Patents

Literature

4687results about "Crucible furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

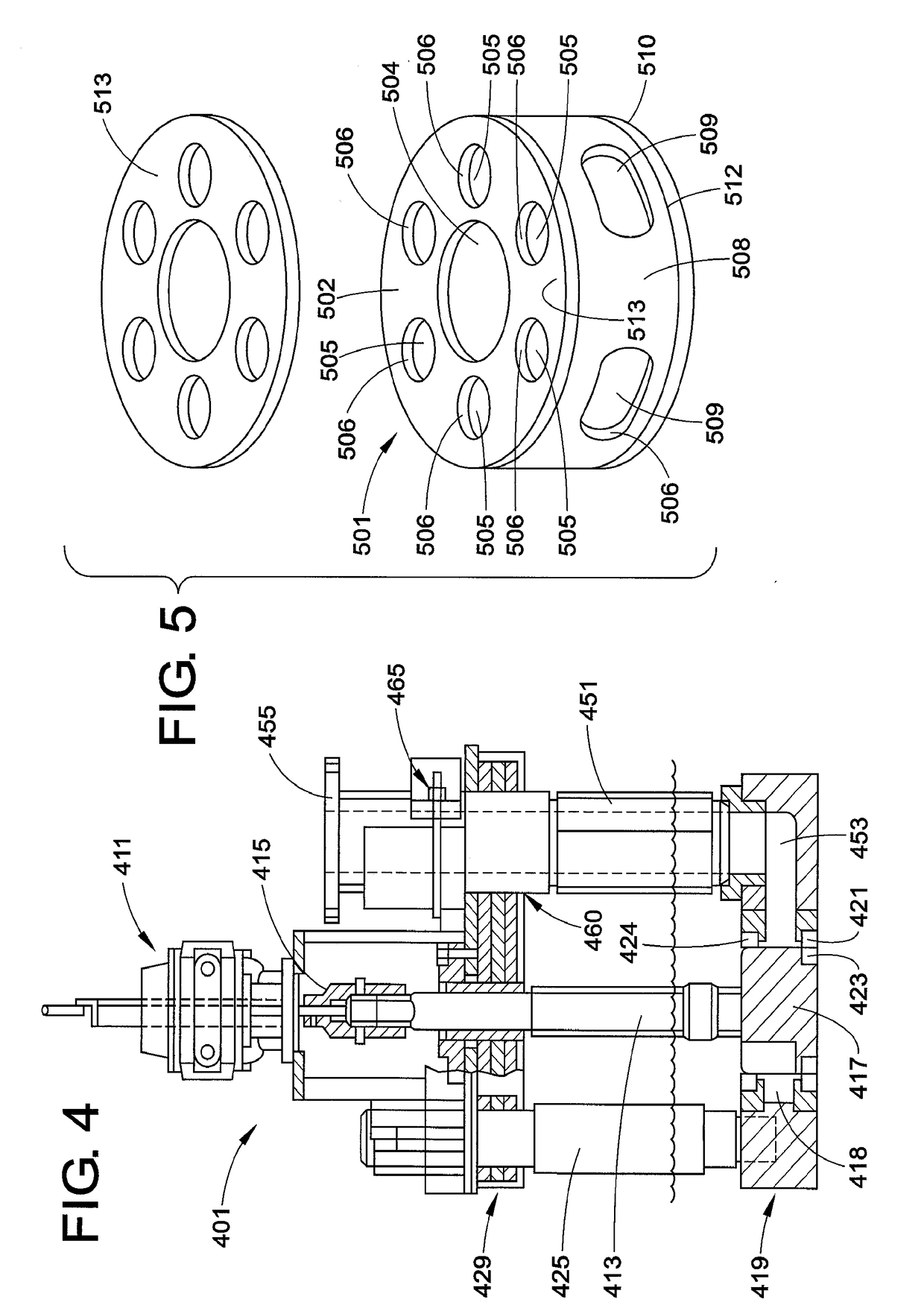

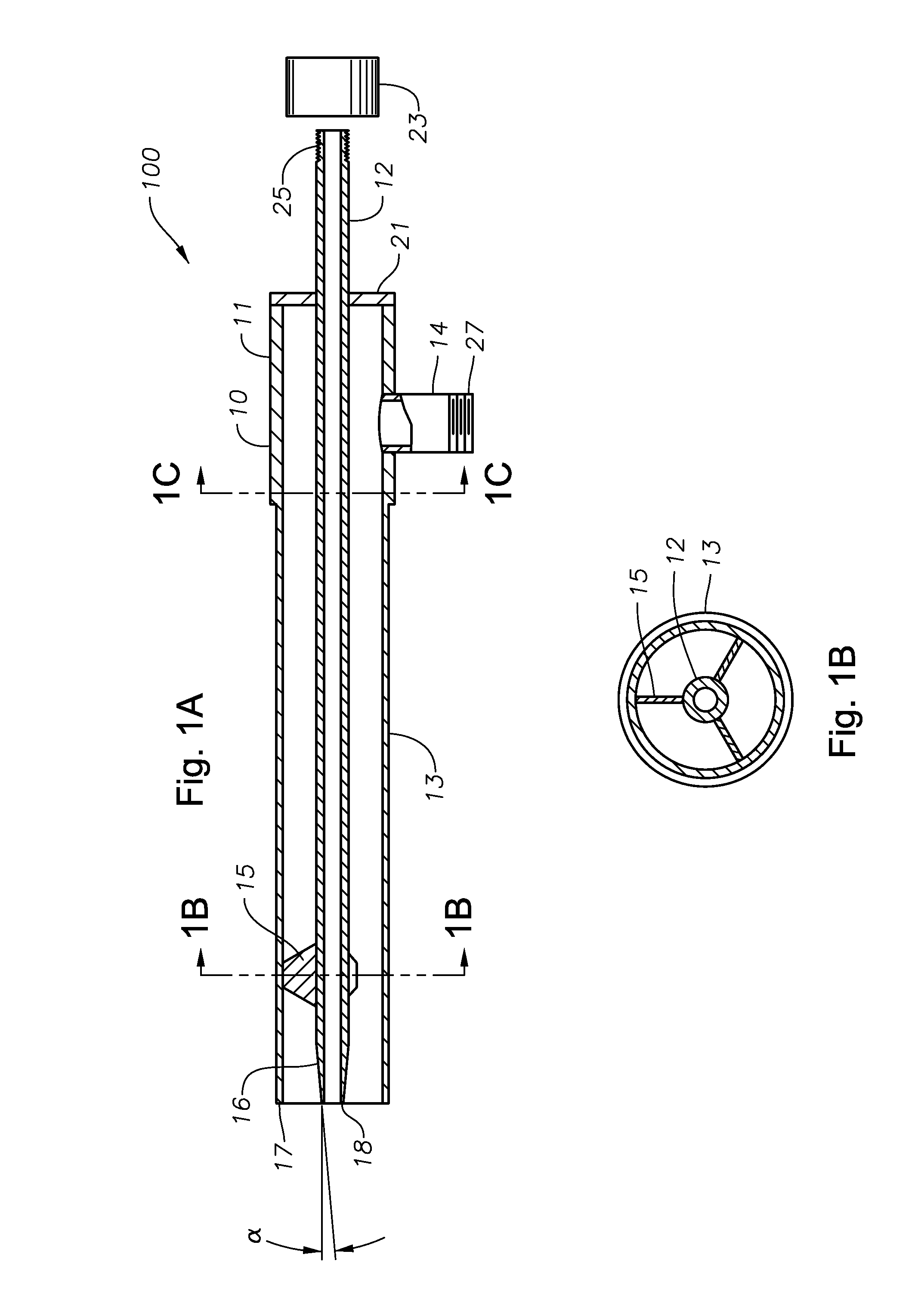

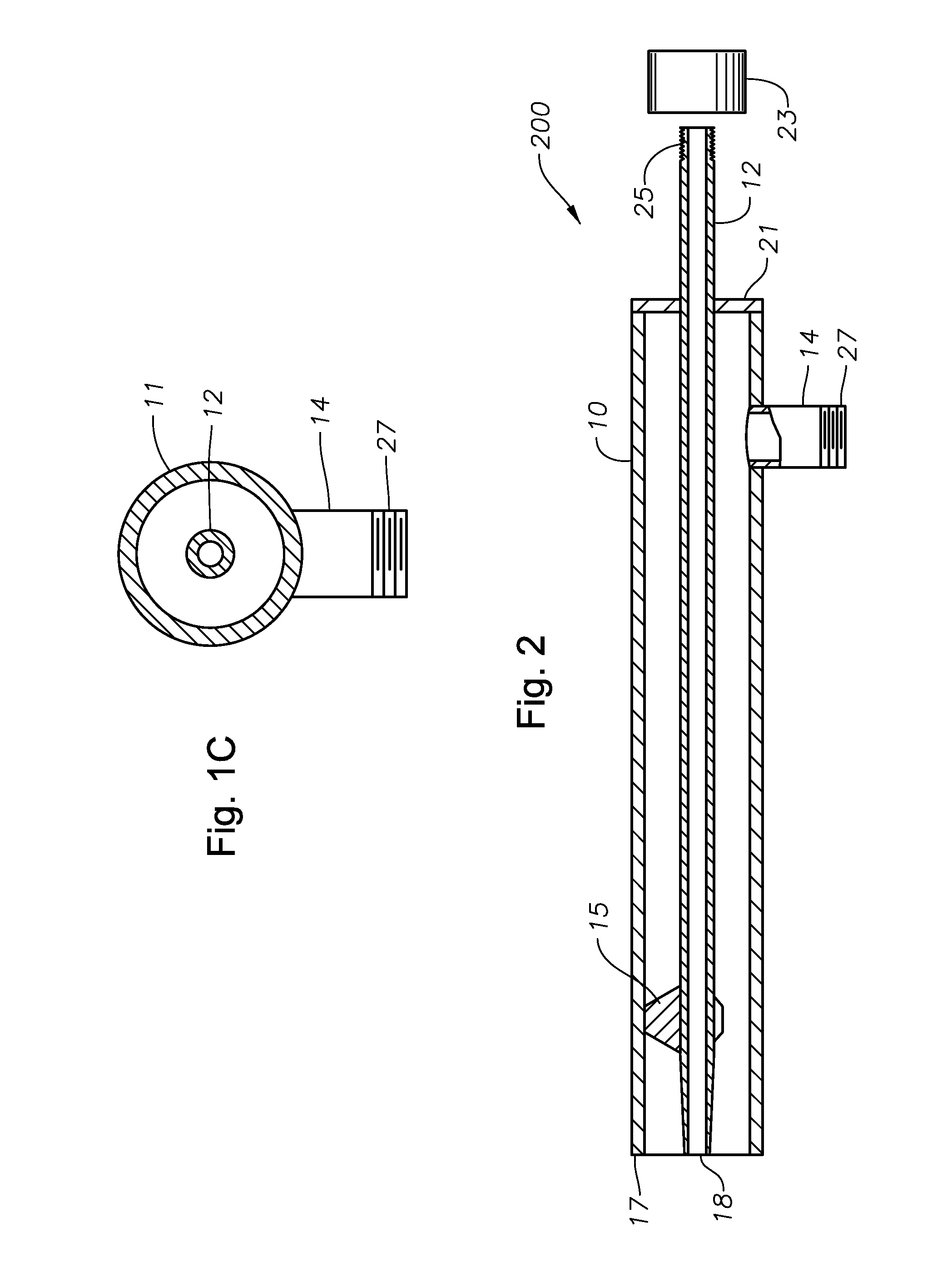

Multi-layered radiant thermal evaporator and method of use

InactiveUS20050072361A1Stable and reliableHigh quality usefulnessVacuum evaporation coatingSputtering coatingCrucibleVacuum chamber

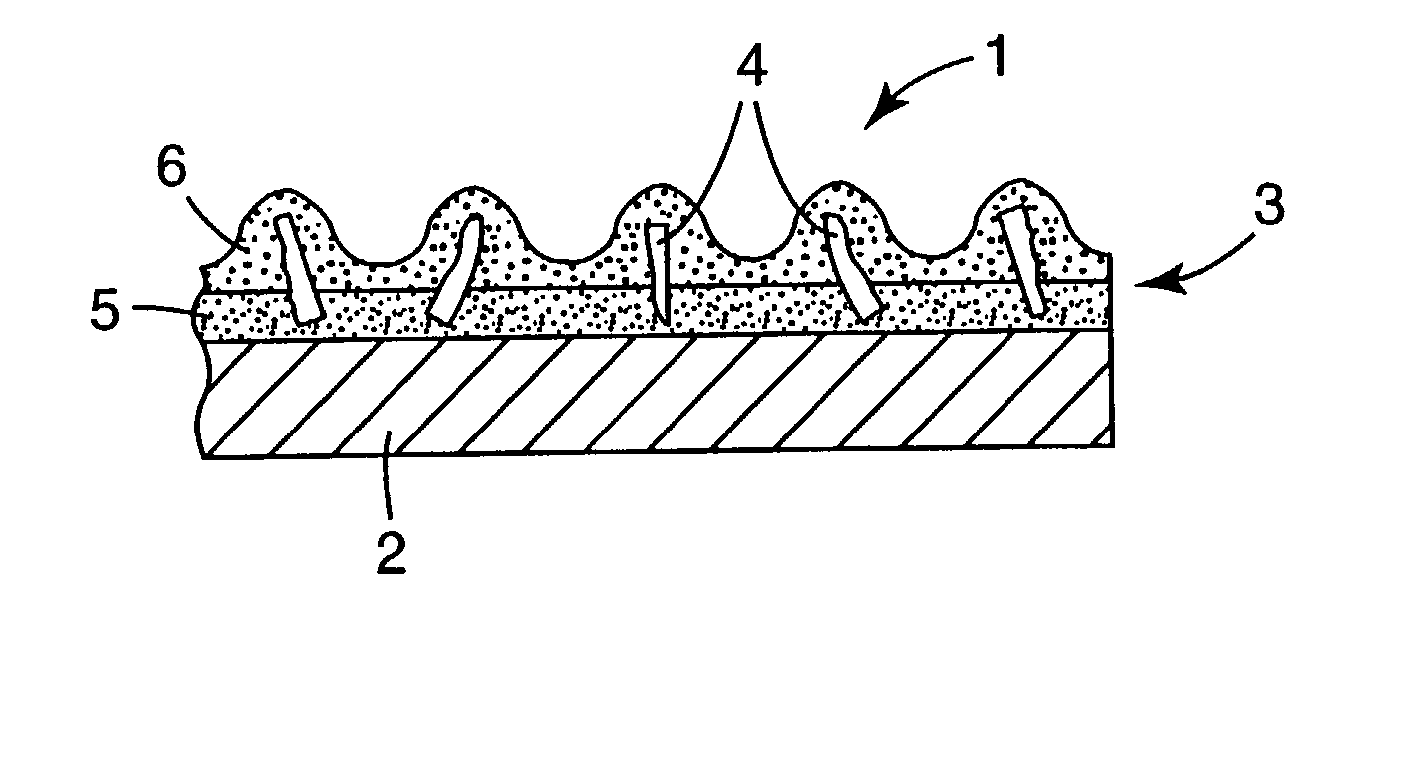

The present invention provides a system and method for uniform coating of a substrate at high deposition rates by evaporating a coating material in a vacuum chamber. The system includes an evaporator having a heating crucible for containing a coating material to be evaporated and a generally planar heat source disposed so as to heat a surface of a coating material contained in the heating crucible. Preferably, the heat source is manufactured from a ceramic or intermetallic material and includes a first layer defining a first set of openings and a second layer defining a second set of openings wherein the second layer overlies the first layer and is spaced apart therefrom. The first and second sets of openings allow the evaporated coating material to pass therethrough for dispersion of the coating material in a deposition zone defined by a containment shield disposed above the heat source.

Owner:DARLY CUSTOM TECH

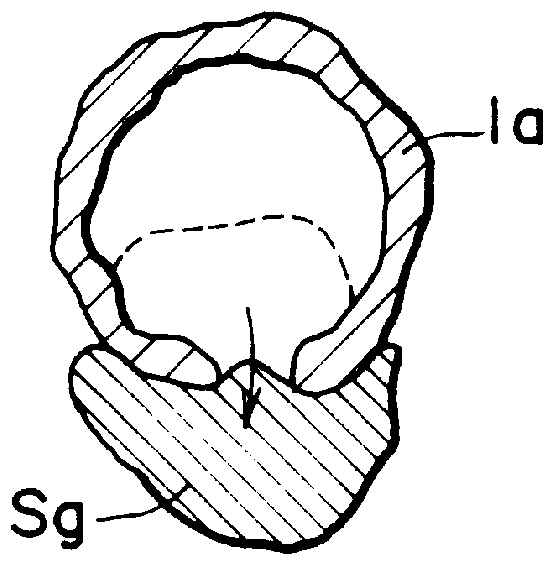

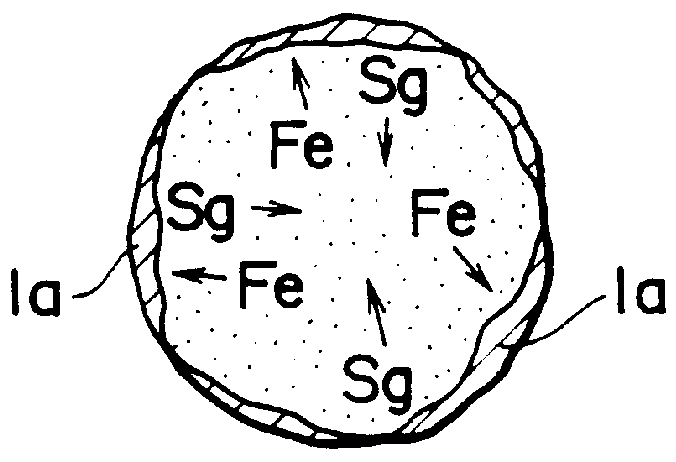

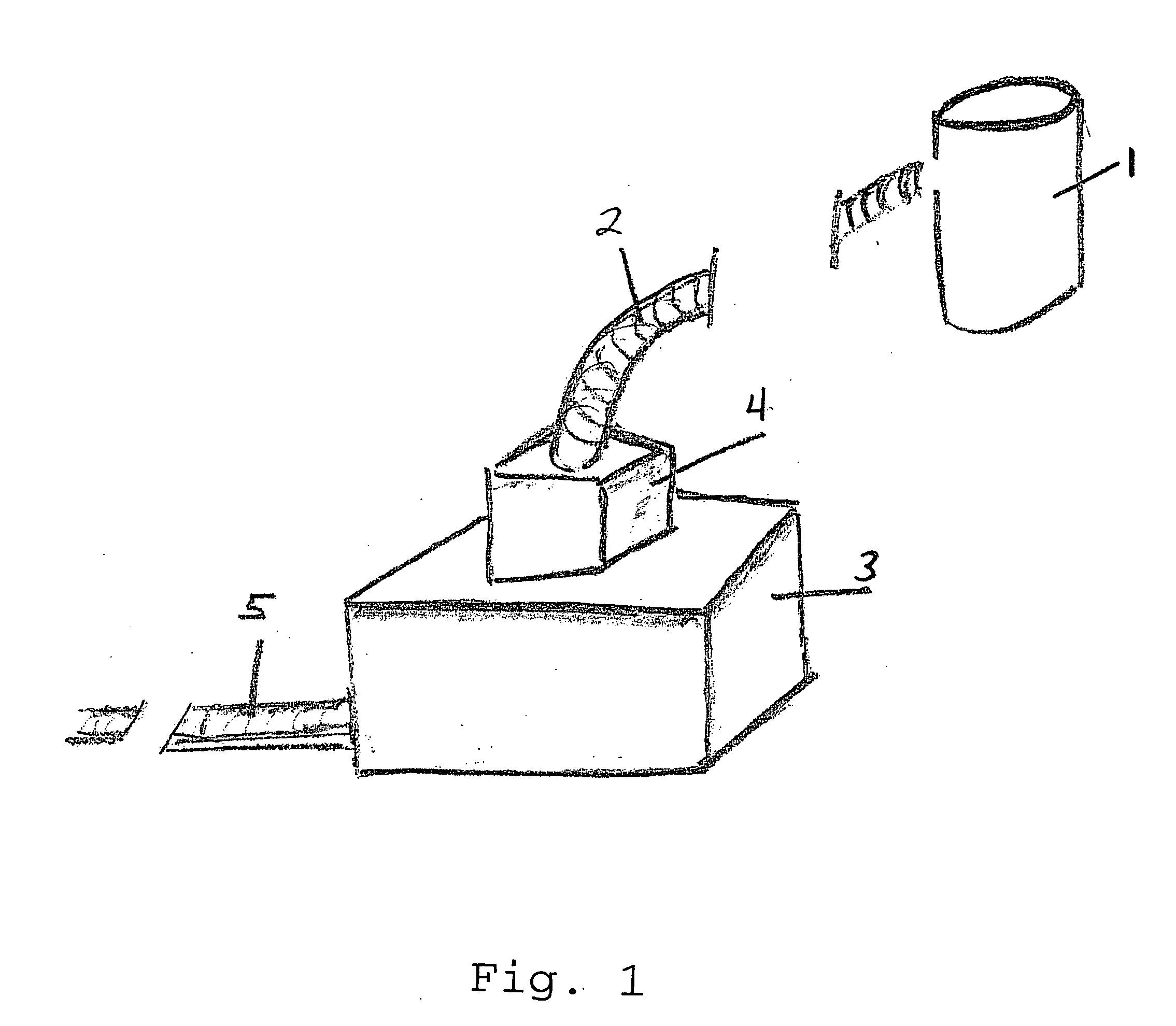

Method and apparatus for making metallic iron

InactiveUS6036744AHigh purityReadily and efficiently madeBlast furnace componentsRotary drum furnacesMolten slagCoal

A method of making metallic iron in which a compact, containing iron oxide such as iron ore or the like and a carbonaceous reductant such as coal or the like, is used as material, and the iron oxide is reduced through the application of heat, thereby making metallic iron. In the course of this reduction, a shell composed of metallic iron is generated and grown on the surface of the compact, and slag aggregates inside the shell. This reduction continues until substantially no iron oxide is present within the metallic iron shell. Subsequently, heating is further performed to melt the metallic iron and slag. Molten metallic iron and molten slag are separated one from the other, thereby obtaining metallic iron with a relatively high metallization ratio. Through the employment of an apparatus for making metallic iron of the present invention, the above-described method is efficiently carried out, and metallic iron having a high iron purity can be made continuously as well as productively not only from iron oxide having a high iron content but also from iron oxide having a relatively low iron content.

Owner:KOBE STEEL LTD

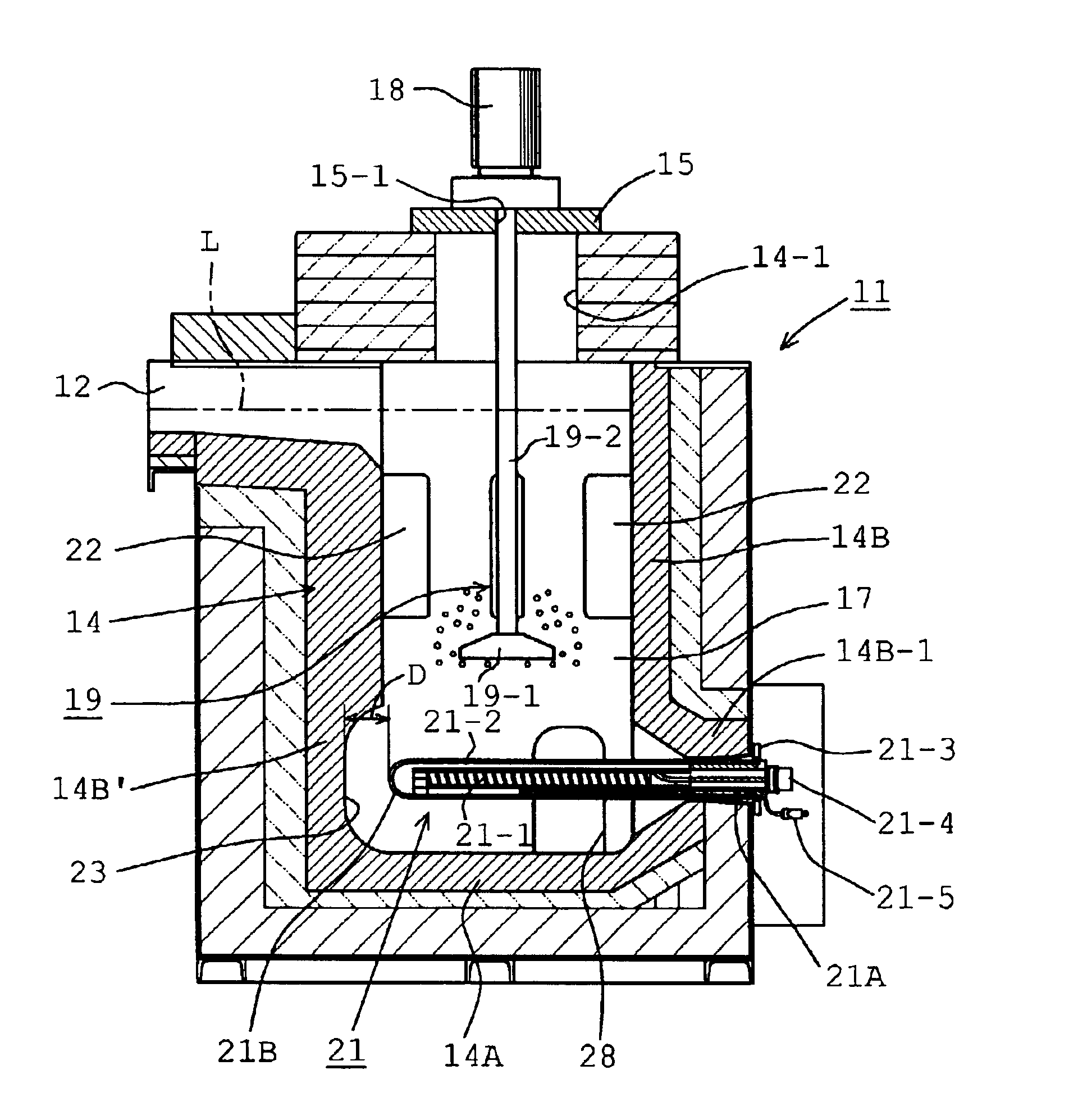

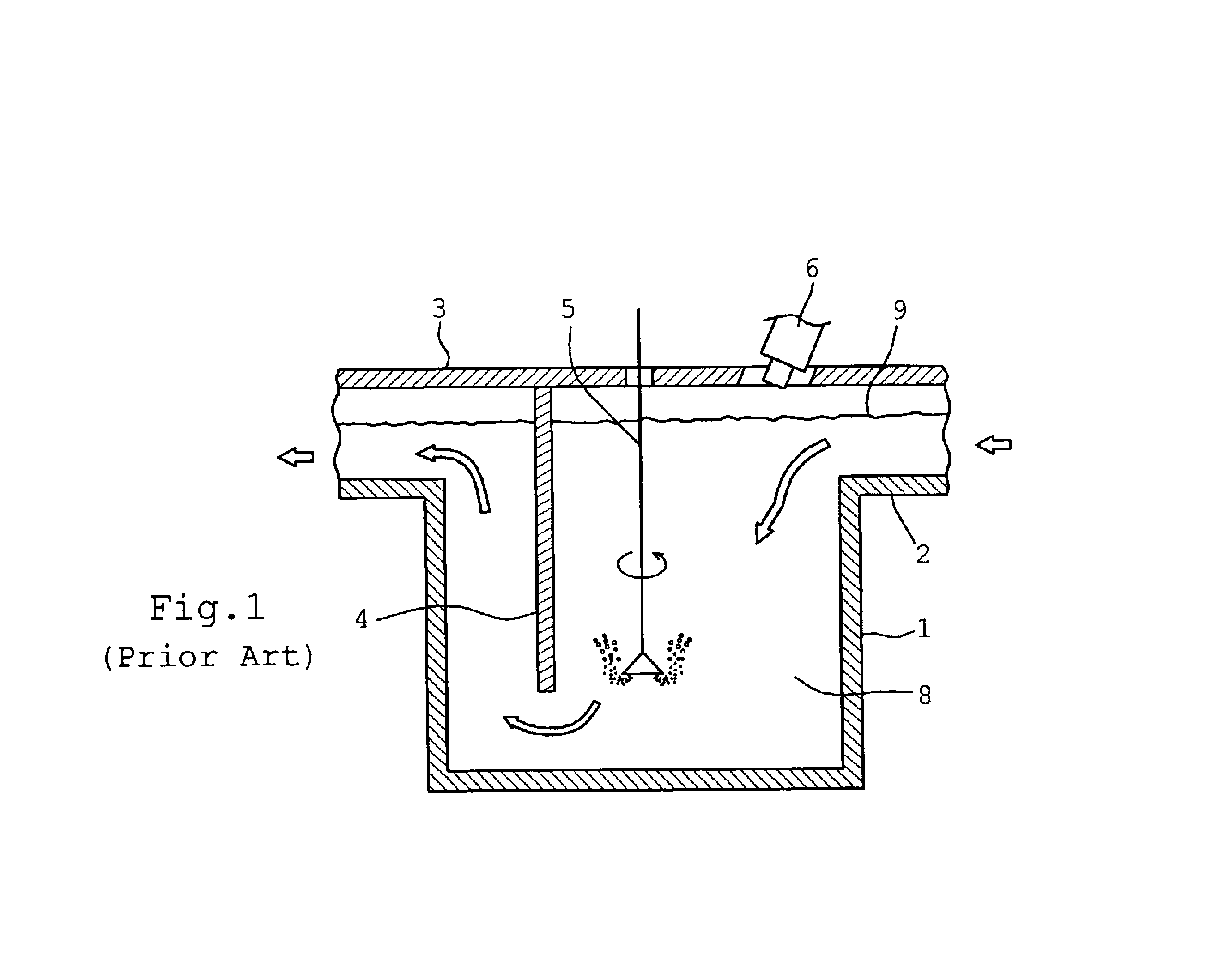

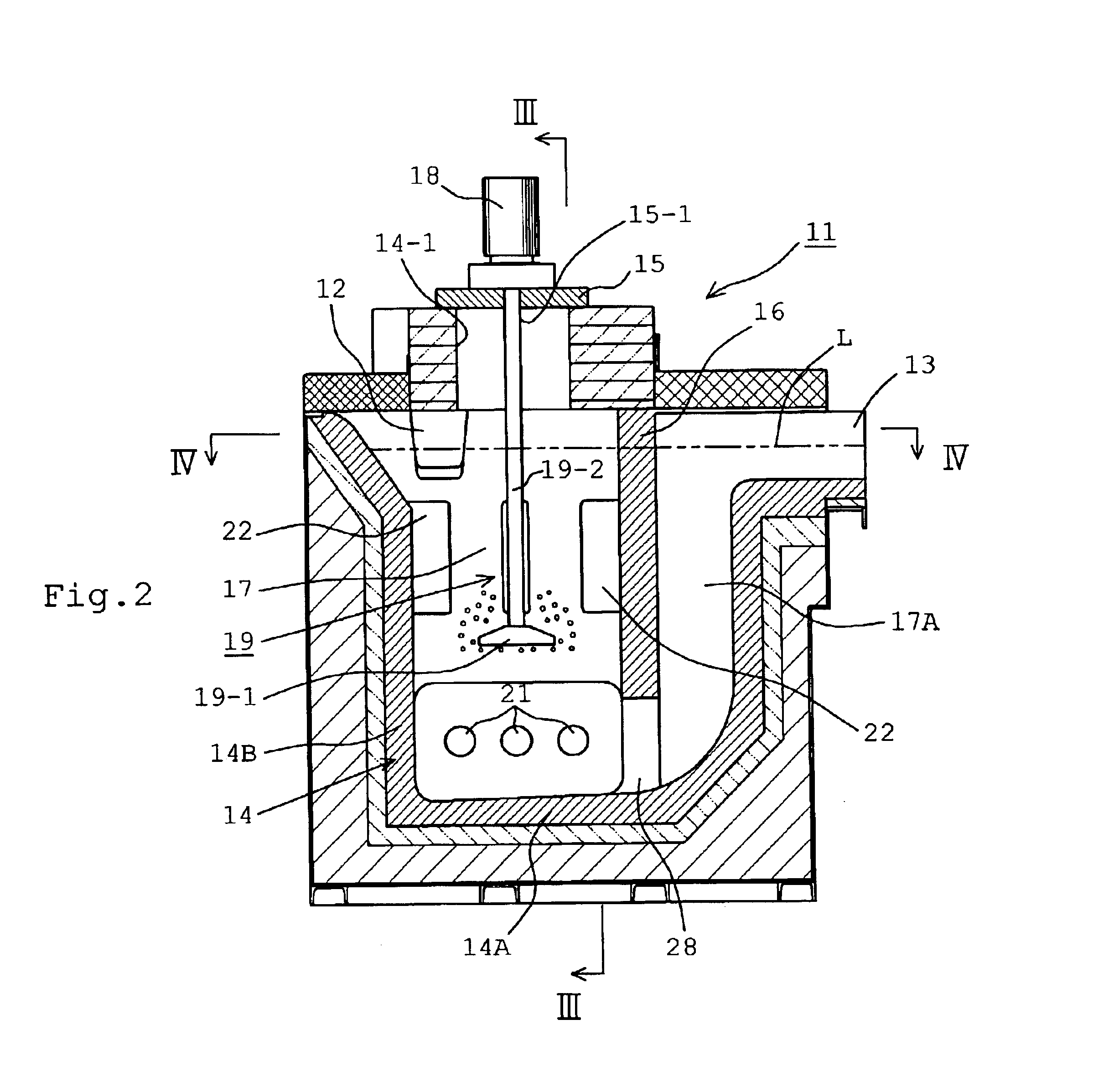

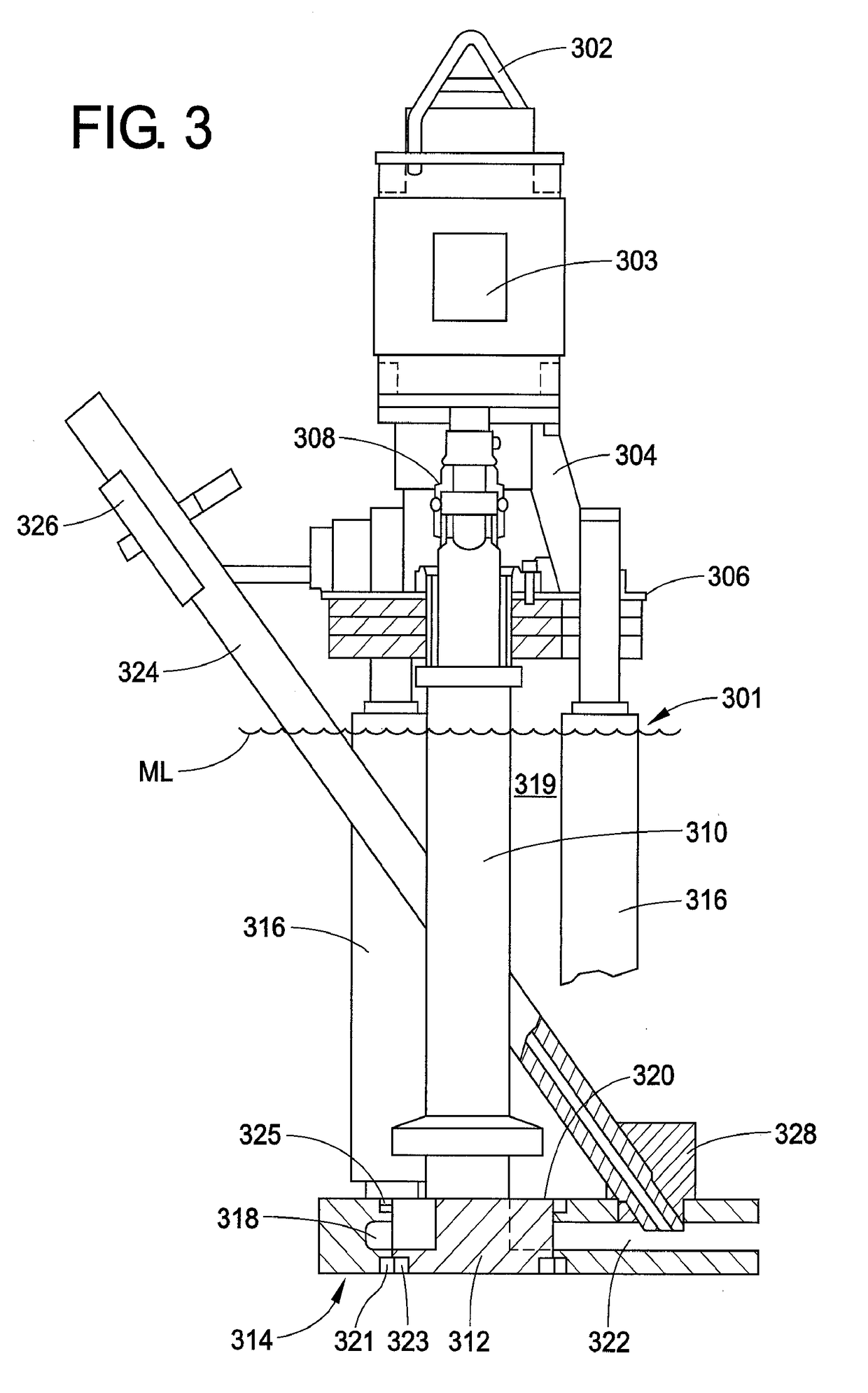

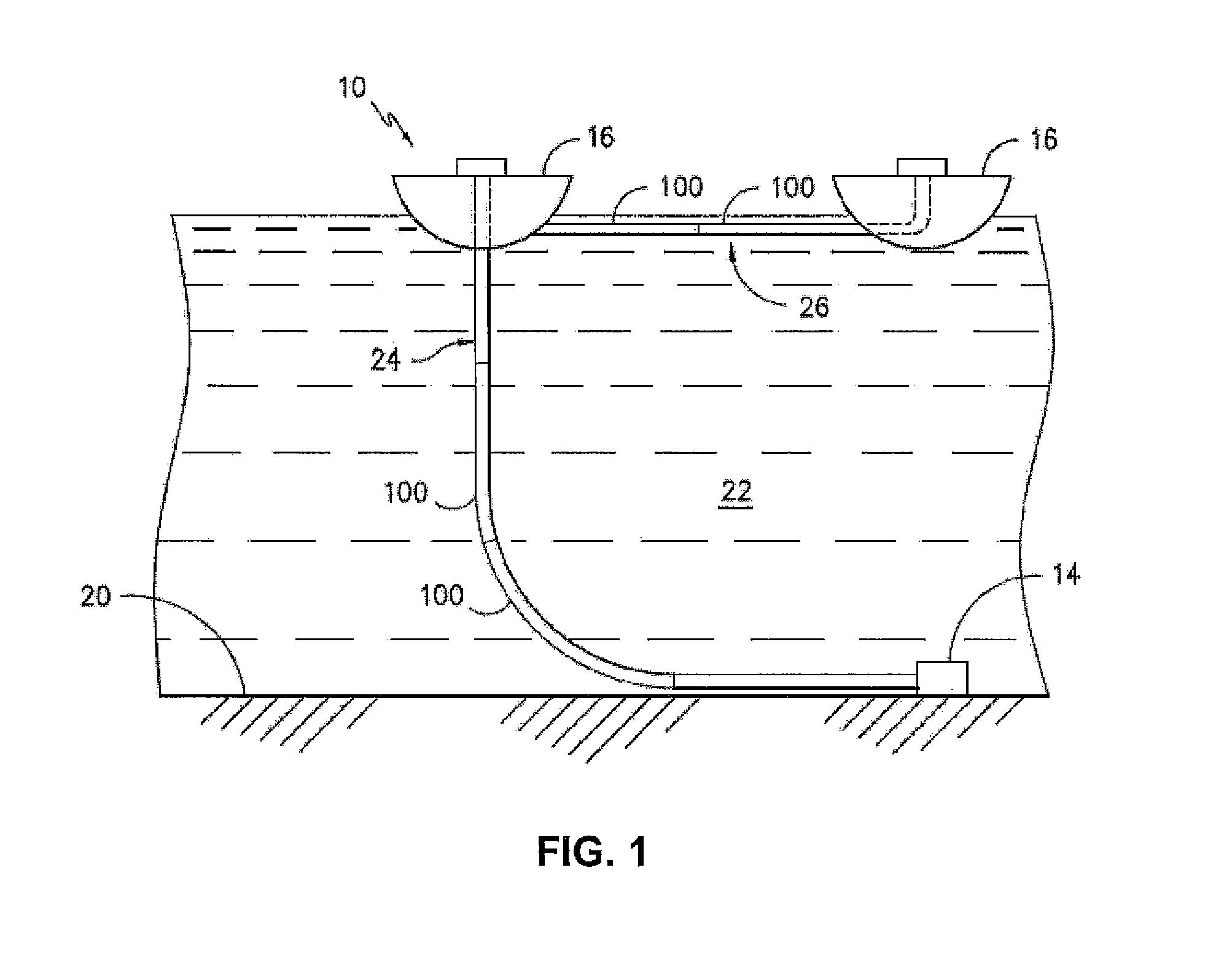

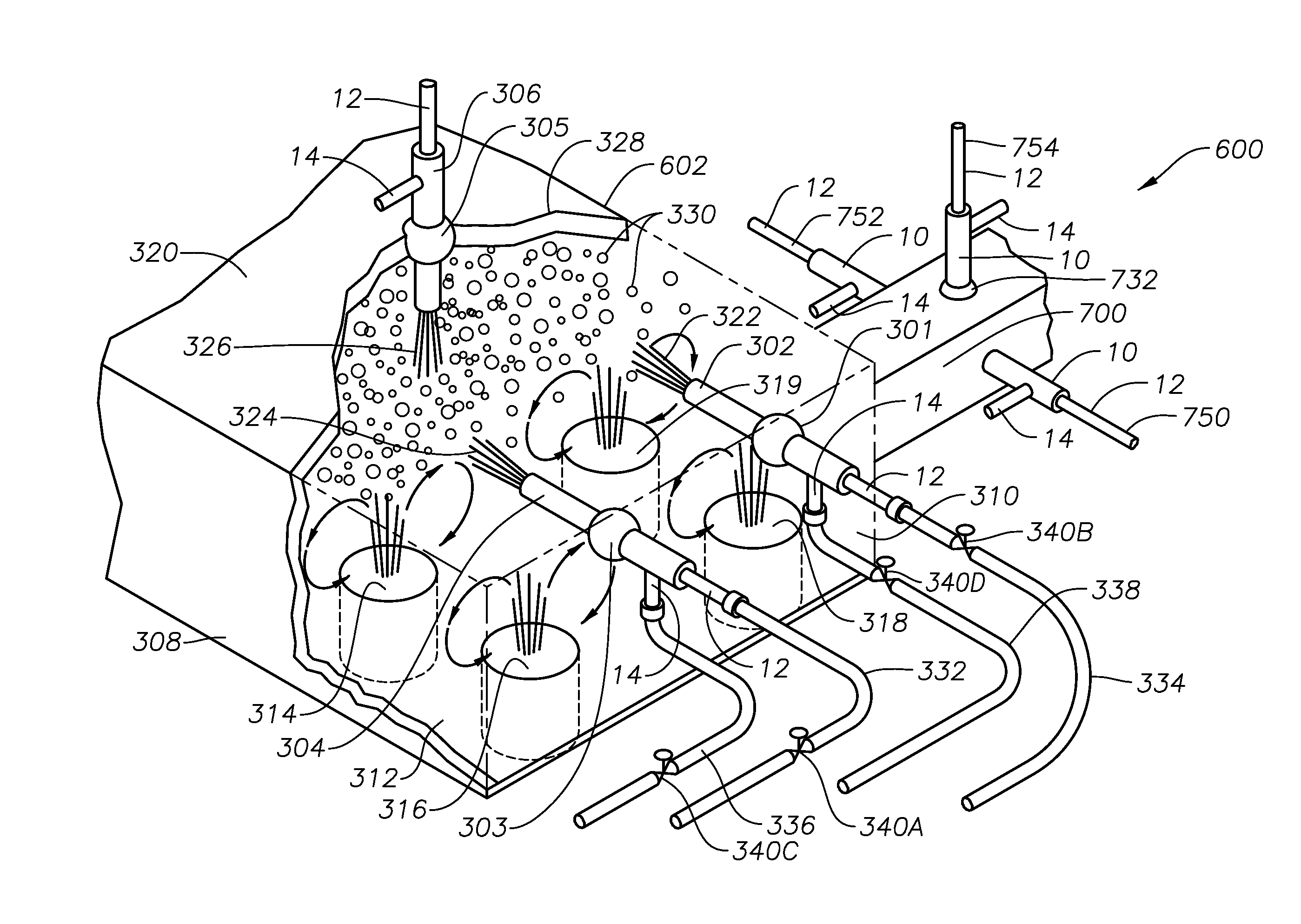

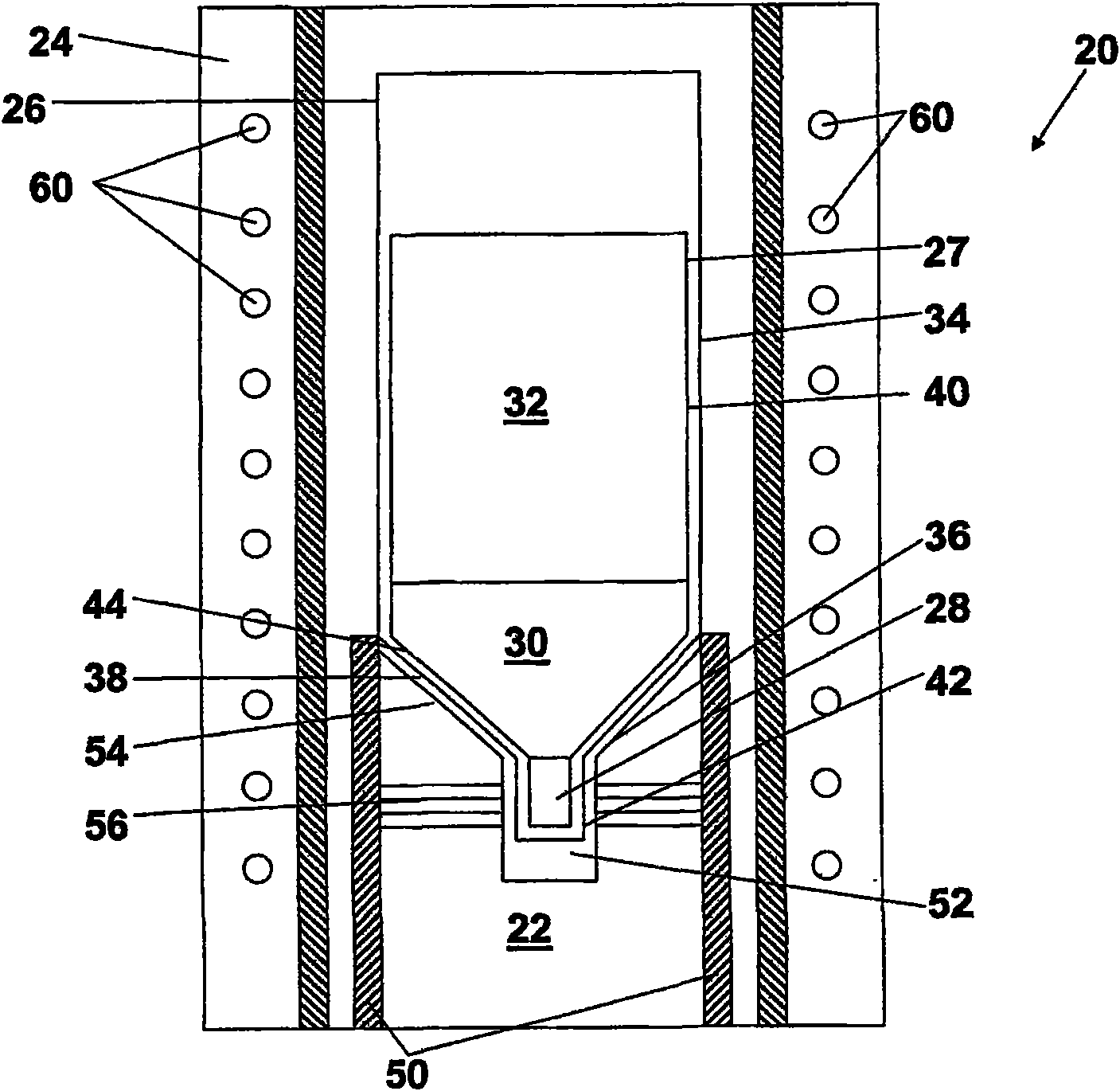

Inline degassing apparatus

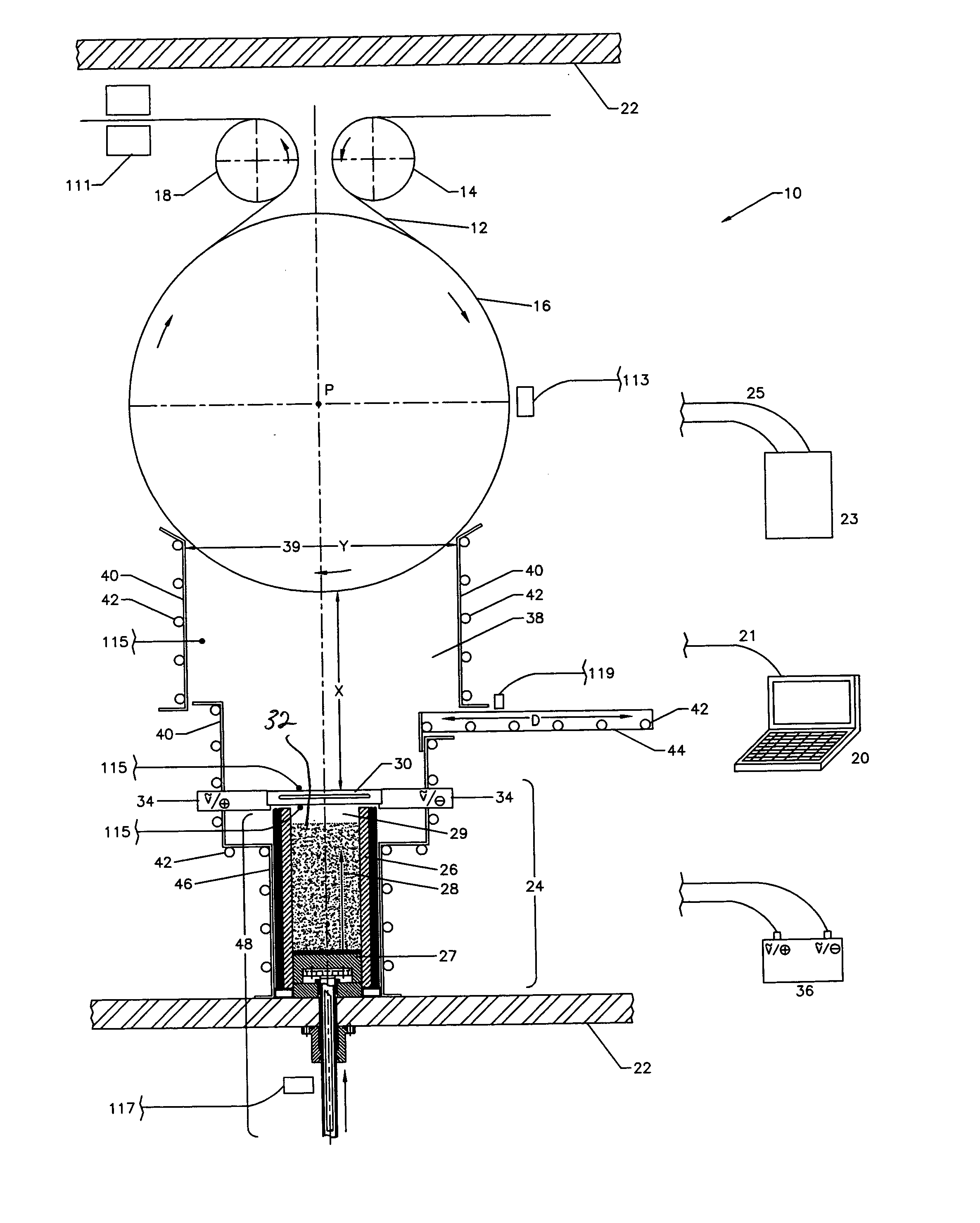

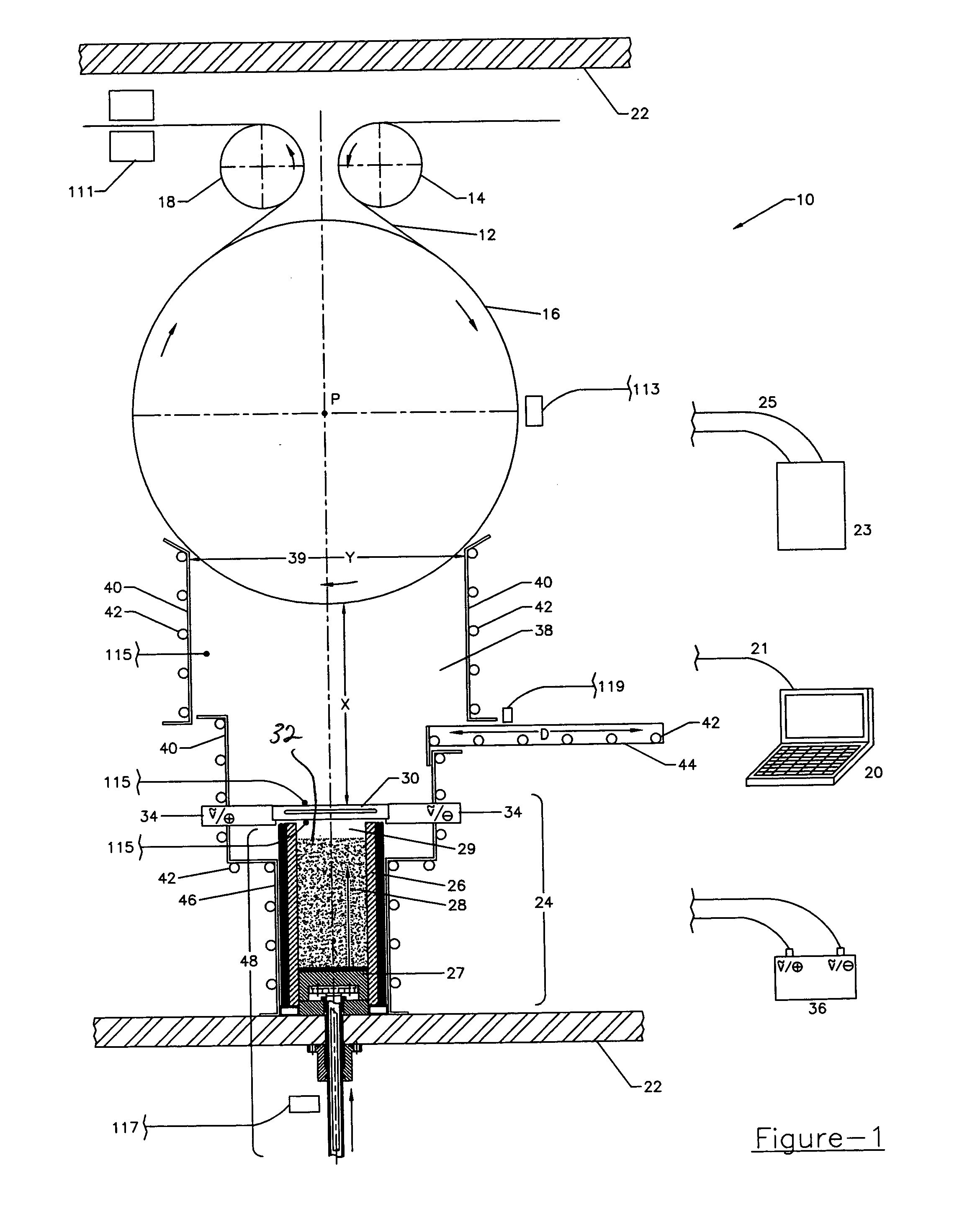

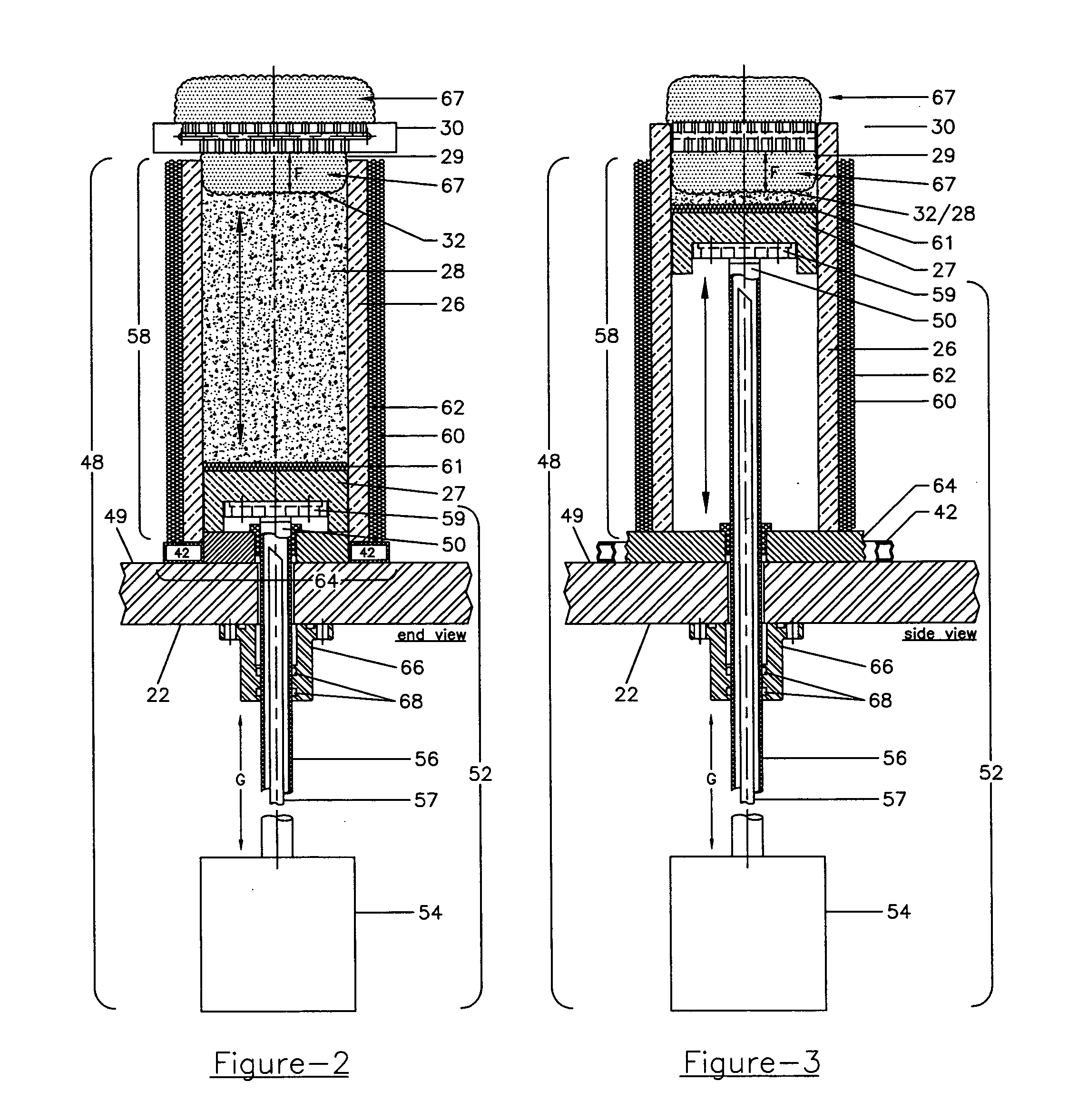

InactiveUS6887424B2Reduce the amount requiredSmall volumeMelt-holding vesselsMechanical apparatusNon-metallic inclusionsSolid solution

An inline degassing apparatus for removing solid solution gases as well as nonmetallic inclusions from molten metal in a degassing container, to which the molten metal is continuously introduced for degassing operation and from which the degassed molten metal is continuously removed. A rotary diffusing device is arranged in the degassing container for generating bubbles of inert gas diffused into the molten metal, thereby entrapping solid solution gases as well as nonmetallic inclusions into the bubbles, which are then floated and separated. Heaters are provided, which extend, in a cantilever fashion, from a side wall of container at a position adjacent the bottom wall of the container substantially parallel to the bottom wall.

Owner:PYROTEK JAPAN +1

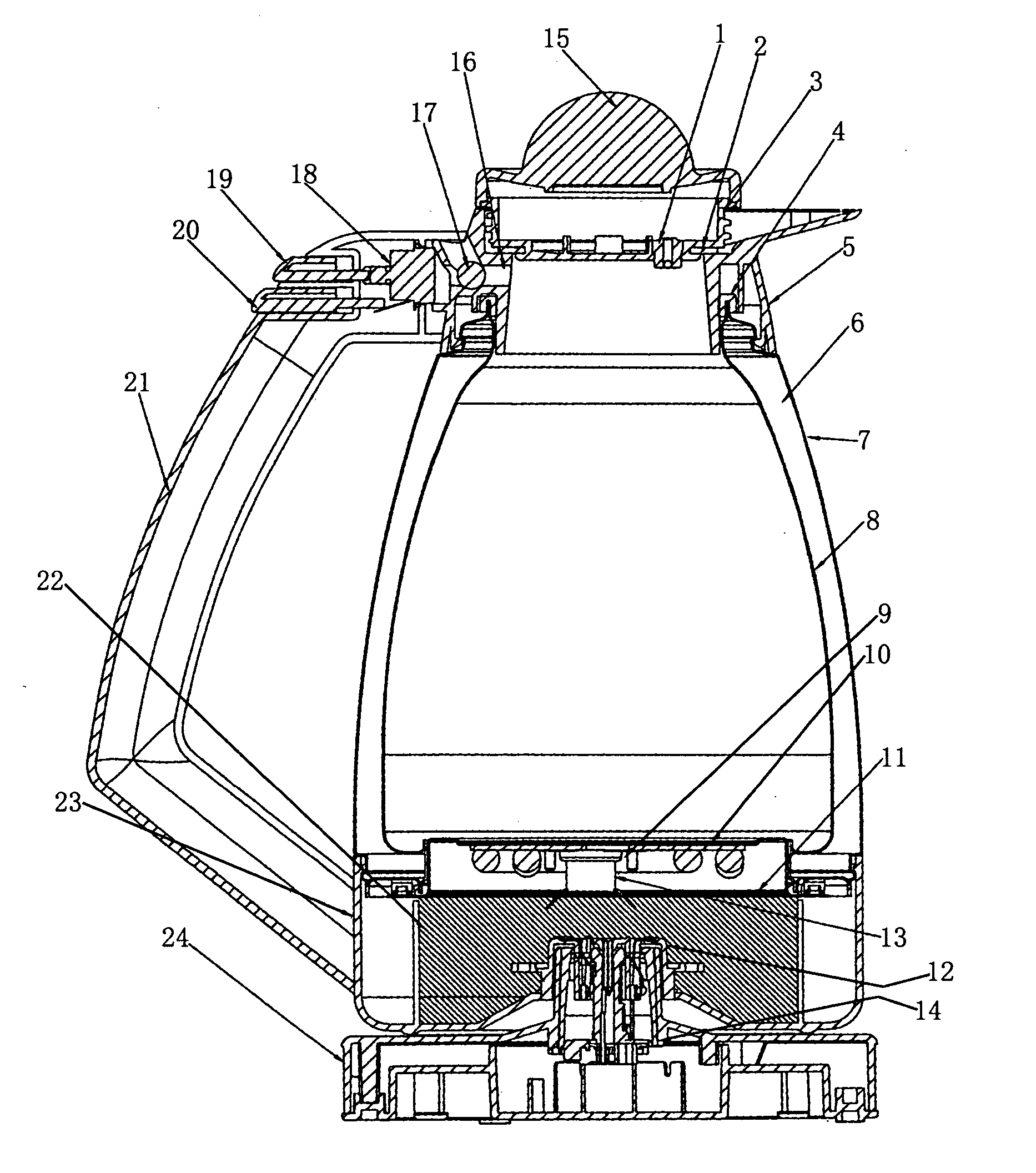

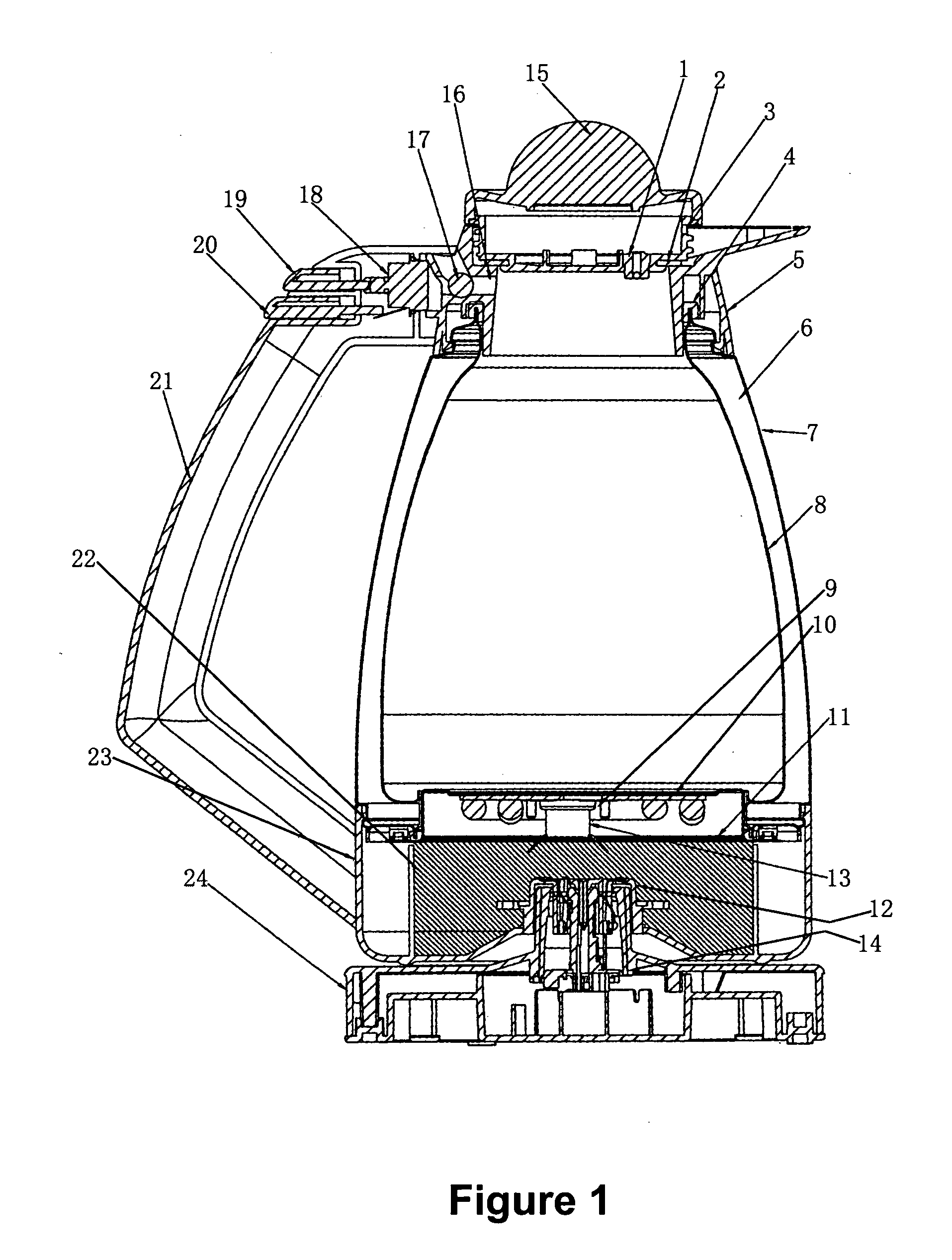

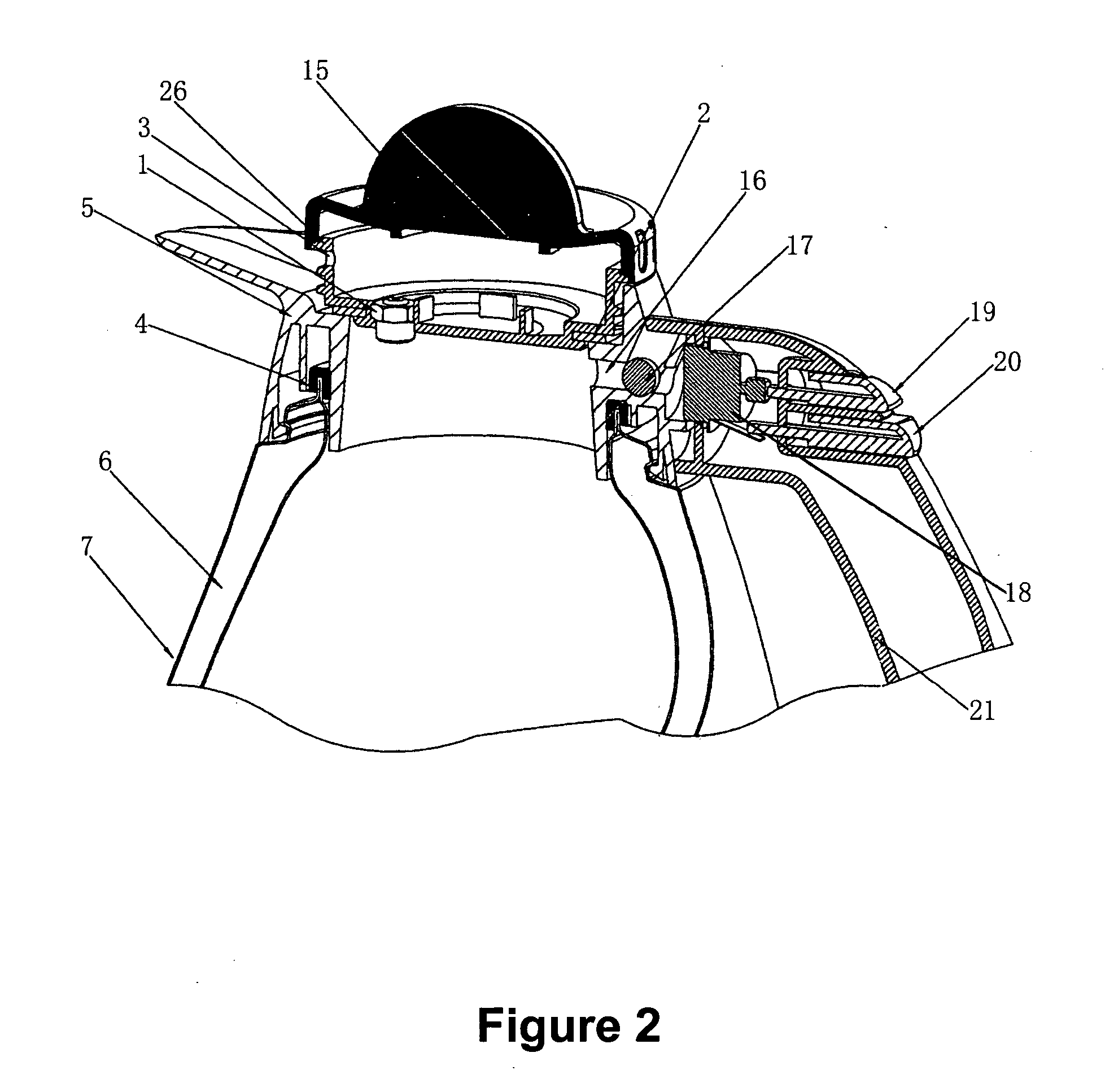

Electric thermos jug

InactiveUS7091455B2Improve air tightnessEasy to useCooking-vessel materialsDomestic cooling apparatusElectricityWater quality

Owner:FUNG SHIU PO

Method of making amorphous materials and ceramics

InactiveUS20030110709A1Facilitates formation and homogeneityEliminates and minimizes heat transferWood working apparatusCeramic shaping apparatusCeramicAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

Exothermic feeder

An exothermal feeder mass is described, containing aluminum and magnesium, at least one oxidizing agent, a SiO2-containing filler, and an alkali silicate as the binder; it is characterized in that it contains roughly 2.5 to 20% by weight of a reactive aluminum oxide with a specific surface of at least roughly 0.5 m2 / g and an average particle diameter (d50) from roughly 0.5 to 8 microns and is essentially free of fluoride-containing fluxes.

Owner:AS LINGEN GMBH & CO KG

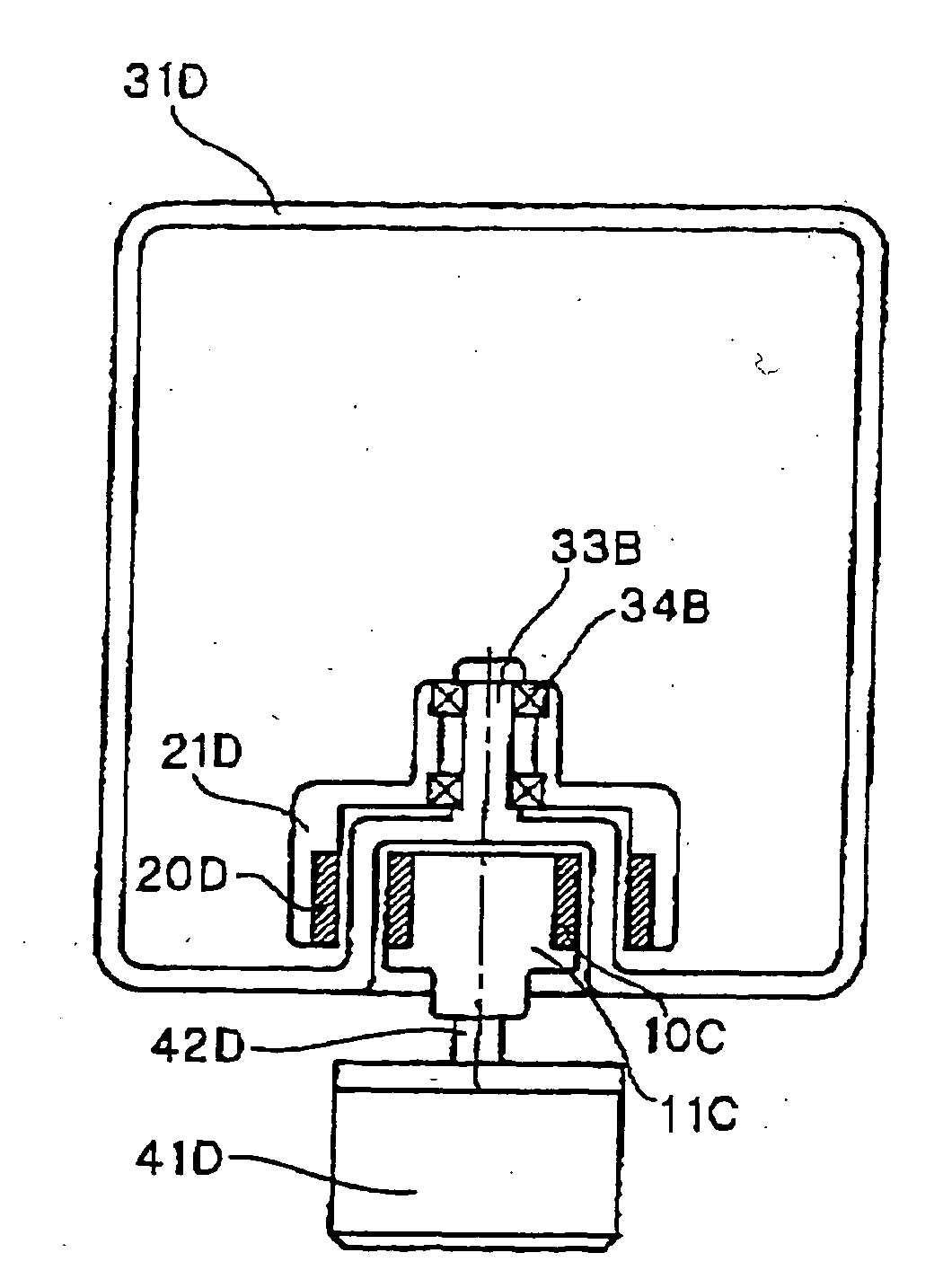

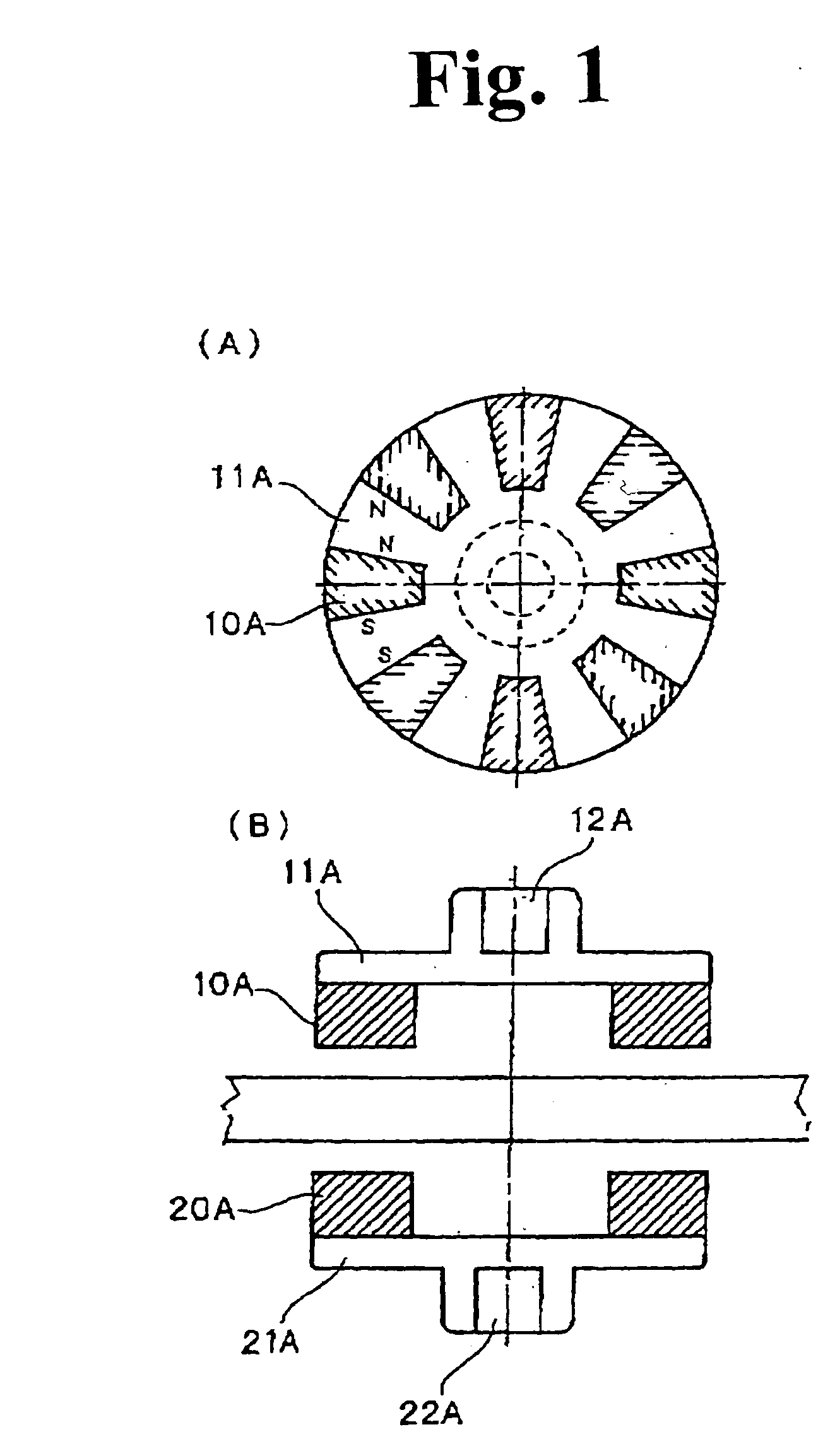

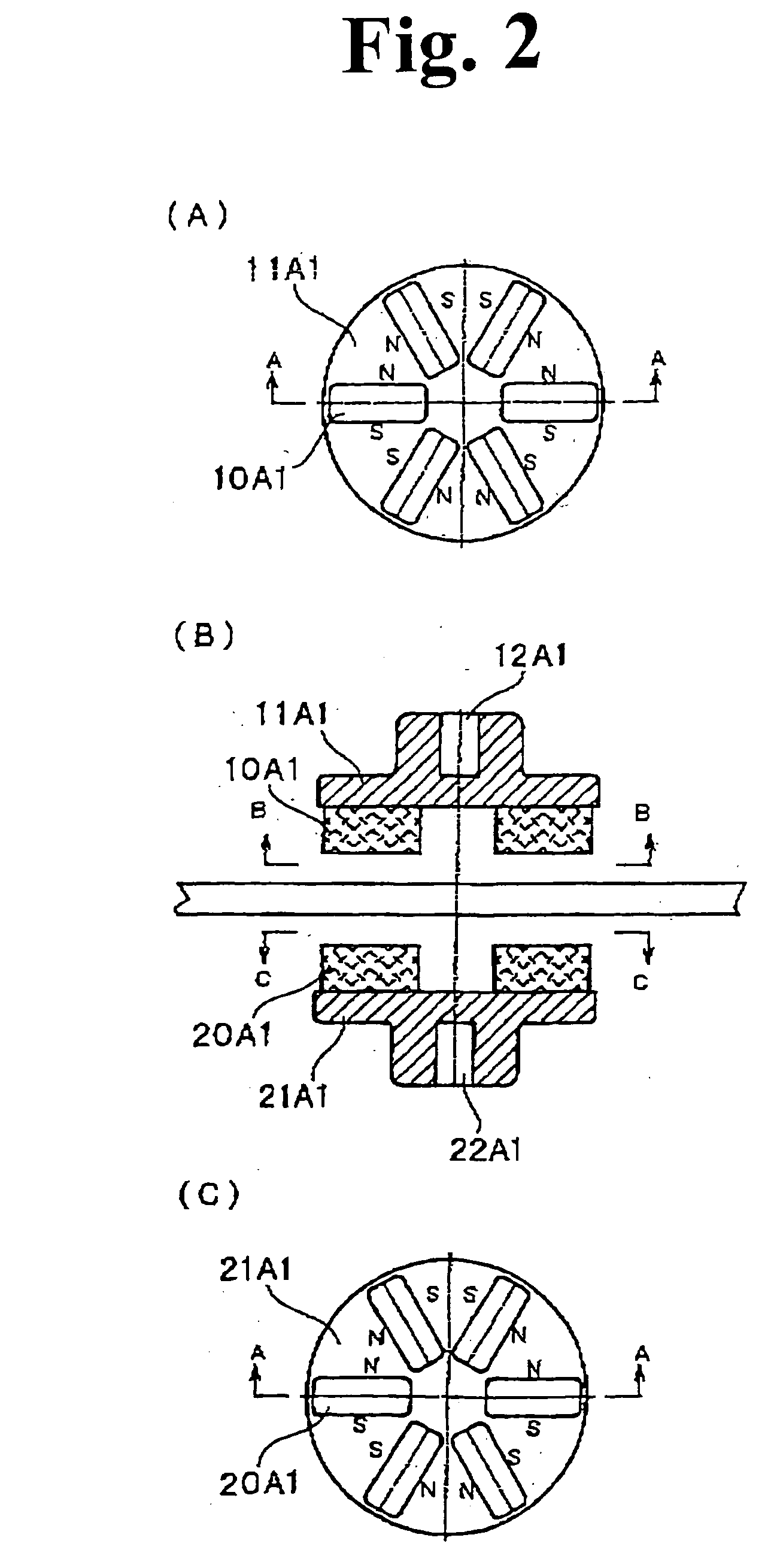

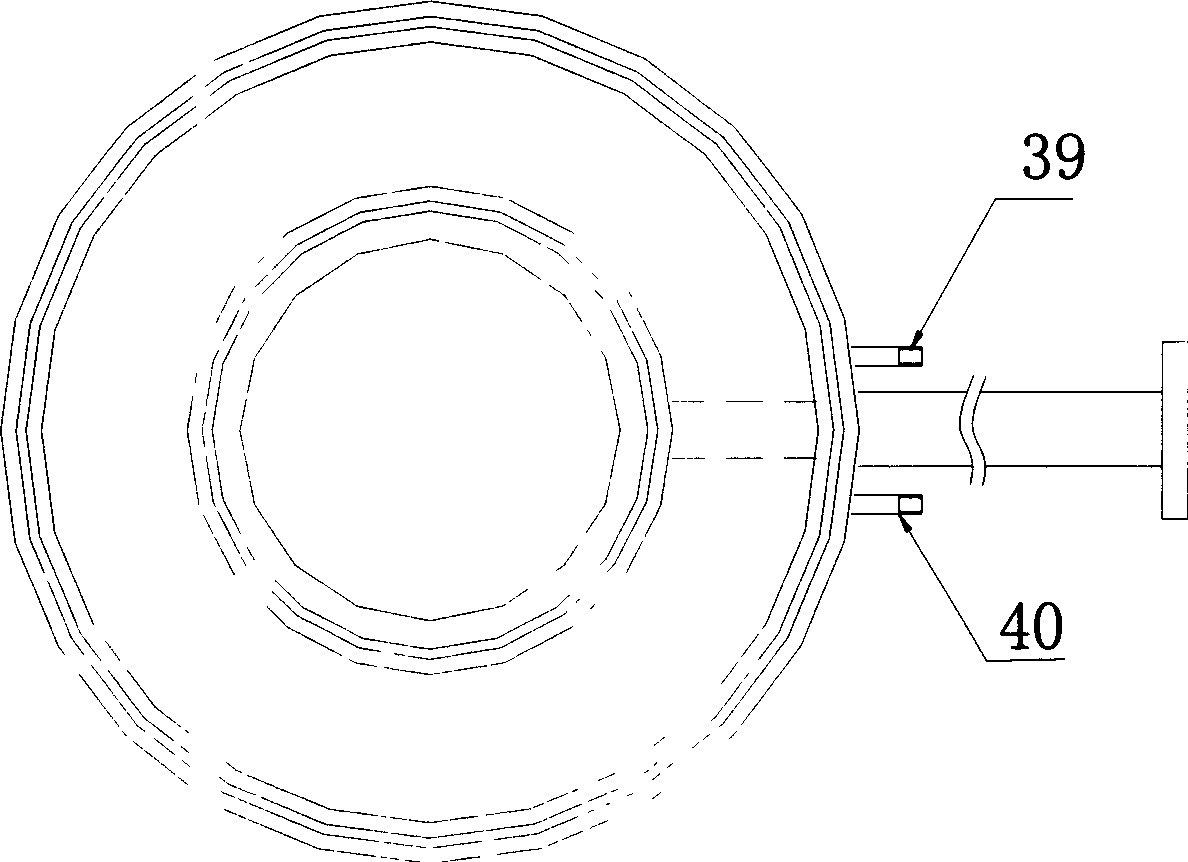

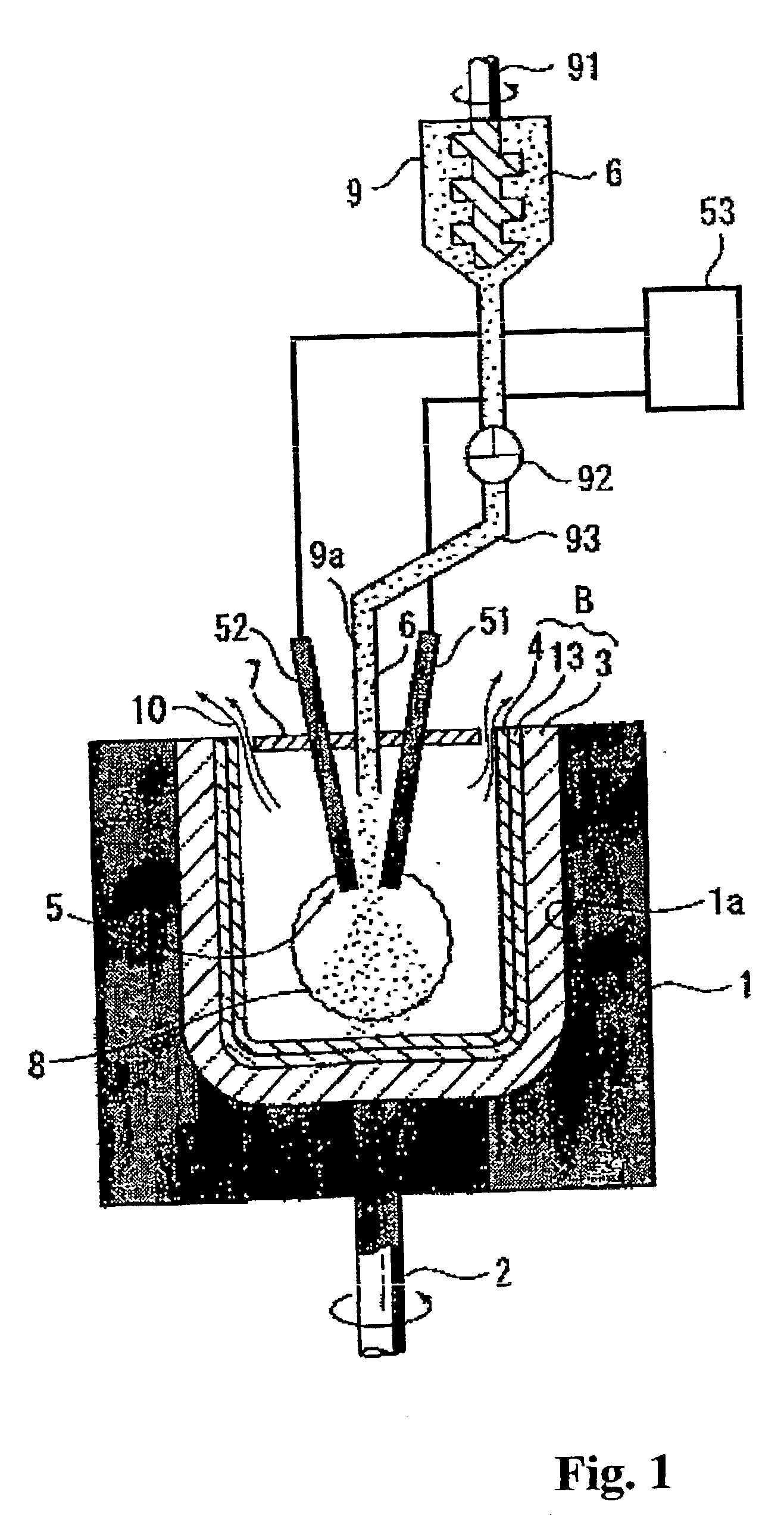

Magnetic rotation transmitting device, hermetic stirring unit, and electric furnace

InactiveUS20050206260A1Dynamo-electric brakes/clutchesRotary stirring mixersElectric arc furnaceMagnetic rotation

In order to provide a magnetic rotation transmitting device capable of obtaining a large transmitting torque without using a large-sized permanent magnet, in an axial-type magnetic rotation transmitting device, which includes a driving rotation body having one or plural magnetic line(s) in which plural first magnets (10A) are disposed in a circumferential direction on a first disk (11A) at almost equal intervals, a drive source rotationally driving a drive shaft of the driving rotation body, and a driven rotation body having one or plural magnet line(s) in which second magnets (20A) of the same number as the first magnets (10A) are disposed in the circumferential direction on a second disk (21A) at almost equal intervals, symmetrically disposed to, and magnetically coupled with the driving rotation body with a magnetic coupling gap and, which utilizes a magnetic operation and which allows the driven rotation body to rotate by rotationally driving the drive shaft by means of the drive source, the first magnet (10A) has a N-magnetic pole portion and a S-magnetic pole portion, and an extended surface of a boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driving center line as being a rotation center line of the driving rotation body, the second magnet (20A) has the N-magnetic pole portion and the S-magnetic pole portion, and the extended surface of the boundary surface between the N-magnetic pole portion and the S-magnetic pole portion approximately overlaps with a driven center line as being the rotation center line of the driven rotation body, adjacent and facing surfaces of the first magnets (10A) adjacent to each other on the first disk (11A) are disposed so that magnetic pole faces having the same polarity make pairs, and adjacent and facing surfaces of the second magnets (20A) adjacent to each other on the second disk (21A) are disposed so that the magnetic pole faces having the same polarity make pairs.

Owner:MAGUNEO

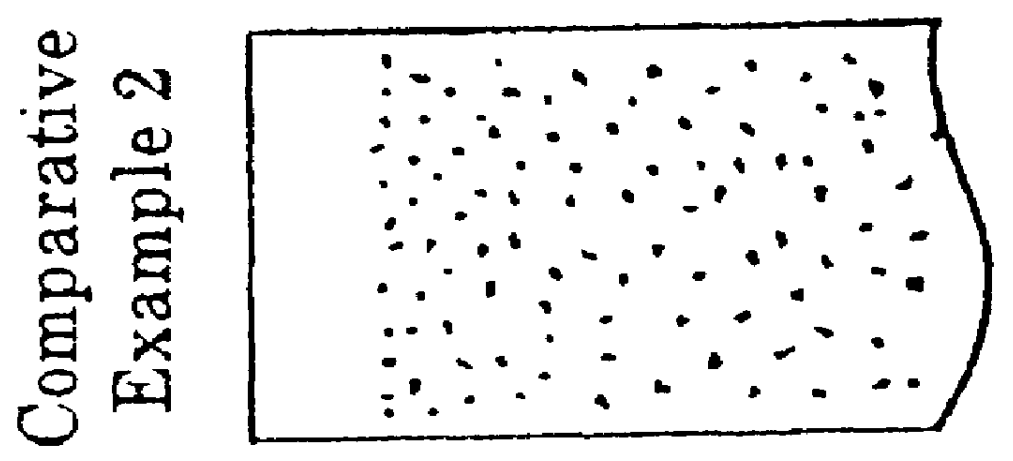

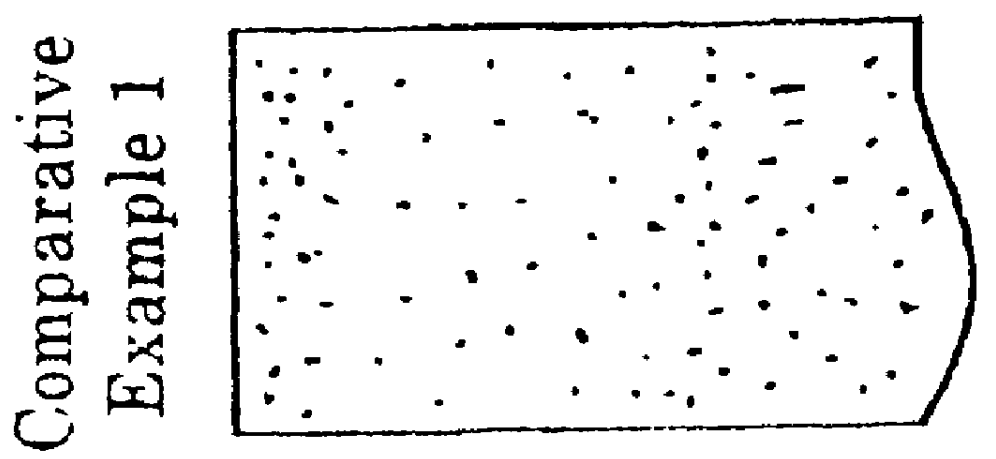

Cast iron inoculant and method for production of cast iron inoculant

InactiveUS6102983AEliminate segregationIncrease the number ofBlast furnace componentsBlast furnace detailsCeriumManganese

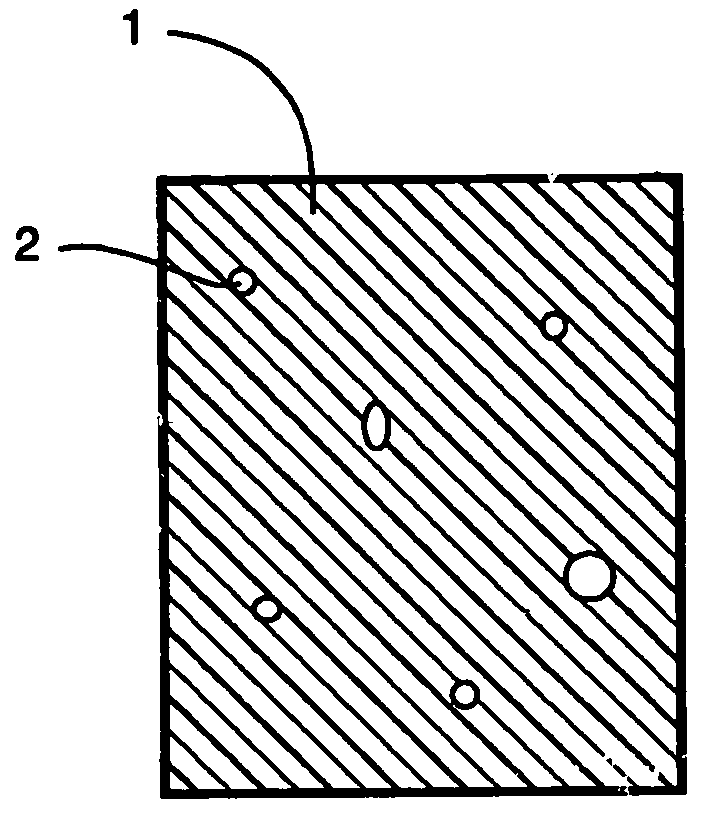

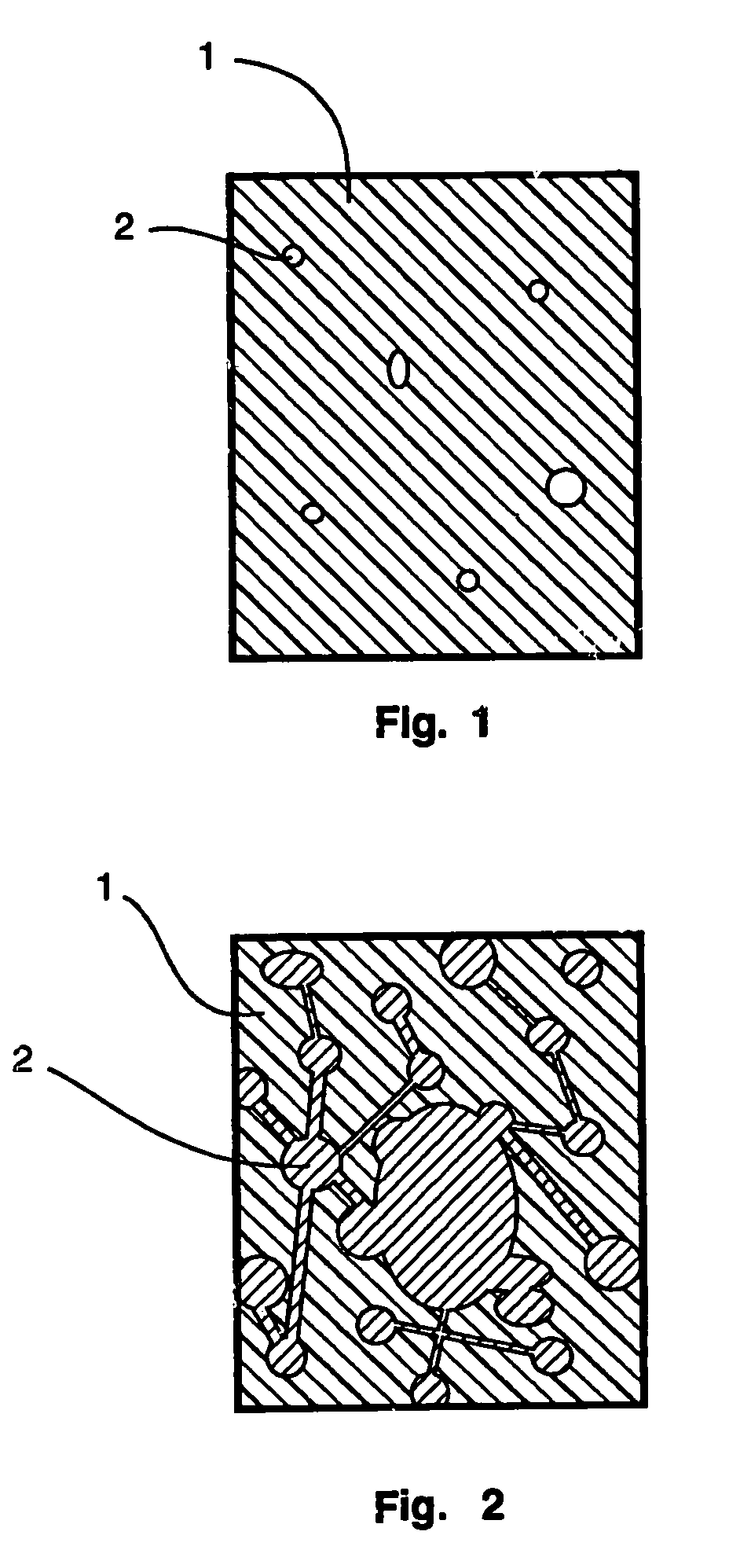

The invention relates to an inoculant for the manufacture of cast iron with lamellar, compacted or spheroidal graphite. The inoculant comprises between 40 and 80% by weight of silicon, between 0.5 and 10% by weight of calcium and / or strontium and / or barium, between 0 and 10% by weight of cerium and / or lanthanum, between 0 and 5% by weight of magnesium, less than 5% by weight of aluminium, between 0 and 10% by weight of manganese and / or titanium and / or zirconium, between 0.5 and 10% by weight of oxygen in the form of one or more metal oxides, the balance being iron, said inoculant further comprising between 0,1 and 10% by weight of sulphur in the form of one or more metal sulphides. The invention further relates to a method for the production of the inoculant.

Owner:ELKEM

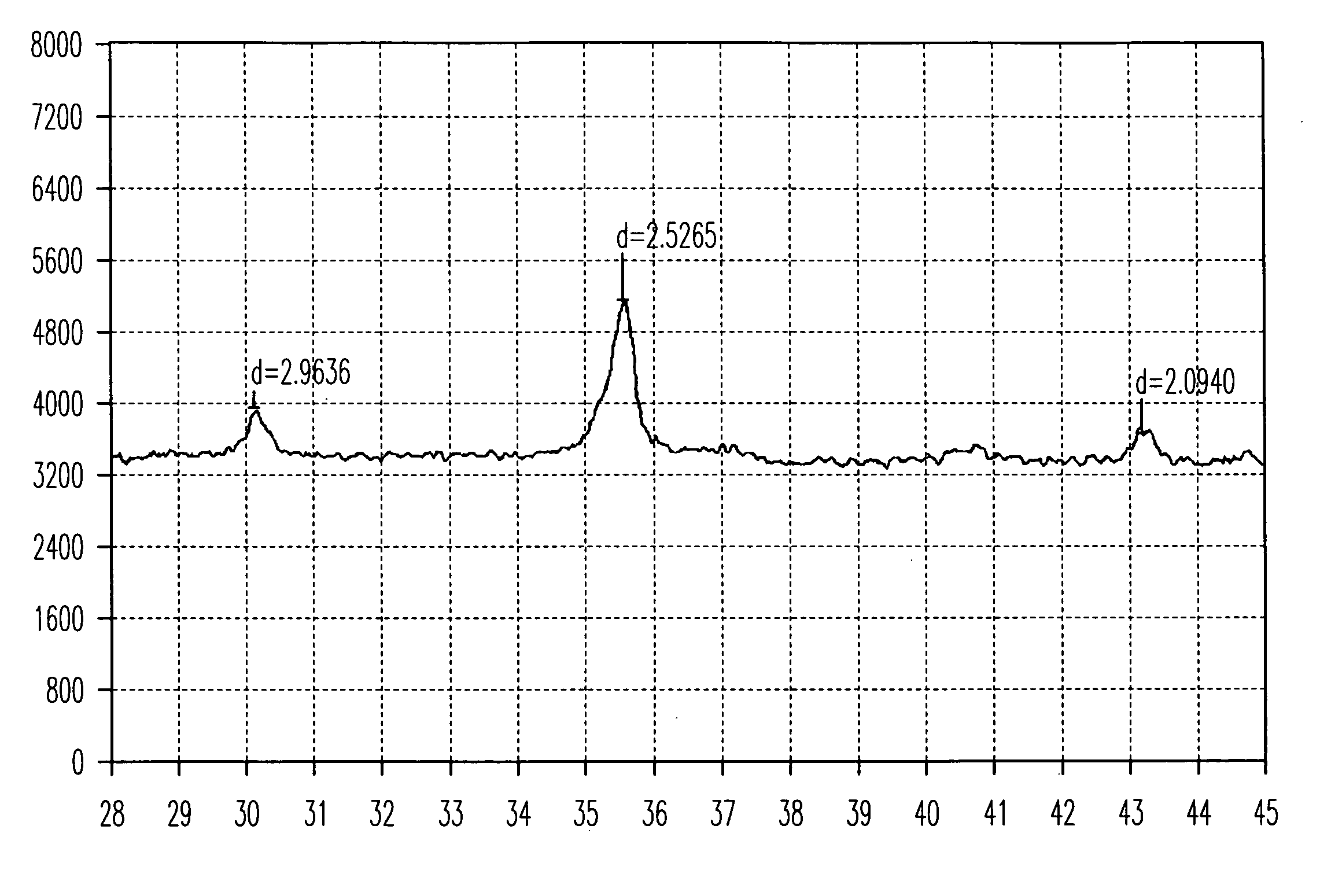

Composition for a desulfurizer with a high sulfur capacity and the process of making the same

ActiveUS20080047395A1Quality improvementEasy to operateGas treatmentBlast furnace componentsActive componentLiquid state

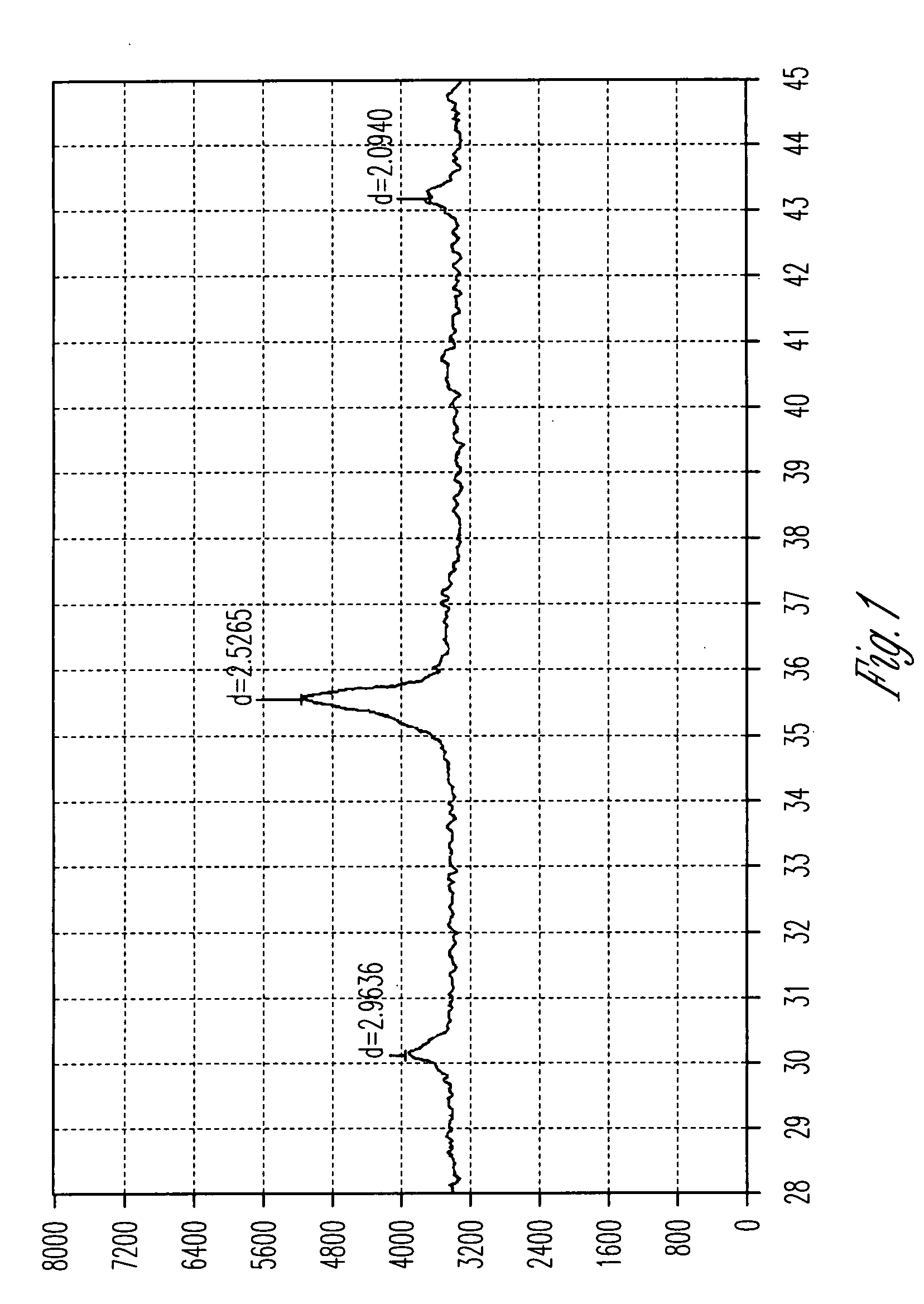

The present invention discloses a composition for a desulfurizer with a high sulfur capacity and a process for making the same. The composition comprises the active components of three kinds of iron oxides and is used in the desulfurizer to remove hydrogen sulfide from the gaseous and liquid state feed stocks. The above-mentioned composition comprises cubic ferroferric oxide in the form of crystalline phase (Fe3O4), amorphous ferric oxide (Fe2O3) and amorphous ferric oxide monohydrate (Fe2O3.H2O). The composition has a sulfur capacity of at least 40%. The process for preparing the composition comprises the following steps: (1) mixing a solid ferrous compound with a solid hydroxide at a molar ratio of iron to hydroxyl being in the range from 1:2 to 1:3; (2) kneading the mixture feeds obtained in step (1) and making them react completely; (3) drying the products obtained in step (2) in the air; (4) washing and filtering the feeds obtained in the step (3); (5) naturally drying or baking the solids obtained in step (4) to form a composition for a desulfurizer with a high sulfur capacity. The process of the present invention is simple and easy to operate, consumes less energy and produces the products with a stable quality.

Owner:BEIJING HAIXIN ENERGY TECH CO LTD

Quart crucible with large diameter for pulling single crystal and method of producing the same

InactiveUS6136092ASmall volume expansionAvoid deformationLayered productsBy pulling from meltCrucibleSingle crystal

Owner:SHIN ETABU QUARTZ PRODS

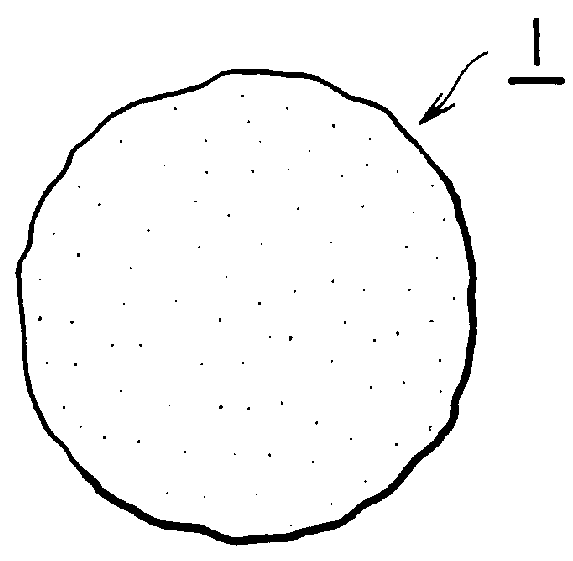

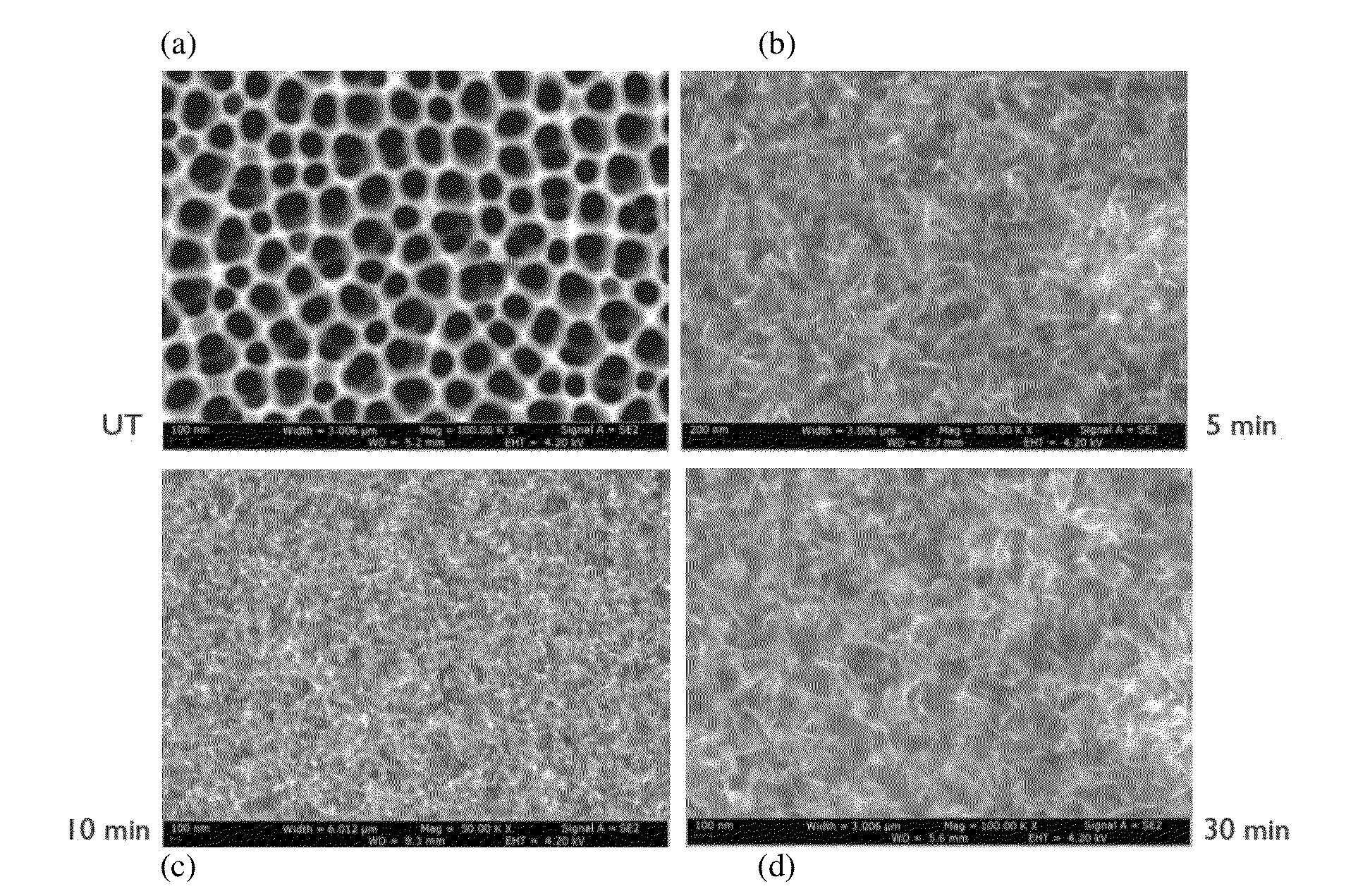

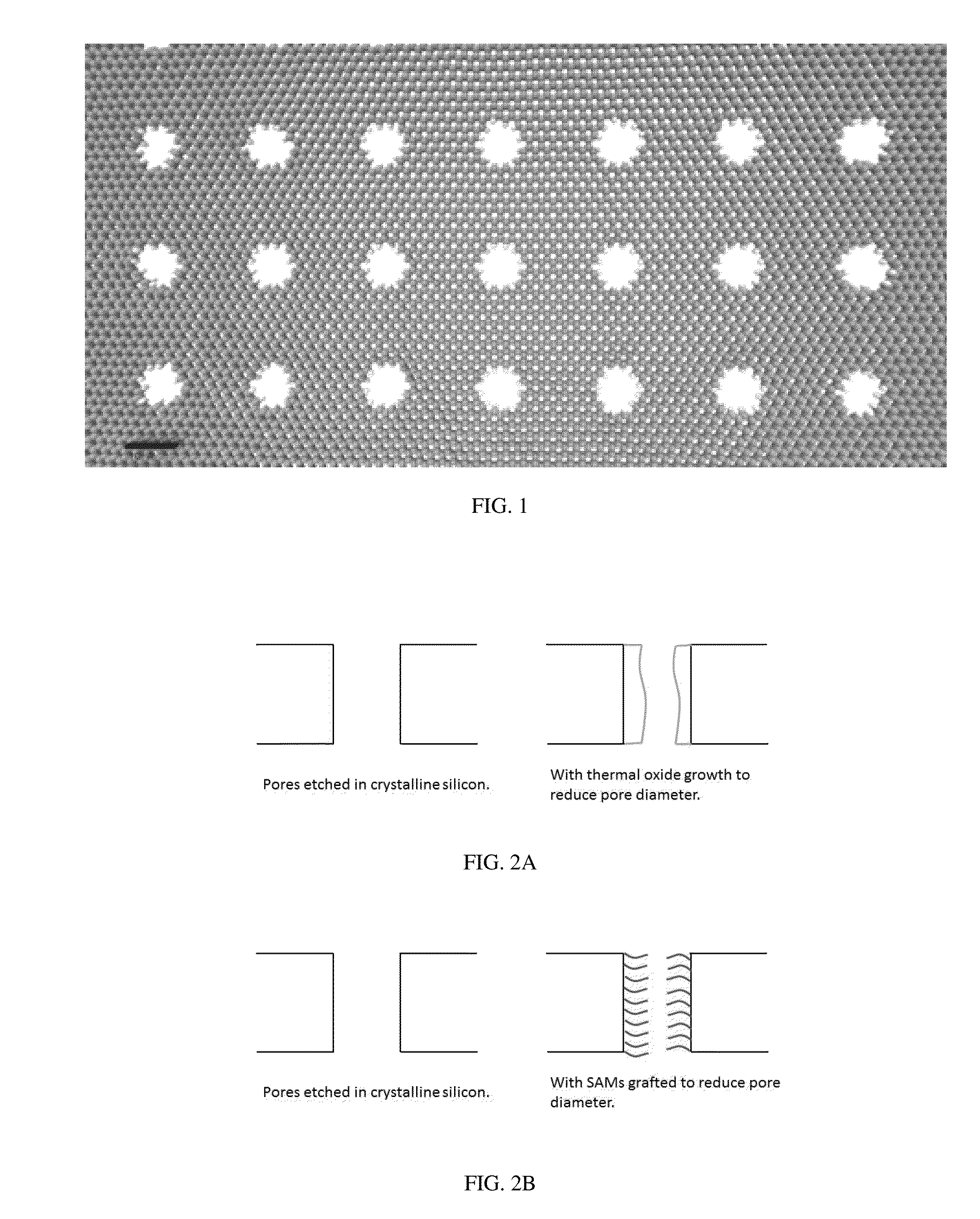

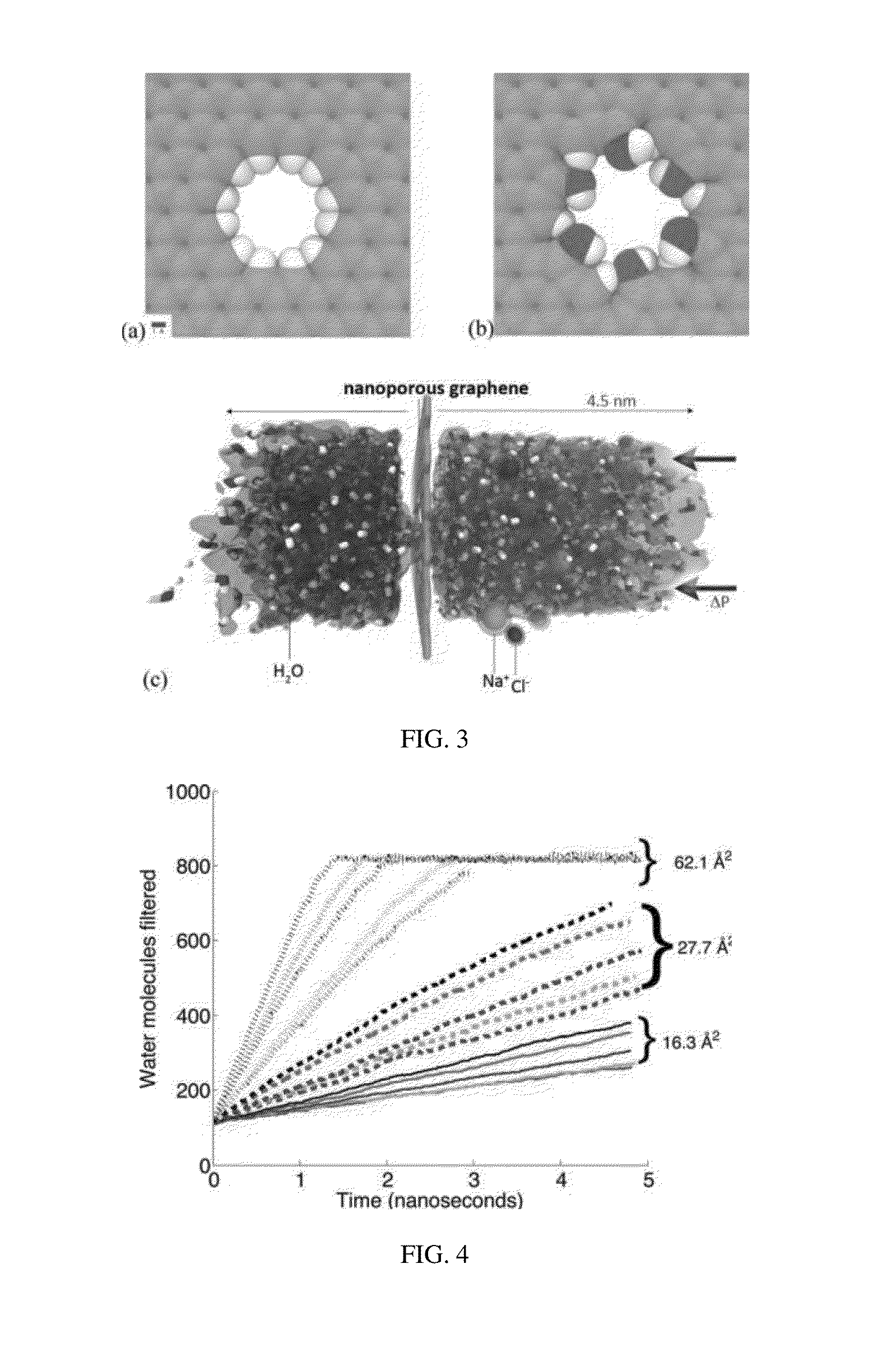

Porous materials and methods including nanoporous materials for water filtration

Embodiments described herein relate to porous materials that may be employed in various filtration, purification, and / or separation applications. In some cases, the porous materials may be thin, flexible, and fabricated with control over average pore size and / or the spatial distribution of pores. Such porous materials may be useful in, for example, desalination.

Owner:MASSACHUSETTS INST OF TECH

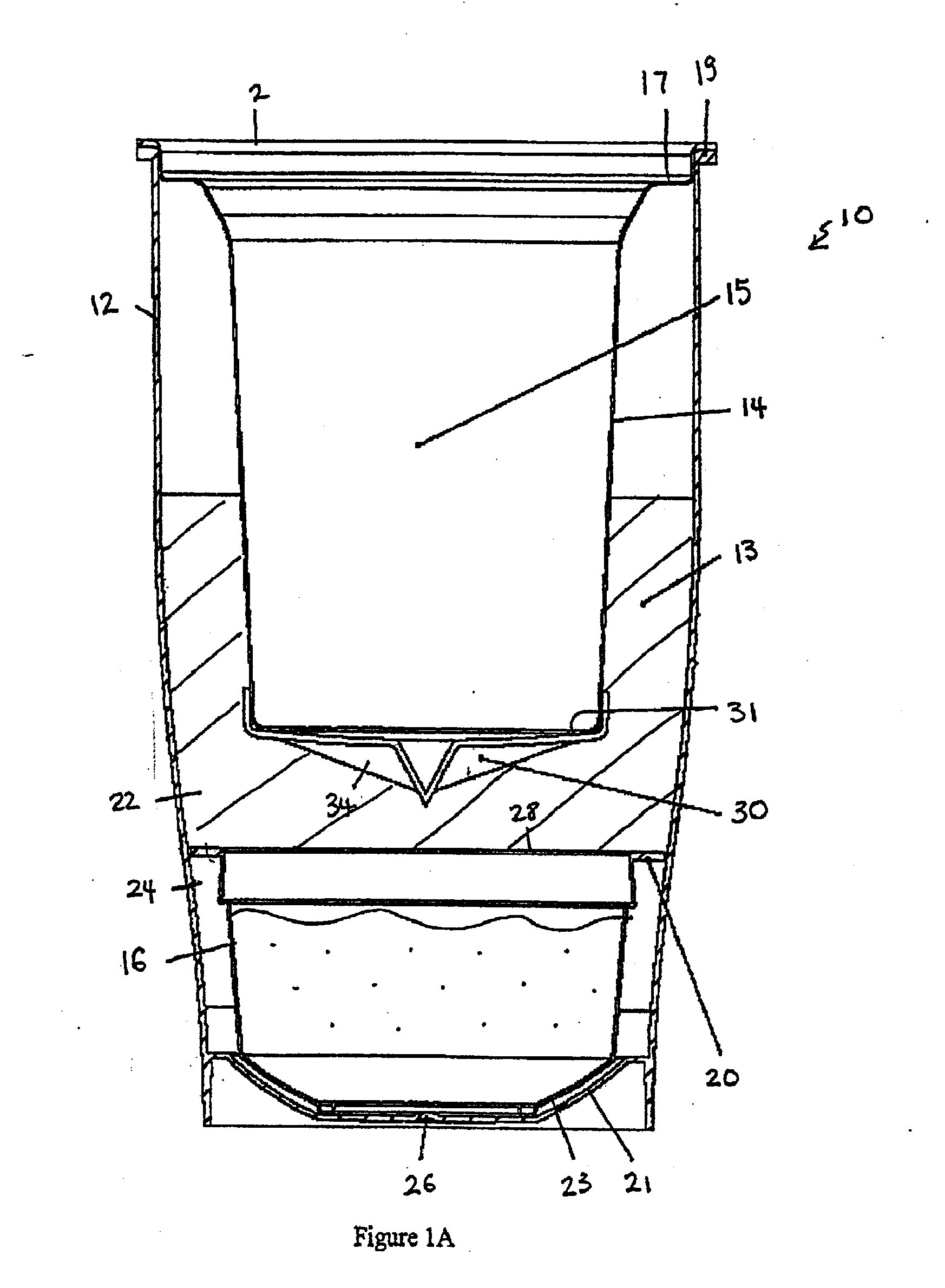

Self-heating apparatuses using solid chemical reactants

InactiveUS20090078711A1Exothermal chemical reaction heat productionDomestic cooling apparatusCompound (substance)Chloride

Owner:HEAT WAVE TECH

Pressure adjustable casting method and crucible therefor

Owner:BEIJING JIAOTONG UNIV

PCR method for amplifying a gene using metallic sample container having inner surface coated with a resin or metal oxide

InactiveUS6140613ABioreactor/fermenter combinationsHeating or cooling apparatusPcr methodMaterials science

A sample container for heating a sample stored therein includes a resin layer on the whole inner surface of the container made of metal having a thickness ranging from 0.02 mm to 1.0 mm and the resin layer having a thickness ranging from 1 mu m to 100 mu m. A sample container for heating a sample stored therein includes a metal oxide layer on at least the whole inner surface of the container made of metal having a thickness ranging from 0.02 mm to 1.0 mm.

Owner:NGK INSULATORS LTD

Integrated low application temperature hot melt adhesive processing system

ActiveUS20070080157A1Extends of componentOvercome short pot lifeLiquid surface applicatorsLiquid transferring devicesMetallurgyHot melt

Owner:HENKEL KGAA

Advanced material for molten metal processing equipment

A molten metal processing apparatus selected from a pump, a degasser, a flux injector, and a scrap submergence device constructed to include at least one element comprised of C / C composite.

Owner:PYROTECK INC

Flux for soldering and circuit board

InactiveUS20060147683A1High bonding strengthSuppress DiffuseBlast furnace componentsBlast furnace detailsSolventCopper complex

A flux contains resin having film forming ability, activator, solvent, and at least one complex selected from silver complex and copper complex. The flux is used when soldering is performed onto a circuit having electroless nickel plating or further having gold plating on the electroless nickel plating. Allowing a barrier layer of silver or copper to deposit on the surfaces of lands suppresses the diffusion of nickel into the melted solder alloy during soldering, and also prevents phosphorous concentration. This improves the bonding strength of soldering and suppresses the reduction deposition of silver and / or copper to portions other than circuit patterns.

Owner:HARIMA CHEM INC

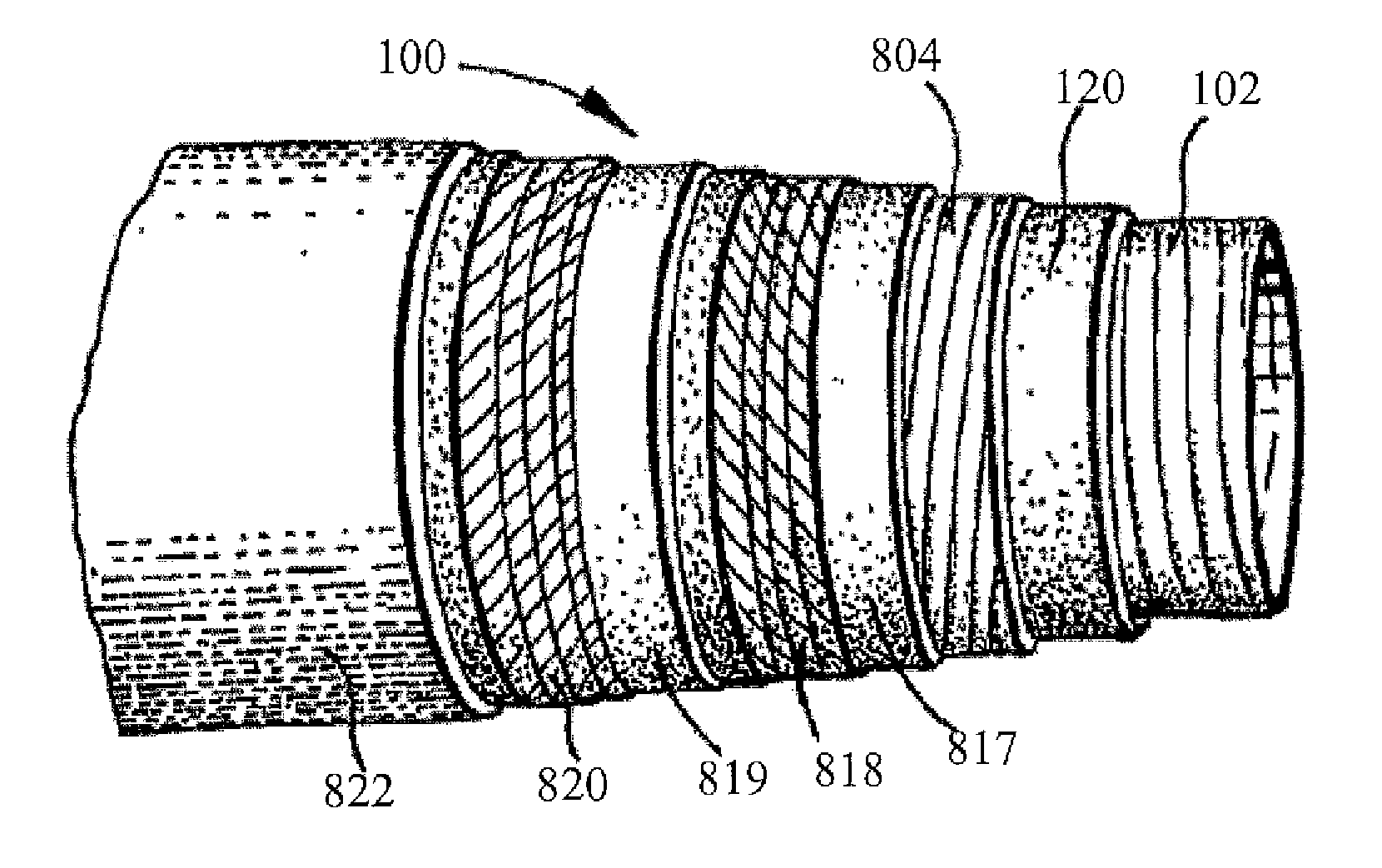

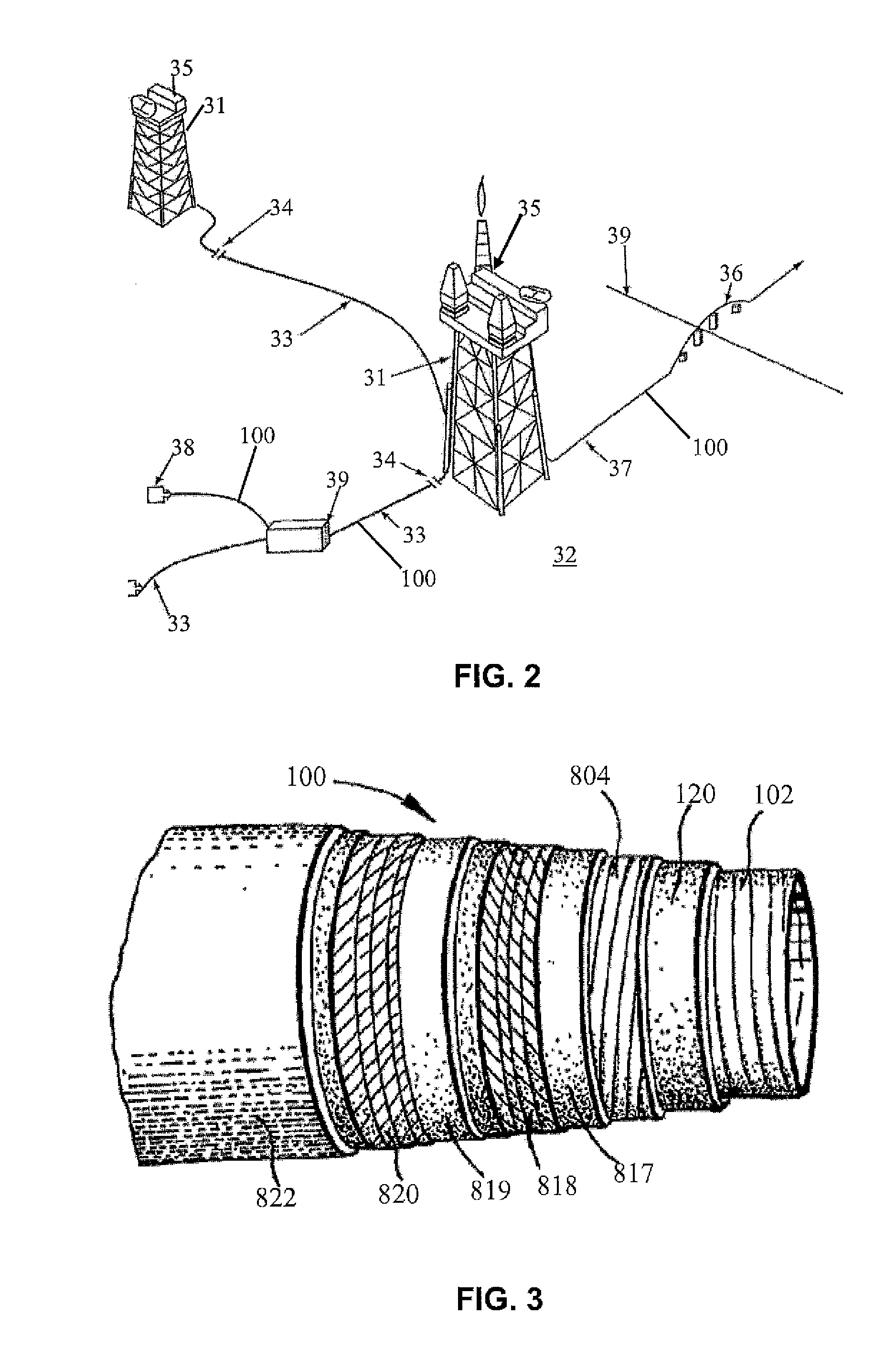

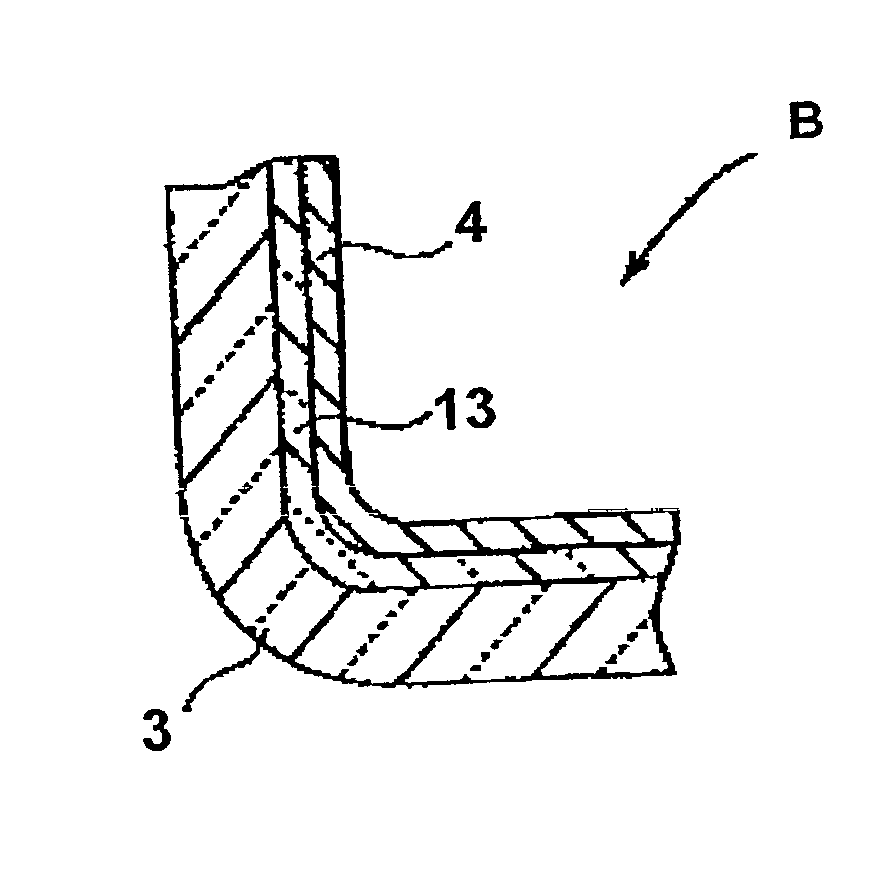

Pipe Section Having Bonded Composite Barrier Layer

InactiveUS20130269819A1Pipe protection against corrosion/incrustationCoatingsMetallic materialsMetal

Pipe sections and methods for forming pipe sections are disclosed. A pipe section includes a hollow body formed from a metal material, the hollow body having an inner surface and an outer surface, the inner surface defining an interior. The pipe section further includes a barrier layer surrounding and bonded to the hollow body, the barrier layer having an inner surface and an outer surface. The barrier layer is formed from a continuous fiber reinforced thermoplastic material. Such pipe sections may be lightweight and flexible while exhibiting improved strength characteristics.

Owner:TICONA LLC

Pyrolysis furnace and process tubes

ActiveUS20090252660A1Increase volumeReduce maintenanceThermal non-catalytic crackingLiquid surface applicatorsColloidal silicaCombustion chamber

A cracking furnace construction includes a firebox defining a chamber having a high emissivity thermal protective coating disposed on at least part of the refractory walls and / or on process tubes disposed within the chamber. The coating contains an inorganic adhesive for metal / alloy tubes or colloidal silica and / or colloidal alumina for refractory walls or ceramic tubes, a filler, and one or more emissivity agents. A method of coating the firebox chamber includes preparing the surface of the tubes / refractory walls, preparing the coating, and applying the coating to the surface.

Owner:EMISSHIELD

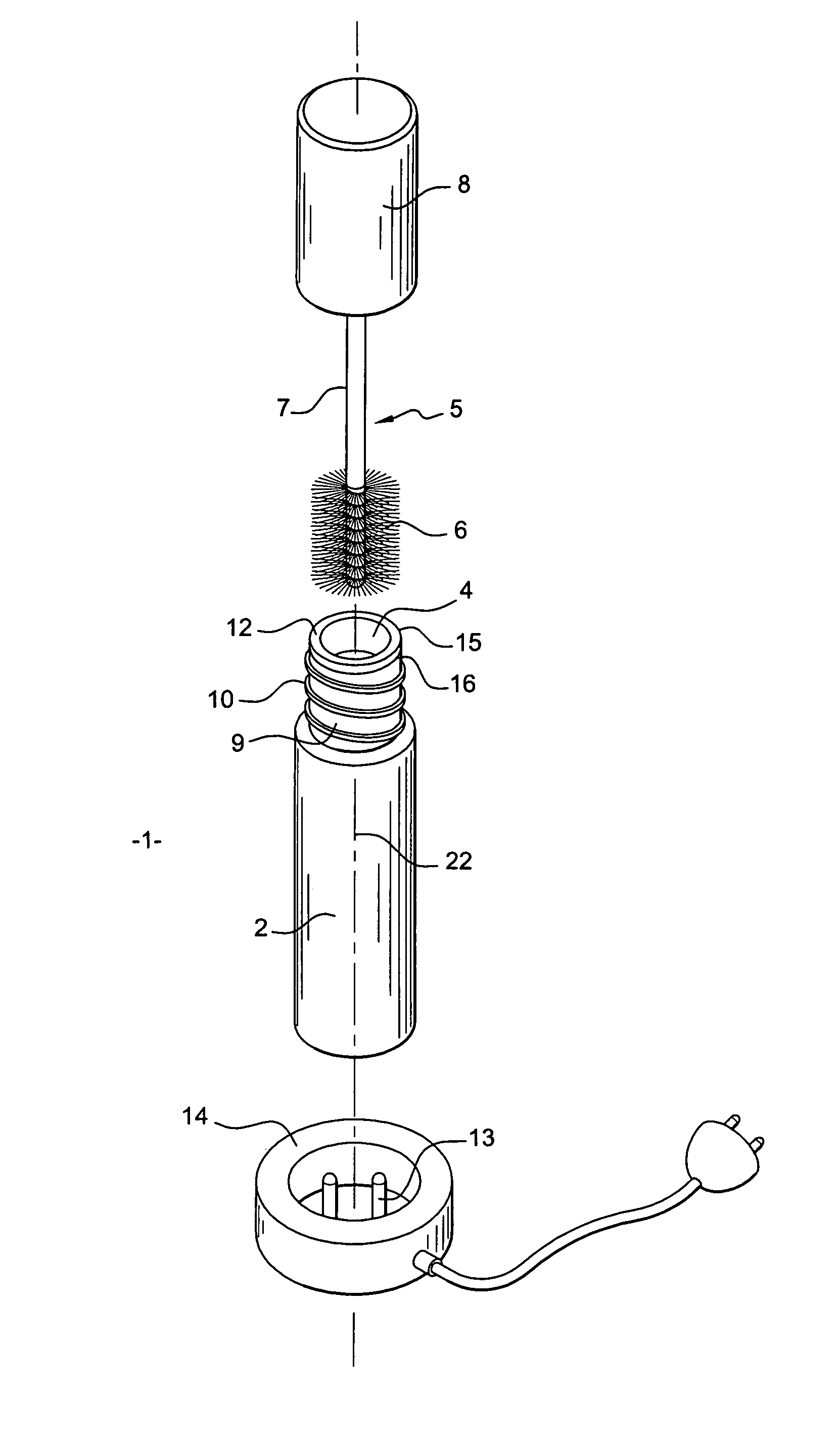

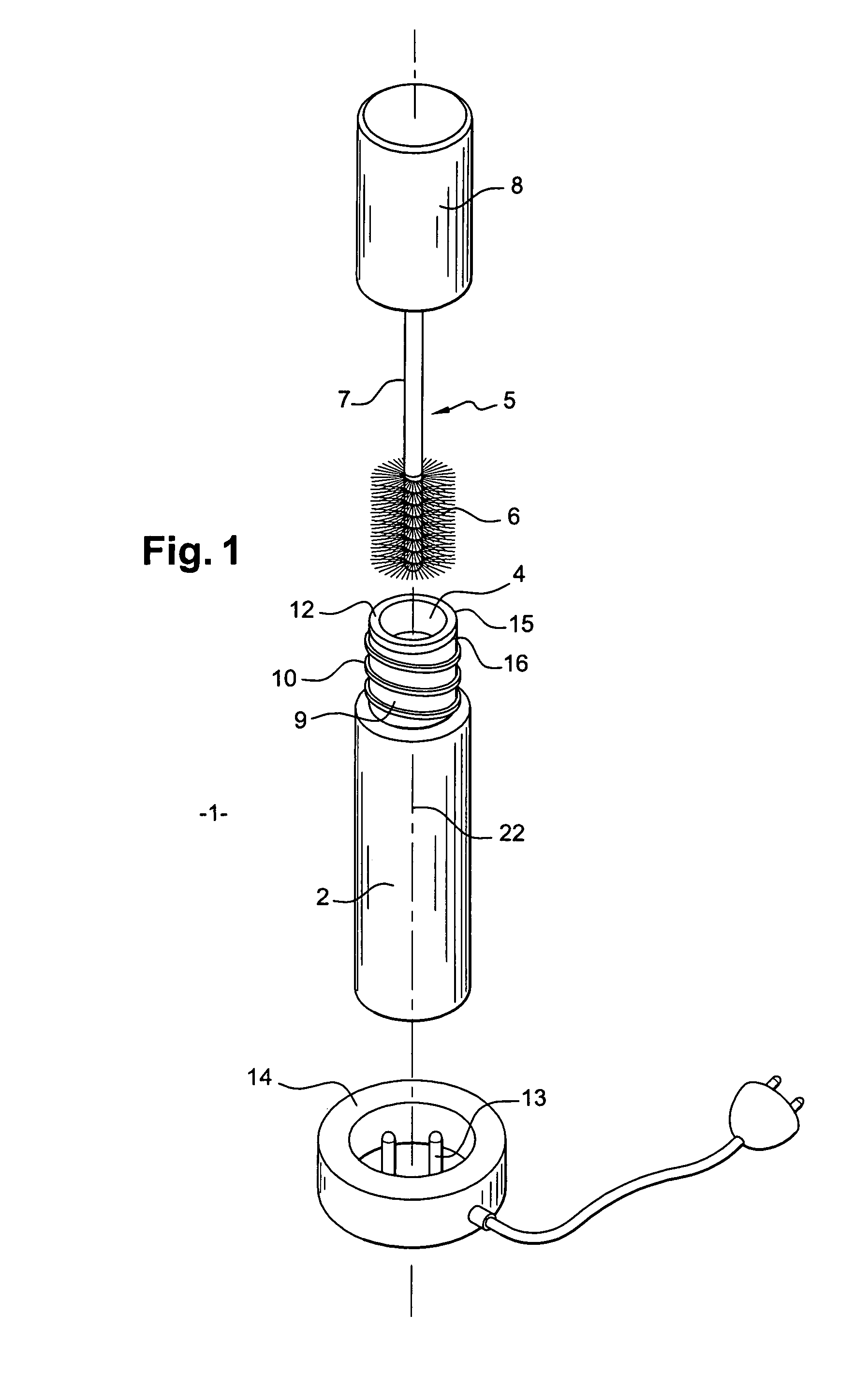

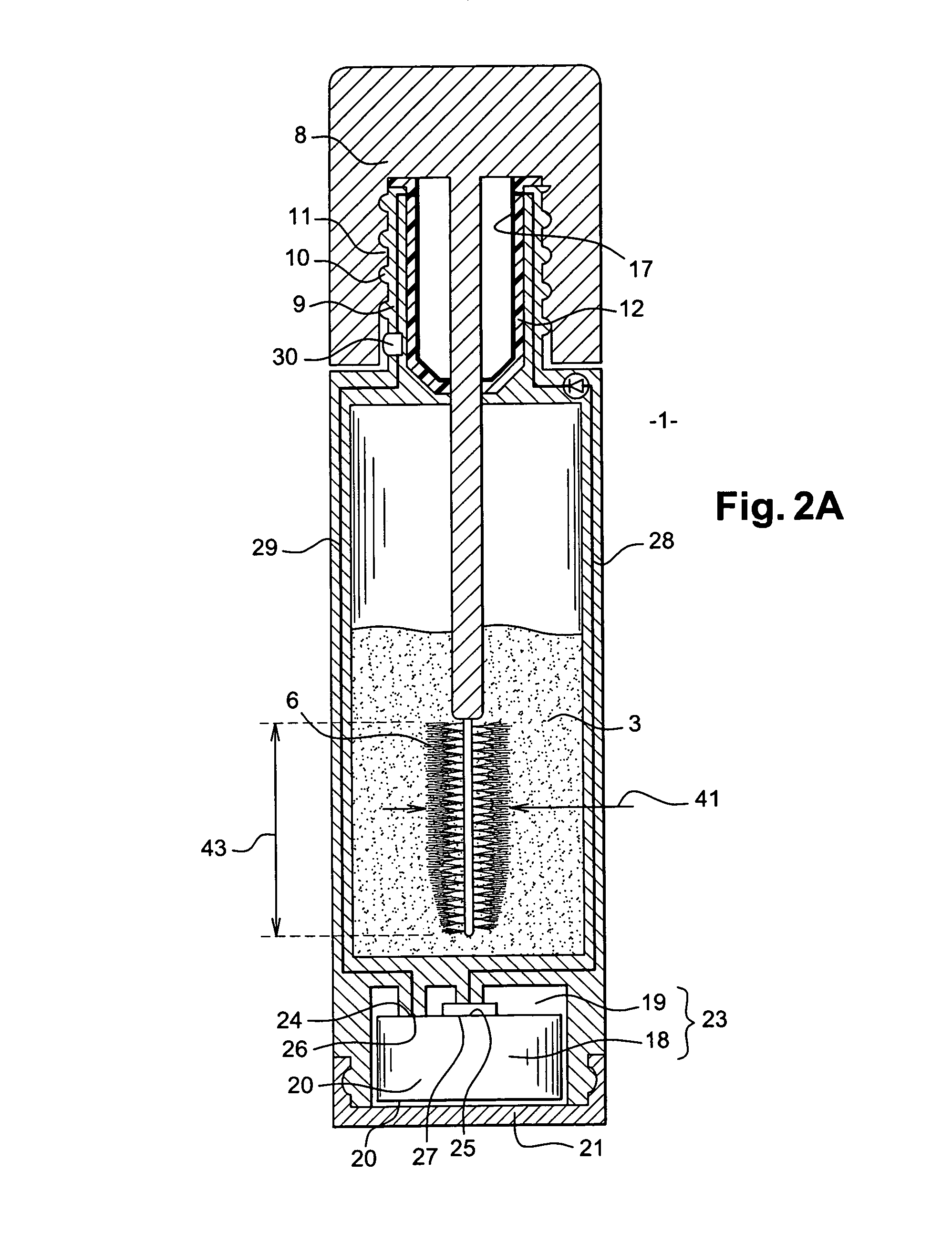

Packaging and applicator device for a cosmetic product and/or a beauty care product incorporating a means of heating

InactiveUS7108438B2Simple actionLimiting and reducing aging and potential deteriorationDispensing apparatusBristleFiberBiomedical engineering

Owner:LOREAL SA

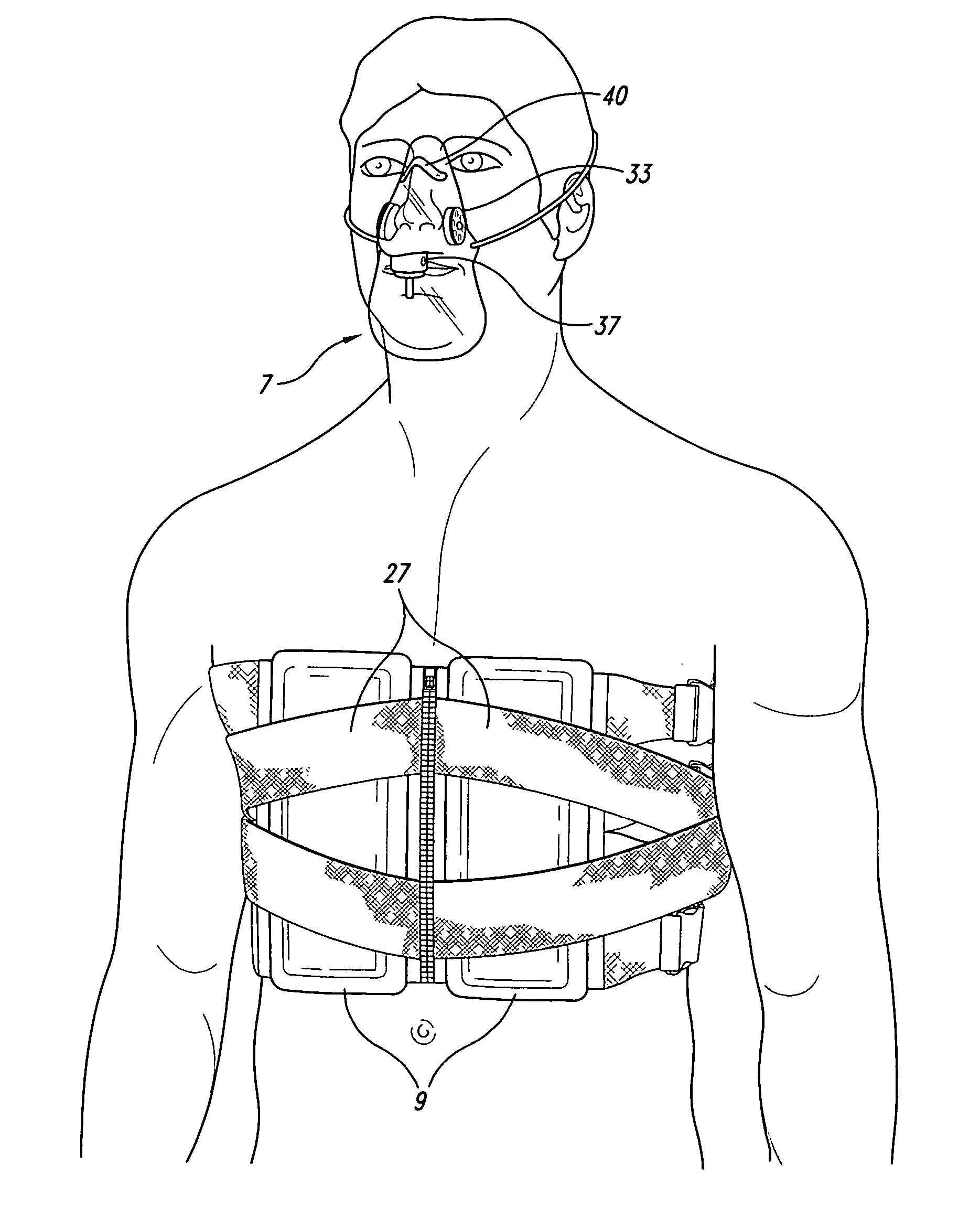

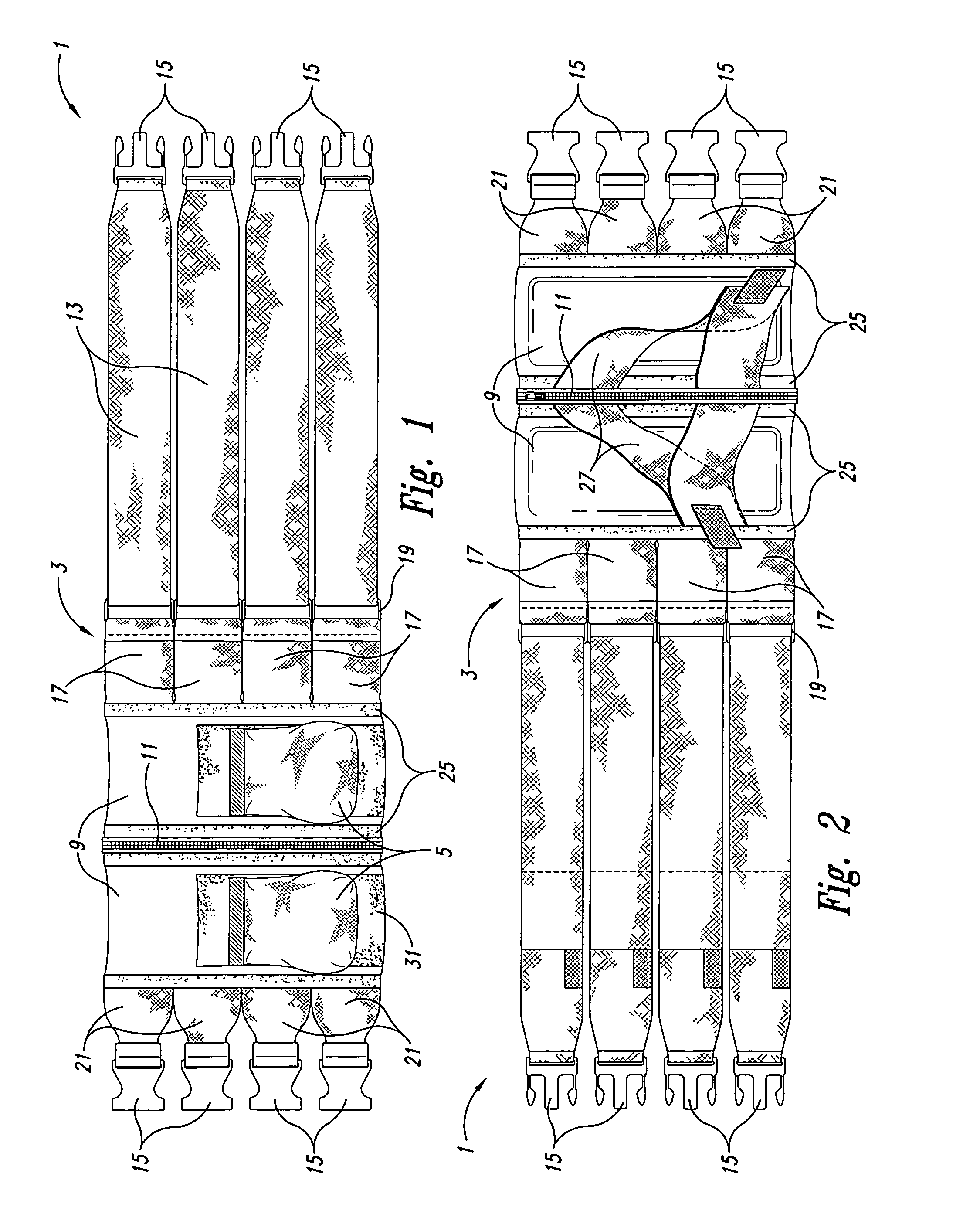

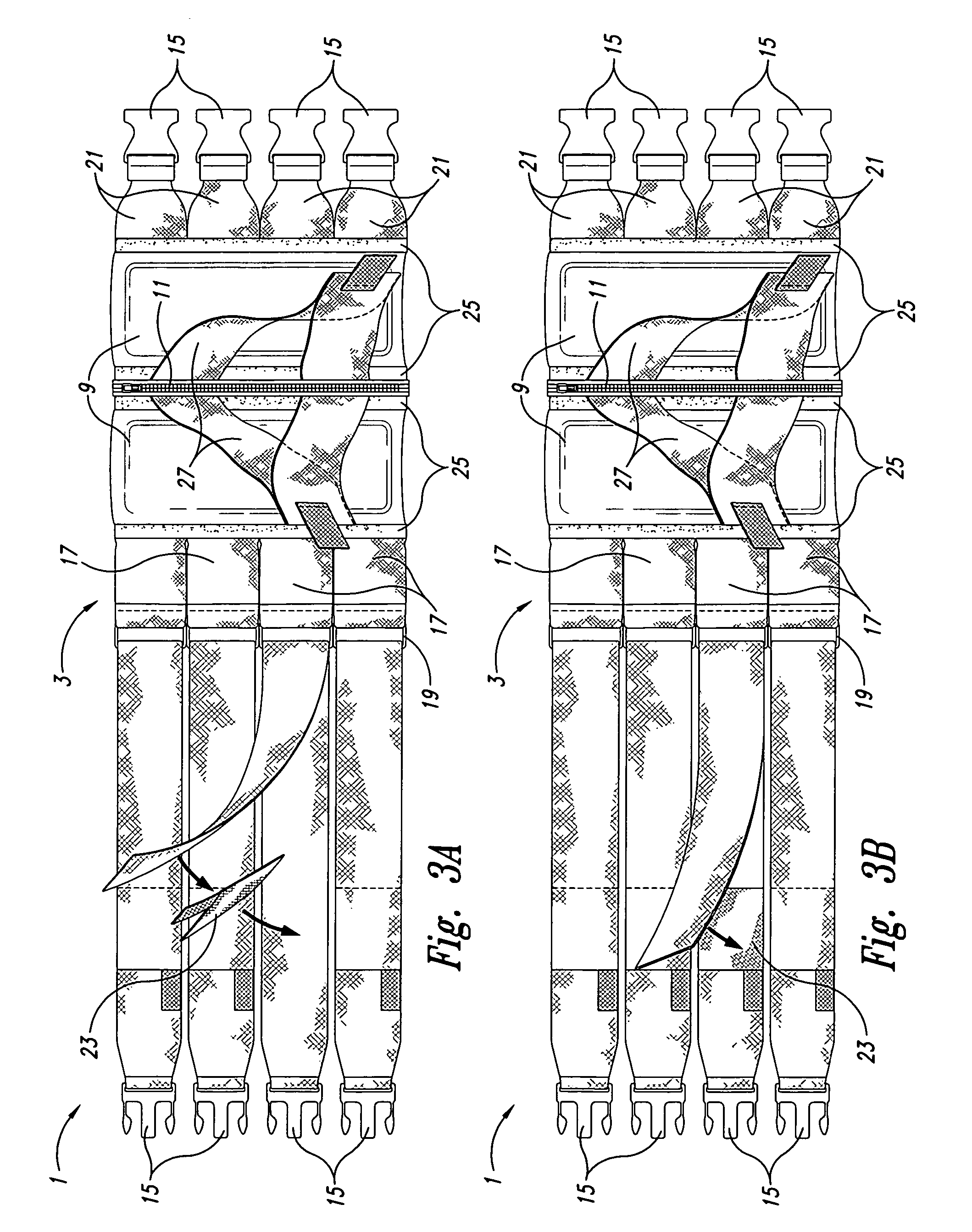

Chronic obstructive pulmonary disease simulator

InactiveUS20070196780A1Crucible furnacesEducational modelsObstructive Pulmonary DiseasesPhysical therapy

Particular aspects provide a garment for simulating chronic obstructive pulmonary disease (COPD), comprising a particularly efficacious combination of a thorax-constricting garment portion, and a diaphragm-impeding garment portion, along with an optional restrictive airway mask. The thorax-constricting portion has a frontal abdominal-thoracic plate member and tensioning means extendible around a wearer's thoracic circumference to provide for constrictive thoracic-abdominal tensioning. The diaphragm-impeding portion has a projection (e.g., weighted projection or pouch) projecting away from the wearer-proximal surface of the frontal plate member, which is operative with the thorax-constricting portion to simultaneously constrict thorax expansion while impeding diaphragm contraction and downward movement. Additional aspects provide a method for simulating COPD, comprising tensioning a thoracic-abdominal constricting garment, having diaphragm-impeding means and optional restrictive airway mask, around a wearer's thoracic-abdominal area at a tension, and for a time period sufficient to simulate at least one symptom or effect of COPD.

Owner:WARE LINDA M +1

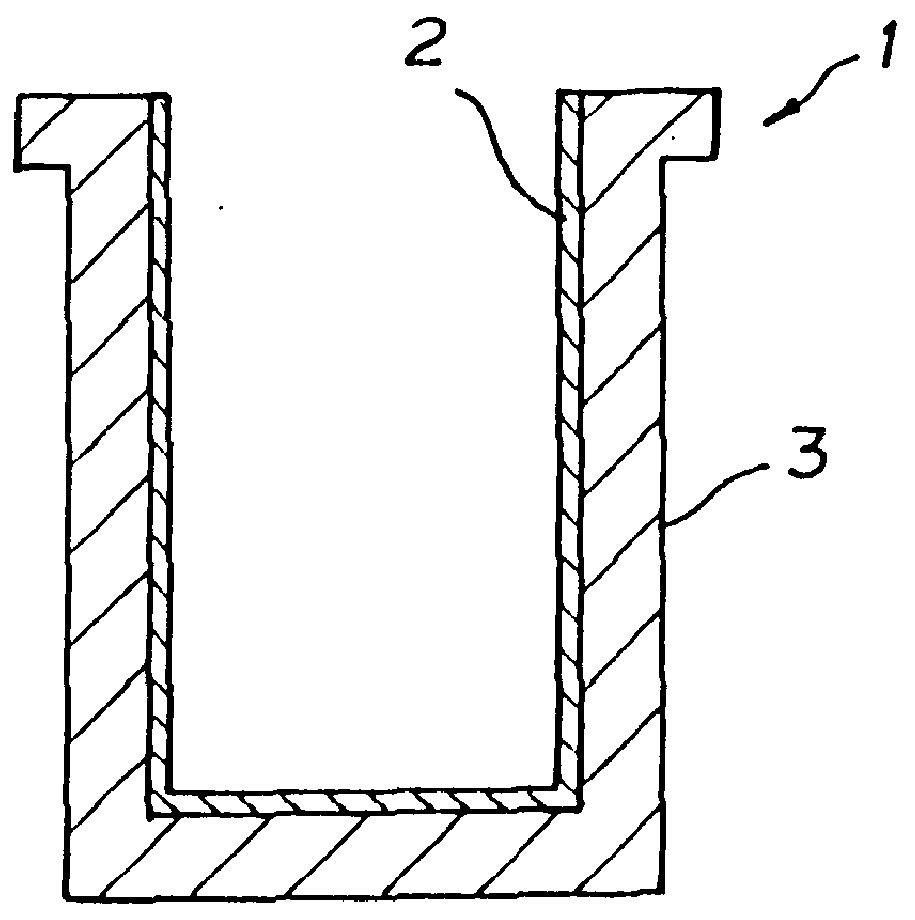

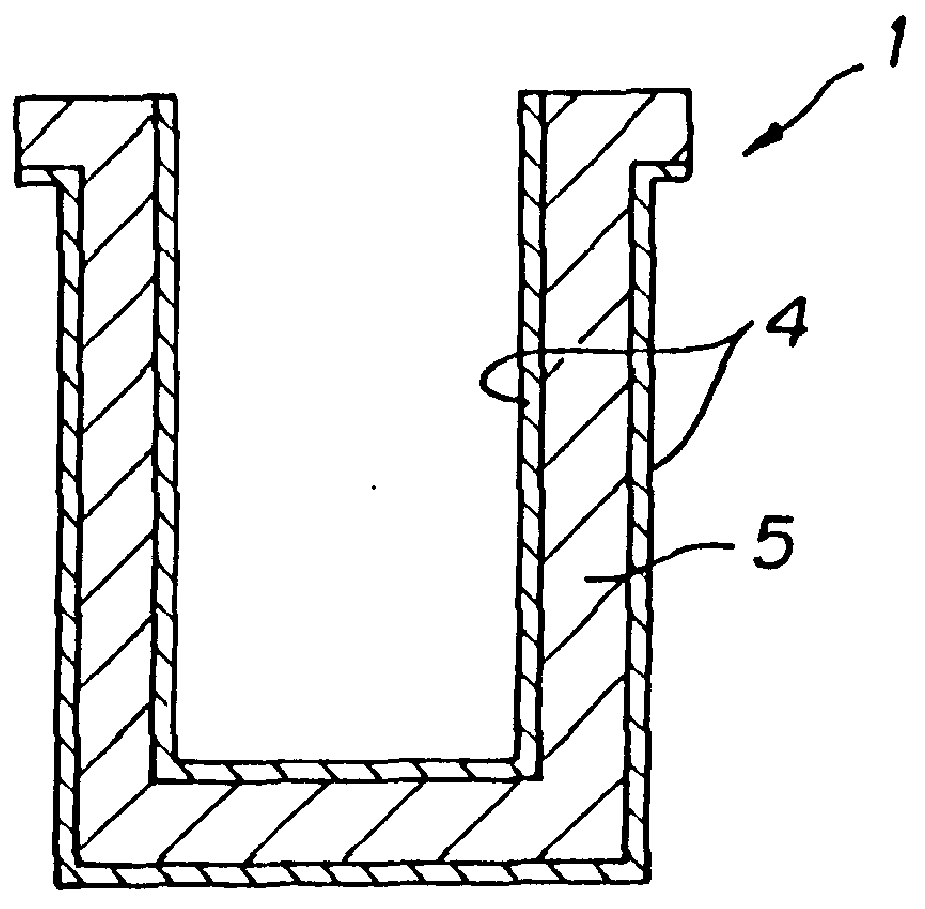

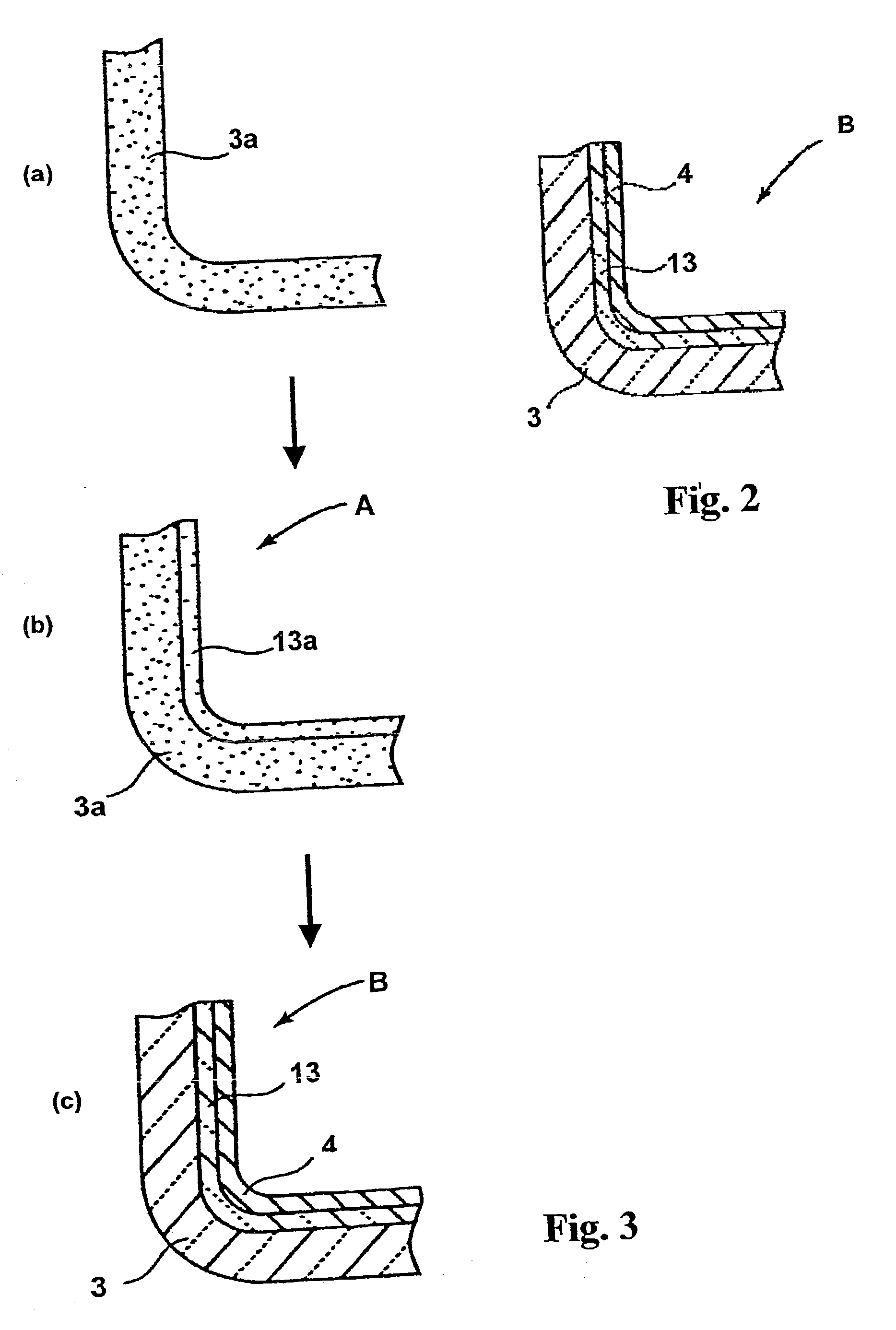

Crucible for fusing titan and method of preparation thereof

The invention relates to a crucible for fusing titanium and a production method thereof, mainly used for fusing titanium alloy as well as for fusion cast of other special alloys. Highly stable compounds (yttrium oxide, calcium zirconate or cerium sulphide, etc.) are used as the outer layer of the crucible for fusing titanium; refractory metals (tungsten, molybdenum or tantalum) and the like are combined with the compounds to form transition gradient coating; hot spray processes (laser cladding, plasma spraying, etc.) are used for spraying the transition layers and the transition gradient coating onto the inner surface of a graphite container layer by layer to form a firm and compact composite coating with good thermal shock resistance. By adopting the crucible of the invention to carry out vacuum induction fusion of titanium and titanium alloy, the fused alloy has uniform component, the fusion process consumes less energy and the crucible produces less contamination to the molten titanium.

Owner:SHANGHAI UNIV

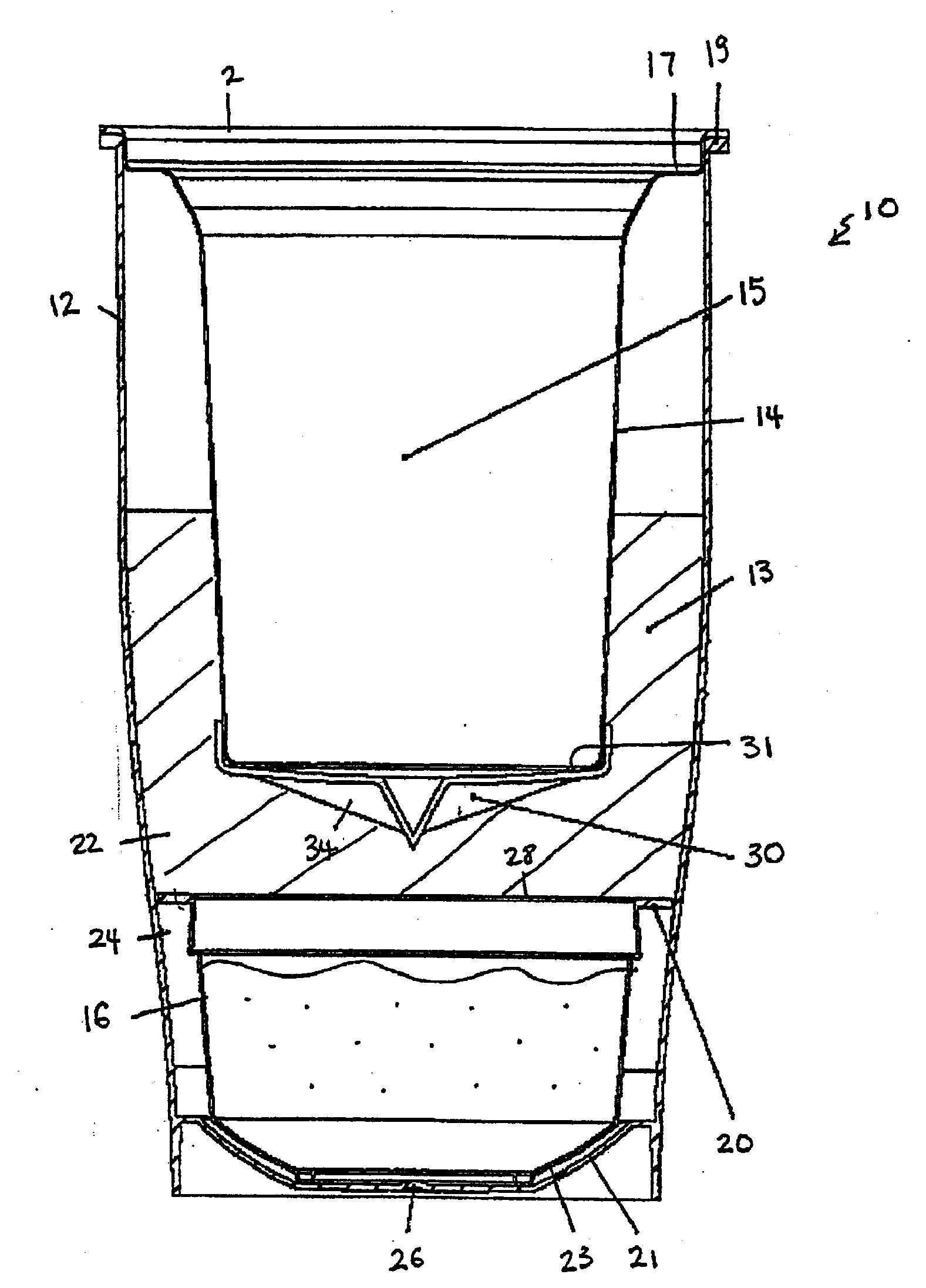

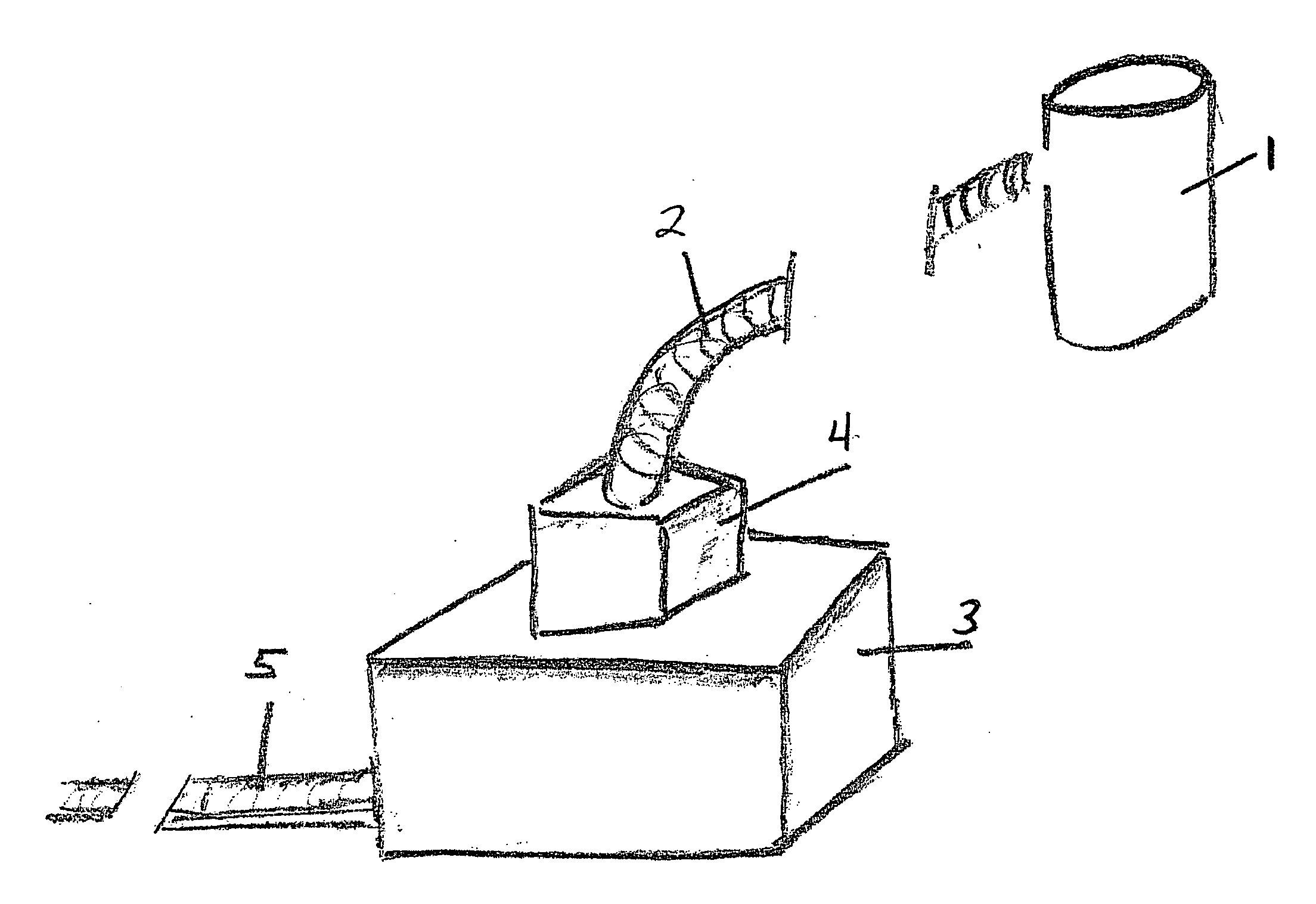

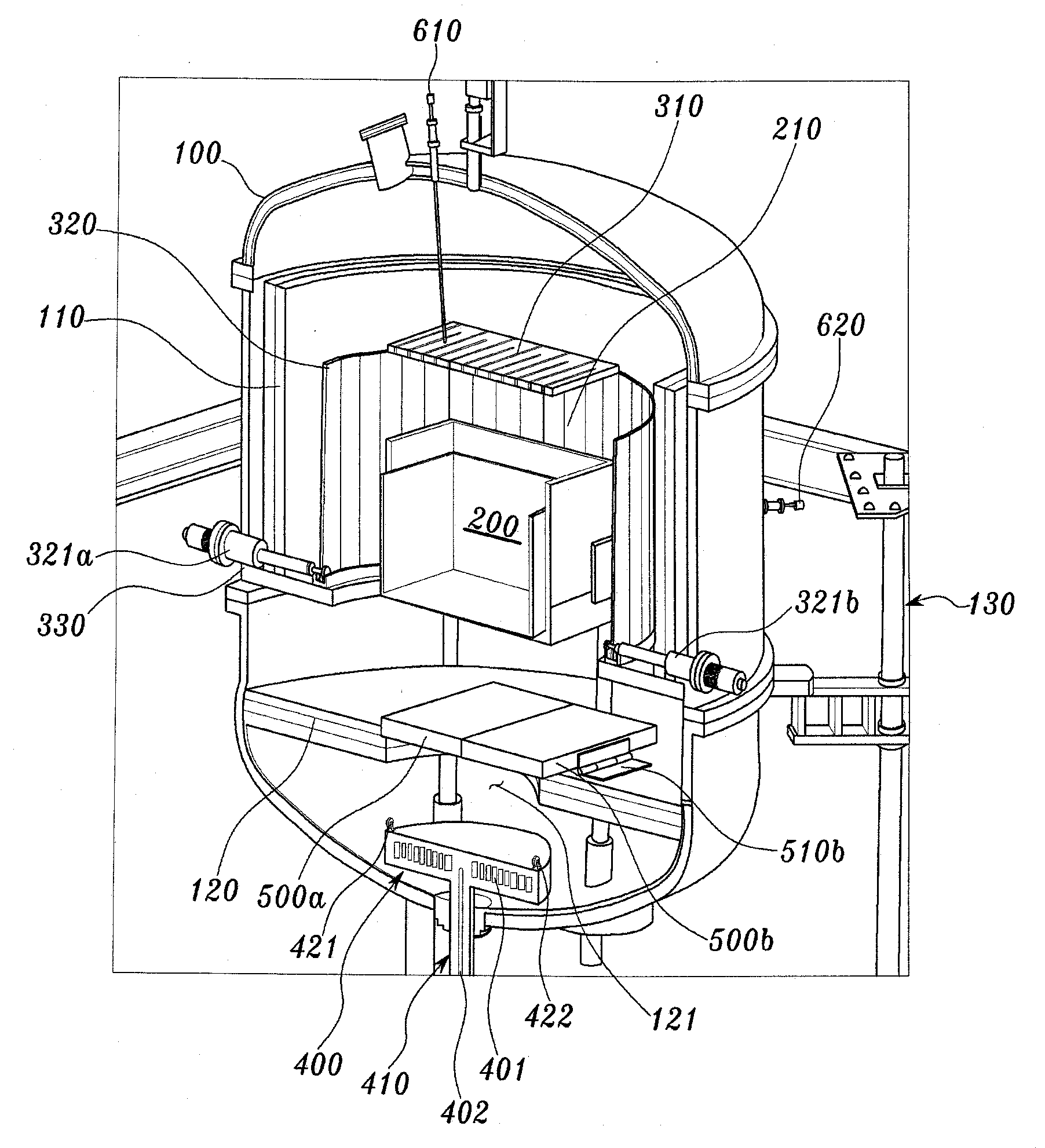

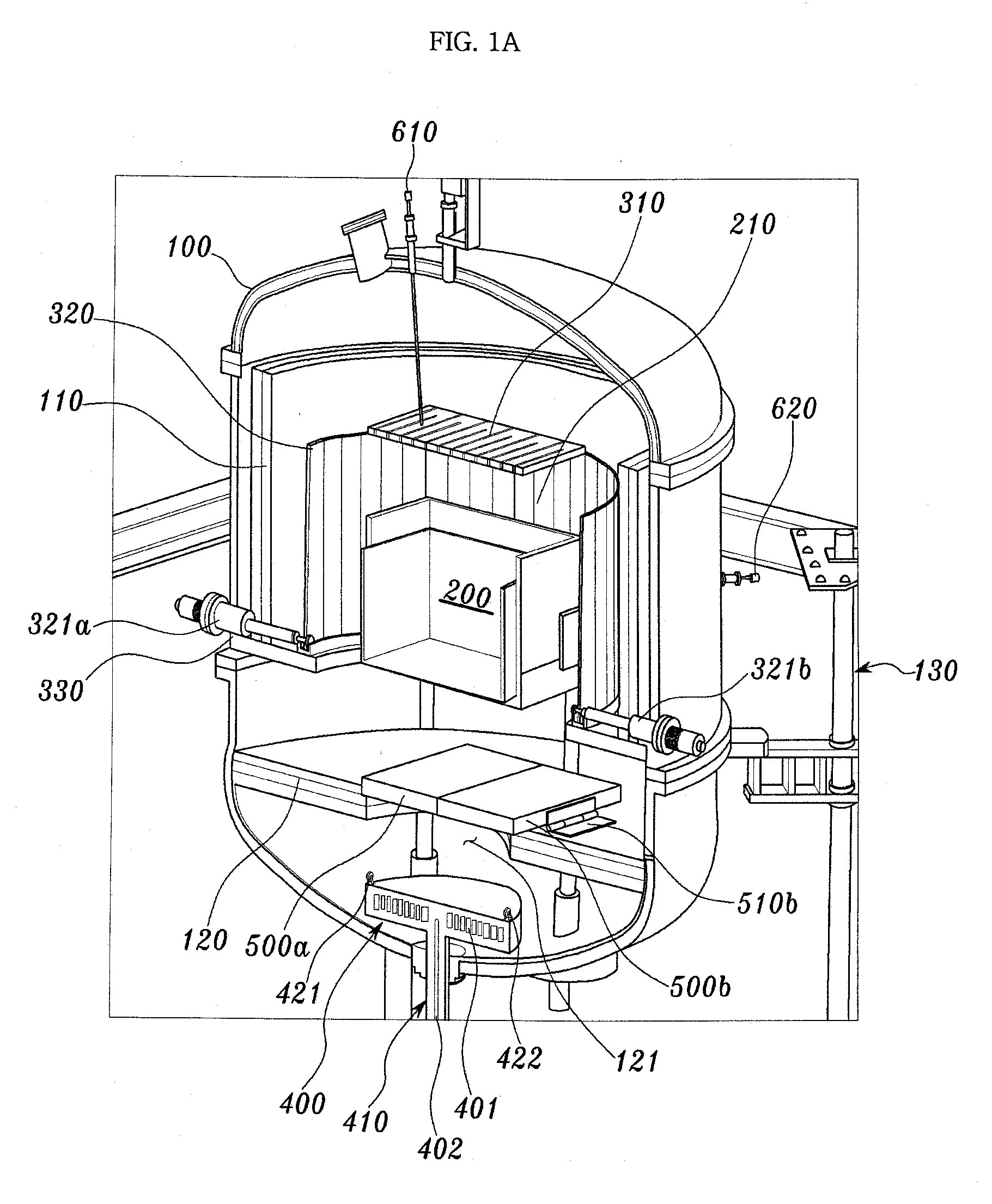

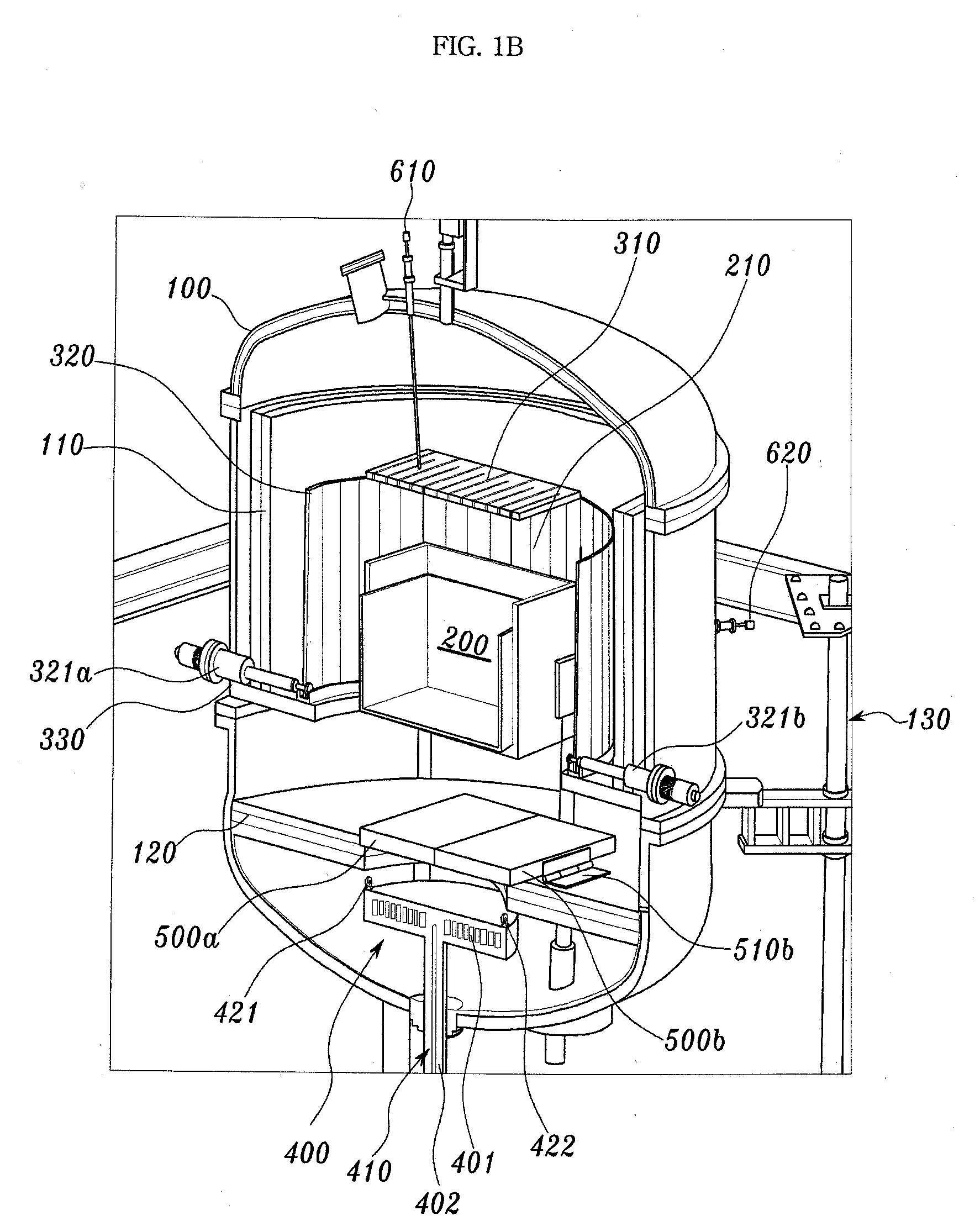

Apparatus for manufacturing poly crystaline silicon ingot for solar battery having door open/close device using hinge

InactiveUS20090090296A1Avoid scratchesBy zone-melting liquidsMaintainance of heating chambersSusceptorElectrical battery

Disclosed herein is an apparatus for manufacturing a polycrystalline silicon ingot for solar batteries having a door control device using a hinge. The apparatus includes a vacuum chamber, a crucible, a susceptor which surrounds the crucible, a heater which heats the crucible, and an insulation plate which is disposed below the susceptor and has an opening therein. The apparatus further includes a cooling plate which moves upwards through the opening of the insulation plate and comes into close contact with or approaches the lower end of the susceptor, a cooling plate moving unit which actuates the cooling plate, a temperature sensor which measures the temperature of the crucible, and a control unit which controls the temperature in the crucible and the cooling plate moving unit. Furthermore, a door is provided on the insulation plate to open or close the opening of the insulation plate. The hinge is provided between the door and the insulation plate. Thus, after the raw silicon material is melted, when the cooling plate moves upwards to cool the crucible and thus pushes the lower surface of the door upwards, the door is opened by the hinge in a swinging manner, and when the cooling plate approaches or comes into contact with the lower end of the susceptor, one end of the opened door is leaned on a corresponding surface of the cooling plate.

Owner:KOREA RES INST OF CHEM TECH

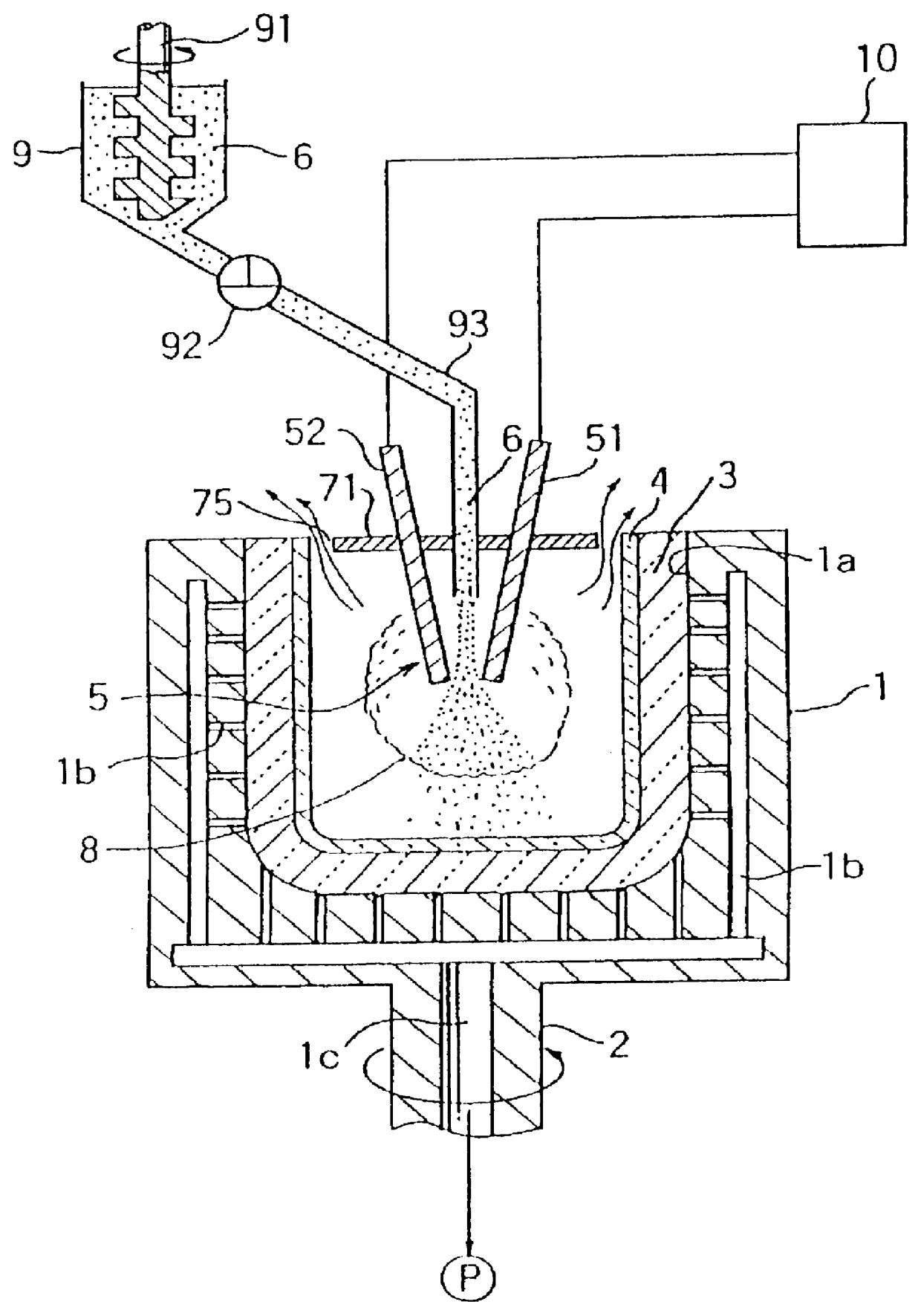

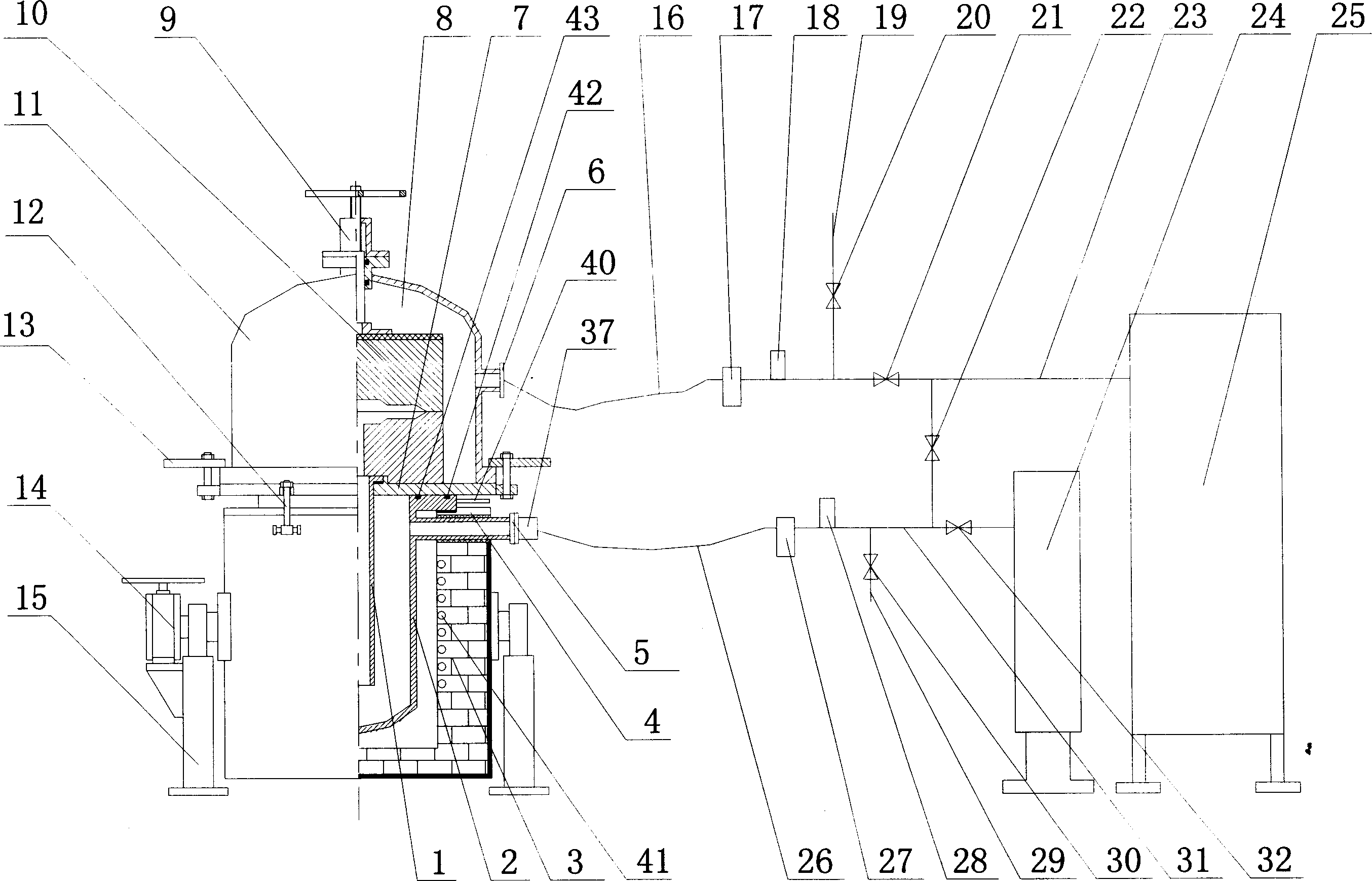

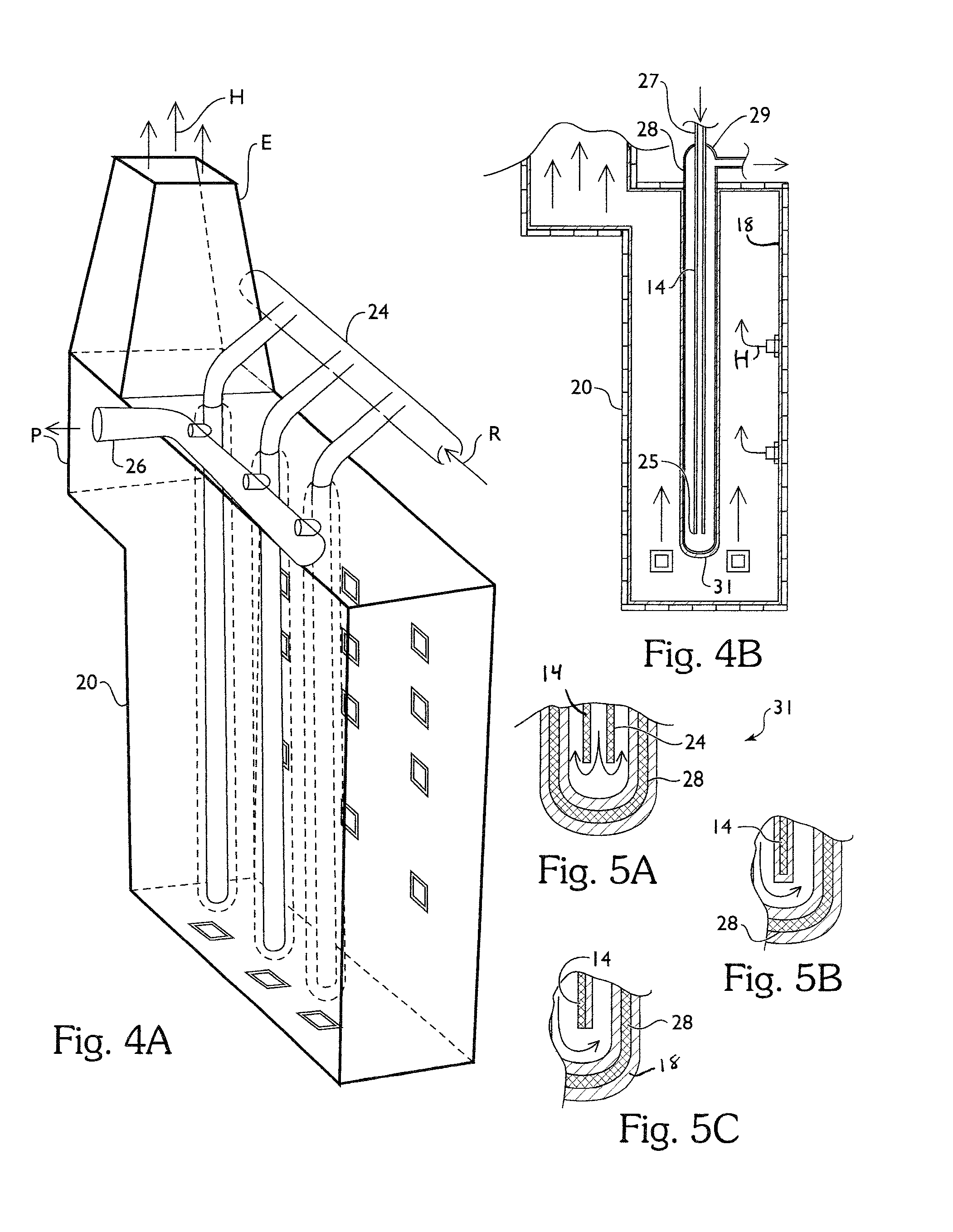

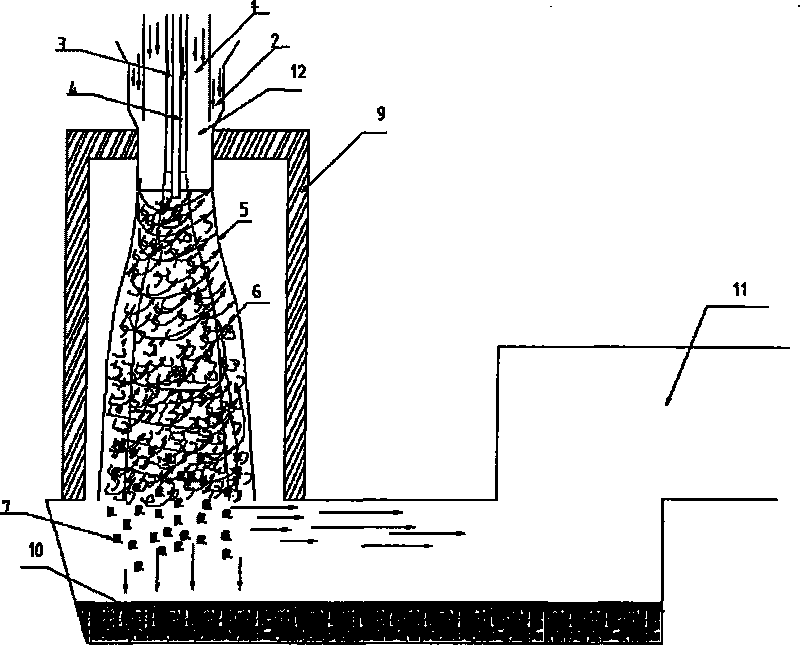

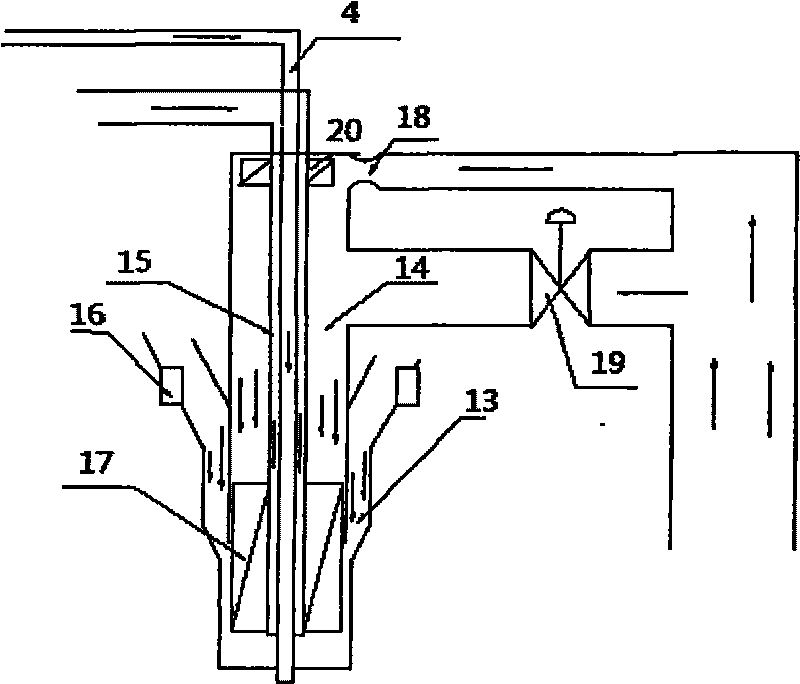

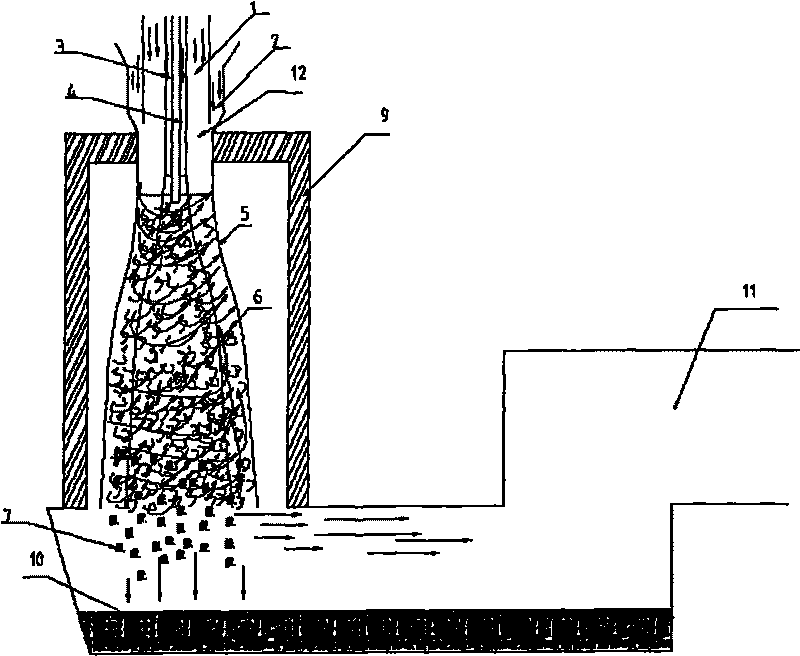

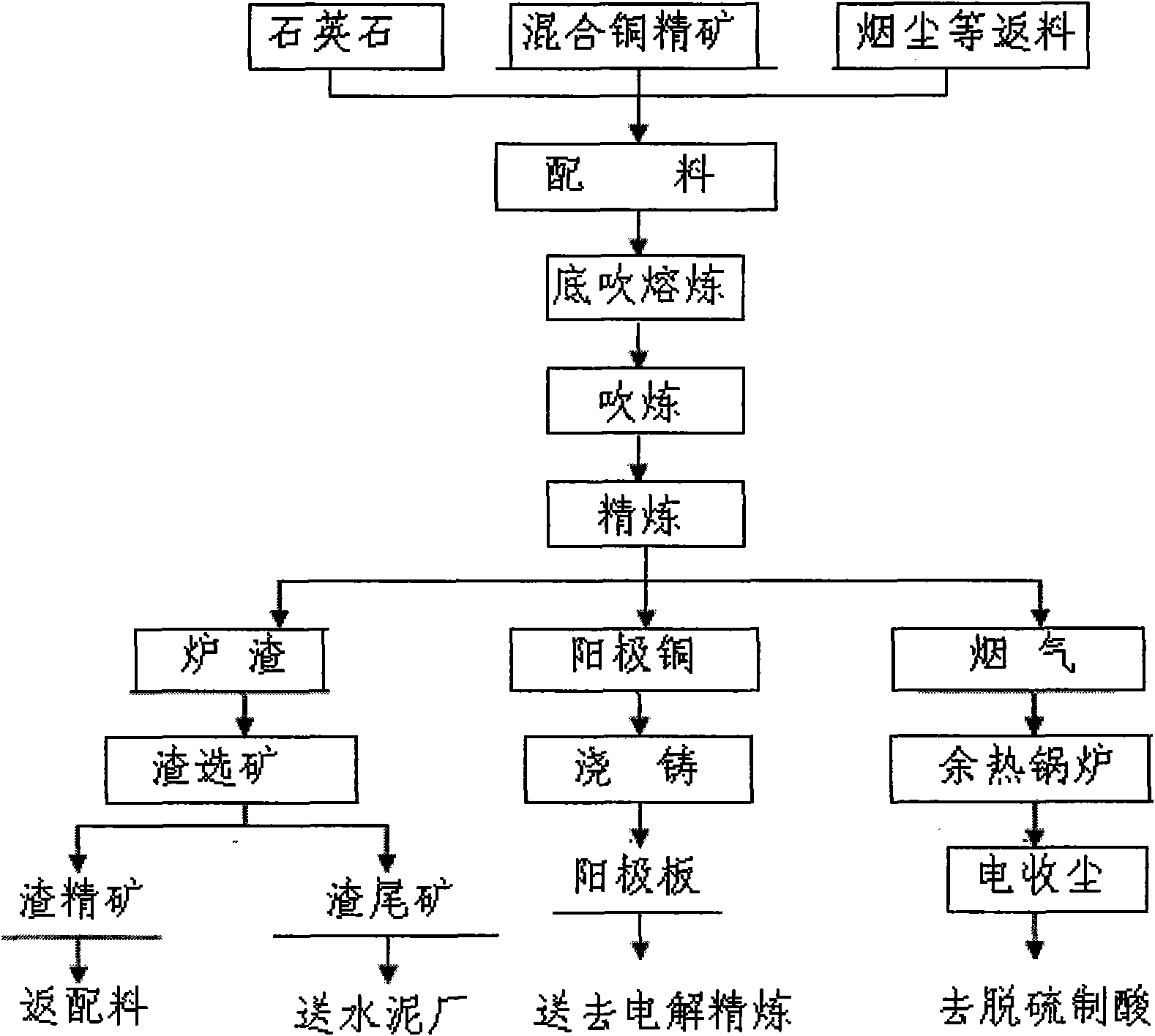

Process and device for smelting copper by pulsation vortex method

ActiveCN101705369AIncreased chance of collisionHigh oxygen utilizationRotary drum furnacesCrucible furnacesSlagProcess engineering

The invention relates to a process and a device for smelting copper by a pulsation vortex method. The process comprises the following steps of: mixing dry copper concentrate powder or matte powder with oxygen-enriched air, and putting the mixture in a reactor to form high-speed vortex taking an axis as a center; introducing pulsation oxygen into the center of the high-speed vortex, performing pulsation combustion to generate pulsation turbulent flow in the high-speed vortex so as to promote particles to collide with one another, then forming a pulsation vortex reaction area with a high-temperature field, a high oxygen field and a high particle field, and completing a reaction of manufacturing the matte and slag from the copper concentrate or manufacturing crude copper and slag from the matte; after the reaction, precipitating fused materials in a fusing pool at the bottom of the reactor, and then separating the matte and slag or the crude copper and slag; and sending SO2 gas fume to an acid preparation process. The process and the device have the advantages of: 1, high reaction efficiency, high oxygen utilization efficiency and low fume yield; 2, high capacity, low energy consumption, small reaction space, centralized heat energy reacted, low loss of a refractory material of a furnace body, no need of a huge metallurgical hearth and low investment cost; and 3, environmental protection and simple, convenient and reliable technological operation.

Owner:YANGGU XIANGGUANG COPPER

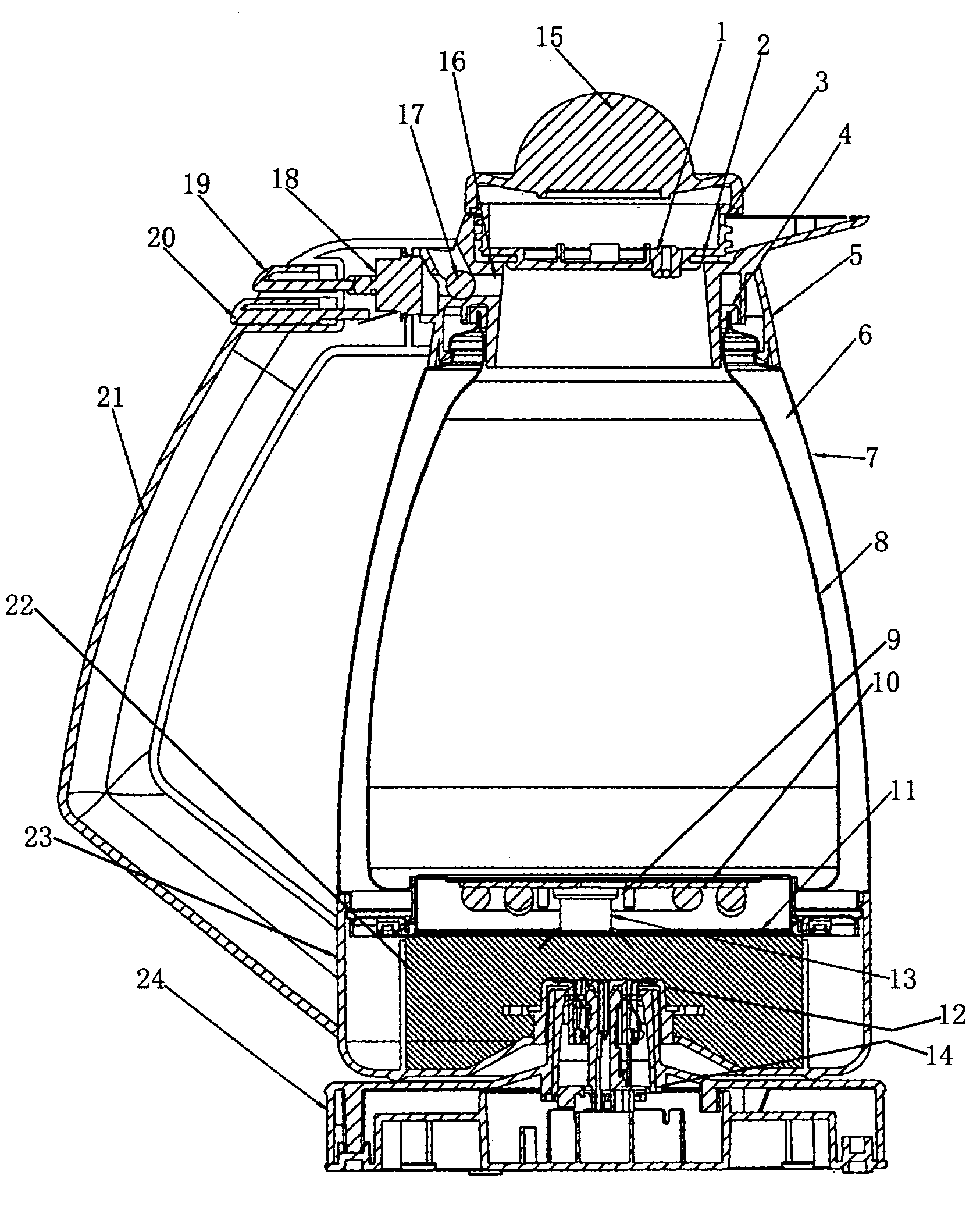

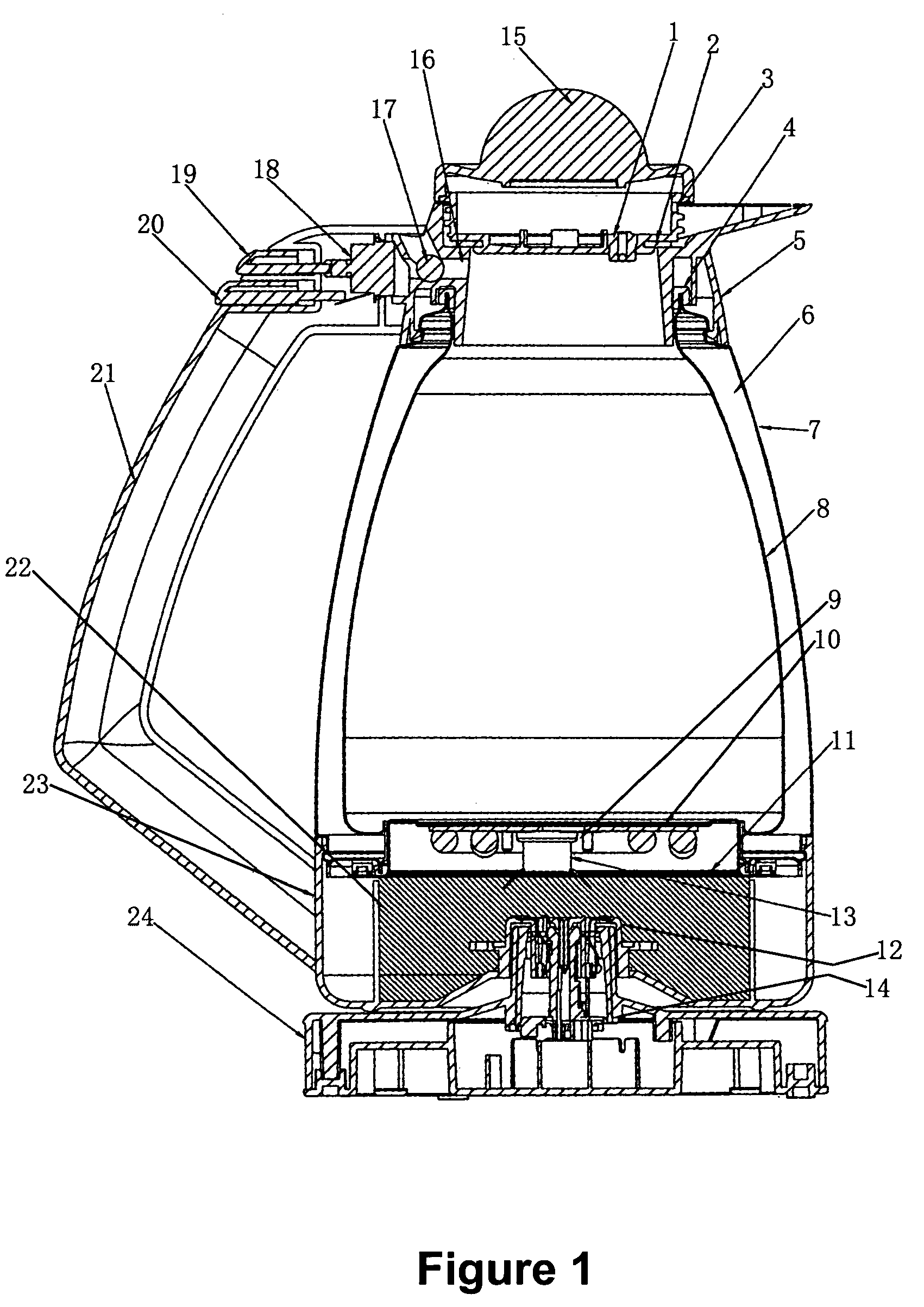

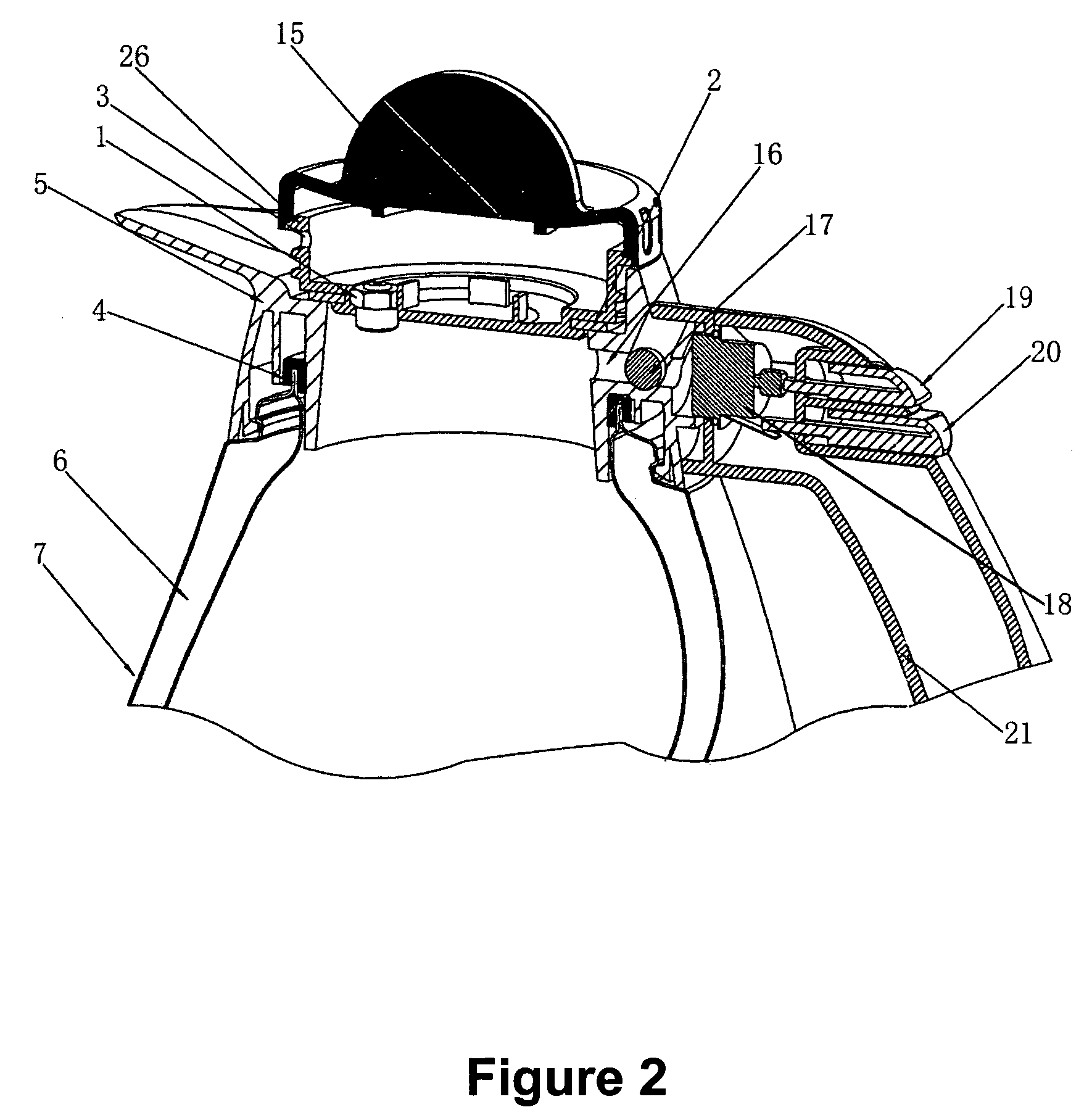

Electric thermos jug

InactiveUS20050284861A1Easy to useImprove air tightnessCooking-vessel materialsDomestic cooling apparatusWater qualityEngineering

An electric thermos jug comprises generally from the top to the bottom a lid assembly, a spout assembly, a double-layer vacuum body, a heating element, an underbody, and a base. An insulating plate and an insulating material layer are provided under the heating element inside the underbody of the jug. The lid is two-layer structure comprising an upper lid and lower lid with an air plenum in between. The electric thermos is convenient for use and effective in heat insulation due to the excellent air tightness of the components. The temperature inside the jug can be maintained for a long time without the need of repetitive heating. As a result, it can maintain a good water quality and is energy efficient. A safety valve is also employed.

Owner:FUNG SHIU PO

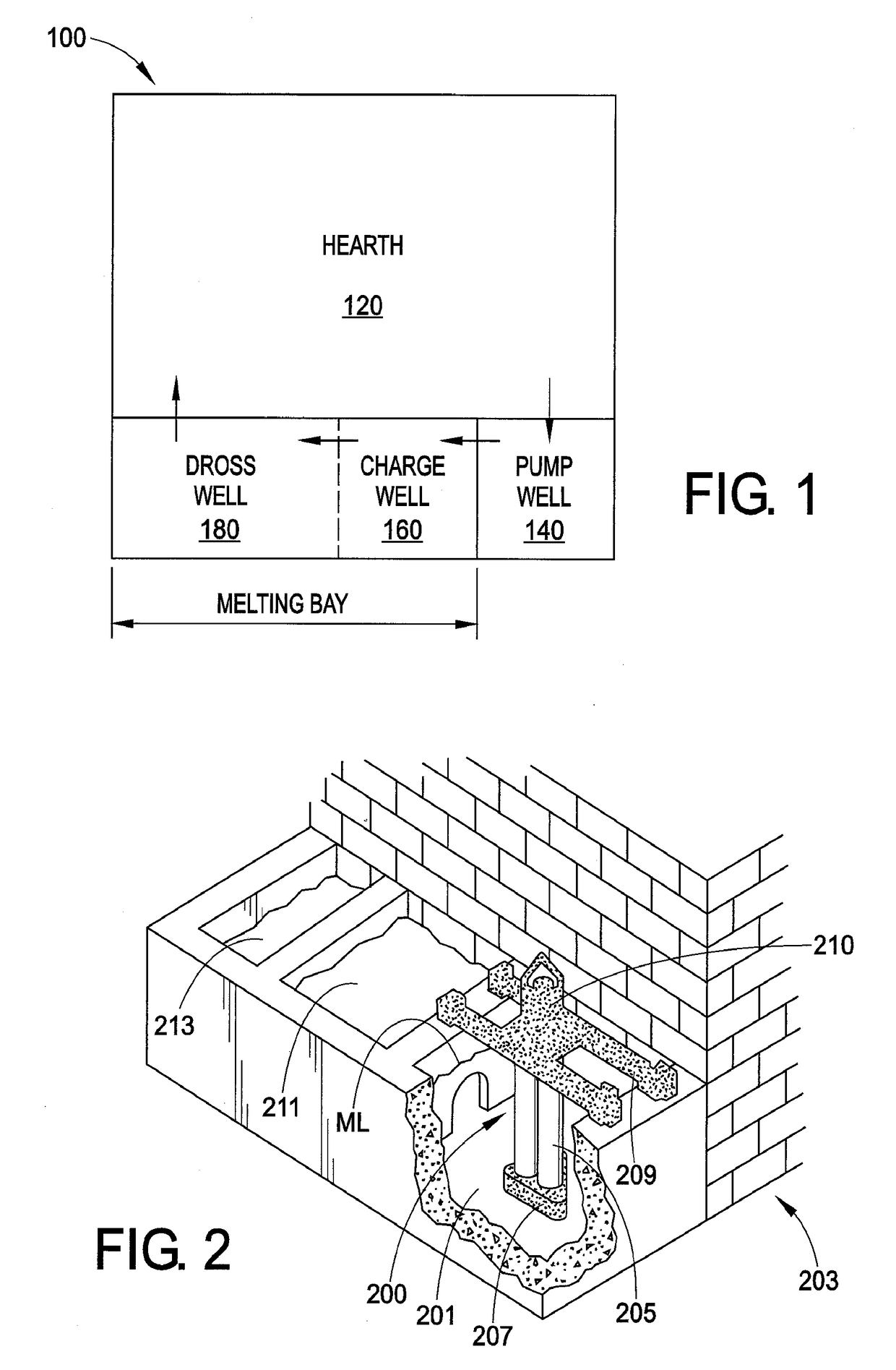

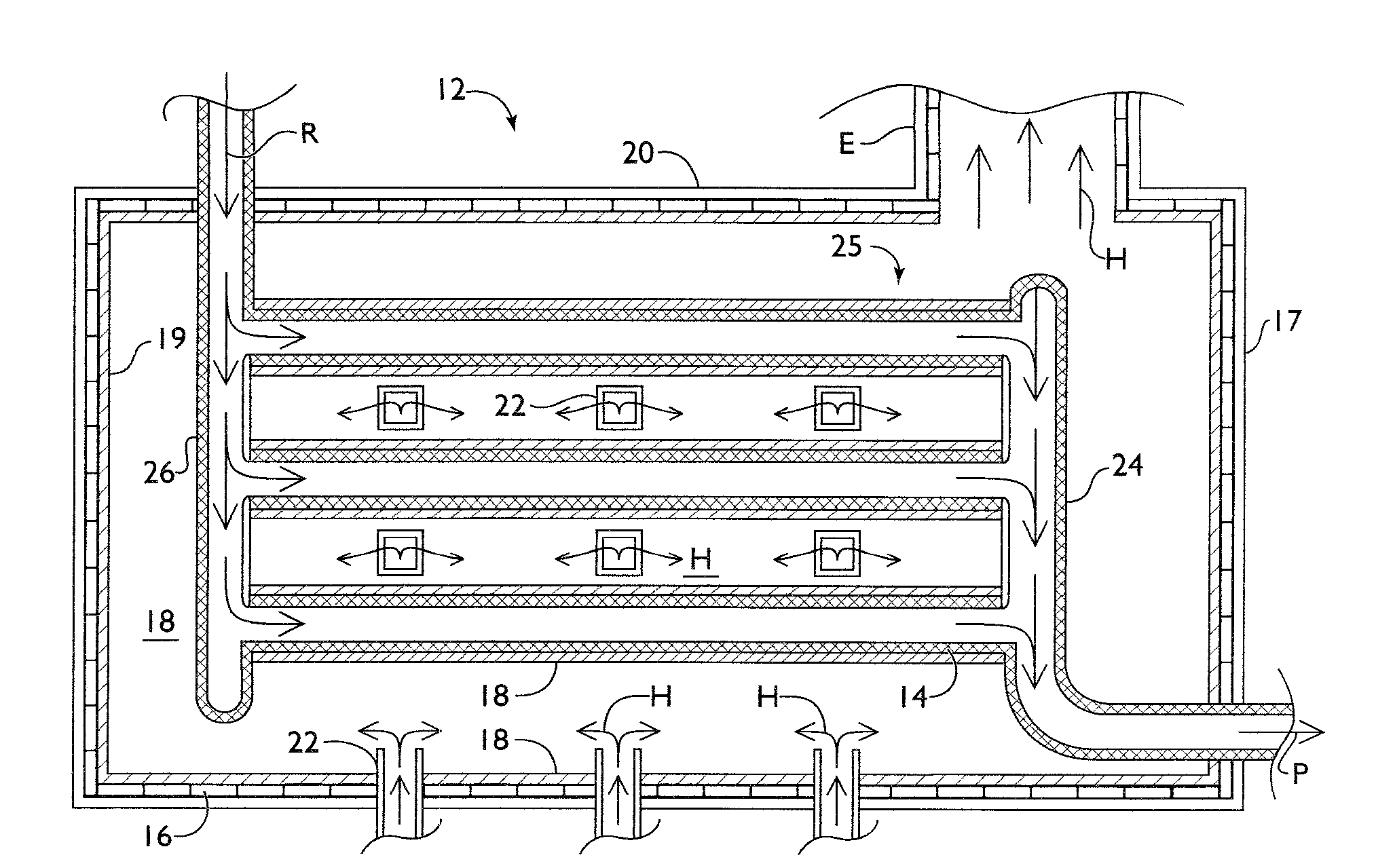

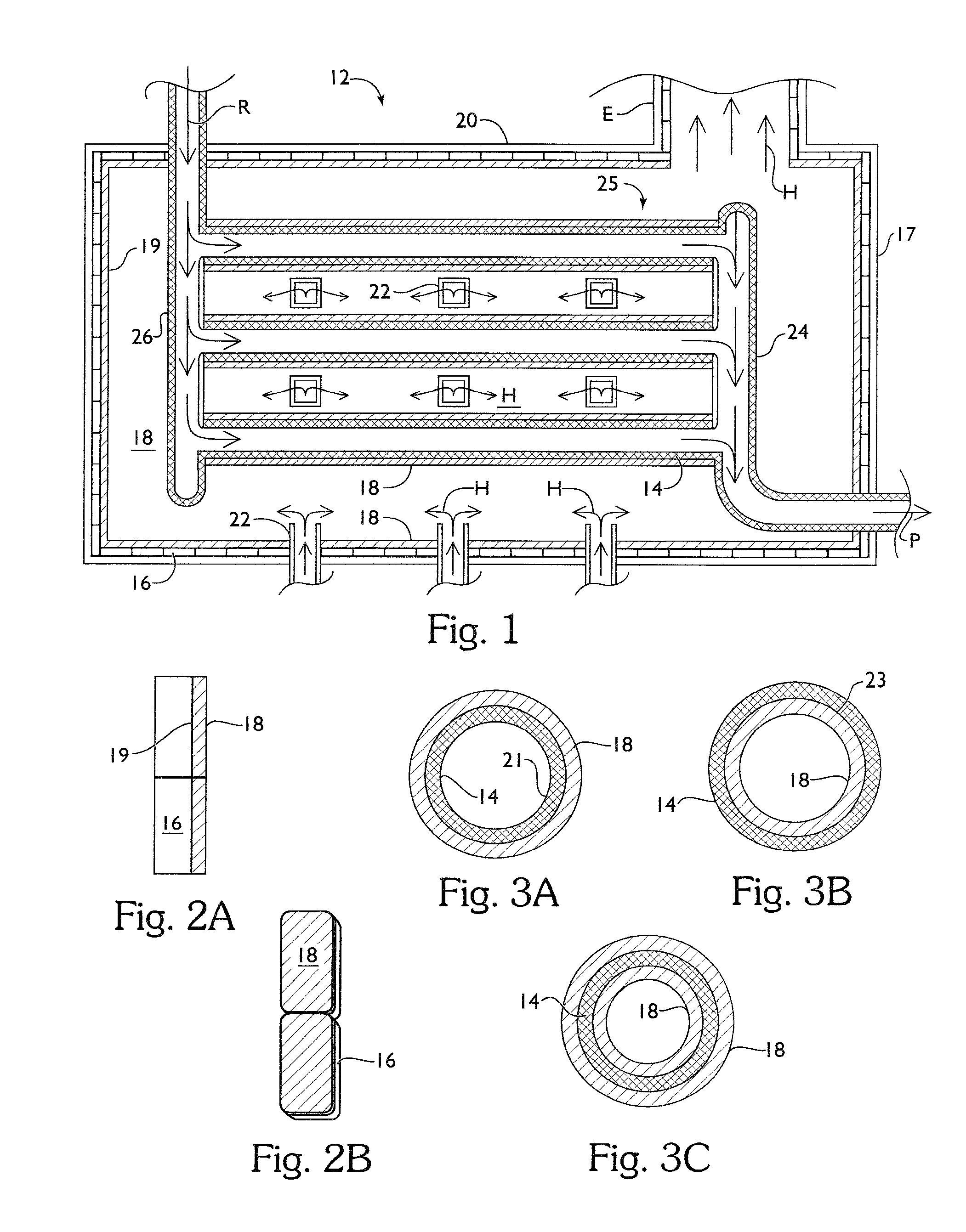

Systems and methods for glass manufacturing

Submerged combustion systems and methods of use to produce glass. One system includes a submerged combustion melter having a roof, a floor, a wall structure connecting the roof and floor, and an outlet, the melter producing an initial foamy molten glass. One or more non-submerged auxiliary burners are positioned in the roof and / or wall structure and configured to deliver combustion products to impact at least a portion of the bubbles with sufficient force and / or heat to burst at least some of the bubbles and form a reduced foam molten glass.

Owner:JOHNS MANVILLE CORP

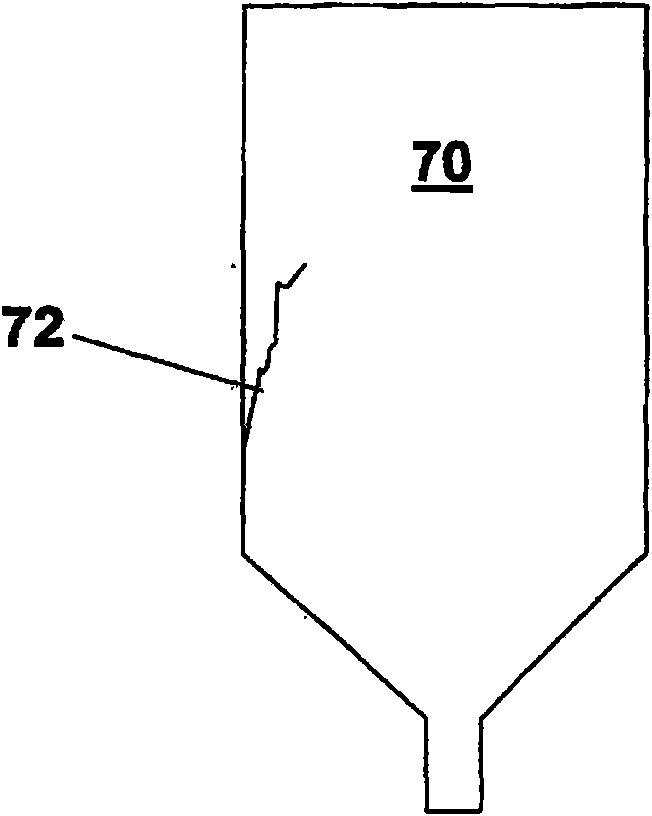

Multilayer structured quartz glass crucible and method for producing the same

InactiveUS20020192409A1Oscillation suppressionReduce transmittanceEnvelopes/bags making machineryCrystallization separationInter layerCrucible

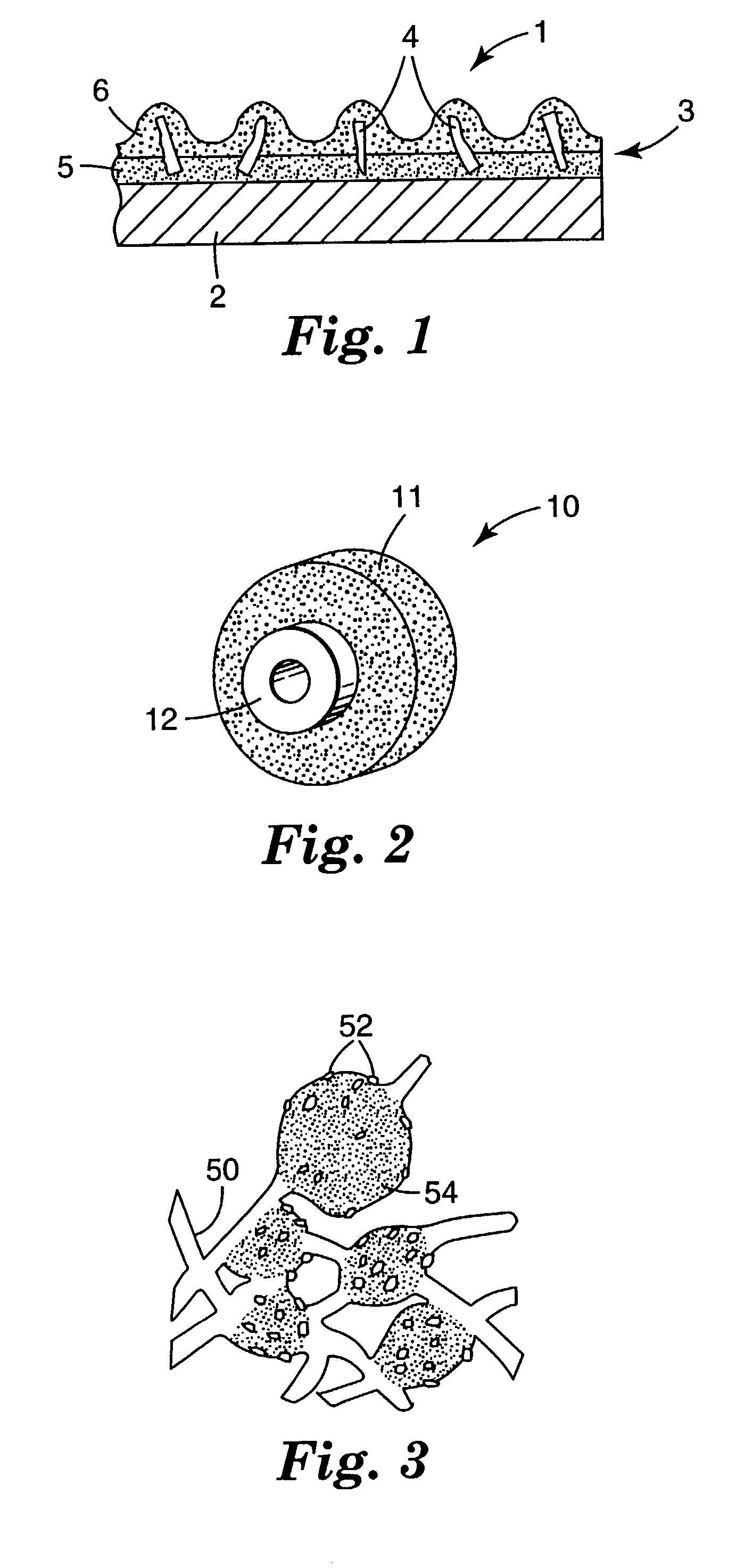

Disclosed is a multilayer structured quartz glass crucible, for pulling up silicon single crystal, whose structure has at least three layers comprising: a translucent outer layer made of naturally occurring quartz glass and having a large number of pores, a translucent intermediate layer, made of synthetic quartz glass and having a large number of pores, and a transparent inner layer substantially free from pores and made of a synthetic quartz glass. Thermal convection within the silicon melt is suppressed by use of the quartz glass crucible, thereby preventing oscillation on the surface of the silicon melt. A method for producing the quartz glas crucible is also disclosed.

Owner:HERAEUS QUARZGLAS +1

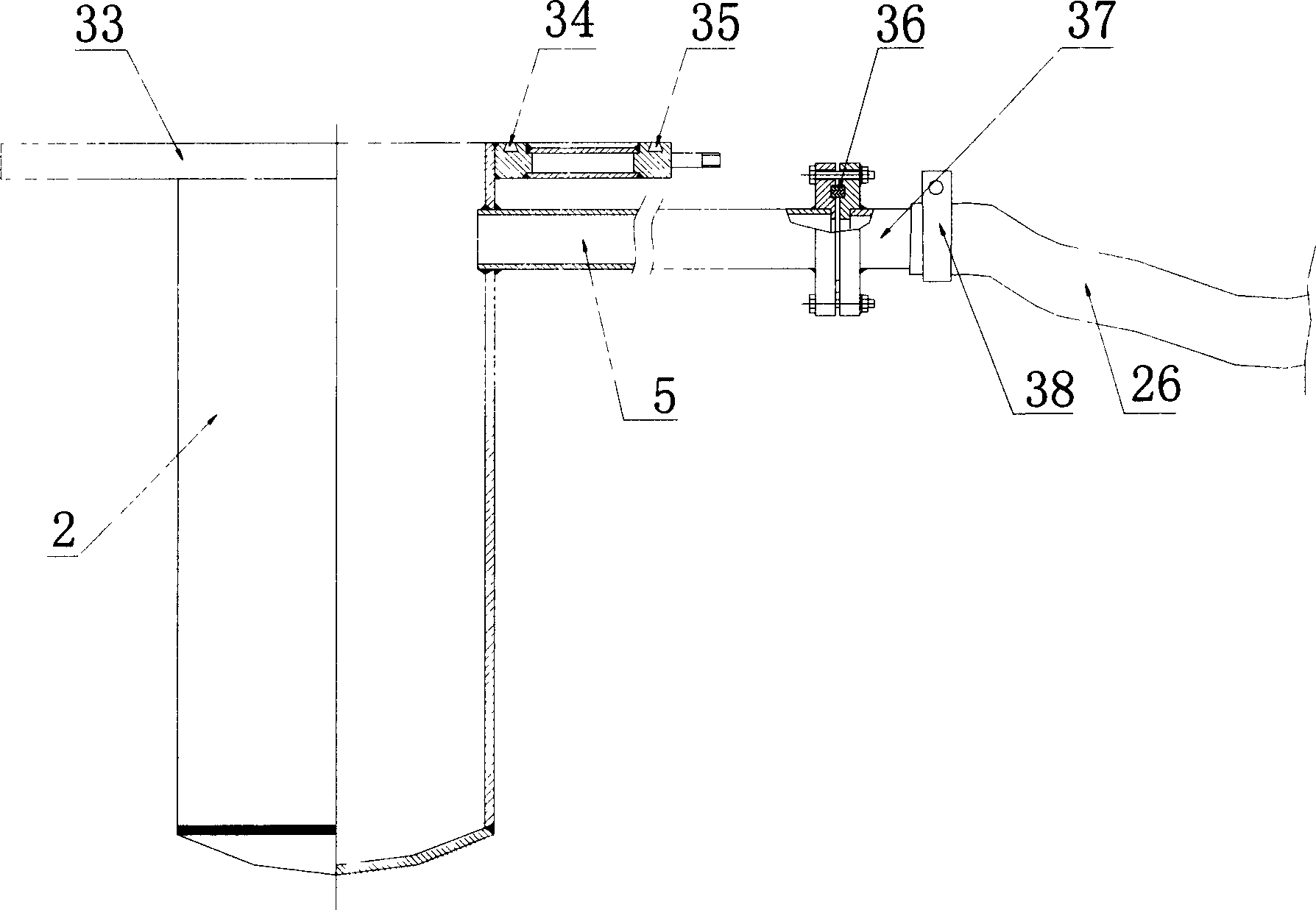

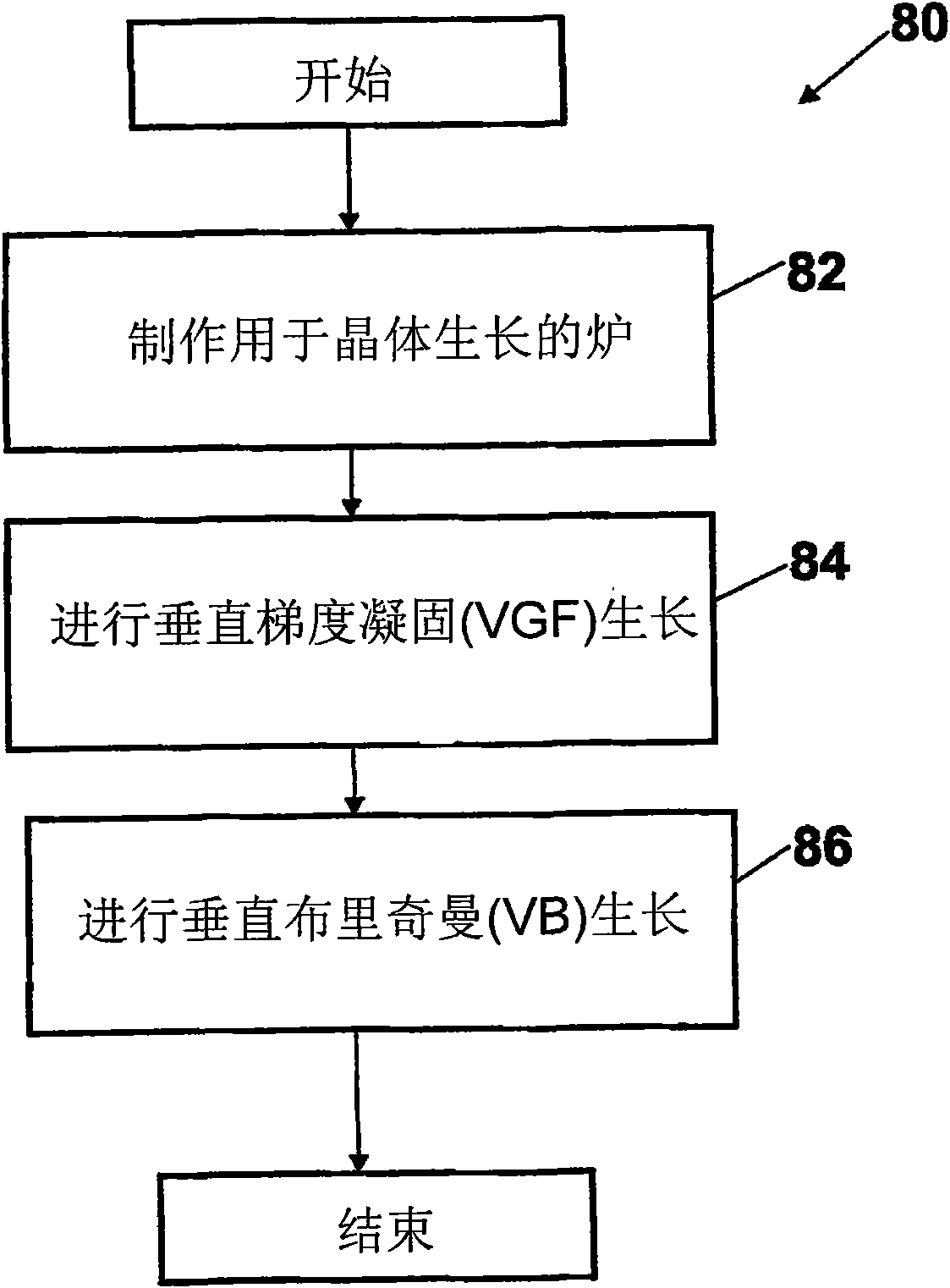

Crystal growing device and method

InactiveCN101555620AAfter-treatment apparatusPolycrystalline material growthVertical gradientCrucible

The invention discloses a system and a method using VGF and VB growing technology to carry out crystal growth to reduce body inlaid crystal. In a demonstration embodiment, an ampoule bottle containing a raw material is inserted into a furnace with a heating resource, and a vertical gradient solidifying technology is used for crystal growth, wherein the crystallizing temperature gradient can move corresponding to the crystal and / or the furnace to melt the raw material and convert the raw material into monocrystal compound; and a vertical Bridgman technology is used for crystal growth on a crucible, wherein the ampoule bottle / heating source can relatively move to continuously melt the raw material and convert the raw material into monocrystal compound.

Owner:AXT INC +1

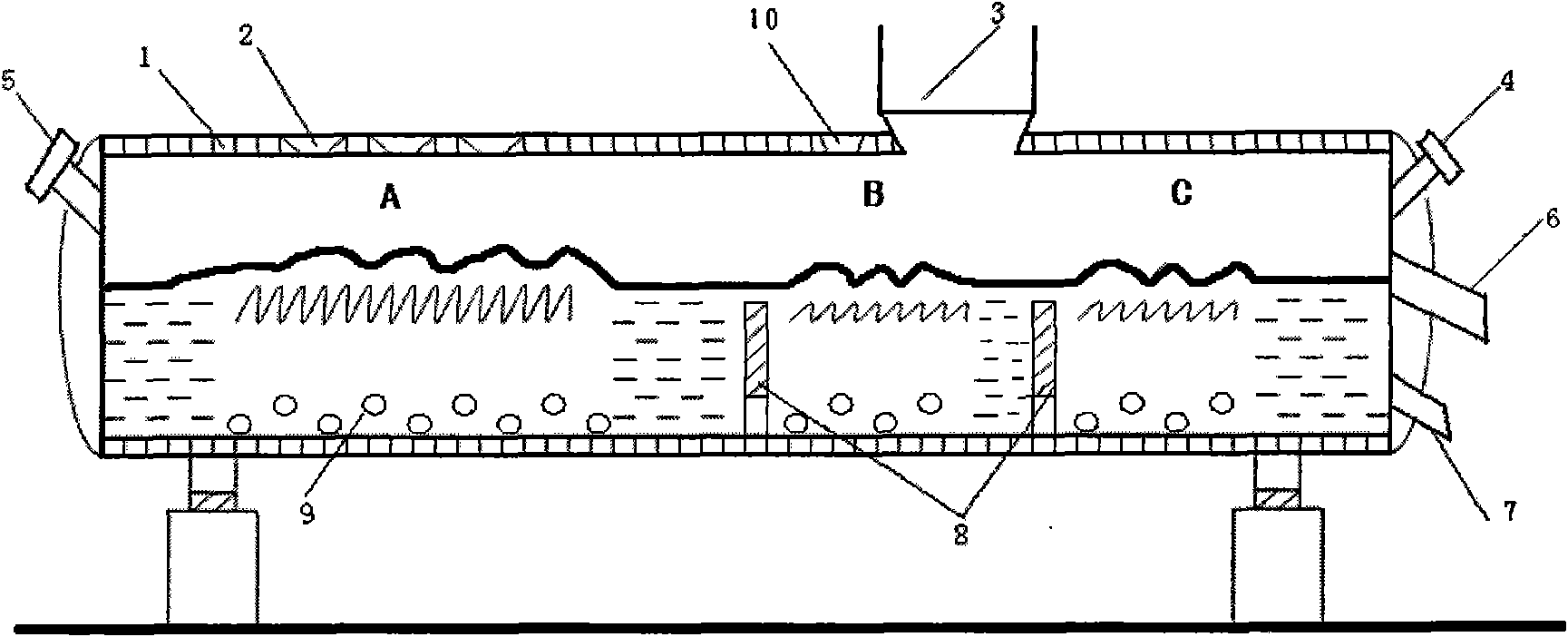

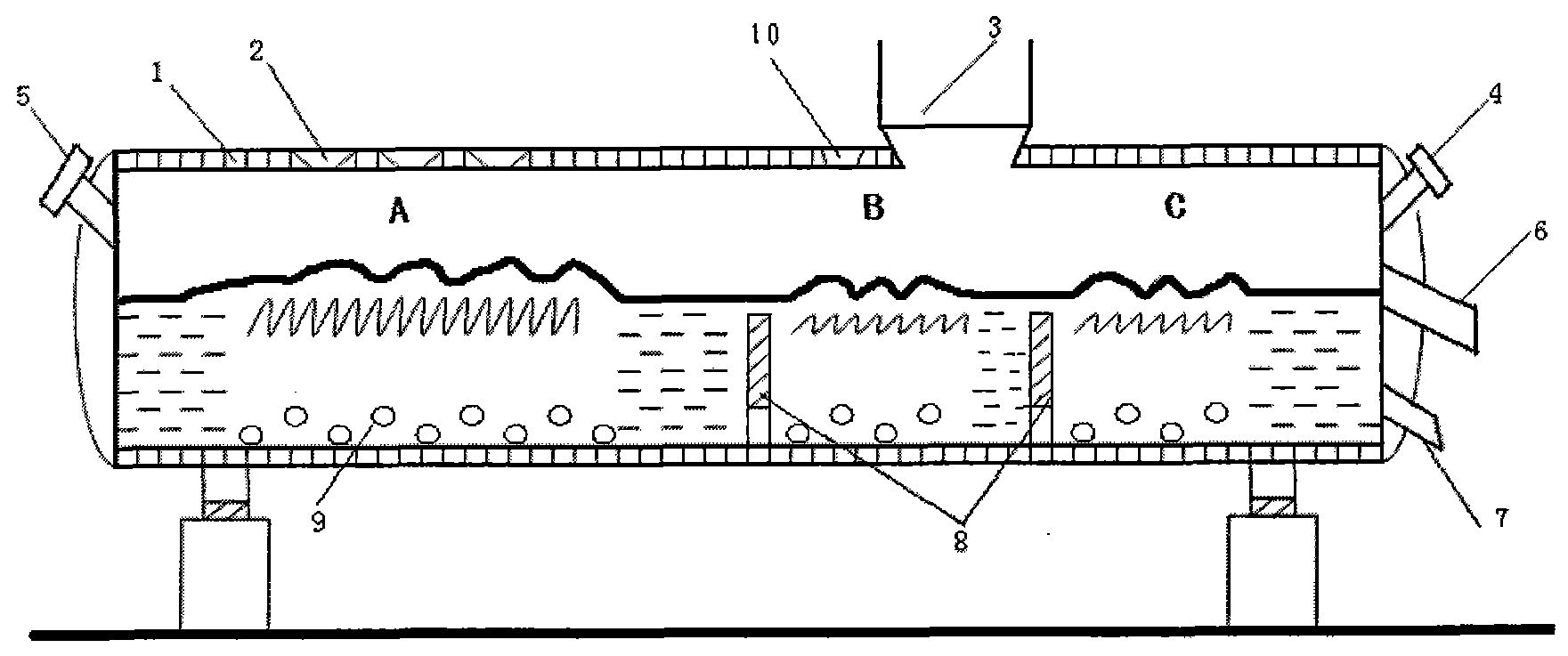

Copper smelting device and process

InactiveCN102181661AAchieve positive resultsReduce bad luckRotary drum furnacesCrucible furnacesBrickSmelting process

The invention provides a copper smelting device and a copper smelting process. In the device, a shell of a rotary horizontal type cylindrical furnace body is made of a steel plate; an inner liner is made of a refractory material; the furnace body passes through two supporting rings and is supported on a foundation through four supporting rollers; one side of the furnace body is provided with a transmission mechanism; a motor is used for driving a speed reducer to drive the furnace body to rotate along a central shaft through a gear and a gear ring on a cylinder; the furnace body is partitioned into a smelting area, a blowing area and a refining area by a refractory brick retaining wall; a gap is formed at the bottom of the retaining wall; the bottoms of all areas are provided with a spray gun respectively; a charging hole is formed above the smelting area; a flue hole and a fluxing agent hole are formed above the blowing area; a main burner nozzle and an auxiliary burner nozzle are arranged on the shell of the furnace body end close to the two sides of the smelting area and the refining area respectively; and a slagging hole and a copper discharging hole are formed on the shell of the furnace body end on one side of the auxiliary burner nozzle. The device has a simple structure, a reasonable design and extremely good popularization value and application value and is energy-saving and environment-friendly.

Owner:DONGYING LUFANG METAL MATERIAL

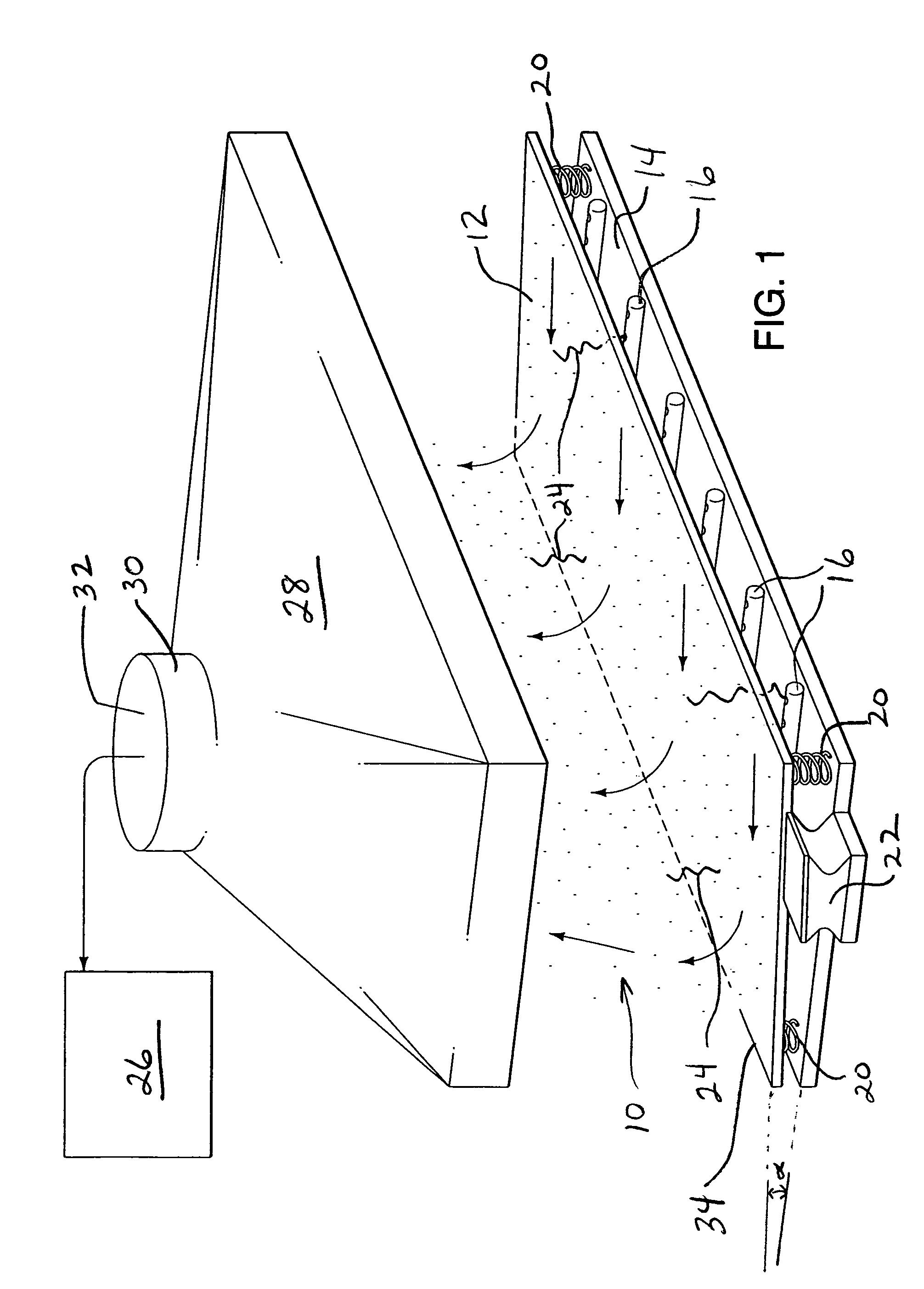

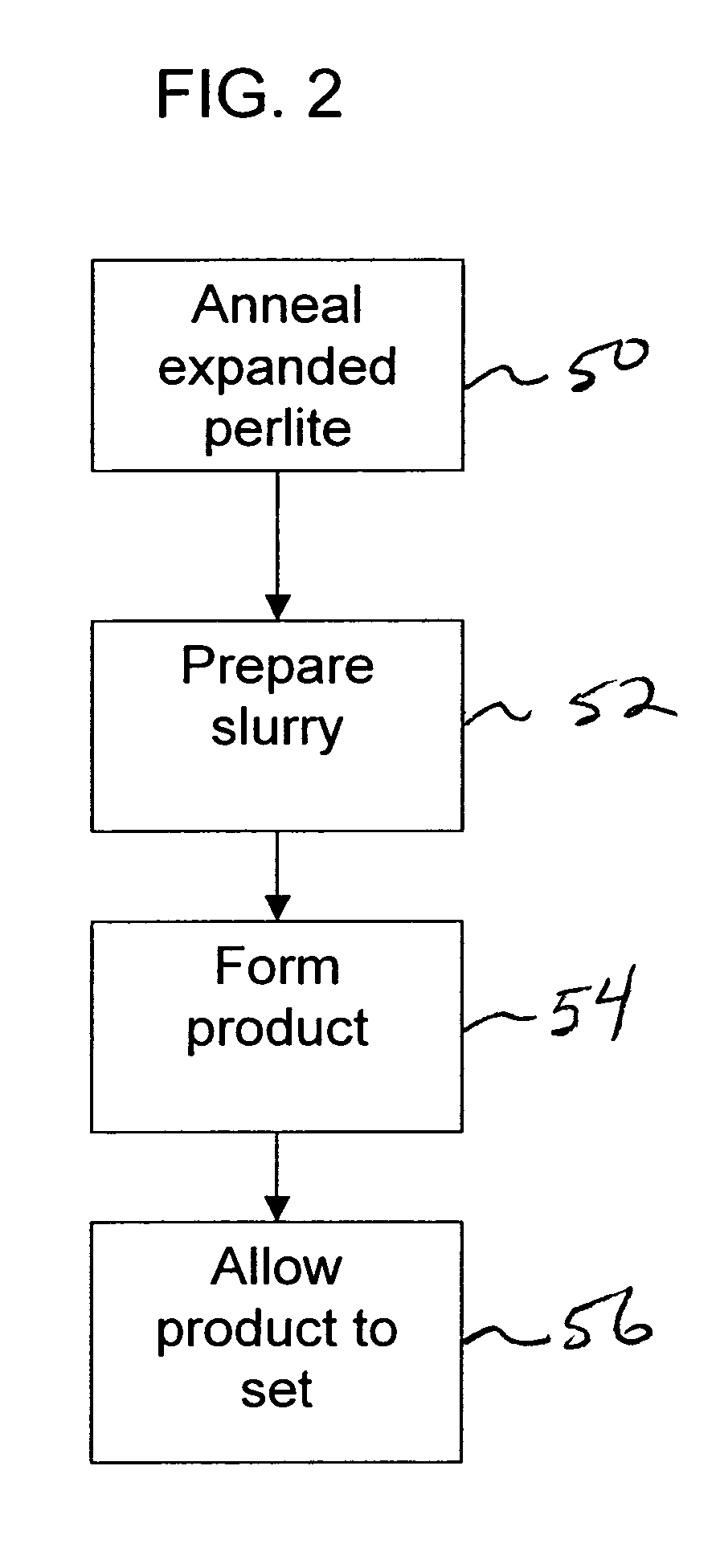

Expanded perlite annealing process

InactiveUS7381261B1Reduce its water intakeReduce weightNon-fibrous pulp additionNatural cellulose pulp/paperCombustorSlurry

This invention is directed to a method of reducing the water demand of expanded perlite that includes obtaining a vibrating screen supported at an angle and placing expanded perlite on the vibrating screen. The expanded perlite is moved over the screen past toward a burner at a rate that heats the expanded perlite to a temperature sufficient to anneal it. The expanded perlite is then moved away from the burner and allowed to cool. Another embodiment of this invention is directed to a method of making a gypsum product. The method includes annealing perlite by the method described above, then preparing a slurry of calcium sulfate hemihydrate, additives, water and the annealed perlite. The slurry is formed into the shape of the gypsum product and allowed to set. This process is particularly useful in making gypsum panels and acoustical panels that benefit from the use of lightweight materials.

Owner:UNITED STATES GYPSUM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com