Patents

Literature

1280 results about "Pulse energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

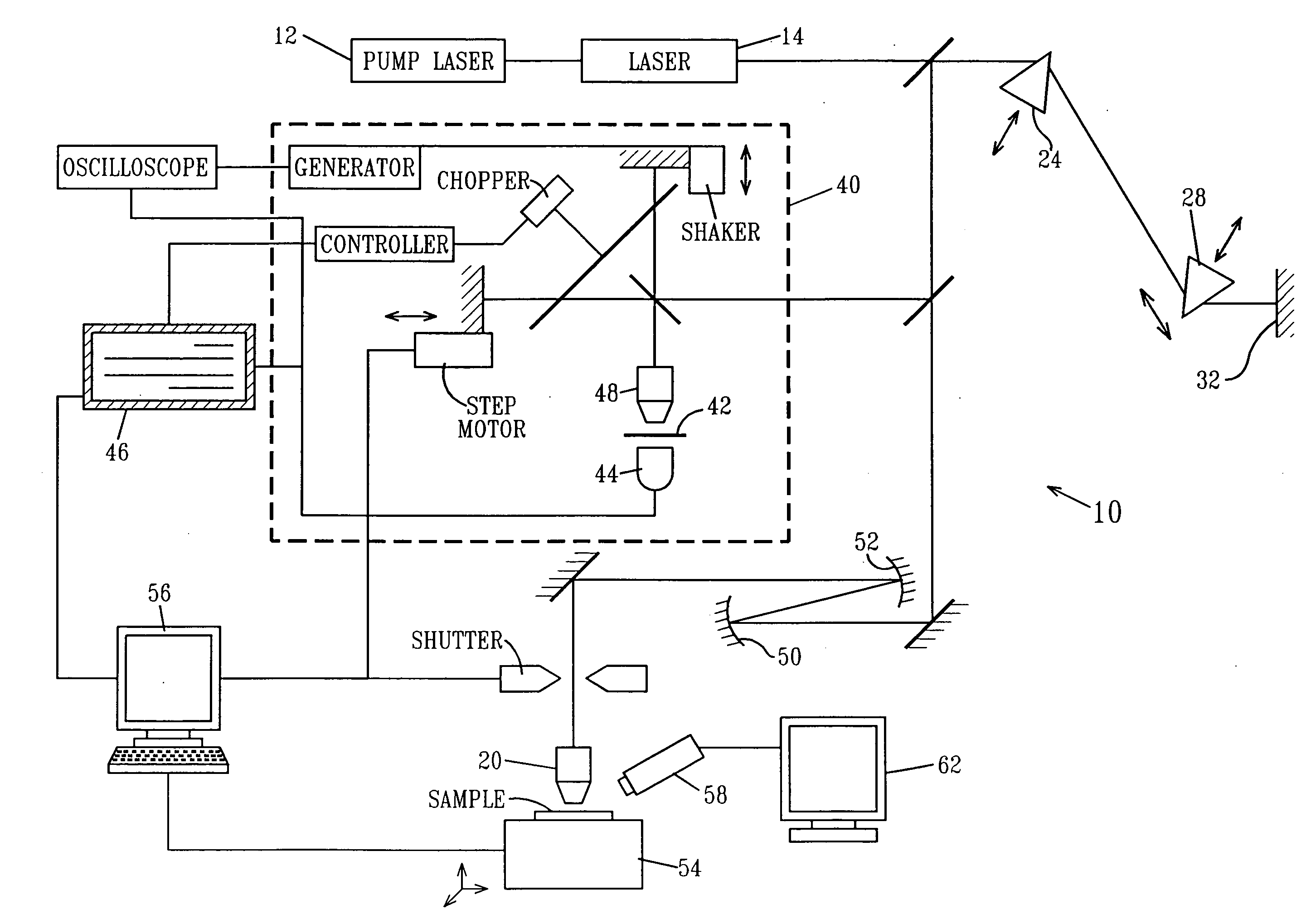

Acoustic-optical therapeutical devices and methods

InactiveUS20050137656A1Effective and specific body therapyUltrasound therapyElectrotherapyMicrometerMedicine

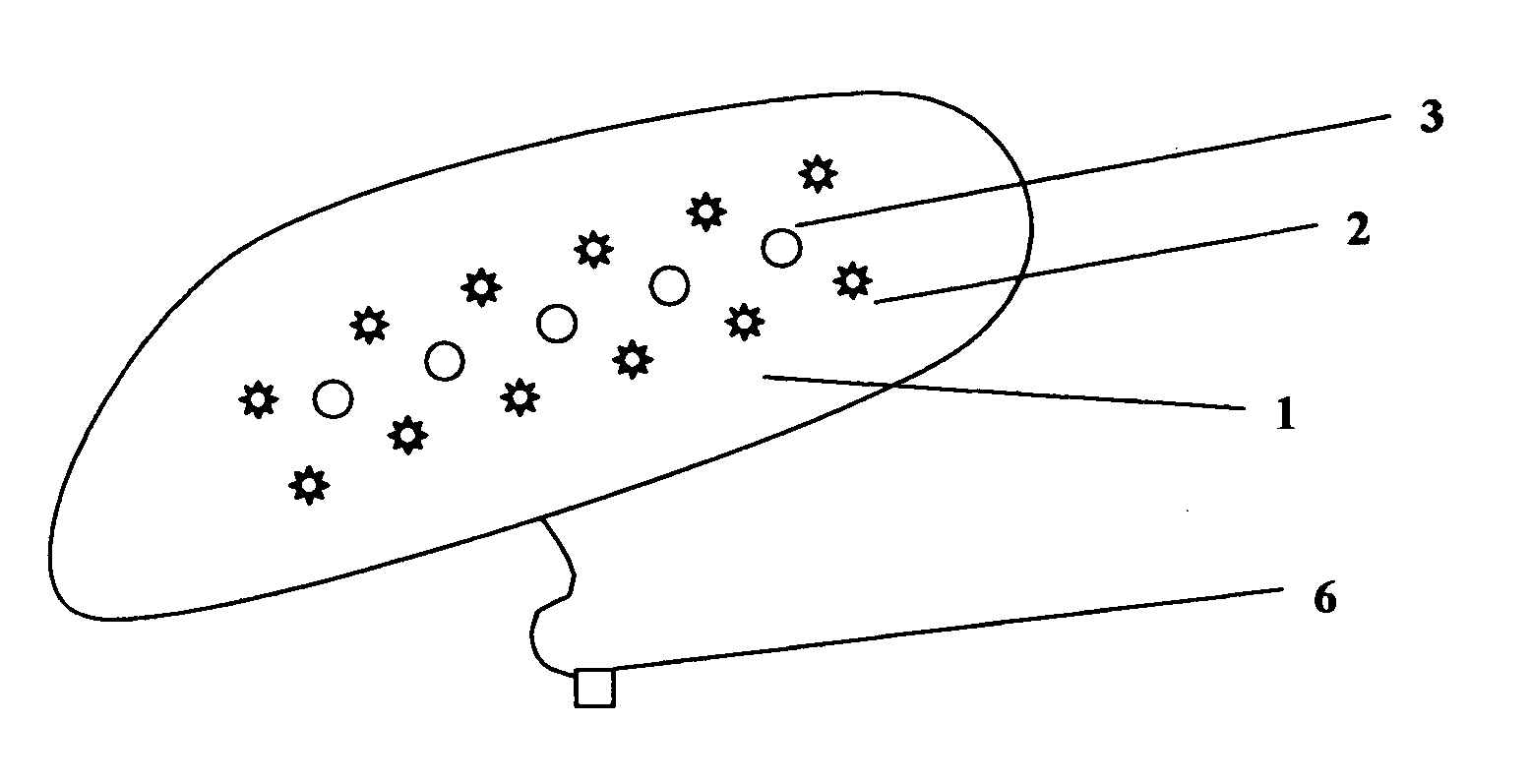

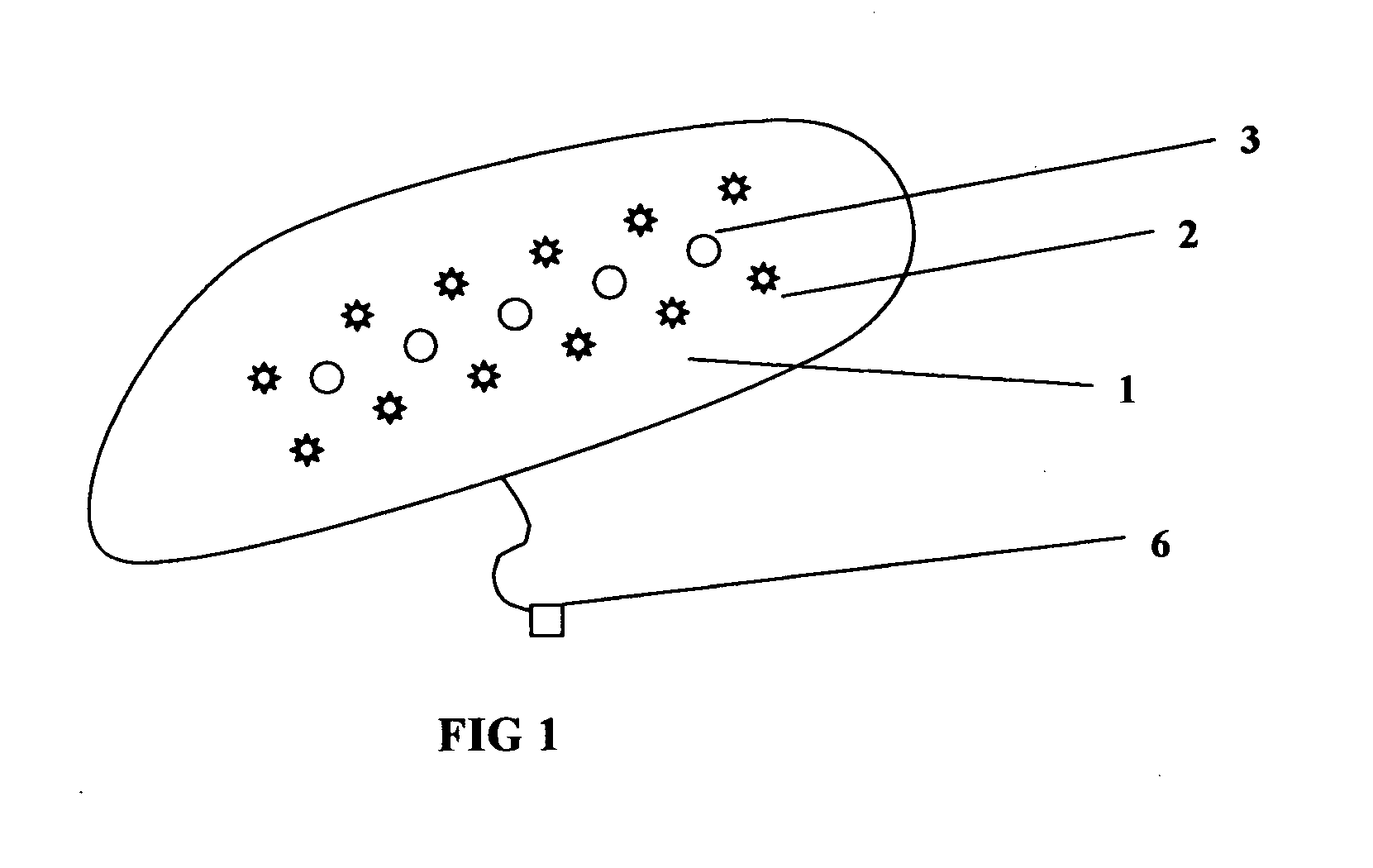

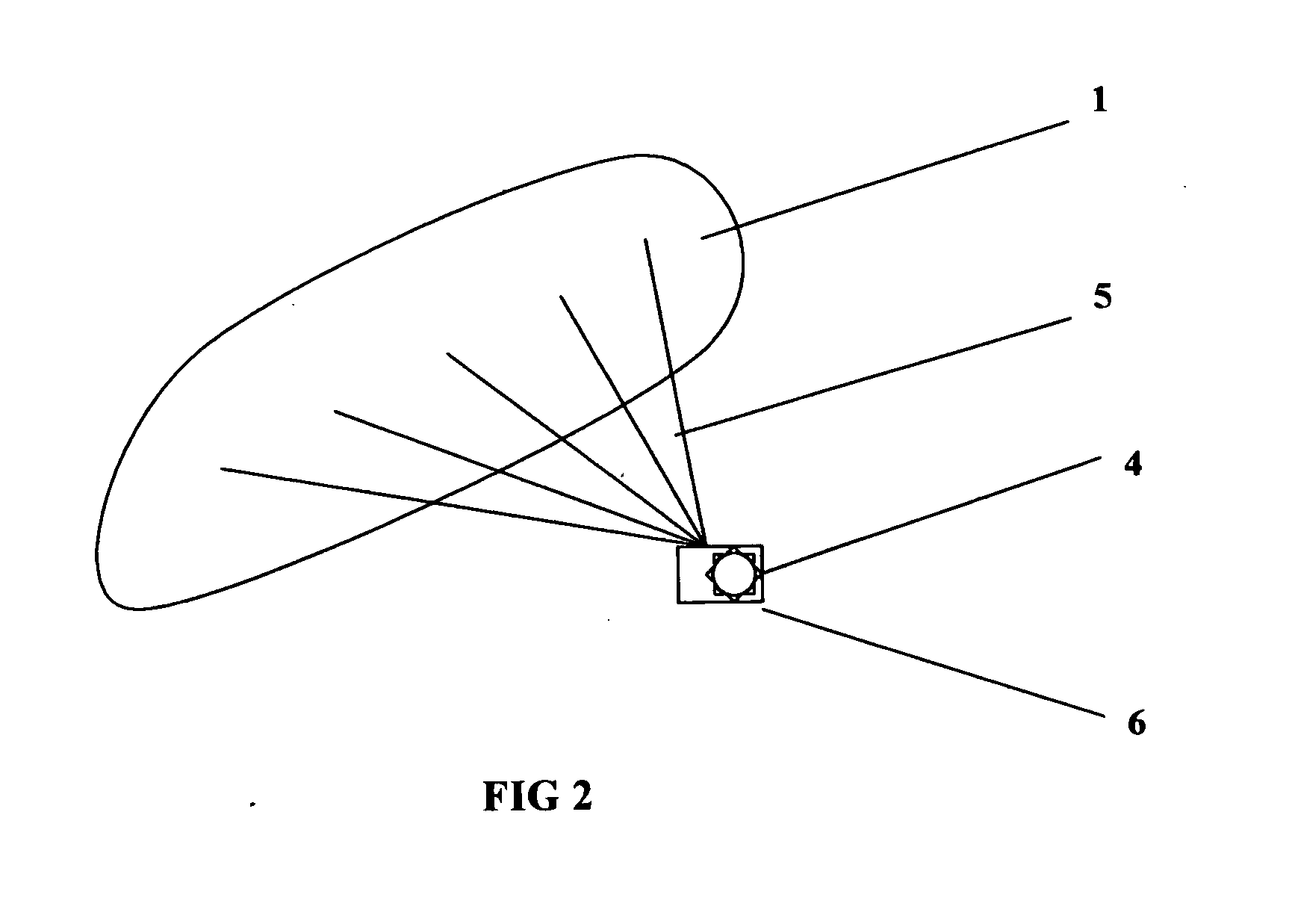

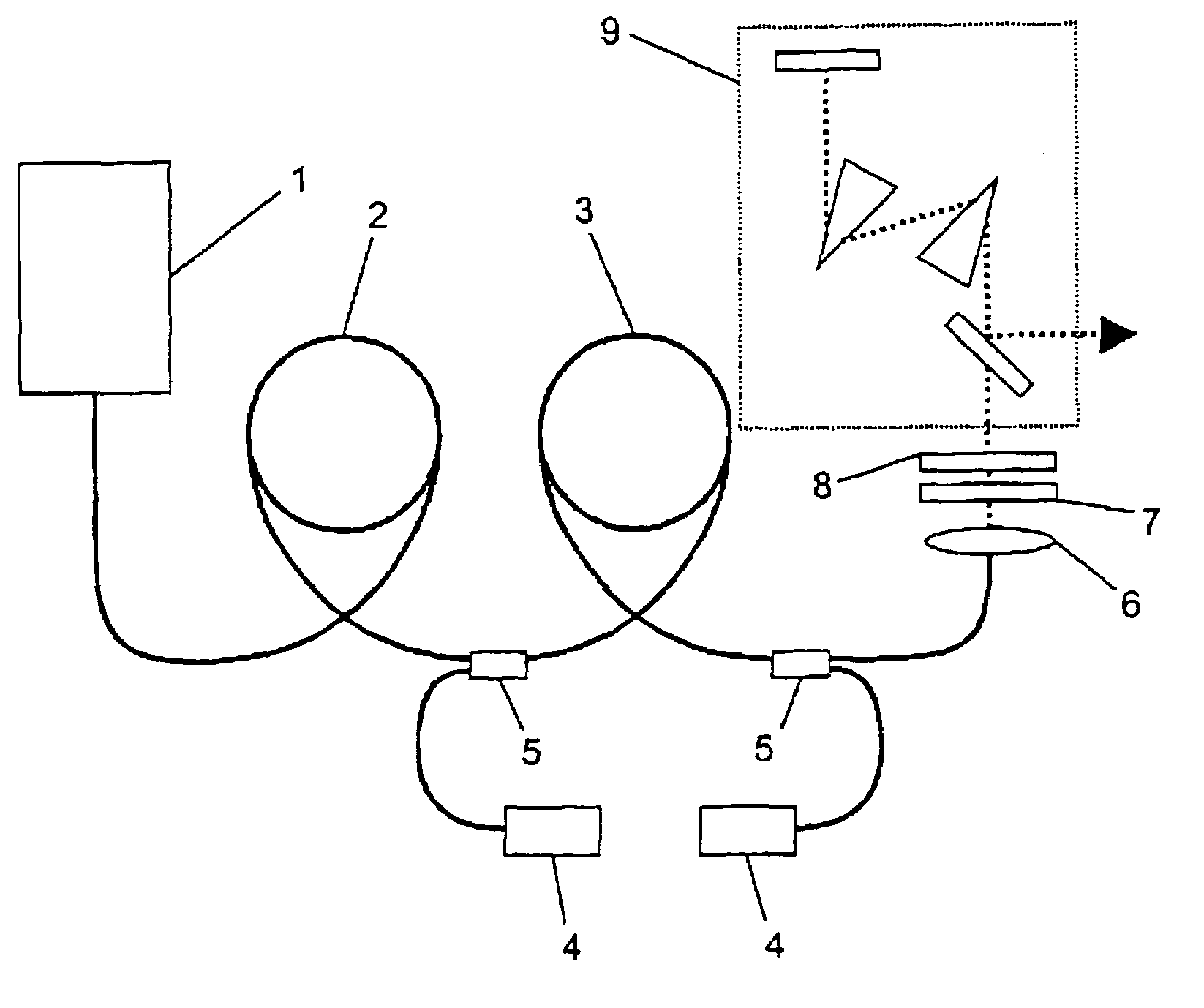

Acoustic-optical therapy devices and methods for therapeutical purposes are disclosed in this invention. The devices provide a combination of ultrasound energy and optical pulsed energy exposed to human and animal body at frequencies of ultrasound and optical pulses within the range of 1 Hz to 1 GHz and at wavelengths from 0.2 micrometer to 20 micrometers. Both ultrasound energy and pulsed light radiation are delivered in effective combinations to maximize the therapy. Because of different interaction nature of ultrasound and light with body, the new invented devices will provide much more effective and specific body treatment.

Owner:UNITED LAB & MFG

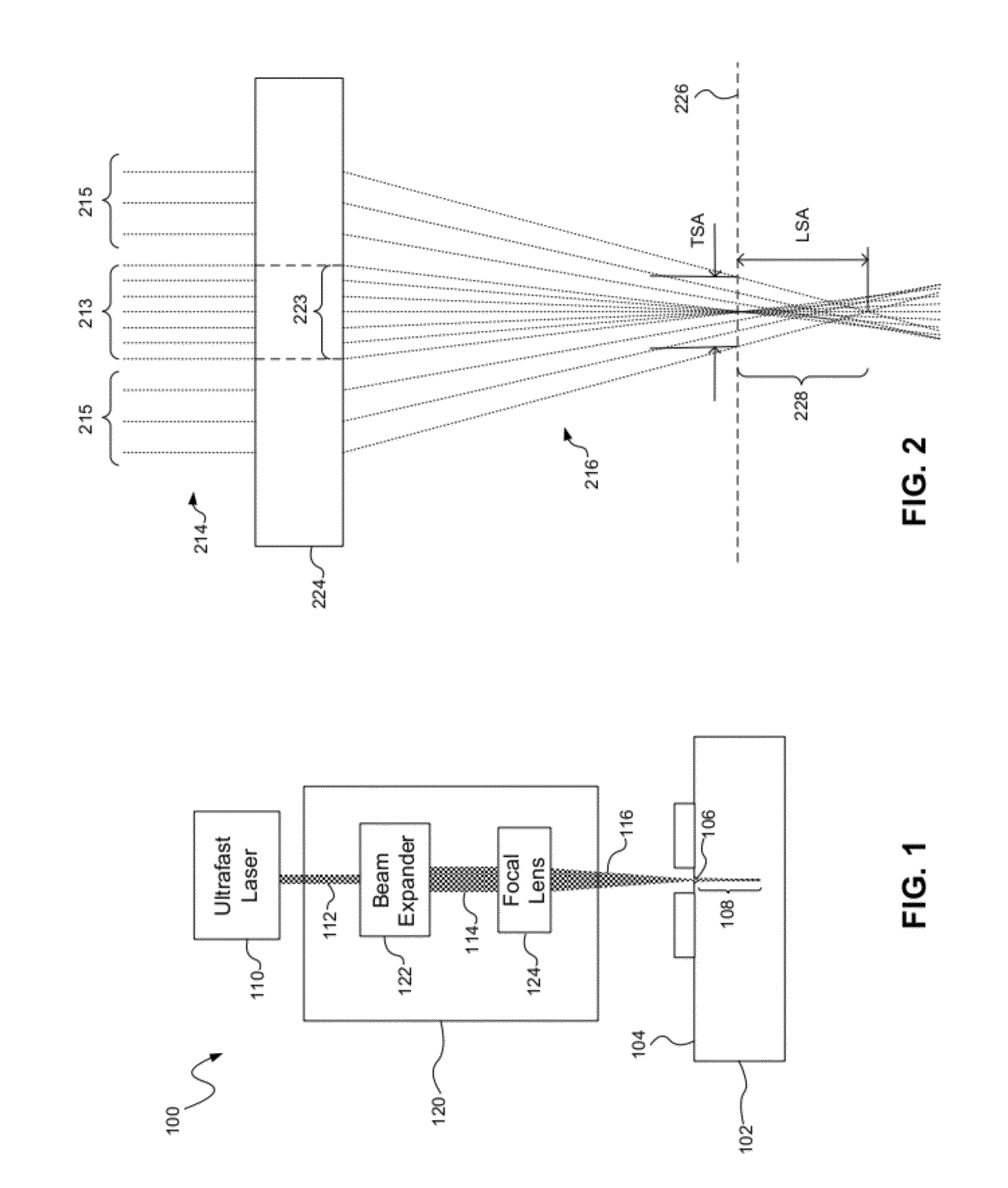

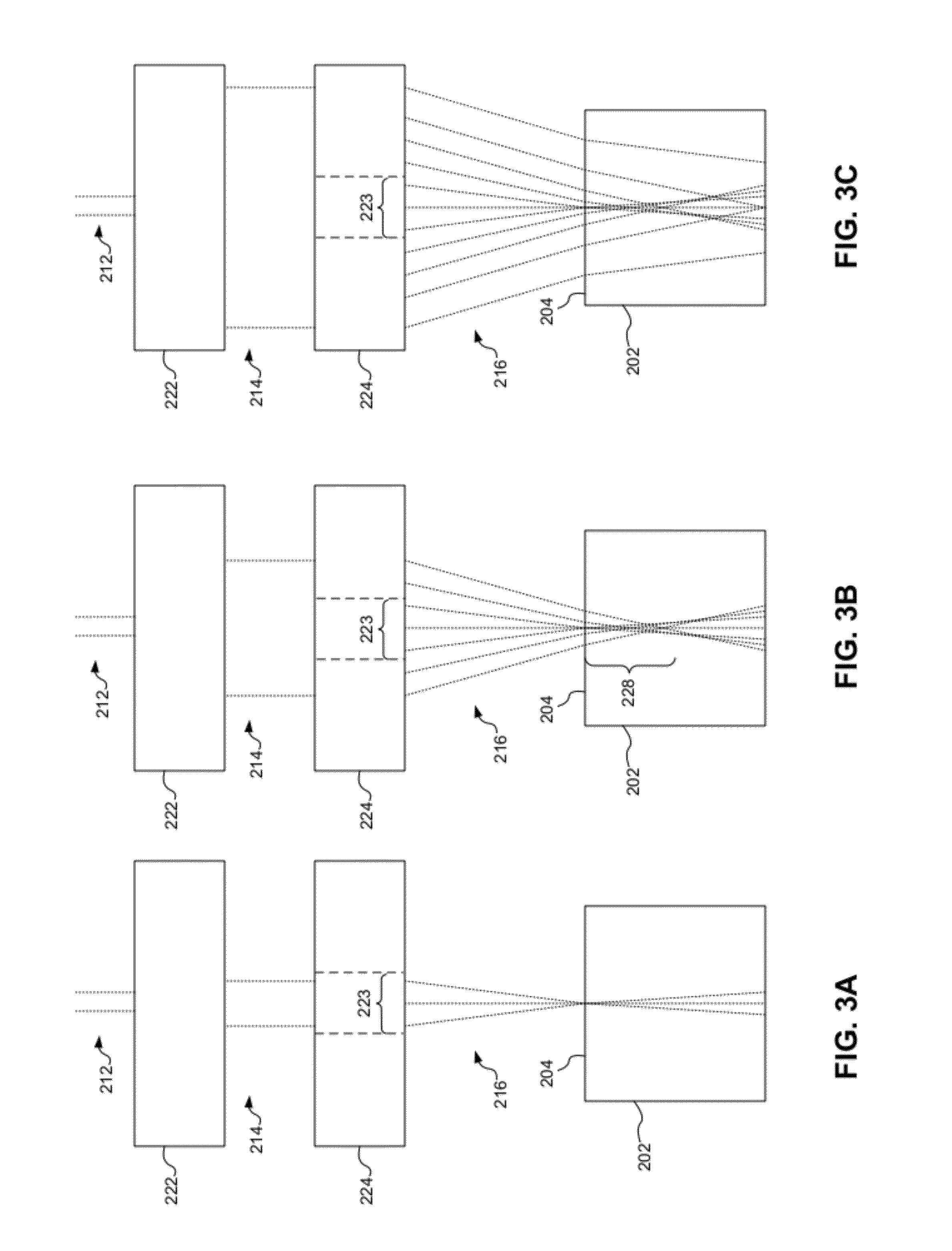

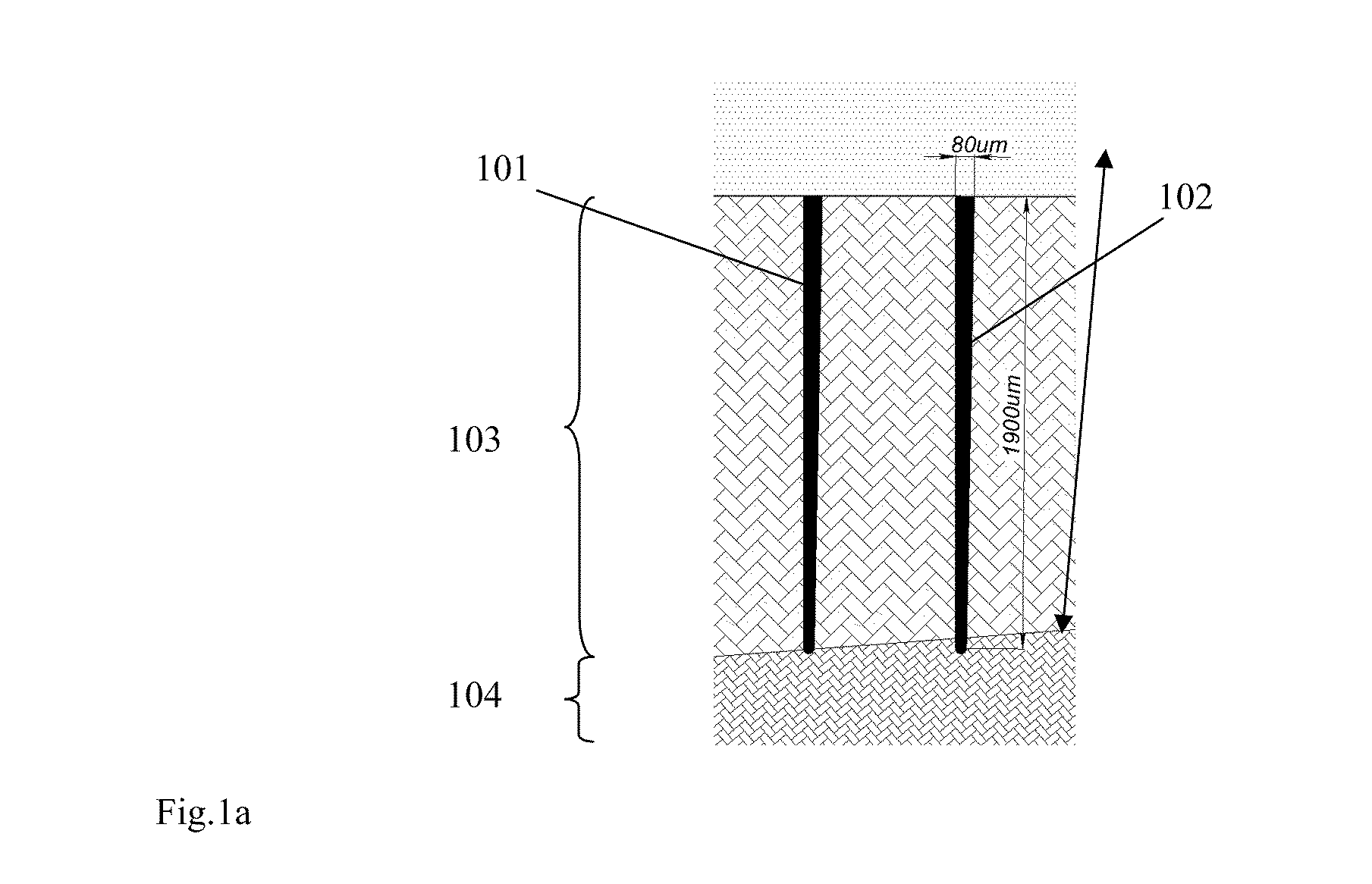

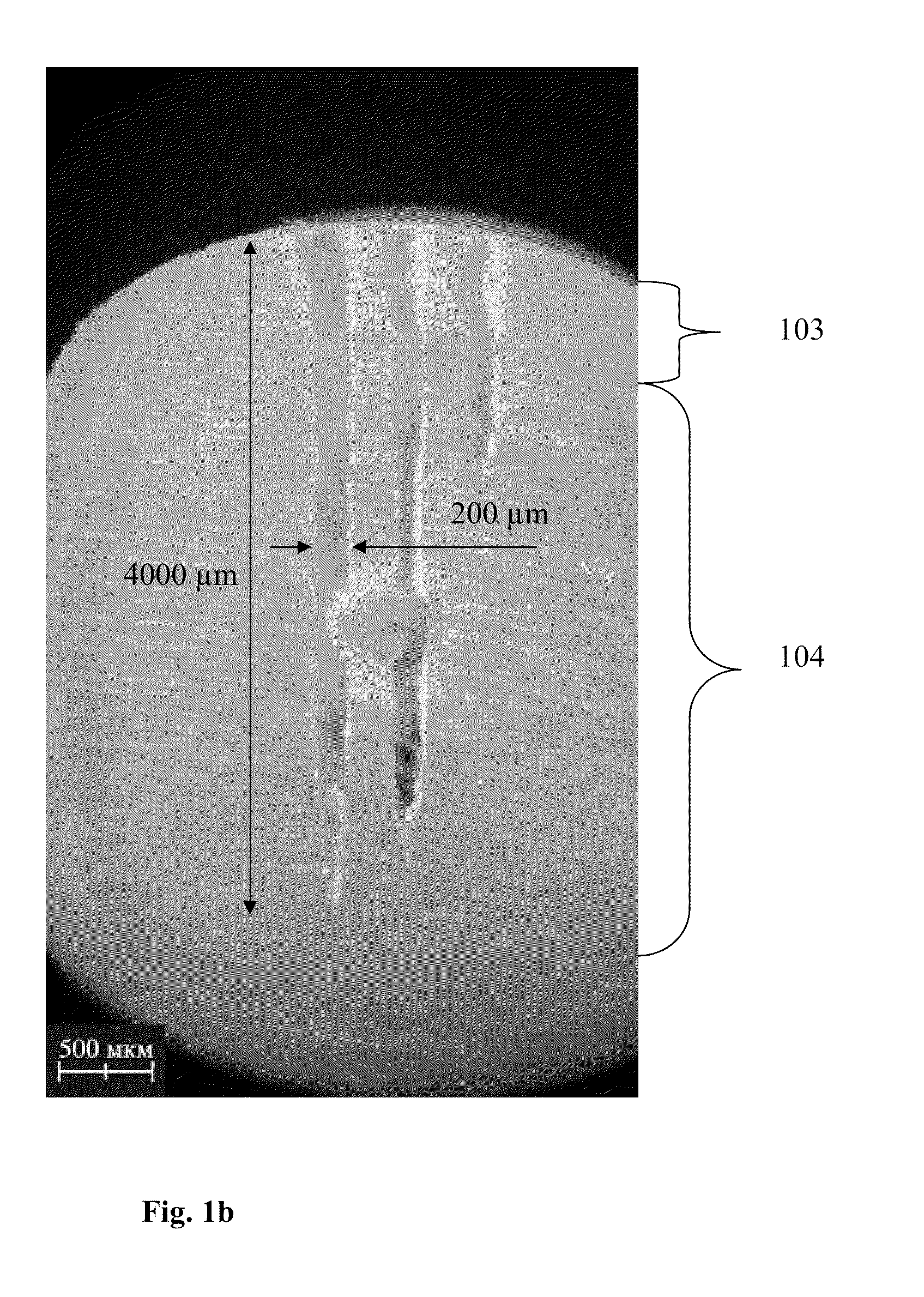

Laser scribing with extended depth affectation into a workplace

InactiveUS20120234807A1Welding/soldering/cutting articlesMetal working apparatusPulse energyLight beam

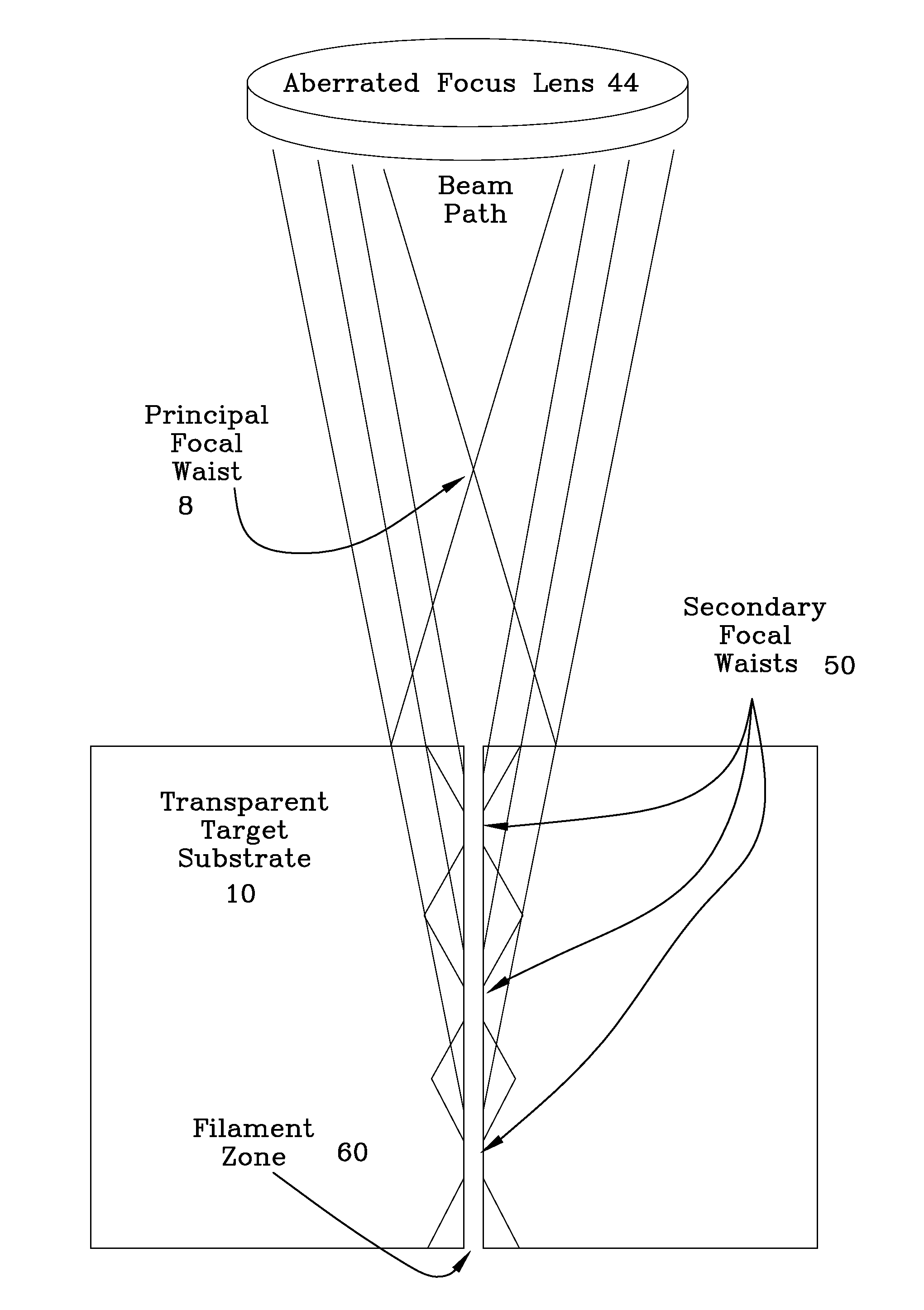

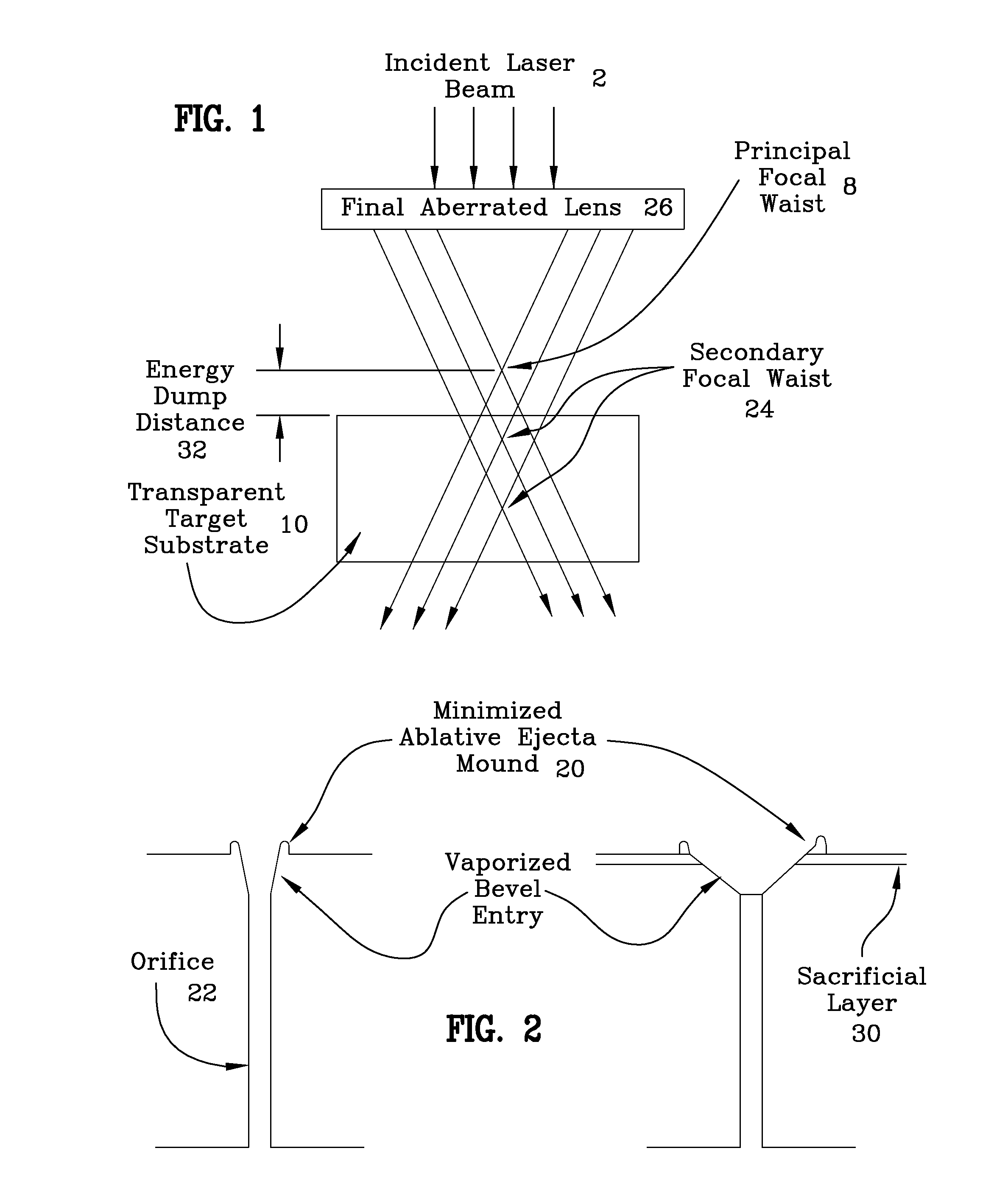

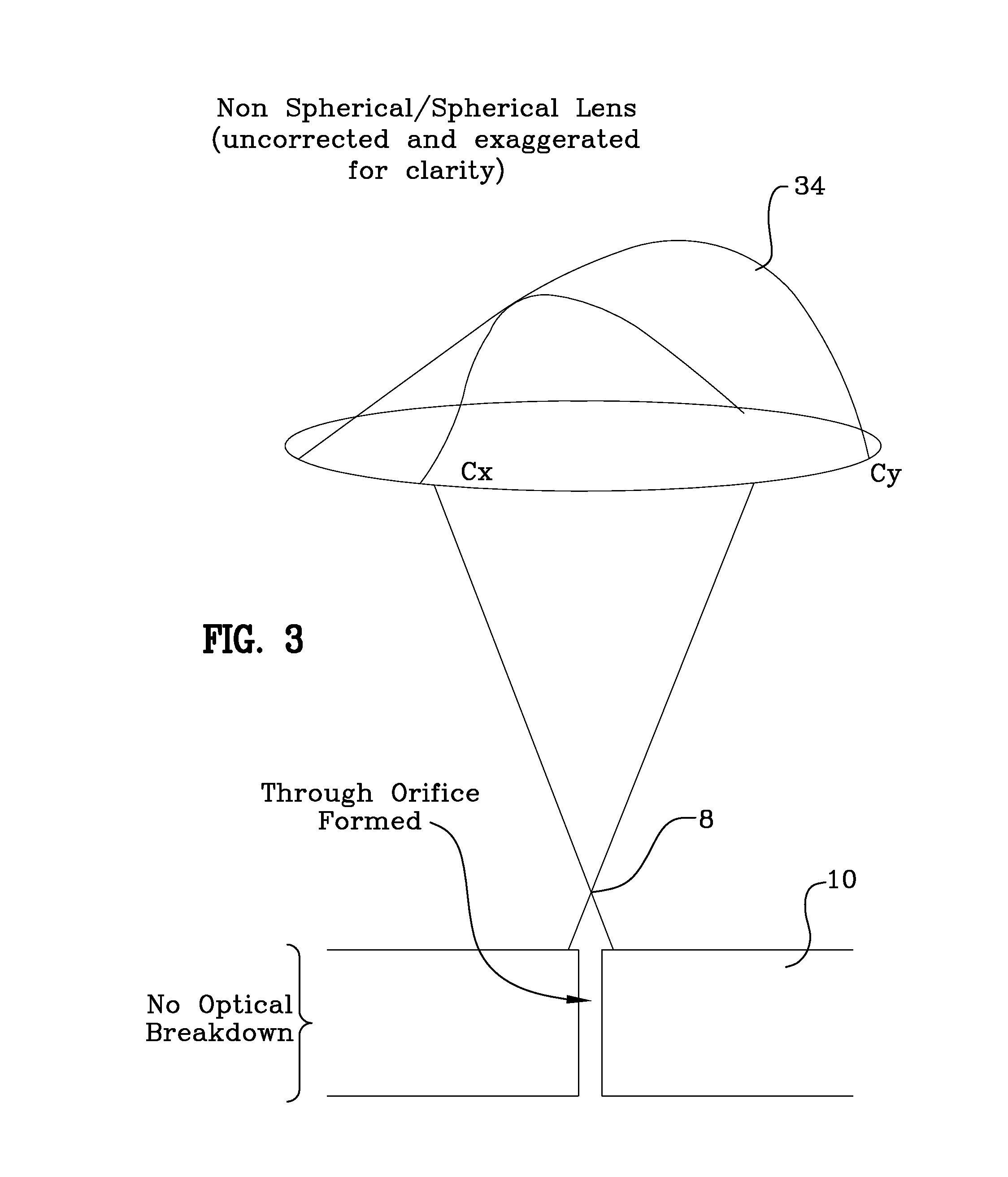

Systems and methods for laser scribing provide extended depth affectation into a substrate or workpiece by focusing a laser beam such that the beam passes into the workpiece using a waveguide, self-focusing effect to cause internal crystal damage along a channel extending into the workpiece. Different optical effects may be used to facilitate the waveguide, self-focusing effect, such as multi-photon absorption in the material of the workpiece, transparency of the material of the workpiece, and aberrations of the focused laser. The laser beam may have a wavelength, pulse duration, and pulse energy, for example, to provide transmission through the material and multi-photon absorption in the material. An aberrated, focused laser beam may also be used to provide a longitudinal spherical aberration range sufficient to extend the effective depth of field (DOF) into the workpiece.

Owner:IPG PHOTONICS CORP

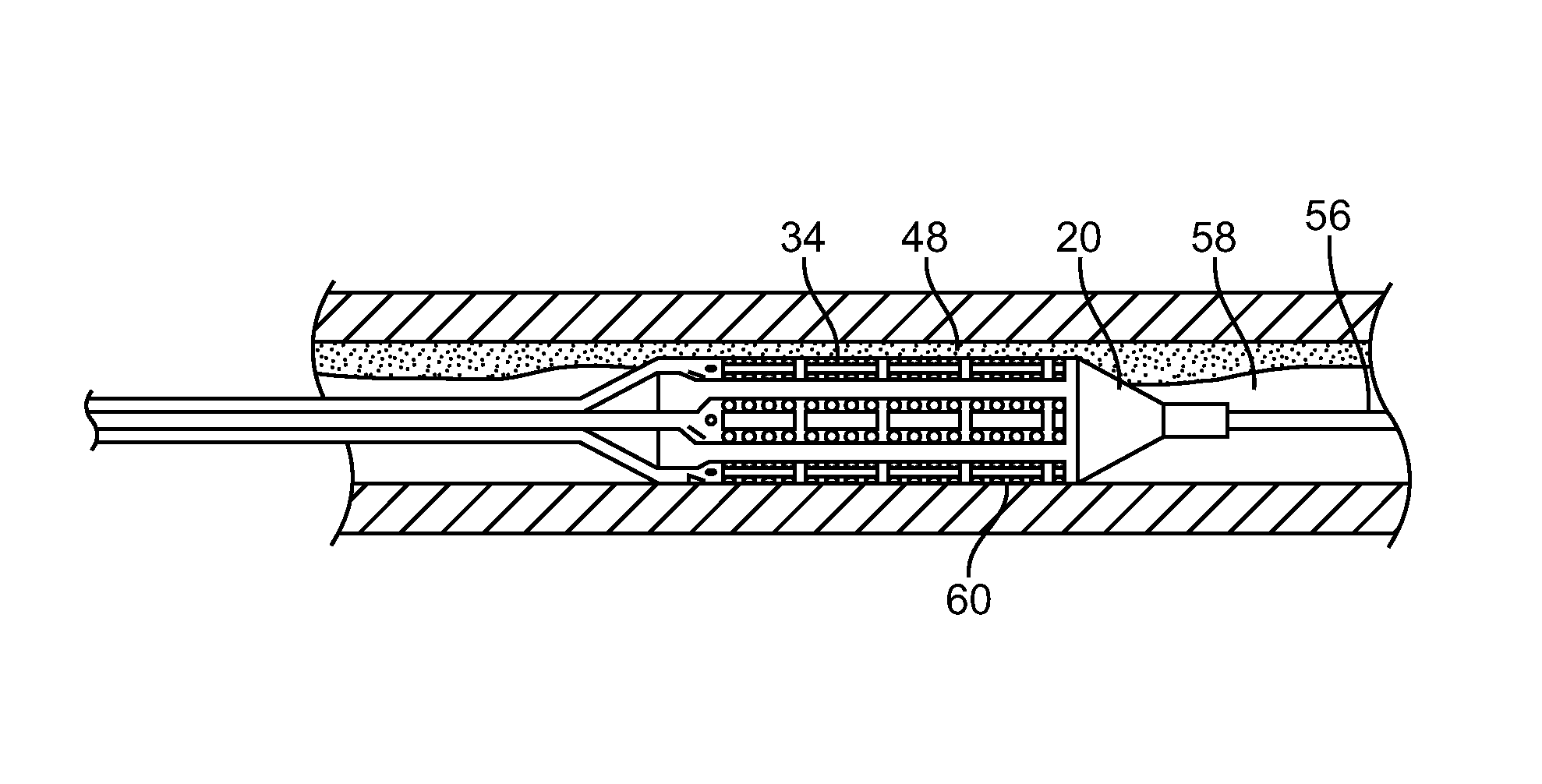

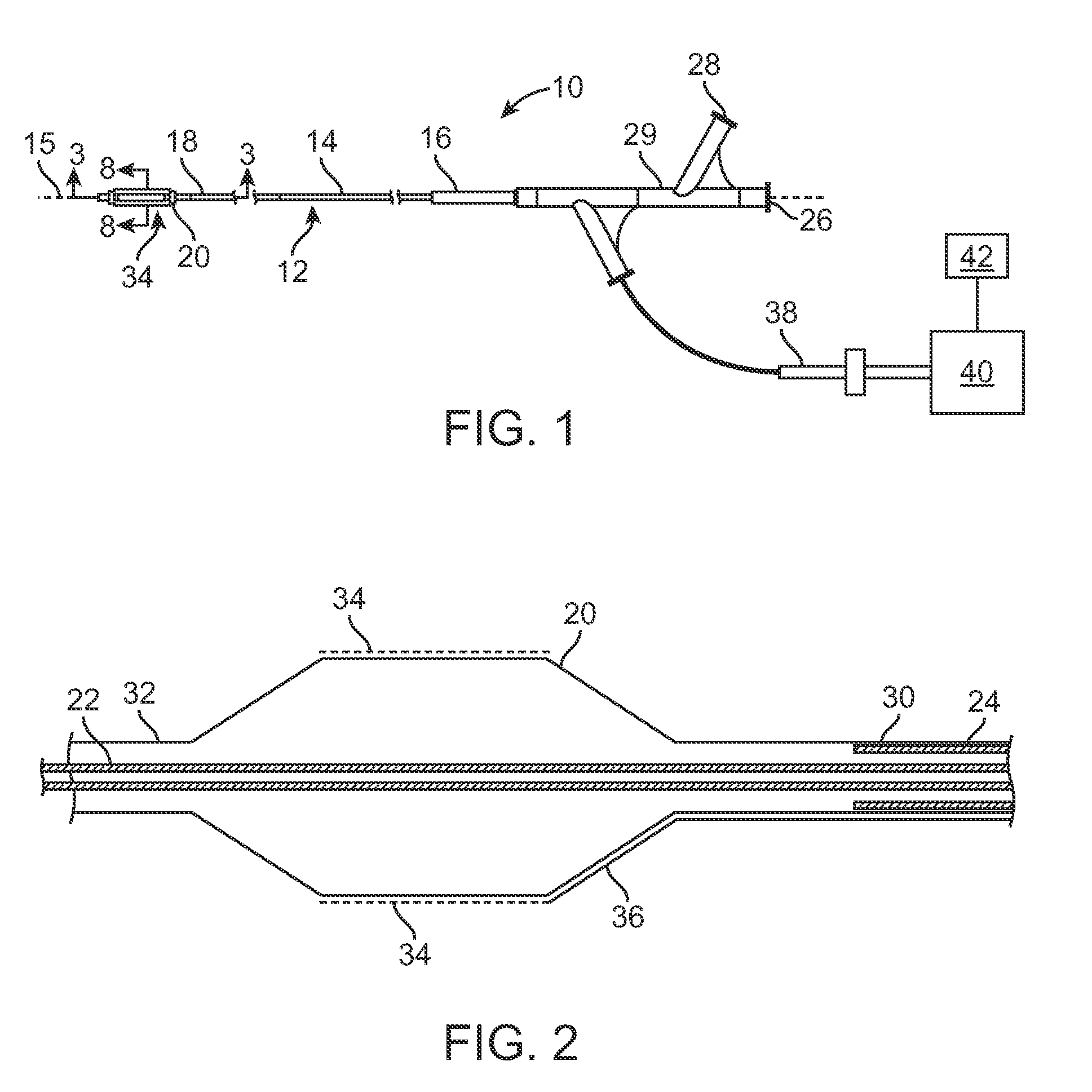

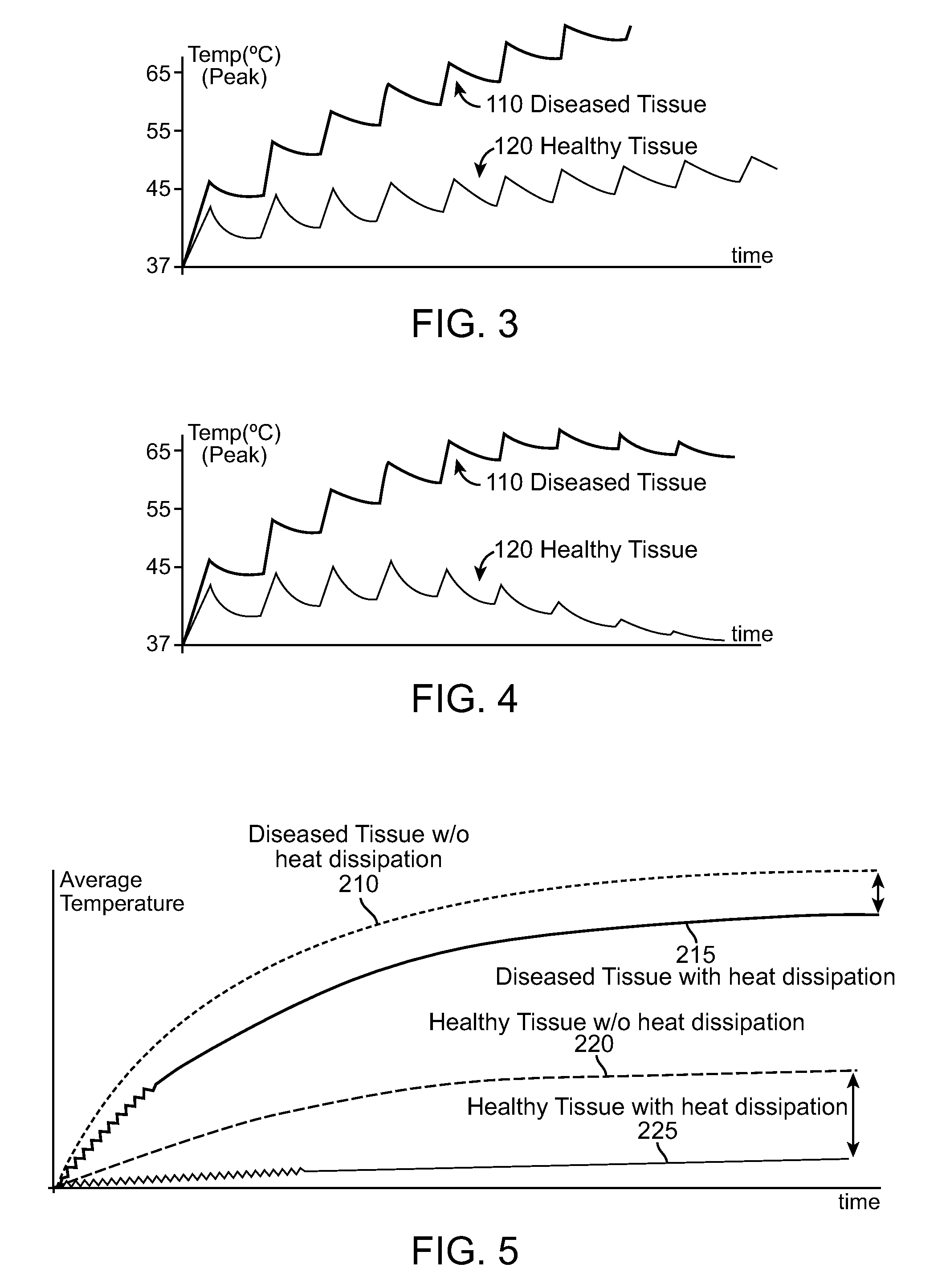

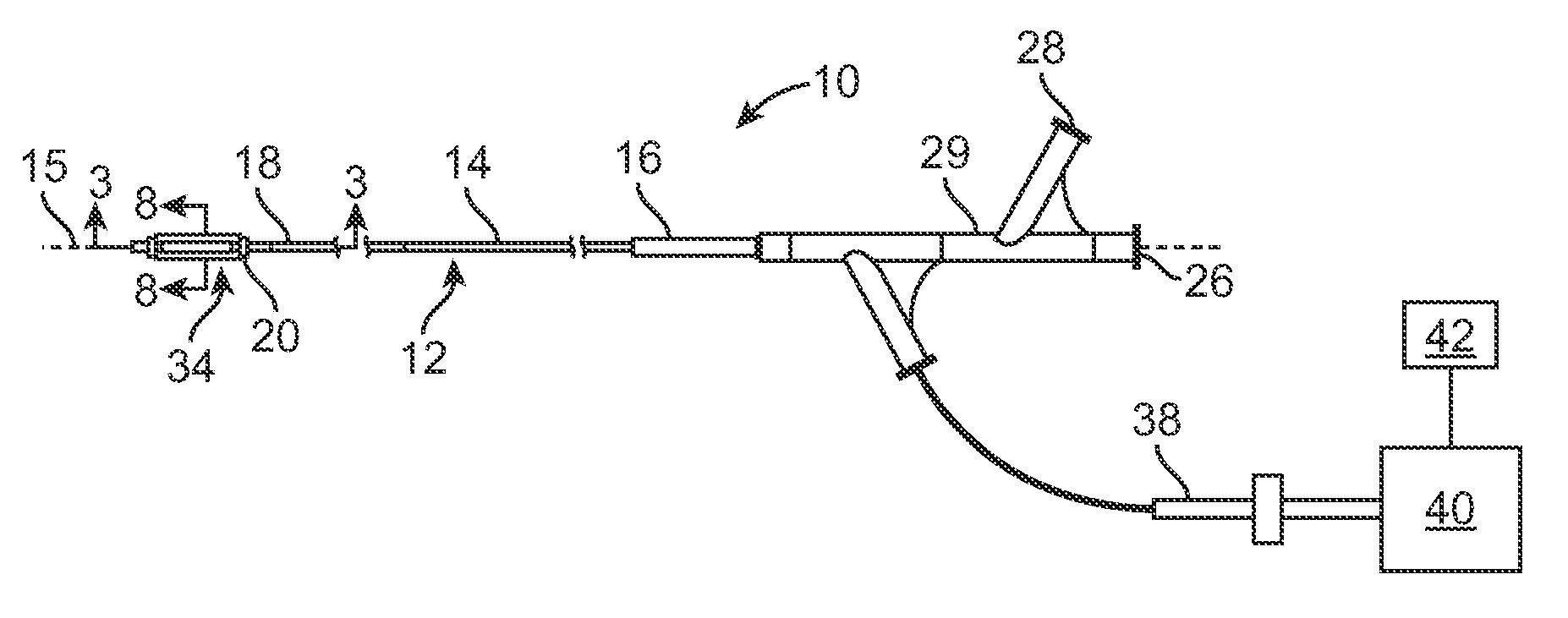

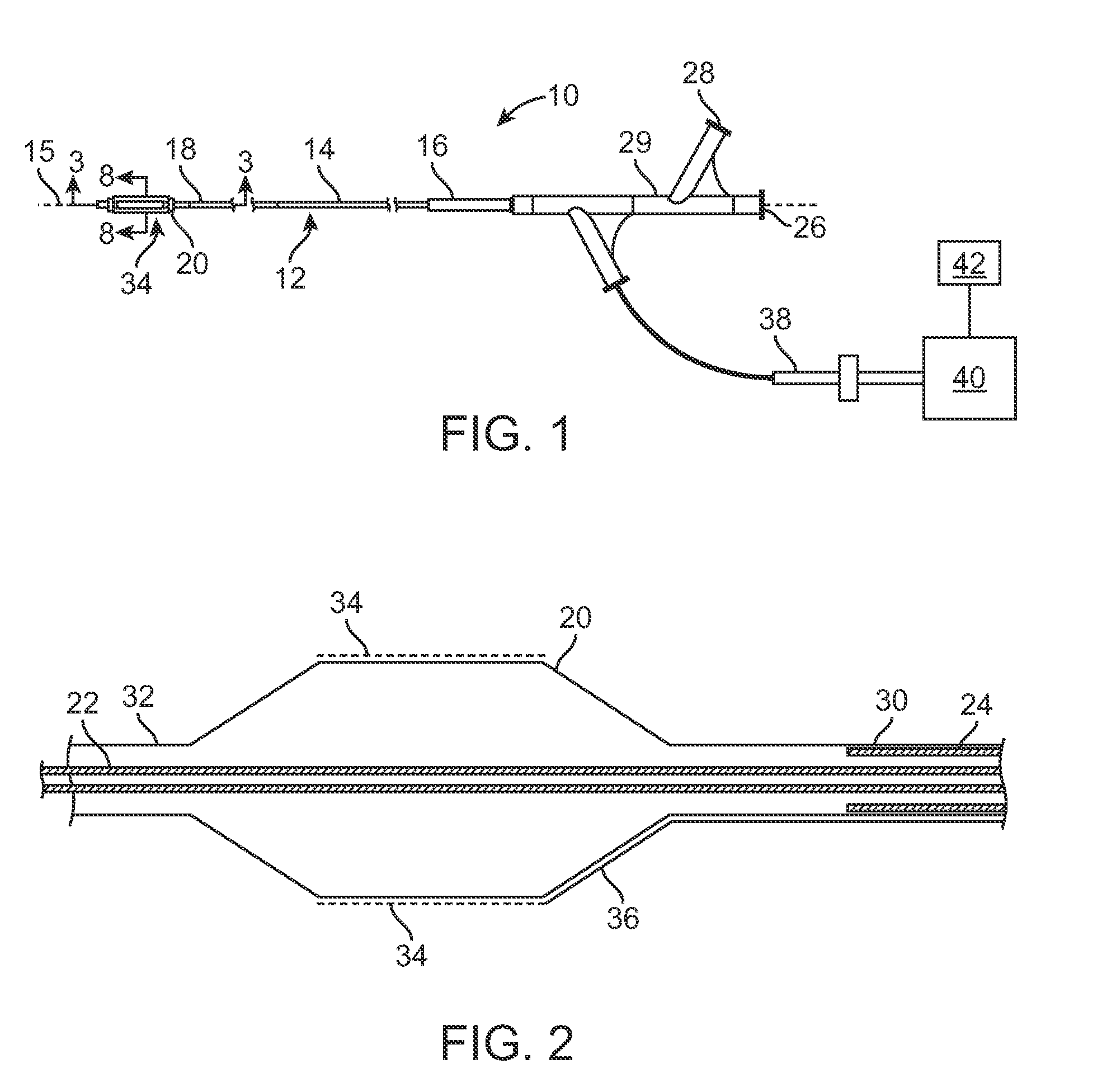

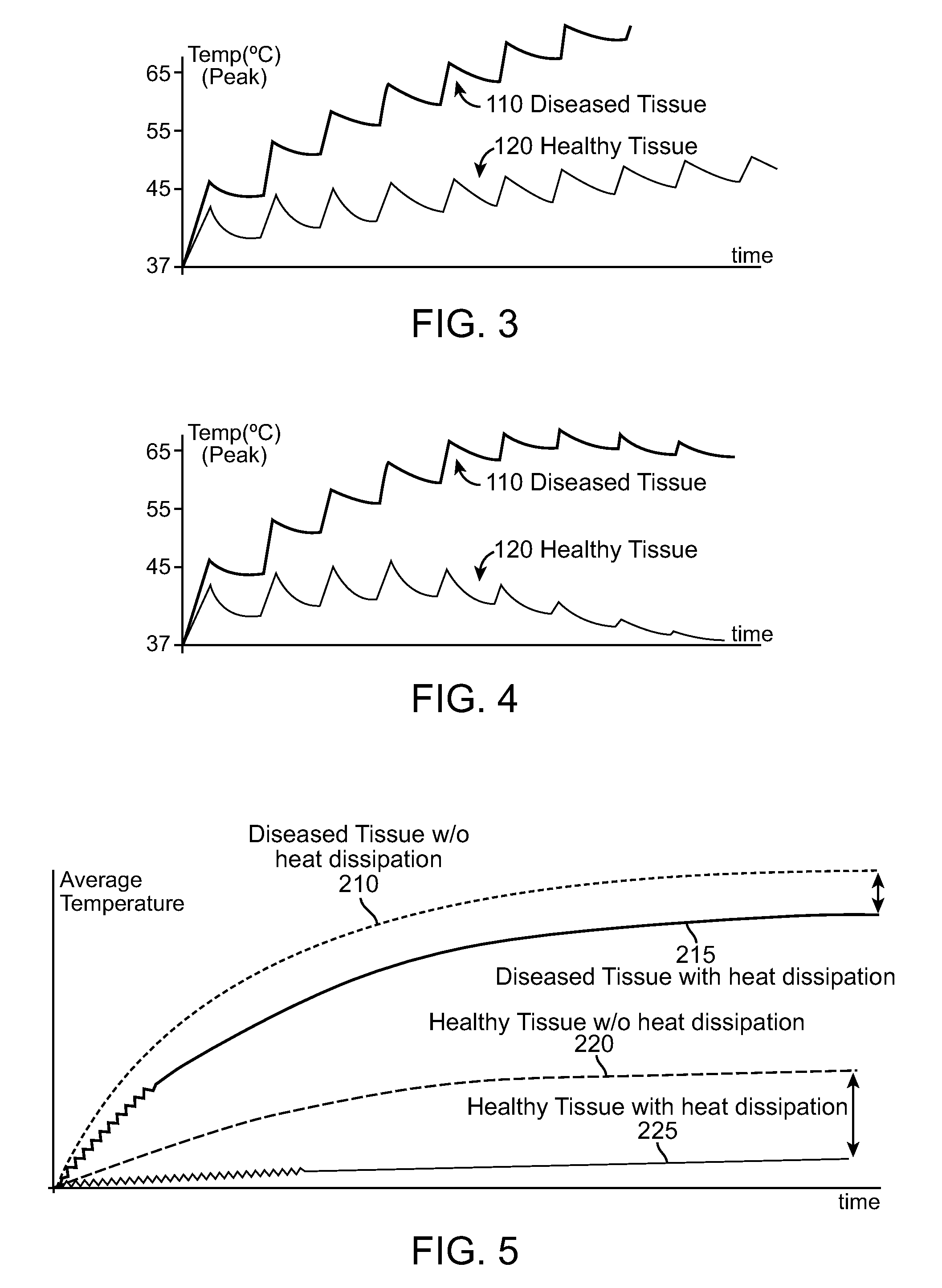

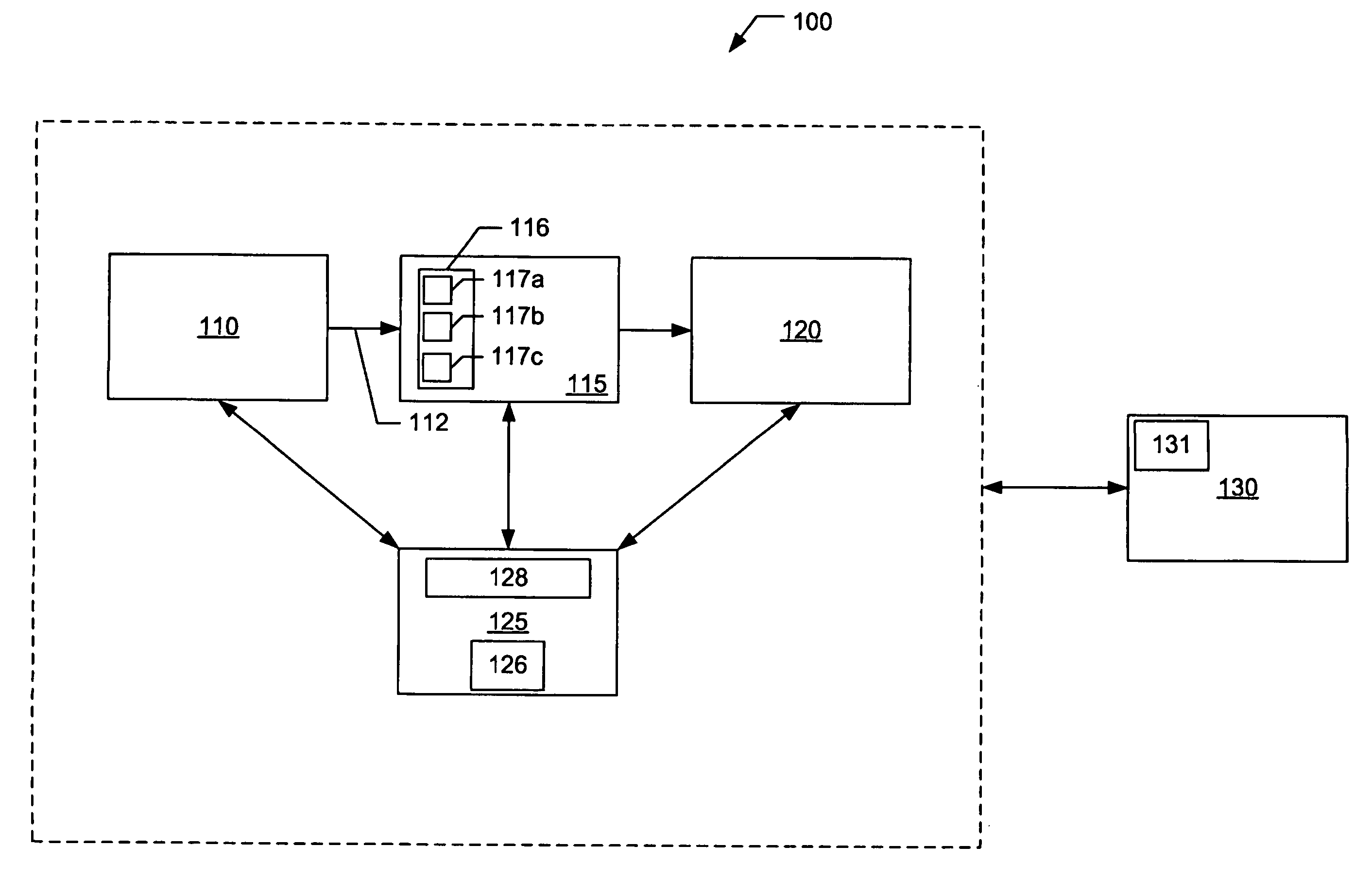

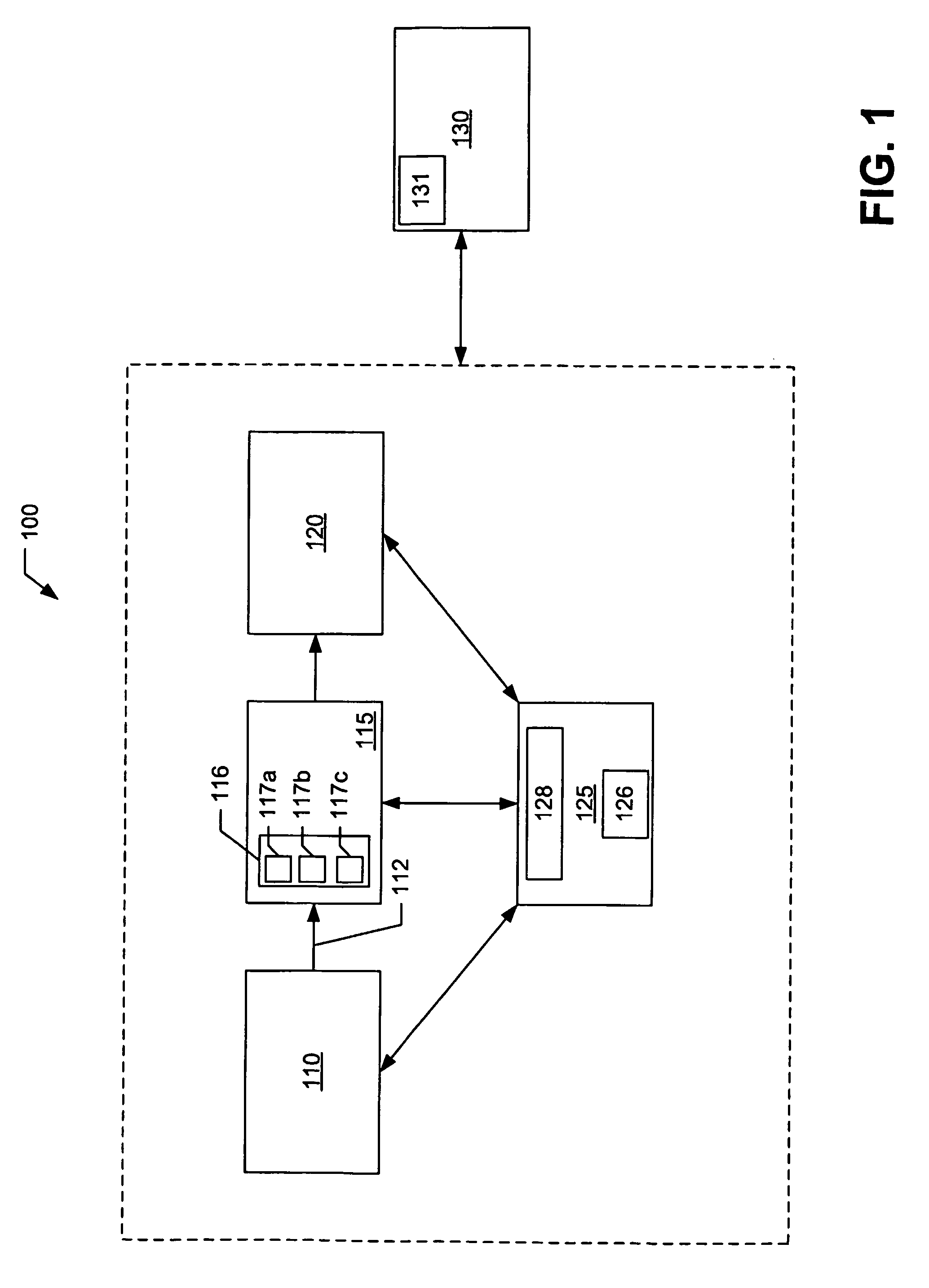

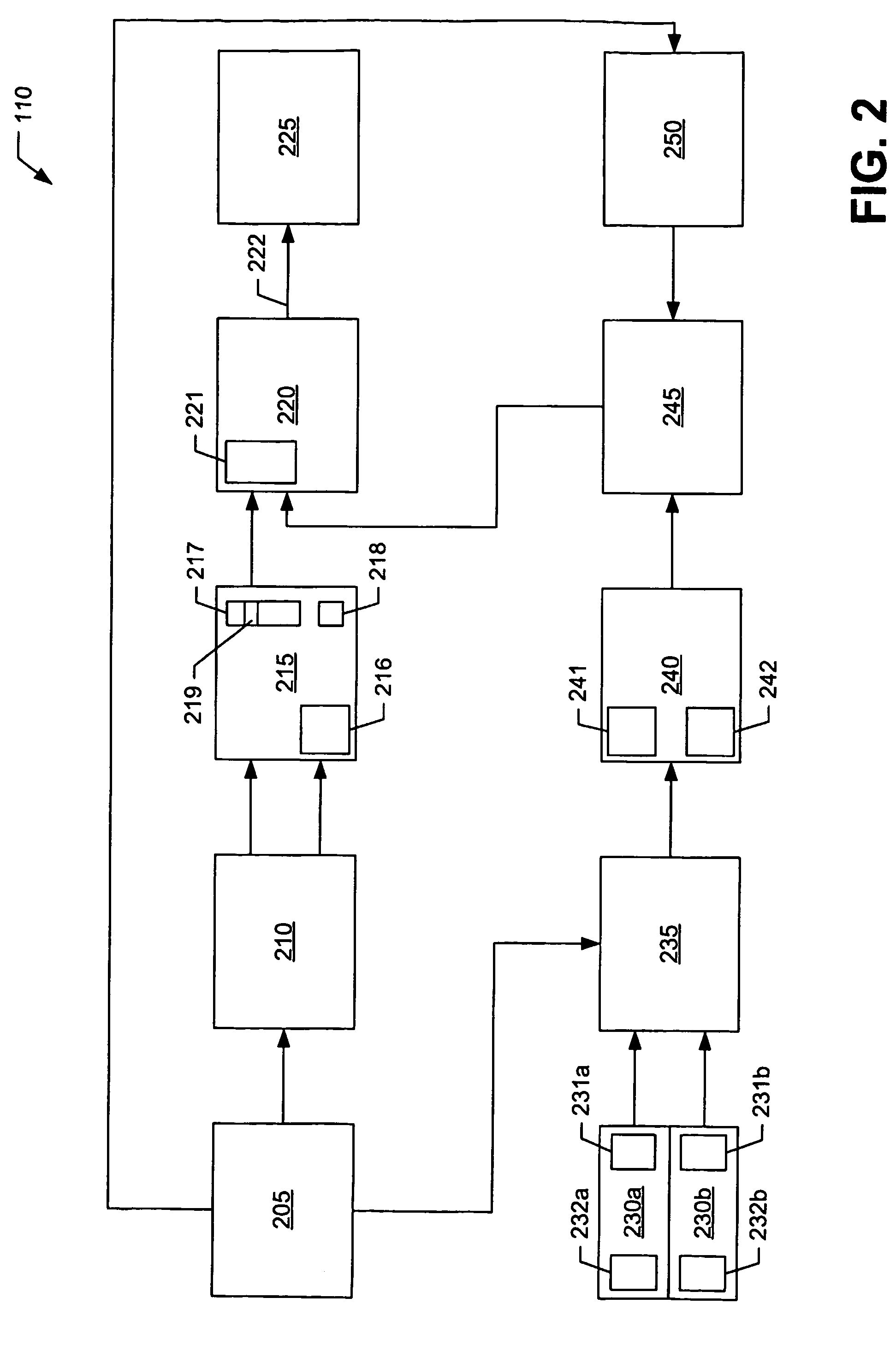

Selective accumulation of energy with or without knowledge of tissue topography

ActiveUS8401667B2Avoids significant thermal damageSignificant thermal damageUltrasound therapyChiropractic devicesMedicinePulse energy

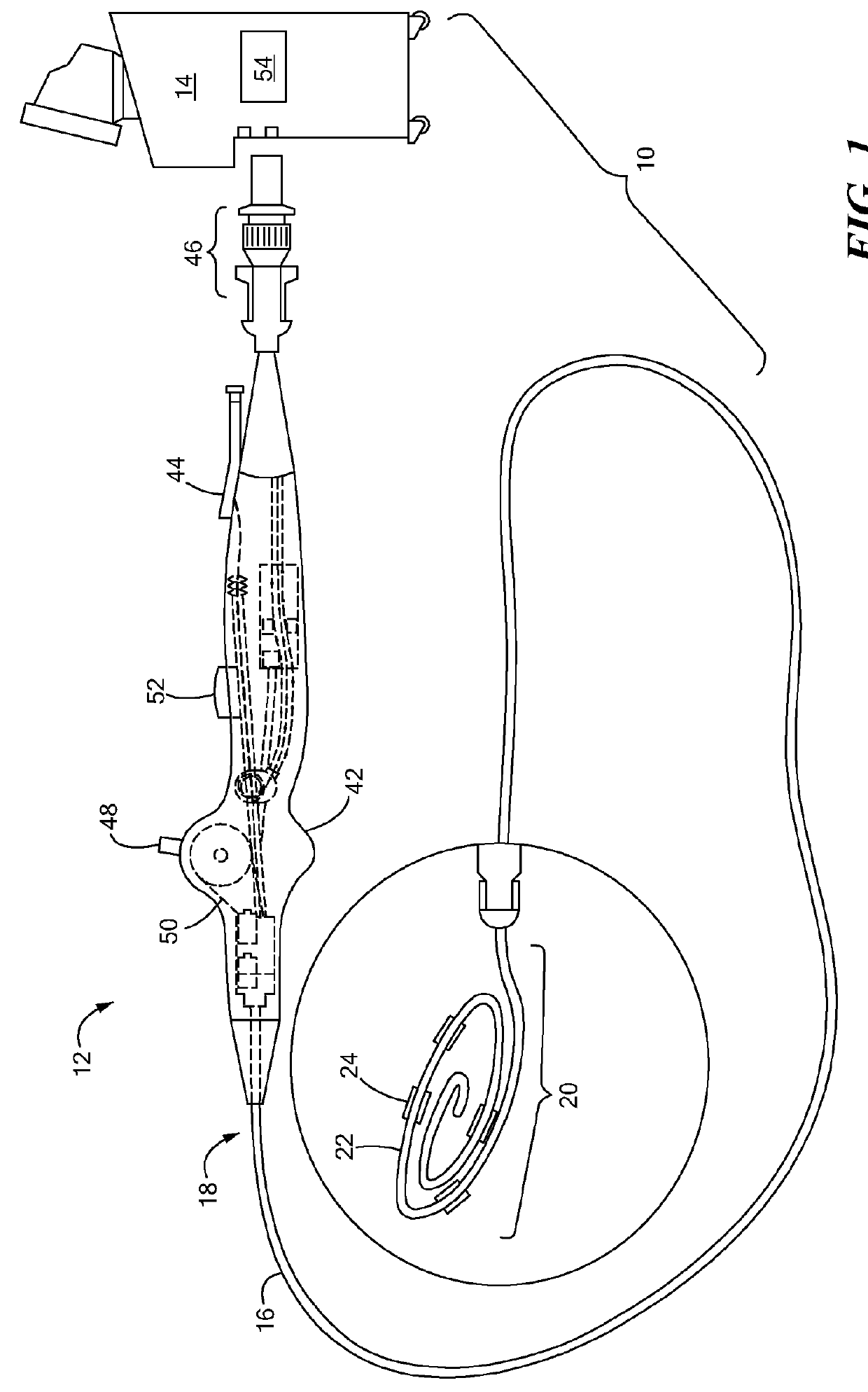

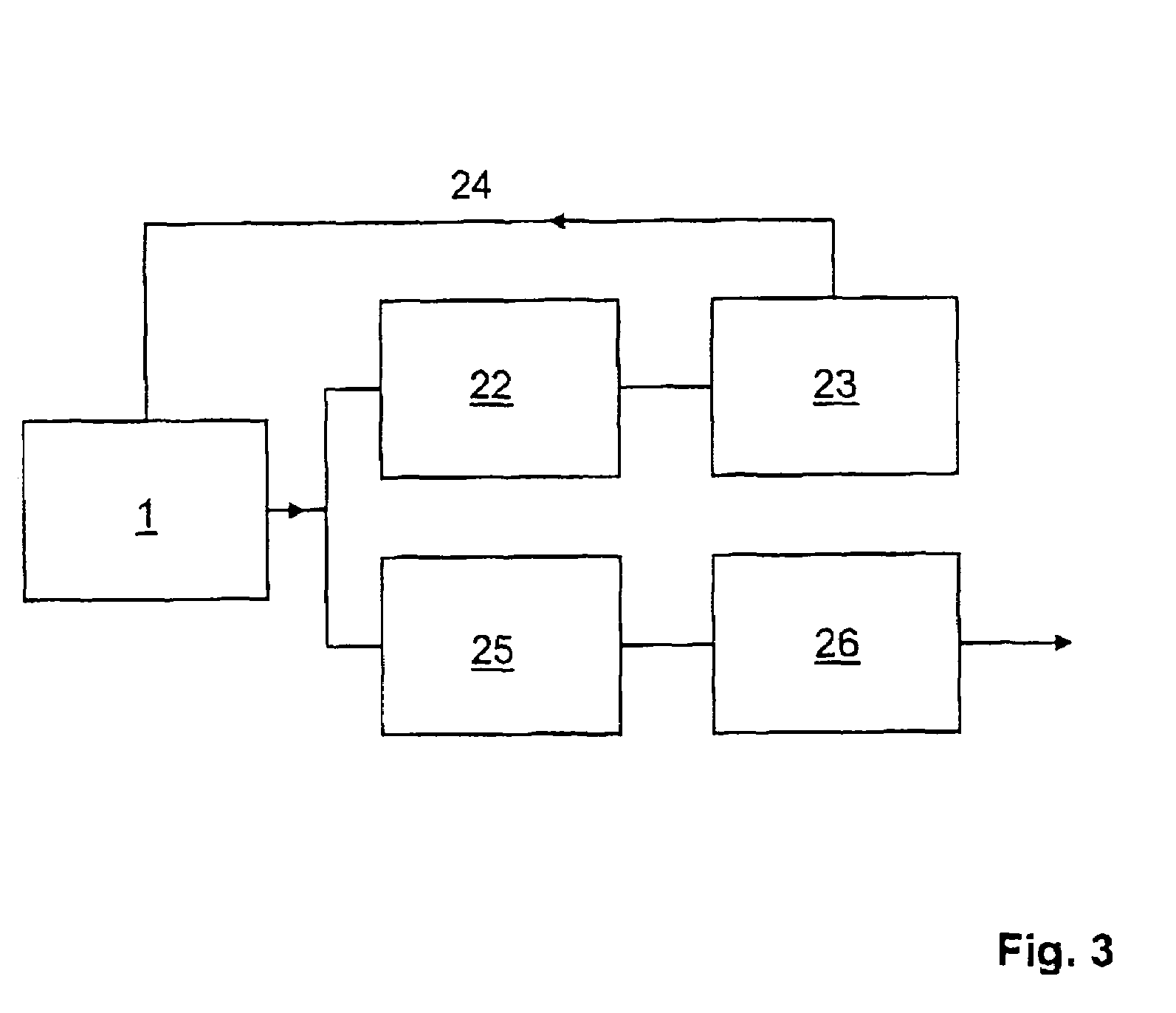

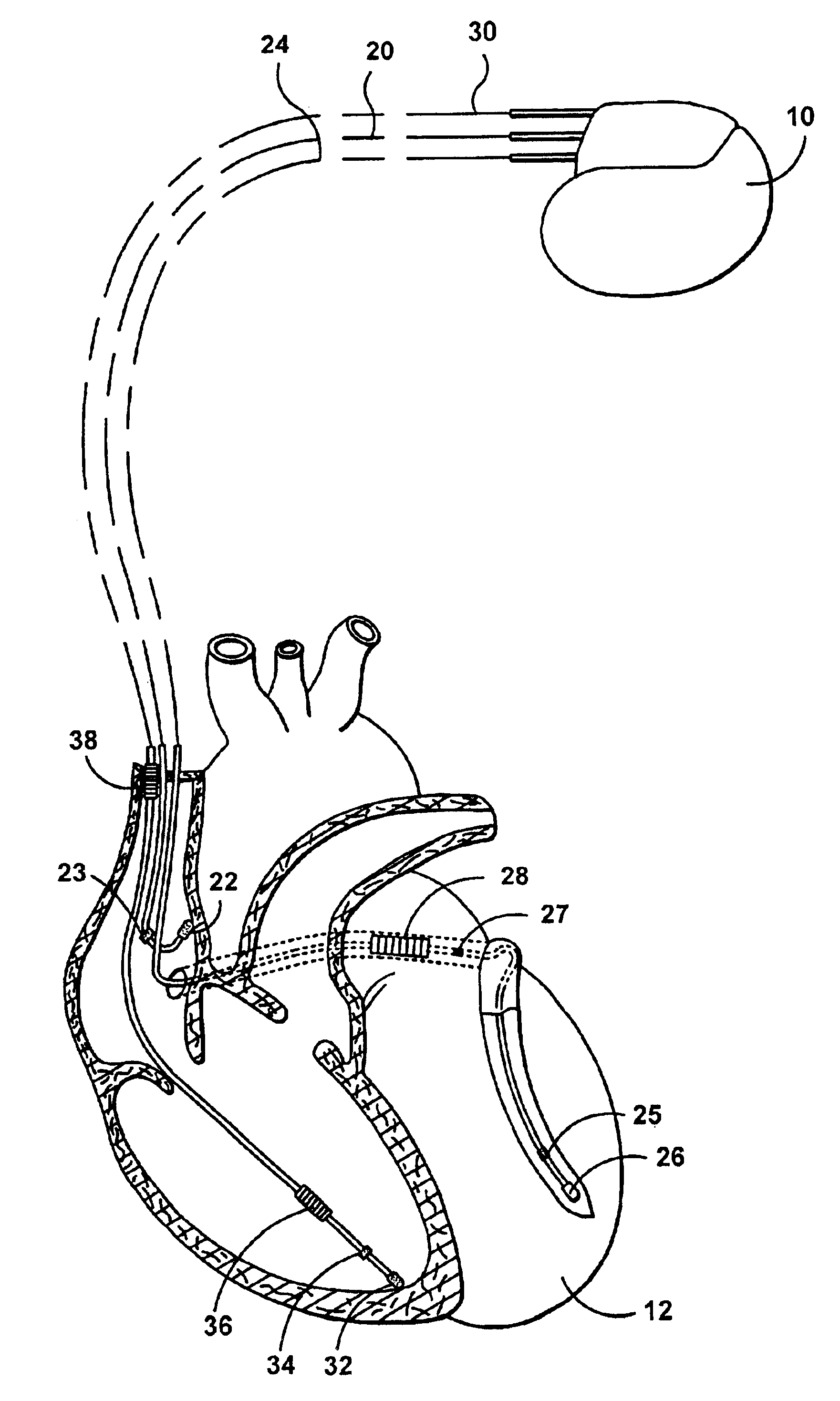

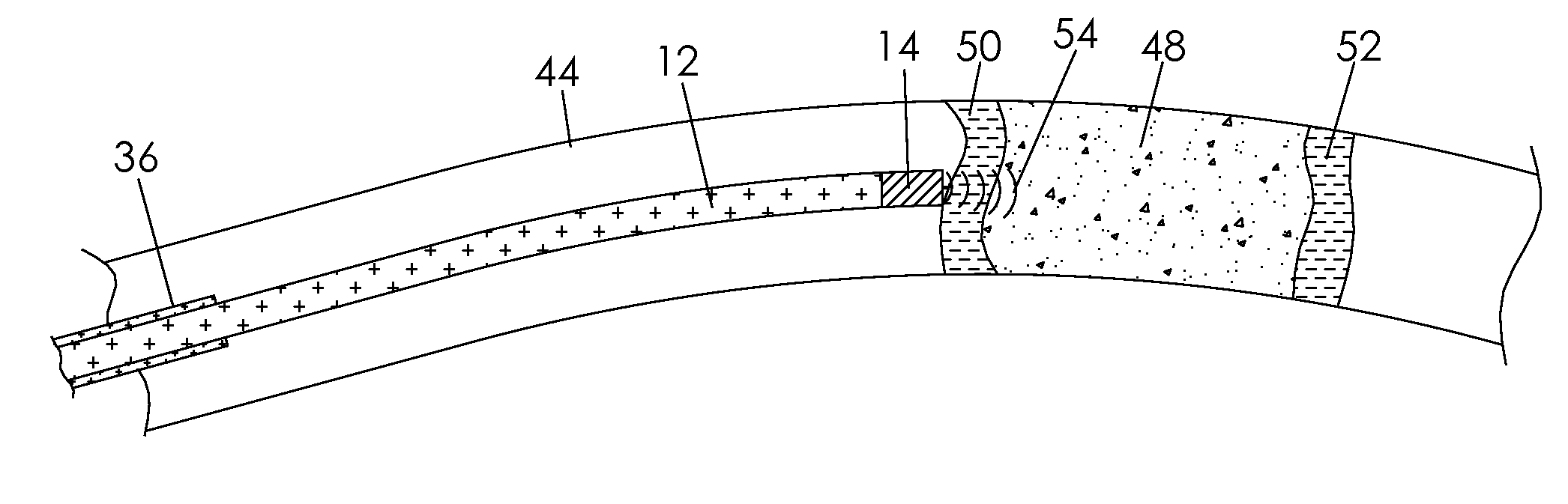

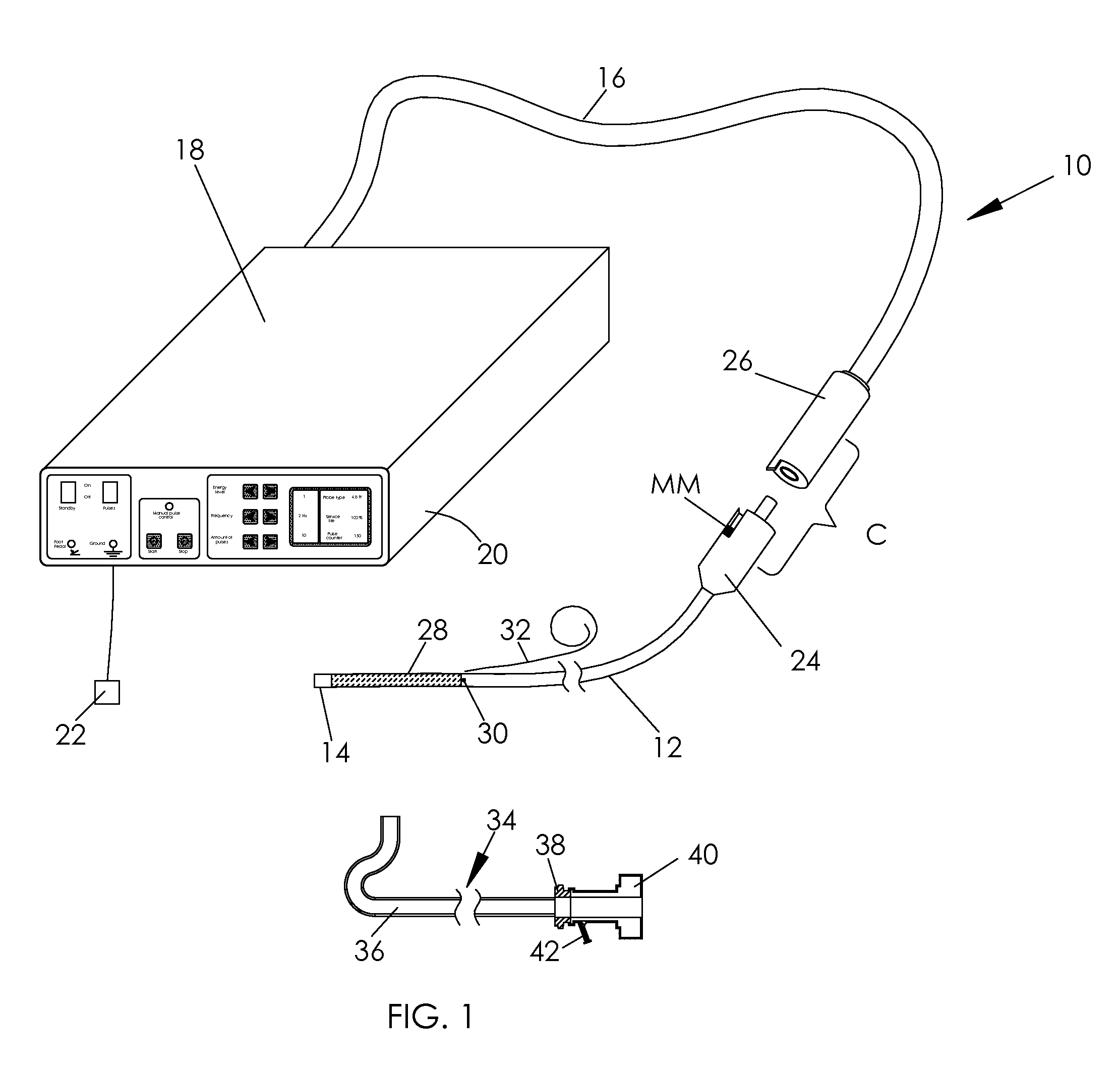

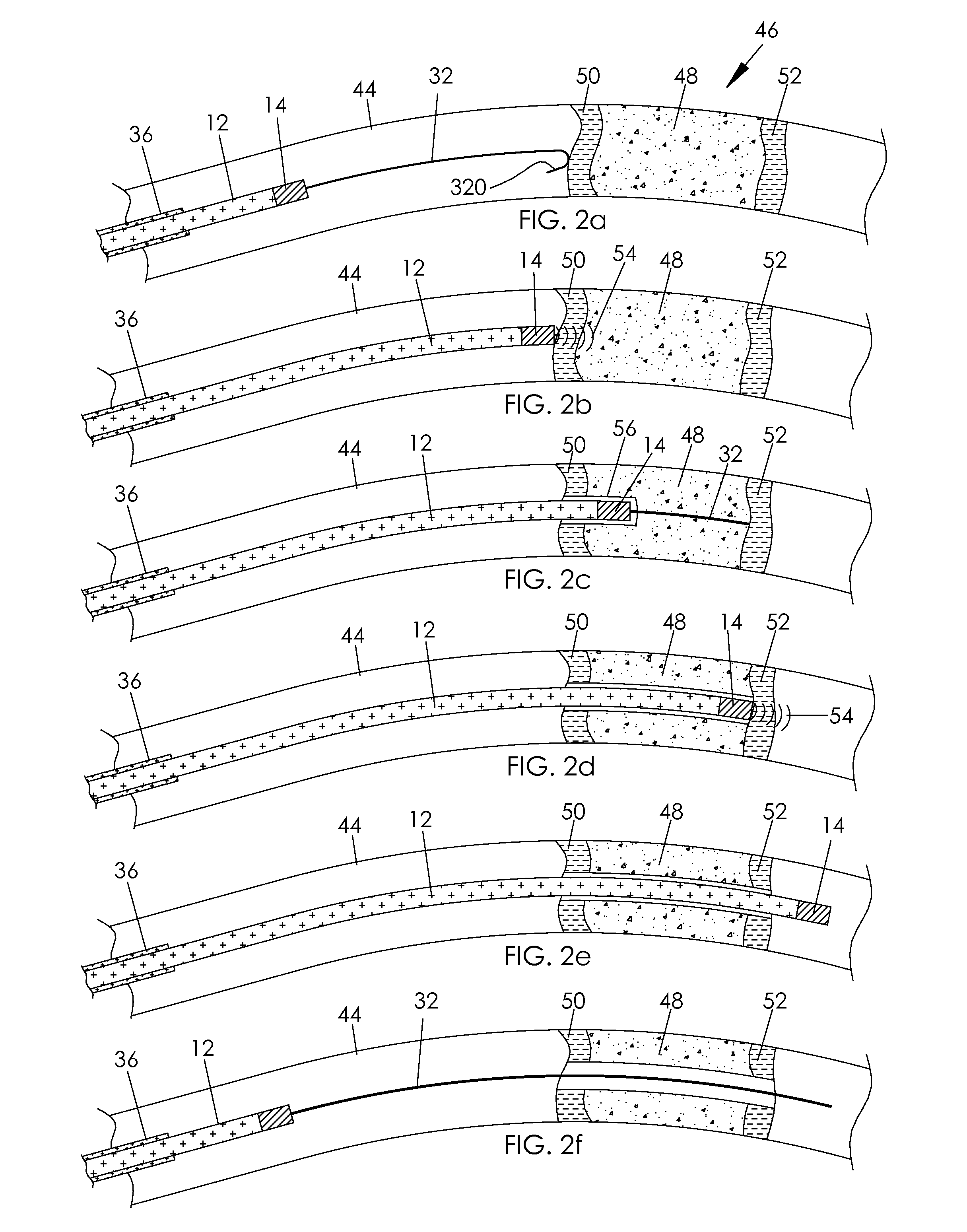

Methods and systems for heating a body tissue region adjacent a body lumen using selective accumulation of energy without knowledge of tissue topography. Methods include positioning an energy delivery portion of a catheter within the lumen adjacent the body tissue region, determining a pulse characteristic in response to a thermal property of a first tissue type and applying pulsed energy with the characteristic to treat a second tissue type within the region by drawing heat from the first tissue at a rate that inhibits thermal damage to the first tissue while building-up heat in the second tissue. Systems include a catheter body having an energy delivery portion processor configured to control a pulse characteristic of pulsed energy to therapeutically treat the second tissue by drawing heat from the first tissue at a rate that inhibits thermal damage to the first tissue while building-up heat in the second tissue.

Owner:BOSTON SCI SCIMED INC

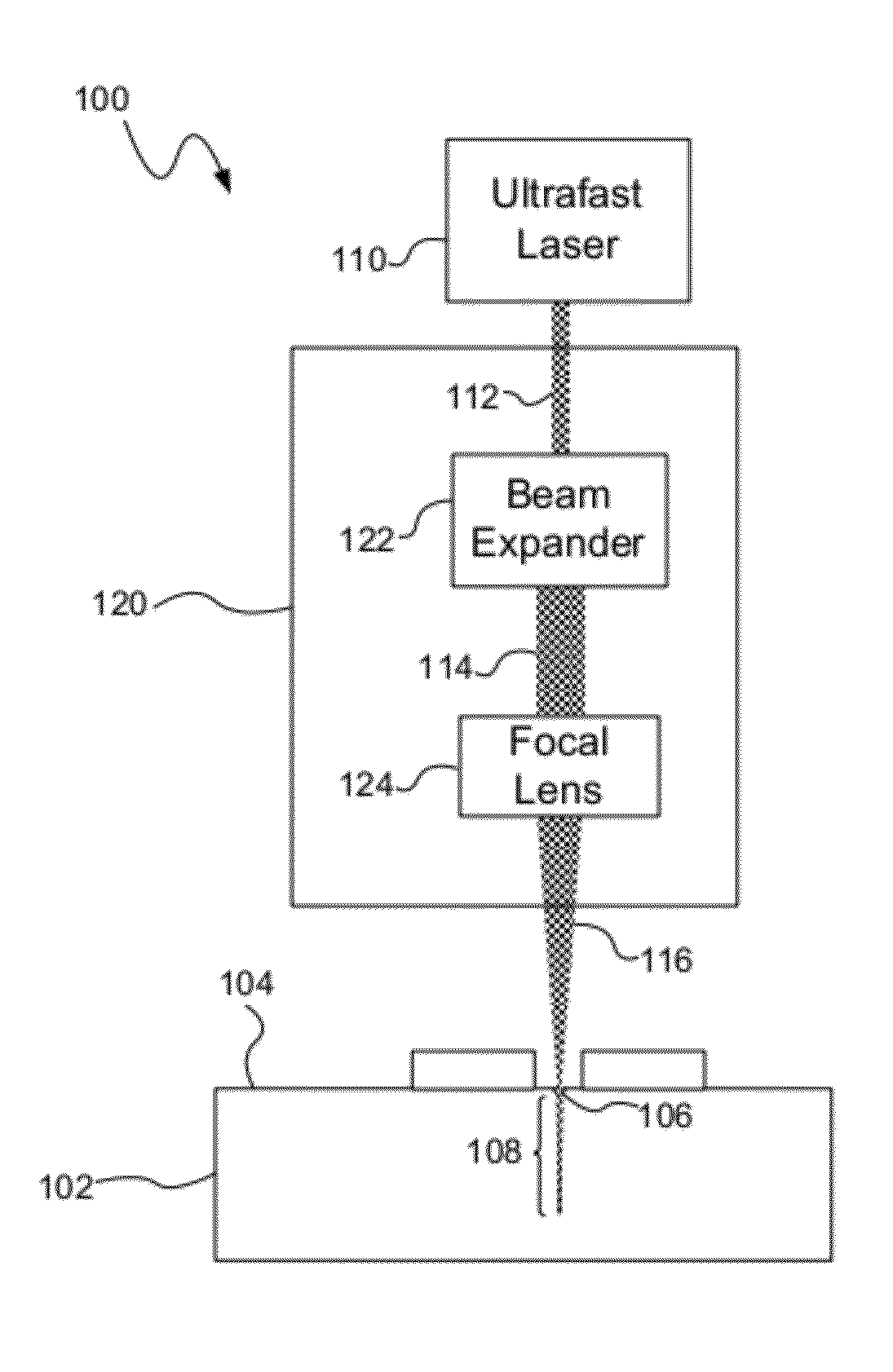

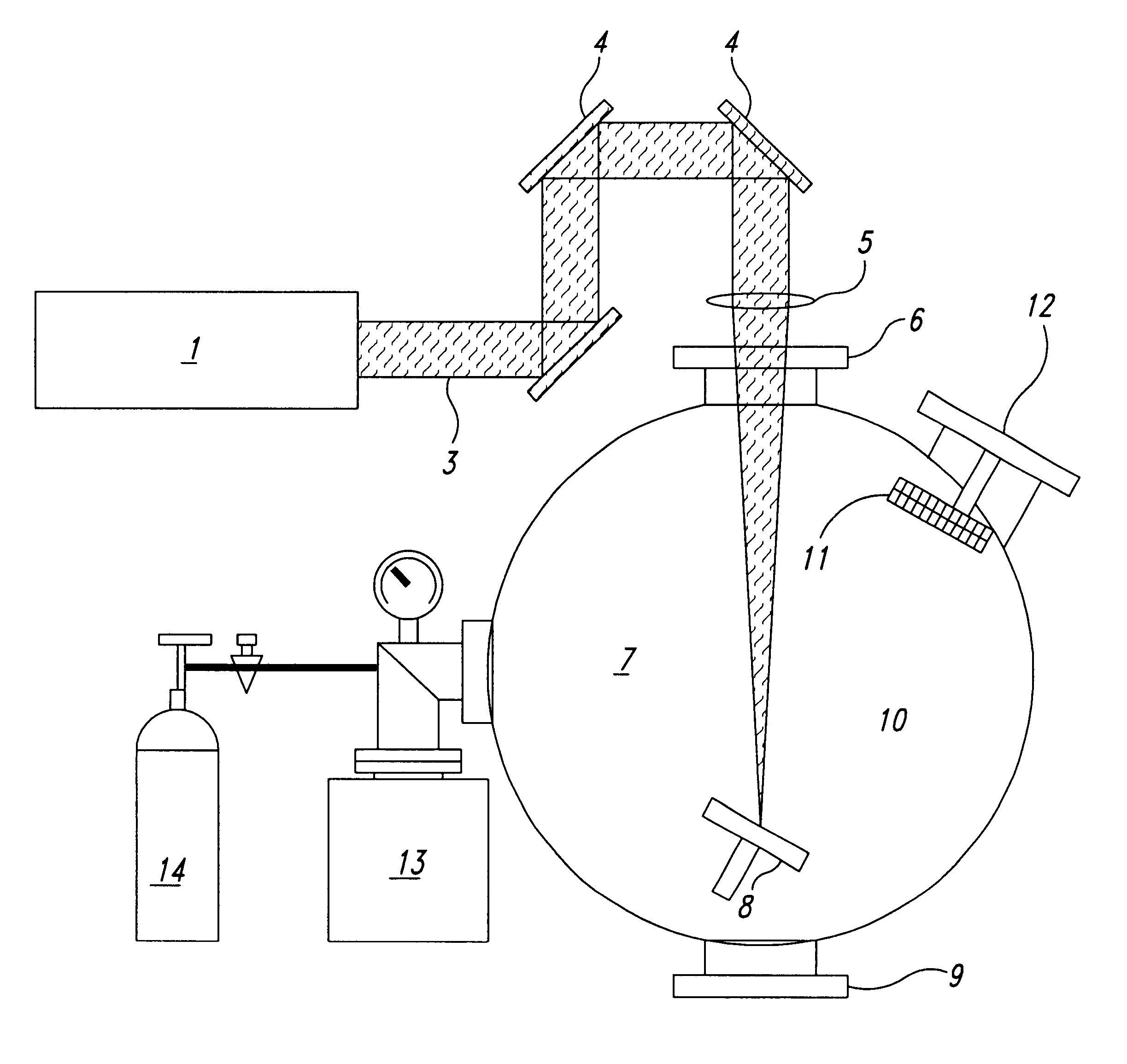

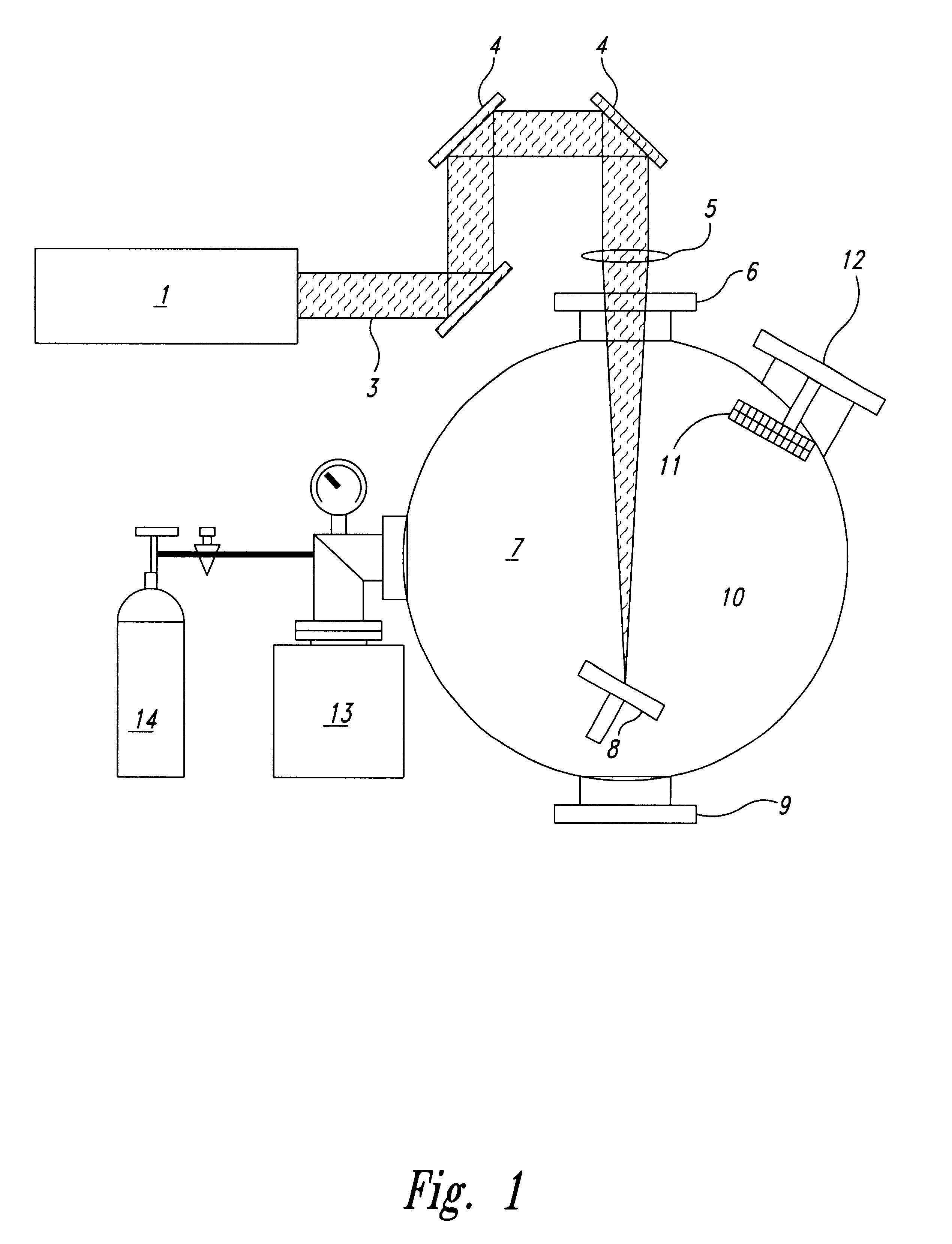

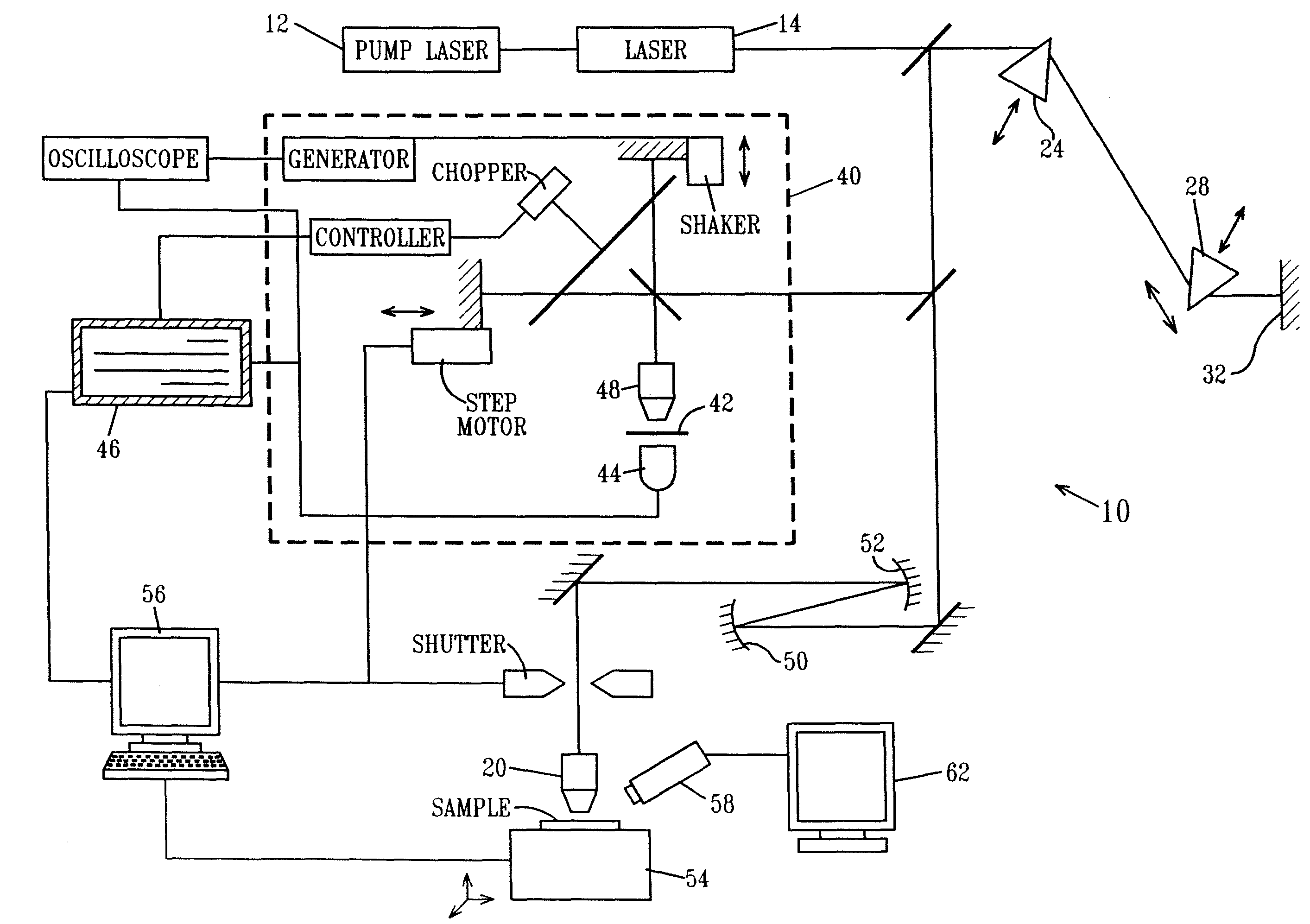

Method of deposition of thin films of amorphous and crystalline microstructures based on ultrafast pulsed laser deposition

InactiveUS6312768B1Improve surface qualityImprove efficiencyMaterial nanotechnologyElectric discharge heatingMacroscopic scaleCarbon nanotube

Powerful nanosecond-range lasers using low repetition rate pulsed laser deposition produce numerous macroscopic size particles and droplets, which embed in thin film coatings. This problem has been addressed by lowering the pulse energy, keeping the laser intensity optional for evaporation, so that significant numbers of the macroscopic particles and droplets are no longer present in the evaporated plume. The result is deposition of evaporated plume on a substrate to form thin film of very high surface quality. Preferably, the laser pulses have a repetition rate to produce a continuous flow of evaporated material at the substrate. Pulse-range is typically picosecond and femtosecond and repetition rate kilohertz to hundreds of megahertz. The process may be carried out in the presence of a buffer gas, which may be inert or reactive, and the increased vapour density and therefore the collision frequency between evaporated atoms leads to the formation of nanostructured materials of increasing interest, because of their peculiar structural, electronic and mechanical properties. One of these is carbon nanotubes, which is a new form of carbon belonging to the fullerene (C60) family. Carbon nanotubes are seamless, single or multishell co-axial cylindrical tubules with or without dome caps at the extremities. Typically diameters range from 1 nm to 50 nm with a length >1 mum. The electronic structure may be either metallic or semiconducting without any change in the chemical bonding or adding of dopant. In addition, the materials have application to a wide range of established thin film applications.

Owner:AUSTRALIEN NAT UNIV

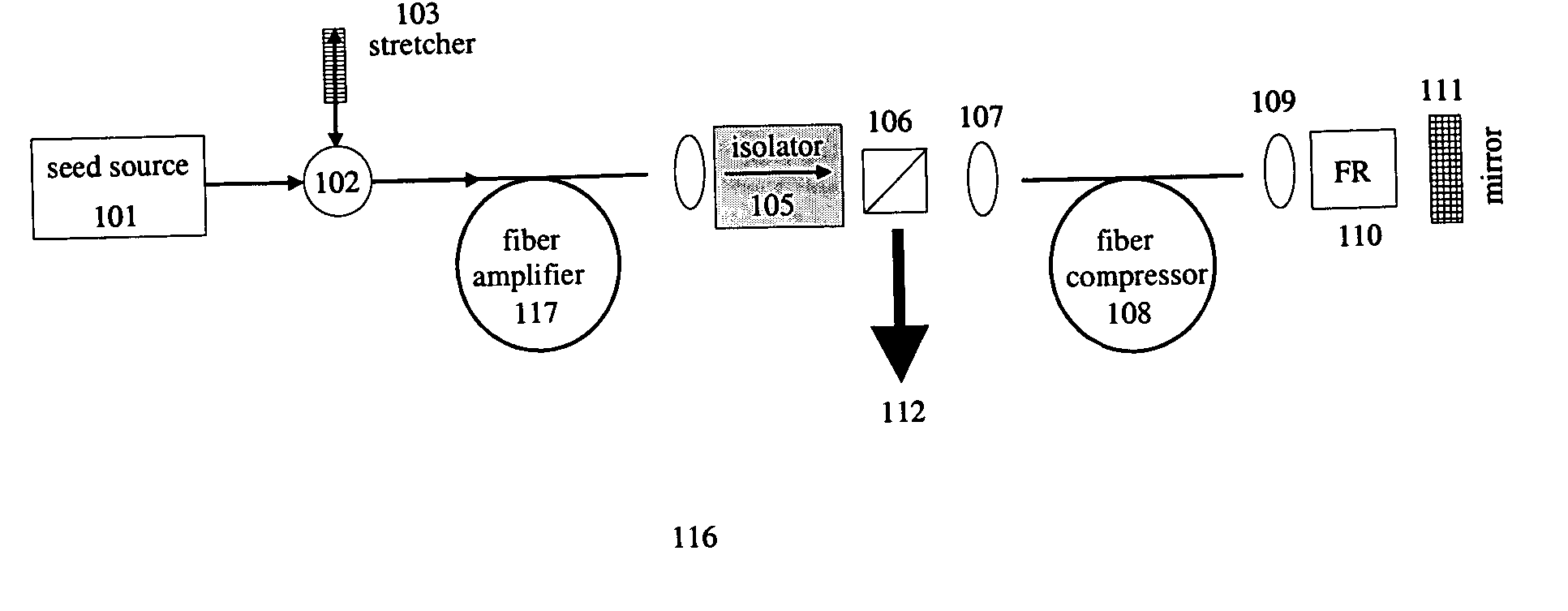

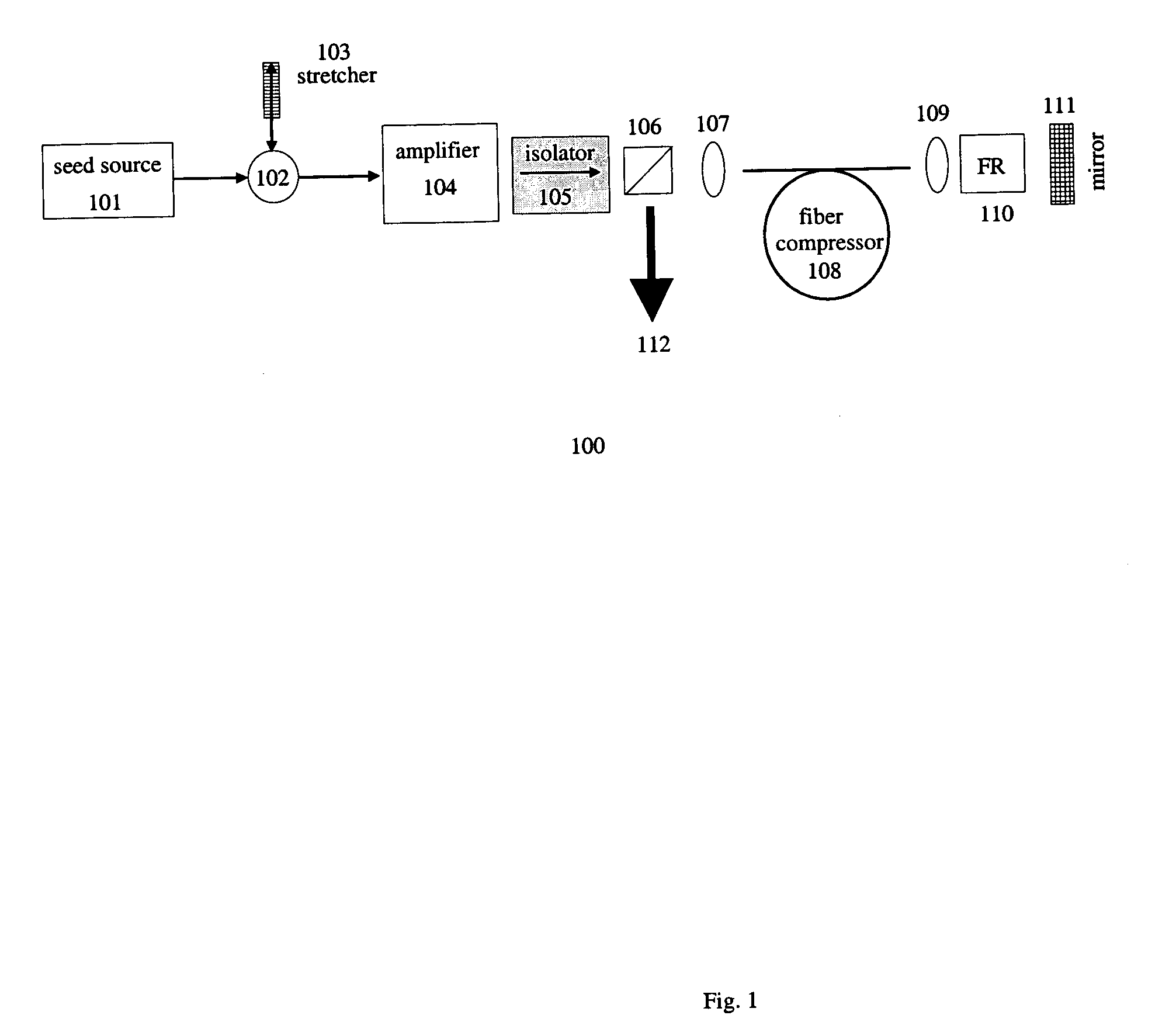

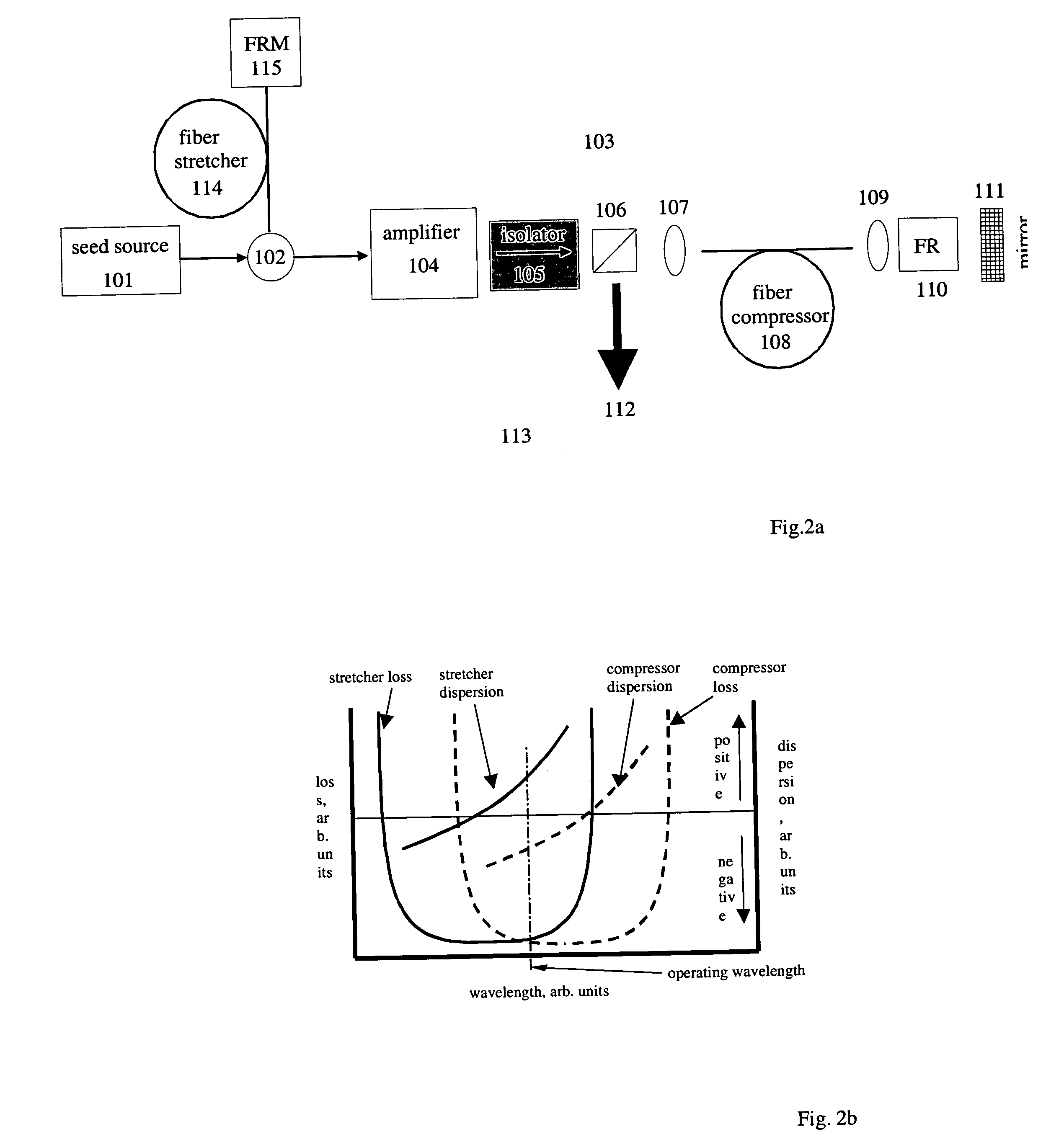

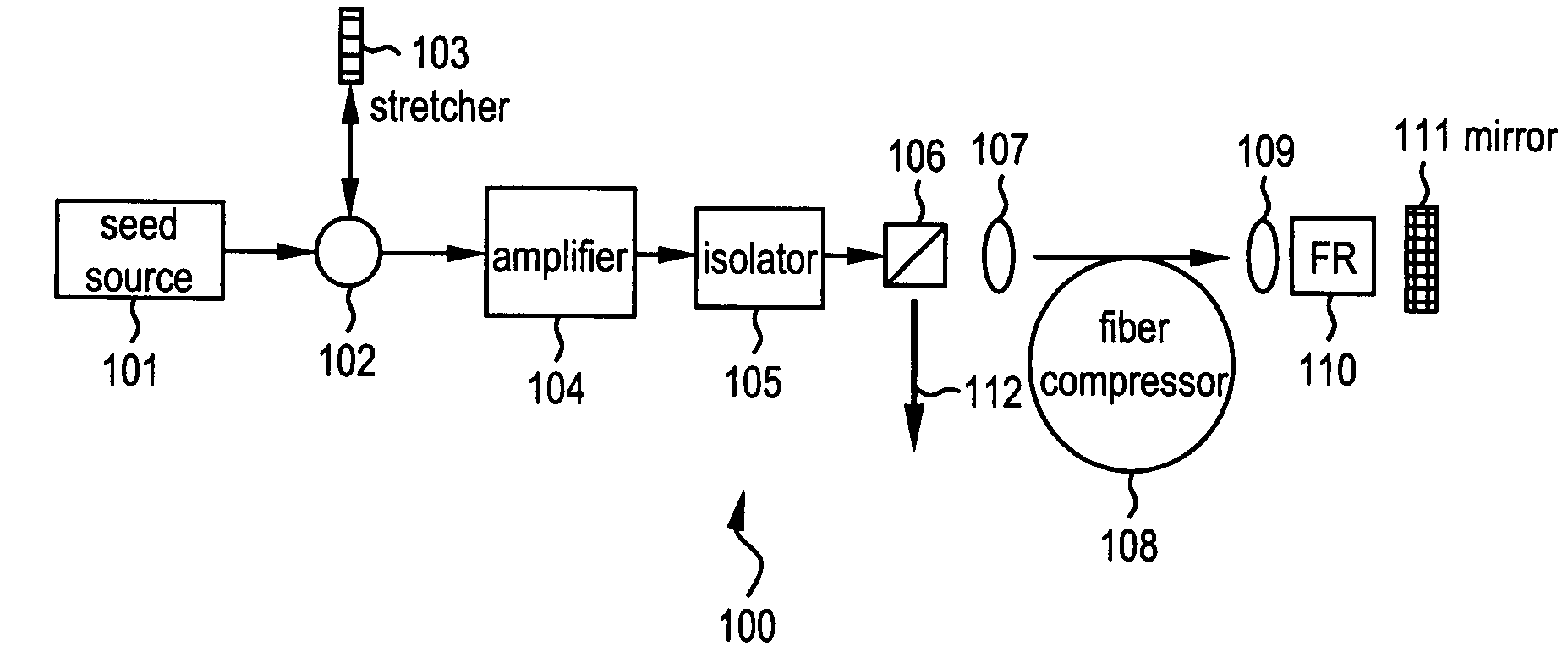

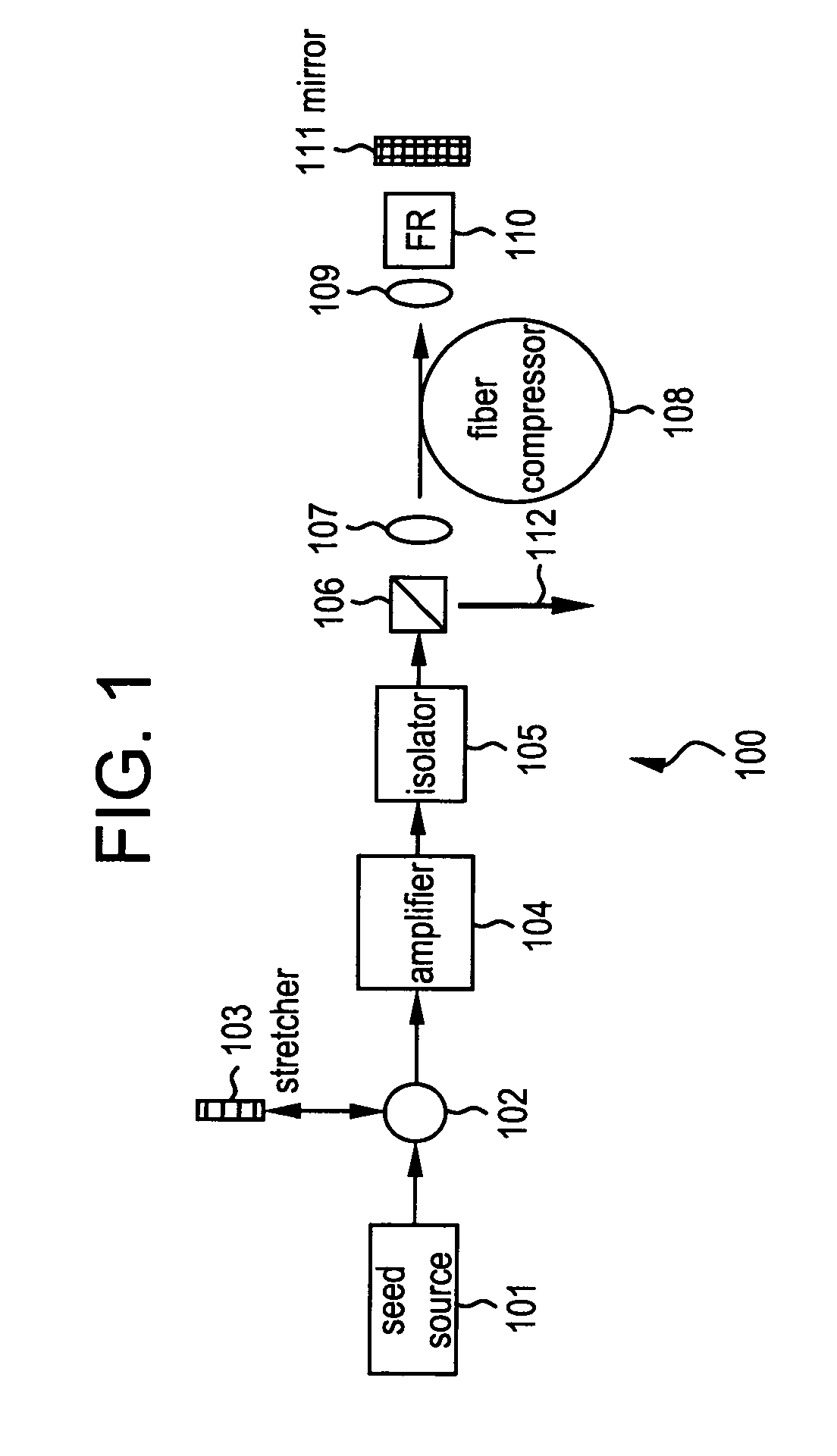

All-fiber chirped pulse amplification systems

InactiveUS20050105865A1Improve overall utilizationImprove performanceFibre transmissionCoupling light guidesLow noiseGrating

By compensating polarization mode-dispersion as well chromatic dispersion in photonic crystal fiber pulse compressors, high pulse energies can be obtained from all-fiber chirped pulse amplification systems. By inducing third-order dispersion in fiber amplifiers via self-phase modulation, the third-order chromatic dispersion from bulk grating pulse compressors can be compensated and the pulse quality of hybrid fiber / bulk chirped pulse amplification systems can be improved. Finally, by amplifying positively chirped pulses in negative dispersion fiber amplifiers, low noise wavelength tunable seed source via anti-Stokes frequency shifting can be obtained.

Owner:IMRA AMERICA

Selective Accumulation of Energy With or Without Knowledge of Tissue Topography

ActiveUS20100125268A1Avoids significant thermal damageSignificant thermal damageUltrasound therapyChiropractic devicesPulse energyPulse characteristics

Methods and systems for heating a body tissue region adjacent a body lumen with diseased and healthy portions using selective accumulation of energy in the artery tissue with or without knowledge of tissue topography. The method includes positioning an energy delivery portion of a catheter body within the lumen adjacent the body tissue region to be heated, determining a pulse characteristic in response to a thermal property of a first tissue type and applying pulsed energy with the pulse characteristic from the energy delivery portion so as to therapeutically treat the second tissue type within the body tissue region by drawing heat from the first tissue type at a rate that avoids significant thermal damage to the first tissue type while building-up heat in the second tissue type. The system includes an elongate flexible catheter body having a proximal end and a distal end with an axis therebetween, an energy delivery portion proximate the distal end, an energy source coupled to the energy delivery portion and a processor coupled to the energy source, the processor configured to control a pulse characteristic of pulsed energy transmitted from the energy source to the energy delivery portion so as to therapeutically treat the second tissue type within the body tissue region by drawing heat from the first tissue type at a rate that avoids significant thermal damage to the first tissue type while building-up heat in the second tissue type.

Owner:BOSTON SCI SCIMED INC

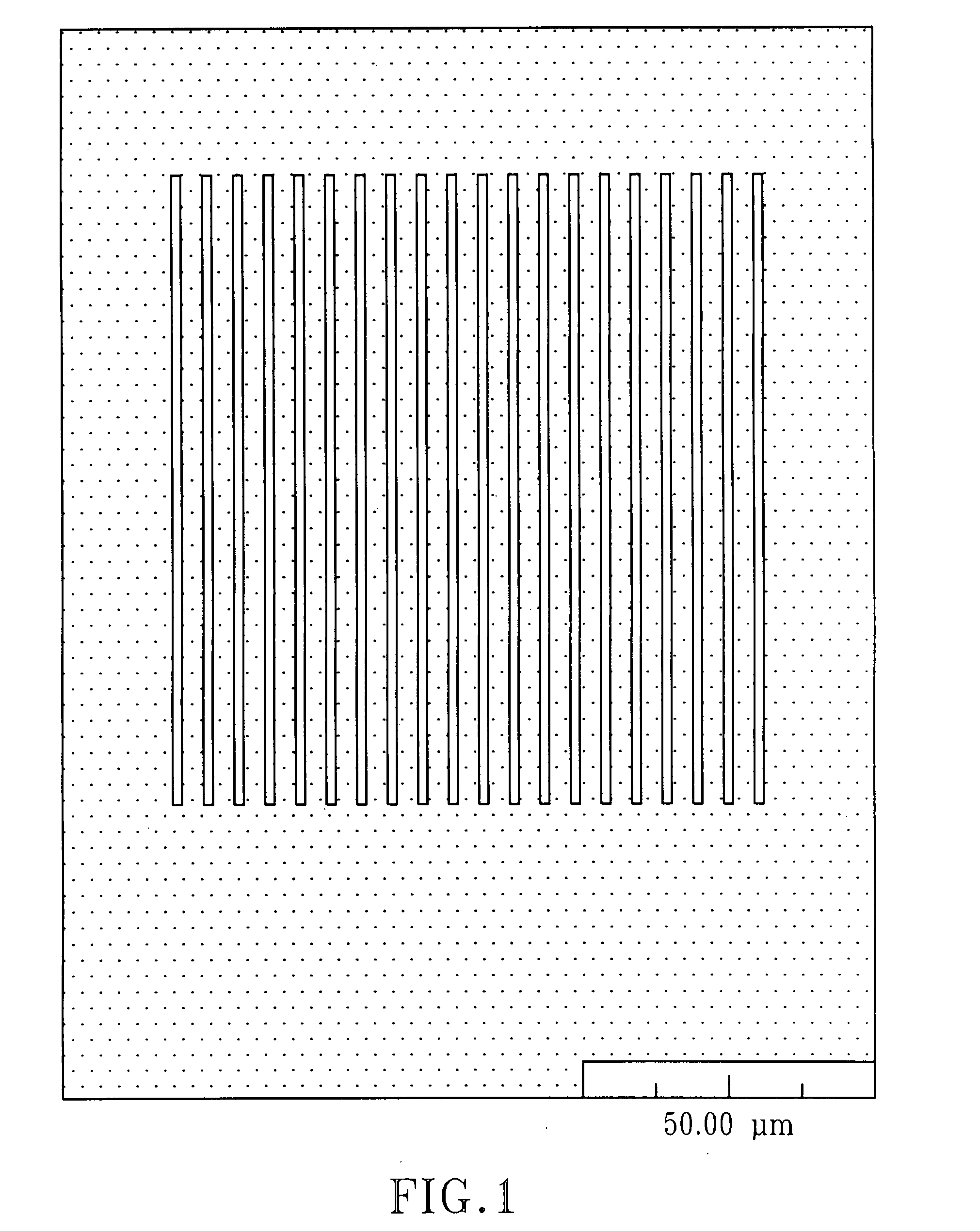

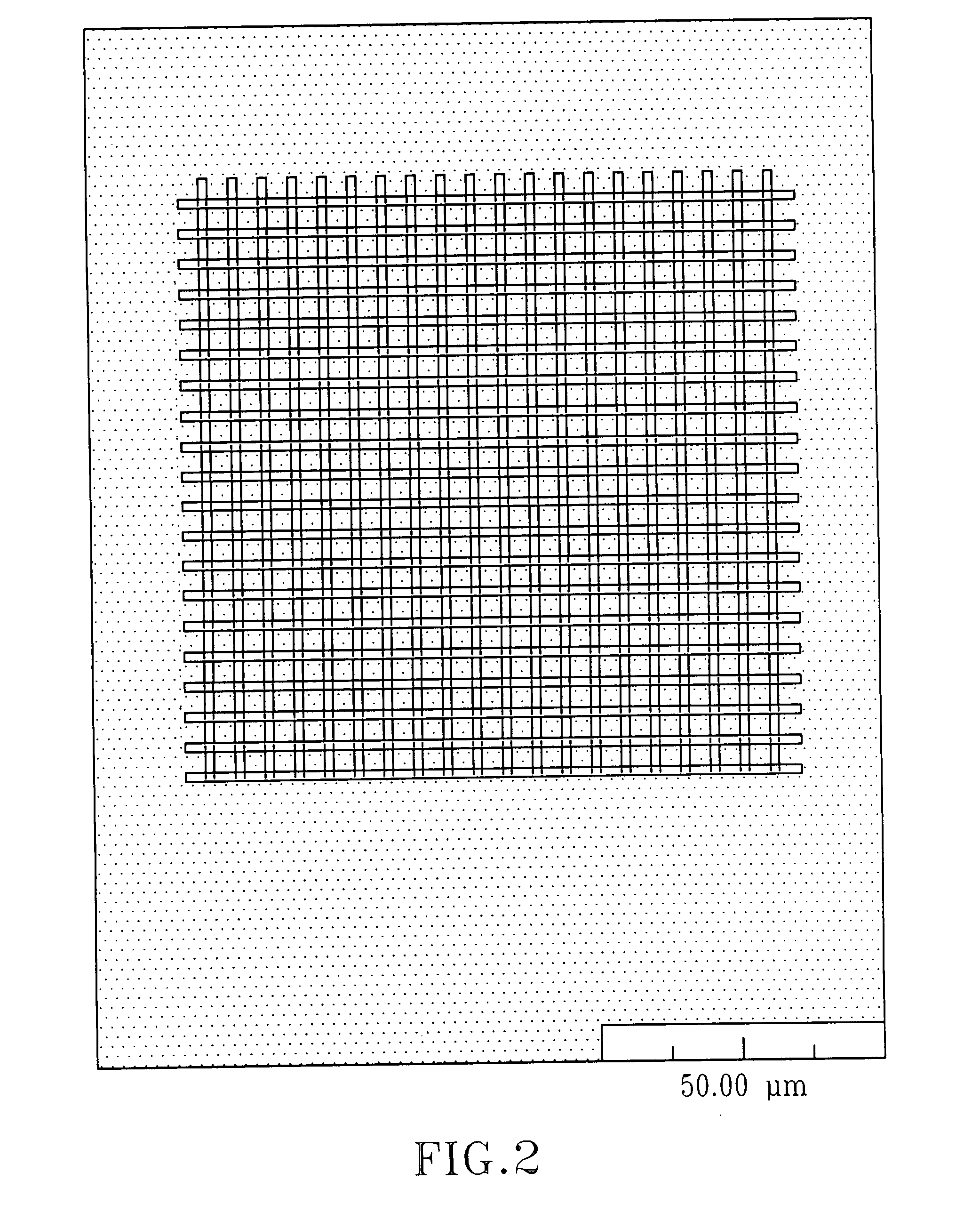

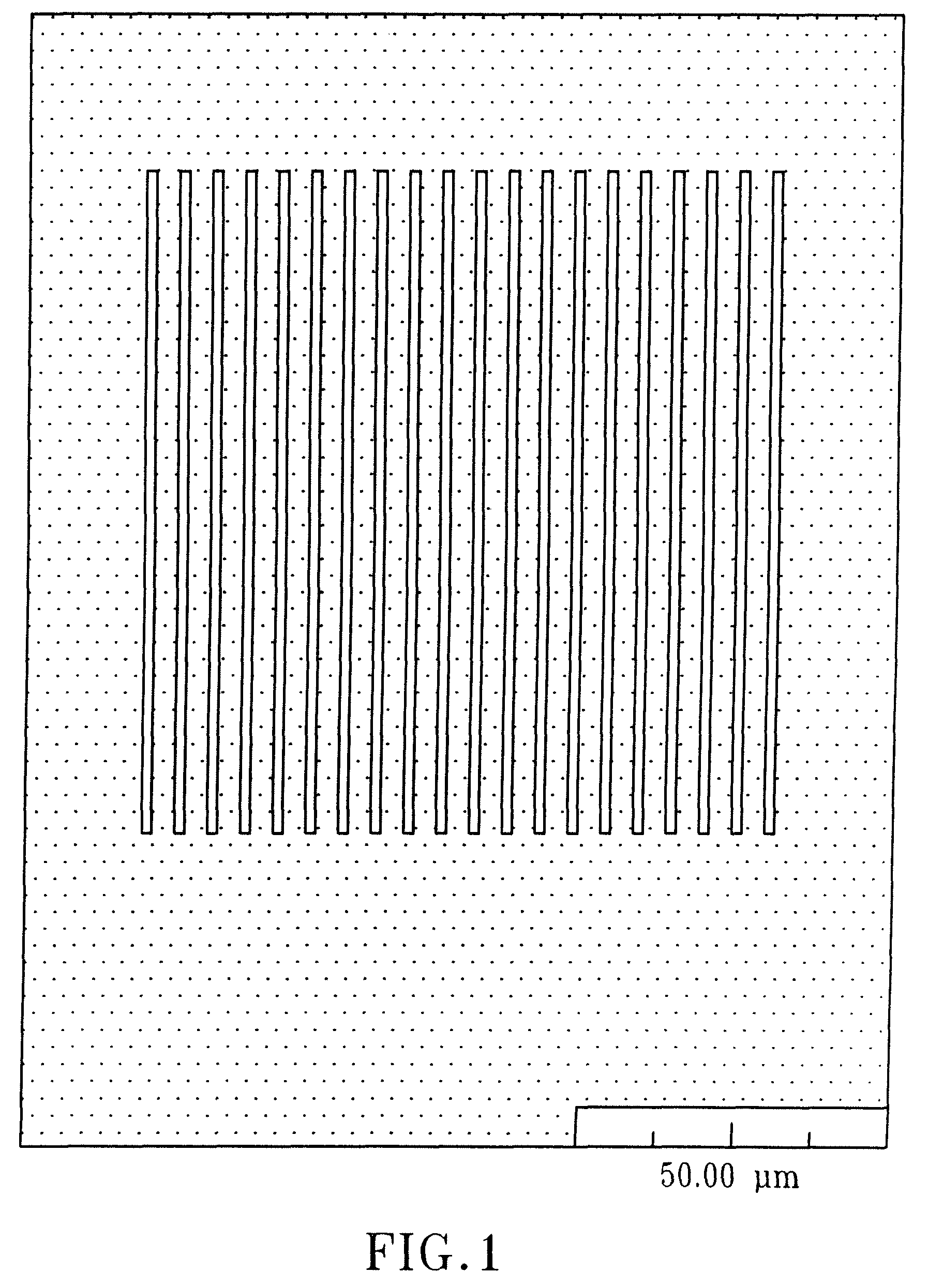

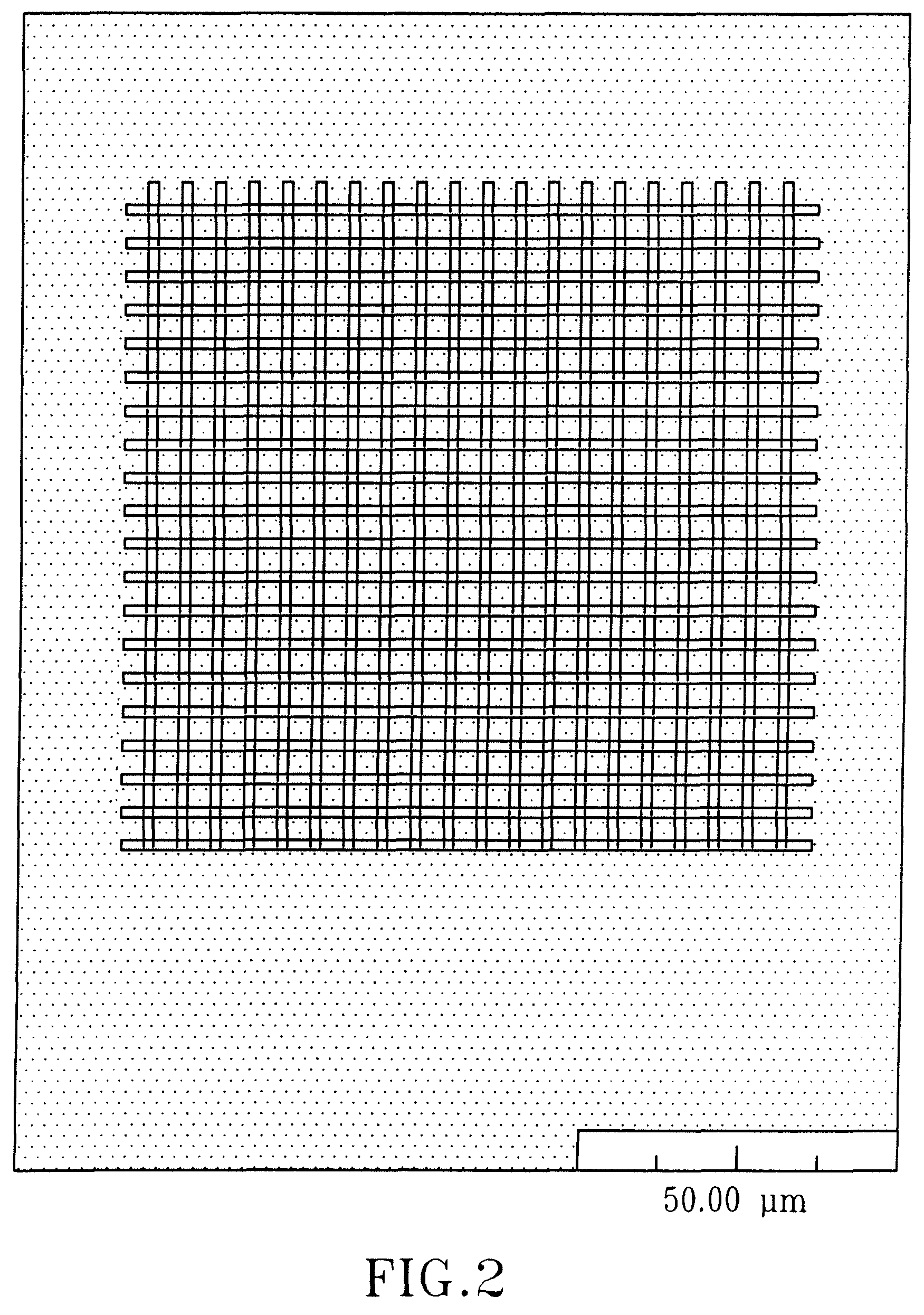

Optical Material and Method for Modifying the Refractive Index

InactiveUS20080001320A1Little and no scattering lossPositive changeSpectales/gogglesLaser surgeryIntraocular lensNear infrared laser

A method for modifying the refractive index of an optical, polymeric material. The method comprises irradiating select regions of the optical, polymeric material with a focused, visible or near-IR laser having a pulse energy from 0.05 nJ to 1000 nJ. The irradiation results in the formation of refractive optical structures, which exhibit little or no scattering loss. The method can be used to modify the refractive index of an intraocular lens following the surgical implantation of the intraocular lens in a human eye. The invention is also directed to an optical device comprising refractive optical structures, which exhibit little or no scattering loss and are characterized by a positive change in refractive index.

Owner:UNIVERSITY OF ROCHESTER

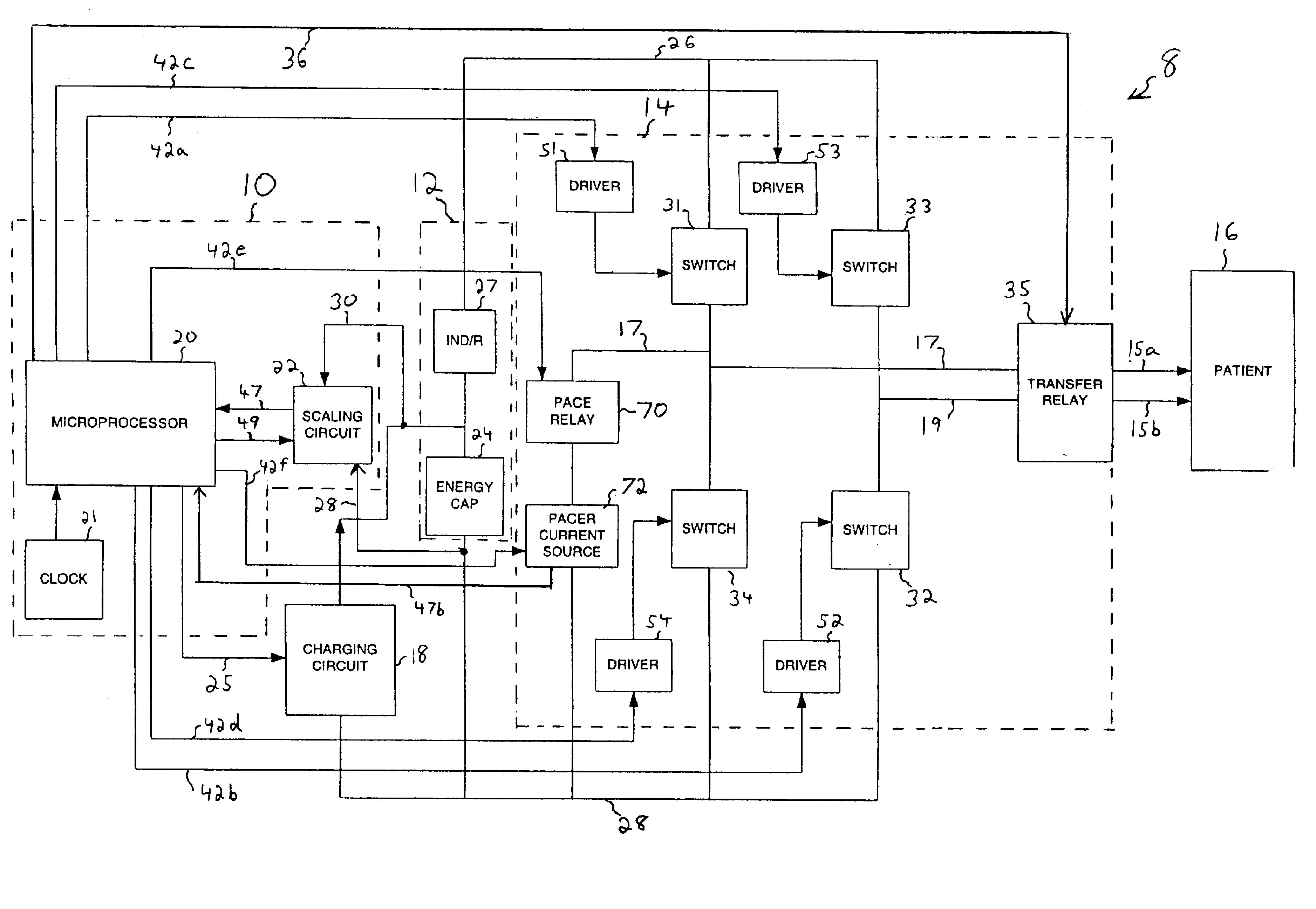

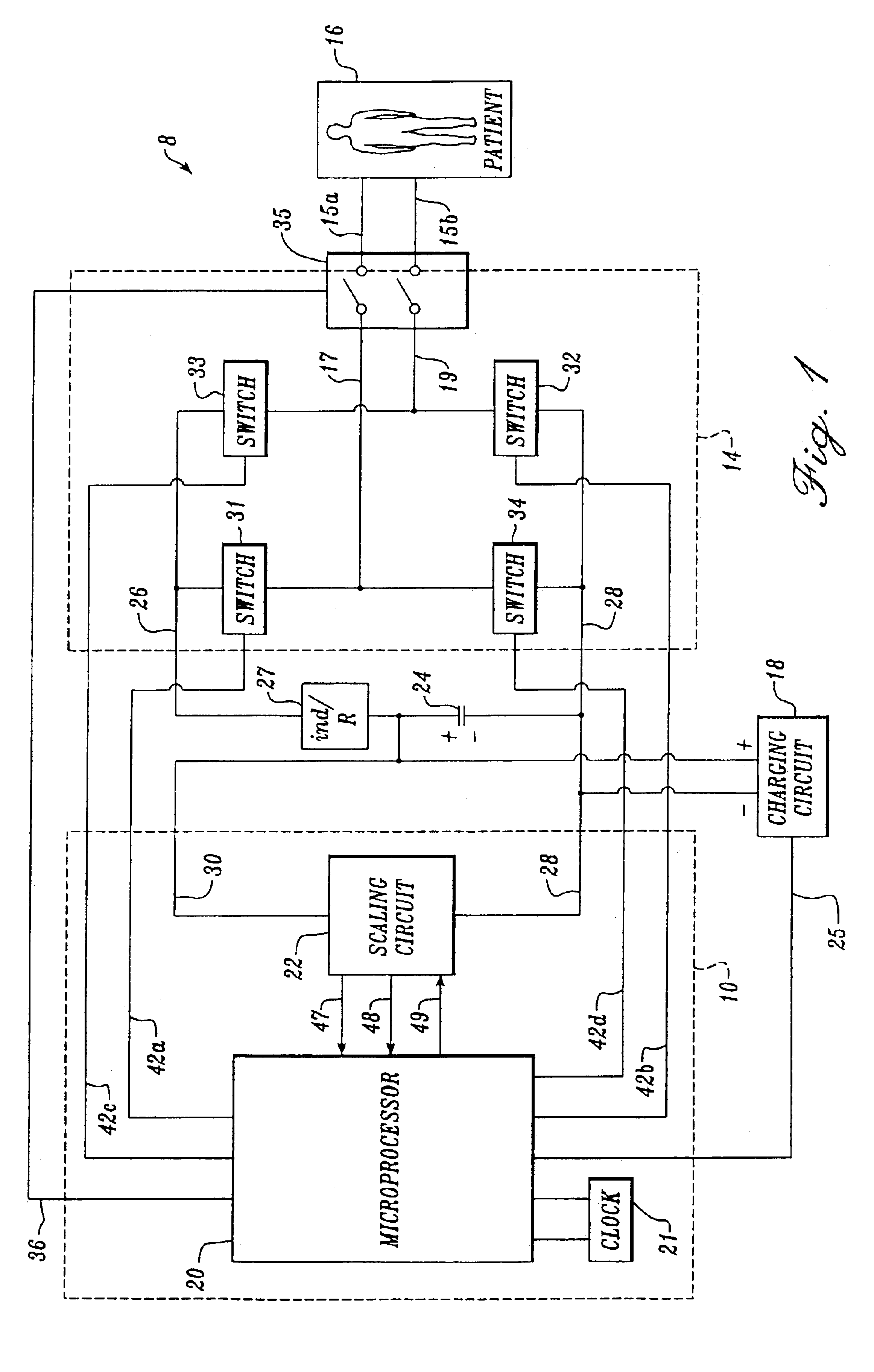

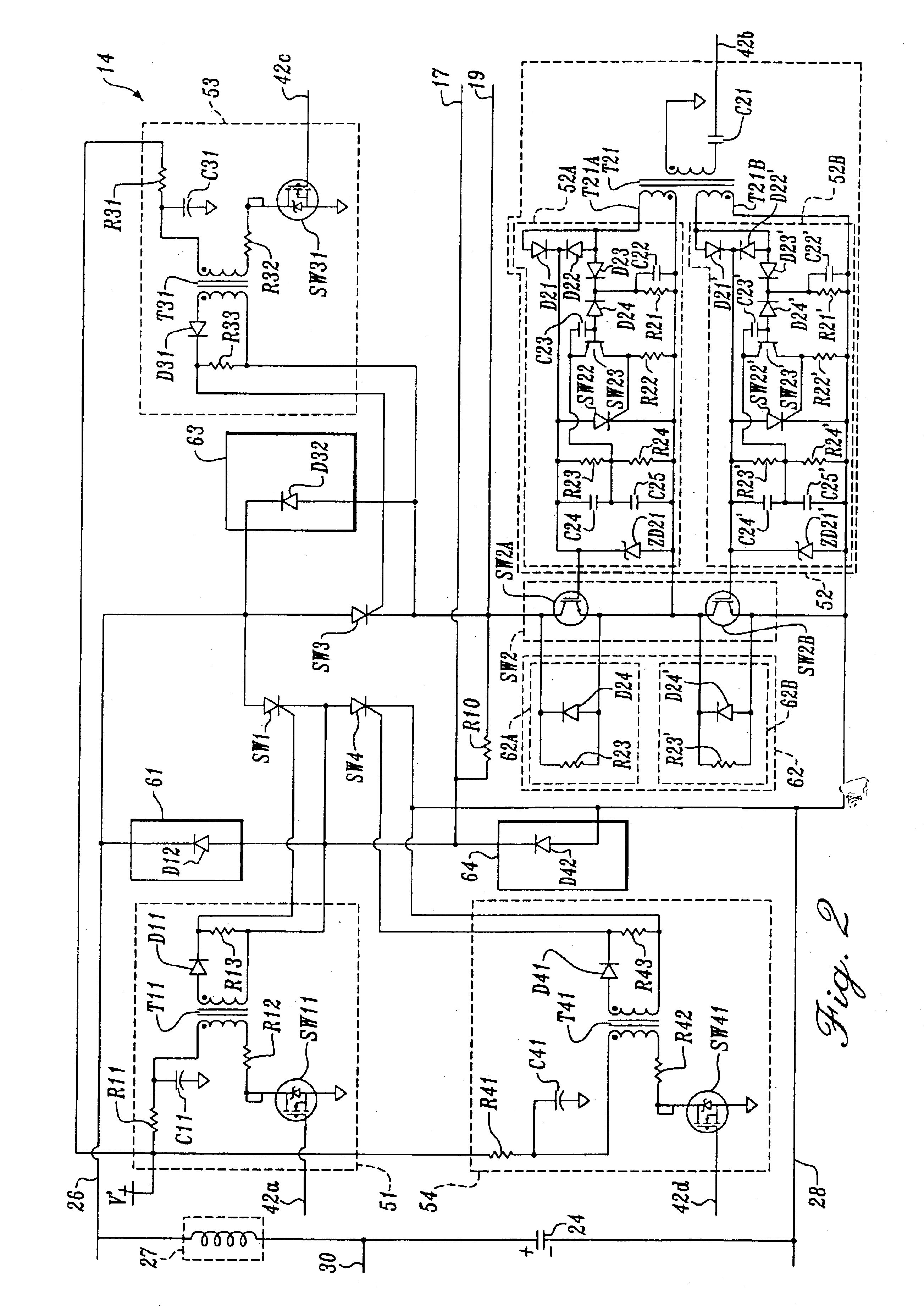

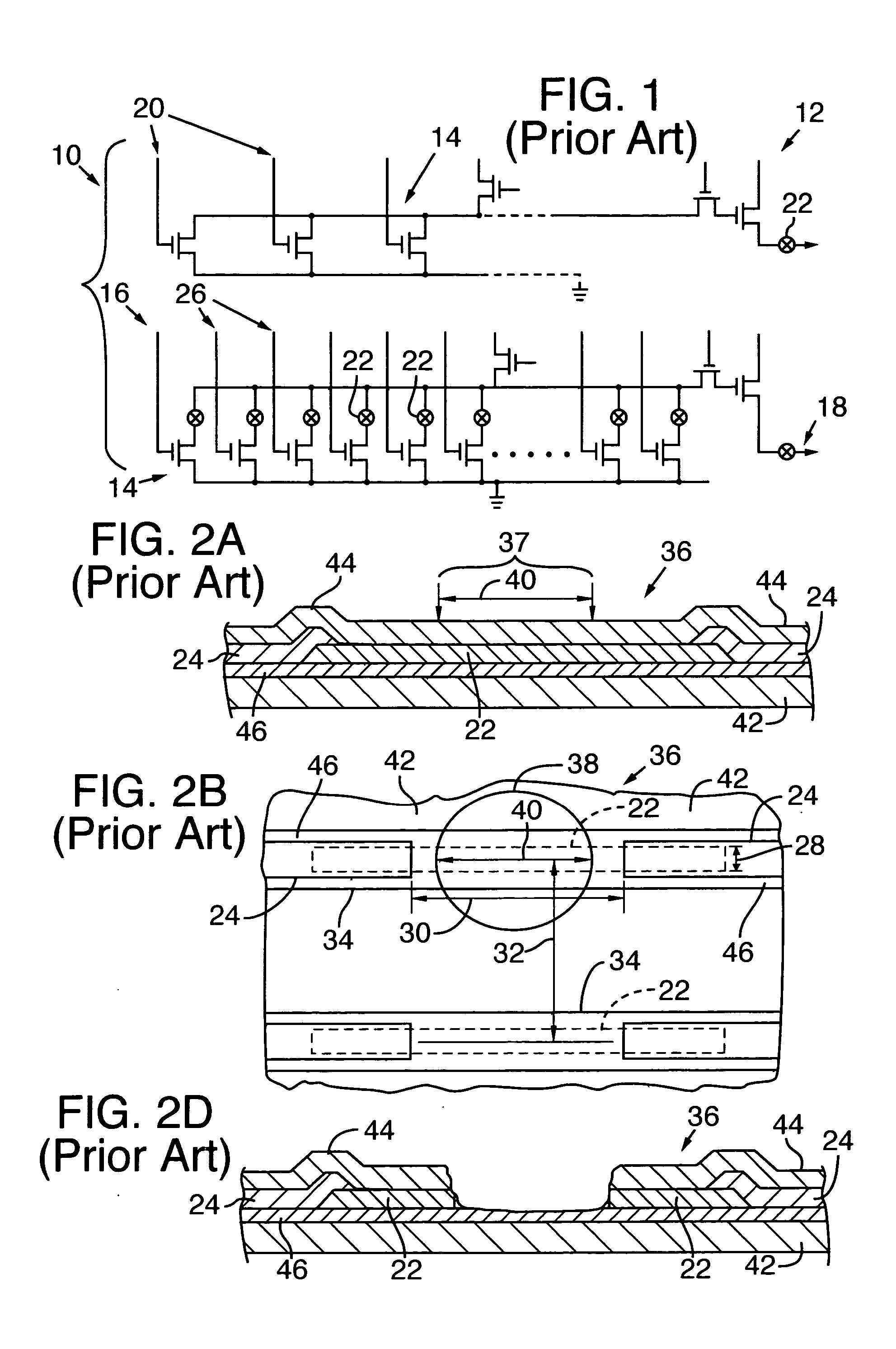

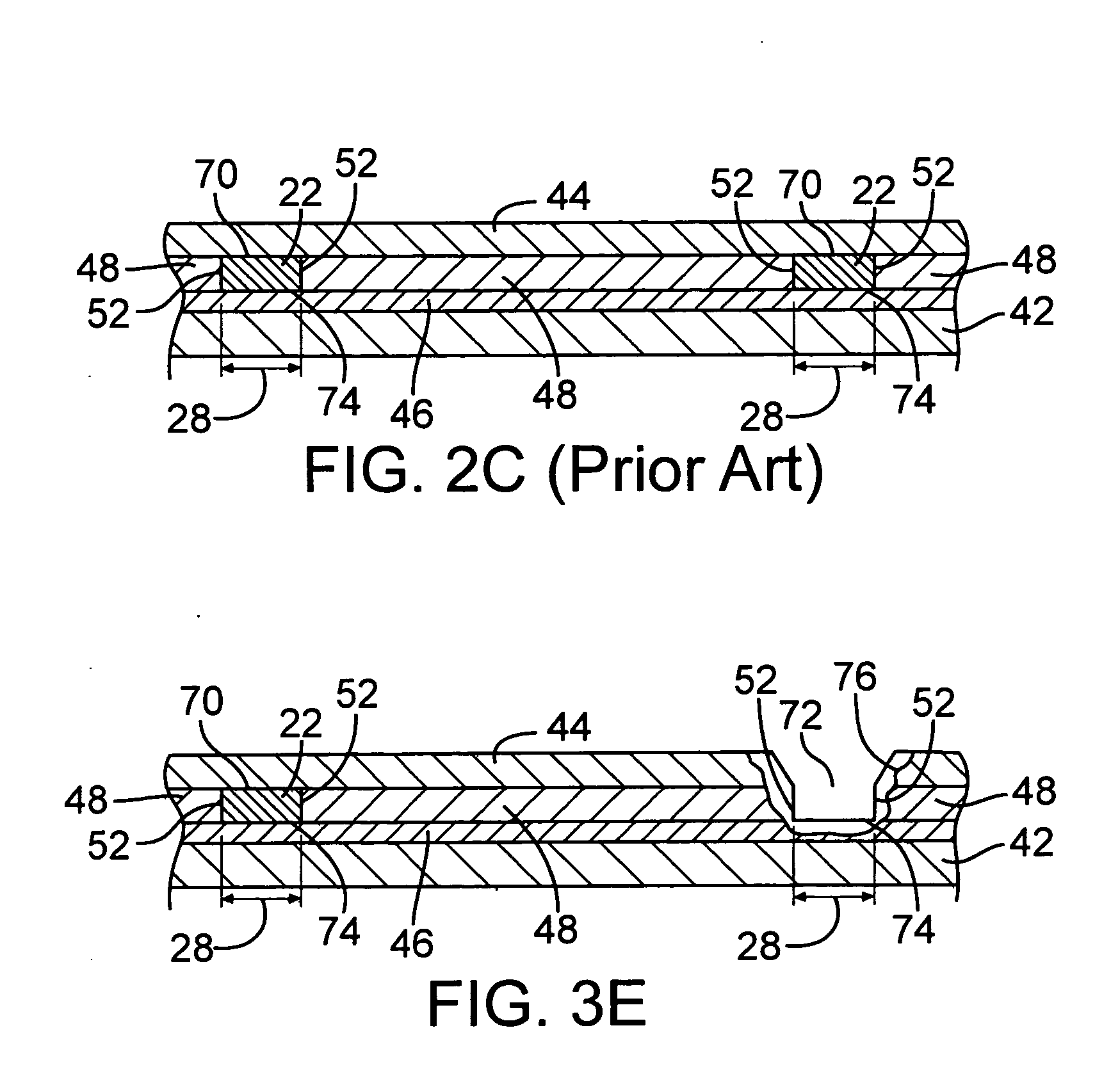

H-bridge circuit for generating a high-energy biphasic waveform in an external defibrillator using single SCR and IGBT switches in an integrated package

An external defibrillator with an output circuit having four legs arrayed in the form of an “H” (an “H-bridge”) is disclosed. The output circuit is designed to be able to conduct a range of defibrillation pulse energies, from below 50 joules to above 200 joules. Each leg of the output circuit contains a solid-state switch. By selectively switching on pairs of switches in the H-bridge, a biphasic defibrillation pulse may be applied to a patient. The switches in three of the legs of the H-bridge output circuit are preferably SCR switches, while the fourth leg includes an IGBT switch. In one embodiment, a single power switch is utilized in each of the legs of the H-bridge output circuit, and are included in a single integrated module or package. The use of single semiconductor switches in an integrated surface mountable module or package simplifies the assembly and manufacturing of the defibrillator device. The use of a single IGBT in a leg of the H-bridge (as opposed to two or more IGBTs in series) also greatly simplifies the drive circuitry required to turn on and off the IGBT.

Owner:PHYSIO CONTROL INC

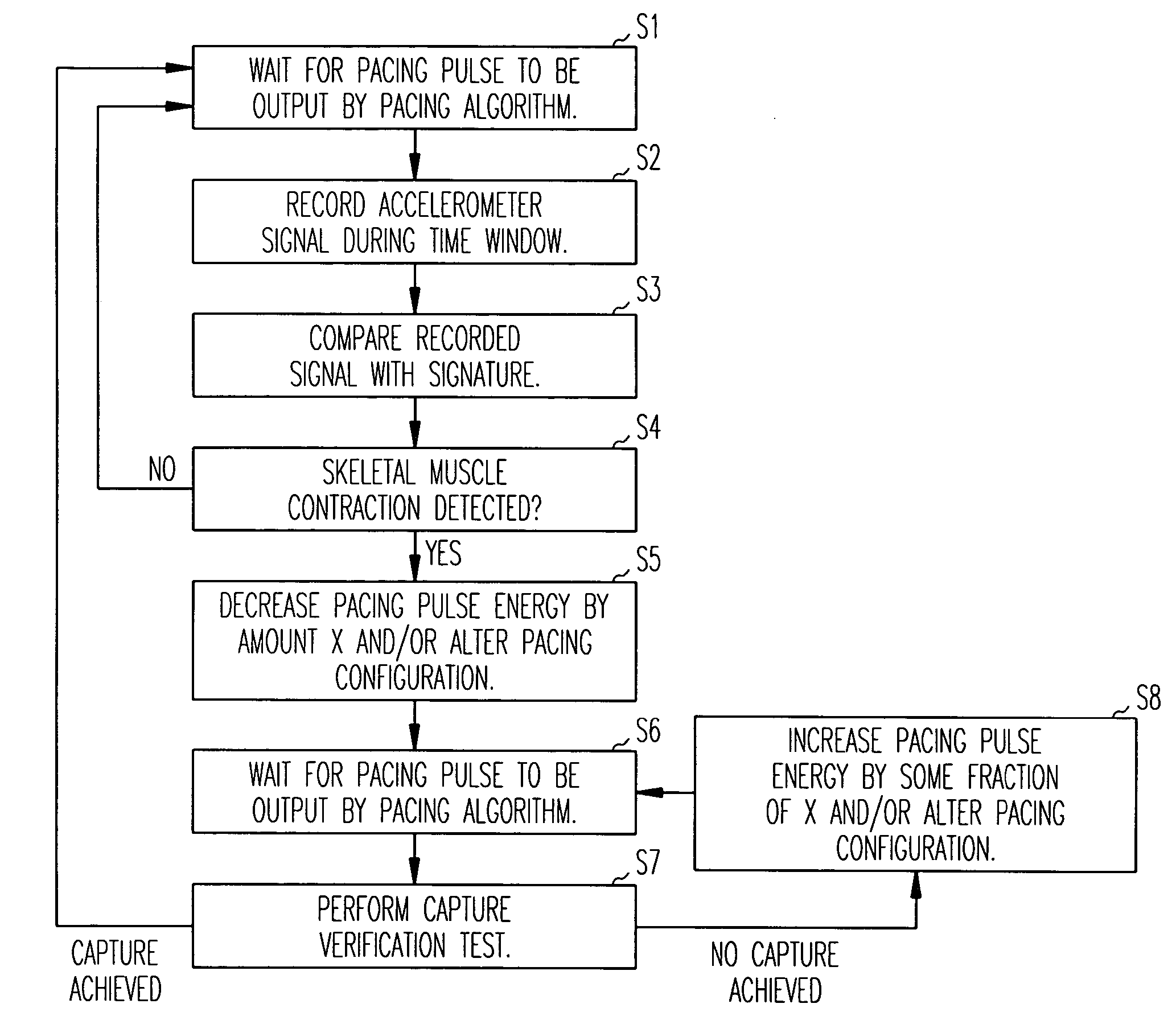

Method and apparatus for avoidance of phrenic nerve stimulation during cardiac pacing

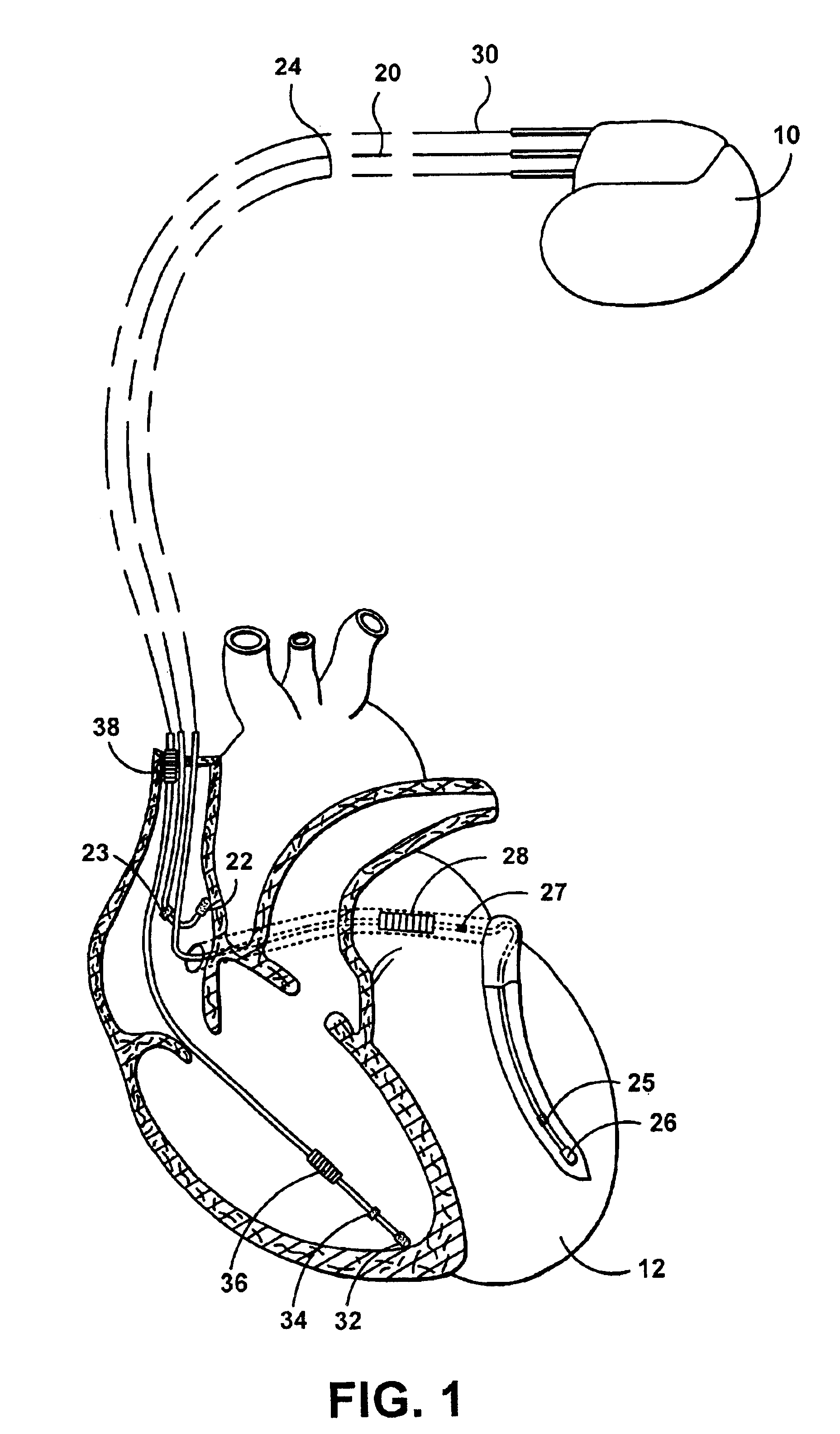

A cardiac rhythm management device in which an accelerometer is used to detect diaphragmatic or other skeletal muscle contraction associated with the output of a pacing pulse. Upon detection of diaphragmatic contraction, the device may be configured to automatically adjust the pacing pulse energy and / or pacing configuration.

Owner:CARDIAC PACEMAKERS INC

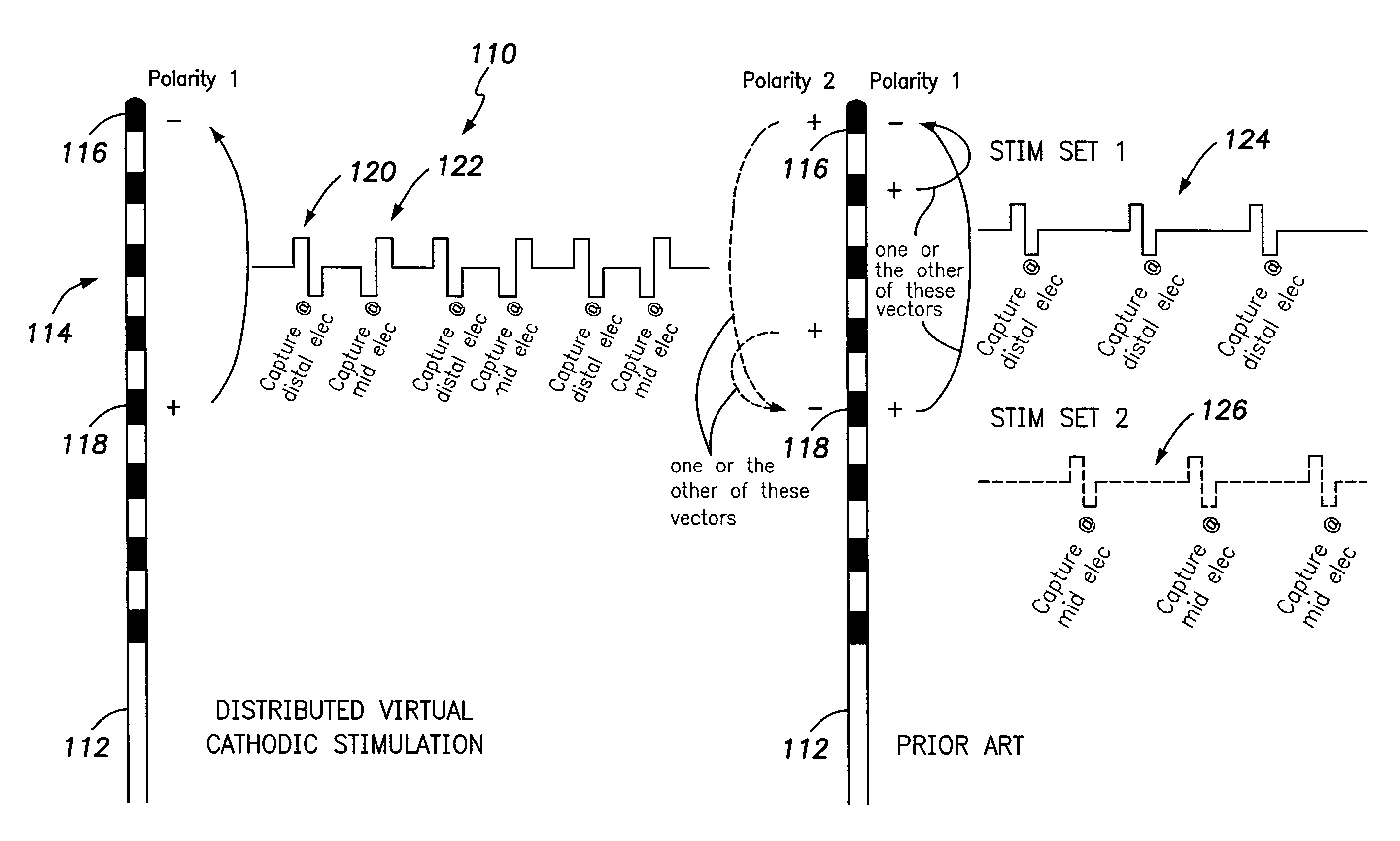

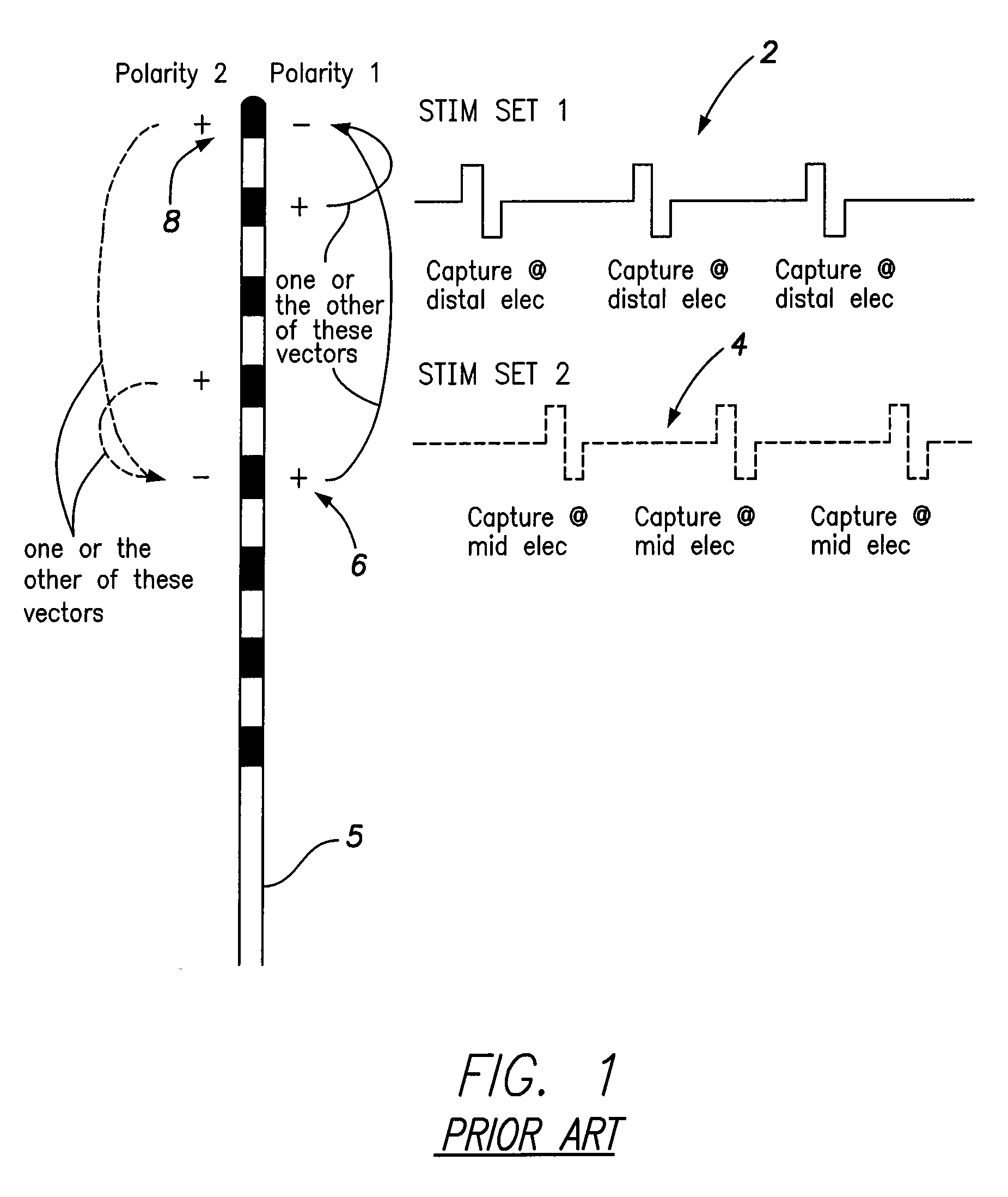

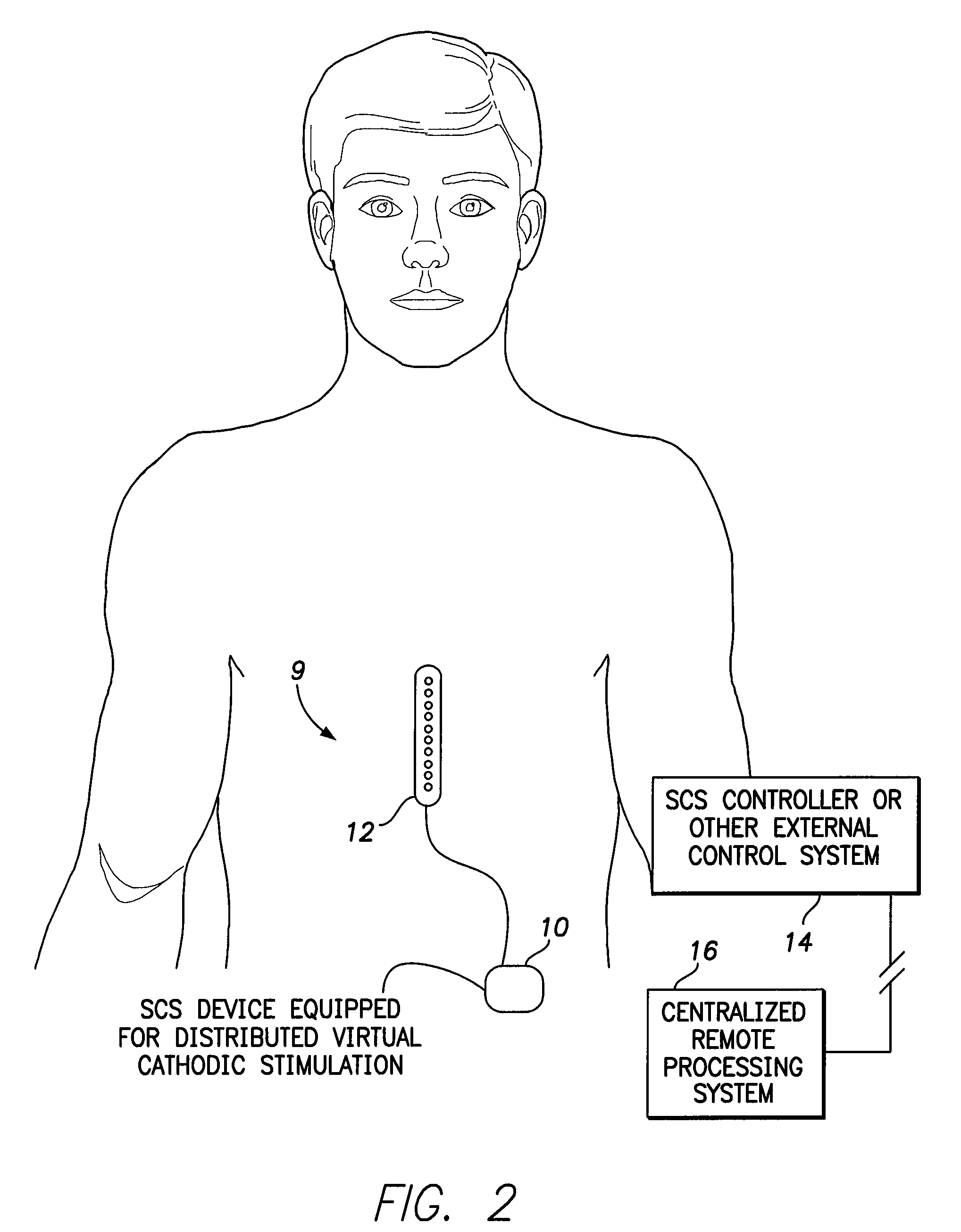

Systems and methods for providing a distributed virtual stimulation cathode for use with an implantable neurostimulation system

ActiveUS9044610B2Increased energy consumption/current drainExpand coverageSpinal electrodesExternal electrodesPulse energyBiomedical engineering

Techniques are provided for controlling and delivering spinal cord stimulation (SCS) or other forms of neurostimulation. In one example, neurostimulation pulses are generated wherein successive pulses alternate in polarity so that a pair of electrodes alternate as cathodes. Each pulse has a cathodic amplitude sufficient to achieve cathodic capture of tissues adjacent the particular electrode used as the cathode for the pulse. The neurostimulation pulses are delivered to patient tissues using the electrodes to alternatingly capture tissues adjacent opposing electrodes via cathodic capture to achieve a distributed virtual stimulation cathode. Various pulse energy savings techniques are also set forth that exploit the distributed virtual stimulation cathode.

Owner:PACESETTER INC

All-fiber chirped pulse amplification systems

InactiveUS7414780B2Improve overall utilizationImprove performanceCoupling light guidesFibre transmissionLow noiseGrating

By compensating polarization mode-dispersion as well chromatic dispersion in photonic crystal fiber pulse compressors, high pulse energies can be obtained from all-fiber chirped pulse amplification systems. By inducing third-order dispersion in fiber amplifiers via self-phase modulation, the third-order chromatic dispersion from bulk grating pulse compressors can be compensated and the pulse quality of hybrid fiber / bulk chirped pulse amplification systems can be improved. Finally, by amplifying positively chirped pulses in negative dispersion fiber amplifiers, low noise wavelength tunable seed source via anti-Stokes frequency shifting can be obtained.

Owner:IMRA AMERICA

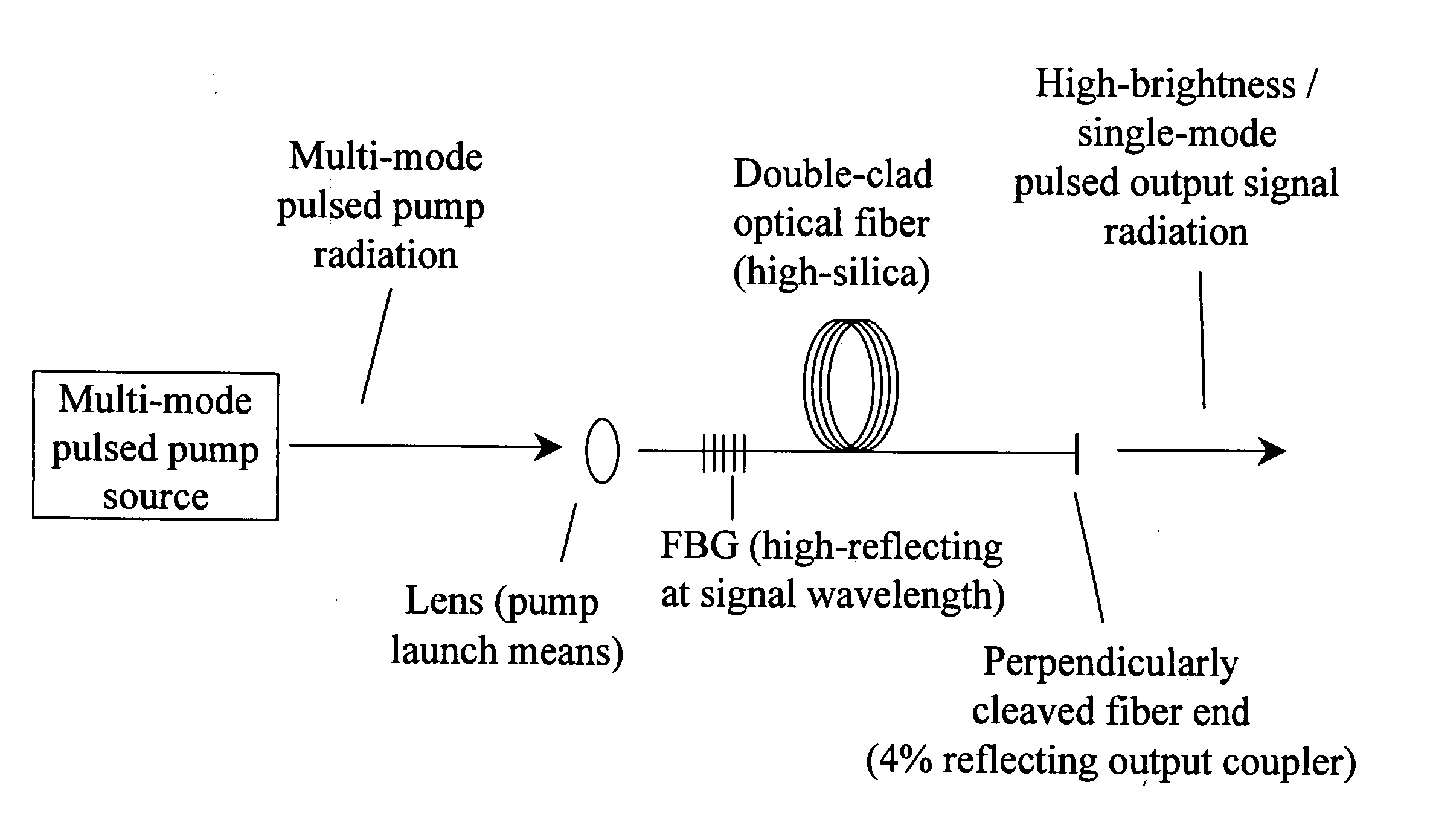

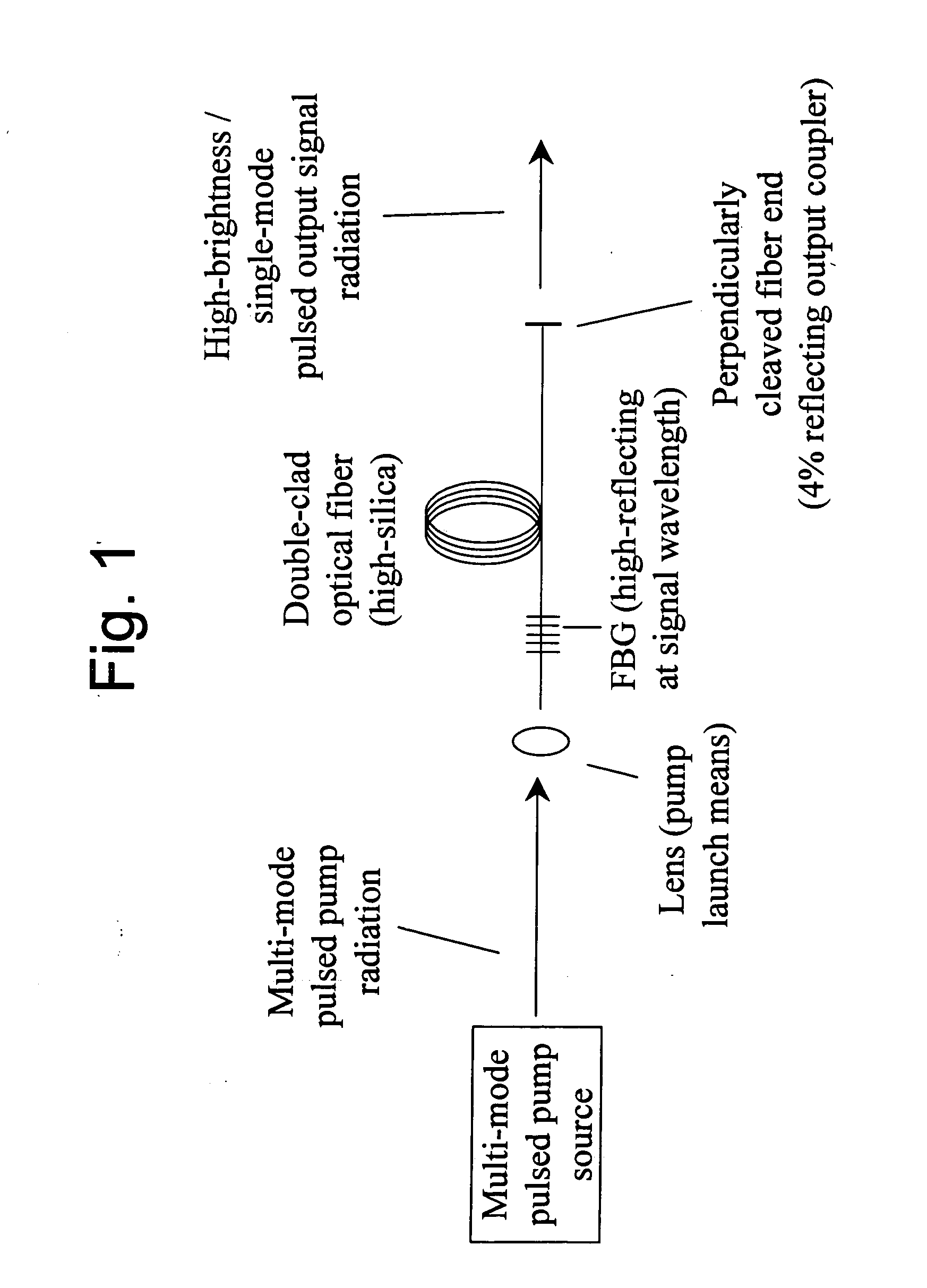

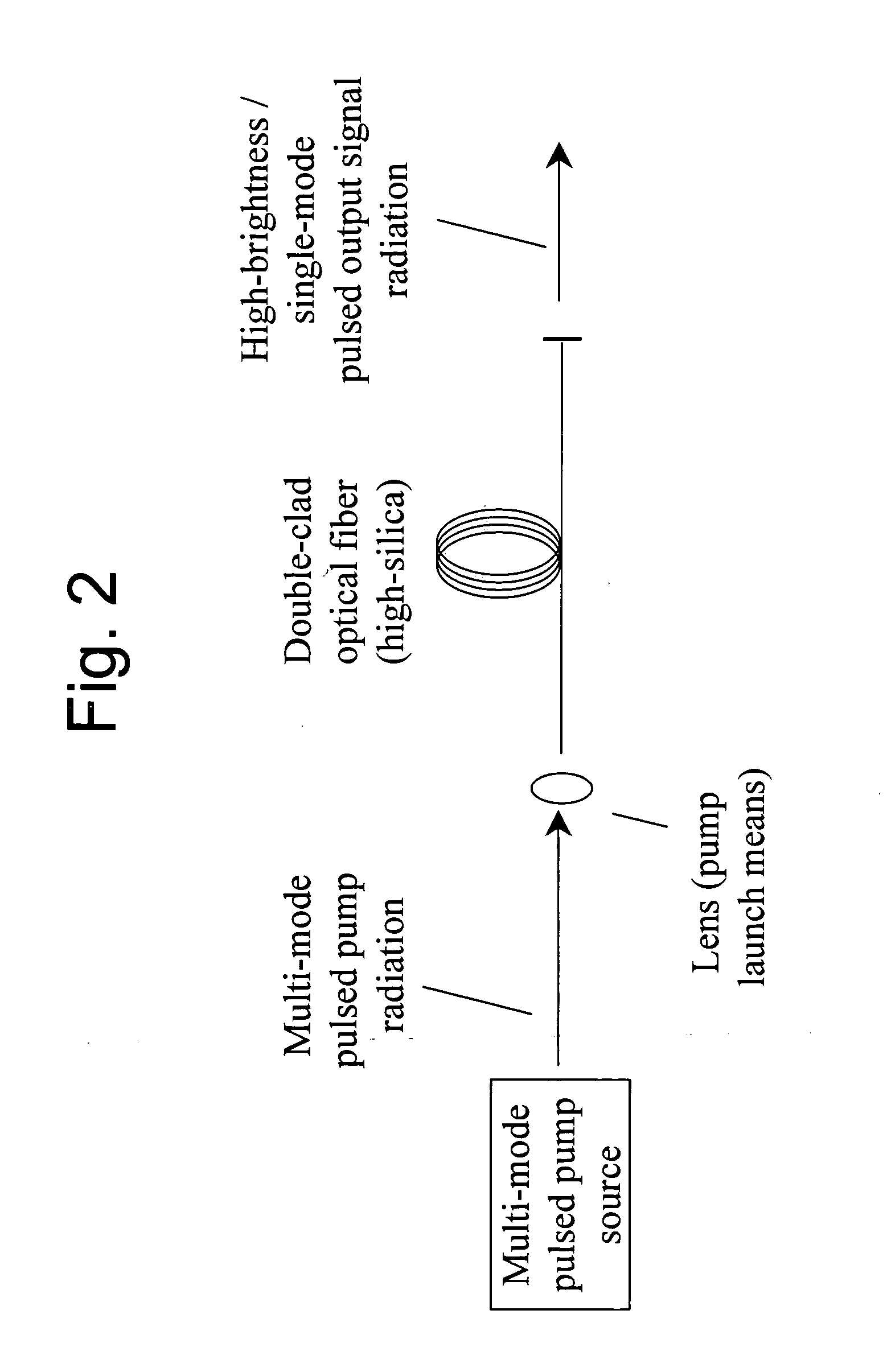

Optical device with immediate gain for brightness enhancement of optical pulses

InactiveUS20050024716A1Promote efficient conversionImproved thermal managementLaser using scattering effectsFibre transmissionPulse energyLight beam

Amplifying optical waveguide devices, which, by combining an instantaneous or nearly instantaneous gain medium with pulsed cladding-pumping can convert the multimode pump pulses to higher-brightness (even single-mode) signal pulses. The operating parameters can be carefully matched to the interaction length of the amplifying optical device to promote efficient conversion. The invention combines attractive features of cladding-pumped waveguide devices such as robustness and good thermal management properties with those of synchronously pumped devices. Thus, the pulse energy of the generated beam is not limited by the energy that can be stored in the gain medium.

Owner:UNIV OF SOUTHAMPTON

Methods of and laser systems for link processing using laser pulses with specially tailored power profiles

ActiveUS20050067388A1Improve removal qualityImprove processing qualityLaser detailsSemiconductor/solid-state device detailsPulse energyUltraviolet

Owner:ELECTRO SCI IND INC

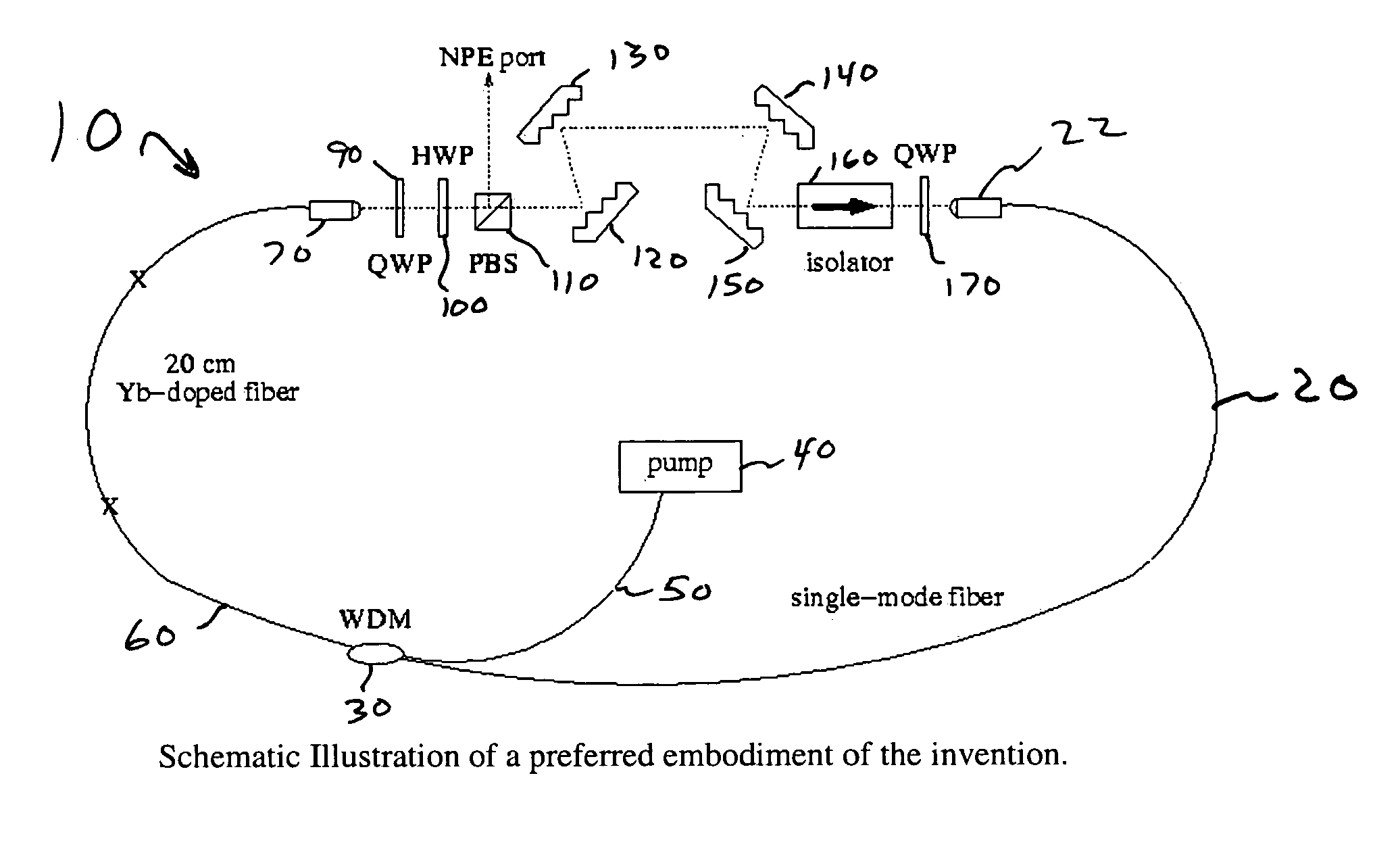

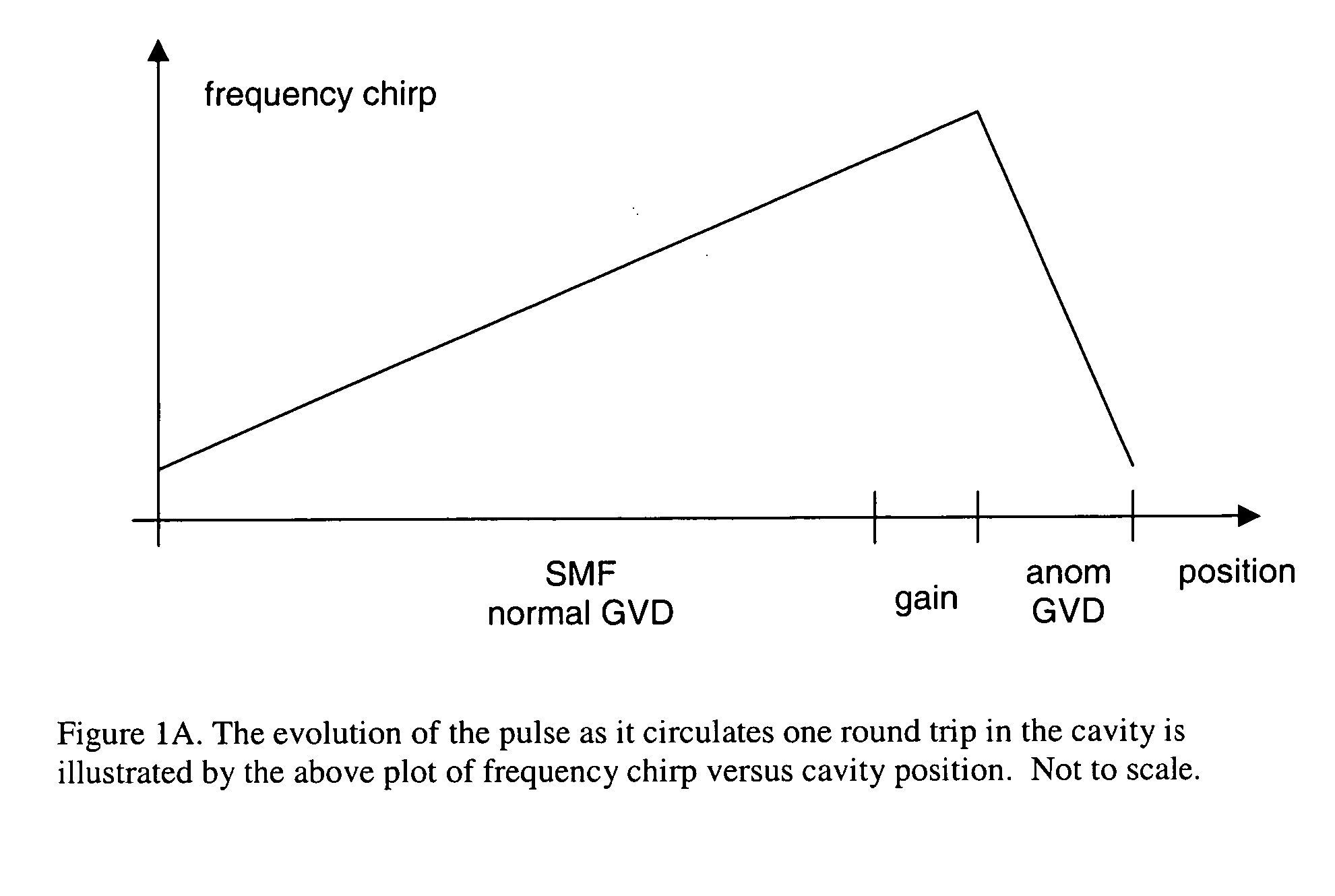

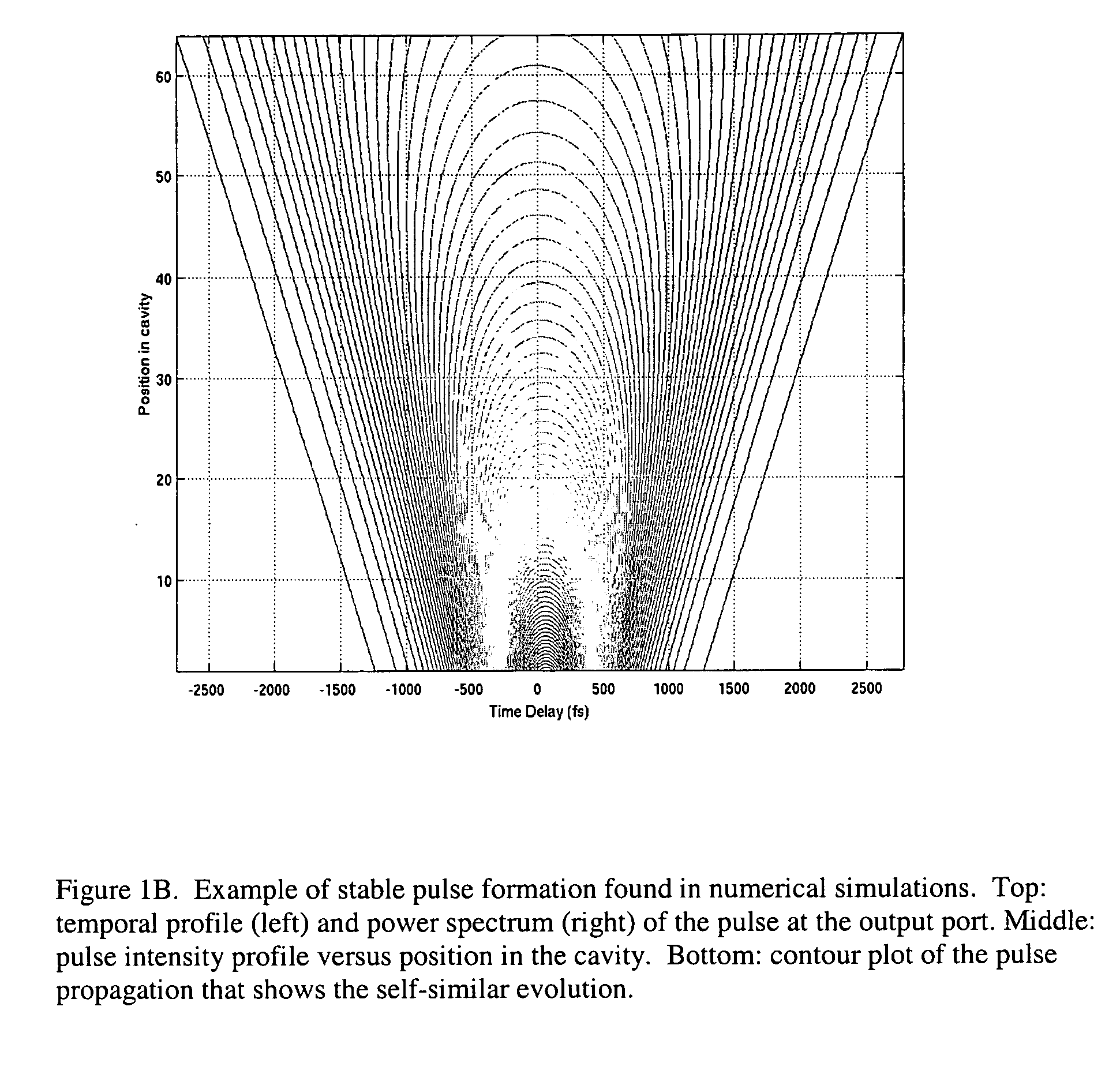

Self-similar laser oscillator

InactiveUS20050169324A1Stable operation of laserHigh bandwidthLaser using scattering effectsActive medium materialState of artHigh energy

A laser producing high energy ultrashort laser pulses comprises a normal dispersion segment, a gain segment, an anomalous dispersion segment with negligible nonlinearity and an effective saturable absorber arranged to form a laser cavity. Each segment is optically interconnected so that a laser pulse will propagate self-similarly therein. (A pulse that propagates in a self-similar manner is sometimes referred to as a “similariton.”) With this laser the limitations of prior art laser oscillators are avoided. Also provided are means for pumping the gain medium in the laser cavity, and means for extracting laser pulses from the laser cavity. The laser cavity is preferably a ring cavity. Preferably the laser is configured to achieve unidirectional circulation of laser pulses therein. This configuration is scalable to much higher pulse energy than lasers based on soliton-like pulse shaping.

Owner:CORNELL RES FOUNDATION INC

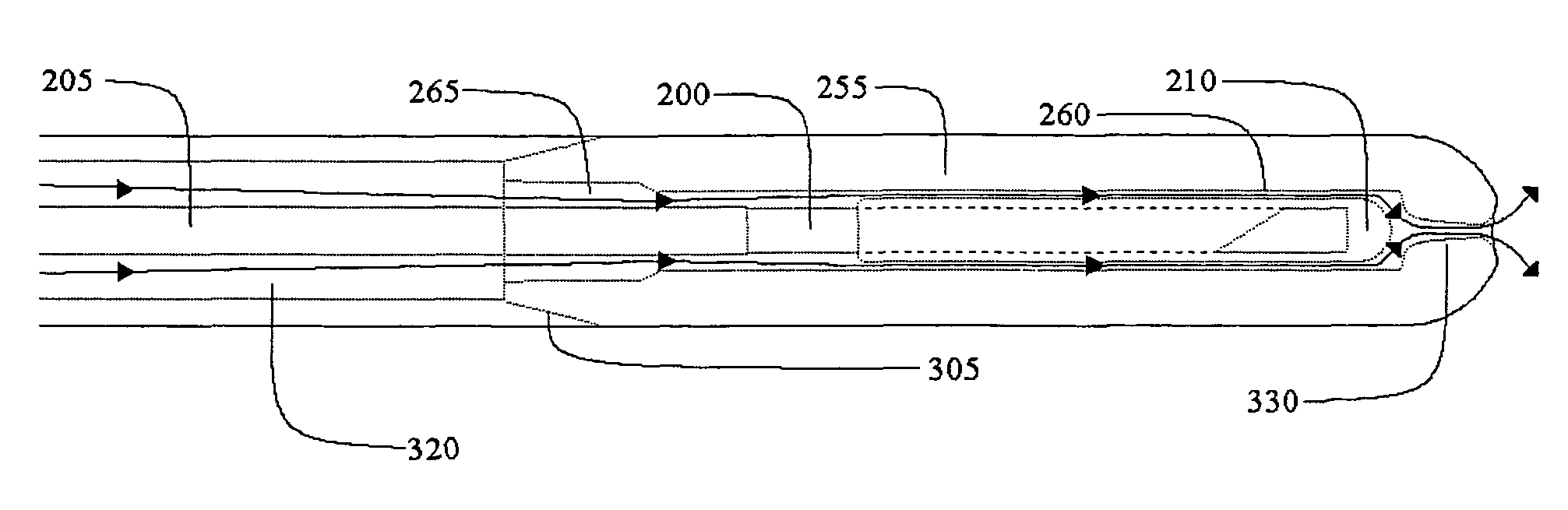

Lateral laser fiber for high average power and peak pulse energy

ActiveUS7909817B2Minimize reflectionAvoid seizuresSurgical instrument detailsFree rotationRefractive index

An improved optical fiber comprising a waveguide with an input for coupling focused laser energy into the waveguide and communicating electromagnetic radiation in a propagation direction to an internally reflective tip of the waveguide, a tissue contacting surface wherein the light path from the reflecting surface to the transmitting surface in substantially homogenous in refractive index and cooled by fluid flow. In minimizing the variations in refractive index within the lateral light path, while providing active cooling directly below the tissue contact surface, the invention prevents internal reflections and beam distortion and greatly improves the efficiency and durability of the laterally directing probe. Free rotation of the tissue contact surface, about the lateral tip, may be provided and tissue vaporization efficiency may be improved by providing a morcellating tool on the tissue contact surface.

Owner:BOSTON SCI SCIMED INC

Method and apparatus for laser processing of silicon by filamentation of burst ultrafast laser pulses

ActiveUS20150151380A1Easy to separateMinimize distortionLayered productsWelding/soldering/cutting articlesFilamentationPulse energy

A method for laser processing of Silicon includes placing a Kerr material into engagement with the Silicon forming an interface therebetween. A laser beam is applied having at least one subpulse in a burst envelope operating at a first wavelength. The laser beam passes through a distributive lens focusing assembly and to the Kerr material. The first wavelength is modified to a plurality of second wavelengths, some of which are effective for processing Silicon. Photoacoustic compression processing is produced by the laser pulse energy by a portion of second wavelengths delivered through the interface and to the Silcon which initiates Kerr Effect self focusing which is propagated in the Silicon by additional energy input to the Silicon thus producing a filament within the Silicon.

Owner:ROFIN SINAR TECH

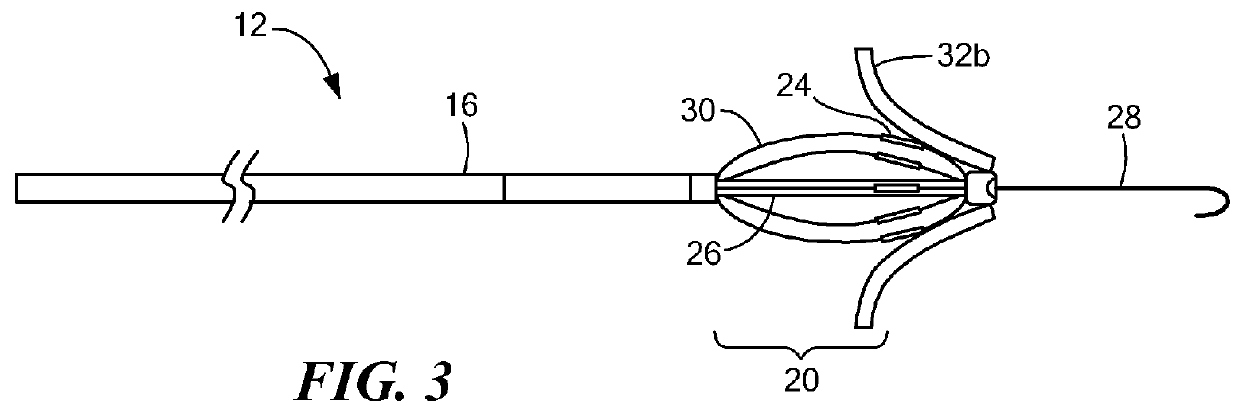

Intracardiac tools and methods for delivery of electroporation therapies

ActiveUS20160051324A1ElectrotherapySurgical instruments for heatingElectroporation therapyEngineering

A medical system, including a medical device having a plurality of deployable arms, and at least one electrode on at least one of the plurality of arms; and an electric signal generator in communication with the medical device, the electric signal generator programmed to deliver pulsed energy to the medical device sufficient to induce irreversible electroporation ablation.

Owner:HONDA MOTOR CO LTD +1

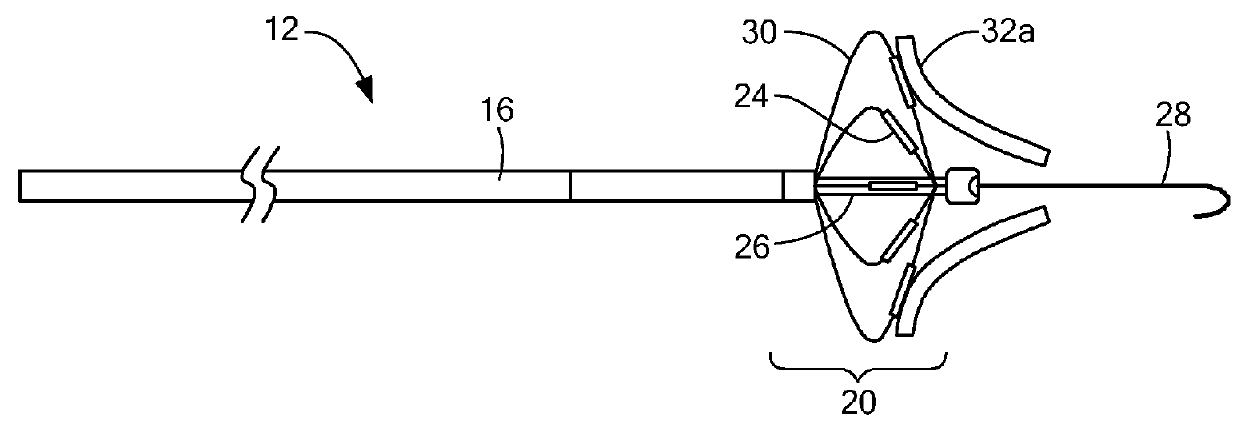

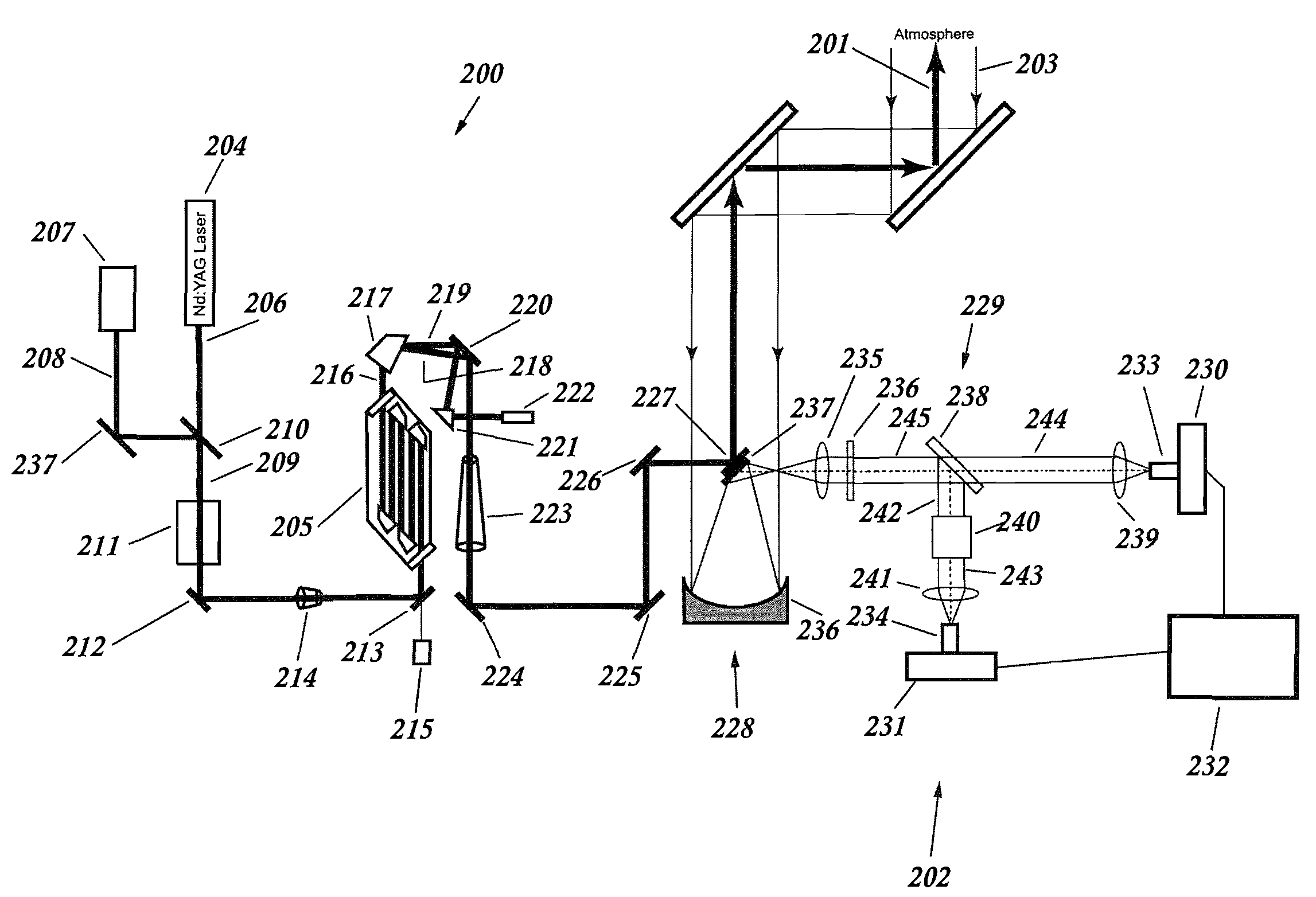

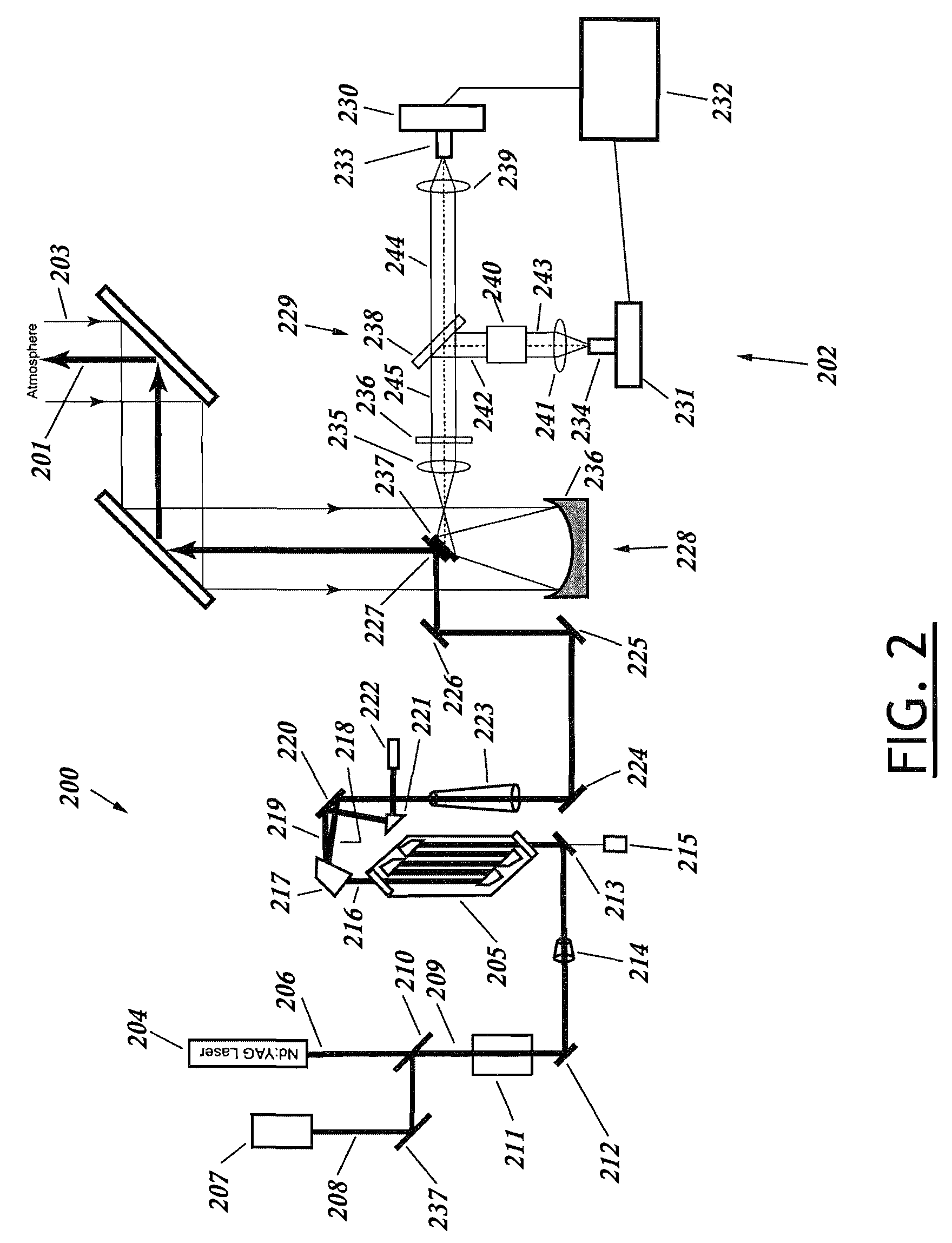

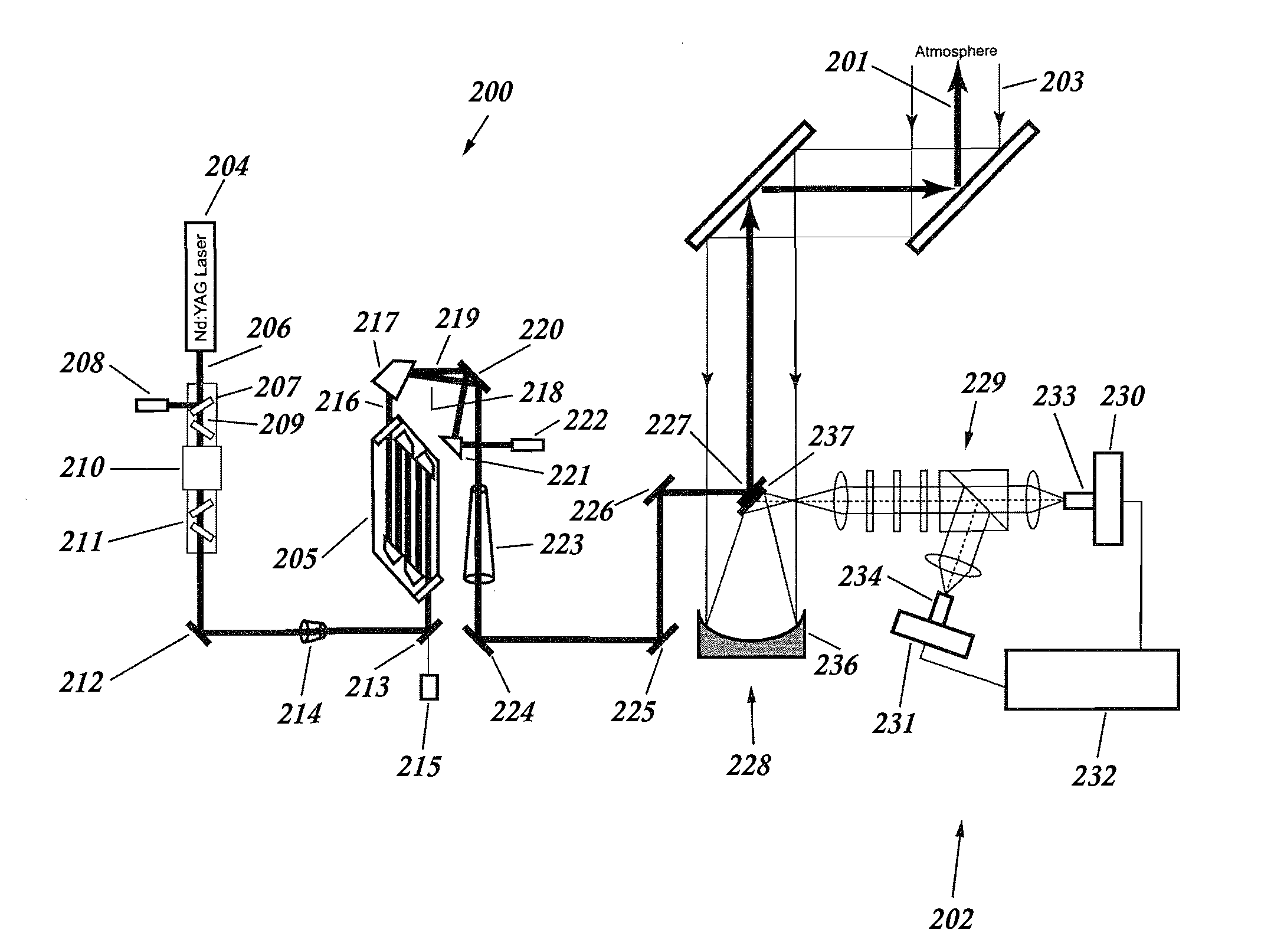

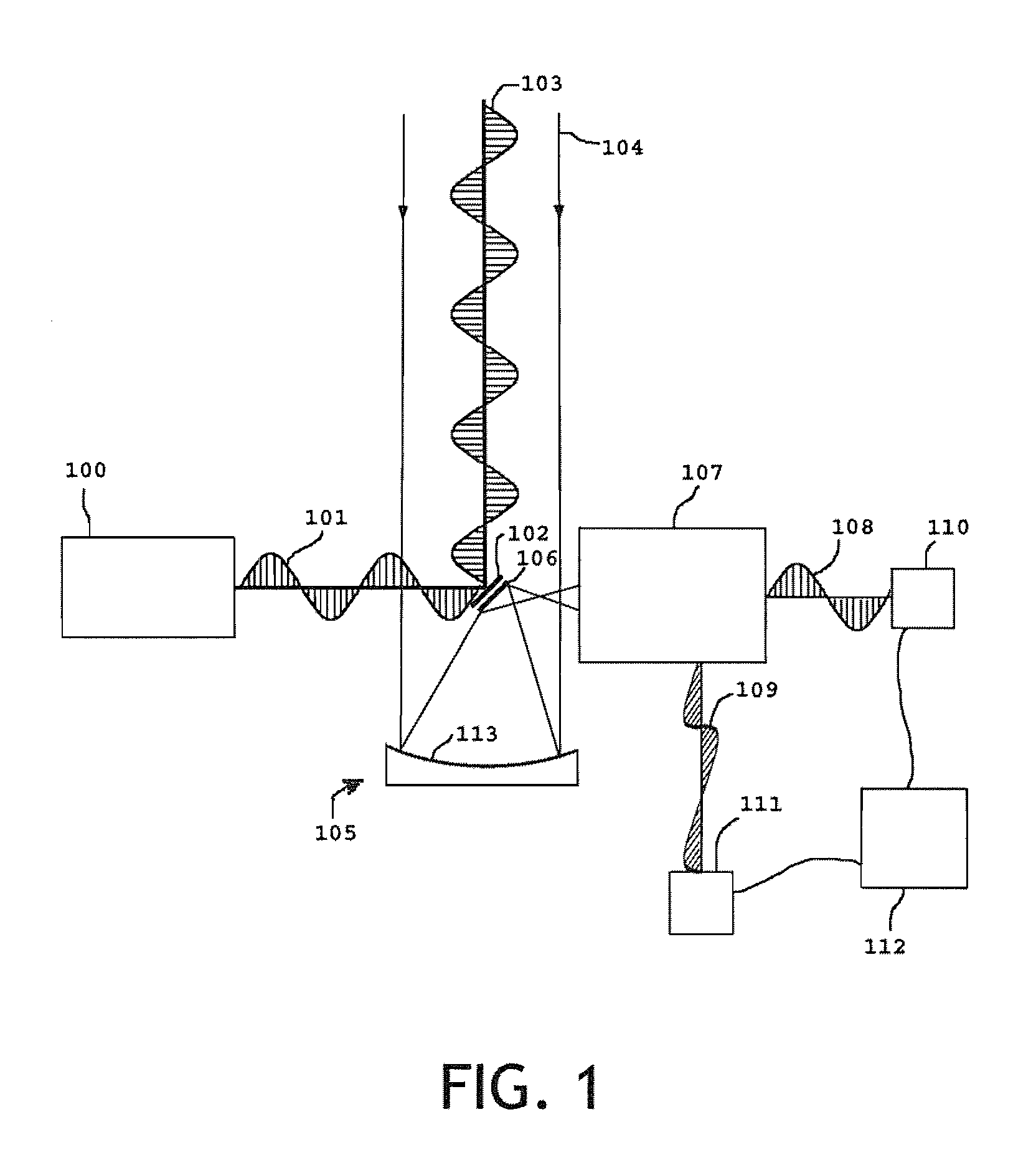

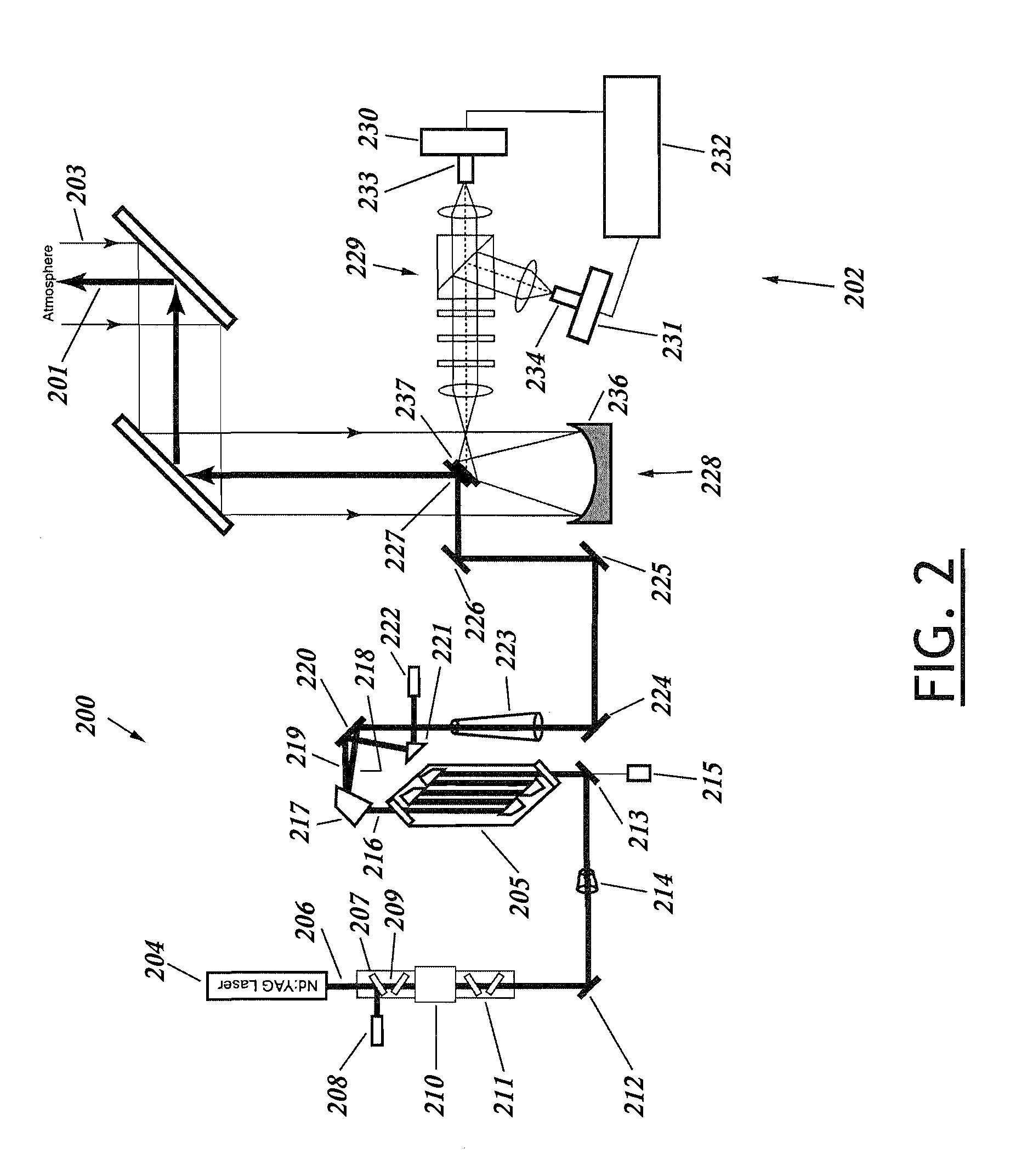

Lidar system for remote determination of calibrated, absolute aerosol backscatter coefficients

ActiveUS7656526B1Effort directedSafely and quickly and efficiently identifyRaman scatteringParticle size analysisBeam splitterAerosol backscatter

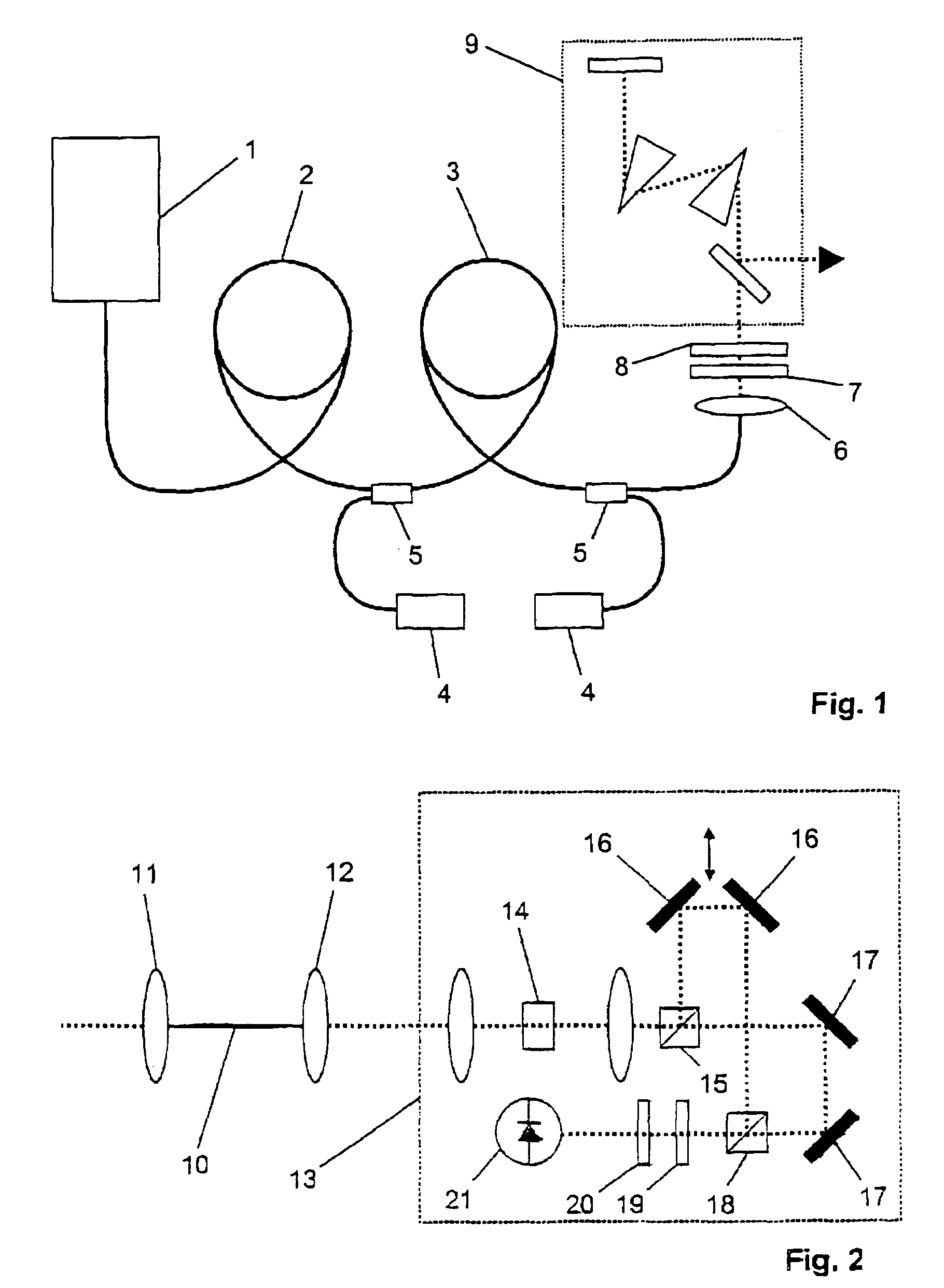

A lidar system capable of remotely identifying calibrated absolute aerosol backscatter coefficients of atmospheric aerosol particles by transmitting a beam of light and spectrally separating the intensity of Rayleigh and Mie backscattering is disclosed. The transmitter features high pulse energy to generate sufficient Rayleigh backscattering, enabling atmospheric scanning in a timely manner. The transmitter employs a seeded Nd:YAG laser and a seeded stimulated Raman scattering wavelength shifter to achieve narrow bandwidth, eye-safe laser pulses. The receiver employs a telescope, collimating lens, beam splitter, molecular absorption filter, focusing lenses, and avalanche photodiodes. Mie backscattering is blocked by the molecular absorption filter to provide a Rayleigh signal, which is used with knowledge of atmospheric density to calibrate the Mie signal. The system is intended for atmospheric research and aerosol monitoring applications where calibrated Mie scattering intensity is necessary to measure the optical depths of aerosol structures such as plumes, clouds, and layers.

Owner:UNIV FOR ATMOSPHERIC RES

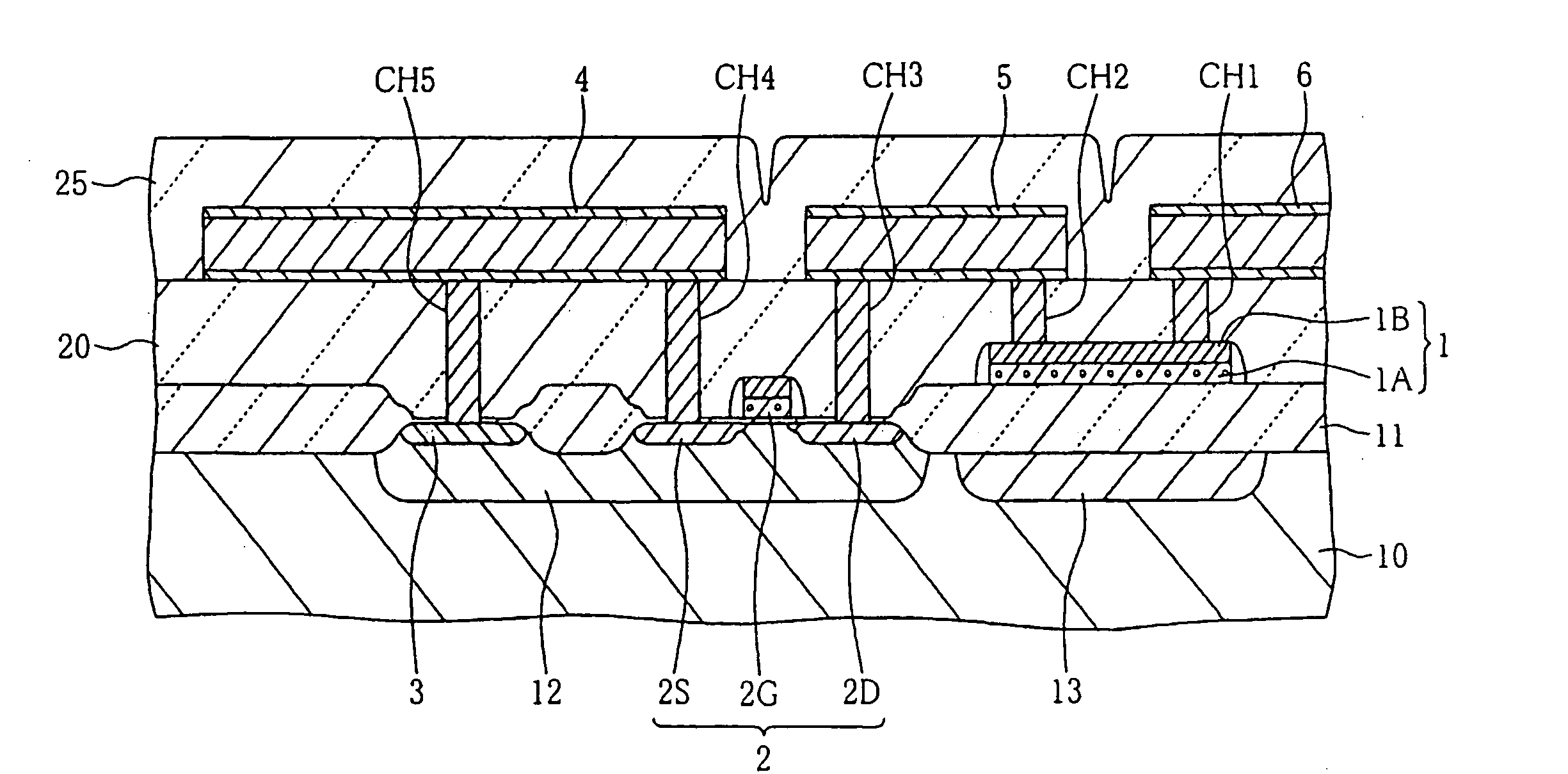

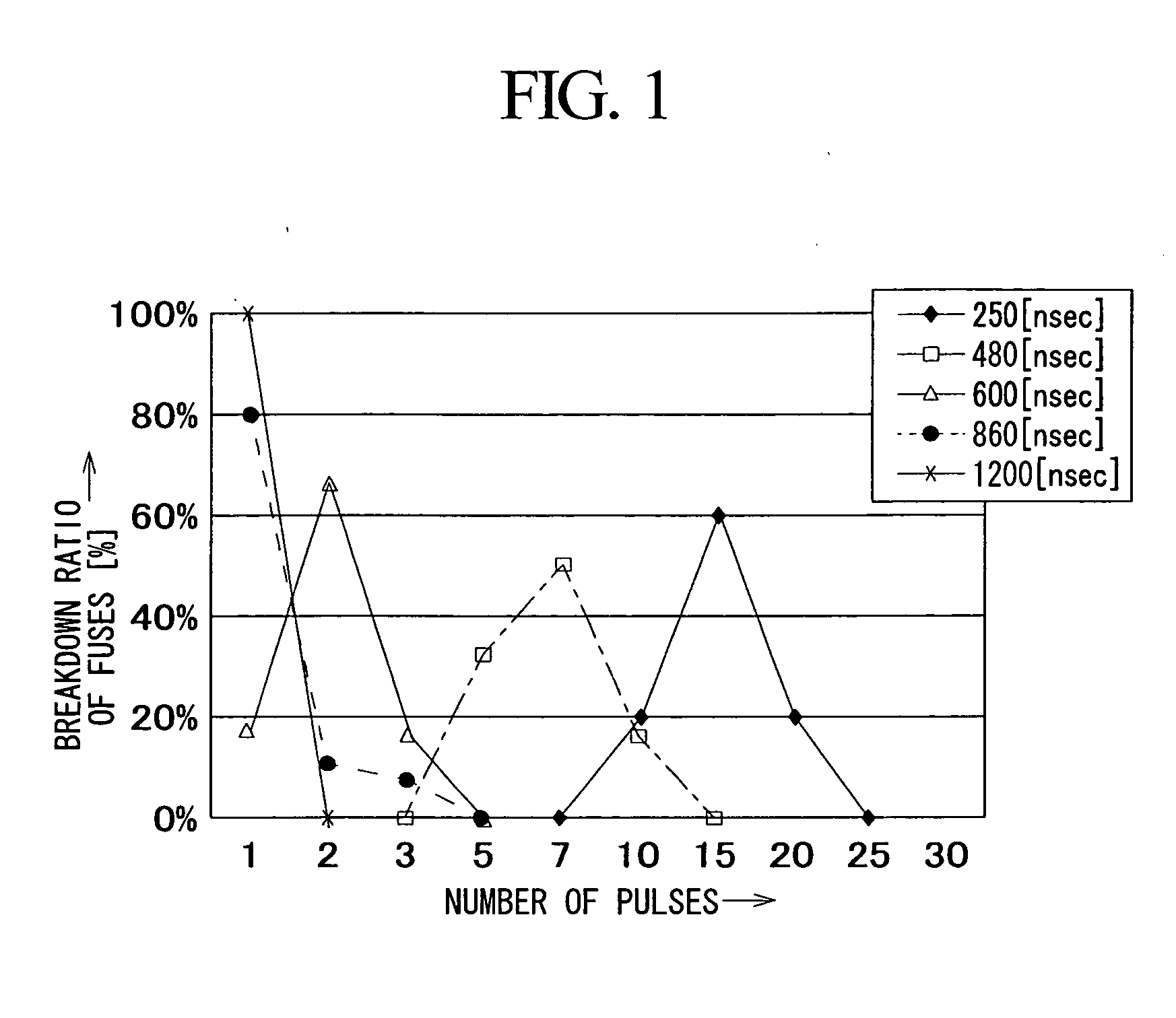

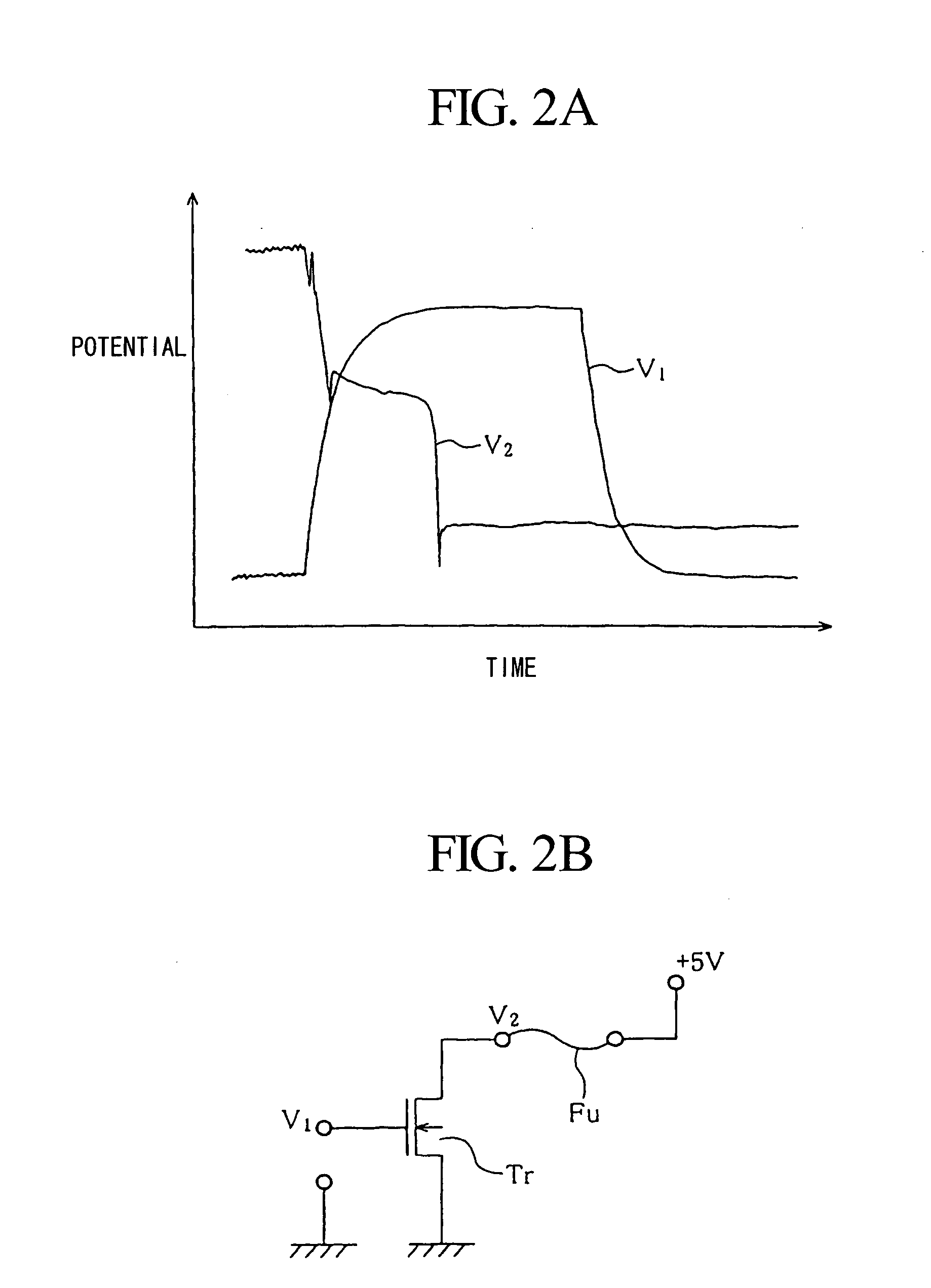

Fuse breakdown method adapted to semiconductor device

InactiveUS20070007621A1Increase distanceInhibit degassingTransistorSemiconductor/solid-state device detailsDevice materialEvaporation

A plurality of pulses each having relatively low energy are consecutively applied to a subject fuse to cause breakdown, wherein the total energy of pulses is set in light of a prescribed breakdown threshold, which is calculated in advance. The subject fuse has a pair of terminals and an interconnection portion that is narrowly constricted in the middle so as to realize fuse breakdown with ease. A pulse generator generates pulses, which are repeatedly applied to the subject fuse by way of a transistor; then, it stops generating pulses upon detection of fuse breakdown. Side wall spacers are formed on side walls of fuses, which are processed in a tapered shape so as to reduce thermal stress applied to coating insulating films. In addition, pulse energy is appropriately determined so as to cause electro-migration in the subject fuse, which is thus increased in resistance without causing instantaneous meltdown or evaporation.

Owner:YAMAHA CORP

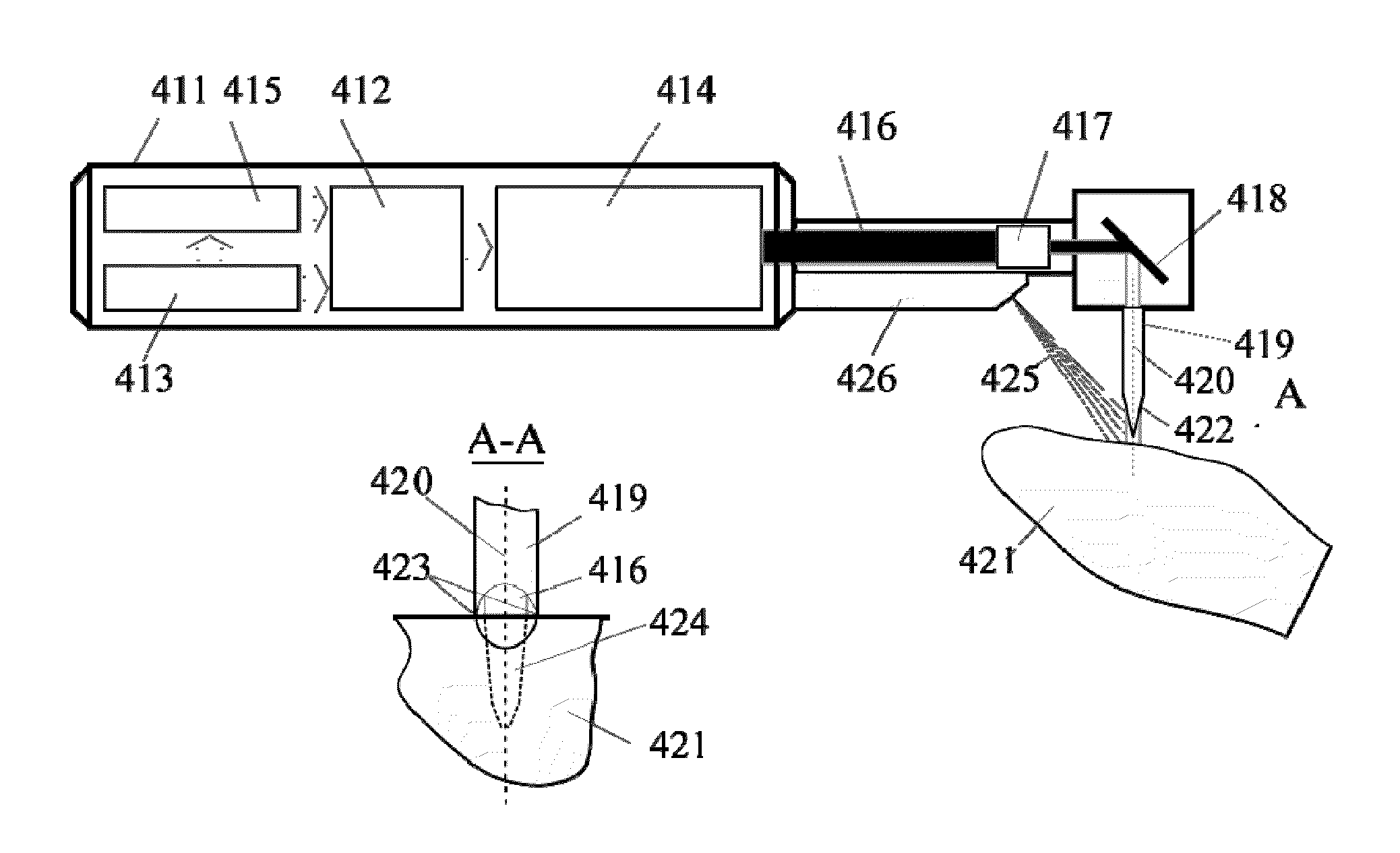

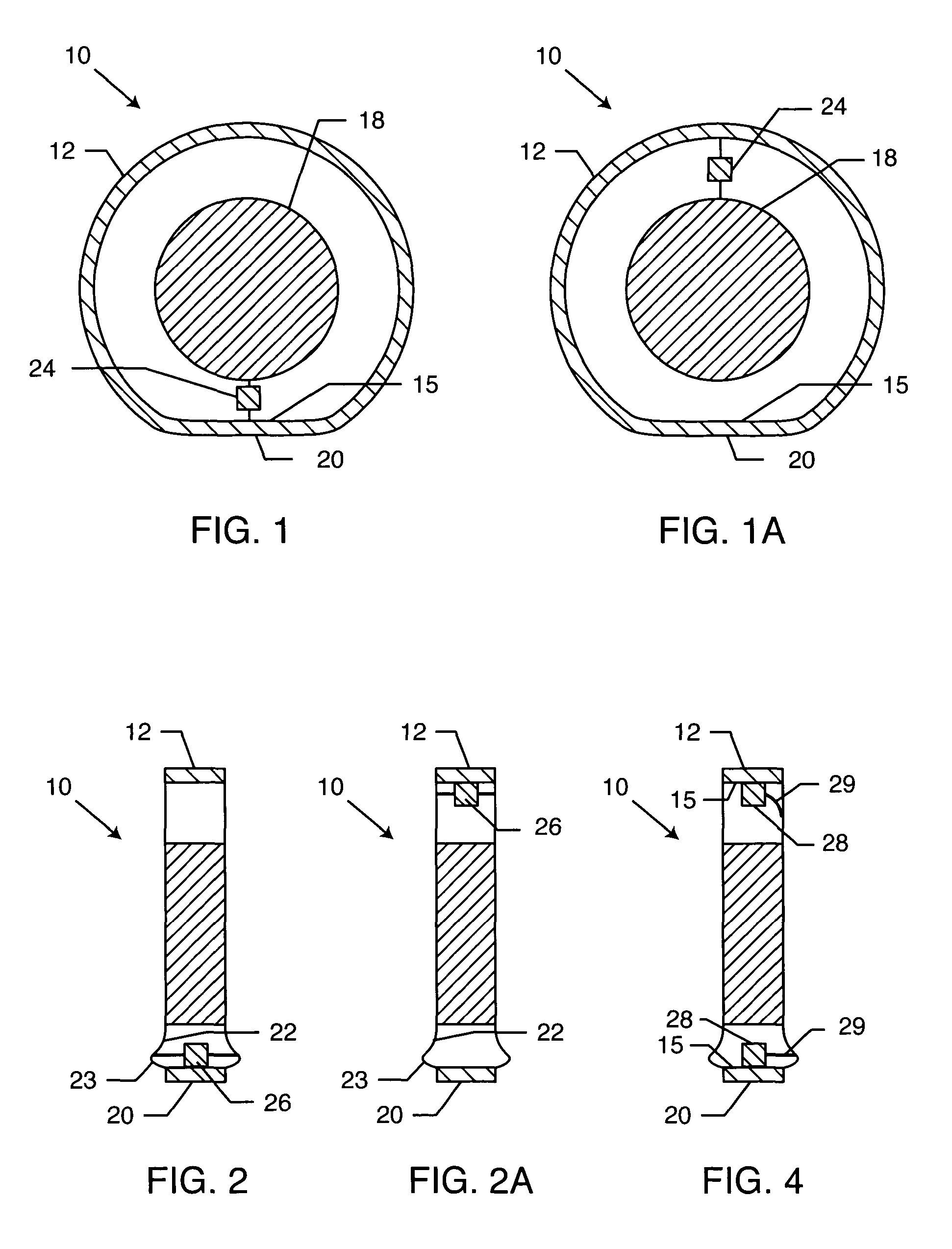

Method and apparatus for diagnostic and treatment using hard tissue or material microperforation

InactiveUS20100015576A1Reliable and minimally invasive fasteningControlled diffusionTeeth fillingDiagnostic recording/measuringPulse energyLight beam

A method of modifying or treating biological tissue by microperforating hard tissue is disclosed. The method comprises identifying a target area associated with the hard tissue, using a laser beam to perforate at least one incision in the hard tissue, wherein at least one incision has a diameter from a range of 0.001 mm to 0.5 mm and an aspect ratio from a range of 1 to 100 times, introducing a treatment substance into the incision, and causing the treatment substance to interact with the target area. Also a device for microperforating hard biological tissue is disclosed, comprising a laser pump system and a laser head coupled to the laser pump system for generating a pulsed laser having ranges of wavelengths, a pulse duration, pulse energy from a selected range, a beam divergence factor less than 5, a repetition rate higher than 50 Hz; and a beam delivery system comprised of a focusing system for creating a beam having a diameter from a range of 0.001 mm to 0.5 mm.

Owner:REJUVEDENT

Optical material and method for modifying the refractive index

ActiveUS7789910B2Little and no scattering lossSpectales/gogglesOptical articlesIntraocular lensNear infrared laser

A method for modifying the refractive index of an optical, polymeric material. The method comprises irradiating select regions of the optical, polymeric material with a focused, visible or near-IR laser having a pulse energy from 0.05 nJ to 1000 nJ. The irradiation results in the formation of refractive optical structures, characterized by a change in refractive index, exhibit little or no scattering loss, and exhibit no significant differences in the Raman spectrum with respect to the non-irradiated optical, polymeric material. The method can be used to modify the refractive index of an intraocular lens following the surgical implantation of the intraocular lens in a human eye. The invention is also directed to an optical device comprising refractive optical structures, wherein the refractive structures are characterized by a change in refractive index, exhibit little or no scattering loss, and exhibit no significant differences in the Raman spectrum with respect to the non-irradiated optical, polymeric material.

Owner:UNIVERSITY OF ROCHESTER

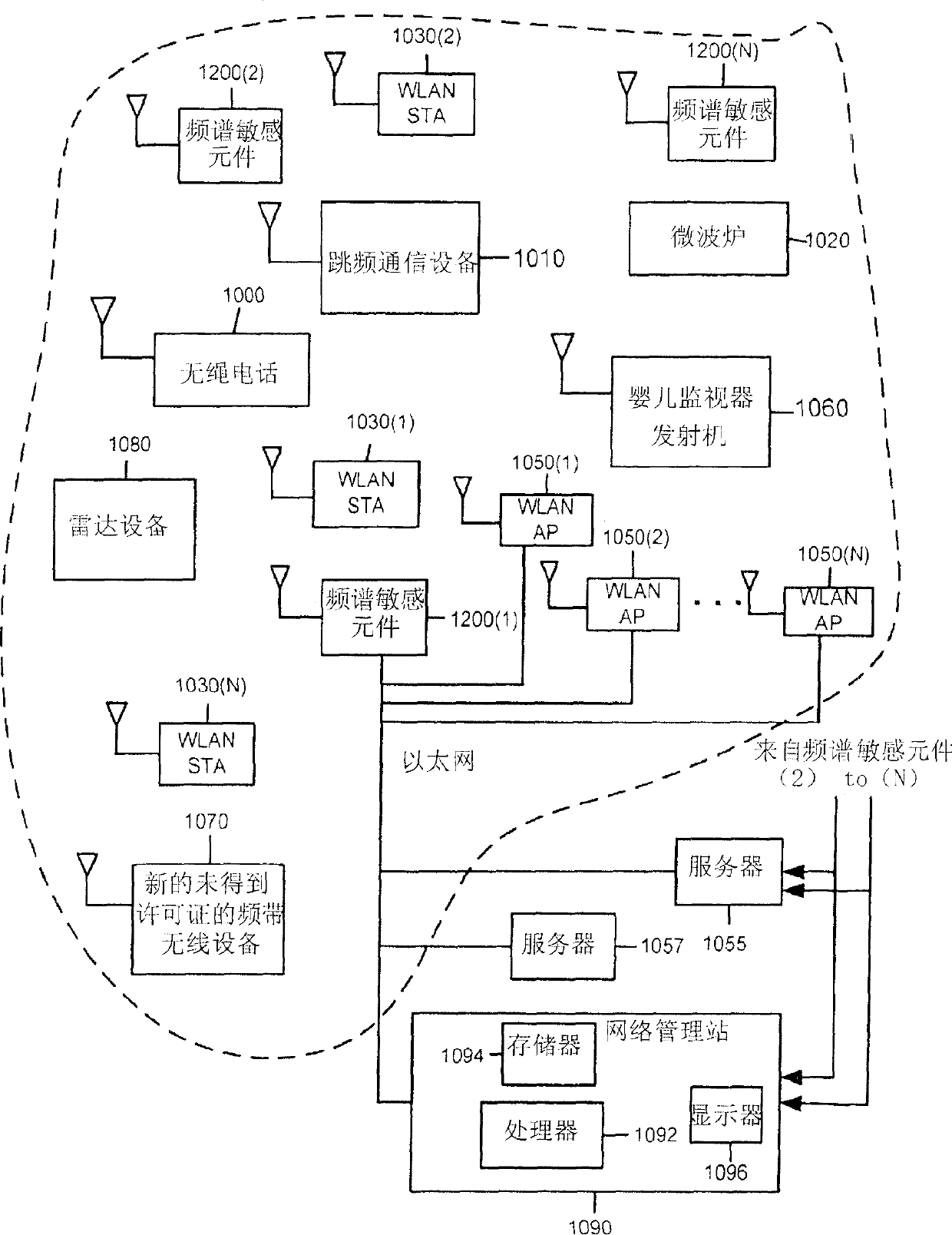

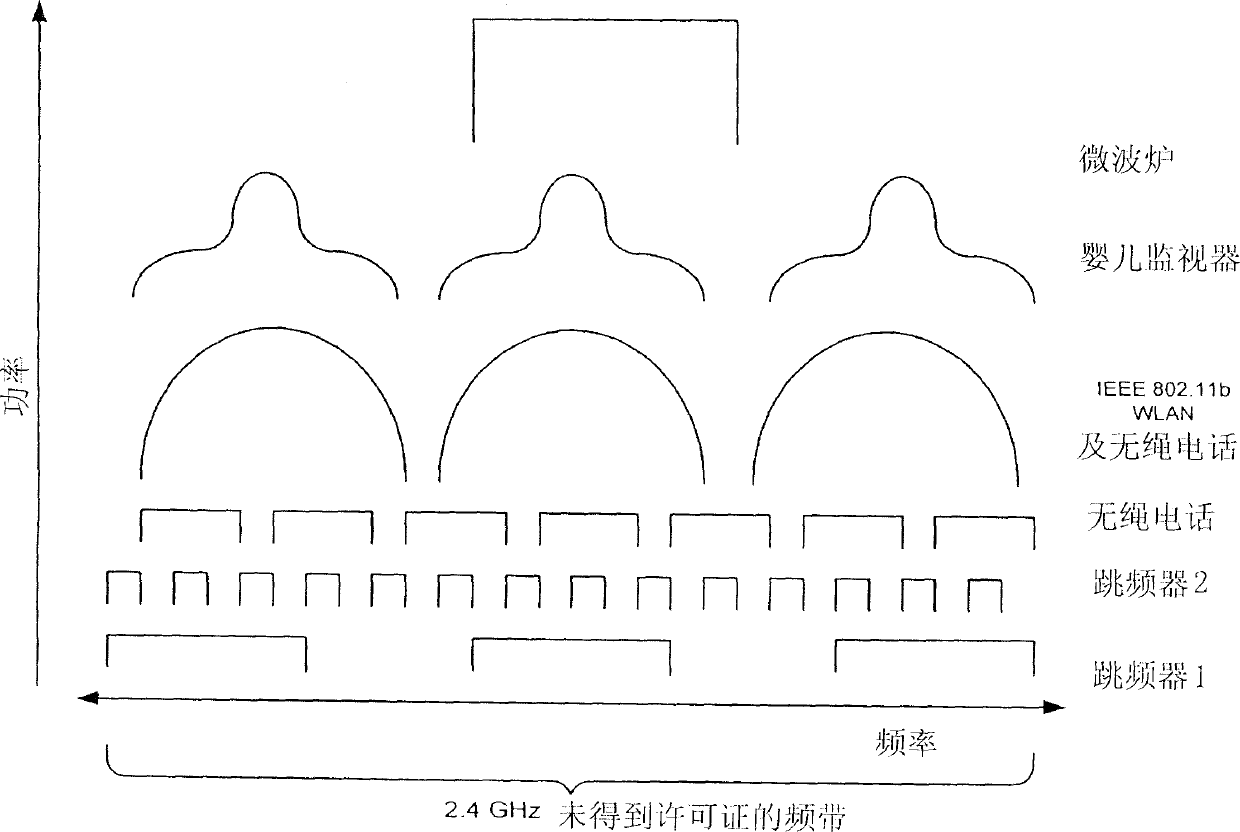

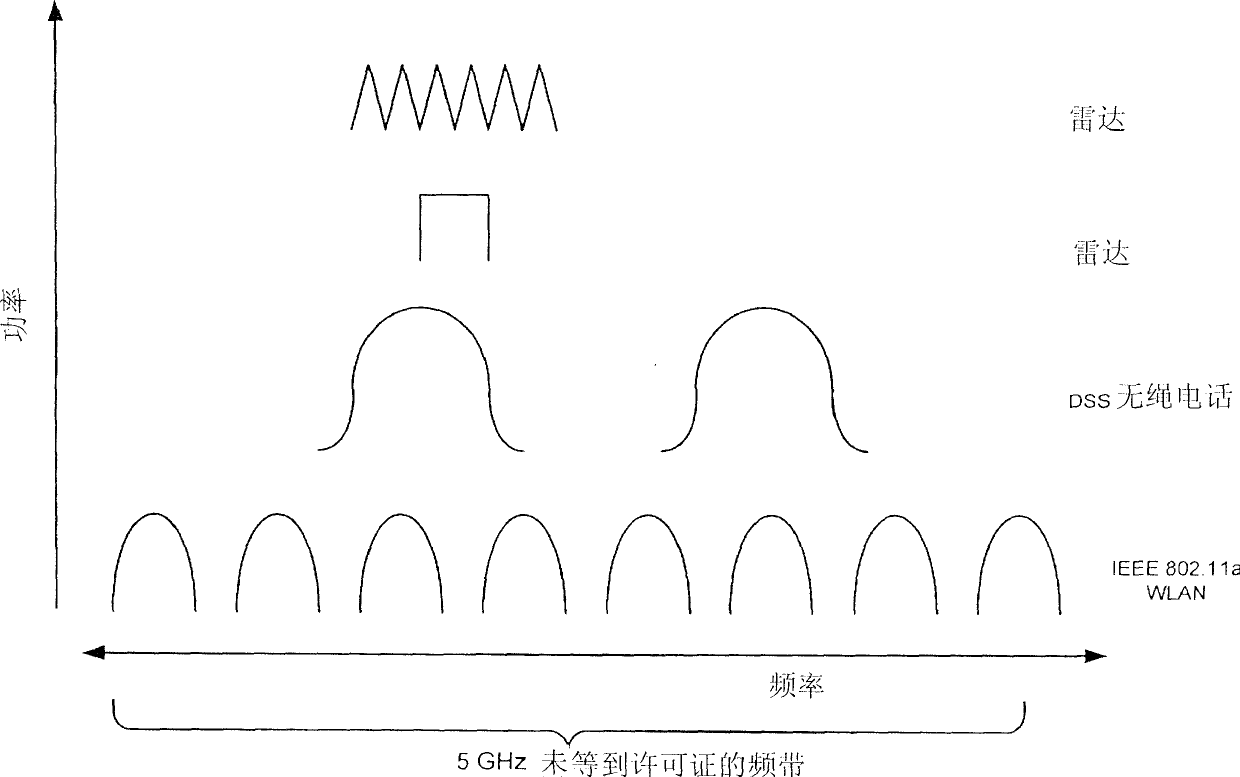

System and method for management of a shared frequency band

InactiveCN1663156AError prevention/detection by using return channelData switching by path configurationFrequency spectrumRadio frequency energy

A system, method, software and related functions are provided for managing activity in a radio frequency band that is shared, both in frequency and time, by signals of multiple types. An example of such a frequency band is an unlicensed frequency band. Radio frequency energy in the frequency band is captured at one or more devices and / or locations in a region where activity in the frequency band is happening. Signals occurring in the frequency band are detected by sampling part or the entire frequency band for time intervals. Signals pulse energy in the band is detected and is used to classify signals according to signal type. Using knowledge of the types of signals occurring in the frequency band and other spectrum activity related statistics (referred to as spectrum intelligence), actions can be taken in a device or network of devices to avoid interfering with other signals, and in general to optimize simultaneous use of the frequency band with the other signals. The spectrum intelligence may be used to suggest actions to a device user or network administrator, or to automatically invoke actions in a device or network of devices to maintain desirable performance.

Owner:CISCO TECH INC

Polarization lidar for the remote detection of aerosol particle shape

InactiveUS7580127B1Safely dispersedEasy to usePolarisation-affecting propertiesElectromagnetic wave reradiationBeam splitterPolarizer

A polarization lidar system capable of remotely identifying characteristics of atmospheric aerosol particles by transmitting a polarized beam of light and analyzing polarization characteristics of received backscatter is disclosed. The transmitter features high pulse energy to remotely identify aerosol particles with substantially one pulse. The transmitter employs a thin film plate polarizer and a Raman wavelength shifter to achieve eye-safe, single-plane linearly polarized energy. The transmit beam and receiver field of view are coaxial. The receiver employs a telescope, a collimating lens, and a beam splitter. The beam splitter splits the received backscatter into a single-plane polarized beam whose polarization plane is parallel to the plane of transmission and a single-plane polarized beam whose polarization plane is perpendicular to the plane of transmission. Each split beam is directed through separate focusing lenses onto separate detectors. The detector signals are amplified and processed to remotely determine atmospheric aerosol particle characteristics.

Owner:UNIV FOR ATMOSPHERIC RES

Fiber-optic amplification of light pulses

ActiveUS7224518B2High energyAvoid disadvantagesLaser arrangementsActive medium materialFiberGroup velocity dispersion

A device for amplifying light pulses has an optical stretcher, in which the light pulses of a pulsed laser light source are temporally stretched, and an optically pumped amplifier fiber, in which the light pulses are amplified and, at the same time, temporally compressed. In order to improve such a system with regard to the pulse duration and the pulse energy that can be achieved, the amplifier fiber has a positive group velocity dispersion, whereby the amplifier fiber has non-linear optical properties, so that the optical spectrum of the light pulses is broadened during the amplification process, taking advantage of non-linear self-phase modulation.

Owner:TOPTICA PHOTONICS AG

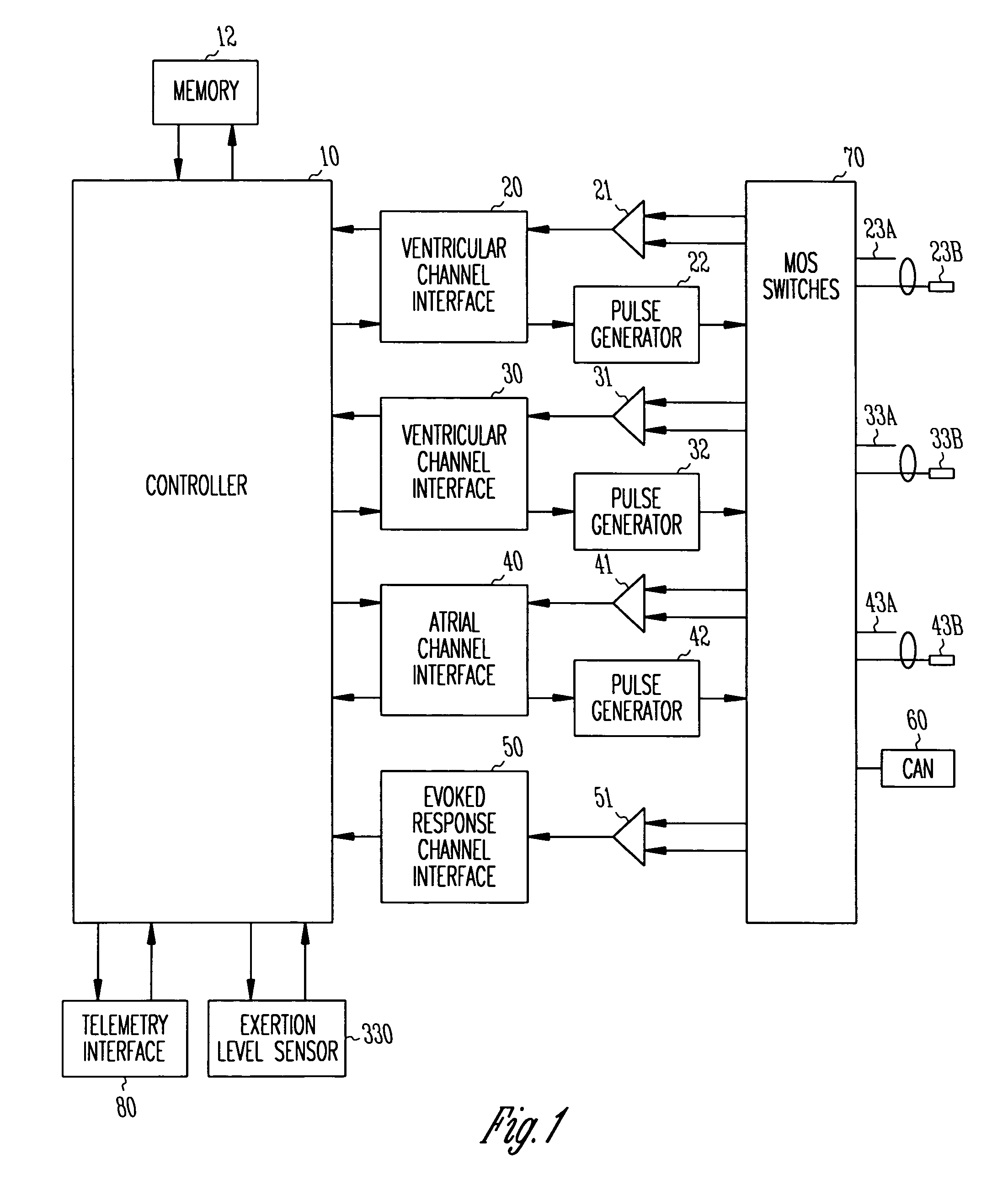

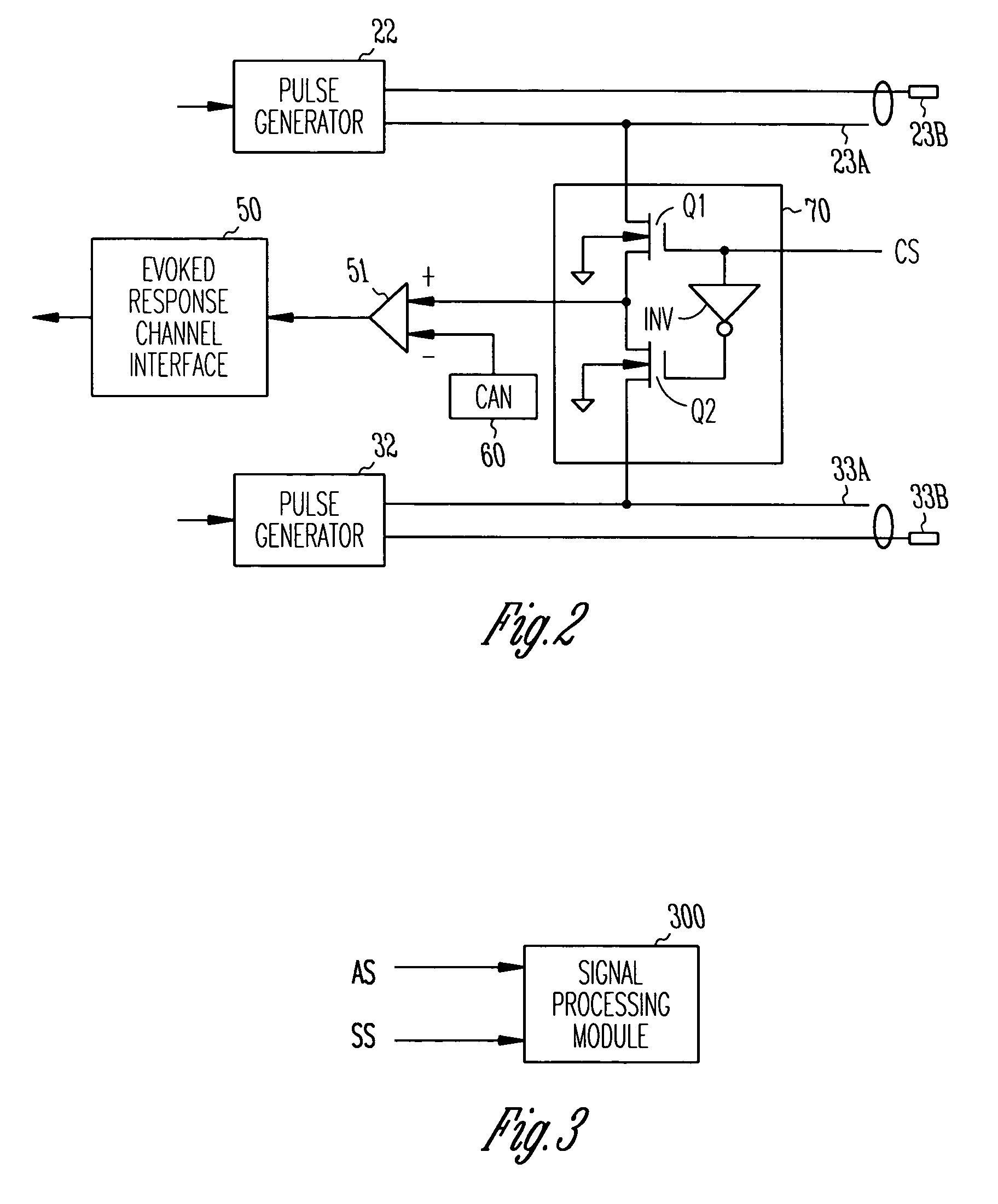

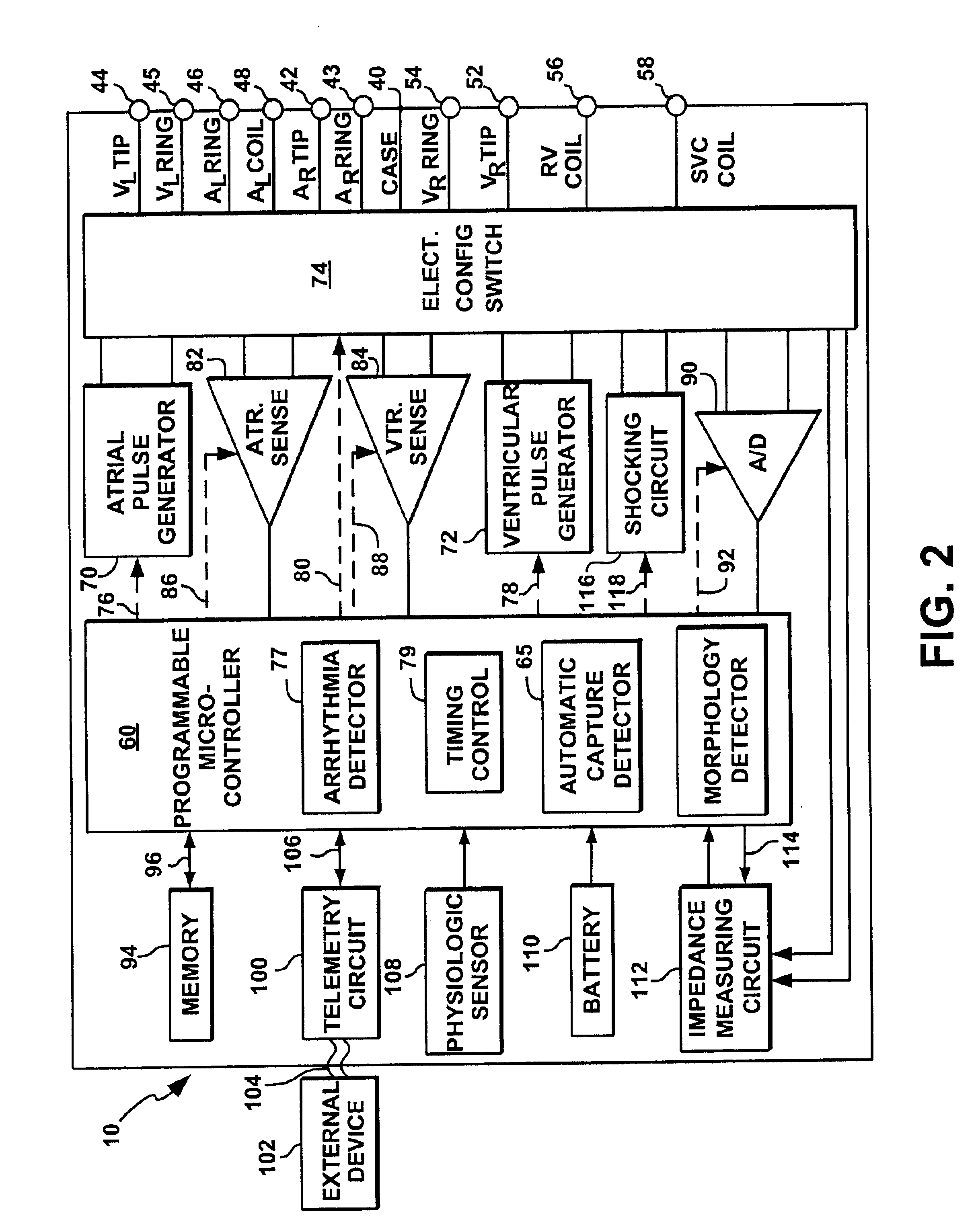

Automatic capture using independent channels in bi-chamber stimulation

InactiveUS6915164B2Extend battery lifeIncreased longevityHeart stimulatorsLeft cardiac chamberPulse energy

A cardiac stimulation device and method deliver independent stimulation pulses to right and left cardiac chambers, based on the capture thresholds of each chamber, and confirm capture in each chamber. A threshold test is performed in one chamber while stimulating the opposite chamber at increased pulse energy and adjusted interchamber delay.

Owner:PACESETTER INC

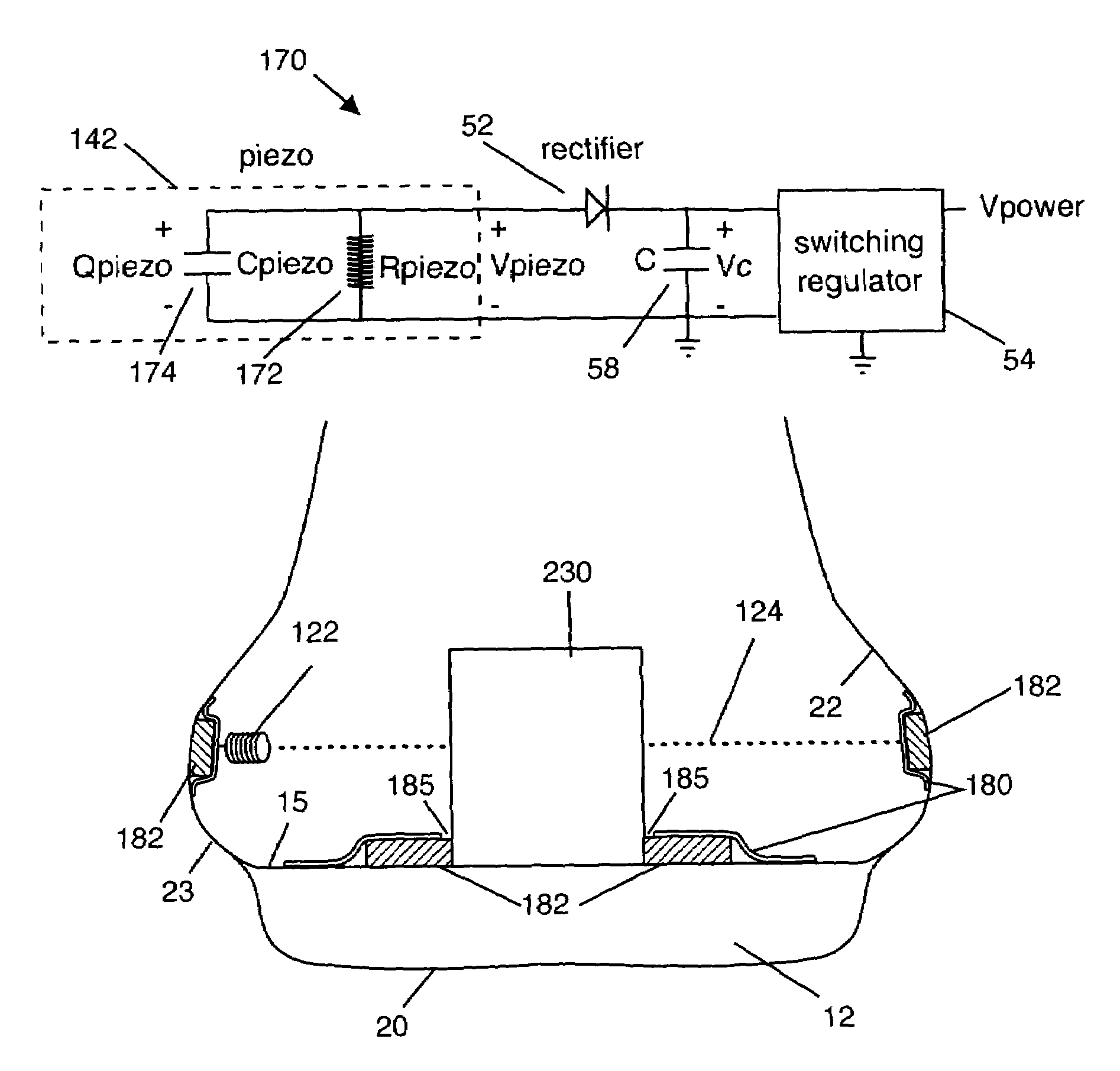

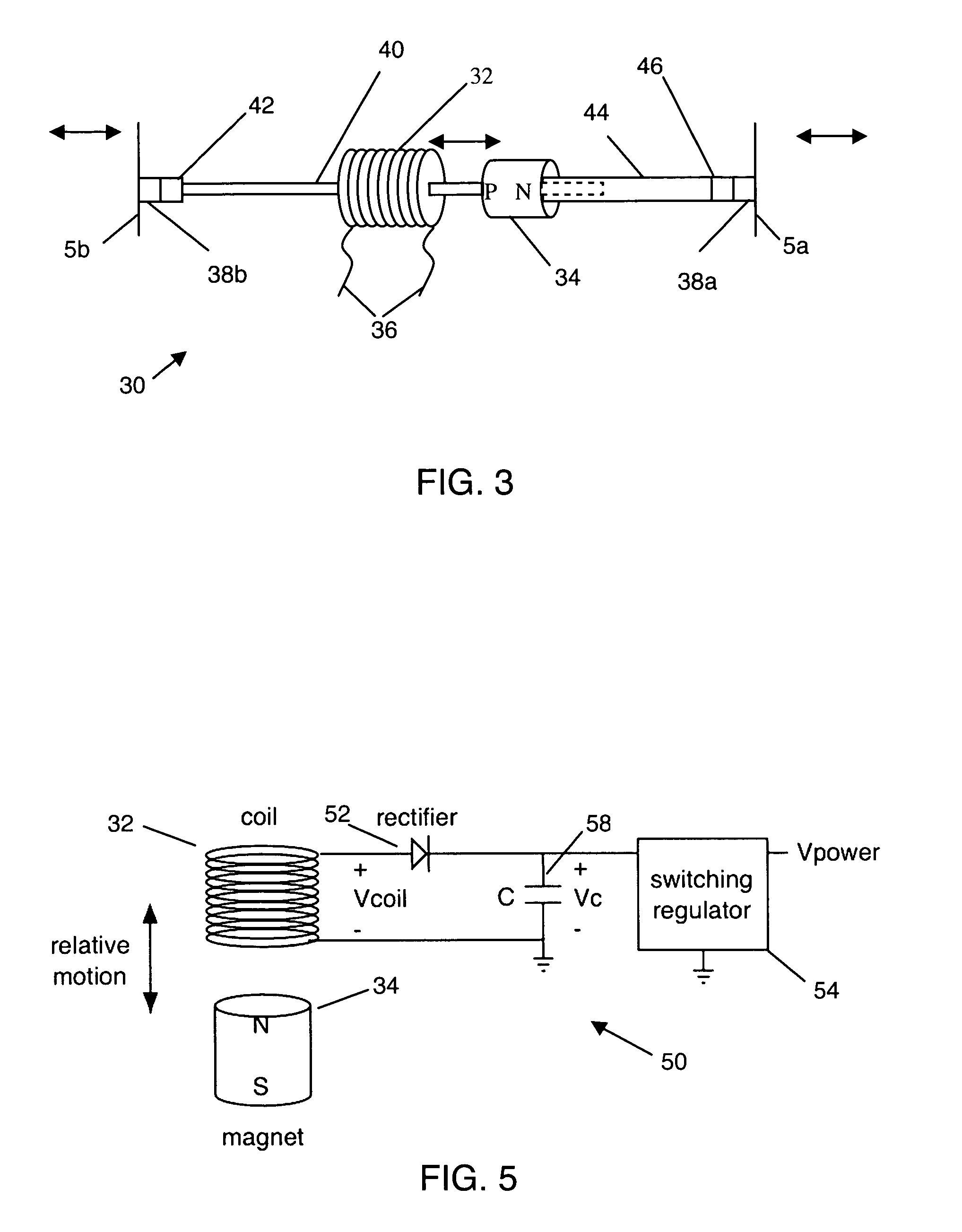

Apparatus and method for energy generation within a tire

InactiveUS7285868B2Sufficient powerEliminate needFlexible wall reciprocating enginesTyre measurementsCapacitanceRotary pump

Energy for in-tire use is generated from the load induced reciprocating deflection of the tire inner walls above the tire-to-road contact patch adjacent to the shoulder of the tire. This energy is used to power in-tire monitoring electronics. For pulsatile energy generation with capacitive capture, the capacitor is optimally selected in real-time as a function of pulse width to maximize energy capture, or as a function of the pulse-captured energy. The resulting energy pulses are also used to measure the time duration of the contact patch from which the contact patch length is determined thus providing real-time tire geometry and, with tire pressure, real time tire load and, with temperature, tire air molar content. The loads on all tires provide real time vehicle mass and mass distribution. For electrical energy generation, magnet-coil, piezo-electric, and other power conversions are applicable. For non-electric energy generation, fluid bellows, rotary pump, and other power conversions are applicable. Further, run flat tires are designed with a cutout to accommodate and protect electronic devices mounted on an inner surface when running flat.

Owner:WILSON KITCHENER CLARK

System for alternately pulsing energy of accelerated electrons bombarding a conversion target

InactiveUS7130371B2Laser detailsCathode ray concentrating/focusing/directingElectron currentPulse energy

A RF linear electron accelerator system for generating a beam of accelerated electrons bunched in pulses having different energy spectra from pulse to pulse. The system is operable to generate a beam of high energy X-rays from such beam of accelerated electrons, using a conversion target, with pulses of the X-ray beam having energy spectra which are different from X-ray pulse to X-ray pulse. Preferably, the pulses of the electron beam have energy spectra which alternate from pulse to pulse and, correspondingly, the pulses of the X-ray beam have energy spectra which alternate from pulse to pulse. Also preferably, the current of electrons injected into the system's accelerating section and the frequency of the pulse RF power supplied to the accelerating section are changed in a synchronized manner to generate the electron beam. The system is employable in an inspection system for discriminating materials present in containers by atomic numbers.

Owner:SCANTECHIBS IP HLDG

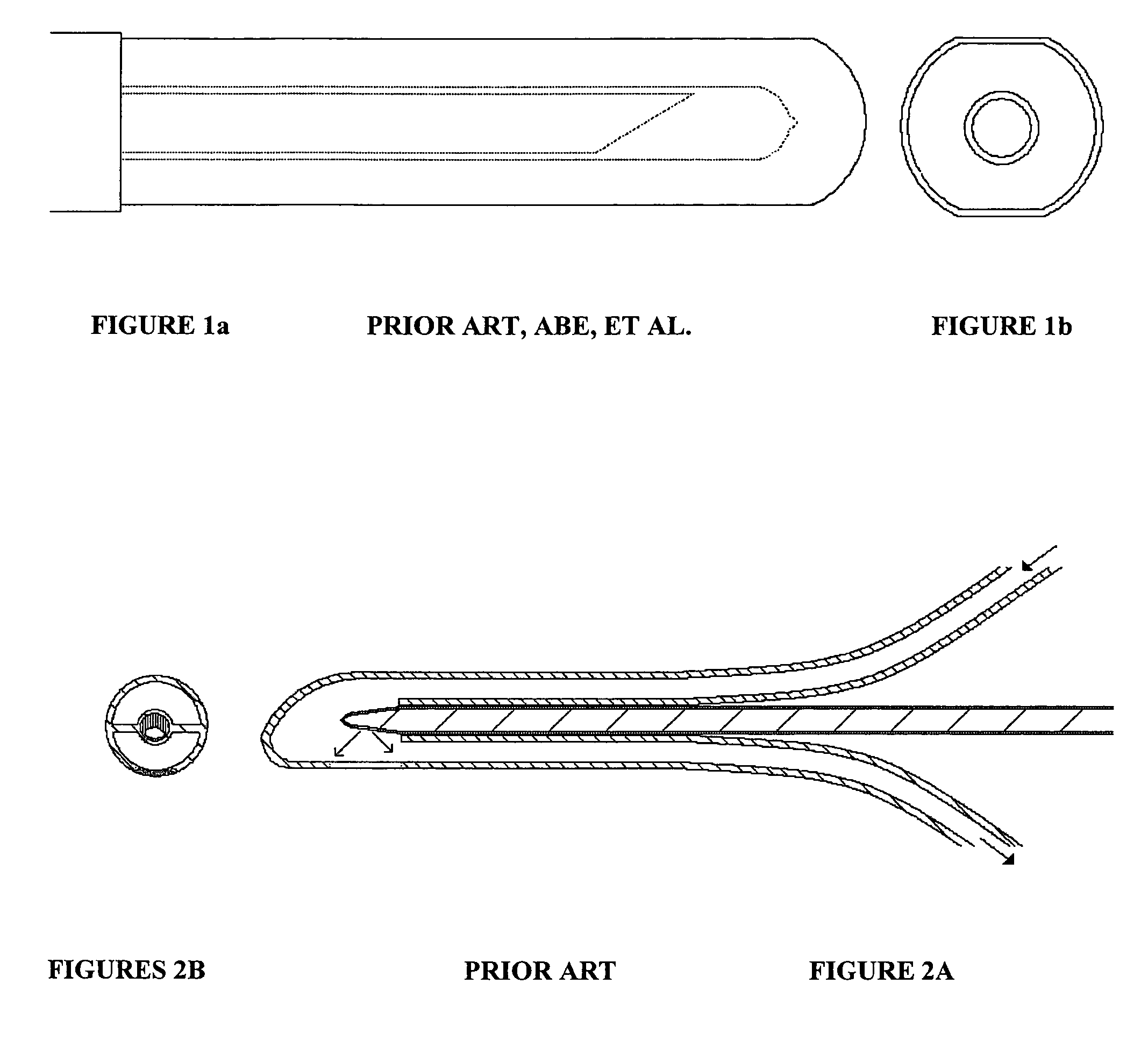

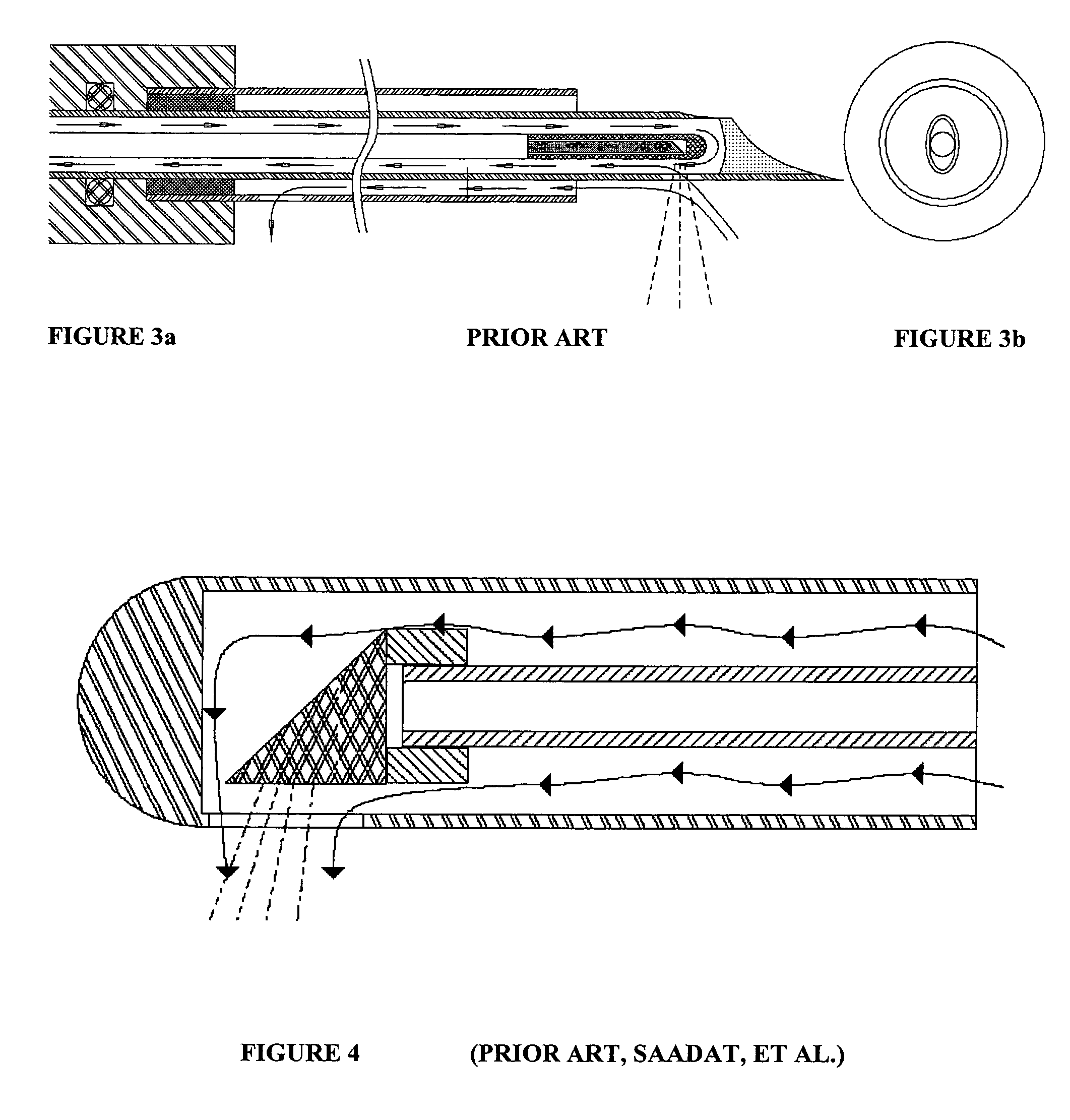

Method and system for assisting a wire guide to cross occluded ducts

InactiveUS20110208185A1Prevent bending of the probeGuide wiresSurgical instruments for heatingPulse energyEngineering

A method and a system for assisting a wire guide to cross obstructed ducts in mammalian body are described. The method and system is based on applying pulsed energy to occlusion obstructing the duct. The pulsed energy is applied by means of an auxiliary probe. The auxiliary probe is relatively displaceable with respect to the wire guide along a lumen provided within the probe. The distal region of the probe is provided with enhanced flexibility comparing with the reminder portion of the probe.

Owner:SAFEPASS VASCULAR

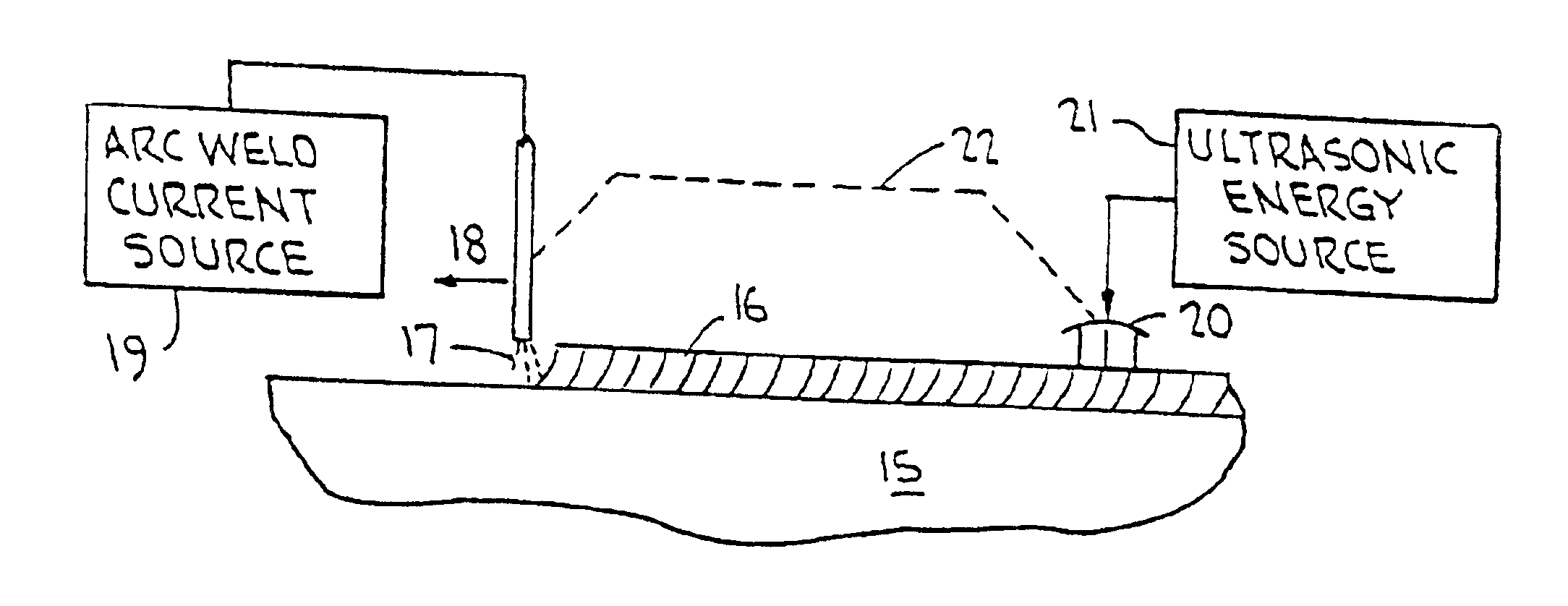

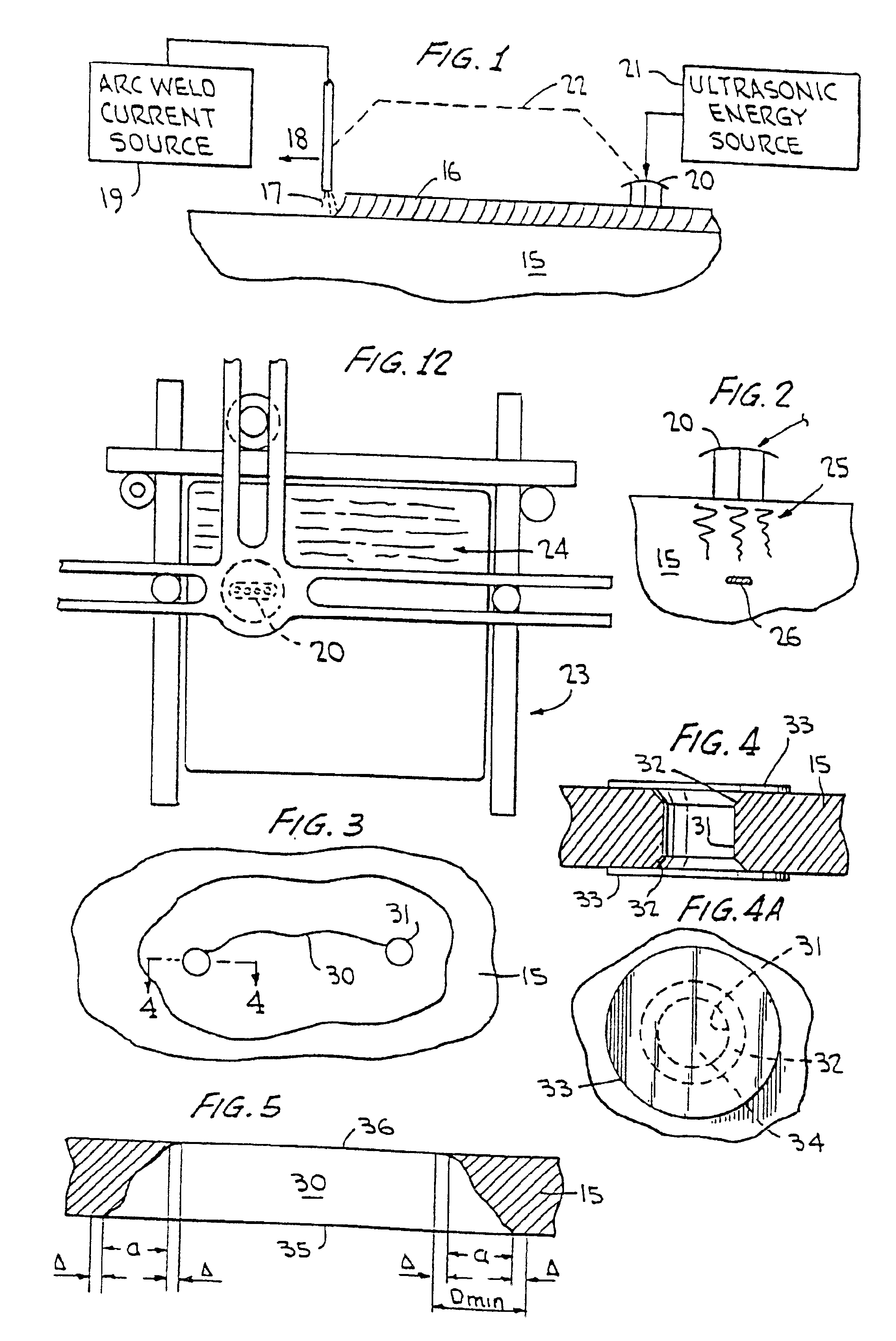

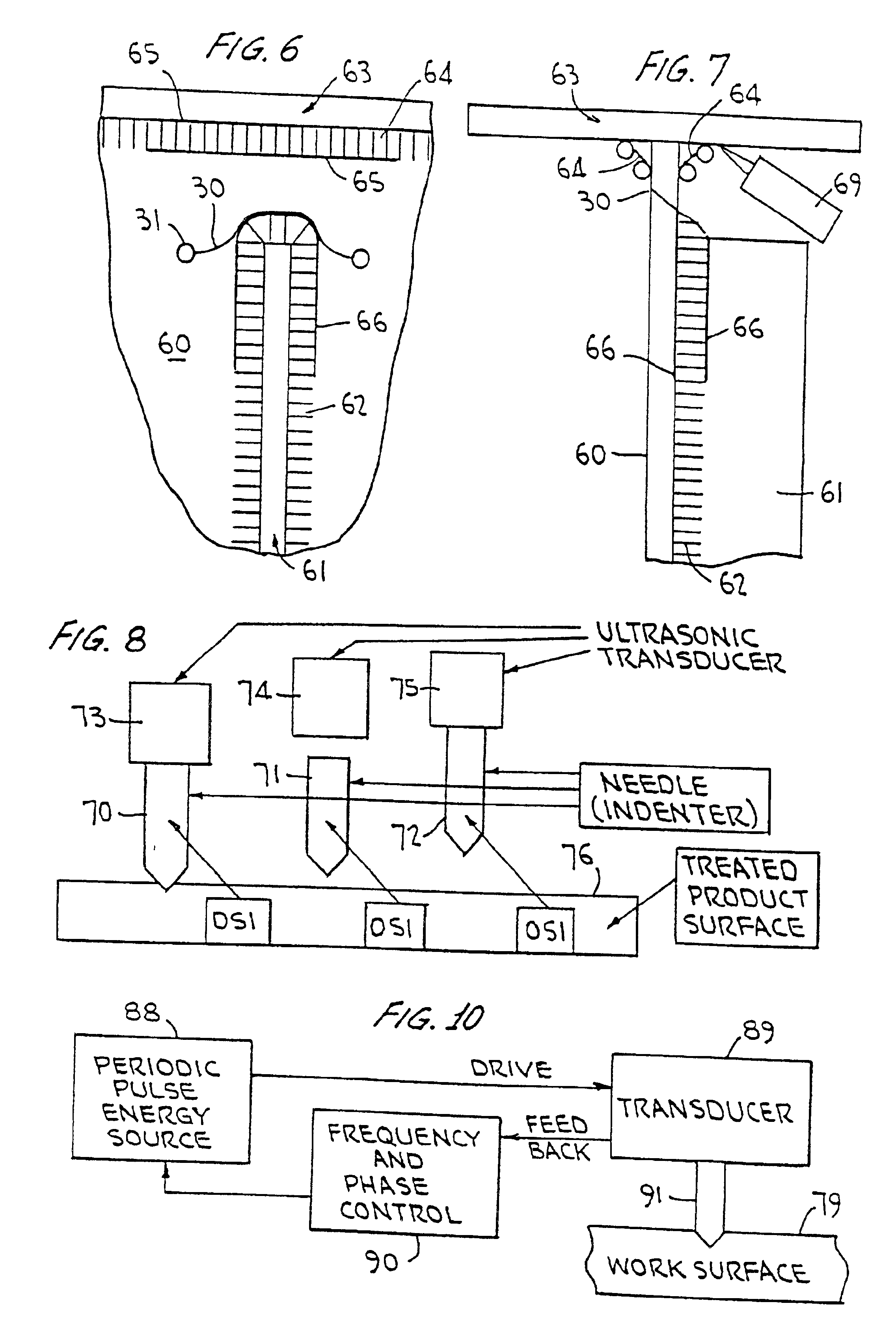

Ultrasonic impact methods for treatment of welded structures

InactiveUS6843957B2Improve corrosion fatigue strengthIncreased durabilityBlast furnace detailsHigh frequency current welding apparatusUltrasonic sensorEngineering

This invention provides methods of treatment for work products of materials such as steel, bronze, plastic, etc. and particularly welded steel bodies by pulse impact energy, preferably ultrasonic, to relax fatigue and aging and extend expectant life. The treatment may occur (a) at original production, (b) during the active life period for maintenance or (c) after failure in a repair stage. The ultrasonic treatment improves the work product strength. In welded products residual stress patterns near the weld sites are relaxed and micro-stress defects such as voids and unusual grain boundaries are reduced. The basic method steps are non-destructive in nature, inducing interior pulse compression waves with ultrasonic transducers and accessory tools impacting an external product surface with enough impulse energy to heat and temporarily plasticize the metal interior and relax stresses. The nature of the work product interior structure being treated is determined by sensing the mechanical movement at the impact surface of the work body to produce feedback frequency and phase signals responsive to input impact signals. These signals automatically conform driving pulse energy frequency and phase to the input transducers to match the mechanical resonance frequency of the working transducers and increase efficiency of energy transfer. Such feedback signals also are available for automated procedures which can improve product quality and consistency.

Owner:PROGRESS RAIL SERVICES

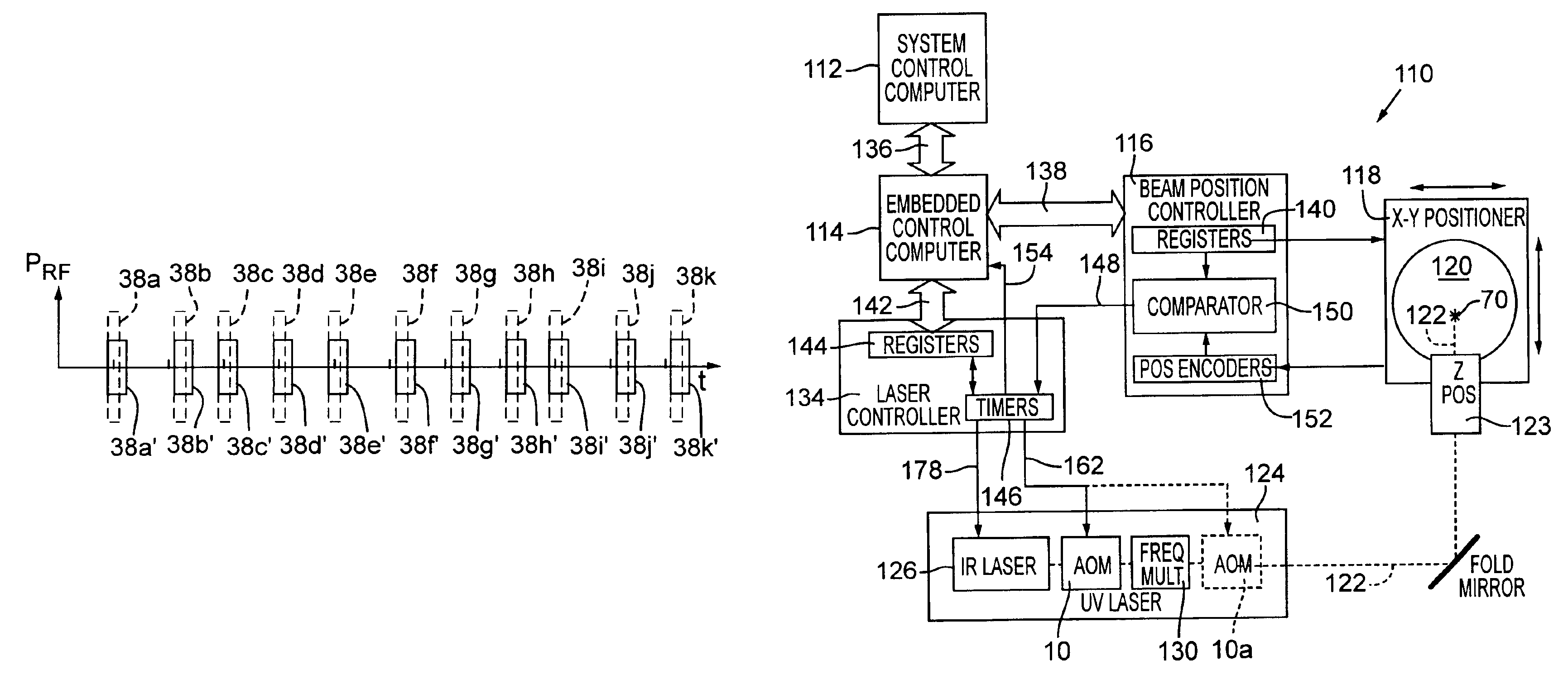

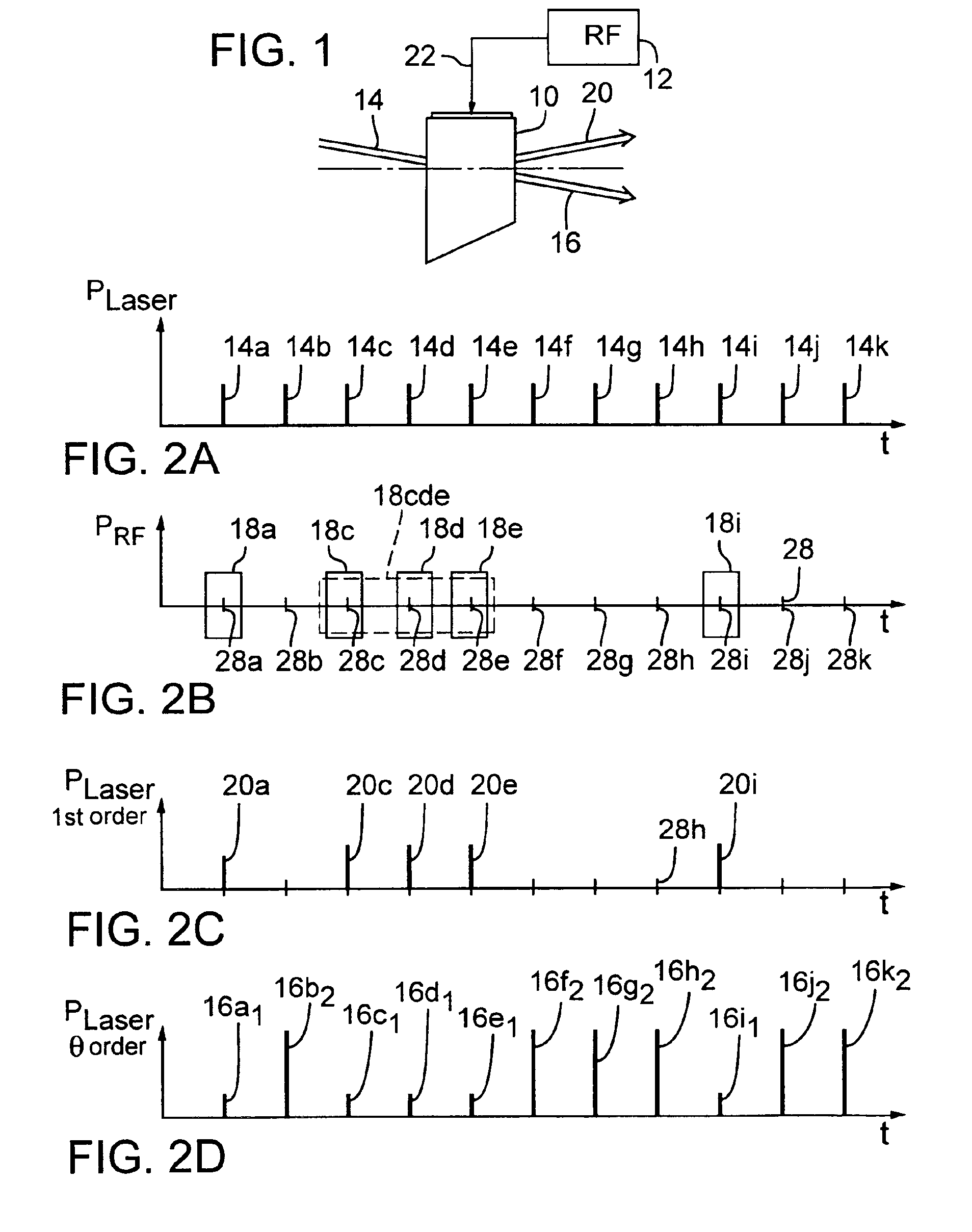

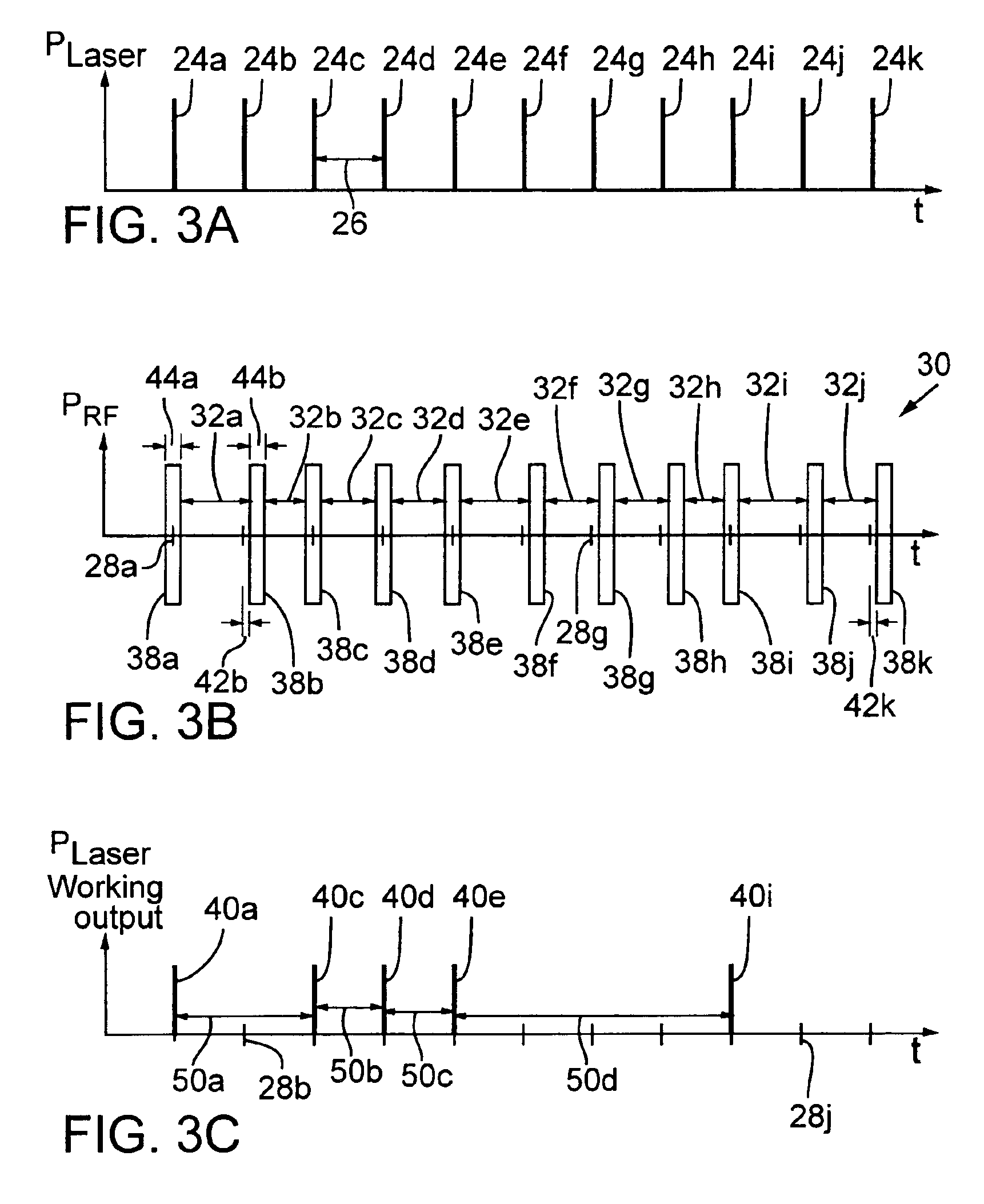

Laser pulse picking employing controlled AOM loading

ActiveUS6947454B2Constant RF powerConstant thermal loadingExcitation process/apparatusSemiconductor/solid-state device manufacturingPulse energyOptoelectronics

A laser (126) and an AOM (10) are pulsed at substantially regular and substantially similar constant high repetition rates to provide working laser outputs (40) with variable nonimpingement intervals (50) without sacrificing laser pulse-to-pulse energy stability. When a working laser output (40) is demanded, an RF pulse (38) is applied to the AOM (10) in coincidence with the laser output (24) to transmit it to a target. When no working laser output (40) is demanded, an RF pulse (38) is applied to the AOM (10) in noncoincidence with the laser output (24) so it gets blocked. So the average thermal loading on the AOM (10) remains substantially constant regardless of how randomly the working laser outputs (40) are demanded. The AOM (10) can also be used to control the energy of the working laser output (40) by controlling the power of the RF pulse (38) applied. When the RF power is changed, the RF duration (44) of the RF pulse (38) is modified to maintain the constant average RF power. Consistent loading on the AOM (10) eliminates deterioration of laser beam quality and laser beam pointing accuracy associated with thermal loading variation on the AOM (10) and is advantageous for applications such as IC chip link processing where stable working laser outputs (40) with variable output intervals (50) are needed.

Owner:ELECTRO SCI IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com