Patents

Literature

67results about How to "Reduce pumping loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

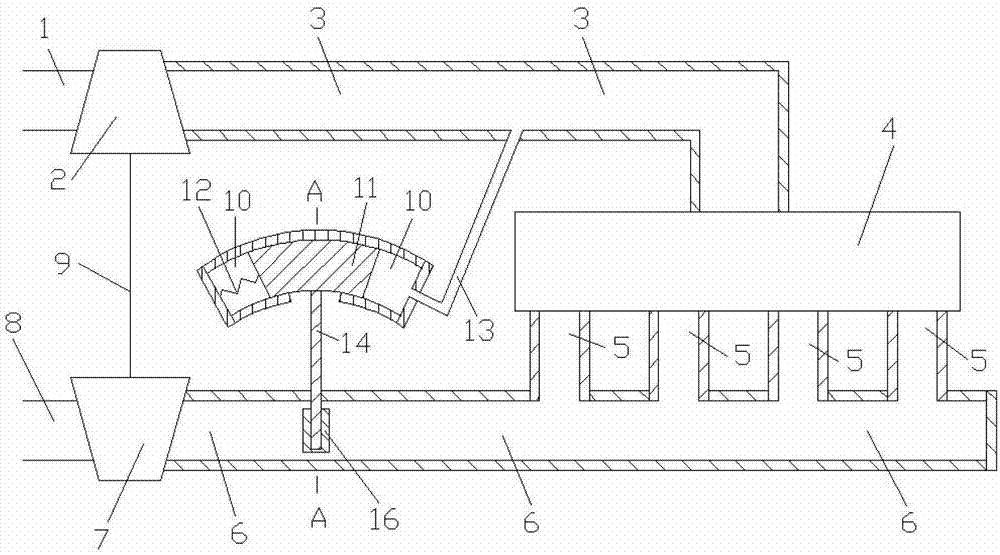

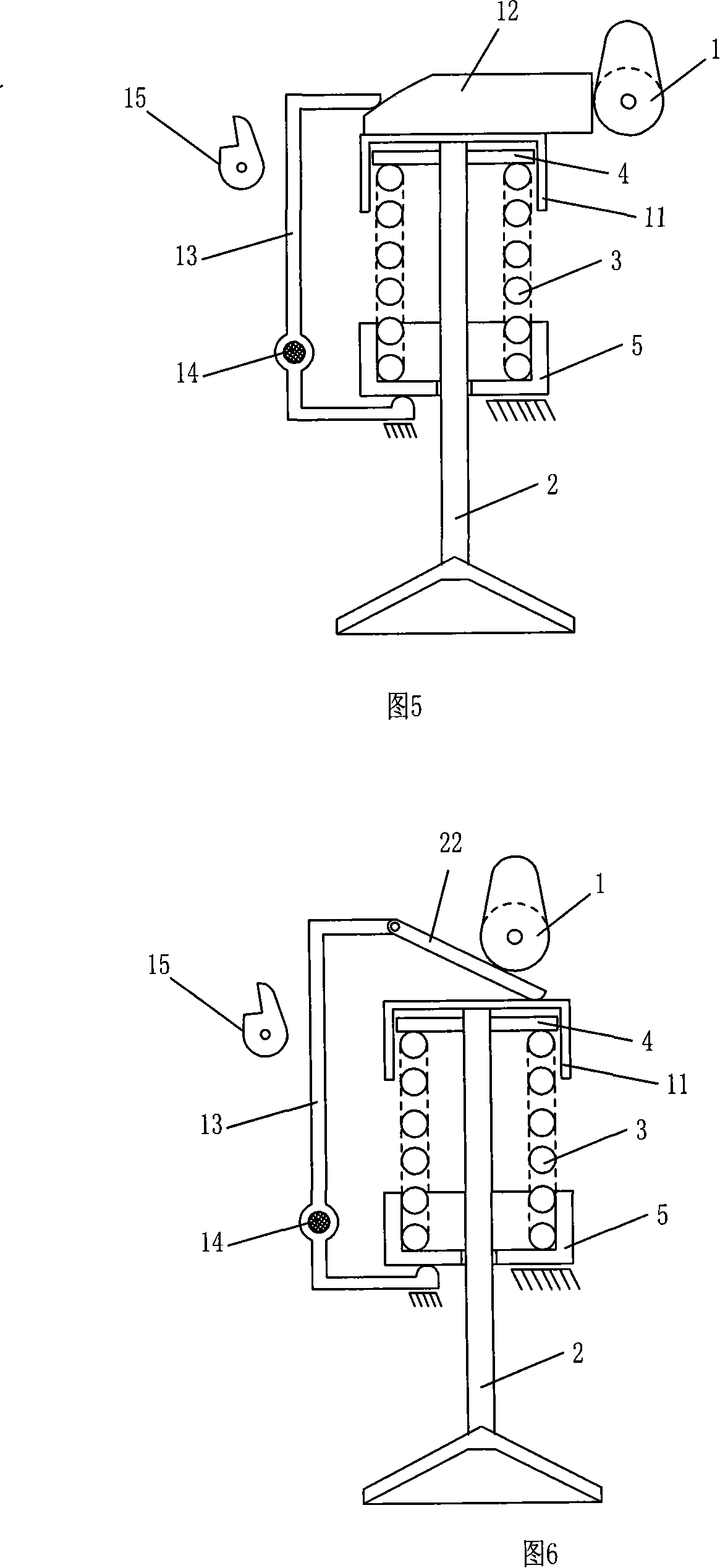

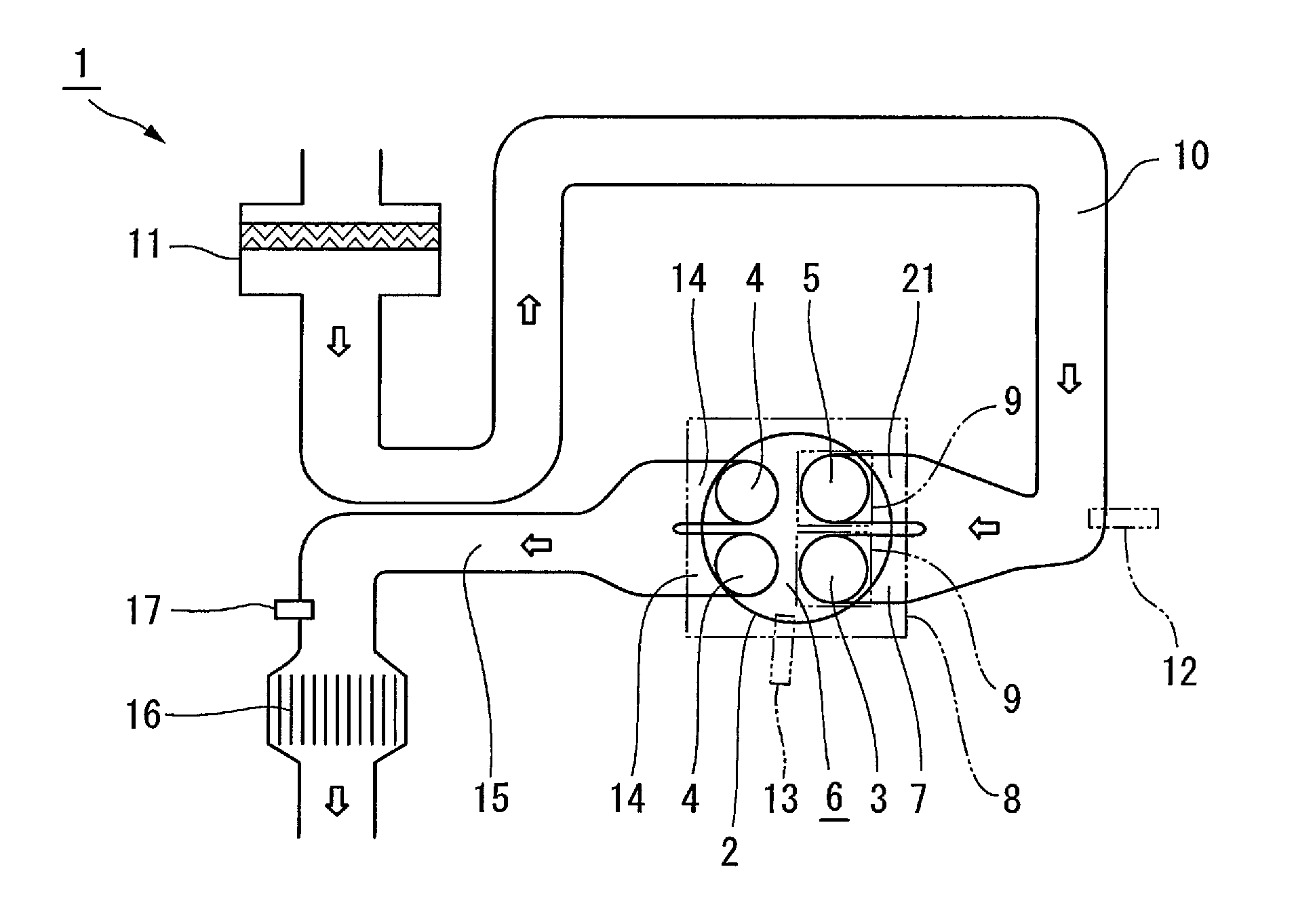

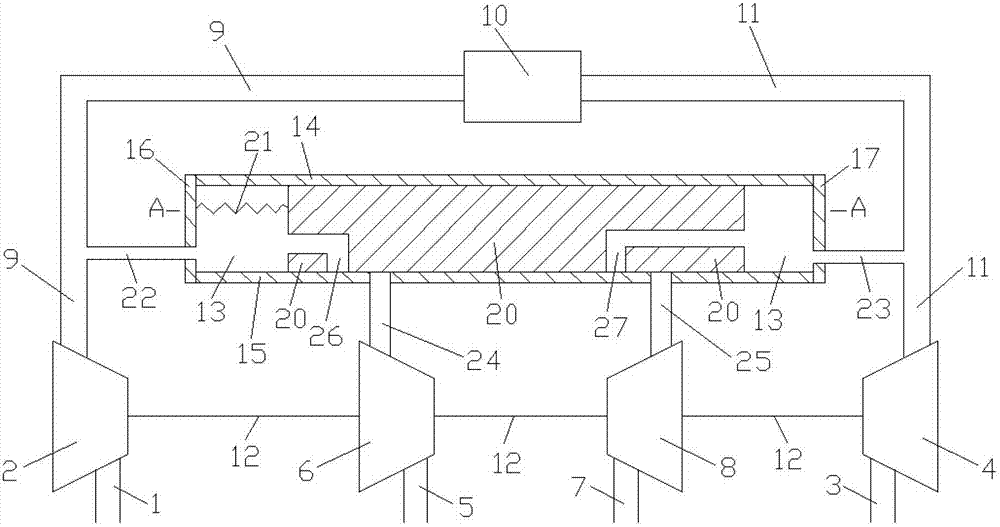

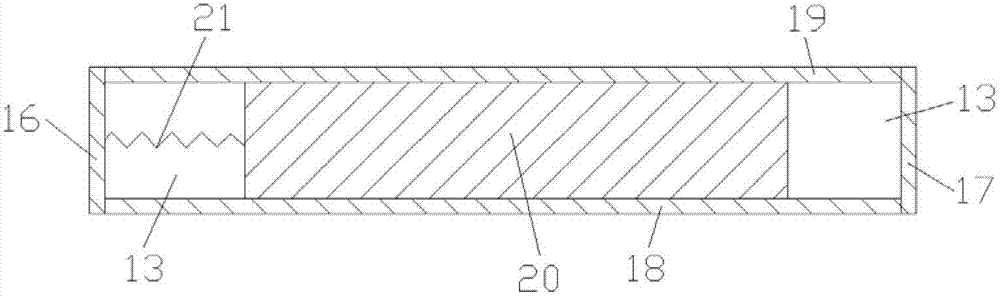

Variable air exhaust through flow area air inlet pressure control type adjusting device for turbocharged engine

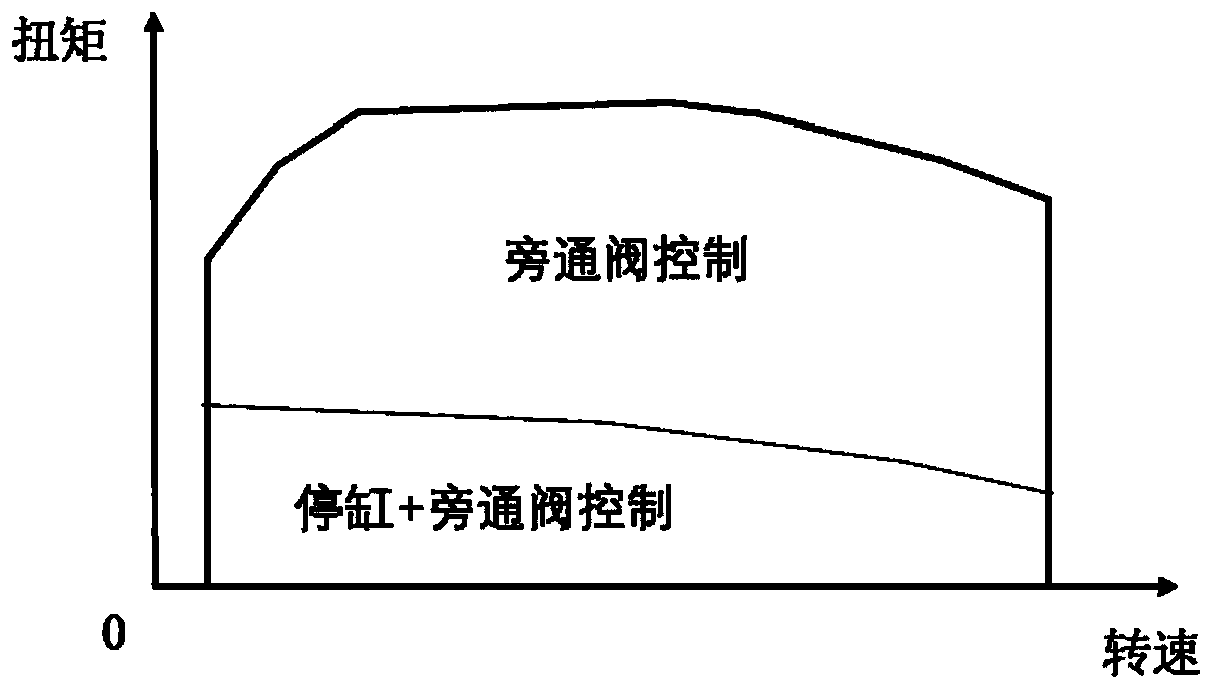

InactiveCN103089409AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesInlet pressureAir compressor

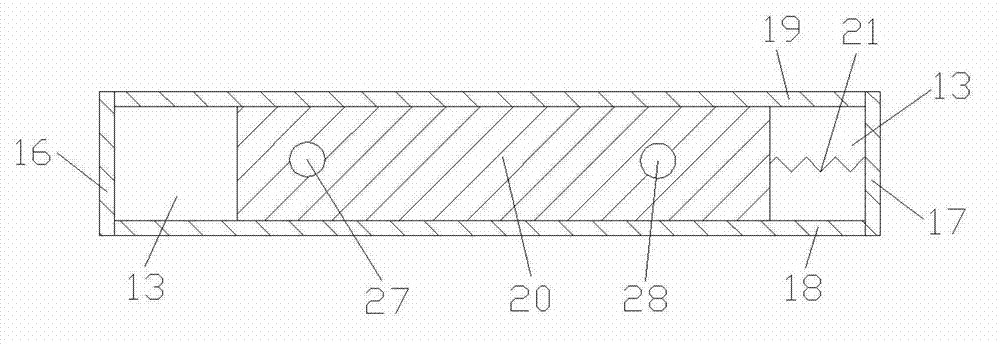

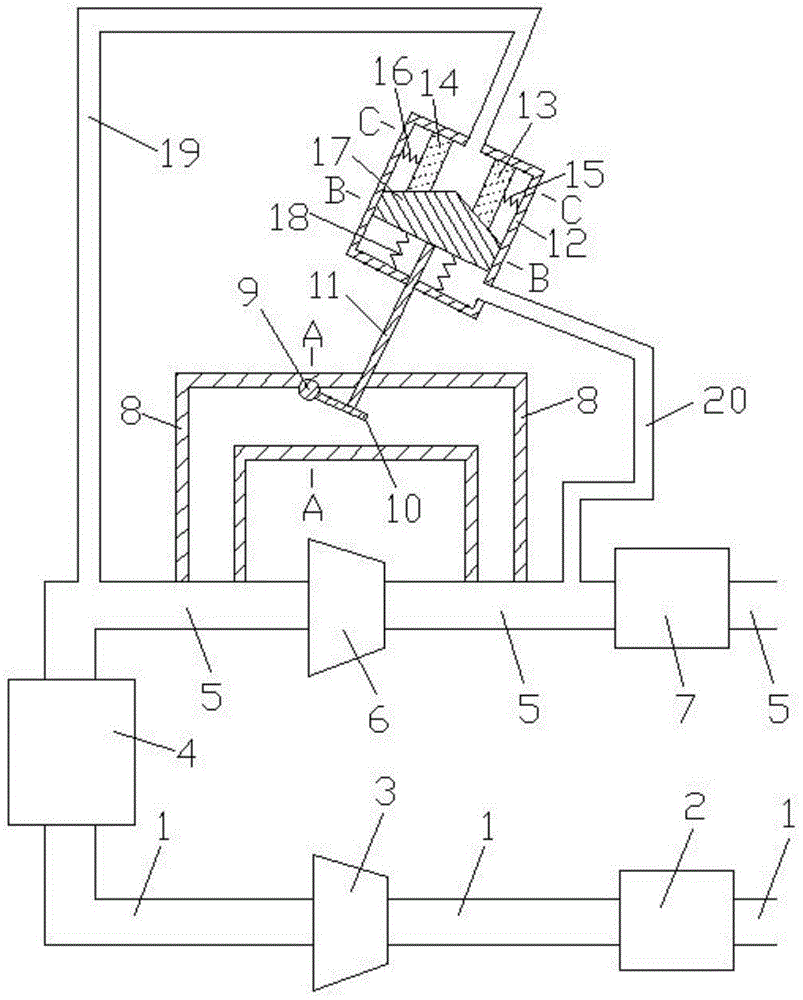

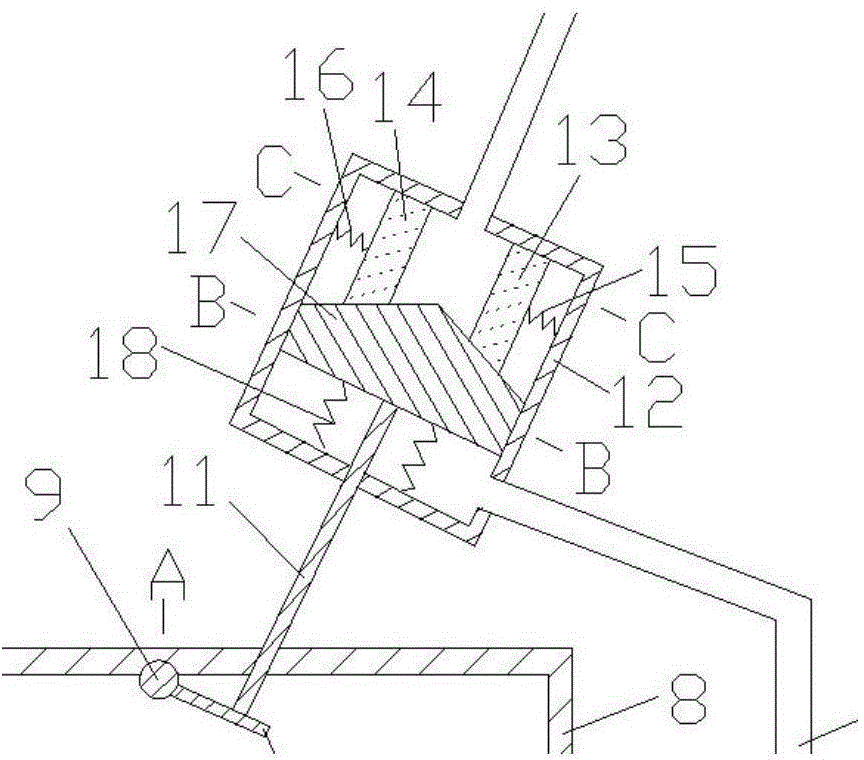

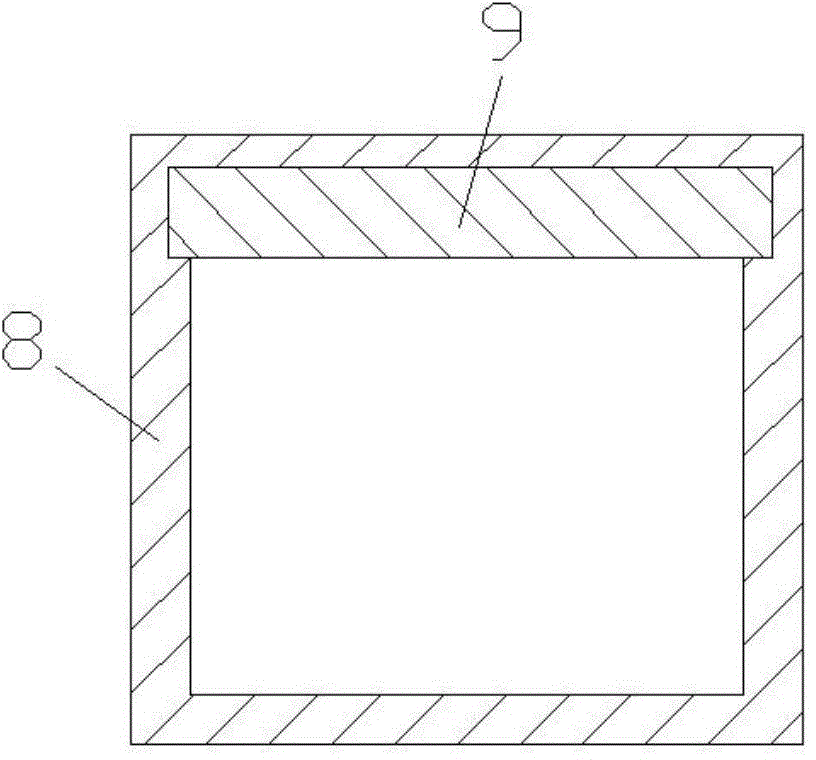

A variable air exhaust through flow area air inlet pressure control type adjusting device for a turbocharged engine belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, a volume cavity, a rotation body, a spring, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in an air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and an air inlet pipe of the engine. When pressure in the air inlet pipe of the engine is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air inlet pipe of the engine is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The variable air exhaust through flow area air inlet pressure control type adjusting device for the turbocharged engine is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

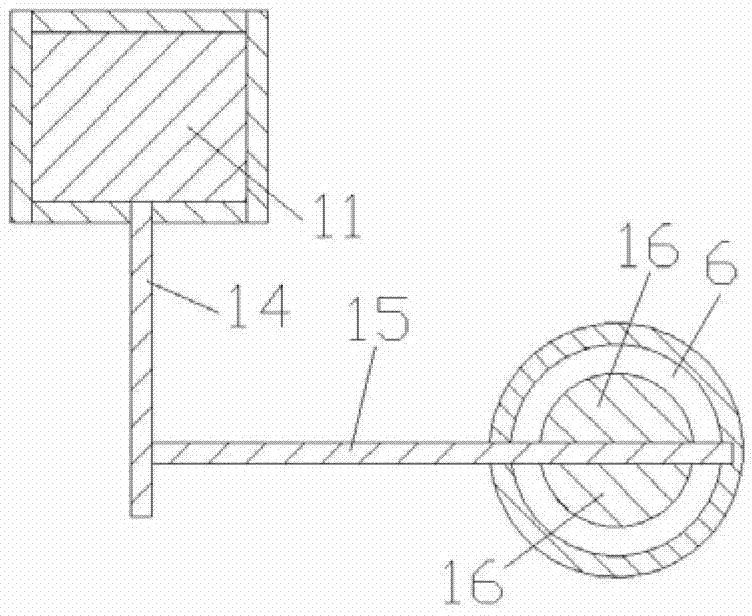

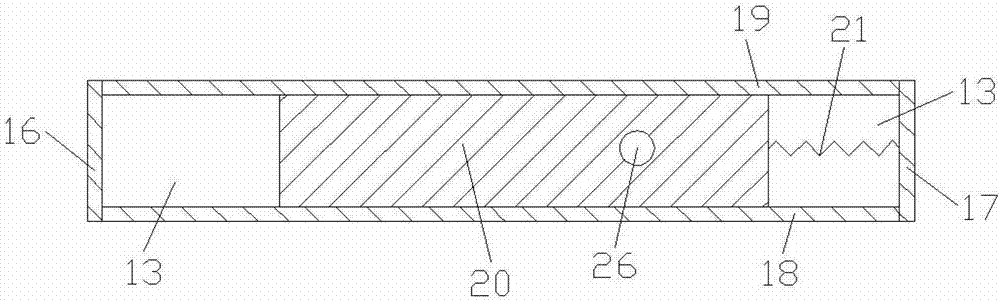

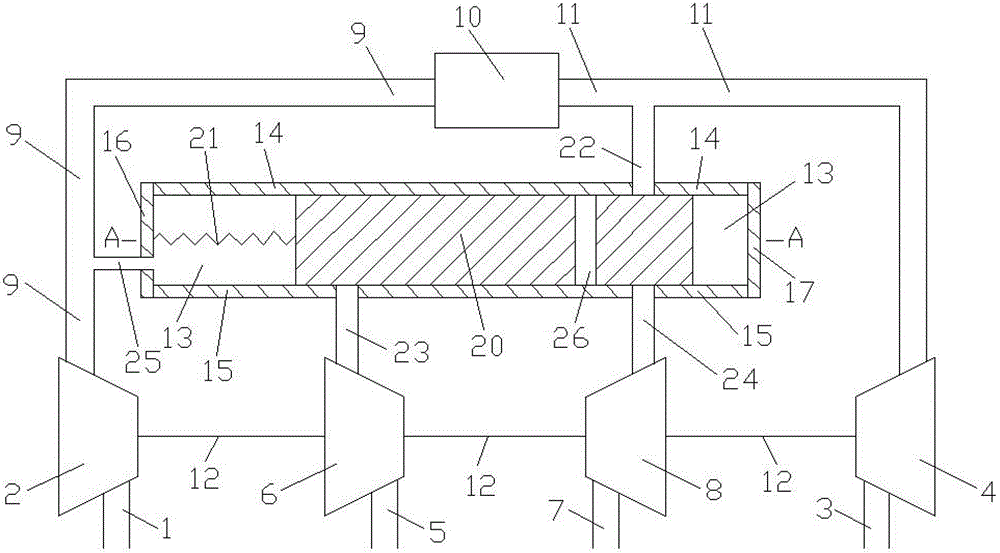

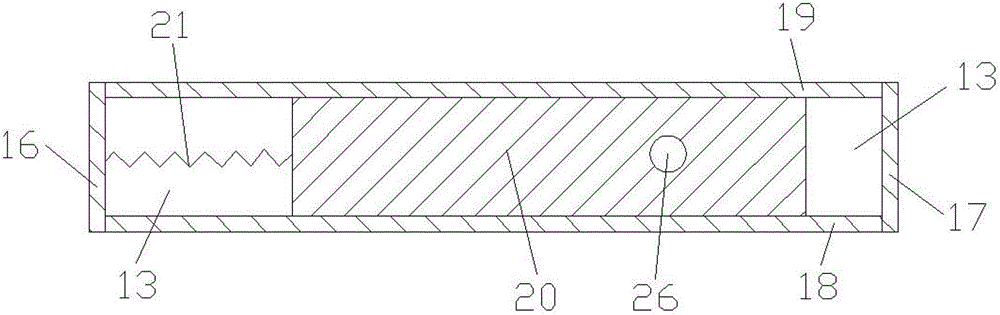

Rotation control type pipeline reducing rate variable device

ActiveCN103089410AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesGas compressorInlet pressure

A rotation control type pipeline reducing rate variable device belongs to the technical field of mechanical design and comprises an air compressor, an engine, an air exhaust pipe, a turbine, a volume cavity, a rotation body, a spring, a connection pipe, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in the air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air inlet pipe of the engine is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air inlet pipe of the engine is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The rotation control type pipeline reducing rate variable device is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SUZHOU INTI AUTOMOTIVE TECH CO LTD

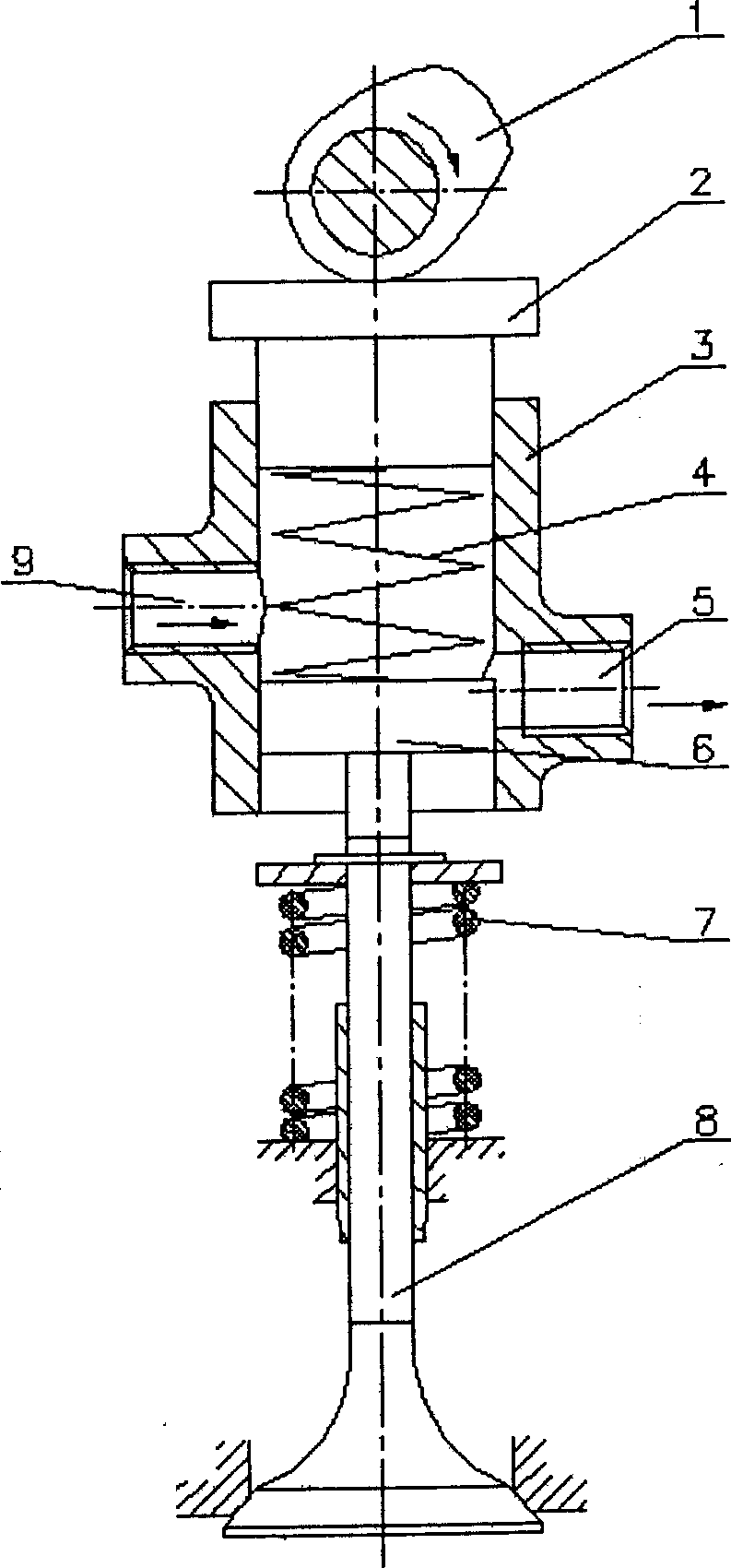

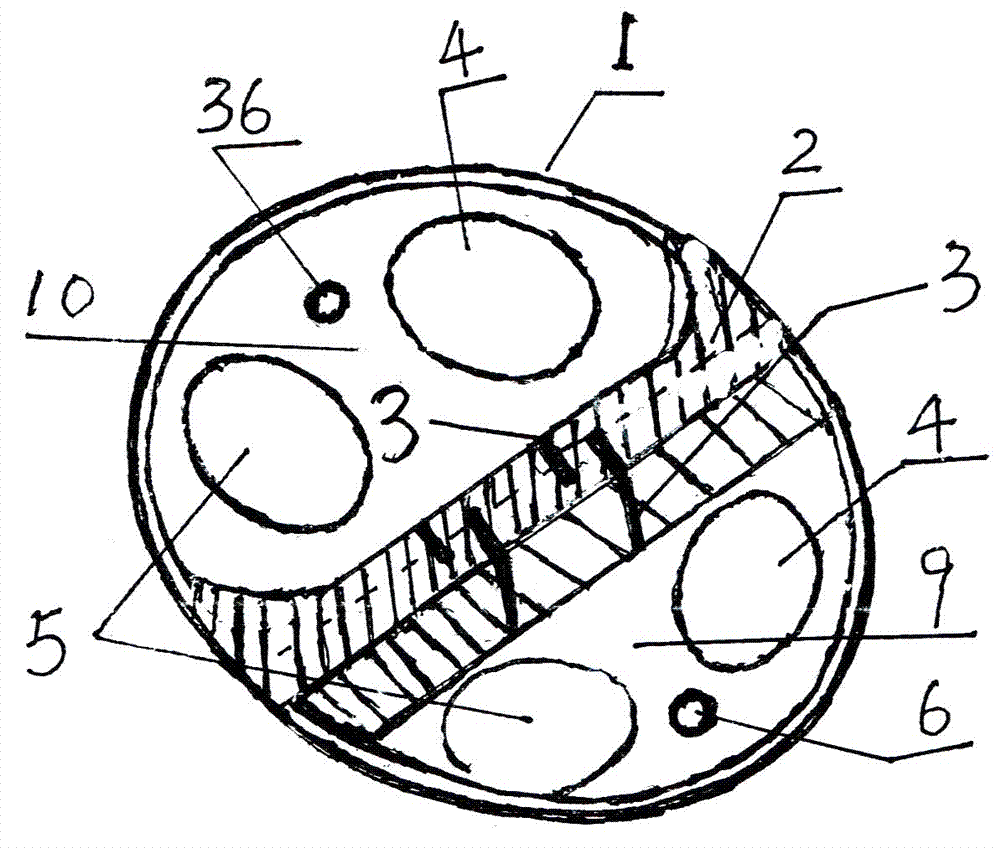

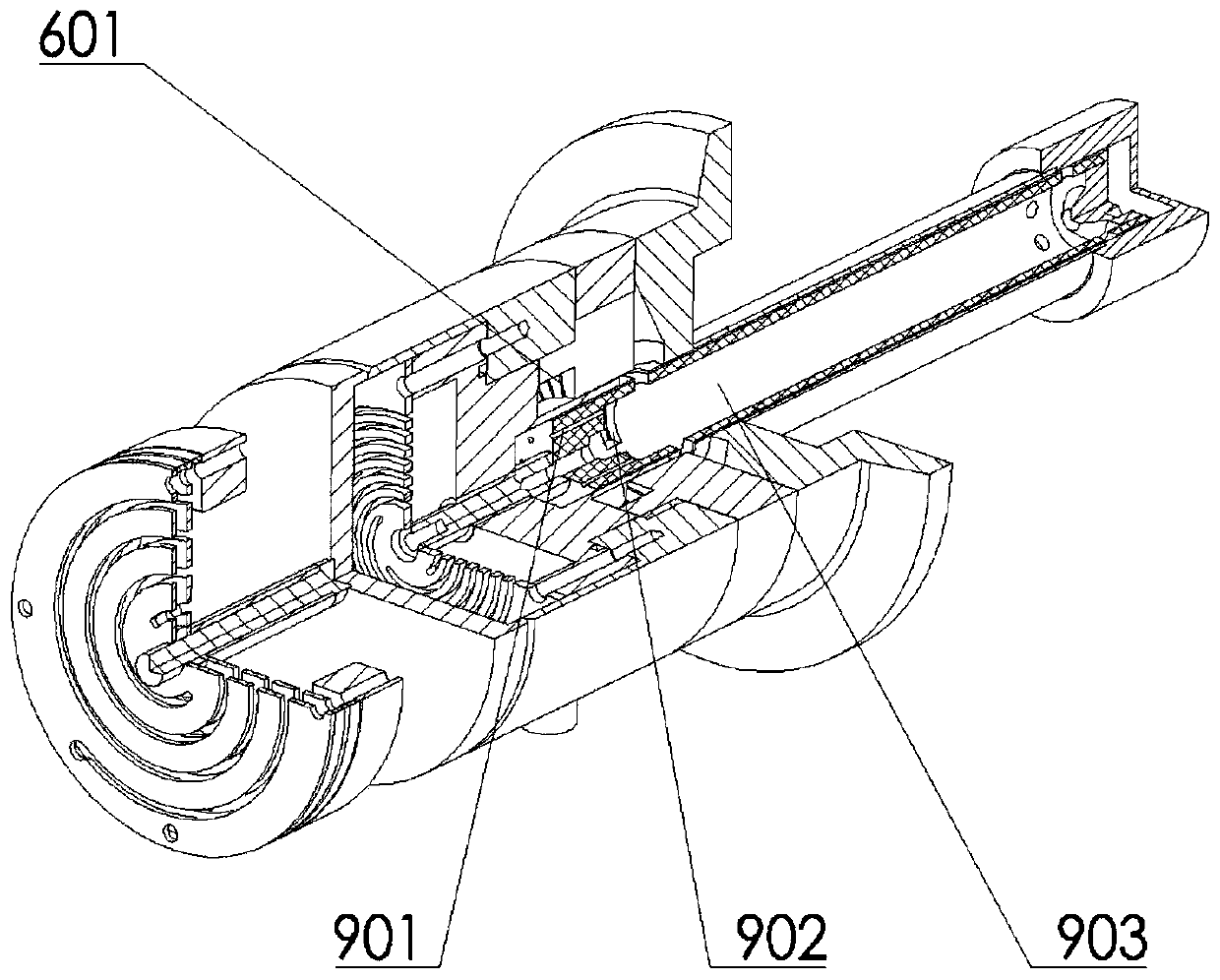

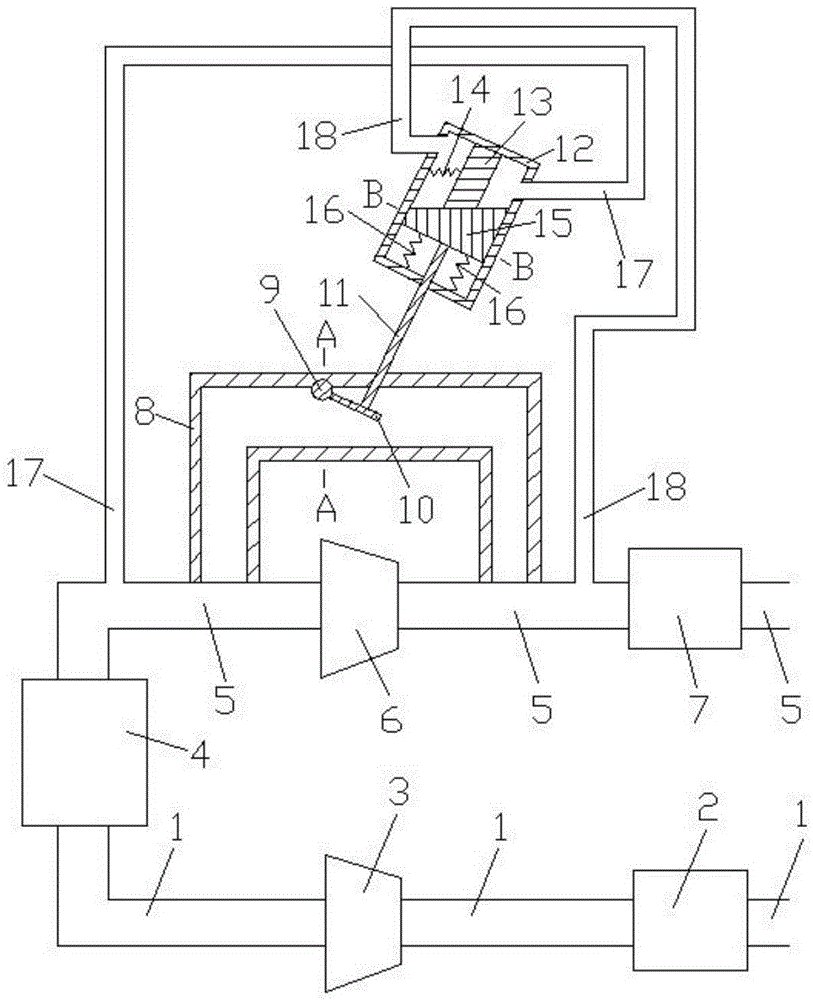

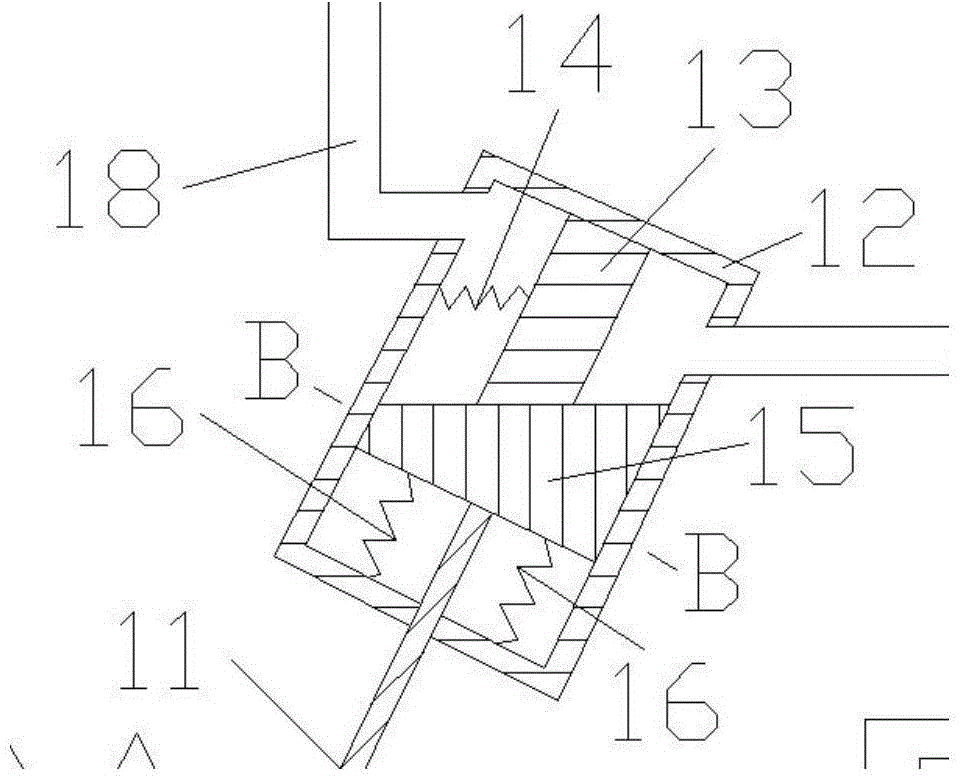

Valve timing continuously variable internal combustion engine valve system

ActiveCN1804383AReduce pumping lossImprove fuel economyInternal combustion piston enginesOutput powerCamInternal combustion engine

The invention relates to an air distribution device and fuel feeding system of internal-combustion engine, especially relating to the ignition internal-combustion engine. It is formed by an air gate element, a hydraulic cylinder element, a hydraulic cylinder outlet control device, a hydraulic cylinder inlet control device and a camshaft transmission element. Wherein, the open and lifting of air gate are controlled by the ascending part of cam; the reduction and close of air gate are controlled by the discharge time of liquid inside the hydraulic cylinder; the outlet control device comprises a rotor and a rotor sheath; when the rotor

Owner:SHANDONG UNIV

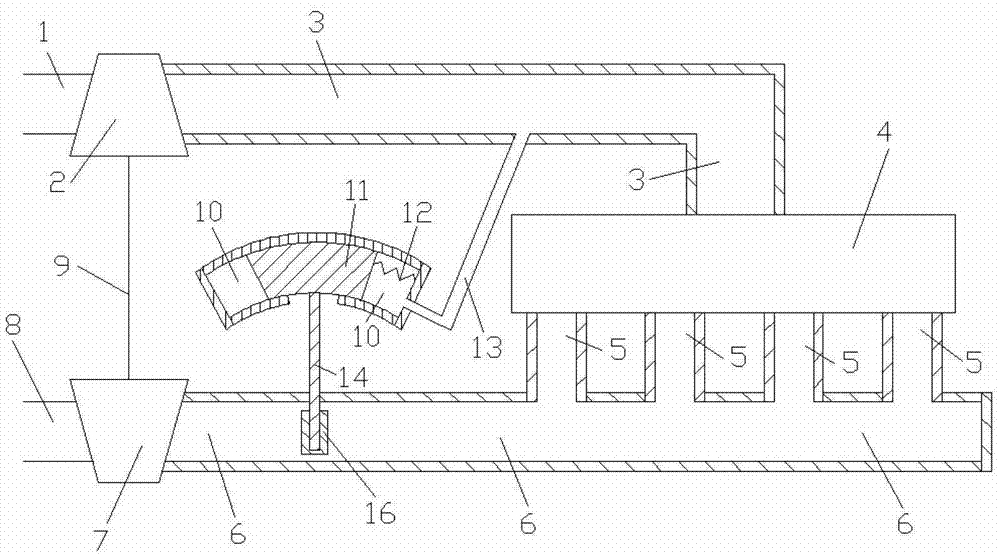

Variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for turbocharged engine

InactiveCN103089411ALarge throat areaIncrease intake pressureInternal combustion piston enginesInlet pressureAir compressor

A variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for a turbocharged engine belongs to the technical field of mechanical design and comprises an air compressor, an engine, a turbine, a volume cavity, a rotation body, a spring, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in an air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of a connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air exhaust pipe in front of the rotation plate is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air exhaust pipe in front of the rotation plate is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The variable air exhaust through flow area air exhaust pressure control type adjusting mechanism for the turbocharged engine is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

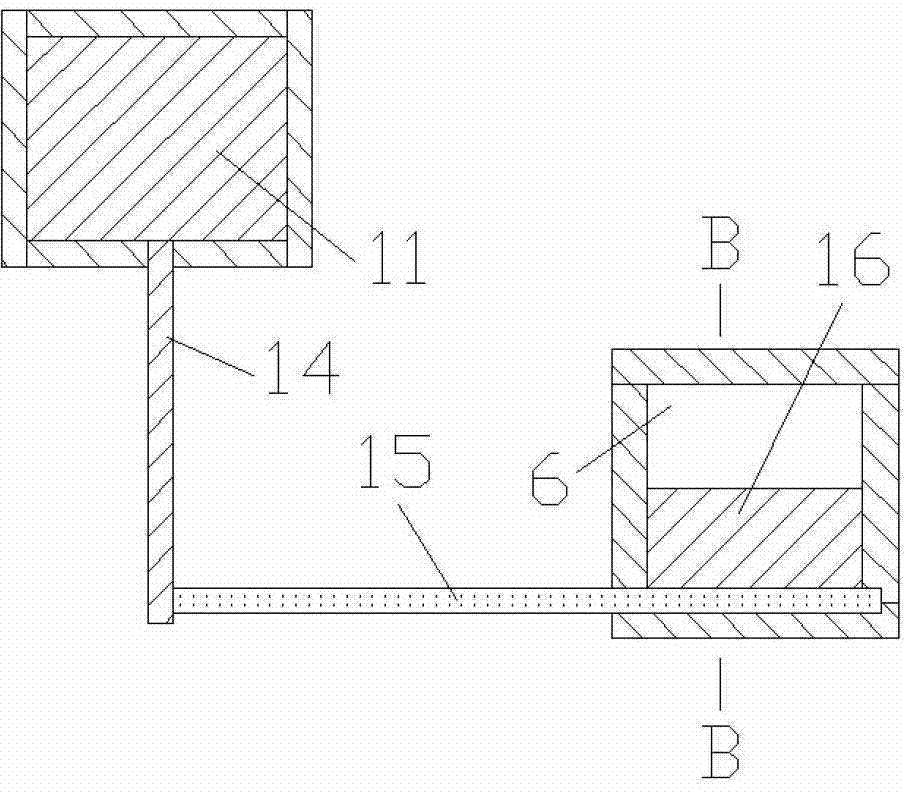

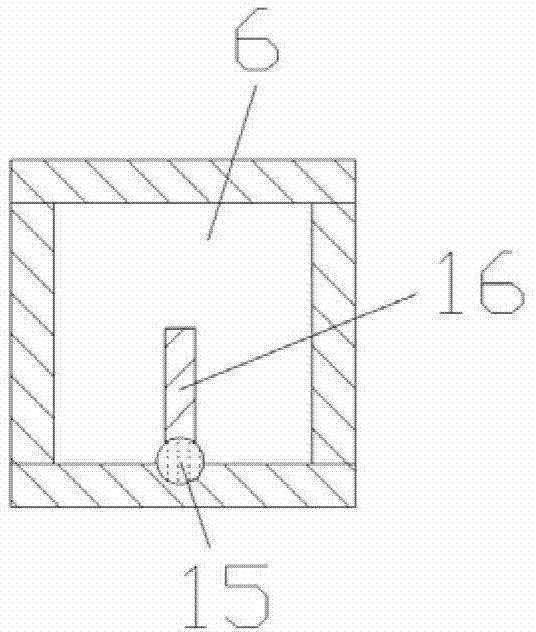

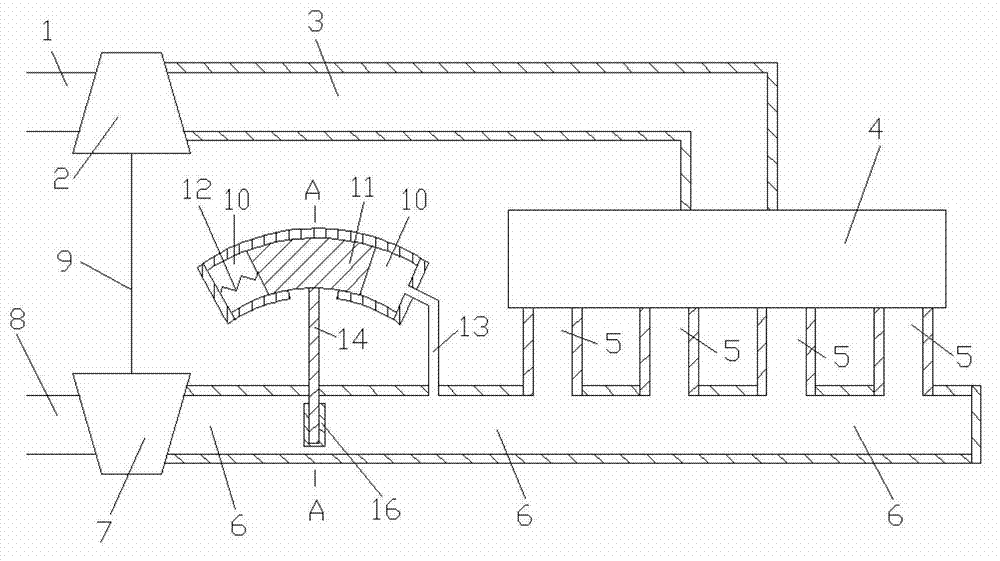

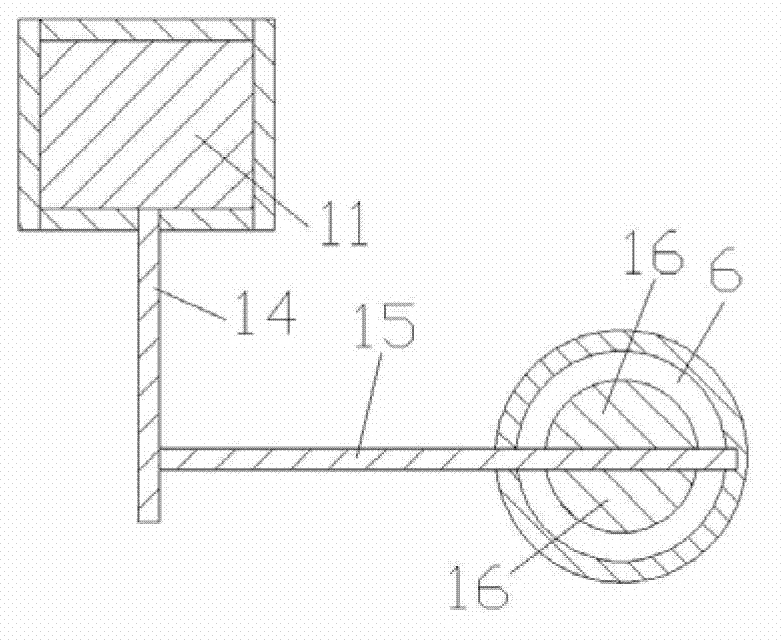

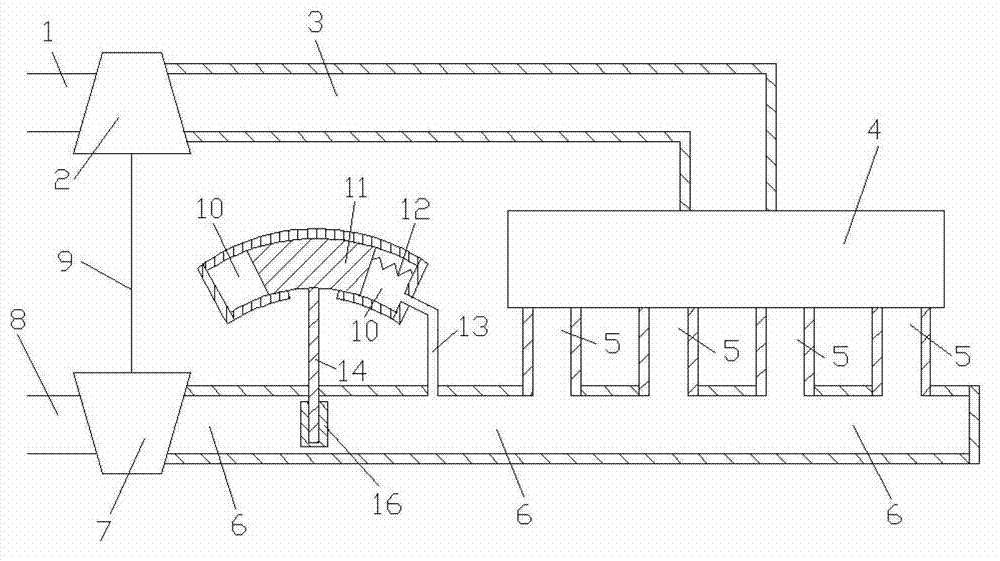

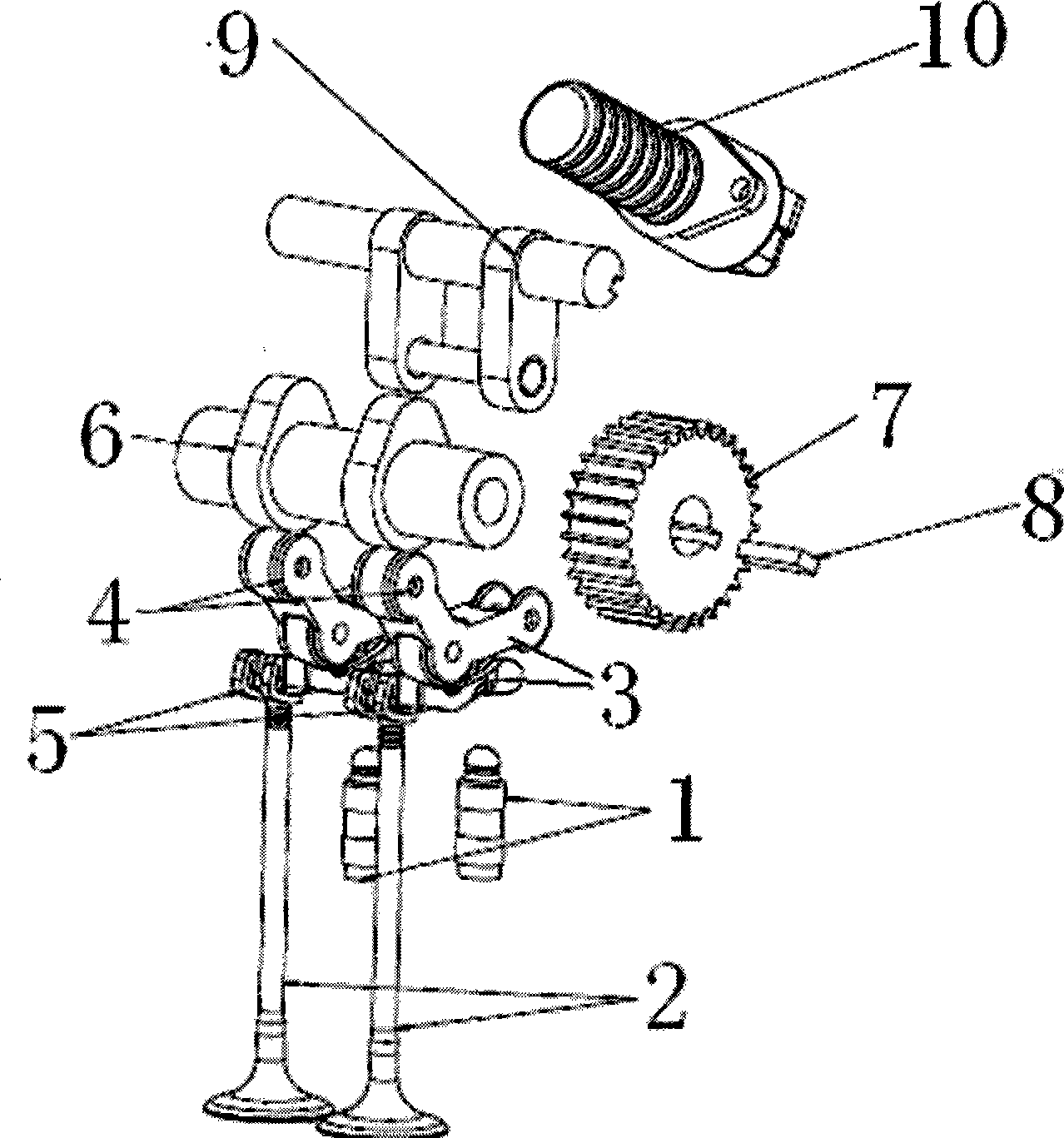

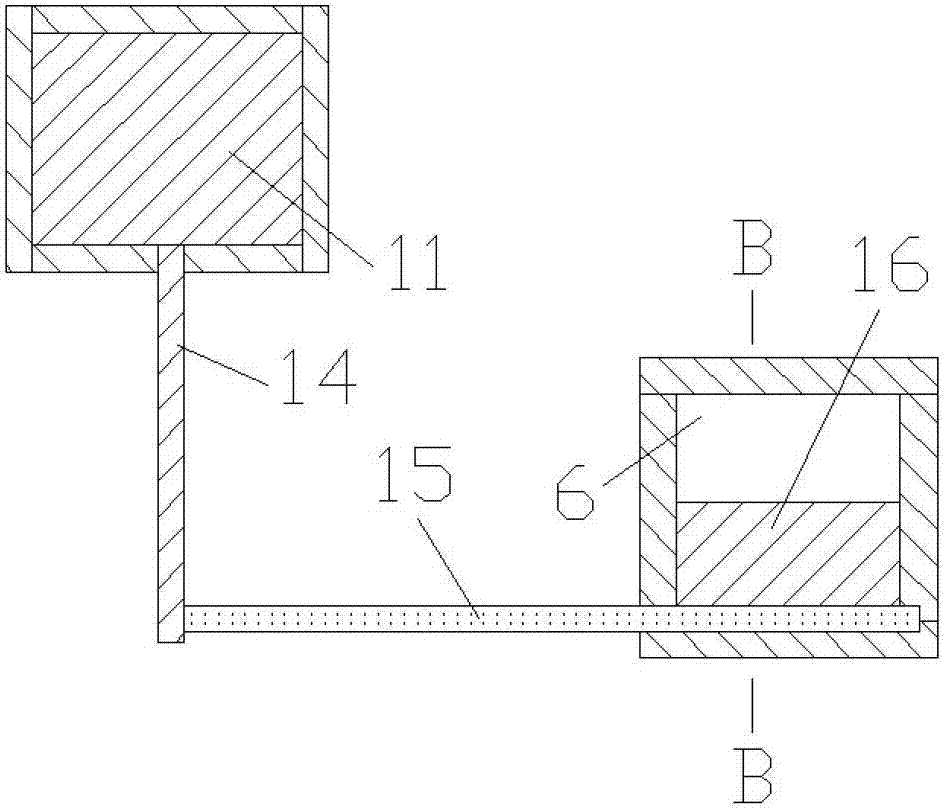

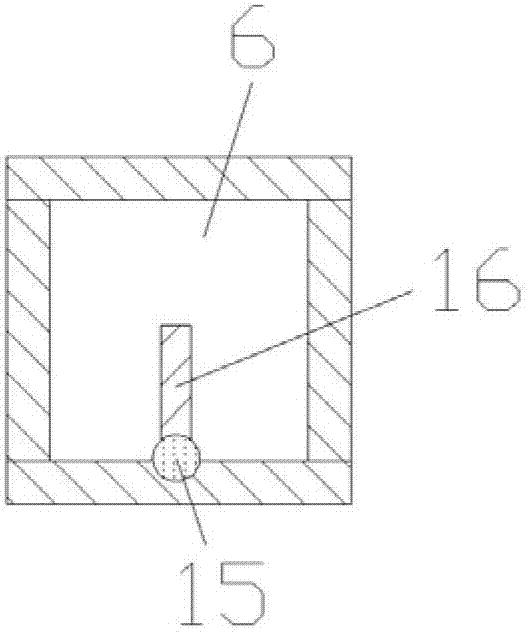

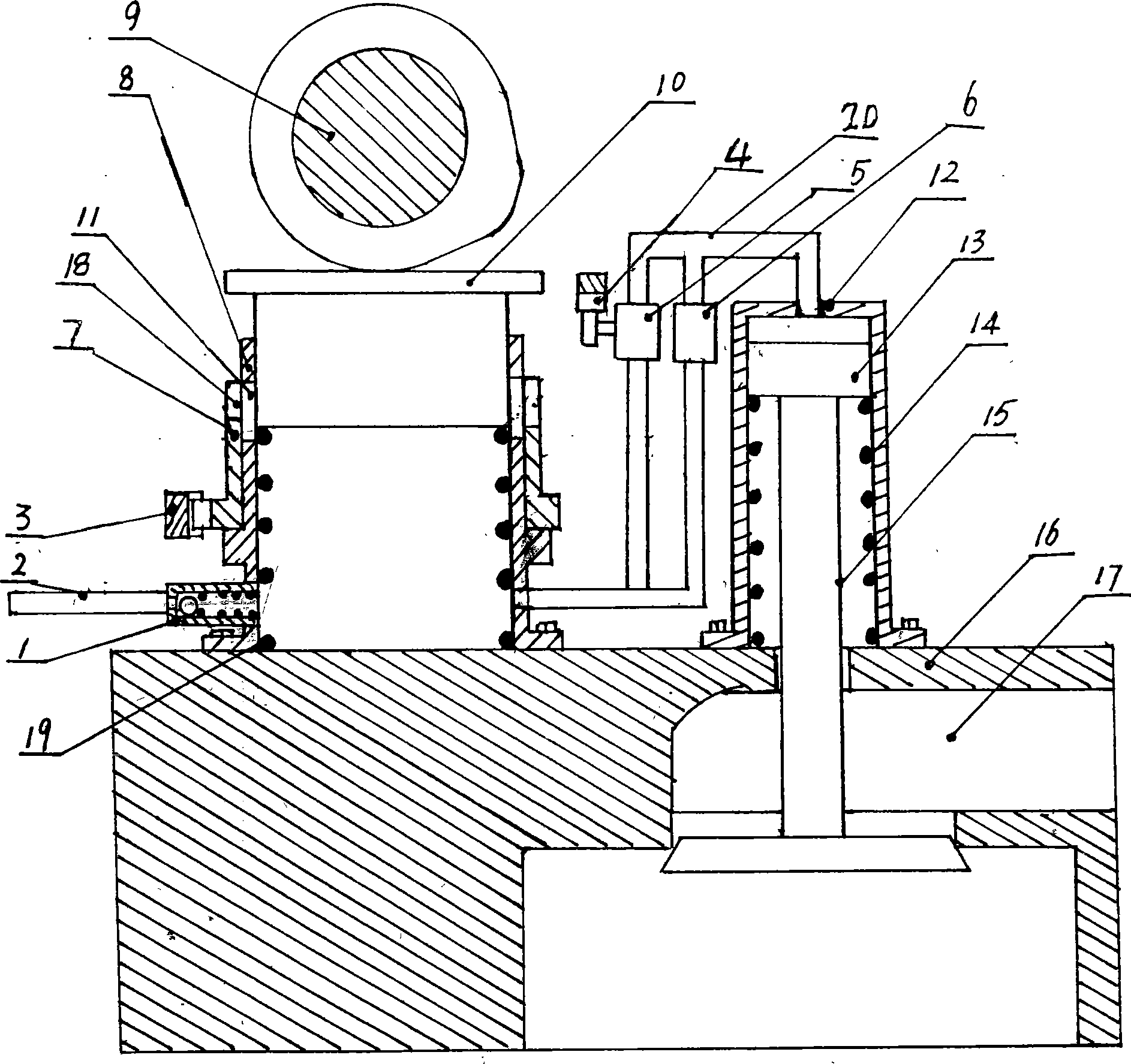

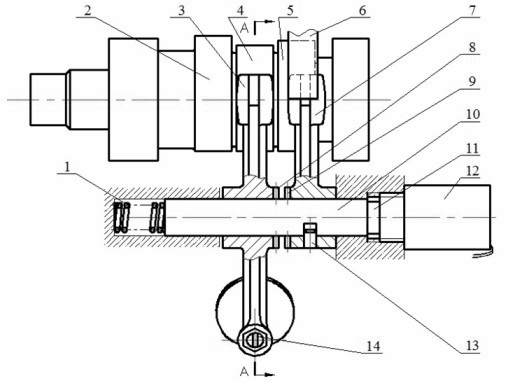

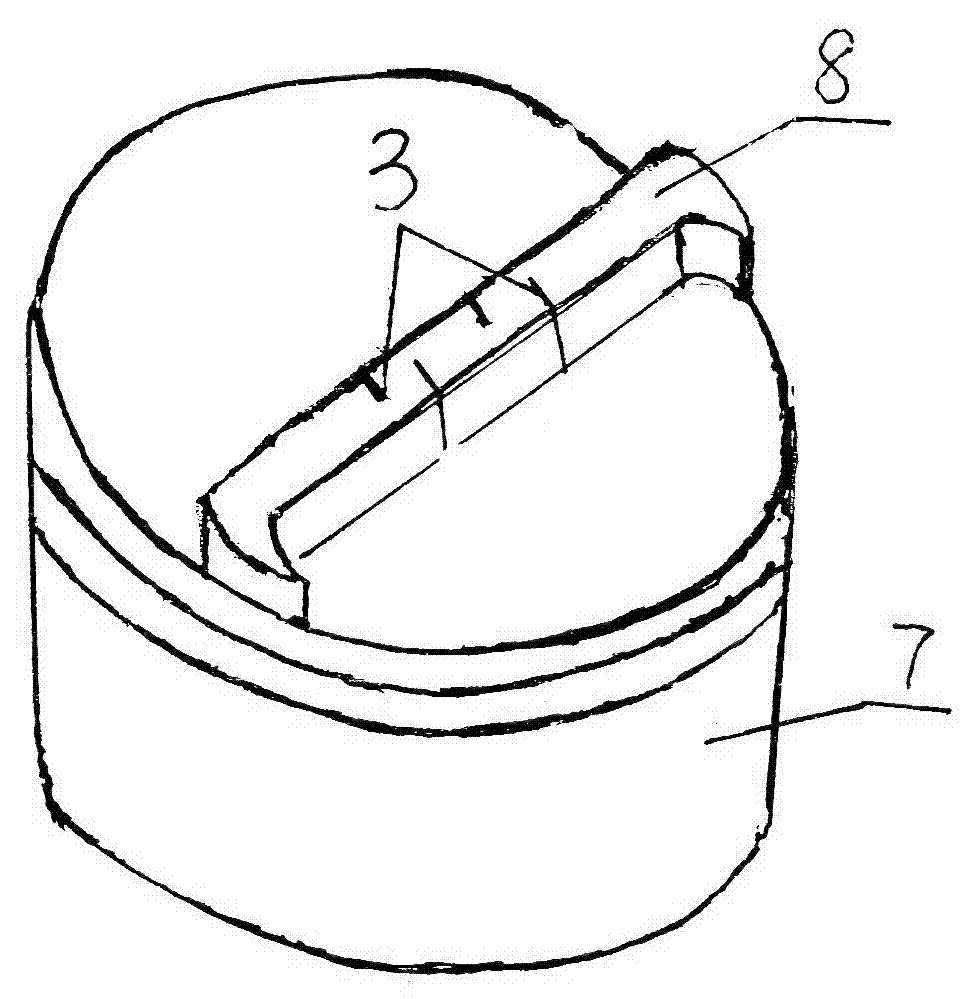

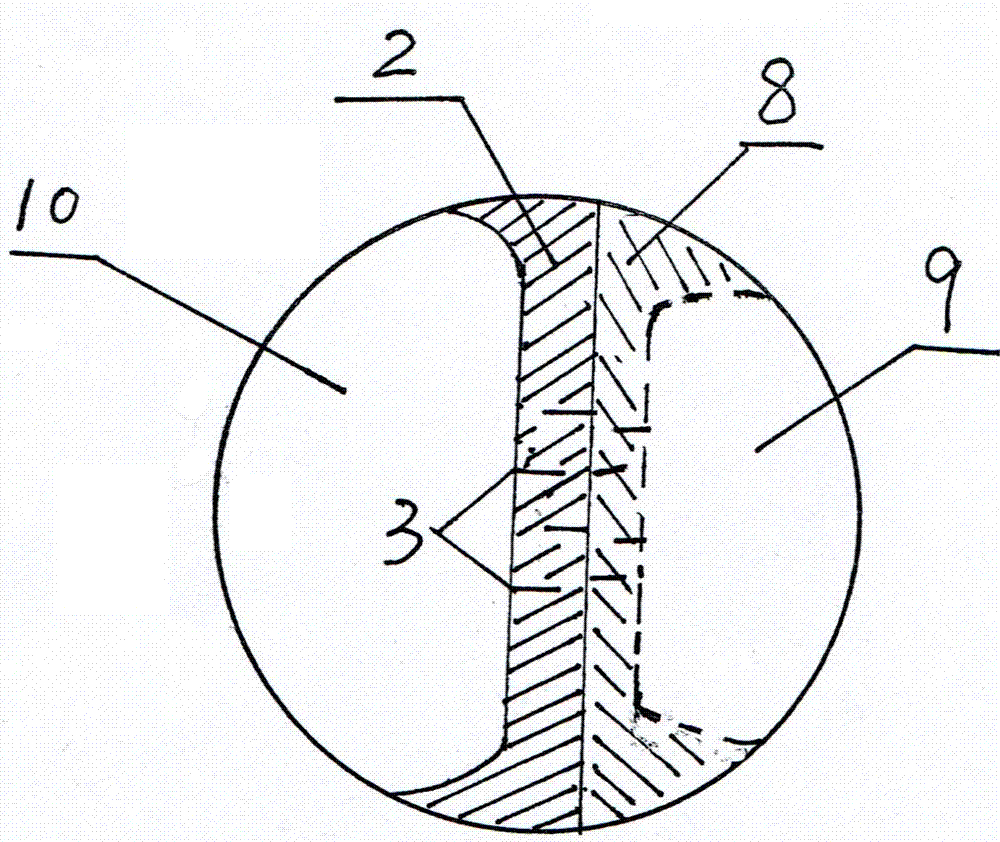

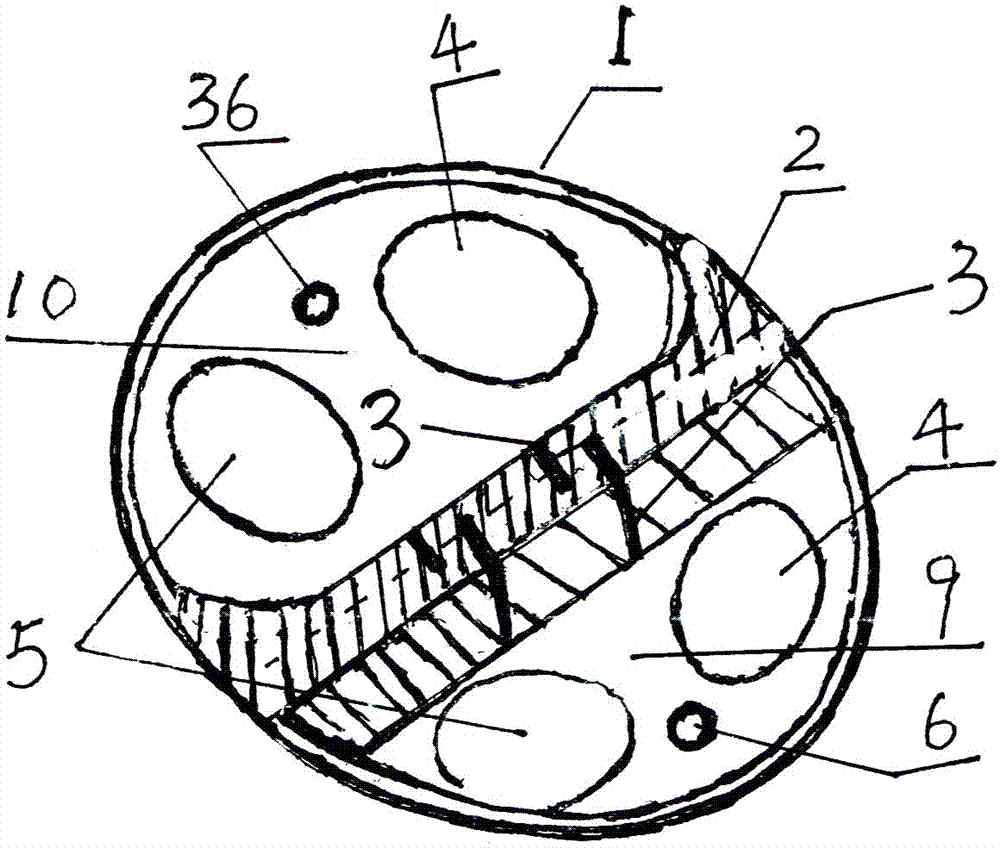

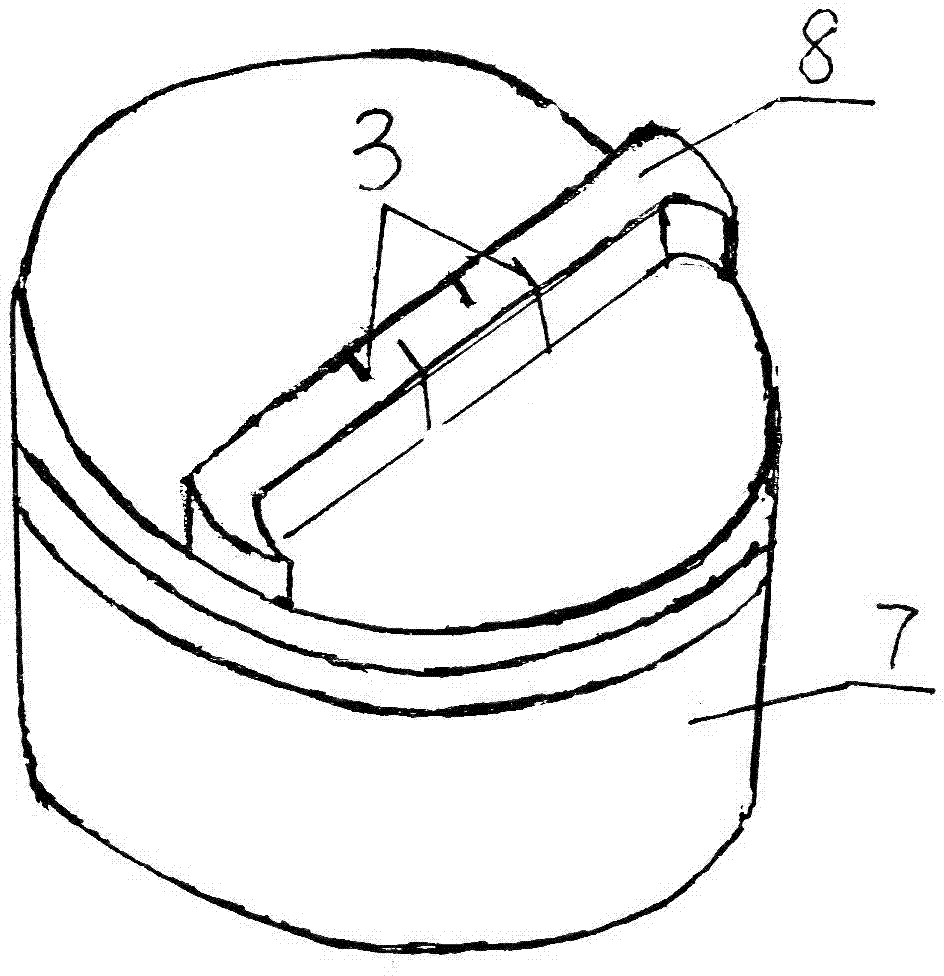

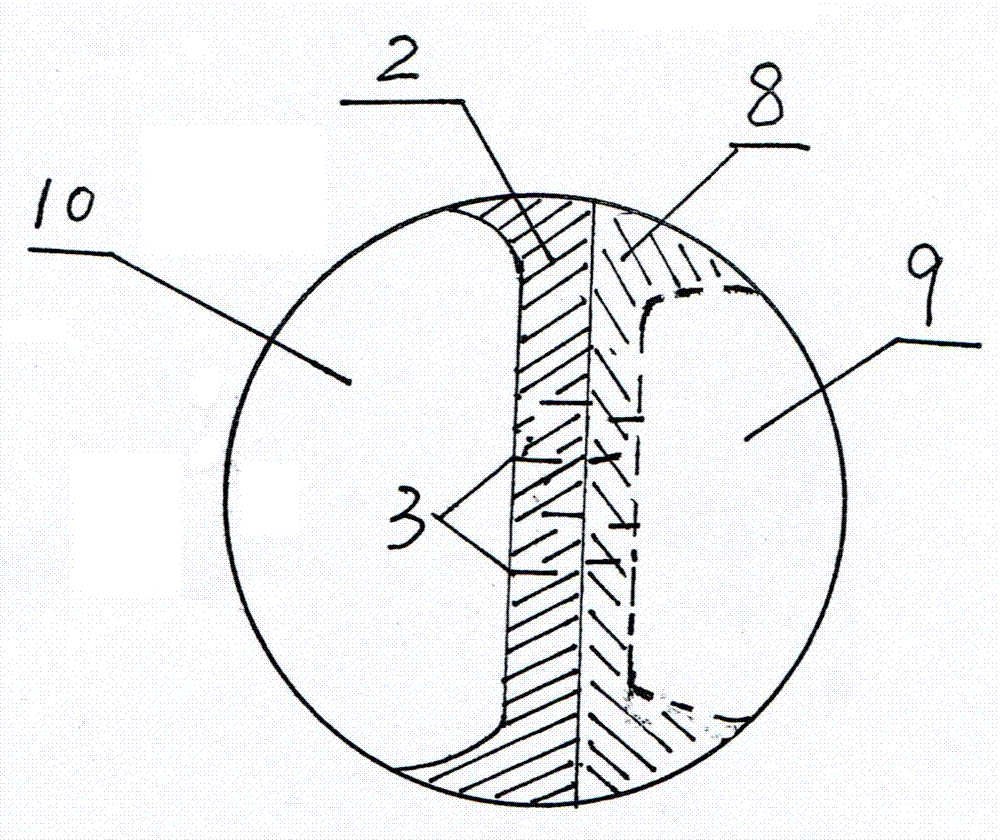

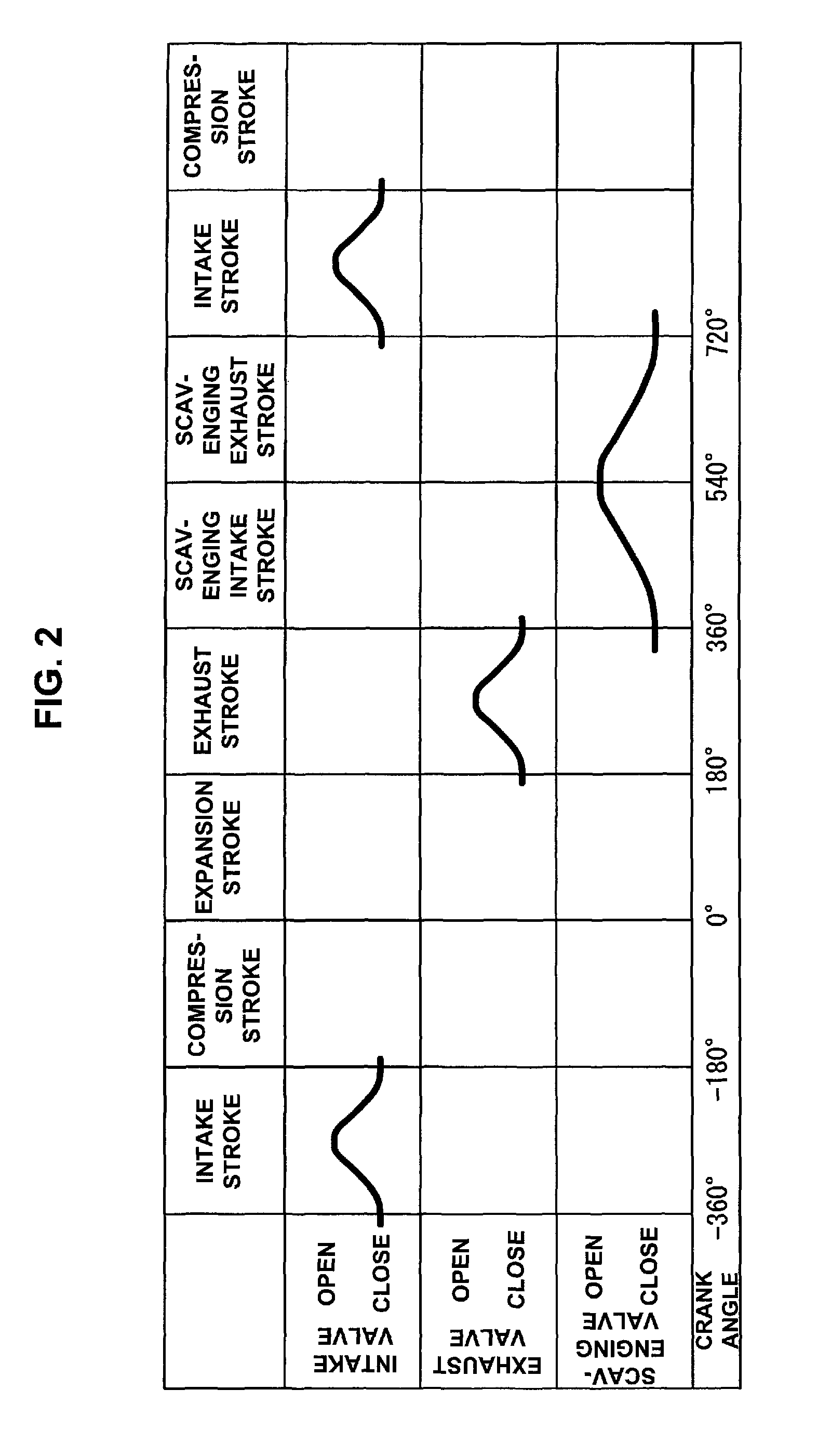

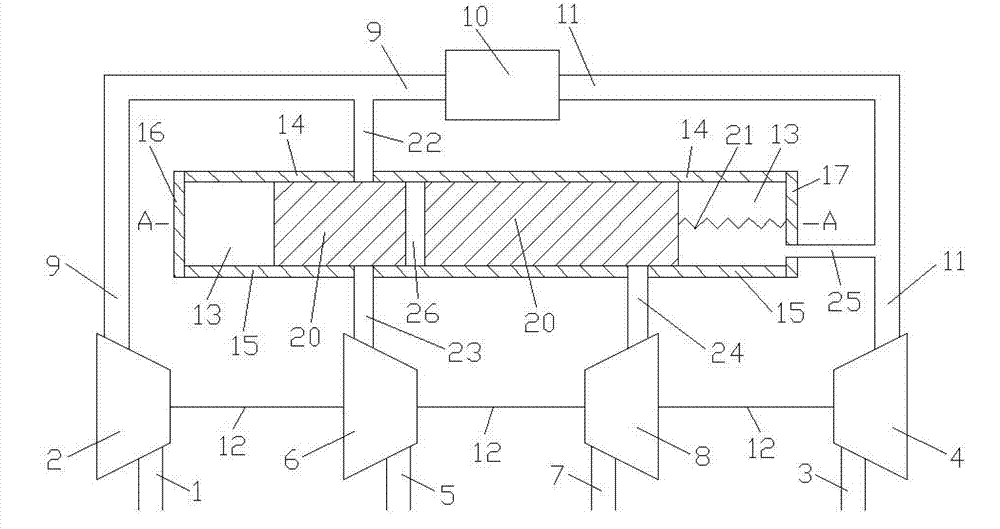

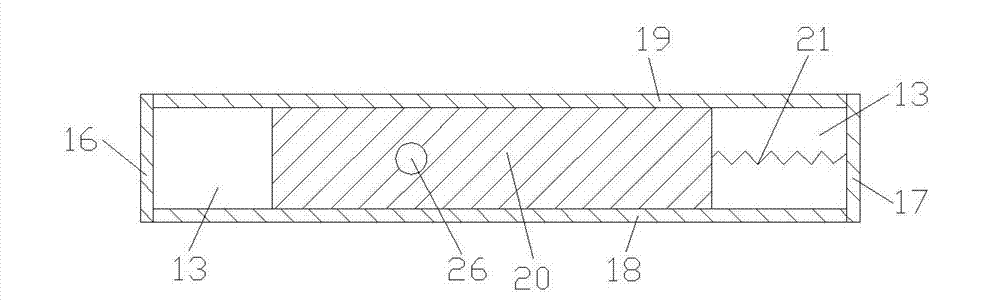

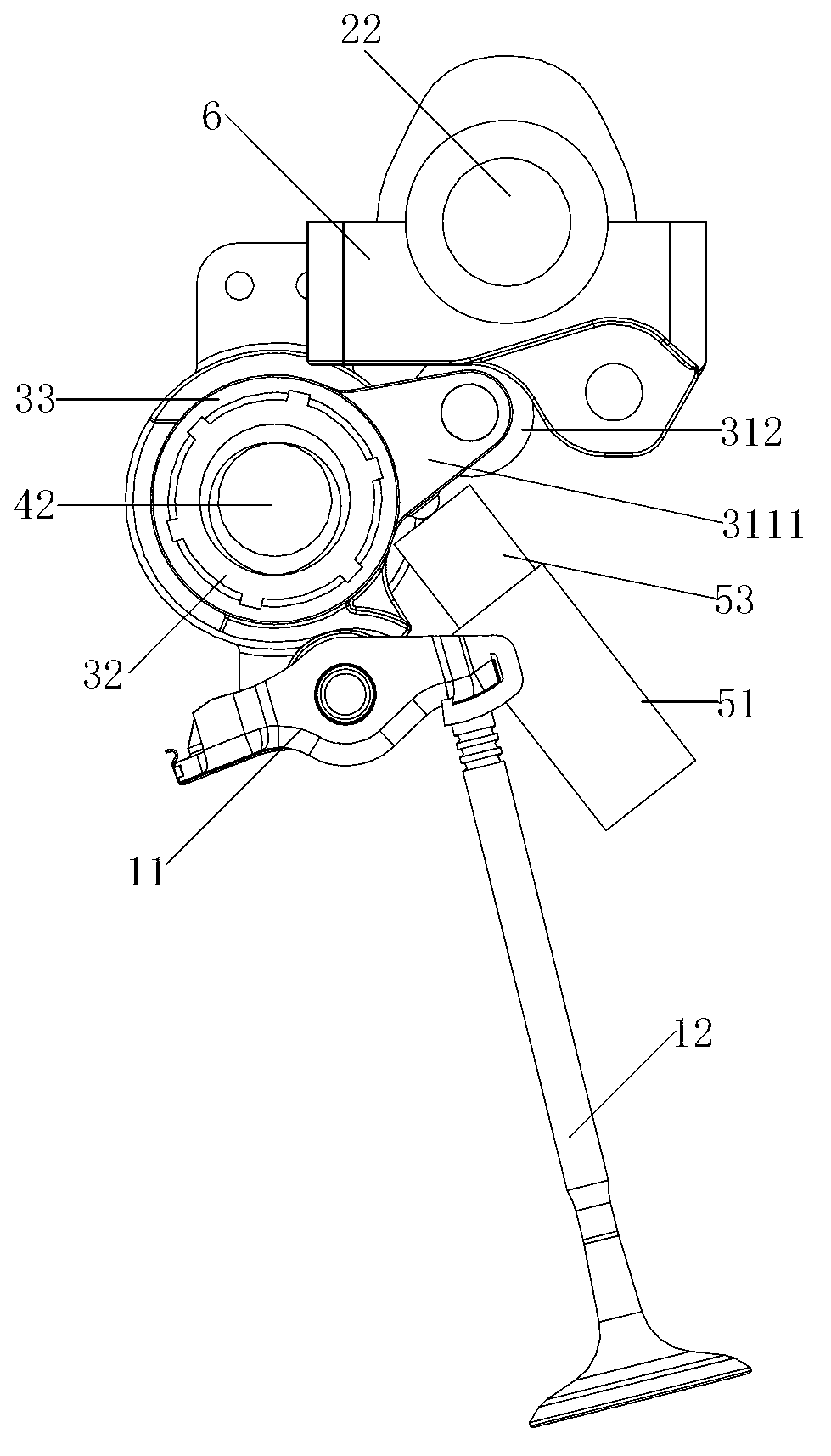

Novel air distribution system with variable lift

ActiveCN101446218AReduce frictionReduce pumping lossValve arrangementsInternal combustion piston enginesDistribution systemEngineering

The invention provides a novel air distribution system with variable lift, which is applied to the field of the internal-combustion engine of the motor vehicle. The novel air distribution system with variable lift comprises a hydraulic tappet (1), an air valve (2) and a rocking arm (3), and further comprises a transmission gear (7), an adjusting rod (9) and a stepping motor (10), wherein, a cam shaft (6) is arranged between the rocking arm (3) and the adjusting rod (9), the cam of the cam shaft is in contact with the adjusting rod (9), the adjusting rod (9) is connected with the transmission gear (7), and the transmission gear (7) is meshed with the stepping motor (10). By adopting the technical scheme, the invention has the advantages that the purpose that the air valve is changed along with the demands of the operating conditions is achieved, and the performance of the engine is optimized to the utmost extent; the structure is simple and compact, and the design is reasonable; and the modification of the engine applying the mechanism is small. Furthermore, the invention is suitable for upgrading for the production products.

Owner:CHERY AUTOMOBILE CO LTD

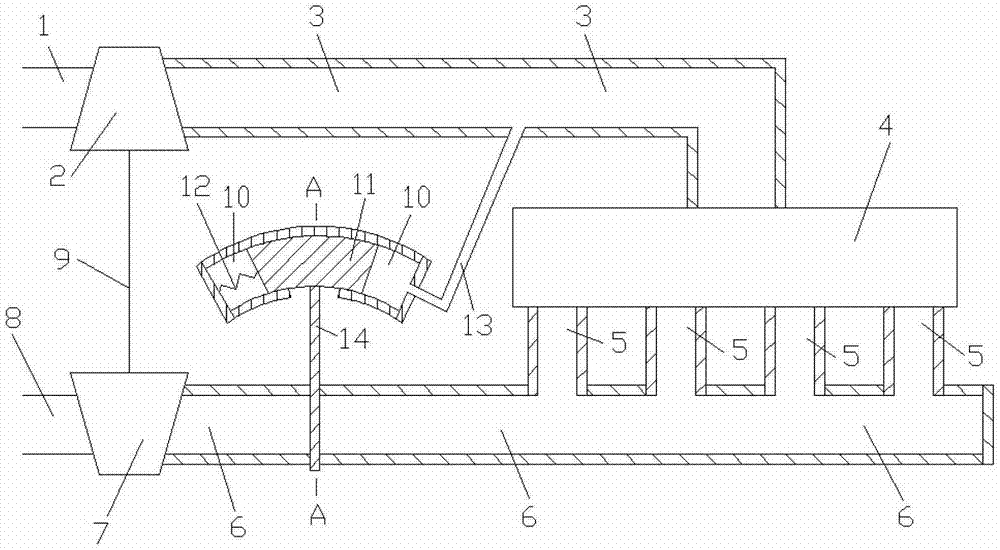

Rotation control type air exhaust pipe outlet area variable device

ActiveCN103089412AReasonable designSimple structureInternal combustion piston enginesIntake pressureMechanical design

A rotation control type air exhaust pipe outlet area variable device belongs to the technical field of mechanical design and comprises an air compressor, an engine, an air exhaust pipe, a turbine, a volume cavity, a rotation body, a spring, a connection pipe, a rotation rod, a rotation shaft and a rotation plate. The longitudinal sections of the volume cavity and the rotation body are both in arc shapes, the rotation plate is installed in the air exhaust pipe, the rotation plate and the rotation shaft are fixed together, the left wall of the rotation body is connected with the left wall of the volume cavity through the spring, and two ends of the connection pipe are respectively communicated with the right wall of the volume cavity and the air exhaust pipe. When pressure in the air exhaust pipe in front of the rotation plate is high, the rotation body drives the rotation plate to rotate in a counterclockwise mode, pumping loss of the engine is small, and the whole performance is excellent. When pressure in the air exhaust pipe in front of the rotation plate is low, the rotation body drives the rotation plate to rotate in a clockwise mode, available energy in front of the turbine is more, air inlet pressure of the engine is high, and the whole performance is excellent. The rotation control type air exhaust pipe outlet area variable device is reasonable in design, simple in structure and suitable for a turbine single inlet turbocharged system.

Owner:SHANGHAI JIAO TONG UNIV

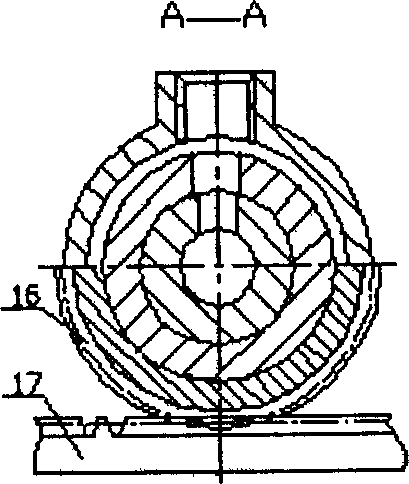

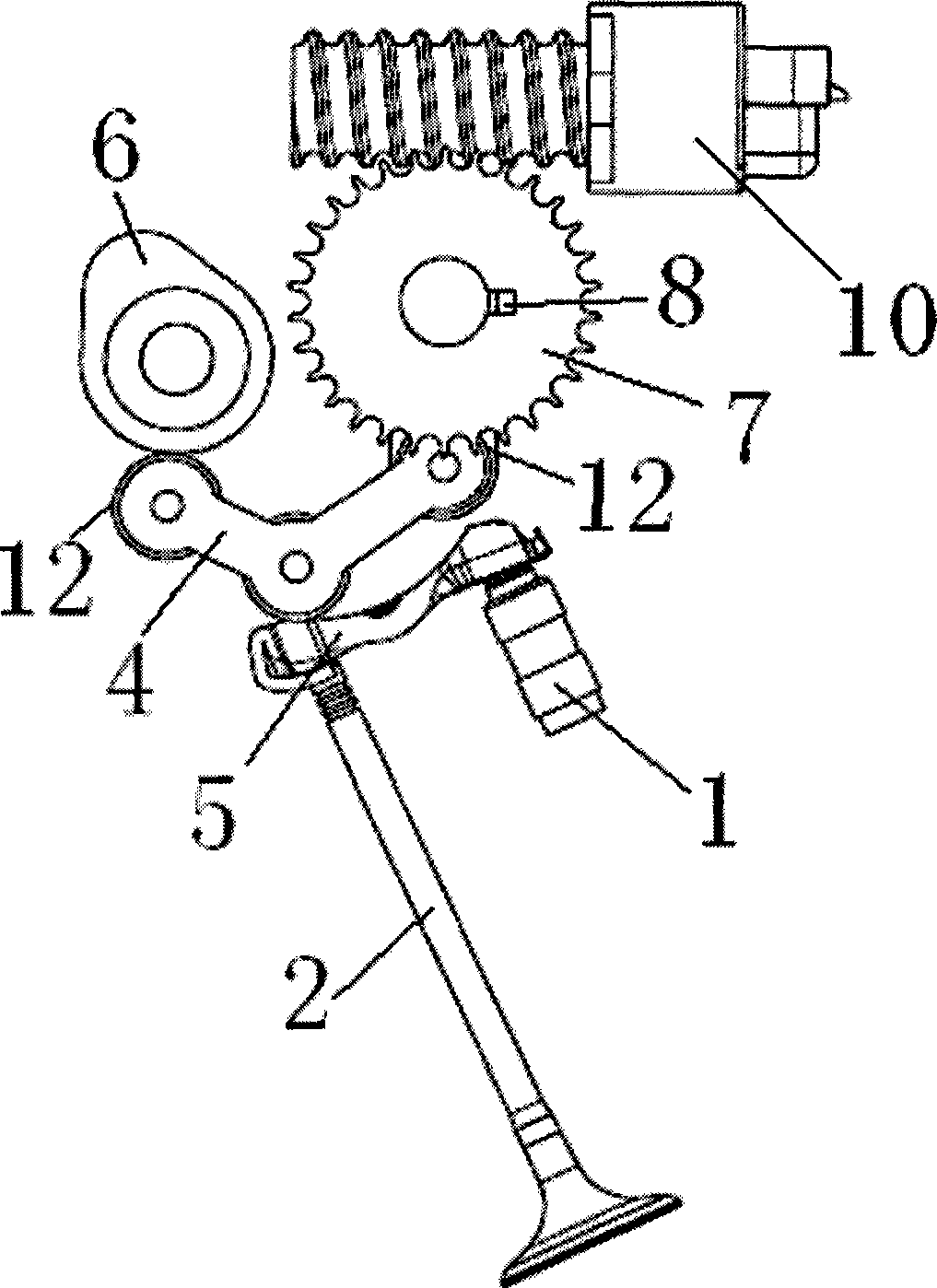

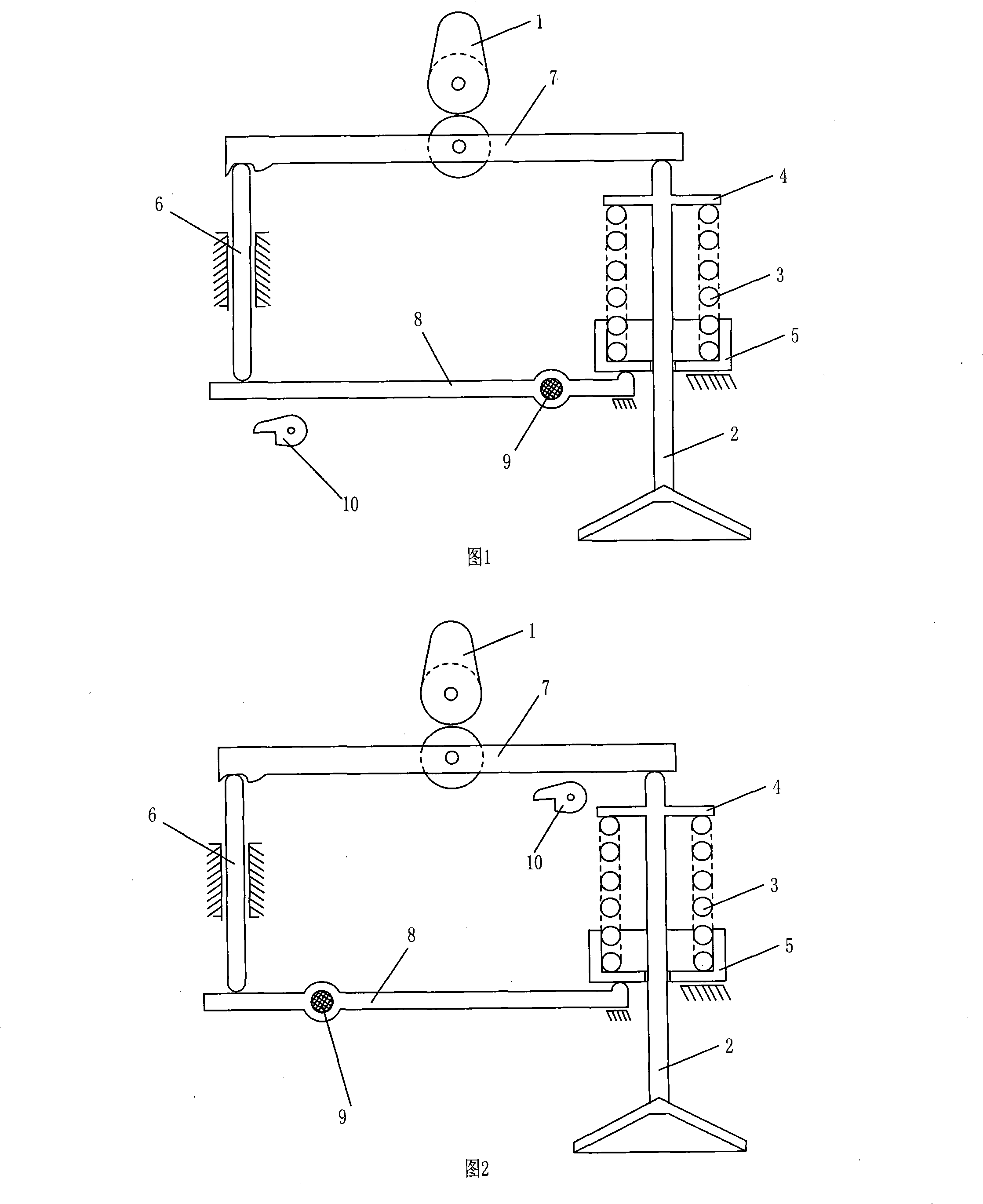

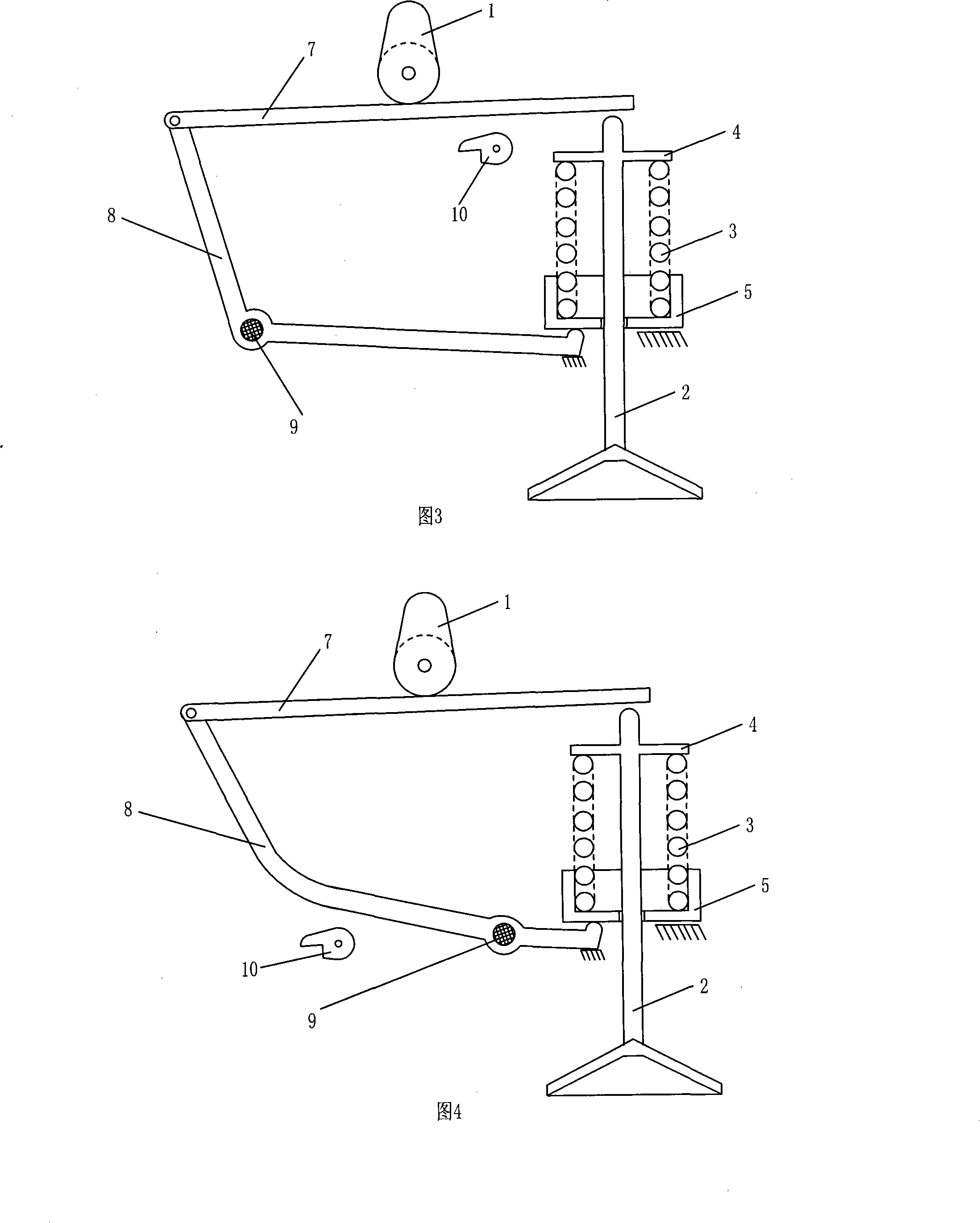

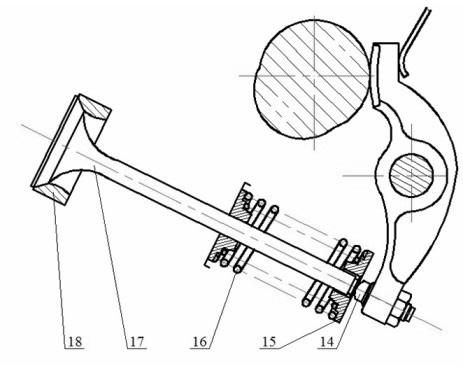

Variable spiracula lifting device

InactiveCN101225759AReduce pumping lossReduce fuel consumptionValve arrangementsMachines/enginesFuel oilCam

The invention relates to a lift device for variable valves, comprising a valve arranged in the air passage of cylinder cover, a cam rotated synchronously with the engine crankshaft and a valve spring sleeved on the valve, which is characterized in that an upper seat of the spring is arranged on the upper end of the valve spring; the upper seat of the spring is fixedly connected with the valve; the lower end of the valve spring is arranged in the cylinder cover through the lower seat cup of the spring; a lever mechanism for controlling the valve action conveniently is connected between the cam and the valve. The lift device for variable valves has the advantages that the purpose of controlling valve action can be reached by adding a lever mechanism, the device is simple in structure and convenient in control, can reduce the pumping loss and the fuel oil consumption of engine.

Owner:许小法

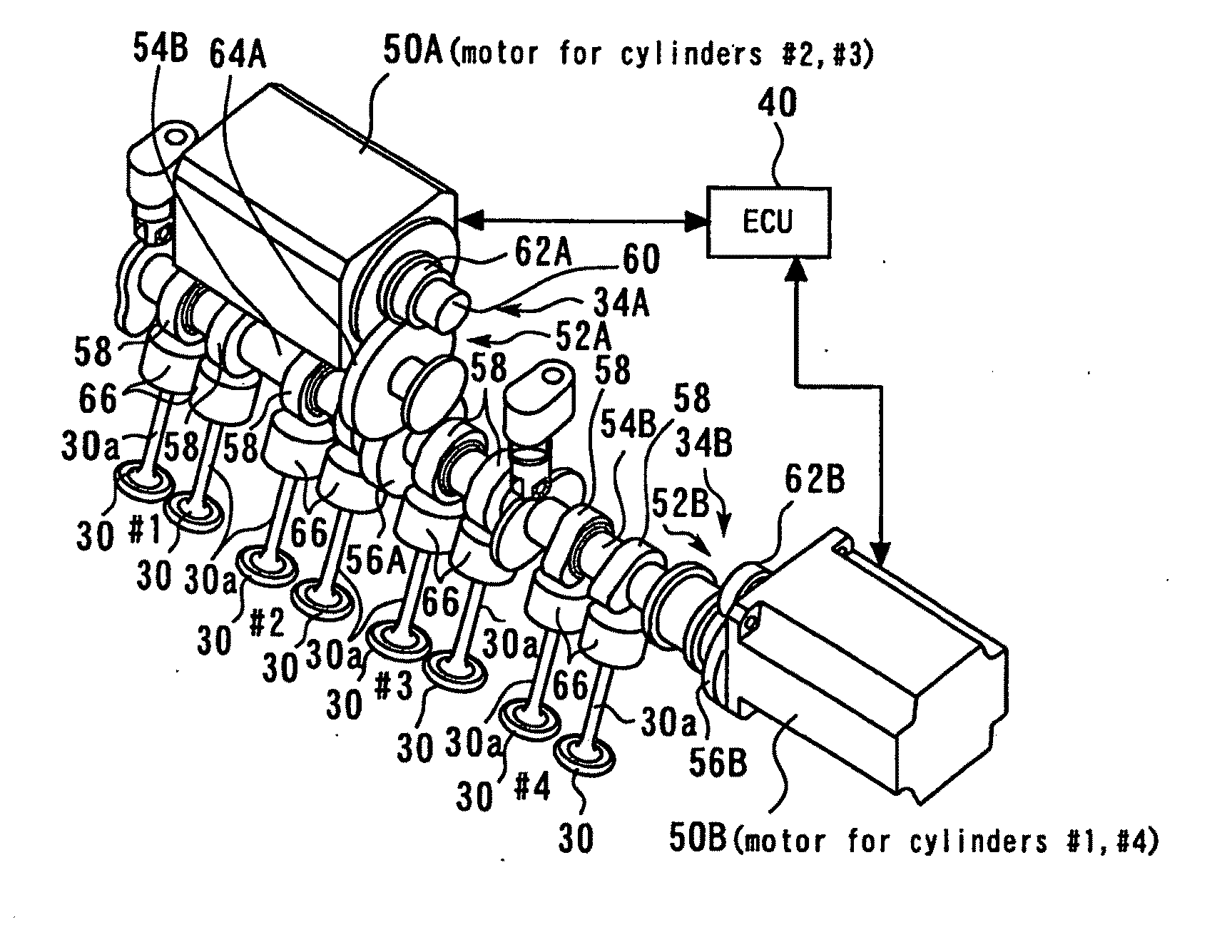

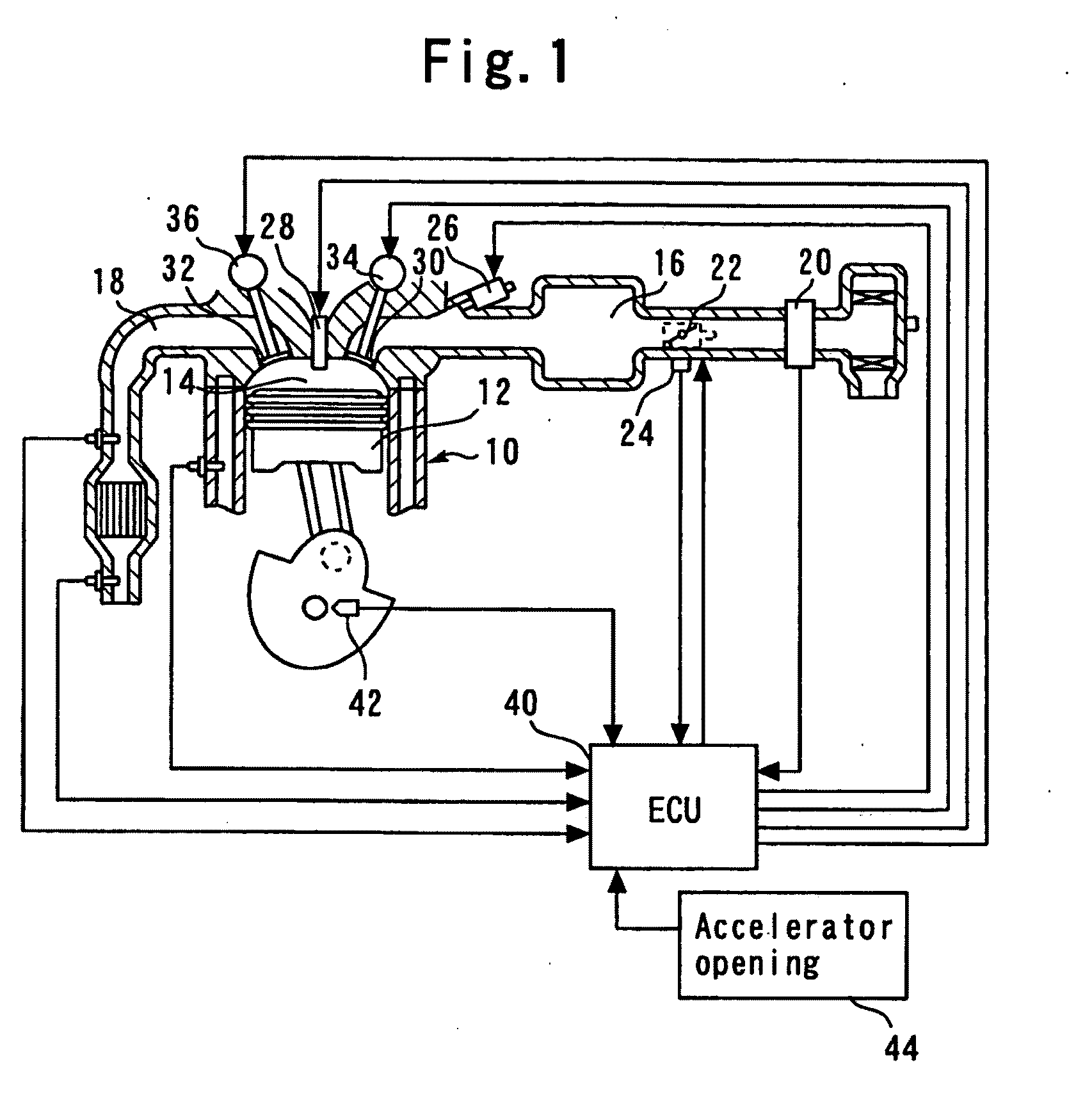

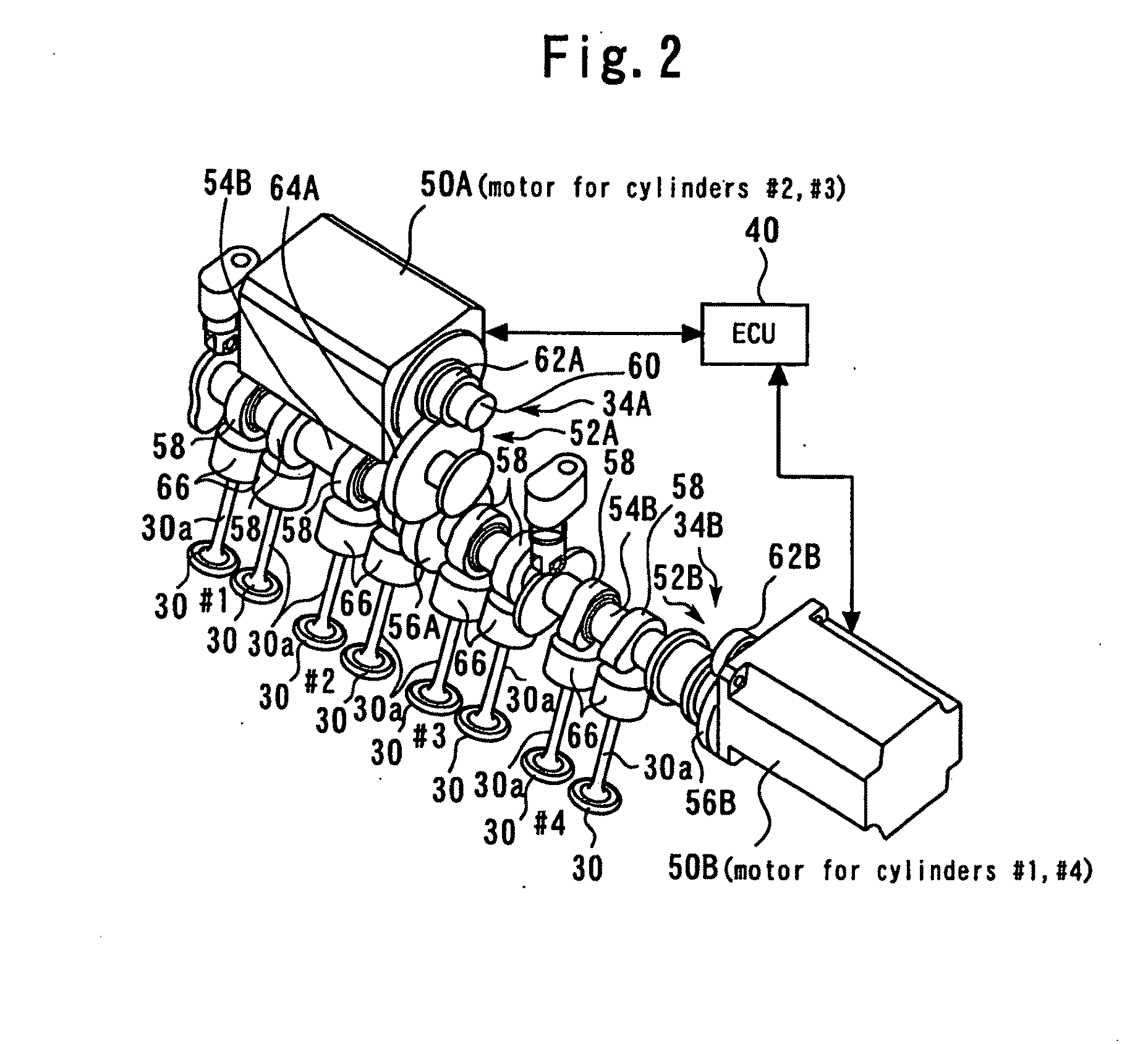

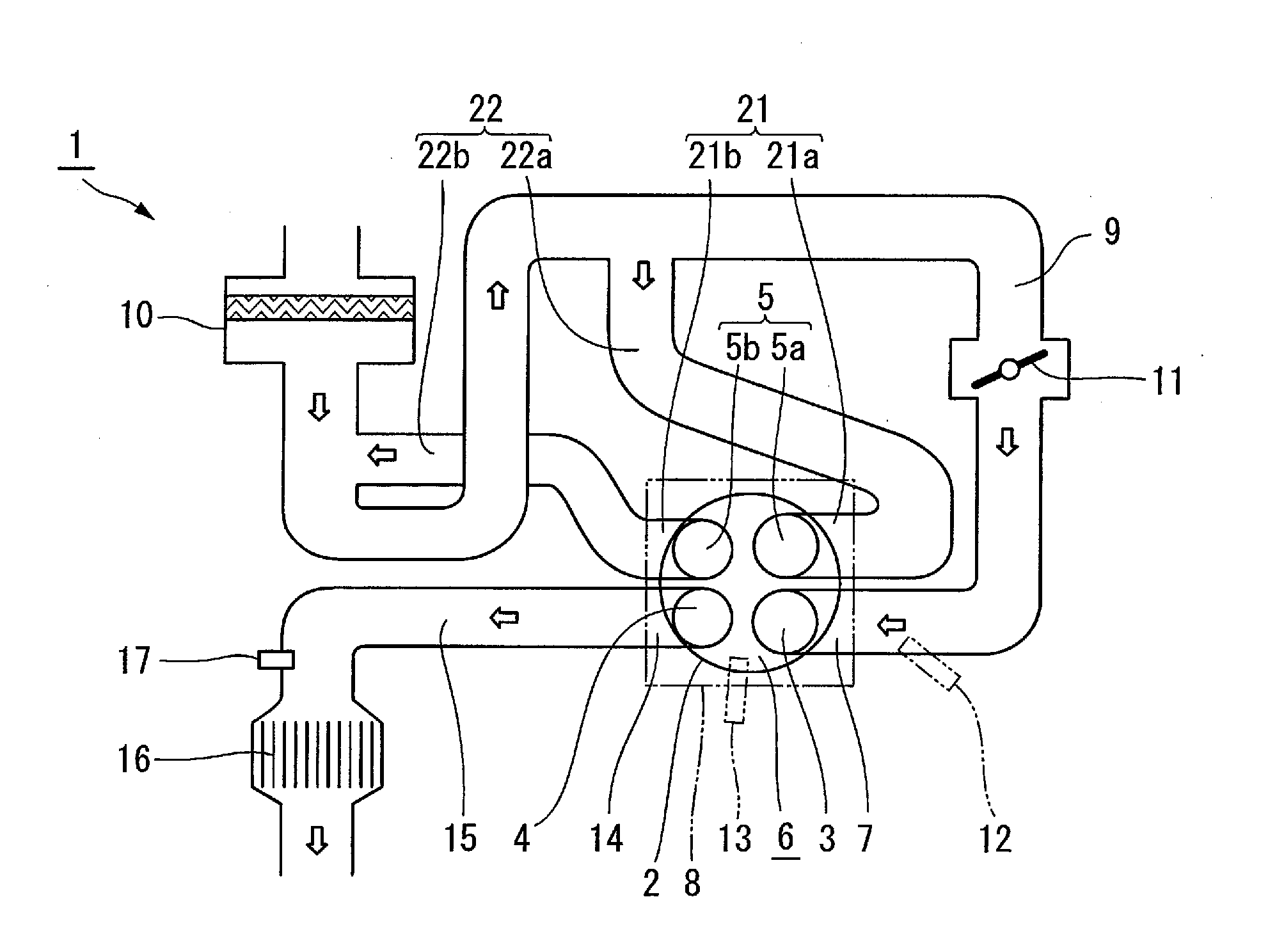

Control apparatus for internal-combustion engine with variable valve mechanism

InactiveUS20100175644A1Appropriate settingAvoid changeValve arrangementsInternal combustion piston enginesLow loadInlet valve

An intake variable valve mechanism 34 is provided that allows closing timing of an air intake valve 30 to be varied. The intake variable valve mechanism 34 has a first control mode that controls IVC timing of the intake valve 30 at an angle-advancing side relative to a certain range including an air intake bottom dead center BDC, and a second control mode that controls the IVC timing of the intake valve 30 at an angle-retarding side relative to the certain range. IVC variable control (first control mode) for making the IVC timing of the intake valve 30 variable according to load is selected for operation in a region of relative low loads, and intake valve closing retardation control (second control mode) for controlling the intake valve 30 in fully retarded IVC timing is selected for operation in a region of relatively high loads.

Owner:TOYOTA JIDOSHA KK

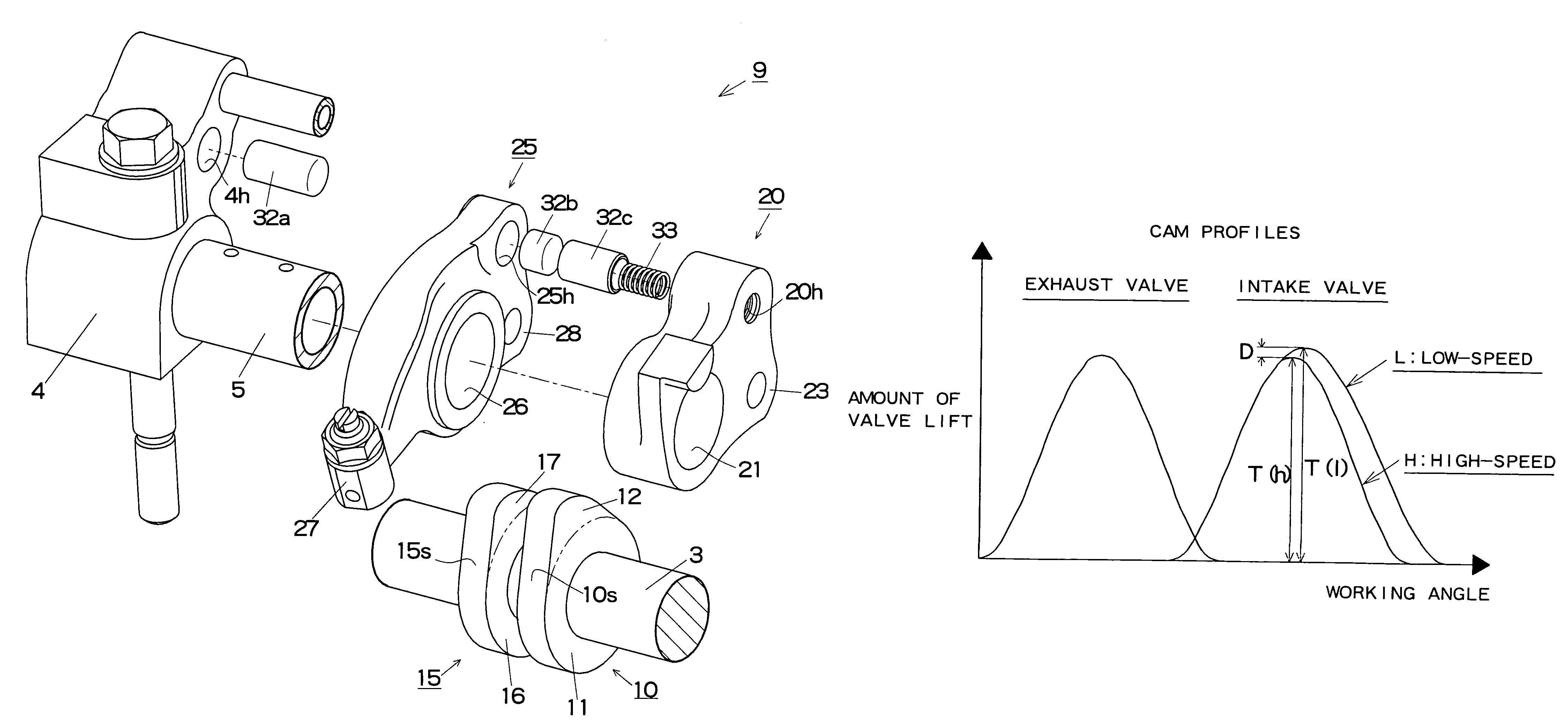

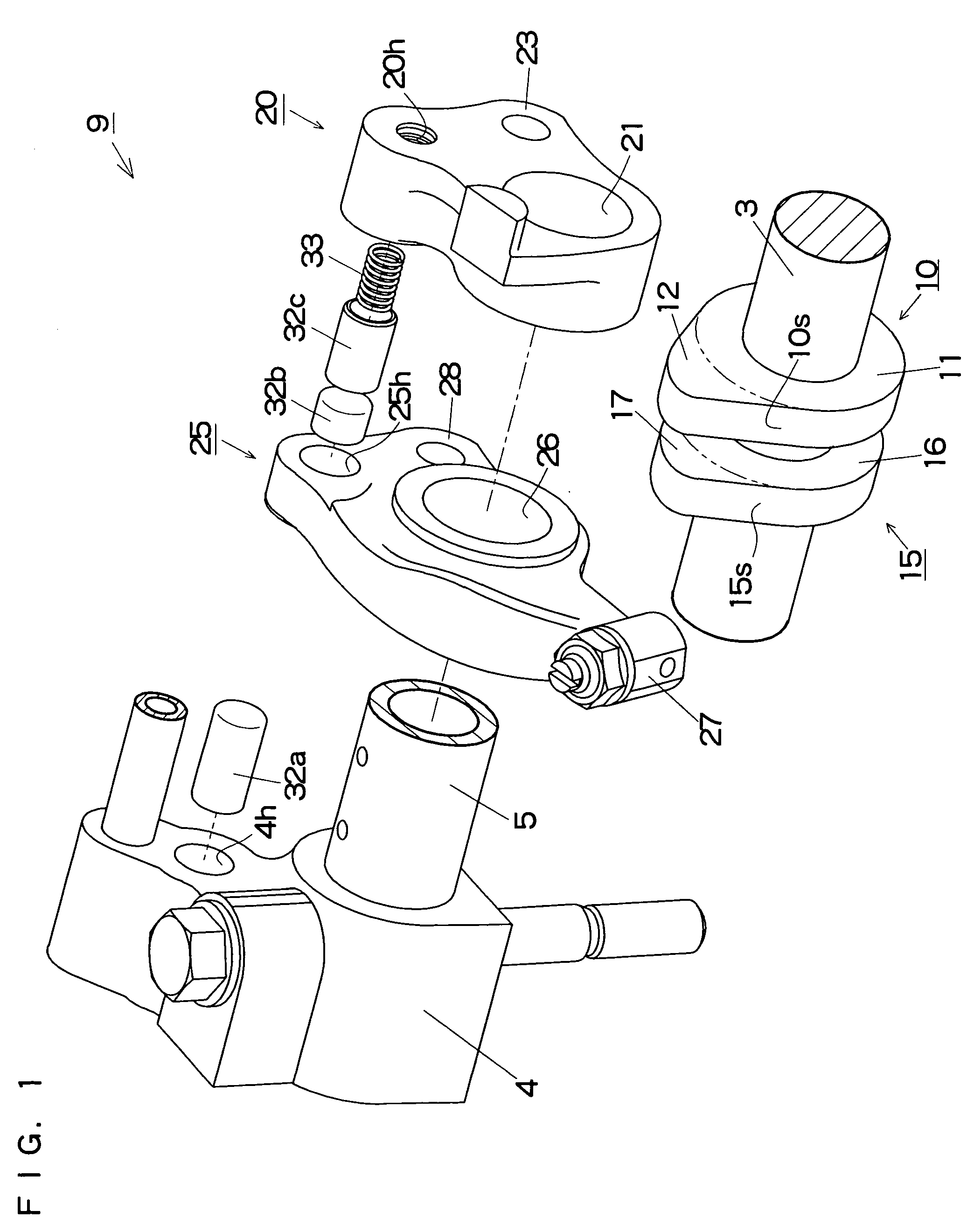

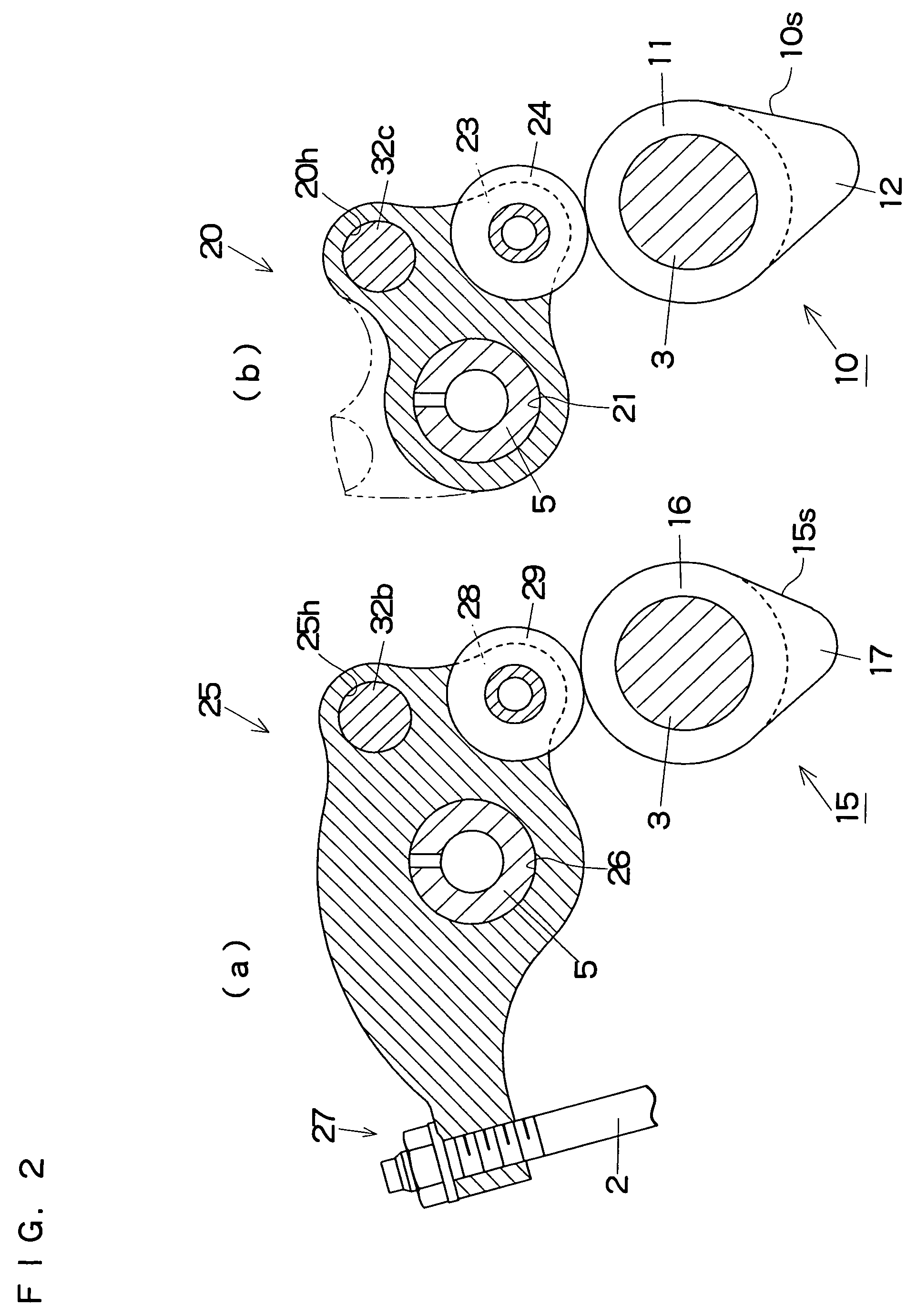

Variable valve mechanism

A variable valve mechanism includes a low-speed cam, a high-speed cam, a low-speed rocker arm driven by the low-speed cam, a high-speed rocker arm driven by the high-speed cam, and a switching mechanism. A cam profile of the high-speed cam is set such that it does not exceed a cam profile of the low-speed cam. During low-speed operation, the switching mechanism links the low-speed and the high-speed rocker arms such that the low-speed cam causes the high-speed rocker arm to rock together with the low-speed rocker arm and to open and close a valve. During high-speed operation, the switching mechanism de-links the low-speed rocker arm and the high-speed rocker arm such that the low-speed cam causes the low-speed rocker arm to rock idly and the high-speed cam causes the high-speed rocker arm to rock independently and to open and close the valve. The cam profile of the low-speed cam is set such that the valve closes later than it does with the cam profile of the high-speed cam.

Owner:OTICS CORP

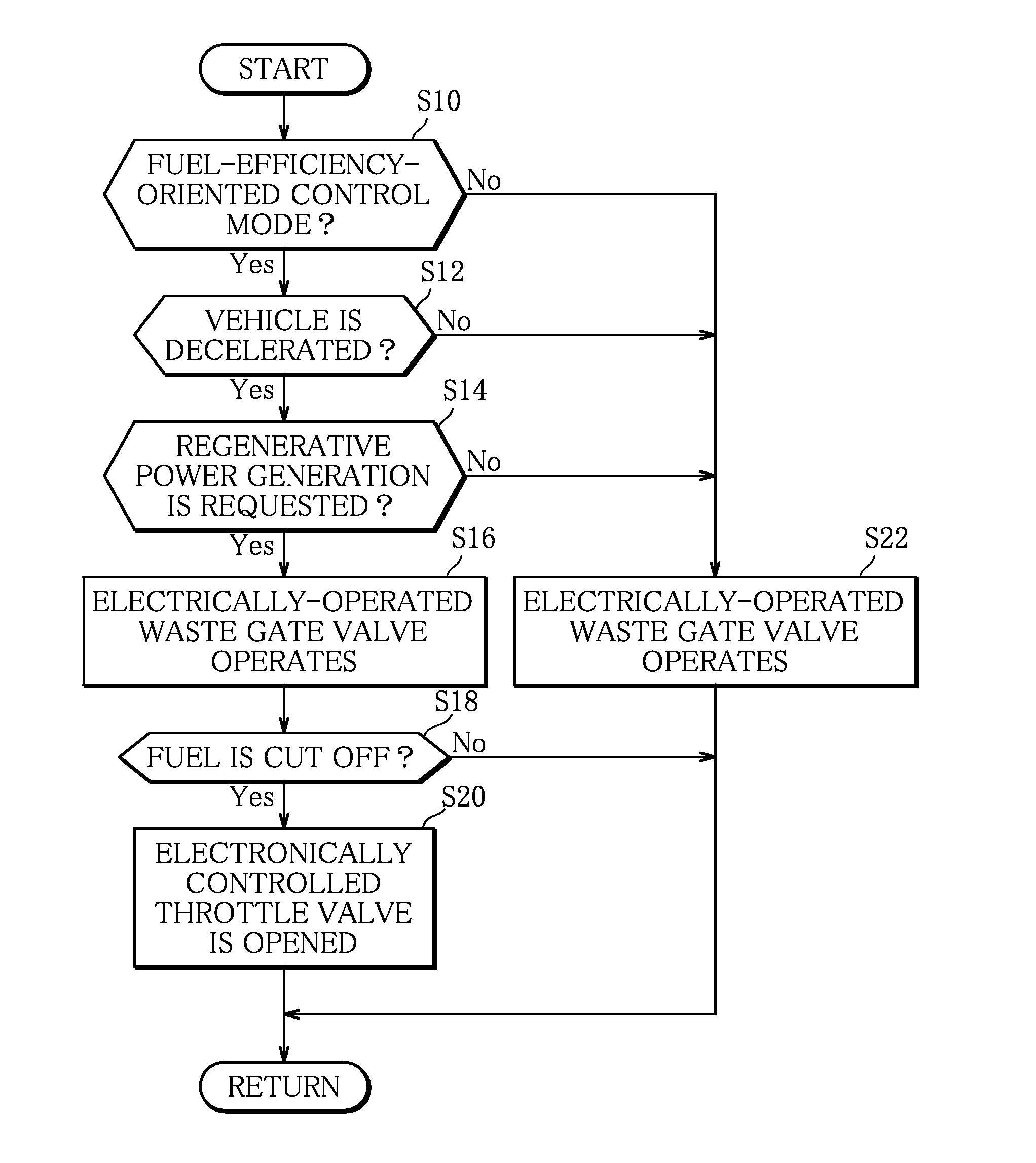

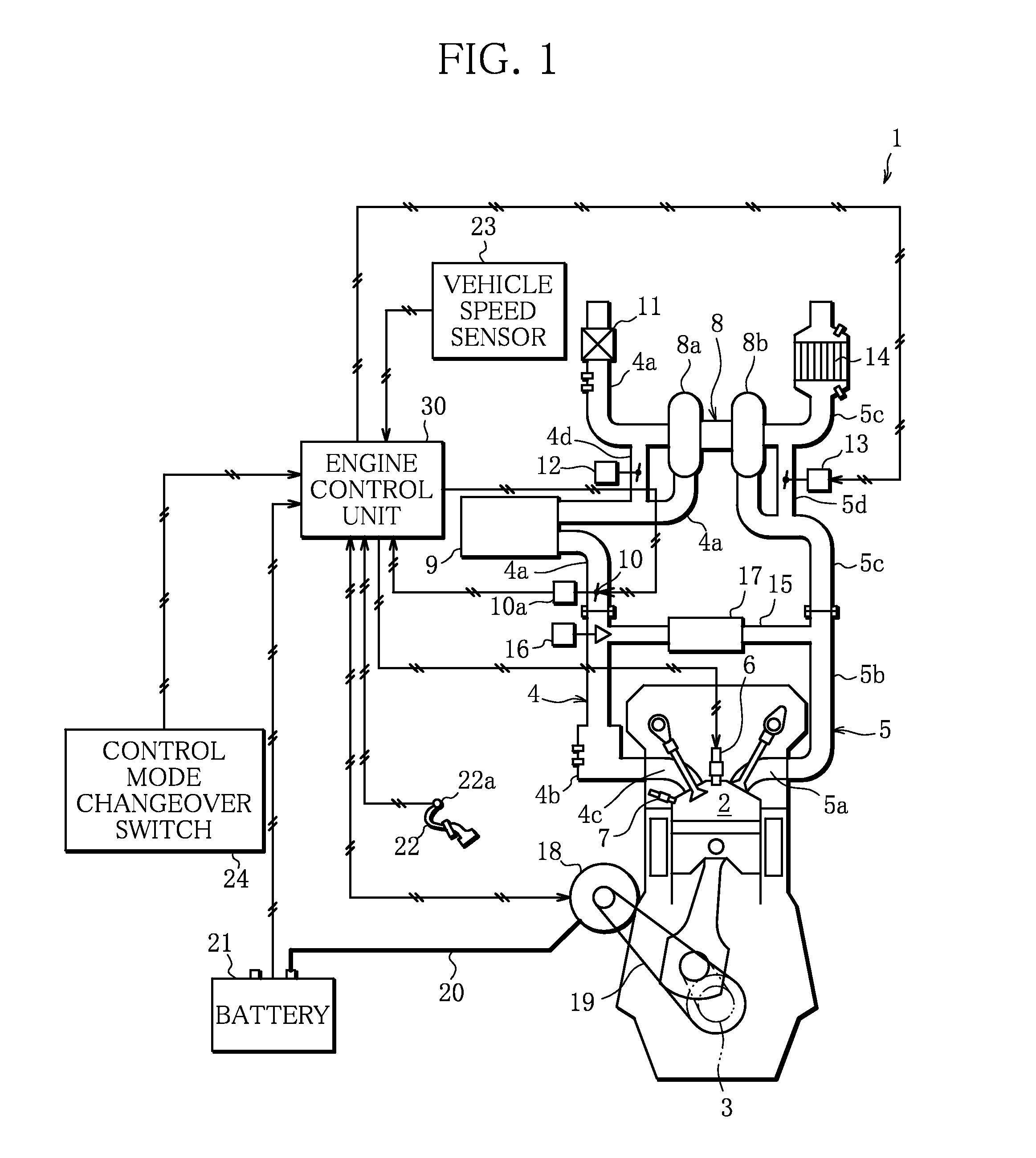

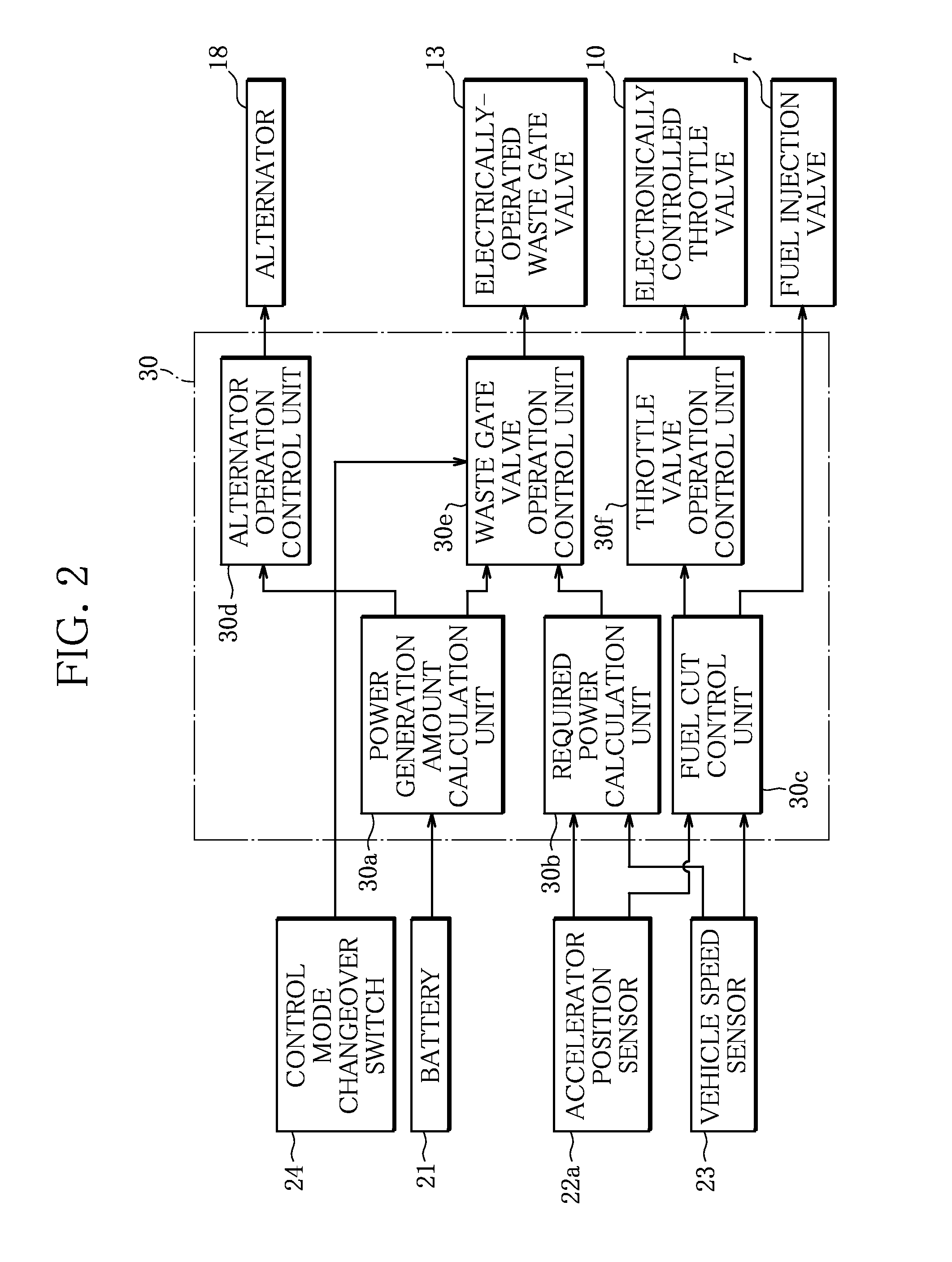

Controller for vehicle

ActiveUS20160251011A1Flow rateReduction in pressure of exhaust gasHybrid vehiclesElectrical controlFuel efficiencyControl mode

According to the present invention, if a required power generation signal is supplied while a vehicle is decelerated in a fuel-efficiency-oriented control mode, an electrically-operated waste gate valve is operated so that opening of the electrically-operated waste gate valve is increased as the required power generation amount increases. Then, if it is determined that the vehicle is decelerated on the basis of accelerator opening and a vehicle speed, and fuel is cut off, an electronically controlled throttle valve is operated toward a fully opened side. In addition, if any one of following conditions is satisfied: the fuel-efficiency-oriented control mode is not selected; there is supply of a required output signal; and the vehicle is not decelerated, opening of the electrically-operated waste gate valve is adjusted so that output torque of an engine becomes a required output value.

Owner:MITSUBISHI MOTORS CORP

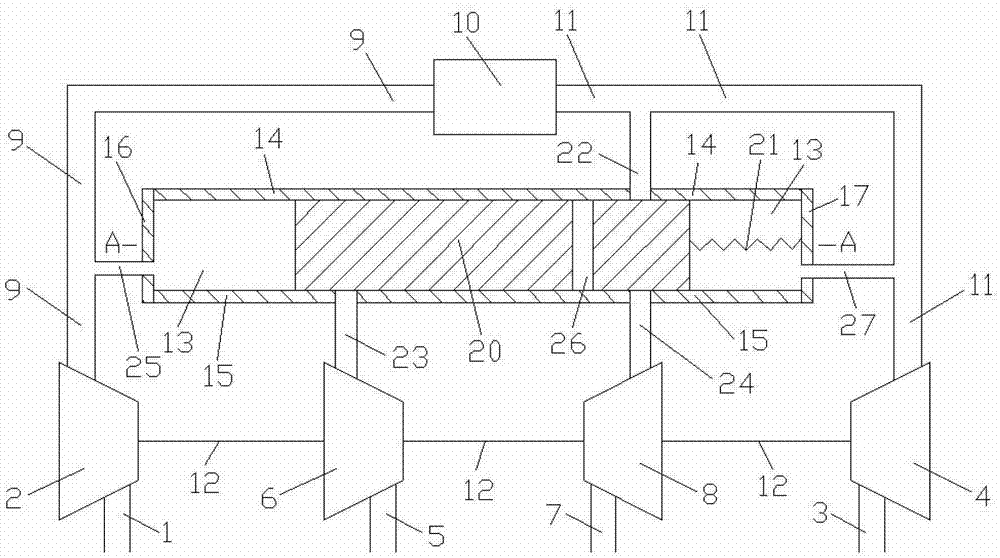

Air inlet pressure main control type pipeline device

InactiveCN102889121AReasonable designSimple structureInternal combustion piston enginesIntake pressureMechanical design

The invention discloses an air inlet pressure main control type pipeline device, and belongs to the technical field of mechanical design. The air inlet pressure main control type pipeline device comprises air compressors, an air inlet pipe, an engine, an air exhaust pipe, turbines, a volume cavity, a connection pipe, a moving body, a spring and penetration pipes, wherein the moving body is arranged in the volume cavity and is in sealing contact with the inner wall surface of the volume cavity; the first penetration pipe and the second penetration pipe penetrate through the upper wall surface and the lower wall surface of the moving body; and the right wall surface of the moving body is connected with the right wall surface of the volume cavity through the spring. When the engine is in a high-speed working condition, the moving body moves rightwards, the first air compressor, the second air compressor, the first turbine and the second turbine work synchronously, the air pumping loss of the engine is relatively low, and the overall performance of the engine is relatively high; and when the engine is in a low-speed working condition, the moving body moves leftwards, only the first air compressor and the first turbine work, pulse energy is fully used, the air inlet pressure of the engine is relatively high, and the overall performance of the engine is relatively high. The air inlet pressure main control type pipeline device is rational in design, simple in structure and suitable for turbine pressurization systems with double turbines and double air compressors.

Owner:SHANGHAI JIAO TONG UNIV

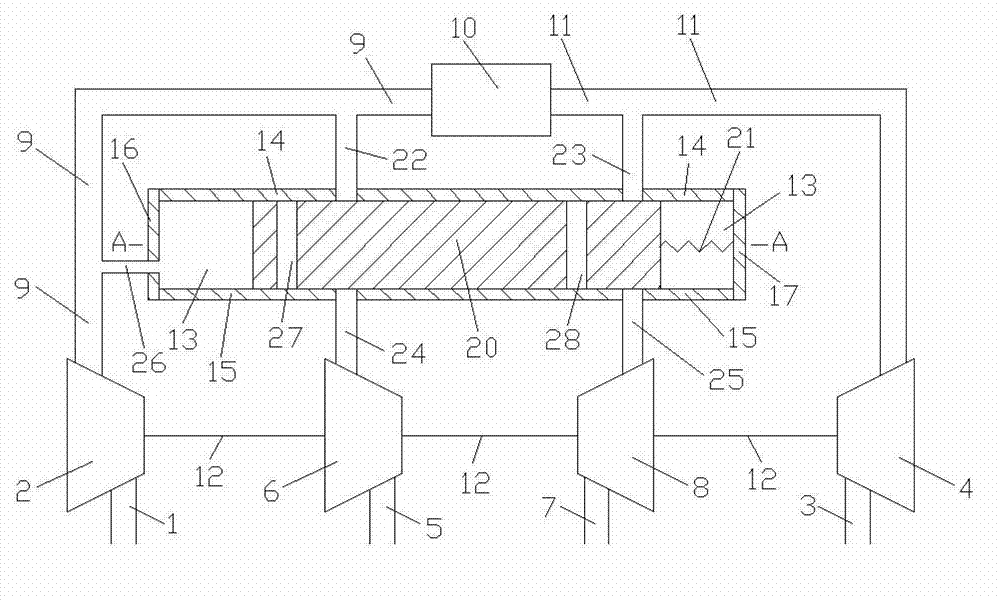

Pipeline system capable of controlling intake pressure and exhaust pressure synchronously and mainly

InactiveCN102877933AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesLow speedPulse energy

A pipeline system capable of controlling intake pressure and exhaust pressure synchronously and mainly belongs to the technical field of mechanical design, and comprises air compressors, an air intake pipe, an engine, an exhaust pipe, turbines, a volume cavity, a connecting pipe, a moving body, a spring and a penetrating pipe, wherein the moving body is mounted in the volume cavity and in sealed contact with the inner wall of the volume cavity; the penetrating pipe penetrates the upper wall and the lower wall of the moving body; and the right wall of the moving body is connected with the right wall of the volume cavity through the spring. When the engine is in a high-speed working condition, the moving body moves rightwards, a first air compressor, a second air compressor, a first turbine and a second turbine work simultaneously, so that the pumping loss of the engine is lower, and the performance of the whole engine is better; and when the engine is in a low-speed working condition, the moving body moves leftwards, only the first air compressor and the first turbine work, so that pulse energy can be utilized fully, the intake pressure of the engine is higher, and the performance of the whole engine is better. The pipeline system is designed reasonably, simple in structure, and suitable for a turbo-charging system with double turbines and double air compressors.

Owner:SHANGHAI JIAO TONG UNIV

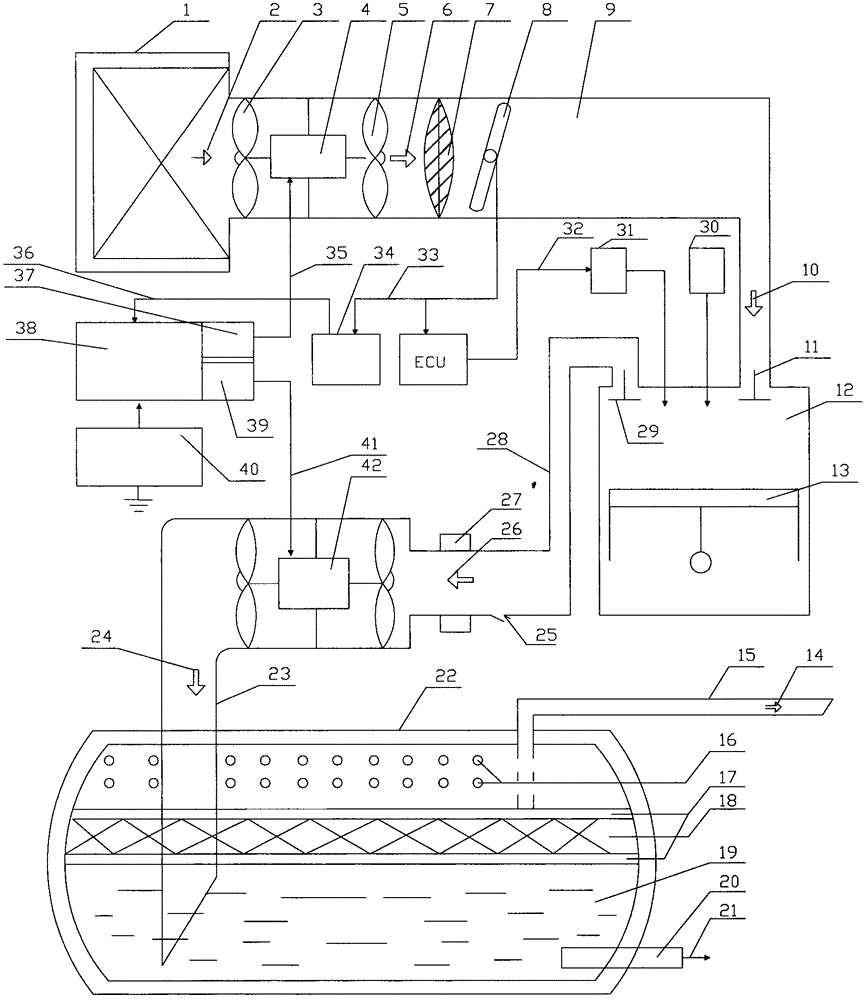

Automotive engine boost and tail gas purification technology and combination

InactiveCN104912653AIncrease relative compression ratioImprove powerElectrical controlExhaust apparatusAir filterEngine power

The invention discloses an automotive engine booster and a tail gas purifier technology; and the two are combined as a whole, so that the effects of oil saving and emission reduction of an automotive engine are the best, and the protection of natural environment atmosphere is facilitated. Two times of dual boost are performed for air (2) by a double-turbine air pump (4) mounted in an engine air filter (1) to form a boost eddy current (6); the boost eddy current is adjusted through a throttle valve (8), and enters an engine cylinder (12) for compressing to improve a relative compression ratio of the engine; and after mixed gas is combusted, the power of the engine is increased, and fuel is relatively decreased. Discharged tail gas pollutants (26, 24) enter tail gas purifiers (42, 18, 17, 16) for purifying; and the purifying treatment adopts two modes of an alkali liquid (19) absorption method and a solid (18, 16) absorption method. Purified gas (14) is exhausted to the atmosphere through a purifying exhaust pipe (15). A synchronous controller assembly (38) can keep synchronous implementation of the engine boost and the tail gas purification. A tail gas boost air pump (42) is mounted in a tail gas purifier air inlet pipe (23) for performing the gas boost for the tail gas pollutants. A vehicle-mounted accumulator (40) provides electric energy to the synchronous controller assembly.

Owner:郑春初 +1

Variable valve system

InactiveCN101509404AReduce negative pressureReduce pumping lossInternal combustion piston enginesOutput powerPistonCombustion chamber

The invention provides a changeable valve system, wherein the switch of the internal-combustion engine valve can be controlled by hydraulic pressure and the phase of valve distribution can be changed continuously. The system consists of a cylinder cap, a valve, a valve piston, a valve piston cylinder, a main piston, a main piston cylinder and a cam shaft. The working principle is as follows: when the internal-combustion is working, the cam pushes the main piston downwards, when the lower end of the main piston moves downwards to the upper brim of the slant face of a regulator cylinder before sealing the oil outlet, the valve piston stands still, and the valve is in a closed state under the action of the valve spring; when the lower end of the main piston moves downwards to the upper brim of the slant face of a regulator cylinder and seals the oil outlet, the oil in the main piston cylinder enters into the valve piston cylinder by passing an oil transporting pipe to push the valve piston to open the valve, so that the gas enters into or is discharged out of a combustion chamber through a gas channel, thus realizing gas exchange. The opening time and the lift range of the valve can be regulated by just adjusting the position of the regulator cylinder, the delay shut angle of the valve can be changed by regulating the opening degree of a throttle valve, and the phase of the valve distribution can be changed continuously.

Owner:蔡学功

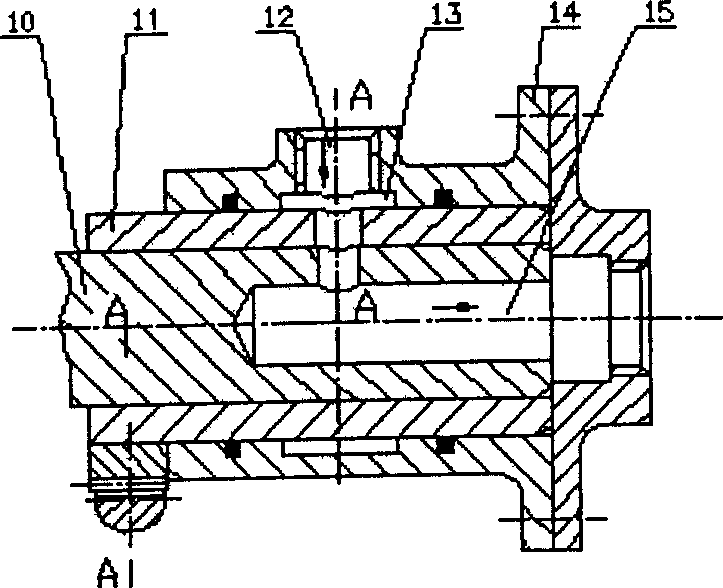

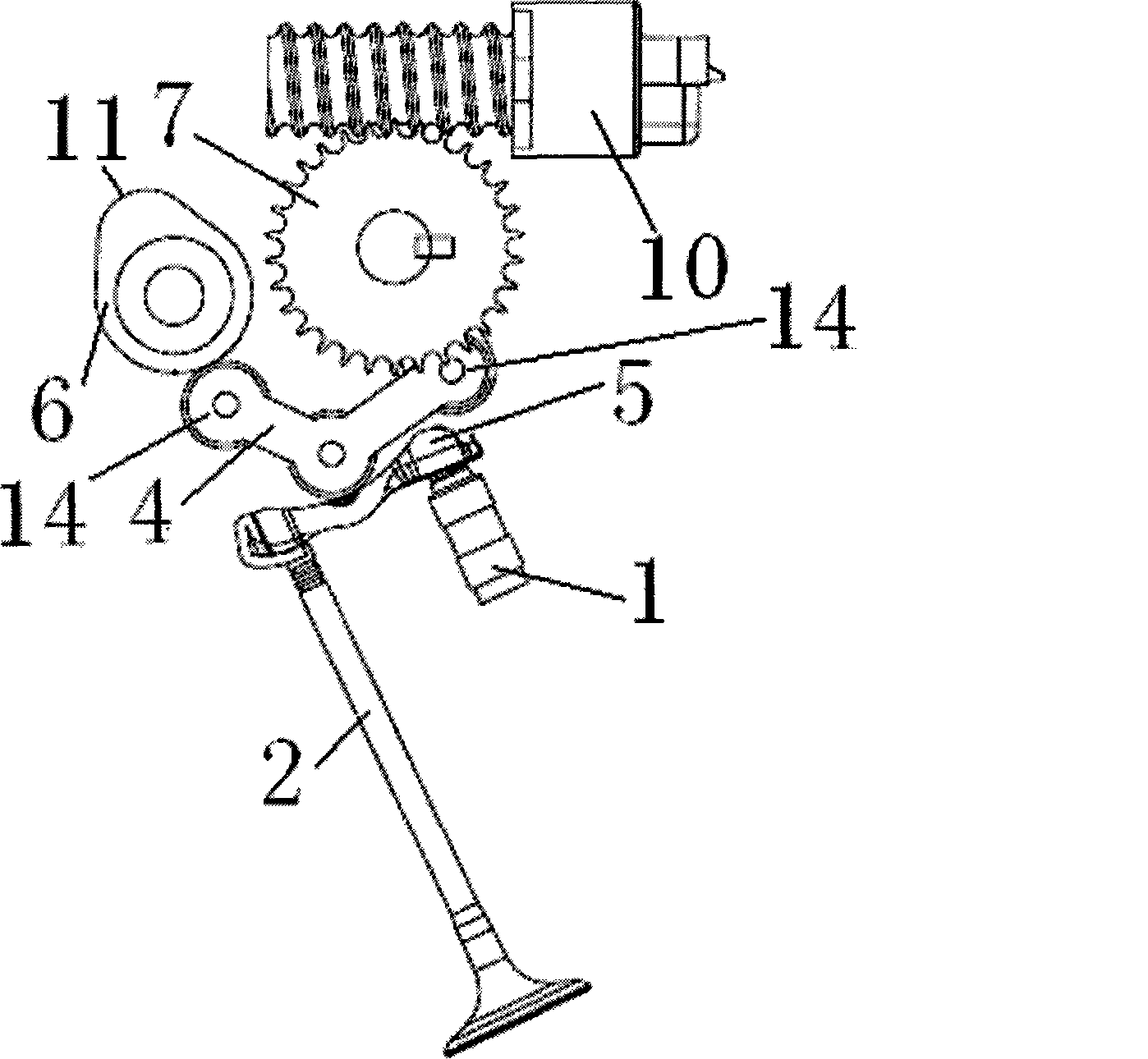

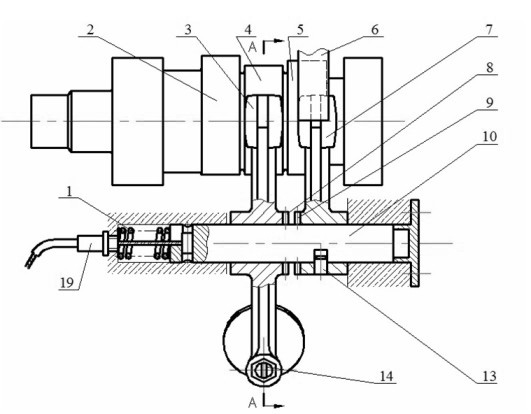

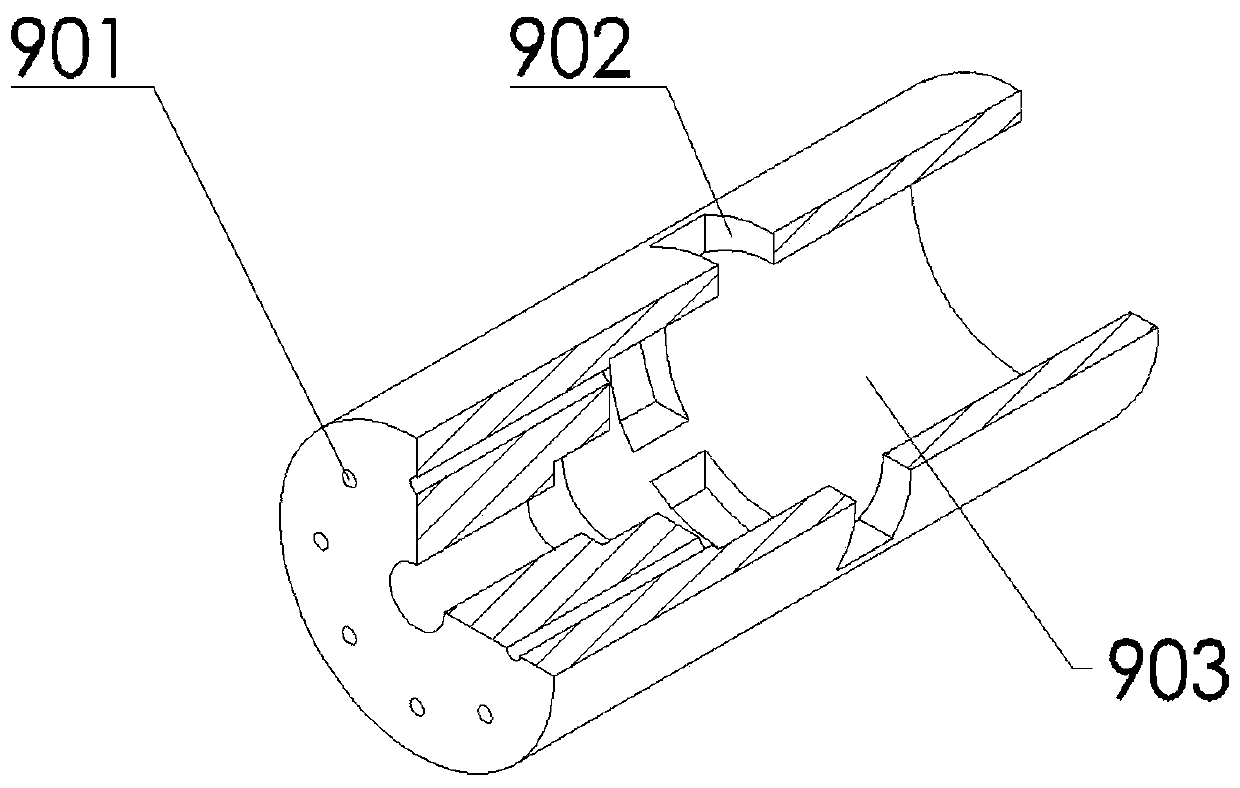

Mobile rocker arm shaft type variable valve timing mechanism

ActiveCN102071982AImprove power performanceReduce pumping lossValve arrangementsInternal combustion piston enginesRocker armWheel drive

The invention relates to a mobile rocker arm shaft type variable valve timing mechanism of a single-cylinder internal combustion engine. The mechanism is structurally characterized in that: a rocker arm shaft and a high-speed rocker arm can move together along the axis of the rocker arm shaft; and the high-speed rocker arm and a low-speed rocker arm are combined or separated. When the high-speed rocker arm and the low-speed rocker arm are in a combination state, a high-speed cam drives the high-speed rocker arm and drives the low-speed rocker arm to swing together, and the high-speed cam drives a valve to open and close, so the mechanism is suitable for the high-speed and large-load working conditions of the internal combustion engine; and when the high-speed rocker arm and the low-speed rocker arm are in a separation state, a low-speed cam drives the low-speed rocker arm and the valve to open and close, so the mechanism is suitable for the low-speed working conditions and small-load working conditions of a gasoline engine. The variable valve timing mechanism has simple structure, can obviously enhance the dynamic property and economy of the internal combustion engine, and is particularly suitable for a single overhead camshaft type single-cylinder four-stroke internal combustion engine.

Owner:SHANDONG UNIV

Zoned and layered thin combustion engine control device

InactiveCN104500210AReduce pumping lossIncrease the air-fuel ratioInternal combustion piston enginesNon-fuel substance addition to fuelExhaust gasElectronic control unit

The invention discloses a zoned and layered thin combustion engine control device. The zoned and layered thin combustion engine control device comprises an electromagnetic controller, as well as a gas-in changeover valve I, a gas-in changeover valve II, an oil sprayer I and an oil sprayer II, which are respectively connected to an electronic control unit, wherein a combustion chamber is separated into a small combustion zone and a large combustion zone; cylinder gas-in pipes are respectively connected to the large combustion zone and the small combustion zone, a cylinder gas-in pipe shunting plate is arranged in each cylinder gas-in pipe, and each cylinder gas-in pipe is divided into a large gas-in pipe and a small gas-in pipe. As engine zoned and layered combustion is realized, when an automobile is at idle speed or carries small load or medium load, the combustion efficiency of fuel oil in the engine is improved, the oil consumption and the emitted exhaust gas of the engine are reduced, and the safe use of the engine during large load is ensured. Therefore, the environmental-friendly performance of the automobile during running is improved, and the use cost is reduced.

Owner:李伟

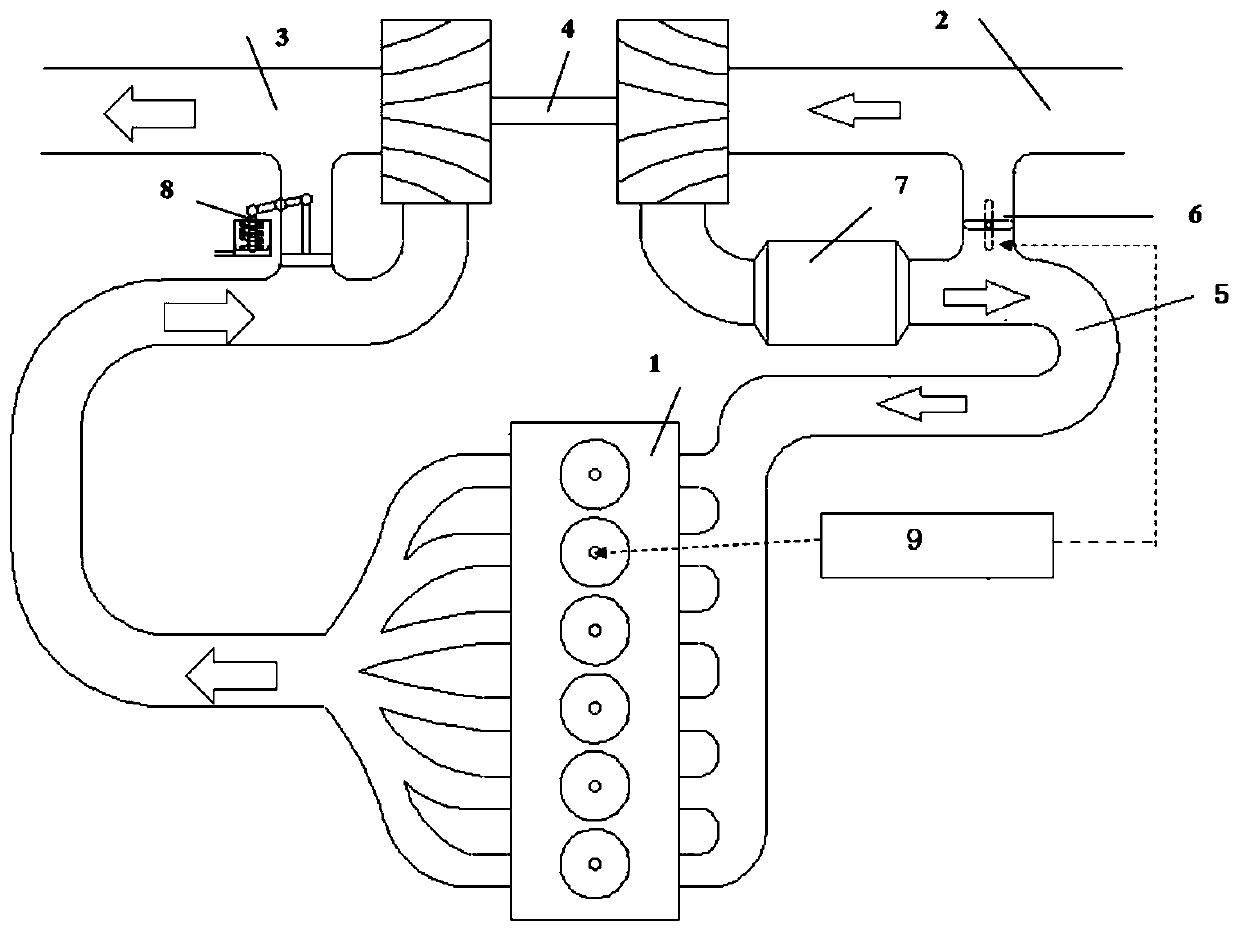

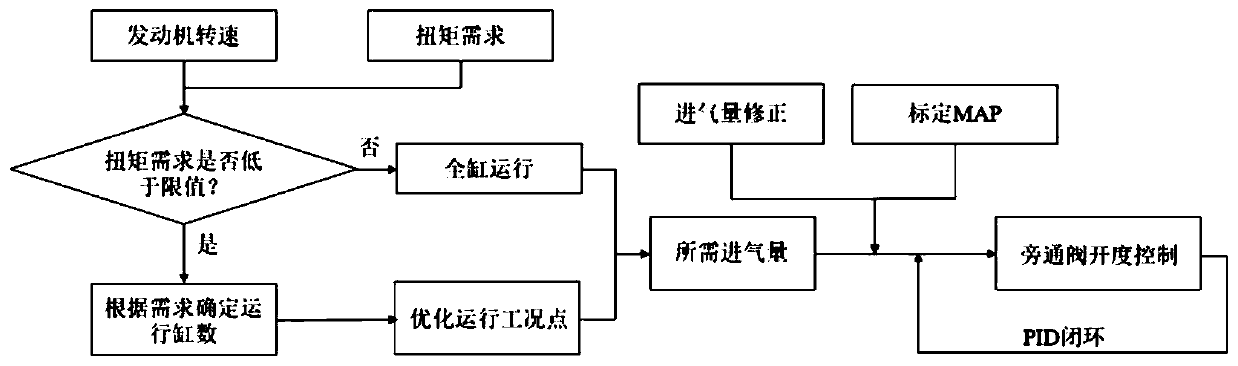

Ignition type engine throttle-valve-free air intake system and power control method

InactiveCN110748442AEasy to controlReduce pumping lossElectrical controlInternal combustion piston enginesIntercoolerButterfly valve

The invention relates to an ignition type engine throttle-valve-free air intake system. The system comprises an air intake pipe (2), a pressurizer (4), an intercooler (7), an intercooler air outlet pipe (5) and an engine (1) which communicate in sequence. The pressurizer (4), the intercooler (7) and the engine (1) are connected with an electronic control unit (9), the air intake pipe (2) and the intercooler air outlet pipe (5) communicate through a butterfly valve (6), and the electronic control unit (9) carries out opening degree control over the butterfly valve (6). Compared with the prior art, a throttle valve is not needed, engine pump gas losses are reduced, and the economic property of the engine is improved.

Owner:TONGJI UNIV

Sectional and layered lean-burn engine cylinder cover

ActiveCN104500252AReduce pumping lossIncrease the air-fuel ratioInternal combustion piston enginesCylinder headsAutomotive engineeringCombustion chamber

The invention discloses a sectional and layered lean-burn engine cylinder cover. The sectional and layered lean-burn engine cylinder cover is connected to a cylinder on the engine. A sectional partition is arranged on the cylinder cover and divides a combustion chamber of the cylinder into a small combustion area and a large combustion area. According to the combustion chamber structure, fuel combustion efficiency of the engine is improved in the case of idling and low and middle load of the vehicle, waste gas exhausted and fuel combustion of the engine are reduced, safety utilization of the engine in the case of large load is guaranteed, and accordingly environmental performance of the vehicle is improved during driving, with lowered cost required.

Owner:CHONGQING FEIKANG MACHINERY CO LTD

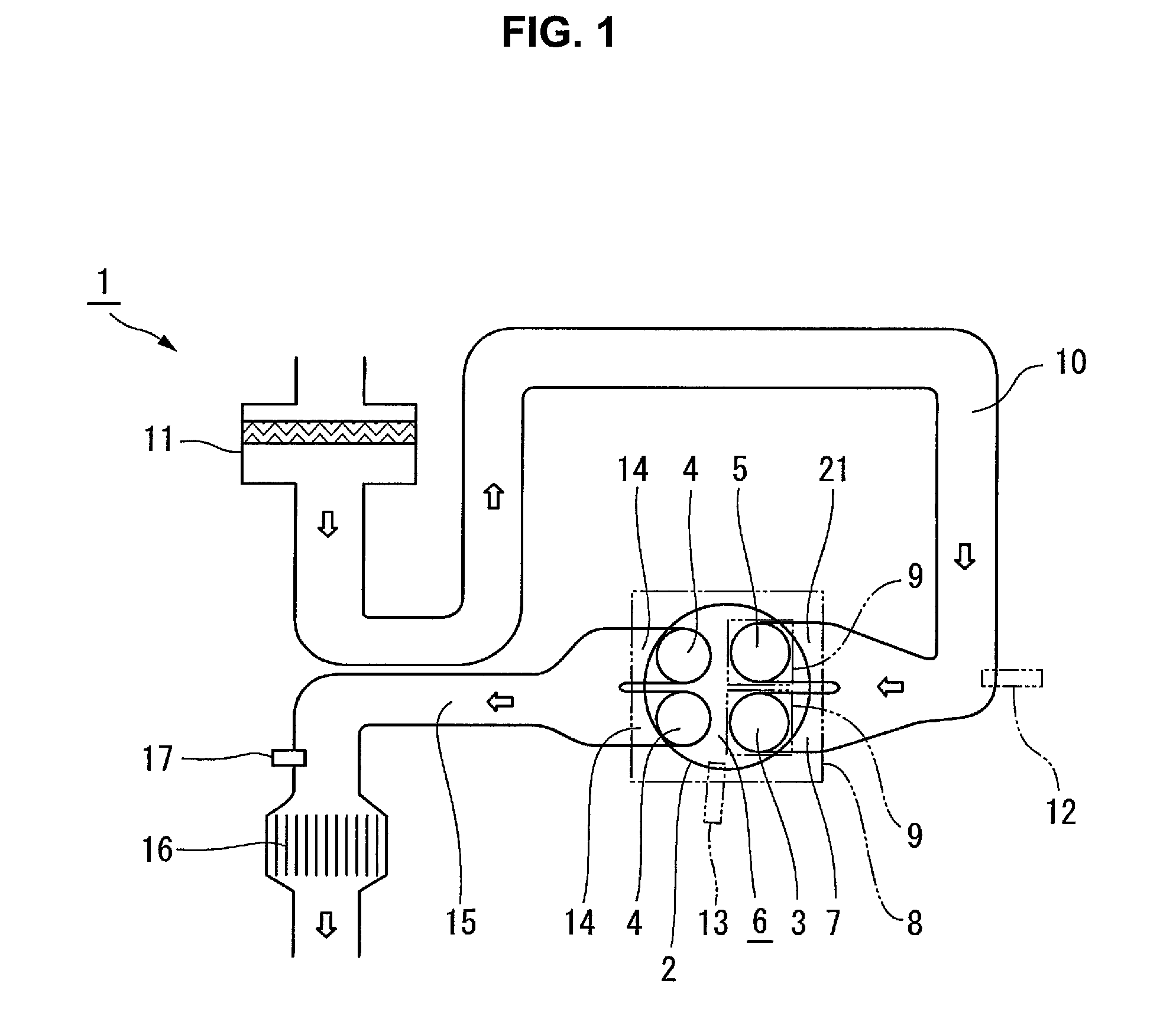

Six-stroke cycle engine having scavenging stroke

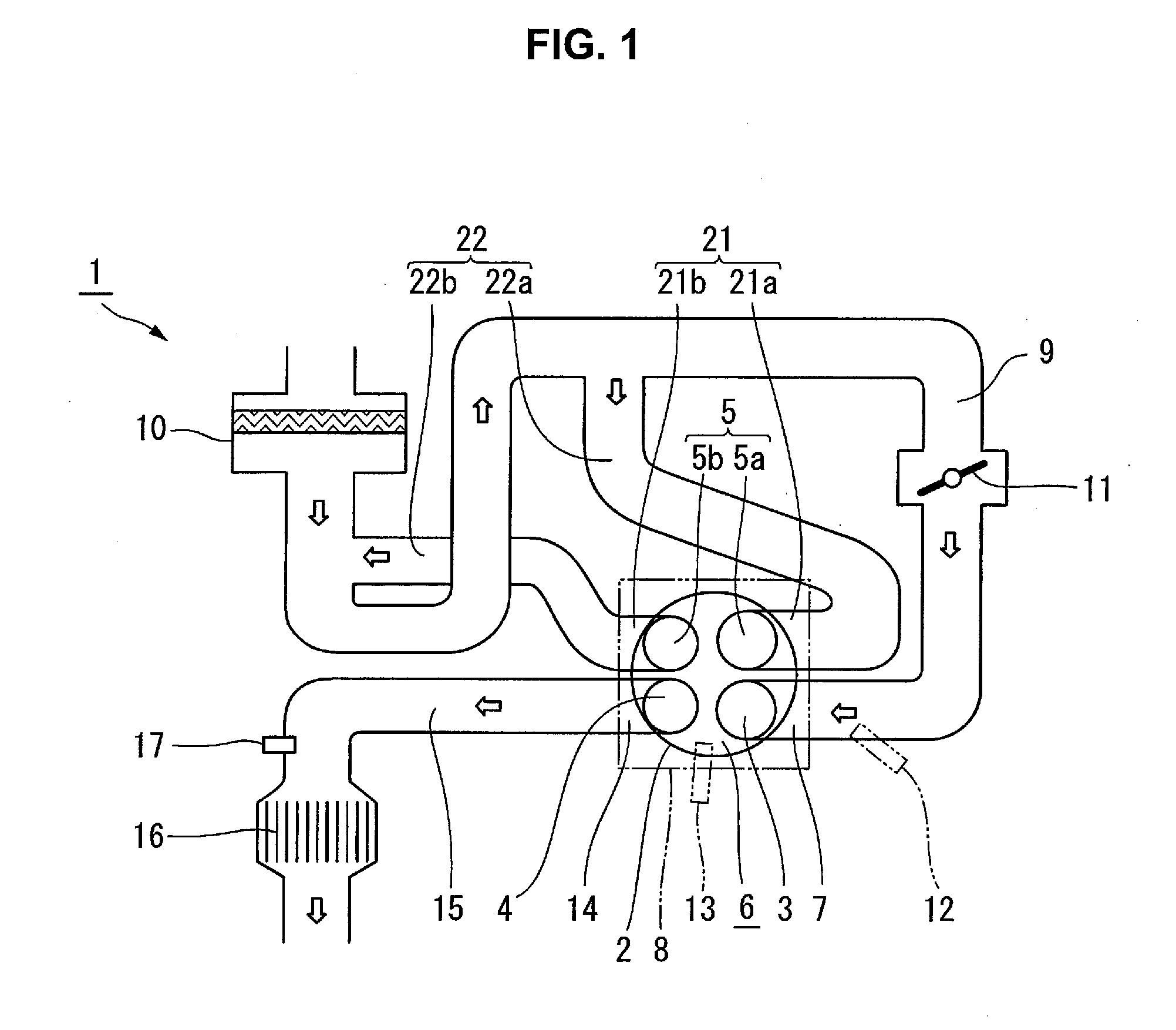

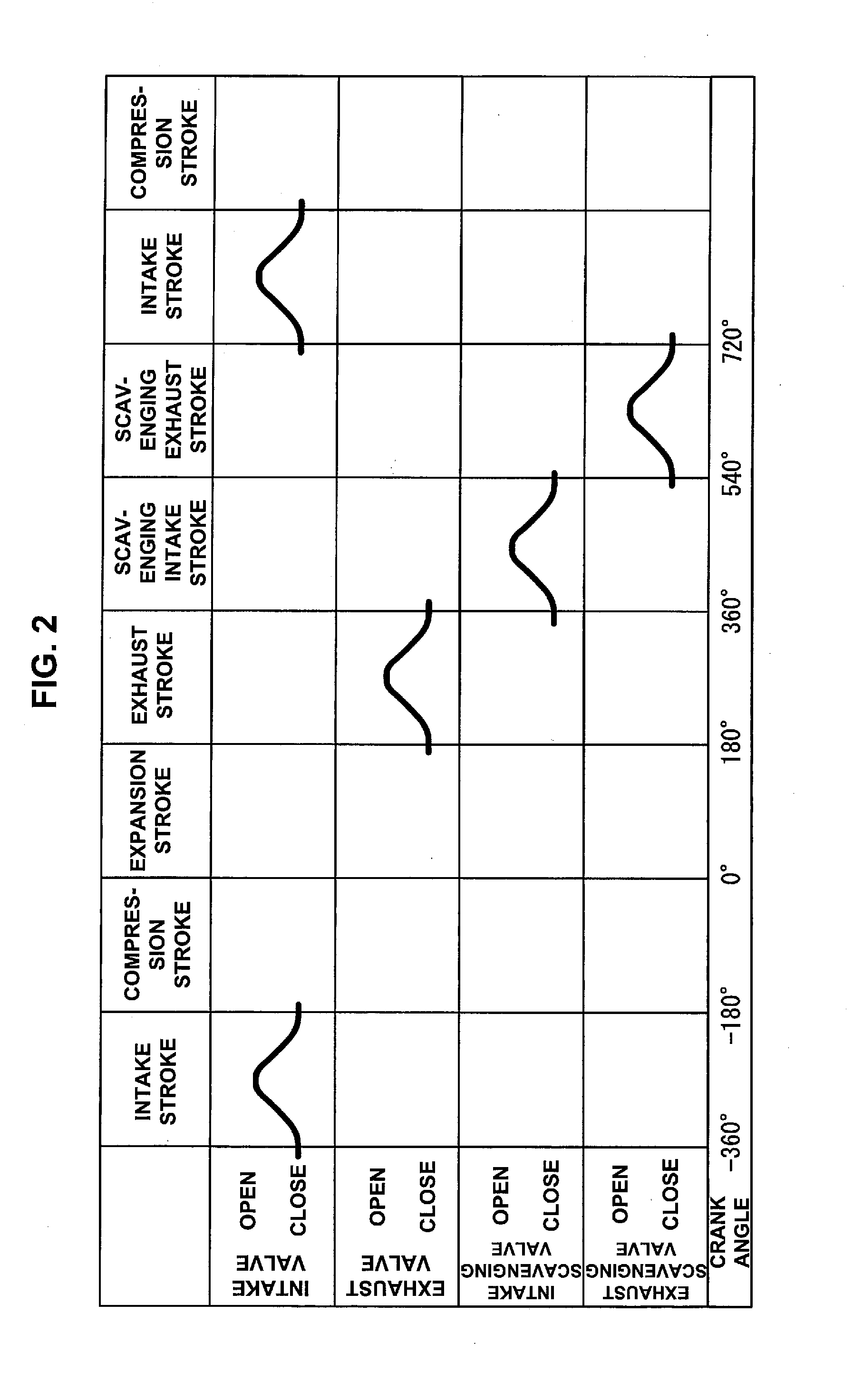

InactiveUS9284892B2Reduce pumping lossAvoid dischargeValve arrangementsElectrical controlCombustion chamberRisk stroke

A six-stroke cycle engine includes an intake passage including a downstream end connected to a combustion chamber and no throttle valve therein, and an exhaust passage including a catalyst and an upstream end connected to the combustion chamber. The six-stroke cycle engine includes a first valve configured to open and close the intake passage, a second valve configured to open and close the exhaust passage, a valve gear configured to operate the first valve and the second valve so that an intake stroke, a compression stroke, an expansion stroke, and an exhaust stroke are executed, in this order, and to operate only the first valve so that a scavenging intake stroke and a scavenging exhaust stroke are executed, in this order, following the exhaust stroke. The valve gear includes a variable valve mechanism configured to continuously change an opening and closing timing and a lift amount of the first valve.

Owner:YAMAHA MOTOR CO LTD

Double-turbine coaxially-connected device

InactiveCN102926859AReduce pumping lossImprove machine performanceInternal combustion piston enginesLow speedCombustion

The invention relates to a double-turbine coaxially-connected device which belongs to the technical field of internal-combustion engines. The double-turbine coaxially-connected device comprises air compressors, an air inlet pipe, an engine, an air exhaust pipe, turbines, a volume cavity, a connecting pipe, a movable body, a spring and through tubes, wherein the movable body is arranged in the volume cavity and is hermetically contact with the inner wall surface of the volume cavity; the first through tube and the second through tube both penetrate through the upper wall surface and the lower wall surface of the movable body; and the right wall surface of the movable body is connected with the right wall surface of the volume cavity through the spring. When the engine is under a high-speed working condition, the movable body moves towards right, the first air compressor, the second air compressor, the first turbine and the second turbine work simultaneously, and the engine is lower in pumping loss, so that the engine is better in overall machine performance; when the engine is under a low-speed working condition, the movable body moves towards left, only the first air compressor and the first turbine work, pulse energy is sufficiently utilized, and the engine is higher in inlet pressure, so that the engine is better in overall machine performance. The double-turbine coaxially-connected device is reasonable in design, simple in structure and suitable for a turbocharging system with double turbines and double air compressors.

Owner:SHANGHAI JIAO TONG UNIV

Pneumatic elastic pressure regulating device

InactiveCN104806348ALarge amount of deflationIncrease air intakeInternal combustion piston enginesCombustionExternal combustion engine

The invention provides a pneumatic elastic pressure regulating device, and belongs to the technical field of internal combustion engines. The device comprises an air discharging tube, a rotating shaft, a rotating plate, a regulating rod, a control cavity, a spring, moving bodies and a control tube; one end of the first control tube passes through the upper wall surface of the control cavity to be communicated with a cavity between the first moving body and the second moving body; the other end of the first control tube is communicated with an exhaust tube between an engine and a turbine; one end of the second control tube passes through the right wall surface of the control cavity to be communicated with an inner cavity; the other end of the second control tube is communicated with the exhaust tube between the turbine and a muffler. According to the device, the air discharging quantity of the turbine is large while the engine has a large load; the air discharging quantity of the turbine is small while the engine has a small load. The device is reasonable in design, simple in structure, and suitable for design of an engine turbine boosting system.

Owner:SHANGHAI 01 POWER TECH

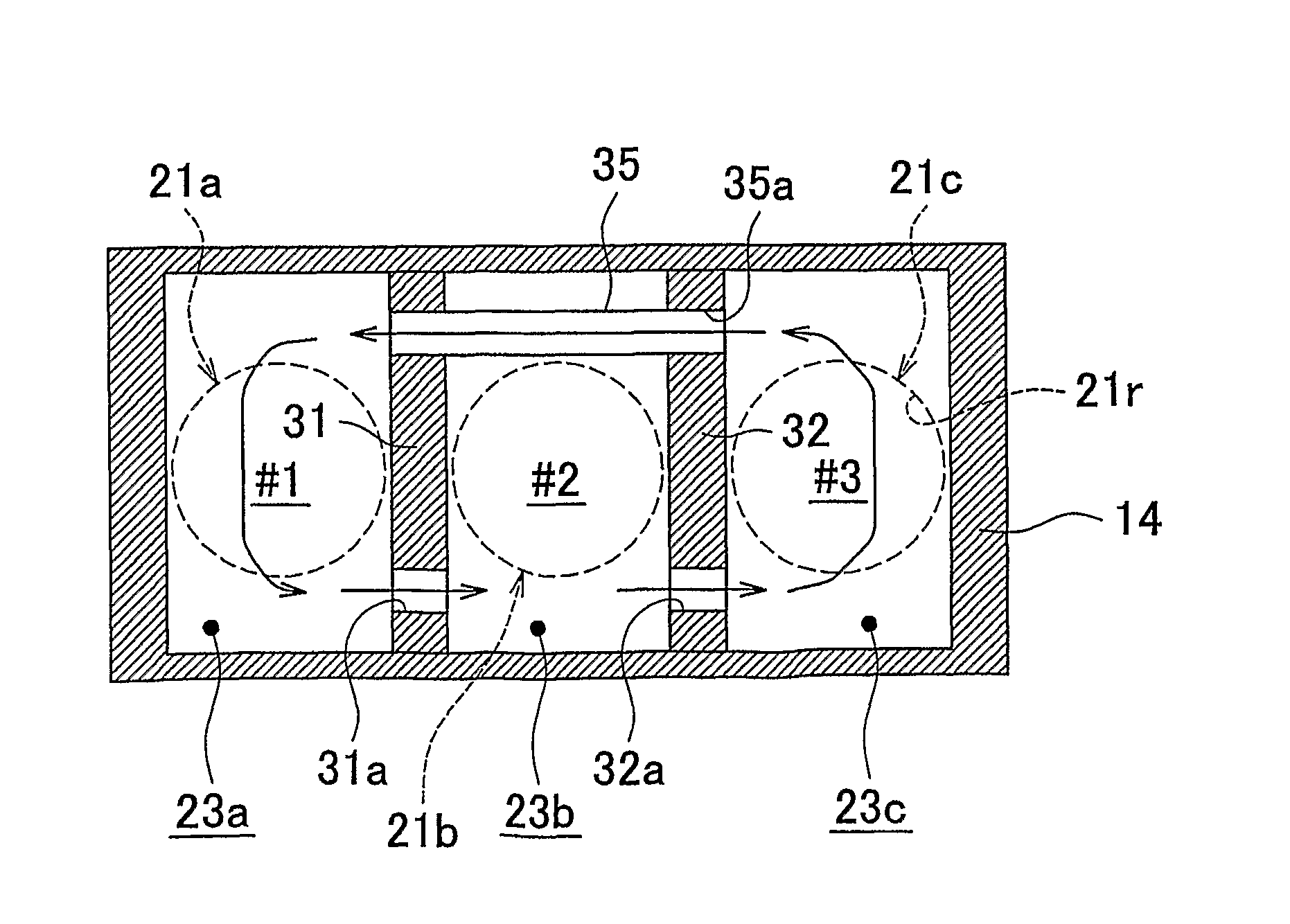

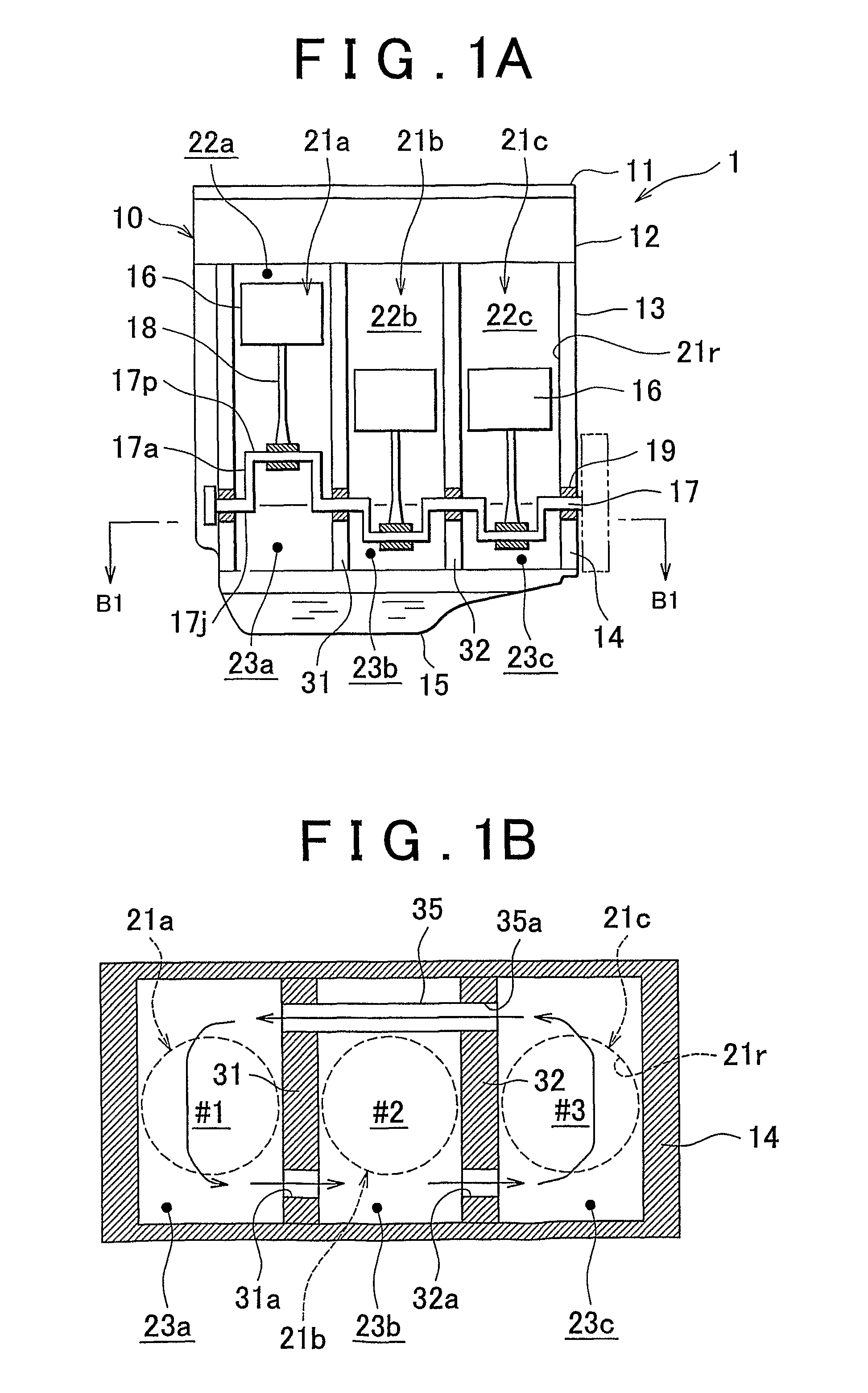

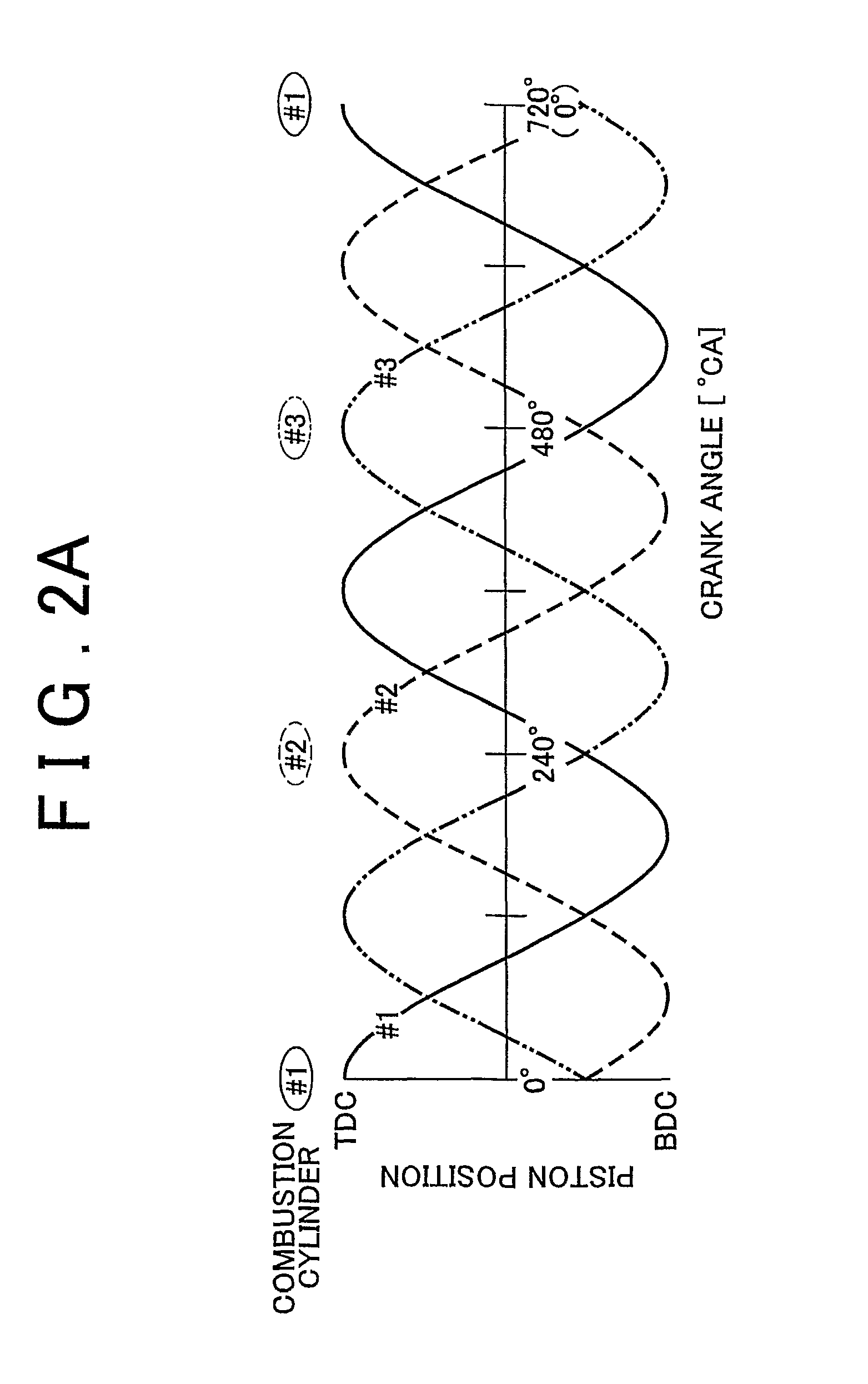

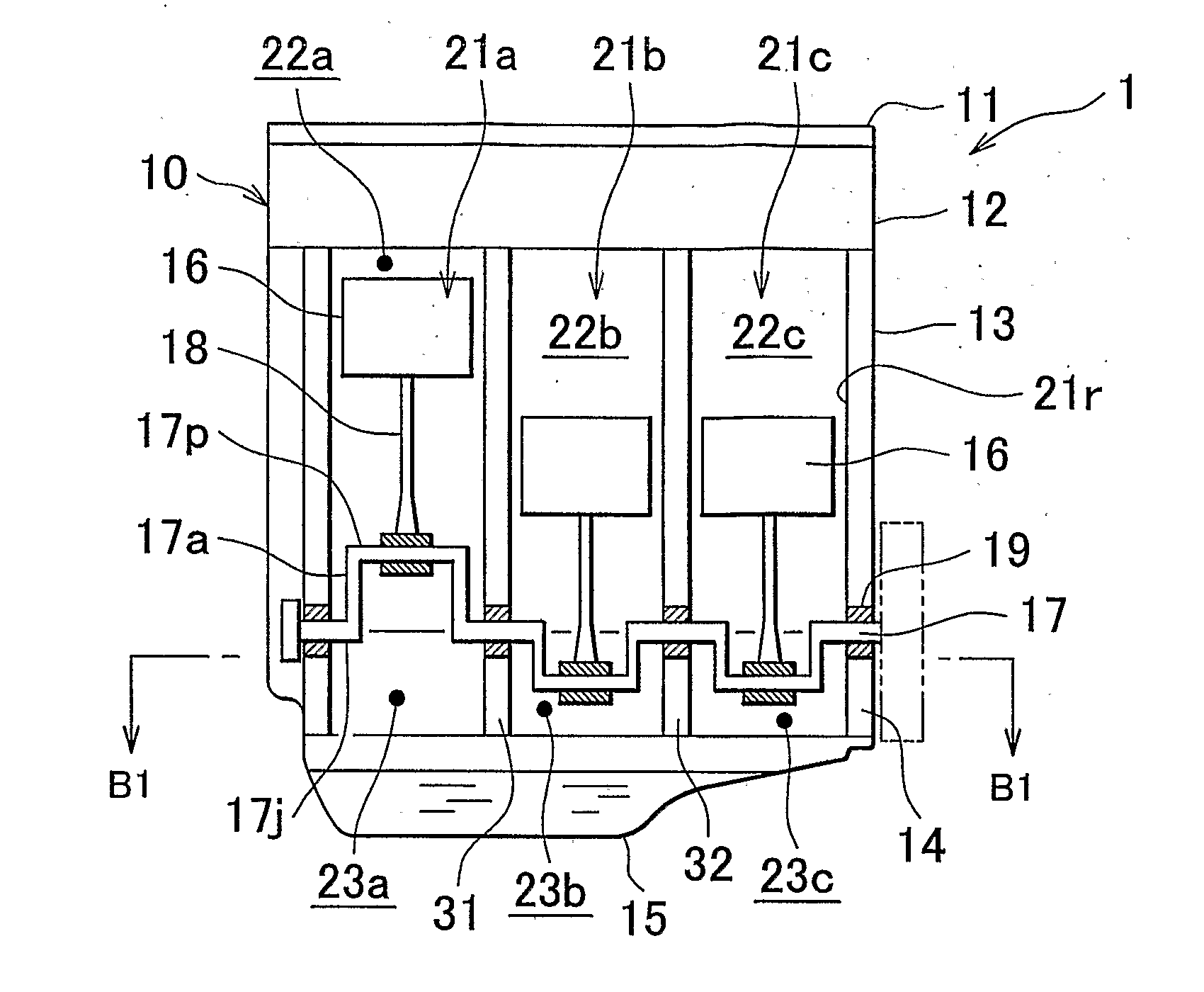

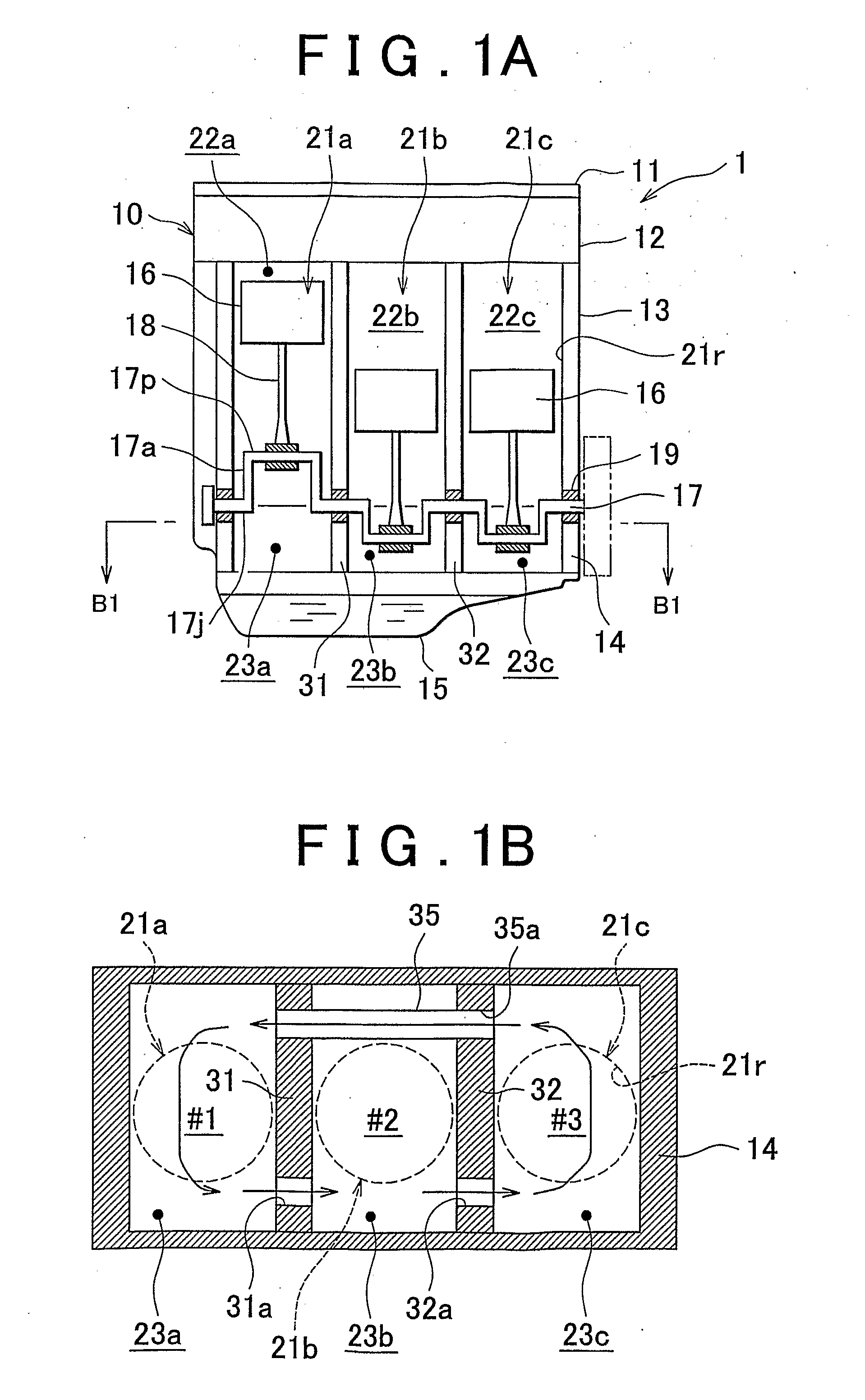

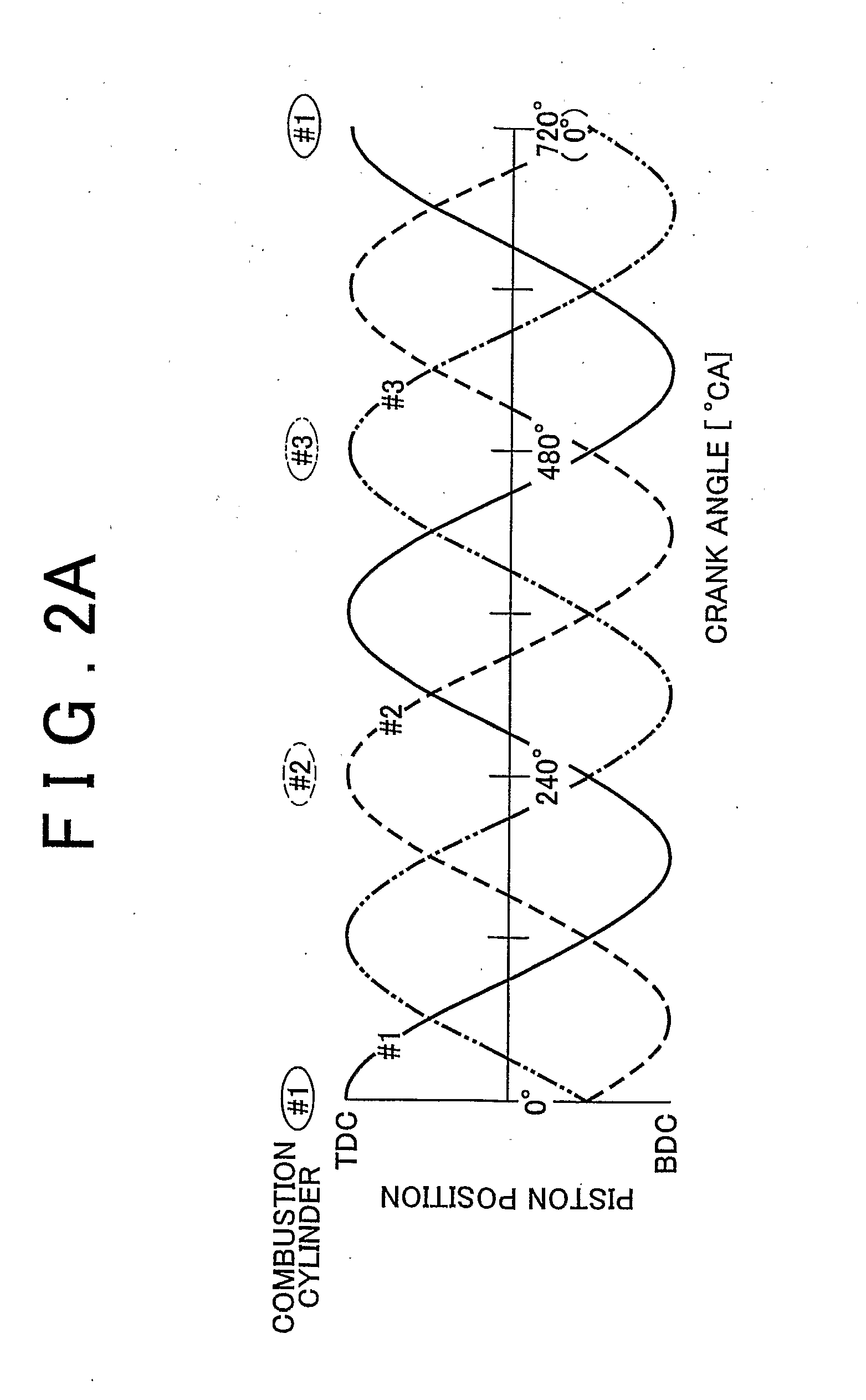

Crank chamber communication structure of multi-cylinder internal combustion engine

A crank chamber communication structure for a multi-cylinder internal combustion engine having a plurality of partition walls that are formed by a cylinder block and a crankcase, that are formed to support a crankshaft and to define a plurality of crank chambers that correspond to the plurality of cylinders, the structure including: a plurality of respective first communicating holes formed in the plurality of partition walls for communication between respective pairs of adjoining crank chambers separated by an interposed partition wall; and a second communicating hole that is formed at least either of the cylinder block or the crankcase, and that is interposed between a pair of non-adjoining crank chambers between which at least two partition walls among the plurality of partition walls are interposed for direct communication between the pair of non-adjoining crank chambers.

Owner:TOYOTA JIDOSHA KK

Six-stroke cycle engine having scavenging stroke

InactiveUS20140366819A1Reduce pumping lossAvoid dischargeInternal combustion piston enginesCombustion-air/fuel-air treatmentExhaust valveInlet valve

A six-stroke cycle engine includes an intake passage including a throttle valve, and an exhaust passage including a catalyst. The six-stroke cycle engine includes a scavenging passage including a first end defined by a scavenging port and a second other end connected to the intake passage upstream of the throttle valve. The six-stroke cycle engine includes an intake valve, an exhaust valve, a scavenging valve, and a valve gear configured to operate these valves. The valve gear closes the scavenging valve and operates the intake valve and the exhaust valve so as to execute an intake stroke, a compression stroke, an expansion stroke, and an exhaust stroke, in this order. The valve gear also operates only the scavenging valve so as to execute a scavenging intake stroke and a scavenging exhaust stroke, in this order, following the exhaust stroke.

Owner:YAMAHA MOTOR CO LTD

Peripheral gas path system of marine engine

InactiveCN102966428AReasonable designSimple structureInternal combustion piston enginesIntake pressurePulse energy

The invention relates to a peripheral gas path system of a marine engine. The peripheral gas path system of the marine engine comprises gas compressors, a gas inlet pipe, an engine, a gas exhaust pipe, turbines, a volume chamber, connecting pipes, a movable body, a spring and a through pipe, wherein the movable body is installed in the volume chamber and is in hermetical contact with the inner wall surface of the volume chamber, the through pipe penetrates through the upper wall surface and the lower wall surface of the movable body, and the right wall surface of the movable body is connected with the right wall surface of the volume chamber through the spring. When the engine is under a high-speed working condition, the movable body moves leftwards, a first gas compressor, a second gas compressor, a first turbine and a second turbine work at the same time, the pumping loss of the engine is smaller and the performance of the entire engine is better; and when the engine is under a low-speed working condition, the movable body moves rightwards, only the first gas compressor and the first turbine work, the pulse energy is fully utilized, the gas inlet pressure of the engine is higher and the performance of the entire engine is better. The peripheral gas path system of the marine engine has the advantages of reasonable design and simple structure, and is suitable for a turbine supercharging system with double turbines and double gas compressors.

Owner:SHANGHAI JIAO TONG UNIV

Crank chamber communication structure of multi-cylinder internal combustion engine

A crank chamber communication structure for a multi-cylinder internal combustion engine having a plurality of partition walls that are formed by a cylinder block and a crankcase, that are formed to support a crankshaft and to define a plurality of crank chambers that correspond to the plurality of cylinders, the structure including: a plurality of respective first communicating holes formed in the plurality of partition walls for communication between respective pairs of adjoining crank chambers separated by an interposed partition wall; and a second communicating hole that is formed at least either of the cylinder block or the crankcase, and that is interposed between a pair of non-adjoining crank chambers between which at least two partition walls among the plurality of partition walls are interposed for direct communication between the pair of non-adjoining crank chambers.

Owner:TOYOTA JIDOSHA KK

Split Stirling Expansion Machine

PendingCN110736263AReduce pumping lossReduce lossesMechanical apparatusEvaporators/condensersEngineeringMechanical engineering

The invention discloses a split Stirling expansion machine. The split Stirling expansion machine comprises a shell unit and a motion unit, the shell unit comprises a bottom shell, a middle shell, a slit heat exchanger, an expansion cylinder, an inner liner and a cold head which are connected in sequence, one end of the slit heat exchanger is connected with one end of the expansion cylinder, the inner liner is arranged in the middle shell, the side surface and the end surface of the inner liner are connected with the middle shell and a small disc respectively, the motion unit comprises an expansion machine plate spring, an evacuator rod and a regenerator shell, the expansion machine plate spring is fixedly connected with the inner liner, one end of the regenerator shell is arranged in the inner liner, the other end of the regenerator shell is arranged in the cylindrical air cylinder, and the evacuator rod is arranged in the inner liner. According to the expansion machine, a traditionalwater cooling sleeve structure is eliminated, a hot end slit type heat exchanger is adopted for replacing, gas working medium releases enough heat to the environment through the hot end heat exchanger, and the requirements of the expansion machine on the gas working medium heat dissipation amount under different working conditions can be correspondingly met by changing the number, the width and the like of the slits of the hot end heat exchanger.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

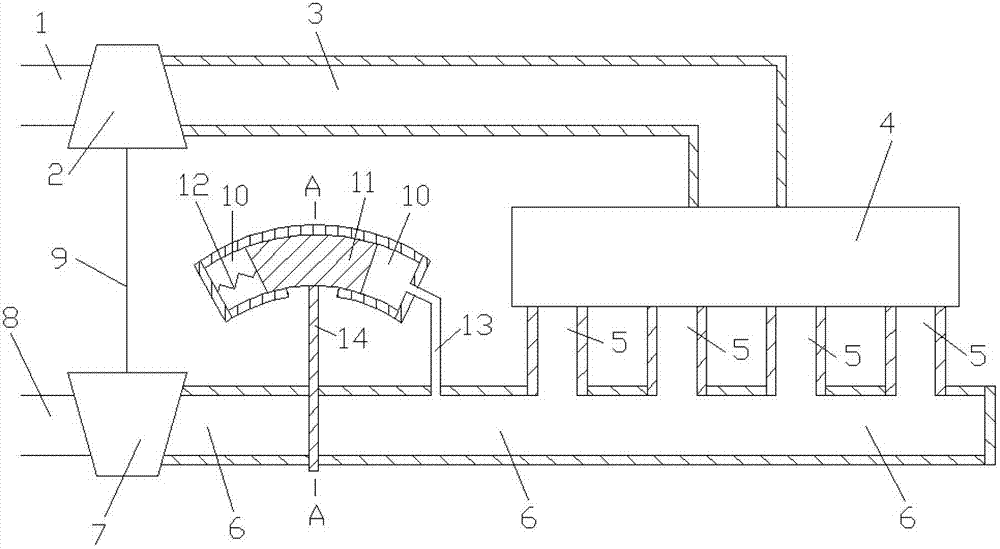

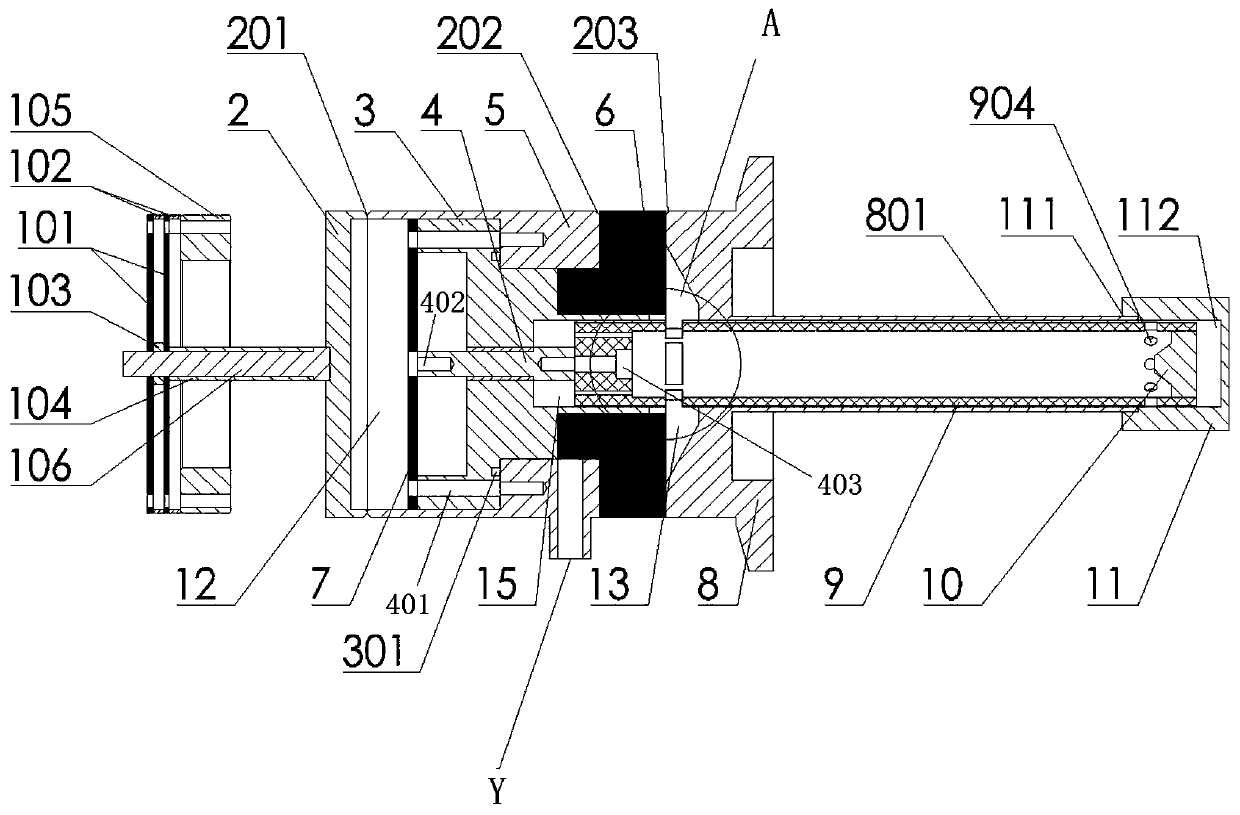

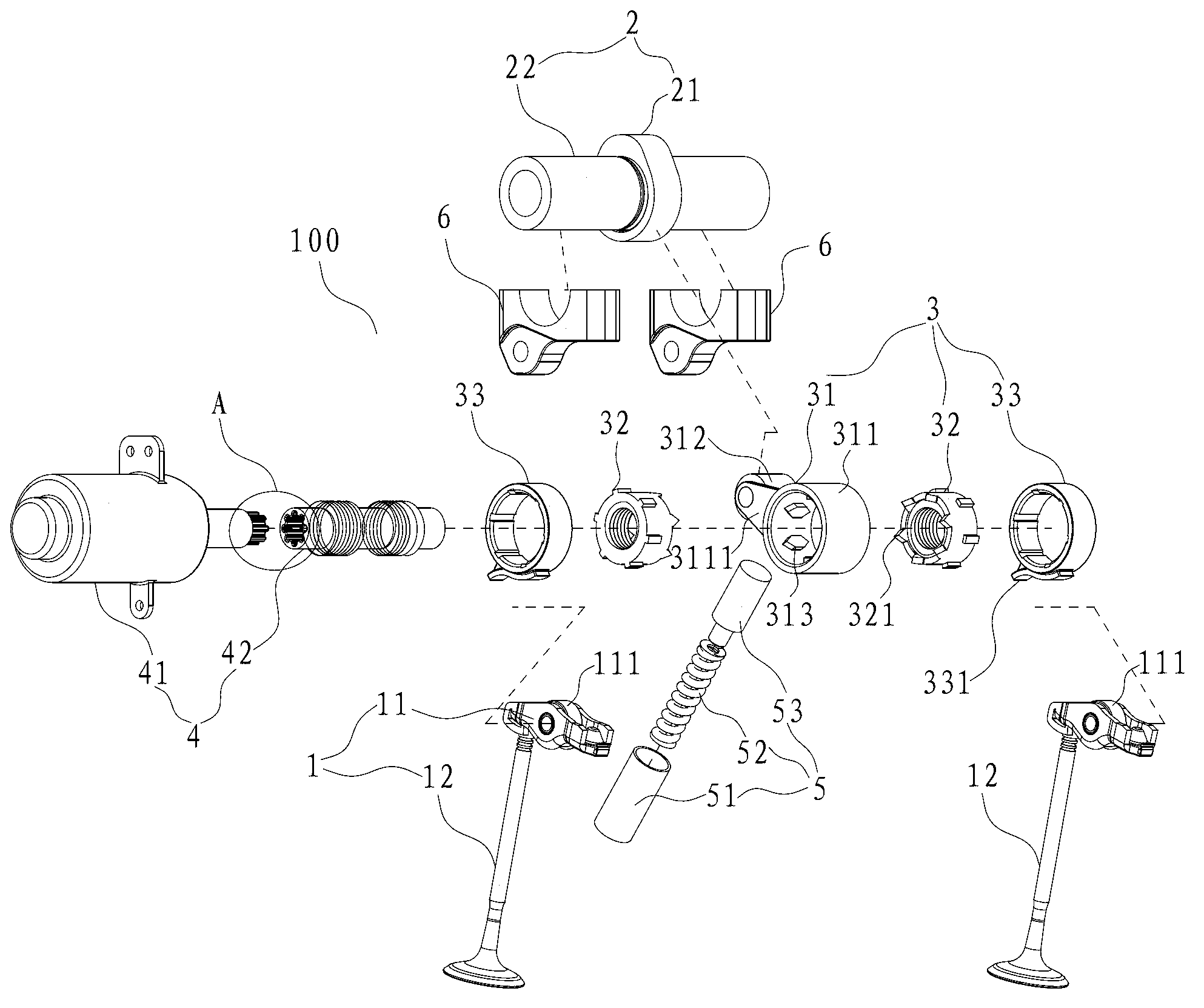

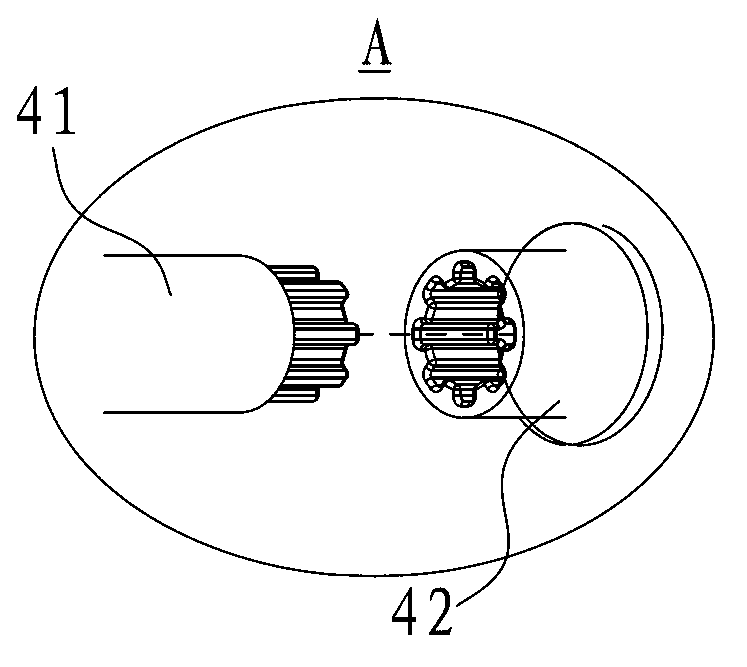

Air valve lifting device for engine, engine comprising same, and automobile comprising same

ActiveCN103216291ASolve the requirements of gas distributionImprove work efficiencyValve arrangementsMachines/enginesLow speedEngineering

The invention discloses an air valve lifting device for an engine, the engine comprising the same, and an automobile comprising the same. The air valve lifting device comprises an air valve mechanism, a cam shaft mechanism, a swing arm mechanism and an actuating mechanism, wherein the top of the air valve mechanism is provided with a roller arm, the cam shaft mechanism is arranged above the air valve mechanism, the cam shaft mechanism comprises a cam, the swing arm mechanism is arranged between the roller arm and the cam shaft mechanism and is driven by the cam to swing around the swing arm rotary axis of the swing arm mechanism, the actuating mechanism is used for driving the swing arm mechanism to rotate around the regulating rotary axis of the actuating mechanism to continuously and changeably regulate the lift of the air valve mechanism, and the swing arm rotary axis is coincident with the regulating rotary axis. According to the air valve lifting device, different air valve lifts can be achieved according to requirements of different working conditions of the engine, and pump gas loss and mechanical loss in the low-speed load working condition are reduced. Meanwhile, continuation and changeability of the air valve lifts are achieved, and work efficiency of the engine is improved.

Owner:GREAT WALL MOTOR CO LTD

Controllable turbine air discharging system

InactiveCN104806347ALarge amount of deflationIncrease air intakeInternal combustion piston enginesCombustionDischarge rate

The invention provides a controllable turbine air discharging system, and belongs to the technical field of internal combustion engines. The system comprises an air discharging tube, a rotating shaft, a rotating plate, an adjusting rod, a control cavity, a spring, a moving body, a first control tube and a second control tube; one end of the first control tube passes through the right wall surface of the control cavity to be communicated with an inner cavity; the other end of the first control tube is communicated with an air exhaust tube between an engine and a turbine; one end of the second control tube passes through the left wall surface of the control cavity to be communicated with the inner cavity, while the other end of the second control tube is communicated with the air exhaust tube between the turbine and a muffler. According to the system, the air discharging rate of the turbine is large while the engine has a large load; the air discharging rate of the turbine is small while the engine has a small load. The system is reasonable in design, simple in structure, and suitable for design of a diesel engine turbine boosting system.

Owner:SHANGHAI 01 POWER TECH

Switching system between single turbine and double turbines

InactiveCN103089398AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesAxial compressorPulse energy

A switching system between a single turbine and double turbines relates to the technical field of mechanical design and comprises air compressors, an air inlet pipe, an engine, an air exhaust pipe, turbines, a volume cavity, a connection pipe, a movable body, a spring and a communication pipe. The movable body is installed in the volume cavity and is in sealing contact with the inner wall of the volume cavity, and the left wall of the movable body is connected with the left wall of the volume cavity through the spring. When pressure in the air inlet pipe of the engine is high, the moveable body can move towards right, a first air compressor, a second air compressor, a first turbine and a second turbine can work simultaneously, pumping loss of the engine is small, and whole performance of the engine is excellent. When pressure in the air inlet pipe of the engine is low, the moveable body moves towards left, only the first air compressor and the first turbine work, pulse energy is fully utilized, air inlet pressure of the engine is high, and whole performance of the engine is excellent. The switching system is reasonable in design, simple in structure and suitable for turbine boost systems with double turbines and double air compressors.

Owner:SHANGHAI JIAO TONG UNIV

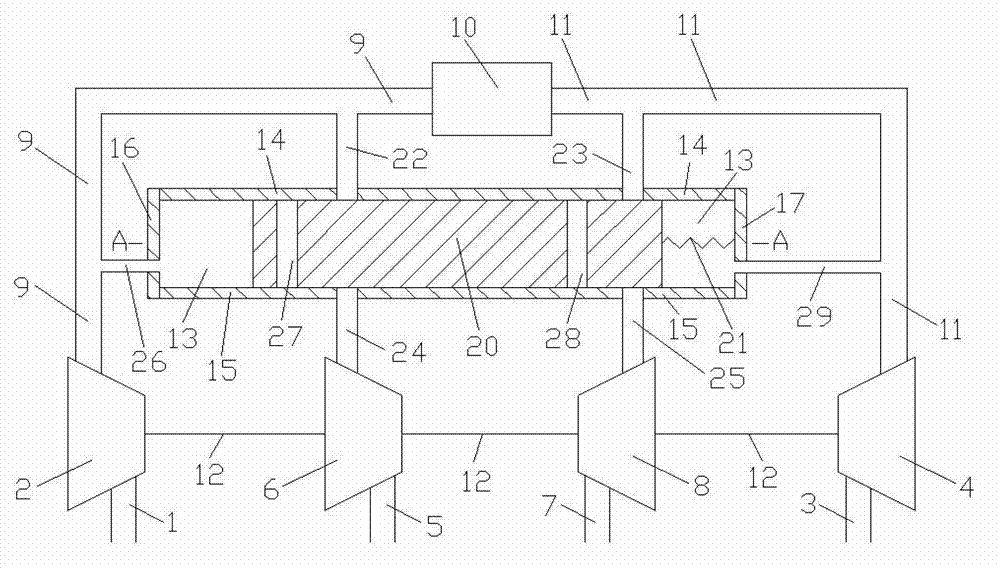

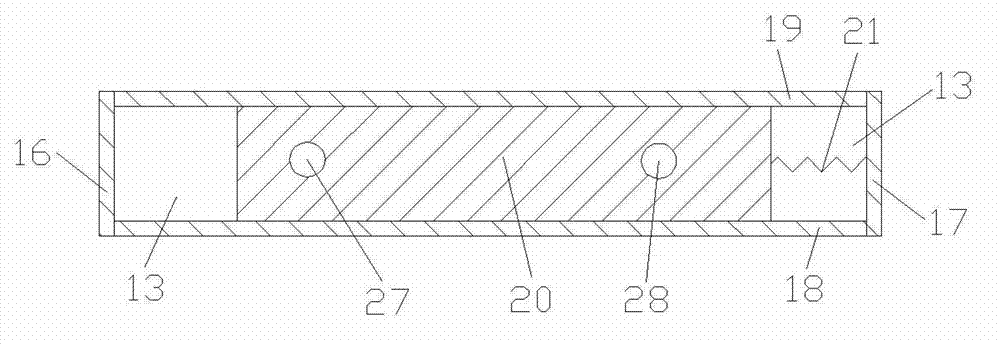

Horizontal moving mechanical regulation system

InactiveCN102913320AConsidering both high and low speed conditionsReasonable designInternal combustion piston enginesLow speedCombustion

A horizontal moving mechanical regulation system in the technical field of combustion engines comprises compressors, a gas inlet pipe, an engine, an exhaust pipe, turbines, a volume cavity, a connection pipe, a moving body, a spring and a through pipe; the moving body is mounted in the volume cavity and is in sealed contact with the inner wall surface of the volume cavity, the through pipe penetrates through the upper and lower wall surfaces of the moving body, and the left wall surface of the moving body is connected with the left wall surface of the volume cavity through the spring. When the engine in a high speed work condition, the moving body moves towards the right, the first compressor, the second compressor, the first turbine and the second turbine works at the same time, so that the pumping loss of the engine is less and the performance of the whole engine is better; when the engine is in a low speed work condition, the moving body moves towards the left, only the first compressor and the first turbine work, so that the pulse energy is fully used, the gas inlet pressure of the engine is higher, and the performance of the whole engine is better. The horizontal moving mechanical regulation system is reasonable in design and simple in structure, and is applicable to a turbine pressurization system with dual turbines and double compressors.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com