Patents

Literature

218results about How to "Guaranteed forming quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

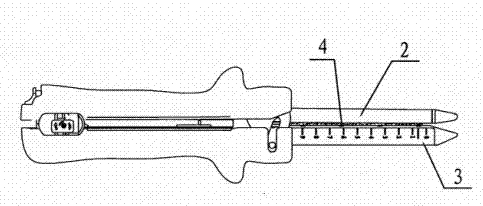

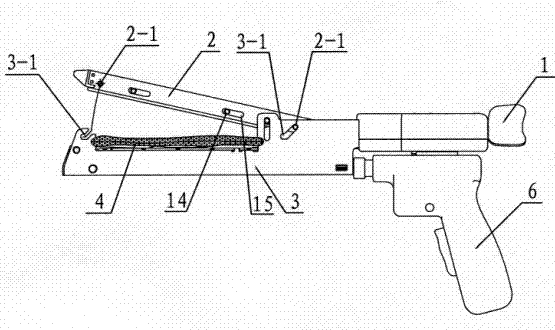

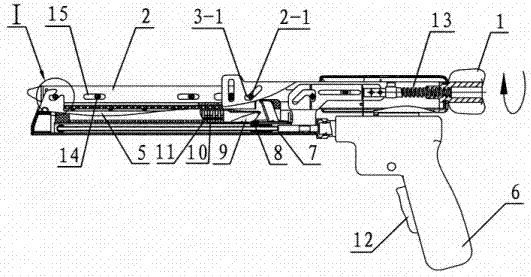

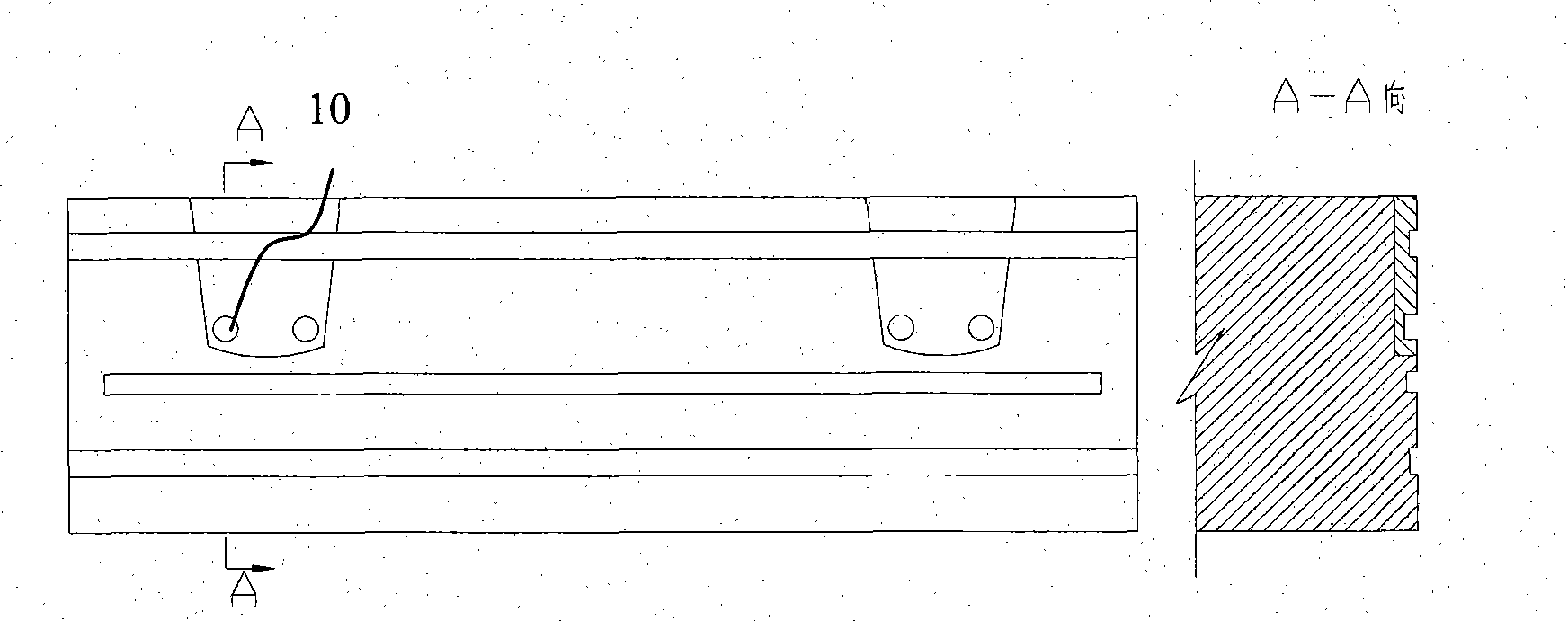

Cutter stapler for surgery

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

Method for removing cracks of Rene104 nickel-based superalloy during laser additive manufacturing

ActiveCN108941560AEliminate cracksInhibition of large size cracksAdditive manufacturing apparatusTransportation and packagingRoom temperatureStress relief

Owner:CENT SOUTH UNIV

Metal laser selective melting method

InactiveCN105665704AQuick scanEnsure surface refinementAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningMetal powder

The invention provides a metal laser selective melting method. The metal laser selective melting method is characterized in that two kinds of lasers with different powers are adopted for conducting laser melting on metal powder zones needling to be melted; during melting, the lasers with the low power firstly conduct scanning on outline boundaries of the metal powder zones; then the lasers with the high power conduct scanning on internal zones of the metal powder zones; and during scanning, the thickness of a metal powder layer obtained by scanning with the lasers with the high power one time is integral multiples of the thickness of the metal powder layer obtained by scanning with the lasers with the low power one time. According to the metal laser selective melting method, the efficiency of the laser molding process is improved, and meanwhile, the surface quality of a metal part is guaranteed; and in other words, while the stability and the molding quality of the overall process are guaranteed, the building speed of metal laser selective melting equipment is improved as a whole.

Owner:ANHUI TUO BAO ADDITIVE MFG TECH CO LTD

Method for improving precision of stepped components in laser spot-changing direct formation mode

ActiveCN104923784APlay a compensatory roleSolve the problem of inconsistent growth heightAdditive manufacturing apparatusIncreasing energy efficiencyLifting capacitySpray nozzle

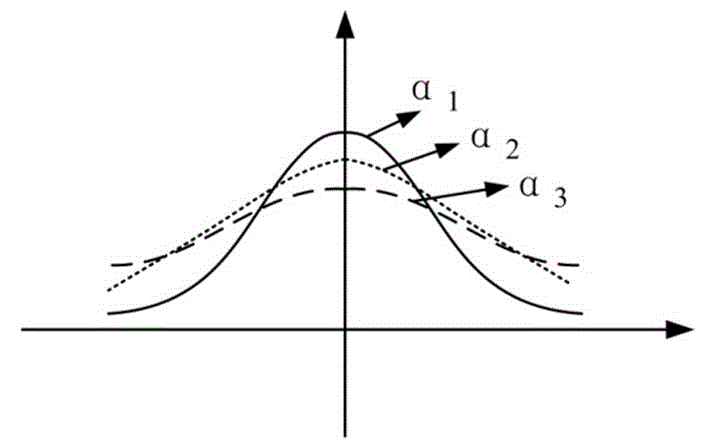

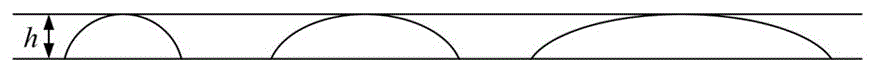

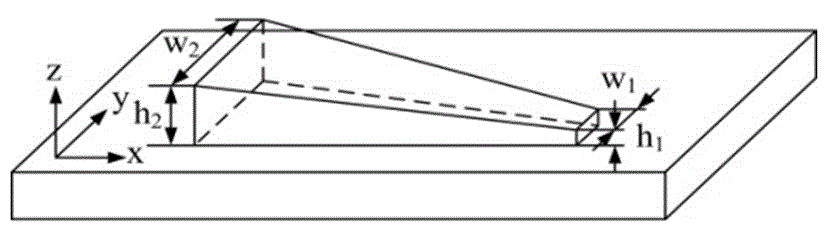

The invention discloses a method for improving precision of stepped components in a laser spot-changing direct formation mode. The method includes the steps that a cladding test is performed firstly, the sectional width and height data of a single-track cladding layer under different technological parameters are obtained, orders of a sectional curve of the cladding layer under different aspect ratios are fitted out, and the function relationship between the orders of the sectional curve of the cladding layer under the different aspect ratios and the height and lifting capacity of the single-track cladding layer is built; then single step-shaped tracks corresponding to the same lifting capacity are built, the technological parameters of the laser spot-changing cladding single tracks are determined according to the single step-shaped tracks, and a highly-smooth cladding layer is formed in a cladding mode through laser spot-changing direct formation; after one cladding layer is completed, a spray nozzle is lifted by a layering height, new fusion tracks are formed in a cladding mode through the single step-shaped tracks, and operations circulate until manufacturing of a three-dimensional part is completed. By means of the method, the highly-smooth cladding layer is obtained, the phenomenon that the top of the cladding layer is not even and portions of small aspect ratios are prone to tension fracture is avoided, and the method improves formation precision and guarantees formation quality.

Owner:KUSN BAOJIN LASER TAILOR WELDED

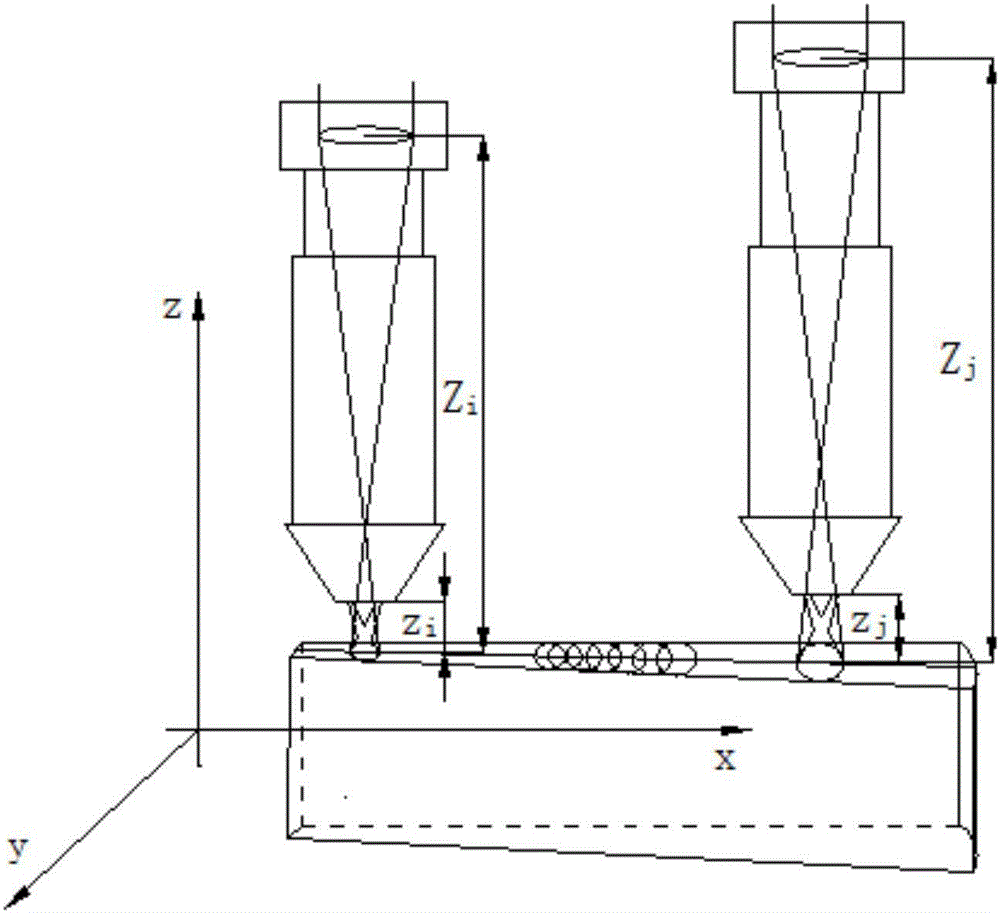

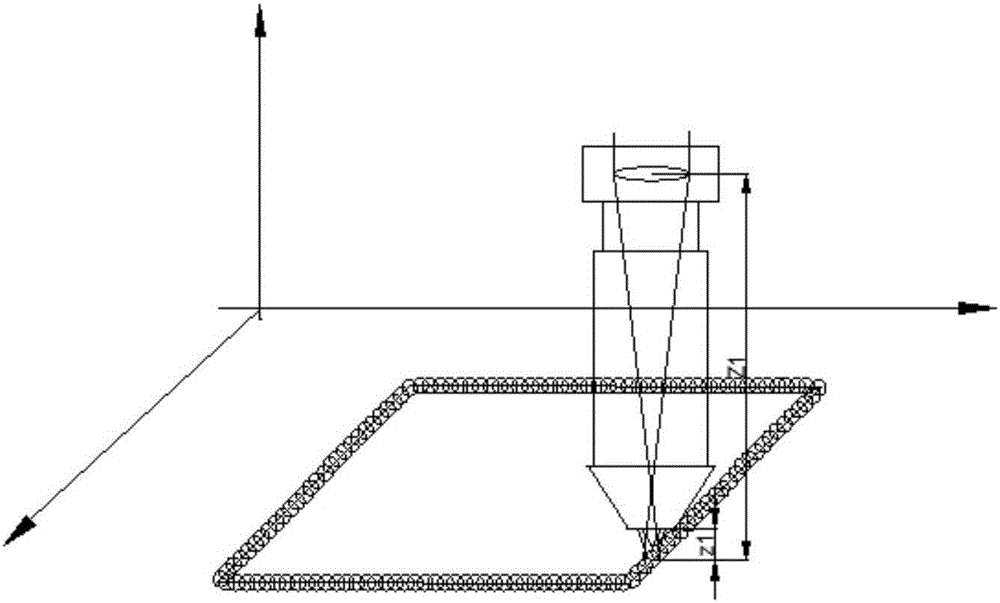

Light spot and powder spot automatic collaboration controlled laser metal added material manufacturing device and method

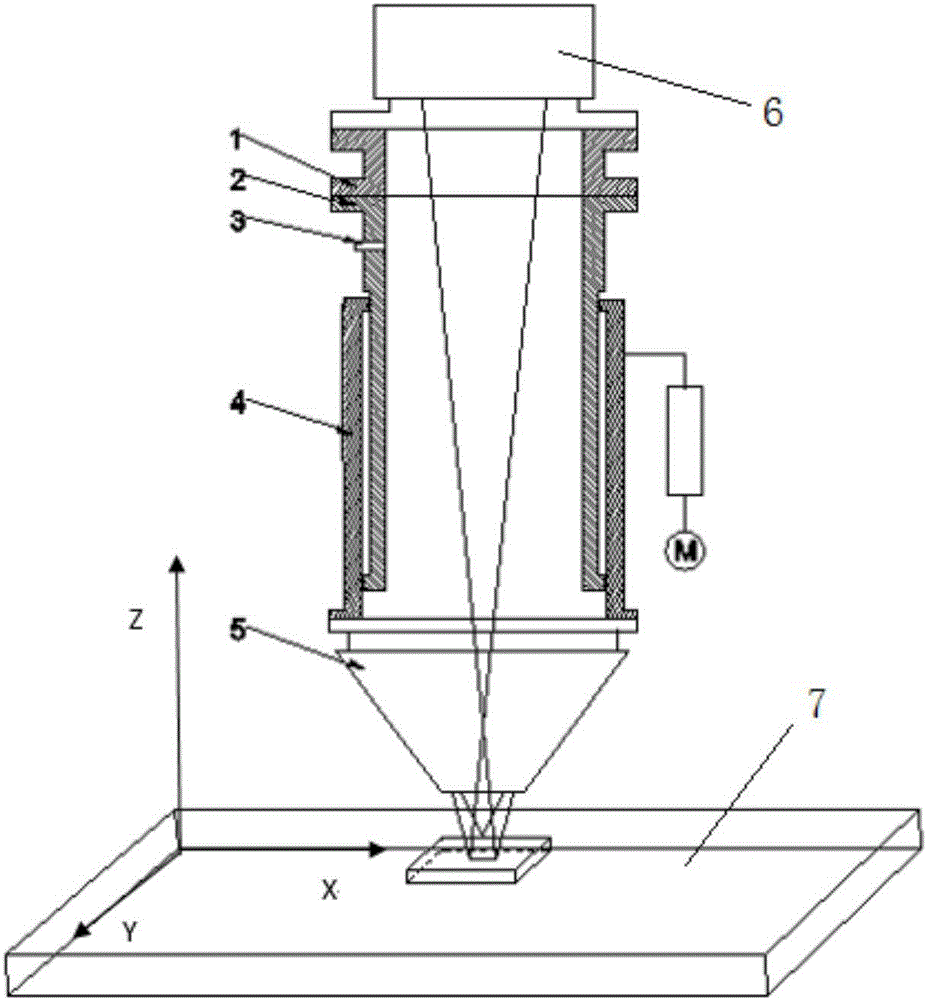

ActiveCN106513676AImprove matchThe cladding process is stableAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlAdditive layer manufacturing

The invention discloses a light spot and powder spot automatic collaboration controlled laser metal added material manufacturing device and a method. The device comprises a connecting joint, a laser focusing head and a sleeve respectively fixed at the upper end and the lower end of the connecting joint, a mobile sleeve slidingly coating the sleeve, a powder feeding nozzle fixed at the lower end of the mobile sleeve, and a numerical control worktable for placing workpieces; the laser focusing head is used for forming light spots on workpiece machined surfaces of a focusing mirror; the powder feeding nozzle is used for gathering powder currents to feed in a machining position to form powder spots on the workpiece machined surfaces; the centers of the light spots and the powder spots are overlapped always; the numerical control worktable is used for driving the workpieces to perform the space movement corresponding to the focusing mirror to control the out-of-focus distance; and a driving device is arranged on the mobile sleeve for driving the powder feeding nozzle to move up and down through the mobile sleeve to control the sizes of the powder spots. When the method forms thick and large workpieces with the cladding layer sizes exceeding the adjusting range, the profile scanning and filling scanning combined path formation is adopted.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

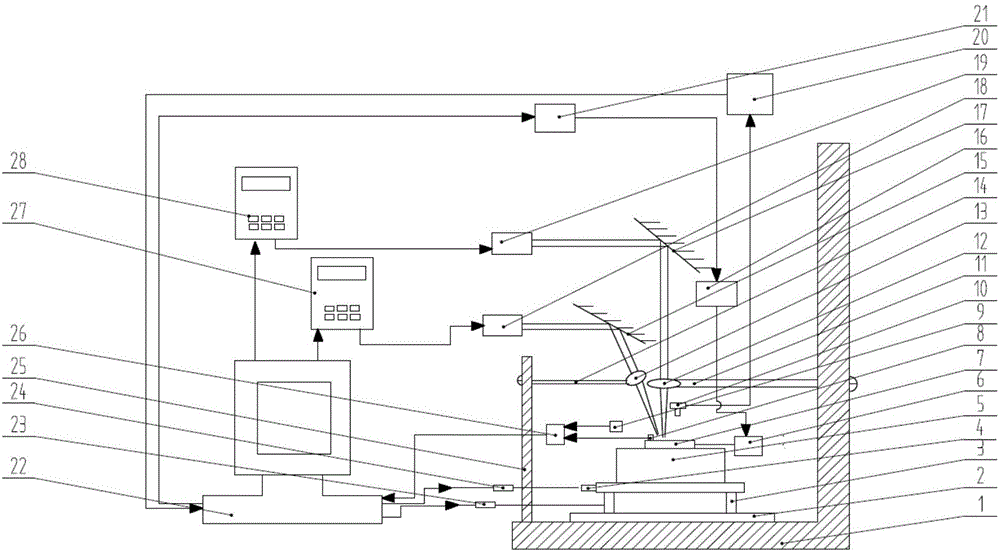

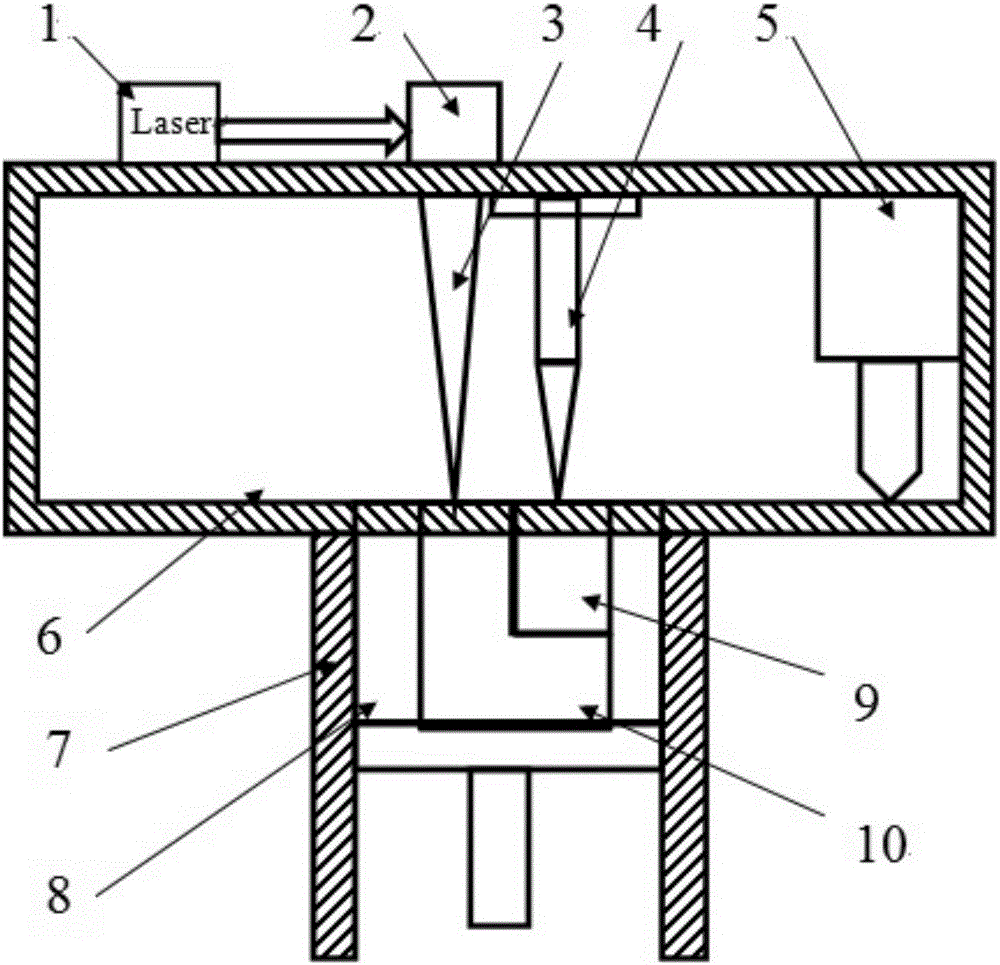

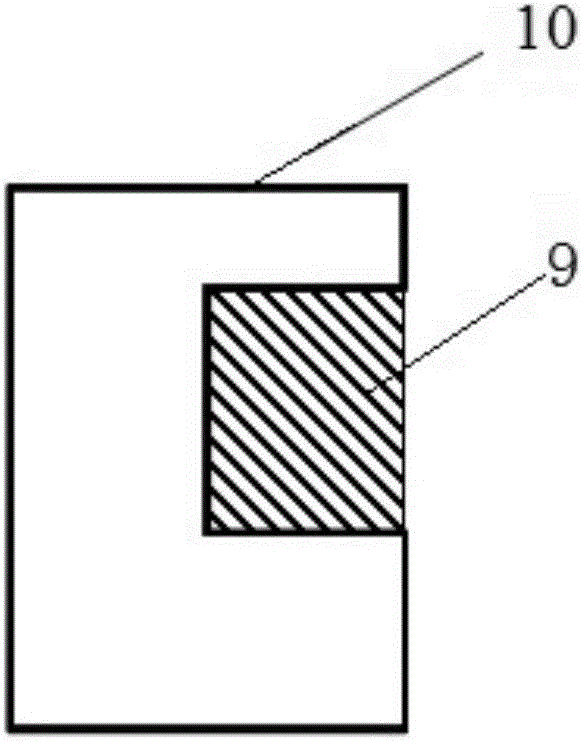

Novel laser indirect impact micro-forming device and method

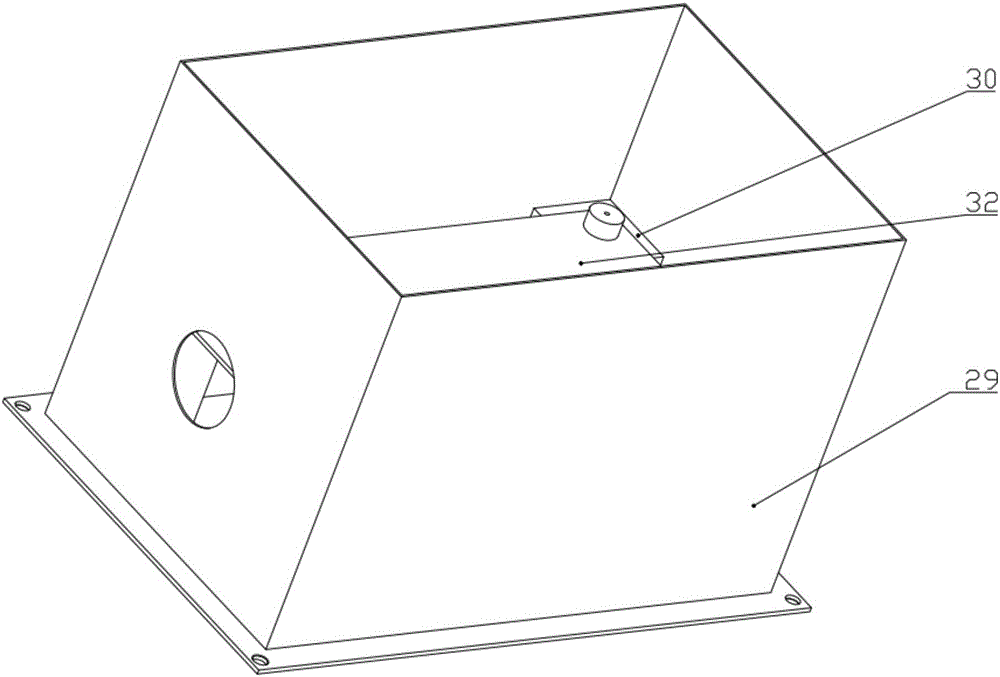

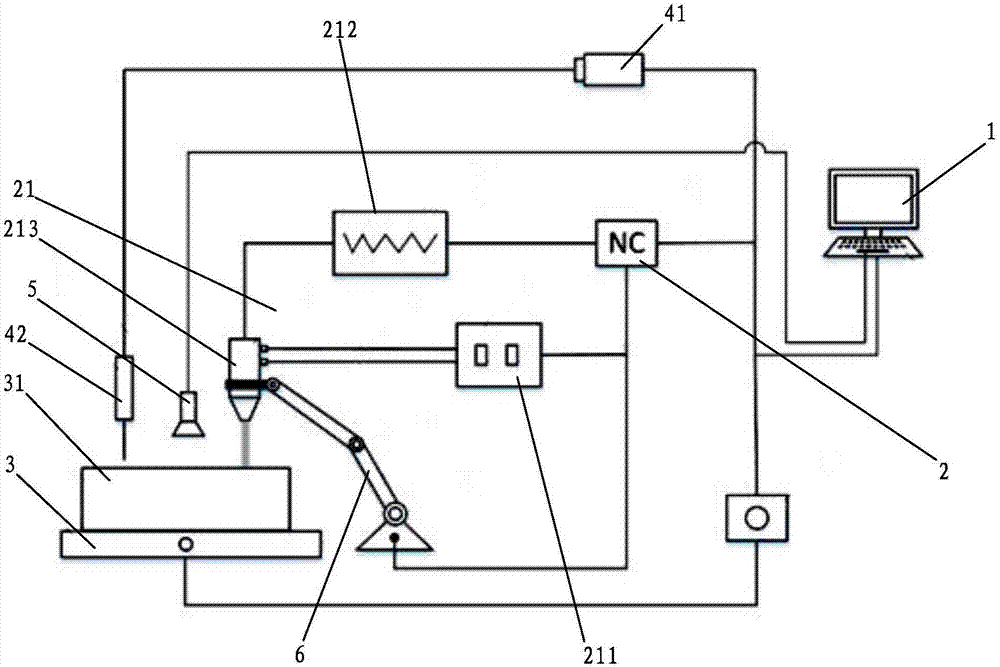

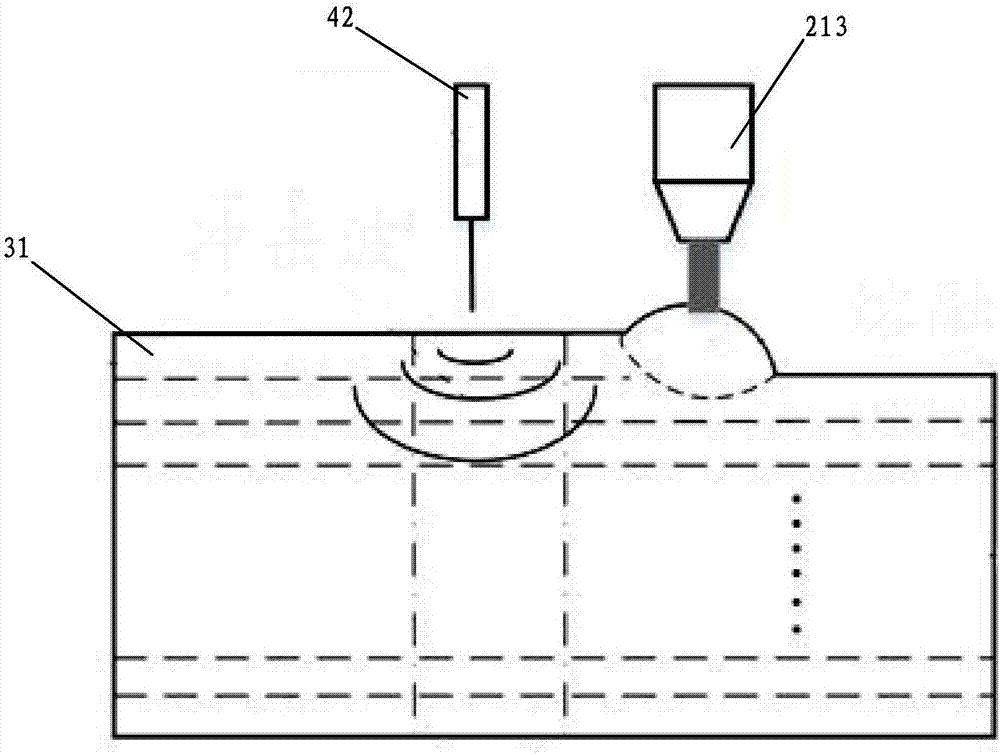

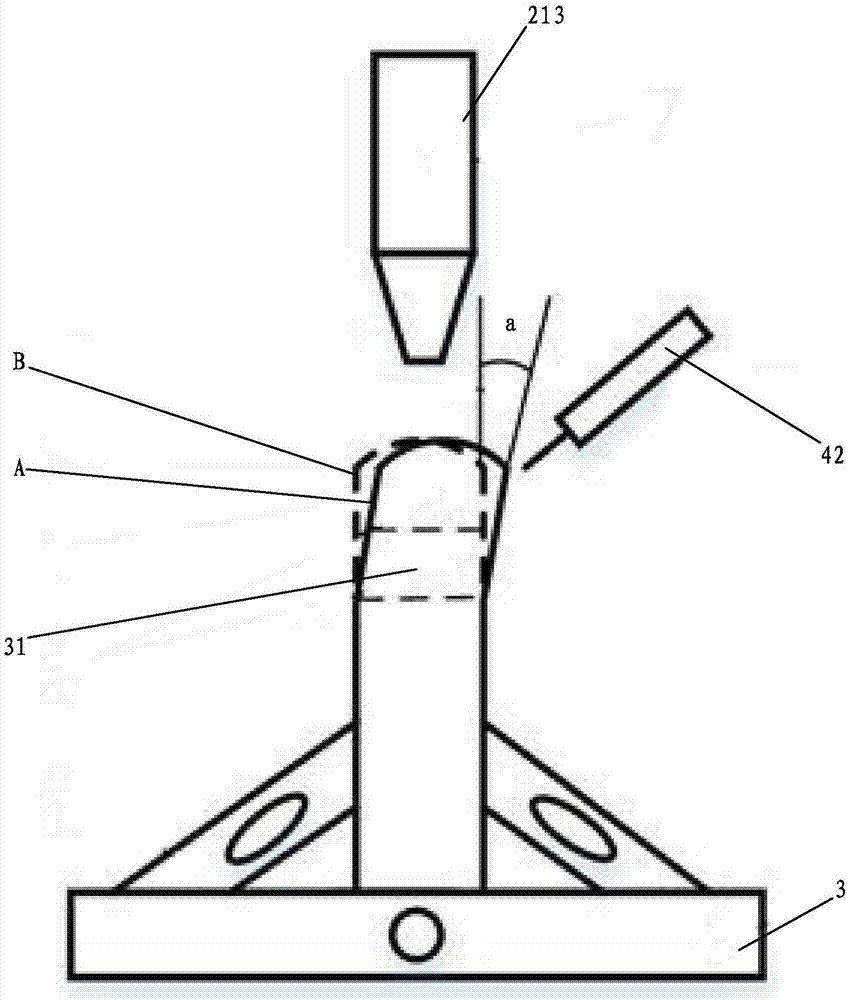

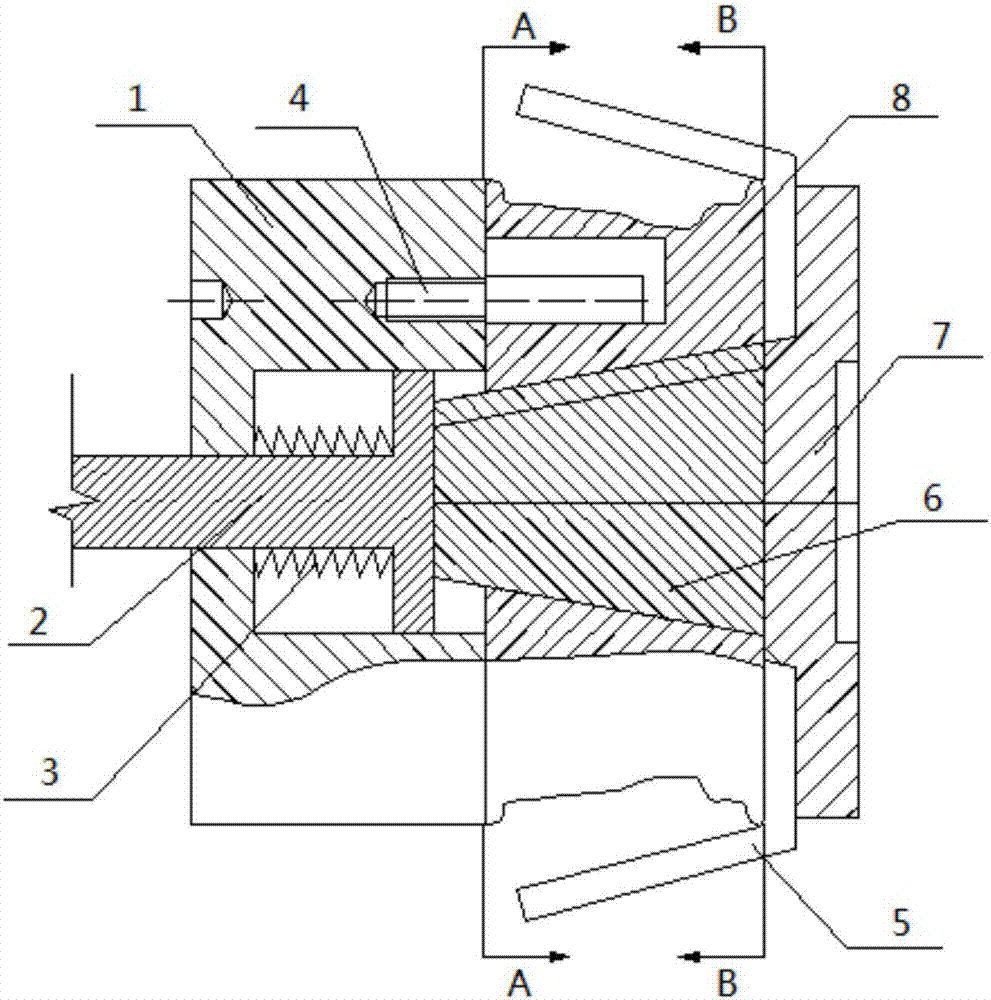

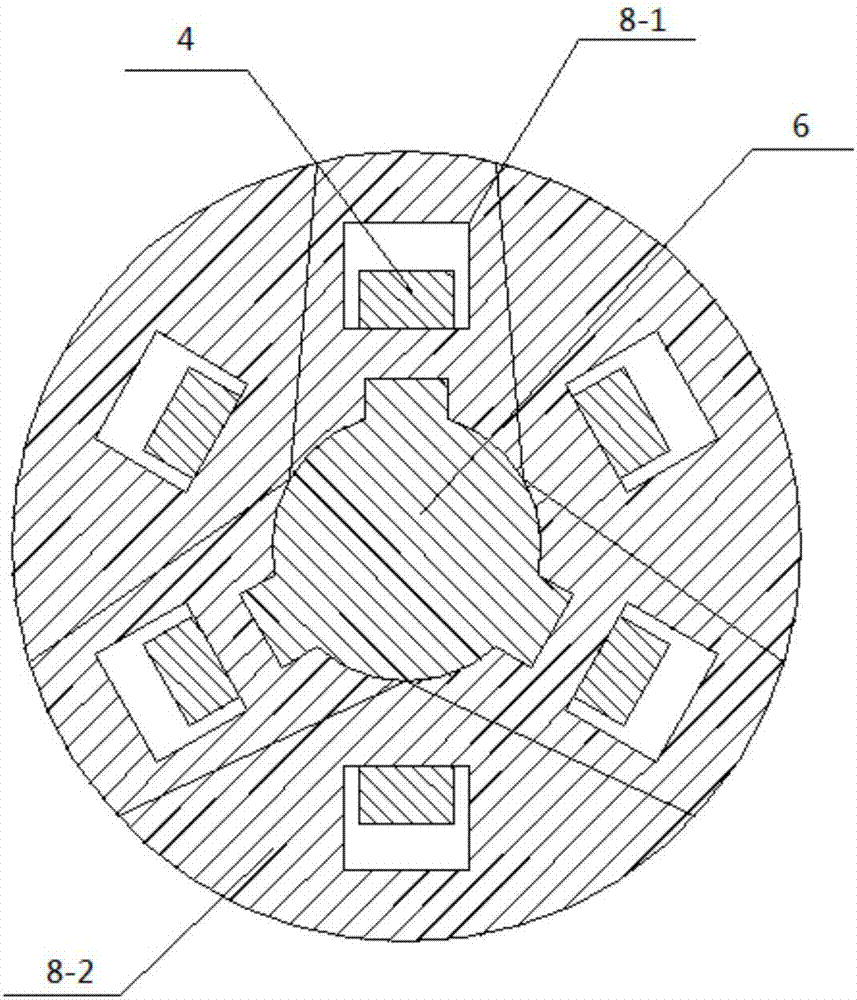

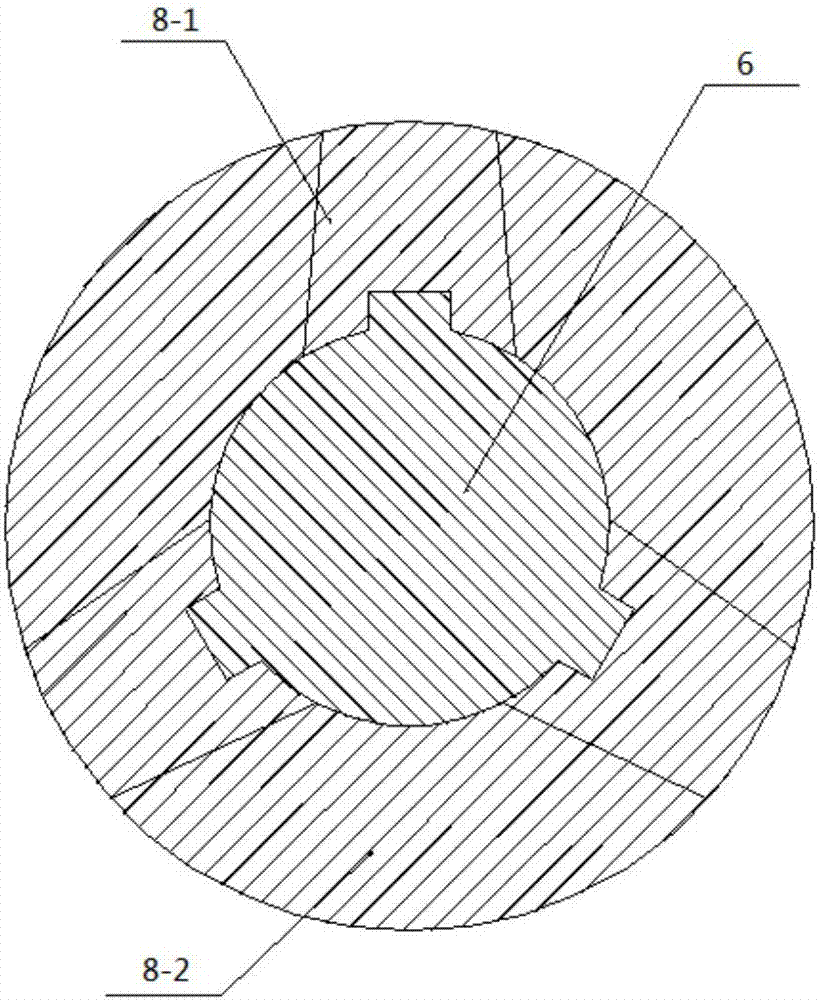

InactiveCN107520538AGuaranteed forming qualityReduce scrap rateLaser beam welding apparatusControl systemContact type

The invention discloses a novel laser indirect impact micro-forming device and method. The device and method are mainly applied to plastic forming technique and manufacturing of fine micro parts. The device and method solve the problem that a conventional laser impact micro-forming method is difficult in forming, and materials cannot be formed. The device comprises a mold-debug light spot centering assembly, a workpiece positioning assembly, a workpiece assembly, an Nd:YAG pulsed laser system used for impact forming, a CW optical fiber laser system used for heating, an ultrasonic vibration system and a control system. The device can achieve the aim that pulsed laser impact force is adopted to serve as an energy source, meanwhile, ultrasonic vibration is applied to a mold and a workpiece, or, a laser beam sent out by a CW optical fiber laser is used for carrying out non-contact type quasi-static heating on the surface of the workpiece, or, under the joint effect, workpiece micro-forming is achieved; due to the design, work efficiency is improved, design is reasonable, control performance is good, quality and precision of micro-forming parts are ensured, and the device is suitable for industrialized application.

Owner:JIANGSU UNIV

Rapid electric arc fused deposition and laser shock forging combined part forming method and device

ActiveCN107262930AGrain refinementGuaranteed forming qualityAdditive manufacturing apparatusArc welding apparatusNumerical controlEngineering

Owner:GUANGDONG UNIV OF TECH

Method and device for manufacturing metal additive materials

ActiveCN105834422AGuaranteed forming qualitySimple structureAdditive manufacturing apparatusIncreasing energy efficiencyOrganic solventMetal powder

The invention discloses a method for manufacturing metal additive materials. The method includes the steps that a part structure and a supporting structure are built layer by layer, wherein the supporting structure is built by using an adhesive agent for bonding metal powder materials; and after part formation is completed, the adhesive agent is melted by high-temperature heating or dissolved by an organic solvent, and the supporting structure is removed. The invention further discloses a device for manufacturing the metal additive materials, and the device is included in the method. The device comprises a high-energy beam source, an optical unit, a forming chamber, a forming cylinder and a powder laying device, wherein the forming cylinder and the powder laying device are located in the forming chamber; the forming chamber is further provided with an adhesive spraying device which is used for providing the adhesive agent needed for building the supporting structure included in the method. The supporting structure built by the adoption of the method and device can be removed only by making the adhesive agent melted with high-temperature heating or dissolved with the organic solvent after part formation is completed, and no subsequent machining treatment is needed, so that cost for the subsequent treatment is reduced, and the forming efficiency is improved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

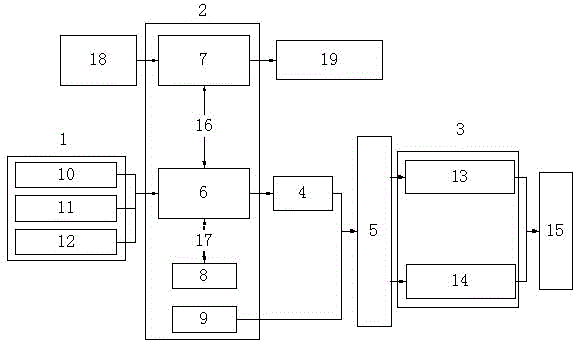

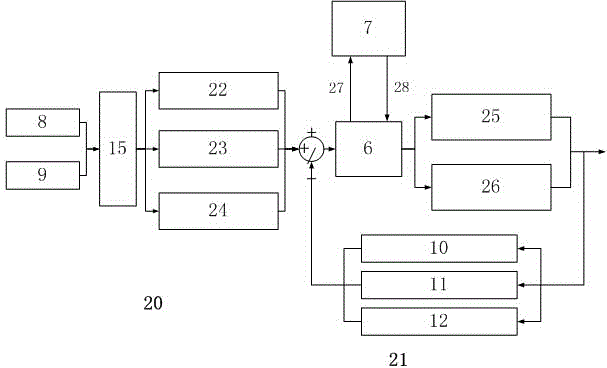

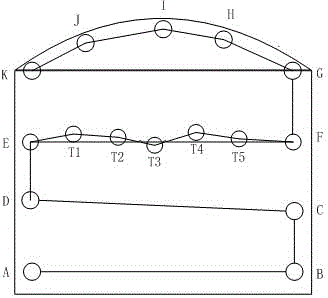

Heading machine memory cutting control system and method thereof

InactiveCN103147756AReduce labor intensityImprove efficiencySlitting machinesAutomatic controlControl function

The invention relates to a heading machine memory cutting control system and a method of the heading machine memory cutting control system. The heading machine memory cutting control system is composed of a detection unit, a control unit, a proportion amplification plate, a load sensitivity type proportion reversal valve group and an execution unit, wherein the control unit comprises a PCC (programmable computer controller), an intelligent operation control panel, a remote controller and a machine body operating handle; and heading machine memory cutting comprises a manual demonstration process and a memory automatic cutting process. The method comprises the following steps that: firstly, a heading machine driver utilizes the remote controller or the machine body operating handle to operate the heading machine to cut once according to a top plate and a bottom plate of a coal seam and the coal rock distribution condition, and an airborne computer control system records information a demonstration path detected by the detection unit; and then the recorded keypoint data is subjected to path matching and intelligent optimization, a control signal is sent to the execution unit according to the path after optimizing, so that a cutting head is automatically controlled to move along a demonstration track, and the memory automatic cutting is performed. The heading machine memory cutting control system is also provided with a boundary control function in the whole memory cutting process, and the tunnel shaping quality when the manual cutting and memory automatic cutting are performed is ensured. The heading machine memory cutting control system and the method of the heading machine memory cutting control system provide a new control means for heading of a coal road boom-type roadheader under the condition with stable surrounding rock of roadway.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

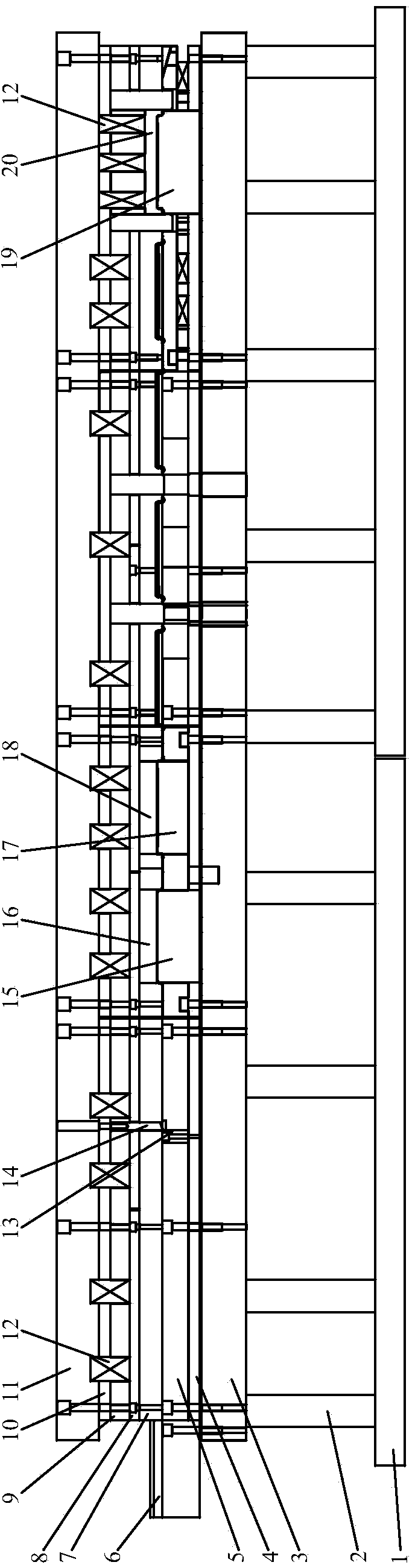

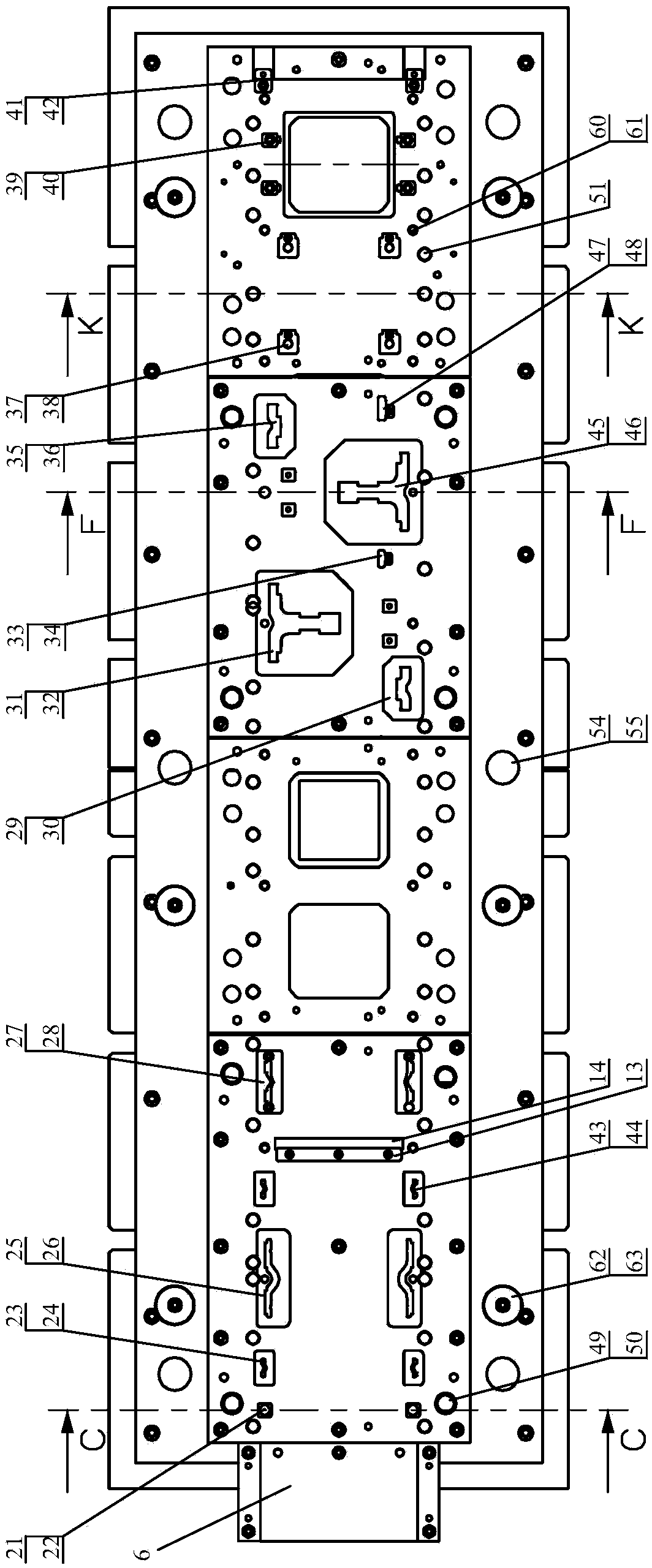

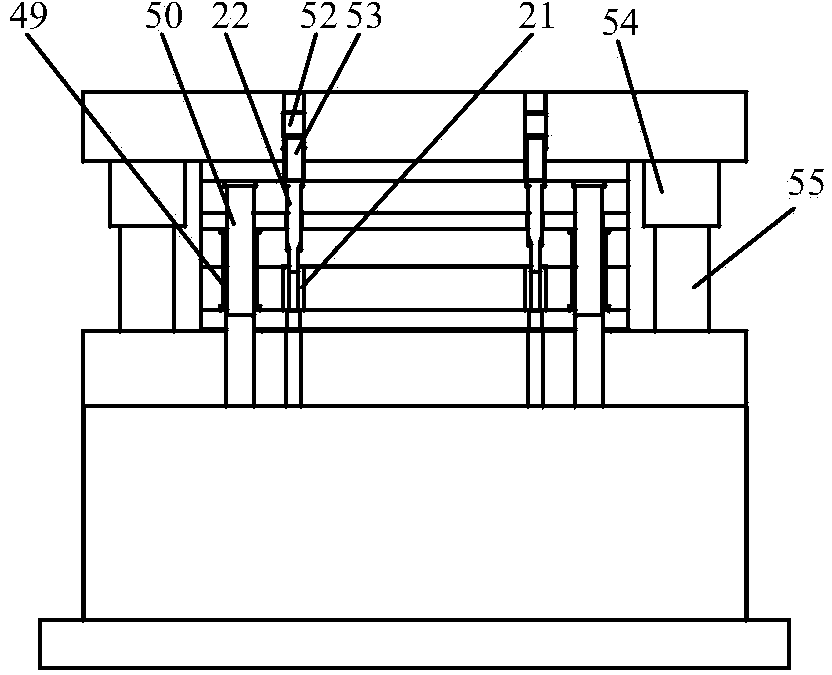

Suspension supporting base multi-station progressive die

ActiveCN103962452ACompact structureHigh guiding precisionShaping toolsPerforating toolsPunchingEngineering

The invention relates to a suspension supporting base multi-station progressive die which comprises an upper die assembly, a lower die assembly, an unloading plate, an unloading plate base plate and a mis-feeding detection device. The upper die assembly is sequentially provided with a corresponding male die in the feeding direction, the lower die assembly is sequentially provided with a female die embedding sleeve matched with the male die of the upper die assembly, corresponding positions on the unloading plate and on the unloading plate base plate are provided with a through hole capable of penetrating through the male die of the upper die assembly, the unloading plate is disposed on the unloading plate base plate, and the unloading plate base plate is arranged on the upper die assembly through an unloading spring. By means of the progressive die, suspension supporting bases are produced in a continuous drawing progressive die mode. The mechanism is compact in structure, high in guide precision, stable in unloading and precise in pitch fixing, and feeding and discharging are convenient to achieve. A quick replacement structure is adopted to a punching male die, and maintenance and replacement time of the die is effectively shortened. After being tried, the mechanism is good in use effect and can meet requirements for high efficiency and high precision of stamping production.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

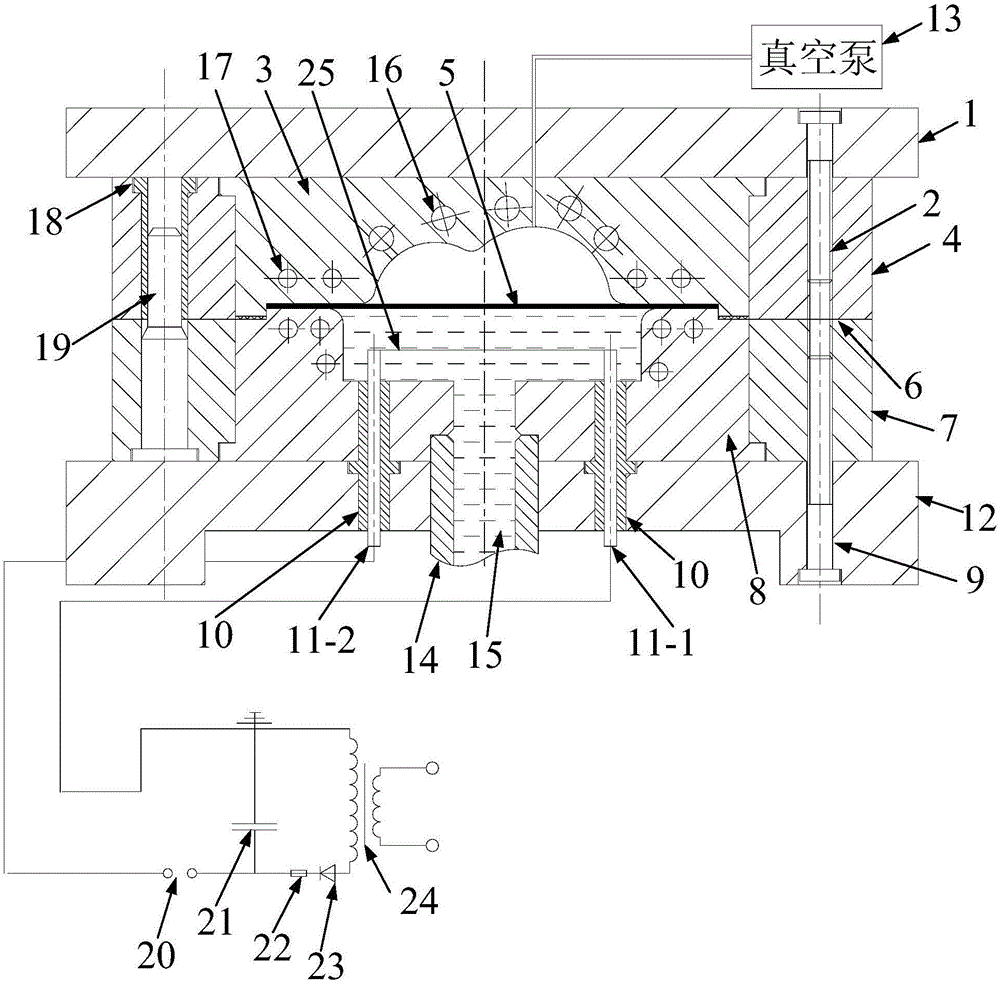

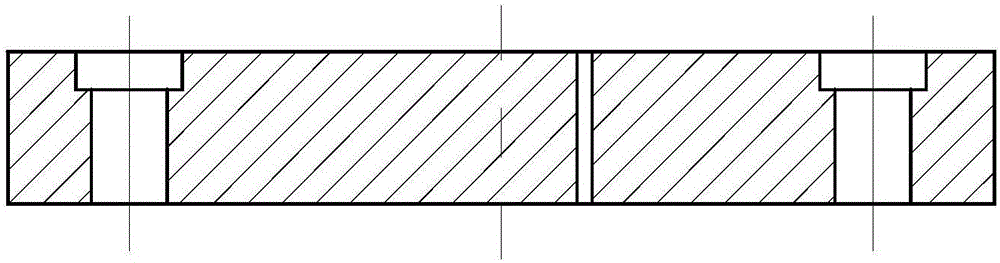

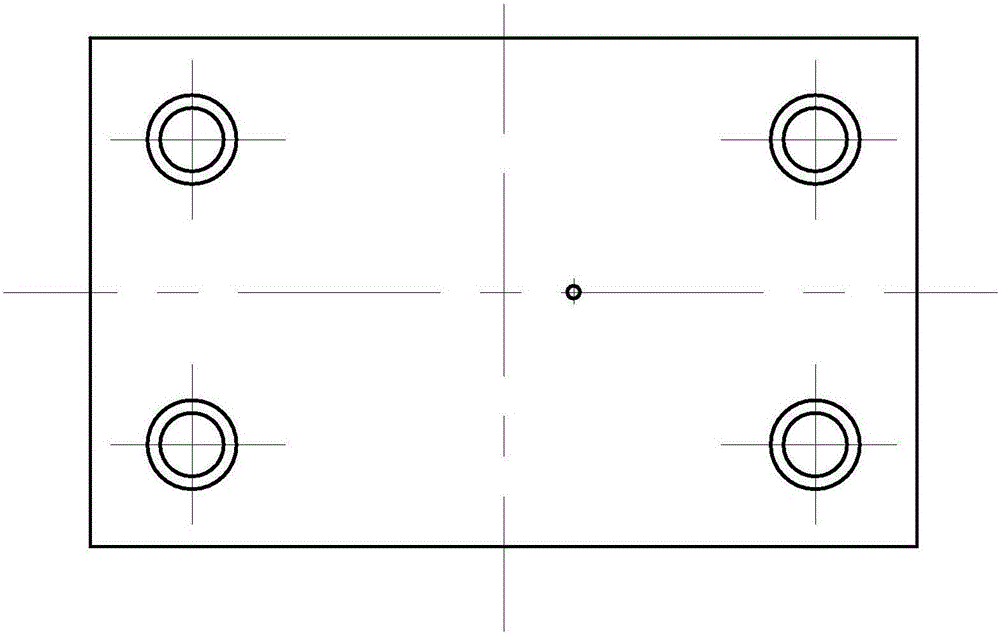

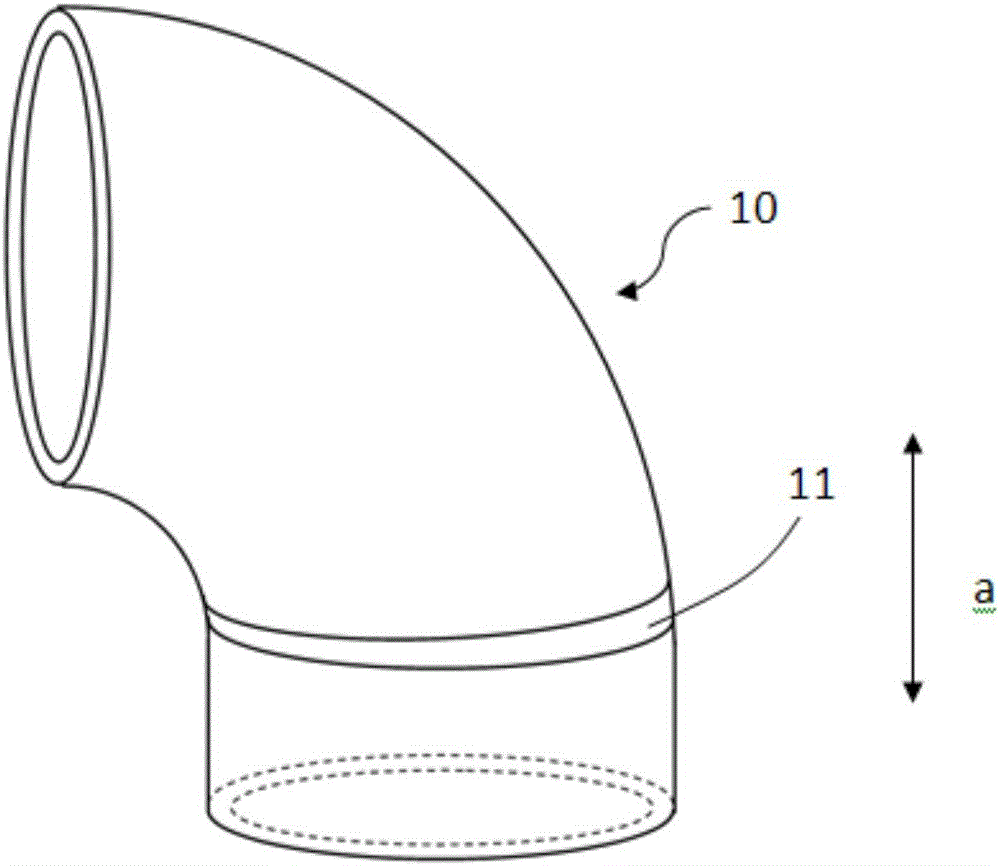

Plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and plate forming method achieved by adopting device

InactiveCN106734499AGuaranteed forming qualityAvoid crackingShaping toolsElectro hydraulicEngineering

The invention discloses a plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and a plate forming method achieved by adopting the device and relates to the field of metal material processing forming to solve the problems that forming of plates and complex parts is difficult, film attaching is poor, and deformation is not even. A vacuum pump is used for pumping out gas in a female die cavity; a fluid injection device is adopted for injecting high-temperature-resisting liquid to a liquid chamber; a heating device is used for heating the female die cavity, the high-temperature-resisting liquid in the liquid chamber is heated, preheating on a to-be-processed plate is completed, and heat preservation is conducted on the to-be-processed plate; an electromagnetic forming system is used for conducting discharging forming on the to-be-processed plate; high-pressure warm liquid is slowly injected into the liquid chamber under the quasi static condition, and quasi static hydraulic forming is conducted on the to-be-processed plate; and the high-pressure warm liquid in the liquid chamber is cooled to the room temperature within a period of time, waste liquid is recycled, an electro-hydraulic forming die is opened, and the to-be-processed plate is taken away. The device and the method are used for forming plates.

Owner:XIANGTAN UNIV

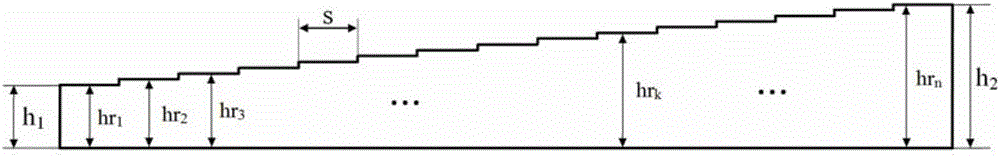

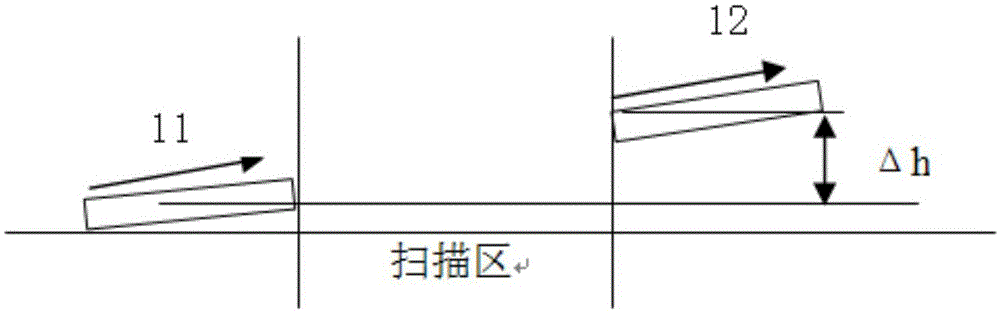

Method for forming uniformly-variable-height component through laser

ActiveCN106216678ARealize closed-loop controlConstant widthAdditive manufacturing apparatusIncreasing energy efficiencyLoop controlClosed loop

The invention relates to a method for forming a uniformly-variable-height component through laser. According to the method, each cladding layer is segmented through normal direction layering, then, the difference value between the actual stacking height of each small segment of each layer and the ideal stacking height of the small segment is measured and calculated, the scanning speed of each small segment of the next cladding layer is corrected through calculating, and thus closed-loop control of the cladding layer height is achieved; the cladding layers with continuously variable heights can be automatically formed through the method for forming the uniformly-variable-height component through the laser, meanwhile, the width of the cladding layers is kept to be constant, the bevel step effect is eliminated, the complexity and the forming efficiency of the laser 3D forming component are improved, and the forming quality is ensured. Compared with the prior art, the uniformly-variable-height component formed through the method is high in stability and precision, a lot of earlier-stage cladding layer orthogonal tests are omitted, a large amount of time can be saved, and a large amount of cost can be reduced. The forming process is completed fully automatically, process parameters can be subjected to self adaptation and correction according to feedback data of a layer-height control sensor, and manual intervention can be avoided.

Owner:SUZHOU UNIV

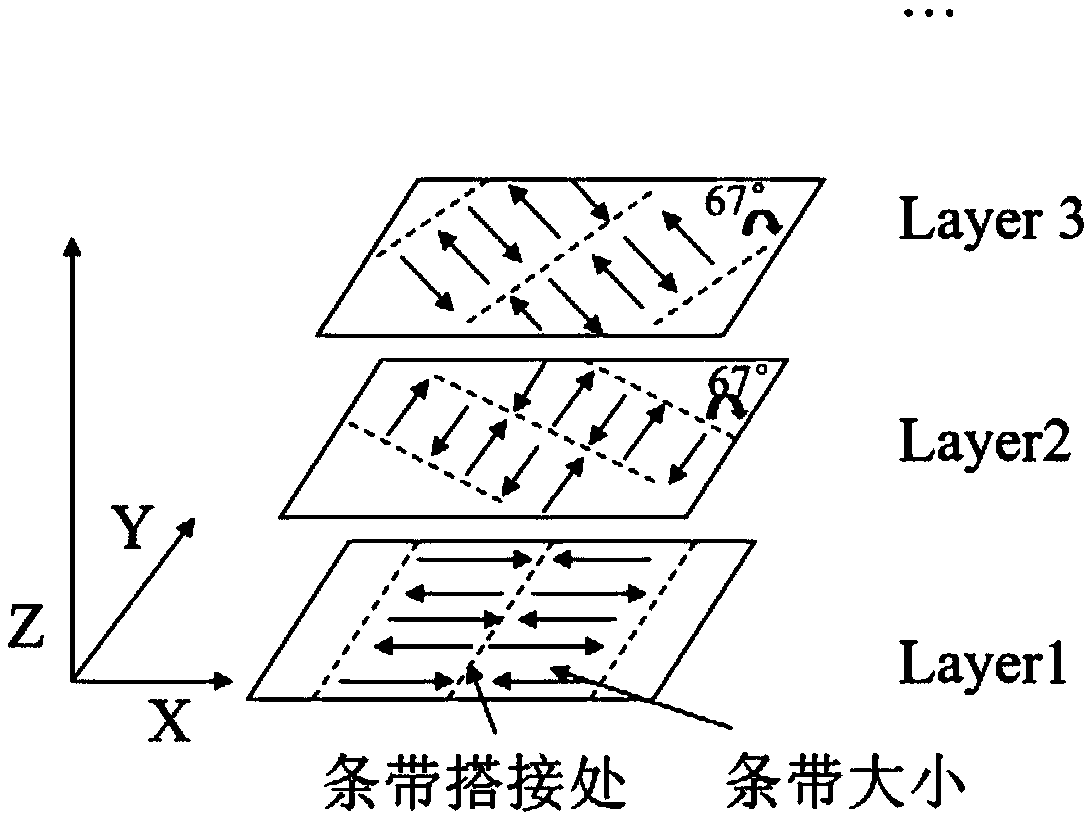

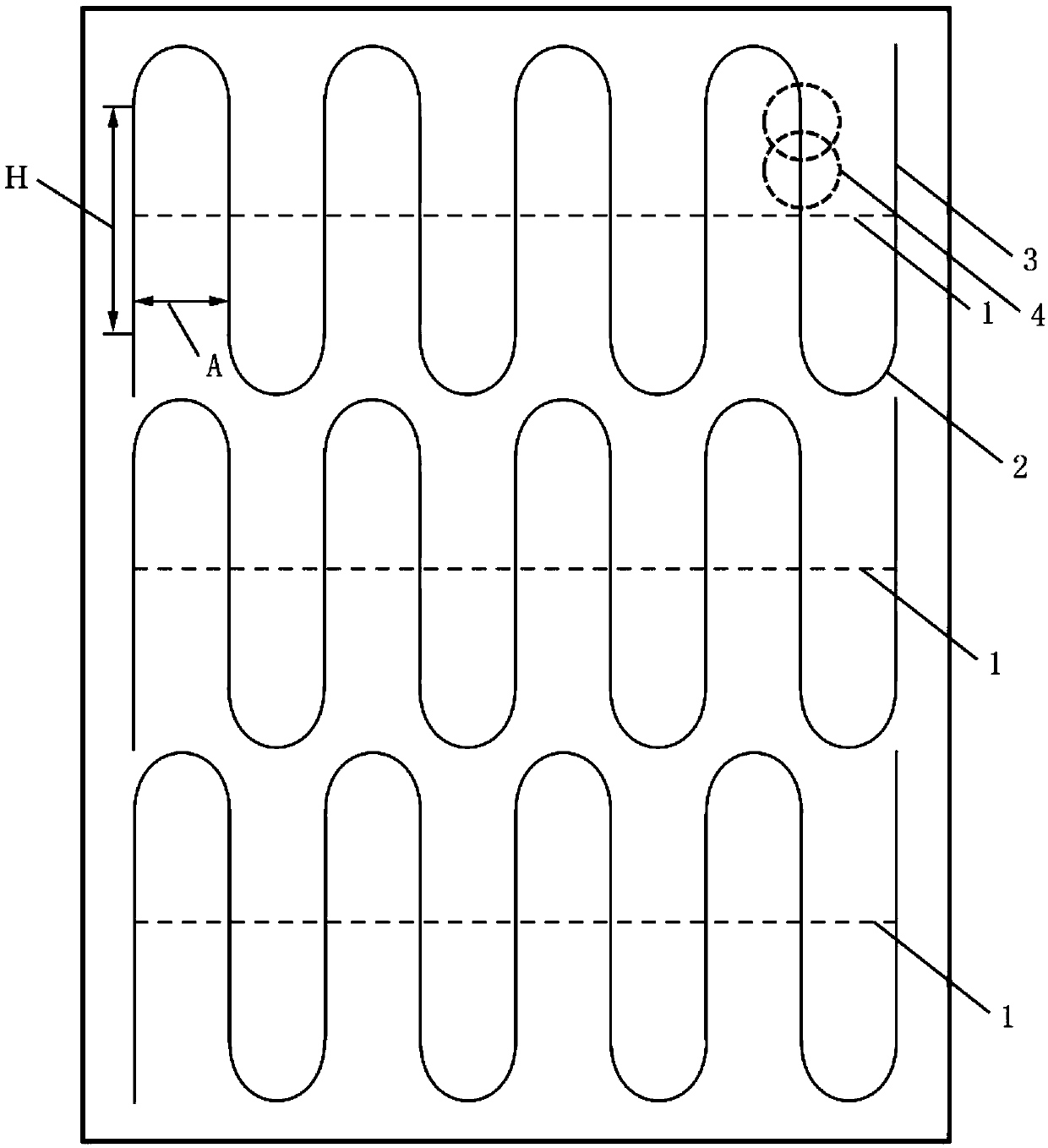

Strip-mode laser scanning path planning method

ActiveCN105773967AAvoid uneven stressQuality improvementAdditive manufacturing apparatusPath lengthLaser scanning

The invention discloses a strip-mode laser scanning path planning method. The method includes the step that an excessively short path in each strip partition of a part single-layer section is combined with a scanning path, located on the same path with the excessively short path, in an adjacent partition. The paths are selectively combined so that the problem that when a laser device is continuously switched on or off in the scanning process when encountering excessively short paths, and accordingly stress on a part contour boundary is not uniform can be effectively solved. The service life of the laser device is prolonged while the quality of a part is improved. Meanwhile, a user can set a shortest path length parameter by himself or herself according to characteristics of the part to be machined, and part forming quality is guaranteed.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

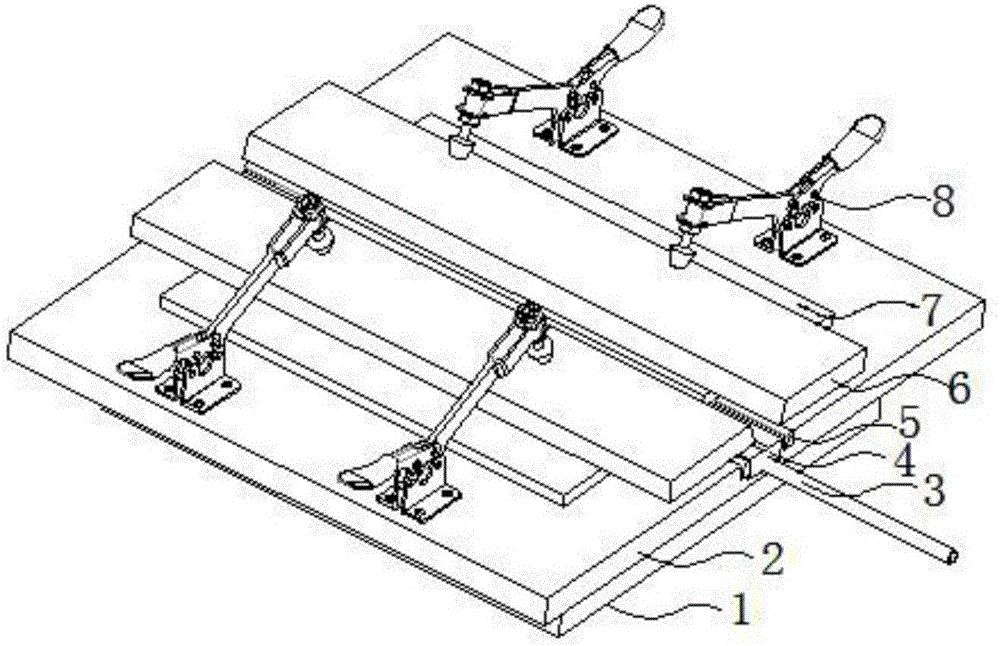

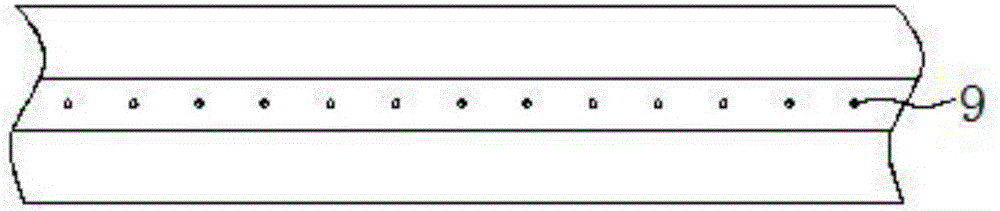

Adjustable reverse-deformation welding jig for titanium alloy

ActiveCN106112341ASimple and fast operationGuaranteed forming qualityWelding/cutting auxillary devicesAuxillary welding devicesWelding deformationTitanium alloy

Disclosed is an adjustable reverse-deformation welding jig for titanium alloy. The adjustable reverse-deformation welding jig for titanium alloy comprises a base and a clamping platform, wherein the clamping platform is located on the base. A first square groove is formed in the middle of the clamping platform, a reverse side gasket is fixedly arranged in the first square groove, and reverse deformation cushion strips are placed on the two sides of the reverse side gasket. A titanium alloy test plate is placed on the clamping platform, and a left press plate and a right press plate are placed on the titanium alloy test plate. Rapid clamps are installed on the clamping platform and tightly press the titanium alloy test plate by tightly pressing the left press plate and the right press plate. The reverse side gasket, an air pipe, the reverse deformation cushion strips, the left press plate and the right press plate are made of materials easy to achieve heat dissipation. The adjustable reverse-deformation welding jig for titanium alloy can provide reverse side protection in the process of titanium alloy welding, ensure the forming quality of the reverse side, and effectively reduce welding deformation.

Owner:JIANGSU UNIV OF SCI & TECH

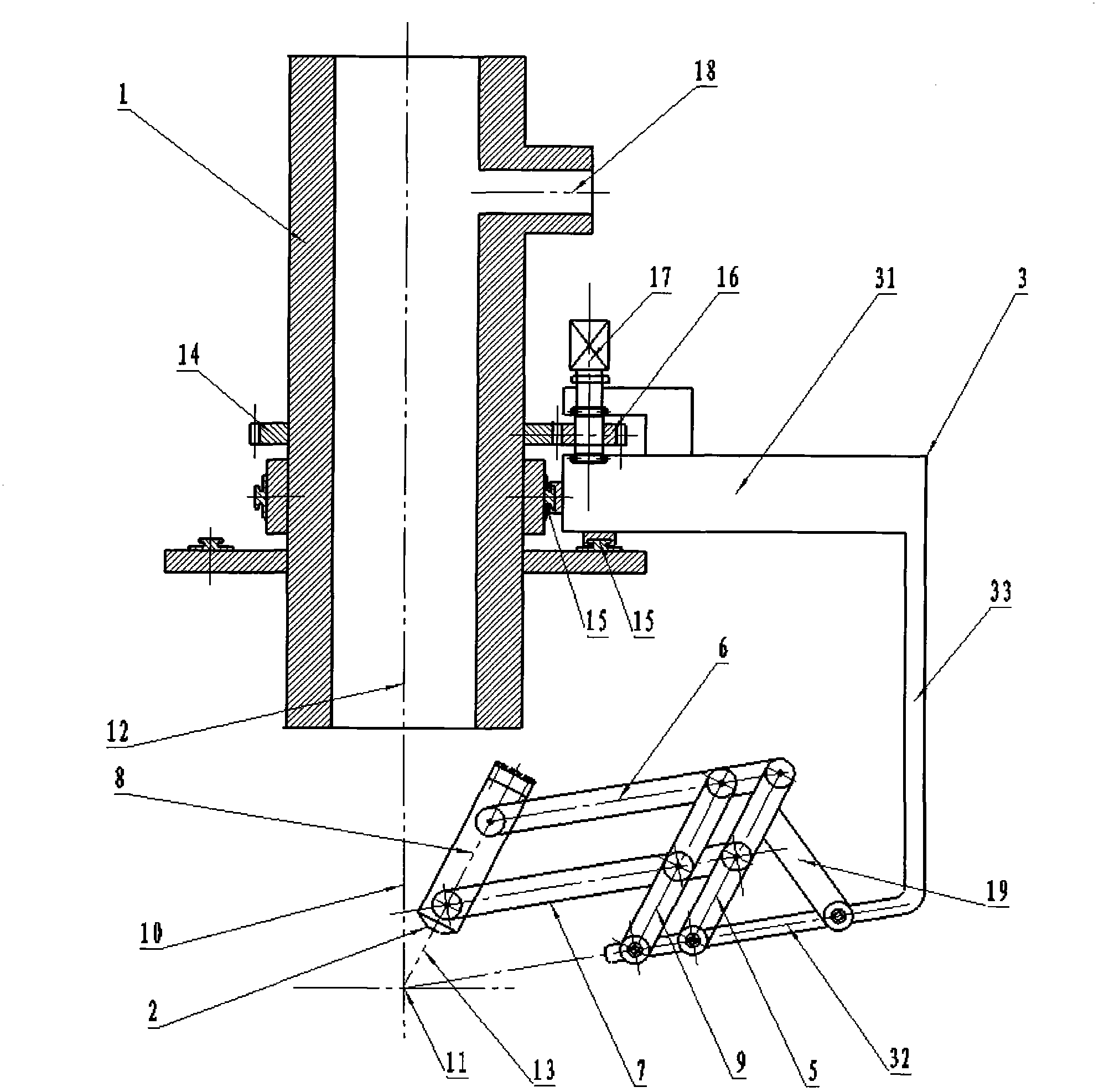

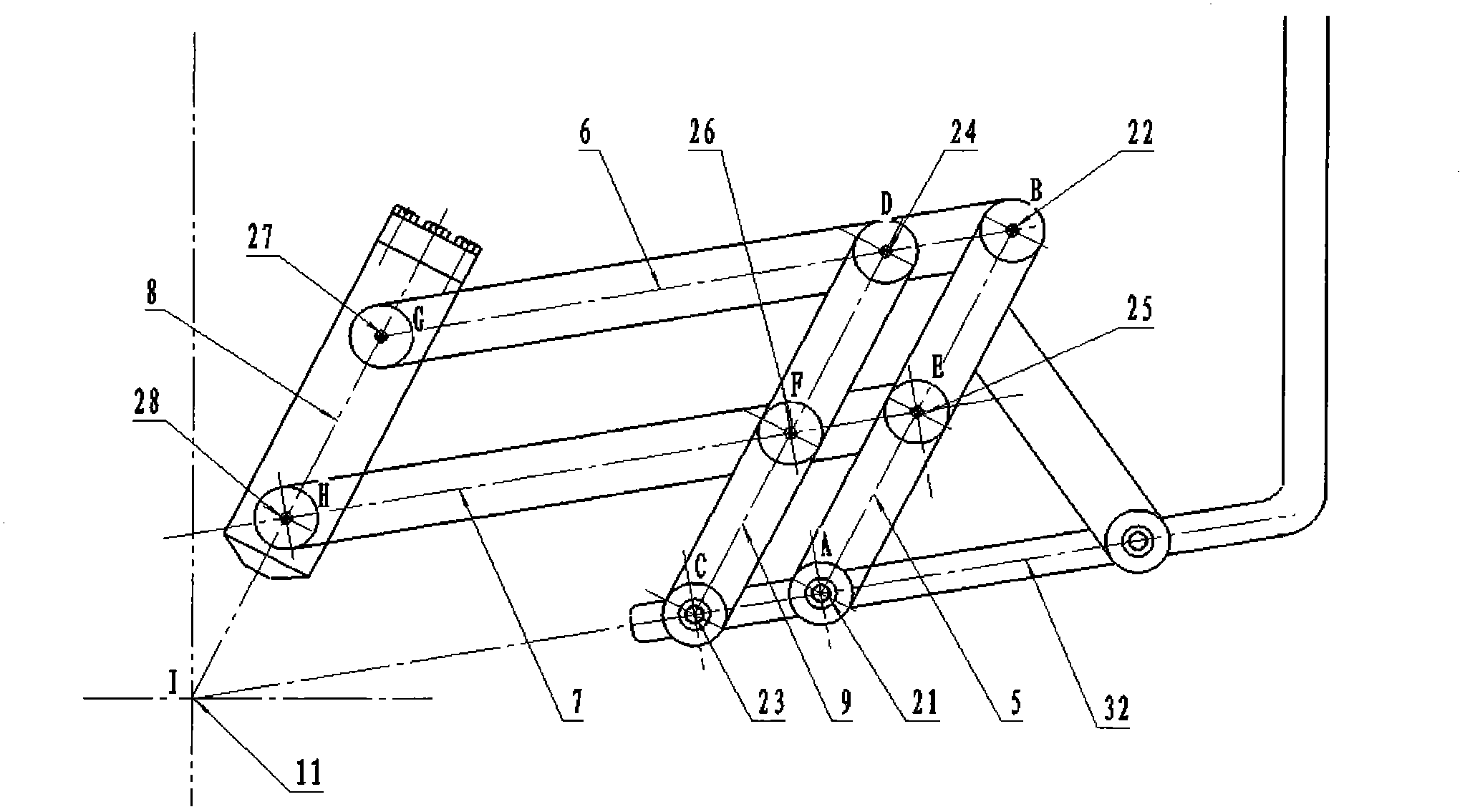

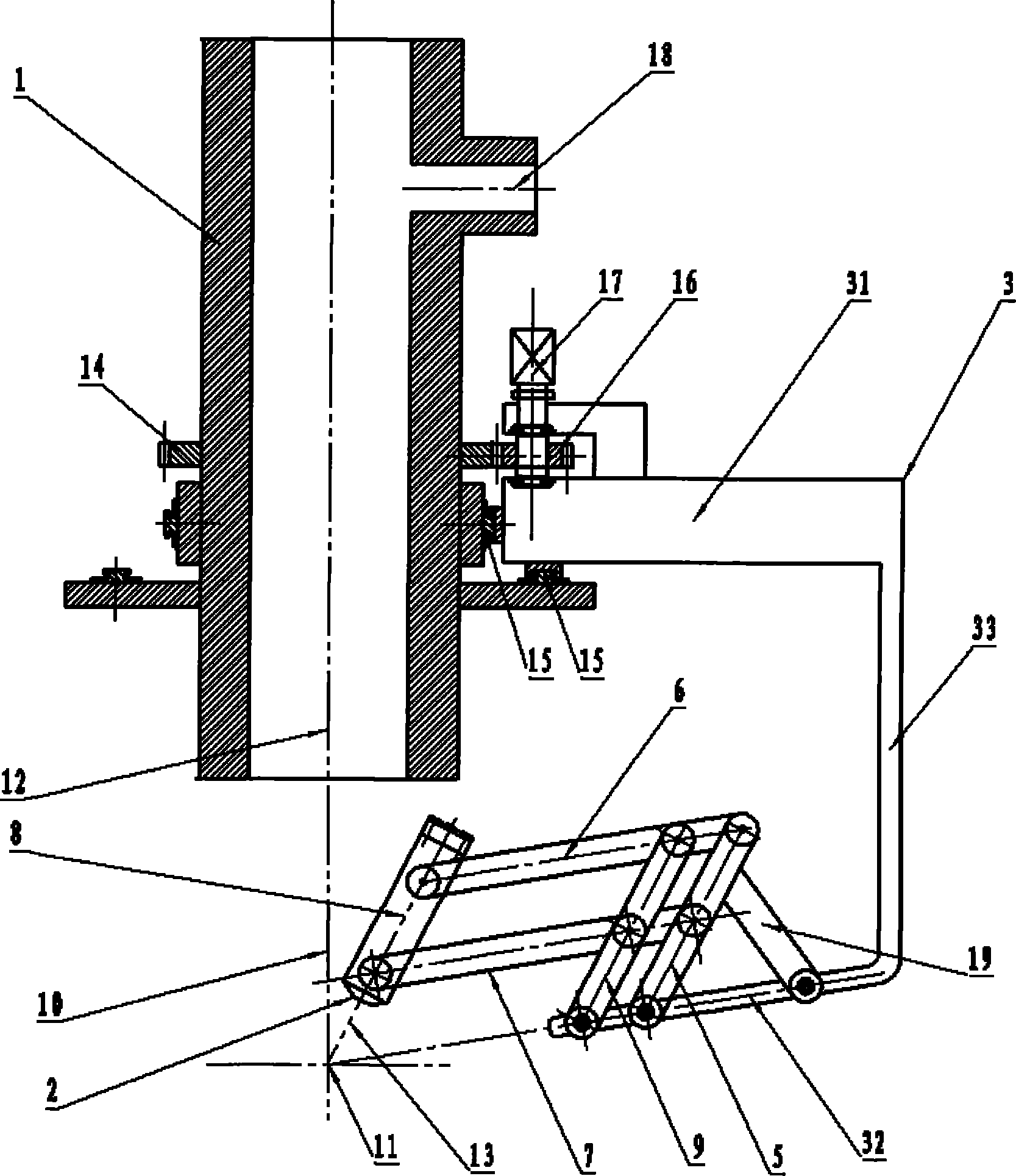

Laser cladding lateral powder feed processing head

ActiveCN102703895AUniform distribution of beam energyImprove utilization efficiencyMetallic material coating processesLaser beam welding apparatusSpray nozzleLight beam

The invention provides a laser cladding lateral powder feed processing head, a laser tube, a powder spray nozzle and a powder spray nozzle clamping mechanism, wherein the powder spray nozzle clamping mechanism includes a support arm and a parallel linkage mechanism; the support arm takes the shape of a square without the left edge; the support arm is mounted on the laser tube in a supported manner; the parallel linkage mechanism includes a driving link, an upper driven link, a linkage link, a clamp link and a driving unit; the powder spray nozzle is mounted on the clamp link; and further, three points, namely the focus point of focused laser beam emitted by the laser tube, the convergent point of powder beams sprayed out by the powder spray nozzle, and a first top point coincide. The laser cladding lateral powder feed processing head enables light beam energy to be distributed uniformly on the surface of a workpiece, improves the powder utilization rate and formation quality of laser cladding, simplifies control technical requirements for coordinate operation of a worktable, improves simplicity and flexibility degrees of process parameter adjustment, and further provides an incidence angle for automatically adjusting the powder beams to enter a laser cladding bath according to the practical situation during the processing, thereby realizing feasibility of better laser cladding formation quality.

Owner:WENZHOU UNIVERSITY

Stamping device of corrugated foils and production device of corrugated foils

ActiveCN103537539AStamping is effectiveEffective realization of stamping formingShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention is applied to the field of production equipment of corrugated foils and discloses a stamping device of corrugated foils. The stamping device comprises a first frame, a conveying mechanism, a forming die, a stamping head, a first lifting component, a pressure-holding shaping plate, and a second lifting component, wherein the conveying mechanism having a conveying component is mounted on the first frame, the forming die having a forming recess is mounted on the conveying component and capable of conveying and moving foils, the stamping head disposed above the forming die is used for pressing one foil into the forming recess to shape the foil, the first lifting component is used for driving the stamping head to ascend and descend, the pressure-holding shaping plate disposed above the forming die is used for pressure-held shaping of the shaped foil, and the second lifting component is used for driving the pressure-holding shaping plate to ascend and descend. A conveying direction of the pressure-holding shaping plate is behind the stamping head. The invention further discloses a production device of the corrugated foils. The production device comprises a shaping device of the corrugated foils and a conveying device used for conveying the foils to the stamping die. The stamping device and the production device have the advantages that production efficiency is high and shaping quality of the corrugated foils is good.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

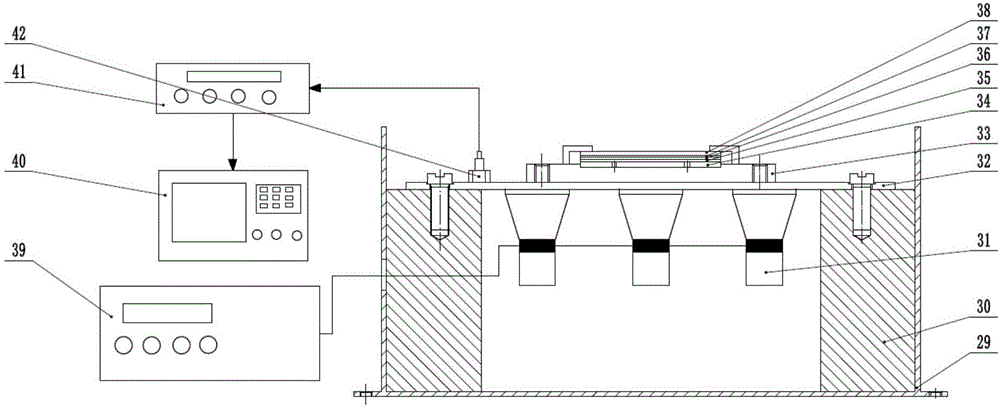

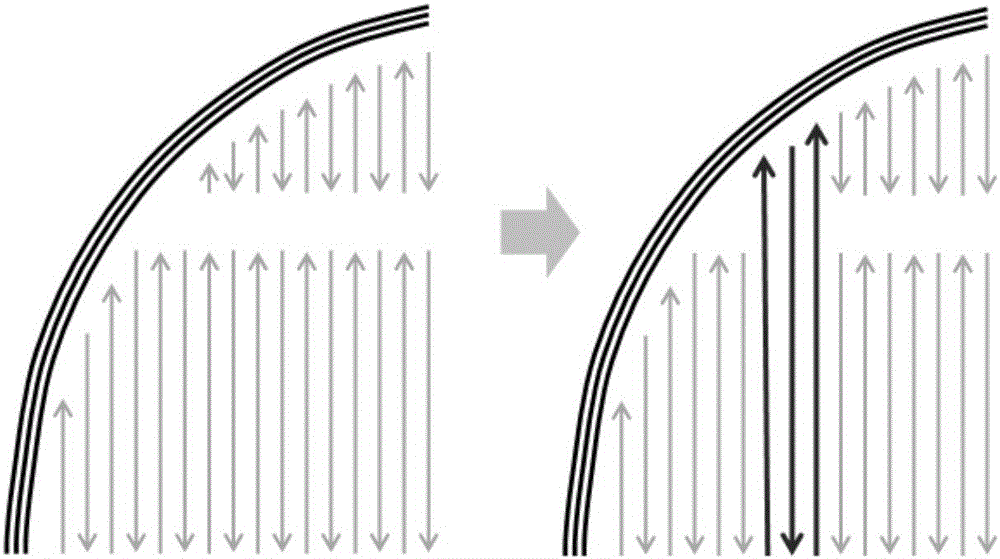

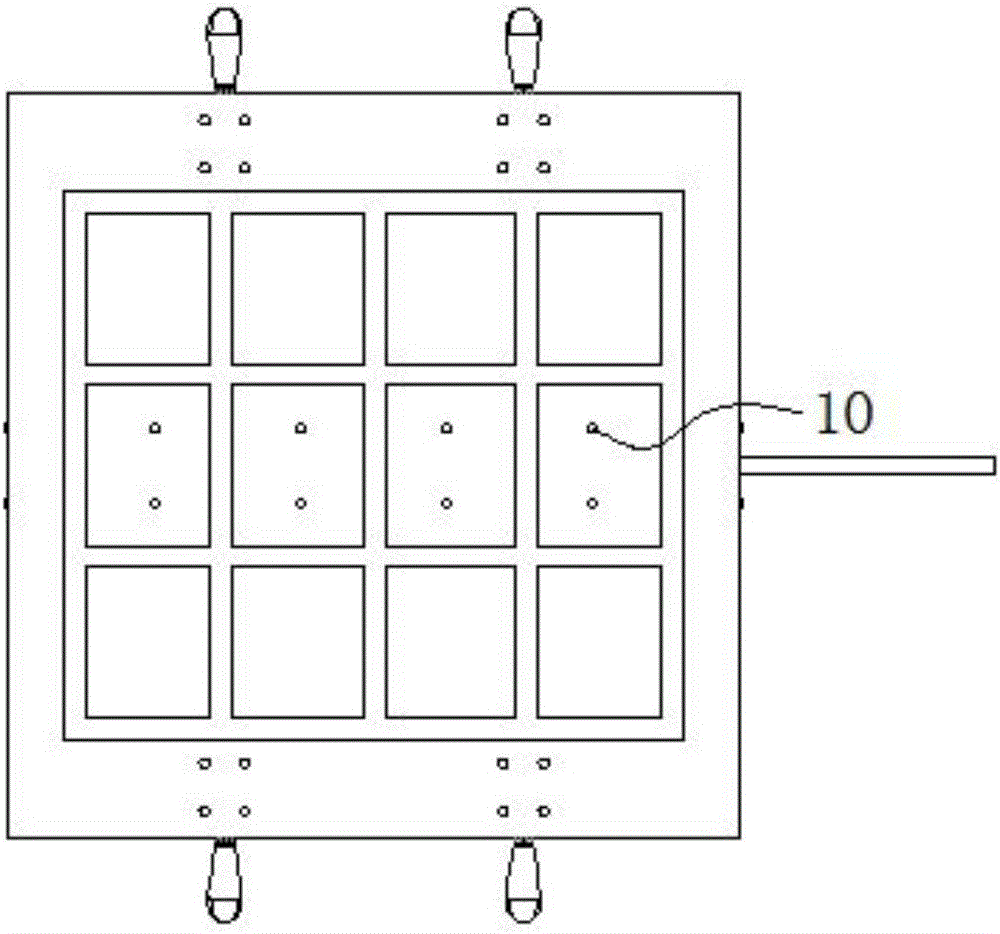

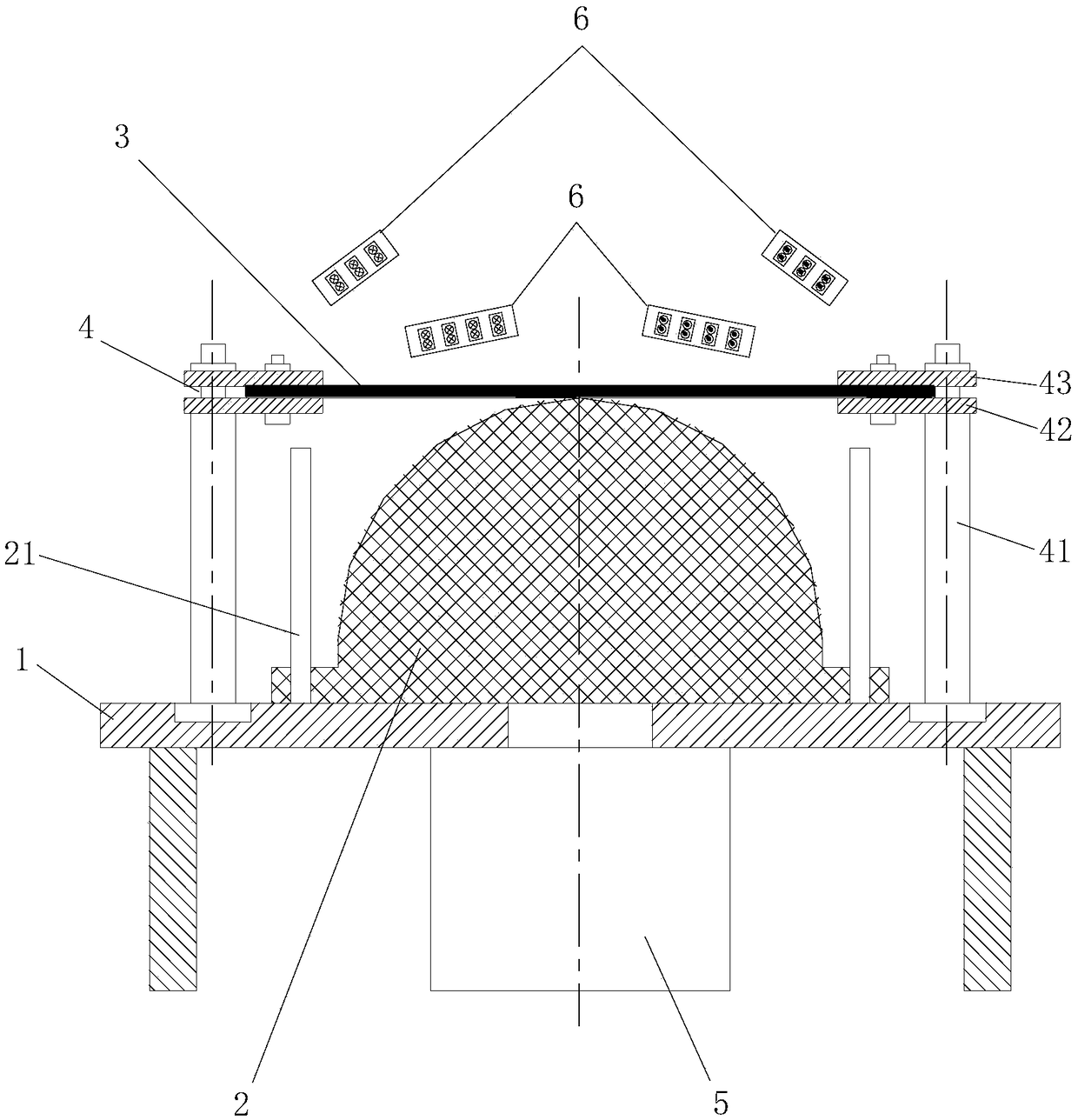

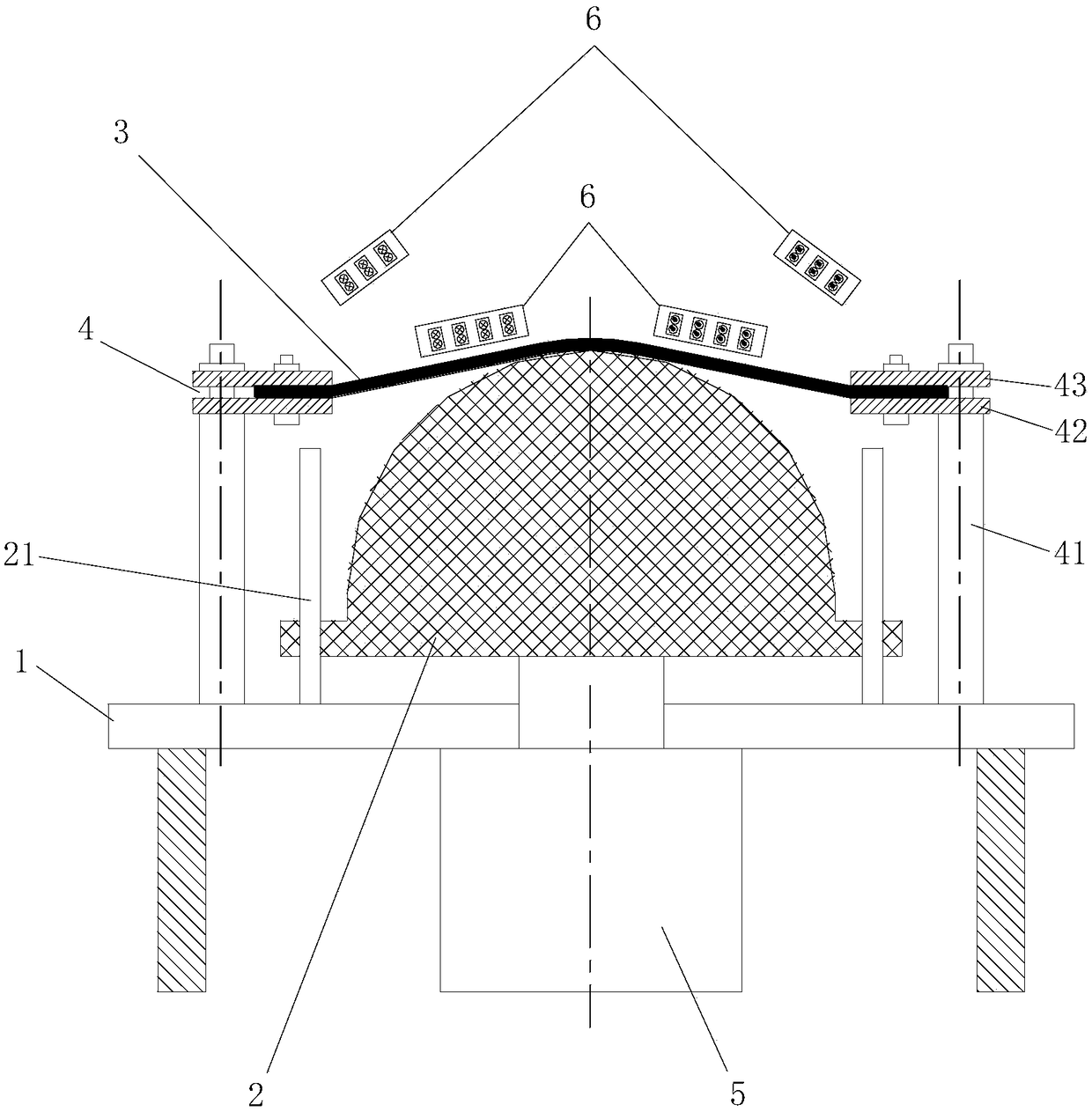

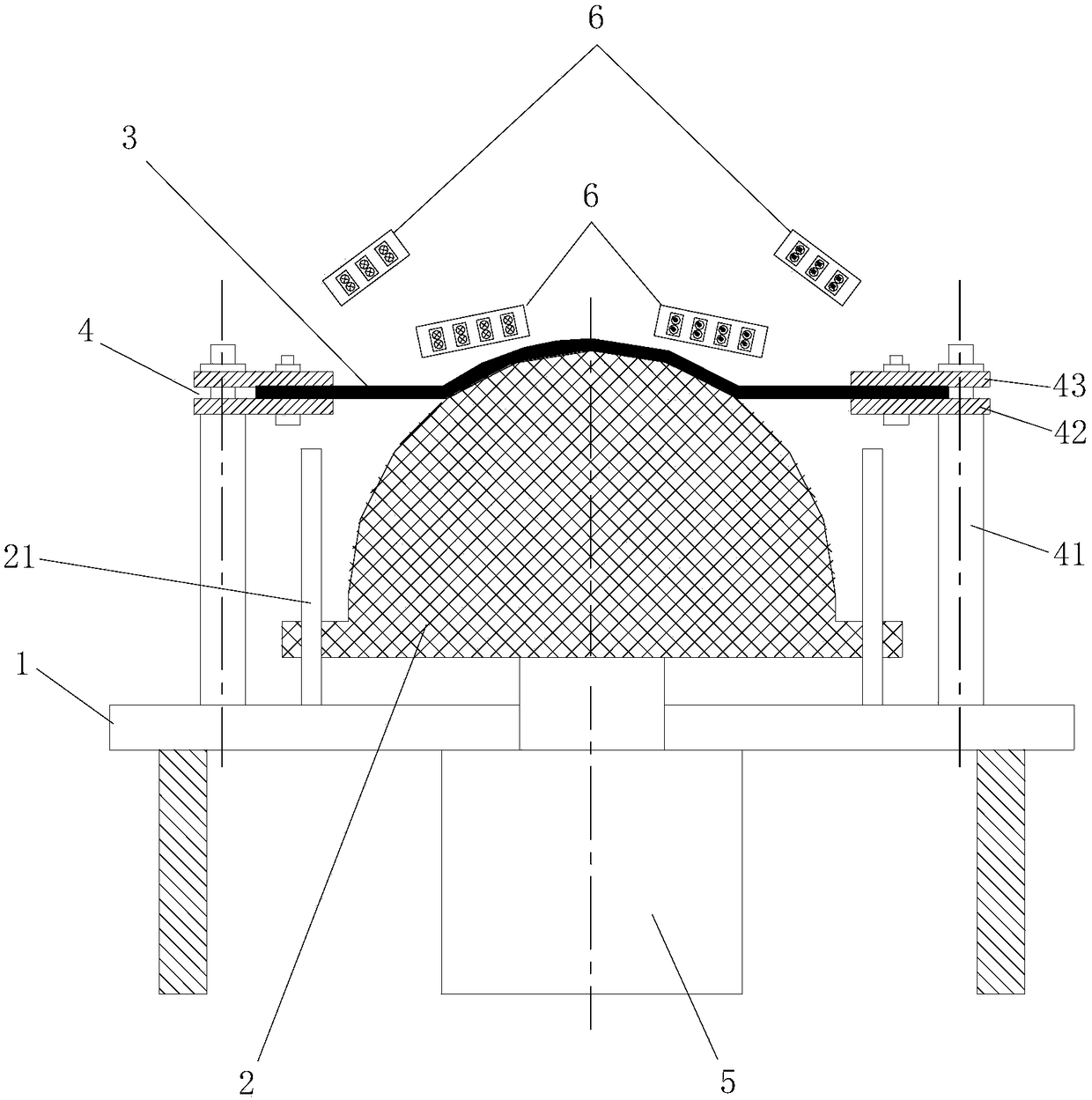

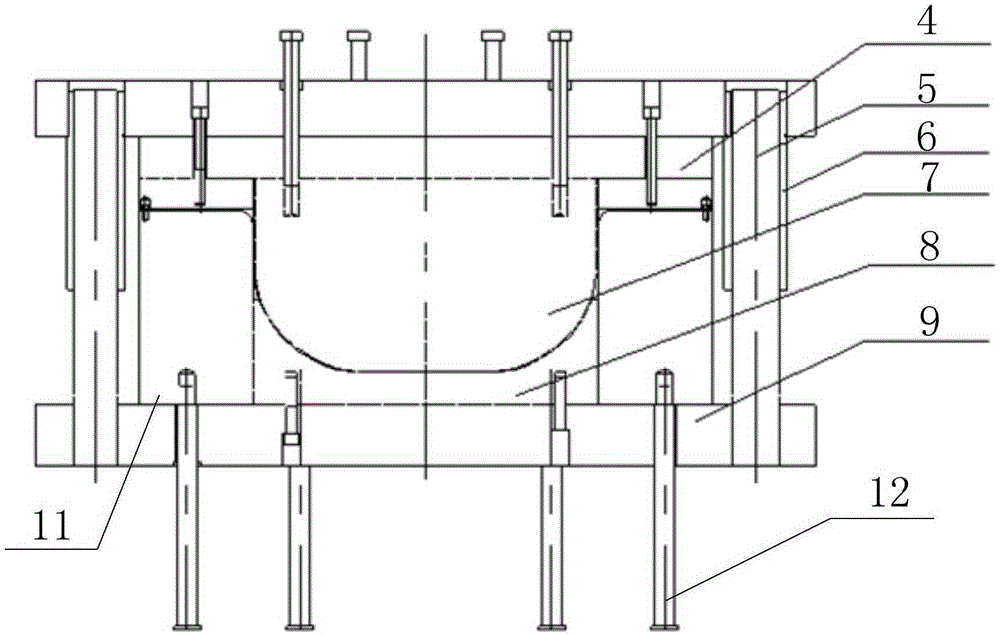

Workpiece electromagnetic incremental forming device provided with profile-followed arrangement coils, and workpiece electromagnetic incremental forming method

ActiveCN108856444AGuaranteed forming qualityIncrease forming heightEngineeringElectromagnetic forming

The invention discloses a workpiece electromagnetic incremental forming device provided with profile-followed arrangement coils, and further discloses a workpiece electromagnetic incremental forming method. The workpiece electromagnetic incremental forming device comprises a supporting frame, a mould, a plate, plate clamping assemblies for fixedly clamping the plate, and a driving piece for driving the mould to move so as to conduct stretch forming on the plate, and further comprises the multiple profile-followed arrangement coils. The plate clamping assemblies are arranged on the supporting frame; the plate is fixedly clamped between the plate clamping assemblies; the driving piece is connected with the mould; the profile-followed arrangement coils are arranged on the periphery of the surface of the plate subjected to stretch forming by the mould in a surrounding mode; and all the profile-followed arrangement coils are arranged on layers of different heights above the plate correspondingly. The workpiece electromagnetic incremental forming method comprises the steps of plate fixing, stretch forming of the plate, electromagnetic forming through the profile-followed arrangement coils and the like, and the plate and the mould are attached by repeatedly executing plate stretch forming and electromagnetic forming. The workpiece electromagnetic incremental forming device and methodhave the advantages of being high in forming precision, good in forming quality, high in efficiency, high in utilization rate of discharge energy, low in equipment energy demand and the like.

Owner:CENT SOUTH UNIV

Laser scanning path planning method used for additive-manufacturing three-dimensional object

ActiveCN109648080ASolve the problems of difficult control and low forming efficiencyHigh energyAdditive manufacturing apparatusIncreasing energy efficiencyLight spotHigh energy

The invention discloses a laser scanning path planning used for additive-manufacturing a three-dimensional object. The laser scanning path planning method comprises the following steps: firstly, inputting each layer of slice files of a part model; then, determining a partition datum line according to structural features of a part and user settings, and partitioning each layer of slices of the part; and finally, performing S-shaped scanning planning in each partition, wherein an S-shaped scanning path comprises a datum line, a circular-arc section and a linear section. According to the method disclosed by the invention, S-shaped scanning path planning is performed on sliced files, heat input can be improved in a scanning process, relatively high energy is kept, and the forming quality problem due to the fact that burning loss is caused as thermal stress is too great or scanning speed is low while cold speed is too high during great-width and large-light-spot part processing can be effectively solved. While part quality is improved, skip reduction is realized through circular-arc oscillation, so that the service life of a laser unit is prolonged.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

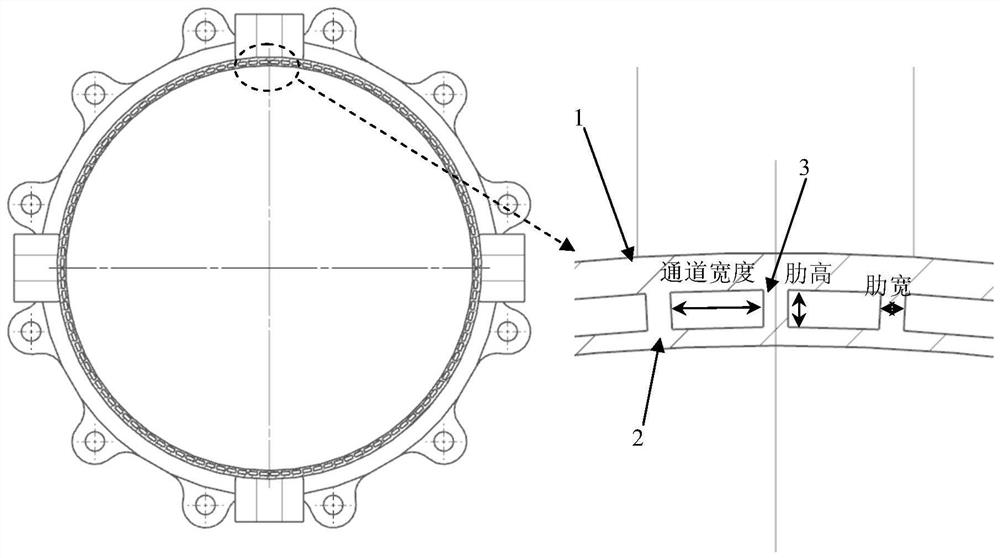

Selective laser melting forming and post-treatment method for thin-wall interlayer cooling structure

ActiveCN112496341AAvoid deformationGuaranteed structural strengthAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing technology

The invention relates to the technical field of additive manufacturing, and discloses a selective laser melting forming and post-treatment method for a thin-wall interlayer cooling structure. The method comprises the following steps that (1) a three-dimensional model is optimized and established based on the design of an additive manufacturing technology; (2) the established model is placed as required; (3) a local part is cut out to carry out forming and post-treatment testing, and iterative optimization is carried out on the model according to a liquid flow result; (4) supports are added; (5) selective laser melting forming is carried out; (6) powder is cleaned away, and wax filling protection is carried out; (7) the external support is removed by adopting methods of wire cut electricaldischarge machining, machining, manual polishing and the like, and then dewaxing treatment is carried out after the above operation is finished; and (8) heat treatment is carried out, finishing is carried out on the inner surface of a thin-wall interlayer through chemical polishing, and the smoothness of an inner cavity meets the requirement.

Owner:XIAN SPACE ENGINE CO LTD

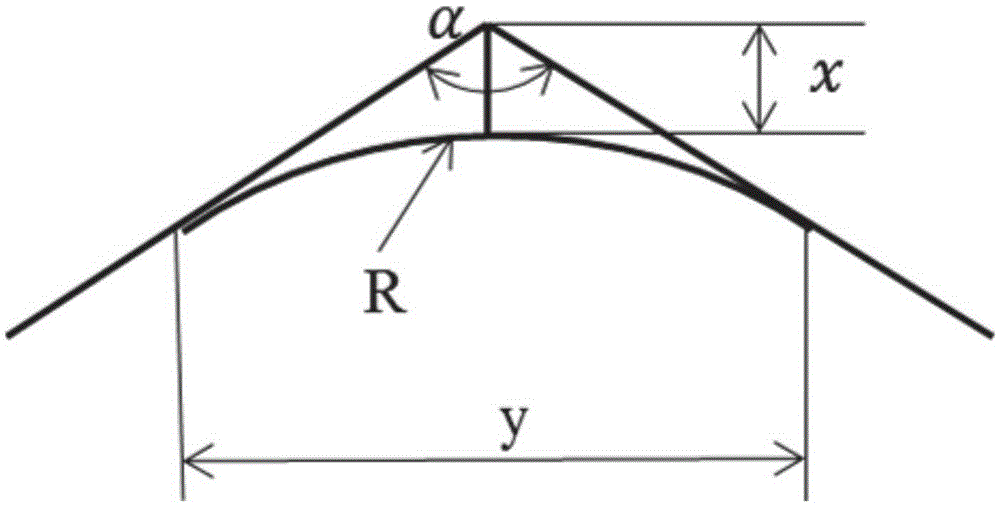

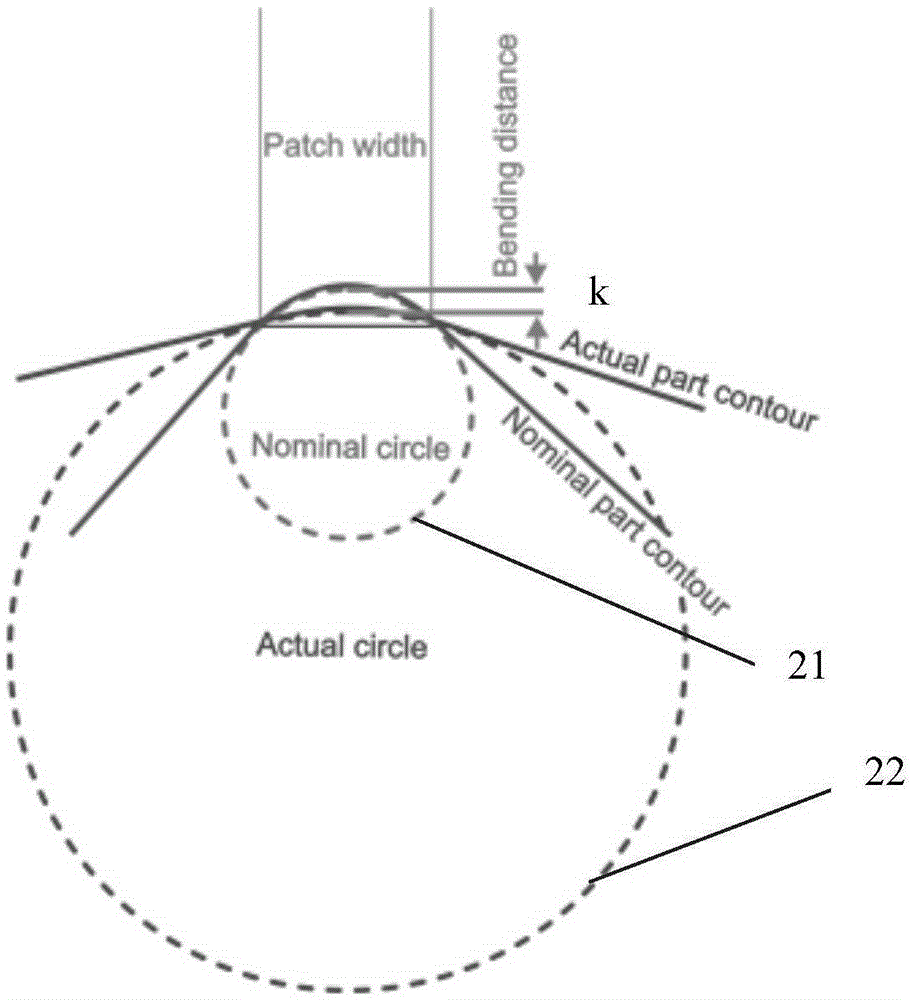

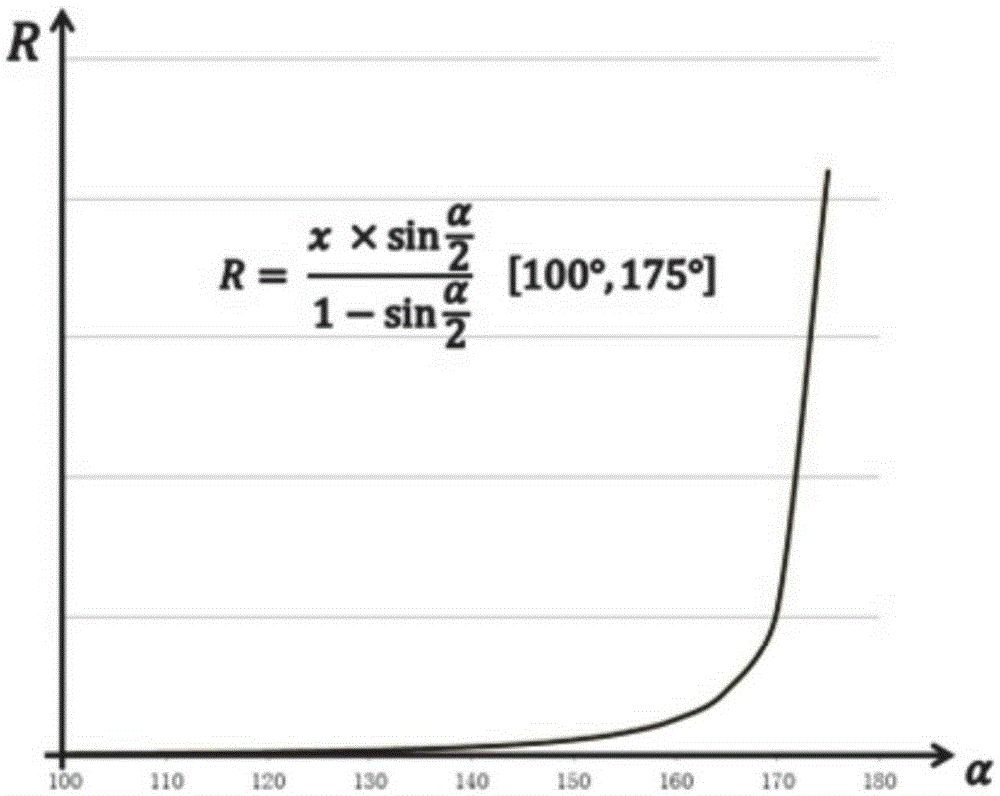

Design method of die profile of automobile covering part characteristic line area

ActiveCN105268865AGuaranteed forming qualityShorten the manufacturing cycleShaping toolsEngineeringUltimate tensile strength

The invention provides a design method of a die profile of an automobile covering part characteristic line area. The design method comprises the step that a punch-cum-blanking die machining fillet radius R+ is determined according to the fillet radius R of an automobile covering part characteristic line, wherein the punch-cum-blanking die machining fillet radius R+ is equal 0 mm when R is smaller than or equal to 3 mm, is equal to 1.5 mm when R is larger than 3 mm and smaller than 4 mm, and is equal to R-2 mm when R is larger than or equal to 4 mm. According to the design method of the die profile of the automobile covering part characteristic line area, characteristic line precision and covering part monolithic forming quality can be ensured, meanwhile, the strength and difficulty of later-period debugging carried out by a bench worker can be greatly lowered, and the whole die manufacturing period is shortened.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

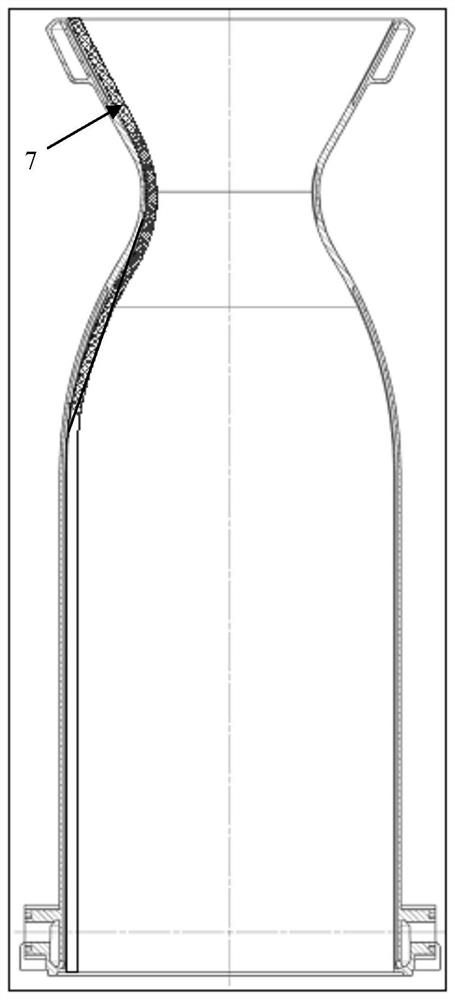

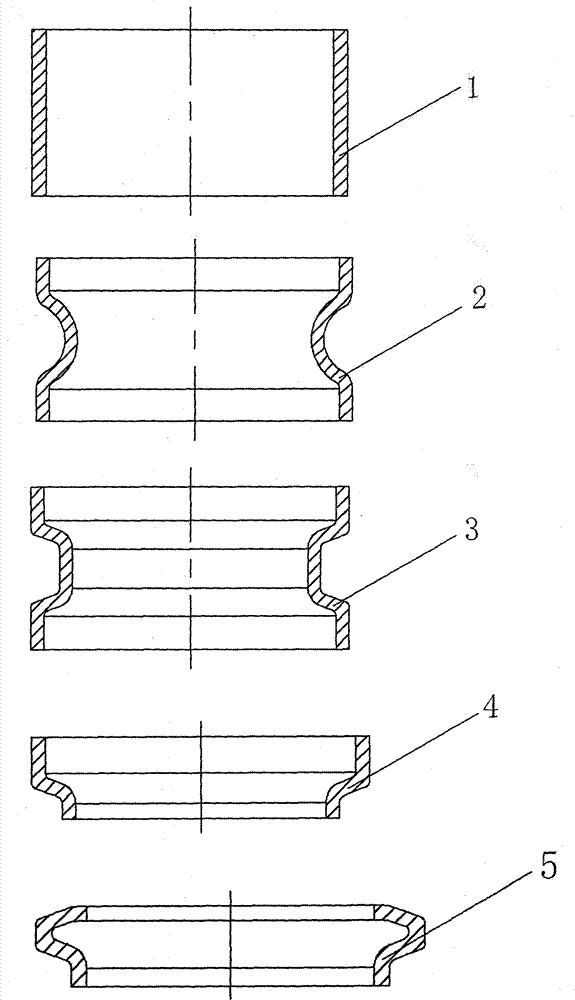

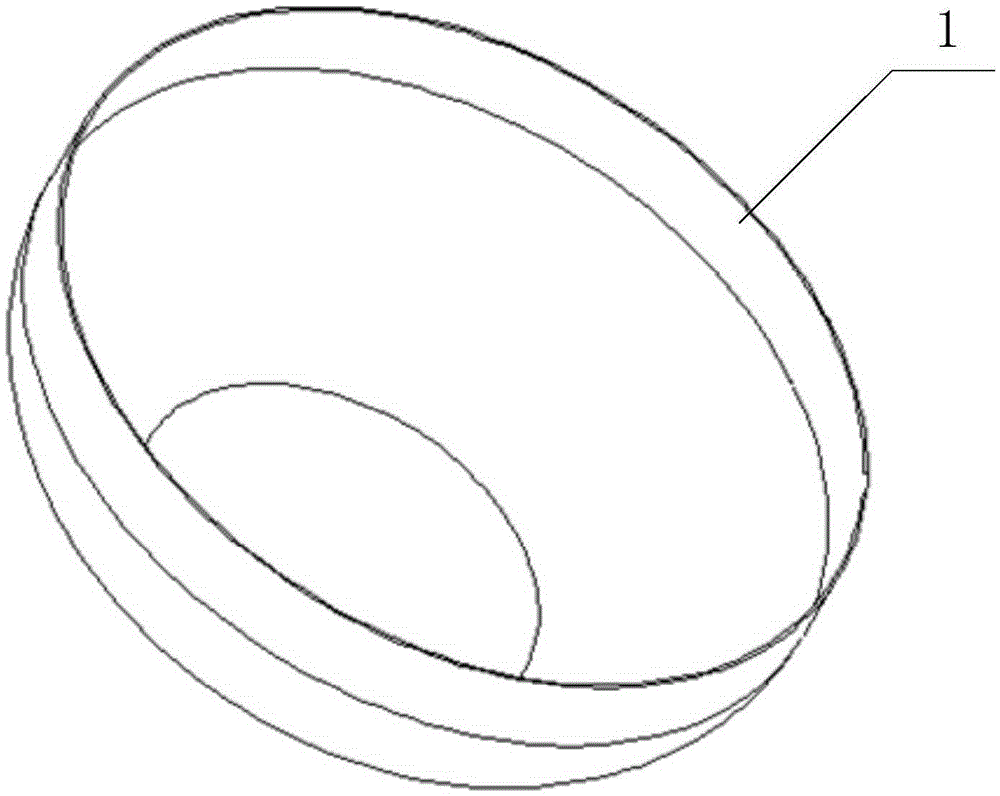

Forming method of flange ring for automobile tail gas recycling device

ActiveCN104209699AGuaranteed forming accuracyGuaranteed forming qualityShaping toolsExhaust apparatusProduction rateEngineering

The invention provides a forming method of a flange ring for an automobile tail gas recycling device. By combining necking in spindown with reducing spinning, a tube billet can be directly formed to obtain the flange ring for the automobile tail gas recycling device, so the surface quality and integral mechanical property of the flange ring are improved; meanwhile, the productivity and the utilization rate of materials are improved.

Owner:NANTONG FULEDA AUTOMOBILE FITTINGS

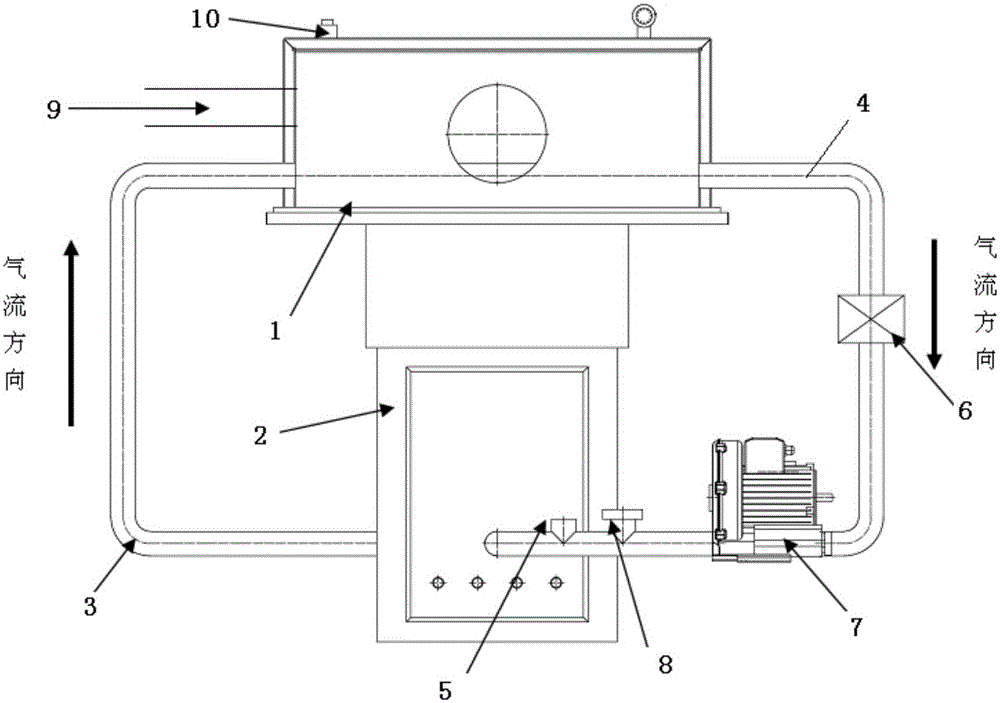

Laser melting forming dust-removing system with multifunctional circulating air flow and dust-removing method

ActiveCN105642891APrevent influence of forming qualityImprove forming rateAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringMetal powder

The invention provides a laser melting forming dust-removing system with multifunctional circulating air flow and a dust-removing method. The dust-removing system comprises an upper cavity and a lower cavity. Three induced air ways are led out of an air inlet of the upper cavity and are the first induced air way, the second induced air way and the third induced air way. The first induced air way communicates with a dust-removing subsystem in a scanning area. The second induced air way communicates with a dust-removing subsystem of a laser protection mirror. The third induced air way communicates with a dust-removing subsystem of a movement sliding table cavity. The laser melting forming dust-removing system with multifunctional circulating air flow and the dust-removing method have the beneficial effects that in the whole laser melting forming process, smoke-shaped dust generated when lasers act on metal powder can be absorbed into a dust filter in time under the effect of a draught fan, dust generated by part forming is filtered out in time through the dust filter, the influences, on the subsequent forming quality, of the smoke-shaped dust are prevented, and the forming rate is increased; and in addition, the dust is prevented from rising to the position near the laser protection mirror located over the scanning area, and the dust is prevented from entering a sliding table guide rail in the sliding table cavity.

Owner:HARBIN FORWEDO MULTI DIMENSIONAL INTELLIGENT EQUIP CO LTD

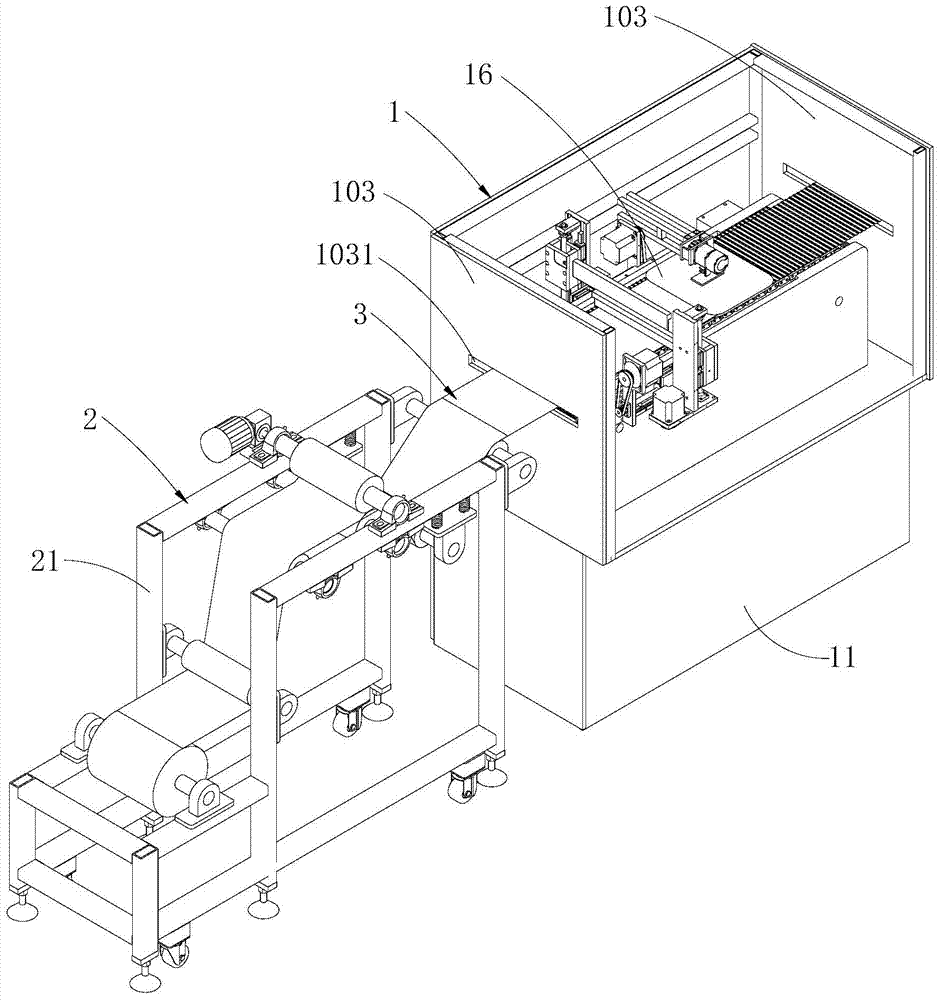

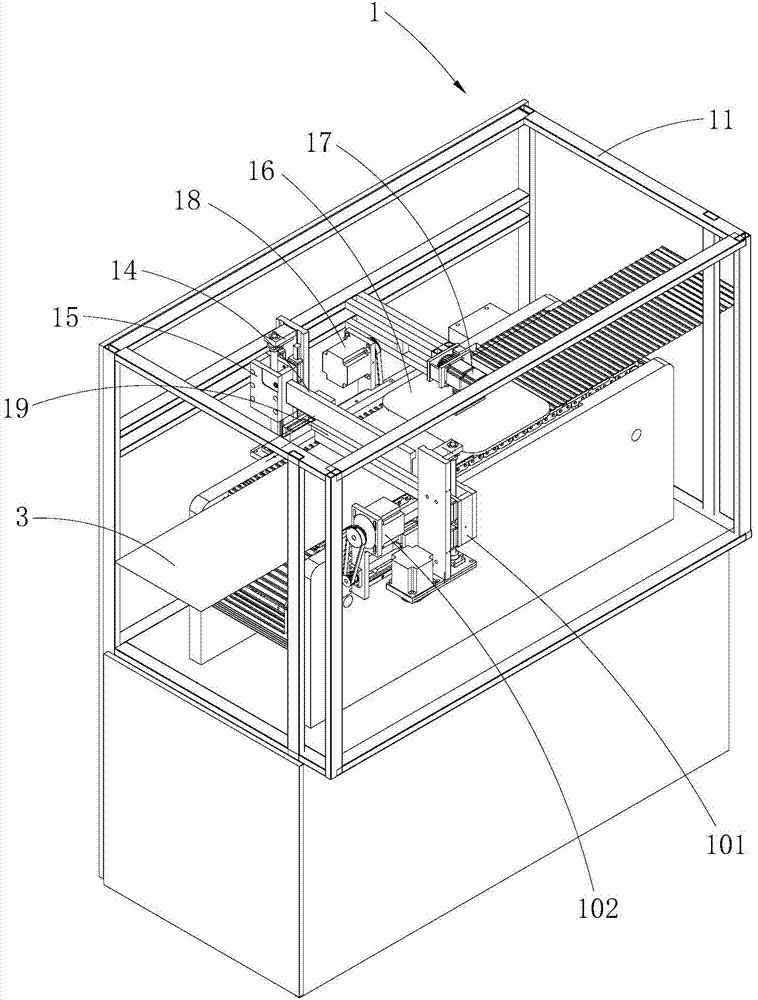

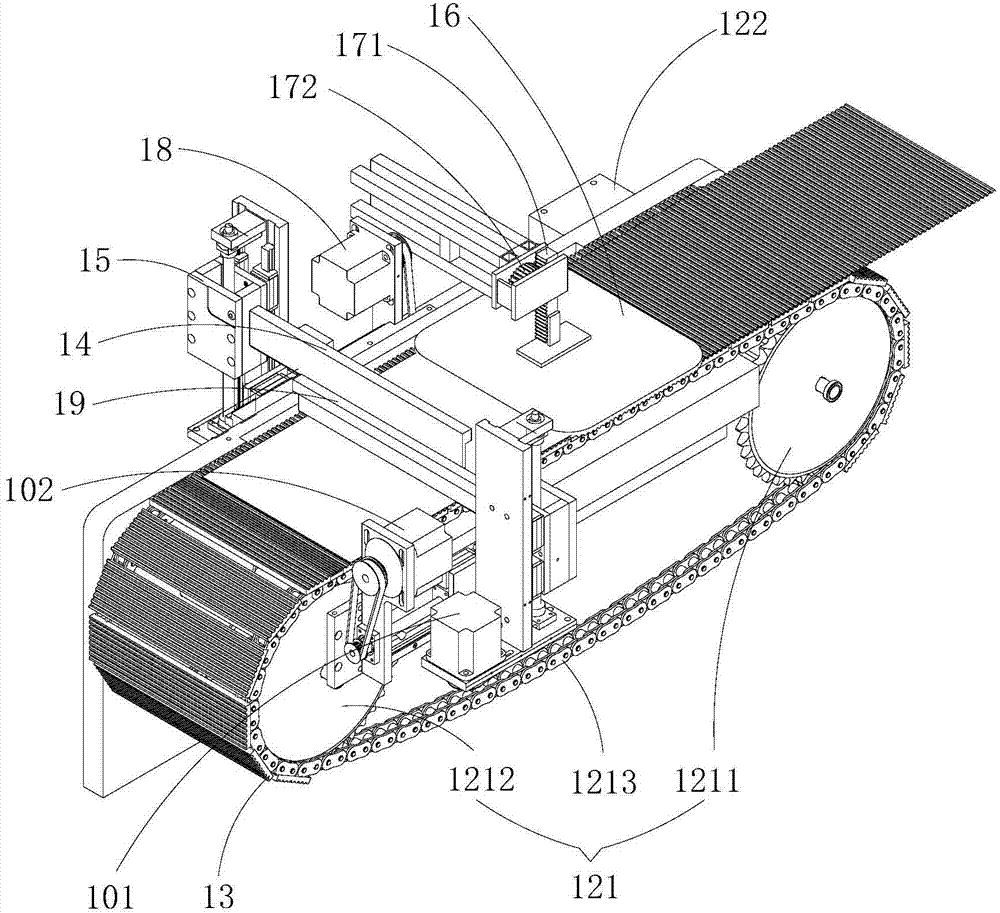

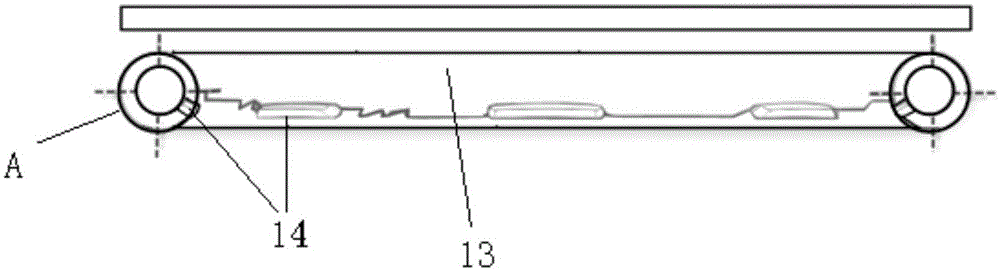

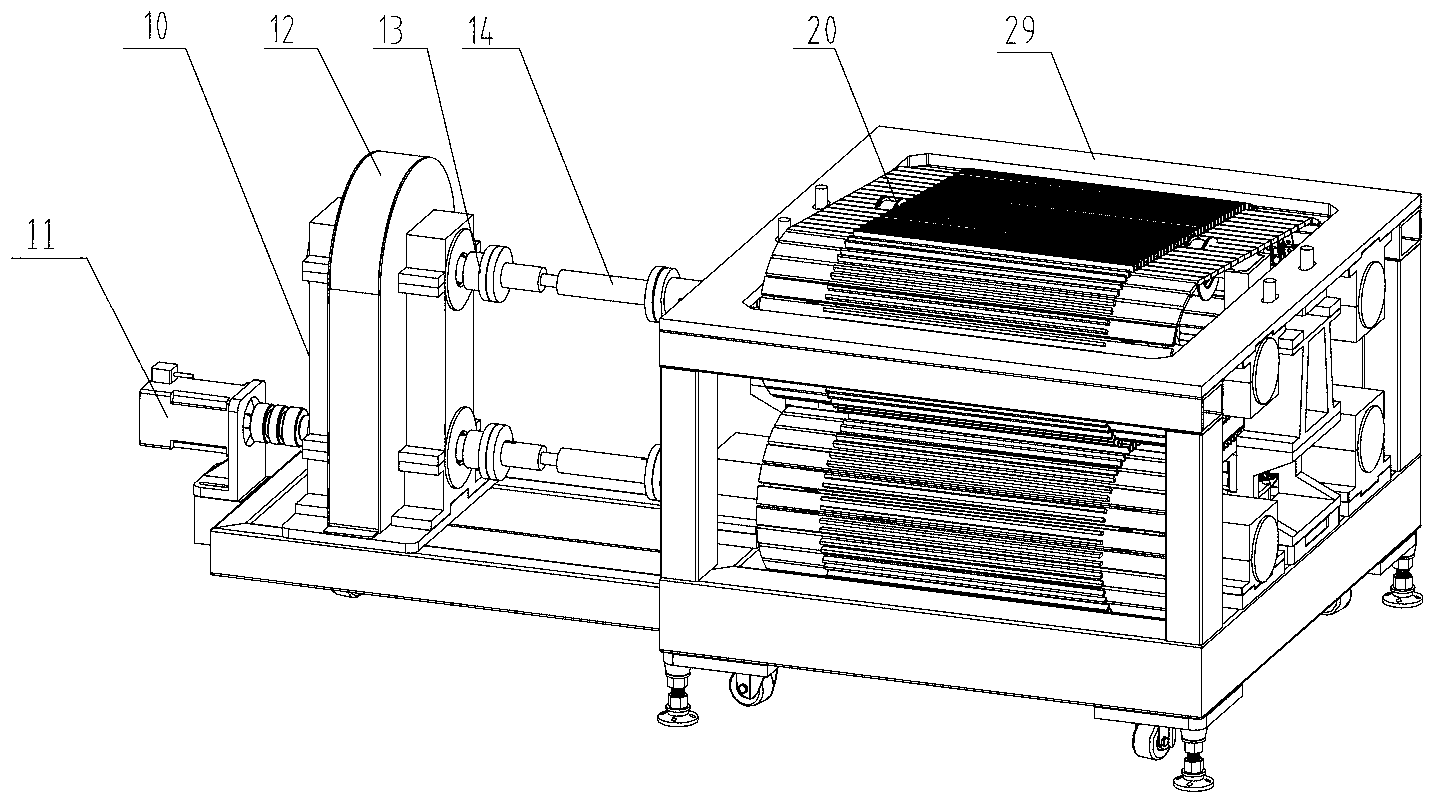

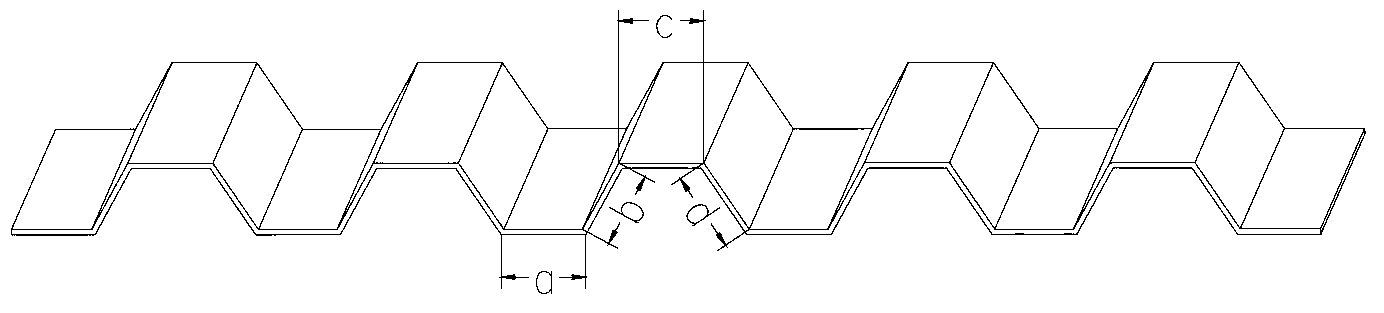

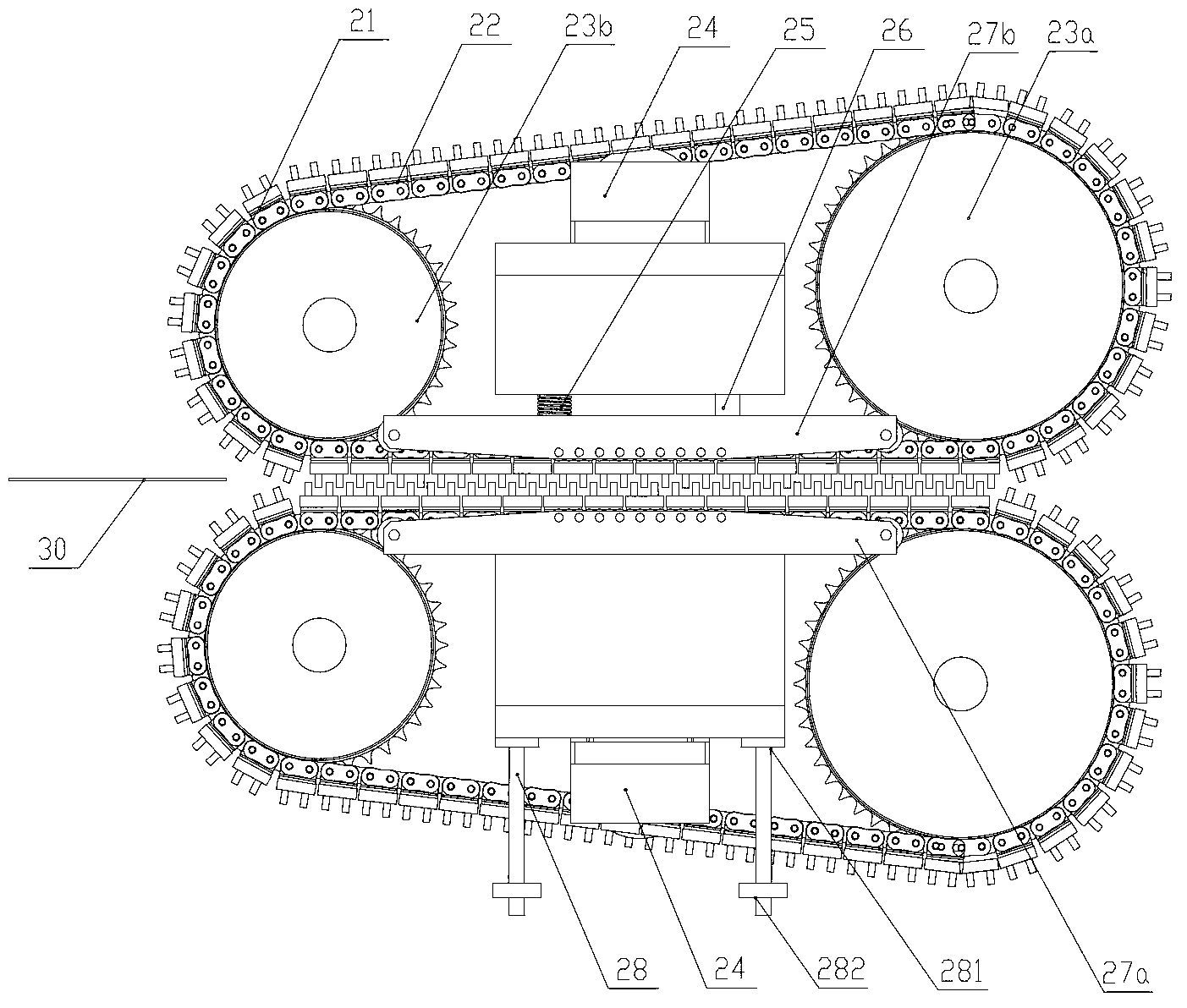

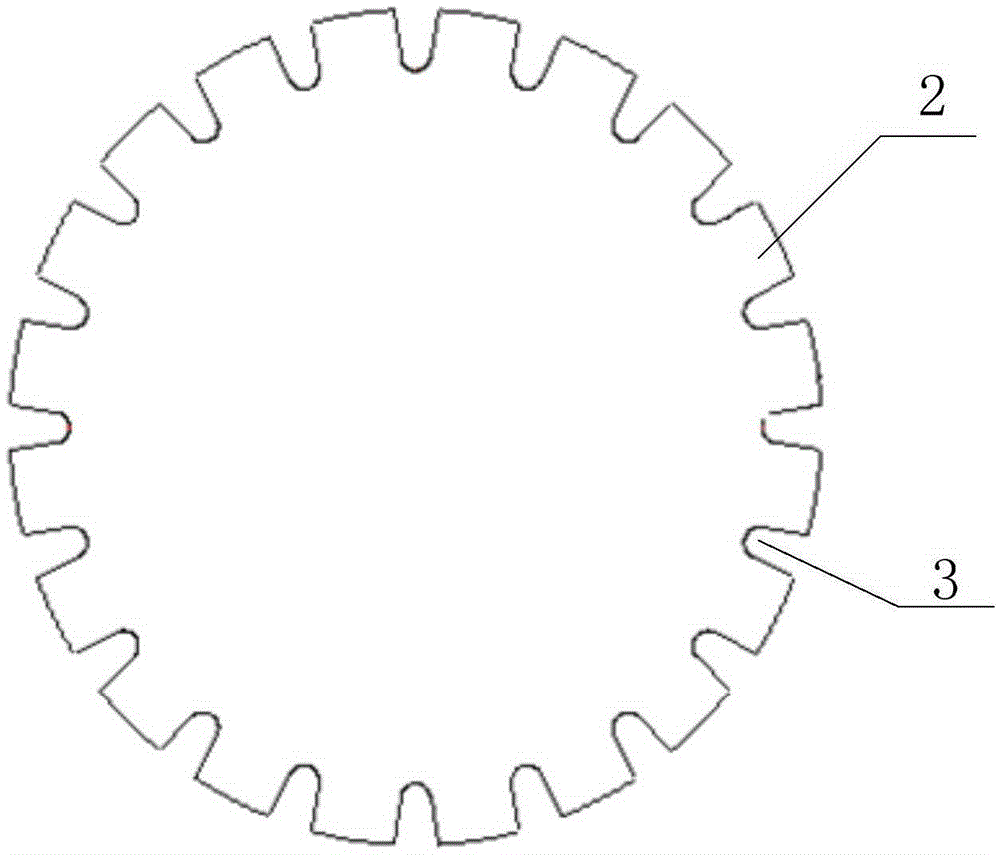

Forming device and forming method for corrugated foil of metal honeycomb core

The invention provides a forming device and a forming method for a corrugated foil of a metal honeycomb core. The forming device comprises a frame and two forming mechanisms, wherein two forming mechanisms are vertically arranged in the frame in parallel, each forming mechanism mainly comprises a drive chain wheel rotatably arranged on the frame, a driven chain wheel rotatably arranged on the frame and spaced with the driven chain wheel, a chain sheathed on the drive chain wheel and the driven chain wheel, multiple forming toothed bars connected with the chain in sequence through chain accessories, a tension device docked with the inner side of the chain so as to tense the chain through the tension device, a slide guide mechanism located at the inner side of the chain, a pressure application device arranged on one end of the slide guide mechanism, and a setting device arranged on the other end of the slide guide mechanism. According to the forming device and the forming method, the forming efficiency is improved, the forming quality is ensured, the complexity of the forming device is reduced, and automatic production of forming of the corrugated foil is realized.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

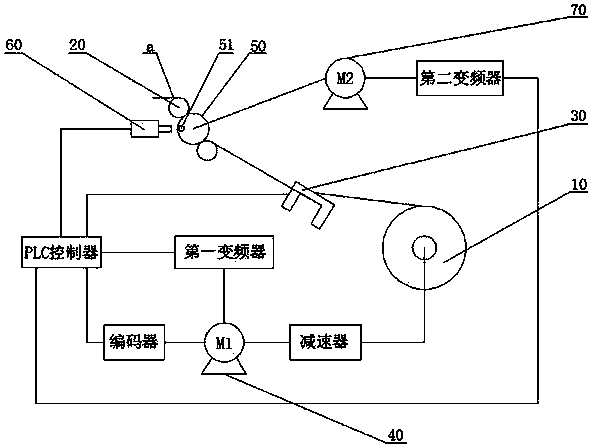

Constant-tension control device for winding device

InactiveCN103523597AMake sure the tension is constantGuaranteed forming qualityFilament handlingFrequency changerYarn

The invention relates to a constant-tension control device for a winding device. The constant-tension control device for the winding device comprises yarn guide rolls, wherein the yarn guide rolls are used for conveying yarn to a winding pan head in a guiding mode, the rotating speed of the winding pan head is controlled by a PLC and is adjusted through the PLC when different winding diameters are adopted, a pressure sensor is arranged between the winding pan head and the yarn guide rolls, the yarn which is led out through the yarn guide rolls penetrates through the pressure sensor and is conveyed to the winding pan head in the guiding mode, the output end of the pressure sensor is connected to the PLC, the winding pan head is driven by a winding motor to rotate, the winding motor is connected with a first frequency converter and an encoder, the first frequency converter and the encoder are connected to the PLC, and the frequency of the first frequency converter is controlled by the encoder through the PLC.

Owner:WUJIANG WEIQI FABRIC

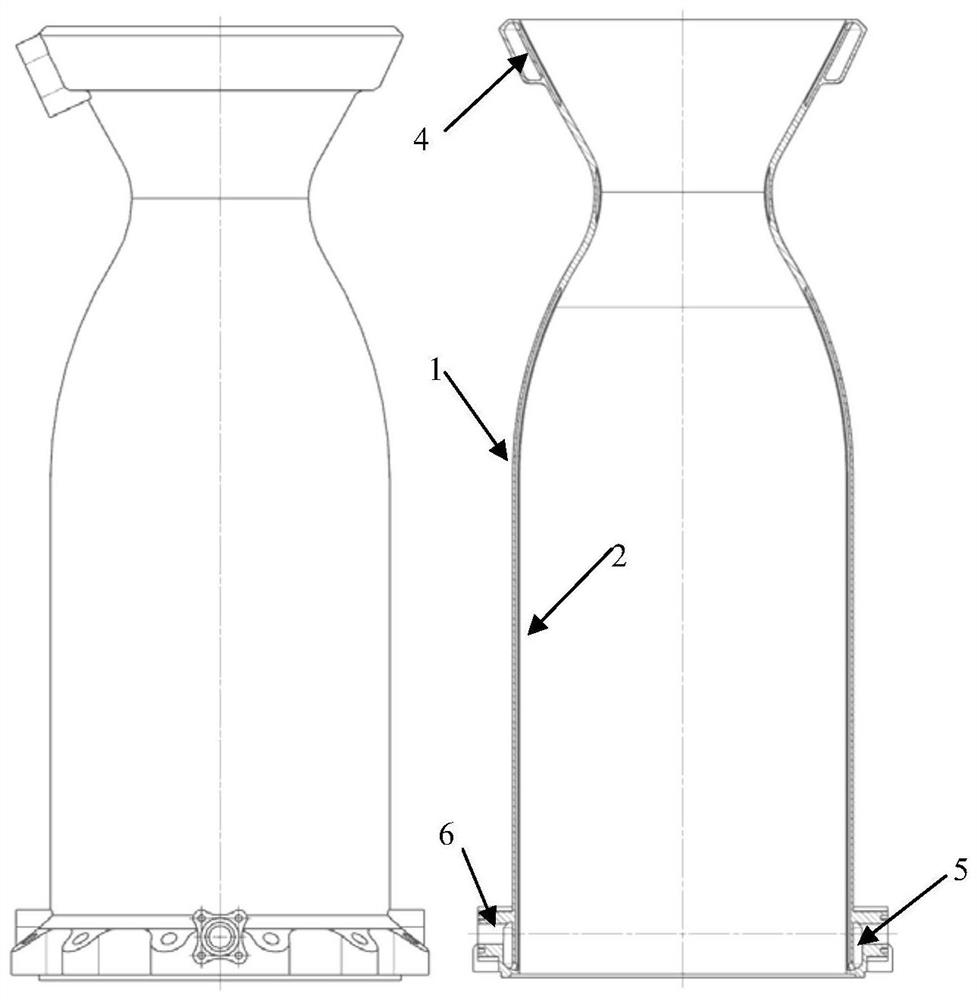

Drawing forming device and method of rotary part

ActiveCN105414299AAvoid wrinklesImprove wear resistanceMetal working apparatusEngineeringMaterials processing

The invention relates to the technical field of metal material machining, in particular to a drawing forcing device and method of a rotary part. The device comprises an upper combined die, a male die, a female die, a female die frame, a lower die, a guide column, a guide sleeve, an ejection rod and an ejection plate. The male die is fixedly connected with the lower end of a lower combined die, the female die is arranged in the female die frame, the female die is fixedly connected with the upper end of the lower die, the lower end of the ejection rod is connected with the ejection plate, and the upper end of the ejection rod penetrates the lower die to be fixedly connected with the female die frame; and the female die is arranged below the male die, and the axis of the male die coincides with the axis of the female die. One end of the guide sleeve is fixedly connected with the upper combined die, and fixedly connected with the lower die, and the other end of the guide column is inserted in the other end of the guide sleeve in a penetrating manner. The method comprises blank manufacturing, blank positioning, blank drawing, blank annealing, die pressure maintaining and mechanical machining. According to the drawing forcing device and method of the rotary part, the problem that in the drawing process of the rotary part, ripping, wrinkling and scrapping are prone to appearing is solved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

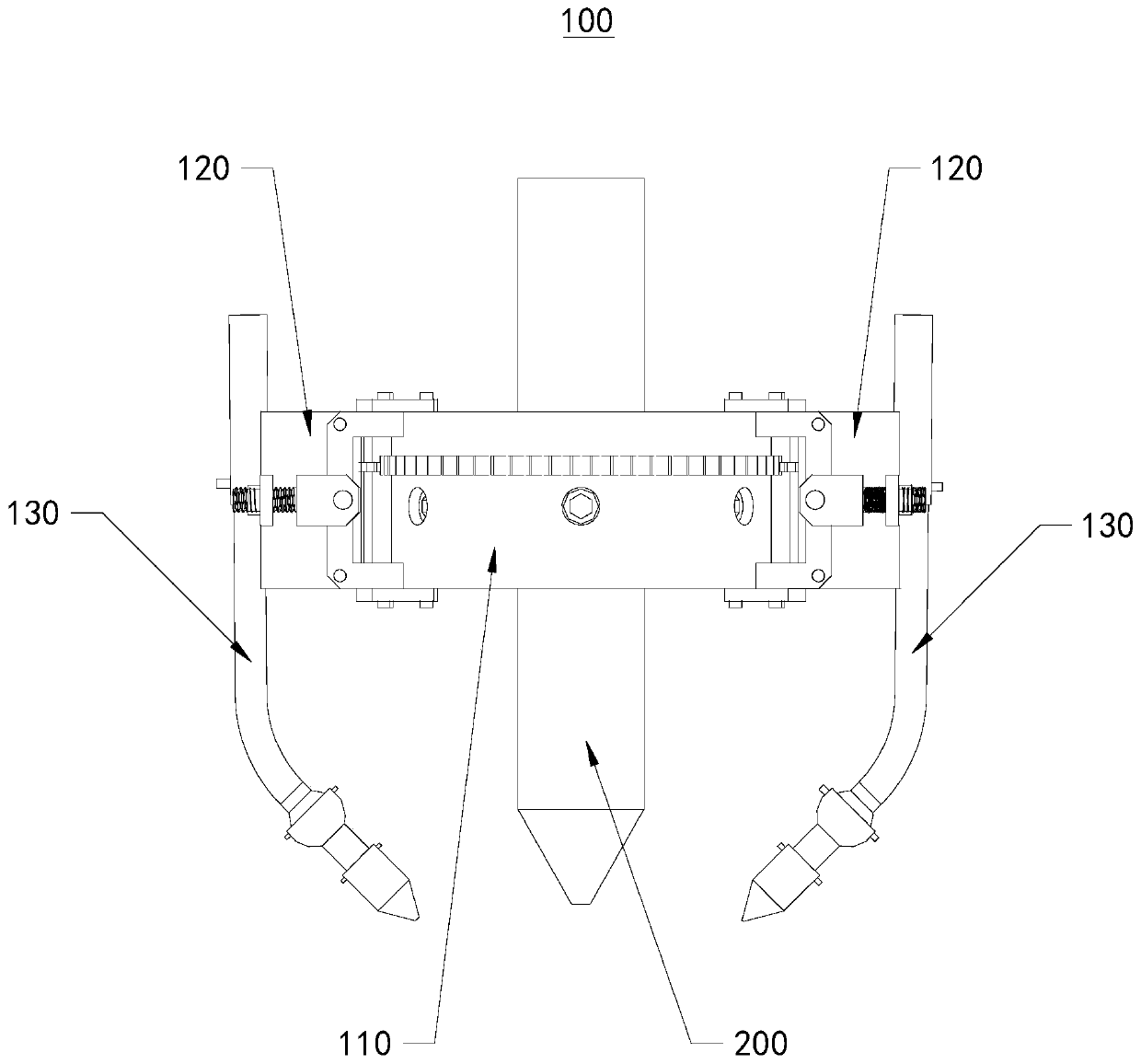

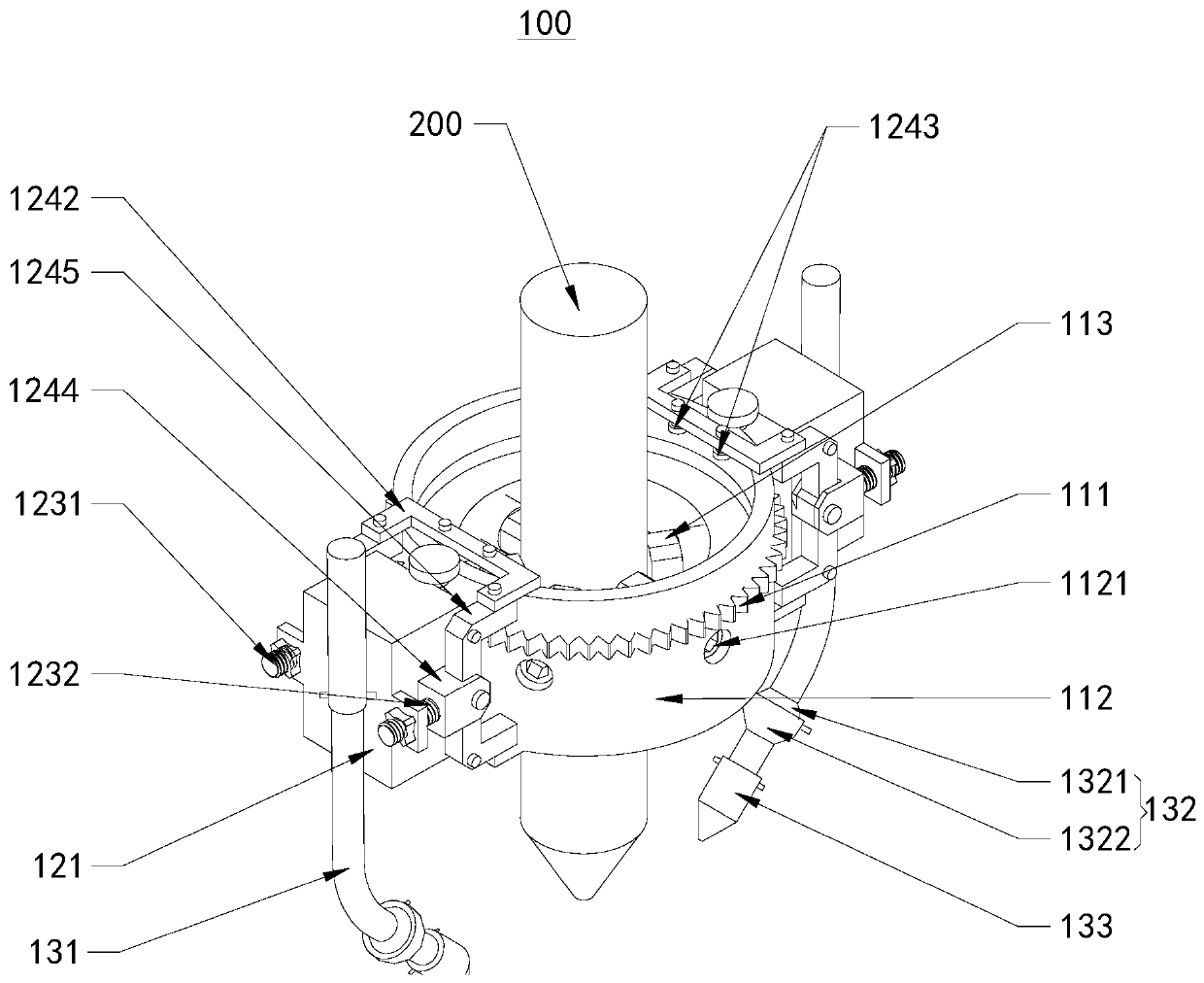

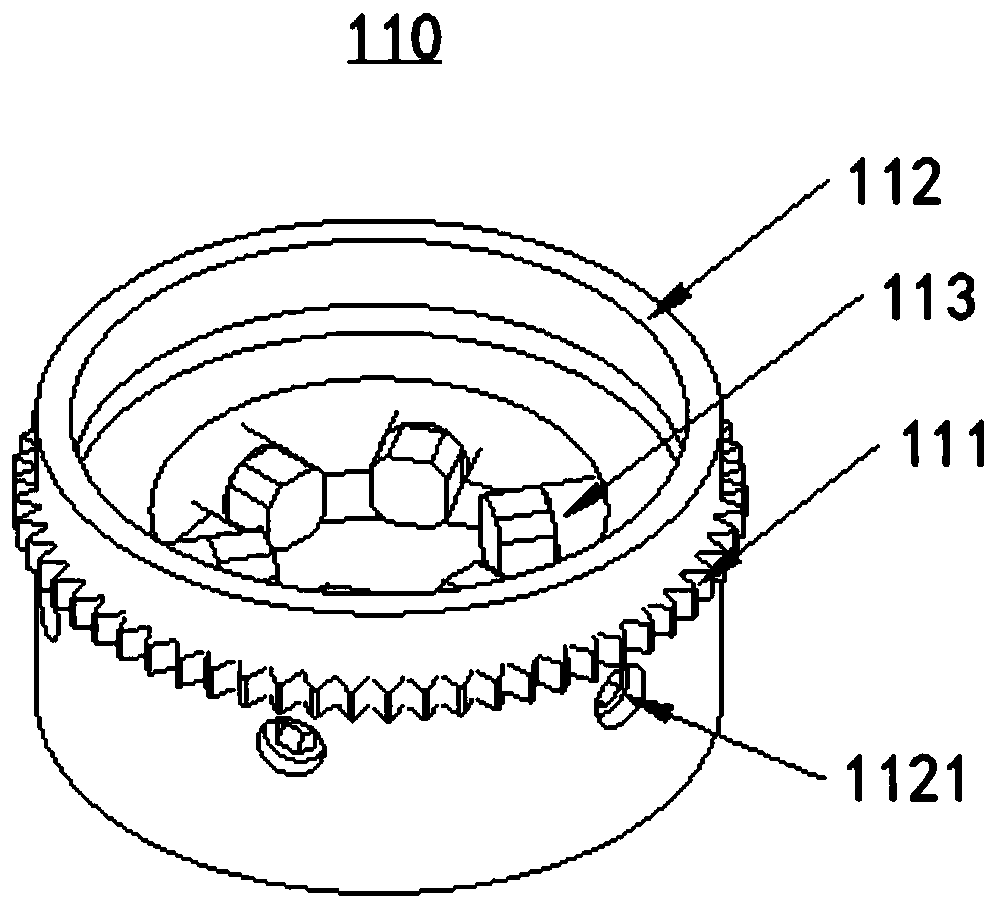

Paraxial wire feeding device and additive manufacturing system

ActiveCN110421231AGood wire feeding angleGood welding performanceWelding accessoriesIncreasing energy efficiencyEngineeringManufacturing systems

The invention discloses a paraxial wire feeding device and an additive manufacturing system, and relates to the field of additive manufacturing equipment. The device comprises a mounting mechanism, atravelling mechanism and a wire guide mechanism, wherein the mounting mechanism is used for mounting a welding gun; the travelling mechanism comprises a fixed part and a drive part; the fixed part ispositioned at the outer side of the welding gun; the drive part is connected to the fixed part, and the fixed part is driven to perform peripheral motion at the periphery of the welding gun; the wireguide mechanism is mounted on the fixed part, and is provided with a wire guide nozzle towards the welding gun; the wire guide mechanism is provided with a movable part for regulating an angle of thewire guide nozzle and / or length of the wire guide mechanism. The paraxial wire feeding device can regulate a wire feeding direction and an included angle between a welding wire and the welding gun inreal time, so that forming quality is guaranteed and stacking efficiency is improved. Besides, the additive manufacturing system provided by the invention is good in universality, is high in degree ofautomation, easily achieves a proper wire feeding direction and a proper wire feeding angle, and is good in additive manufacturing effect.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

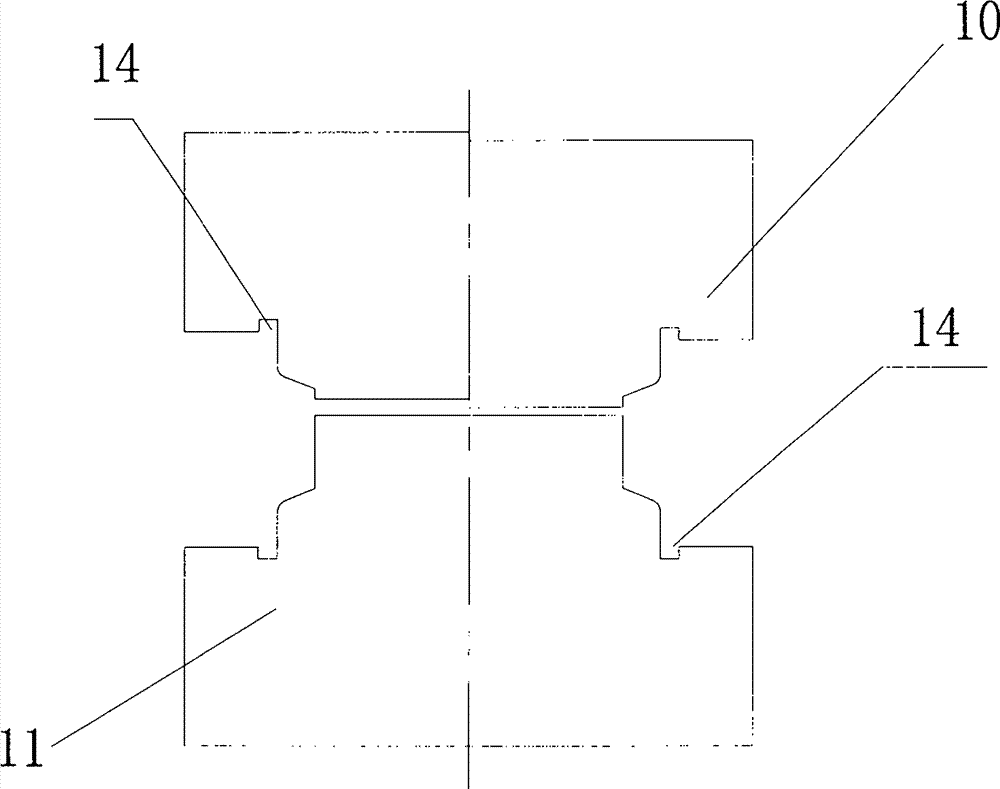

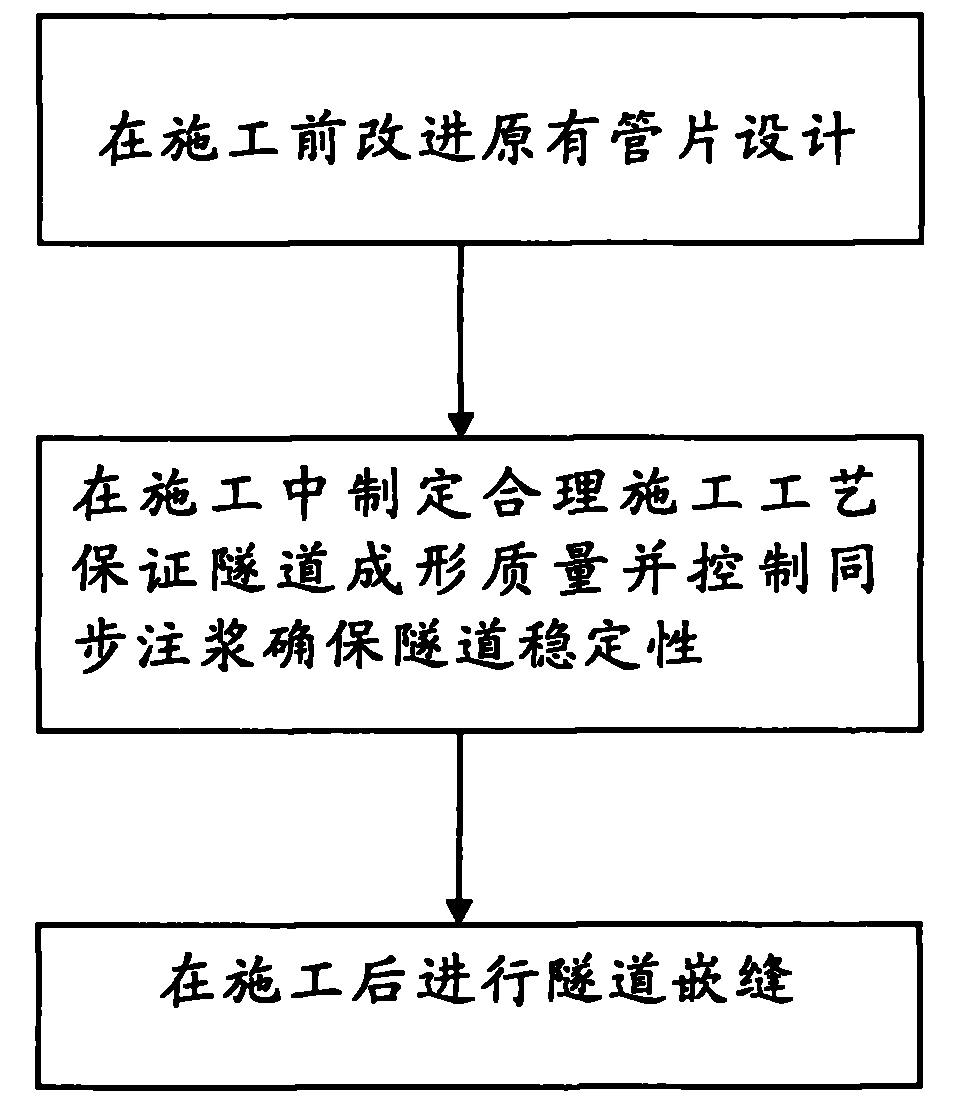

Water-proof method for seepagetunnel with super burial depth

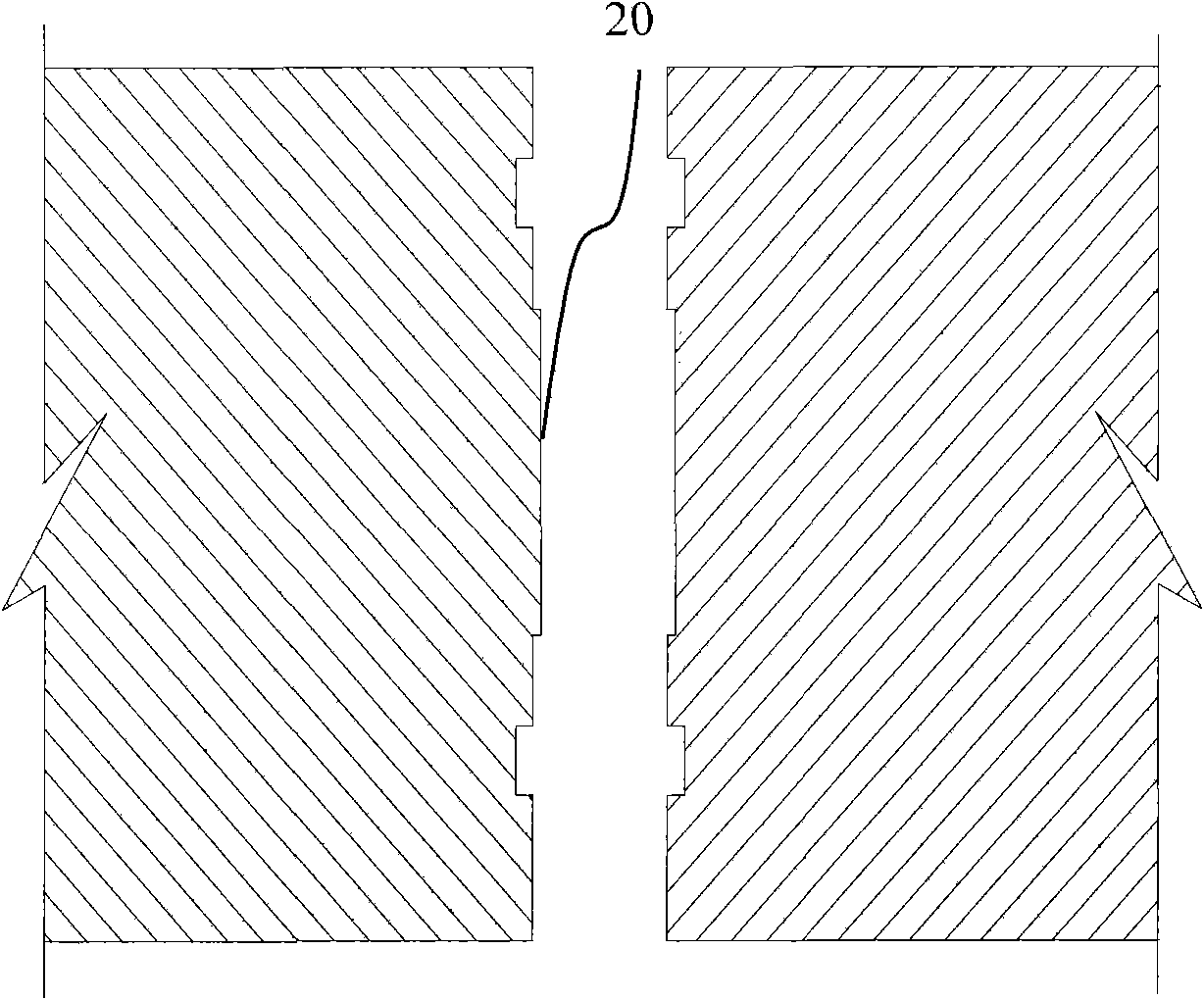

InactiveCN101871352AMeet waterproof requirementsGuaranteed forming qualityUnderground chambersTunnel liningMechanical engineeringWedge shape

The invention provides a water-proof method for a seepagetunnel with super burial depth. The method comprises the following steps: before the construction, carrying out the step of increasing the thickness of duct pieces and the step of enhancing the connection between contact surfaces and end faces of the duct pieces, wherein the step of enhancing the connection between the contact surfaces and the end faces of the duct pieces comprises the following steps: increasing the quantity of annular bolts and adding a rebate groove on the annular surfaces of the duct pieces; and increasing positioning rods and double-channel waterstop bands on the end faces of the duct pieces; during the construction, sealing the top of a tube piece lining with a top block of small size when assembling the wedged tube pieces; and selecting rational grouting points on the assembled duct pieces to synchronous grout the duct pieces; and after the construction, filling and blocking handholes and caulked joints of the duct pieces. By using the technical scheme, improving the original duct piece design and constituting a rational construction process, the method ensures the forming quality of the tunnel and controls the synchronous grouting and ensures the stability of the tunnel and the caulked joints of the tunnel and the like so as to meet the water-proof requirement of the seepagetunnel with super burial depth.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD. +1

Aluminum alloy hub powerful spinning machining molding method and demolding mechanism

The invention discloses an aluminum alloy hub powerful spinning machining molding method and a demolding mechanism. The demolding mechanism comprises a core mold structure which comprises an inner core mold and an outer core mold connected to the exterior of the inner core mold in a sleeving manner, and the demolding mechanism further comprises a suppressing block and a limiting stretching mechanism, wherein the suppressing block and the outer core mold which is stressed to move in the radial direction are fixedly locked, and the limiting stretching mechanism is used for pushing the core mold structure to move and driving the outer core mold to separate from the suppressing block. The machining molding method comprises the steps that a plate is jacked to the core mold structure through a tail jacking part to be fixed, the inner core mold is extruded, and the outer core mold is stressed to move in the radial direction to be matched and locked with the suppressing block; the core mold structure is rotated to drive the tail jacking device and the plate to rotate; and hub molding is carried out through a multi-wheel spinning process. By means of the aluminum alloy hub powerful spinning machining molding method and the demolding mechanism, the problem that demolding is difficult after complex section hub spinning molding is solved, the demolding principle is simple, and universality is high.

Owner:DORCEN AUTO CO LTD

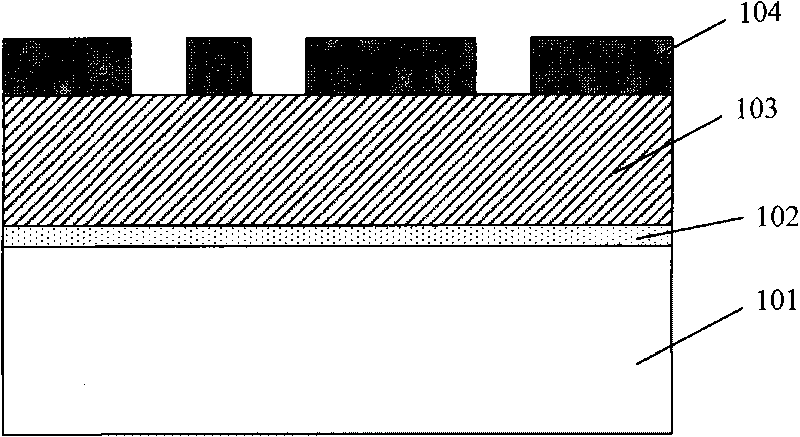

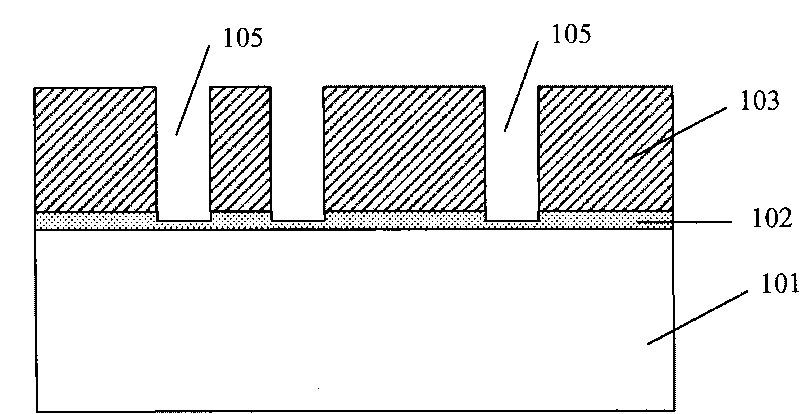

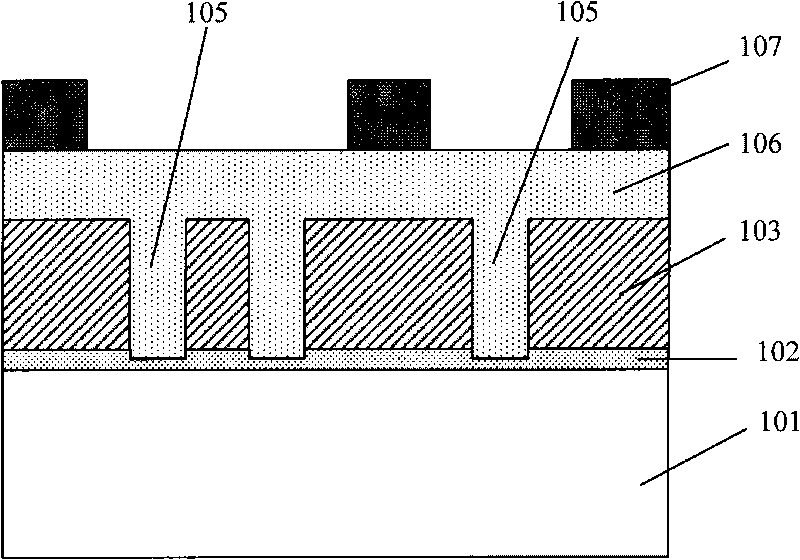

Semiconductor device with dual-mosaic structure and forming method thereof

ActiveCN101740475AGuaranteed forming qualityLower the K valueSemiconductor/solid-state device detailsSolid-state devicesEtchingProcess conditions

The invention discloses a method for forming a semiconductor device with a dual-mosaic structure, which comprises the following steps of: providing a substrate; forming a first dielectric layer on the substrate; forming a through hole pattern on the first dielectric layer; forming an opening of a through hole; detecting the remaining thickness of the first dielectric layer which remains at the bottom of the opening of the through hole; forming a second dielectric layer on the first dielectric layer and in the opening of the through hole; forming a trench pattern on second dielectric layer; forming a trench; removing the second dielectric layer; adjusting process conditions of the third etching according to the remaining thickness; performing the third etching to remove the first dielectric layer which remains at the bottom of the opening of the through hole; and forming the dual-mosaic structure. The invention also discloses the semiconductor device with the dual-mosaic structure. The semiconductor device with the dual-mosaic structure and the forming method thereof of the invention form high-quality dual-mosaic structure below a stop layer without etching and effectively reduce k value of the dual-mosaic structure.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

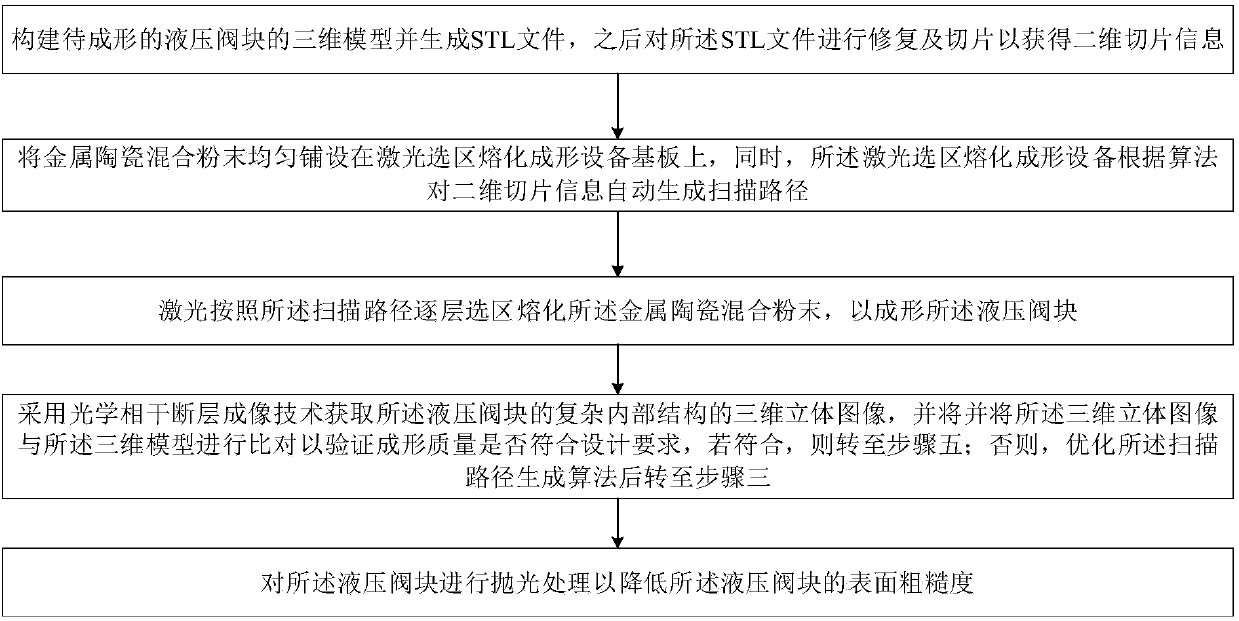

Laser selective melting forming method suitable for hydraulic valve block

InactiveCN107866568AShort processAvoid time costAdditive manufacturing apparatusIncreasing energy efficiencyEconomic benefitsImaging technique

The invention belongs to the related technical field of additive manufacturing, and discloses a laser selective melting forming method suitable for a hydraulic valve block. The laser selective meltingforming method comprises the following steps that (1) a three-dimensional model of the to-be-formed hydraulic valve block is constructed, and two-dimensional slicing information is obtained; (2) laser selective melting forming equipment is laid with metal ceramic mixed powder, and a scanning path of the two-dimensional slicing information is automatically generated by the laser selective meltingforming equipment according to an algorithm; (3) layer-by-layer selective melting is conducted on the metal ceramic mixed powder by lasers according to the scanning path, and the hydraulic valve blockis formed; and (4) a three-dimensional image of a complex internal structure of the hydraulic valve block is obtained by adopting an optical coherence tomography, whether the forming quality meets design requirements or not is verified, if yes, forming is completed, and if no, the step (3) is repeated after the algorithm is generated by optimizing the scanning path. According to the laser selective melting forming method, the technological process is shortened, the cost is reduced, the economic benefit is improved, and the flexibility is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com