Patents

Literature

44results about How to "Inhibit degassing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

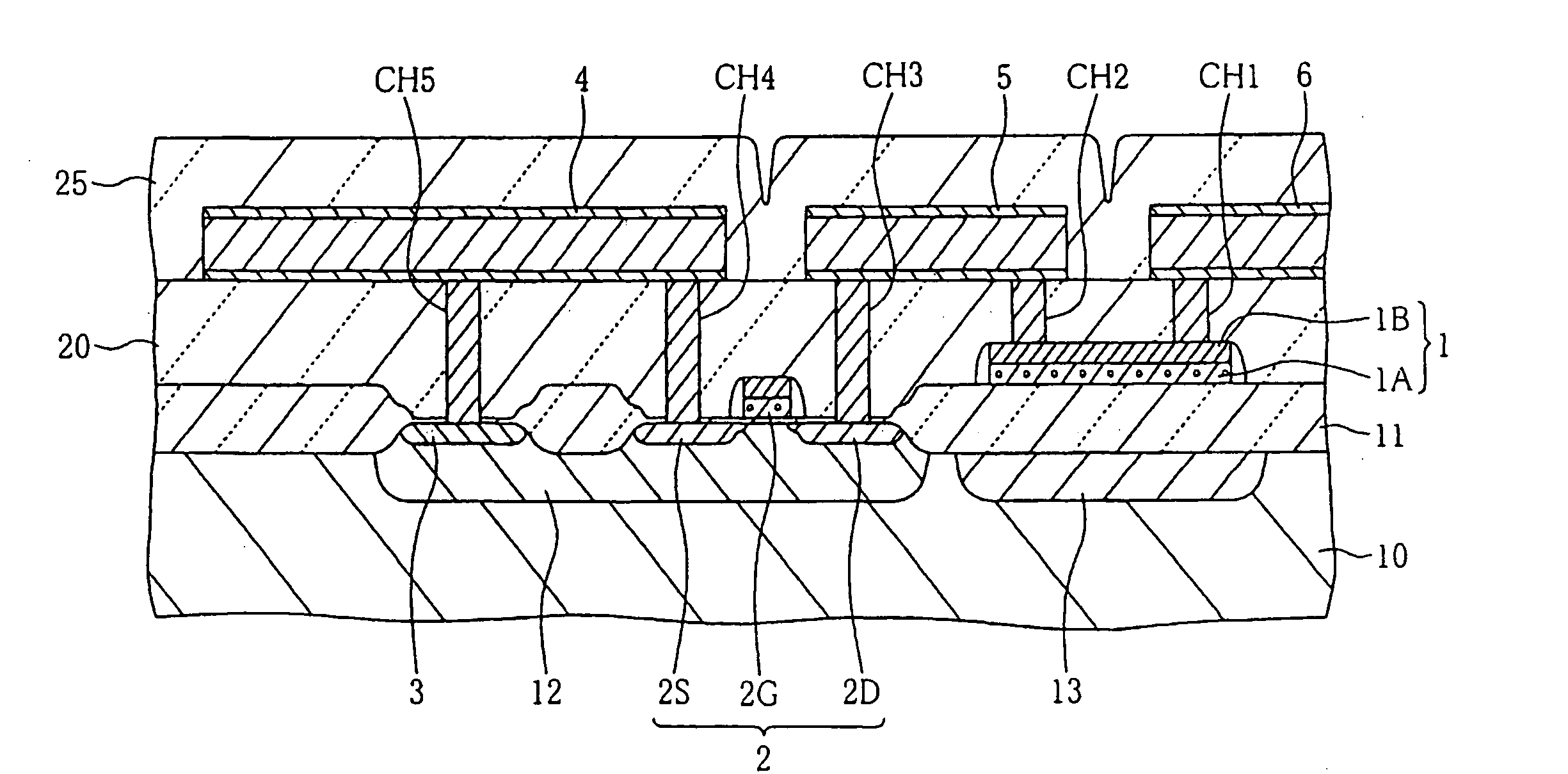

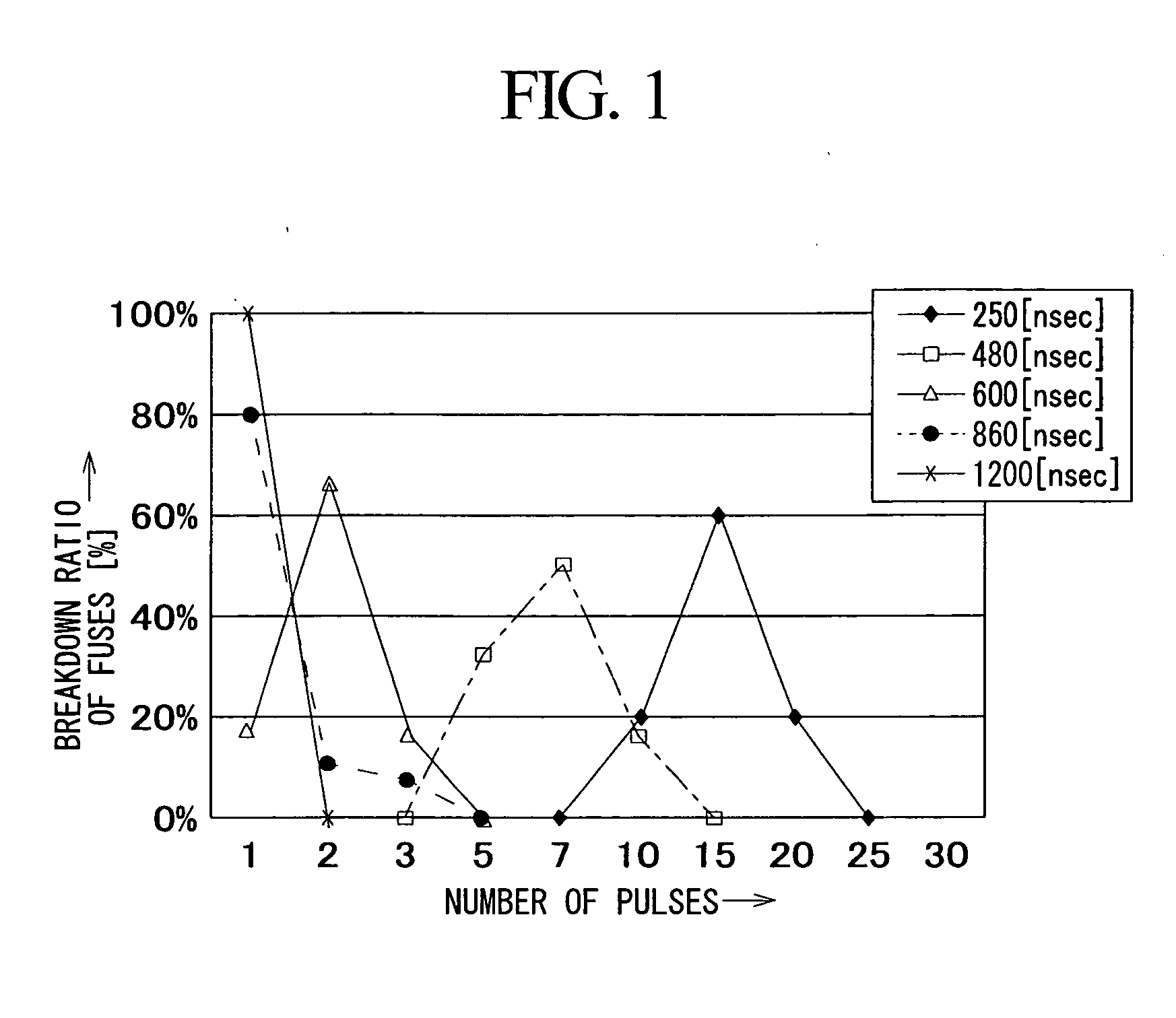

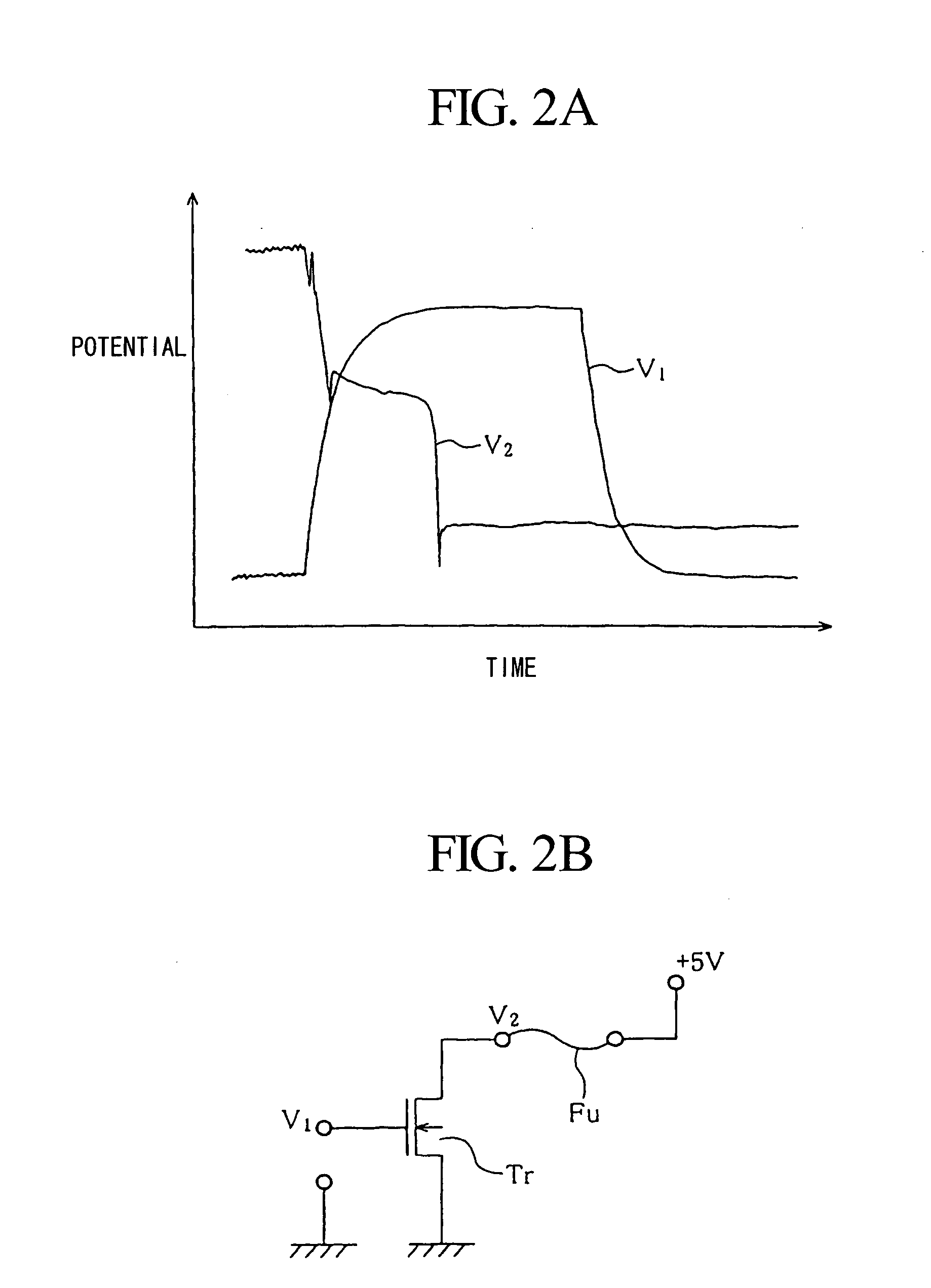

Fuse breakdown method adapted to semiconductor device

InactiveUS20070007621A1Increase distanceInhibit degassingTransistorSemiconductor/solid-state device detailsDevice materialEvaporation

A plurality of pulses each having relatively low energy are consecutively applied to a subject fuse to cause breakdown, wherein the total energy of pulses is set in light of a prescribed breakdown threshold, which is calculated in advance. The subject fuse has a pair of terminals and an interconnection portion that is narrowly constricted in the middle so as to realize fuse breakdown with ease. A pulse generator generates pulses, which are repeatedly applied to the subject fuse by way of a transistor; then, it stops generating pulses upon detection of fuse breakdown. Side wall spacers are formed on side walls of fuses, which are processed in a tapered shape so as to reduce thermal stress applied to coating insulating films. In addition, pulse energy is appropriately determined so as to cause electro-migration in the subject fuse, which is thus increased in resistance without causing instantaneous meltdown or evaporation.

Owner:YAMAHA CORP

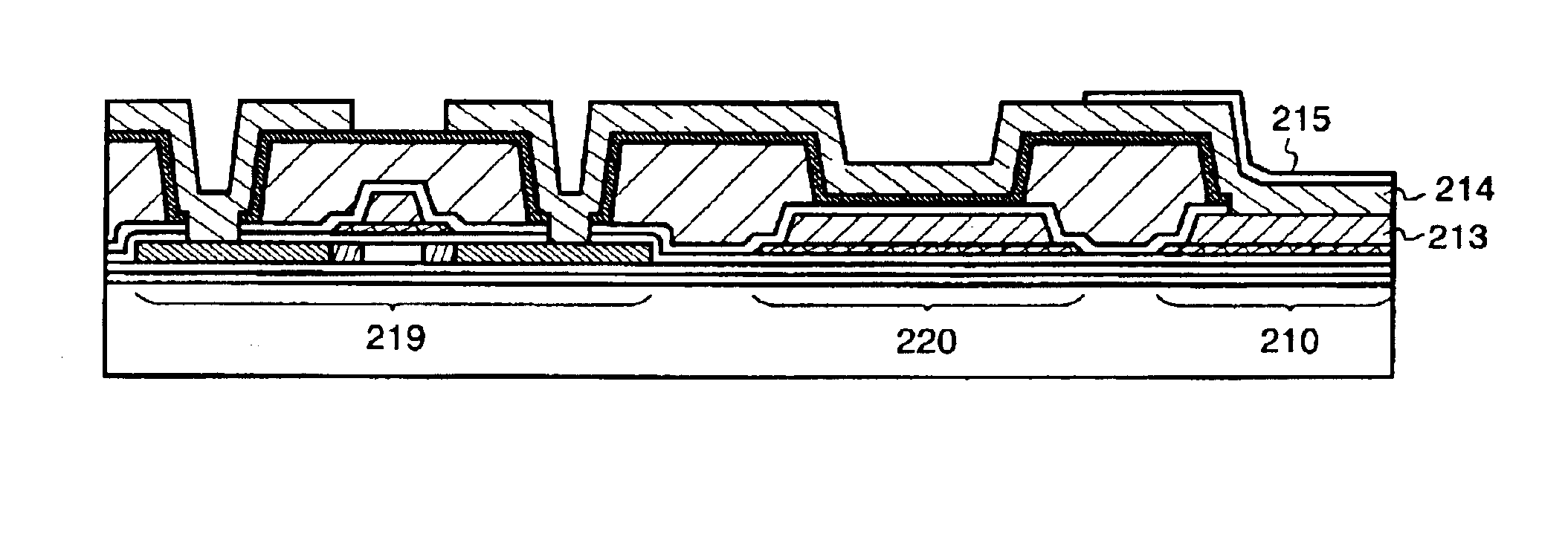

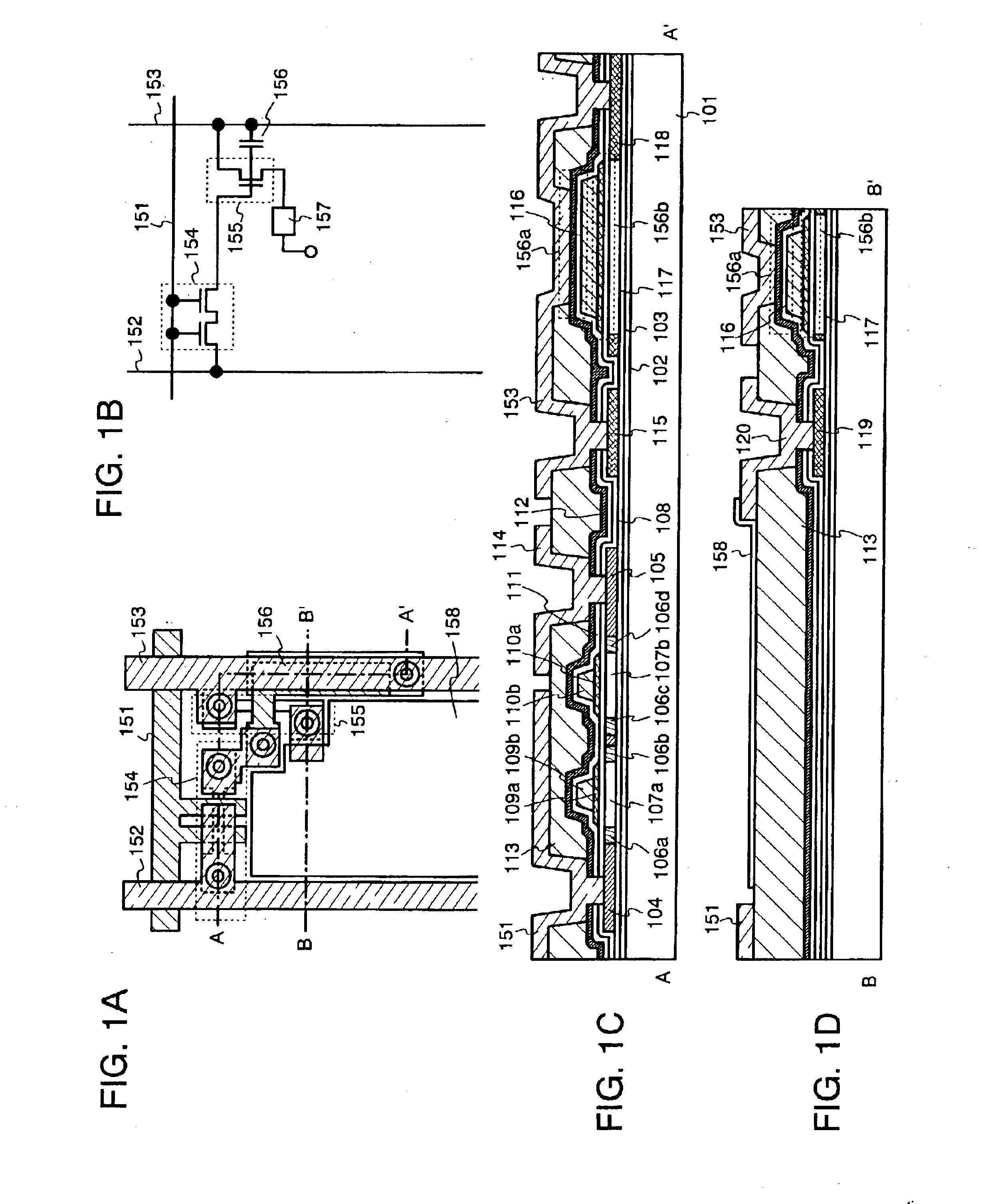

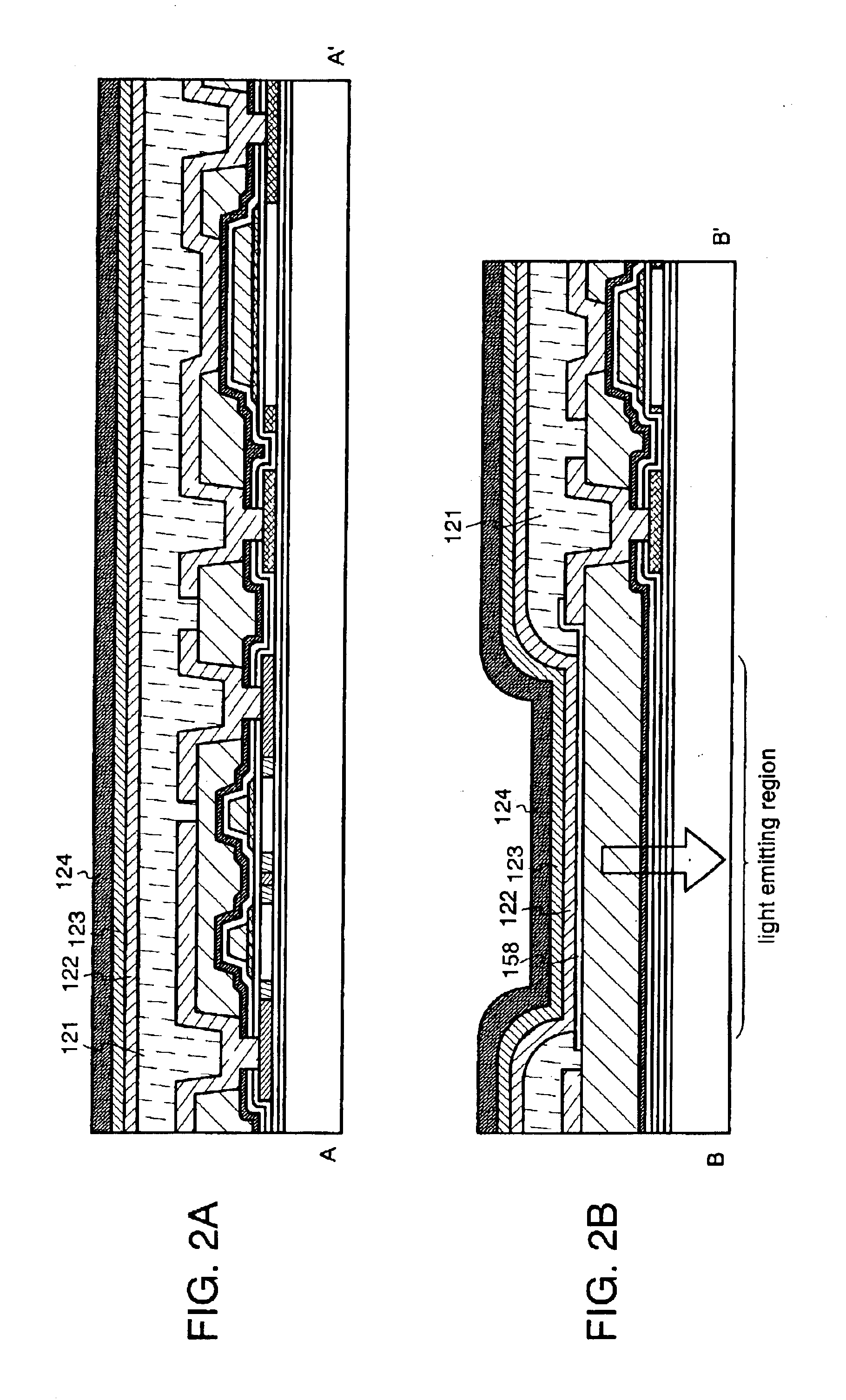

Display device

InactiveUS6960786B2Reduce impactSuppress mutationTransistorElectroluminescent light sourcesDisplay deviceOptoelectronics

Owner:SEMICON ENERGY LAB CO LTD

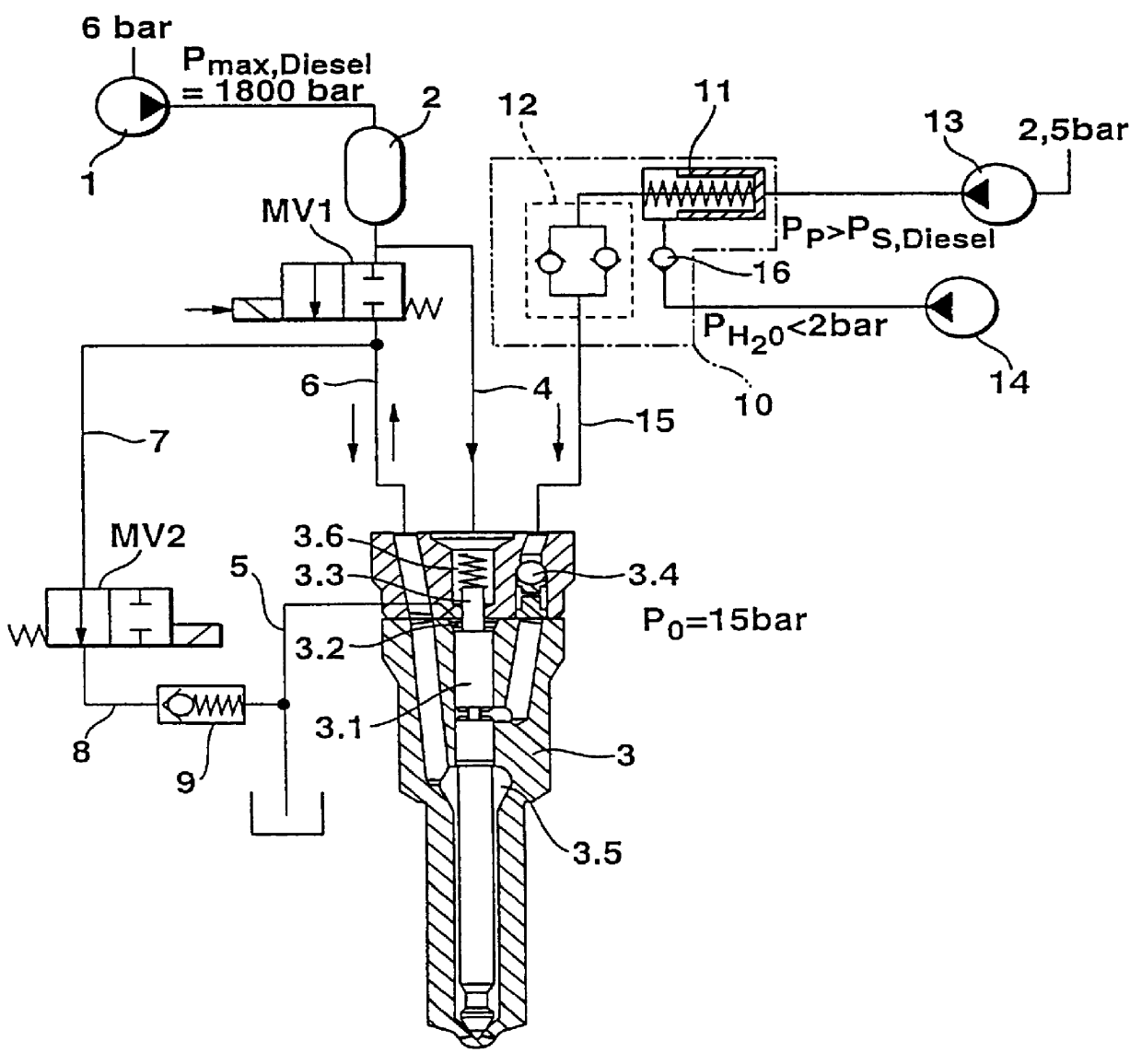

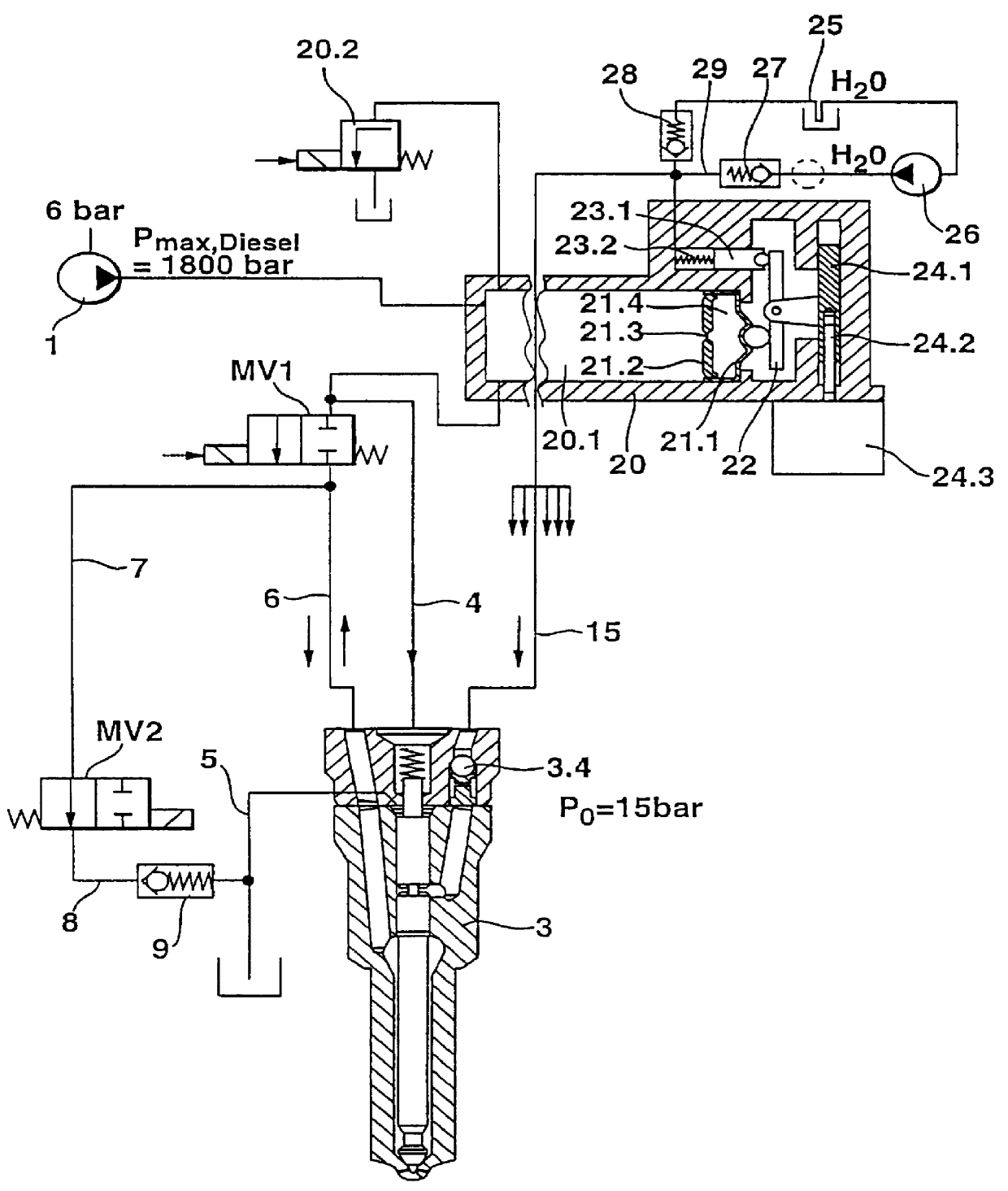

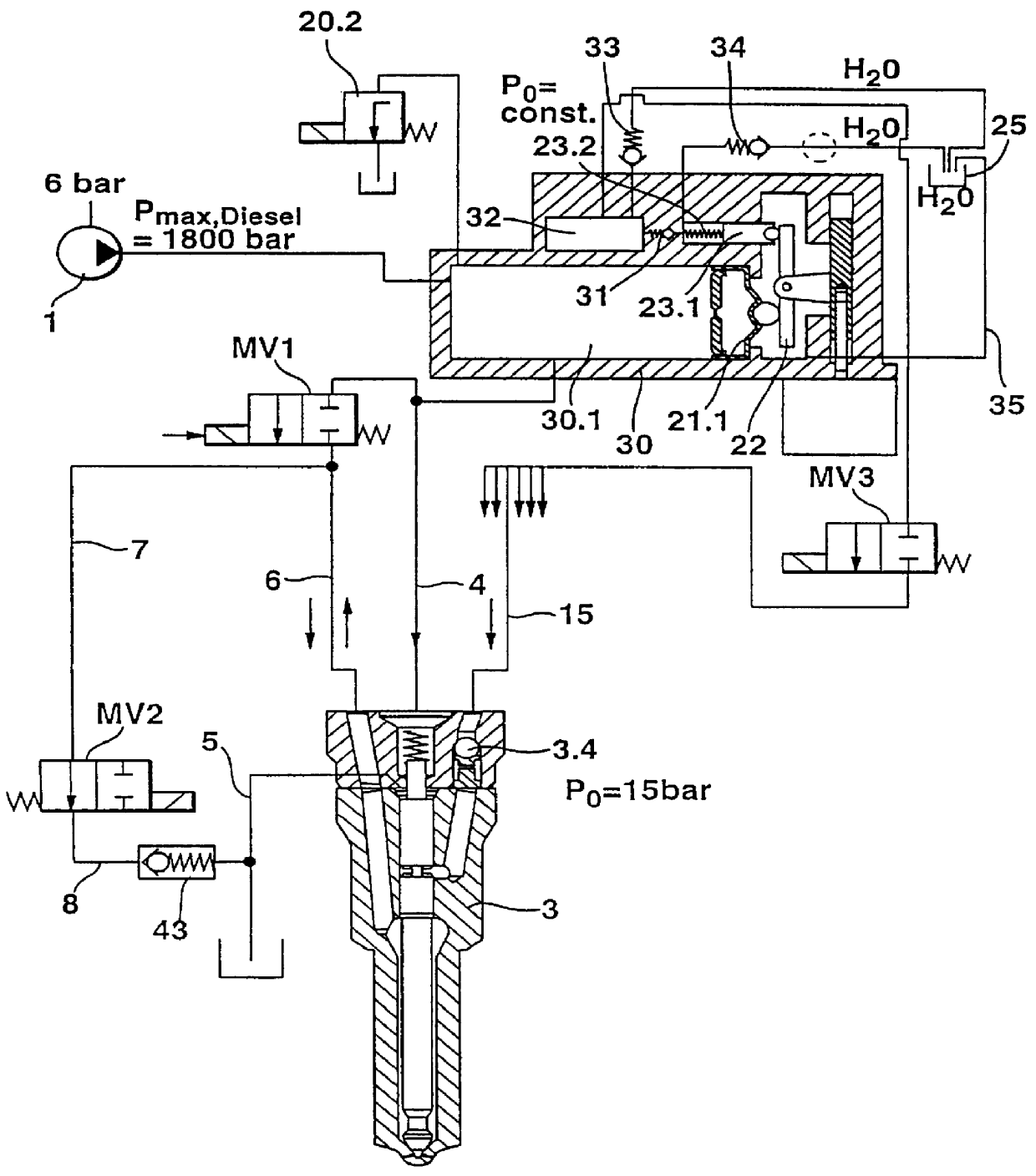

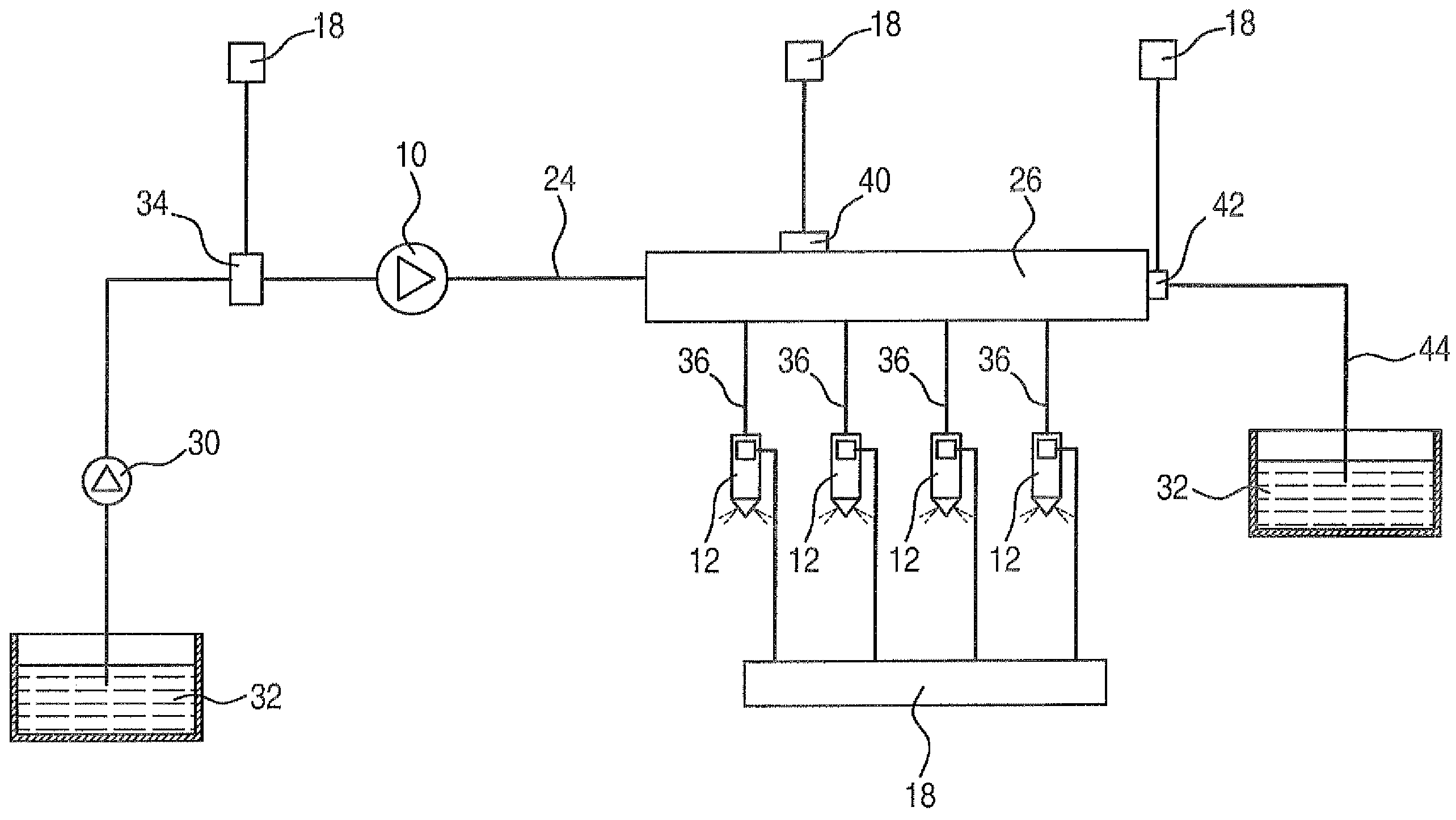

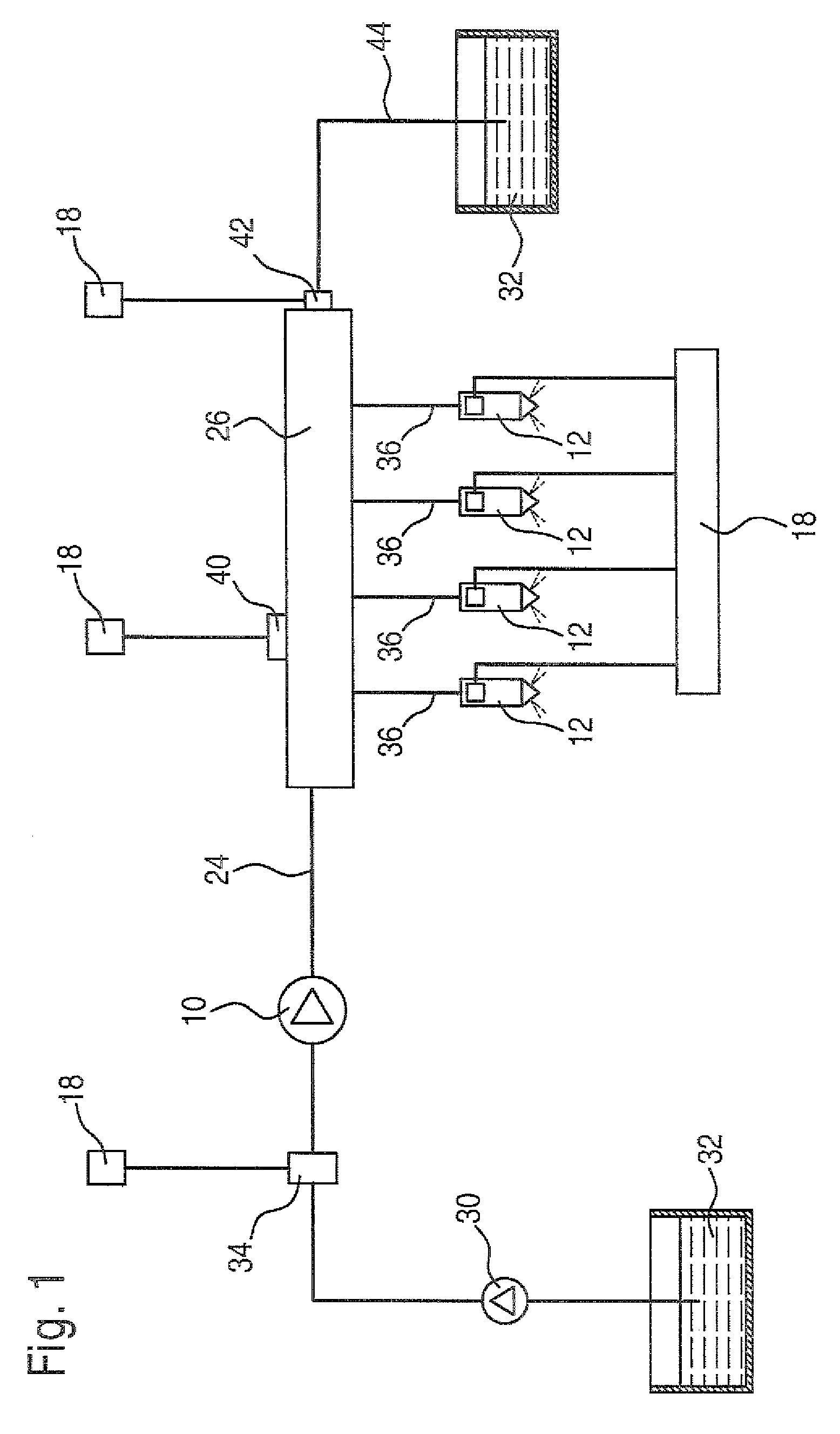

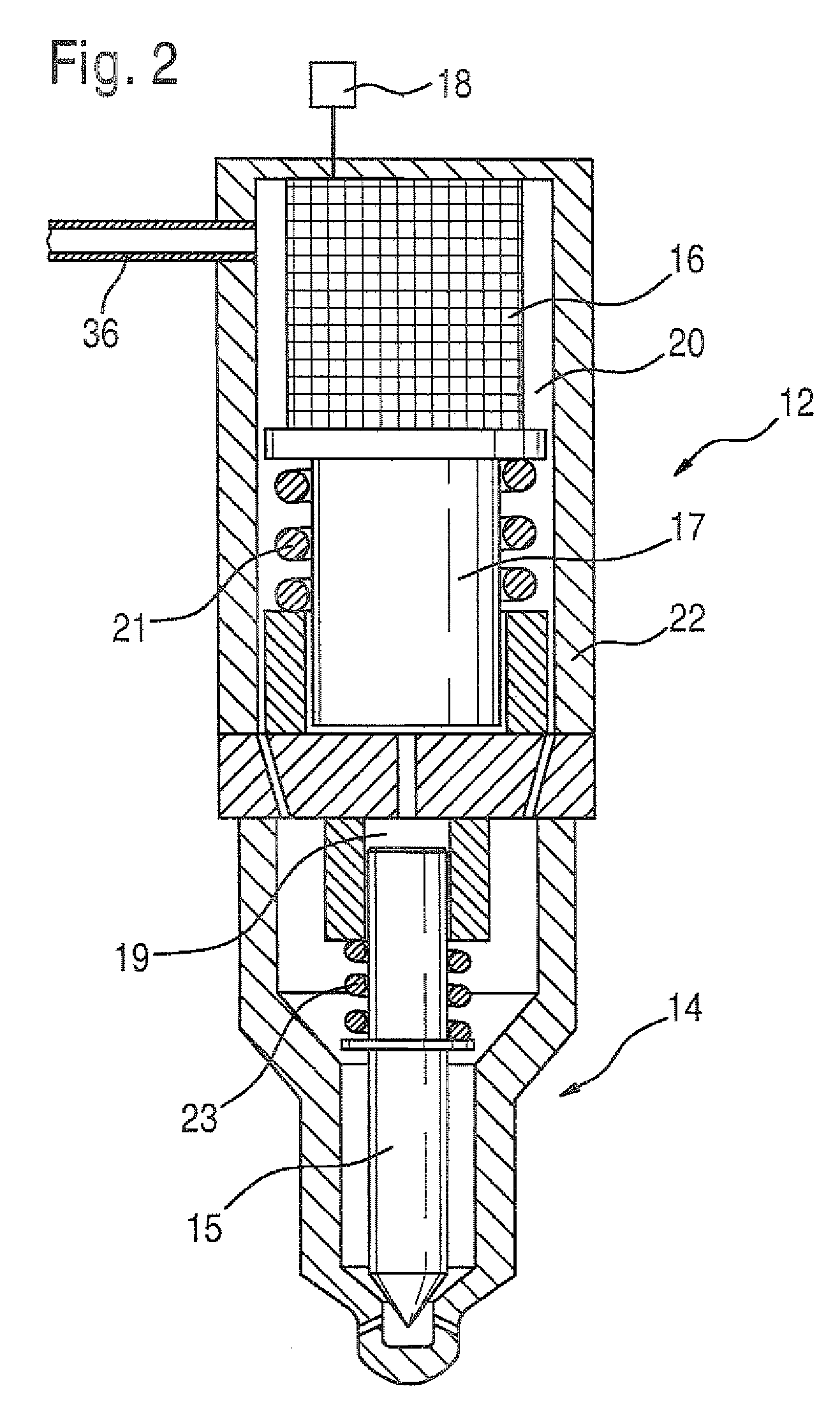

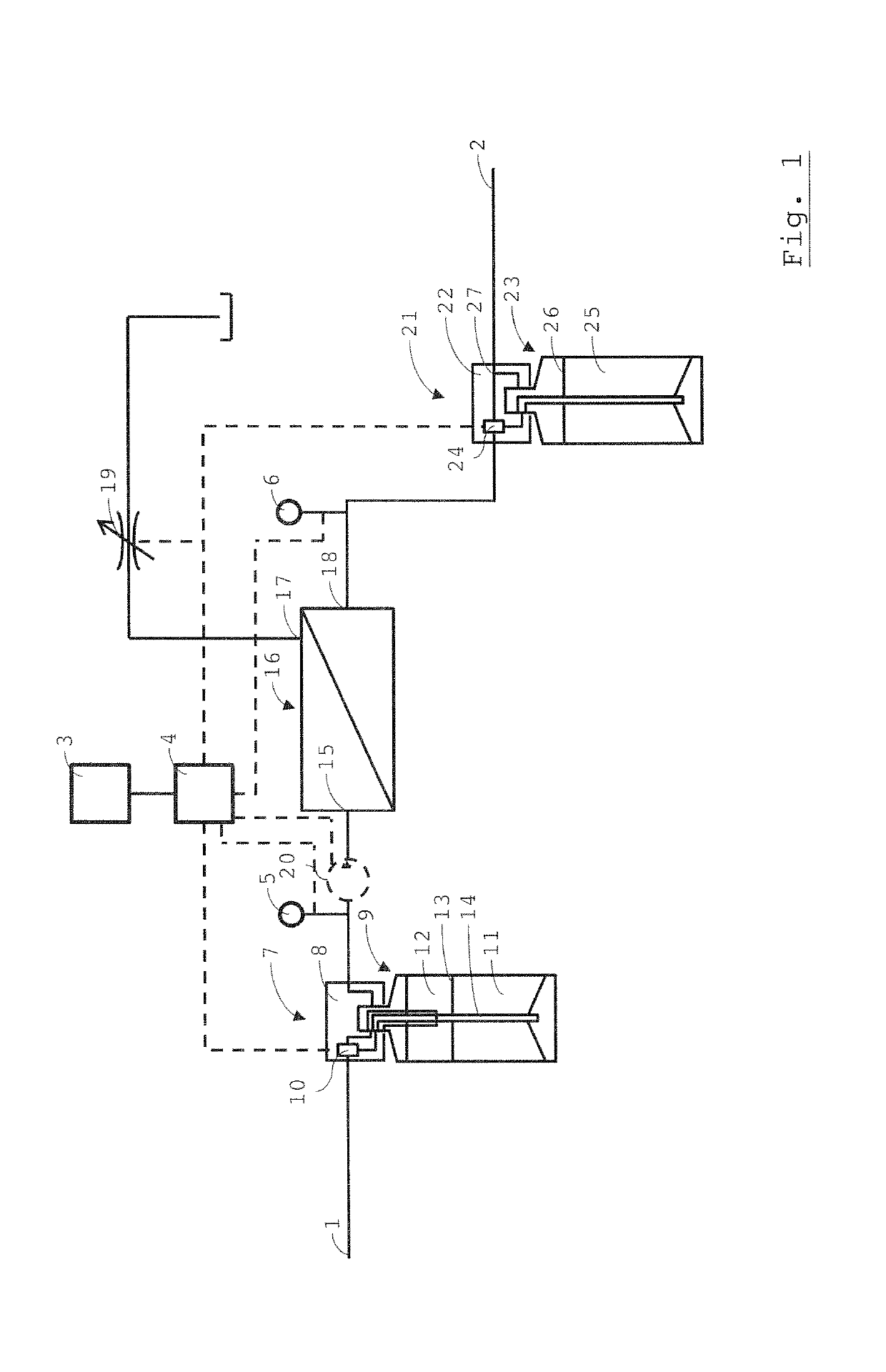

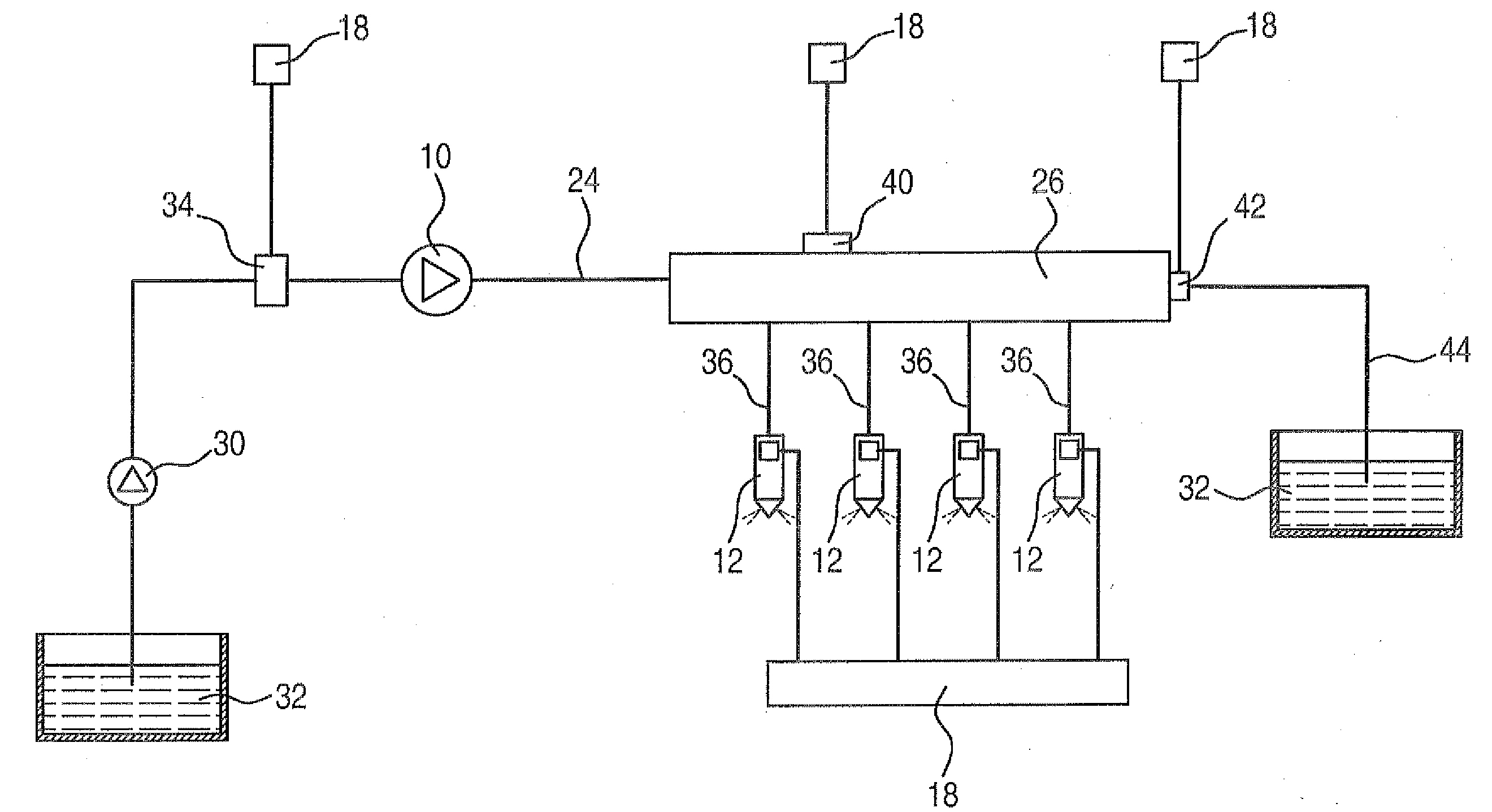

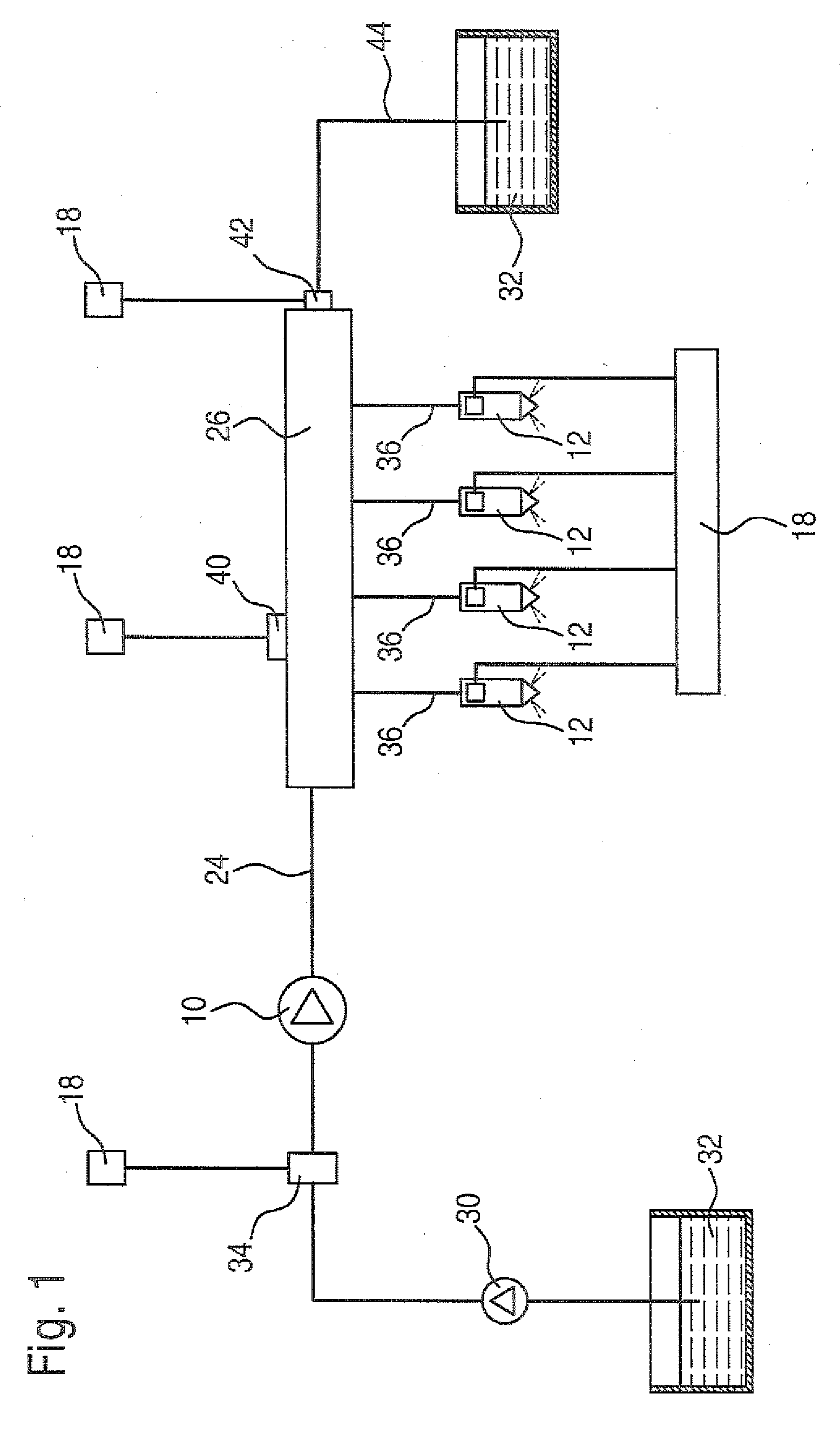

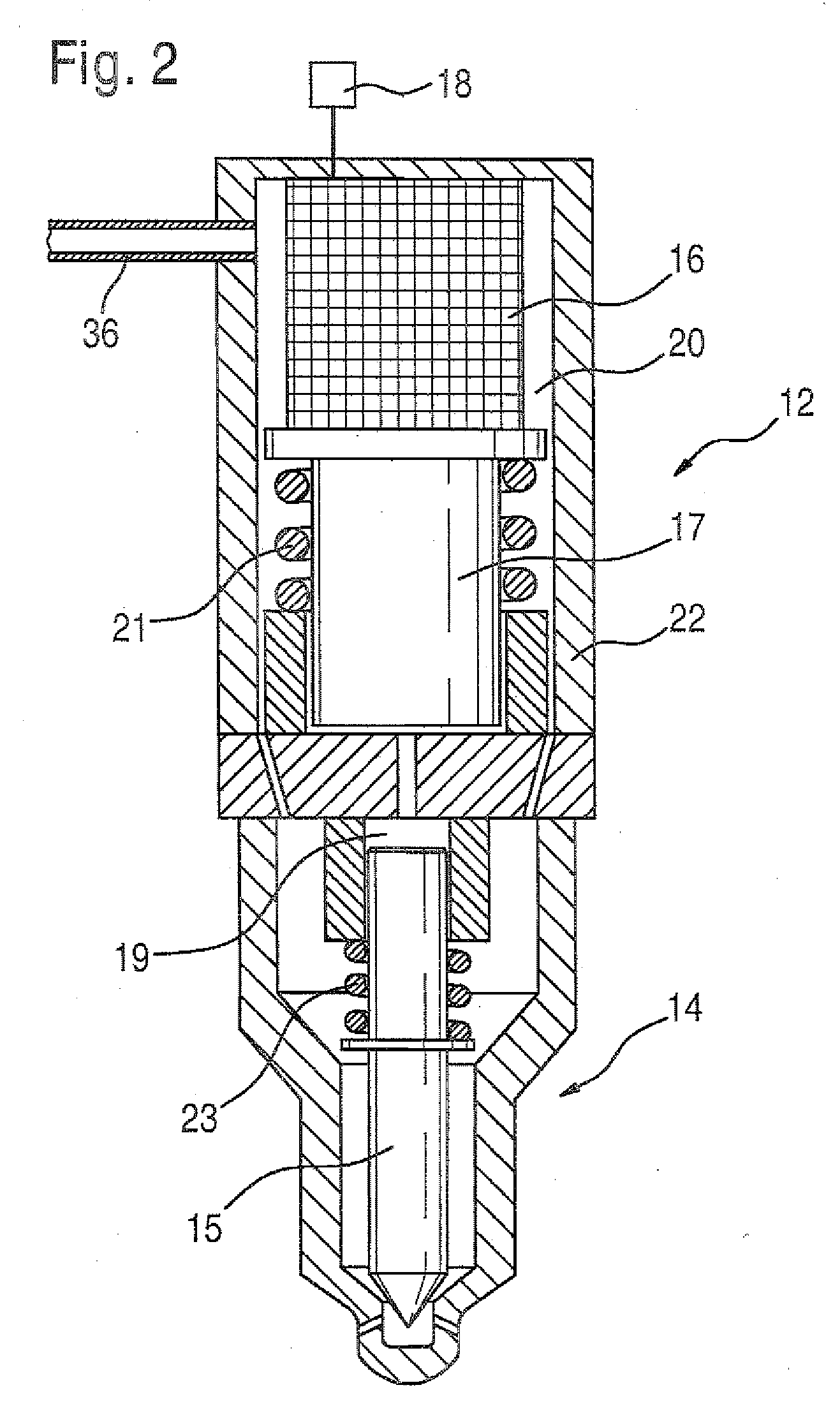

Fuel injection system for an internal combustion engine

InactiveUS6067964AAccurate supervisionHigh degreeCombustion enginesFuel injecting pumpsCommon railEngineering

PCT No. PCT / DE98 / 02771 Sec. 371 Date Jul. 23, 1999 Sec. 102(e) Date Jul. 23, 1999 PCT Filed Sep. 18, 1998 PCT Pub. No. WO99 / 20893 PCT Pub. Date Apr. 29, 1999A fuel injection system having a common rail pressure reservoir filled with high-pressure fuel and having a dual-fuel injector for a bi-fluid injection of fuel and an additive fluid into an internal combustion engine. The system includes a first 2 / 2-way valve in the injection line between the common rail pressure reservoir and a pressure chamber encompassing the injector needle of the dual-fuel injector as well as a second 2 / 2-way valve, whose inlet is connected via a supply line to the injection line at a point between the first 2 / 2-way valve and the pressure chamber, and whose outlet is connected to the low-pressure fuel side by way of an outlet line. As a result, the otherwise conventional 3 / 2-way solenoid control valves, which are significantly more complex technically, can be replaced by more reasonably priced 2 / 2-way valves. At the same time, this raises the possibility of shifting the quantity metering for additive fluid to a single metering valve that serves an entire group of injectors.

Owner:ROBERT BOSCH GMBH

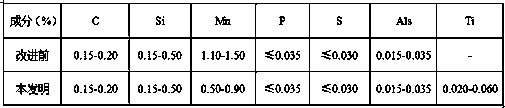

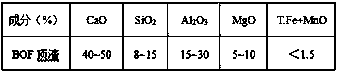

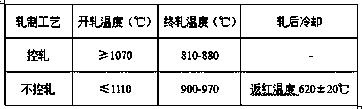

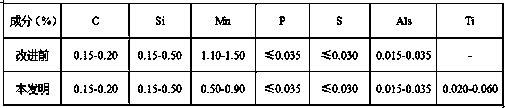

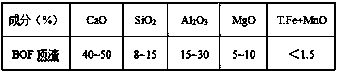

Low-cost manufacturing method of flaw-detection-ensured Q345B stage steel plate

The invention discloses a low-cost manufacturing method of a flaw-detection-ensured Q345B stage steel plate. The steel plate comprises, by mass percent, 0.15 to 0.20% of C, 0.15 to 0.50% of Si, 0.50 to 0.90% of Mn, not larger than 0.035% of P, not larger than 0.025% of S, 0.020 to 0.060% of Ti, 0.015 to 0.035% of Als, and the balance Fe and inevitable impurities. During preparing, molten iron is subject to KR desulfurization treatment firstly, the molten iron obtained after desulfurization treatment is subject to slag removal, the molten iron is converted into a converter to be smelted, outputmolten steel is subject to continuous casting and rolling, finally, the rolled steel plate is subject to stacking for slow-cooling for 24 to 72 hours, and then sampling inspection is carried out; thechemical components and the production process of the prepared Q345B stage steel plate are simple, the production cost is low, the flaw detection property is good, and the method has the good application and popularization prospects.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

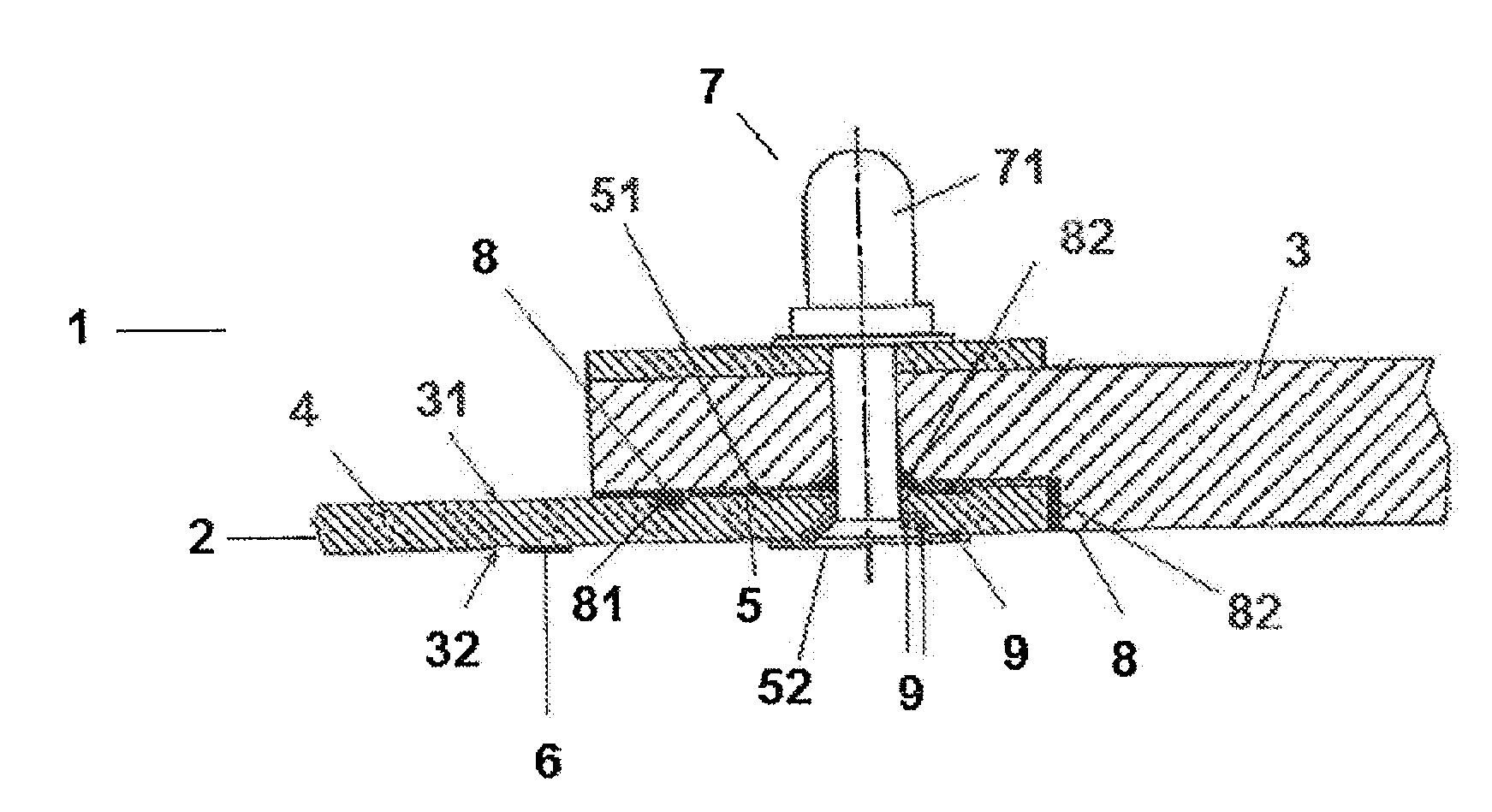

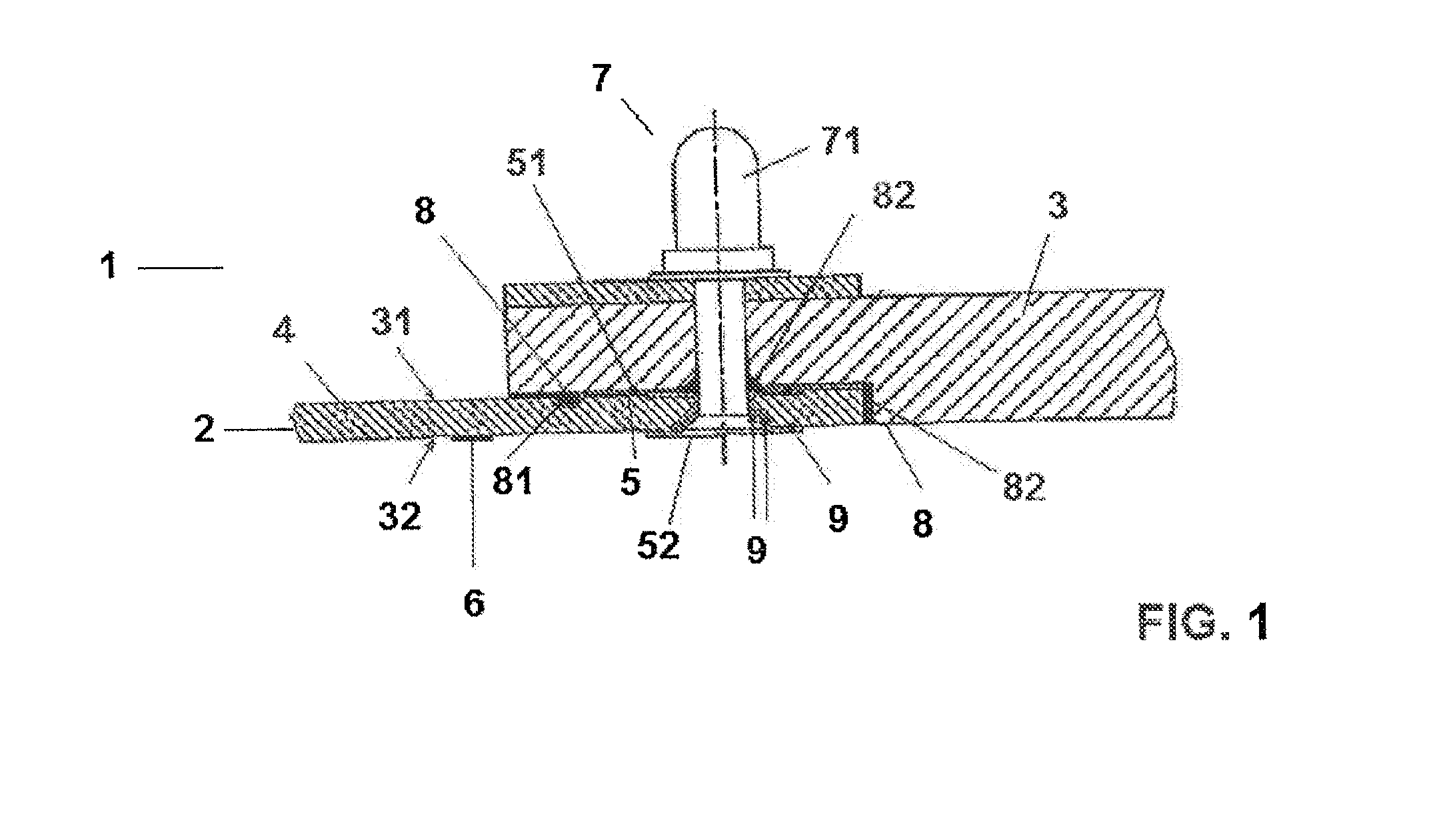

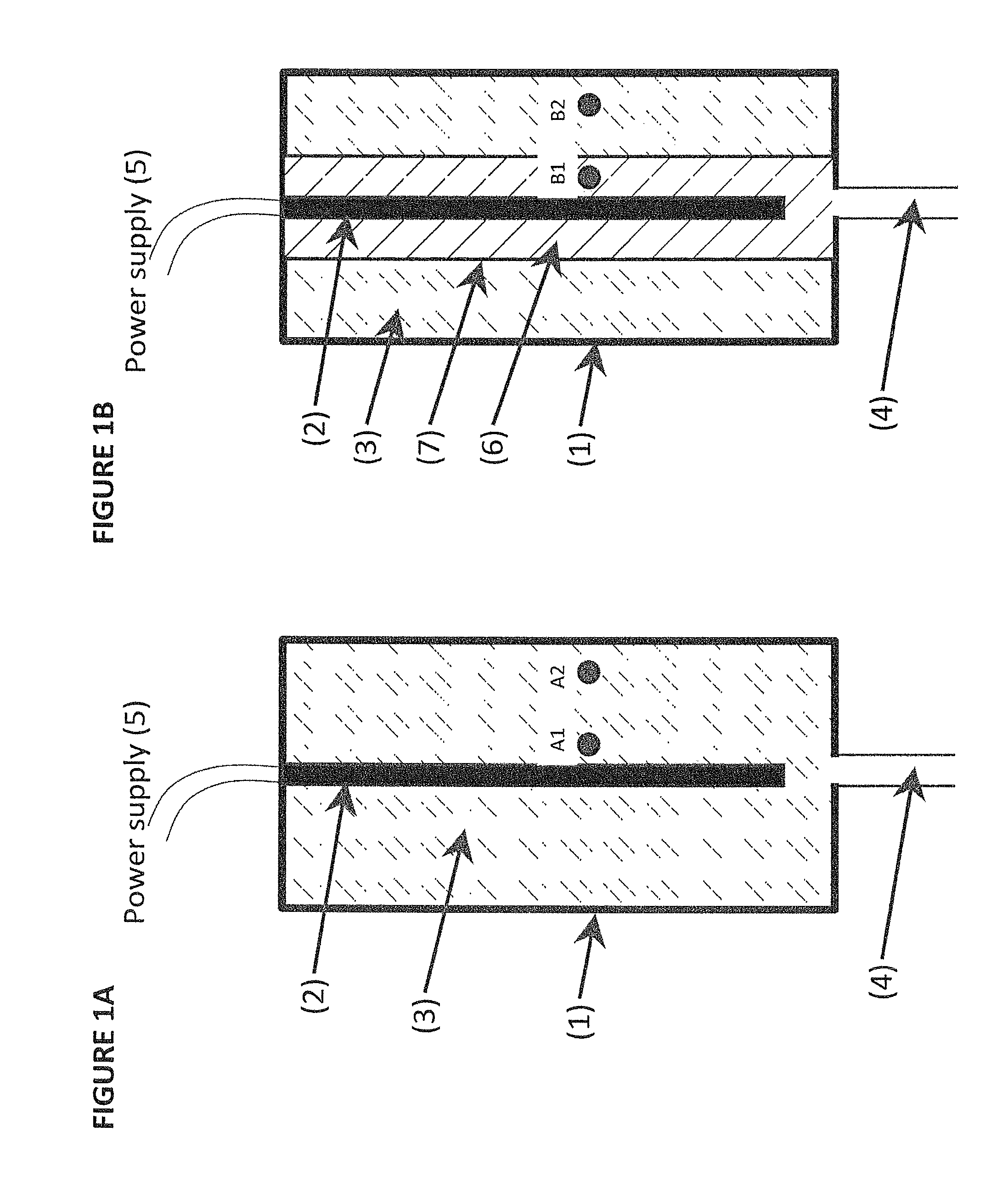

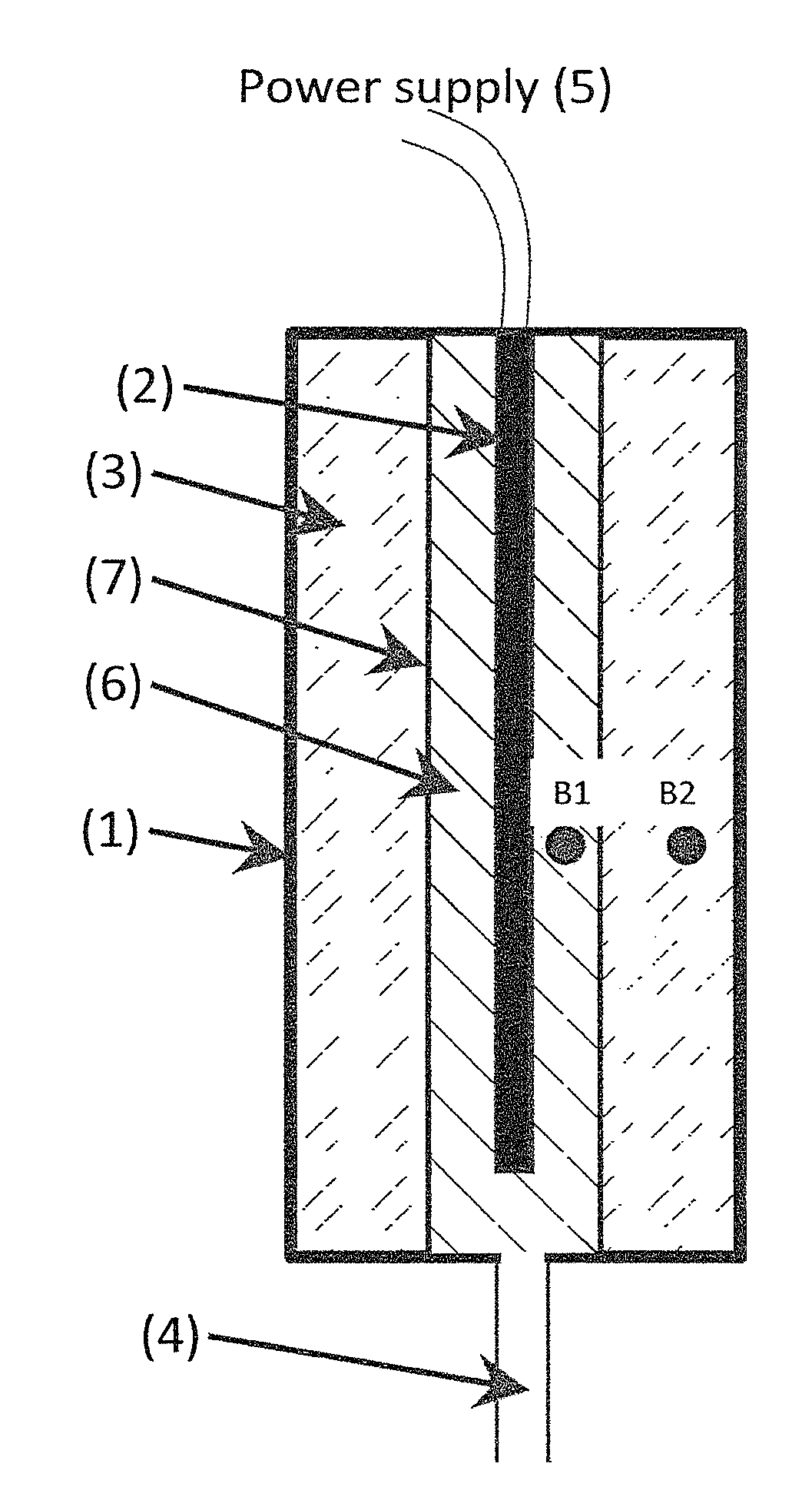

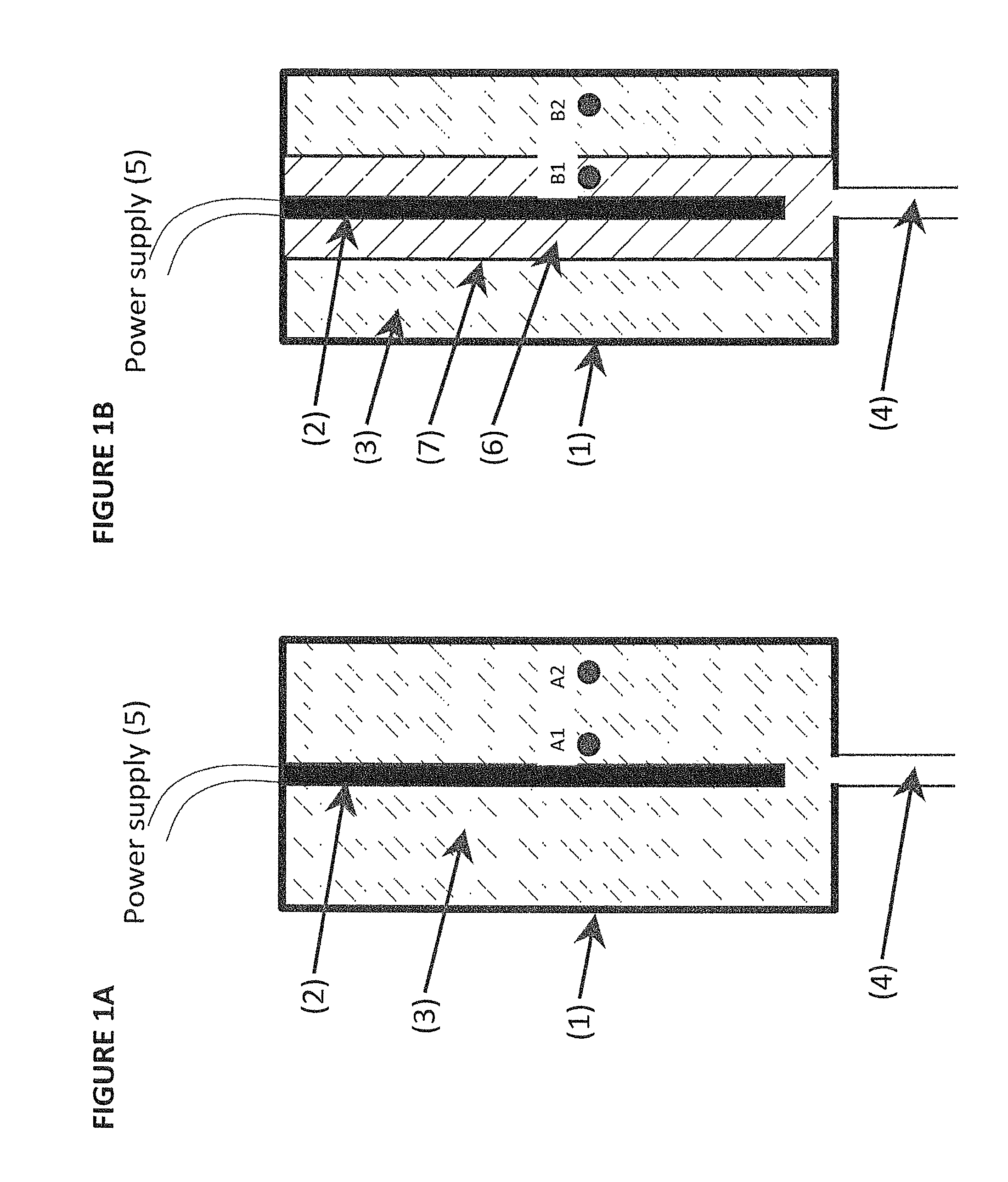

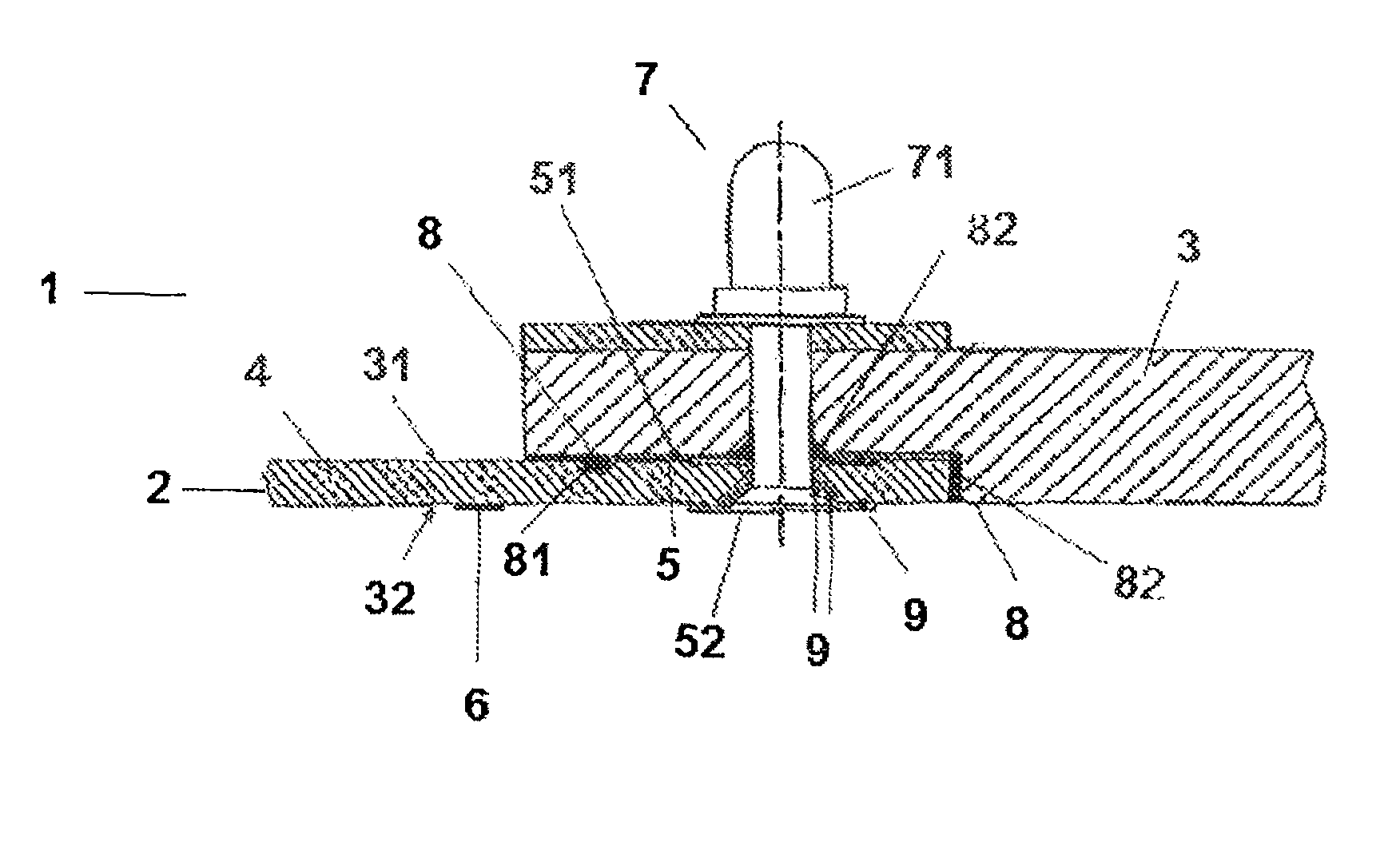

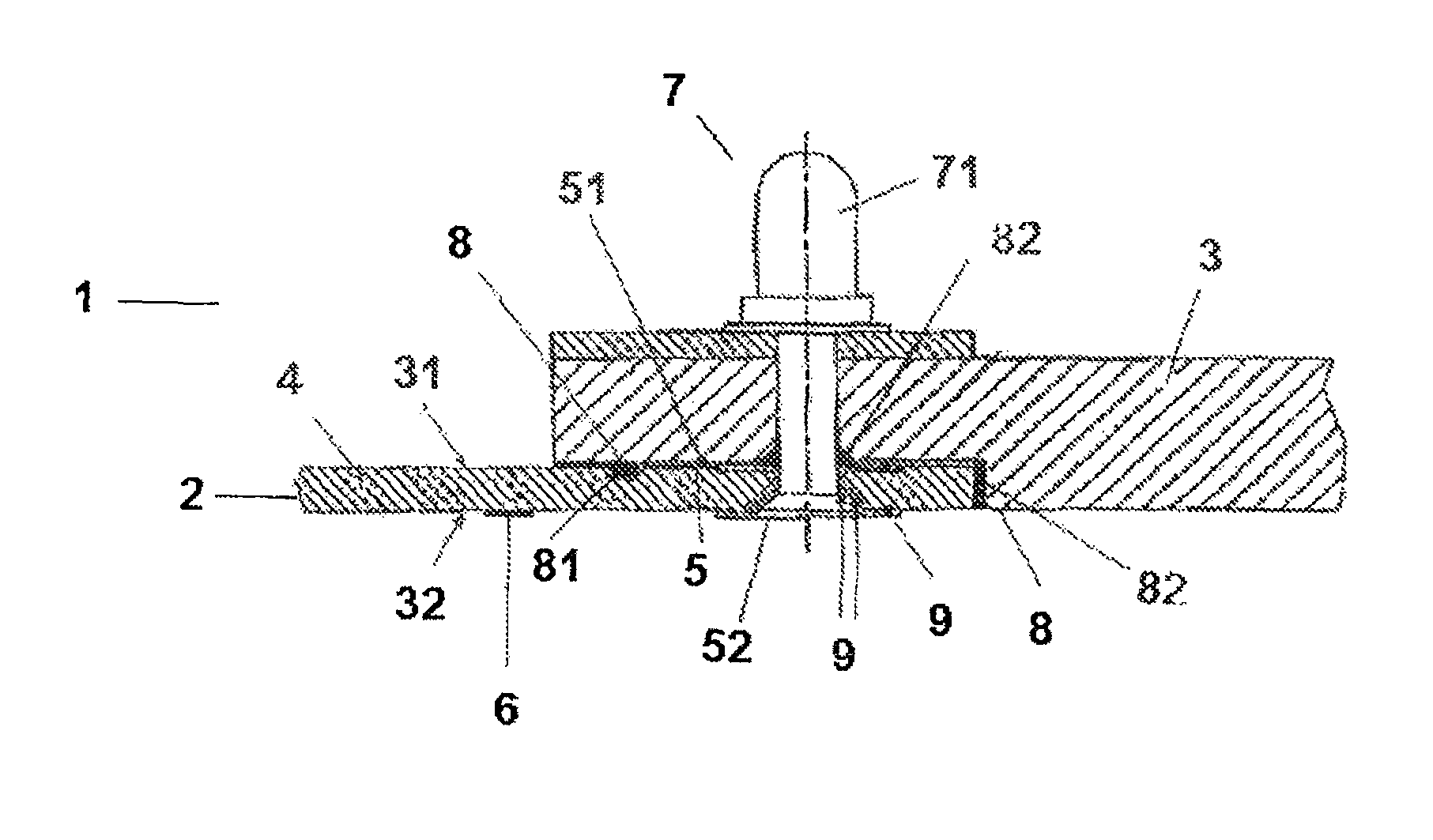

Device for installing conducting components in structures

ActiveUS20110247203A1Prevent degasificationLower impedanceFuel tank safety measuresAircraft lighting protectorsElectrically conductiveMaterial structure

A device (1) for the installation of a conducting component (2) on a structure (3) made from composite material, the inside of this structure (3) comprising a substance which can be ignited, which comprises an installation element (4) onto which the conducting component (2) is positioned, a conducting insert element (5), by means of which the installation element (4) is joined to the composite material structure (3) by its internal part, a conducting layer (6) arranged on the external part of the installation element (4) and a conducting fixing element (7) which joins the structure (3) and the installation element (4) to the insert element (5) and the conducting layer (6) so that the device (1) defines a low impedance current path through the conducting layer (6) and the insert element (5) through which the energy is dissipated from an atmospheric discharge to the component (2) or to the structure (3), the interior face of the structure (3) remaining isolated.

Owner:AIRBUS OPERATIONS SL

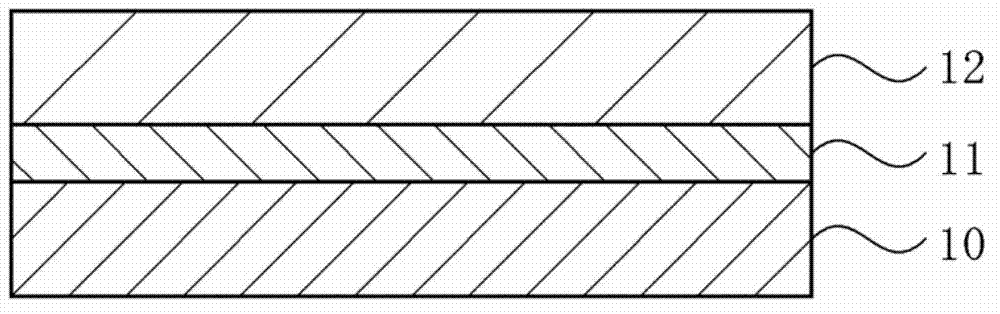

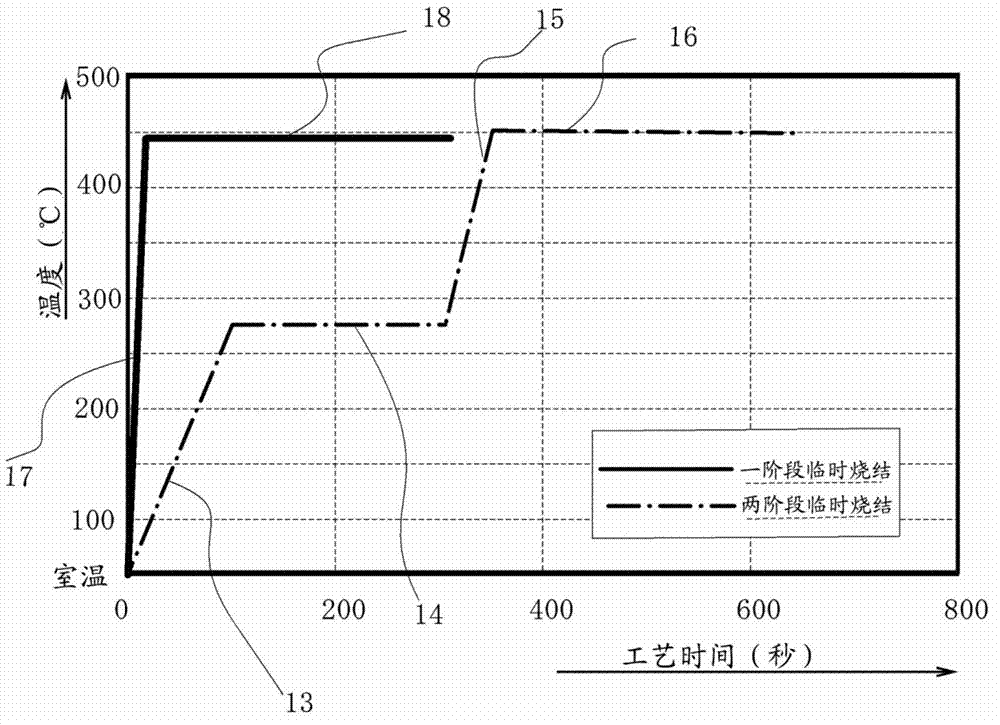

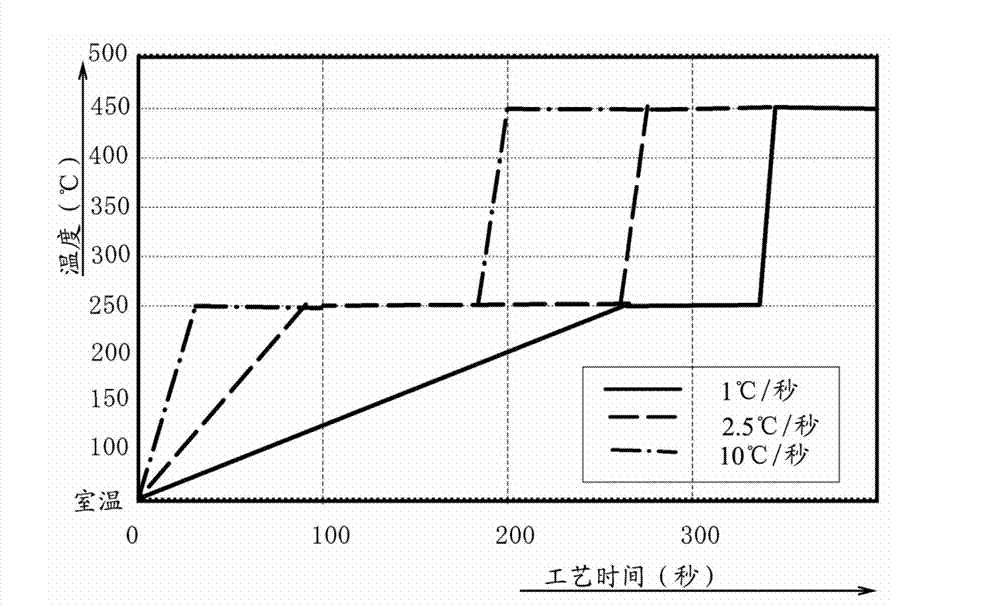

Method of manufacturing PZT-based ferroelectric thin film and PZT-based ferroelectric thin film

InactiveCN103359785AAvoid thermal decompositionInhibit degassingPiezoelectric/electrostriction/magnetostriction machinesZirconium compoundsInfraredFerroelectric thin films

The invention provides a method of manufacturing PZT-based ferroelectric thin film and a PZT-based ferroelectric thin film. Disclosed is the method of manufacturing a PZT-based ferroelectric thin film on a lower electrode by coating, calcining, and then firing so as to crystallize a PZT-based ferroelectric thin film-forming composition on the lower electrode of a substrate having the lower electrode in which a crystal plane is oriented in a (111) axis direction. A PZT-based ferroelectric thin film-forming composition is coated on the surface of the lower electrode using a CSD method. Calcination is slowly carried out on a formed sol film in a temperature pattern including a first holding step in which the temperature of the composition is increased from a predetermined temperature such as room temperature using infrared rays and the composition is held at a temperature in a range of 200 DEG C. to 350 DEG C. and a second holding step in which the temperature of composition is increased from the holding temperature of the first holding step and is held at a temperature in a range of 350 DEG C. to 500 DEG C. higher than the holding temperature of the first holding step.

Owner:MITSUBISHI MATERIALS CORP

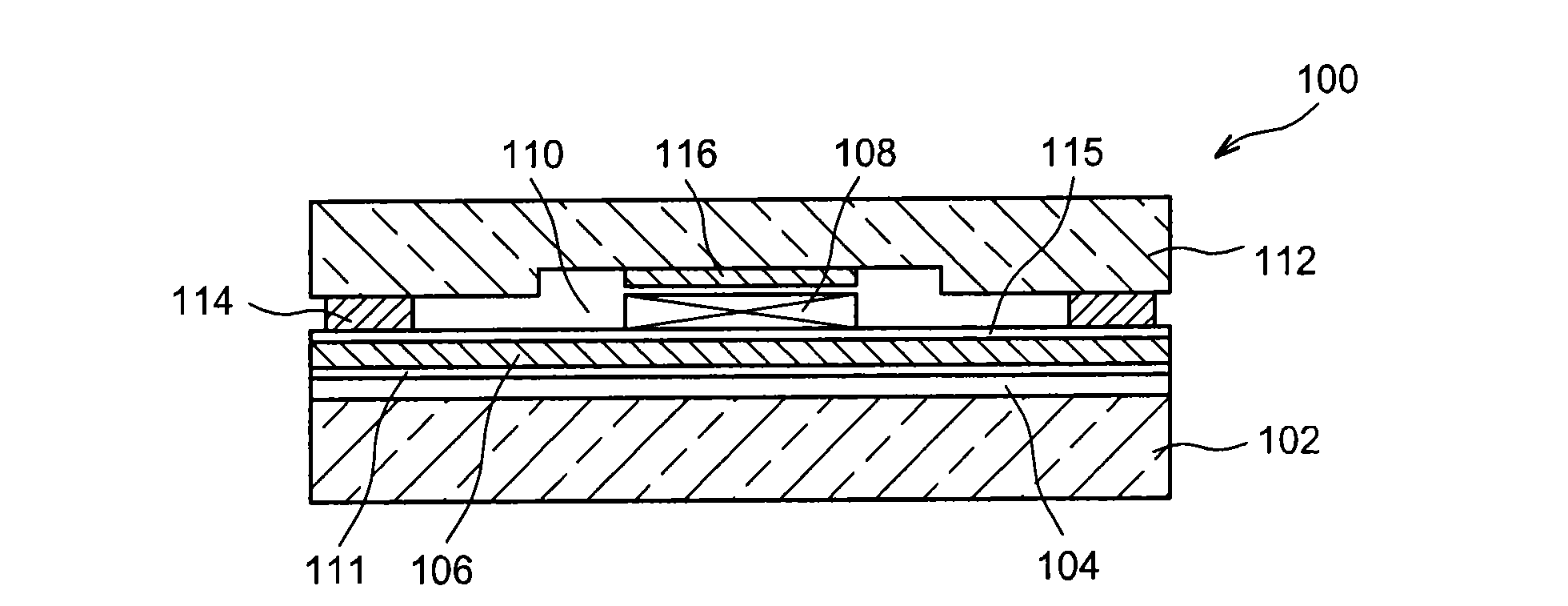

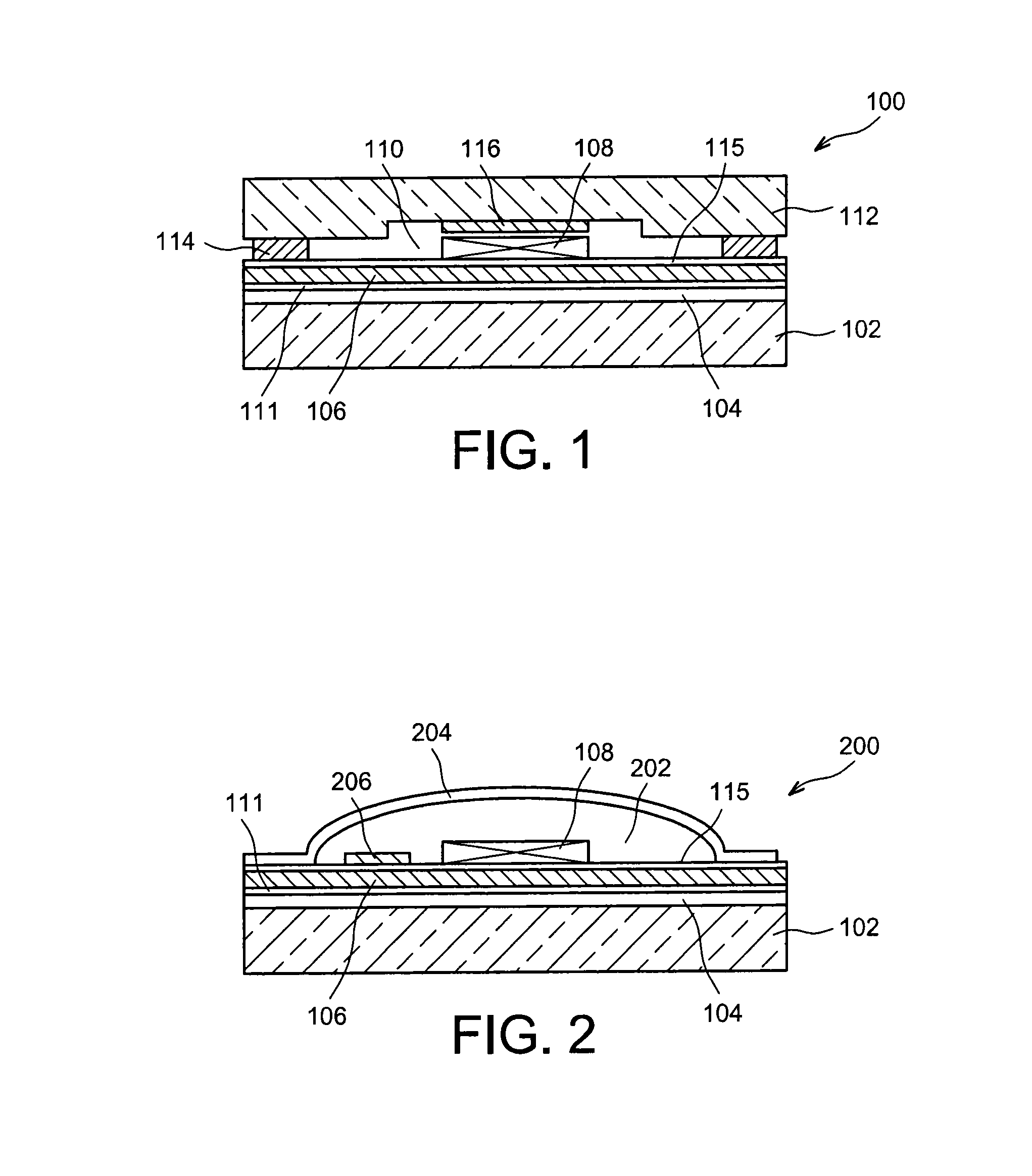

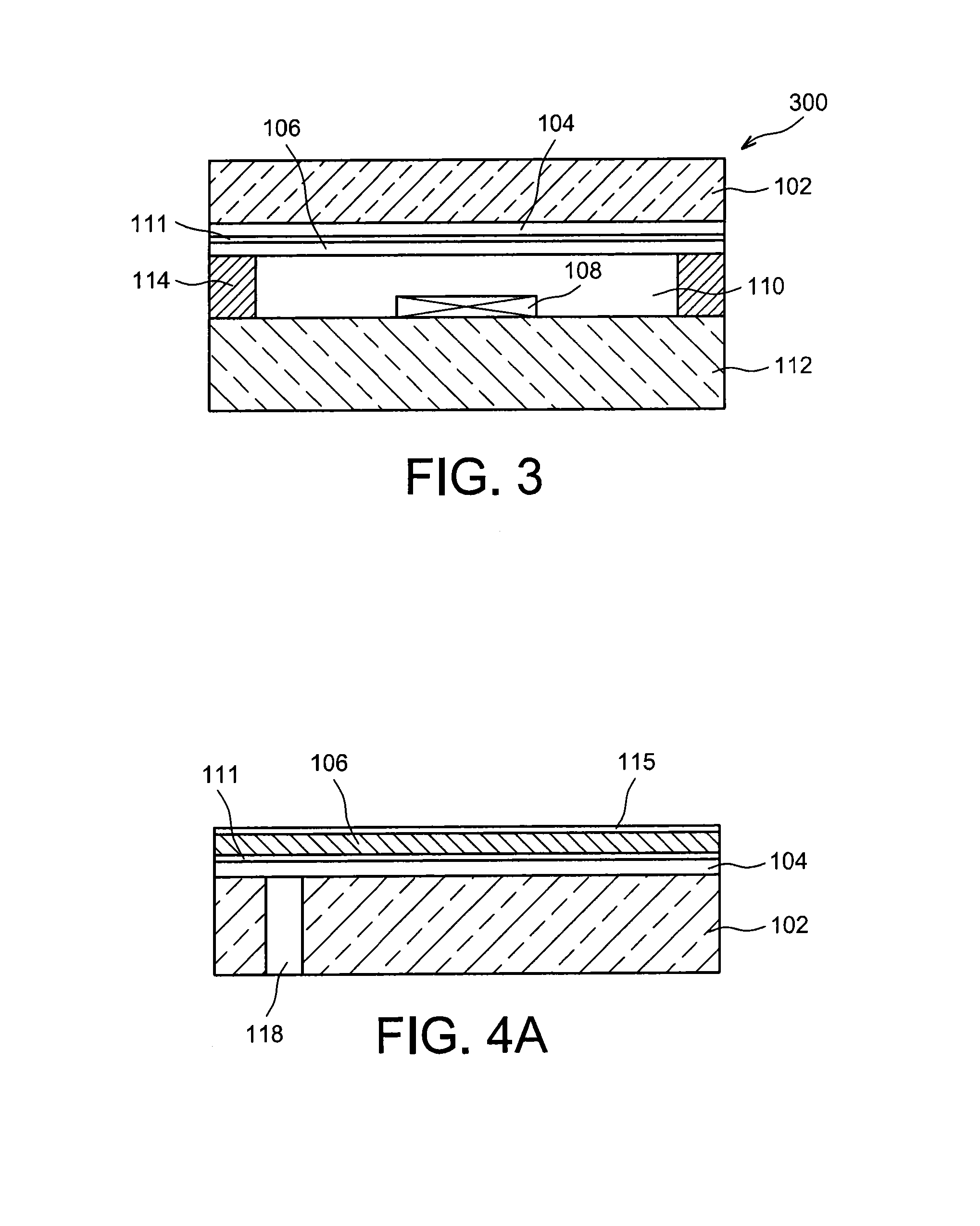

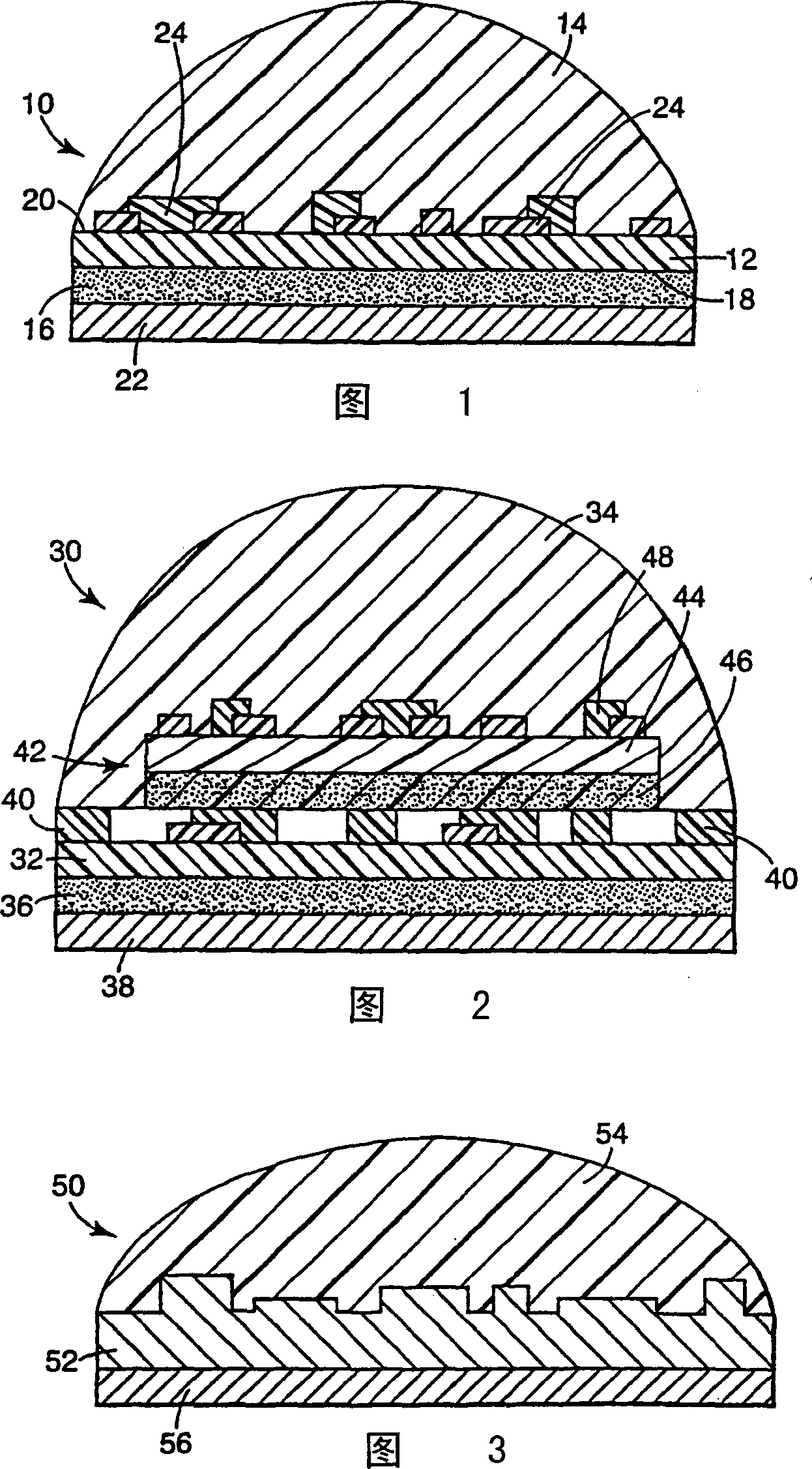

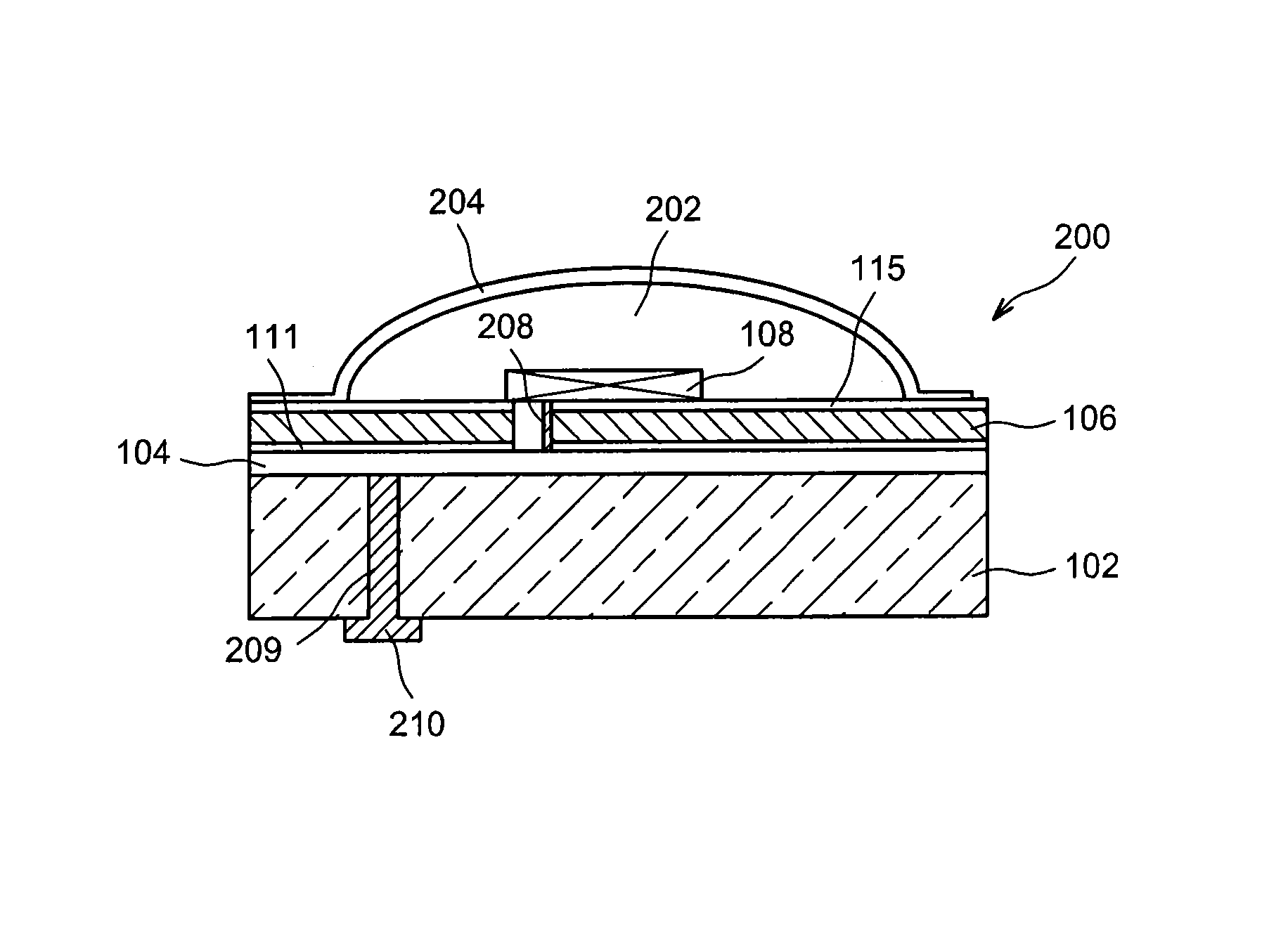

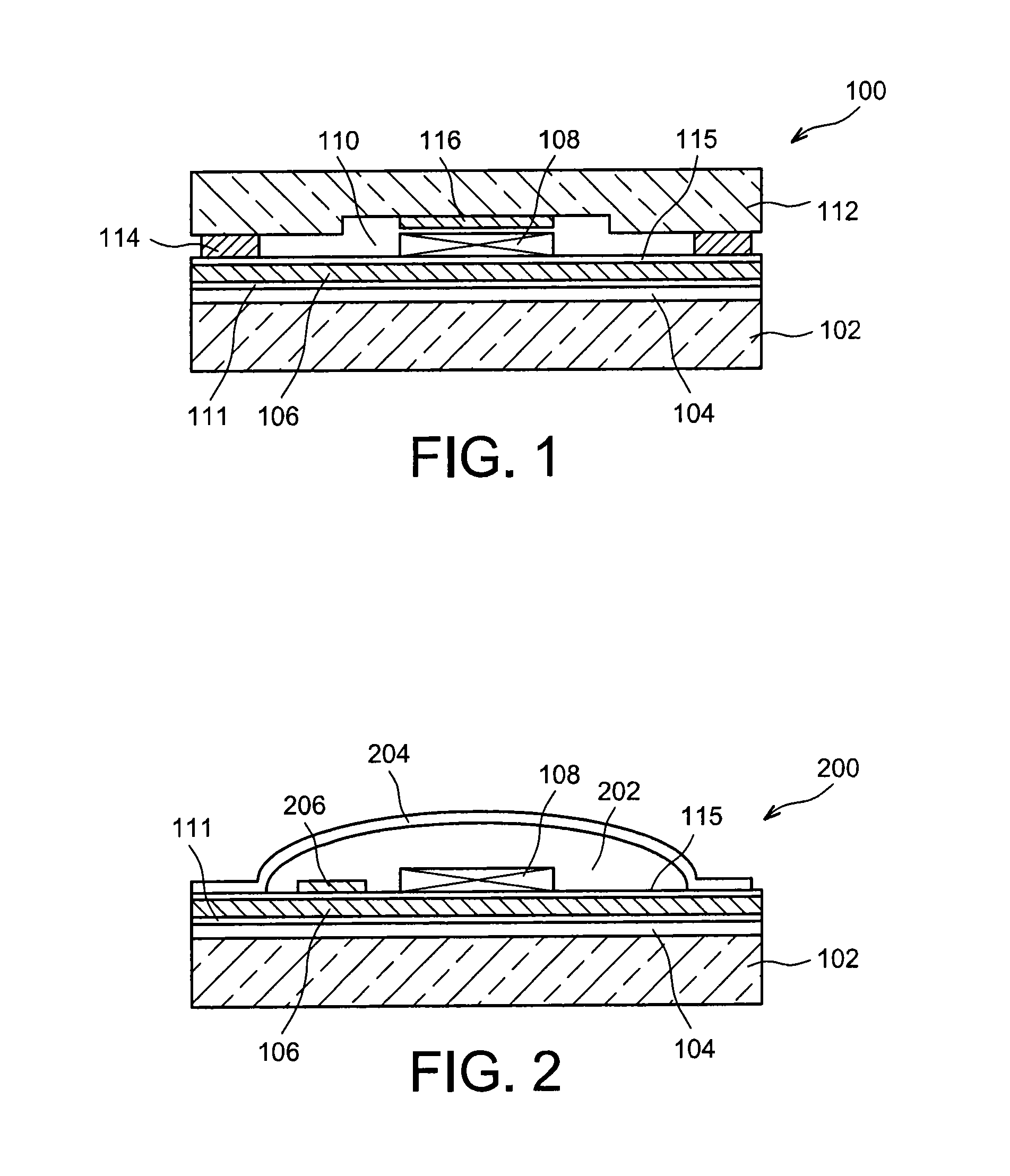

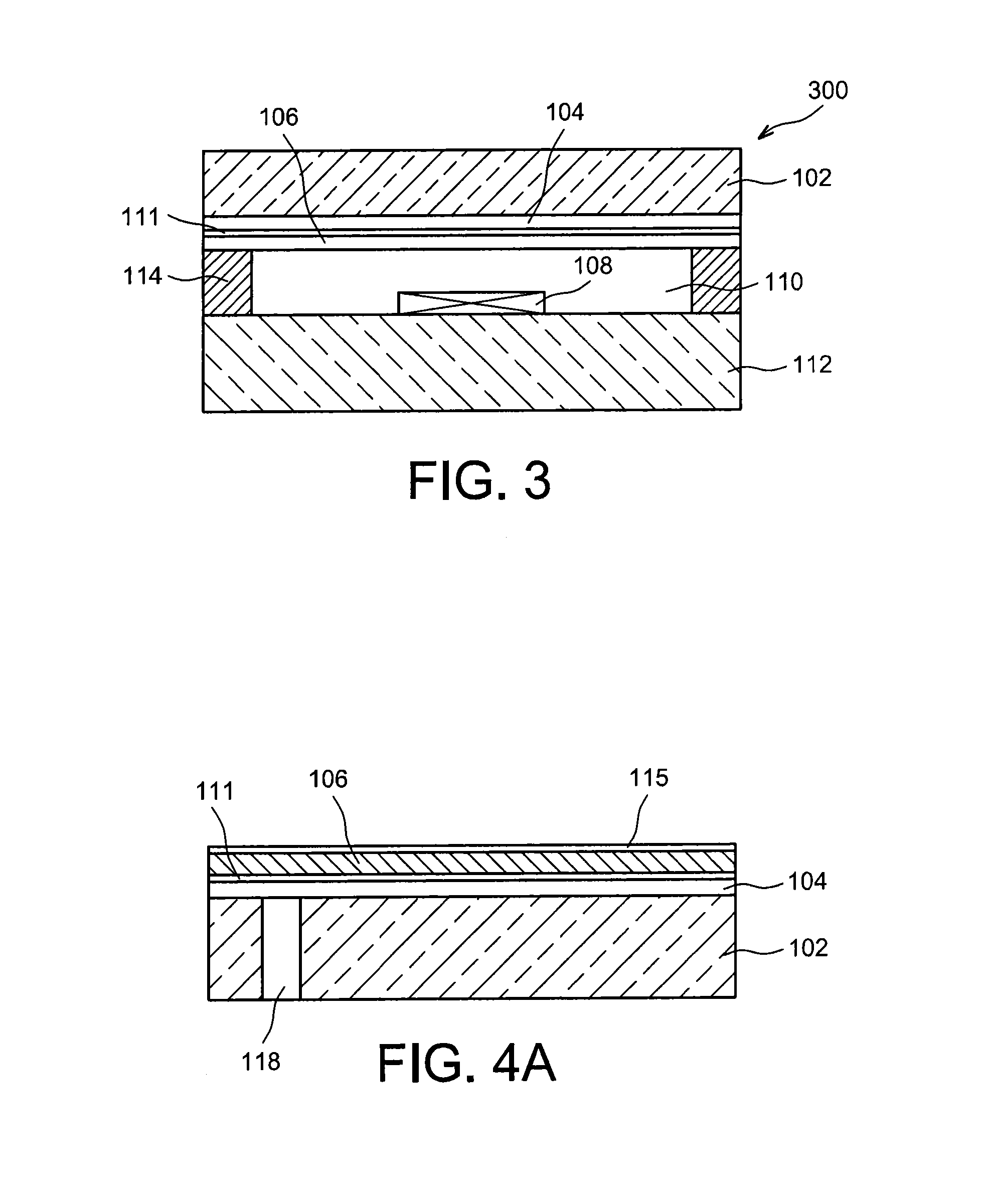

Structure for hermetic encapsulation of a device and an electronic component

ActiveUS20130105959A1Inhibit degassingHigh densitySemiconductor/solid-state device detailsSolid-state devicesHermetic sealElectronic component

An encapsulation structure comprising at least one hermetically sealed cavity in which at least the following are encapsulated:a device,an electronic component produced on a first substrate, anda getter material layer covering the electronic component in order to block the gases capable of being degassed by the electronic component,and in which the device is not covered by the getter material layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

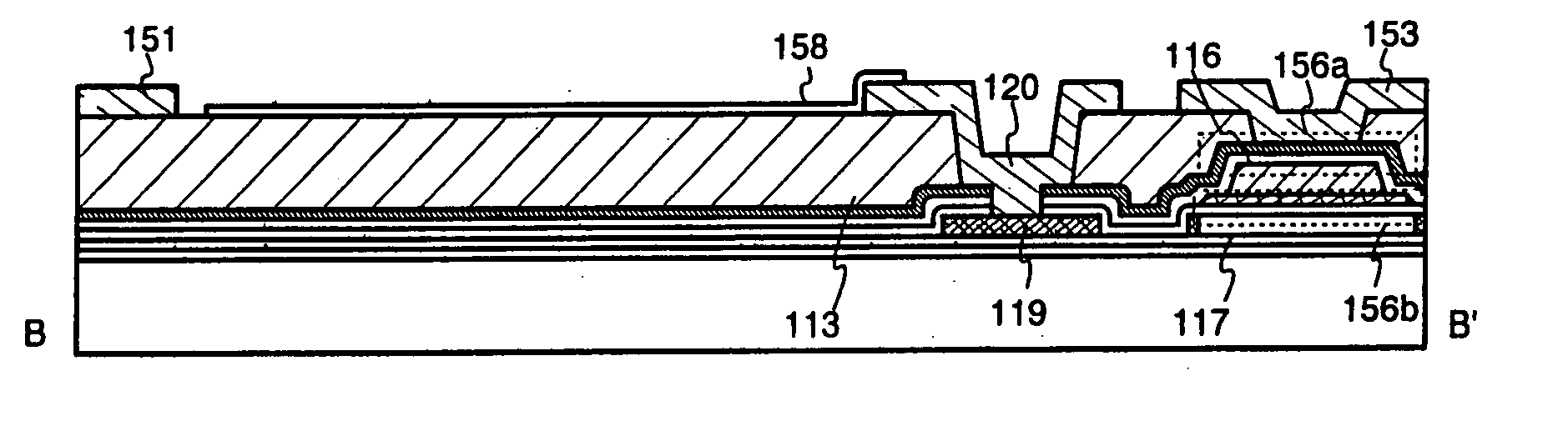

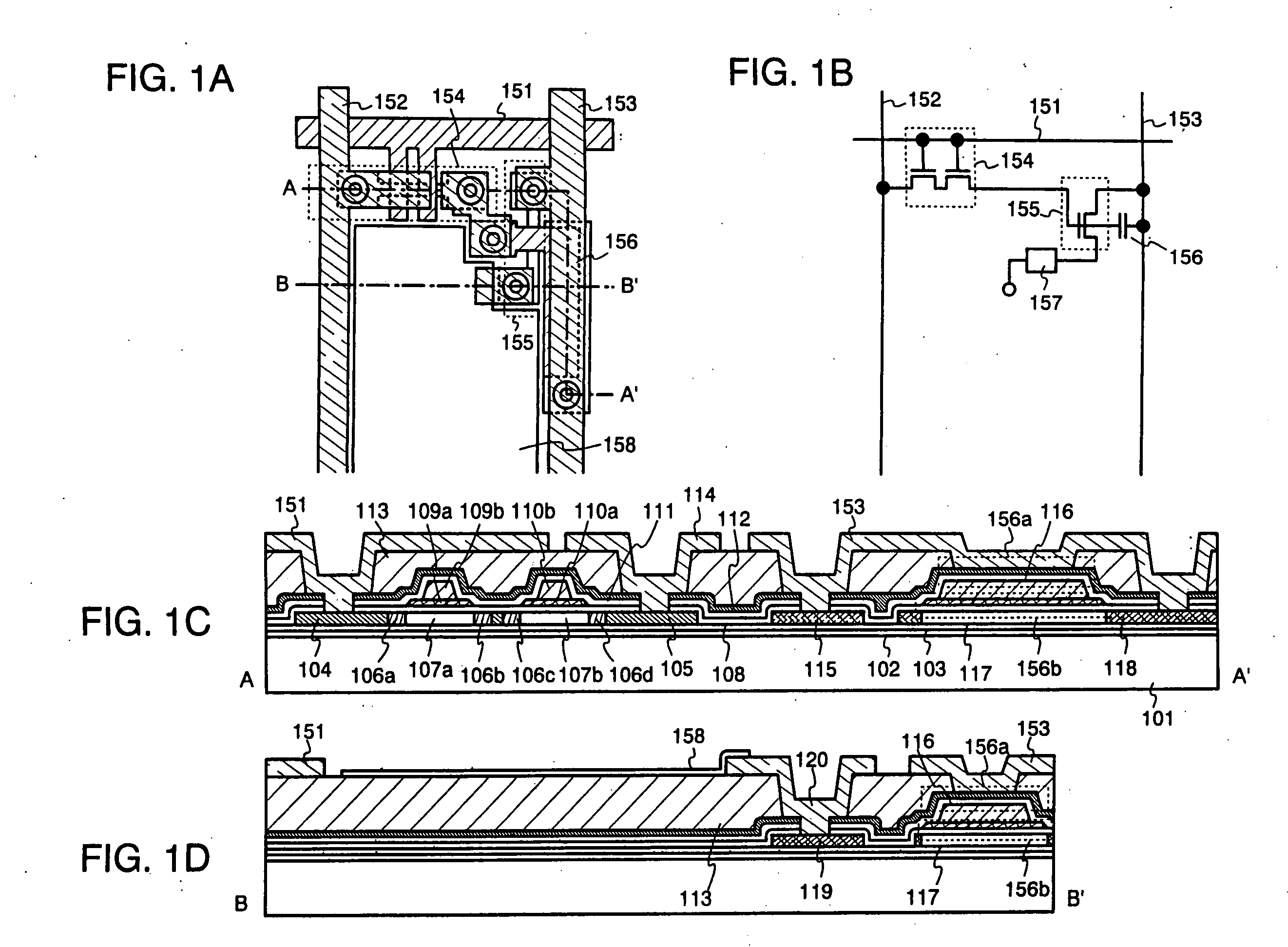

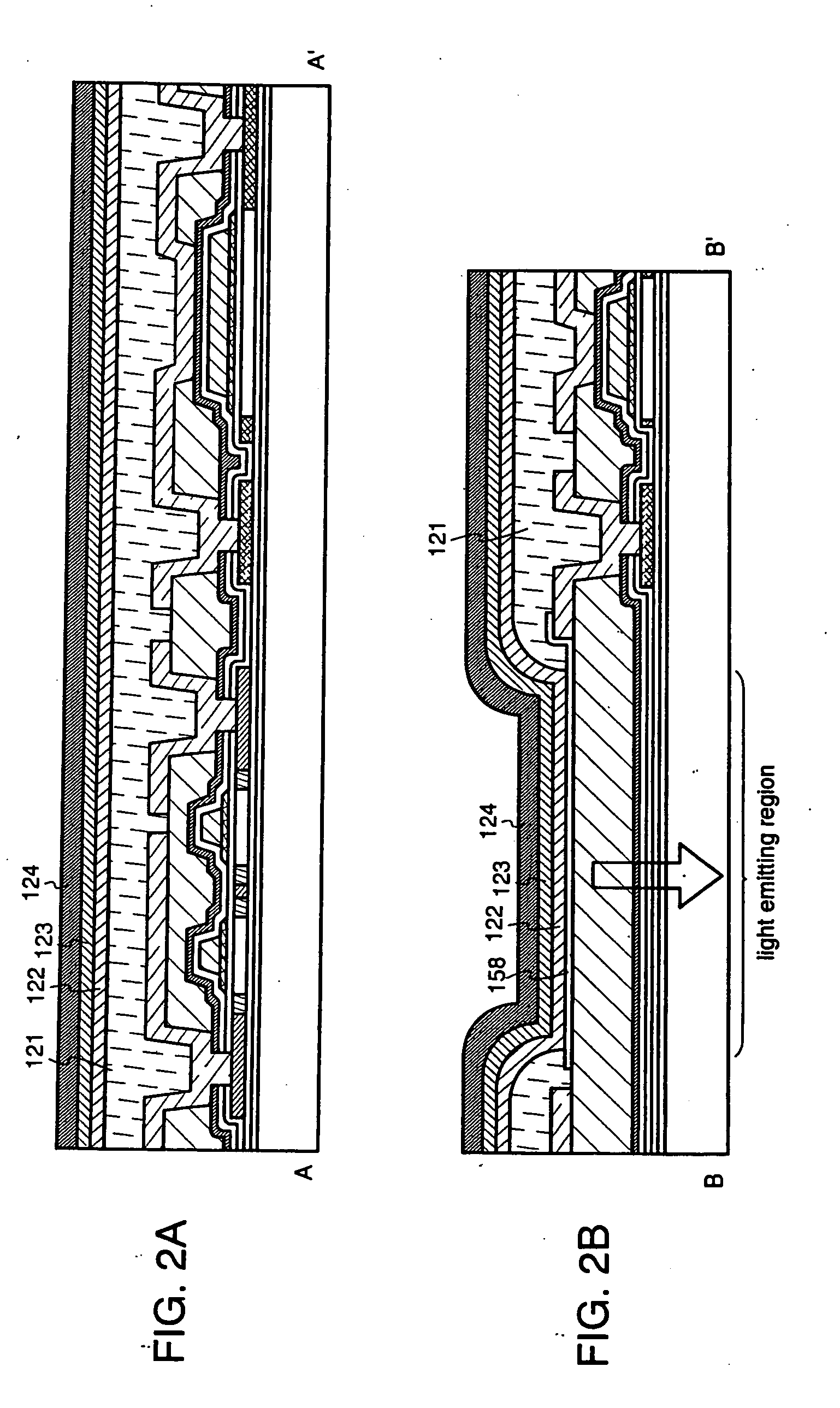

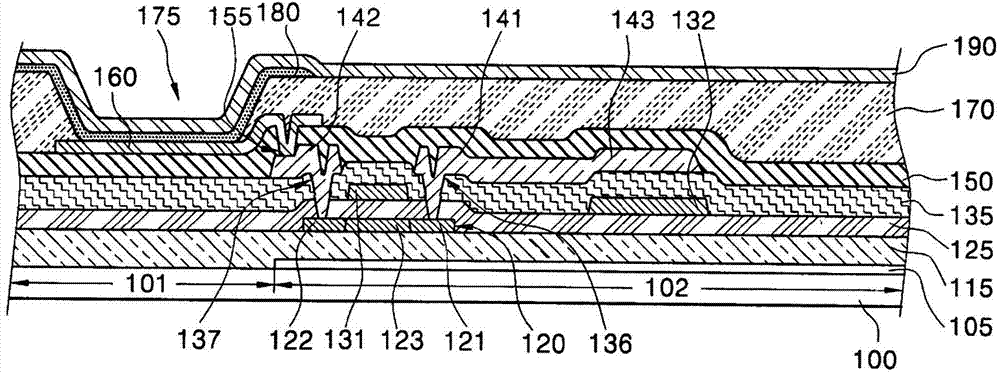

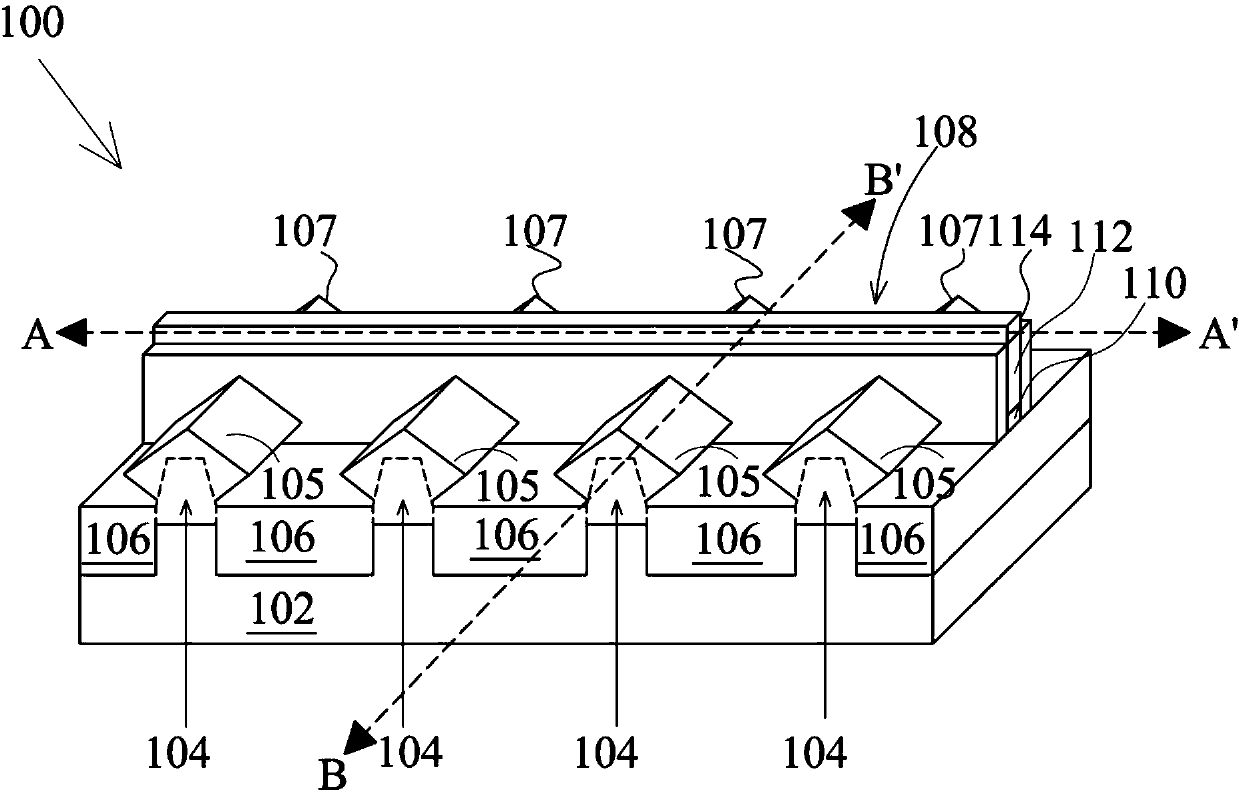

Display device

ActiveUS20050218452A1Reduce impactSuppress mutationTransistorElectroluminescent light sourcesDisplay deviceOptoelectronics

A display device according to the present invention includes: a planarization layer for insulating between a gate electrode etc. and a data wiring, a drain electrode, or the like of the transistor; and a barrier layer that is formed on an upper surface or lower surface of the planarization layer and at the same time, adapted to suppress diffusion of moisture or degassing components from the planarization layer. The display device adopts a device structure effective in reducing the plasma damage on the planarization layer by devising a positional relationship between the planarization layer and the barrier layer. Also, in combination with a novel structure as a structure for a pixel electrode, effects such as an increase in luminance can be provided as well.

Owner:SEMICON ENERGY LAB CO LTD

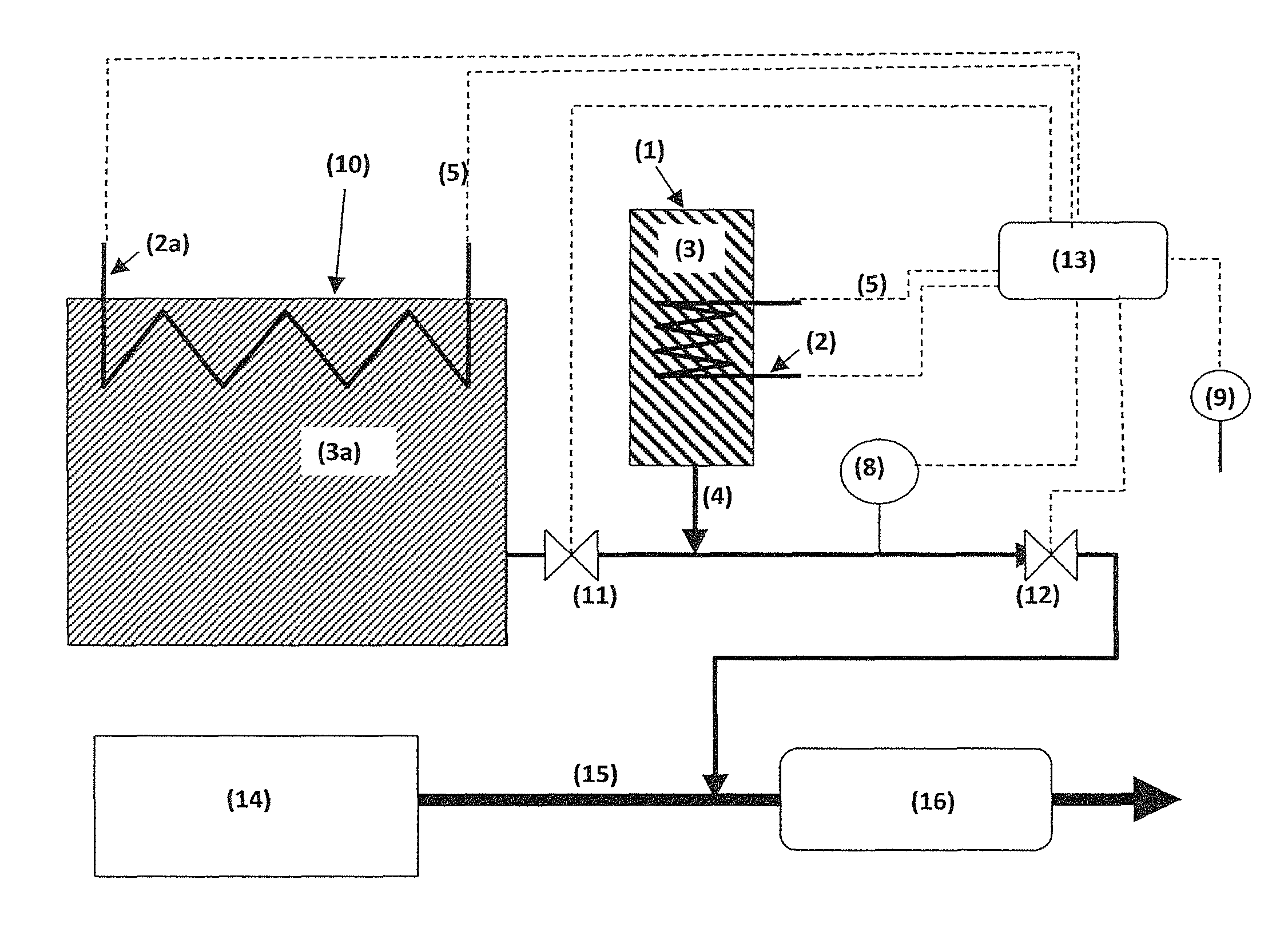

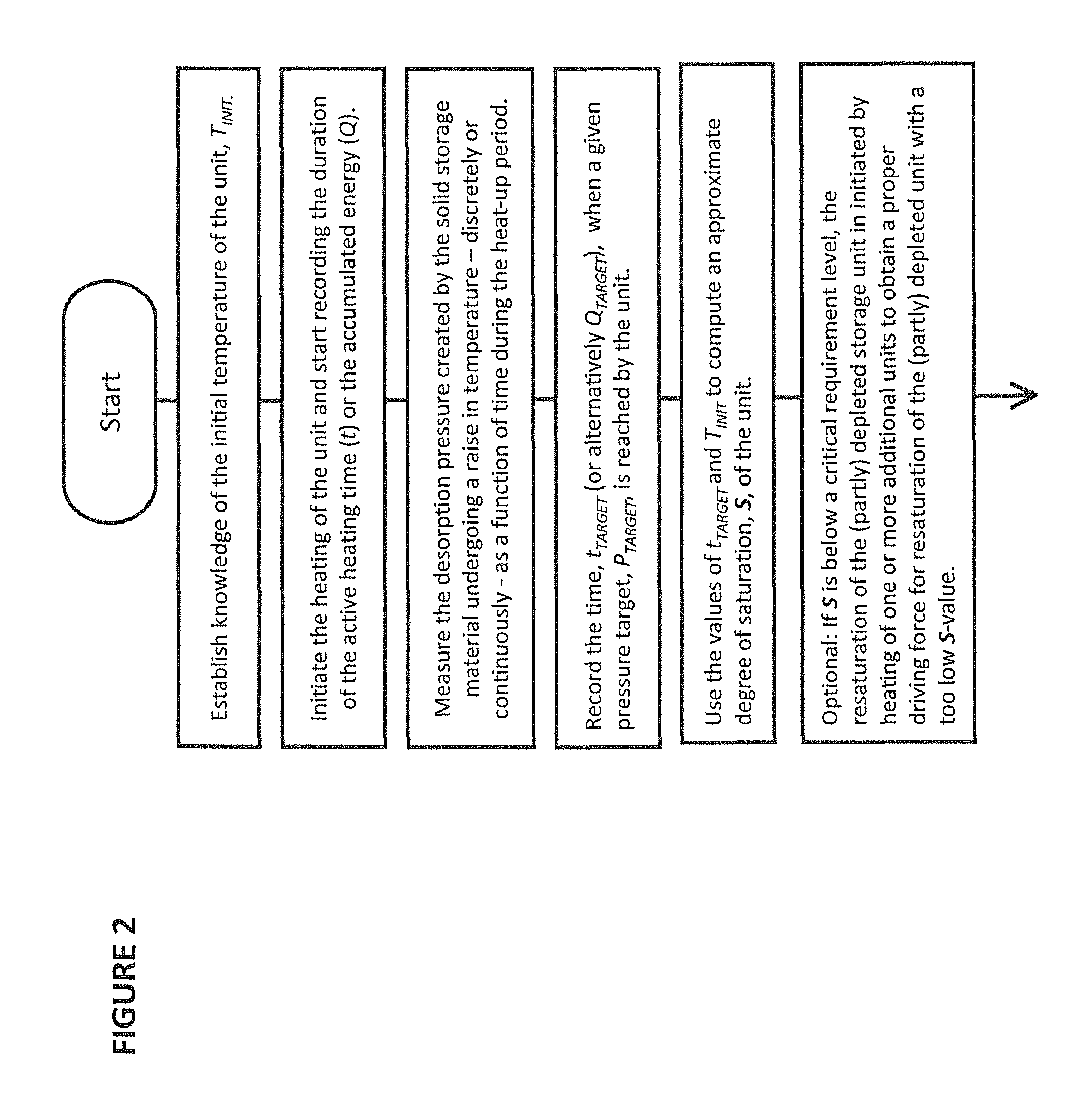

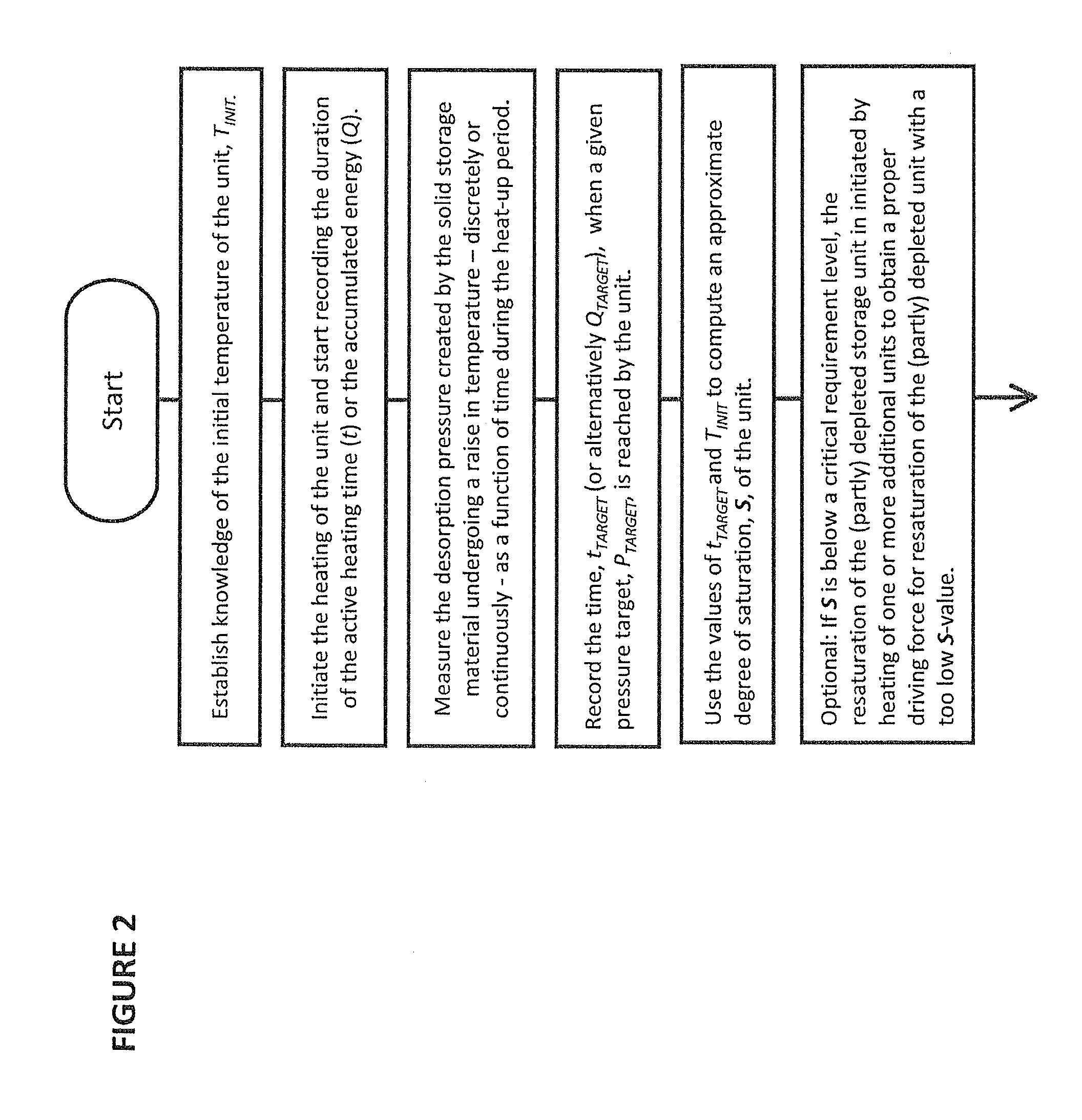

Method for determining the degree of saturation of solid ammonia storage materials in containers

InactiveUS8834603B2Reduce stepsImprove resaturationInternal combustion piston enginesDispersed particle filtrationActive timeDesorption

A method is provided for estimating the degree of saturation (S) of a reversible solid ammonia storage material (3) in a storage unit (1). The storage unit (1) is equipped with a heater (2) to release ammonia and a connected tube (4) for ammonia flow. The initial temperature (TINIT) is measured with a sensor (9) in or around the storage unit (1) before any heating is initiated. Heating is initiated while recording the active time of heating (t) or the amount of energy (Q) released by the heater. The desorption pressure created by solid storage material in the storage unit (1) is measured via a pressure sensor (8) in fluid communication with the storage unit (1). The time (tTARGET), or the heat (QTARGET) where the pressure reaches a certain target pressure (PTARGET) is recorded. The values of the target-pressure time (tTARGET), or the target-pressure heat (QTARGET), and the initial temperature (TINIT) are used to compute an approximate degree of saturation (S).

Owner:AMMINEX EMISSIONS TECH

Sputtering target and organic light-emitting display device including black matrix deposited thereby

InactiveCN103590009AReduce transmittanceHigh resistivityVacuum evaporation coatingSolid-state devicesHigh resistanceDisplay device

A sputtering target that can form a black matrix having high-resistance and low-reflection characteristics and an organic light-emitting display device including the black matrix deposited thereby. The sputtering target that is used in a sputtering process for depositing a black matrix contains one selected from the group consisting of Mo-Si-O, W-Si-O and Mo-W-Si-O, the content of the Mo or W being at least 0.5 times the content of the Si.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

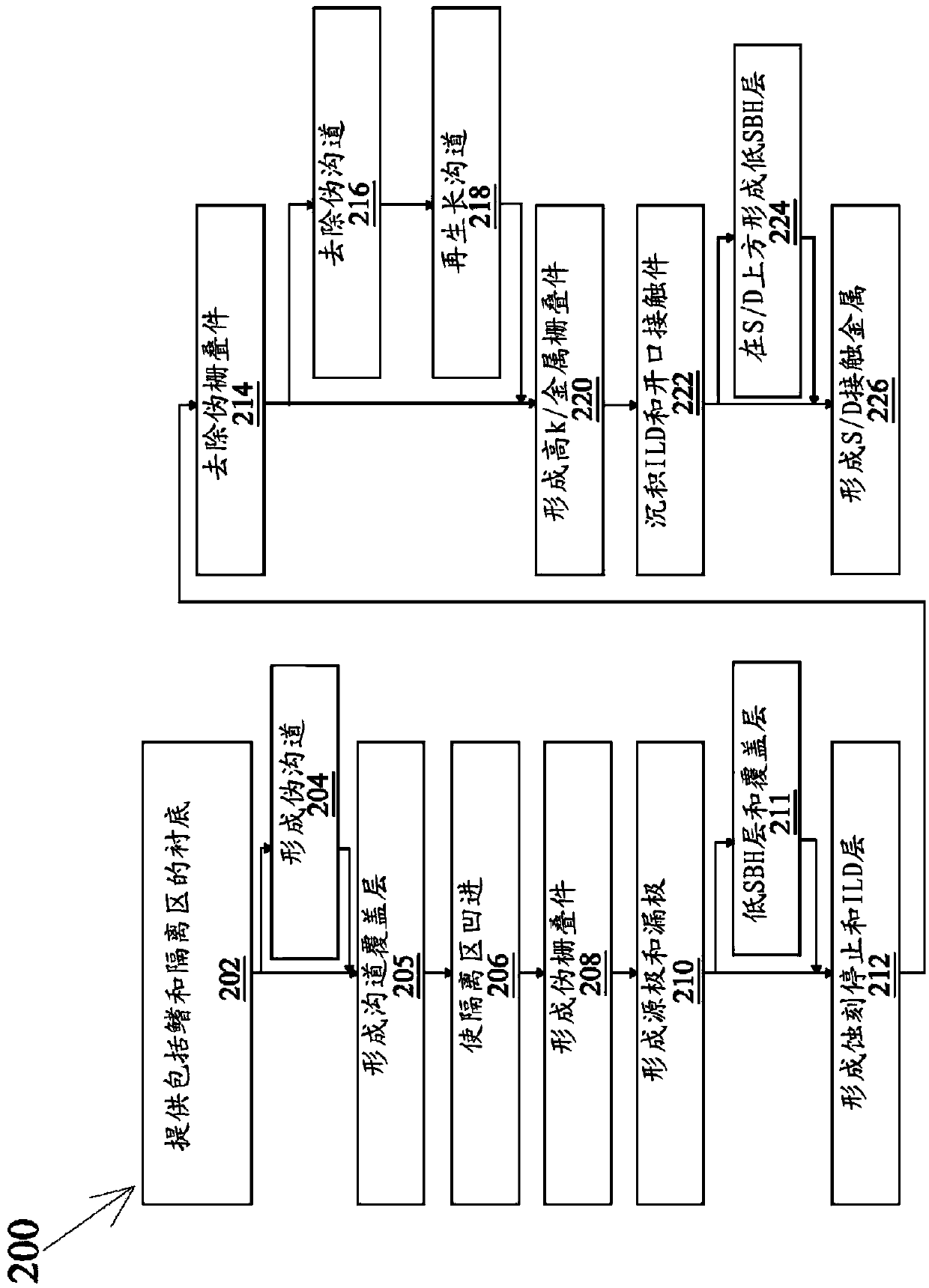

Finfet thermal protection methods and related structures

ActiveCN105321818AInhibit degassingAvoid exposureSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringGate stack

A method and structure for protecting high-mobility materials from exposure to high temperature processes includes providing a substrate having at least one fin extending therefrom. The at least one fin includes a dummy channel and source / drain regions. A dummy gate stack is formed over the dummy channel. A first inter-layer dielectric (ILD) layer is formed on the substrate including the fin. The first ILD layer is planarized to expose the dummy gate stack. After planarizing the first ILD layer, the dummy gate stack and the dummy channel are removed to form a recess, and a high-mobility material channel region is formed in the recess. After forming the high-mobility material channel region, contact openings are formed within a second ILD layer overlying the source / drain regions, and a low Schottky barrier height (SBH) material is formed over the source / drain regions.

Owner:TAIWAN SEMICON MFG CO LTD

Method for determining the degree of saturation of solid ammonia storage materials in containers

InactiveUS20130209316A1Reduce power consumptionImprove resaturationInternal combustion piston enginesExhaust apparatusActive timeAmmonia storage

A method is provided for estimating the degree of saturation (S) of a reversible solid ammonia storage material (3) in a storage unit (1). The storage unit (1) is equipped with a heater (2) to release ammonia and a connected tube (4) for ammonia flow. The initial temperature (TINIT) is measured with a sensor (9) in or around the storage unit (1) before any heating is initiated. Heating is initiated while recording the active time of heating (t) or the amount of energy (Q) released by the heater. The desorption pressure created by solid storage material in the storage unit (1) is measured via a pressure sensor (8) in fluid communication with the storage unit (1). The time (tTARGET), or the heat (QTARGET) where the pressure reaches a certain target pressure (PTARGET) is recorded. The values of the target-pressure time (tTARGET), or the target-pressure heat (QTARGET), and the initial temperature (TINIT) are used to compute an approximate degree of saturation (S).

Owner:AMMINEX EMISSIONS TECH

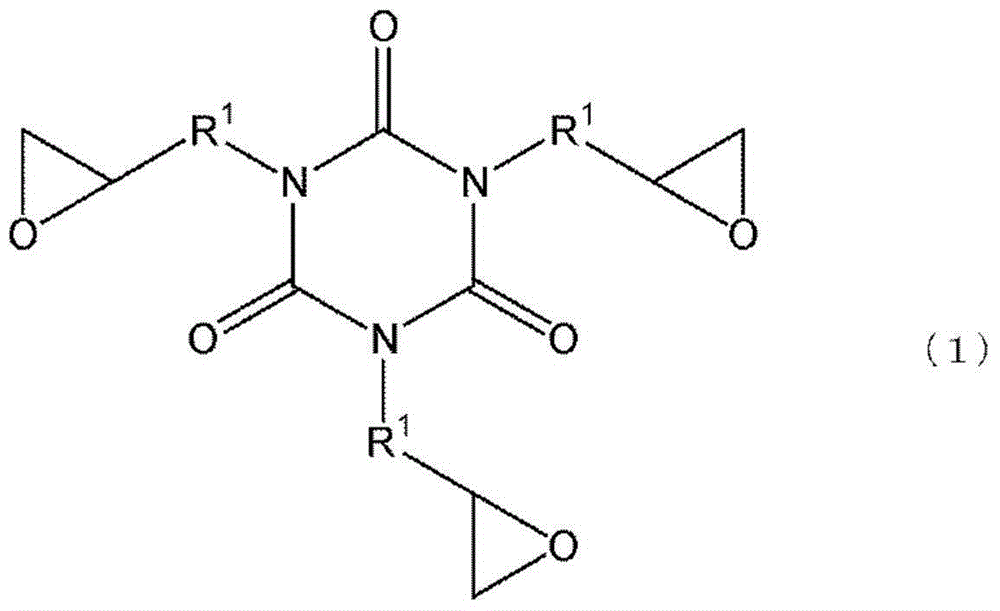

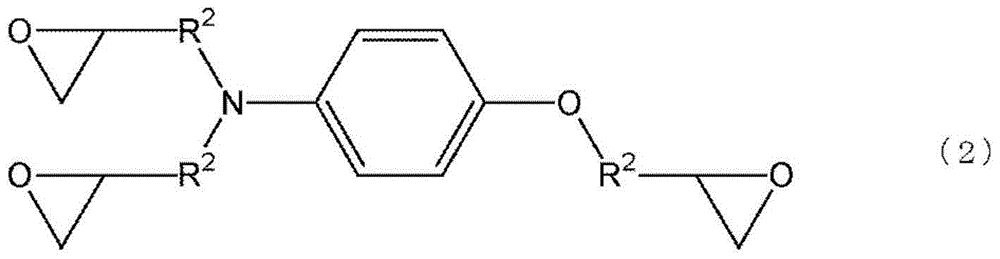

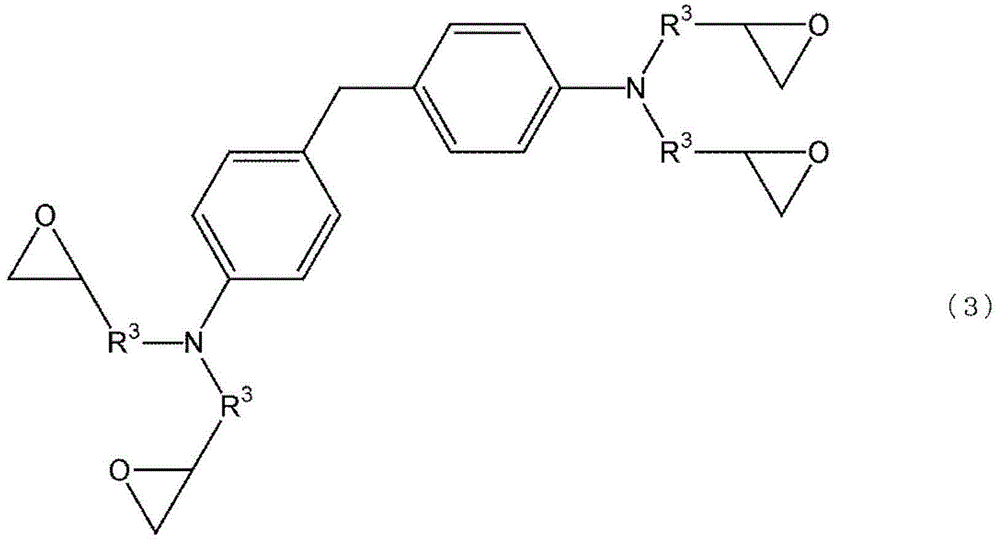

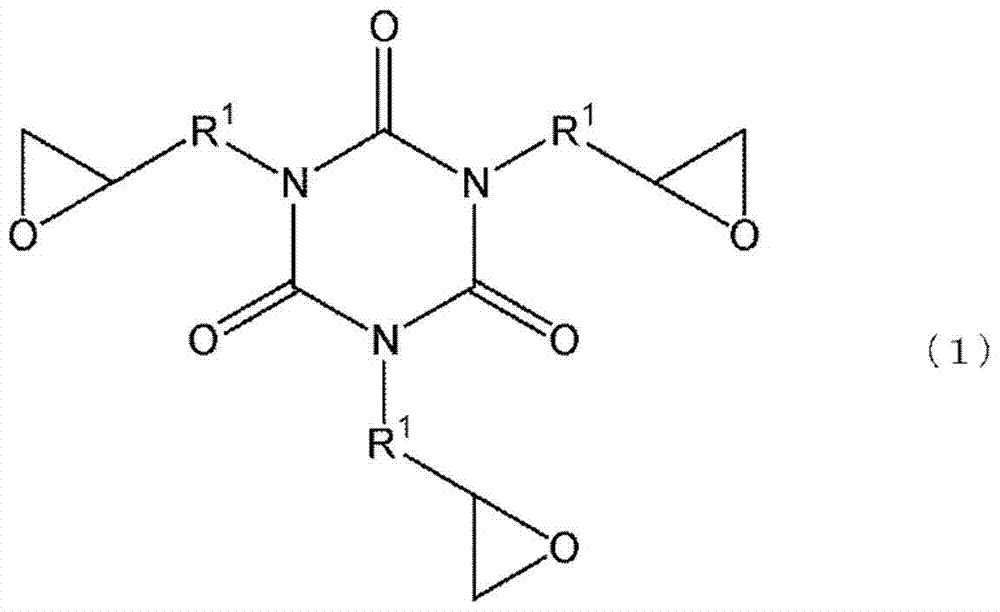

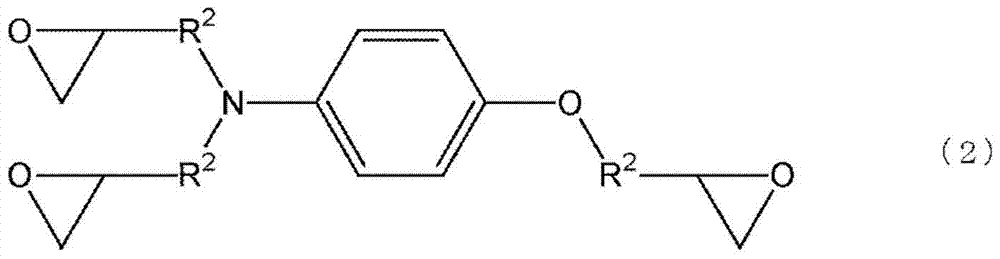

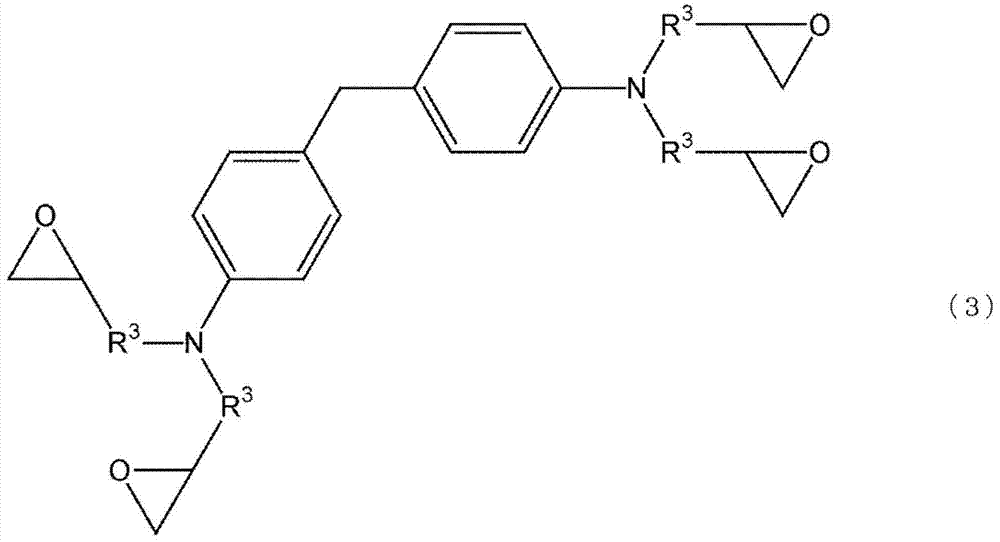

Photo-post-curing resin composition

The purpose of the present invention is to provide a photo-post-curing resin composition that makes it possible to suppress the generation of outgas and has exceptional transparency and reliability. The present invention is a photo-post-curing resin composition containing a cationically curable resin, a photo-cationic polymerization initiator, and a compound having amino groups and cationically polymerizable functional groups.

Owner:SEKISUI CHEM CO LTD

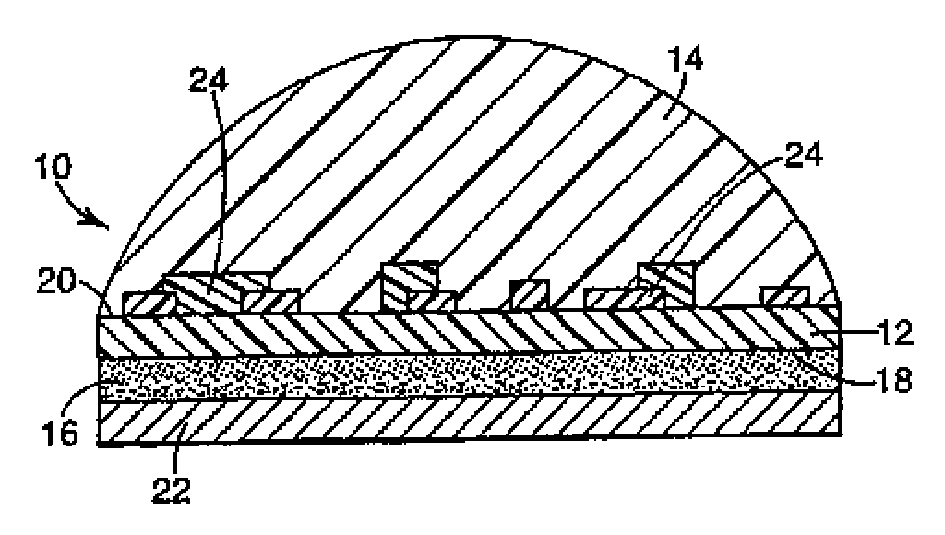

Flexible polyurethane material

The present invention provides a flexible two component polyurethane and method for producing the polyurethane. The cured polyurethane is flexible, durable and weather resistant. The polyurethane is suitable for use as a protective layer on various substrates.The flexible polyurethane is the reaction product of solvent-free reaction components. The first component includes one or more polyols, optionally, one or more diols, and a catalyst. The second component includes a primary aliphatic isocyanate crosslinker.

Owner:3M CO

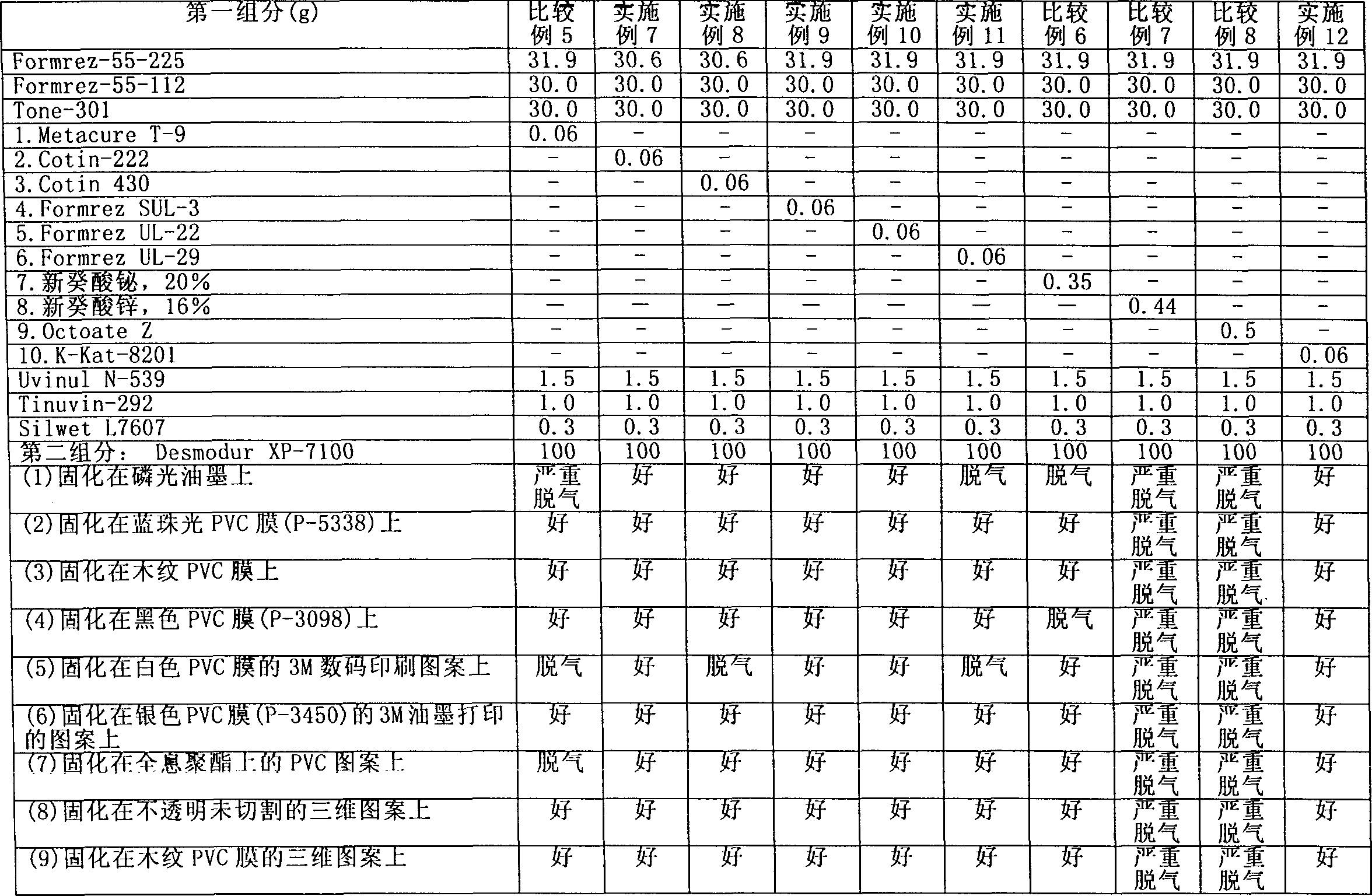

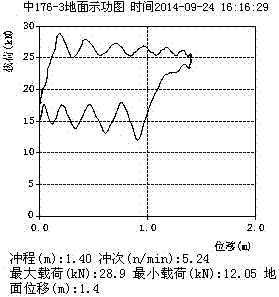

Method of increasing single well production by building pressure

InactiveCN106968656AIncrease productionInhibit degassingFluid removalIndicator diagramOil production

The invention discloses a method of increasing single well production by building pressure, and belongs to the production technique of an oil producing well. In the lifting process of crude oil, the pressure inside a wellbore is gradually reduced, the crude oil is degassed seriously, so that oil supply is insufficient, gas volume in an oil pipe is large, pump efficiency of an oil well pump is low, and oil well production is low. In view of this problem, pressure influences on gas degassing within the wellbore, the opening of a pressure returning valve is controlled to conduct appropriate pressure building to the oil pipes, the pressure inside the oil pipe is increased to curb the degassing of the crude oil, so that the working conditions of the oil well pump are improved, by comparing indicator diagrams of pressure-building and unpressured-building oil production, the building pressure method improving the pump efficiency can be seen, and the single well production is increased.

Owner:SOUTHWEST PETROLEUM UNIV

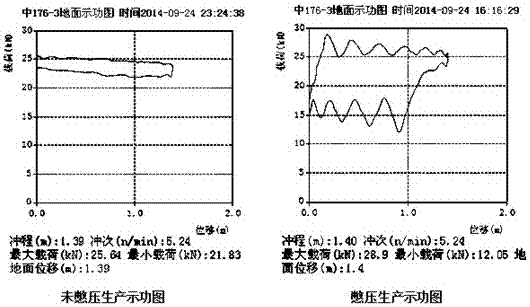

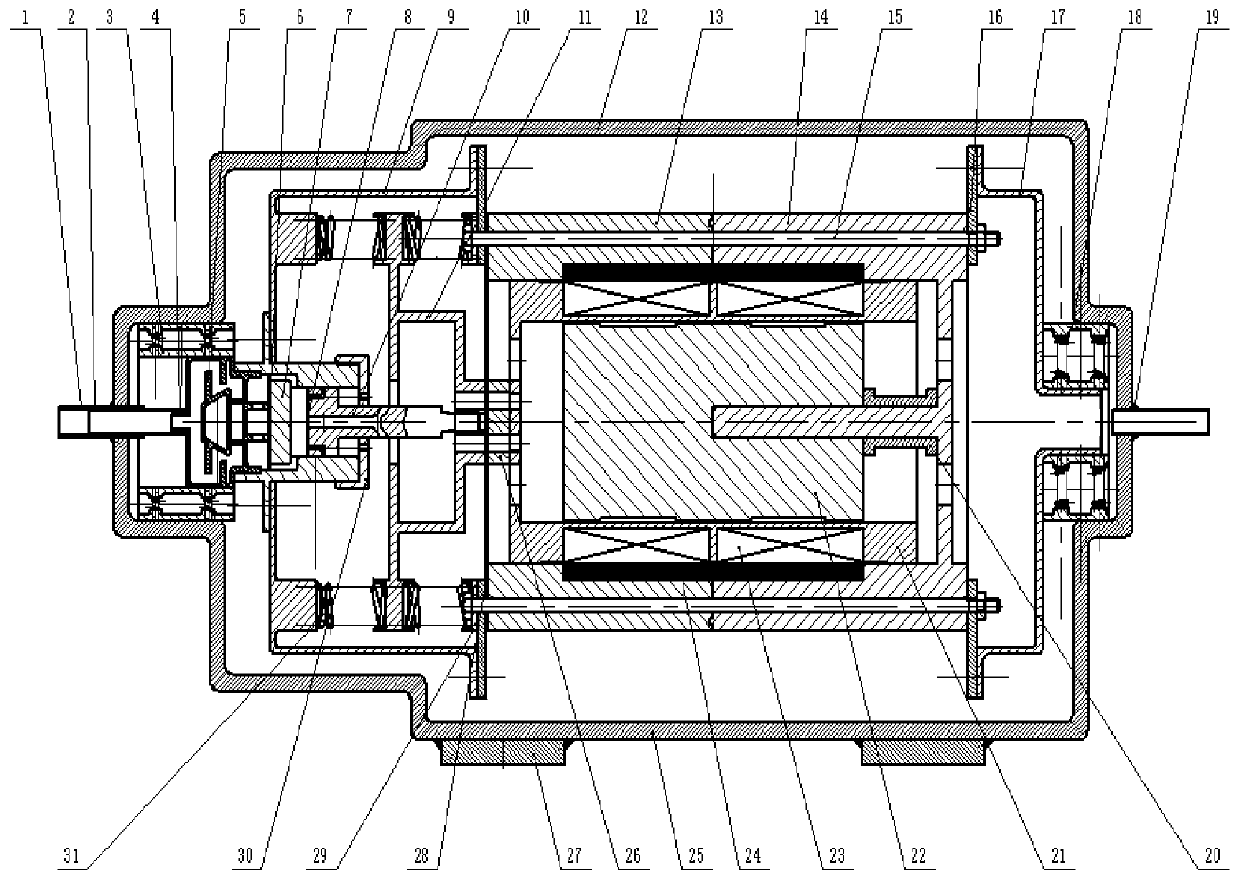

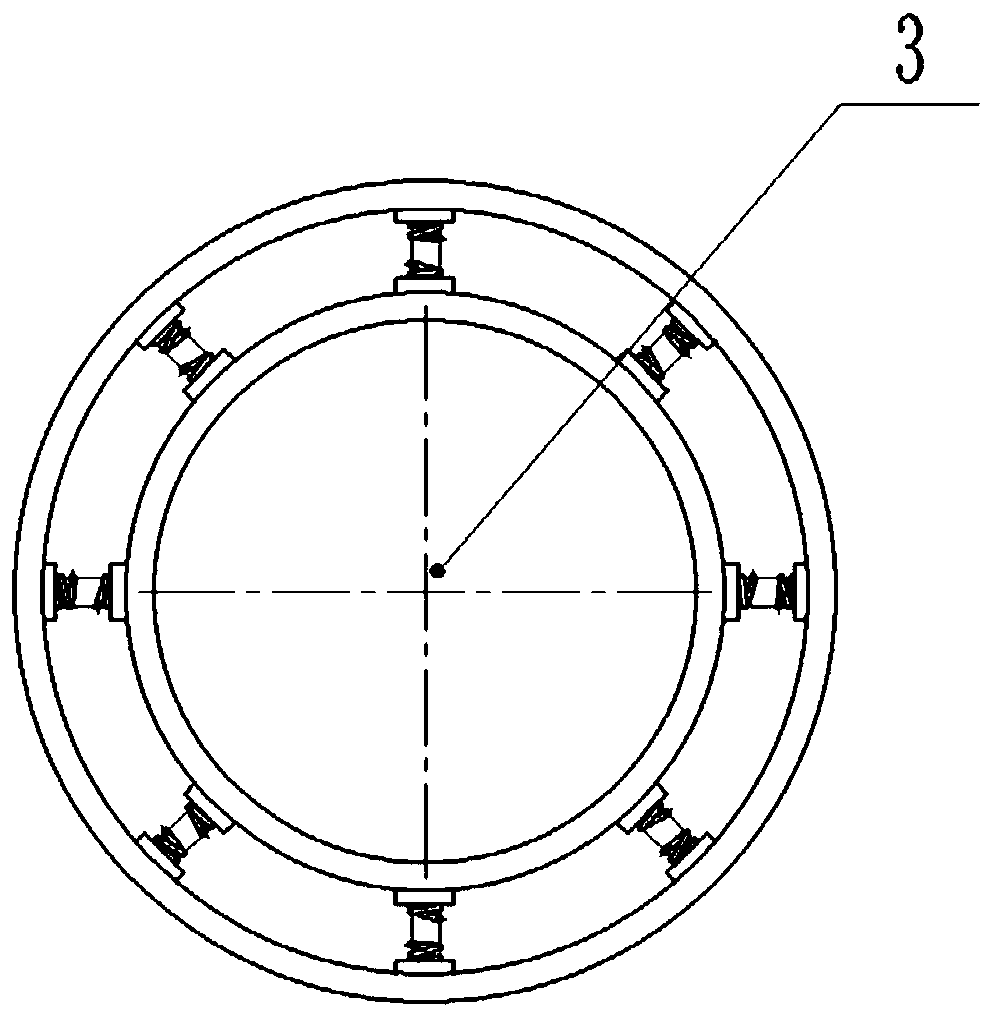

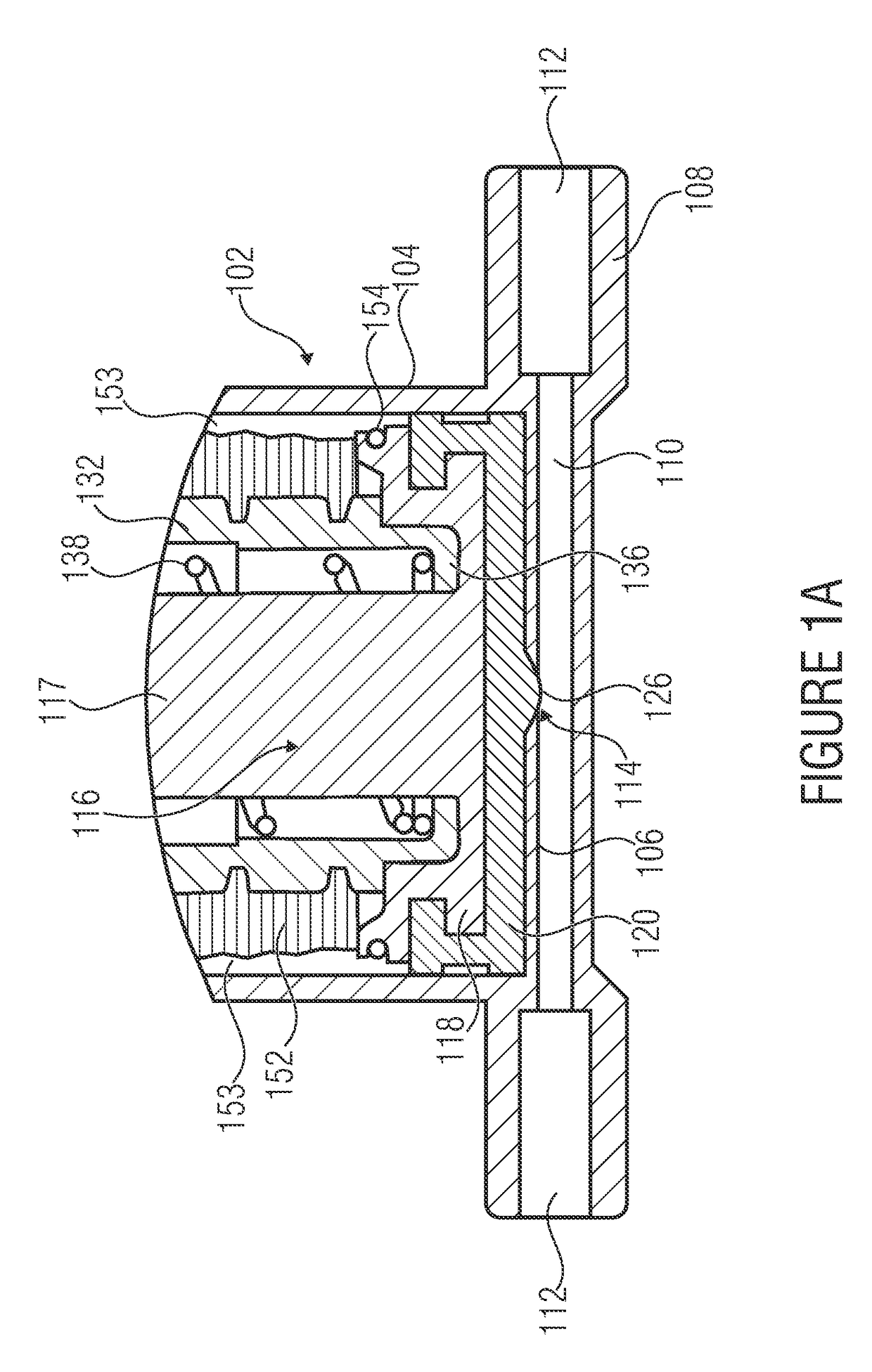

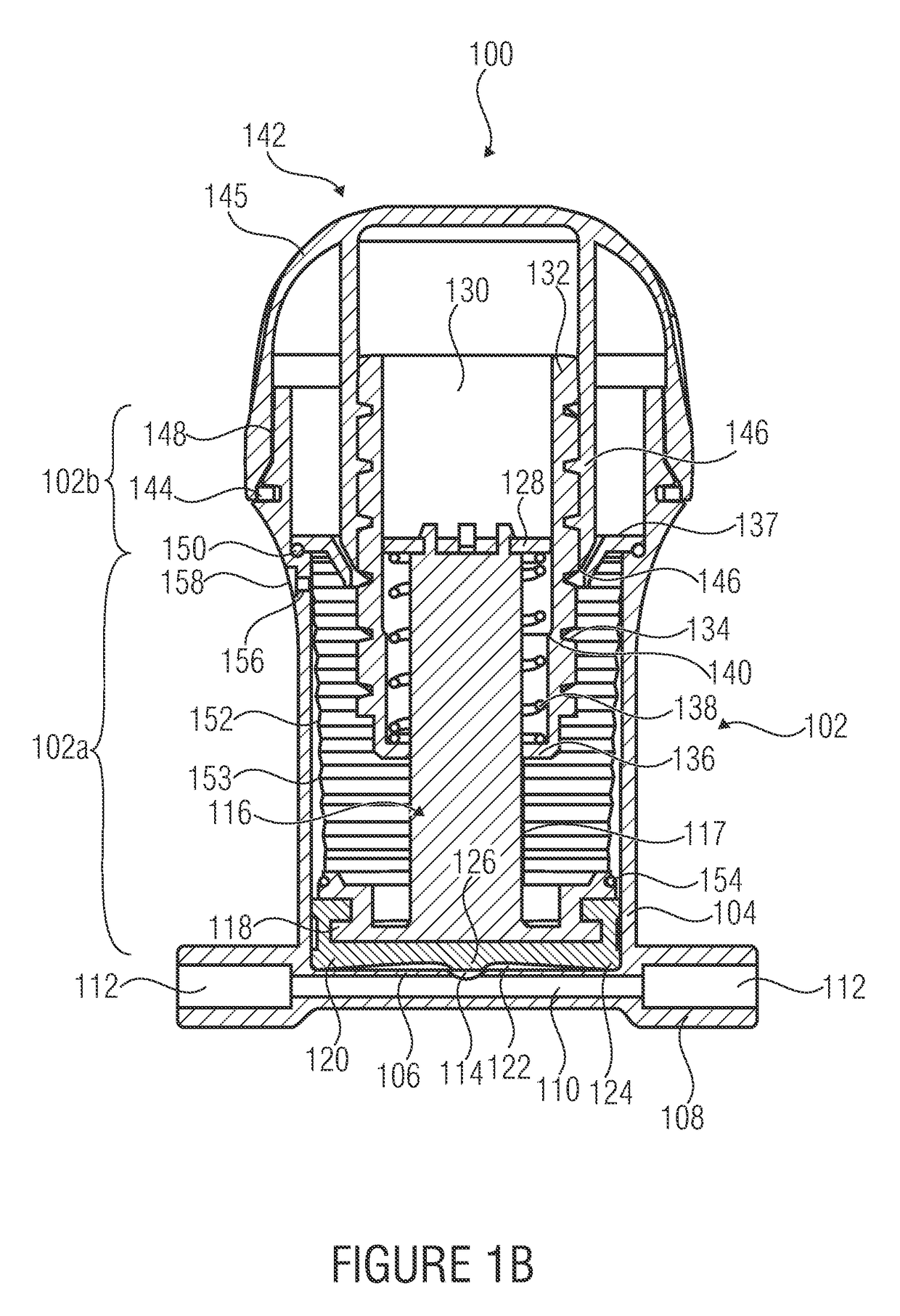

Dynamic ring type linear compressor

PendingCN110005590AGood filter vibrationReduce air gapPositive displacement pump componentsPiston pumpsLinear compressorRing type

The invention provides a dynamic ring type linear compressor. The dynamic ring type linear compressor comprises a compressor shell, a stator assembly and a rotor assembly, wherein the rotor assembly comprises a wire wrapping frame located between an inner stator and a split type outer stator, and a coil wound around the wire wrapping frame, the left end of the wire wrapping frame is connected witha piston rod of an air cylinder through a connecting frame, an inner ring of the split type outer stator is provided with a permanent magnet magnetic ring, the wire wrapping frame is driven to move through the magnetic field force generated between the permanent magnet magnetic ring and the coil, and then the piston of the air cylinder is driven to compress air for doing action. According to thedynamic ring type linear compressor, a damping supporting piece is of a structure which is internally provided with a cylindrical spring and is arranged between two circular rings and plays a role indamping and supporting the internal structure of the compressor, then the transmission of the vibration generated by the movement of the internal structure of the compressor to the shell is reduced, and the effect of better filtering the vibration is achieved; and a certain restoring force is given to a piston and the rotor assembly in the whole process of working of the compressor through a resonance spring assembly, so that the whole compressor system achieves a more ideal working state, and the stability and reliability are good.

Owner:LIAONING TECHNICAL UNIVERSITY

Fuel injection device for an internal combustion engine

InactiveUS7574297B2Inhibit degassingElectrical controlDigital data processing detailsHigh-pressure areaEngineering

A fuel injection device comprising a high-pressure pump supplying a fuel to a high-pressure area in which an injector for injecting fuel into an internal combustion engine cylinder is arranged. An electric control unit for controlling fuel injection by at least one injector is provided. A pressure adjusting valve which adjusts a pressure in the high-pressure area and controls a connection between said high pressure area and a low-pressure fuel-filled area is controlled by the control unit. When the pressure adjusting valve is not controlled by the control unit it is placed in an open switching position in such a way that the connection between the high- low-pressure areas is opened, thereby preventing a gas formation in the high pressure area when the internal combustion engine is switched off and the fuel is cooled.

Owner:ROBERT BOSCH GMBH

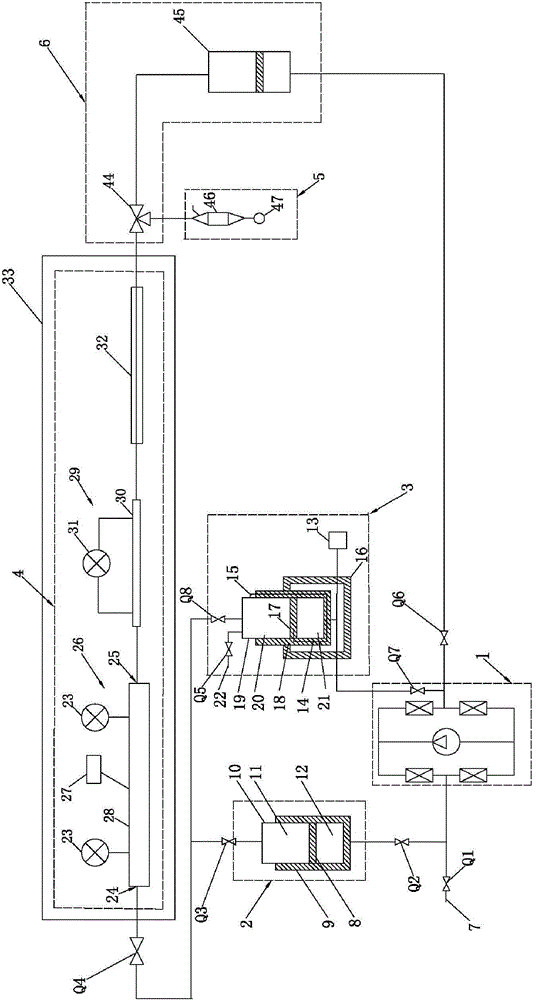

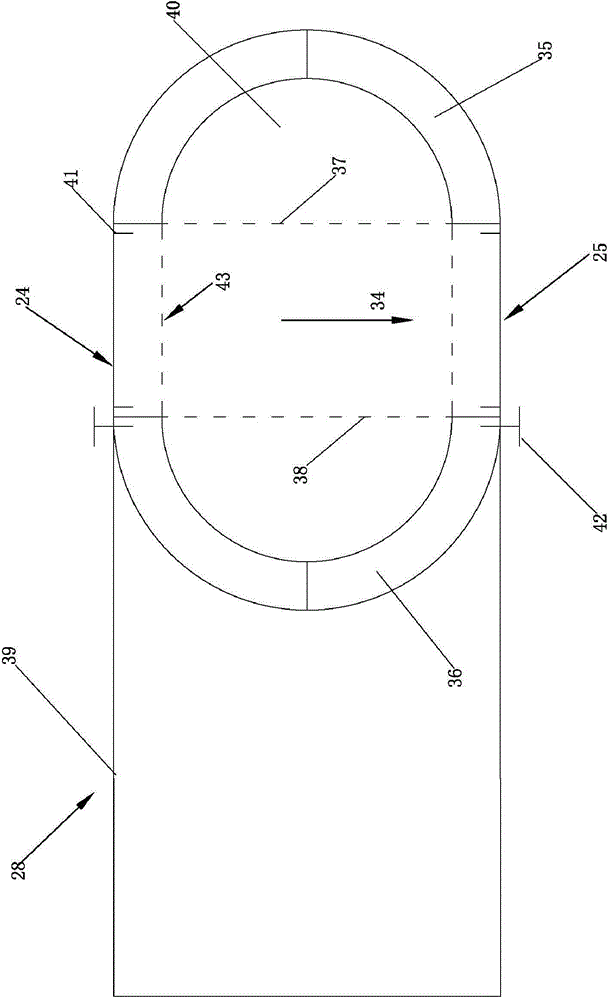

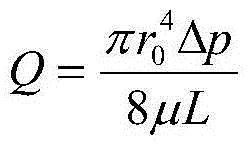

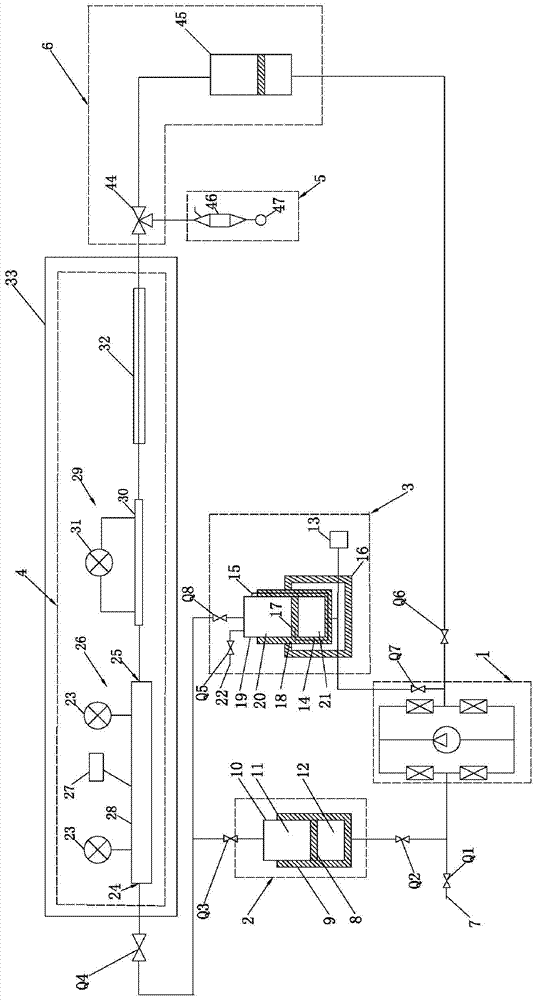

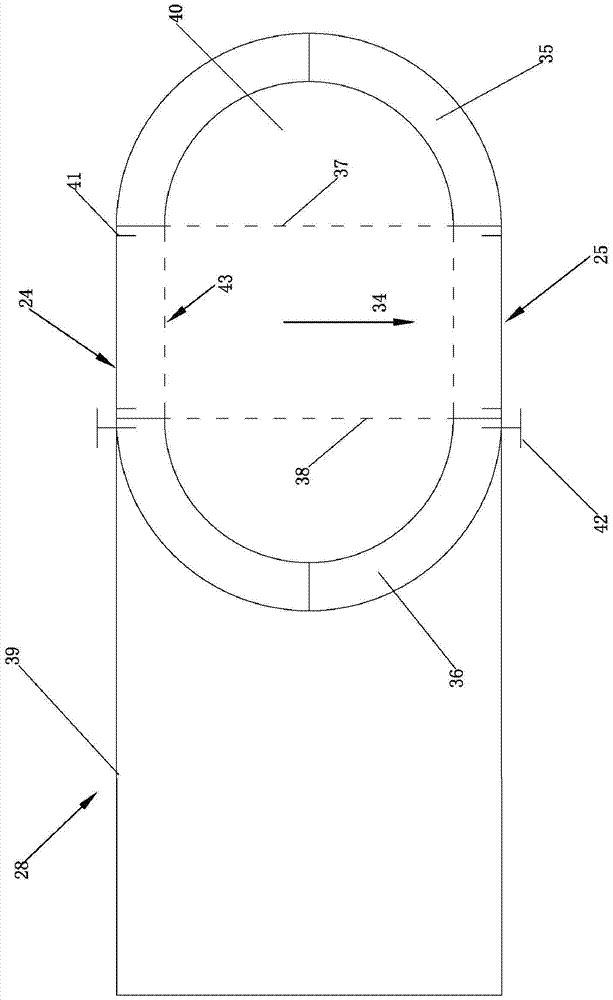

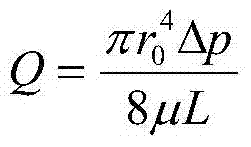

Stratum mobility simulating device

The invention provides a stratum mobility simulating device. The stratum mobility simulating device comprises a constant speed and constant pressure pump, an intermediate container, a high temperature and high pressure sample allocation device and a model mechanism, wherein one end of the intermediate container is connected with the constant speed and constant pressure pump, one end of the high temperature and high pressure sample allocation device is provided with an air infusion port, the other end of the high temperature and high pressure sample allocation device is connected with the constant speed and constant pressure pump, the model mechanism comprises a flowing section, a capillary tube section and a phase volume fraction tester, the flowing section is provided with a mold section, the mold section comprises a fixed clamping groove and a movable clamping groove, the movable clamping groove can be movably arranged in a scale sliding groove, flat panel grooves are formed in the scale sliding groove, a convection current channel is formed between the fixed clamping groove and the movable clamping groove, the two ends of the convection current channel are the inlet end and the outlet end, the inlet end is connected with the other end of the intermediate container and the end, where the air infusion port is formed, of the high temperature and high pressure sample allocation device, and the outlet end is sequentially connected with the capillary tube section and the phase volume fraction tester. The stratum mobility simulating device is capable of simulating fissures of different opening degrees and stratums with different roughness and the flowing of single-phase fluid or multi-phase fluid in the stratums at different flowing speed, through the arrangement of a corestone, the conditions of the stratums can be simulated in a more realistic mode, the data are accurate, and the application range is wide.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Apparatus and method for treating an aqueous liquid

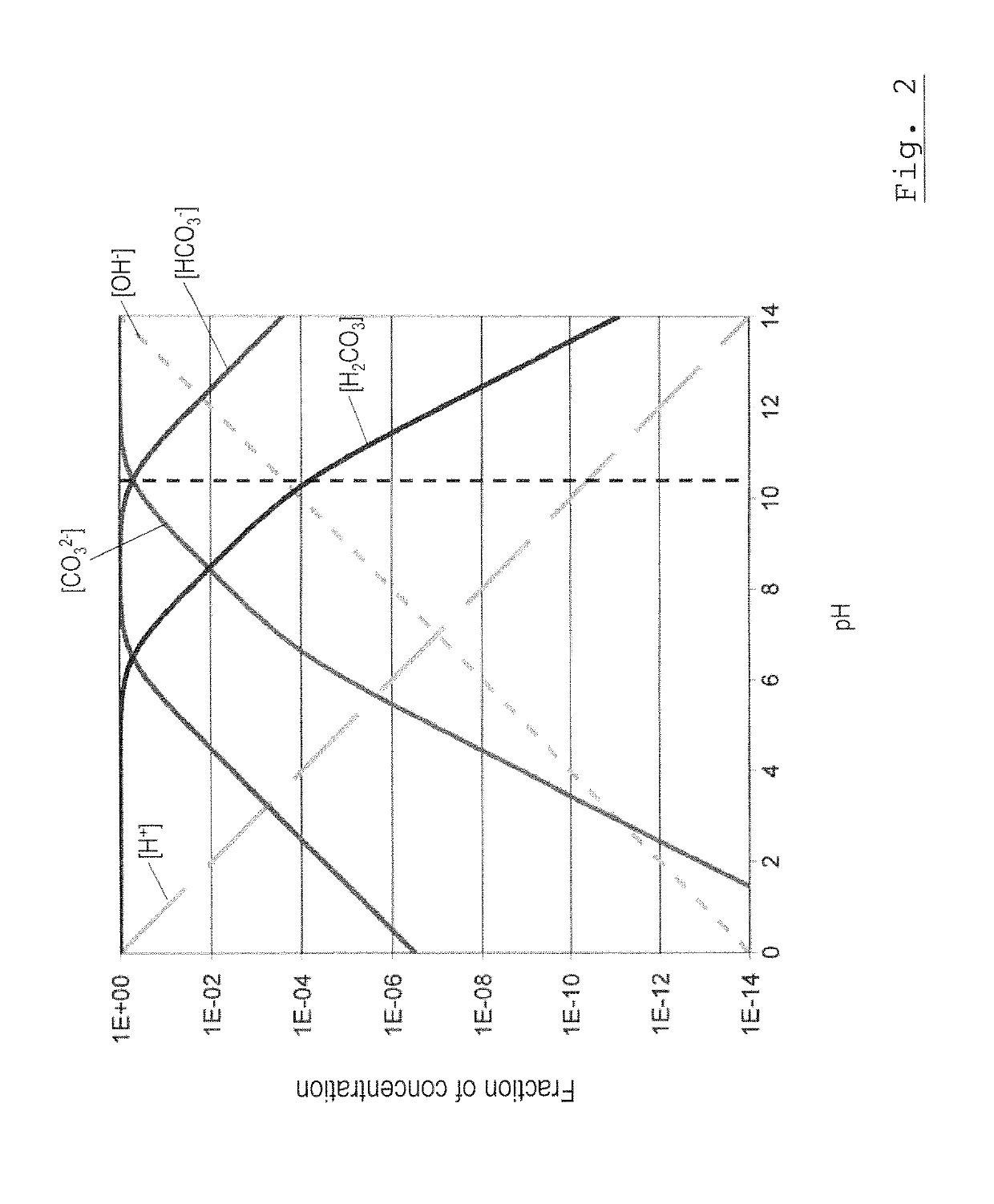

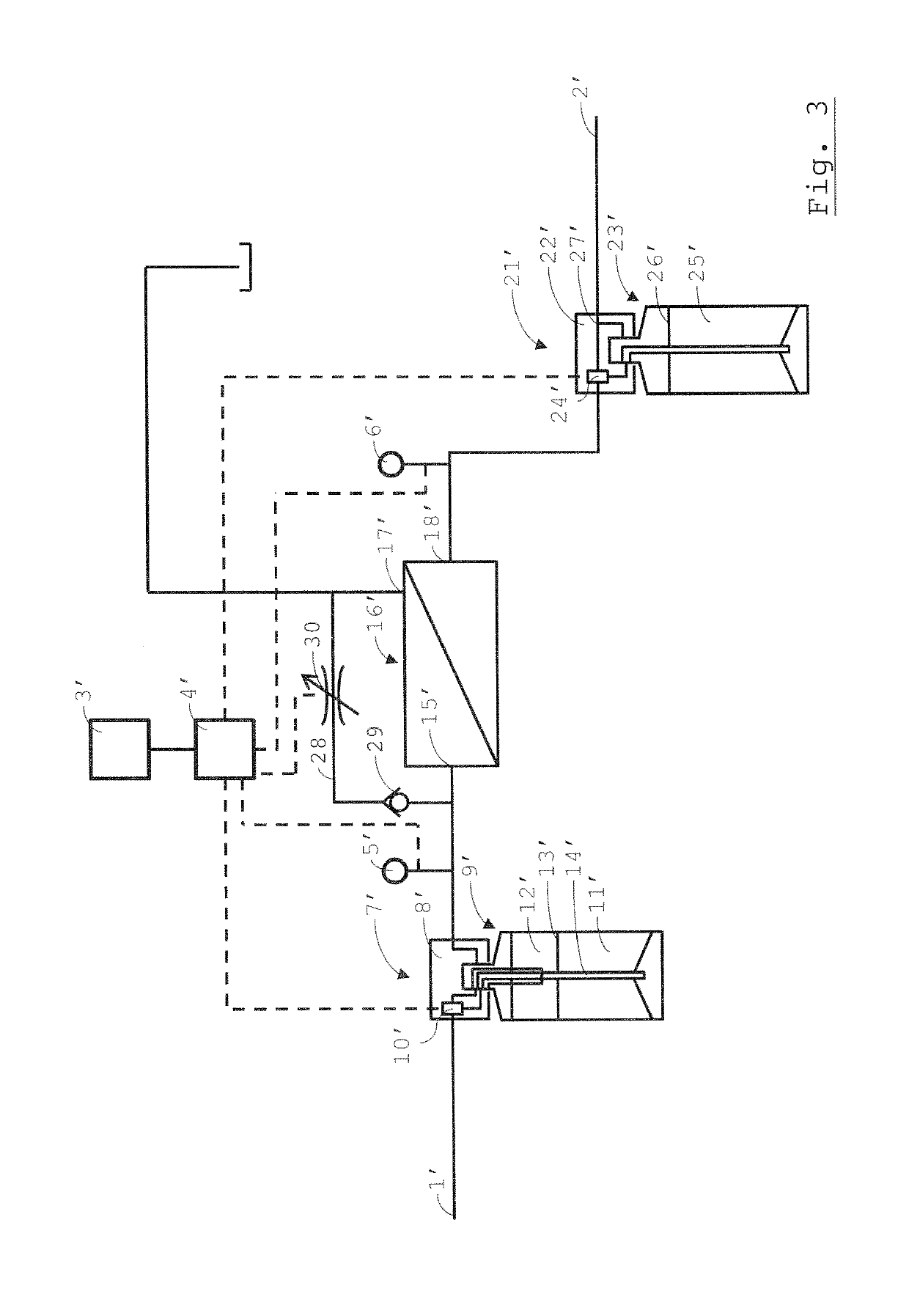

PendingUS20190119137A1Inhibit degassingIncreasing amount of freeWater treatment parameter controlSiccativesHydrogenFiltration

An apparatus for conditioning an aqueous liquid includes at least one inlet, at least one liquid treatment device for the treatment of liquid by ion exchange including a cation exchange material of which at least a portion is in the hydrogen form, a membrane filtration device and a section arranged to process filtrate produced by the membrane filtration device. This section includes a liquid treatment device for dissolving at least one mineral contributing to carbonate hardness in water into at least some of the liquid passing through the section. At least one of the at least one inlets is connected to an inlet of the membrane filtration device via at least one of the at least one liquid treatment devices for the treatment of liquid by ion exchange.

Owner:BRITA GMBH

Heat exchange in fluid degassing

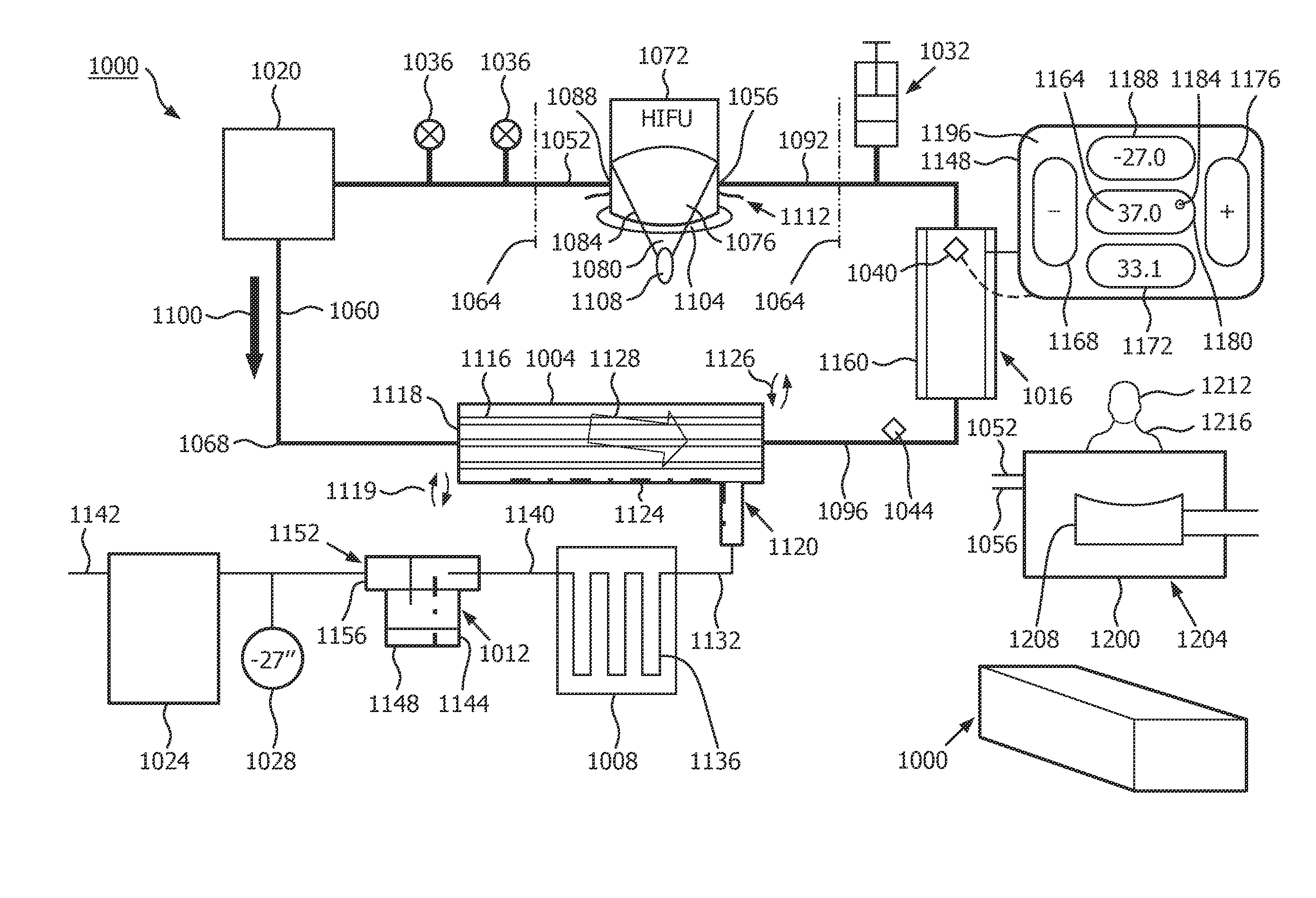

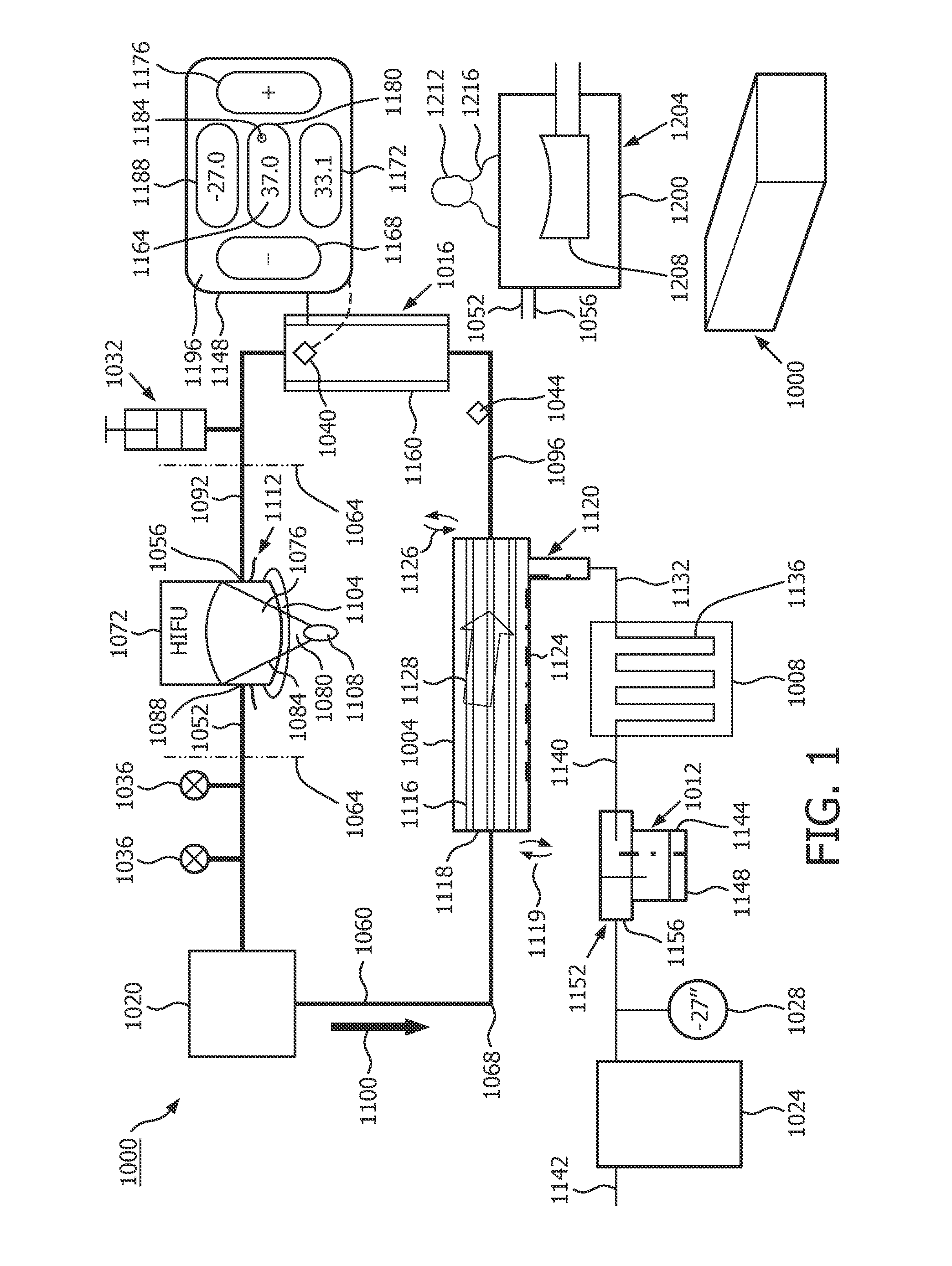

ActiveUS20140196607A1Inhibit degassingEffectively actUltrasonic/sonic/infrasonic diagnosticsFlash degasificationTemperature controlUltrasonic sensor

In one variation, a temperature-maintenance device includes a heater (1016) and is placeable in a circulation loop of an ultrasound transducer coupling bolus (1076), for degassing circulating liquid of the loop and for operating the heater for performing temperature control of the liquid. A temperature setpoint, such as a normal body temperature, for the liquid at the bolus may be entered. A device, either open- or closed-looped with respect to fluid flow, may include, in some variations, a degassing chamber, a water trap (1012), and an intervening cooler, all vacuumized by a vacuum pump (1024). The chamber may be configured and aligned for letting condensation automatically drain out. The water trap may be emptied, automatically and without the need for user intervention, by a motorized trap emptier and / or be emptiable by the user.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Fuel Injection Device for an Internal Combustion Engine

InactiveUS20080189025A1Inhibit degassingElectrical controlDigital data processing detailsHigh-pressure areaLow-pressure area

A fuel injection device comprising a high-pressure pump supplying a fuel to a high-pressure area in which an injector for injecting fuel into an internal combustion engine cylinder is arranged. An electric control unit for controlling fuel injection by at least one injector is provided. A pressure adjusting valve which adjusts a pressure in the high-pressure area and controls a connection between said high pressure area and a low-pressure fuel-filled area is controlled by the control unit. When the pressure adjusting valve is not controlled by the control unit it is placed in an open switching position in such a way that the connection between the high- low-pressure areas is opened, thereby preventing a gas formation in the high pressure area when the internal combustion engine is switched off and the fuel is cooled.

Owner:ROBERT BOSCH GMBH

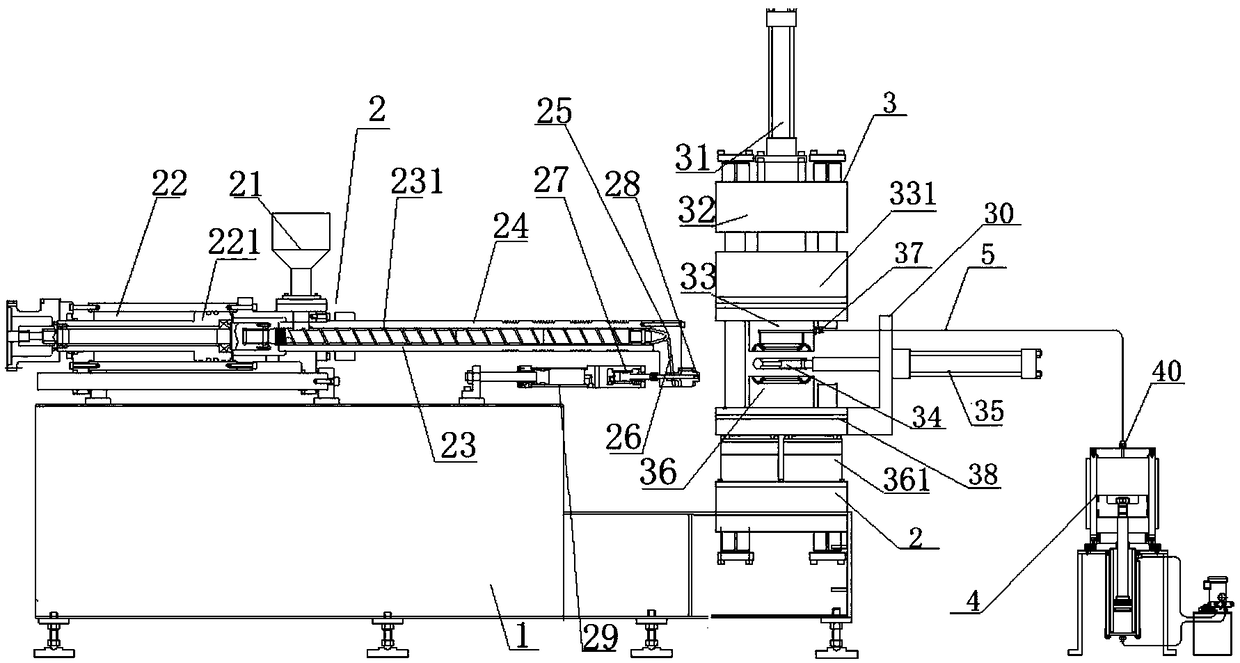

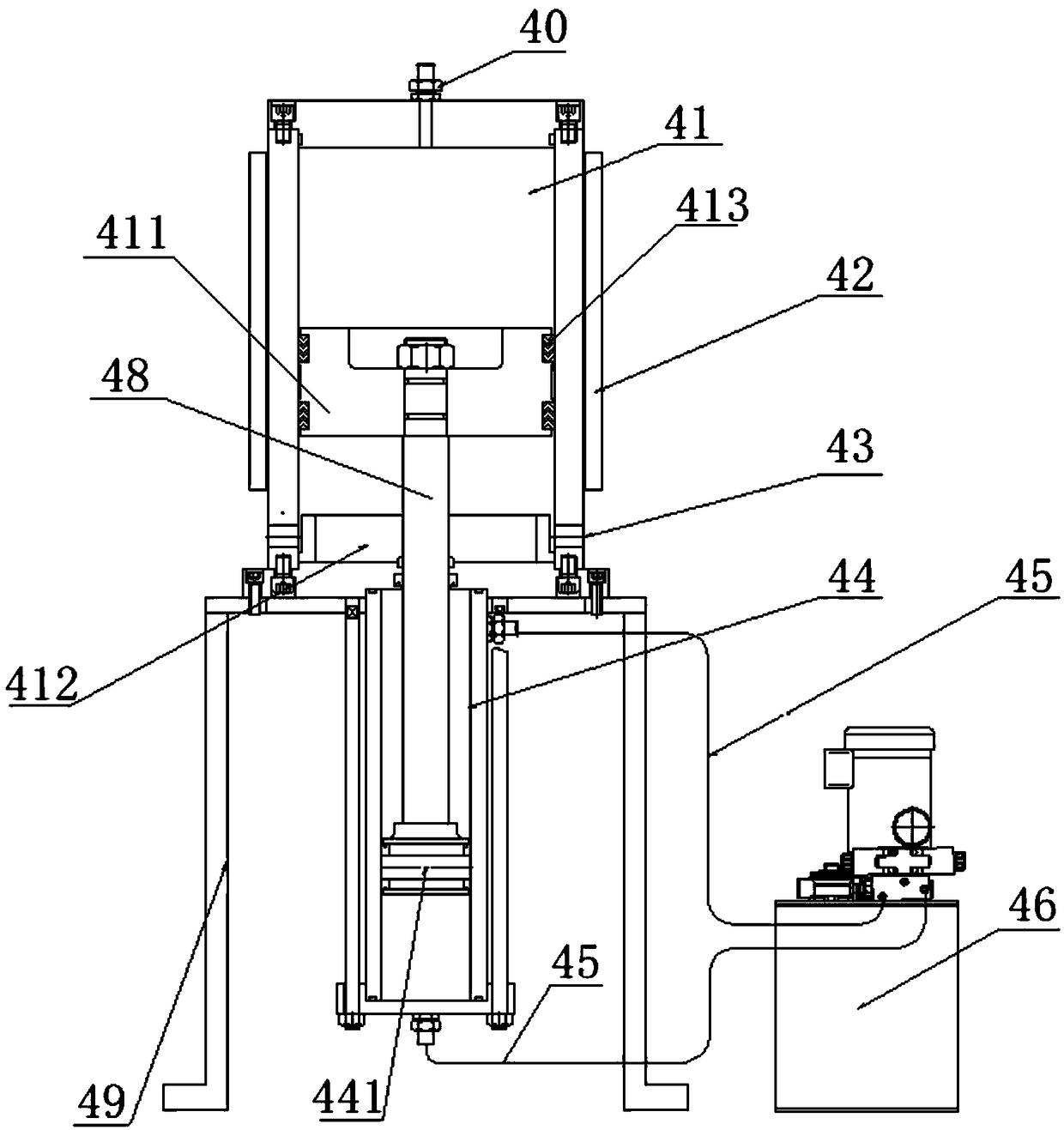

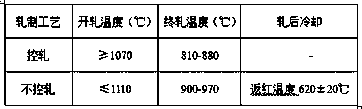

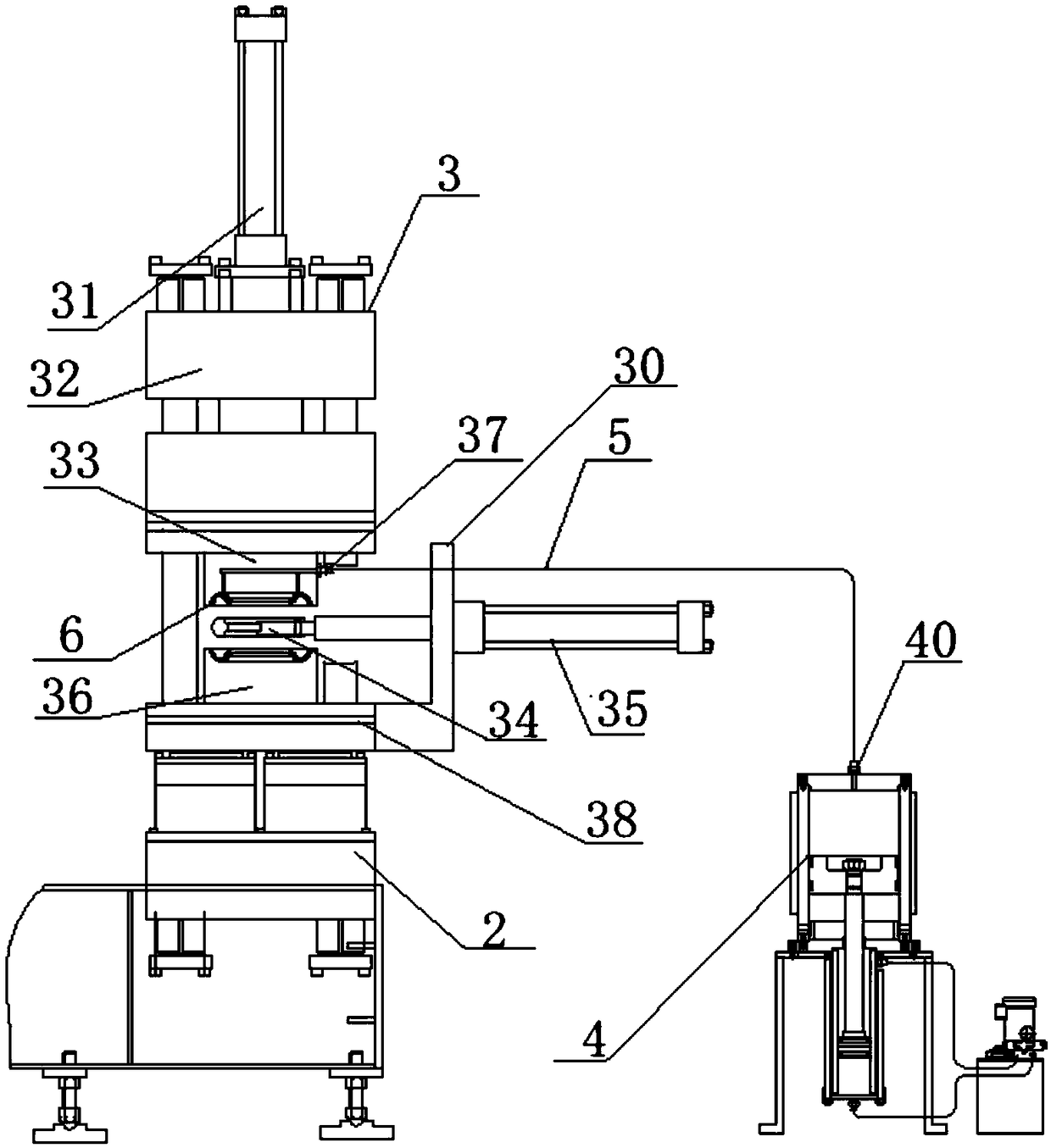

In-mold foaming forming system and technology for rubber double-density product

The invention discloses an in-mold foaming forming system and technology for a rubber double-density product, and belongs to the technical field of rubber product technologies. The system comprises amold exhaust and hollow inflation mechanism, and further comprises an injection machine base, a foaming and vulcanization molding pedestal, an injection device and a foaming and vulcanization moldingdevice, wherein the injection device and the foaming and vulcanization molding device are fixed to the injection machine base and the foaming and vulcanization molding pedestal, wherein the injectiondevice is communicated with a mold of the foaming and vulcanization molding device correspondingly; the mold exhaust and hollow inflation mechanism comprises a support, an air cylinder, an oil cylinder body and a hydraulic station; the support is an annular rack with a through hole in the middle; the air cylinder is fixed to an annular table board of the support; the oil cylinder body is fixed tothe bottom of the annular table board of the support; the air cylinder and the oil cylinder body are internally connected with a cylinder piston and an oil cylinder piston of a piston rod correspondingly; and the top of the air cylinder communicates with an inner cavity of a mold of the foaming and vulcanization molding device through an air pipe. According to the system and the technology, injection, foaming and vulcanization of the rubber product can be completed in one mold, the circulation of the product in each process is avoided, and therefore the production cost is lowered.

Owner:安徽世界村智能装备有限公司

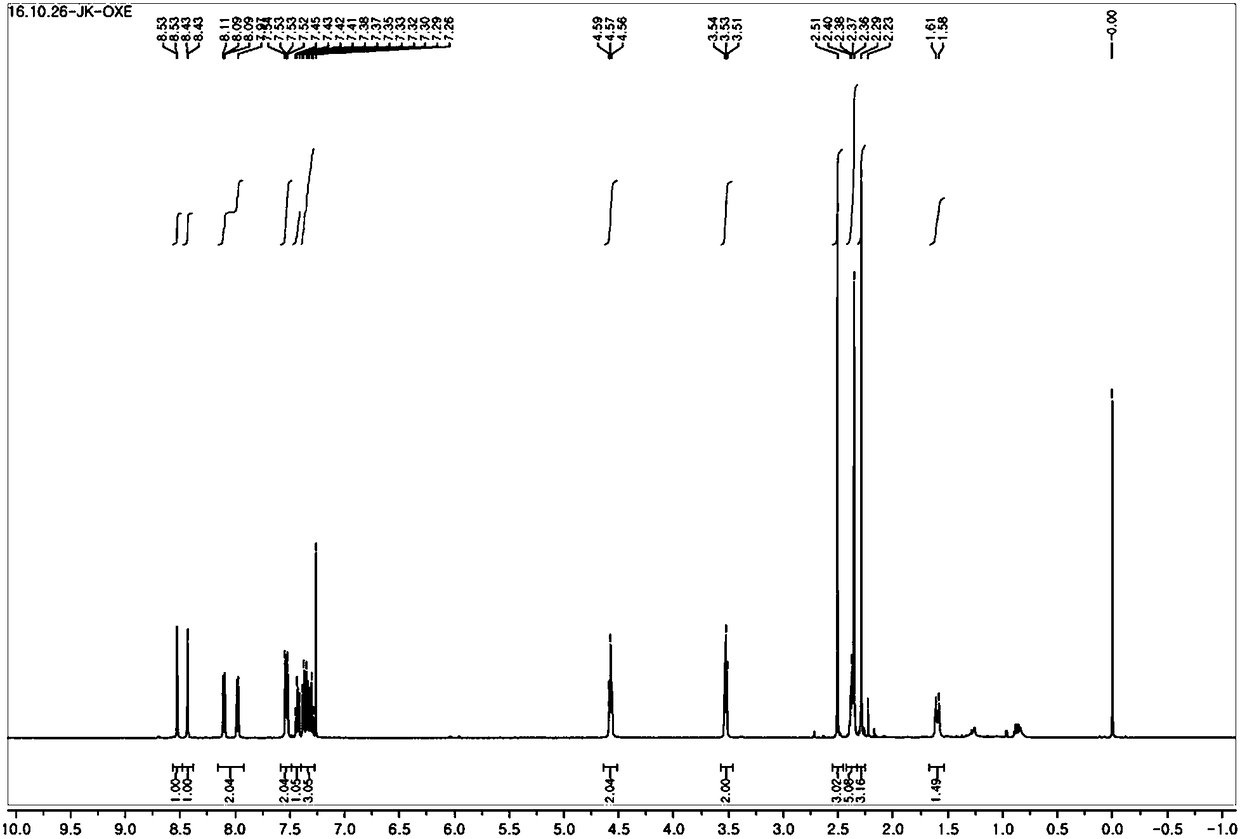

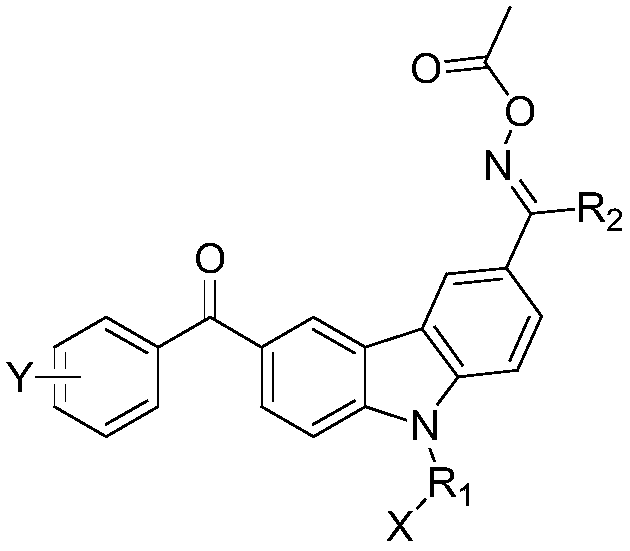

Oxime ester compound and a photocurable composition comprising the same

ActiveCN108503577ADissolution inhibitionReduce defective rateOrganic chemistryPhotosensitive materials for photomechanical apparatusHydrogenHalogen

The present invention provides an oxime ester-based compound and a photocurable composition containing the oxime ester-based compound, and more particularly, it relates to a photocurable compound comprising a photocurable compound and a photopolymerization initiator, and the photopolymerization initiator contains an oxime ester-based compound. In the photocurable composition, the photocurable composition can suppress the occurrence of outgassing while suppressing the occurrence of degassing, thereby suppressing the elution of the solvent and improving the problem of liquid crystal contamination caused by solvent elution of the contaminated liquid crystal. The oxime ester compound is represented by the following Chemical Formula 1, wherein R1 is a C1 to C12 linear or branched alkyl group; and the R2 is a C1 to C12 linear or branched alkyl group; X is any one selected from the group consisting of Cl, Br and I; the Y is hydrogen, a C1-C12 linear or branched alkyl group, a halogen atom, anamino group or a C1-C4 alkoxy group.

Owner:DONGWOO FINE CHEM CO LTD

Structure for hermetic encapsulation of a device and an electronic component

ActiveUS8884331B2Inhibit degassingHigh densityDecorative surface effectsSemiconductor/solid-state device detailsHermetic sealElectronic component

An encapsulation structure including at least one hermetically sealed cavity in which a device, an electronic component produced on a first substrate, and a getter material layer covering the electronic component in order to block the gases capable of being degassed by the electronic component, are enclosed. A top surface of the device is free of contact with the getter material layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

A low-cost manufacturing method for flaw detection q345b grade steel plate

ActiveCN108660381BReduce the amount addedReduce temperature lossManufacturing convertersChemical compositionSheet steel

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Air-discharging and air-filling device and production technology thereof for molding sulfuration molds of rubber injection hollow products

The invention discloses an air-discharging and air-filling device and a production technology thereof for molding sulfuration molds of rubber injection hollow products and belongs to the technical field of rubber product technology. The air-discharging and air-filling device comprises a compression molding sulfuration mechanism and a mold air-discharging and hollow air-filling mechanism. The moldair-discharging and hollow air-filling mechanism comprises a support, a cylinder, an oil cylinder body and a hydraulic station. The support is an annular rack with a through hole in the middle. The cylinder is fixed to an annular table surface of the support. The oil cylinder body is fixed to the bottom of the annular table surface of the support. The cylinder and the oil cylinder body are connected with a cylinder piston and an oil cylinder piston of the same piston rod in an internally-arranged manner respectively. The top of the cylinder communicates with the mold inner cavity of the compression molding sulfuration mechanism through an air pipe. The oil cylinder body is divided into an upper cavity body and a lower cavity body by the oil cylinder piston. The upper cavity body and the lower cavity body communicate with the hydraulic station respectively through an oil pipe. The air-discharging and air-filling device is integrated through the same piston rod; high pressure oil flow isadjusted; operation speed of the piston can be controlled; air-filling flow can be satisfied; and then air-filling pressure and air-discharging vacuum degree requirements are reached.

Owner:安徽世界村智能装备有限公司

Formation Mobility Simulator

The invention provides a stratum mobility simulating device. The stratum mobility simulating device comprises a constant speed and constant pressure pump, an intermediate container, a high temperature and high pressure sample allocation device and a model mechanism, wherein one end of the intermediate container is connected with the constant speed and constant pressure pump, one end of the high temperature and high pressure sample allocation device is provided with an air infusion port, the other end of the high temperature and high pressure sample allocation device is connected with the constant speed and constant pressure pump, the model mechanism comprises a flowing section, a capillary tube section and a phase volume fraction tester, the flowing section is provided with a mold section, the mold section comprises a fixed clamping groove and a movable clamping groove, the movable clamping groove can be movably arranged in a scale sliding groove, flat panel grooves are formed in the scale sliding groove, a convection current channel is formed between the fixed clamping groove and the movable clamping groove, the two ends of the convection current channel are the inlet end and the outlet end, the inlet end is connected with the other end of the intermediate container and the end, where the air infusion port is formed, of the high temperature and high pressure sample allocation device, and the outlet end is sequentially connected with the capillary tube section and the phase volume fraction tester. The stratum mobility simulating device is capable of simulating fissures of different opening degrees and stratums with different roughness and the flowing of single-phase fluid or multi-phase fluid in the stratums at different flowing speed, through the arrangement of a corestone, the conditions of the stratums can be simulated in a more realistic mode, the data are accurate, and the application range is wide.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

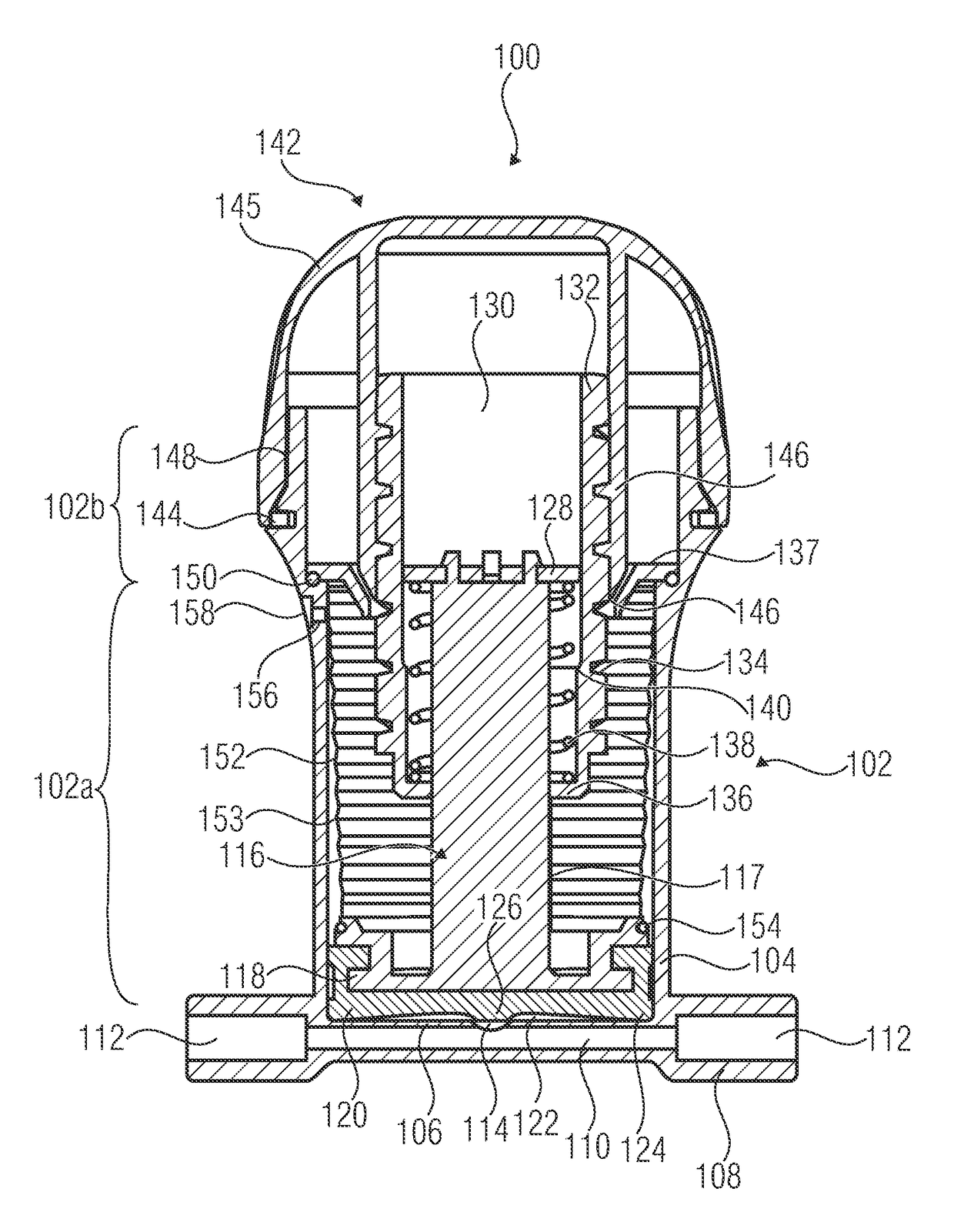

Fluid handling device having a spring mechanism

A fluid handling device includes a receiving container with a piston arranged therein in a displaceable manner, such that the volume of a fluid receiving reservoir may be changed by a displacement of the piston. In addition, the fluid handling device includes an actuation mechanism configured to displace a carrier bearing upon actuation of the former. Finally, the fluid handling device includes a spring mechanism configured to transfer a force from the carrier bearing to the piston so as to effect, in response to displacement of the carrier bearing in a first direction, a displacement of the piston within the receiving container such that a volume of the fluid reservoir is increased.

Owner:SMITHS MEDICAL DEUTLAND

Device for installing conducting components in structures

ActiveUS8711540B2Lower impedanceNot to damageAircraft lighting protectorsFuel tank safety measuresPower flowEngineering

Owner:AIRBUS OPERATIONS SL

Photocurable resin composition

The purpose of the present invention is to provide a photo-post-curing resin composition that makes it possible to suppress the generation of outgas and has exceptional transparency and reliability. The present invention is a photo-post-curing resin composition containing a cationically curable resin, a photo-cationic polymerization initiator, and a compound having amino groups and cationically polymerizable functional groups.

Owner:SEKISUI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com