Patents

Literature

494results about How to "Improve machine performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

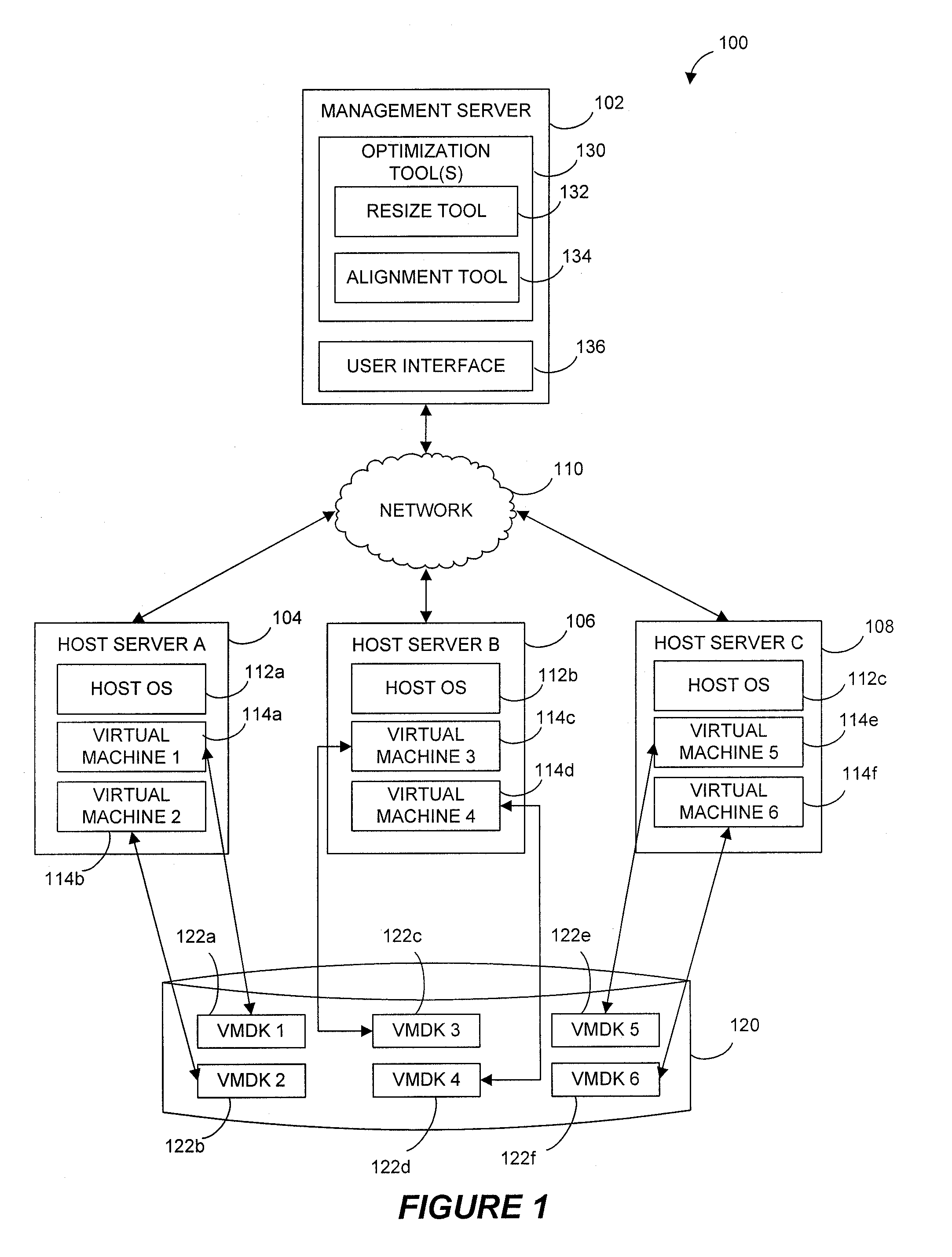

Systems and methods for improving virtual machine performance

ActiveUS8332571B1Improve machine performanceEffectively preventing painful and costly virtual machine outagesComputer security arrangementsProgram controlContent replicationBusiness enterprise

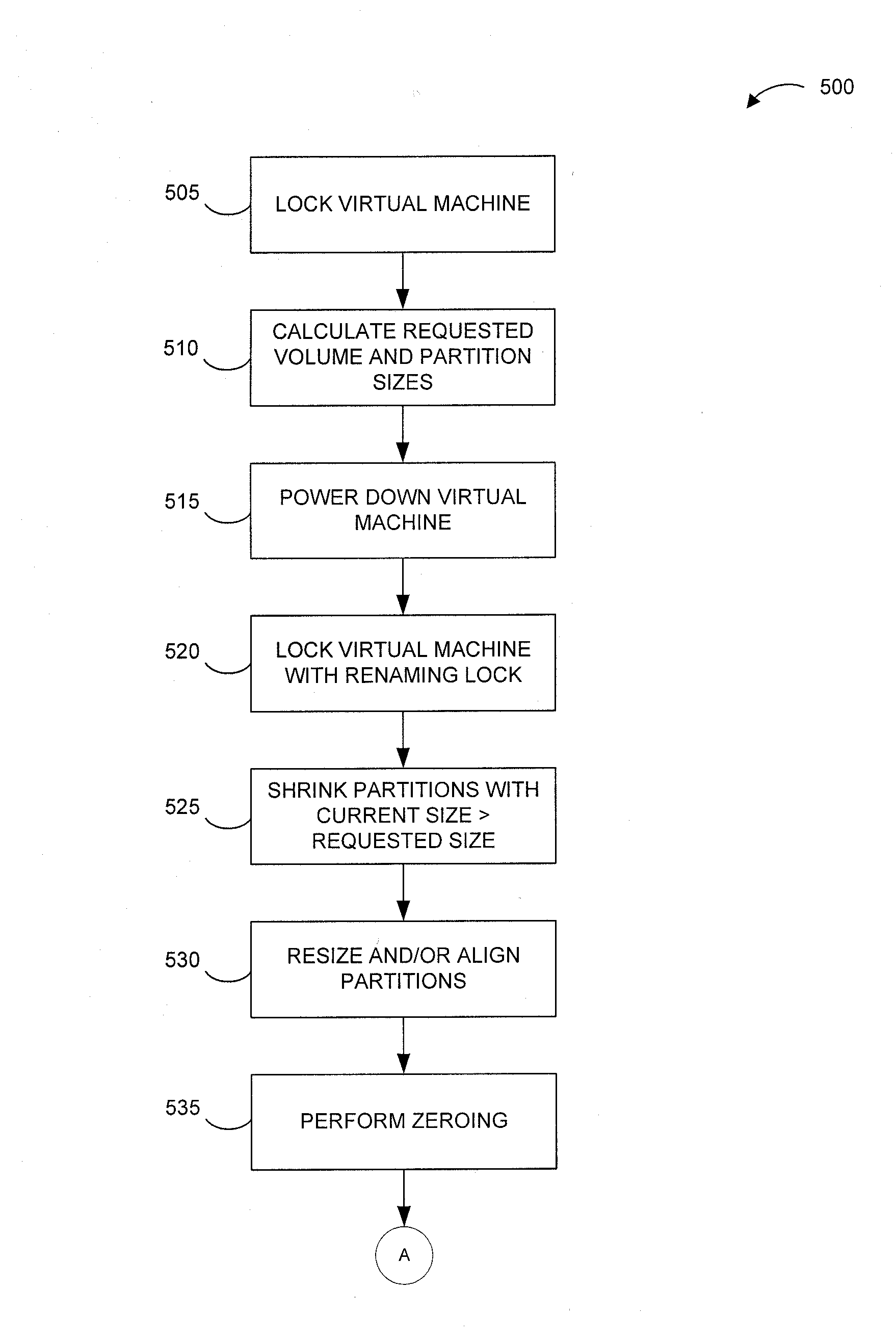

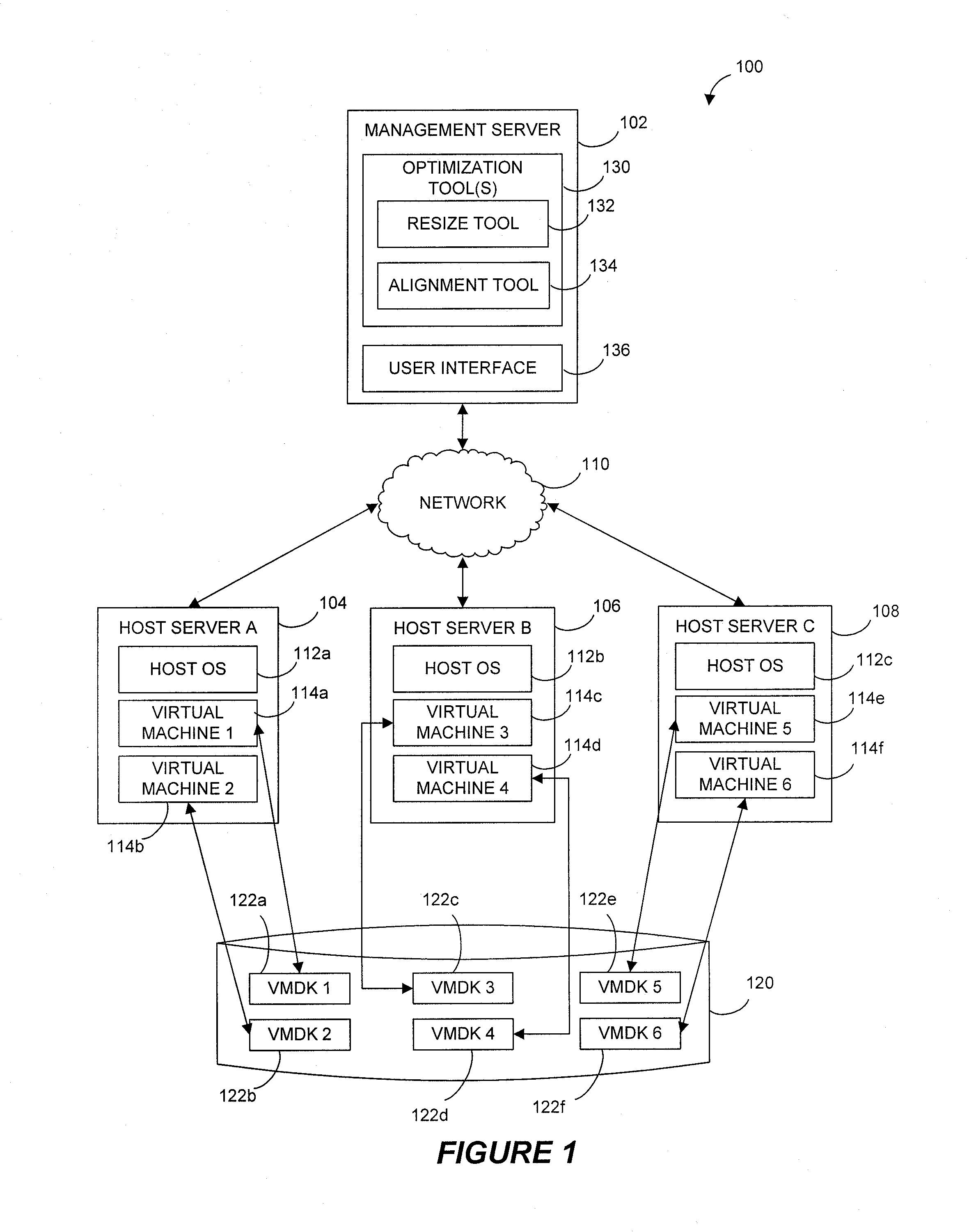

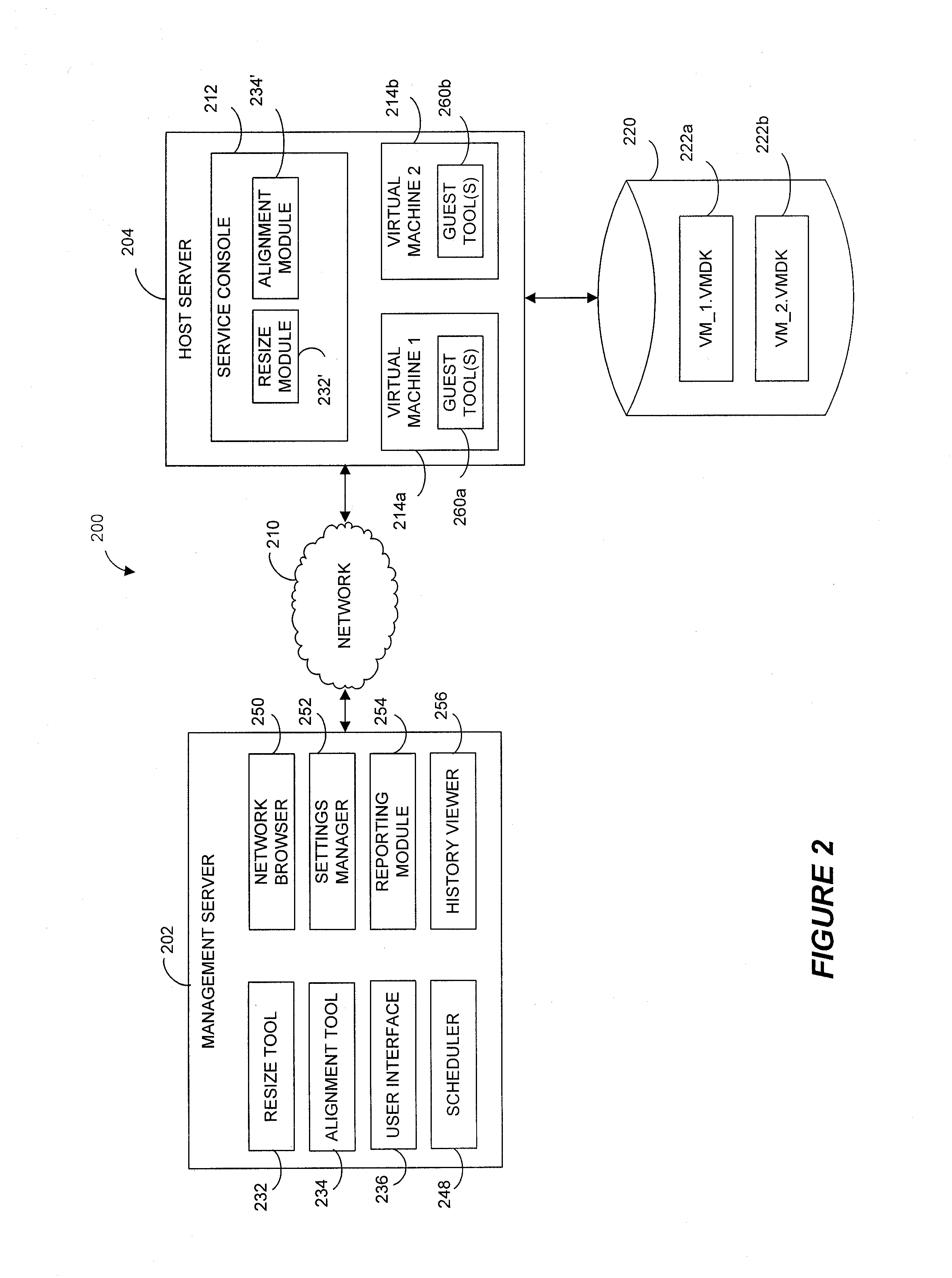

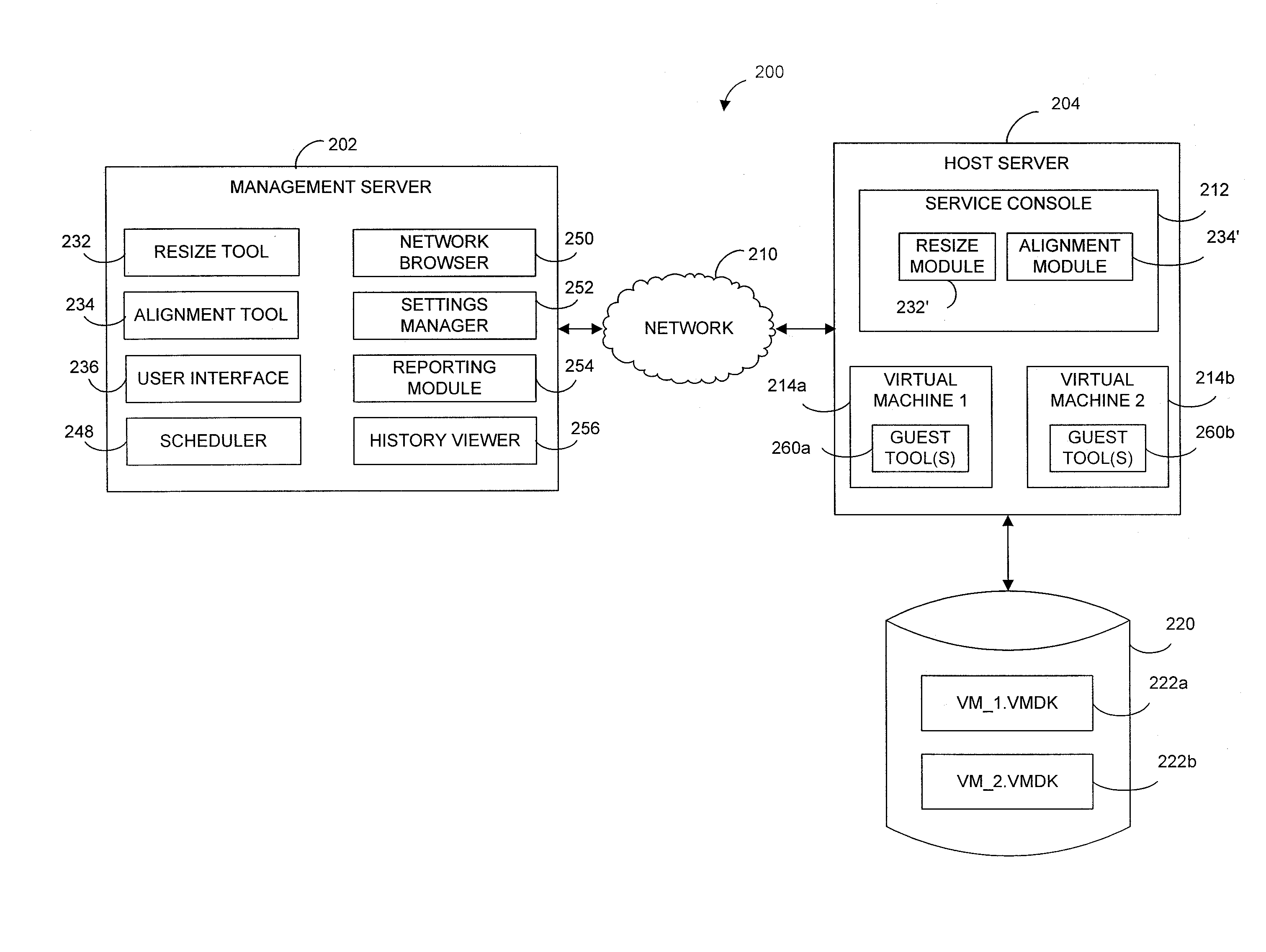

Virtual machine optimization and / or storage reclamation solutions are disclosed that manage virtual machine sprawl and / or growing enterprise storage costs. For instance, certain solutions receive recommendations based on one or more rules, policies and / or user preferences that identify storage and / or alignment criteria for virtual machine disk (VMDK) partition(s). In certain examples, a resize tool that operates within a host operating system of a host server dynamically resizes and / or aligns one or more VMDK partitions of a powered-down virtual machine. For instance, the resize tool can be injected to the host server from a remote management server and can resize and / or align the VMDK partitions without requiring contents of the VMDK to be copied to another VMDK. By reallocating storage and / or aligning the VMDK partitions, embodiments of the invention can increase virtual machine performance and improve storage management.

Owner:QUEST SOFTWARE INC

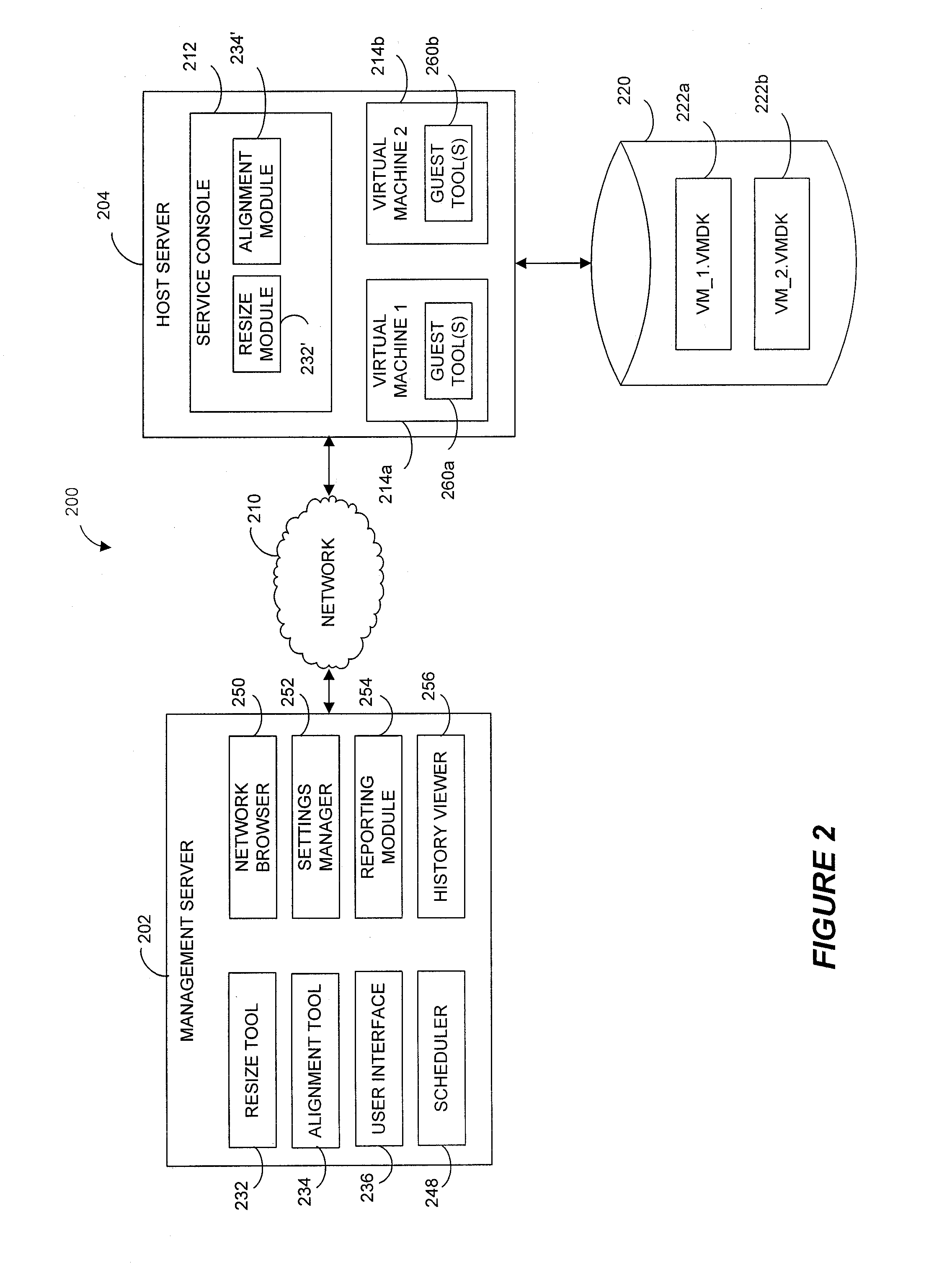

Systems and methods for improving virtual machine performance

ActiveUS8171201B1Improve machine performanceEffectively preventing painful and costly virtual machine outagesComputer security arrangementsProgram controlElectricityOperational system

Virtual machine optimization and / or storage reclamation solutions are disclosed that manage virtual machine sprawl and / or growing enterprise storage costs. For instance, certain solutions receive recommendations based on one or more rules, policies and / or user preferences that identify storage and / or alignment criteria for virtual machine disk (VMDK) partition(s). In certain examples, a resize tool that operates within a host operating system of a host server dynamically resizes and / or aligns one or more VMDK partitions of a powered-down virtual machine. For instance, the resize tool can be injected to the host server from a remote management server and can resize and / or align the VMDK partitions without requiring contents of the VMDK to be copied to another VMDK. By reallocating storage and / or aligning the VMDK partitions, embodiments of the invention can increase virtual machine performance and improve storage management.

Owner:QUEST SOFTWARE INC

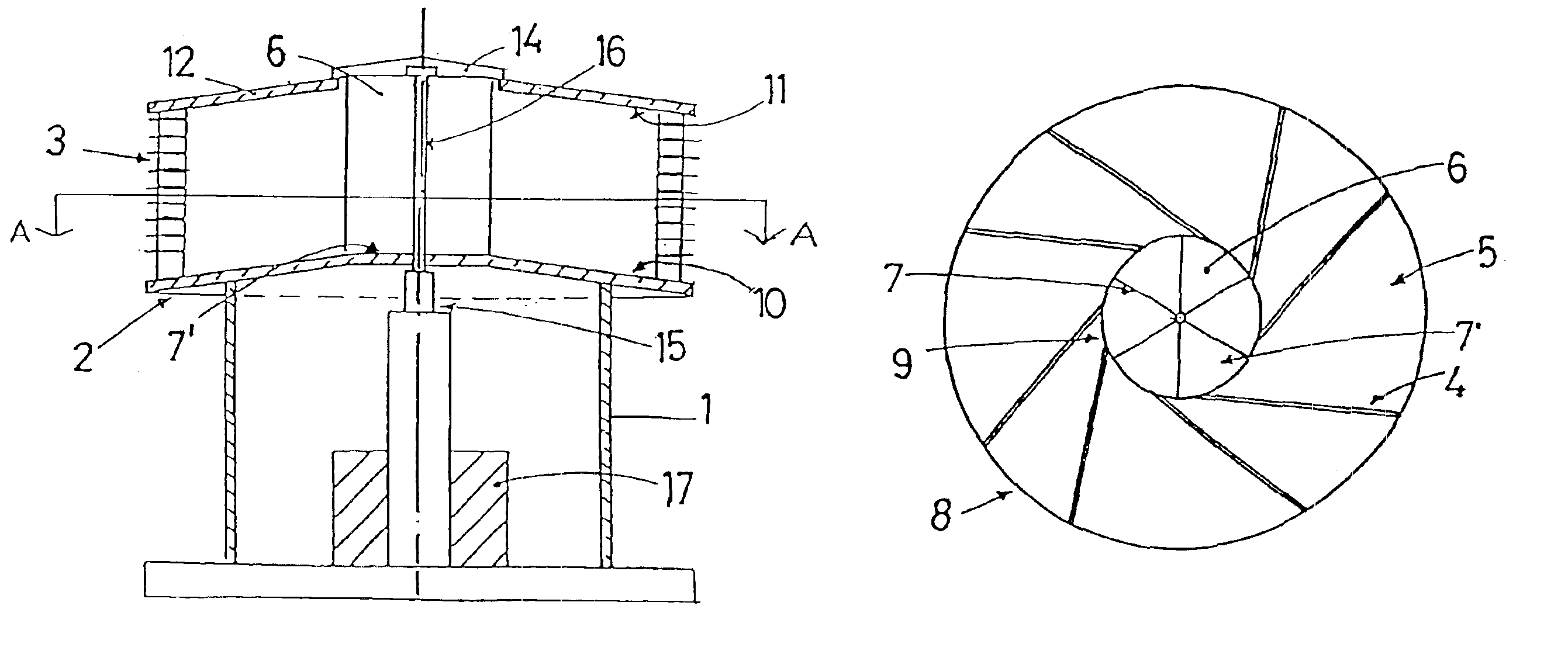

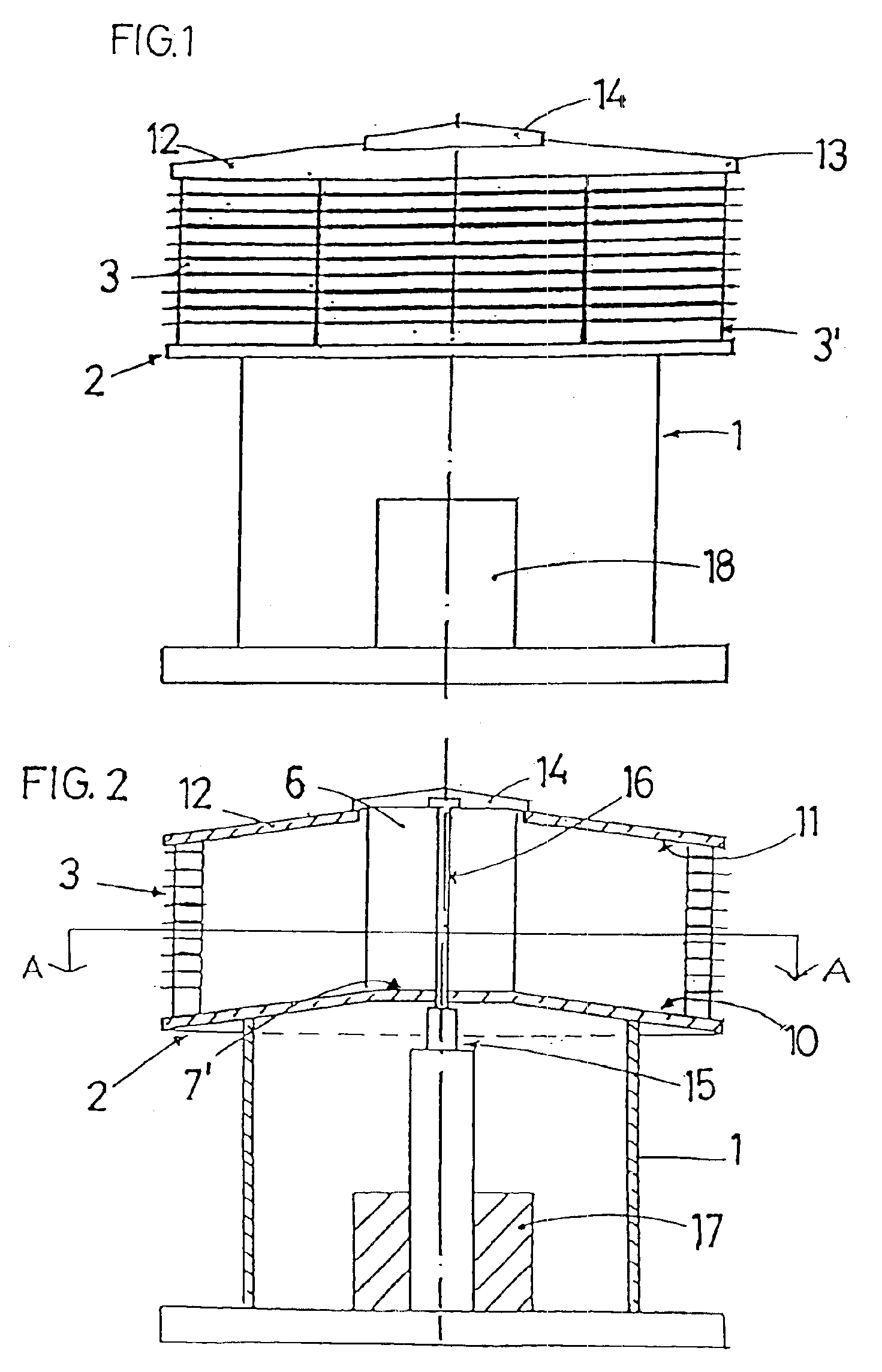

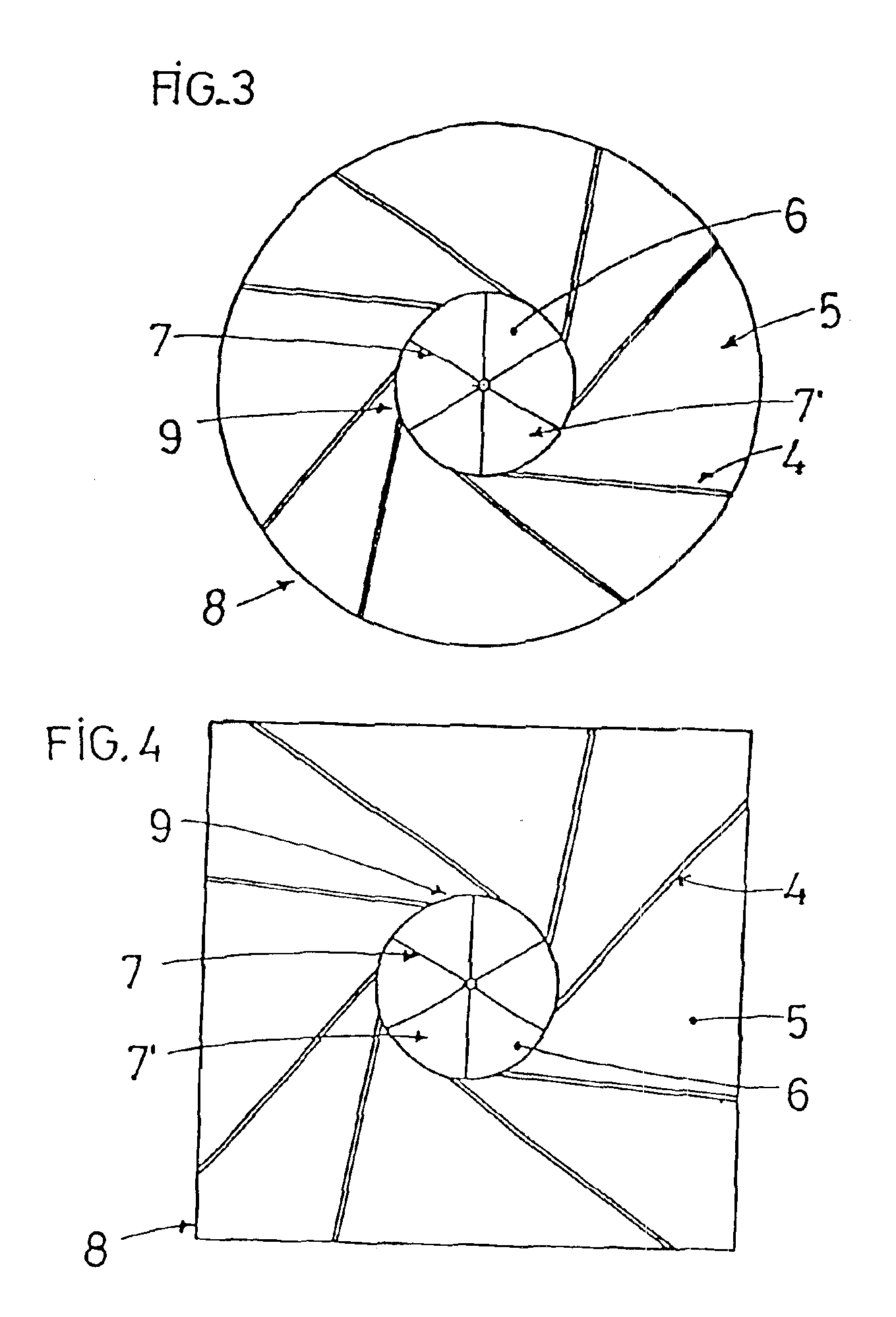

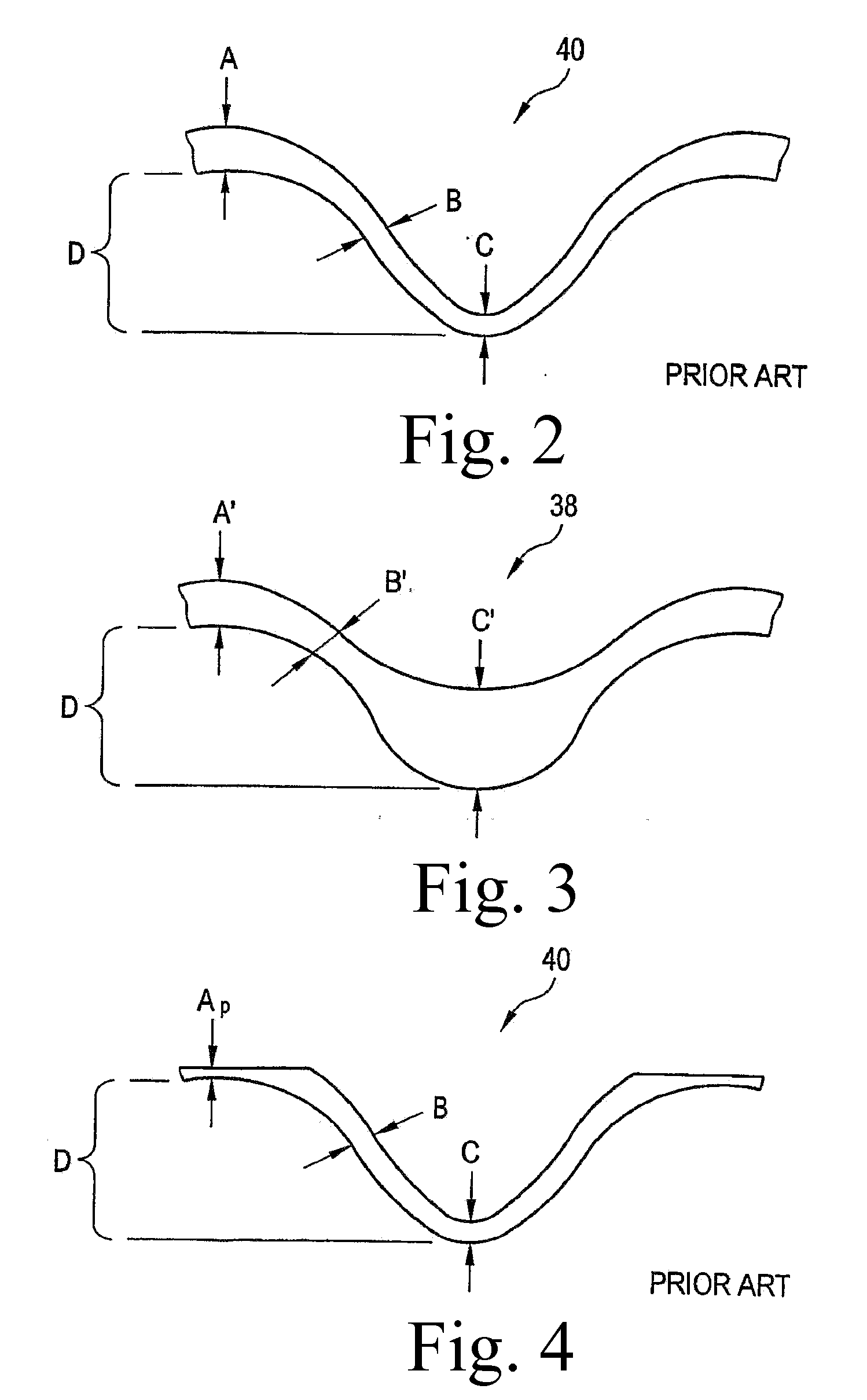

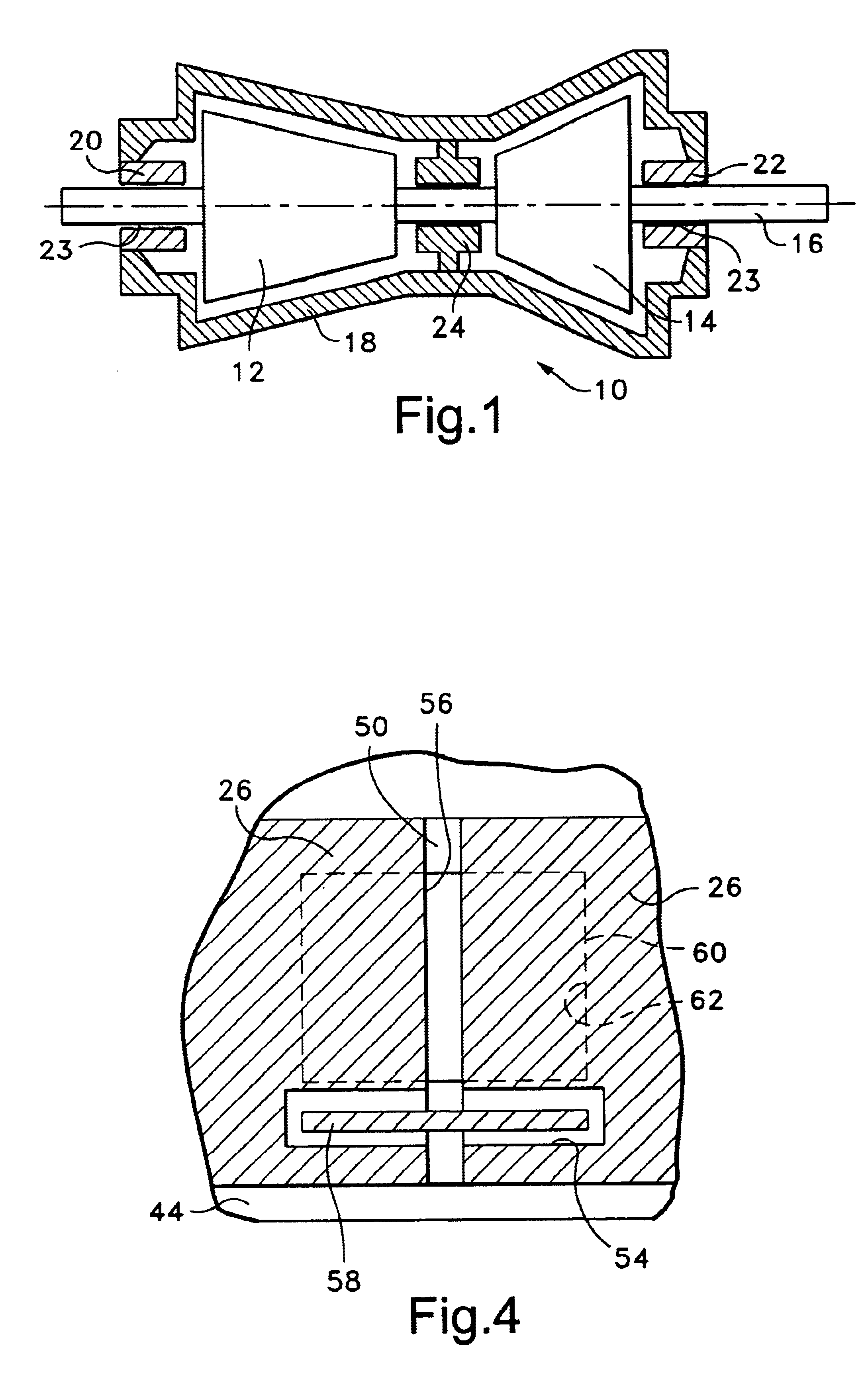

Wind power generator having wind channeling body with progressively reduced section

InactiveUS6841894B2Improve machine performanceImprove performanceWind motor supports/mountsWind motor combinationsTowerWind force

A wind power recovery device has a tower, a rotor arranged on the tower and including a plurality of blades rotatable under the action of wind, the rotor also having an axis for transmitting the rotation of the rotor to another apparatus, a wind channeling body provided with a series of walls which form channelings with a section which is progressively reduced from an entry side of the wind channeling body to an exit side of the channeling body toward the rotor to affect tangentially the blades of the rotor at a speed higher than at the entry side of the body, the wind channeling body having a side face, and a blind protecting the side face of the channeling body.

Owner:GOMEZ GOMAR JOSEP LLUIS

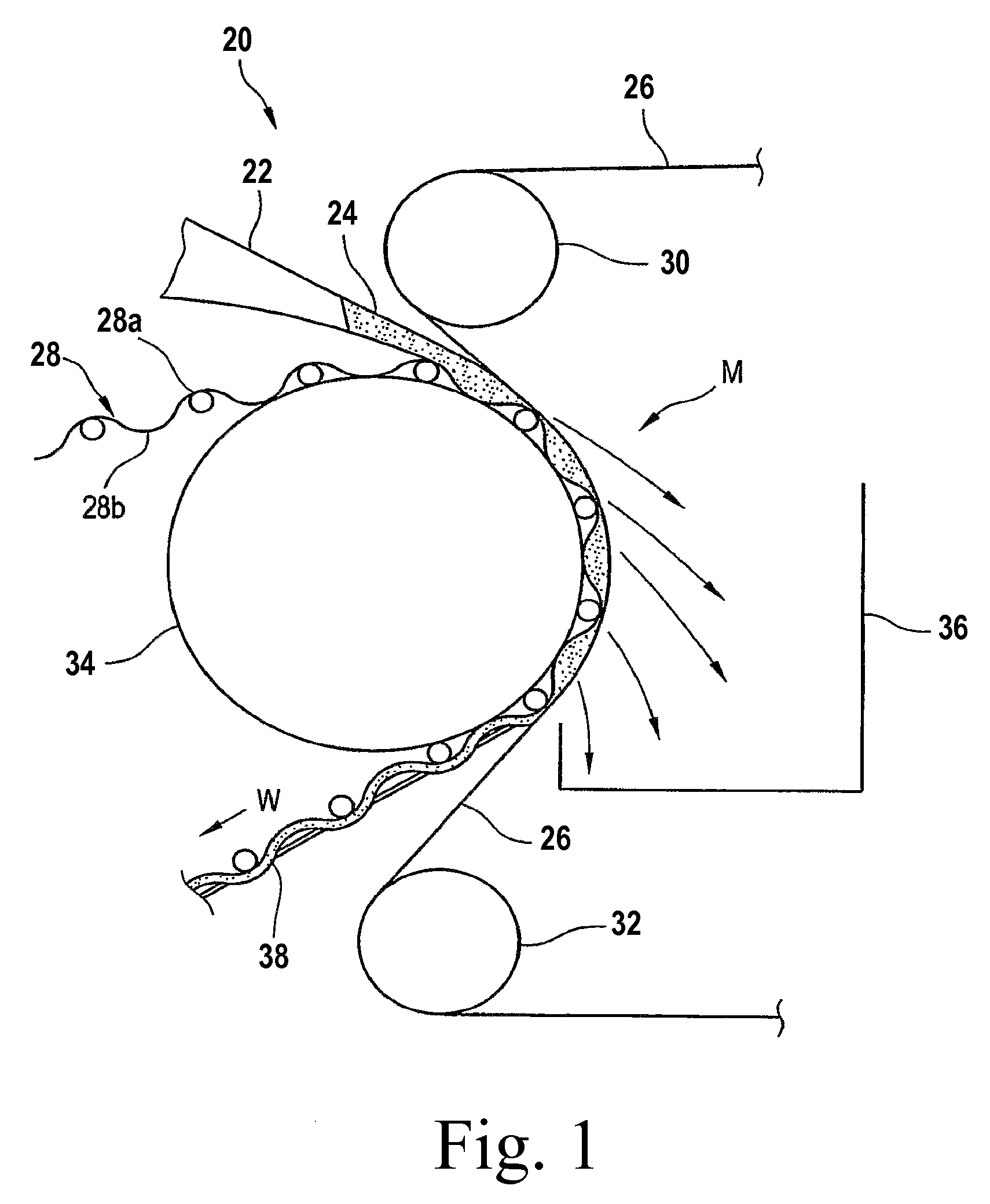

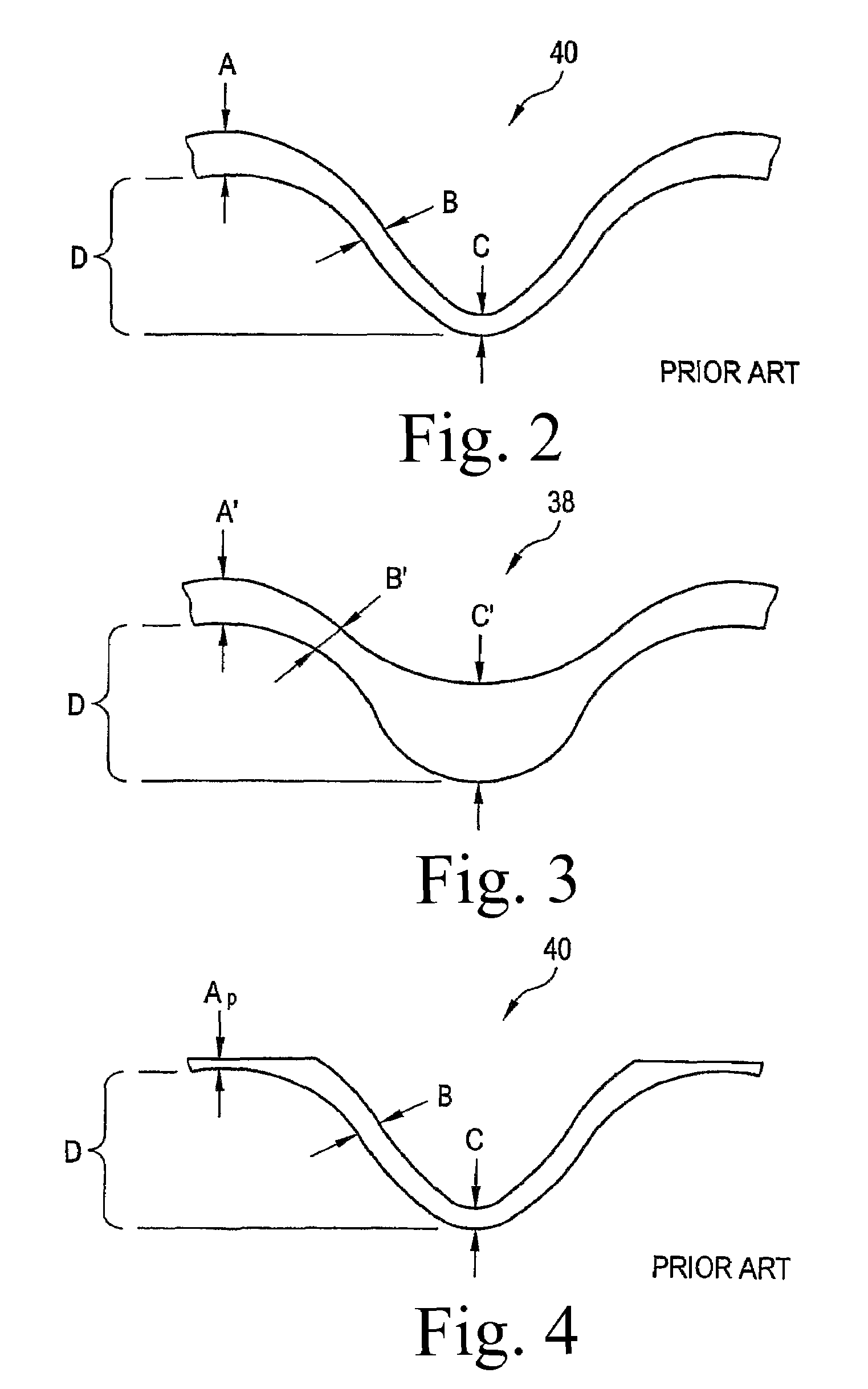

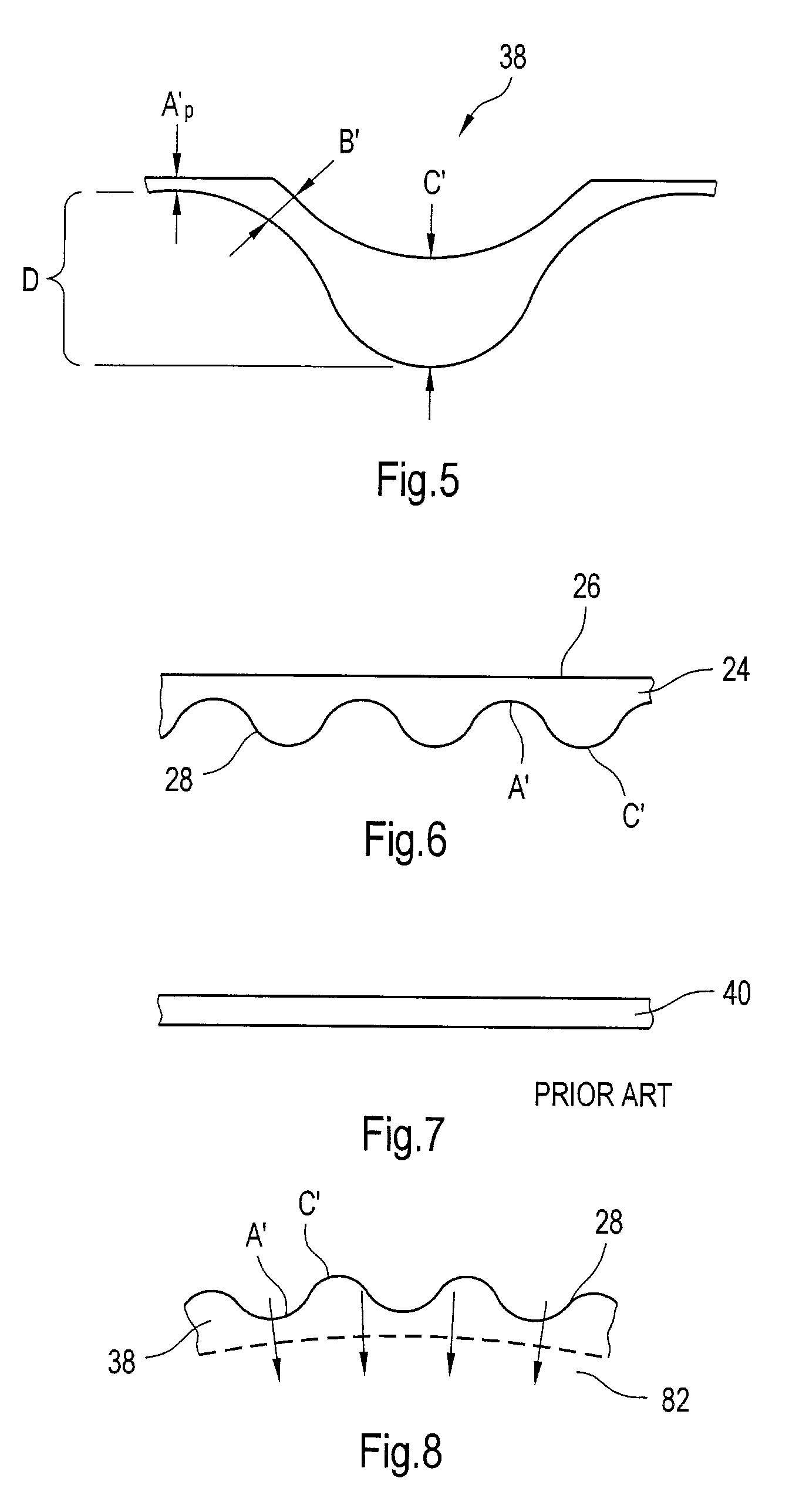

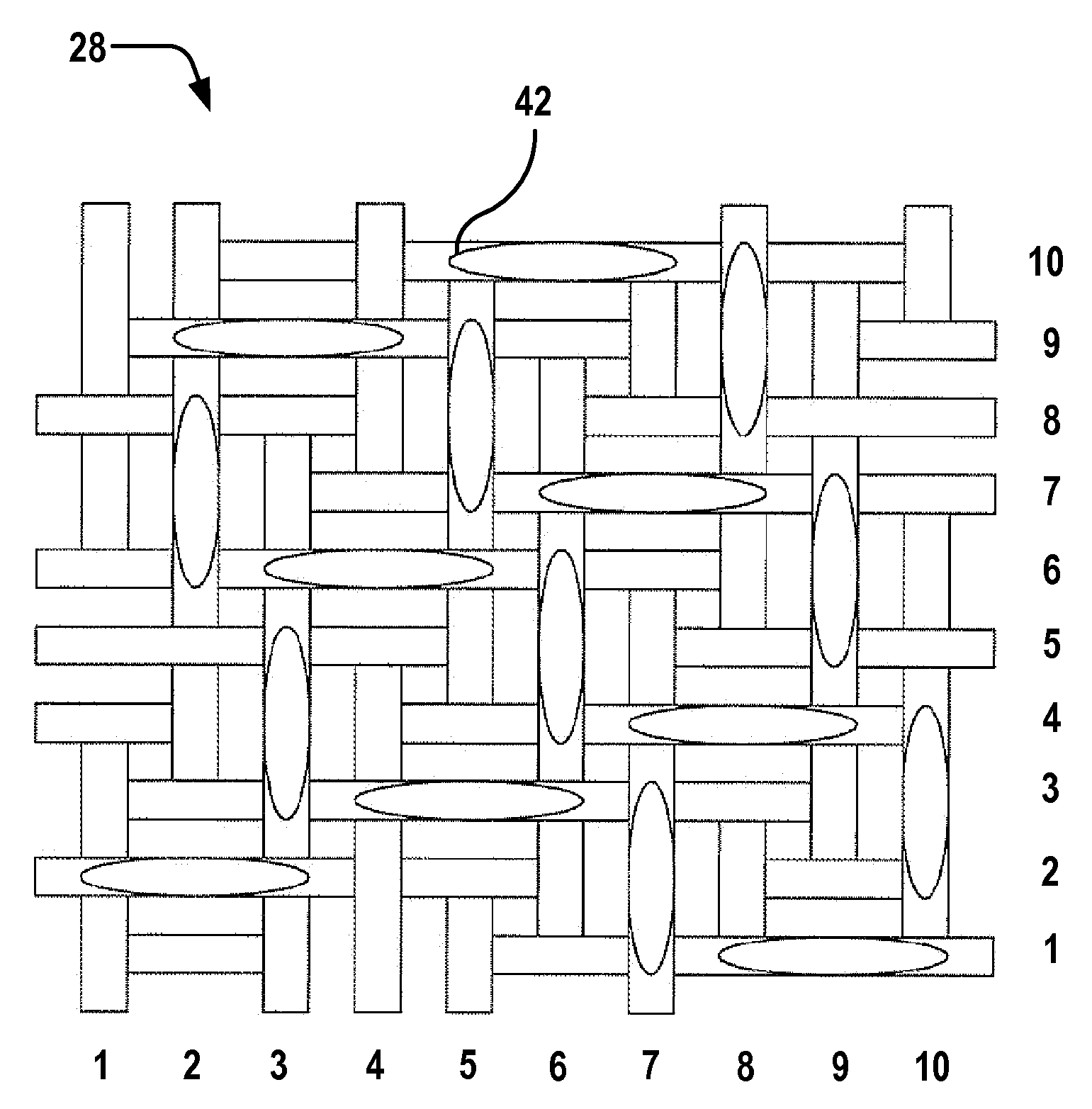

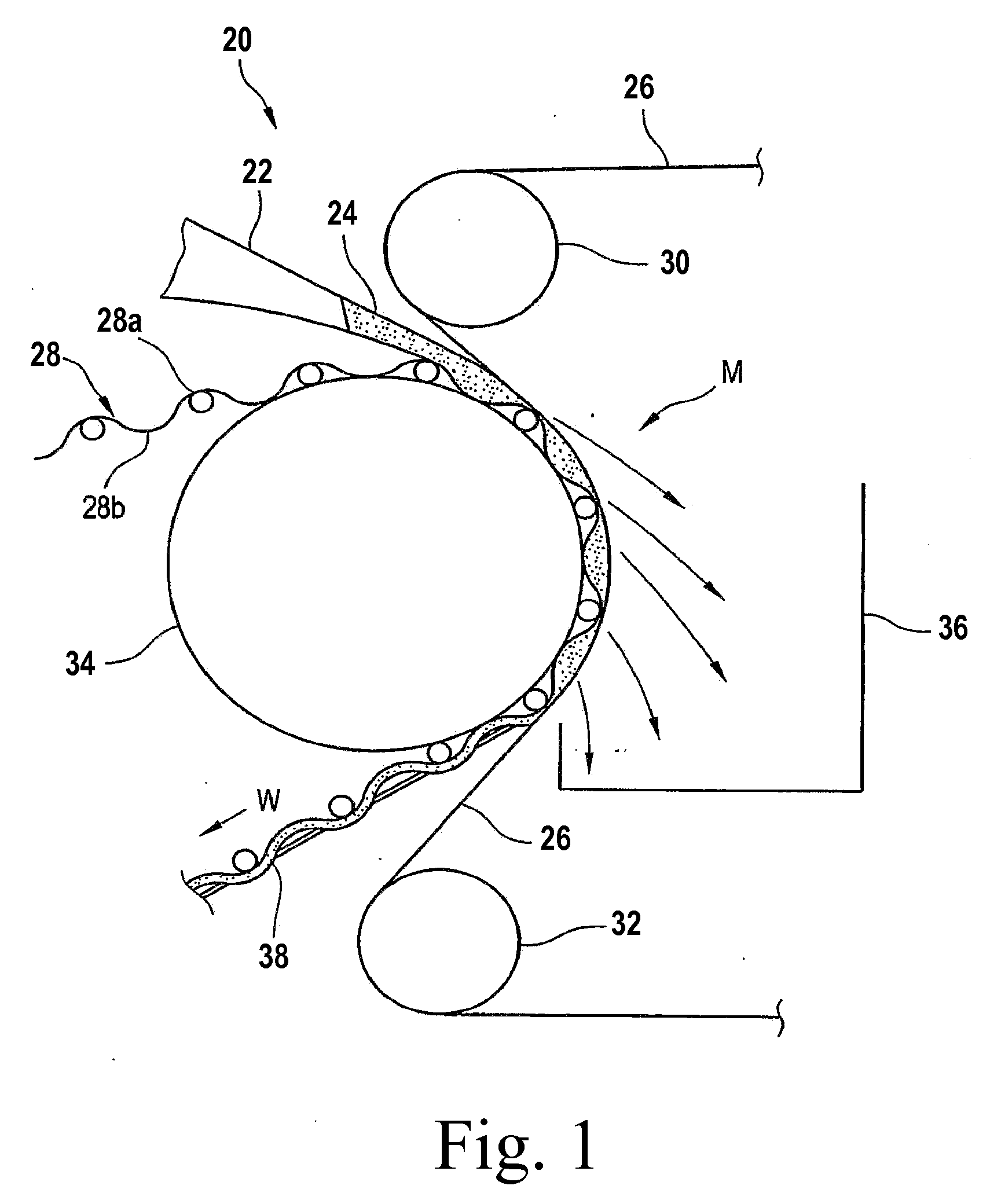

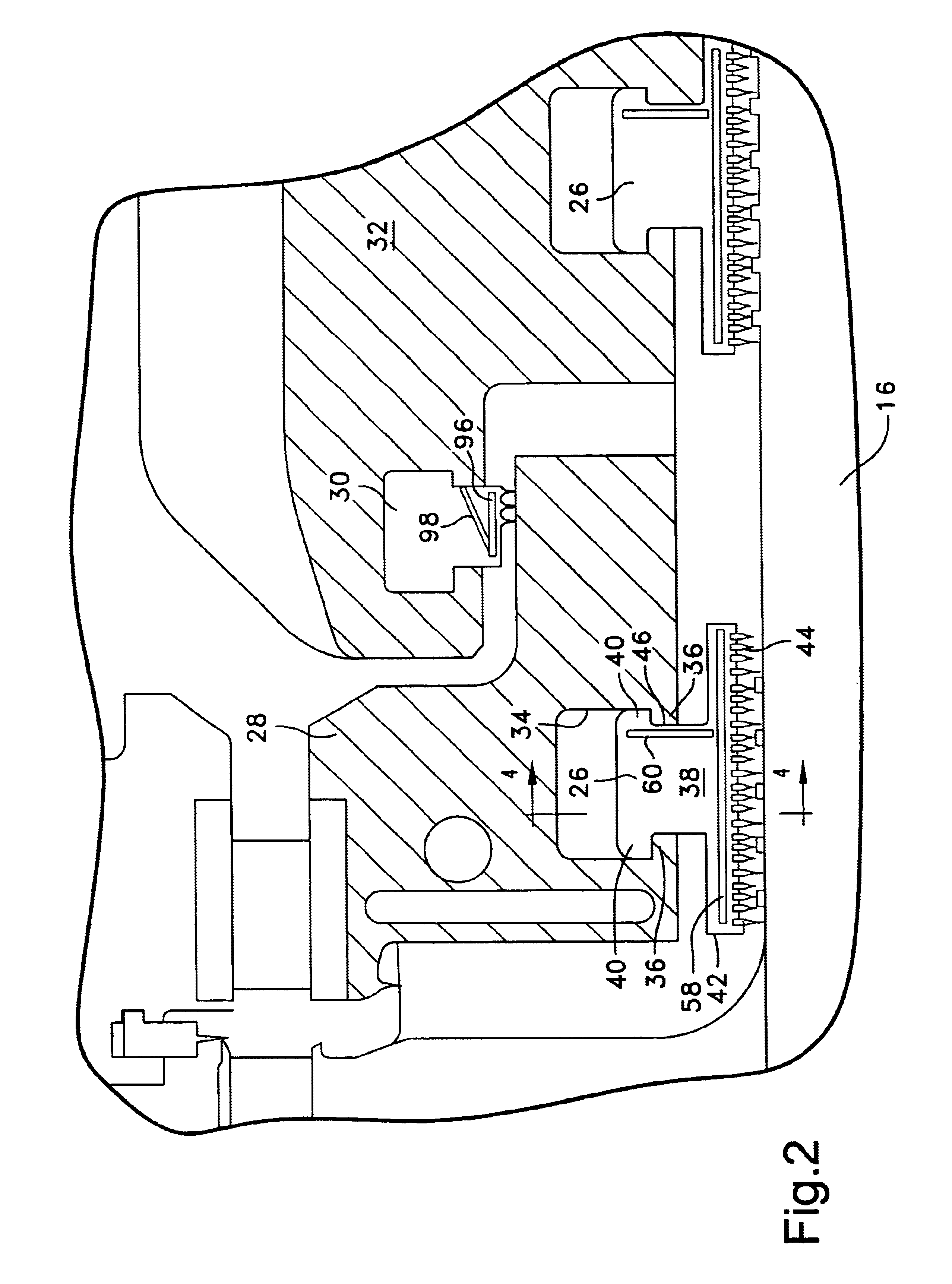

Structured forming fabric

InactiveUS7585395B2Increase surface areaImprove machine performanceFibreboardNon-fibrous pulp additionPulp and paper industryWeft yarn

A fabric for use by a papermaking machine, the fabric including a plurality of weft yarns, a plurality of warp yarns, and a woven fabric resulting from a repeating pattern of the weft yarns and warp yarns. Each of the weft yarn in the repeating pattern having a sequence of starting at a starting point then sequentially going over three adjacent warp yarns, under one warp yarn, over one warp yarn, under three warp yarns, over one warp yarn and under one warp yarn, the sequence then repeating.

Owner:VOITH PATENT GMBH

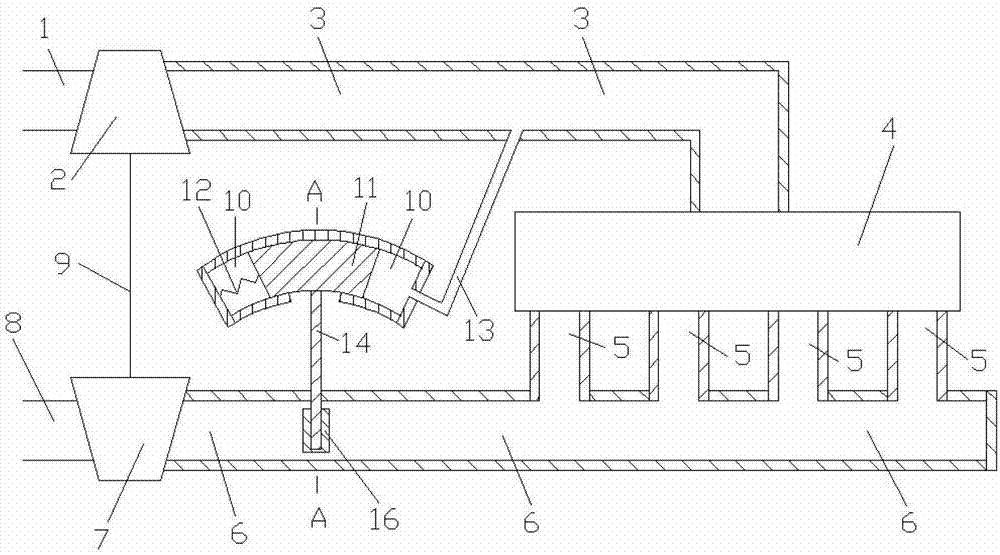

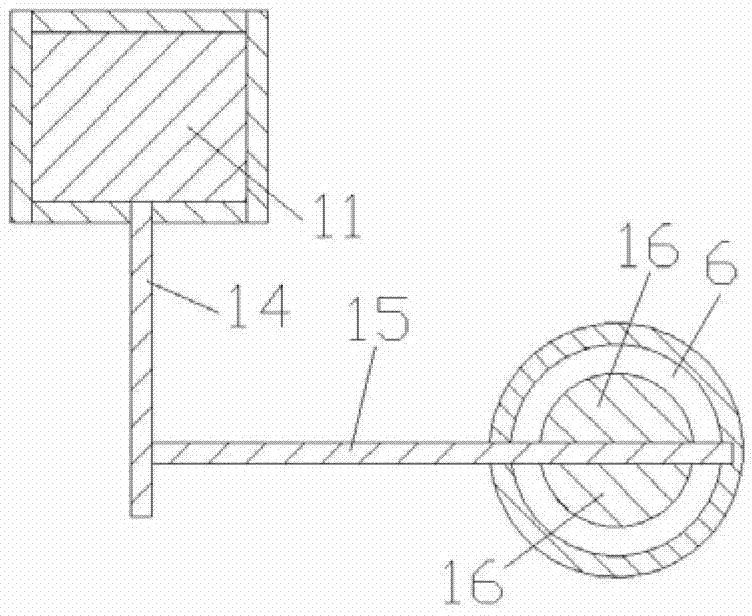

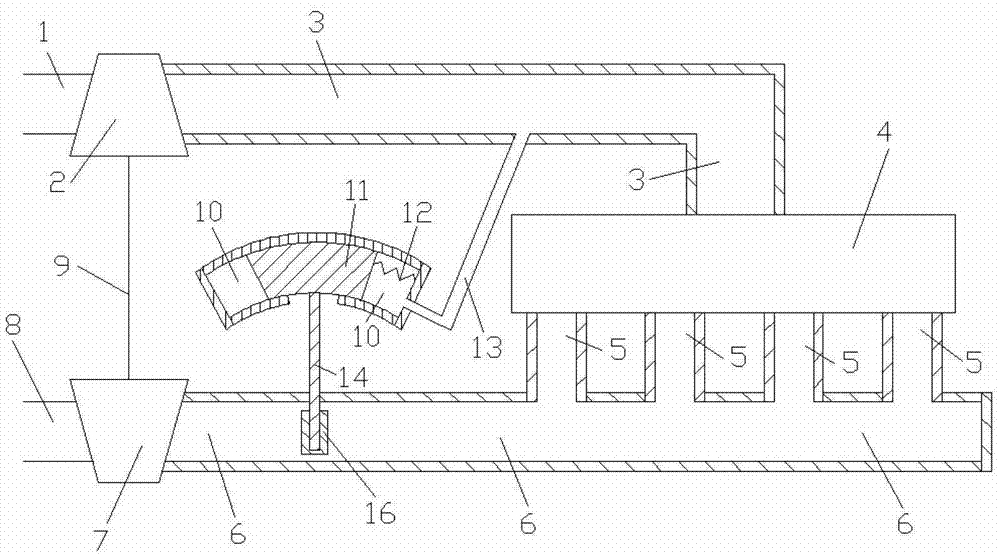

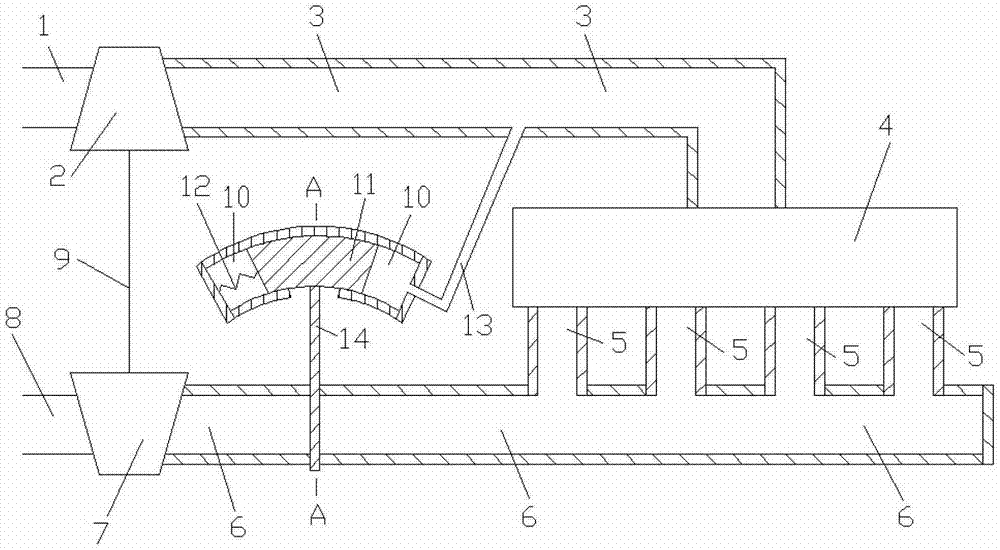

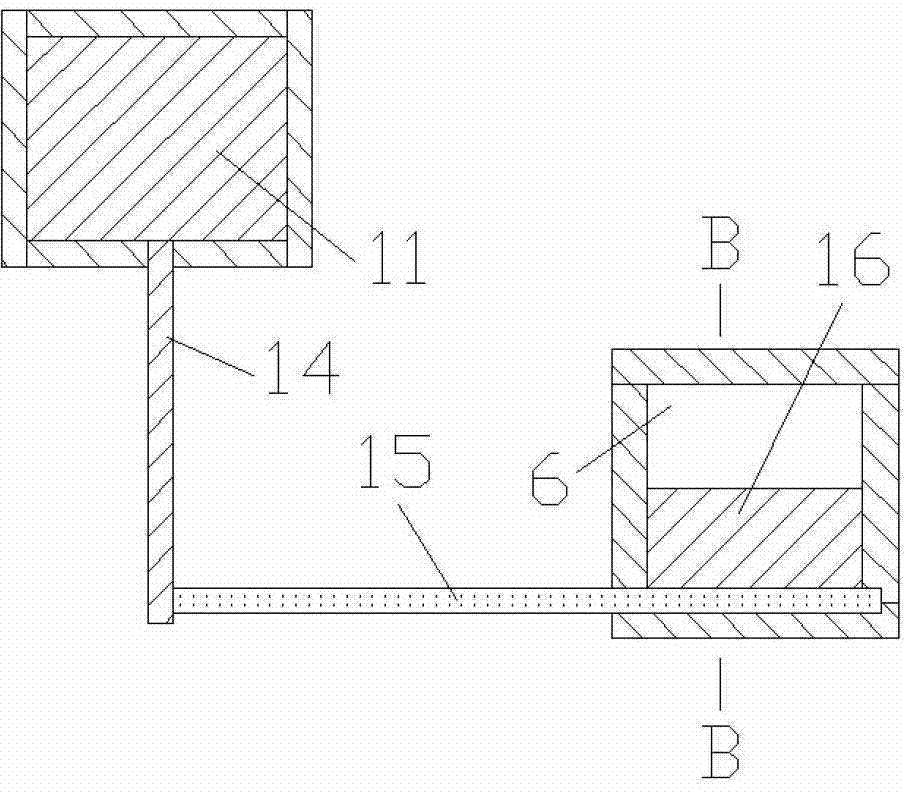

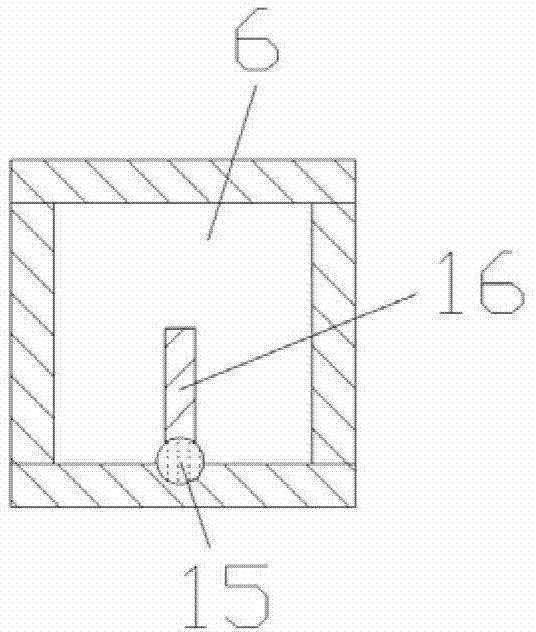

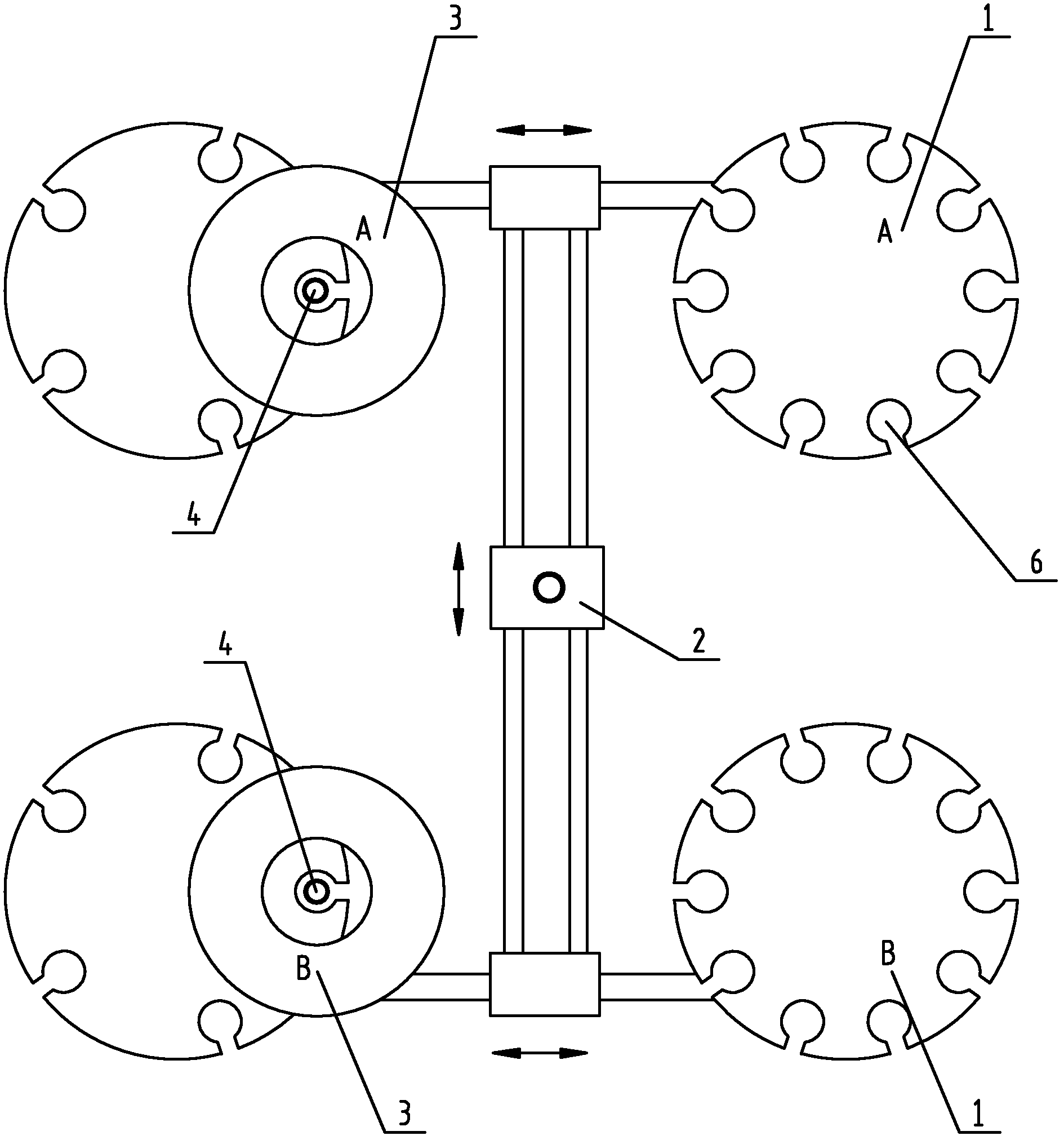

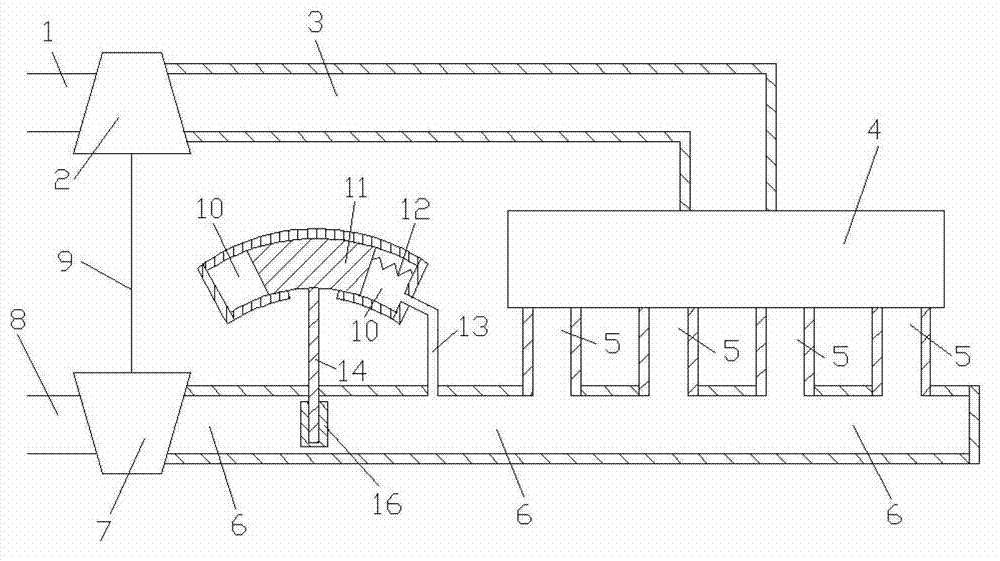

Variable air exhaust through flow area air inlet pressure control type adjusting device for turbocharged engine

InactiveCN103089409AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesInlet pressureAir compressor

A variable air exhaust through flow area air inlet pressure control type adjusting device for a turbocharged engine belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, a volume cavity, a rotation body, a spring, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in an air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and an air inlet pipe of the engine. When pressure in the air inlet pipe of the engine is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air inlet pipe of the engine is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The variable air exhaust through flow area air inlet pressure control type adjusting device for the turbocharged engine is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

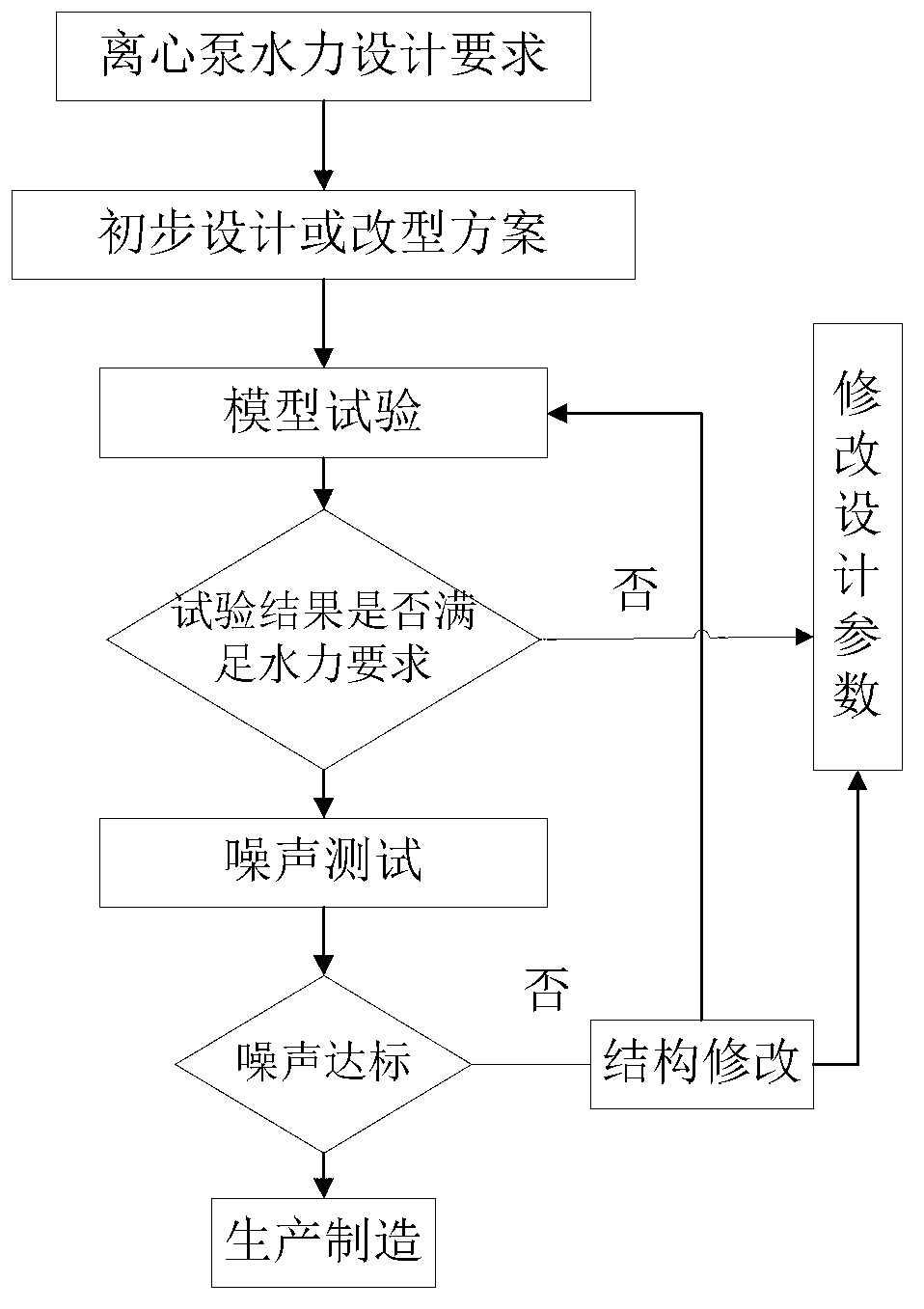

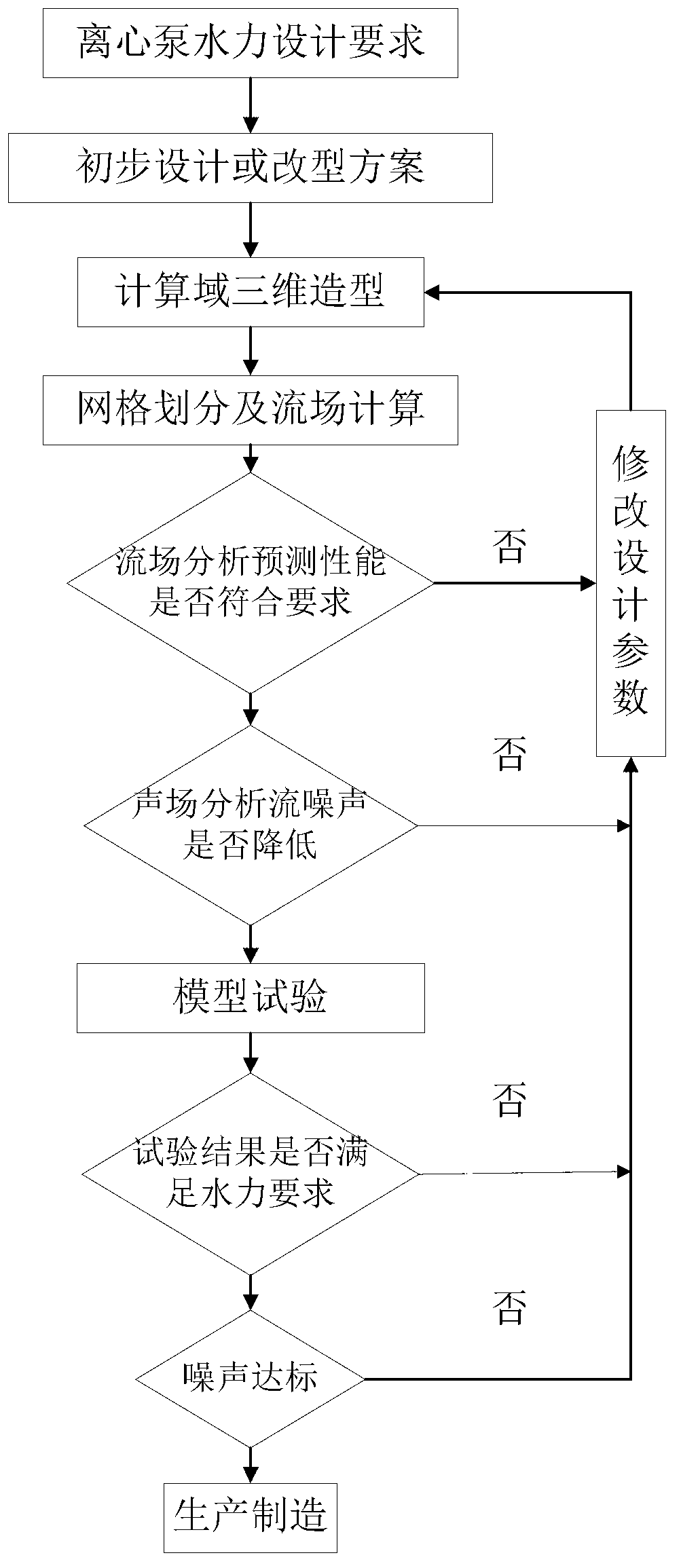

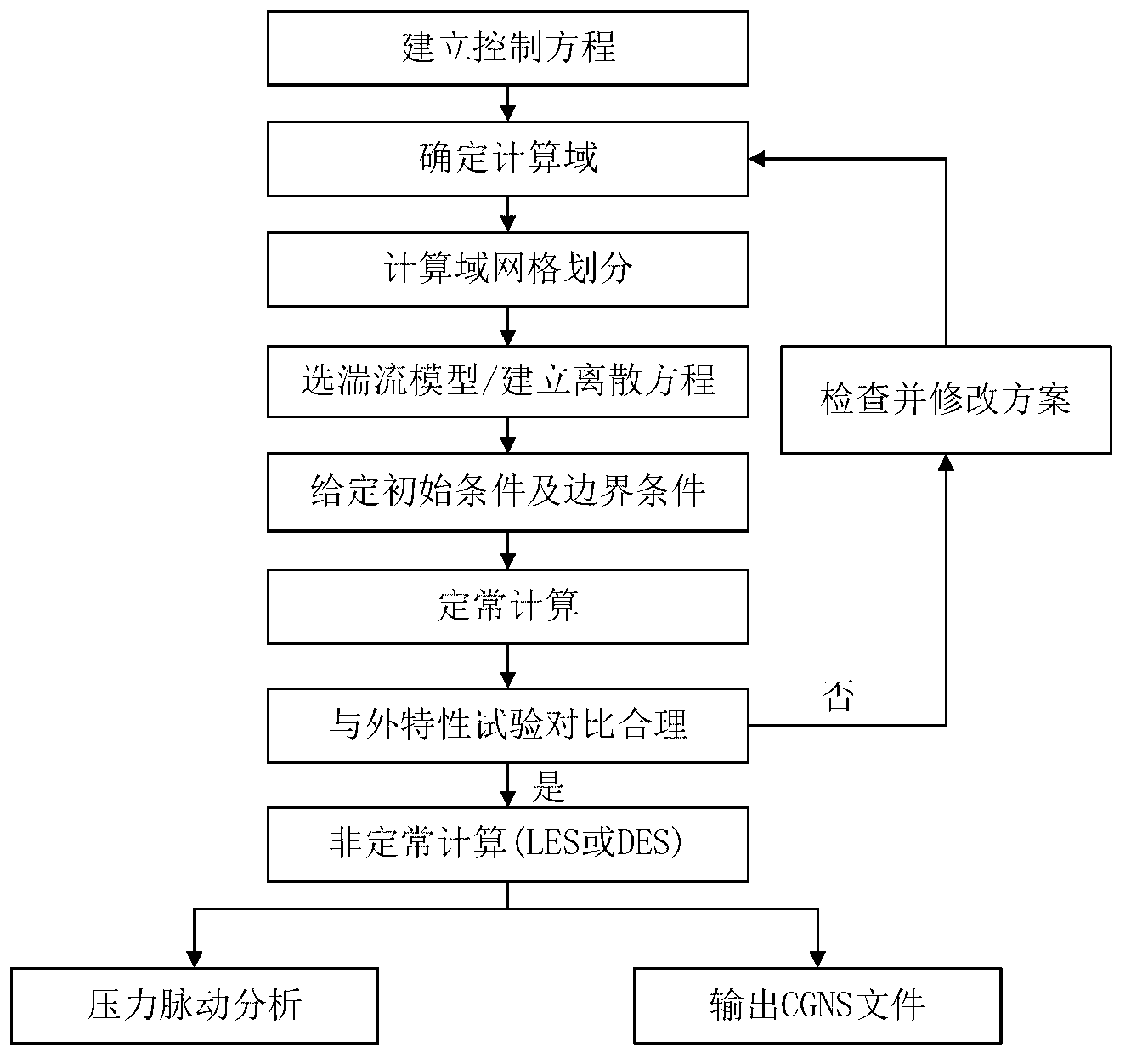

Low-noise hydraulic design method of centrifugal pump with low specific speed

ActiveCN103306985AImprove design qualityImprove machine performancePump componentsSpecial data processing applicationsLow noiseComputational acoustics

The invention discloses a low-noise design method of a centrifugal pump with low specific speed, and relates to an active control method of flow noise of turbomachinery. The design method comprises the steps that firstly, main structural dimensions of a centrifugal pump impeller and a helical pumping chamber (volute) are obtained by the traditional low-specific-speed pump design method; secondly, an internal flow field of the pump is computed by a computational fluid mechanics method; the performance of the pump is predicted whether to meet a design requirement; an optimum design improvement is performed by analyzing a stationary flow field; thirdly, flow induction noise of the pump with low specific speed is predicted by a computational acoustics method; if a flow noise index is qualified, the design is accomplished; if the flow noise index is disqualified, subsequent steps are performed; fourthly, the diameter of the impeller basically meeting a performance requirement in the design is adjusted to allow a gap between the impeller and a volute tongue to be increased continuously to 20%; splitter blades are added in the middles of blades to increase the lift, control the flow situation, and ensure the efficiency; and finally, the pump subjected to the impeller improvement design is subjected to noise prediction; if the flow noise index is qualified, the design is accomplished; and if the flow noise index is disqualified, the beginning step is repeated. The design method shortens the research and development period, saves the development cost, effectively improves the design quality of the centrifugal pump, can simultaneously meet low-noise requirements of the lift and the efficiency, and realizes optimization of the performance of the complete centrifugal pump with low specific speed.

Owner:JIANGSU UNIV

Structured forming fabric

InactiveUS20070272385A1Improve surface areaImprove machine performanceFibreboardNon-fibrous pulp additionWoven fabricYarn

A fabric for use by a papermaking machine, the fabric including a plurality of weft yarns, a plurality of warp yarns, and a woven fabric resulting from a repeating pattern of the weft yarns and warp yarns. Each of the weft yarn in the repeating pattern having a sequence of starting at a starting point then sequentially going over three adjacent warp yarns, under one warp yarn, over one warp yarn, under three warp yarns, over one warp yarn and under one warp yarn, the sequence then repeating.

Owner:VOITH PATENT GMBH

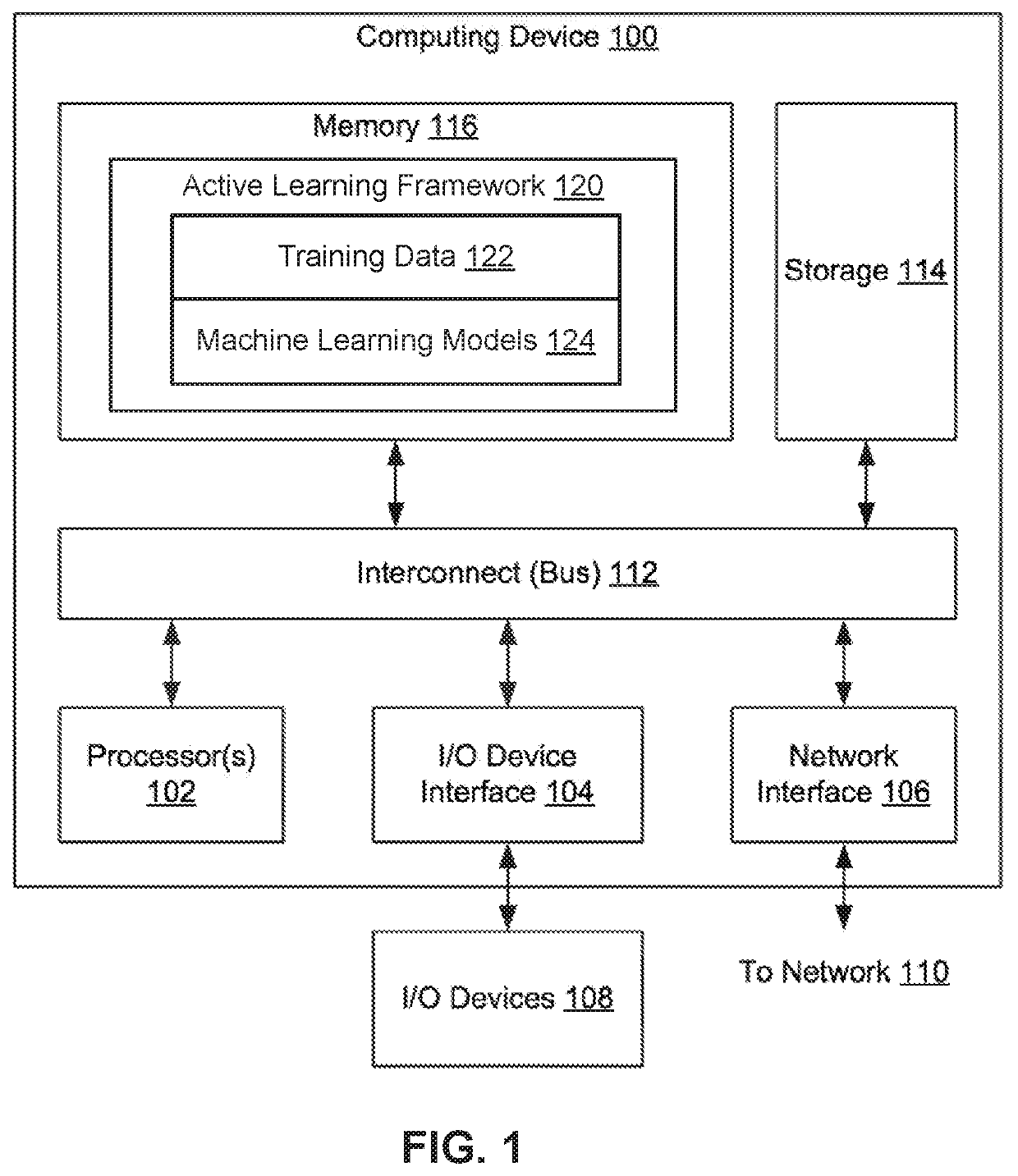

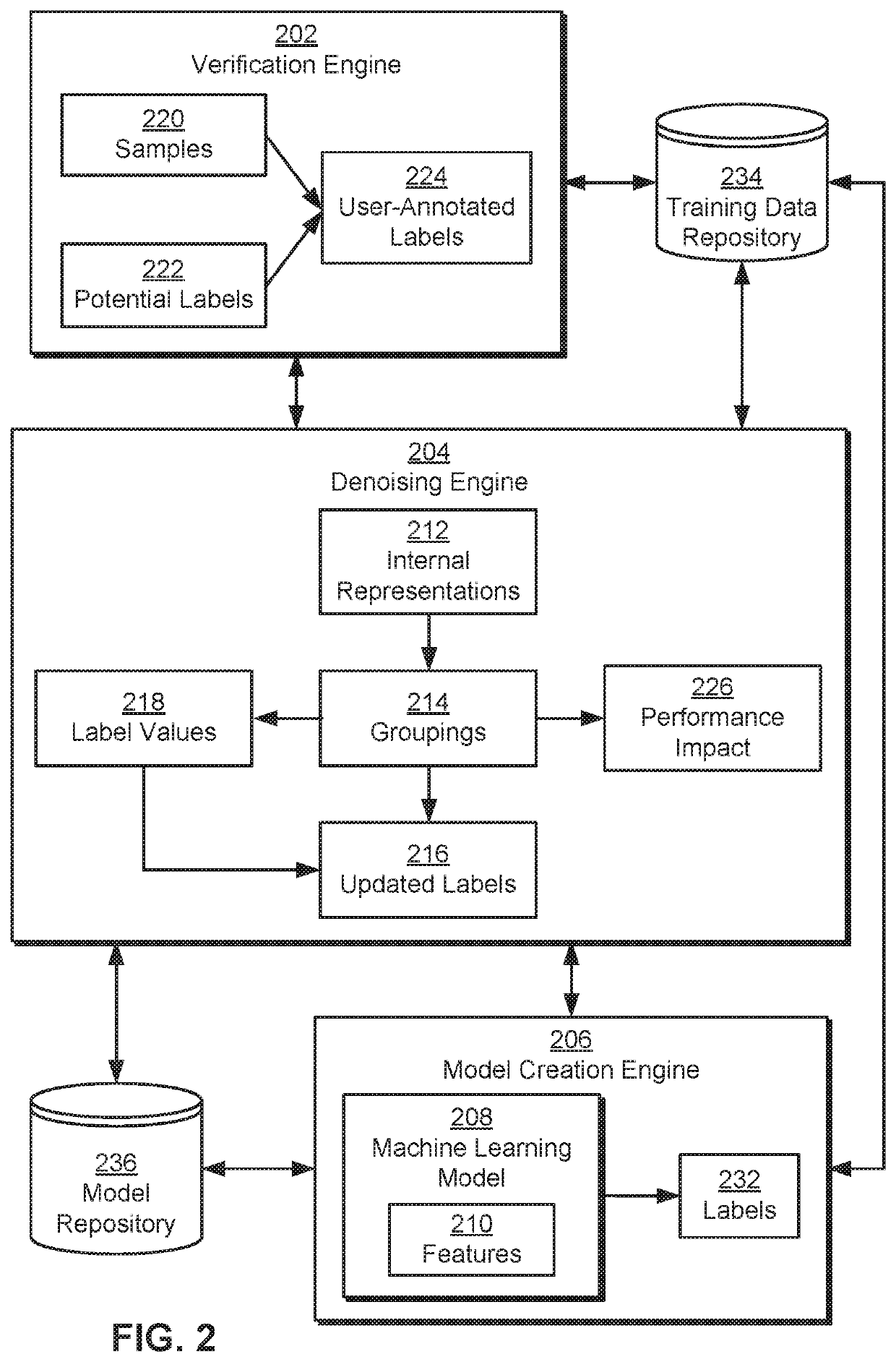

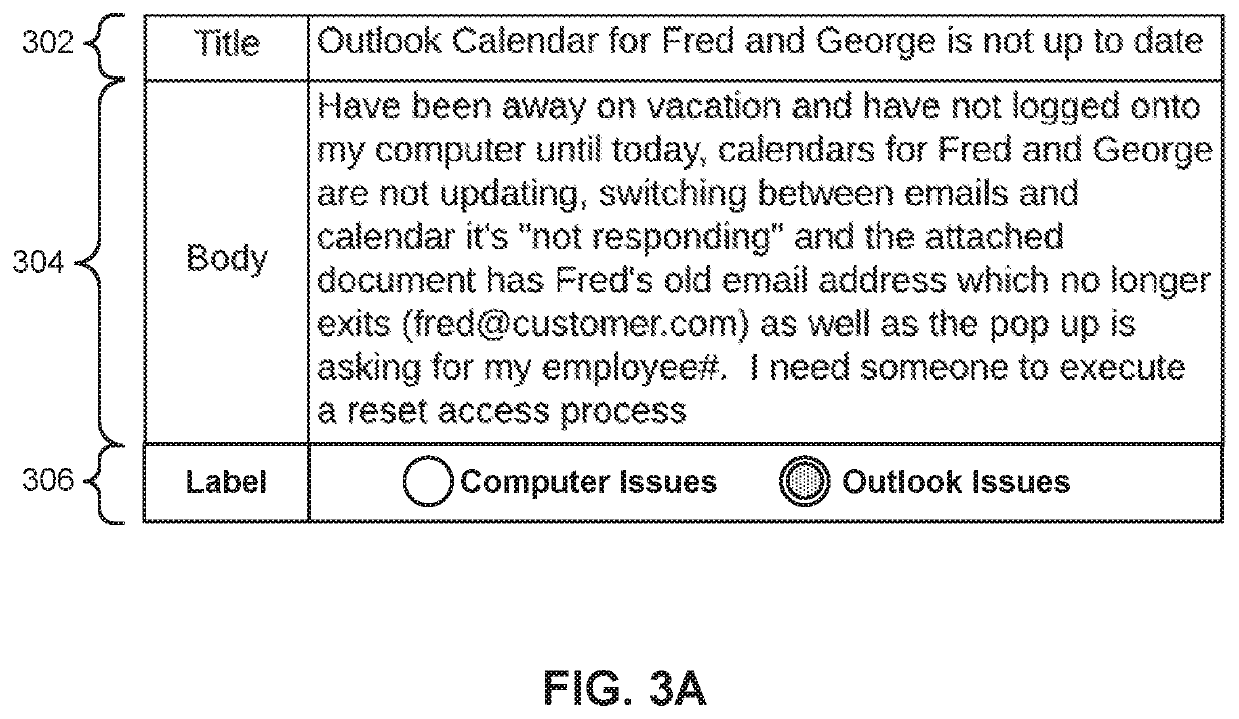

Active learning to reduce noise in labels

InactiveUS20190354810A1Reduce noiseReduce inconsistencyMathematical modelsCharacter and pattern recognitionProactive learningMachine learning

One embodiment of the present invention sets forth a technique for processing training data for a machine learning model. The technique includes training the machine learning model using training data comprising a set of features and a set of original labels associated with the set of features. The technique also includes generating multiple groupings of the training data based on internal representations of the training data in the machine learning model. The technique further includes replacing, in a first subset of groupings of the training data, a first subset of the original labels with updated labels based at least on occurrences of values for the original labels in the first subset of groupings.

Owner:ASTOUND AI INC

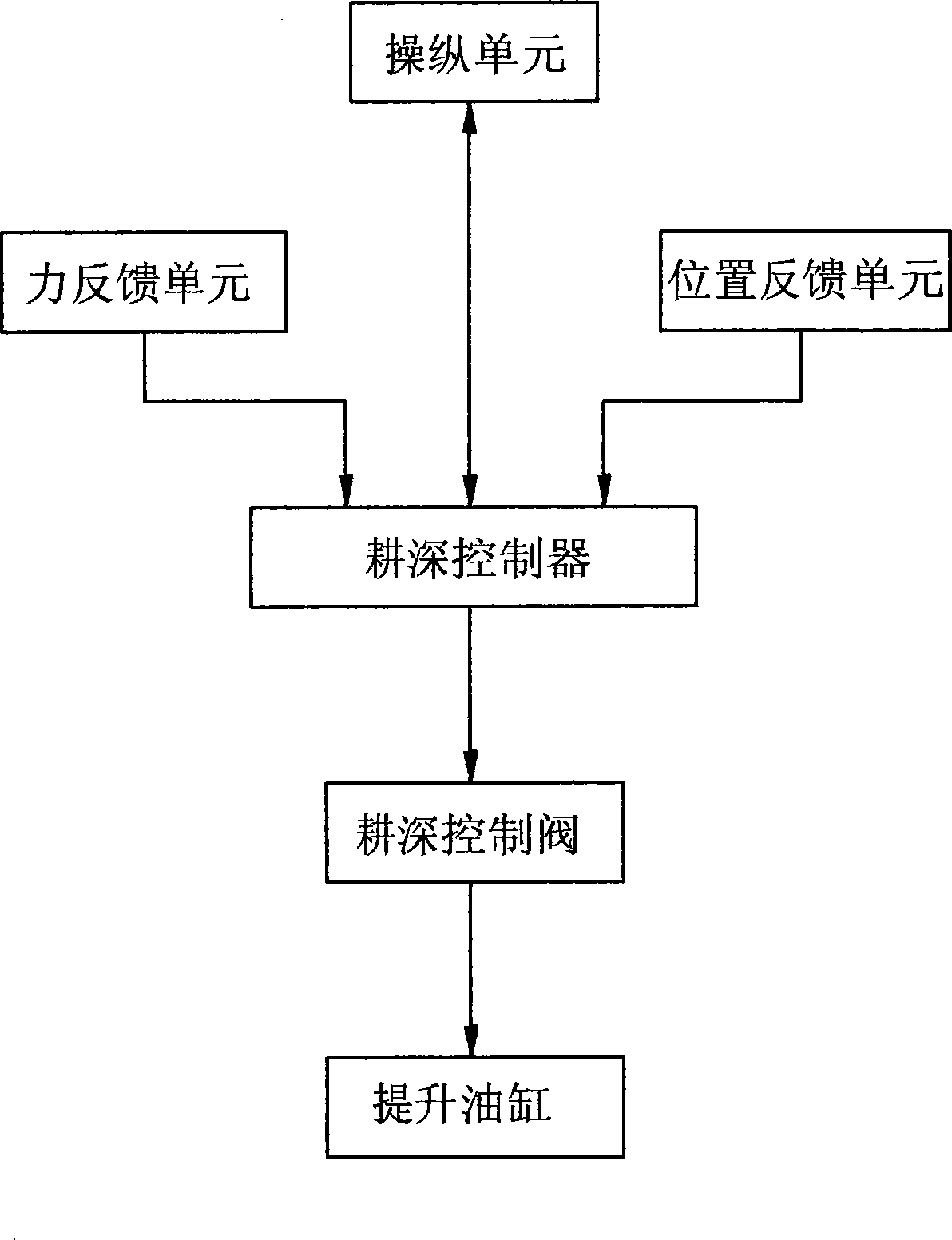

Deep-plowing raiser for tractor

InactiveCN101080968AHigh precisionAchieving force controlAgricultural machinesAdjusting devicesTractorControl valves

The plow depth raiser for a tractor includes one raising oil cylinder for controlling the elevation of the suspension system, one plow depth controlling valve connected to the raising oil cylinder, one force feedback unit for measuring and acquiring the stress information of the pull rod in the suspension system, one position feedback unit for measuring and acquiring the rotation angle of the lift arm in the suspension system, one plow depth controller connected to the force feedback unit and the position feedback unit, and one operation unit connected to the plow depth controller, with the plow depth controller being connected also to the plow depth controlling valve. The present invention has raised plow depth controlling accuracy and high operation reliability of the hydraulic system.

Owner:LOVOL HEAVY IND

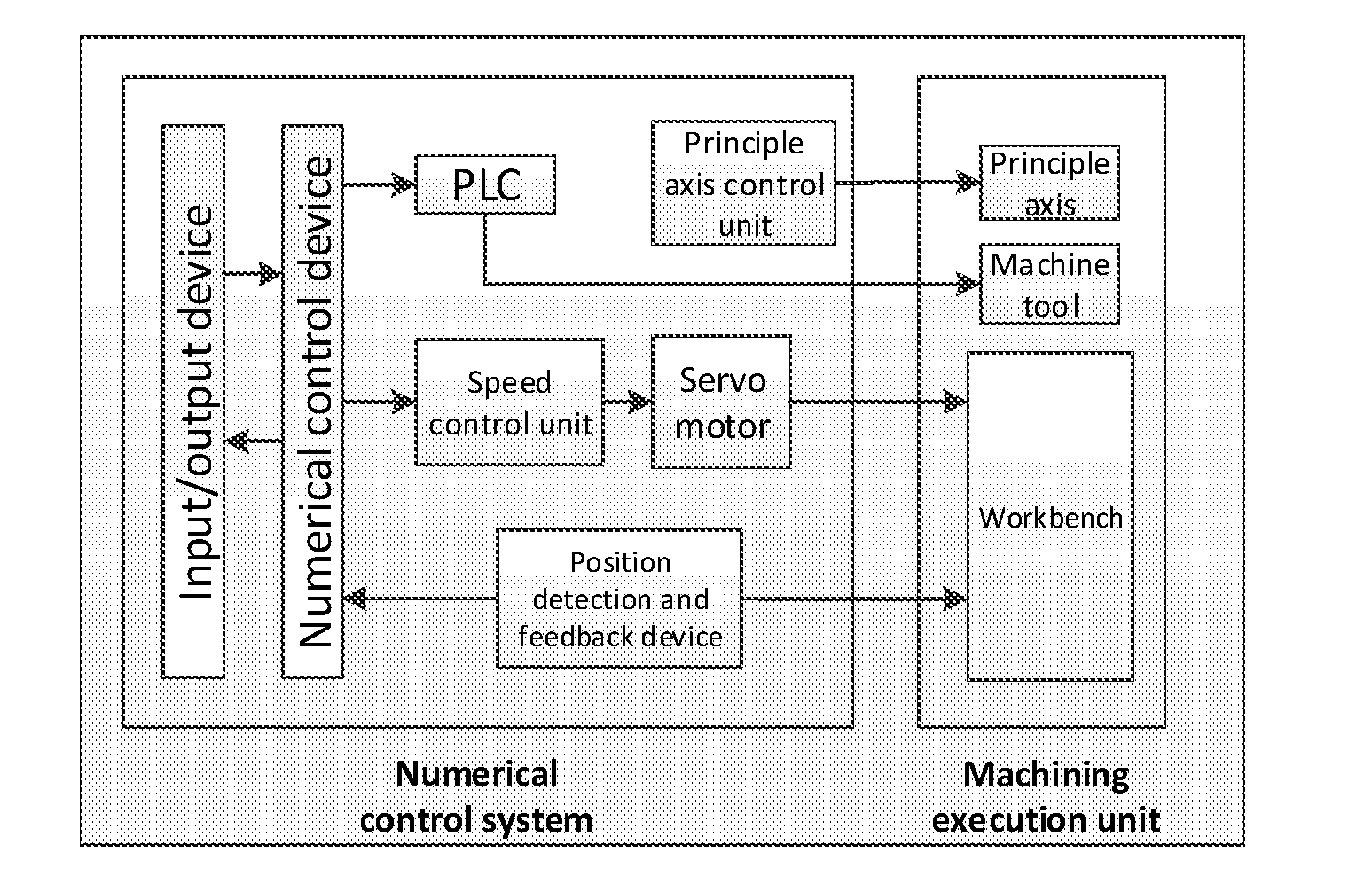

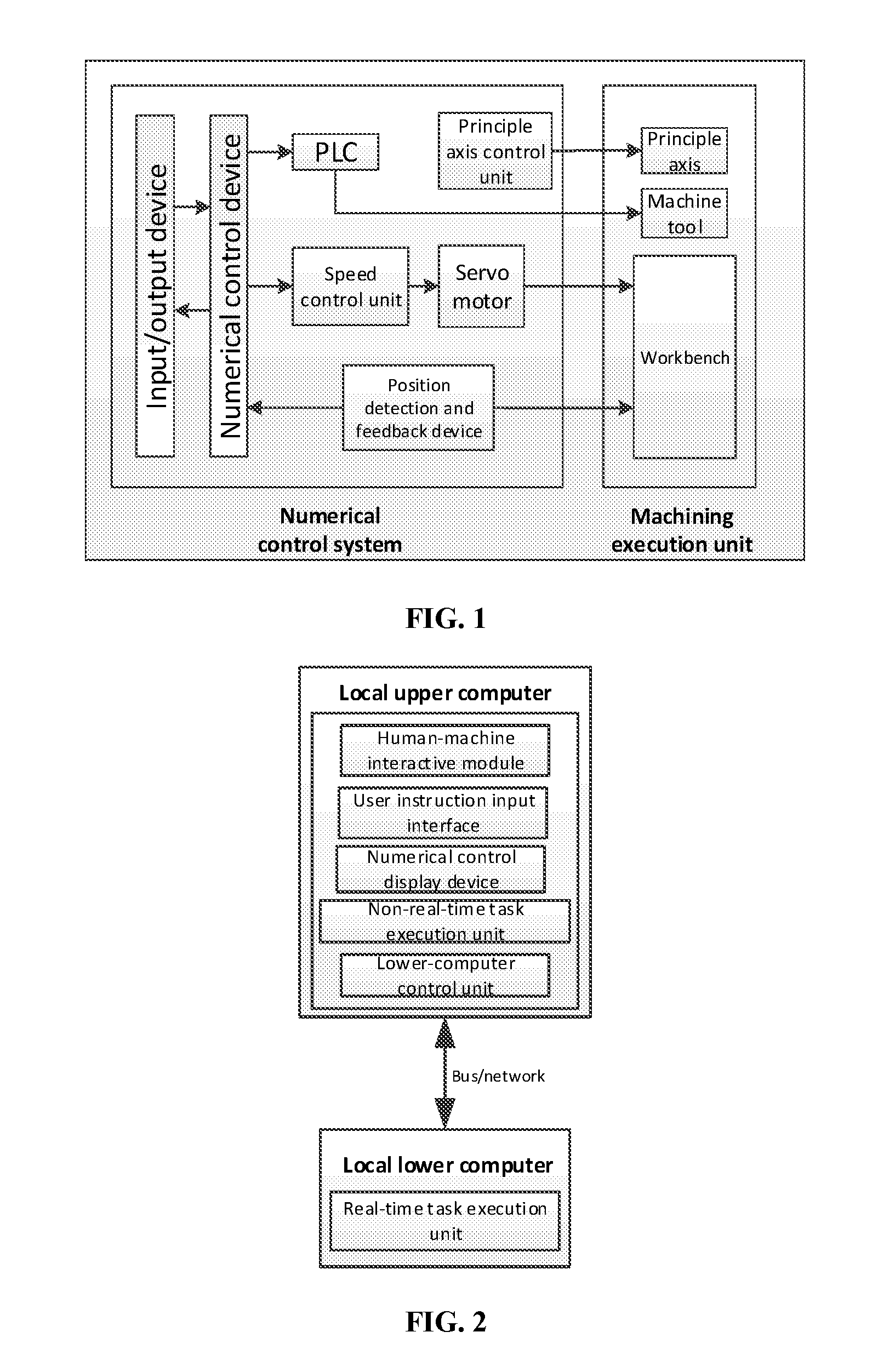

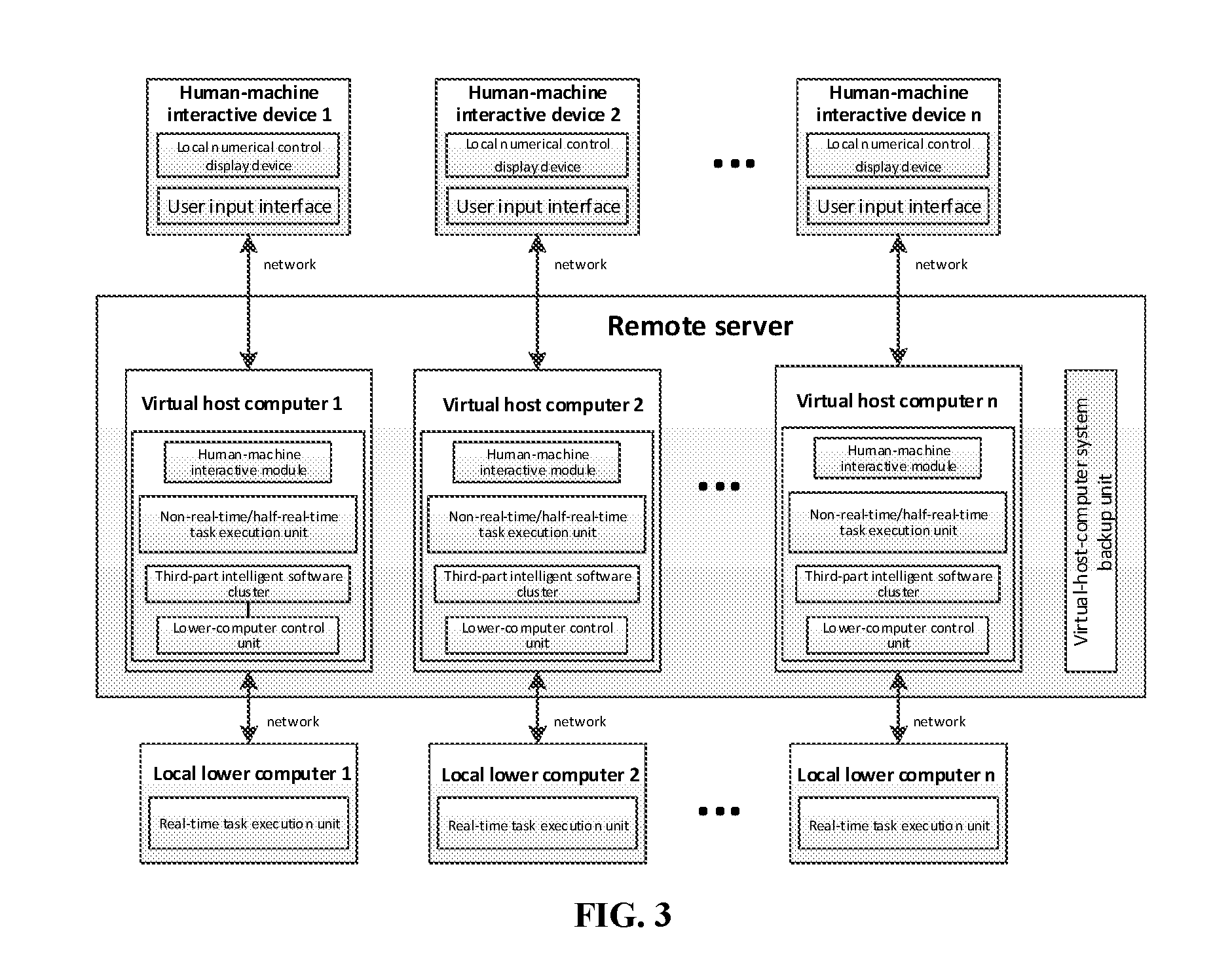

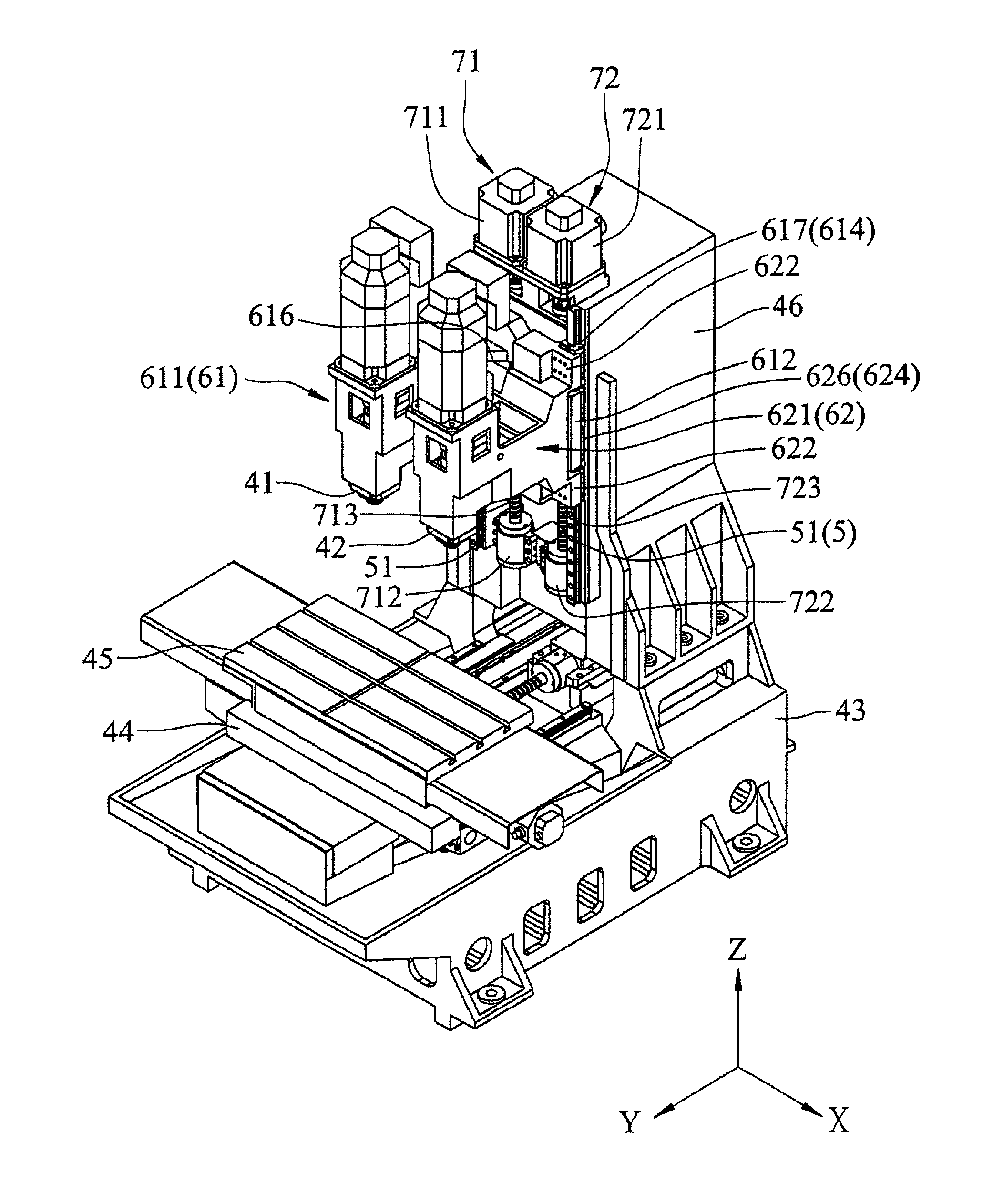

Numerical control system based on virtual host computer

ActiveUS20170045879A1Optimize data processingImprove performanceComputer controlSimulator controlProcessing InstructionMachine tool control

The invention discloses a numerical control (NC) system based on a virtual host computer, the NC system comprising the virtual host computer arranged on a remote server, a local lower computer and a human-machine interactive device for human-machine interaction. The human-machine interactive device is used for providing a human-machine interactive input / output interface. The virtual host computer integrates a human-machine interactive module, a non-real-time / half-real-time task execution unit and a lower-computer control unit, and is used for receiving a NC machining instruction, processing the instruction to form a machine-tool control instruction through the non-real-time / half-real-time task execution unit, and transmitting the control data to the local lower computer through the lower-computer control unit by utilizing a network. The local lower computer controls a machine tool to execute real-time motion control and logic control. The NC system employs a new architecture formed by the upper computer and the lower computer by utilizing virtualization technology, and solves the restriction problems of data processing capability, HMI function expansion and remote machining of a conventional NC system.

Owner:HUAZHONG UNIV OF SCI & TECH

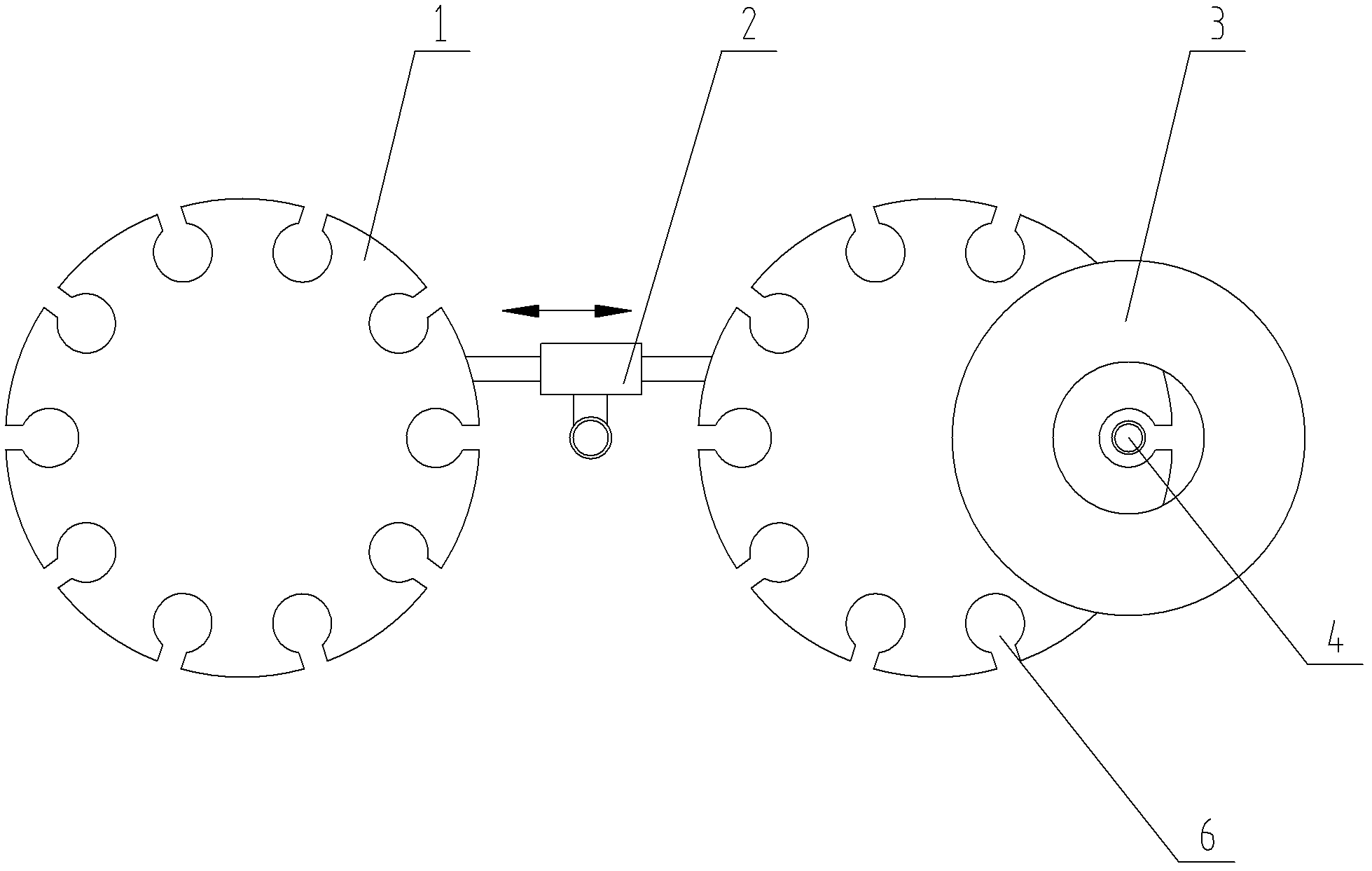

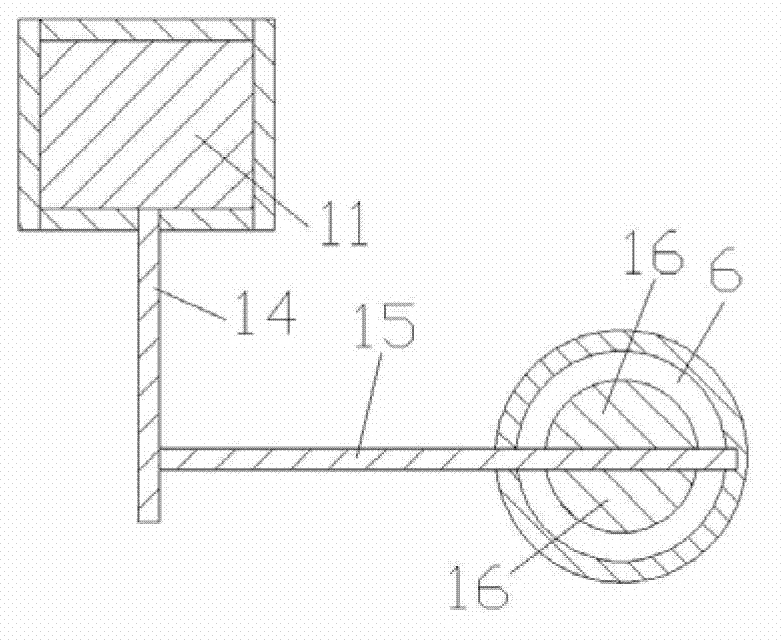

Rotation control type pipeline reducing rate variable device

ActiveCN103089410AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesGas compressorInlet pressure

A rotation control type pipeline reducing rate variable device belongs to the technical field of mechanical design and comprises an air compressor, an engine, an air exhaust pipe, a turbine, a volume cavity, a rotation body, a spring, a connection pipe, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in the air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air inlet pipe of the engine is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air inlet pipe of the engine is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The rotation control type pipeline reducing rate variable device is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SUZHOU INTI AUTOMOTIVE TECH CO LTD

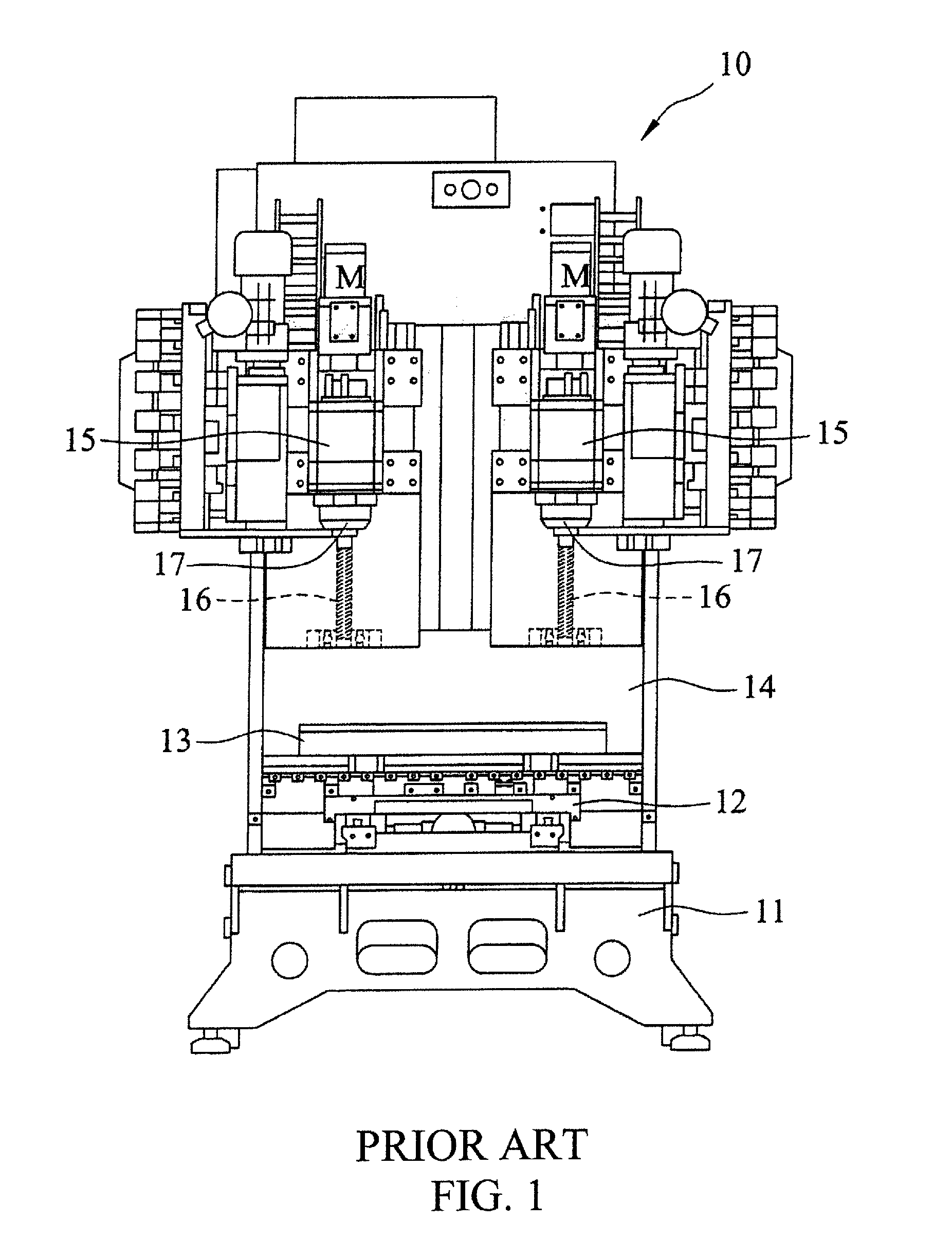

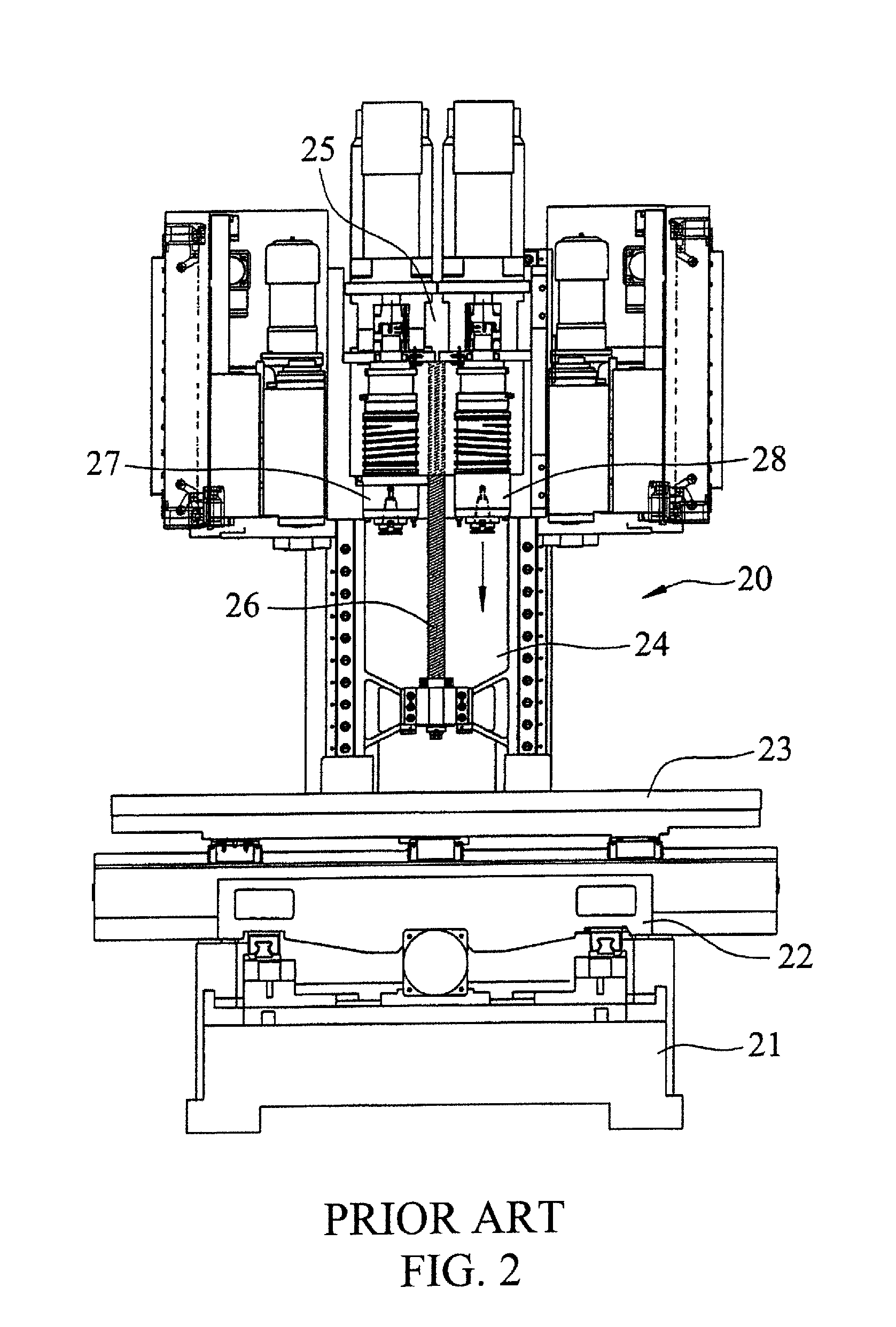

CNC dual-spindle transmission device

ActiveUS20160193669A1Size of machine can be effectivelyReduce sizeMilling machinesFeeding apparatusDual axisPower unit

A CNC dual-spindle transmission device is installable on a CNC dual-spindle machining center to receive first and second spindles of the CNC dual-spindle machining center to mount thereto. The CNC dual-spindle machining center includes a base, a machining table movably mounted on the base, and a vertical column erected upright at a rear portion of the base. The CNC dual-spindle transmission device includes a linear rail assembly mounted to the vertical column, a first slide seat slidably mounted to the linear rail assembly and receiving the first spindle to mount thereto, a second slide seat extending across the first slide seat and slidably mounted to the linear rail assembly in a manner of being spaced from the first slide seat to receive the second spindle to mount thereto, and first and second power units mounted to the vertical column to respectively driven the first and second slide seats to move.

Owner:BAIZHENG INNOVATION TECHNOLOGY CO LTD

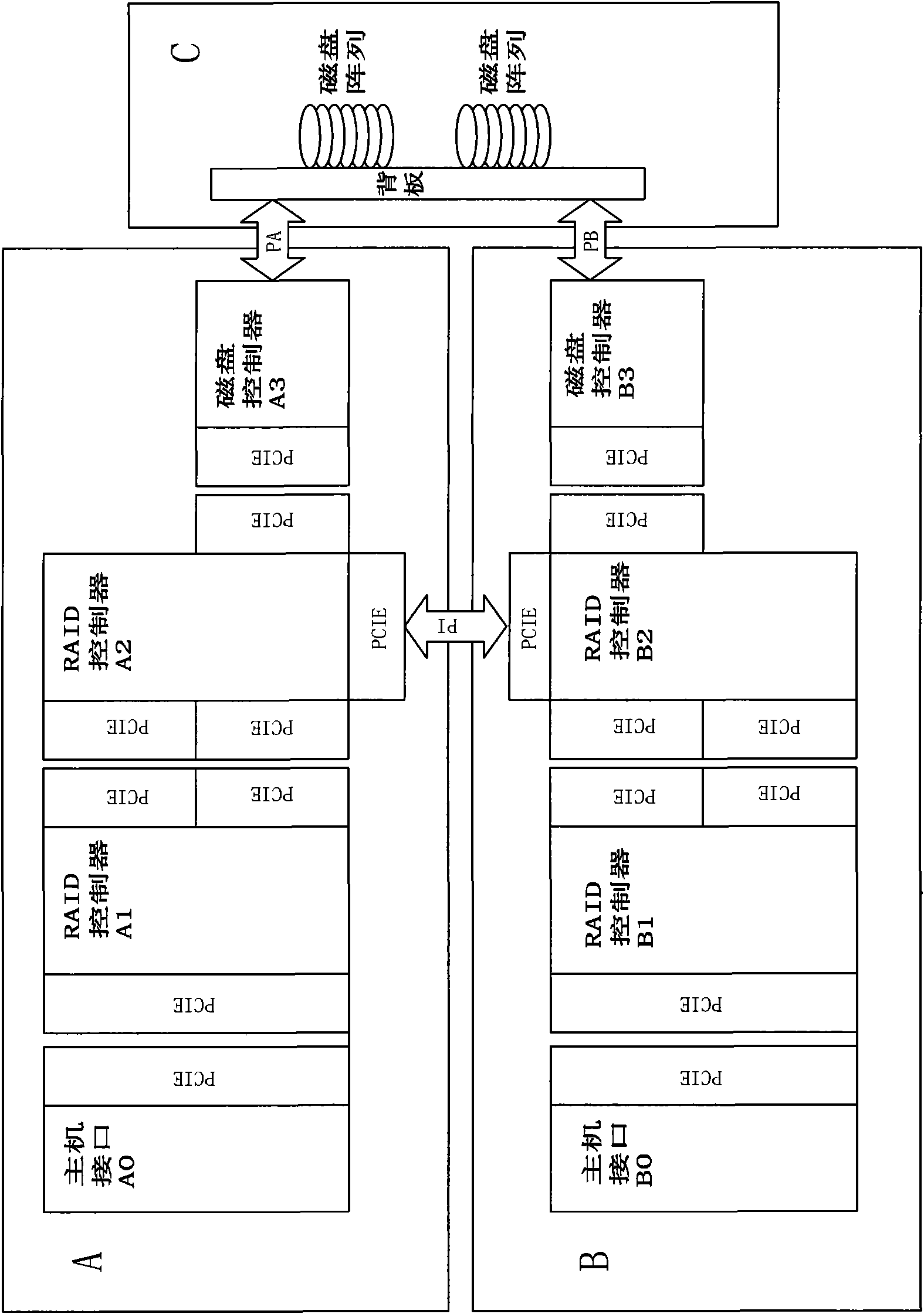

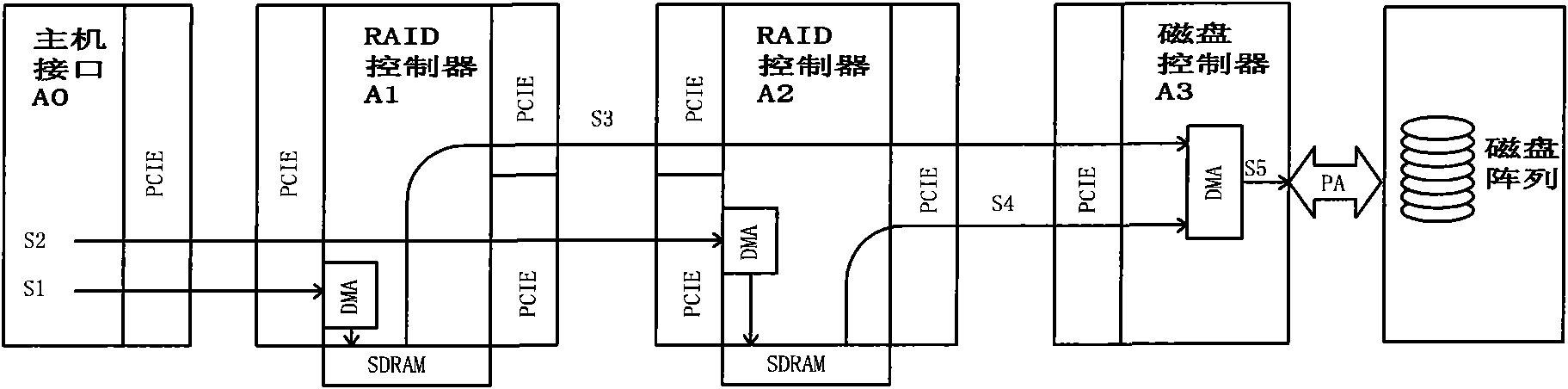

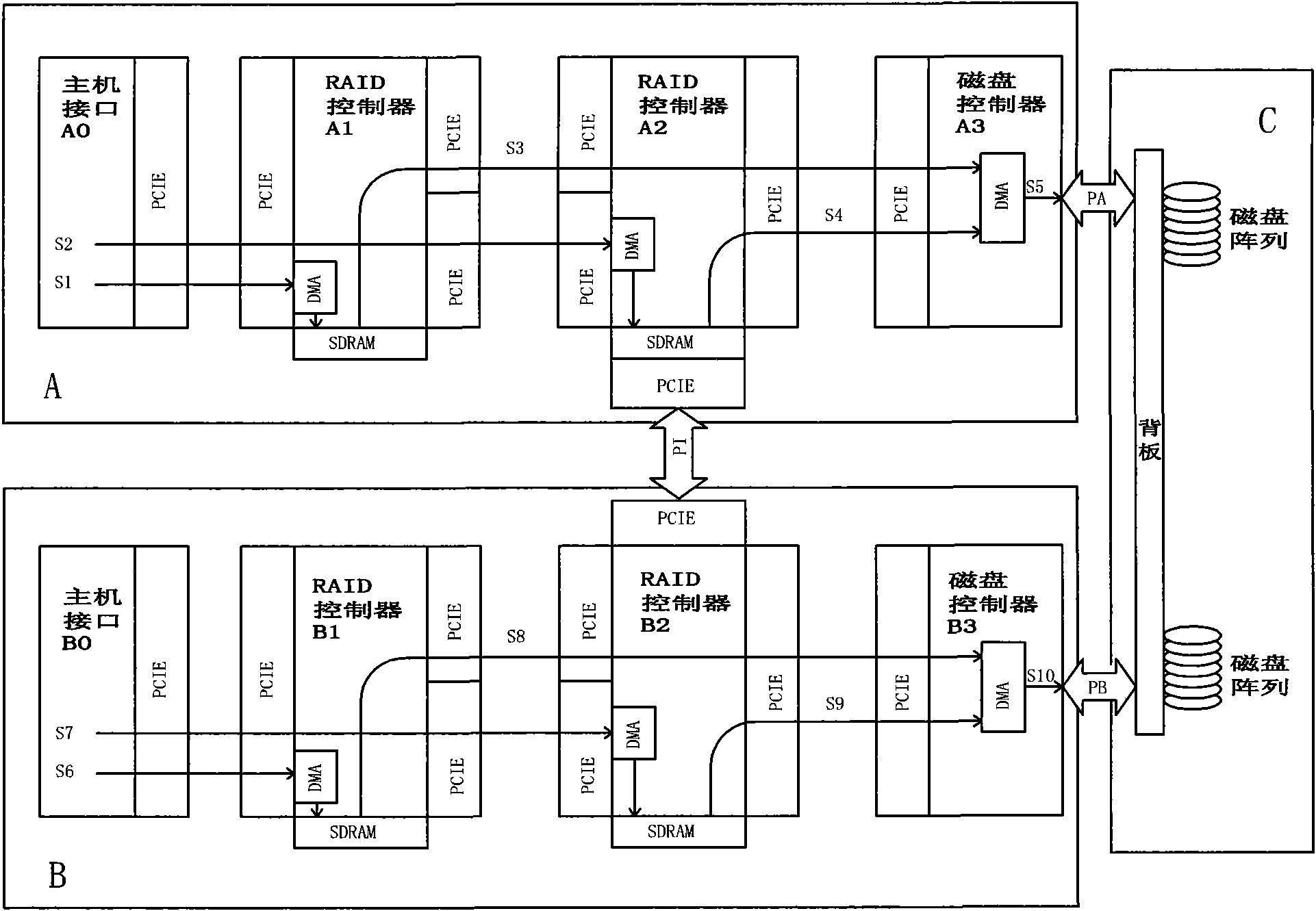

Parallel processing-based multi-host interface redundancy SAN controller

InactiveCN101576805AImprove machine performanceInput/output to record carriersFault responseRAIDParallel processing

The invention relates to a parallel processing-based multi-host interface redundancy SAN controller and belongs to a controller. The structure of the parallel processing-based multi-host interface redundancy SAN controller comprises a controller redundant module A, a controller redundant module B and a backboard module C, wherein the controller redundant module A is connected with the controller redundant module B by a high-speed PCIE bus P1 and is connected with the backboard module C by a non-high speed mutual connection access PA; the controller redundant module B is connected with the backboard module C by a non-high speed mutual connection access PB. Compared with the prior art, the parallel processing-based multi-host interface redundancy SAN controller adopts double controller double DMA channel parallel processing, a structure configured with two redundancy controller modules, and parallel processing of RAID and other data in each controller redundancy module and between the two controller redundancy modules and can greatly improve the whole performance of the controller without losing reliability.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

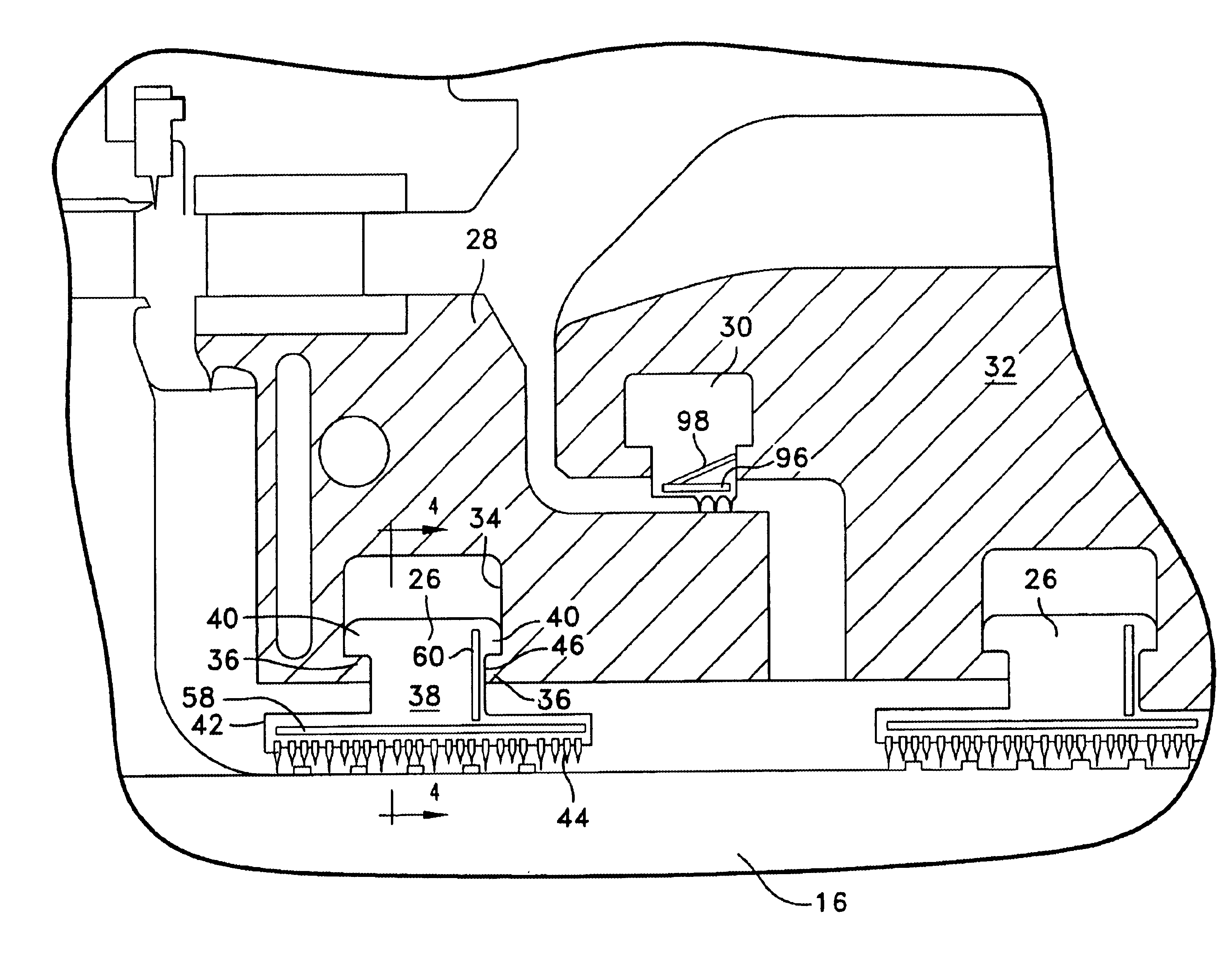

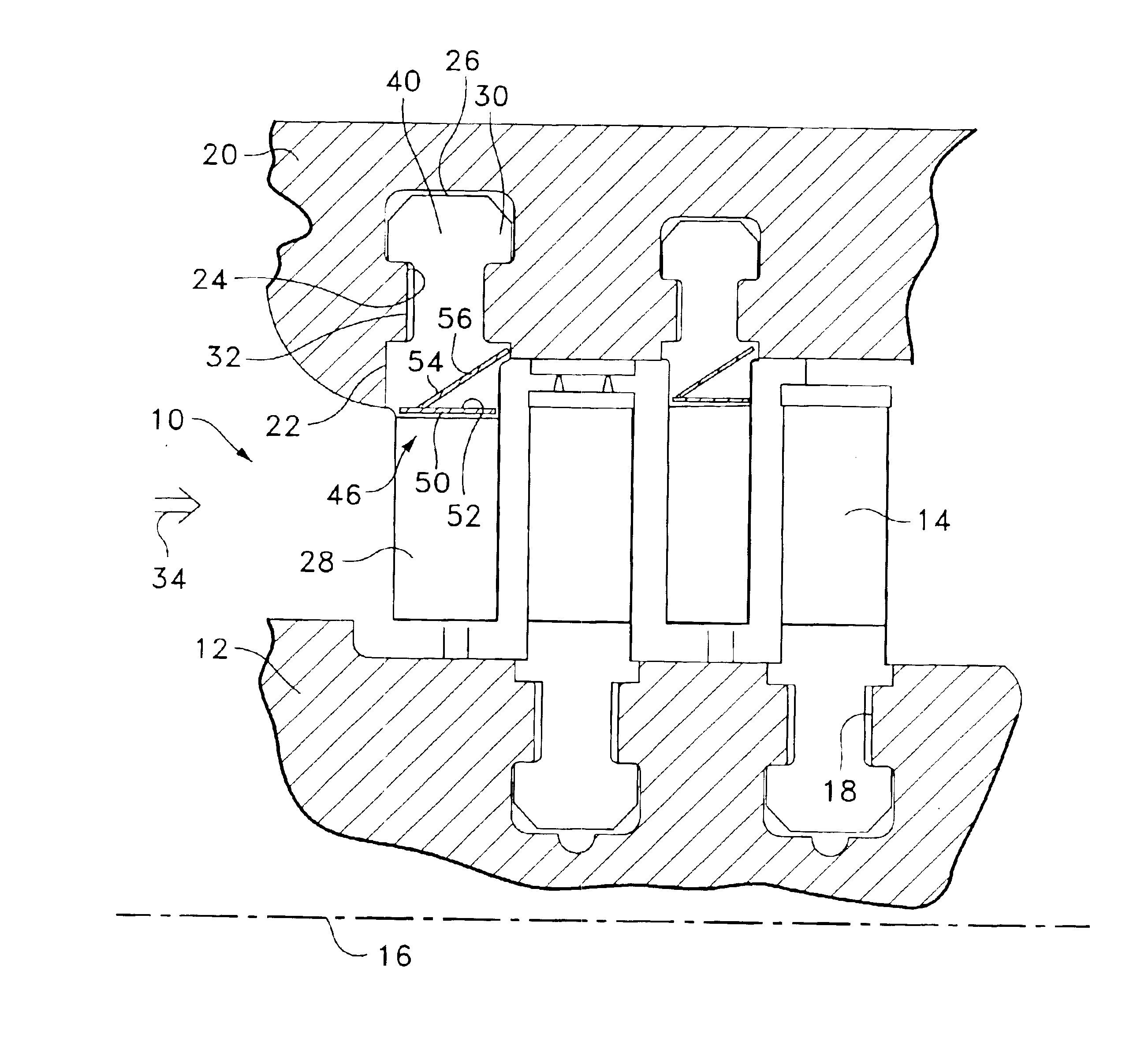

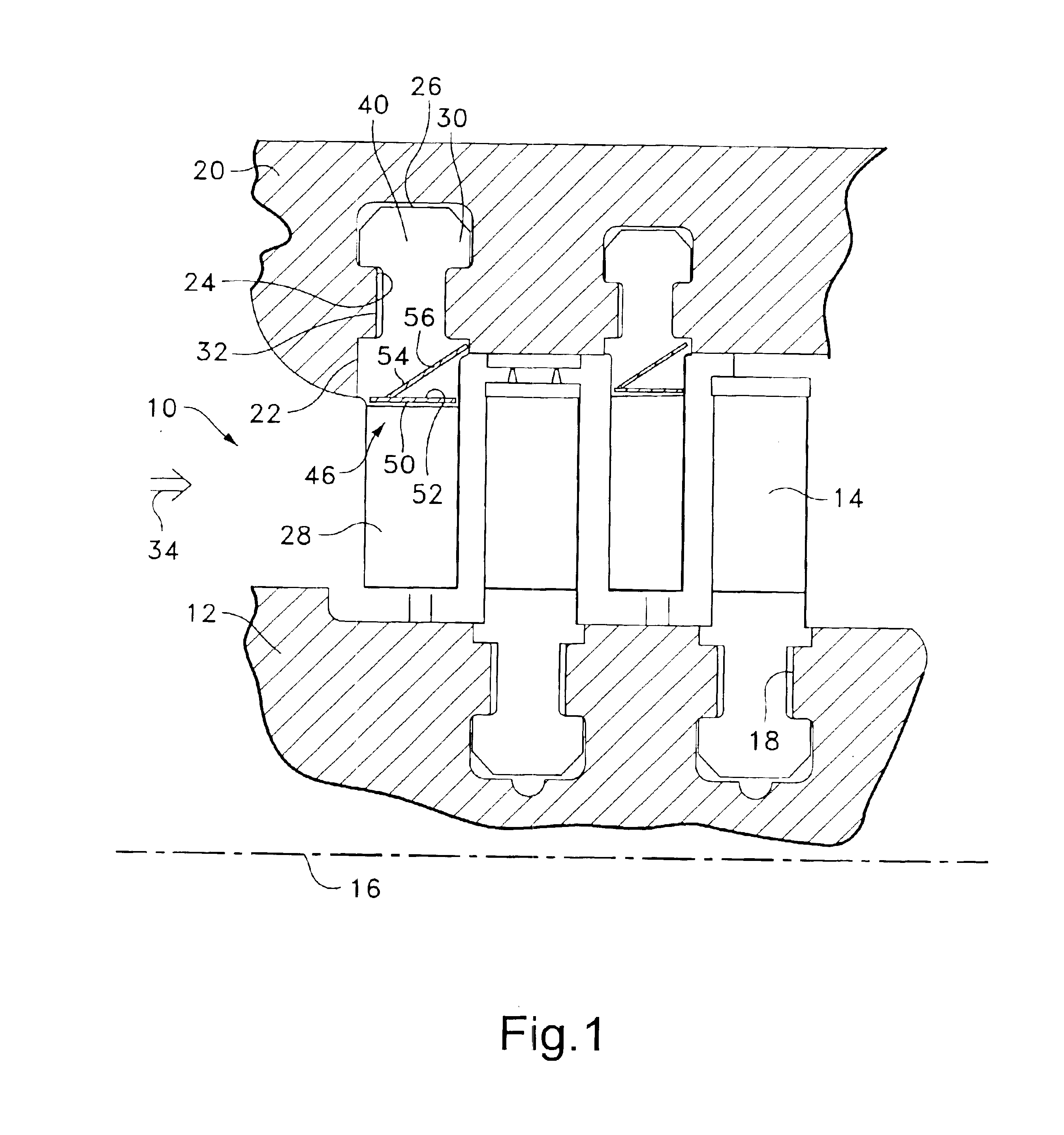

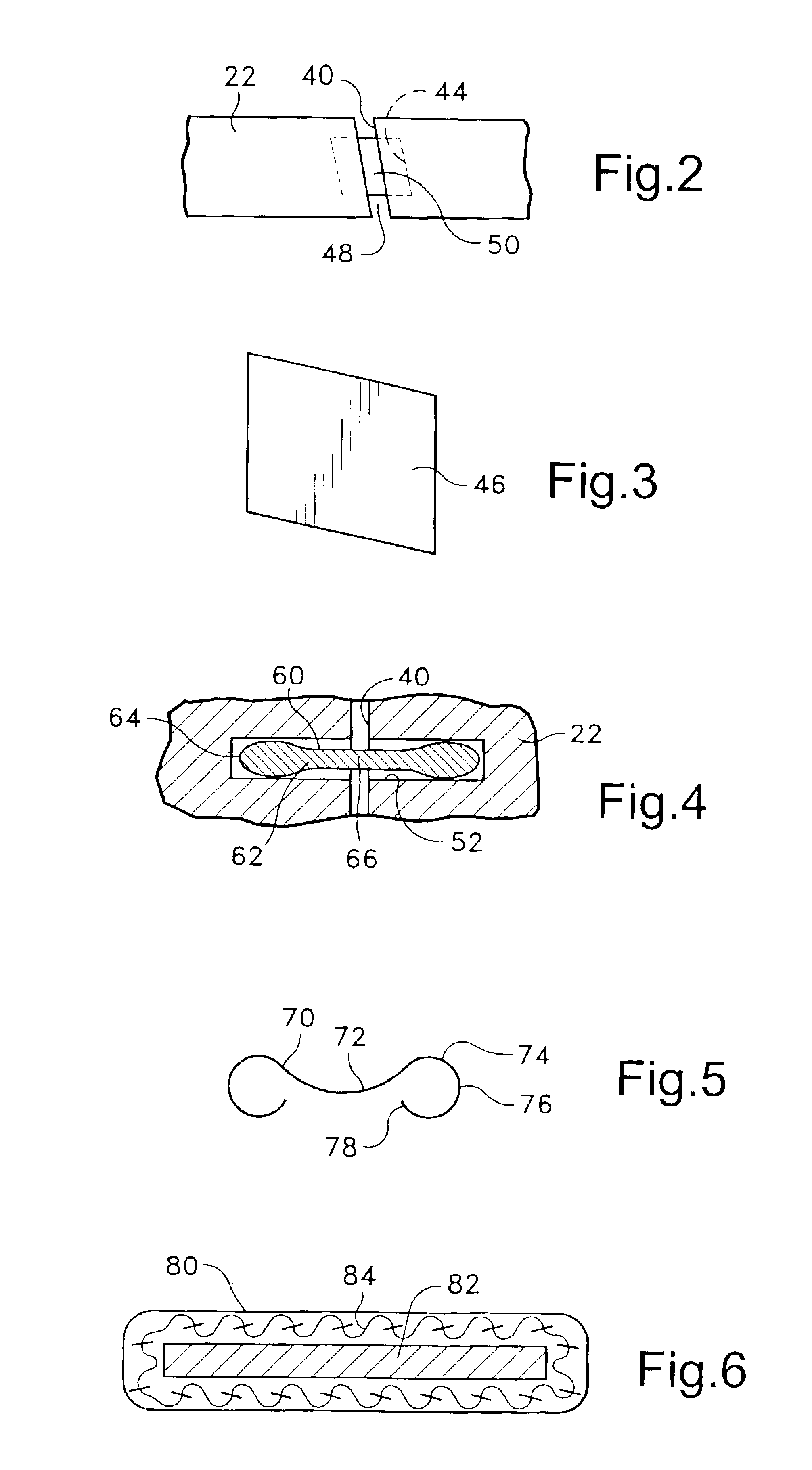

Endface gap sealing of steam turbine packing seal segments and retrofitting thereof

InactiveUS6722850B2Improve machine performanceReducing steam leakage pathPump componentsPumpsEngineeringSteam turbine

Spline seals are disposed in circumferentially registering slots of adjacent arcuate sealing segments disposed in grooves of the casing of a steam turbine about a rotor. The spline seals extend in the gap between the endfaces of the segments and minimize or preclude steam leakage past the endfaces. The spline seals may be oriented axially or inclined radially to minimize leakage paths in the radial inclined and axial directions, respectively. The spline seals are disposed in the slots which may be formed as part of original equipment manufacture or may be machined in segments with the spline seals provided as retrofits.

Owner:GENERAL ELECTRIC CO

Sealing of nozzle slashfaces in a steam turbine

InactiveUS6843479B2Reduce steam leakage pathImprove machine performanceEngine sealsLeakage preventionEngineeringStreamflow

Nozzle segments mounting vanes are received in circumferentially extending, generally dovetail-shaped grooves in an outer casing of a steam turbine, the nozzle segments forming part of a stage with rotating buckets of the steam turbine. The inclined slashfaces of the adjoining bases of the nozzle segments are provided with circumferentially opening slots to receive spline seals. The spline seals preclude or minimize steam leakage flow past the gap between the adjoining nozzle segments thereby enhancing the steam flow through the partitions of the nozzles.

Owner:GENERAL ELECTRIC CO

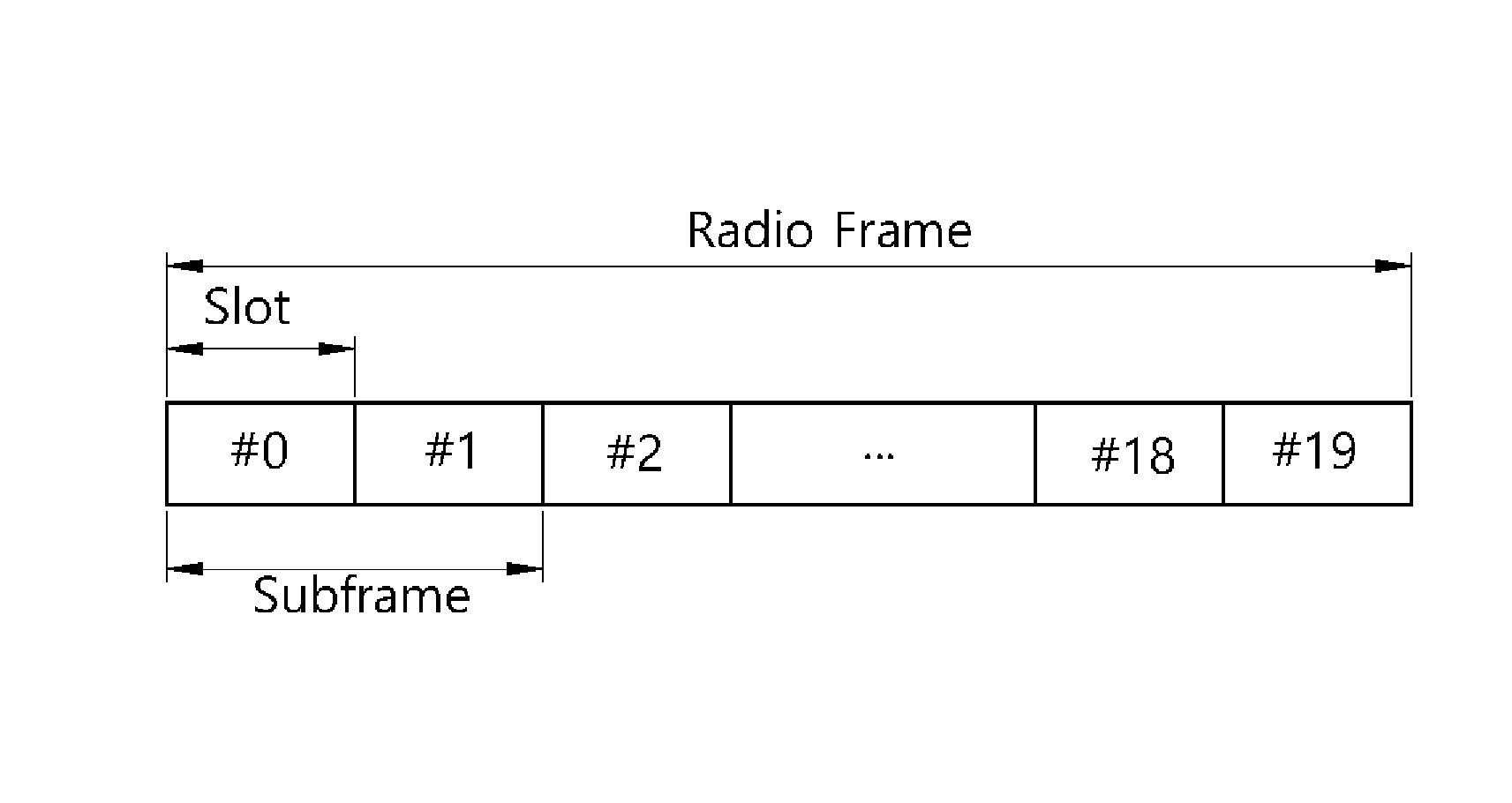

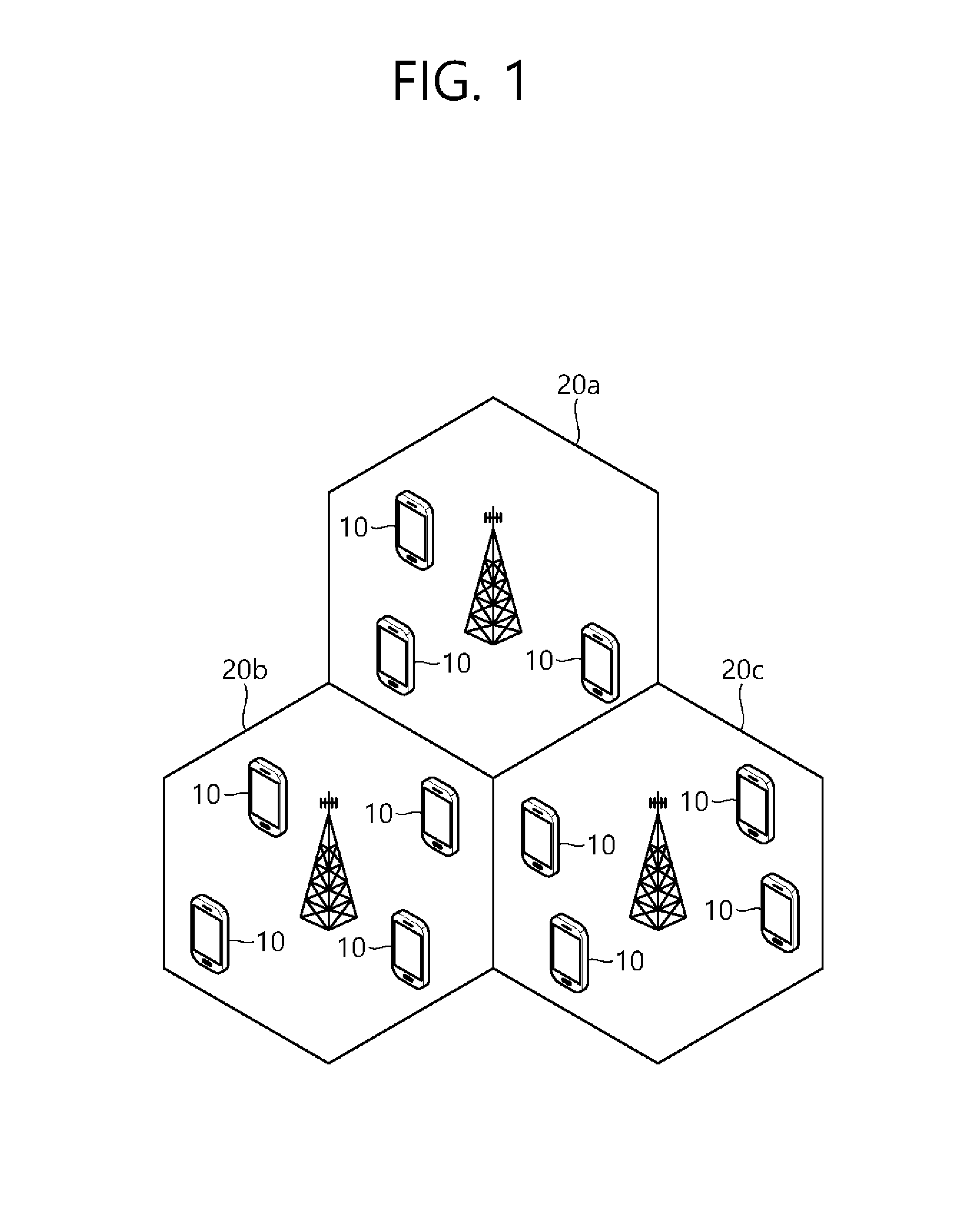

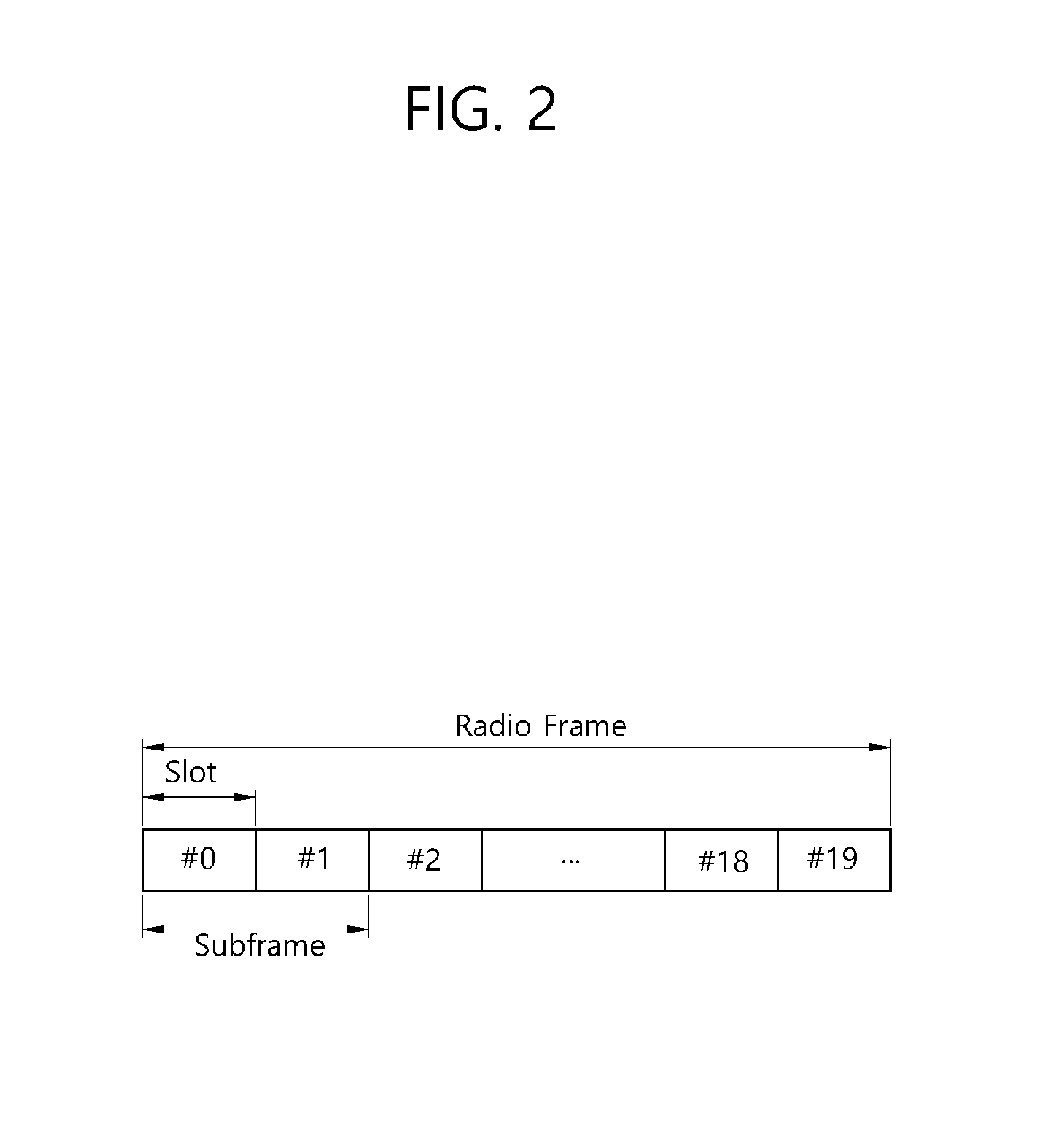

Method for transmitting and receiving uplink/downlink data with mtc device

InactiveUS20160211949A1Improve machine performanceSolve the real problemError prevention/detection by using return channelWireless commuication servicesHybrid automatic repeat requestRepetition Number

According to an embodiment of the present specification, a method for transmitting uplink data in a machine type communication (MTC) device is provided. The method may comprise the steps of: initially transmitting repetitive bundles of physical uplink shared channel (PUSCH) data including identical uplink data in a plurality of uplink subframes to a base station; receiving a hybrid automatic repeat request (HARQ) response signal with respect to the repetitive bundles of PUSCH; if the HARQ response signal is a negative-acknowledgement (NACK), determining the number of repetitions of the PUSCH including identical uplink data; and re-transmitting the PUSCH bundles repeatedly for the determined number of times on the plurality of uplink subframes to the base station.

Owner:LG ELECTRONICS INC

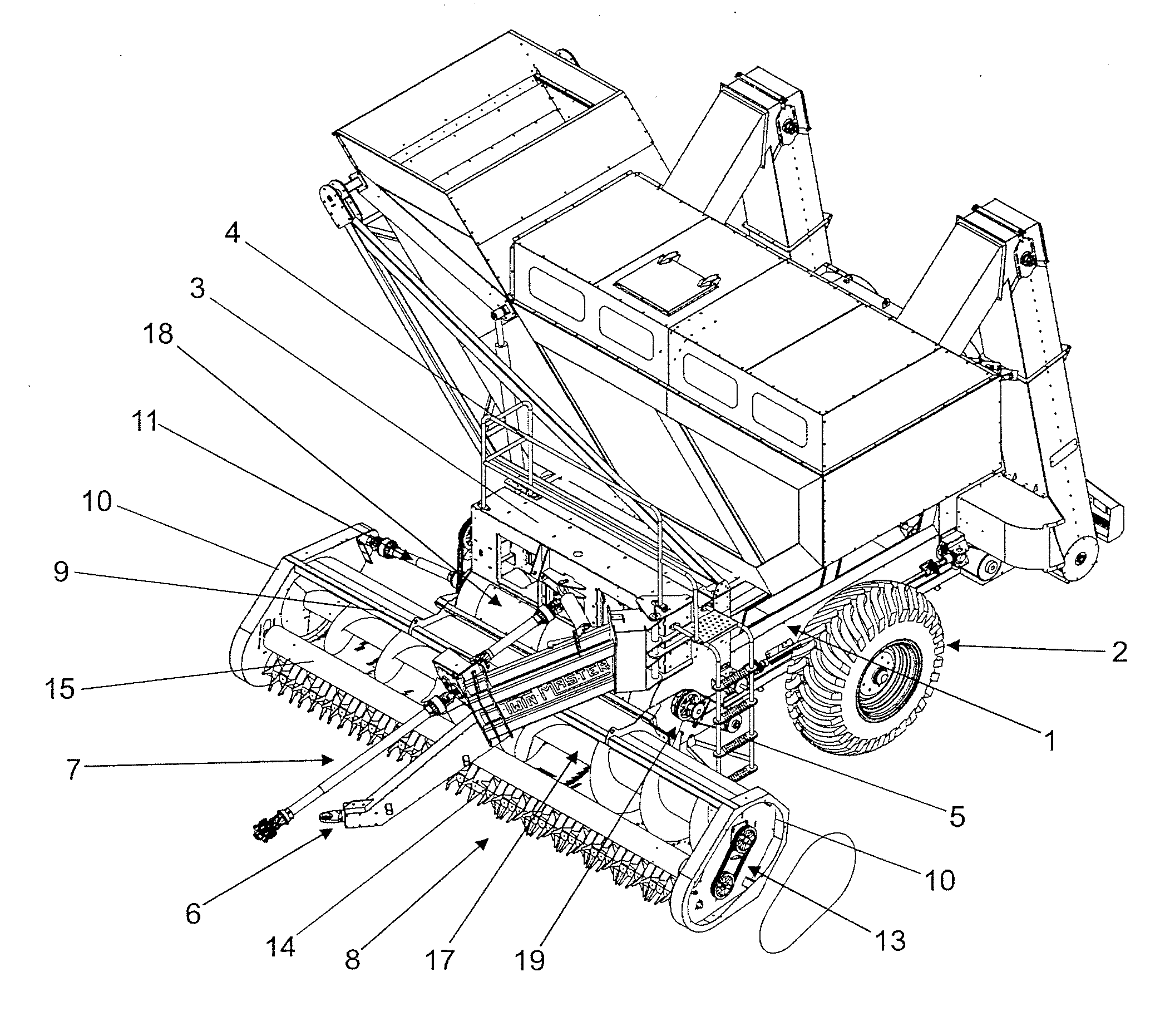

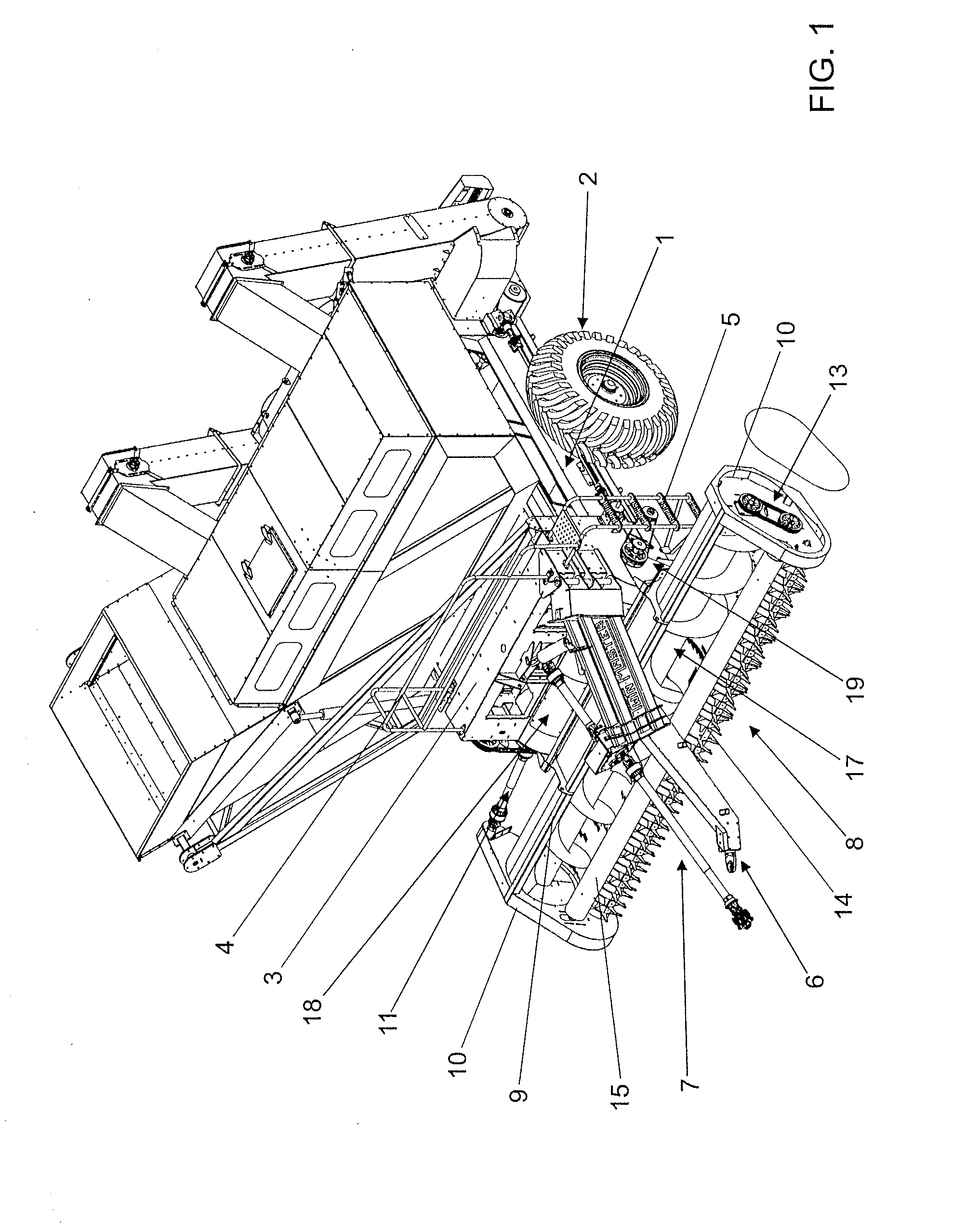

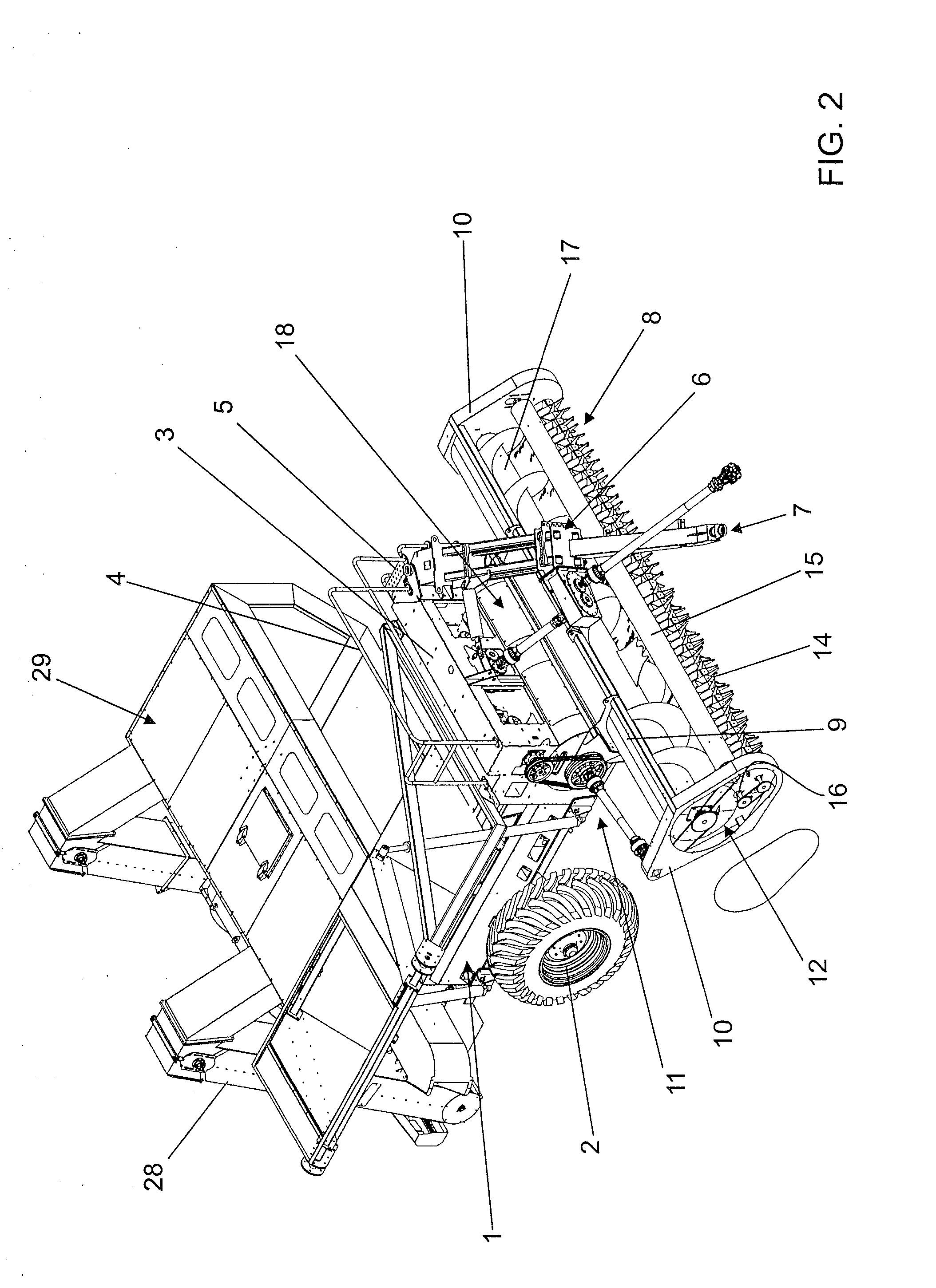

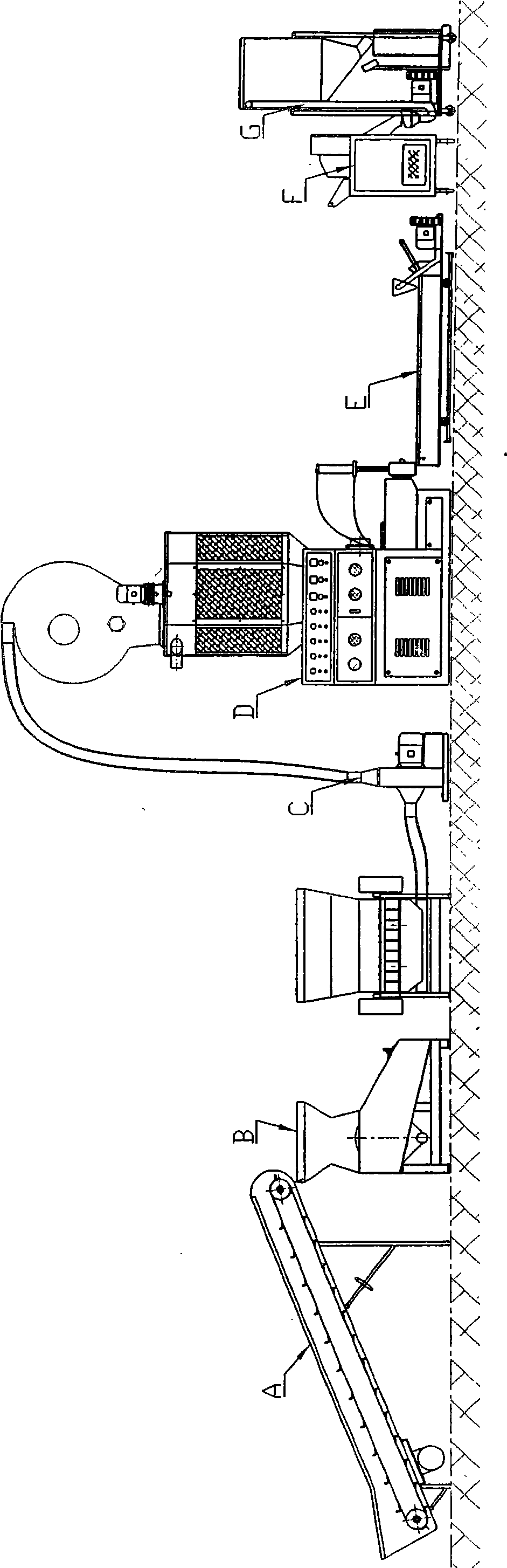

Grain reaper

ActiveUS20080295476A1The process is simple and fastWork resistanceMowersDigger harvestersEngineeringReaper

The present invention relates to a reaper for grains, specially for the bean grains. More specifically, the present invention refers to technical and functional improvements specially developed and introduced which configures a bean reaper that is classified as a trailer to carry out two different operations, the first one of which is gathering various plants, such as bean plants, peanuts and other grains, plants which are previously plucked and aligned, whereas the second function of which is to perform a whole cleaning process by separating the grains (seeds) from the remaining unwanted parts.

Owner:IND REUNIDAS COLOMBO LTD

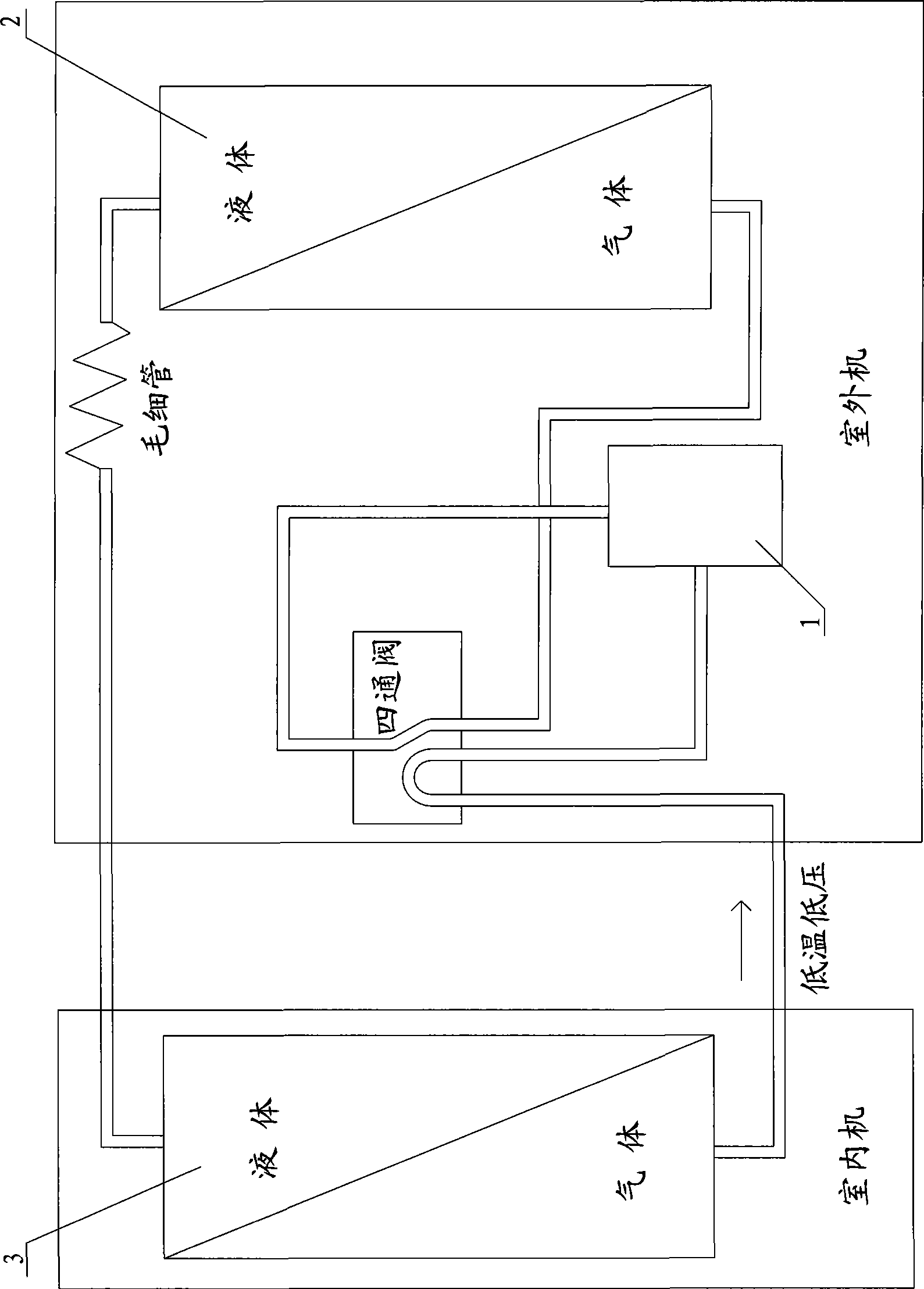

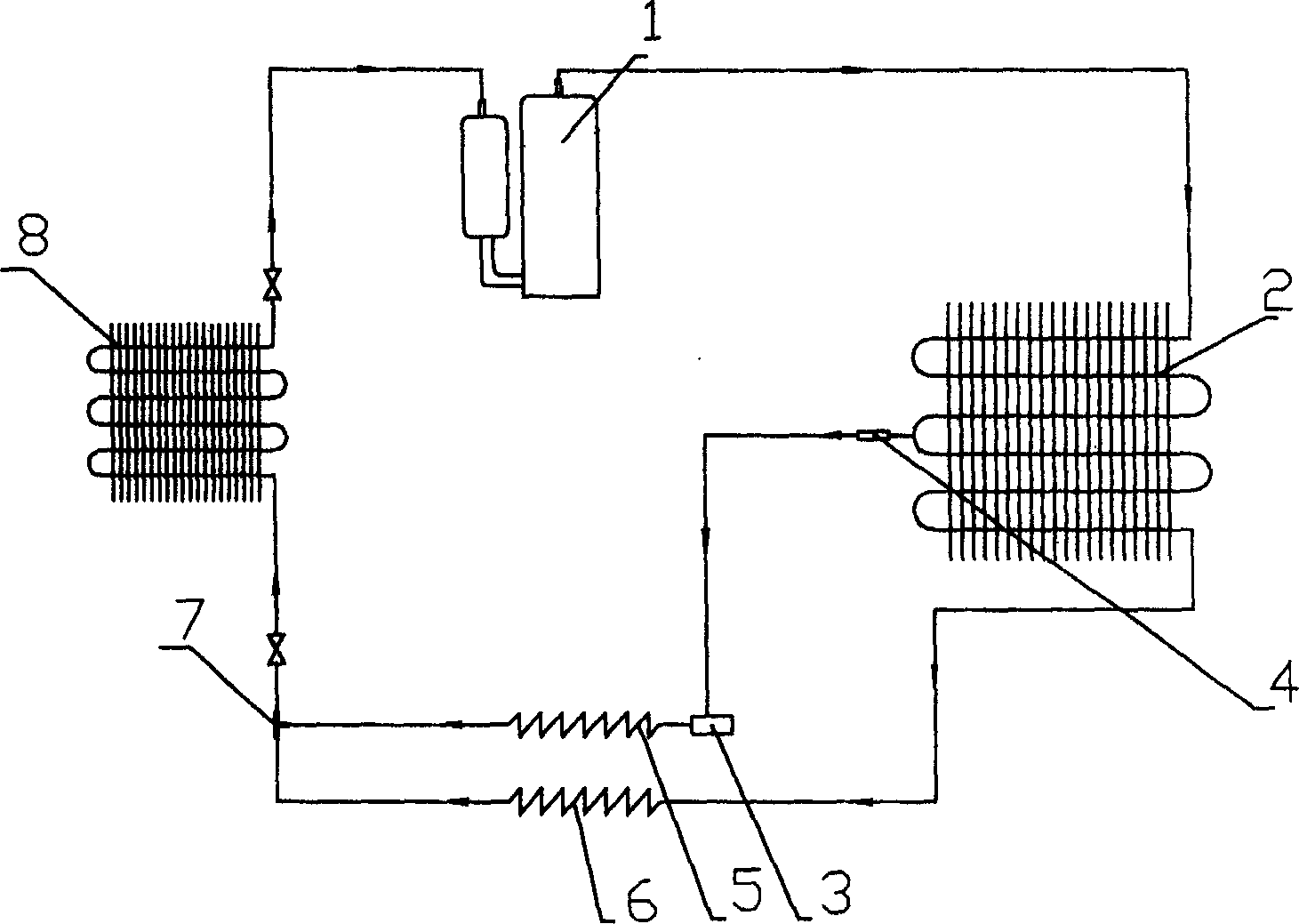

Antifreezing control method of air conditioner evaporator

InactiveCN101509692AImprove machine performanceImprove user satisfactionSpace heating and ventilation safety systemsLighting and heating apparatusUser satisfactionEvaporator

The invention discloses a method for controlling the anti-freezing of the evaporator of an air conditioner. The method mainly comprises the steps as follows: the temperature of the pipe coil of the evaporator is collected by a singlechip (5); subsequently, according to the collected temperature, corresponding conversion and control to the rotation speed of the motor of an indoor machine, and the starting and stopping of a compressor (1) are carried out. The method for controlling the anti-freezing of the evaporator of the air conditioner can lead the air conditioner work under different environments and improve the performance of the whole machine and the satisfaction degree of the user.

Owner:宁波海诚电器有限公司

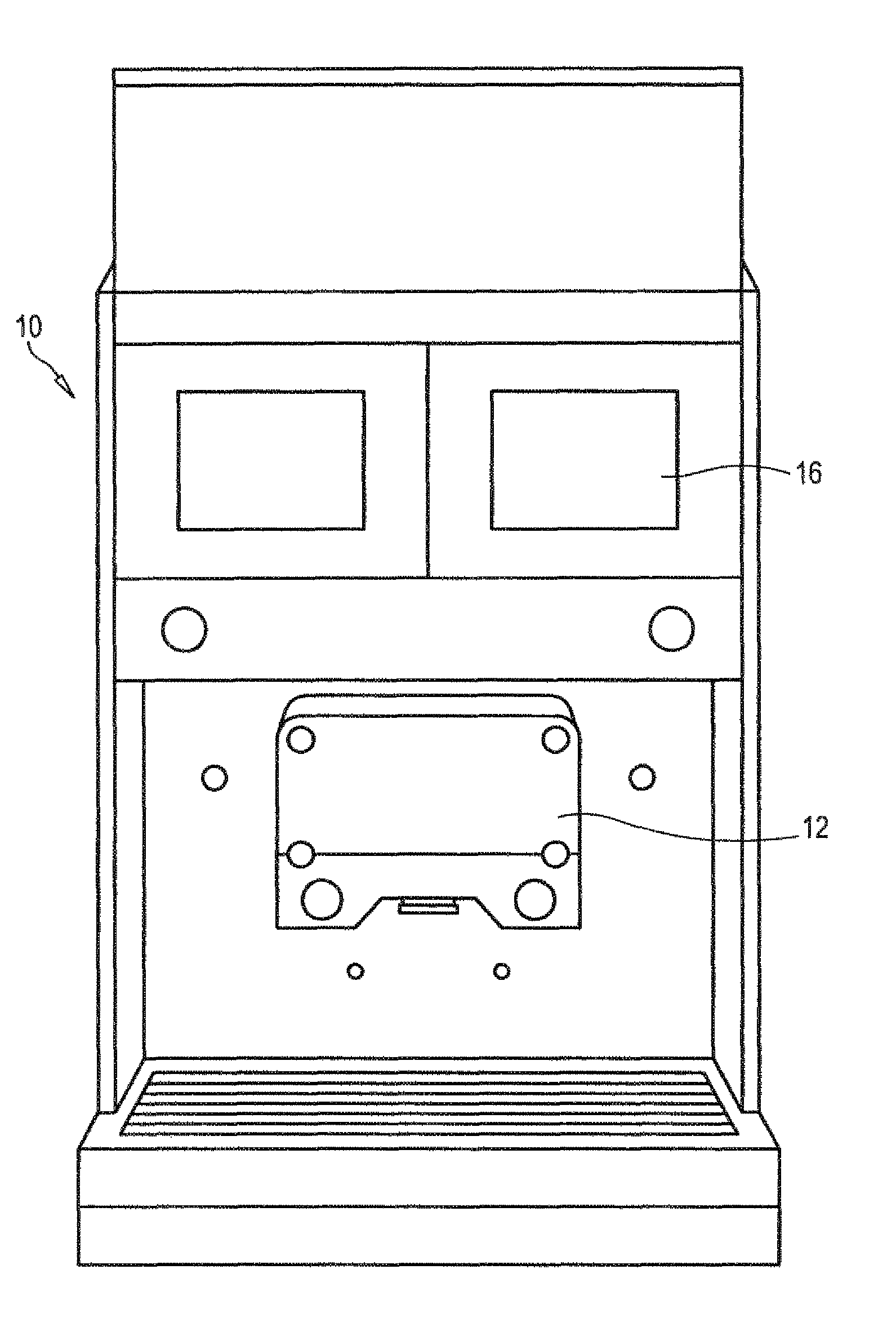

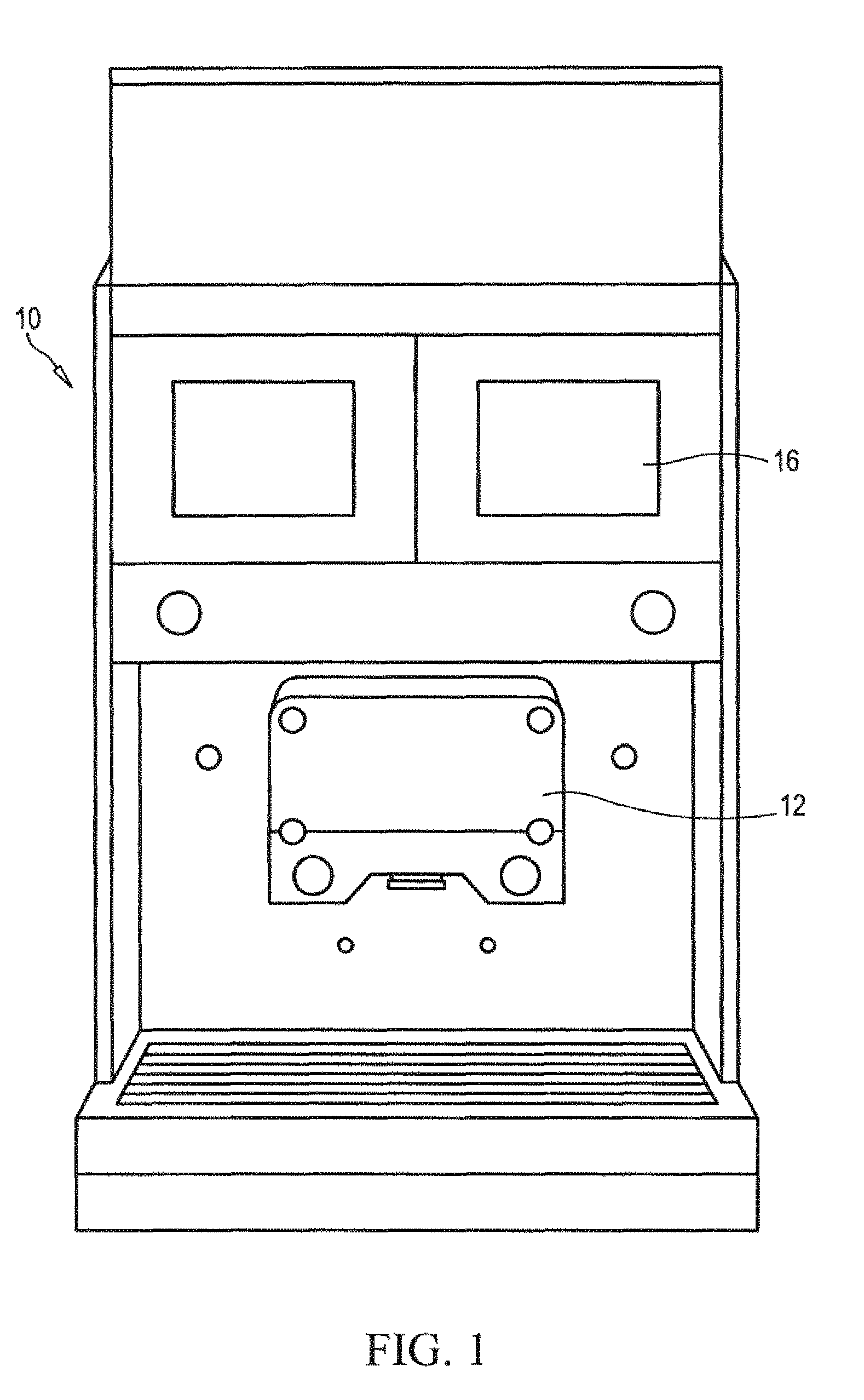

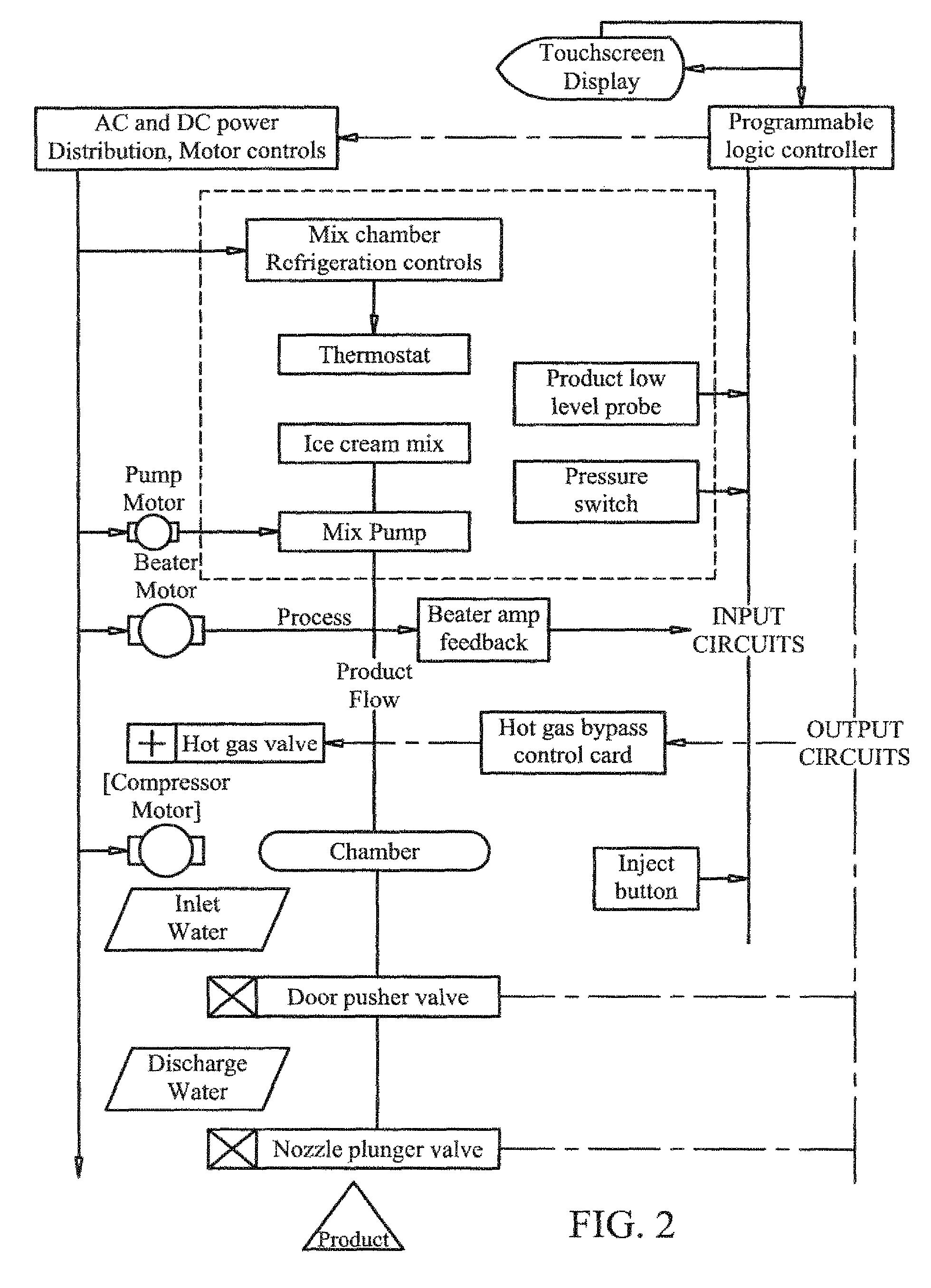

Frozen confection machine

ActiveUS8335587B2Reduce frequencyImprove machine performancePower operated devicesVolume/mass flow measurementDisplay deviceProduct Identifier

Owner:FEOLA ANTHONY V

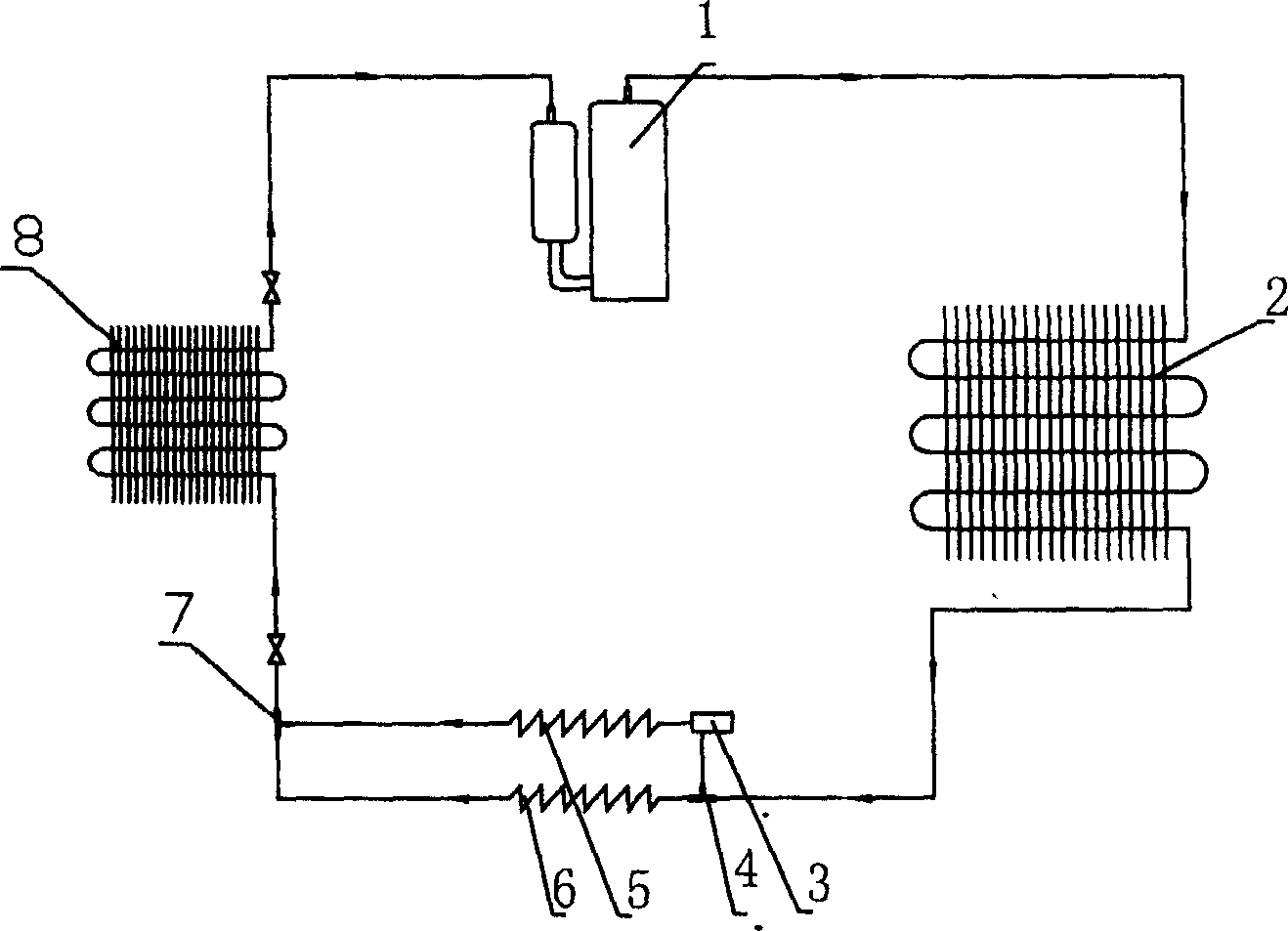

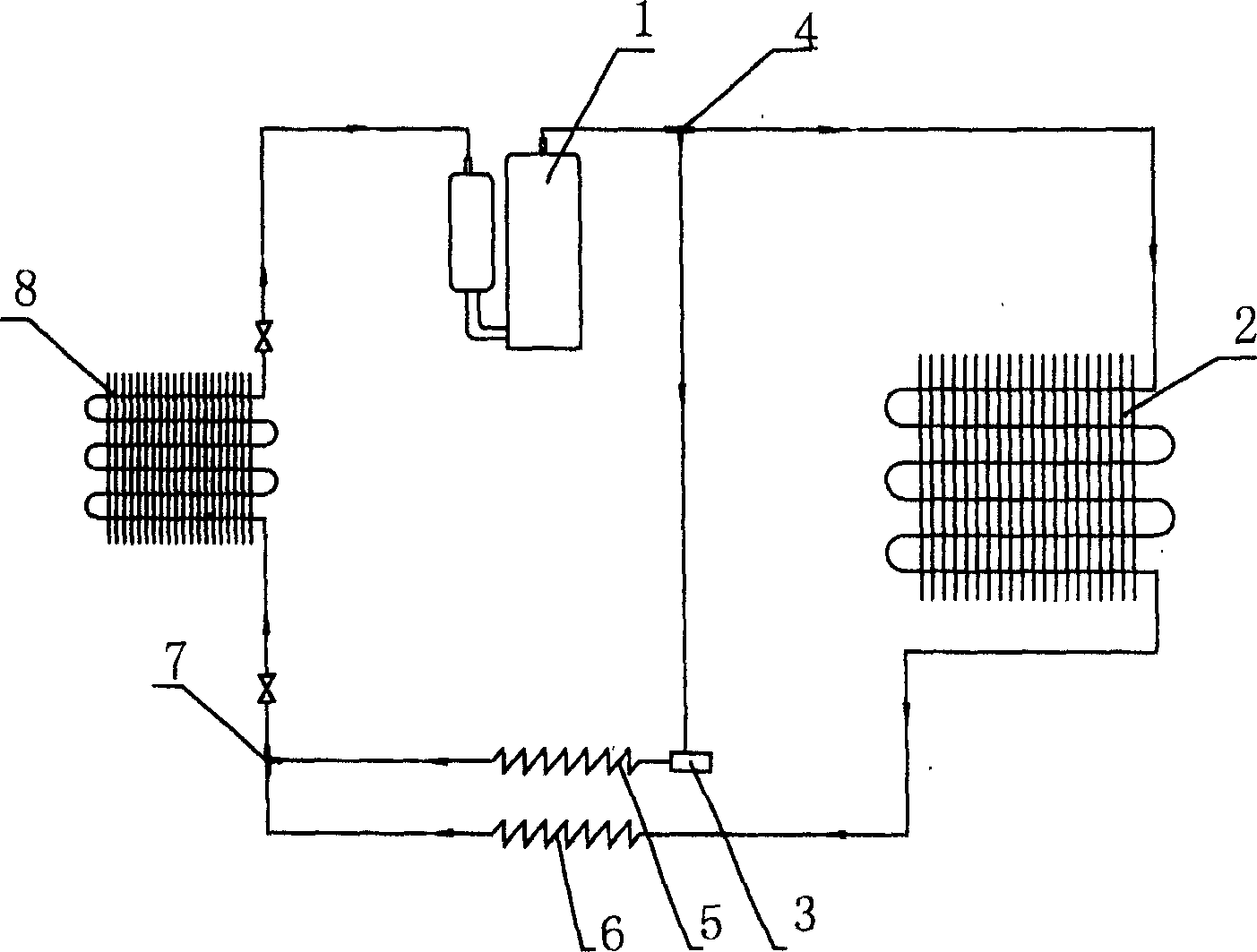

High temperature self-adaption separated air conditioners

InactiveCN1645016AImprove flow coefficientHigh trafficMechanical apparatusSpace heating and ventilation safety systemsDecreased pressureHigh pressure

A high temperature self-adapting air conditioner comprises a refrigerating circle which is composed by a compressor, a condenser, main capillary, an evaporator. The refrigerating circle is parallel connected by a subsidiary throttle sidecut which is composed by a filter, an unloading valve and subsidiary capillary. Due to the subsidiary throttle sidecut, upon the side condenser's pressure exceeds the safety limit, the unloading valve opens and the subsidiary sidecut got through; then the flux index of the capillary will be increased, refrigerant flux will be increased; then lower down the pressure of the condenser; then the compressor will be protected for a continuous running.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

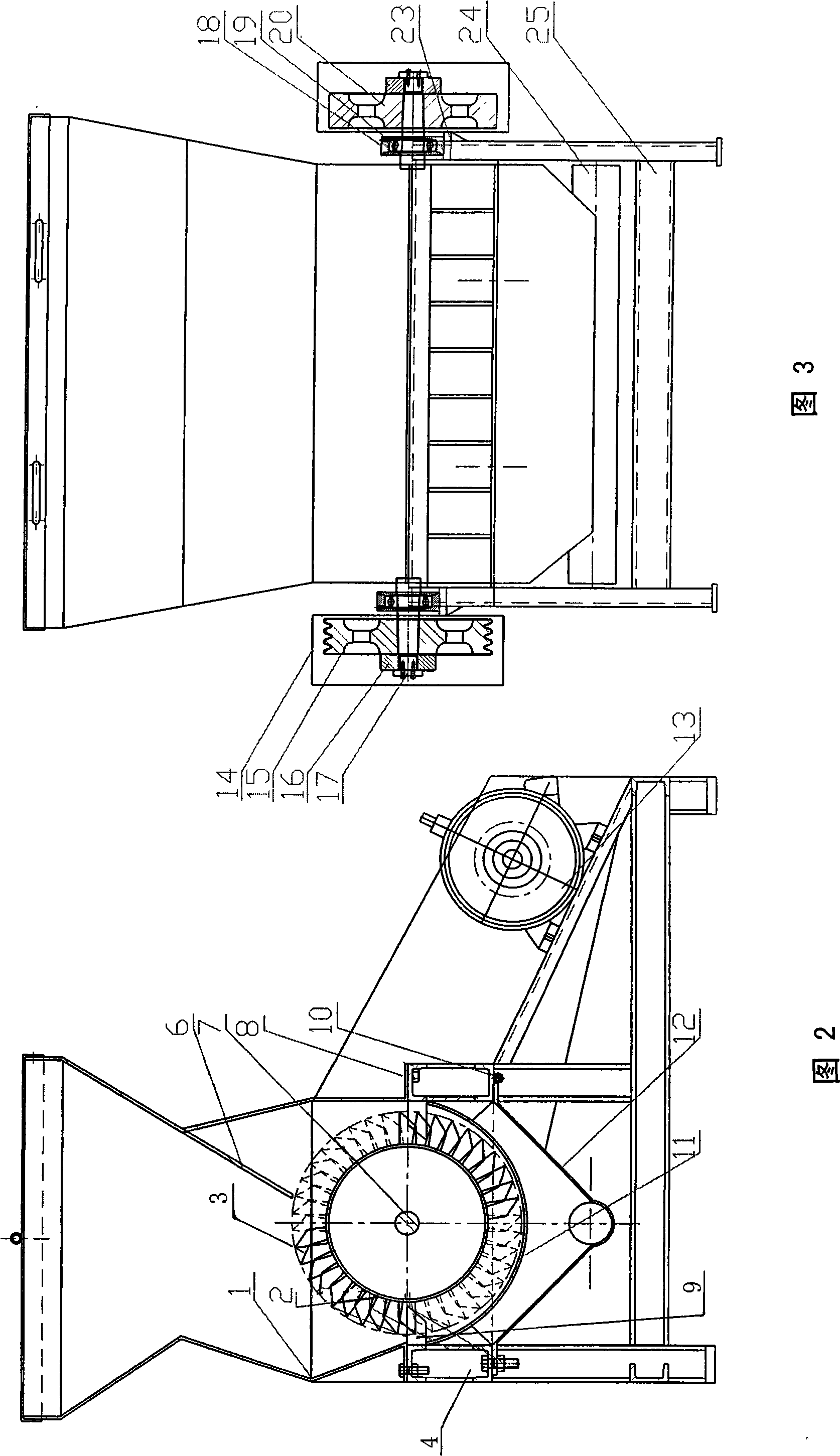

Environment friendly recycling prilling unit for plastic foam

InactiveCN101486234AEasy accessEasy access to crushing processGrain treatmentsMaterial supplyEnergy loss

The invention relates to a foamed plastic environment-friendly recovery granulating machine set. A pulverizer comprises a feeding main body, a pulverizing roller which is arranged in the feeding main body, a screen mesh plate which is arranged below the pulverizing roller and a wind gathering discharge hopper which is connected with the feeding main body. A conveyer pipeline comprises a radial material loading pipeline consisting of a material loading blower and a pipeline, a tangential feeder which is connected with the radial material loading pipeline and a regular polygon feeding tank which is connected with the tangential feeder. A host machine comprises a primary compression extruding part and a secondary compression extruding part which is connected with the primary compression extruding part. The foamed plastic environment-friendly recovery granulating machine set adopts a closed circular material supply system, improves the environment-friendly regeneration utilization rate, reduces the recovery cost, saves the energy loss, and reduces the recovery secondary pollution.

Owner:余姚市绿岛橡塑机械设备有限公司

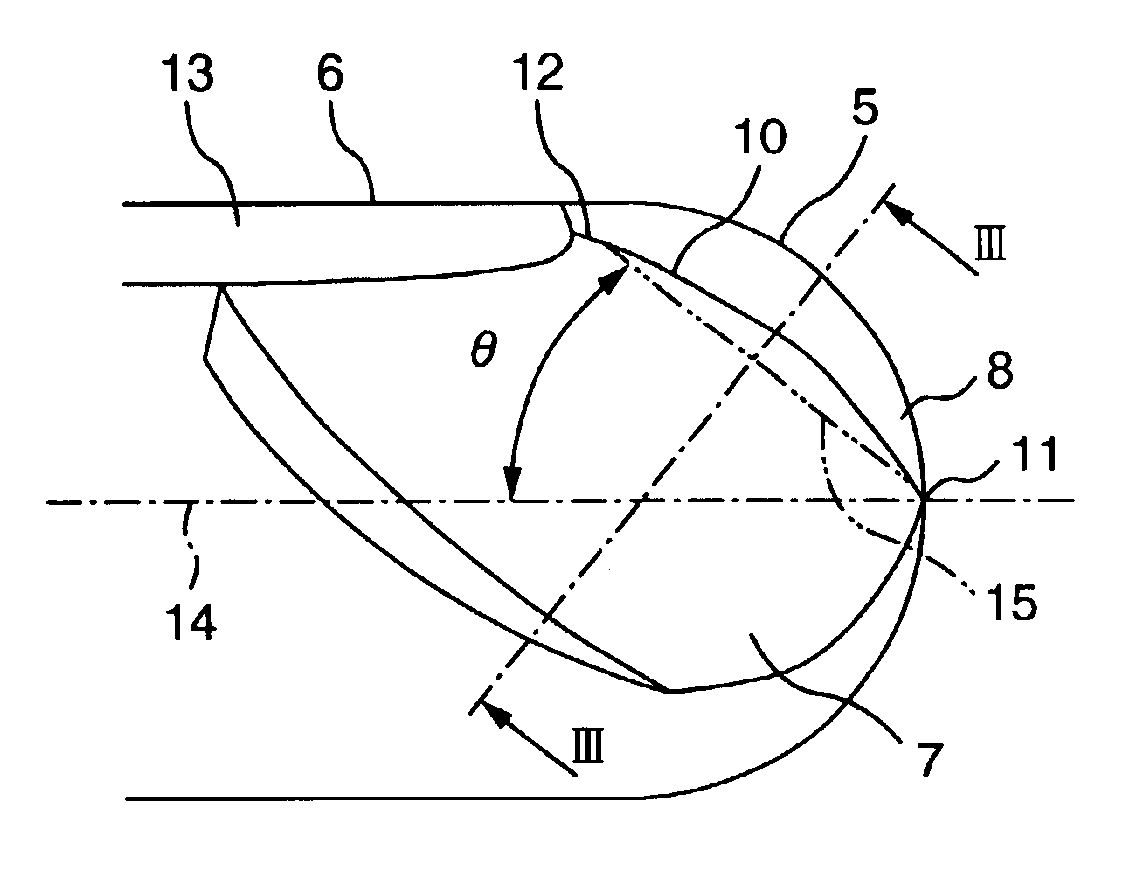

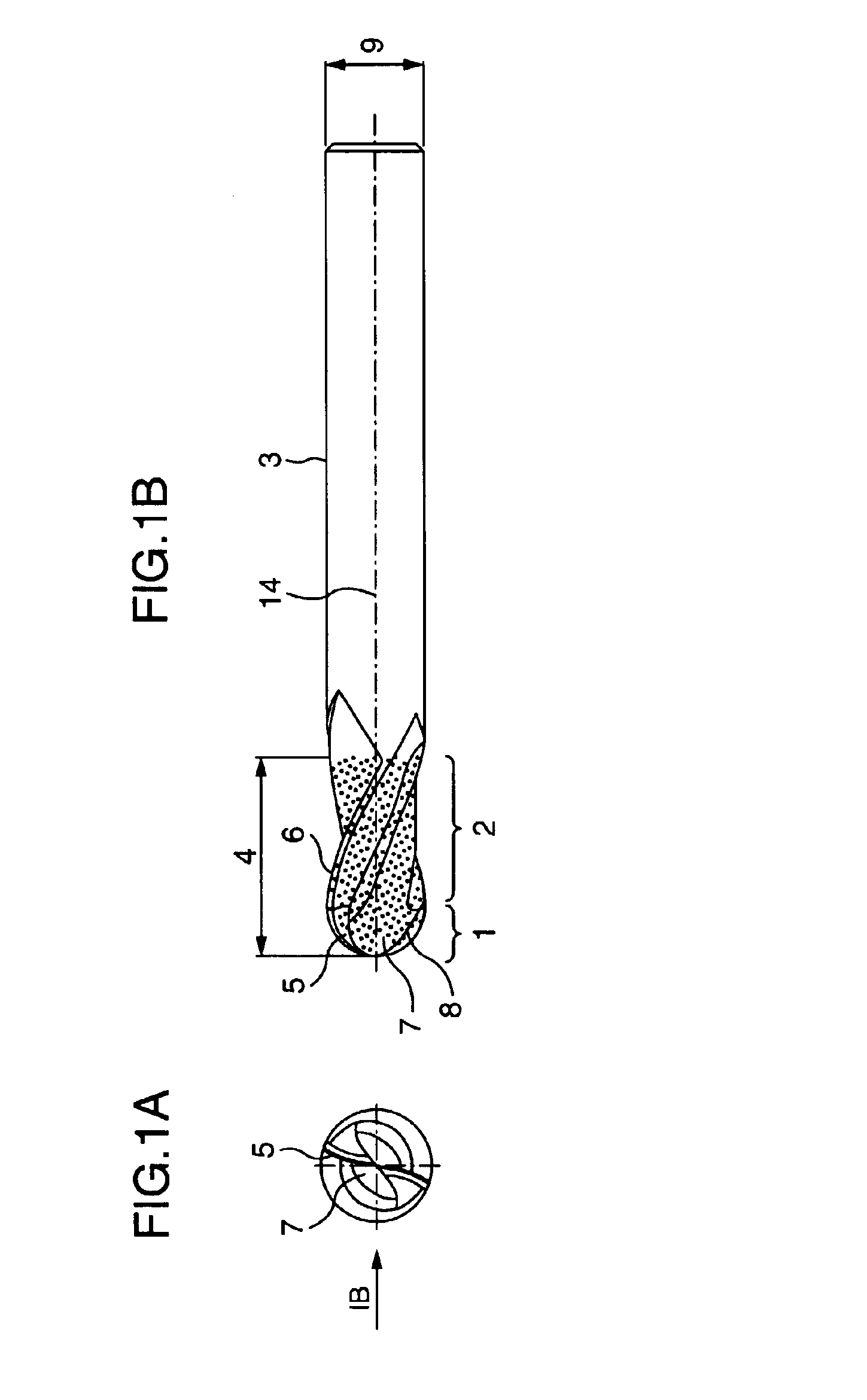

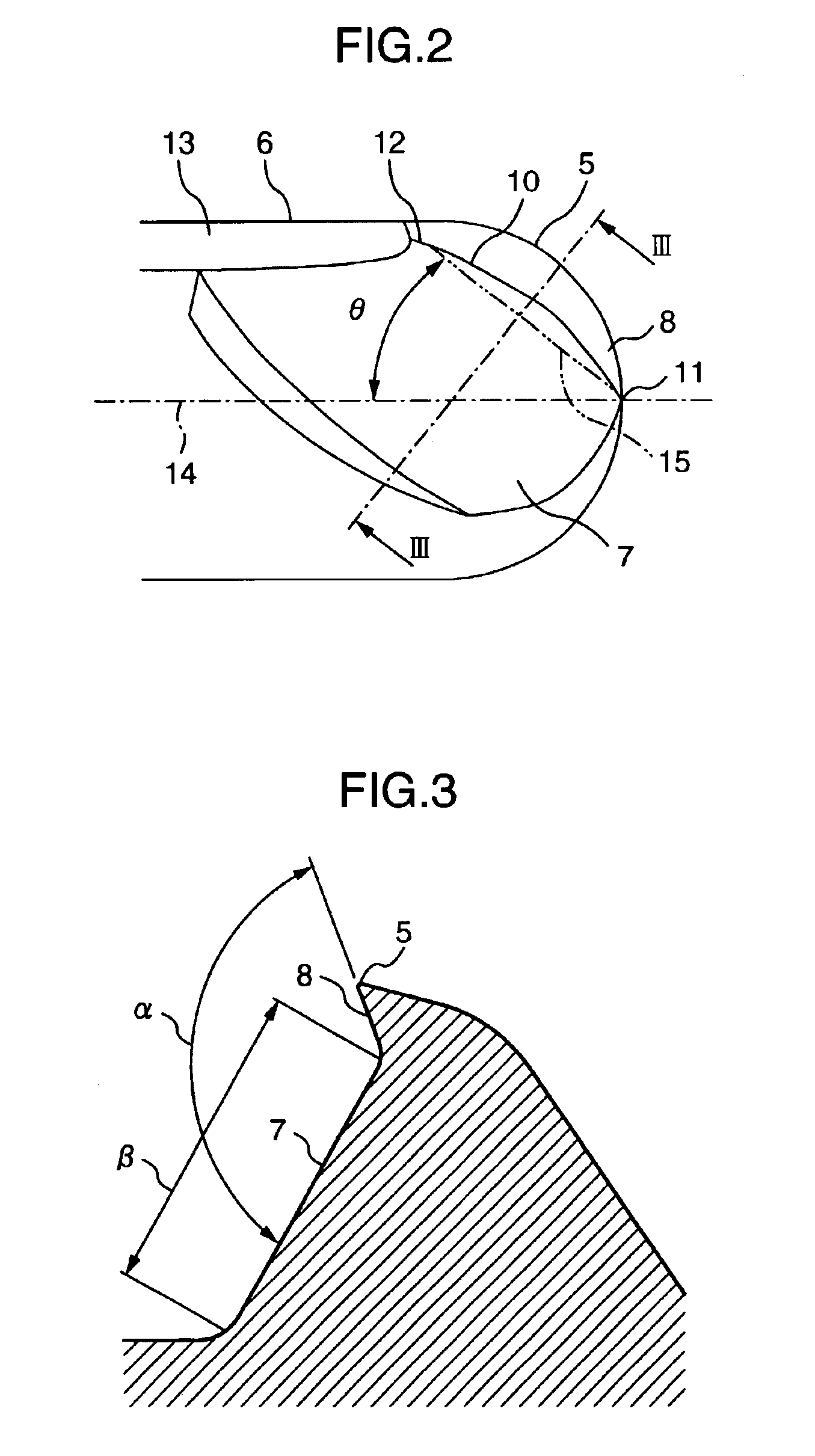

Cemented carbide ball end mill

InactiveUS6953310B2Improve machine performanceImprove performanceMilling cuttersWorkpiecesFluteCemented carbide

A cemented carbide ball end mill comprises a cutting portion with a semi-spherical ball portion at a tip thereof. The cutting edge portion has a cutting edge rake face and a chip evacuating flute at the ball portion. An angle formed by a straight line connecting a vertex of the ball portion, where an intersection line passes through, and another end of the intersection line with respect to the central axis, is from 30° to 50°. Further, and angle formed by the rake face and the chip evacuating flute is from 100° to 150°, and a width of the chip evacuating flute is 0.5 to 5 times as large as a radius of the ball portion.

Owner:NACHI-FUJIKOSHI

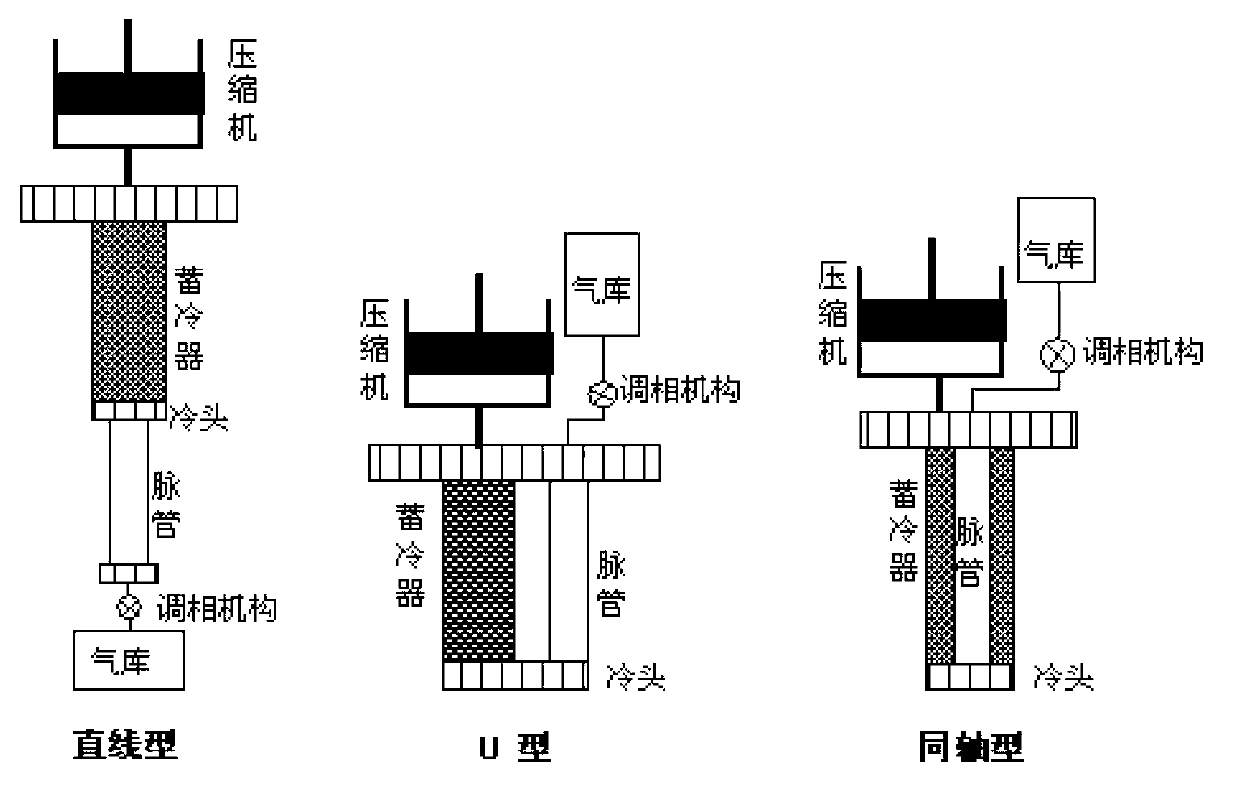

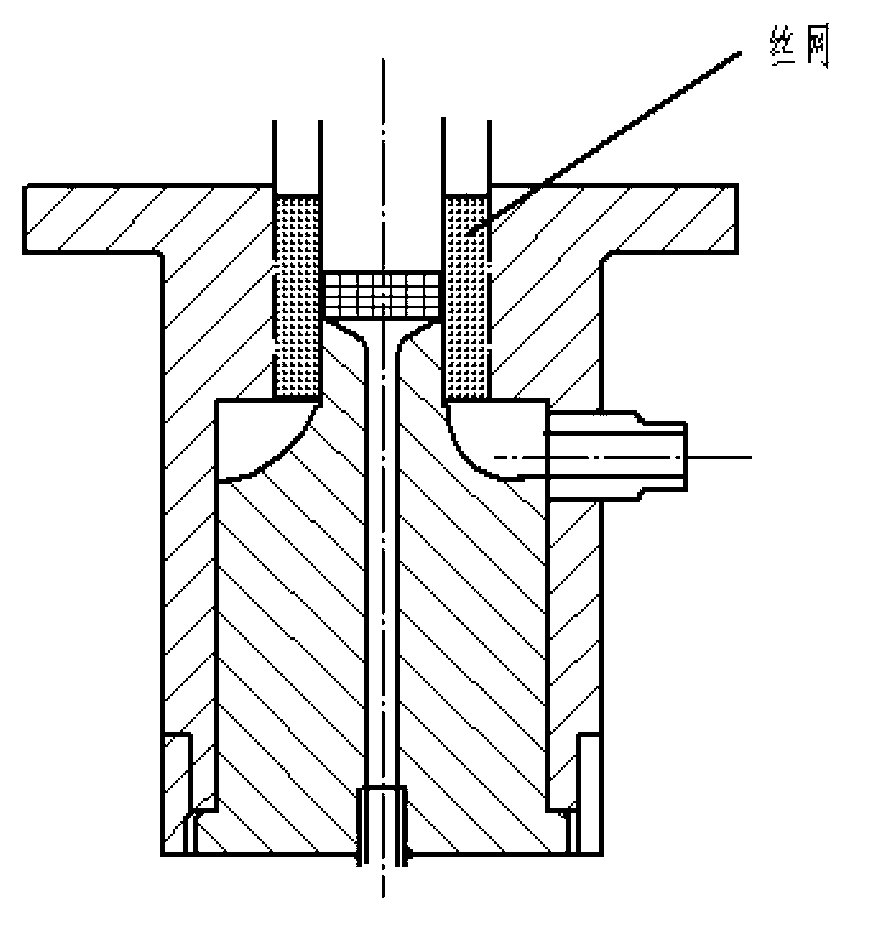

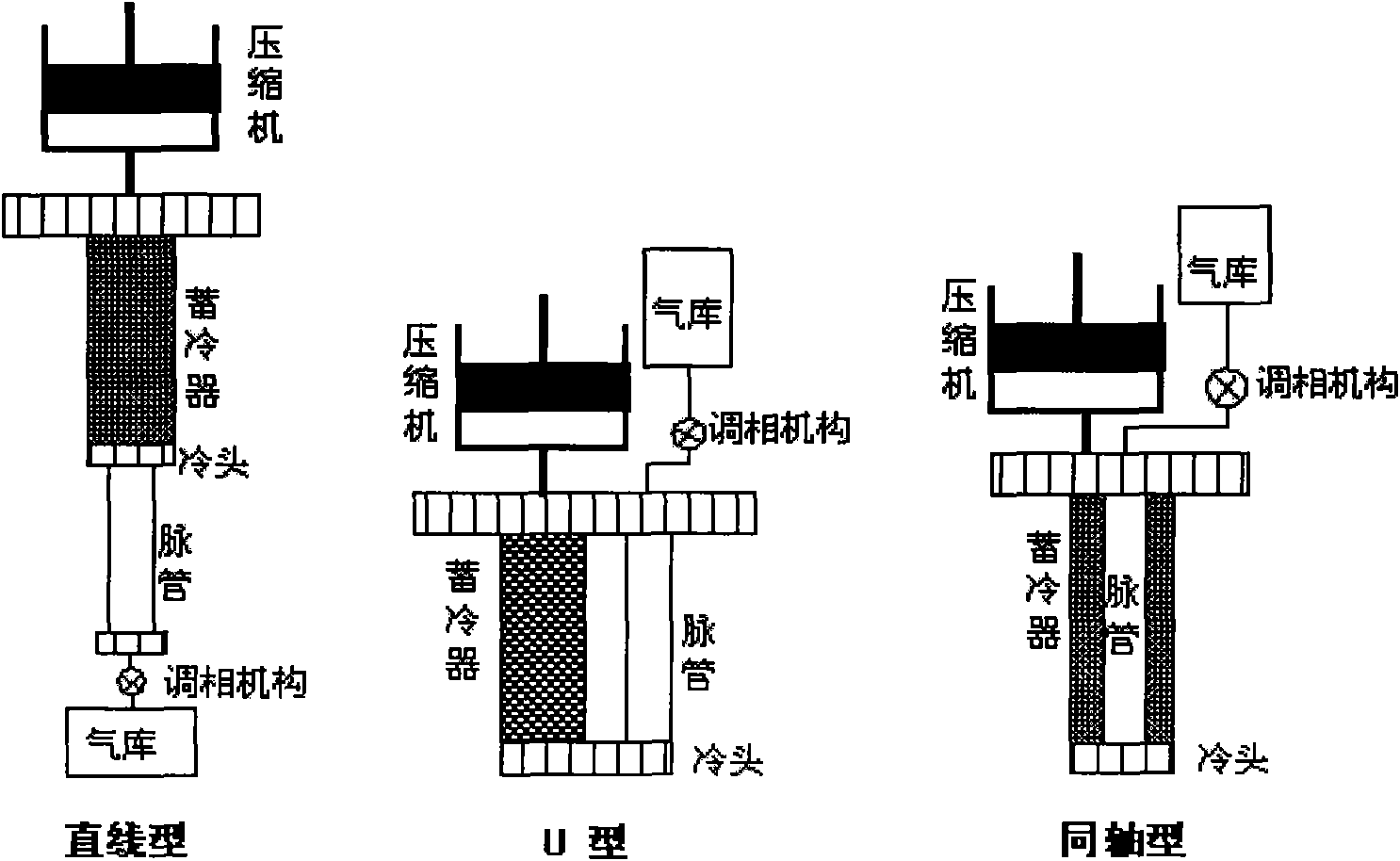

Conical slit-type hot end heat exchanger of coaxial pulse tube refrigerator and manufacturing method

ActiveCN102735088AImprove thermodynamic performanceImprove machine performanceCompression machinesSoldering apparatusPulse tube refrigeratorEngineering

The invention discloses a conical slit-type hot end heat exchanger of a coaxial pulse tube refrigerator and a manufacturing method. The heat exchanger structurally consists of a hot end flange, a conical slit and a hot end plug, wherein the conical slit is inserted into the hot end flange in a tight fit way, the radius of a circle of contact on the top of a cone frustum is equal to the radius of a cold accumulator and the radius of the bottom of the cone frustum is equal to the radius of the hot end plug. The hot end plug and the hot end flange not only can be connected through bolts to form a detachable split-type hot end heat exchanger, but also can be hermetically welded to form an integrated hot end radiator. The conical slit-type hot end heat exchanger has the advantages that the structure is simple, compact and high-efficiency, the hot end radiating capacity of the refrigerator can be exerted to the utmost extent and the hot end pressure ratio of the pulse tube refrigerator is increased at the same time. The structure can intensively realize the major functions of a high-efficiency hot end heat exchanger, a hot end gas flow guide device of the pulse tube refrigerator and a hot end gas even distributor of the cold accumulator, and can improve the performance of the entire pulse tube refrigerator to a great extent.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

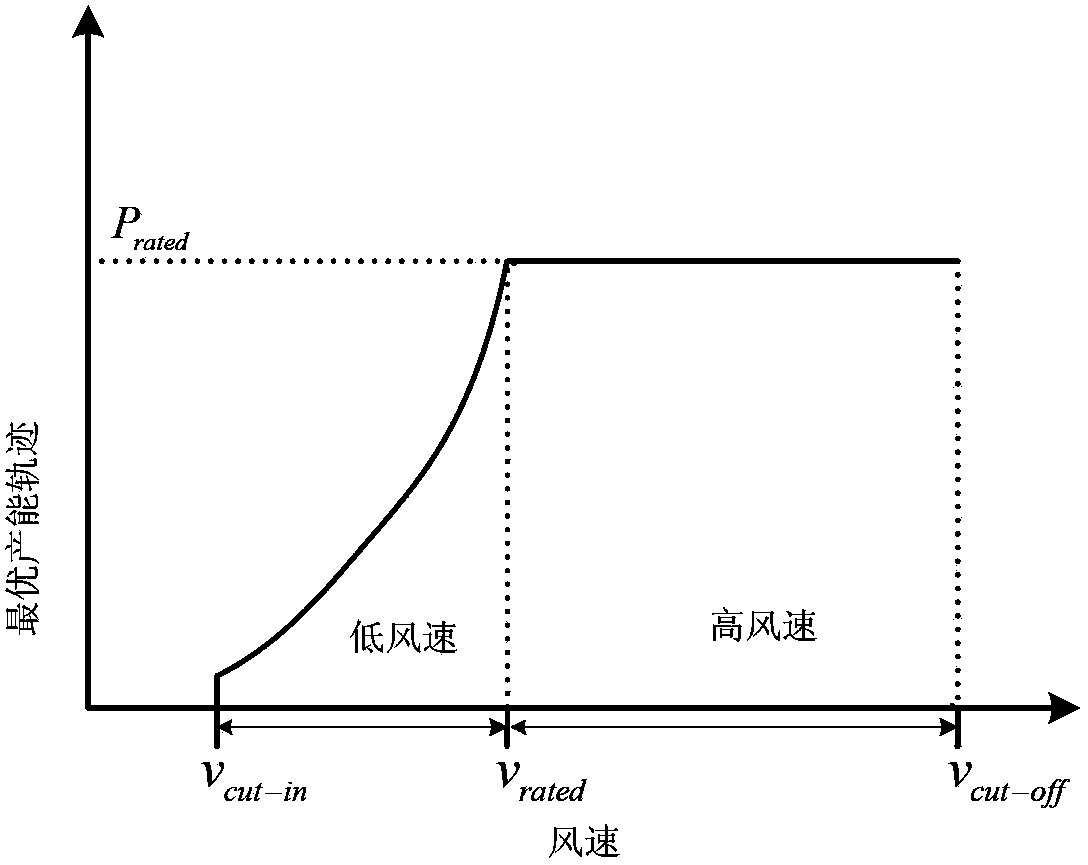

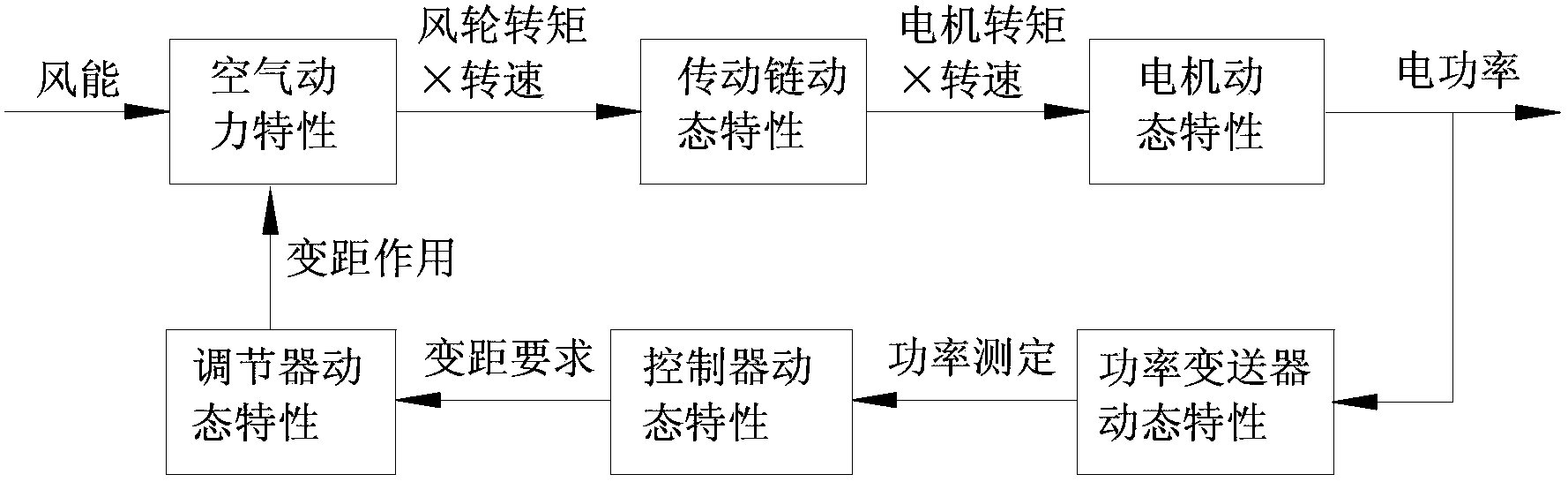

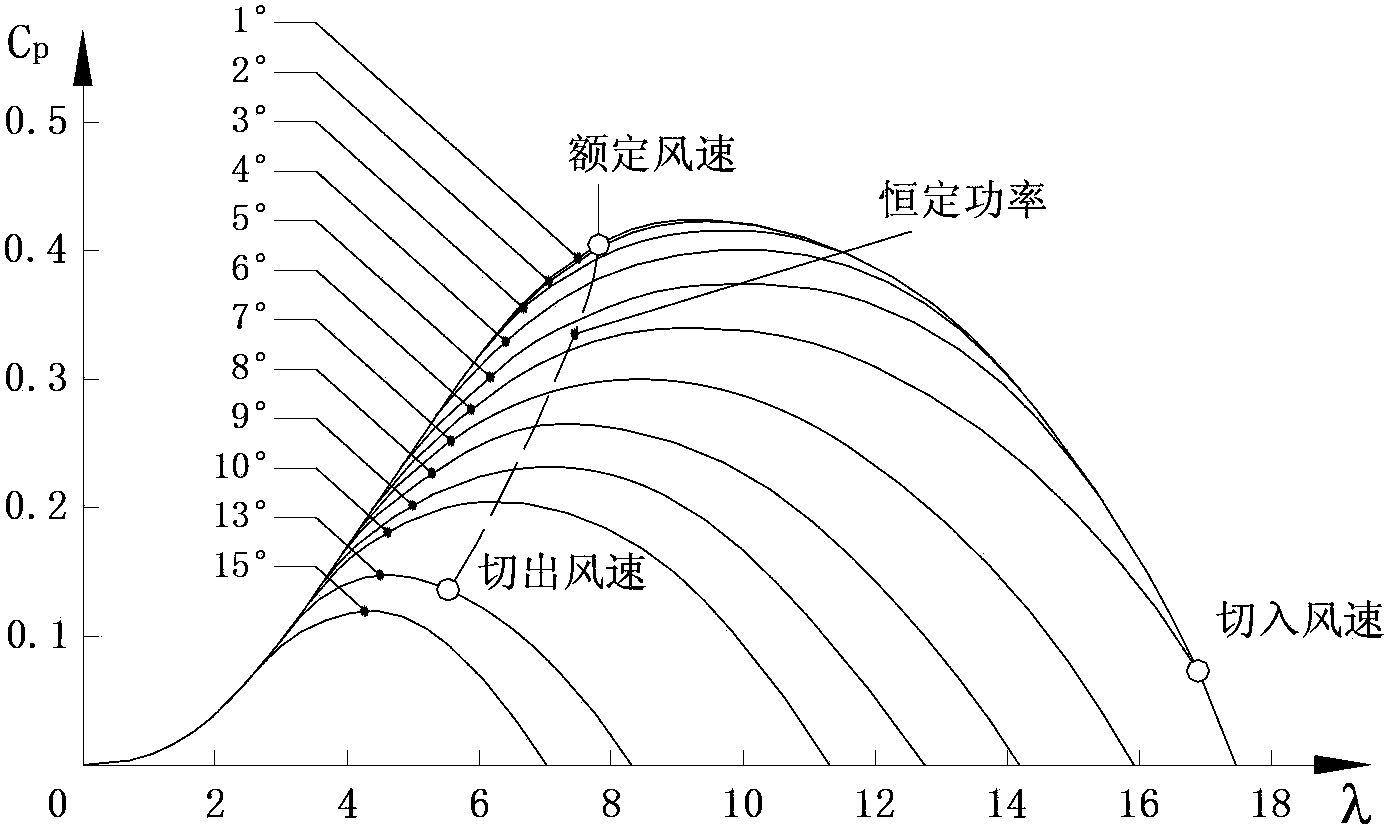

Effective wind speed obtaining method of wind generating set based on High-Gain observer

ActiveCN103410659AImprove real-time performanceImprove effectivenessWind motor controlMachines/enginesElectric power systemEngineering

The invention discloses an effective wind speed obtaining method of a wind generating set based on a High-Gain observer. The effective wind speed obtaining method includes the following steps that firstly, a sensor is used for collecting a rotor speed omega r of a wind wheel of the wind generating set and data are filter, sorted and preprocessed, high-frequency disturbance from a wind power plant circumstance and a wind generating set tower body is eliminated, mechanical and electrical features of the wind generating set are combined to set up the High-Gain observer and finally, an effective wind speed estimation value is obtained through a Cp secondary surface fitting polynomial function. The effective wind speed estimation value serves as the important reference input of a wind generating set controlling system, is applied to torque control, pitch angle control and yaw control of the wind generating set and also can be applied to analysis of reliability and economic benefits of a wind power station and estimation and analysis on influences on a power system by the wind power station which accesses to the power grid. The effective wind speed obtaining method of the wind generating set based on the High-Gain observer has great scientific significance and application value in planning and design of grid connection of the wind power station, analysis and calculation on safety and stability of the power grid including wind power and configuration and setting of a protection and safety automatic device.

Owner:ZHEJIANG UNIV

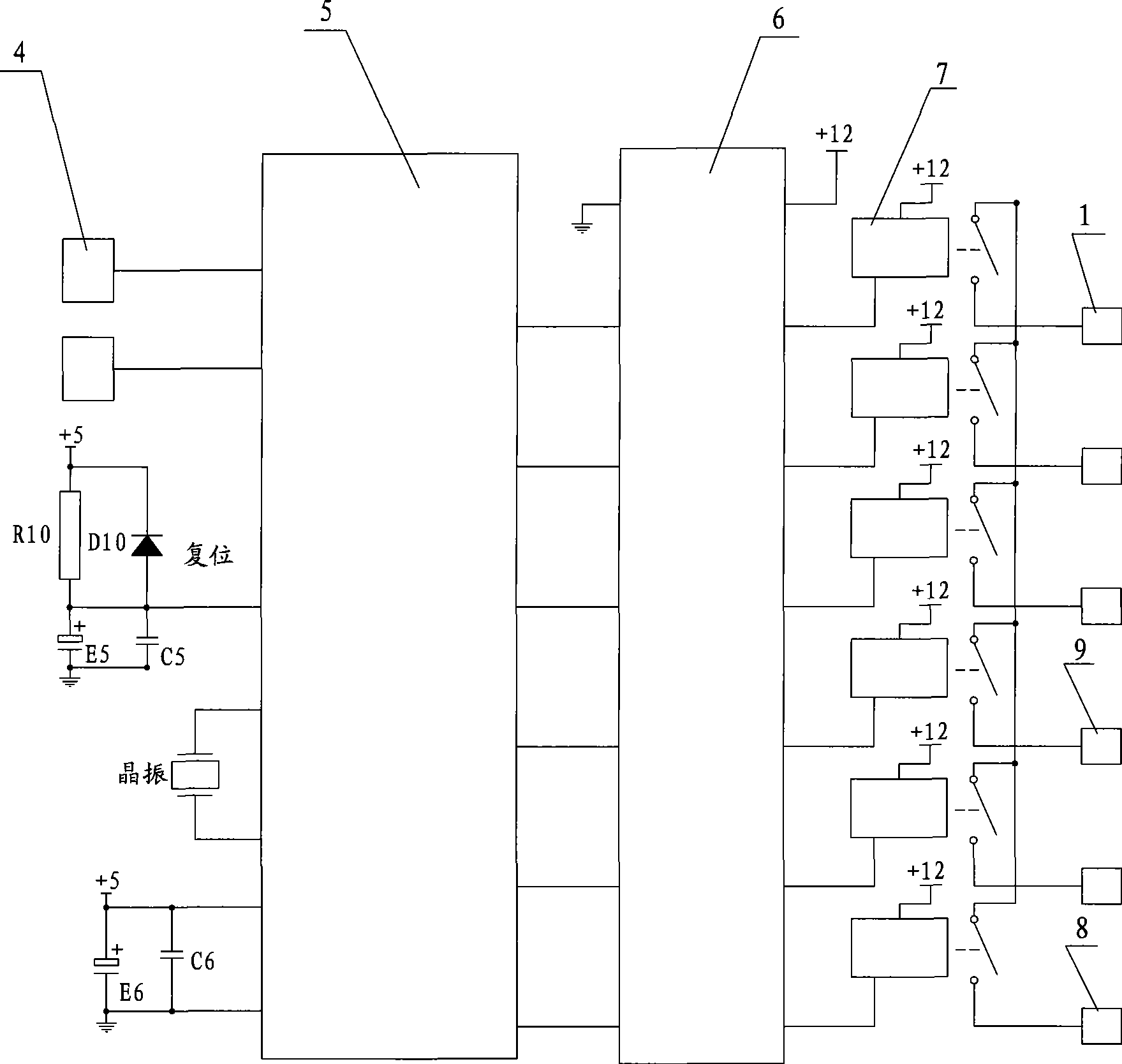

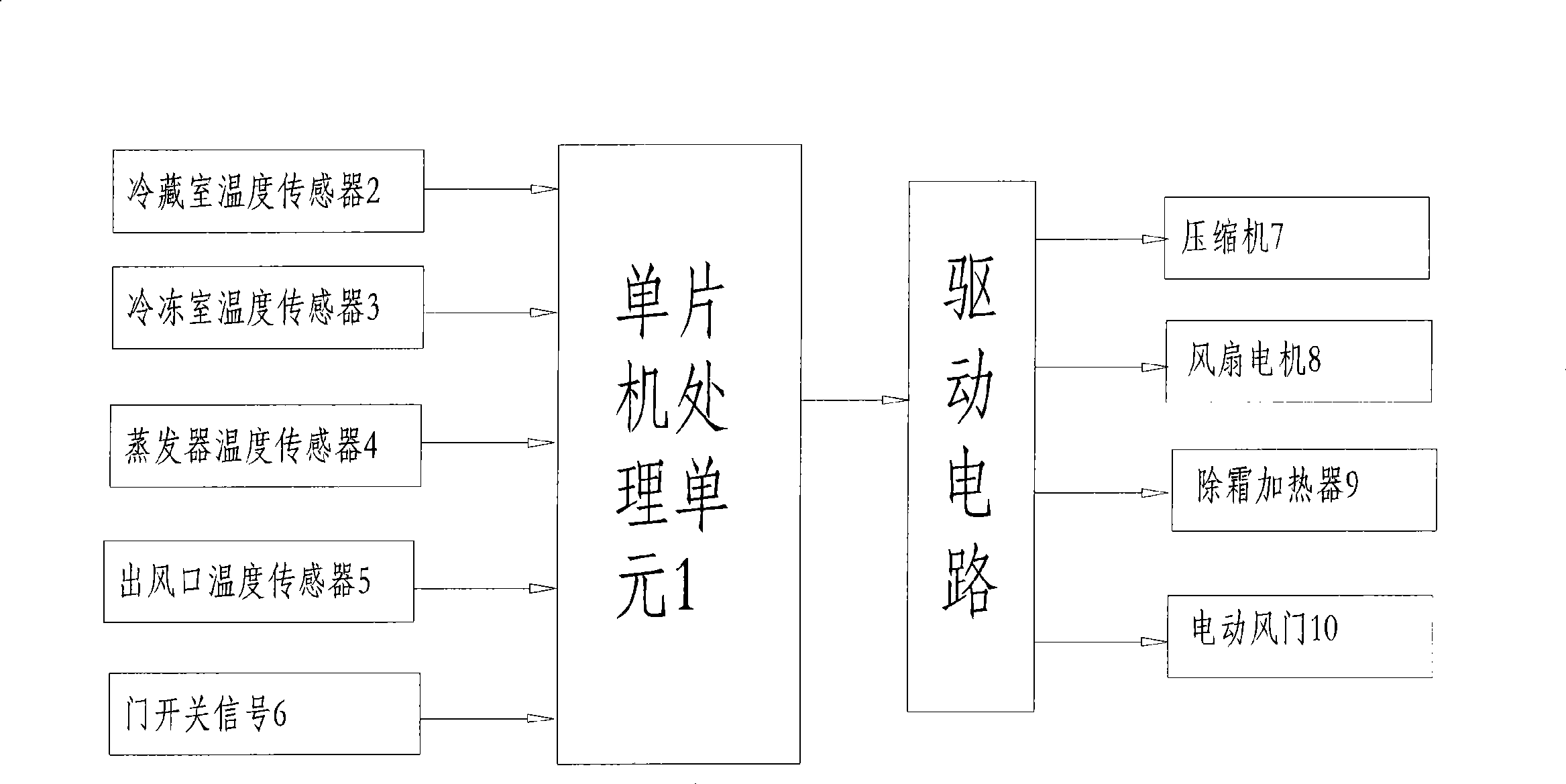

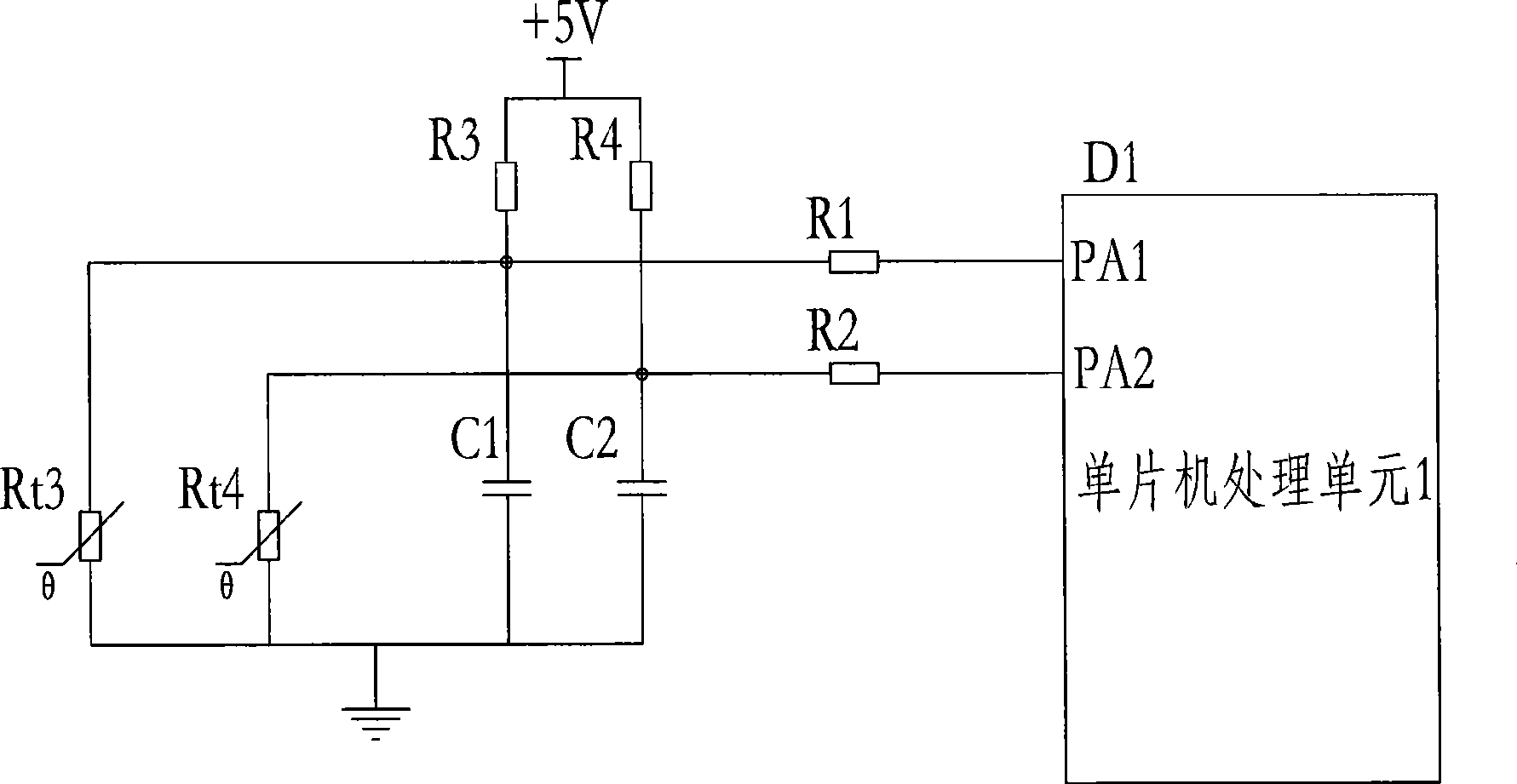

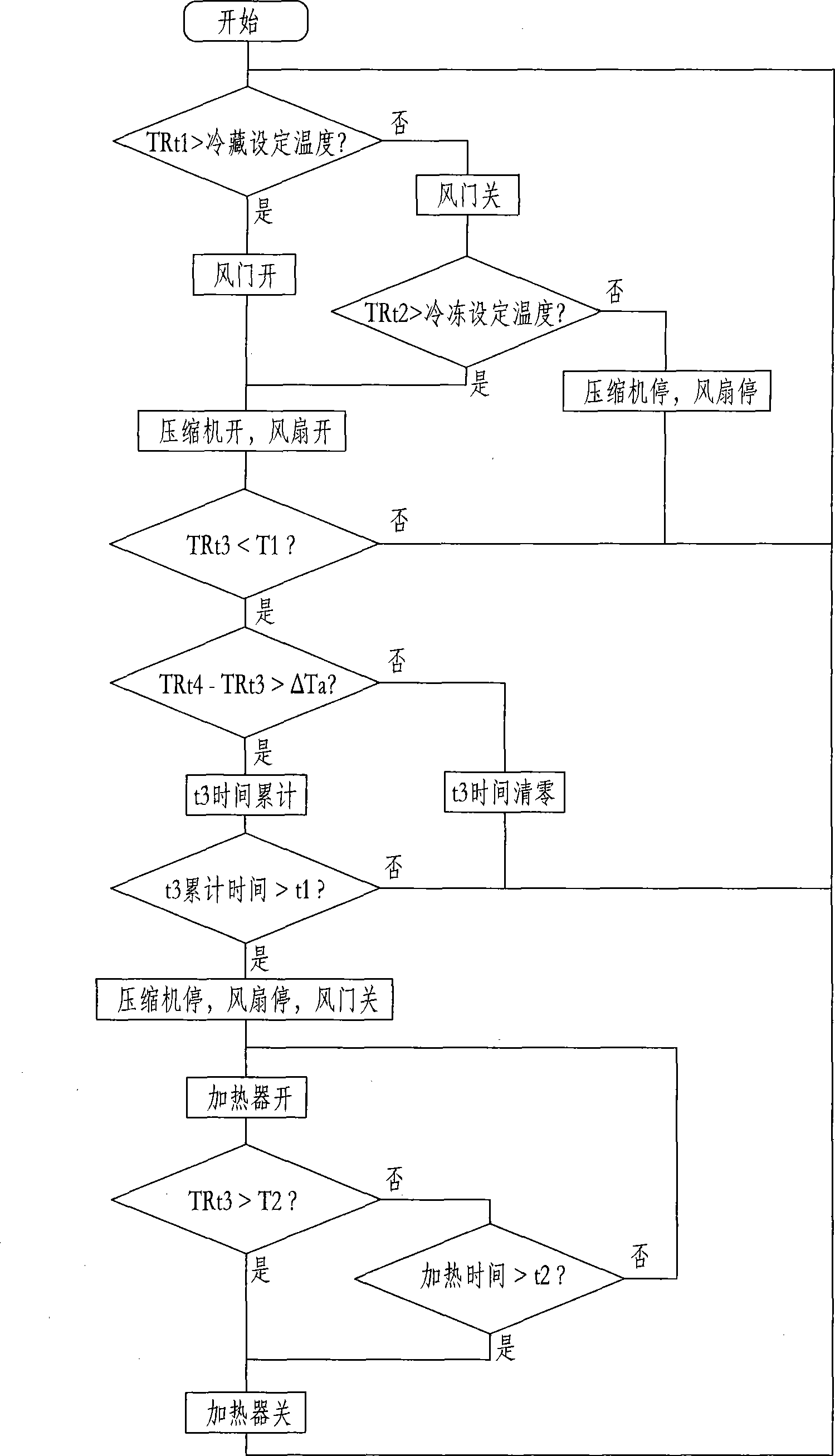

Non-frost refrigerator control system and defrosting control method thereof

ActiveCN101392977AReduce energy consumptionImprove machine performanceCorrosion preventionRefrigeration safety arrangementMicrocontrollerEngineering

The invention relates to a control system for a frost-free refrigerator, which comprises a singlechip processor, and a refrigerating chamber temperature sensor, a freezing chamber temperature sensor, an evaporator temperature sensor and a door switch signal which are connected with the singlechip processor respectively, wherein the singlechip processor is respectively connected with a compressor, a fan motor, a defrosting heater and an electric air door through a drive circuit. The control system for the frost-free refrigerator also comprises an air outlet temperature sensor which is connected with the singlechip processor, wherein the air outlet temperature sensor is arranged on an air outlet of the fan motor of an evaporator. The invention also comprises a defrosting control method for the control system of the frost-free refrigerator, which can control the refrigerator to perform heating defrosting only when the frosting degree of the evaporator influences the refrigerating effect by taking the temperature difference of the evaporator temperature sensor and the air outlet temperature sensor as the basis for judgment, and is not influenced by the ambient humidity and the service condition. Under the condition of actual use, the control system and the defrosting control method can reduce the energy consumption of the refrigerator and the temperature fluctuation in the refrigerator, and achieve the aim of improving the complete machine performance of the refrigerator.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

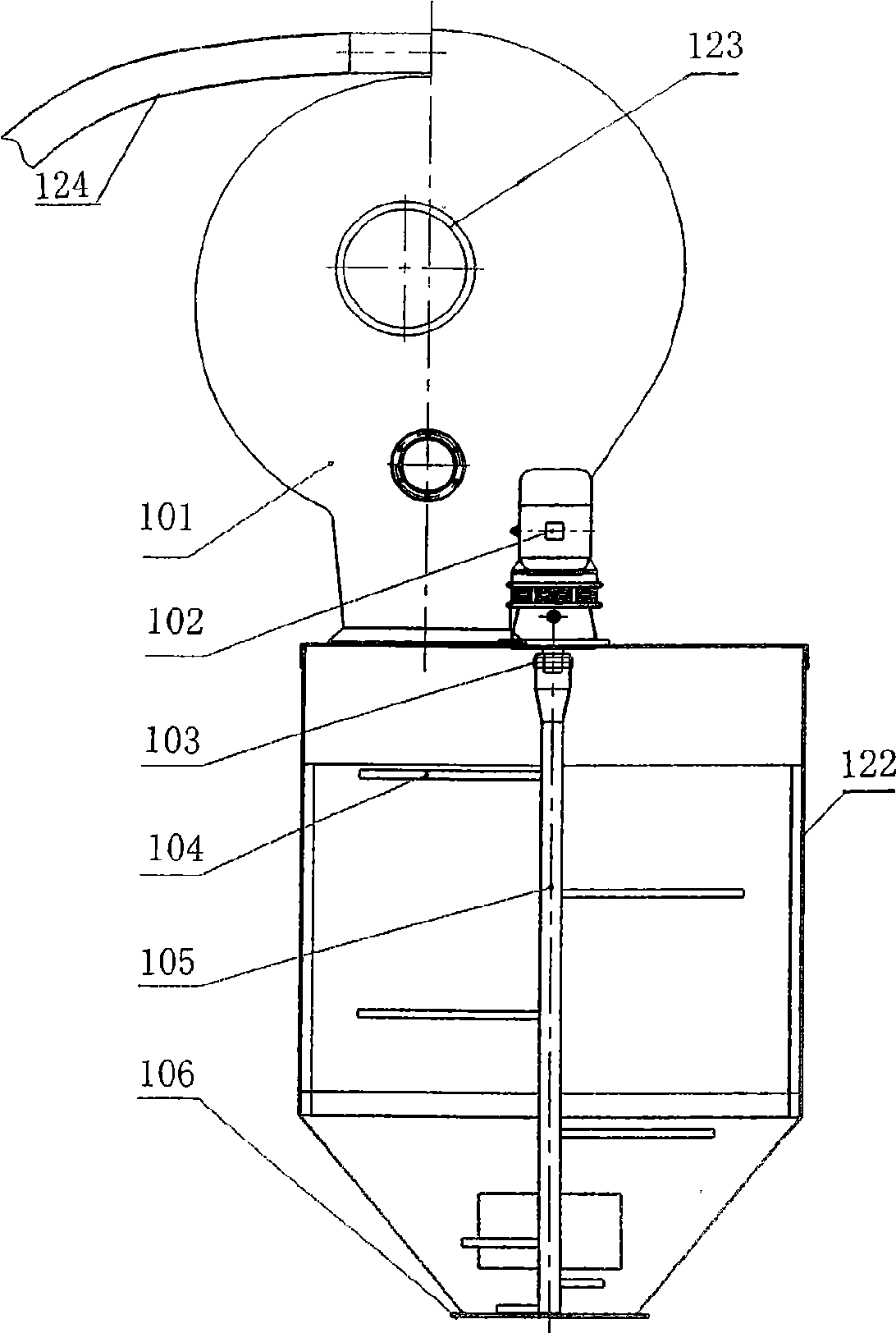

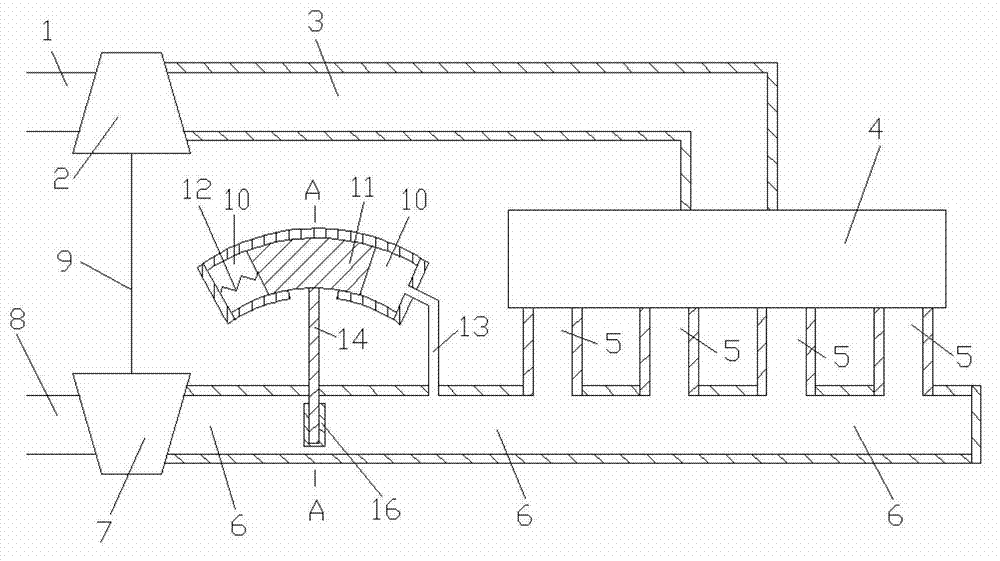

Intelligent industrial analyzer

InactiveCN102519827AImprove machine performanceImprove efficiencyWeighing by removing componentCombustionCrucible

The invention discloses an intelligent industrial analyzer, comprising at least a combustion device, at least a sample weighing device, and at least a delivering sampling device for transferring a crucible between the combustion device and the sample weighing device, wherein the delivering sampling device comprises a manipulator for capturing the crucible, a elevating mechanism for driving the manipulator to elevate, and a rotary mechanism for driving the manipulator to rotate. According to the invention, the transfer of the crucible between the combustion device and the delivering sampling device is realized by the delivering sampling device; the up-and-down motion of the manipulator is realized by the elevating mechanism of the delivering sampling device, the rotation of the manipulator around any plane is realized by the rotary mechanism of the delivering sampling device, thus the manipulator can be guaranteed to deliver and sample in X, Y and Z axis at will, and the whole machine functions and efficiency of the industrial analyzer are greatly raised.

Owner:CHANGSHA KAIYUAN INSTR

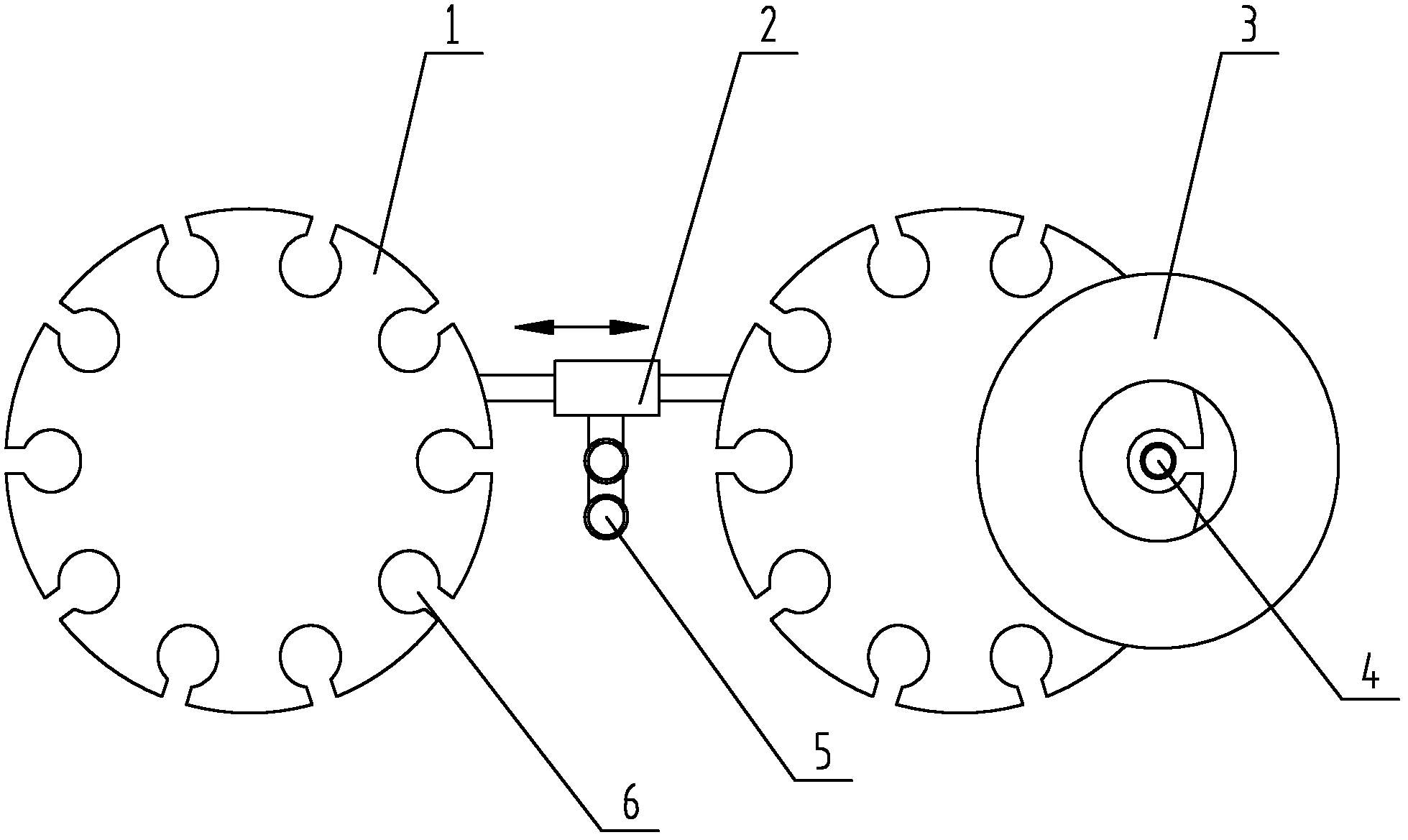

Variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for turbocharged engine

InactiveCN103089411ALarge throat areaIncrease intake pressureInternal combustion piston enginesInlet pressureAir compressor

A variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for a turbocharged engine belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, a volume cavity, a rotation body, a spring, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in an air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of a connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air exhaust pipe in front of the rotation plate is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air exhaust pipe in front of the rotation plate is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for the turbocharged engine is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

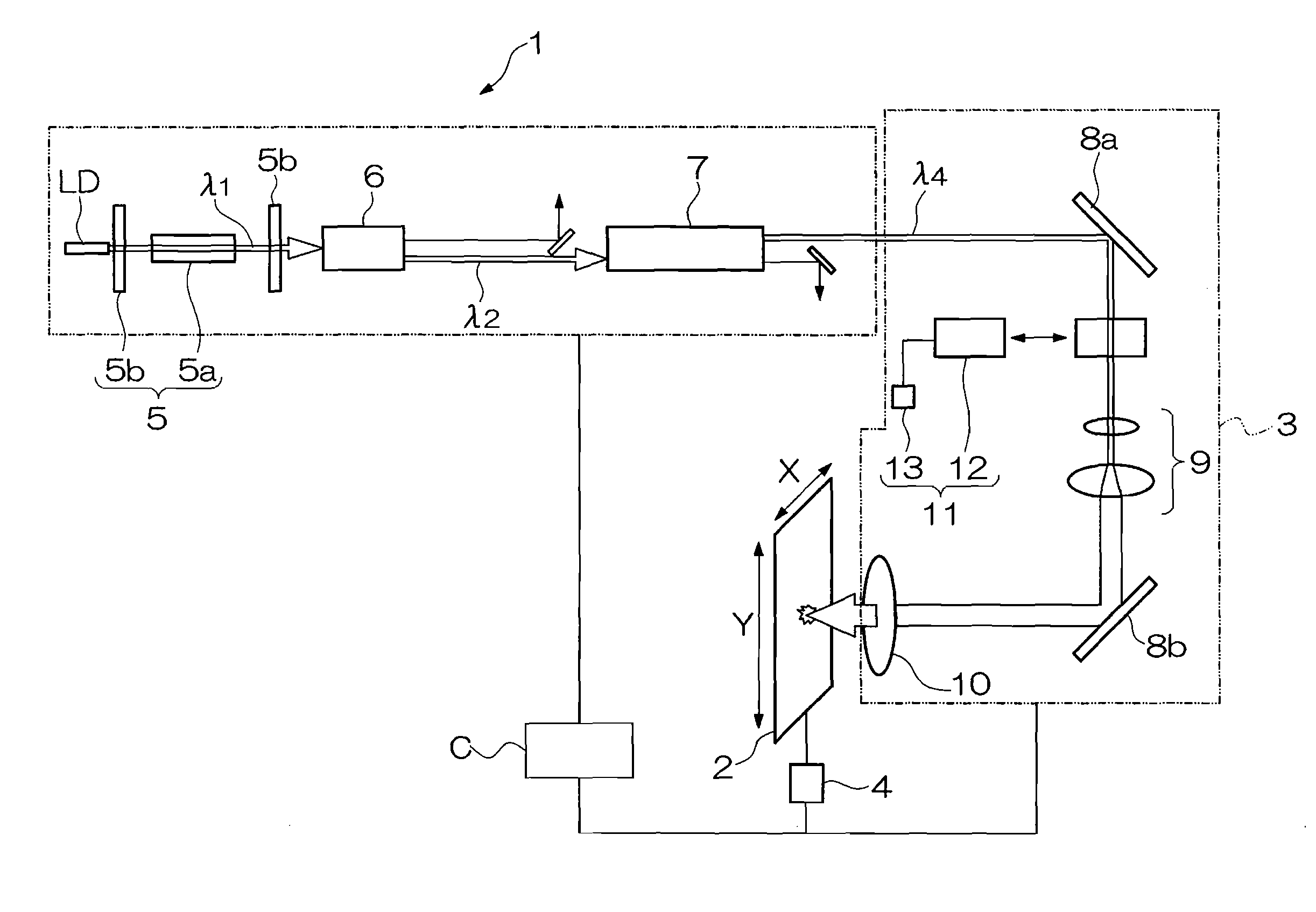

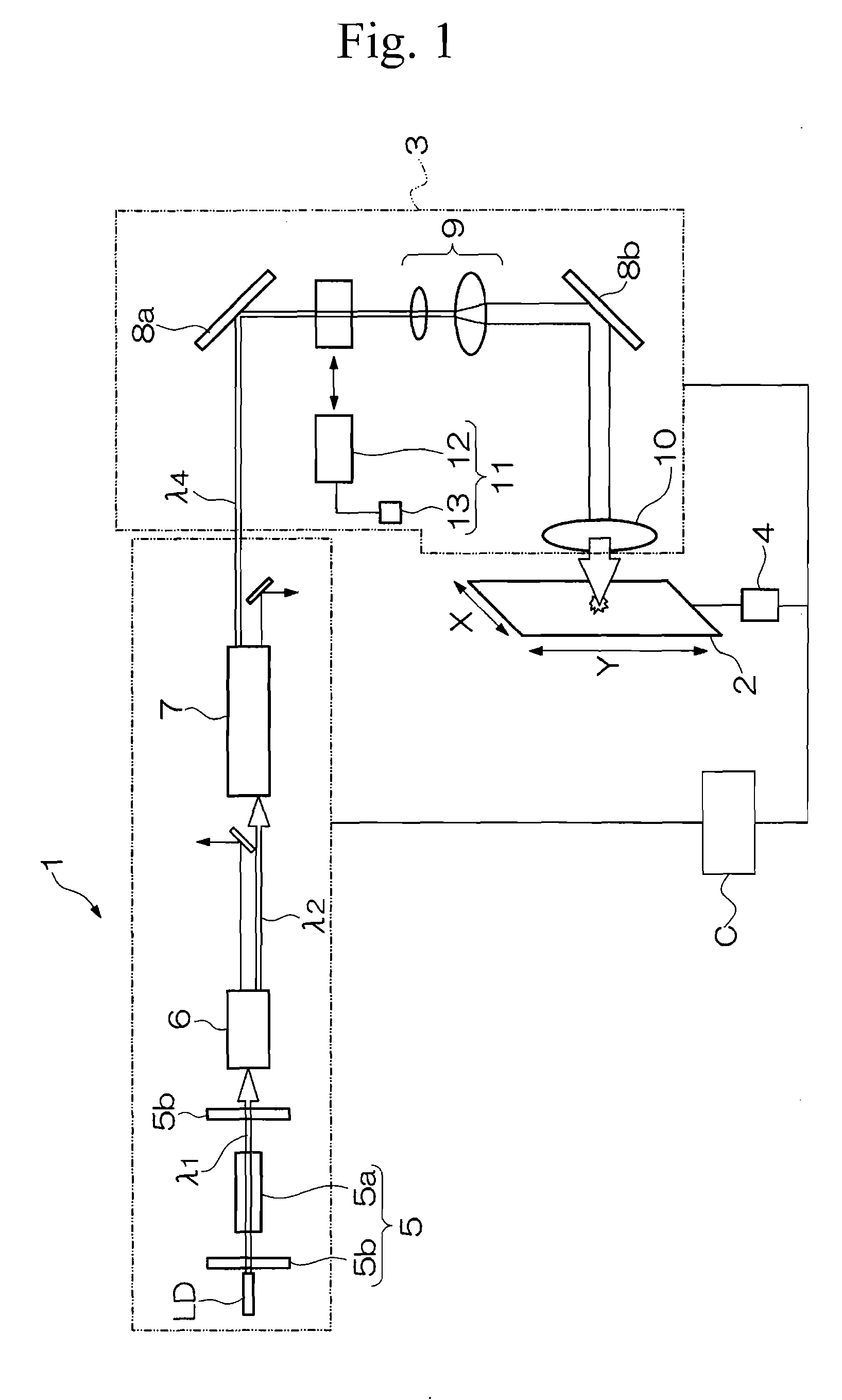

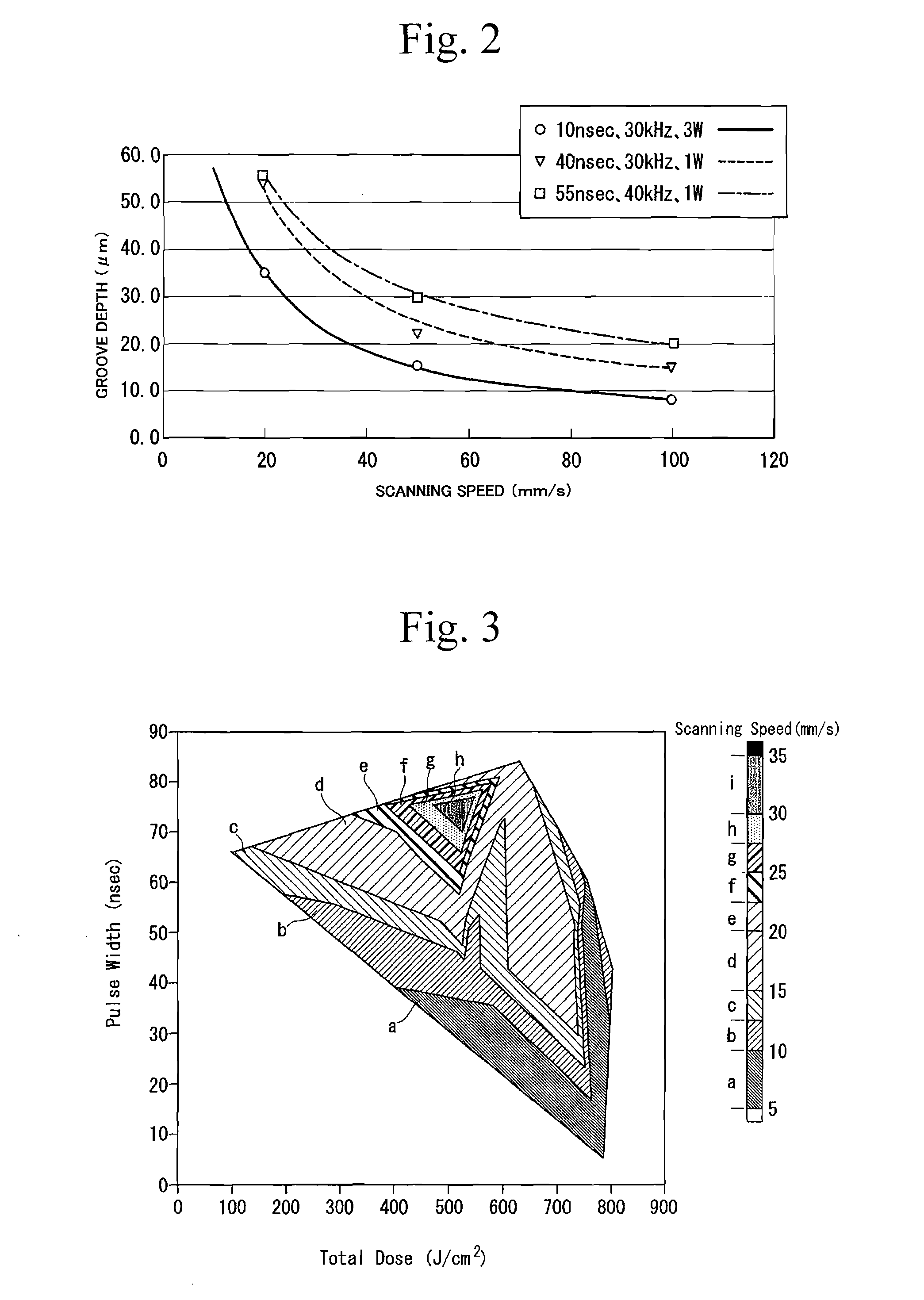

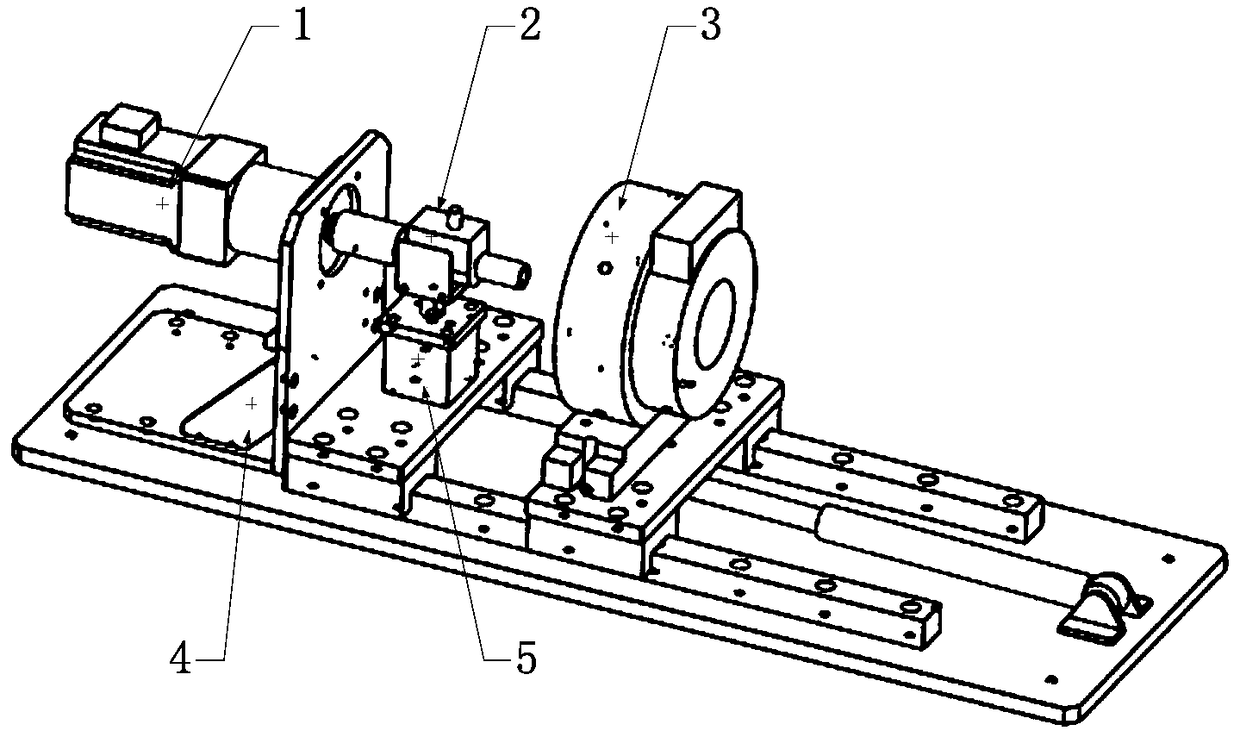

Laser beam machining method and laser beam machining apparatus

InactiveUS20070215581A1Increase the pulse widthImprove machine performanceFine working devicesWelding/soldering/cutting articlesSemiconductor materialsLaser beam machining

In a laser beam machining method and a laser beam machining apparatus, a higher improvement in machining ability is required for grooving and cutting of a semiconducting material or a ceramic material. In order to meet this requirement, the invention provides a laser beam machining apparatus and a laser beam machining method in which an ultraviolet laser beam is irradiated in pulses onto a workpiece made of an inorganic material to groove or cut the workpiece. In this laser beam machining apparatus and laser beam machining method, as the scanning speed of the ultraviolet laser beam is higher, or as the machining depth of the grooving or the cutting is greater, the pulse width of the ultraviolet laser beam is set to be greater. This can significantly improve the machining ability compared with a case where the average power is increased.

Owner:MITSUBISHI MATERIALS CORP

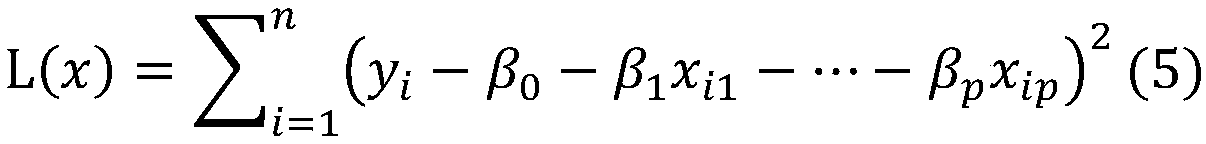

Bolt pre-tightening force prediction method based on machine learning

InactiveCN109238546APreload controlGood machine performanceMeasurement of torque/twisting force while tighteningData averagingData acquisition

The invention belongs to the technical field of assembly and fastening, and provides a bolt pre-tightening force prediction method based on machine learning. The method comprises the following steps of data acquisition, data-based problem analysis, data averaging processing, multiple regression modeling, model parameter identification, statistic inspection and model verification and analysis, wherein tightening torque, a tightening angle and a nut end surface friction coefficient are used as input parameters, and the pre-tightening force is used as a prediction value. According to the method,the pre-tightening force can be effectively controlled through prediction, and a foundation is laid for obtaining good machine performance. The metod can be widely popularized in the technical field of assembly and fastening.

Owner:DALIAN UNIV OF TECH

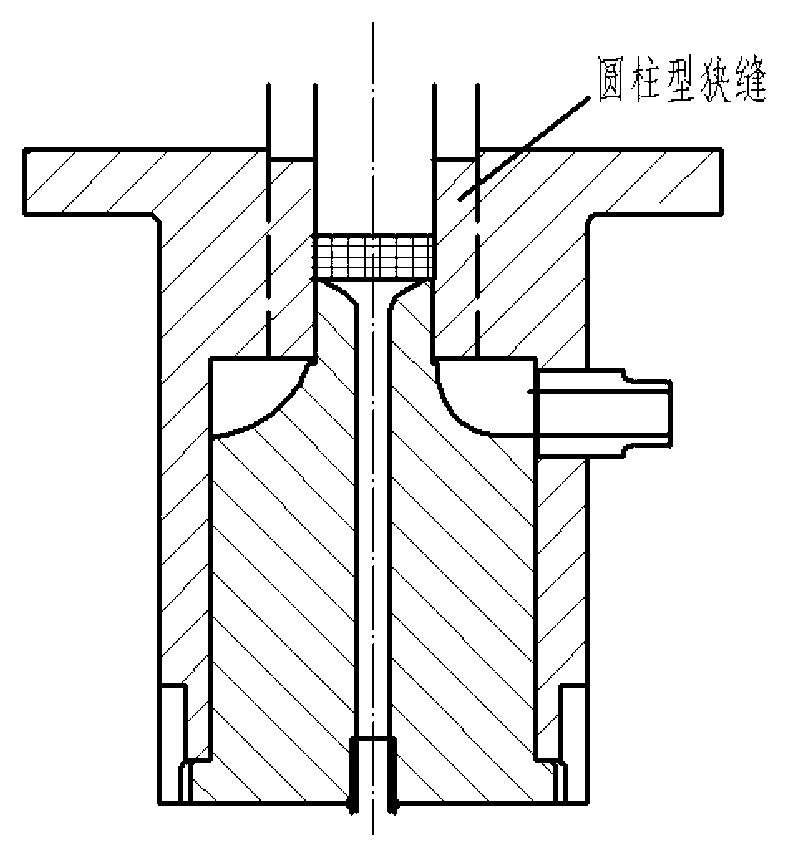

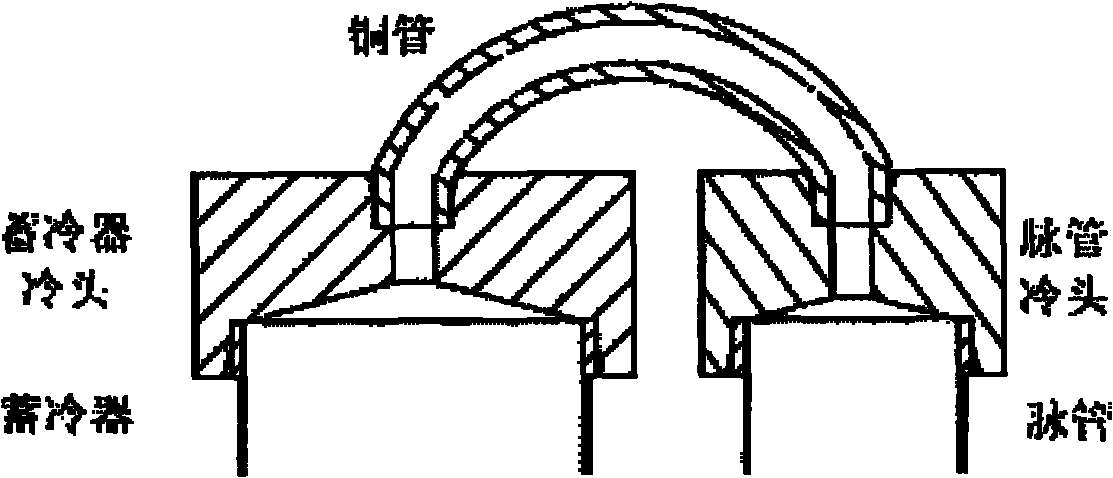

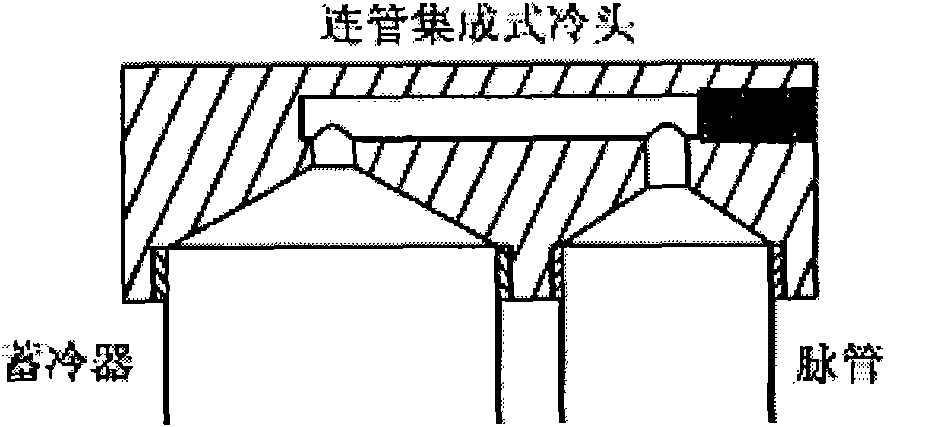

Integrated slit cold head of U-shaped pulse tube refrigerating machine and manufacturing method

InactiveCN102042711AMaintain laminar effectImprove thermodynamic performanceCompression machinesGas cycle refrigeration machinesEngineeringTop cap

The invention discloses an integrated slit cold head of a U-shaped pulse tube refrigerating machine and a manufacturing method. The cold head comprises two parts of a top cover and a lower flange, wherein two cylindrical lug bosses protrude below a big lug boss of the top cover, outer diameters of the two cylindrical lug bosses are respectively equal to inner diameters of a cold regenerator and a pulse tube; the two lug bosses integrally cut and penetrate through a slit in parallel horizontally and uniformly; through insertion holes matched with the cylindrical lug bosses of the top cover are arranged on the lower flange, a sealing groove and a location groove matched with the big lug boss of the top cover are cut on the upper surface of the lower flange, the lower flange, the cold regenerator and the pulse tube are hermetically welded to form an assembly; the top cover and the lower flange not only can be connected by bolts to form a detachable split cold head, but also can be hermetically welded to form an integrated cold head. In the invention, the main functions of three parts of an efficient cold end heat exchanger, a pulse tube cold end gas director and a cold regenerator cold end gas distributor can be intensively realized in an integrated slit cold head structure, the overall performance of the U-shaped pulse tube refrigerating machine is enhanced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com