Split Stirling Expansion Machine

An expander, separate technology, used in refrigerators, compressors, mechanical equipment, etc., can solve the problem of cooling efficiency decline, and achieve the effect of reducing dead volume, convenient processing and manufacturing, and reducing weight and volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

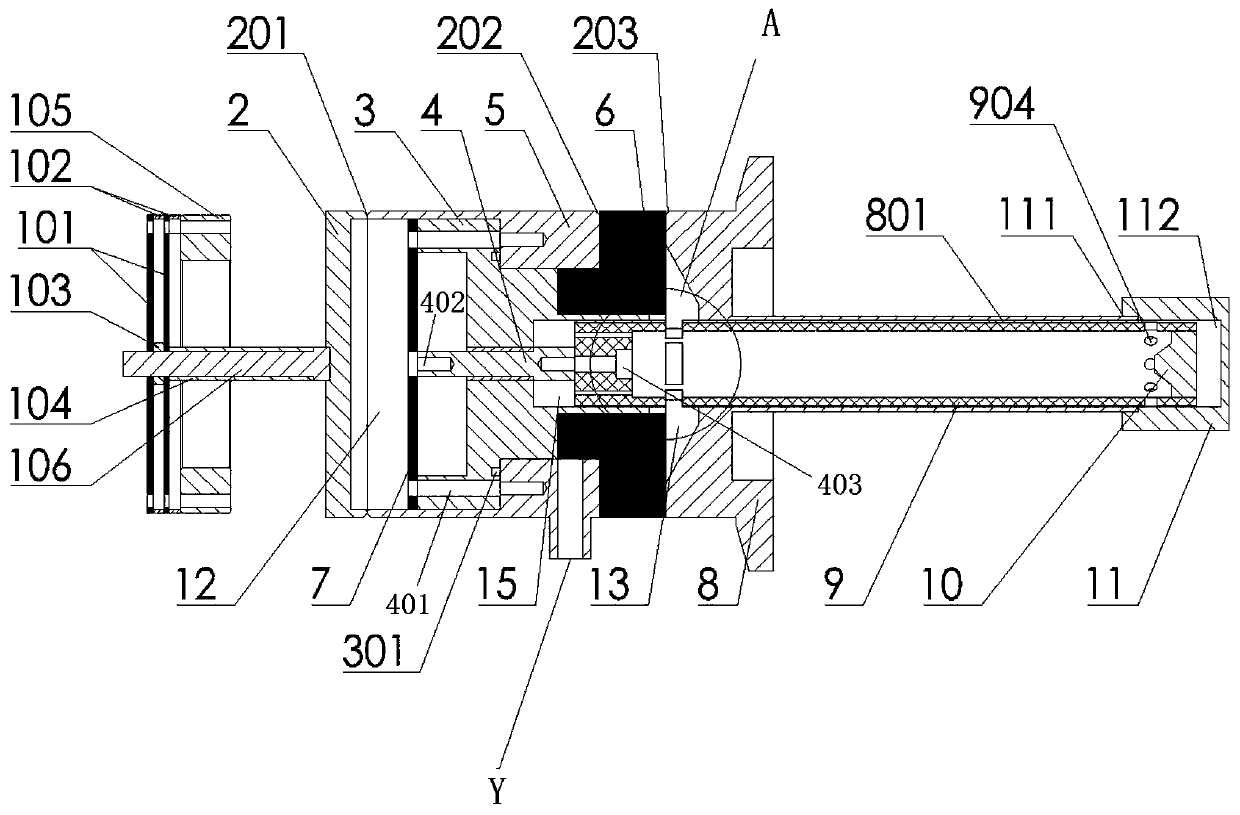

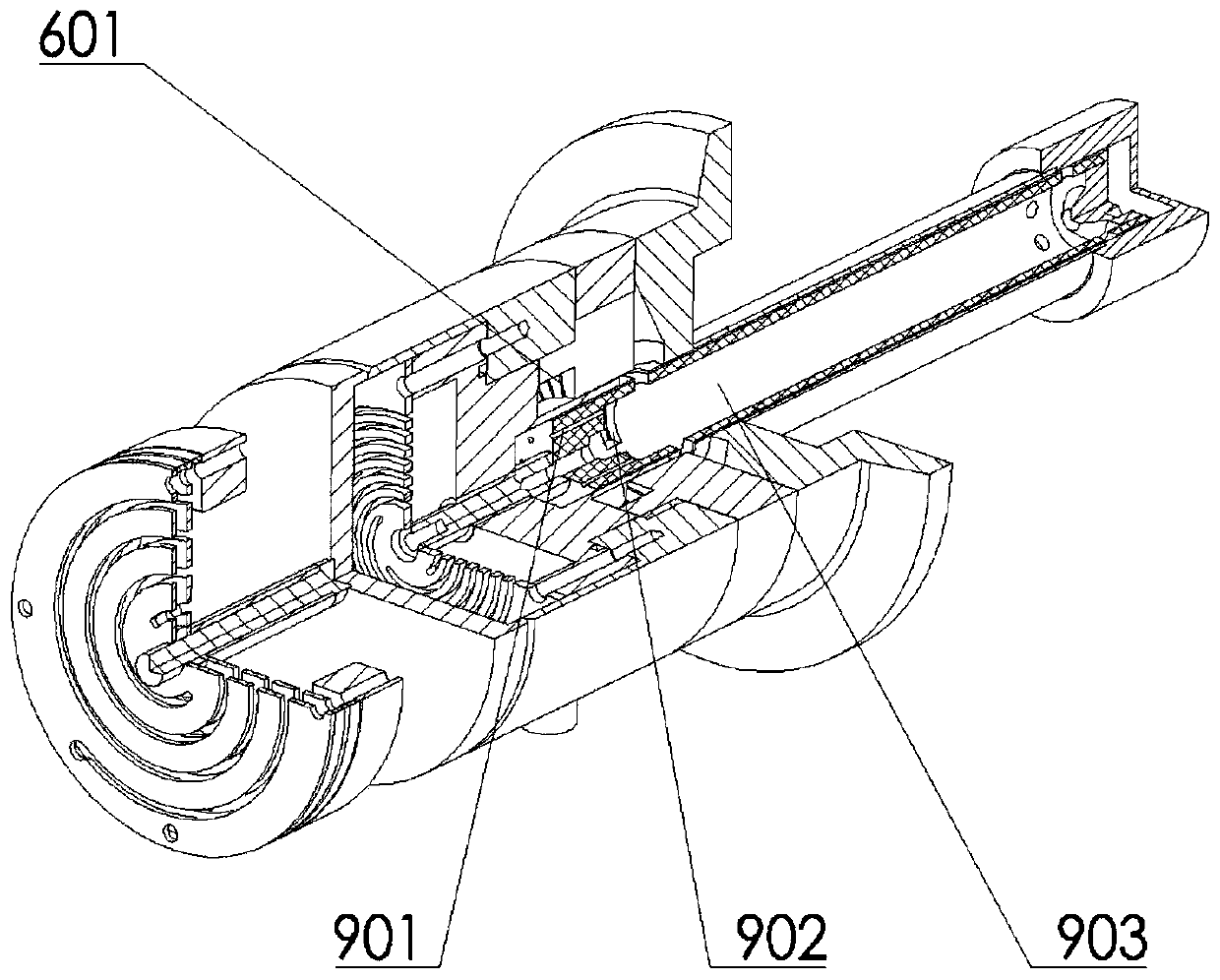

[0034] The split Stirling expander includes a shell unit, a motion unit and a shock absorber unit.

[0035] Such as figure 1 and figure 2 as shown,

[0036] The shell unit includes a bottom shell 2 , a middle shell 5 , a slit heat exchanger 6 , an expansion cylinder 8 , an inner liner 3 and a cold head 11 which are connected in sequence.

[0037] In the embodiment, the bottom shell 2 is disc-shaped.

[0038] The middle shell 5 is cylindrical, with openings at both ends, and has two connected coaxial cylindrical cavities inside, and the two cavities have different diameters. The end with a larger diameter of the cavity is connected to the bottom shell 2 , and the bottom shell 2 and the middle shell 5 are welded at the welding port 201 .

[0039] Such as Figure 5 , 6 As shown, the slit heat exchanger 6 is a hot-end heat exchanger, which is sandwiched between the middle shell 5 and the expansion cylinder 8. The slit heat exchanger 6 is in the shape of a flange and has a c...

Embodiment 2

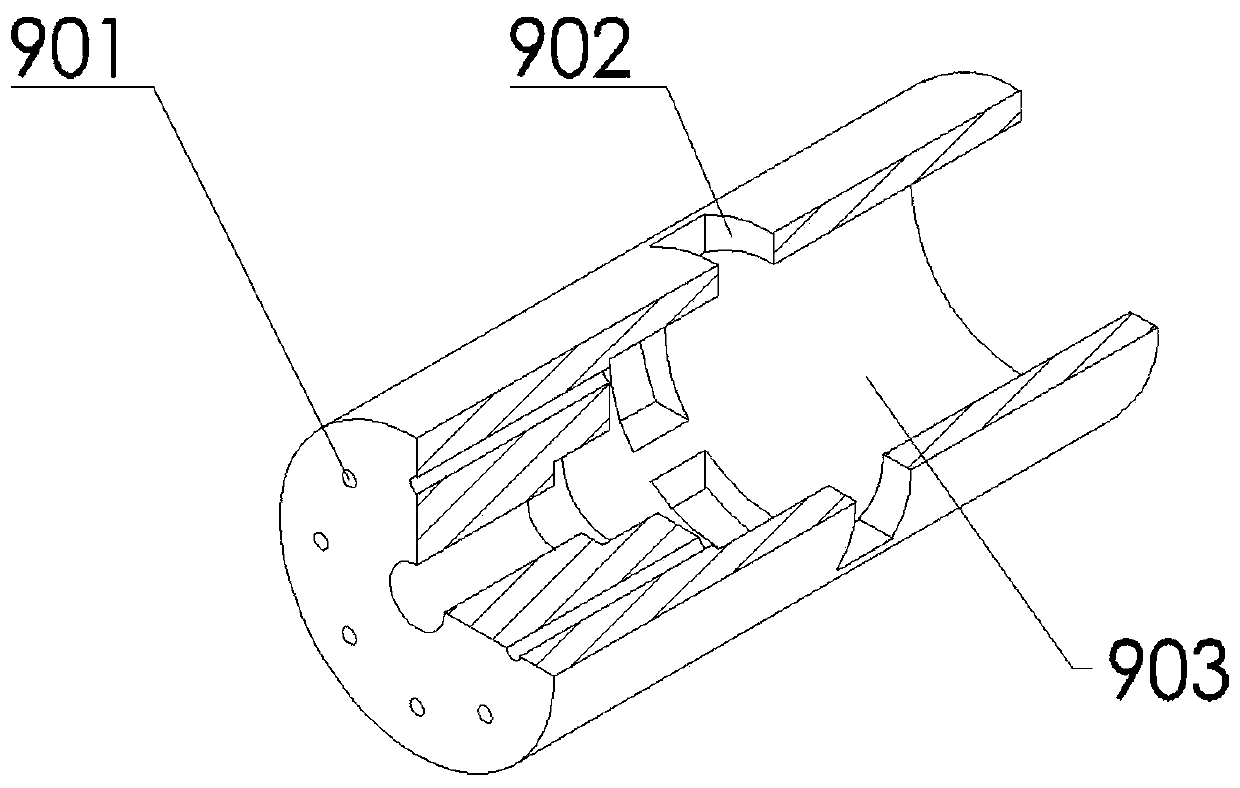

[0065] The structure of this embodiment is the same as that of the first embodiment, except that the structure of the regenerator shell 14 in this embodiment is different from that of the regenerator shell 9 in the first embodiment.

[0066] Such as Figure 10 As shown, in this embodiment, there is no vent hole on the bottom end surface of the regenerator shell 14, and there is a gap between the cylindrical surface of the regenerator shell 14 and the inner wall surface of the inner bushing 3, and the unilateral gap is 0.3-0.5 mm. The shell main chamber 13 and the shell sub-chamber 15 are connected through a gap. During the operation of the expander, the pressures in the shell main chamber 13 and the shell sub-chamber 15 always maintain a dynamic balance, which is beneficial to reduce the pressure on the regenerator shell 9. Radial vibration ensures the stability of the operating conditions of the expander.

[0067] Function and effect of embodiment

[0068] According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com