Patents

Literature

779 results about "Tire manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pneumatic tires are manufactured according to relatively standardized processes and machinery, in around 455 tire factories in the world. With over 1 billion tires manufactured worldwide annually, the tire industry is the major consumer of natural rubber. Tire factories start with bulk raw materials such as synthetic rubber (60% -70% of total rubber in the tire industry), carbon black, and chemicals and produce numerous specialized components that are assembled and cured. This article describes the components assembled to make a tire, the various materials used, the manufacturing processes and machinery, and the overall business model.

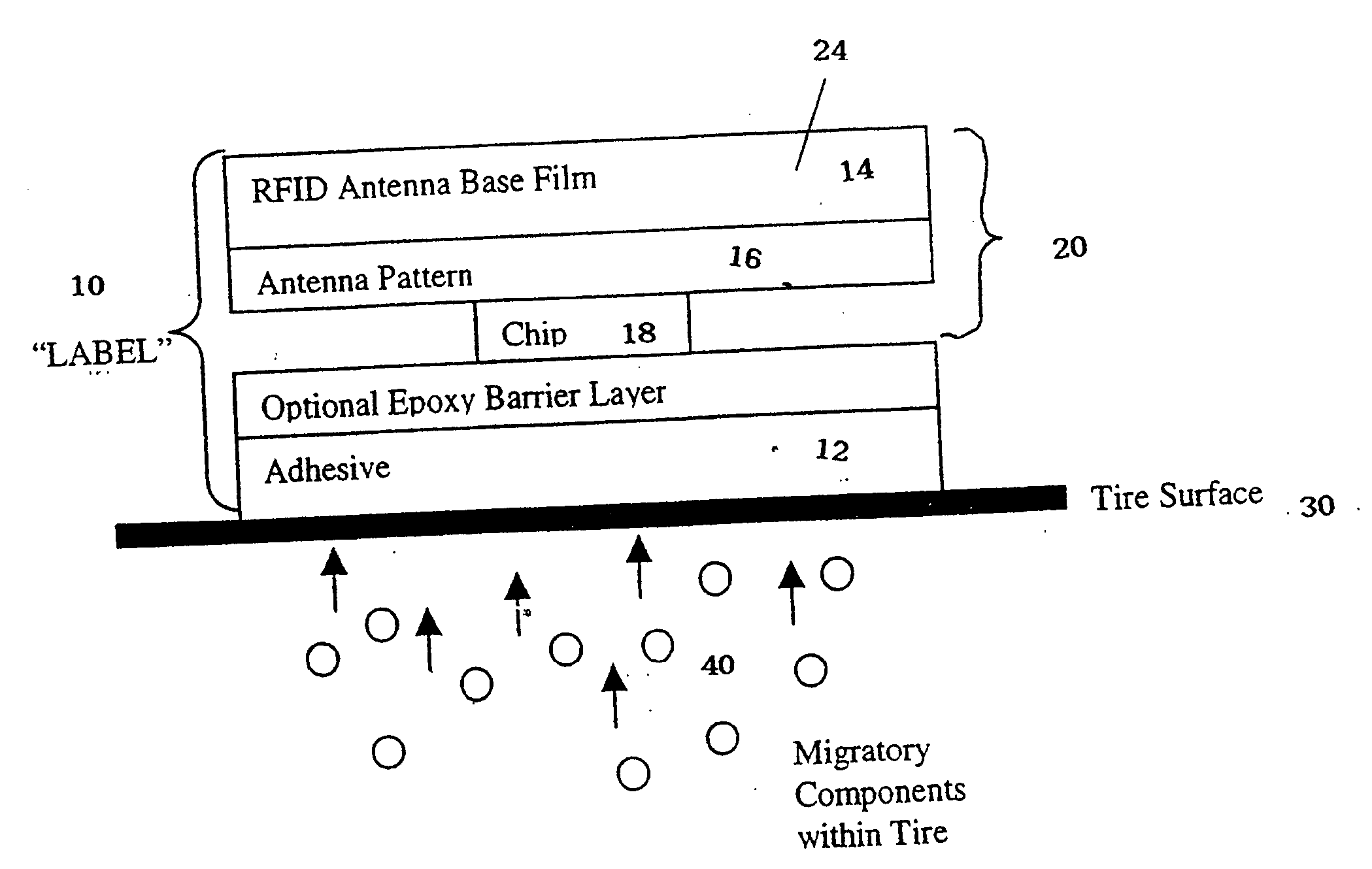

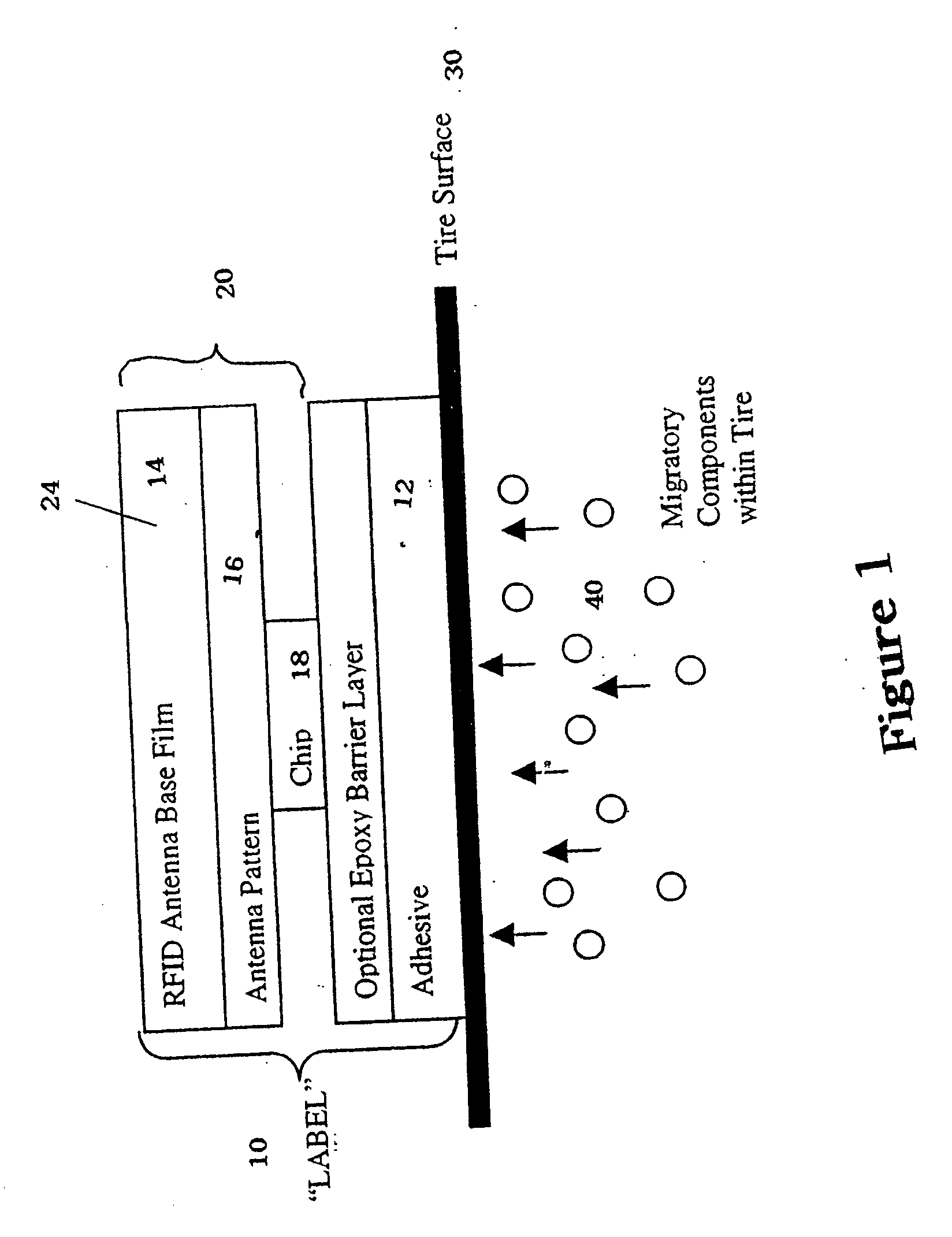

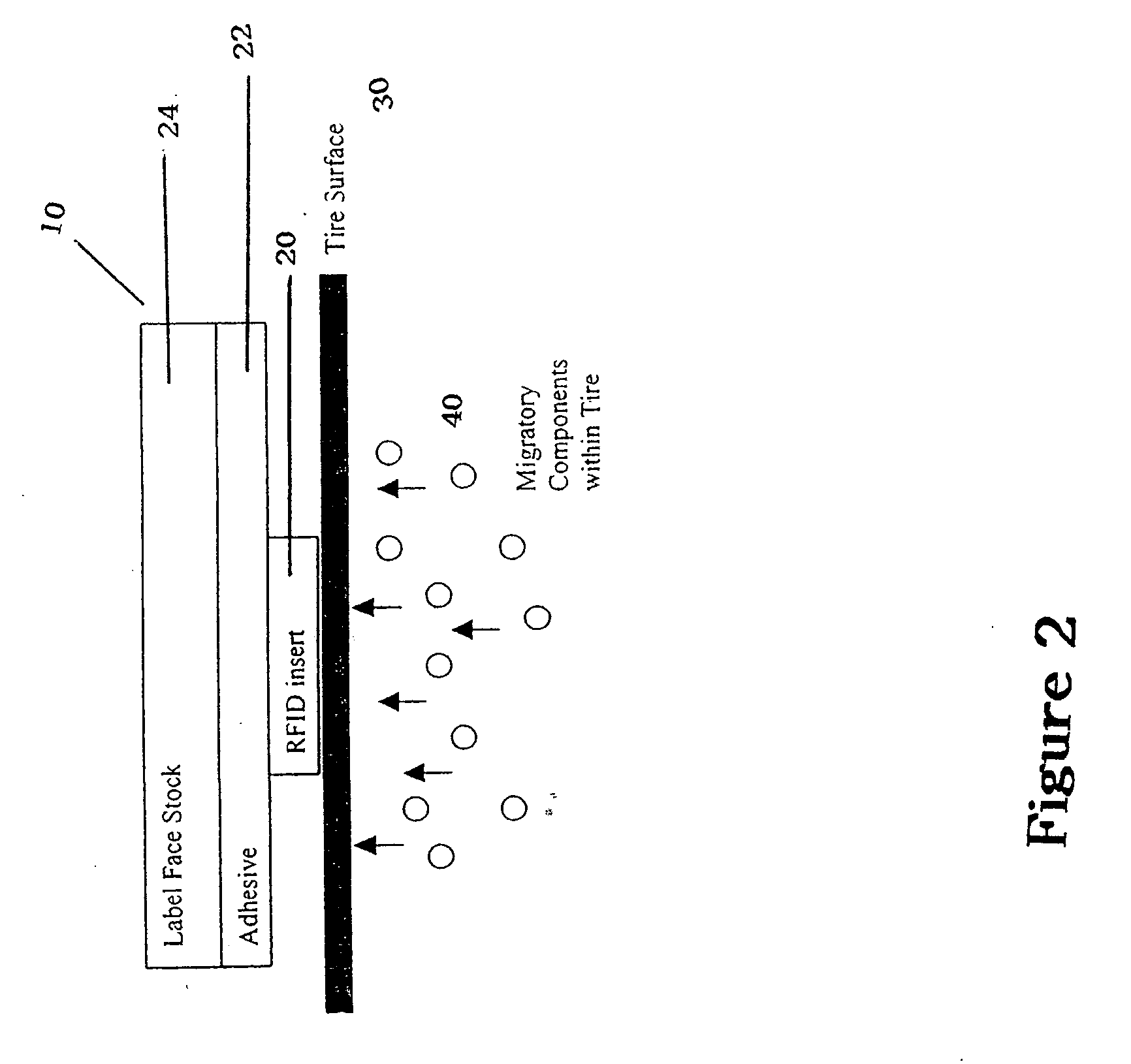

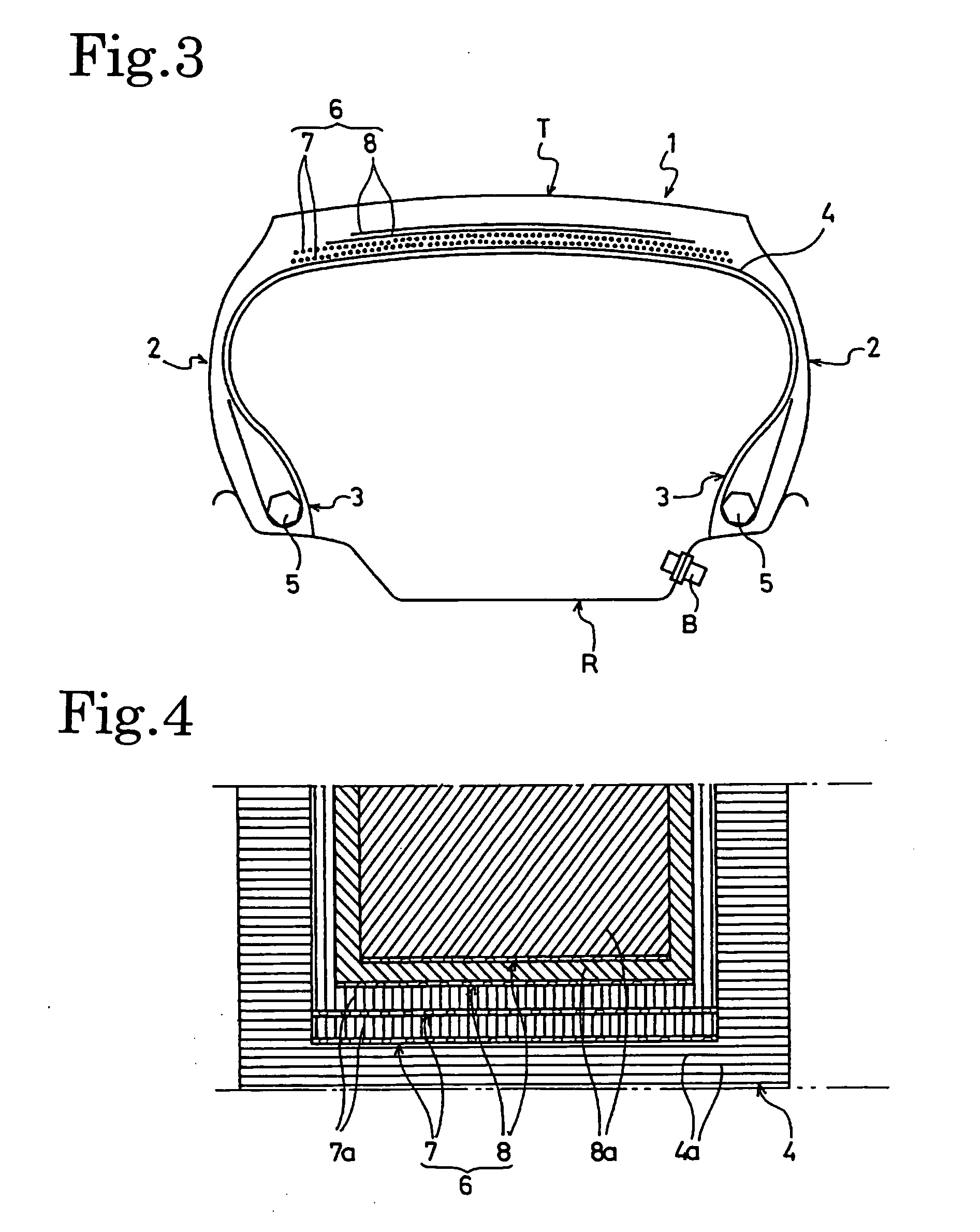

RFID tire label

InactiveUS20060290505A1Fast and reliable and accurate data collectionLower resistanceSolid-state devicesSensing record carriersFace sheetPressure sensitive

A smart RFID tire label in which the RFID antenna base film is the label face sheet. The antenna pattern, chip and pressure sensitive adhesive are on one side of the base film. This side is applied against the tire surface. The antenna base film acts as the durable label material protecting the antenna and chip from harsh environments associated with tire manufacturing and the wheel / chassis assembly process. The label may be large enough to seal the RFID insert when the label is attached to a tire, thus further protecting the RFID insert from damage.

Owner:INTERMEC IP

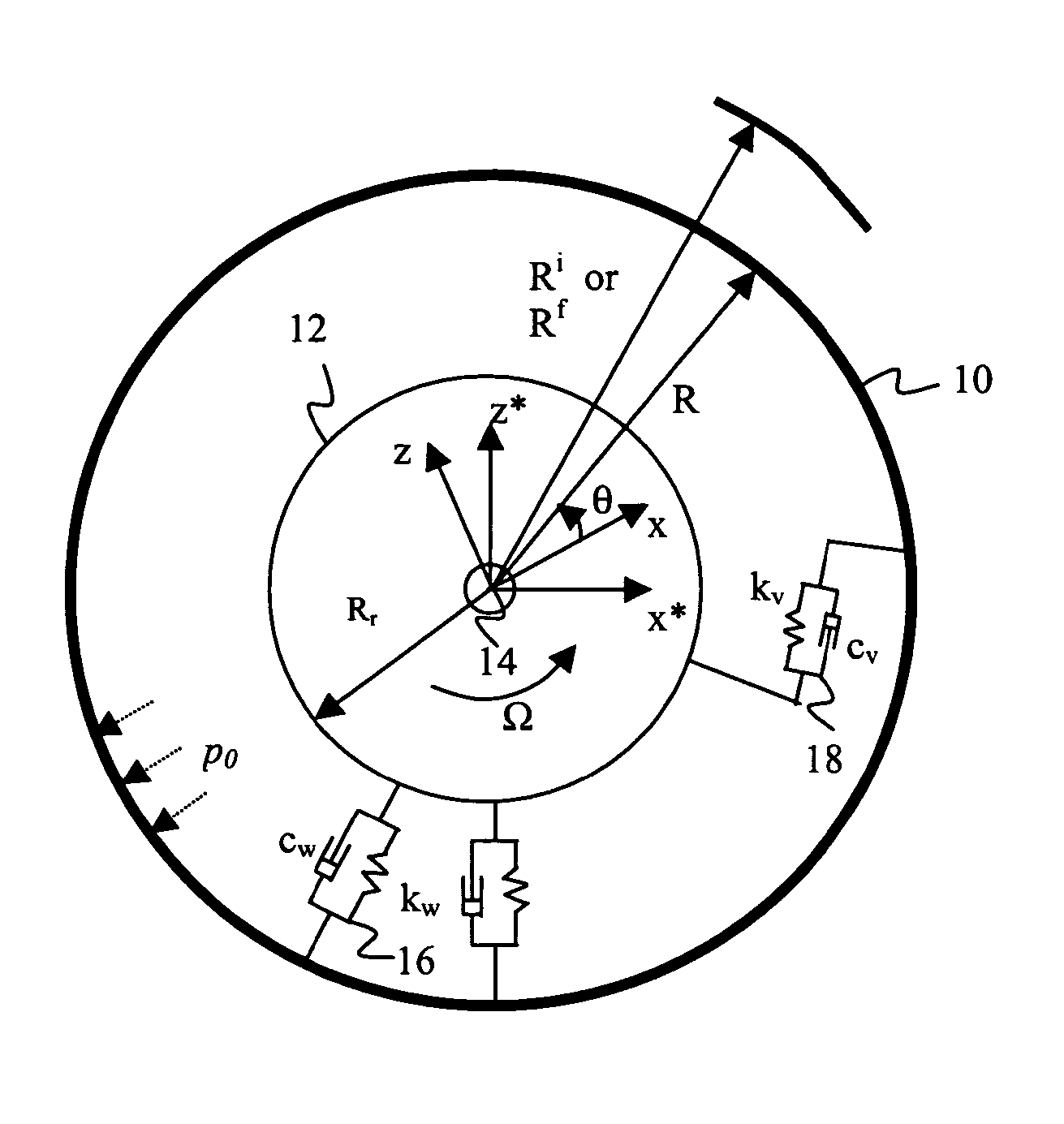

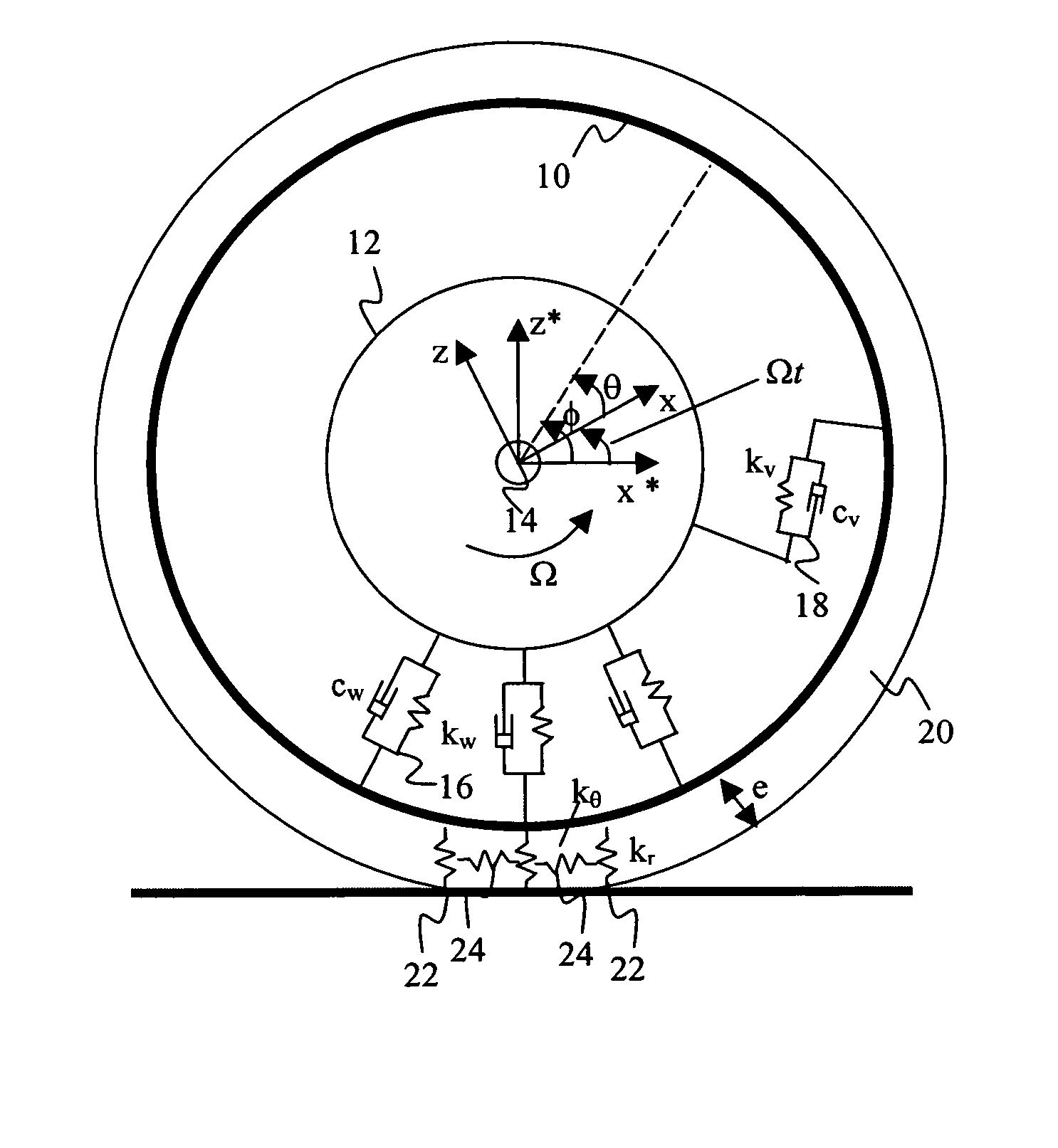

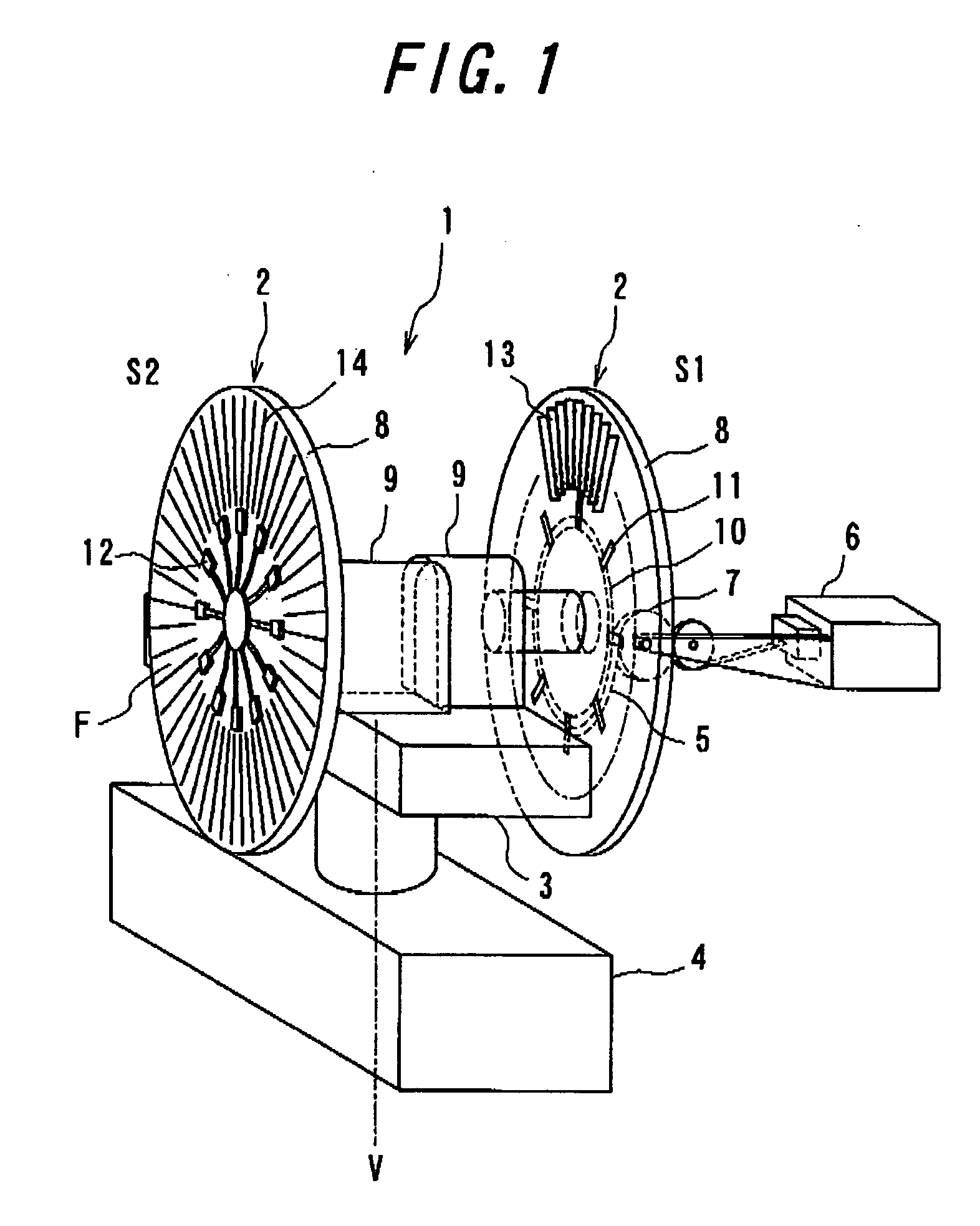

Prediction and control of mass unbalance and high speed uniformity

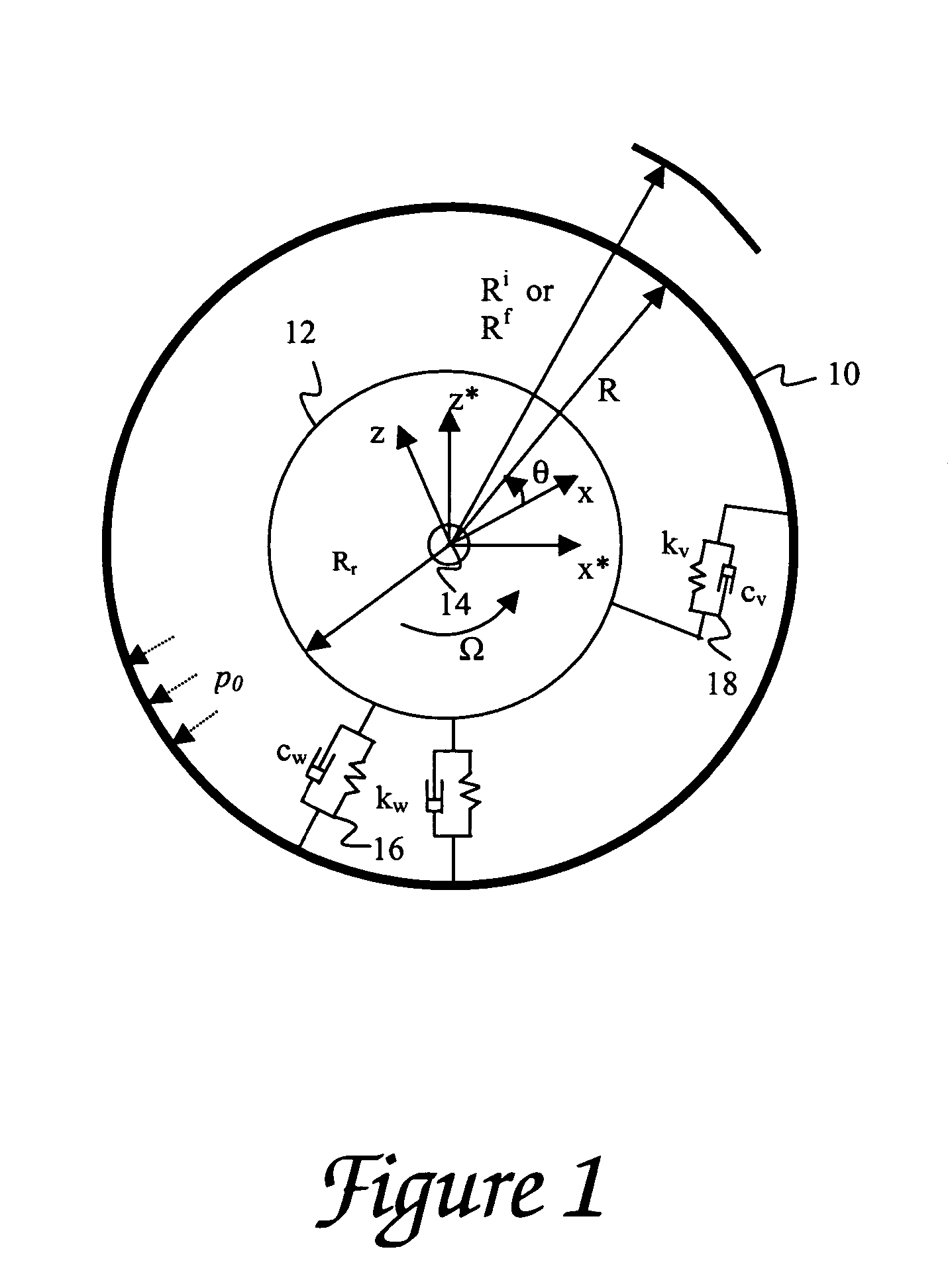

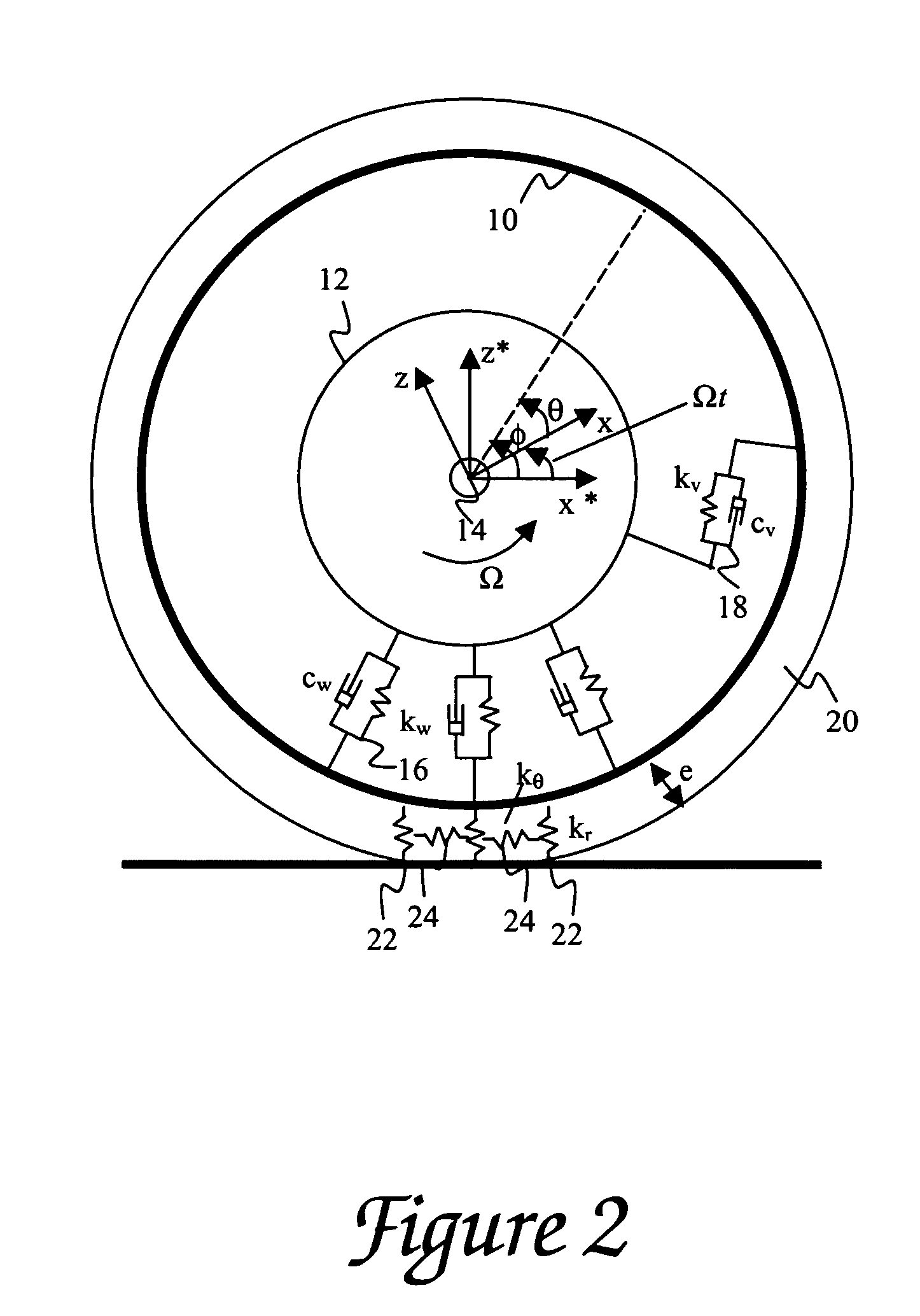

ActiveUS20050081614A1Little effectAdvanced technologyRoads maintainenceVehicle tyre testingLow speedHarmonic

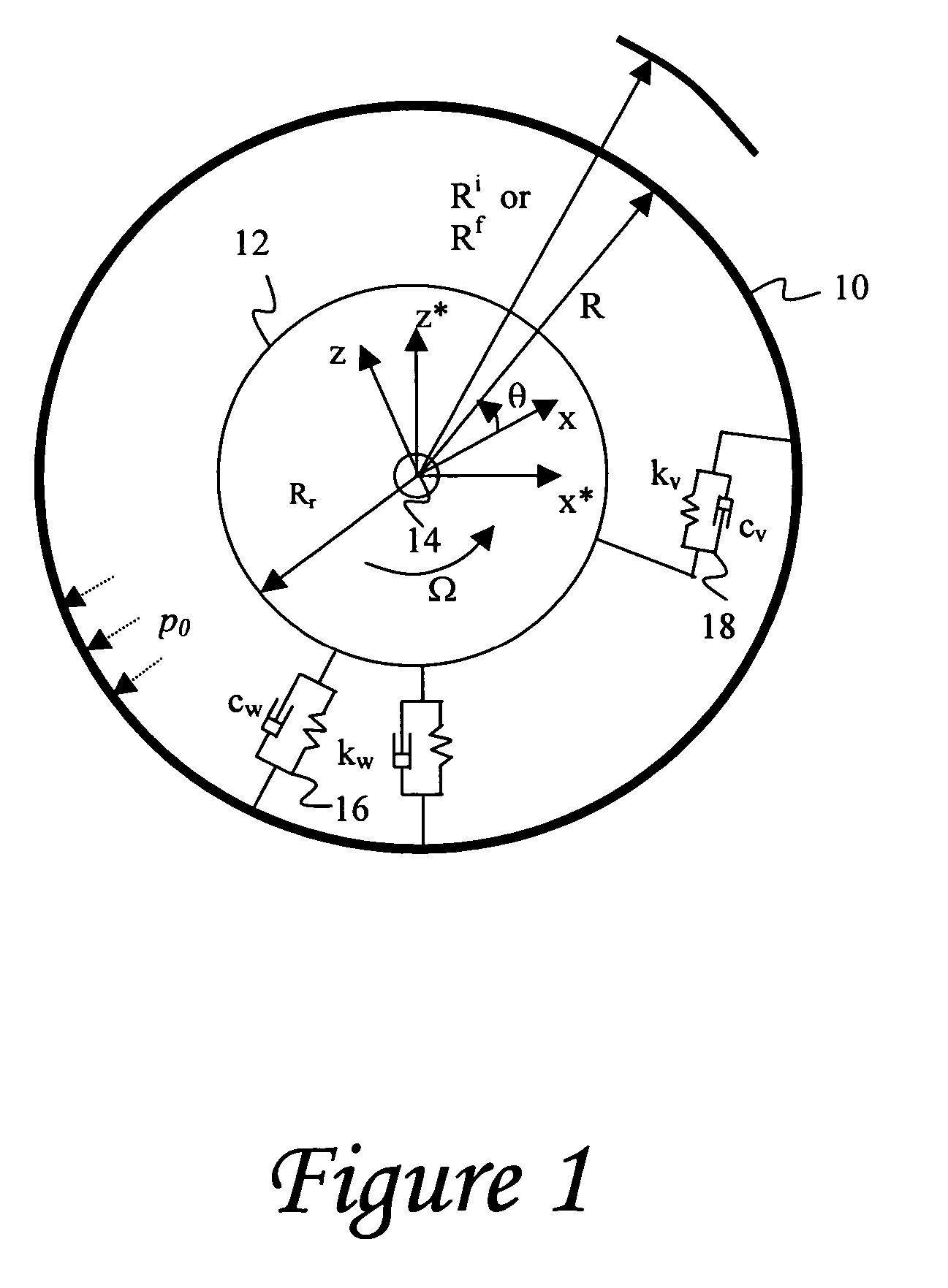

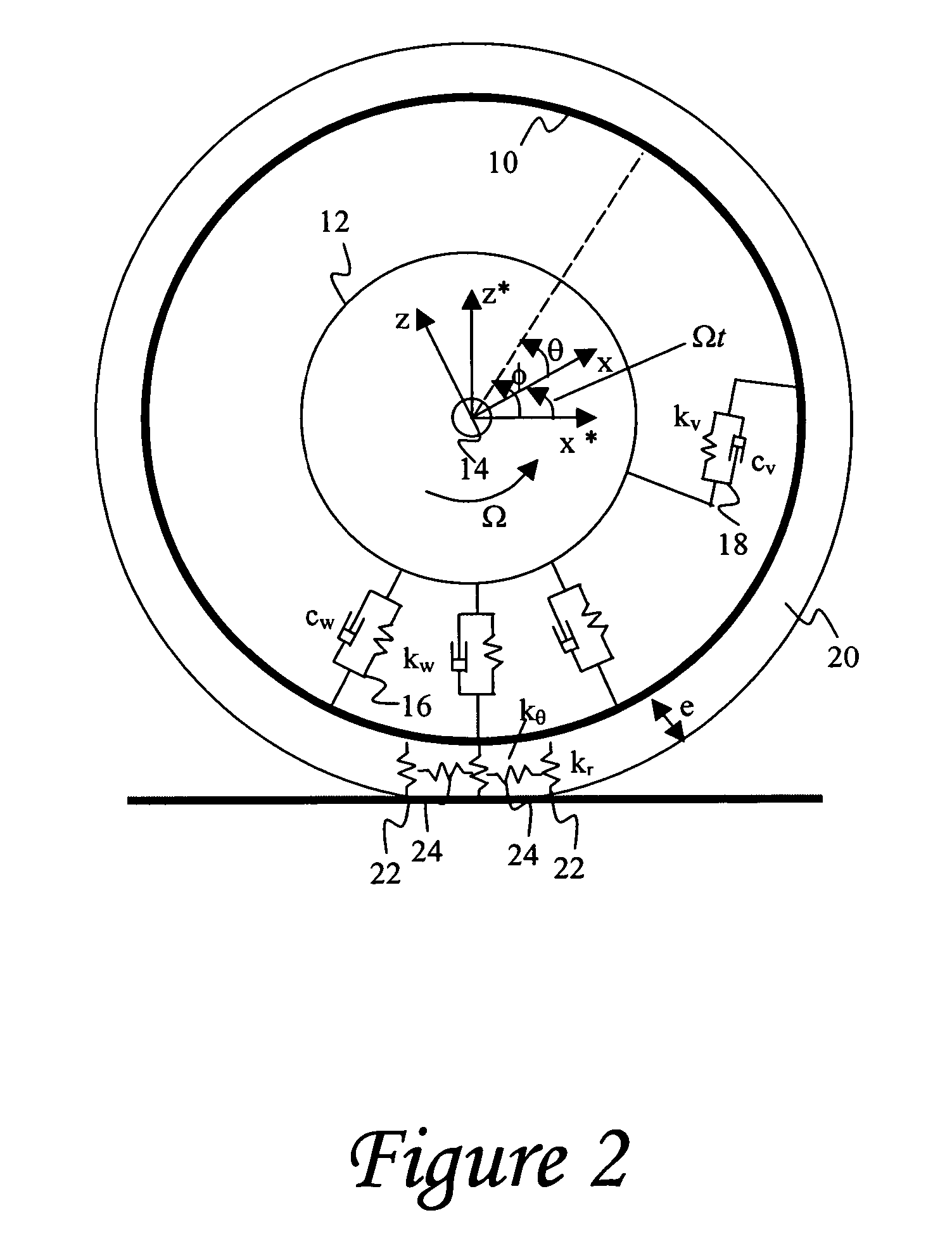

Methodology for characterizing non-uniformity forces at a tire spindle, such as low and high speed radial force variations and high speed tangential force variations include the steps of measuring radial run out and radial or tangential force variations at high and / or low speeds. From such measurements, the contribution of a predetermined type of stiffness variation (e.g. radial, tangential, extensional, bending) to respective radial and / or tangential force variations can be determined. Signature analysis statistical methods may also be utilized to characterize such tire non-uniform forces for different steps and reference physical angles of a tire construction process. Based on the characterization of such tire non-uniform forces, additional process steps may further correspond to tire grading and / or sorting processes, physical tire modification processes and tire manufacturing processes. Tire correction mechanisms and / or feedback control in a tire manufacturing process preferably yield tires having radial run out and stiffness variation parameters that are out of phase for one or more harmonics, thus yielding a reduction in the non-uniformity forces such as radial and tangential force variations at a tire spindle.

Owner:MICHELIN RECH & TECH SA

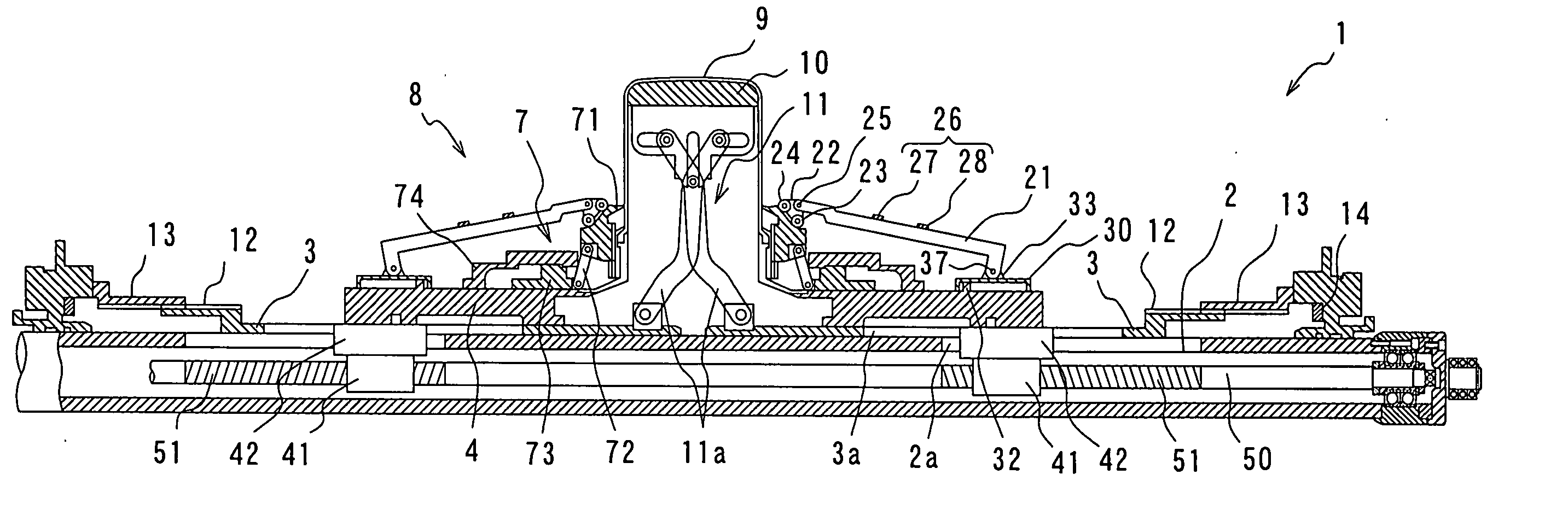

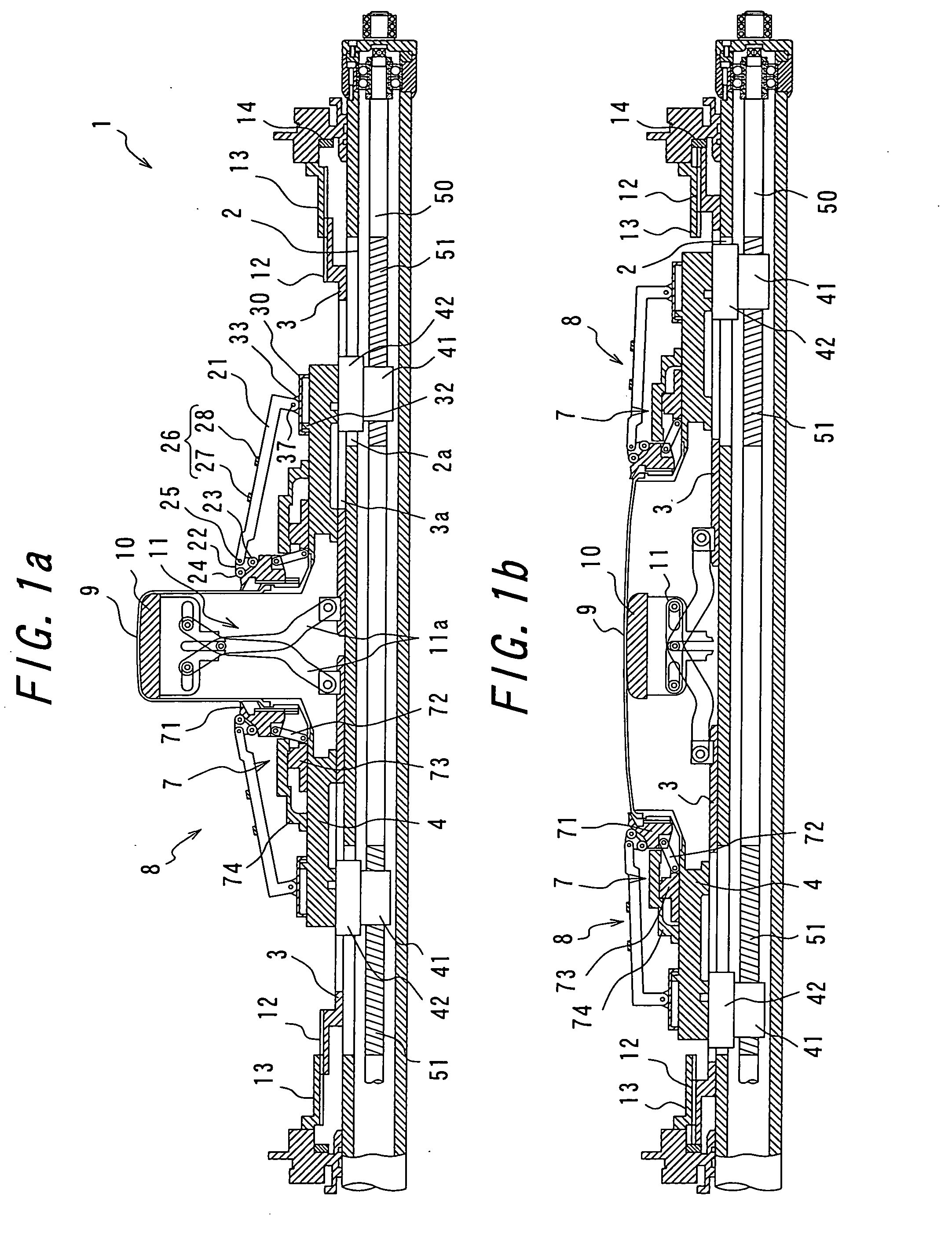

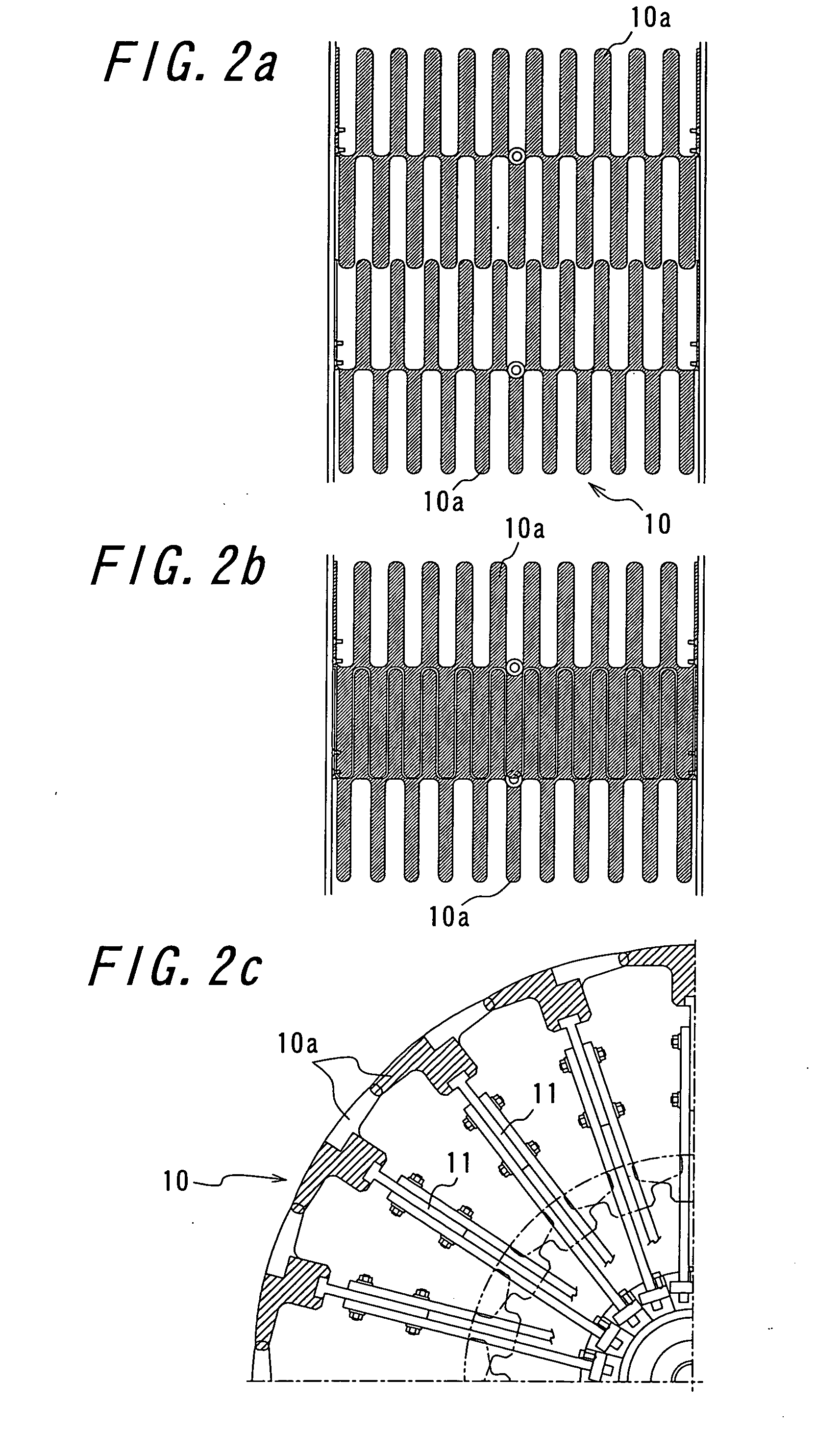

Tire building drum and tire building method

Tire building drum and tire building method, capable of assembling tire component members with high accuracy. A tire building drum is used, which includes at least one core body, which is disposed at an axial inside of a pair of bead lock means, and which comprises a plurality of sheets of rigid support members disposed in a toroidal shape and adapted to be displaced and thereby expanded or contracted. Bead cores are locked by the bead lock means, respectively, and a center portion of a carcass band is bulged while displacing the bead lock means close to each other. Back side portions of the carcass band are folded to radial outsides around the bead cores, respectively. The core body is then radially expanded to the maximum diameter while locking the bead cores, and tire component members are assembled onto the radially expanded core body.

Owner:BRIDGESTONE CORP

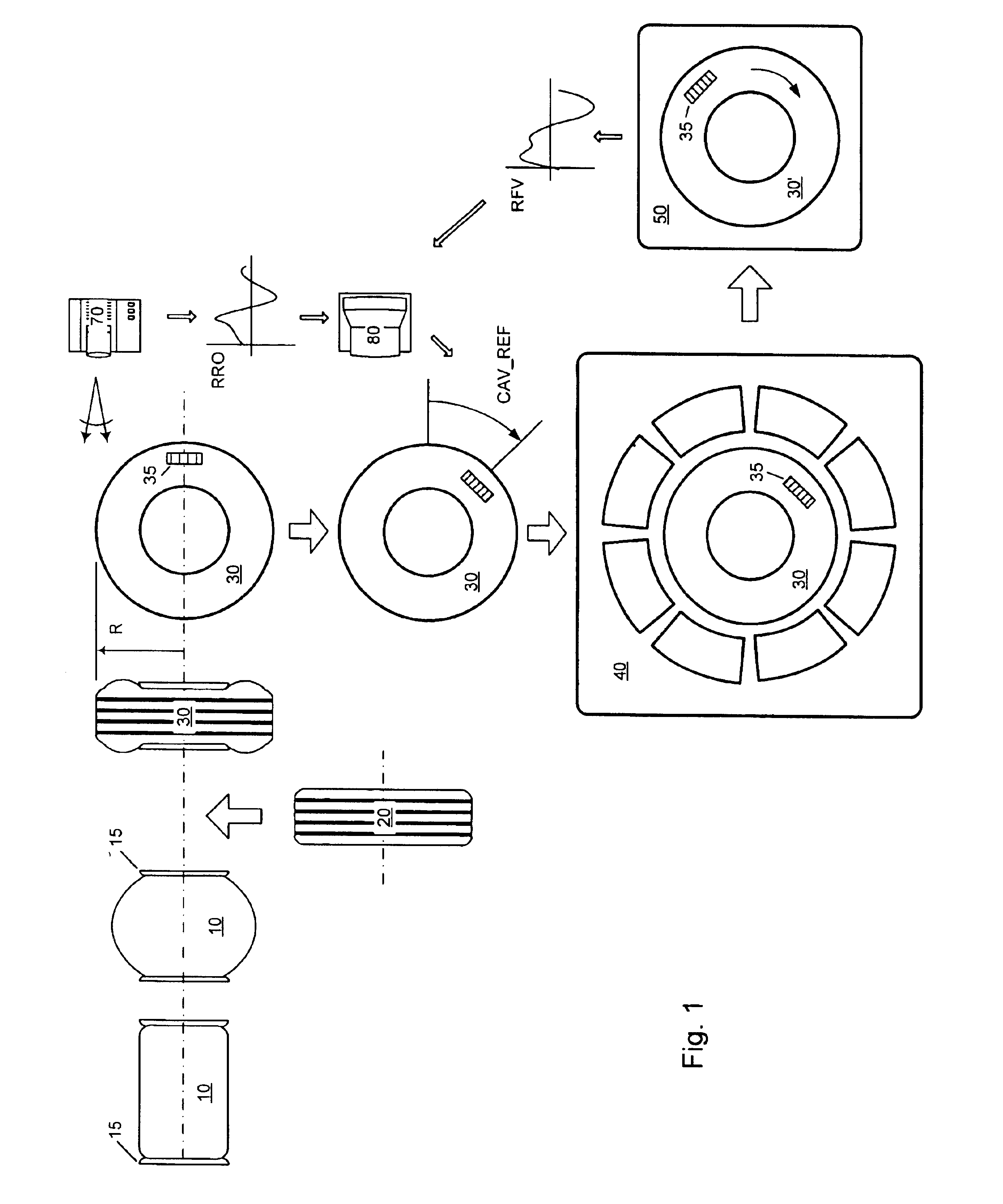

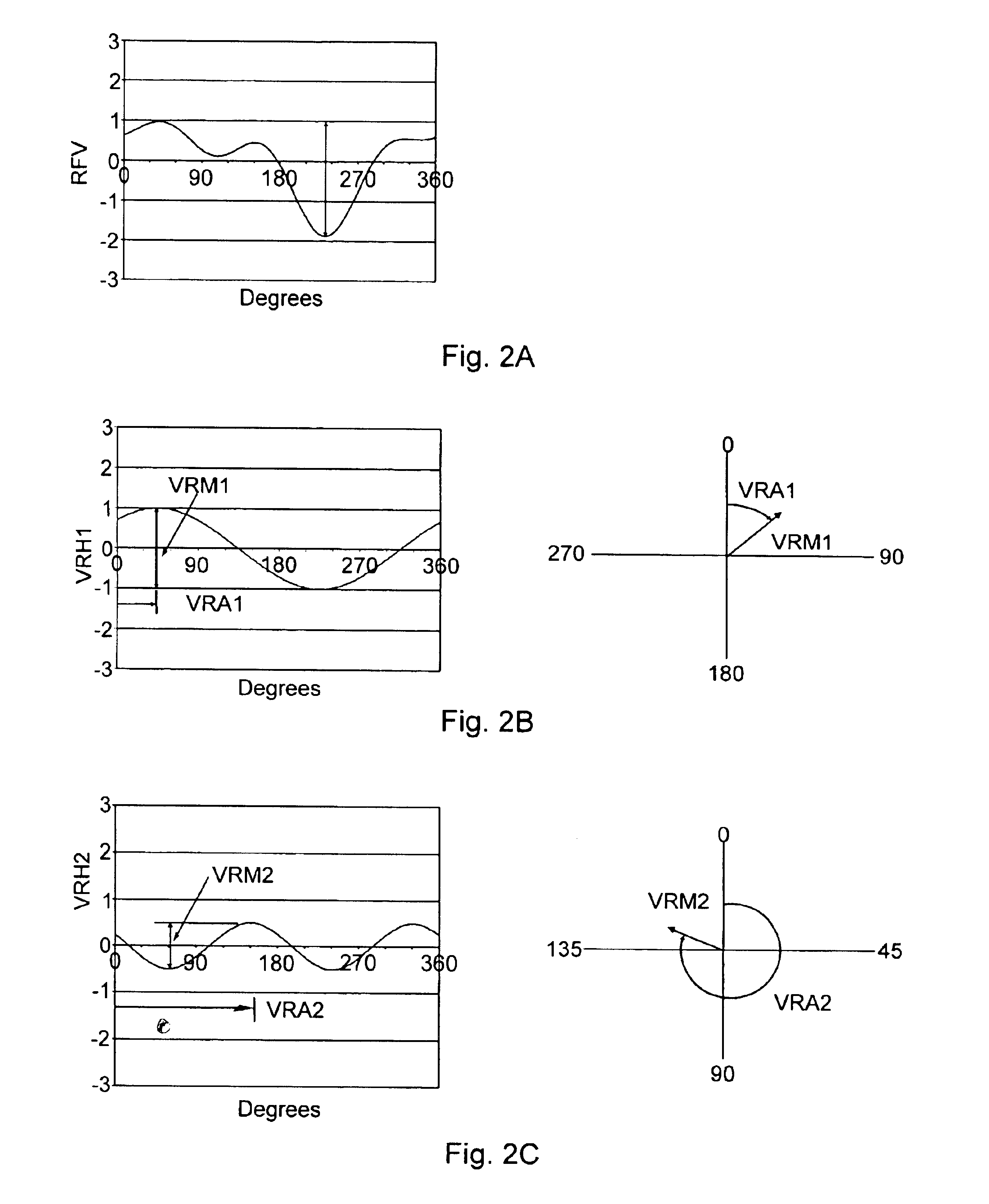

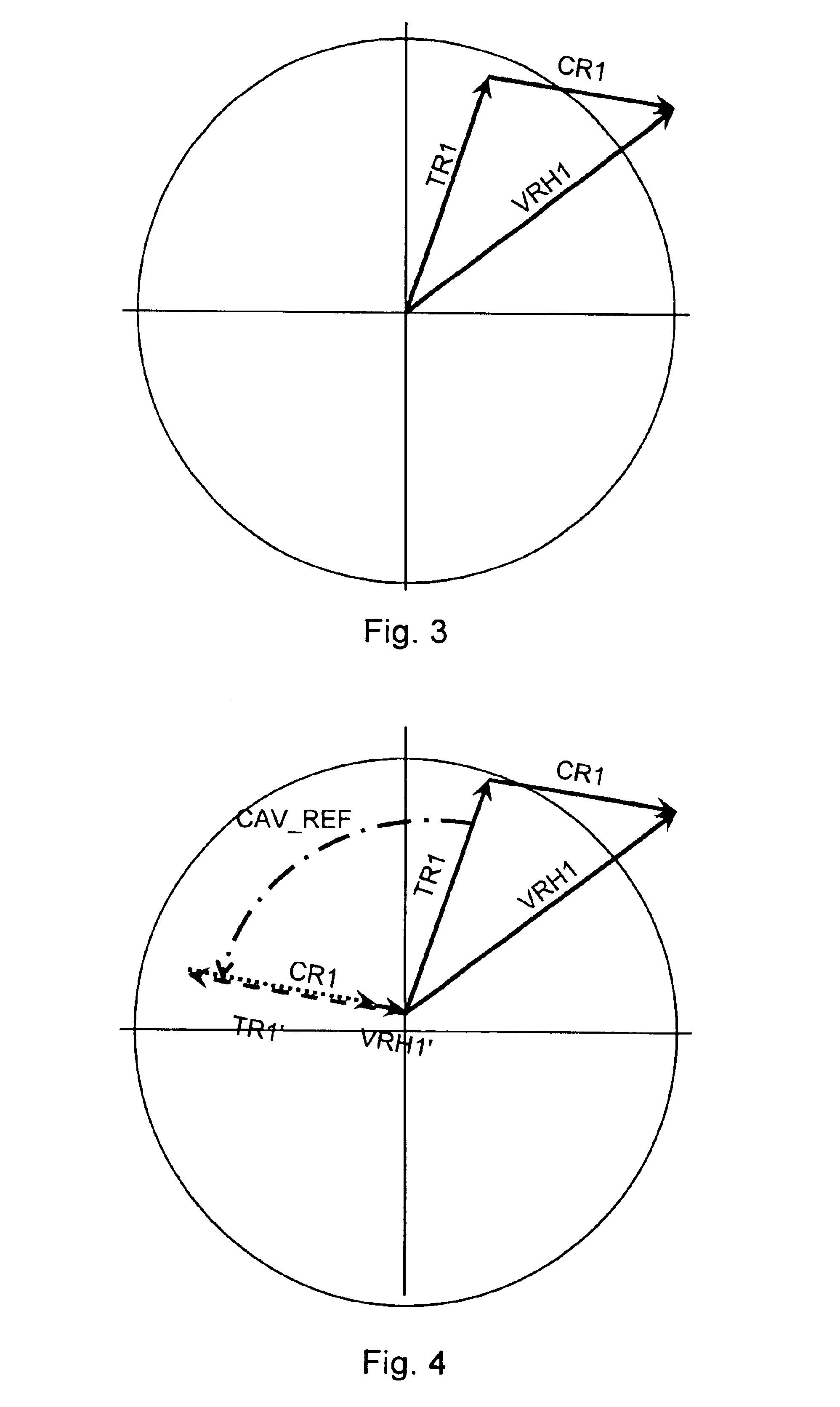

Tire manufacturing method for improving the uniformity of a tire

ActiveUS6856929B1Easy to calculateTyresSpecial data processing applicationsTire uniformityVulcanization

A tire manufacturing method includes a method for optimizing the uniformity of a tire by reducing the after cure radial force variation. The after cure radial force variation vector is modeled as a vector sum of each presenting contributions arising from the tire building steps—the “tire room effect vector” and a vector representing contributions arising from the vulcanization and uniformity measurement steps—the “curing room effect vector.” In further detail, both the tire room and curing room effect vectors can be further decomposed into sub-vectors representing each radial force variation contribution for which a measurable indicator is available. For a series of tires, the method obtains such measurements as the before cure radial runout (RRO) at one or more stages of the building sequence, measurements of loading angles on the tire building equipment, and measurements made during vulcanization process.

Owner:MICHELIN RECH & TECH SA

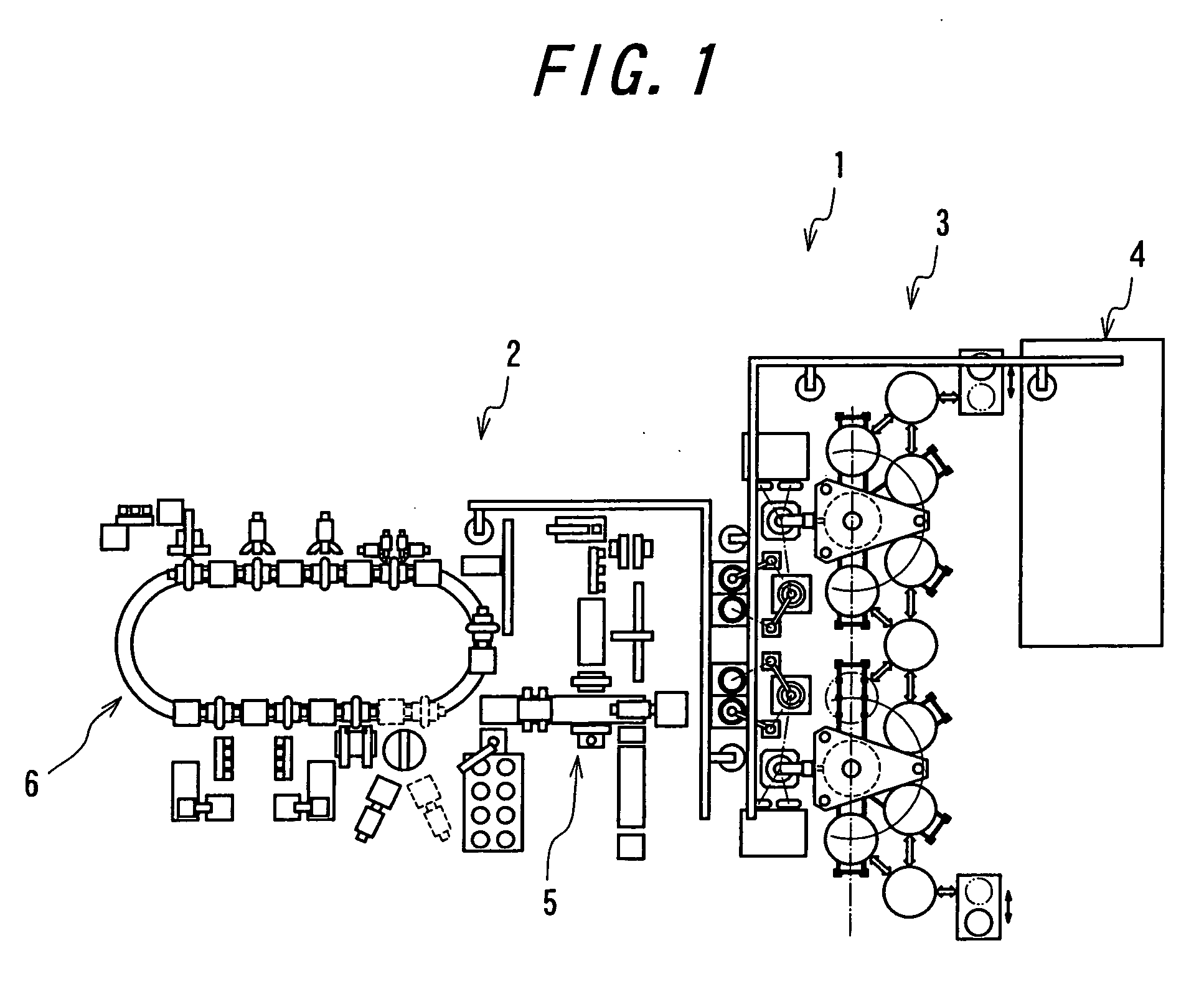

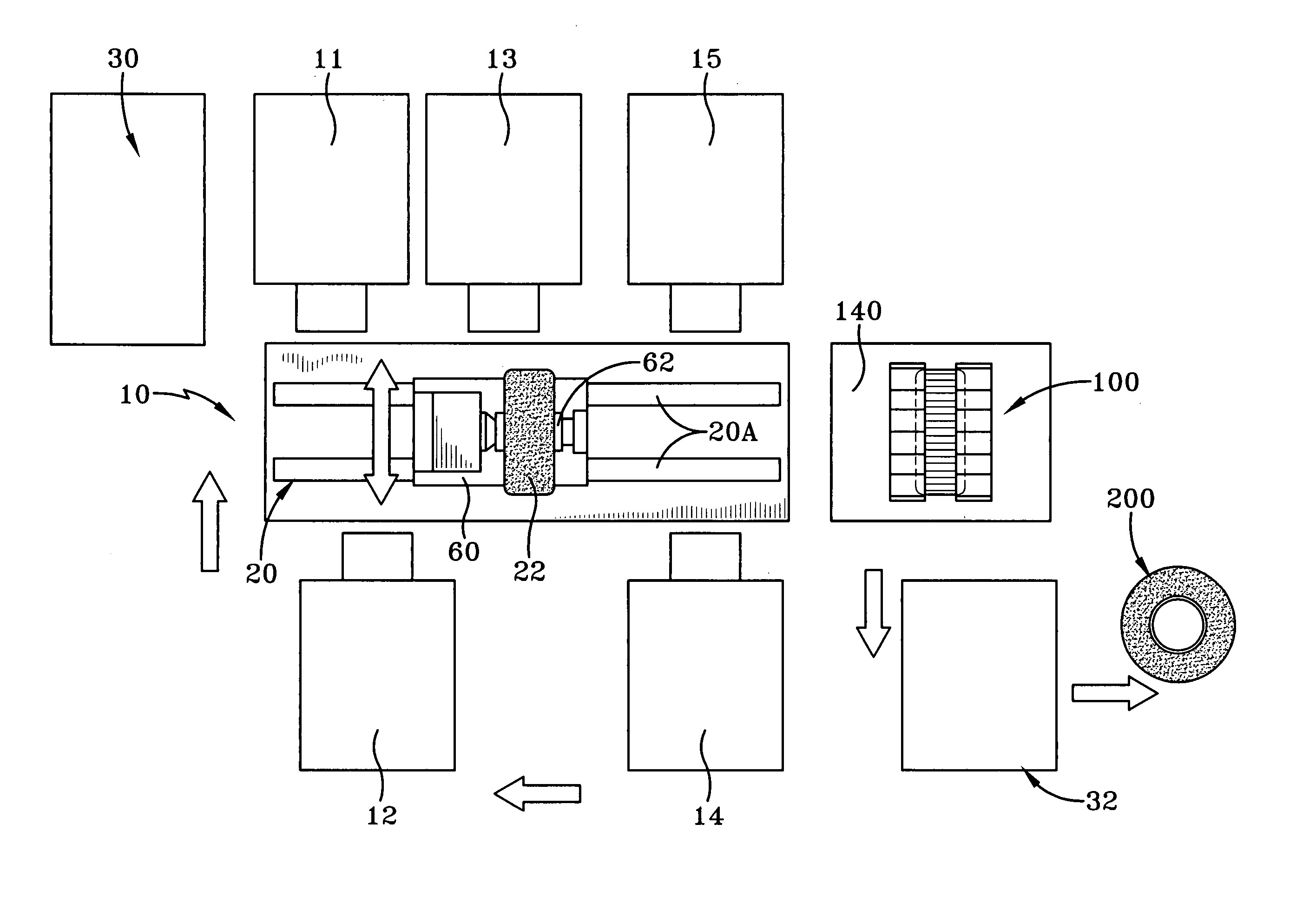

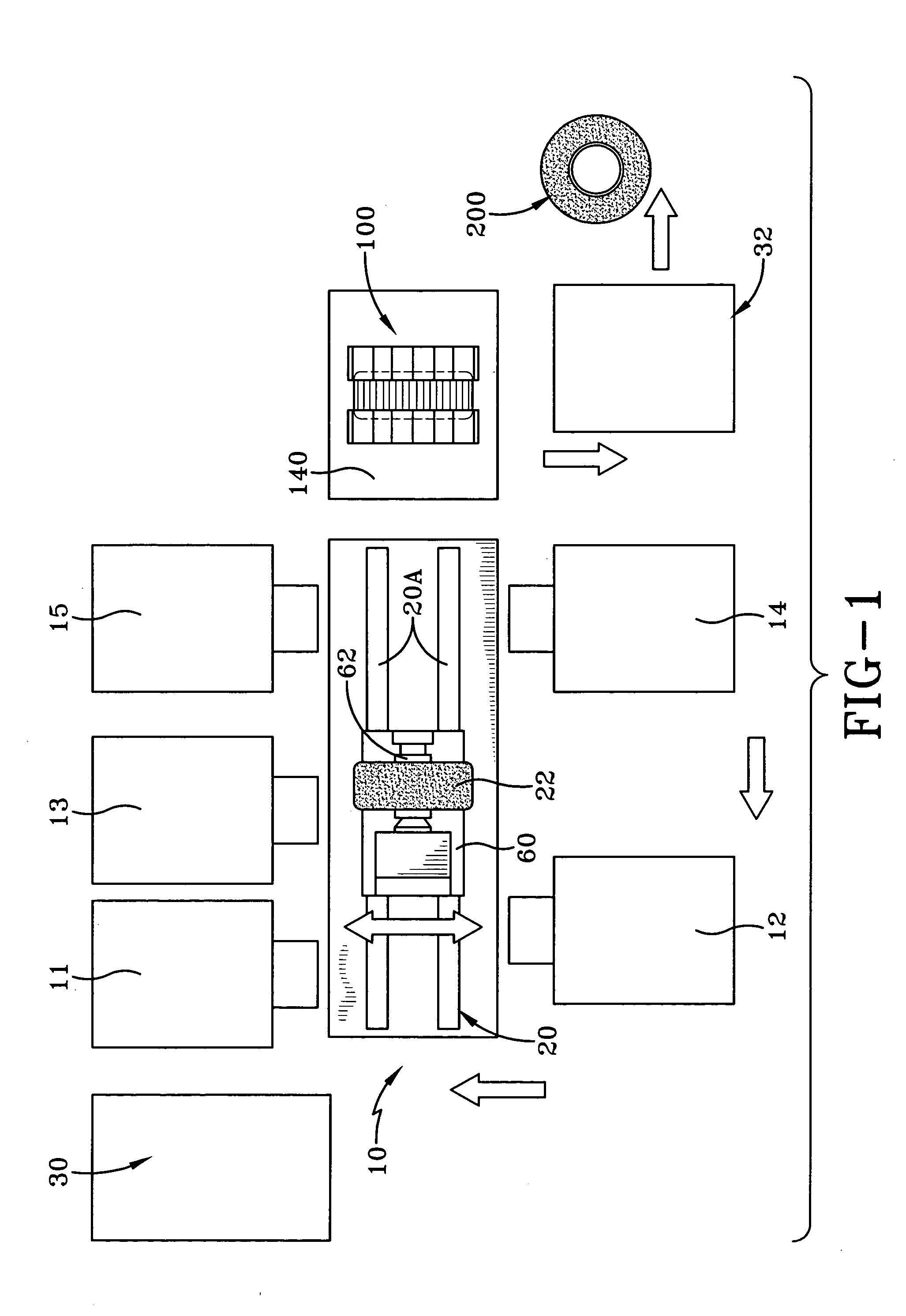

Methods and apparatus for making tires and for converting an assembly line for making different types of tires

A tire manufacturing assembly line is disclosed which can be reconfigured for making different types of tires in shorter runs. The assembly line can interchangeably use components from centralized preparation or integrated preparation, and interchangeably use storage reels of any form from the centralized preparation.

Owner:MICHELIN RECH & TECH SA

Tire uniformity through compensation between radial run out and stiffness variation

Methodology for characterizing non-uniformity forces at a tire spindle, such as low and high speed radial force variations and high speed tangential force variations include the steps of measuring radial run out and radial or tangential force variations at high and / or low speeds. From such measurements, the contribution of a predetermined type of stiffness variation (e.g. radial, tangential, extensional, bending) to respective radial and / or tangential force variations can be determined. Signature analysis statistical methods may also be utilized to characterize such tire non-uniform forces for different steps and reference physical angles of a tire construction process. Based on the characterization of such tire non-uniform forces, additional process steps may further correspond to tire grading and / or sorting processes, physical tire modification processes and tire manufacturing processes. Tire correction mechanisms and / or feedback control in a tire manufacturing process preferably yield tires having radial run out and stiffness variation parameters that are out of phase for one or more harmonics, thus yielding a reduction in the non-uniformity forces such as radial and tangential force variations at a tire spindle.

Owner:MICHELIN RECH & TECH SA

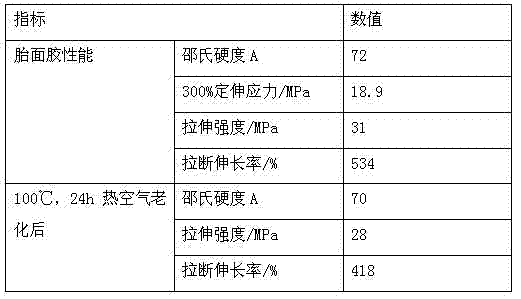

Tire apex composition for improving bond system and its preparation method and application

The invention relates to the tire manufacture field, especially to a tire apex composition for improving a bond system and its preparation method and application. The tire apex composition for improving the bond system is formed by the mixing of the following ingredients of: by weight, 70-100 parts of natural rubber, 0-30 parts of styrene-butadiene rubber, 55-75 parts of carbon black, 1.0-4.0 parts of resorcinol, 0.2-3.0 parts of cobalt decanoate, 3-8 parts of a methylene donator adhesive, 0-20 parts of white carbon black, 3-8 parts of a vulcanizing agent and a sulfuration promoter and other processing auxiliary agents. The tire apex composition for improving a bond system obviously raises modulus and binding property, decreases heat generation, minimizes modulus loss at high temperature,and simultaneously reduces formula cost. By employing BTR tires under the precondition of unchanged structure, the hard apex strength and hardness can be guaranteed not to be decreased, the modulus is substantially increased, the bond performance between the apex and steel wires / steel wire cords is remarkably improved, and the anti-destroy performance of tire bead positions is raised.

Owner:ZHONGCE RUBBER GRP CO LTD

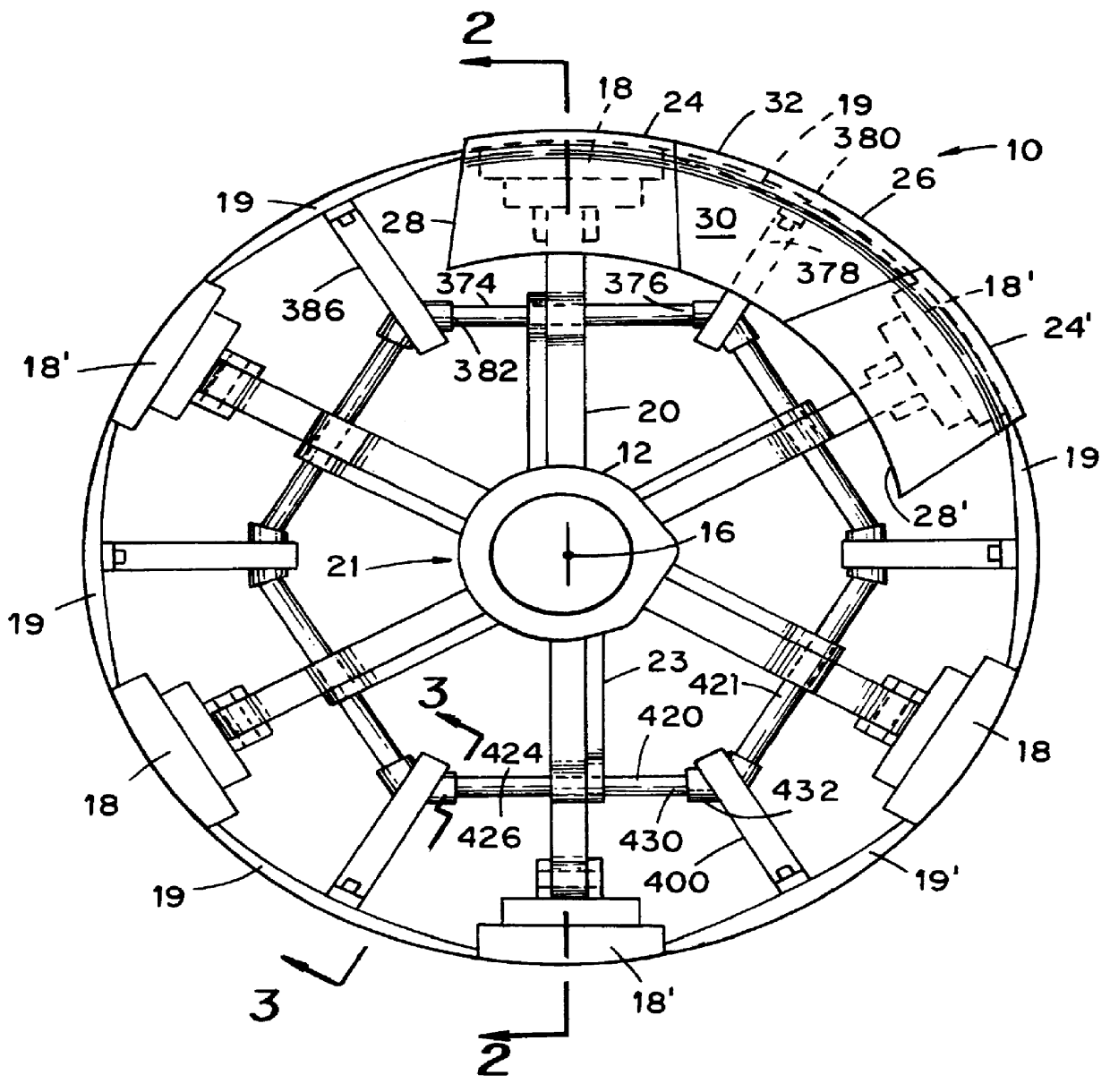

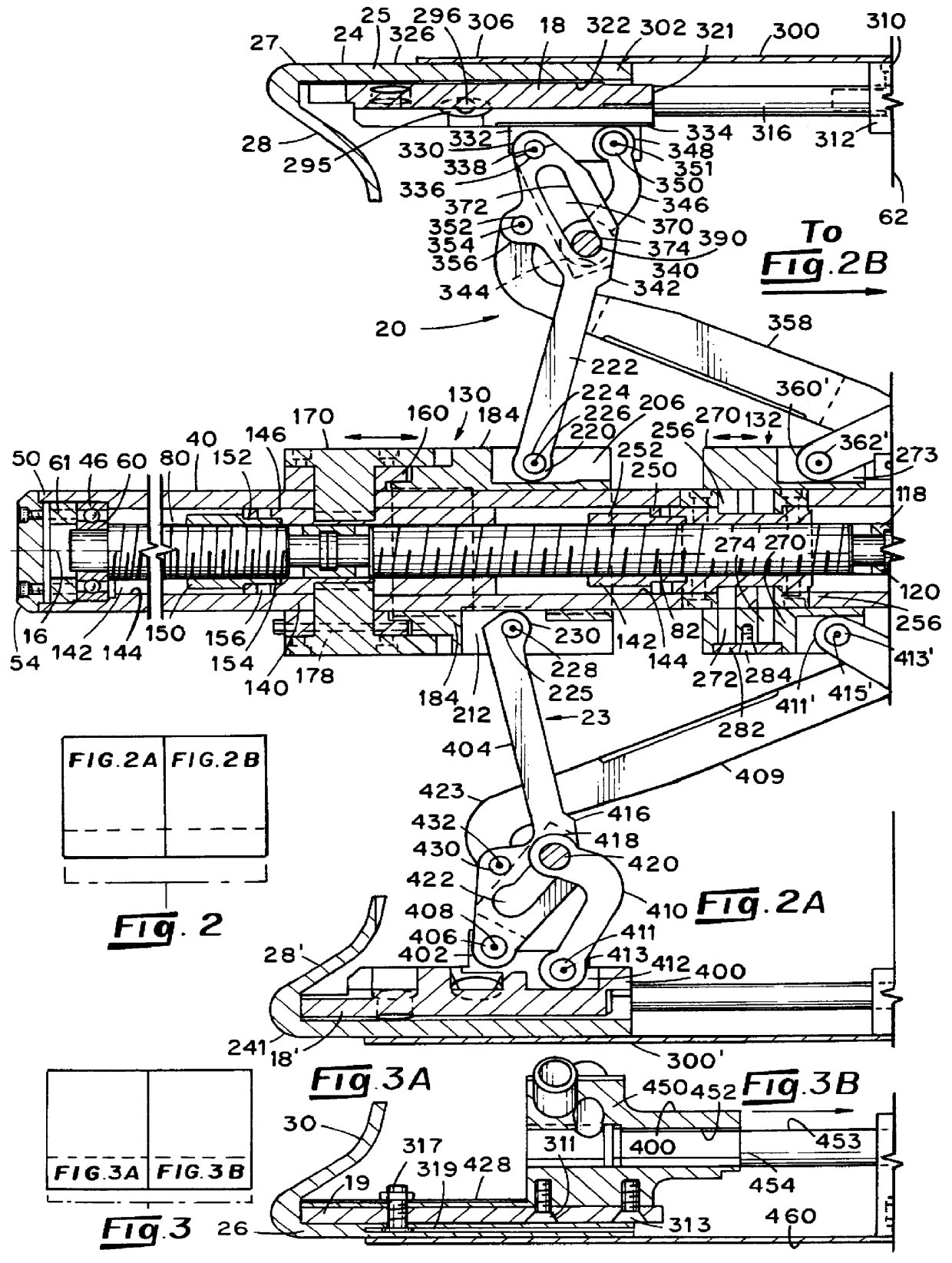

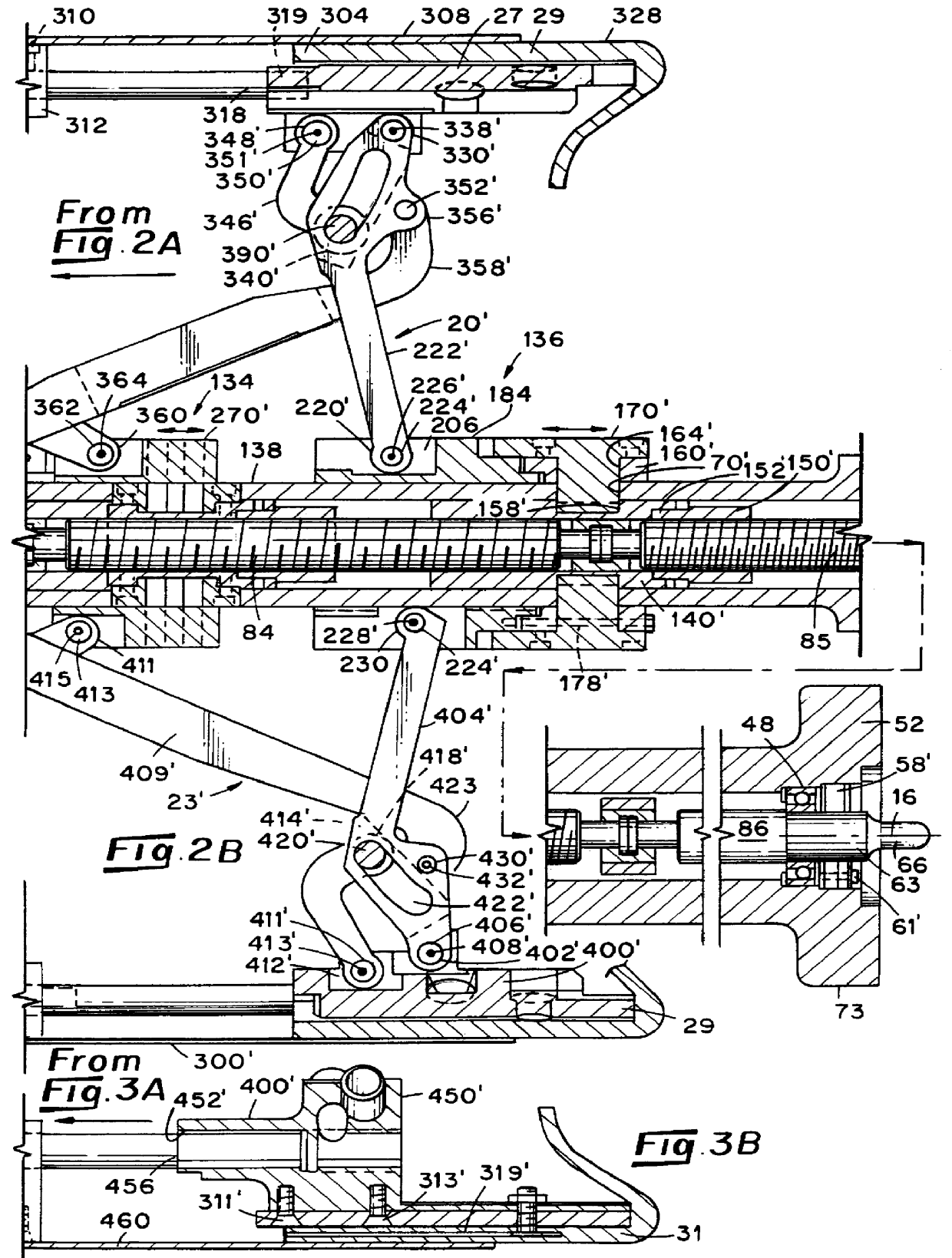

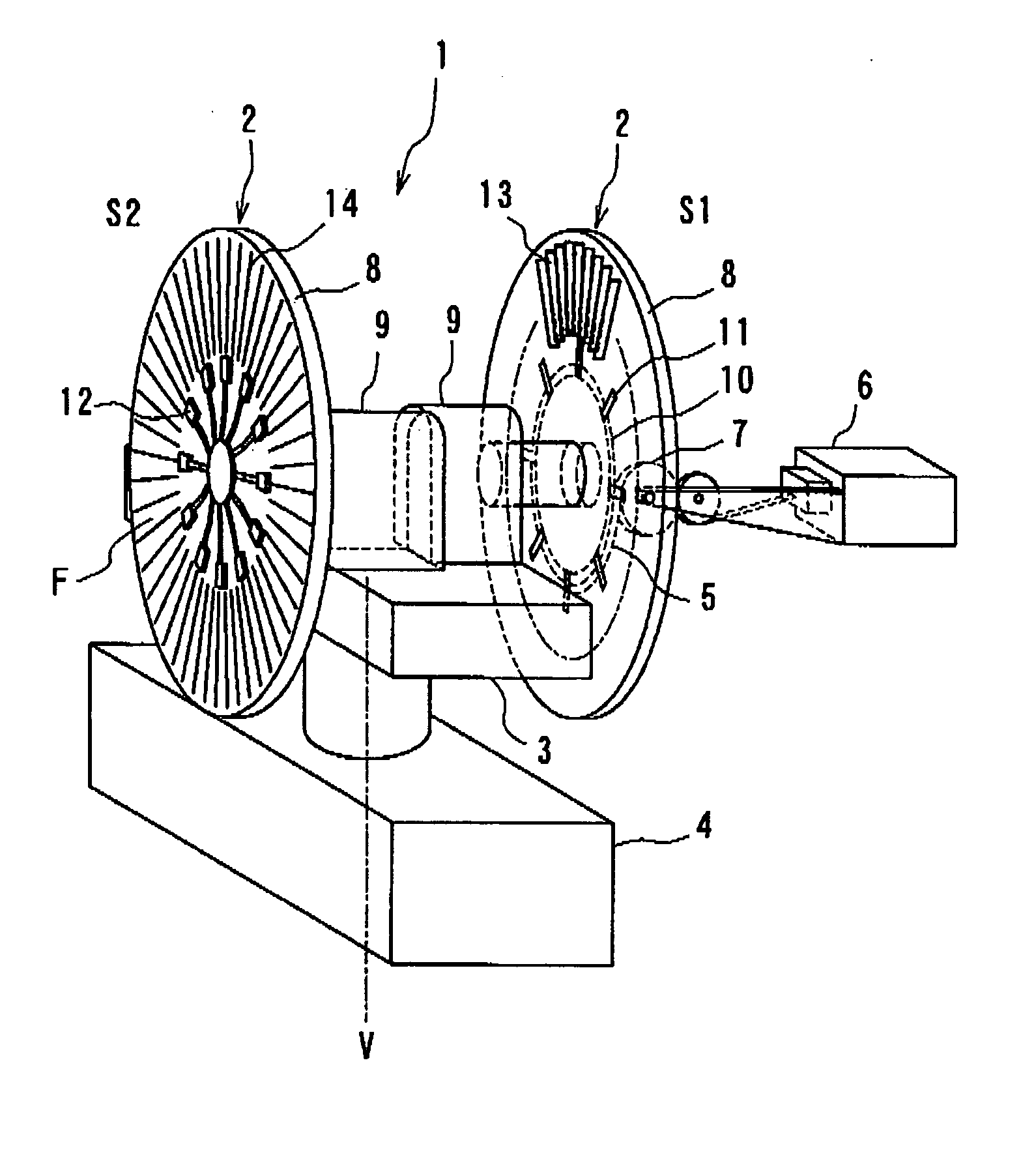

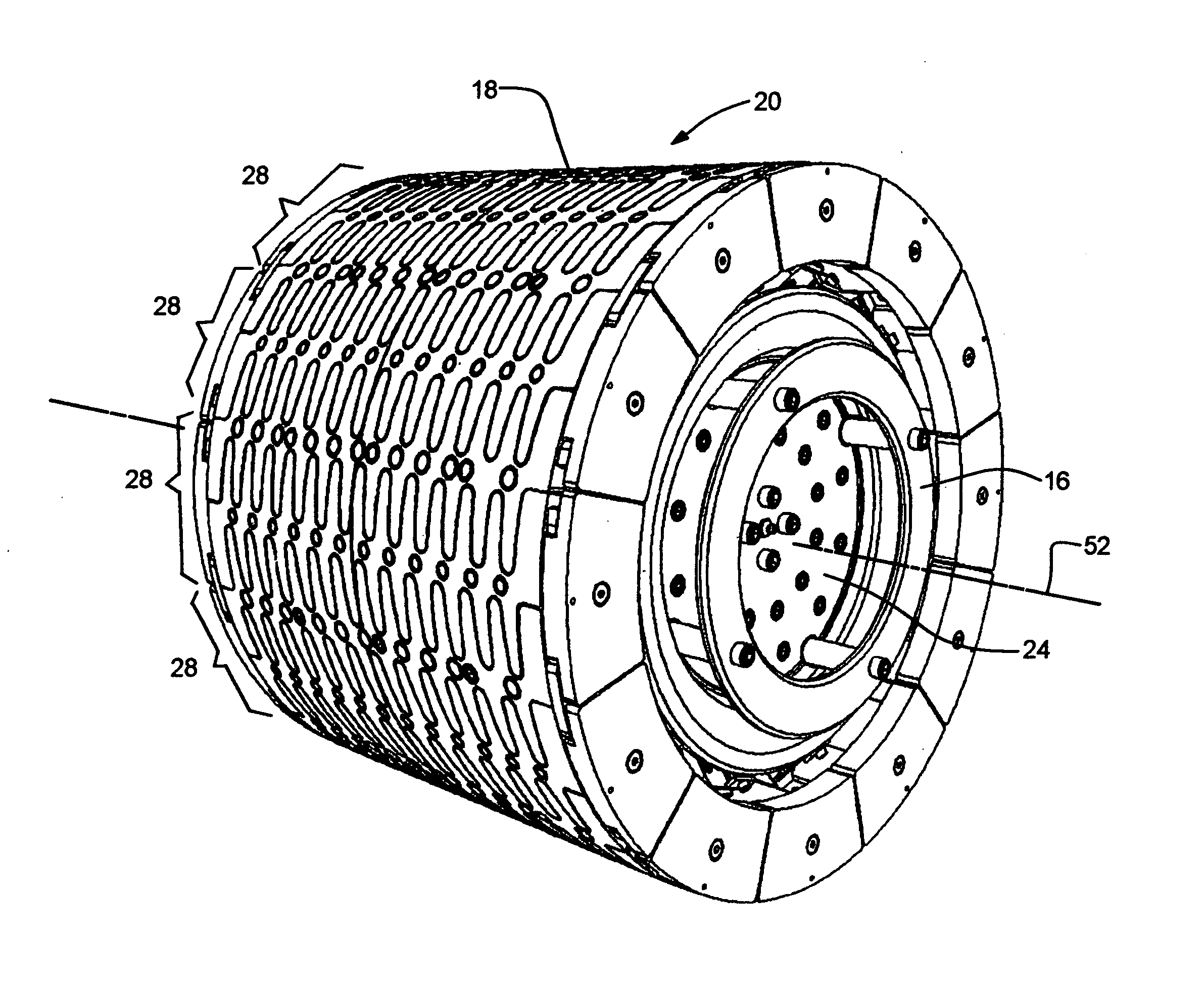

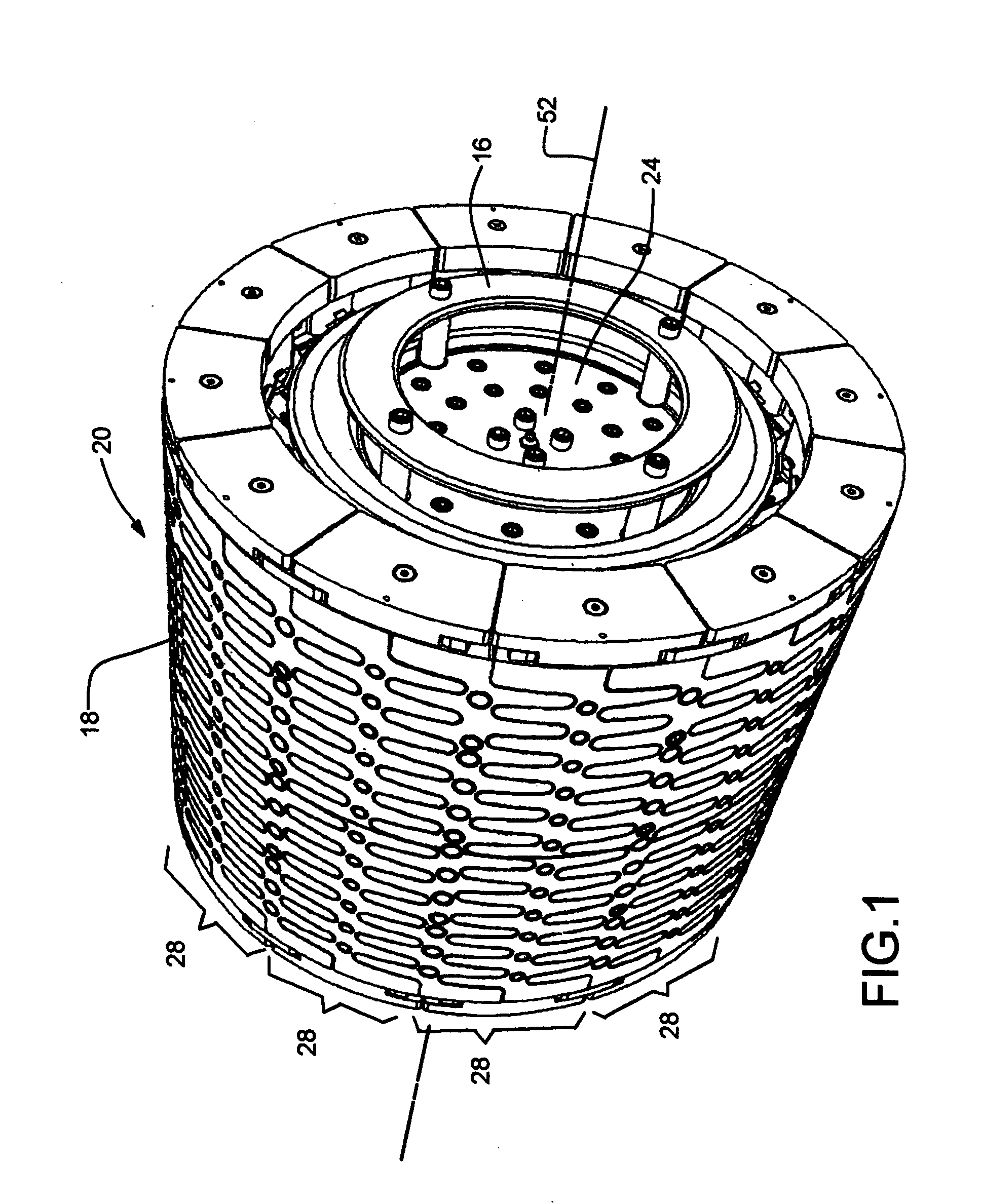

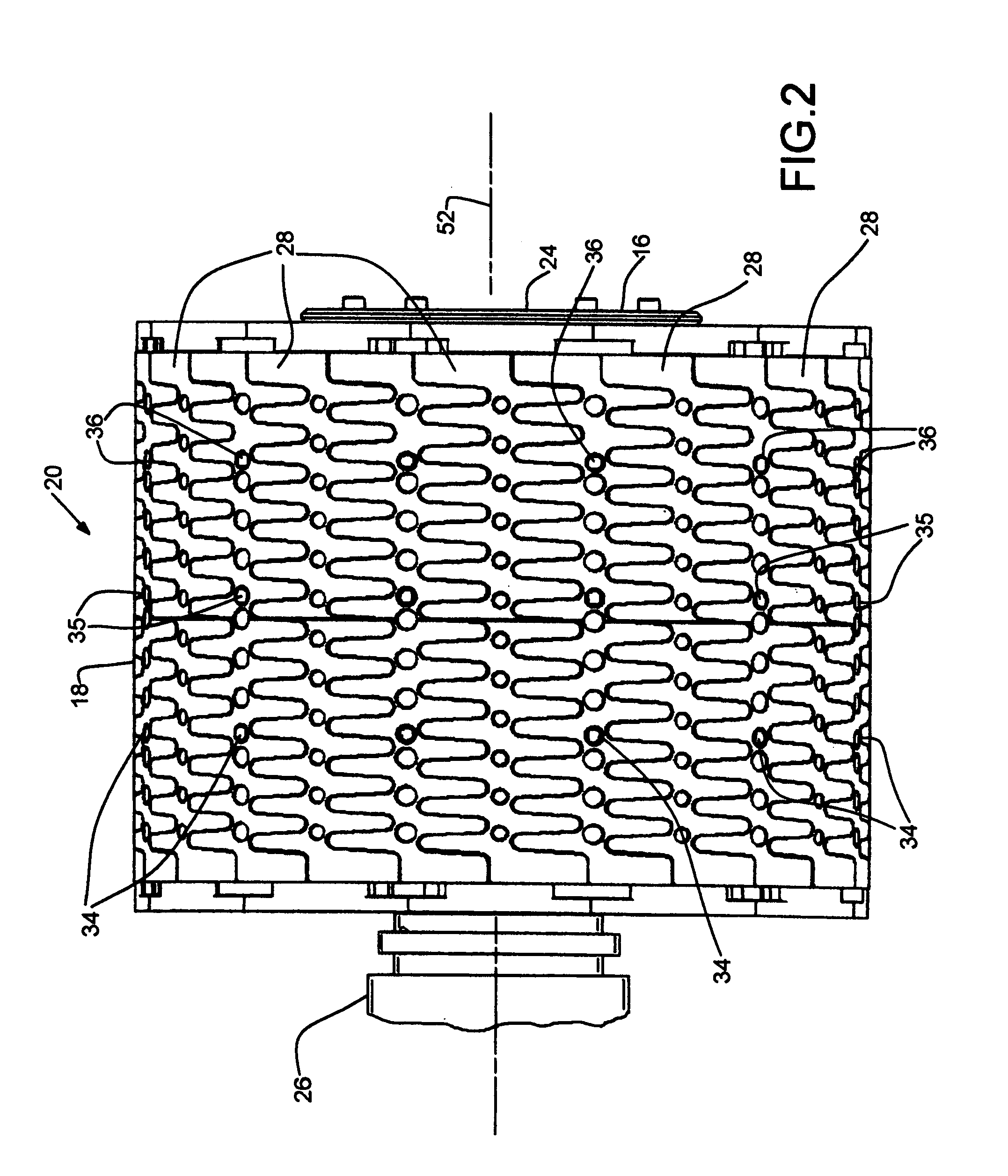

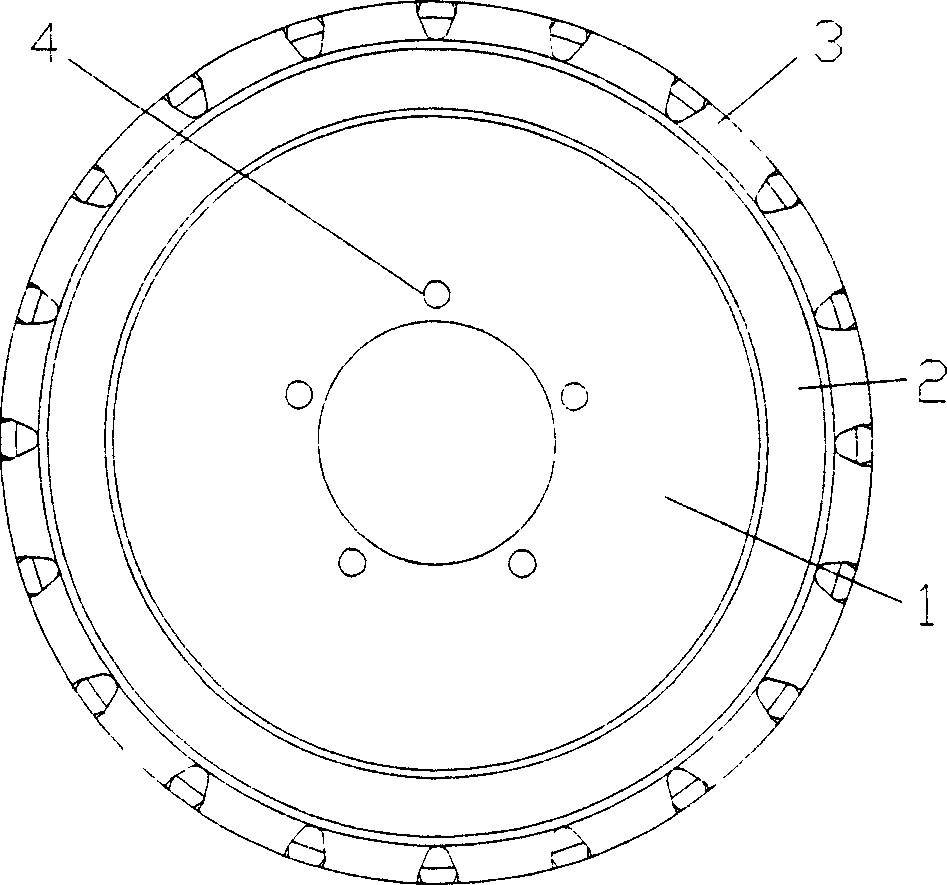

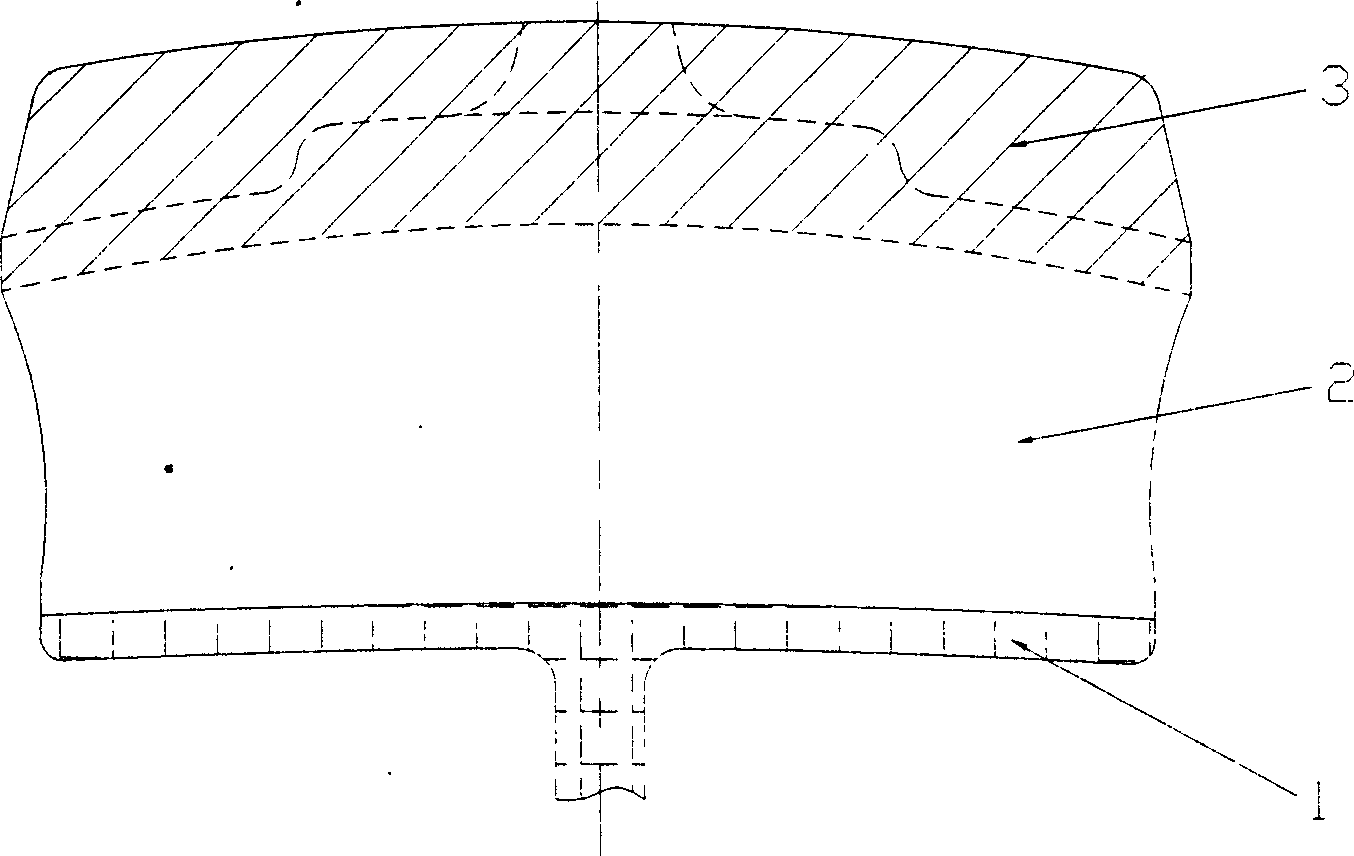

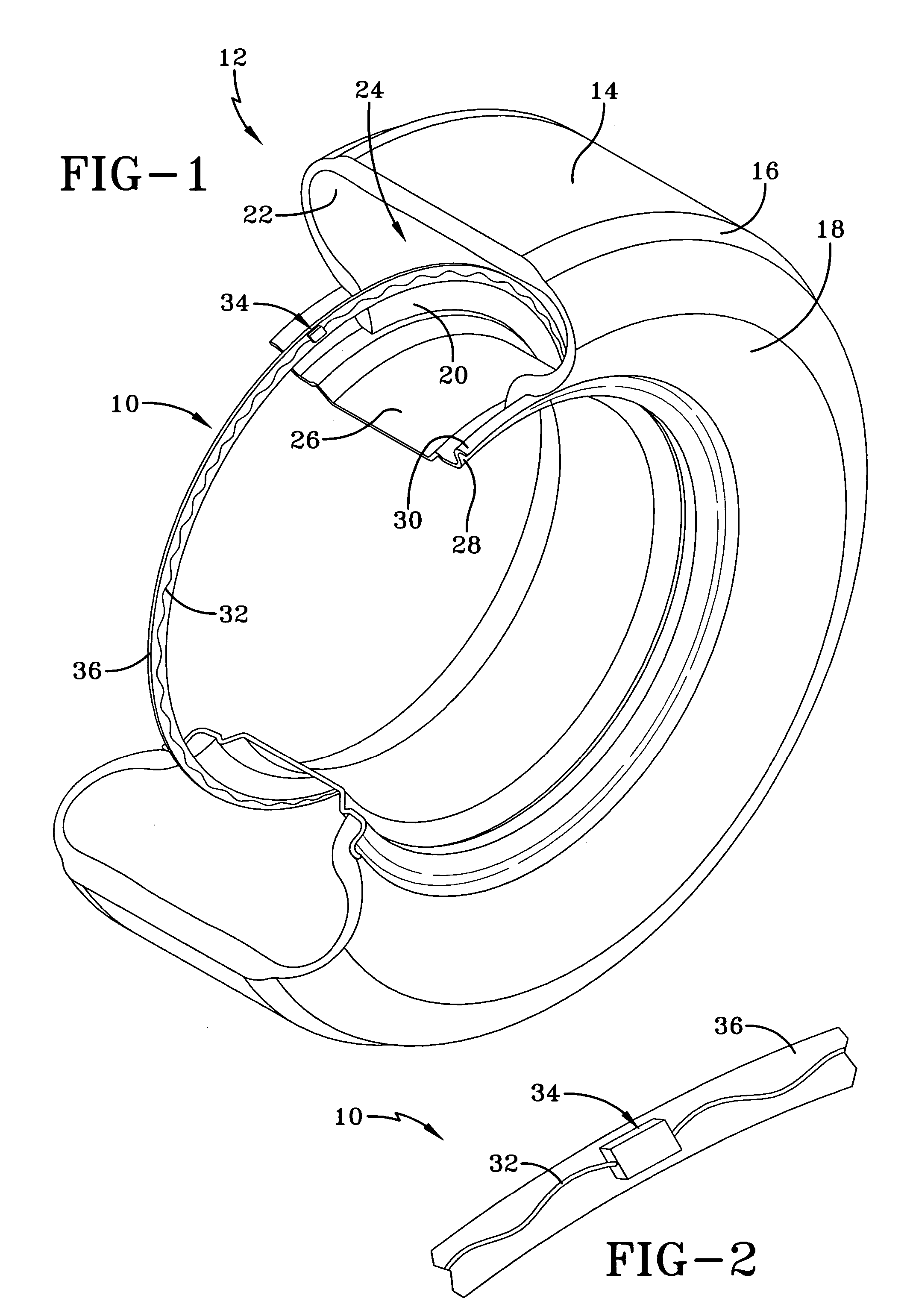

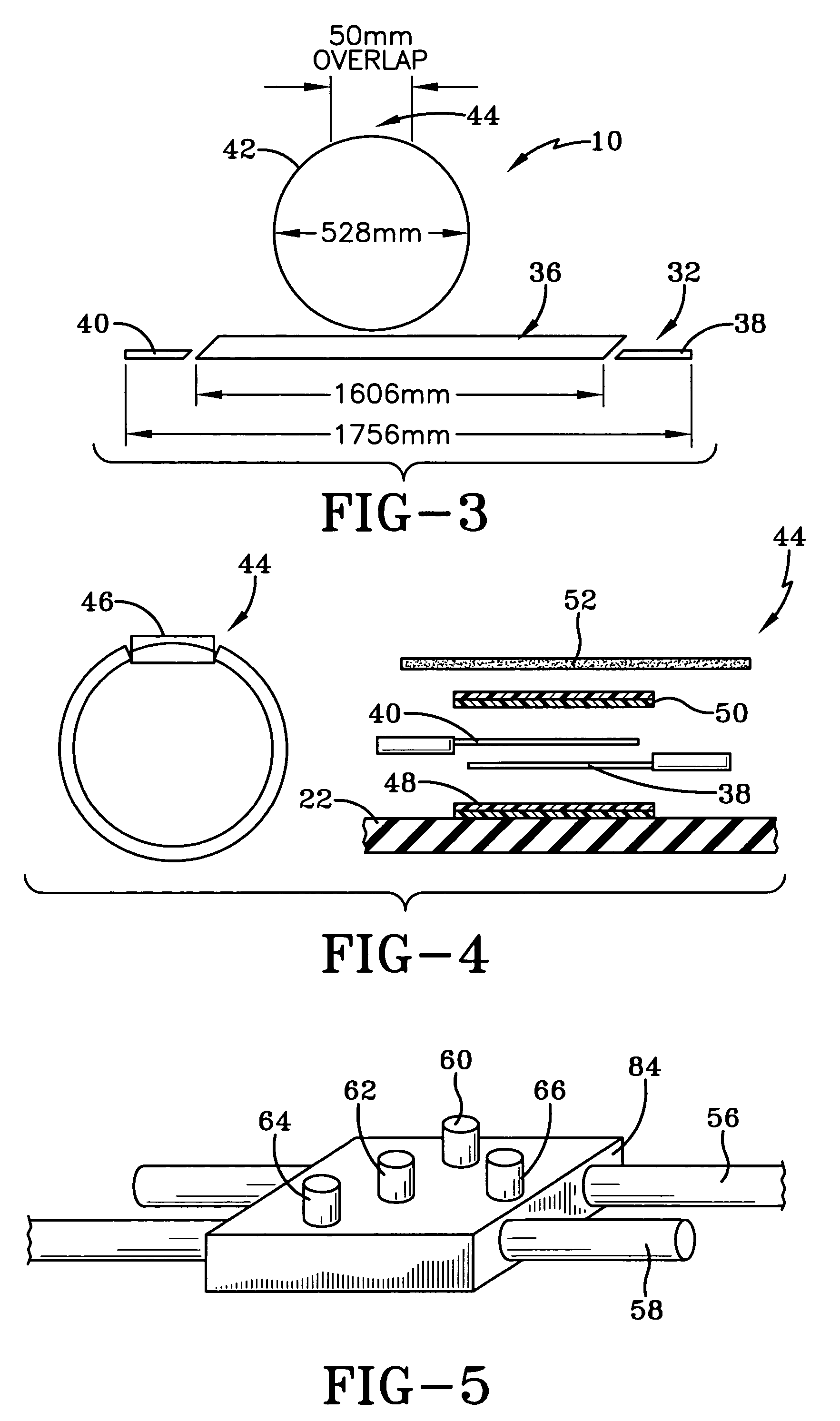

Tire manufacturing drum having simultaneous axial and radial adjustability

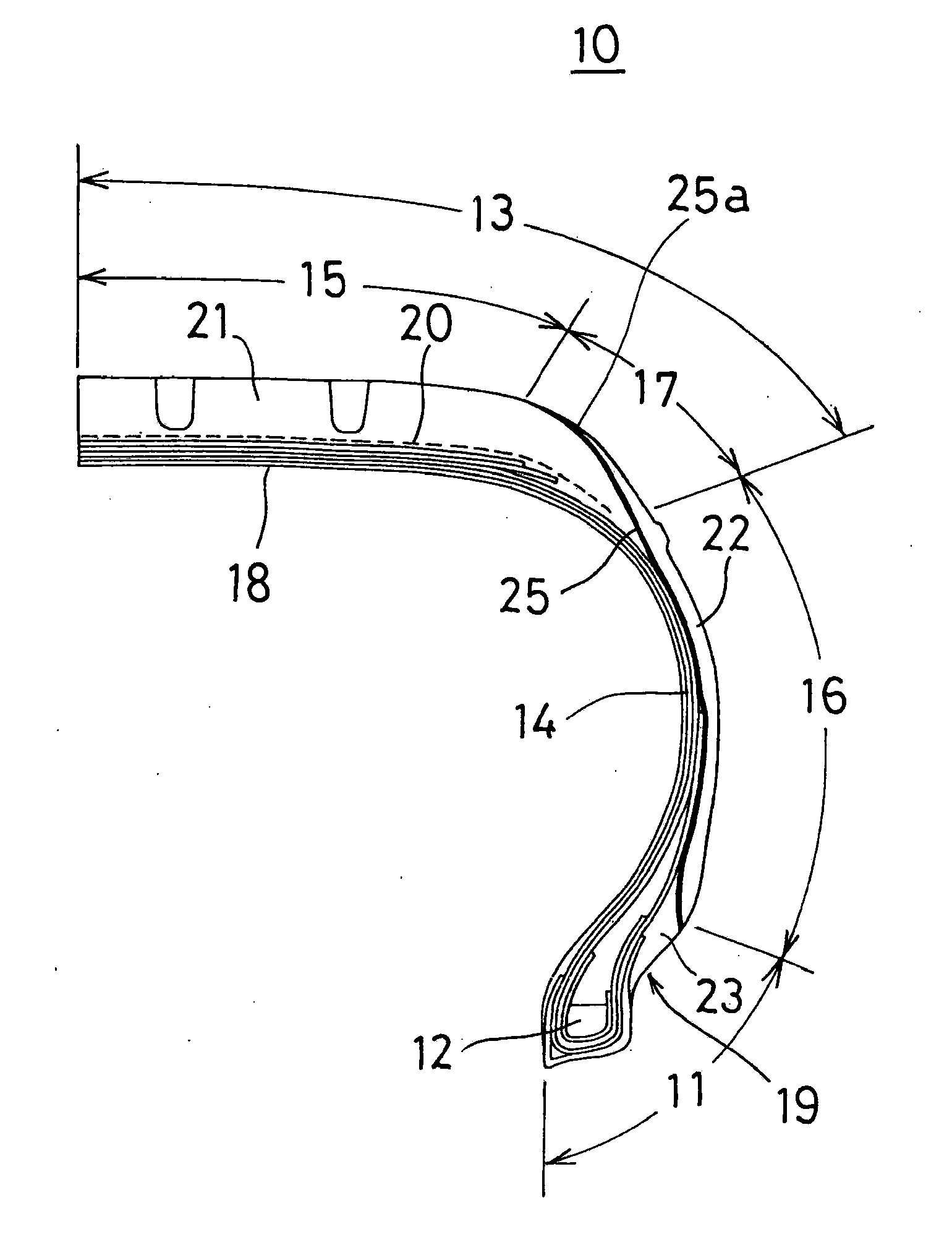

A rotatable drum (10) for use in the manufacture of vehicle tires, the drum including a plurality of segments which collectively define an outer circumference (32) of the drum. The segments are divided into first and second end portions (15,17) which are individually mounted for axial and radial movement between expanded and retracted positions relative to the rotational axis (16) of the drum. Each end portion of segments is further divided into first and second groupings (23,25), the segments (18,18') of the first and second groupings (23,25) being disposed in alternating juxtaposition with respect to the segments of the second grouping (18') and with the segments of the first grouping being movable axially further and radially faster than the segments of the second grouping as the segments are moved between their expanded and retracted positions so that the segments of the second grouping are received in overlying relationship to the segments of the first grouping as the segments of the first and second groupings are simultaneously moved radially inward toward the rotational axis of the drum. A third grouping 23 of the segments of each end portion of segments is provided for, with these segments (19,19') being received in overlying relationship to the segments of the first and second groupings. Further, in a preferred embodiment, each segment is provided with a shell member (24,26), with the shell members collectively defining the outer cylindrical surface (32) of the drum. A method for the production of a rotatable cylindrical drum (10) and a method for the manufacture of an OTR vehicle tire are disclosed.

Owner:DAVIAN ENTERPRISES LLC

Inner Liner of Pneumatic Tire

InactiveUS20080047646A1Avoid stickingEasy to packWithout separate inflatable insertsWith separate inflatable insertsElastomerRoom temperature

The present invention provides an inner liner of pneumatic tires that is formed from a non-drawn film of a polymer composition including 60 to 90 wt. % of a thermoplastic resin and 10 to 40 wt. % of an elastomer to have an oxygen permeation rate of less than 15×10−3 ccm / m2 24 hratm, and a fracture elongation of more than 200% at the room temperature. The tire thus manufacture has no fracture under a severe deformation during the tire shaping process, facilitating the tire manufacture, and exhibits an air permeation preventive property as an excellent air permeation preventive layer.

Owner:KOLON IND INC

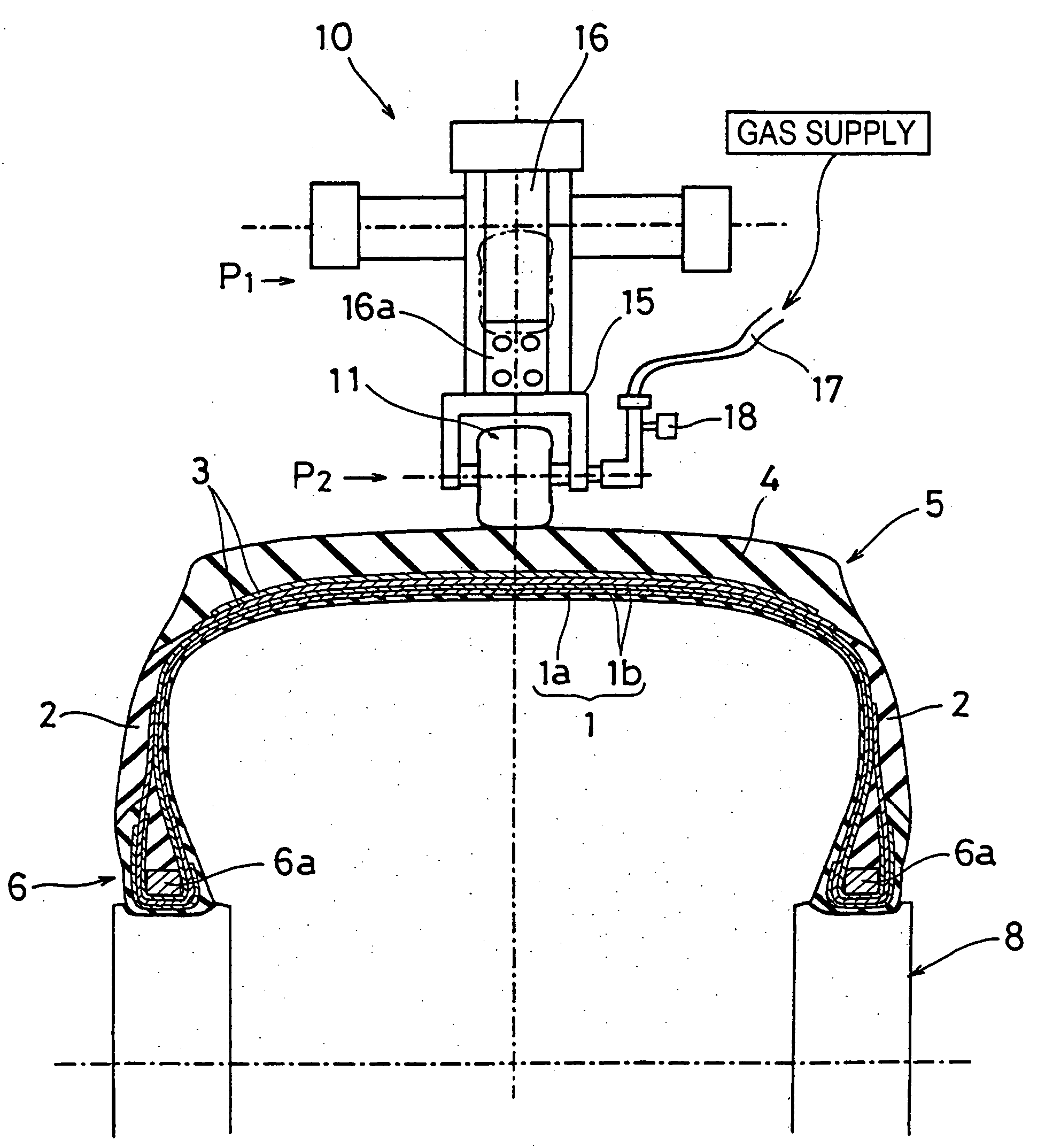

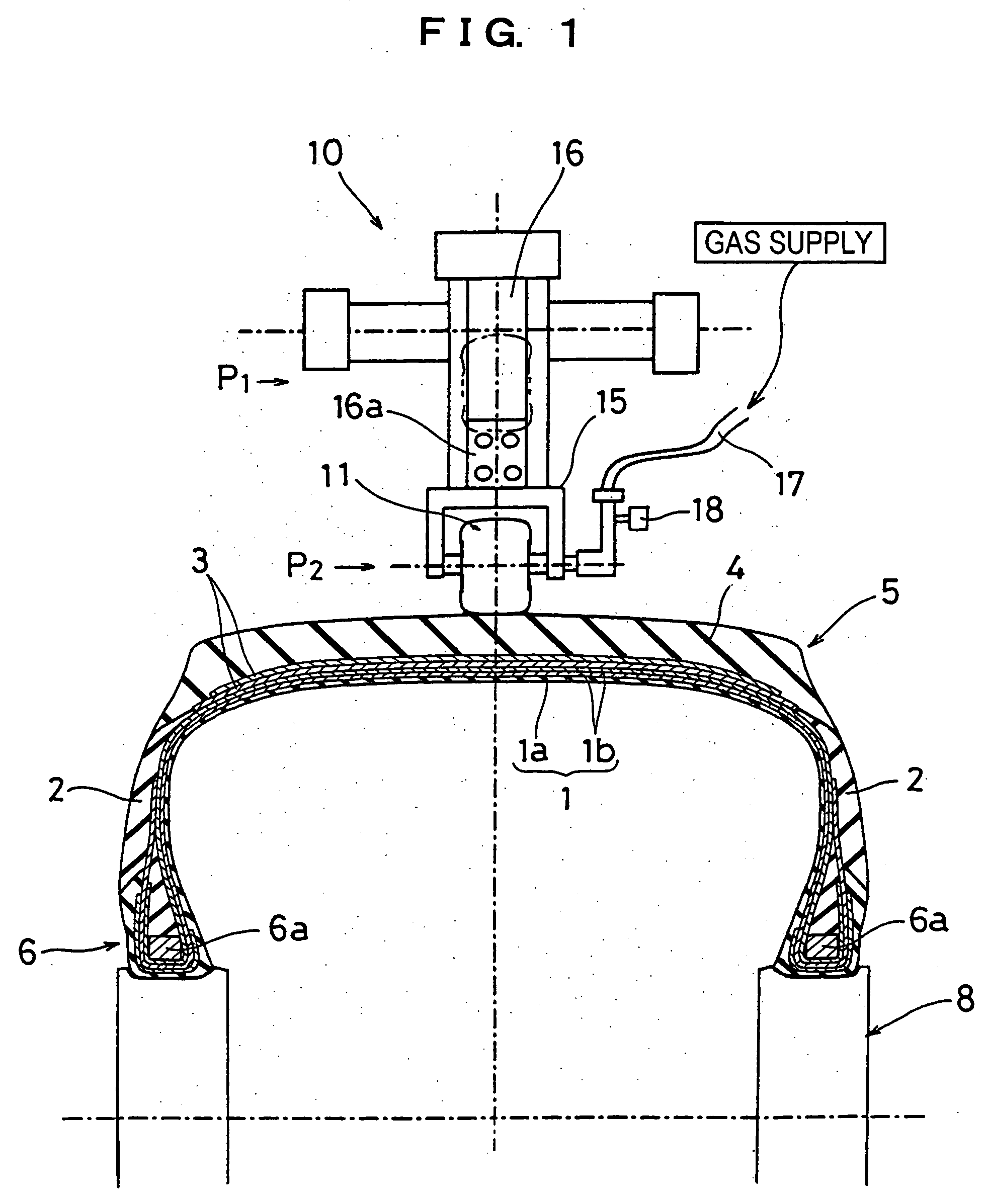

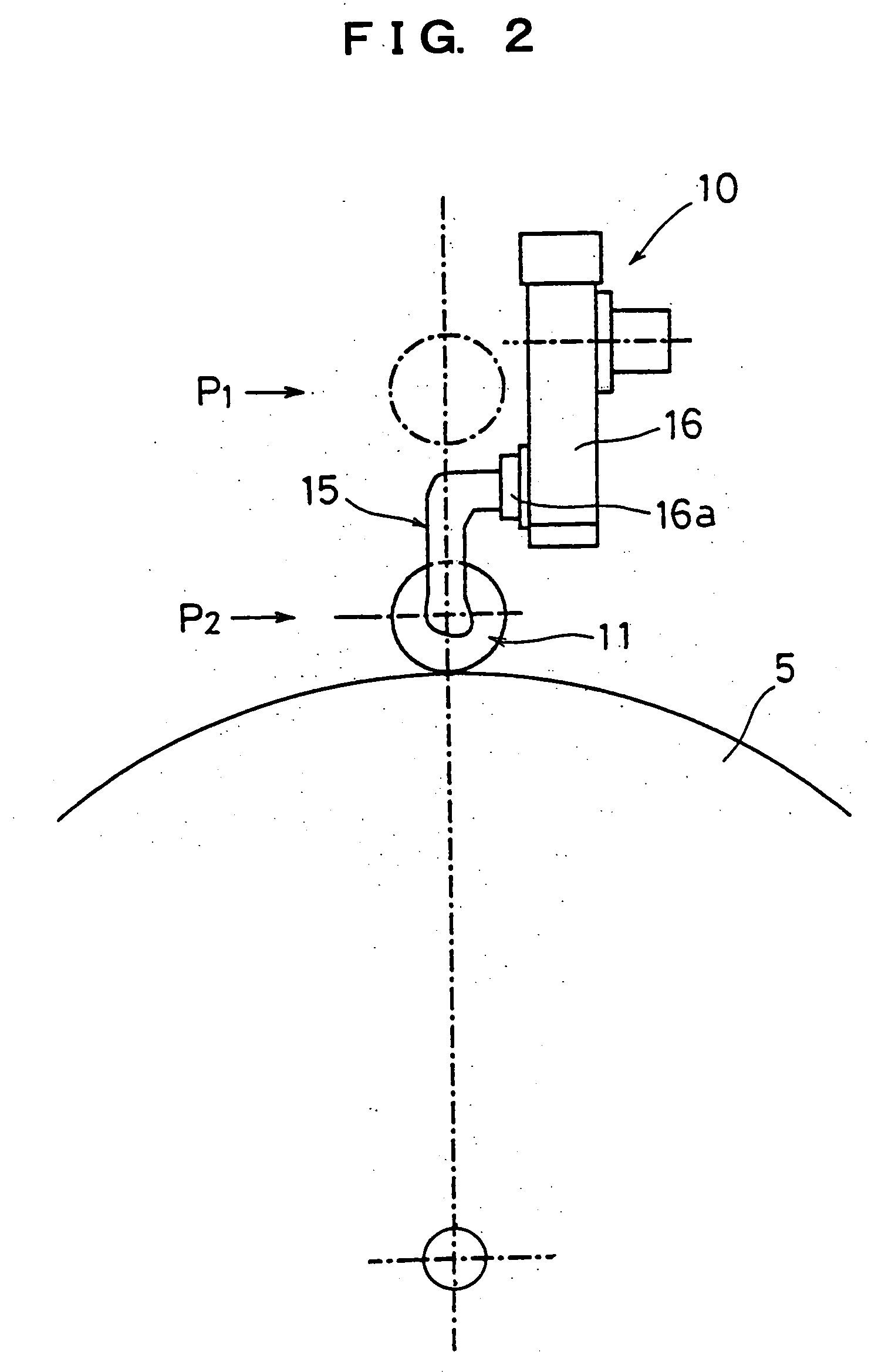

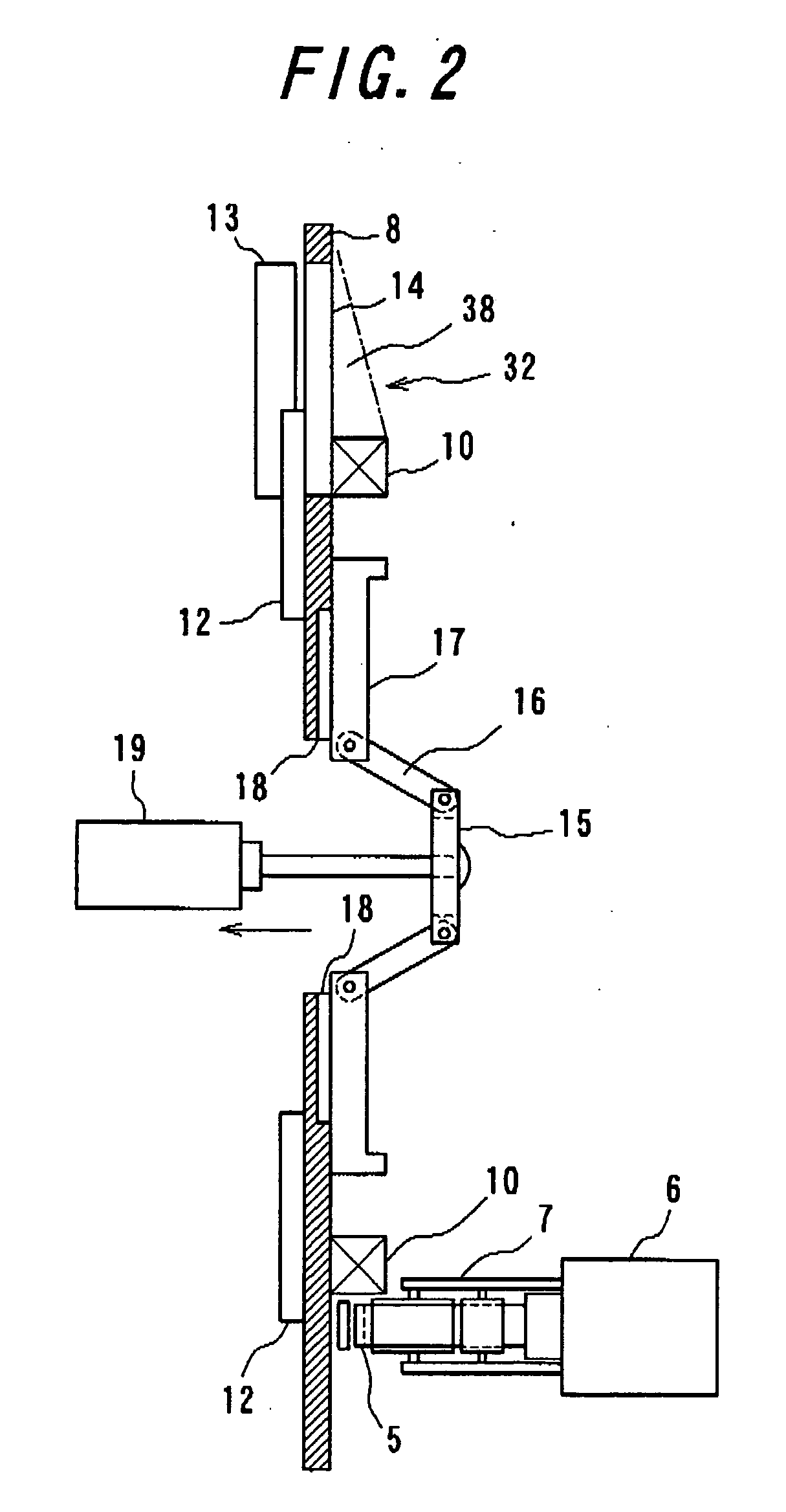

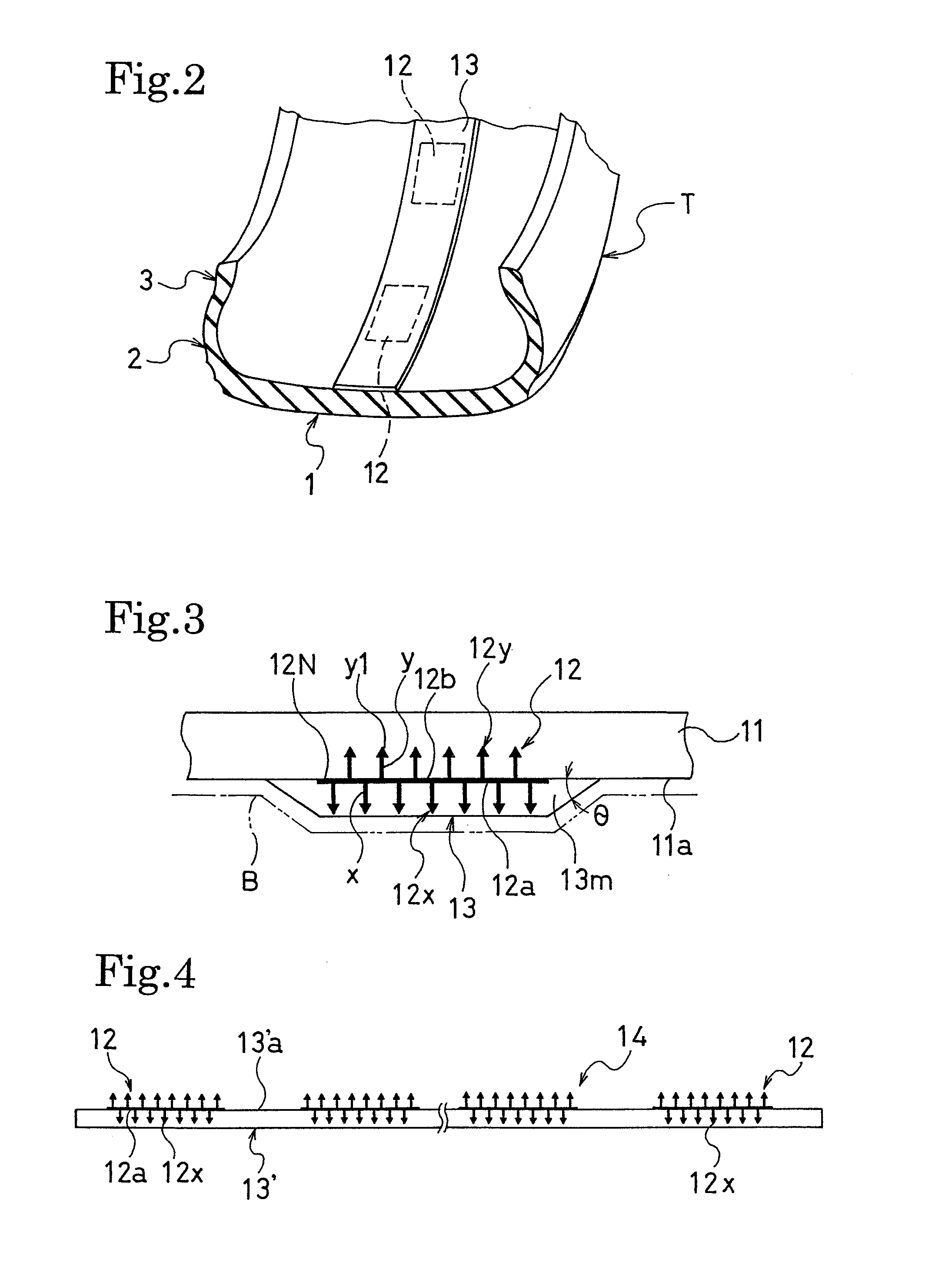

Tire building method and stitcher device

InactiveUS20060048884A1Well-balanced mannerIncrease the pressing areaTyresEngineeringProcess efficiency

A tire building method and a stitcher device therefore, which are aiming for achieving reliable pressing for bonding between a plurality of tire members all over outer face of the tire members, without forming a void between them, even though the outer face of the tire members have ups and downs, so as to curb strain in a carcass cord and to improve process efficiency. The method comprising: laying one or more of the tire members on a rotary support body such as a building drum; and press-contacting a press-contact part of a stitcher device on said one or more of the tire members on the rotary support while the rotary support being rotated, so as to bond together said one or more of the tire members; said press-contact part being a pneumatic-tire roller maintained with a certain level of inner pressure.

Owner:TOYO TIRE & RUBBER CO LTD

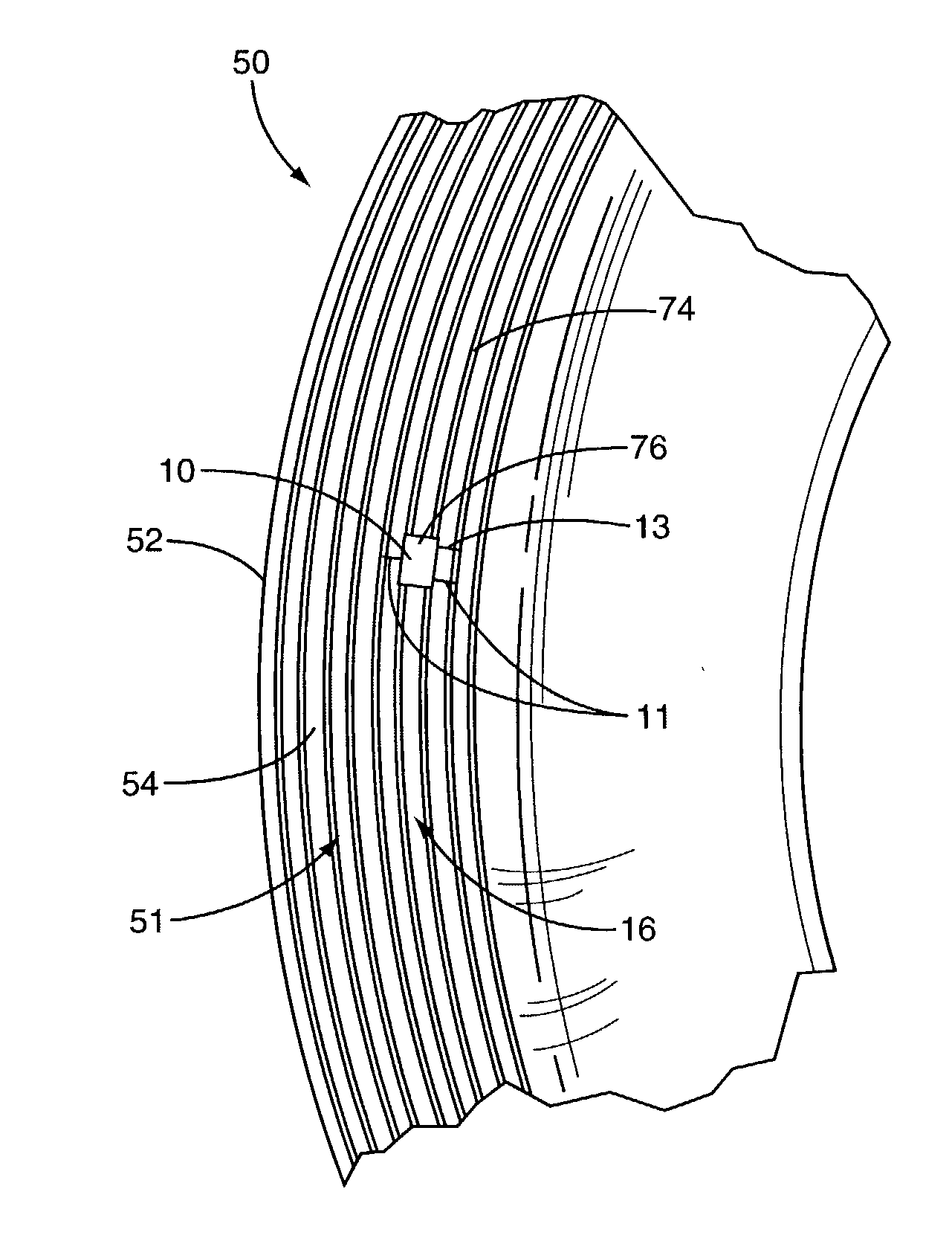

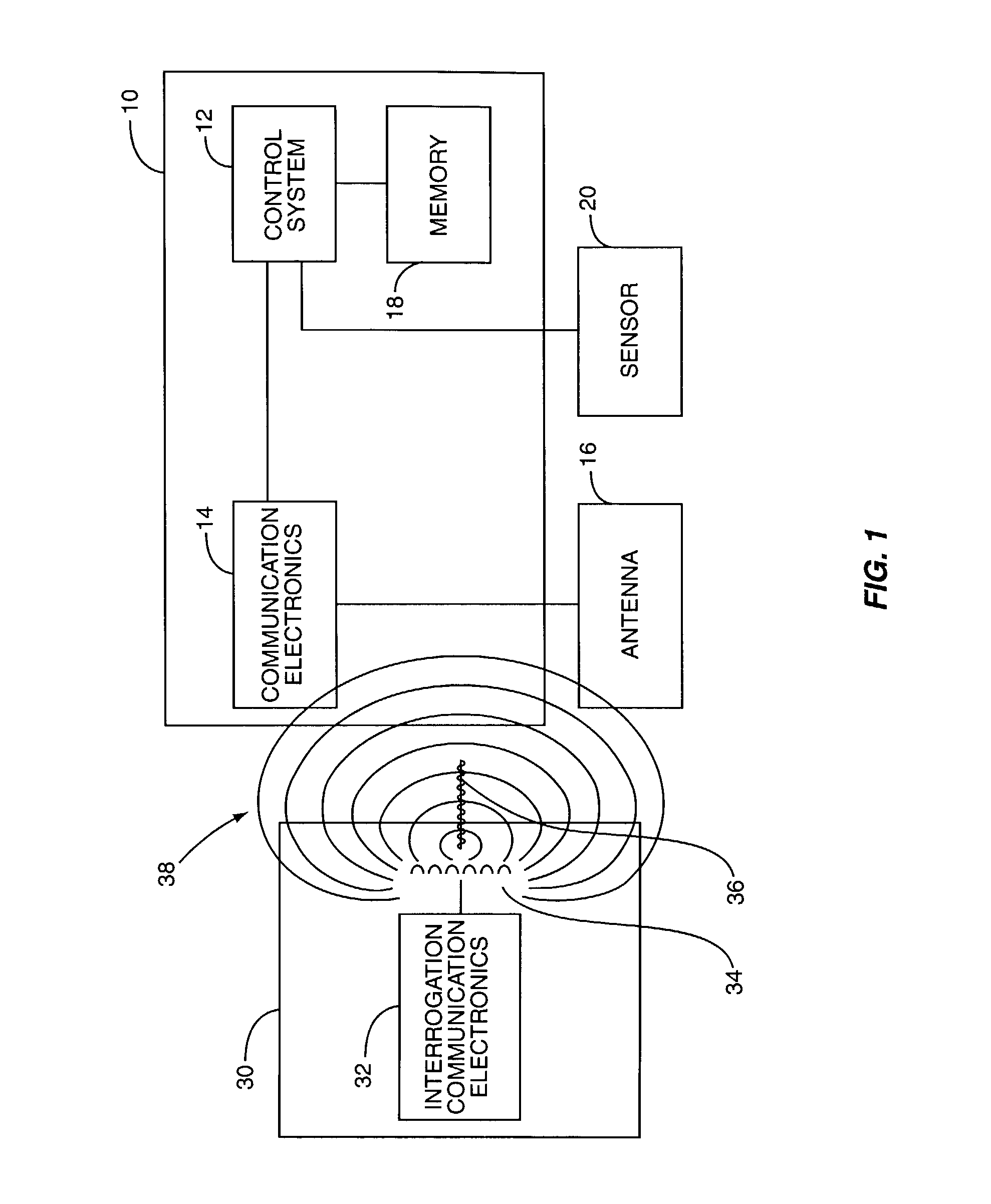

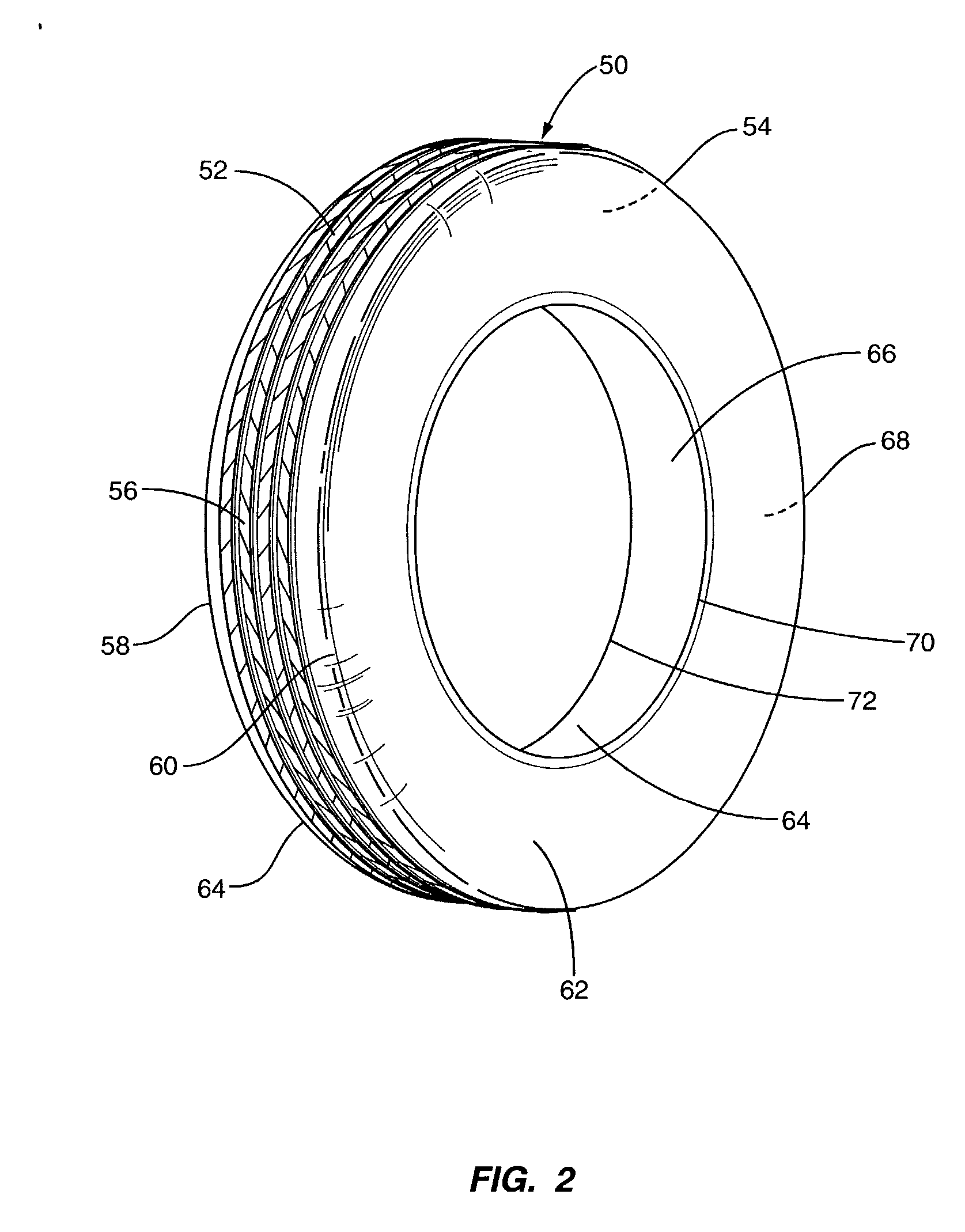

RFID tire belt antenna system and method

ActiveUS20050093761A1Transmission systemsAntenna supports/mountingsCapacitanceRadio frequency communication

The invention relates to a RFID chip that is contained inside a rubber tire to provide wireless communication of information concerning the tire. For instance, it may be desirable to communicate pressure and temperature information concerning a tire during its manufacture and / or usage. The RFID chip is attached to the inside of the rubber tire and is capacitvely coupled to a conductive belt contained inside the tire to provide an antenna for radio-frequency communications and reception.

Owner:MINERAL LASSEN

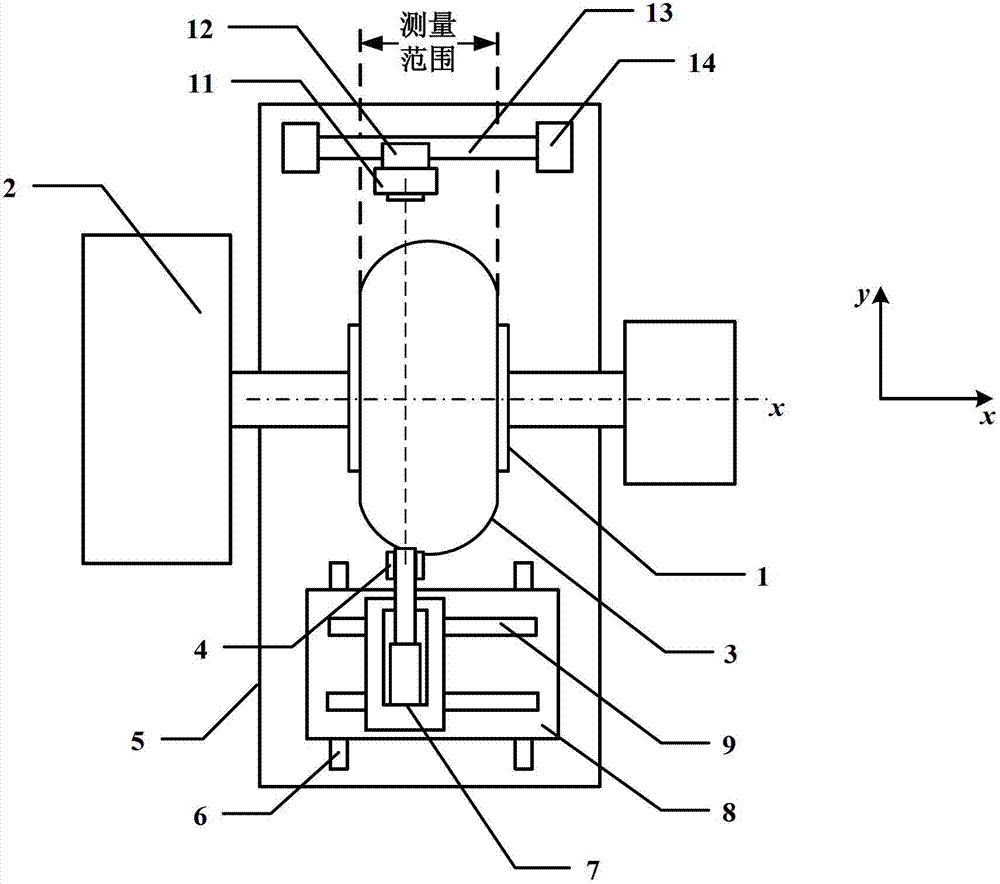

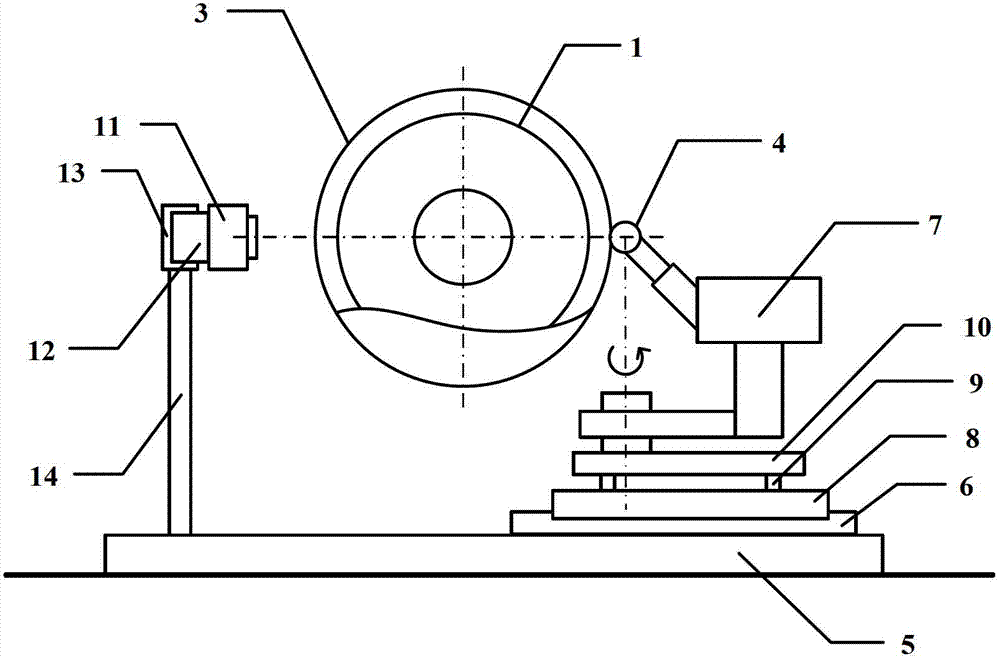

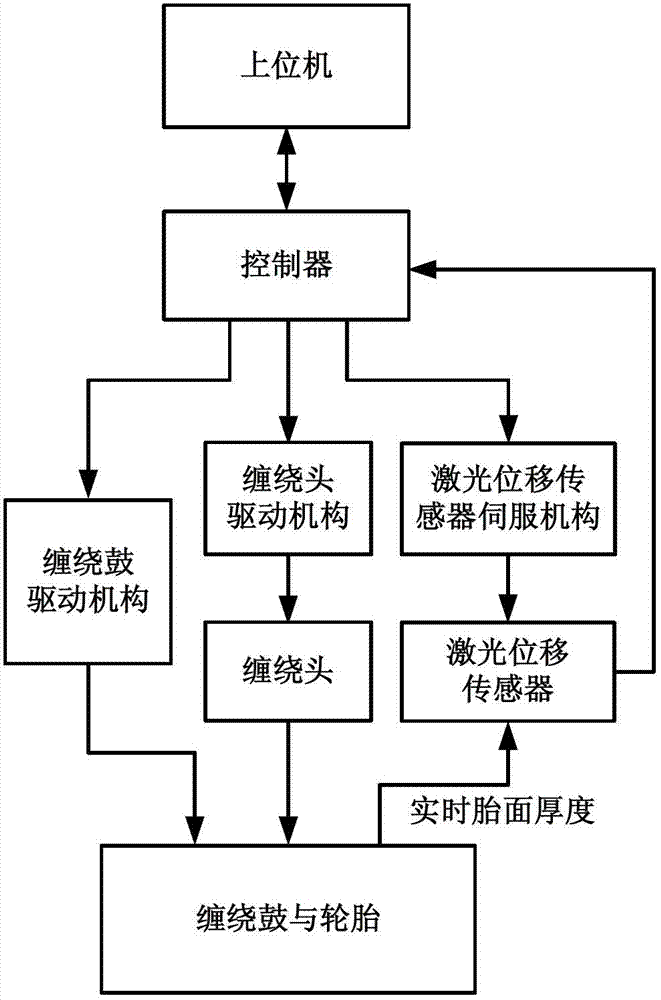

Online measuring device and measuring and controlling method for tread thickness of tire tread winding

ActiveCN102778203AImprove quality and efficiencyIncrease productivityUsing optical meansEngineeringControl theory

The invention belongs to the field of tire manufacturing equipment and relates to an online measuring device for tread thickness of tire tread winding. The online measuring device comprises a controller, a laser displacement sensor and a laser displacement sensor servo mechanism, wherein the servo mechanism comprises a sensor bracket, a guide rail and a sensor servo motor; the laser displacement sensor and the sensor servo motor are fixed on the sensor bracket; the controller is respectively connected with a control input end of the sensor servo motor and a signal output end of the laser displacement sensor; the sensor bracket is mounted on the other side of the processed tire opposite to a winding head; under the control of the controller, the sensor servo motor can drive the laser displacement sensor to do the transverse motion parallel to the axis of a winding drum along the guide rail; and the measuring range can cover the whole tire tread. The invention further provides a tread thickness measuring and controlling method realized by using the measuring device. The online measuring device and the measuring and controlling method provided by the invention have the advantages of non-contact, high measuring precision, quick response speed and the like; and the tread winding quality and production efficiency can be greatly improved.

Owner:TIANJIN SAIXIANG TECH

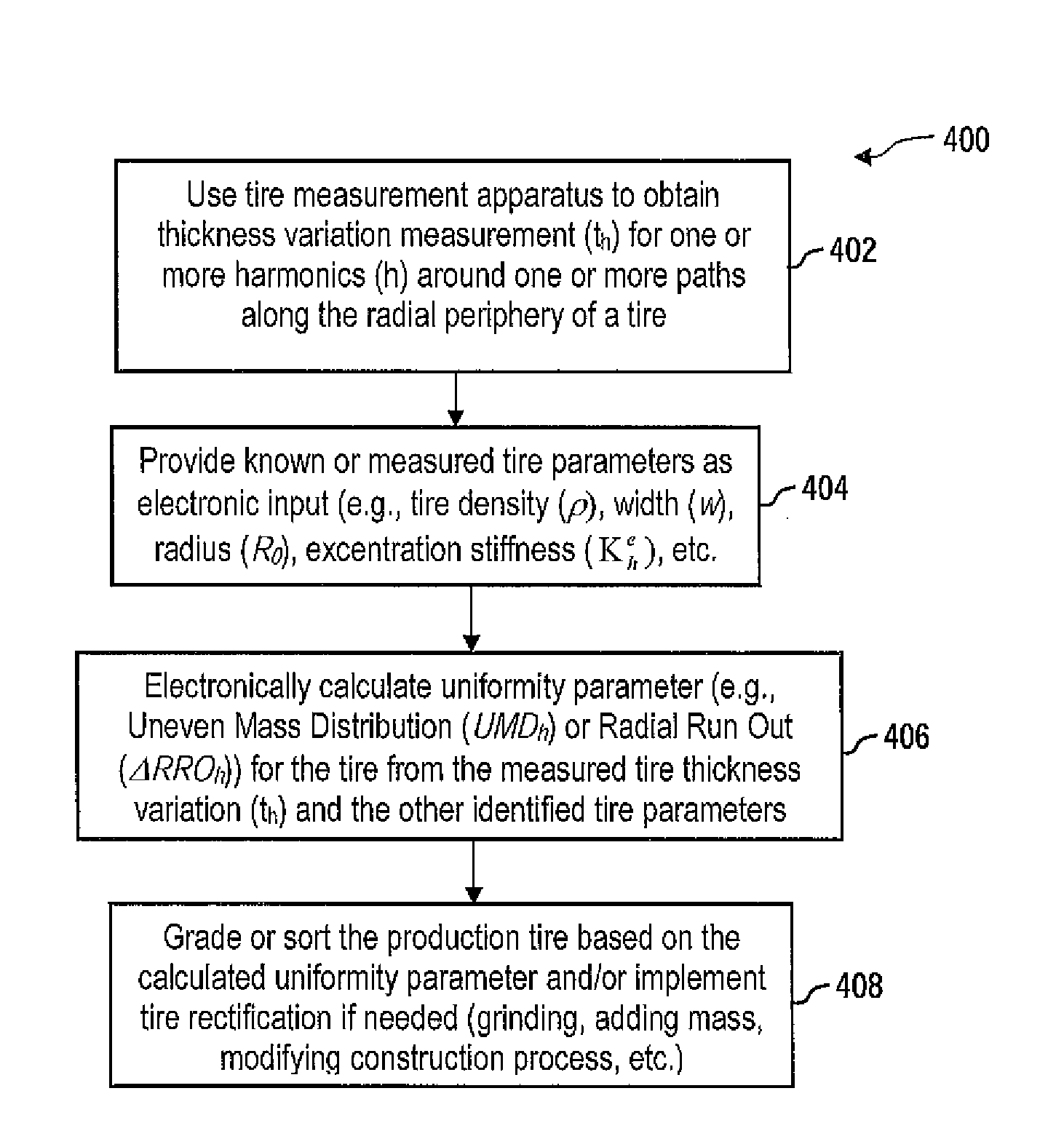

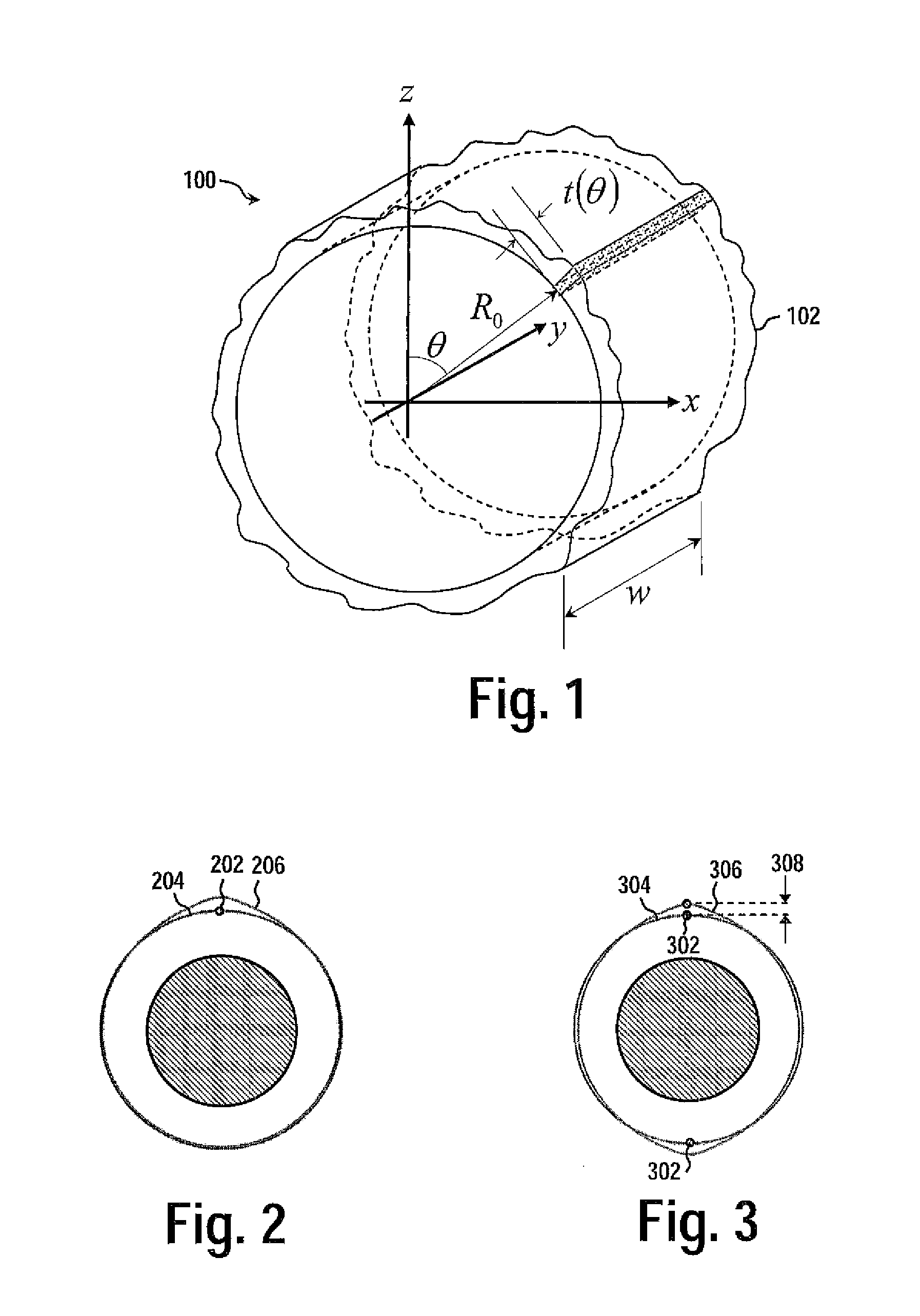

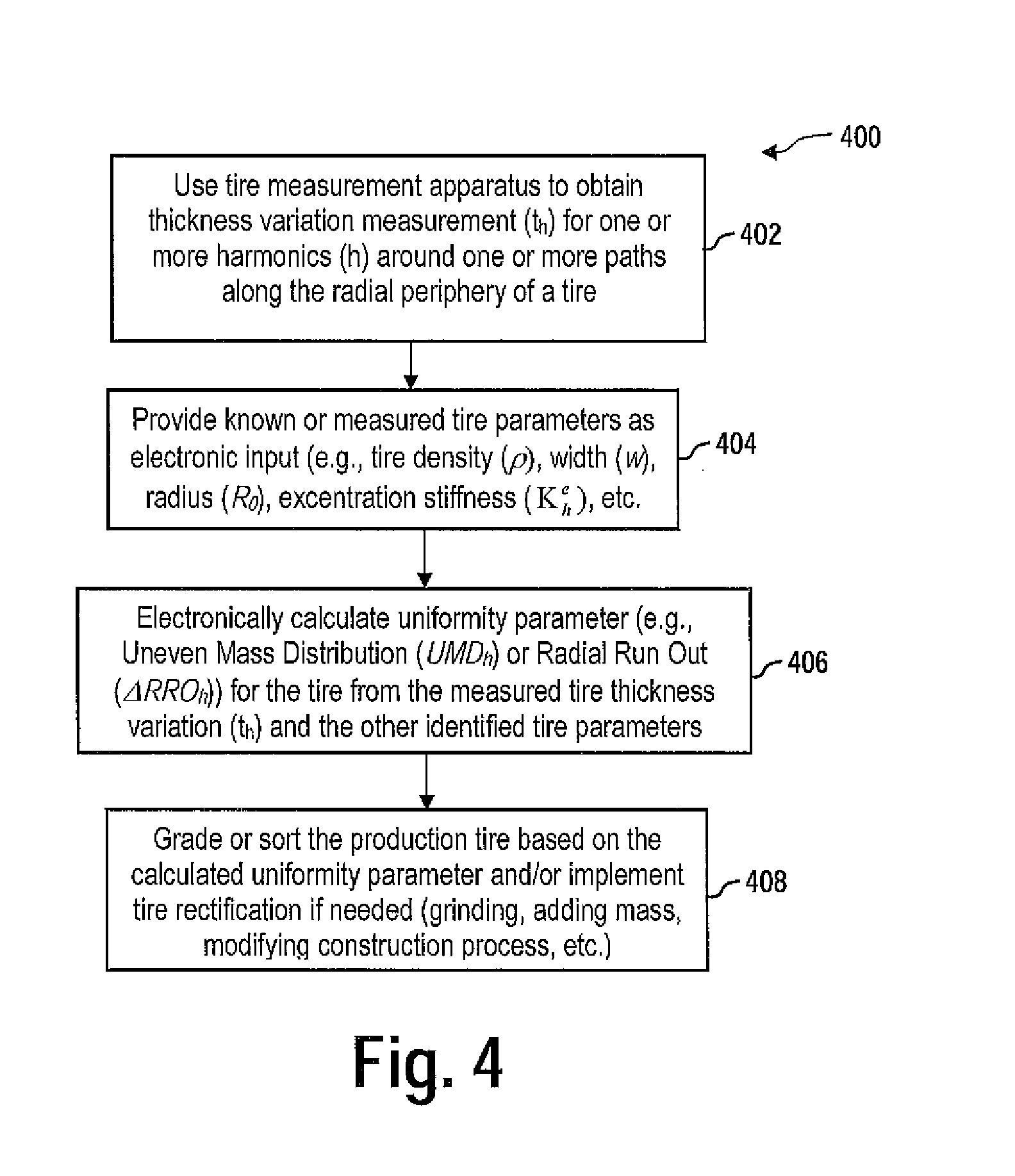

Method for prediction and control of tire uniformity parameters from crown thickness variation

Improved and more easily implemented methods for predicting uniformity parameters such as uneven mass distribution, radial run out and high speed radial force variation utilize other measurements such as the tire crown thickness variation. When high speed radial force variation is calculated, low speed radial force variation is also measured. Tire crown thickness variation can be measured in different fashions depending on the particular tire manufacturing process employed. By electronically determining resultant uniformity parameters, tires can be improved by rectification to address the uniformity levels. In addition, tire manufacturing can be improved by altering the resultant location of tire crown thickness variation relative to other aspects of the tire and / or tire manufacturing process.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

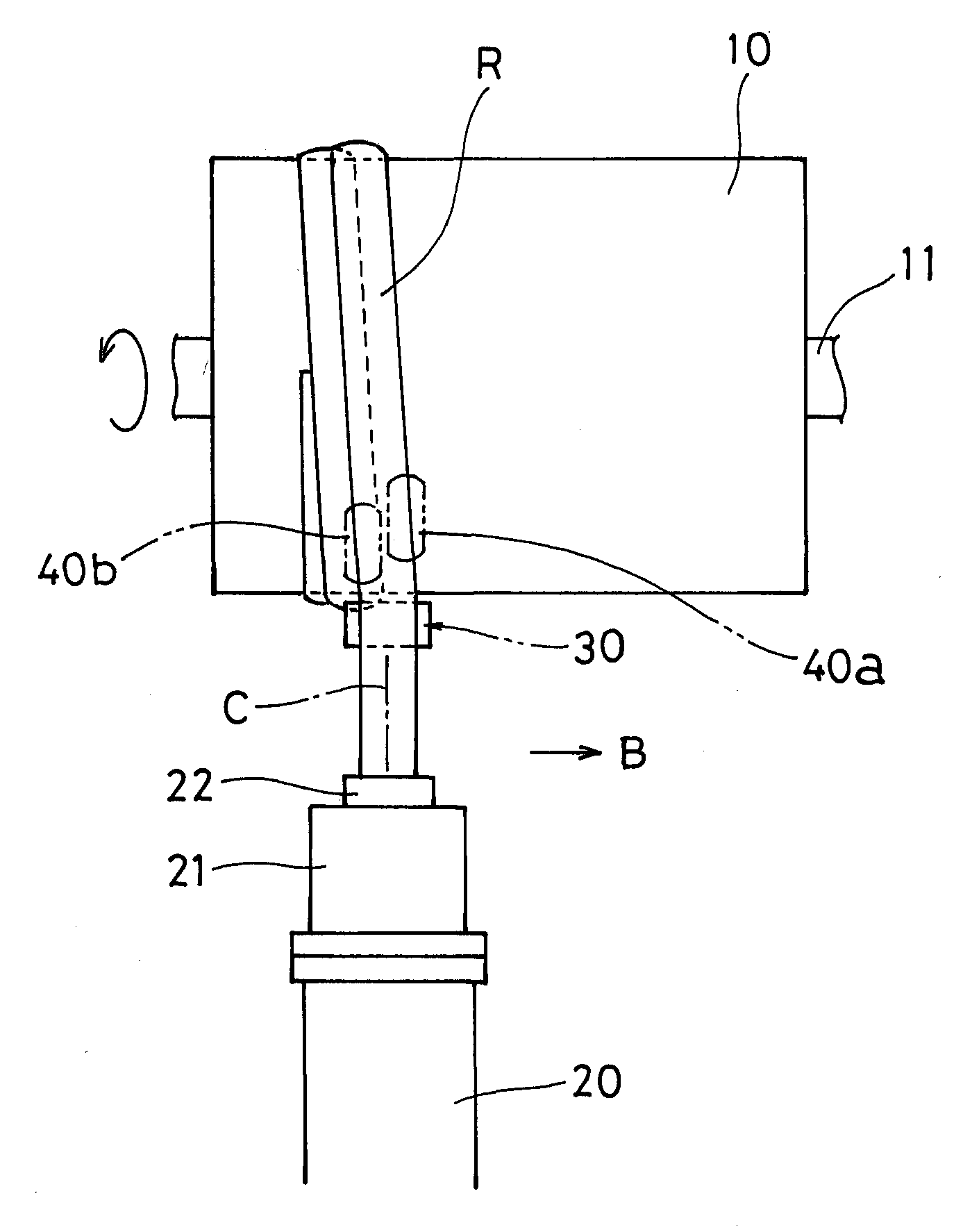

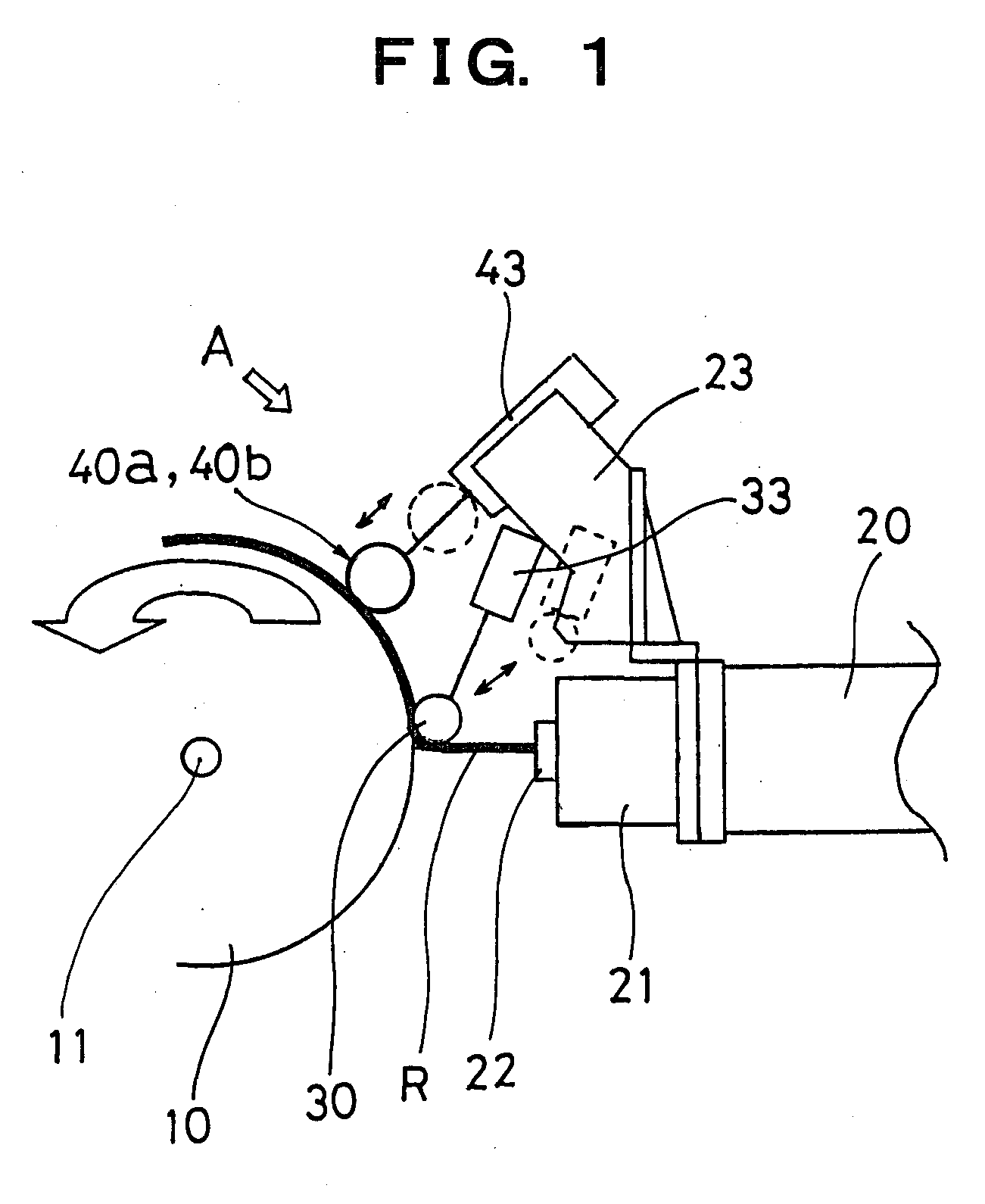

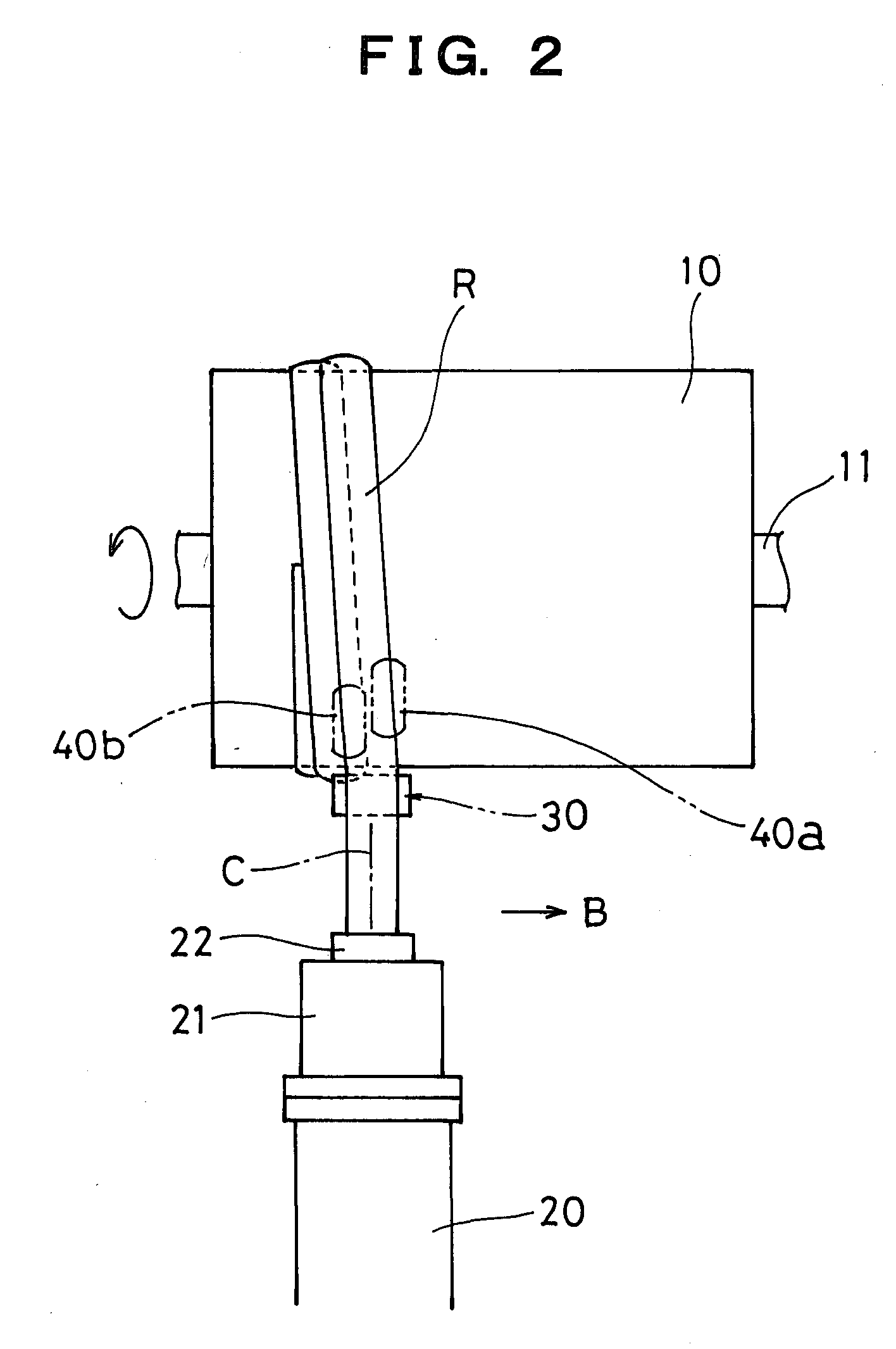

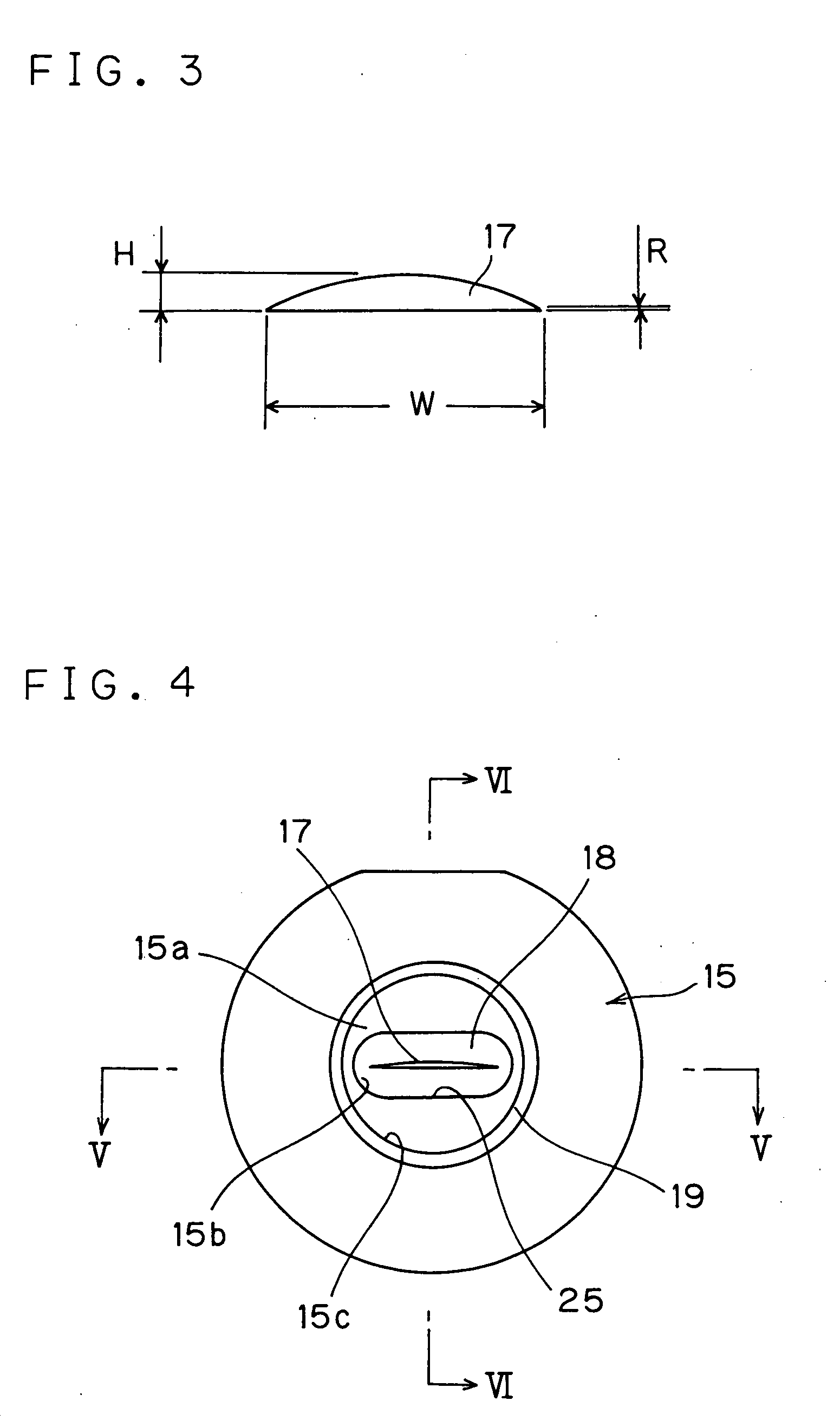

Tire building method and rubber strip bonding apparatus

The invention can surely accomplish lamination without the generation of voids in building a tire constructed to comprise a plurality of rubber members for a tire when a ribbon-shaped rubber strip (R) is spirally wound and laminated, and uses holding rolls (30) and two sets of stitching rolls (40a), (40b) arranged in parallel with a center of a rubber strip width (W) therebetween to enable performing of an independent pressing motion, such that the rubber strip (R) is pressed and bonded by the holding rolls (30) in a position, in which the rubber strip (R) is wound, and the stitching roll (40a) or (40b) positioned fore in an advancing direction of traverse movement, out of the two sets, is caused to perform a pressing motion in a regional part just after the press whereby a fore part of the rubber strip in the advancing direction is pressed and bonded.

Owner:TOYO TIRE & RUBBER CO LTD

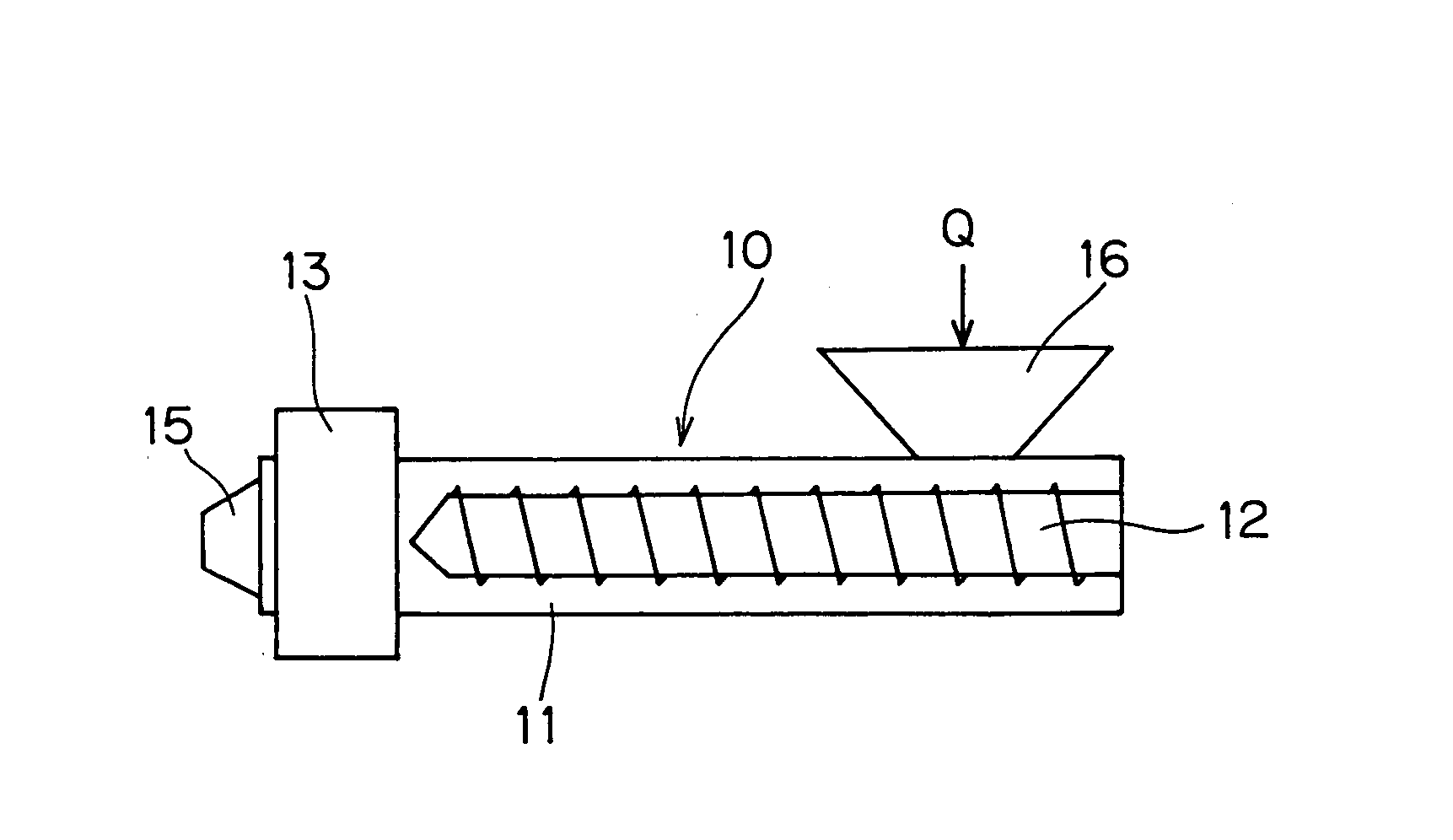

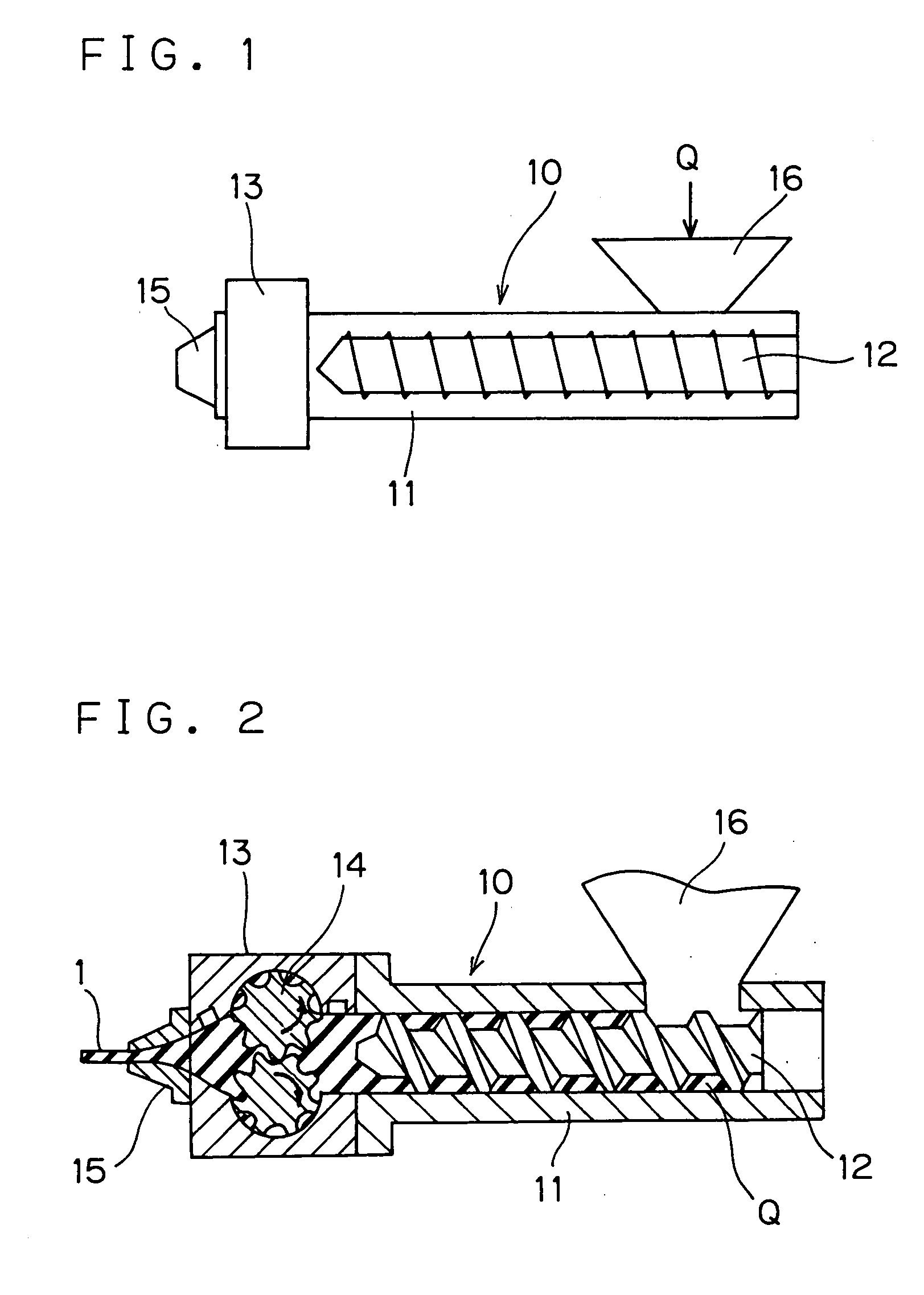

Method of and apparatus for forming rubber strip materials for building tires and method of building tires

ActiveUS20050189061A1Shorten cycle timeEfficient preparationTyresAuxillary shaping apparatusRubber materialBand shape

[Problems to be solved] It is to provide a method for forming a rubber strip which enables a wider rubber of small thickness without lowering an extruding speed and enables to reduce a building cycle time, thereby increasing the efficiency of tire manufacturing. [Means for Solving the Problems] Temperatures at a main-part casing 11, a screw shaft 12 and a head region included with the die 13 are controlled to be different from each other in a manner that: the temperature as controlled in the main-part casing 11 is higher than that in the screw shaft 12; and the temperature as controlled in the head region is higher than that in the main-part casing 11, when continuously extruding a rubber material in a form of a ribbon in forming a rubber strip 1.

Owner:TOYO TIRE & RUBBER CO LTD

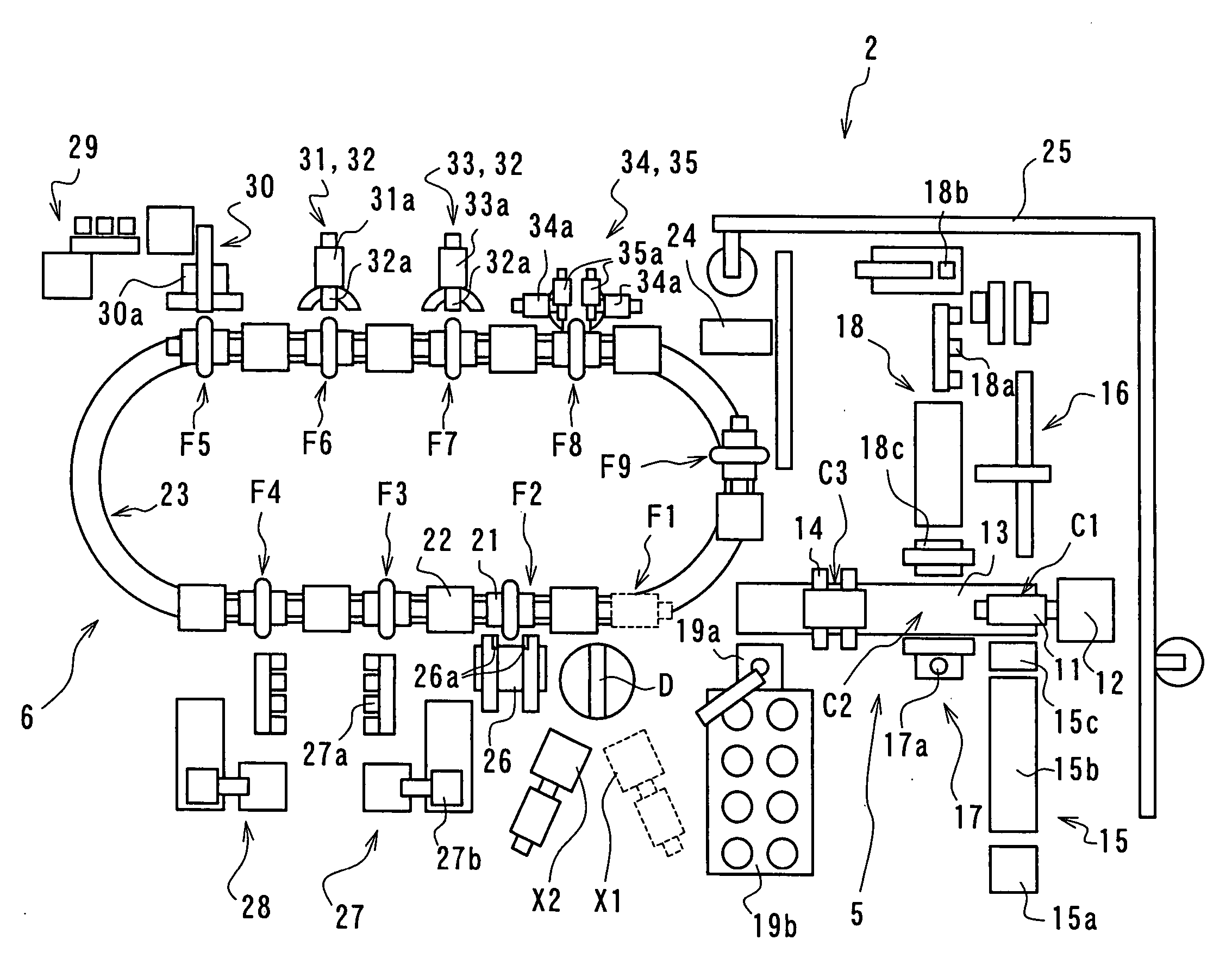

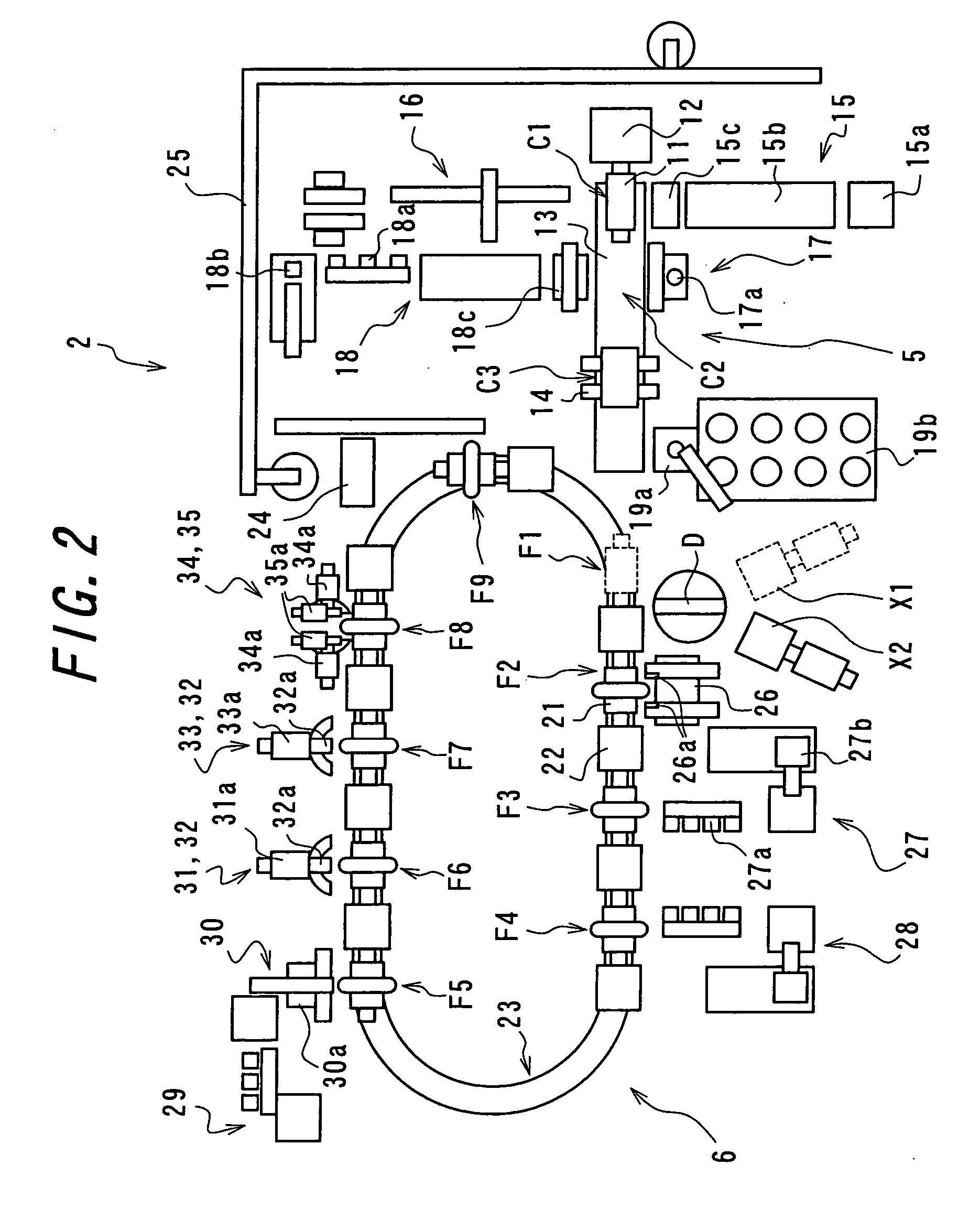

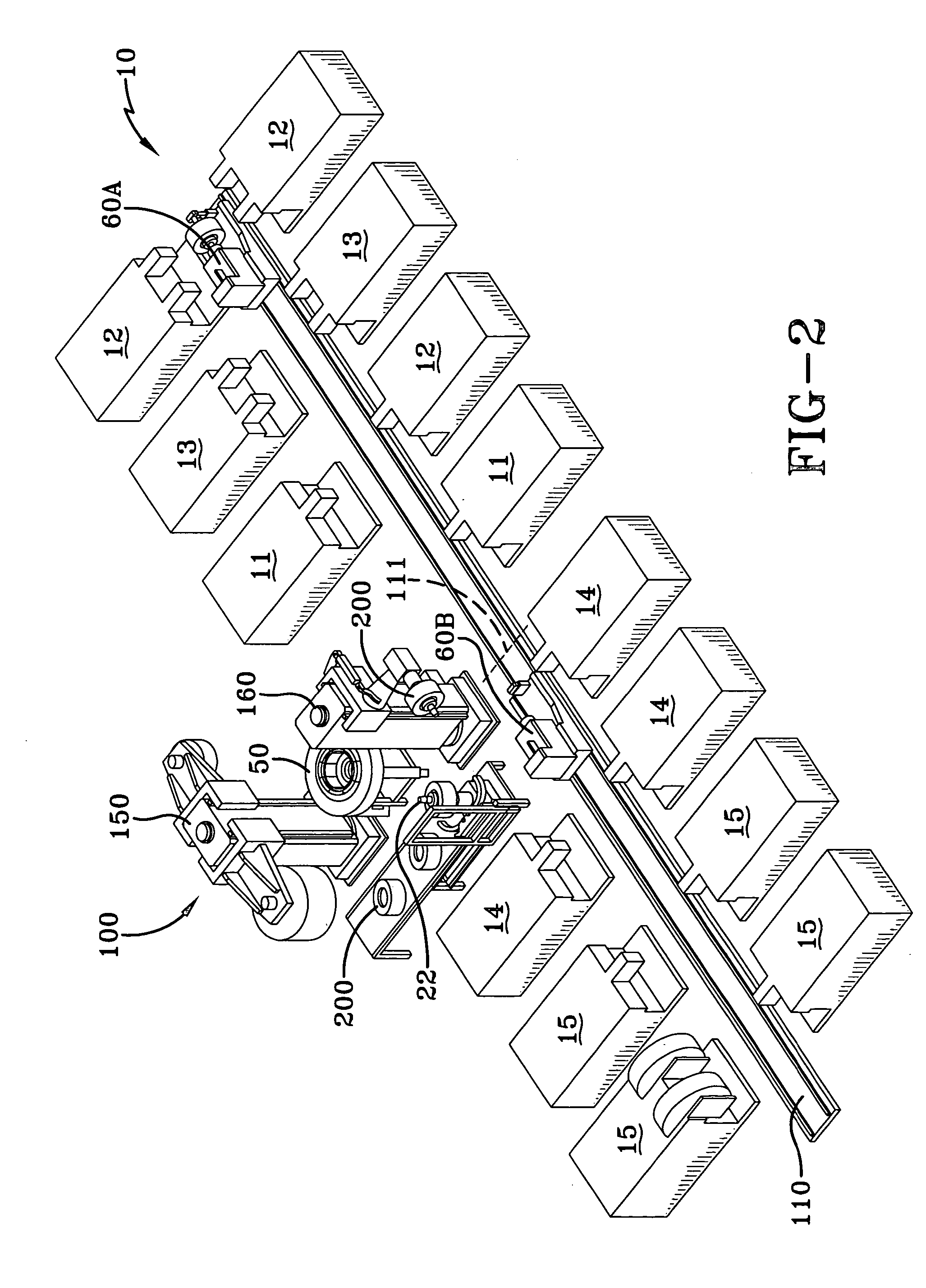

Tire building system, tire manufacturing system having the same, and tire manufacturing method

InactiveUS20060169392A1Improve accuracyDeformationTyresPneumatic tyre reinforcementsVehicle frameEngineering

A tire building system, which does not require prolonging tact time for tire building, specific occupying space for endless circulative traveling of a building carriage, and increasing noises and vibrations, and which is free from possibility of premature deterioration of carriage positioning accuracy. The system includes workstations configured to mount applicable tire components onto a building drum, respectively; a building carriage configured to support the building drum to thereby move the building drum among the respective workstations; and carriage guiding means for guiding a movement of the building carriage on a predetermined path. The carriage guiding means includes two inner and outer endless rails, and wheels provided on the building carriage, the wheels each being configured to roll on opposite side surfaces of associated one of the endless rails to thereby restrict a carriage position in a direction orthogonal to an extending direction of the endless rails. The endless rails are each configured with a straight portion and an arcuate portion which are smoothly continued to each other, and the arcuate portion has a rail width W narrower than a rail width of the straight portion.

Owner:BRIDGESTONE CORP

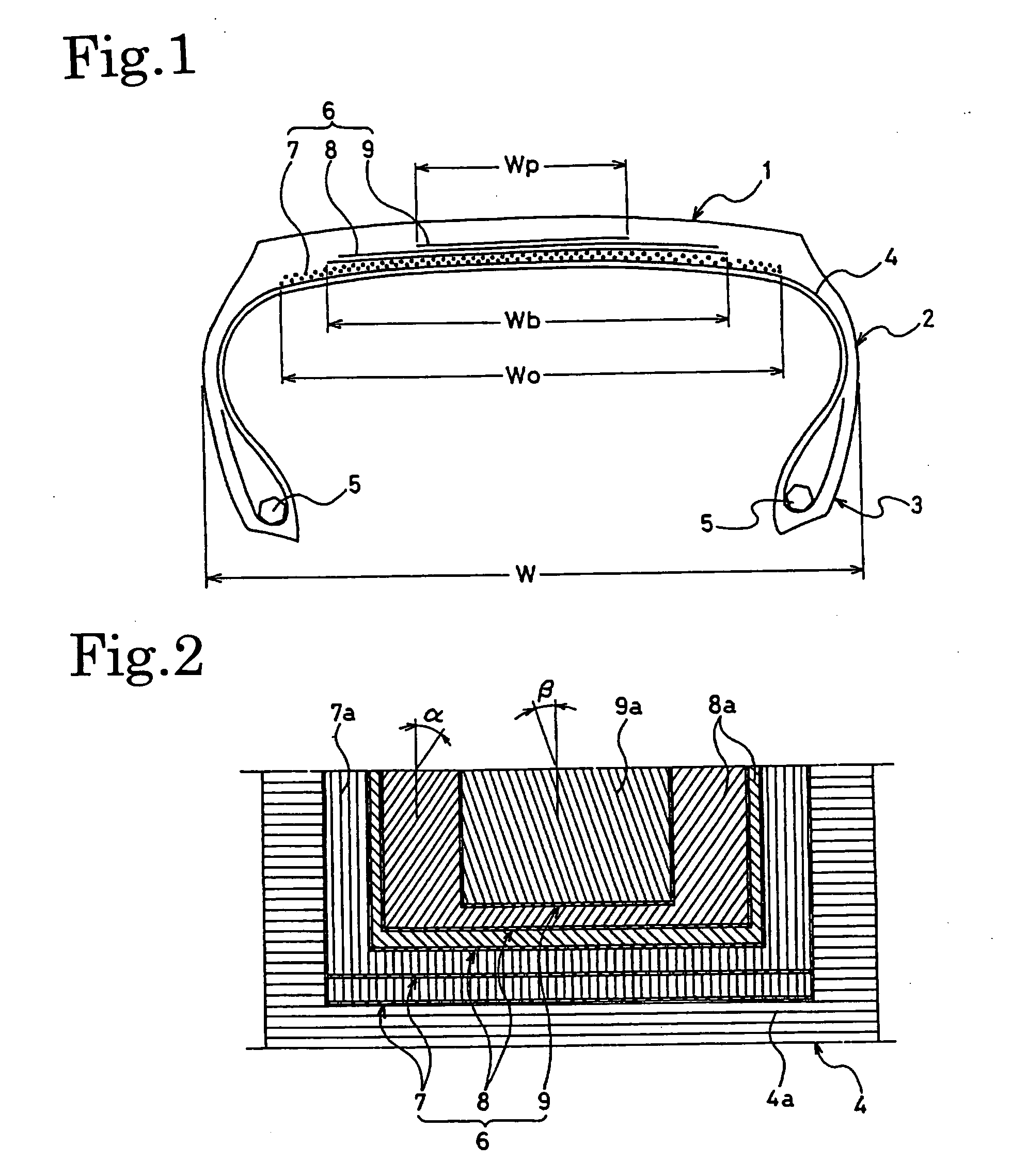

Flat Heavy-Duty Pneumatic Radial Tire and Method of Manufacturing the Same

InactiveUS20090211685A1Improving its durability and partial-wear resistance and its driving stabilityIncrease stiffnessPneumatic tyre reinforcementsWood working apparatusShell moldingEngineering

A flat heavy-duty pneumatic radial tire having a 0-degree belt layer formed of steel cords and increased in durability, wherein multiple plies of steel cord belt layers (6) are disposed on the outer periphery of a carcass layer (4). The steel cord belt layers (6) includes at least one ply of the 0-degree belt layer with a cord angle of substantially 0° relative to the circumferential direction of the tire and at least two plies of bias belt layers (8) with a cord angle substantially equal to an equilibrium angle of within a range of 45° to 65° relative to the circumferential direction of the tire. The tire is manufactured as follows. The tire cured and molded in a mold is released from the mold, assembled with a rim to be inflated while the tire is hot, and then cooled to normal temperature under the inflated condition.

Owner:THE YOKOHAMA RUBBER CO LTD

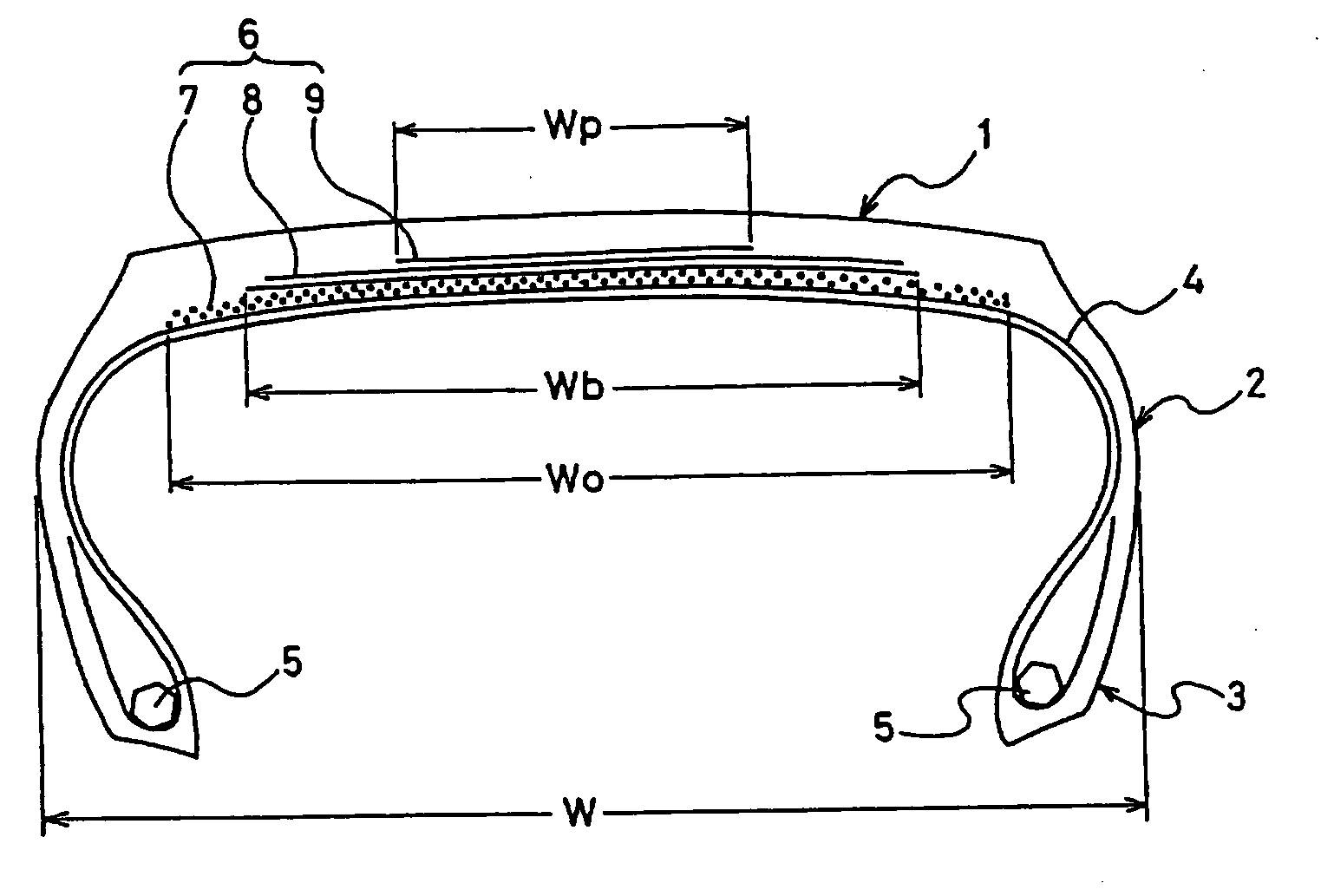

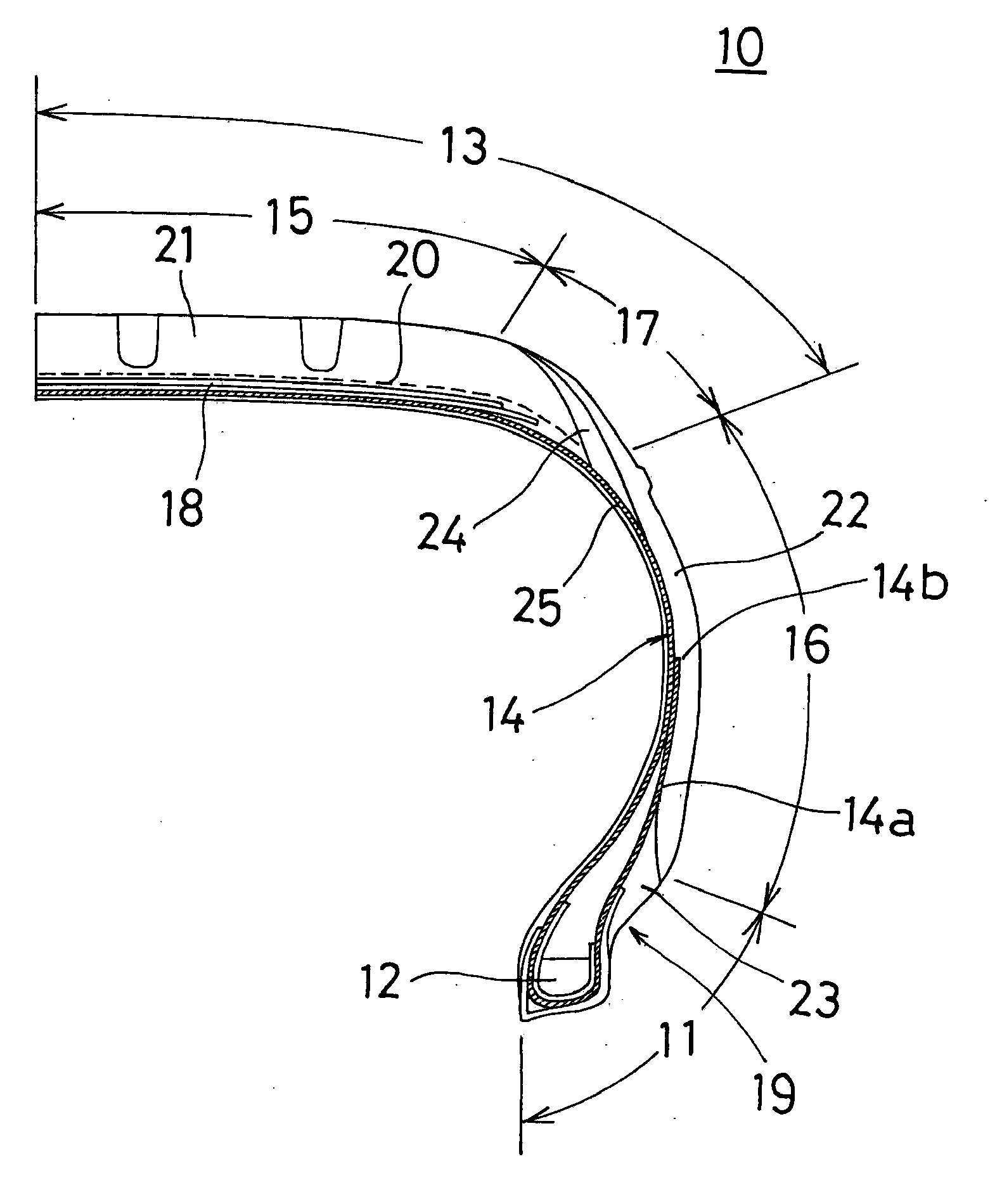

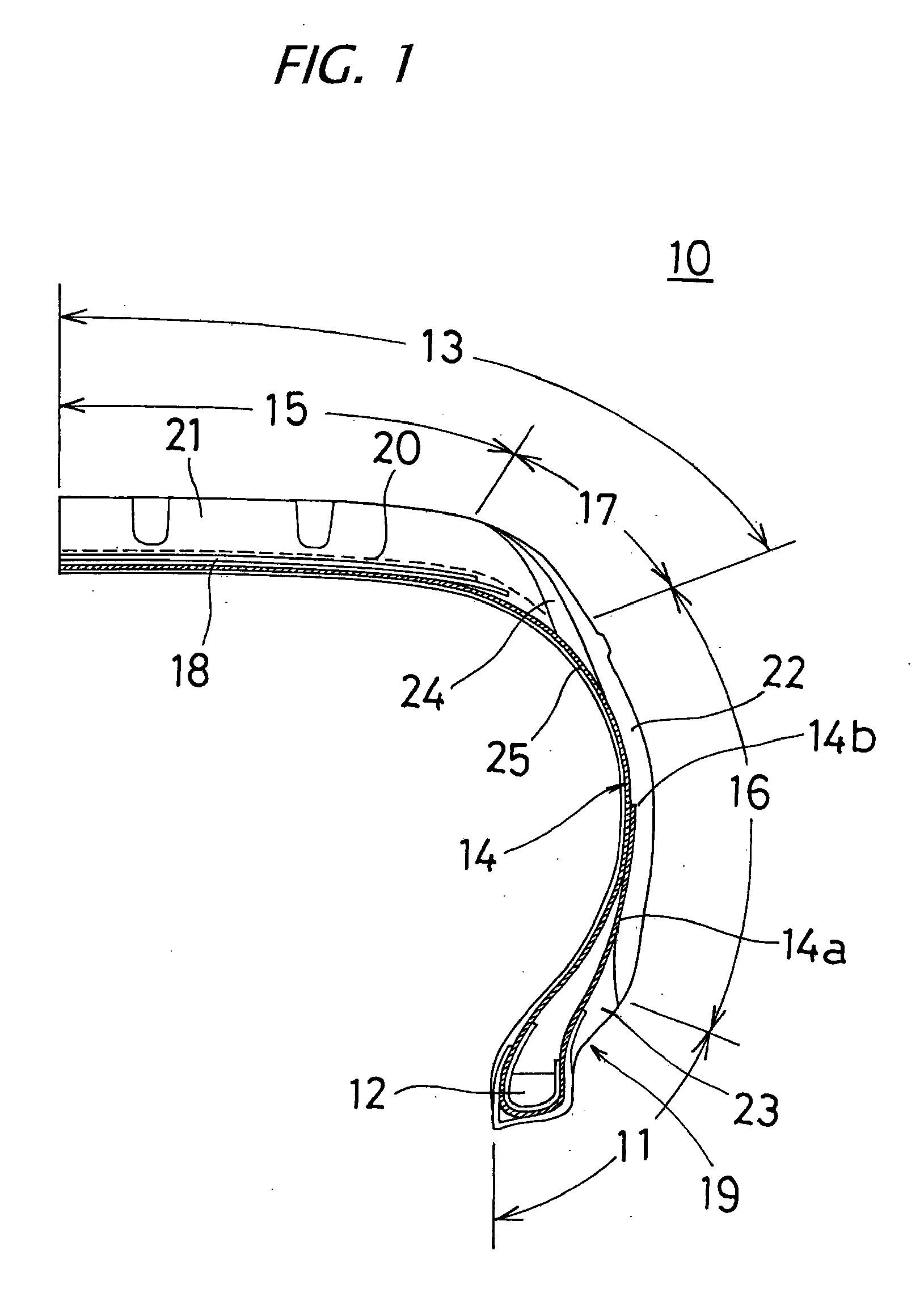

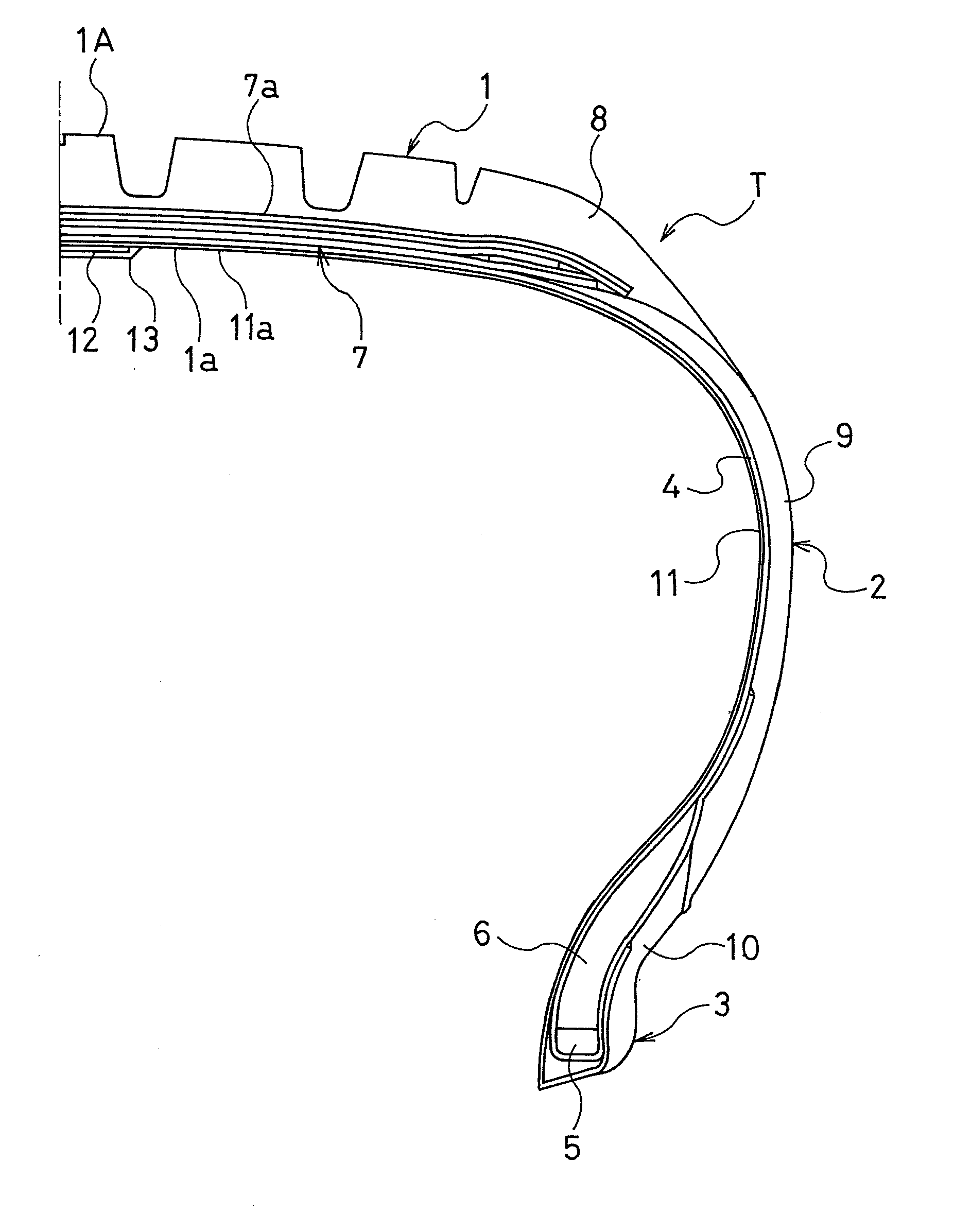

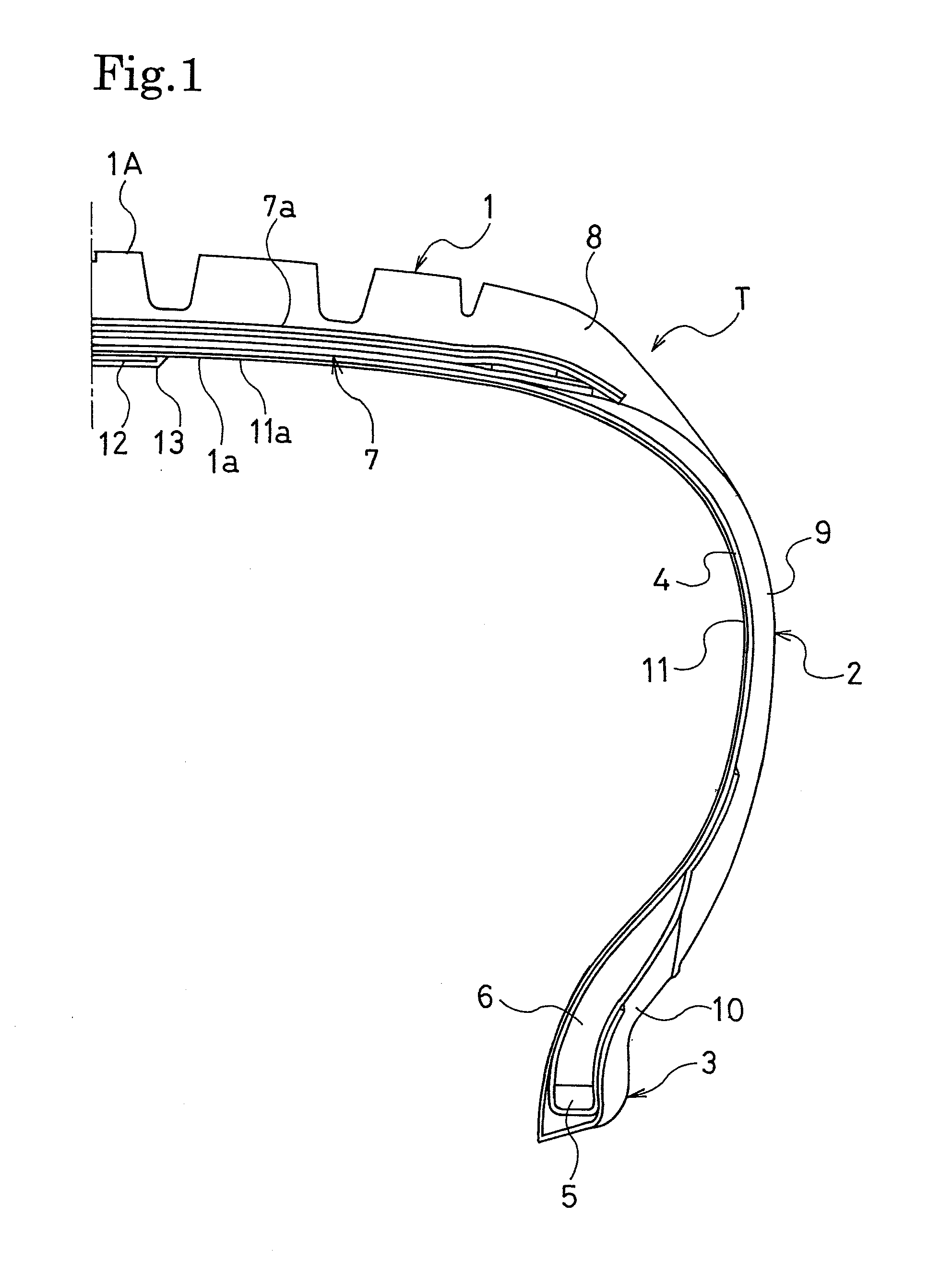

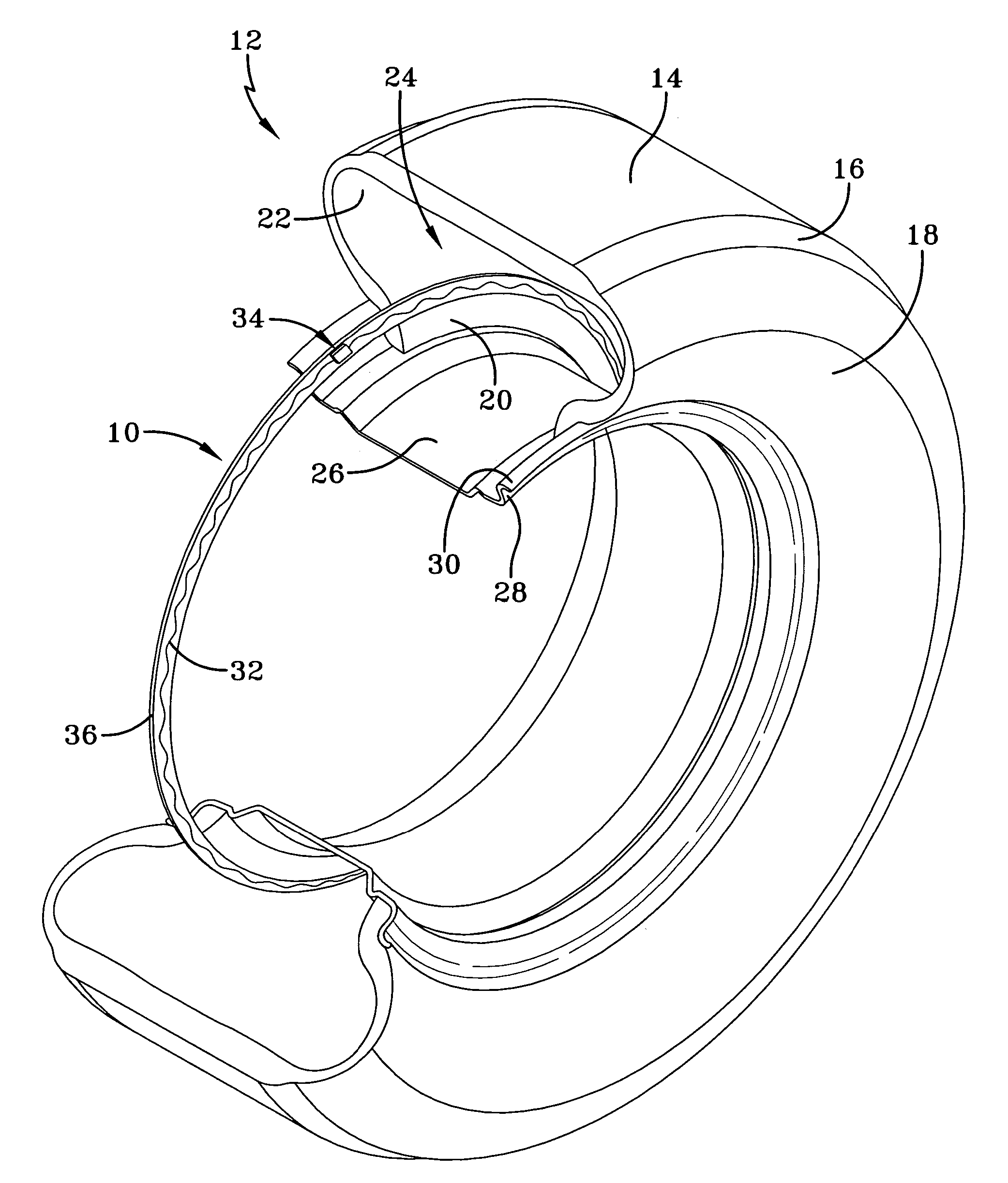

Pneumatic Tire

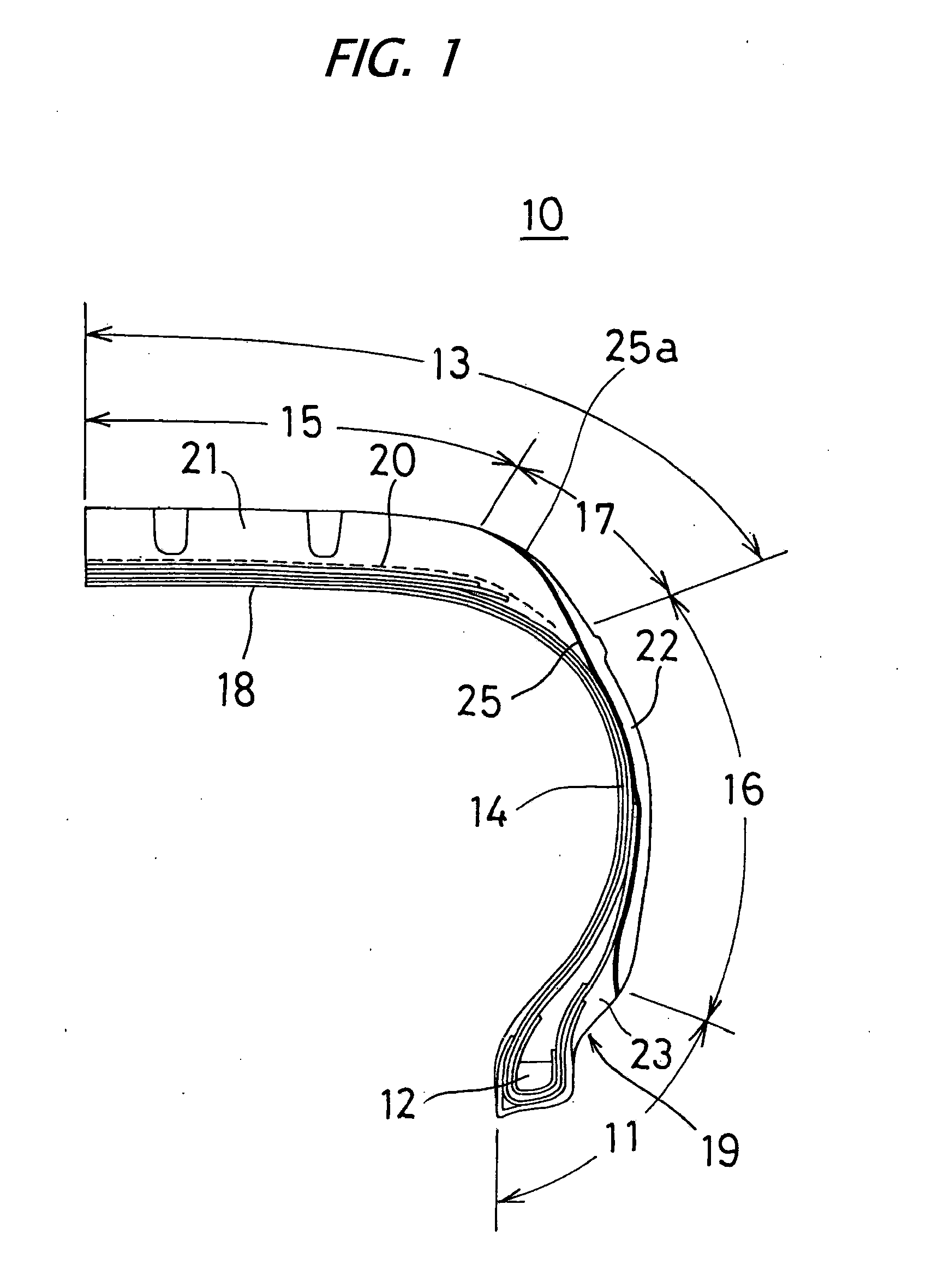

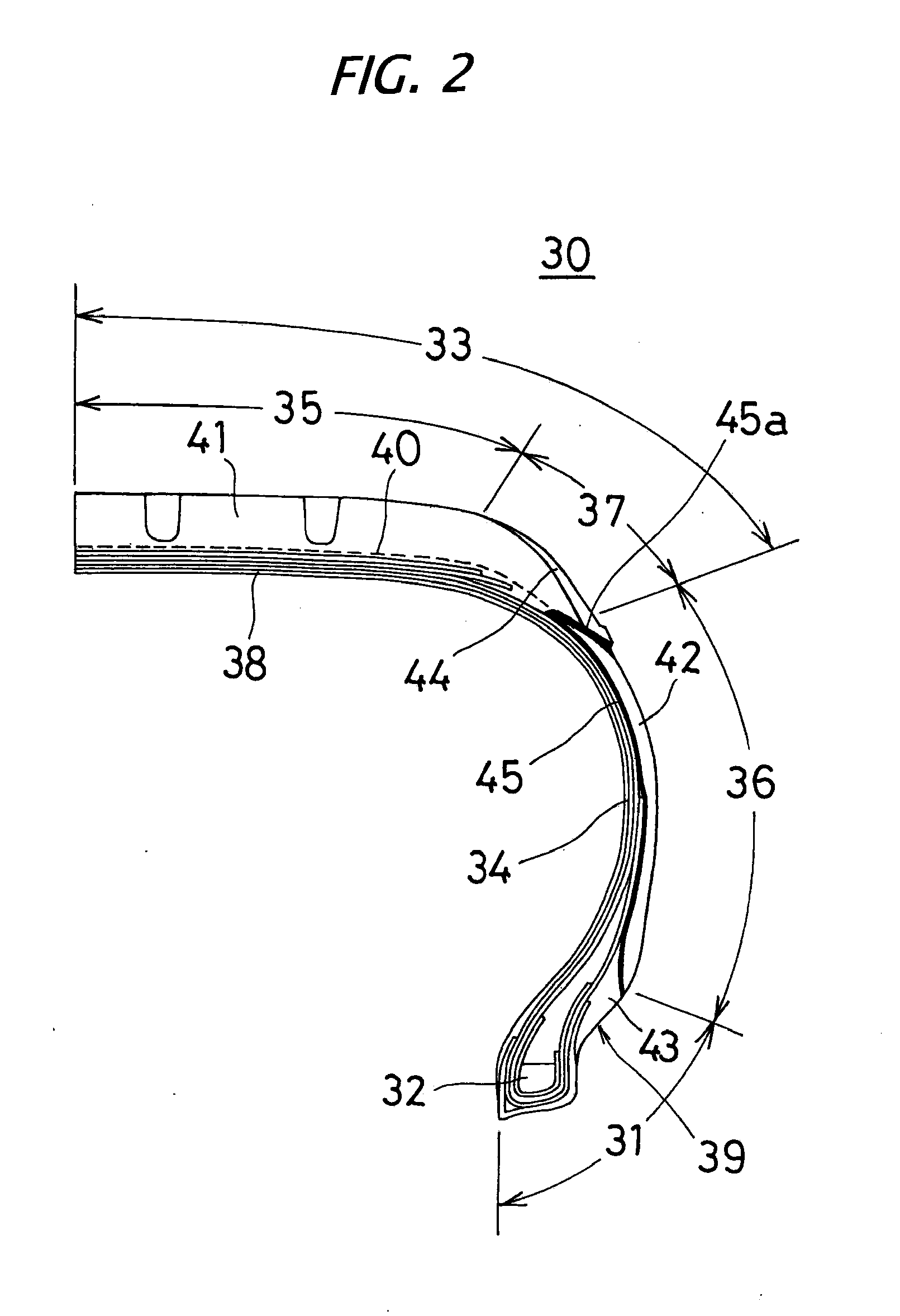

ActiveUS20100078103A1Improve rolling resistanceGood wetting propertiesSpecial tyresTyre beadsGround contactRubber material

A pneumatic tire that can be manufactured according to the conventional method without requiring special tire manufacturing steps and without needing addition of material members and production steps, and having excellent rolling resistance and wet properties, and having conductivity is to be provided. A pneumatic tire 10 comprises a carcass 14 having a ply which is turned back and locked around a bead core 12, a rim strip 19 provided in a bead part 11, and a wing 24 in which one edge thereof is contacted with the carcass 14 and the other edge is exposed to the surface of a ground contact edge region of a tread part 13, wherein a covering rubber of a carcass ply 25, the rim strip 19 and the wing 24 are formed into a continuous conductive path by a conductive rubber material, only the conductive path is used as a conducting path of the tire 10, and members other than the conducting path are selected and used from a conductive rubber material or a nonconductive rubber material.

Owner:TOYO TIRE & RUBBER CO LTD

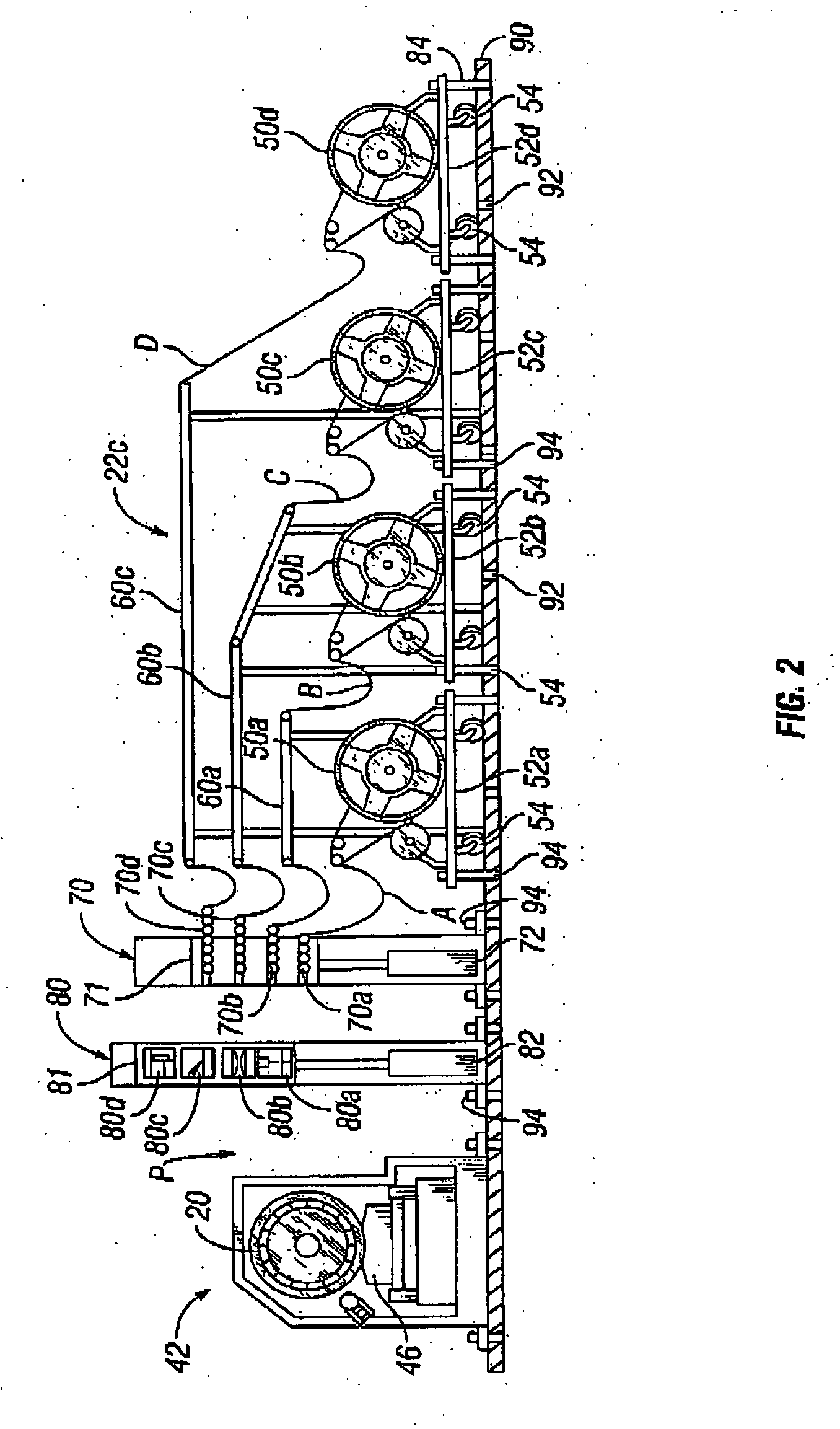

Tire manufacturing module and method of manufacturing tires

InactiveUS20050126684A1Easy to changeEfficient productionTyresPneumatic tyre reinforcementsElastomerTire manufacturing

A module for manufacturing a cured tire from a plurality of tire components is disclosed. The module has a plurality of component appliers located at spaced locations along a predetermined path, and a mobile tire building trolley for movement along the predetermined path and two detachable tire building drums for mounting on the movable trolley. A tire curing station has one tire mold for curing the assembled tire components while mounted on one of the detachable tire building drums. The tire is cured as the other detachable tire building drum on the mobile tire building trolley is having tire components applied. One or more of the plurality of component appliers includes a means for forming the tire component at the location of the applier. The applied components include a liner, a pair of bead cores, a ply, a pair of sidewalls, a pair of chafers, and one or more belt layers and a tread. Optionally the applied components may also include an apex, wedges, overlays, underlays, gum strips, and elastomeric inserts. The module has a means for transferring the detachable tire building drums to the tire mold and further has a means for extracting the cured tire while mounted on a tire building drum from the mold. The tire curing station includes an induction curing means.

Owner:THE GOODYEAR TIRE & RUBBER CO

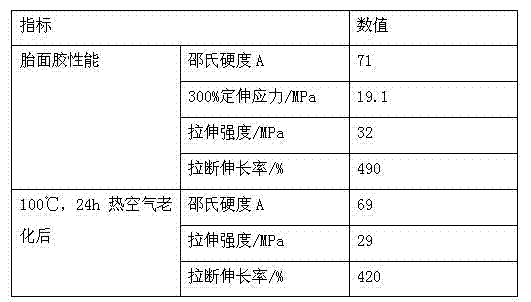

Liquid isoprene rubber containing bead filler composition of tire as well as preparation method and application thereof

ActiveCN102134336AGuaranteed stiffnessGuaranteed physical and mechanical propertiesSpecial tyresRubber materialVulcanization

The invention relates to the field of manufacture of tires, in particular to a liquid isoprene rubber containing bead filler composition of a tire as well as a preparation method and application thereof. The liquid isoprene rubber containing bead filler composition of the tire is formed by mixing the following components in parts by weight: 85-97 parts of natural rubber, 3-15 parts of liquid isoprene rubber, 65-75 parts of carbon black, 4-8 parts of vulcanizing agent and vulcanization accelerator and the balance of processing assistants. In the invention, the stiffness of parts can be sufficiently ensured, and the deformation of the parts in the processing process can be prevented; and moreover, the higher processing safety of rubber materials can be ensured due to longer scorching time. When an all-steel radial truck tire provided by the invention is adopted, the high extrusion temperature rise is reduced, the production efficiency is increased, the technical loss is reduced and the like on the premise that the structure is unchanged, and the main physical mechanical properties of hard bead filler materials, the dimension stability of the parts, and the technical viscidity is notunreduced.

Owner:ZHONGCE RUBBER GRP CO LTD

Tire Manufacturing Method, Preset Bead Molding Apparatus, and Preset Bead Molding

There is provided a method of tire manufacturing a tire in which preset-beads each preformed by mounting a bead filler on a bead core are disposed radially outward of a carcass band and both side portions of the carcass band are turned around the preset beads to build the tire. The method eliminates a need to bold the considerable intermediate stocks and does not deteriorate the tire uniformity due to the unevenness of the preset bead in the circumference direction. There are also provided an apparatus of forming a preset bead used therefore and a system of forming a preset bead. In the method of manufacturing a tire in which preset-beads each preformed by mounting a bead filler on a bead core are disposed radially outward of a carcass band and both side portions of the carcass band are turned around the preset beads to build the tire, the preset bead is formed by winding and laminating a ribbon-shaped filler rubber 5 radially outward of the bead core 10 over several laps.

Owner:BRIDGESTONE CORP

Sidewall rubber of automobile tire

InactiveCN103467793AGood extensibilityFree from mechanical damagePolymer scienceManufacturing technology

The invention belongs to the field of tire manufacturing technology, and specifically relates to a sidewall rubber of an automobile tire. The sidewall rubber of the automobile tire is characterized in that the sidewall rubber comprising the following components of natural rubber, butadiene rubber, styrene butadiene rubber, ethylene propylene diene monomer rubber, polybutadiene rubber, zinc carbonate, light calcium carbonate, stearic acid, talcum powder, titanium dioxide, low structure high-abrasion furnace black, white clay, zinc oxide, stearic acid, Santo white crystal, high aromatic hydrocarbon oil, an accelerant, paraffin, Santo flacks, insoluble sulfur, carbon black, aluminium hydroxide, alkyl phenol disulfide and magnesium oxide. By adopting the formula composed by the above components, the sidewall rubber of the automobile tire has relatively good strength and elongation property, can endure atmospheric aging, flex cracks and mechanical damages, can protect the tire body from corrosion of the mechanical damages, sunlight, wind and rains.

Owner:SHANDONG YONGTAI CHEM GROUP

Pneumatic tire manufacturing method and pneumatic tire

ActiveUS20090159172A1Improve productivityGood adhesionTyresPneumatic tyre reinforcementsEngineeringFastener

Provided is a pneumatic tire manufacturing method capable of improving the productivity of pneumatic tires each having surface fasteners in its tire inner surface, and of avoiding manufacturing a pneumatic tire having a deteriorated uniformity, as well as of preventing engagement elements of each surface fastener from being crushed. Also, provided is a pneumatic tire manufactured by the pneumatic tire manufacturing method. The pneumatic tire manufacturing method according to the present invention includes the steps of, in making a green tire having two-side fasteners in its tire inner surface in its tire circumferential direction, each two-side fastener including an engagement element group on both sides: covering the engagement element groups on first sides of the two-side fasteners with a protective rubber layer made of an uncured rubber; making a cylindrical first formed body on a making drum, with the two-side fasteners covered with the protective rubber layer being intermittently attached to an inner circumferential surface of the first forming body in a circumferential direction thereof with the engagement element groups on second sides of the two-side fasteners being interposed in between; bonding the first formed body to an inner circumference of an annular second formed body by compression through expanding the first formed body into a toroidal shape, and thereby making the green tire; and curing the green tire inside a mold of a curing machine while pressing the green tire from its inside by a bladder.

Owner:YOKOHAMA RUBBER CO LTD

Polyurethane solid tyre and manufacturing method thereof

The invention relates the making method of polyurethane solid tyre used for industry vehicle. The polyurethane solid tyre comprises the metal rim which has supporting and conveying action and the single-lay or double-lay polyurethane which is bonded on metal rim. The single-lay or double-lay polyurethane used in outer layer is oligomer polyatomic alcohol- methyl diphenylene diisocyanate / toluene diisocyanate, and the single-lay or double-lay polyurethane used in inner layer is oligomer polyatomic alcohol-3,3'- dimethyl-4,4'-biphenyl diisocyanate. The carcass has the advantages of long lifetime, non pollution, good heat-sinking capability and not blasting. The cost is low, technology is simple, and it is easy to realize the industrial production.

Owner:SOUTH CHINA UNIV OF TECH

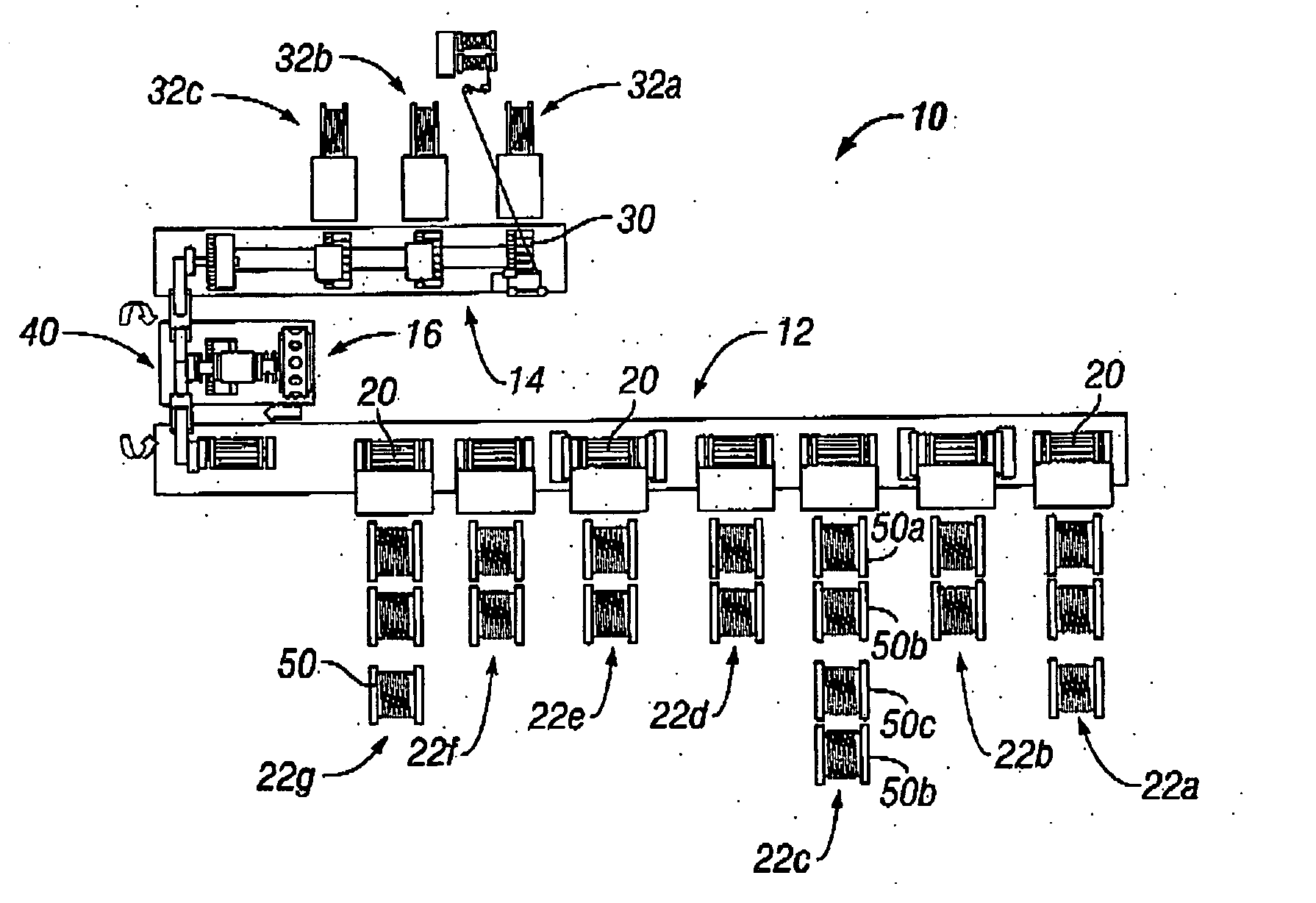

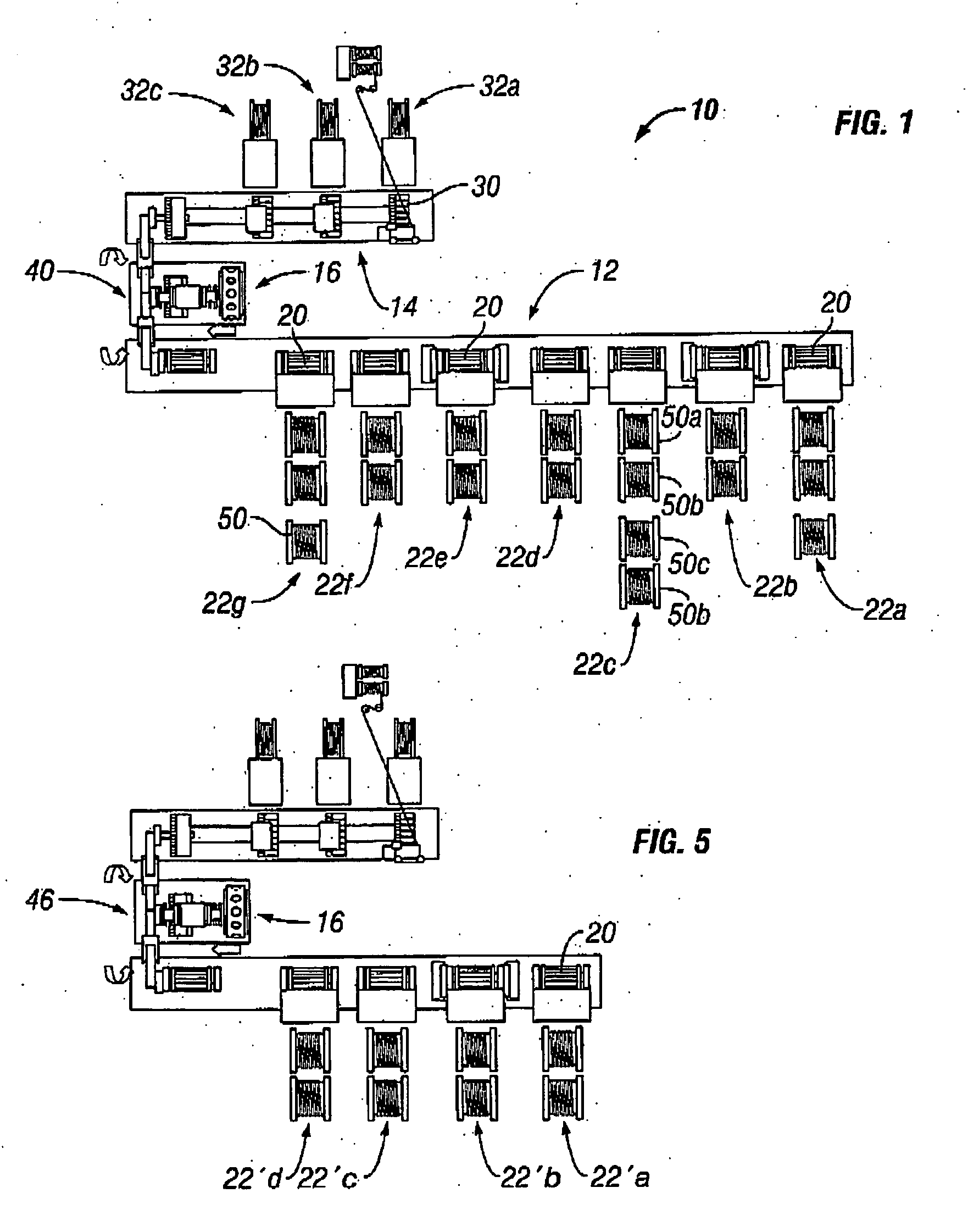

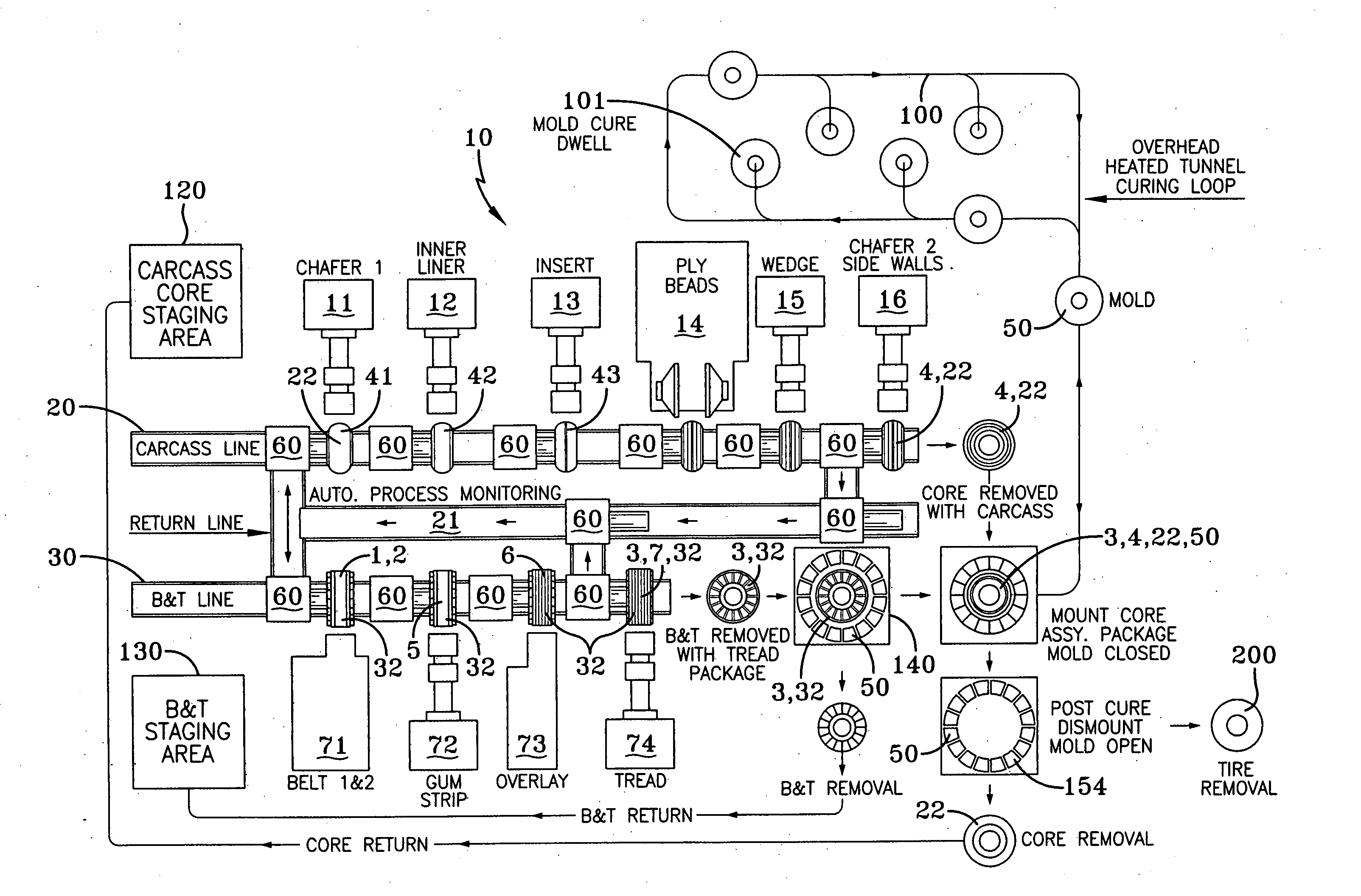

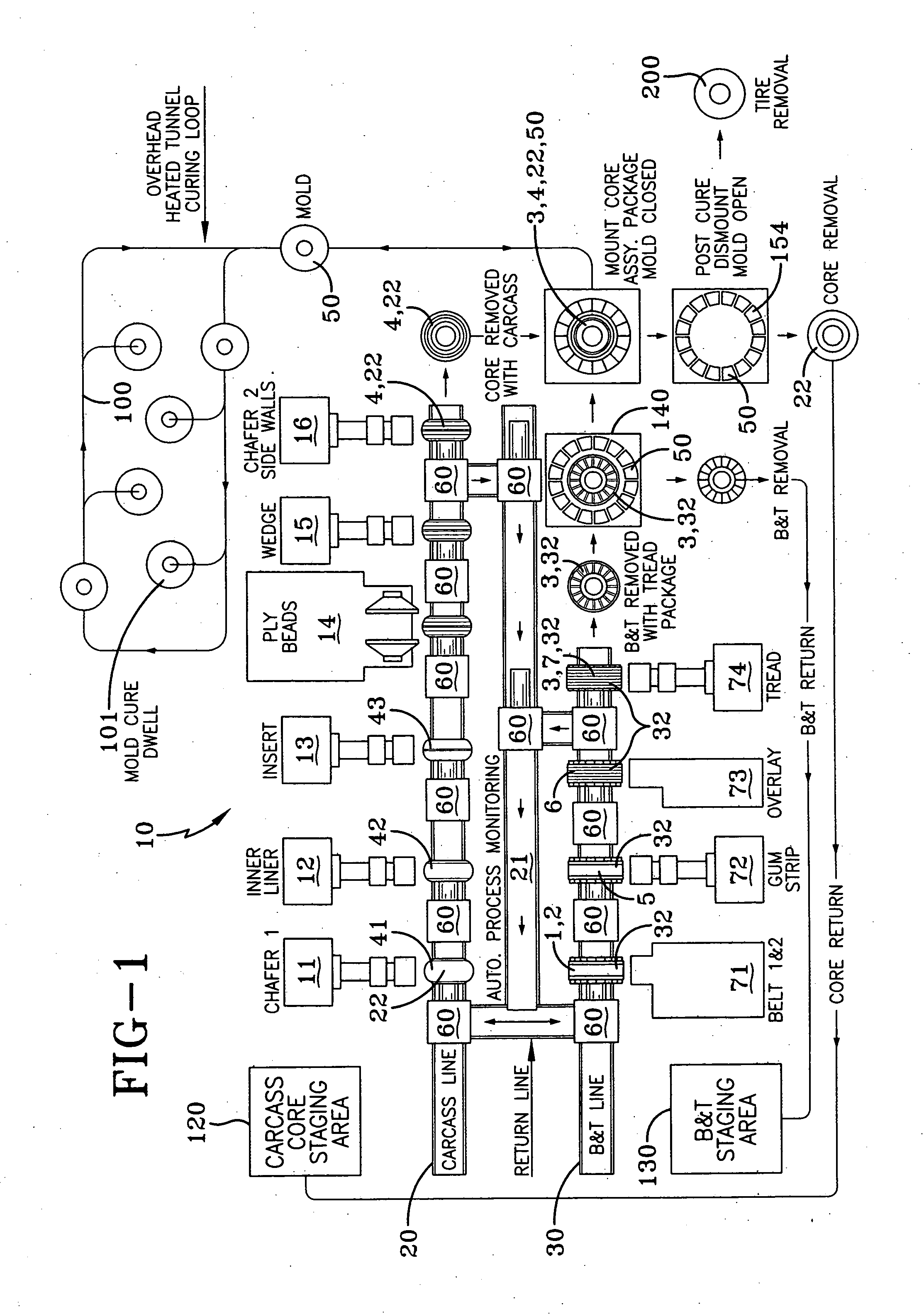

Method for manufacturing tires on a flexible manufacturing system

A method of simultaneously producing production runs of tires 200 on a multi-station sequential tire manufacturing system 10, the tires 200 being from a group of tire types of different build specifications in lot sizes of one or more tires is disclosed. The steps include: scheduling the production run by imputing tire build software, wherein the software program performs the steps of: selecting the tire building equipment and materials required for the respective tire types; calculating the corresponding number of cycles each piece of building equipment must perform to build a given lot; and automatically changing to a second build specification at a lot change by switching to the second build specification after the last tire 200 of the first build specification passes; repeating the automated changing to the next build specification at each station 11-16 and 71-74) as each last tire 200 of each prior lot passes until a final lot is produced. The multi-station sequential tire manufacturing system 10 has at least four stations for carcass 4 building, each station (11-16) being spaced at a predetermined distance and preferably a multistation tread belt assembly line 30 having workstations (71-74) separate from the carcass building line 20 wherein the carcass 4 and the tread belt assemblies 3 are joined in a segmented self-locking mold 50.

Owner:THE GOODYEAR TIRE & RUBBER CO

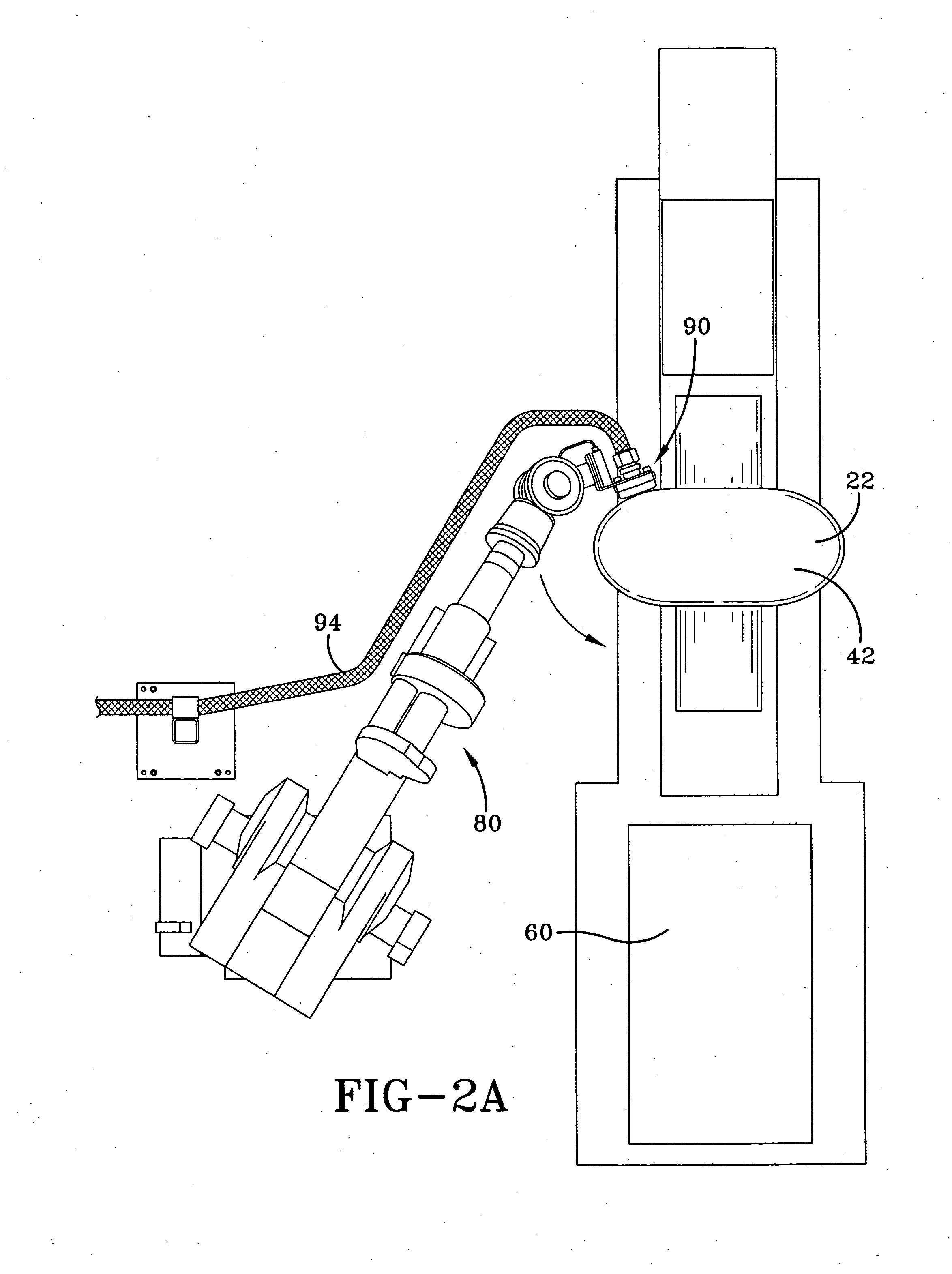

Method and assembly of sensor ready tires

InactiveUS6978669B2Electric signal transmission systemsAntenna supports/mountingsEngineeringPost cure

Apparatus and method for post-cure application of electronics to a tire includes the steps: forming an antenna wire into a predetermined shape having first and second free ends; creating a transponder splice region between the first and second free antenna ends, incorporating transponder splice region identification indicia; curing the antenna wire into a tire during a tire manufacturing procedure; locating the transponder splice region by means of the transponder splice region identification indicia; and splicing the antenna wire ends to a sensor in a post-cure procedure. The transponder splice region identification indicia may include sandwiching a junction box or the overlapped ends of the antenna wire or wires between layers of select material that will not bond to the tire inner liner or antenna cover compounds and incorporating an air pocket in the sandwiched region. Alternatively, or in conjunction with the air pocket, a unique cover layer differentiated by color or other discernible means may be utilized to seal and cover the transponder splice region.

Owner:THE GOODYEAR TIRE & RUBBER CO

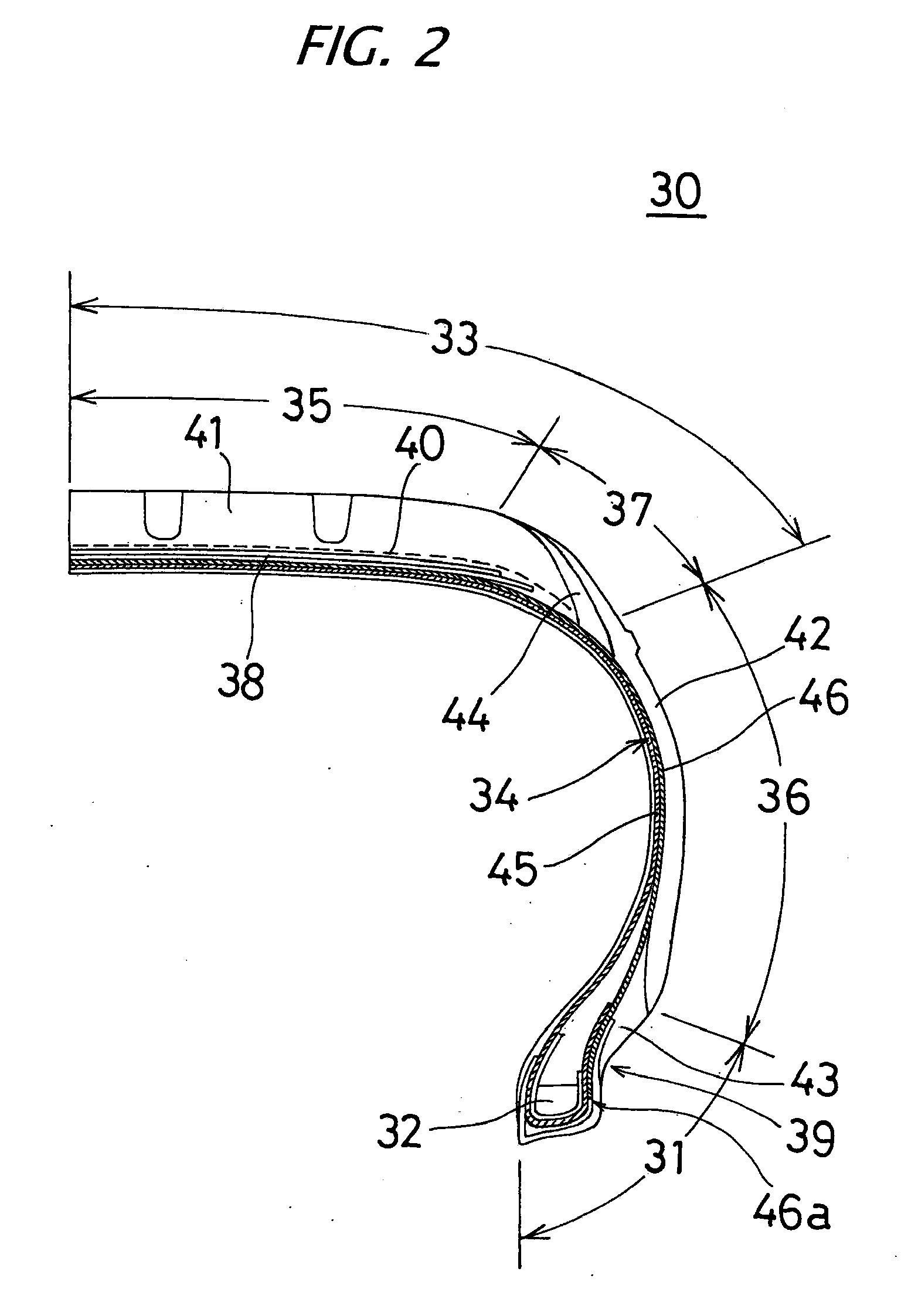

Pneumatic Tire

InactiveUS20090308512A1Improve adhesionMaintain good propertiesTyre sidewallsGround contactRubber material

A pneumatic tire that can be manufactured according to the conventional method without requiring special tire manufacturing steps and without needing addition of material members and production steps, has excellent rolling resistance and wet properties, and has conductivity. The pneumatic tire 10 has a sheet-like cushion rubber 25 having a thickness of 1 mm or less, disposed on a tire inside face side of a side wall rubber, the cushion rubber 25 is in contact with a rim strip 19 and exposed to a surface of a ground contact edge region of a tread part 13 through a side wall part 16, and is characterized in that on the circumference of unilateral or bilateral side portions of the tire 10, the rim strip 19 and the cushion rubber 25 are formed into a continuous conductive path by a conductive rubber material, only the conductive path is used as a conducting path of the tire 10, and members other than the conducting path are selected and used from a conductive rubber material or a nonconductive rubber material.

Owner:TOYO TIRE & RUBBER CO LTD

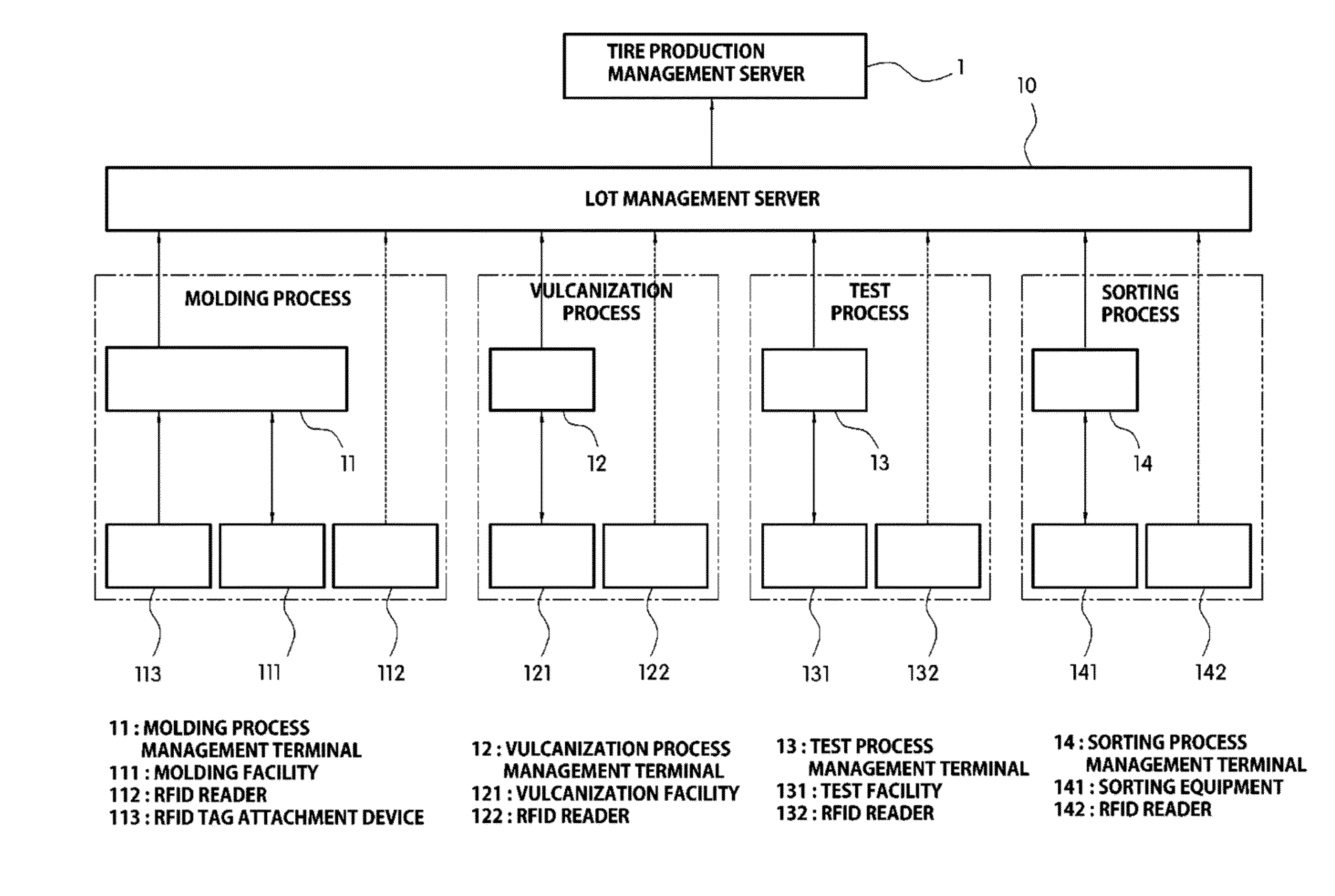

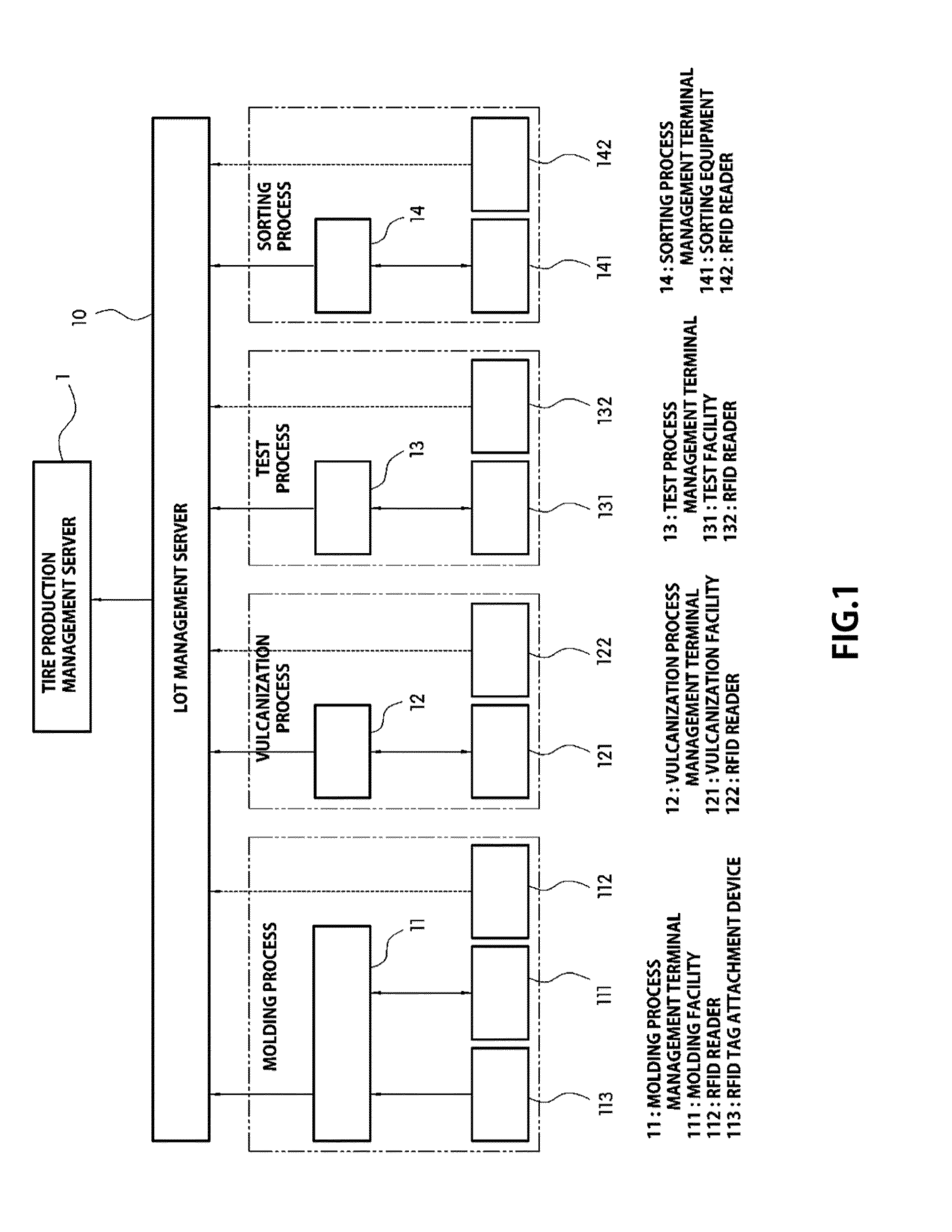

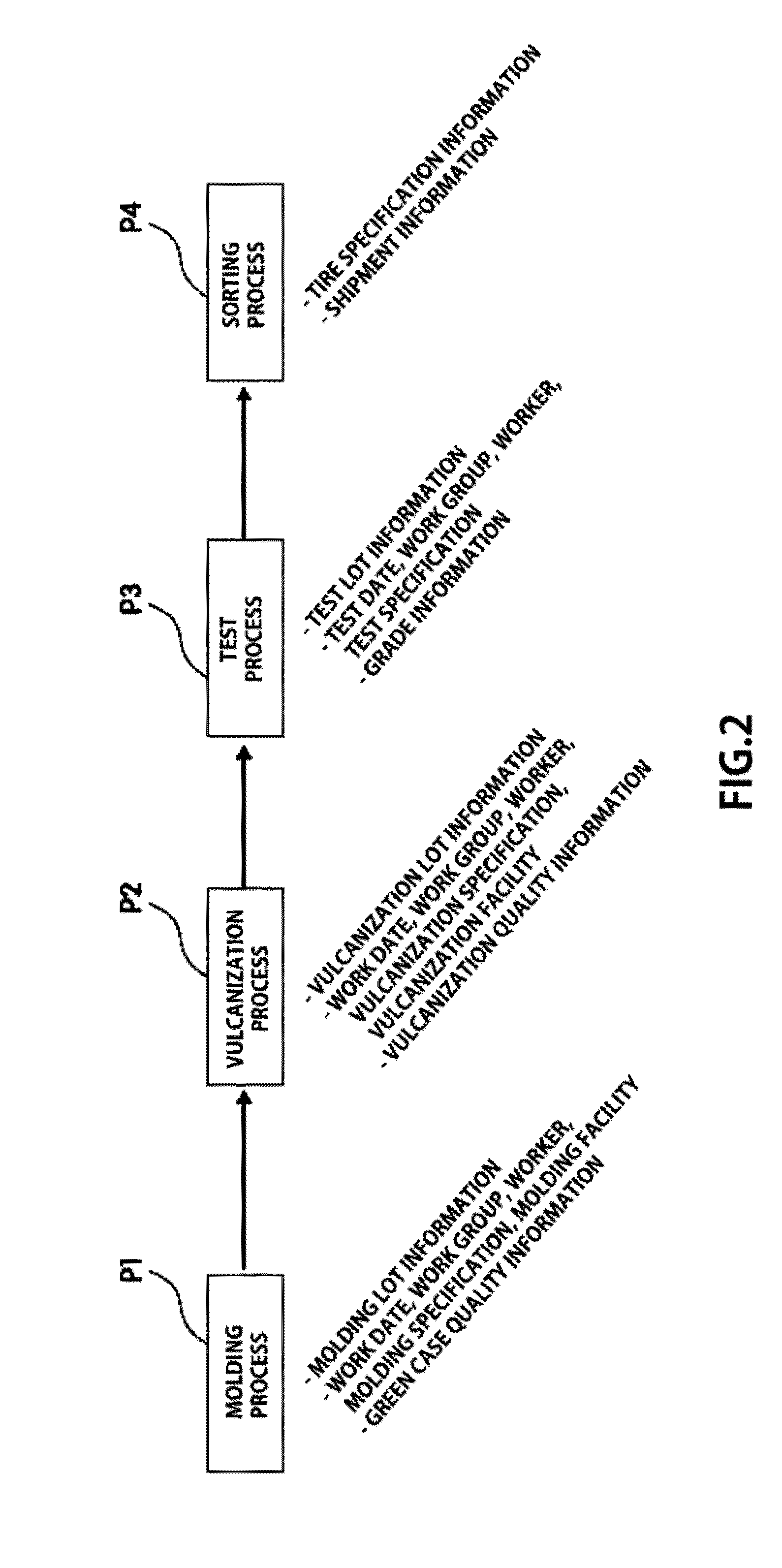

Tire production management system using RFID tag

Disclosed is a tire production management system, and more particularly to, a tire production management system using a radio frequency identification (RFID) tag, which may attach an RFID tag to a tire before producing a finished tire in tire manufacturing processes, recognize the tire tag attached to the tire in each of manufacturing processes, and thus manage information according to a manufacturing process on an individual tire. The tire production management system using an RFID tag comprises: an RFID tag attachment part; a plurality of RFID readers; a plurality of management terminals for respective processes; a lot management server; and a tire production management server.

Owner:ASIANA IDT

Automobile tire tread rubber

InactiveCN103483627AGood anti-aging performanceImprove wet skid resistanceSpecial tyresWear resistantEngineering

The invention specifically relates to an automobile tire tread rubber, which belongs to the field of tire manufacturing technology. The automobile tire tread rubber is characterized by comprising the following components: natural rubber, butadiene styrene rubber, polybutadiene rubber, brominated butyl rubber, stearic acid, sulphur, carbon black, paraffin, a coumarone resin, sixth line distillate, zinc oxide, pine tar, ISAF, a promoter DM, a promoter CZ, an anti-aging agent, highly wear-resistant furnace black and gas carbon black. The invention has the following beneficial effects: appropriate parts by weight of the above-mentioned components are employed for preparation of the tread rubber, so a tire has good wear resistance, ageing resistance and wet skid resistance; aging resistance of the natural rubber is inferior to that of the butadiene styrene rubber, so combination of the natural rubber and the butadiene styrene rubber and addition of the anti-aging agent enable the anti-aging performance of the rubber to be improved.

Owner:广州安耐特再生胶轮有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com