Patents

Literature

789results about How to "Improve the exhaust effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

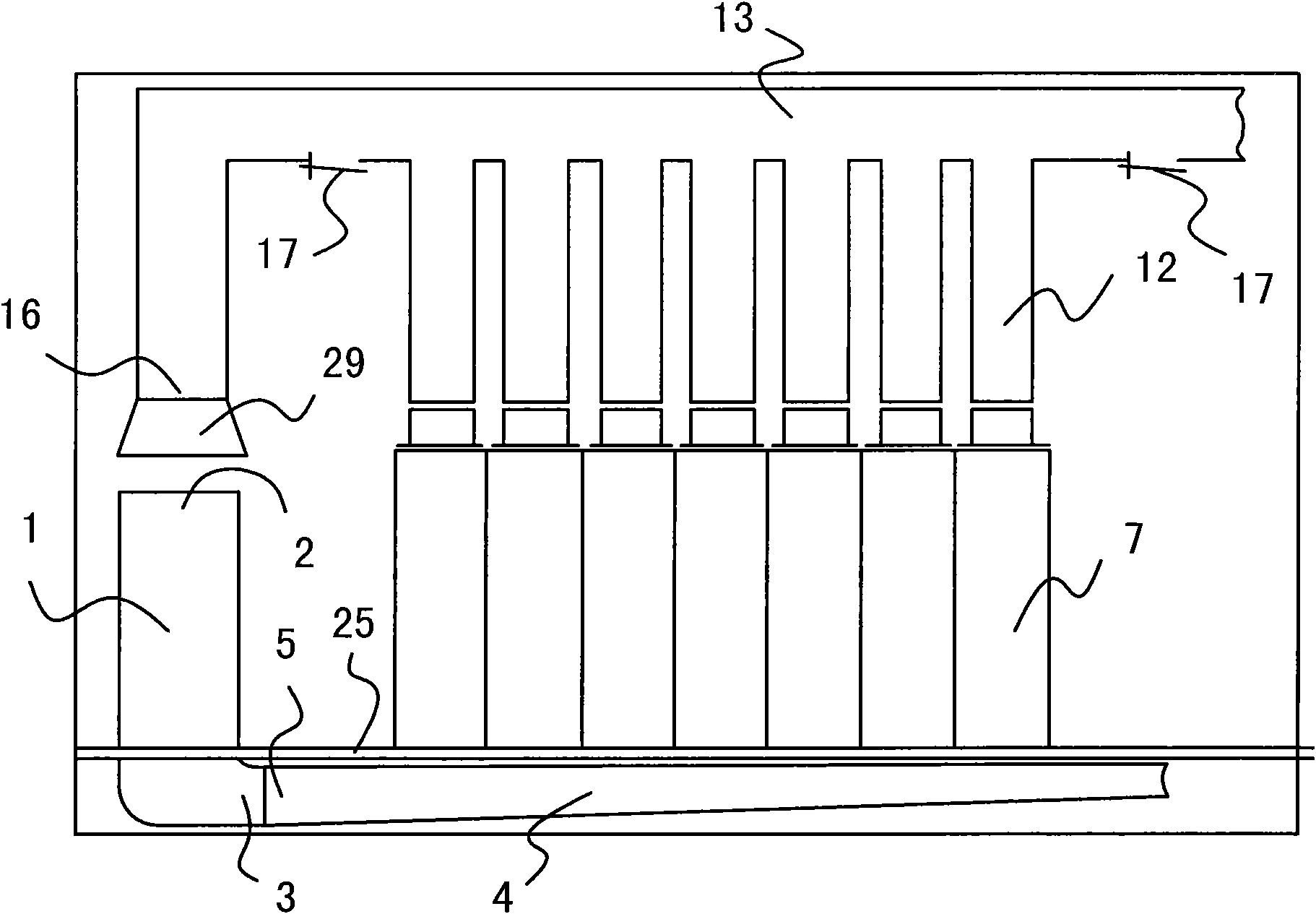

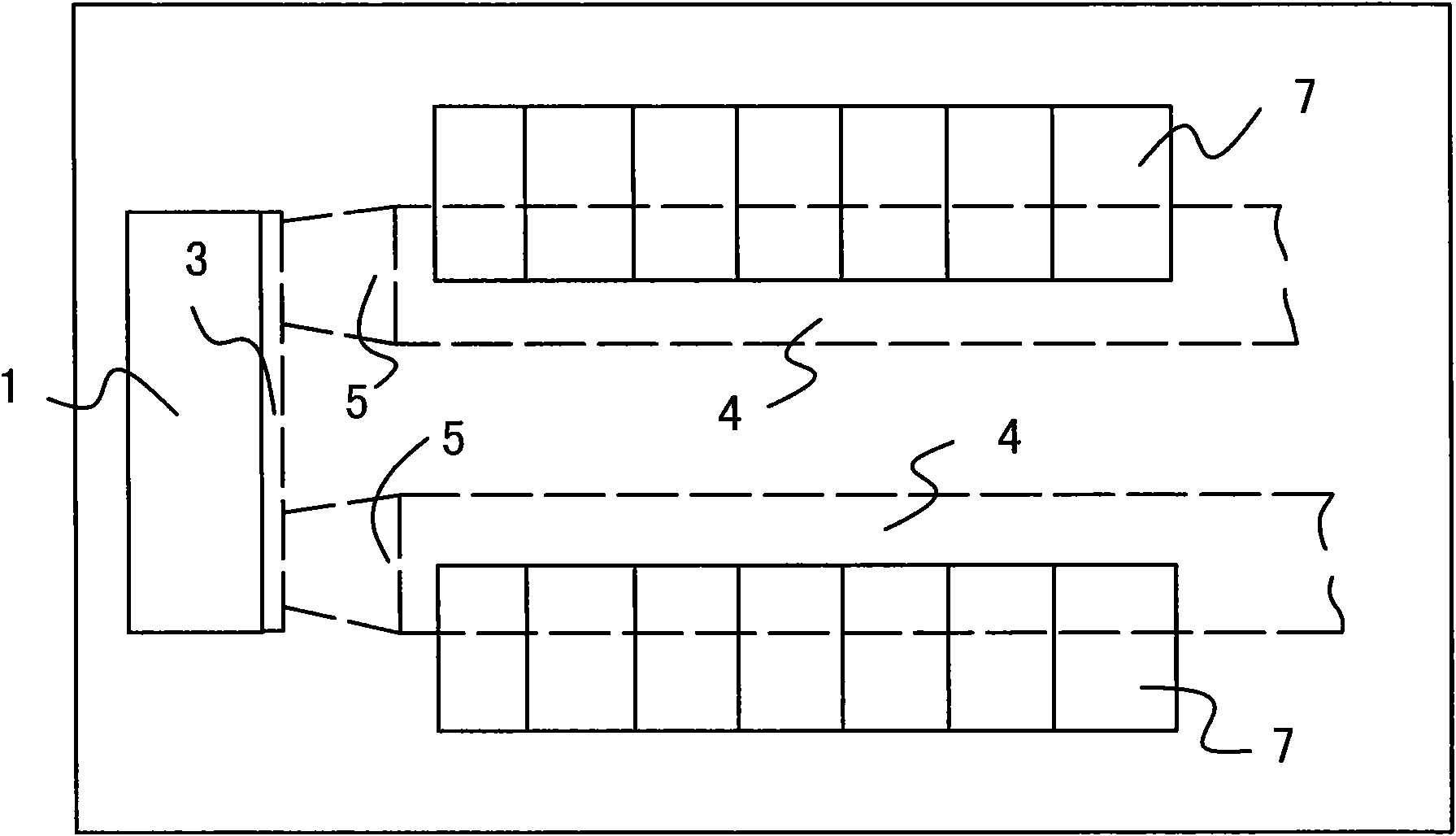

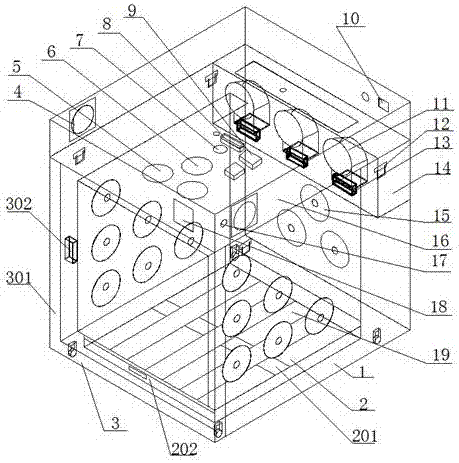

Data center machine room cooling system featuring cool air distribution according to needs

ActiveCN101790300AFacilitate conductionReduce energy consumptionDucting arrangementsCooling/ventilation/heating modificationsCold airData center

The invention relates to a data center machine room cooling system featuring cool air distribution according to needs, comprising an air-conditioning unit and a heat dissipation air channel. Cold air provided by a refrigerating unit is distributed to equipment cabinets through an air inlet header pipe and an air inlet adapter pipe according to cold energy the equipment cabinets need and then is distributed to servers according to the cold energy the servers in the equipment cabinet need through a cold air distribution box, so as to carry out forced air cooling on heated components. The cooling system optimizes airflow movement and realizes air distribution according to needs, thus being an efficient and energy-saving data center machine room cooling system heat dissipation solution.

Owner:傅建勋

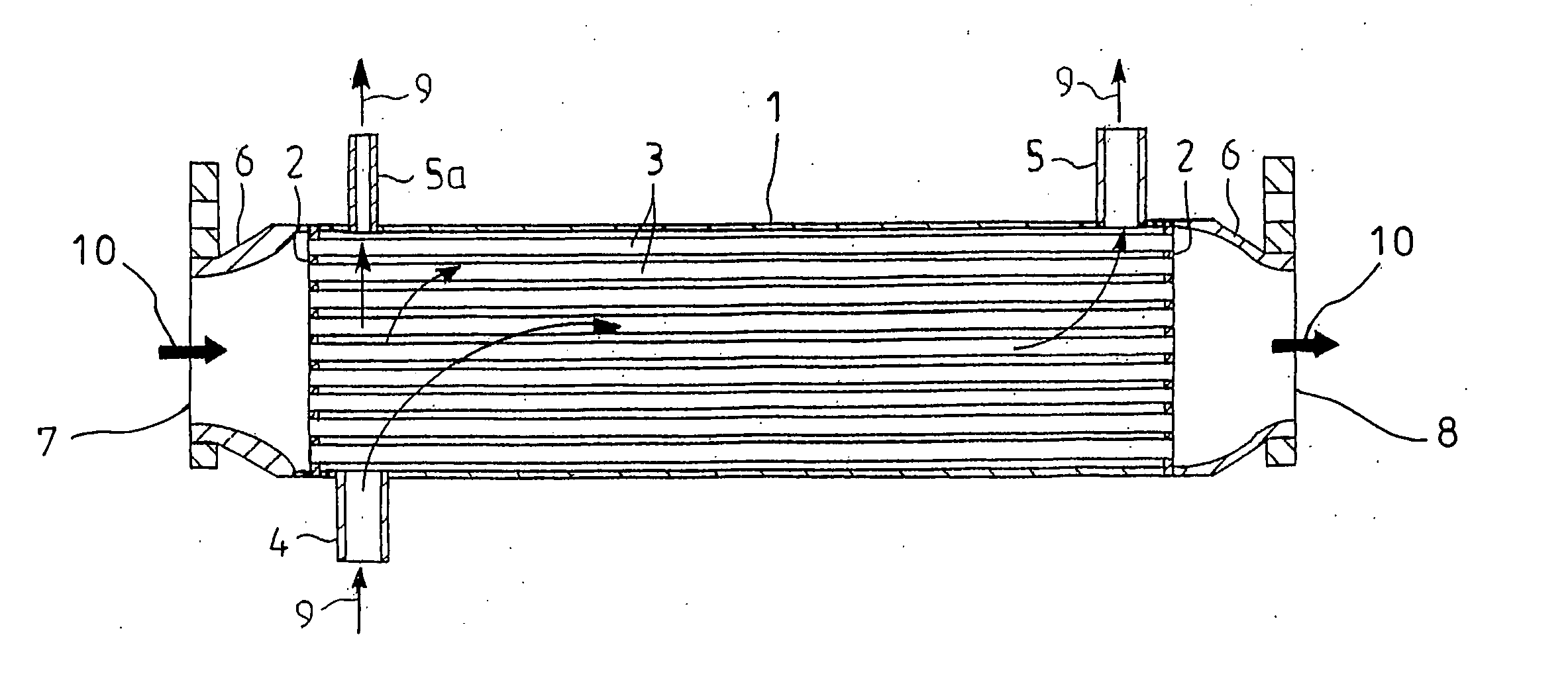

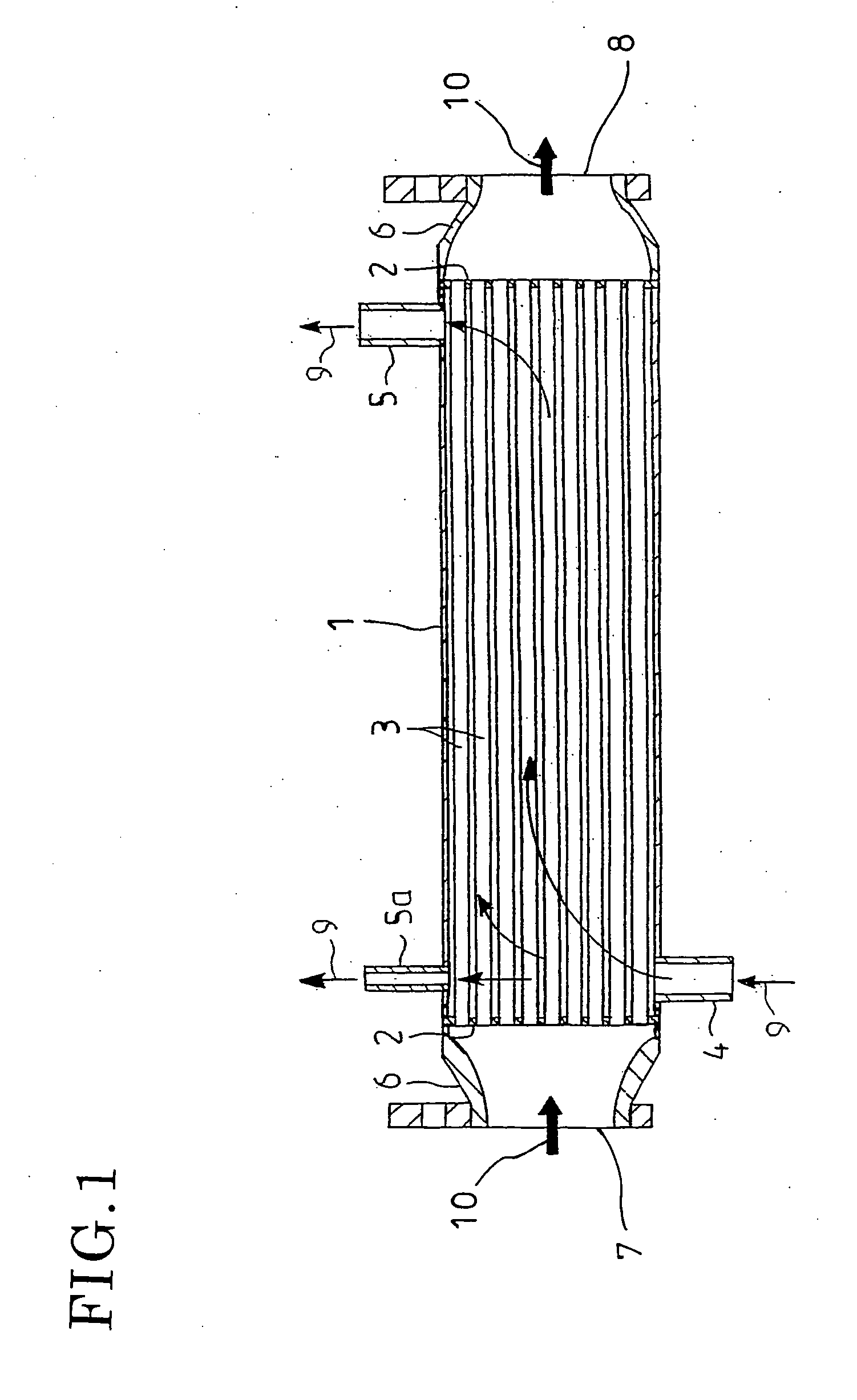

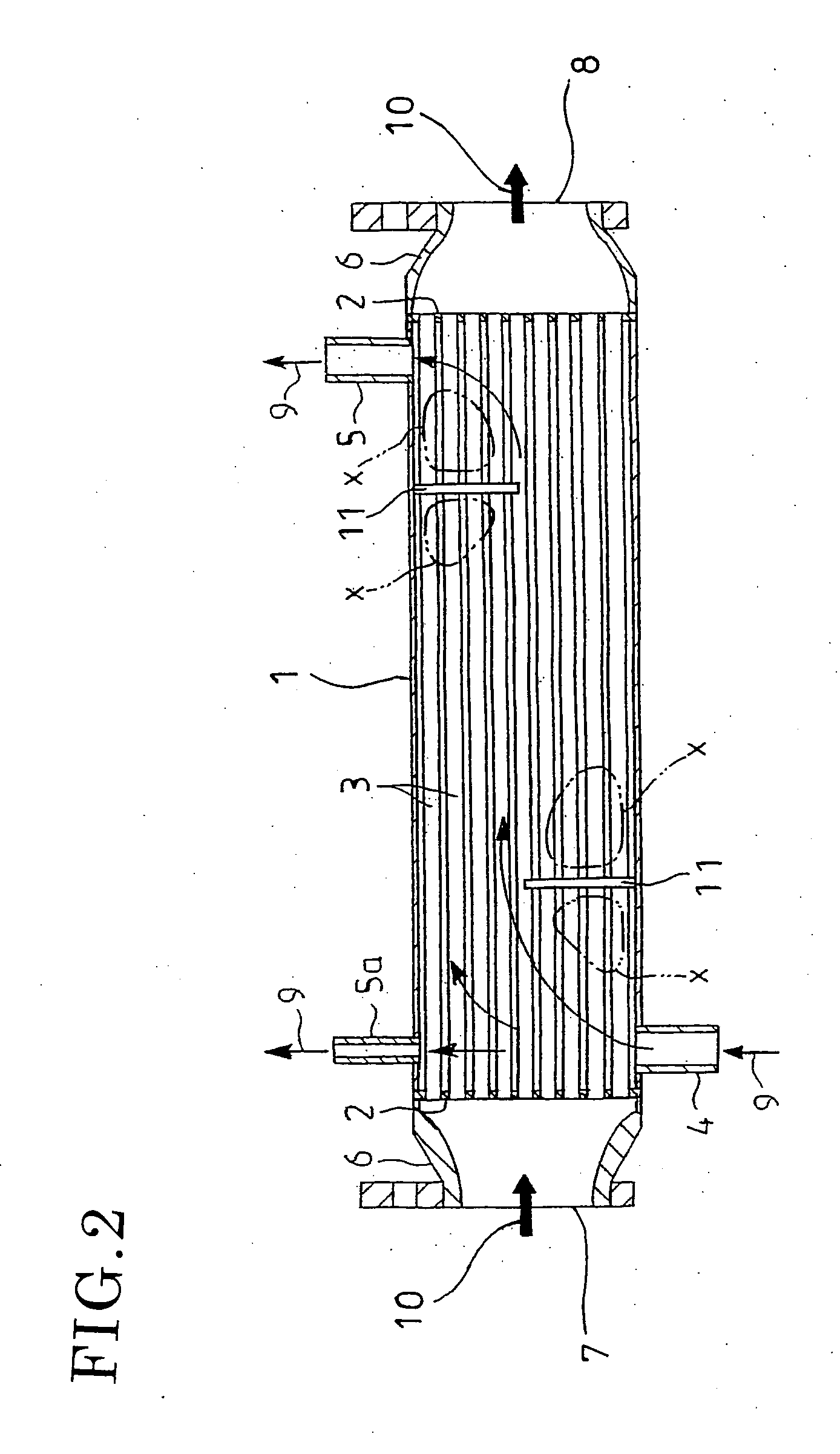

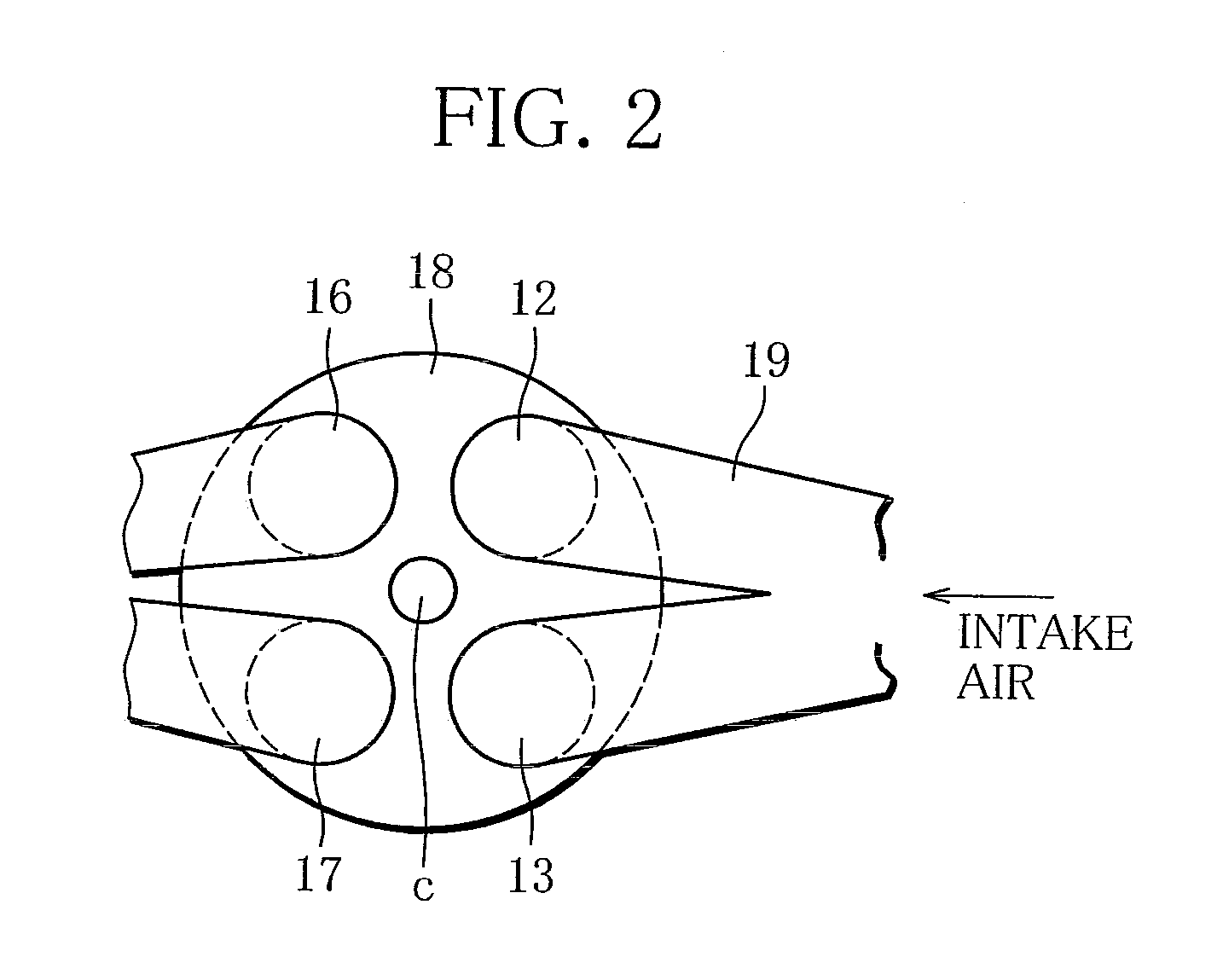

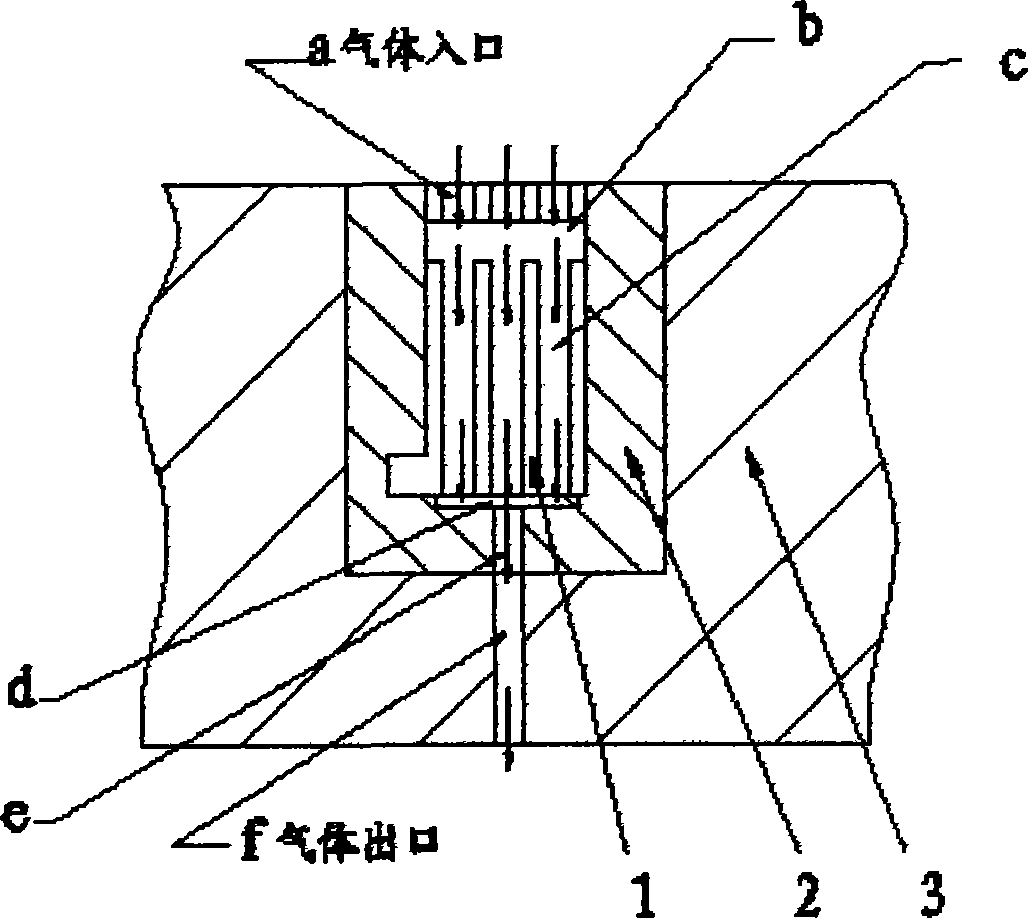

Egr cooler

InactiveUS20060231243A1Increased pressure lossImprove the exhaust effectNon-fuel substance addition to fuelInternal combustion piston enginesThermal deformationEngineering

Provided is an EGR cooler which can solve the problem of the vibrated tubes without causing thermal deformation due to stagnation of the coolant water, without complexity of piping in the coolant water system and without increase in pressure loss. The EGR cooler comprises tubes 3 and a shell surrounding the tubes 3, the coolant water being supplied and discharged to and from the shell 1 and being passed through the respective tubes 3 so as to make heat exchange of the exhaust gas with the coolant water. In the shell 1, an intermediate support plate 13 with a plurality of through-holes 14 is arranged and mutually adjacent ones of the tubes 3 are grouped for penetratingly fixture to the through-hole 14. A coolant water passage 15 is ensured between the tubes 3 grouped and penetratingly fixed to the same through-hole 14 of the intermediate support plate 13 for free communication between the tubes 3.

Owner:HINO MOTORS LTD +1

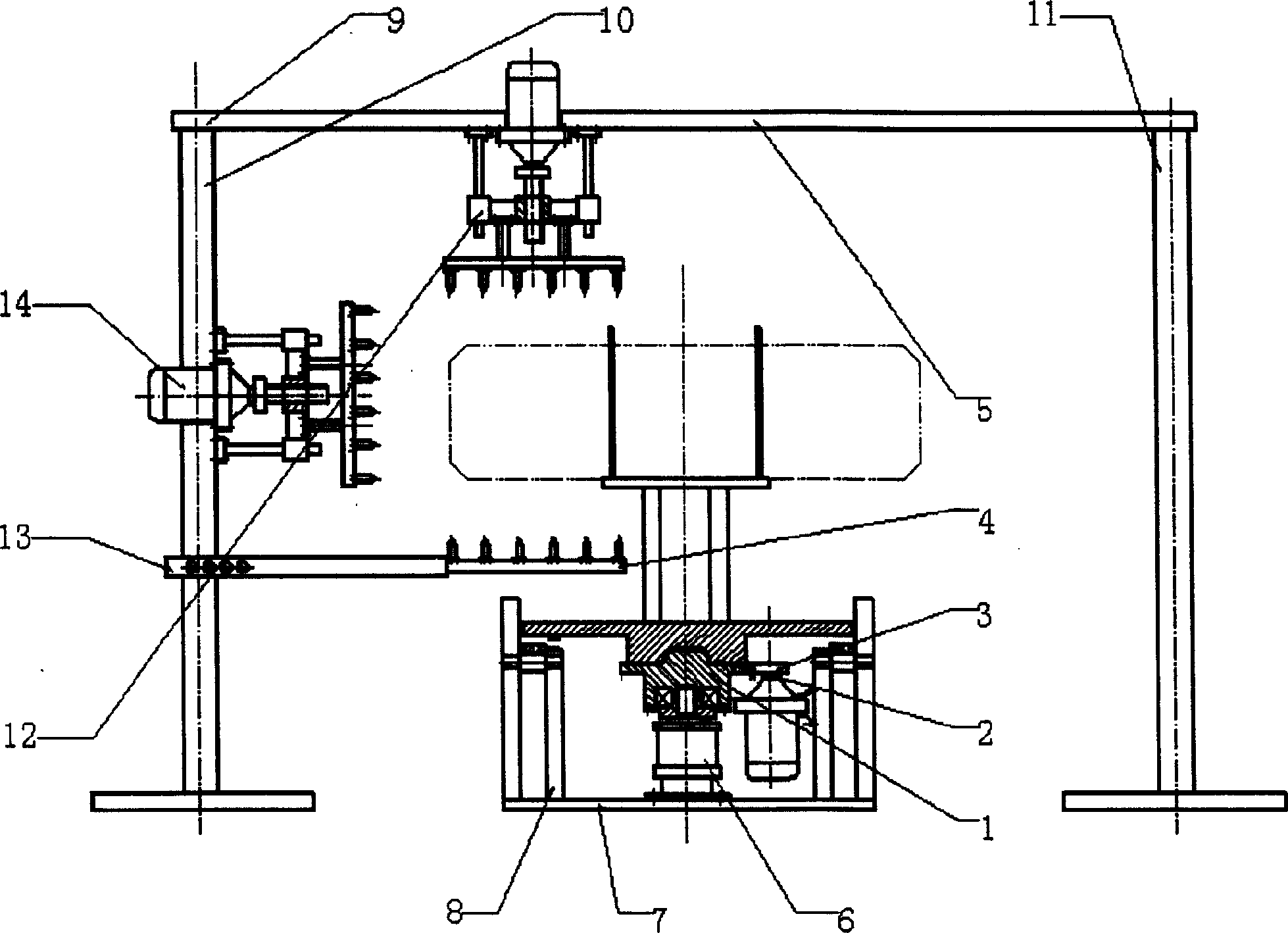

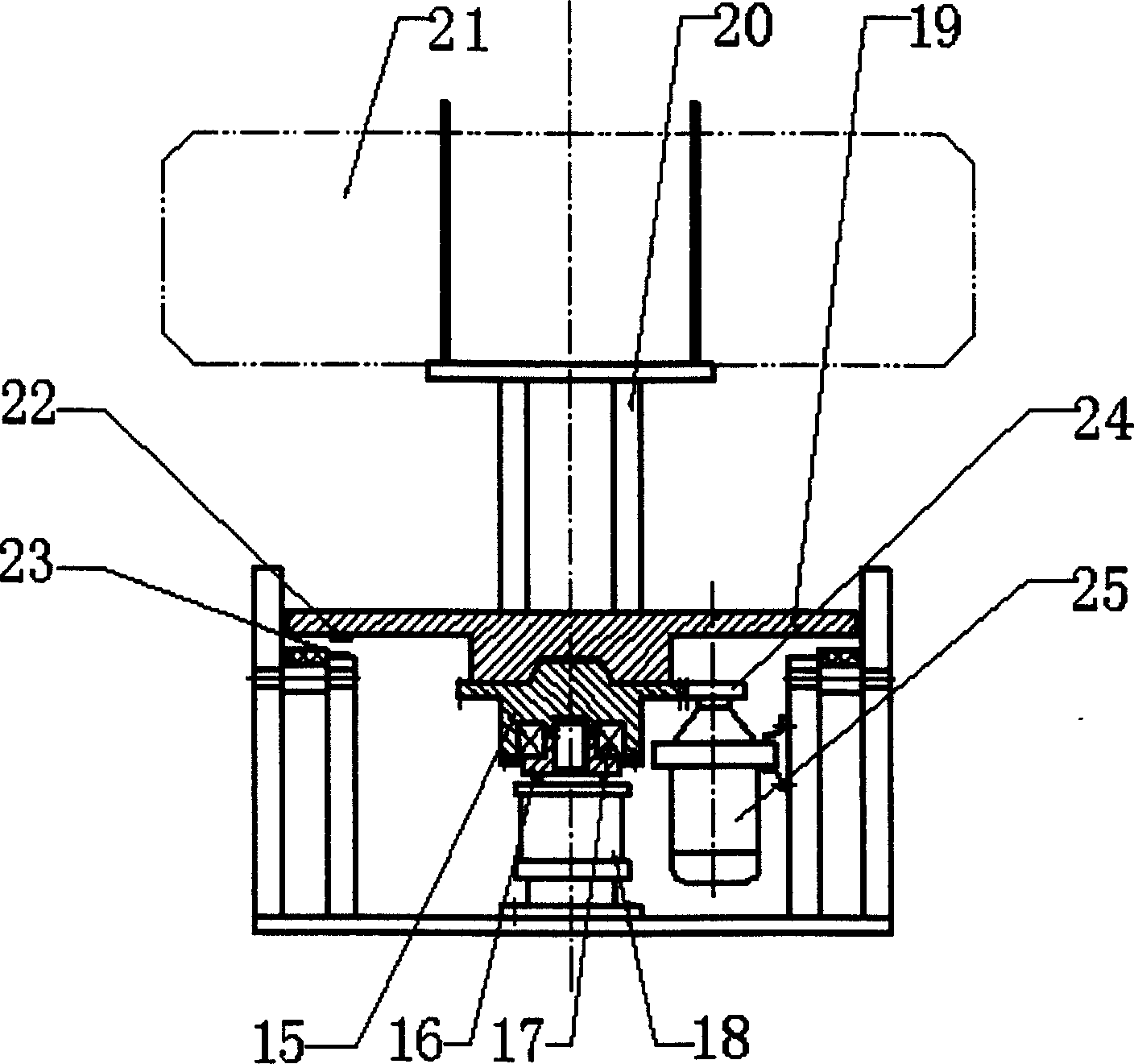

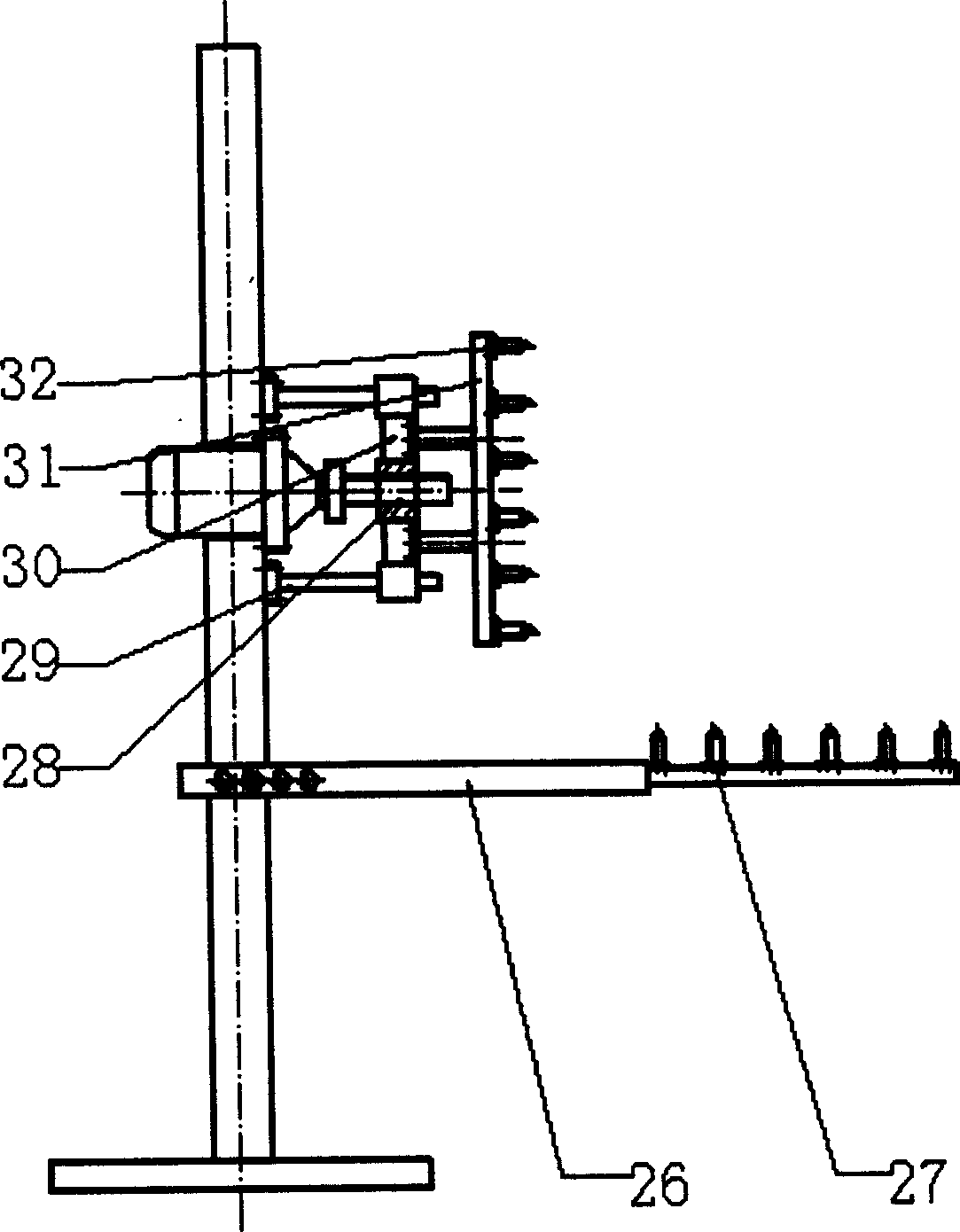

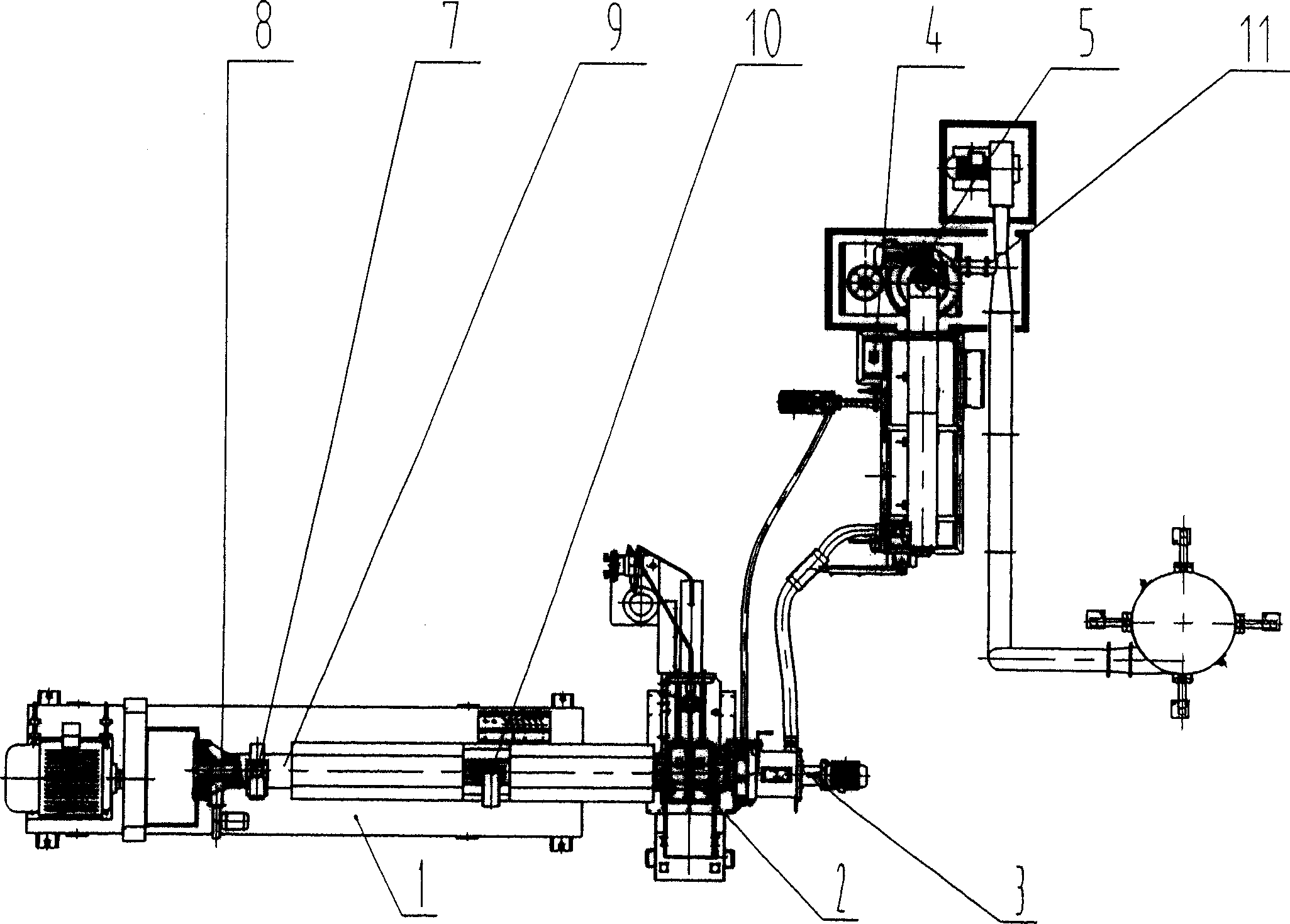

Spray-coating machine for external surface of tire

The tyre surface spray-coating machine mainly includes tyre lifting device, tyre conveyer device, tyre-turning device, tyre nozzle group and supporting frame. Its connection mode; the lifting cylinder of tyre lifting device is mounted on the base plate of supporting frame, when the tyre conveyer device is lifted up, the tyre lifting device and tyre conveyer device are matched and positioned by means of oblique surface embossed structure, the tyre turning device is fixed on the side face supporting frame, and the side face supporting frame is mounted on the base plate of supporting frame, the tyre turning device is connected with tyre conveyer device by means of gear transmission, and the tyre nozzle group is mounted on the supporting frame.

Owner:SHANGHAI JIAO TONG UNIV

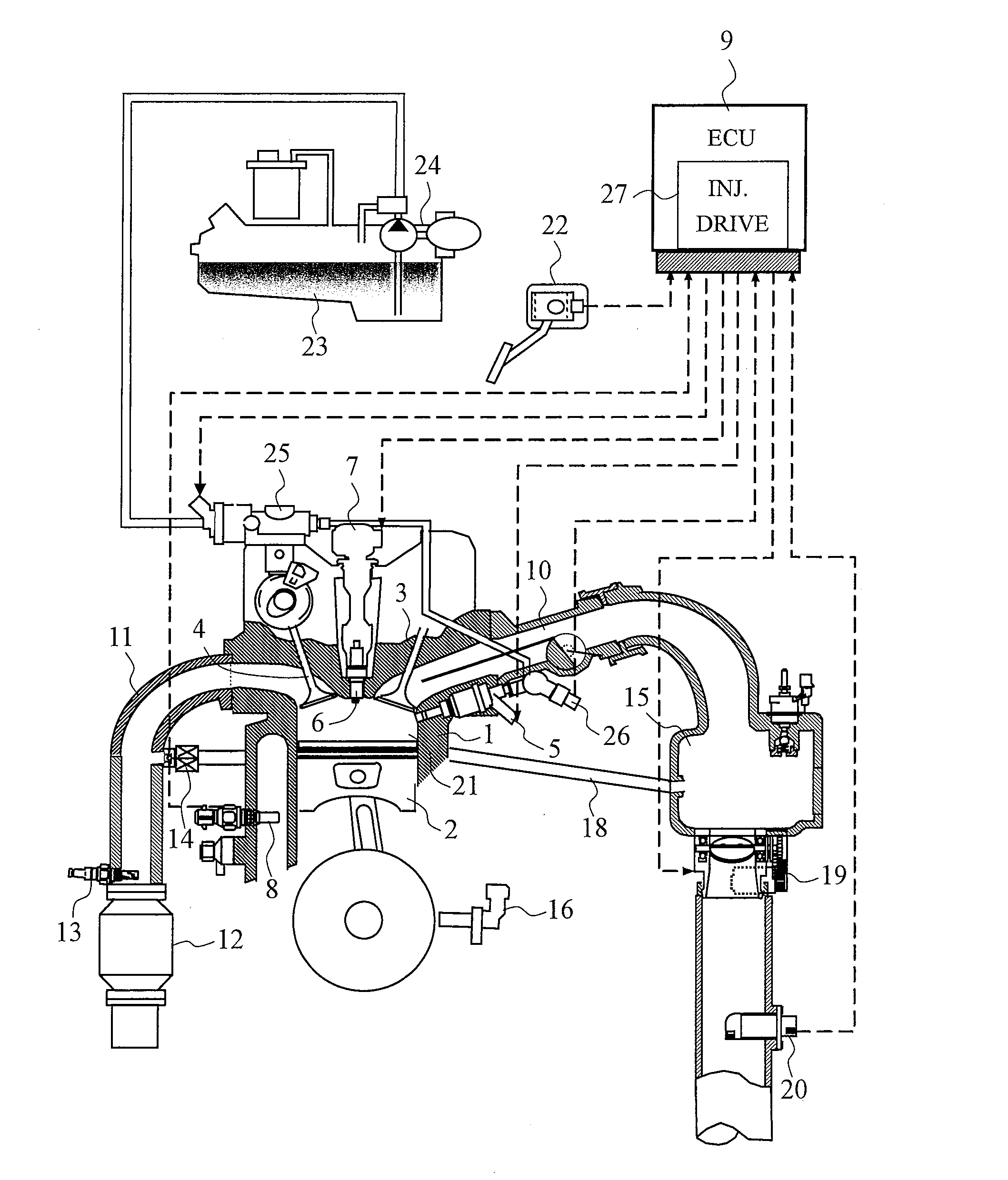

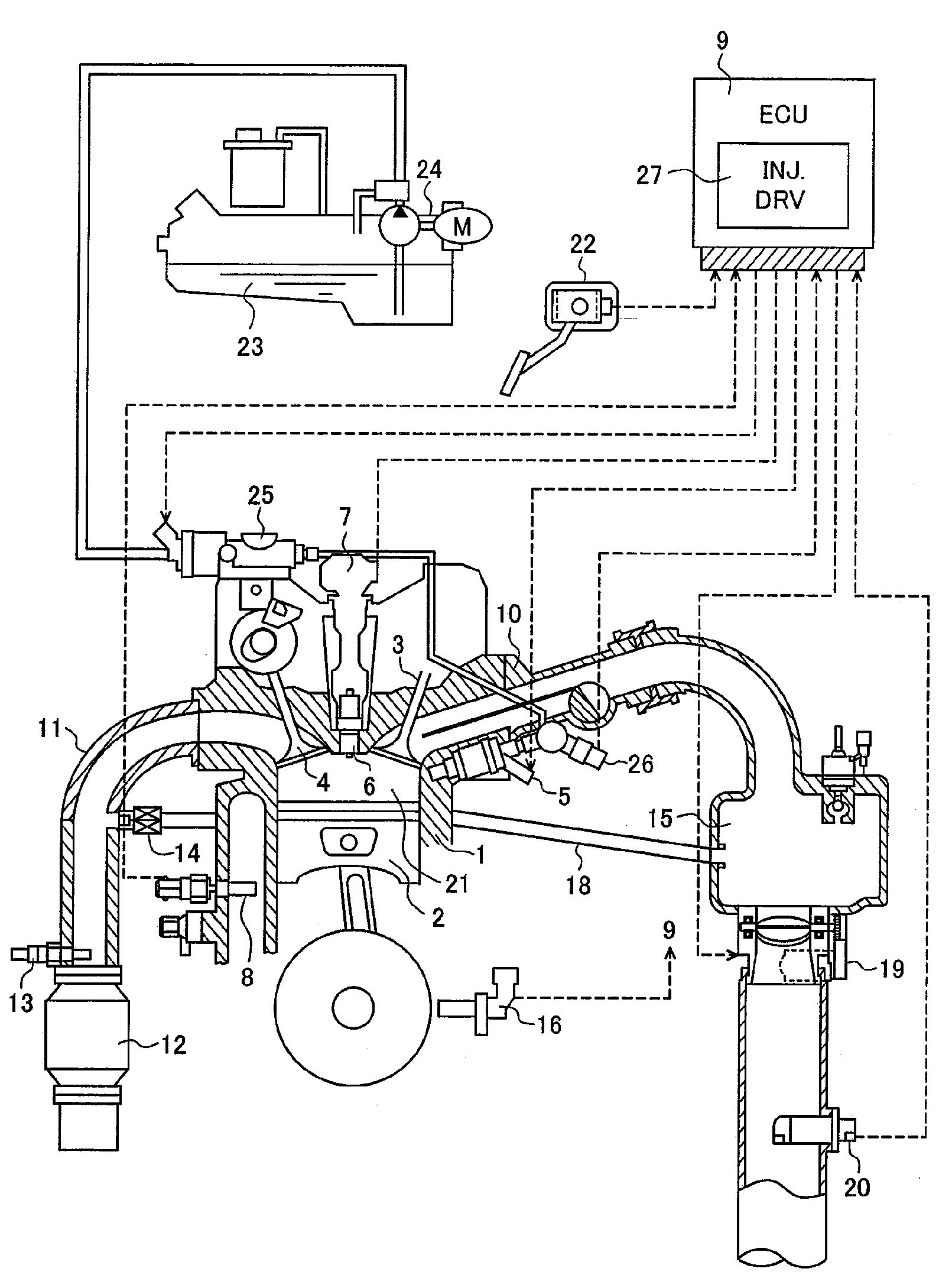

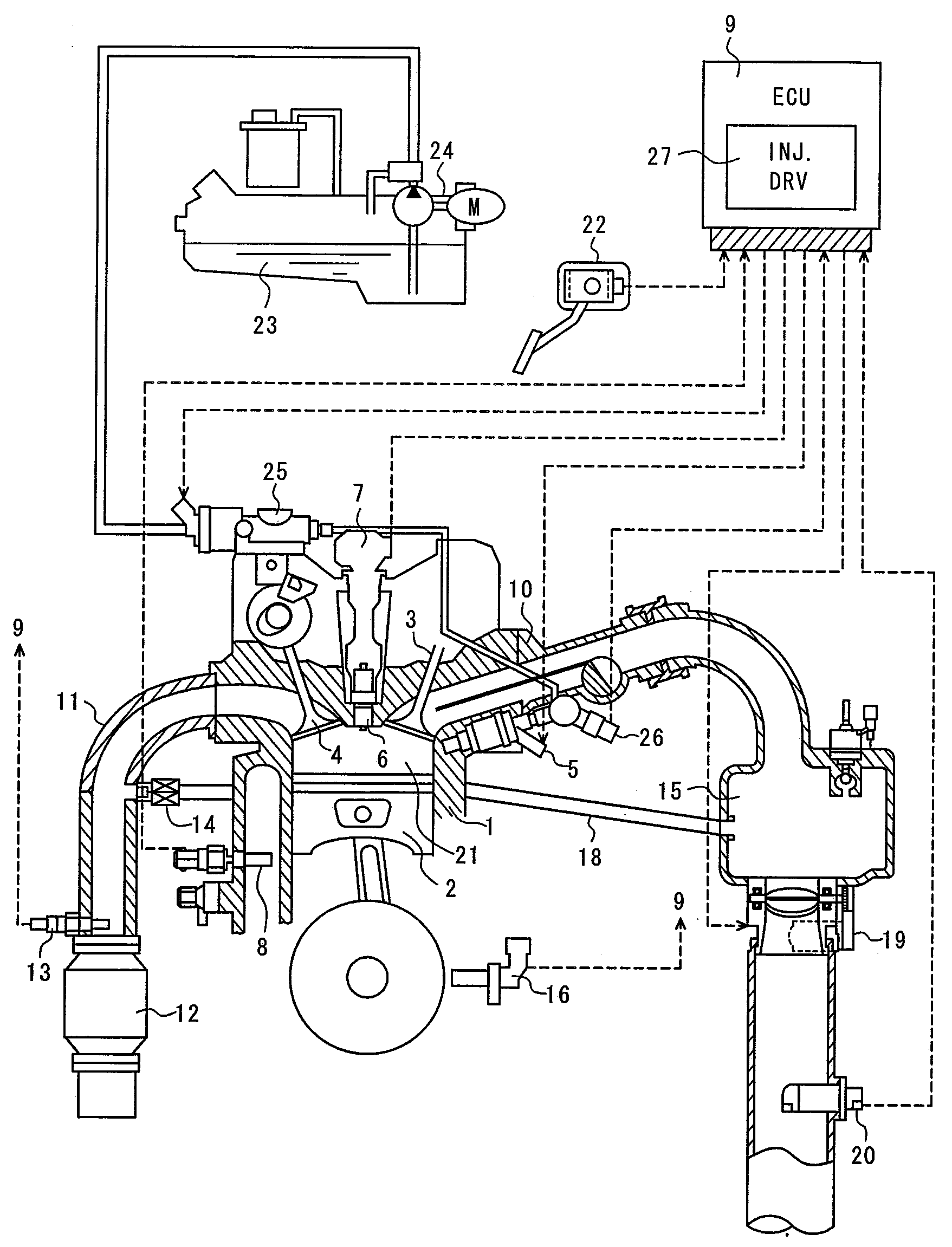

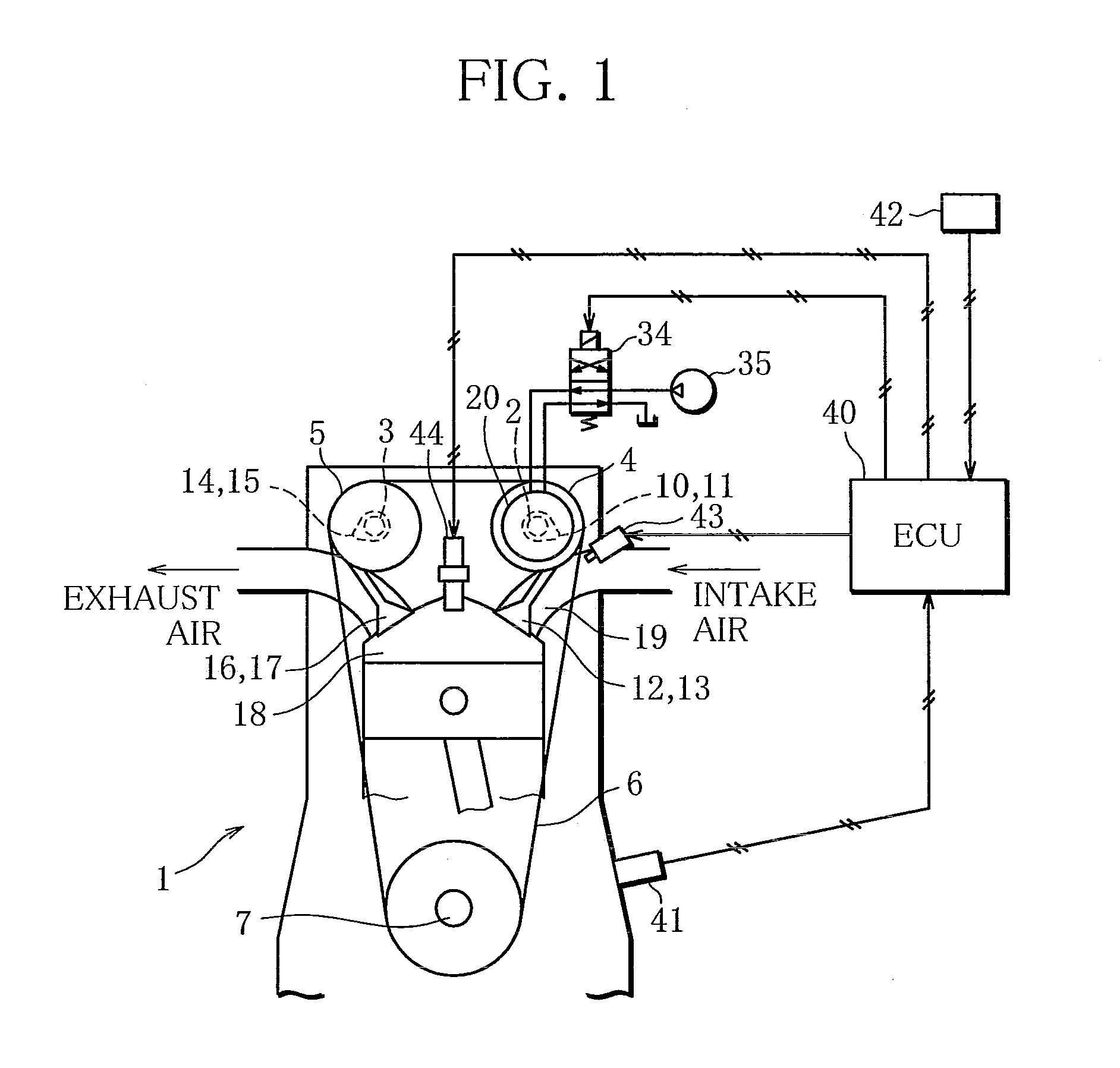

Control Apparatus for Internal Combustion Engine

ActiveUS20110100333A1Minimizing amount of fuelImprove performanceElectrical controlInternal combustion piston enginesDriving currentExternal combustion engine

A fuel injection control apparatus for an internal combustion engine which can inject a fuel injection quantity to a fuel injector with accuracy even when the fuel injection quantity is reduced than before is provided. A fuel injection control apparatus of a direct cylinder injection type of internal combustion engine, including a fuel injector which performs fuel injection by supplying a drive current to a solenoid, a fuel pressure sensor which detects fuel pressure supplied to the fuel injector, and operation state detecting means which detects the operation state of the internal combustion engine, comprises current profile changing means 100 which has multiple current profiles of the drive current and changes current profiles based on the operation state and the fuel pressure, valid pulse width calculating means 701 which calculates a valid pulse width for opening and driving the fuel injector, invalid pulse width calculating means 103 which calculates an invalid pulse width, and fuel injector control means which calculates a fuel injection pulse width based on the valid pulse width and the invalid pulse width, and controls the fuel injector based on the fuel injection pulse width, wherein the invalid pulse width calculating means 103 calculates an invalid pulse width corresponding to the current profiles to be changed before the current profiles are changed.

Owner:HITACHI ASTEMO LTD

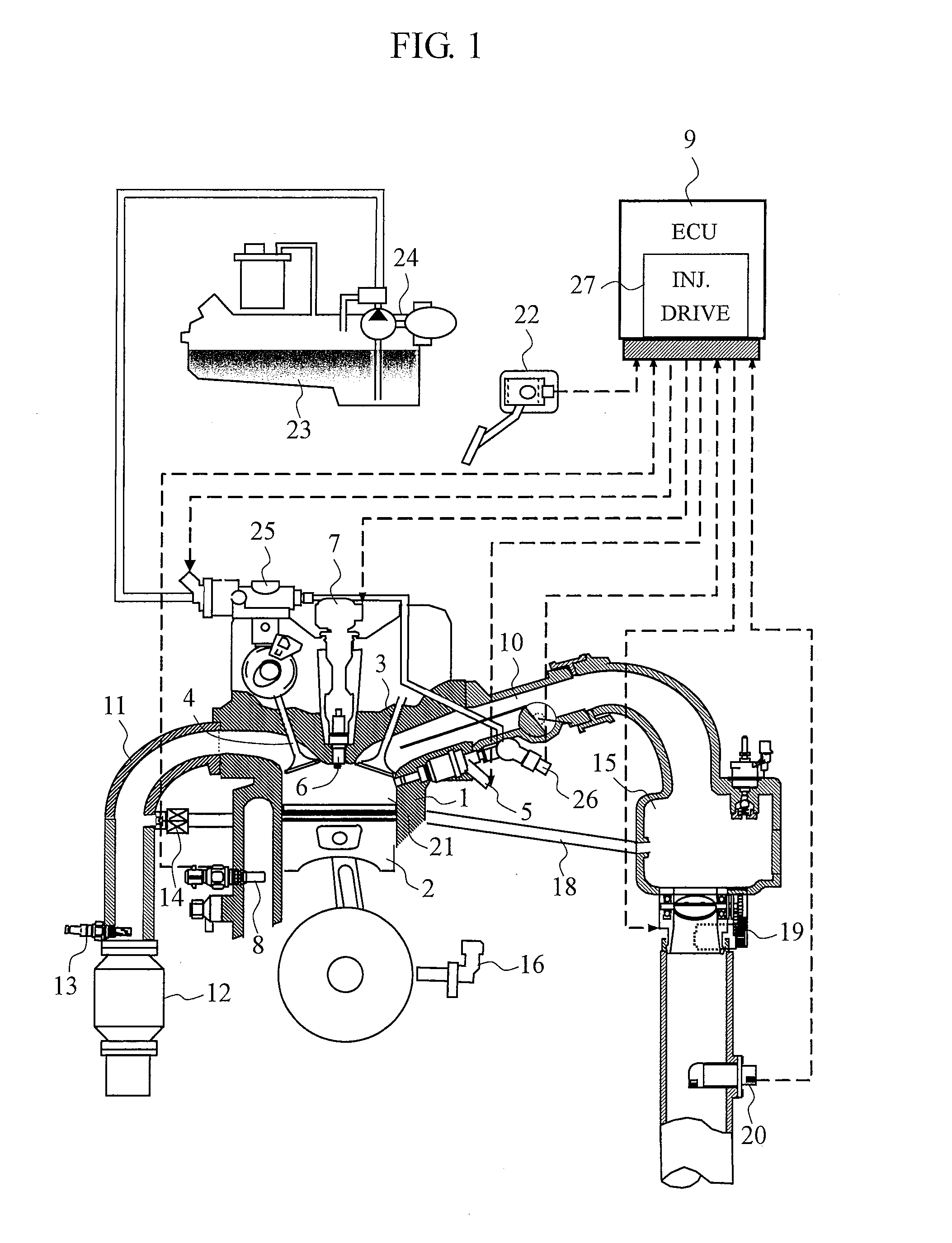

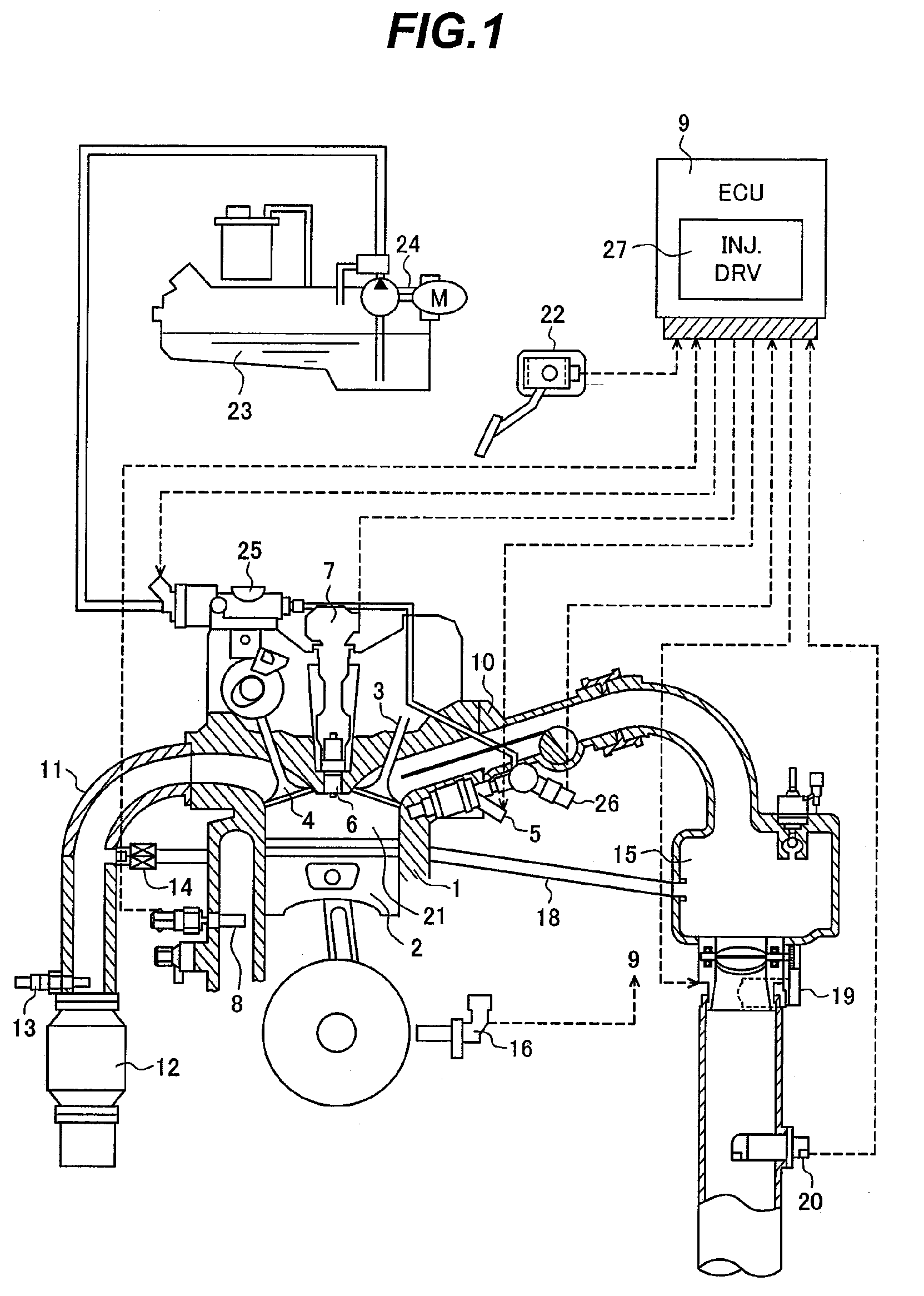

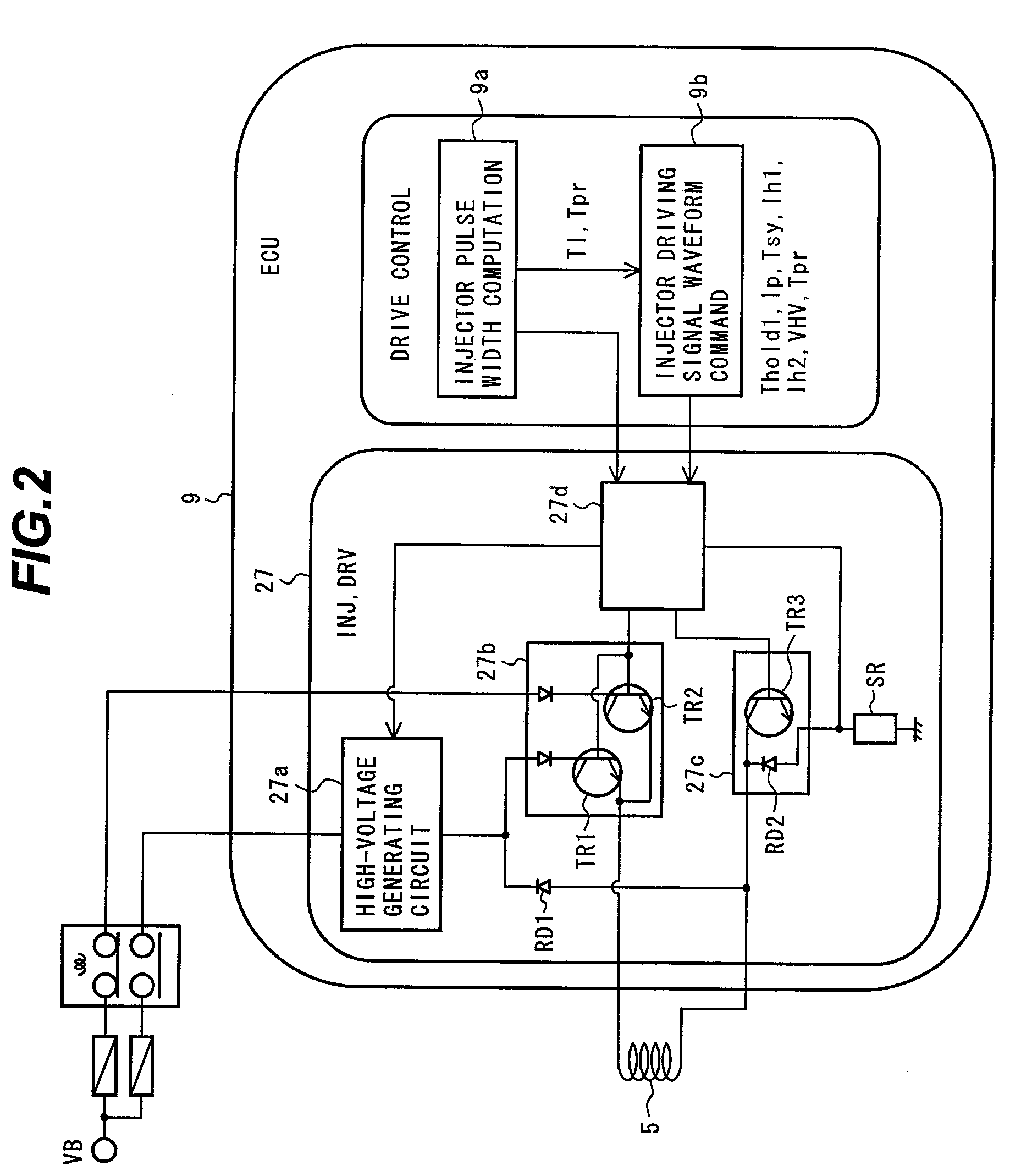

Fuel injection control apparatus

ActiveUS20090177369A1Reduce fuel consumptionImprove performanceElectrical controlDigital data processing detailsMicrocomputerLow voltage

To provide a fuel injection control apparatus capable of reducing the minimum quantity of fuel injection without reducing the maximum quantity of injection.For fuel injector valve opening, a driving circuit 56 supplies an electric current from a high-voltage power supply VH to the fuel injector 53, then after valve opening, switches the high-voltage power supply VH to a low-voltage power supply LV, and retains the open state of the valve. A microcomputer 57 is adapted such that for opening the valve of the fuel injector, the microcomputer, after supplying the current from the high-voltage power supply to the injector 53, discharges the current rapidly for a decrease below a first current level Ihold1 at which the open state of the valve cannot be retained, and then controls the supply current to the injector 53 so as to supply a current of a second current level Ihold2 at which the open state of the valve can be retained.

Owner:HITACHI ASTEMO LTD

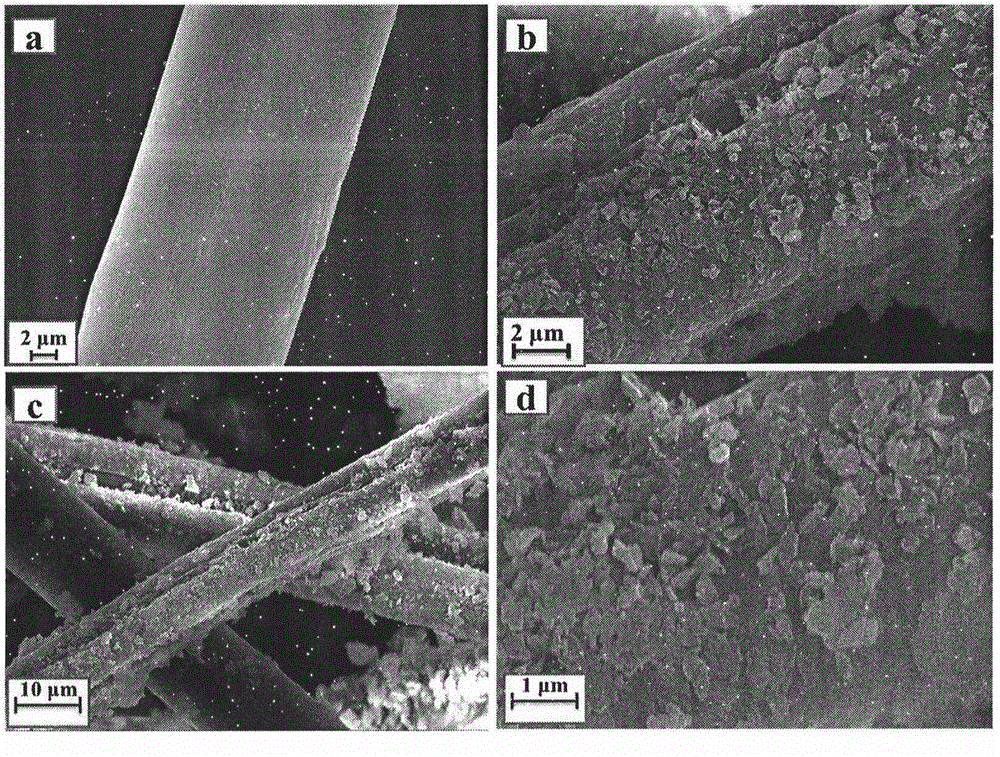

Multifunctional material integrating bactericidal and hemostatic properties and chemical and biological warfare agent protective properties and preparation method of multifunctional material

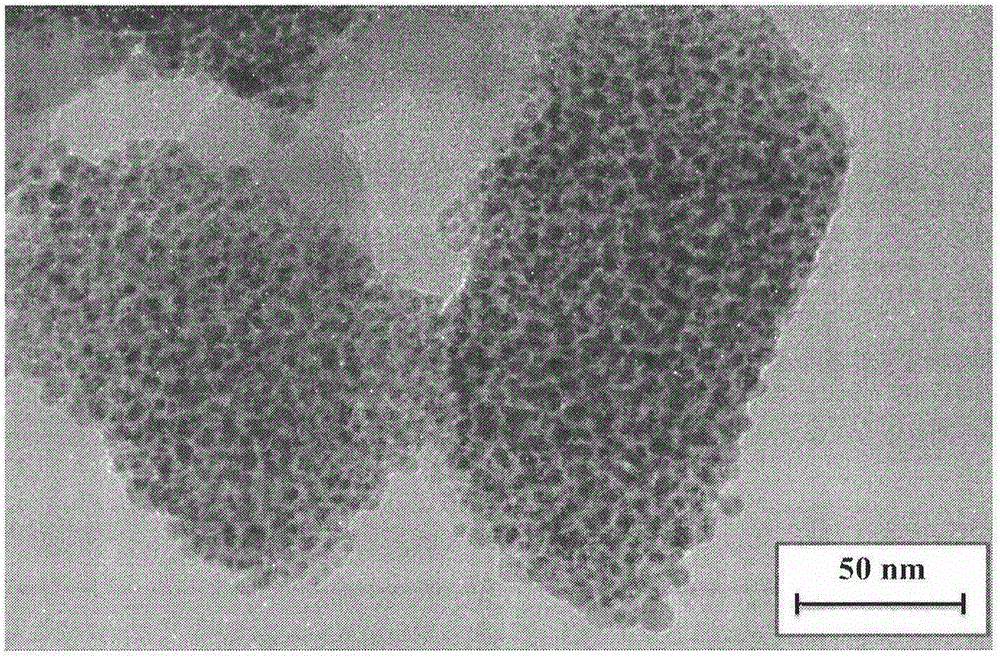

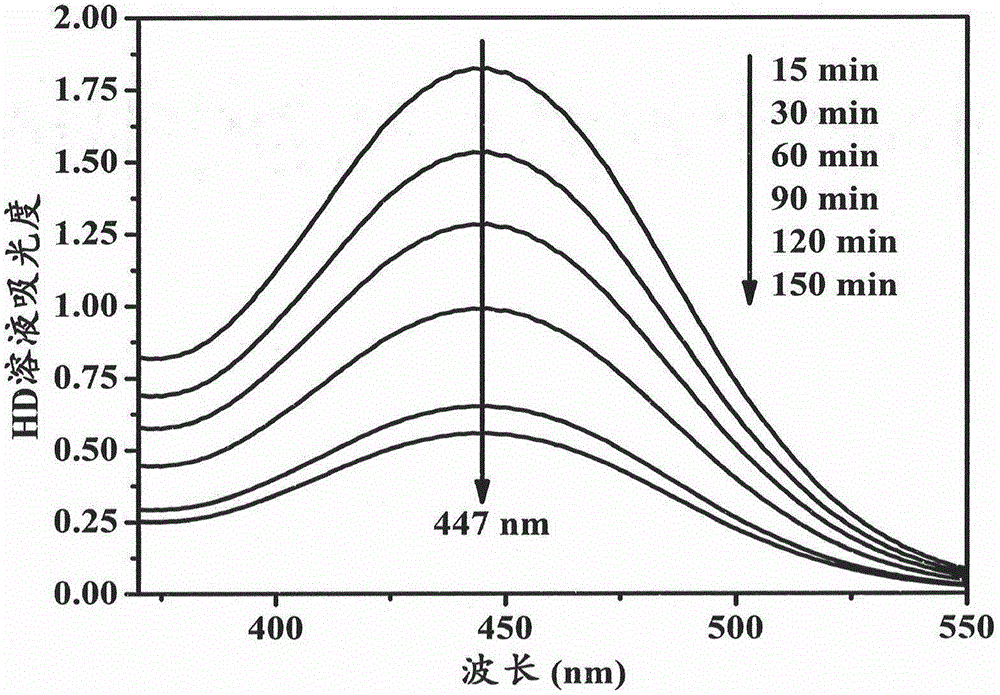

InactiveCN106267300AExcellent decontamination efficiencyImprove stabilityAbsorbent padsBandagesFiberSodium chloroacetate

The invention relates to a nano-silver @MOF-5@ natural biological fiber multifunctional composite material integrating good bactericidal and hemostatic properties and chemical and biological warfare agent protective properties and a preparation method of the multifunctional composite material. The preparation method comprises the following steps: (1) impregnating natural biological fibers in a NaOH solution containing sodium chloroacetate, taking out the natural biological fibers and flushing the natural biological fibers by virtue of distilled water; (2) impregnating a material obtained in the step (1) alternately in a DMF solution of zinc acetate and a mixed solution of DMF of terephthalic acid and triethylamine in a circulating mode, and washing the material by virtue of DMF after each impregnating so as to obtain (MOF-5)n@ natural biological fibers through such alternate circulating precipitation; and (3) washing the material by virtue of a DMF solution, impregnating the material in CHCl3, and conducting vacuum drying; then impregnating the material in AgNO3 ethanol and water solution, conducting ultraviolet irradiation, flushing the material by virtue of de-ionized water and conducting vacuum drying. The multifunctional composite material disclosed by the invention is simple and easily controllable in preparation process, easily available in raw materials and low in production cost.

Owner:BEIJING UNIV OF CHEM TECH +1

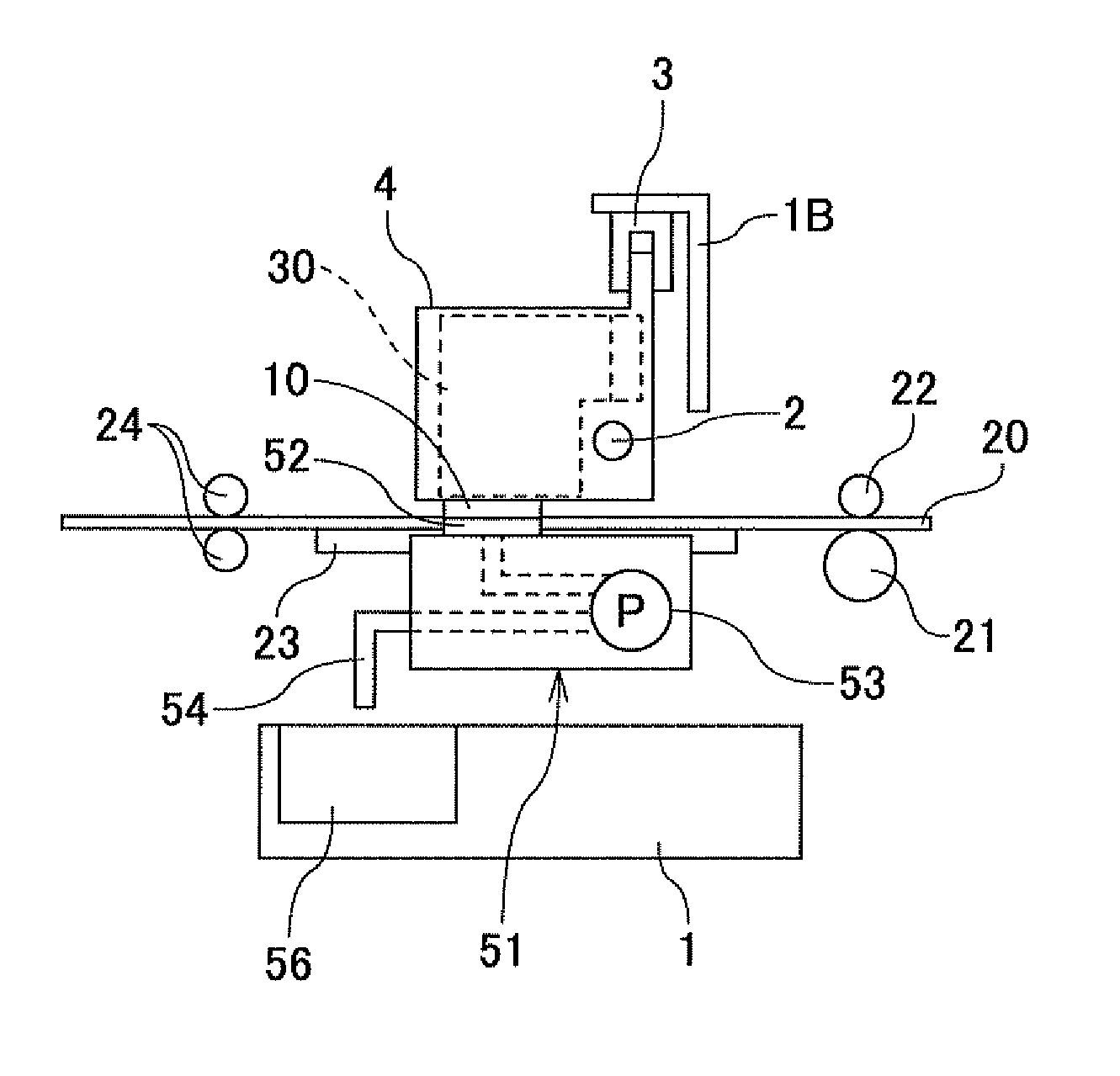

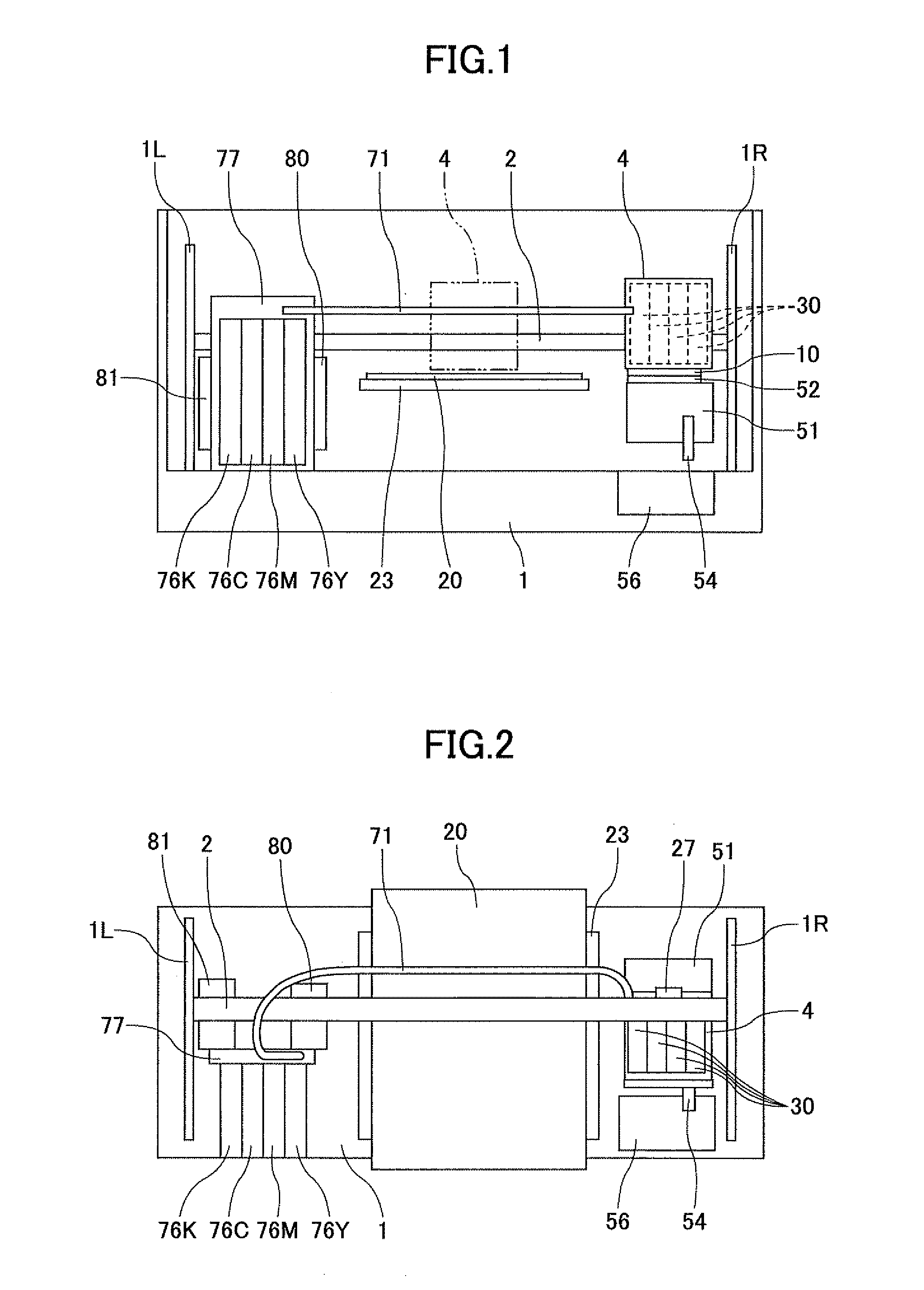

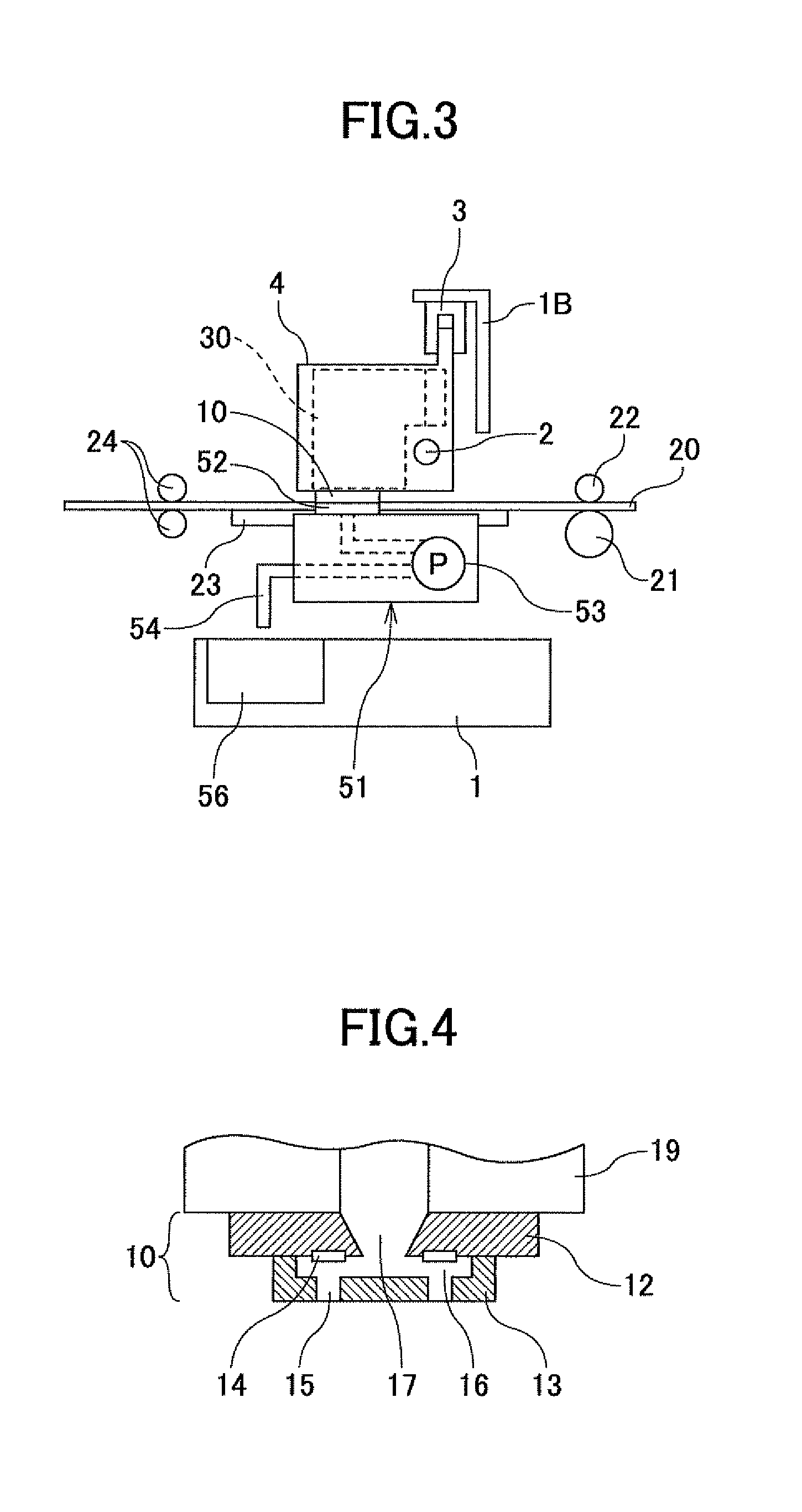

Image forming apparatus

InactiveUS20110134184A1Simple configurationStable negative pressureOperating means/releasing devices for valvesPrintingImage formationRecording head

An image forming apparatus includes a recording head, a liquid tank, a first fluid flow path supplying liquid to the recording head, a second fluid flow path being in communication with the liquid tank, a pressure adjusting valve allowing fluid communication between the first and the second fluid flow paths, a cap member covering a nozzle surface of the recording head, and a suction unit being in communication with the cap member. The pressure adjusting valve includes a movable member movably disposed in the internal fluid flow path, wherein the movable member includes a sealing unit that seals the communication between the first and the second fluid flow paths when the cap member covers the nozzle surface of the recording head and a negative pressure is generated in a cap-member space formed between the cap member and the nozzle surface by driving the suction unit.

Owner:RICOH KK

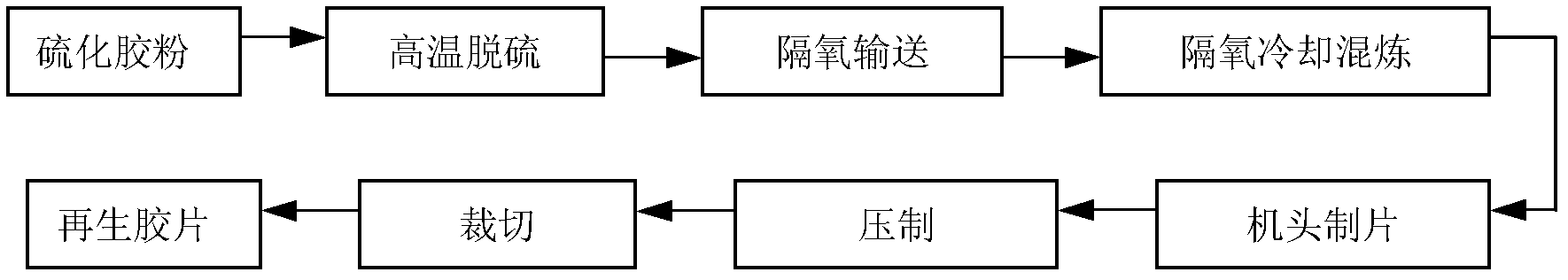

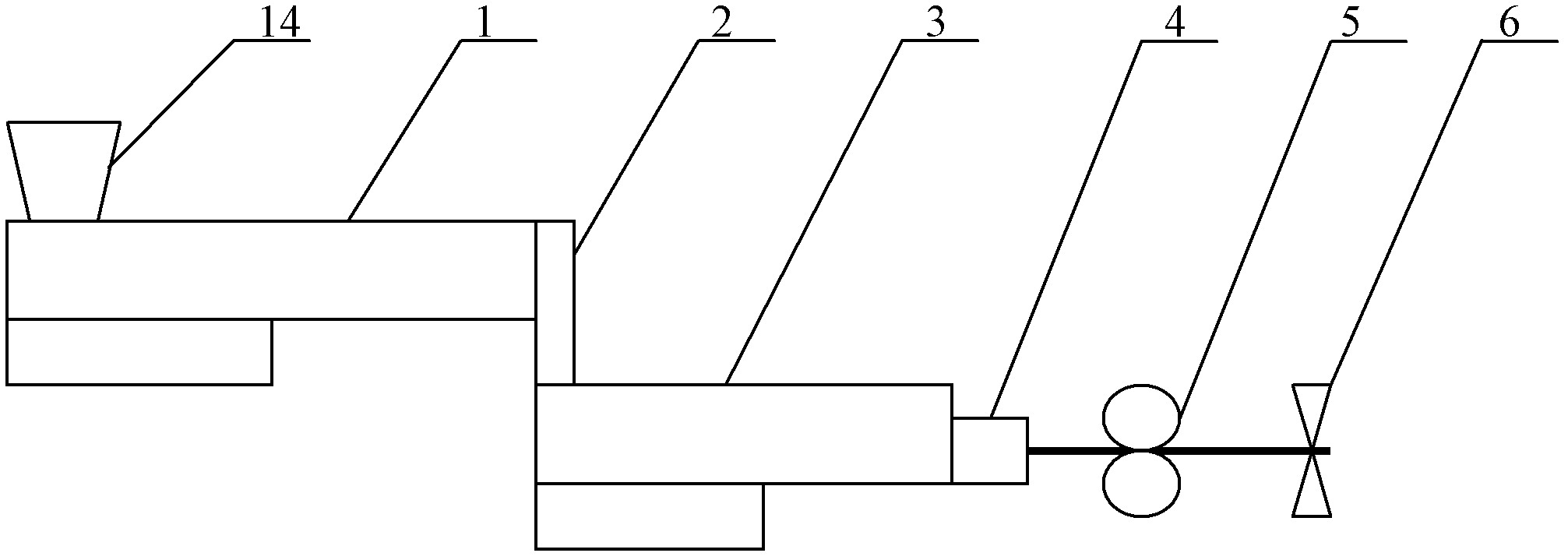

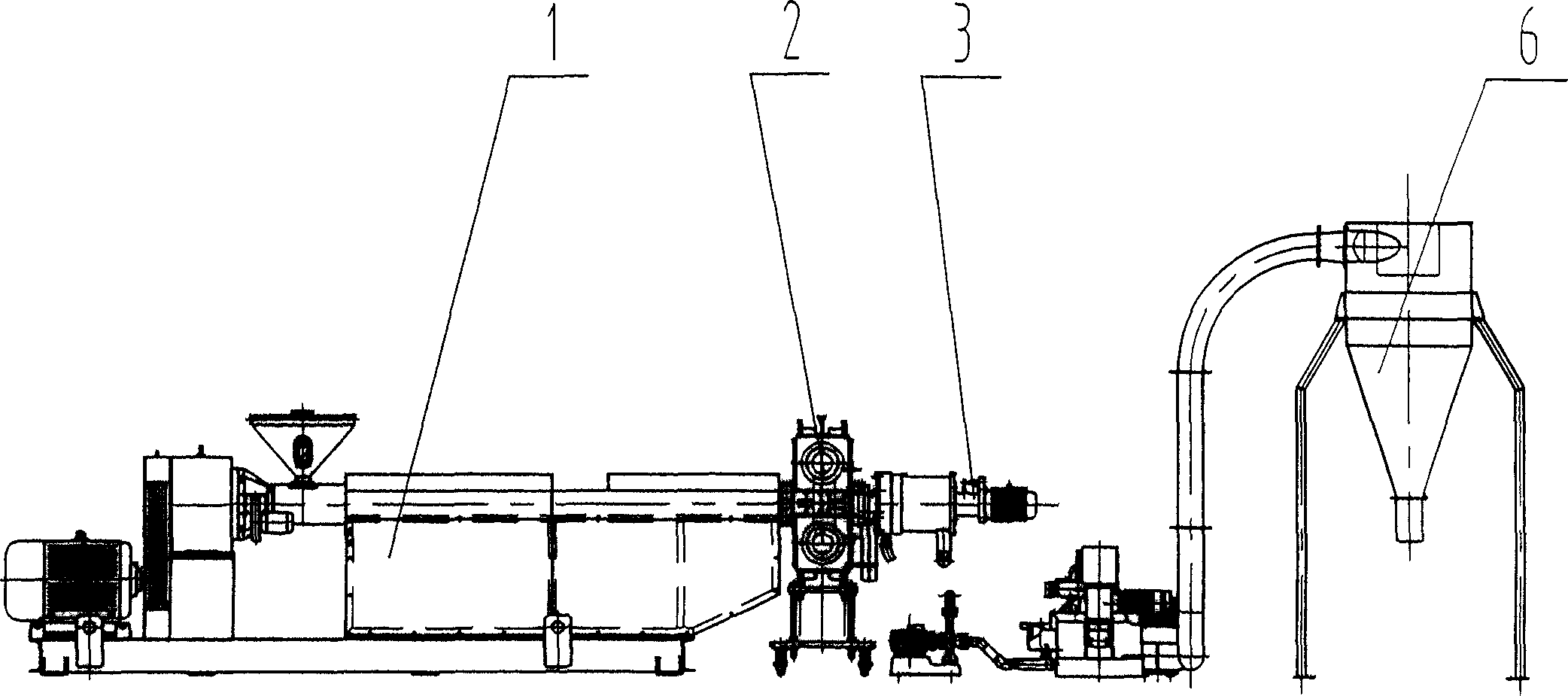

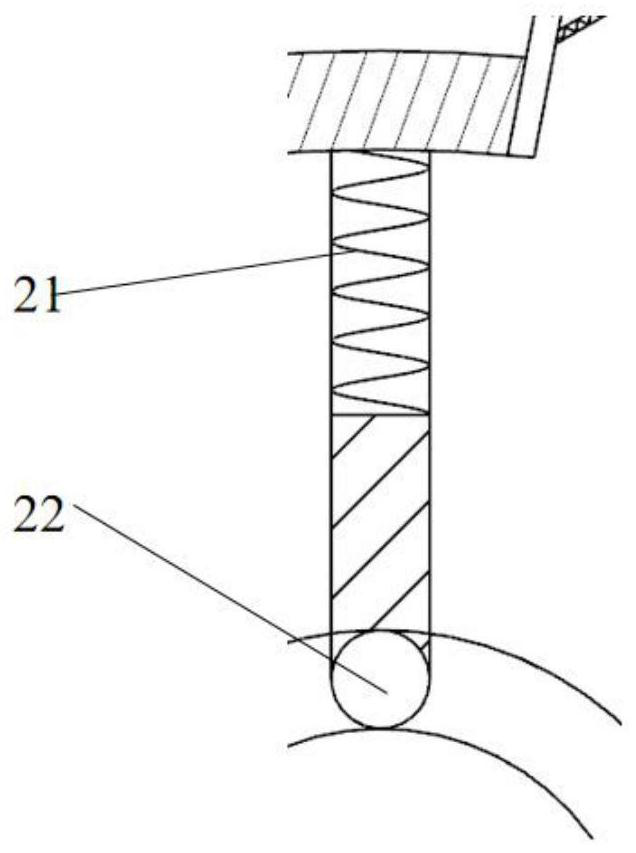

Device and method for directly preparing regenerated rubber sheet by continually cooling and mixing desulfurized rubber powder

The invention relates to device and method for preparing a regenerated rubber sheet by continually cooling and mixing desulfurized rubber powder. The device comprises a continuous production line consisting of a rubber desulfurizing device with a hopper, a transition conveyer, a single-screw oxygen isolating cooling device, a sheet handpiece, a pair of compression rollers and a shearing device, wherein the discharging hole of the rubber desulfurizing device is connected with the feeding hole of the single-screw oxygen isolating cooling device through the transition conveyer; and the discharging hole of the single-screw oxygen isolating cooling device is connected with the feeding hole of the sheet handpiece. In the invention, a double-screw rubber desulfurizing device is meshed in the same direction, so that mixing is uniform and the energy consumption is low. The preparation method comprises the following process steps of: (a) desulfurizing; (b) conveying in an oxygen isolating way; (c) cooling and mixing in an oxygen isolating way; (d) sheeting; (e) pressing; and (f) cutting. Due to the adoption of the oxygen isolating conveying as well as oxygen isolating cooling and mixing, high-temperature oxidation of high-temperature desulfurizing rubber powder is prevented, the mechanical property of the regenerated rubber is improved, the production is continuous and safe, and no waste is discharged.

Owner:溧阳常大技术转移中心有限公司

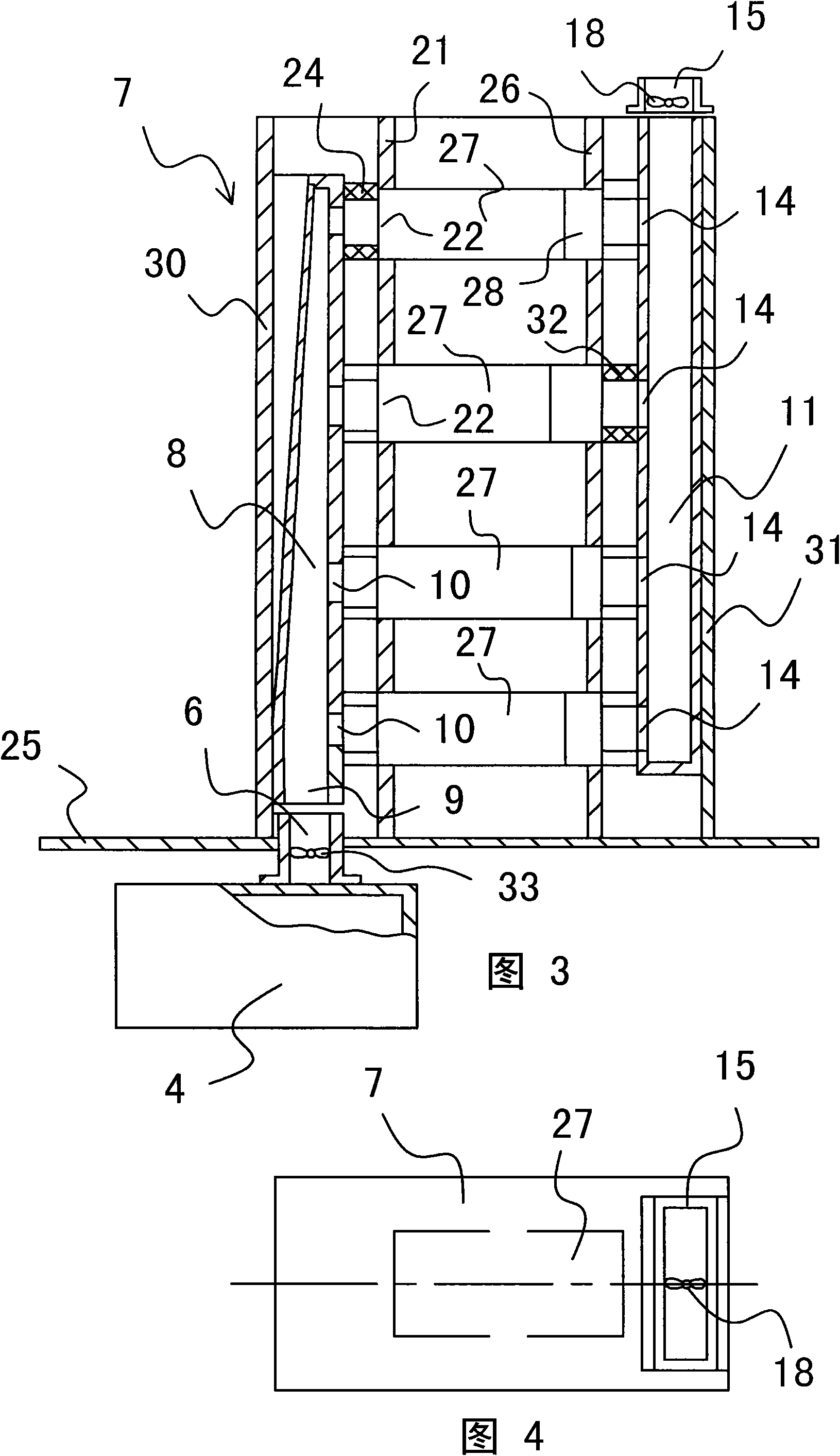

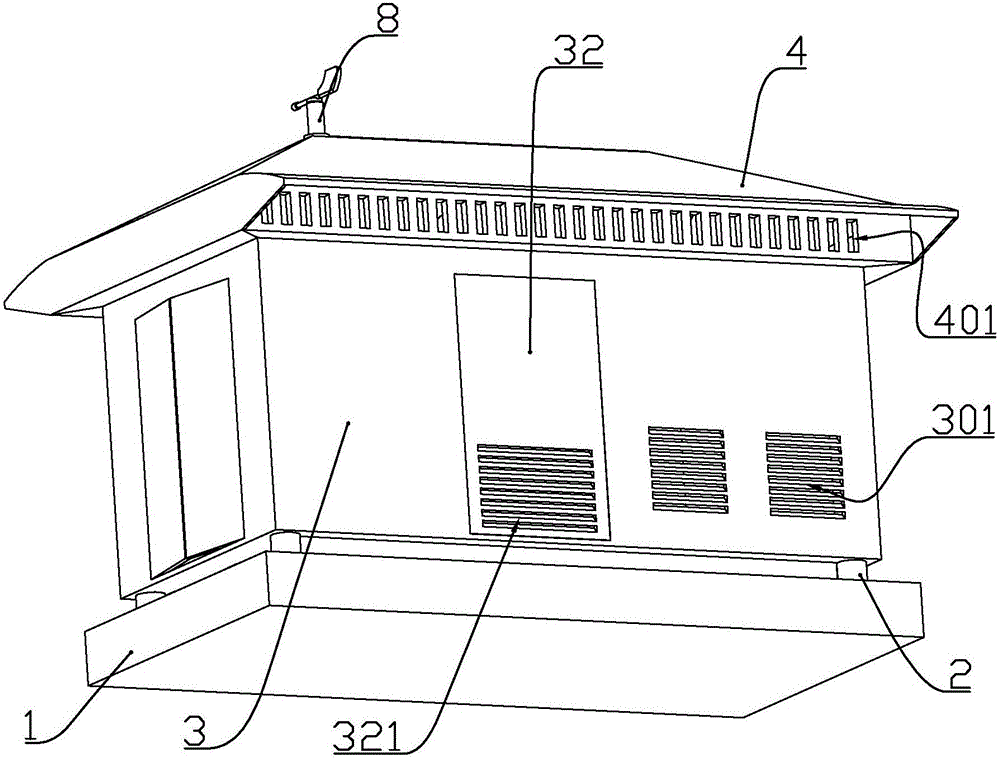

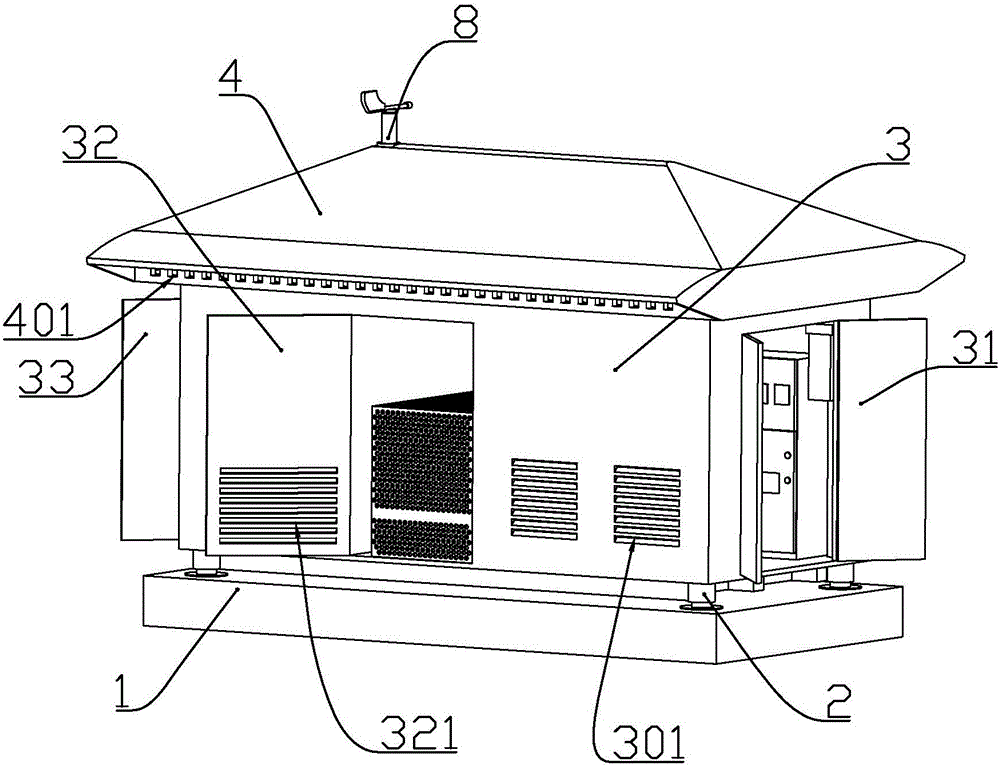

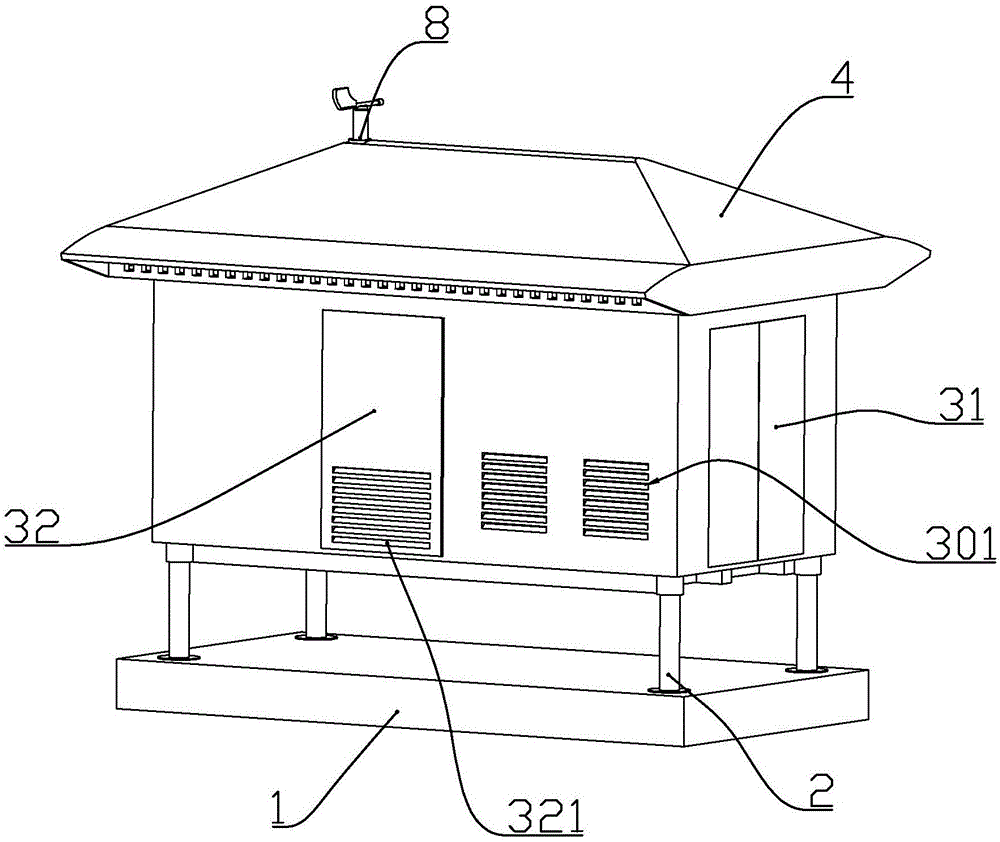

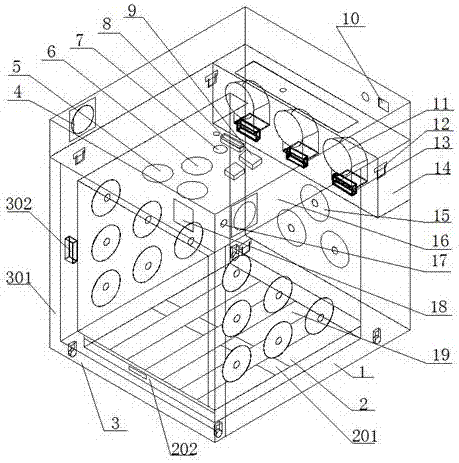

Adjustable box-type substation

ActiveCN106129829AEasy to buildWill not corrodeTransformers/inductances coolingEnclosed substationsCooling effectEngineering

The invention discloses an adjustable box-type substation, which comprises a base and a box body arranged at the upper part of the base, wherein the upper part of the box body is connected with a head cover; the head cover comprises longitudinal walls and slope walls; the lower parts of the longitudinal walls are fixedly connected with horizontally arranged transverse walls; exhaust outlets are uniformly formed in two groups of longitudinal walls, along the length direction, of the head cover; slide chute sockets are formed in the positions, corresponding to the exhaust outlets, of the transverse walls; wind grid plates are connected to the inside of the slide chute sockets in a sliding manner; grid plate openings which are used in fit with the exhaust outlets are formed in the corresponding wind grid plates; grid plate push rods are arranged on the inner walls of the transverse walls, along the width direction, of the head cover; an output rod of each grid plate push rod is fixedly connected with the end part of the corresponding wind grid plate; and a wind direction sensor is also arranged at the upper end of the head cover. The adjustable box-type substation is compact in structure, reasonable in design, convenient to construct and good in cooling effect.

Owner:山东恒东实业集团有限公司

Mold releasing coating for centrifugal casting and painting method of mold releasing coating

ActiveCN105127364AImprove adhesionLow gas productionFoundry mouldsFoundry coresPolyacrylamideNuclear power plant

The invention relates to a mold releasing coating for a centrifugal casting and a painting method of the mold releasing coating, in particular to a mold releasing coating for a nuclear power station main pipe in the centrifugal casting and a painting method of the mold releasing coating. The mold releasing coating comprises a base coating and a surface coating, wherein the base coating is used for coating the surface of a cast mold, and the surface coating is used for coating the base coating layer on the surface of the cast mold. The base coating comprises a component A, a component B, a component C and a component D, wherein the component A is graphite powder, the component B is bauxite or kieselguhr, the component C is talcum powder, and the component D is silica solution or aluminum phosphate. The surface coating comprises a component E, a component F, a component G, a component H and a component I, wherein the component E is quartz powder or high-aluminum powder or zirconium oxide powder, the component F is zirconium silicate powder or zircon powder or emery powder or bauxite, the component G is silica powder or kieselguhr, the component H is boracic slag powder, and the component I is a hydroxymethyl cellulose water solution or polyacrylamide hydroxyl or sodium alginate.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Full-automatic dryer of pet

InactiveCN107950424ASimple structureEasy to produceGrooming devicesAgricultural engineeringHeating system

The invention provides a full-automatic dryer of a pet. A plurality of blow-off nozzles are arranged on the left side, the right side and the rear side of a drying room; the blow-off nozzles are fixedby nail-free glue; a plurality of discharge outlets, a red-blue soft LED lamp, a white LED illuminating lamp and an ozone disinfection lamp are formed in the top end of the drying room; a draining device is arranged at the bottom of the drying room; a door lock device is arranged on the front surface of the drying room; a discharge room is arranged at the upper part of the drying room; a circuitboard is arranged on the bottom surface of the discharge room; exhaust outlets are formed in the two sides of the discharge room; a power starting switch is arranged on one side of the discharge roomnear the exhaust outlet; a touch control display screen is arranged on the front surface of the discharge room; a fixed bracket is horizontally arranged on the back surface inside the drying room; three groups of fans are uniformly distributed at the upper end of the fixed bracket; three PTC heating systems are uniformly distributed at the lower end of the fixed bracket. The full-automatic dryer is simple in structure, easy in production, low in cost, and easy to use and promote.

Owner:苏州机灵自动化设备科技有限公司

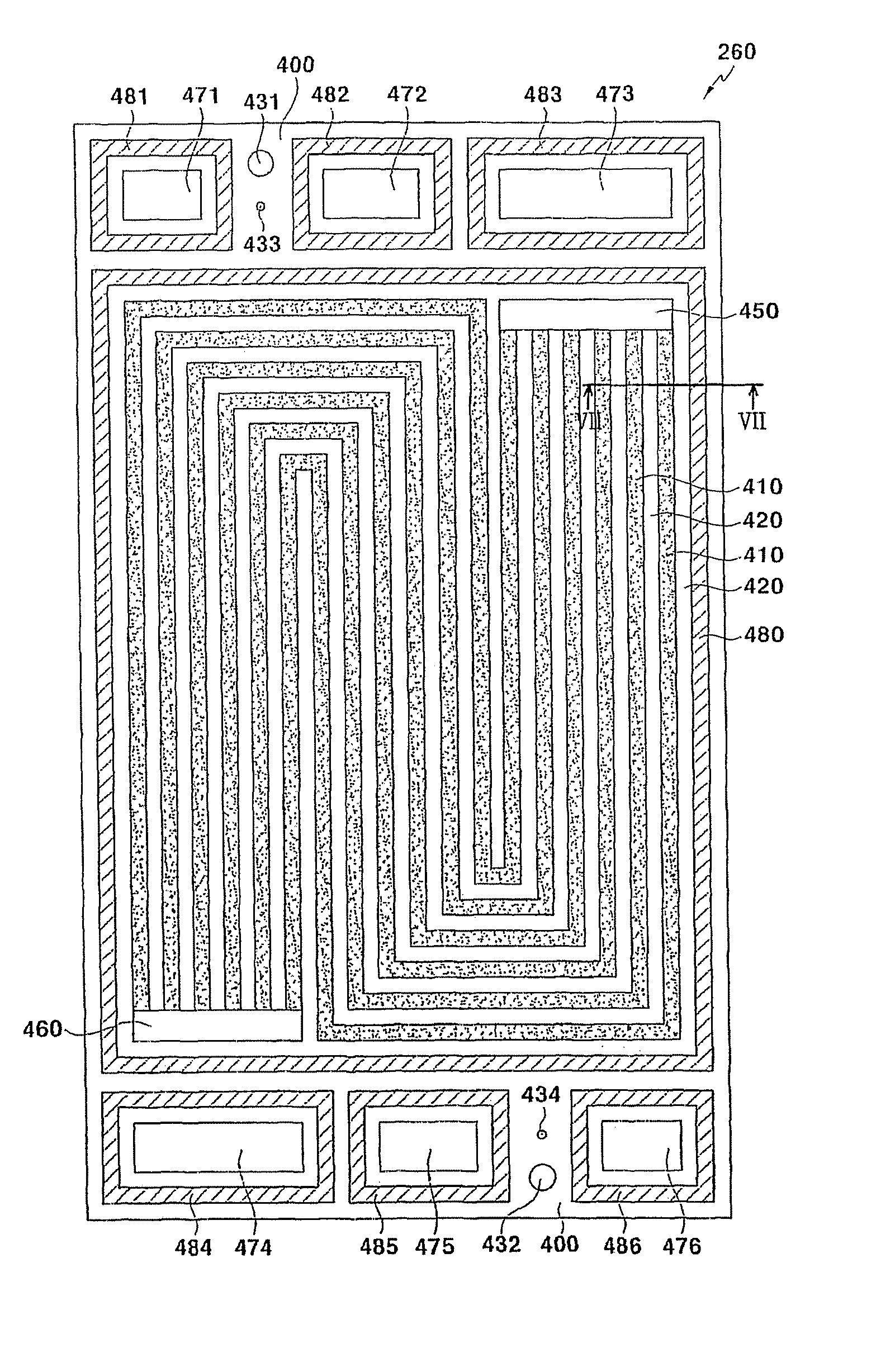

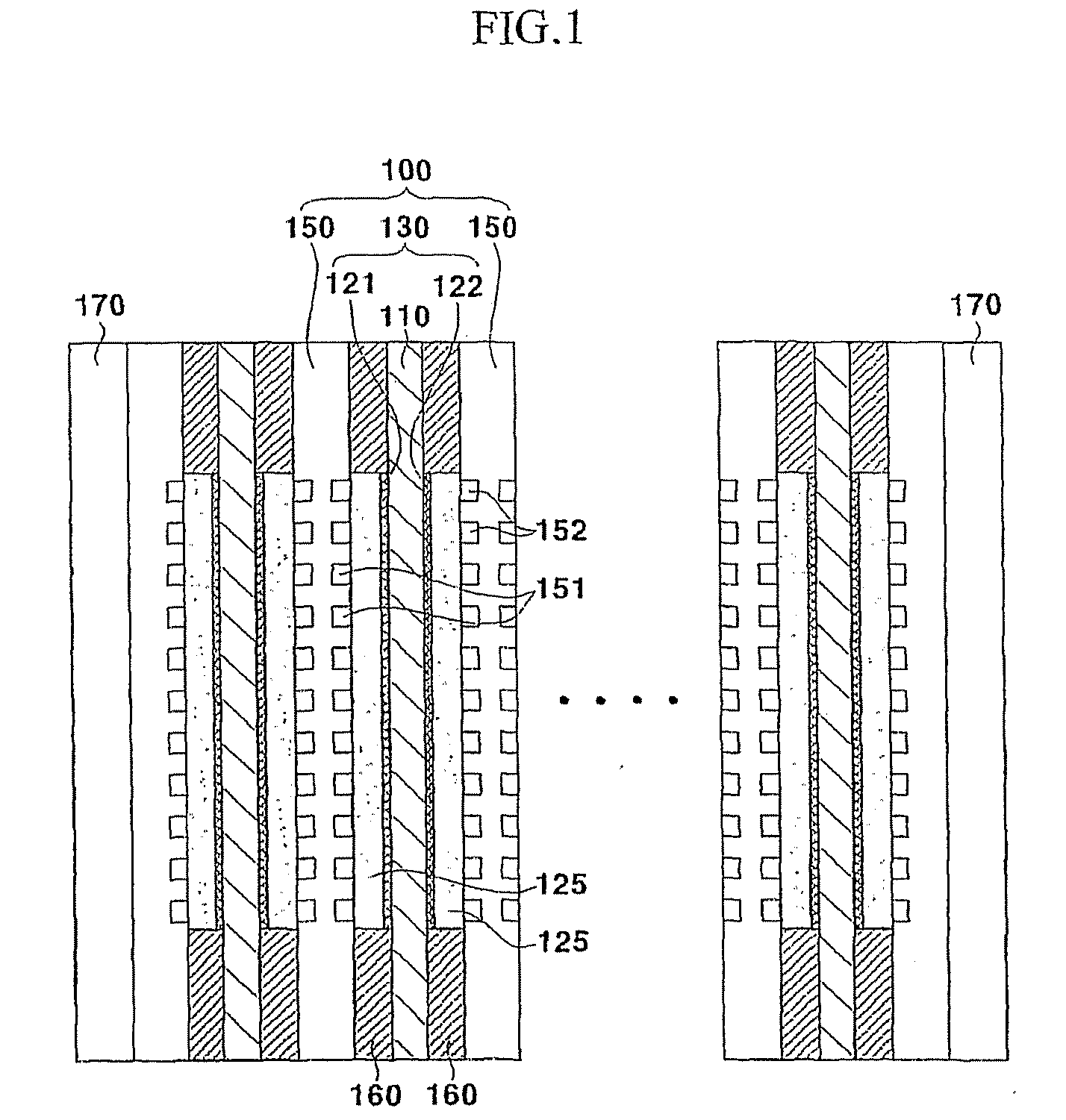

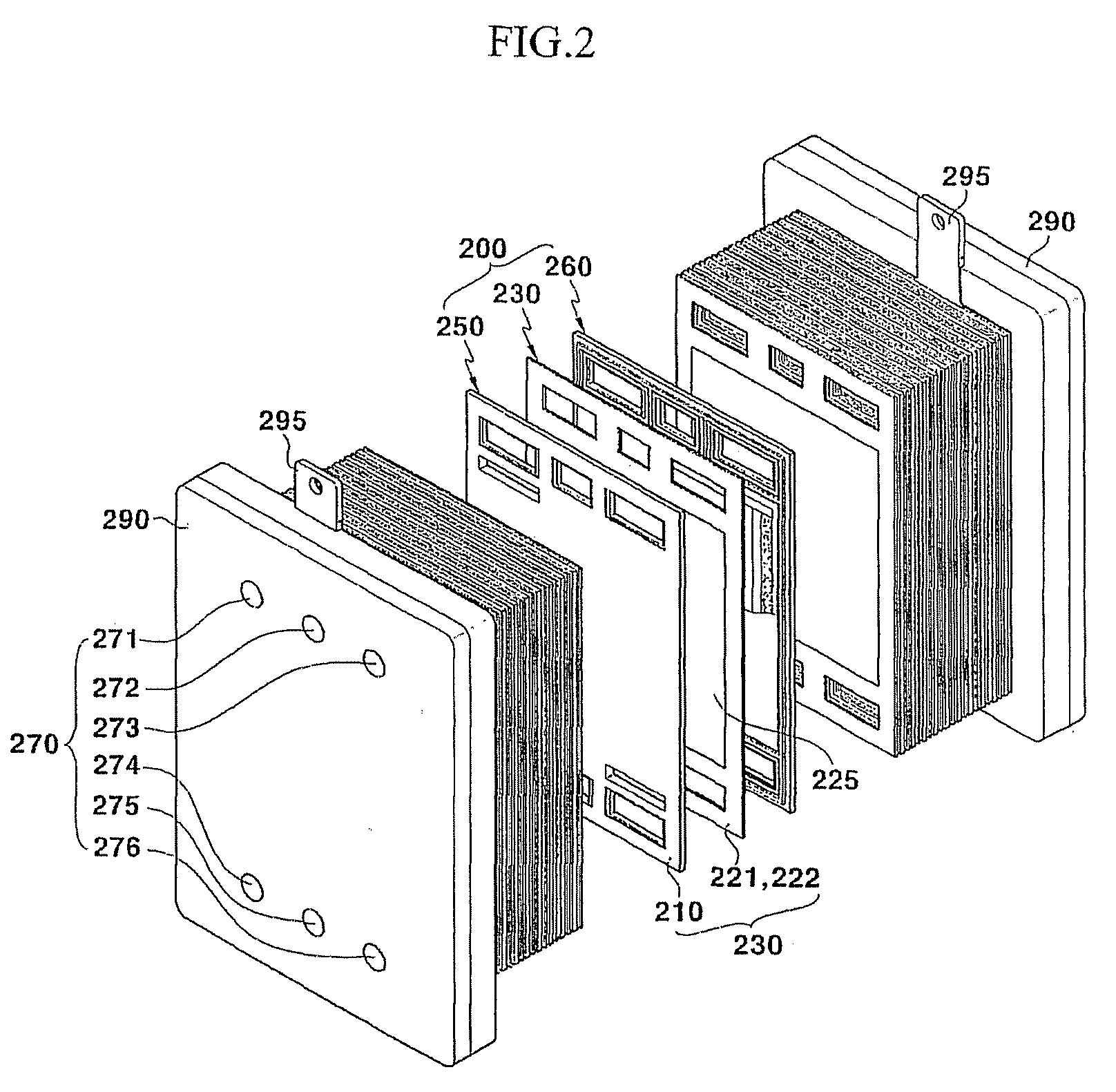

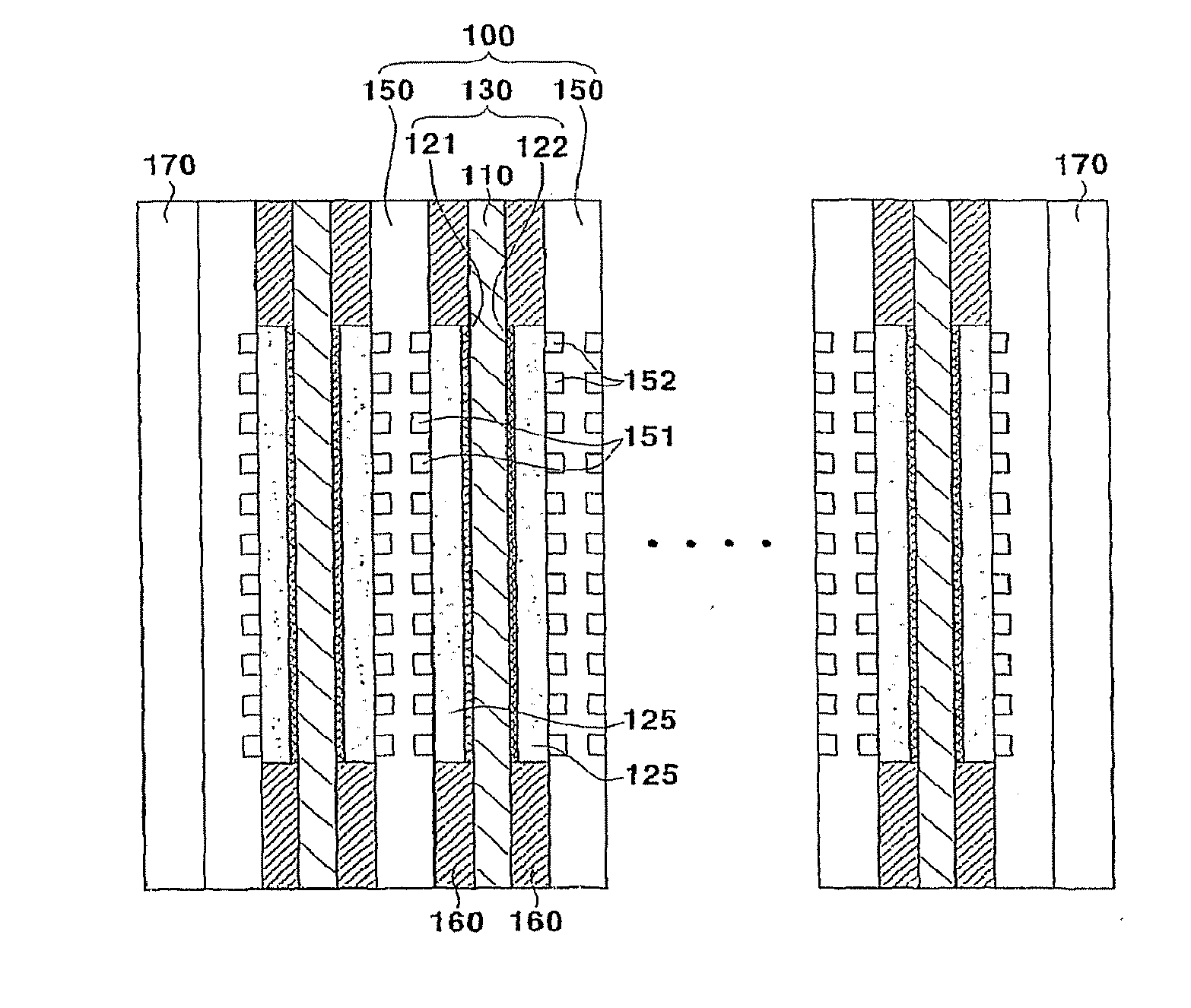

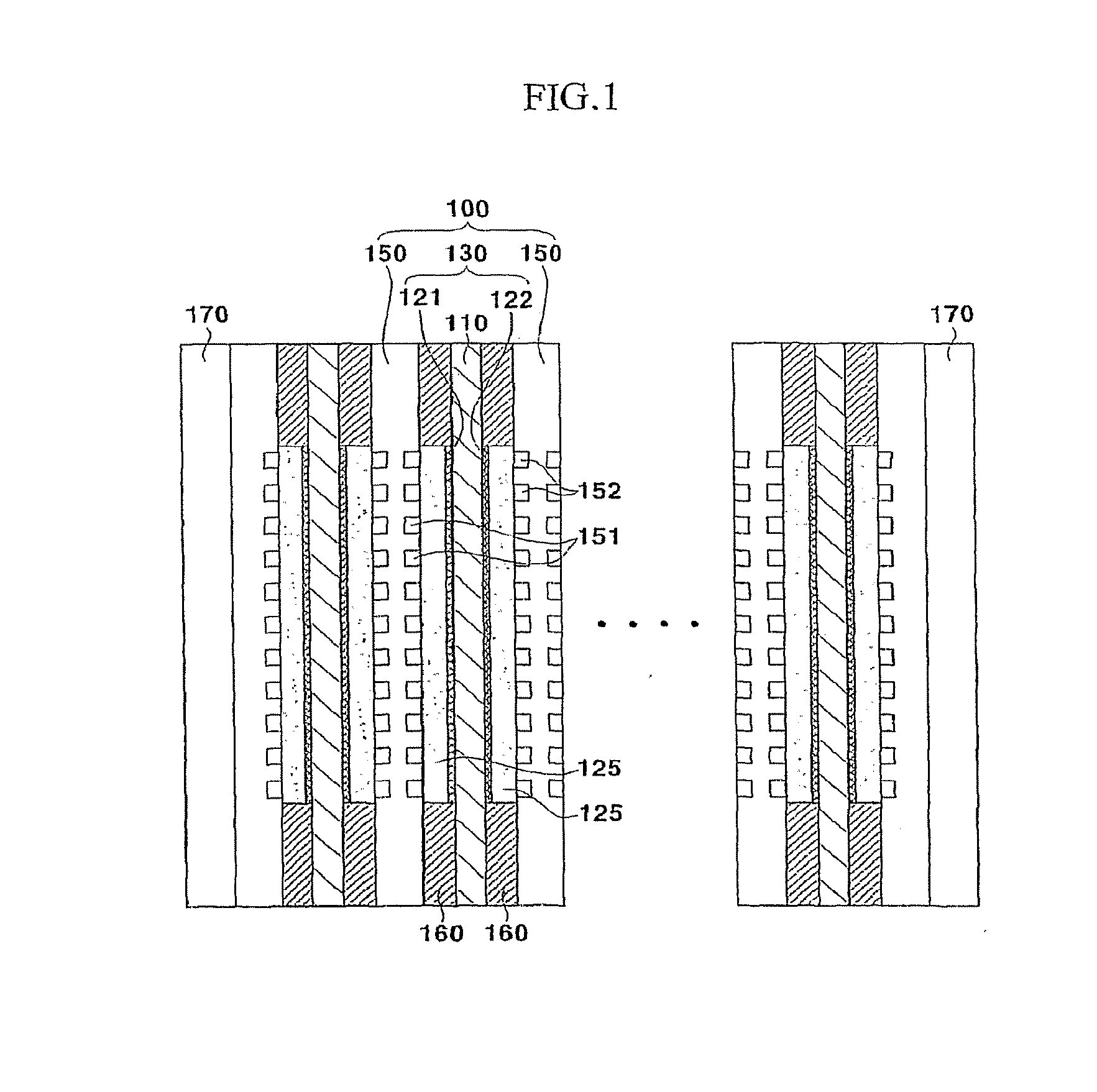

Separator for fuel cell, manufacturing method thereof, and fuel cell having such a separator

ActiveUS20070190392A1Improve the exhaust effectIncreased durabilityBatteries circuit arrangementsFuel cells groupingEngineeringLamellar structure

A lamellar structure graphite foil is used as a material for a separator for a fuel cell, and a hydrophobic layer is formed by impregnation on flow-field channels of the graphite foil. Such a separator is manufactured by forming the flow field channel by etching the graphite foil formed with the mask pattern thereon and forming a hydrophobic layer by impregnation. According to such a separator, performance of a fuel cell stack is enhanced and the manufacturing process of a separator is simplified.

Owner:DOOSAN CORP

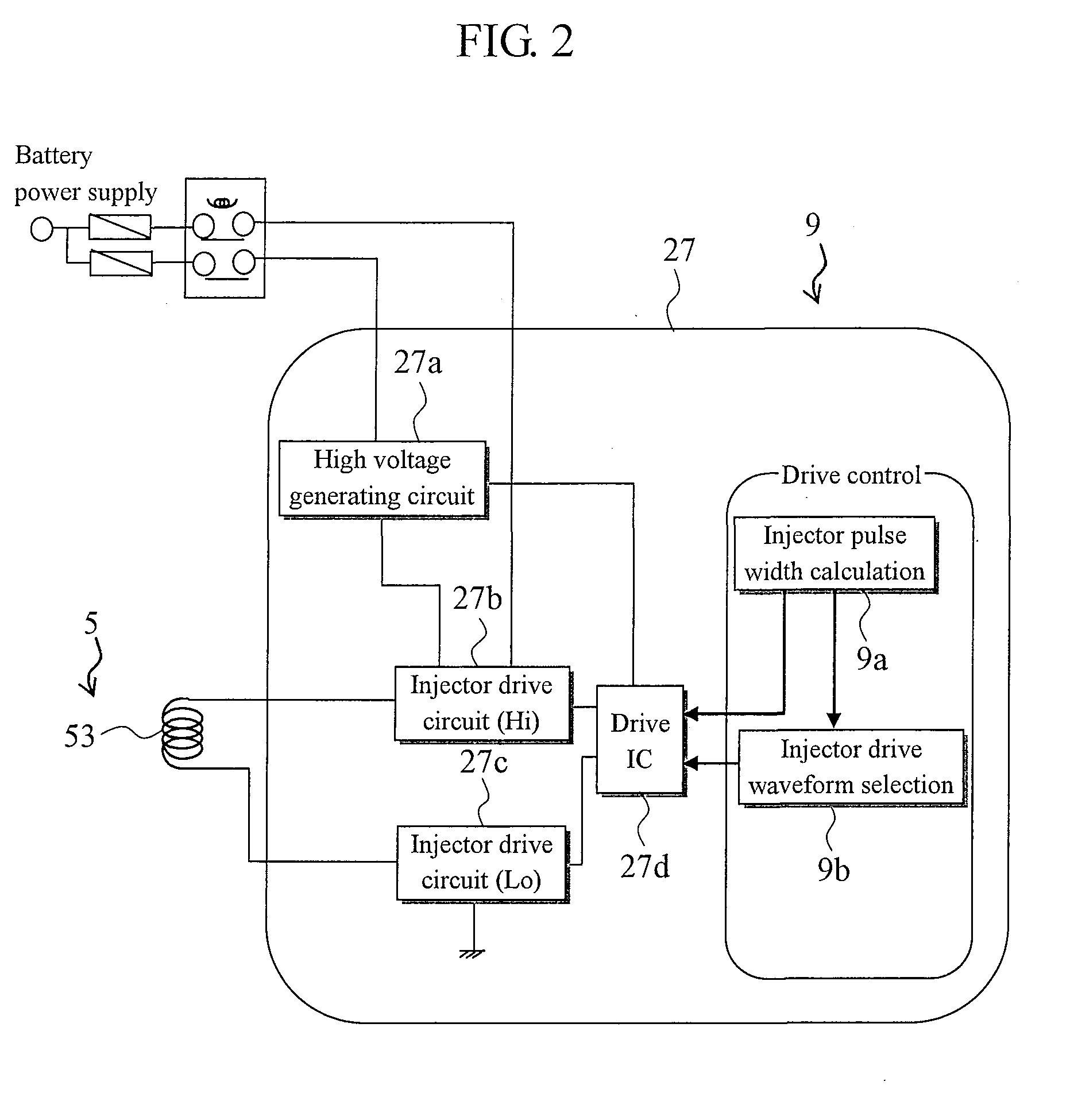

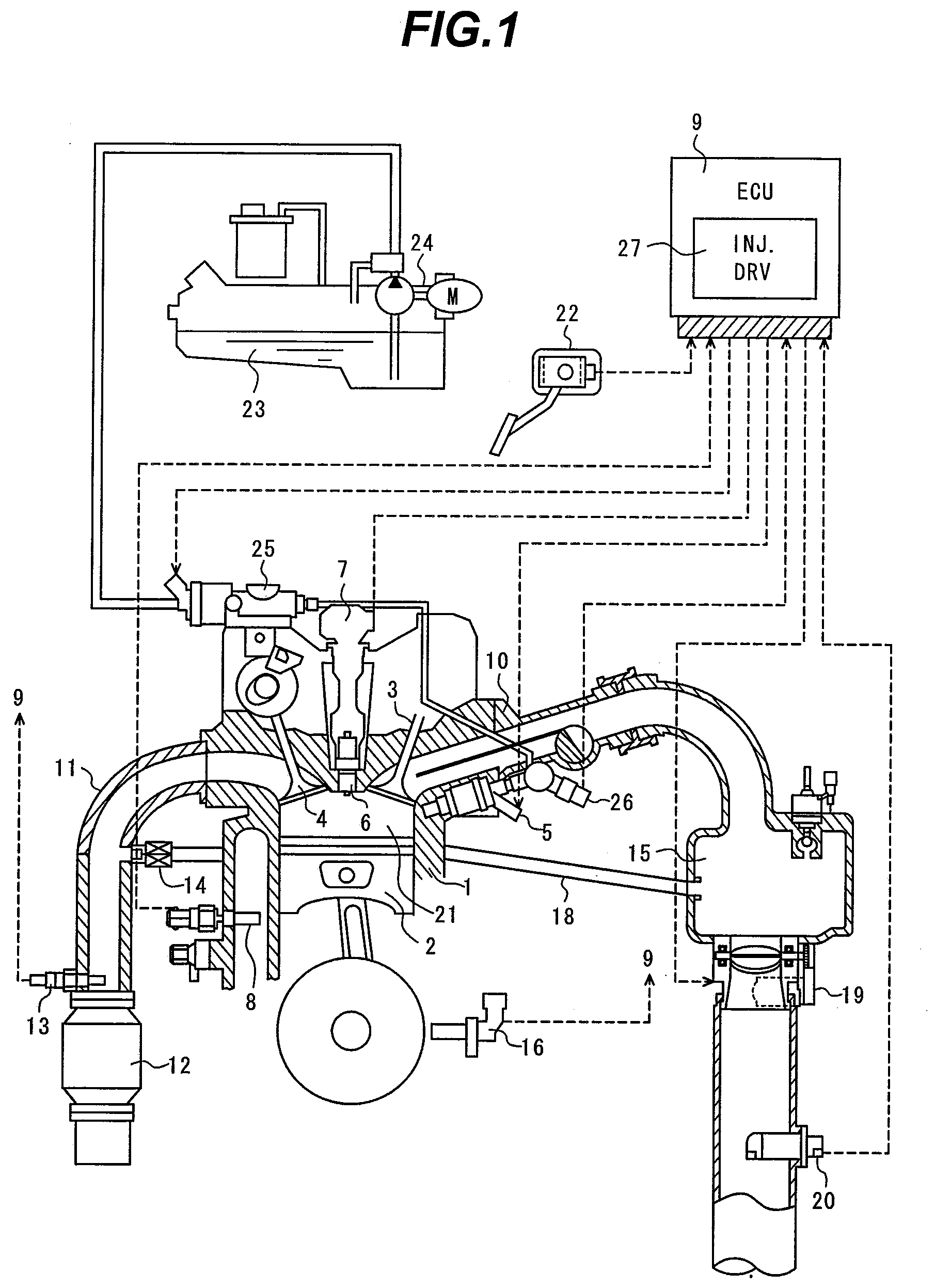

Fuel injection control apparatus for internal combustion engine

InactiveUS20090177367A1Open and close accuratelyImprove performanceElectrical controlDigital data processing detailsInjectorPulse duration

Disclosed herein is a fuel injection control apparatus for an internal combustion engine, capable of opening and closing accurately a valve of the fuel injector even when the quantity of injection required is small and a pulse duration of a driving pulse signal to the fuel injector is short.A fuel injector pulse width computing unit 9a calculates, from the operational state of the internal combustion engine and the fuel pressure detected by a fuel pressure sensor, pulse width of a pulse signal which drives the valve of the fuel injector. After an valve-opening command has turned on and a high valve-opening current for opening the fuel injector valve has been supplied from a high-voltage source to the fuel injector, a fuel injector driving signal waveform command unit 9b discharges the current and supplies from a low-voltage source a small hold current Ih2 that allows the fuel injector to maintain the valve-open state. Also, during the time from supply of the valve-opening current to an arrival at the value of the hold current Ih2, after the elapse of a previously assigned rapid-discharge starting time Tsy from the turn-on of the valve-opening command, the fuel injector driving signal waveform command unit 9b rapidly discharges the current until the hold current Ih2 has been reached.

Owner:HITACHI LTD

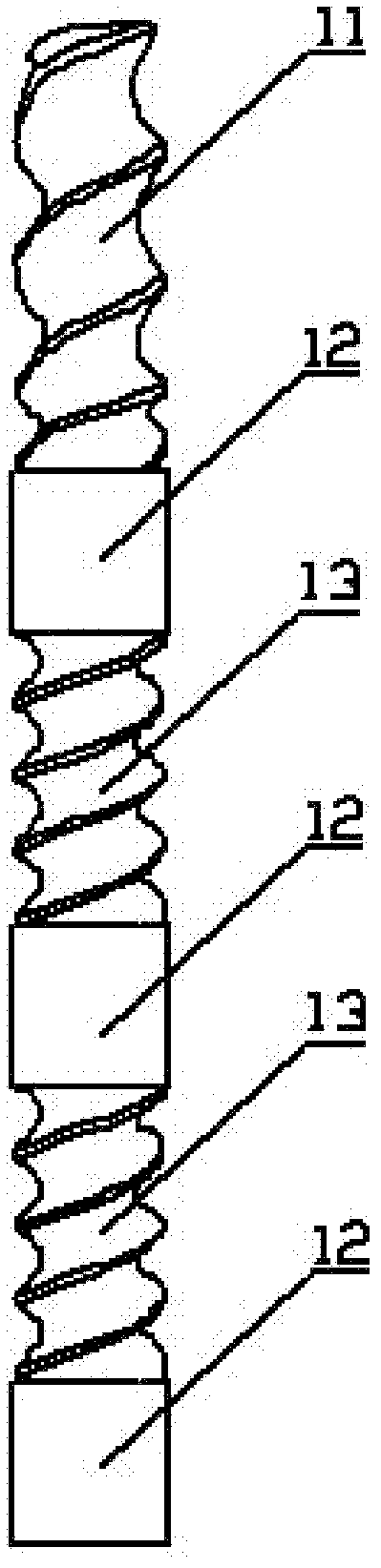

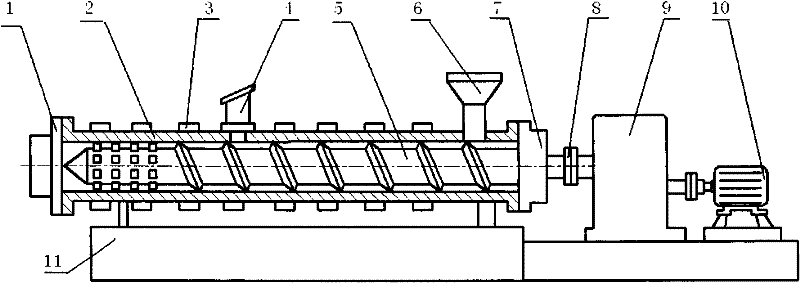

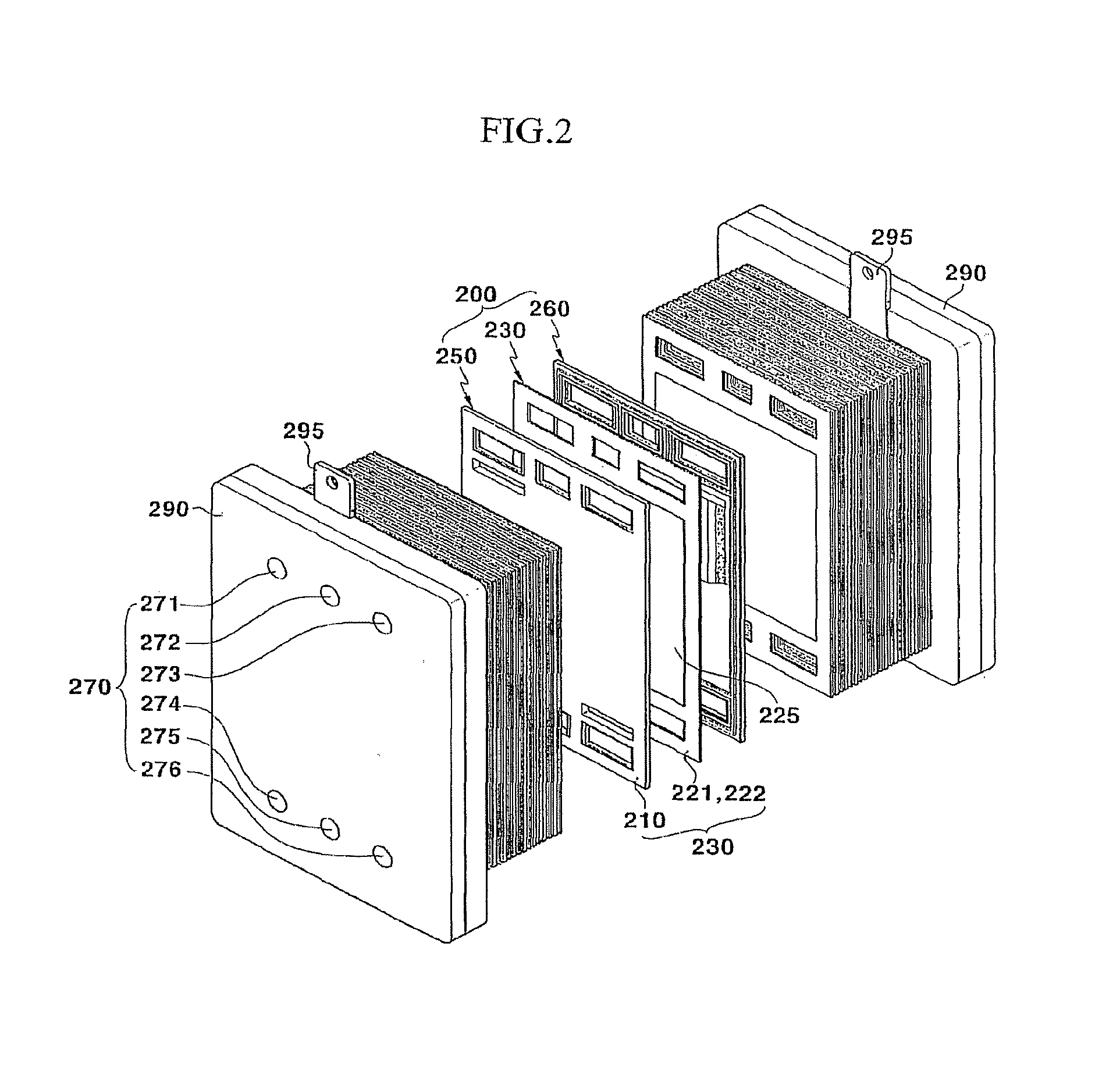

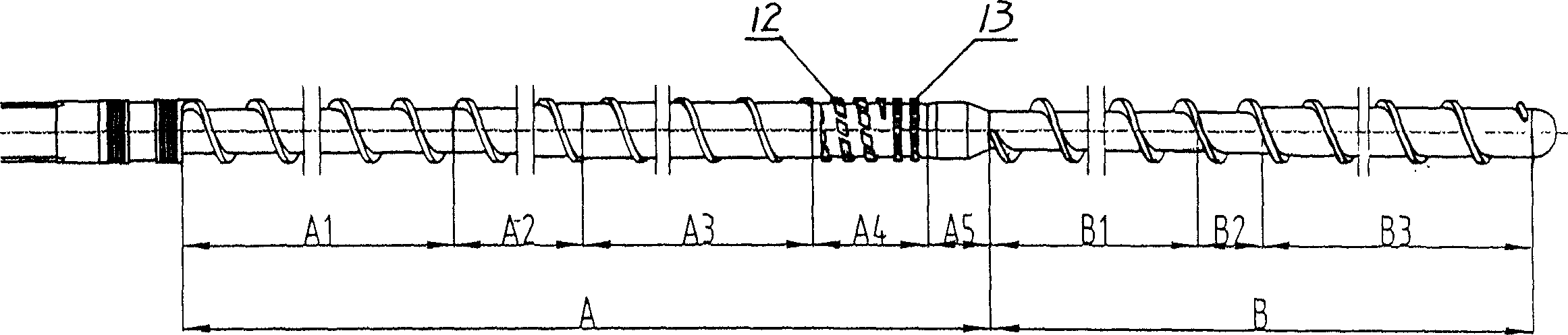

Exhaust-type differential double-screw extruder

The invention relates to an exhaust-type differential double-screw extruder, mainly comprising a feeder, a cylinder, screws, a machine head, a heating and cooling device, an exhaust outlet, a motor and a driving device, wherein one screw is a male rotor, and the other screw is a female rotor; at least one screw thread engaging region is arranged when the screws are combined, the screw socket number of the female rotor in the region is integral multiples of that of the male rotor, the rotating speeds of the female rotor and the male rotor are in inverse proportion to the screw socket number, and differential rotation and no interference during movement can be realized for the female rotor and the male rotor. At least one exhaust outlet is arranged on a material cylinder so as to remove moisture and other volatile components, and the screw configuration distribution meets the exhausting requirement. According to material processing requirements, screw thread sections or other forms with different leads and section shaped lines can be arranged on different sections of a charging section, a fusion section, an exhausting section and a metering section of the screws; when the screws are installed, besides at least one screw thread engaging region with differential rotation is ensured, the screws in different sections can be engaged and can be also unengaged so as to reinforce mixing or other functions. The extruder has favorable mixing, plasticizing and conveying capabilities and is suitable for processing and forming various granules, powder materials or even block materials, such as plastics, rubbers, food, explosives and the like.

Owner:BEIJING UNIV OF CHEM TECH

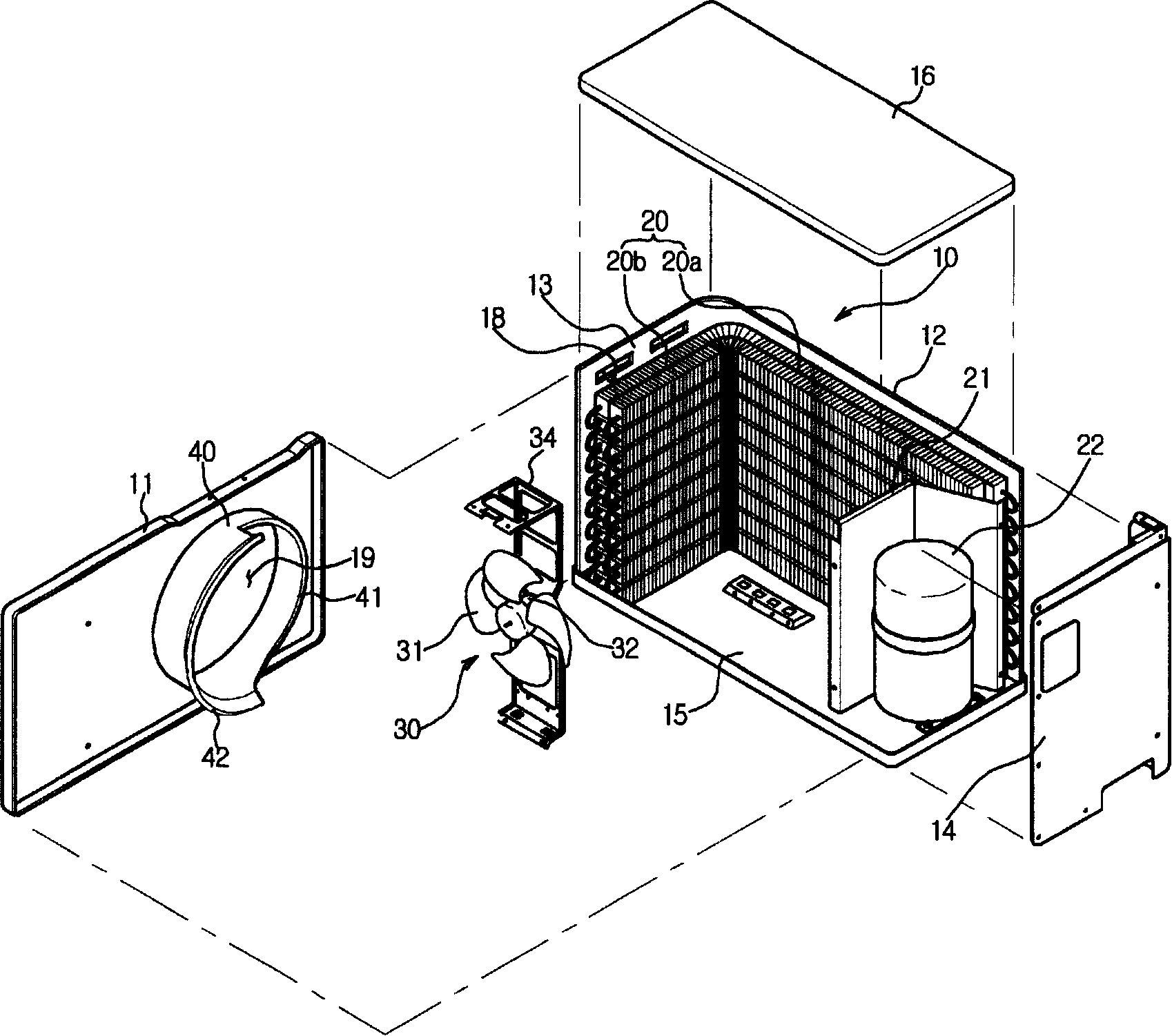

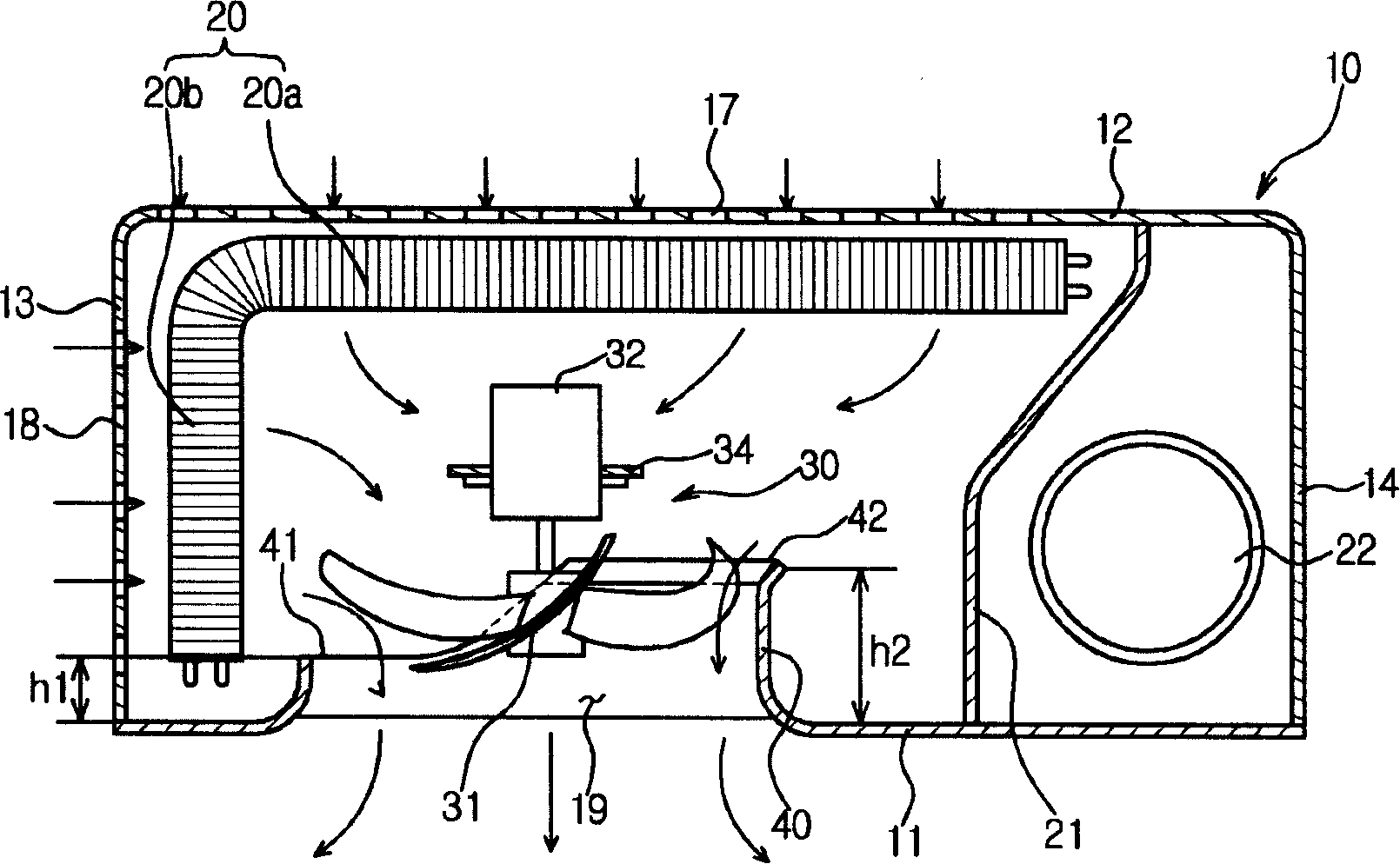

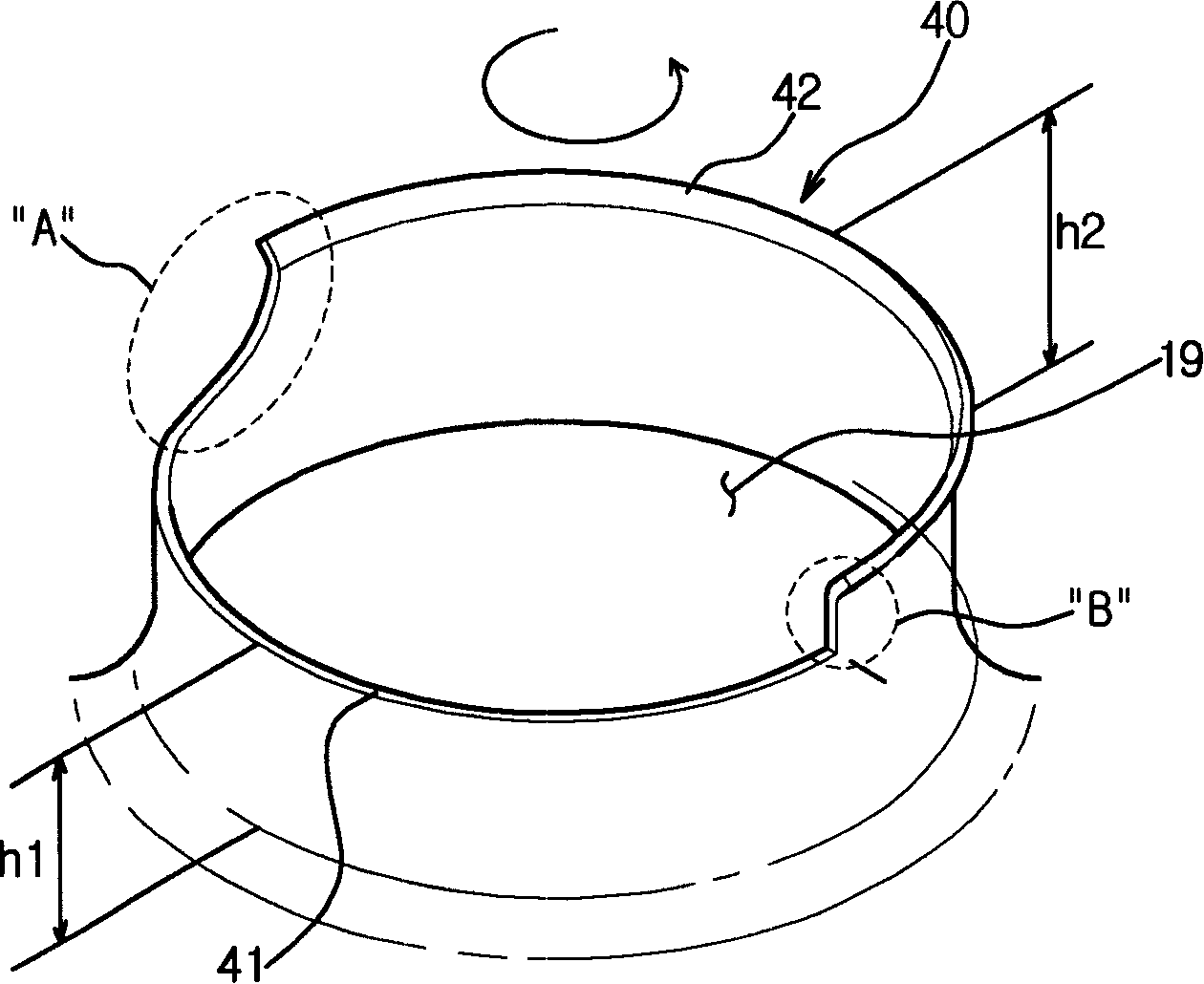

Outdoor unit of air conditioner

InactiveCN101196315AReduce exhaust noiseImprove the exhaust effectLighting and heating apparatusSpace heating and ventilation detailsEngineeringHeat exchanger

The invention discloses an air conditioner outdoor unit which facilitates that the air favorably flows into from the back of the casing and the side suction inlet and at the same time can reduce the air exhausting noise and increases the air exhausting capability. The air conditioner outdoor unit includes the following components: a casing which is respectively arranged with a suction inlet at the back and the side surface and is arranged with a discharging outlet at the front; a heat exchanger which is arranged at the back suction inlet and the side suction inlet at the inner side of the casing; a ventilating fan which is used for discharging air to the discharging outlet and is arranged at the inner side of the casing; a draft tube which is arranged at the discharging outlet for guiding the discharged air; and the draft tube is formed that the height at the side of the side suction inlet is lower than the rest part.

Owner:SAMSUNG ELECTRONICS CO LTD

Separator for fuel cell, manufacturing method thereof, and fuel cell having such a separator

ActiveUS20150004516A1Improve the exhaust effectIncreased durabilityBatteries circuit arrangementsFuel cells groupingFuel cellsManufacturing technology

A lamellar structure graphite foil is used as a material for a separator for a fuel cell, and a hydrophobic layer is formed by impregnation on flow-field channels of the graphite foil. Such a separator is manufactured by forming the flow field channel by etching the graphite foil formed with the mask pattern thereon and forming a hydrophobic layer by impregnation. According to such a separator, performance of a fuel cell stack is enhanced and the manufacturing process of a separator is simplified.

Owner:DOOSAN CORP

Regeneration pelletizer for worn-out plastic

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Benzene-free high-speed alumite stamping gum

InactiveCN103254869AImprove adhesionImprove brittlenessMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesBenzenePolymer science

The invention relates to a benzene-free high-speed alumite stamping gum comprising the following chemical components in weight ratio: 15-30 of adhesion promotion resin, 20-45 of packing resin, 1-5 of wetting agents, 5-10 of additives and 70-90 of organic solvents. The used solvents are all non-benzene and non-benzene-series solvents and meet the requirement for limiting a non-benzene VOC (Volatile Organic Compound) in a special industry; the used special modified chlorinated polyolefin resin and ester soluble acrylic resin are used for improving the adhesion of the gum; the used packing resin is used for ensuring that the gum has better brittleness; the gum and a stamping substrate can achieve an ideal wetting effect by using the wetting agent; the gum is better in coating uniformity and favorable in temperature resistance and exhausting performance by using the additives; the stamping gum belongs to a universal gum and has better adhesion for common untreated paper, inked paper and composite paper; and the benzene-free high-speed alumite stamping gum is integrated in stamping pattern, good in trimming, free of mutilation and leak stamping and good in glossiness.

Owner:GUANGDONG BANGGU CHEM TECH

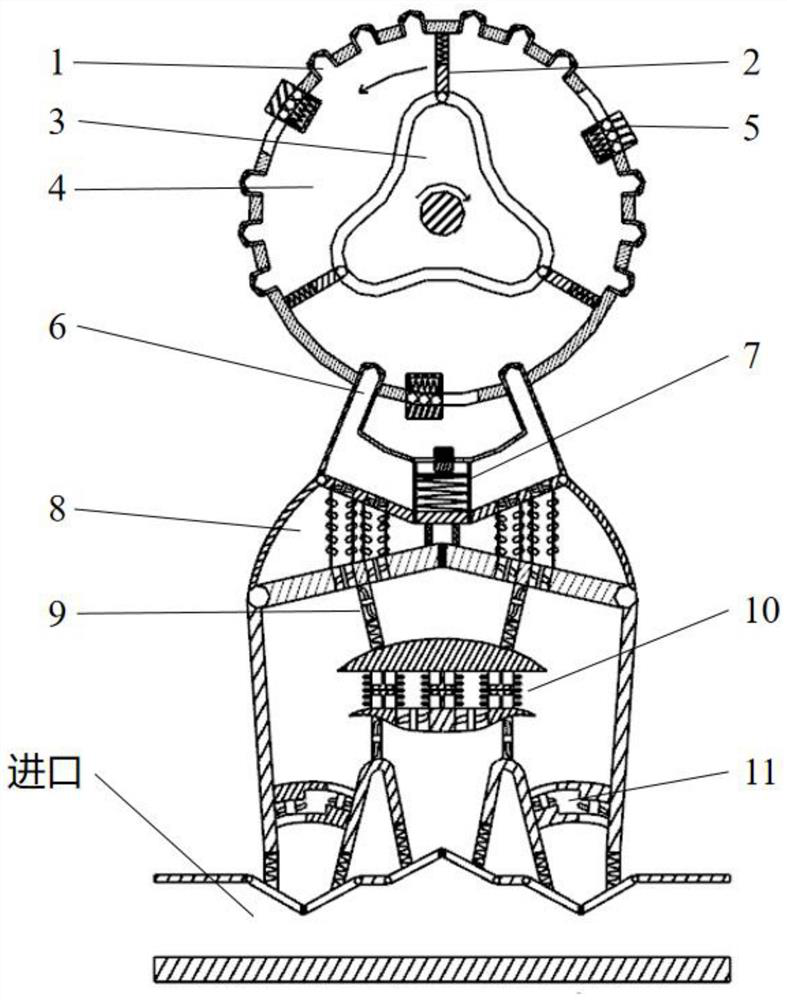

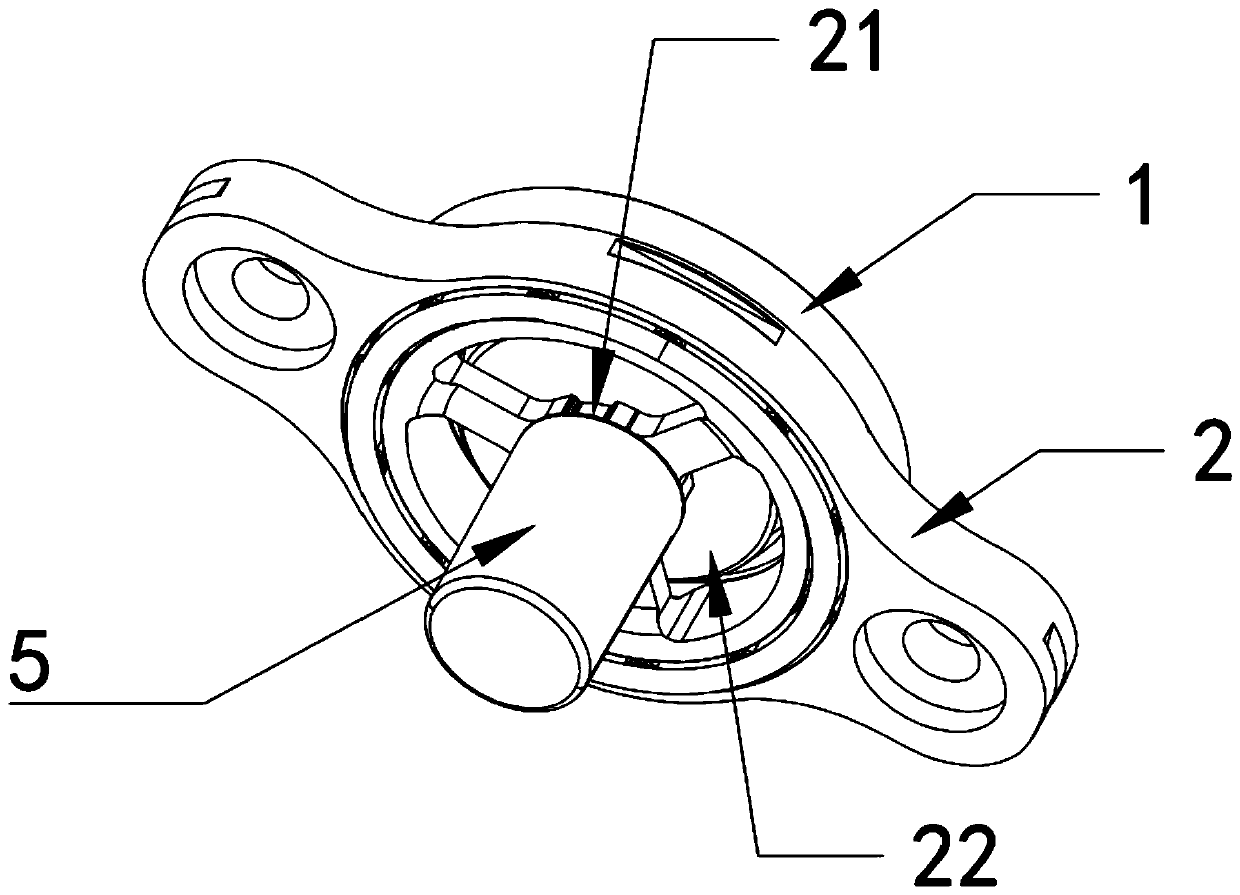

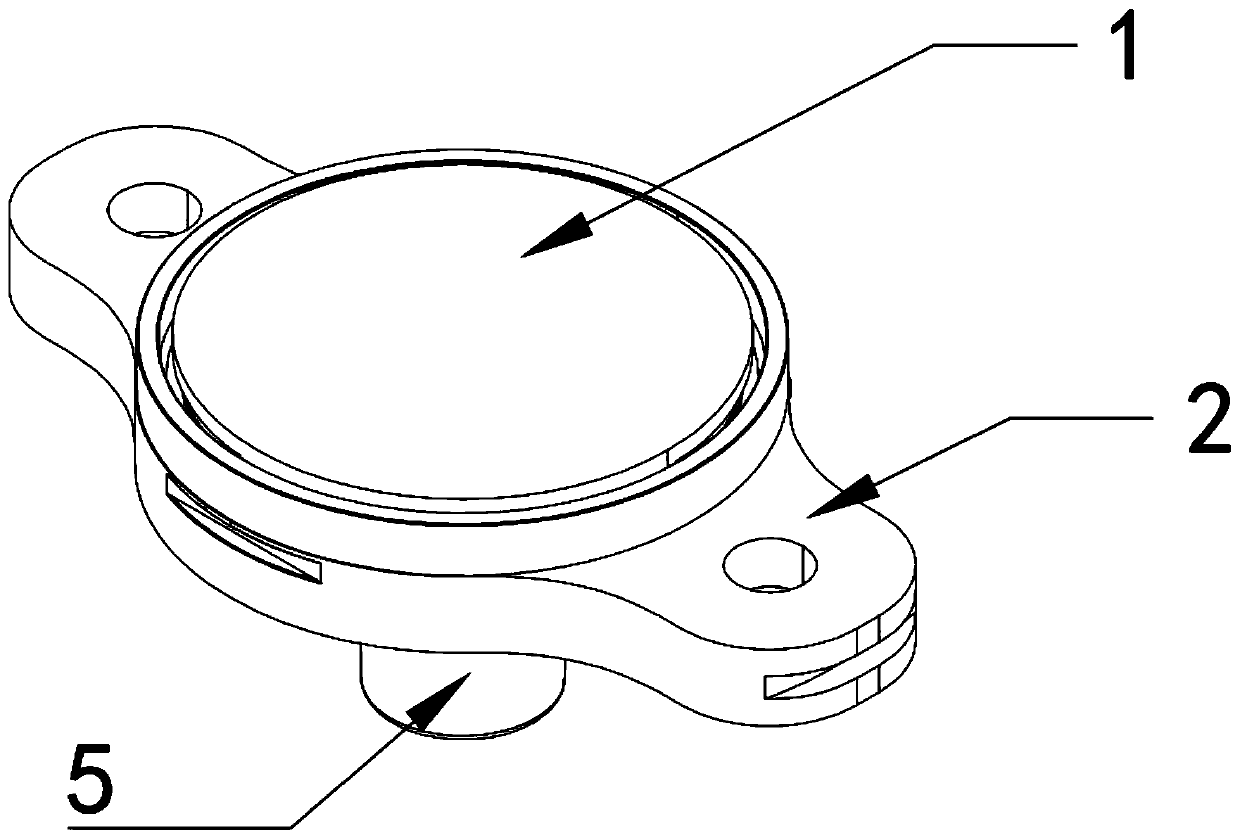

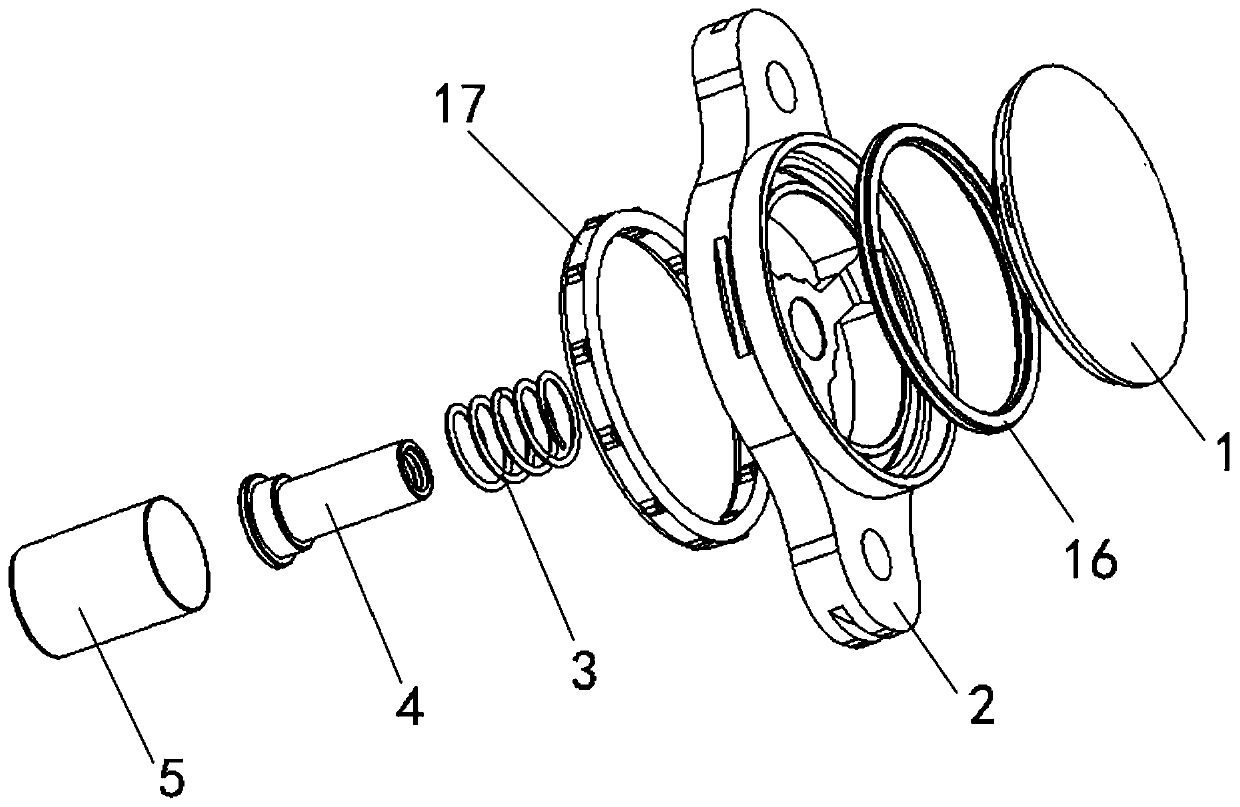

Quick water-free starting device applied to centrifugal pump

ActiveCN113464450AImprove sealingImprove exhaust capacityPriming pumpNon-positive displacement fluid enginesCentrifugal pumpEngineering

The invention provides a quick water-free starting device applied to a centrifugal pump. The quick water-free starting device comprises a one-way channel, a self-suction cavity shell, a sliding device, a self-suction cavity, a concave-convex impeller, two side inlet flow channels connected with the self-suction cavity, a spring device of an upper side x-shaped gas-liquid separation device, an upper side x-shaped gas-liquid separation device, an upper and middle side gas-liquid separation device connecting shaft, a middle side gas-liquid separation device, a lower side backflow type gas-liquid separation device, a v-shaped backflow flow channel, an inverted v-shaped inlet flow channel and an inlet which are sequentially arranged from top to bottom. According to the quick water-free starting device, the centrifugal pump can directly enter the normal operation working condition after water-free starting, and 36 times of exhaust can be completed by rotating an impeller in a self-suction cavity by a circle in the earlier stage. In addition, the device is provided with an upper gas-liquid separation device, a middle gas-liquid separation device and a lower gas-liquid separation device, gas-liquid separation is fully achieved, gas can be exhausted more quickly, a cavity is filled with water, the working efficiency can be remarkably improved, and the operation process is greatly simplified.

Owner:JIANGSU UNIV

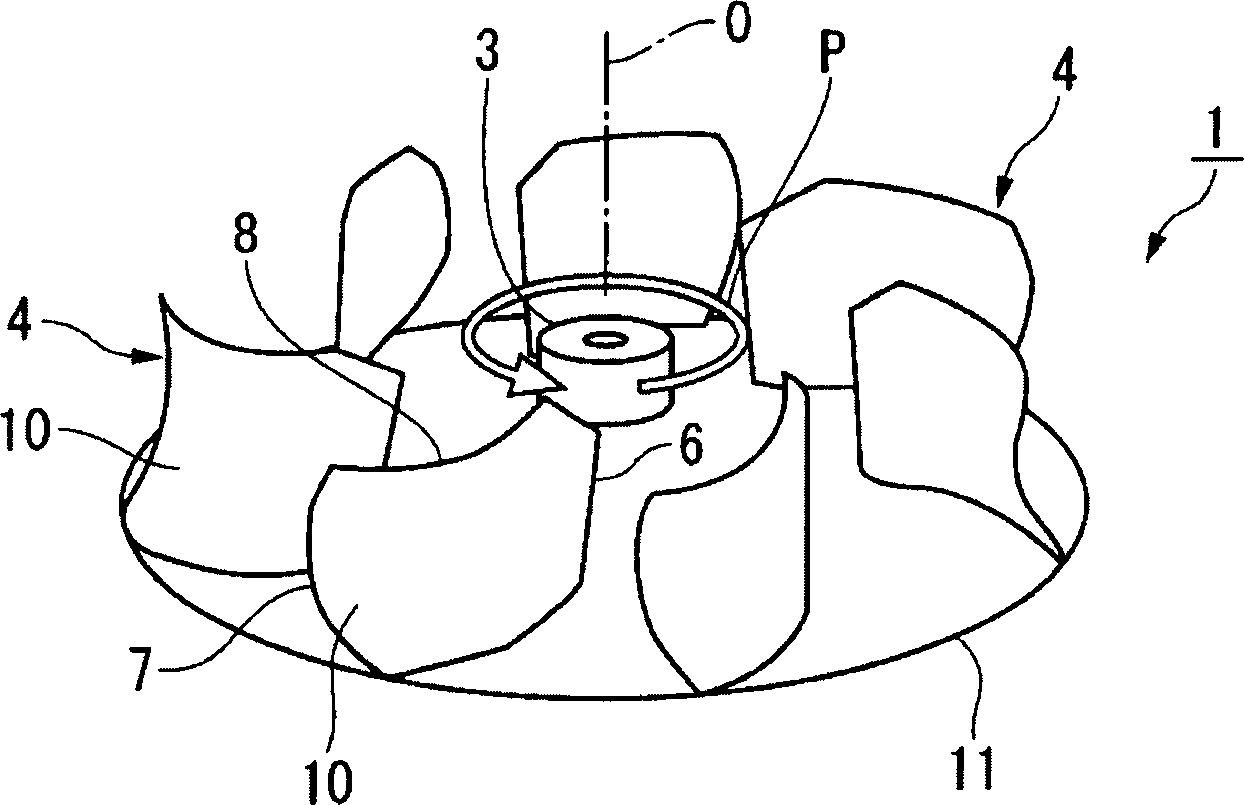

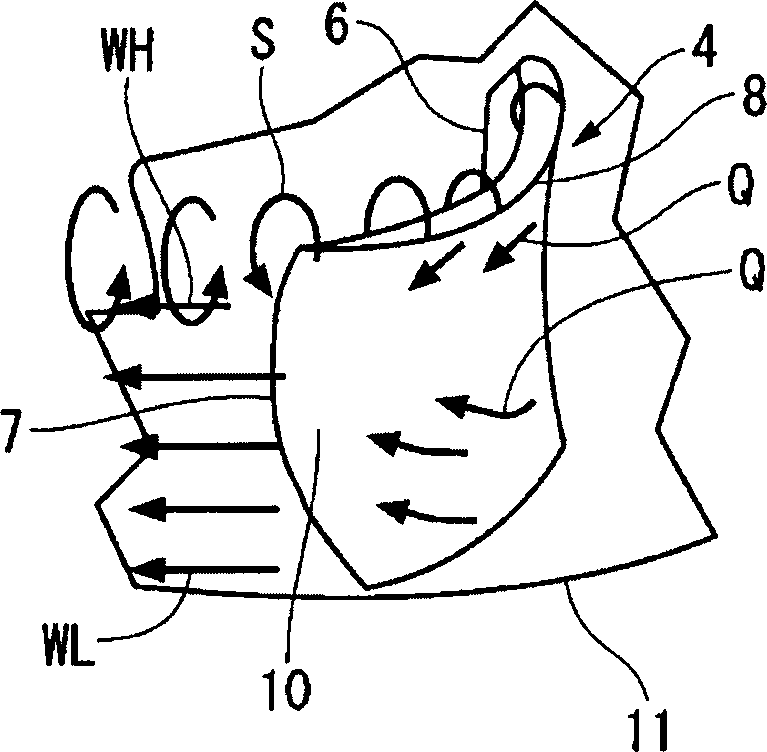

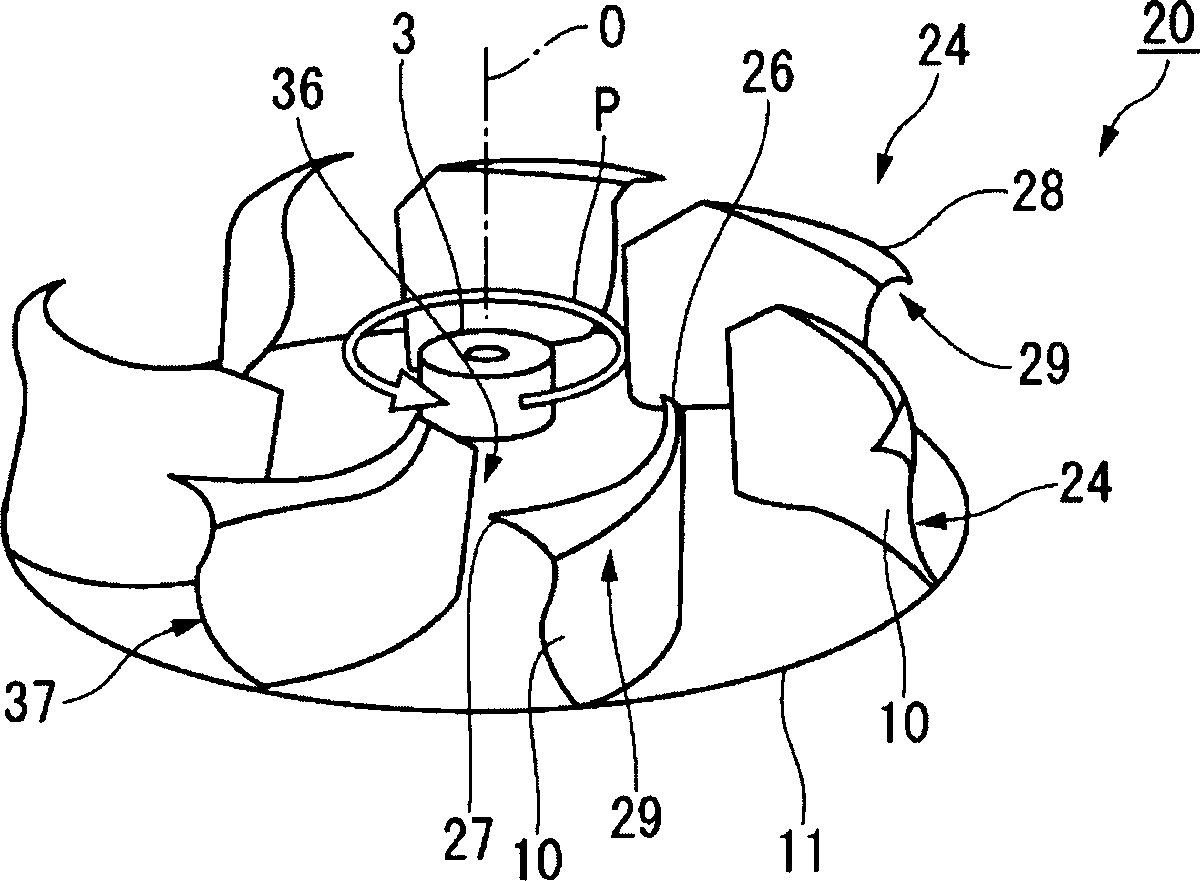

Eccentric fan and air conditioner therewith

InactiveCN1712733ASuppress wing tip vortex increaseLow costPump componentsOther chemical processesLeading edgeRadial position

PROBLEM TO BE SOLVED: To provide a centrifugal fan capable of increasing marketability by suppressing noise while reducing cost, and an air conditioner using the centrifugal fan. SOLUTION: This centrifugal fan comprises a main plate 11 rotatable in a prescribed direction P around a rotating axis O and vanes 4 disposed on the main plate 11. The cross sections of the vanes 4 at the same radial position of the main plate 11 including at least the trailing edge 7 positioned on the outer peripheral side of the main plate 11 are curved to be projected in the anti-rotating direction (-P direction) of the main plate 11. The curve is gradually increased from the leading edge 6 to the trailing edge 7 of the vanes 4. COPYRIGHT: (C)2006,JPO&NCIPI

Owner:SAMSUNG ELECTRONICS CO LTD

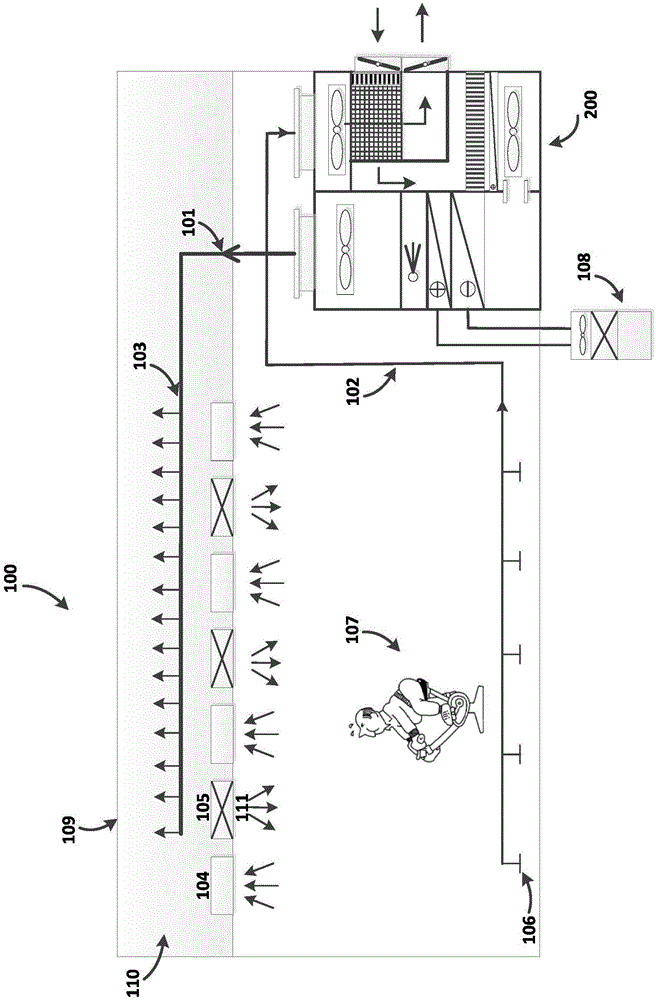

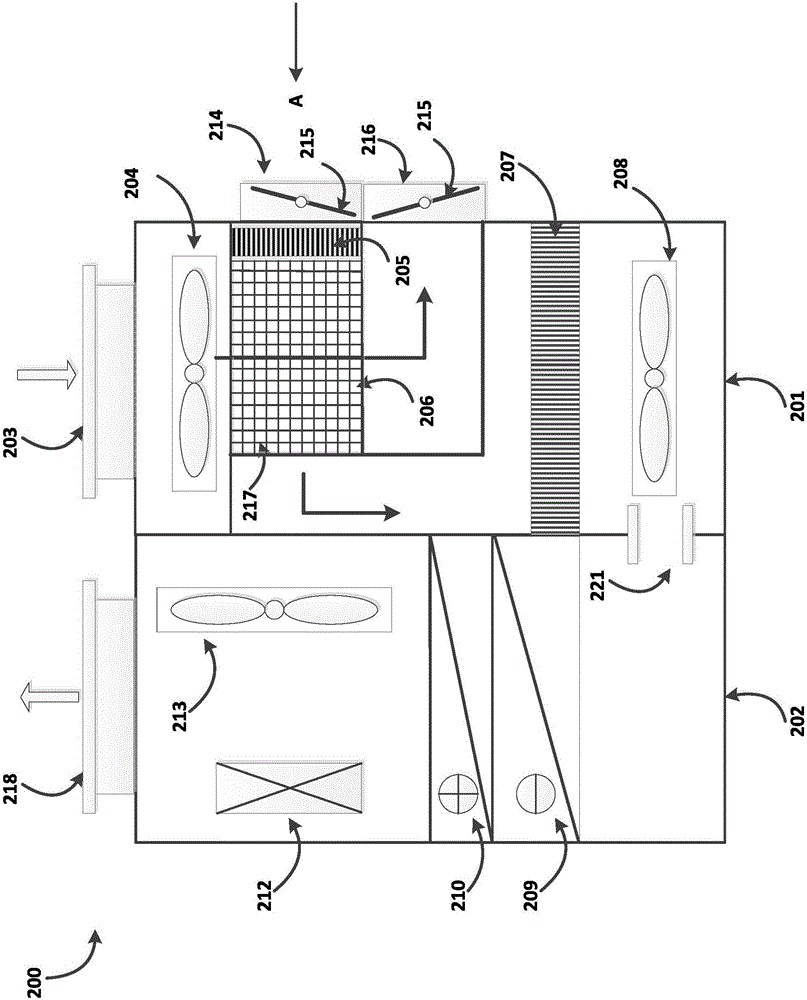

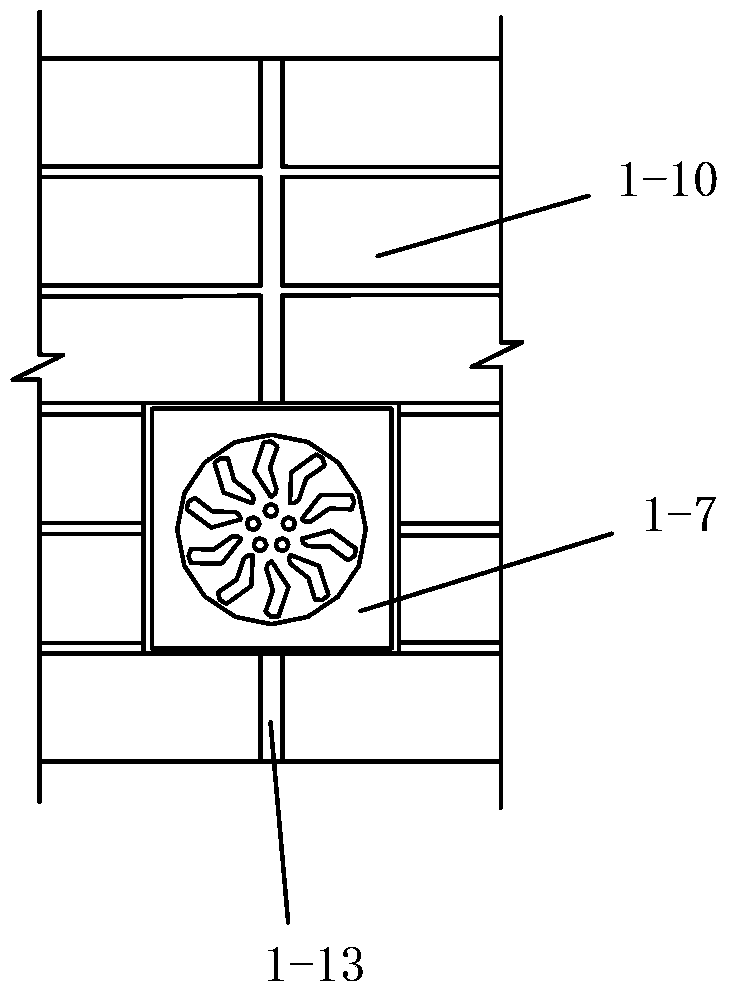

Upper-supply and upper-return type air purification system

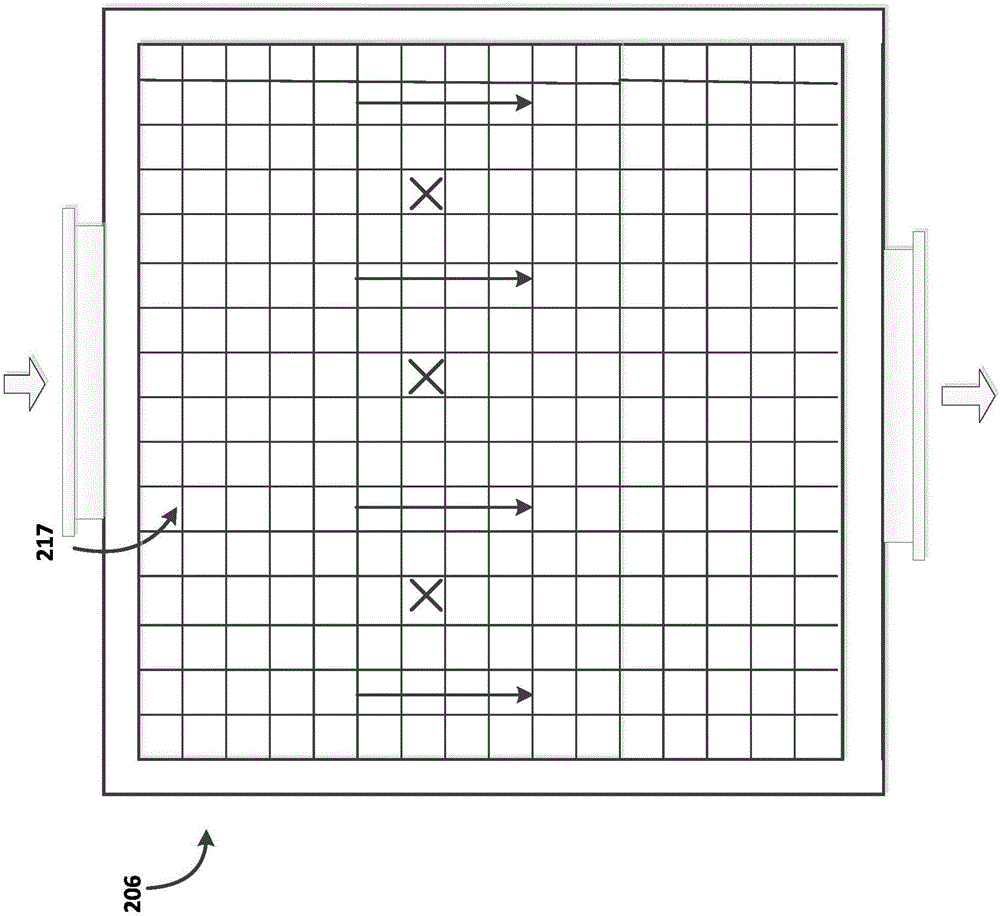

InactiveCN106403137AReduce equipment costsReduce installation costsEnergy recovery in ventilation and heatingMechanical apparatusAir treatmentAir purification

The invention relates to an upper-supply and upper-return type air purification system which comprises a gym air exhaust and ventilation integrated cabinet, an air supply ceiling and an exhaust port, wherein the gym air exhaust and ventilation integrated cabinet is used for inputting fresh air and air to be exhausted, treating the fresh air and the air to be exhausted and outputting the fresh air and the air to be exhausted; the air supply ceiling is used for evenly mixing the induced fresh air and returned air, filtering the induced fresh air and the returned air and outputting the induced fresh air and the returned air into a room; and the exhaust port is used for outputting the air to be exhausted in the room to the outside through the gym air exhaust and ventilation integrated cabinet. Through the air purification system, a plurality of treatment functions including ventilation, exhaust, dehumidification, temperature adjustment, purification and the like are achieved at a time, and waste heat / waste cold is utilized so that energy saving can be achieved, the fresh air treatment function and the returned air treatment function are completely separated, and energy saving is achieved; through a fan filter unit (FFU) installed in the position of the air supply ceiling, fresh air is input into the room (upper supply), returned air is sucked through an air return port in the position of the air supply ceiling (upper return), and an independently arranged air return treatment device, an air return pipeline and a passageway are completely omitted; and the returned air and the fresh air can be evenly mixed, and the outlet air quality is improved.

Owner:殷晓冬

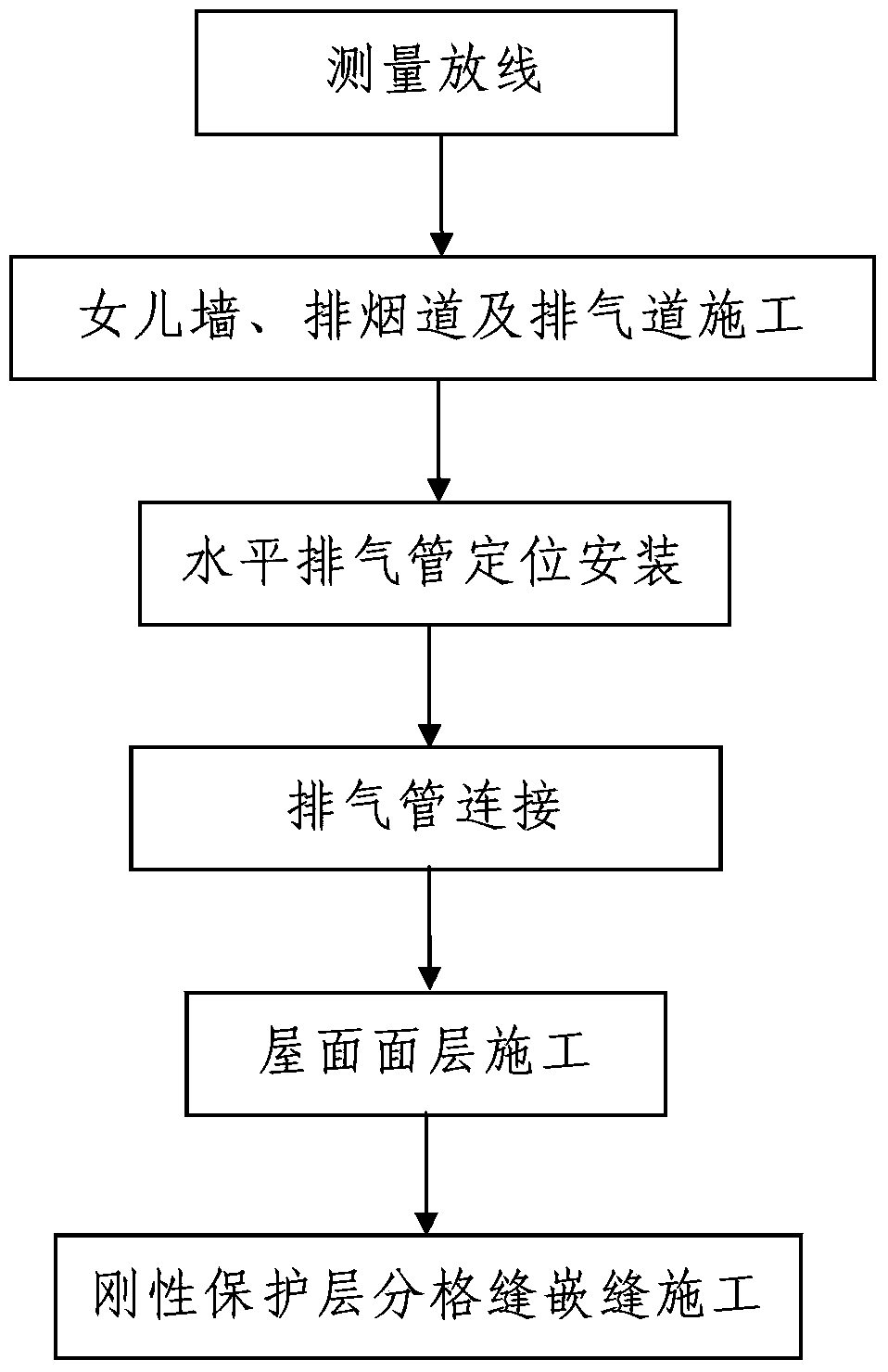

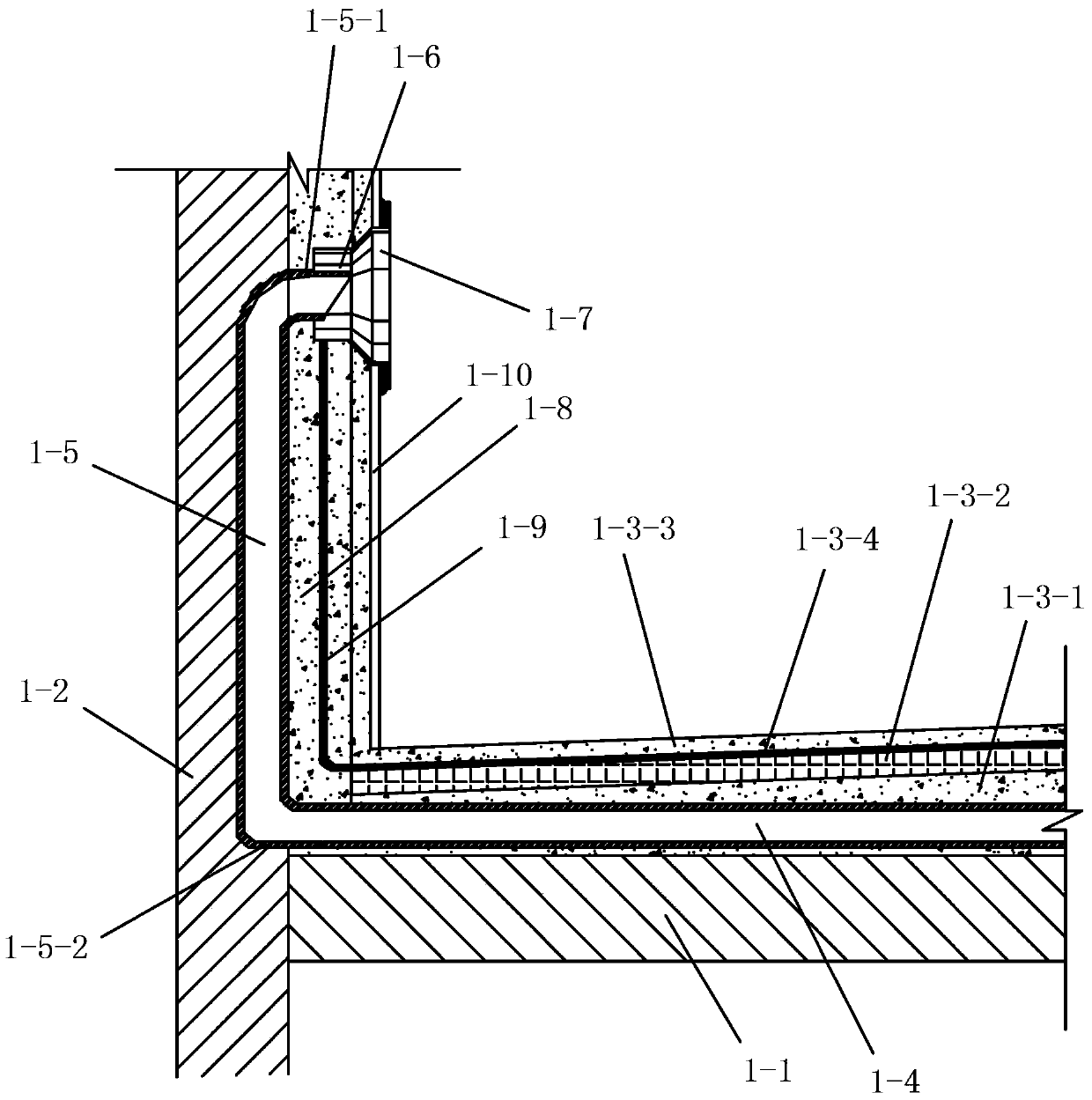

Building roof construction process

InactiveCN103362254ASimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

The invention discloses a building roof construction process. A construction roof comprises a roof structure plate, a parapet wall and a roof surface layer, wherein the parapet wall is arranged above the roof structure plate, the roof surface layer is paved on the roof structure plate, a roof exhaust system is arranged on the construction roof and comprises a plurality of first horizontal exhaust pipes, the first horizontal exhaust pipes are respectively laid in a slope finding layer or a heat insulation layer in the roof surface layer, two ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe, and the vertical exhaust pipes are embedded in the side walls of the parapet wall and a discharge flue or the side wall of an exhaust passage. The construction process of a construction roof comprises the steps of 1, surveying and setting out; 2, parapet wall, discharge flue and exhaust passage construction; 3, horizontal exhaust pipe positioning installation; 4, exhaust pipe connection; 5, roof surface layer construction; and 6, rigid protecting layer mesh division and caulking construction. The construction process has the advantages that the steps are simple, the operability is high, the realization is convenient, in addition, the work efficiency is high, the construction effect is good, and the construction quality of the construction forming building roof can be effectively ensured.

Owner:陕西建工集团有限公司 +1

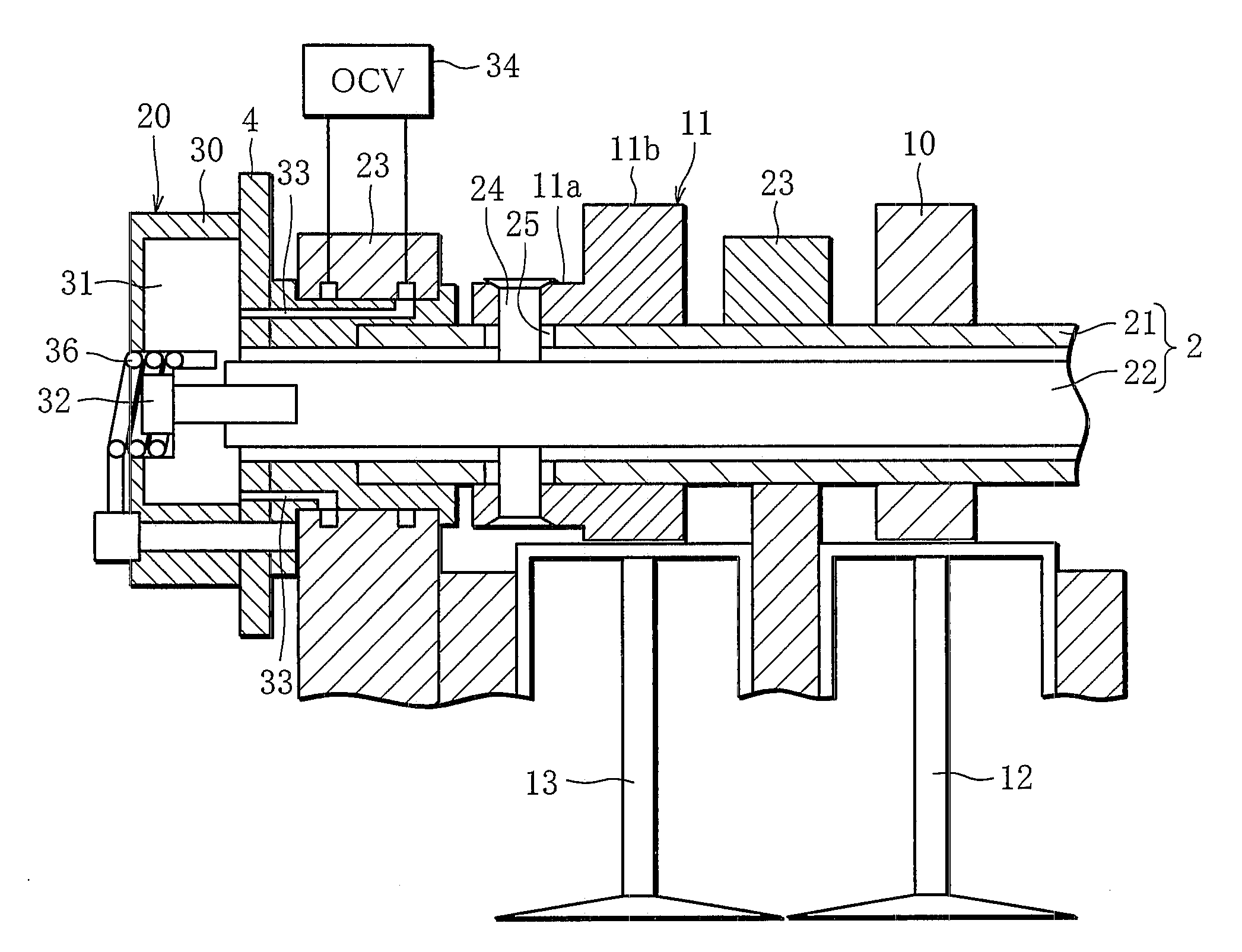

Internal combustion engine with variable valve gear

ActiveUS20100212618A1Improve combustibilityImprove exhaust performanceValve arrangementsInternal combustion piston enginesExternal combustion engineInlet valve

In an engine which comprises a first intake valve and a second intake valve for each cylinder, configured to be driven by a first intake cam and a second intake cam, respectively, and a cam phase change mechanism configured to vary the phase of the second intake cam, the cam phase change mechanism is controlled so that the opening timing of the second intake valve is advanced ahead of that of the first intake valve in a start mode.

Owner:MITSUBISHI MOTORS CORP

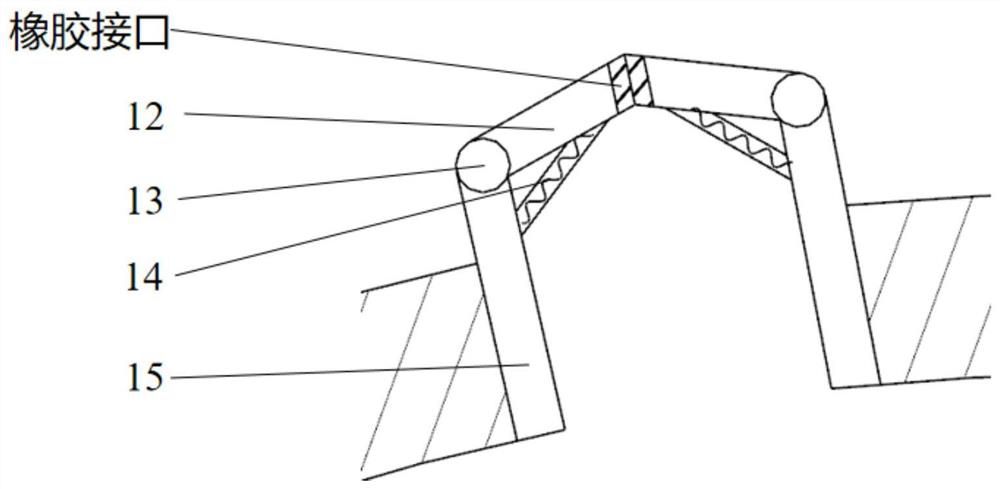

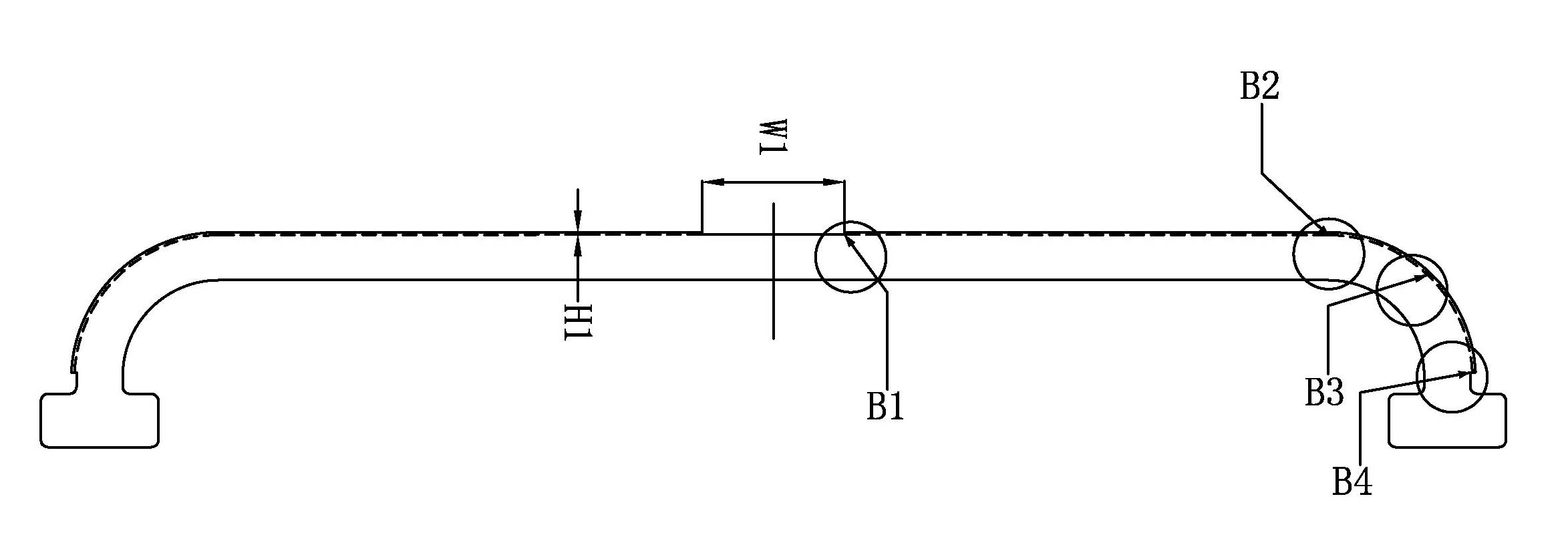

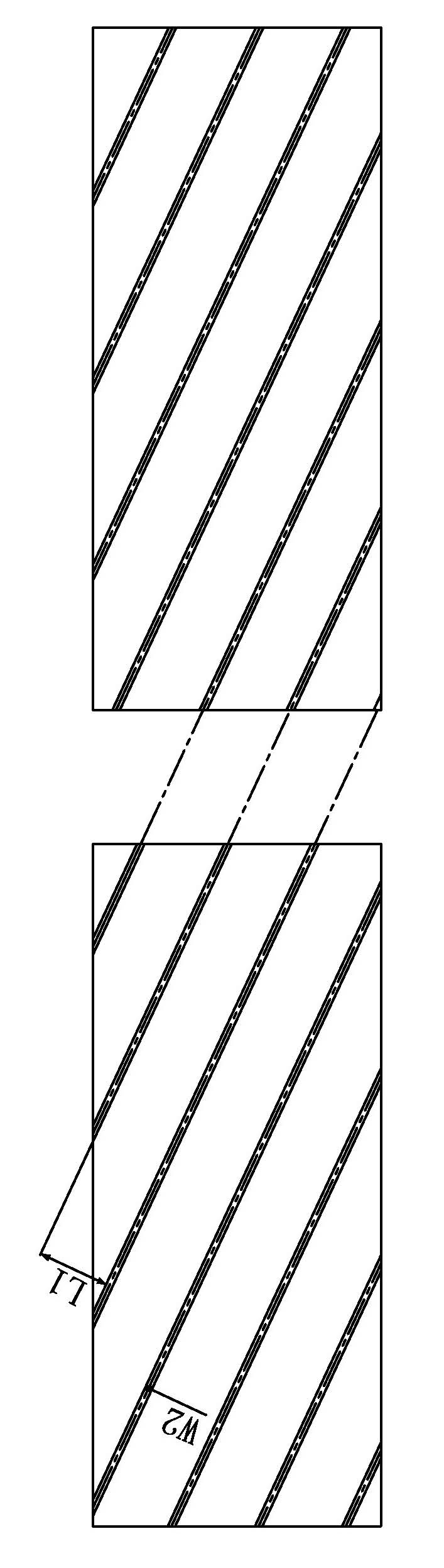

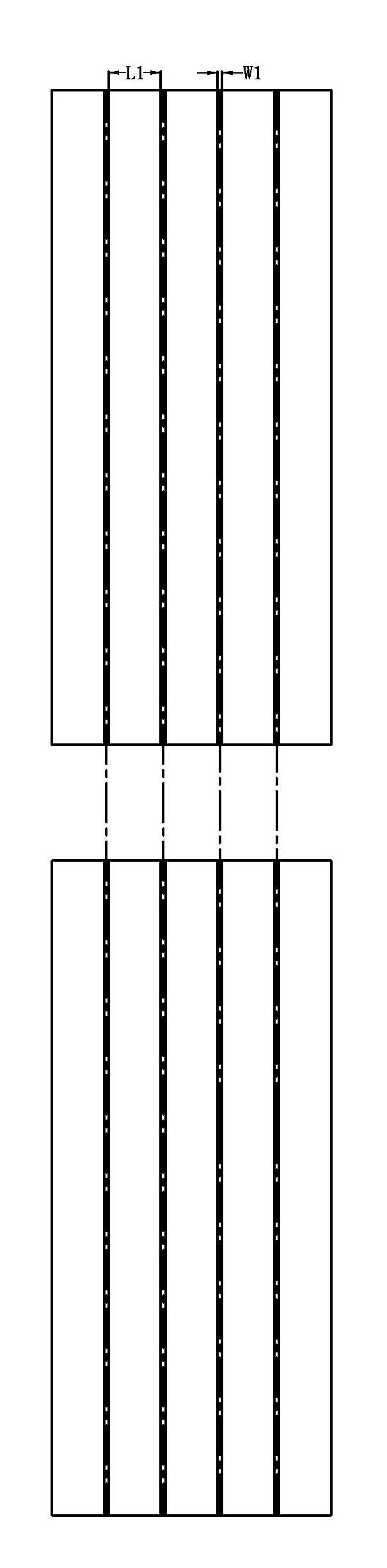

Tire vulcanization capsule structure

InactiveCN102615750AImprove moisture problemsIncrease the exhaust channelTyresVulcanizationMechanical engineering

The invention discloses a tire vulcanization capsule structure which is an air bag corresponding to the shape of the inner surface of a tire. The outer surface of the tire vulcanization capsule structure is contacted with the inner surface of the tire; a pattern-free smooth surface is formed on the outer surface of a capsule, which is opposite to a crown region of the tire; continuous linear or inclined air exhaust trenches which are opposite to a tread region, a transition region between a tread and a tire shoulder, a tire shoulder region and a tire shoulder and bead region of the tire are formed on the outer surface of the capsule and parallel to one another; galalith patterned blocks are distributed among the air exhaust trenches of the tread region, the transition region between the tread and the tire shoulder, the tire shoulder region and the tire shoulder and the bead region of the tire on the outer surface of the capsule; and each galalith patterned block is formed by encircling three or more trenches which are not positioned on the same straight line. Due to the galalith patterned blocks, the number of air exhaust channels on the surface of the capsule is increased greatly, the air exhaust performance is improved, and the problem of low moisture in the tire is solved effectively; and the service life of the tire vulcanization capsule is prolonged.

Owner:CHENG SHIN RUBBER (XIAMEN) IND LTD

Anti-blocking explosion-proof valve and preparation method thereof

ActiveCN111490212ASmall compression strokeFlexible selectionCell lids/coversCell sealing materialsEngineeringMechanical engineering

The invention discloses an anti-blocking explosion-proof valve which comprises a piston, a valve body, a spring and a connecting shaft. A first through hole is formed in a connecting shaft in a penetrating mode, and a protective cover is installed on the valve body around an outer side of the spring. The valve body comprises a plurality of first air leakage gaps corresponding to the protective cover, and first air holes are formed in a cavity between the first air leakage gaps and the protective cover. The piston comprises a piston body, a breathable membrane and an upper cover, a second through hole longitudinally penetrates through the piston body and corresponds to the first through hole, a plurality of through grooves horizontally penetrate through the second through hole and are connected with the second through hole, and second breathable holes are formed in cavities between the through grooves and the upper cover. The invention further discloses a preparation method of the anti-blocking anti-explosion valve. According to the anti-blocking explosion-proof valve, the protective cover is arranged on the outer side of the spring such that combustion eruption objects are effectively prevented from accumulating and adhering to the spring to shorten the compression stroke of the spring, and the opening effect and the exhaust pressure relief efficiency of the explosion-proof valve are prevented from being affected.

Owner:DONGGUAN PUW EPTFE MATERIAL CO LTD

Metallurgical slag sintered bricks and preparation method thereof

InactiveCN106431350AReduce energy consumptionImprove the exhaust effectCeramic materials productionClaywaresMetallurgical slagMineral Sources

The invention provides metallurgical slag sintered bricks and a preparation method thereof. The preparation method comprises the following steps: mixing metallurgical slag, clay and / or shale and an additive, which meet a preset condition, according to preset proportions; aging the mixture obtained after mixing, and then performing forming to obtain green bricks; and drying the green bricks, and then burning the green bricks in a kiln to obtain the sintered bricks. According to the preparation method provided by the invention, by controlling the preset condition of the metallurgical slag, the clay and the additive can be directly mixed with the metallurgical slag by stirring, and secondary breaking is not needed, so that the energy consumption of the preparation is greatly reduced; the metallurgical slag has a function of reducing the melting point, so that the temperature of a sintering reaction can be reduced; and by controlling factors including the content of ferric oxide in the metallurgical slag, the sintering temperature and the sintering atmosphere, sintered bricks with different colors can be obtained without adding an expensive coloring agent, so that large-scale utilization of the metallurgical slag is achieved, mineral resources are saved, and meanwhile, qualified sintered bricks are produced with low cost, low energy consumption and a high efficiency, thereby achieving comprehensive utilization of resources, and protecting the environment.

Owner:UNIV OF SCI & TECH BEIJING

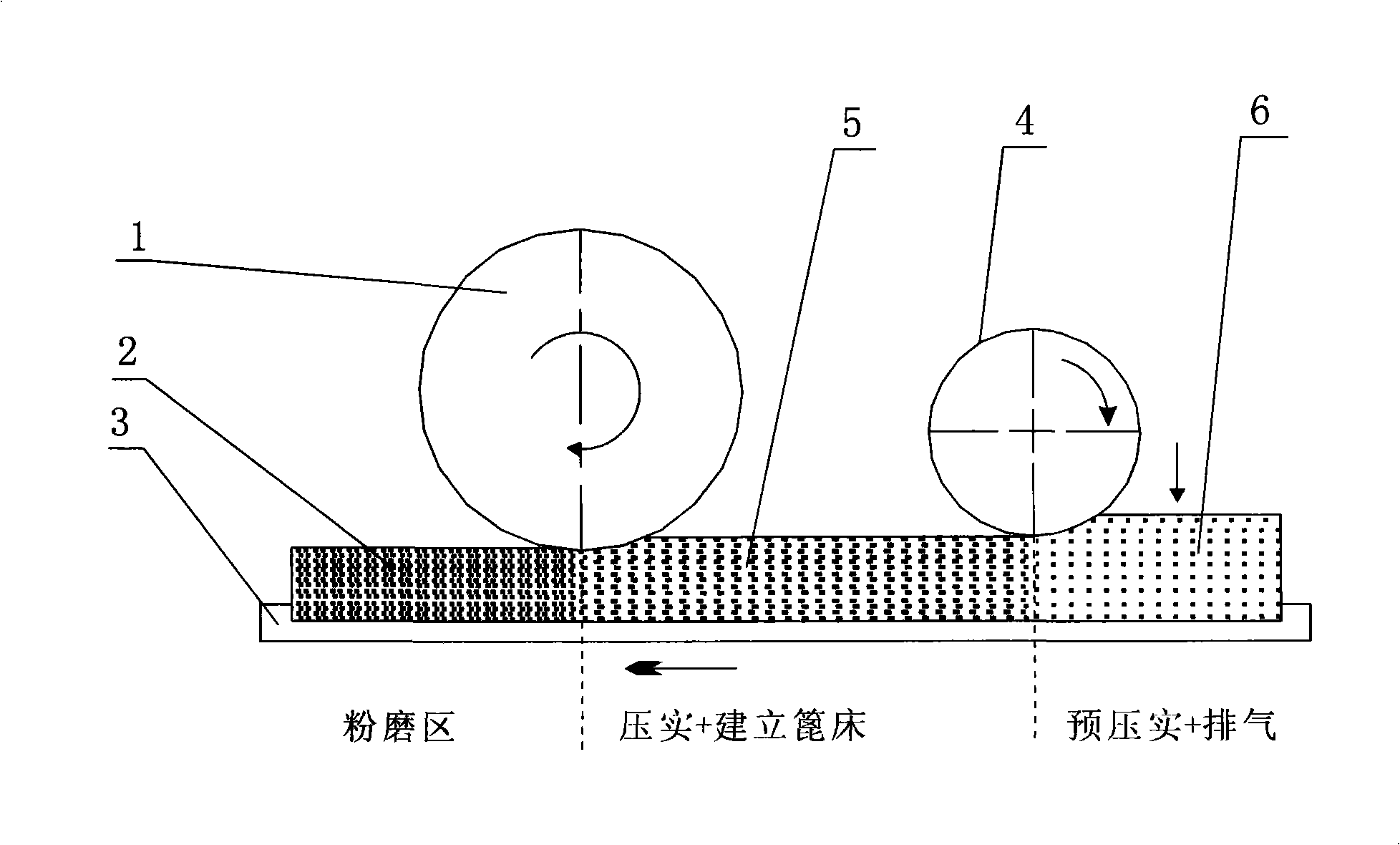

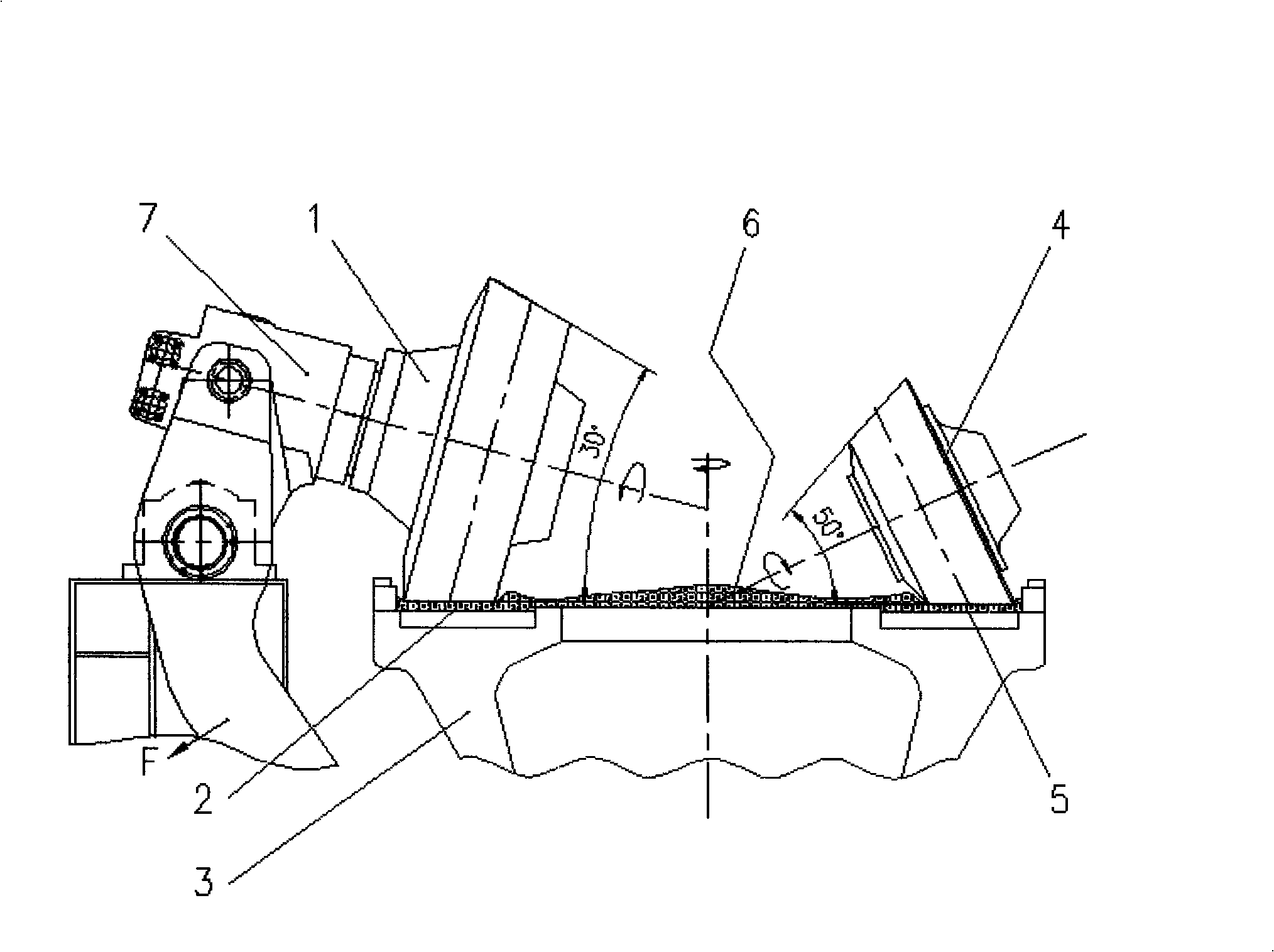

Method and apparatus for flattening, compacting and crushing material

The invention discloses a method and a device for flattening, compacting and grinding the materials to be ground into powder. The original packing material layer (6) is continuously arranged on a millstone (3) which rotates around an axis and has a disc structure with a fixed-diameter. A passive flattening-compacting roller (4) with an included angle of 50 degrees flattens and compacts the material in advance and exhausts gas. The flattening-compacting roller and the material layer keep a pure rolling friction state. Owing to the weight of the flattening-compacting roller and certain roll surface angle, the undulating material layer is flattened and compacted under the action of the flattening-compacting roller. With the rotation of the millstone, the flattened and compacted material layer (5) rotates to a passive grinding roller (1) which has an included angel of 30 degrees to be ground into powder and to get a ground material layer (2). In addition to the weight of the grinding roller and certain roll surface angle, the grinding roller is also connected with a grinding roller pressure device (7) which can continuously grind the flattened and compacted material layer. By adopting the method and device, the material can be pre-flattened and pre-compacted and then continuously ground, thus the efficiency is greatly improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

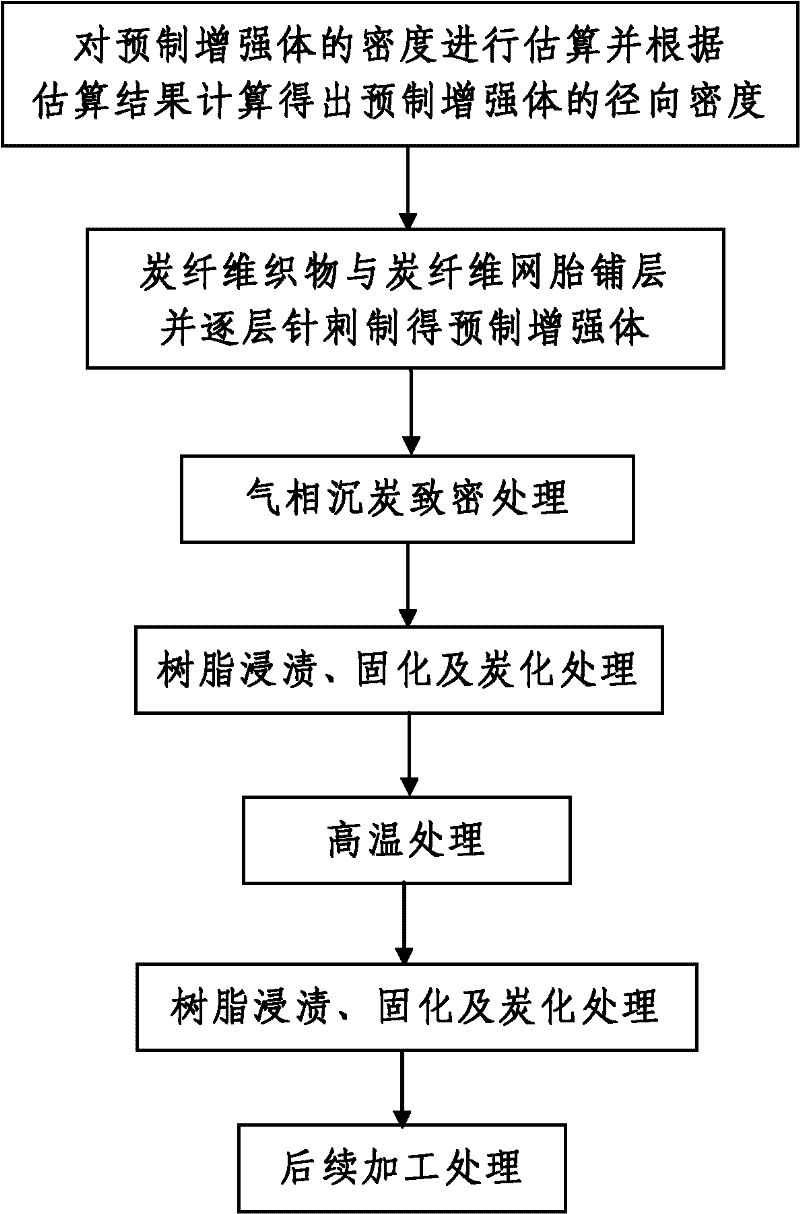

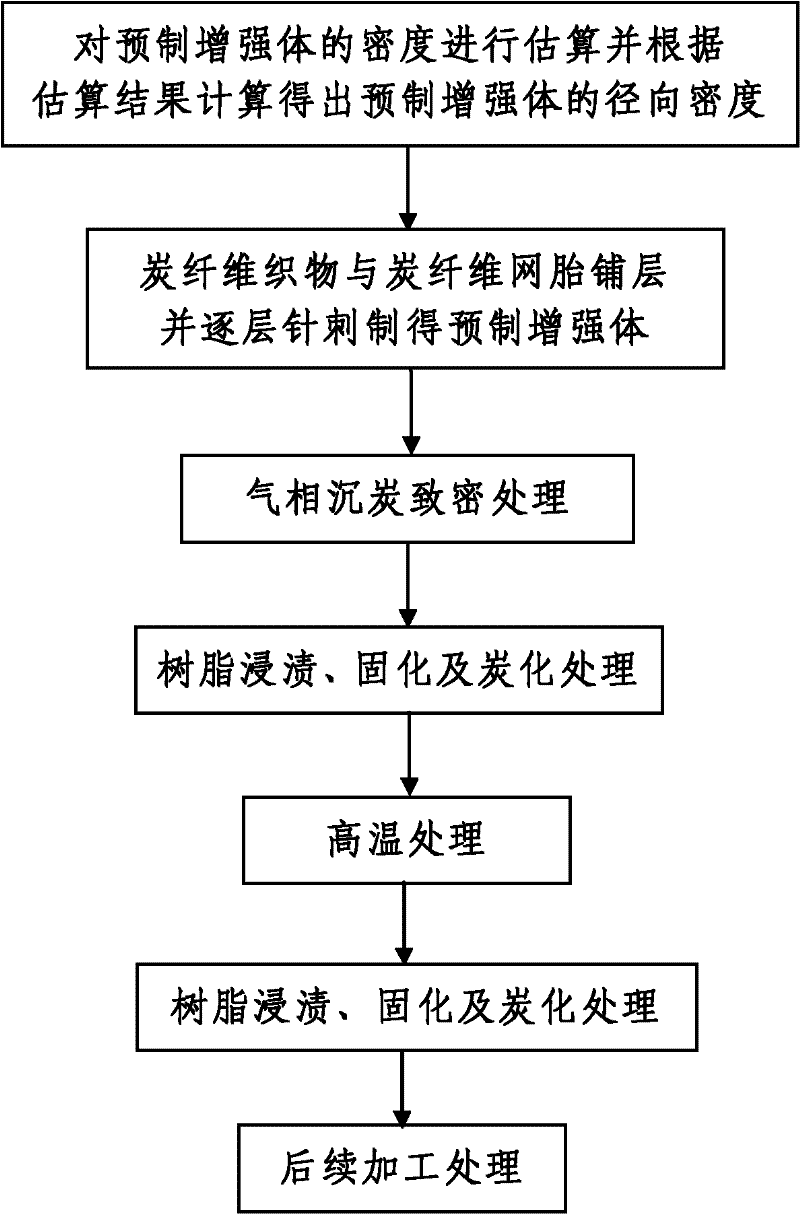

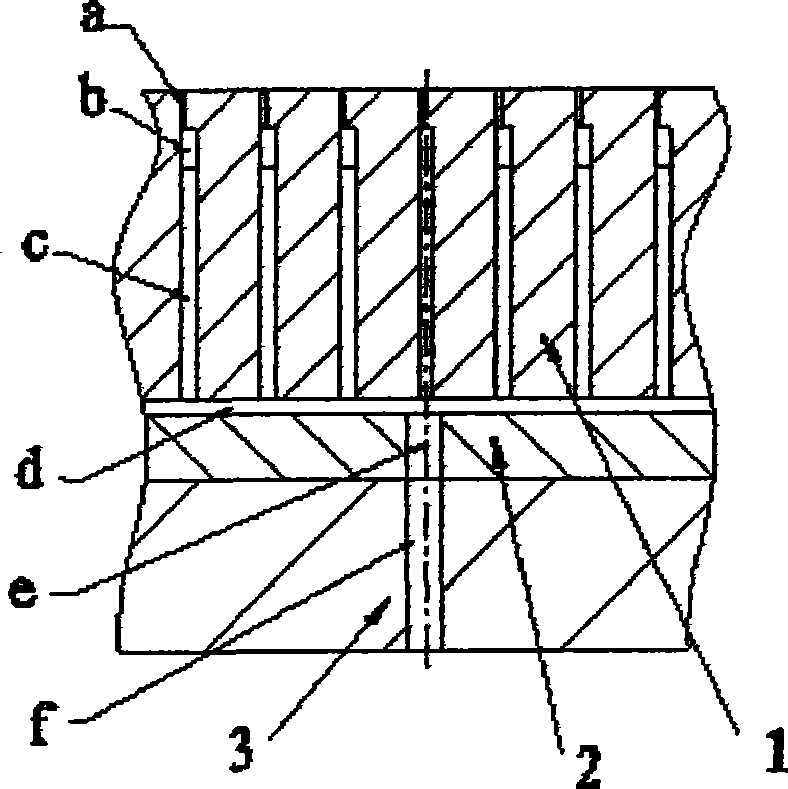

Preparation method of C/C composite tube of optical telescope

The invention discloses a preparation method of a C / C composite tube of an optical telescope. The method comprises the following steps: 1) carbon fiber fabrics and carbon fiber felts are spread layer by layer, needle-punching is performed on each layer to prepare a preformed reinforcement body, the density of the preformed reinforcement body is estimated before layer spreading and the radial density of the preformed reinforcement body is calculated according to the estimation result; 2) composite densifying is performed; 3) high temperature treatment is performed; and 4) the subsequent treatment is performed. The densifying process comprises the following steps: 201) performing gas-phase carbon-settling densifying treatment, namely using a gas-phase carbon-settling device to perform gas-phase carbon-settling treatment; and 202) performing resin impregnation, curing and carbonization treatment, namely performing further densifying treatment on the preformed reinforcement body after thegas-phase carbon-settling densifying treatment. The method has reasonable design, simple processing steps, low input cost, simpleness in operation and convenience in quality control; and the processed C / C composite tube has good performance, higher overall strength and stability and an ultralow thermal expansion coefficient.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

Circular-to-circular high-speed hot gold stamping gum

InactiveCN103242782AGood compatibilityHot stamping integrity is goodMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesHot stampingRough surface

The invention relates to a circular-to-circular high-speed hot gold stamping gum comprising the following components in weight ratio: 15-30 of acrylic copolymers, 10-20 of rosin resin, 10-20 of petroleum resin, 5-15 of chlorinated polyolefin resin, 10-20 of EVA (Ethylene-Vinyl Acetate) solid resin, 5-10 of additives and 70-90 of organic solvents. The circular-to-circular high-speed hot gold stamping gum has better adhesive force and good wettability for some hot stamping substrates with lower surface energy, the system has favorable initial adhesive force and holding power for various smooth and rough surfaces and has excellent hot stamping and edge scrapping performances, and different resins in the system have better compatibility; and the circular-to-circular high-speed hot gold stamping gum has a better stamping property for various substrates such as common untreated paper, composite paper, parts of UV (Ultraviolet) glazed paper and the like, and is suitable for circular-to-circular high-speed hot stamping, flat-to-flat hot stamping and circular-to-flat hot stamping, favorable in edge scrapping property and adhesive force, good in glossiness, integral in hot stamping, free of leak stamping and gold flying, good in hot stamping integrity for some rough substrates, wide in application range and strong in generality.

Owner:GUANGDONG BANGGU CHEM TECH

Exhausting structure of thin-wall injection molding die

The invention discloses an exhaust structure for a thin-walled injection mould, which consists of a group of exhaust plates, a pedestal and a die cavity plate. The structure is characterized in that the group of the exhaust plates are arranged in the pedestal in sequence by a positioning mode of a hanging table; and then an assembly is arranged in the die cavity plate; the pedestal and the die cavity plate are connected by a mode of fixing by bolts; lateral surfaces of each exhaust plate are provided with a transverse exhaust slot and a vertical exhaust slot respectively; the upper part of the transverse exhaust slots on the lateral surface of the exhaust plate is provided with a plurality of shallow vertical exhaust slits communicated with the transverse exhaust slot; and during exhausting, gas in a die cavity reaches the transverse exhaust slot on the exhaust plate from the exhaust slits on the exhaust plate, enters the vertical exhaust slot on the exhaust plate, enters a vertical exhaust groove on the pedestal, reaches an exhaust hole on the pedestal, and is exhausted out of the die cavity through an exhaust hole on the die cavity plate.

Owner:DONGMING XINGYE SCI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com