Patents

Literature

189 results about "Post cure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Post cure inflation is the process of cooling the tyre under pressure immediately after it has been cured. This is done by inflating the tyre using specified air pressure after mounting the tyre on the specified rim. This is done for one or two cycles (one cycle is equal to the time taken for one curing cycle)...

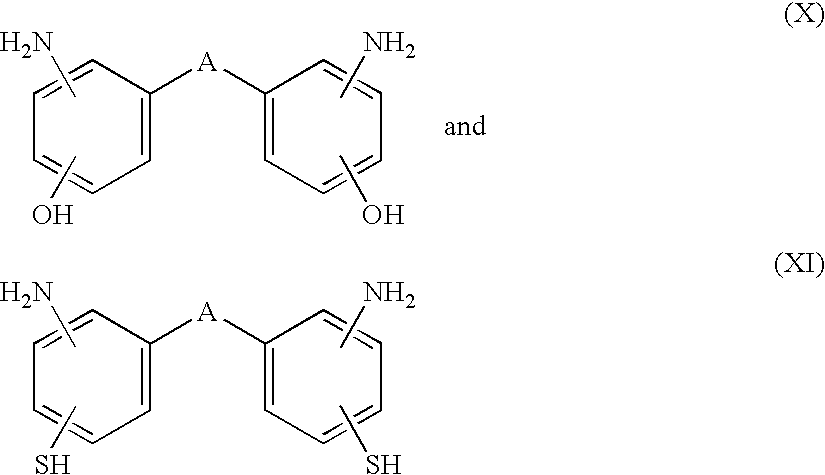

Process to mold a plastic optical article with integrated hard coating

Disclosed is a process for molding plastic optical articles with a hard coated film, comprising steps of coating one side of an optical film with a hard coating, pre-curing the hard coating to a tack free state while still maintaining the coating flexibility, making an insert from the coated film for the desired optical article, molding the plastic resin onto the insert through insert injection molding, and post-curing the molded article. The utilization of the pre-curing and post-curing steps have been found to eliminate hard coating cracks during the insert making and the molding step, while providing a hard coating with desired properties. Such an optical article possesses a hard coating integrated on its surface, thus, eliminating the need to further coat the optical article.

Owner:HOYA OPTICAL LABS OF AMERICA INC

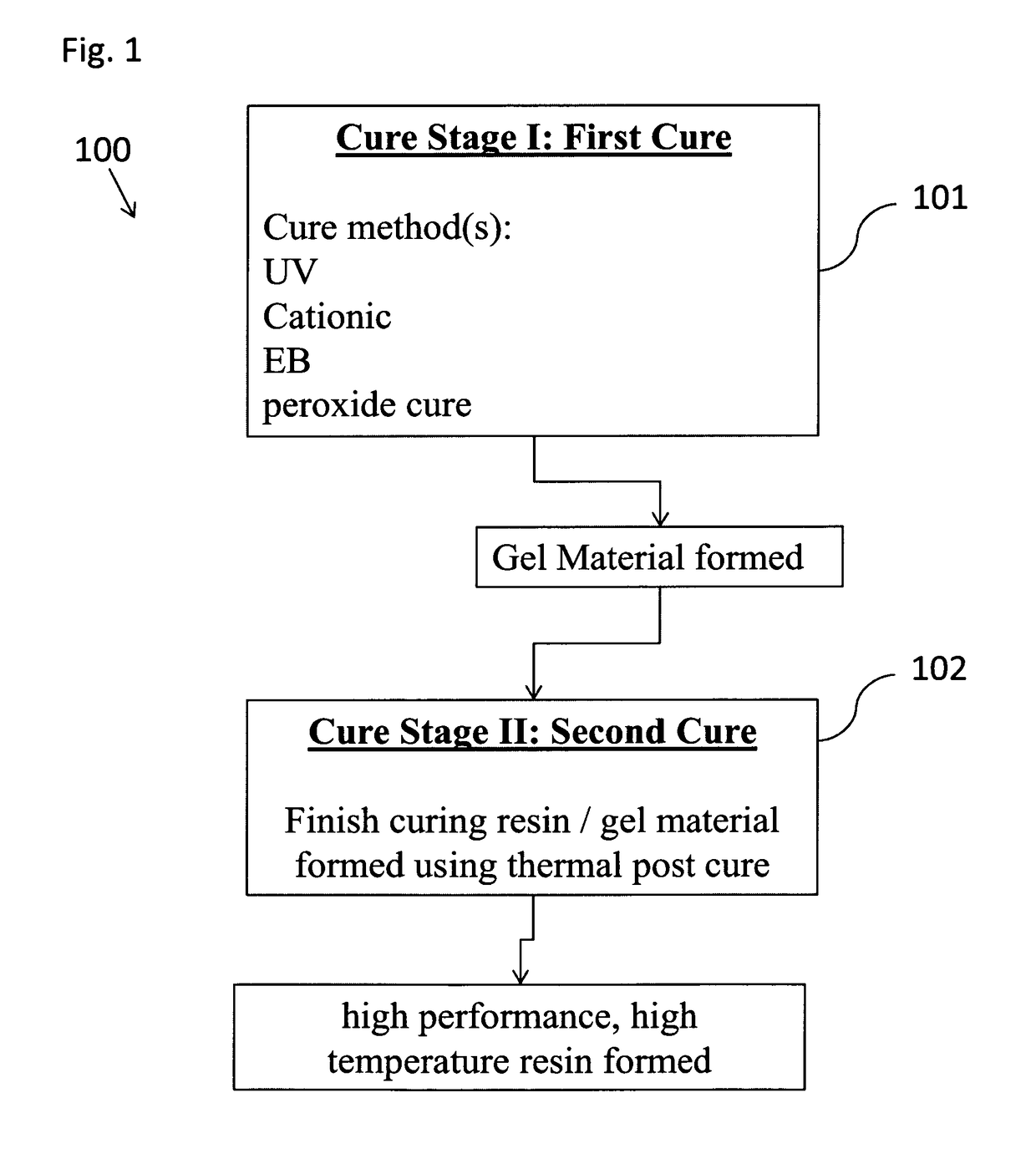

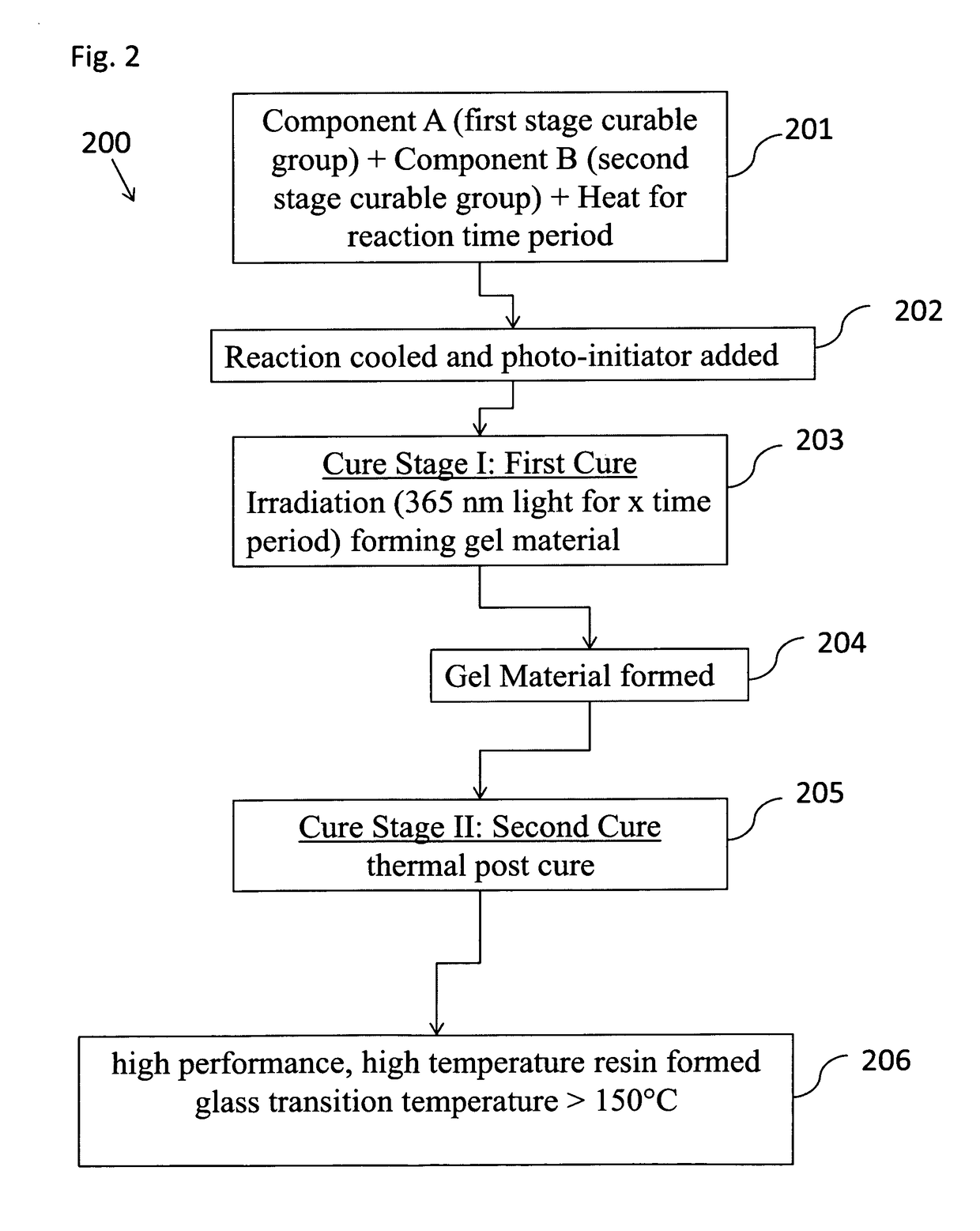

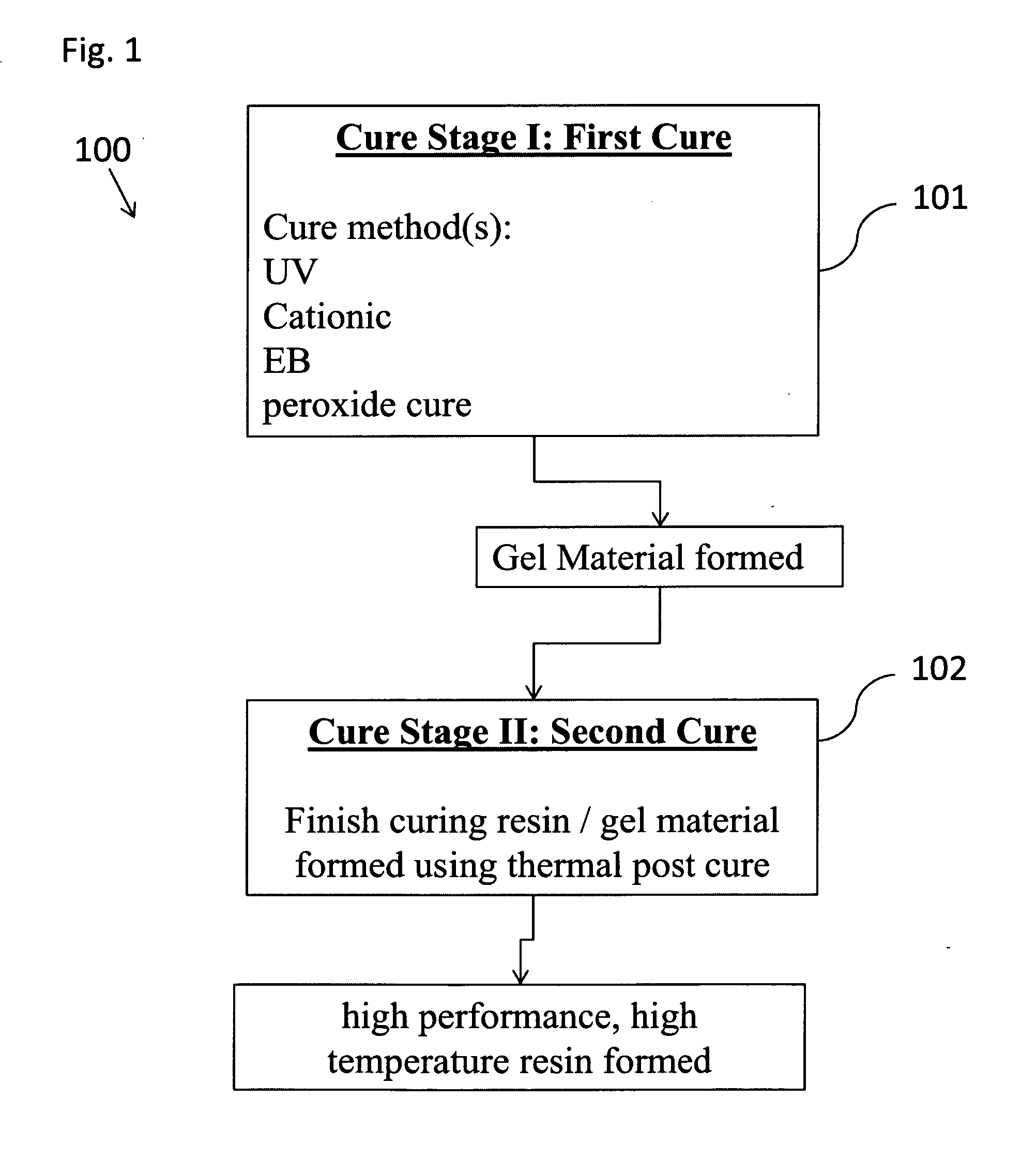

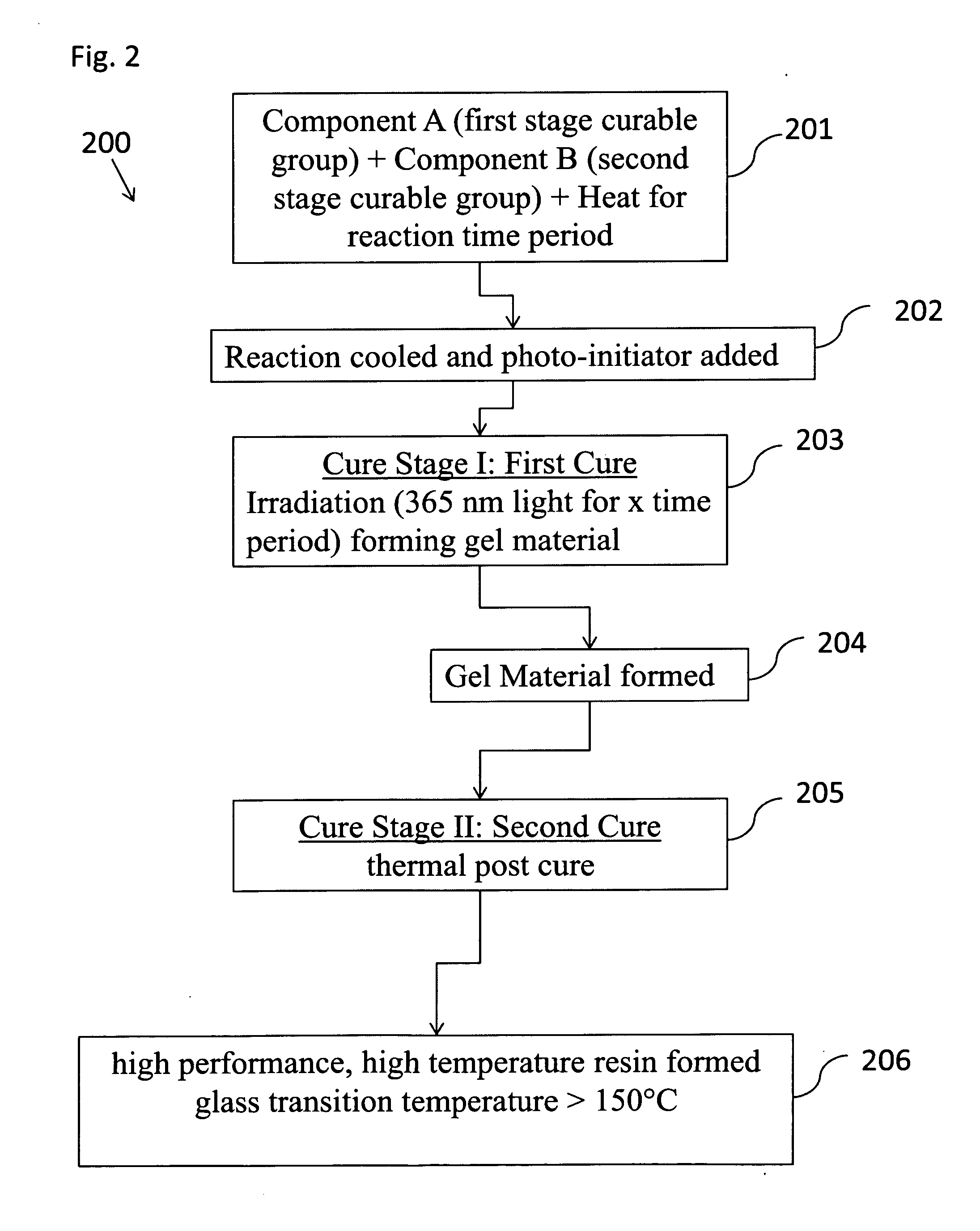

High temperature three dimensional printing compositions

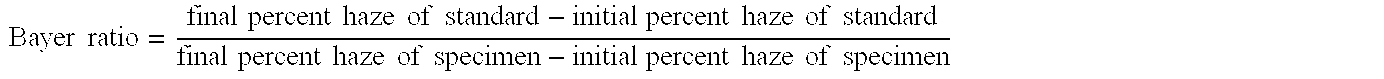

ActiveUS9708440B2Improve performanceHigh-temperature resinAdditive manufacturing apparatusMetal catalystRoom temperature

A thermosetting resin composition has particular applications in three dimensional (3-D) printing. The thermosetting resin composition exhibits high performance and is characterized by a high temperature two stage cure resin composition. The thermosetting resin composition comprises cyanate esters and other high temperature resins, photo curable monomers, photo initiator, metal catalyst or ionic liquid catalyst. The thermosetting resin composition cures at room temperature to form 3-D objects and upon further post cure these objects exhibit high temperature properties enabling use at temperatures exceeding 150 C.

Owner:NOVOSET

High temperature three dimensional printing compositions

ActiveUS20160369040A1High modulusHigh elongationAdditive manufacturing apparatusPolymer scienceMetal catalyst

A thermosetting resin composition has particular applications in three dimensional (3-D) printing. The thermosetting resin composition exhibits high performance and is characterized by a high temperature two stage cure resin composition. The thermosetting resin composition comprises cyanate esters and other high temperature resins, photo curable monomers, photo initiator, metal catalyst or ionic liquid catalyst. The thermosetting resin composition cures at room temperature to form 3-D objects and upon further post cure these objects exhibit high temperature properties enabling use at temperatures exceeding 150C.

Owner:NOVOSET

Functionalized poly(arylene ether) composition and method

A curable composition includes an olefinically unsaturated monomer and a poly(arylene ether) having two polymerizable groups and an intrinsic viscosity of about 0.05 to about 0.30 deciliters per gram. The composition exhibits an improved combination of high flow during molding and high post-cure stiffness and impact strength. The composition is particularly useful for fabricating plastic-packaged electronic devices.

Owner:SHPP GLOBAL TECH BV

Functionalized poly(arylene ether) composition and method

A curable composition includes an olefinically unsaturated monomer and a poly(arylene ether) having two polymerizable groups and an intrinsic viscosity of about 0.05 to about 0.30 deciliters per gram. The composition exhibits an improved combination of high flow during molding and high post-cure stiffness and impact strength. The composition is particularly useful for fabricating plastic-packaged electronic devices.

Owner:SHPP GLOBAL TECH BV

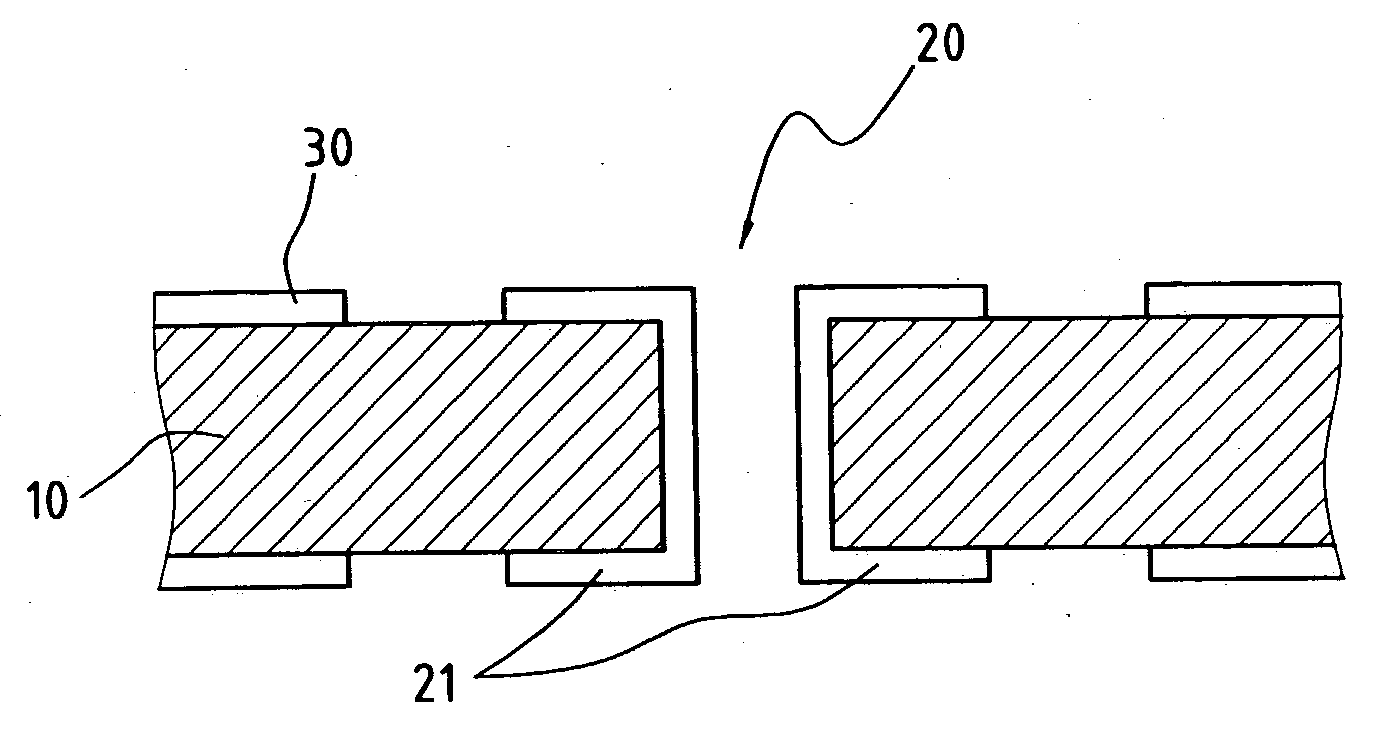

Process to mold a plastic optical article with integrated hard coating

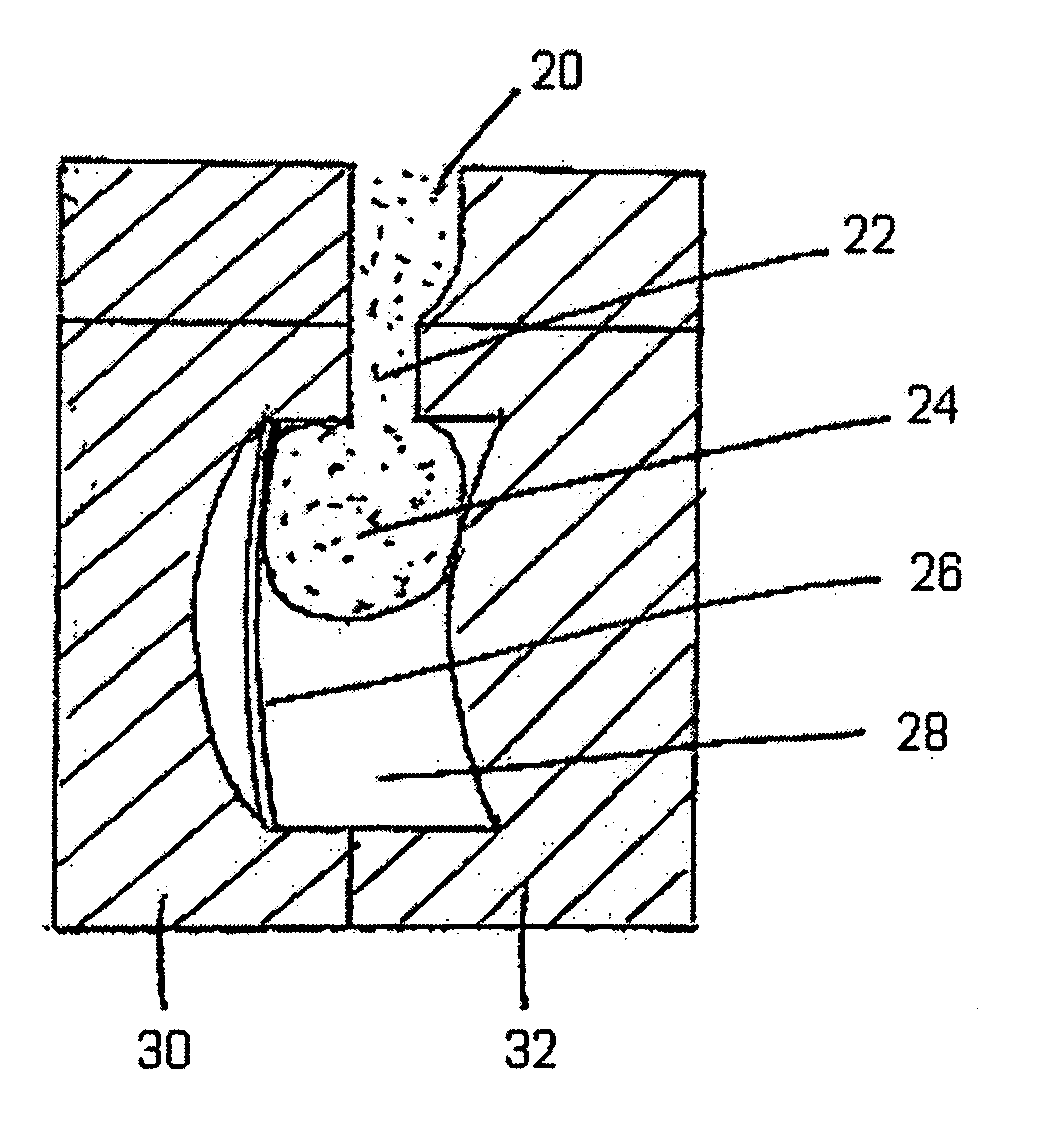

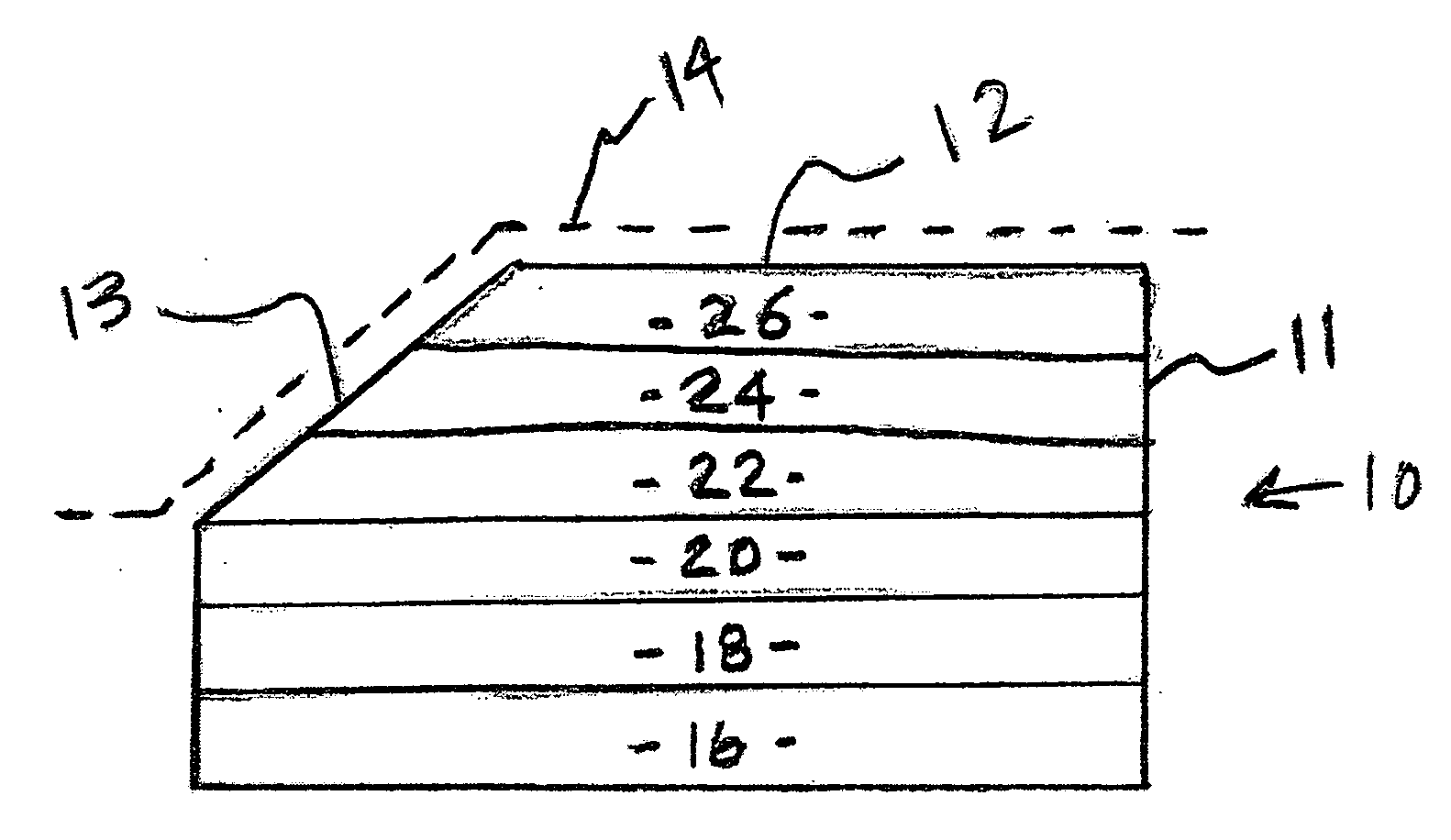

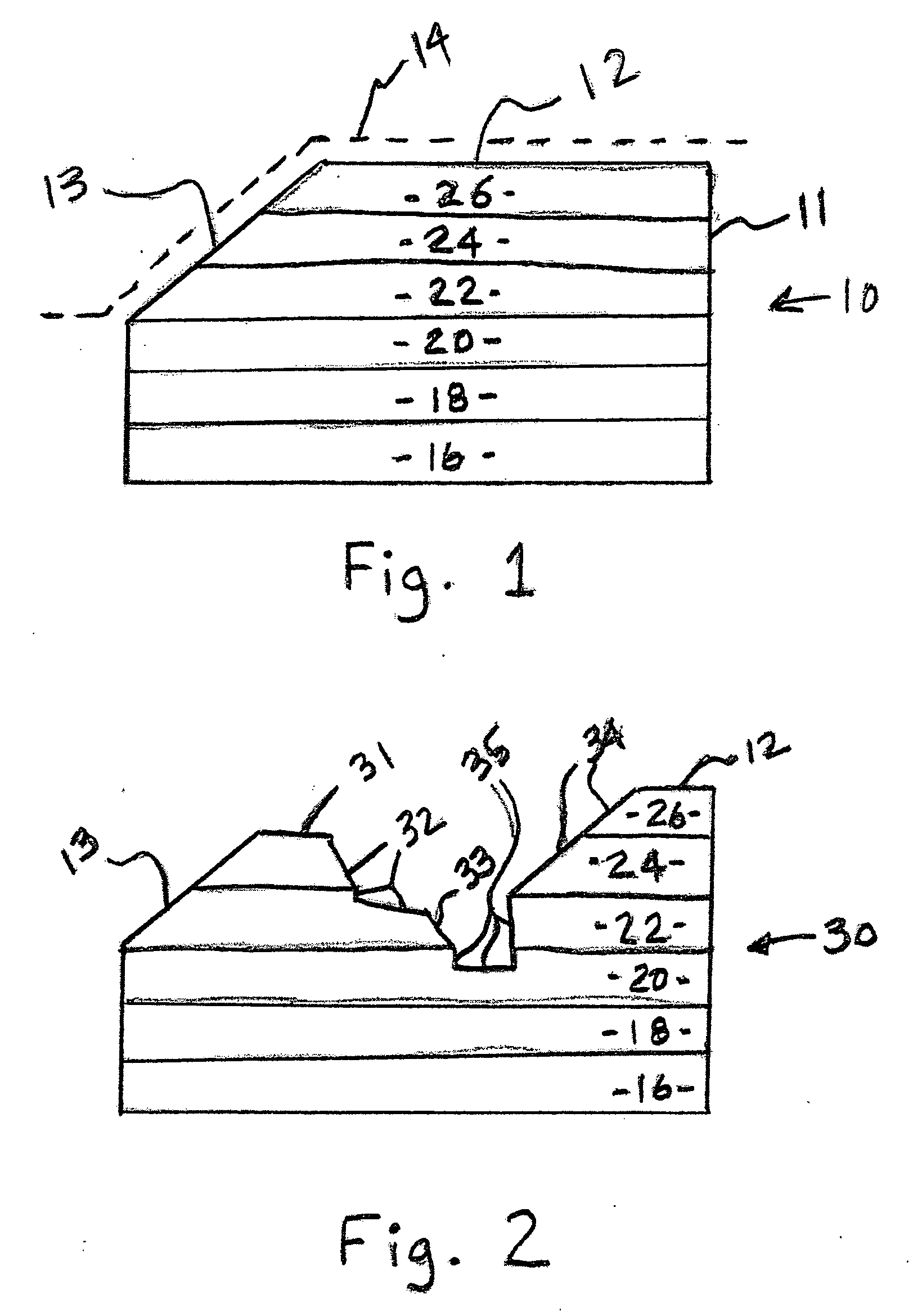

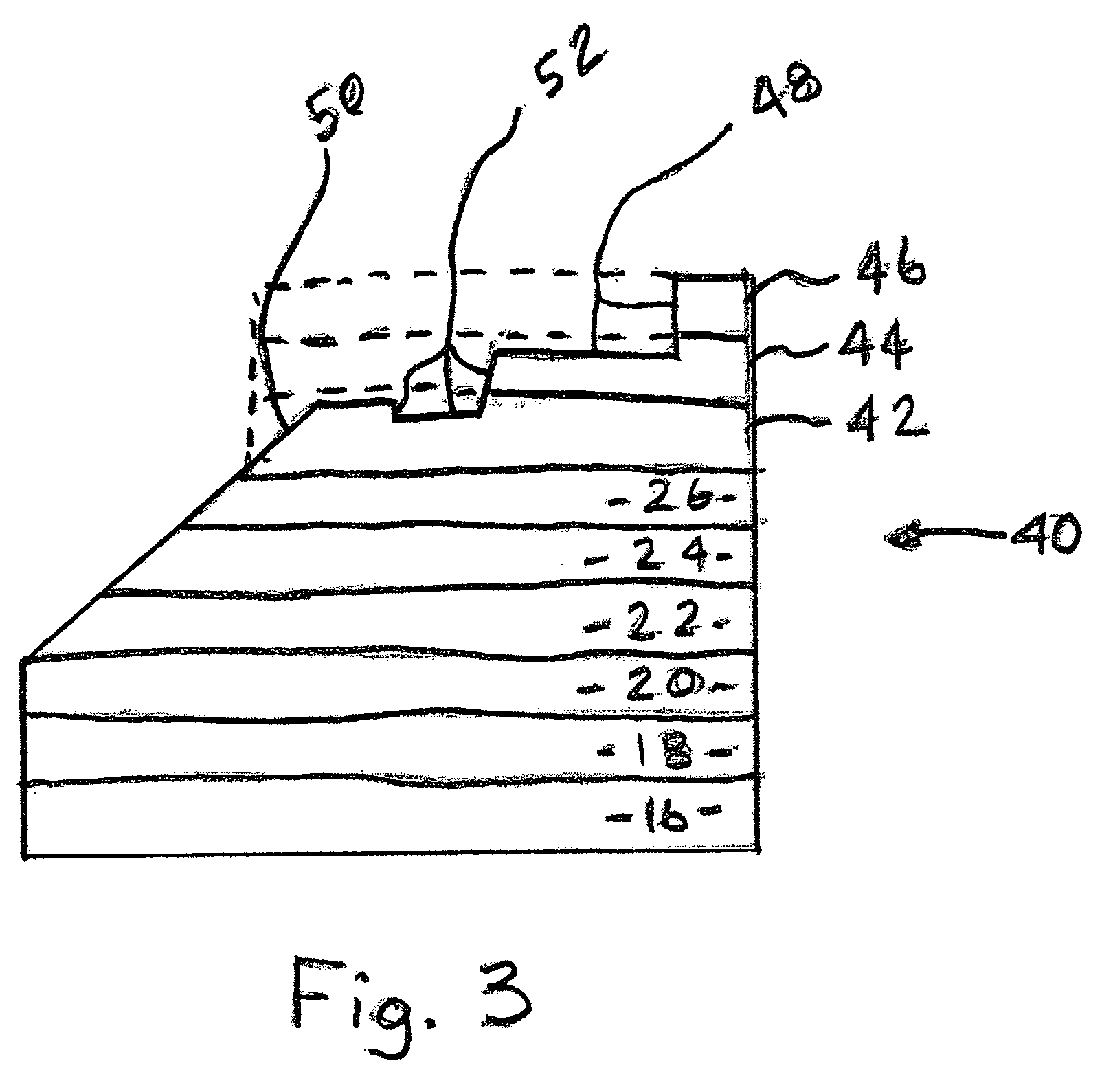

InactiveUS7025458B2Excellent surface optical qualityDesired abrasion and scratching resistanceOptical articlesEye diagnosticsShell moldingFree state

Disclosed is a process for molding plastic optical articles with a hard coated film, comprising steps of coating one side of an optical film with a hard coating, pre-curing the hard coating to a tack free state while still maintaining the coating flexibility, making an insert from the coated film for the desired optical article, molding the plastic resin onto the insert through insert injection molding, and post-curing the molded article. The utilization of the pre-curing and post-curing steps have been found to eliminate hard coating cracks during the insert making and the molding step, while providing a hard coating with desired properties. Such an optical article possesses a hard coating integrated on its surface, thus, eliminating the need to further coat the optical article.

Owner:HOYA OPTICAL LABS OF AMERICA INC

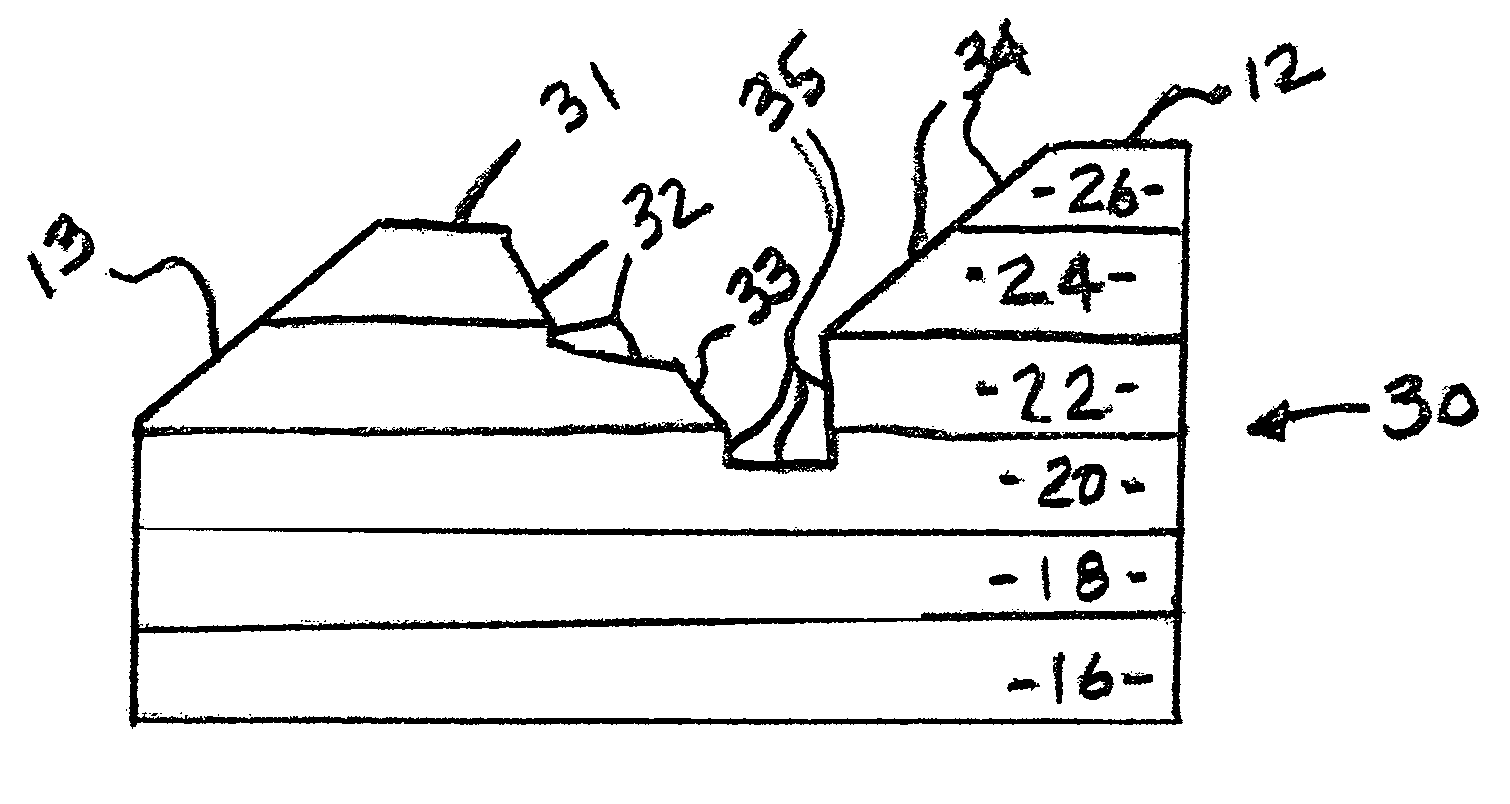

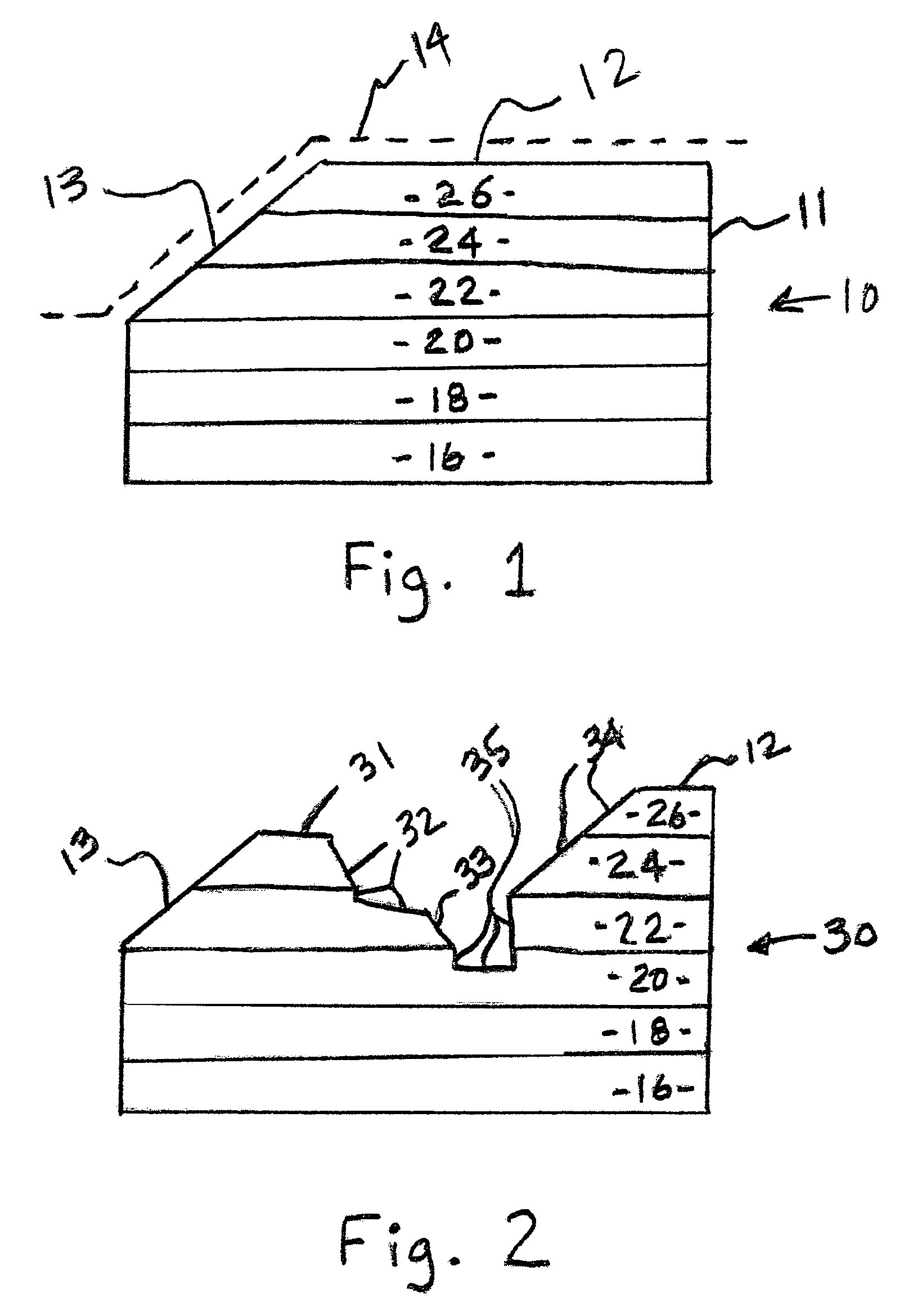

Machinable composite mold

Machinable composite molds for use in making a composite structure. The mold includes a mold body having a tool surface that is shaped to provide the molded surface of the composite structure. The mold body is made up of at least one mold layer composed of a quasi-isotropic material composed of a plurality of randomly oriented fiber bundles or chips impregnated with a resin. The use of randomly oriented fiber chips allows post-cure machining of the mold body.

Owner:HEXCEL

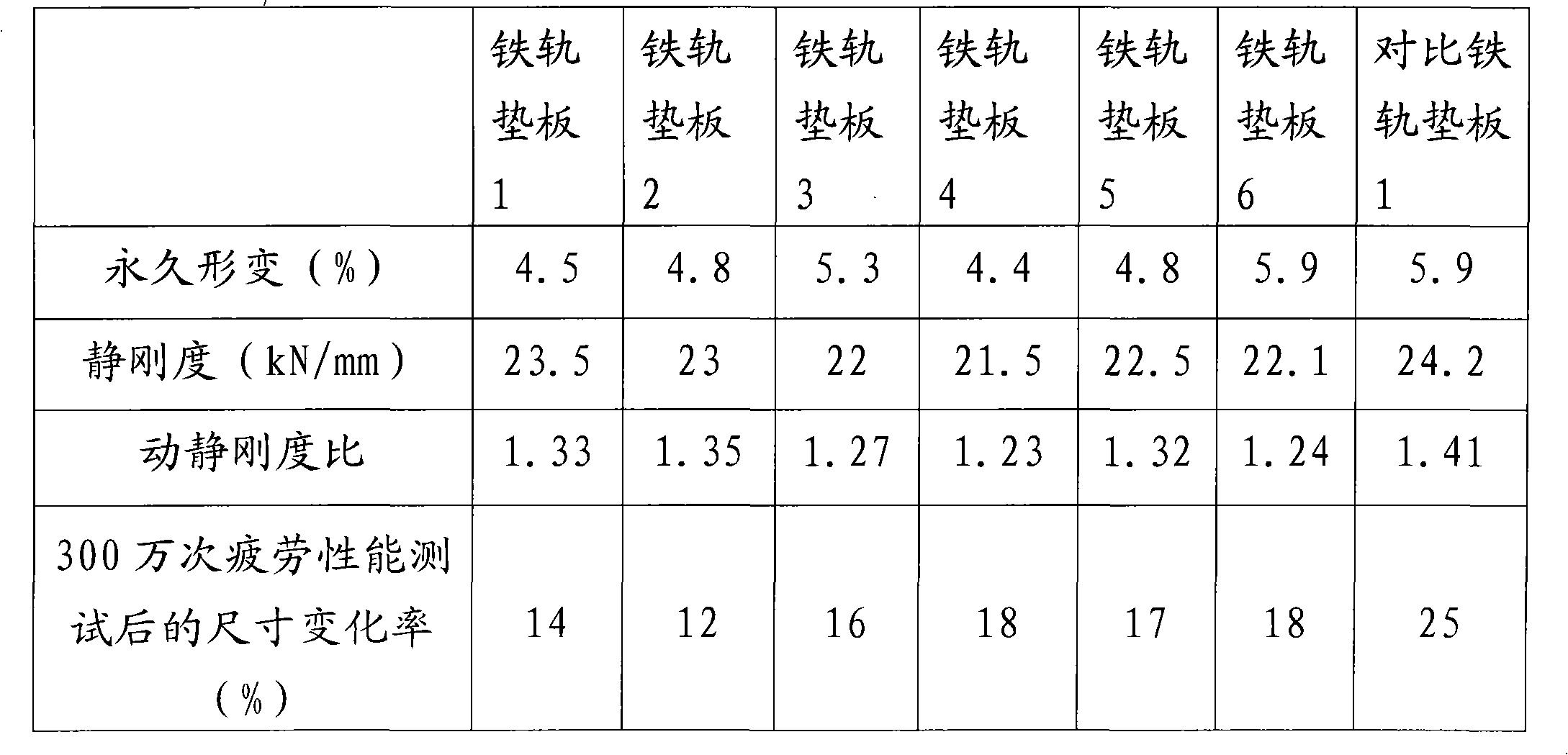

Rail tie plate and preparation method thereof

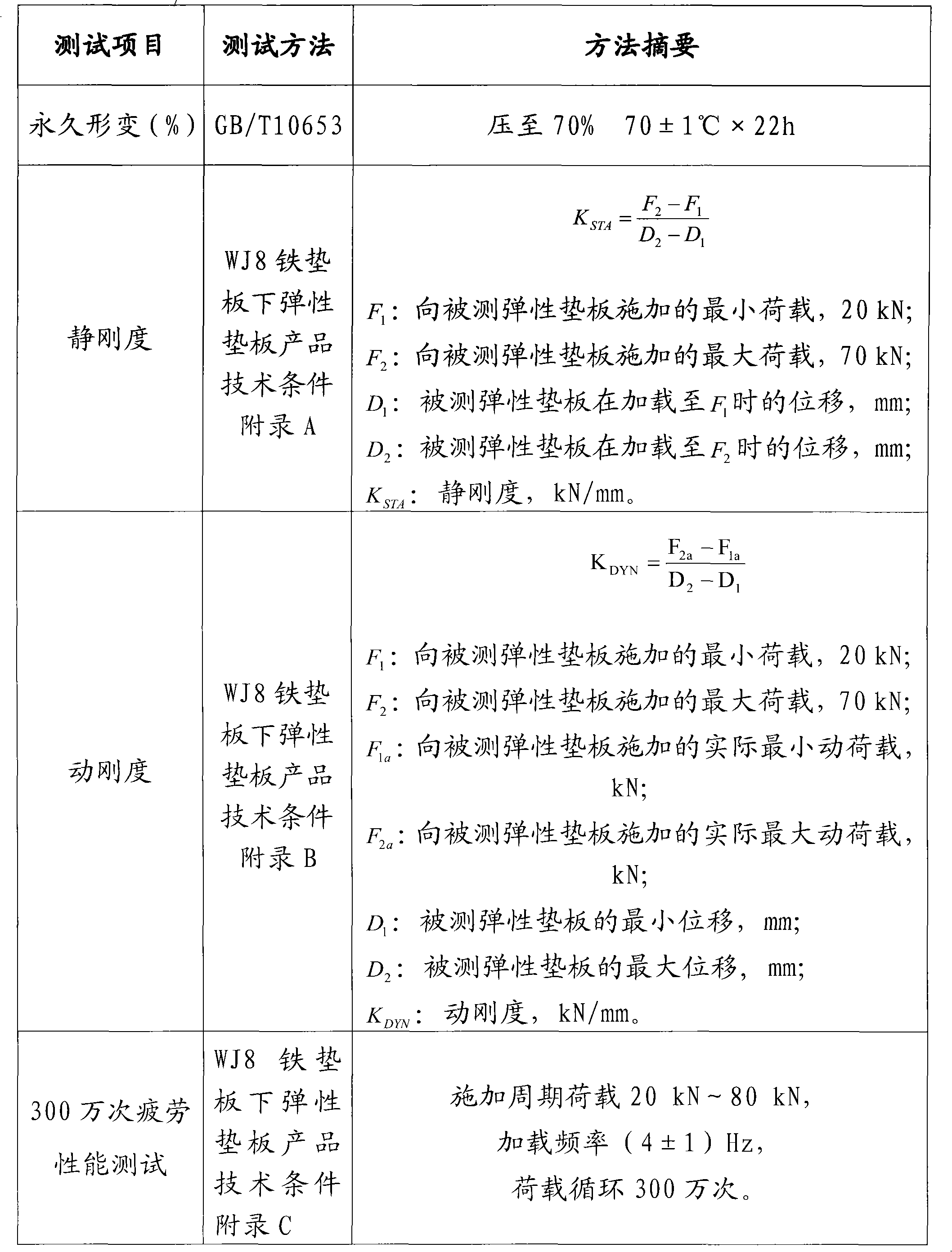

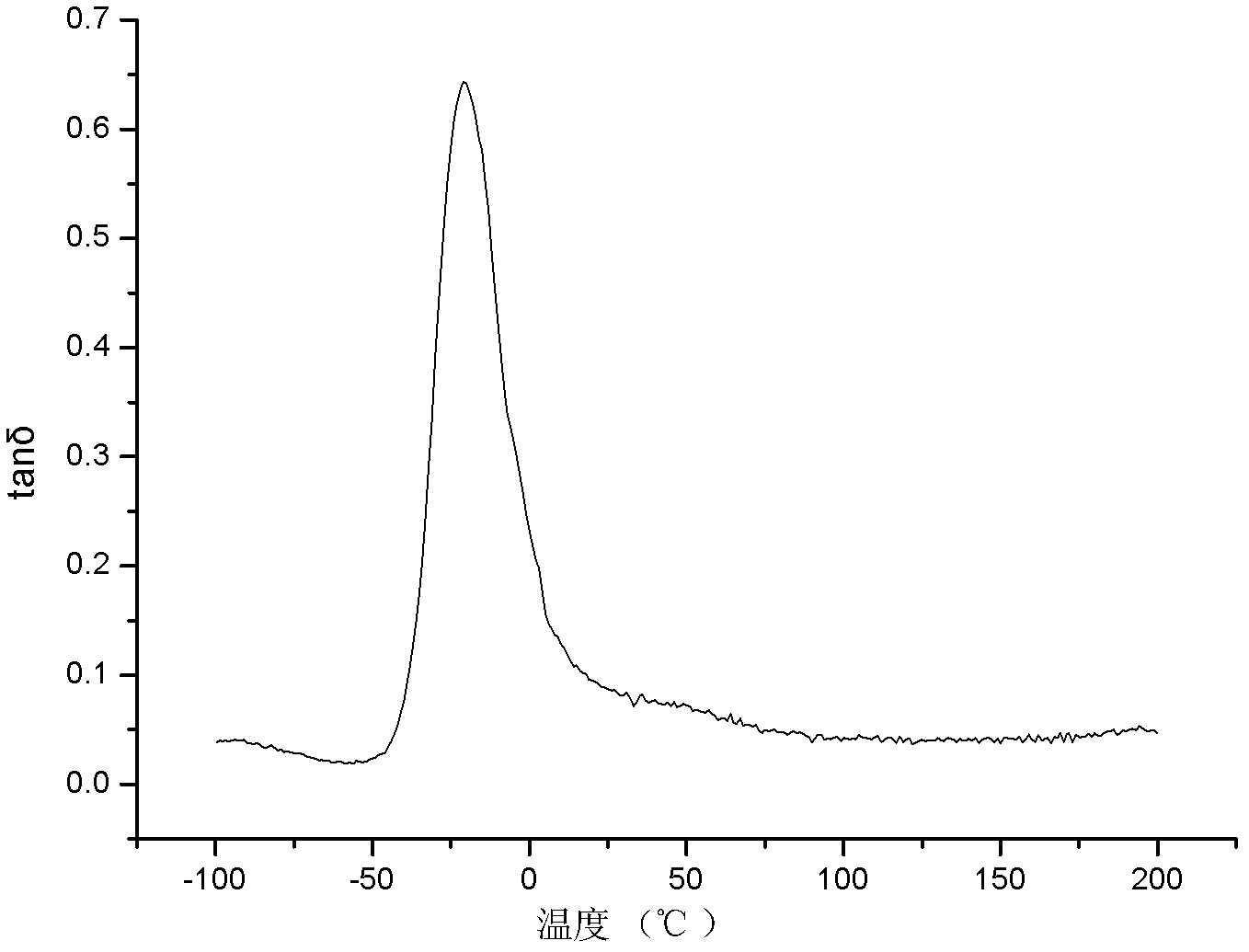

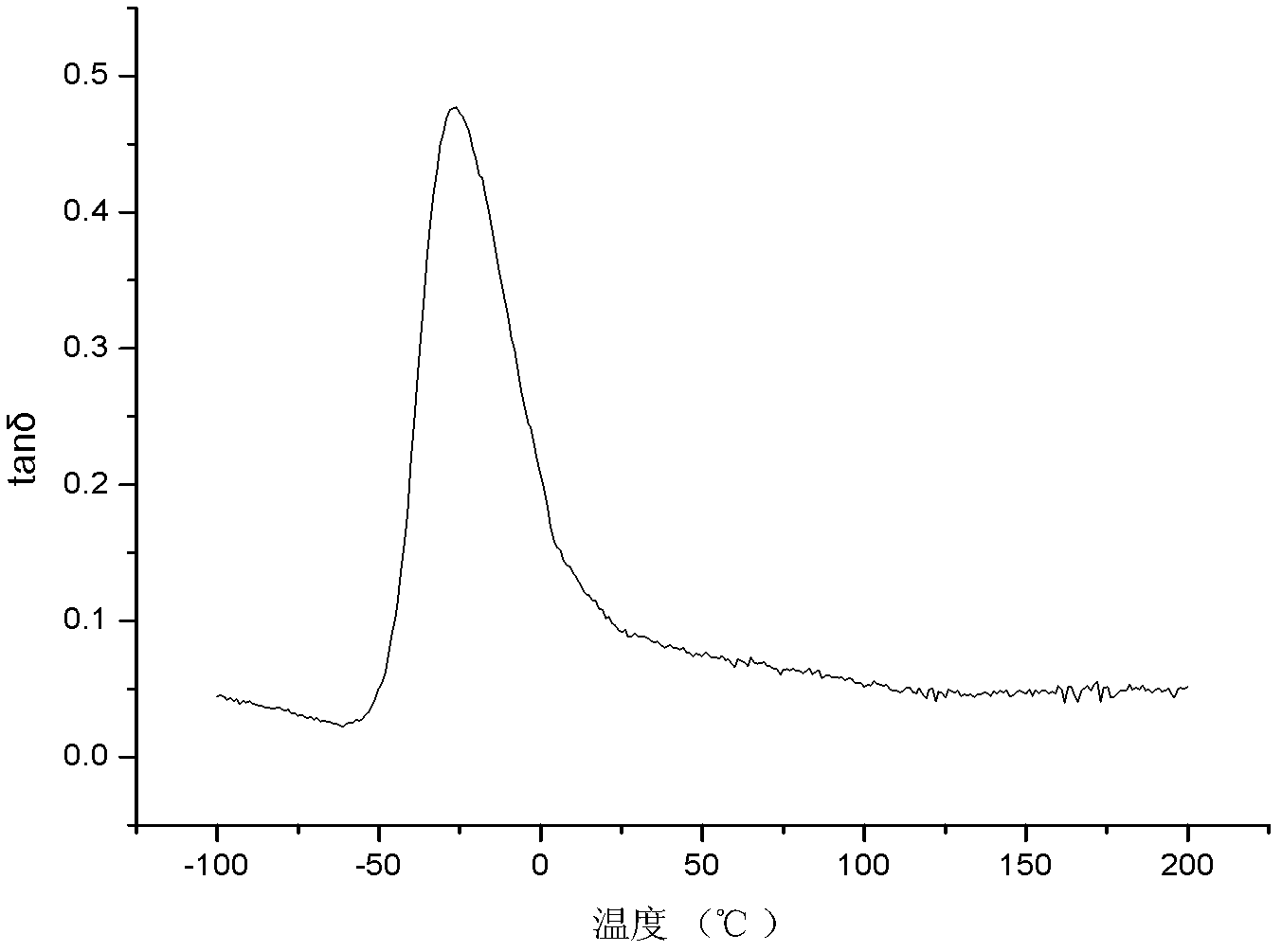

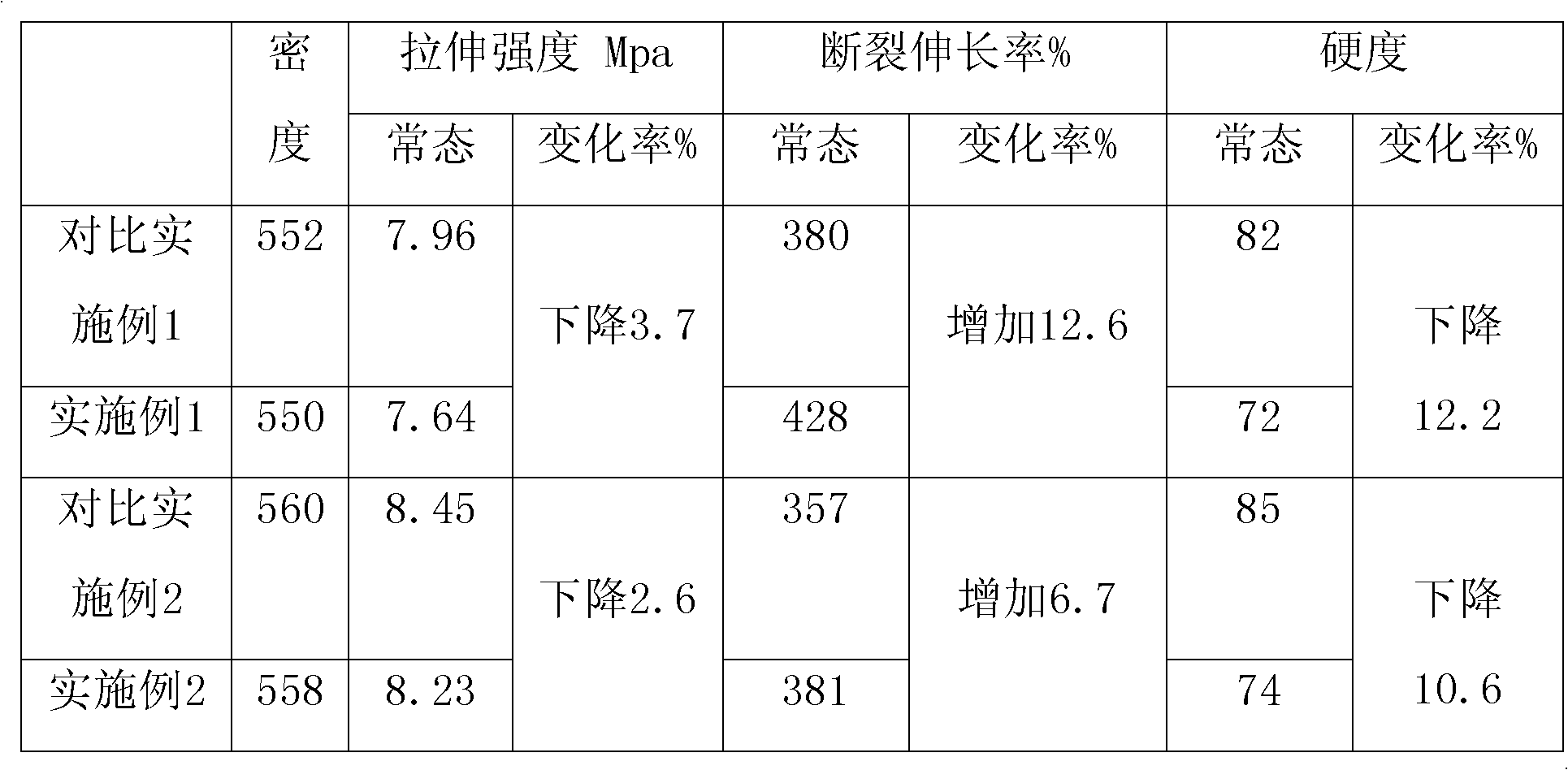

ActiveCN101942786AFlexible and adjustable static stiffnessAdapt to requirementsRail fastenersCushioningPolyurethane elastomer

The invention provides a polyurethane rail tie plate which is a microporous polyurethane elastomer made from raw materials of a polyalcohol composition, an NCO-blocking modified isocyanate curing agent and a foaming agent. The invention further provides a preparation method of the polyurethane tie plate, comprising the following steps: adding the foaming agent to the polyalcohol composition; adding the modified isocyanate curing agent to a mixture of the polyalcohol composition and the foaming agent according to a certain proportion at the temperature of 25-60 DEG C; and stirring and evenly mixing the obtained mixture, casting for molding, curing, taking out and then post-curing to obtain the polyurethane tie plate. The dynamic-static stiffness ratio of the tie plate is not more than 1.5; fatigue tests for 3 million times show no damage to appearance of the tie plate and low dimensional change rate of not more than 30%, thus achieving good damping and cushioning effects and enhancing comfortableness when a train runs; and meanwhile the rail tie plate has good durability.

Owner:WANHUA CHEM BEIJING +1

Machinable composite mold

Machinable composite molds for use in making a composite structure. The mold includes a mold body having a tool surface that is shaped to provide the molded surface of the composite structure. The mold body is made up of at least one mold layer composed of a quasi-isotropic material composed of a plurality of randomly oriented fiber bundles or chips impregnated with a resin. The use of randomly oriented fiber chips allows post-cure machining of the mold body.

Owner:HEXCEL

Paste-like bone cement

ActiveUS20110313078A1High initial stabilityLow post-cureImpression capsSurgical adhesivesHeavy metal compoundCompound (substance)

A kit is provided based on two pastes designed to produce bone cement with high initial stability and therefore low post-cure. The kit includes a paste A and a paste B, wherein paste A contains (a1) a polymerizable monomer having a pH in water in the range of 5-9, (a2) a filling agent insoluble in (a1), and (a3) a barbituric acid derivative selected from the group consisting of 1,5-disubstituted barbiturates, 1,3,5-trisubstituted barbiturates, and 1,3,5-tetrasubstituted barbiturates, and paste B contains (b1) a polymerizable monomer having a pH in water in the range of 5-9, (b2) a filling agent insoluble in (b1), (b3) a peroxide soluble in (b1), (b4) a heavy metal compound insoluble in (b1) and selected from the group consisting of heavy metal salts and heavy metal complexes, and wherein at least one of the pastes A and B contains a halide salt.

Owner:HERAEUS MEDICAL

Preparation method of1,5-naphthalene diisocyanate-based polyurethane microcellular elastomer

The invention discloses a preparation method of a 1,5-naphthalene diisocyanate-based polyurethane microcellular elastomer. The preparation method comprises the following steps of: 1, dewatering polymer polyhydric alcohol by stirring under a vacuum condition at 80 to 150 DEG C; 2, under the protection of nitrogen, reacting excessive 1,5-naphthalene diisocyanate-based polyurethane with the polymer polyhydric alcohol at 100 to 150 DEG C so as to generate a prepolymer containing redundant -NCO groups; 3, performing chain extension by adopting a full pre-polymerization method, mixing a prepolymer component with a chain extender component according to a proportion, and stirring at a high speed, injecting the mixture solution into a mould of which the temperature is between 80 and 110 DEG C, and demoulding after precuring for 10 to 60 minutes, wherein the chain extender component does not contain the polymer polyhydric alcohol; and 4, post-curing the product subjected to demoulding, for 13 to 18 hours at 100 to 120 DEG C. The 1,5-naphthalene diisocyanate-based polyurethane microcellular elastomer prepared by using the method disclosed by the invention is used as a high-strength damping material for bearing dynamic fatigue, such as buffering damping components of an elevator motor and other equipment which can easily generate acting force with a certain frequency.

Owner:POLYMERCHEM

Solventless thermosetting photosensitive via-filling material

A via-filling material improves a via-filling process in manufacturing multi-layered printed circuit boards. The via-filling material is capable of undergoing UV pre-cure and thermal post-cure step. Exposed to ultraviolet light, the via-filling material filled up the two ends of the via form solid barrier films so that the inside via-filling material will not flow out during a thermal post curing process due to an lower viscosity of said material. The dual-cure treatment resolves the problems of polishing, sagging and bubbling in the via-filling process and ensures the integrity of the filling material. As a result, the via-filling material with smooth surface and a solid inside without void or hole therein formed.

Owner:YEH TODD

Method for preparing leather sample observed by metallurgical microscope

InactiveCN102305736AFast penetrationFully infiltratedPreparing sample for investigationFiberMicroscopic observation

The invention relates to a method for preparing a leather sample observed by a metallurgical microscope, and belongs to the technical field of leather inspection. The method comprises the following steps of: (1) adding a promoter into an unsaturated polyester resin, stirring, adding a curing agent, stirring, standing, and discharging the mixed air to obtain an immobilized resin; (2) immersing a sample into the immobilized resin, and curing to obtain a cured sample; (3) grinding both ends of the cured sample until the ends are flat, fixing in a mould, injecting the immobilized resin into the mould, curing, demoulding, and post-curing to obtain a post-cured sample block; and (4) grinding and polishing the post-cured sample block by using abrasive paper to obtain the leather sample observed by the metallurgical microscope. In the method, the unsaturated polyester resin is used as a main ingredient of the immobilized resin, and operation steps are designed according to a capillary action principle to ensure that the immobilized resin can be quickly and fully permeated into the leather sample, so the adhesion and deformation of section fiber of leather are furthest avoided.

Owner:QILU UNIV OF TECH

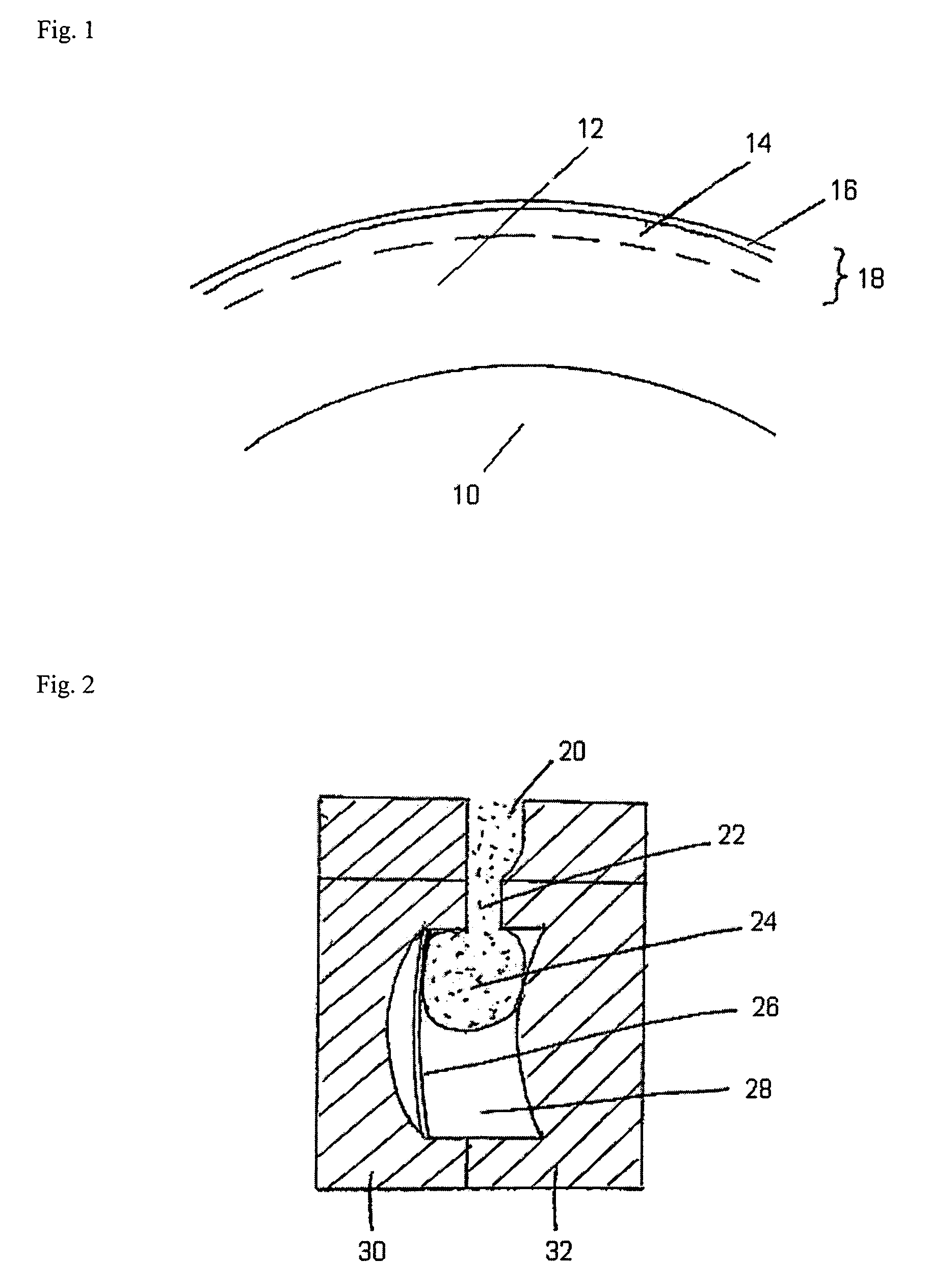

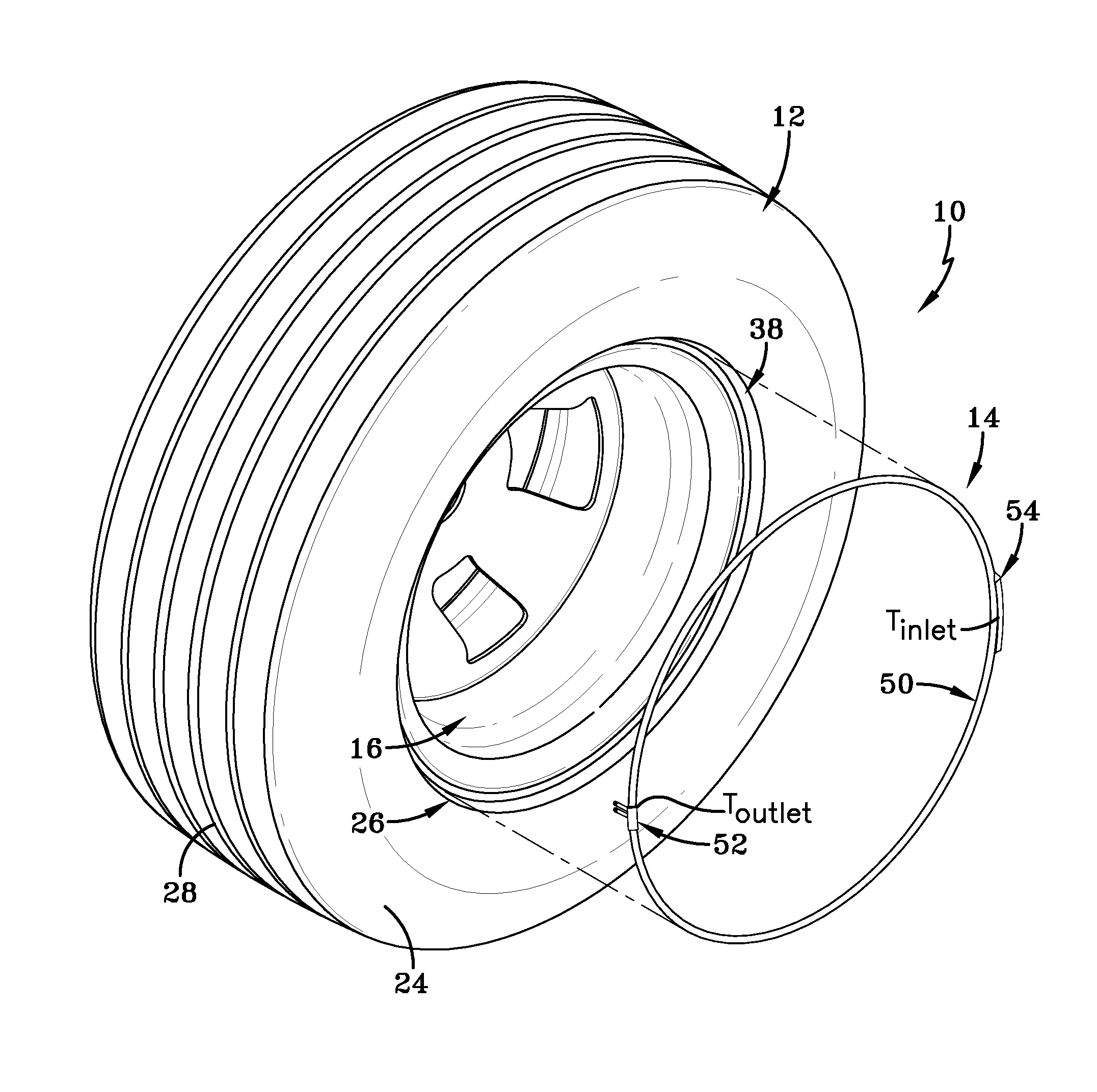

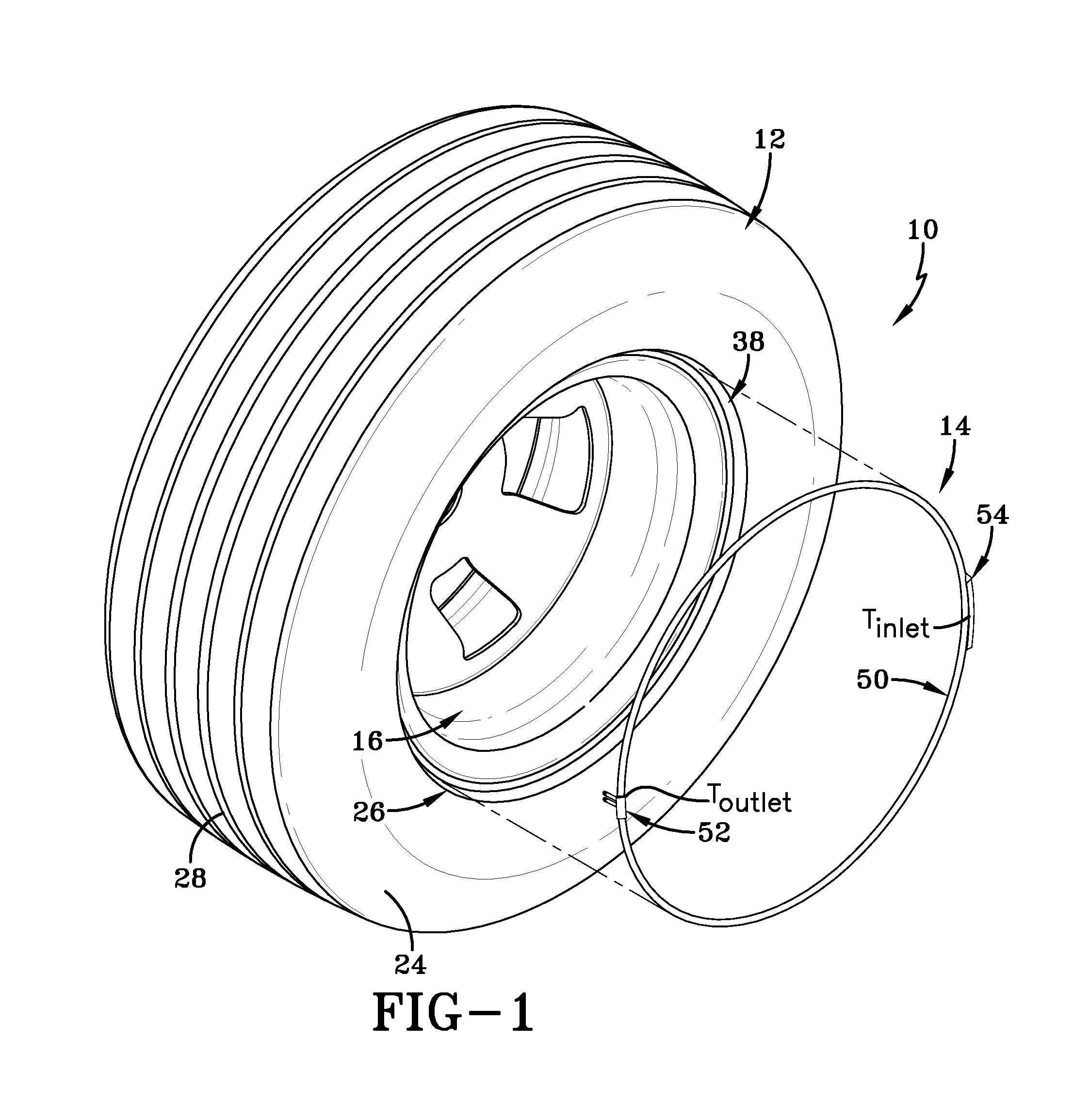

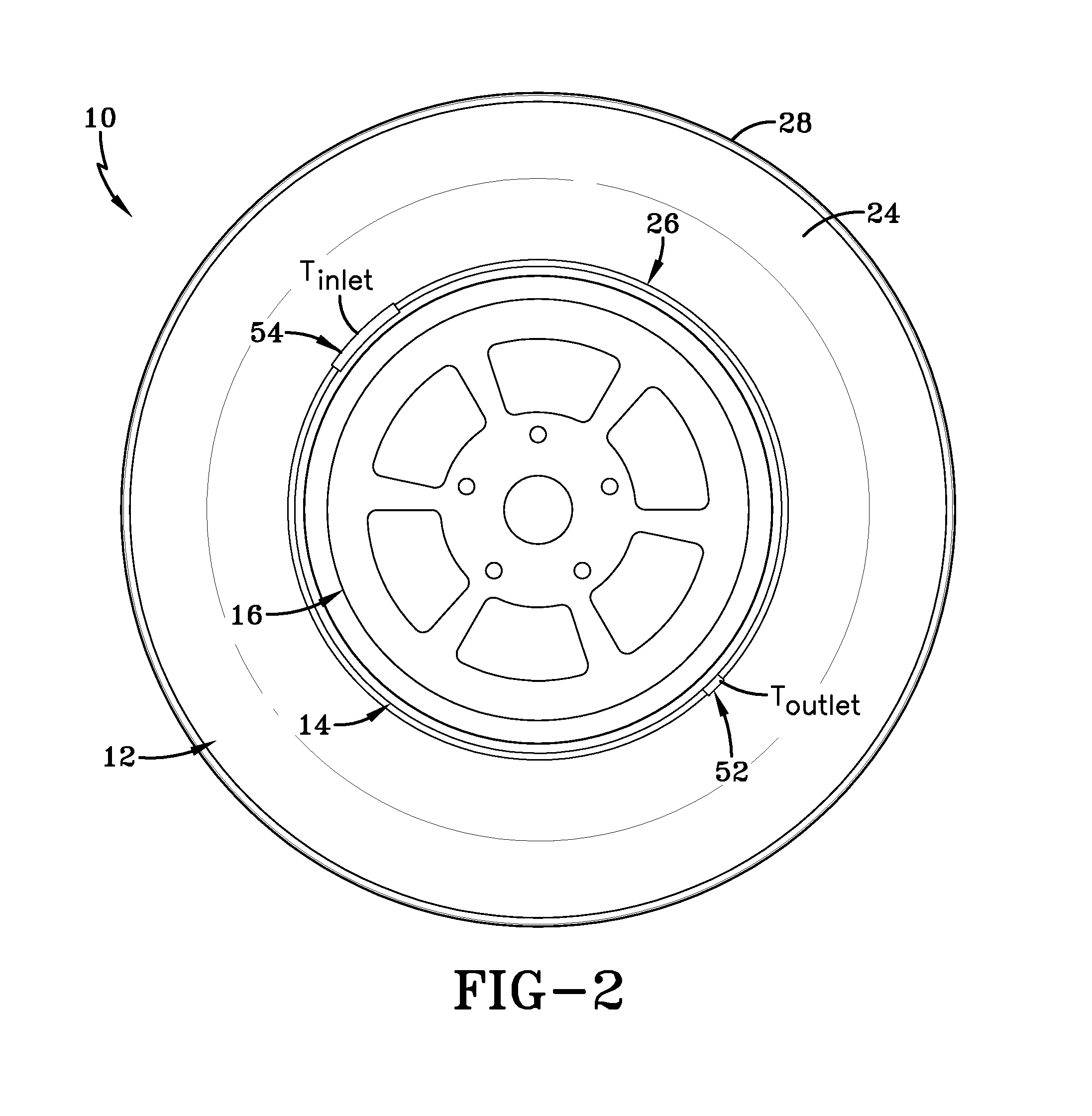

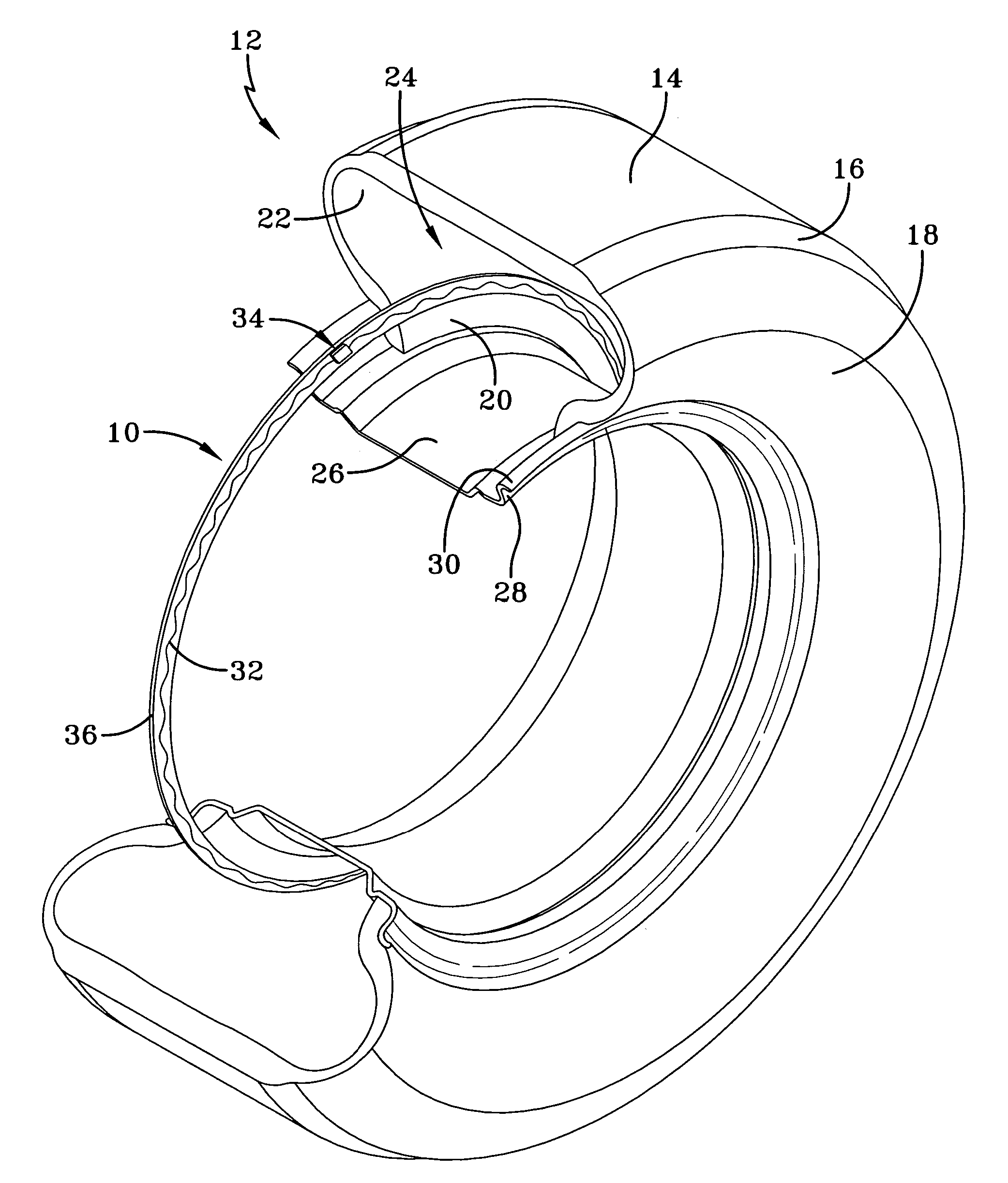

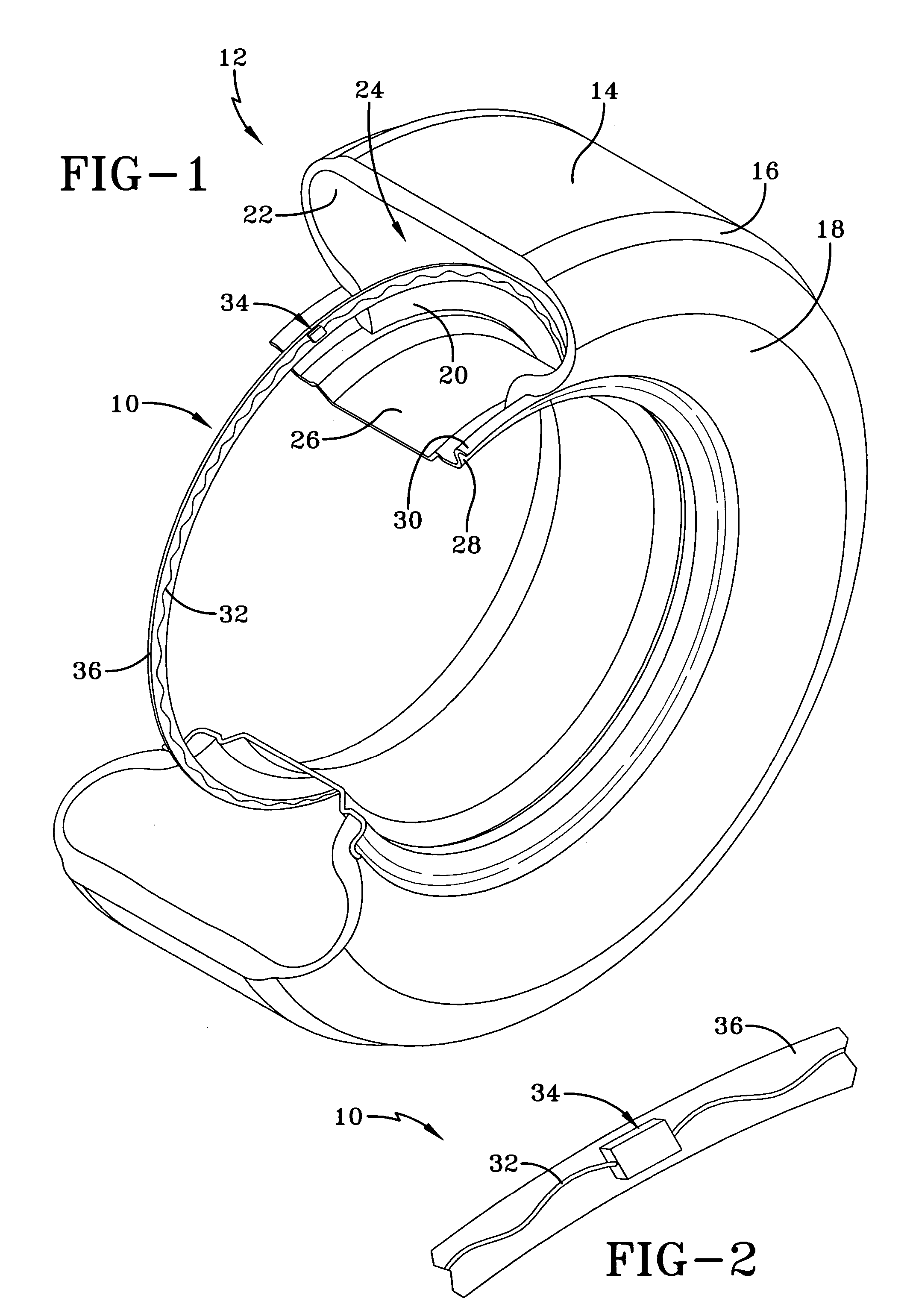

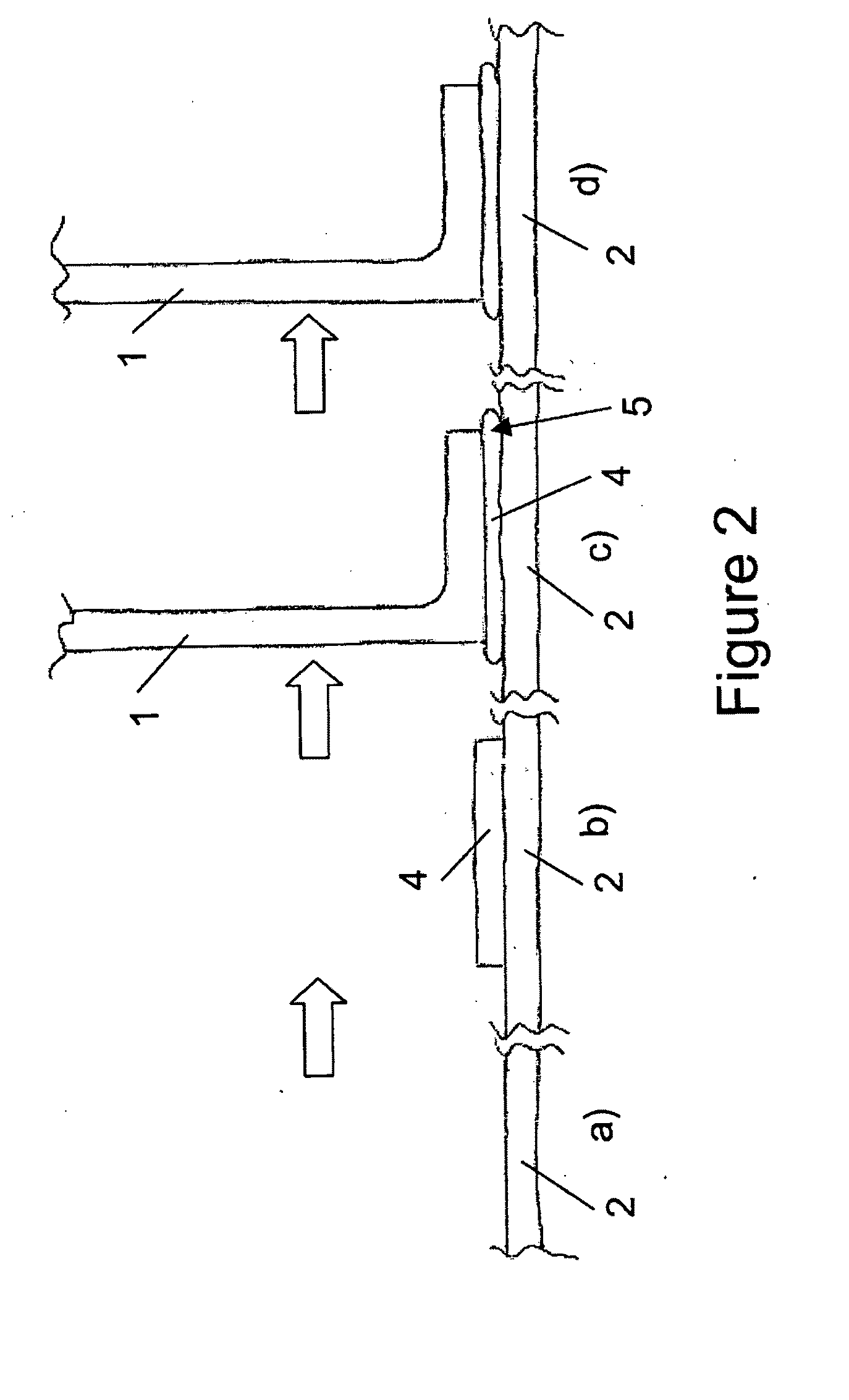

Method of manufacturing a self-inflating tire

Owner:THE GOODYEAR TIRE & RUBBER CO

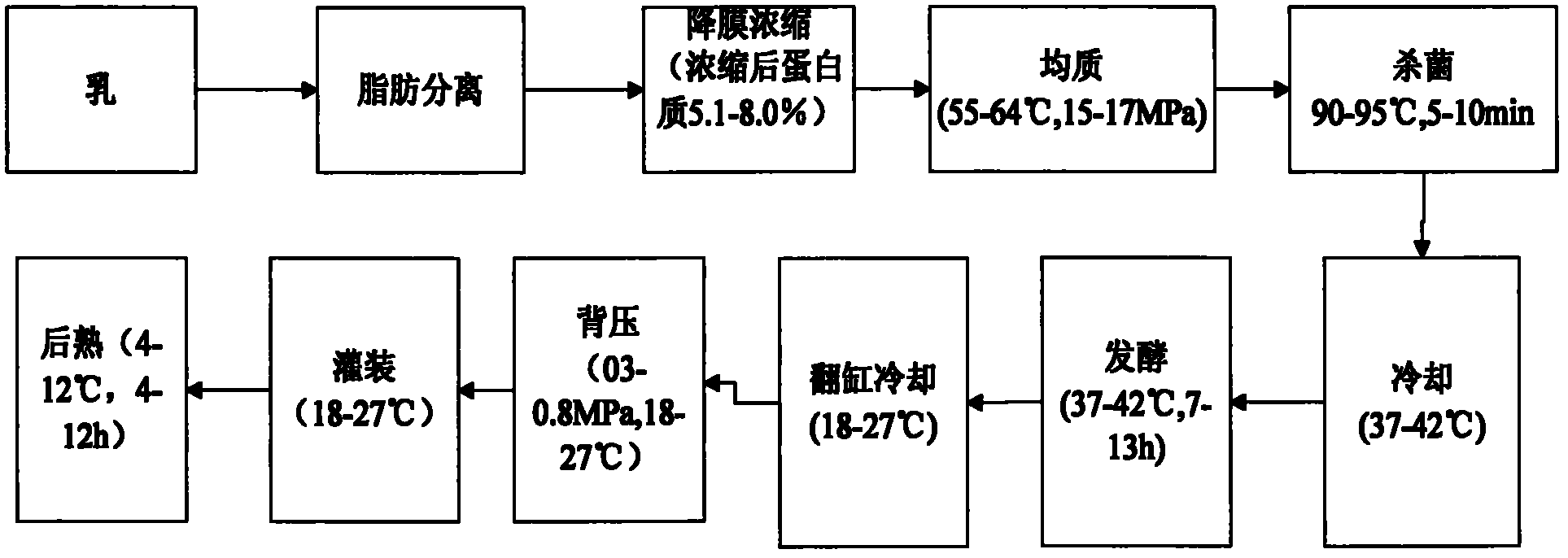

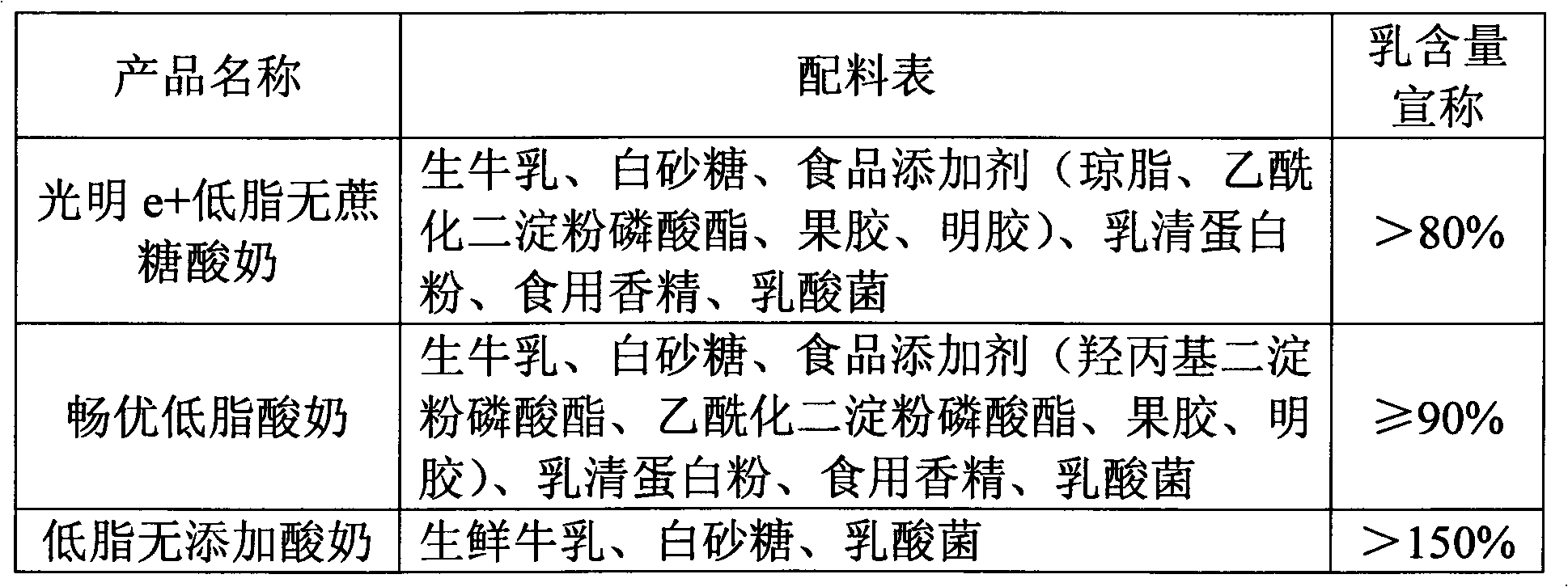

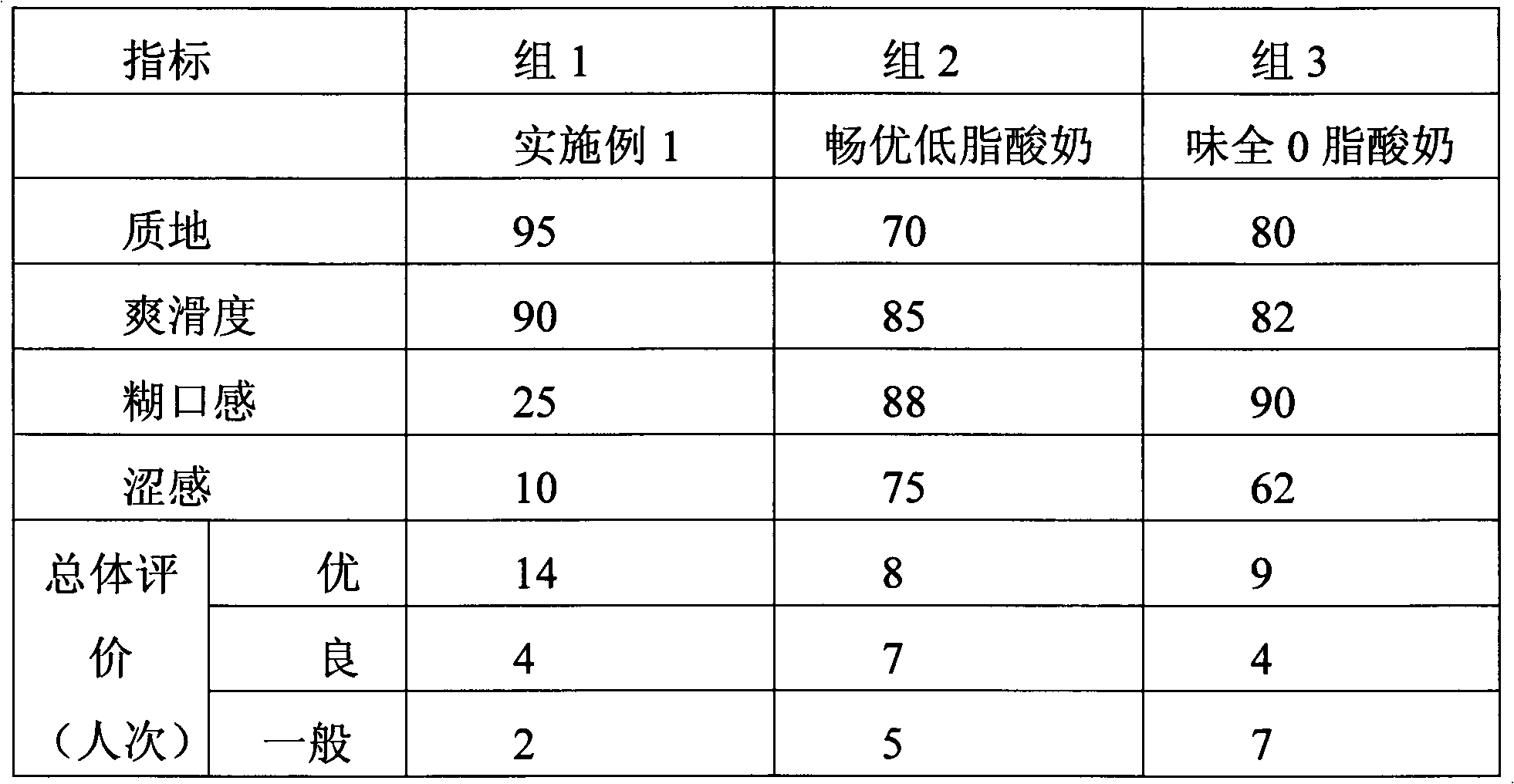

Low-fat additive-free yogurt and preparation method thereof

The invention discloses low-fat additive-free yogurt and a preparation method thereof. The low-fat additive-free yogurt includes main ingredients such as raw milk and fermenting agent, and raw milk is degreased, concentrated, fermented with fermenting culture, cooled, counterbalanced, filled and post-cured to be made into the additive-free yogurt with low content of fat. According to the low-fat additive-free yogurt and the preparation method thereof, by increasing the content of proteins inside the raw milk and prolonging the fermentation time, partial proteins are modified, a substance with the structure and taste being similar to that of the fat is generated, and a taste of smoothness and coolness is applied to the low-fat yogurt; and through the counterbalancing processing technique, protein particles in the yogurt can be eliminated, an exquisite taste is applied to the yogurt, and the viscosity of the yogurt is greatly improved by utilizing the yogurt post-curing technique. On the premise that no external fat substitute is used and no additive such as a thickening agent and essence is utilized, the low-fat additive-free yogurt with a taste being similar to that of whole fermented milk is developed only by improving the raw material and yogurt manufacturing technique conditions.

Owner:BRIGHT DAIRY & FOOD

Method and assembly of sensor ready tires

InactiveUS6978669B2Electric signal transmission systemsAntenna supports/mountingsEngineeringPost cure

Apparatus and method for post-cure application of electronics to a tire includes the steps: forming an antenna wire into a predetermined shape having first and second free ends; creating a transponder splice region between the first and second free antenna ends, incorporating transponder splice region identification indicia; curing the antenna wire into a tire during a tire manufacturing procedure; locating the transponder splice region by means of the transponder splice region identification indicia; and splicing the antenna wire ends to a sensor in a post-cure procedure. The transponder splice region identification indicia may include sandwiching a junction box or the overlapped ends of the antenna wire or wires between layers of select material that will not bond to the tire inner liner or antenna cover compounds and incorporating an air pocket in the sandwiched region. Alternatively, or in conjunction with the air pocket, a unique cover layer differentiated by color or other discernible means may be utilized to seal and cover the transponder splice region.

Owner:THE GOODYEAR TIRE & RUBBER CO

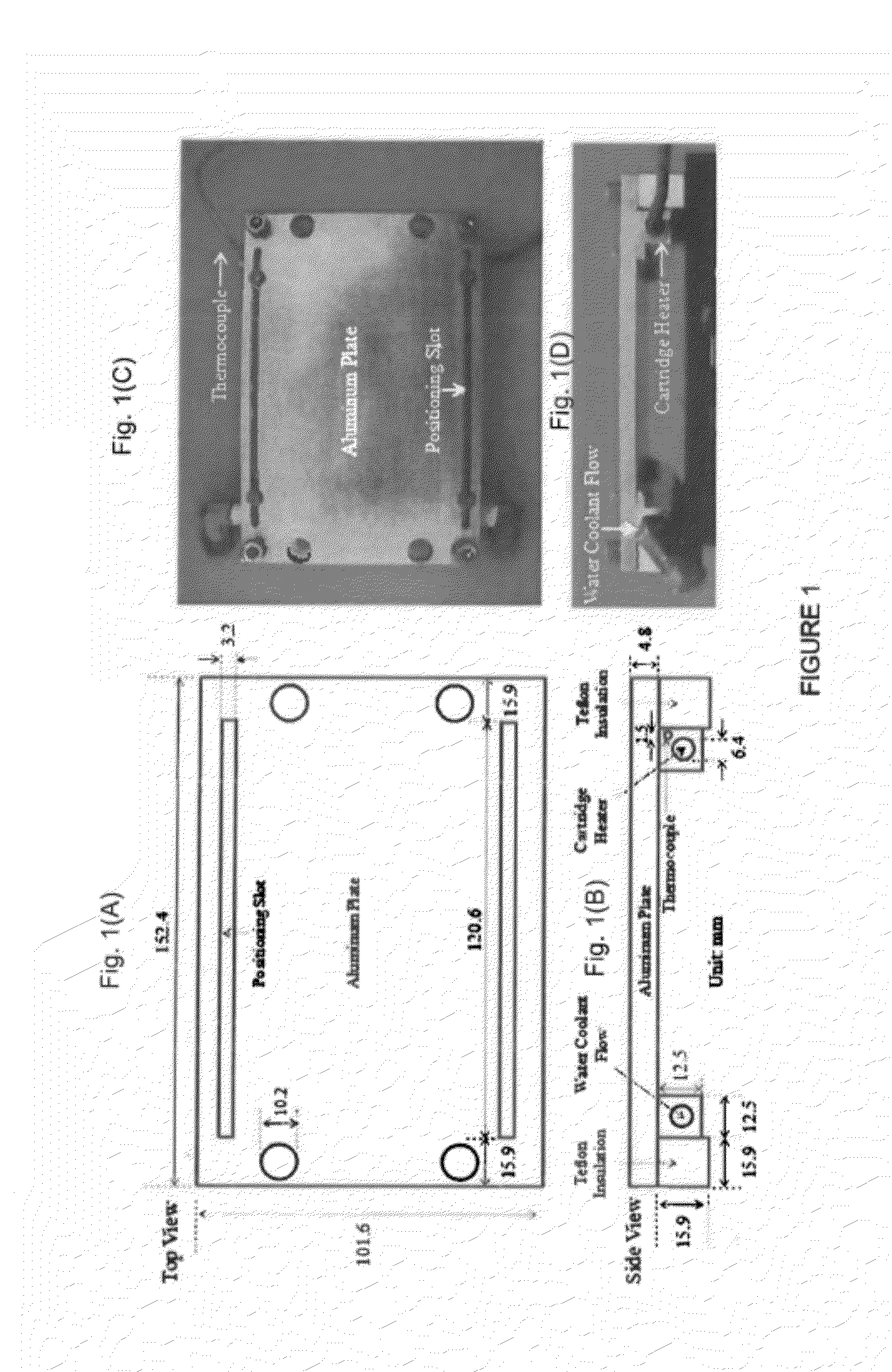

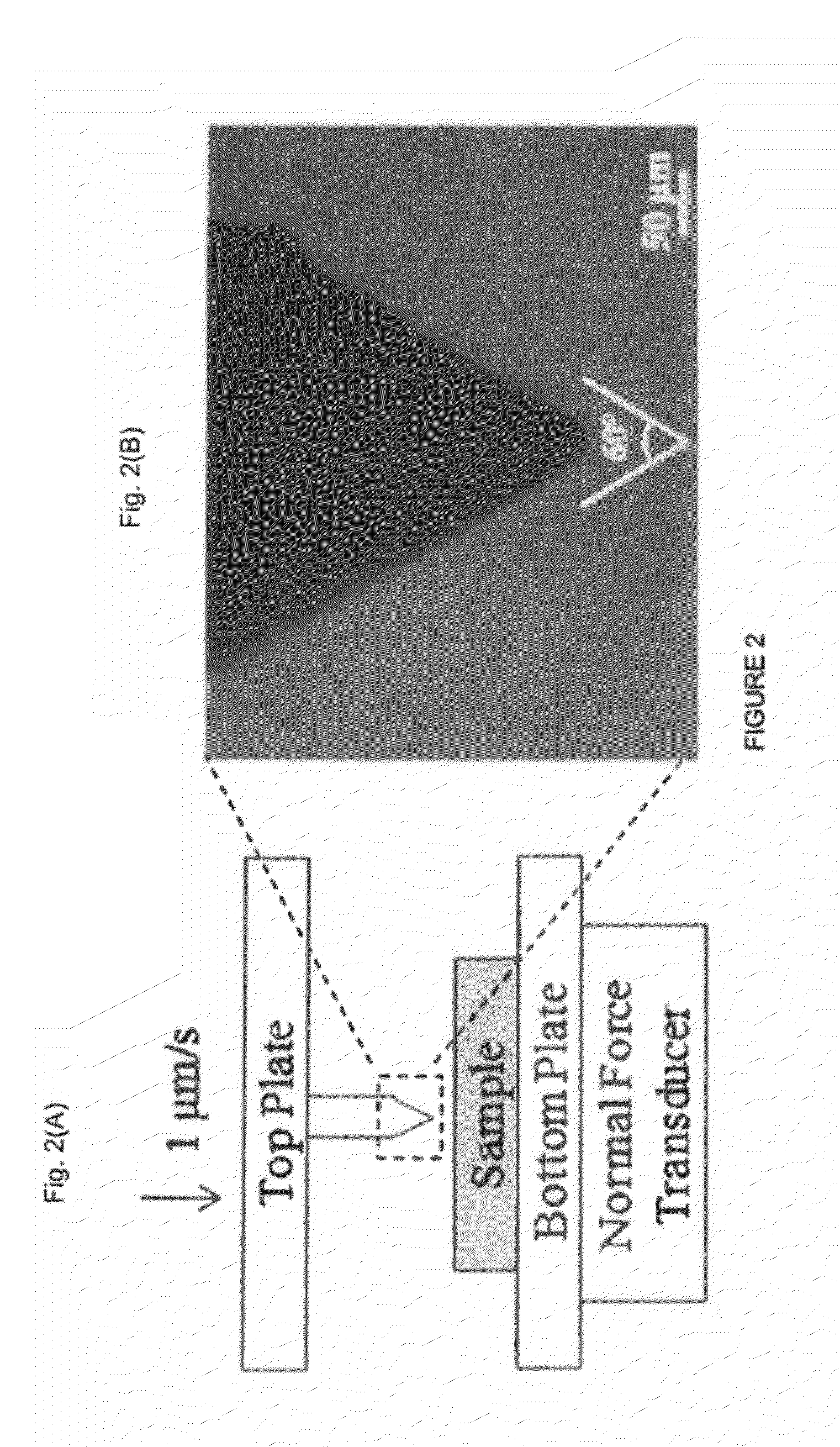

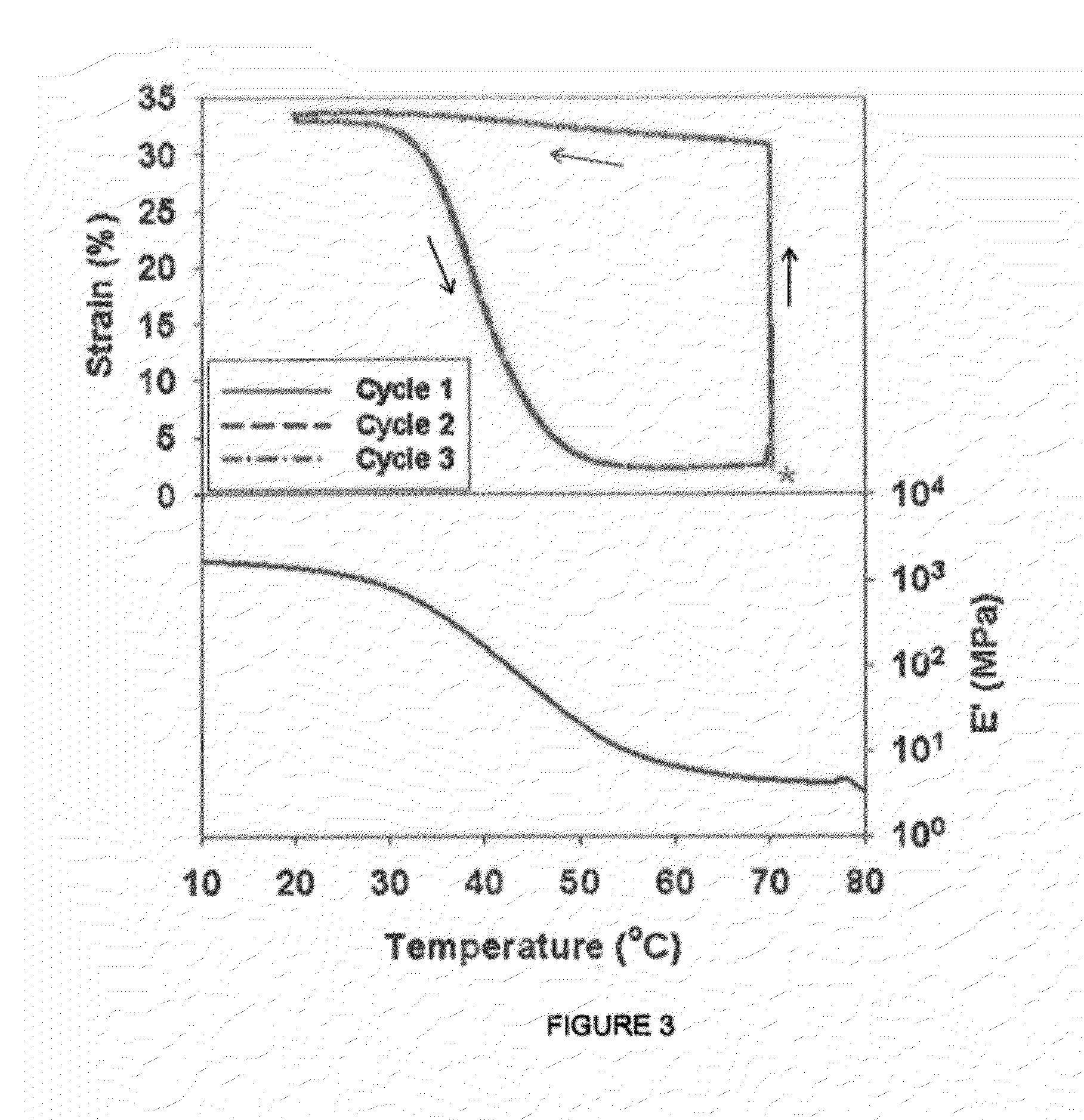

Functionally Graded Shape Memory Polymer

InactiveUS20120213969A1Less exposure timeLow TgImpression capsSynthetic resin layered productsOptical measurementsGlass transition

A functionally graded shape memory polymer (SMP) that has a range of transition temperatures that are spatially distributed in a gradient fashion within one single article. The SMP is formed by post-curing a pre-cured glassy SMP in a linear temperature gradient that imposes different vitrification temperature limits at different positions along the gradient. Utilizing indentation-based surface shape memory coupled with optical measurements of photoelastic response, the capability of this material to respond over a wide range of thermal triggers is correlated with the graded glass transition behavior. This new class of SMP offers great potential for such applications as passive temperature sensing and precise control of shape evolution during a thermally triggered shape recovery.

Owner:SYRACUSE UNIVERSITY

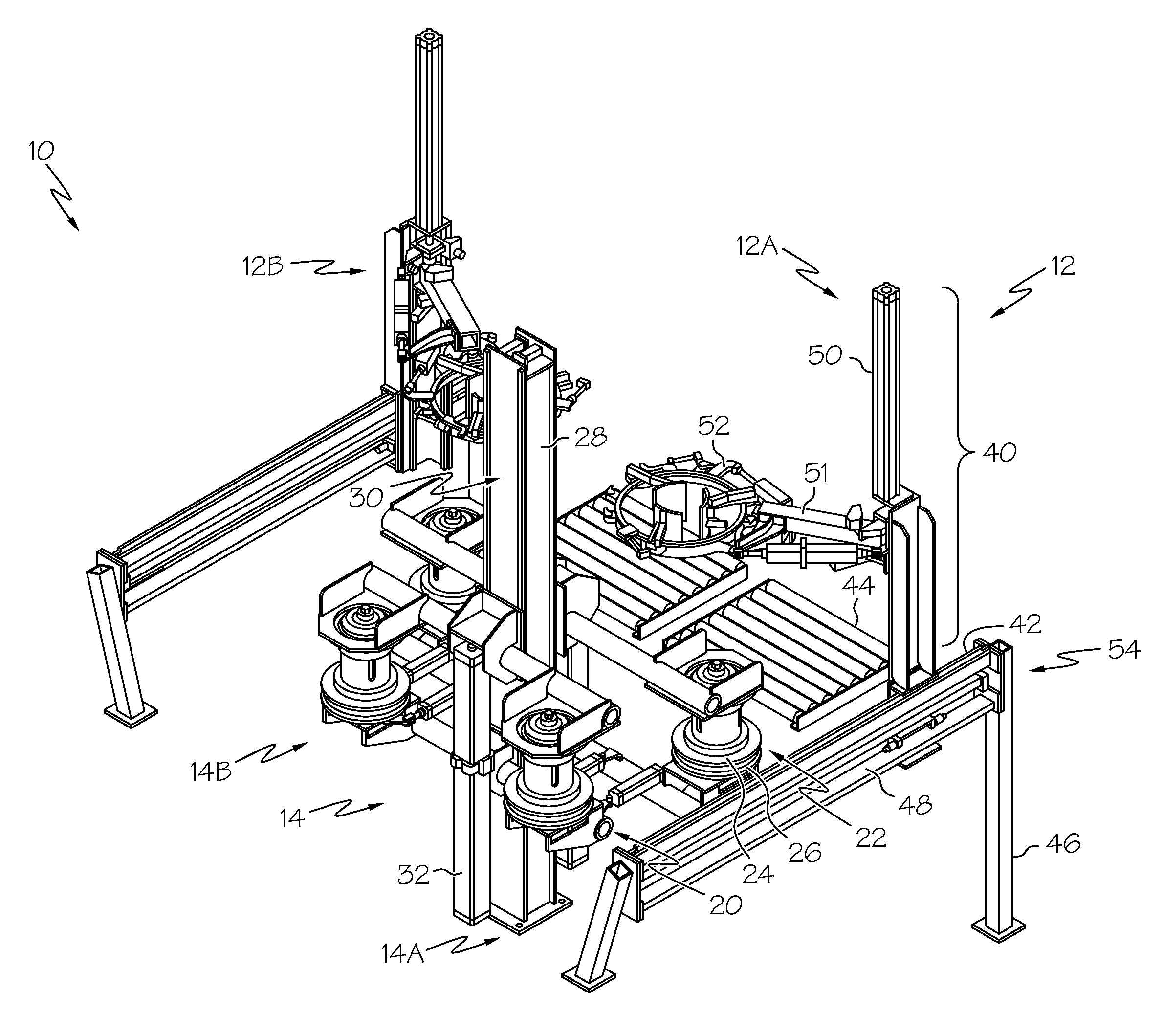

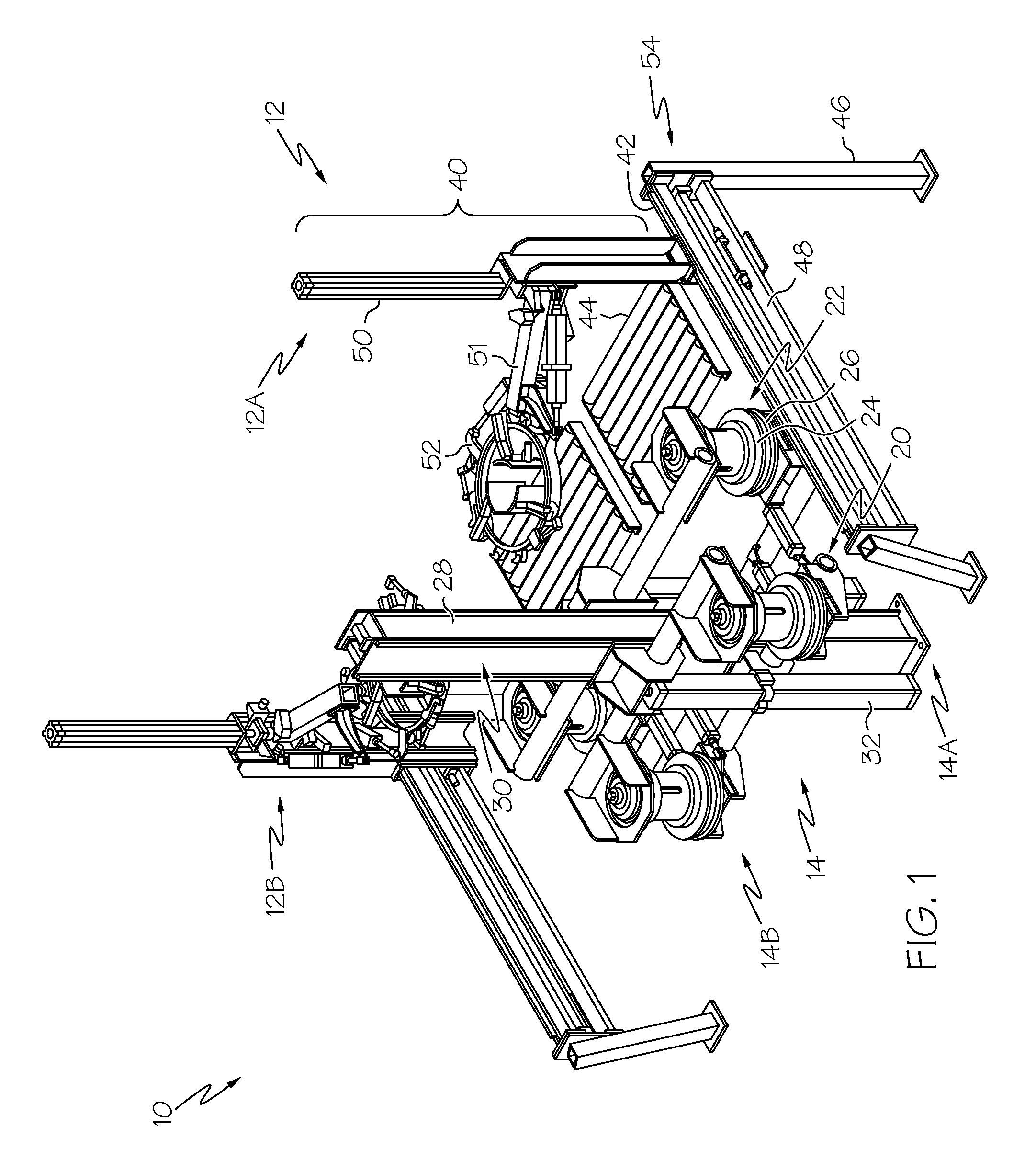

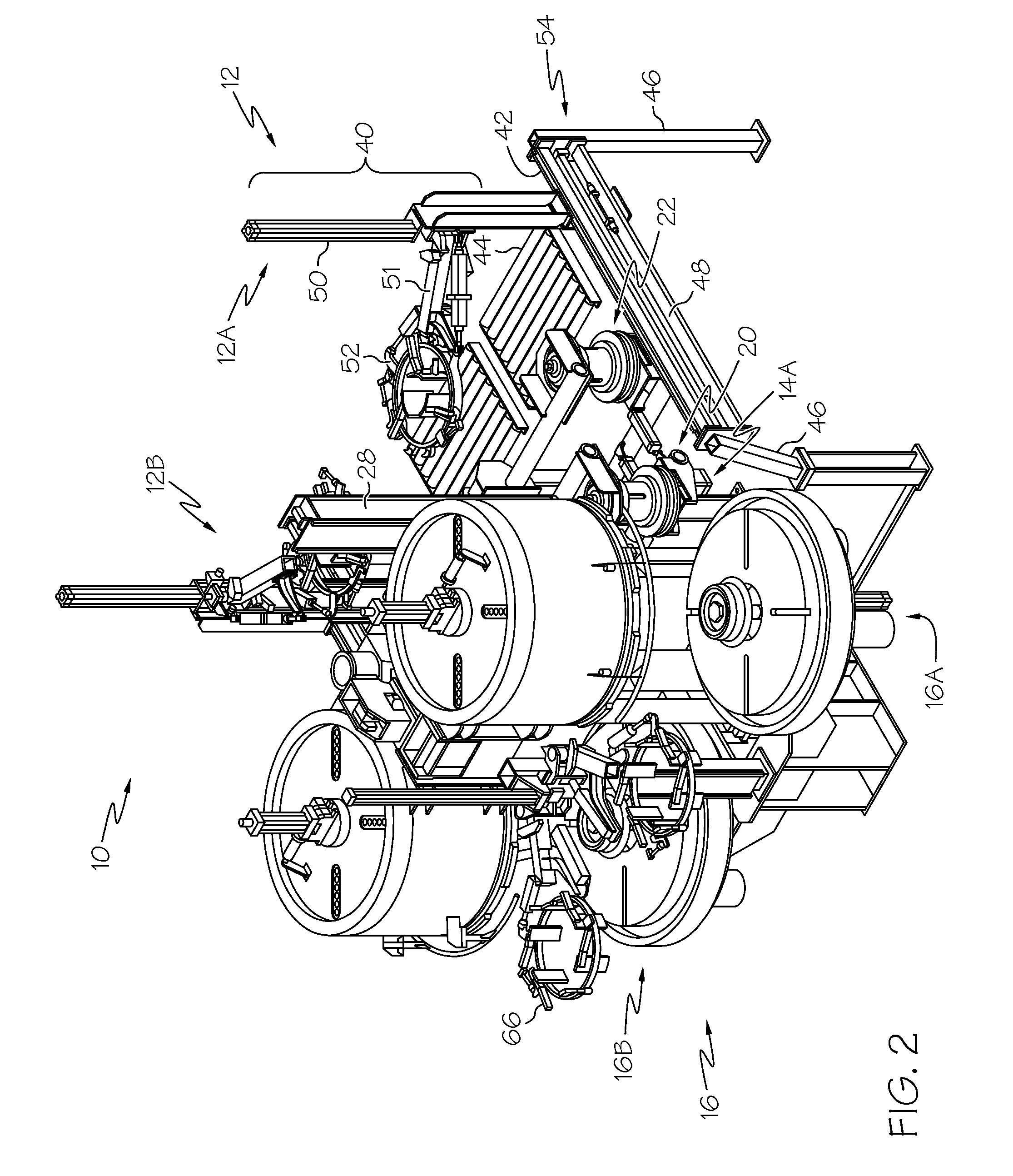

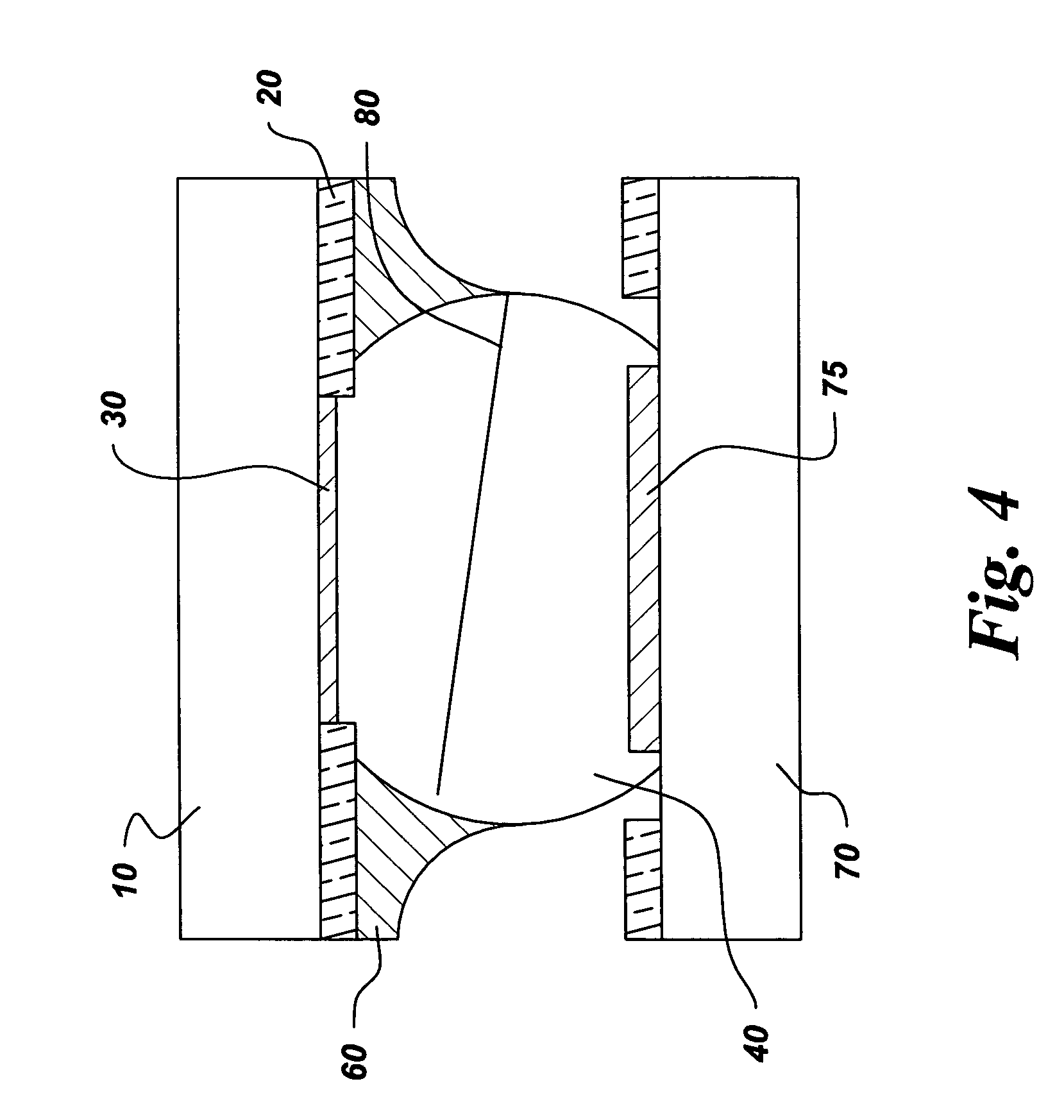

Combination loader and post cure inflator

A combination loader and post cure tire inflator for use with a tire press is provided. A post cure inflator for inflating and curing vulcanized tires includes a plurality of inflator stations with each inflator station including a pair of axially aligned, vertically separable tire inflating chuck rings. A loading apparatus includes a loading arm movable along a linear track relative to the plurality of inflator stations to load and unload each vulcanized tire in a selected one of the plurality of inflator stations without rotating the vulcanized tires in a turnover operation.

Owner:MCNEIL & NRM

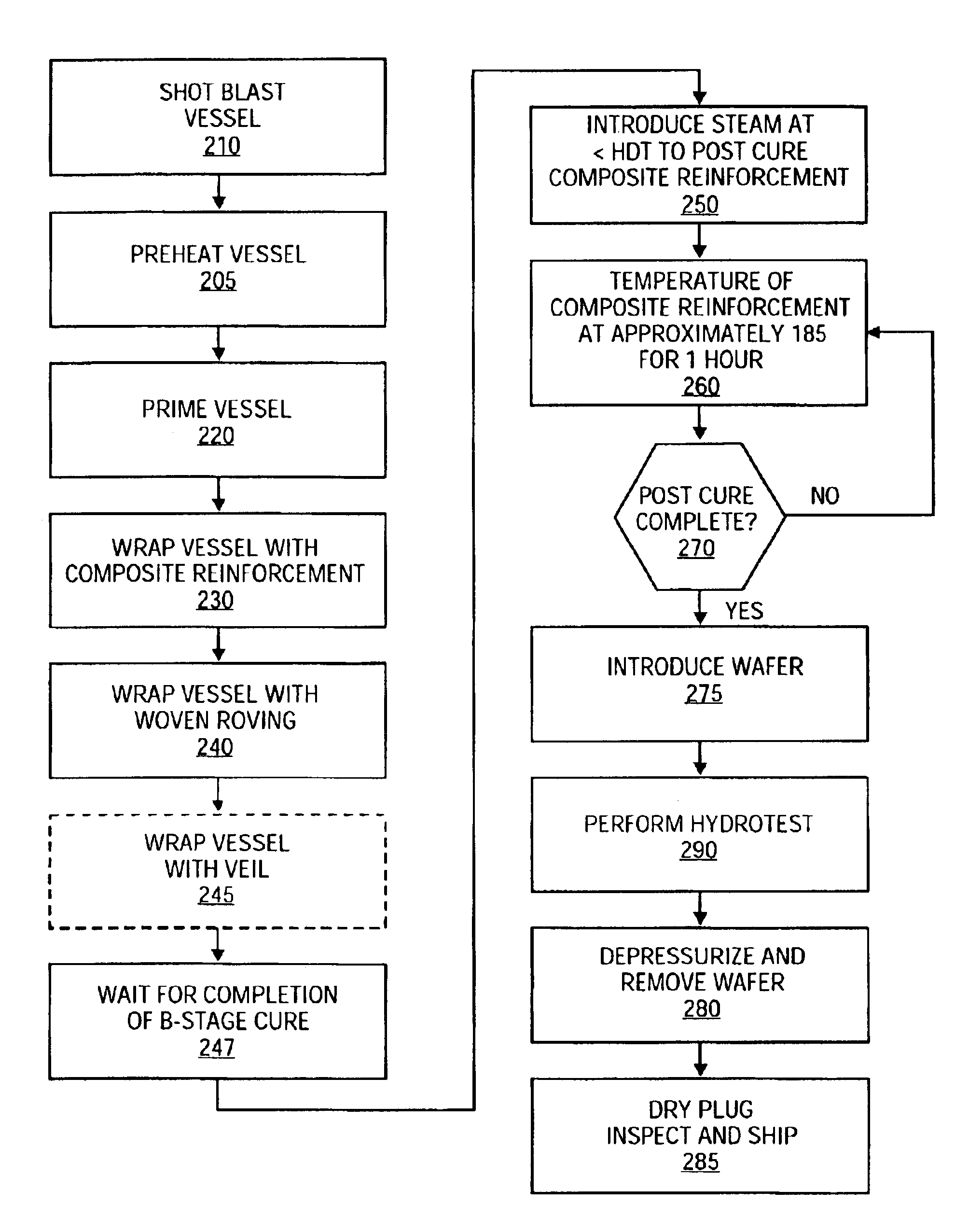

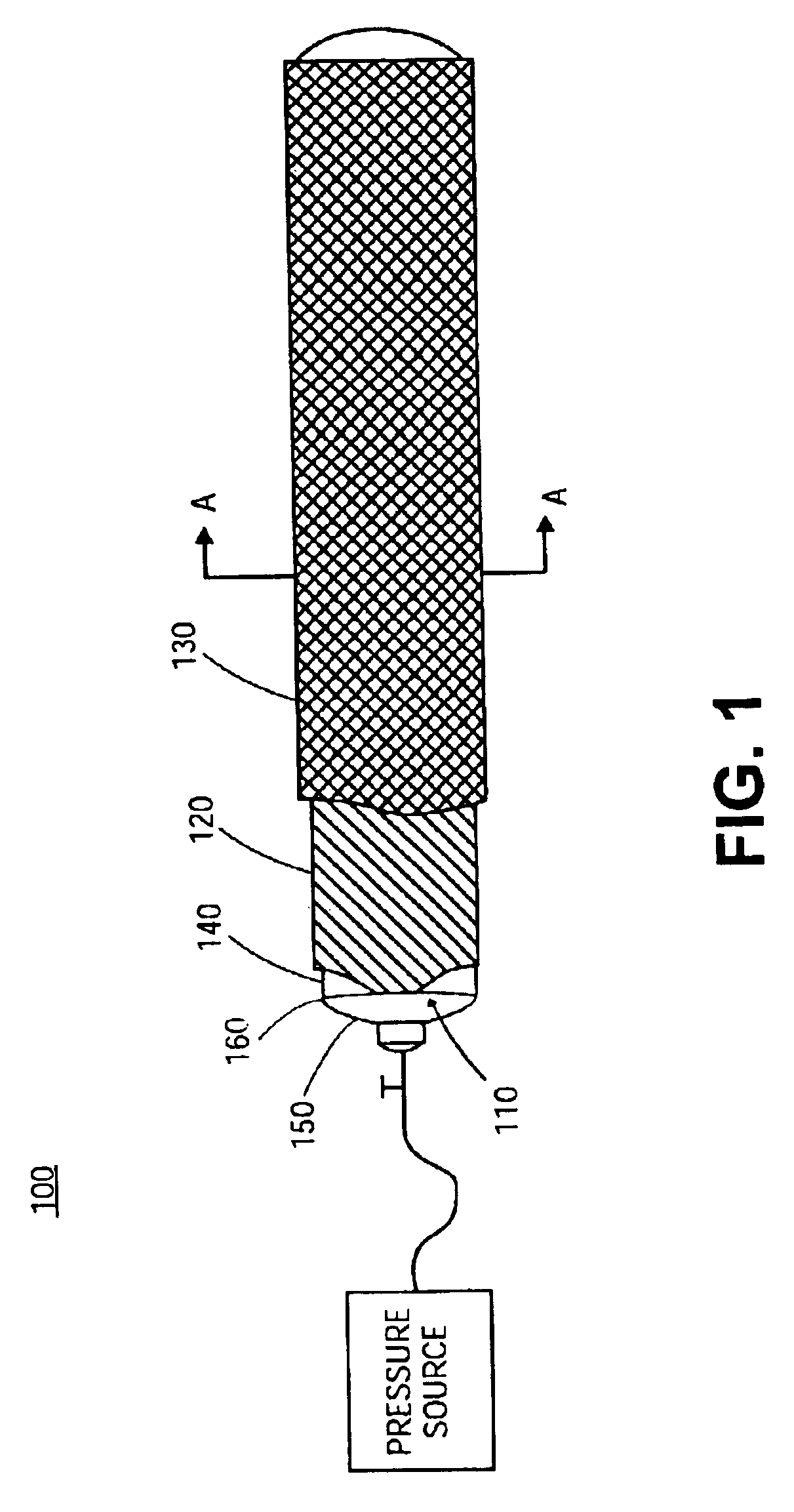

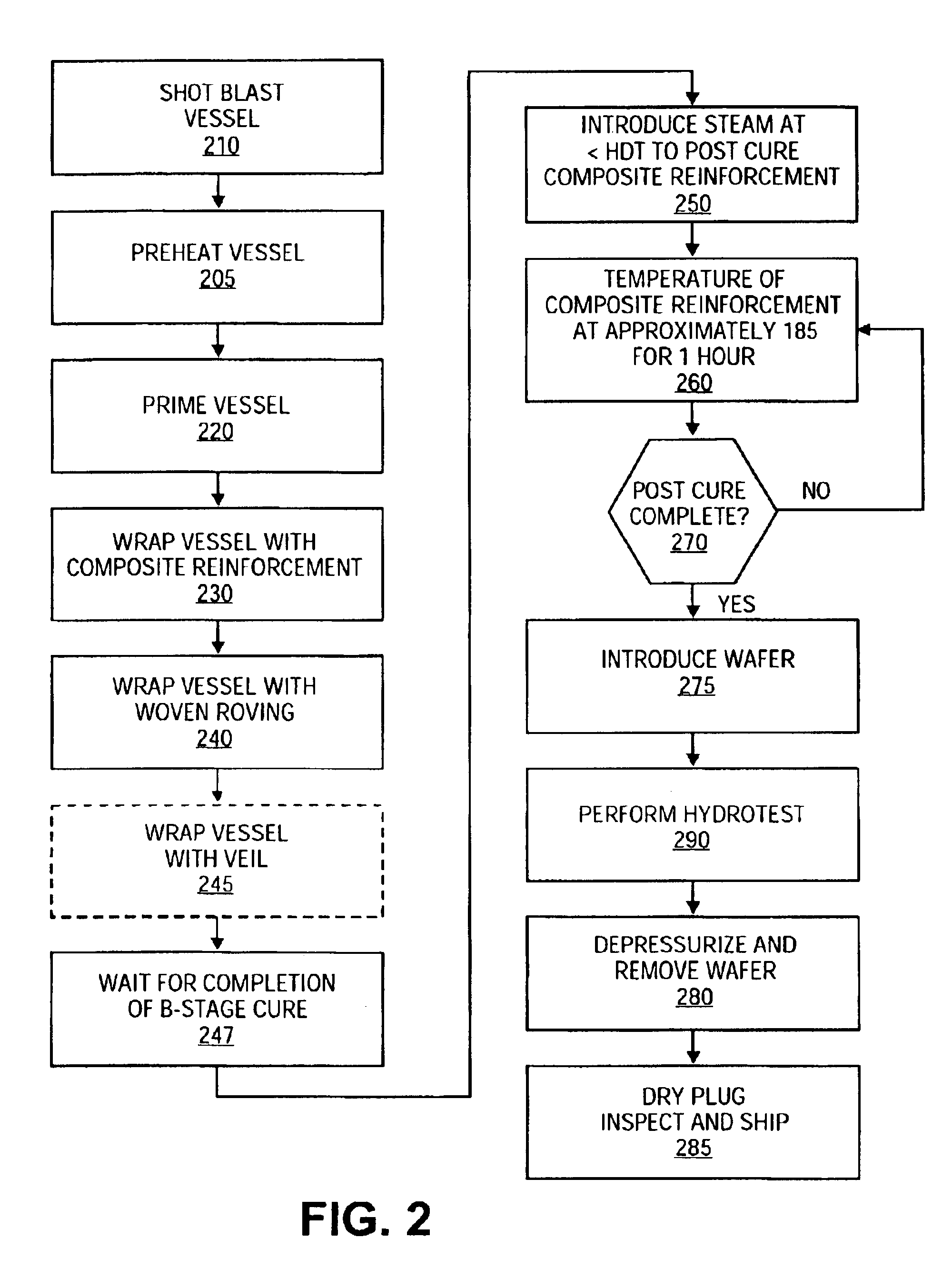

Composite reinforced gas transport module

A system is disclosed for the manufacture and use of a composite reinforced gas transport module ("GTM"). A metal shell of the system is wrapped circumferentially with a composite reinforcement, the composite reinforcement is post cured and the metal shell is then pressurized beyond the yield point of its material to load the composite reinforcement. The system is then brought to ambient temperature. The expansion deformation of the metal shell due to pressurization beyond the yield point results in a loading of the metal shell by the cured composite reinforcement at ambient temperature. Thus, a negative hoop stress condition is created in the metal shell at ambient to reduce the hoop stresses created during subsequent pressured operation.

Owner:NCF INDS

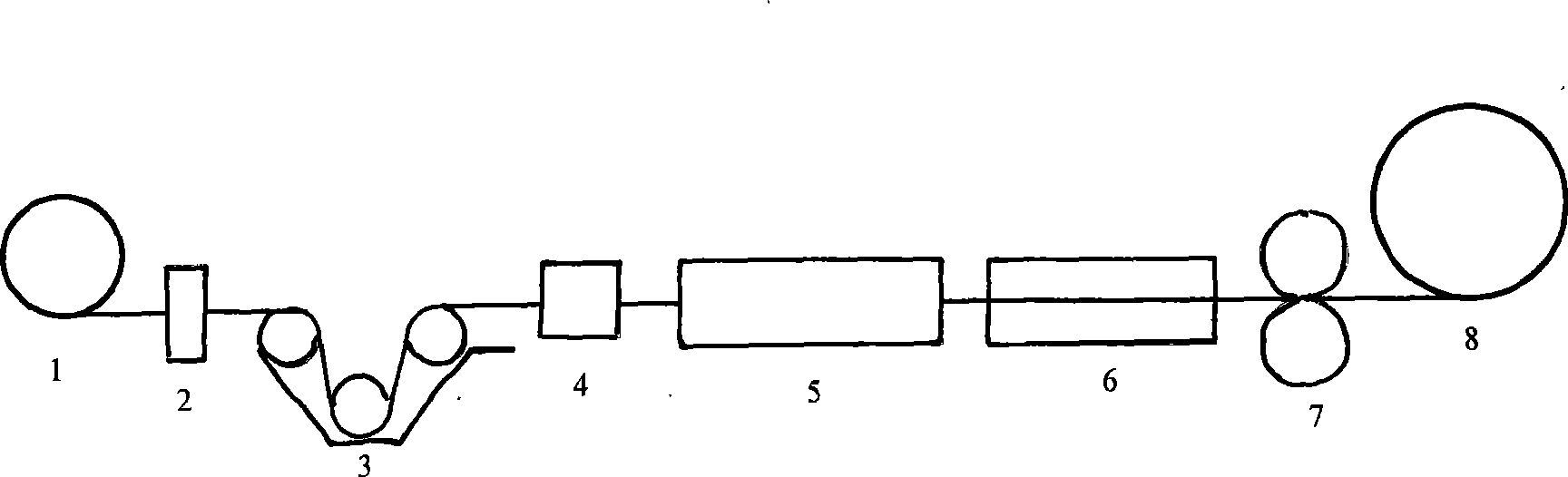

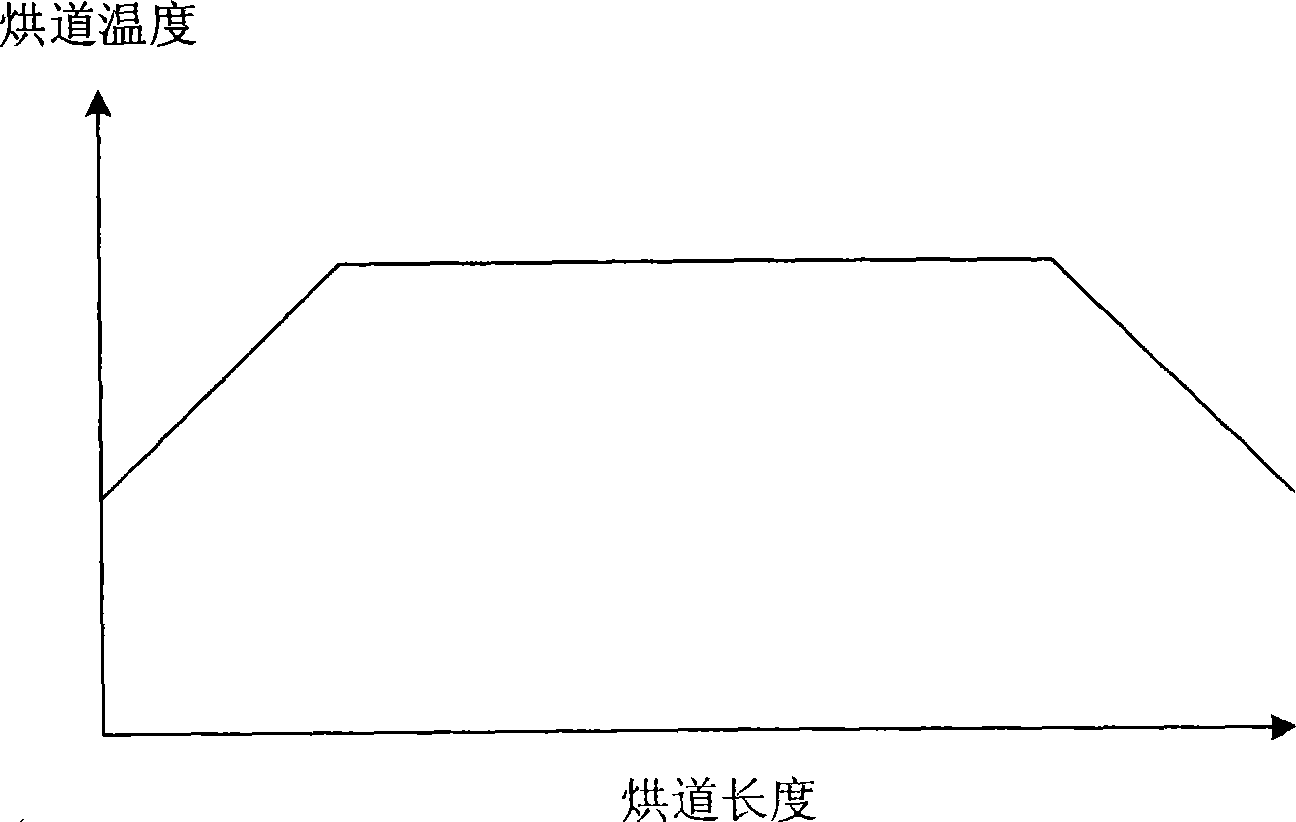

Composite material pulling and extruding molding method by heating baking-path to solidify

InactiveCN101508176ASolve the problem of dead mold caused by excessive frictional resistanceSolve the difficulties that are difficult to achieve pultrusion productionYarnPost cure

The invention discloses a pultrusion molding method for a drying tunnel-assisted post-cured composite material, which belongs to the technical field of composite material molding. The method is characterized by comprising the following steps that: (1) reinforced fibers are released through a yarn releasing device and enter a steeping vat through a guide device; (2) fibers impregnated with resin are cured in a hot mold into a gel state; (3) the gel-like composite material product out of the mold is cured in a heating drying tunnel; and (4) the cured composite material is coiled by a coiling device under the traction of a traction unit. The method solves the problem of the prior method that the friction in the curing area of a pultrusion mold is overlarge to cause dead mold, and is particularly applicable to pultruded products with a large specific surface area.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

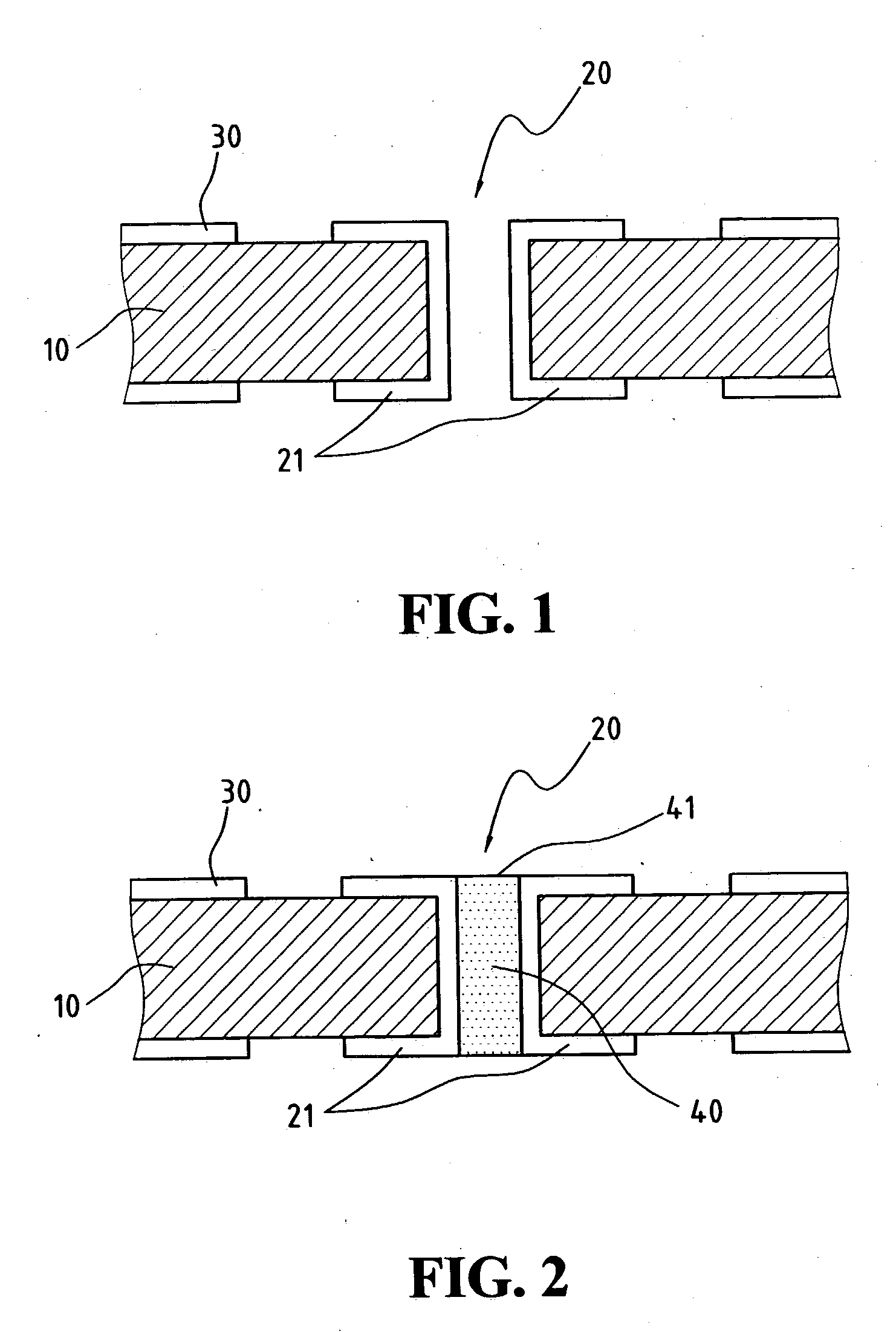

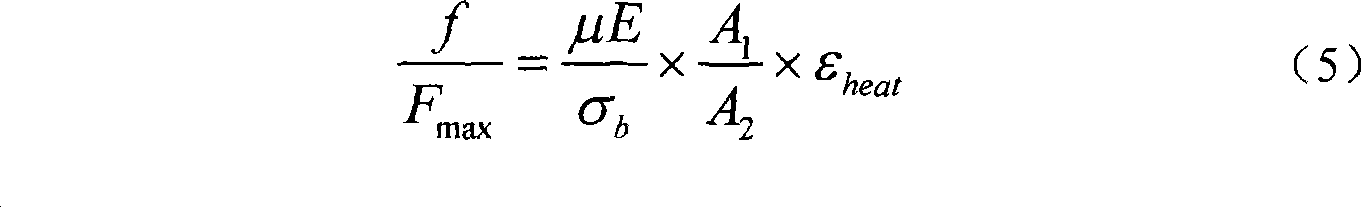

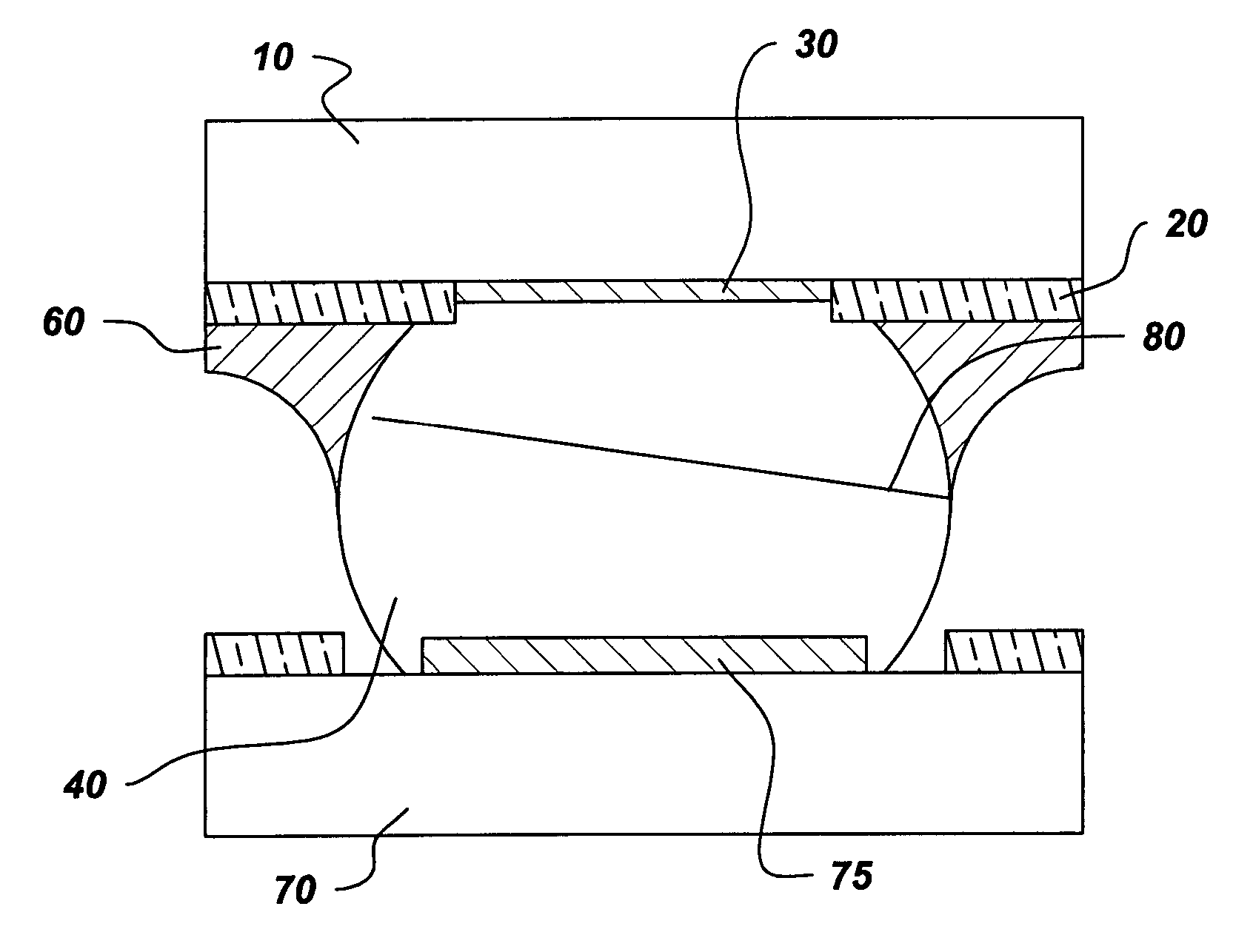

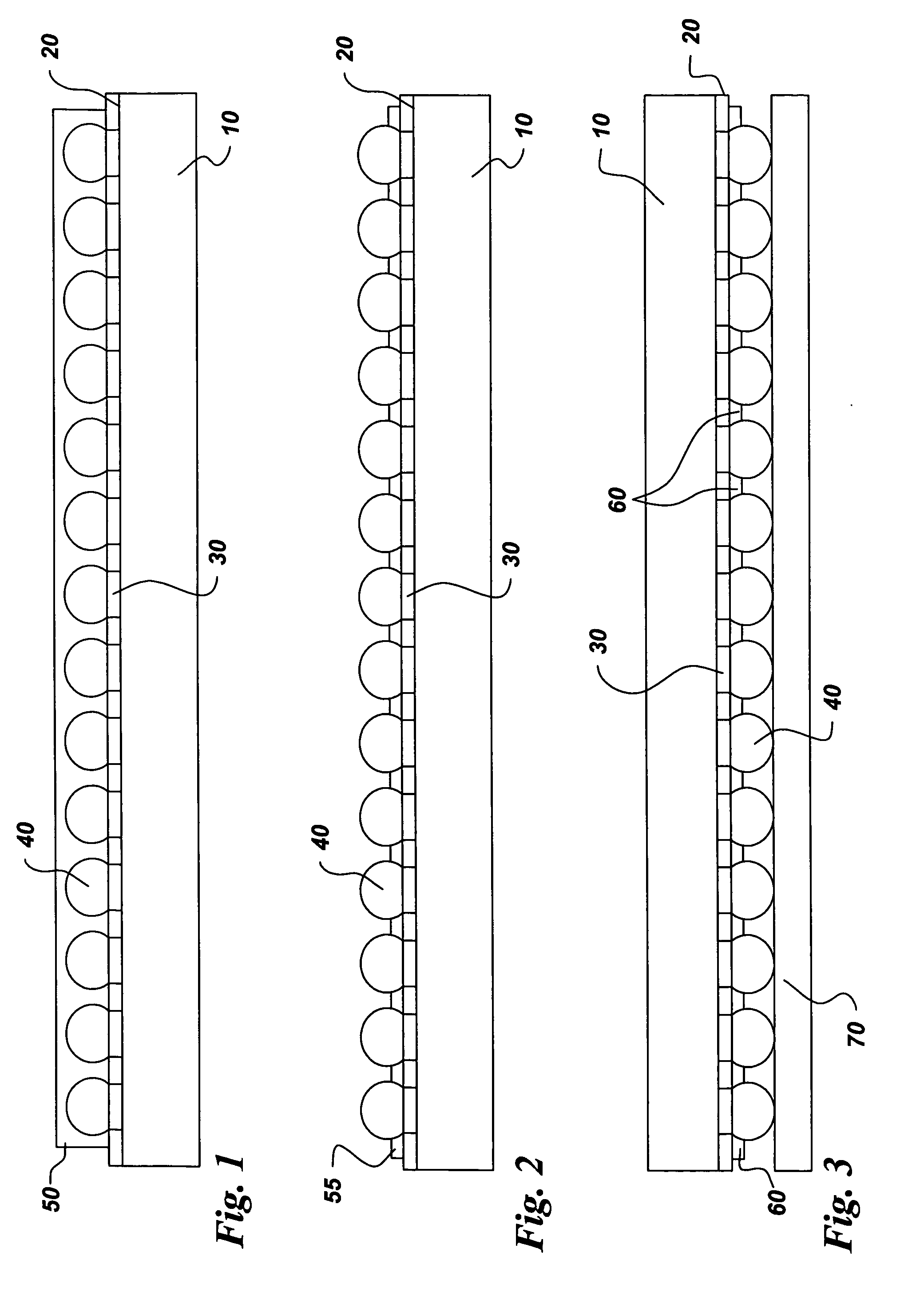

Method of forming electronic devices

InactiveUS20060192280A1Final product manufactureSemiconductor/solid-state device detailsPolymer scienceInterconnection

A method of forming polymer reinforced solder-bumped containing device or substrate is described. The method comprises the following steps: providing a device or substrate having at least one solder bump formed thereon; coating a predetermined portion of the device or substrate with a curable polymer reinforcement material forming a layer on the device or substrate, partially curing the curable polymer reinforcement material to provide a solder-bumped structure comprising a partially cured polymer reinforcement material, and, making a connection between the solder-bumped structure formed and a printed circuit board or array of attachment pads and fully curing the partially cured polymer reinforcement material to provide a reinforced interconnection. Full curing of the polymer reinforcement material may take place either during the “reflow step” or subsequent to it (post-curing).

Owner:GENERAL ELECTRIC CO

Formula and production process of dairy cow protein particle feed

InactiveCN101731485AImprove utilization efficiencyIncrease expansionAnimal feeding stuffFiberAntioxidant

The invention relates to a formula of dairy cow protein particle feed which comprises the following components by weigh percent: 15-40 percent of energy feed, 40-80 percent of protein feed, 0-9 percent of oil and fat, 0-18 percent of amino acid, 0-2.3 percent of vitamin, 1.6-2 percent of calcium carbonate, 0-1 percent of adhesive, 0-0.1 percent of antioxidant and 0-0.3 percent of antimold agent. The production process of the dairy cow protein particle feed comprises the following steps: a, weighting the components according to the weight percent thereof; b, grinding the components; c, mixing the ground components; d, tempering the mixture; e, granulating the mixture; f, post-curing the granules; g, drying the granules; and h making the granules into the dairy cow protein particle feed which has the diameter of less than 4 mm and the length of 1 to 2 times of the diameter and contains the dry matter of more than 88 percent. The dry matter contains the crude protein of more than 20 percent and the crude fiber of less than 18 percent. The dairy cow protein particle feed can be kept stable in water for more than 5 min and has the dispersion rate of less than 12 percent in water. The protein in the dairy cow protein particle feed is less degraded by the rumen microorganisms, the rumen bypass efficiency of the protein is improved, the need of the essential amino acids in the nutrient of protein in the dairy cow body is balanced, the efficiency of using the dairy cow protein particle feed by the dairy cow is increased, the health status of the dairy cow body is improved and the pollution of the nitrogen in the excrement of the dairy cow to the environment is reduced.

Owner:ZHEJIANG KESHENG FEED CO LTD

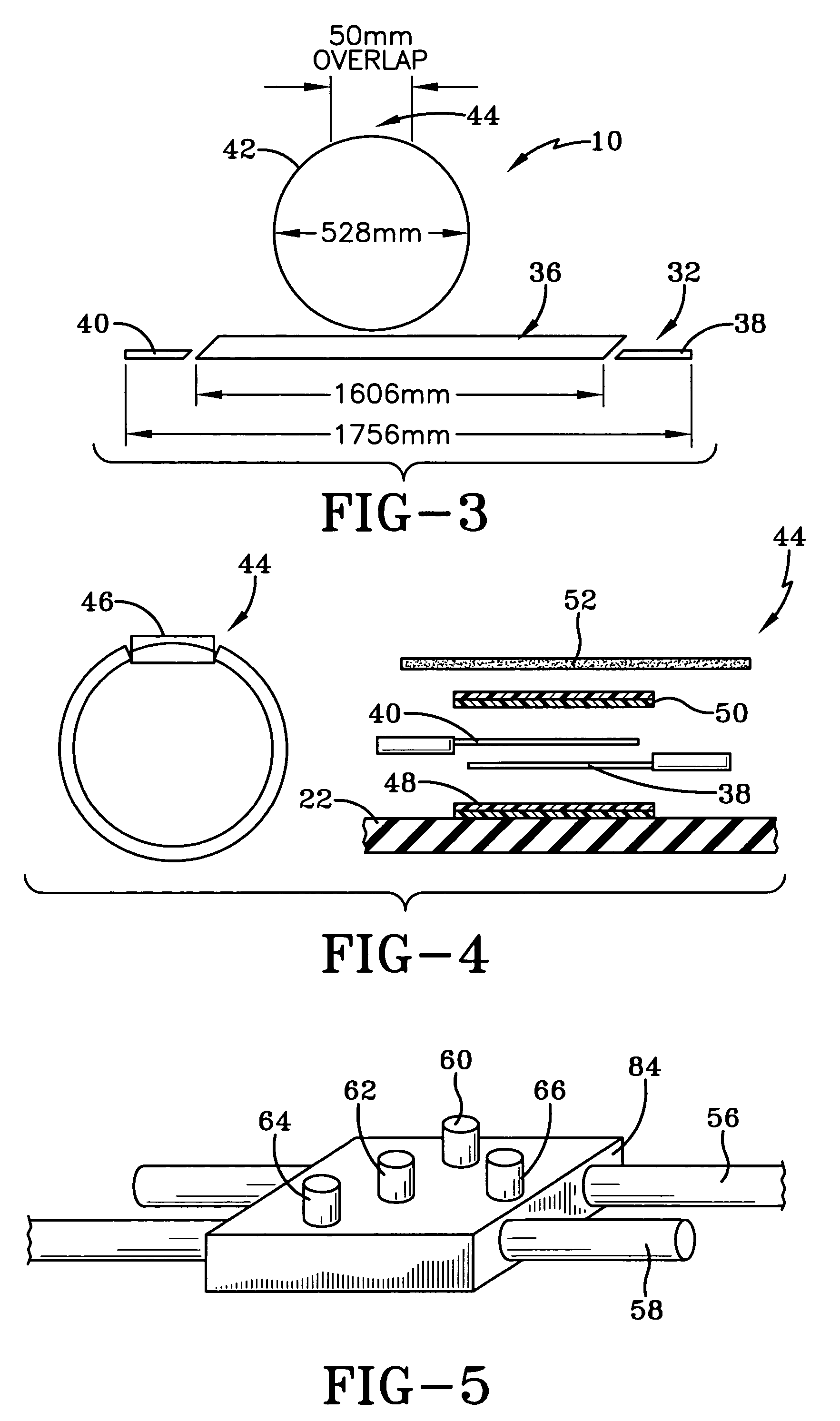

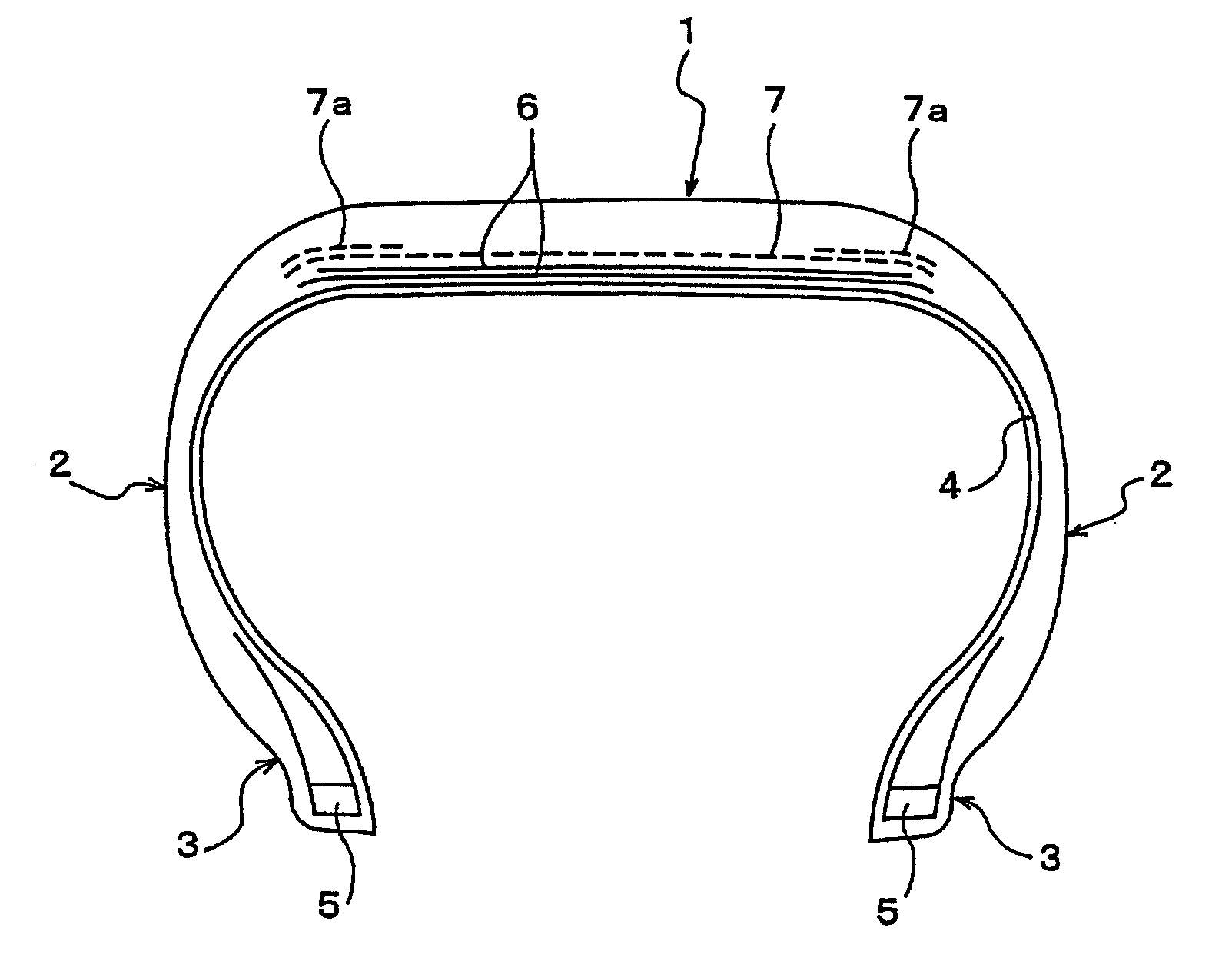

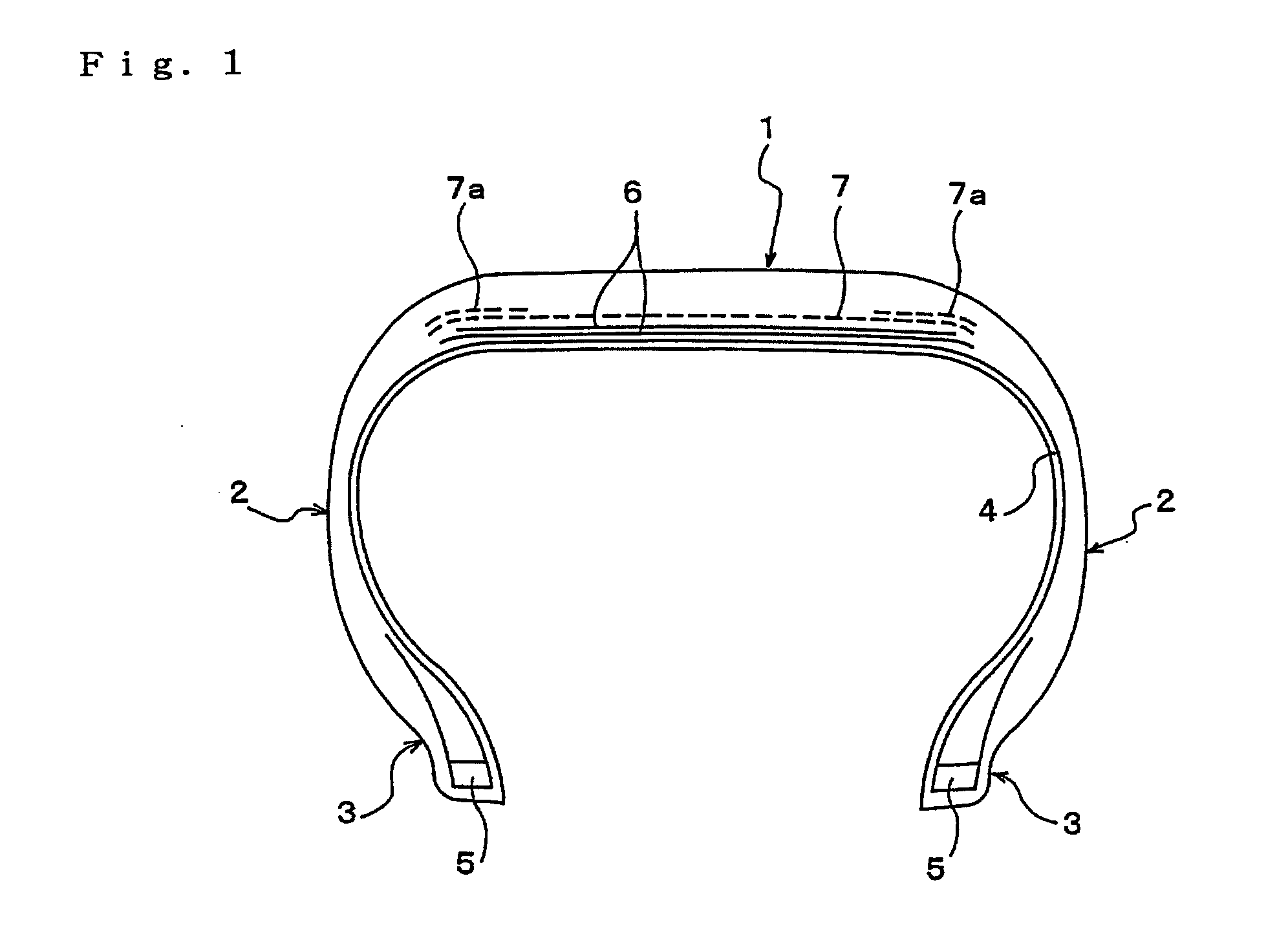

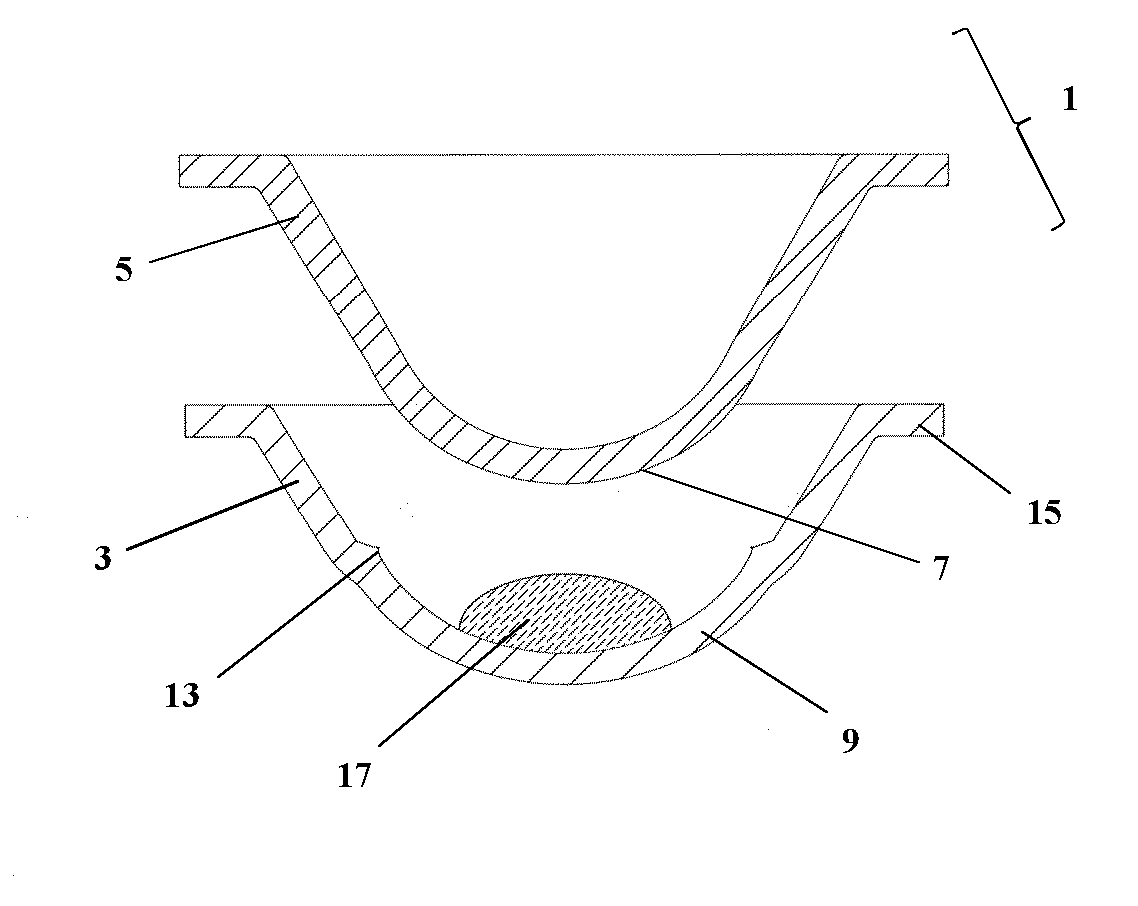

Pneumatic tire

InactiveUS20100276051A1Improve drivabilityReduce weightPneumatic tyre reinforcementsWheelsFiberDry heat

This invention relates to a pneumatic tire with an improved driveability and a reduced weight as well as a maintained traveling durability, and particularly a pneumatic tire having a high post cure inflation pressure, and being best suited as a pneumatic tire for a light truck with a high air pressure. In the pneumatic tire, twisted cords formed of a polyketone fiber represented by the following formula (a), and having a thermal shrinkage stress value, at a dry heat temperature of 150° C., of not less than 0.19 cN / dtex are used as cords for forming a carcass layer:—(CH2—CH2—CO)n-(R—CO—)m- formula (a);where the relationship between n and m is represented by the following formula (b), and R represents an alkylene group having 3 or more carbon atoms:1.05≧(n+m) / n≧1.00 formula (b).

Owner:YOKOHAMA RUBBER CO LTD

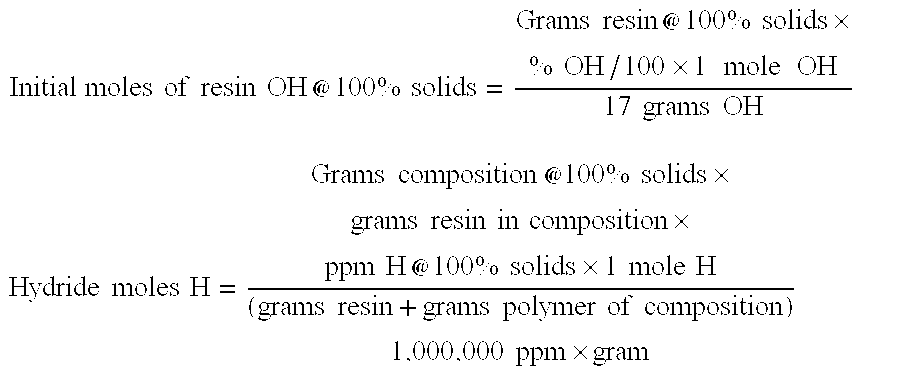

Self-crosslinking Silicone Pressure Sensitive Adhesive Compositions, Process For Making and Articles Made Thereof

Disclosed herein are self-crosslinking compositions containing a hydrosilation catalyst and the reaction product of a mixture comprising (i) a resinous copolymer having both silicon-bonded hydrogen and silanol groups, and (ii) one or more vinyl-functional polyorganosiloxanes. These compositions have stable post-cure adhesive properties and are suitable for use in electronic applications.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Preparation method of antibacterial polyurethane automobile shock damping bumper block

InactiveCN102633982AMeet antibacterial requirementsSolve the problem of instability and easy hydrolysisAutomobile marketPrepolymer

The invention discloses a preparation method of an antibacterial polyurethane automobile shock damping bumper block. The method comprises the following steps: 1) preparing an antibacterial polyalcohol; 2) preparing a prepolymer; 3) molding by casting; 4) precuring and demolding; and 5) post-curing to obtain the antibacterial polyurethane automobile shock damping bumper block. On the premise of maintaining the dynamic fatigue deformation rate and comprehensive mechanical performance of the bumper block, the antibacterial property of the automobile bumping block is improved. According to the preparation method of the environmentally-friendly antibacterial polyurethane automobile shock damping bumper block, a natural biological antibacterial agent is adopted to overcome the defect that other antibacterial agents are not stable and are easily hydrolyzed, and the requirement of medium and high end automobile market for the antibacterial property of the automobile bumper block is fulfilled.

Owner:奥斯汀新材料(张家港)有限公司

Adjustable shim

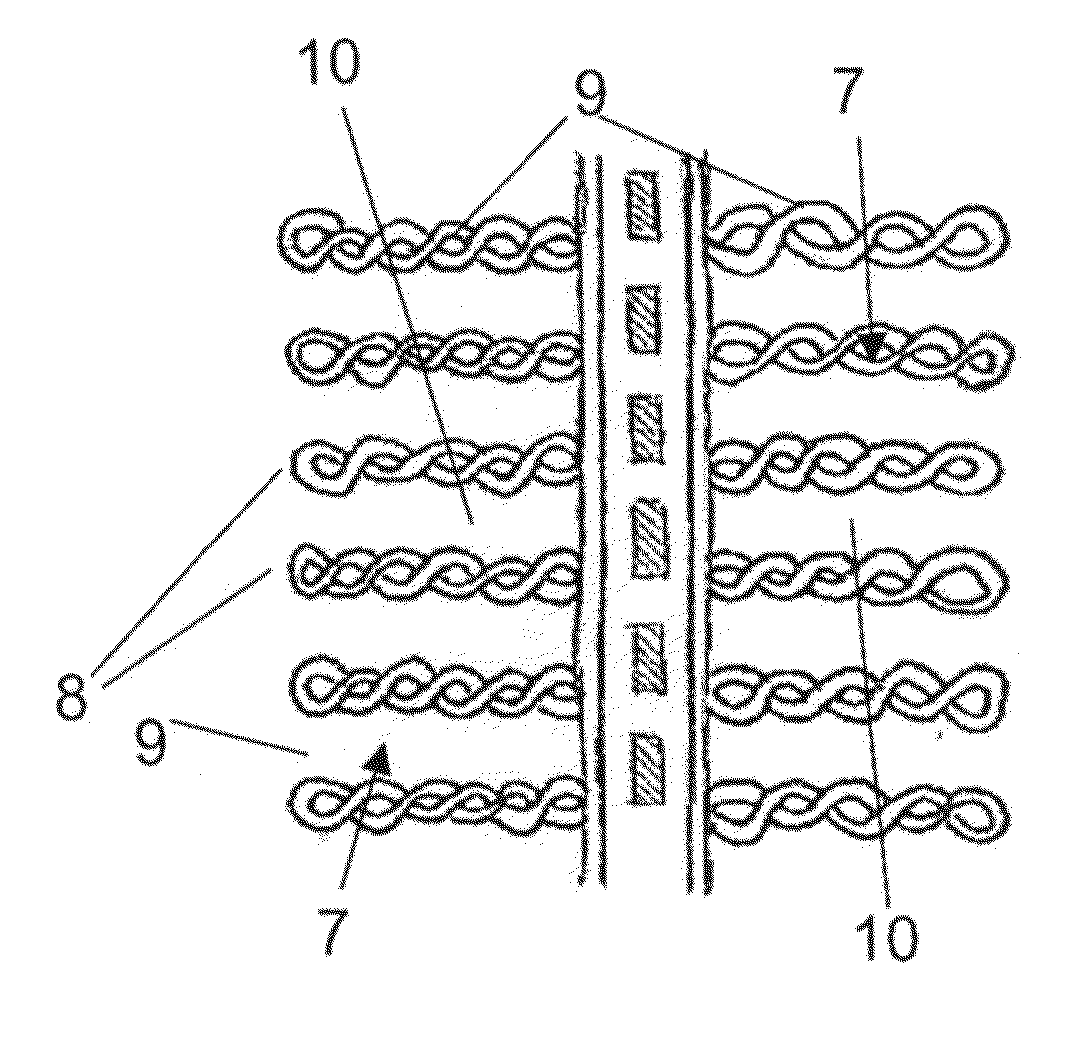

ActiveUS20110028061A1Easy to handleEasilyLamination ancillary operationsWarp knittingFiberPlastic materials

An adjustable shim comprises a stack of plies comprising plastics material reinforced with a three-dimensional fibre layer, the plastics material being flowable under compressive force prior to cure for adjusting the thickness of the shim. The shim may be used to fill a void between two structural components joined together. Also, a method of filling a void between two structural components using the shim. The shim is easy to handle, can easily be laid up to a variety of thicknesses, and is quick to cure (depending on the plastics material used). The three-dimensional fibre layers make the shim highly compressible prior to cure, and provide significant reinforcement to the plastics material of the plies to support compressive stresses in the shim post cure.

Owner:AIRBUS OPERATIONS LTD

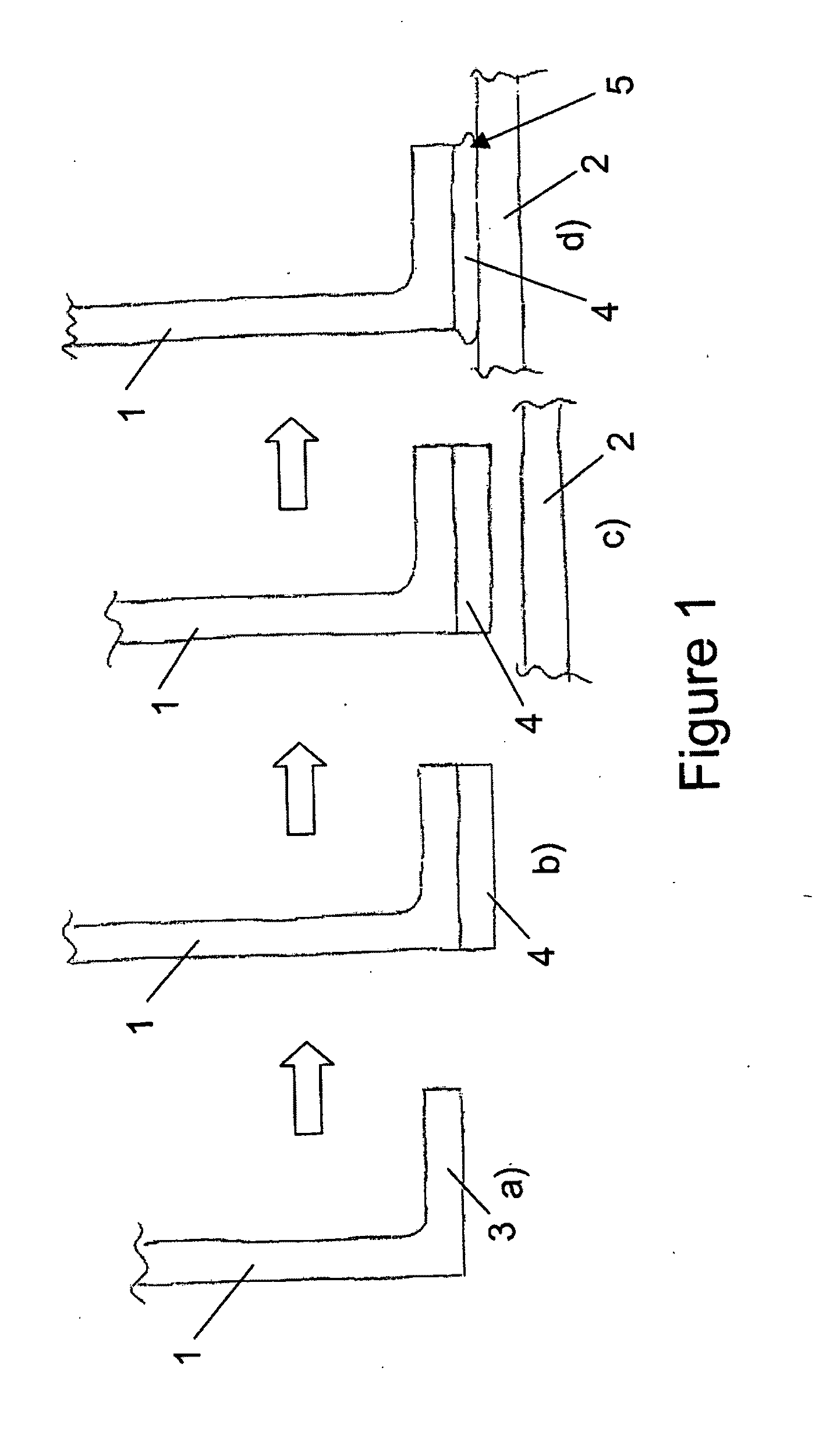

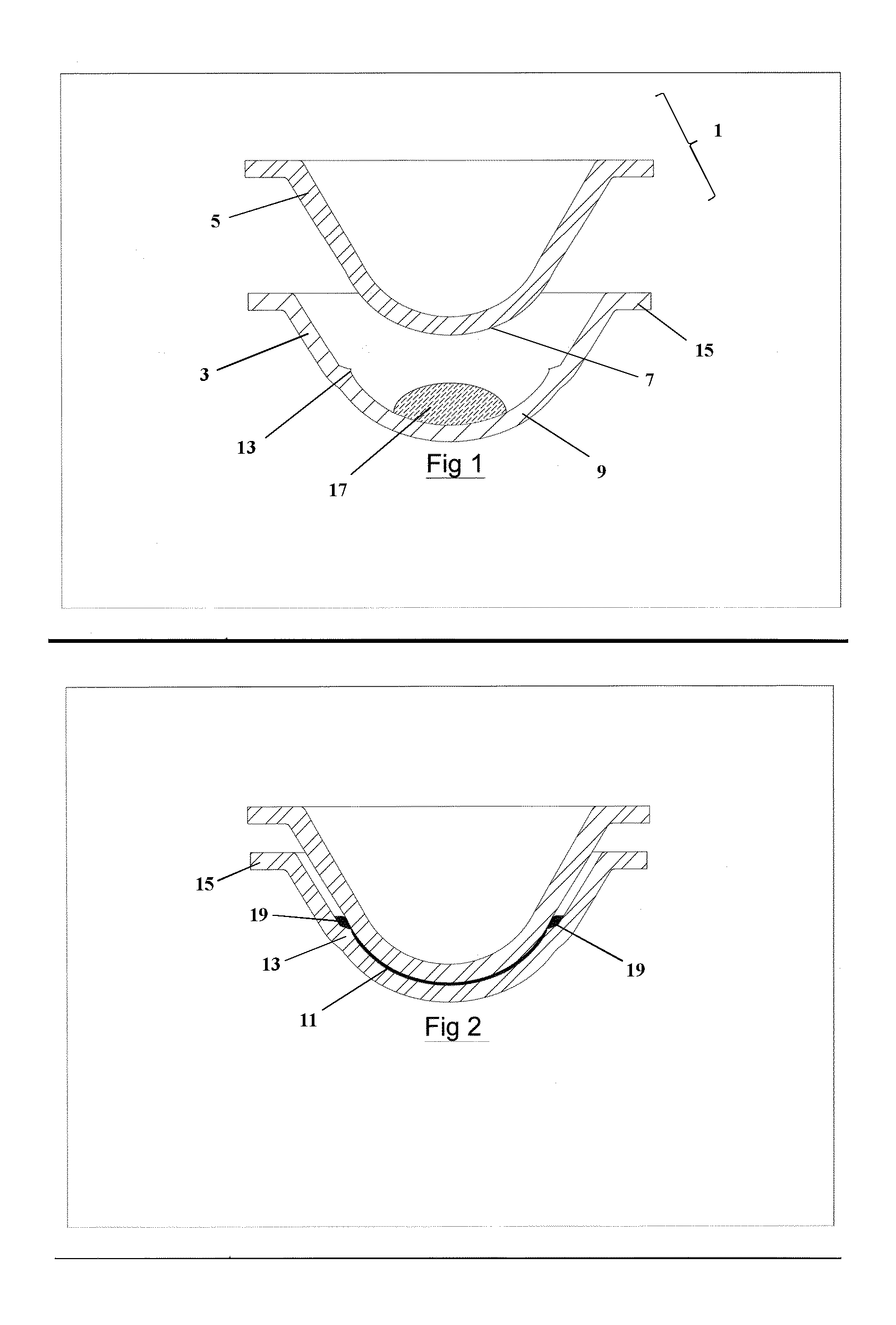

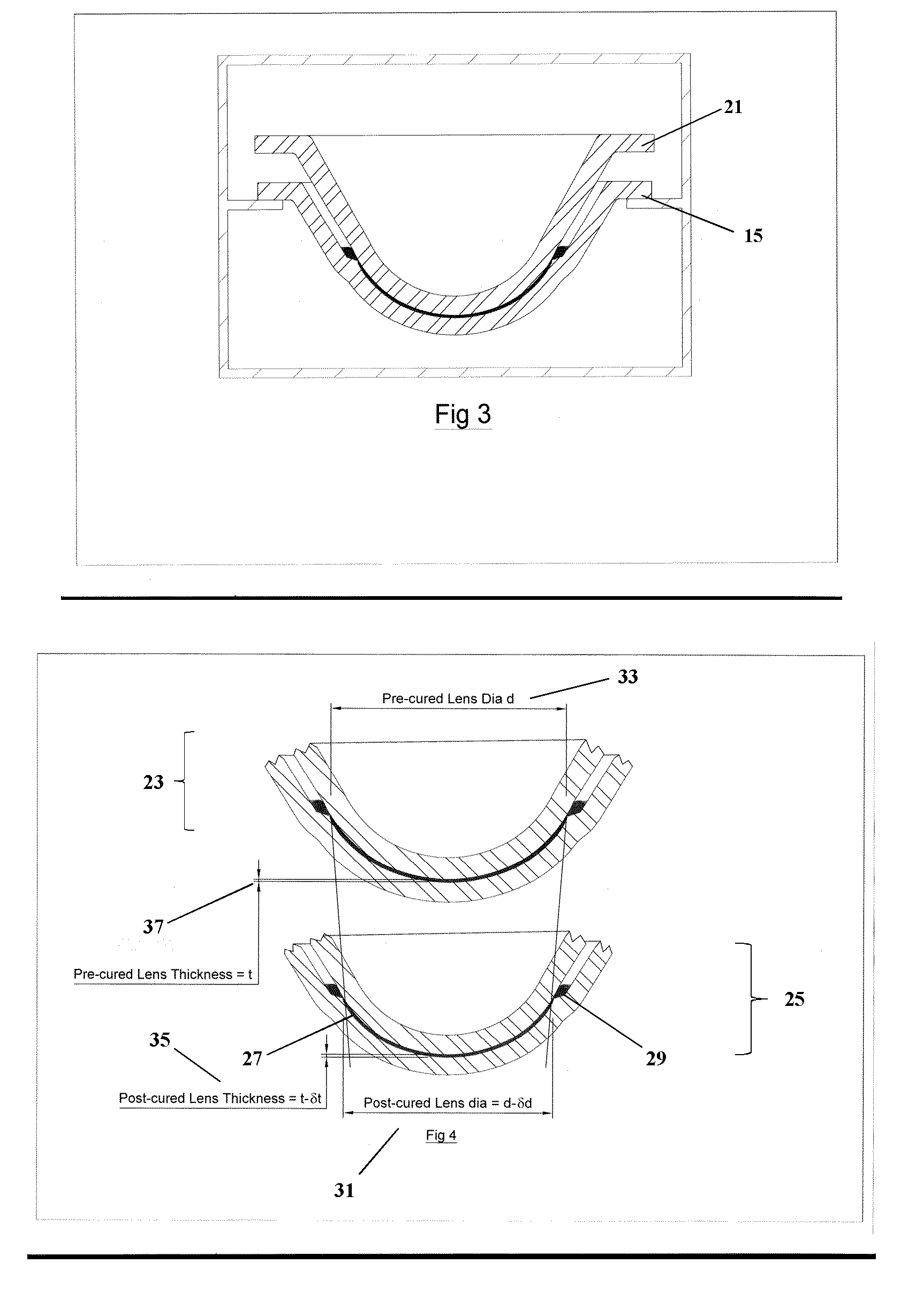

Contact lens manufacturing method

ActiveUS20140035176A1Efficient preparationImprove efficiencyOptical articlesCheese manufactureBlistersPost cure

In manufacturing a contact lens, a contact lens mould arrangement in which the engagement between the mould halves is unconstrained and at least one mould half is sufficiently pliable or flexible that during the curing of the contact lens composition at one mold half may move or flex relative to the other to define a post-cure mould cavity of smaller volume than the pre-cure mould cavity and during which the curvatures of the first and / or second mould surfaces are allowed to change provides a significantly more efficient manufacturing process and enables one mould half to be readily utilized as a blister cup for contact lens packaging.

Owner:DAYSOFT

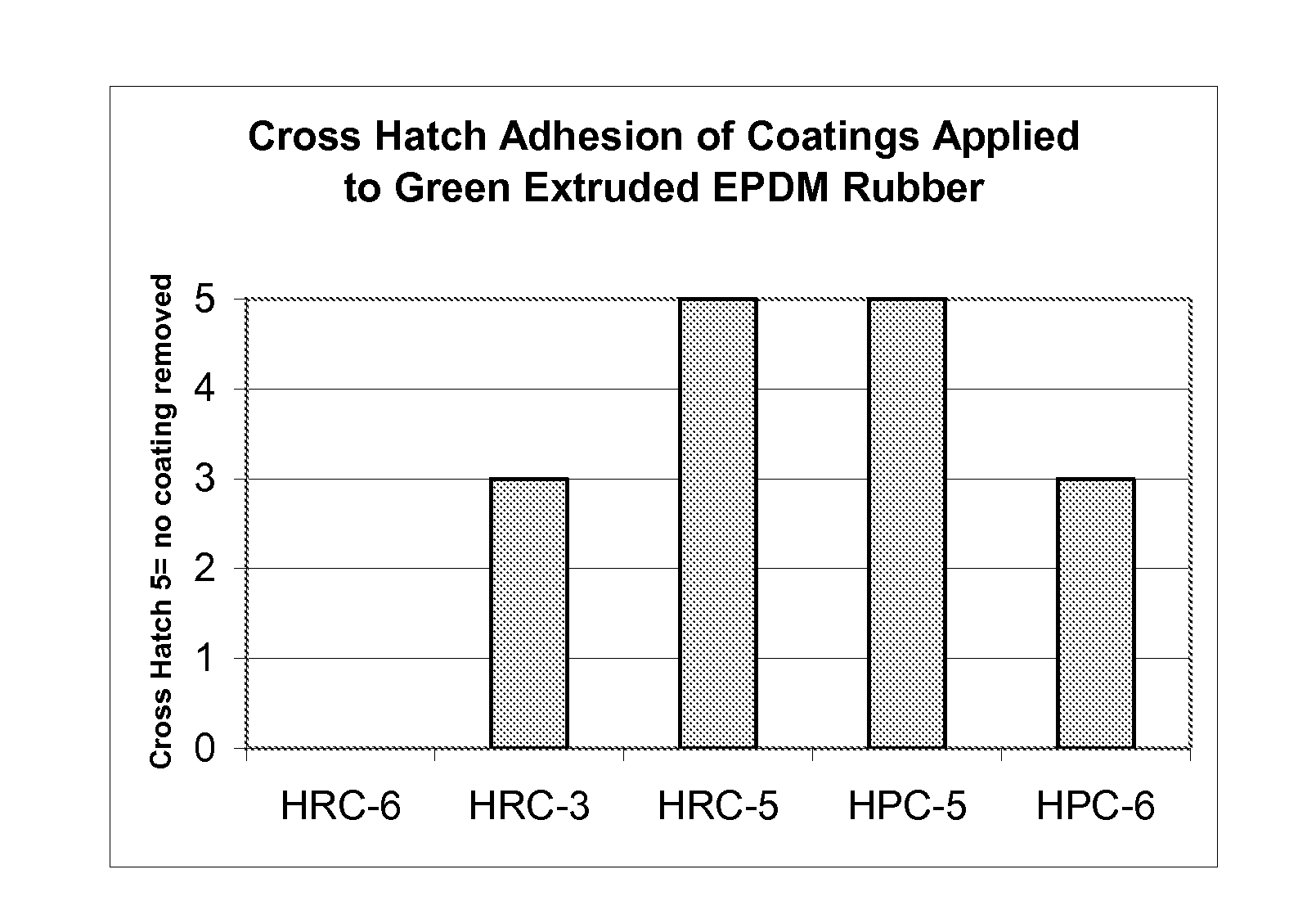

Methods of applying high performance coatings

InactiveUS20070275172A1Improve the immunityEffective coolingPretreated surfacesLiquid/solution decomposition chemical coatingElastomerEngine mount

The present invention relates to coating compositions suitable for coating flexible substrates, such as the myriad molded elastomeric materials in pre-cured or post-cured condition. The coatings are applied to the entire exterior surface thereof. The coating compositions can be applied to shaped or molded articles such as those made from thermoplastic vulcanizates or thermosettable rubber. The coating compositions of the present invention are particularly suitable for coating cured rubber engine mounting devices which are comprised of vulcanized elastomeric parts that have been bonded to metal parts.

Owner:LORD CORP

Bonding perfluoroelastomers to aluminum

A surface of an aluminum substrate is anodized. A curable perfluoroelastomer composition is then compression molded and vulcanized onto the anodized aluminum surface. The bonded part may then be post cured in order to improve both the tensile properties of the vulcanized perfluoroelastomer and the bond strength to the surface of the aluminum substrate.

Owner:DUPONT PERFORMANCE ELASTOMERS L L C

Preparation method of high-hardness thermoplastic polyurethane elastomer

The invention discloses a preparation method of a high hardness polyurethane thermoplastic elastomer. The method comprises the following steps: 1) adding polyester macromolecular dihydric alcohol and a catalyst into a reaction kettle, heating for a vacuum dehydration reaction, then adding 3-3-di methyl-4,4-biphenyl diisocyanate, and conducting heating reaction to obtain a polyurethane prepolymer; and 2) heating and melting the polyester macromolecular dihydric alcohol, catalyst, a chain extender, an antioxidant and a light stabilizer, and fully mixing the mixture with the polyurethane prepolymer obtained in the step 1) to obtain a thermoplastic polyurethane elastomer; and conducting post curing to obtain the high hardness thermoplastic polyurethane elastomer. The high hardness thermoplastic polyurethane elastomer prepared by the method disclosed by the invention can be used in the occasions of guide roller frames, brassie, machinery parts, seals or auto parts, has good comprehensive properties and processing properties, and is an environment-friendly product used as a substitute for general plastics and part of the engineering plastics.

Owner:苏州奥斯汀新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com