System and apparatus for enhancing convection in electrolytes to achieve improved electrodeposition of copper and other non ferrous metals in industrial electrolytic cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

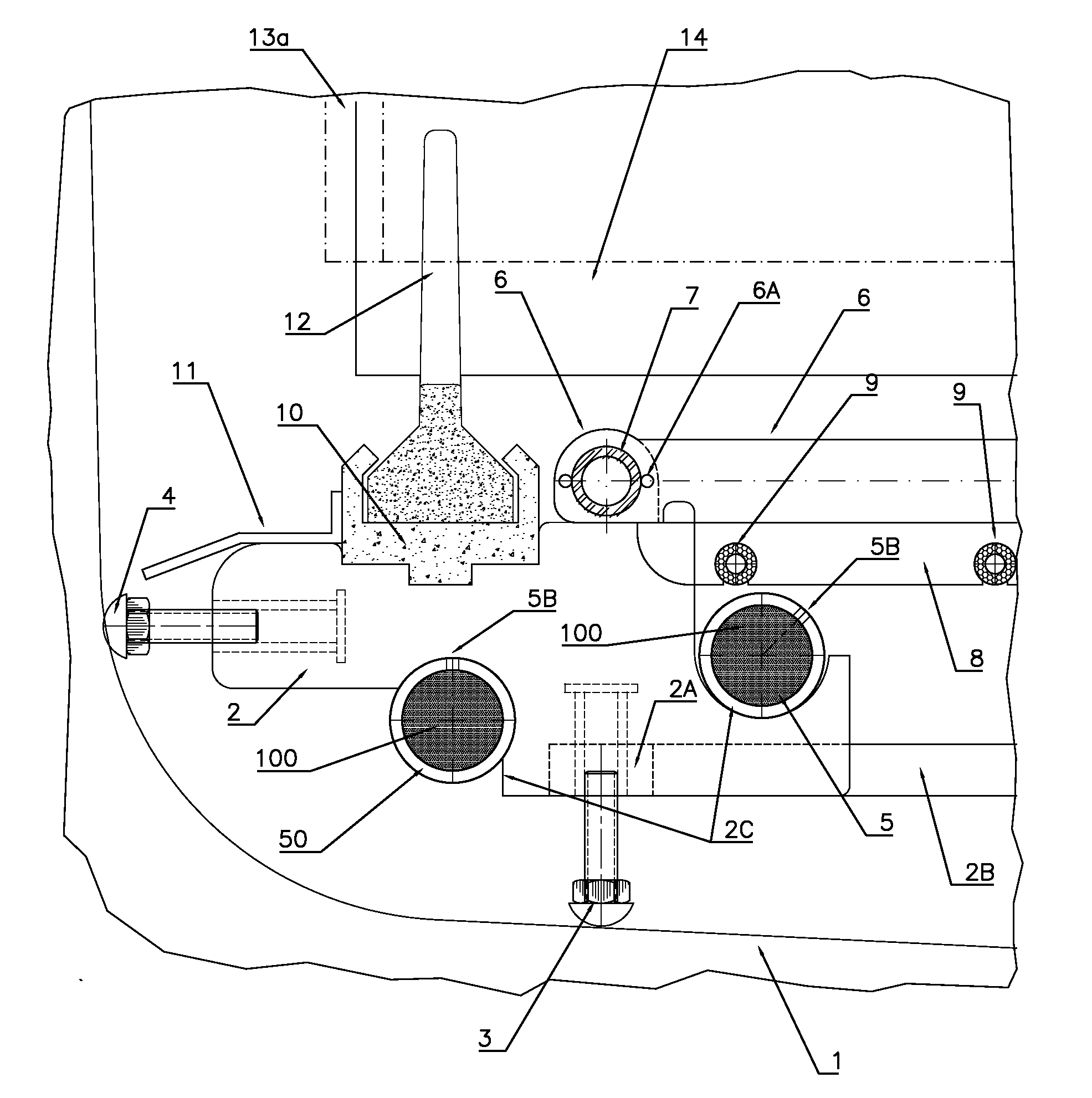

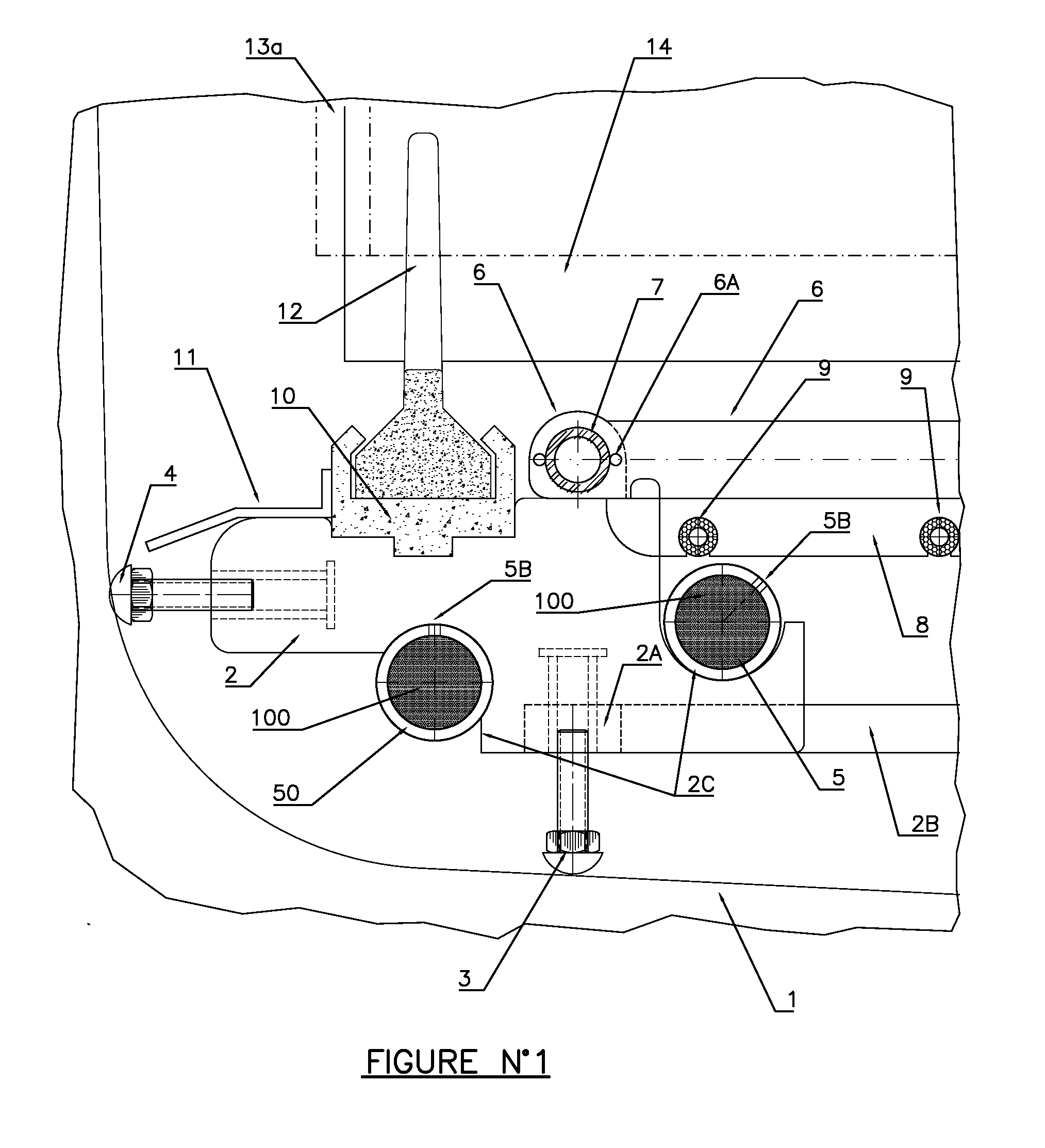

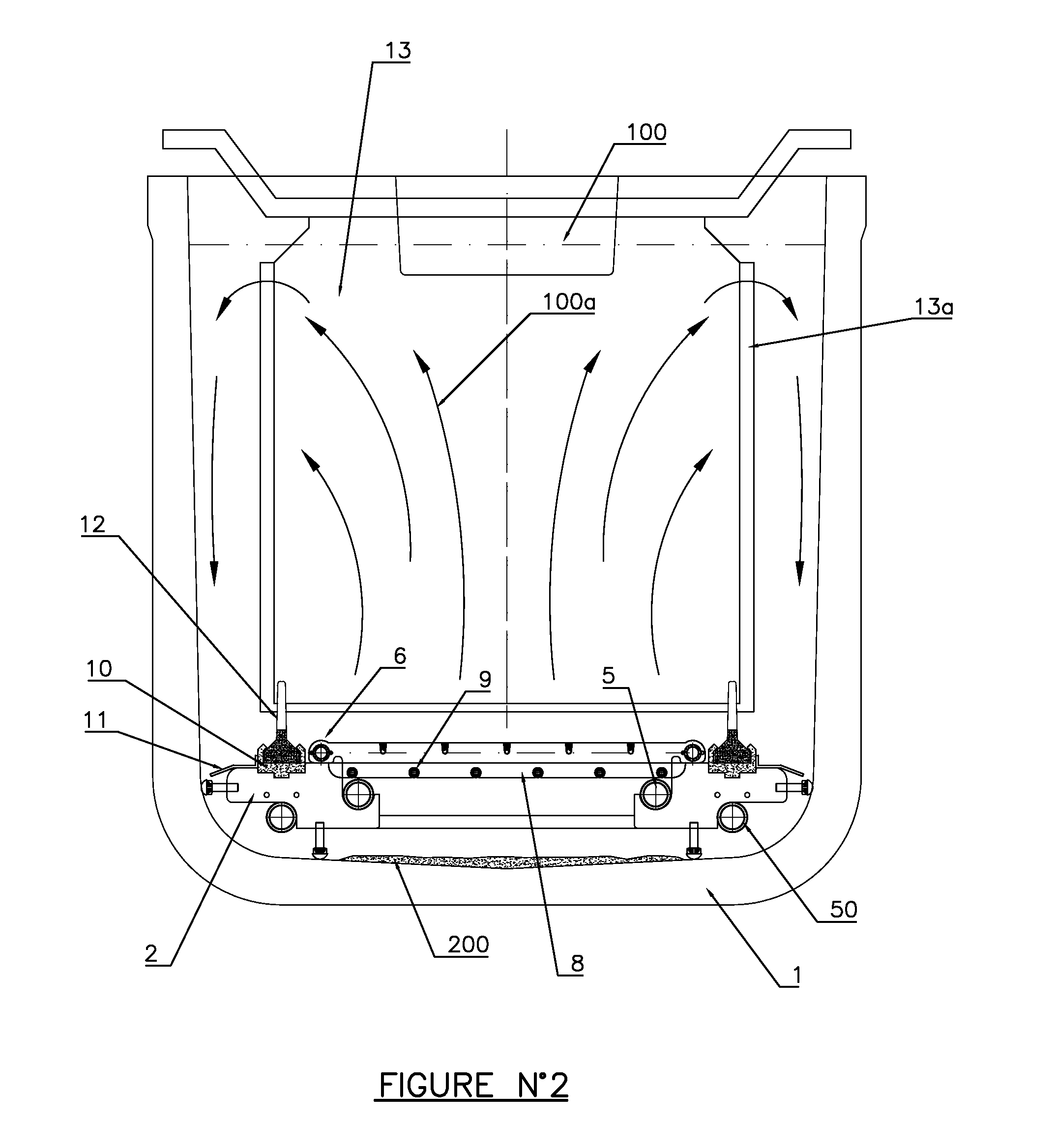

[0031]Many aspects of the invention can be better understood with the references made to the drawings below. The components in the drawings are not necessarily drawn to scale. Instead, emphasis is placed upon clearly illustrating the components of the present invention. Moreover, like reference numerals designate corresponding parts through the several views in the drawings.

[0032]In the description that follows, all specialty polymer composite materials used are formulated according to U.S. Pat. No. 6,143,219 of the same inventor, and use only thermosetting polymer resins and consequently, the polymer composite materials made according to that patent are also substantially gas occlusion-free and highly compacted materials of suitable structural, dielectric, and corrosion resistance to withstand permanent 100% immersion in electrolyte that is required in the described applications. Most ordinary thermoplastic polymers are not suitable for this type heavy-duty service and simply canno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com