Patents

Literature

113results about How to "Avoid uneven stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible loading device and method for simulating uniform stress on surface of cylindrical anchorage model

ActiveCN107505205AComply with the force characteristicsThe pull test is real and effectiveMaterial strength using tensile/compressive forcesClimate change adaptationEngineeringMechanical engineering

Owner:SHANDONG JIANZHU UNIV

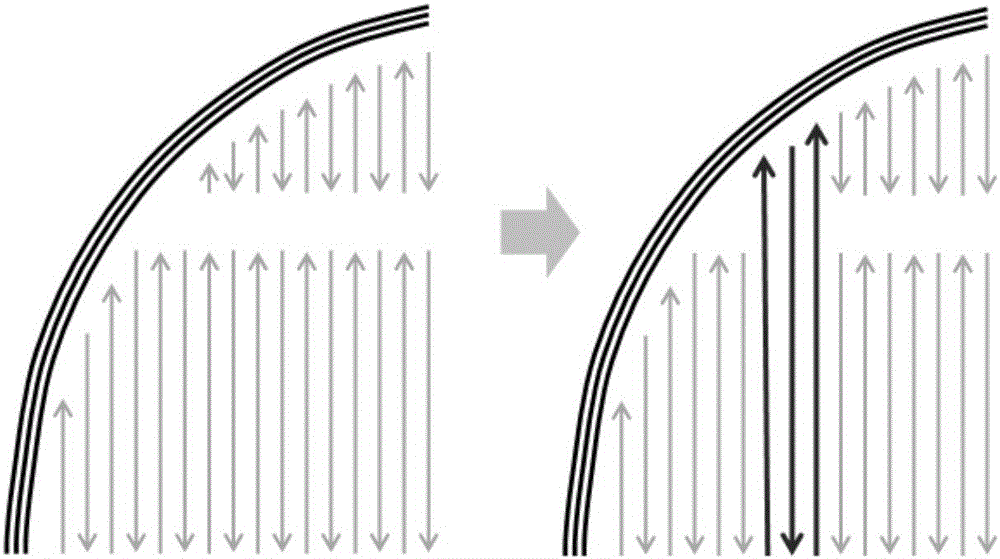

Strip-mode laser scanning path planning method

ActiveCN105773967AAvoid uneven stressQuality improvementAdditive manufacturing apparatusPath lengthLaser scanning

The invention discloses a strip-mode laser scanning path planning method. The method includes the step that an excessively short path in each strip partition of a part single-layer section is combined with a scanning path, located on the same path with the excessively short path, in an adjacent partition. The paths are selectively combined so that the problem that when a laser device is continuously switched on or off in the scanning process when encountering excessively short paths, and accordingly stress on a part contour boundary is not uniform can be effectively solved. The service life of the laser device is prolonged while the quality of a part is improved. Meanwhile, a user can set a shortest path length parameter by himself or herself according to characteristics of the part to be machined, and part forming quality is guaranteed.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

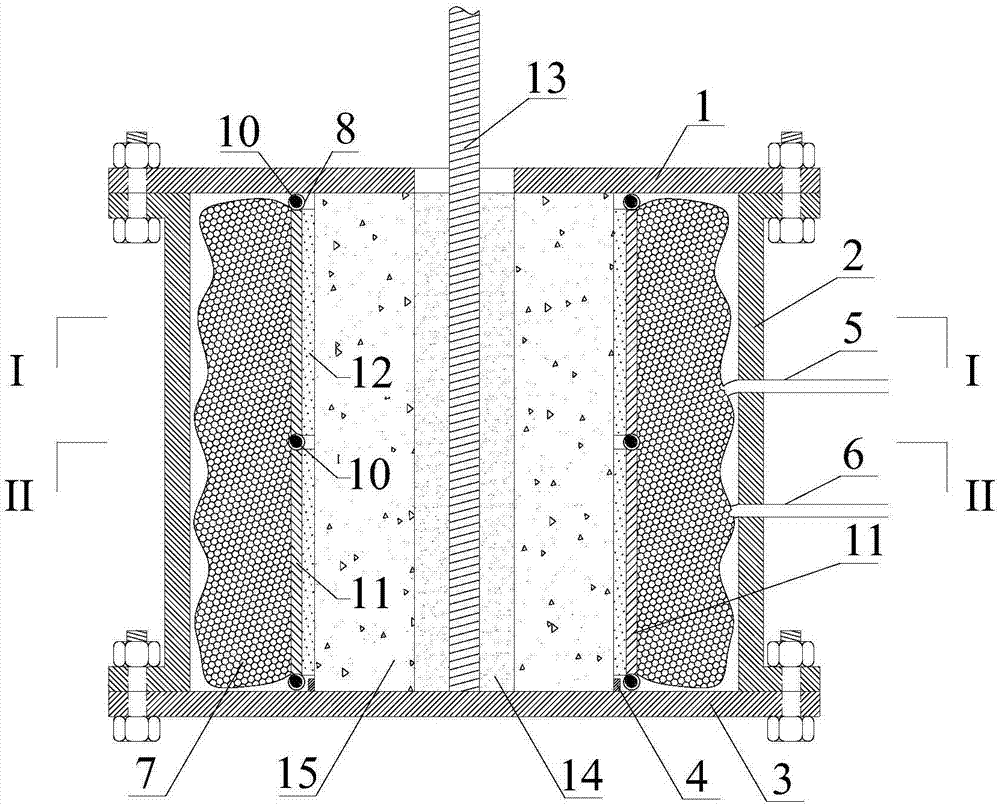

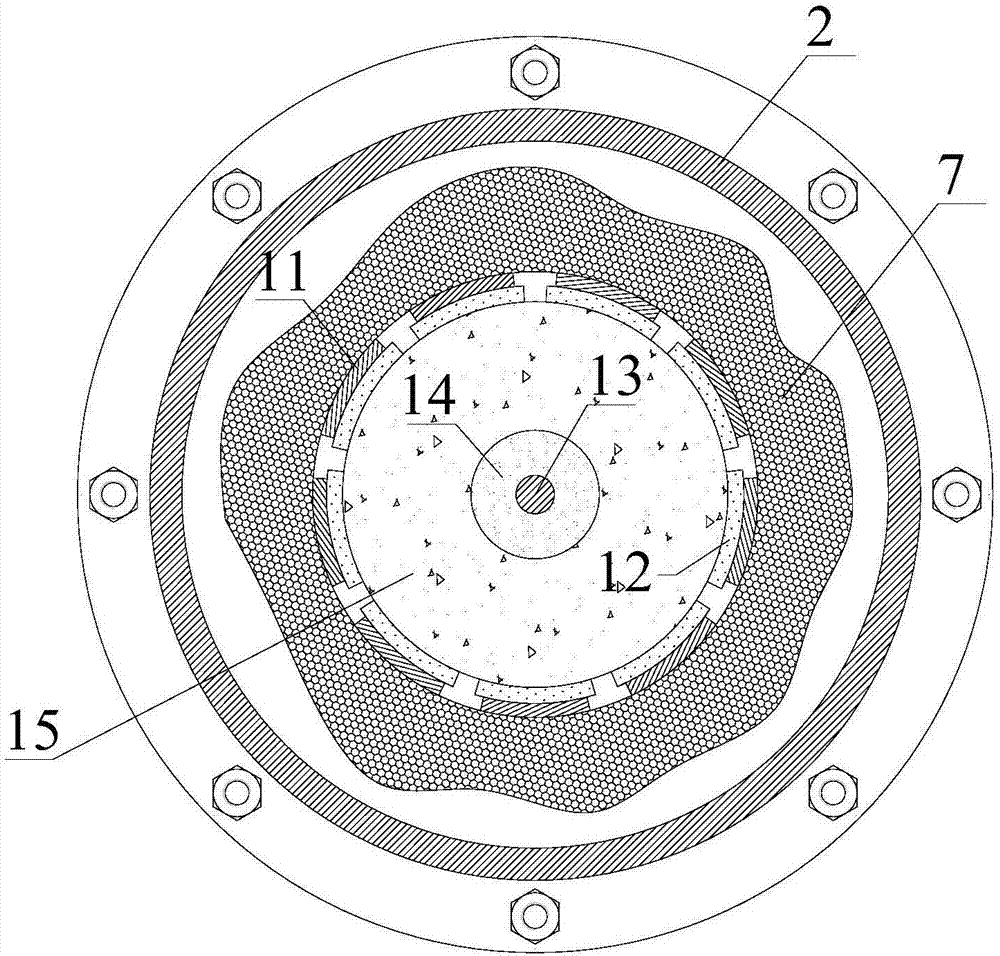

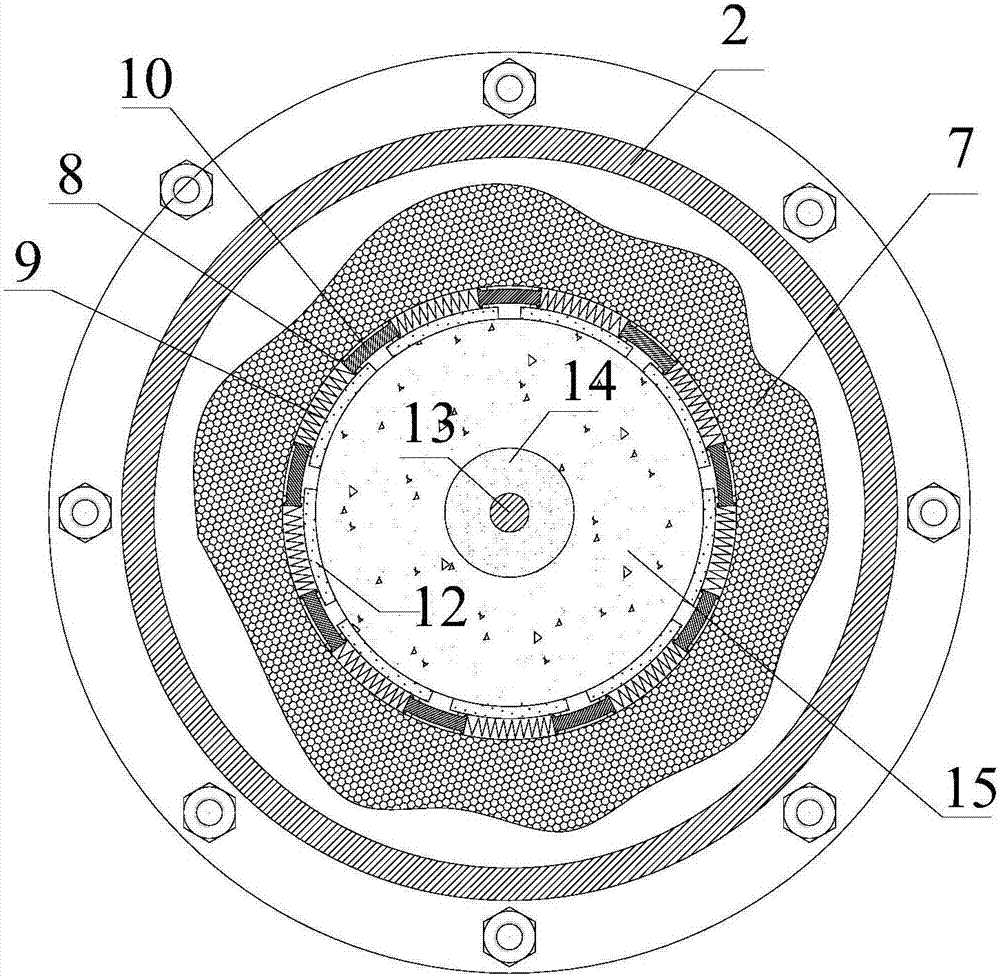

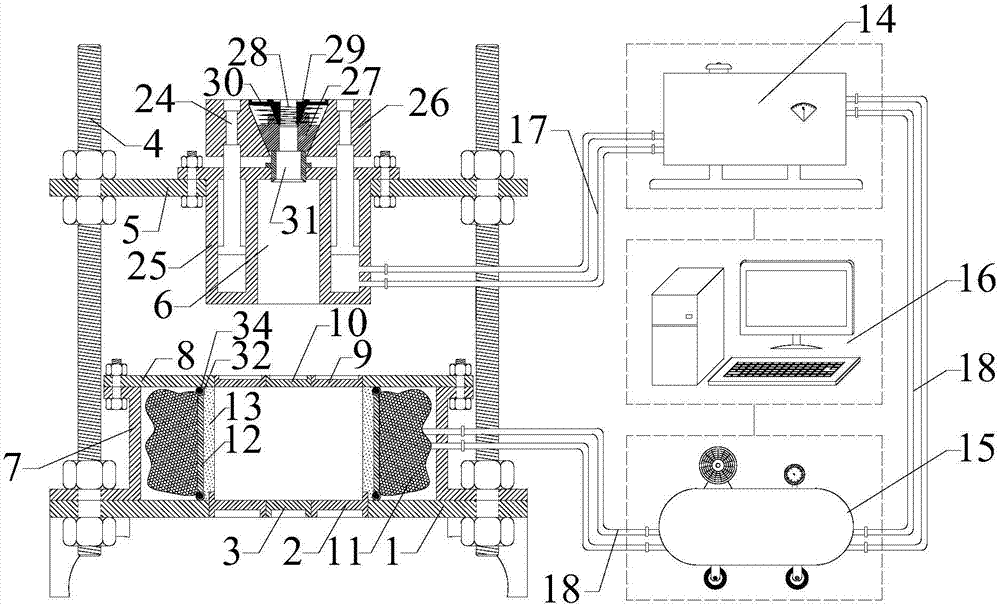

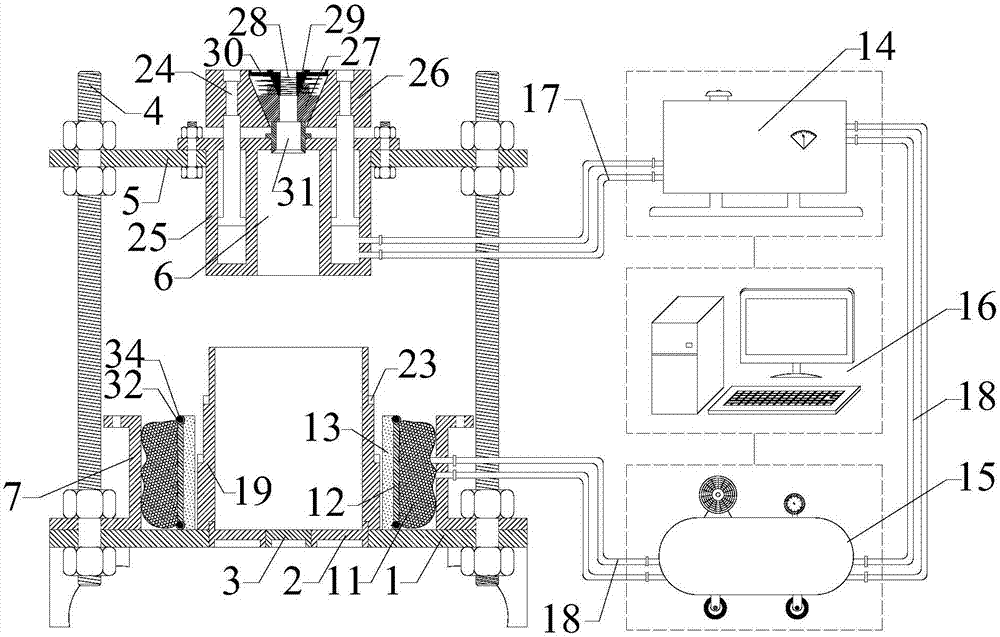

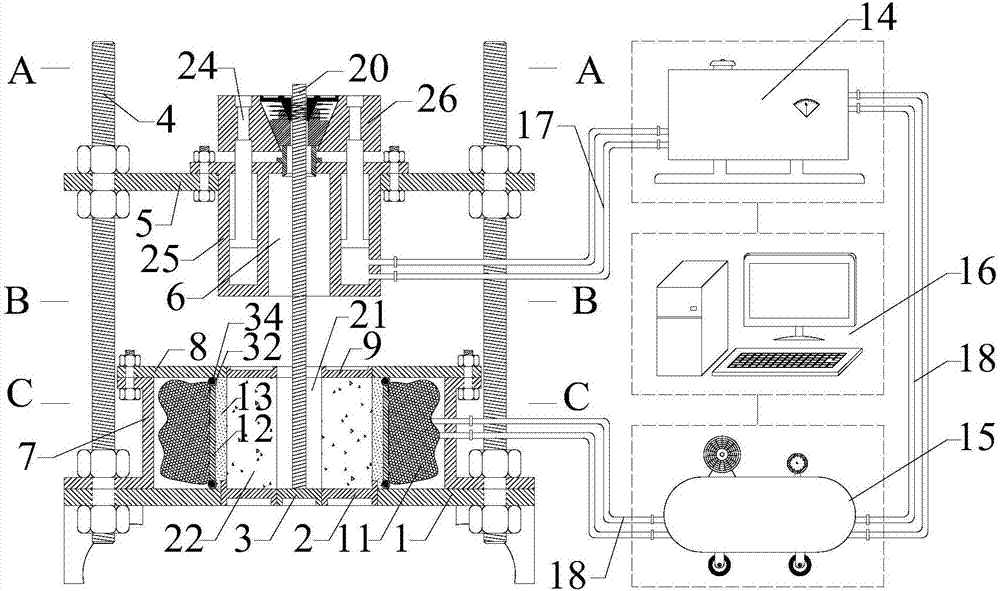

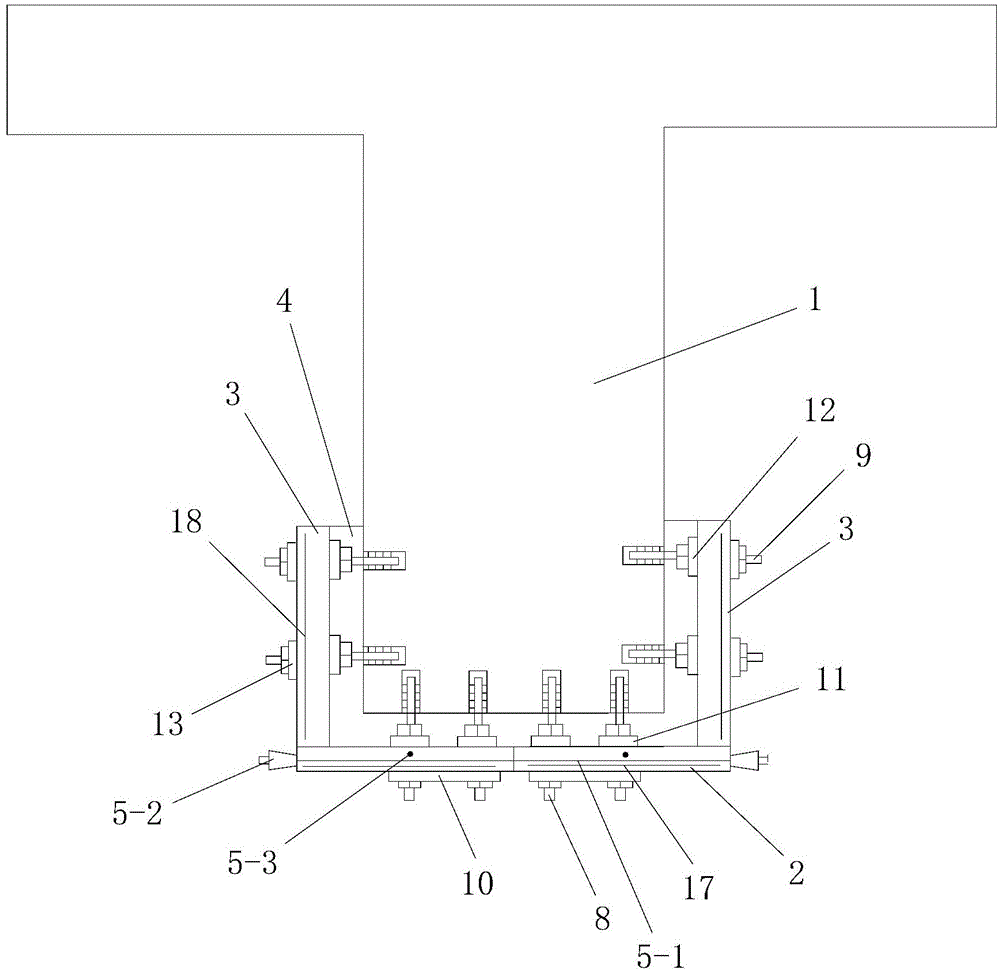

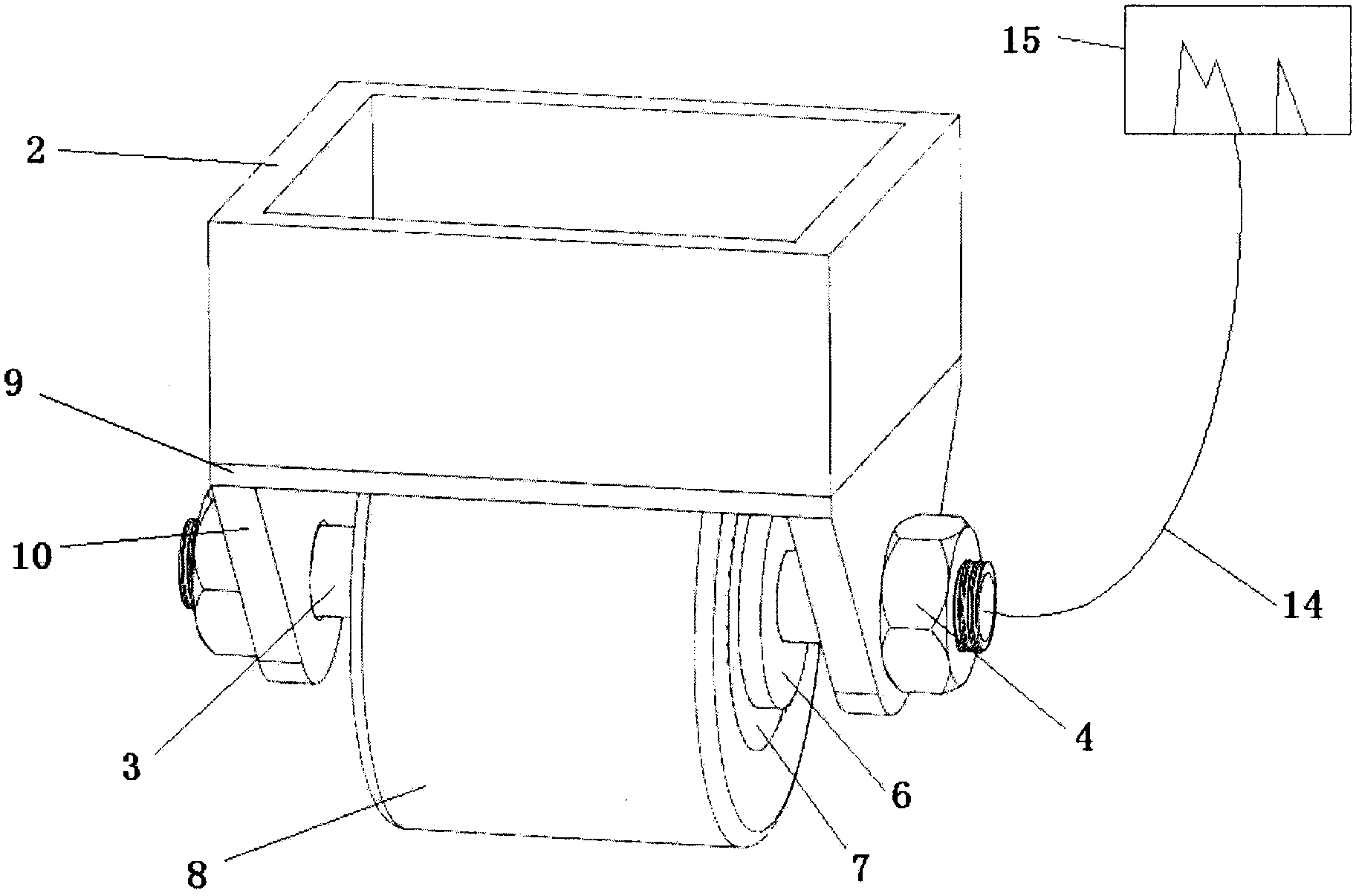

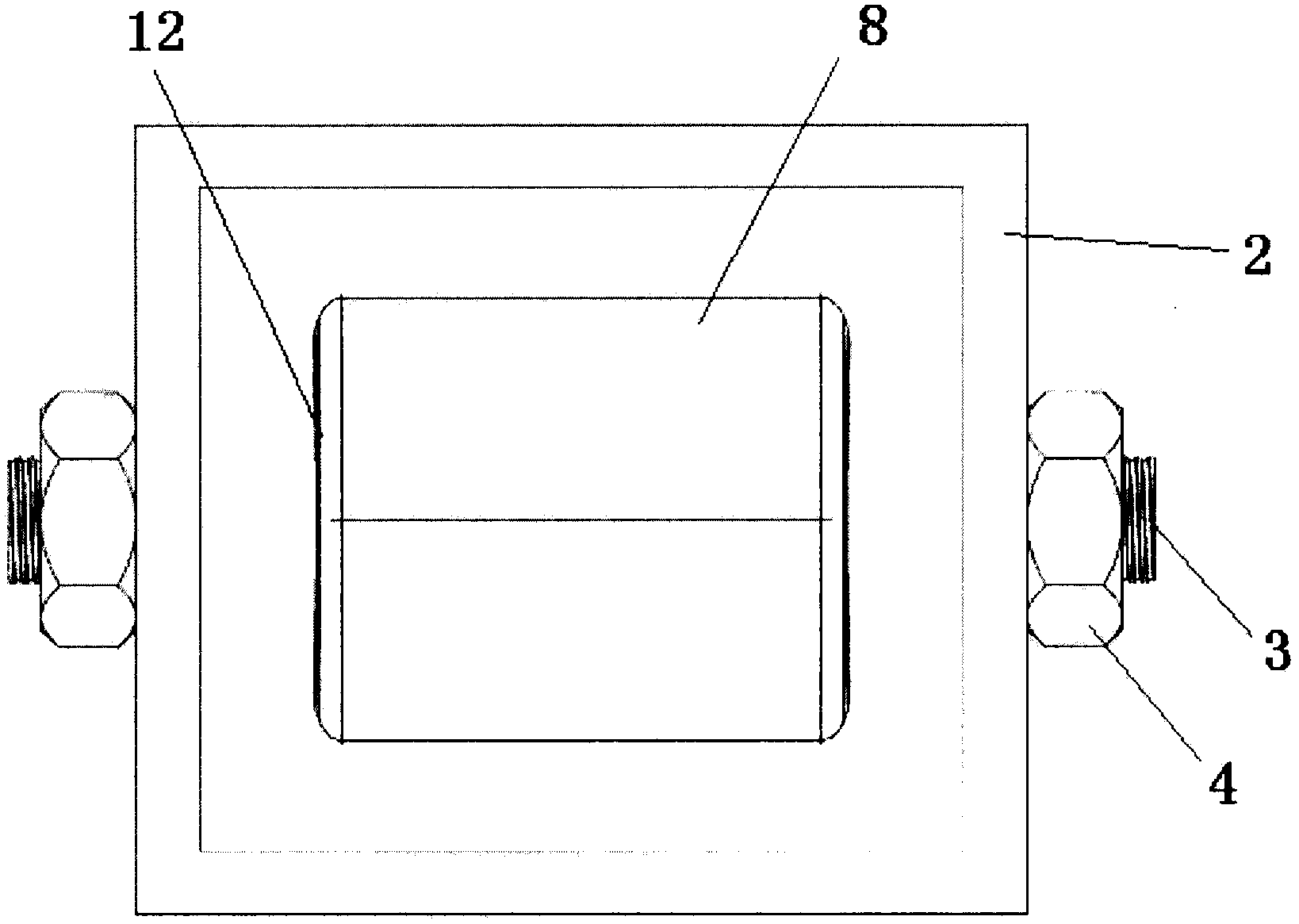

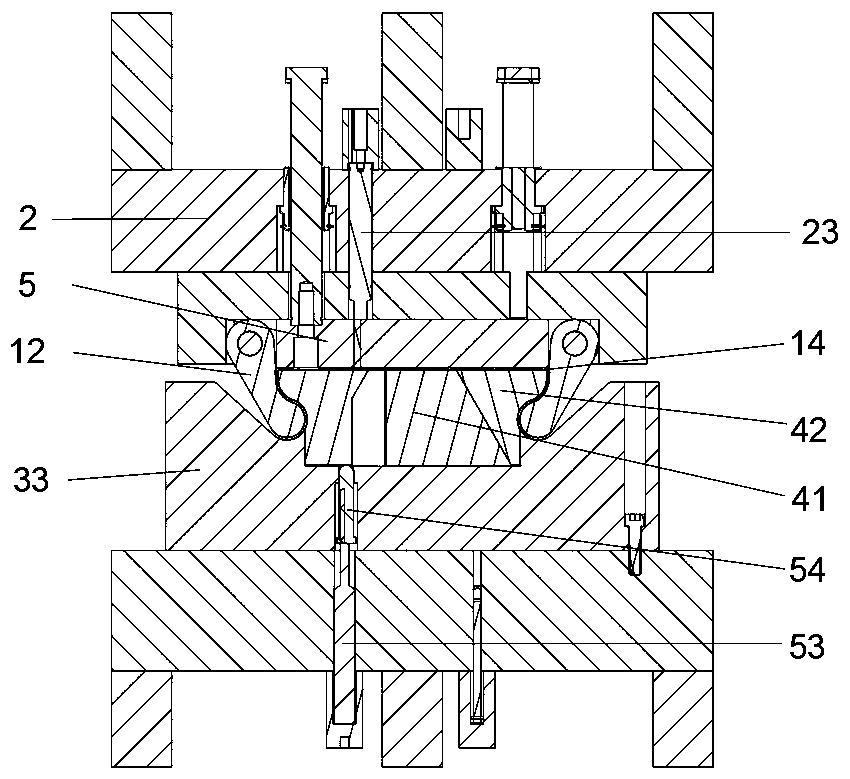

Testing system and method for testing mechanical property of anchor rod or anchor cable anchoring interface in high-stress environment

InactiveCN107268637AComply with the force characteristicsThe pull test is real and effectiveFoundation testingExcavationsClassical mechanicsAir pump

The invention discloses a testing system and method for testing the mechanical property of an anchor rod or anchor cable anchoring interface in a high-stress environment. The testing system comprises an anchor rod or anchor cable clamping mechanism for a test, the anchor rod or anchor cable clamping mechanism is installed at the upper end of a counterforce device, and automatic clamping and loosening of a to-be-tested anchoring body model, namely an anchor rod or an anchor cable can be achieved; and an annular high-pressure loading air bag is of an annular barrel structure, and a flexible constraint hoop is pasted to the inner wall of the annular high-pressure loading air bag, is composed of end arc sleeves, arc pressure springs, arc connection rods and arc force transferring plates and is of a barrel-shaped structure. Under the loading constraint action of the annular high-pressure loading air bag, the flexible constraint hoop can be shrunk inwards automatically, it is guaranteed that in the shrinking process, the cross section is always round, and loading of the stress of surrounding rocks uniformly distributed on the surface of the cylinder-shaped anchoring body model can be achieved. Through cooperation with a pneumatic oil tank pump, a high-pressure air pump and a controller, the mechanical property of the anchor rod or anchor cable anchoring body model interface can be effectively tested in different surrounding rock states and loading manners.

Owner:SHANDONG JIANZHU UNIV

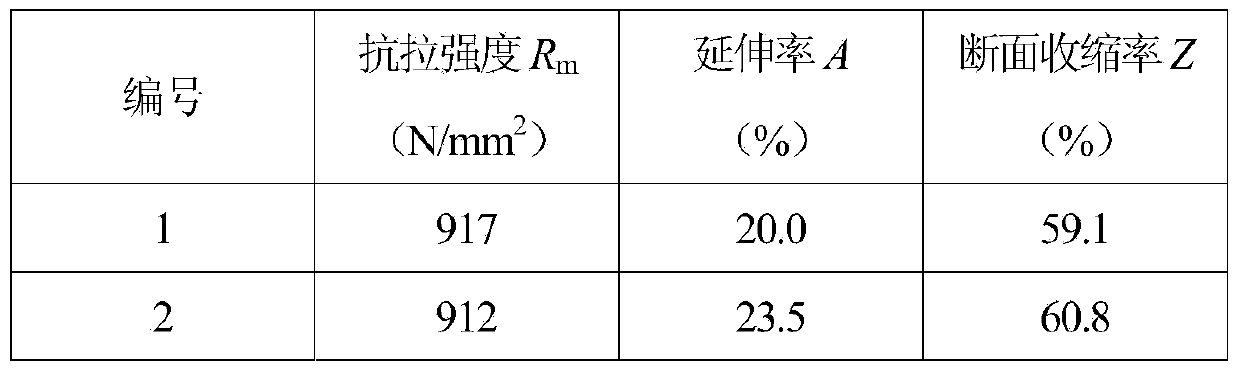

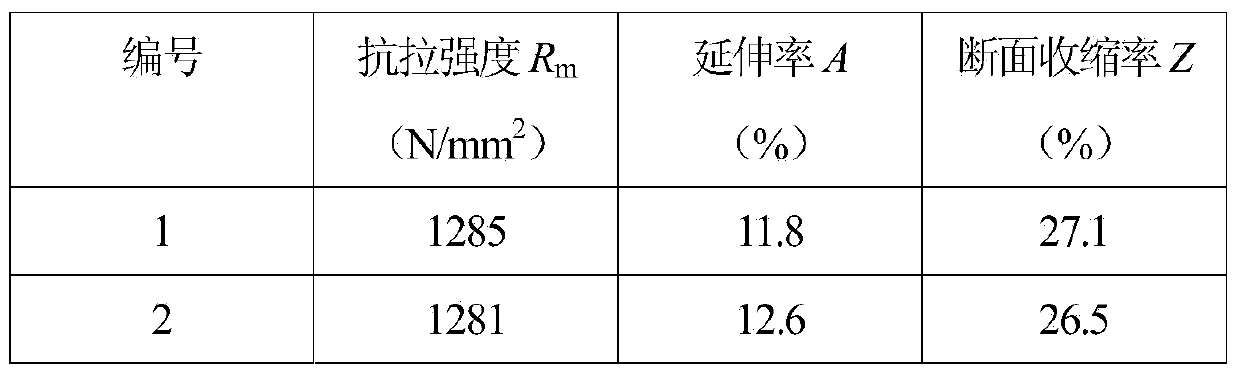

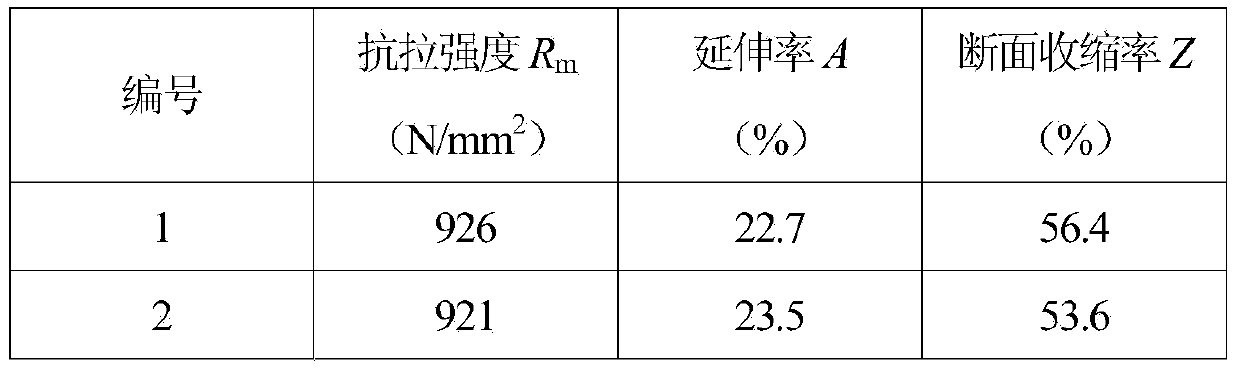

Preparation method of titanium alloy spring made of wire with specially-shaped section

The invention relates to a preparation method of a titanium alloy spring made of a wire with a specially-shaped section and belongs to the technical field of springs. The spring is formed by winding of the titanium alloy wire with the specially-shaped section; the titanium alloy wire comprises the components in percentage by mass as follows: 2-4 of Al, 6-10 of V, 4-8 of Cr, 2-6 of Mo, 2-6 of Zr, 0.1-0.3 of Fe, 0.03-0.15 of Si and the balance of Ti. The section of the titanium alloy spring wire can be rectangular, square, orthohexagonal or oval. The titanium alloy wire wound into the spring is prepared with forging, pressing and hot rolling technologies, the wire is subjected to solution treatment before being wound into the spring, and a finished product of the spring is subjected to aging and strengthening treatment. A titanium alloy which is used for preparing the spring can play a weight reduction role, and meanwhile, the titanium alloy has the good corrosion resistance and the long fatigue life in an ocean environment. With the adoption of the wire with the specially-shaped section, the section area can be increased under the condition that specifications of wires are similar, so that the rigidity of the spring is improved, and the usage requirement of the titanium alloy spring under the high workload can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

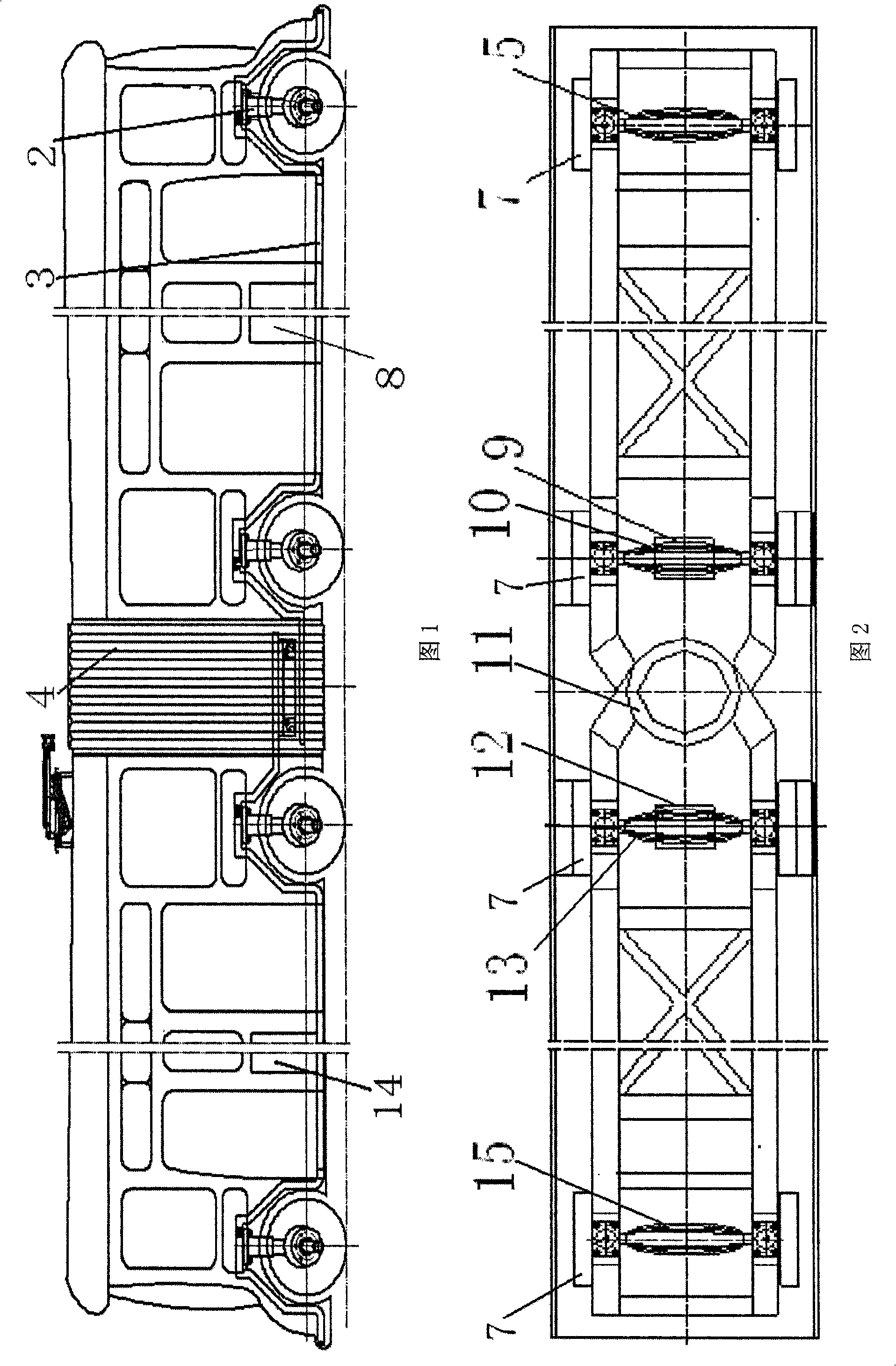

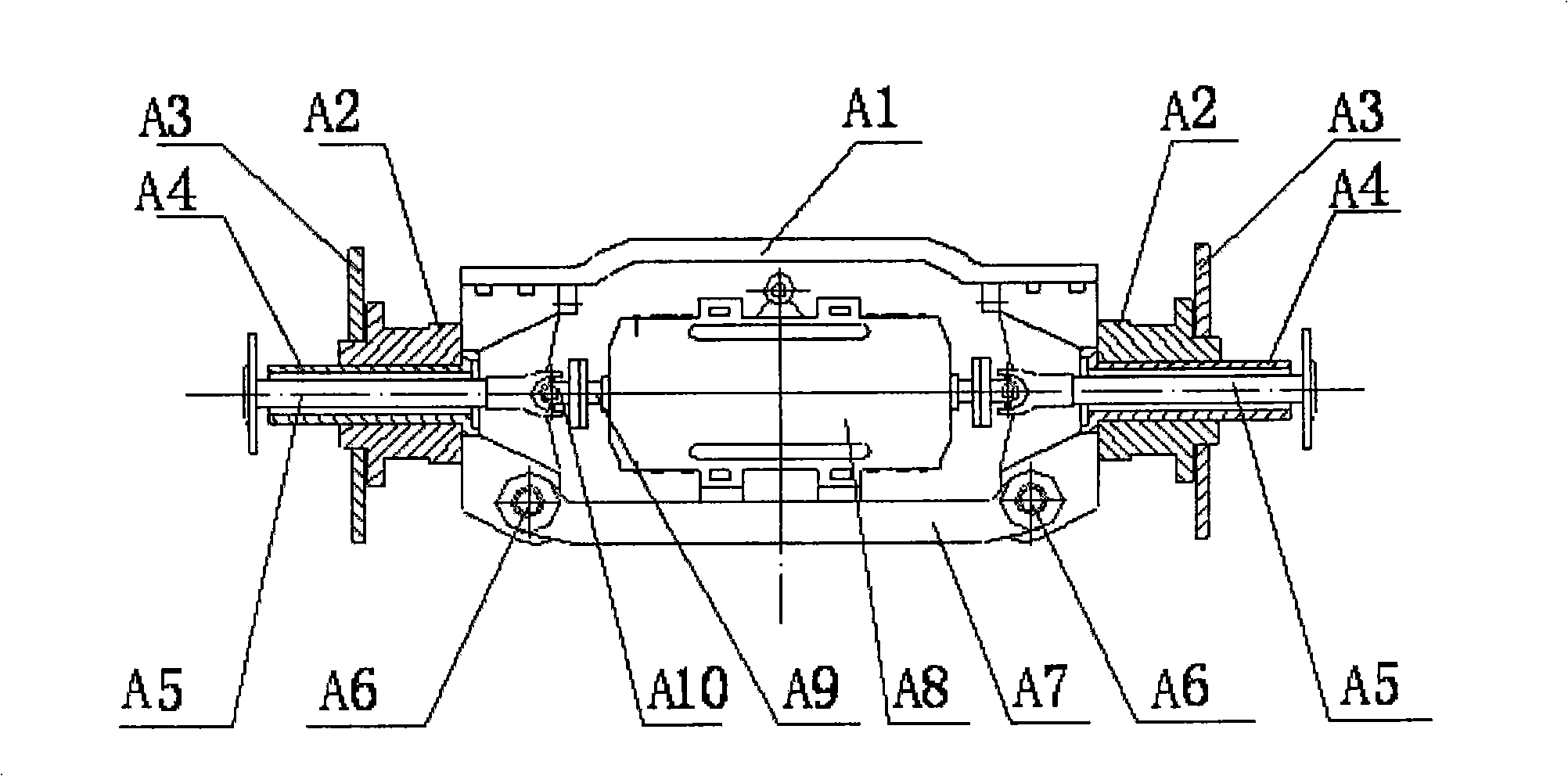

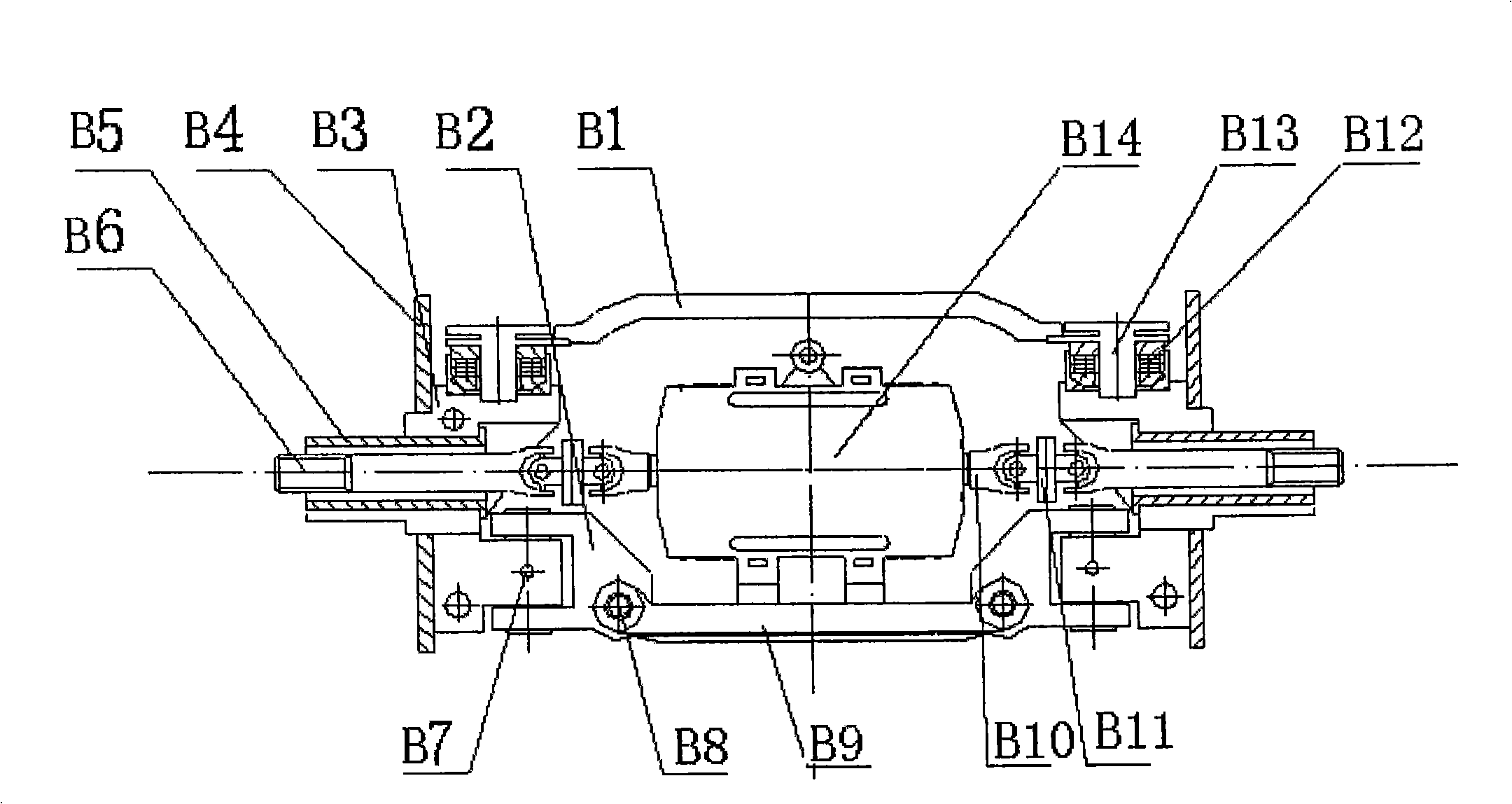

Articulated multiple-shaft drive bidirectional driving electric motor coach

InactiveCN101323255AEasy to driveImprove climbing abilitySteering linkagesControl devicesVehicle frameControl theory

The invention relates to an articulated multiaxial drive and bidirectional driving electric bus, belonging to the technical field of electric bus structure. The articulated multiaxial and bidirectional driving electric bus is characterized in that a chassis frame is provided with two differential driving axles, two differential driving steering axles, a front cab and a back cab; wherein, the differential driving axles are arranged in the middle of a bus body; In the middle of the differential driving axles, a first differential motor and a second differential motor are respectively used for supplying a torque for wheels at both ends; the two axles are articulated by a bus passage turntable; the part of the bus body, where the two axles are articulated, is provided with passage soft connection matched with the bus passage turntable; the differential driving steering axles are respectively arranged at the front side and back side of the bus body. The articulated multiaxial and bidirectional driving electric bus of the invention has simple structure and convenient maintenance as well as realizes articulated connection, multiaxial drive and bidirectional driving. The adoption of the differential driving axles and differential driving steering axles reduces intermediate link, so the bus starts rapidly, which has low noise, flexible steering and saving power supply.

Owner:上海中上汽车科技有限公司

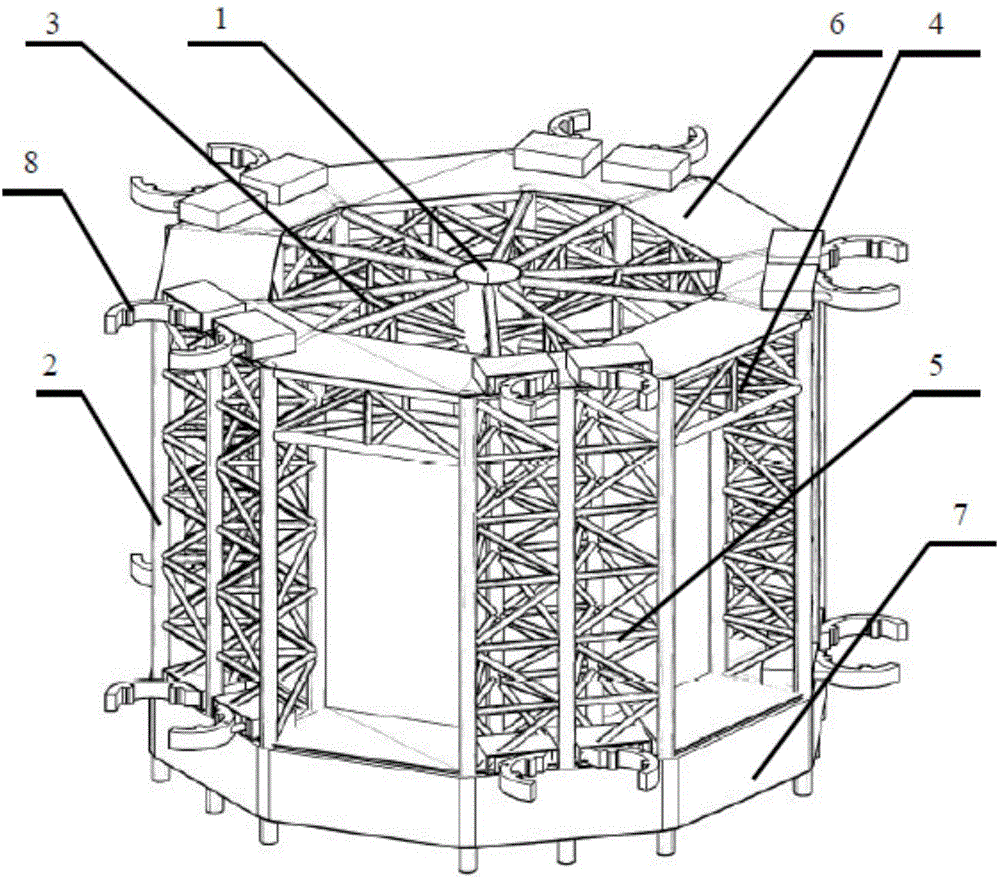

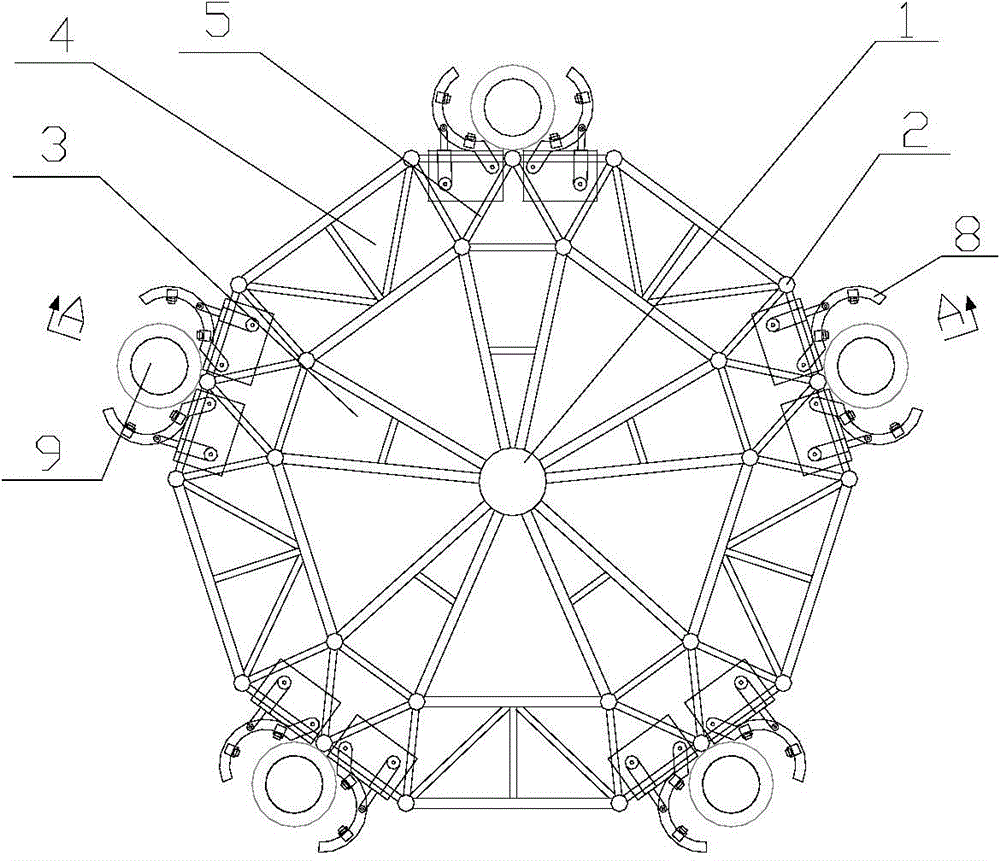

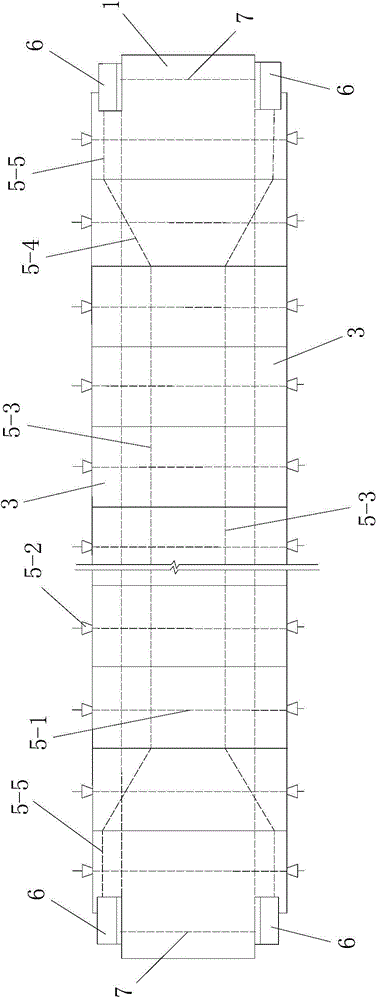

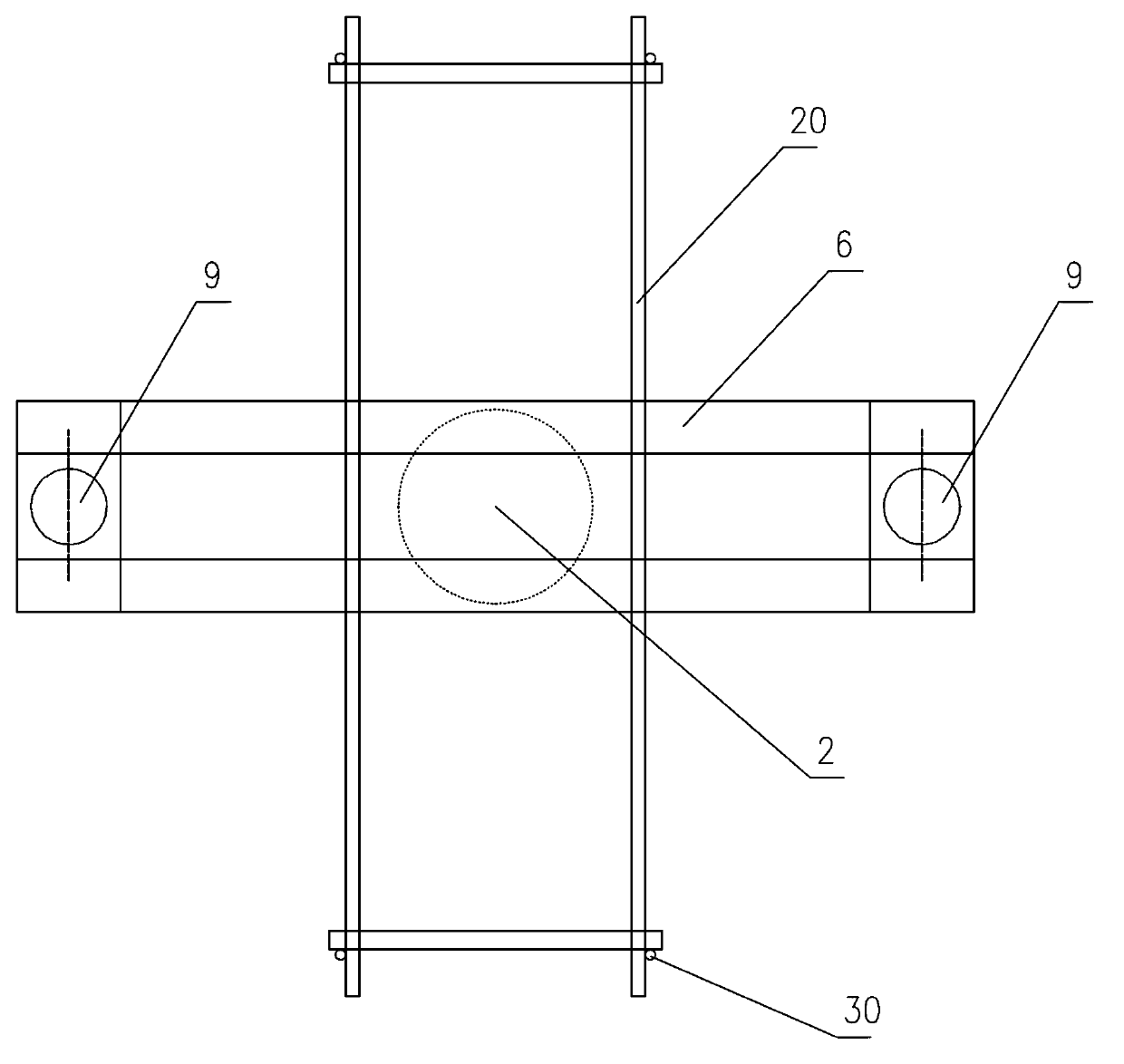

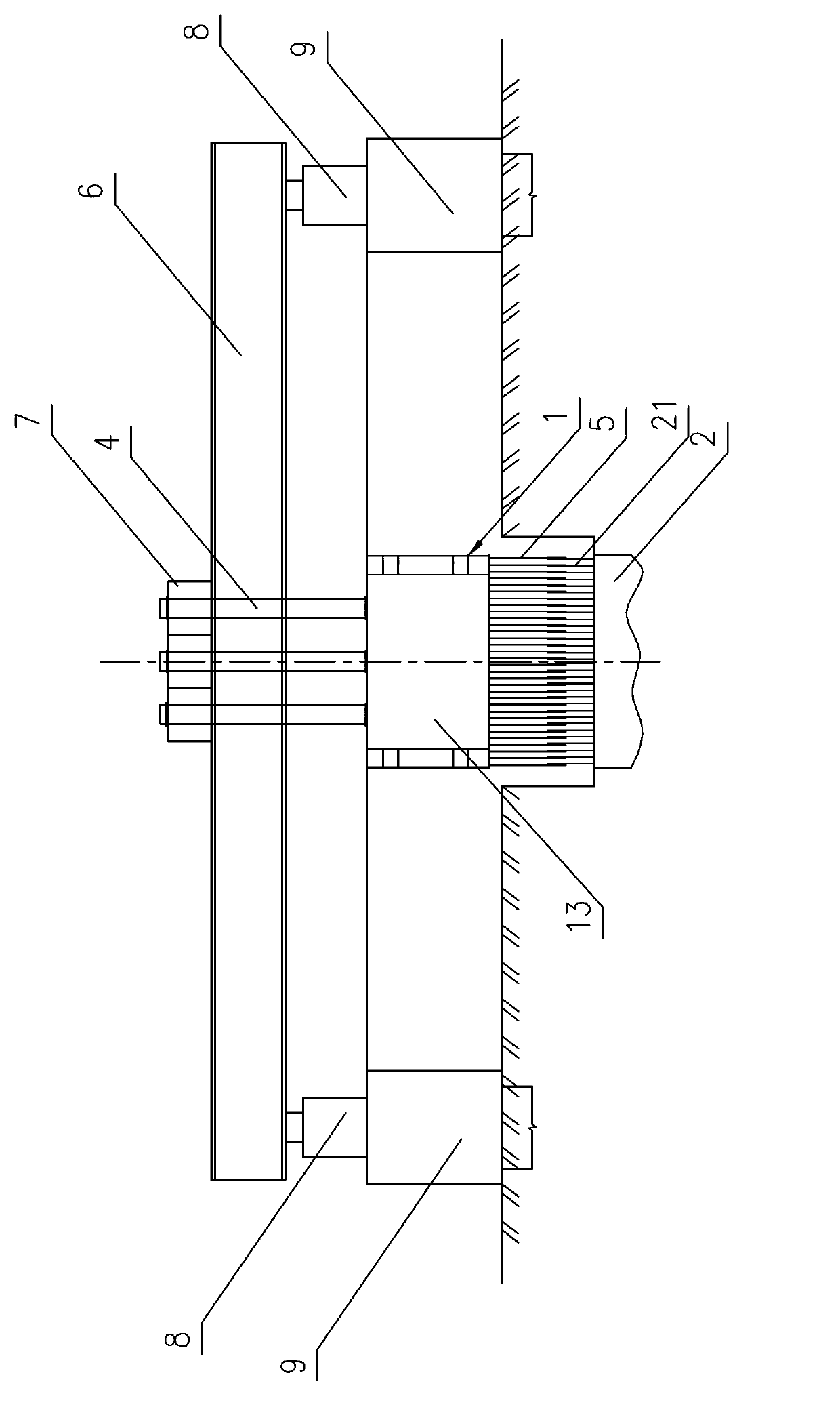

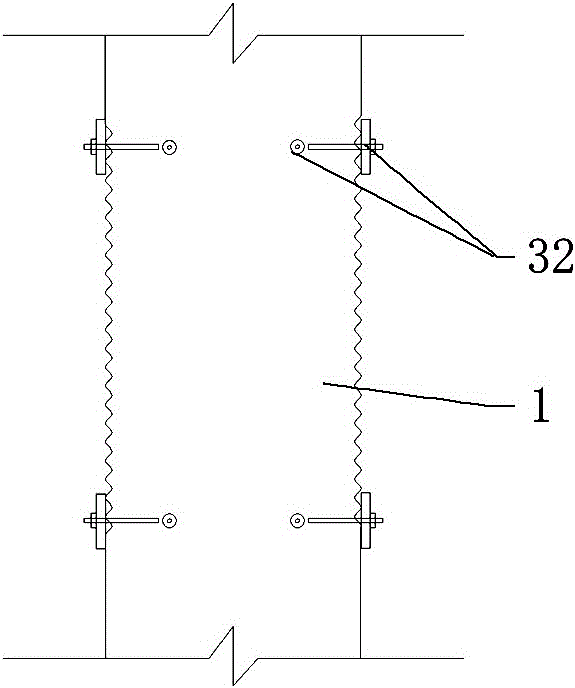

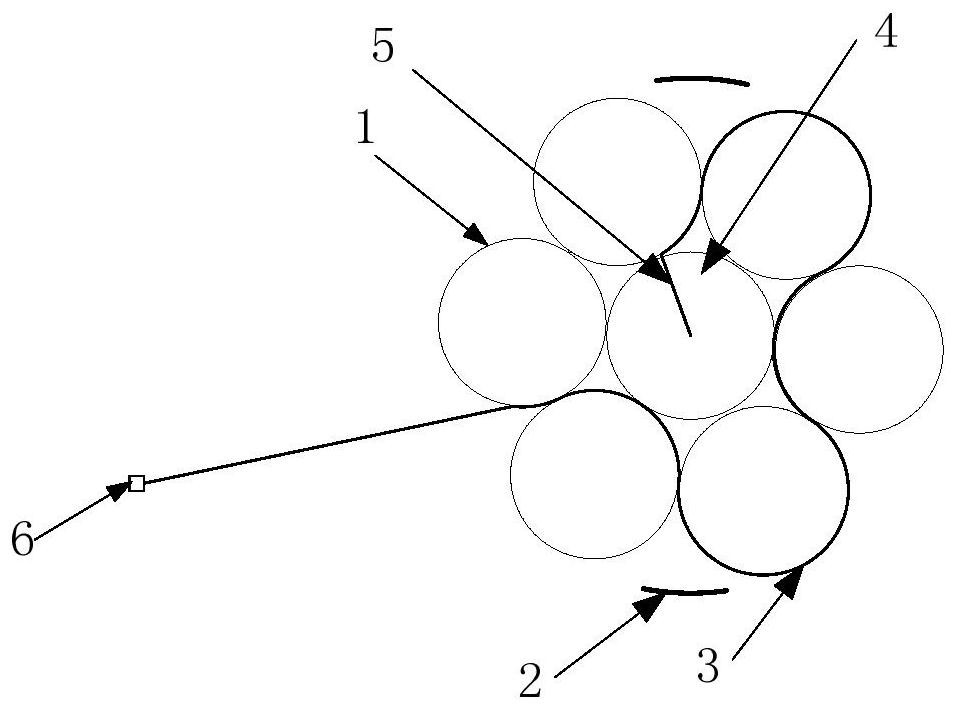

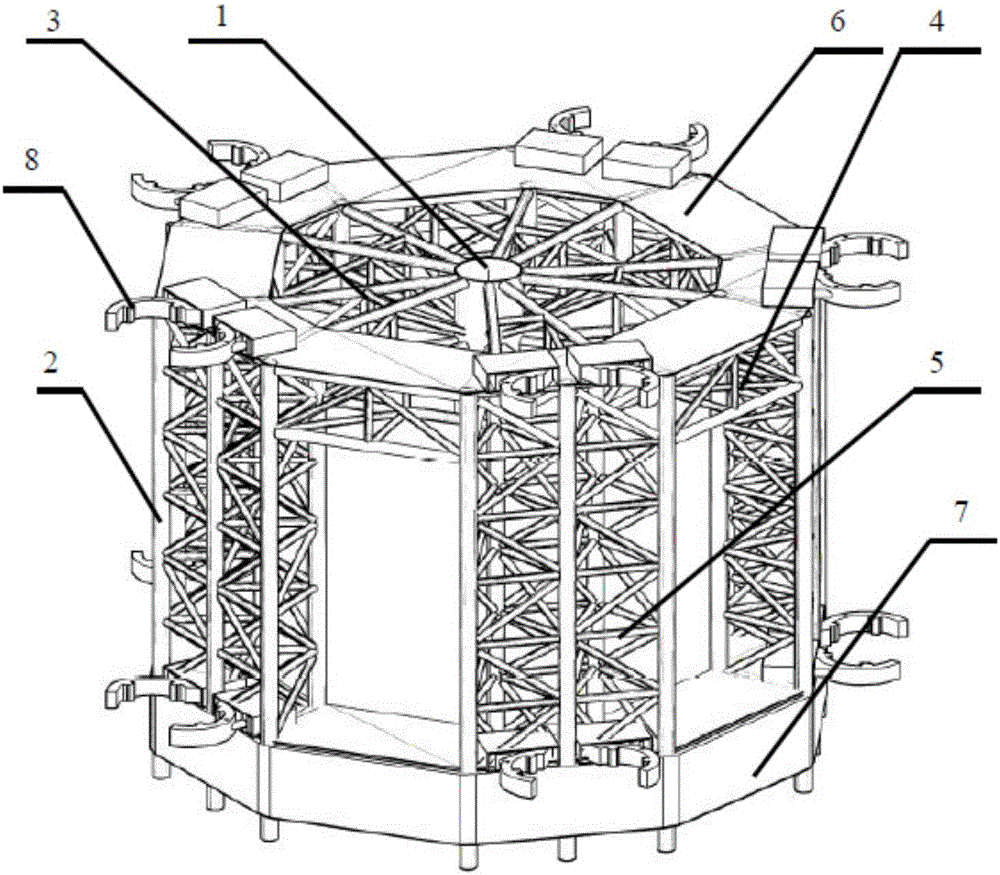

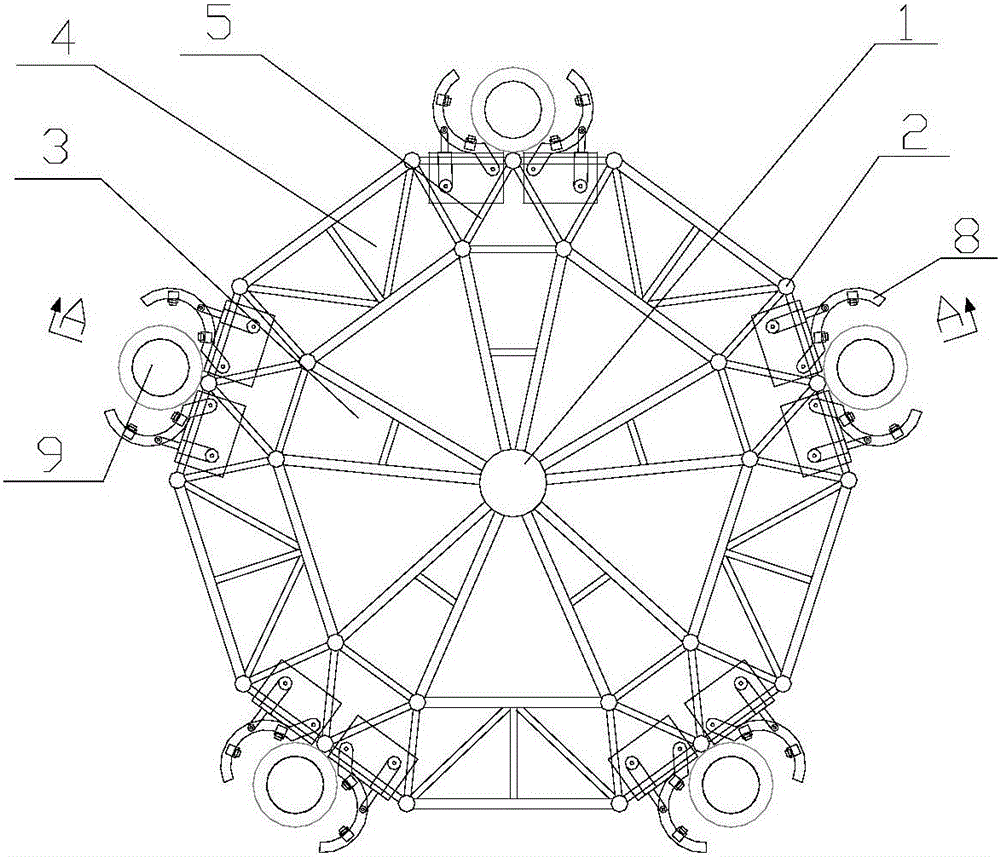

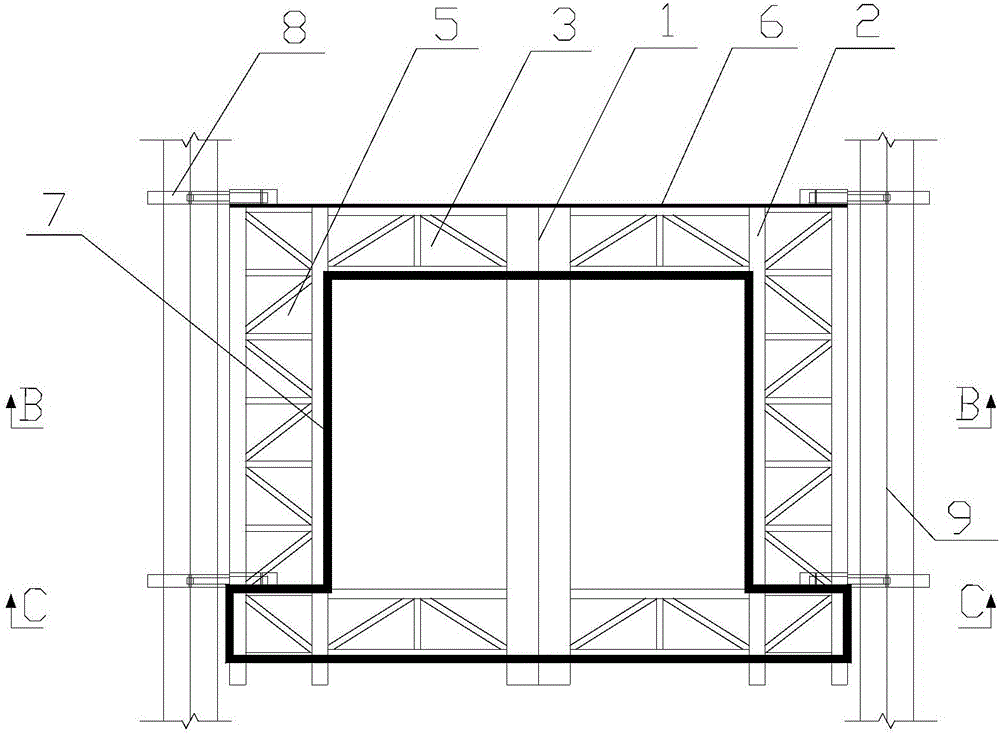

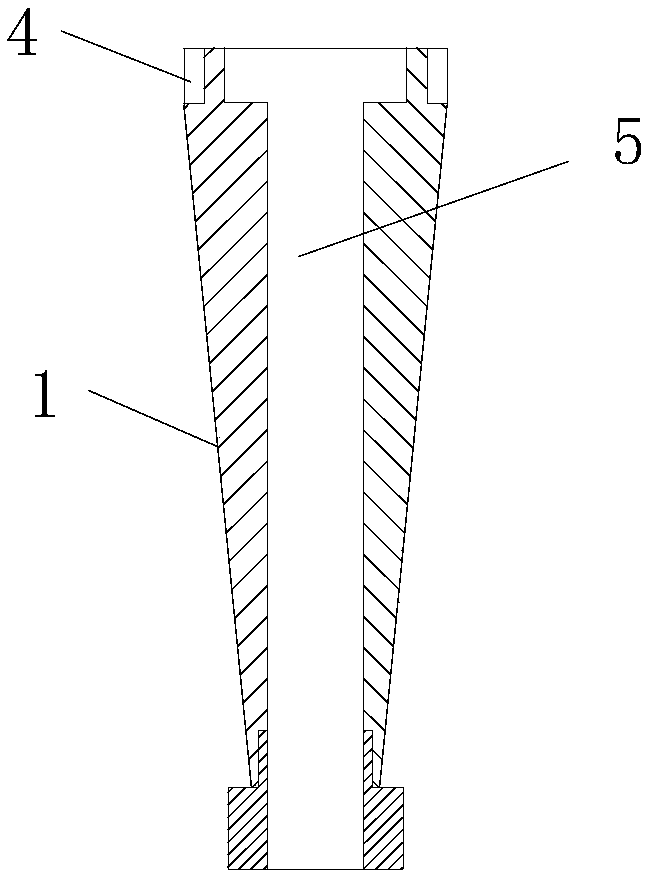

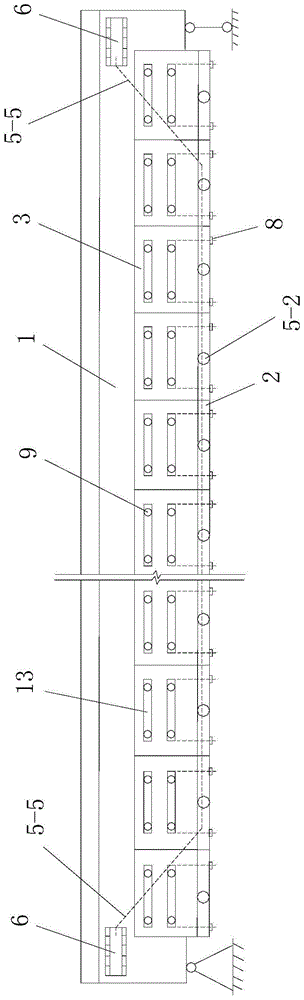

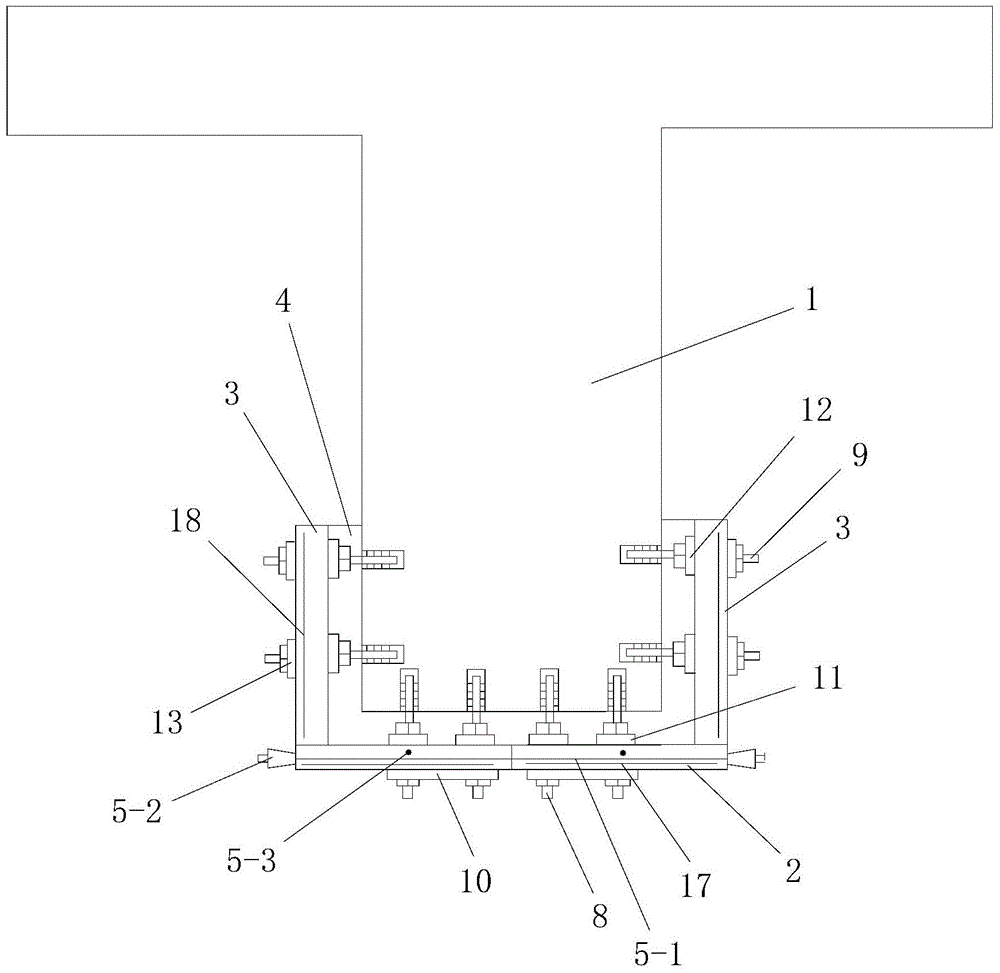

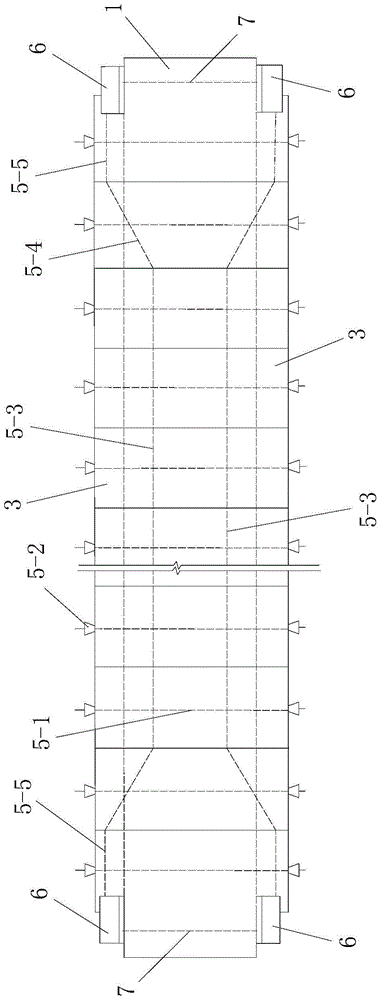

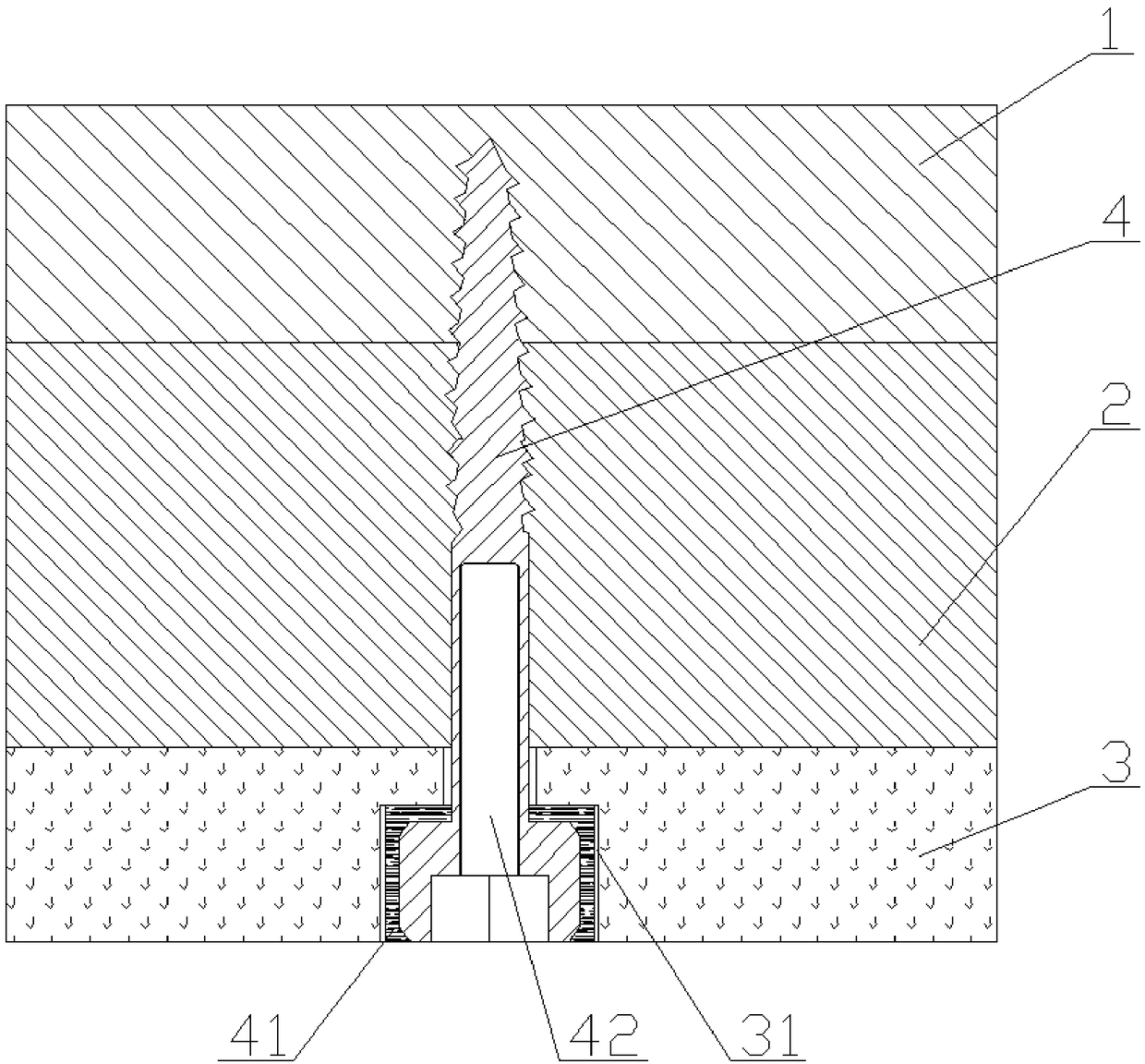

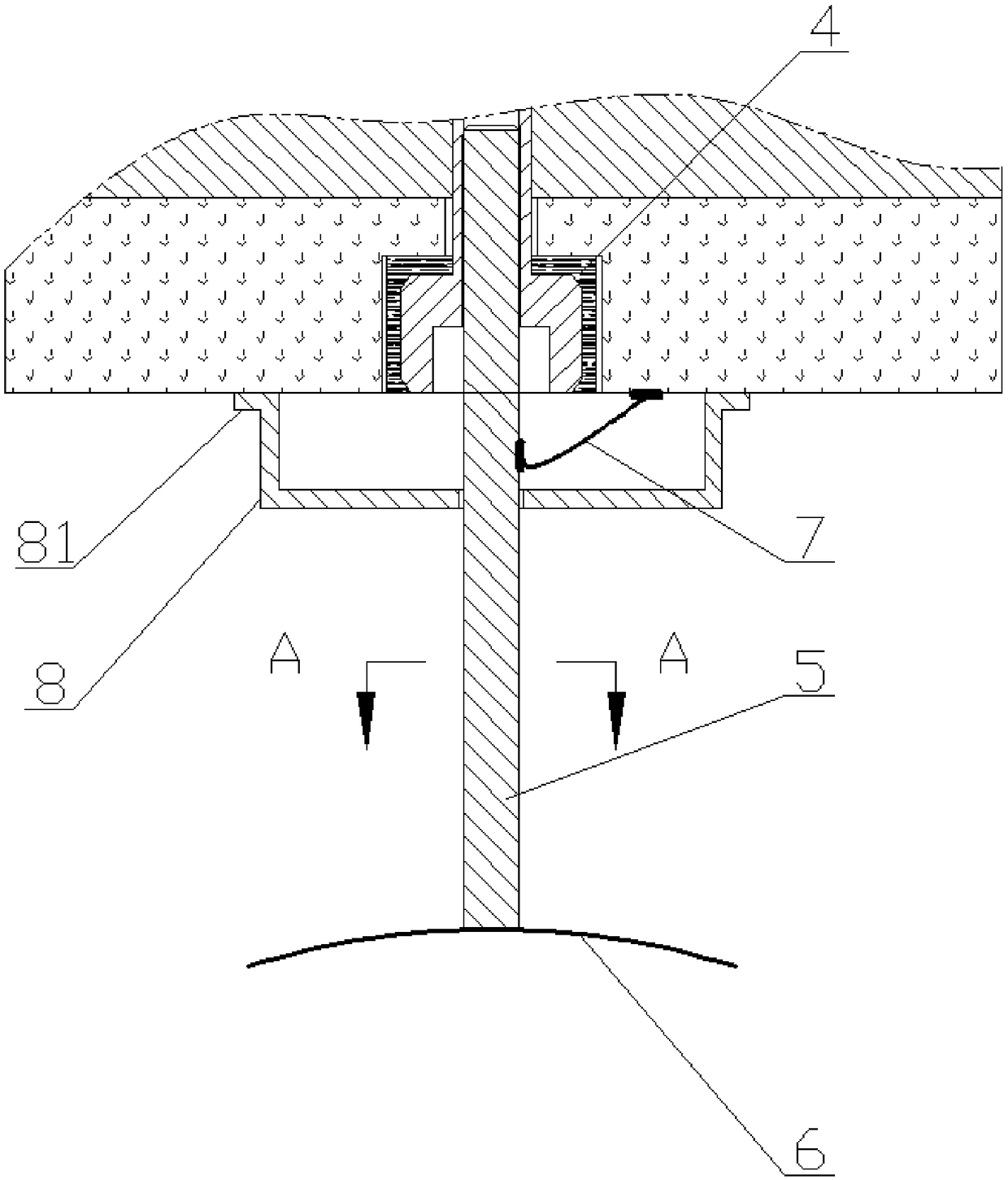

Piling limiting frame for intertidal zone offshore wind power foundation pile sinking and construction method thereof

The invention relates to a method for construction of intertidal zone offshore wind power multi-pile conduit frame foundation pile sinking. The method is characterized in that pile sinking positioning and perpendicularity control are performed on steel pipe piles through a piling limiting frame, and a floating crane hydraulic impact hammer setting on a beach is utilized to perform hanging up and beating for pile sinking. The method comprises the steps of performing steel pipe pile processing and marine transportation, performing ship positioning, leveling the beach face of a pile sinking area, placing the piling limiting frame, injecting water to a water containing cavity in the piling limiting frame, adjusting the levelness of the piling limiting frame, vertically lifting the steel pipe piles, inserting the steel pipe piles in a pile holding device of the piling limiting frame, utilizing a piling hammer for pile pressing and utilizing the piling hammer for pile sinking. The method has the advantages that the steel pipe piles are guided and limited through the piling limiting frame, pile sinking perpendicularity is guaranteed, accuracy of relative positions of the steel pipe piles of every foundation is guaranteed, construction of a whole fan foundation can be finished by one-time ship parking, a construction process is simplified, and construction efficiency is greatly improved.

Owner:天津港航工程有限公司

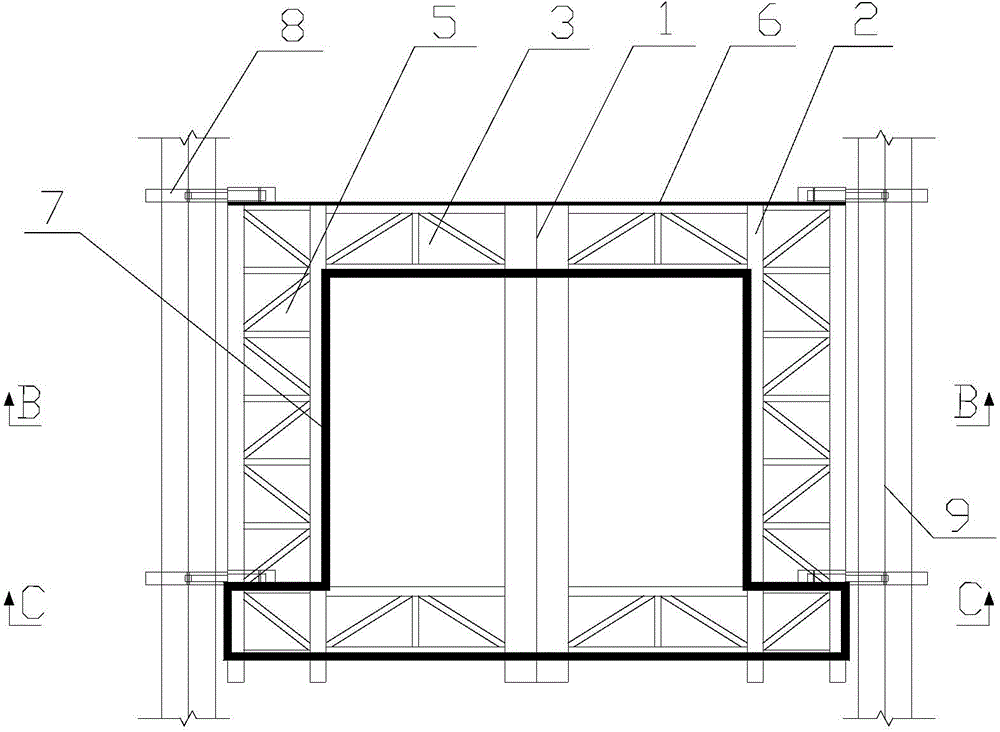

Reinforced concrete girder bridge girder reinforcing structure and method

ActiveCN104947603ASimple structureReasonable designBridge erection/assemblyBridge strengtheningReinforced concretePre stress

The invention discloses a reinforced concrete girder bridge girder reinforcing structure and method. The reinforcing structure comprises a reinforcing form board, a concrete structure located in a cavity between the reinforcing form board and a to-be-reinforced girder and a prestress system arranged on the reinforcing form board, wherein the reinforcing form board includes a girder-bottom form board and two girder-side form boards; the prestress system comprises two longitudinal prestress steel strands penetrating the reinforcing form board and a plurality of first transverse prestress steel strands penetrating the girder-bottom form board, four steel anchor boxes are disposed on the to-be-reinforced girder, and the two longitudinal prestress steel strands, two second transverse prestress steel strands and the four steel anchor boxes form the annular prestress system. The reinforcing method includes the steps of firstly, prefabricating the reinforcing form board; secondly, arranging anchor parts; thirdly, hoisting and fixing the reinforcing form board; fourthly, pouring concrete; performing prestress tension. The reinforcing structure and method is reasonable in design, simple in construction, good in reinforcing effect and capable of solve various problems of existing reinforcing methods.

Owner:XIAN UNIV OF SCI & TECH

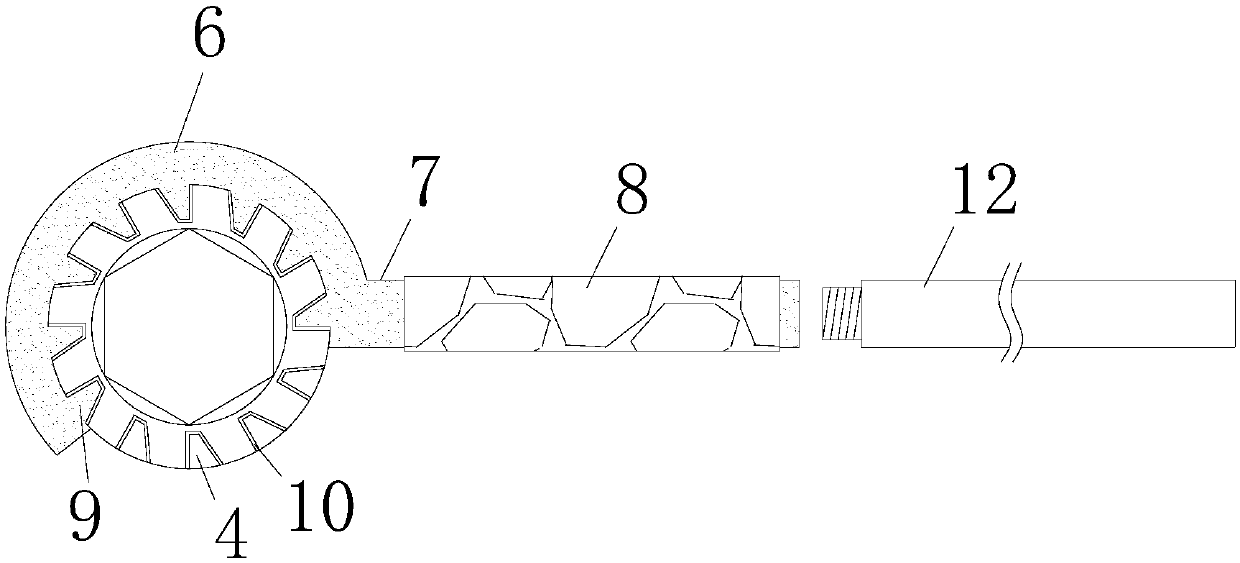

Self-coupling ultrasonic detection probe device

InactiveCN104267106AGood coupling effectAvoid uneven forceMaterial analysis using sonic/ultrasonic/infrasonic wavesRubber membraneBiomedical engineering

The invention relates to a self-coupling ultrasonic detection probe device. The device comprises a supporting component and a rolling component, wherein the supporting component comprises a support, a water tank, a hollow shaft and nuts, the water tank is installed above the support, the hollow shaft penetrates through the lower end of the support, and two ends of the hollow shaft are fastened through the nuts; the rolling component comprises a probe, two sealing bearings, round plates and a rubber membrane, the probe is installed on the hollow shaft and located between the two sealing bearings, the sealing bearings are embedded in circle centers of the round plates and installed on the hollow shaft, a position between the two round plates is coated with the rubber membrane, a sealed space is formed between the two round plates, and the probe is connected with an ultrasonic detector through a lead. The self-coupling ultrasonic detection probe device is simple in structure, convenient to operate and high in detection efficiency.

Owner:NANTONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF THE PEOPLES REPUBLIC OF CHINA

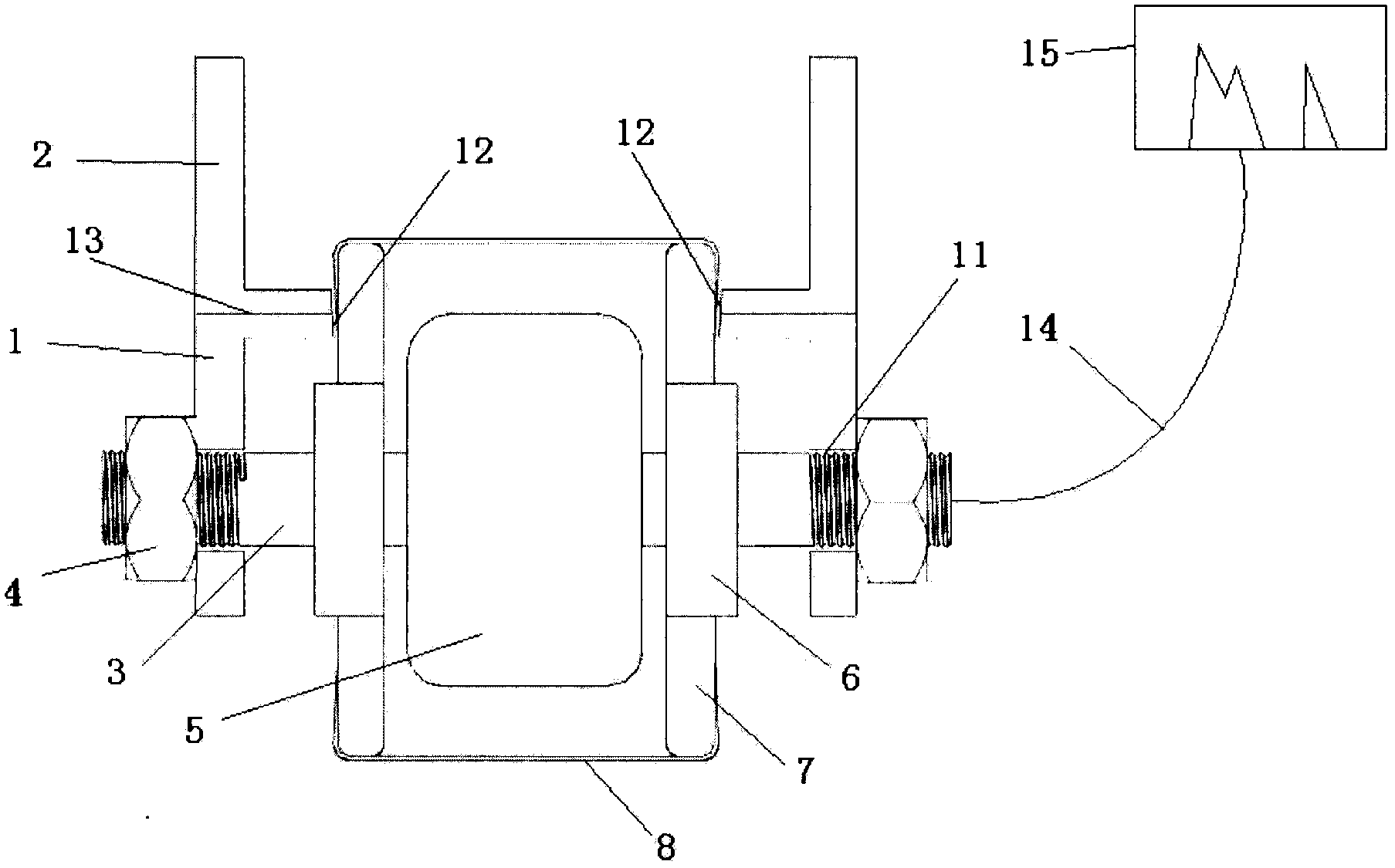

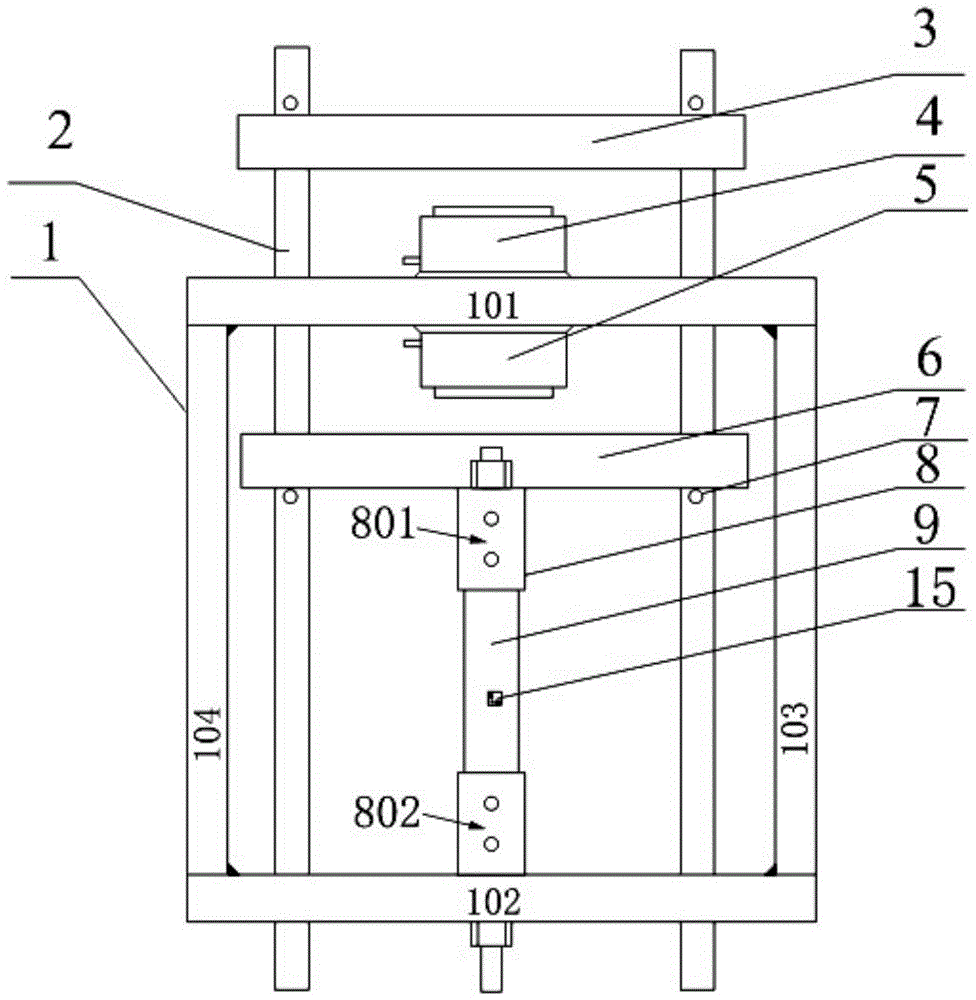

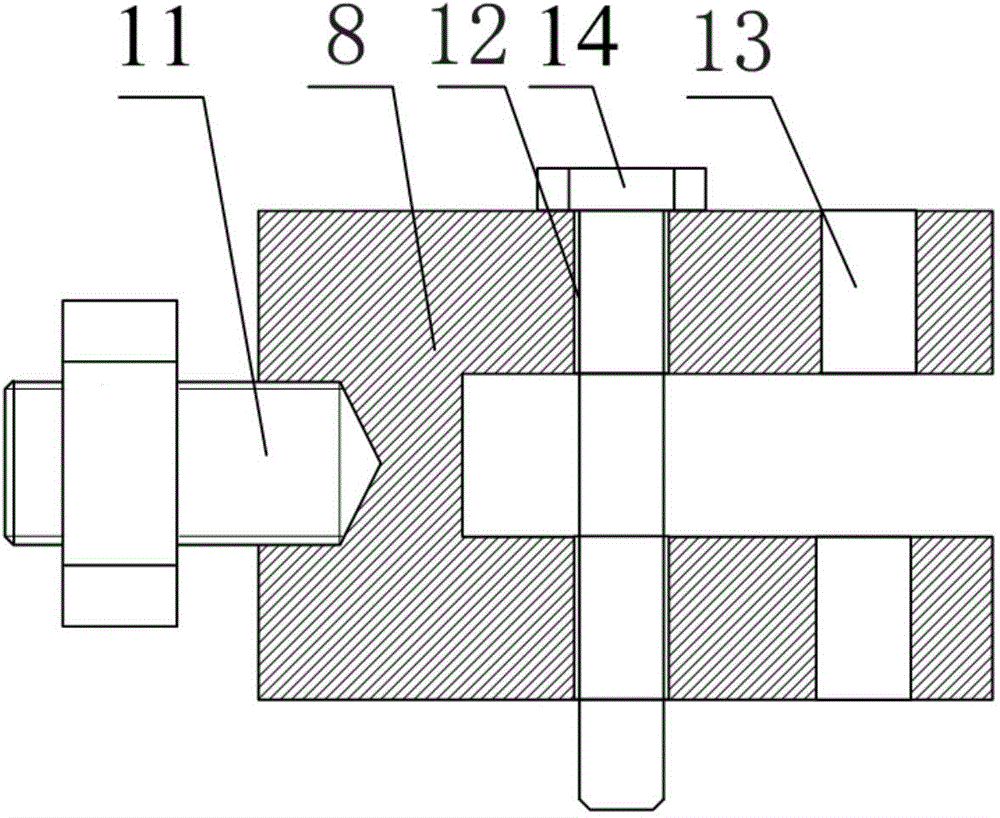

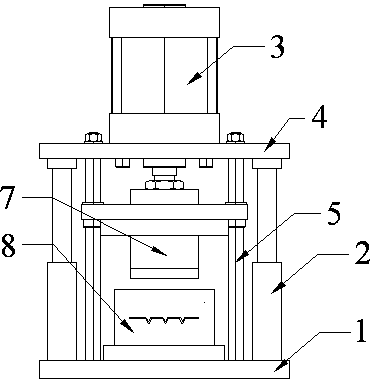

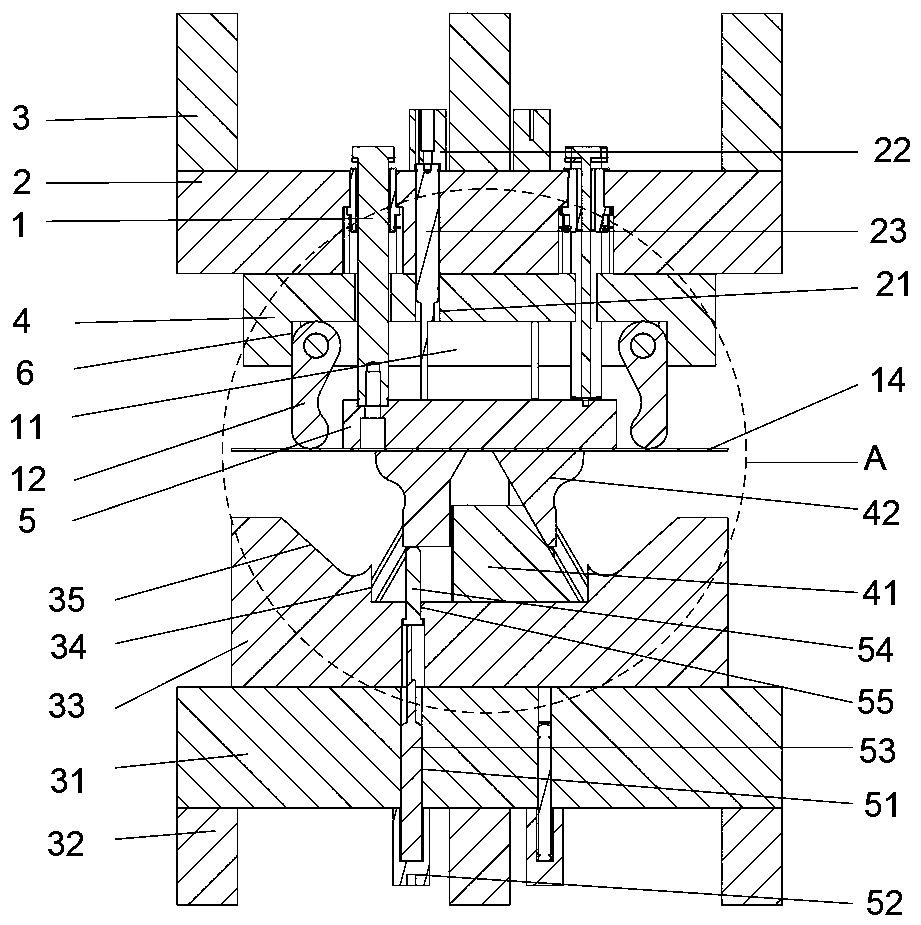

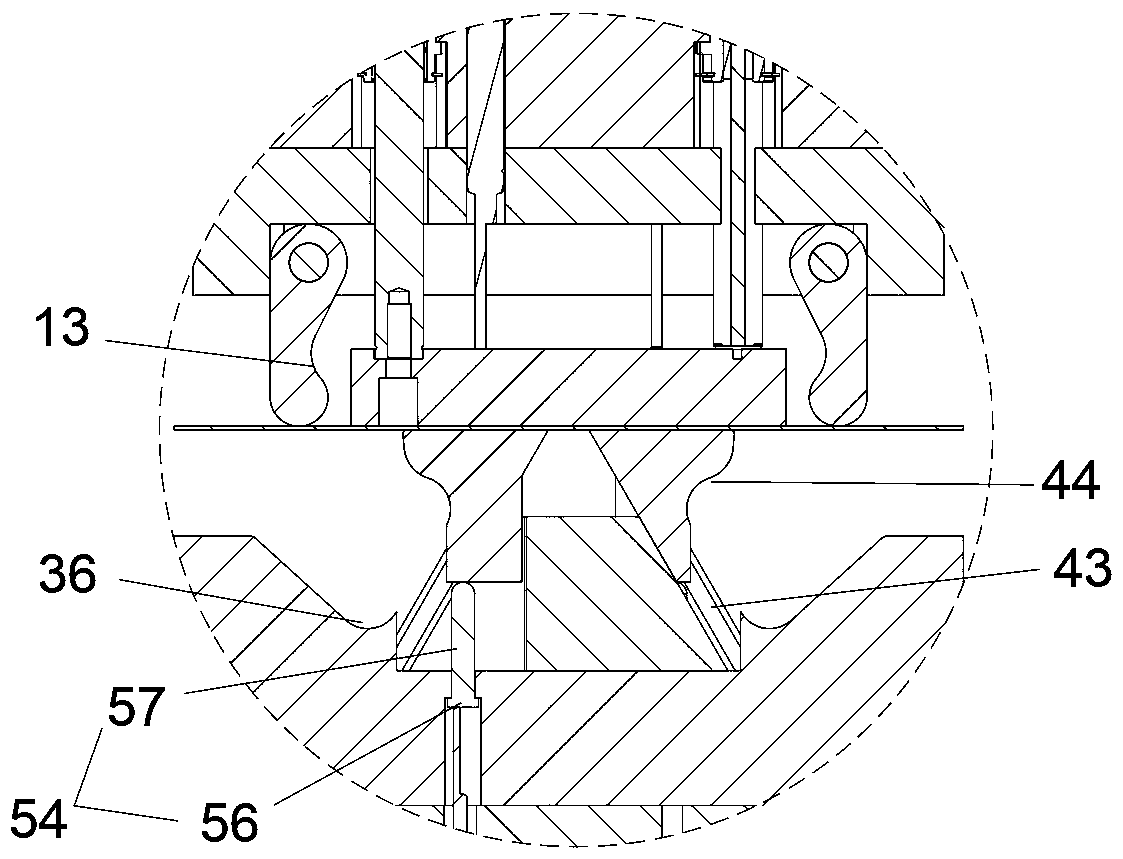

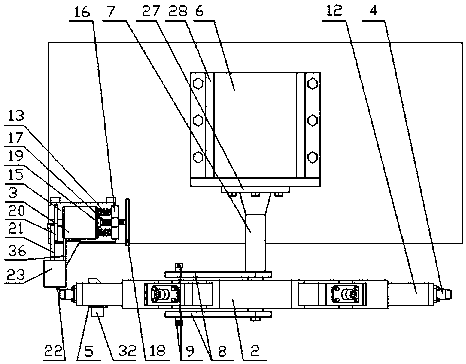

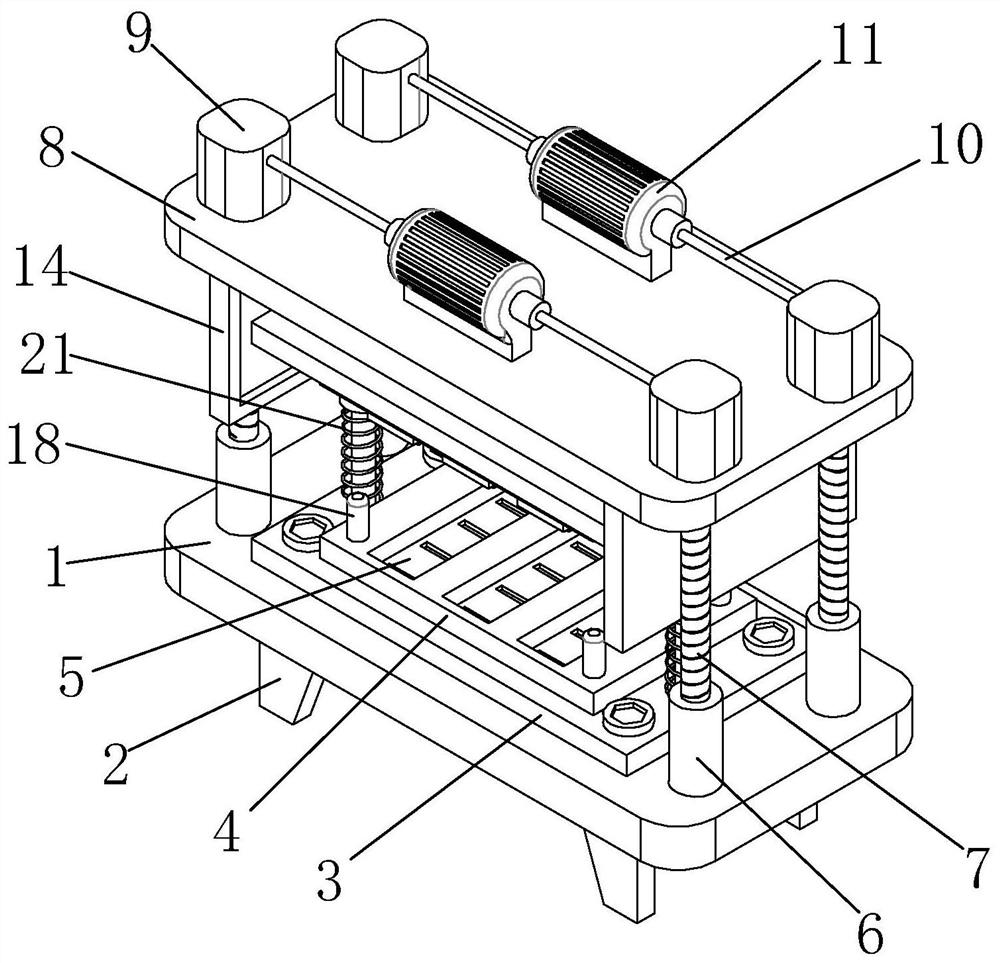

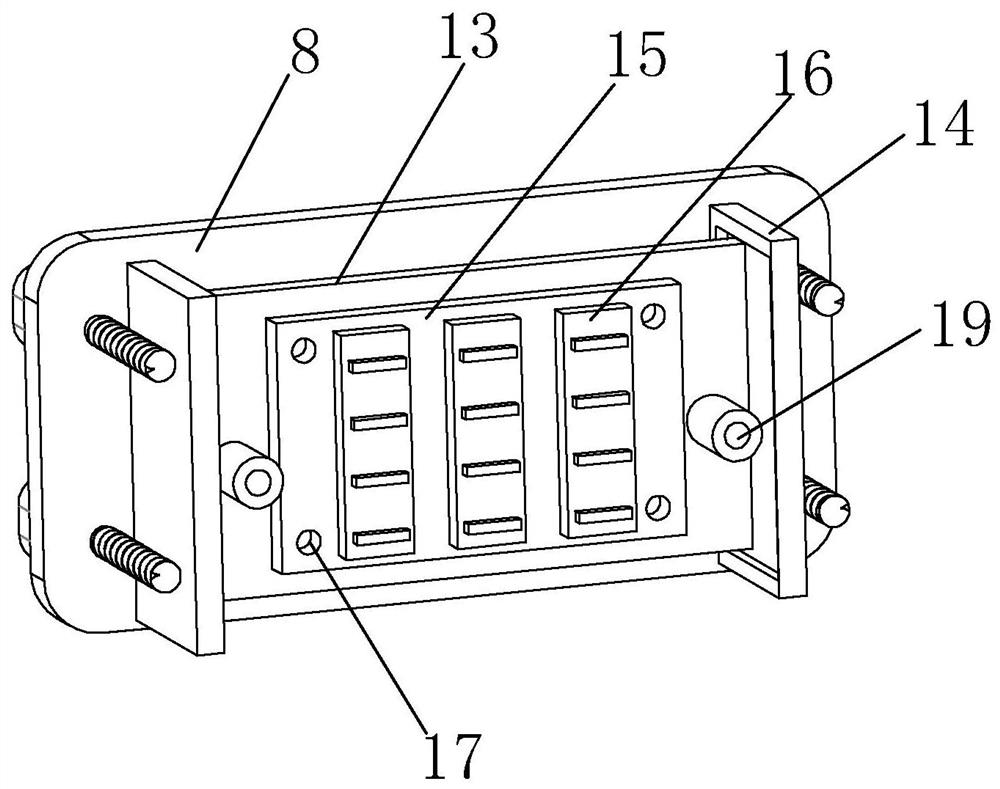

Device for calibrating tension and compression type residual stress

ActiveCN106153458AEasy and accurate calibrationThe stress-strain relationship is convenient and accurateMaterial strength using tensile/compressive forcesStress measurementEngineering

The invention discloses a tension-compression type residual stress calibration device, which belongs to the technical field of experimental stress measurement in material processing. The device includes a tension and compression loading mechanism, a clamping mechanism and a supporting mechanism. The tension-compression loading mechanism applies uniform tensile or compressive stress in the direction of the entire thickness of the calibration material; the clamping mechanism can adjust the clamping position according to the tension-compression type of the calibration material; the tension-compression loading mechanism and Clamping mechanism, and can adjust the height by itself. The present invention can be used as a supporting loading device for residual stress detection methods such as blind hole method, indentation strain method, etc., to accurately calibrate the stress-strain relationship of materials under tensile stress state and compressive stress state. It solves the problems of convenience and ease of use but uneven stress field during three-point bending loading, or the need for large-size samples and difficult loading when using a tensile testing machine for calibration.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Simple hexagonal brick laying device

The invention discloses a simple hexagonal brick laying device. The simple hexagonal brick laying device comprises a supporting bottom plate, side supporting plates arranged at the left and right endsof the supporting bottom plate, screw rods arranged in the middles of the side supporting plates and brick boxes arranged at the upper ends of the screw rods, wherein the left and right ends of the upper end face of the supporting bottom plate are symmetrically provided with the two plate-shaped side supporting plates, and two cylindrical rod-shaped guide shafts are symmetrically arranged at front and back between the side supporting plates; hexagonal bricks are introduced into a guiding groove from an inclined supporting plate along a conveying port through the vibration of a vibration motor, the hexagonal bricks slide down to the front end of the guiding groove and fall into a laying layer on the ground from a laying groove, and a driving motor drives the screw rods to drive the brick boxes to move so that an entire machine completes automatic laying, thereby improving the laying efficiency and reducing the construction cost; when the hexagonal bricks fall onto the ground from the laying groove, a hydraulic cylinder drives a pushing and pressing rod and an elastic pad to press the hexagonal bricks, so that the hexagonal bricks are laid on the ground compactly, thereby avoiding the uneven stress during laying, and therefore the quality of the laid brick layer is better.

Owner:吴子侠

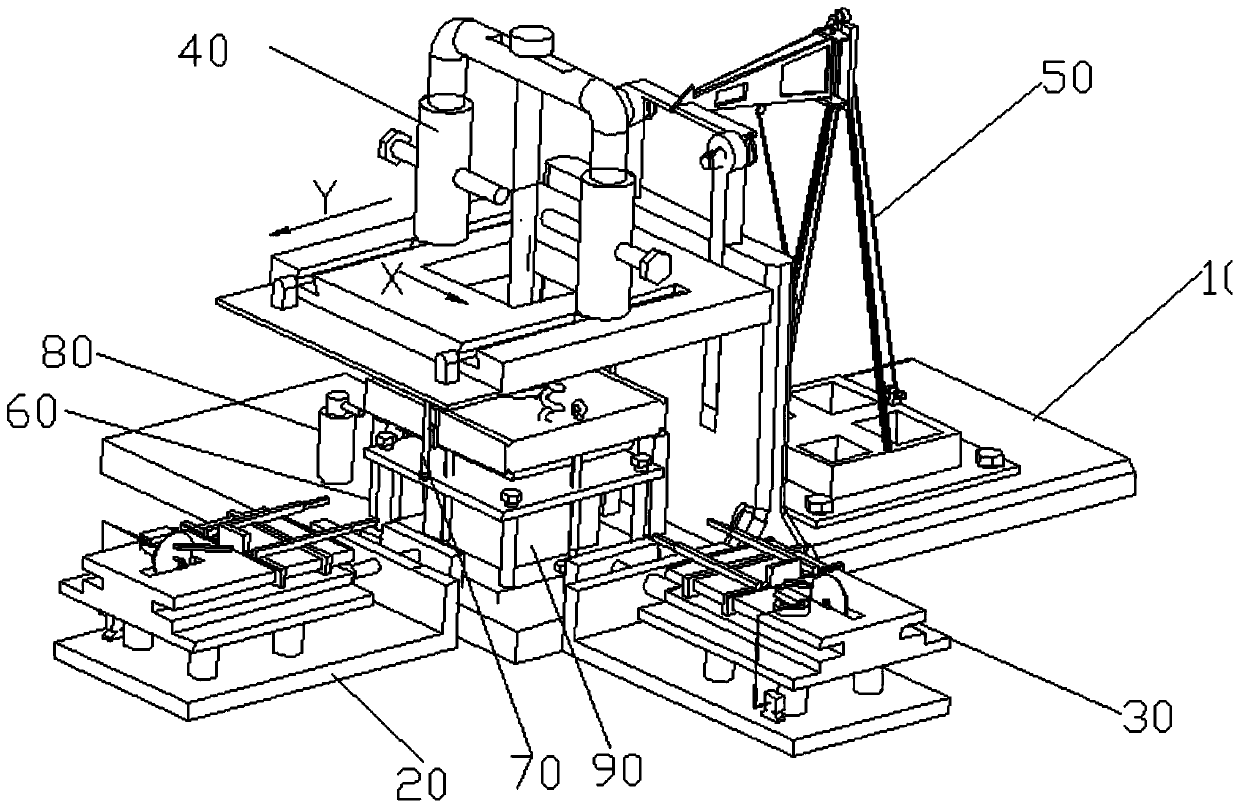

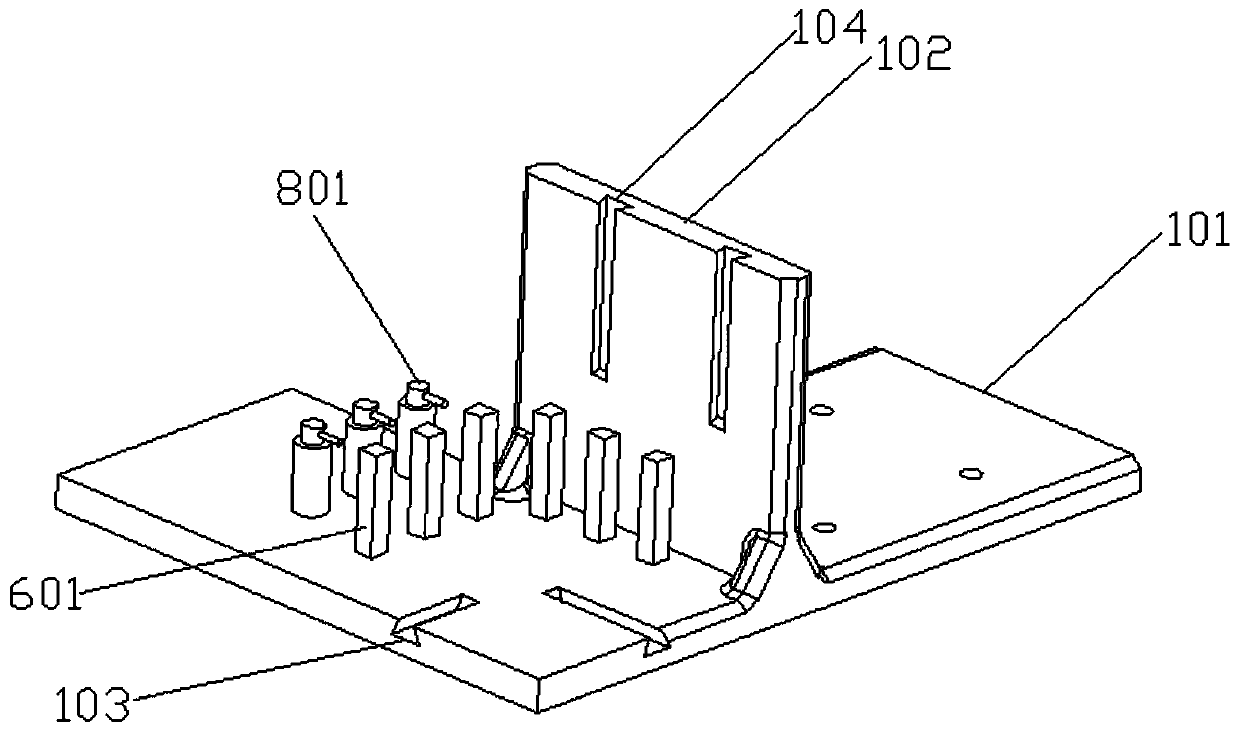

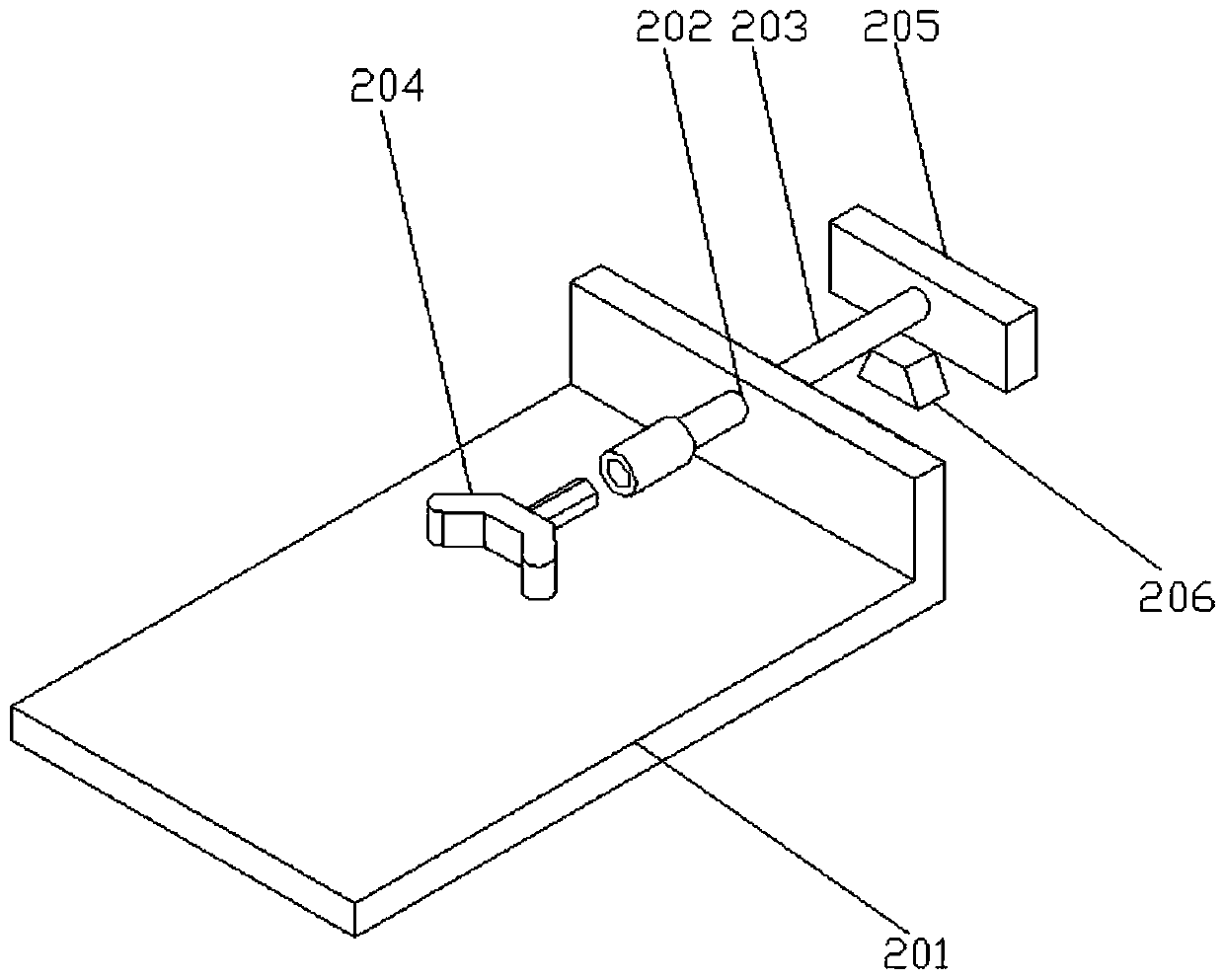

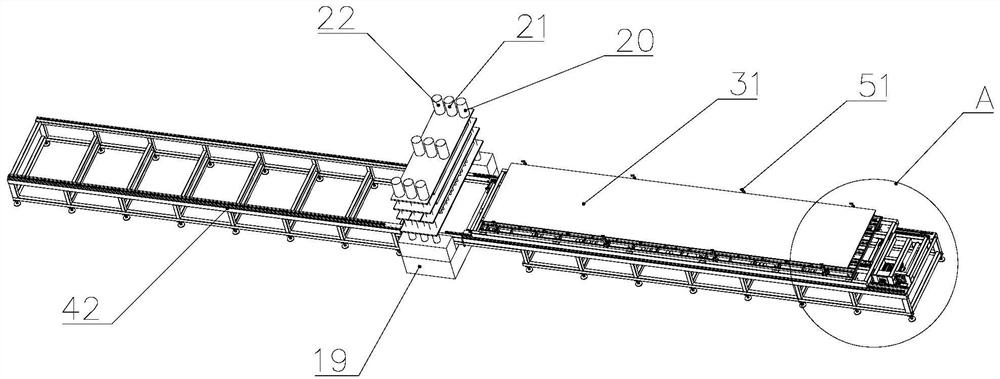

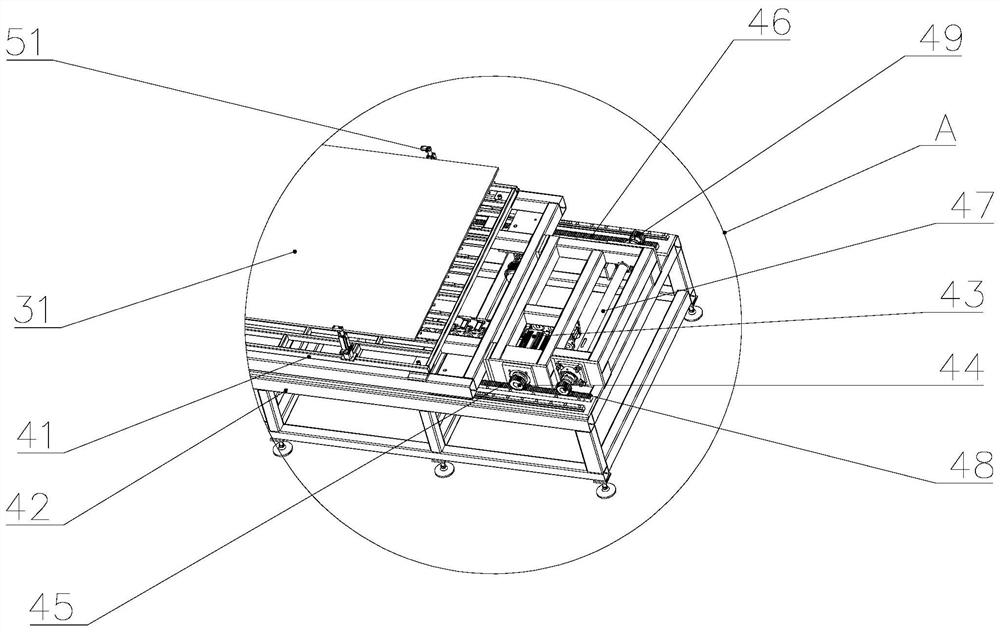

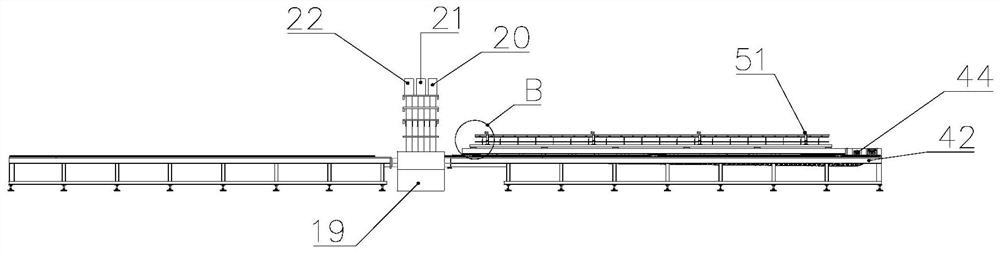

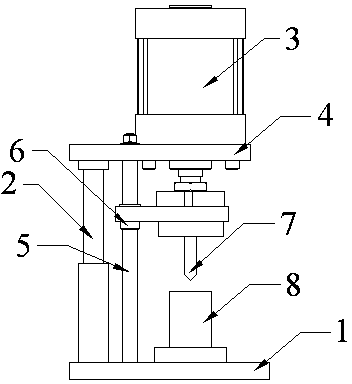

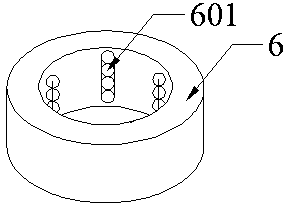

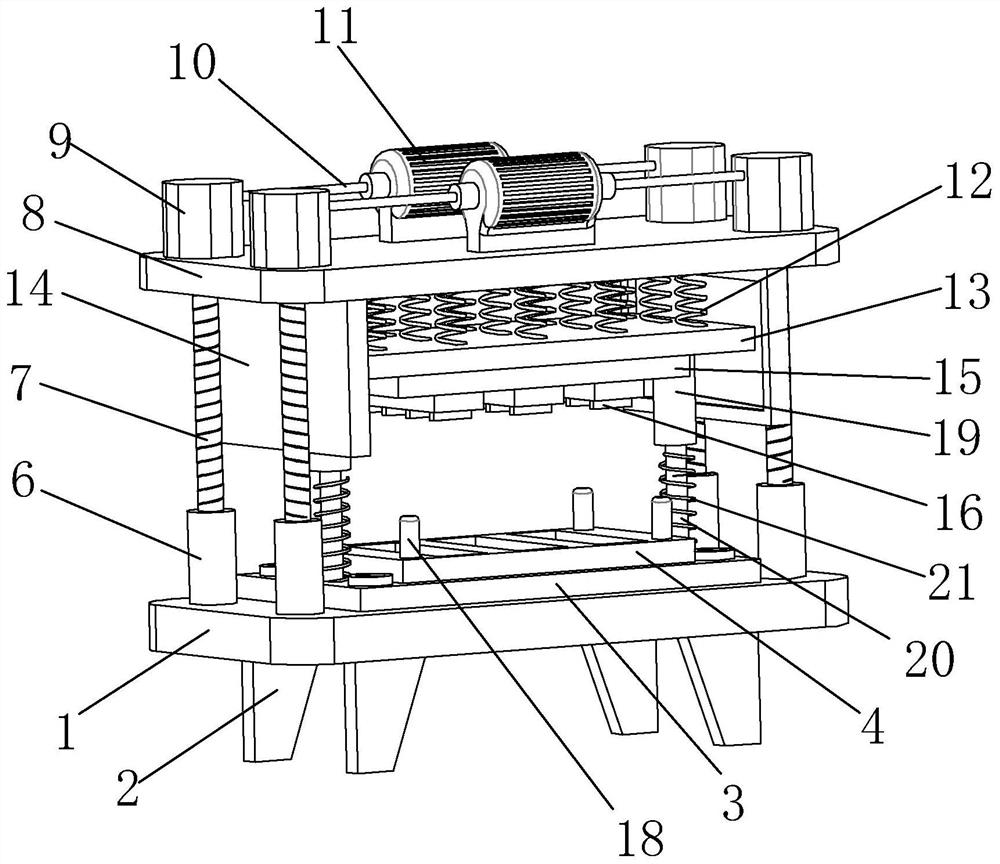

Automatic fuel cell stack assembling and detecting device

The invention discloses an automatic fuel cell stack assembling and detecting device, which comprises a rack, a material conveying assembly used for conveying different assemblies forming an electricpile to a designated position, an electric pile output assembly used for outputting assembled electric piles, a pressing assembly used for providing stable and accurate pressure for the electric piles, an automatic lifting assembly used for enabling a hydraulic workbench of the pressing assembly to be located at different heights so as to adapt to electric piles of different specifications, a limiting assembly used for limiting the stacking position of an electric pile assembly on the bottom plate of the rack, an automatic tightening assembly comprising an electric screwdriver, and an air tightness detecting assembly comprising an air cylinder, a connecting pipeline of the air cylinder and a quick-screwing plug and used for detecting the air tightness of the electric piles. The device is high in automation degree, manpower is greatly saved, and the phenomenon that the parts of an electric pile are stressed unevenly is avoided. A positioning pin can be pulled out stably by an automaticpin pulling device, and damage to the electric pile assembly in the manual pin pulling process is avoided.

Owner:WUHAN UNIV OF TECH

Large-tonnage foundation pile uplift-resistant static test connection device, loading counter-force system and method

ActiveCN102995669AGuaranteed accuracyImprove the state of stressFoundation testingStructural engineering

Owner:广东省建设工程质量安全检测总站有限公司

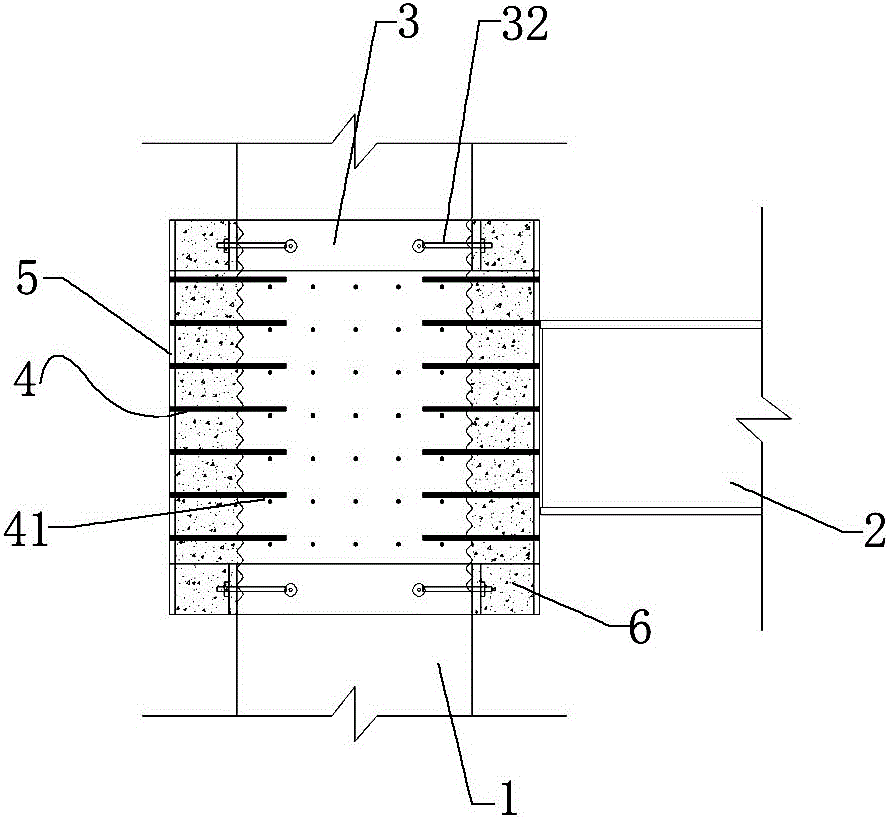

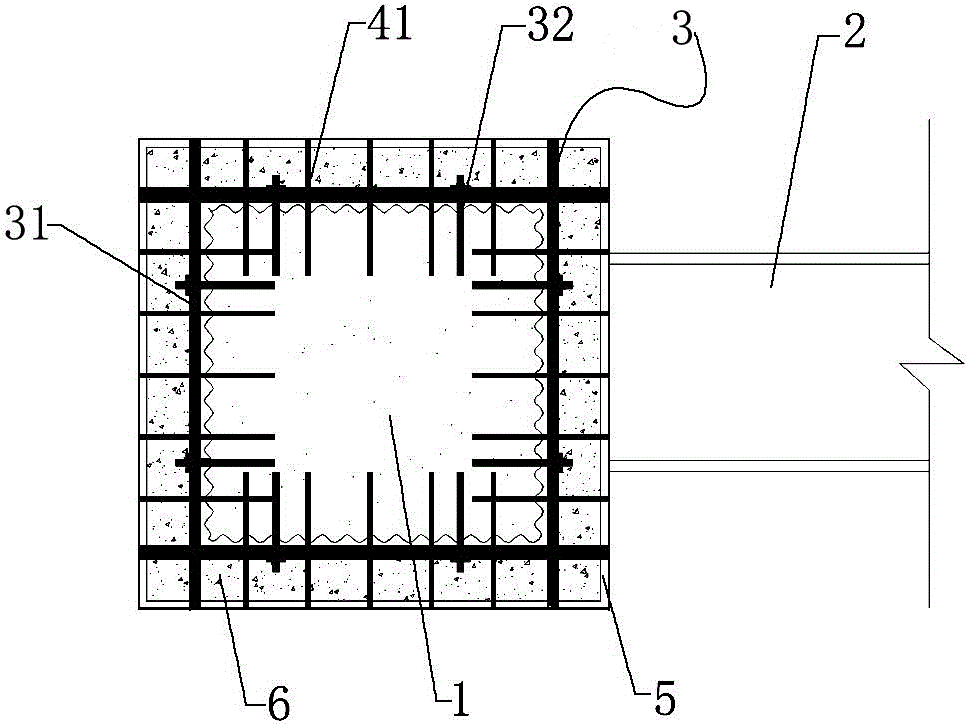

Newly-added steel girder and original reinforced concrete column hoop connecting joint and connecting method thereof

InactiveCN106703432AIncrease the bearing areaEven by forceBuilding repairsReinforced concrete columnRebar

The invention relates to the technical field of reinforced concrete column modified connecting joints, and discloses a newly-added steel girder and original reinforced concrete column hoop connecting joint and a connecting method thereof. The connecting joint comprises an original reinforced concrete column, a newly-added steel girder and a connecting element of a connecting portion which is arranged on the original reinforced concrete column and connected with the newly-added steel girder. The connecting element comprises an inner hoop fixed to the periphery of the original reinforced concrete column, a steel reinforcement framework implanted into the connecting portion, an outer hoop fixed to the periphery of the steel reinforcement framework, and an intra-hoop concrete structure poured between the outer hoop and the side wall of the original reinforced concrete column. The upper and lower ends of the connecting portion are sleeved with the inner hoop. The inner hoop is a horizontally-arranged groined frame. The steel reinforcement framework is composed of longitudinally-arranged layered anchor bars. The inner side wall of the outer hoop, the outer ends of the anchor bars and the outer end of the inner hoop are welded and fixed. The newly-added steel girder and the side wall of the outer hoop are perpendicularly fixed. The connecting joint is simple in structure, wide in application range and capable of forming an overall core joint with an original structure.

Owner:BEIJING URBAN CONSTR YATAI GRP

Truss 3D floor plate perforating machine

ActiveCN113020653AReduce damageReduce the breakage rateMetal working apparatusStone-like material working toolsFloor levelFloor plate

The invention discloses a truss 3D floor plate perforating machine, and belongs to the field of floor plate production equipment. The perforating machine comprises a screw feeding mechanism, wherein the screw feeding mechanism comprises a first perforating assembly, a second perforating assembly and a screw feeding assembly, the first perforating assembly comprises a plurality of first perforating drill bits, and the first perforating drill bits are used for perforating a first workpiece; the second perforating assembly comprises a plurality of second perforating drill bits, and the second perforating drill bits are used for perforating a second workpiece; the screw feeding assembly comprises a plurality of screw feeding heads, and the screw feeding heads are used for fastening the first workpiece and the second workpiece; and under the action of a conveying mechanism, the first perforating assembly is used for perforating the first workpiece to form a first hole, the second perforating assembly is used for continuously perforating the second workpiece along the first hole to form a second hole, and then the second workpiece is conveyed to the screw feeding assembly to connect the first hole with the second hole.

Owner:山东七星绿色建筑科技有限公司

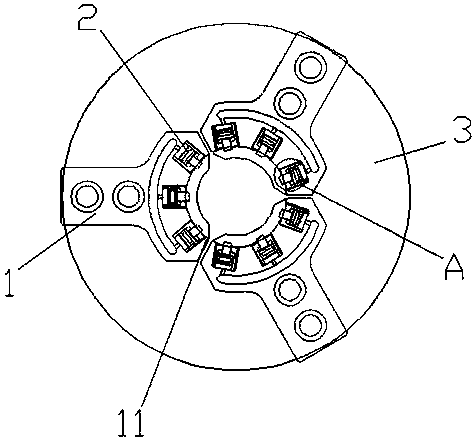

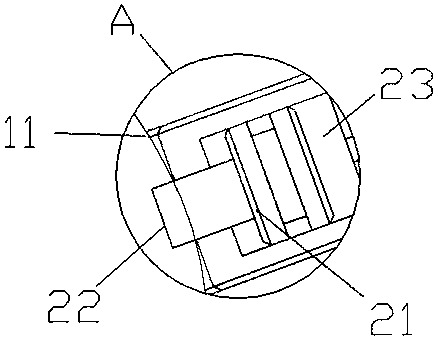

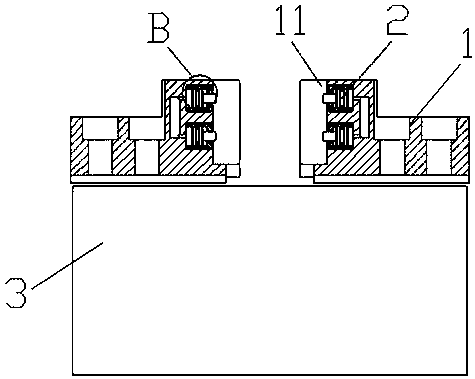

Multi-point equal clamping device

The invention discloses a multi-point equal clamping device applied to the field of mechanical tools. The multi-point equal clamping device is characterized by structurally comprising a plurality of claw fingers and a claw finger drive device, wherein each claw finger comprises a clamping part, and the position, towards a clamped object, of each clamping part is uniformly equipped with a pluralityof hydraulic cylinders; each hydraulic cylinder comprises an oil cylinder piston and a pressure cavity; the pressure cavity on the same claw finger is in communication; and each oil cylinder piston comprises a clamping end which extends to the outside of the corresponding clamping part. The clamping ends of the hydraulic cylinders are utilized to perform clamping operation; pressure cavities of the hydraulic cylinders communicate with one another, so that the position of hydraulic oil also can be transferred according to different pressure, and therefore, the occurrence of a condition that acting force between the clamping ends and workpieces is too high is avoided. Circulating action of the hydraulic oil guarantees stress uniformity of the surface of the clamped object, so that a workpiece damage rate is effectively reduced, and the take-up effect of the clamped object is guaranteed. Meanwhile, weakening, caused by stress deformation, of clamping force can be eliminated during claw clamping by uniform stress, so that guarantee is provided for clamping force, on the clamped objects, of the claw fingers.

Owner:苏州磐岩精密机械有限公司

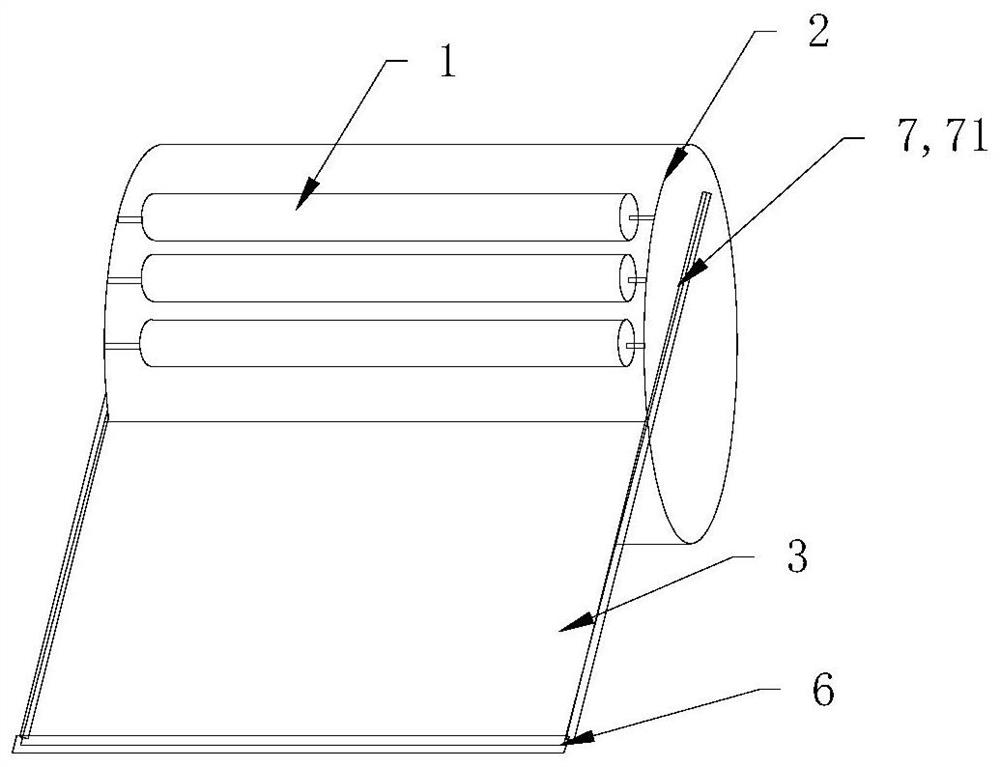

Curling device

ActiveCN112331073AReduce the difference in radius of curvatureImprove uniformitySolid-state devicesIdentification meansPhysicsEngineering

The invention relates to the technical field of display, and in particular, relates to a curling device which is used for curling a flexible screen body and comprises a plurality of first reels and asupporting frame, and the shaft radiuses of the first reels are the same. The supporting frame supports the multiple first reels, so that the multiple first reels are arranged in parallel, and for atleast two adjacent first reels continuously wound on the flexible screen body, the connecting line of the centers of every two adjacent first reels located at the interval of every two adjacent firstreels is completely located in the flexible screen body. According to the embodiment of the invention, the curling stress borne by the flexible screen body during curling is relatively uniform, and the uniformity of the flexible screen body at different positions is high, so that the display effect of the flexible screen body is improved.

Owner:HEFEI VISIONOX TECH CO LTD

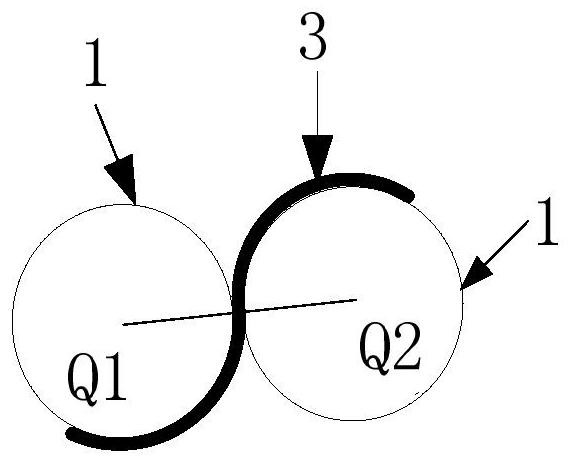

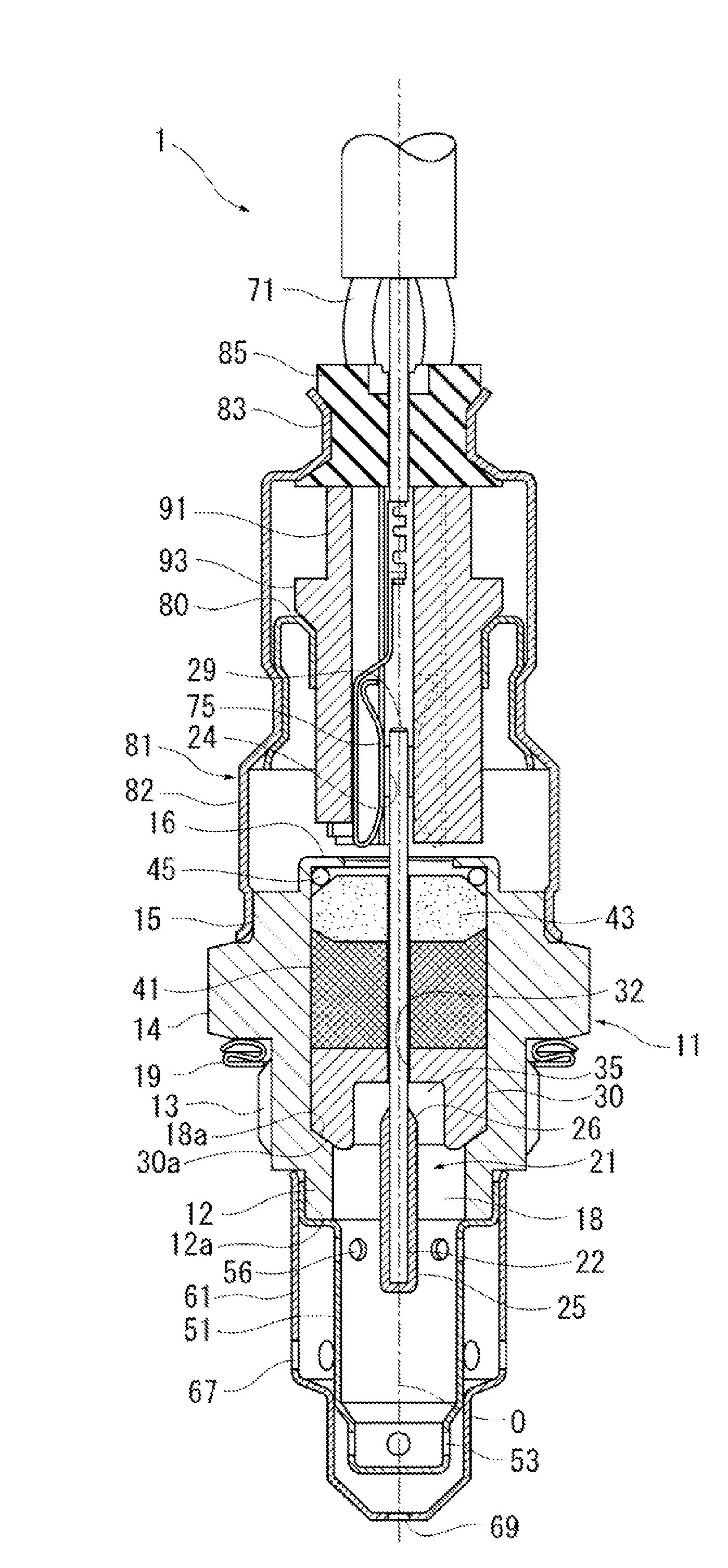

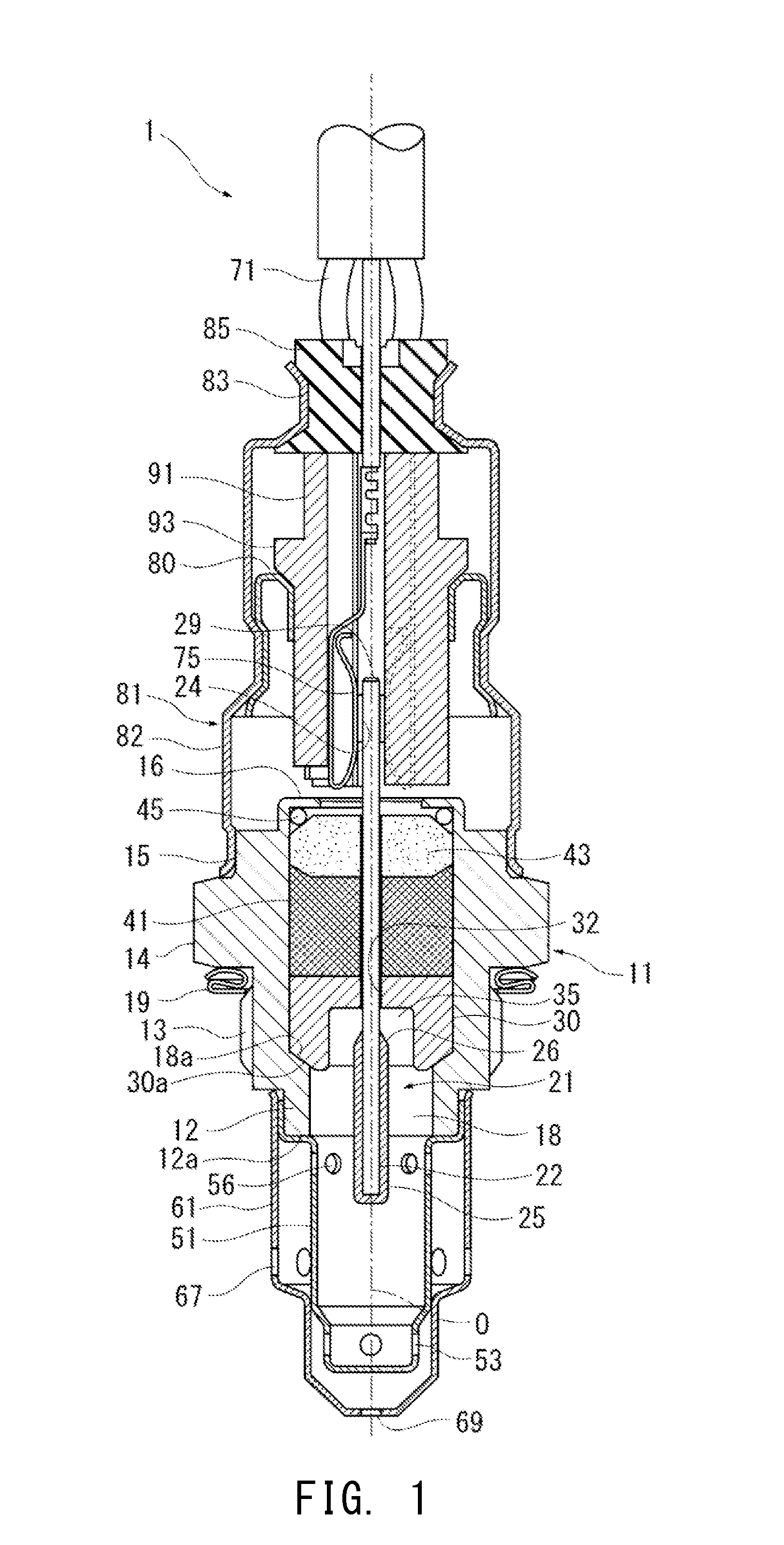

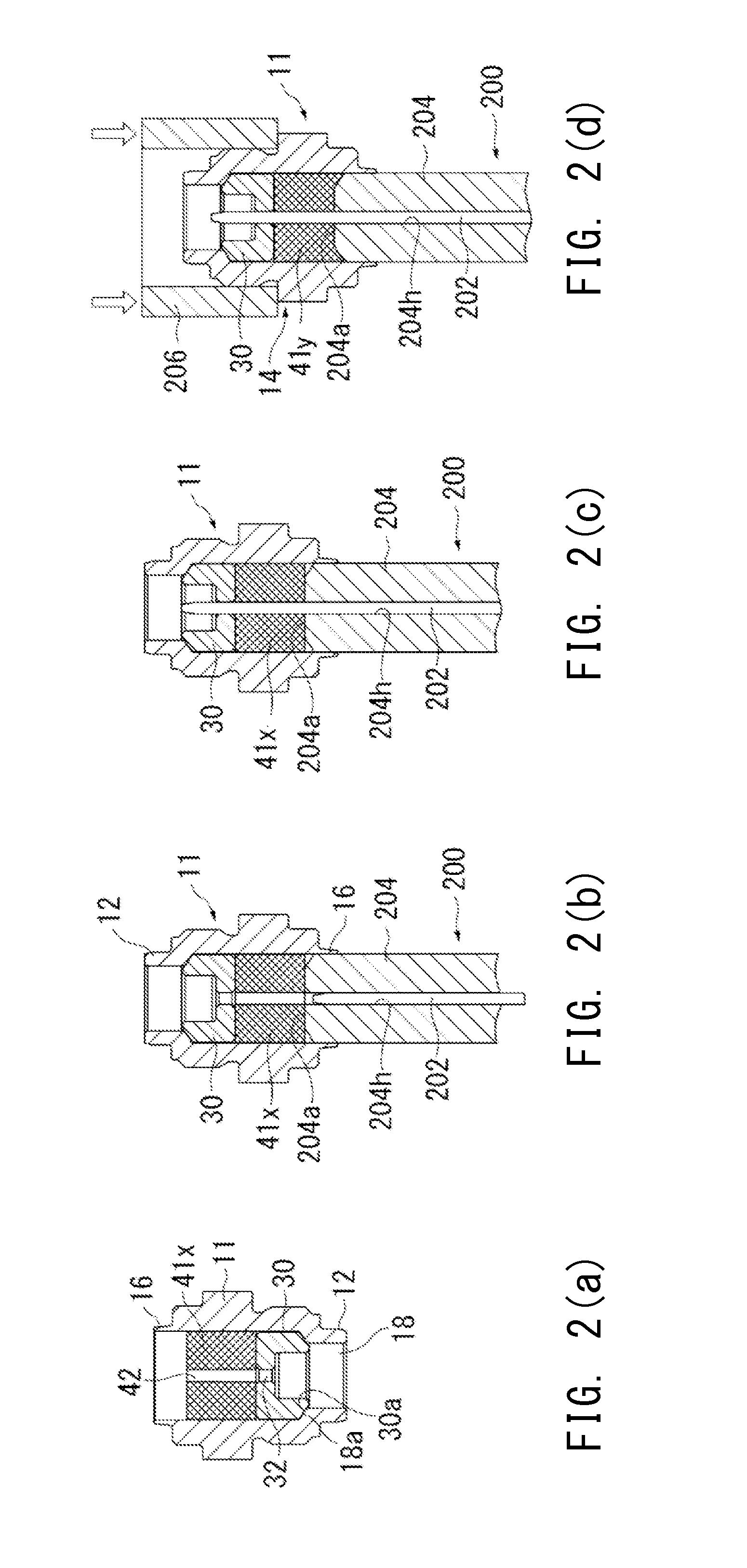

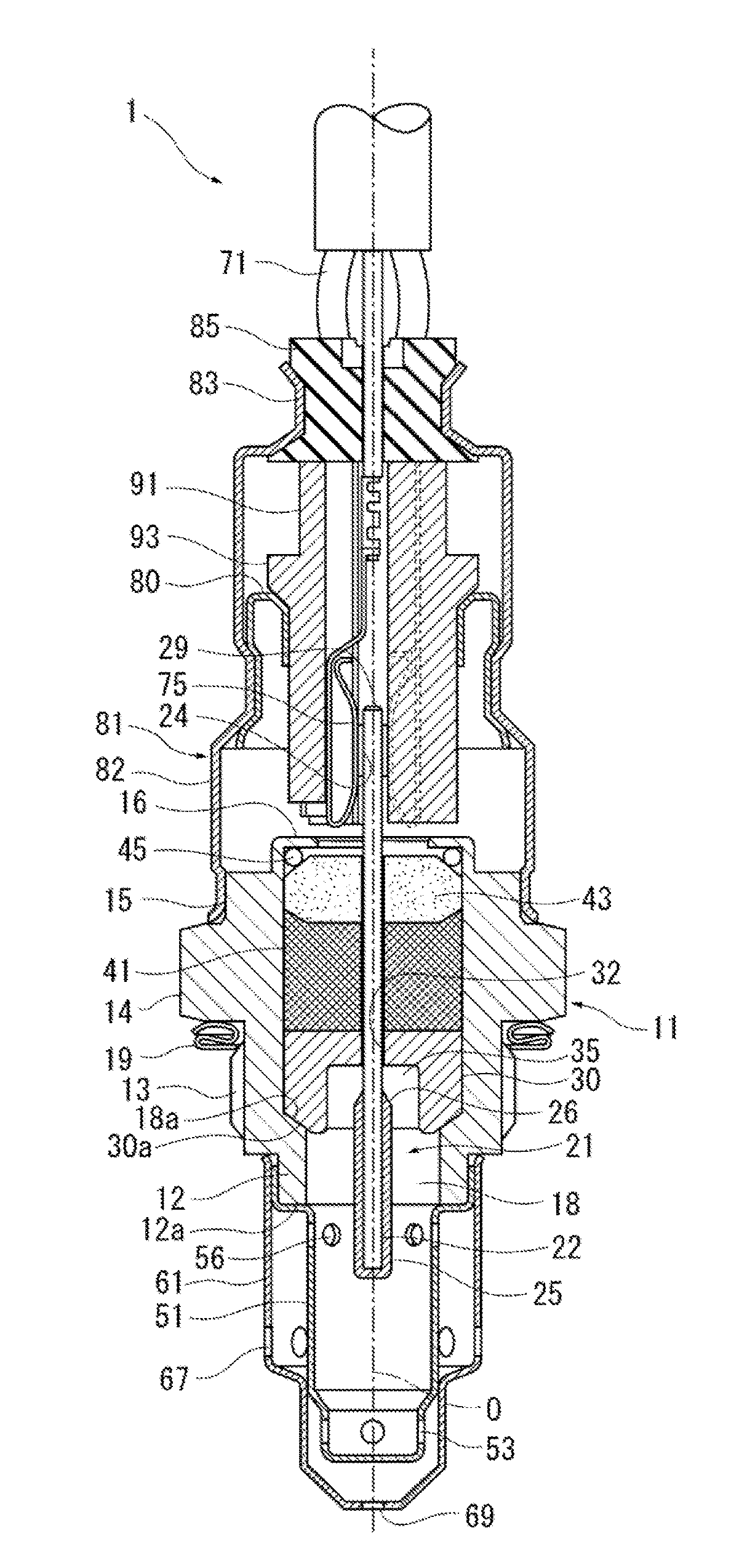

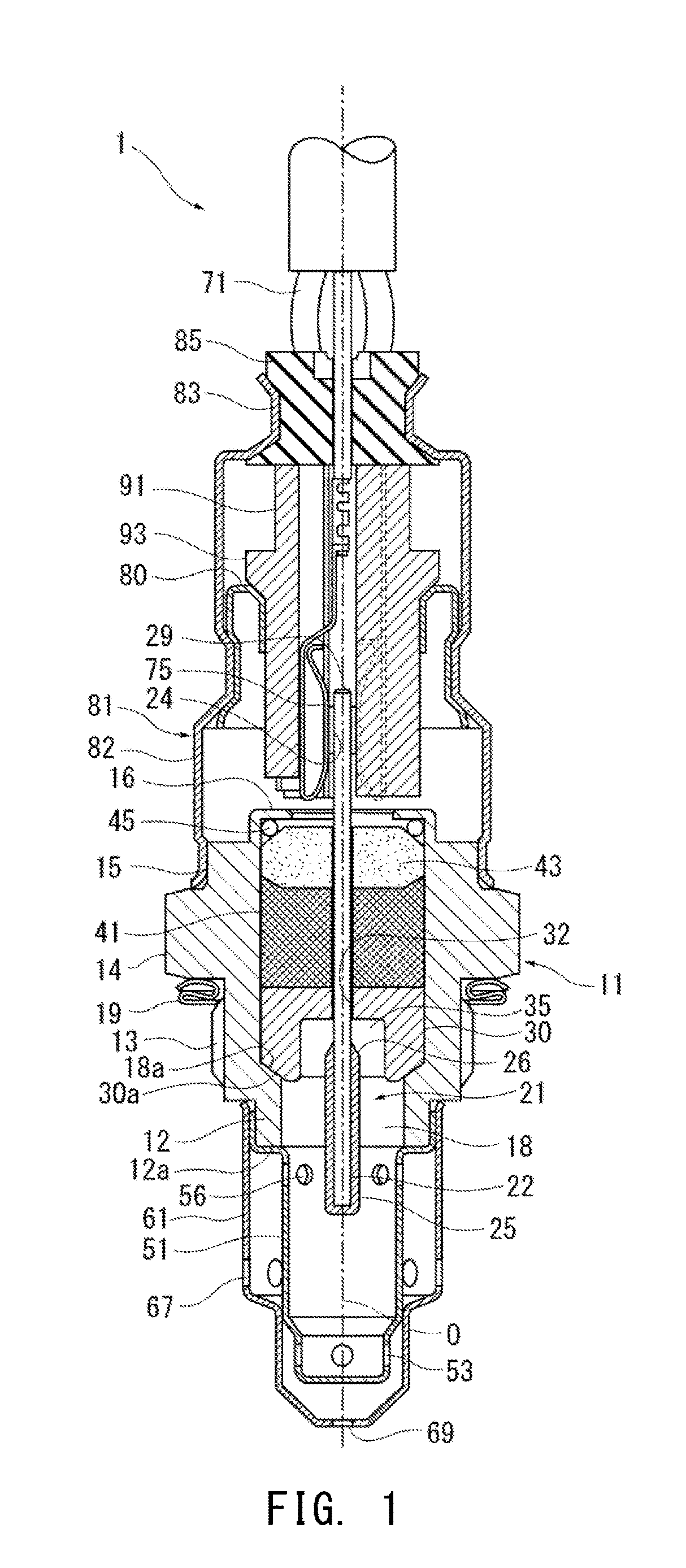

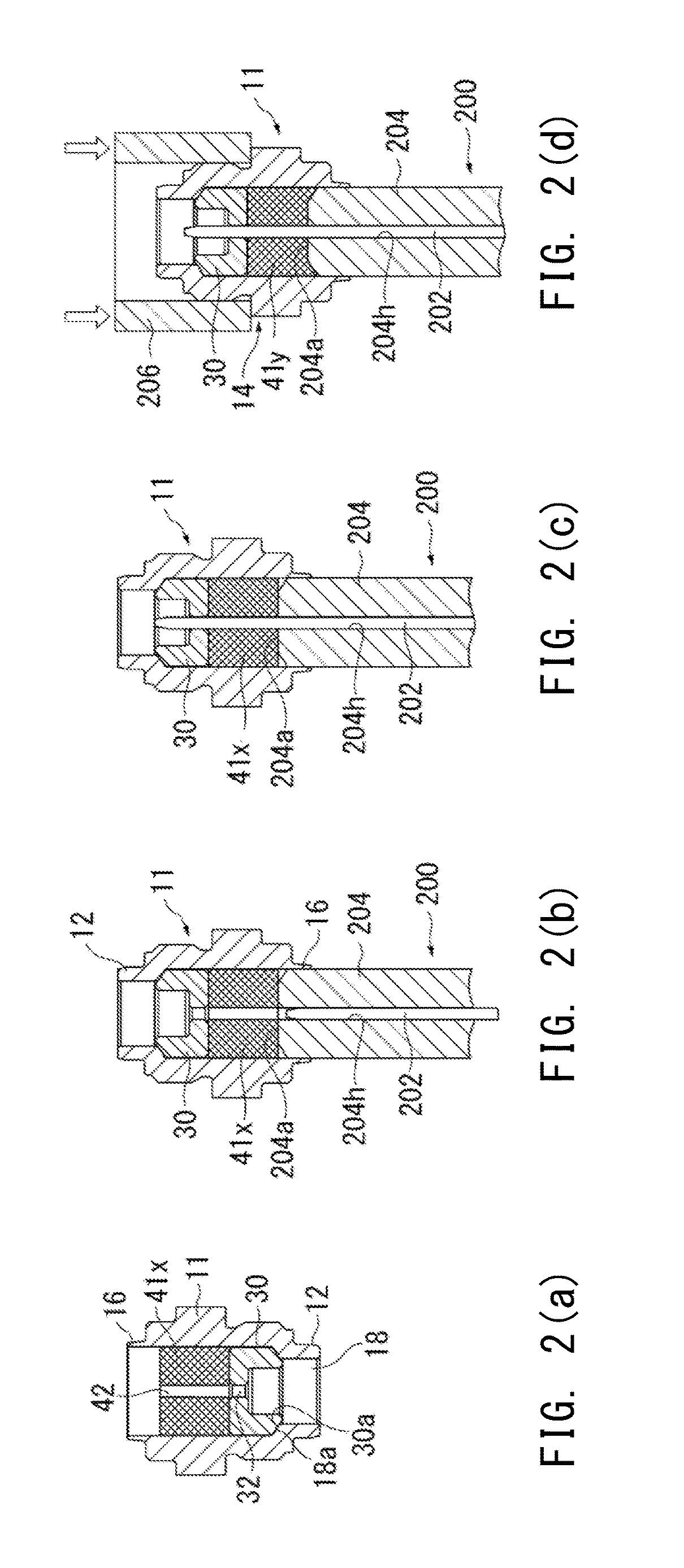

Method for manufacturing sensor intermediate product and method for manufacturing sensor

ActiveUS20150330939A1Avoid breakingAvoid uneven stressElectrolytic capacitorsMaterial analysis by electric/magnetic meansBiomedical engineeringFirst insertion

A method for manufacturing a sensor intermediate product includes: disposing a tubular holder and a tubular compact in a tubular metallic shell, and inserting a metallic pin into a first insertion hole of the holder and a second insertion hole of the compact; compressing the compact so as to form a filling member intermediate having a shape which brings the filling member intermediate into pressure contact with the inner wall surface of the metallic shell and allows removal of the metallic pin from the second insertion hole; pulling out the metallic pin from the first insertion hole and the second insertion hole; inserting a sensor element into the first insertion hole and the second insertion hole; and compressing the filling member intermediate to thereby form a filling member which fixes the sensor element inside of the metallic shell.

Owner:NGK SPARK PLUG CO LTD

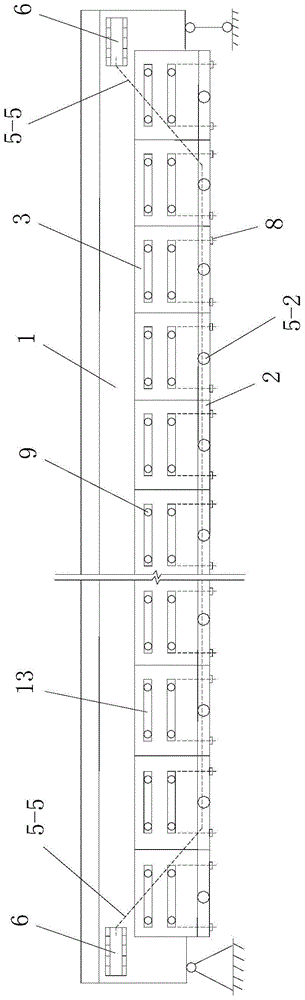

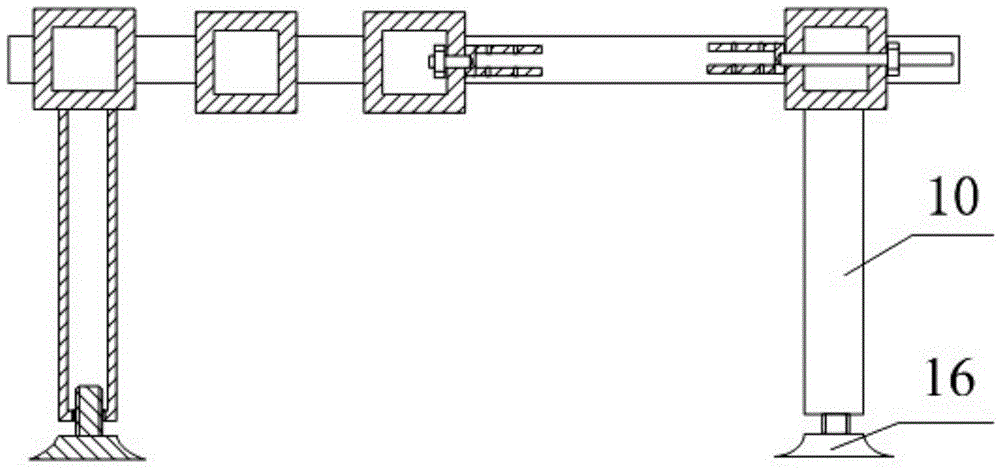

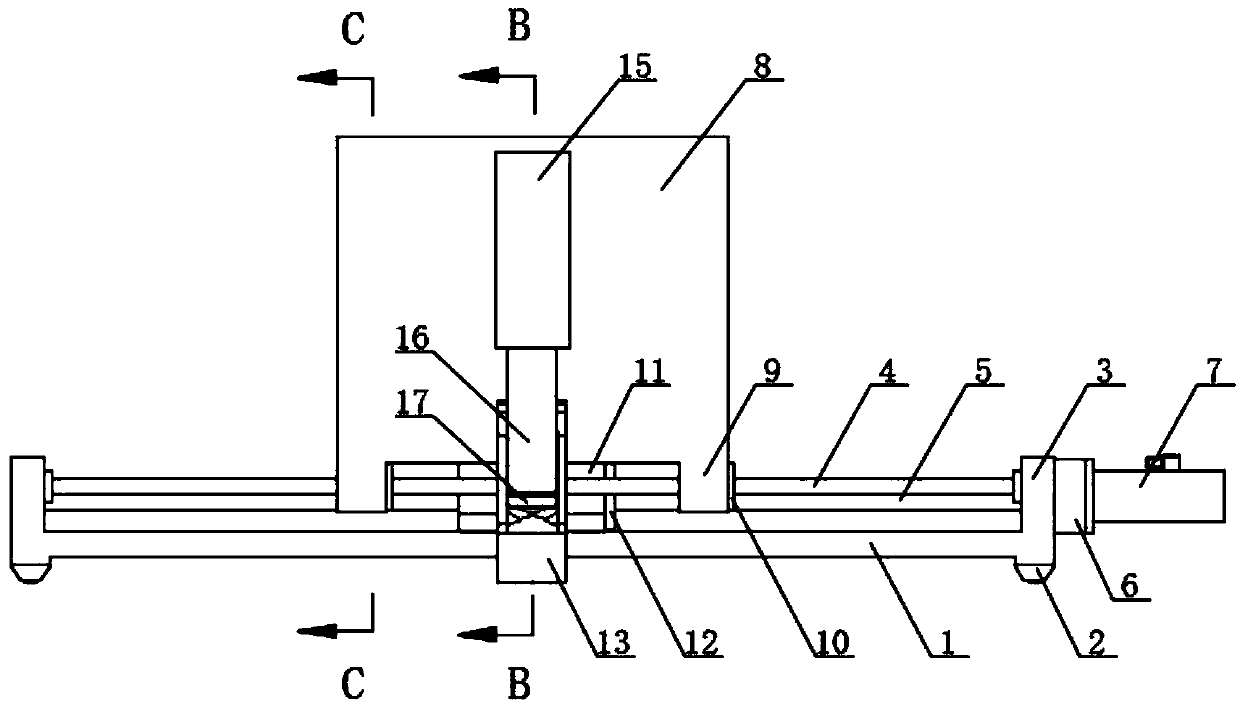

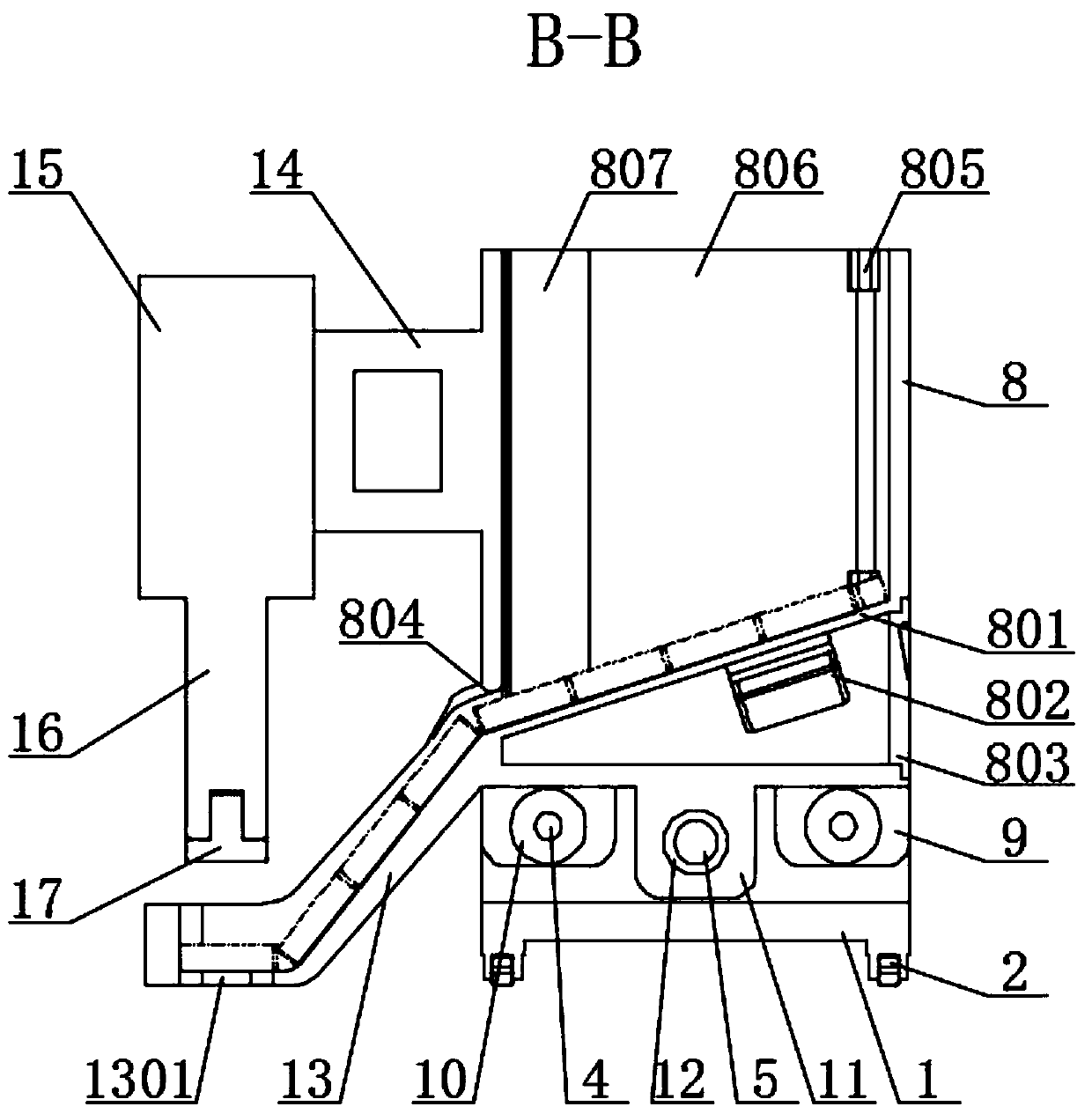

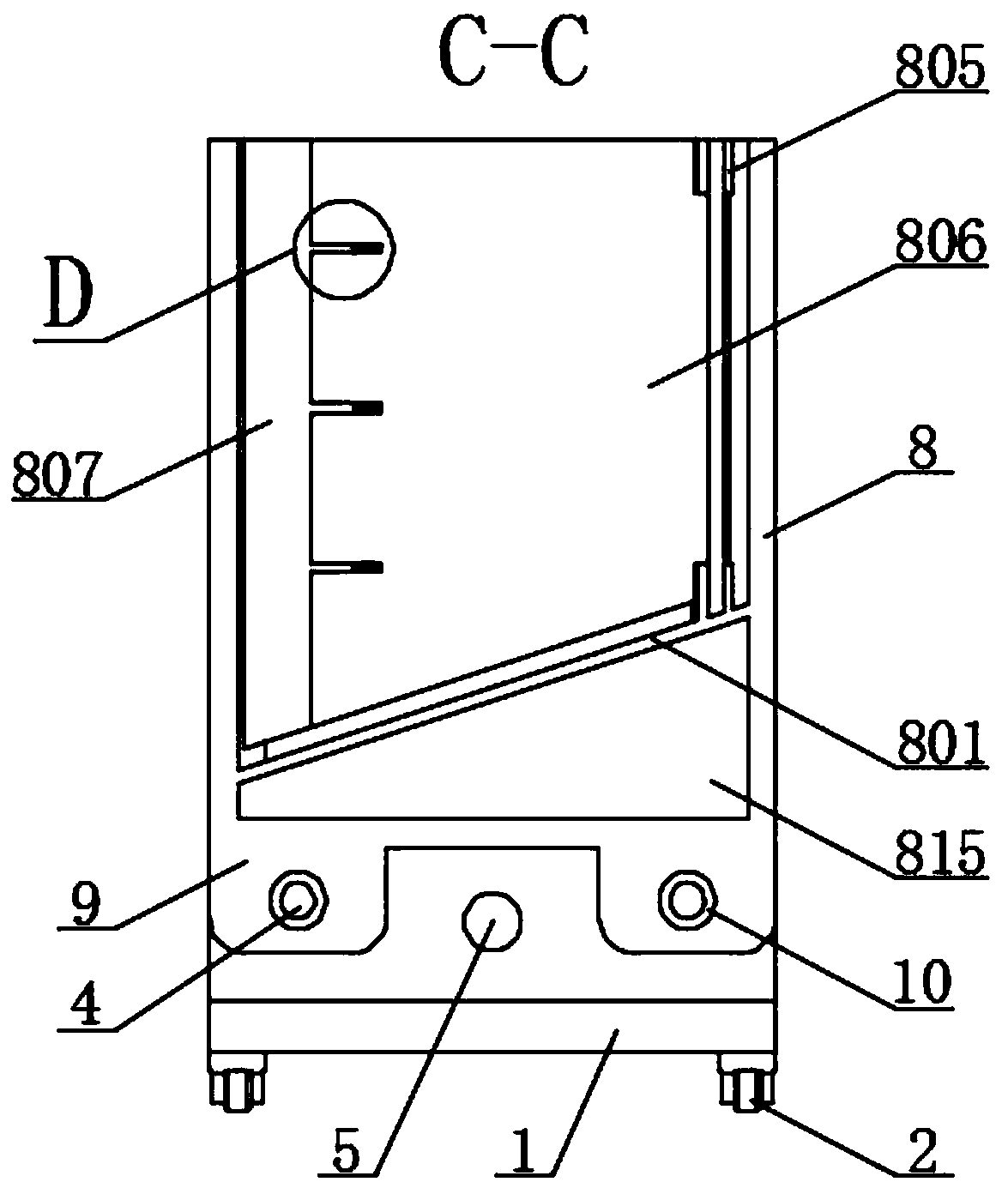

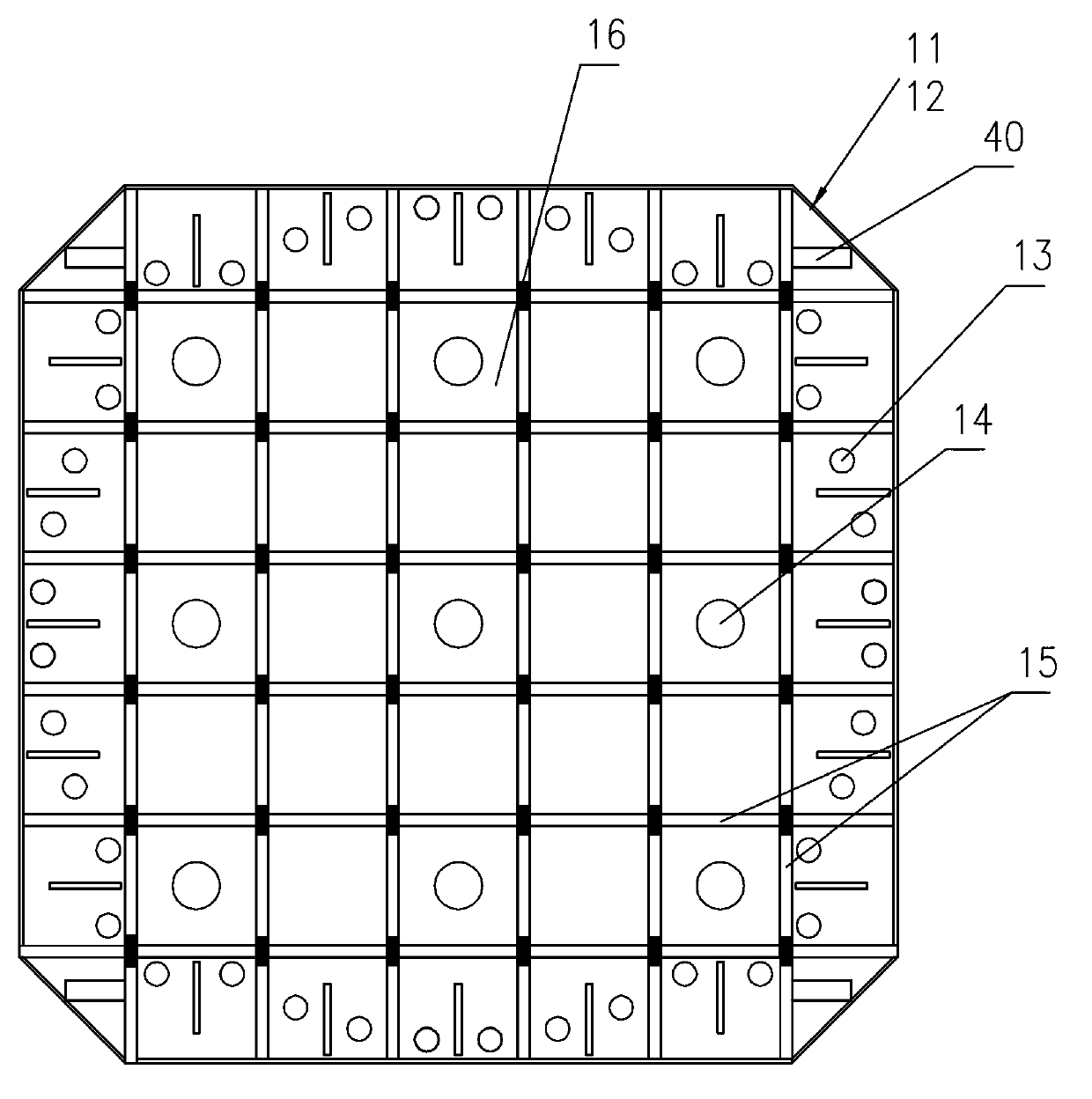

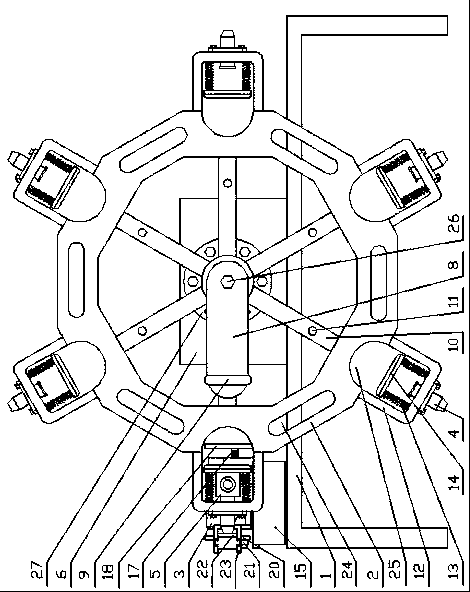

Pile driving limit frame and construction method for offshore wind power foundation pile sinking in intertidal zone

ActiveCN103981867BGuaranteed verticalityGuaranteed accuracyBulkheads/pilesElectricityOffshore wind power

The invention relates to a method for construction of intertidal zone offshore wind power multi-pile conduit frame foundation pile sinking. The method is characterized in that pile sinking positioning and perpendicularity control are performed on steel pipe piles through a piling limiting frame, and a floating crane hydraulic impact hammer setting on a beach is utilized to perform hanging up and beating for pile sinking. The method comprises the steps of performing steel pipe pile processing and marine transportation, performing ship positioning, leveling the beach face of a pile sinking area, placing the piling limiting frame, injecting water to a water containing cavity in the piling limiting frame, adjusting the levelness of the piling limiting frame, vertically lifting the steel pipe piles, inserting the steel pipe piles in a pile holding device of the piling limiting frame, utilizing a piling hammer for pile pressing and utilizing the piling hammer for pile sinking. The method has the advantages that the steel pipe piles are guided and limited through the piling limiting frame, pile sinking perpendicularity is guaranteed, accuracy of relative positions of the steel pipe piles of every foundation is guaranteed, construction of a whole fan foundation can be finished by one-time ship parking, a construction process is simplified, and construction efficiency is greatly improved.

Owner:天津港航工程有限公司

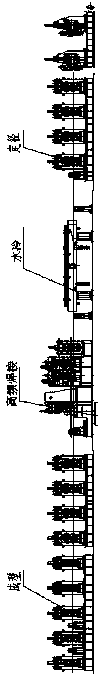

Special-shaped steel tube forming technology and mold replacement device for semitrailer fence

InactiveCN108526241AGuaranteed continuous productionIncrease productivityShaping toolsButt weldingButt joint

The invention relates to a special-shaped steel tube forming technology for a semitrailer fence. The special-shaped steel tube forming technology for the semitrailer fence comprises the steps of first, uncoiling, wherein steel strip rolls are unfolded; second, leveling, wherein unfolded steel strips are leveled, and are conveyed to a next station; third, end flattening and butt welding, wherein the head portion and the tail portion of one leveled steel strip are cut to be flattened, and the material tail of the steel strip with ends cut to be flattened and the material head of a next steel strip with ends cut to be flattened are welded together; fourth, beforehand storage, wherein the steel strips subjected to butt joint are sent into a loop storage silo; fifth, forming, wherein the steelstrips in the loop storage silo are sent to a forming machine, and are sequentially bent into tube blanks to be welded; sixth, high efficiency welding, wherein high efficiency welding is carried out after the two ends, in butt joint, of every two adjacent tube blanks are pressed to form a certain open angle; seventh, water cooling, wherein the steel tubes subjected to high efficiency welding are cooled to the room temperature in a spraying manner; eighth, special shape gradual sizing, wherein the steel tubes subjected to water cooling are sized through a sizing unit; and ninth, profile machining, wherein the sized steel tubes are segmented into steel tube bodies of specific lengths.

Owner:山东舜世高科实业有限公司

Lifting type sheet metal part punching device

The invention belongs to the technical field of sheet metal part machining equipment, and particularly relates to a lifting type sheet metal part punching device. The lifting type sheet metal part punching device comprises a retractable movable sleeve, an air cylinder, a guide rod, a guide sleeve and a male die base. The air cylinder is located on a top plate, and a piston of the air cylinder is connected with the middle of the male die base. The retractable movable sleeve and the guide rod are fixed on one side, far away from a feed port, of a bottom plate. The top end of the retractable movable sleeve is fixed to the lower surface of the top plate. The guide rod penetrates through the top plate and is fixed through a nut. The guide rod is sleeved with the guide sleeve, and the guide sleeve is connected with the two ends of the male die base. A roll ball is arranged inside the guide sleeve, a male die is fixed below the male die base, and the lower end face of the male die is in a conical shape. According to the lifting type sheet metal part punching device, a whole punching tool can ascend and descend through the additionally arranged retractable piston. The guide sleeve with the roll ball is matched with a guide column, so that the guide sleeve slides more continuously, smoothly and stably. A conical notch is adopted so that high quality can be achieved. The cutting can be carried out efficiently.

Owner:HOTOLI GUANGDONG ELECTRIC CO LTD

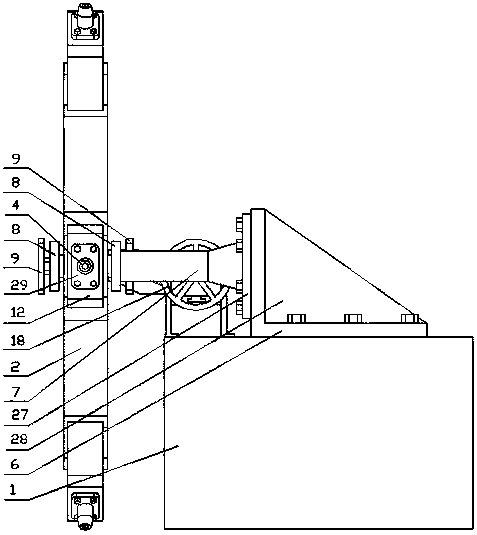

Bending die capable of controlling high-strength steel springback and application method thereof

The invention discloses a bending die capable of controlling high-strength steel springback and an application method thereof. The bending die capable of controlling high-strength steel springback comprises an upper die and a lower die which can be opened and closed relatively. The upper die comprises an upper die base, an upper padding plate and a pressing plate which are connected through a guide column. The upper die further comprises a punching pin assembly and an upper die spring. The lower die comprises a lower die base, lower padding feet, a lower padding plate, a sliding block assemblyand a lower die resetting assembly. According to the bending die capable of controlling high-strength steel springback, products are bent and formed through the punching pin assembly, the sliding block assembly, the lower die resetting assembly and under the action of a punching machine; besides, the bending die is of a purely mechanical structure and applicable to machining of steel plates of different thickness and sizes; compared with a former manner that a cylinder is used to conduct bending, the bending die has the advantage that the volume is small; materials used by the die are reduced; repeated debugging of cylinder pressure is not needed, and the research and development costs are reduced; nitrogen springs are adopted by both the upper die spring and the lower die spring; the elastic curve is gentle; pre-tightening is not needed; steel movement in the loading process is prevented; and in addition, the whole process of forming is uniform in pressure, and the condition that stress is uneven is prevented from occurring.

Owner:广东天倬智能装备科技有限公司

Multi-bit rapid switching and discharging device for food processing

ActiveCN107912485AQuick disassembly workFlexible rotationDough shaping and cutting apparatusFood shapingEngineeringIngested food

The invention discloses a multi-bit rapid switching and discharging device for food processing, which comprises an installing frame, a rotary framework, a cutting motor, a discharging head and a transfer joint; the middle of the upper part of the installing frame is detachably connected with a right angle plate frame, and the right angle plate frame is detachably connected with the fixing shaft; the rotary framework is rotationally fit with the fixing shaft; two positioning cross frames are mounted on the fixing shaft, and extruding frames are evenly distributed on the outer edge of the rotaryframework; the extruding frames are connected with a splint through a group of tension spring, and the cutting motor is matched with an eccentric wheel; the eccentric wheel is connected with a pushing cutter through a link rod, the push cutter is glidingly fit with a chute cutter rest installed on one side of the cutting motor. The multi-bit rapid switching and discharging device for food processing can rapidly replace discharging heads to reach the purpose of processing different shapes of foods; the multi-bit rapid switching and discharging device is simple in operation, low in manufacturing cost, convenient to repair, and avoids the problem of single food processing shape in the traditional processing work.

Owner:崔斯特创新技术(深圳)有限公司

a stamping device

The invention relates to the technical field of stamping equipment, in particular to a stamping device. The stamping device includes a base plate, supporting seats are arranged at the bottom of the base plate, and a lower mold base is arranged at the top of the base plate; a lower mold is arranged at the top of the lower mold base; spring piece pressing cavities are formed in the lower mold; threaded seats are arranged at the top of the base plate; screw rods are arranged on the threaded seats; a top plate is arranged at the top ends of the screw rods; worm and gear mechanism shell bodies arearranged on the top plate; gears are arranged in the worm and gear mechanism shell bodies; double-shaft motors are arranged at the top of the top plate; rotating shafts are correspondingly arranged atthe two ends of the double-shaft motors; first springs are arranged at the bottom of the top plate; an upper mold base is arranged at the bottom ends of the first springs; clamping plates are arranged at the bottom of the top plate; guiding seats are arranged at the bottom of the upper mold seat; guiding rods are arranged in the guiding seats; second springs are arranged on the guiding rods; an upper mold is arranged at the bottom of the upper mold seat; convex blocks are arranged at the bottom of the upper mold; slots are formed in the upper mold; and inserted rods are arranged on the lowermold seat. The stamping device has the advantages that the production efficiency is high, the force bearing of shrapnel processing is uniform, and the quality of finished products is high.

Owner:WENZHOU LIANFENG ELECTRICAL

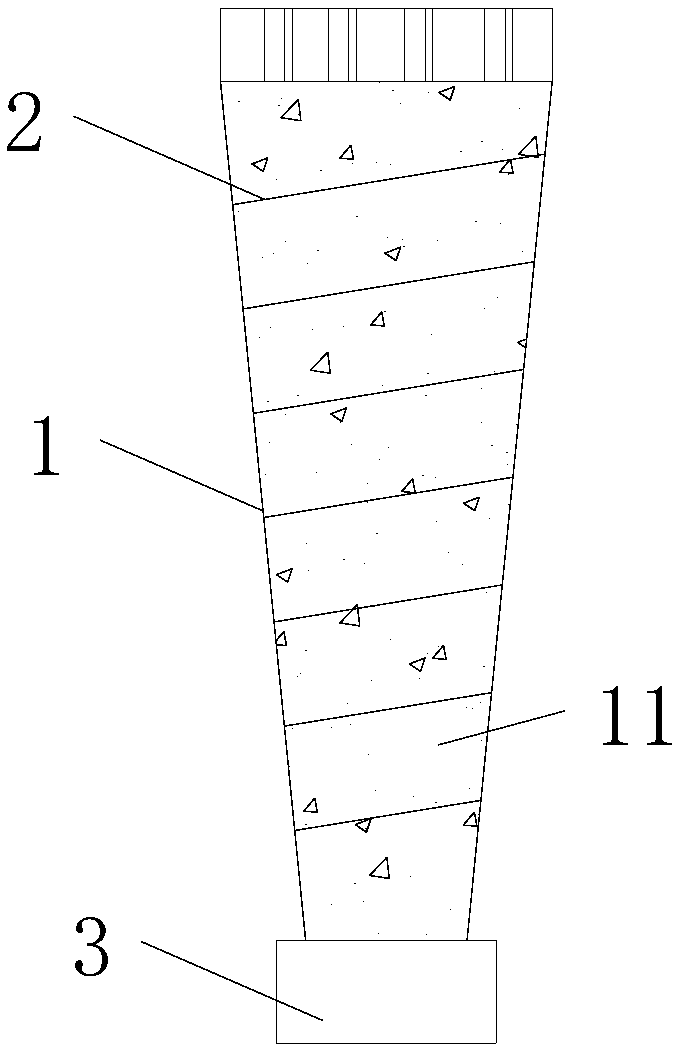

Recycled conical wall drilling device

InactiveCN109537888AReduced service lifeAvoid uneven stressForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksScrew threadPetroleum engineering

The invention discloses a recycled conical wall drilling device, and aims at solving the problems that when an existing conical sleeve tube is dismantled, the force borne by the sleeve tube is nonuniform when knocking is conducted by adopting a dismantling tool, a small head of the sleeve tube is easily damaged, the using time of the sleeve tube cannot be ensured, the recycling time of a wall drilling sleeve tube is reduced, and therefore the service life of the wall drilling sleeve tube is reduced. The device comprises a conical wall drilling sleeve tube body and a dismantling handle, a microthreaded groove is formed in the outer surface of the conical wall drilling sleeve tube body, the outer surface of the conical wall drilling sleeve tube body is coated with a wear resisting layer, and foot cups are in threaded connection with the bottom end of the conical wall drilling sleeve tube body. The recycled conical wall drilling device has the advantages that the conical wall drilling sleeve body is driven to rotate by a rotary handle by rotating the dismantling handle, so that the conical wall drilling sleeve tube body is dismantled through rotation, a knocking manner is replaced with a rotation manner, and therefore the reduction of the service life caused by nonuniform force bearing by adopting knocking is avoided.

Owner:XINJIANG CONSTR ENG GRP

Method for manufacturing sensor intermediate product and method for manufacturing sensor

ActiveUS20170059512A1Avoid breakingAvoid uneven stressMaterial analysis by electric/magnetic meansBiomedical engineeringFirst insertion

A method for manufacturing a gas sensor includes: disposing a tubular holder and a tubular compact in a tubular metallic shell defining a through hole, the tubular holder defining a first insertion hole, and the tubular compact defining a second insertion hole; preparing a preliminary assembly in which a pin is inserted into the first insertion hole and the second insertion hole; pulling out the pin from the first insertion hole and the second insertion hole and inserting a sensor element into the first insertion hole and the second insertion hole such that a forward end of the pin will come into contact with an end of the sensor element; compressing the compact to thereby fix the sensor element inside of the metallic shell; welding a protection sleeve to the metallic shell to thereby form a semi-assembly; and combining the semi-assembly with another semi-assembly to thereby form the gas sensor.

Owner:NGK SPARK PLUG CO LTD

Reinforcement structure and reinforcement method of main girder of reinforced concrete girder bridge

ActiveCN104947603BSimple structureReasonable designBridge erection/assemblyBridge strengtheningReinforced concretePre stress

The invention discloses a reinforced concrete girder bridge girder reinforcing structure and method. The reinforcing structure comprises a reinforcing form board, a concrete structure located in a cavity between the reinforcing form board and a to-be-reinforced girder and a prestress system arranged on the reinforcing form board, wherein the reinforcing form board includes a girder-bottom form board and two girder-side form boards; the prestress system comprises two longitudinal prestress steel strands penetrating the reinforcing form board and a plurality of first transverse prestress steel strands penetrating the girder-bottom form board, four steel anchor boxes are disposed on the to-be-reinforced girder, and the two longitudinal prestress steel strands, two second transverse prestress steel strands and the four steel anchor boxes form the annular prestress system. The reinforcing method includes the steps of firstly, prefabricating the reinforcing form board; secondly, arranging anchor parts; thirdly, hoisting and fixing the reinforcing form board; fourthly, pouring concrete; performing prestress tension. The reinforcing structure and method is reasonable in design, simple in construction, good in reinforcing effect and capable of solve various problems of existing reinforcing methods.

Owner:陕西中项建材科技有限公司

High-intensity tempering process of heat-resistant glass

InactiveCN112110641AUniform quenching temperatureAvoid uneven stressGlass tempering apparatusQuenchingComposite material

The invention relates to the technical field of heat-resistant glass, in particular to a high-intensity tempering process of heat-resistant glass. The process comprises the steps of heating of the heat-resistant glass, spraying cold quenching, air cooling of the heat-resistant glass, liquid cooling of the heat-resistant glass and drying of the heat-resistant glass drying. Compared with a traditional mode of quenching via a single quenching medium, a multi-layer cold quenching mode in the invention forms a temperature step, and cold quenching temperature is more uniform from high to low, so thecracking of the heat-resistant glass caused by uneven stress on the heat-resistant glass is prevented, the probability of spontaneous explosion in the toughening process of the heat-resistant glass is reduced, and the strength of the heat-resistant glass after toughening is effectively improved.

Owner:惠州市嘉耀华玻璃有限公司

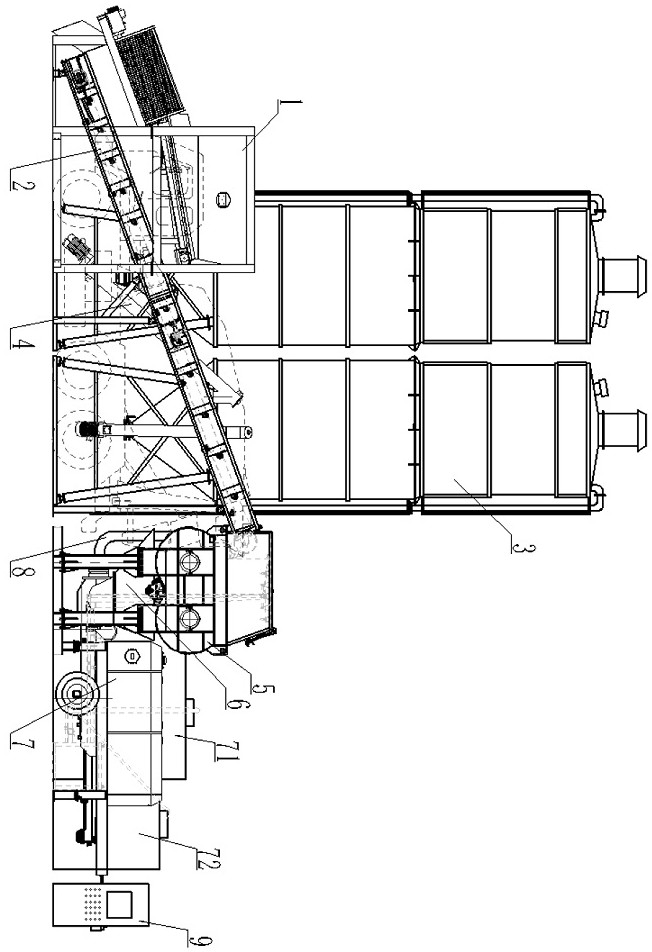

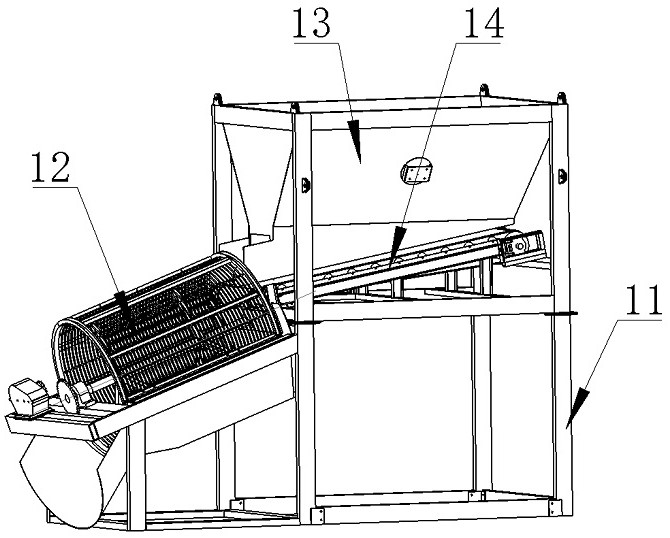

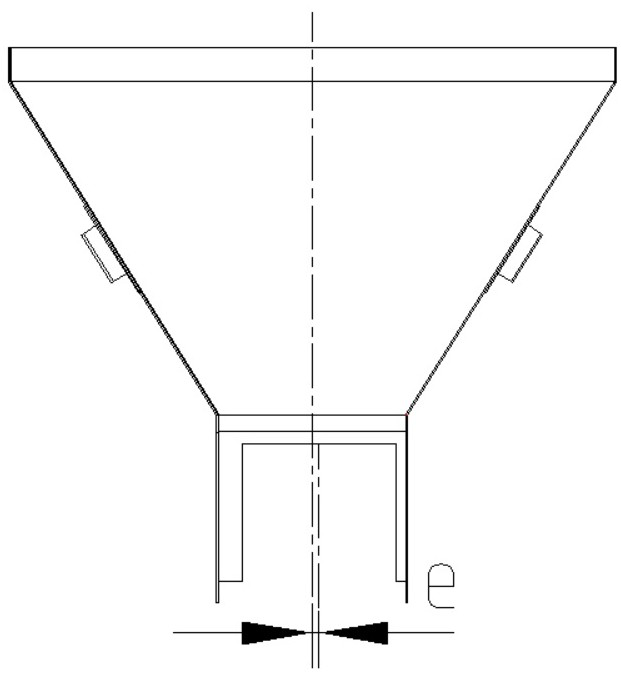

Complete equipment for preparing liquefied consolidated soil from waste residue soil and construction method of complete equipment

PendingCN112776182AWell mixedQuality improvementIngredients weighing apparatusCement mixing apparatusProcess engineeringMaterial storage

The invention discloses complete equipment for preparing liquefied consolidated soil from waste residue soil and a construction method of the complete equipment. The complete equipment comprises a screening device, an ingredient conveying device, a material storage device, a material conveying device, a stirring device, a finished product material temporary storage bin, a pumping device, a finished product material conveying pump and a control device. The discharging end of the screening device is connected with the feeding end of the ingredient conveying device. The discharging ends of the ingredient conveying device and the pumping device are both connected with the feeding end of the stirring device, the discharging end of the stirring device is connected with a feeding port of the finished product material temporary storage bin, a discharging port of the material storage device is connected with a feeding port of the material conveying device, and a discharging port of the material conveying device is connected with the ingredient conveying device. The finished product material conveying pump is connected with a discharging port of the finished product material temporary storage bin through a pipeline, and the screening device and the ingredient conveying device are arranged in a radial offset mode. In general, the complete equipment for preparing the liquefied consolidated soil from the waste residue soil and the construction method of the complete equipment have the advantages of being convenient to use, accurate and stable in metering, small in operation difficulty, short in construction period and good in construction quality.

Owner:河南绿岩工程科技有限公司

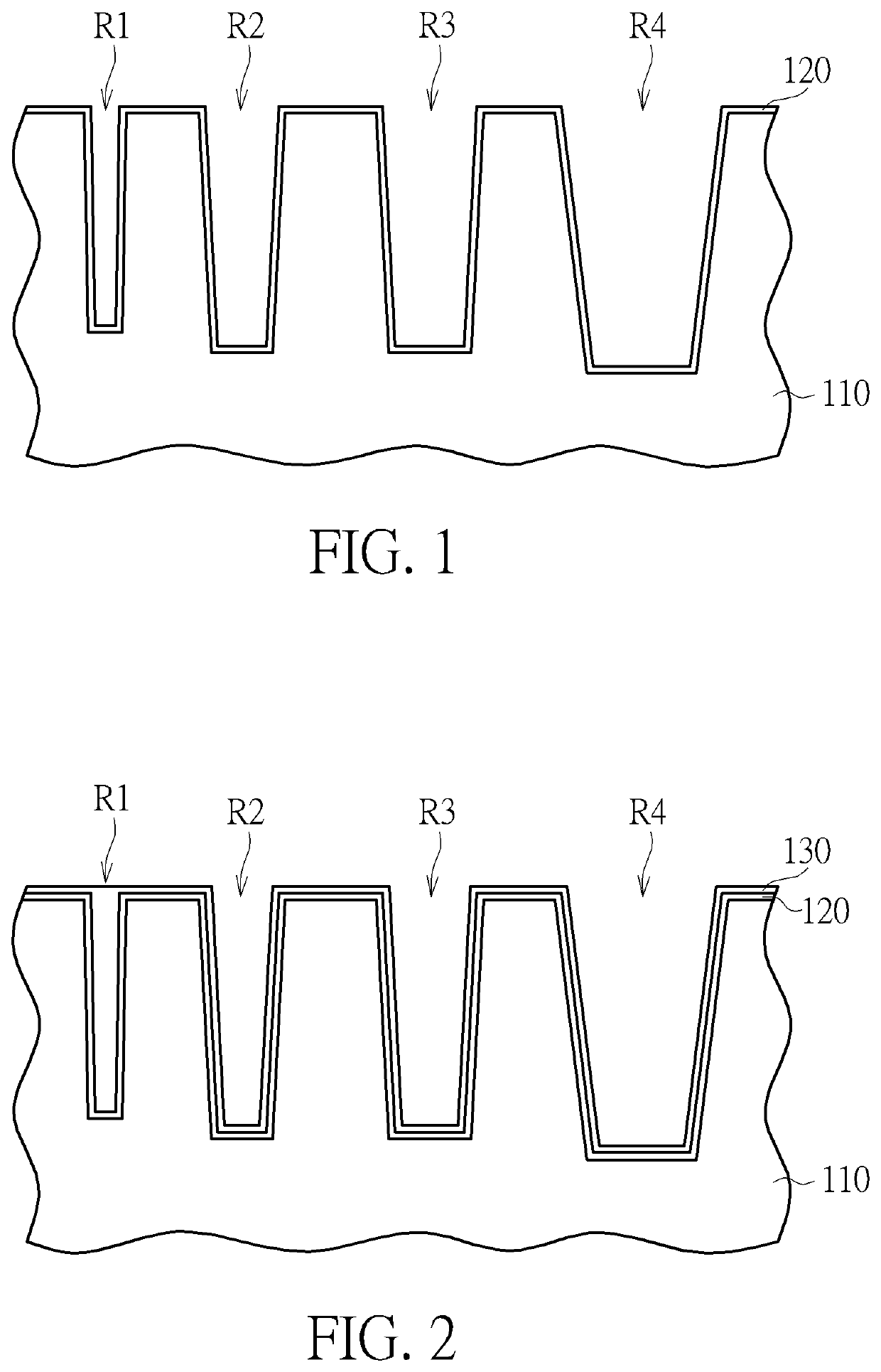

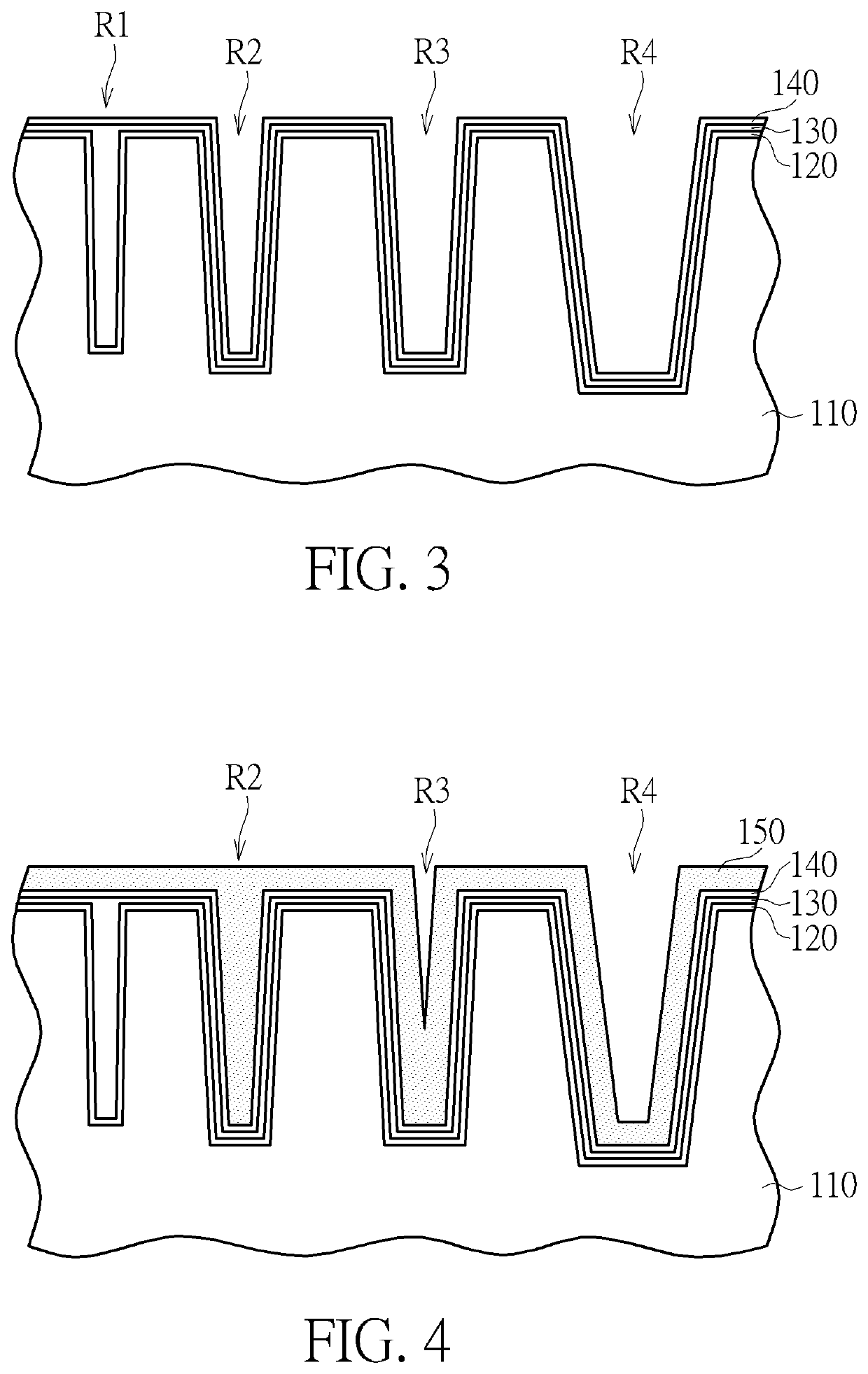

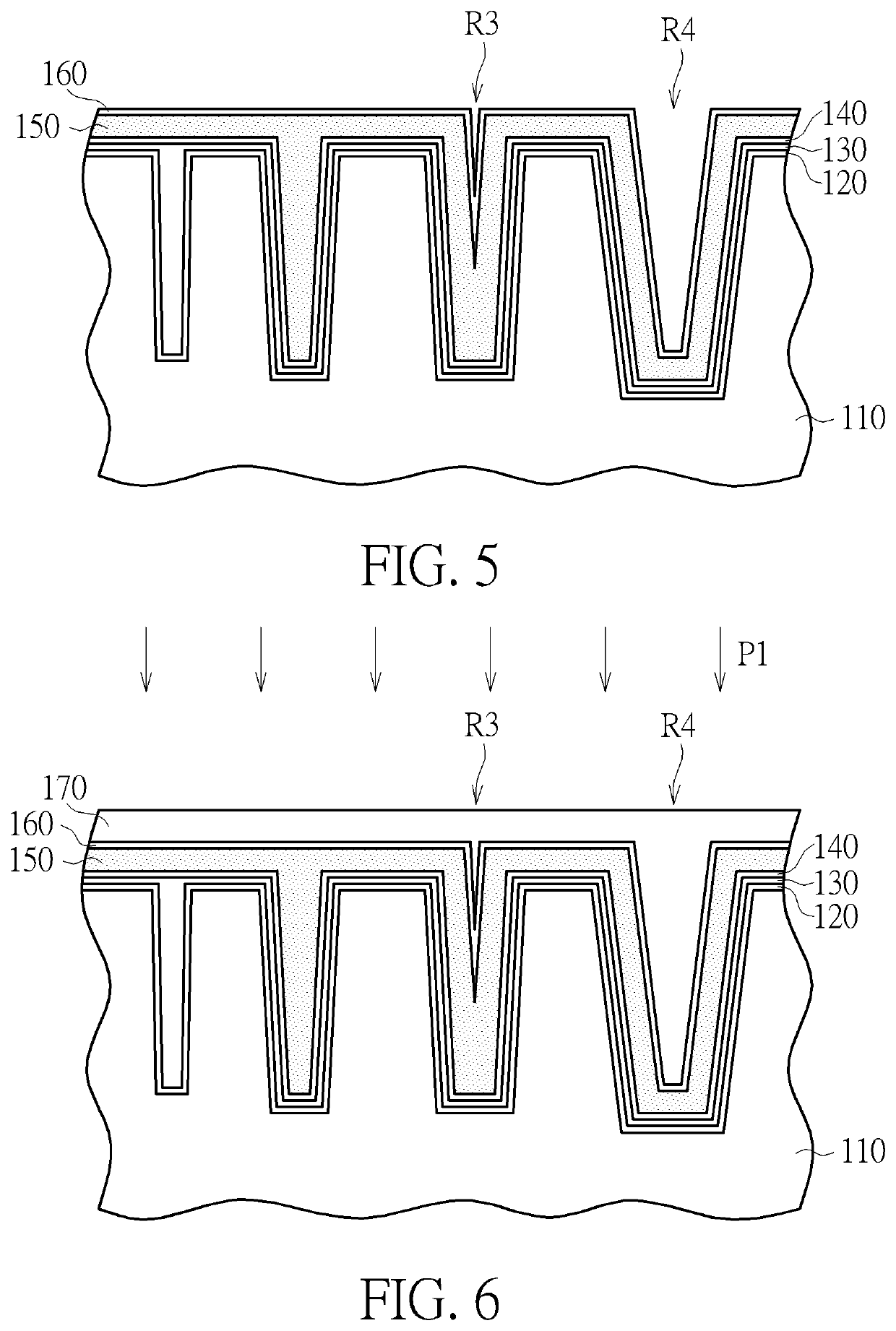

Method of forming isolation structure

ActiveUS20200075397A1Avoid uneven stressStrong Gap Filling CapabilitySemiconductor/solid-state device manufacturingEngineering physicsAtomic layer deposition

A method of forming an isolation structure includes the following steps. A substrate having a first trench, a second trench and a third trench is provided, wherein the opening of the third trench is larger than the opening of the second trench, and the opening of the second trench is larger than the opening of the first trench. A first oxide layer is formed to conformally cover the first trench, the second trench and the third trench by an atomic layer deposition (ALD) process. A second oxide layer fills up the first trench by an in-situ steam generation (ISSG) process.

Owner:UNITED MICROELECTRONICS CORP +1

Irregular glass ceiling connection structure and ceiling lamp connection structure matched with irregular glass ceiling connection structure

The invention provides a glass ceiling connection structure. The glass ceiling connection structure comprises a keel, a fire retardant panel and art glass which are arranged from top to bottom in sequence, and a through hole is only formed in the art glass. A tapping screw passes through the through hole, so that it is achieved that the art glass, the fire retardant panel and the keel are fixed. The through hole is a counter bored hole. An elastic layer is arranged at the head of the tapping screw, so that the tapping screw is isolated from the bottom wall and the side wall of the counter bored hole. In this way, in the installation construction process of a single piece of art glass, the tapping screw makes elastic contact with the bottom wall of the counter bored hole, and in the compression process, the phenomenon that stress of joint parts is not uniform can be effectively avoided. Besides, even when the tapping screw is obliquely inserted, the tapping screw can be prevented from making rigid contact with the art glass, so that cracks are generated in the contact part of the art glass, and the construction reliability is improved. Besides, the invention further provides a ceiling lamp connection structure matched with the glass ceiling connection structure.

Owner:GOLD MANTIS CONSTR DECORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com