Patents

Literature

781 results about "Forced convection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forced convection is a mechanism, or type of transport in which fluid motion is generated by an external source (like a pump, fan, suction device, etc.). Alongside natural convection, thermal radiation and thermal conduction it is one of the methods of heat transfer and allows significant amounts of heat energy to be transported very efficiently.

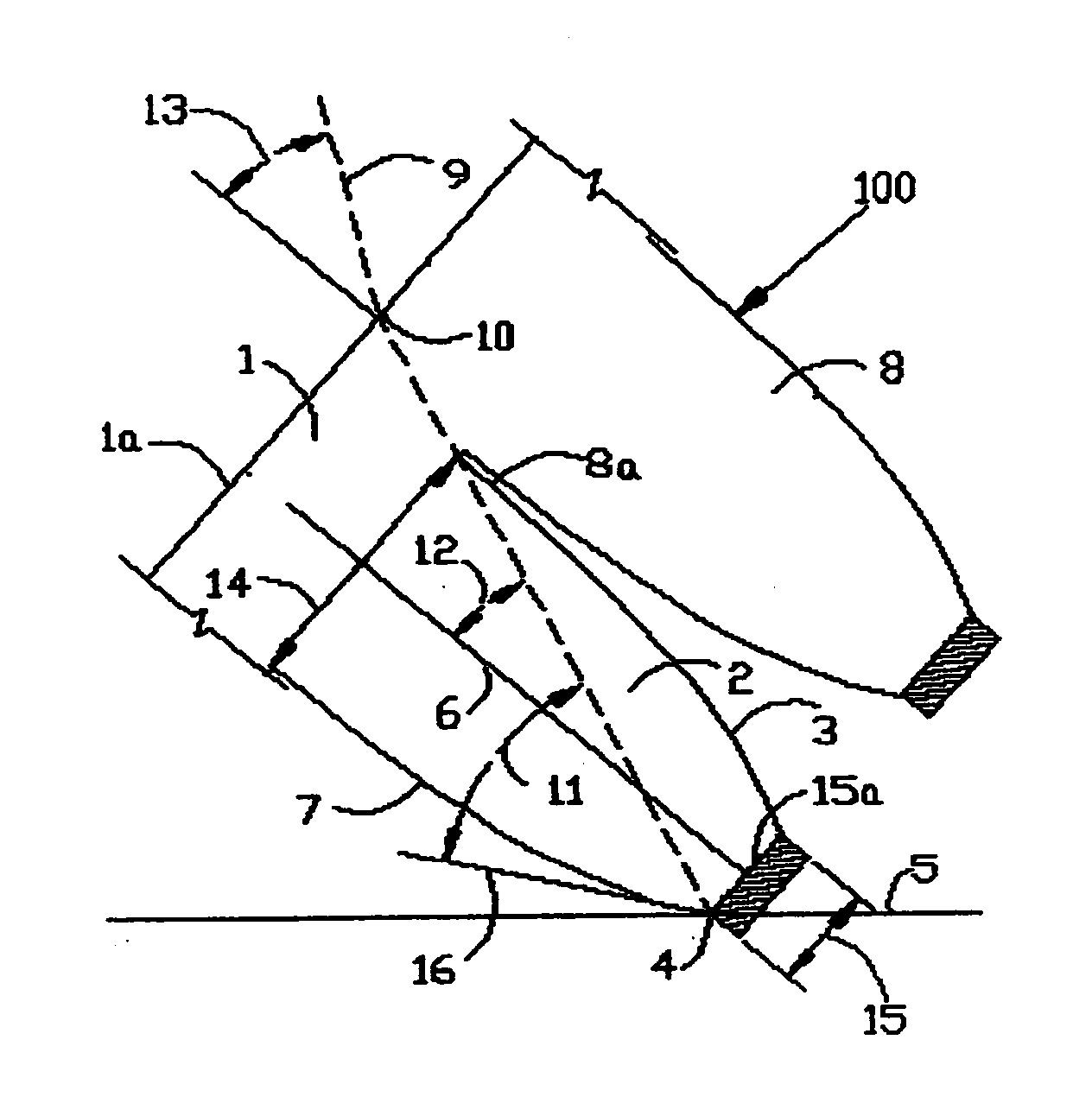

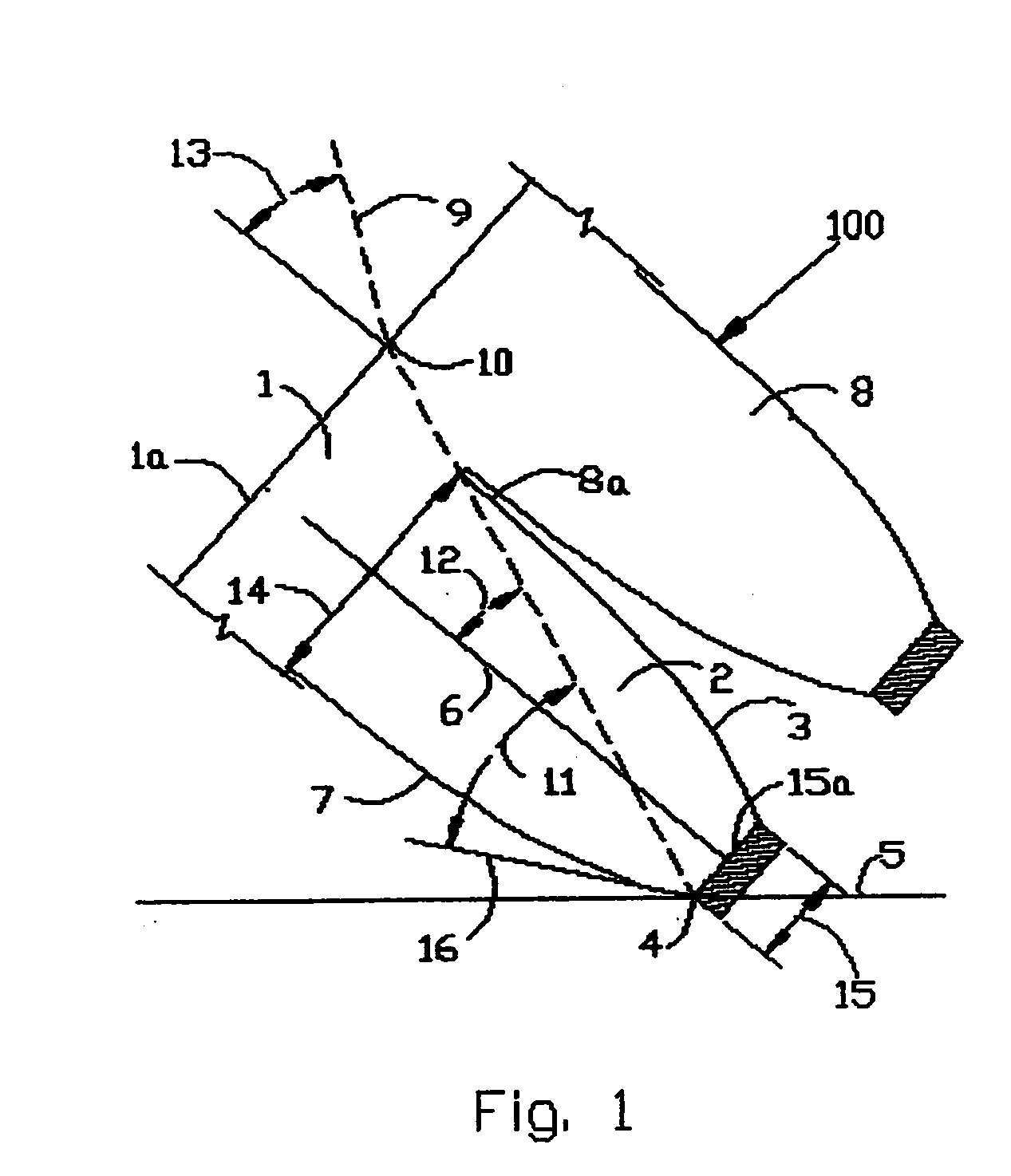

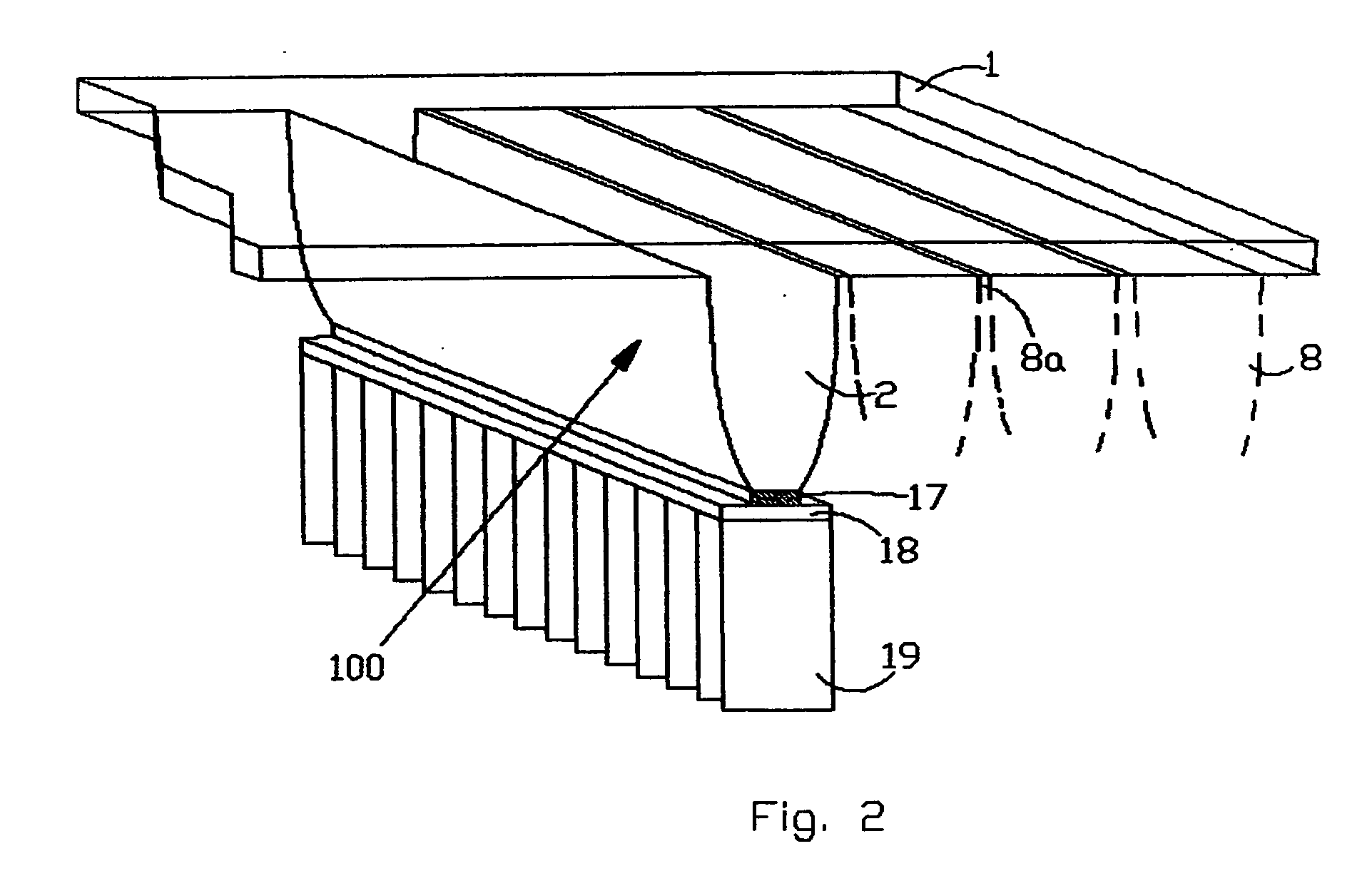

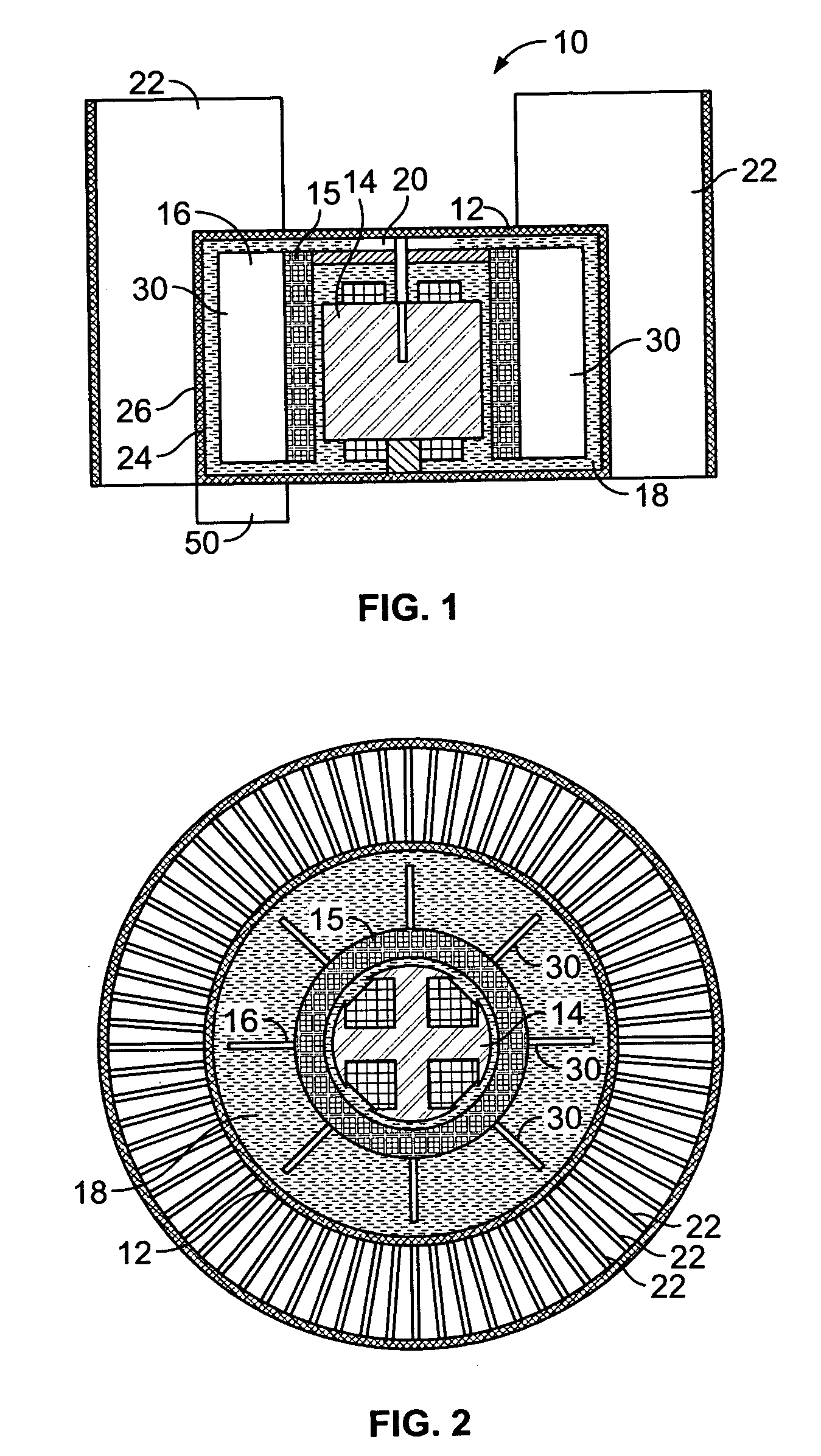

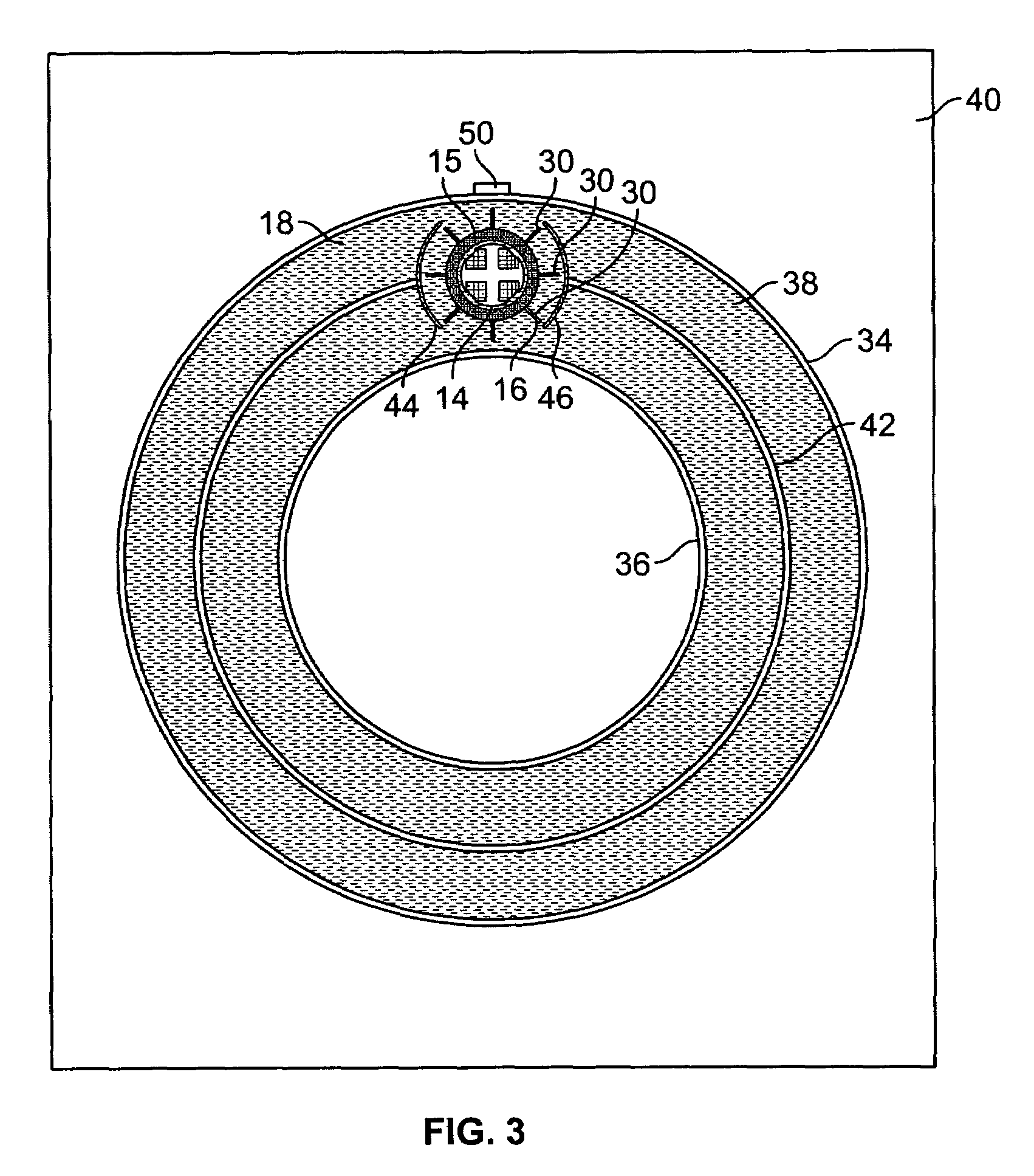

Concentrating solar roofing shingle

InactiveUS20050081909A1Reduce the amount requiredPrevent edgePhotovoltaic supportsSolar heating energyRoof tileEngineering

This invention describes a non-imaging, non-tracking, integrally-formed solar radiation concentrator that passively concentrates both diffuse and direct solar radiation onto photovoltaic cells to produce electricity, incorporating its features into a shingle-like element useful as a roofing material and in other structural applications. The substantially transparent, solar concentrating elements of the invention may also incorporate a system to remove waste energy in the form of heat that is not utilized in the generation of electricity. The invention further provides a thermal energy recovery system including a forced convection air system for removing waste heat from the concentrating shingle assembly and using it, if desired, for building space heat or domestic water heating.

Owner:STELLARIS

Process for drawing gel-spun polyethylene yarns

InactiveUS20050093200A1Domestic articlesMonocomponent polyolefin artificial filamentProduction rateForced convection

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

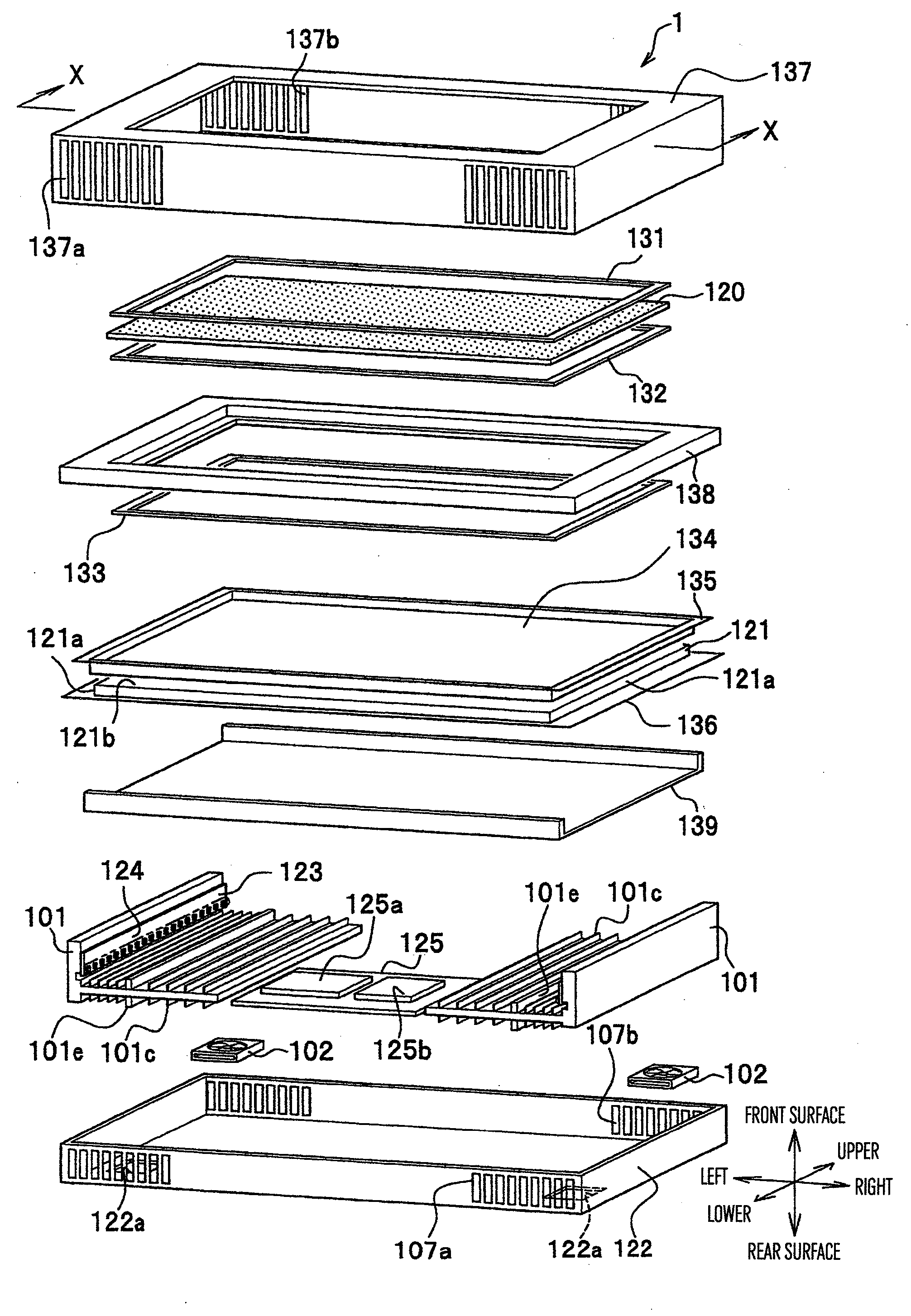

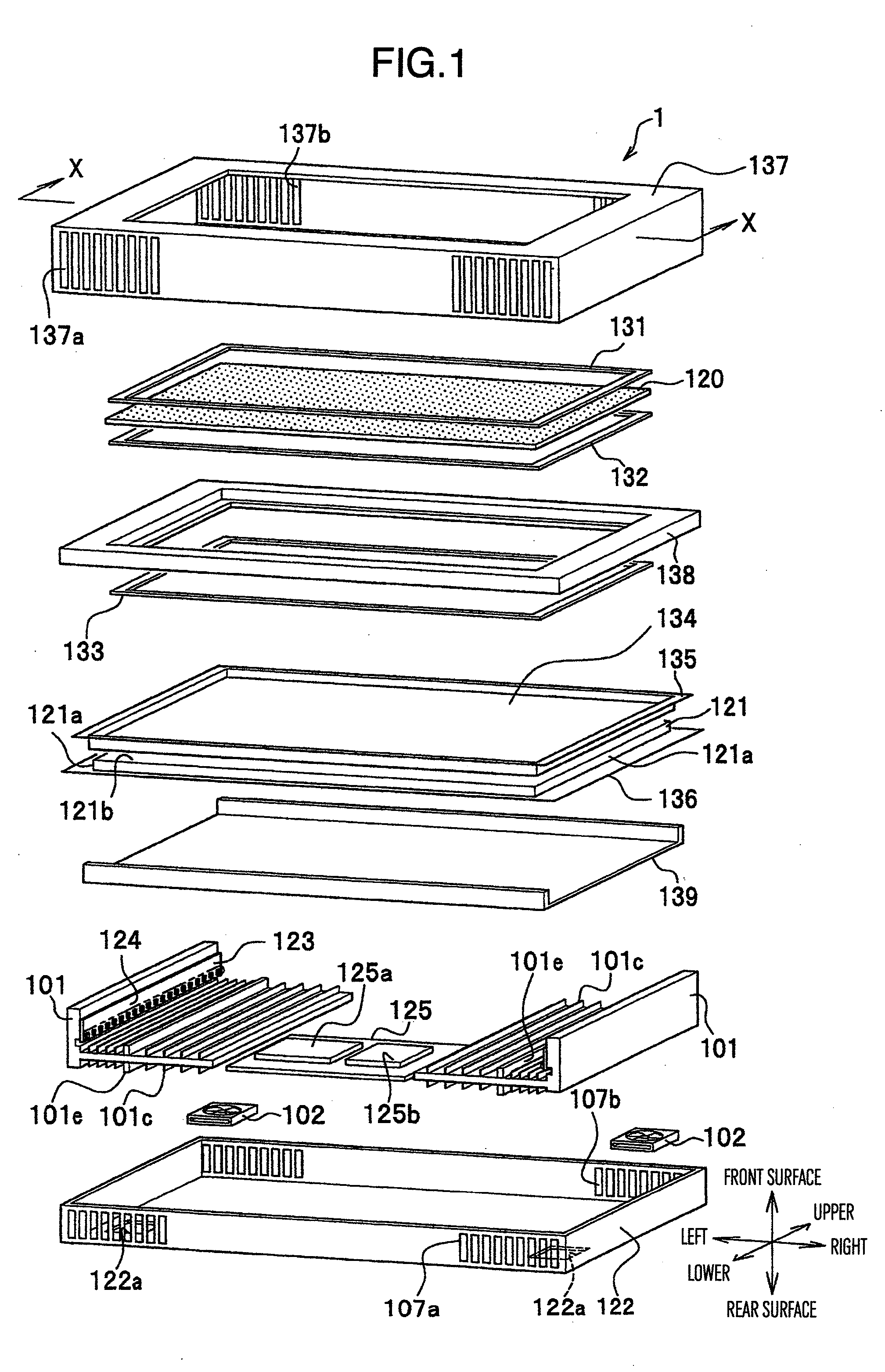

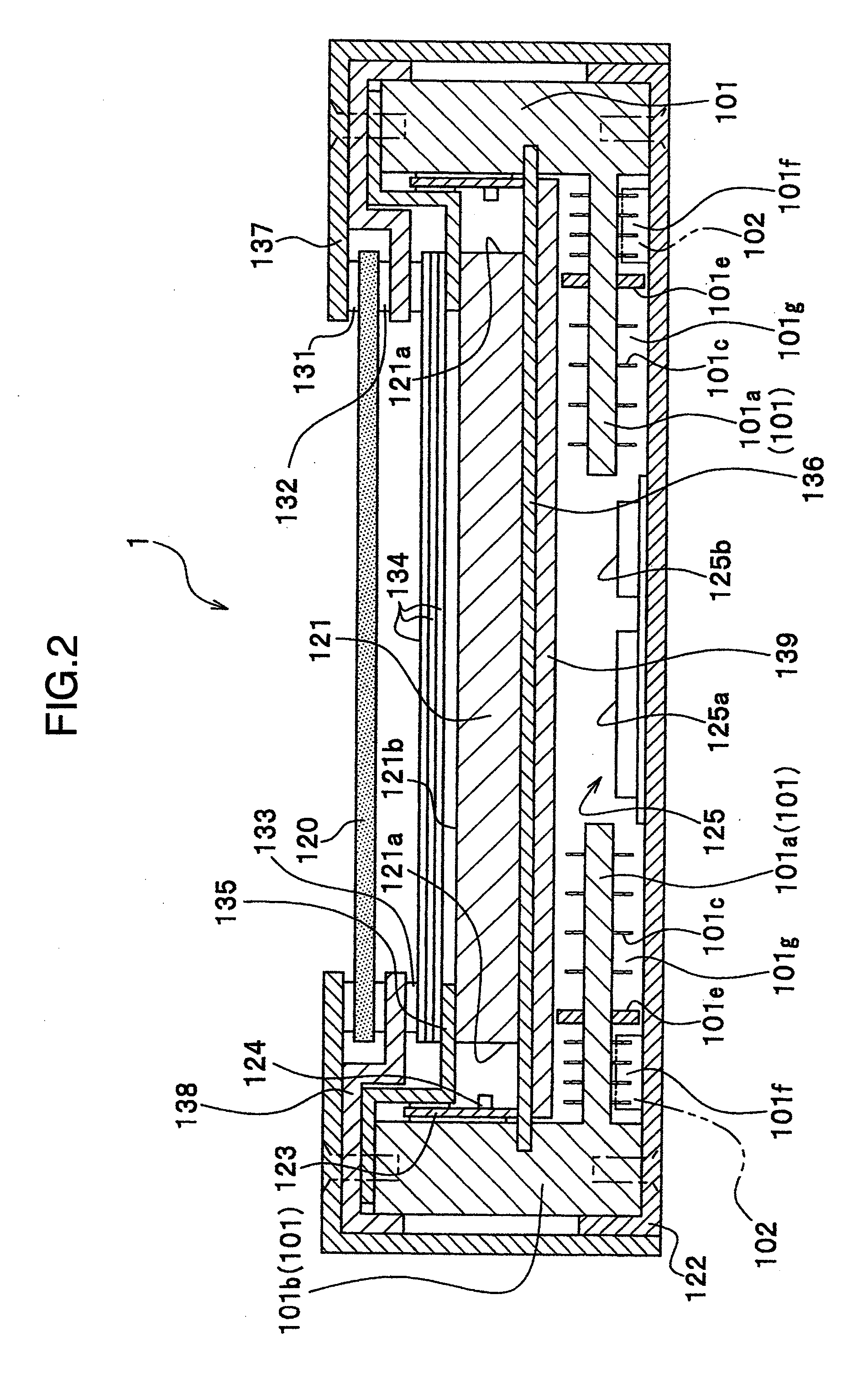

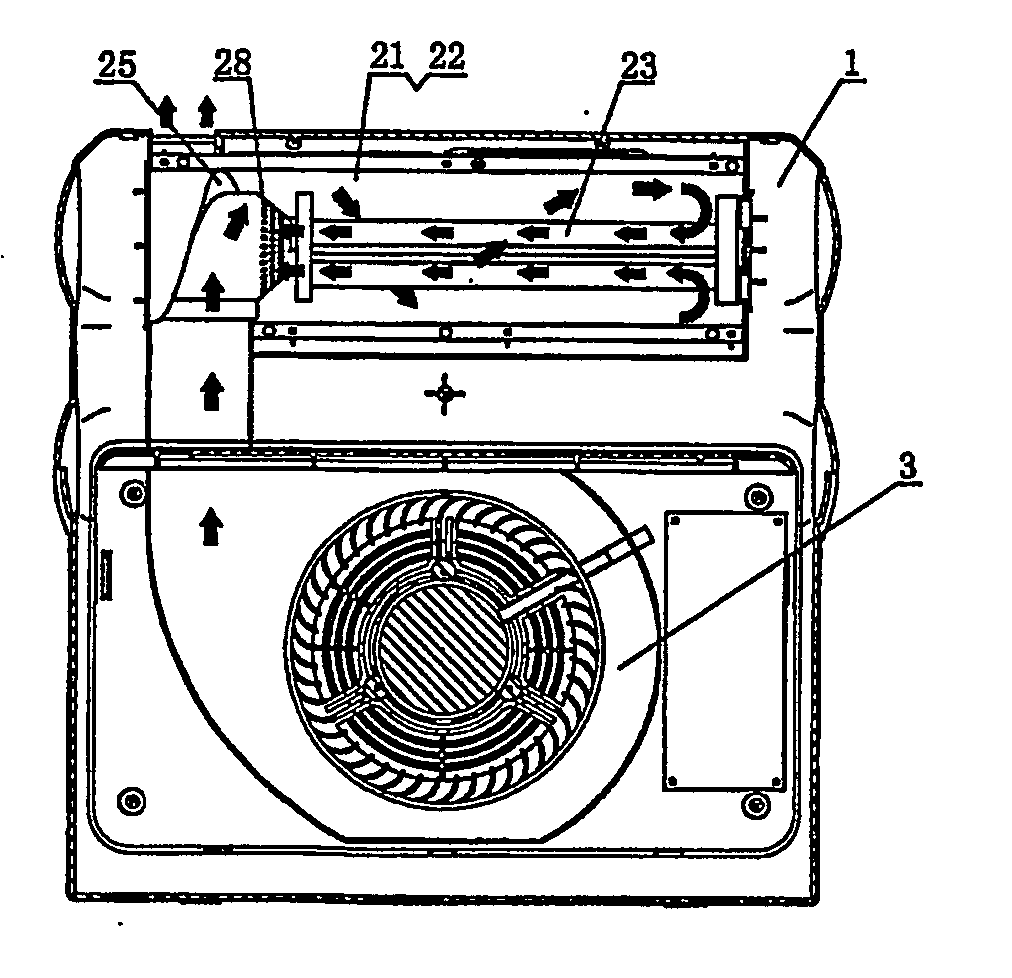

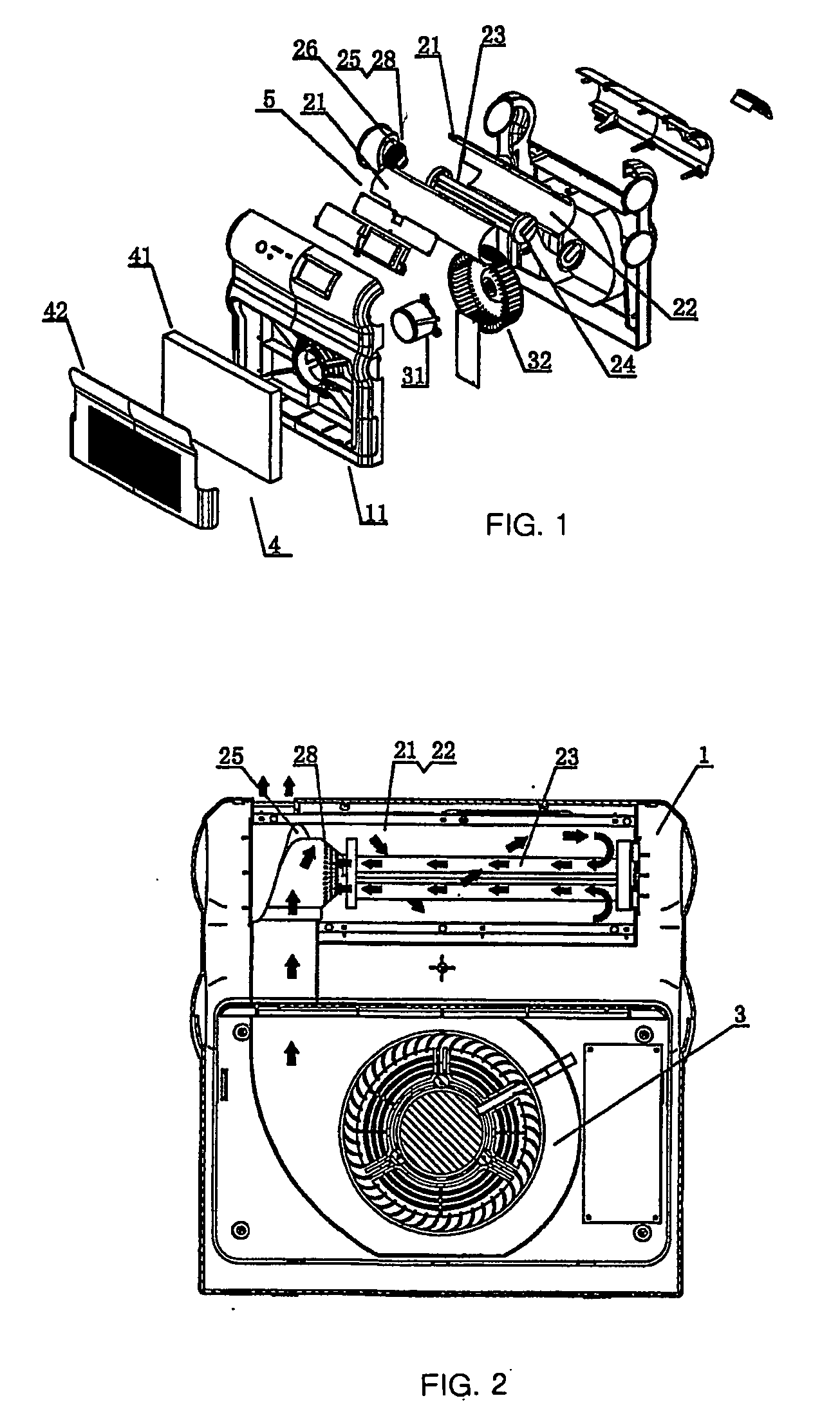

Liquid crystal display device

InactiveUS20080285290A1Lighting heating/cooling arrangementsPlanar/plate-like light guidesLiquid-crystal displayNatural convection

If a forced convection is generated by a cooling fan, there is generated a problem that a natural convection is prevented and a cooling effect in a region of the natural convection is lowered. The invention provides a structure in which an air flow generated by a forced convection does not come into contact with an air flow generated by a natural convection, by setting a partition all between a forced convection path in which the air flows on the basis of a forced convection generated by a cooling fan, and a natural convection path in which the air flows on the basis of a natural convection. Further, the partition wall is not provided near an upper end so as to draw in the air flowing through the natural convection path to a side of the forced convection path, thereby promoting the natural convection of the natural convection path.

Owner:MAXELL HLDG LTD

Process for drawing gel-spun polyethylene yarns

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

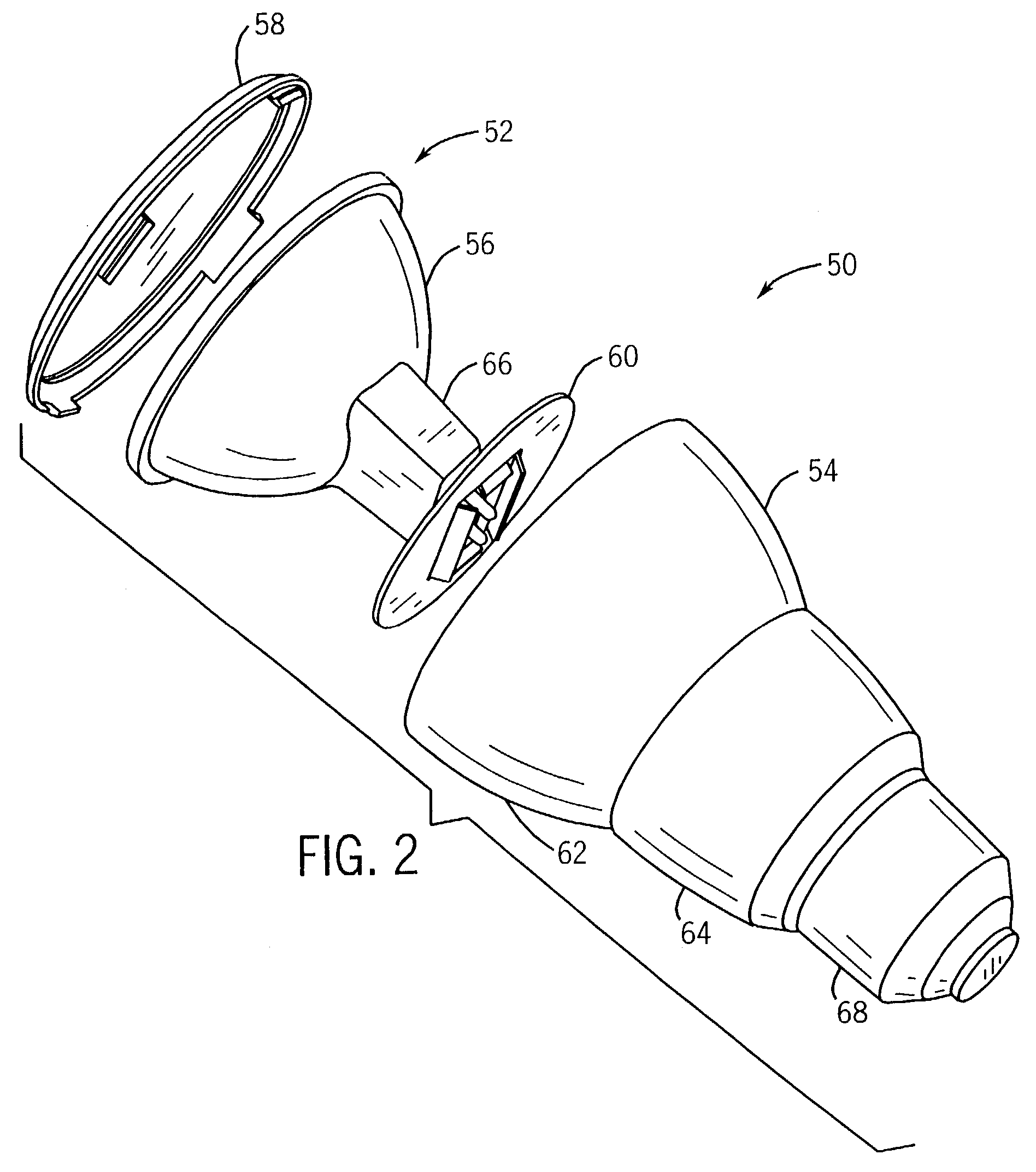

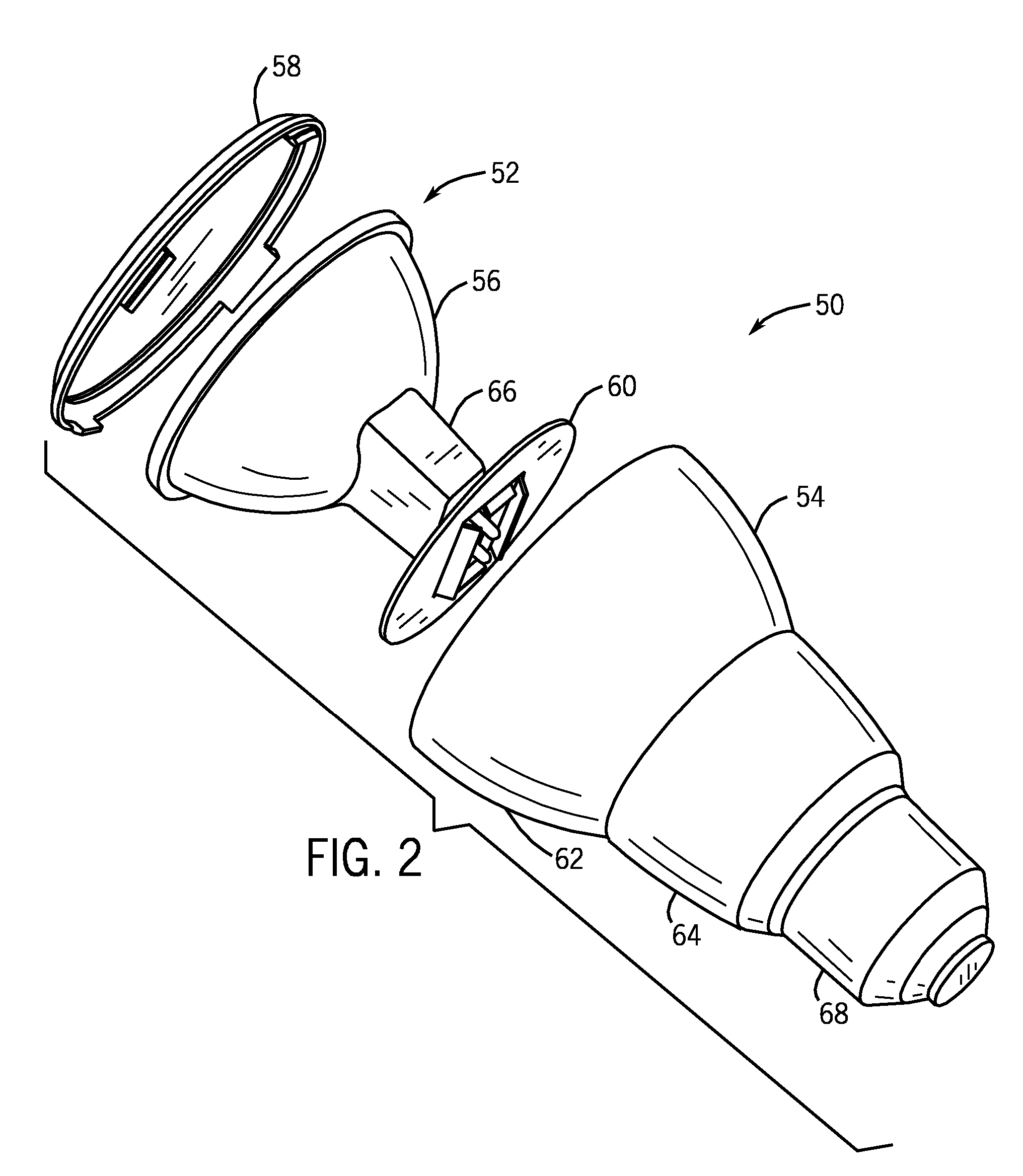

Integral ballast lamp thermal management method and apparatus

A lamp having a lighting source, integral electronics, and a thermal distribution mechanism disposed in a housing. The thermal distribution mechanism may include a For example, the lamp may include a thermal shield between the lighting source and the integral electronics. The lamp also may have a forced convection mechanism, such as an air-moving device, disposed adjacent the integral electronics. A heat pipe, a heat sink, or another conductive heat transfer member also may be disposed in thermal communication with one or more of the integral electronics. For example, the integral electronics may be mounted to a thermally conductive board. The housing itself also may be thermally conductive to conductively spread the heat and convect / radiate the heat away from the lamp.

Owner:GENERAL ELECTRIC CO

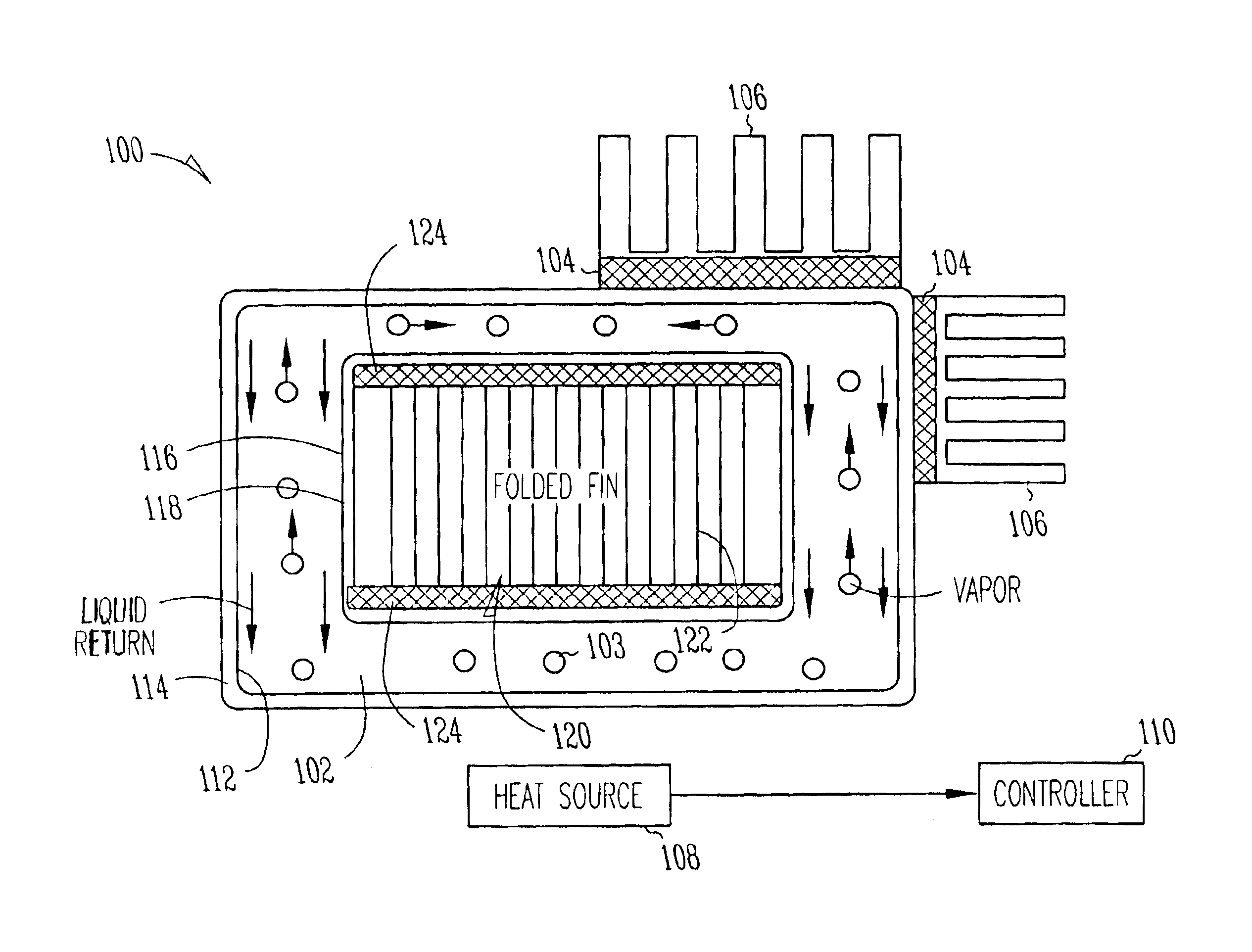

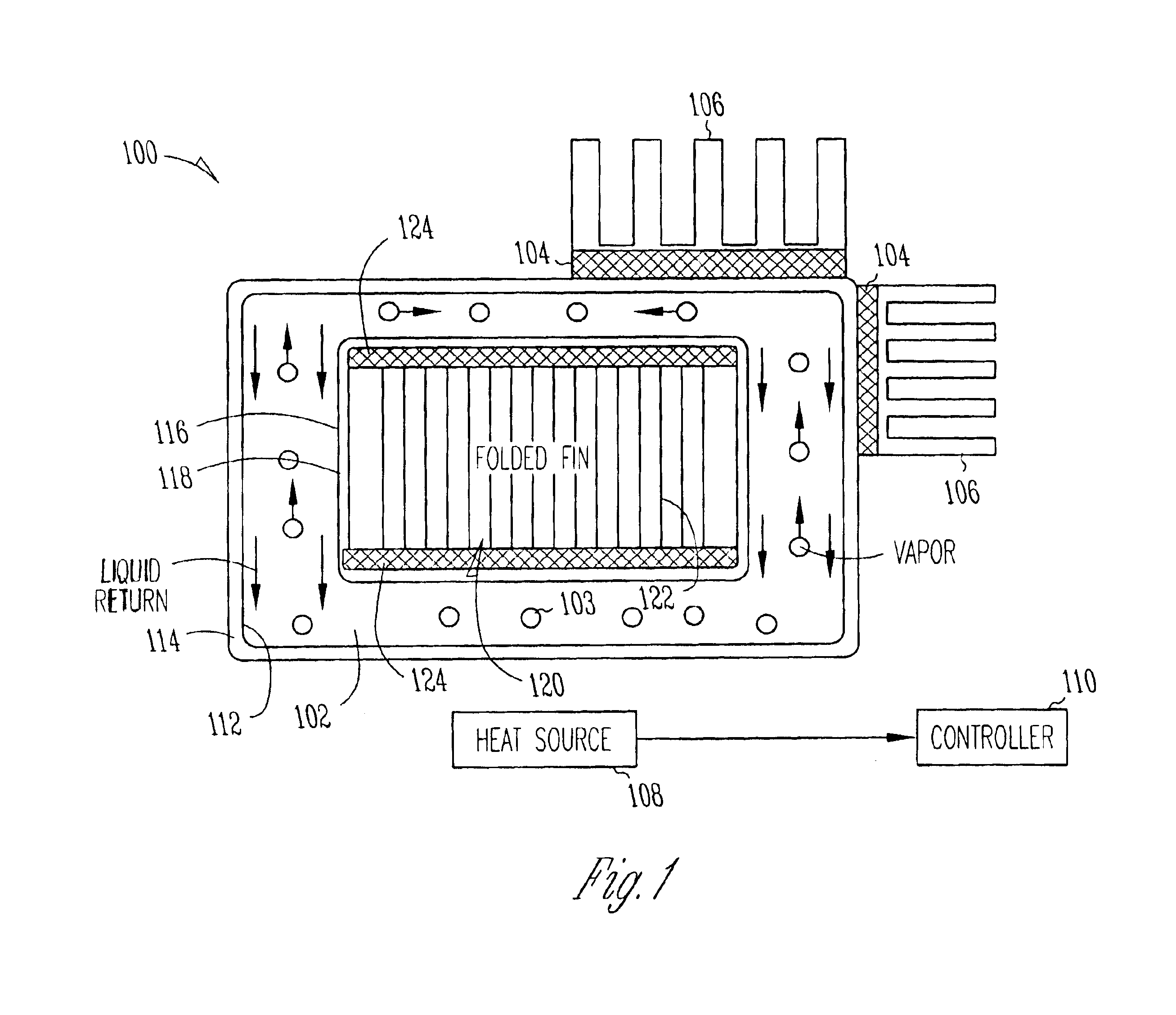

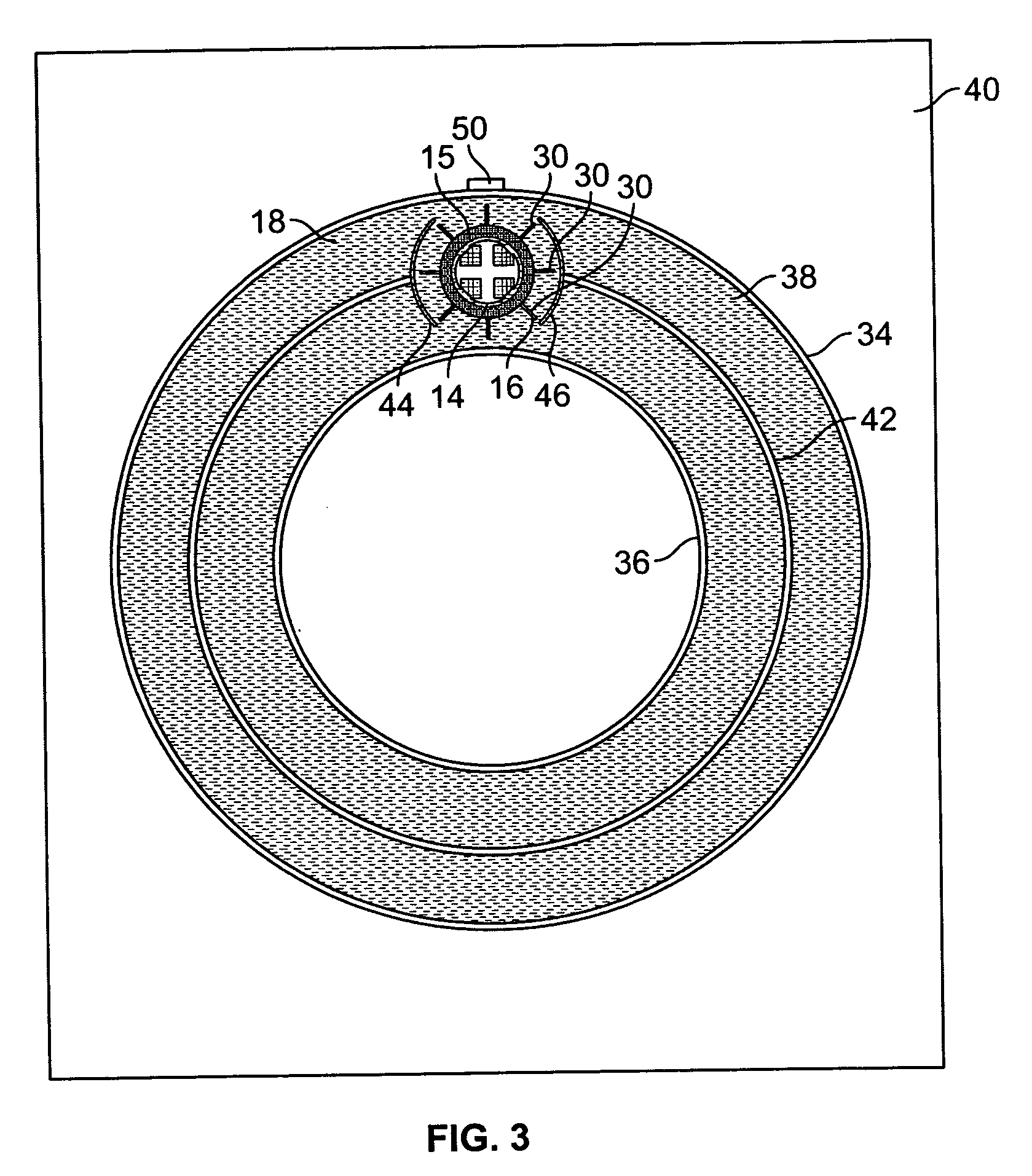

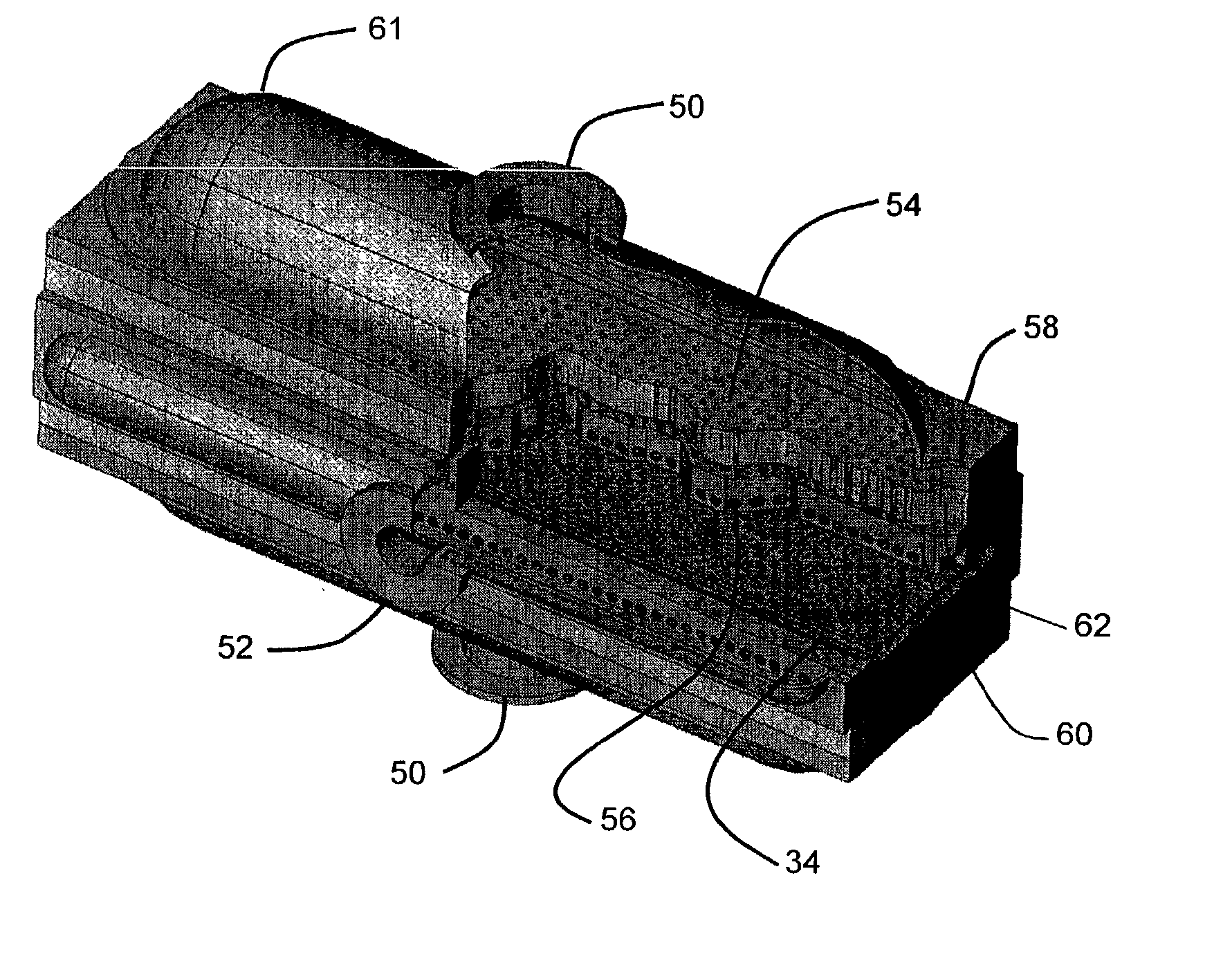

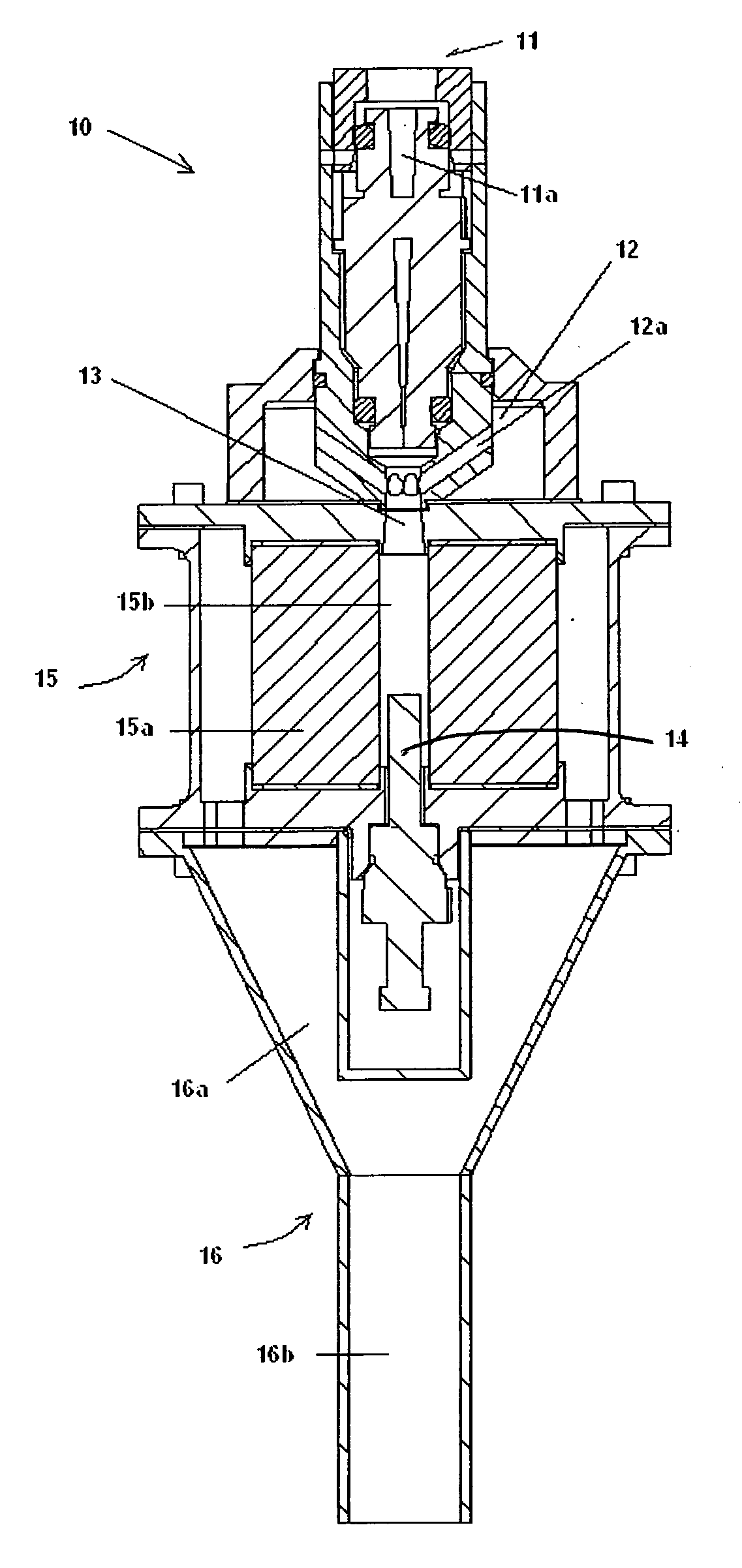

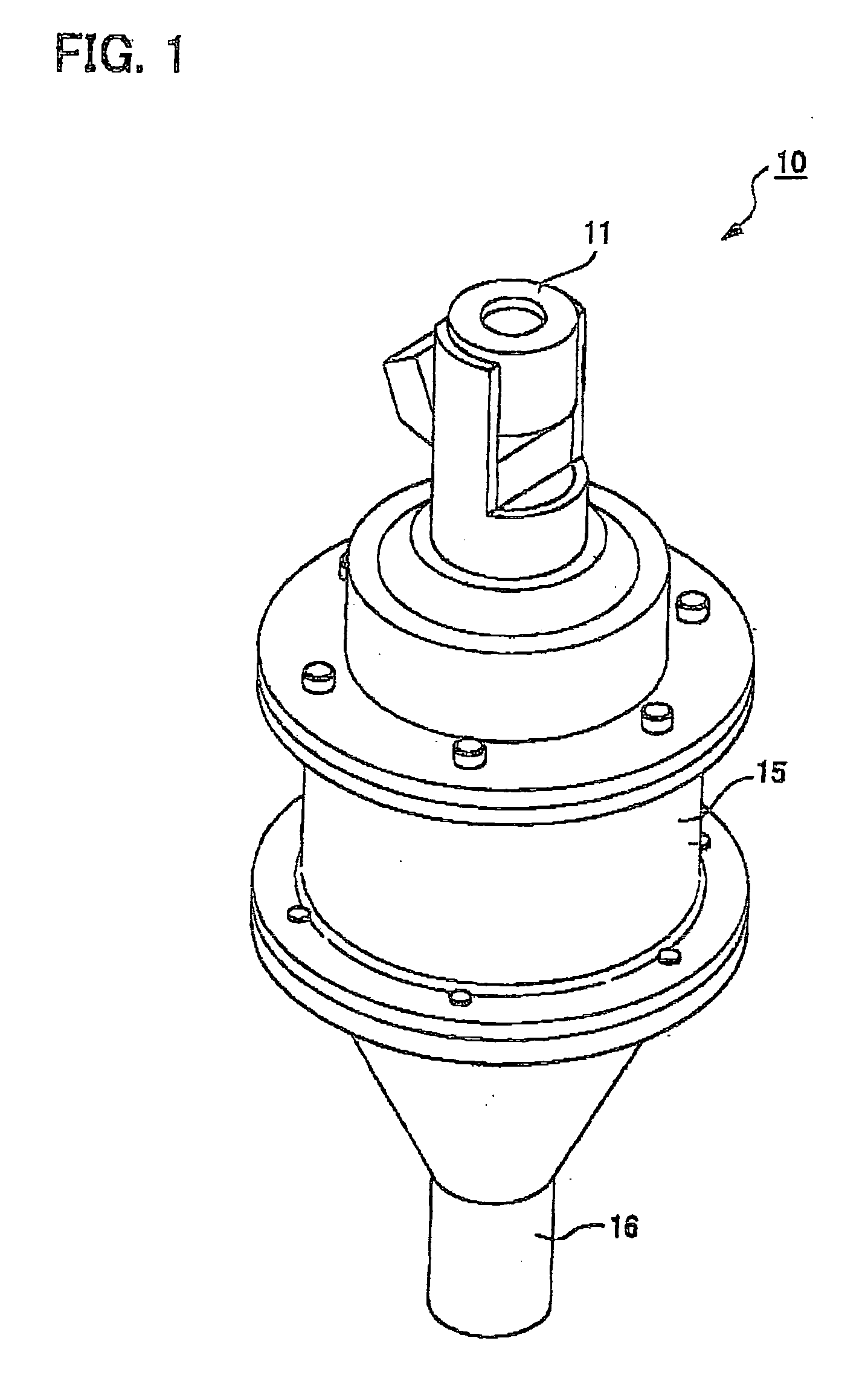

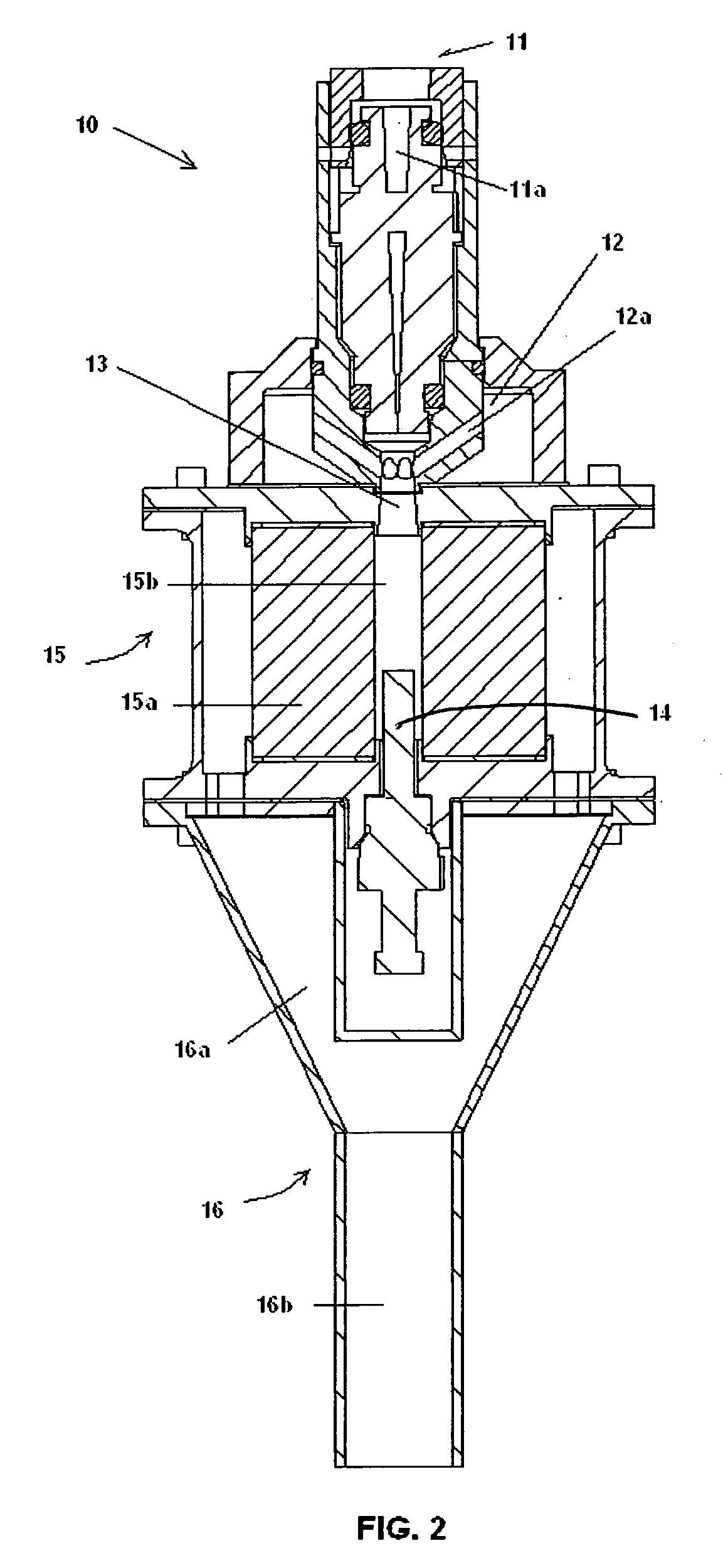

Phase-change refrigeration apparatus with thermoelectric cooling element and methods

InactiveUS6845622B2Thermoelectric device with peltier/seeback effectIndirect heat exchangersEnergy transferThermoelectric cooling

A heat-transfer device has a sealed vapor chamber with a phase-change fluid therein, and a thermoelectric cooling (TEC) element with a cooled side in thermal contact with the vapor chamber and a heated side in contact with heat-dissipation fins. The TEC element decreases the temperature of the vapor chamber and increases the temperature of the fins for improved efficiency. The vapor chamber is defined between concentrically positioned tubes, and a tunnel region is located within the inner tube. Additional TEC elements within the tunnel region further dissipate heat. In two-phase natural convection embodiments, TEC elements may further cool liquid returning to the heat source. Parallel heat dissipation paths may also be provided. In a two-phase forced convection embodiment, a TEC element may further cool liquid returning to the heat source, and additional TEC elements may be provided on the condenser. In some embodiments, active feedback controls the amount of energy transferred by a TEC element.

Owner:INTEL CORP

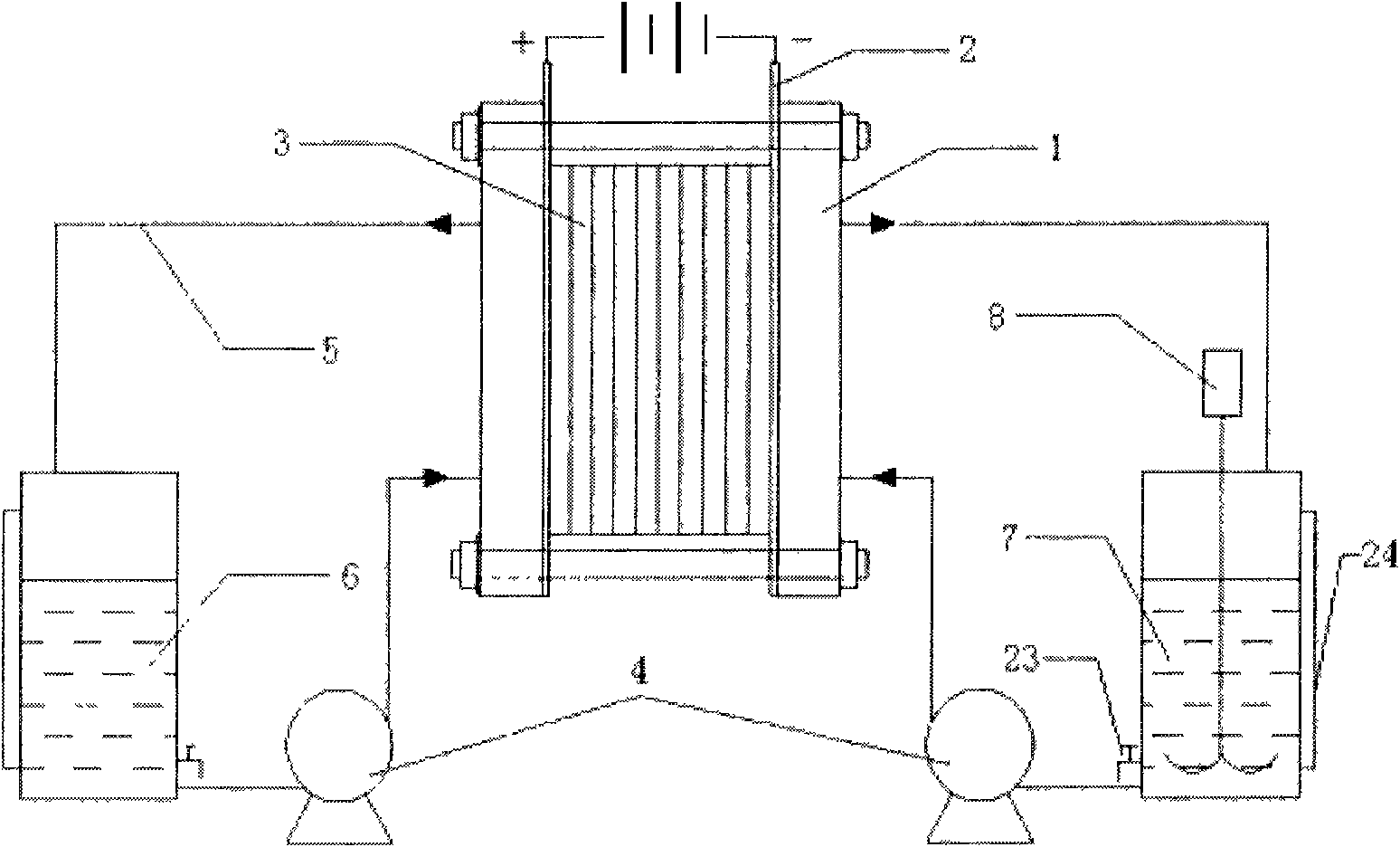

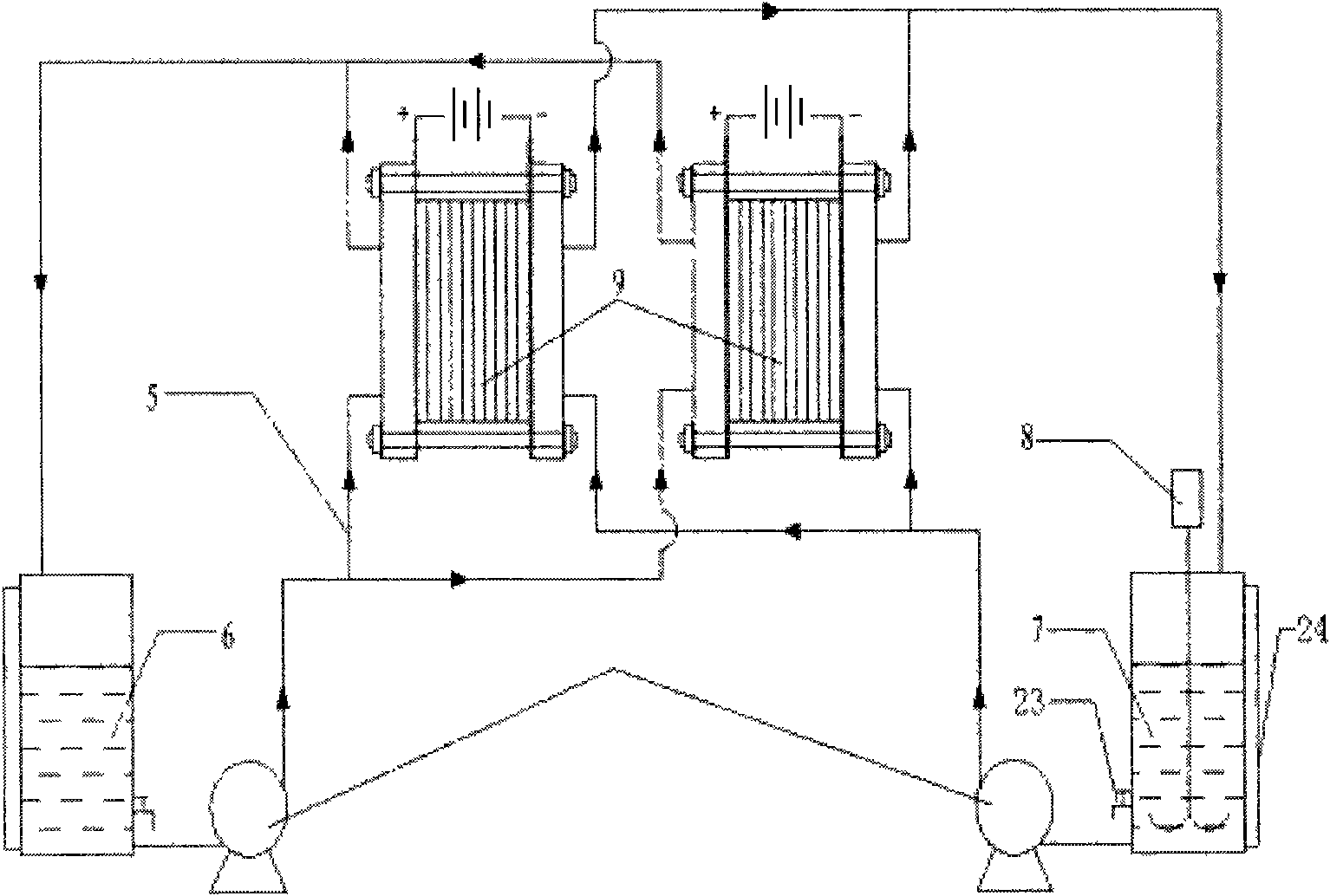

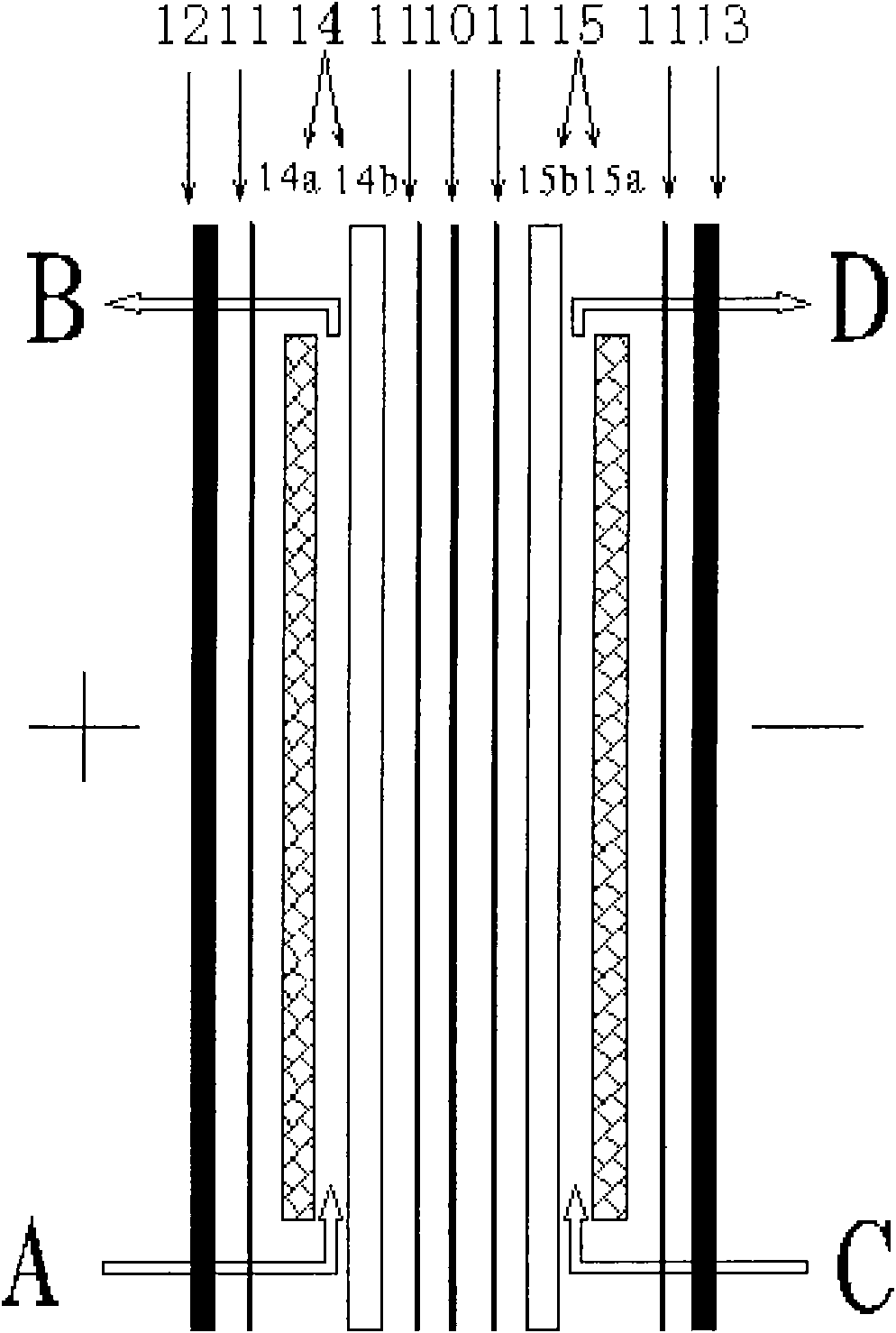

Method for preparing vanadium battery solution or adjusting capacity and special device thereof

InactiveCN101619465ARapid responseContinuous operationElectrolysis componentsRegenerative fuel cellsVanadium CompoundsOxygen

The invention relates to a method for preparing vanadium battery solution or adjusting the capacity, wherein an adopted electrolysis unit comprises an electrolytic cell group, an anode electrolyte storage tank, a cathode electrolyte storage tank, a liquid conveying pipeline and a pump, a mode of forced convection is adopted so that the anode electrolyte and the cathode electrolyte stored in the anode electrolyte storage tank and the cathode electrolyte storage tank respectively flow through the anode and the cathode of the electrolytic cell group respectively, a voltage is applied between the anode and the cathode of the electrolytic cell group to generate direct current capable of generating oxygen and deoxidizing a vanadium compound, and after finishing electrochemical oxidation and reduction reaction, the anode electrolyte and the cathode electrolyte flowing through the anode and the cathode of the electrolytic cell group return to the anode electrolyte storage tank and the cathode electrolyte storage tank. The electrolysis method is applied to preparing electrolyte for a full vanadium liquid stream battery and restoring the capacity of the full vanadium liquid stream battery off line or on line.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

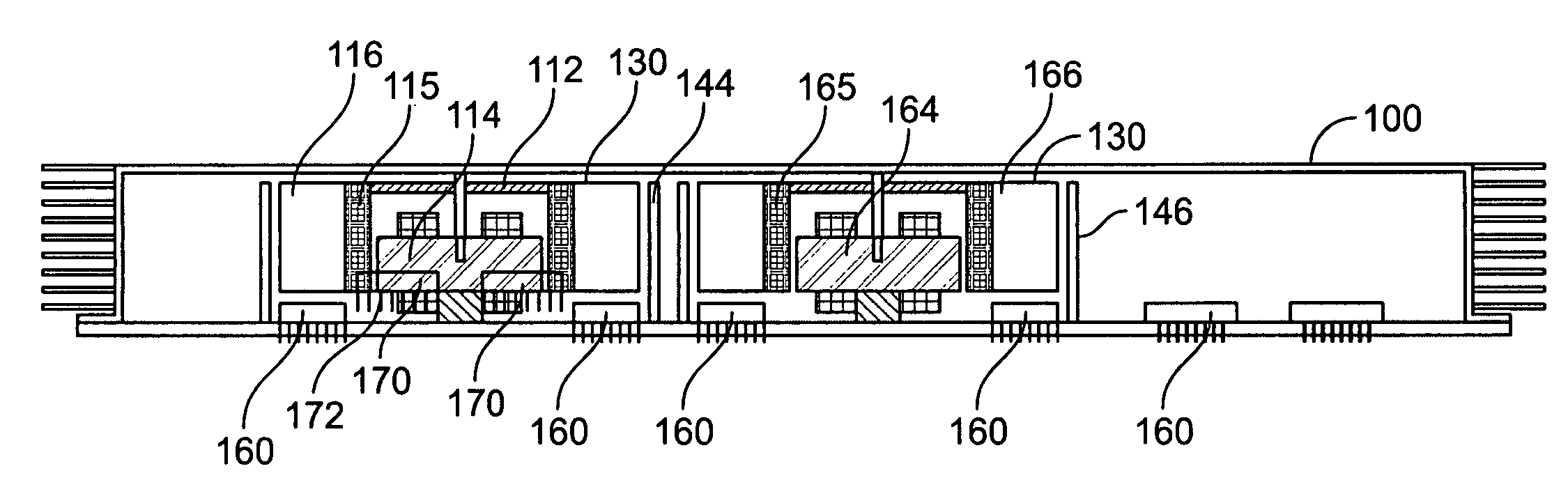

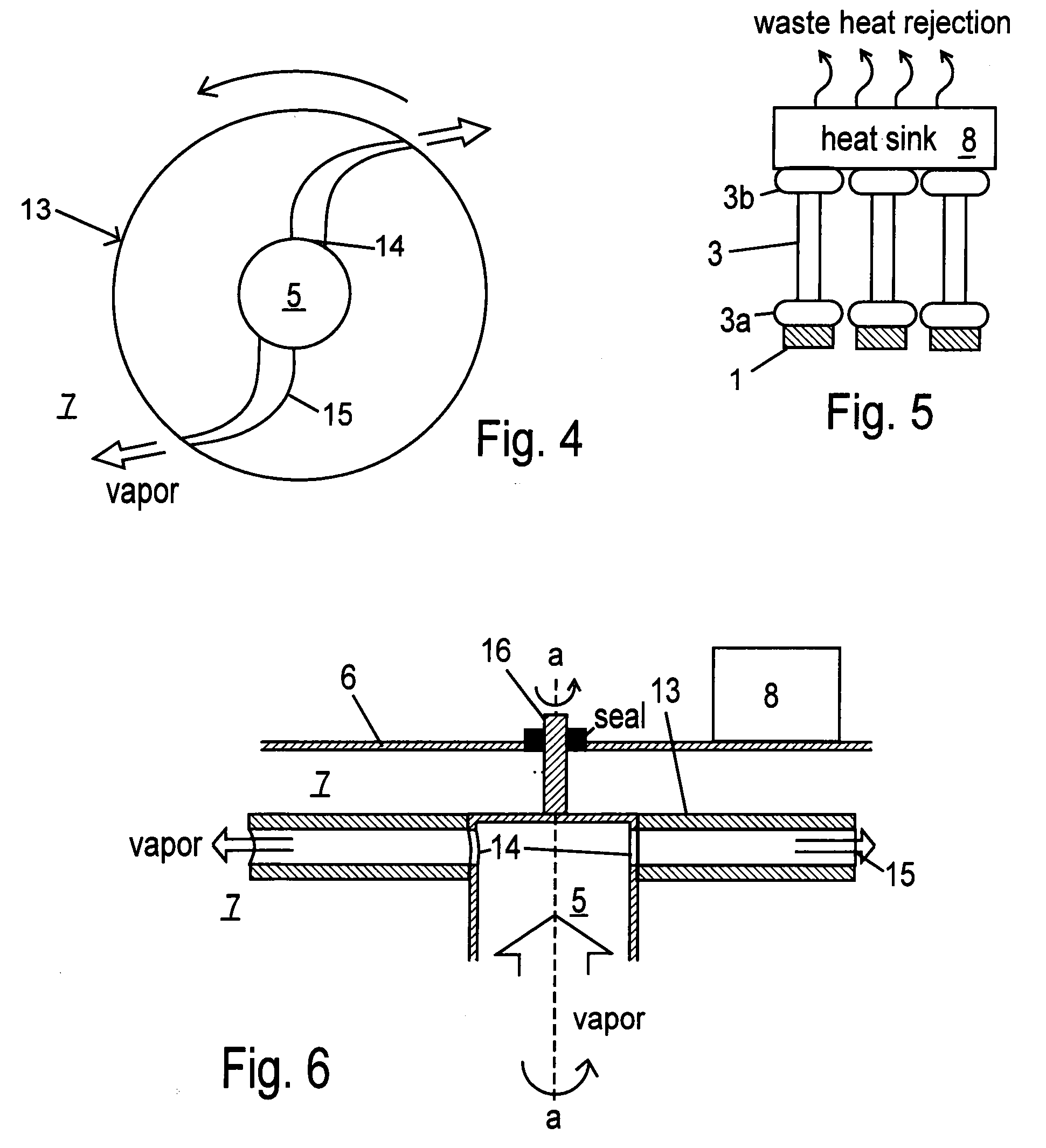

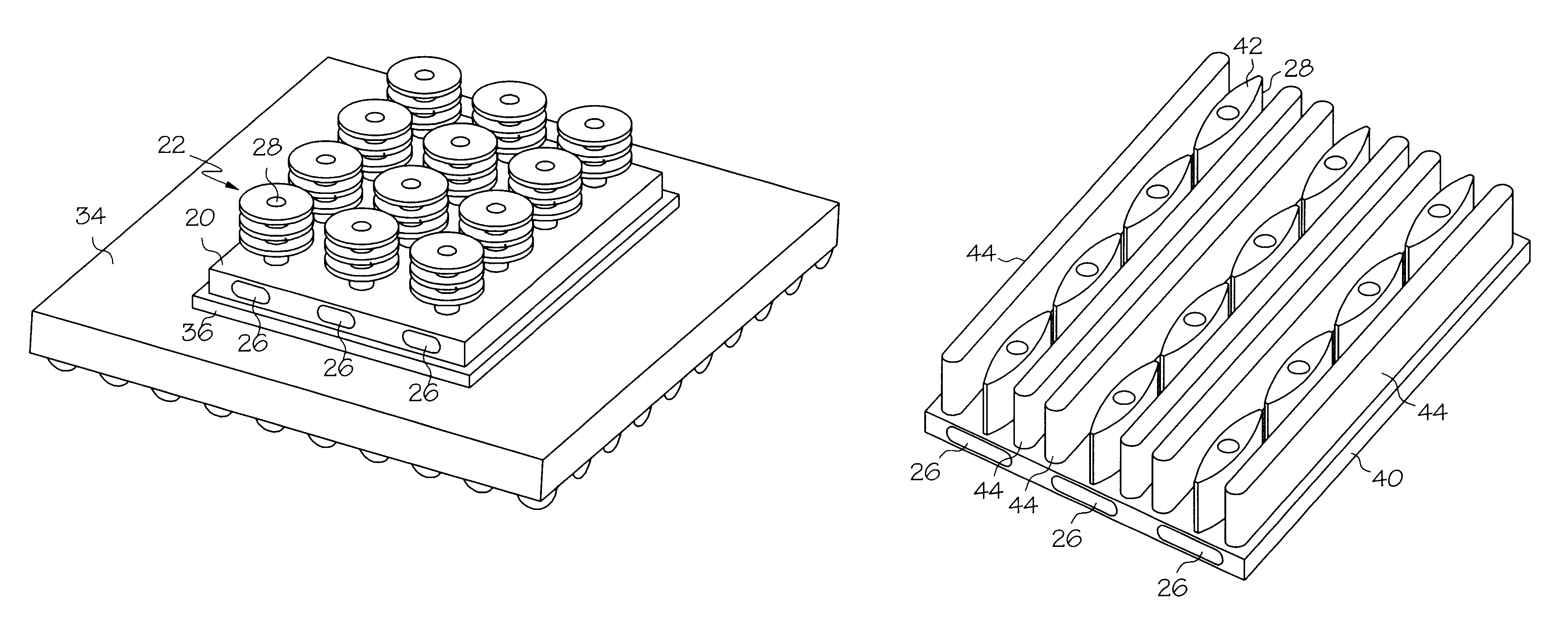

Integrated liquid cooling device with immersed electronic components

InactiveUS20060007656A1Increase surface areaImprove cooling effectDomestic cooling apparatusSemiconductor/solid-state device detailsThermal energyEngineering

An integrated liquid cooling device for electronic components addresses the need for efficient cooling created by ever increasing power densities of electronic components. The integrated liquid cooling device has a housing enclosing the electronic component, cooling liquid contained in the housing, a motor immersed in the cooling liquid and mounted to the housing, an impeller driven by the motor, and cooling surfaces on the exterior of the housing. The motor driven impeller creates a turbulent flow in the cooling liquid and a high velocity liquid flow over the electronic component, which rapidly transfers heat from the electronic component and distributes it throughout the interior of the housing. The cooling surfaces on the exterior of the housing dissipate this heat, either by free or forced convection, into the surrounding environment. Alternately, the integrated liquid cooling device may distribute this heat energy over an equipment case by circulating cooling liquid through a baffled enclosure that provides high velocity cooling liquid flow near the heat generating electronic component. Additional cooling capacity can be gained with the described integrated liquid cooling device by selecting a cooling liquid whose boiling point is near the operating temperature of the electronic component.

Owner:SYMONS ROBERT S

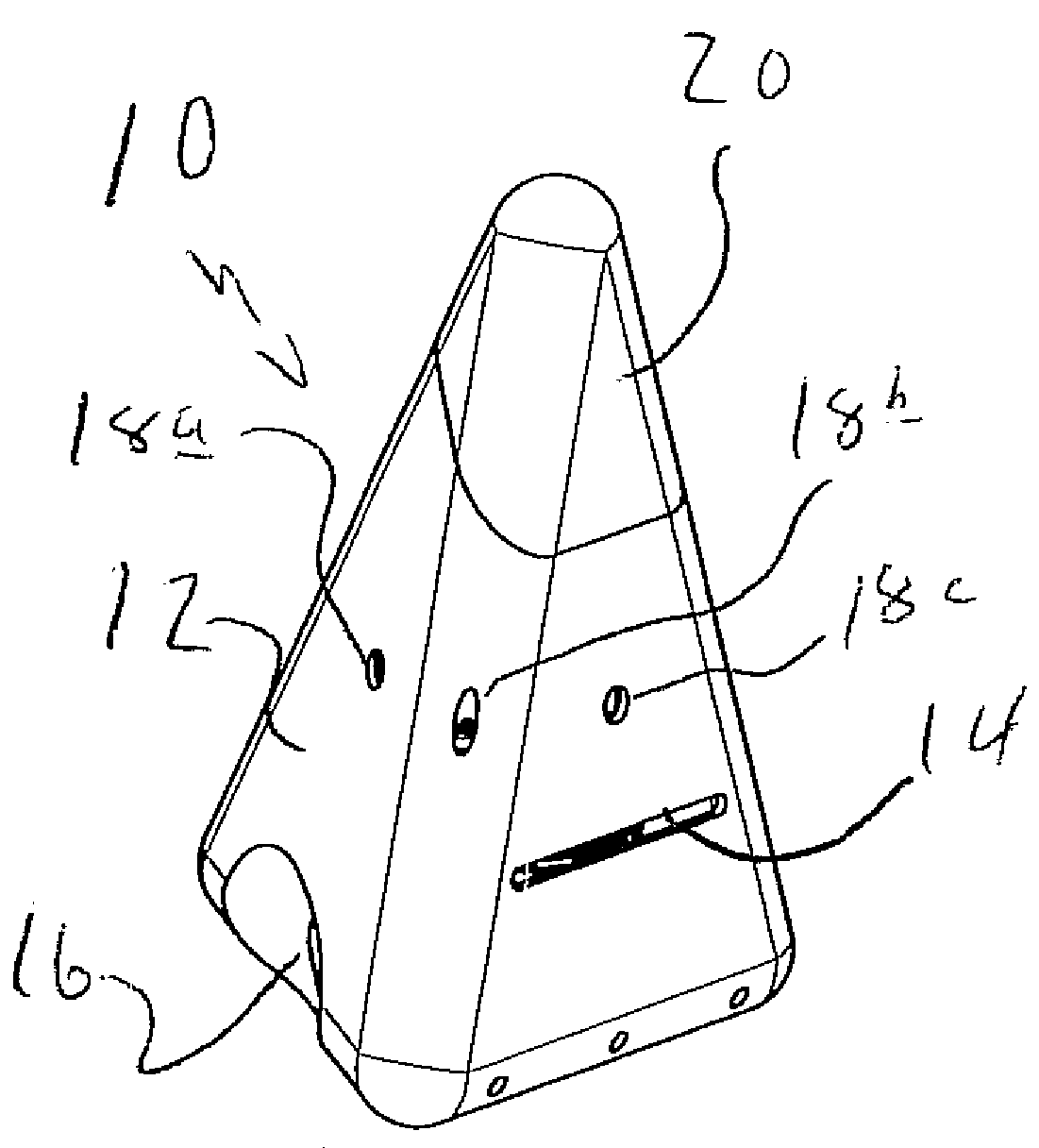

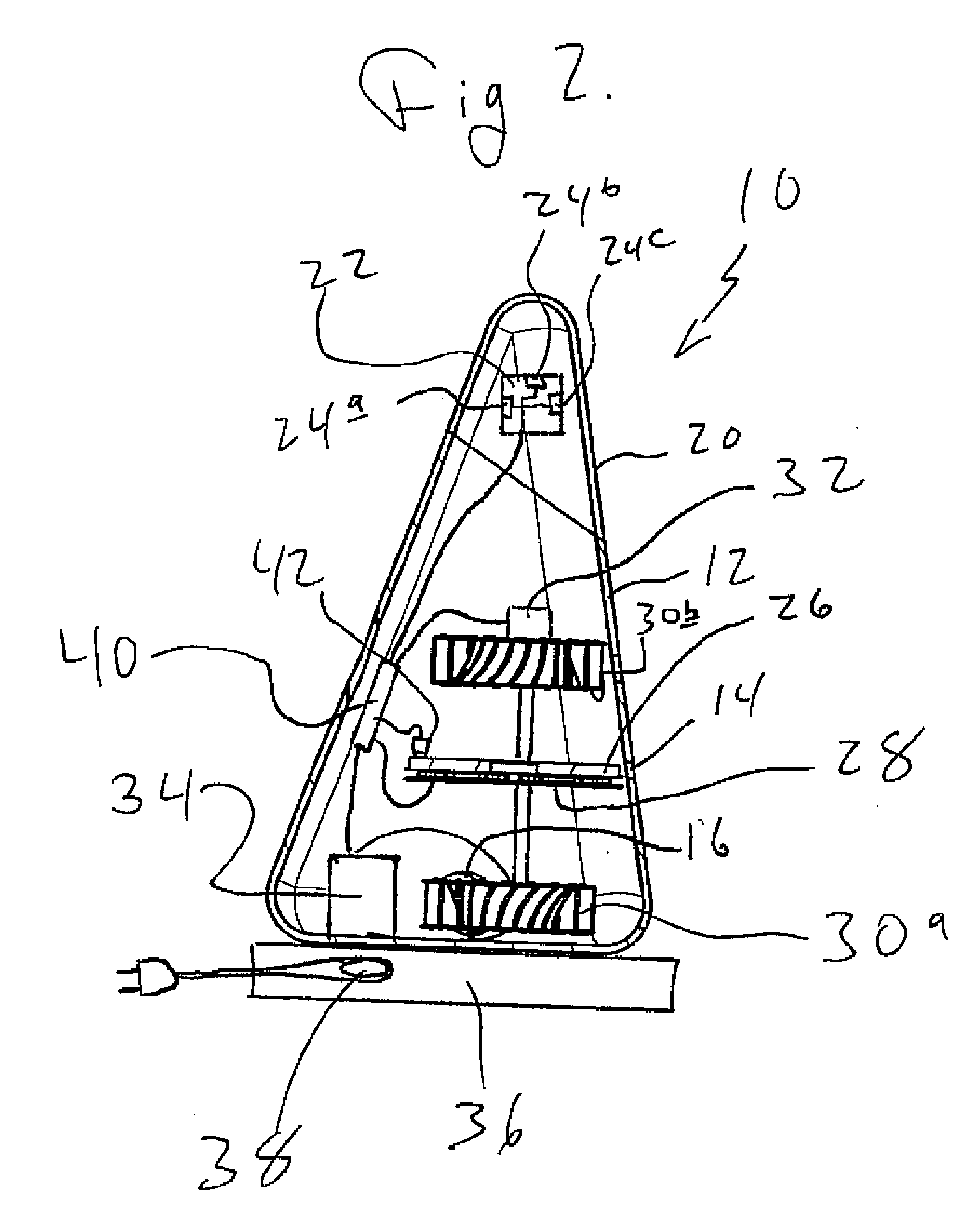

Electronic candle

An electronic candle includes a source of light which provides a spatially and temporally varying pattern of illumination which simulates a candle flame, a volatile release station which operates to release a volatile material such as an aromatic material from a cartridge, and a forced convection system which disperses the volatile material. The candle further includes a controller which coordinates the operation of the release of the volatile material and the light source so that the pattern of light produced by the source is coordinated with an attribute of the volatile material being released.

Owner:JARAMILLO JAMISON

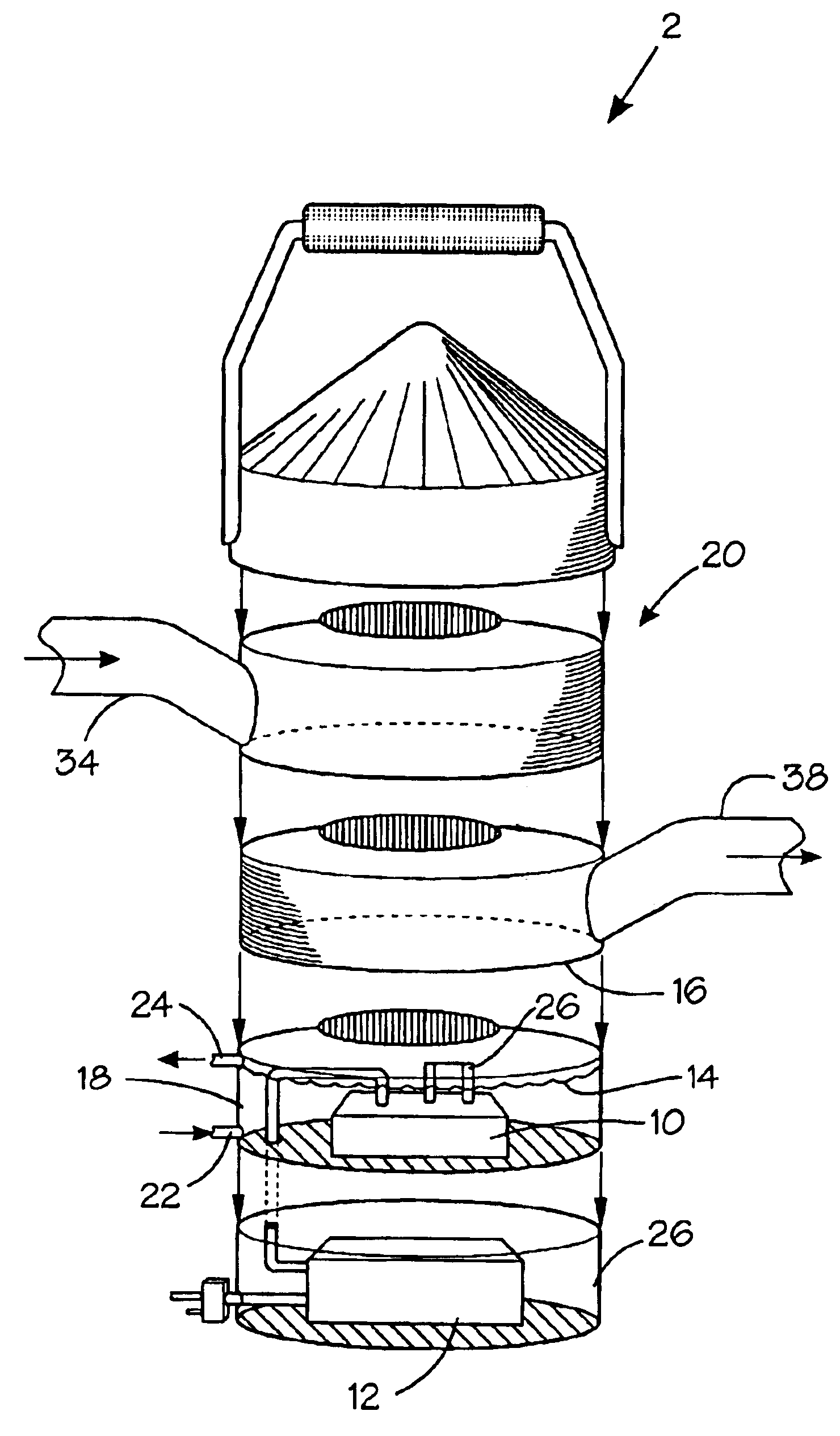

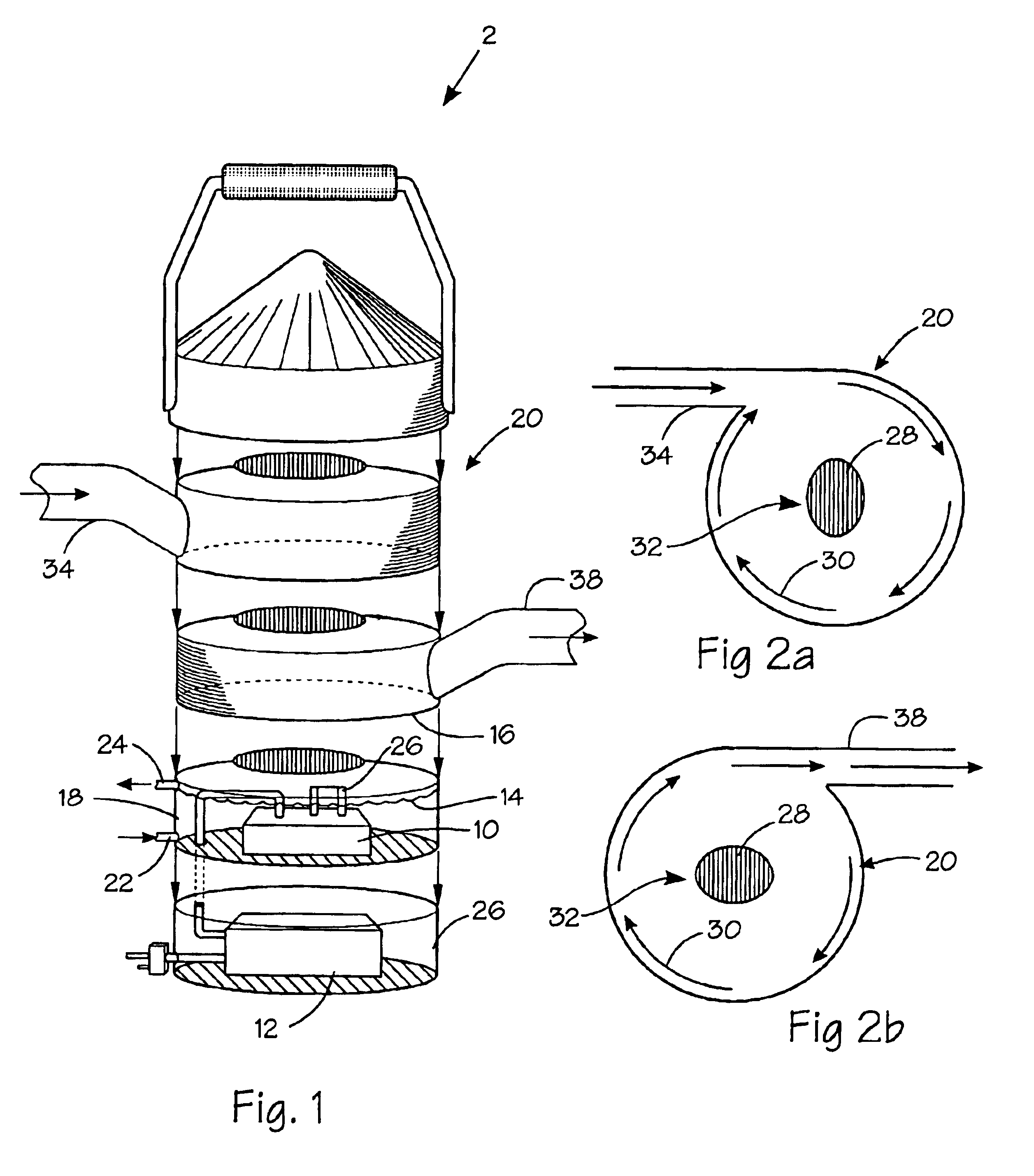

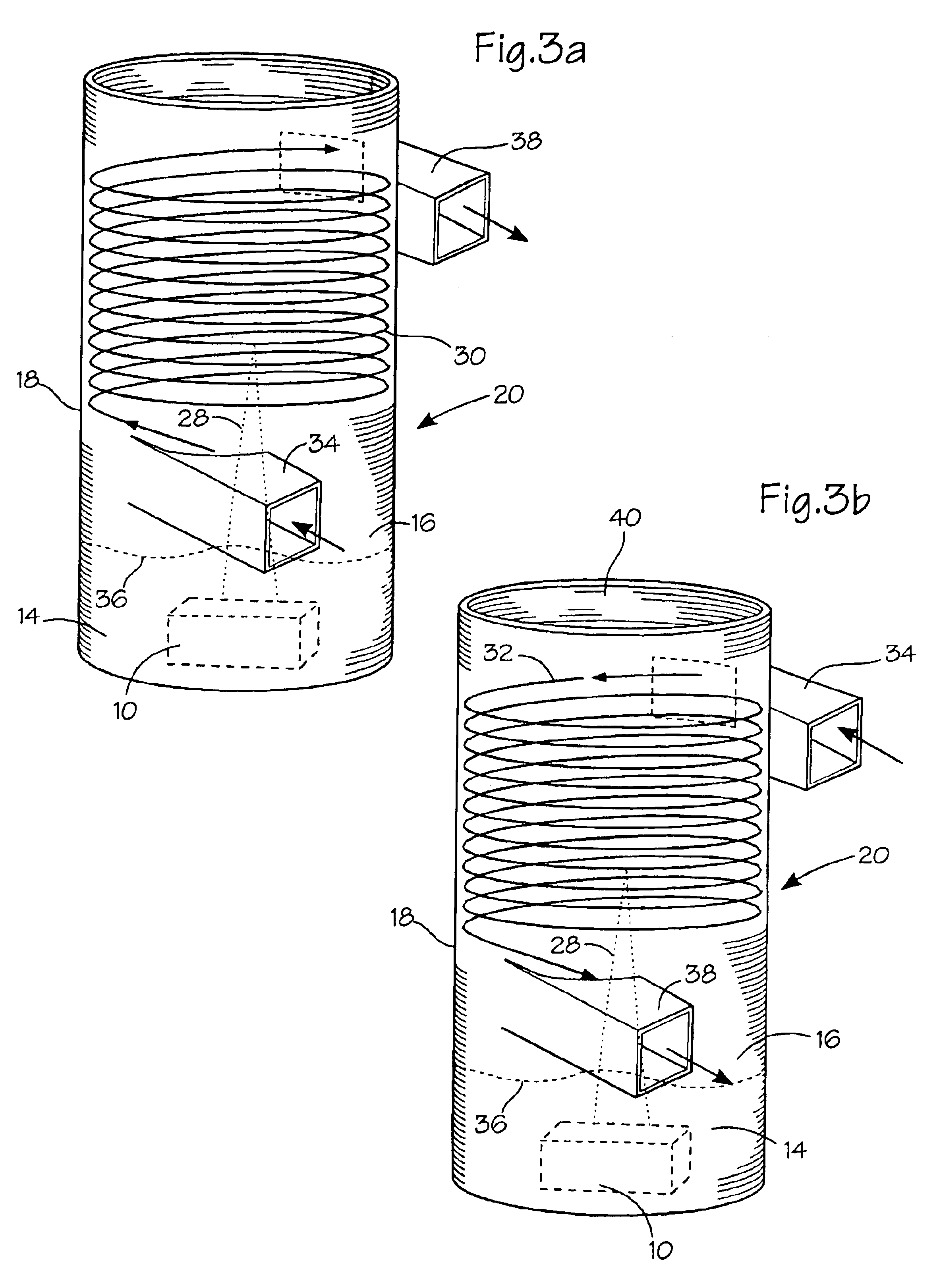

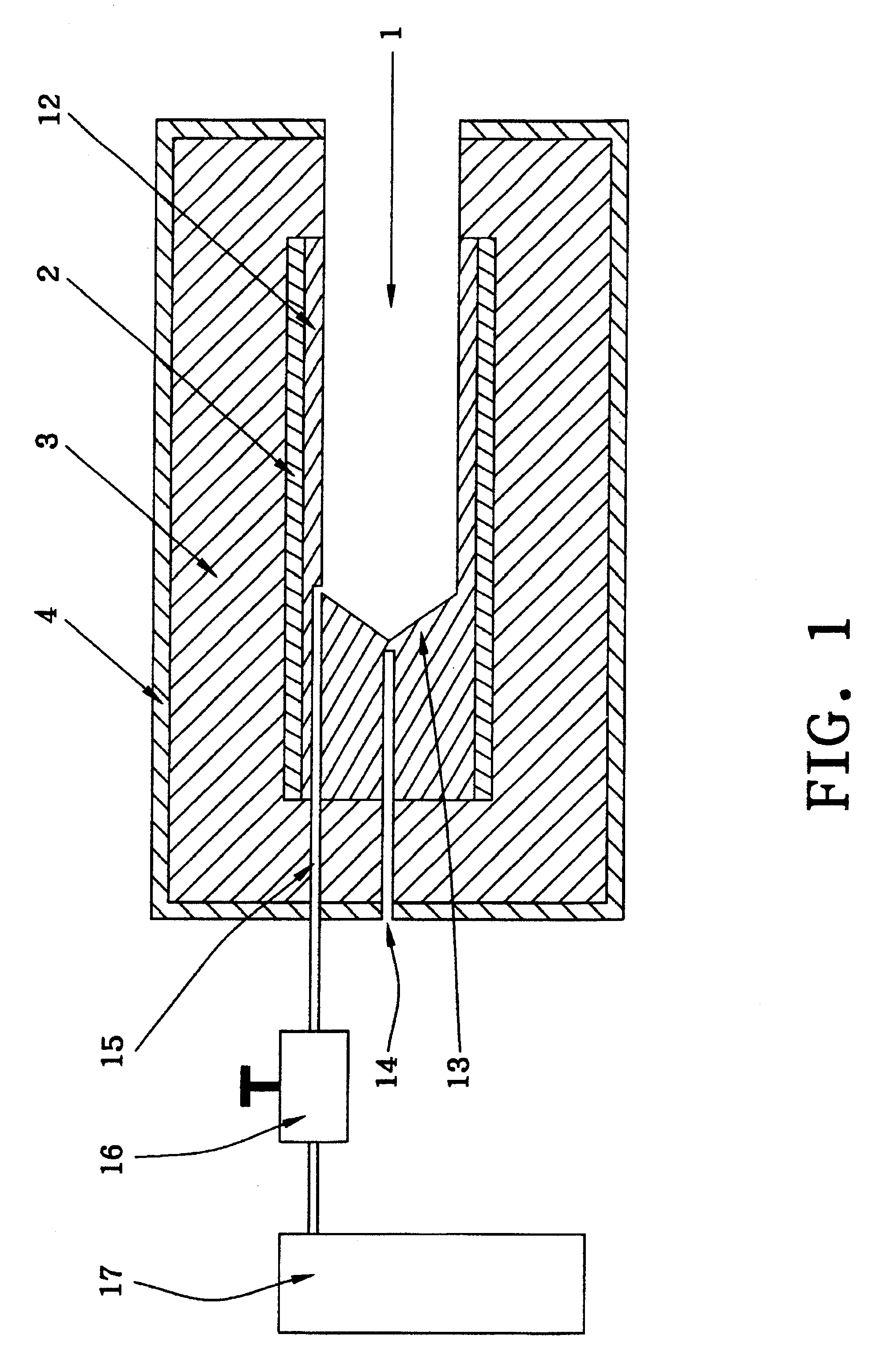

Method and device for production, extraction and delivery of mist with ultrafine droplets

InactiveUS6883724B2Improve carrier gas flowEnhanced ejectionSteam generation heating methodsMovable spraying apparatusAerosol MistEngineering

The present invention provides a method and device for production, extraction and delivery of an aerosol mist with ultrafine droplets. A high frequency wave generating device or other process generates very small particles or droplets from a reservoir of liquid or material to be atomized. A helical flow of a carrier gas medium such as air is directed into a container and creates a high throughput aerosol of air and fine droplets. The aerosol is delivered through a suitable outlet such as by deflecting the aerosol upwards and providing a tube centrally situated with respect to the helical flow such that the aerosol will discharge through the tube in high quantity of throughput and high quality of stable aerosol of very fine mist droplets. The methods described utilize in-situ extraction of fine mist droplets using helical flow behavior as opposed to forced convection ejection of mist or inertial separation of droplets by separators.

Owner:NANOMIST SYST

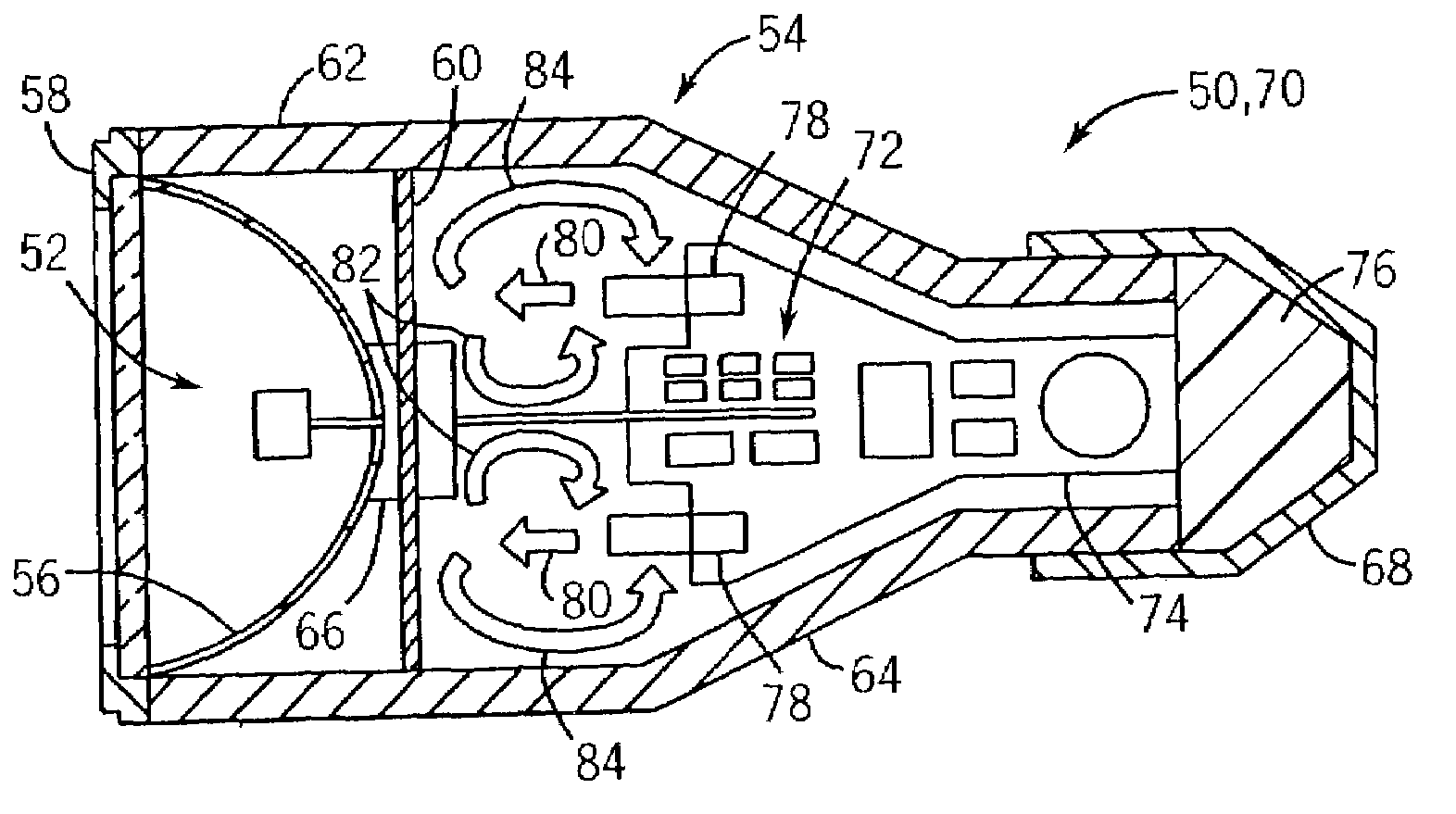

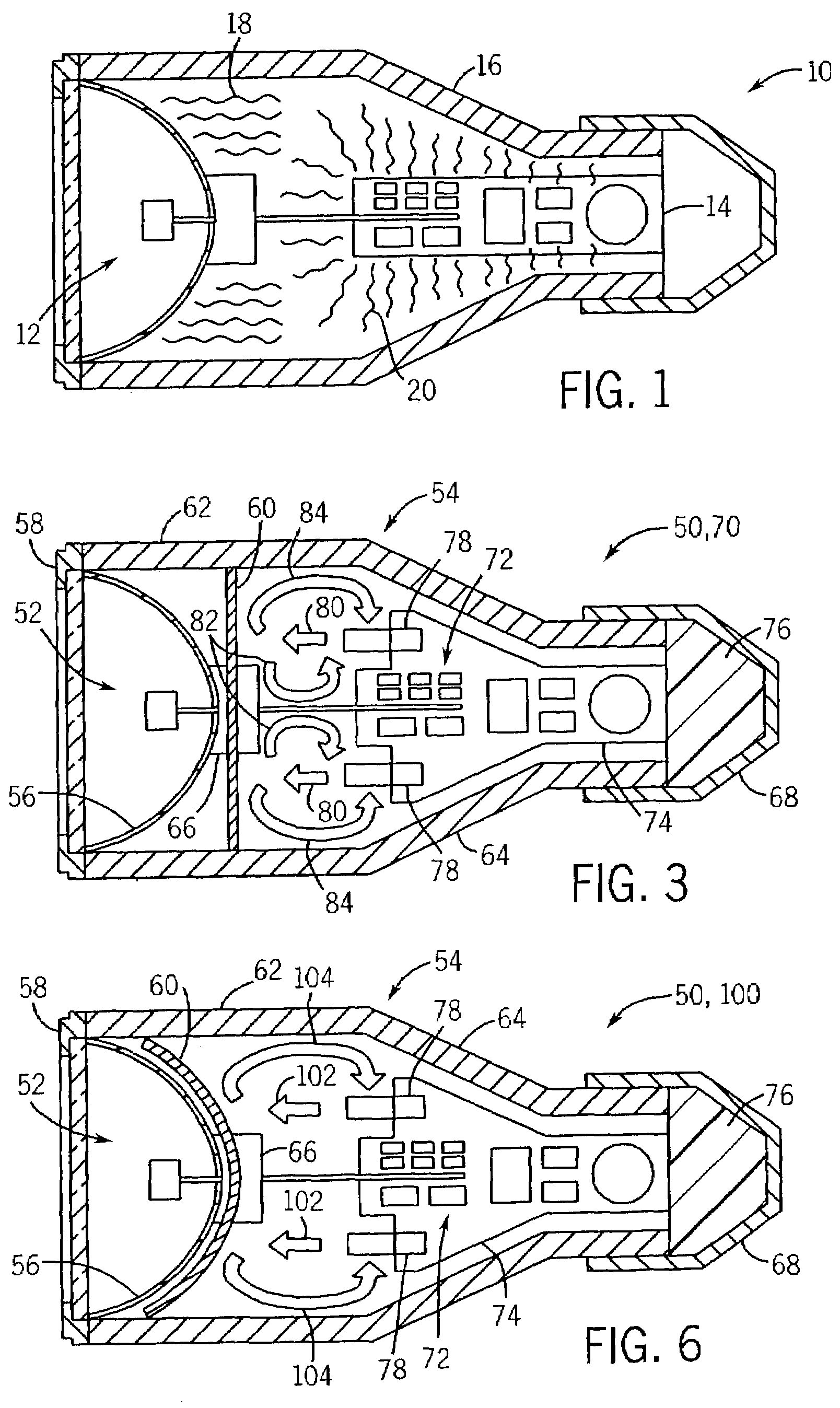

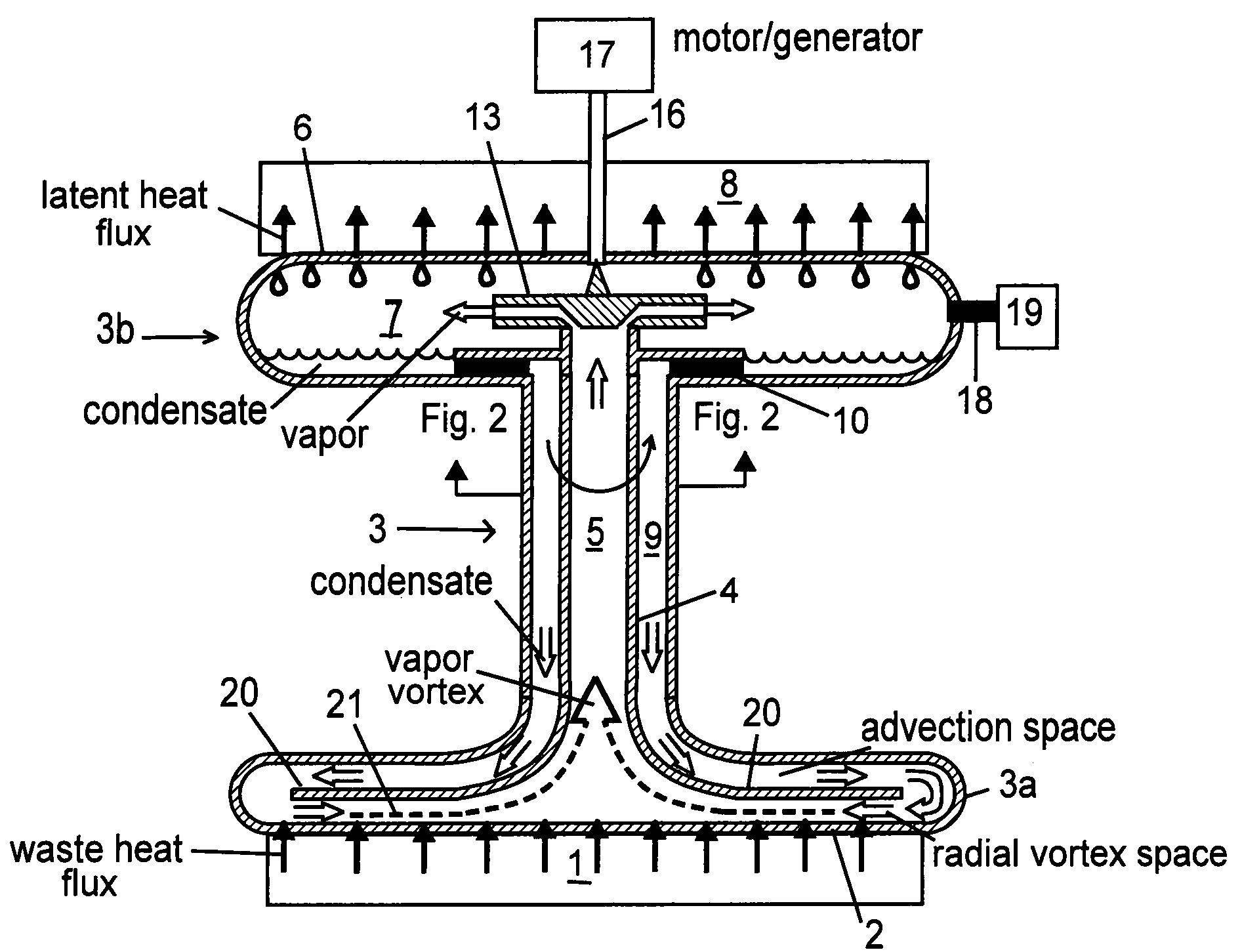

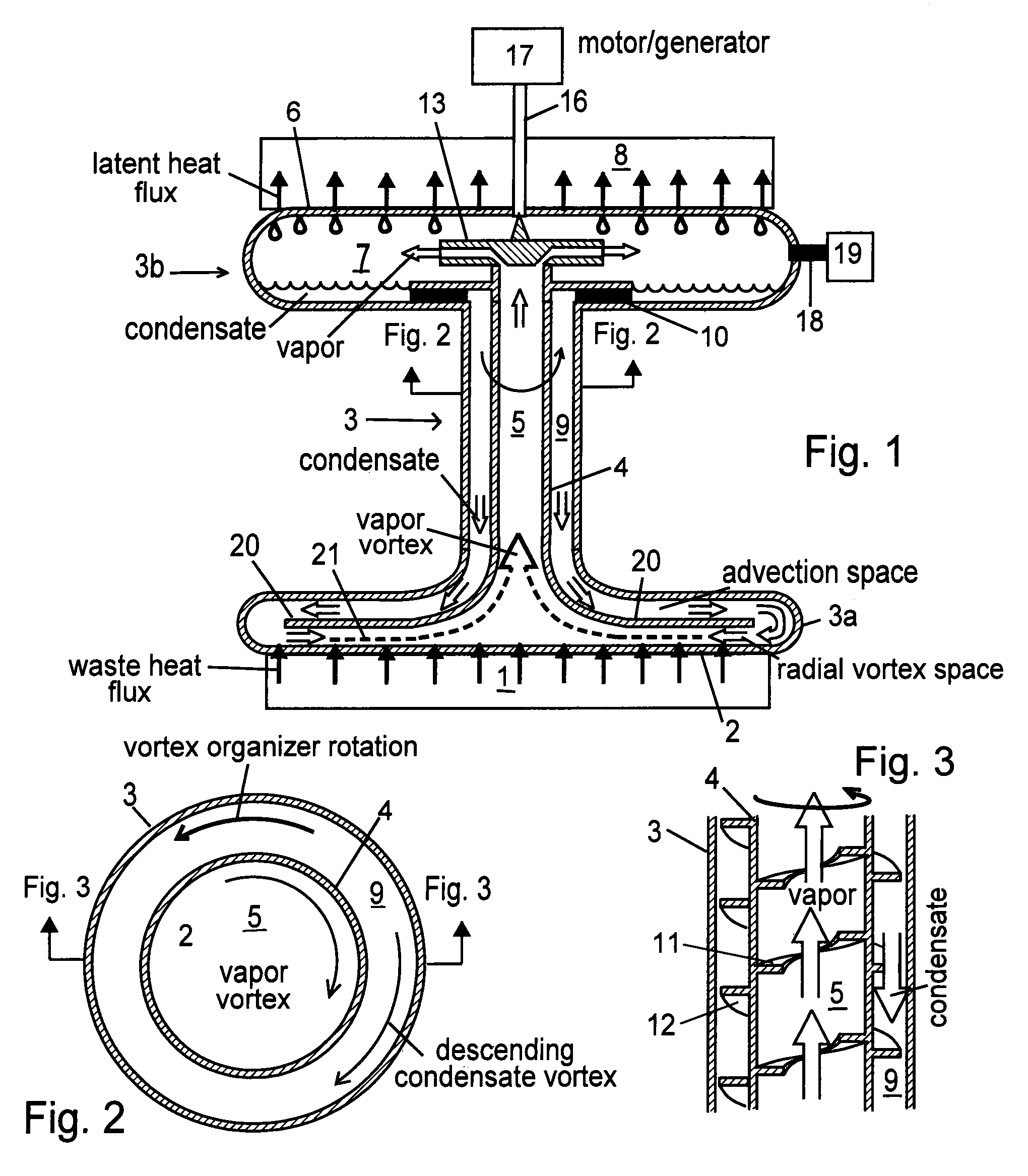

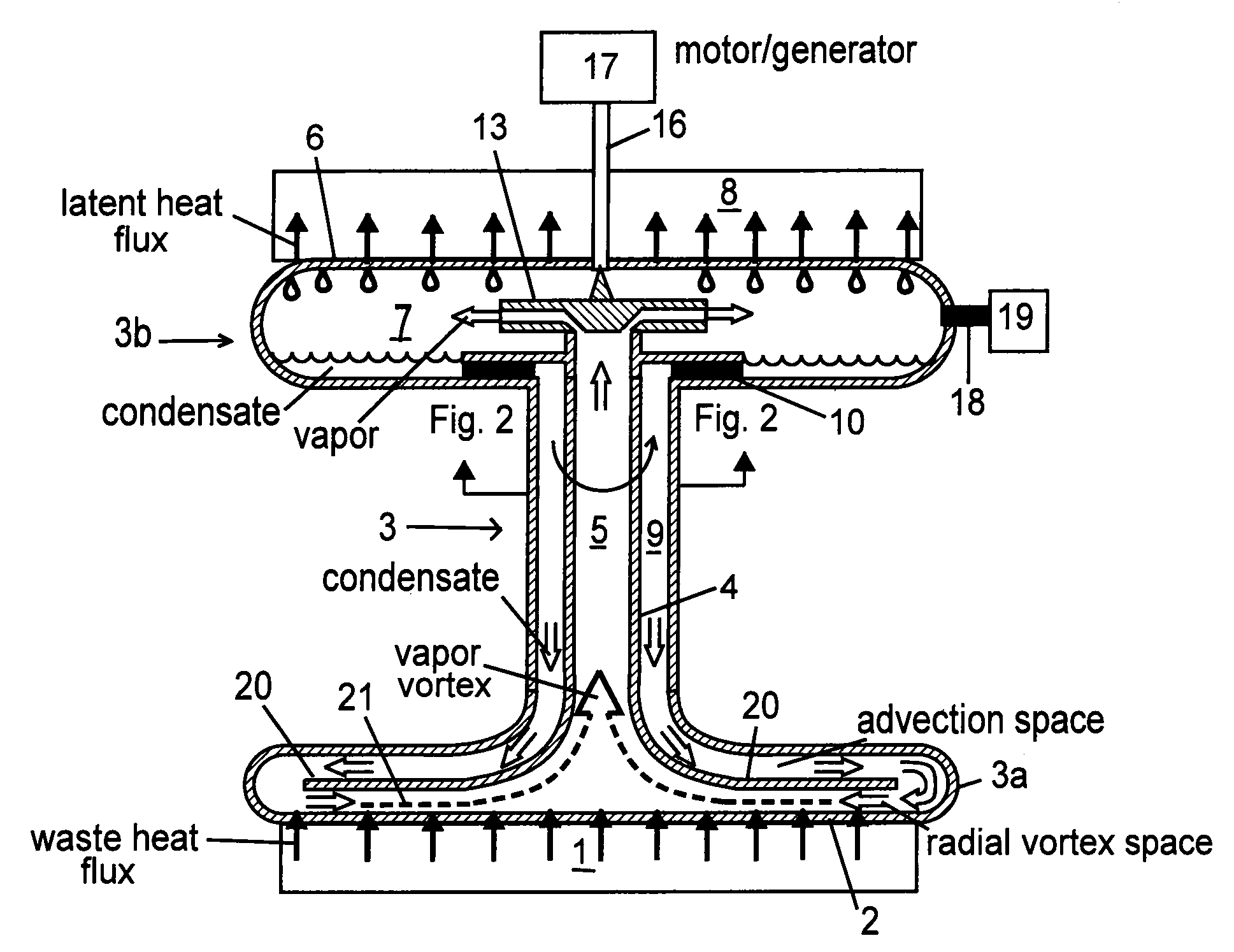

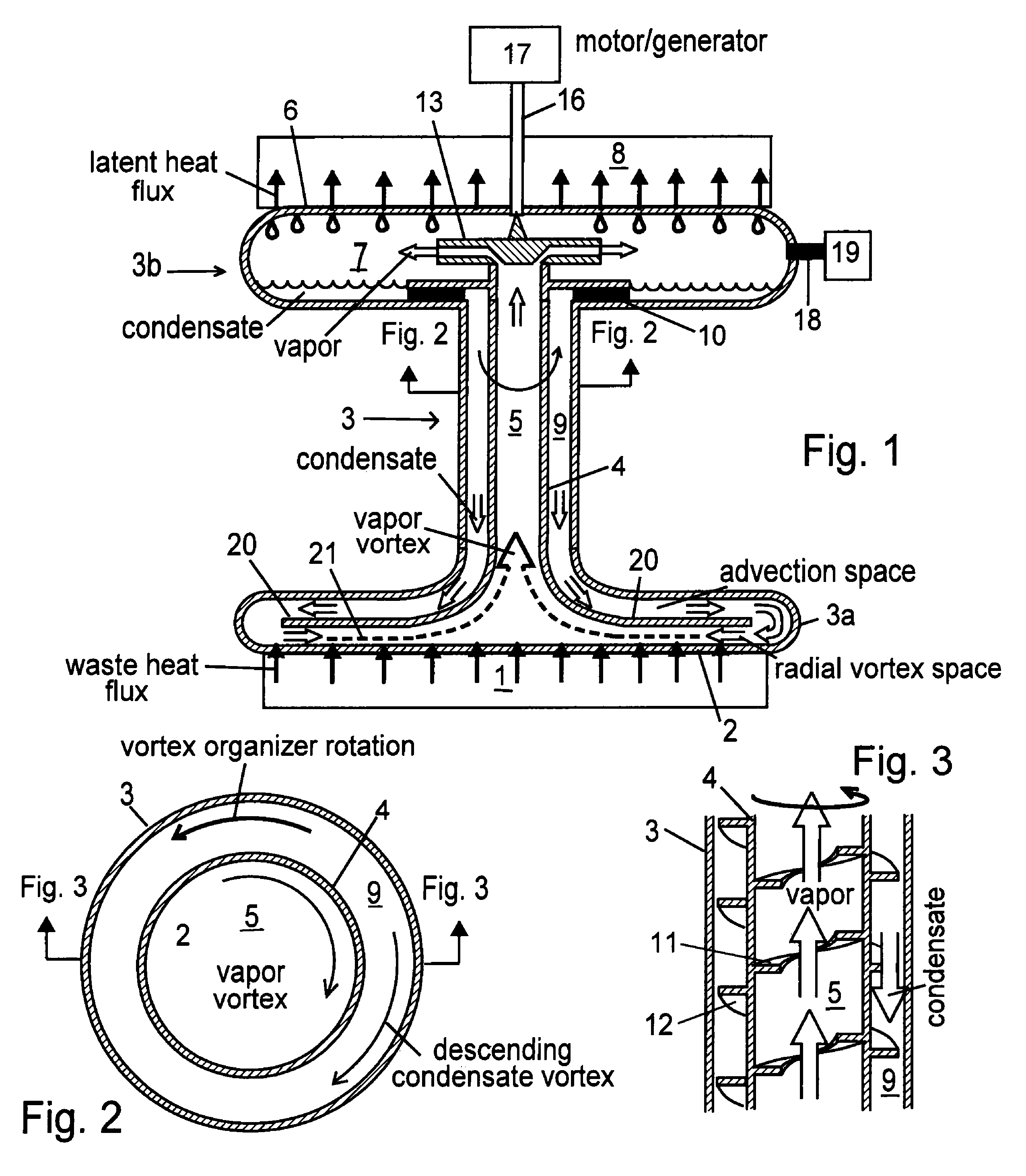

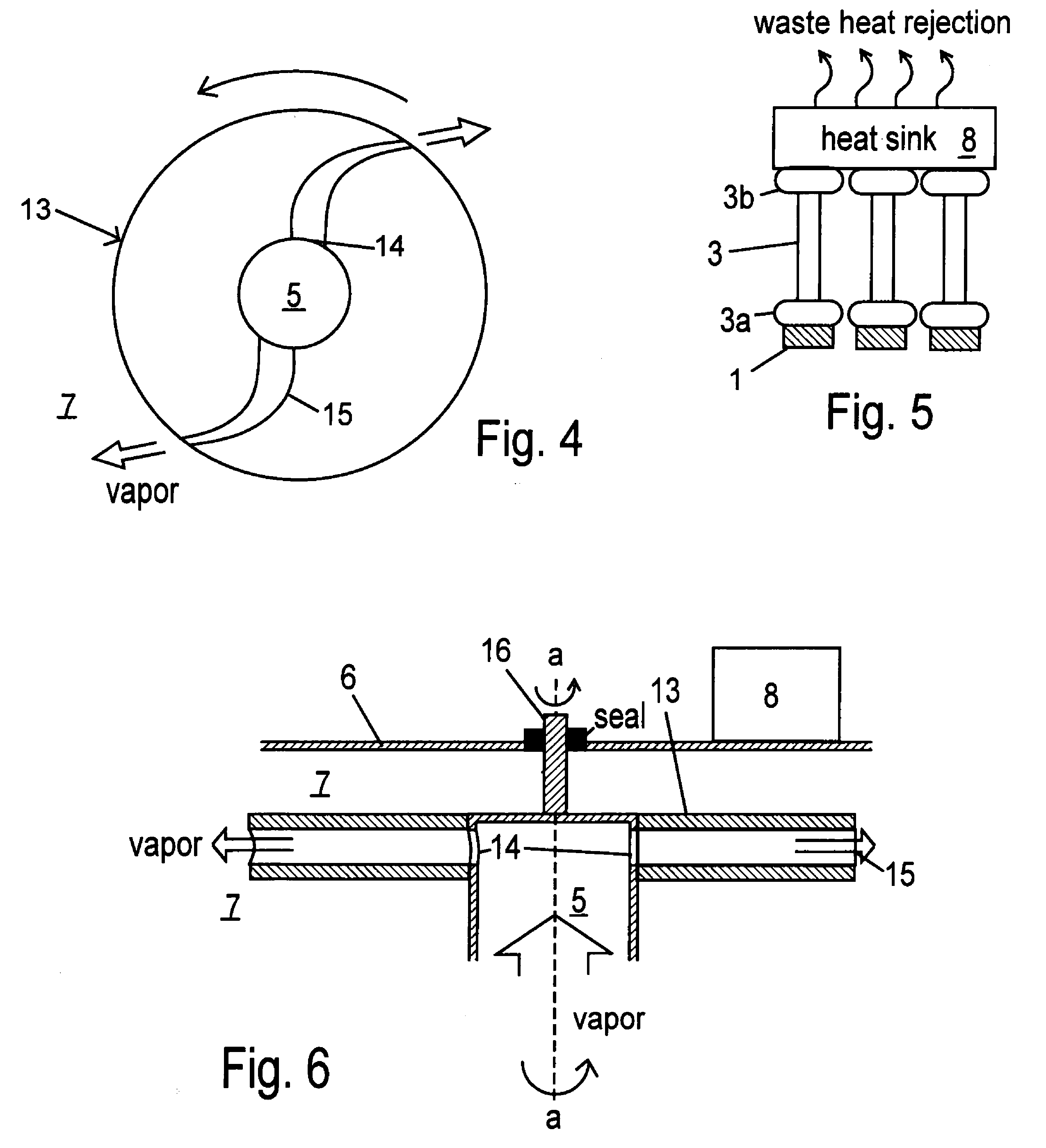

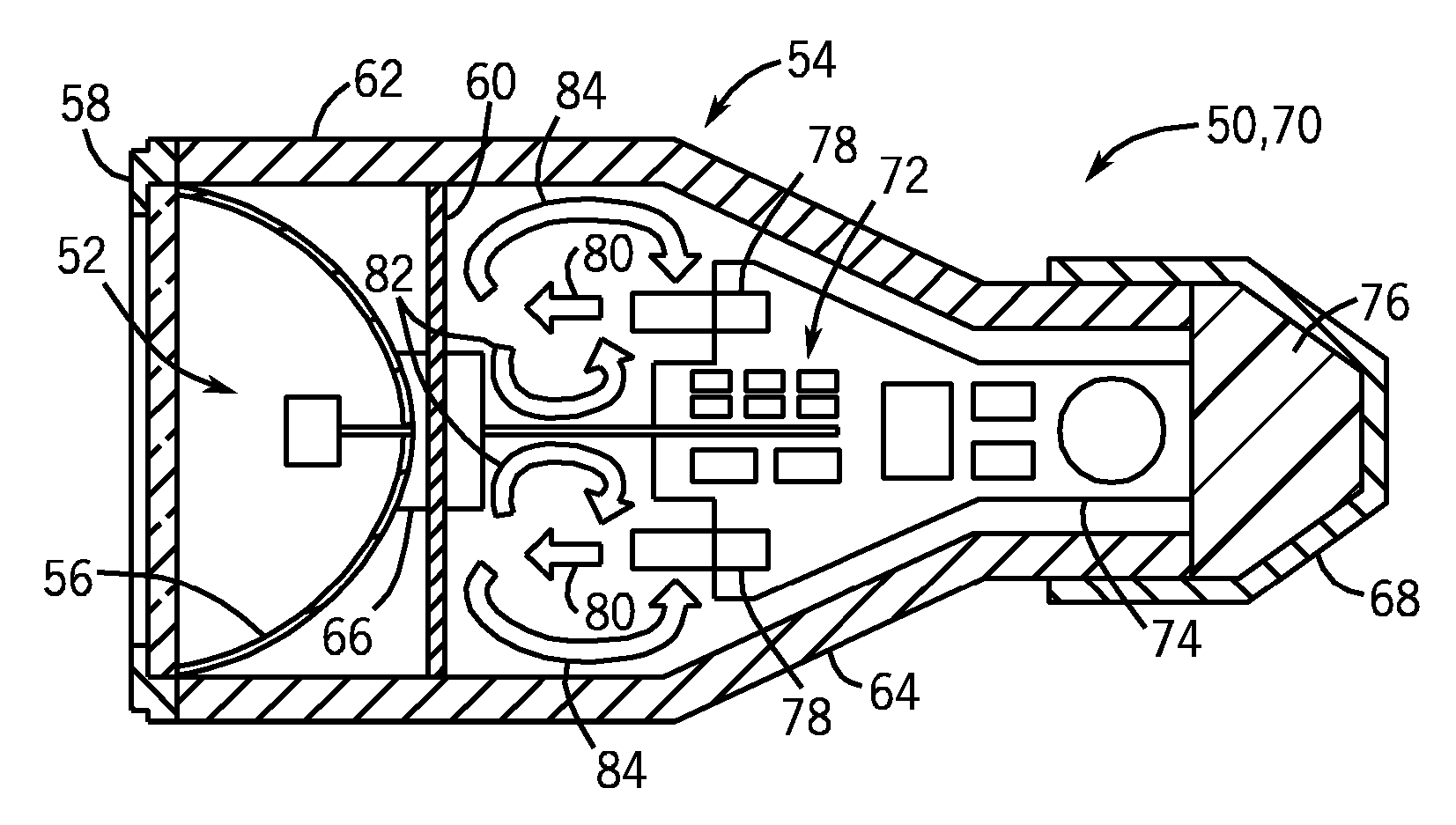

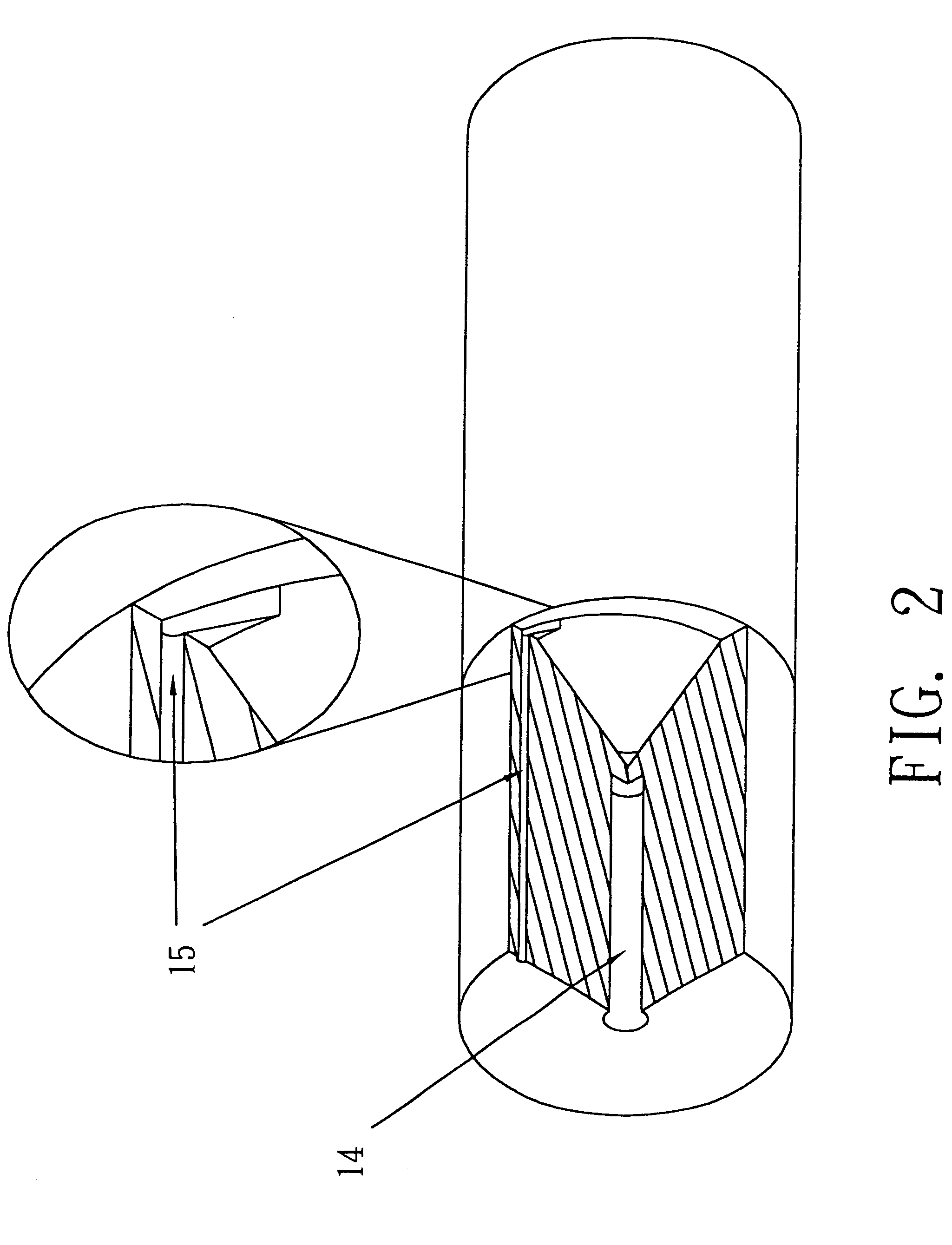

Vapor vortex heat sink

ActiveUS20090242174A1Powerful power generationSemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat flux

A hermetic Rankine cycle in a sealed casing powers an internal centrifugal condensate pump with an internal vapor turbine during forced convective heat transfer between a heat source and a heat sink. No work is imported into the cycle during operation. A centrifugal pumping disk shears the working fluid against a heating surface, sweeping evolving vapor into radial vortices which provide sink flow conduits to a vapor space at the center of the cylindrical turbine. Convective mass flow through the vapor space to the condensing end of the casing spins the turbine and the centrifugal pumping disk which is connected to it. Vapor is continuously swept from the heating surface, so bubbles do not form and superheat while blocking heat flux into liquid working fluid. Vapor is sucked through the radial vortices into the central vapor space and into the condensing end of the casing along the low pressure gradients in vortex cores established by cooling power. A high heat flux surface is thereby thermally connected to a conventional heat sink having high cooling power, for maximal heat extraction at data centers or other heat sources. Vapor vortices organize counterflow of vapor and condensate in a continuous mass flow cycle, and extract work from heat. Organic working fluids can be used in the casing to make even low temperature waste heat a power source.

Owner:MCCUTCHEN CO

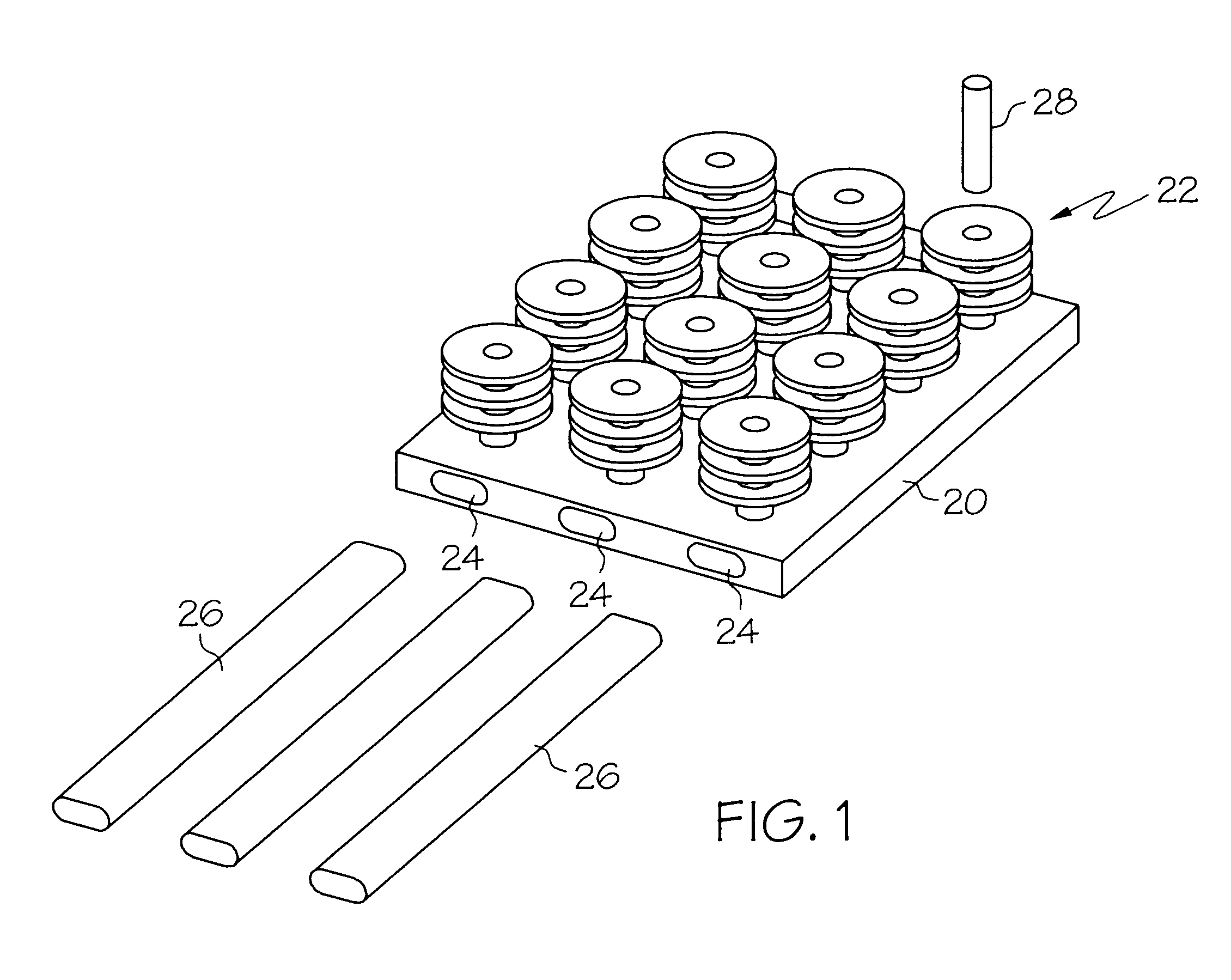

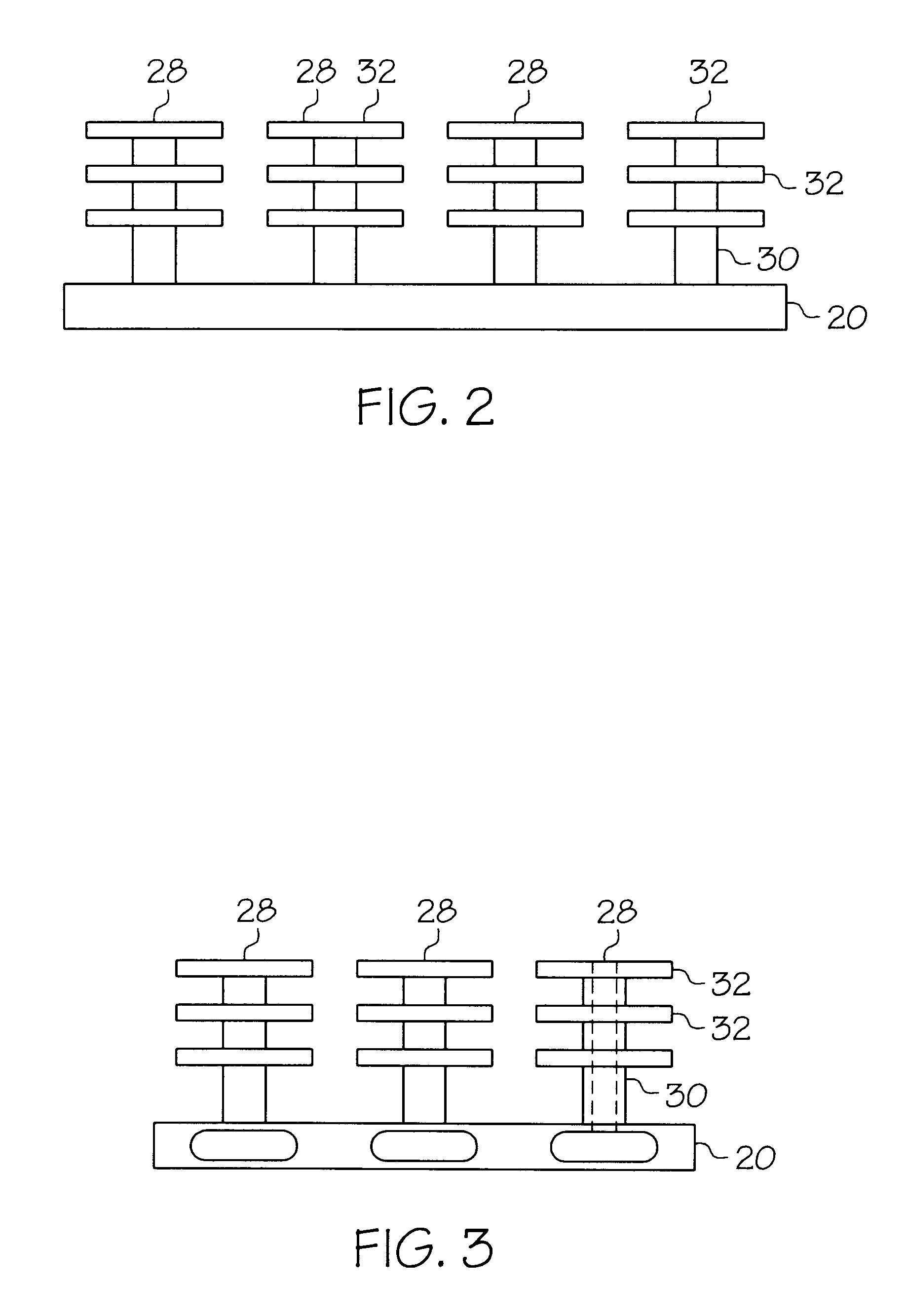

Scalable and modular heat sink-heat pipe cooling system

InactiveUS6374905B1Semiconductor/solid-state device detailsSolid-state devicesEngineeringForced convection

Modular heat sinks utilizing heat pipes to provide a more uniform temperature distribution over a packaged integrated circuit and efficient heat sinking in either free or forced convection environments. The heat sinks utilize both horizontal and vertical heat pipes to transfer heat both horizontally and vertically in the heat sinks. Selection of the number of heat pipes used allows tailoring of the heat sink capabilities for different applications using the same fundamental assemblage of parts. Various embodiments are disclosed.

Owner:SUN MICROSYSTEMS INC

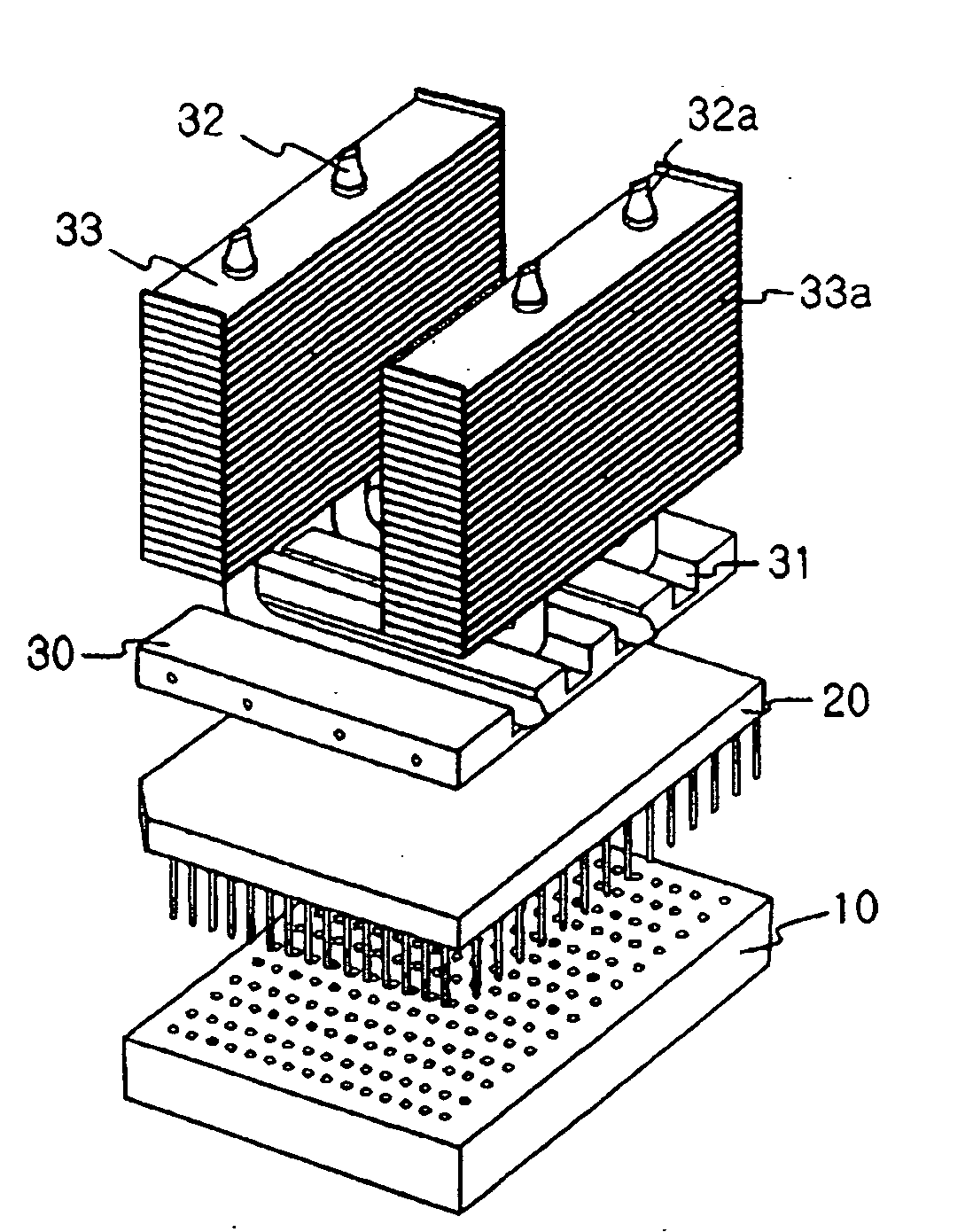

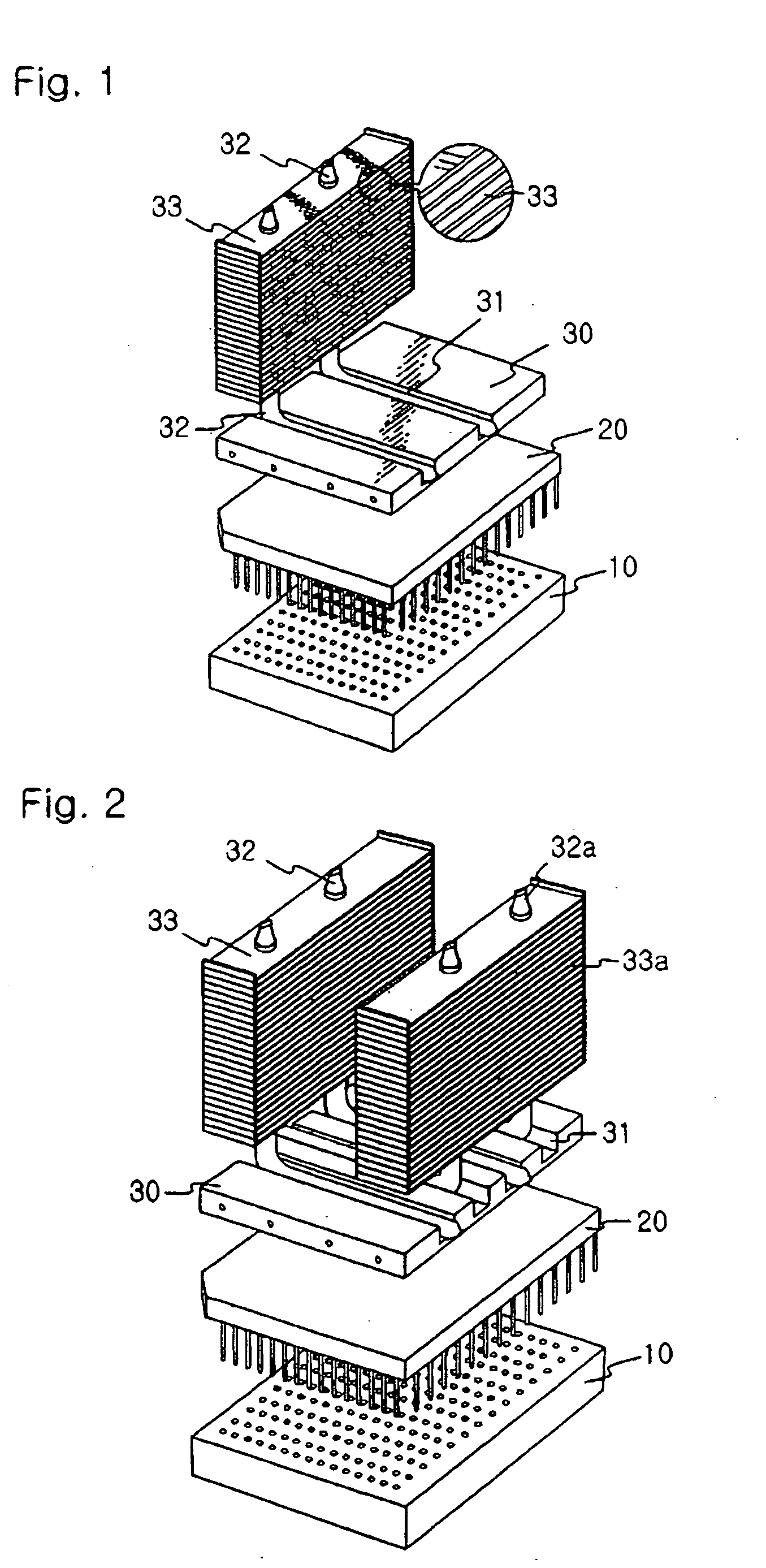

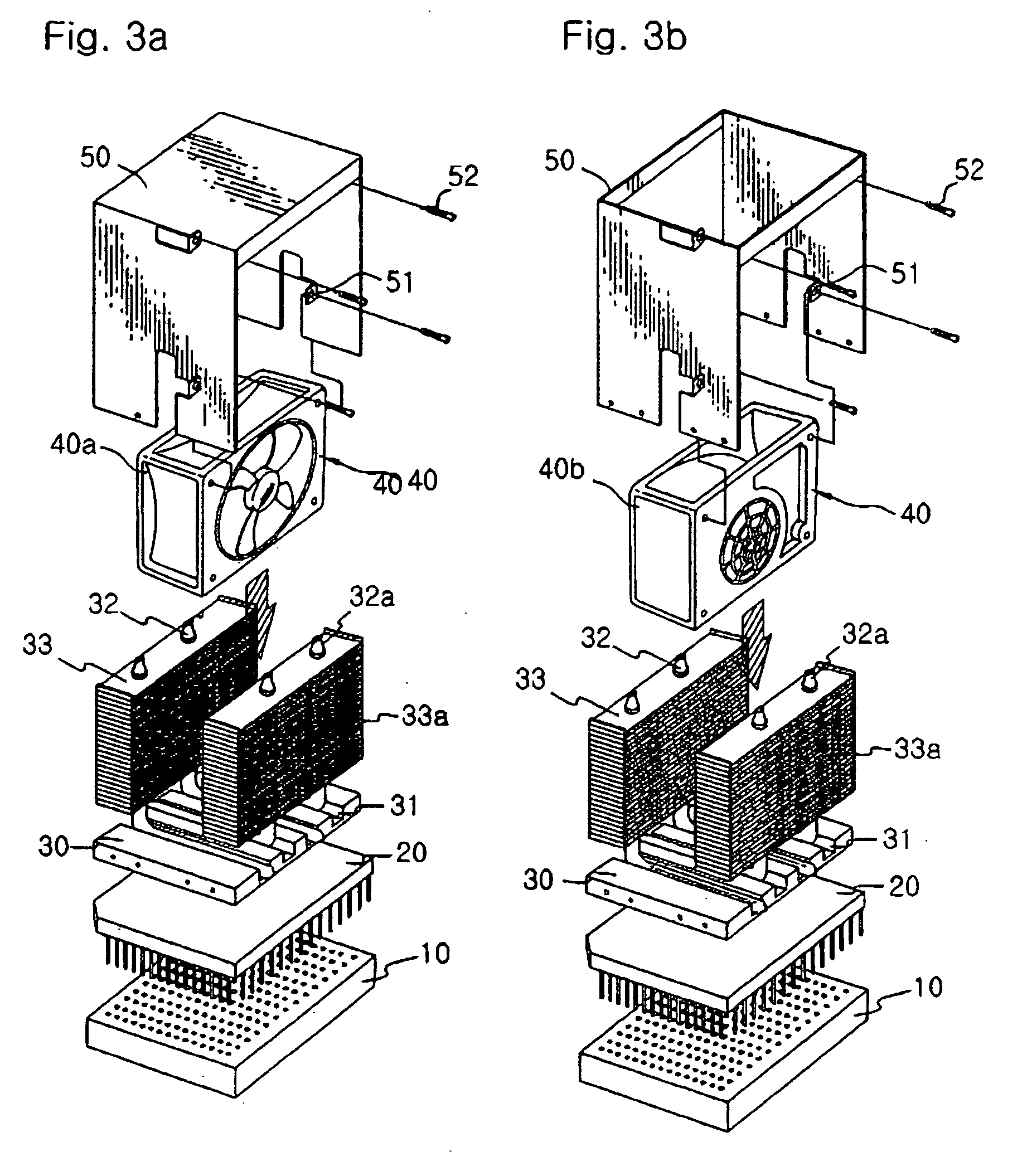

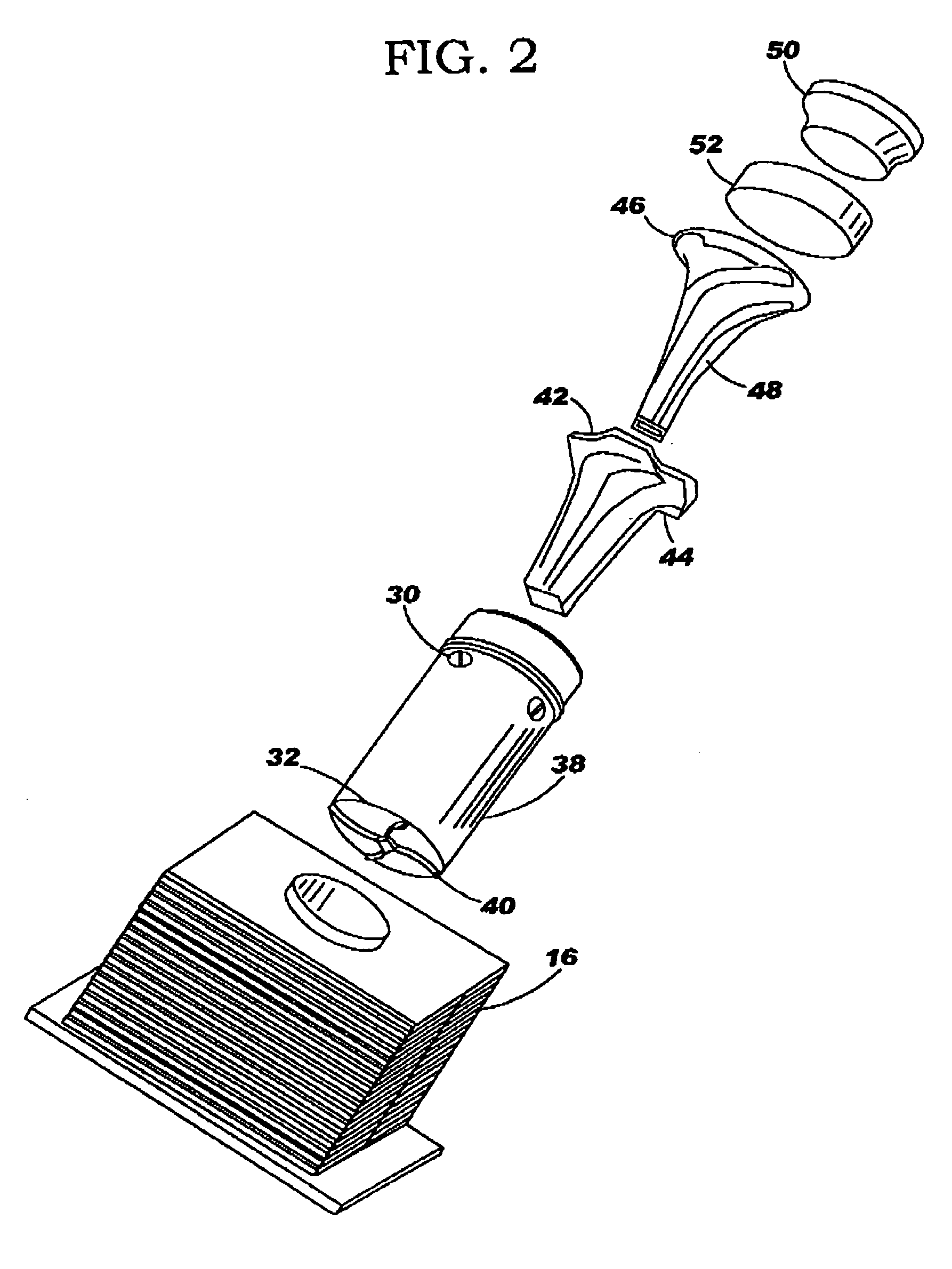

Semiconductor chip cooling module with fin-fan-fin configuration

InactiveUS20050099774A1Improve heating efficiencyImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The present invention relates to a semiconductor chip cooling module with fin-fan-fin configuration employing a heat pipe provided with air ventilating means having a forced convection cooling type radiating method of forcedly cooling heat radiating fins by ventilating a wind to rapidly discharge and cool heat generated from a central processing unit (hereinafter referred to as “CPU”) mounted on a main board of a computer; the present invention comprises a heat radiating plate having a plurality of slots, a pair of heat pipes installed in the slots in a symmetrical relationship, and air ventilating means having a ventilating fan installed between heat radiating pins of the pair of heat pipes, wherein an air is ventilated to the heat radiating pins to forcedly radiate the heat radiating pins. The present invention is capable of embodying a rapid radiation on an overheat of the CPU by employing a forced direct cooling method that air ventilating means is installed at a center of plural rows of heat pipes to ventilate an air to thereby forcedly and directly cool the heat radiating fins mounted on the plural rows of heat pipes.

Owner:APACK +1

Vapor vortex heat sink

InactiveUS7980078B2Semiconductor/solid-state device detailsSolid-state devicesHeat fluxWorking fluid

A hermetic Rankine cycle in a sealed casing powers an internal centrifugal condensate pump with an internal vapor turbine during forced convective heat transfer between a heat source and a heat sink. No work is imported into the cycle during operation. A centrifugal pumping disk shears the working fluid against a heating surface, sweeping evolving vapor into radial vortices which provide sink flow conduits to a vapor space at the center of the cylindrical turbine. Convective mass flow through the vapor space to the condensing end of the casing spins the turbine and the centrifugal pumping disk which is connected to it. Vapor is continuously swept from the heating surface, so bubbles do not form and superheat while blocking heat flux into liquid working fluid. Vapor is sucked through the radial vortices into the central vapor space and into the condensing end of the casing along the low pressure gradients in vortex cores established by cooling power. A high heat flux surface is thereby thermally connected to a conventional heat sink having high cooling power, for maximal heat extraction at data centers or other heat sources. Vapor vortices organize counterflow of vapor and condensate in a continuous mass flow cycle, and extract work from heat. Organic working fluids can be used in the casing to make even low temperature waste heat a power source.

Owner:MCCUTCHEN CO

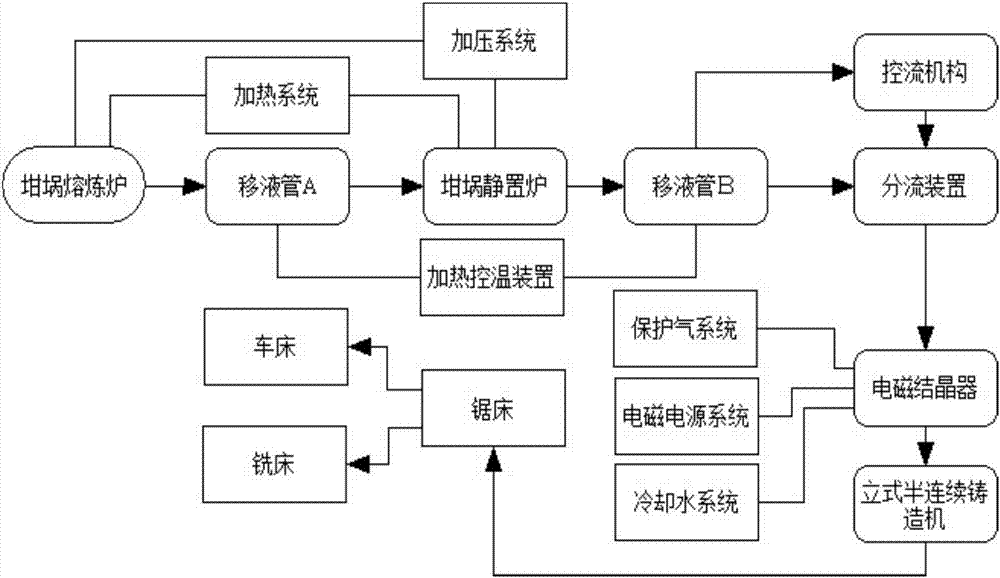

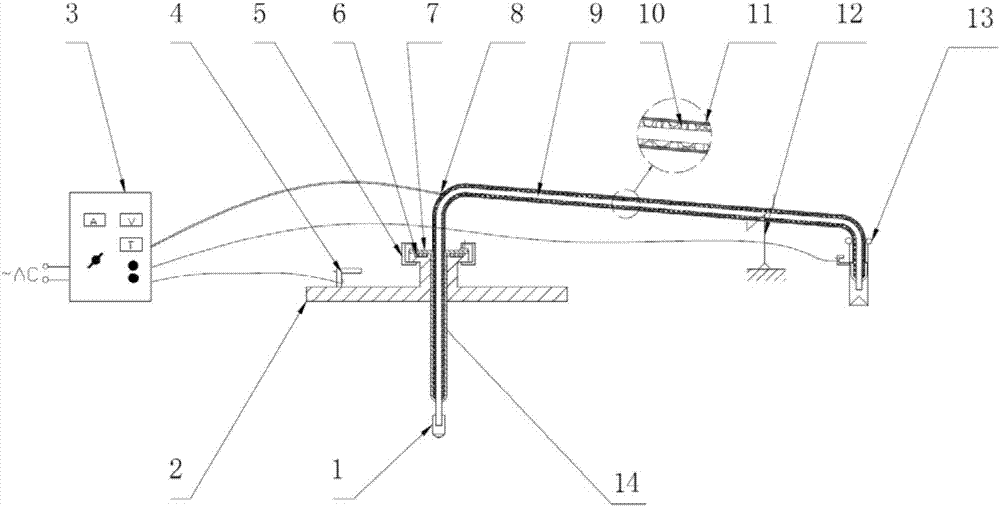

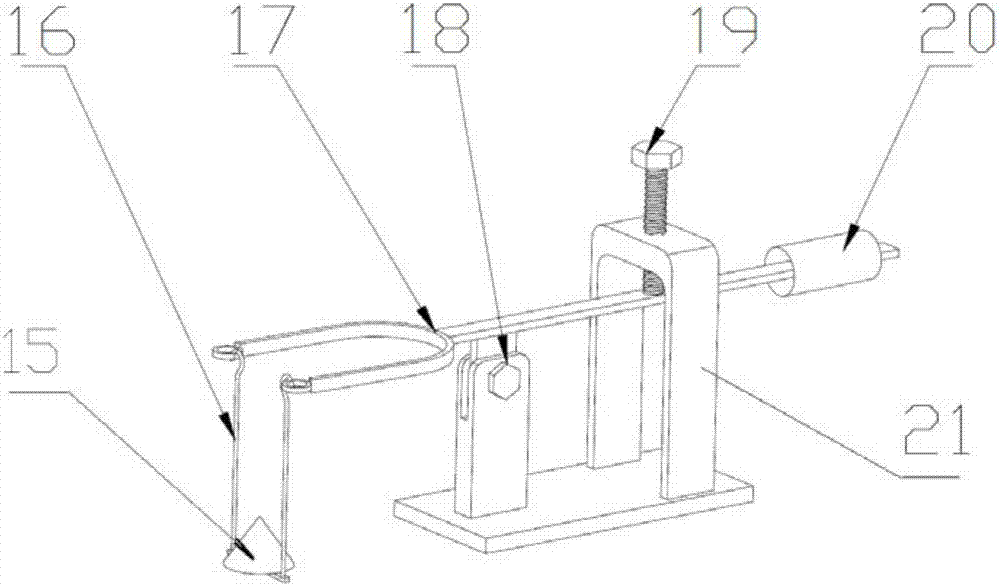

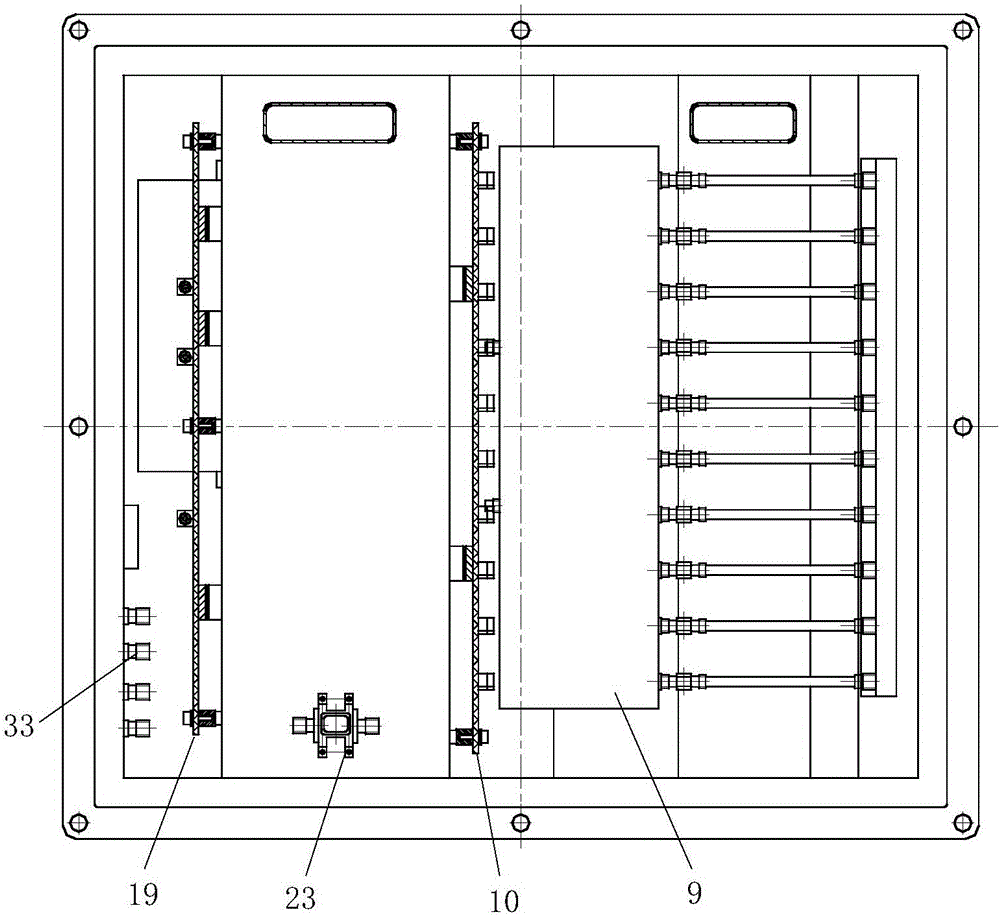

Electromagnetic semicontinuous casting device and casting method thereof

The invention discloses an electromagnetic semicontinuous casting device and a casting method thereof. The electromagnetic semicontinuous casting device comprises a crucible smelting furnace, a crucible standing furnace, a flow control mechanism, a split-flow device, an electromagnetic crystallizer system and a vertical semicontinuous casting machine, wherein the electromagnetic crystallizer system is a metal inner sleeve crystallizer system in which a group of build-in excitation coil is fixed, and comprises a metal inner sleeve, a cooling water cavity, the excitation coil, an oil supply system, an oil distribution system and a protective gas ring. According to the electromagnetic semicontinuous casting device disclosed by the invention, through a method of adjusting the frequency of electrical current, duty ratio and average current strength, the electrical current in a unique wave shape is formed in the single excitation coil placed in the cooling cavity of a crystallizer, so that desired forced convection or shaking effect is formed in the crystallizer with low current intensity; the grain of ingot blank is significantly refined; and columnar crystals are significantly reduced or eliminated to lower macroscopic segregation and realize the technical effect of low-stress casting. Under the condition of similar functional effects, the size of the electromagnetic crystallizer system is one third to one half of that of an original electromagnetic crystallizer system.

Owner:NORTHEASTERN UNIV

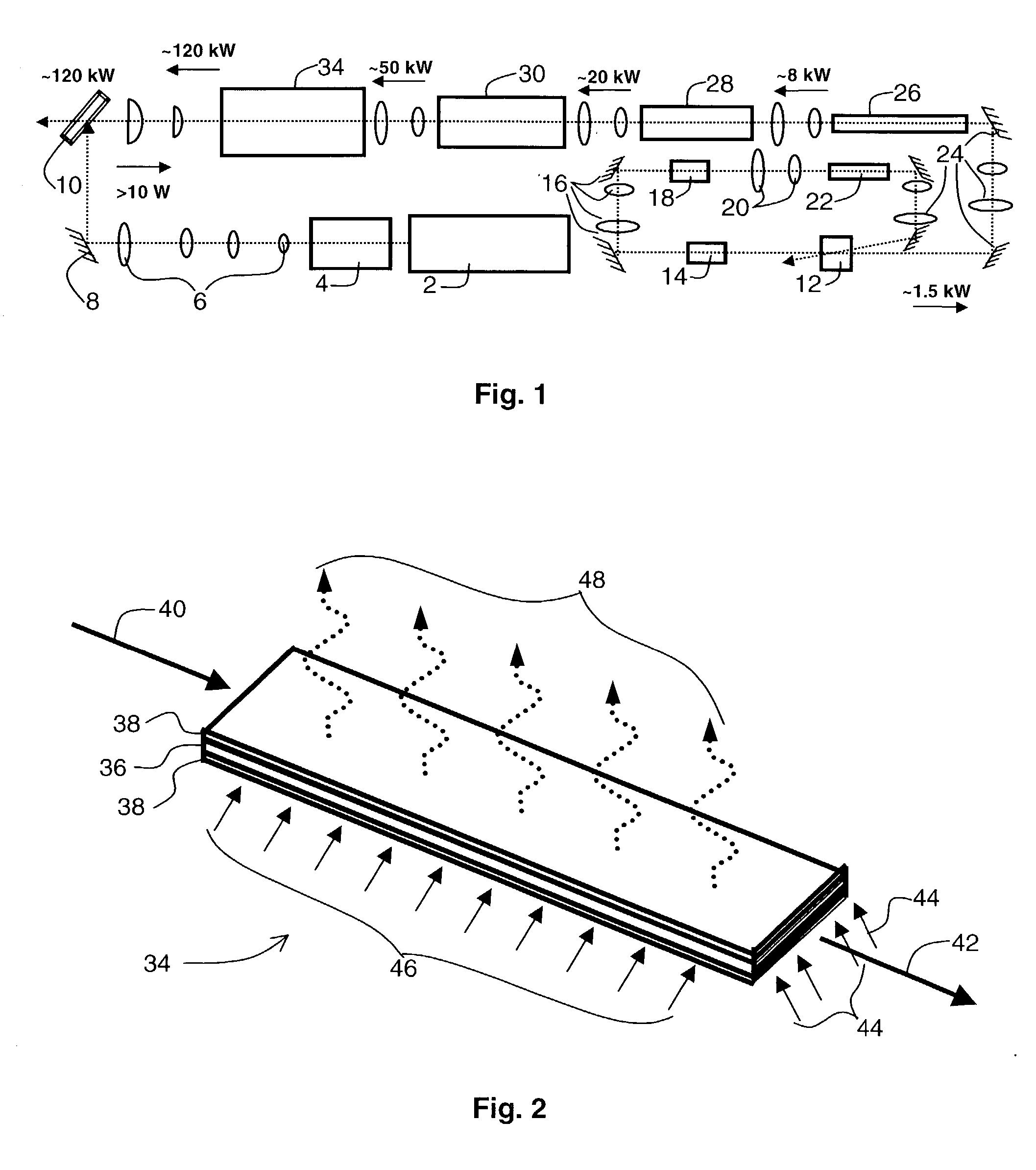

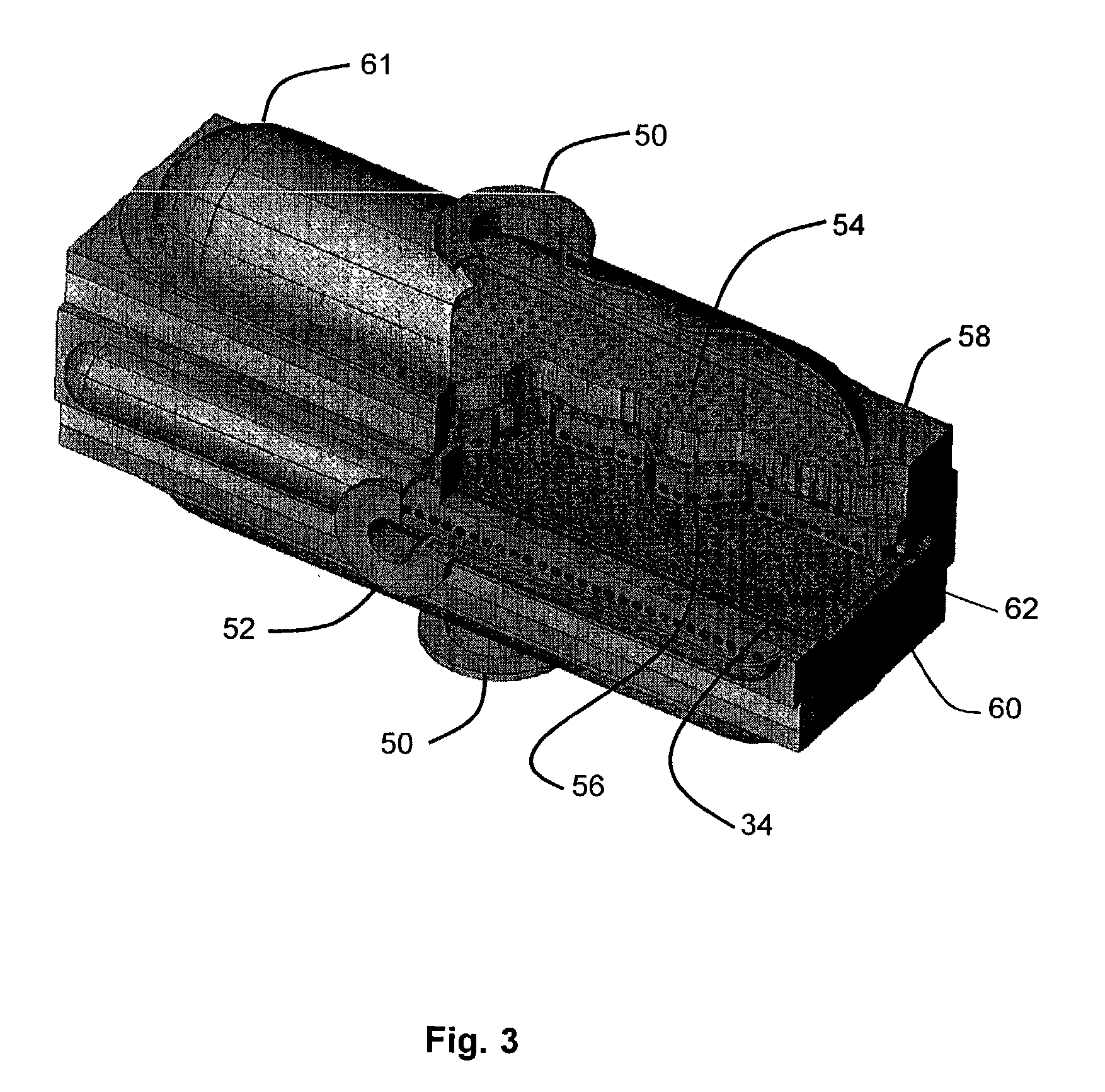

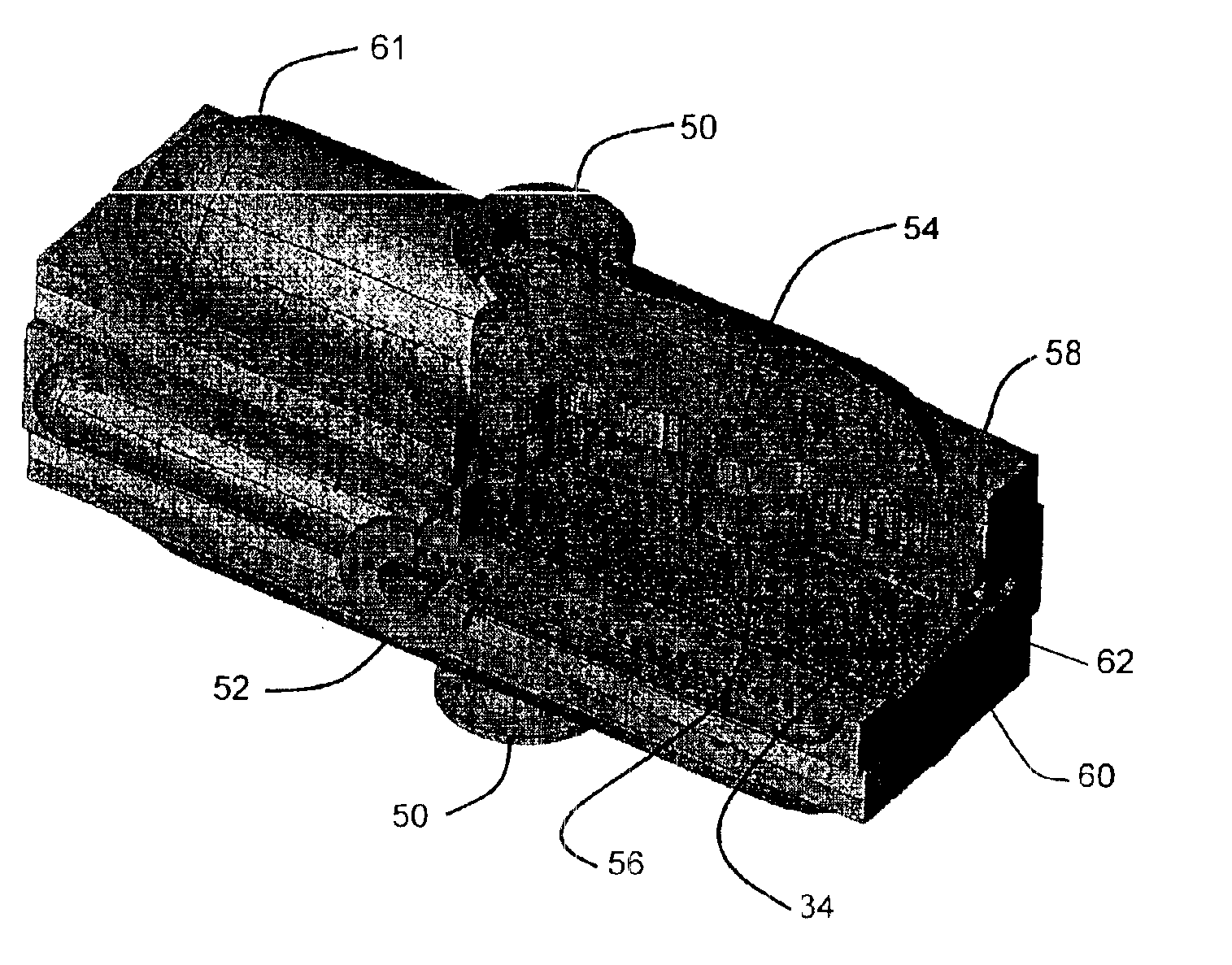

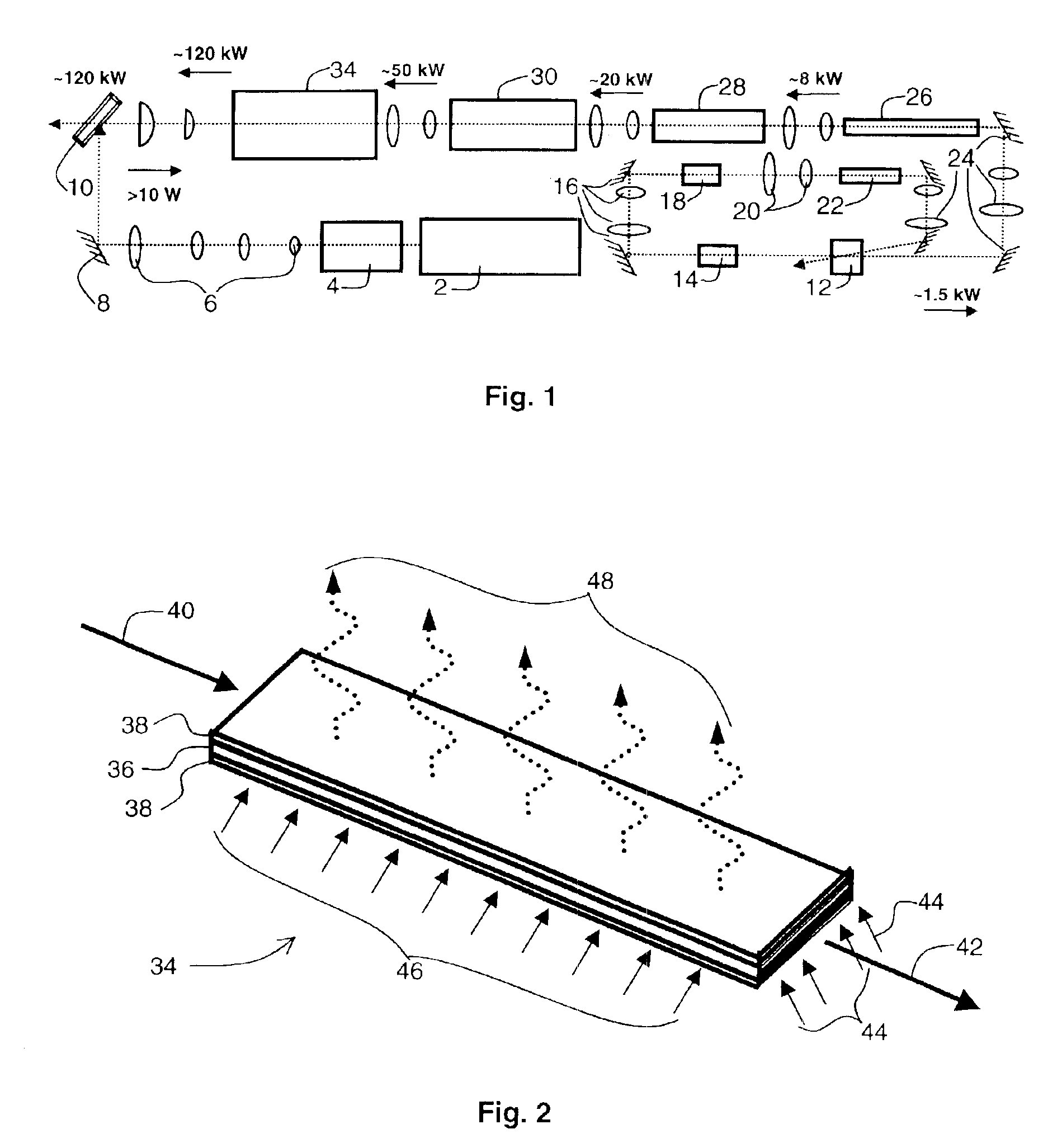

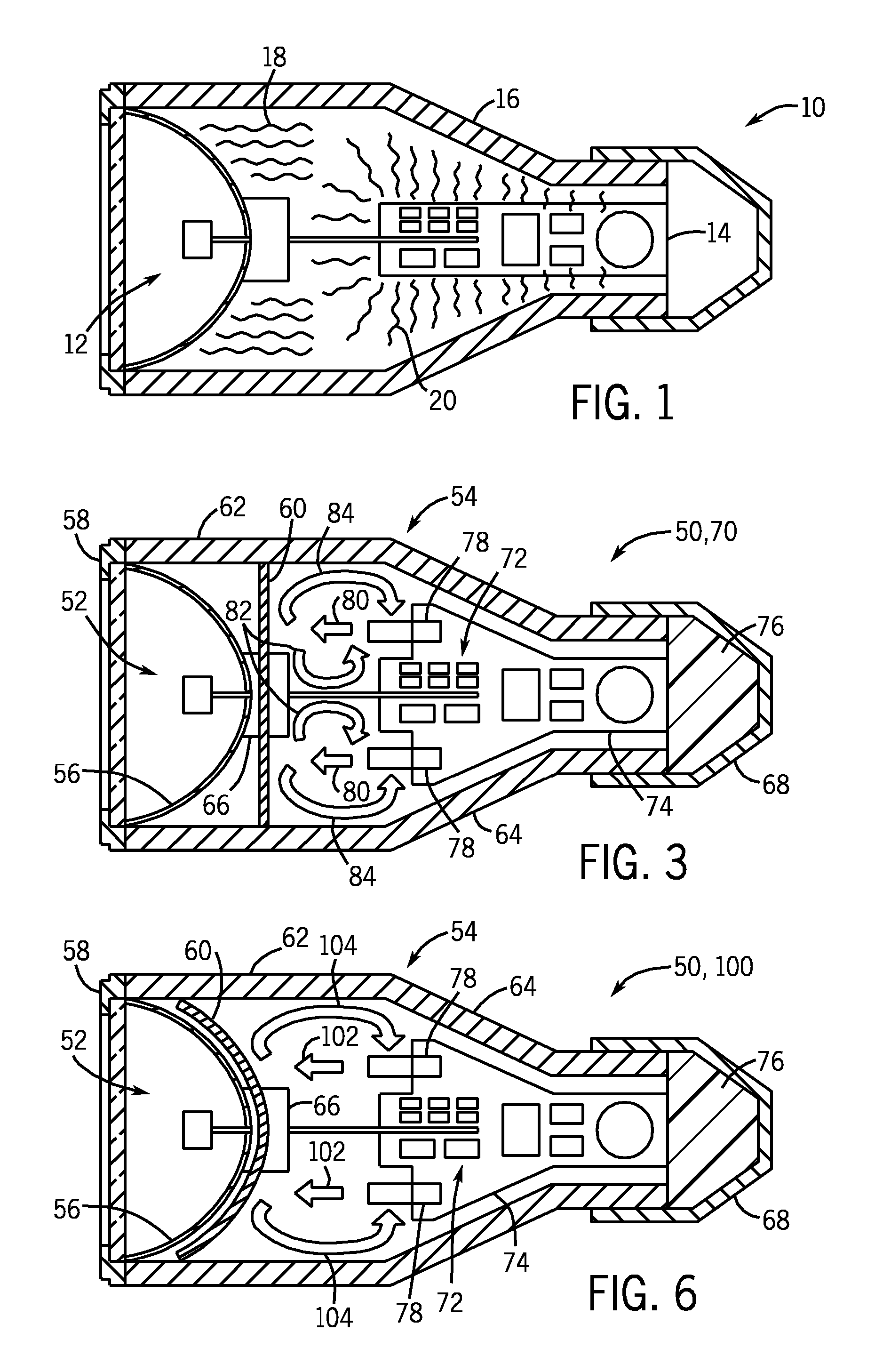

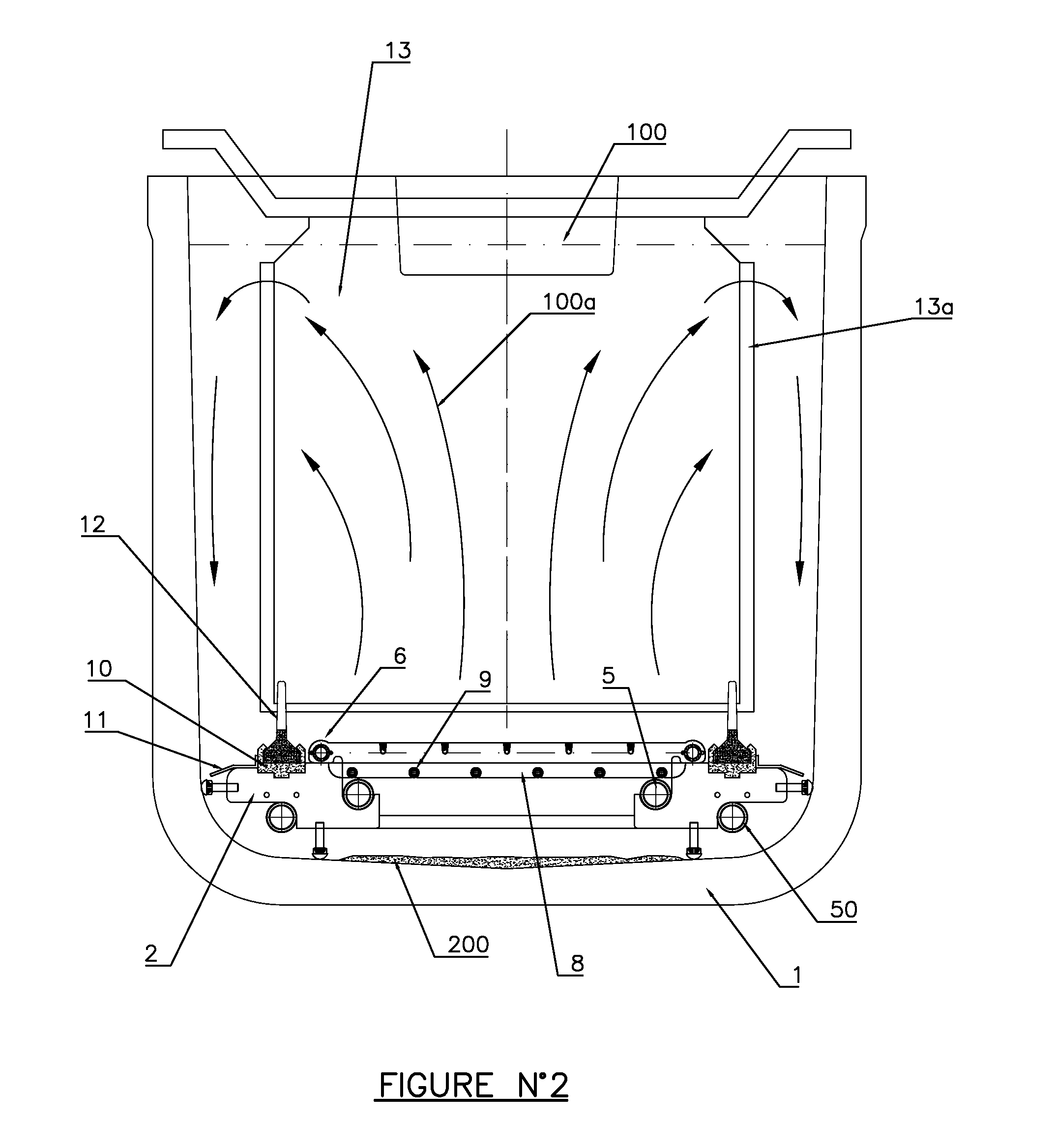

Multi-jet impingement cooled slab laser pumphead and method

InactiveUS20040028094A1Laser arrangementsActive medium shape and constructionSuspended particlesCoolant flow

A system for removing waste energy in the form of sensible heat and fluorescent energy from a solid state laser medium having a broad surface. The system includes a manifold disposed about the laser medium having a plurality of inlet jets interspersed with a plurality of exhaust orifices. Coolant fluid is circulated through the manifold. The fluid is forced through the plurality of inlet jets to impinge the broad face of the laser medium, thereby transferring waste energy by convection from the laser medium to the coolant fluid. The coolant fluid is further circulated to exhaust the pumphead manifold through the plurality of exhaust orifices. The fluorescent energy, which is radiated from the laser medium, is converted to sensible heat by an absorber disposed within the coolant adjacent to the laser medium. The coolant then removes the converted heat by forced convection. The absorber can be suspended particles in the coolant fluid or a porous material supported in the manifold at some distance from the laser medium.

Owner:RAYTHEON CO

Multi-jet impingement cooled slab laser pumphead and method

InactiveUS6859472B2Easy to manufactureLaser arrangementsActive medium shape and constructionSuspended particlesCoolant flow

A system for removing waste energy in the form of sensible heat and fluorescent energy from a solid state laser medium having a broad surface. The system includes a manifold disposed about the laser medium having a plurality of inlet jets interspersed with a plurality of exhaust orifices. Coolant fluid is circulated through the manifold. The fluid is forced through the plurality of inlet jets to impinge the broad face of the laser medium, thereby transferring waste energy by convection from the laser medium to the coolant fluid. The coolant fluid is further circulated to exhaust the pumphead manifold through the plurality of exhaust orifices. The fluorescent energy, which is radiated from the laser medium, is converted to sensible heat by an absorber disposed within the coolant adjacent to the laser medium. The coolant then removes the converted heat by forced convection. The absorber can be suspended particles in the coolant fluid or a porous material supported in the manifold at some distance from the laser medium.

Owner:RAYTHEON CO

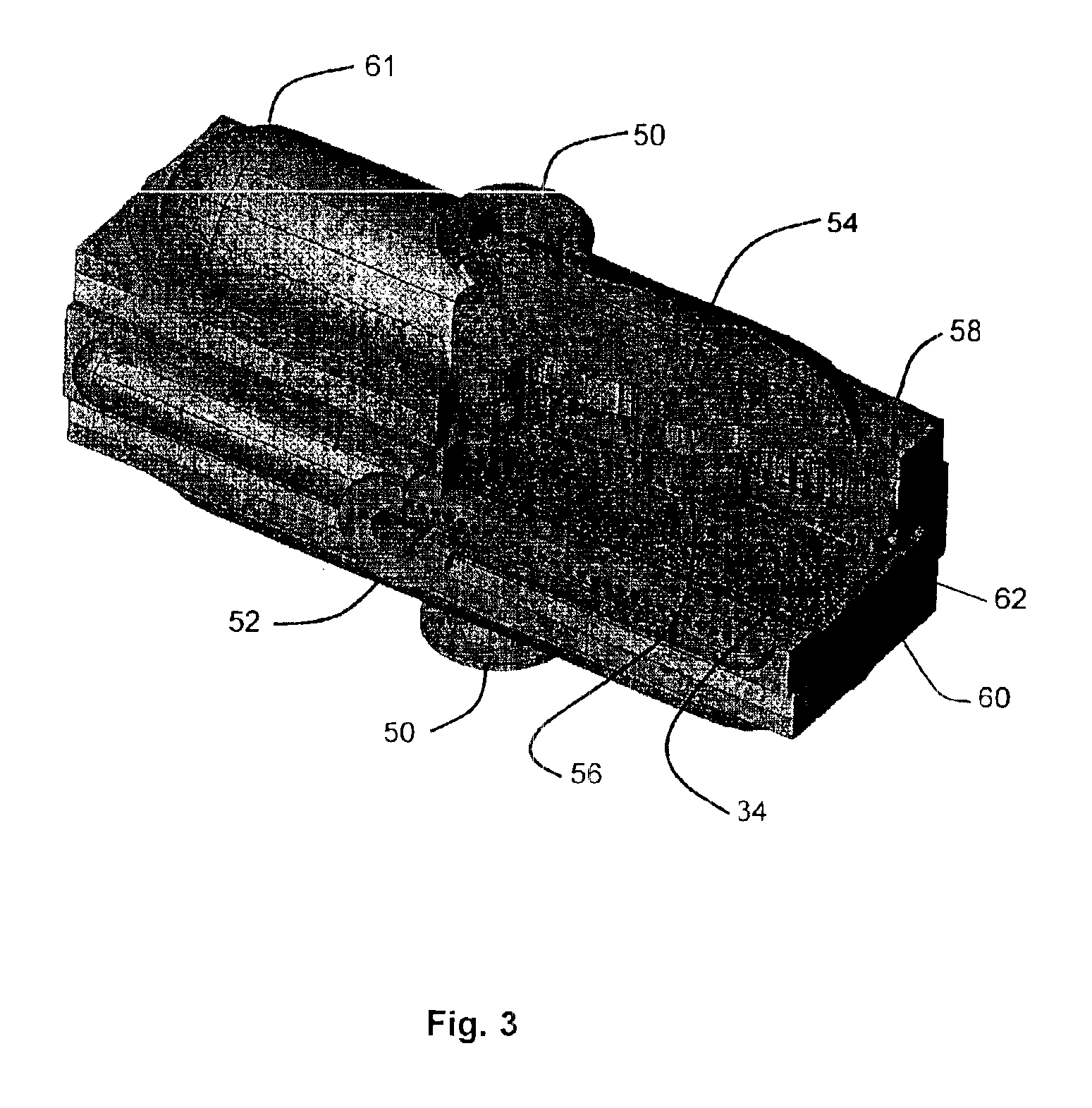

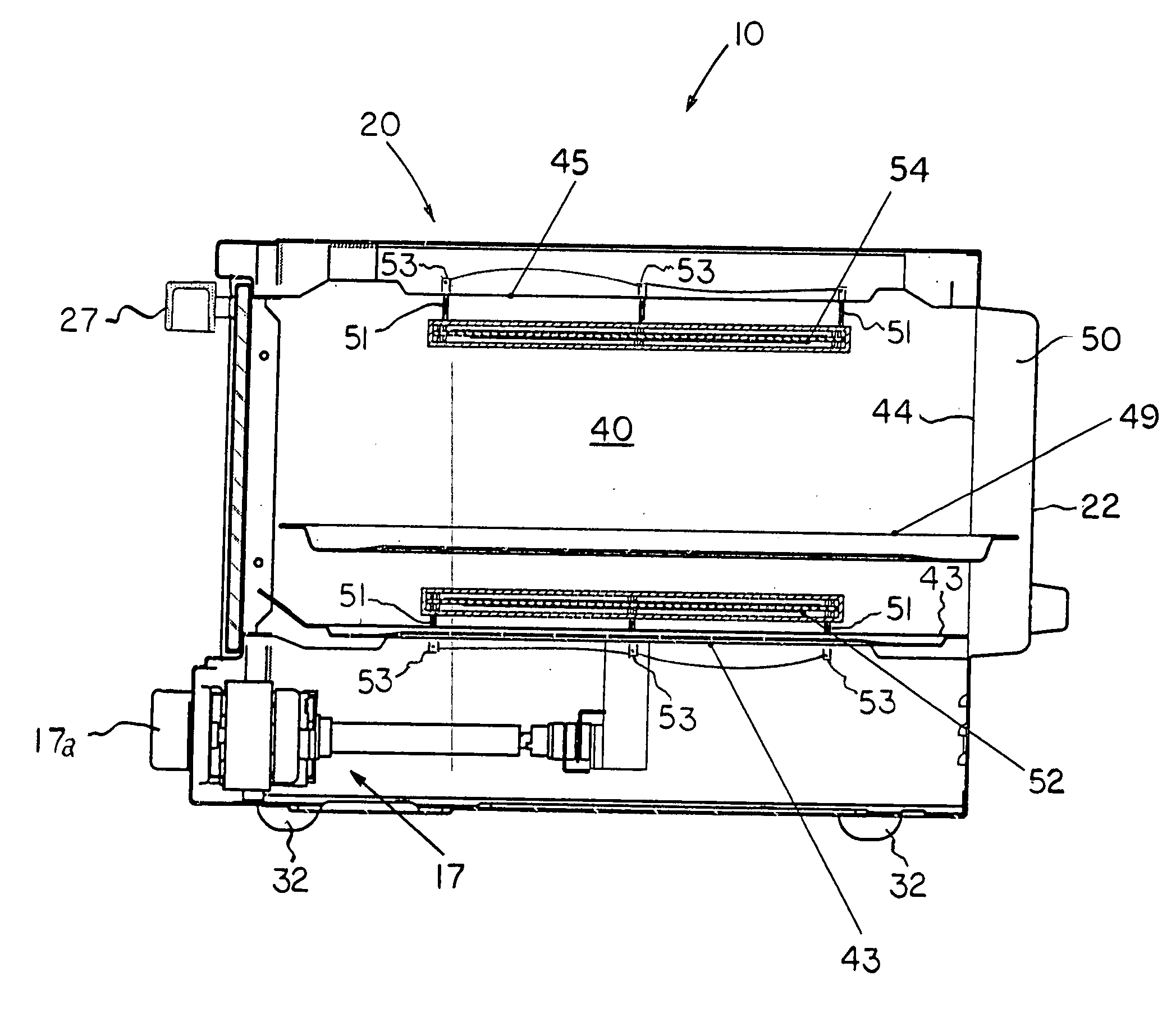

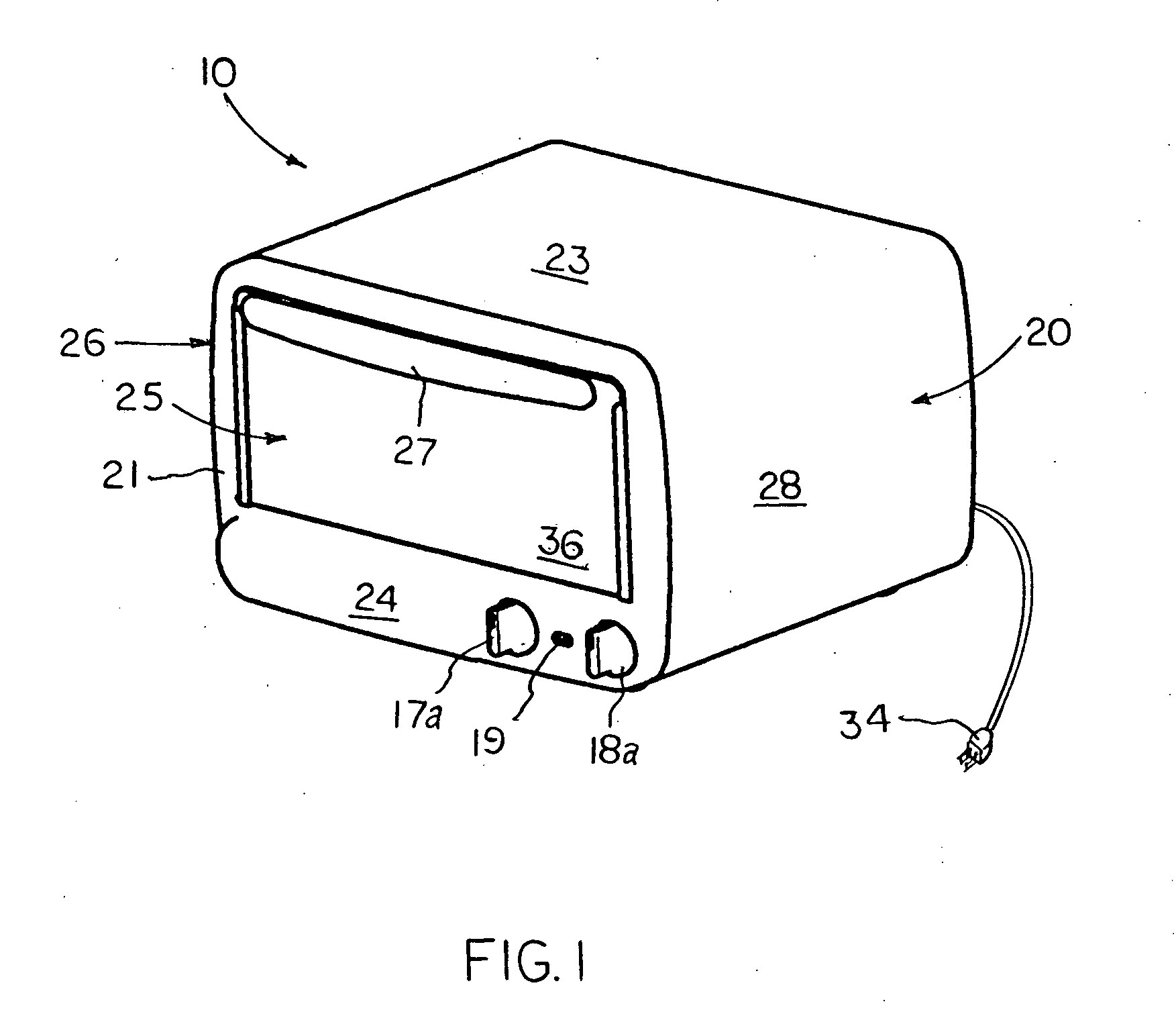

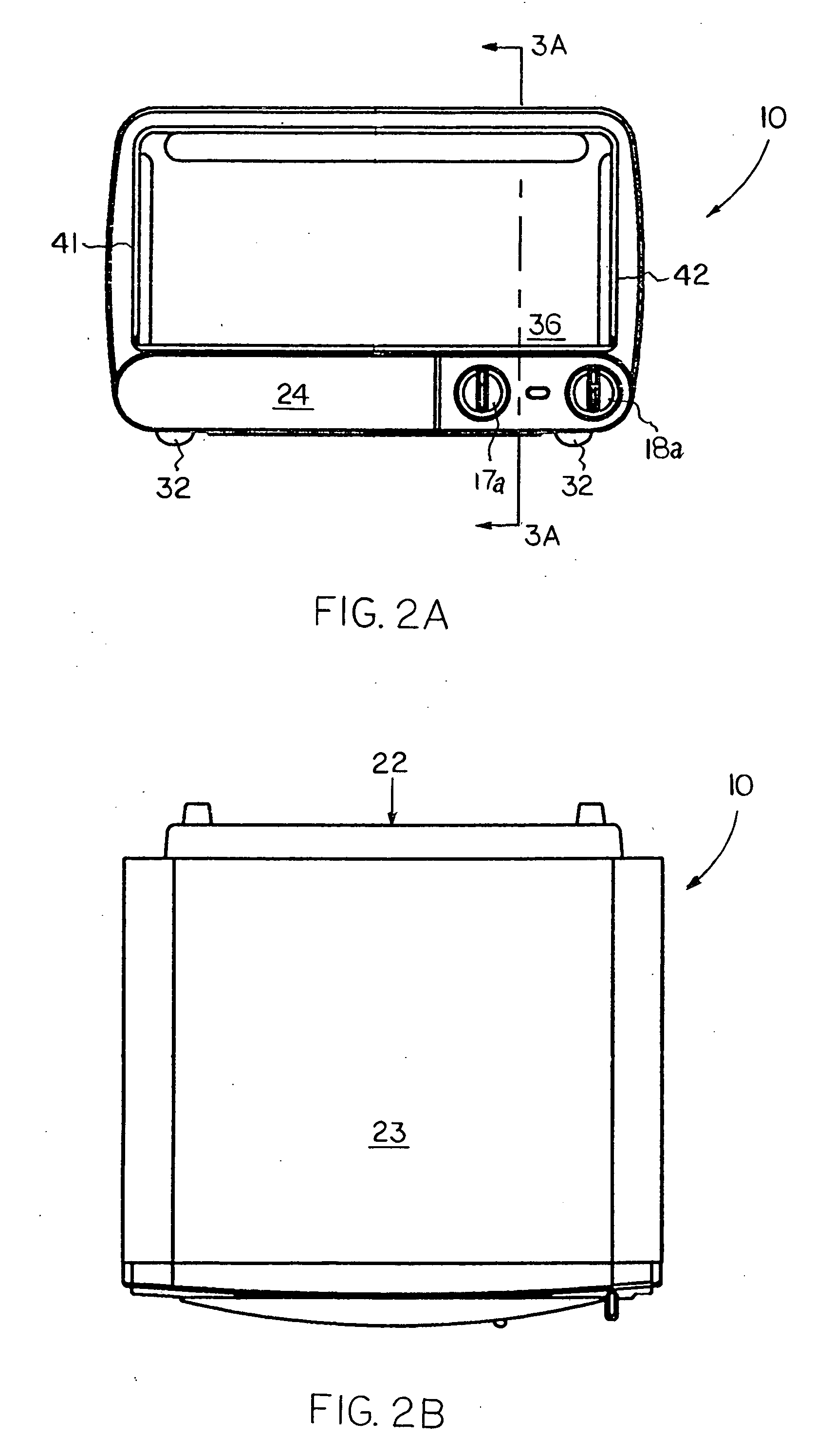

Toaster oven with low-profile heating elements

InactiveUS20080099461A1Increase usable capacityReduce cooking timeDomestic stoves or rangesElectrical heating fuelComputer moduleProcess engineering

A toaster oven appliance including low-profile heating elements having a predetermined single-sided surface area calculated to provide uniform heating within the cooking chamber, facilitate cleaning and to increase its usable capacity is disclosed. Various alternative configurations of top, bottom, and side-mounted heating elements in combination with both fixed and vertically movable heating element embodiments are provided for use with standard and digital controls. The heating elements are positioned both internally and externally of the cooking chamber and are provided in unsheathed, plain-sheathed, and metallic-sheathed types for a given application of the present oven. In one embodiment the heating elements are constructed as removable plug-in modules for convenient cleaning and replacement. The present toaster oven further includes an optional forced convection fan to reduce cooking temperature and shorten cooking cycles. An optional rotisserie mechanism is also provided in conjunction with the aforementioned combinations of heating elements and heating controls.

Owner:ACORNE ENTERPRISES

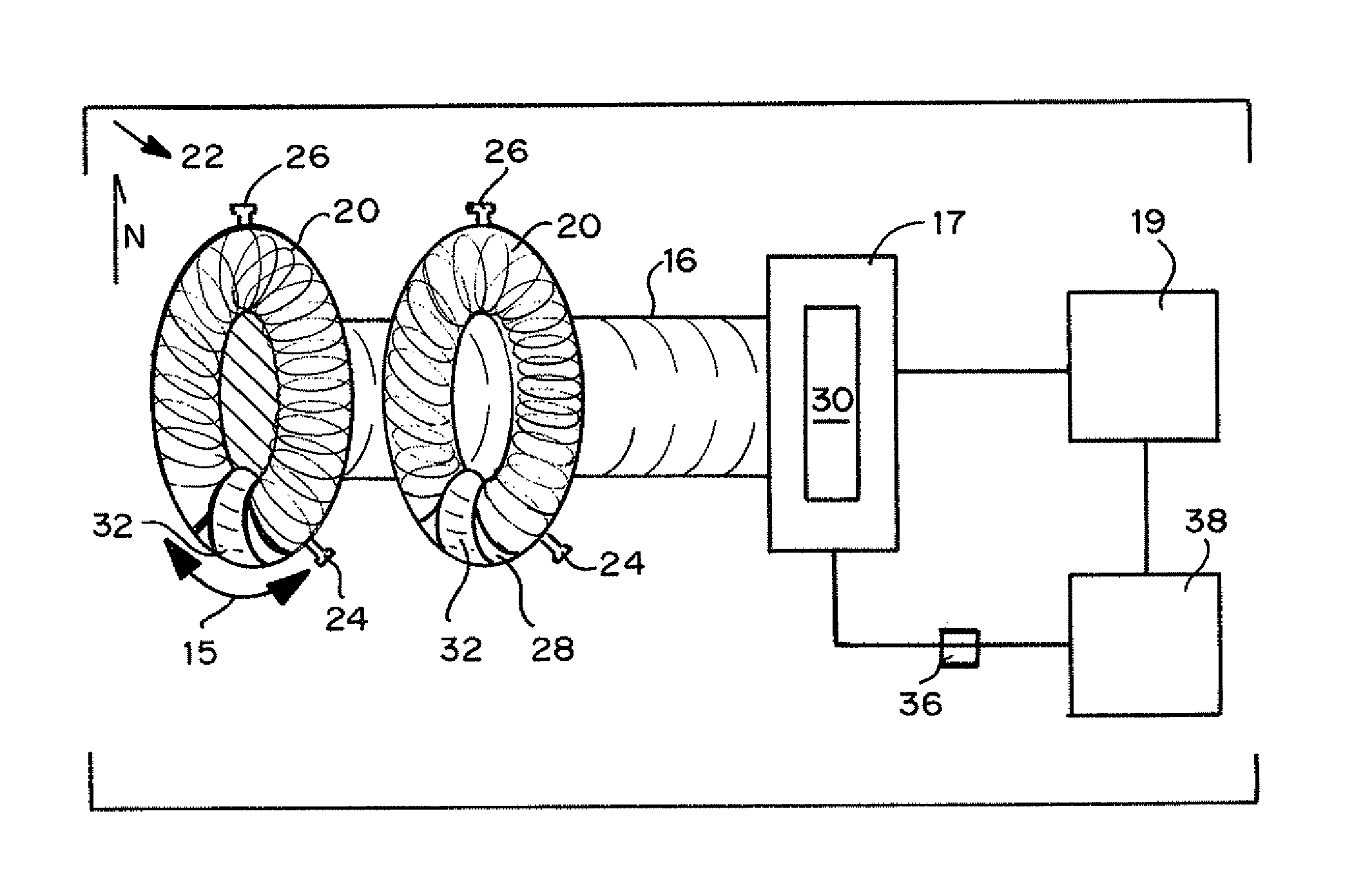

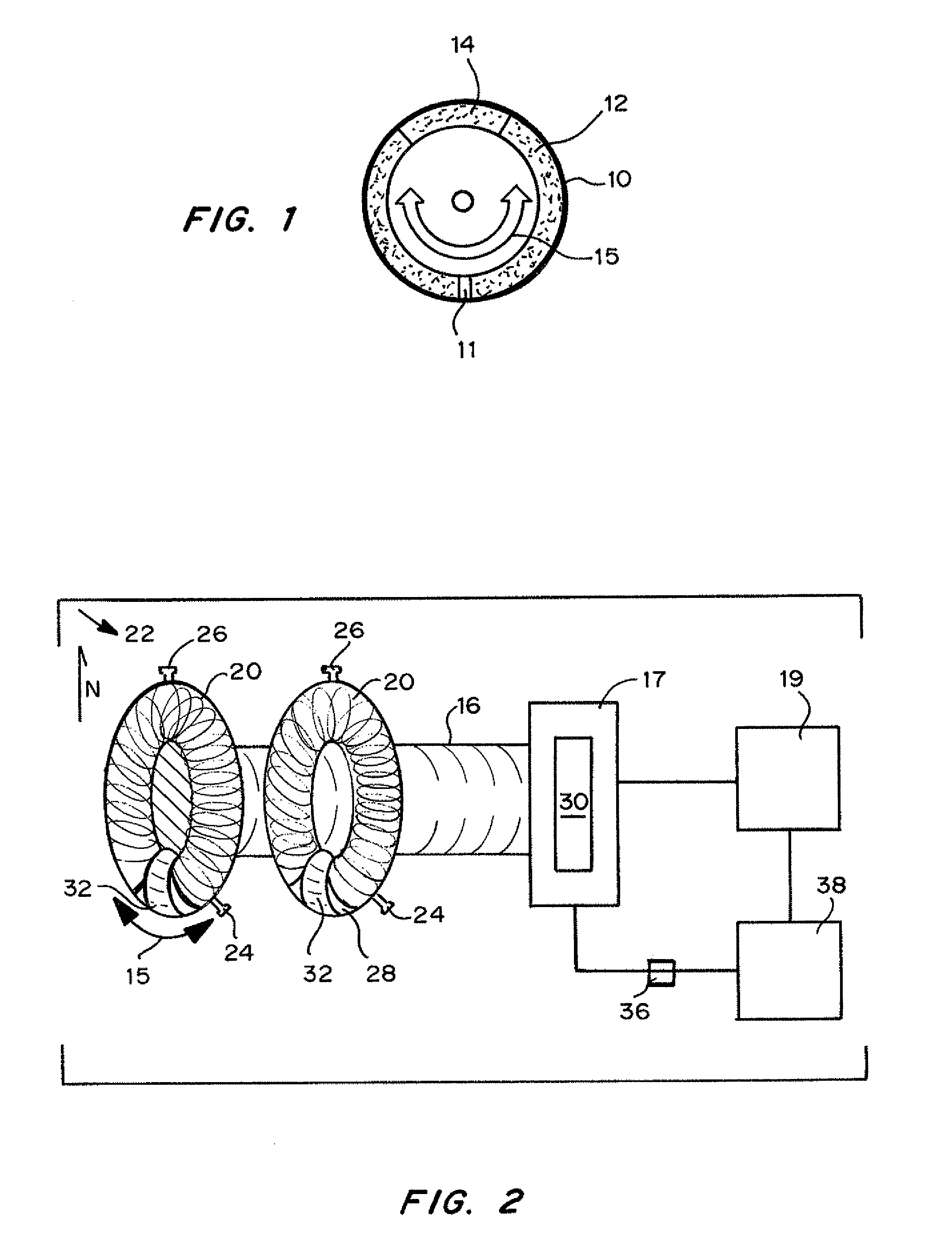

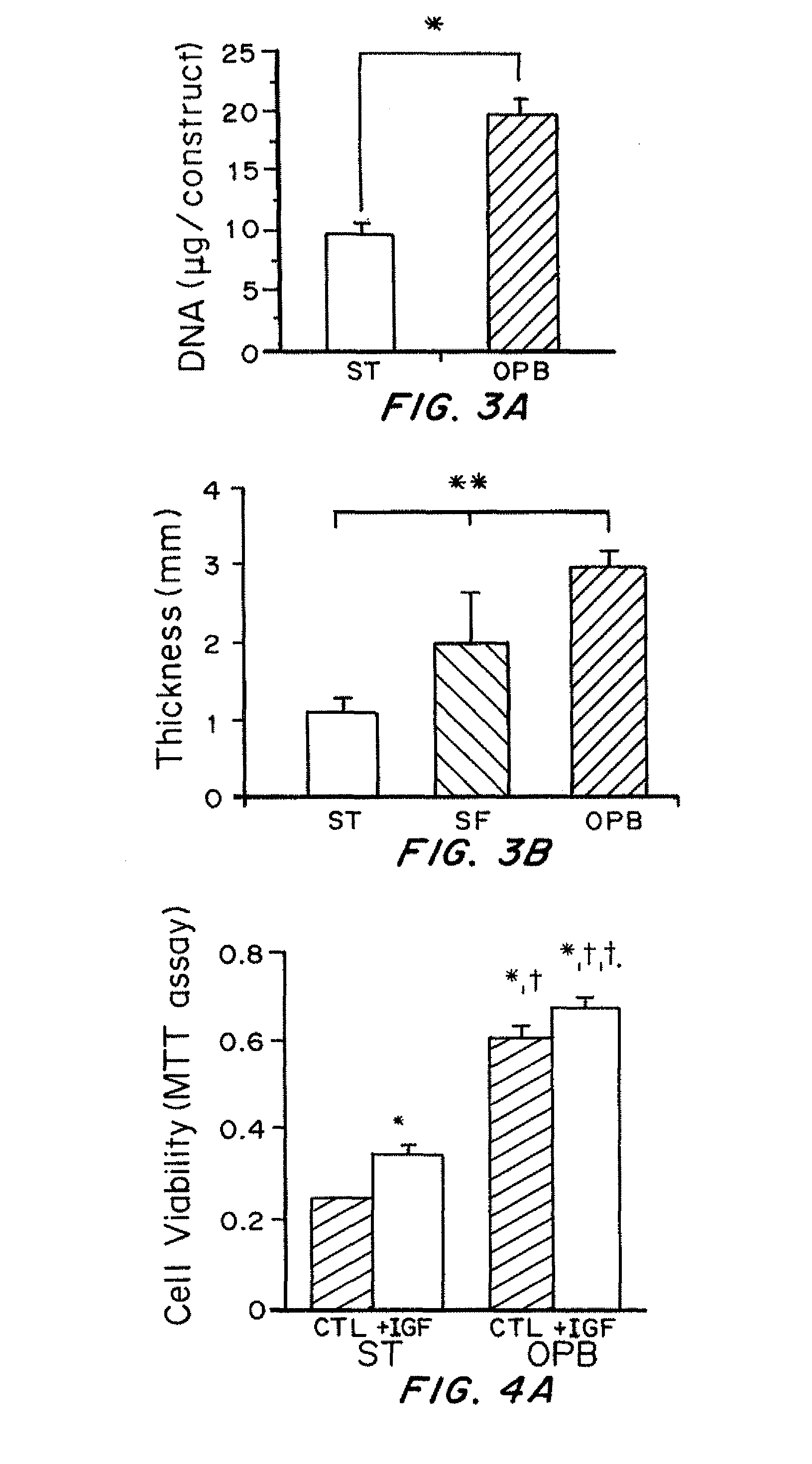

Oscillating cell culture bioreactor

ActiveUS20100297233A1Ease of scale-upEase of automationPowder deliveryBioreactor/fermenter combinationsCulture cellClosed loop

Methods and devices for cell or tissue culture are provided. One aspect provides a bioreactor having a gas permeable, closed-loop chamber for cell or tissue culture, and an oscillating means for moving the gas permeable, closed-loop chamber bidirectionally along an axis horizontal to an axis normal to the closed-loop chamber to force convection of cells and fluid in the gas permeable, closed-loop chamber. The bioreactor optionally includes a tissue engineering scaffold, an inlet means, an outlet means, and integrated sensors. Another aspect provides a bioreactor having a plurality of gas permeable, closed-loop chambers for cell or tissue culture. Methods of culturing cells and producing tissue constructs are also provided.

Owner:MASSACHUSETTS INST OF TECH

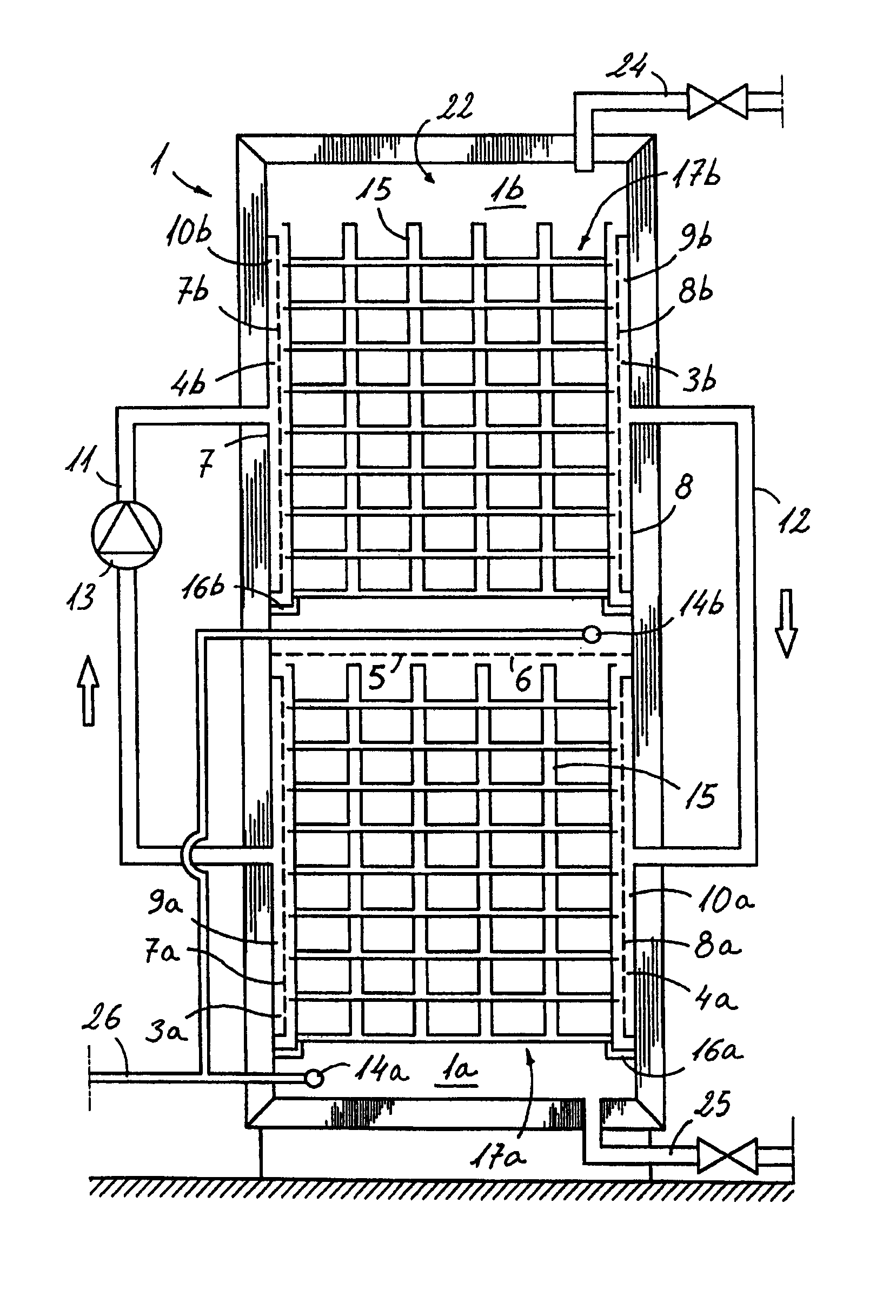

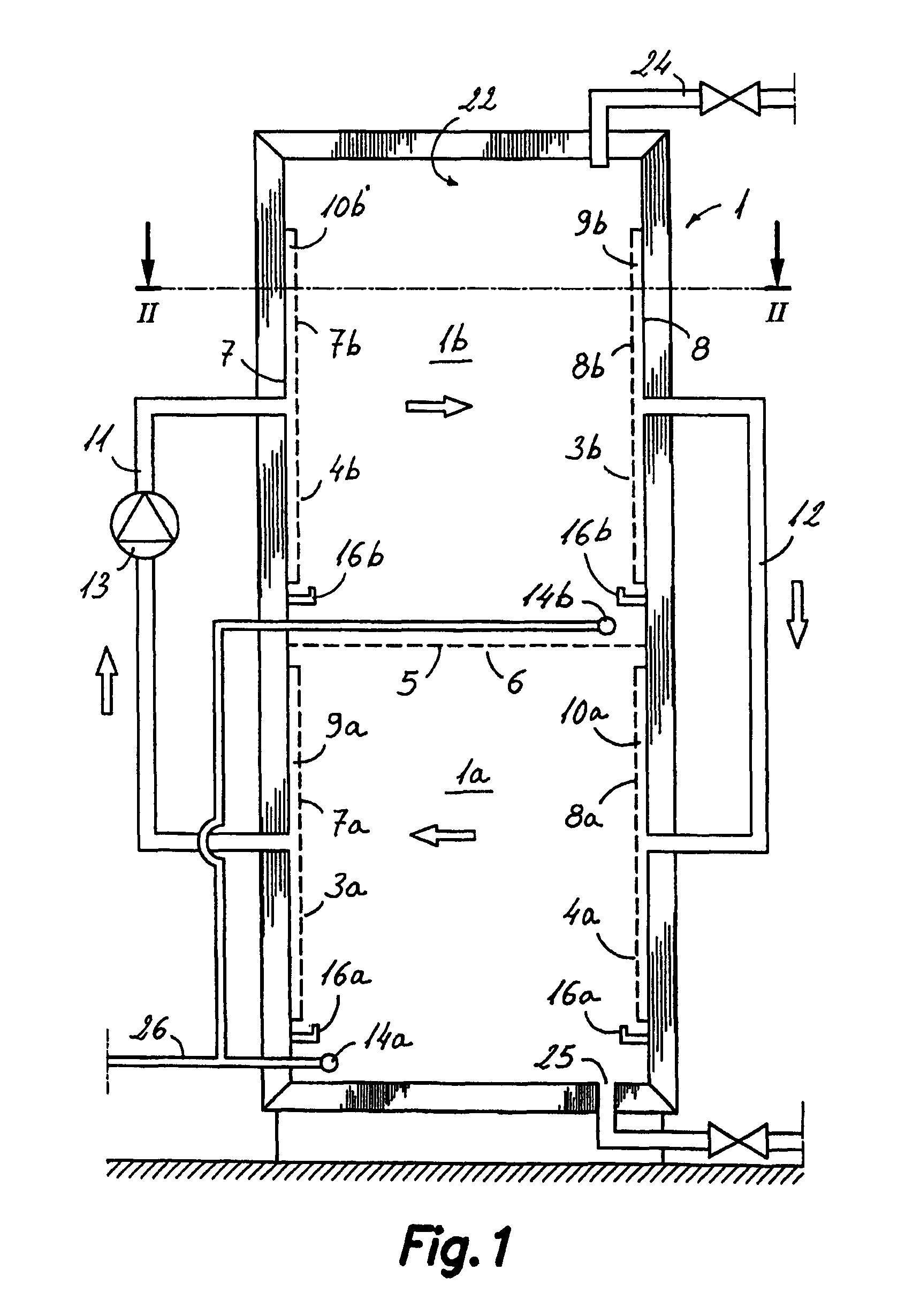

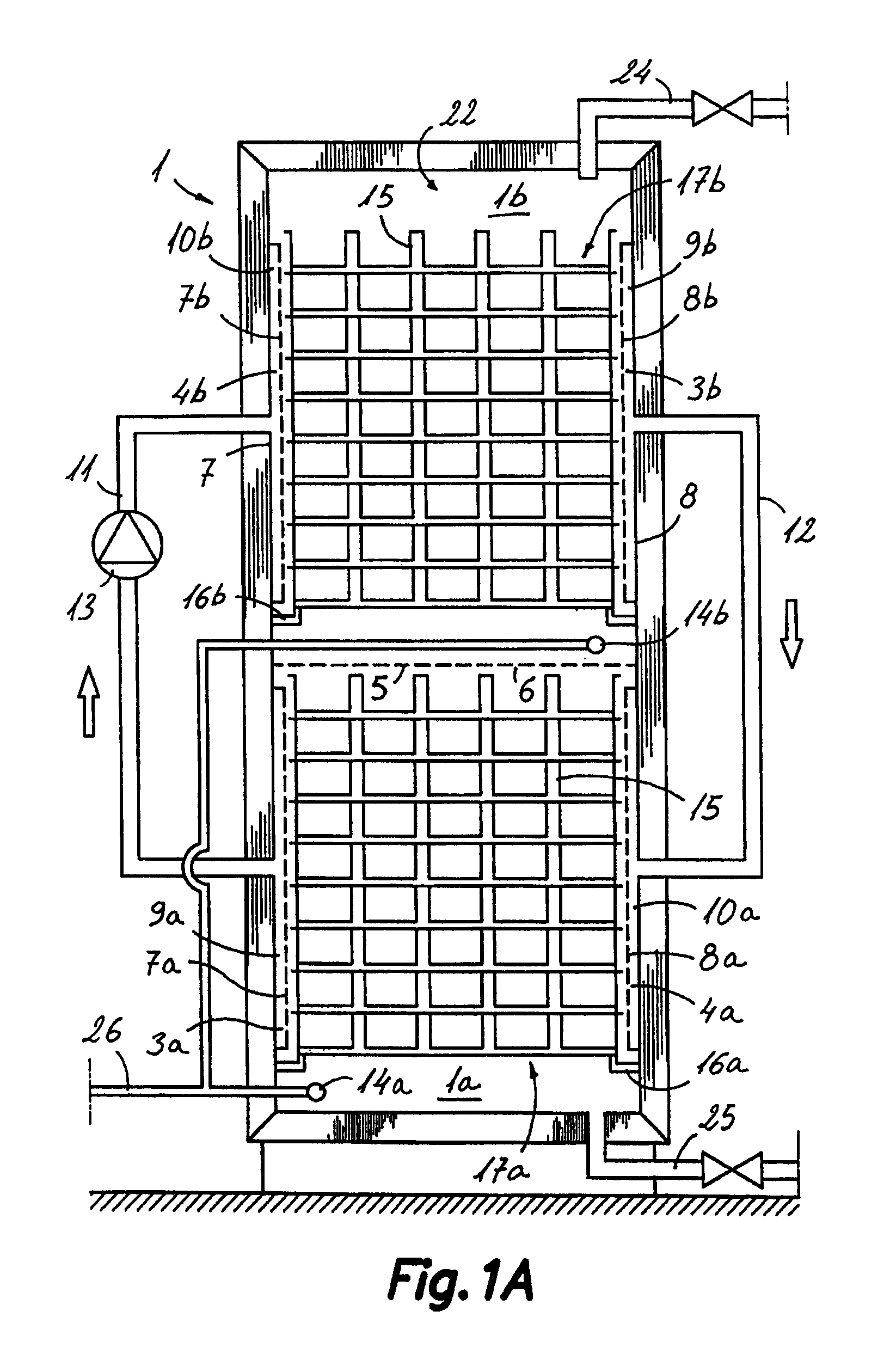

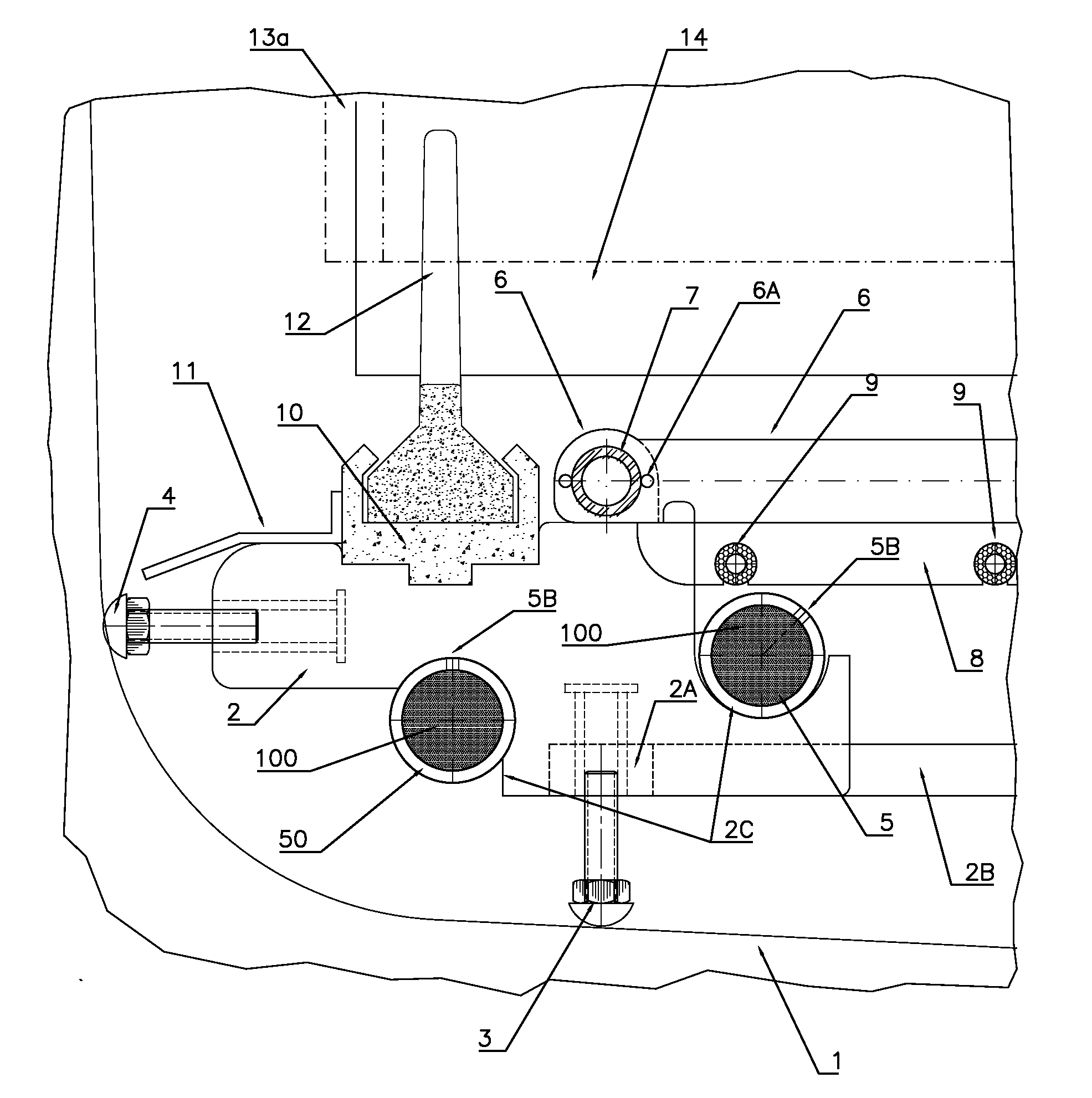

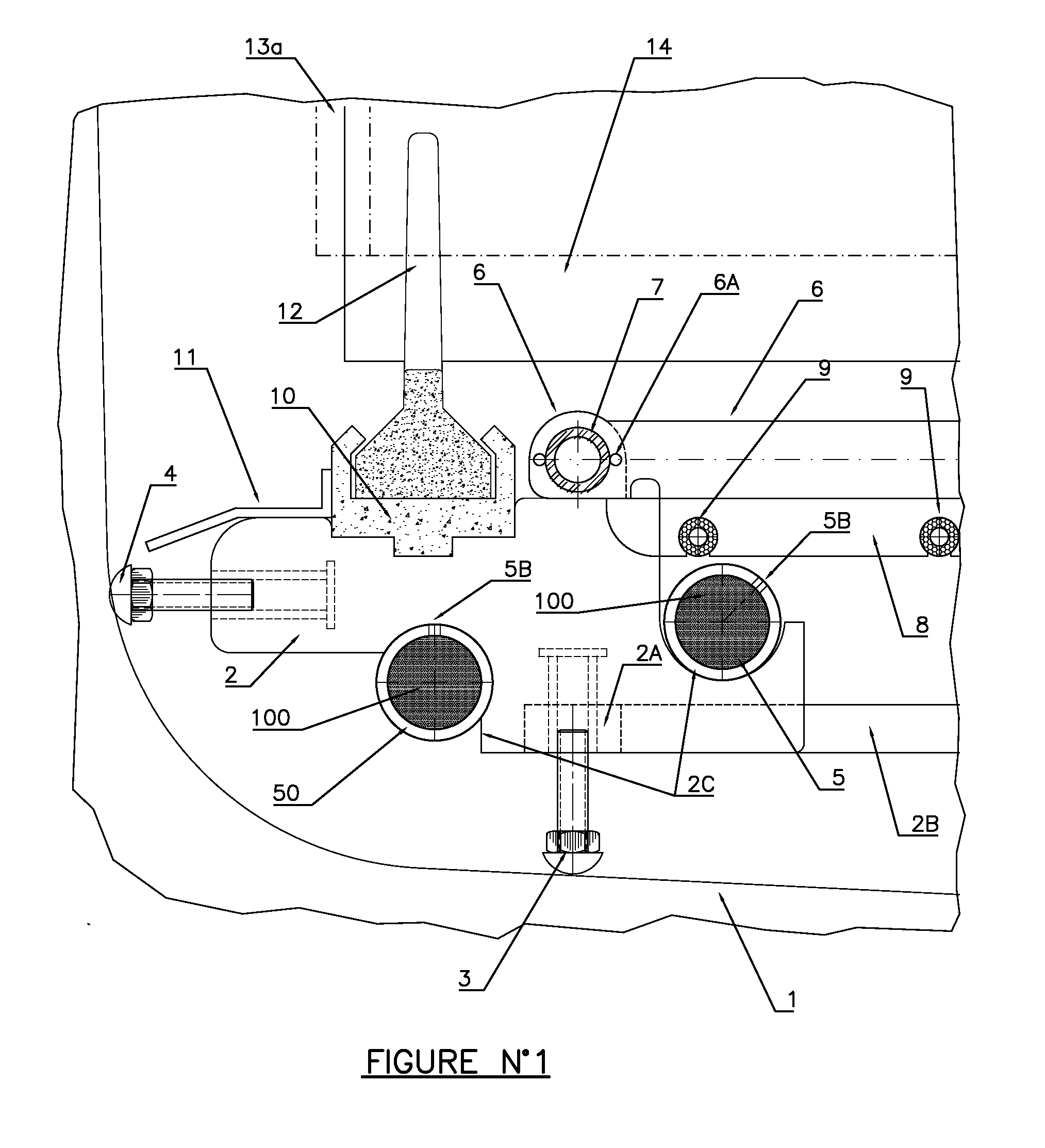

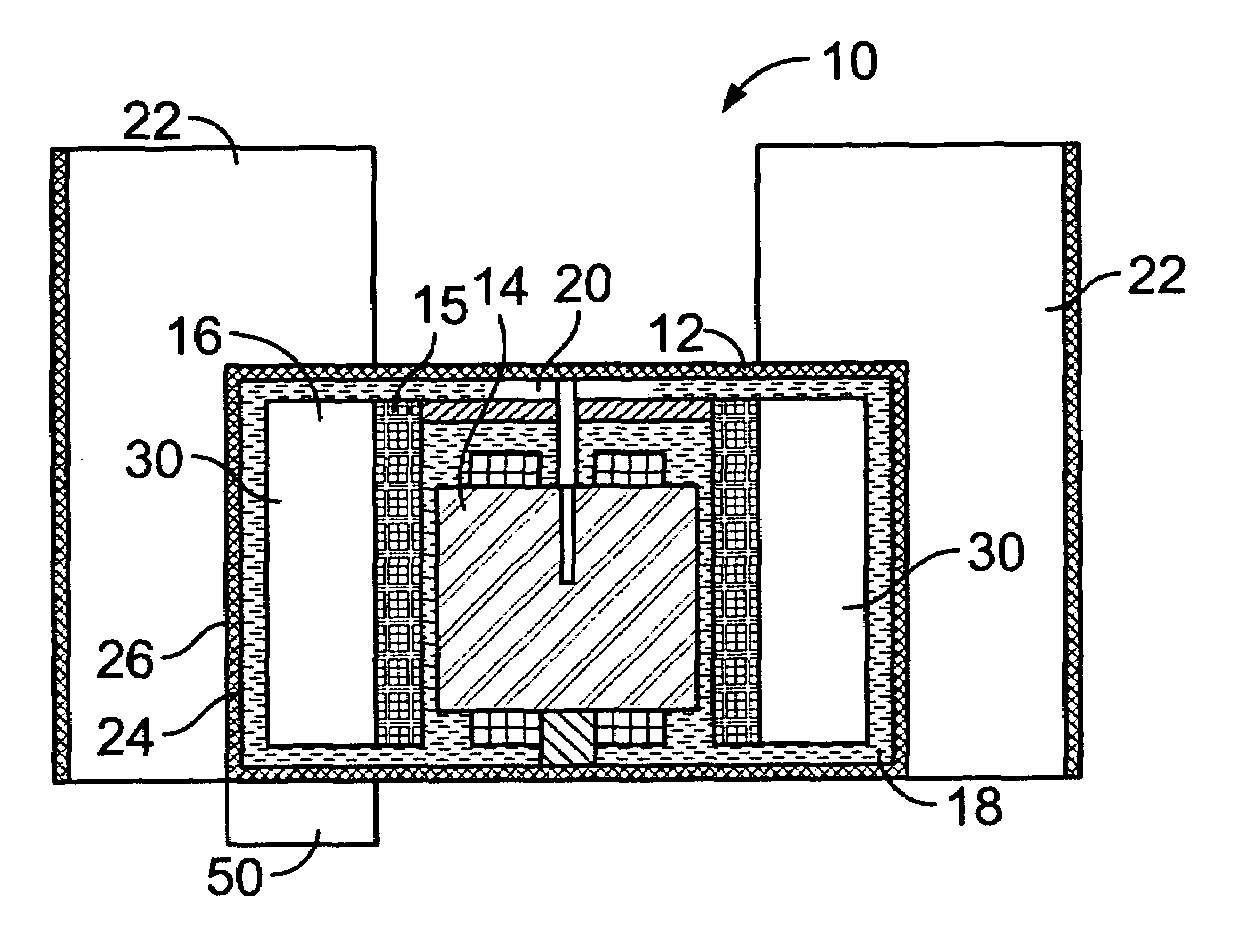

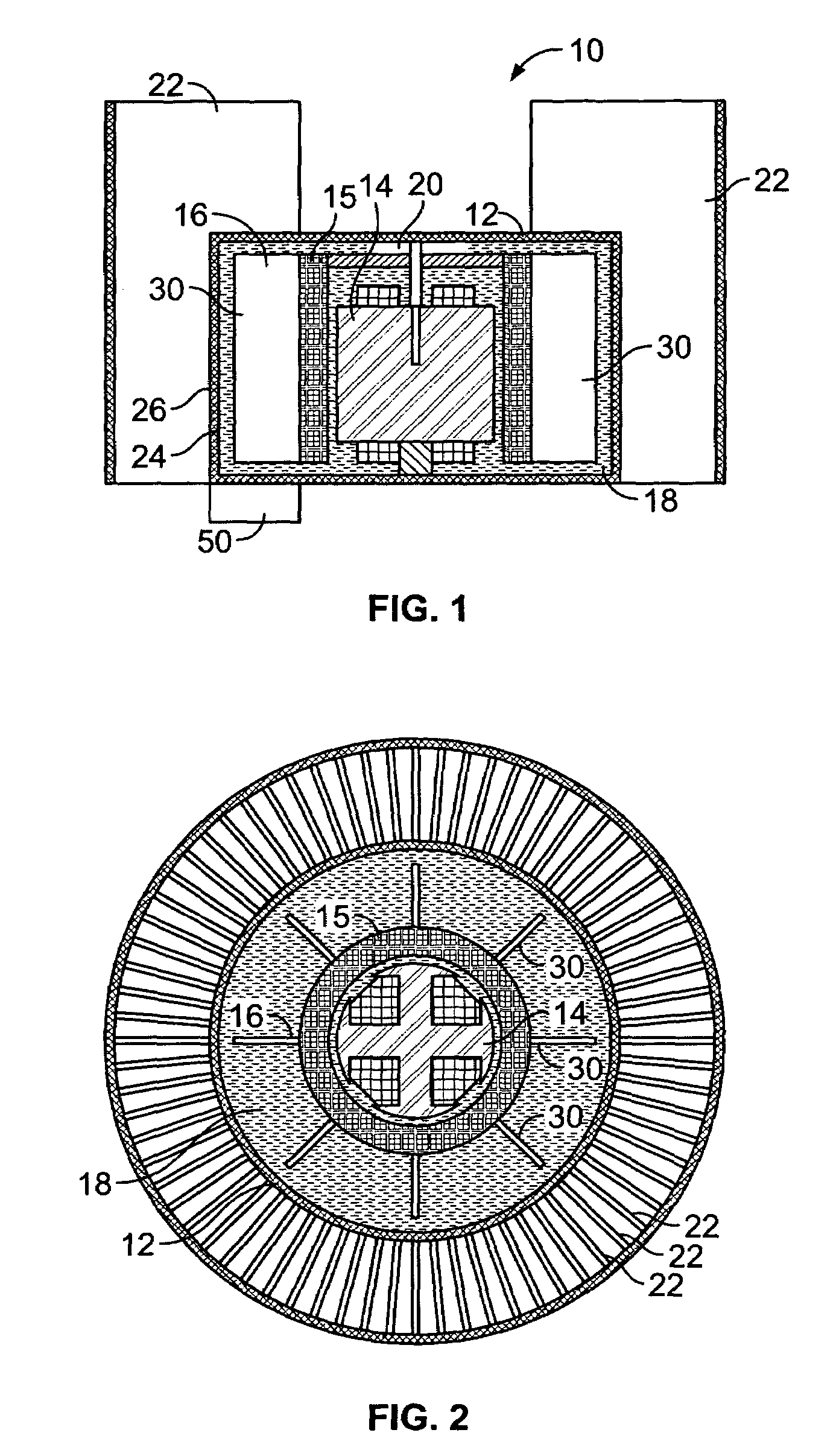

System and method for cooking-cooling food by immersion under forced and diffuse convection

InactiveUS7757601B2Promote circulationFood preservationCooking vesselsForced convectionWaste management

The invention relates to a system and method for the immersion cooking / cooling of food in diffused forced convection. The inventive system comprises: a tank for housing the food to be cooked / cooled, filling / emptying means for filling the vessel with a cooking or cooling liquid and emptying same, and heating means for heating the liquid. The tank comprises a lower region and an upper region, and circulation means which are intended: (i) to collect liquid from the lower region by means of various outlets in a first lower side wall and to introduce said liquid into the upper region through various inlets in a first upper side wall, and (ii) to collect liquid from the upper region by means of various outlets in a second upper side wall and to introduce said liquid into the lower region through various inlets in a second lower side wall, thereby generating diffused forced convection in a turbulent flow.

Owner:METALQUIMIA SA

Integral ballast lamp thermal management method and apparatus

InactiveUS20070285924A1Lighting heating/cooling arrangementsOptical signallingEffect lightEngineering

A lamp having a lighting source, integral electronics, and a thermal distribution mechanism disposed in a housing. The thermal distribution mechanism may include a variety of insulative, radiative, conductive, and convective heat distribution techniques. For example, the lamp may include a thermal shield between the lighting source and the integral electronics. The lamp also may have a forced convection mechanism, such as an air-moving device, disposed adjacent the integral electronics. A heat pipe, a heat sink, or another conductive heat transfer member also may be disposed in thermal communication with one or more of the integral electronics. For example, the integral electronics may be mounted to a thermally conductive board. The housing itself also may be thermally conductive to conductively spread the heat and convect / radiate the heat away from the lamp.

Owner:GENERAL ELECTRIC CO

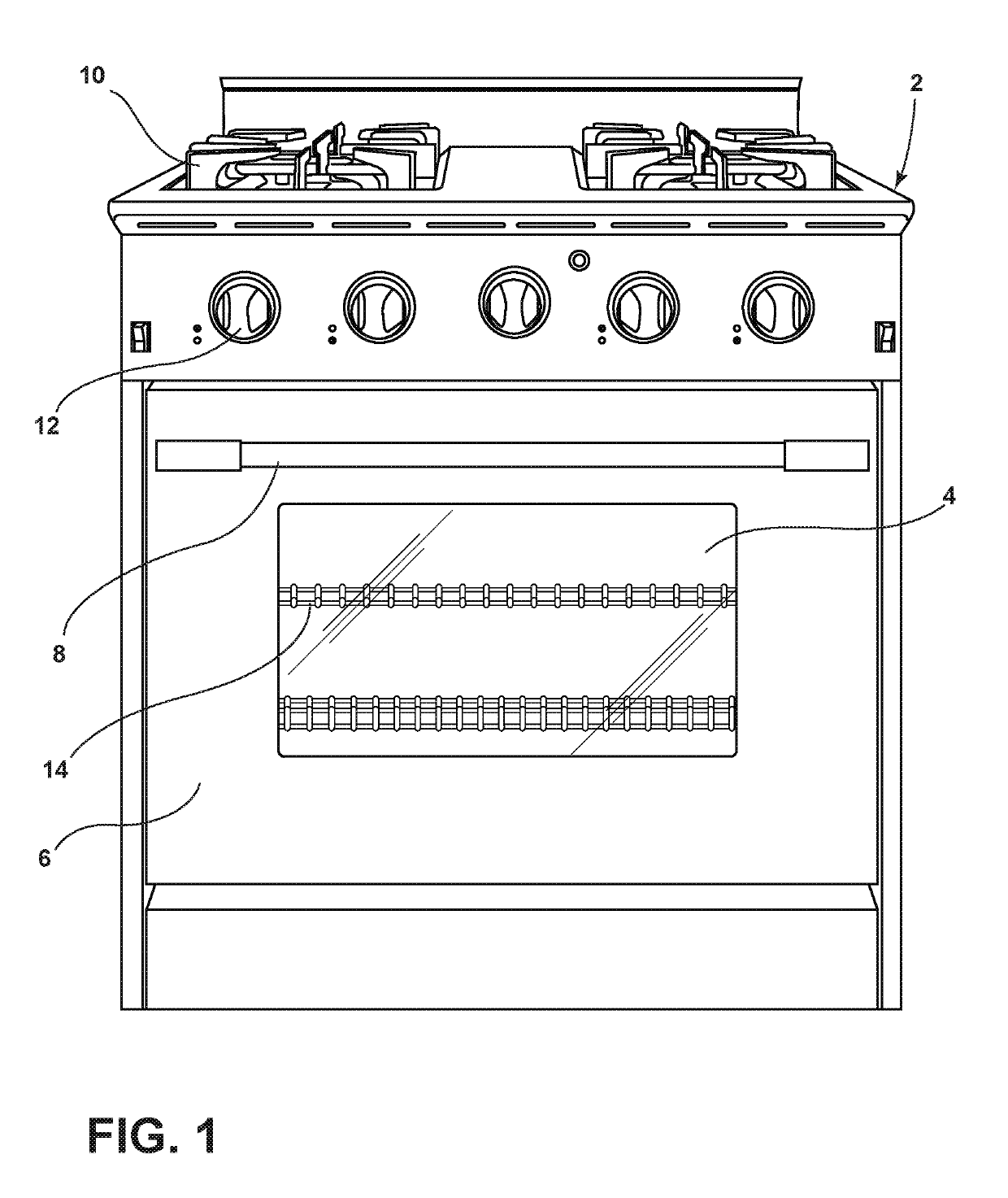

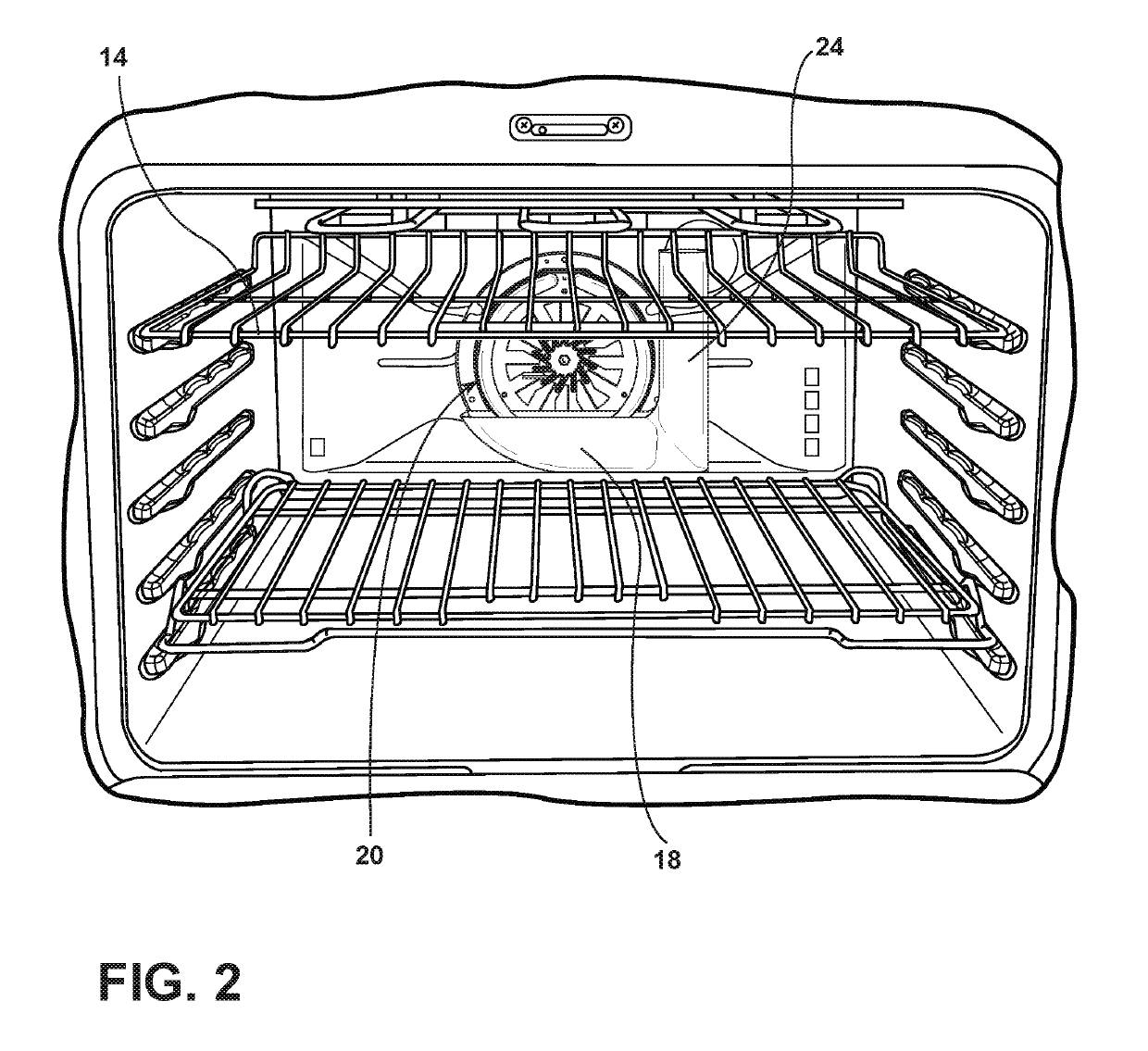

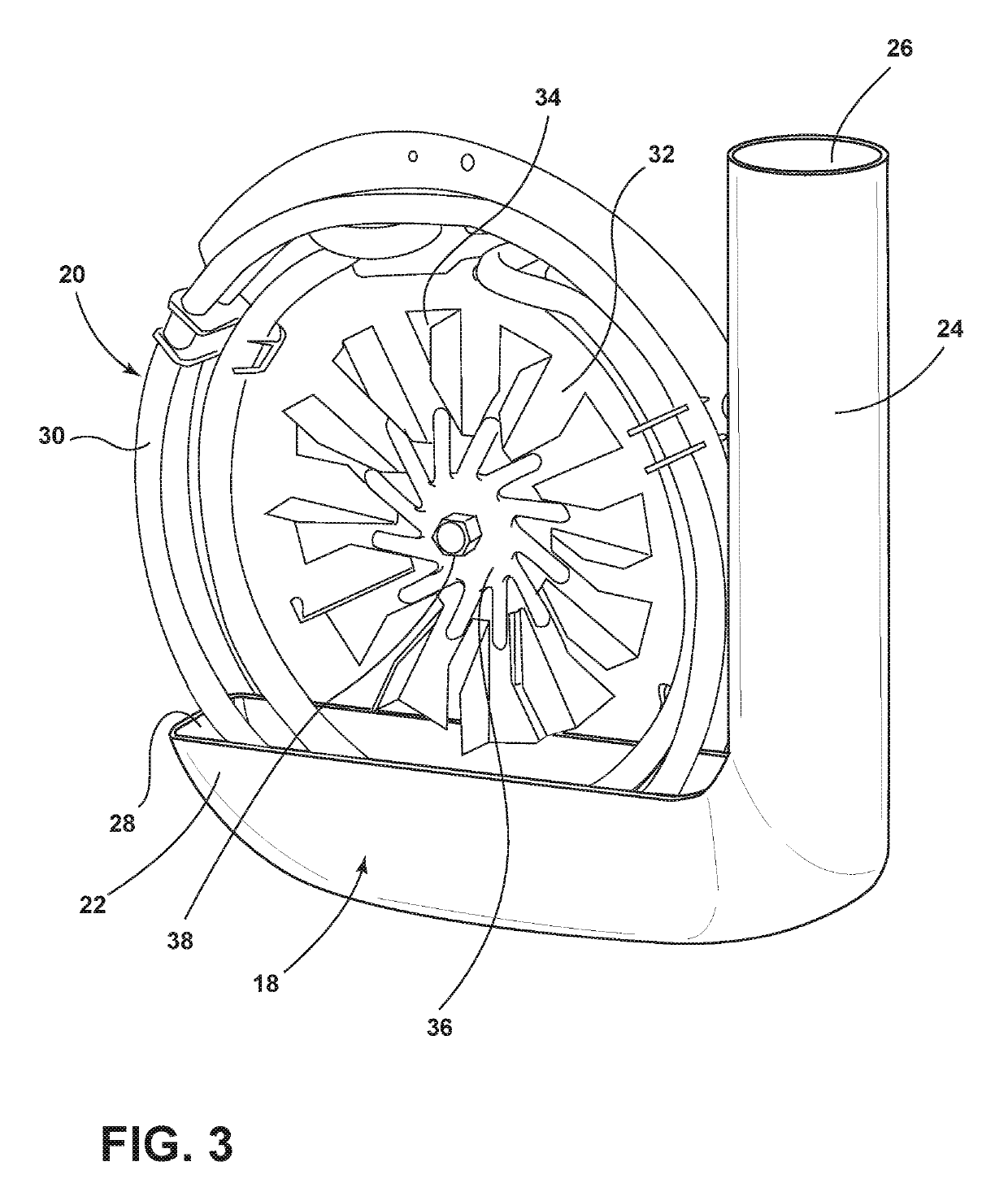

Forced convection steam assembly

ActiveUS10451290B2Domestic stoves or rangesLighting and heating apparatusProcess engineeringForced convection

A convection oven includes a convection fan assembly and a trough assembly that surrounds a portion of the heating element(s) of the convection fan assembly. Fluid in the trough assembly is heated and turned into steam by the heating element(s) and blown into the cooking cavity of the convection oven by the convection fan of the convection fan assembly. The steam in the cooking cavity provides moisture to the items that are being cooked and / or heated in the cooking cavity.

Owner:WHIRLPOOL CORP

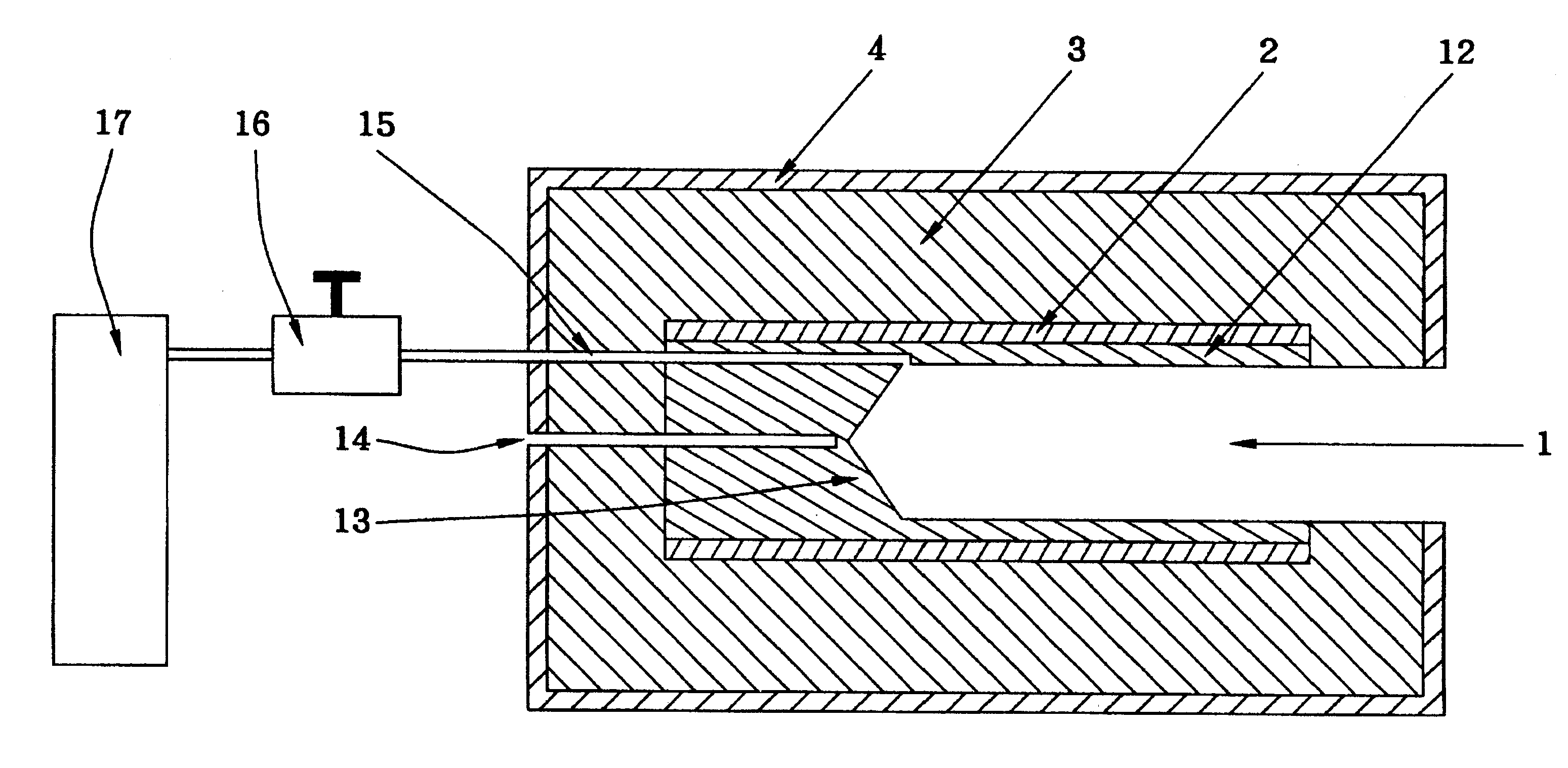

System and apparatus for enhancing convection in electrolytes to achieve improved electrodeposition of copper and other non ferrous metals in industrial electrolytic cells

InactiveUS20100065433A1Enhanced convectionImproved electrodepositionCellsElectrical batteryEngineering

A system and apparatus for enhancing convection in electrolytes for improved electrodeposition of copper and other non ferrous metals in industrial electrolytic cells at given a current density providing exact geometric locations of the electrolyte jet infeed supply system used to impart forced convection in the electrolyte, the gas bubbling system for low pressure / low volume convection enhancement, and the electrode bottom and lateral distancing system, and range of operational parameters, for correct electrolyte flow and air bubbling flow improving cell productivity, quality of metal plates with increased electrical efficiency for its industrial application. The system and apparatus can also be used in industrial cells with same optimal results but at increased current densities, provided sufficient suitable electrolyte and additional electric power is available.

Owner:HEIREMANS VICTOR VIDAURRE

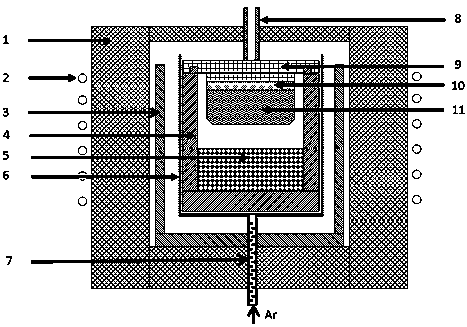

Blackbody furnace

InactiveUS6365877B1Improve cooling efficiencyReduce the temperatureRadiation pyrometryMuffle furnacesTemperature controlRoom temperature

A blackbody furnace, mainly comprising a radiation cavity, a thermally insulating layer, a heater, a housing, a temperature controller, an airflow controller and a high-pressure air source. Besides, a gas channel is provided at the bottom of the radiation cavity to conduct the interior of the furnace chamber with the exterior. In the process of lowering the temperature of the blackbody furnace, the airflow controller could be actuated by the temperature controller or by an operator. Therefore, the room-temperature high-pressure air will enter the radiation cavity through the gas channel to fast cool down the radiation cavity. Finally, heat air will be vented from an opening at the front end of the radiation cavity. The present invention utilizes forced convection to enhance the efficiency of heat dissipation to fast lower the temperature of the blackbody furnace.

Owner:IND TECH RES INST

Integrated liquid cooling device with immersed electronic components

InactiveUS7165413B2Increase surface areaIncrease capacityDomestic cooling apparatusSemiconductor/solid-state device detailsEngineeringForced convection

An integrated liquid cooling device for electronic components addresses the need for efficient cooling created by ever increasing power densities of electronic components. The integrated liquid cooling device has a housing enclosing the electronic component, cooling liquid contained in the housing, a motor immersed in the cooling liquid and mounted to the housing, an impeller driven by the motor, and cooling surfaces on the exterior of the housing. The motor driven impeller creates a turbulent flow in the cooling liquid and a high velocity liquid flow over the electronic component, which rapidly transfers heat from the electronic component and distributes it throughout the interior of the housing. The cooling surfaces on the exterior of the housing dissipate this heat, either by free or forced convection, into the surrounding environment. Alternately, the integrated liquid cooling device may distribute this heat energy over an equipment case by circulating cooling liquid through a baffled enclosure that provides high velocity cooling liquid flow near the heat generating electronic component. Additional cooling capacity can be gained with the described integrated liquid cooling device by selecting a cooling liquid whose boiling point is near the operating temperature of the electronic component.

Owner:SYMONS ROBERT S

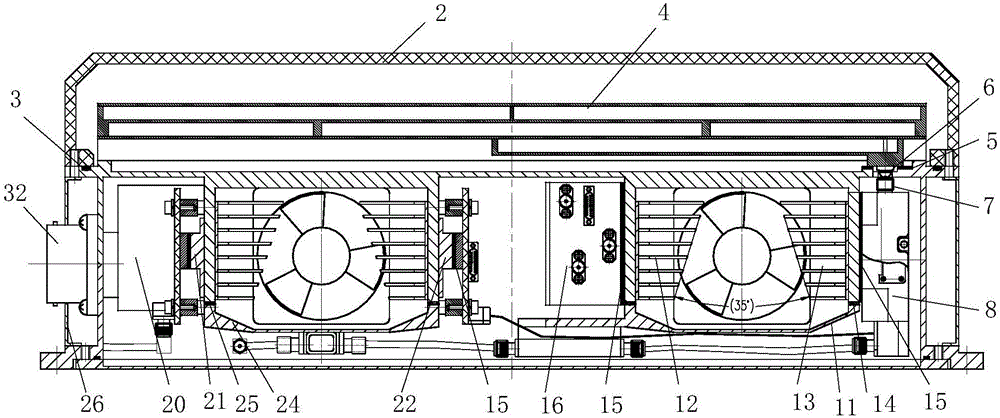

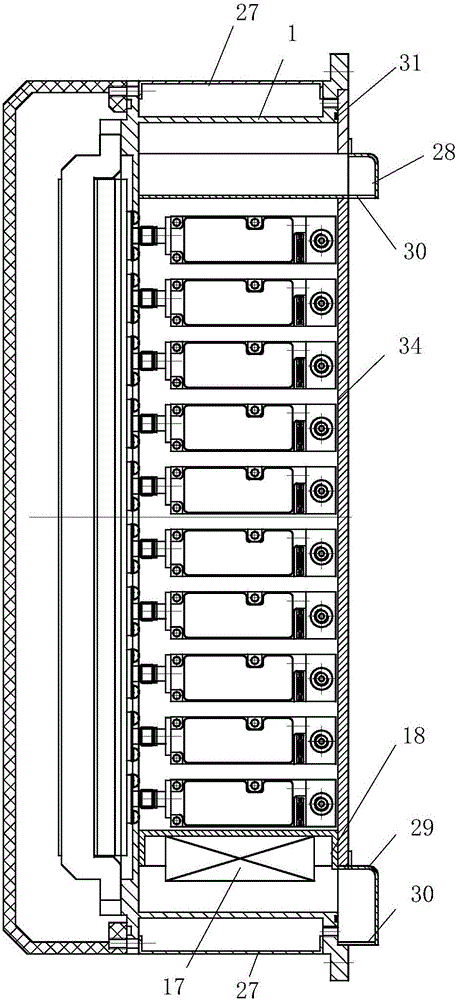

Multi-layer sealed case having a plurality of hollow tapered cooling channels

ActiveCN105699946ASolve the cooling problemSolve densityWave based measurement systemsCasings/cabinets/drawers detailsSurface coolingEngineering

The invention relates to a multi-layer sealed case having a plurality of hollow tapered cooling channels. An antenna cover, a rear cover plate, a left cover plate and a right cover plate, and an upper cover plate and a lower cover plate are sealed at an outermost layer of a transmitting-receiving case; an outer layer cavity structure reserved by the transmitting-receiving case structure forms a third-layer sealing cavity; a left inner air-duct sealing plate and a right inner air-duct sealing plate are installed at left and right inner air-duct cavity mounting end surfaces reserved at the transmitting-receiving case structure to form first layer sealing cavities; and the transmitting-receiving case structure is sealed by the rear cover plate to form a second layer cavity for installing all sub systems. The first layer sealed cavities are hollow cooling channels are distributed in a left-right symmetric mode by inner air-duct tapered left fins and inner air-duct tapered right fins; and unique hollow tapered air ducts are formed at the height and length directions of the cooling fins. All sub systems inside the transmitting-receiving case are attached to external surfaces of a left inner air duct and a right inner air duct by heat-conduction pads; heat of all sub systems is transmitted to inner surface cooling fins of the left inner air duct and the right inner air duct with low thermal resistance; and then the heat is taken away by forced convection of a motor.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

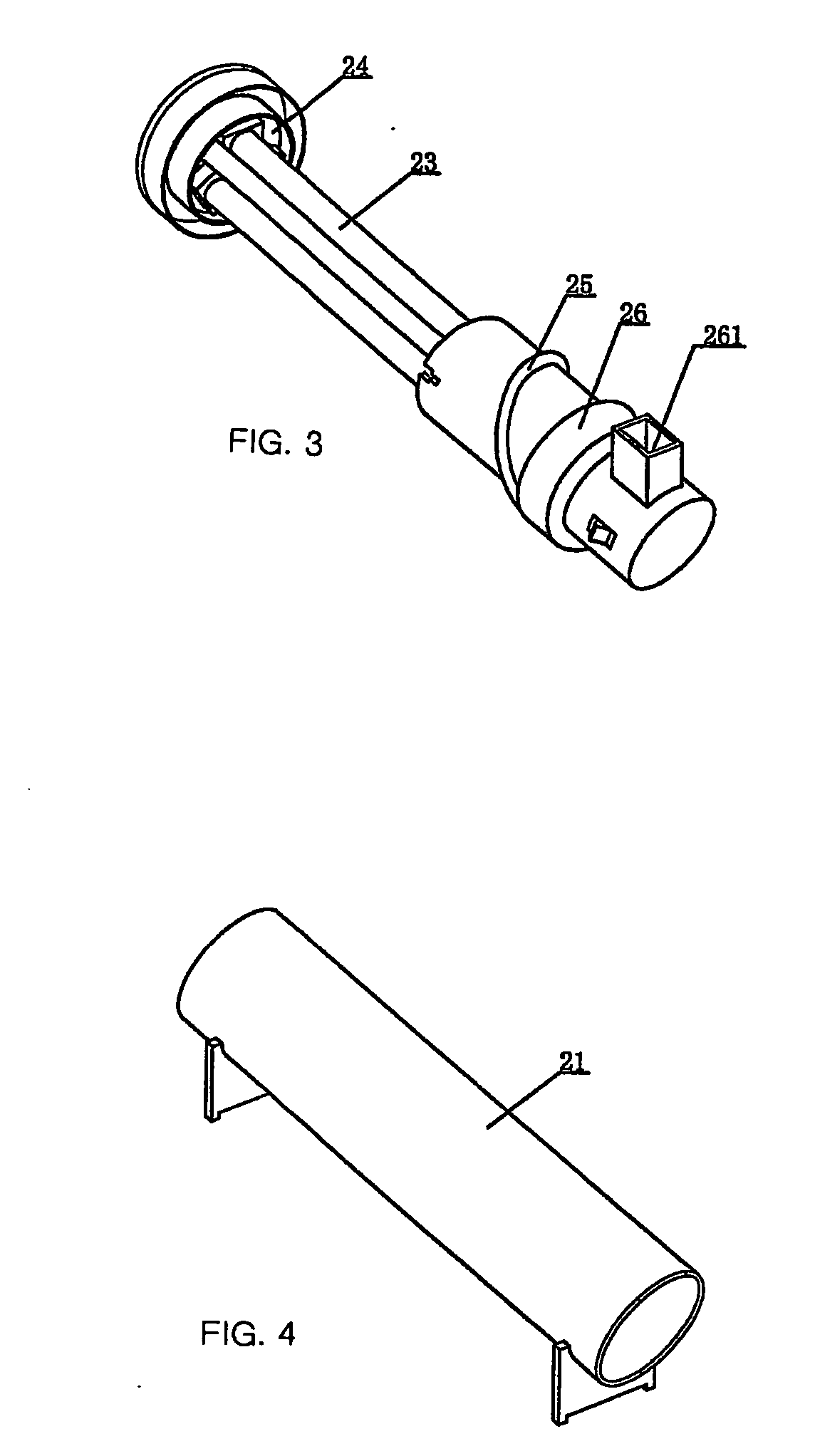

Fuel reformer

InactiveUS20090252661A1Efficiently reformedImprove boot performanceHydrogenPhysical/chemical process catalystsEngineeringForced convection

A fuel reformer includes a reforming portion having a tubular catalytic converter that is composed of a substrate supporting the catalytic component, and is arranged to have a center axis extending along the supply direction of the fuel and oxidizer derived from a supply portion, and a communication passage arranged along an inner wall of the catalytic converter and communicating with the supply portion. The fuel and oxidizer supplied from the supply portion to the communication passage pass from the inner wall of the catalytic converter to an outer wall thereof by forced convection, thereby reforming the fuel.

Owner:PRECISION COMBUSTION +1

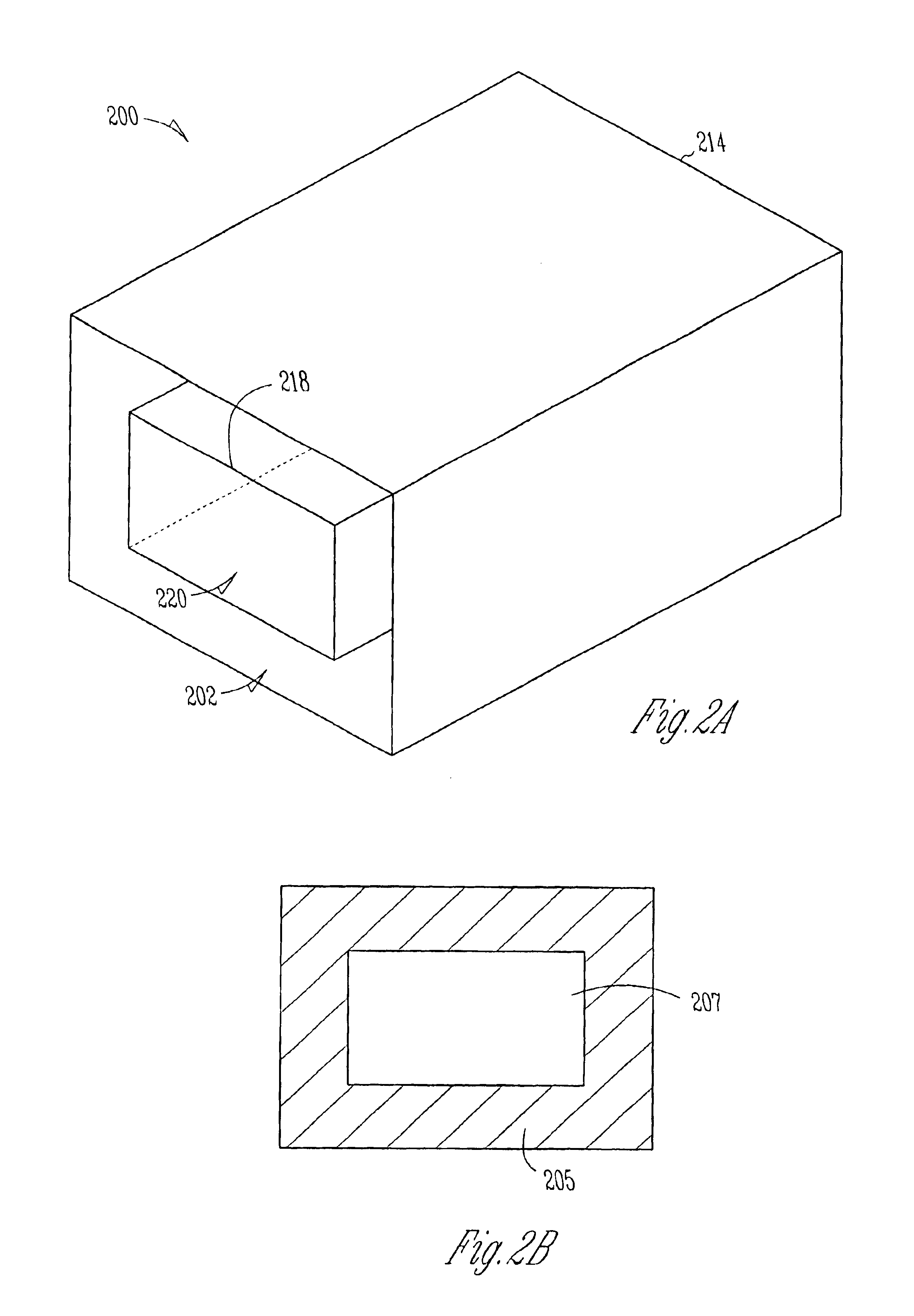

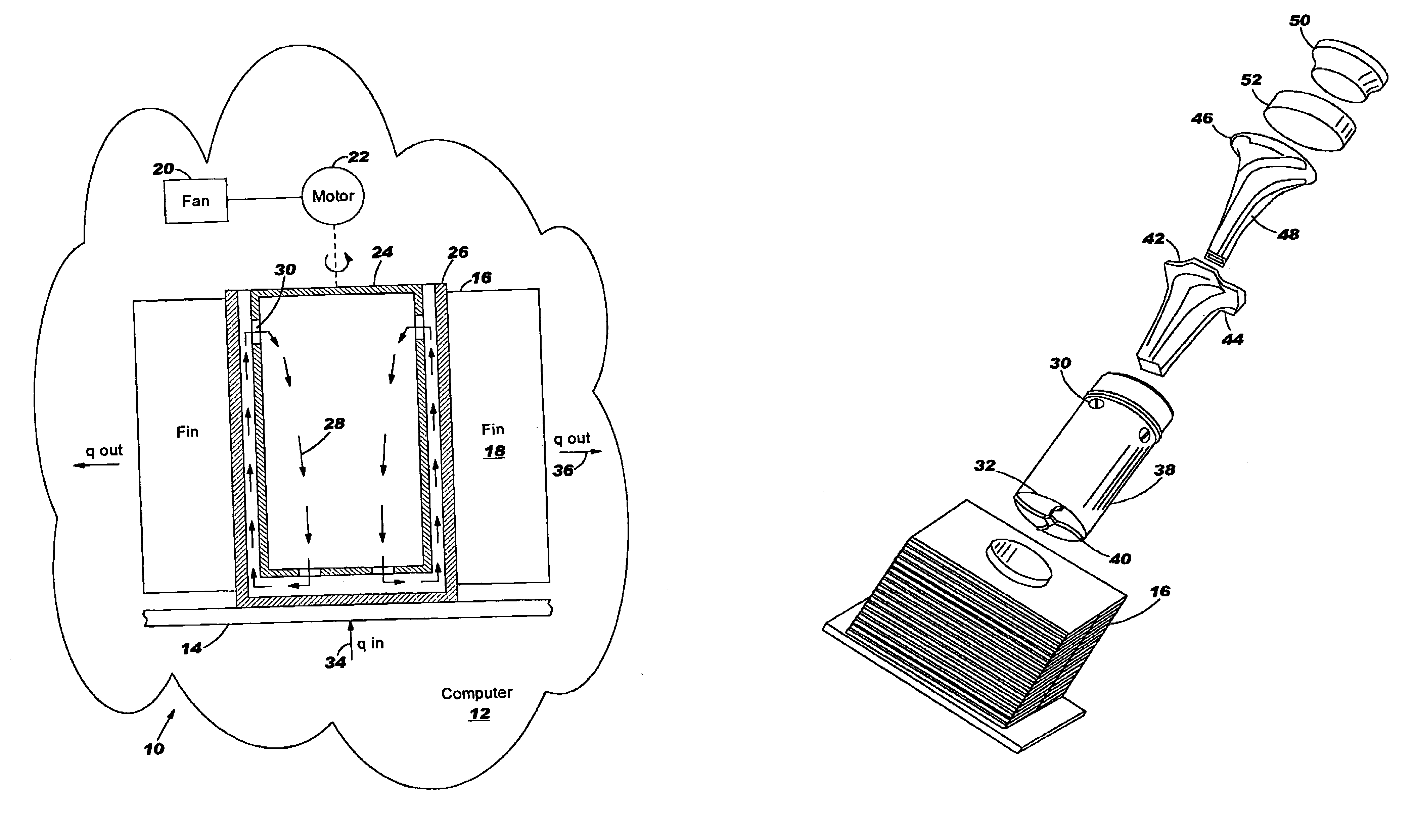

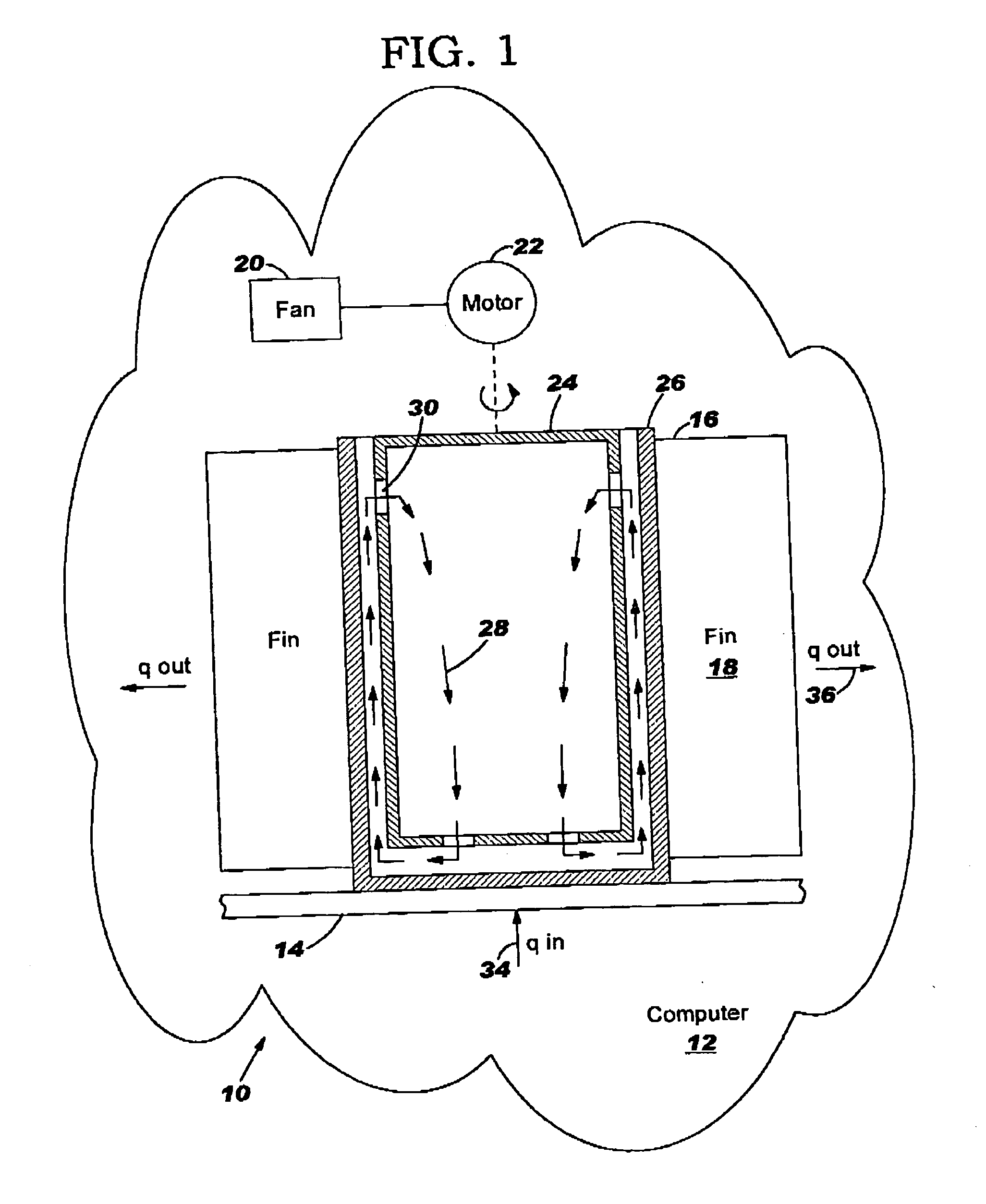

Minimal fluid forced convective heat sink for high power computers

ActiveUS6945314B2Improve efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidClosed loop

A heat removal system for a computer has a heat sink and a spool rotatably disposed in the heat sink. The spool includes fluid inlets and outlets, and water circulates in a closed loop from the inlets, through the spool, through the outlets, past the computer component to be cooled, and between the heat sink and the spool to transfer heat to the heat sink, then back to the inlets. A thermally conductive can is between the heat sink and spool such that the working fluid flows between the can and spool.

Owner:LENOVO PC INT

Air cleaner

InactiveUS20060159598A1Increase contactGood effectGas treatmentDispersed particle separationForced convectionConduit flow

An air cleaner includes a housing, a filter, a photocatalyst reaction unit which can form a spiral air flow, a forced convection device, and an electrocircuit controller. The forced convection device is located between the filter and the photocatalyst reaction unit. Because the air cleaner uses a longitudinal air conduit, an air inlet along a tangential direction of the air conduit, and spiral guide vanes at the inlet, air passing through a fan and into the air conduit flows spirally in the conduit to increase the time during which air contacts the photocatalyst and enables the light of the ultraviolet lamp to radiate the photocatalyst directly so that the cleaning efficiency of the photocatalyst is increased.

Owner:CHIAPHUA INDS

Growth device and growth method for preparing high-purity semi-insulating carbonized silicon single crystals efficiently

ActiveCN107723798AReduce nitrogen impurity contentImprove efficiencyPolycrystalline material growthAfter-treatment detailsSingle crystalNitrogen gas

The invention discloses a growth device and a growth method for preparing high-purity semi-insulating carbonized silicon single crystals efficiently. The growth method is implemented by the carbonizedsilicon single crystal growth device with a structure of an inert gas graphite flow guide tube and a graphite current-limiting cover. Inertia gases generate forced convection under the action of thestructure, and a forced convection layer is formed on the outer wall of a graphite crucible. When speed and flow of the gas convection are high, influences of diffusion on concentration distribution can be inhibited. In the method, directional movement of the forced convection layer can prevent nitrogen molecules outside the graphite crucible from dispersing into the graphite crucible, so that theproblem that adsorption nitrogen serves as a pollution source in a heat insulating system is solved. According to the method, an inertia-gas atmosphere isolation room system is not needed, and a long-term nitrogen removal process based on furnace vacuumizing is also not needed. The growth device and the growth method have the advantages of high efficiency and equipment simplicity, and can be widely applied to multiple carbonized silicon single crystal furnace systems in the field.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com