Suction apparatus and suction method using such suction apparatus

A technology of adsorption device and suction hole, applied in the field of adsorption, can solve problems such as surface scratches of resin molded products, and achieve the effect of improving adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

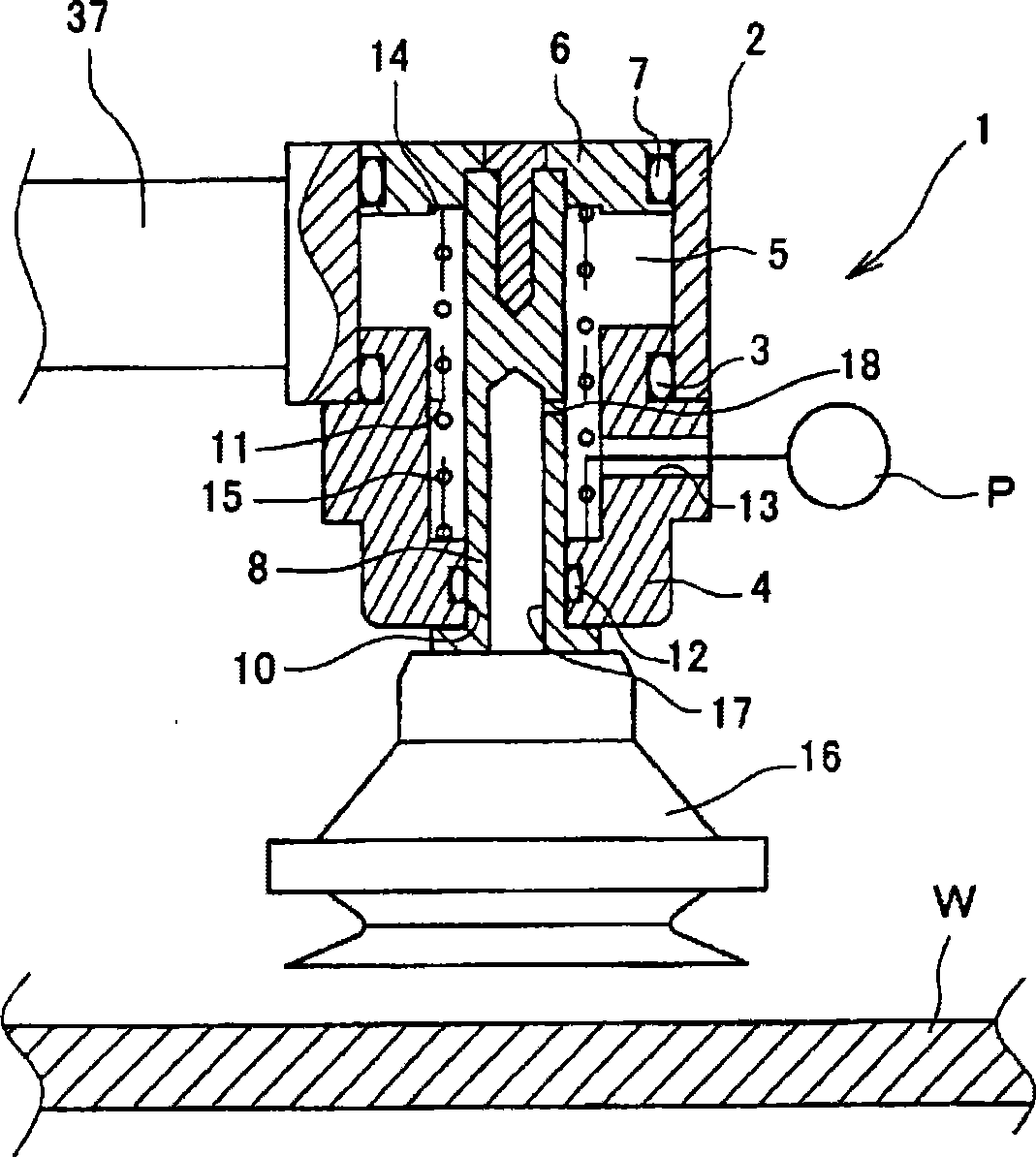

[0017] Embodiments of the present invention will be described with reference to the drawings.

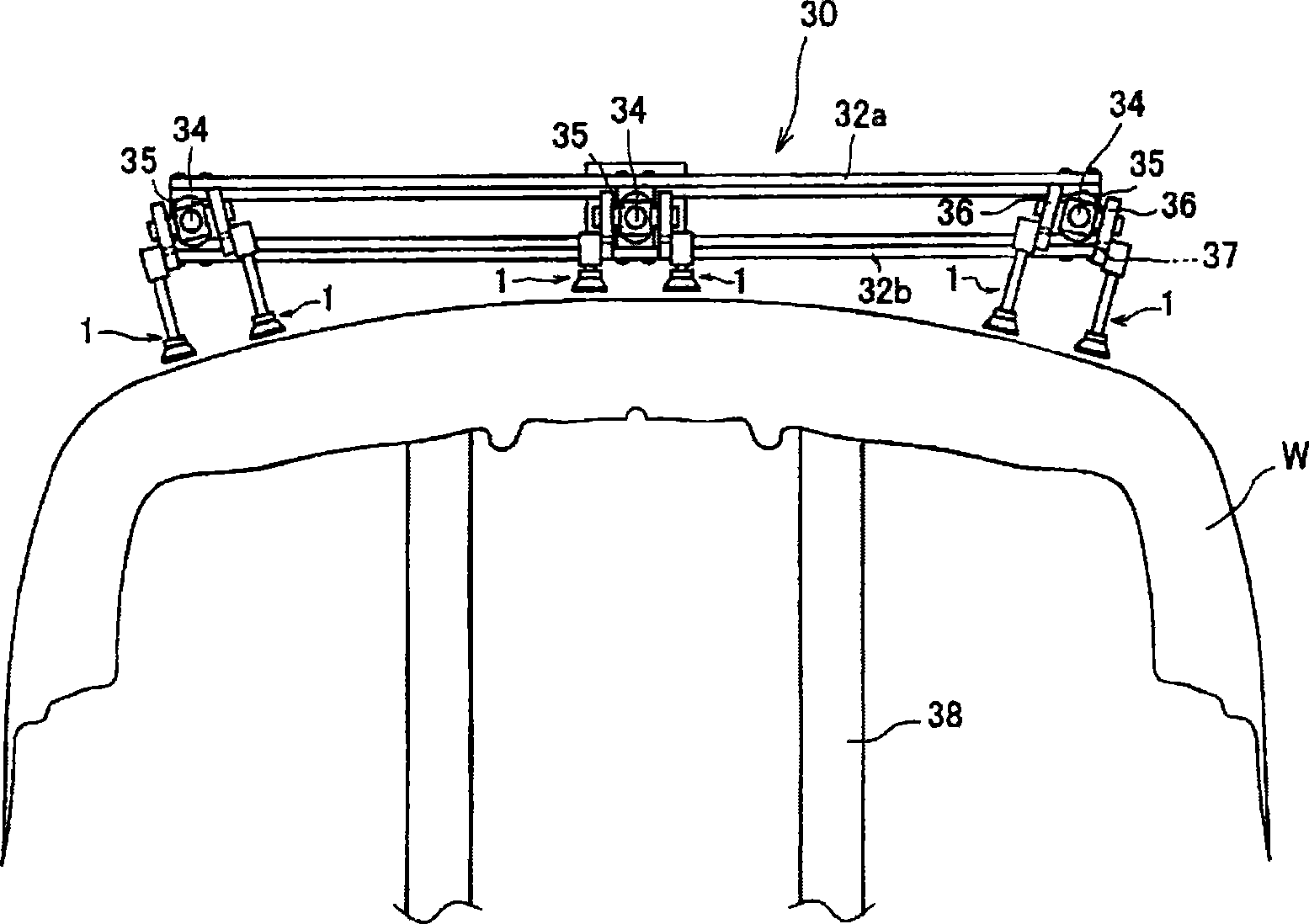

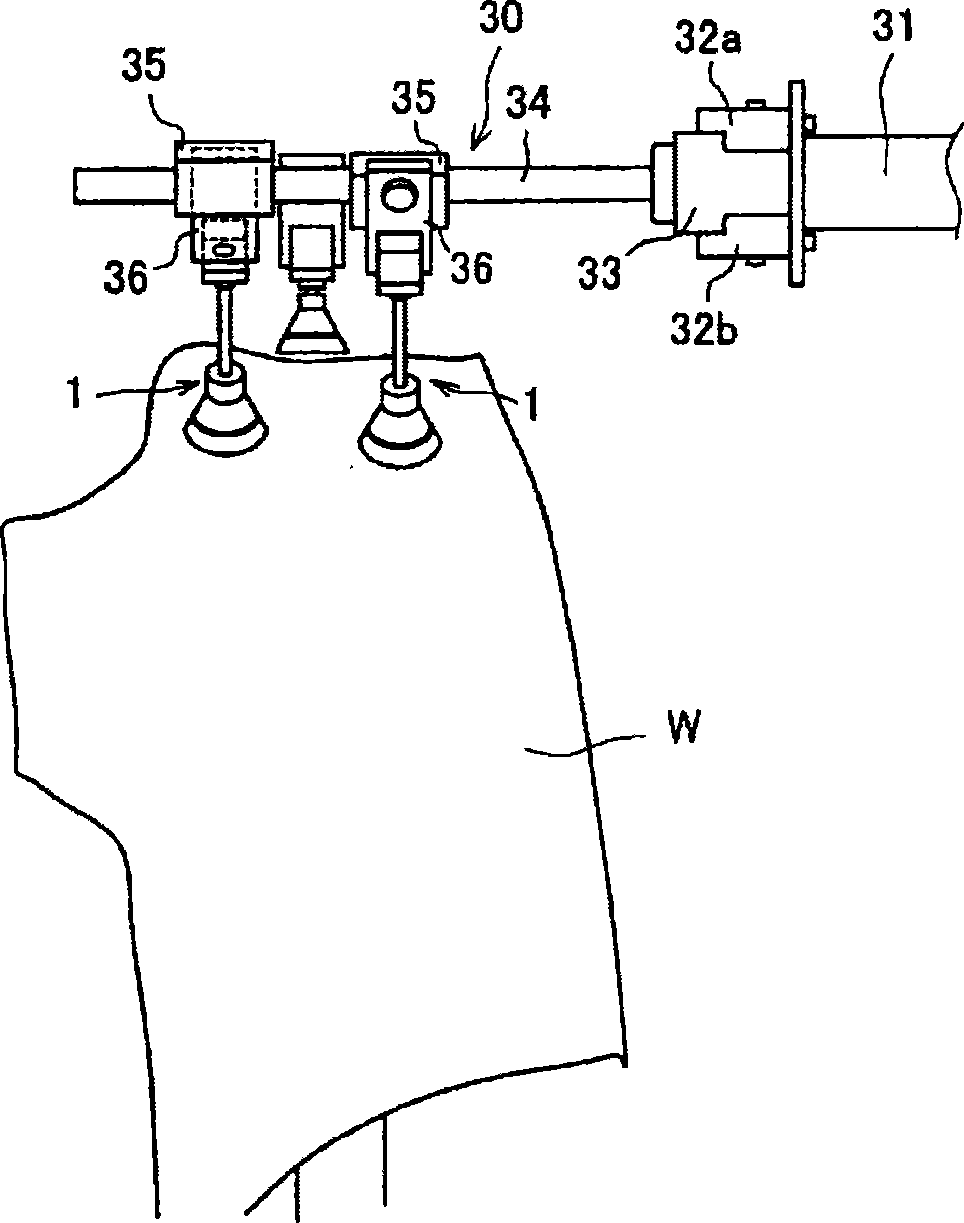

[0018] here, figure 1 is the front view of the transfer device applicable to the adsorption device of the present invention, figure 2 is the side view, image 3 is a partial sectional view showing the internal structure of the adsorption device, Figure 4 It is an explanatory diagram showing the adsorption state.

[0019] The suction device of the present invention can prevent scratches and the like from occurring on the surface of the workpiece even when it sucks and holds the curved portion or the inclined portion of the workpiece, and can hold it reliably. Banpa) W transfer device.

[0020] that is, figure 1 , figure 2 As shown, the bumper W transfer device 30 includes: two upper and lower holding plates 32a, 32b that are arranged at the front end of the robot arm 31 and extend in a direction perpendicular to the extending direction of the arm 31 at the front end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com