Patents

Literature

975results about How to "Crack suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing cracks of Rene104 nickel-based superalloy during laser additive manufacturing

ActiveCN108941560AEliminate cracksInhibition of large size cracksAdditive manufacturing apparatusTransportation and packagingRoom temperatureStress relief

Owner:CENT SOUTH UNIV

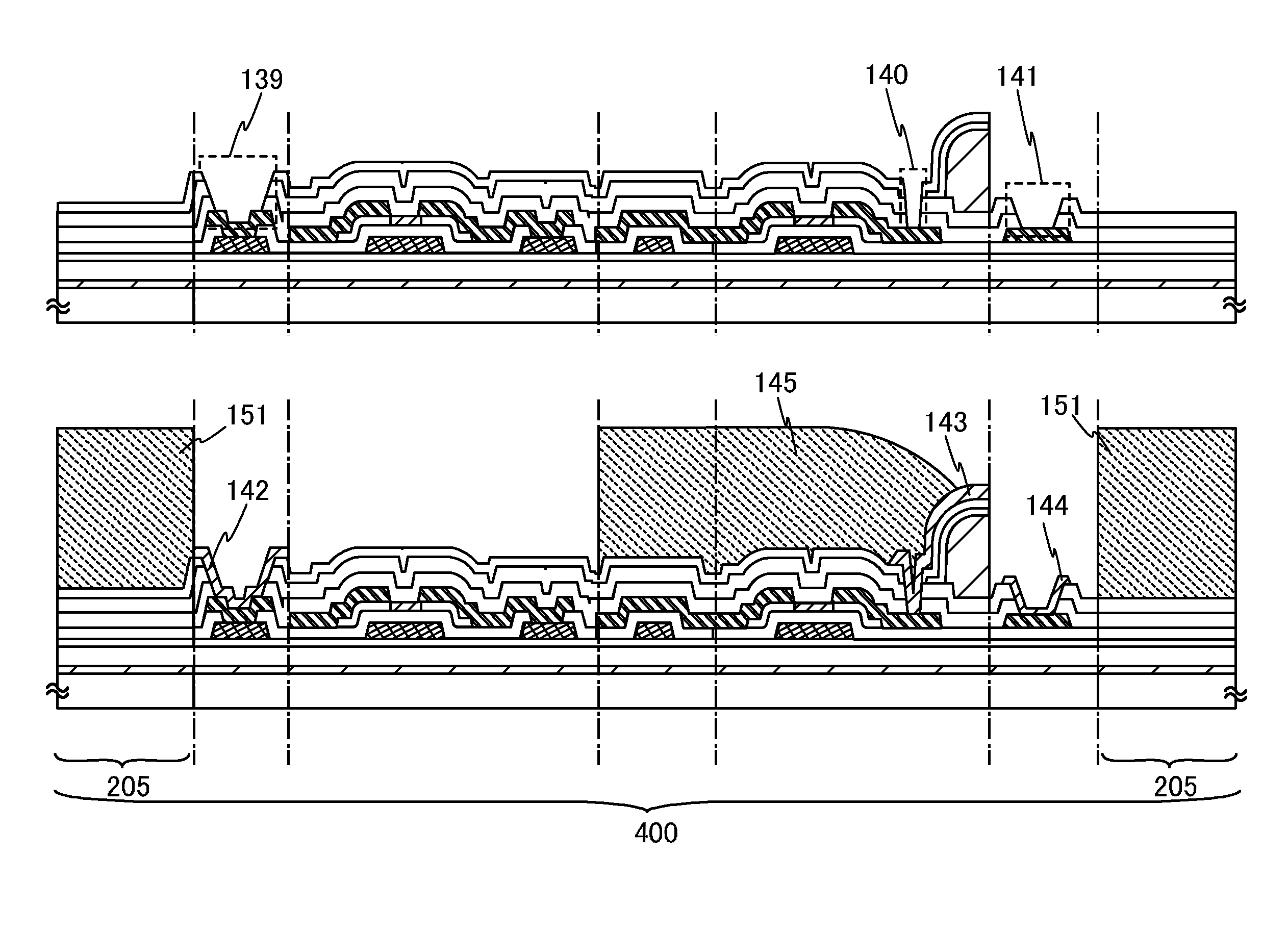

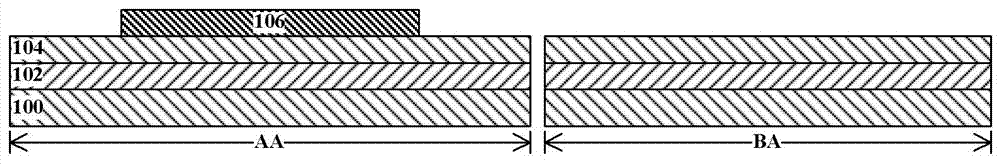

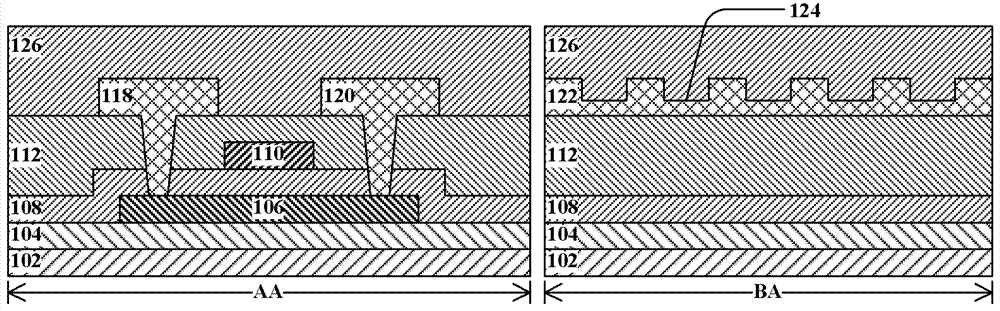

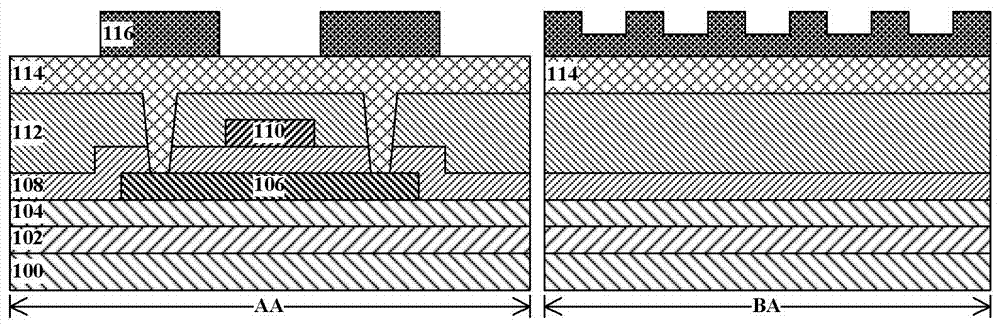

Method for manufacturing semiconductor device

ActiveUS20110318889A1Crack suppressionHigh yield manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal

An object is to provide a manufacturing method of a semiconductor device in which a defect in characteristics due to a crack occurring in a semiconductor device is reduced. Provision of a crack suppression layer formed of a metal film in the periphery of a semiconductor element makes it possible to suppress a crack occurring from the outer periphery of a substrate and reduce damage to the semiconductor element. In addition, even if the semiconductor device is subjected to physical forces from the outer periphery in separation and transposition steps, progression (growth) of a crack to the semiconductor device can be suppressed by the crack suppression layer.

Owner:SEMICON ENERGY LAB CO LTD

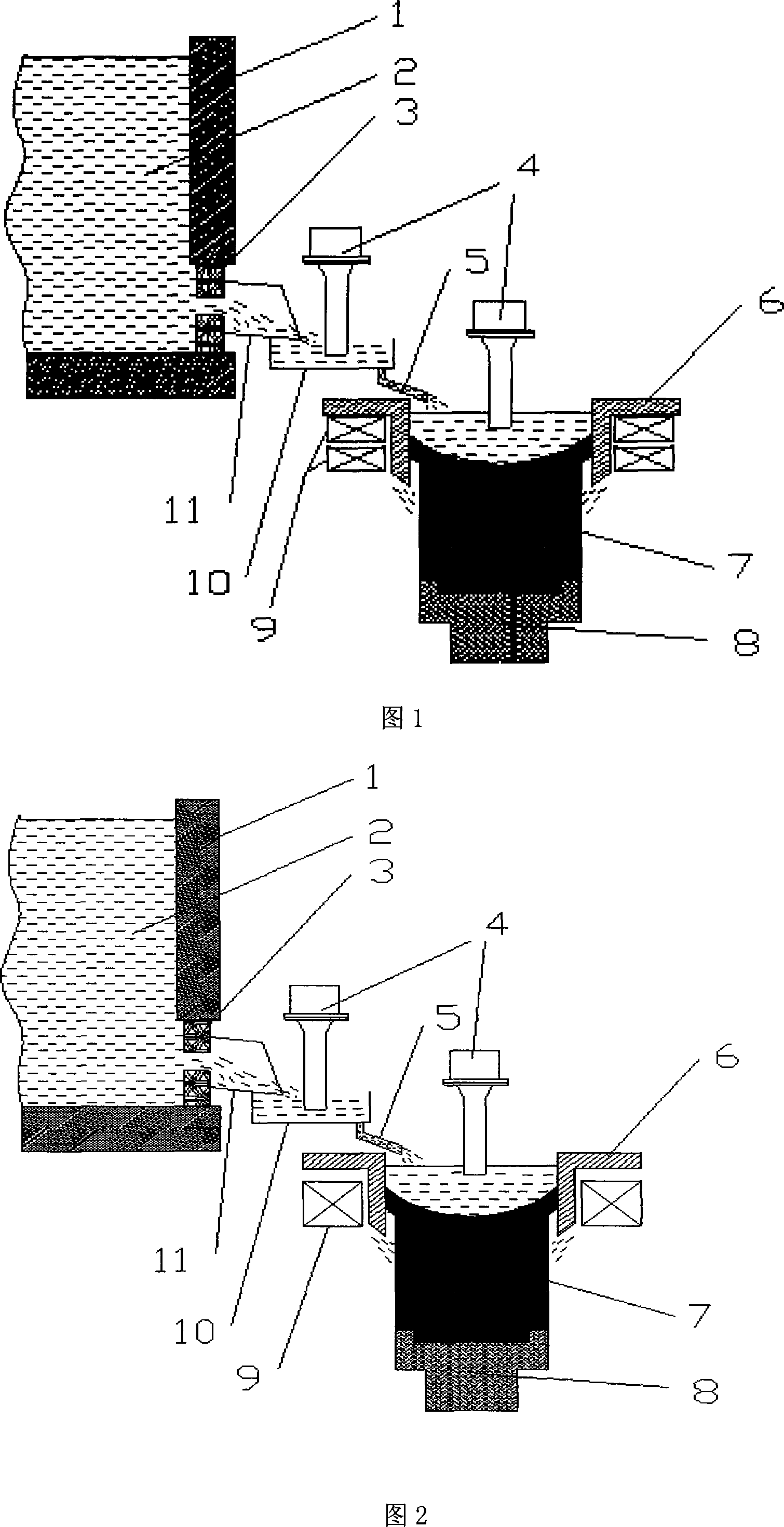

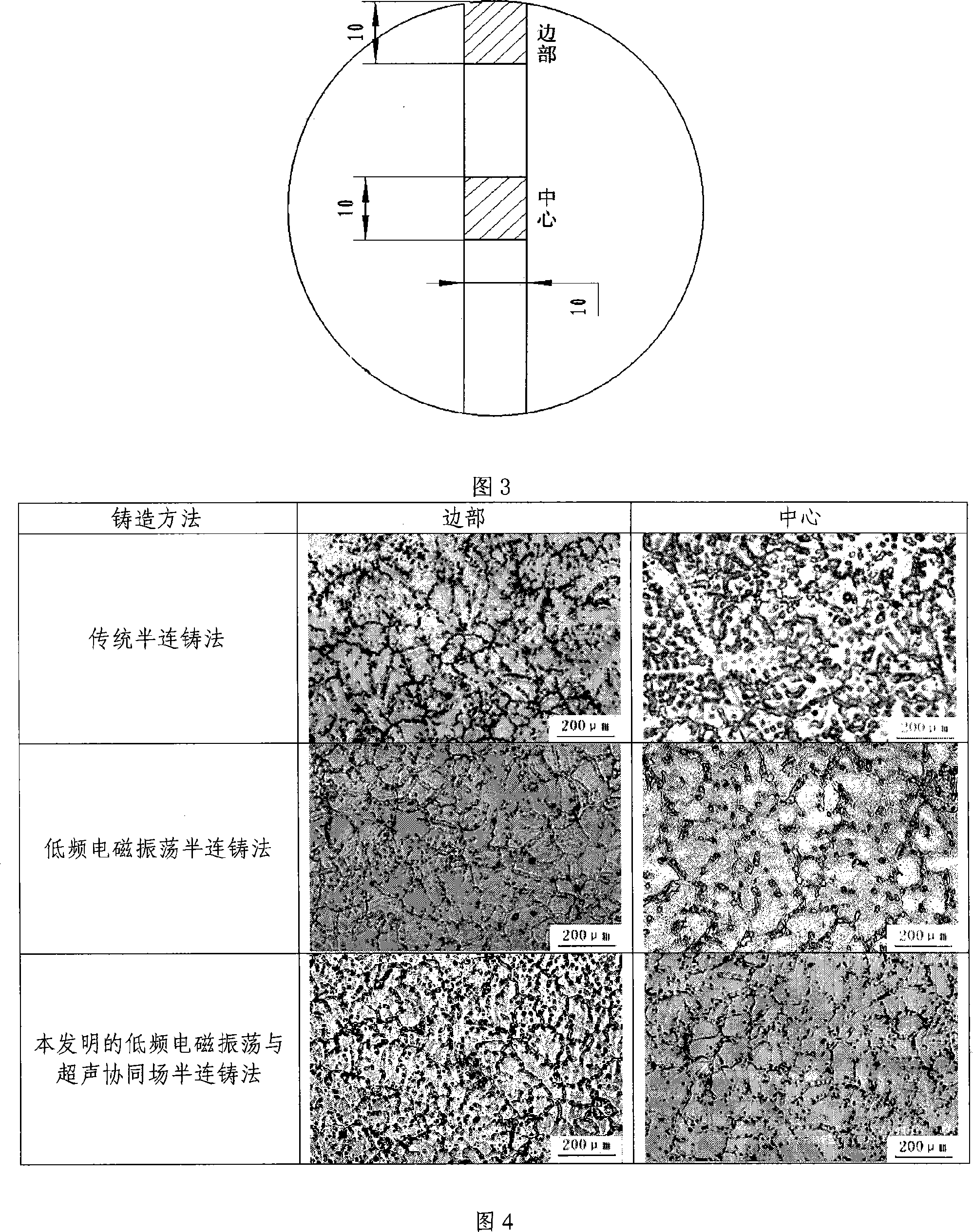

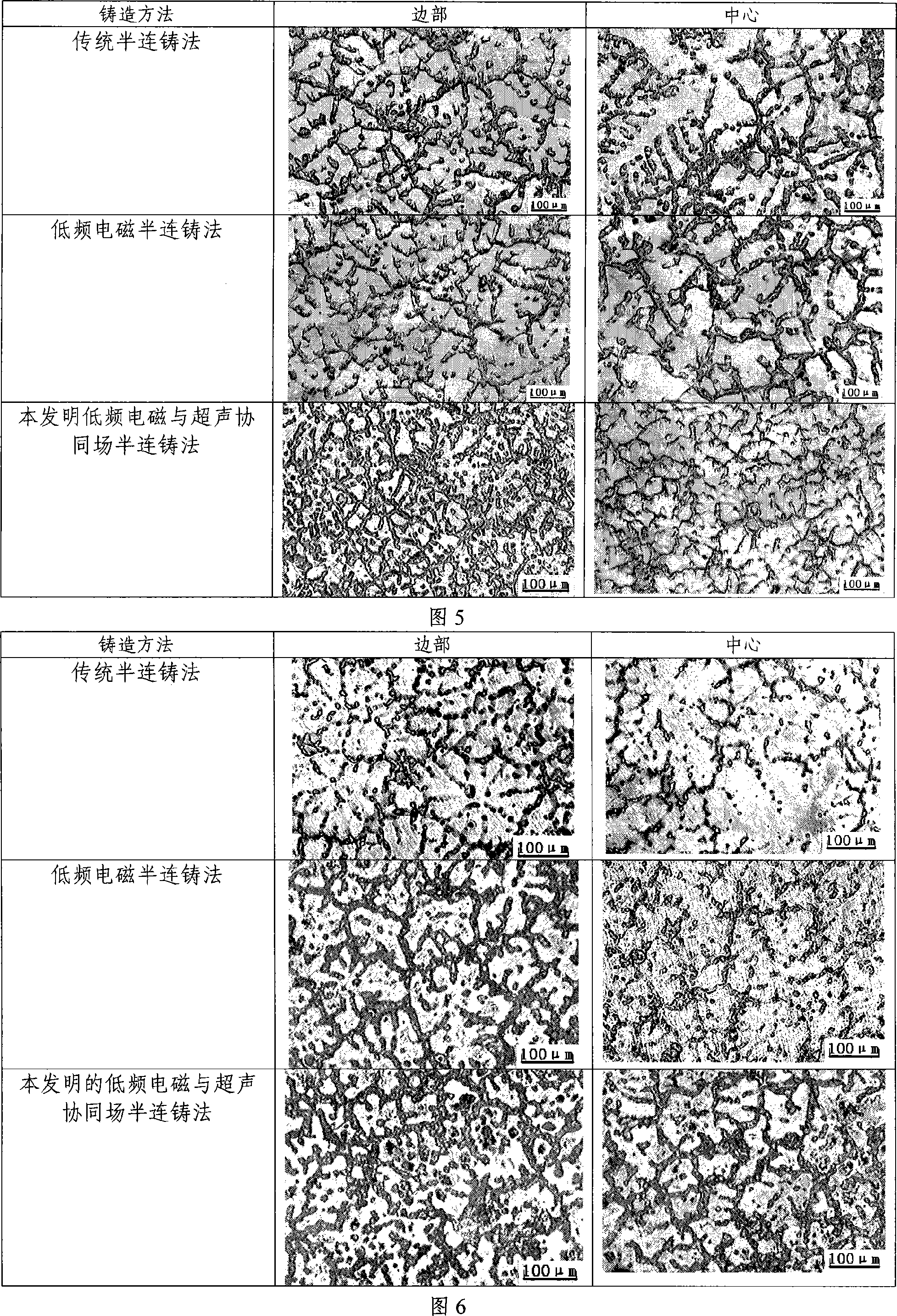

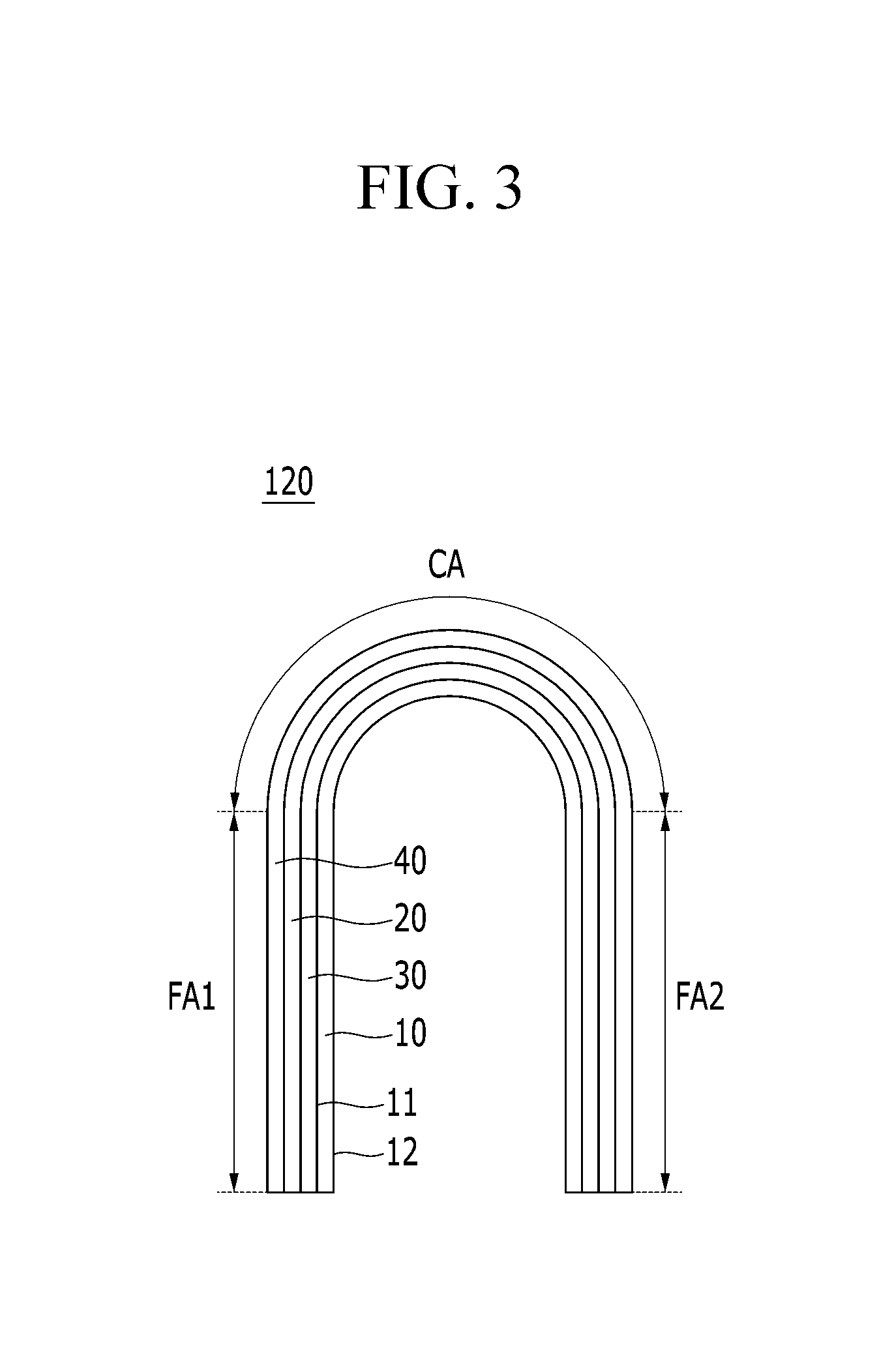

Vertical semi-continuous light alloy ingot casting process and apparatus with cooperation of power ultrasound wave and low frequency electromagnetic wave

InactiveCN101020229AReduced lateral temperature gradientImprove uniformityElectromagnetic fieldIngot casting

The present invention is vertical semi-continuous light alloy casting process and apparatus with cooperation of power ultrasonic field and low frequency electromagnetic field. During casting, one low frequency electromagnetic field acting on the surface of metal molt and one power ultrasonic field acting on the crystallizer axis part are applied simultaneously. The present invention can reduce the transverse temperature gradient in casting blank solidification, alter liquid hole shape, raise the homogeneity of the casting blank and raise casting blank quality.

Owner:NORTHEASTERN UNIV

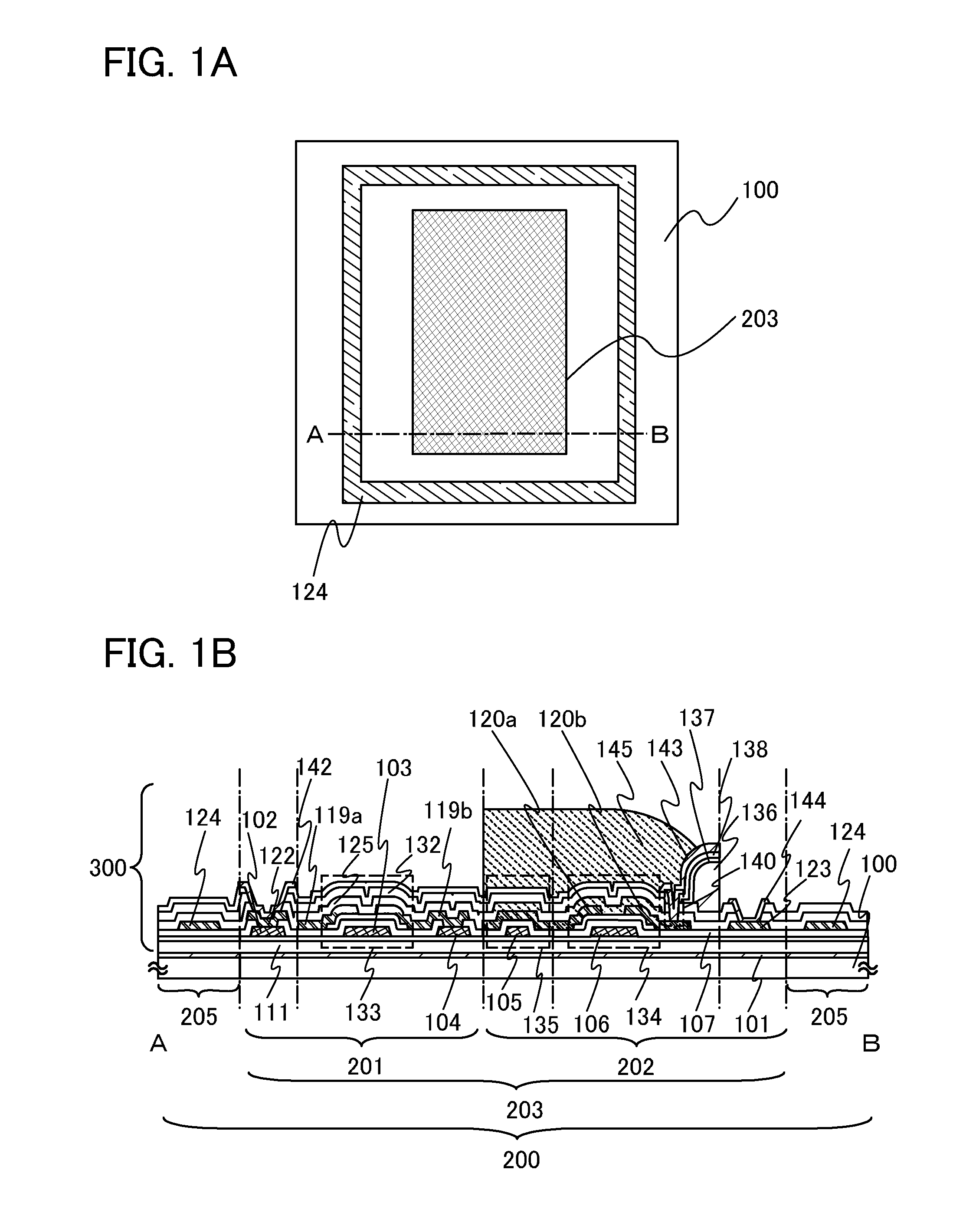

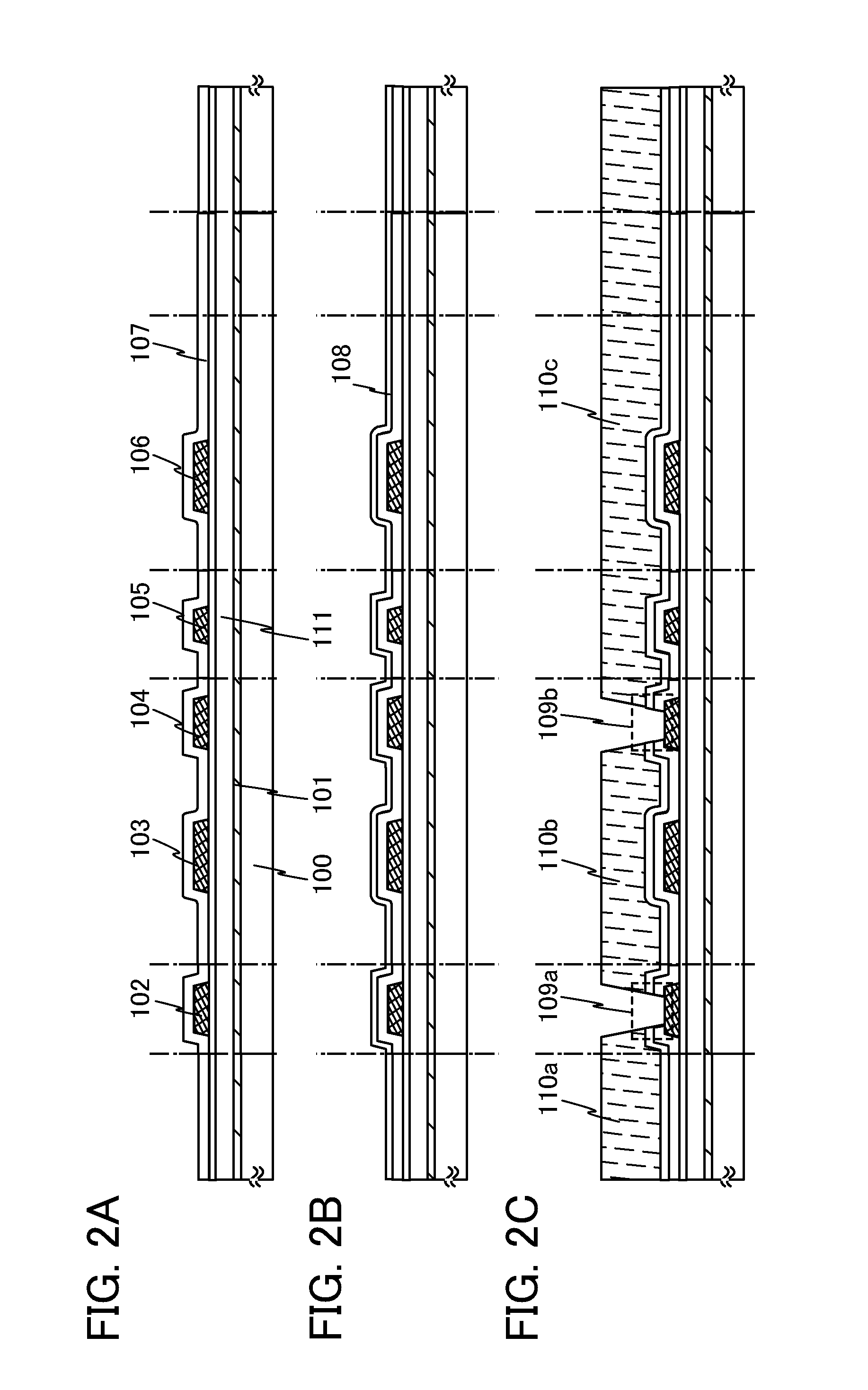

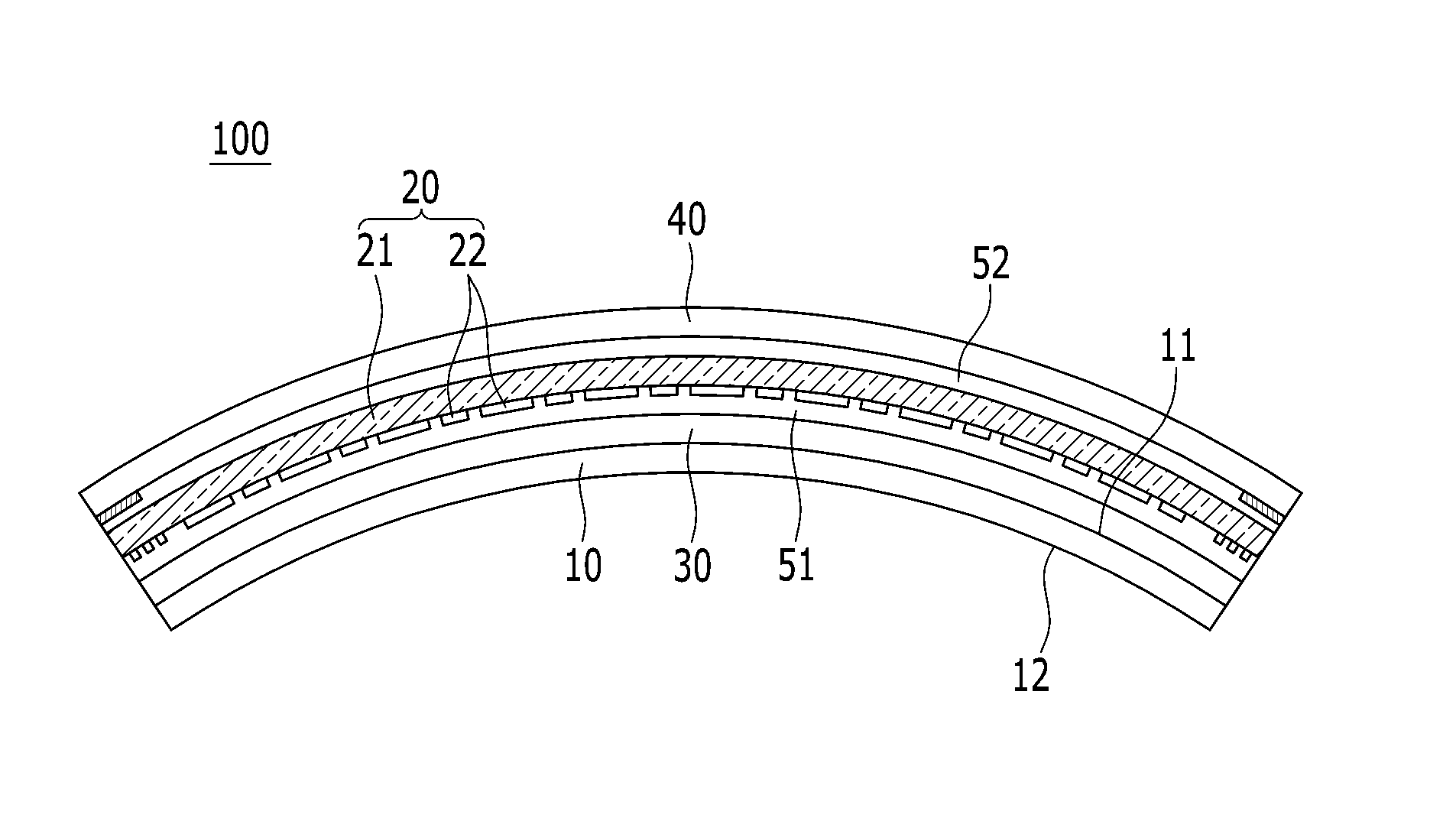

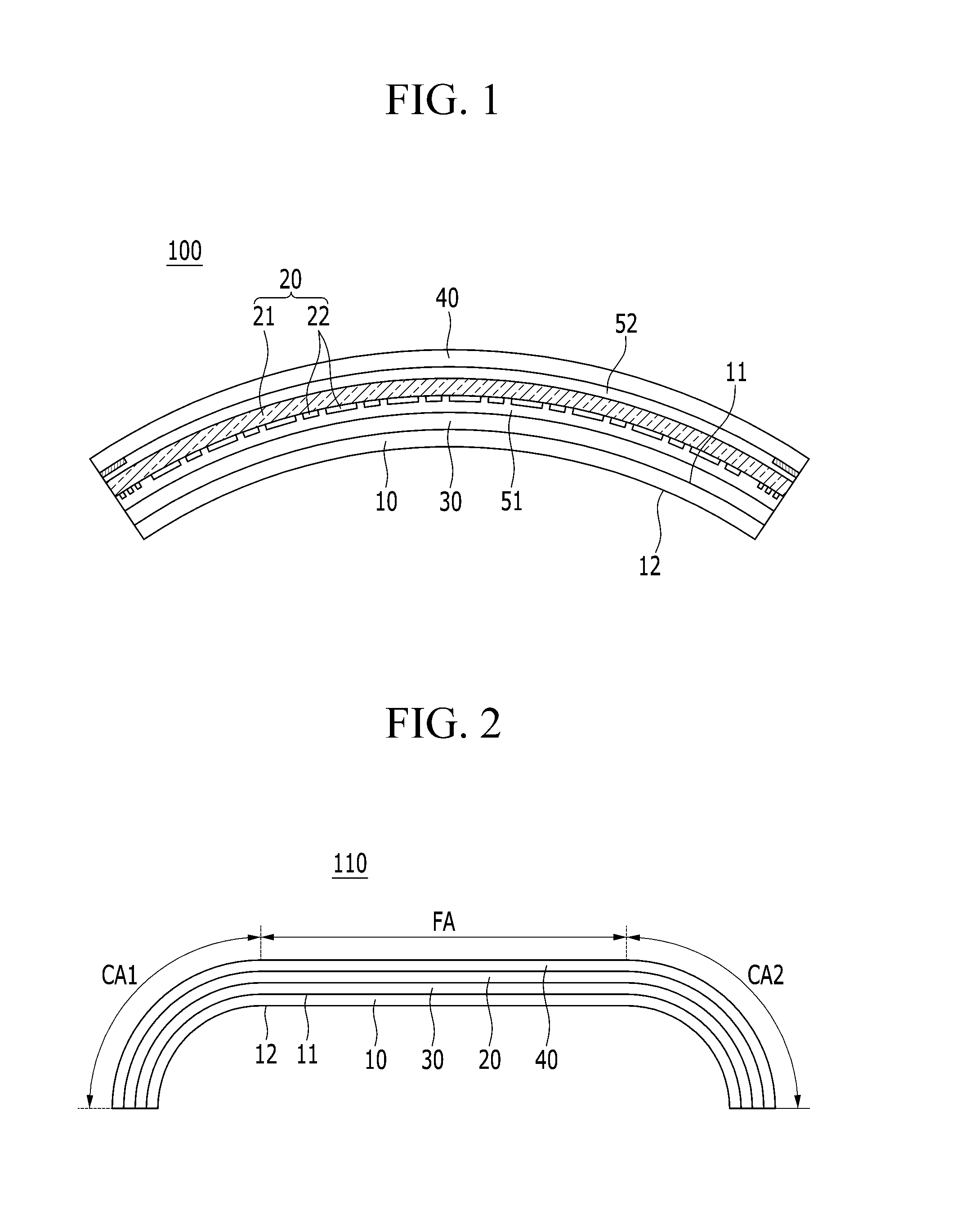

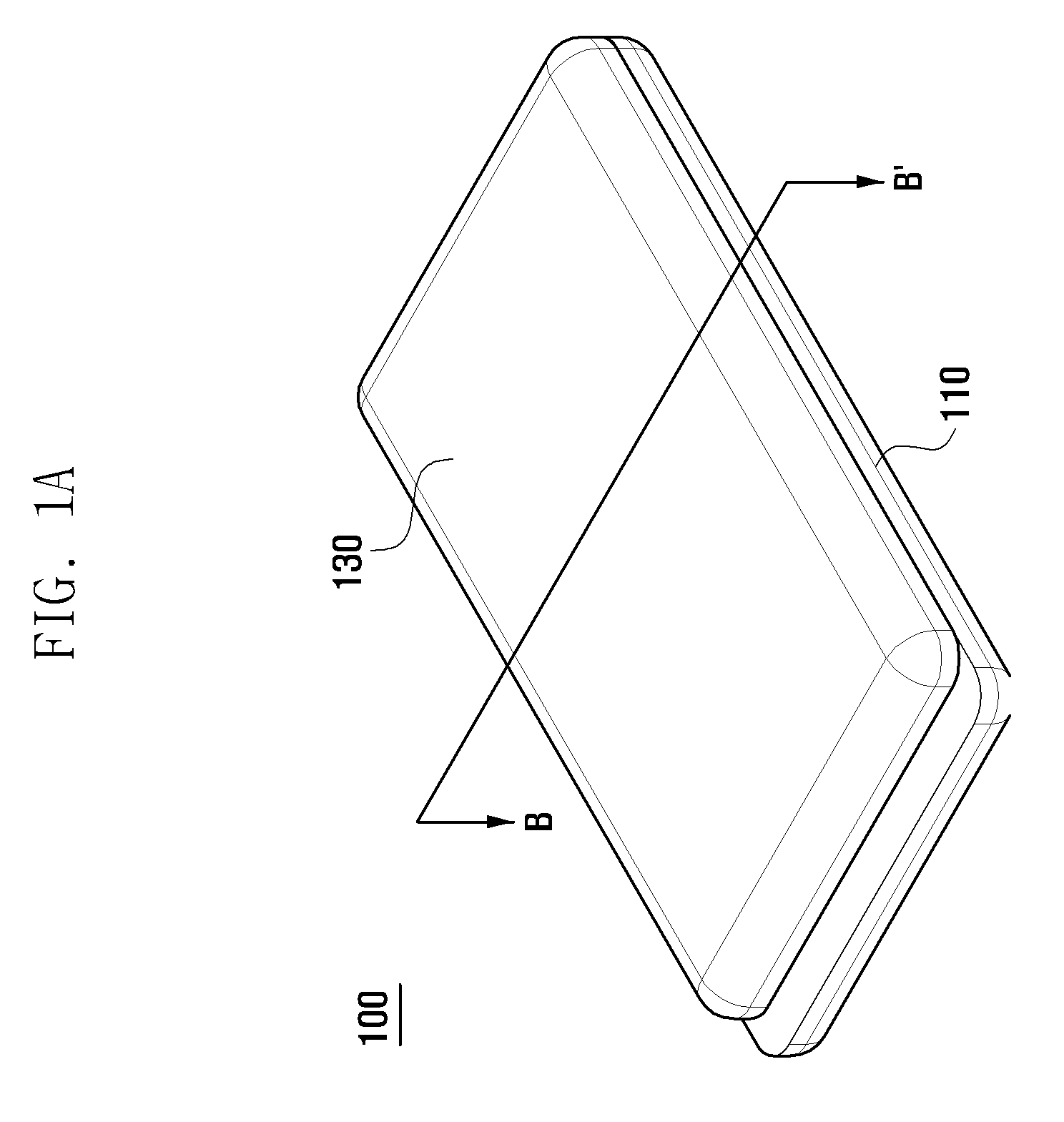

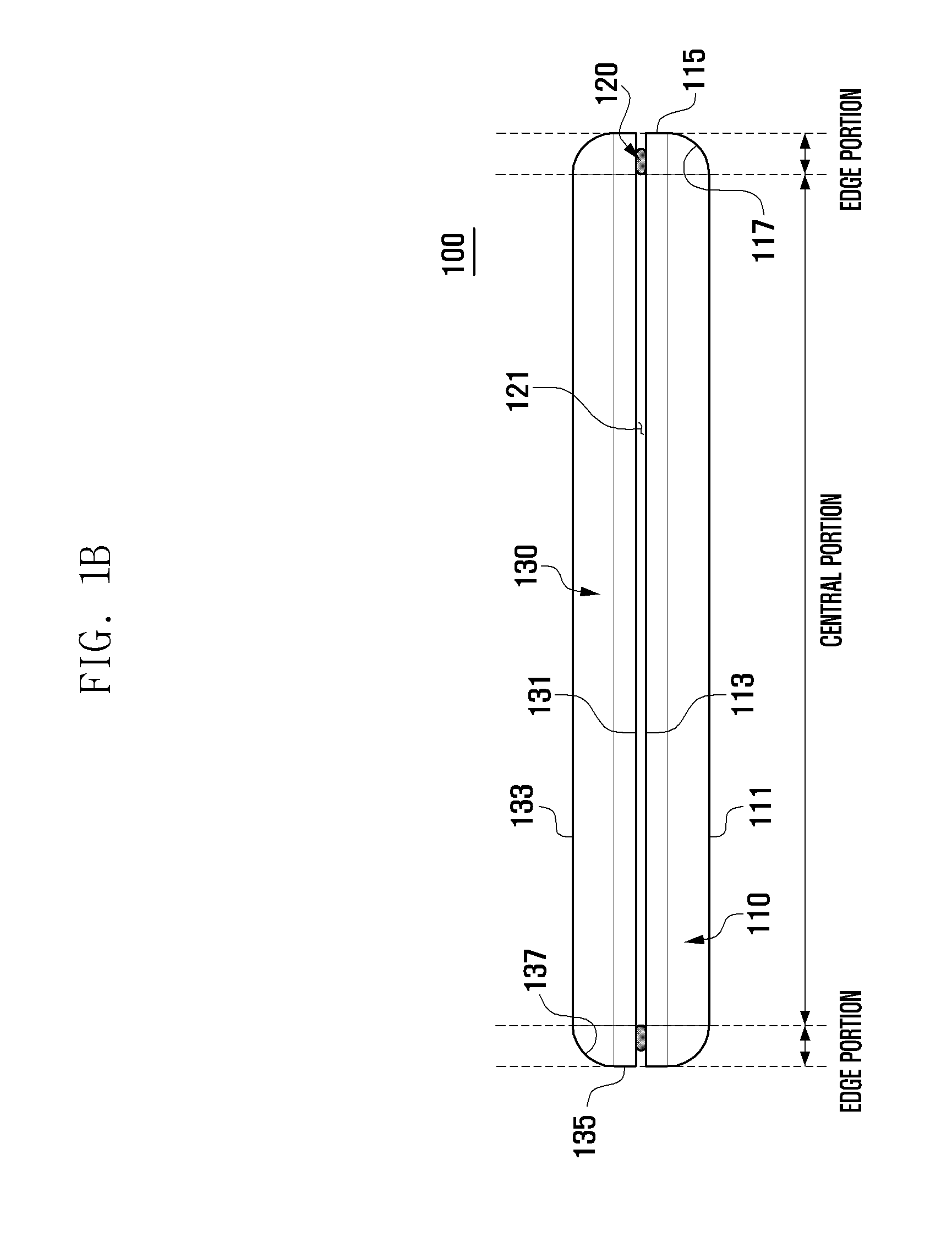

Flexible display device with touch panel

ActiveUS20160011689A1Crack suppressionInhibit the generation of cracksDigital data processing detailsInput/output processes for data processingFlexible displayComputer science

A flexible display device includes a display panel including a first surface including a display area configured to display an image, and a second surface disposed on the opposite side of the display panel from the first surface, and a touch panel disposed on the first surface, the touch panel including a base film and a transparent conductive layer disposed on a surface of the base film facing the display panel, in which at least a portion of each of the display panel and the touch panel is bendable such that centers of curvature of the display panel and the touch panel are positioned outside the second surface.

Owner:SAMSUNG DISPLAY CO LTD

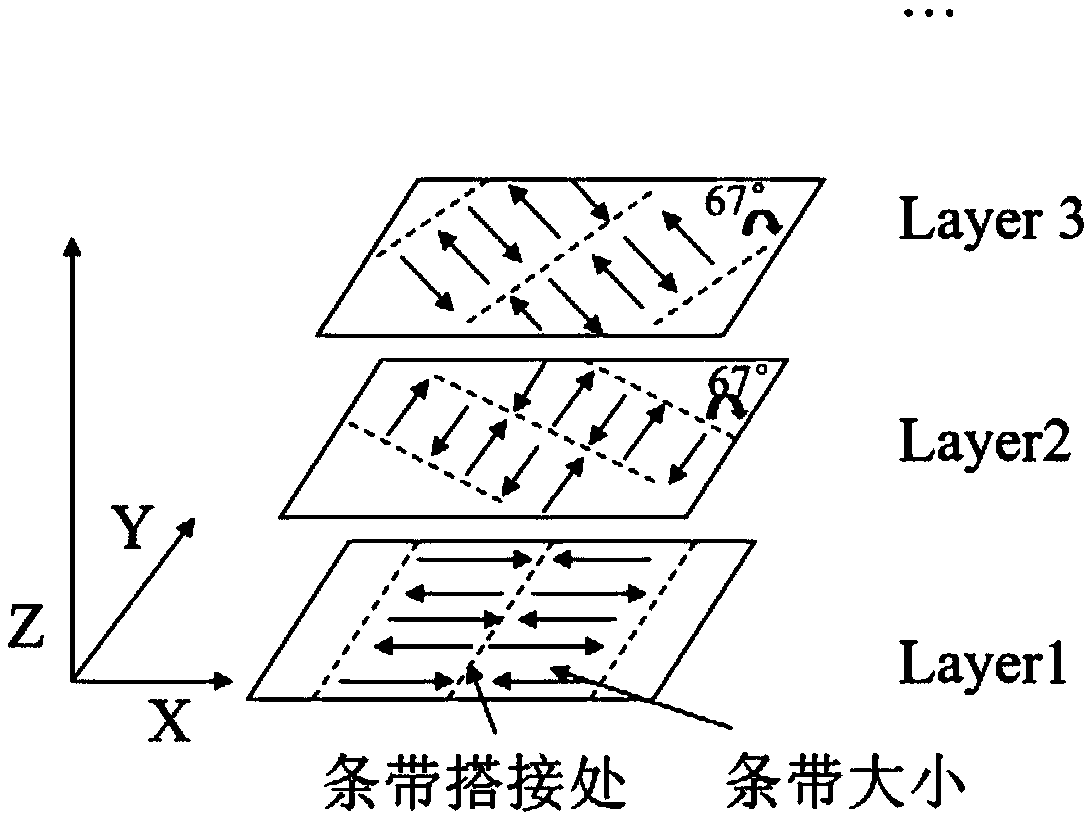

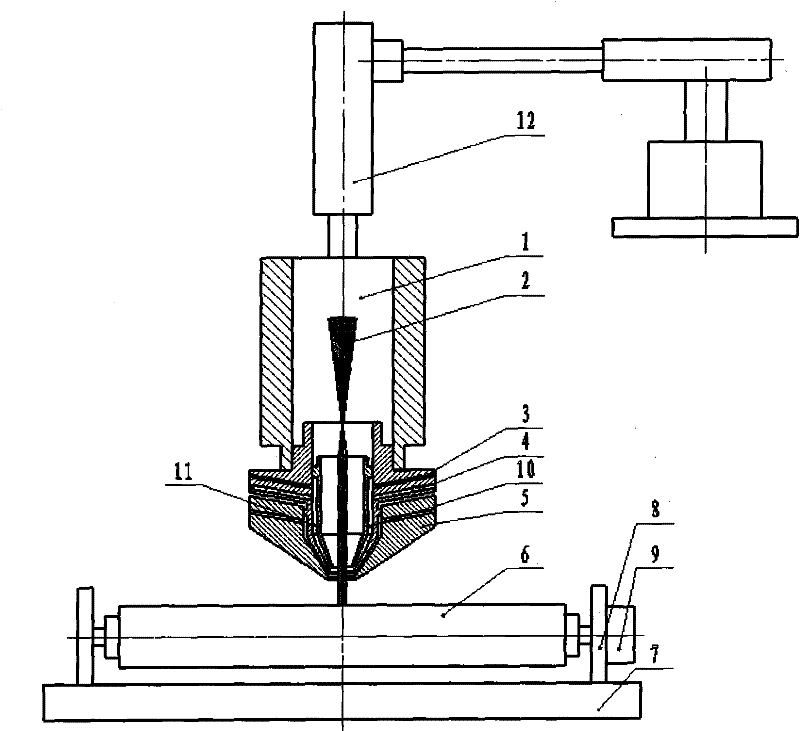

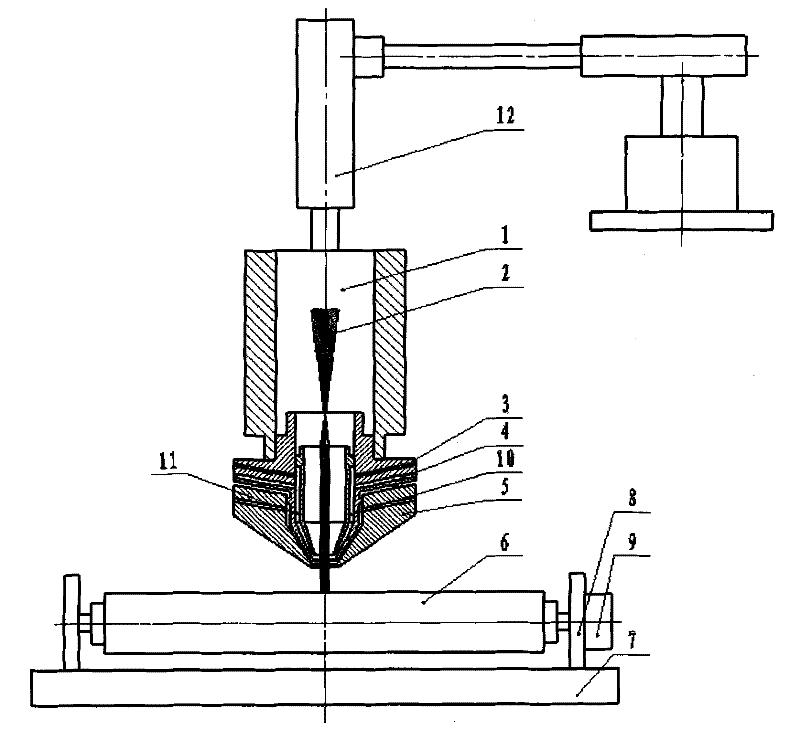

A high-performance composite roll laser injection forming manufacturing and repair method and equipment

InactiveCN102259187AEvenly distributedIncrease the area of actionIncreasing energy efficiencyRollsLaser lightRisk stroke

The invention provides a method and equipment for manufacturing and repairing a high-performance composite roll by laser spray forming, which uses laser spray forming to manufacture the transition layer and the working layer of the roll. It is characterized in that the specific method steps are as follows: A) removing the surface of the core of the roll B) Put the powder of the working layer material and the powder of the roller core into the powder feeding system respectively, and start the laser jet synchronous powder feeding through the surface of the roller whose stroke is controlled by the mechanical arm Direct metal Manufacture the intermediate transition layer of the roll; C) After one layer is deposited, the interlaced deposition is realized by changing the direction of the square spot and the movement direction of the mechanical arm; D) After the transition layer is formed, the spray forming on the surface of the transition layer is completely formed by the added The functional material constitutes the working layer. The invention uses a high-power short-wavelength laser as a processing light source and shapes the light spot of the laser into a rectangle, thereby effectively improving the quality of spray forming and increasing the processing speed.

Owner:周明

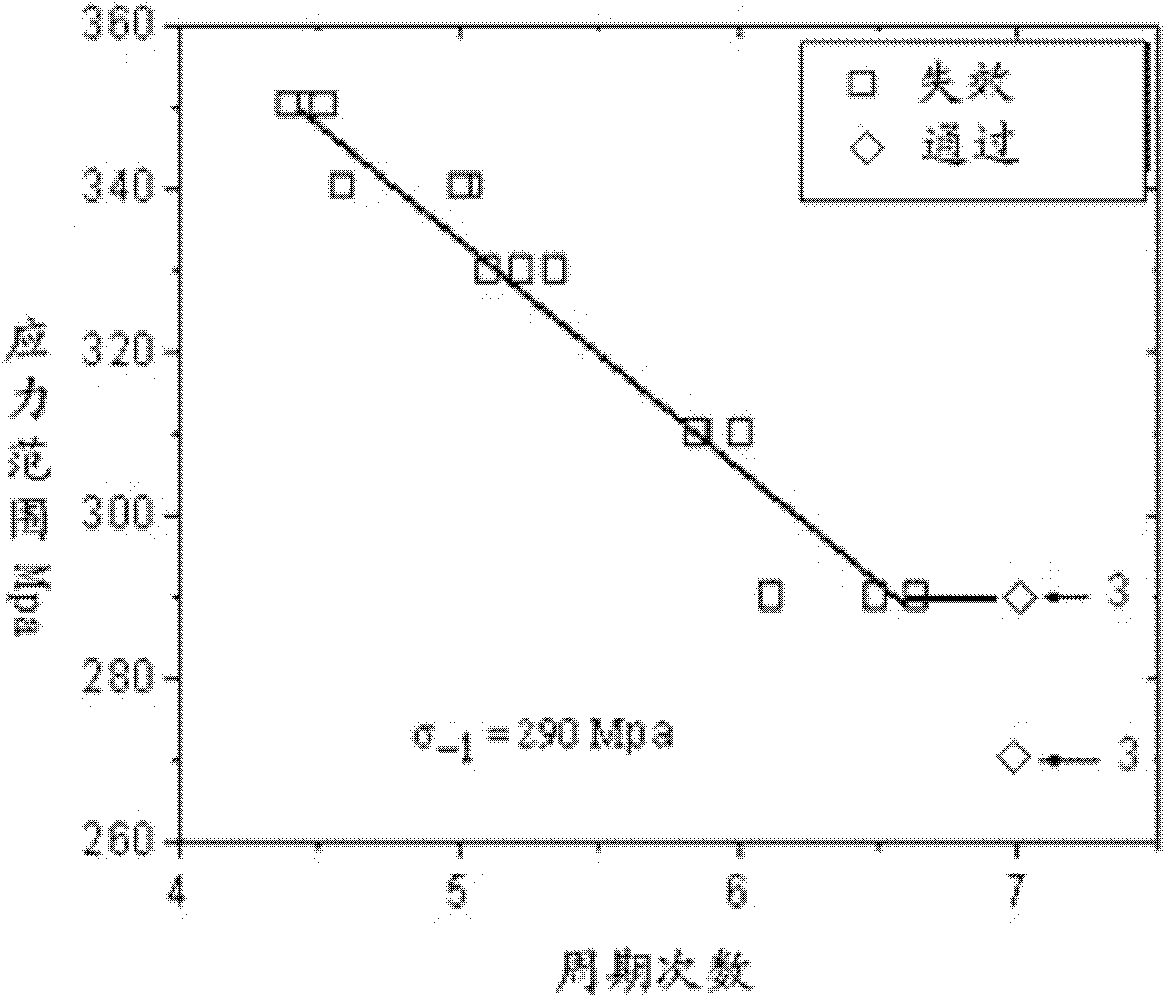

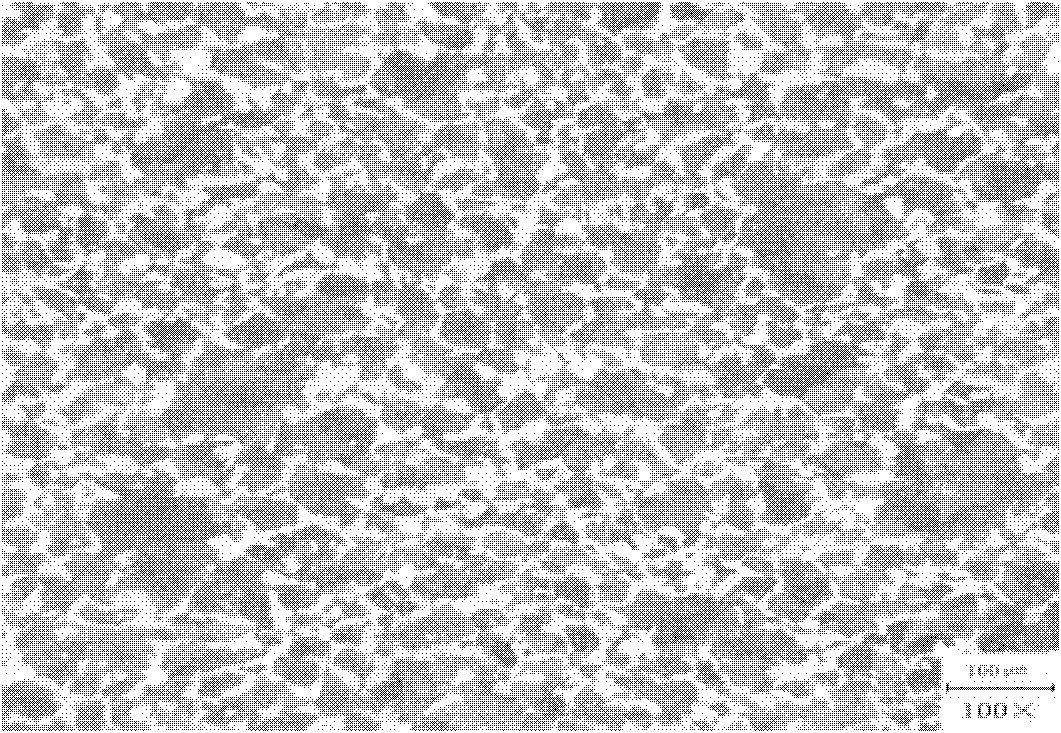

Axletree steel and heat treatment method thereof

ActiveCN102586698AHigh tensile strengthHigh yield strengthShaftsFurnace typesHeavy dutyAcceleration Unit

The invention provides axletree steel and a heat treatment method thereof. The axletree steel comprises the following constituents: 0.42 to 0.45% of C; 0.23 to 0.30% of Si; 0.53 to 0.63% of Cr; 0.73 to 0.83% of Mn; 0.08 to 0.13% of Mo; 0.18 to 0.25% of Ni; 0.05 to 0.15% of Cu; 0.025 to 0.050% of Al; 0.09 to 0.11% of V; 0.015 or less ppm of P; 0.010 or less ppm of S; and Fe and other inevitable elements in balancing amount. The axletree steel has high rotation fatigue point index, yield strength and tensile strength; and an axletree prepared with the axletree steel is not liable to crack in a fatigue use process so as to achieve a longer service life, and can realize the advantage of safe driving under the conditions of acceleration and heavy duty.

Owner:建龙北满特殊钢有限责任公司

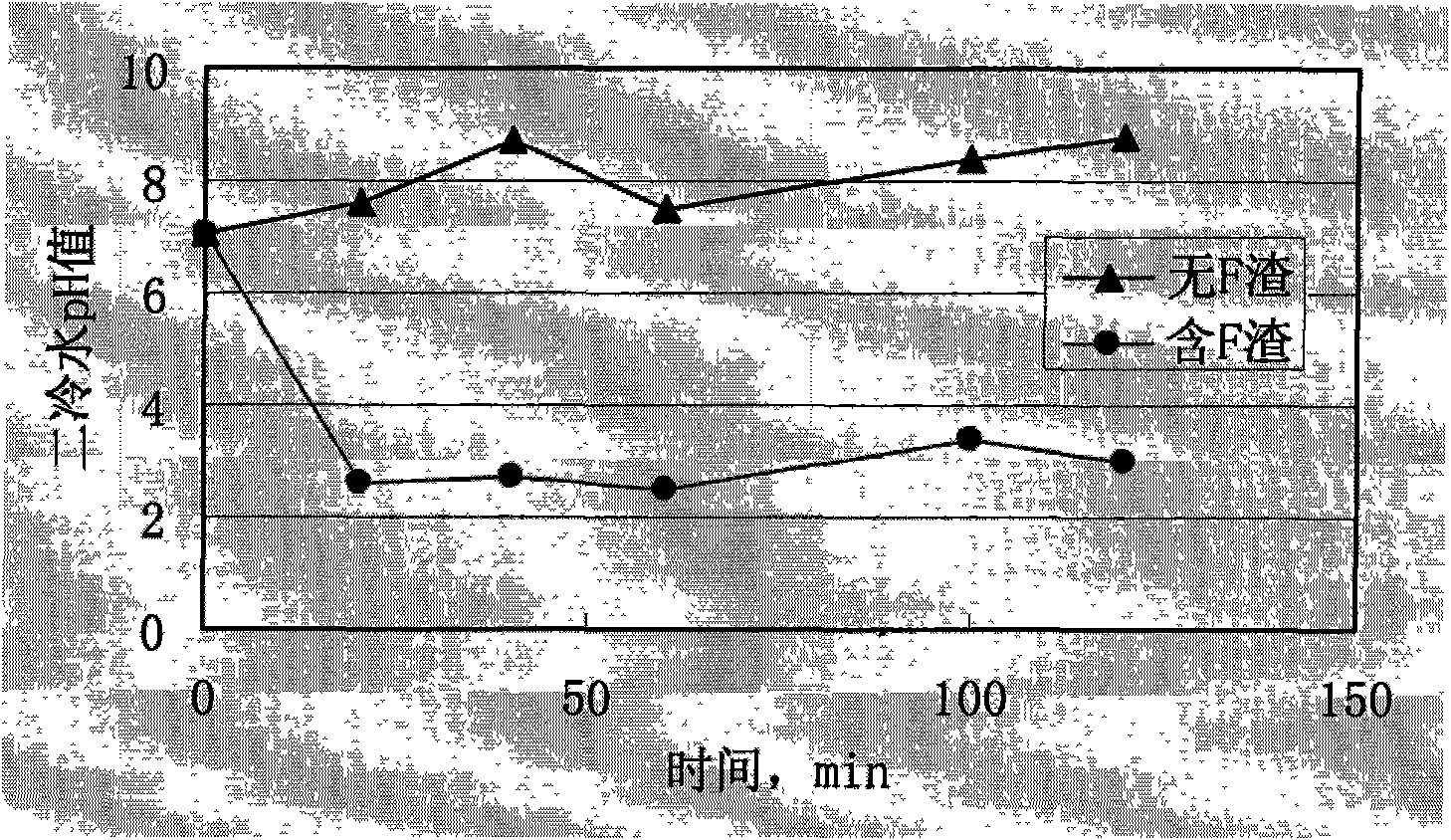

Novel corrosion-resistant alloy steel continuous casting powder and application thereof

The invention relates to novel corrosion-resistant alloy steel continuous casting powder and application thereof, and belongs to the technical field of continuous casting of iron and steel. The casting powder comprises the following components in mass percentage: 17 to 25% of CaO, 23 to 31% of SiO2, 10 to 15% of Al2O3, 1 to 4% of MgO, 10 to 14% of (Na2O+Li2O), 1 to 8% of B2O3, 1 to 6% of TiO, 4 to 8% of BaO, and 10 to 13% of F<->. The casting powder has the characteristics that the melting point is small (865-988 DEG C), the viscosity is small (0.11-0.23Pa.s under 1,300 DEG C), the crystallizing rate is moderate (40-70%), etc. The casting powder can be applied well to the continuous casting of corrosion-resistant alloy steel (Fe-Cr-Ni system) containing 0 to 0.3% of Al and 0.8 to 1.1% of Ti in mass percentage.

Owner:CENT SOUTH UNIV

Flexible display substrate and manufacturing method therefor, and display apparatus

ActiveCN107170758AReduce distortionImprove bending resistanceFinal product manufactureSolid-state devicesEngineering

Disclosed is a flexible display substrate. The flexible display substrate comprises a flexible substrate, and a gate, a source, a drain and multiple conductive wires arranged on the flexible substrate; multiple grooves are formed in each conductive wire in a bending region of the flexible display substrate, so that the damage resistance of the conductive wires is improved in bending; and consequently, the bending resistance effect of the flexible display substrate is improved, and the reliability and service life of the flexible display substrate and a display apparatus are improved and prolonged. The invention also discloses the display apparatus comprising the flexible display substrate and a manufacturing method for the flexible display substrate.

Owner:BOE TECH GRP CO LTD

Freon-free environment-friendly continuous casting slag

The invention provides a freon-free environment-friendly continuous casting slag which comprises the following ingredients by the weight percentage of 3 to 15 percent of Na2O, 3 to 12 percent of MgO, less than 8 percent of Al2O3, 2 to 9 percent of B2O3, 1 to 15 percent of C and the balance of CaO and SiO2, wherein the CaO and SiO2 account for 1.1 to 1.5 percent; and the sum of Na2O and MgO in the casting slag is more than 10 percent; in addition, the freon-free environment-friendly continuous casting slag can also comprise Li2O which accounts for not more than 3 percent. The freon-free environment-friendly continuous casting slag uses merwinite and miserite instead of cuspidine, is free of Freon, and has a value in environment protection and reduction of corrosion of equipments and much higher than the slight increase of raw material cost. The casting slag can be used industrially in batch.

Owner:BAOSHAN IRON & STEEL CO LTD

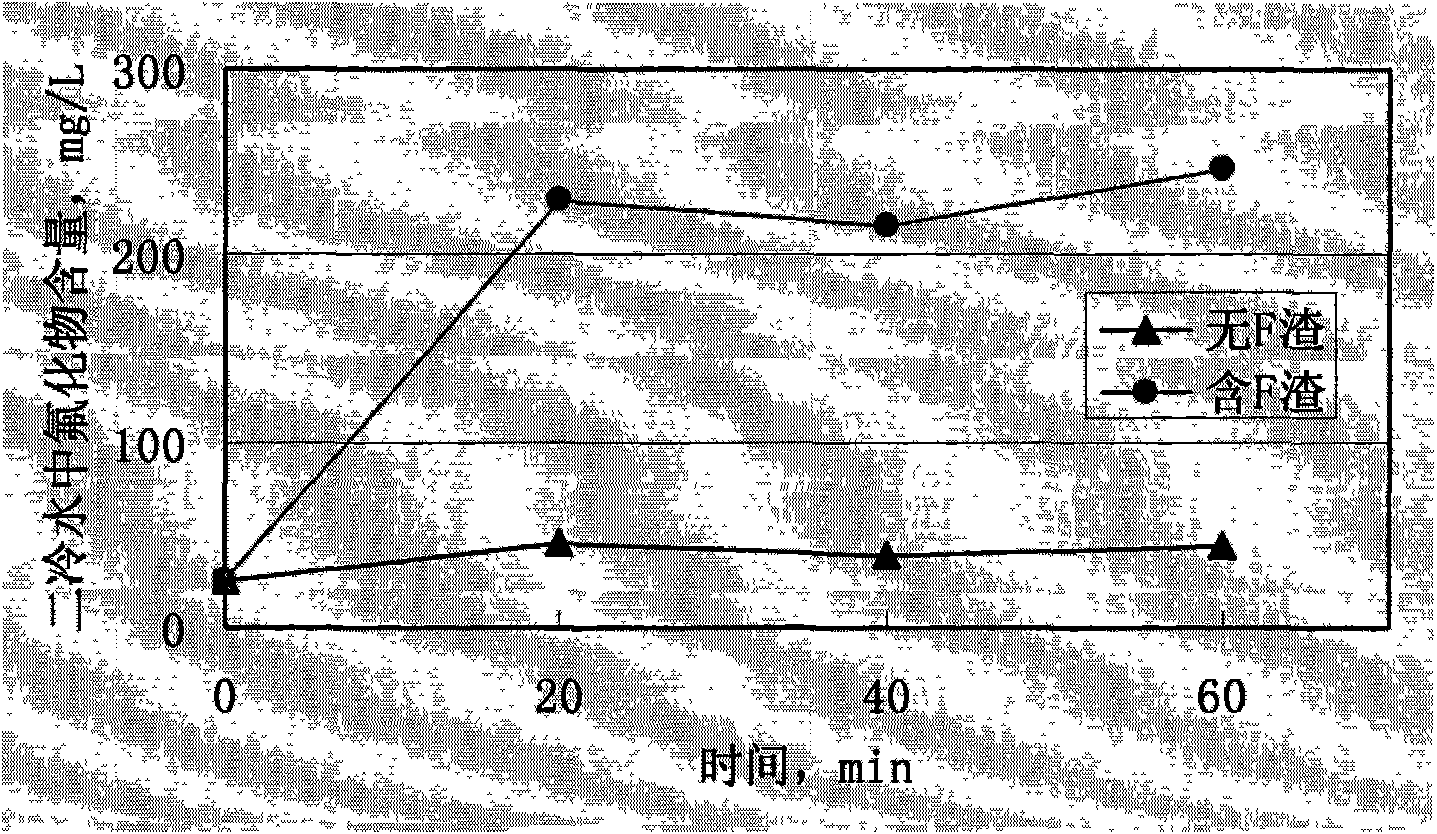

Method for preparing silicon carbide ceramic impeller through gel casting and pressureless sintering

ActiveCN102875150AAvoid uneven dispersionOvercome defects such as uneven curingCarbide siliconGel casting

The invention discloses a method for preparing a silicon carbide ceramic impeller through gel casting and pressureless sintering, and provides a preparation method of a pressureless sintered silicon carbide ceramic impeller with a complex and accurate shape characteristic and an external diameter size capable of reaching over 160 mm. A silicon carbide solid-phase sintering formula system of a boron-containing sintering auxiliary agent and a gel casting and pressureless sintering process are adopted; and the method comprises eight steps of: preparing ceramic slurry; performing injection molding; demolding; drying; machining; degumming; performing pressureless sintering; and machining. According to the method, the technical problems of non-uniform mixing of large-scale ceramic slurry in gel casting, dryness, crack and deformation in a pressureless sintering process and the like are solved, and finally, preparation of the pressureless sintered silicon carbide ceramic impeller is realized. The impeller has good performance such as corrosion resistance, wear resistance, high temperature resistance and the like, and can be widely applied to a centrifugal pump for corrosive liquid conveying of various industries.

Owner:UNIV OF SCI & TECH BEIJING

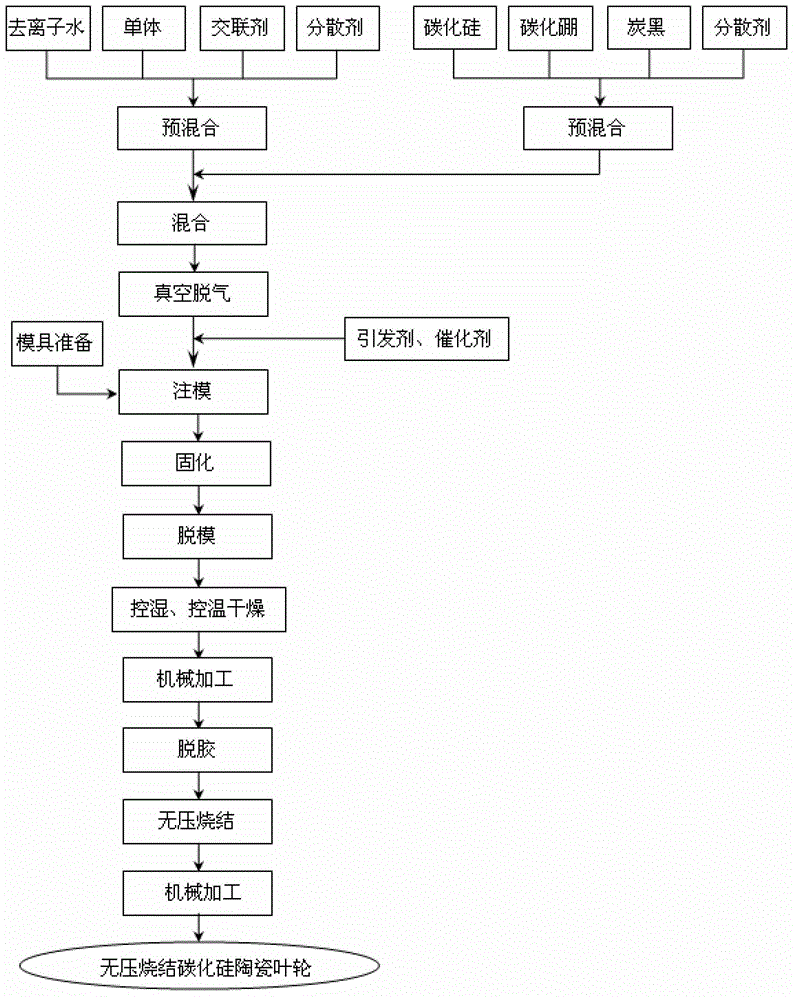

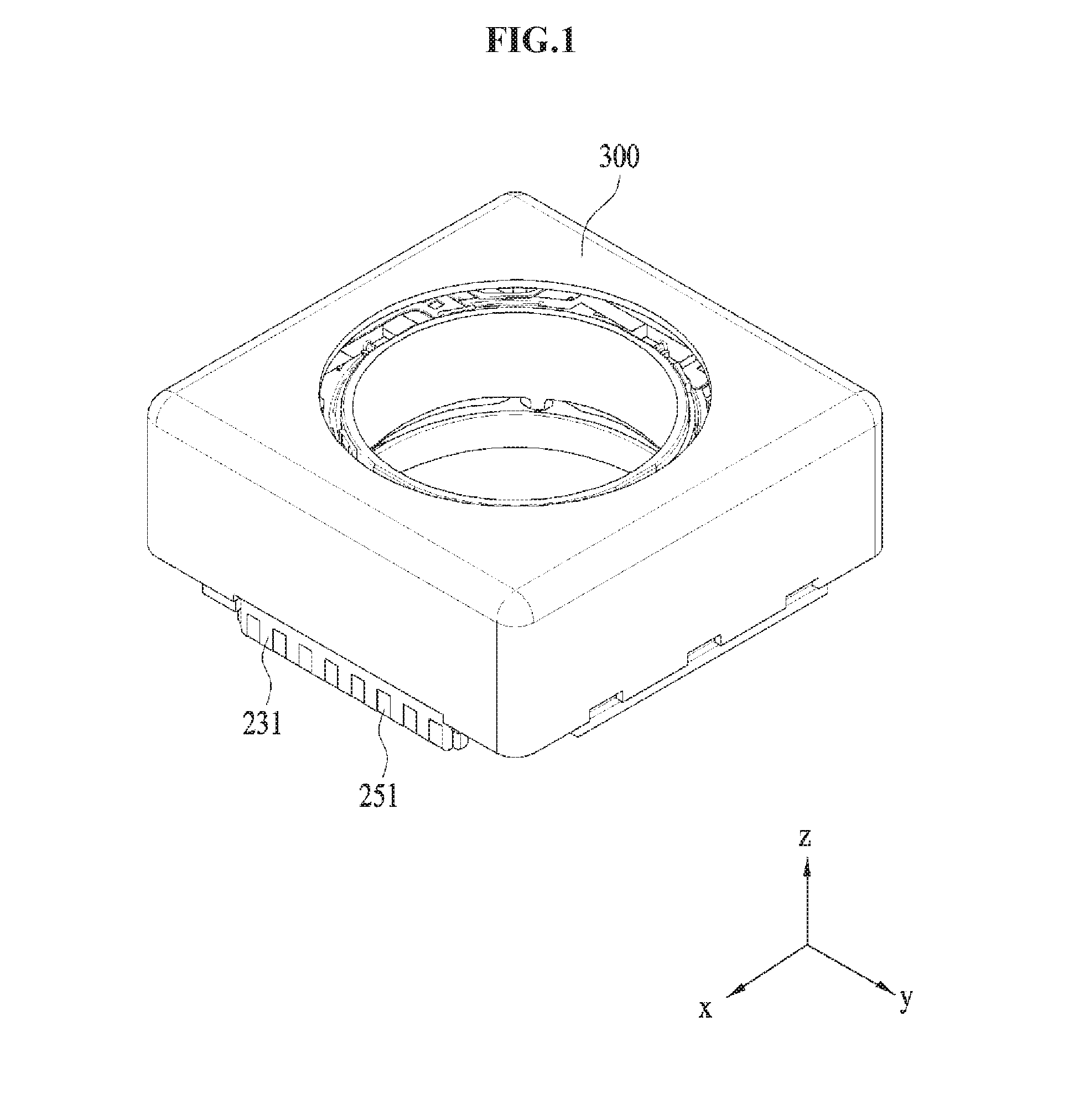

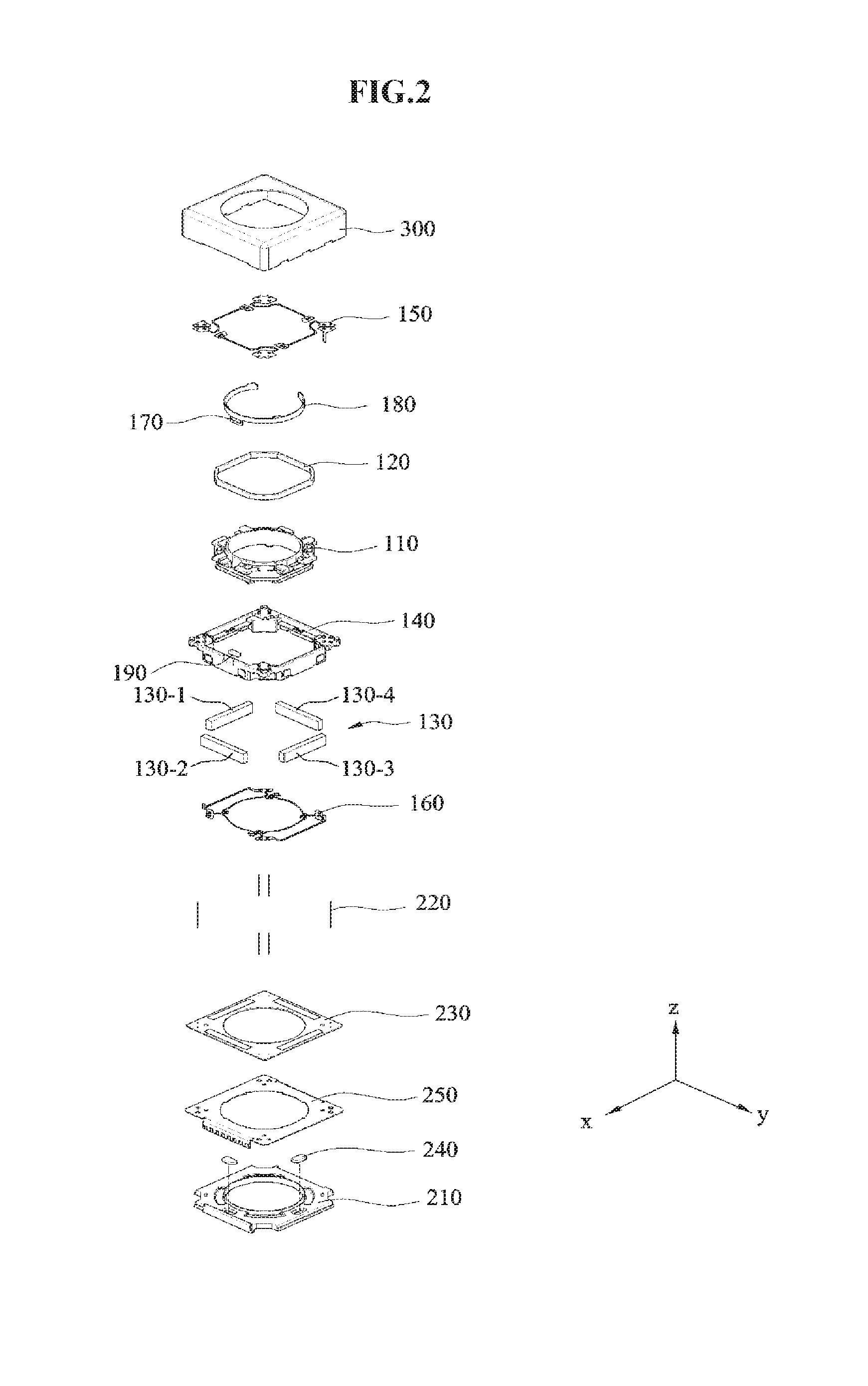

Lens Moving Apparatus and Camera Module and Optical Device Including the Same

ActiveUS20160320585A1Improve reliabilityAutomatically compensate for variationTelevision system detailsColor television detailsBobbinCamera module

Embodiments provide a lens moving apparatus including a bobbin including a first coil disposed on an outer circumferential surface thereof, a housing provided with first and second magnets for moving the bobbin by interaction with the first coil, upper and lower elastic members each coupled to both the bobbin and the housing, and a first position sensor for detecting a sum of intensities of magnetic fields of the first and second magnets, wherein the first position sensor is disposed in a space between the first magnet and the second magnet when the bobbin is disposed at an initial position.

Owner:LG INNOTEK CO LTD

Preparation method of low stress state composite substrate for GaN growth

ActiveCN105514224AReduced stress stateImproving epitaxial growth qualitySemiconductor devicesComposite substrateDielectric layer

The invention discloses a preparation method of a low stress state composite substrate for GaN growth. The preparation method comprises that a GaN monocrystal epitaxial layer is prepared on a sapphire substrate; a stress compensation layer is deposited at the back side of a thermally and electrically conductive transfer substrate of high welding point; bonding dielectric layers of high welding point are prepared at the surfaces of a GaN epitaxial wafer and the transfer substrate respectively; the GaN epitaxial wafer is bonded to the thermally and electrically conductive substrate by the high-temperature diffusion bonding technology; and the composite substrate with high temperature stability and low stress state for GaN growth is obtained. According to the composite substrate of the invention, homoepitaxy can be realized and a vertical structural device can be directly prepared as a traditional composite substrate, the low stress state and high-temperature stability can be also realized, and the quality of subsequent GaN epitaxial growth and chip preparation can be effectively improved.

Owner:SINO NITRIDE SEMICON

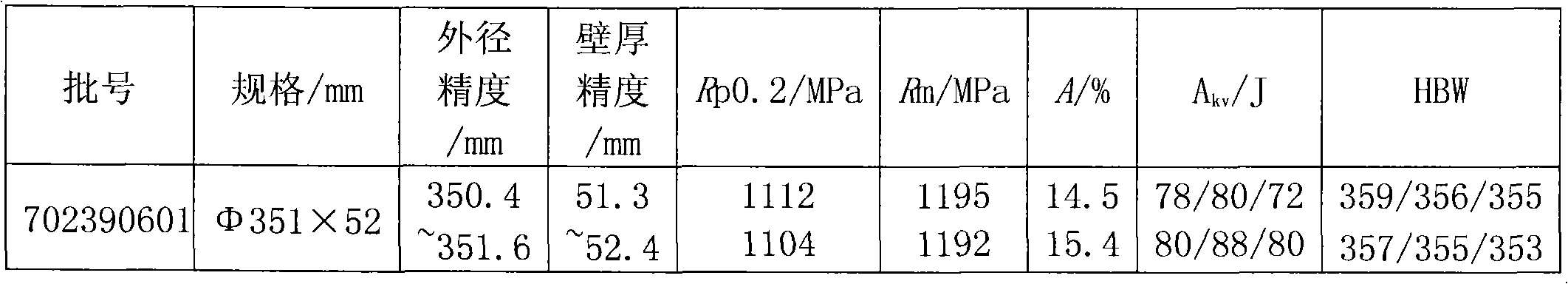

Seamless steel tube for manufacturing hollow core rod and production method

ActiveCN101956137AEnsure dense and uniformCrack suppressionMetal rolling arrangementsSteel tubeHollow core

The invention relates to a seamless steel tube for manufacturing a hollow core rod and a production method. The seamless steel tube comprises the following components in percentage by mass: 0.28 to 0.33 percent of C, 0.45 to 0.65 percent of Si, 0.40 to 0.60 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.02 percent of S, 3.00 to 3.30 percent of Cr, 0.45 to 0.55 percent of Mo, 0.20 to 0.30 percent of V, less than or equal to 0.15 percent of Cu, less than or equal to 0.20 percent of Ni, and the balance of Fe and unavoidable impurities. The production method comprises the following steps of: blanking a tube blank, heating by using an annular furnace, punching by using a Mannesmann piercing mill, rolling the tube by using a pilger mill, cutting a pilger head, heating by using a walking beam furnace, sizing by using a sizing mill, performing heat treatment, straightening, sawing, performing internal and external surface treatment, performing manual inspection, performing ultrasonic wave and eddy current automatically combined flaw detection, performing manual reinspection, cleaning, identifying and packaging, and warehousing.

Owner:HENGYANG VALIN STEEL TUBE

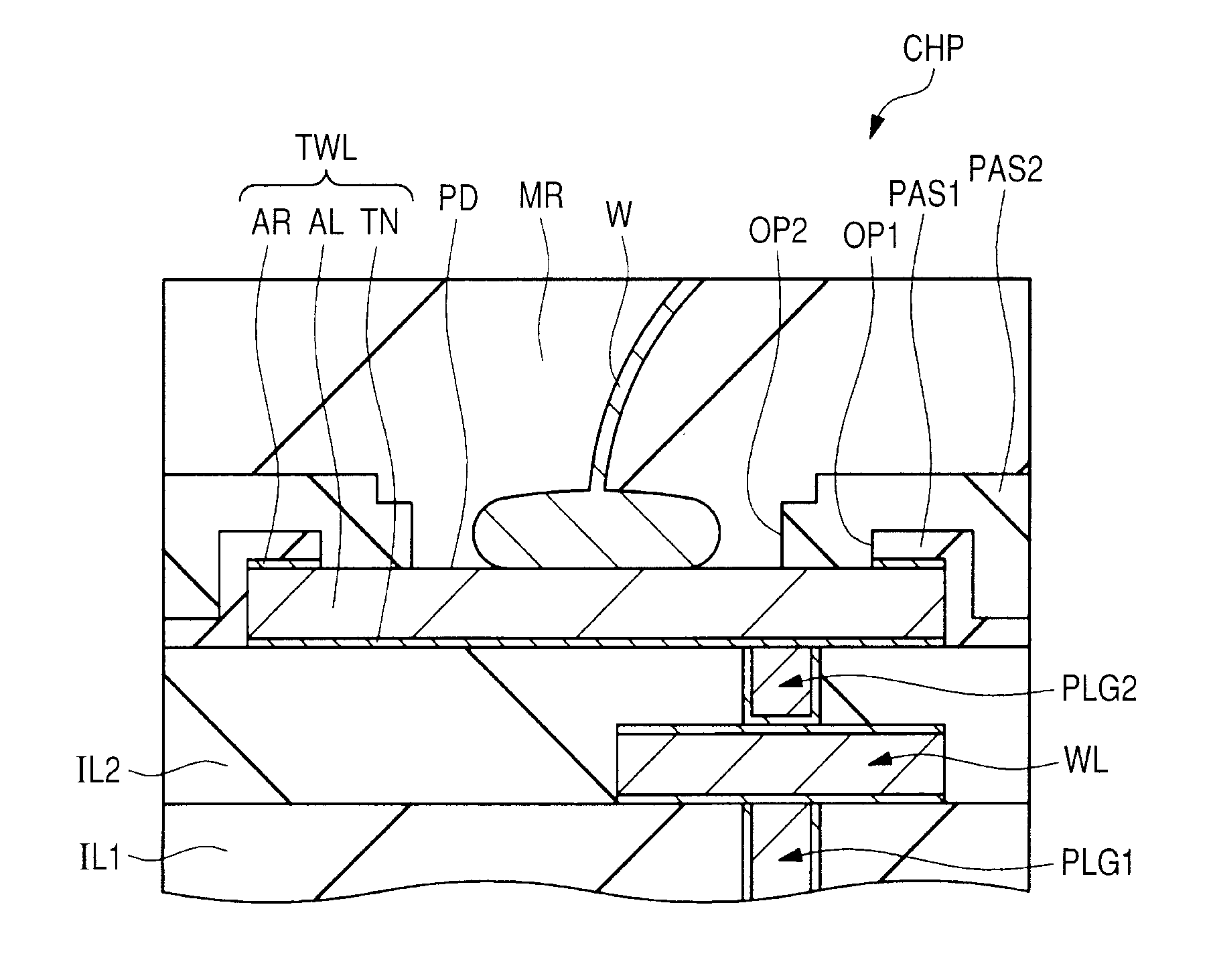

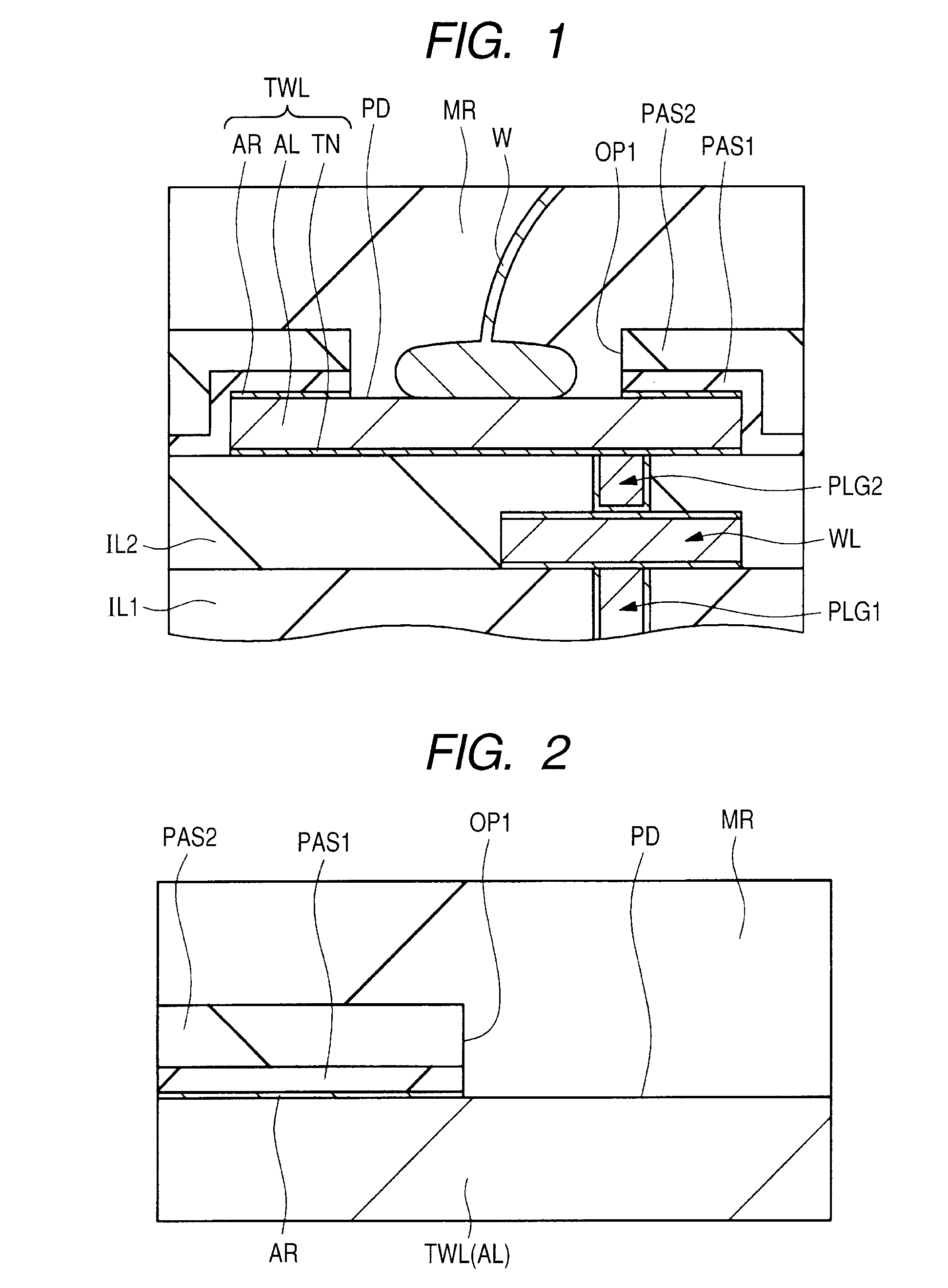

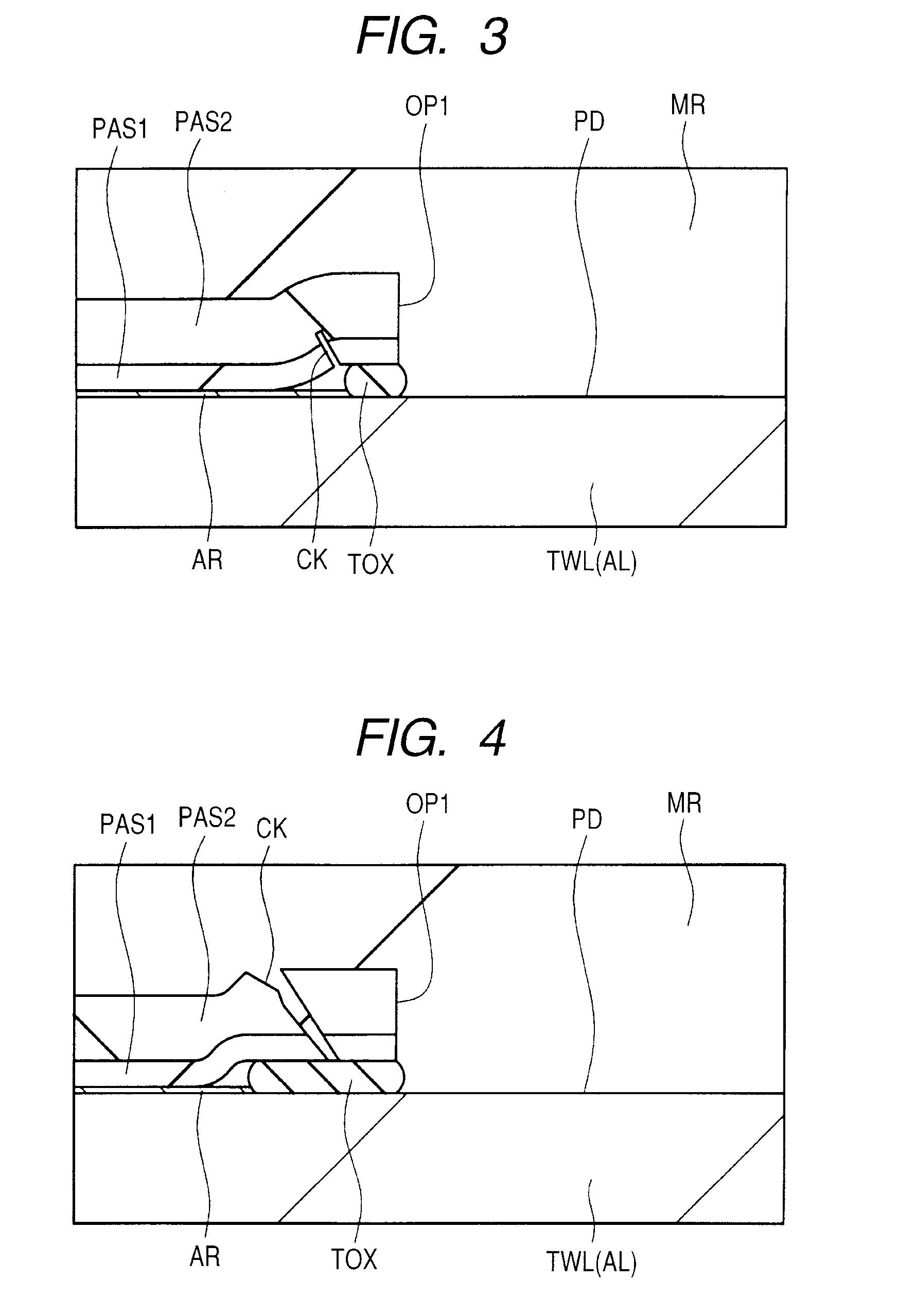

Semiconductor device and method of manufacturing the same

ActiveUS20100295044A1Crack suppressionImprove reliabilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsTitanium nitrideTitanium oxide

To provide: a technique capable of suppressing a titanium nitride film that is exposed at the side surface of an opening from turning into a titanium oxide film even when water permeates the opening over a pad from outside a semiconductor device and thus improving the reliability of the semiconductor device; and a technique capable of suppressing a crack from occurring in a surface protective film of a pad and improving the reliability of a semiconductor device. An opening is formed so that the diameter of the opening is smaller than the diameter of another opening and the opening is included in the other opening. Due to this, it is possible to cover the side surface of an antireflection film that is exposed at the side surface of the other opening with a surface protective film in which the opening is formed. As a result of this, it is possible to form a pad without exposing the side surface of the antireflection film.

Owner:RENESAS ELECTRONICS CORP

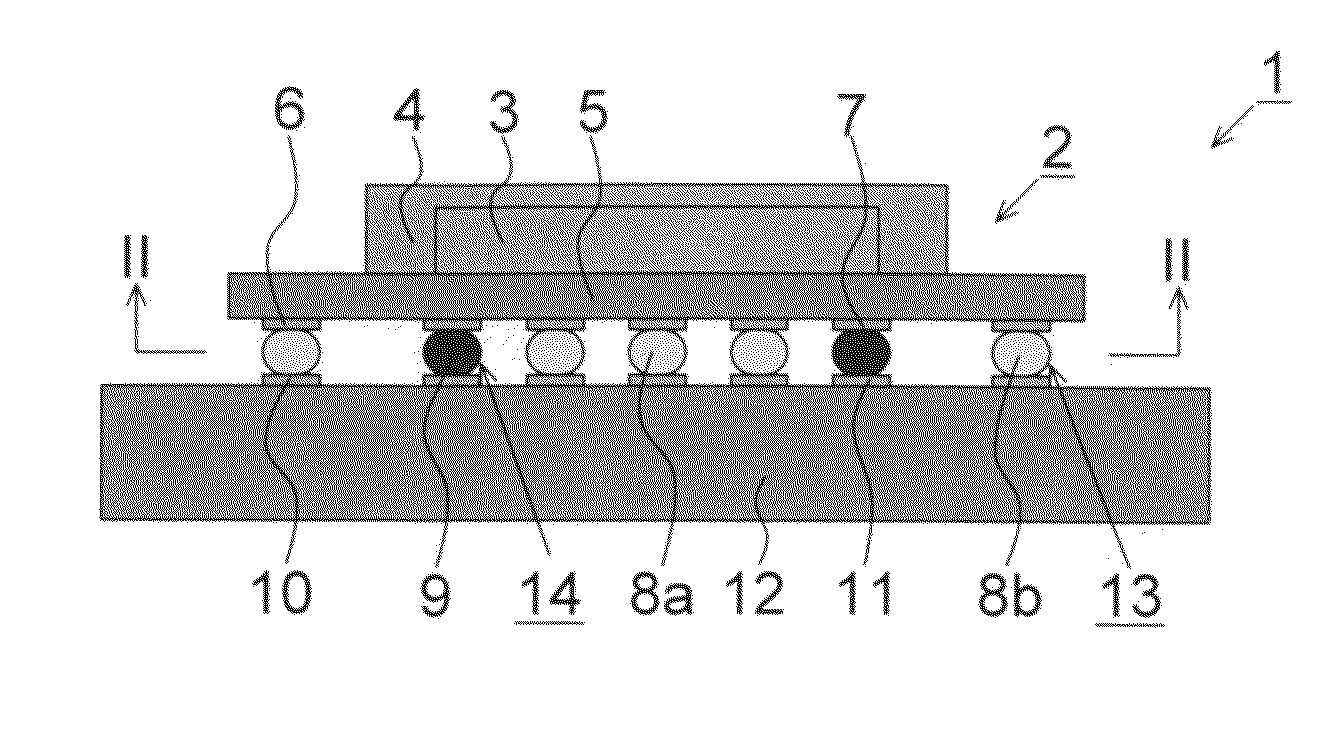

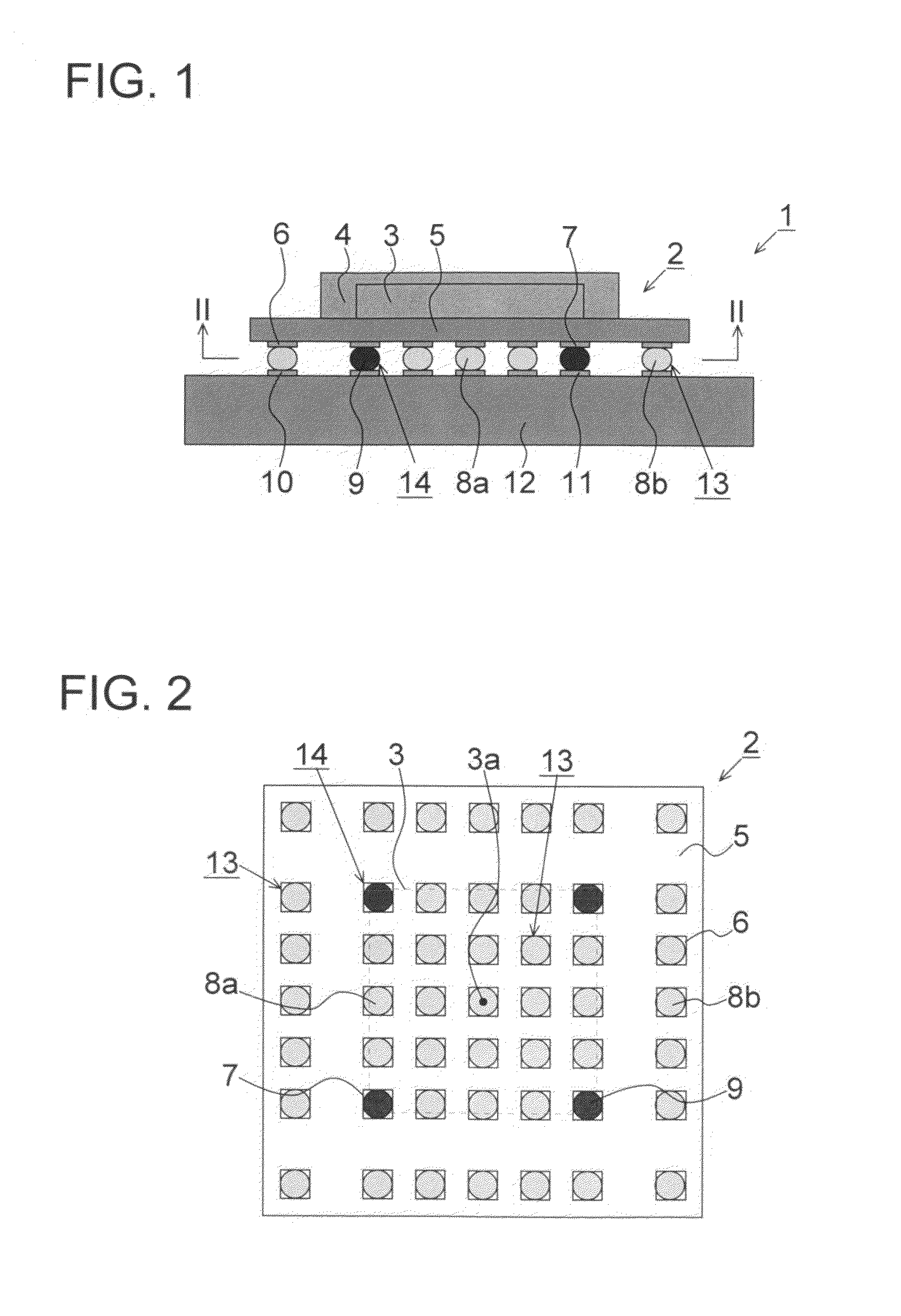

Electronic device and manufacturing method therefor

ActiveUS20110006433A1Crack suppressionPrevent functional deficiencyFinal product manufactureSemiconductor/solid-state device detailsElectrical connectionInterconnection

An electronic device includes the electronic element, the interposer substrate, on one surface of which the electronic element is mounted, and the interconnection substrate, on one surface of which the interposer substrate is mounted. One portion of the connection parts is an electrical connection part that electrically interconnects the interposer substrate and the interconnection substrate. The remaining portion is a dummy connection part that produces no functional deficiency even when the dummy connection part does not electrically interconnect the interposer substrate with the interconnection substrate. The dummy connection part includes at least one of the connection parts that at least partially overlap with the electronic element in a plan projection and are preferably arranged along an outer rim of the plan projection of the electronic element.

Owner:RENESAS ELECTRONICS CORP

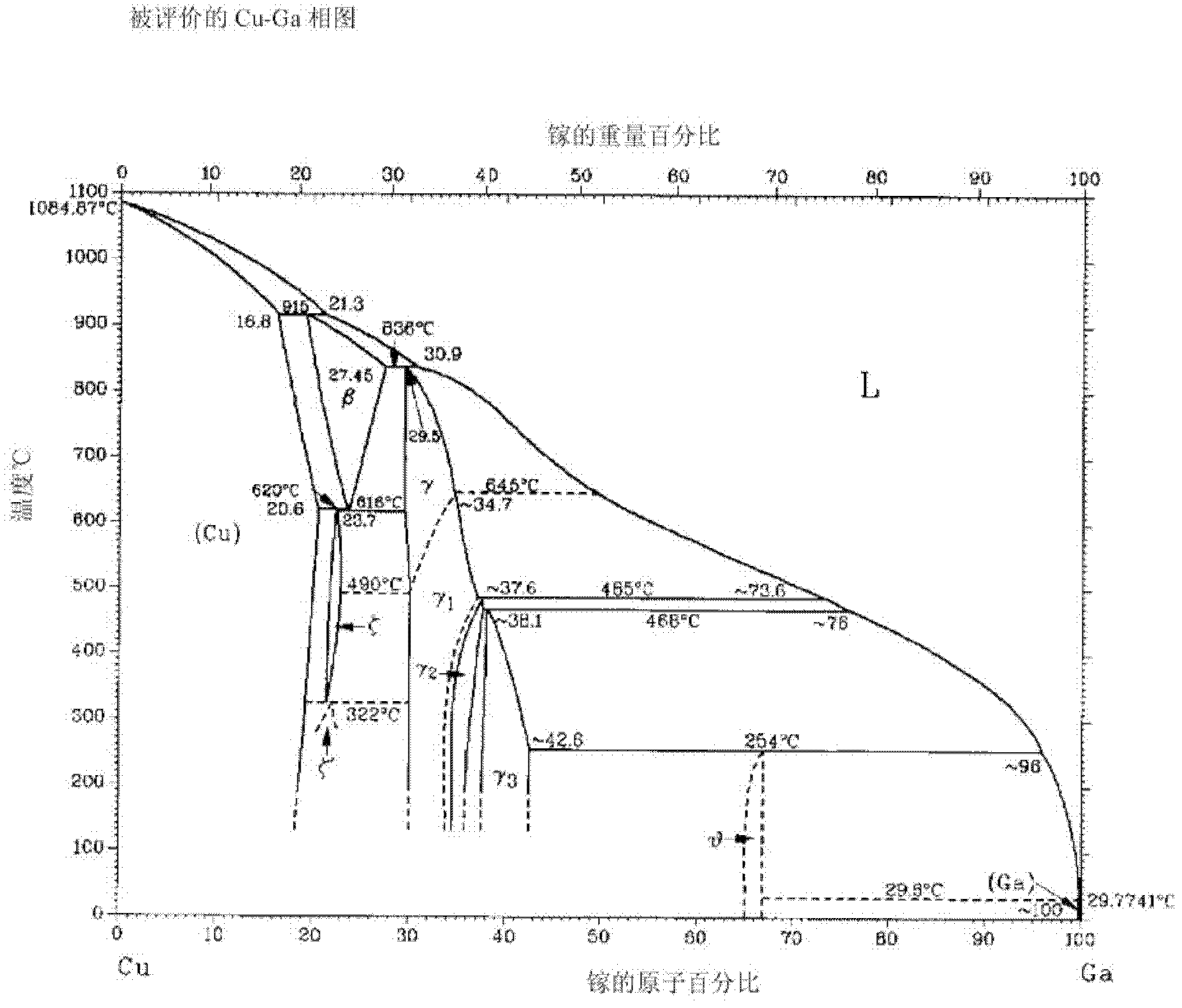

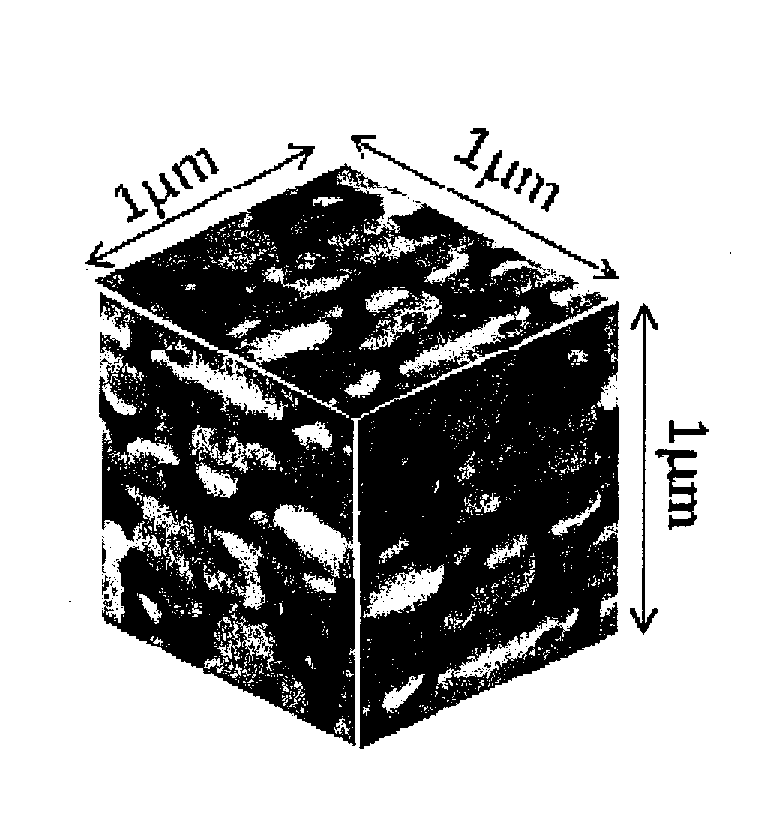

Cu-Ga alloy sputtering target and manufacturing method thereof

InactiveCN102362002AFine crystal grainsReduce porosityVacuum evaporation coatingSputtering coatingPorositySputtering

Owner:KOBELCO RES INST

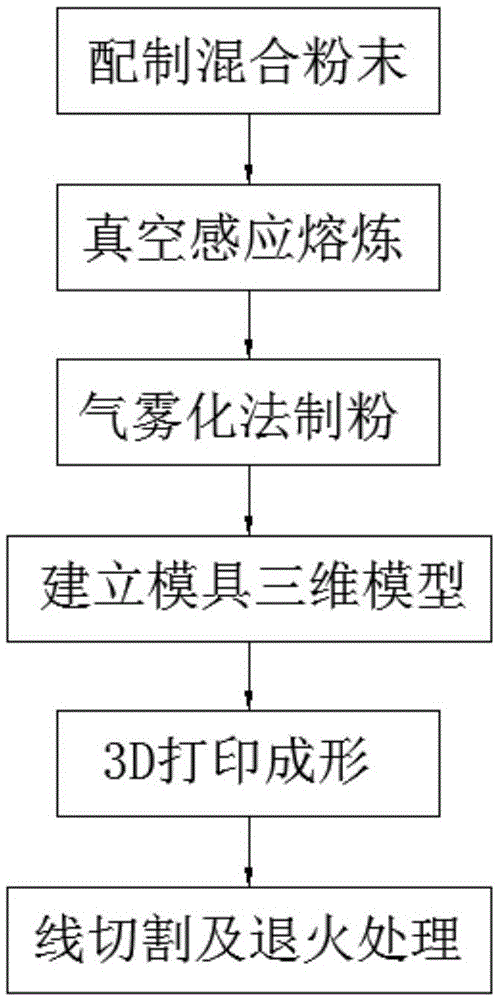

3D printing preparation method for injection mold

InactiveCN105562691AAvoid crackingAdd C elementAdditive manufacturing apparatusIncreasing energy efficiencyPolymer scienceEvaporation

The invention discloses a 3D printing preparation method for an injection mold. The 3D printing preparation method comprises the following steps that 1, mixed powder is prepared, and then vacuum induction melting is carried out, wherein the mixed powder is prepared from, by weight percent, 0.4% to 0.5% of C, 0.7% to 0.75% of Si, 0.35% to 0.45% of Mn, 14% to 15.6% of Cr, 0.25% to 0.35% of V and the balance Fe; 2, an atomization powder preparing method is adopted for preparing the powder; 3, a three-dimensional model is established; 4, the injection mold is formed; and 5, the formed injection mold is separated from a substrate, and then the injection mold is placed in a muffle furnace for annealing to improve the plasticity and toughness of the injection mold. According to the 3D printing preparation method, cracking of mold steel in the 3D printing process can be effectively restrained. Meanwhile, C is added to make up ingredient changes caused by element evaporation and carbonization of the injection mold under the action of lasers.

Owner:HUAZHONG UNIV OF SCI & TECH

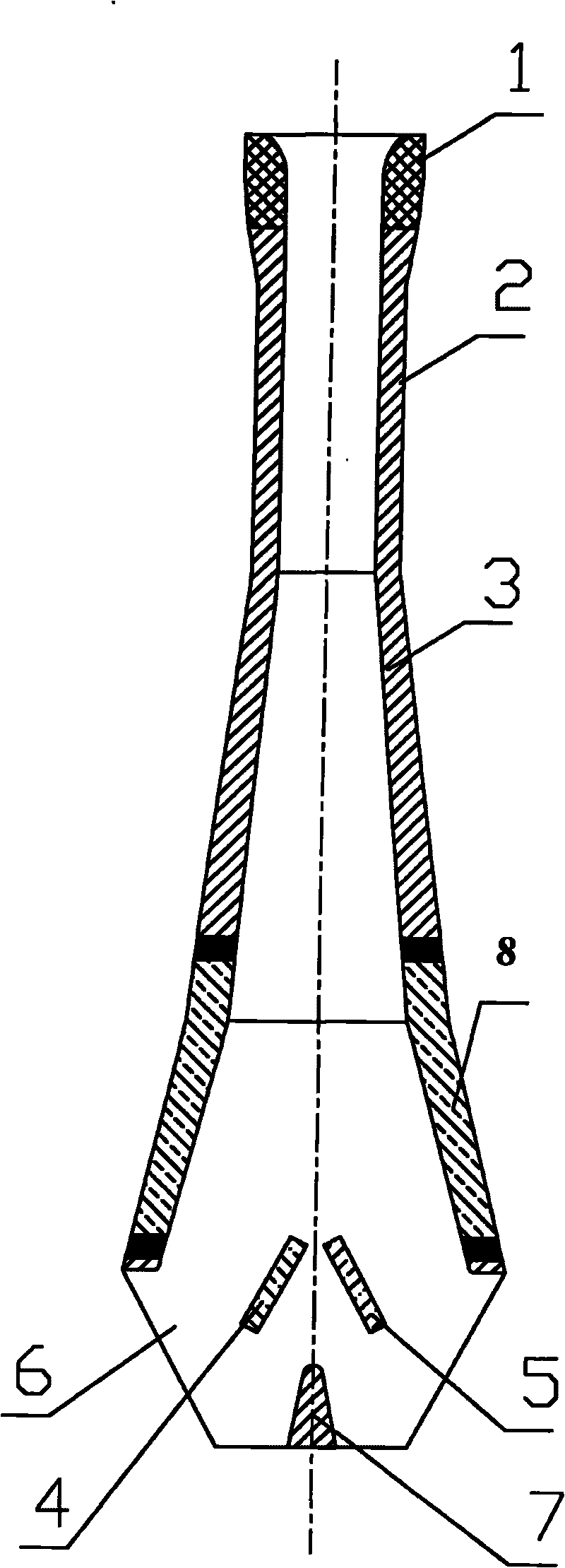

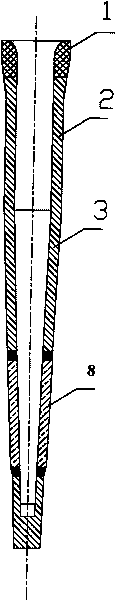

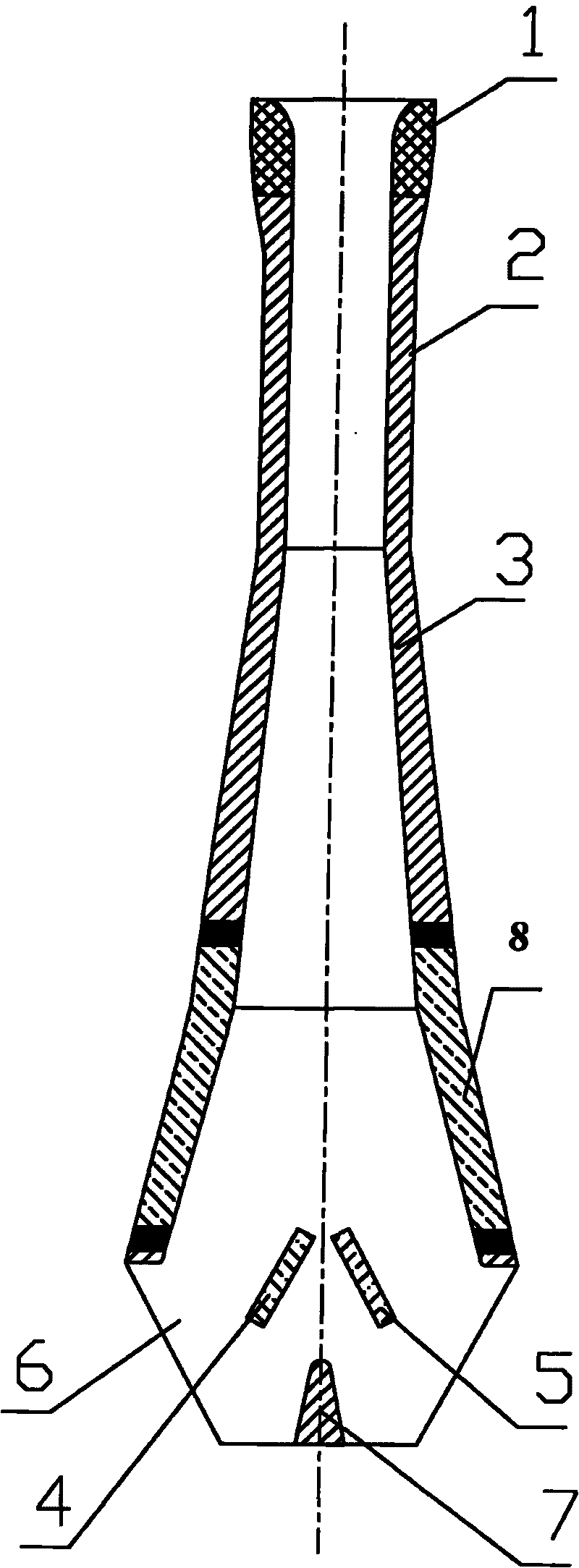

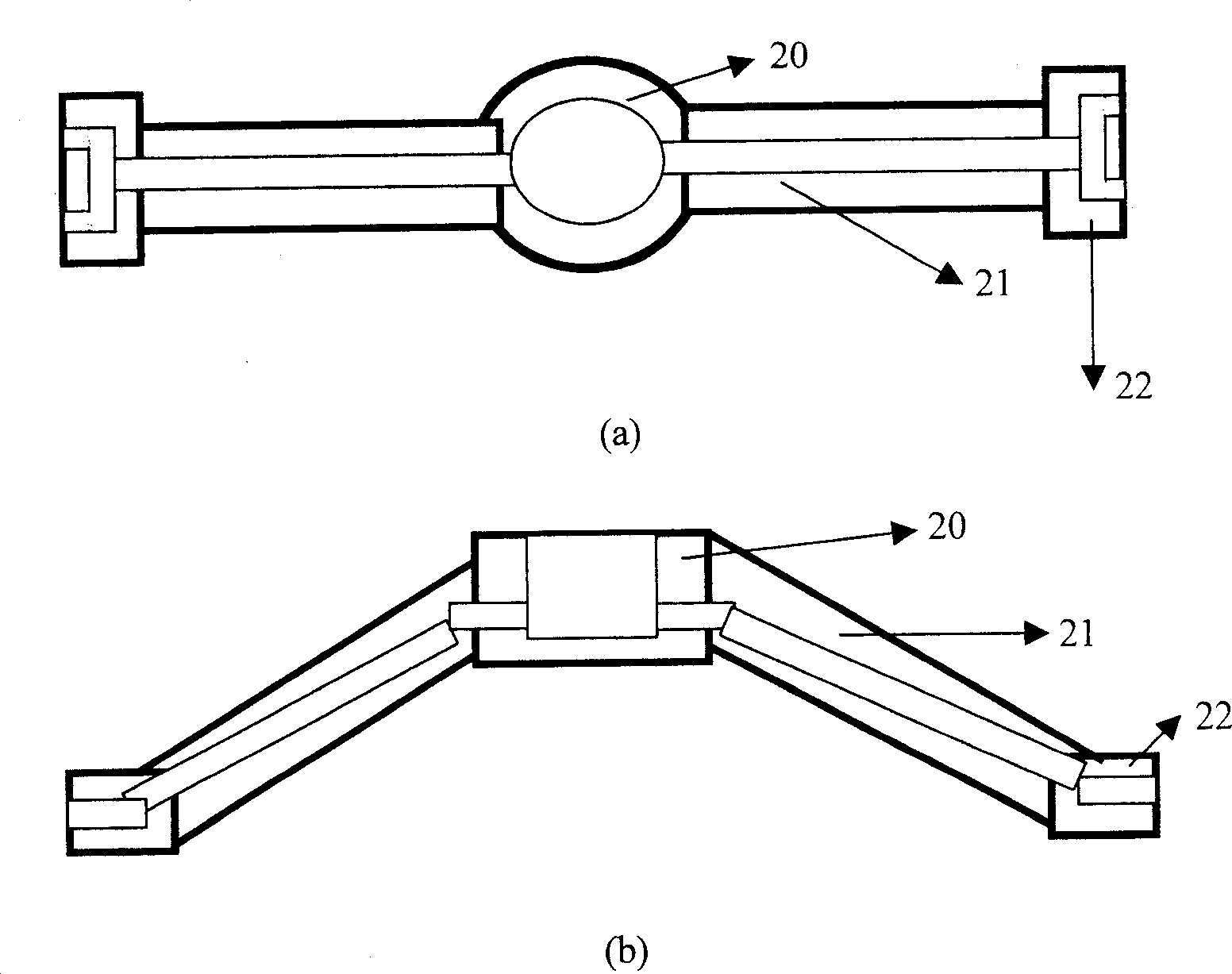

Submerged nozzle for sheet billet continuous casting crystallizer

The invention discloses a submerged nozzle for a sheet billet continuous casting crystallizer, which comprises an upper end and a transition section, wherein the transition section is positioned below the upper end, the transition section is in the shape of a cylindrical constant section, and an upper flat section and a lower flat section are positioned below the transition section; a first guide plate and a second guide plate which are symmetrical are arranged under the lower flat section, two nozzle outlets are formed between the lower end of the lower flat section and the first guide plate and between the lower end of the lower flat section and the second guide plate, and the first guide plate and the second guide plate are cuboid; and a conical flow splitting body is arranged at the middle position below the first guide plate and the second guide plate. The two guide plates are added into the submerged nozzle to perform the action of changing the angle and the speed of molten steel flowing out of the nozzle, so that the liquid level of the crystallizer keeps stable at a high flow speed to achieve the uniform distribution of protective slag, thereby effectively preventing slag entrapment and inhabiting the generation of cracks on a casting blank; and the molten steel can uniformly flow in the crystallizer and achieve reasonable liquid level speed and protective slag coverage.

Owner:CHONGQING UNIV +1

Sintered body of silver fine particle

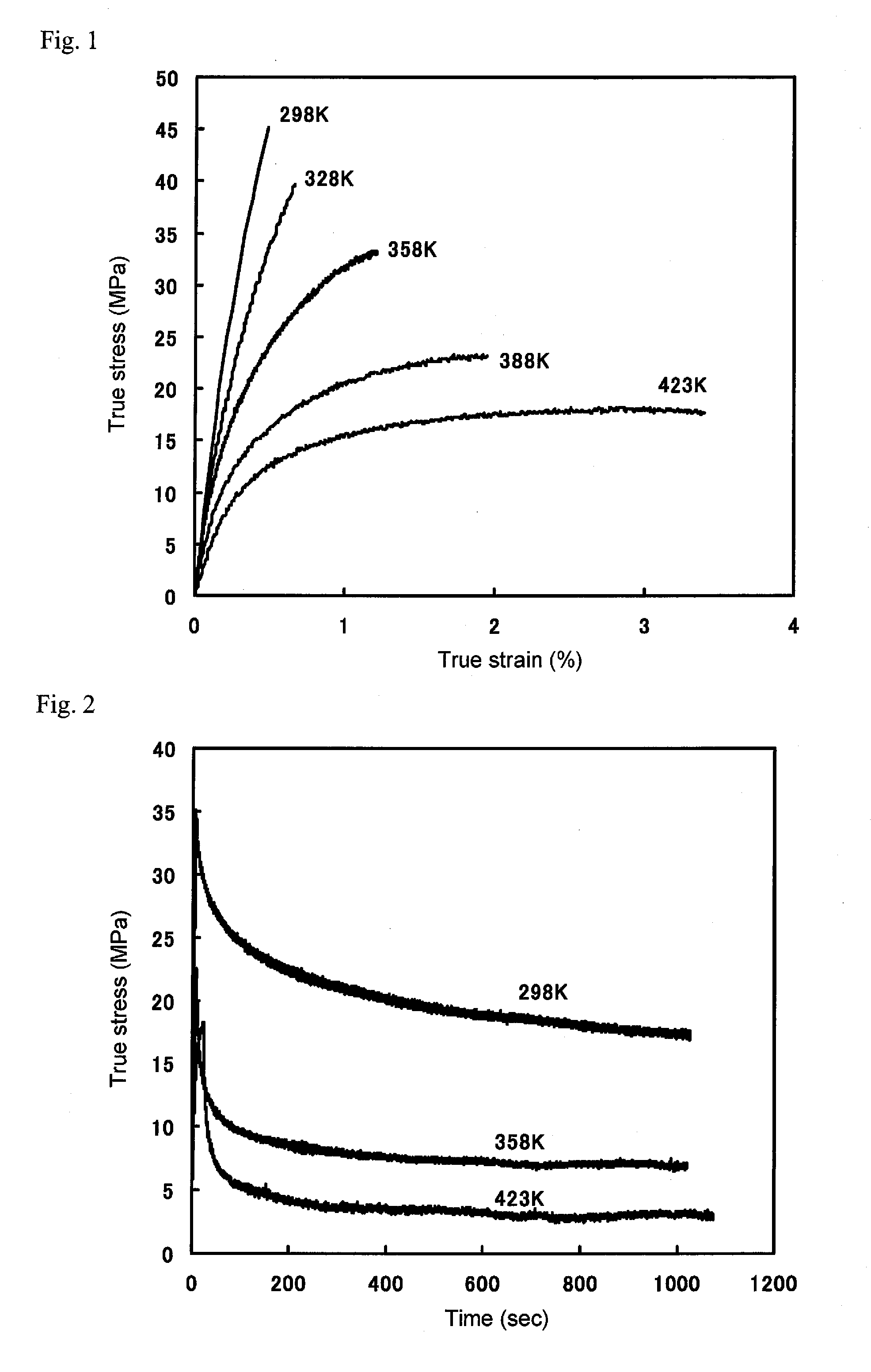

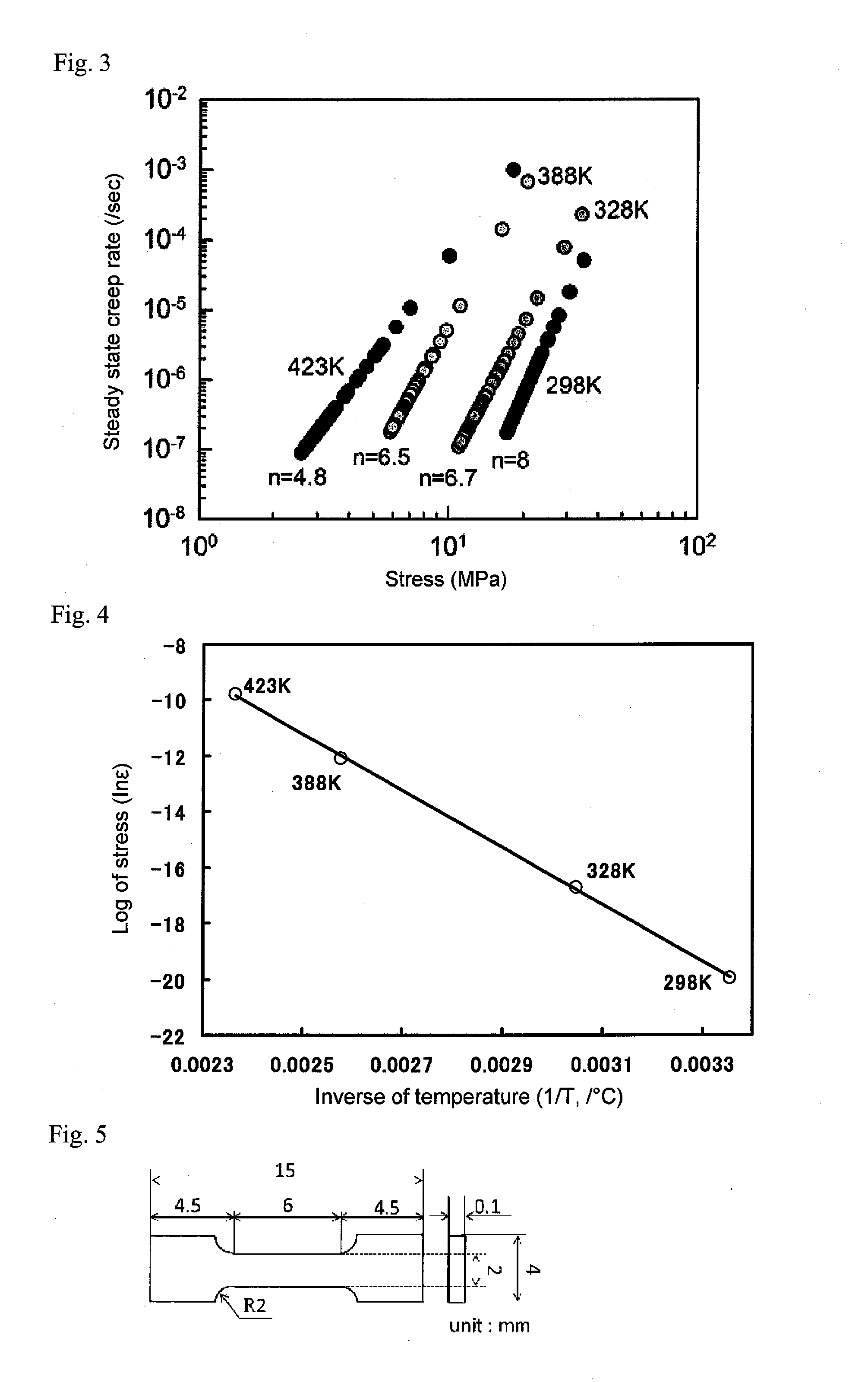

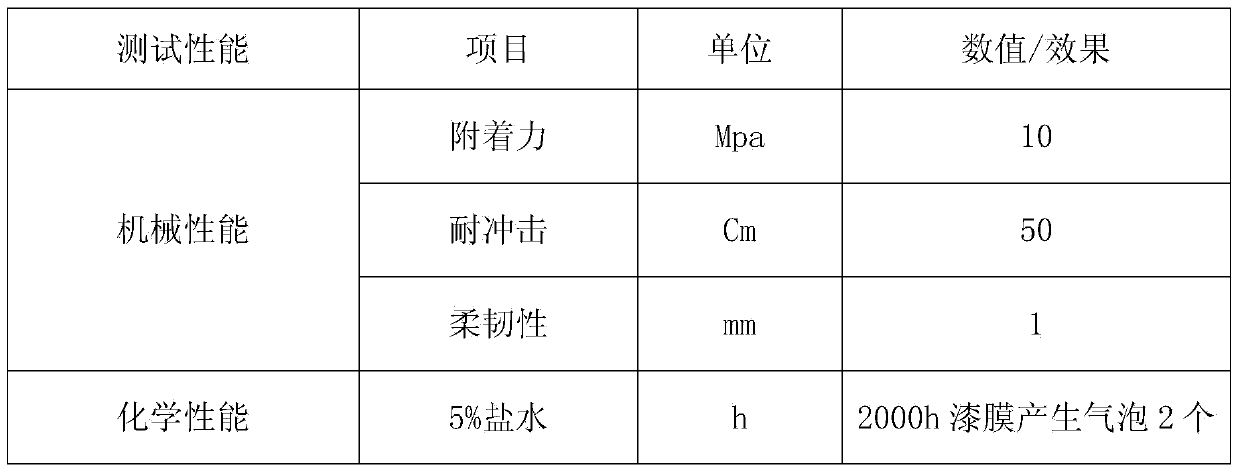

ActiveUS20150041974A1Relieve pressureCrack suppressionMaterial nanotechnologyTransportation and packagingActivation energyMicroparticle

A sintered body of silver fine particles for a bonding member to bond components of a semiconductor device, wherein an activation energy for creep of the sintered body of the silver fine particles is from 0.4 to 0.75 times that of an activation energy for a lattice diffusion of bulk silver.

Owner:NAMICS CORPORATION

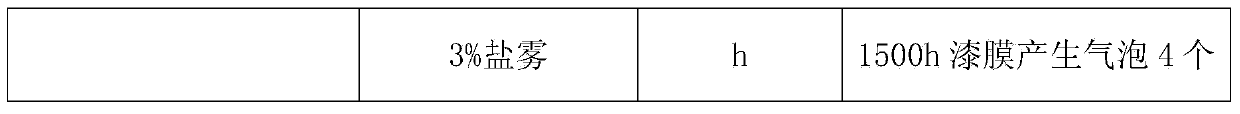

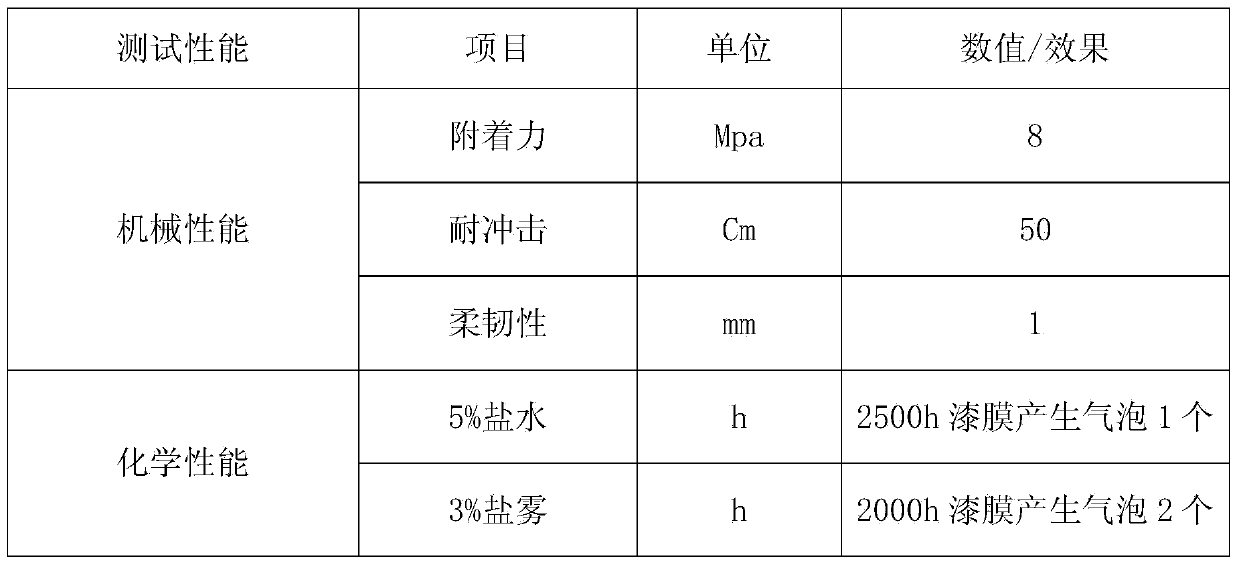

Tetraethylorthosilicate inorganic high-temperature-resistant coating and preparation method thereof

InactiveCN104212206AReduced tendency to crackReduce uneven evaporationAnti-corrosive paintsNanometreAluminium

The invention discloses a tetraethylorthosilicate inorganic high-temperature-resistant coating. The tetraethylorthosilicate inorganic high-temperature-resistant coating comprises the following components in percentage by mass: 28-35% of tetraethylorthosilicate, 35-50% of heat-resistant pigment and filler, 2%-4% of additives and 13-18% of dimethylformamide, wherein the heat-resistant pigment and filler comprises nano-silicon dioxide, a blocking type functional filler and aluminum powder in the mass ratio of 1.5 to 1 to 1. The invention further designs a preparation method of the tetraethylorthosilicate inorganic high-temperature-resistant coating. According to the tetraethylorthosilicate inorganic high-temperature-resistant coating and the preparation method thereof designed by the invention, the adhesion and the hardness of a cured film formed after heat curing of the coating can be significantly improved along with increase in temperature, the adhesion achieves grade one, the pencil hardness is more than 6H, the high temperature above 800 DEG C can be resisted and the cracking tendency of the coated film is greatly reduced.

Owner:JIANGSU MARINE VICTORY COATING

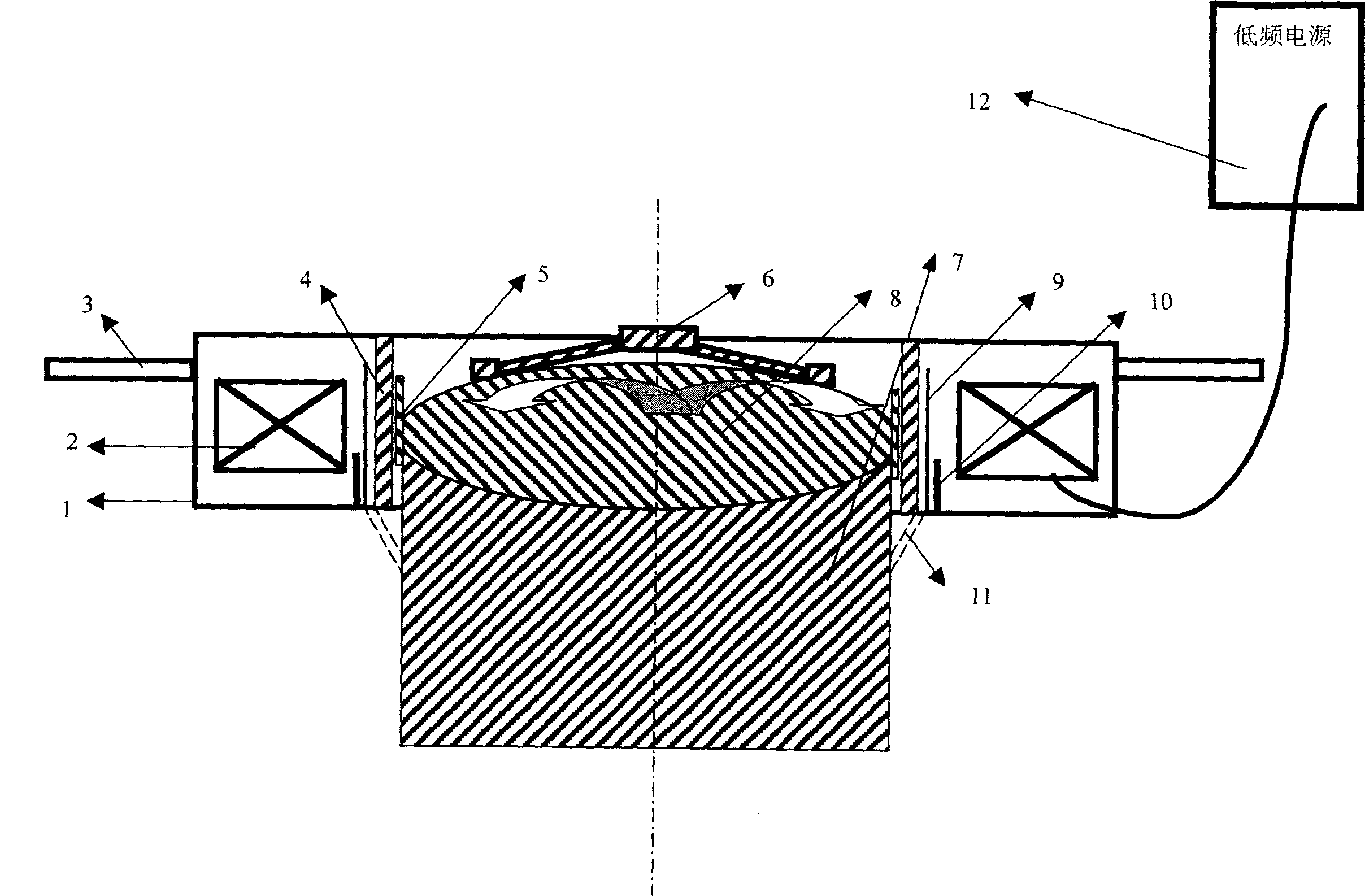

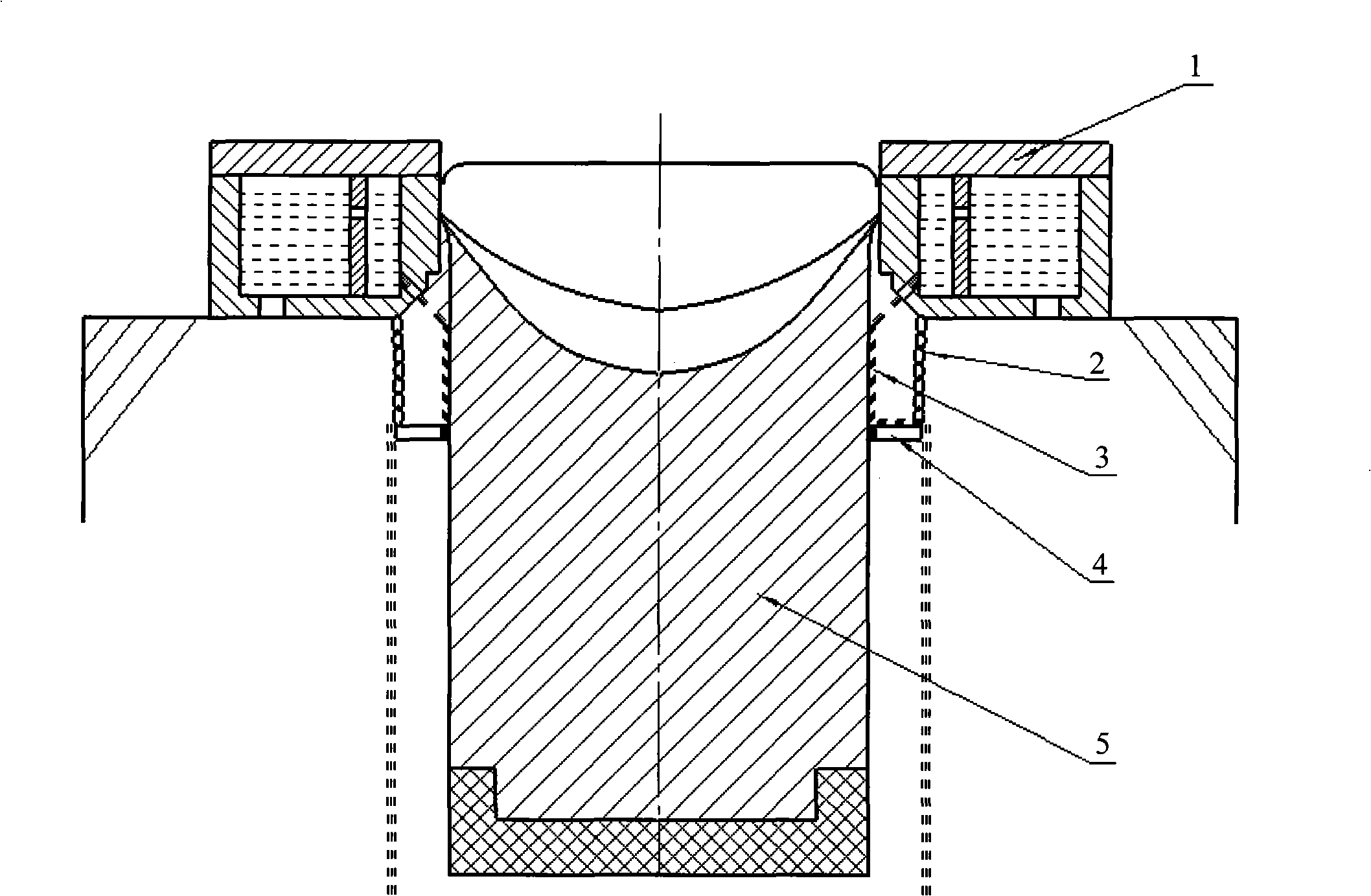

Method and equipment for inhibiting crack of high-alloying aluminium alloy square billet

The invention relates to a method for restraining crack of high-alloyed aluminum alloy and relative device. Said device is the plate blank electromagnetic continuous casting crystallizer, while the electromagnetic coil is inside water tank; the water baffle plate is arranged inside the water tank; and the crystallizer comprises four water supply chambers which are independently arranged in two large surfaces and two small surfaces; the water supply chambers supply water independently while the water amount is controllable; a shield matter is arranged at the angle; the inlet of melt aluminum alloy at the upper part of crystallizer is mounted with a bridge fusion current divider; and the inner side of internal wall of crystallizer is adhered with thermal isolated film. When using said device to 7000 alloy square blanks whose thickness is 150-450mm, the frequency should be 10-50Hz, and the intensity of magnetic field should be 10000-80000 ampere-turns; at the different process of casting, the water supply chambers supply different water amount; the casting speed is 20-50% higher than present technique. The invention can effectively restrain the crack of high-alloyed plate blank.

Owner:NORTHEASTERN UNIV

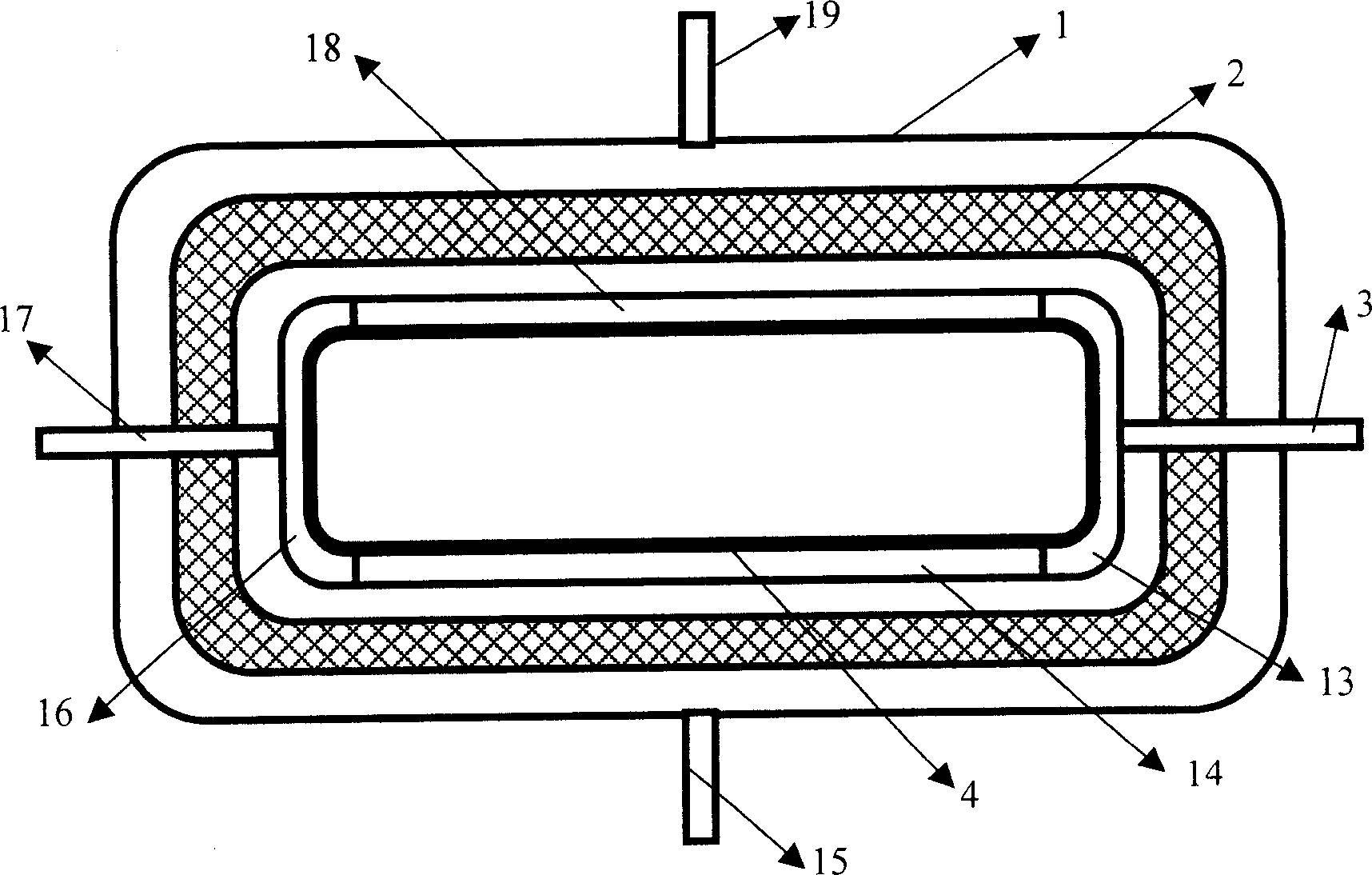

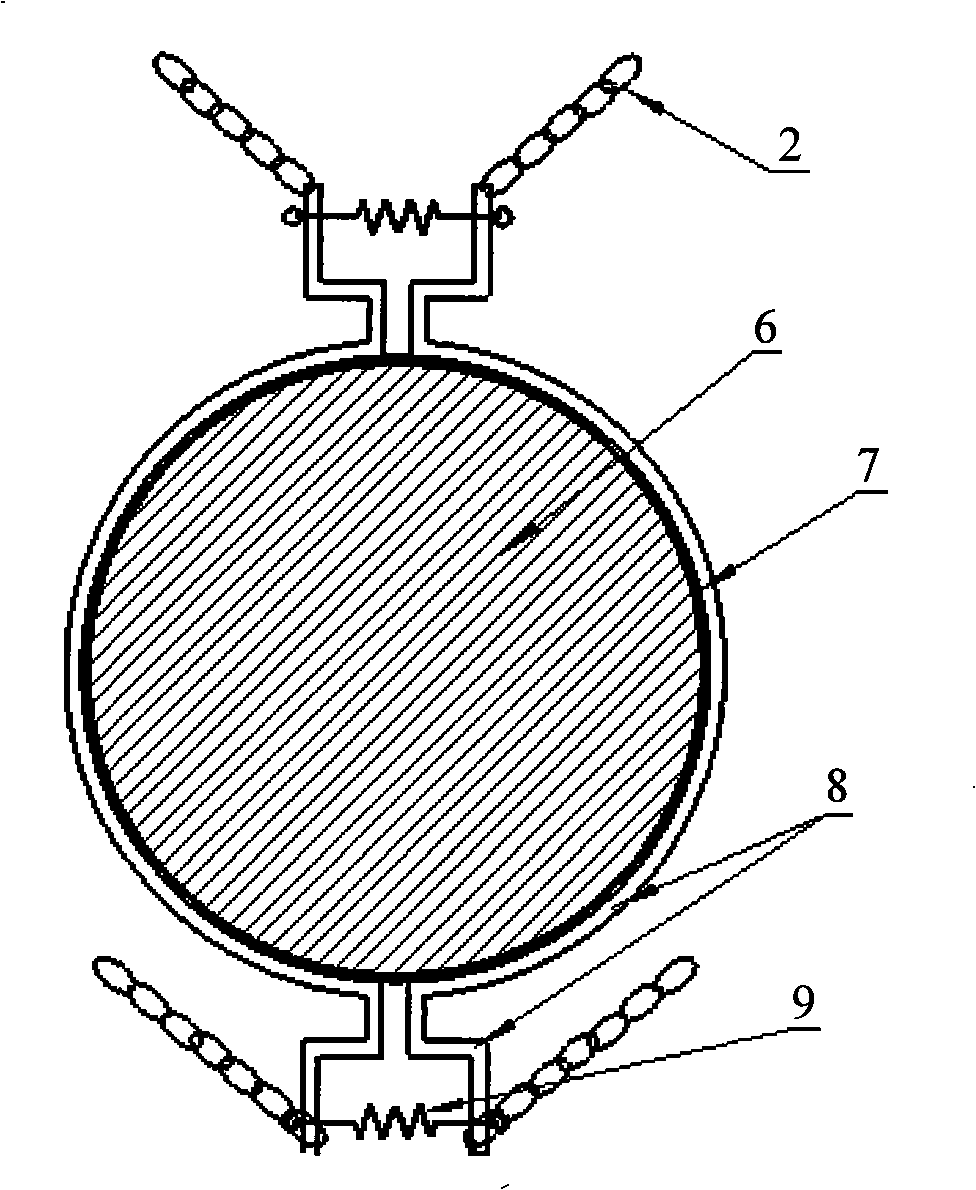

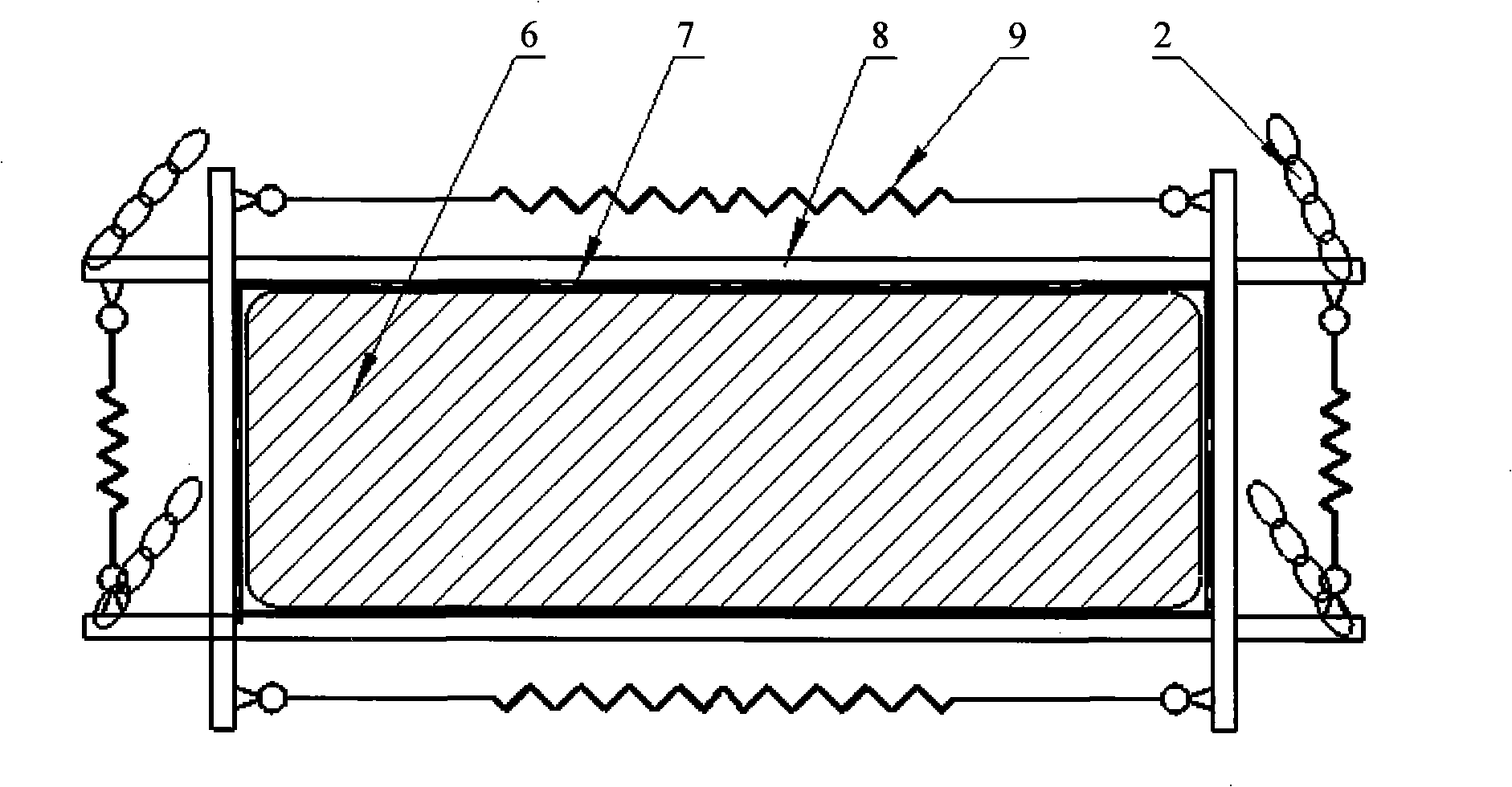

Design method of dash device for hard aluminum alloy semi-continuous casting

The invention provides a design method of a water blocking device for semi-continuous casting of hard aluminum alloy, the water blocking device comprises a water baffle plate body and springs, a divided structure is adopted in the water baffle plate body, all the parts are connected by the springs, the whole water blocking device is suspended under a crystallizer by a hinge or is directly supported on a casting platform, the part of the water baffle plate body which is contacted with the surface of a cast ingot is provided with a polymer material, and the working surface of the water baffle plate body is perpendicular with the surface of the cast ingot or forms a certain angle with the surface of the cast ingot. When in application, the outer surface of the cast ingot is tightly clamped at the same time of not obstructing the casting process, the secondary cooling water of the semi-continuous casting is blocked and shunted at the position of the water baffle plate, the cast ingot only receives part of the water cooling between the crystallizer and the water baffle plate, the lower part of the water baffle plate is carried out the natural air cooling; the cast ingot is repeatedly heated by a high temperature melt of the core part of the cast ingot, thus realizing the self-tempering effect of the cast ingot, effectively reducing the casting internal stress, preventing the cracks of the cast ingot and being applicable to the application of large-scale industrial production.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

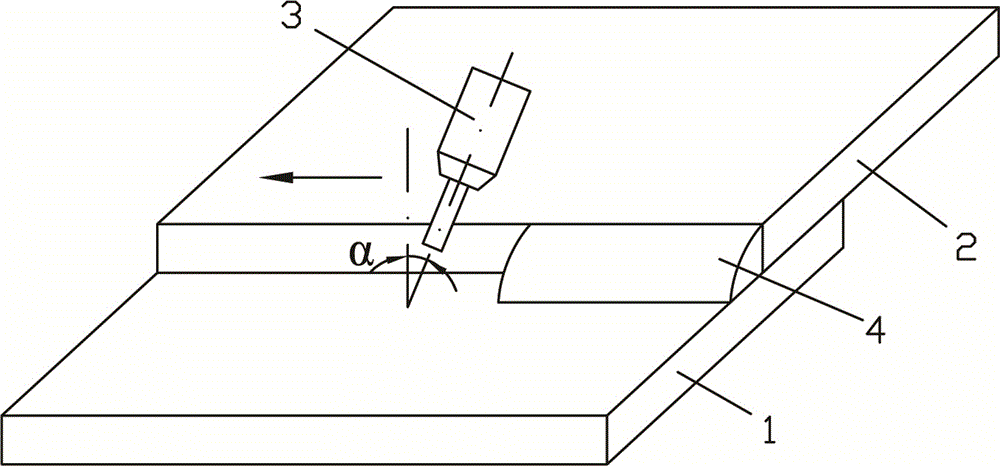

Method for preparing steel-aluminum dissimilar metal overlap joint by adopting CMT technology

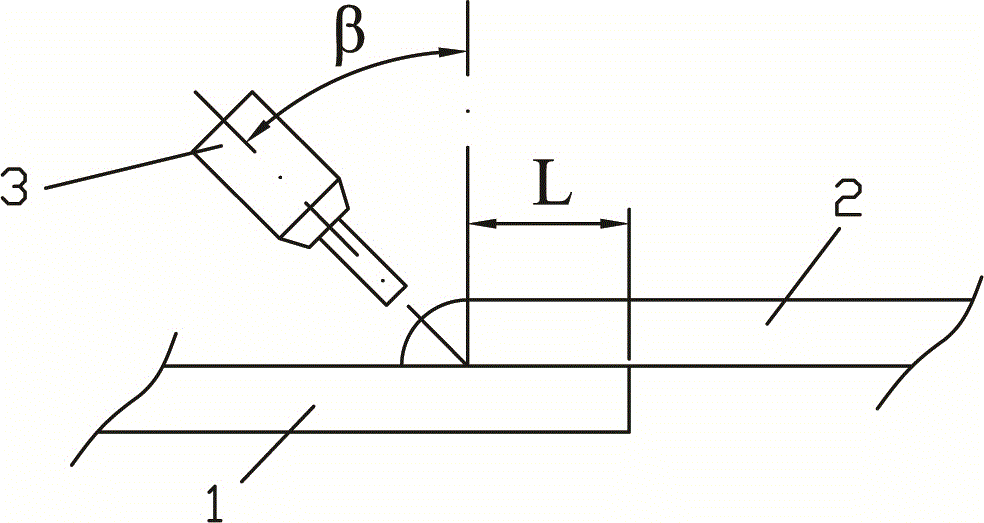

InactiveCN106624281ALow heat inputIncrease heat inputArc welding apparatusWelding/soldering/cutting articlesMetalPerpendicular distance

The invention provides a method for preparing a steel-aluminum dissimilar metal overlap joint by adopting the CMT technology. The method comprises the following steps: an aluminum alloy plate is placed on a galvanized steel plate in an overlap manner and fixed by utilizing a fixture, wherein the overlap amount ranges between 5 mm and 20 mm; and a CMT welding machine is utilized, a welding gun is inclined towards the aluminum alloy plate to form an angle of 1-45 degrees with the vertical direction, the welding gun is inclined towards the forward direction by 5-30 degrees, the perpendicular distance between the welding gun and the galvanized steel plate is 10-20 mm, and the welding speed is 0.4-1.0 m / min. According to the method provided by the invention, the CMT technology is improved based on an original MIG welding power source, thereby converting molten droplet transfer into cold metal transfer, and reducing the metal spatter when the heat input during a welding process is reduced; and accordingly, the method is very suitable for welding of the aluminum alloy plate and the galvanized steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

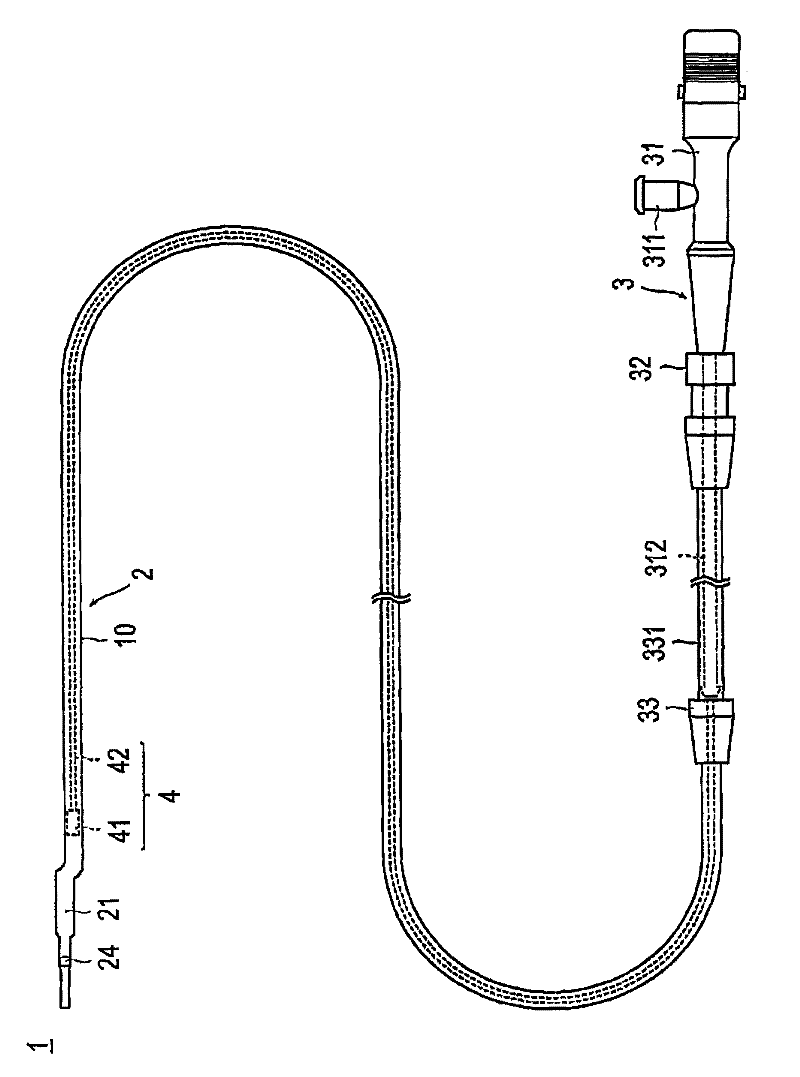

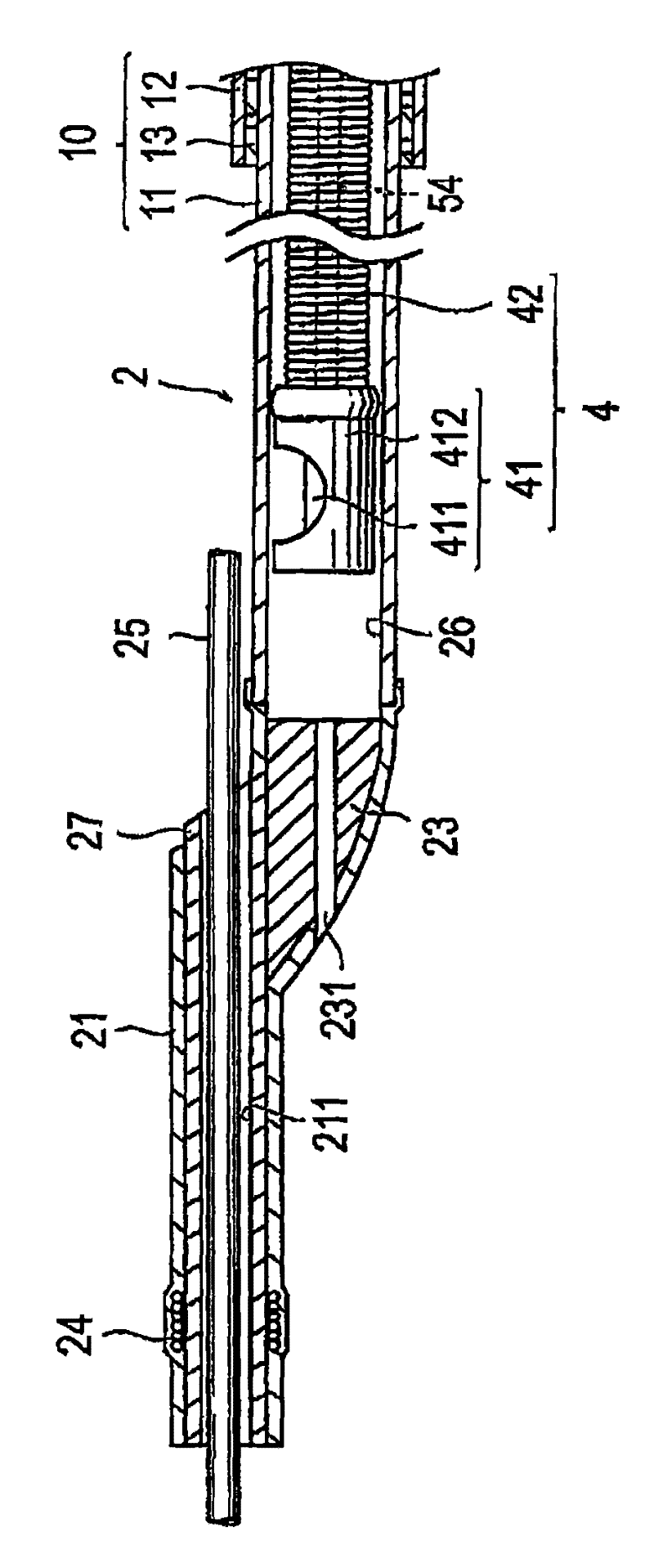

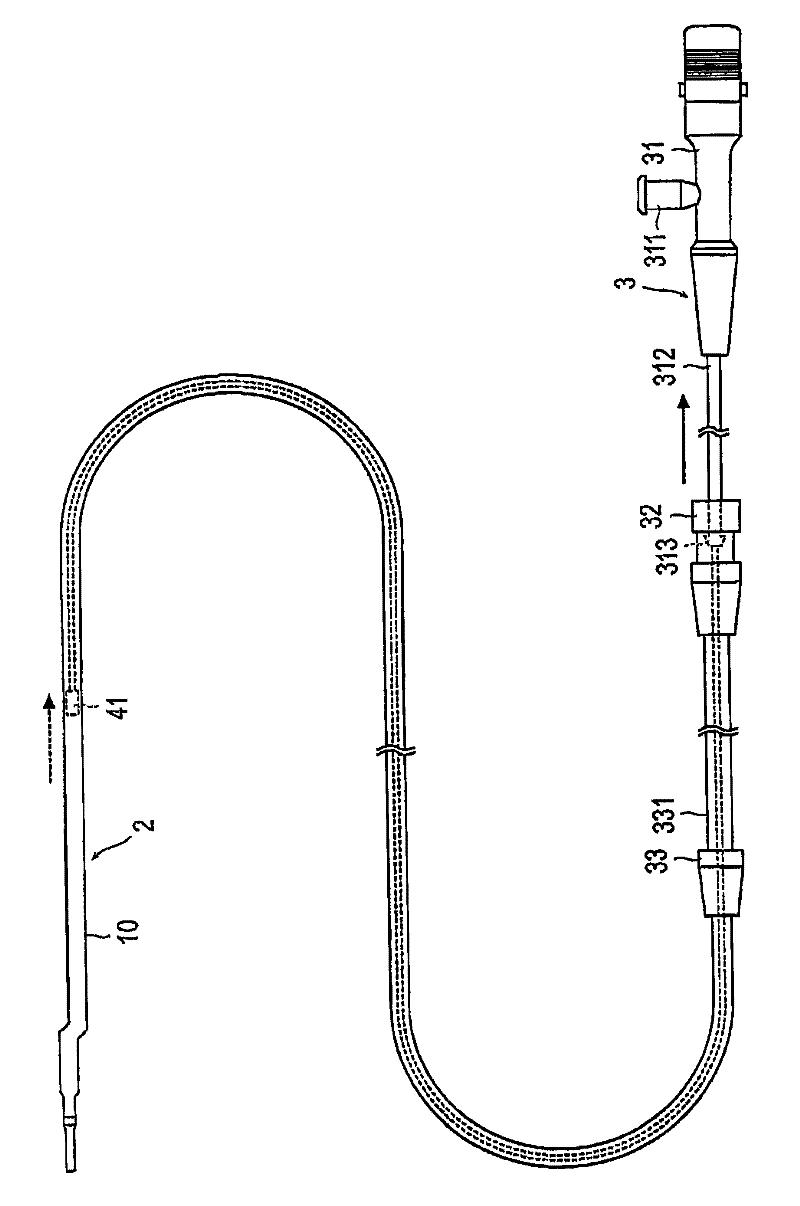

Catheter

ActiveCN102188236AImprove rigidityImprove securityUltrasonic/sonic/infrasonic diagnosticsSurgeryBiological bodyLiving body

The invention relates to a catheter. The occurrence of kinking is reduced, a proximal portion of a sheath exhibits steerability and the occurrence of a crack is suppressed. The catheter comprises a sheath to be inserted into a living body, wherein the sheath includes a tubular reinforcement layer of at least one layer, which is formed with a spiral slit continuous from the distal side to the proximal side thereof; a termination end of the spiral slit is provided on the proximal side of the slit proximal portion at the site of the proximal side of the spiral slit; and at the same time, there is formed a slit termination portion in which inclination angle of the spiral slit with respect to the circumferential direction of the reinforcement layer is larger than that of the slit proximal portion.

Owner:TERUMO KK

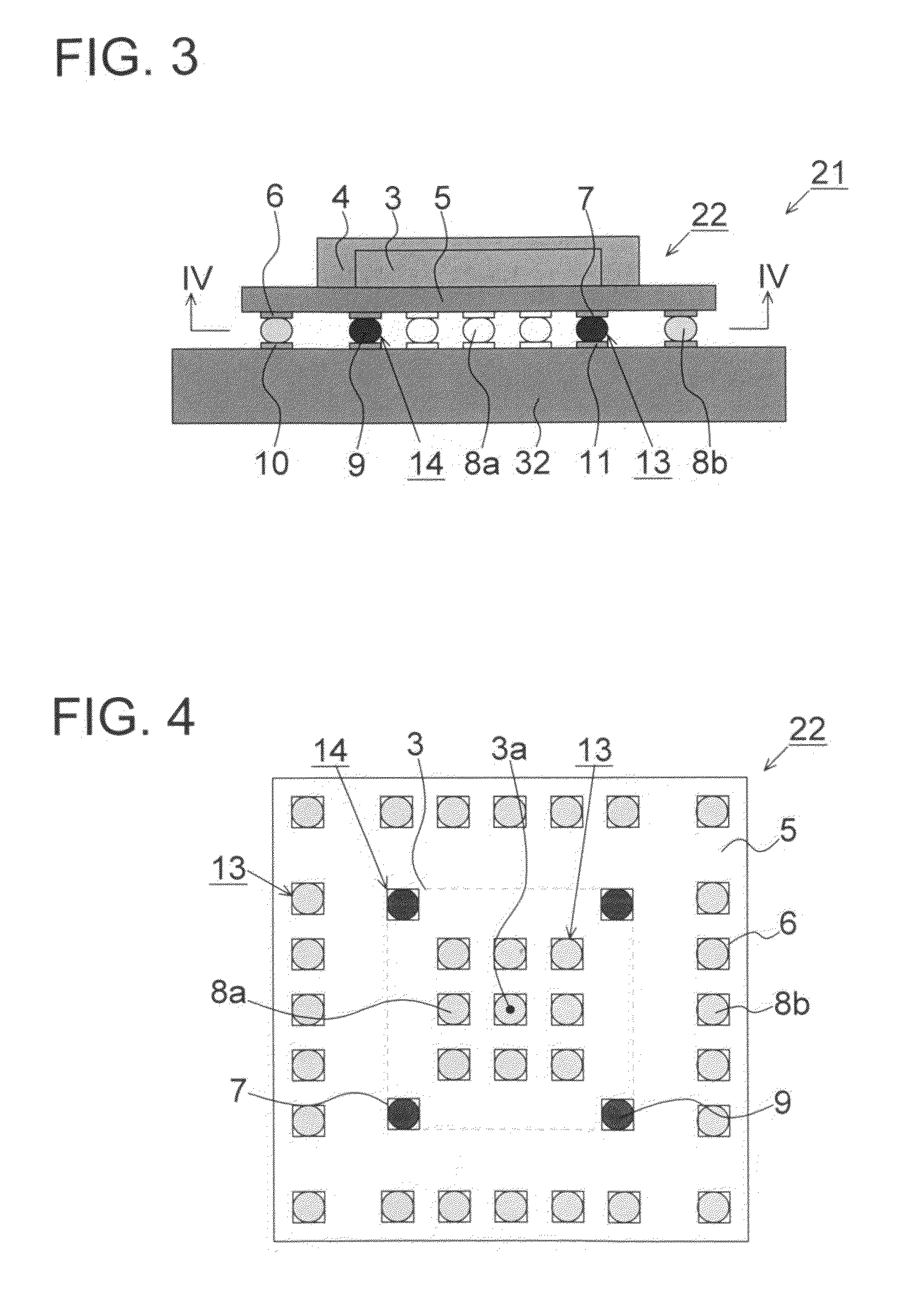

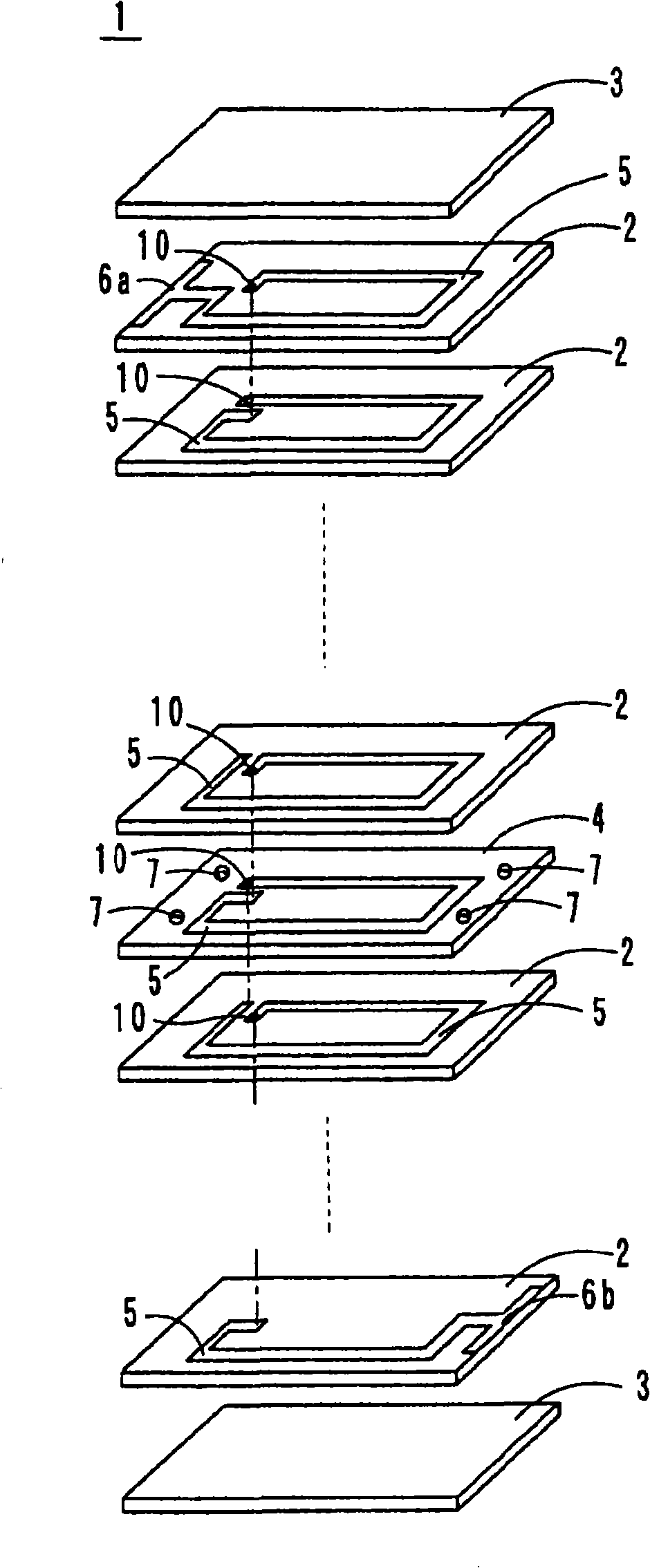

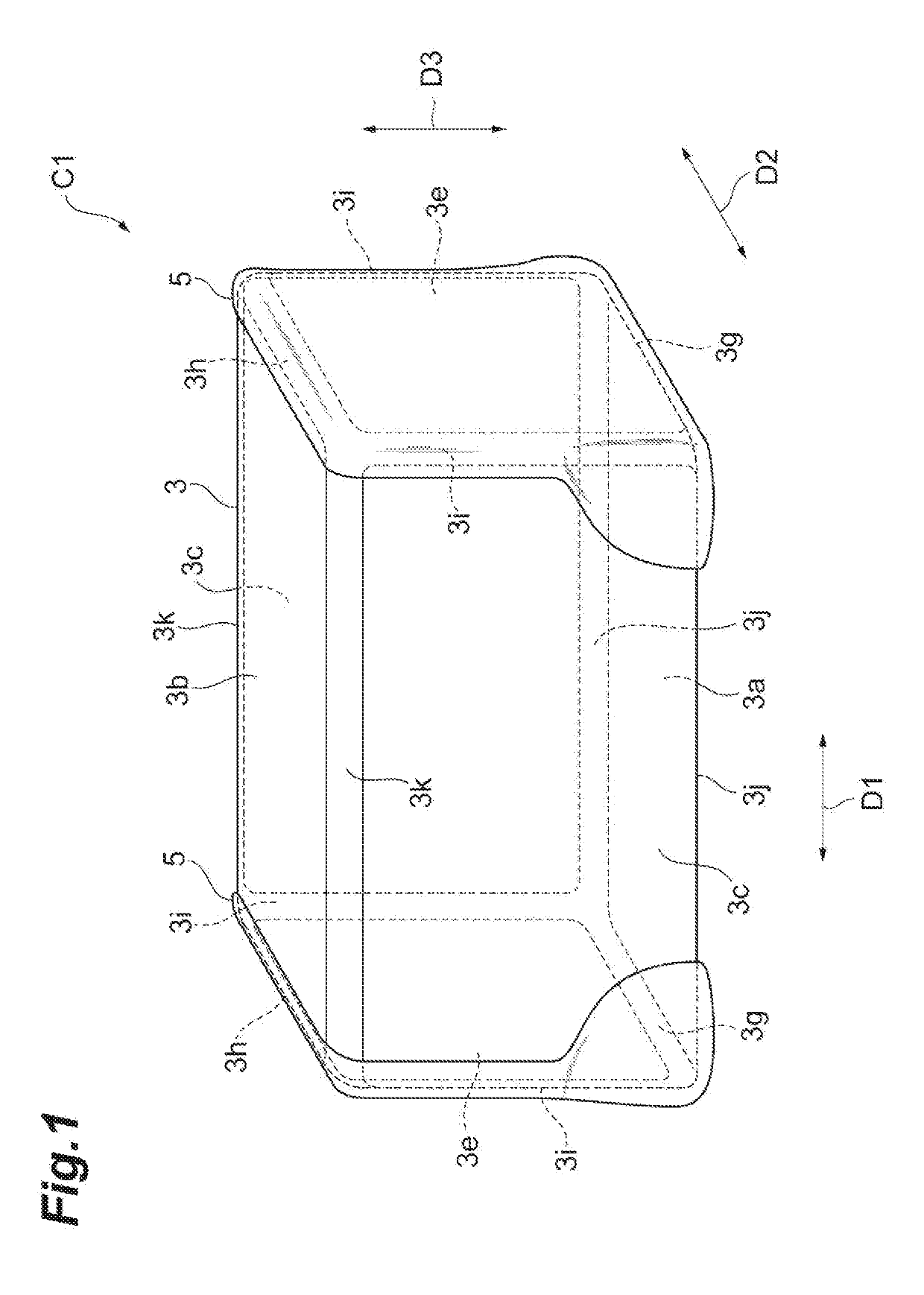

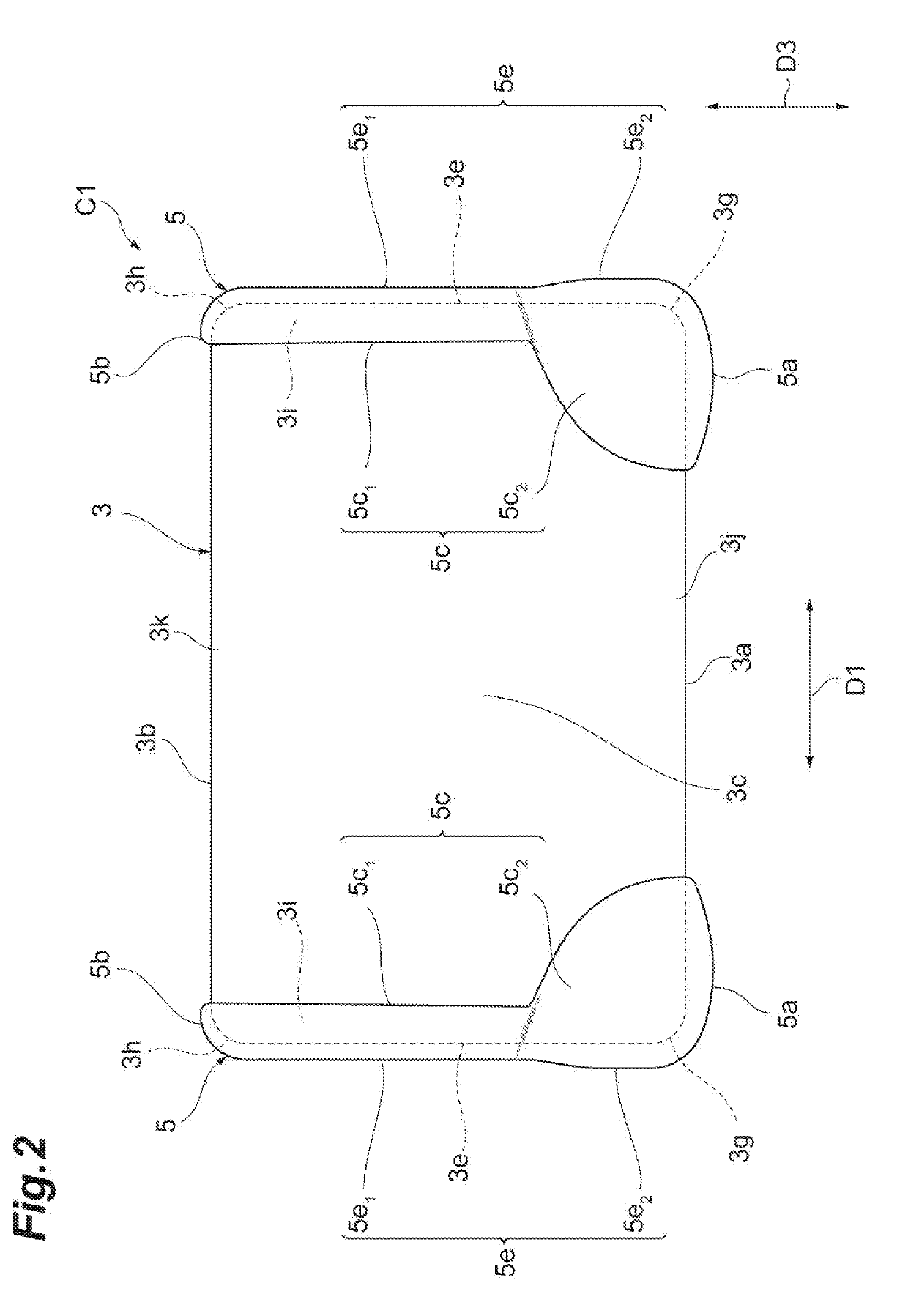

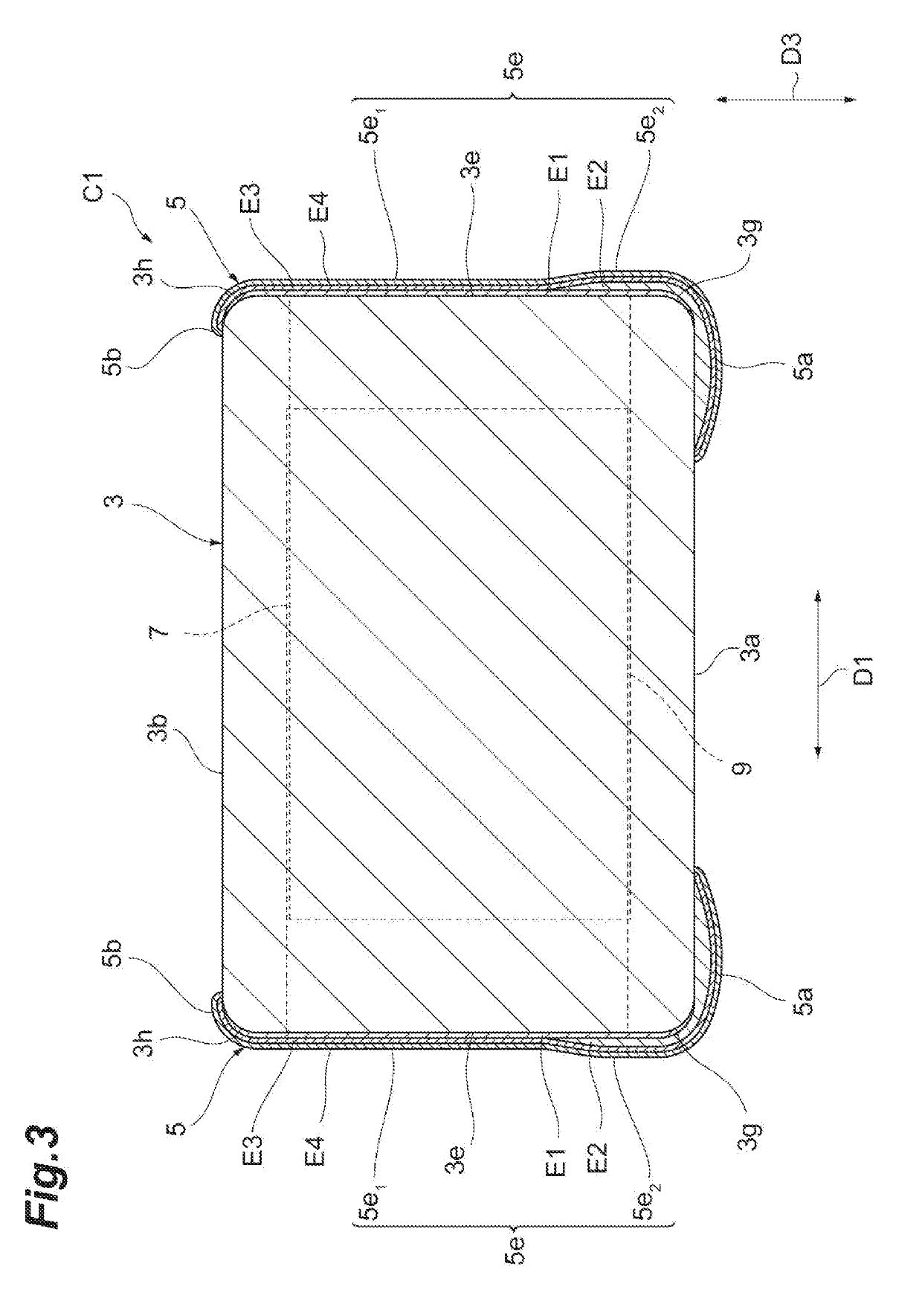

Multilayer coil component and method for manufacturing the same

InactiveCN101356599ACrack suppressionAvoid delaminationCoils manufactureSignal inductance without magnetic coreElectrical conductorMaterials science

A closed magnetic path type multilayer coil component in which cracking or delamination hardly occurs between layers of different permeabilities. A first ceramic sheet (2) on which a conductor pattern (5) for coil is formed and a third ceramic sheet (4) having a permeability lower than that of the first ceramic sheet (2) are laminated, and the conductor patterns (5) for coil are interconnected electrically to constitute a coil being incorporated in a multilayer coil component (1). The third ceramic sheet (4) is sandwiched by the first ceramic sheets (2). A cavity (7) is formed in a major surface of the third ceramic sheet (4) and the first ceramic sheet (2) adjoining the third ceramic sheet (4) is in contact with the inner circumferential surface of the cavity (7).

Owner:MURATA MFG CO LTD

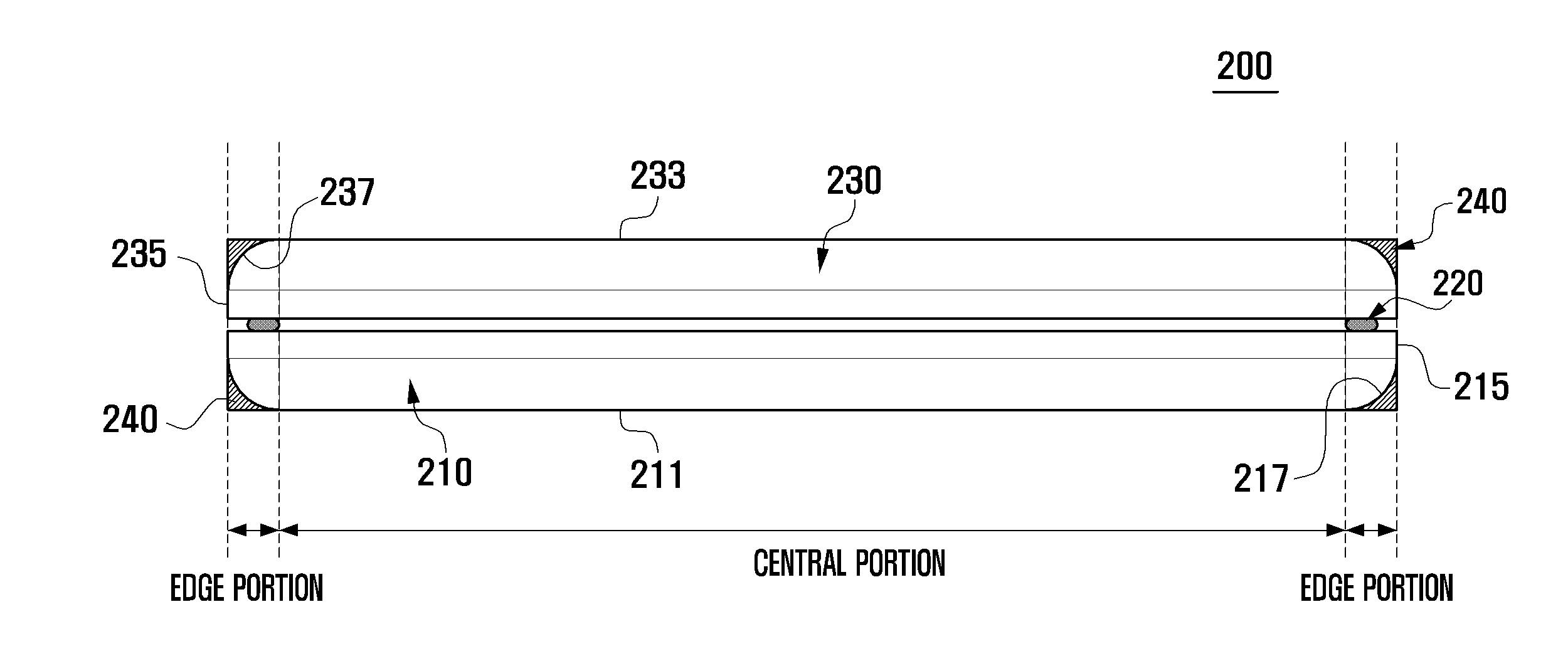

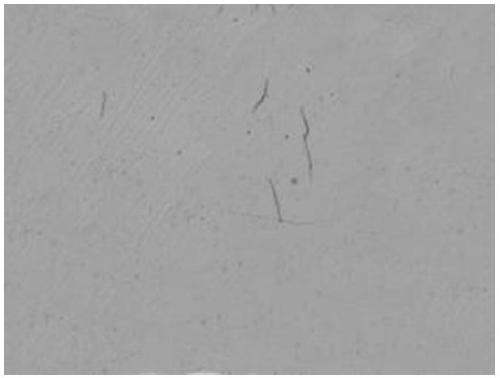

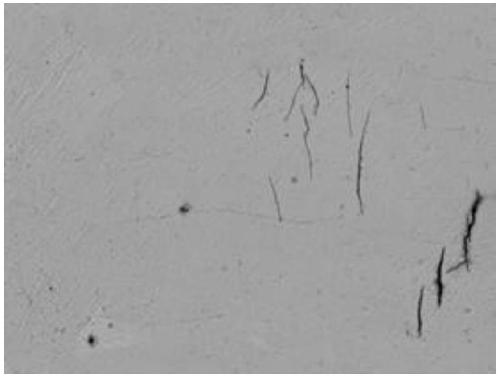

Display panel and method of manufacturing the same

InactiveUS20120075823A1Crack suppressionSuppress transitionWave amplification devicesSolid-state devicesElectrical and Electronics engineeringSurface plate

A display panel and a method of manufacturing the same are provided. The display panel includes a plurality of chip panels, each chip panel having an upper surface, a lower surface disposed parallel to the upper surface, a side surface between the upper surface and the lower surface and a connection portion between the side surface and at least one of the upper surface and the lower surface, the connection portion having a rounded configuration, and an adhesive layer interposed between the chip panels in order to vertically stack the chip panels to connect the chip panels. Therefore, in the display panel, the strength of the edge portion can be improved. Also, by forming a connection portion, a stress can be suppressed from being concentrated at the edge portion by an external mechanical stress.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for preparing TiAl alloy structural member by selective laser melting

InactiveCN109202080AReduce the temperatureReduce internal stressAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention provides a method for preparing a TiAl alloy structural member by selective laser melting, which comprises the steps of 1) drying and heating gas atomization TiAl powder; 2) clamping a base plate on a working platform after being processed, and preheating the base plate; 3) drying and heating an inert protective gas, and then filling the inert protective gas into a working room, wherein the oxygen content of the working room is reduced to 0.01% or below; 4) preparing according to a mode of scanning the TiAl powder by means of low power laser pre-sintering, high-power laser melting and low power laser heat preservation layer by layer by using a selective laser melting technology until a forming member is completely processed; and 5) slowing cooling the forming member to the room temperature in a vacuum environment. The TiAl alloy structural member is prepared according to the procedures of low power laser scanning pre-sintering, high power laser scanning melting and low power laser scanning heat preservation and slow cooling, so that the temperature gradient and internal stress in the forming process of the structural member are greatly reduced, the generation of cracks is effectively inhibited, and a TiAl alloy sample with high density and good comprehensive performance is obtained.

Owner:ZHEJIANG OCEAN UNIV

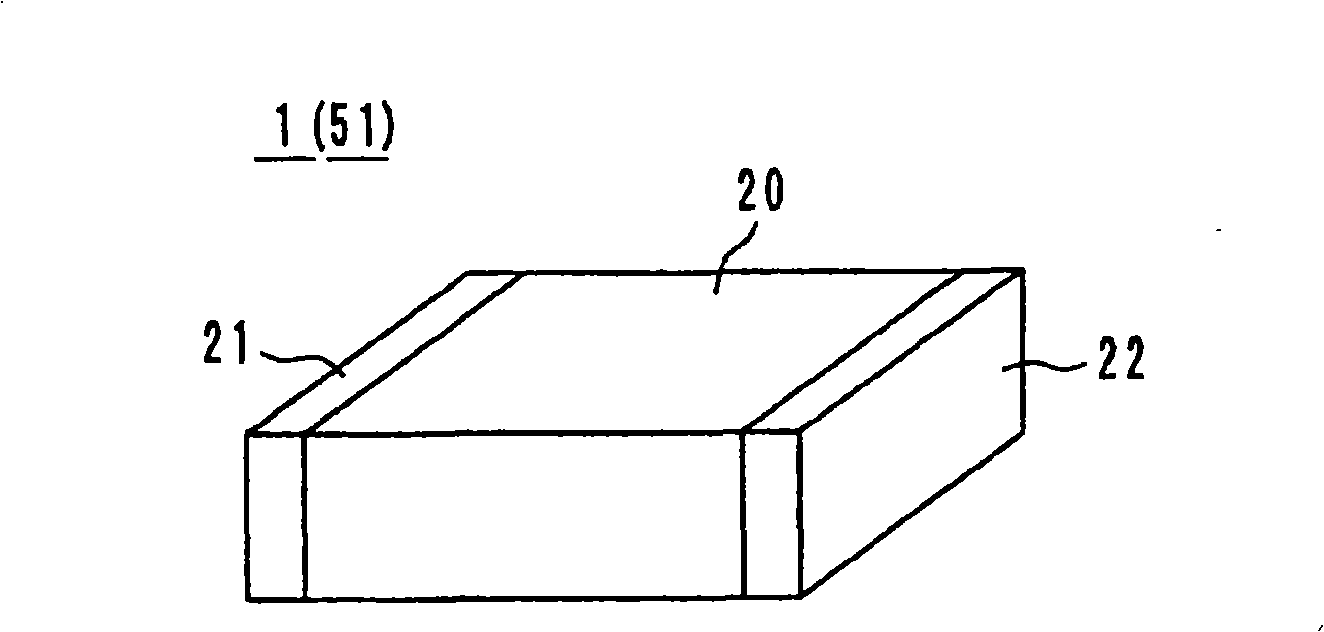

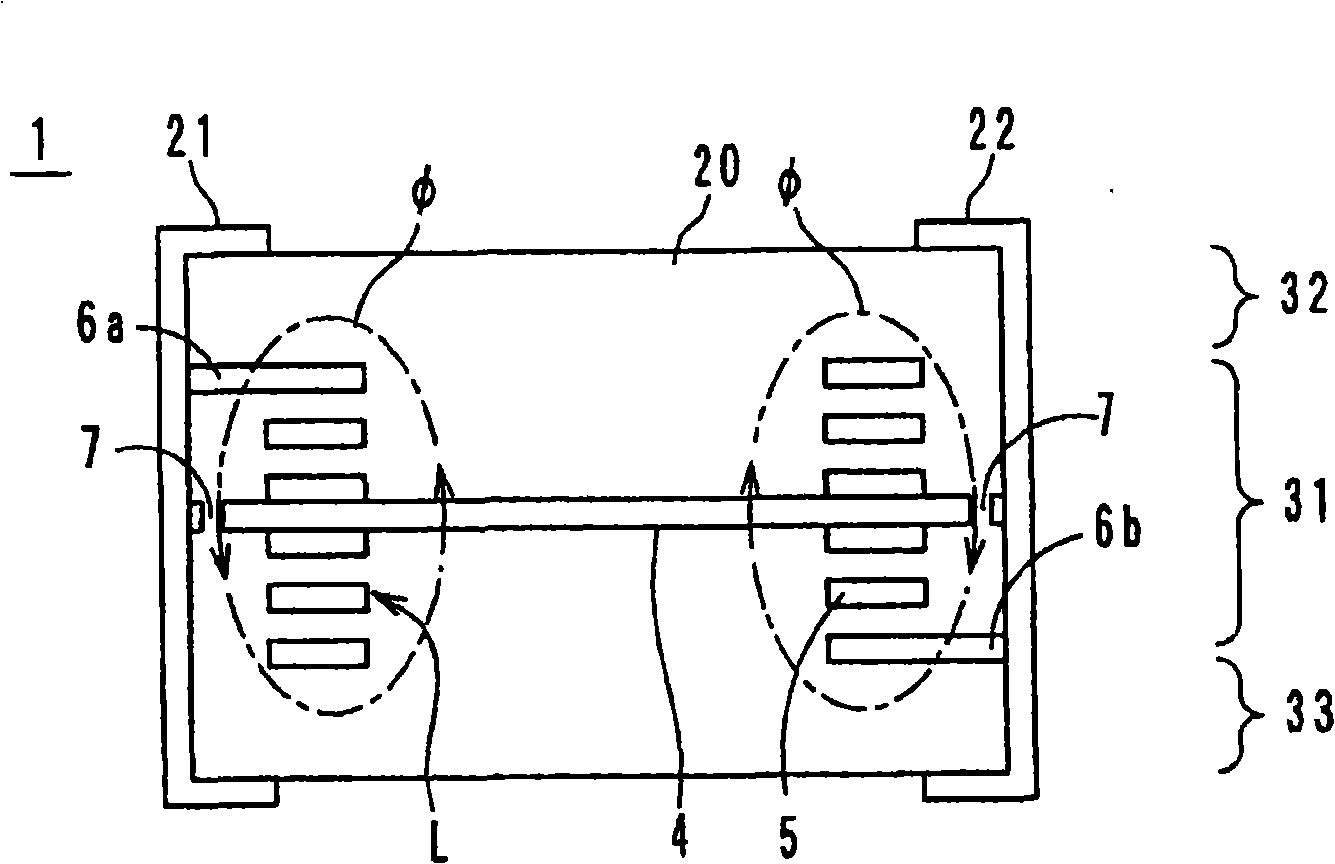

Electronic component

ActiveUS20190237259A1Inhibit the generation of cracksCrack suppressionFixed capacitor electrodesFixed capacitor dielectricElectronic componentMetal

An element body of a rectangular parallelepiped shape includes a principal surface arranged to constitute a mounting surface, a pair of side surfaces opposing each other and adjacent to the principal surface, and a pair of end surfaces opposing each other and adjacent to the principal surface and the pair of side surfaces. An external electrode includes a sintered metal layer disposed on an end portion of the element body, and a conductive resin layer including a portion positioned on the principal surface and a portion positioned on the sintered metal layer. An end edge of the sintered metal layer is positioned closer to the end surface than a maximum thickness position of the portion positioned on the principal surface. A thickness of the conductive resin layer gradually decreases from the maximum thickness position to the portion positioned on the sintered metal layer.

Owner:TDK CORPARATION

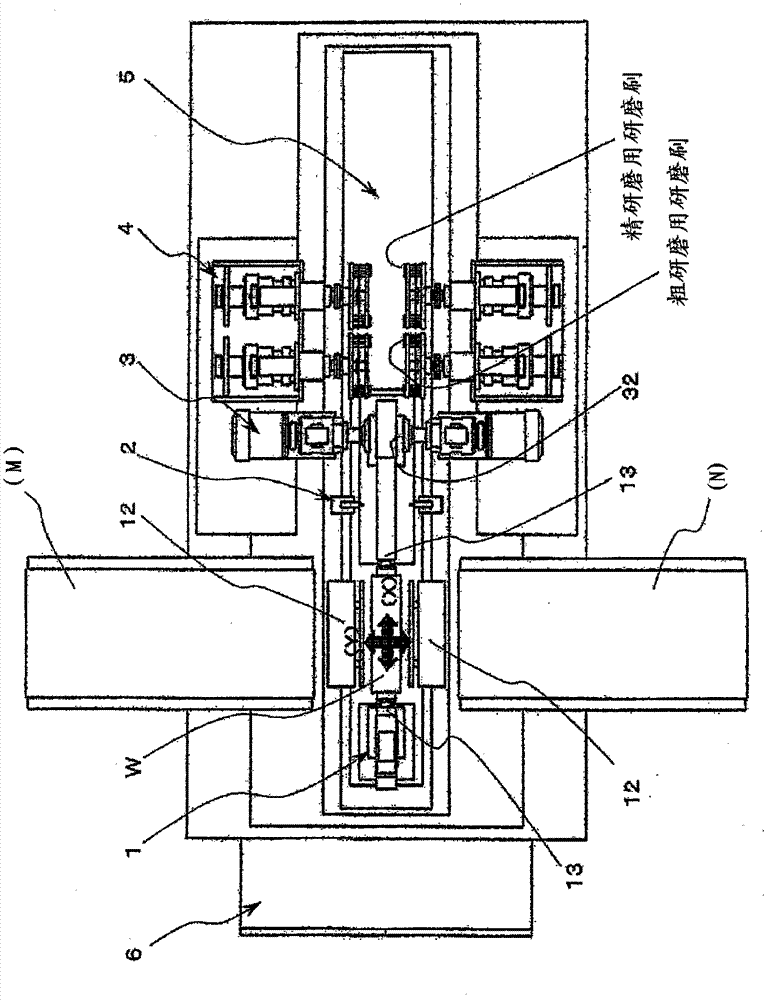

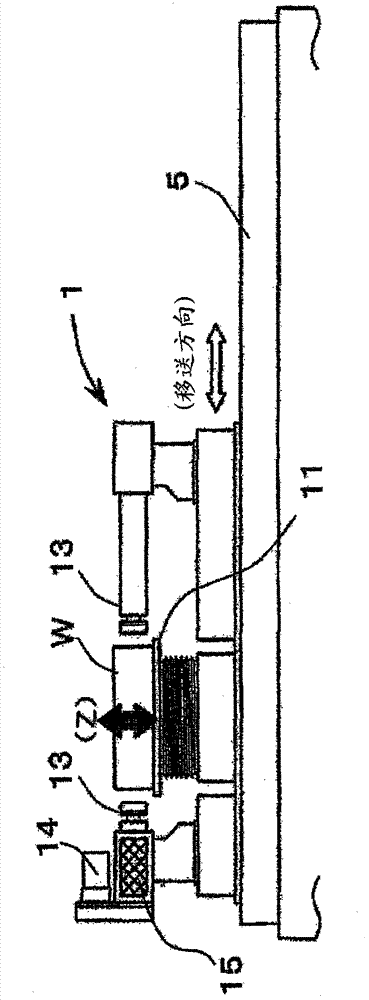

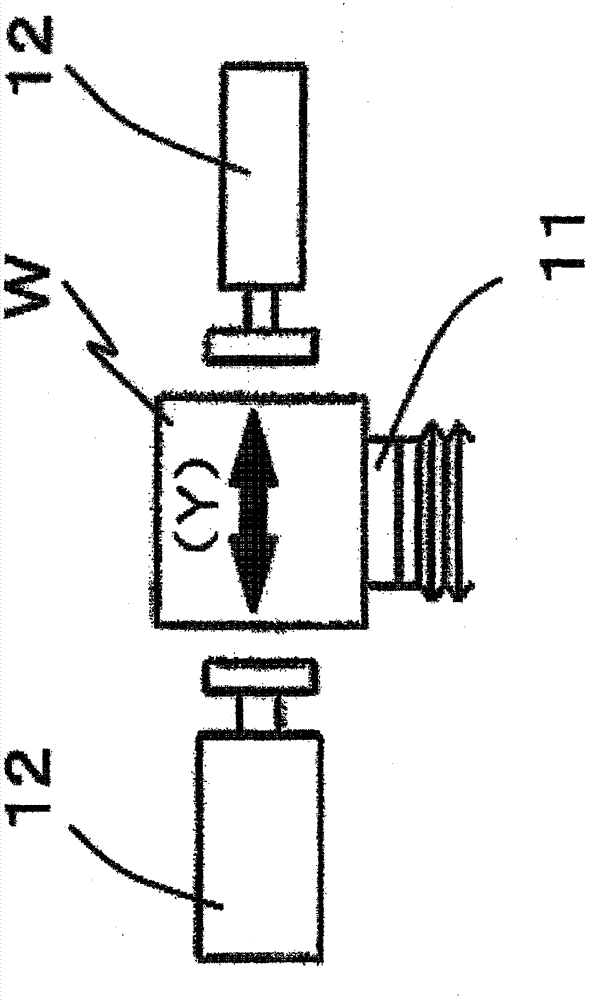

Grinding/polishing device for polygonal column member and grinding/polishing method

ActiveCN102791425AReliable grindingReduce manufacturing costEdge grinding machinesPolishing machinesSurface layerIngot

Provided are: a silicon block grinding / polishing device comprising a grinding function capable of grinding a square column-shaped silicon block within tolerance ranges of +-0.5 mm for the cross-section dimensions thereof and +-0.1 DEG for the perpendicular angles thereof, said block having been formed by cutting a silicon ingot using a wire saw, and comprising a polishing function capable of removing micro cracks in the surface layer of the cut silicon block (W); and a processing method therefor. The device comprises: a holding means (1) that holds the silicon block (W); a measuring means (2) that measures the cross-section dimensions of the silicon block (W); a grinding means (3) that grinds the planar sections (F) and the angular sections (C) of the silicon block (W); a polishing means (4) that polishes the planar sections (F) and the angular sections (C) of the silicon block (W) which has completed grinding and removes micro cracks; a transfer means (5) that transfers the holding means (1) holding the silicon block (W), between the measuring means (2), the grinding means (3), and the polishing means (4); and a control means (6) that operates each of the means.

Owner:SINTOKOGIO LTD

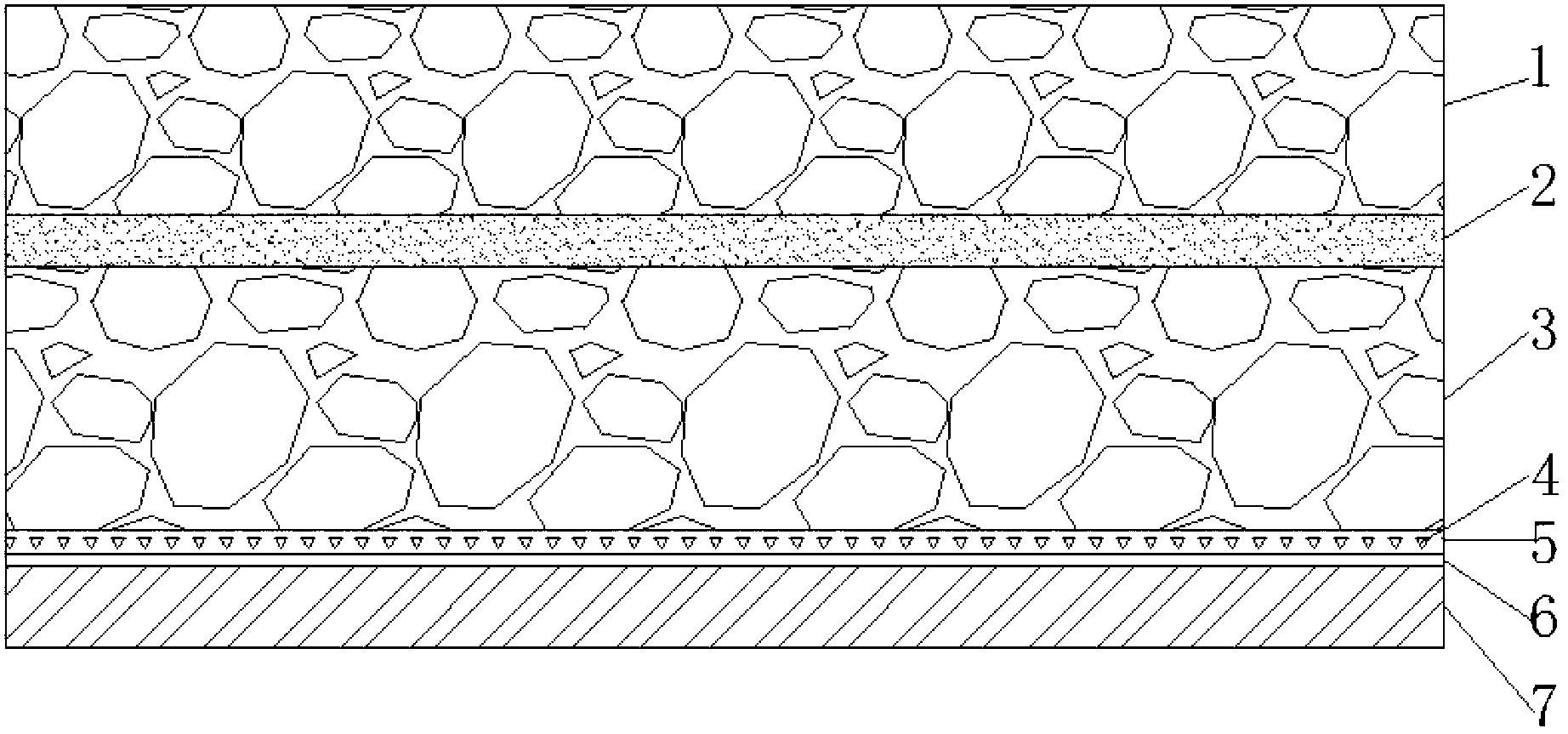

Asphalt concrete steel bridge pavement structure and pavement method thereof

ActiveCN103015316ASolve the problem of permanent deformationStrong adhesionBridge structural detailsBridge erection/assemblySand blastingViscosity

The invention discloses an asphalt concrete steel bridge pavement structure comprising a steel bridge (7) derusted by sandblast, an anticorrosive coating (6), a binding layer (5), high-viscosity asphalt embedded compact granular composition concrete bottom layer (3), an oil sticking layer (2) and a high-viscosity asphalt embedded and compact granular composition concrete top layer (1) which are arranged from bottom to top; and furthermore, the invention also provides a pavement method of the asphalt concrete steel bridge pavement structure. According to the asphalt concrete steel bridge pavement structure, the high-viscosity asphalt embedded compact granular composition concrete layers are used as main pavement layers, so that concrete has favorable interlayer binding force and deformation following performance, the generation of cracks can be restrained, so that the whole steel bridge pavement structure has the advantages of favorable track resistance and water seepage resistance.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com