Preparation method of C/C composite tube of optical telescope

A technology of composite materials and manufacturing methods, which is applied in the field of manufacturing optical telescope C/C composite material lens barrels, can solve the problems such as the report of the manufacturing method of the moon-based optical telescope C/C composite material lens barrel structure, and the late start. , to achieve the effect of good rigidity, less processing steps and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

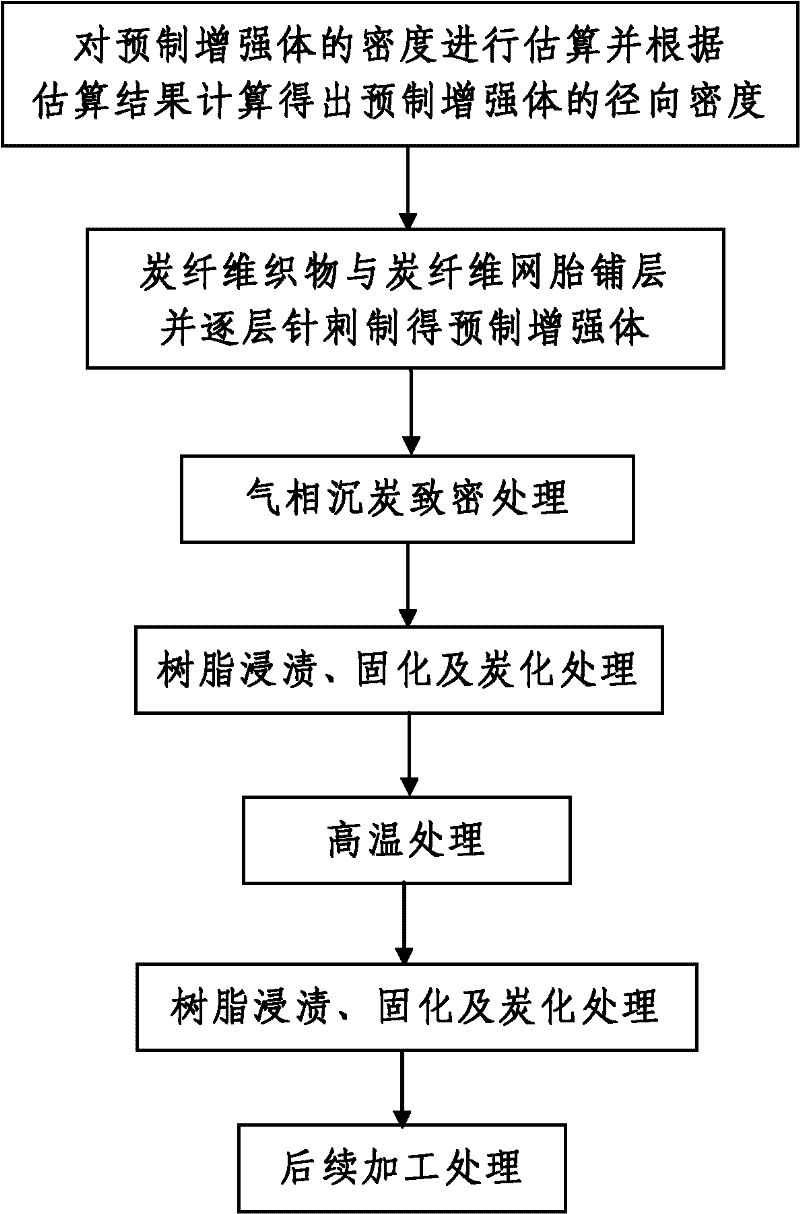

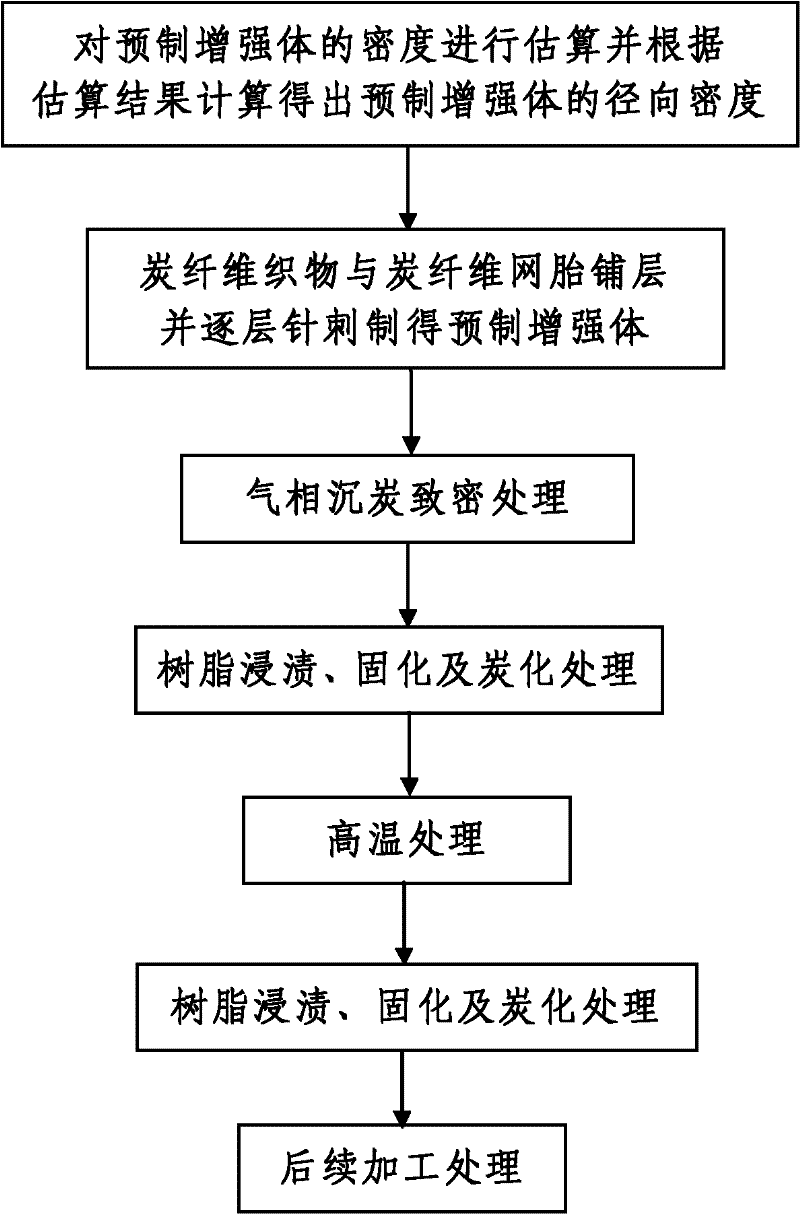

[0052] In this embodiment, the circumferential tensile strength of the finished C / C composite material lens barrel needs to be ≥ 160MPa, and the carbon fiber net tire made of 3K carbon fiber cloth and 12K carbon fiber with a tensile strength greater than 3500MPa is selected as raw materials. The manufacturing process includes the following steps:

[0053] Step 1: laying layers of carbon fiber fabric and carbon fiber net tires and needle-punching the prefabricated reinforcement layer by layer: first, obtain the volume density of the prefabricated reinforcement body to be laid according to the pre-estimation, and calculate the radial direction of the prefabricated reinforcement body The number of plies of the carbon fiber fabric and the carbon fiber mesh tire and the compactness between the adjacent plies; after that, according to the calculated ply number and the compactness between the adjacent plies, and the carbon fiber Fabric and carbon fiber net tires are laminated alterna...

Embodiment 2

[0075] In this embodiment, the difference from Example 1 is that in step 1, carbon fiber fabrics and carbon fiber mesh tires are used to alternately lay layers on the lens barrel forming mandrel along the circumferential direction, and the alternate laying process is divided into multiple steps. Repeat the cyclical layup cycle of the layup, and the angle between the adjacent carbon fiber fabric layup and the carbon fiber mesh tire layup in each cyclical layup cycle is 0°, +45° according to the order of the layup. , 90° and -45°, at this time the formula Where n=4, that is, the layering method is carried out by adopting the layering method of 0° / +45° / 90° / -45°. In this embodiment, other manufacturing steps and principles are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com