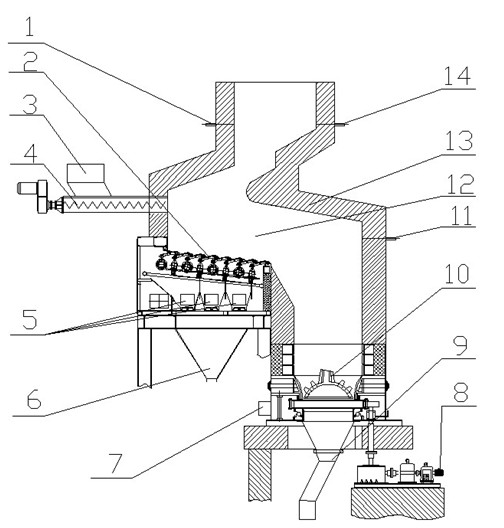

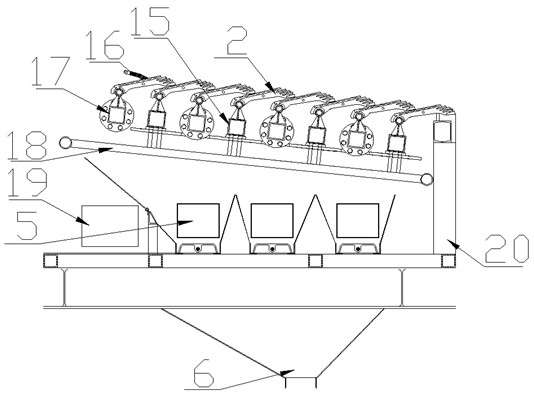

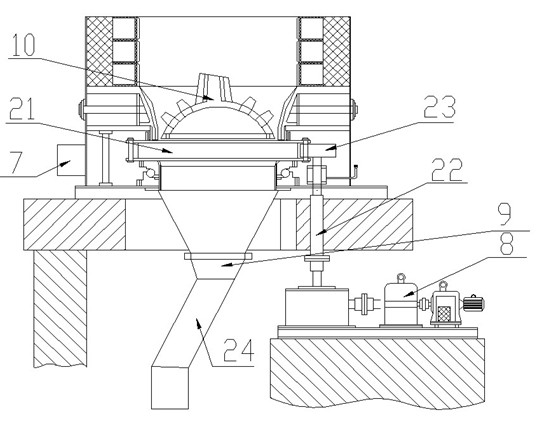

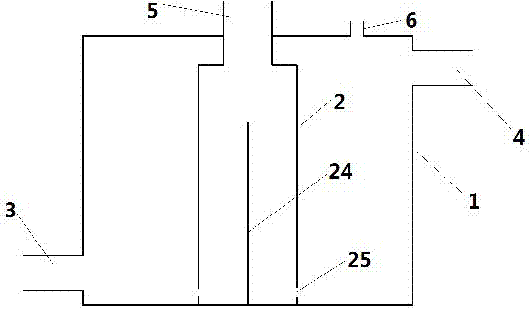

Large-diameter earth pressure balance shield machine

InactiveCN101798928AReduce wear rateChange the situation of uneven damageTunnelsControl theoryEarth pressure balance

The invention relates to a large-diameter earth pressure balance shield machine. The machine comprises a cutterhead, a cutterhead drive part, a propulsion oil cylinder, an erector, spiral conveyors and a frame; the cutterhead is a double-cutterhead which comprises a peripheral large cutterhead and an independent central cutterhead; the cutterhead drive part comprises two driving mechanisms which drive the peripheral large cutterhead and the independent central cutterhead respectively; and the peripheral large cutterhead and the independent central cutterhead rotate independently and bidirectionally. Compared with the prior art, the shield machine adopts the double-cutterhead design, greatly optimizes a cutting speed of the cutterhead on a soil body, further improves a propulsion speed of the shield, optimizes the disturbance effect of the cutterhead on the soil body, and prevents the rolling of a shield machine body; different opening rates are designed on the cutterhead and are suitable for different situations of a central part and a peripheral part when a tunnel is advanced; and three spiral conveyors discharge soil, effectively control the posture of the shield, and prevent the deviation of a tunnel axis.

Owner:SHANGHAI LIXING ENG TECH DEV

Integrated electrolysis nitrogen and phosphorus removal wastewater treatment method

InactiveCN101549896AGood conditionEfficient removalWater/sewage treatmentElectrode polaritySmall footprint

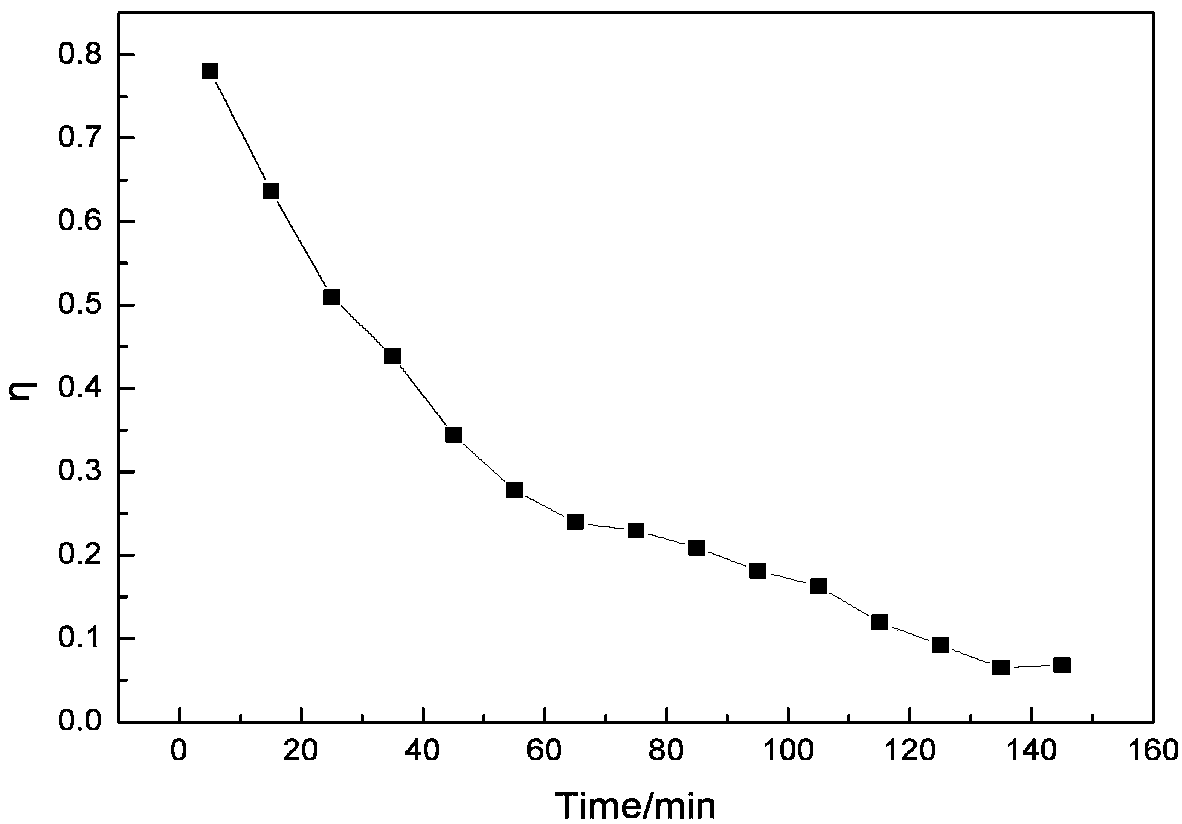

The invention relates to an integrated electrolysis nitrogen and phosphorus removal wastewater treatment method, which realizes to remove the nitrogenous and phosphorus nutrition salt and organic pollutants in wastewater in same electrolytic tank. The invention adopts graphite and iron plate as electrodes, alternates electrolysis phosphorus removal and electrolysis nitrogen removal process by alternating the electrode polarities to remove the nitrogenous and phosphorus nutrition salt and organic pollutants in wastewater. The invention performs optimization and integration according to the change characteristics of the parameters including electrolysis time, current density, pH value, pollutants removal rate in the electrolysis phosphorus removal and electrolysis nitrogen removal process, can remove the nitrogenous and phosphorus nutrition salt and organic pollutants in wastewater in high efficiency in short time without adding any medicament in the process, achieves the advantages of small occupation area, short treatment time and high pollutants removal efficiency.

Owner:SHANGHAI JIAO TONG UNIV

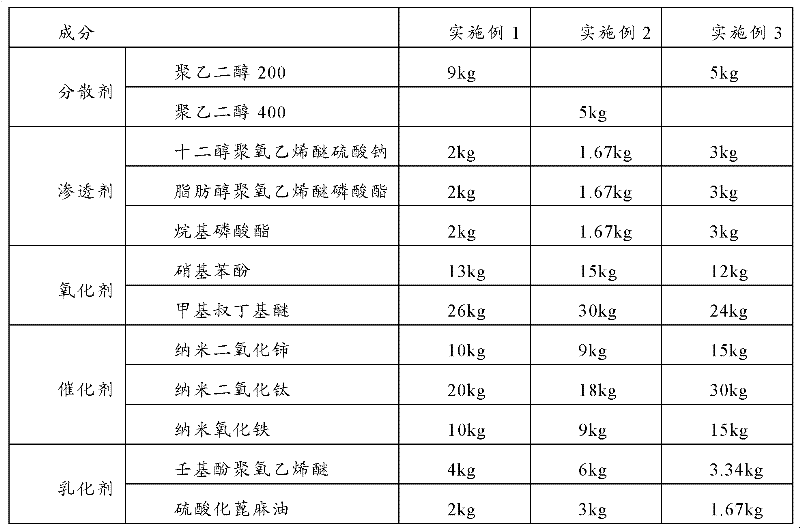

A kind of coal combustion accelerant

The invention provides a coal combustion improver which comprises 5 to 10 percent of dispersing agent, 5 to 10 percent of penetrant, 35 to 50 percent of oxidizing agent, 35 to 50 percent of catalyst and 5 to 10 percent of emulsifying agent, wherein the oxidizing agent is a mixture of nitrophenol and methyl tertiary butyl ether; and the catalyst is nano-scale metallic oxide. The coal combustion improver provided by the invention has high combustion improving efficiency and is safe and environmental-friendly. The invention also provides a method for preparing the coal combustion improver.

Owner:安徽海螺材料科技股份有限公司

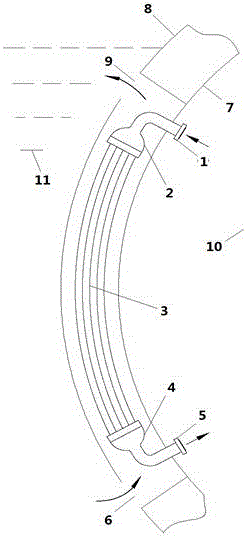

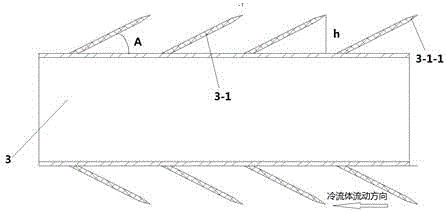

Heat exchange provided with sharp structure out of pipe

ActiveCN106767007ADoes not increase flow resistanceIncrease heat transfer areaStationary conduit assembliesHeat exchanger casingsInlet channelGas phase

The invention provides a heat exchanger. The heat exchanger comprises a pipe pass side and a shell pass side; the pipe pass side includes an inlet pipe, an inlet cavity, a heat transfer pipe bundle, an outlet cavity and an outlet pipe; a hot fluid enters the inlet cavity from the inlet pipe to pass through the heat transfer pipe bundle, the outlet cavity and the outlet pipe in sequence; the shell pass side includes an inlet channel, an inner shell, an outer shell and an outlet cavity; a cold fluid passes through space limited by the inlet channel, the inner shell and the outer shell and the outlet cavity in sequence; the inlet cavity, the heat transfer pipe bundle and the outlet cavity are arranged in space limited by the inner shell and the outer shell; a metal rod outwards extends from the outer wall of the heat transfer pipe bundle; the end part of the metal rod is a sharp structure; and the direction from the outer wall of the heat transfer pipe bundle to the end part of the metal rod is opposite to the flowing direction of the cold fluid. The rod with the sharp end part is arranged at the external of the heat exchange pipe; in flowing of a gas-liquid two-phase flow, on the one hand, the laminar flow bottom layer can be broken, and the heat transfer area is increased for forced heat transfer; because of the rod, the flowing resistance is low, and the shell pass flowing resistance cannot be increased; and as the sharp end part is provided, bubbles can be punctured to realize increment of a gas-liquid interface and a gas-phase boundary layer and reinforcement of the disturbance.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Testing method for working performance of concrete and apparatus implementing same

The invention relates to a testing method for working performance of concrete and an apparatus implementing the same. The testing apparatus comprises a concrete slump tester, a cement mortar fluidity testing jumping table and a circular extending table. In similar testing of the slump of concrete disposed on a large table-board, the jumping table vibrates preset times according to certain frequency and certain vibration amplitude after a slump cylinder is hoisted, which enables the slump and flowing of the concrete to be improved and the concrete to form a circular truncated cone shape with a larger area; the slump H after vibration, the mobile extended diameter D of the concrete, center thickness h1 and edge thickness h2 after vibration are measured, the inclination angle theta of a frustum after slump of the concrete is calculated through conversion, bleeding and the segregation degree of the concrete are observed, and thus, working performance of the concrete can be comprehensively estimated. Compared with the prior art, the invention has the following advantages: working performance of fresh concrete can be conveniently and quickly tested and distinguished, and the method and the apparatus are applicable to a wide variety of concrete.

Owner:TONGJI UNIV

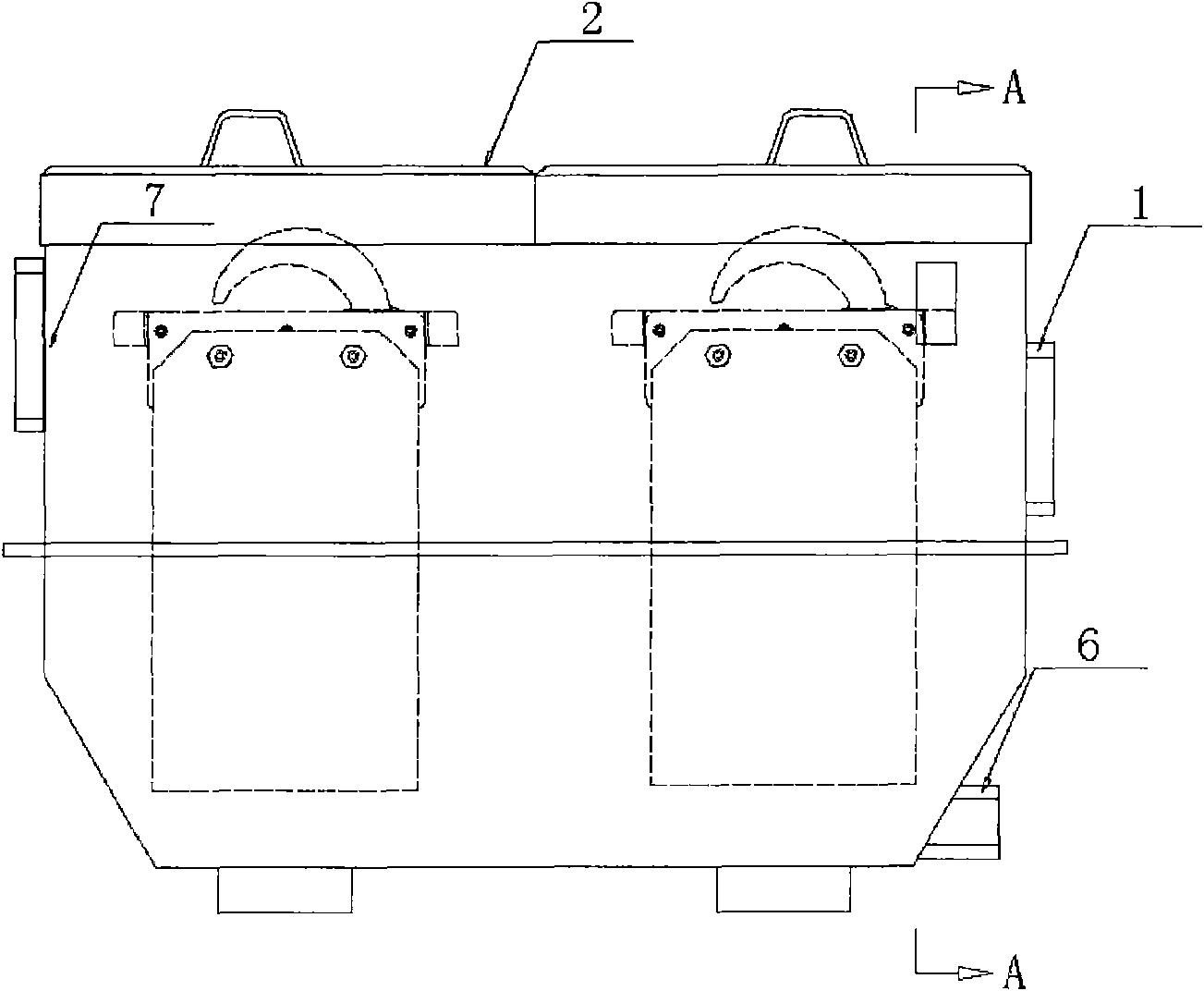

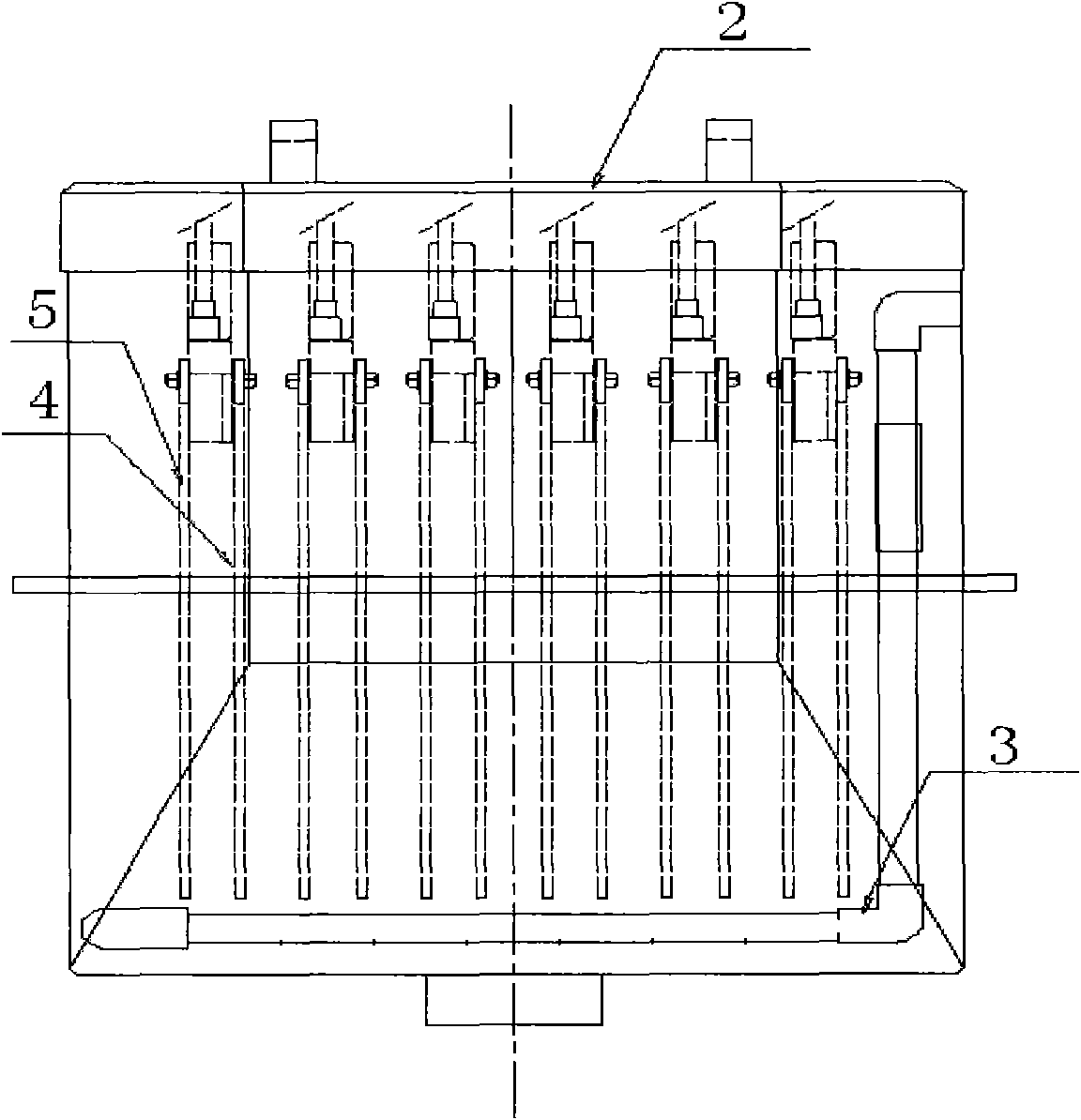

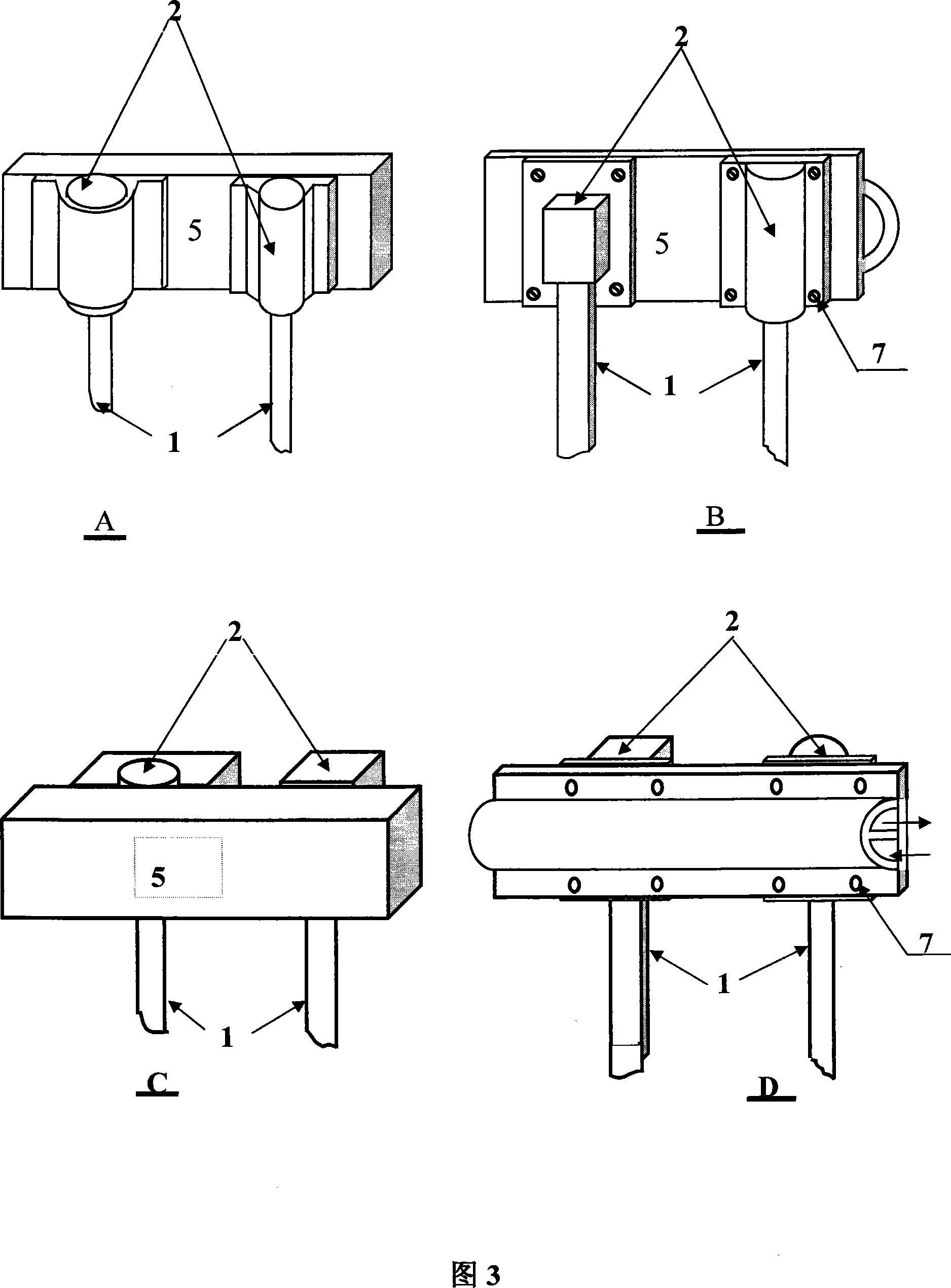

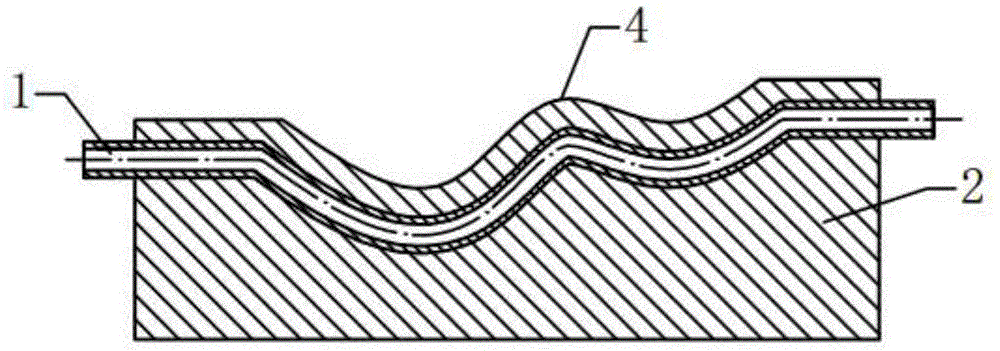

Cooling system of ultra-high strength steel hot stamping forming die

InactiveCN101288890AImprove cooling effectWarranty Strength RequirementsShaping toolsHot stampingSheet steel

The invention discloses a cooling system used for an ultra-high strength steel plate thermal die cutting and forming die. The die comprises a concave die and a concave die seat; a water chamber is arranged between the concave die and the concave die seat; the water chamber is communicated with a water inlet and a water outlet. The water chamber is arranged between the concave die and the concave die seat of the invention; after cooled water is inlet in the water chamber, a steel plate workpiece can be quickly cooled by the thermal conduction between the die and the steel plate so as to meet the quenching condition of the steel plate. Especially, the water chamber is also internally provided with a supporting column; the upper end of the supporting column is contacted with the lower bottom surface of the concave die; the lower end of the supporting column is contacted with the upper bottom surface of the concave die seat; therefore, the structural strength of the concave die is ensured, the flowing direction of the water flow can be guided, flow perturbation conditions can be provided, meanwhile, the heat transfer area is increased, and the heat exchange efficiency between the cooled water and the die is improved.

Owner:TONGJI UNIV +1

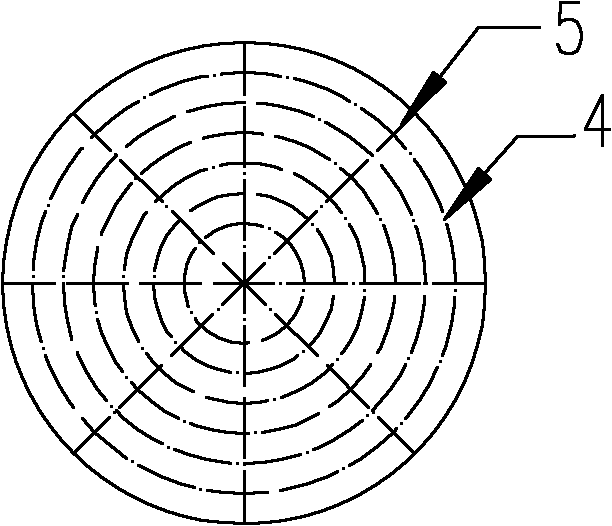

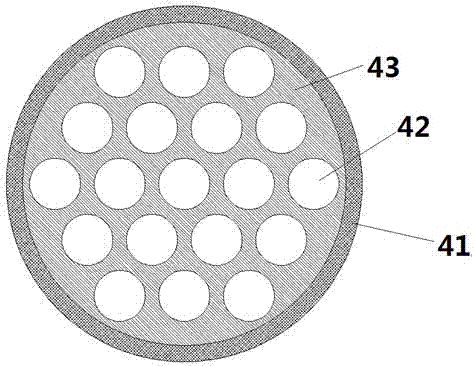

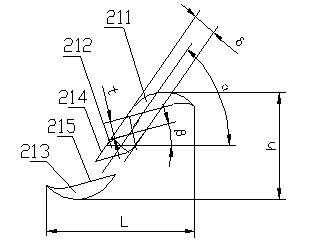

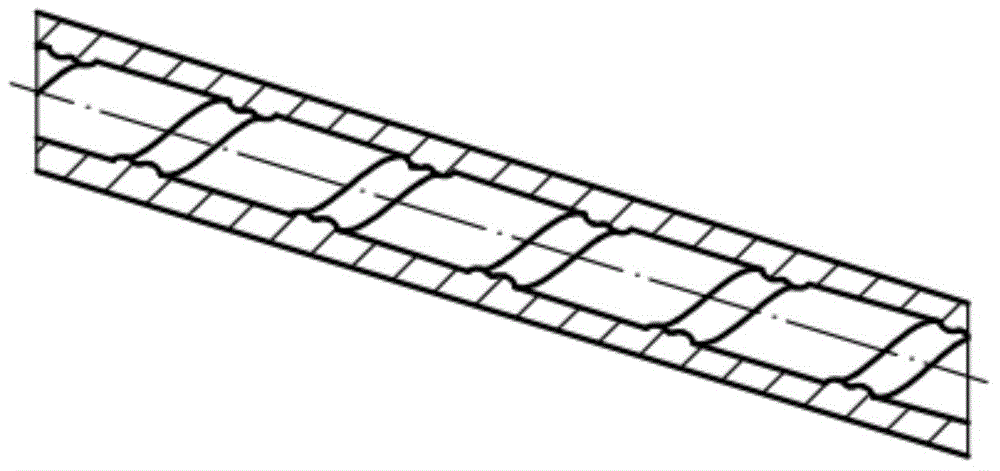

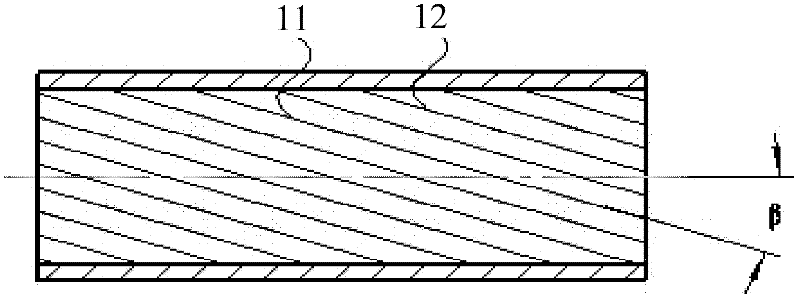

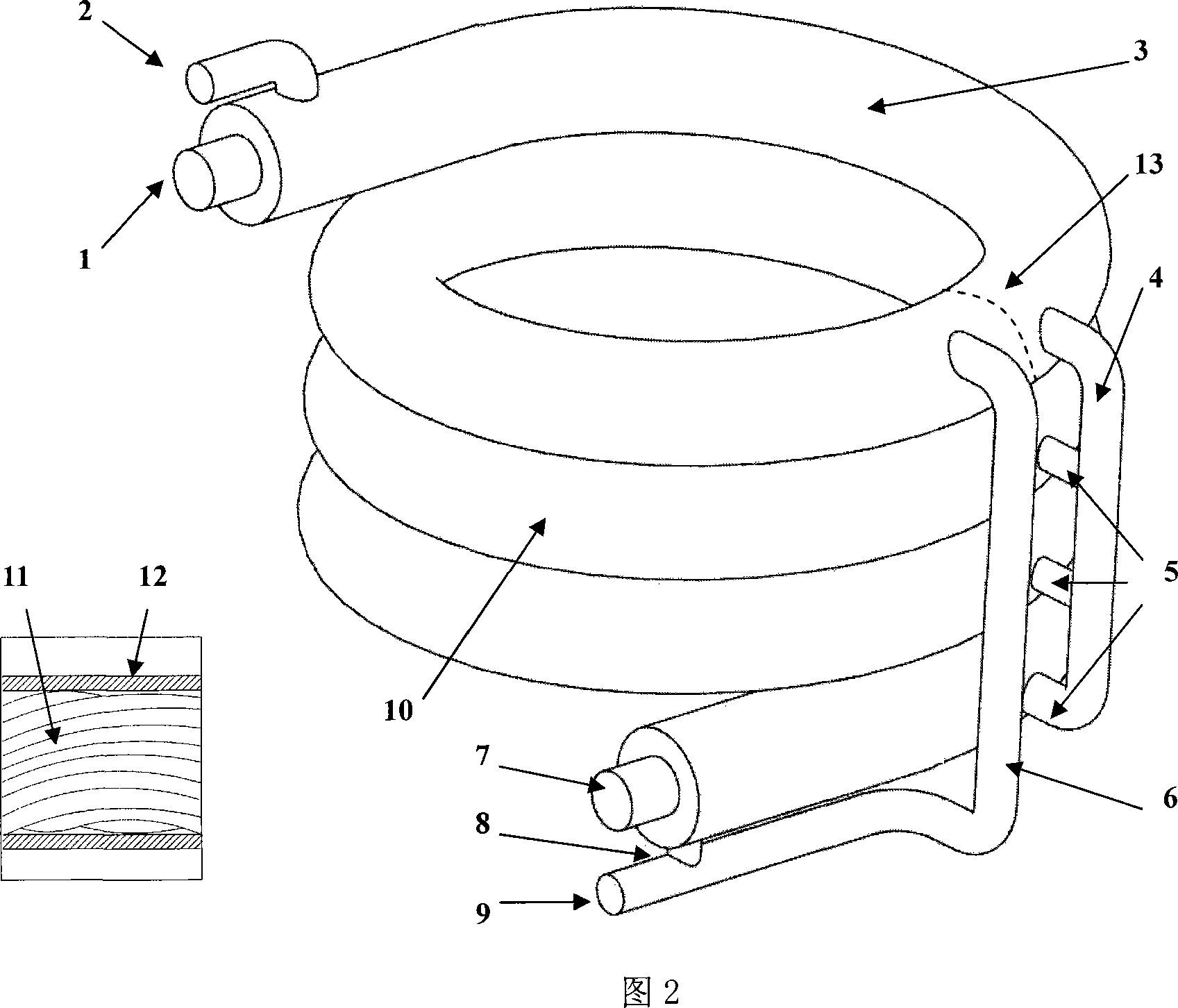

Heat pipe with multi-hole flow stabilizing devices

ActiveCN107044789AReduce vibrationImprove heat transfer performanceIndirect heat exchangersVapor liquidNoise level

The invention provides a heat pipe which comprises an evaporation collecting pipe, a condensation collecting pipe, ascending pipes and return pipes, wherein the ascending pipes are communicated with each of the evaporation collecting pipe and the condensation collecting pipe; the evaporation collecting pipe is positioned at the lower part; the condensation collecting pipe is positioned at the upper part; a fluid absorbs heat and evaporates in the evaporation collecting pipe, the vapor passes through the ascending pipes to enter the condensation collecting pipe and is condensed in the condensation collecting pipe after being subjected to heat exchange, and the condensed fluid returns back into the evaporation collecting pipe through the return pipes; the flow stabilizing devices are arranged in each of the same ascending pipe; the lengths of the flow stabilizing devices are constantly increased in the height directions of the ascending pipes;. According to the heat pipe with multi-hole flow stabilizing devices, the lengths of the flow stabilizing devices are changed, so that when vapor-liquid two-phase flows exist in the ascending pipes, heat transfer is enhanced, the vibration of the ascending pipes is weakened, and the noise level is reduced.

Owner:山东路德交通科技有限公司

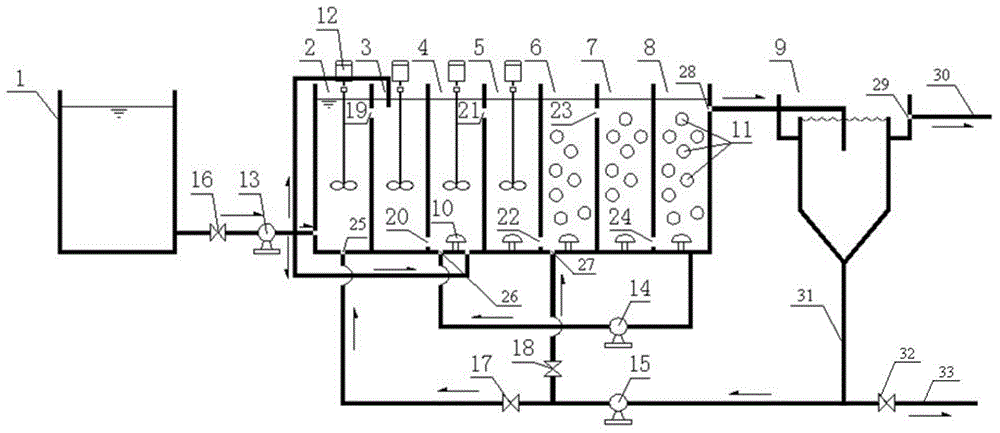

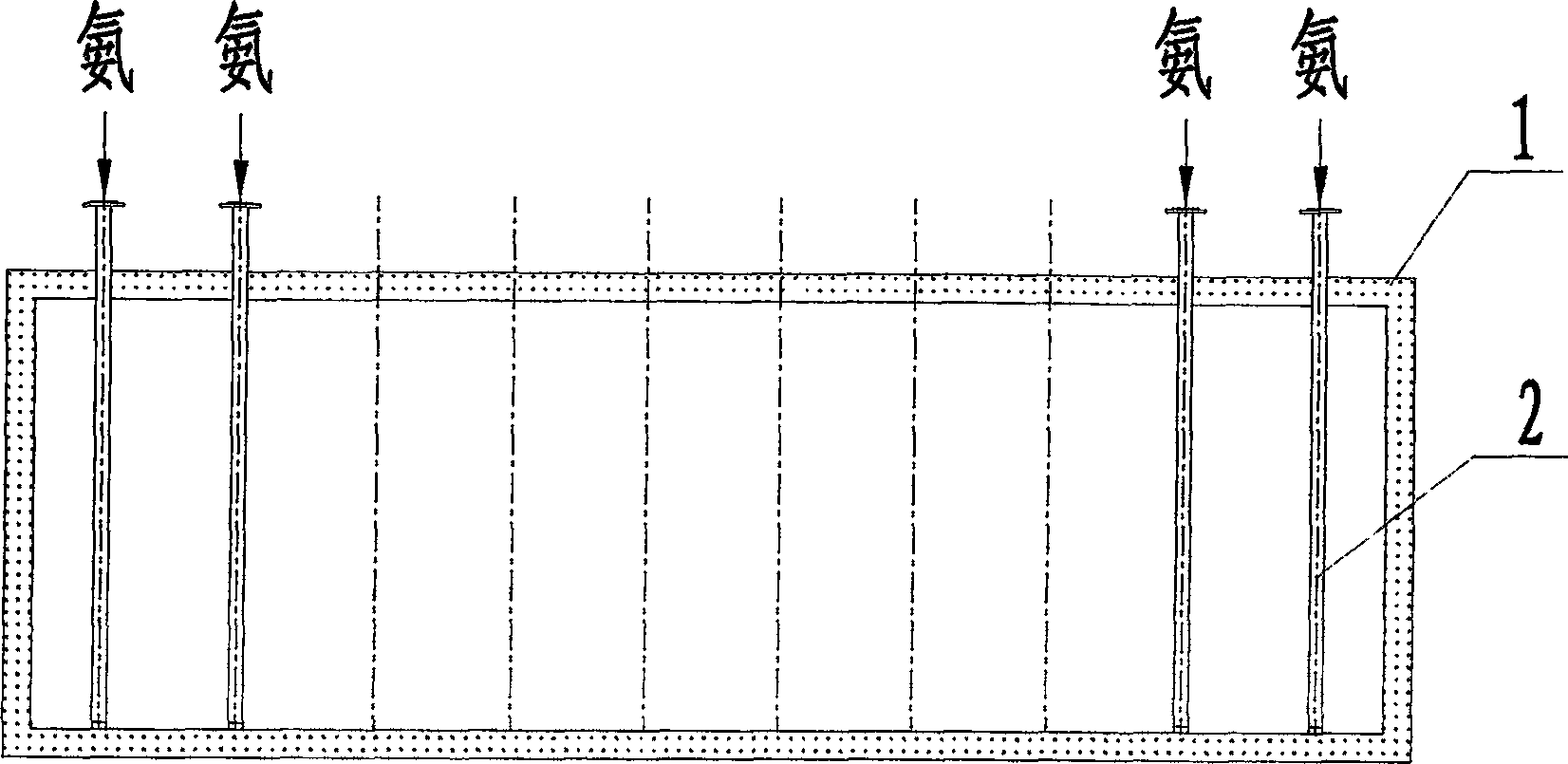

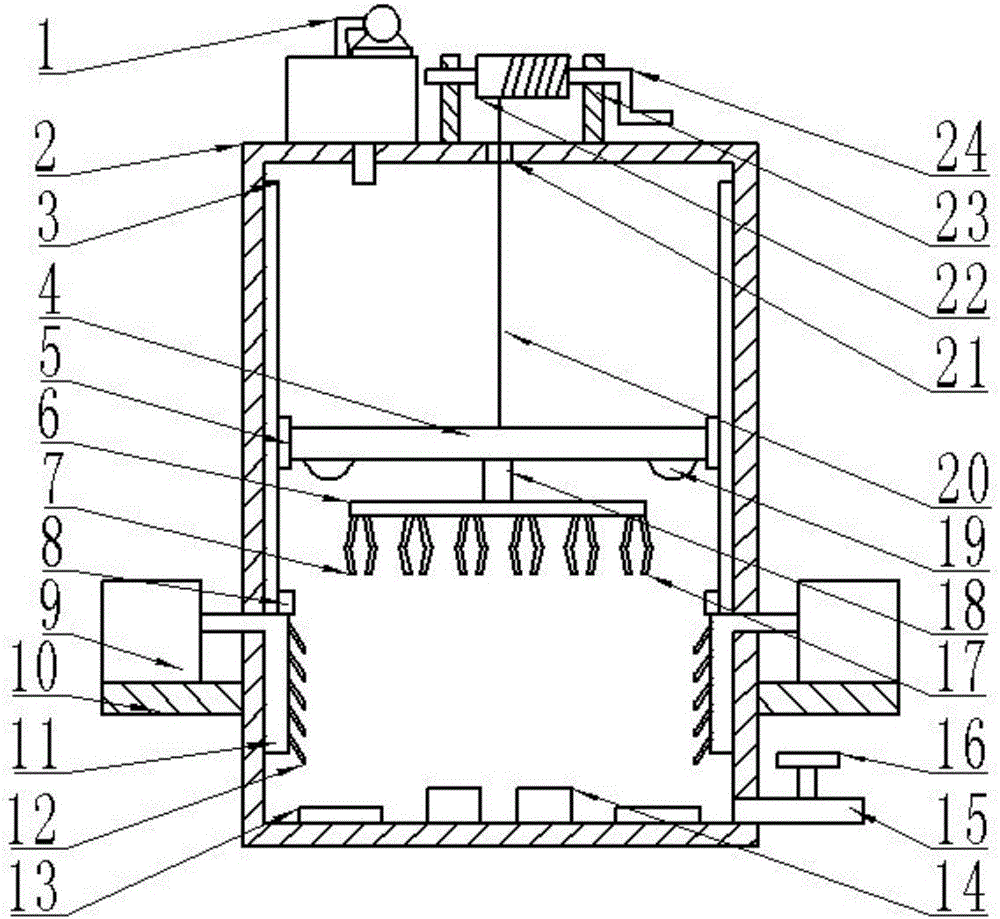

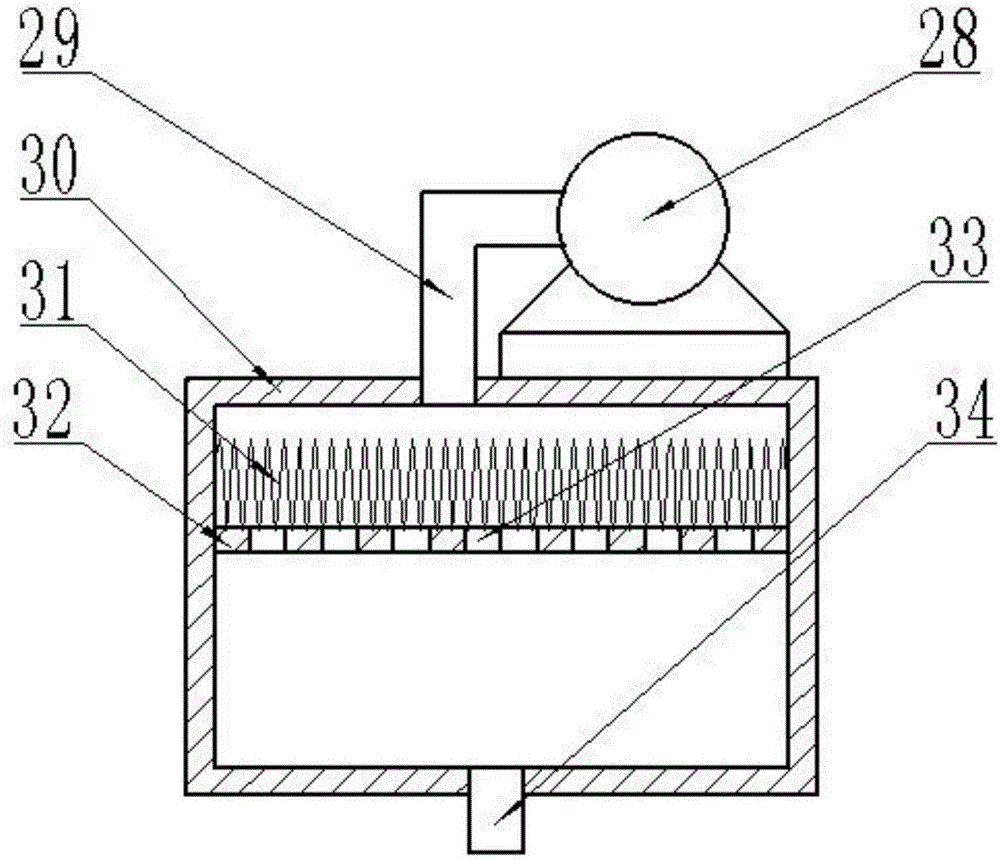

Biology processing apparatus capable of processing sewage at low-temperature with low carbon-nitrogen-ratio in cold region and method for processing sewage at low-temperature with low carbon-nitrogen-ratio in cold region

ActiveCN104150716AIncrease disturbanceEasy to updateMultistage water/sewage treatmentSludgeWater storage tank

The invention relates to a biology processing apparatus capable of processing sewage at low-temperature with low carbon-nitrogen-ratio in a cold region and a method for processing sewage at low-temperature with low carbon-nitrogen-ratio in the cold region, which relates to the biology processing apparatus for processing sewage and the method for processing sewage. According to the invention, problems that the ratio of carbon source and nitrogen source of sewage in winner at the cold region is low, the synchronization nitrogen and phosphorus removal efficiency in the current sewage processing technology is low, the index of nitrogen and phosphor in a processed effluent can not reach the standard can be solved. The apparatus comprises a water storage tank, a pre-conditioning hypoxia pool, an anaerobic pond, an anoxic pool, an aerobic tank, a sedimentation basin, an aeration head, a filling material, a stirrer, a water inlet pump, a reflux pump, a valve, an outlet pipe, a sludge discharge pipe and a residual sludge discharge pipe; The method comprises the following steps: 1)culturing microbe on a filling material; 2)adjusting operation parameter; 3)adjusting reflux ratio parameter; 4)passing the sewage through the pre-conditioning hypoxia pool, the anaerobic pond, the anoxic pool, the aerobic tank and the sedimentation basin for processing to obtain the processed water. The apparatus and the method can be used for construction and reconstruction of the sewage processing technology at low-temperature with low carbon-nitrogen-ratio in a north region.

Owner:HARBIN INST OF TECH

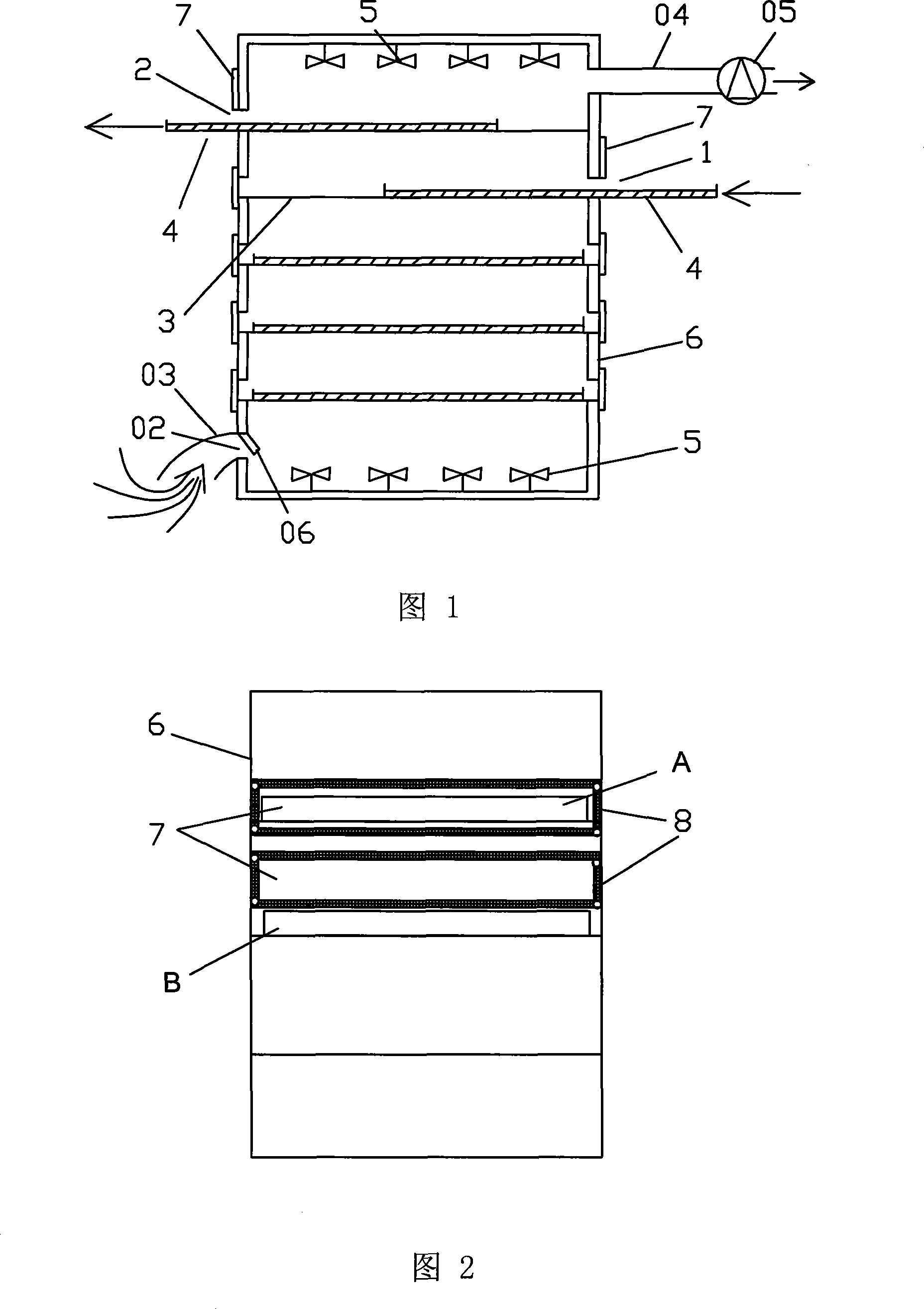

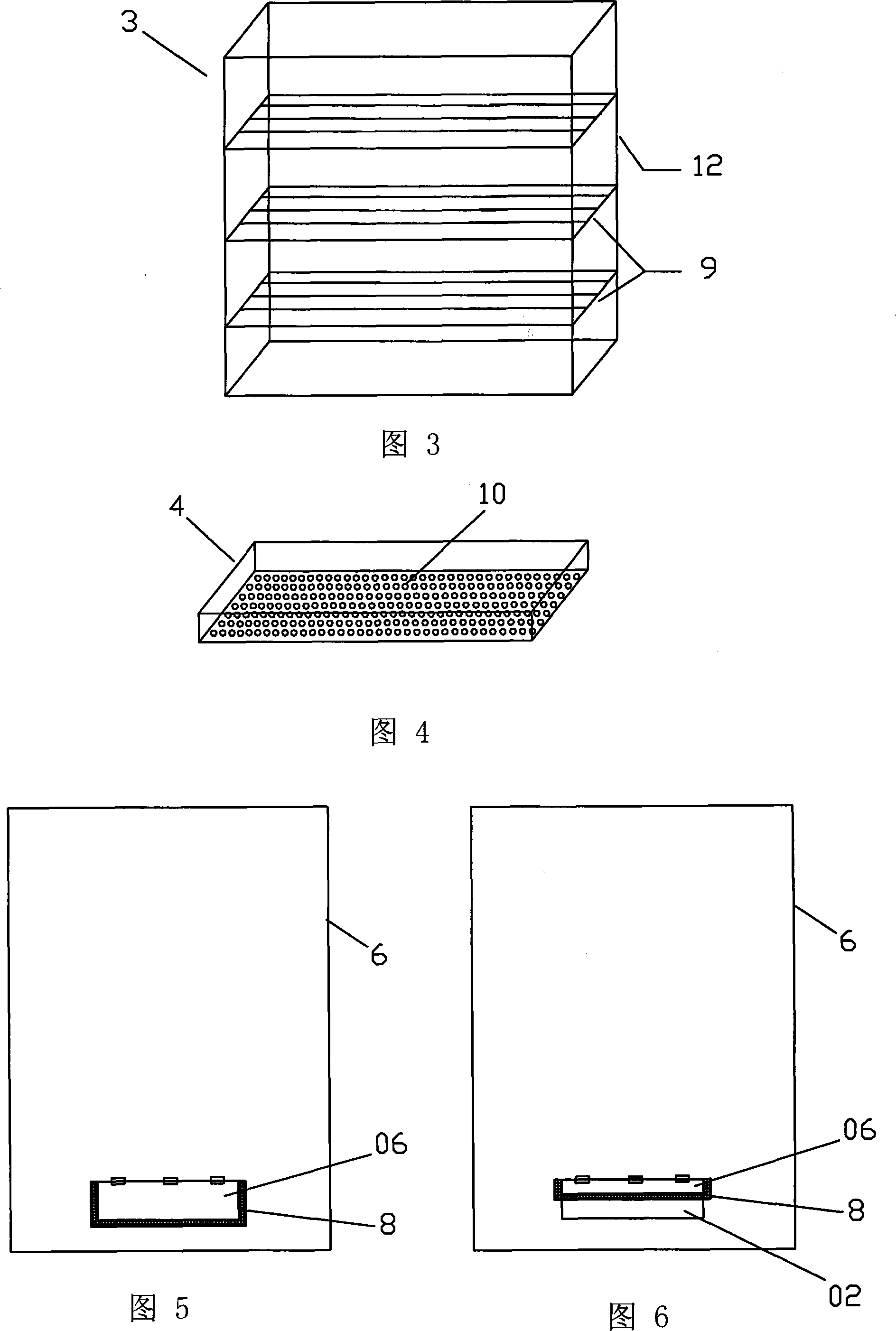

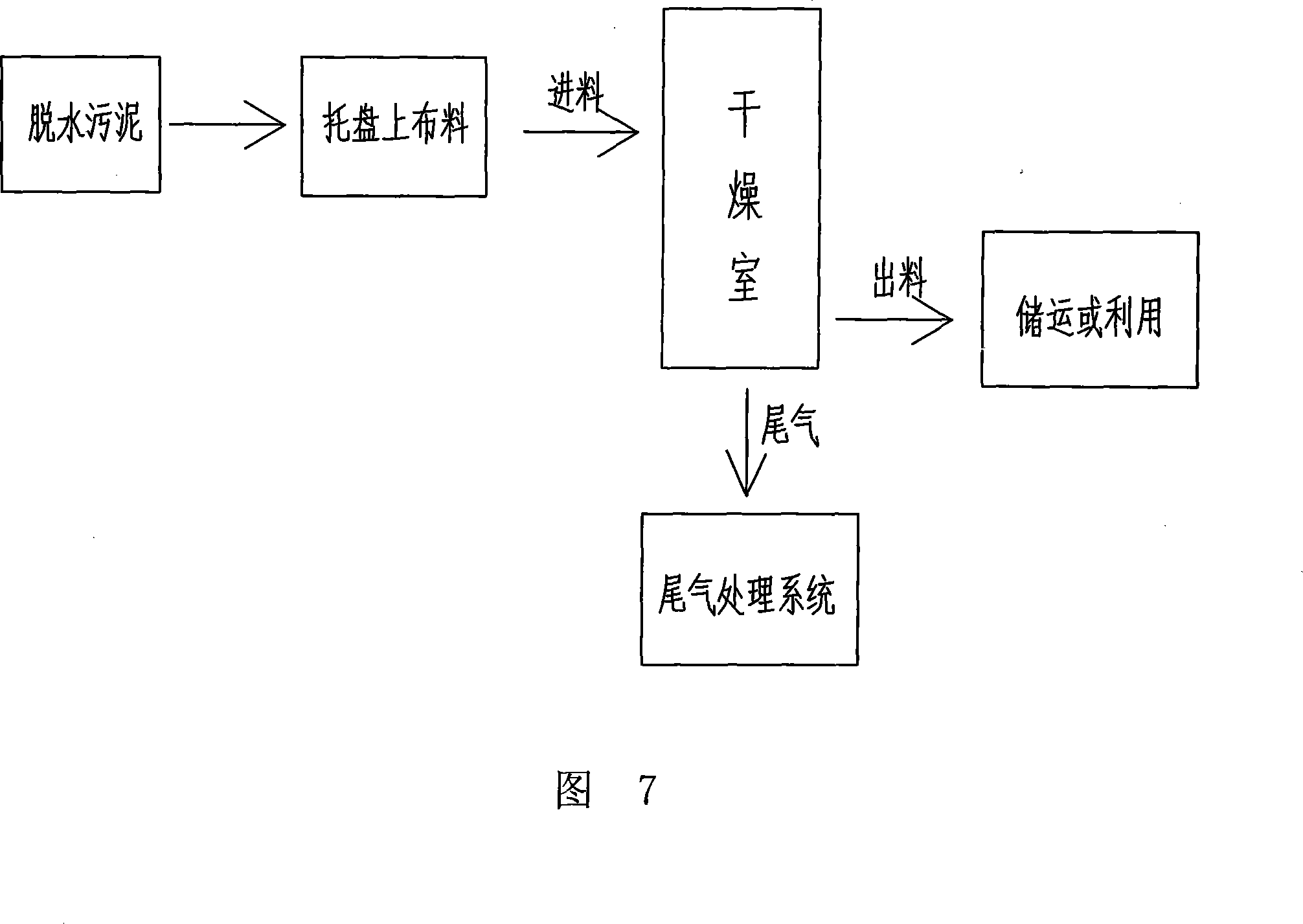

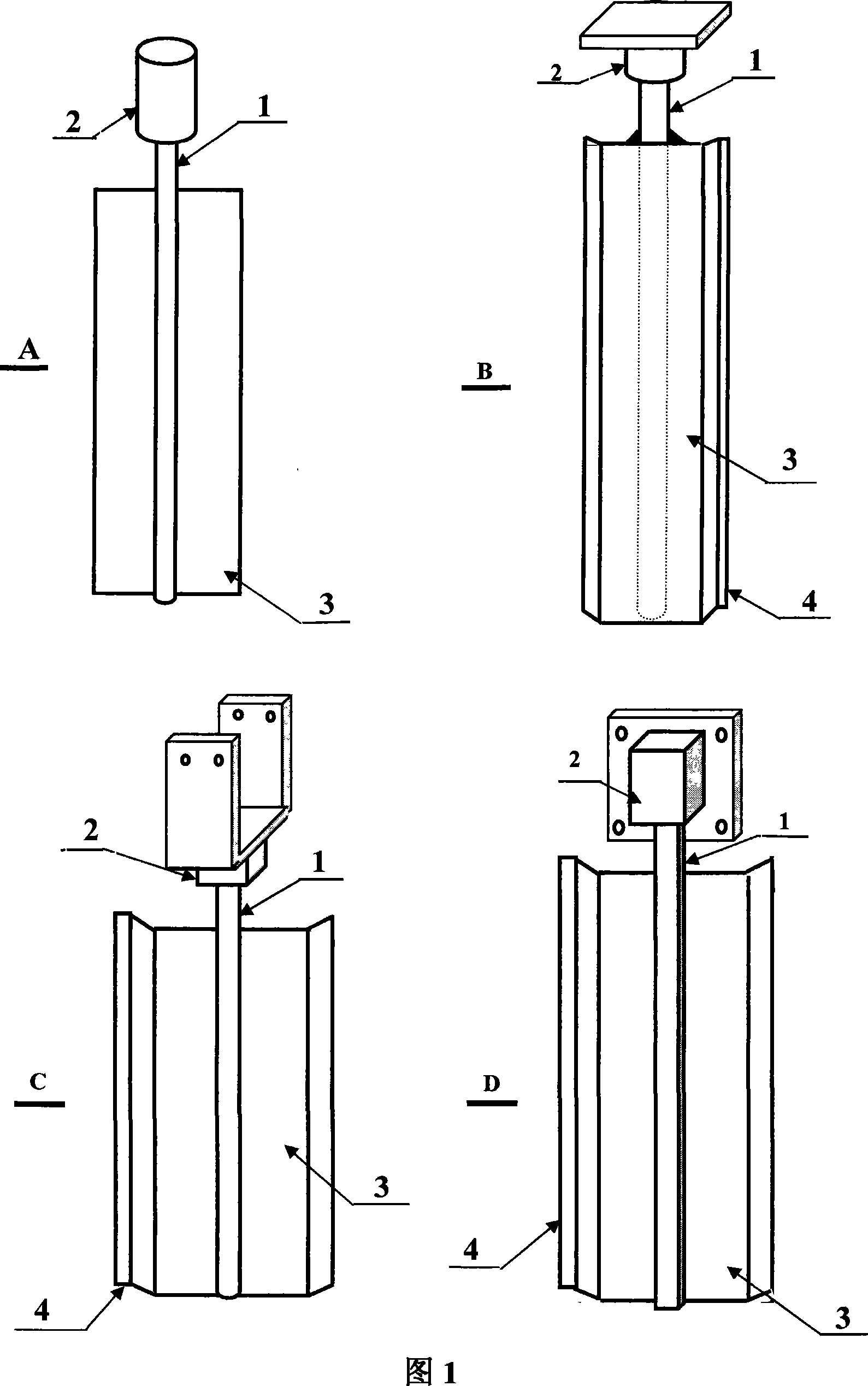

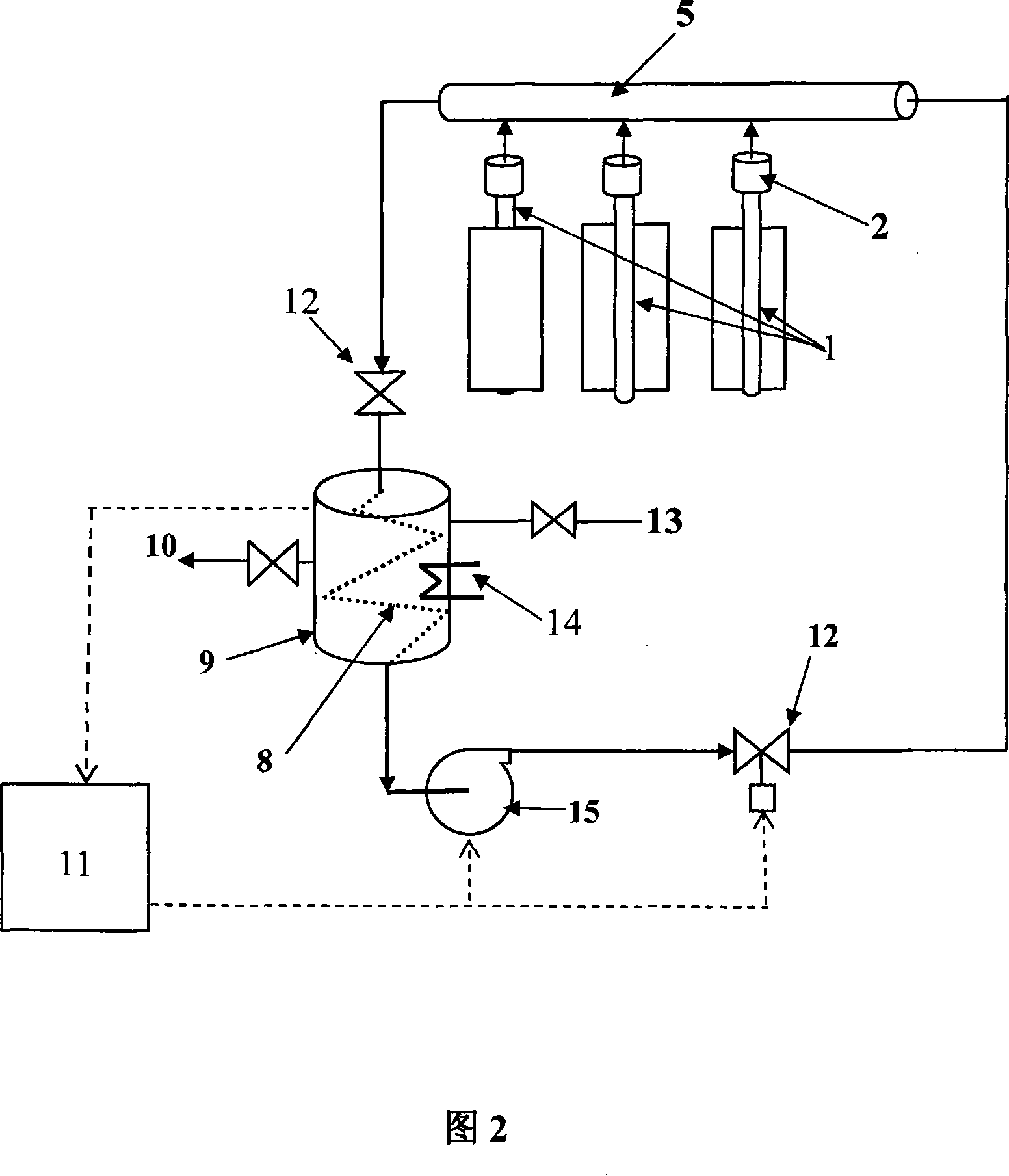

Sludge drying apparatus and sludge drying method using the same

ActiveCN101205111AIncrease temperatureAvoid distributingSludge treatment by de-watering/drying/thickeningGeneral water supply conservationInsertion stentSludge

The invention relates to a sludge drying device and a sludge drying method thereof, wherein, the device comprises a closed transparent glass shell, a plurality of layers of tray stents transversely arranged in a shell, a feed inlet arranged on the transverse side wall of the shell corresponding to each layer of tray stent, a discharge outlet on a side wall corresponding to the feed inlet, a seal plate with transparent glass which can be disassembled and connected with the outer surface of the shell and can respectively seal the feed inlet and the discharge outlet, a material tray which can freely pass through the feed inlet and discharge outlet or is arranged on the tray stent, rectifier fans respectively arranged at the bottom and top of the shell, an air inlet which is arranged at the lower part of one side of the shell, a transparent glass seal-board which is articulated with the top of the air inlet and is matched with the air inlet, a rain insensitive device arranged on the air inlet, an air outlet pipe on the side wall of the shell corresponding to the air inlet, a matched ventilation fan, and a humidity automatic monitoring device which is arranged in the shell and controls the open and close of the ventilation fan.The product discharges the vapor of the sludge to outside to achieve fast drying.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +2

Solar energy construction material and construction integrated solar energy utilization

InactiveCN101067315AIncrease disturbanceFast heat conductionSolar heating energySolar heat devicesEnvironmental resource managementBuilding integration

The integral solar energy utilizing building apparatus with solar energy utilizing building material consists of a solar heat collecting element comprising metal sheet and heat pipe or inorganic heat conducting pipe and serving also as building decorating part, pressure bearing heat energy collecting unit, composite heat insulating layer, etc. It is connected through pipeline with heat exchanger, pump, and energy storing unit or evaporator for supplying hot water, warming, conditioning air, etc. The present invention has low cost.

Owner:肖文昭 +1

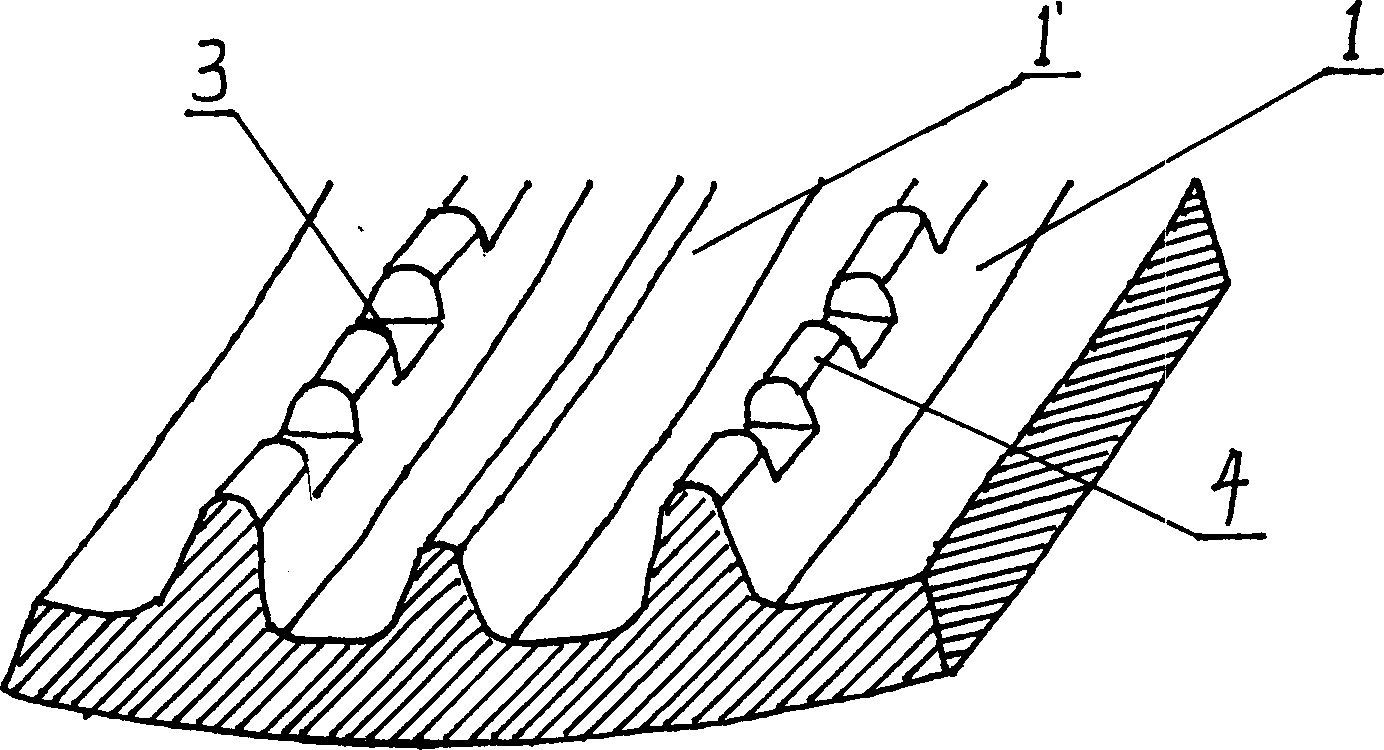

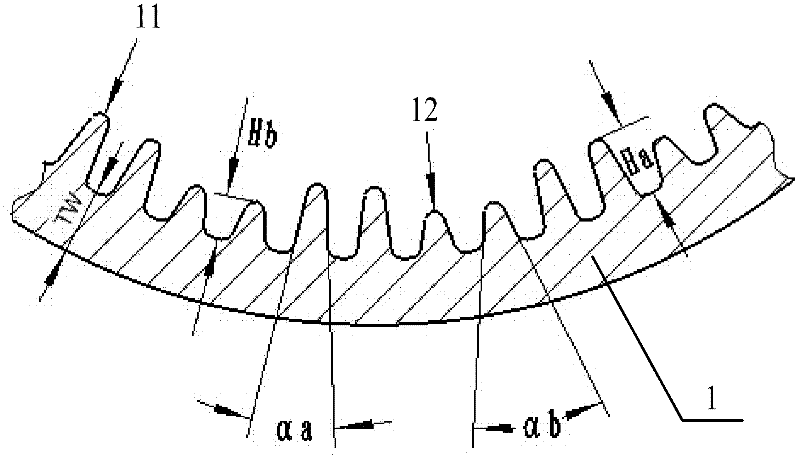

Internal thread heat-transferring pipe

The present invention provides one kind of internal thread heat-transferring pipe for use in the condenser and evaporator of refrigerating equipment and air conditioning equipment with single or mixed refrigerant. In the inner surface of the heat-transferring pipe, there are homogeneously arranged main screw teeth in different height and the relatively higher main screw teeth have miniature protuberance formed in the top. The alternate arrangement of the main screw teeth in different height can reinforce the disturbance to boiling and condensing heat exchange, reduce the heat boundary layer, reduce the angle between the speed vector and the temperature gradient vector, coordinate the speed field and temperature field, strengthen the boiling and condensing heat exchange and raise heat transferring efficiency.

Owner:XI AN JIAOTONG UNIV

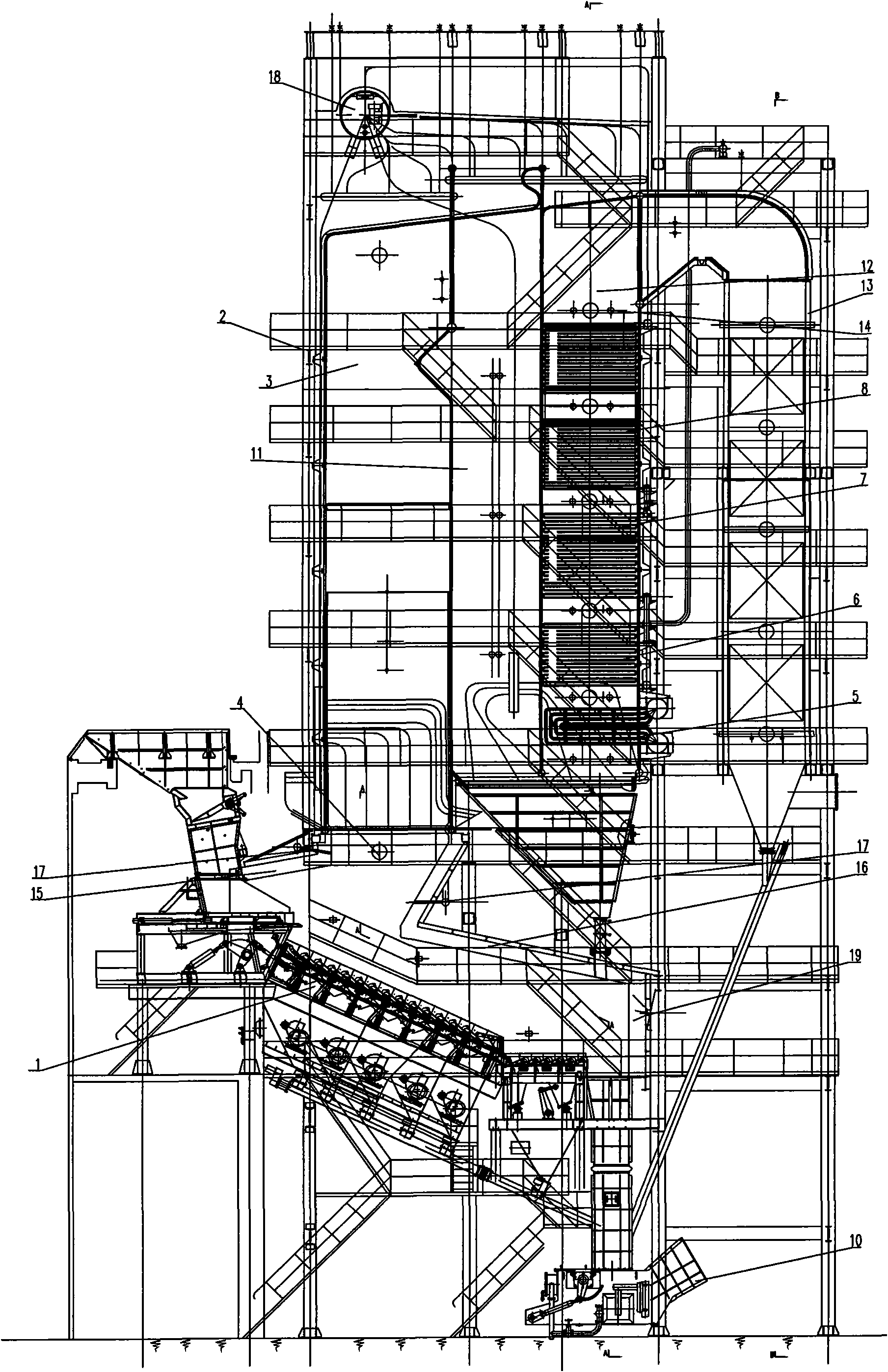

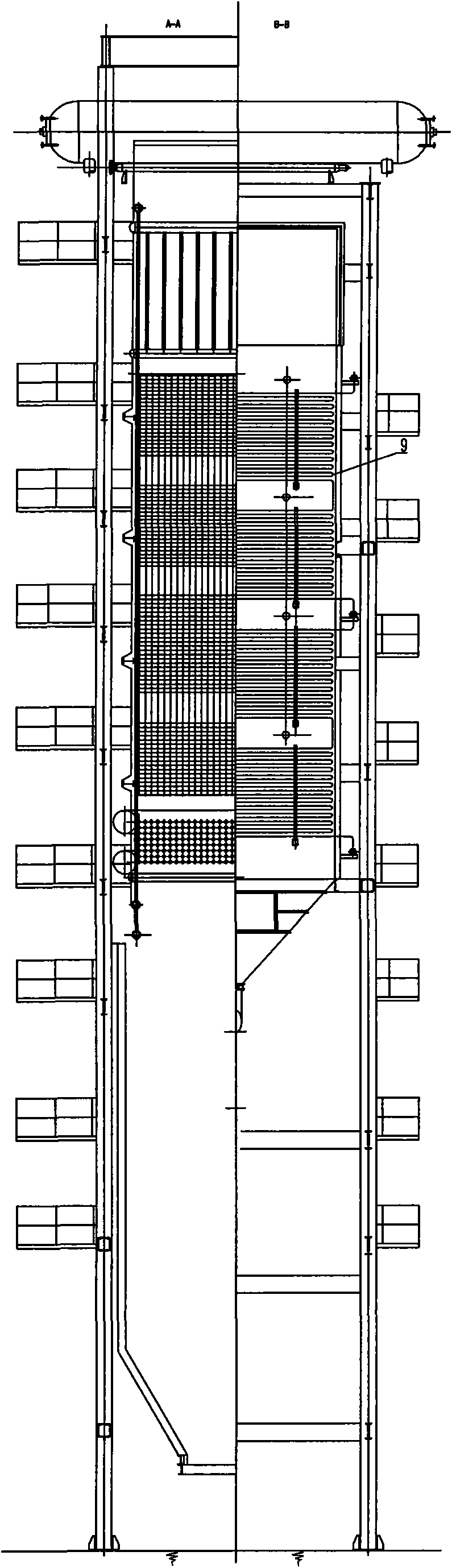

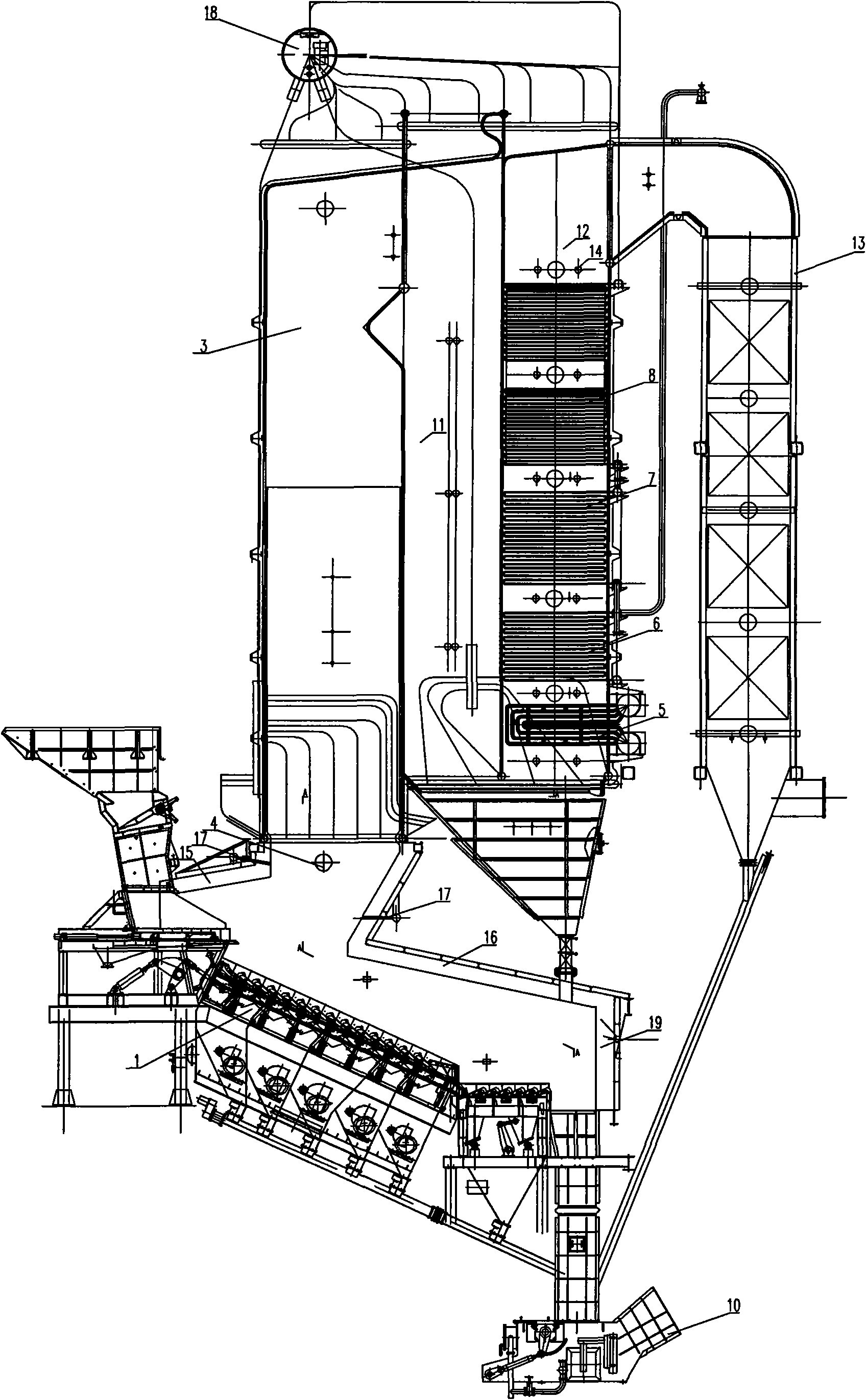

Damping steam boiler

ActiveCN107143837AReduce vibrationImprove heat transfer performanceBoiler water tubesSteam generation using pressureHeat transmissionNoise level

The invention provides a damping steam boiler. The damping steam boiler comprises an upper boiler barrel, a lower boiler barrel, rising pipes and falling pipes, wherein the rising pipes and the falling pipes are connected between the upper boiler barrel and the lower boiler barrel. The rising pipes are internally provided with flow stabilizers, and the multiple flow stabilizers are arranged in the same rising pipe; and the space between every two adjacent flow stabilizers is constantly reduced in the fluid flowing direction of the rising pipes. According to the damping steam boiler, through gap changing of the flow stabilizers, when steam-liquid two phase flowing exists in the rising pipes, heat transmission is reinforced; and meanwhile, vibration of the rising pipes is weakened, and the noise level is reduced.

Owner:连云港虹洋热电有限公司

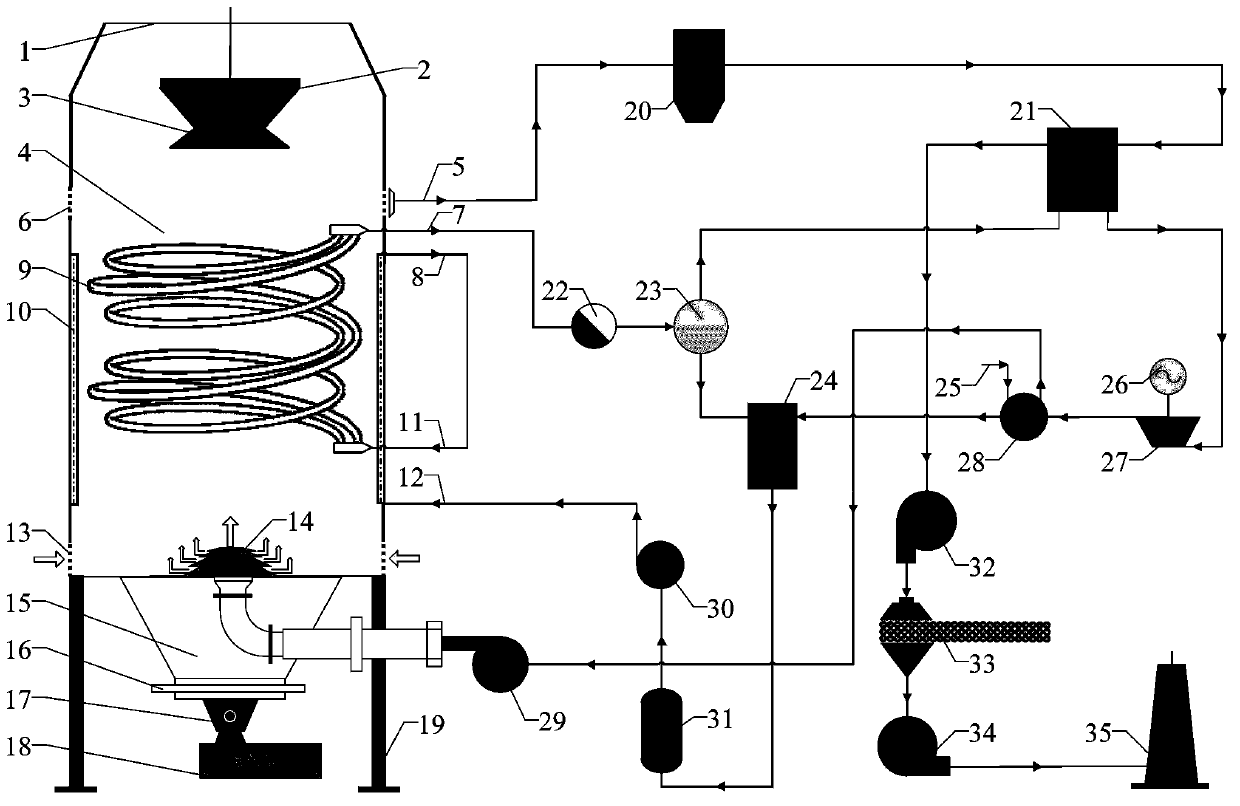

High-temperature material vertical cooler and waste heat using system

ActiveCN103424001AReduce breakageImprove yieldIncreasing energy efficiencyHandling discharged materialSuperheaterEngineering

The invention relates to a high-temperature material vertical cooler and a waste heat using system. The high-temperature material vertical cooler comprises a cylindrical machine body supported by a support, the lower portion of the machine body is a cold air input section, the middle portion of the machine body is a cooling section, and the upper portion of the machine body is a material input section. In the cooling section, materials are cooled by means of combination of air draft and air blowing, heat of the high-temperature materials is obtained by cooling air and a cooling pipe by means of heat conduction and conversion, and preheating is conducted on circulating water through a water cooling wall; the high-temperature cooling air is used for overheating steam generated by the vertical cooler and after the temperature of the cooling air is decreased, the cooling air is led to preheat sintering raw materials in a sintering machine; after air heated by a condenser is mixed with the cold air and the air is led to a central funnel cap; steam generated by the vertical cooler is led to a turbine to drive an electric generator to generate power after passing through a steam super-heater; water output by the condenser and a steam pocket is led to a deoxidizing machine for deoxidization and then is led to a water cooling wall so that circulation can be achieved. The high-temperature material vertical cooler is compact in structure, capable of greatly reducing air leakage of a system, guaranteeing the quality of the materials and effectively recycling the waste heat of the high-temperature materials in a stepped mode.

Owner:XI AN JIAOTONG UNIV

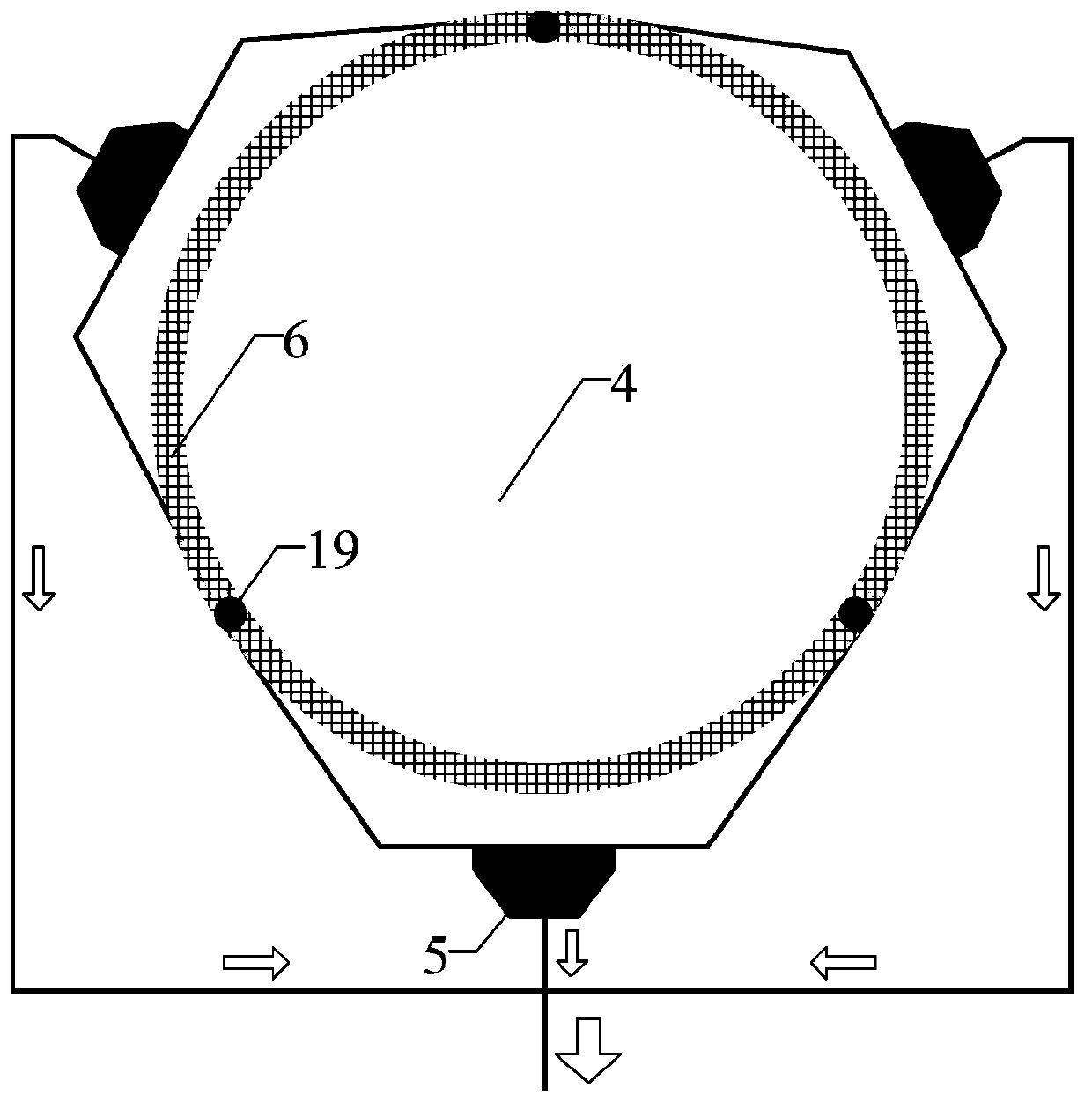

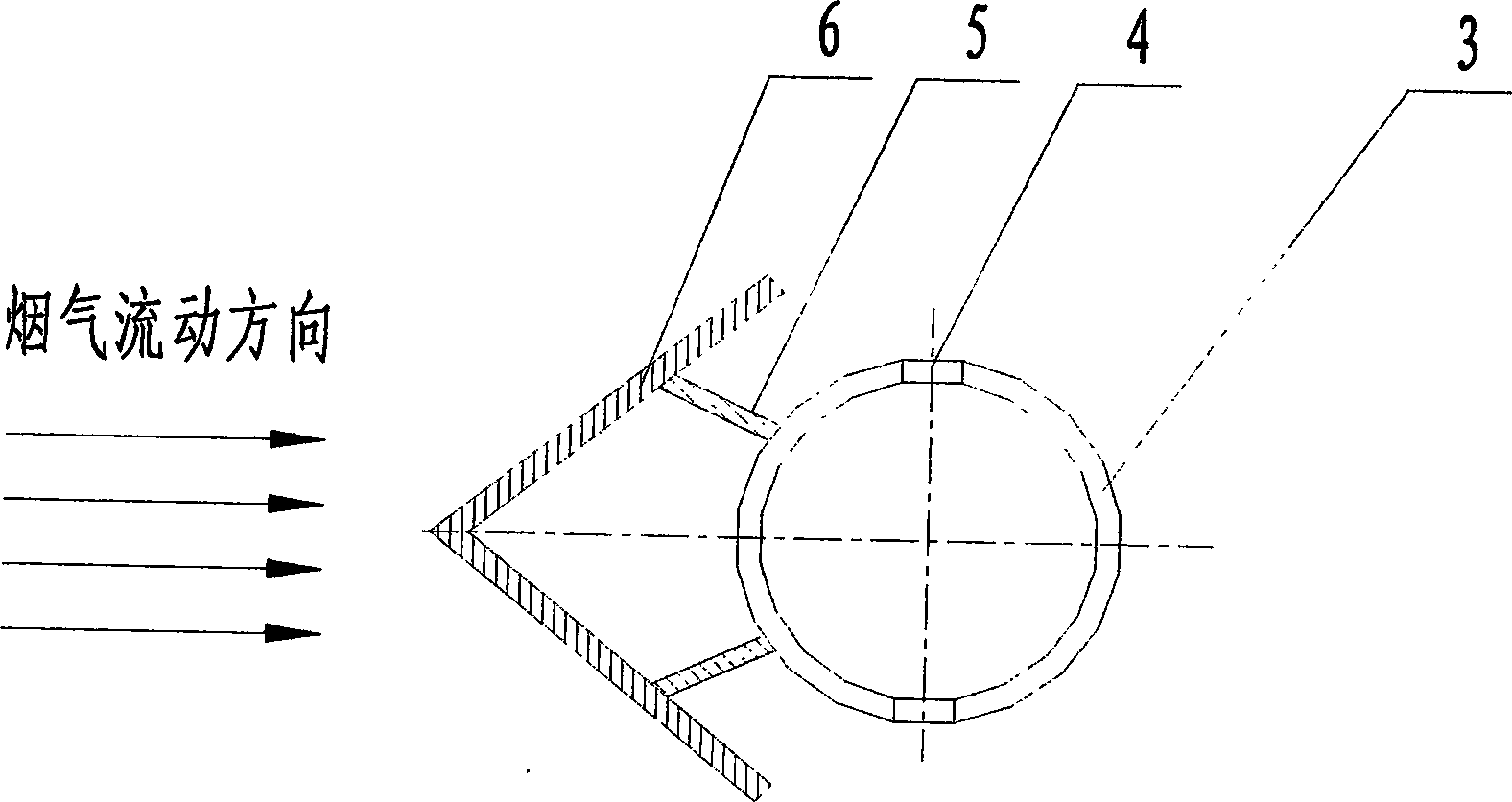

Abrasion proof, vortex street strong mixing equipment in grille of spraying ammonia

InactiveCN1872398AReduce wear rateWell mixedInternal combustion piston enginesDispersed particle separationEngineeringAmmonia

An antiwear eddy mixer for the ammonia spraying grate used for denitrating the fume of boiler (or incinerator or diesel engine) by selective catalytic reduction (SCR) method has several ammonia spraying tubes, which is arranged in flue and has a top end connected to the trunk of ammonia-air mixture, a lower blind end, several ammonia spraying holes, and an antiwear vortex element.

Owner:孙克勤 +3

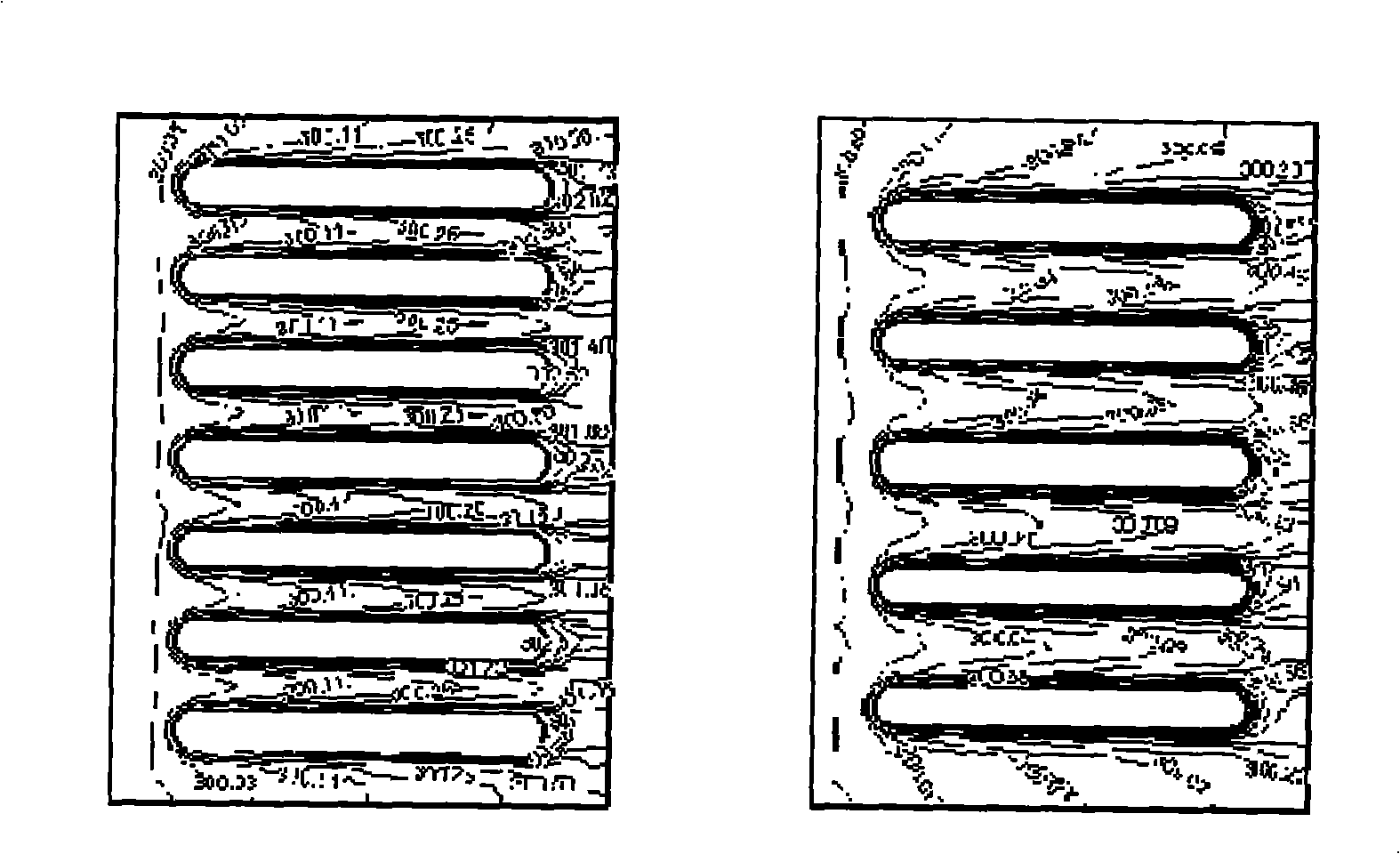

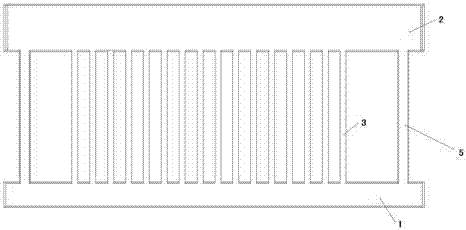

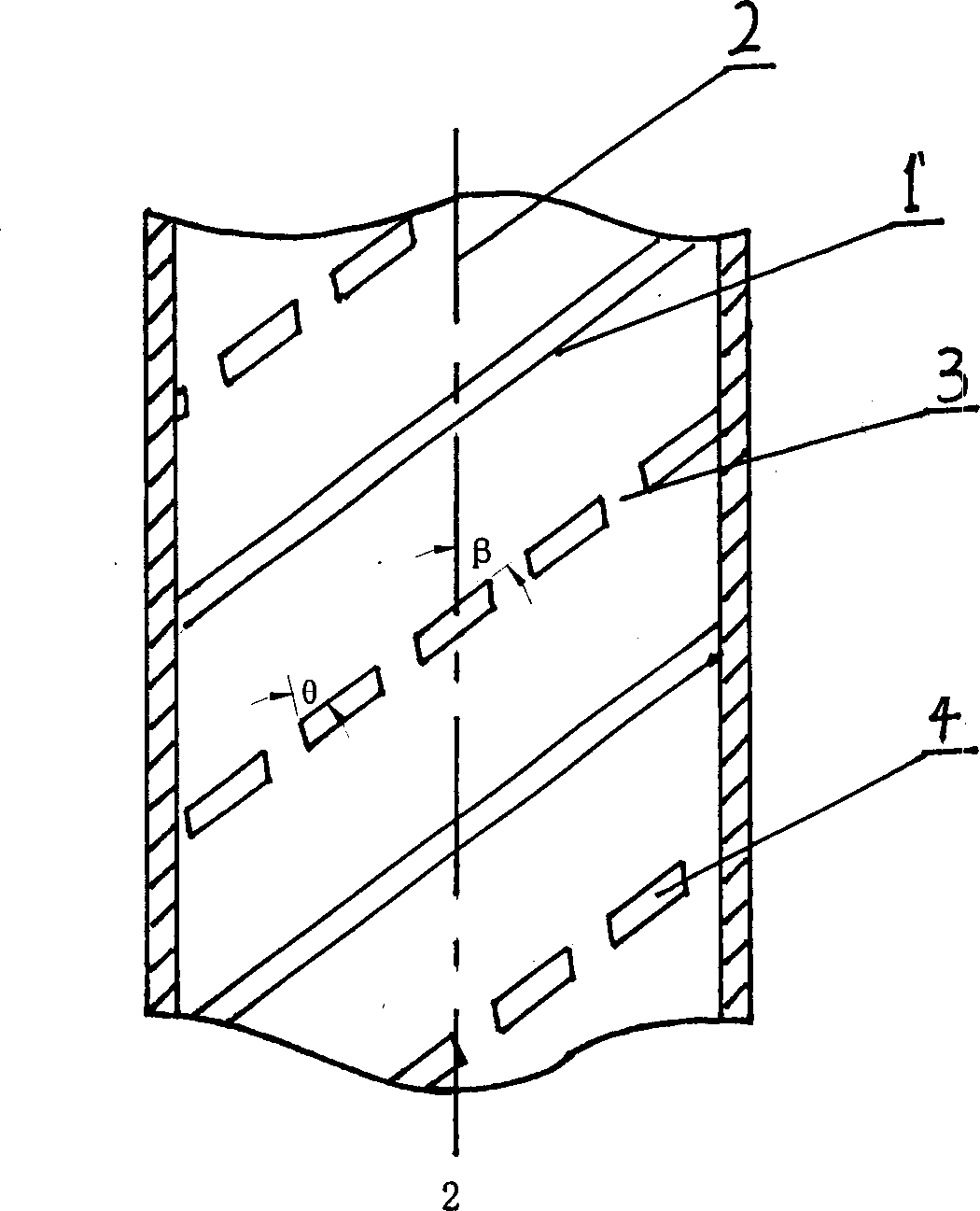

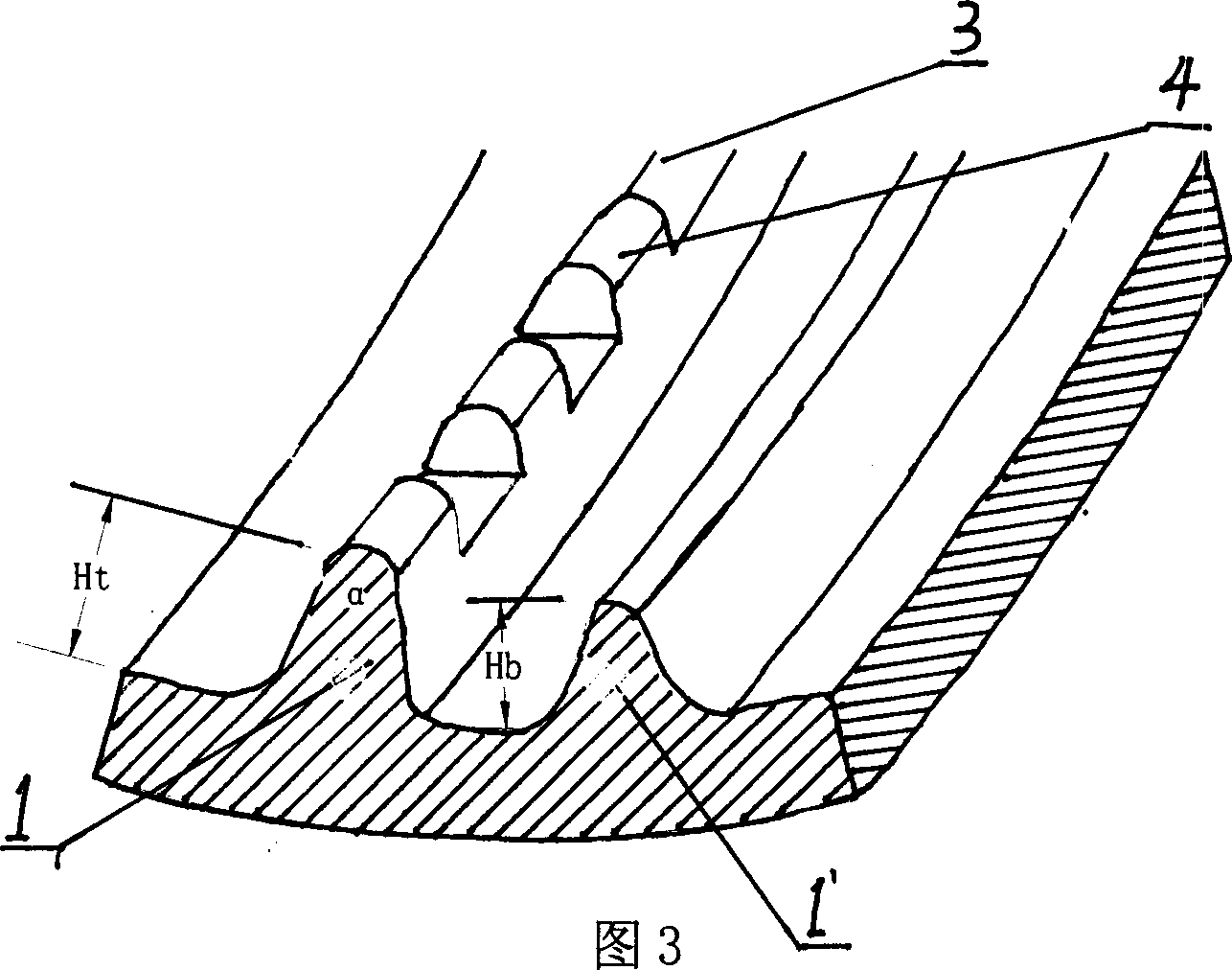

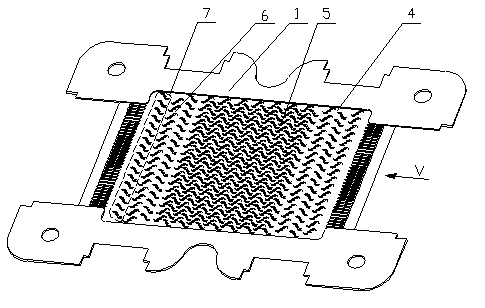

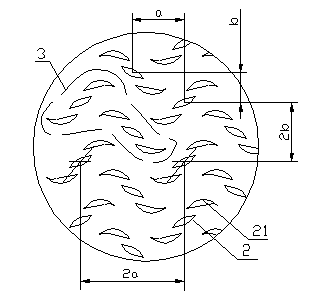

Micro-channel structure of heat exchanger

InactiveCN102706201AReduce resistanceIncrease the heat exchange areaLaminated elementsStationary plate conduit assembliesEngineeringForced convection

The invention discloses a micro-channel structure of a heat exchanger, and a micro-channel is respectively formed among multiple layers of laminated heat exchanging plates (1), each heat exchanging plate (1) is provided with a plurality of fin units (2), the fin units (2) are uniformly distributed along the direction which is vertical to the flowing direction of fluid to form a fin unit group (7), and a plurality of fin unit groups (7) are alternately arranged at intervals along the flowing direction of the fluid; the rear ends of the fin units (2) at the upstream side are arranged in the middle position of every two adjacent fin units (2) at the downstream side; each fin unit (2) consists of at least two sections of fins (21), and the two adjacent fins (21) are separated from each other for a given distance; and the micro-channel is formed by fluid channels respectively between two adjacent fin units (2) and between two adjacent fins (21). Due to the adoption of the micro-channel structure of the heat exchanger, under the situation that the small flowing resistance force is kept, the forced convection heat conduction coefficient is increased, and the heat exchanging capacity of the heat exchanger is enhanced.

Owner:浙江微智源能源技术有限公司 +1

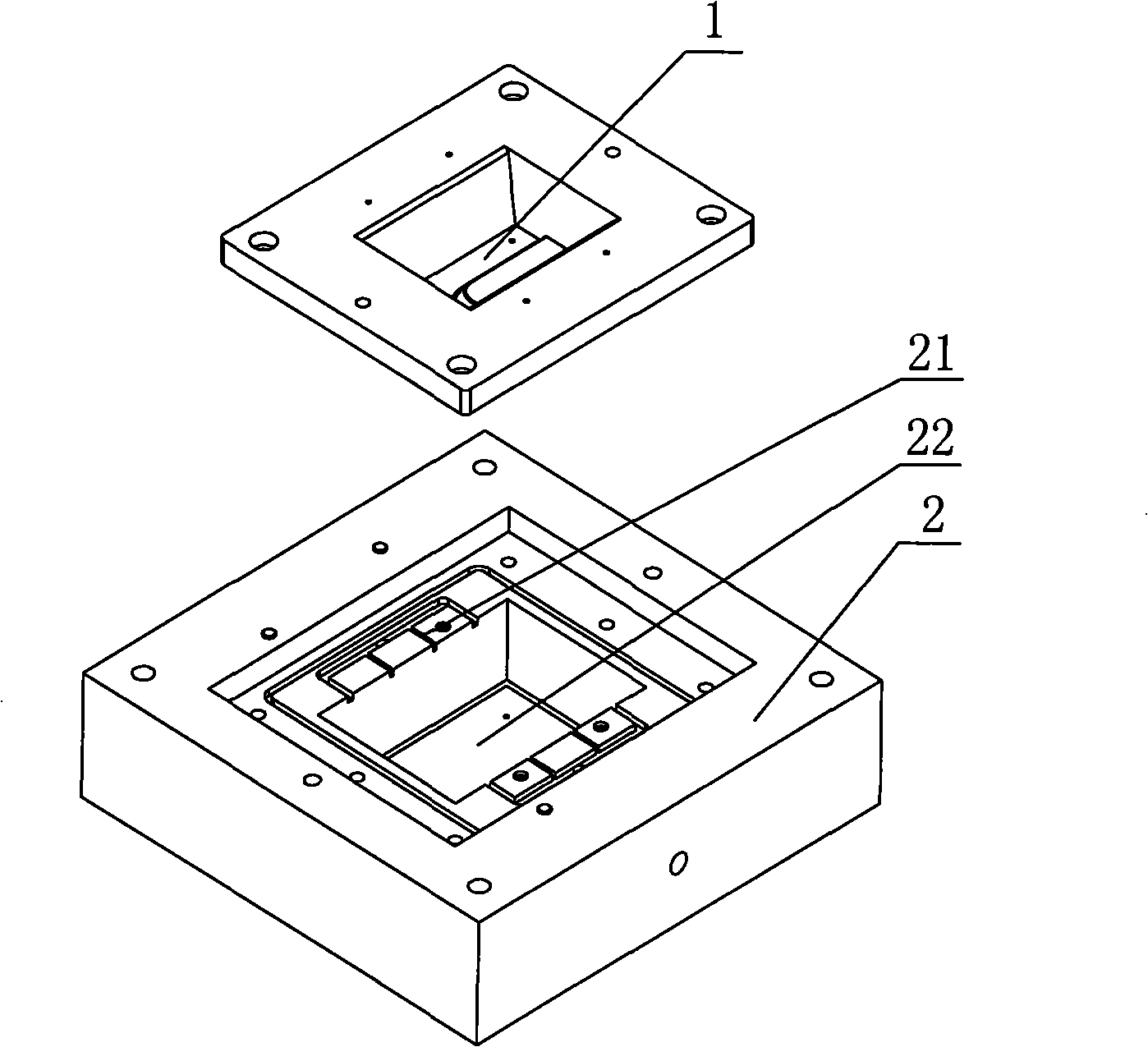

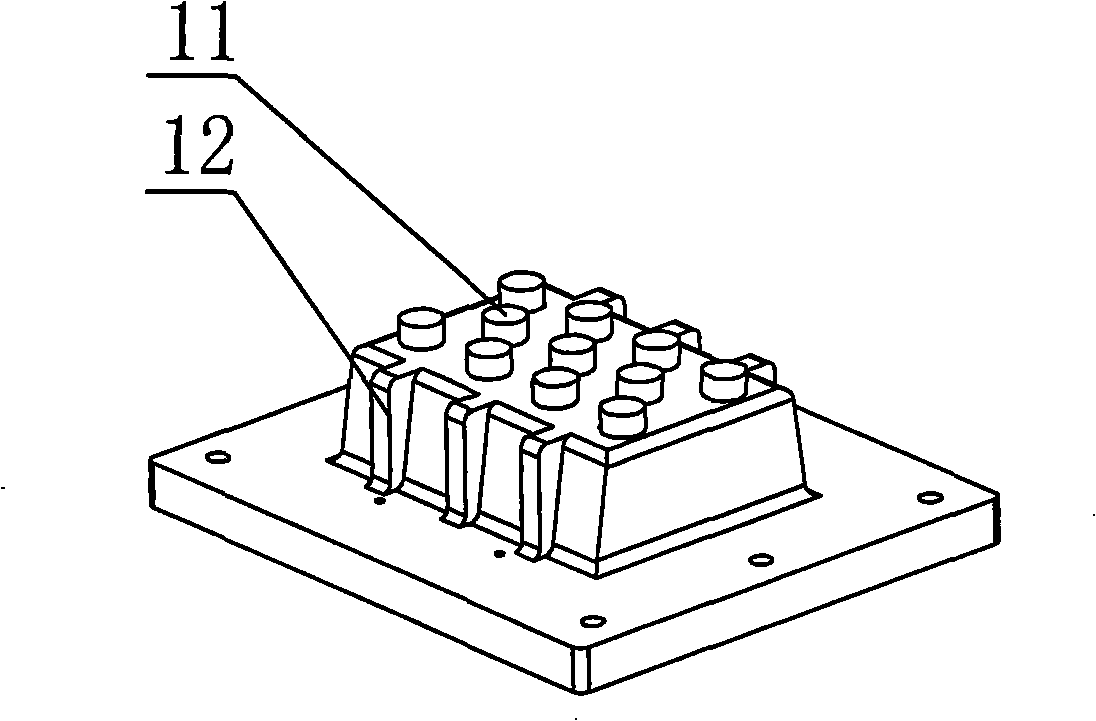

Injection mould with specially-shaped conformal cooling water channel and manufacturing method thereof

InactiveCN104129050AUnaffected by complexityIncrease disturbanceAdditive manufacturingIncreasing energy efficiencyMetal alloyWater channel

A disclosed injection mould with a specially-shaped conformal cooling water channel comprises a mould body provided with a cavity, and the mould body is inside provided with the inbuilt conformal cooling water channel with the profile phase consistent with that of the cavity. The invention also provides a manufacturing method for the injection mould with the specially-shaped conformal cooling water channel. The method comprises the steps: employing a selective laser melting molding technology to manufacture the conformal cooling water channel from a metal powder material; fixedly arranging the conformal cooling water channel in a casting chamber for casting the mould body; employing a casting molding technology to cast the molded mould body from melt single metal or metal alloy; and processing the cavity in the mould body. The conformal cooling water channel is manufactured by directly employing the selective laser melting molding technology, and the manufacturing process is not influenced by the complexity of the conformal cooling water channel. The cooling water channel employs a specially-shaped water channel, so that a turbulent flow is easily formed, the heat conduction effect is enhanced, and processing is convenient.

Owner:SOUTH CHINA UNIV OF TECH

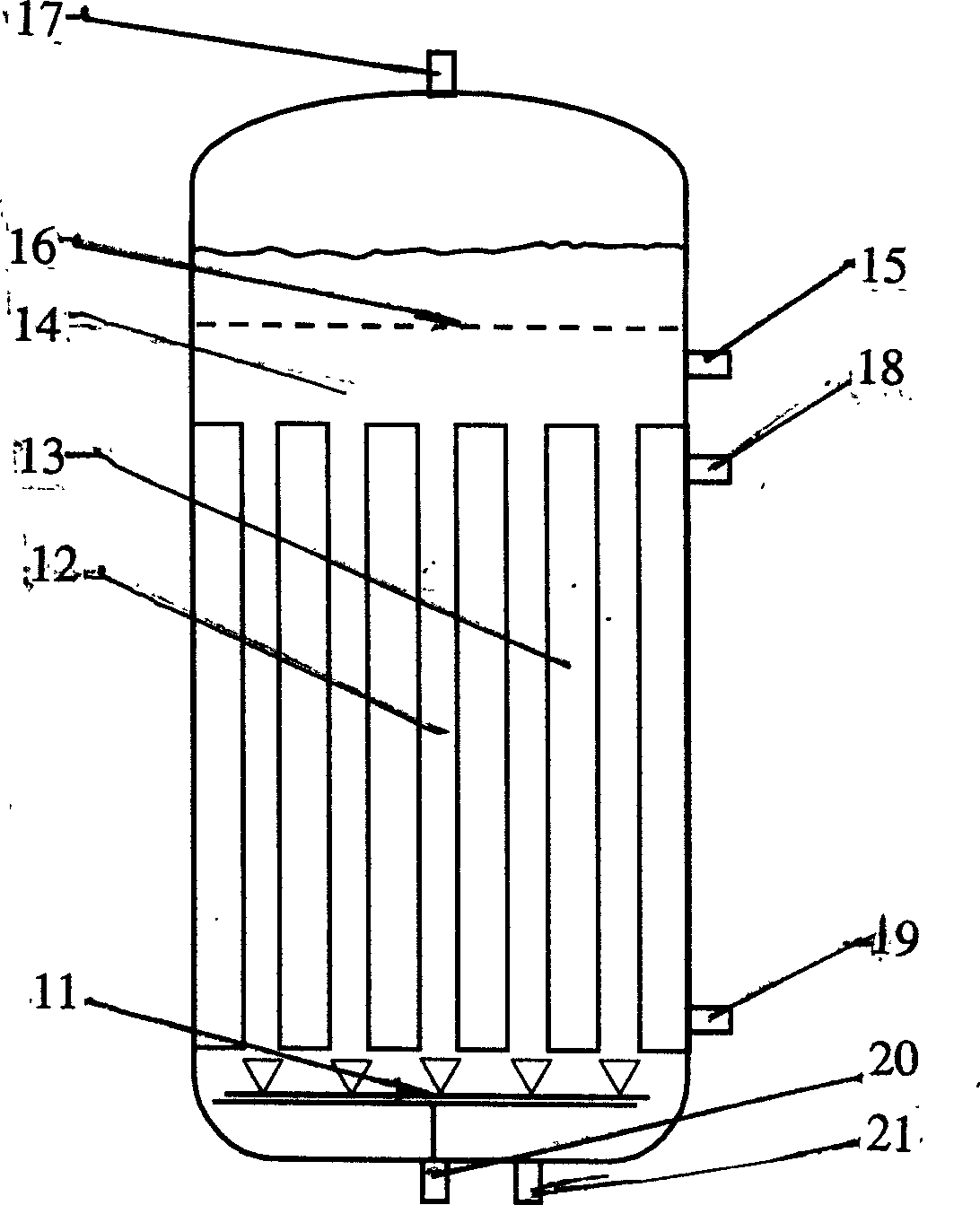

Vertical tube type falling-film evaporator

ActiveCN106178557AGuaranteed centralityHigh recovery rateGeneral water supply conservationEvaporators with vertical tubesVertical tubeEngineering

The invention relates to a vertical tube type falling-film evaporator. The vertical tube type falling-film evaporator comprises an upper tube box, a lower tube box, a casing, multiple heat exchange tubes, an upper tube plate and a lower tube plate, wherein a solution inlet and a secondary steam outlet I are arranged at the upper tube box, a concentrated liquid outlet and a secondary steam outlet II are arranged at the lower tube box, a steam inlet is arranged at the upper part of the casing, and a condensed water outlet is arranged at the lower part of the casing; a film distributing device used for distributing a solution on the inner walls of the heat exchange tubes is arranged in the upper tube box; the film distributing device comprises a liquid bearing plate, a liquid feeding plate, a liquid distributing plate and liquid guiding tubes. By means of a steam stripping effect generated by secondary steam and liquid films, the heat transferring push force and the evaporation efficiency are increased. The liquid films can be uniformly distributed by the film distributing device, the film forming is stable, the wall drying phenomenon is avoided, the recovery rate of secondary steam produced in an evaporator is high, the recovery is convenient, and the heat transferring efficiency is improved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

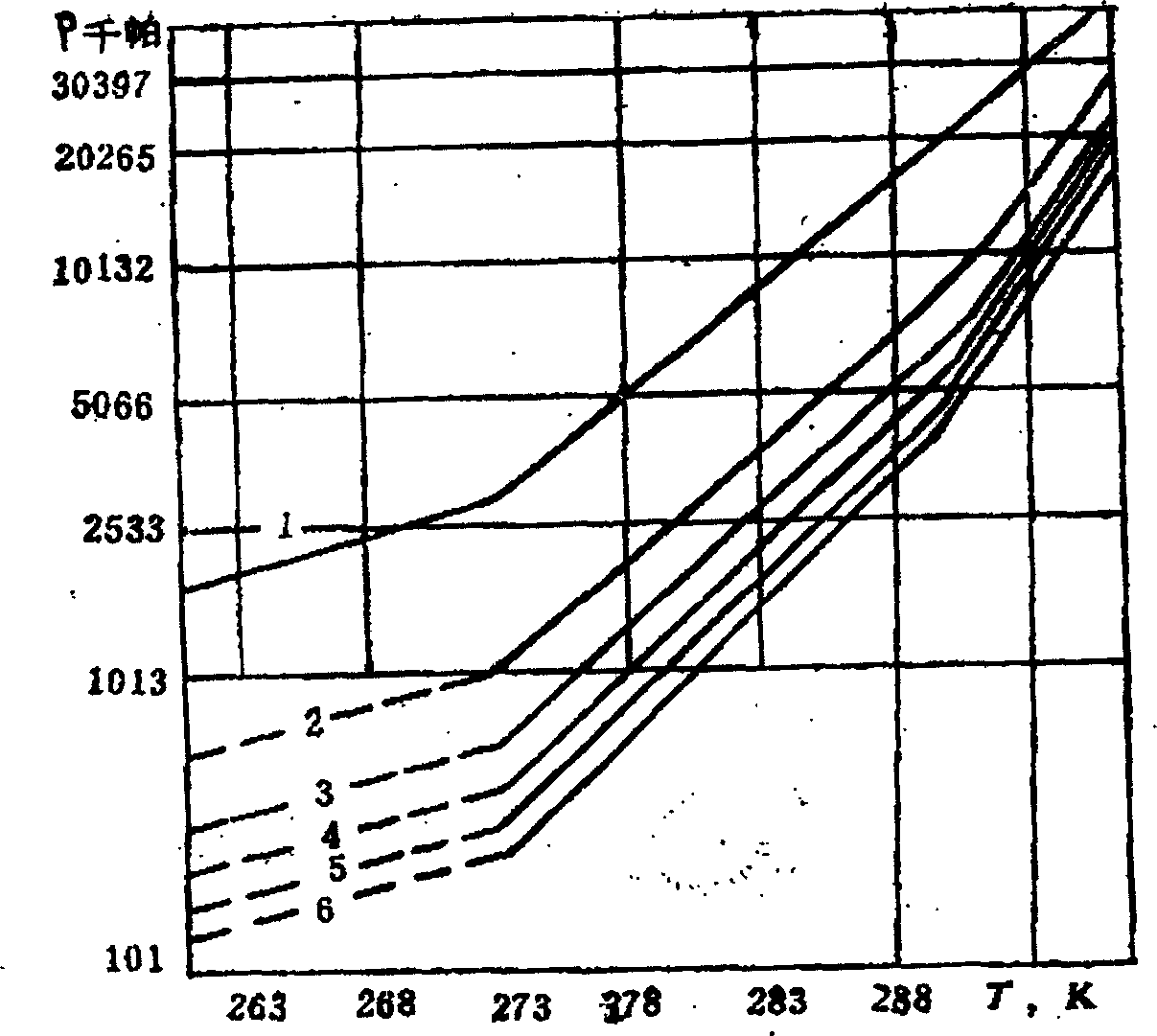

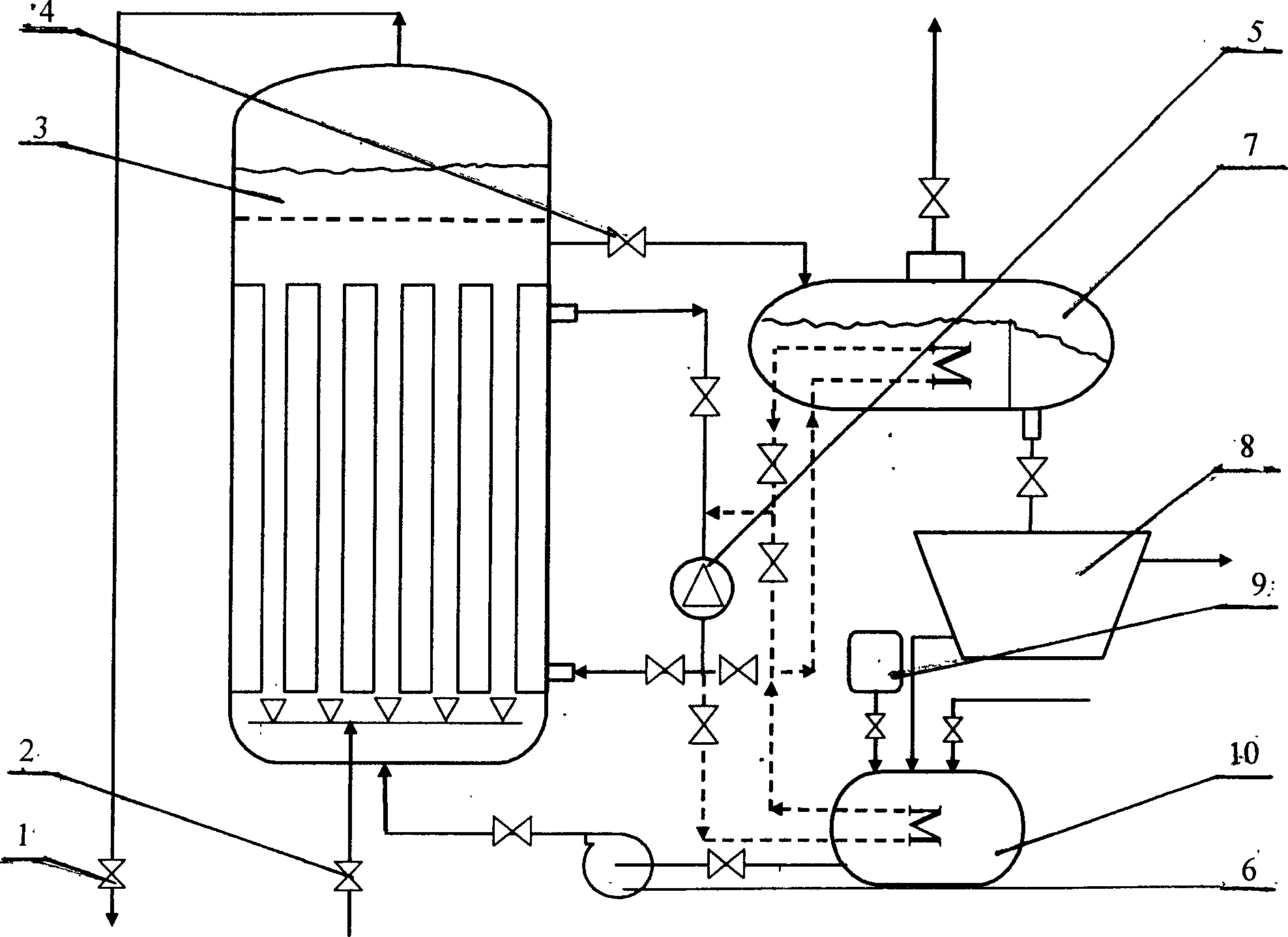

Method and apparatus for preparing solid natural gas

InactiveCN1621502AReduce energy consumptionLow equipment investmentGaseous fuelsSolid fuelsForming gasHigh pressure water

The present invention is solid natural gas preparing process and apparatus with easy implementation, low cost and high efficiency. The technological scheme includes spraying high pressure natural gas via nozzles into low temperature and high pressure water flow in the bottom of the reactor to form fine bubbles and react with water; setting cold trap pipe inside the reactor to remove the creating heat of hydrate and create pressure, temperature and heat transferring conditions for creating hydrate inside the cold trap pipe; forming gas cap in the top of the tower with the un-reacted gas to maintain sufficient pressure; forming flowing slurry with the hydrate and excessive water and making the slurry enter the flash evaporator for gas-liquid separation; filtering the automatically concentrated slurry in a filtering machine to obtain 'dry' hydrate product; and circulating with low temperature water for continuous and efficient reaction.

Owner:SOUTHWEST PETROLEUM UNIV

Novel high-efficiency vaporizing combustion compound furnace grate device with slag disintegrating function

ActiveCN102588950APromote precipitationAchieve emissionsChemical industryRevolving grateSlagEngineering

The invention discloses a novel high-efficiency vaporizing combustion compound furnace grate device with a slag disintegrating function. The traditional incinerator has the disadvantages of lower heat efficiency and high repairing and maintenance cost of a furnace grate due to poor fuel mixture and insufficient combustion. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function adopts a two-section compound structure, wherein on the front section of a reciprocating type furnace grate, wastes are dried, vaporized and partially burned; and the unburned parts fall on a back-end rotary furnace grate device to be extruded, crushed and fully mixed to be burned completely. The reciprocating type furnace grate adopts a multi-air-port segmental air distribution way for reasonable air distribution; the heat radiation on the furnace grate is increased due to a long back arch, thereby facilitating the firing of wastes with low heat values. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function is adopted to effectively improve the disadvantages of poor mixing effect and low burn-off rate of the traditional furnace grate incineration device, and meanwhile, the area of a furnace grate bar with high temperature resistance can be reduced, and the investment is reduced.

Owner:ZHEJIANG UNIV

Steam generator with changeable hole areas in height direction

InactiveCN107314357AReduce dry upImprove heating efficiencySteam generation heating methodsEnergy industryElectric heatingElectricity

The invention provides a steam generator with the changeable hole areas in the height direction. The steam generator comprises a box, an electric heating pipe and a steam outlet. The electric heating pipe is arranged in the box. The electric heating pipe comprises an outer pipe body and an electric heater arranged in the outer pipe body. The electric heating pipe is arranged in the vertical direction. Holes are formed in the lower portion of the outer pipe body. The upper portion of the electric heating pipe is connected with the steam outlet. The multiple rows of holes are formed in the height direction, multiple holes are formed in each row, and the sums of the areas of the holes in each row are gradually reduced in the height direction. The steam generator of a novel structure is designed, through the hole area changes in the height direction, dryness of the electric heating pipe is reduced, and meanwhile the heating efficiency is improved.

Owner:SHANDONG JIAOTONG UNIV

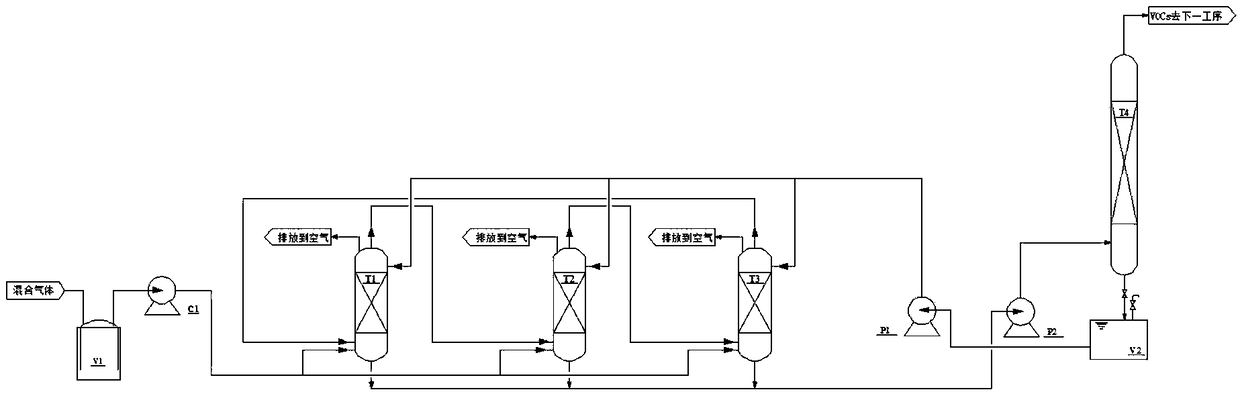

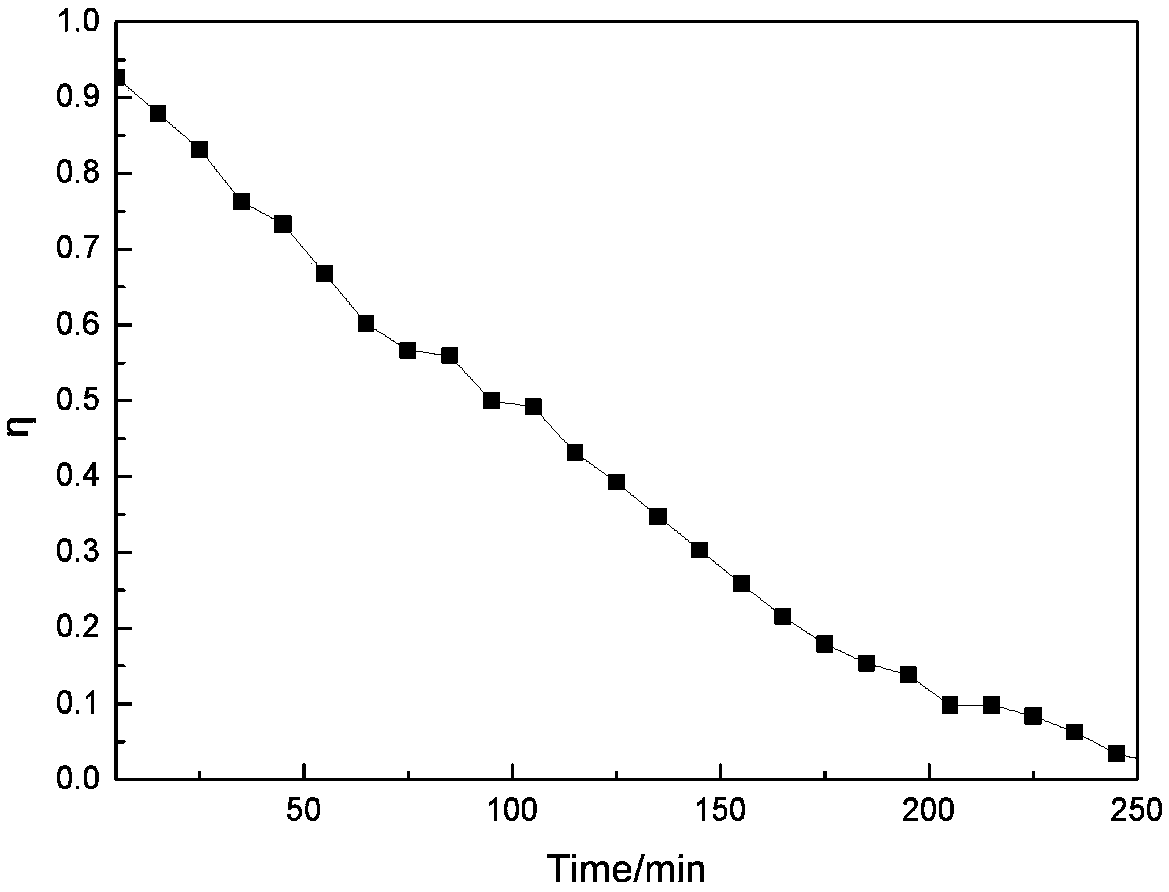

VOCs absorbent and application thereof

ActiveCN108786383AOptimal Intake ConcentrationLow mass transfer efficiencyGas treatmentDispersed particle separationSolubilityBiodiesel

The invention provides a VOCs absorbent and application thereof. The absorbent uses ionic liquid as a polarity phase, a small amount of ion liquid is evenly dispersed in a large amount of water or biodiesel to obtain a microemulsion under the effects of a non-ionic surface active agent and a cosurfactant. The microemulsion has very high VOCs solubleness, and the problems of inorganized VOCs discharge treatment and VOCs recycle of sewage treatment plants are solved.

Owner:HEBEI UNIV OF TECH

Waste incineration boiler

InactiveCN101852438ASuitable for a wide range of calorific valueGreat load adjustment capabilityIncinerator apparatusAir preheaterCombustion chamber

The invention discloses a waste incineration boiler. The waster incineration boiler mainly comprises a hearth and a combustion chamber, three flues and a tail flue which are connected to the hearth sequentially, wherein the upper part of the hearth is provided with a boiler barrel, and the lower part of the hearth is provided with a grate; and a slag and ash discharging device is arranged on the lower part of the grate. The waste incineration boiler is characterized in that the grate is a reciprocating multi-row grate; an auxiliary burner is arranged on the side wall on the lower part of the hearth; a start-up burner is arranged on the rear wall on the lower part of the hearth; and a high-temperature gas-air preheater and a superheater are respectively arranged in the three flues from bottom to top sequentially. The invention makes household waste with low heating value, high moisture content and high ash content sufficiently combusted and burnt out in the waste incineration boiler. The waste incineration boiler can effectively inhibit generation of harmful gas. Steam generated by the boiler is used for generating electricity and supplying steam. The waste incineration boiler realizes reduction, hazard-freetreatment and recycling of waste treatment furthest.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

Cleaning, disinfecting and drying device of B-scan ultrasonography probe

InactiveCN106670163AIncrease disturbanceImprove cleanlinessDrying gas arrangementsCleaning using liquidsUv disinfectionEngineering

The invention provides a cleaning, disinfecting and drying device of a B-scan ultrasonography probe. The cleaning, disinfecting and drying device comprises a case body and a case door. A drying device, a sliding rail, two carrying plates, an aeration device, an ultrasonic wave generator, a water outlet pipe and two supporting plates are arranged on the case body. The drying device comprises a blower, a blowing channel and an electric heater case. A heating wire bearing plate and an air outlet pipe are arranged in the electric heater case. A water tank is placed on each carrying plate. The supporting plates are fixedly welded at the top end of the case body. A manual rotating shaft is arranged on the supporting plates. A limiting hole is formed between the two supporting plates. A winding shaft is arranged on the manual rotating shaft. A pulling rope is wound around the winding shaft. The pulling rope penetrates through the limiting hole. A lifting rod is arranged at the lower end of the pulling rope. Sliding blocks, connecting rods and ultraviolet disinfection lamps are arranged on the lifting rod. An observation window and a handle are arranged on the case door. Cleaning is thorough, manual control can be achieved, cleaning, drying and disinfecting are integrated, and efficiency is high.

Owner:河南常青藤信息科技有限公司

Heat exchanger and internal threaded copper tube thereof

InactiveCN102353296AEnhanced turbulence intensityIncrease disturbanceChemical industryTubular elementsChemical industryHeat transfer efficiency

The invention discloses an internal threaded copper tube. The internal threaded copper tube comprises a tube body (1), wherein internal threaded teeth with different height and various tooth shapes are formed on the inner wall of the tube body (1) and are alternately distributed. Due to the difference of the tooth shapes and the height, the turbulent flow intensity of a coolant is increased, and disturbance on the coolant and heat conduction energy efficiency are improved. In the using process, the tooth shapes of the common internal threaded copper tube are damaged while the tube is expanded, and due to the difference of the tooth shapes and the height, only a part of tooth shapes of the internal threaded copper tube are damaged after the internal threaded copper tube is expanded, and the internal threaded copper tube still has high heat transfer efficiency. By using the optimized design, the weight, production cost and using cost of the tube can be reduced. The internal threaded copper tube is suitable to be widely used in the fields of refrigeration, air conditioning, power generation, sugar making, chemical industry, solar energy and the like.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

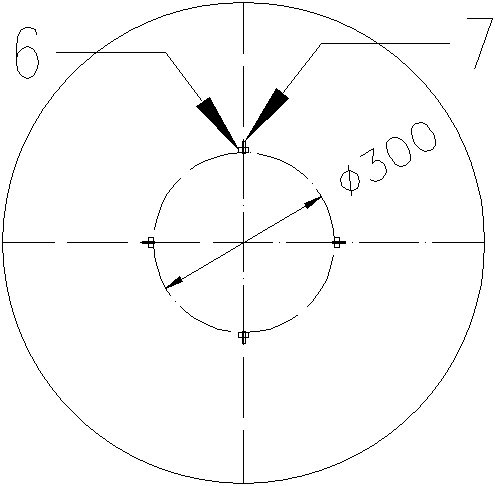

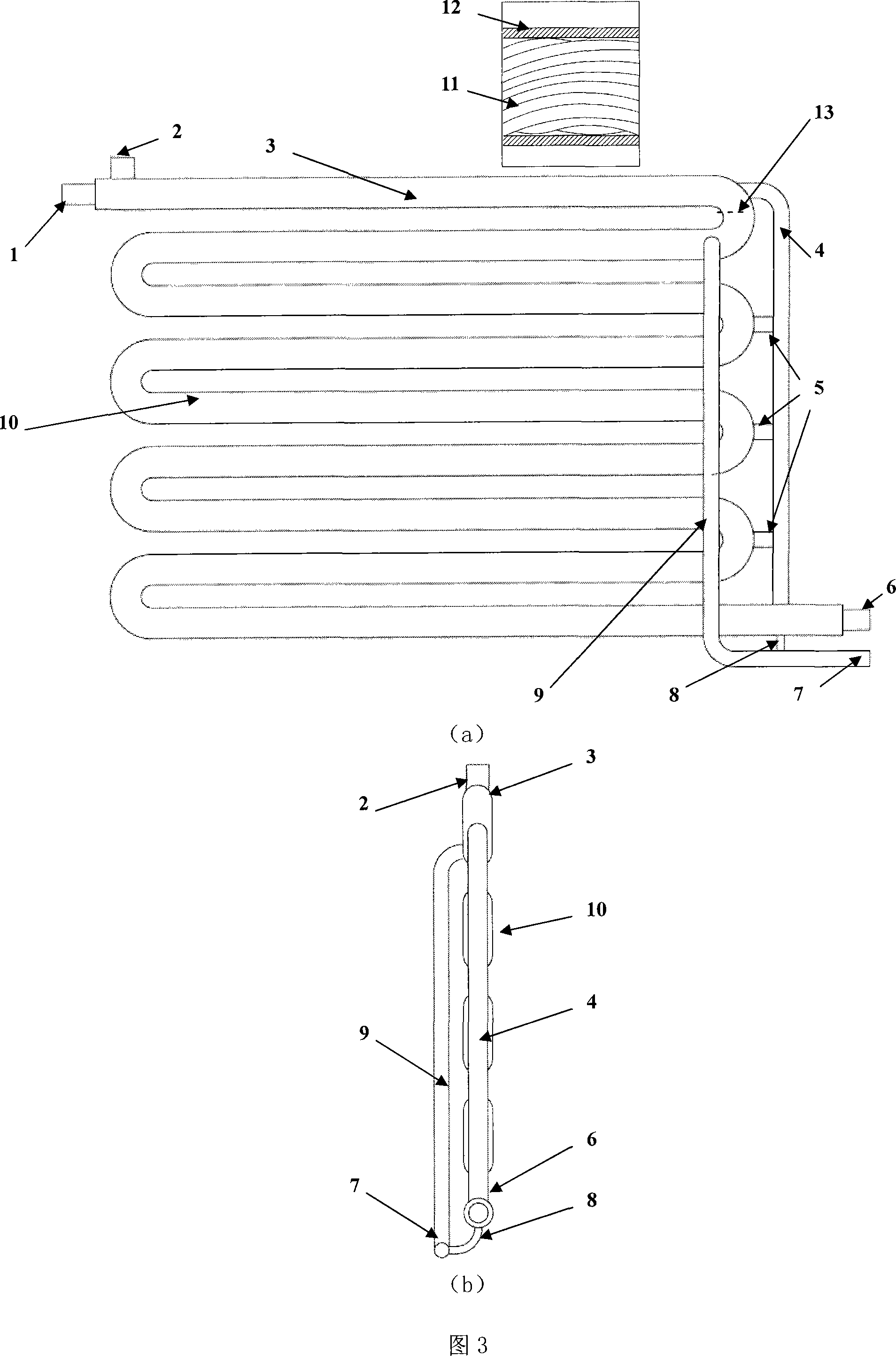

Steam boiler with through hole diameters being changeable

ActiveCN107062187AReduce vibrationReduce noise levelBoiler water tubesSteam generation using pressureNoise levelEngineering

The invention provides a steam boiler. The steam boiler comprises an upper boiler barrel, a lower boiler barrel, ascending pipes and descending pipes, wherein the ascending pipes and the descending pipes are arranged between the upper boiler barrel and the lower boiler barrel; the ascending pipes are internally provided with flow stabilizing devices, the same ascending pipe is internally provided with a plurality of the flow stabilizing devices, and the diameters of through holes of the flow stabilizing devices are smaller and smaller in the fluid flowing direction of the ascending pipes. The steam boiler is provided with the flow stabilizing devices of novel structures, and through the change of the diameters of the through holes, when gas-liquid two-phase flowing exists in the ascending pipes, heat transfer is strengthened; and meanwhile, vibration of the ascending pipes is weakened, and the noise level is lowered.

Owner:王芸芸

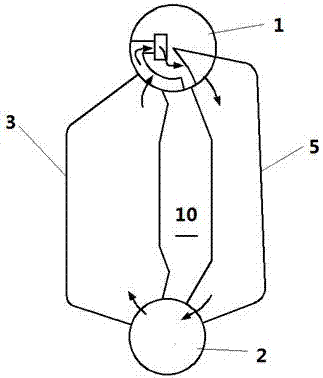

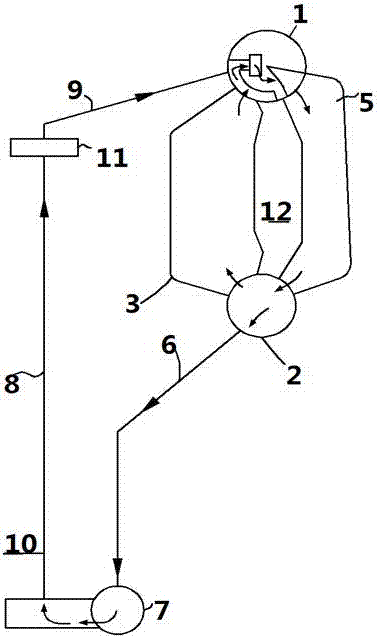

Gas-liquid separation type sleeve evaporator

The utility model relates to a gas-liquid separating bushing evaporator, belonging to the technical field of thermal equipment, which comprises an outer sleeve tube (12) and a plurality of torsion inner tube bundles (11) helically distributed in the outer sleeve tube as the basic heat exchanging part. One end of the inner pipe is an inlet (1) for heating liquid , while the other end is an outlet for heating liquid; the inlet (9) for evaporated liquid is arranged at the bottom of the spiral outer sleeve tube (12), and connected with a liquid phase return pipe (8) for residual evaporated liquid; a gas-collecting exhaust port (5) is communicated with a gas-collecting exhaust pipe (4) at the same location of each layer of spiral jacket; the exhaust port (5) is arranged at the upper reach of the interface of the evaporated liquid inlet (6) and the outer sleeve tube (12) to divide the whole heat exchanging part into a spiral heat exchanging section (10) and a spiral overheating section (3). The utility model also comprises a vertical type S-shaped gas-liquid separating casing evaporator. The utility model has the advantages of simple processing, better overall performance of bushing evaporative heat exchanger, less costs of the manufacture and operation of the evaporator.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com