Patents

Literature

95results about How to "Inhibit chafing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

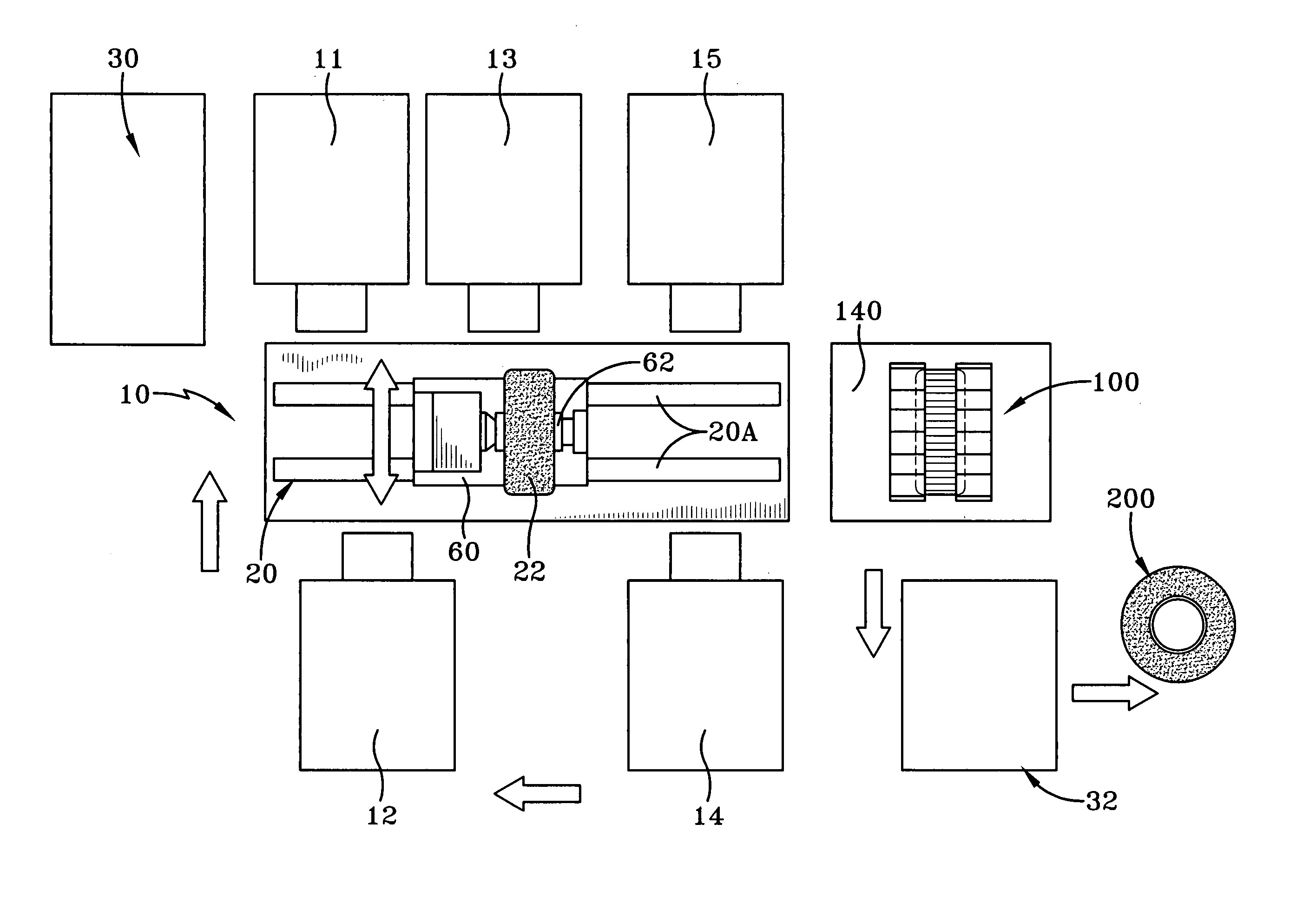

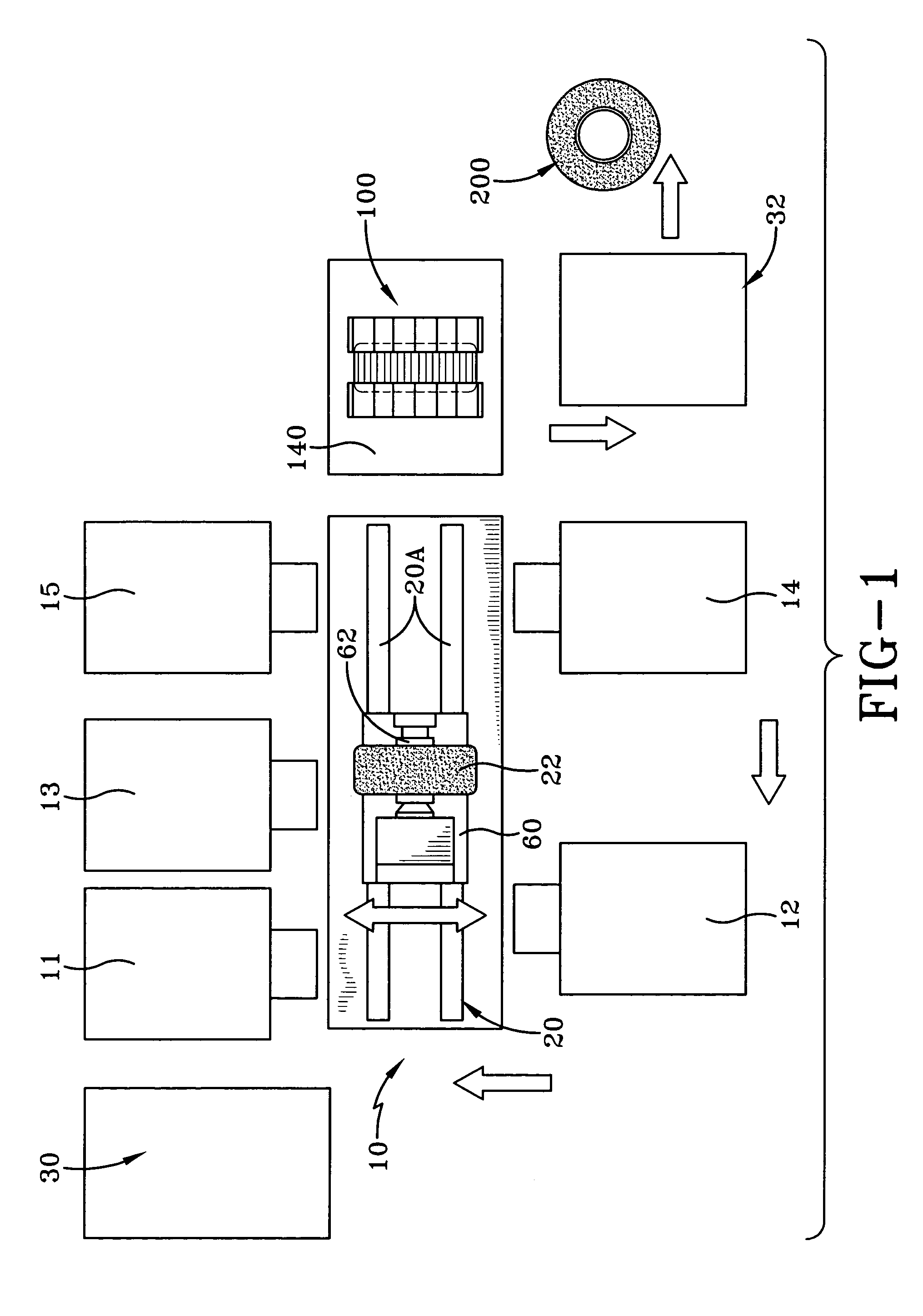

Single station tire curing method and apparatus

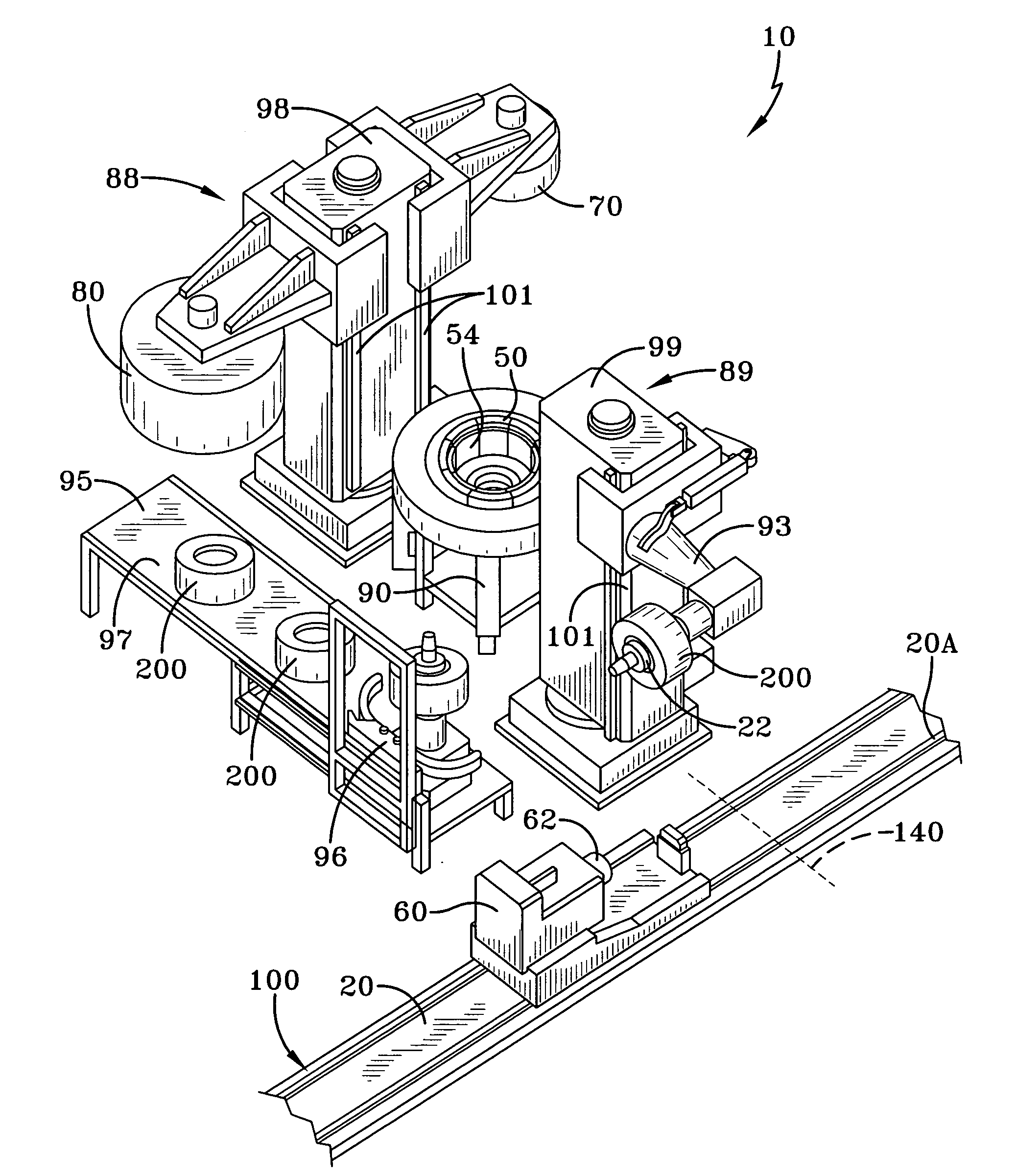

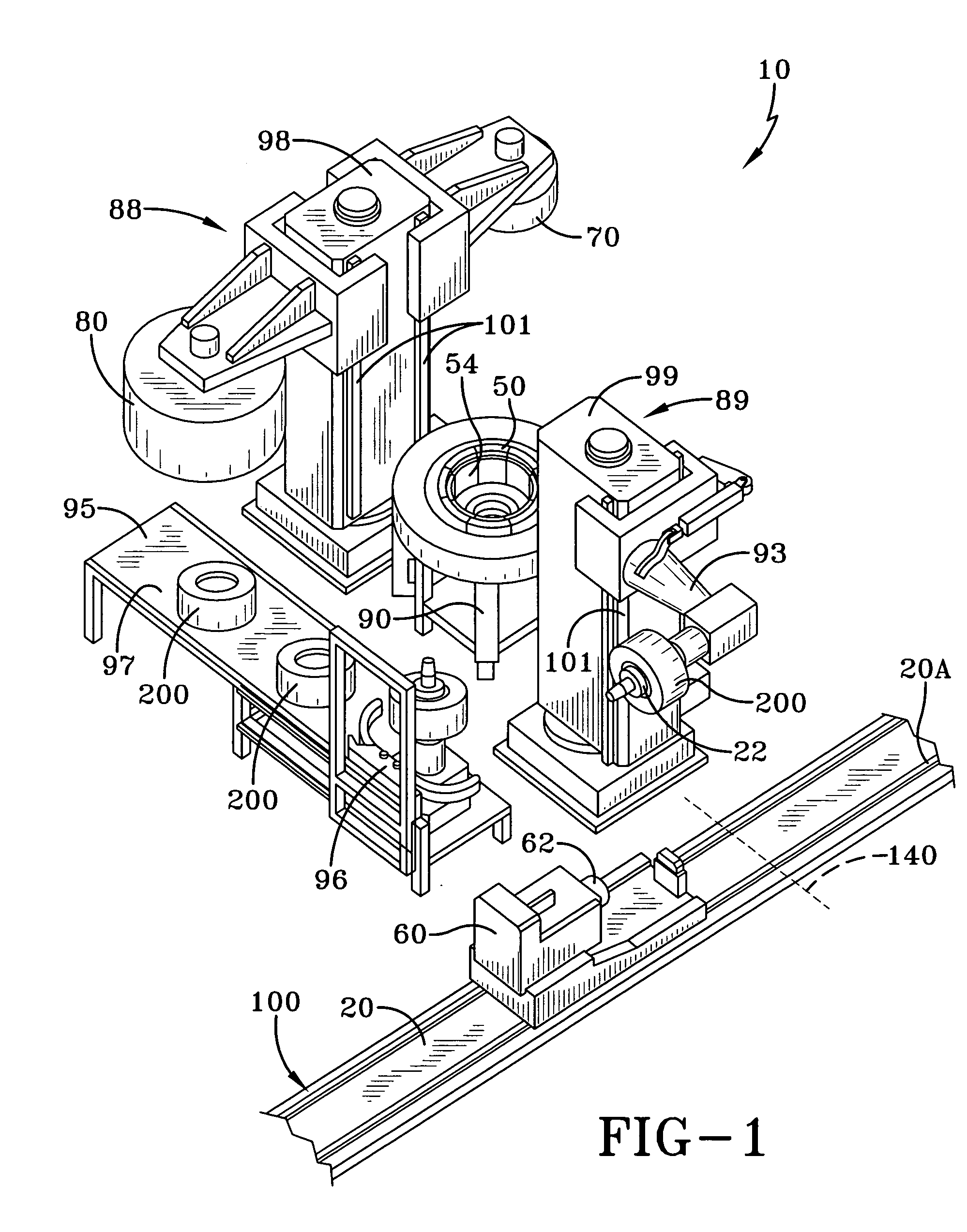

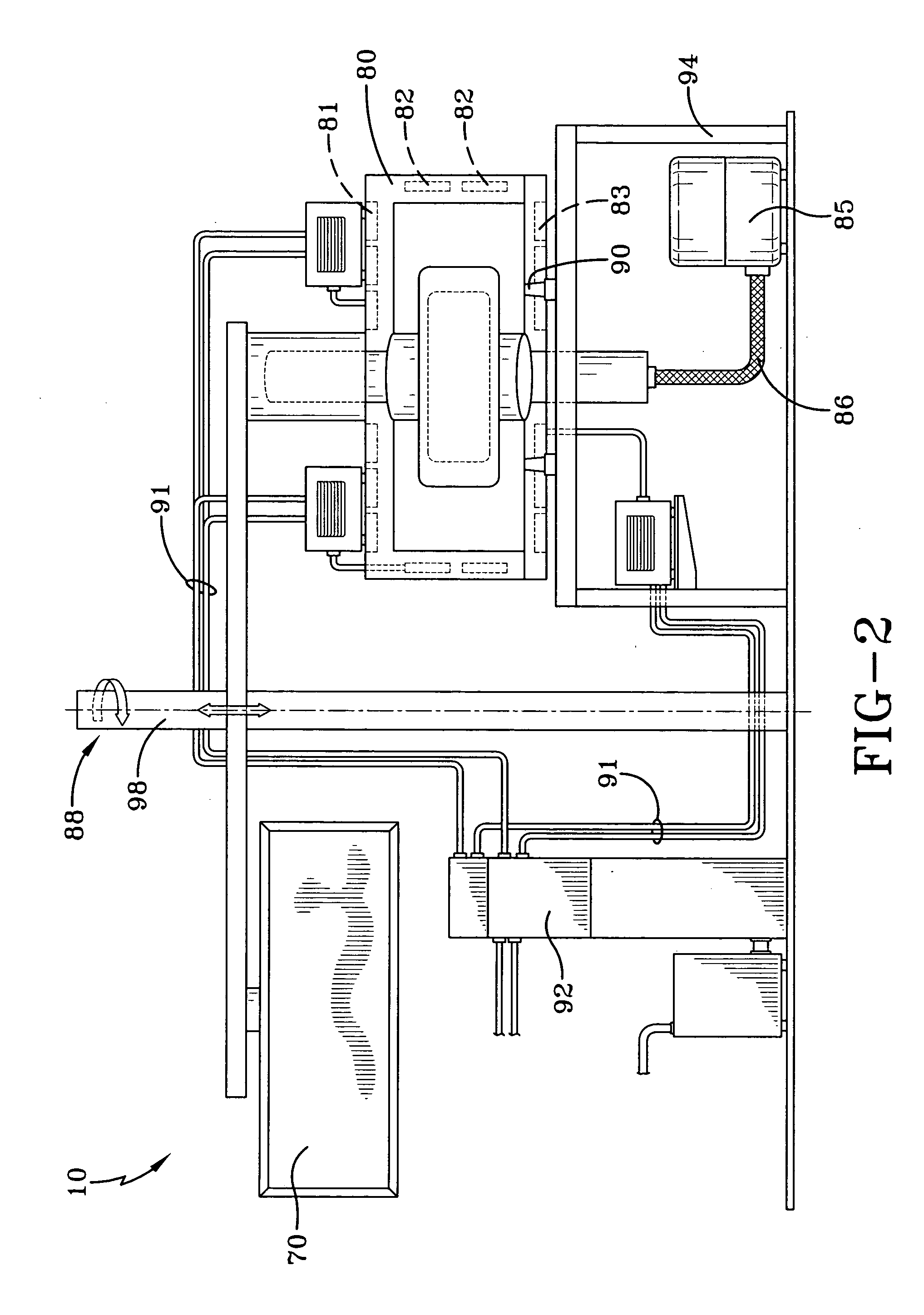

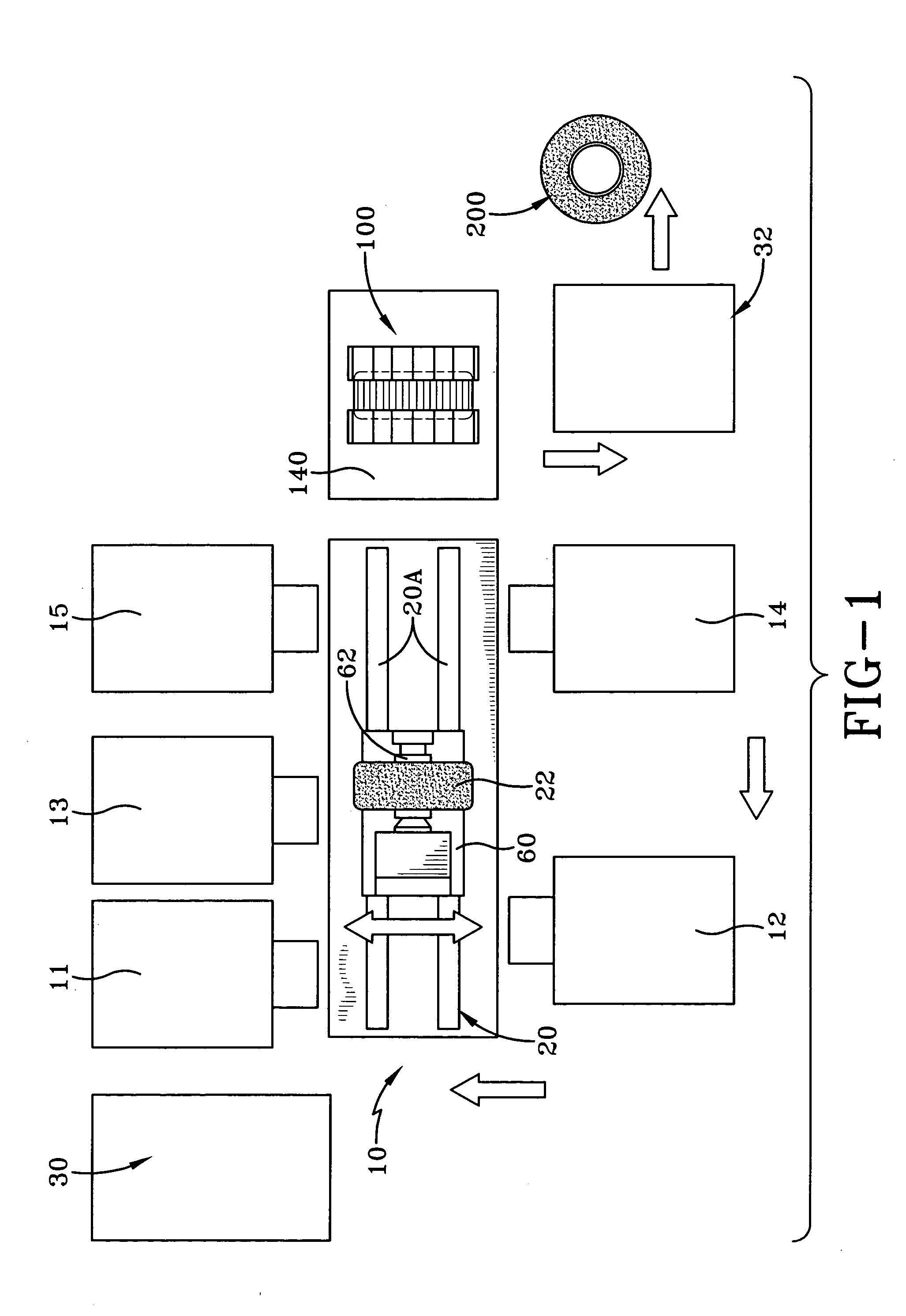

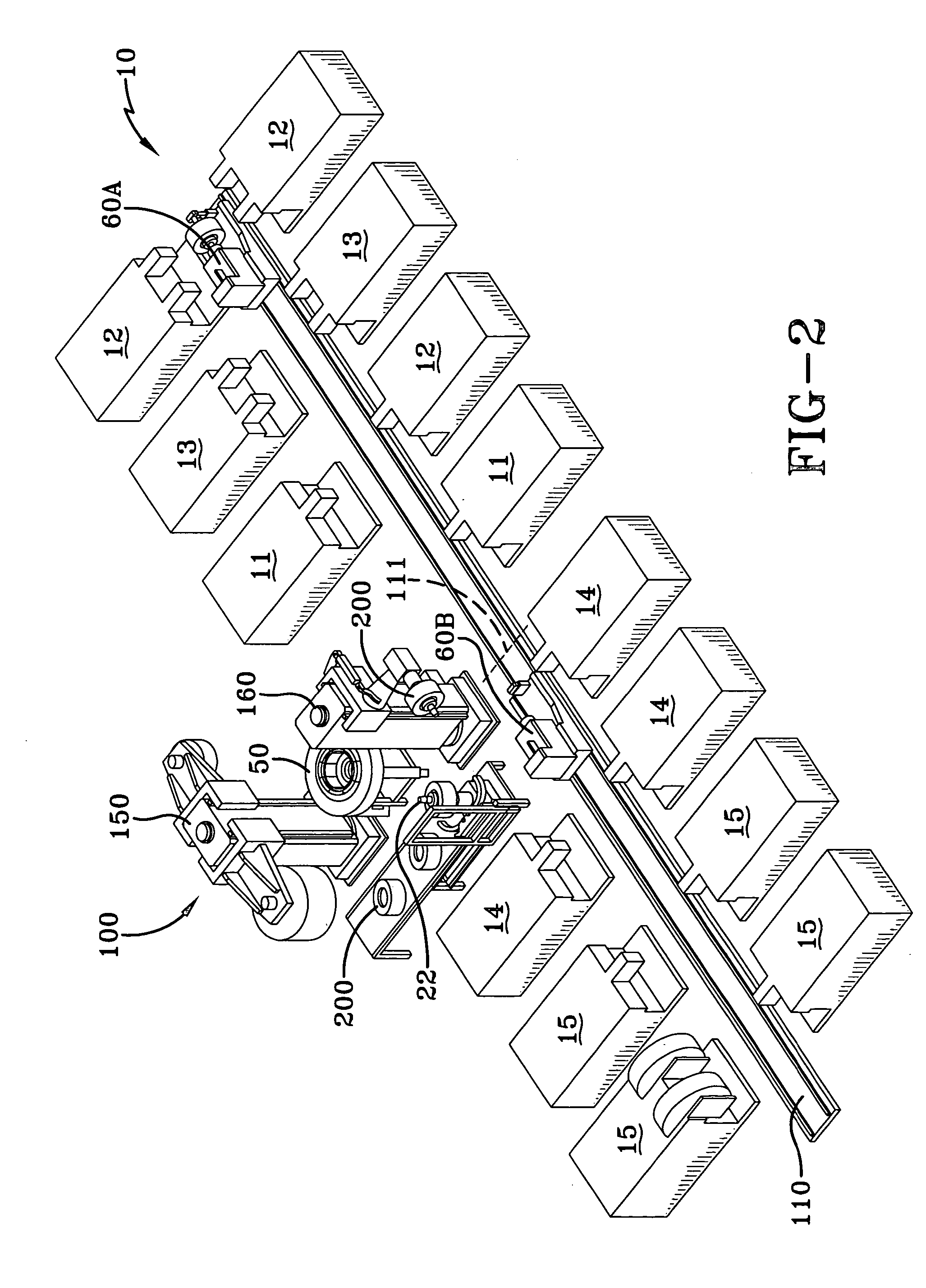

An automated tire manufacturing curing module 10 according to the present invention is illustrated. This system or module 10 provides for the complete vulcanization of pneumatic tires at one tire curing module 10 using only one mold 50 for a particular tire size or style. This curing module 10 is preferably an integral part of a tire building module which forms the tire carcass subassembly 4 and the tire belt tread subassembly 3. These two subassemblies 3, 4 after being formed hot and assembled on a detachable elevated temperature building drum core 22 are shown inserted while on the building drum core 22 into a tire curing mold 50 immediately after their assembly is completed. When at the tire curing station, the mold 50 will then be closed and heated at a mold curing module 10 which permits the tires 200 to be cured or otherwise vulcanized and removed from the mold 50 and the building drum core 22. The curing module preferably has a curing dome 80 having one or more induction heating coils 81, 82, 83.

Owner:SIEVERDING MARK ANTHONY +2

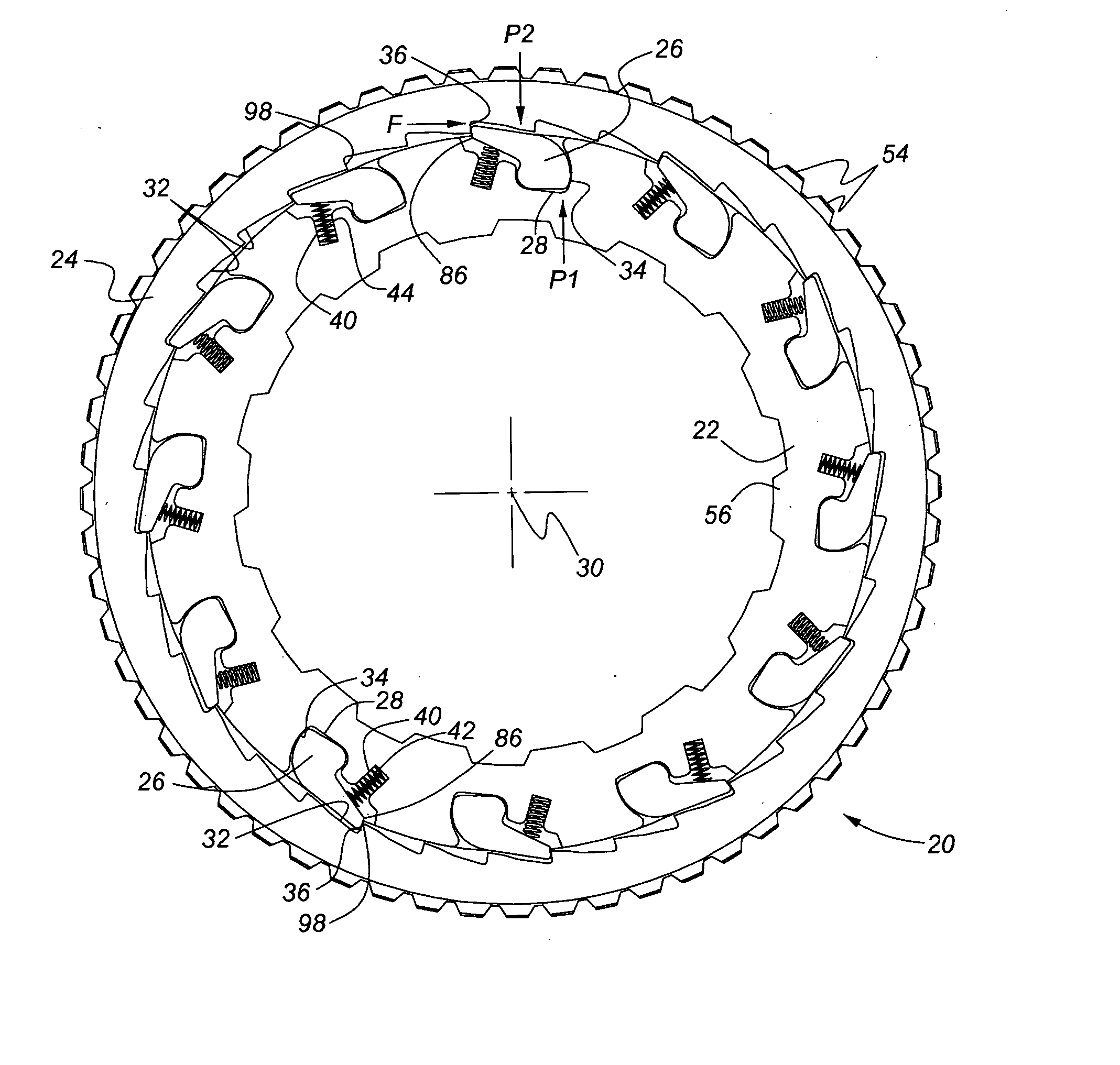

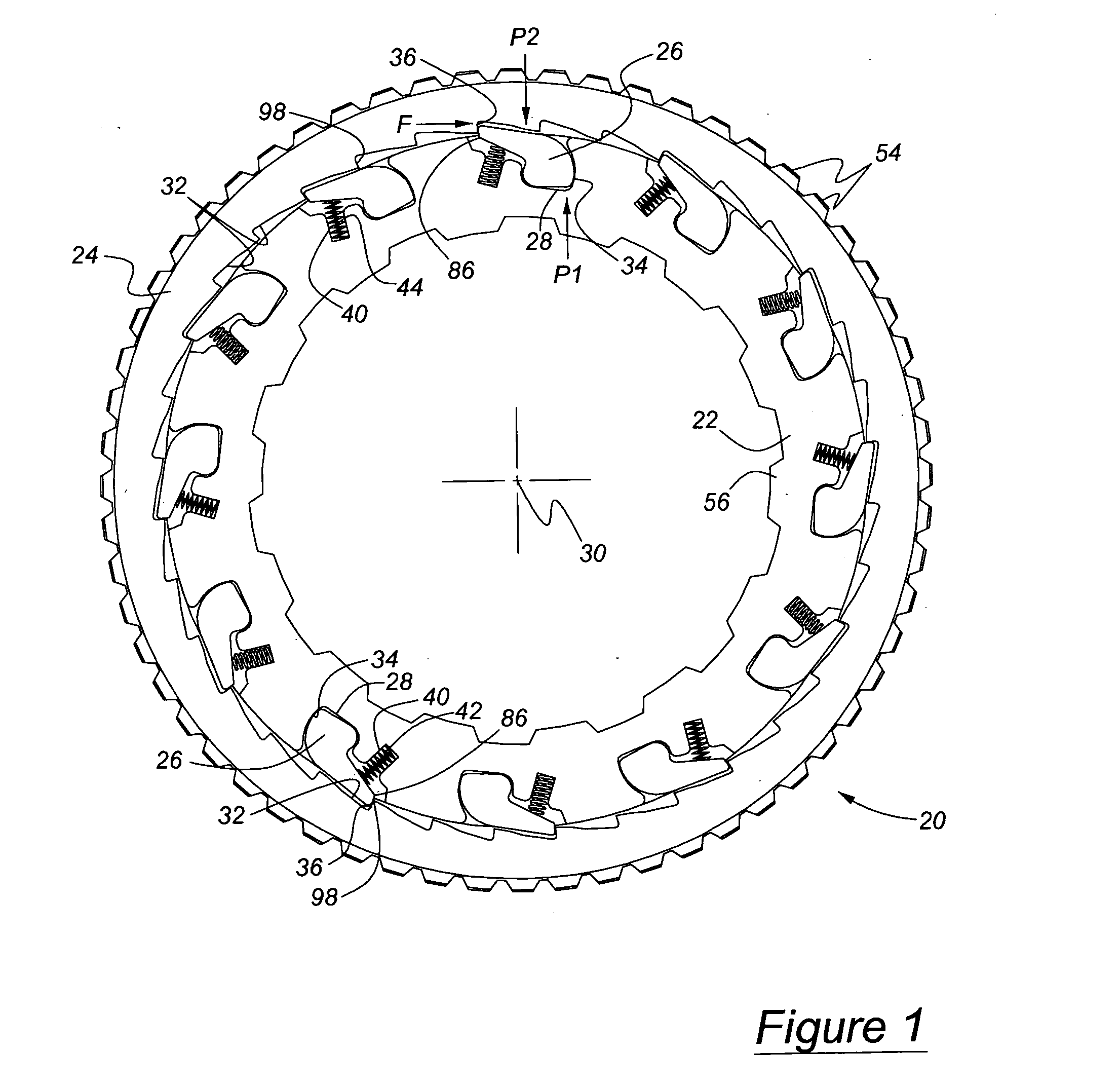

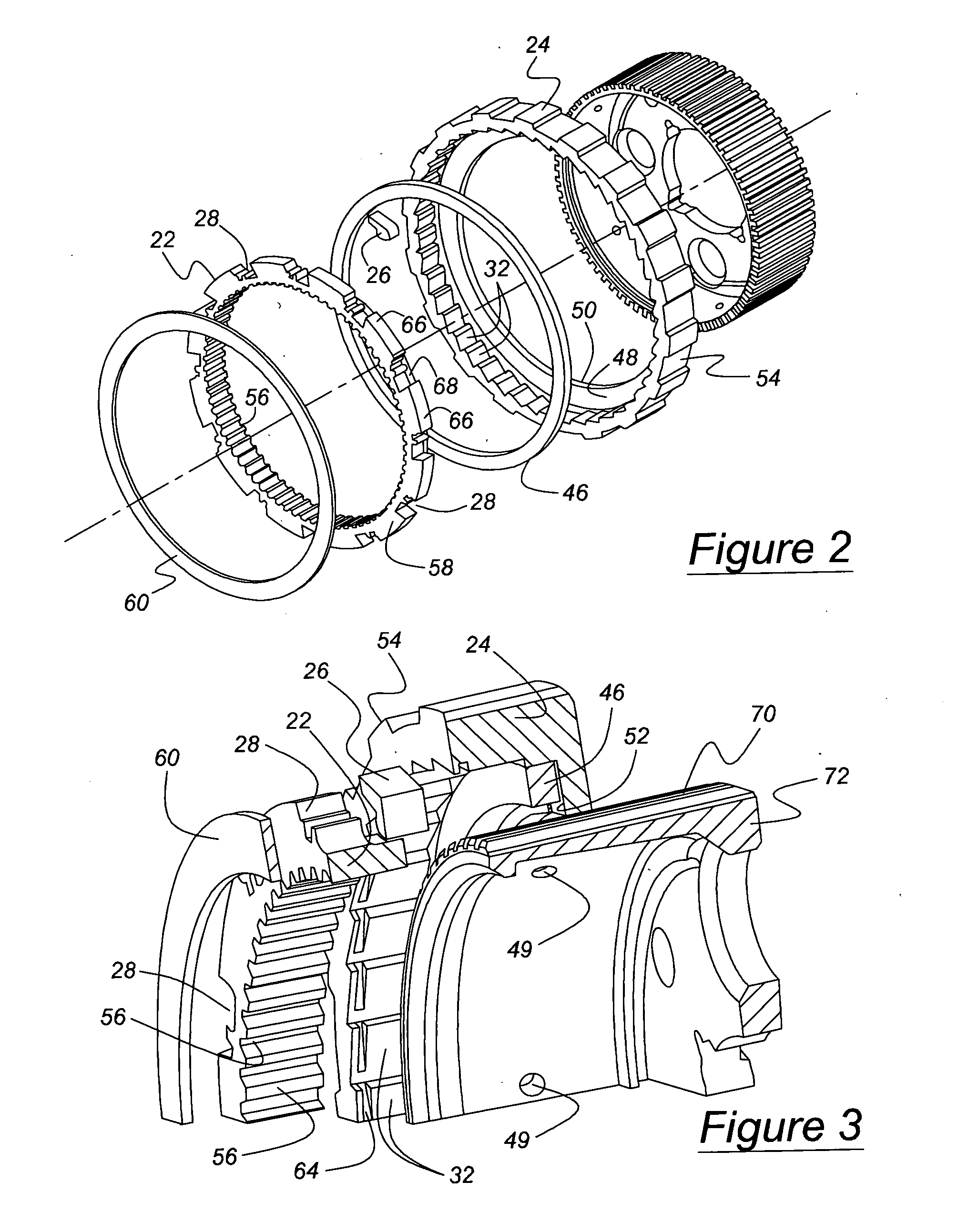

Ratcheting one-way clutch having rockers actuated by centrifugal force

ActiveUS20060021841A1Increase stiffnessHigh strengthFriction clutchesInterengaging clutchesAcute angleEngineering

A ratcheting one-way clutch includes a cam plate formed with cam surfaces angularly spaced about a central axis, and a rocker plate having pockets angularly spaced about the central axis, each pocket including a surface having a pivot axis located within the pocket. A rocker, located in each pocket, pivots about the pivot axis toward and away from the cam surfaces. Each rocker has a center of mass, located relative to the pivot axis when the rocker is retracted into the pocket away from the cam surfaces, such that an acute angle formed between a first line that extends radially from the central axis through the pivot axis and a second line that passes through the center of mass and the pivot axis is equal to or less than twenty degrees.

Owner:FORD GLOBAL TECH LLC

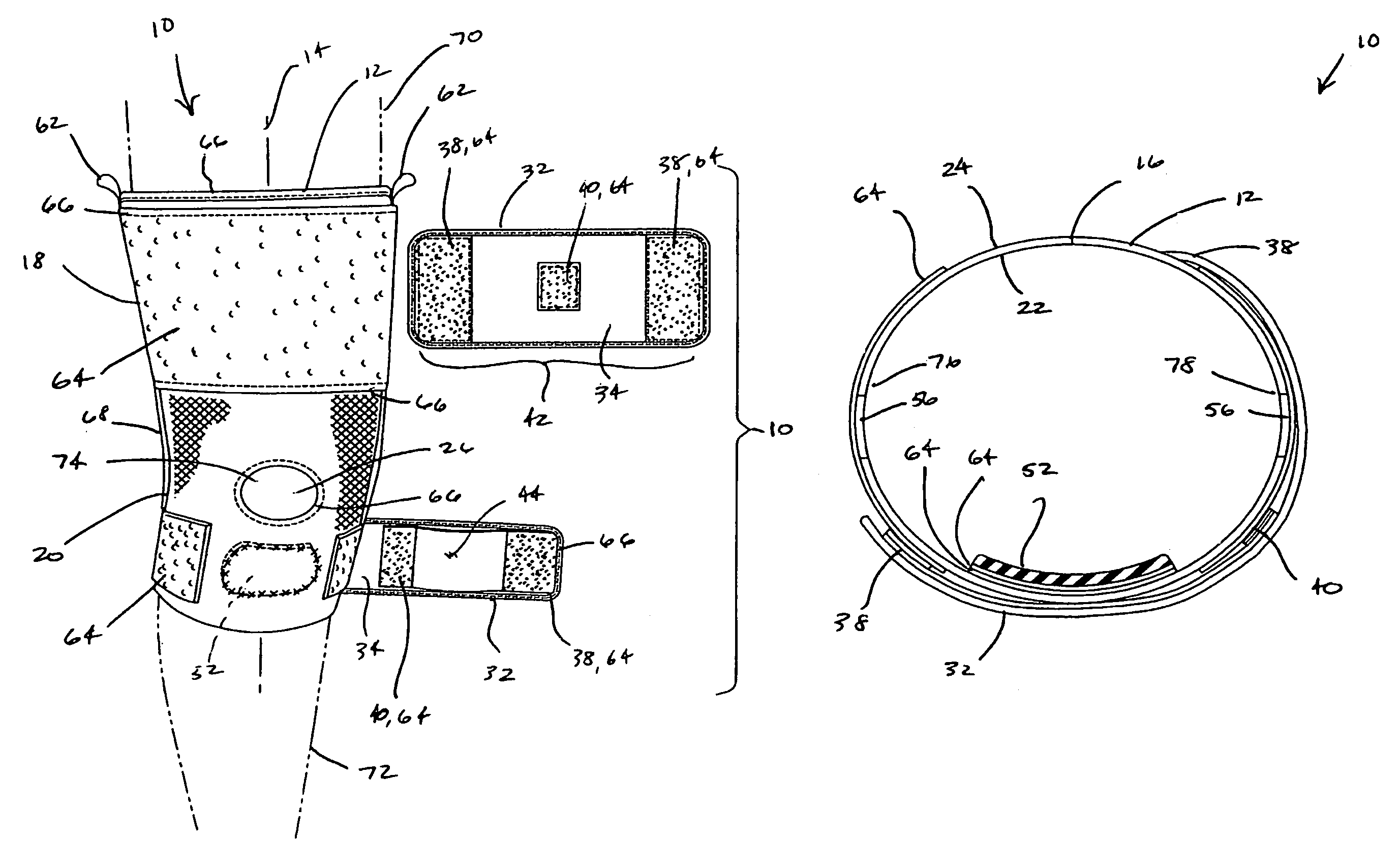

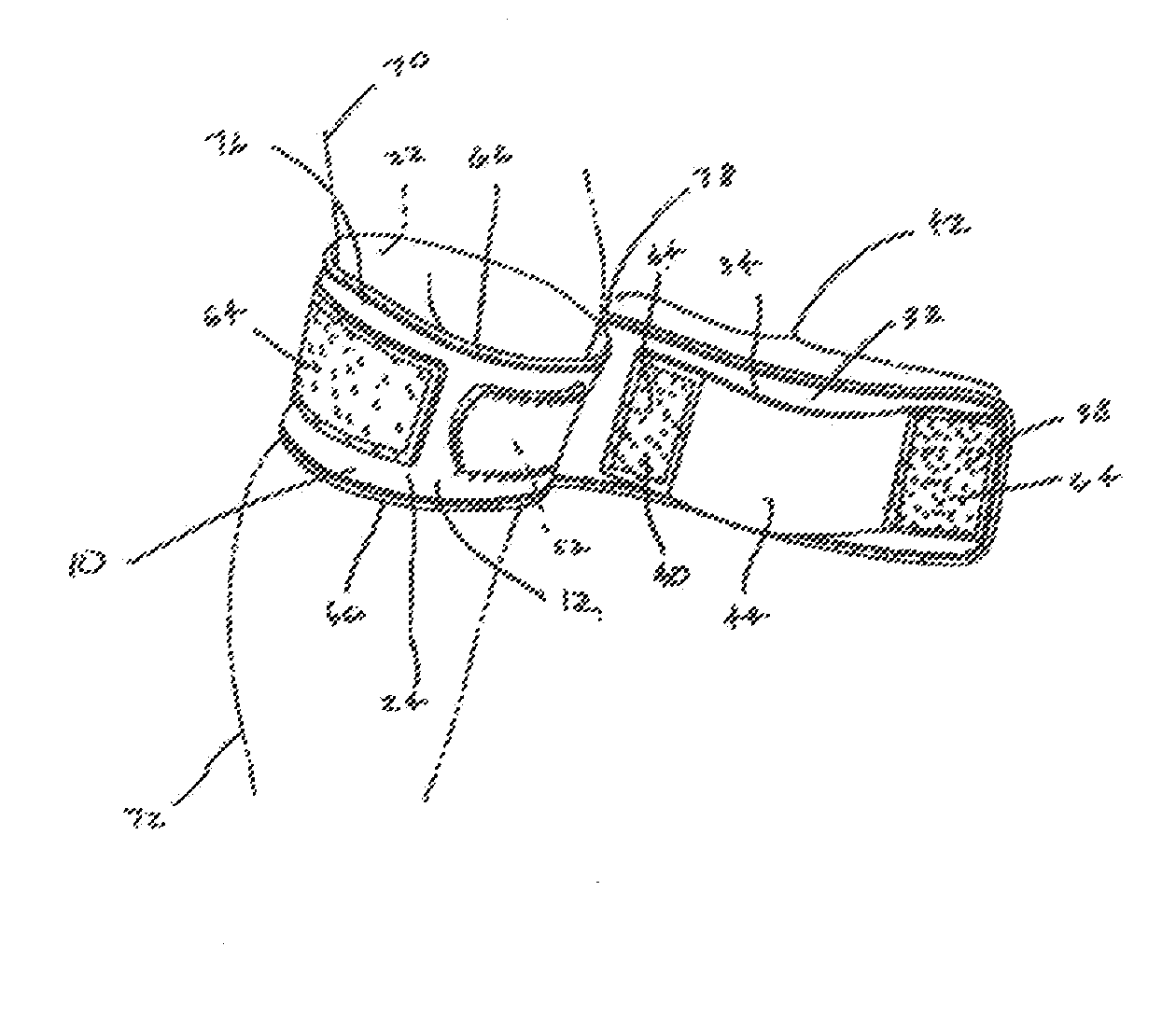

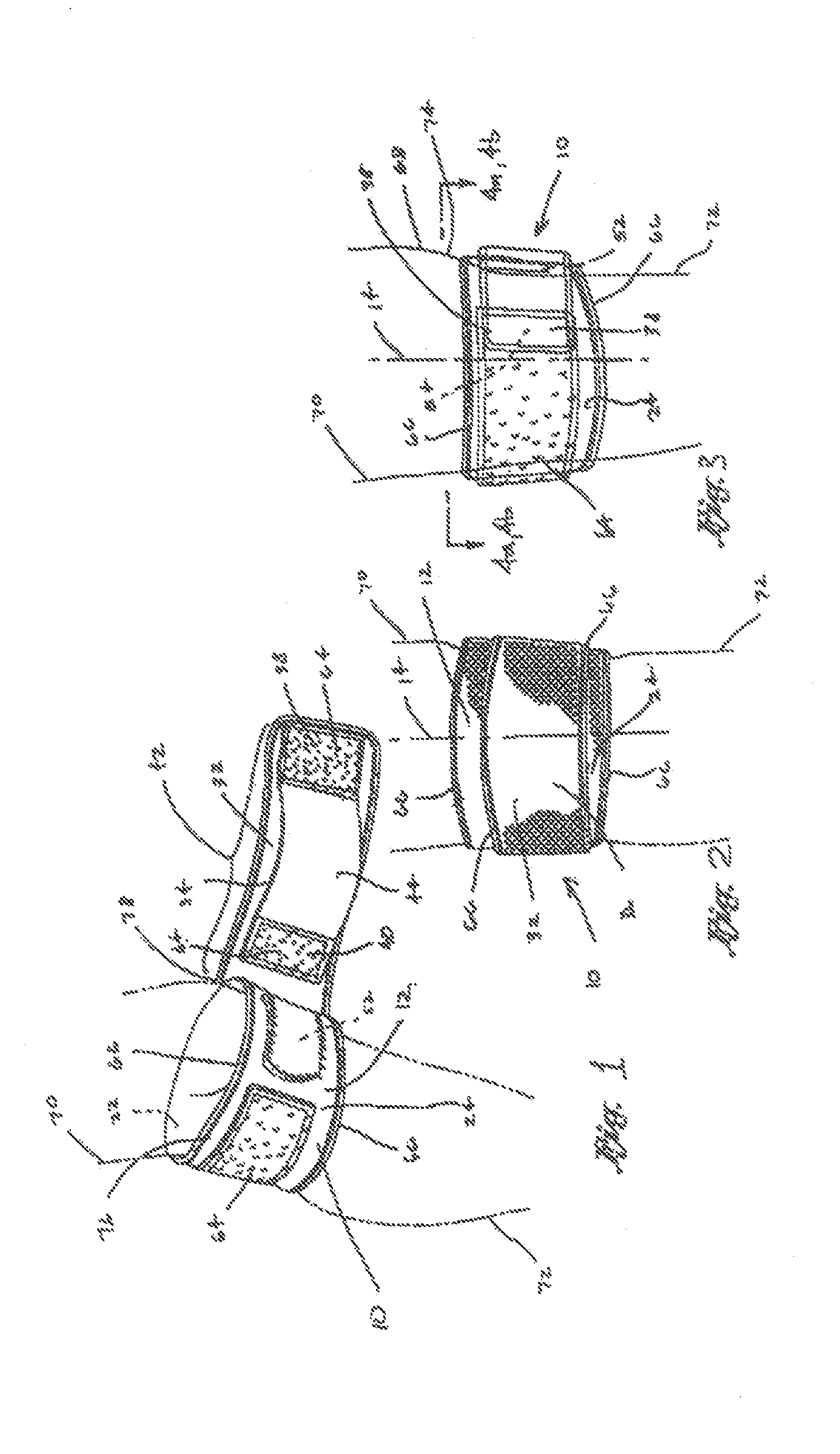

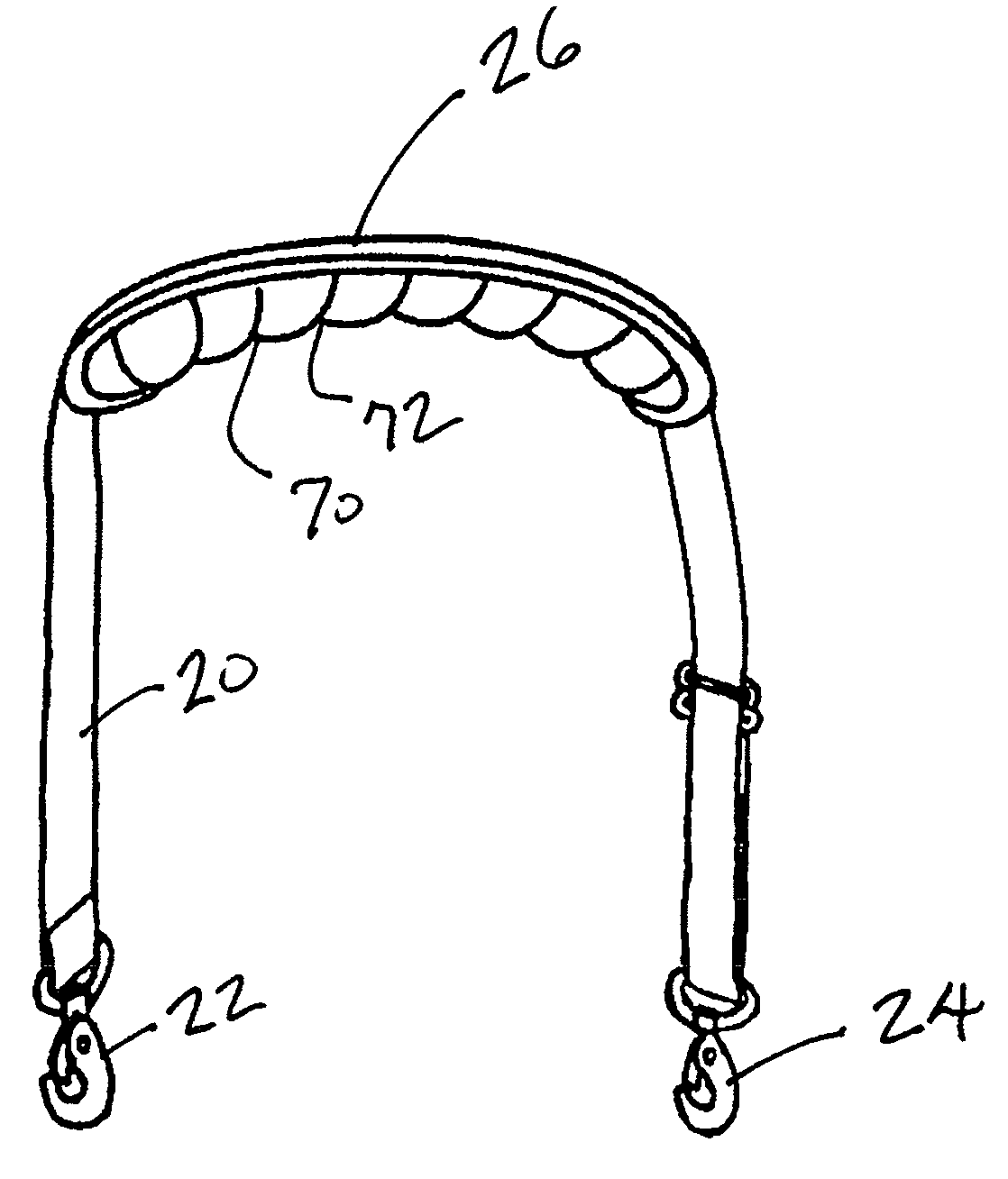

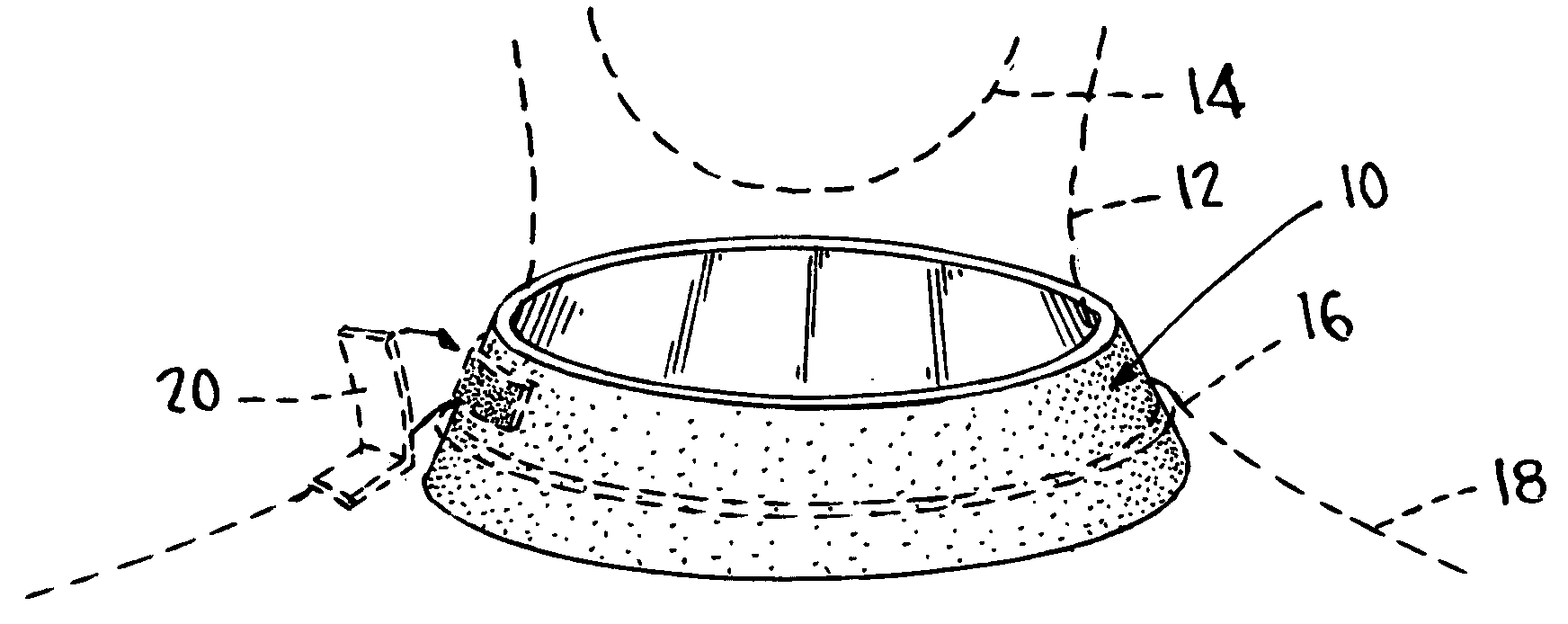

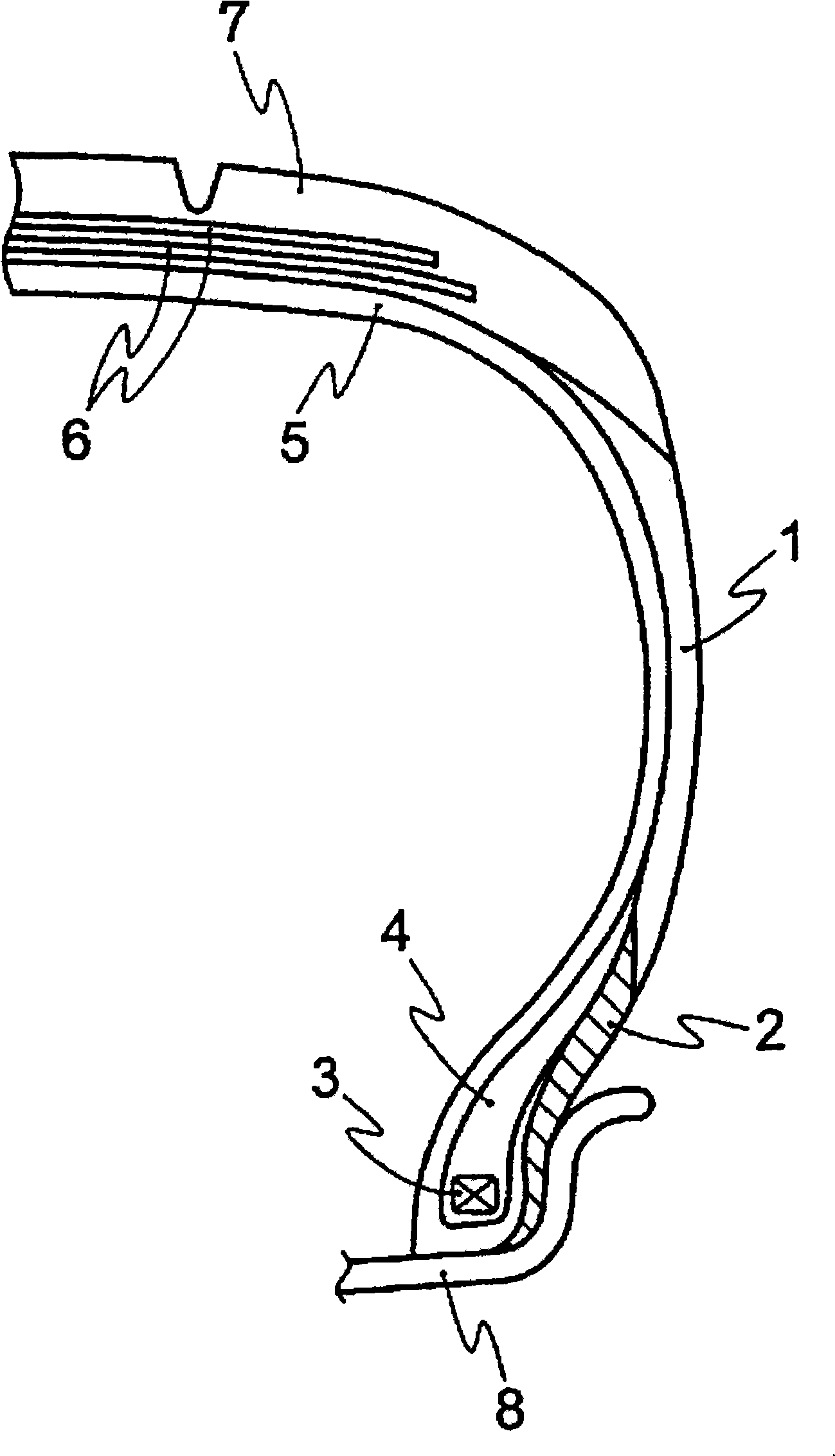

Neuromusculoskeletal knee support device

ActiveUS7862529B2Minimize fraying and tearingInhibit chafingRestraining devicesFeet bandagesKnee supportKnee Joint

A knee brace for proprioceptively treating a patient comprises a sleeve having an anchor strap and a viscoelastic pad. The sleeve defines inner and outer sleeve surfaces and is configured to envelop the patient's knee. The anchor strap is circumferentially wrappable about the outer sleeve surface and defines an inner strap surface. The anchor strap has an intermediate anchor portion disposed on the inner strap surface between opposing end anchor portions that are releasably securable to the outer sleeve surface such that tension in the anchor strap may be selectively adjusted. The knee brace includes an elastic band extending along the inner strap surface. The viscoelastic pad is securable on the inner sleeve surface generally opposite to the elastic band such that pressure may be applied to the patient's infrapatellar tendon when the anchor strap is extended over the outer sleeve surface.

Owner:INTELLISKIN USA

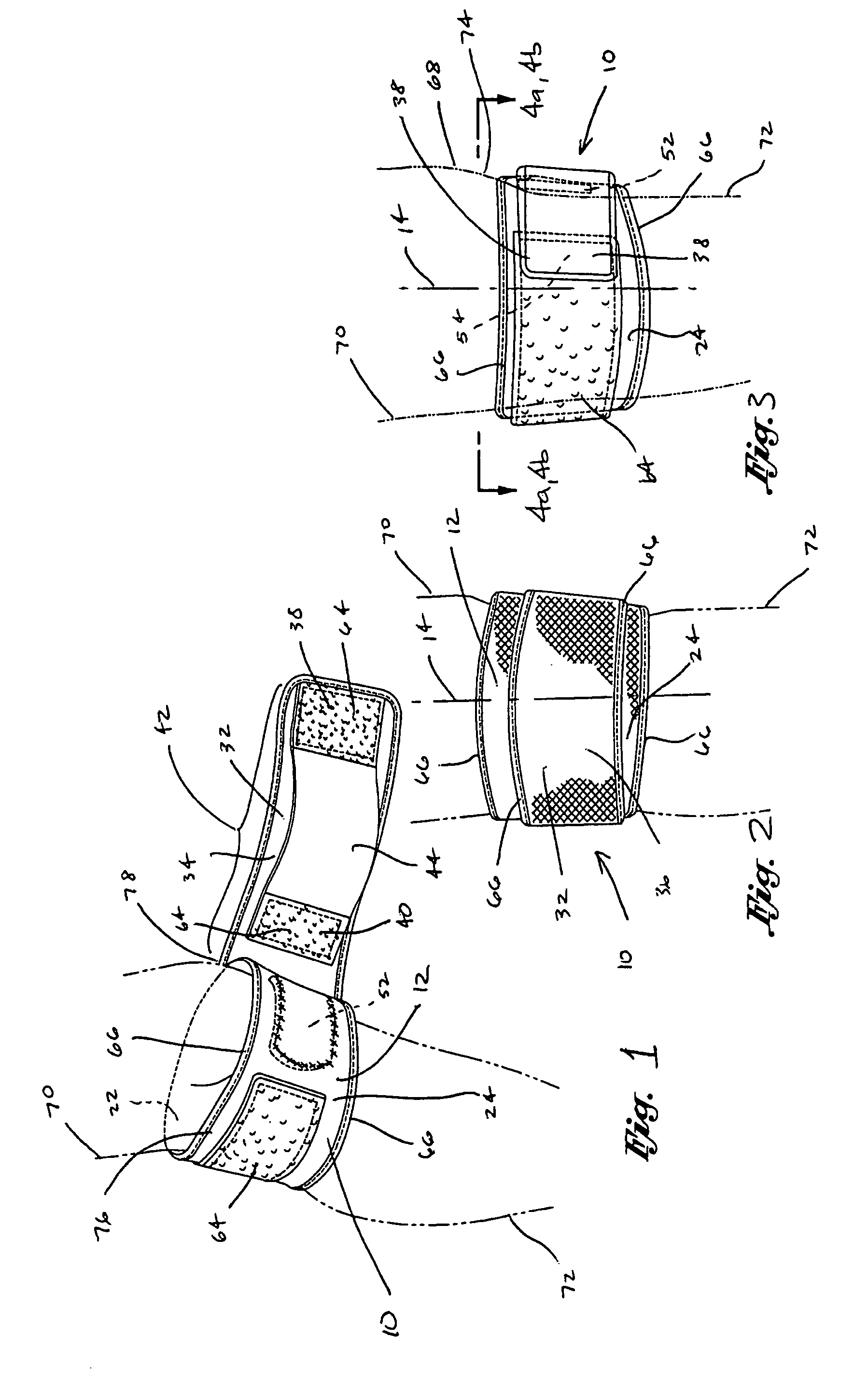

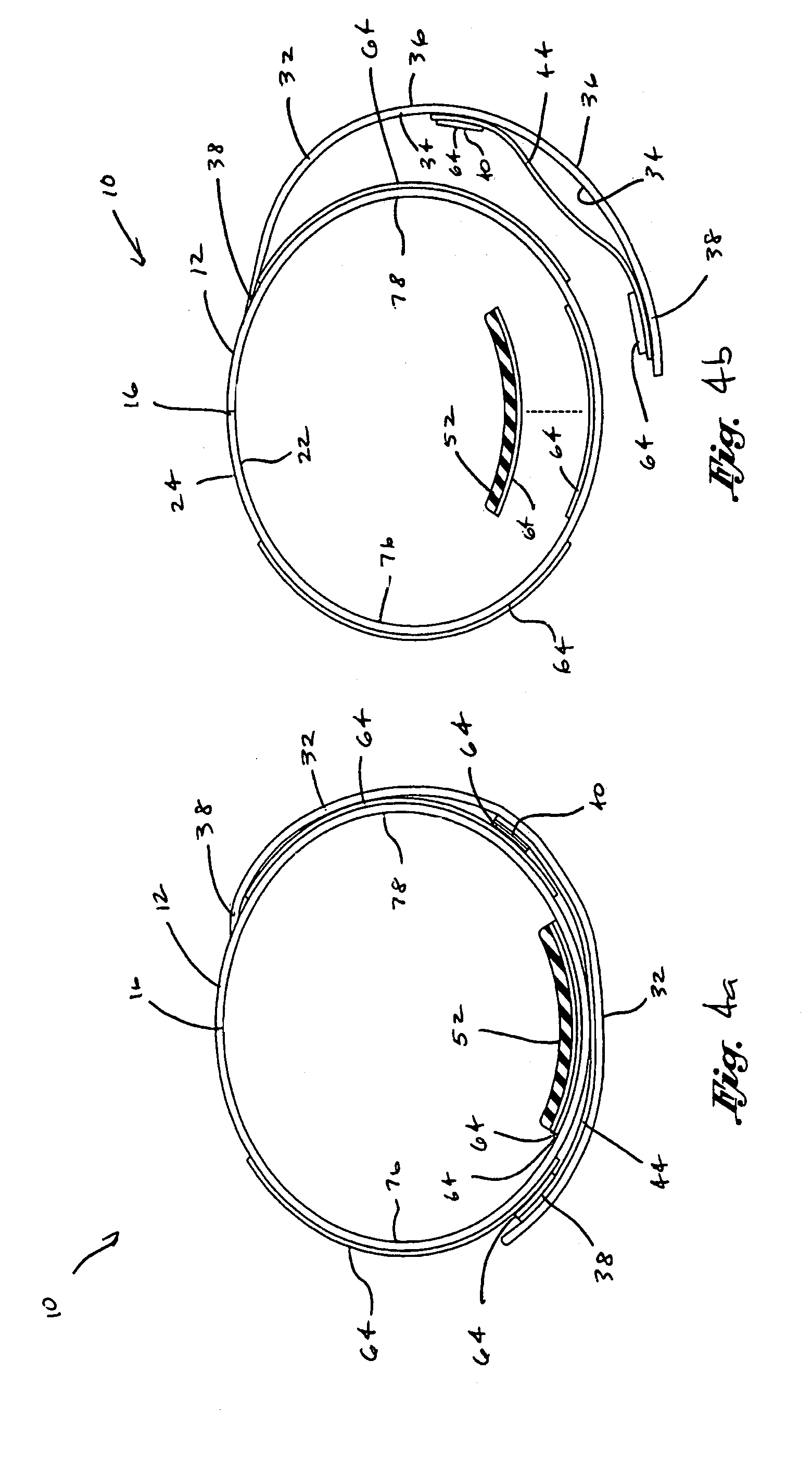

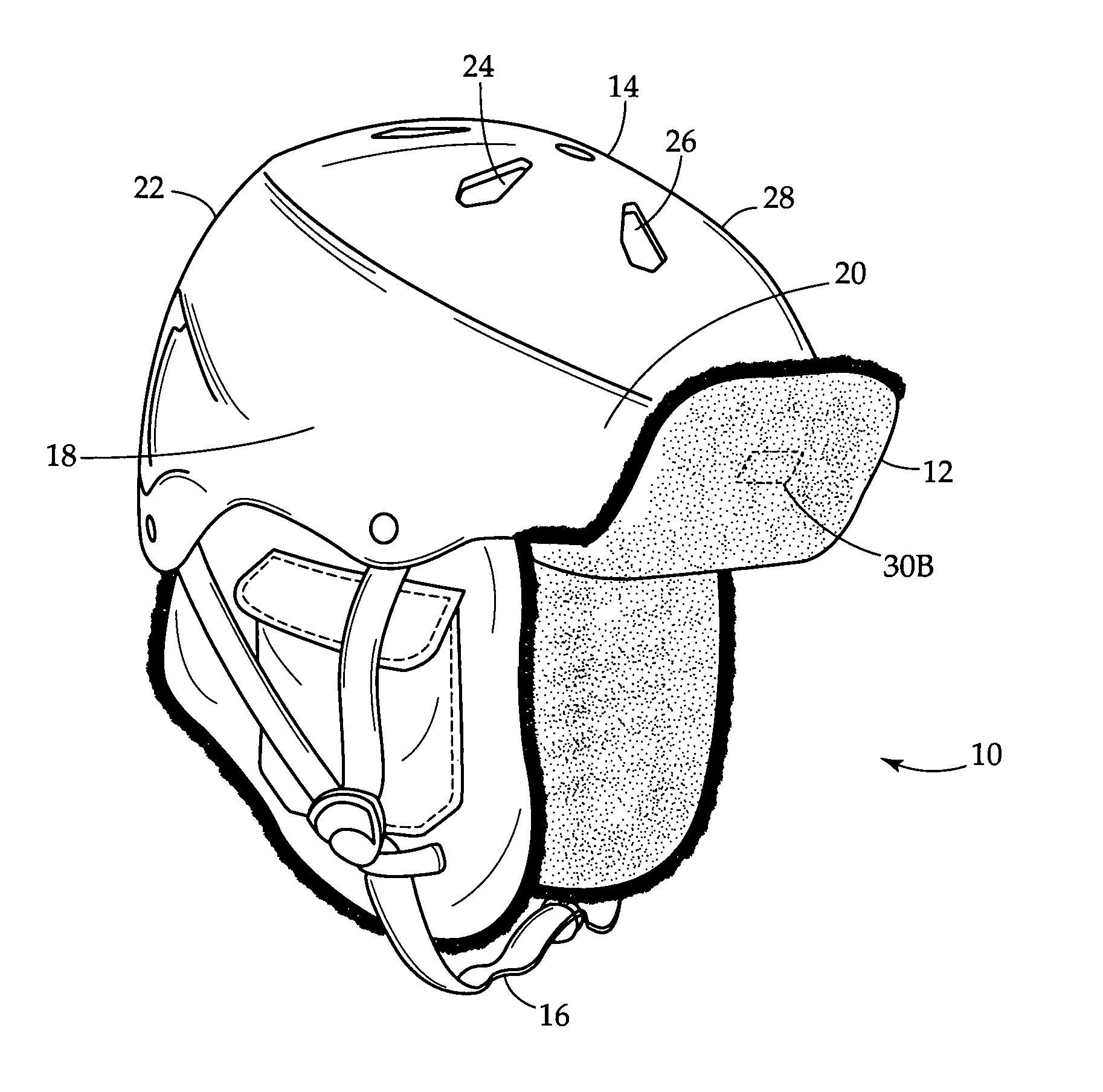

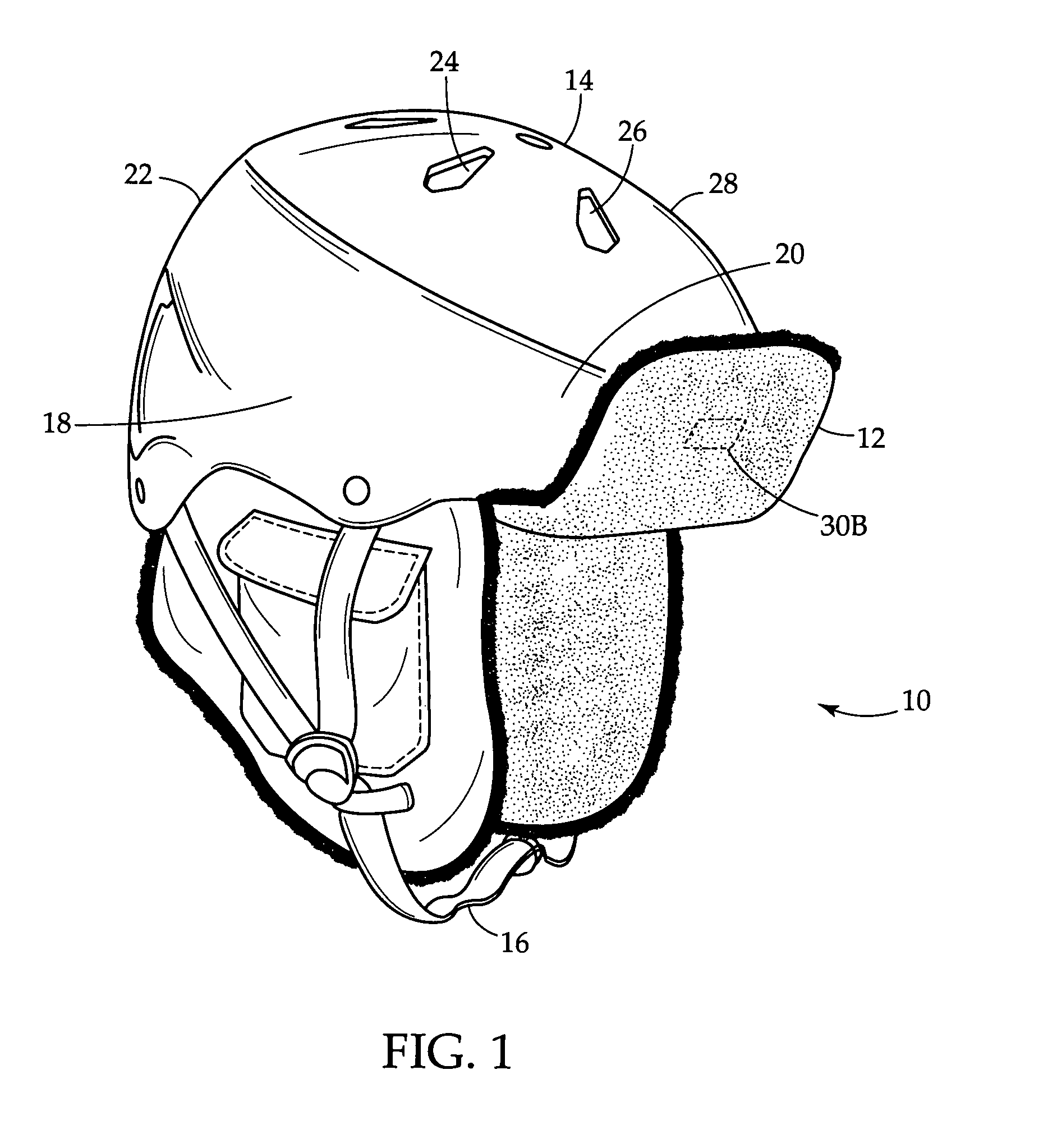

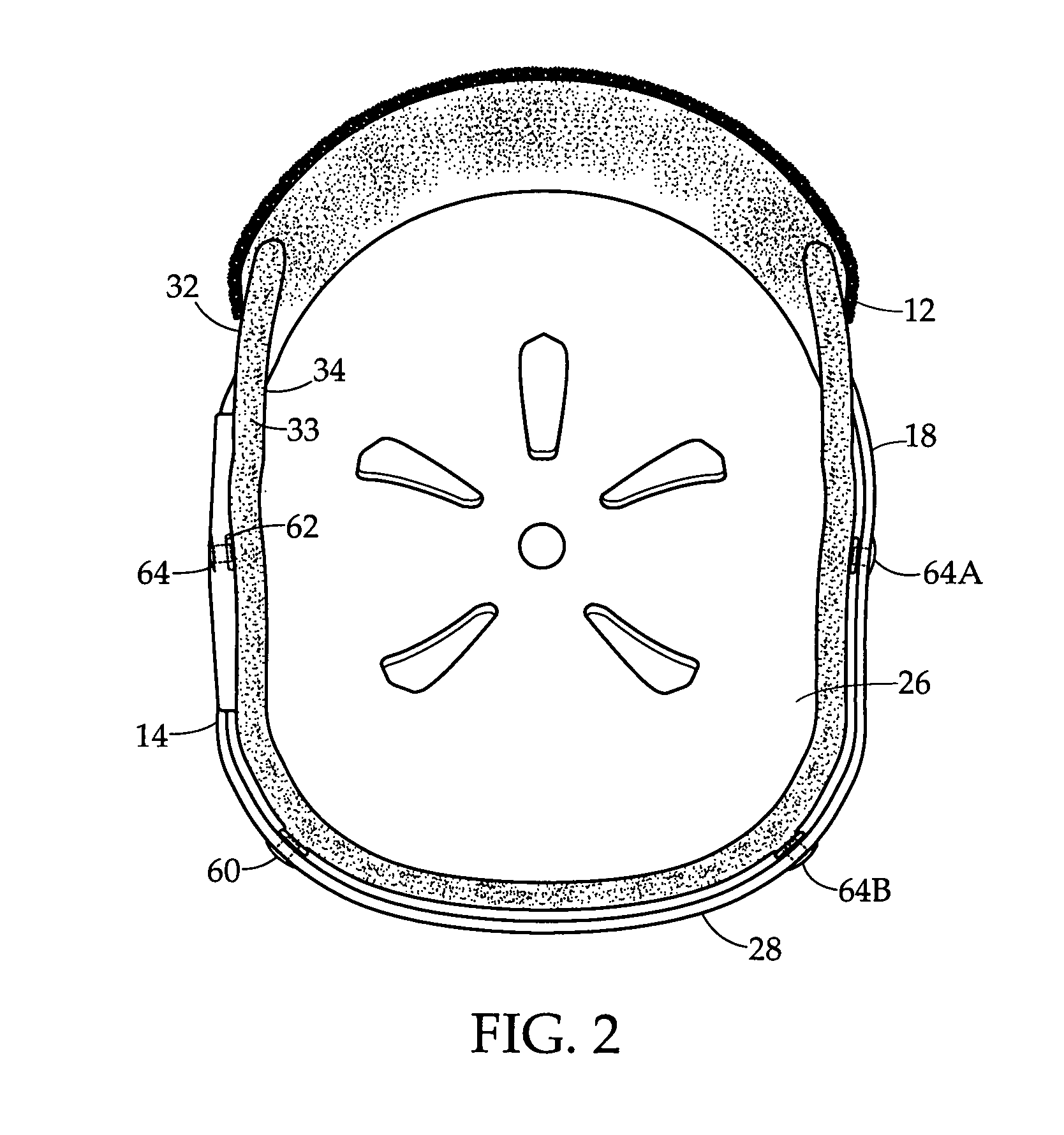

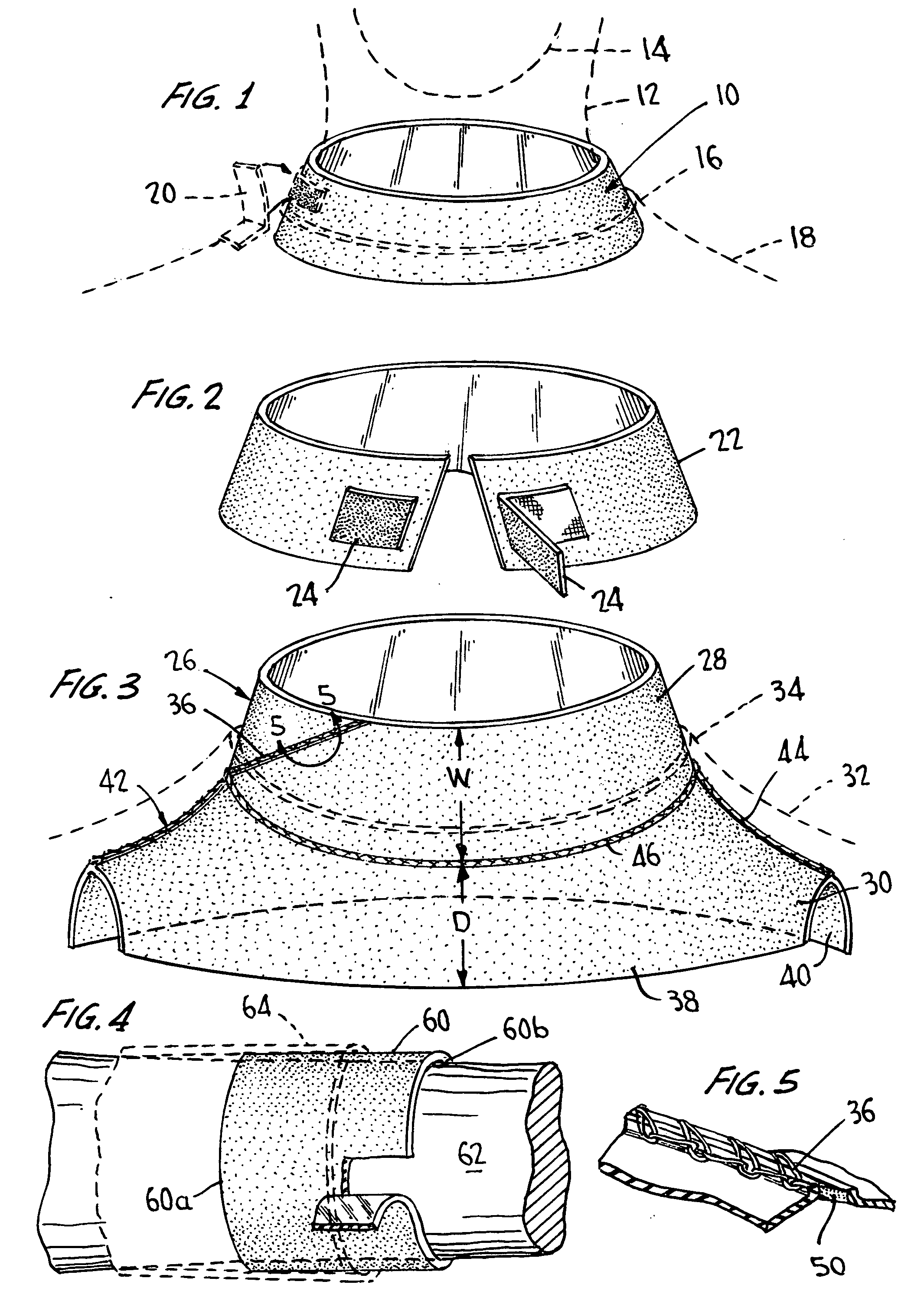

Removable hunter knit liner for use with a protective helmet

A winter liner system, including a hunter knit liner for wear underneath a protective helmet. The hunter knit liner fully encircles, and partially covers, the head of the wearer and includes a decorative exterior layer, an interior layer, and an interior foam layer sandwiched therebetween. The liner has two ear flaps extending downwardly to cover ears, and a looping band on each ear flap for holding the chinstrap of the helmet. At least one ear flap includes a side pocket integrated therein. The liner includes an elongated bill extending downwardly and horizontally across the front portion. The bill has an exterior surface which adheres directly to the front of the helmet. A plurality of snapping mechanisms, which include male snap heads embedded within the helmet and cooperating female snap receptacles integrated into the liner, removably securing the liner into the helmet.

Owner:BERN UNLIMITED

Neuromusculoskeletal Knee Support Device

InactiveUS20110137221A1Minimize fraying and tearingInhibit chafingNon-surgical orthopedic devicesKnee supportKnee Joint

Owner:INTELLISKIN USA

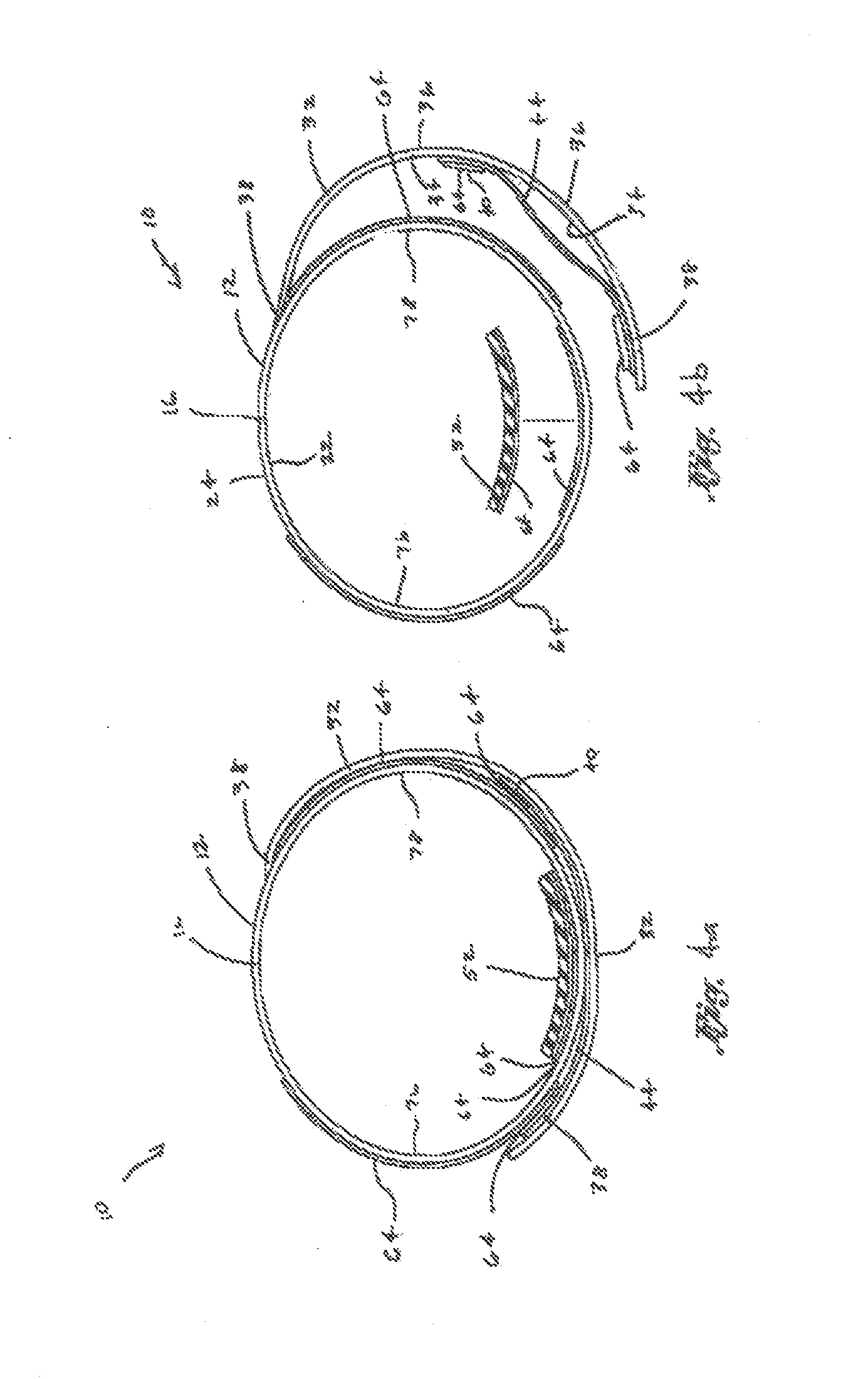

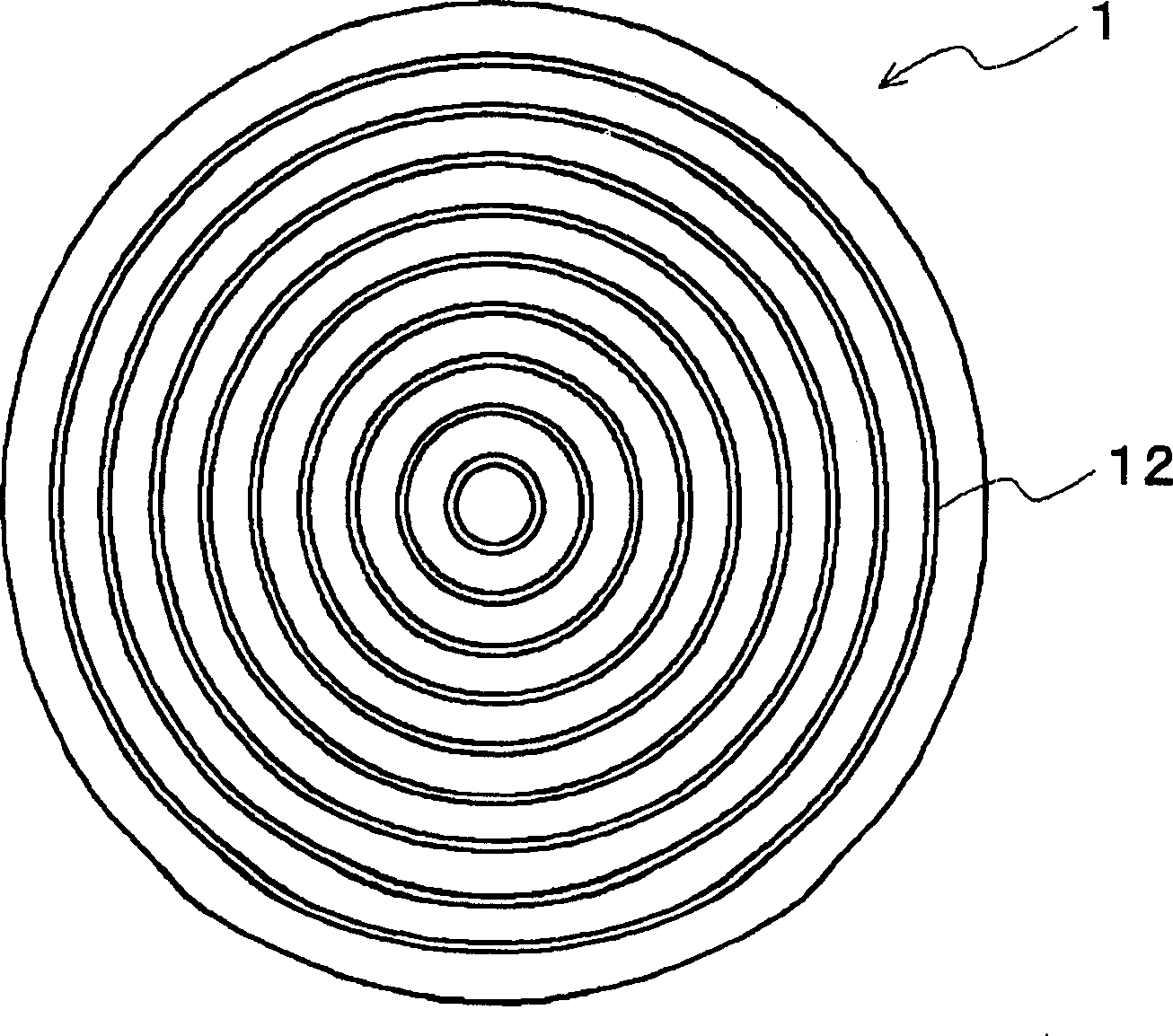

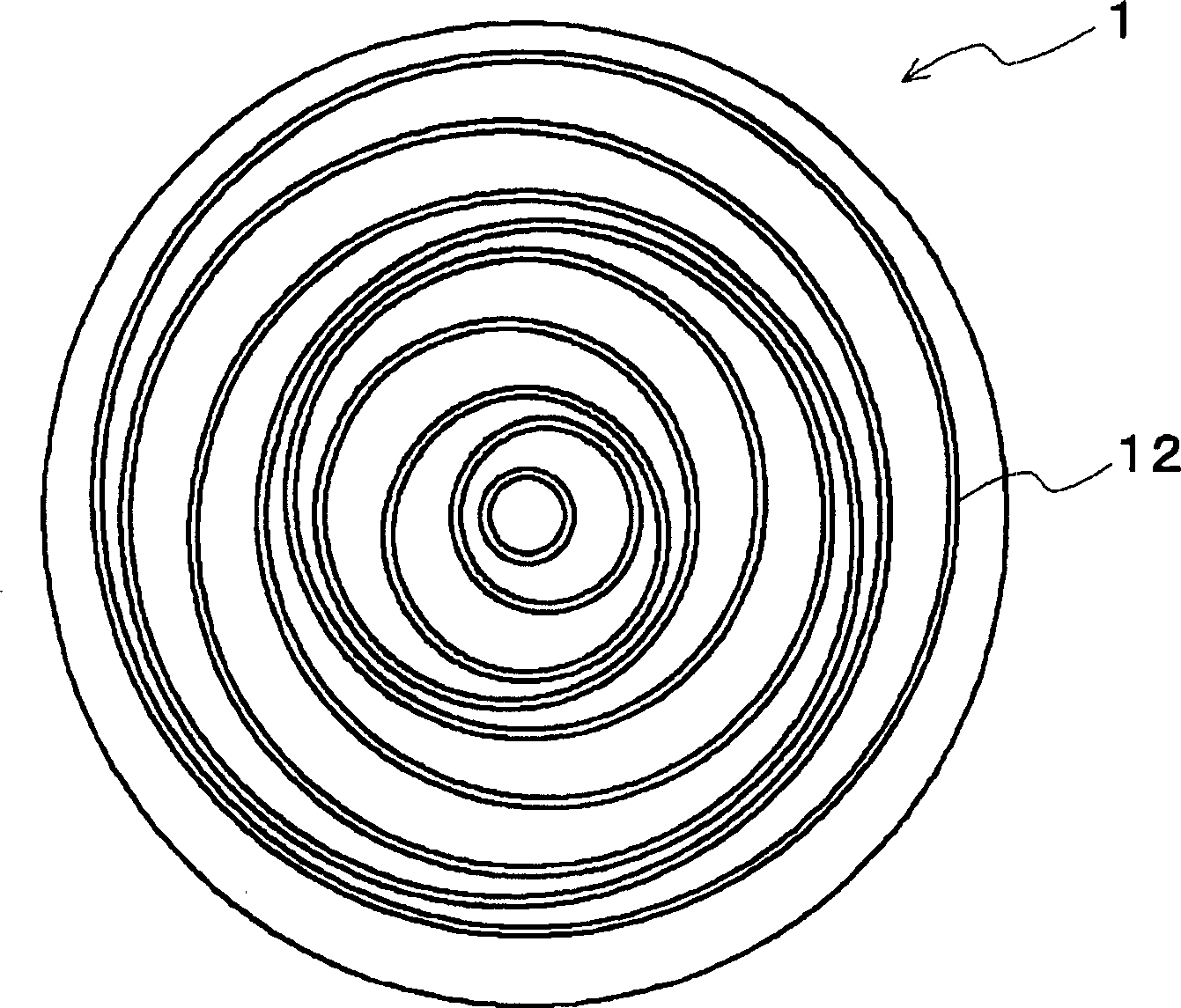

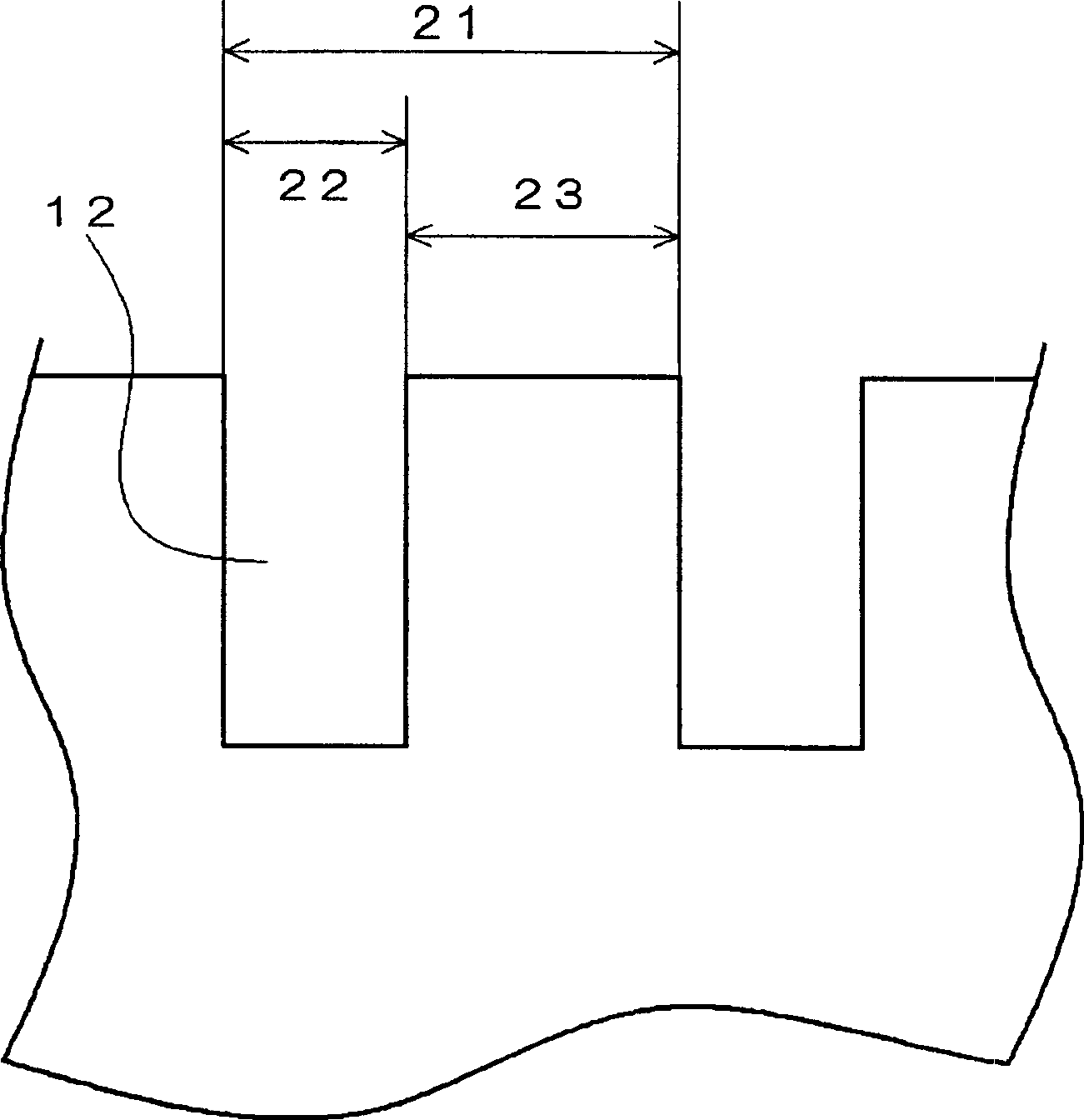

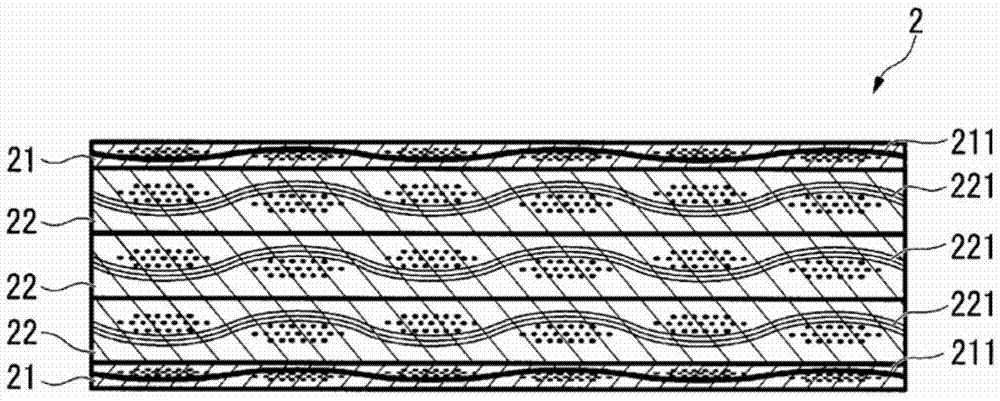

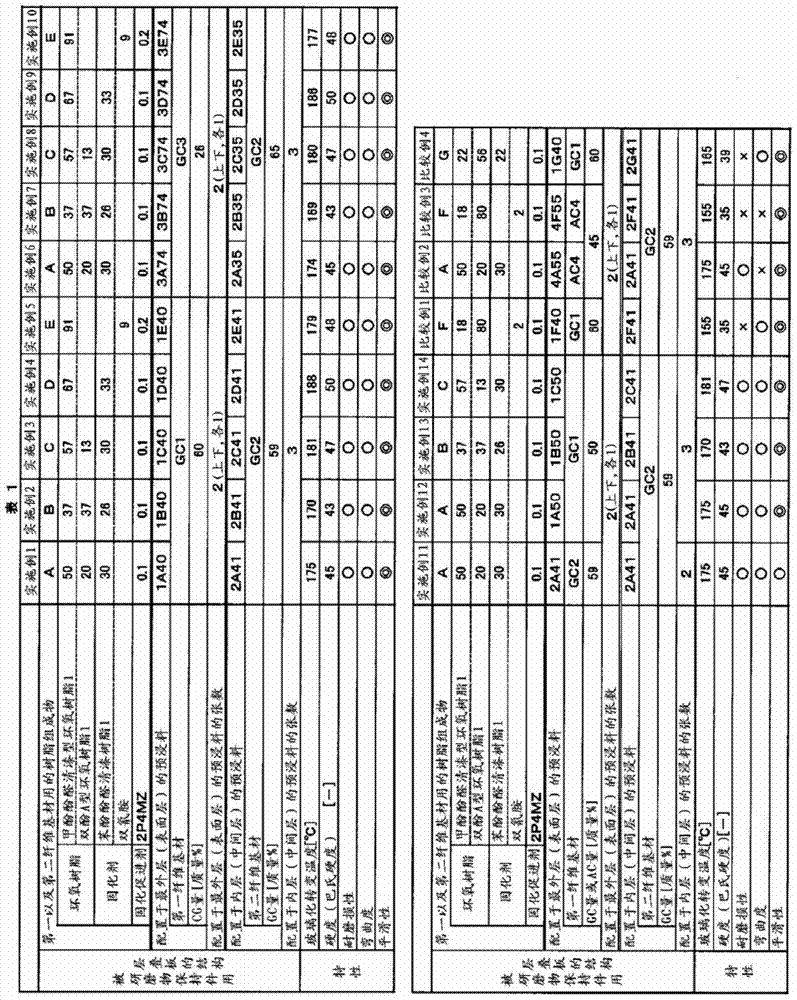

Polishing mattress and multilayer polishing mattress

InactiveCN1494983AInhibit chafingImprove flatnessSemiconductor/solid-state device manufacturingFlexible-parts wheelsSurface roughnessBiomedical engineering

The present invention intends to provide a polishing pad and a multi-layer polishing pad (1) that can particularly effectively suppress scratch from occurring. The polishing pad (1) of the invention comprises at least one part selected from a groove (a) having at least one kind of shape selected from annular, lattice-like and spiral form on a polishing surface side, a concave portion (b) and a through hole (c). In the above, surface roughness of an inner surface of the part is 20 mu m or less and the polishing pad (1) is used for chemical mechanical polishing.

Owner:JSR CORPORATIOON

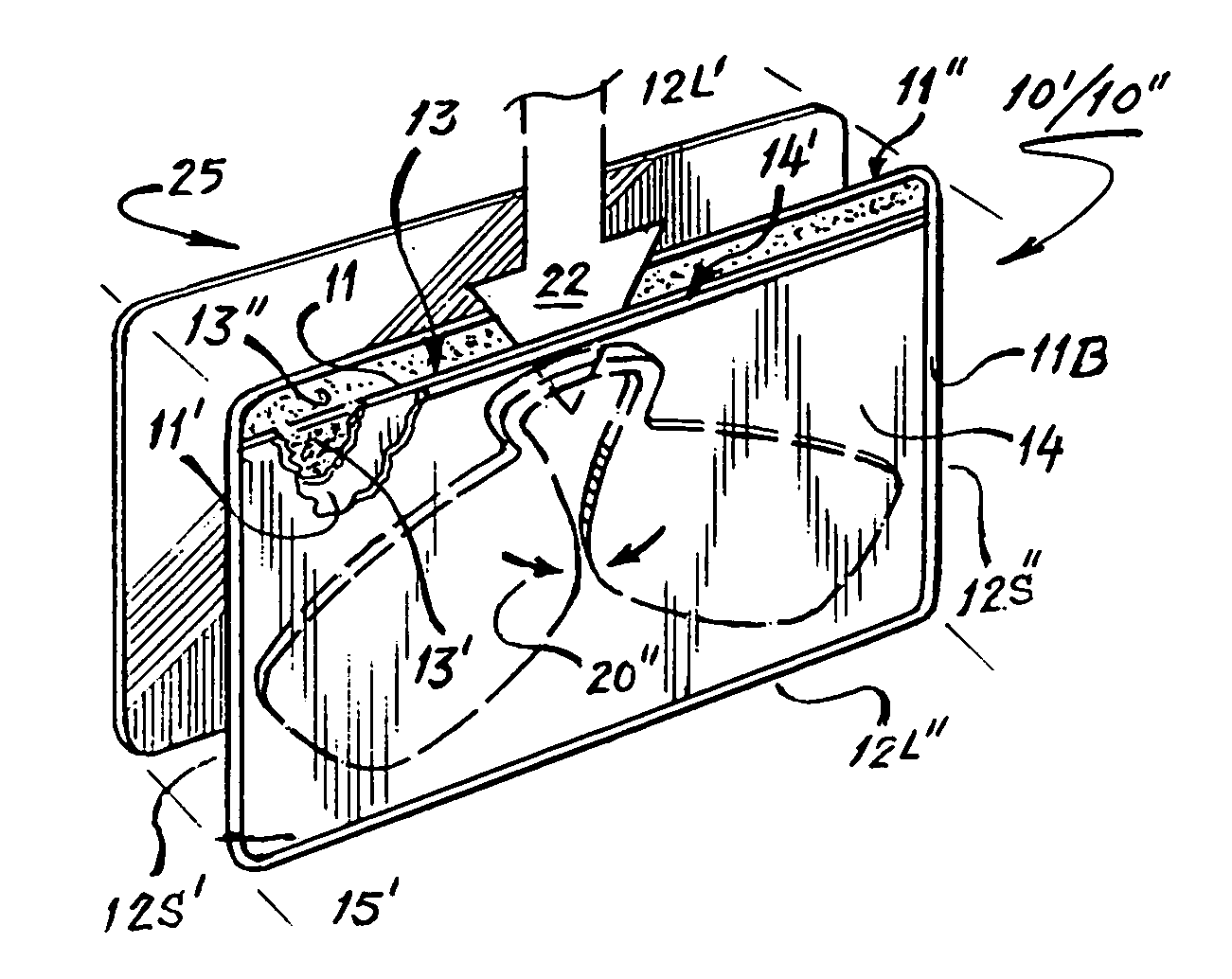

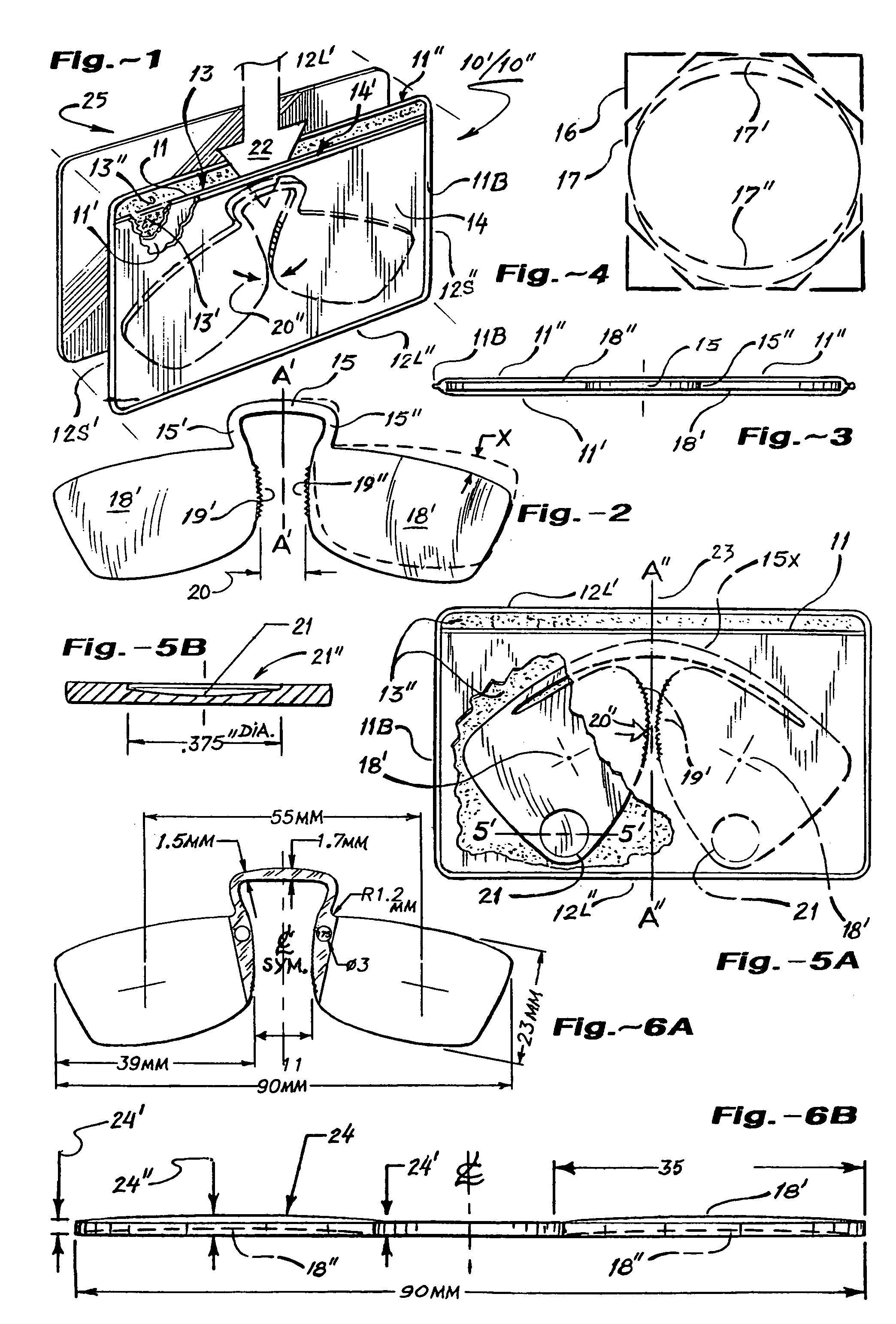

Credit-card modular two-component wallet-reader set

InactiveUS7117990B2Reduce the cross-sectional areaGreat torsional resistancePursesLuggageCredit cardModularity

A credit card modularized set having a flexible stow envelope for receiving a companion nose-clasping type reading glasses, with a length and width approximately that of a conventional credit card; wherein as the set is stacked within a group of conventional credit cards, no portion of the set is substantially protrusive nor recessive of the stacked group. The reading glasses component has a special beam bridge portion having a square cross-sectional shape thereby affording maximum torsional resistance for its diminutive size plus a laterally tapering cross section evenly distributing any imposed bending loads. The modularized set has a minimal thickness enabling its user to slip the set conveniently within the user's wallet modularly among the user's credit cards for ready availability.

Owner:PRESBY

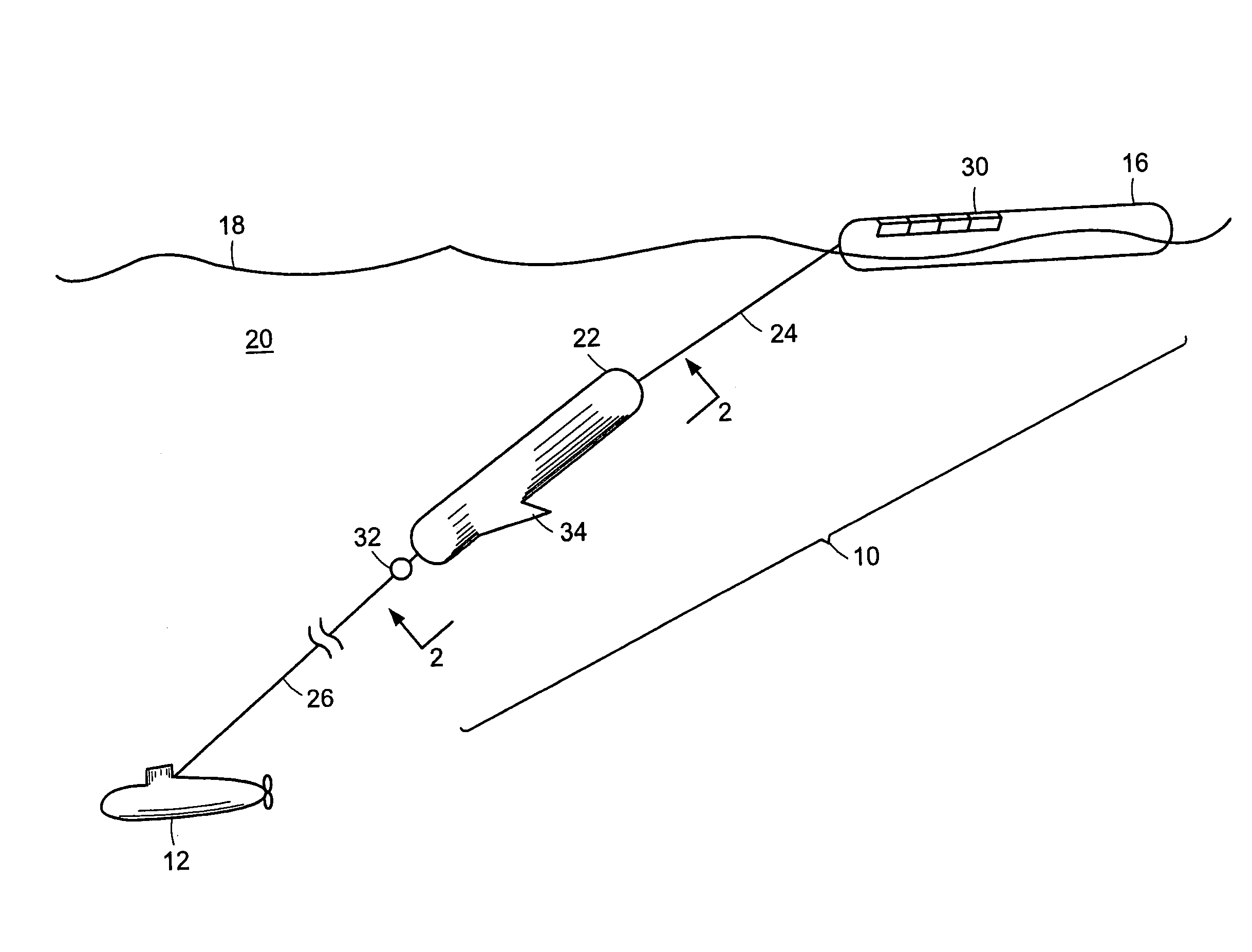

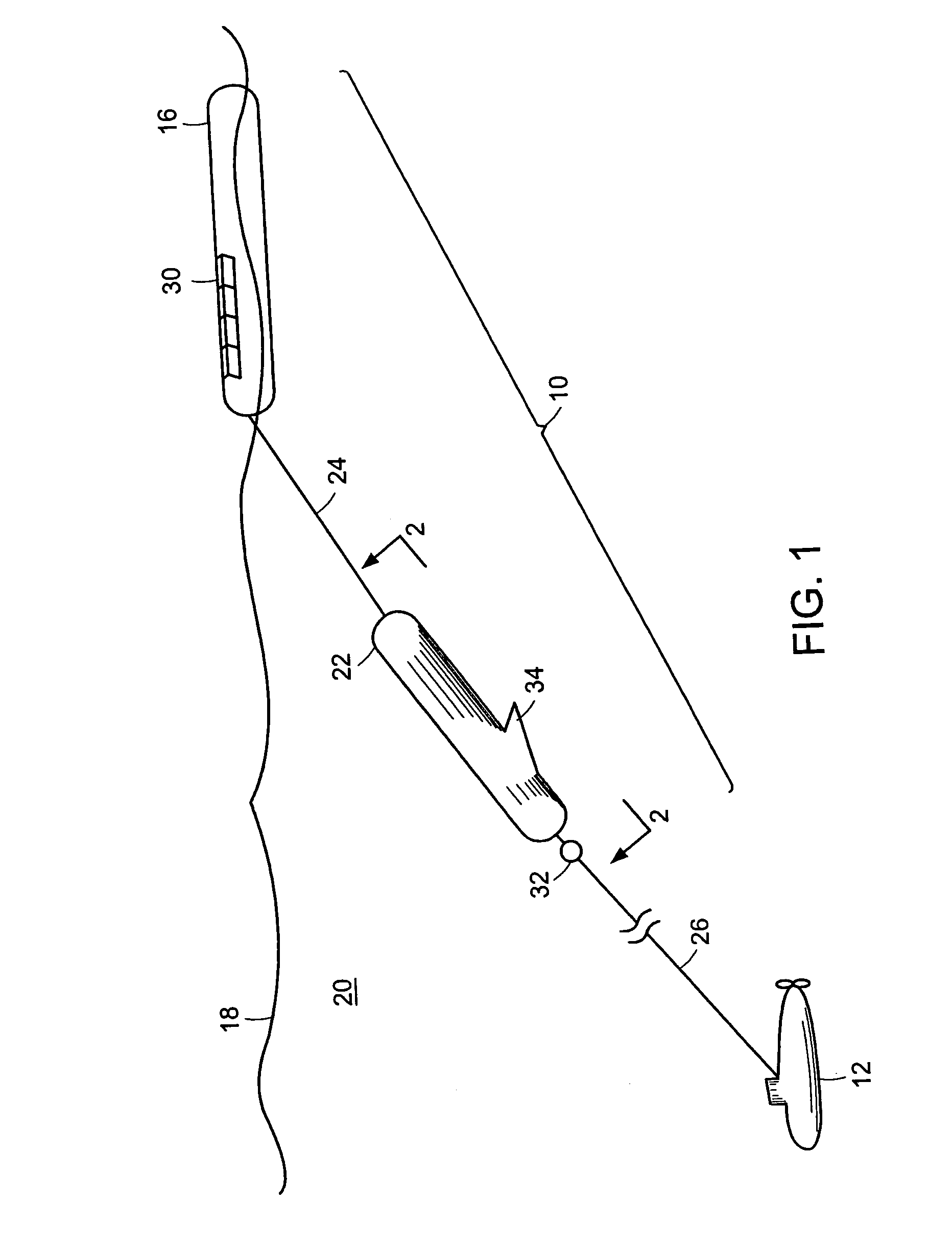

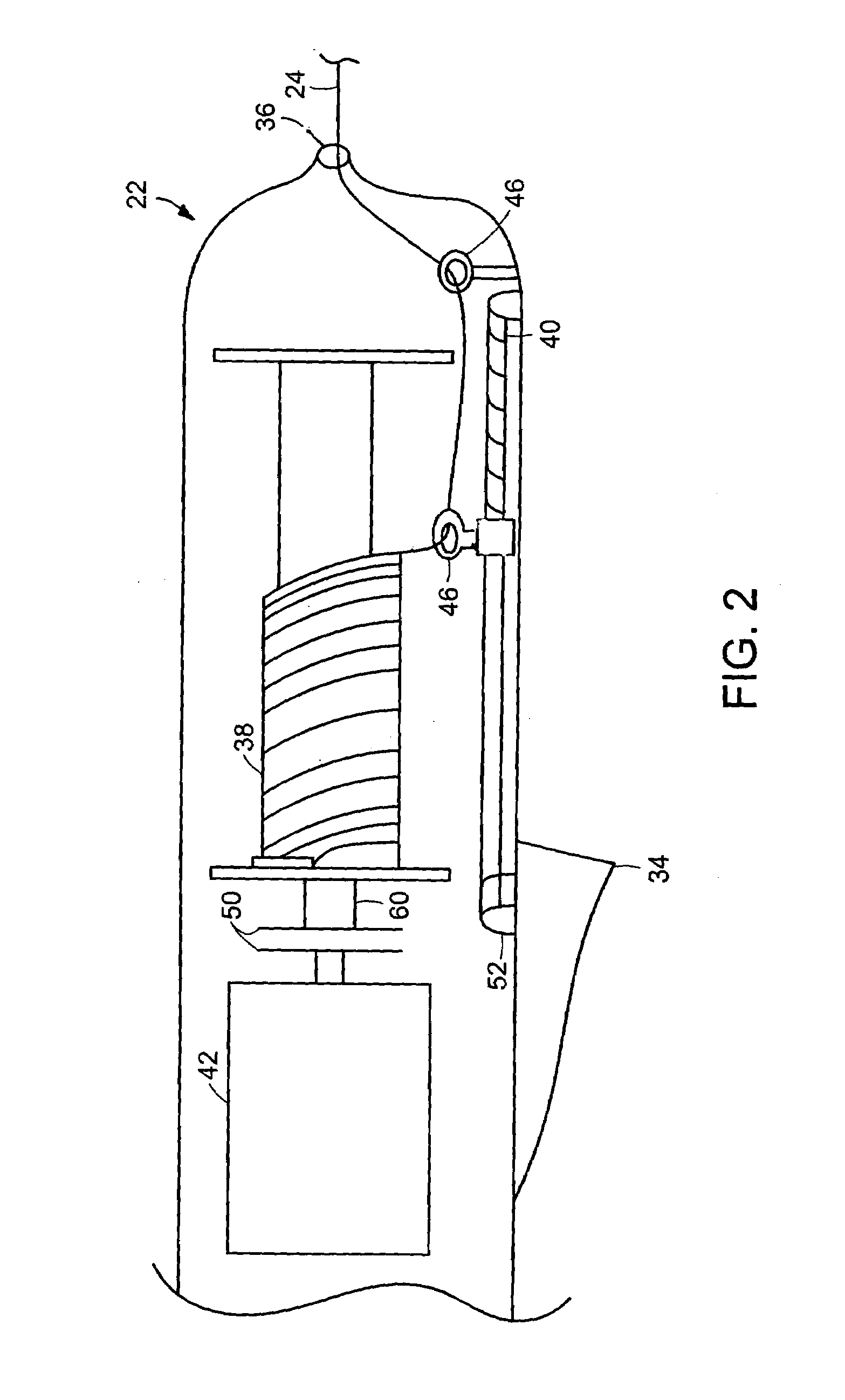

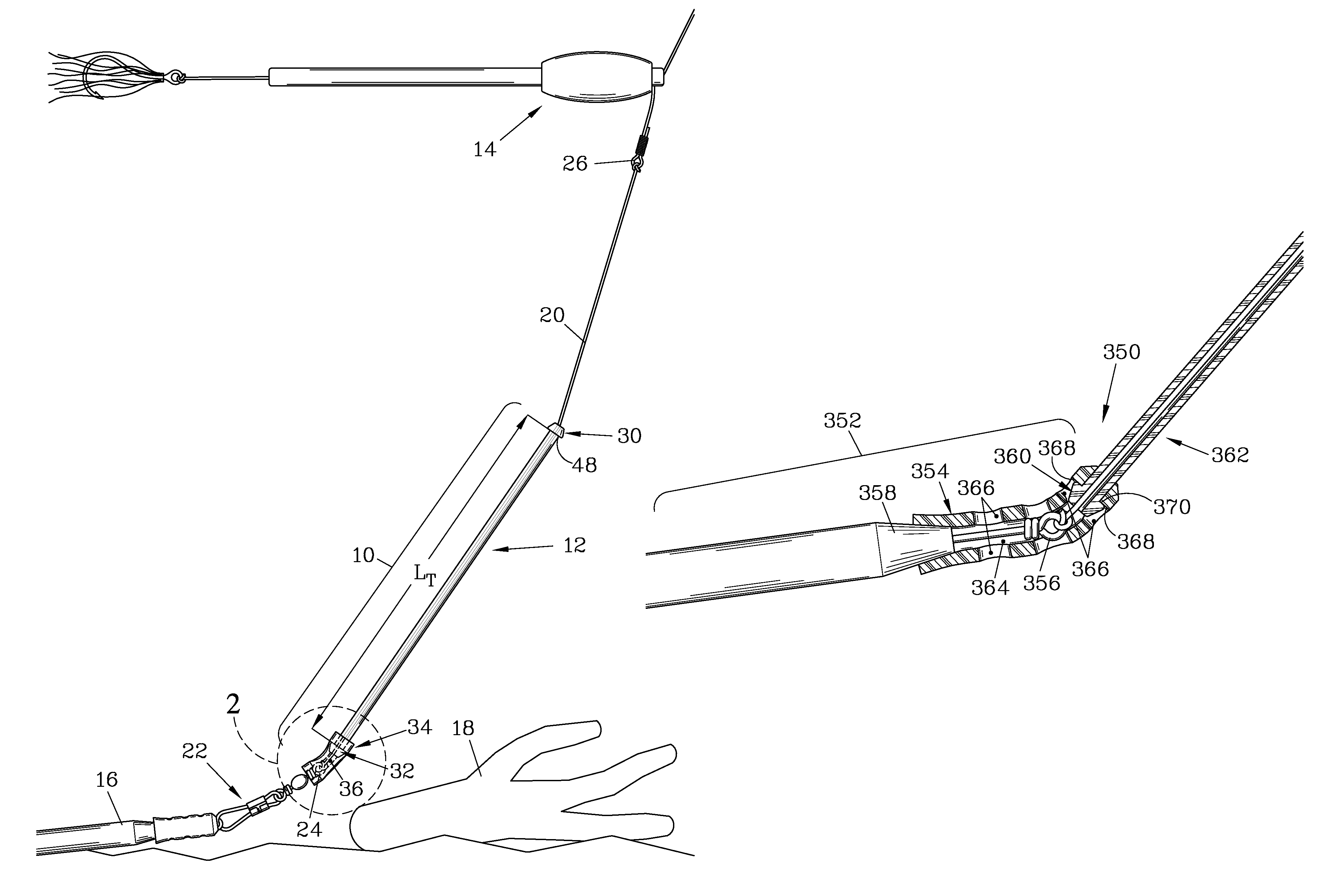

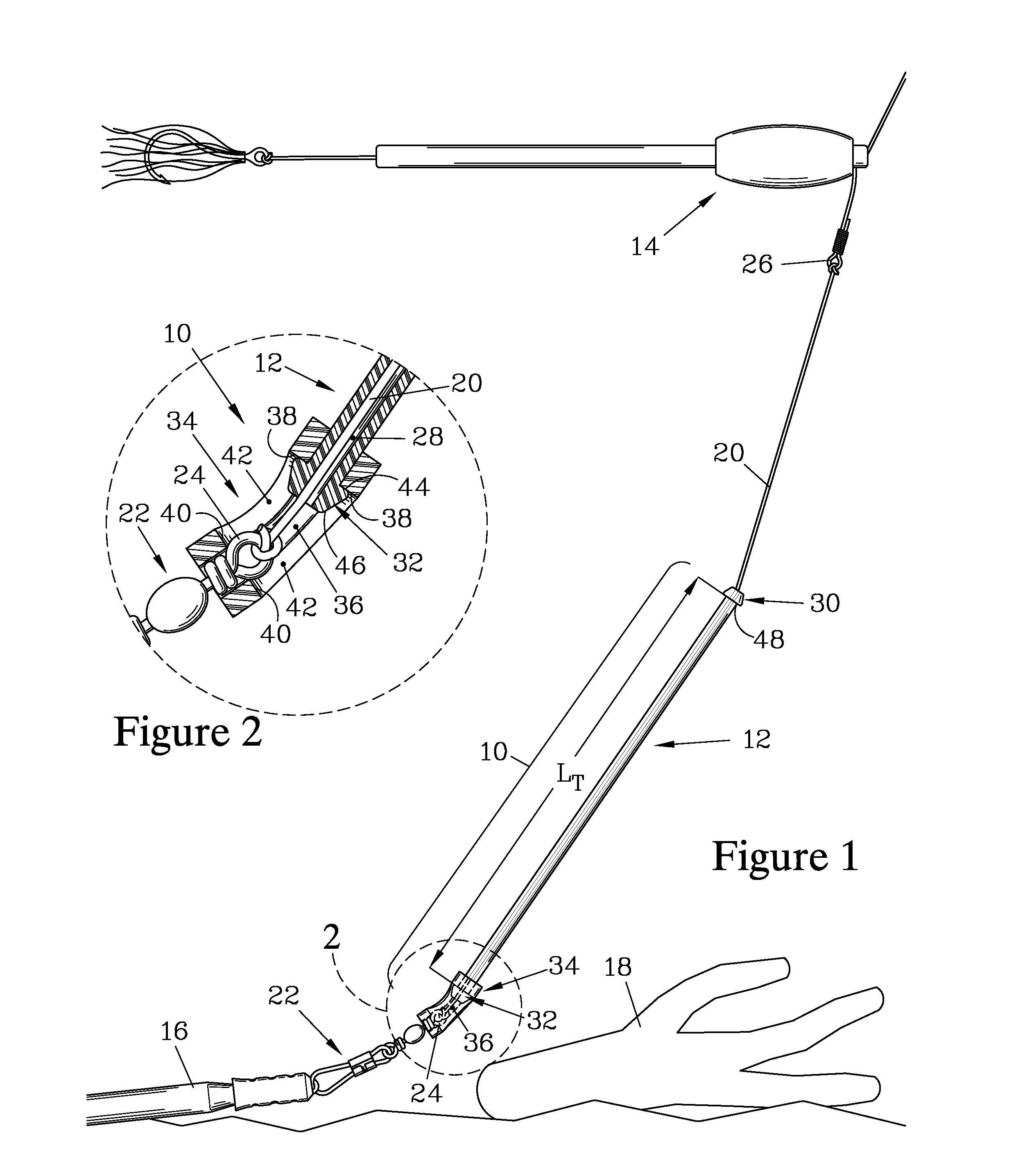

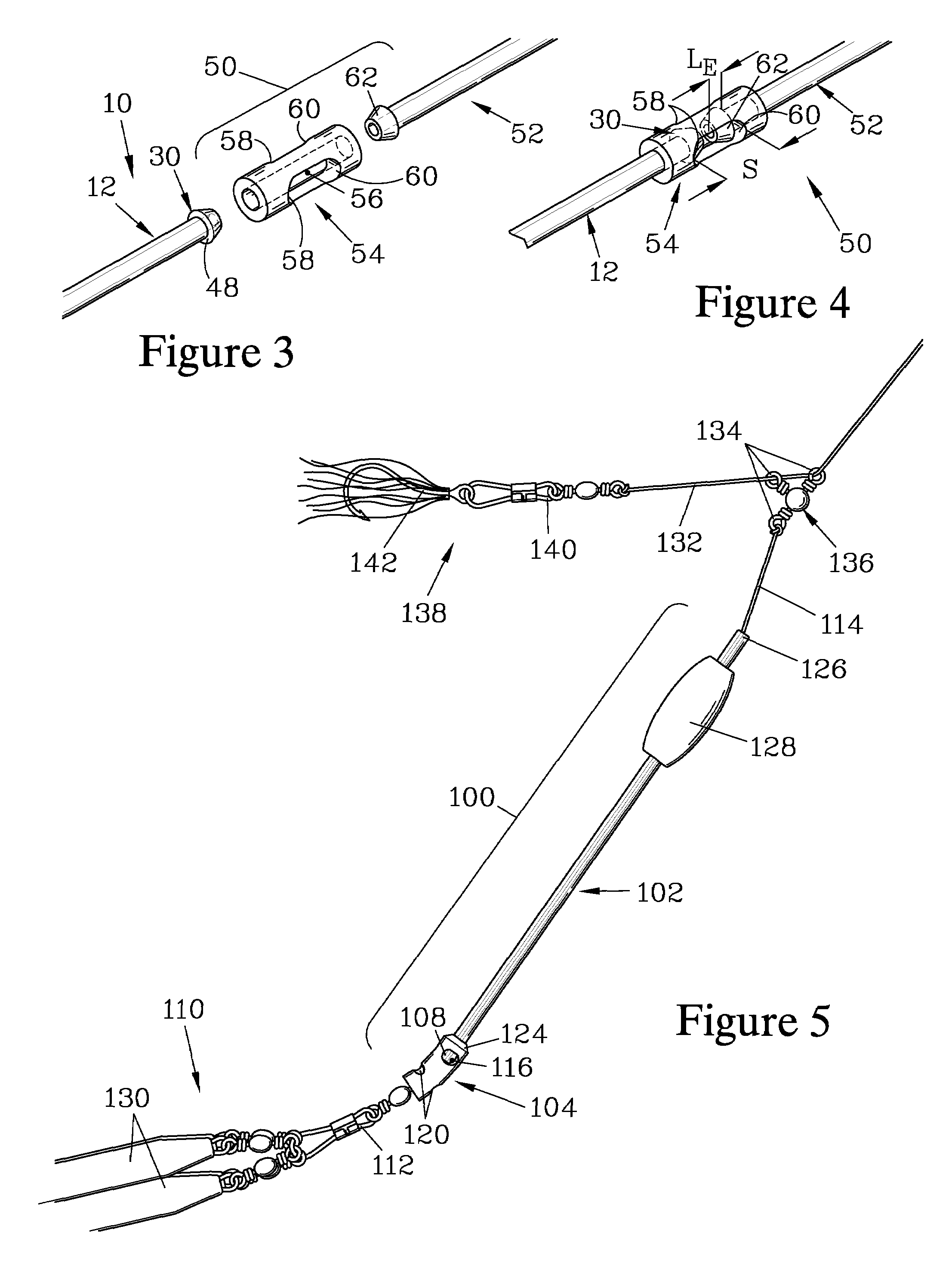

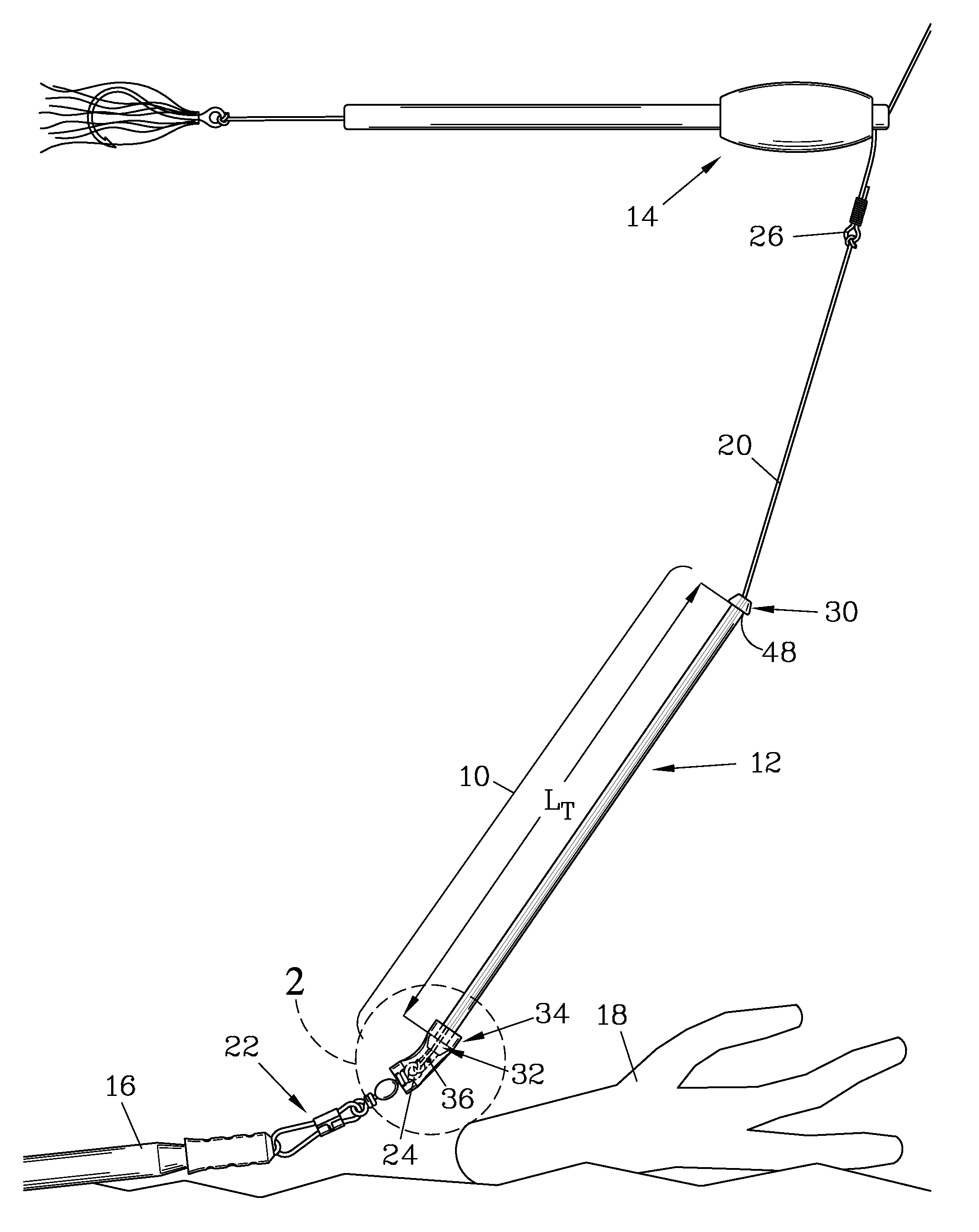

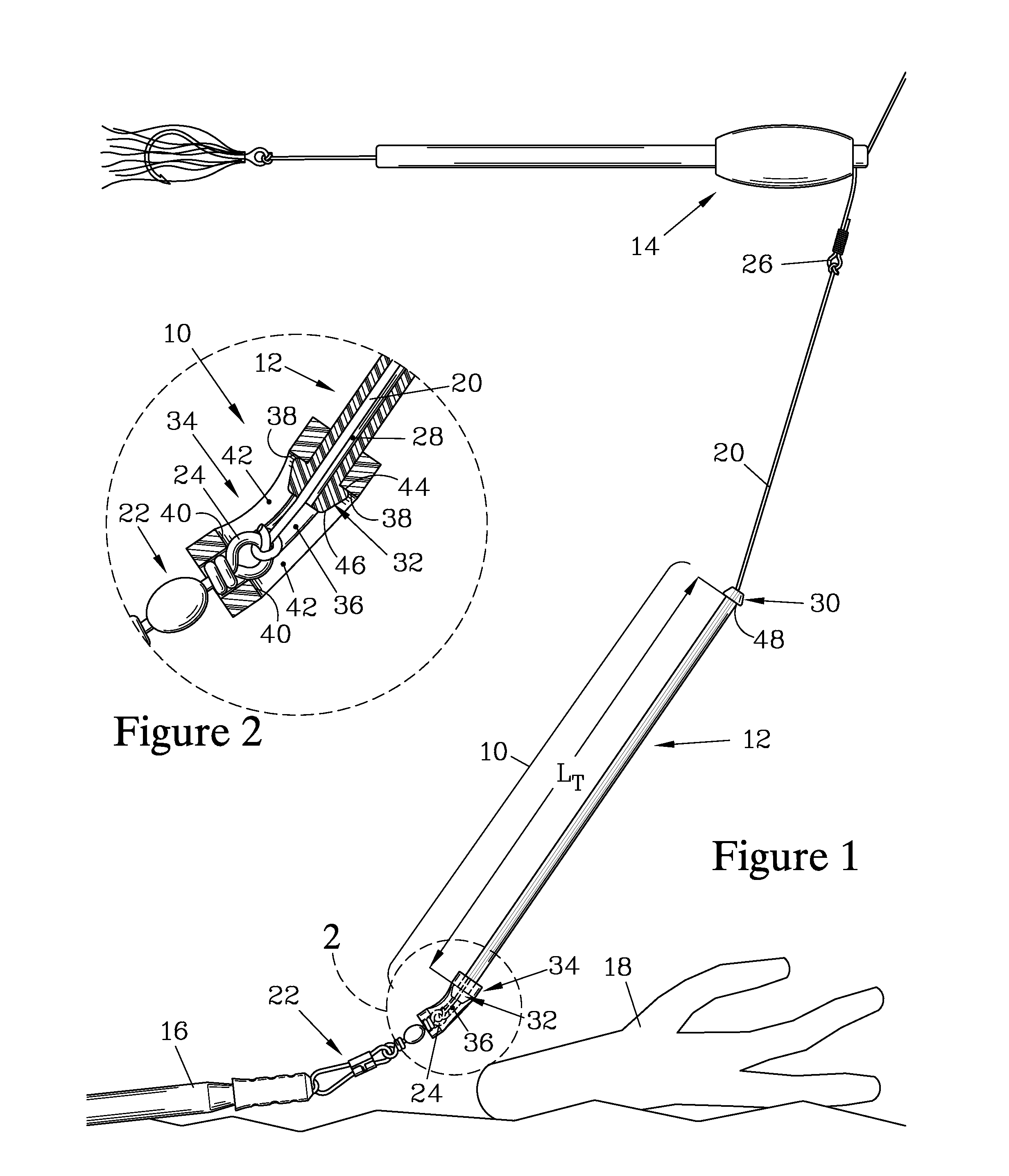

Plunging towed array antenna

InactiveUS6883452B1Efficient communicationInhibit chafingDefensive equipmentTowing/pushing equipmentEngineeringBuoyancy

A towed antenna system and method of use includes a communication device disposed on a buoyant body attached to a housing by a tether. The housing includes a spool, a reel-wire guide, and a motor. The buoyant body and the reel housing are deployed from and towed at from a submerged platform. Hydrodynamic forces from towing prevent the buoyant body from rising to the surface while maintaining the housing at an equilibrium depth. To establish communication, the tether is released from the spool and the buoyant body rises to the surface. The tether is released until the communication session is over or until the tether is fully deployed. The reel-wire guide prevents the tether from becoming snagged during release. Once the communication session has been completed, the tether is retracted and the buoyant body re-establishes its equilibrium depth.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

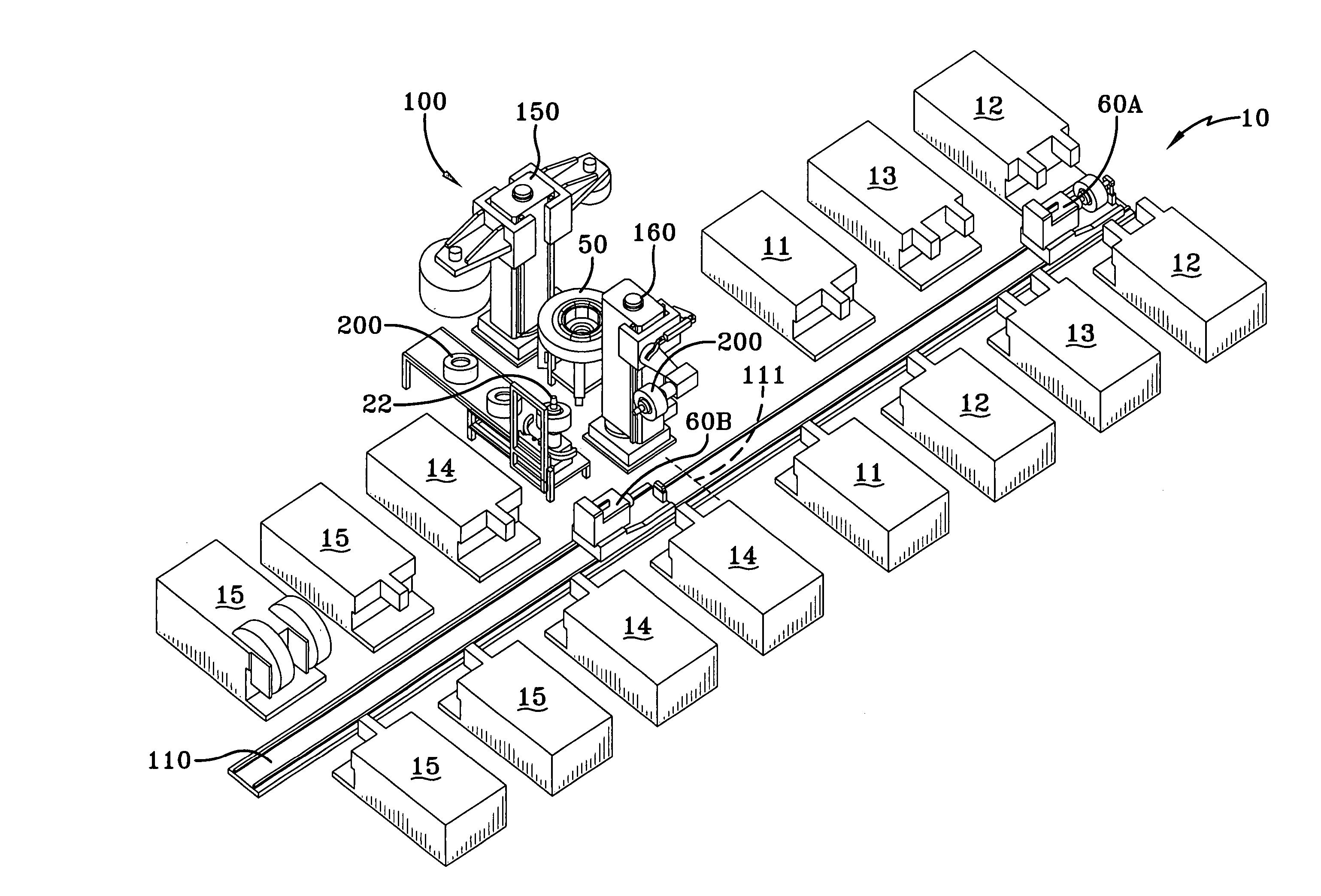

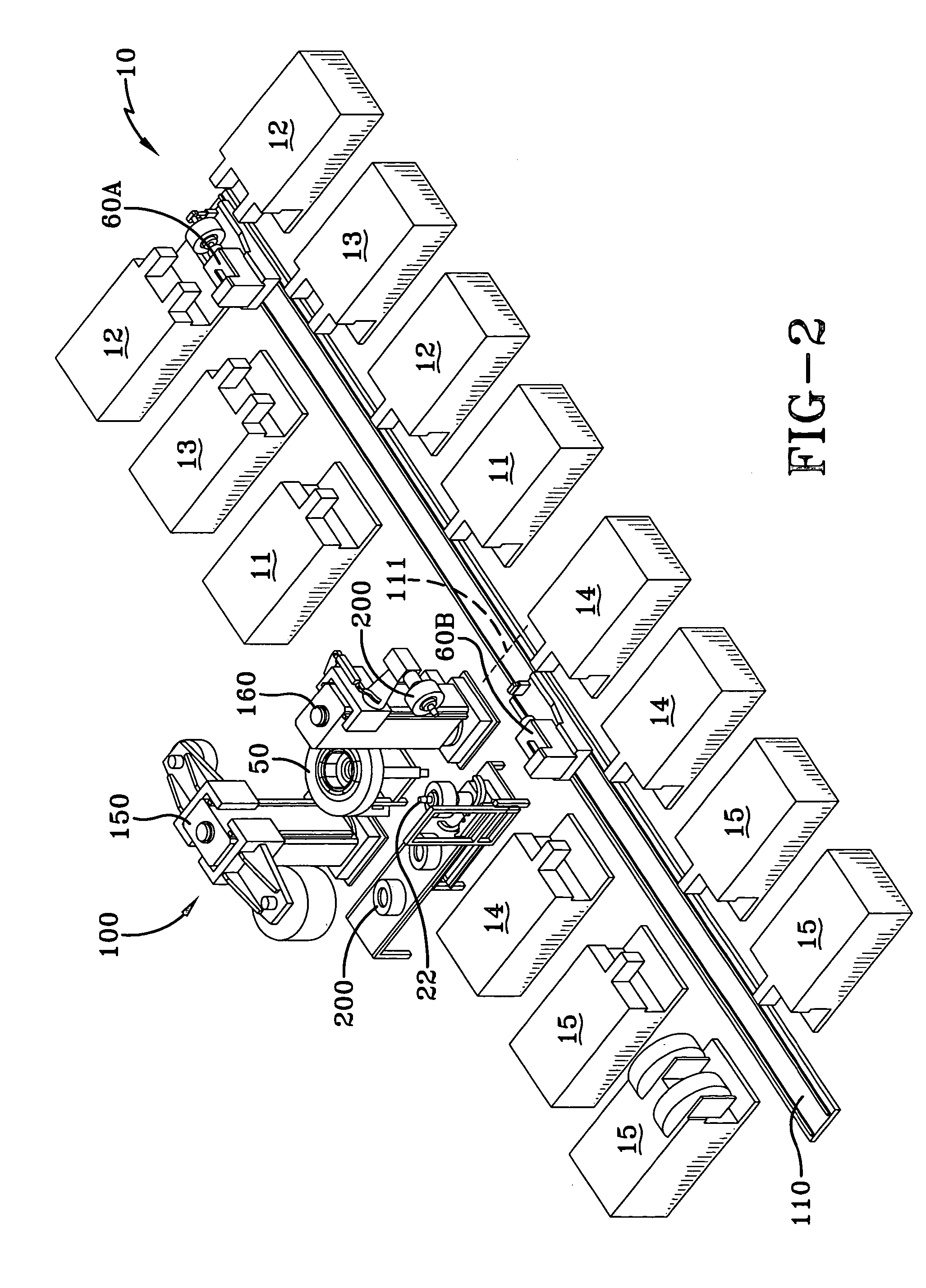

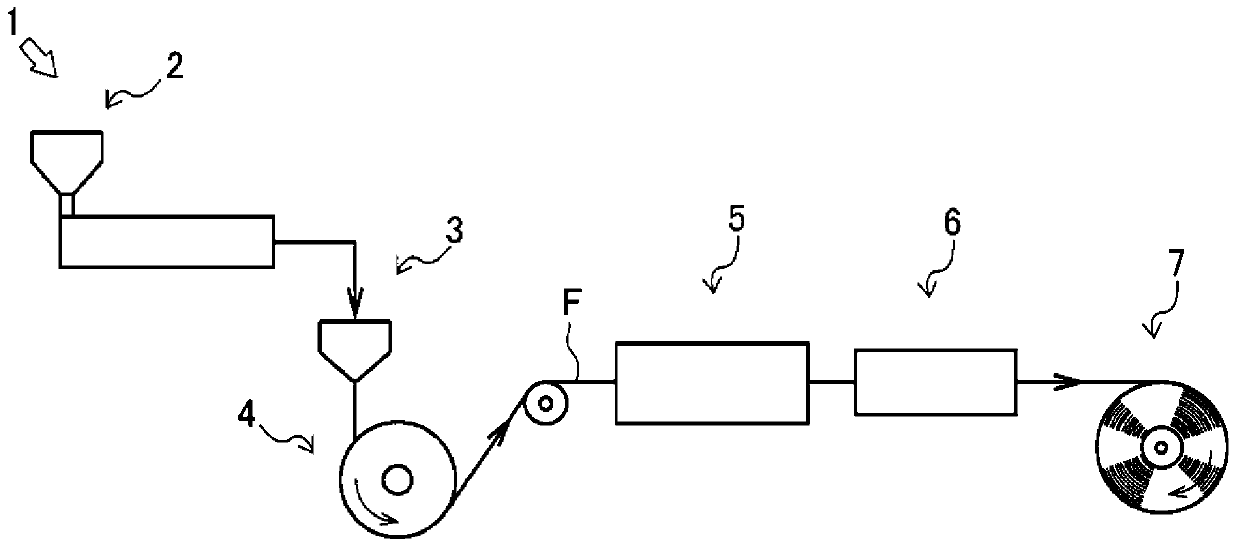

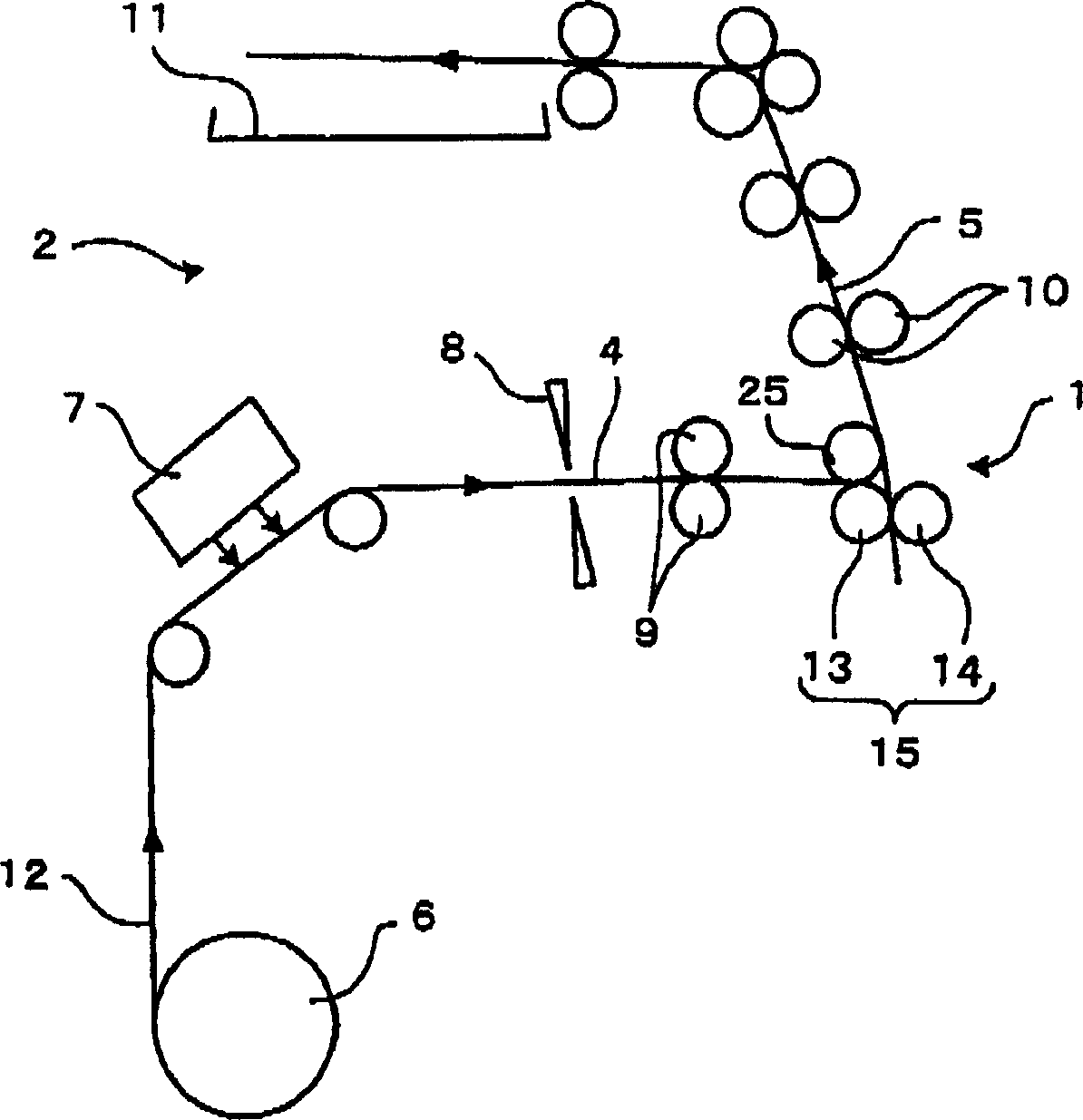

Tire manufacturing module and method of manufacturing tires

InactiveUS20050126684A1Easy to changeEfficient productionTyresPneumatic tyre reinforcementsElastomerTire manufacturing

A module for manufacturing a cured tire from a plurality of tire components is disclosed. The module has a plurality of component appliers located at spaced locations along a predetermined path, and a mobile tire building trolley for movement along the predetermined path and two detachable tire building drums for mounting on the movable trolley. A tire curing station has one tire mold for curing the assembled tire components while mounted on one of the detachable tire building drums. The tire is cured as the other detachable tire building drum on the mobile tire building trolley is having tire components applied. One or more of the plurality of component appliers includes a means for forming the tire component at the location of the applier. The applied components include a liner, a pair of bead cores, a ply, a pair of sidewalls, a pair of chafers, and one or more belt layers and a tread. Optionally the applied components may also include an apex, wedges, overlays, underlays, gum strips, and elastomeric inserts. The module has a means for transferring the detachable tire building drums to the tire mold and further has a means for extracting the cured tire while mounted on a tire building drum from the mold. The tire curing station includes an induction curing means.

Owner:THE GOODYEAR TIRE & RUBBER CO

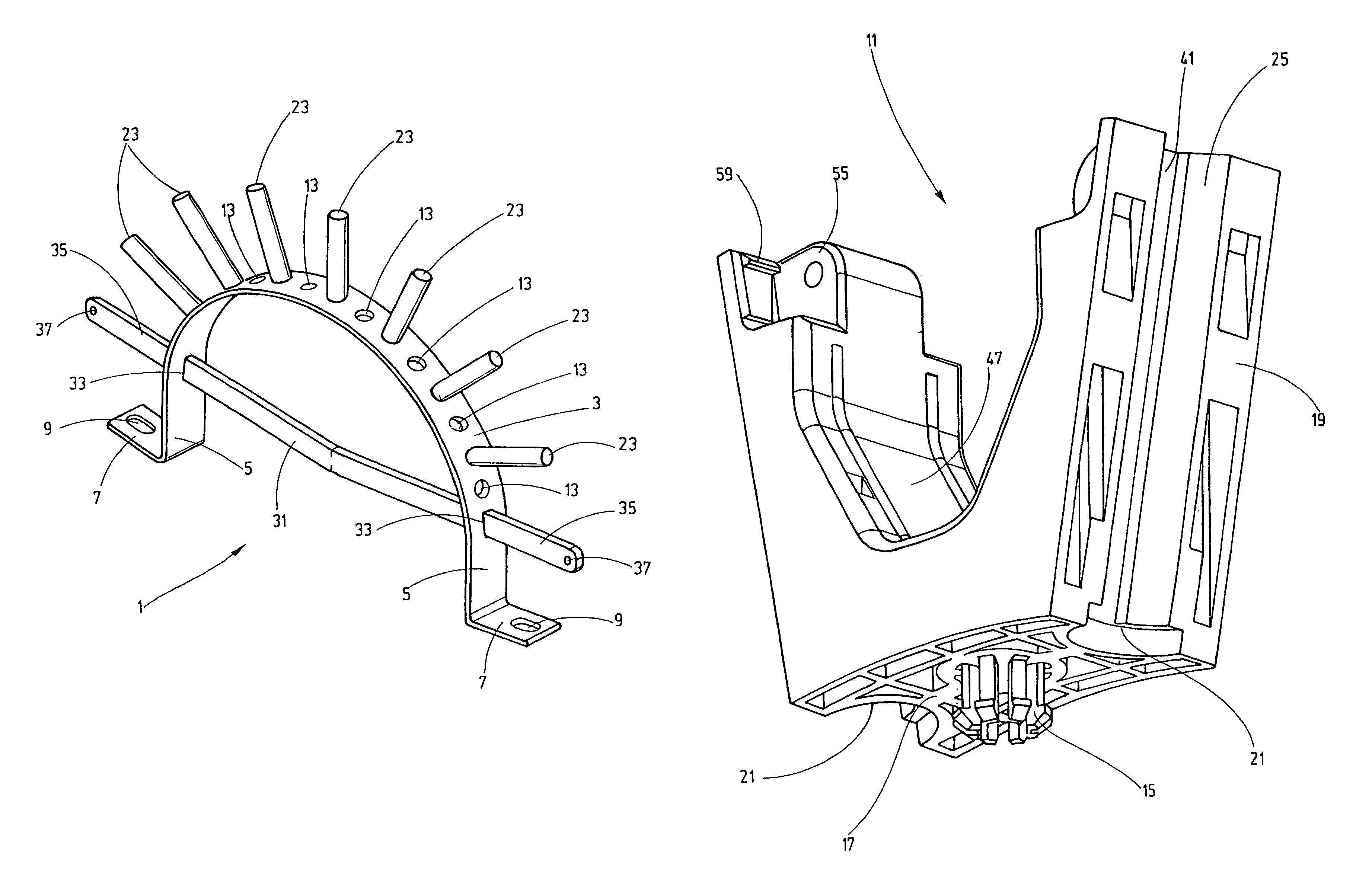

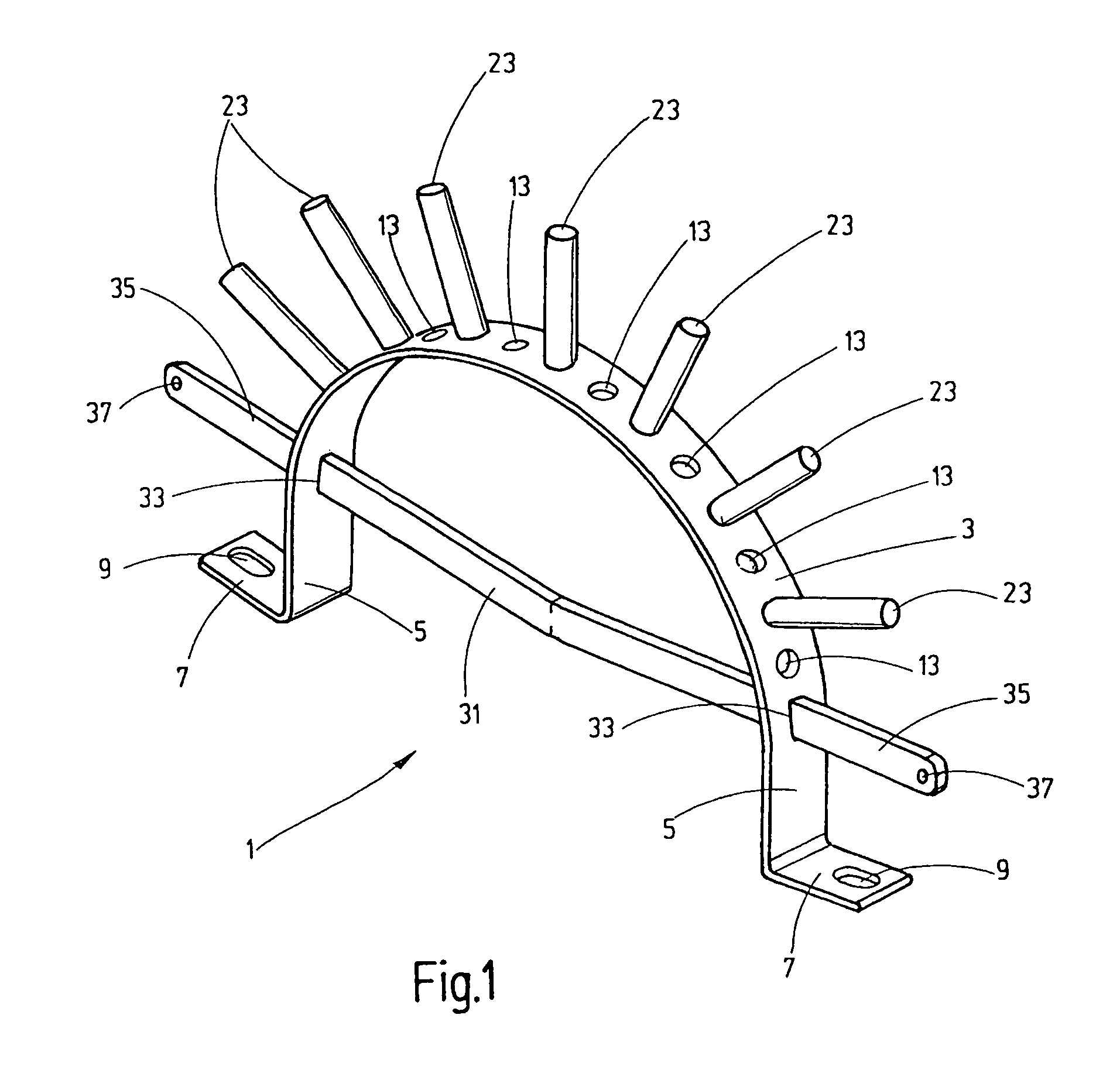

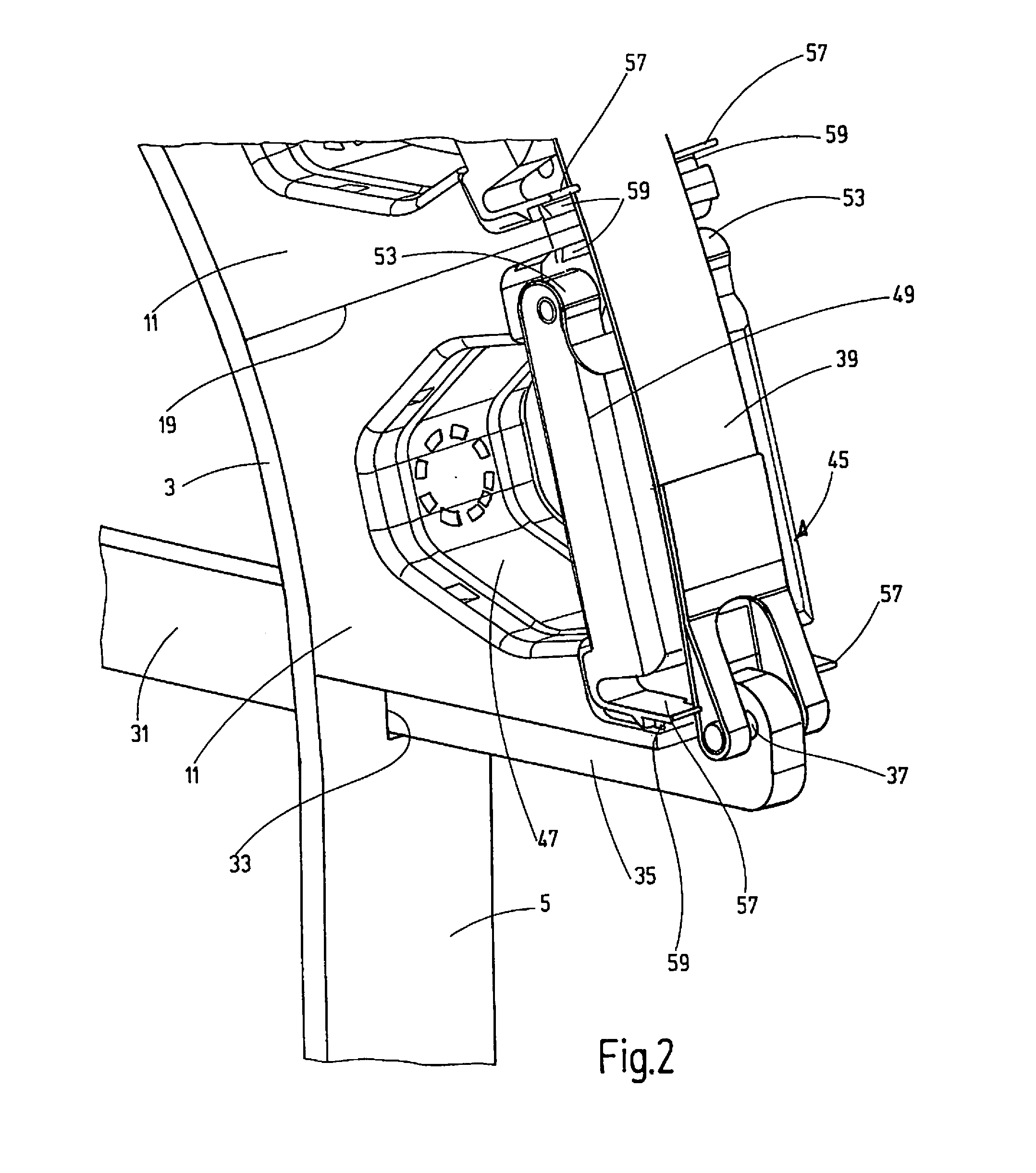

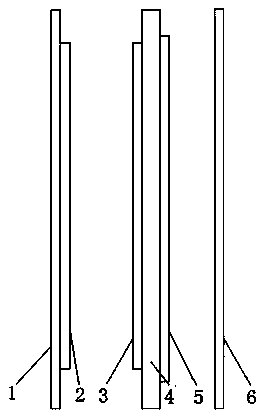

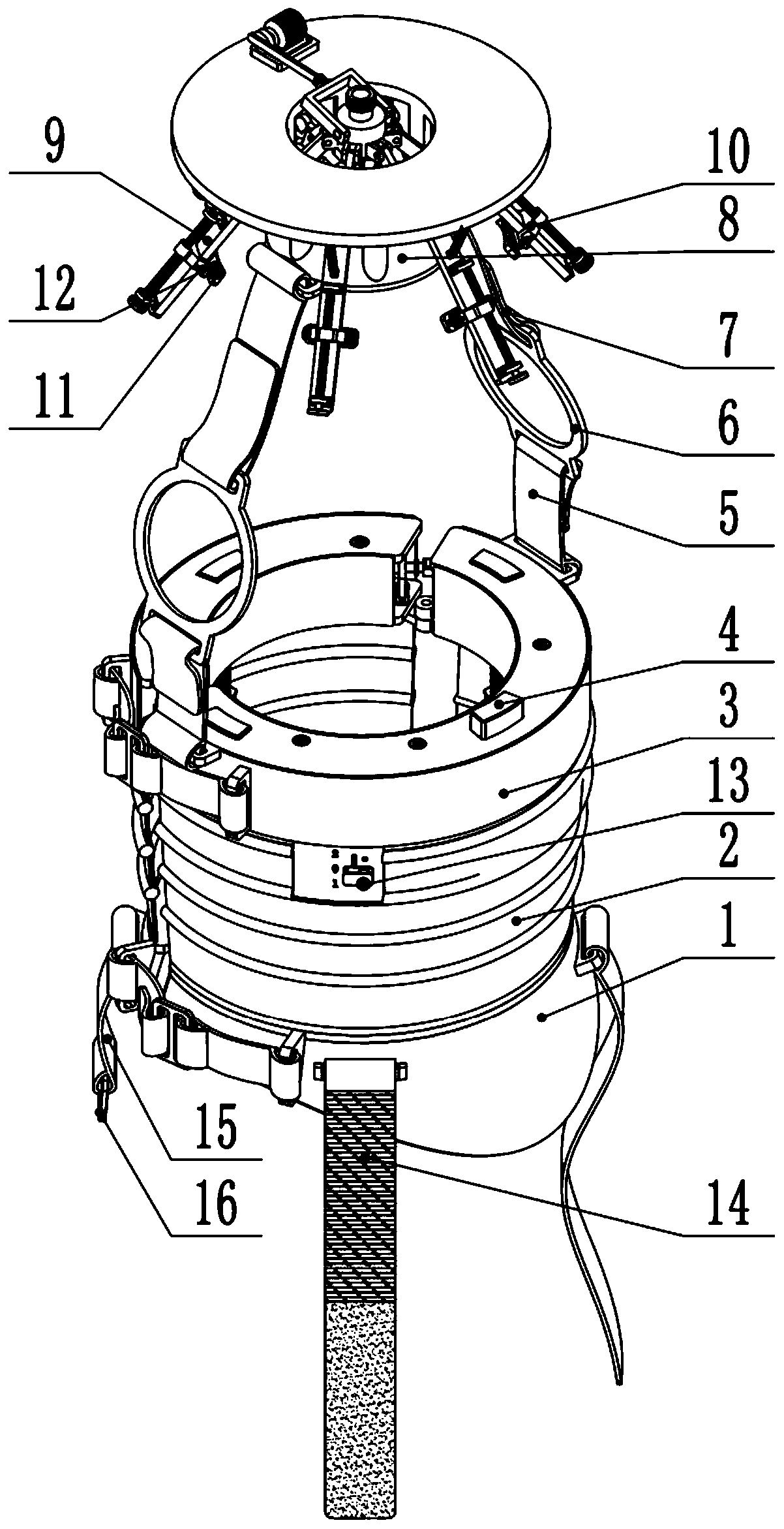

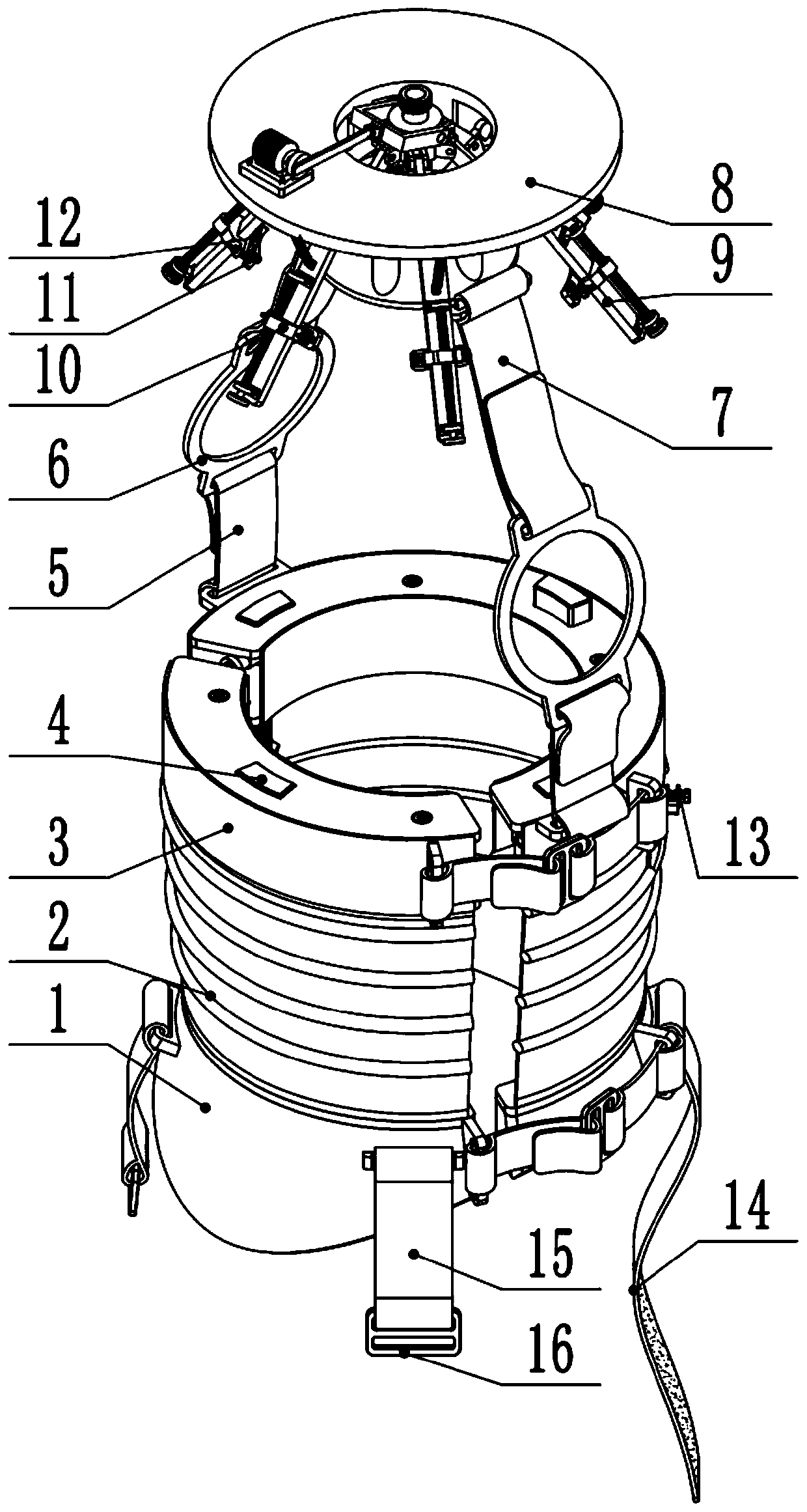

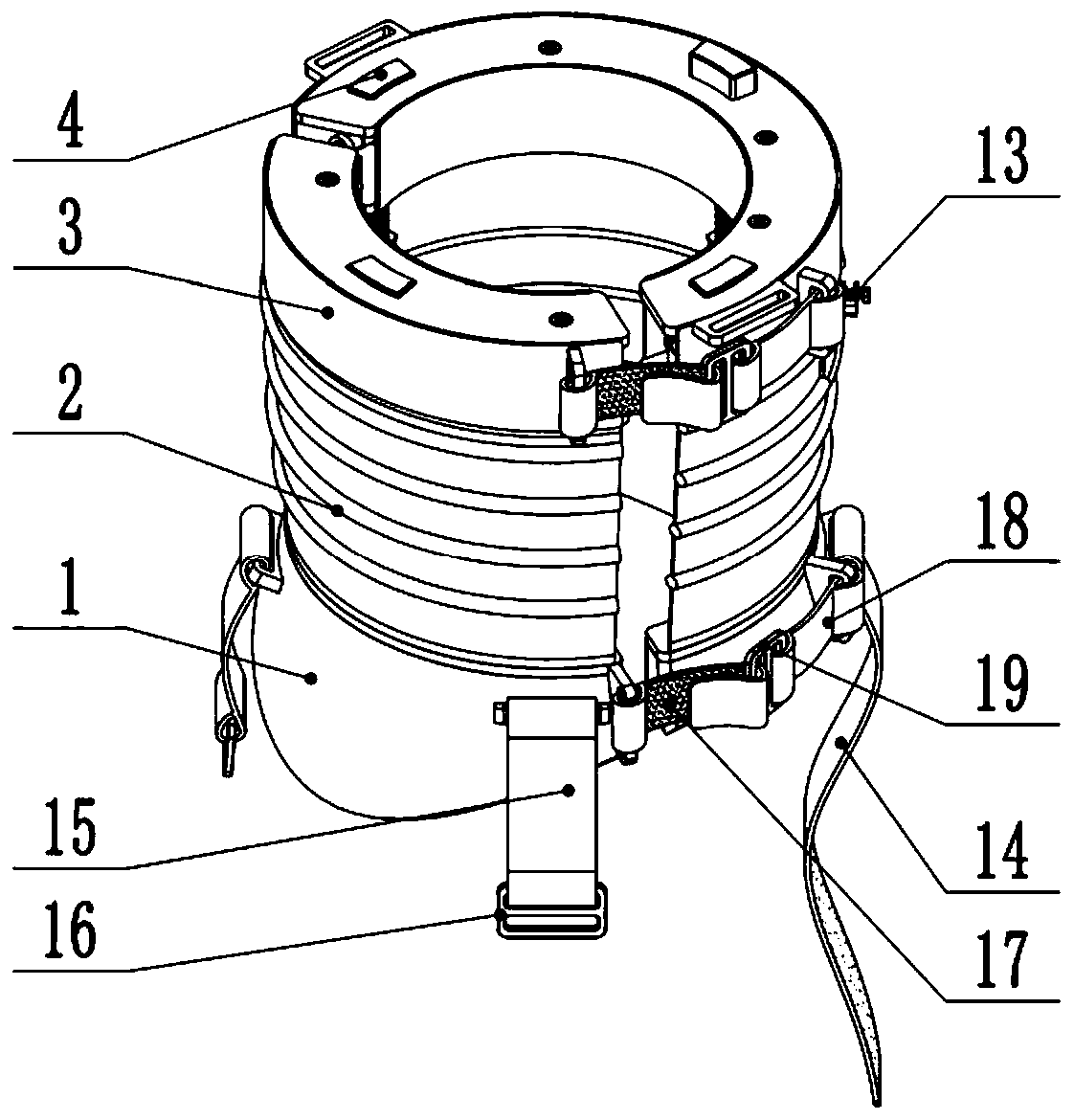

Fixing system for cables, in particular in wind turbines

A fixing system for cables, in particular in wind turbines, includes a main body (1) that can be fixed to a supporting structure and cable holders (11) that have an opening for cables to be inserted. Each opening can be closed by a cover device (45). The cable holders (11) are mounted on the main body (1) and in an arrangement extending at least over a part of a circle with the opening of the cable holders on the outside. The cover device includes retaining elements (45), by which the opening of the respective cable holders (11) can be blocked to secure inserted cables.

Owner:HYDAC ACCESSORIES

Tire manufacturing module and method of manufacturing tires

InactiveUS7195047B2Easy to changeEfficient productionTyresPneumatic tyre reinforcementsElastomerEngineering

Owner:THE GOODYEAR TIRE & RUBBER CO

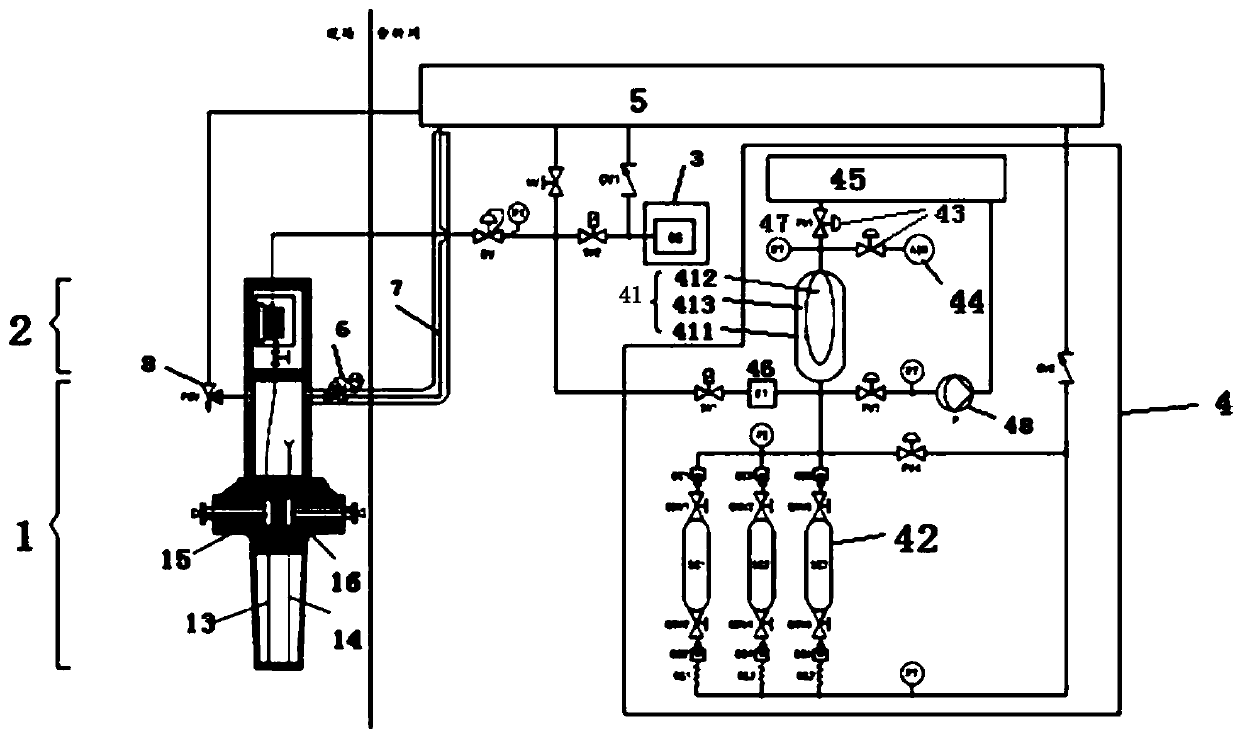

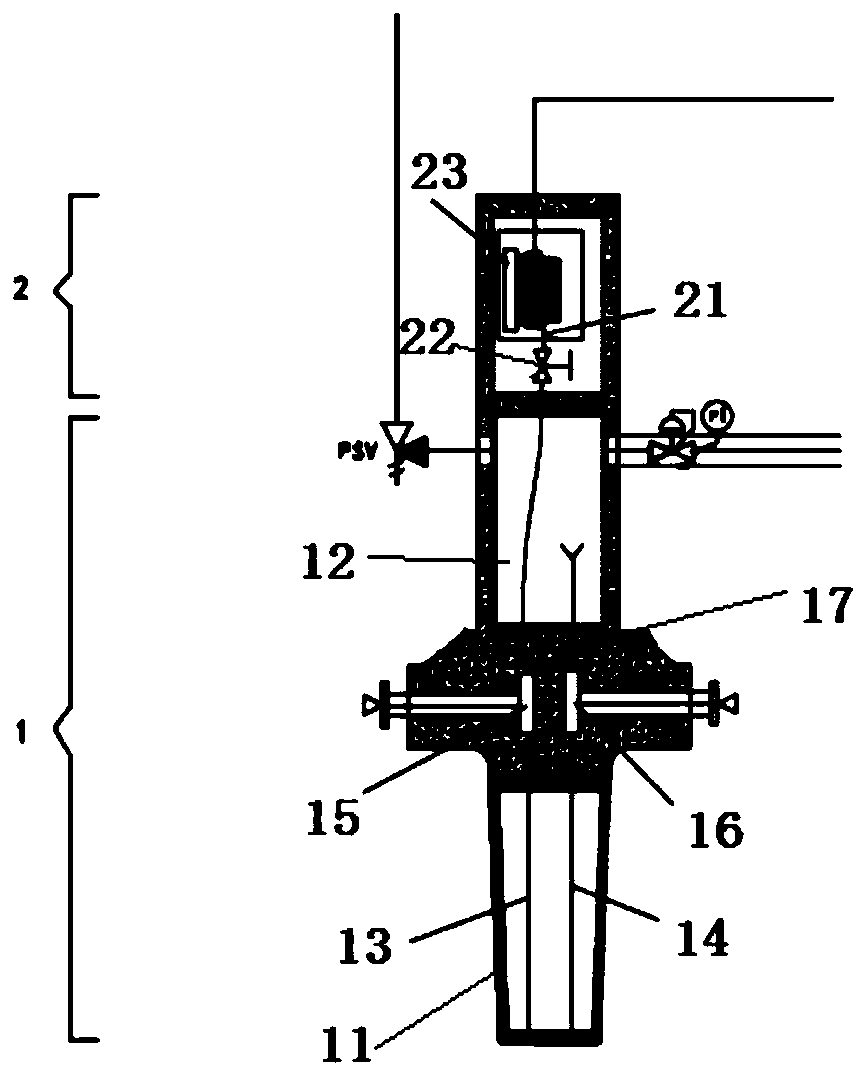

Liquefied natural gas sampling and continuous collecting device

PendingCN110045041AAvoid fractionationInhibition of premature gasificationComponent separationVessel geometry/arrangement/sizeLine tubingCollection system

The invention discloses a liquefied natural gas sampling and continuous collecting device, which comprises a sampling system, a gasification system, an on-line analysis system and a continuous collecting system, wherein the sampling system comprises an LNG sampling probe, a sampling pipeline and an LNG filling pipeline; a closed deep cooling cavity is formed at the front end of the LNG sampling probe; the sampling pipeline is arranged in the LNG sampling probe in a penetrating manner; the LNG filling pipeline is arranged in the LNG sampling probe in a penetrating mode and communicates with a closed deep cooling cavity; one end of the sampling pipeline penetrates through the closed deep cooling cavity and is connected to the gasification system; the gasification system is used for gasifyingan LNG sample conveyed by the sampling pipeline; the on-line analysis system is connected to an outlet of the gasification system and is used for carrying out on-line analysis on a gasified natural gas sample and providing gas component parameters; and the continuous collecting system is connected to the outlet of the gasification system and is used for continuously collecting the gasified natural gas samples.

Owner:CNOOC GAS & POWER GRP

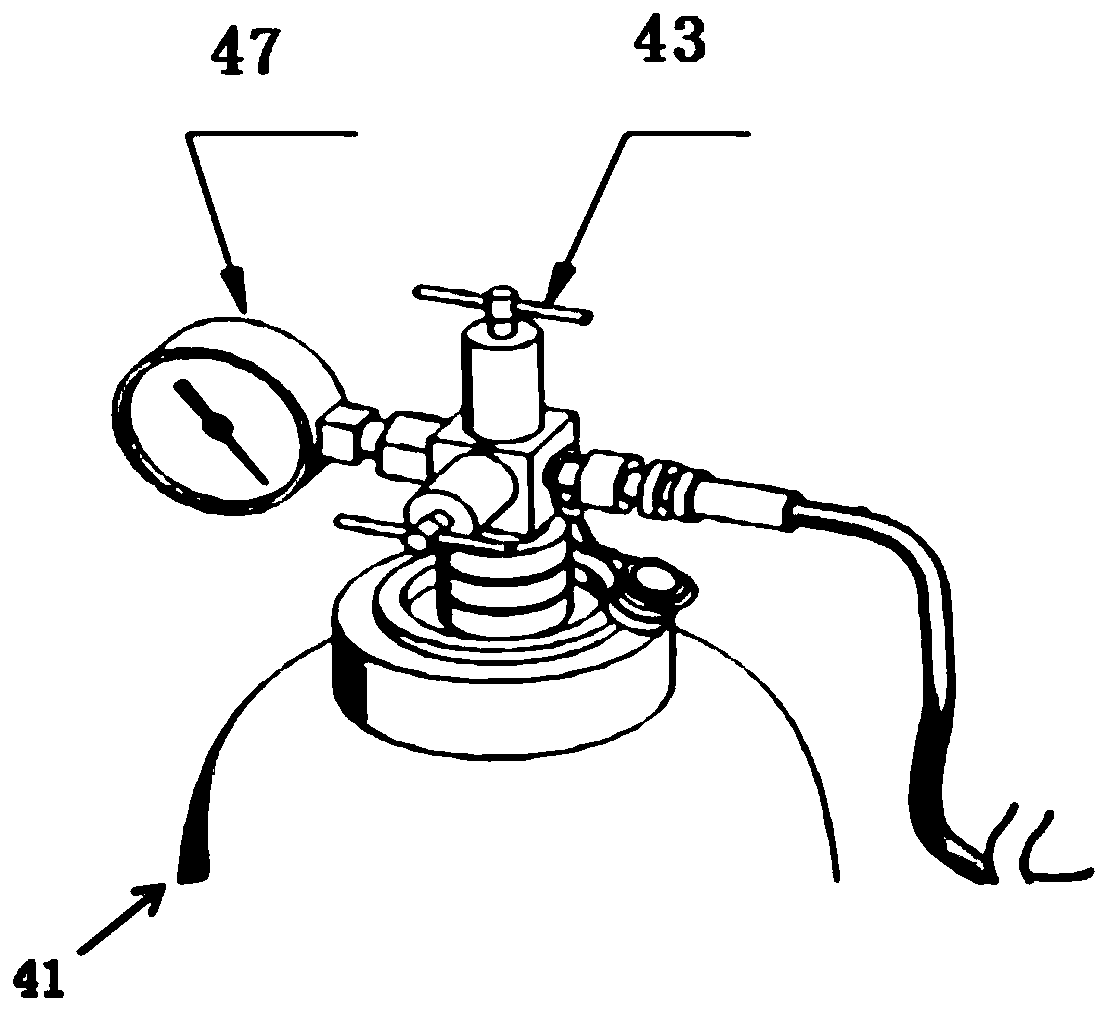

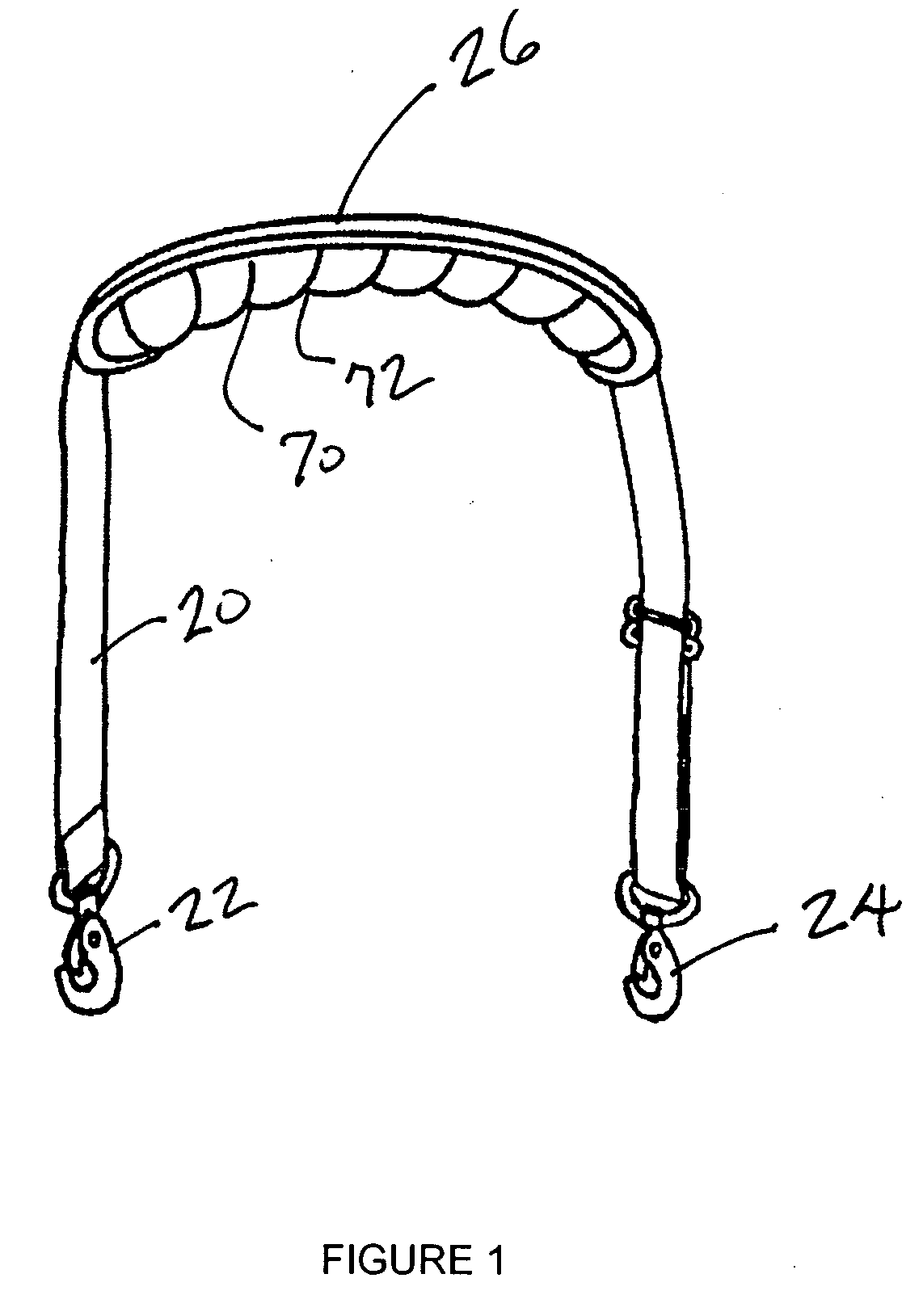

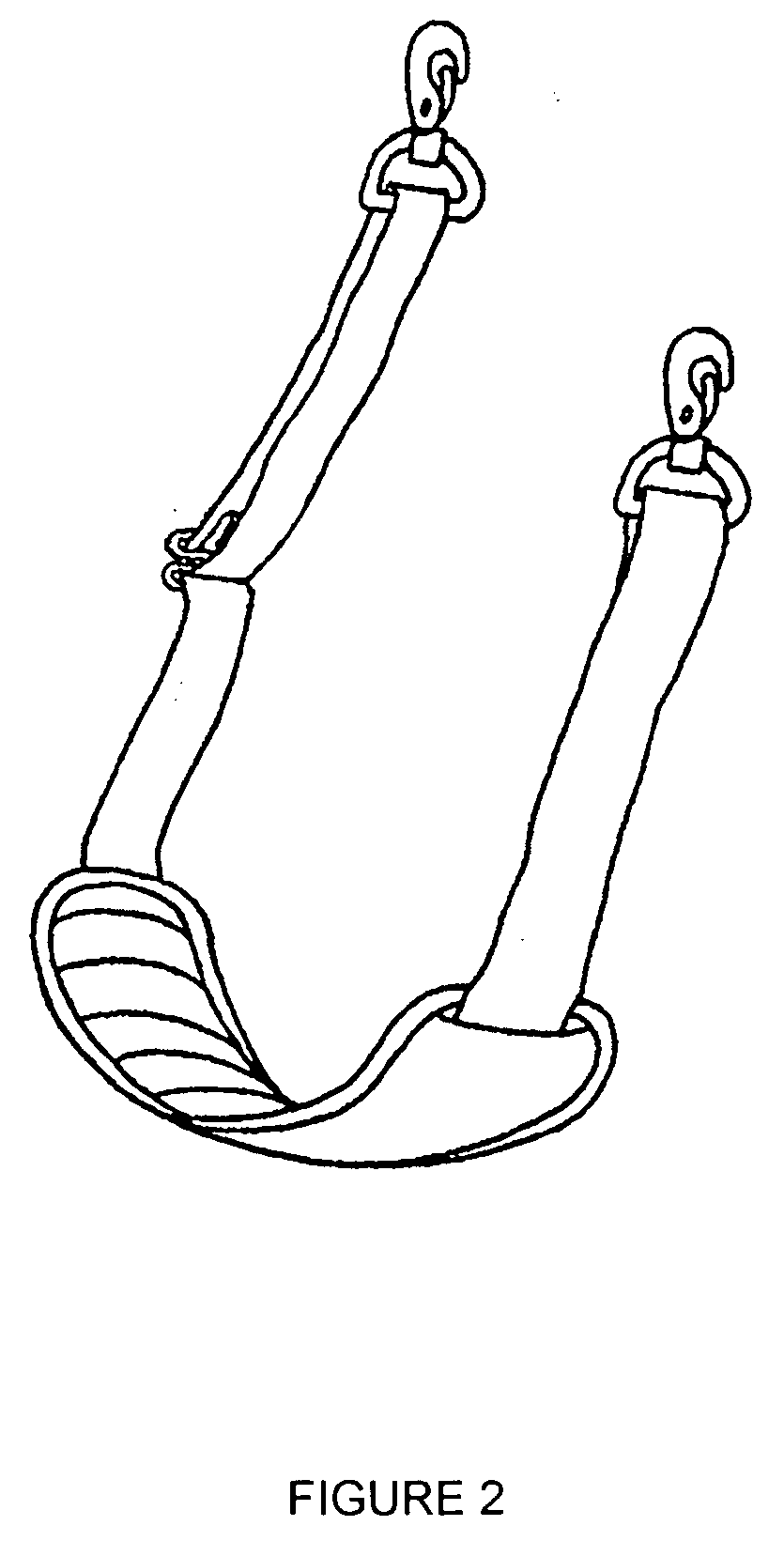

Shoulder strap

InactiveUS20080006661A1Inhibit chafingAvoid diggingTravelling sacksShoulder strapEngineeringShoulder girdle structure

Owner:TRAVEL CADDY

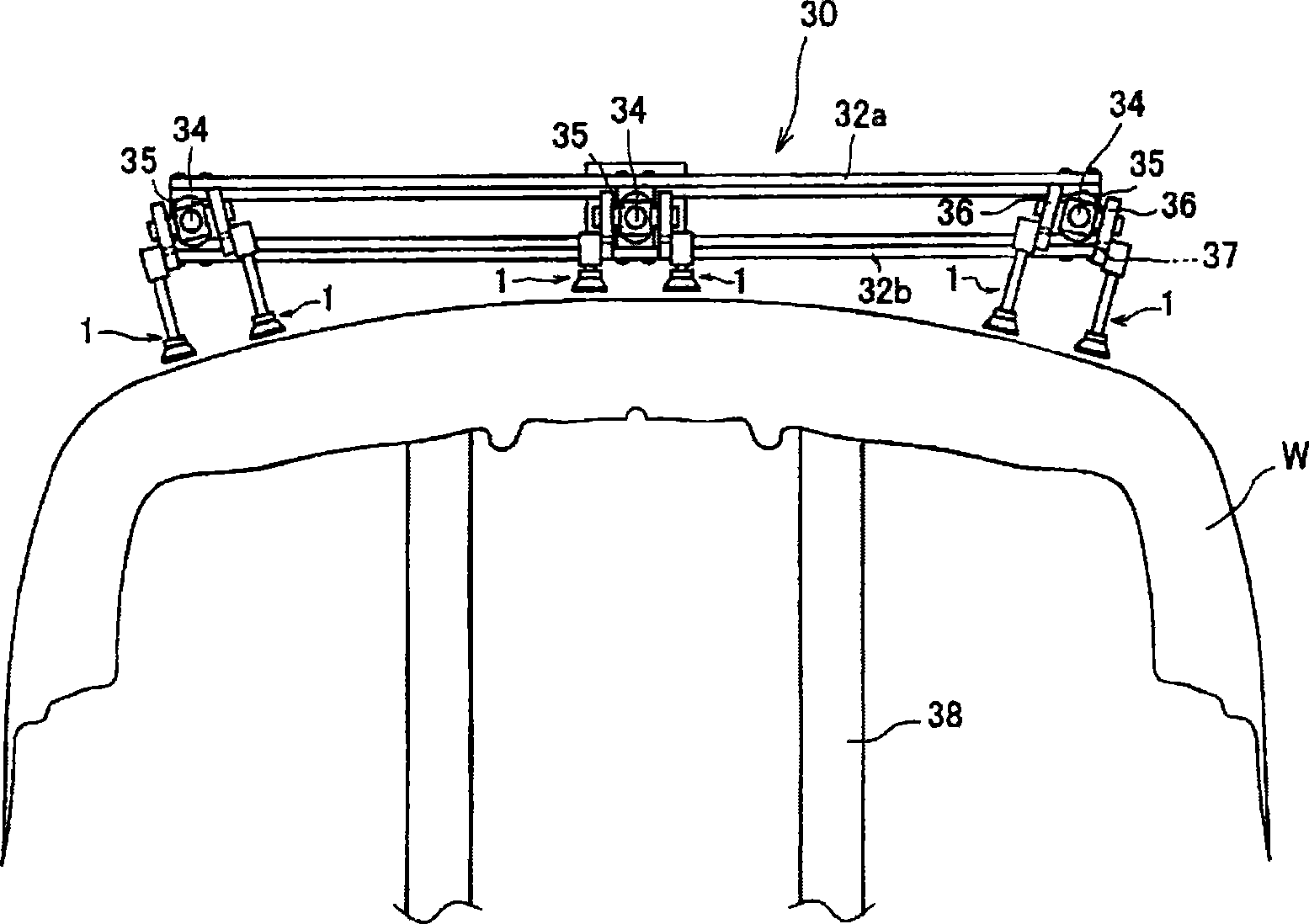

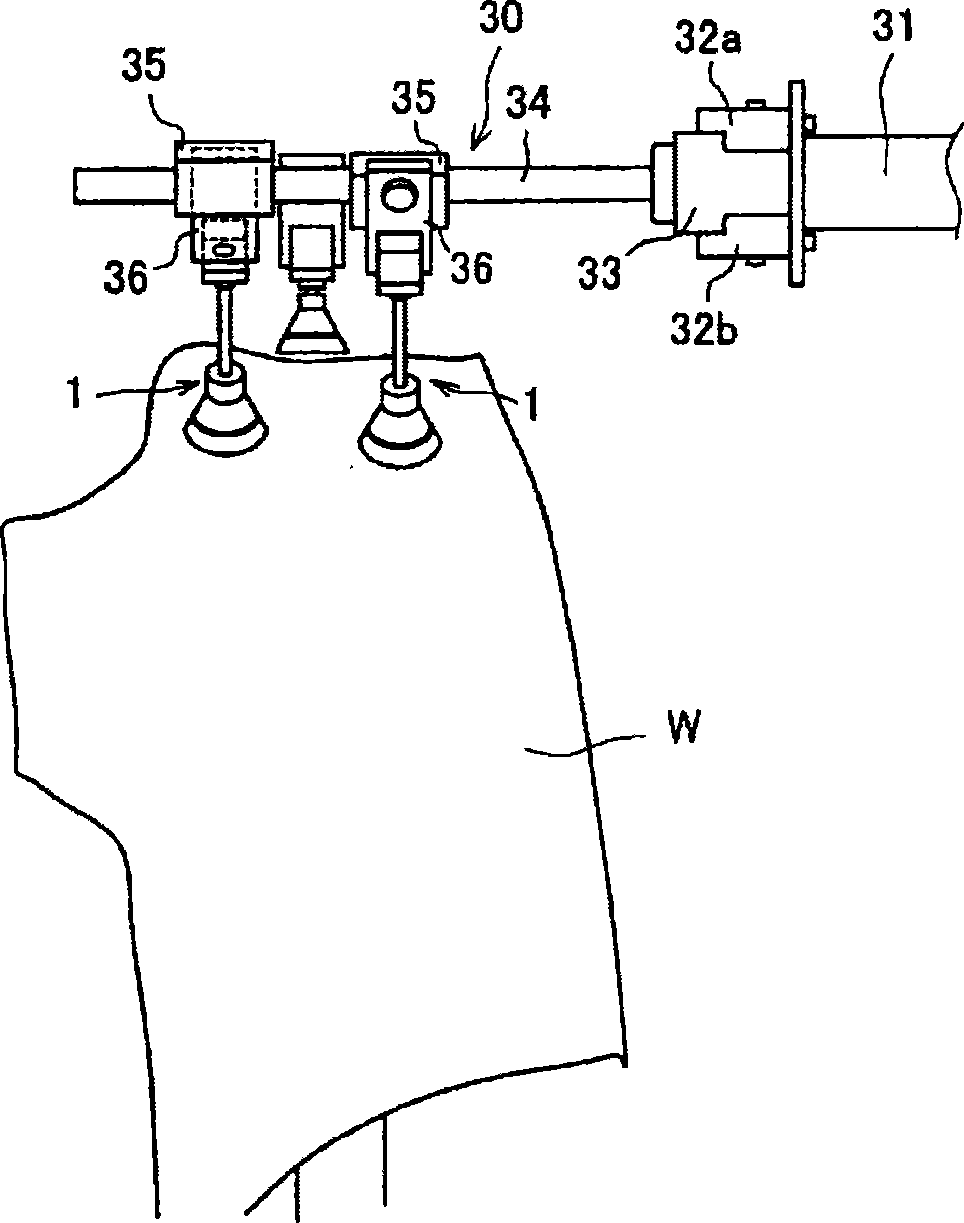

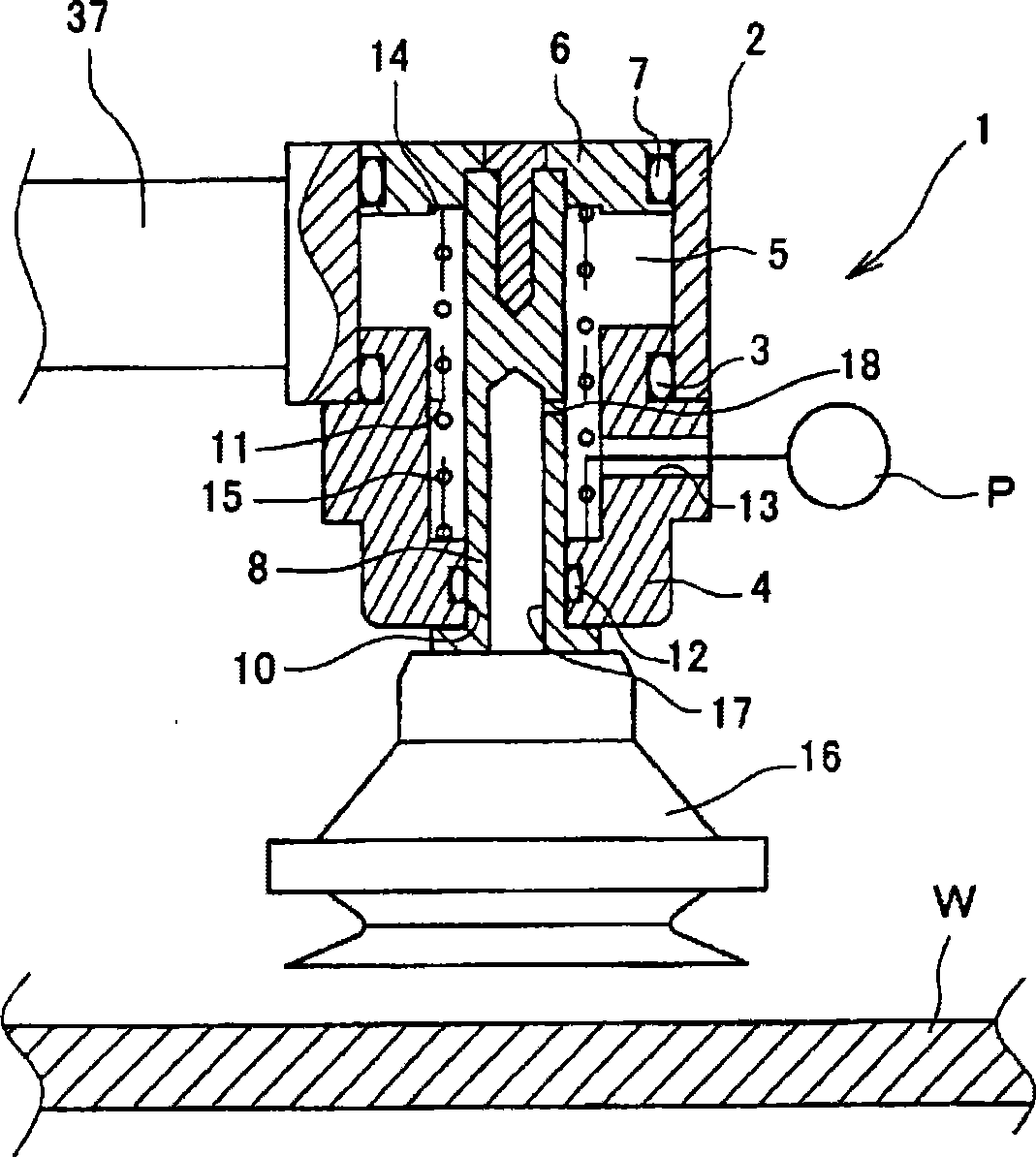

Suction apparatus and suction method using such suction apparatus

InactiveCN101454126AInhibit chafingReduce adsorptionGripping headsConveyor partsEngineeringMechanical engineering

To surely hold a work by preventing generation of scratches or the like on the surface of the work, even in the case of holding by suction the work having a curbed portion, an inclined portion and the like. [MEANS FOR SOLVING PROBLEMS] A supporting member (4) is arranged below a cylindrical section (2) wherein a piston member (6) is mounted, a small diameter hole (10) and a large diameter hole (11) for inserting a piston rod (8) is arranged on the supporting member (4), and a vacuum cup (16) is mounted on the leading end of the piston rod (8). A first suction hole (13) is made from the side surface of the supporting member (4) toward the large diameter hole (11), a third suction hole (17) is opened in the vacuum cup (16), at the center portion of the piston rod (8), and a second suction hole (18) is arranged for permitting the large hole (11) to communicate with the third suction hole (17). The communication area of the second suction hole (18) communicating with the third suction hole (17) is made smaller than the communication area of the large diameter hole (11) communicating with a piston chamber (5).

Owner:HONDA MOTOR CO LTD

Wetsuit neck and arm protective members

ActiveUS20100005576A1Reduce water incursionSecure retentionHead bandagesFinger bandagesRubber materialBand shape

A neck-protective member for preventing chafe encountered when wearing a wetsuit is provided that fits snugly around the wearer's neck, with its lower edge under the edge of the neck opening in the wetsuit. The edge of the neck opening in the wetsuit bears against the protective member rather than the skin of the wearer's neck, preventing painful chafing that can be experienced around a wearer's neck upon prolonged wetsuit use.In a particularly preferred embodiment of the invention, the neck-protective member of the invention comprises a generally conical neck portion, which fits around the wearer's neck, and a skirt portion, which fits over the wearer's shoulders, under the wetsuit. The neck portion may be formed of a single band-like member cut from a sheet of flat material, preferably “smoothskin” neoprene rubber material, oriented such that the smooth surface of the “smoothskin” neoprene rubber material is to the inside and contacts the wearer's neck.Similar members can also be provided for prevention of chafe between the ends of sleeves in the garment and the arms of the wearer.

Owner:ANDREWS WATER SPORTS

Material for holding item to be polished, and laminate plate using same

InactiveCN104245231AEasy to bendImproved plate thickness accuracySemiconductor/solid-state device manufacturingWoven fabricsFiberGlass fiber

Owner:SUMITOMO BAKELITE CO LTD

Anti-glare screen protection film

InactiveCN103507357AEasy to installQuick and automatic exclusionSynthetic resin layered productsVisibilityLiquid-crystal display

The invention discloses an anti-glare screen protection film. The main structure of the anti-glare screen protection film comprises a main film, a mounting adhesive layer, a mounting adhesive protection film, an anti-glare scratch-resistant layer, a protection film adhesive layer and a scratch-resistant layer protection film, wherein the three layers of the main film, the three layers of the mounting adhesive protection film and the scratch-resistant layer protection film are film structures of polyethylene terephthalate (PET) material, and the three layers of the mounting adhesive layer, the anti-glare scratch-resistant layer and the protection film adhesive layer are adhesive structures with different properties. The invention also discloses a making method of the anti-glare screen protection film. The anti-glare screen protection film provided by the invention is easy to mount, and capable of quickly and automatically removing bubbles; no adhesive residue is left on the screen surface after the anti-glare screen protection film is removed; the anti-glare screen protection film can be repeatedly sticked and used after being removed from the screen; the anti-glare screen protection film has the functions of scratch resistance, excellent abradability, stain repellence and the like, and can effectively eliminate reflected light and strong glare in a situation that an extreme brightness contrast exists at a time or in a space so as to cause visual sense uncomfortableness and object visibility reduction; in addition, the anti-glare screen protection film has the characteristics of high fashion property, capability of strengthening liquid crystal picture stereo feeling and making the color more plentiful, and the like, and can be widely applied to screen protection of various liquid crystal display screens. The making method of the anti-glare screen protection film provided by the invention is simple, easy to operate and suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

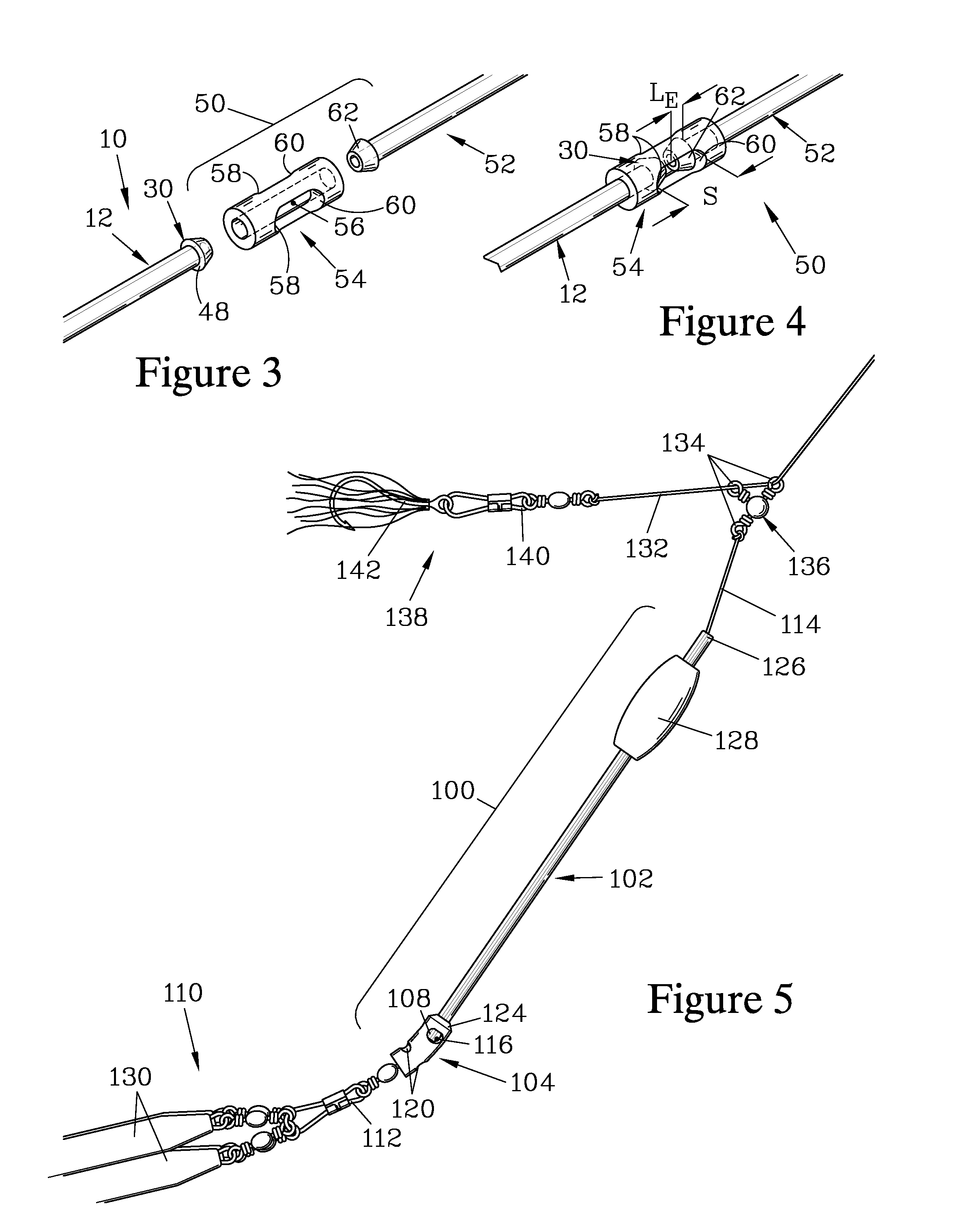

Snag-resistant sinker line shield

Owner:BRASSEUR BERNARD P

Electromagnetic wave shielding protective film and manufacturing method thereof

InactiveCN102152535AEasy to installQuick and automatic exclusionSynthetic resin layered productsMetal layered productsTectorial membraneInfrared

The invention discloses an electromagnetic wave shielding protective film. The protective film mainly comprises a main film, a composite glue layer, a metal nano layer, a composite PET (polyethylene terephthalate) film, an assembly glue layer, an assembly glue protective film, a scratch-resistant layer, a protective film glue layer and a scratch-resistant layer protective film. The protective film has the following advantages: the protective film is easy to assemble; the bubbles can be rapidly and automatically eliminated; the screen surface is free of residual glue after the protective film is removed; the protective film can be repeatedly pasted and used after being removed from the screen and has the functions of resisting scratch, resisting wear and preventing fouling; and due to addition of the metal nano layer, the screen protective film can shield the electromagnetic waves harmful to the human bodies, has the capabilities of eliminating the static electricity, reflecting infrared rays and ultraviolet rays and can be widely used for protecting the screens of various liquid crystal displays. A manufacturing method of the screen protective film is simple, easy to operate and suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Common anti-scratch protective membrane and manufacturing method thereof

InactiveCN102152569AEasy to installEasy to prepareSynthetic resin layered productsLiquid-crystal displayPolyethylene terephthalate

The invention discloses a common anti-scratch protective membrane. The main structure of the membrane comprises a main membrane, a mounting glue layer, a mounting glue protective membrane, an anti-scratch layer, a protective membrane glue layer and an anti-scratch layer protective membrane, wherein the main membrane, the mounting glue protective membrane and the anti-scratch layer protective membrane are polyethylene terephthalate (PET) membranes; and the mounting glue layer, the anti-scratch layer and the protective membrane glue layer are glue structures with different properties. The invention also discloses a manufacturing method for the common anti-scratch protective membrane. The common anti-scratch protective membrane can be arranged easily, air bubbles can be removed quickly and automatically, no glue is resided after the screen is removed, and the membrane can be recycled after the screen is removed; besides, the membrane has the functions of scratch resistance, high wear resistance, fouling resistance and the like and can be widely applied to screen protection of various liquid crystal displays. The manufacturing method for the common anti-scratch protective membrane is simple, convenient to operate and suitable for industrial protection.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Snag-resistant sinker line shield

Owner:BRASSEUR BERNARD P

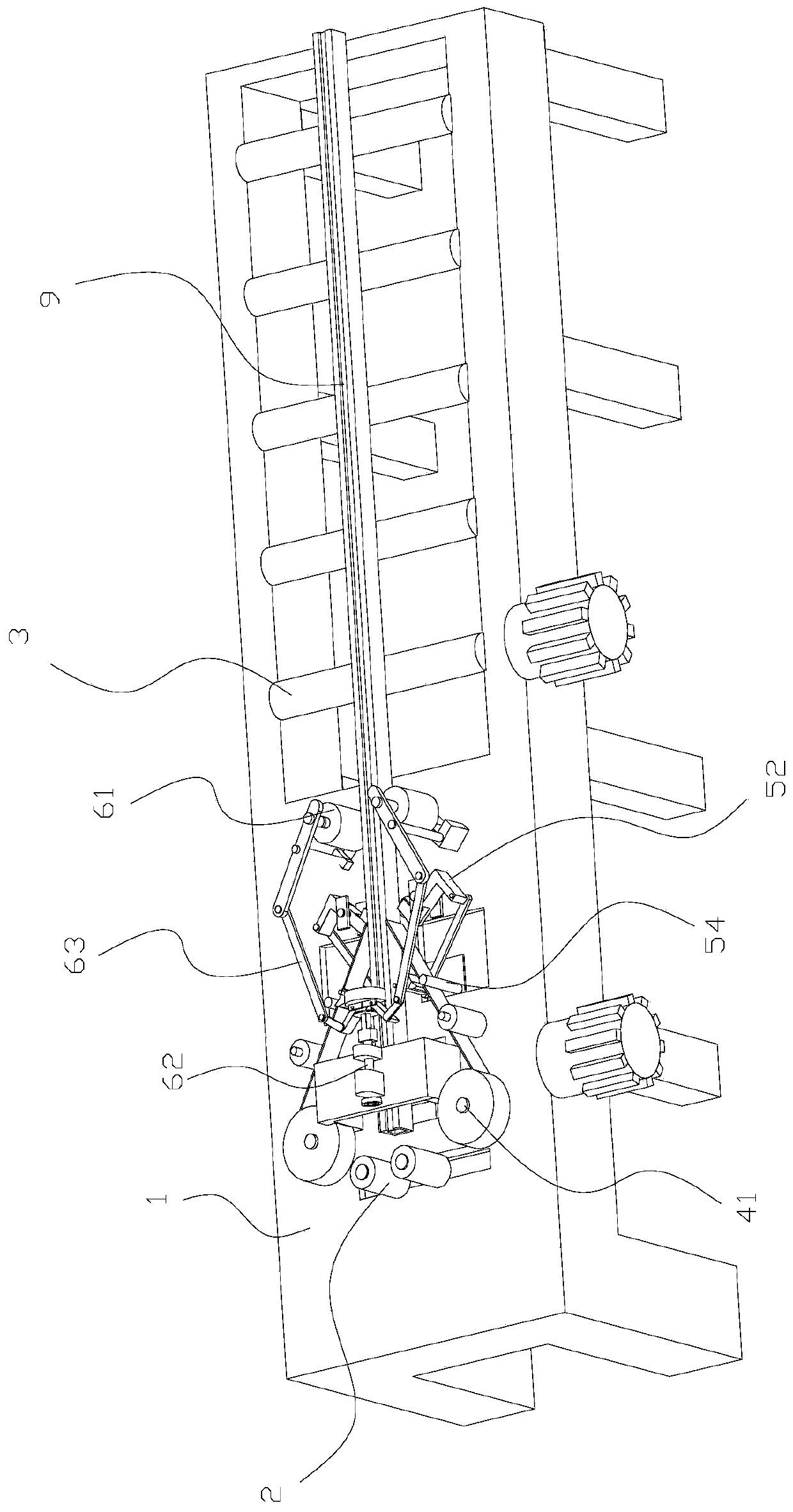

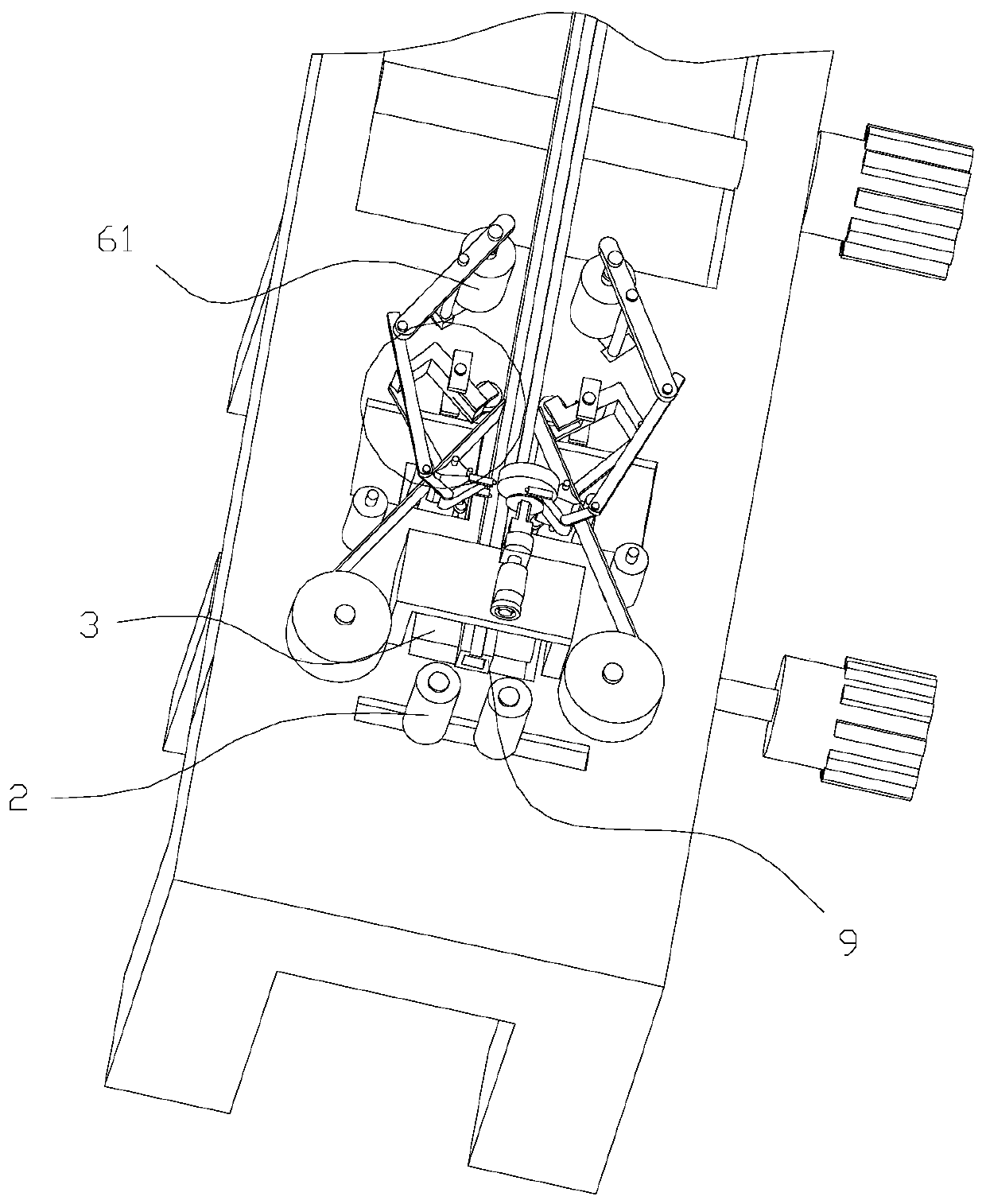

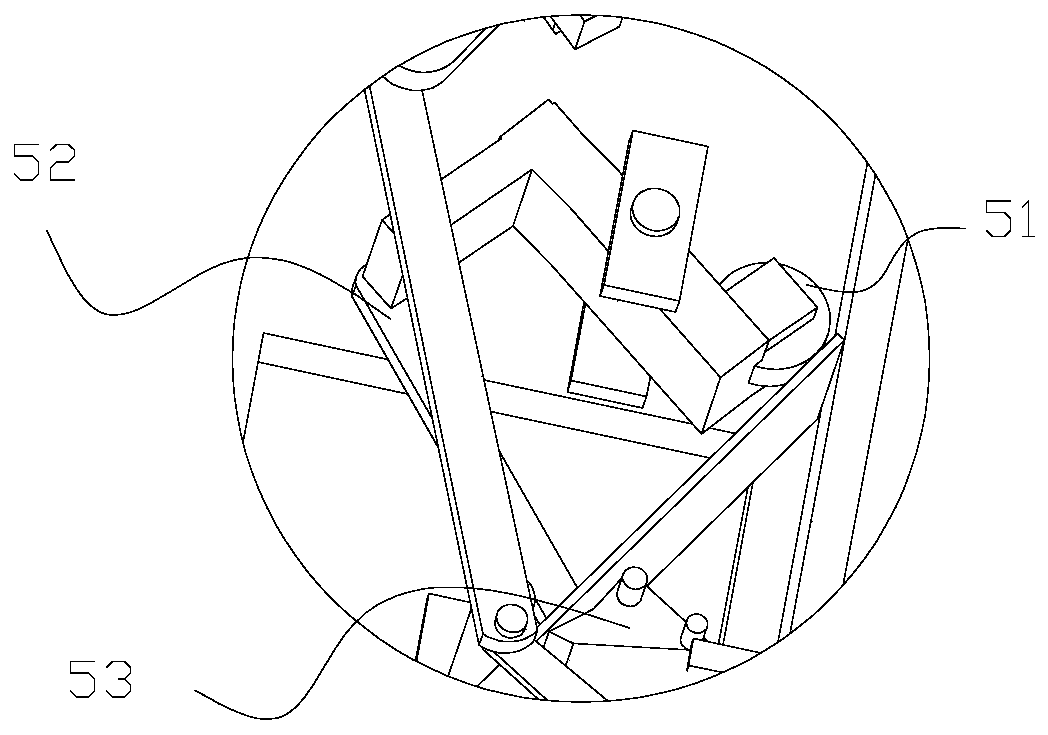

Self-film-cutting type aluminum profile double-side-face synchronous film pasting machine

InactiveCN110697122AImprove film application efficiencyEasy to installPackagingWebs handlingThin membraneEngineering

The invention discloses a self-film-cutting type aluminum profile double-side-face synchronous film pasting machine. A contact roller and a cutting knife are in linkage through a transmission mechanism, wherein the contact roller is located behind a film rolling roller, and a part of the contact roller coincides with the conveying track of an aluminum profile; a knife edge of the cutting knife makes contact with a film guiding roller; when the contact roller rotates to the outer surface of the contact roller through the transmission mechanism to make rolling contact with the outer surface of the area, subjected to film pasting, in the aluminum profile, the cutting knife can rotate, a gap exists between the knife edge of the cutting knife and the film guiding roller, and an elastic device deforms; a film unwound from the film rolling roller can pass through the gap; and two sets of film pressing rollers are symmetrically arranged at the two ends of a clamping mechanism, telescopic rodsdo telescopic motion to be used for adjusting the distance between the two ends of the clamping mechanism, and the two sets of film pressing rollers make rolling contact with the corresponding side faces of the area, subjected to film pasting, in the aluminum profile correspondingly. The self-film-cutting type aluminum profile double-side-face synchronous film pasting machine has the advantages that synchronous film pasting of the two opposite side faces of the aluminum profile is achieved, the mechanical structure for automatically cutting off the film is optimized, and operation convenienceis improved.

Owner:奋安铝业股份有限公司

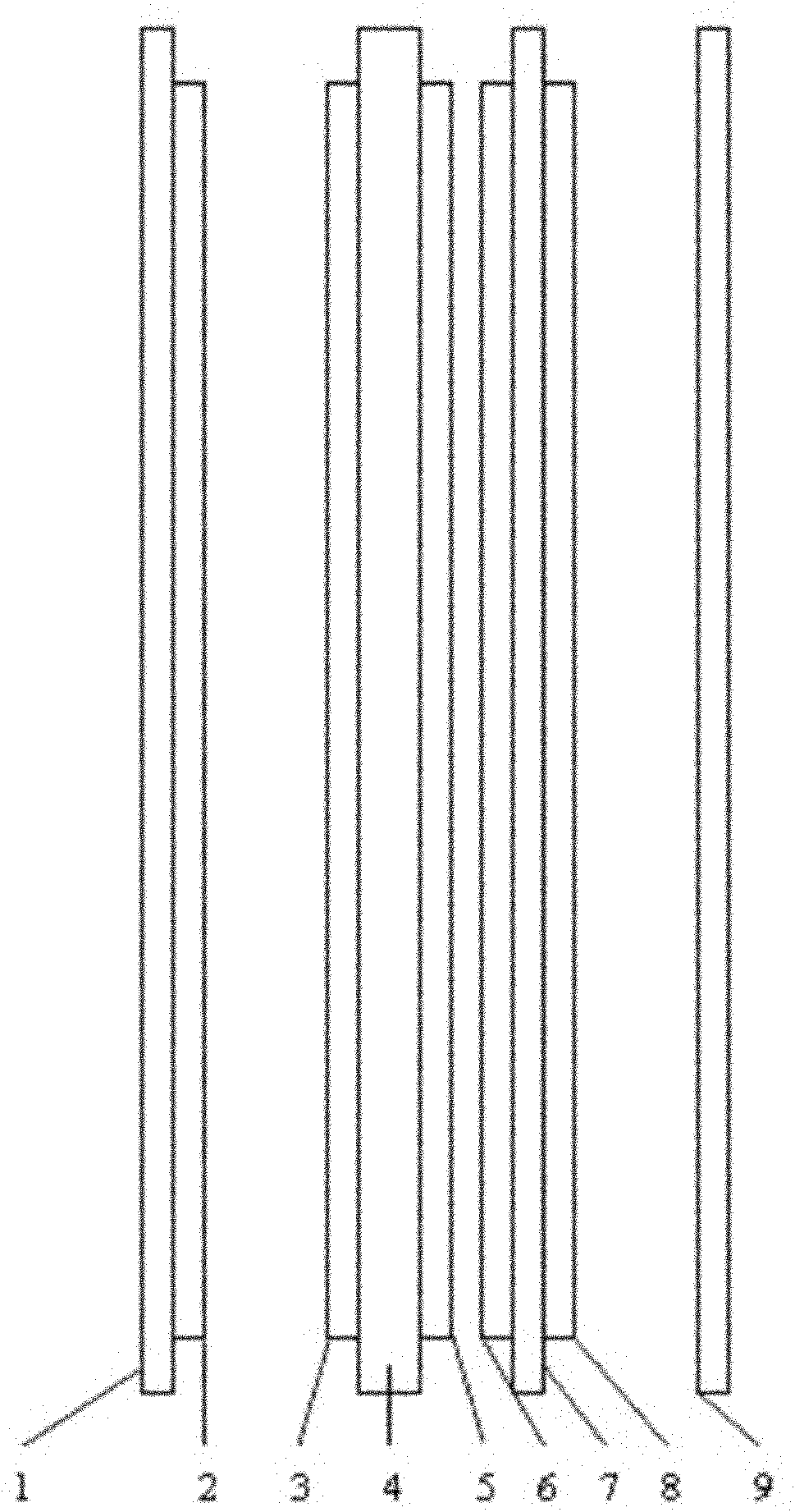

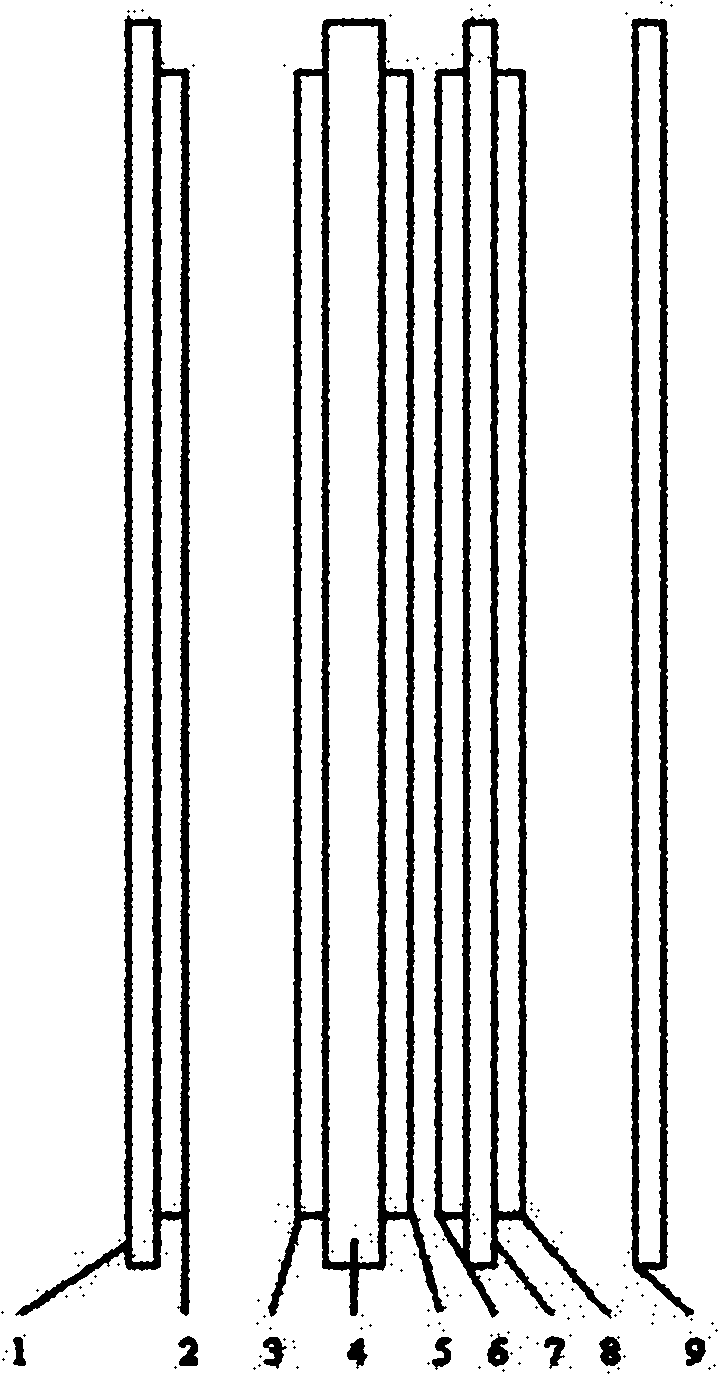

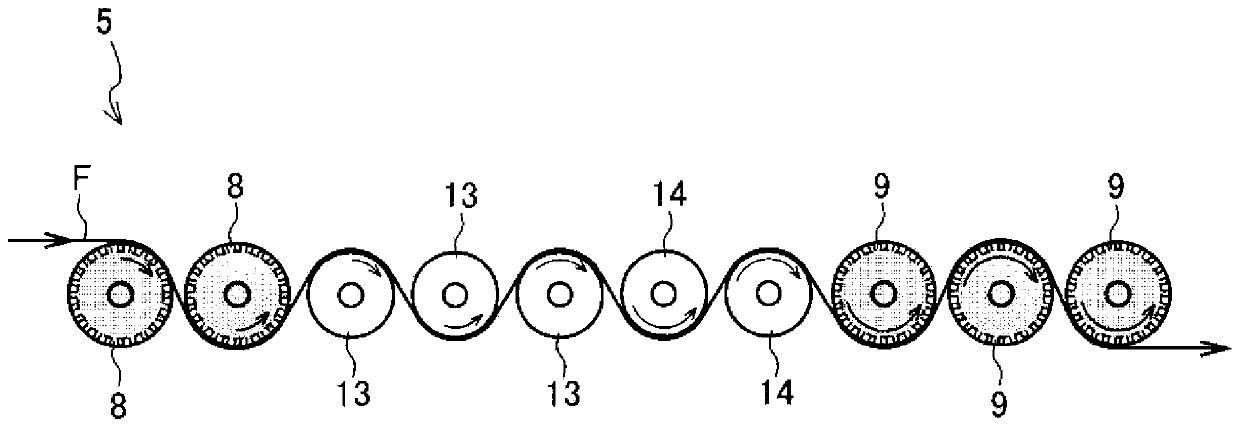

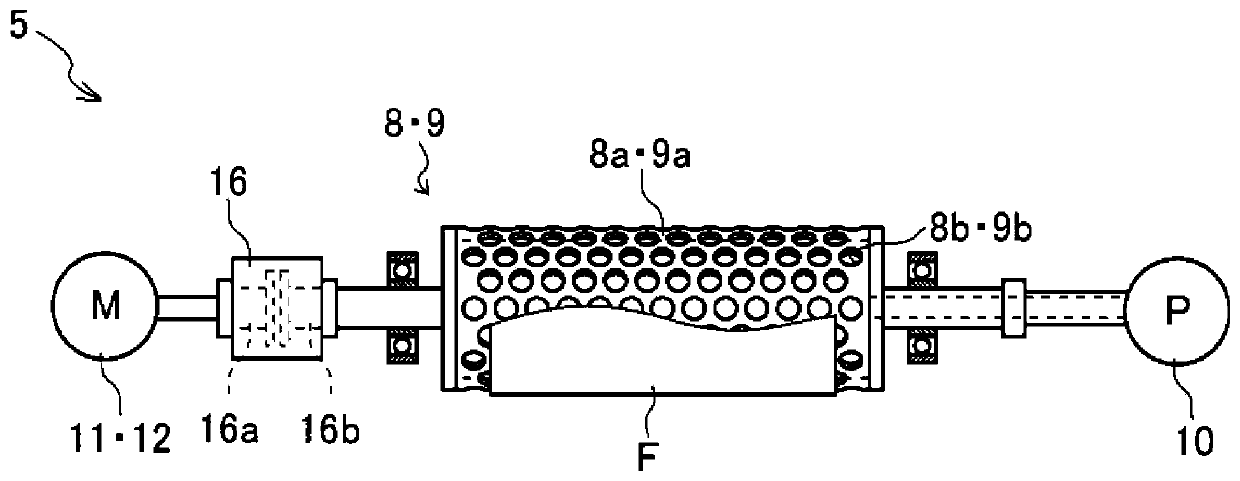

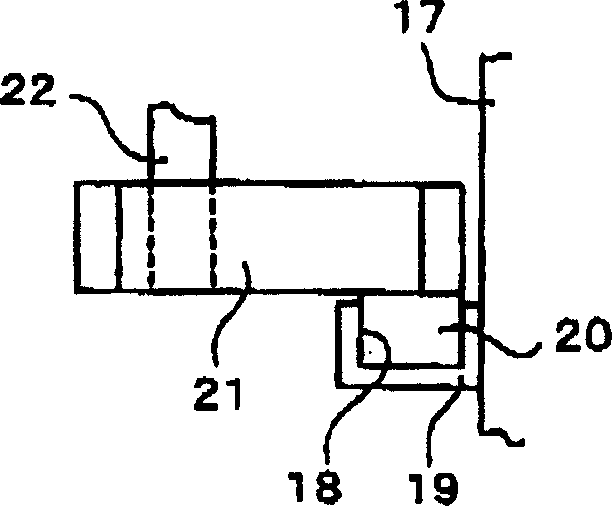

Longitudinal drawing device

Provided is a longitudinal drawing device capable of reducing the occurrence of transfer damage, scratches, or the like on a thermoplastic film when drawn longitudinally. Specifically, a longitudinaldrawing device (5) draws a thermoplastic film (F), heated by heating rolls (13), by means of a difference in peripheral speed between a plurality of low-speed driving rolls (8) and a plurality of high-speed driving rolls (9). The plurality of low-speed driving rolls (8) and the plurality of high-speed driving rolls (9) are respectively composed of suction rolls having low-speed-side suction holes(8b) and high-speed-side suction holes (9b) which are a plurality of suction holes in conveyance surfaces thereof for conveying the thermoplastic film (F). A plurality of the heating rolls (13) are provided between adjacent low-speed driving rolls (8) and high-speed driving rolls (9). Each of the plurality of heating rolls (13) is provided with a following electric motor (15) serving as an actuator. Each of the plurality of heating rolls (13) is configured to be independently rotationally drivable. The output torque of each of the following electric motors (15) is controlled so as to coincidewith a target value set for each of the following electric motors (15).

Owner:TORAY ENG CO LTD

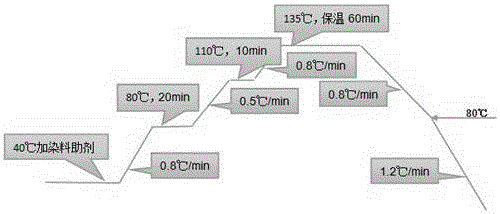

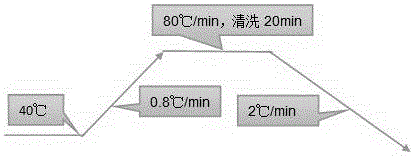

Dyeing and finishing process of double-layer down-proof fabric

InactiveCN105755869ALess damageFeel goodHeating/cooling textile fabricsDry-cleaning apparatus for textilesFiberEngineering

The invention relates to a dyeing and finishing process of double-layer down-proof fabric. The dyeing and finishing process comprises the following steps: desizing, dyeing, setting and drying and waterproof setting, wherein the loose type continuous desizing is adopted. On one hand, through the used loose type continuous desizing, the crease generation probability is reduced; on the other hand, through temperature rise control and active driving performed by a variable frequency motor, the fabric crease generation probability is ensured to be reduced while the fabric shrinks in a relaxed state, so that the damage caused to fibers is minimized in the reduction process. According to the double-layer down-proof fabric prepared by the process, the user demands on air permeability, hand feeling and other aspects are met while the down-proof performance of the double-layer down-proof fabric can also be ensured.

Owner:WUJIANG FUHUA WEAVING

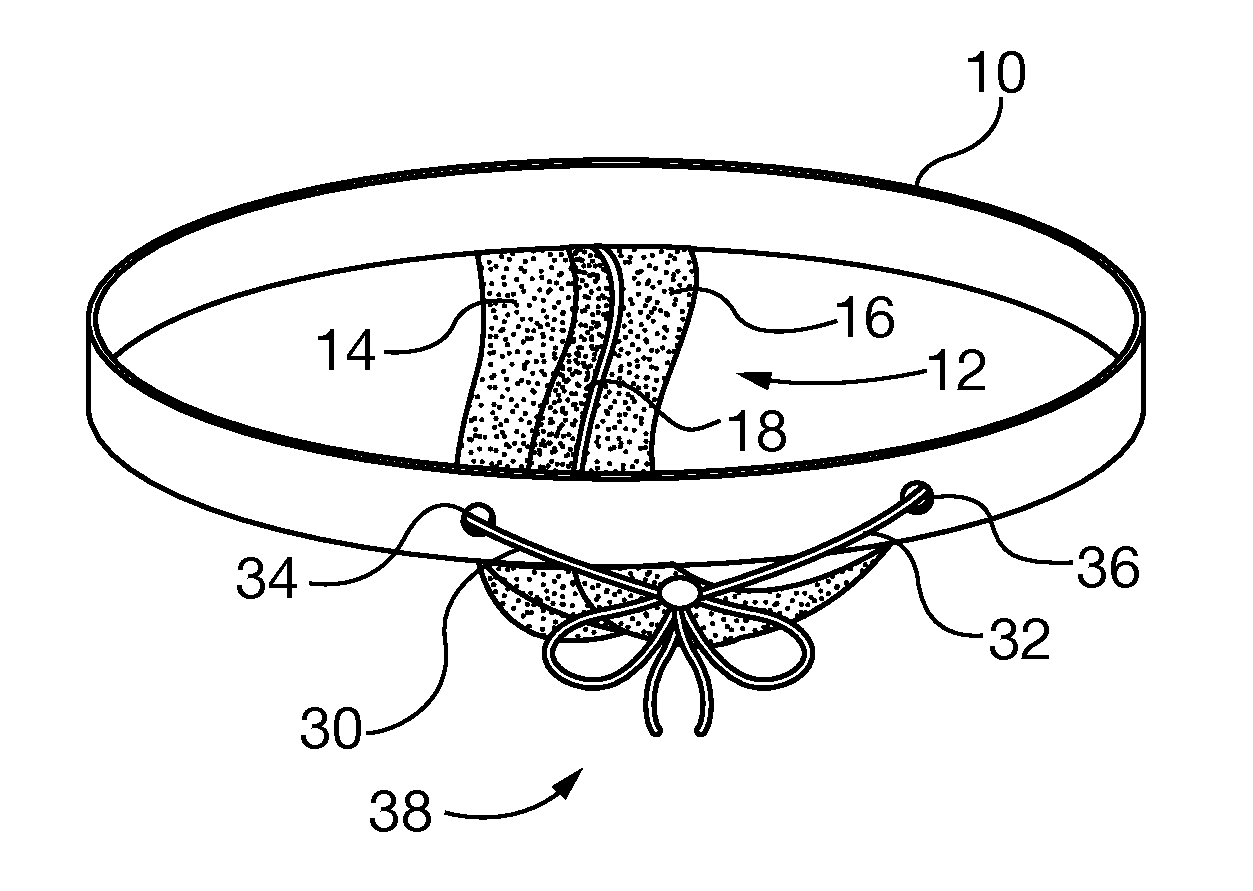

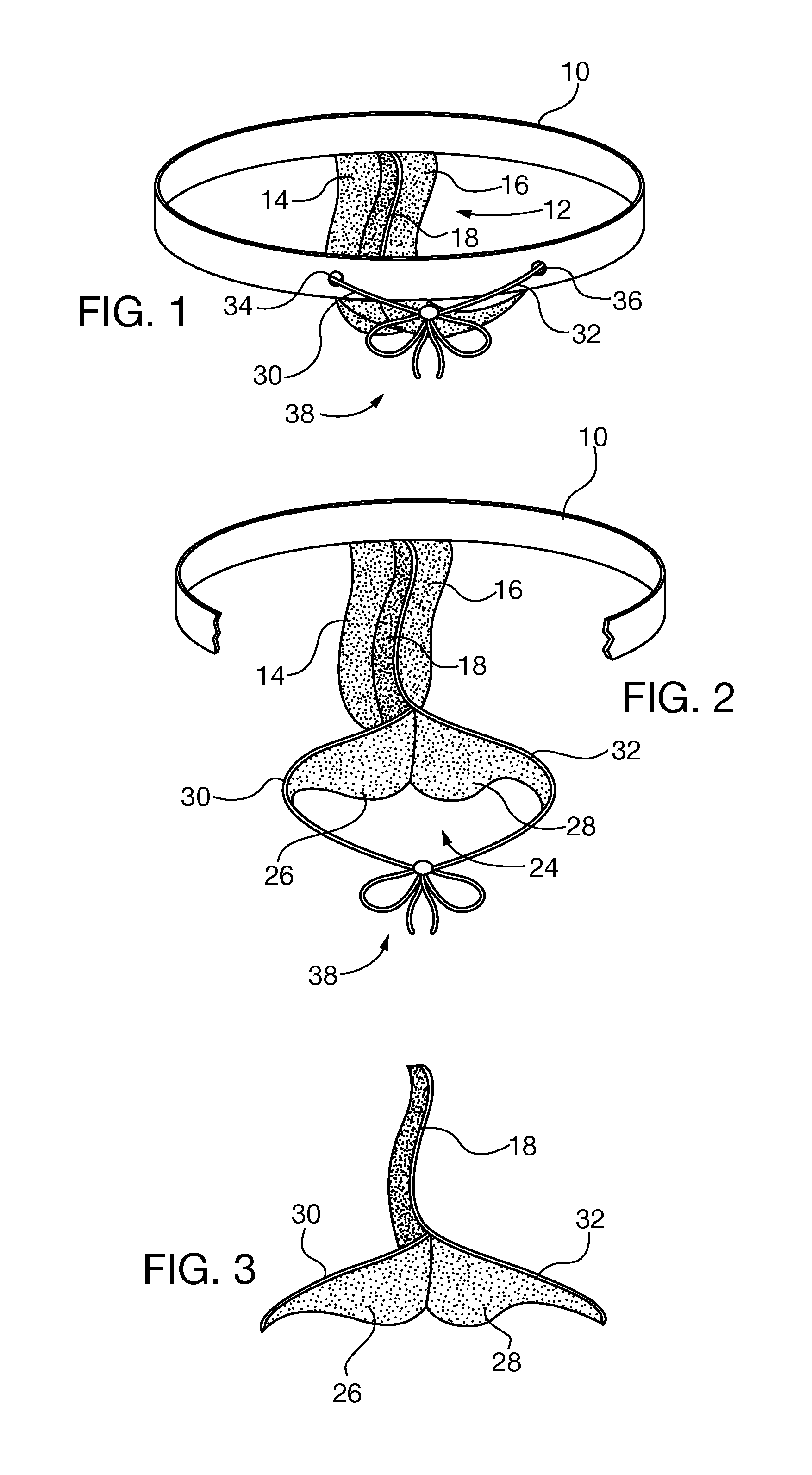

Underwear

ActiveUS20140237704A1Improve hygienePrevent buttock-to-buttock chafingAbsorbent padsUndergarmentsPenisThigh

Underwear adapted to add an inner structure to a traditional covering comprising waistband and fabric panels conventionally covering the buttocks, hips, and genital areas. The inner structure may include a fabric panel bearing a ridge intended to occupy the cleft separating the buttocks, with the fabric panel adhering closely to the buttocks. The inner structure may also or instead include a fabric scrotum guard which covers the rear of the scrotum and which separates the scrotum from the inner thighs and separates the right and left perineal folds where inner thighs meet the lowermost trunk. The scrotum guard may include adjustment structure for adjusting tightness of the fit with the Y formed at the scrotum and the entire perineum. The front of the traditional covering may have an opening for retrieving the penis which opening is arranged horizontally rather than in the traditional generally vertical orientation.

Owner:MEHRABIAN HAMLET

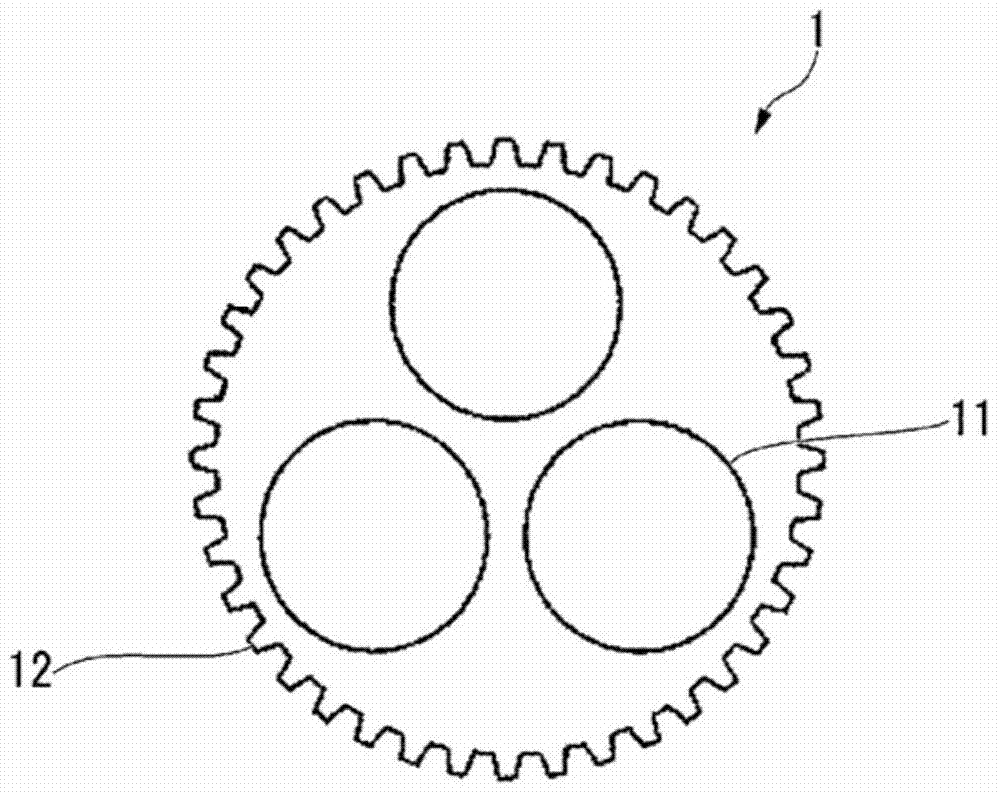

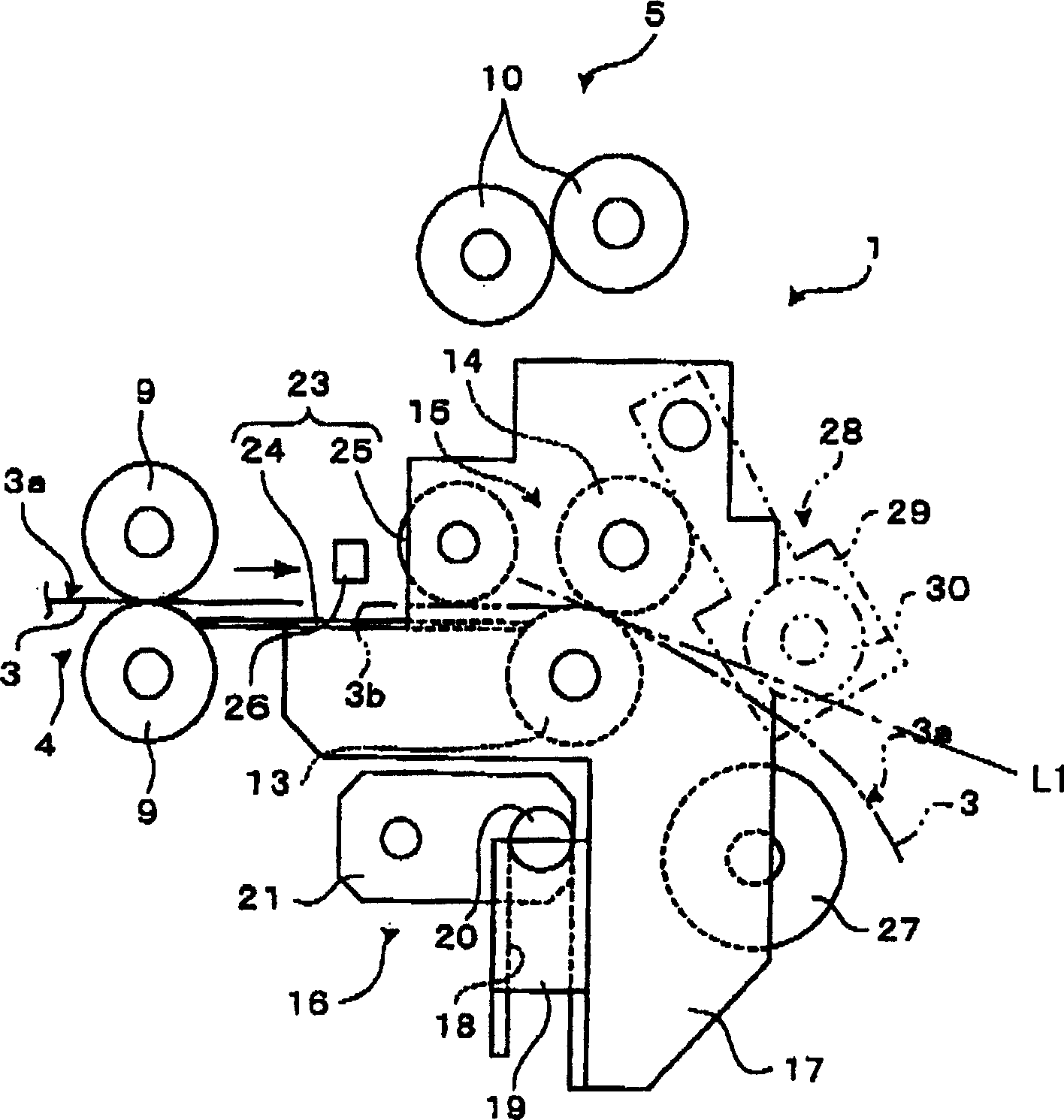

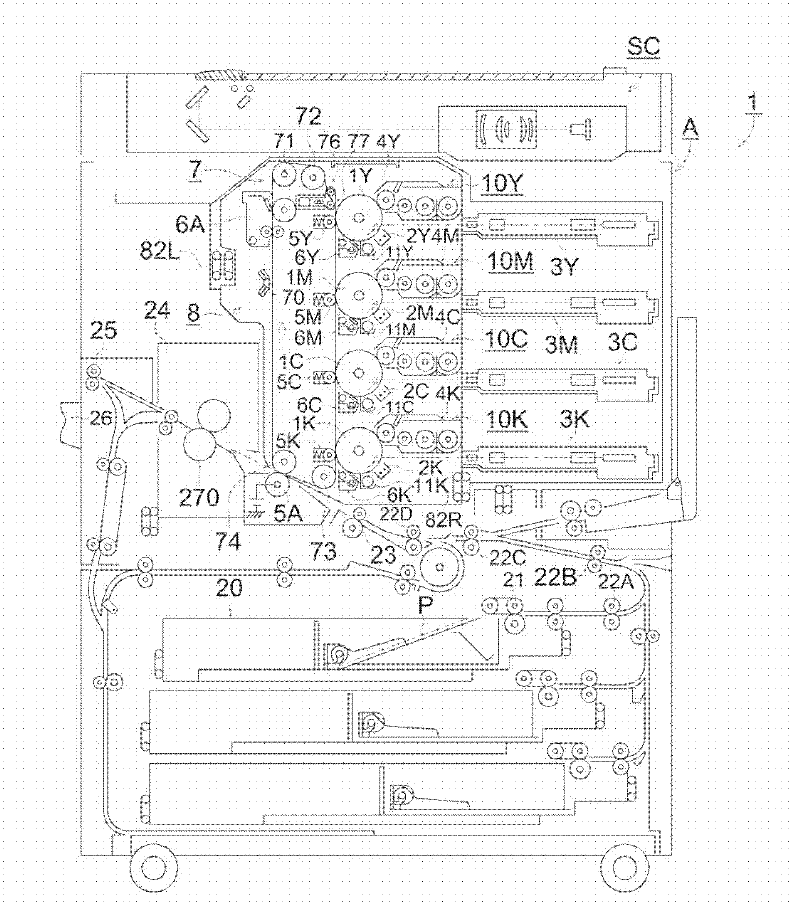

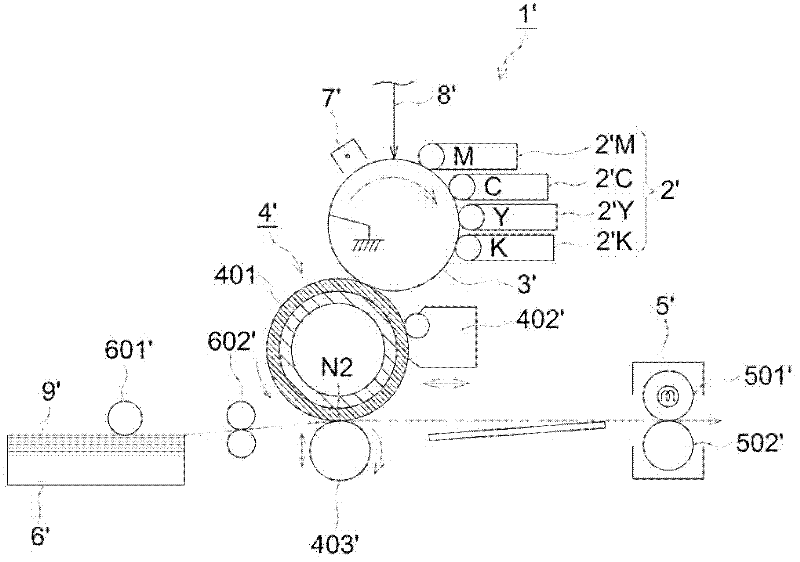

Switchback device and image forming apparatus including it

InactiveCN1595293AInhibit chafingQuality improvementProcessingPhotographic printingImage formationEngineering

To suppress generation of scratches and dirt on a printed face and to intend to reduce in size, a switchback device (1) provided in a conveyance path (12) for a printed medium (3), for reversing the direction of movement of the medium (3) sent from an upstream part (4) of the conveyance path (12) and then delivering the medium (3) to a downstream part (5) of the conveyance path (12), comprises a pair of operation rollers (15) including a drive roller (13) for conveying the medium (3) and a slave roller (14) cooperating with the drive roller (13) to pinch the medium (3); and a changeover mechanism (16) for changing a direction of the pair of operation rollers (15) including the drive roller (13) and the slave roller (14). The medium (3) sent from the upstream part (4) of the conveyance path (12) which is pinched by the pair of operation rollers (15) is, in this state, changed in direction as a result of a change of the direction of the pair of operation rollers (15) by the changeover mechanism (16), and then is delivered to the downstream part (5) of the conveyance path (12) by reversing rotation of the drive roller (13). Thus, generation of scratches and dirt on the printed face (3a) of the medium (3) can be suppressed and the space for taking the medium (3) in upon switchback can be reduced in size.

Owner:NK WORKS CO LTD

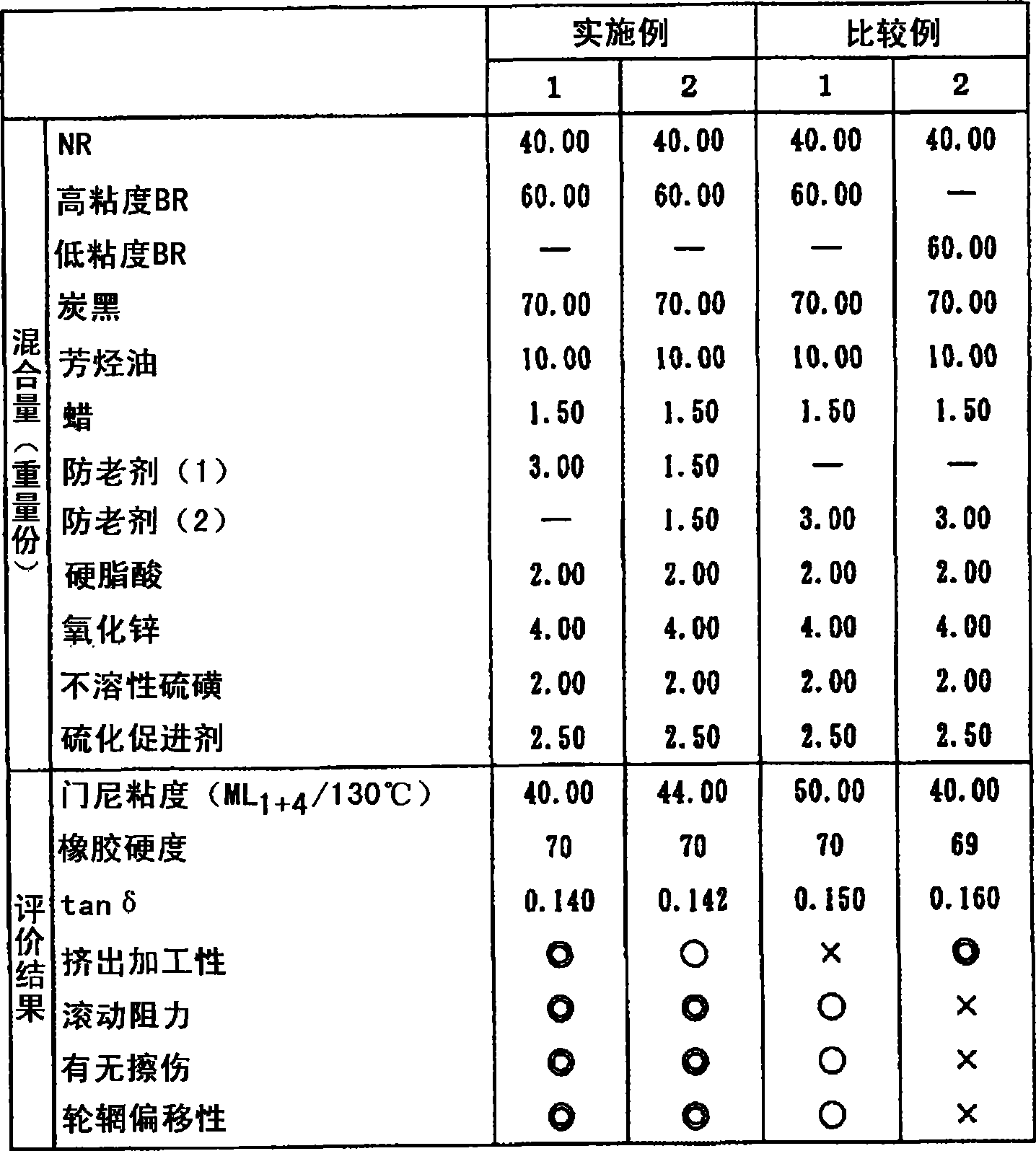

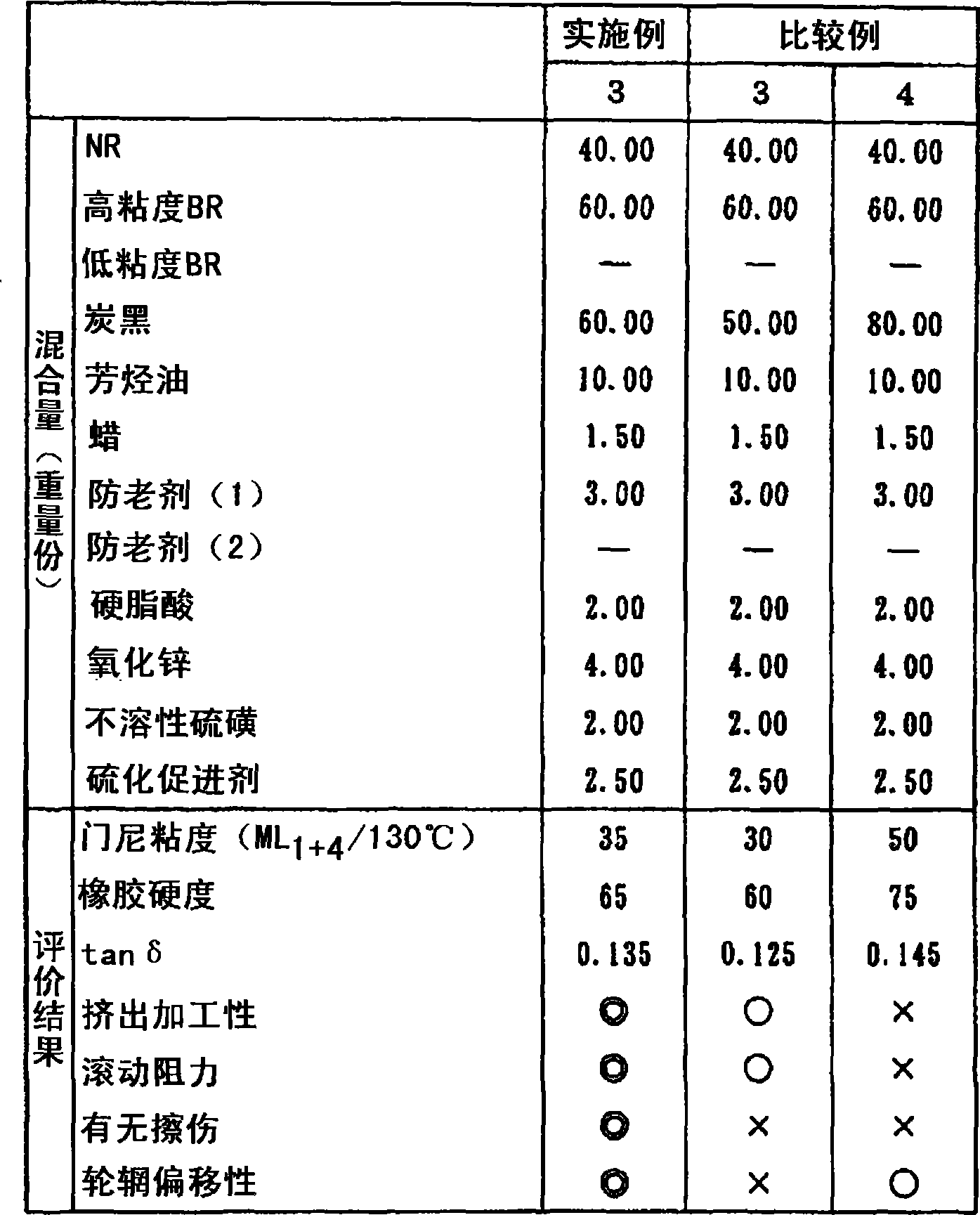

Rubber composition for clinch apex and pneumatic tire with clinch apex utilizing the same

InactiveCN101522779AMaintain a certain hardnessGuaranteed hardnessTyre beadsPolymer scienceRolling resistance

There is provided the rubber composition for a clinch apex keeping hardness constant, suppressing prevulcanization, reducing rolling resistance, improving processability, suppressing generation of chafing between the clinch apex and a rim and hardly causing slipping of the clinch apex on the rim. The rubber composition for a clinch apex comprises 55 to 75 parts by weight of carbon black and 1 to 5 parts by weight of para-benzoquinolinediimine based on 100 parts by weight of a rubber component comprising 10 to 50 % by weight of a natural rubber and / or an isoprene rubber and 50 to 90 % by weight of a butadiene rubber having a Mooney viscosity at 100 DEG C of 30 to 55 in an unvulcanized state, and the pneumatic tire has the clinch apex using the rubber composition.

Owner:SUMITOMO RUBBER IND LTD

Scratch-resistant color screen protective film and manufacturing method thereof

InactiveCN102152572AEasy to installFast automatic exhaustSynthetic resin layered productsLiquid-crystal displayOrganic dye

The invention discloses a scratch-resistant color screen protective film. The protective film mainly comprises a main film, an assembly glue layer, an assembly glue protective film, a scratch-resistant layer with colors, a protective film glue layer and a scratch-resistant layer protective film. The protective film has the following advantages: the protective film is easy to assemble; the bubbles can be rapidly and automatically eliminated; the screen surface is free of residual glue after the protective film is removed; the protective film can be repeatedly pasted and used after being removed from the screen and has the functions of resisting scratch, resisting wear and preventing fouling; and as different colors of organic dyes and other dispersing aids are added to the scratch-resistant layer, the whole protective film has the characteristics of transparent and bright colors, strong fashion sense and the like after uniform dispersion and can be widely used for protecting the screens of various liquid crystal displays. The manufacturing method of the scratch-resistant color screen protective film is simple, easy to operate and suitable for industrial production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Radiotherapy department neck protection device

InactiveCN110226997ARealize all-round protectionIsolate possible damageRoller massageNon-surgical orthopedic devicesMassageEngineering

The present invention discloses a radiotherapy department neck protection device. The radiotherapy department neck protection device comprises a bottom ring, a top end of the bottom ring is fixedly connected with a retractable elastic sleeve, a top end of the elastic sleeve is fixedly connected with a ring-shaped top ring, a top end of the top ring is provided with four massage blocks capable of reciprocating up and down and adjusting movement speeds in front, rear, left and right four directions, an outside of a bottom end of the top ring is provided with a control switch for controlling movement of the massage blocks, and the top ring and bottom ring are connected through four retractable first shock absorbing rods capable of swing front, rear, left and right in front, rear, left and right four directions; the top end of the top ring is connected with a massage cap through a top belt arranged at left and right sides and with adjustable length, a periphery of the massage cap is evenlyprovided with a plurality of massage legs capable of swinging up and down, the massage legs are all provided with adjusting blocks capable of adjusting positions, bottom ends of the adjusting blocksare provided with massage feet capable of adjusting positions, and bottom ends of the massage feet are provided with a plurality of rotatable massage wheels. The radiotherapy department neck protection device effectively solves a problem that currently, a neck is susceptible to infection due to no protection device after the neck is burnt after neck radiotherapy.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

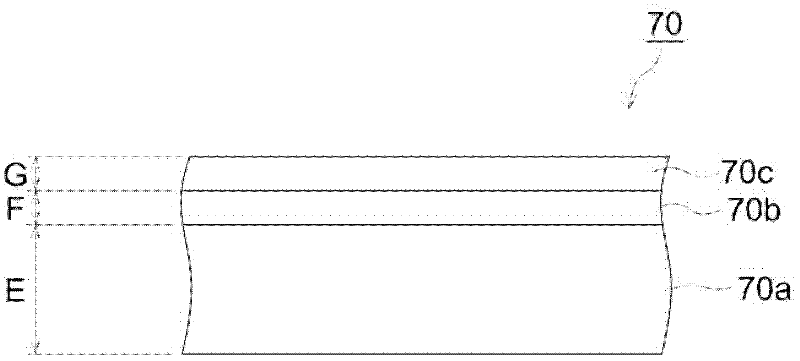

Intermediate transcriptional body

ActiveCN102356359AInhibit chafingCrack suppressionElectrographic process apparatusSurface layerComputer science

Owner:KONICA MINOLTA BUSINESS TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com