Patents

Literature

48results about How to "Avoid affecting test accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

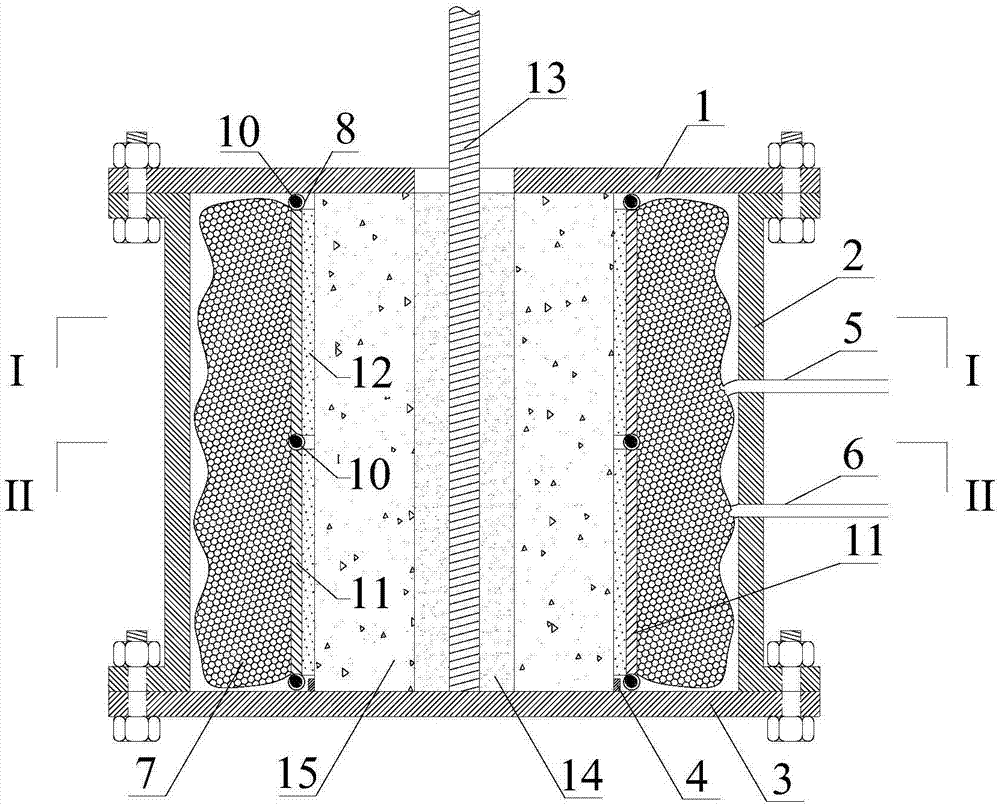

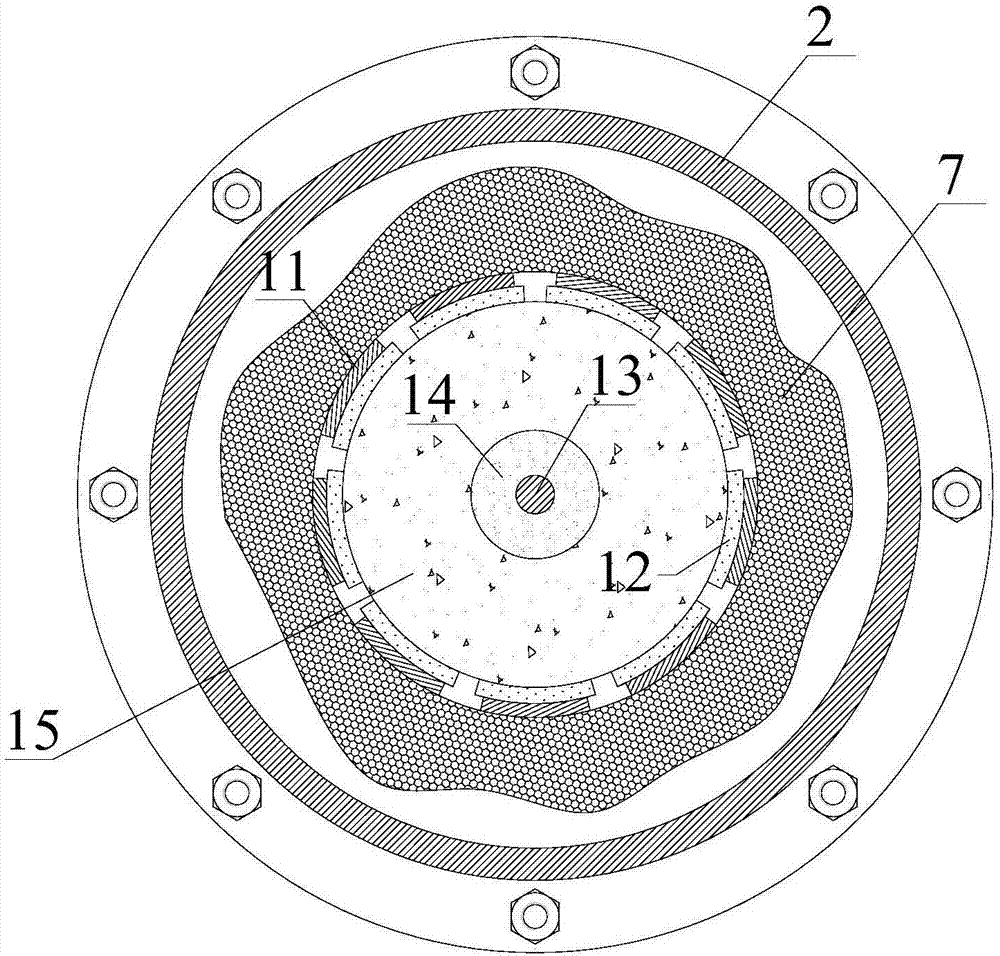

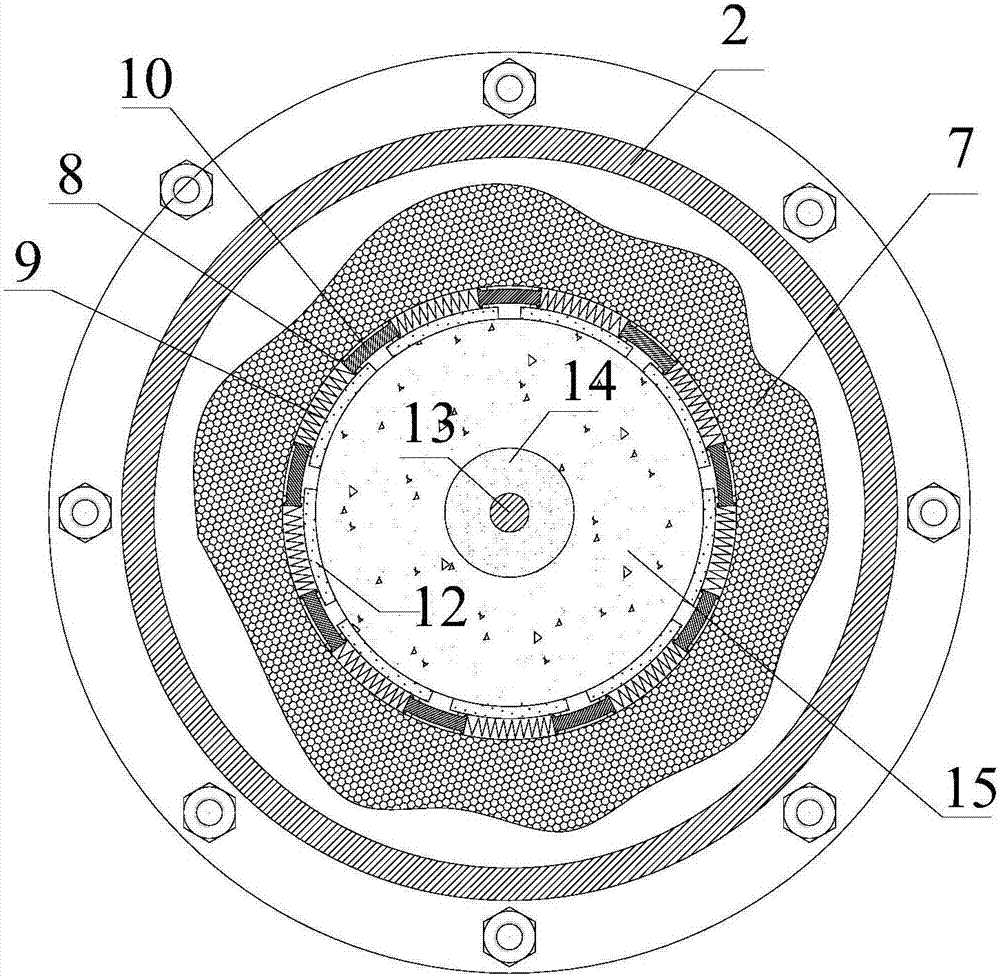

Flexible loading device and method for simulating uniform stress on surface of cylindrical anchorage model

ActiveCN107505205AComply with the force characteristicsThe pull test is real and effectiveMaterial strength using tensile/compressive forcesClimate change adaptationEngineeringMechanical engineering

Owner:SHANDONG JIANZHU UNIV

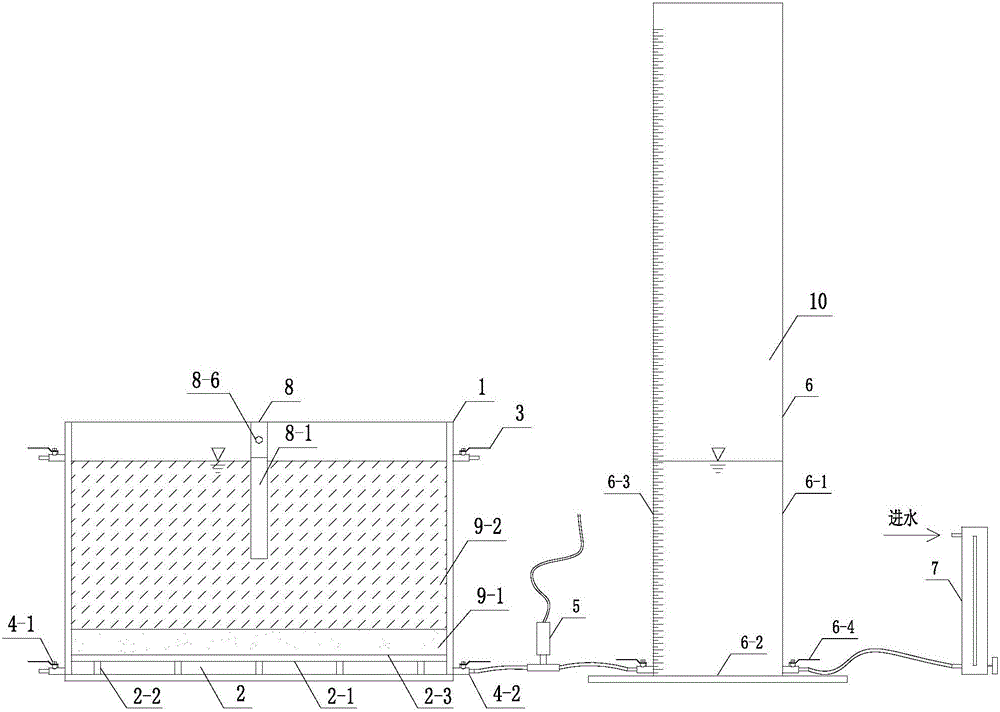

Model testing device for foundation under action of dynamic pressure bearing water

ActiveCN105862933ADoes not affect the microstructureAvoid starvationFoundation testingIn situ soil foundationTransformerEngineering

Owner:ZHEJIANG UNIV

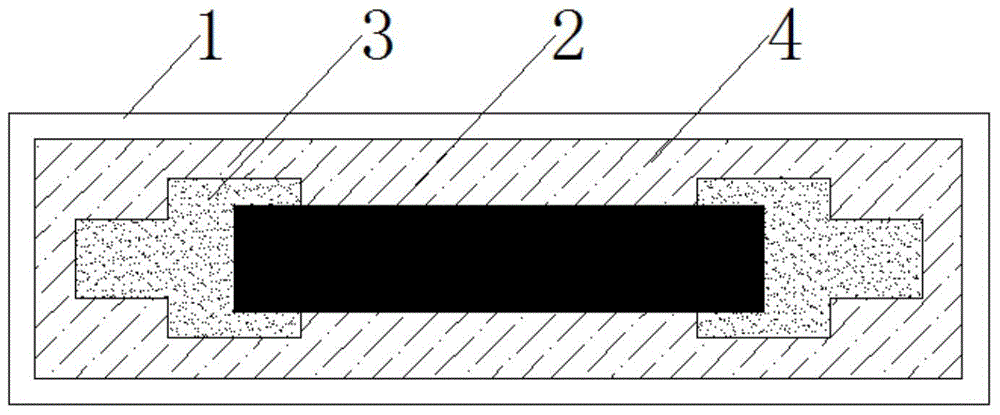

Strain test sensing element with matched modulus and manufacturing method thereof

InactiveCN104913718ASimple structureEasy to makeElectrical/magnetic solid deformation measurementElectricityRubber material

The invention, which belongs to the field of the test sensing element and the manufacturing method thereof, provides a strain test sensing element with matched modulus and a manufacturing method thereof. The sensing element comprises a thin plate arranged at a bottom layer, a sensitive thin film arranged at an intermediate layer, electrodes arranged at the intermediate layer, and an insulating protection film arranged at a top layer. The thin plate arranged at the bottom layer is a plastic or rubber thin plate and is selected and determined based on the modulus of a strain test object. According to the sensitive thin film and the electrodes that are arranged at the intermediate layer, the electrodes are arranged at the two ends of the sensitive thin film; and the sensitive thin film is formed by printing of a conductive macromolecule composite material and the electrodes are formed by printing of conductive silver pastes. The insulating protection film arranged at the top layer is formed by printing of a resin or rubber material. The thin plate at the bottom layer, the sensitive thin film and the electrodes at the intermediate layer, and the insulating protection film at the top layer are selected according to the modulus of the tested object, thereby realizing modulus matching; and then a strain test sensing element is manufactured. Synchronous strain of the sensing element and the tested object can be realized well; the tested strain value becomes accurate; the testing range can be met well; and the test precision is improved. Moreover, the cost is low and the effect is good on the condition of batch production.

Owner:CHINA UNIV OF MINING & TECH

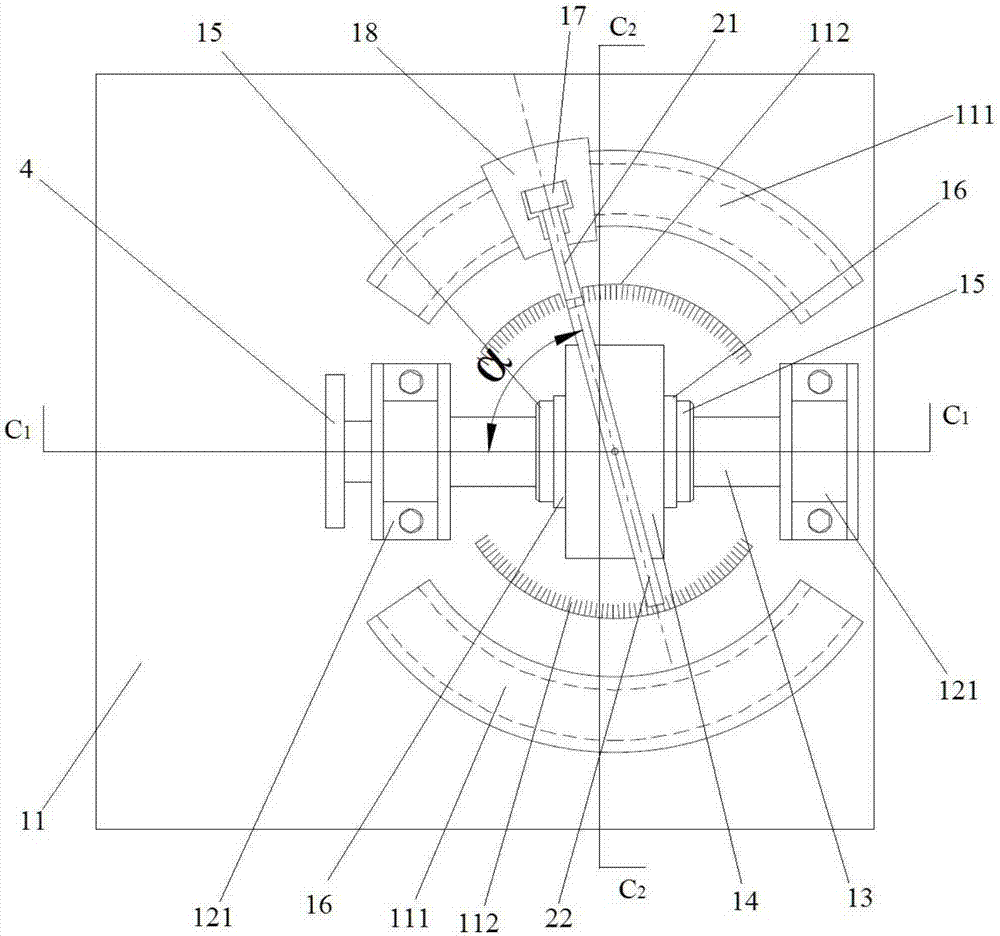

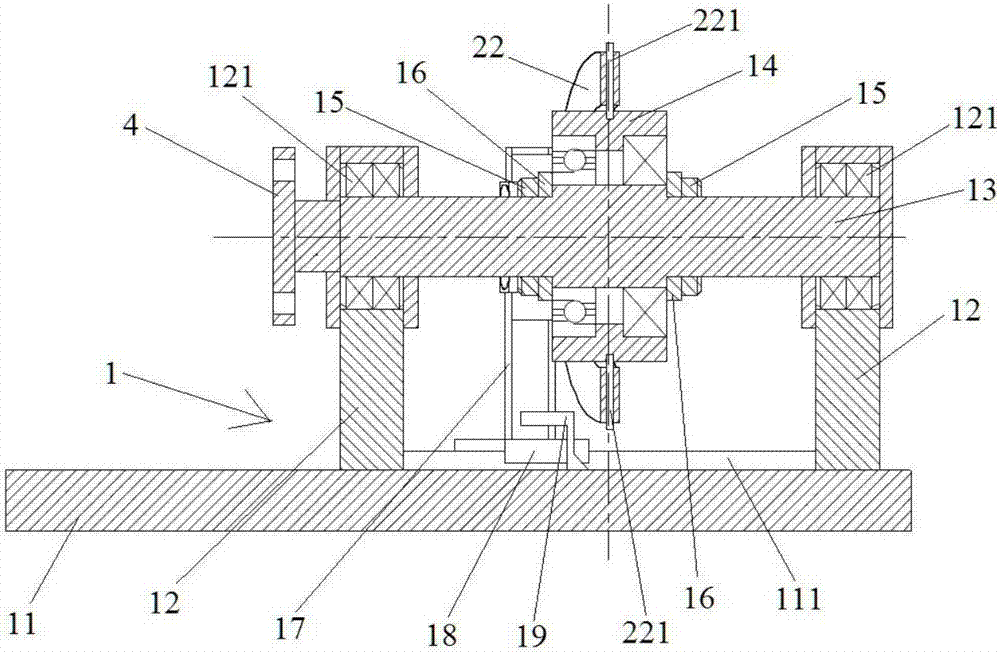

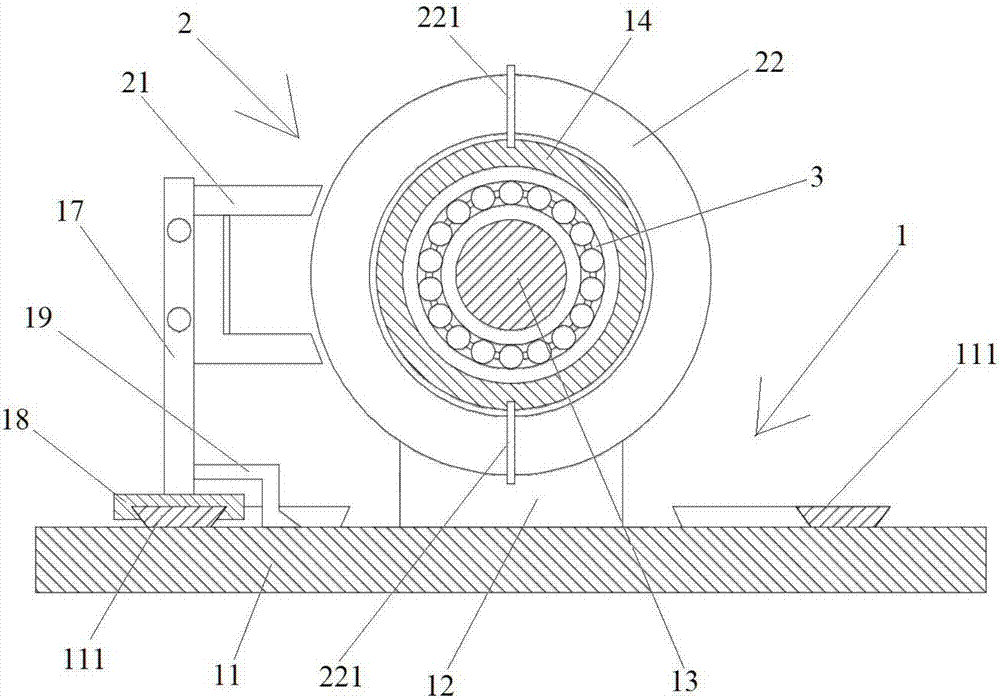

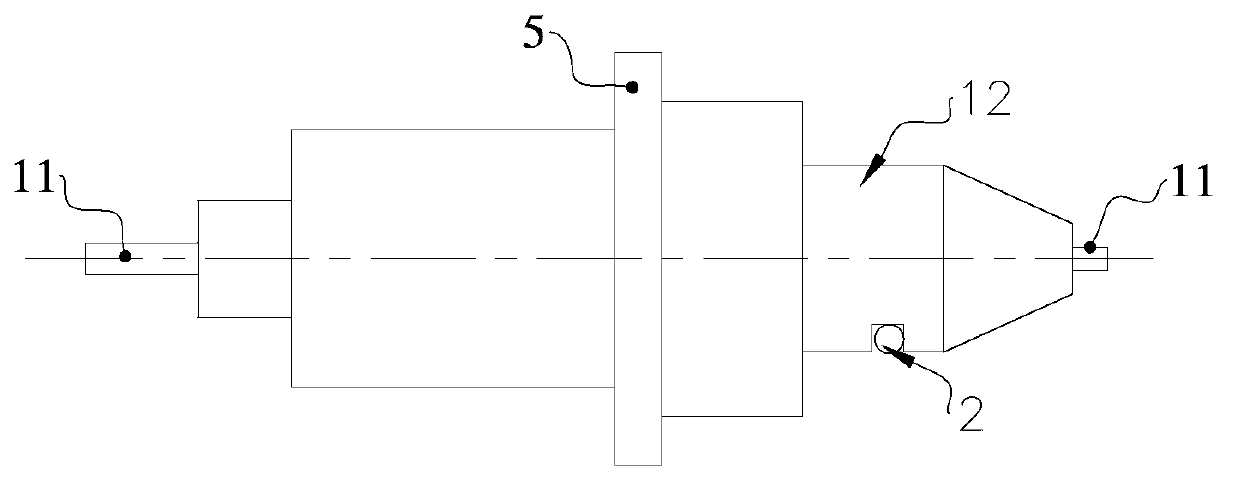

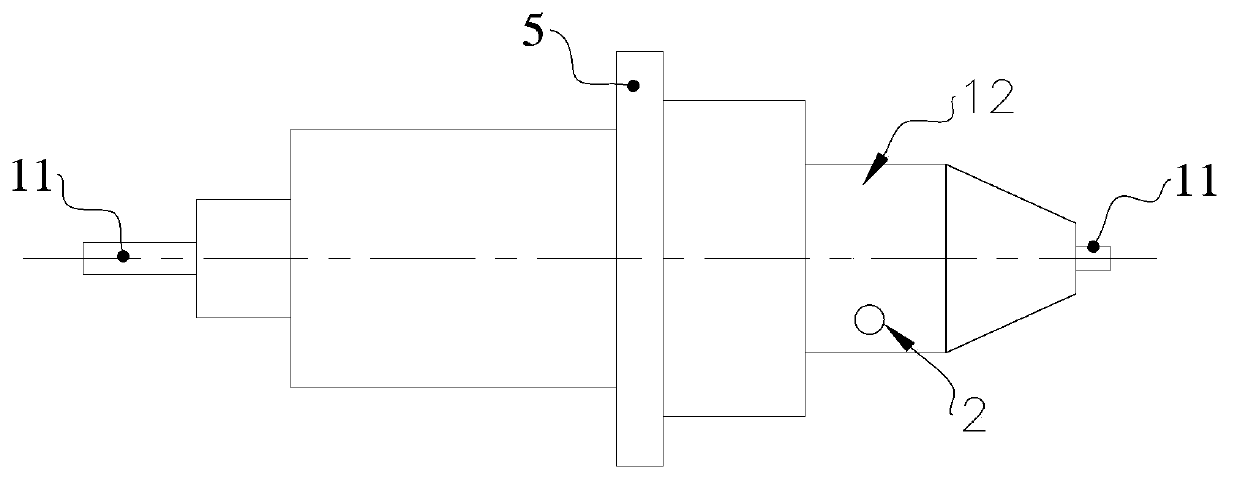

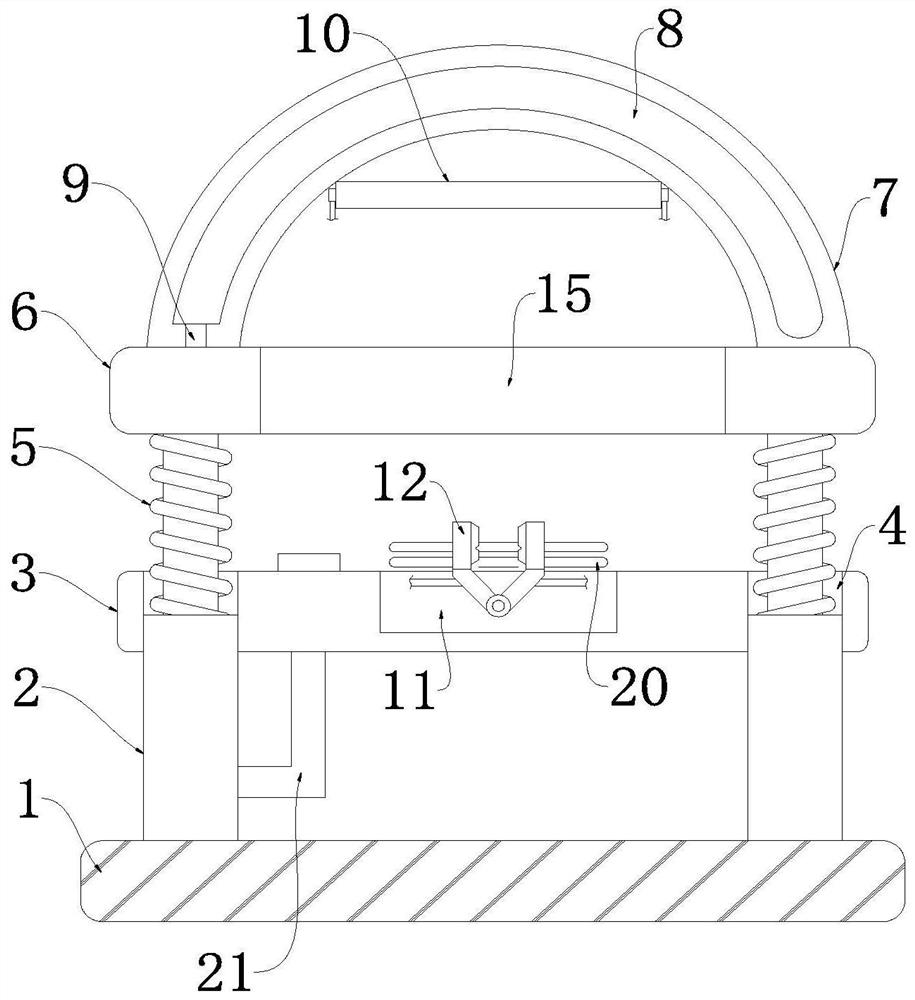

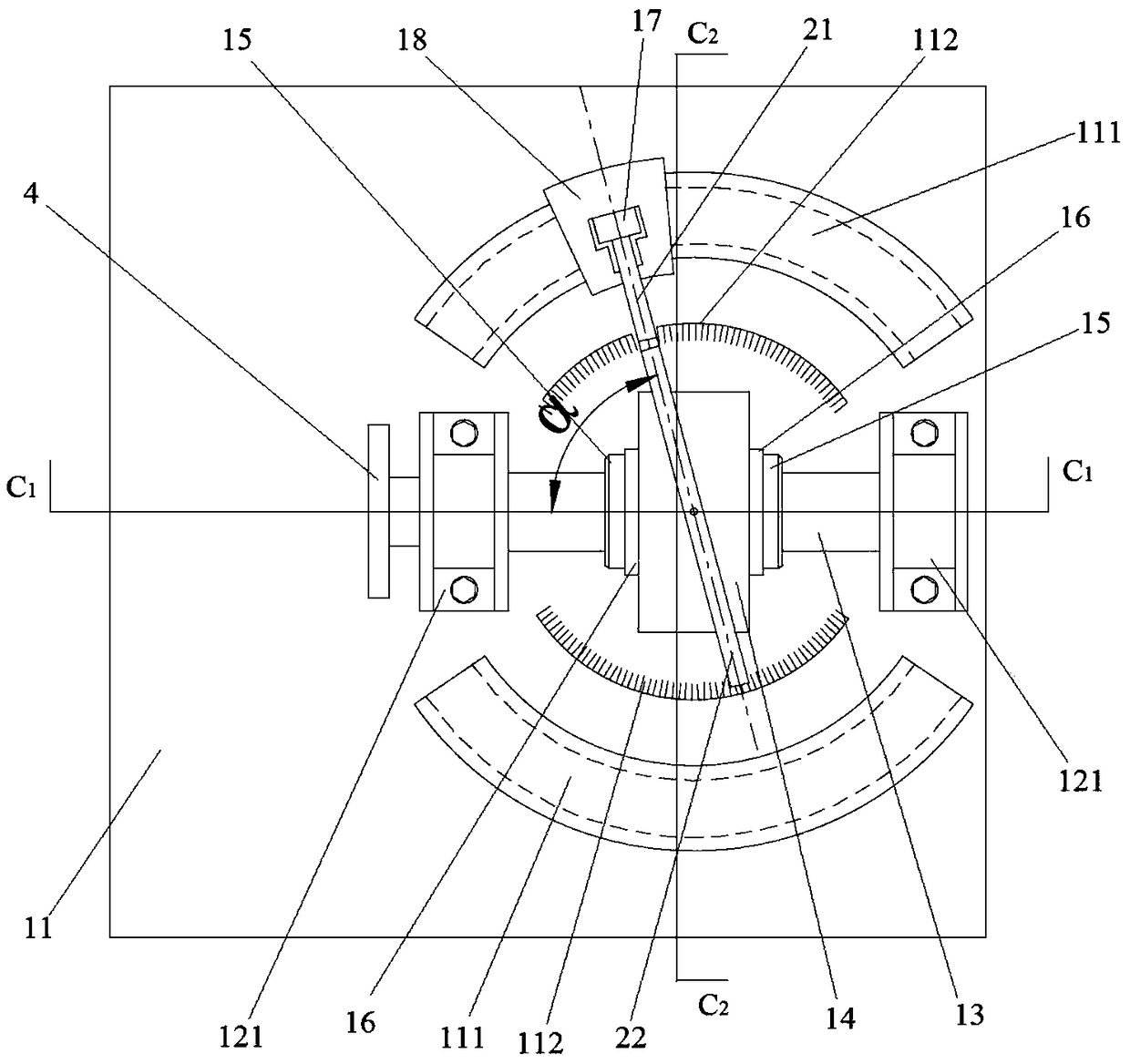

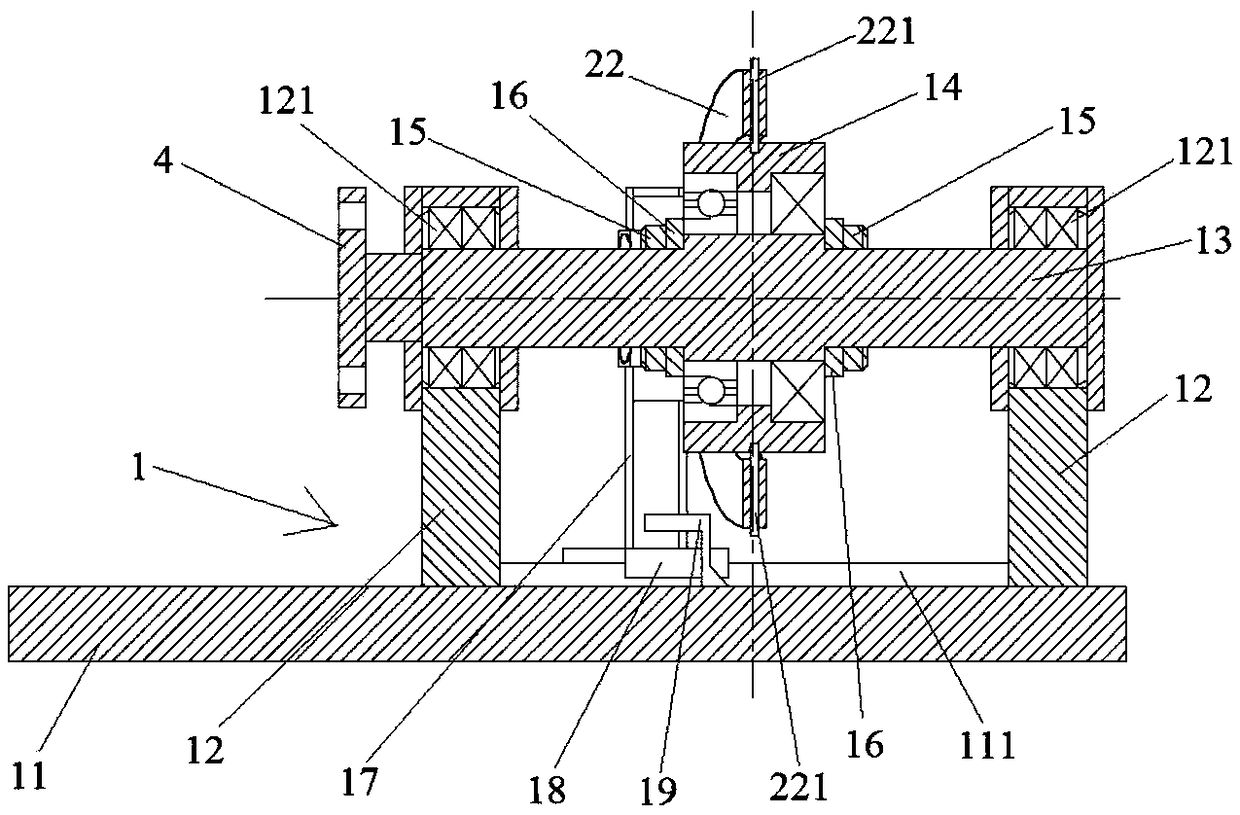

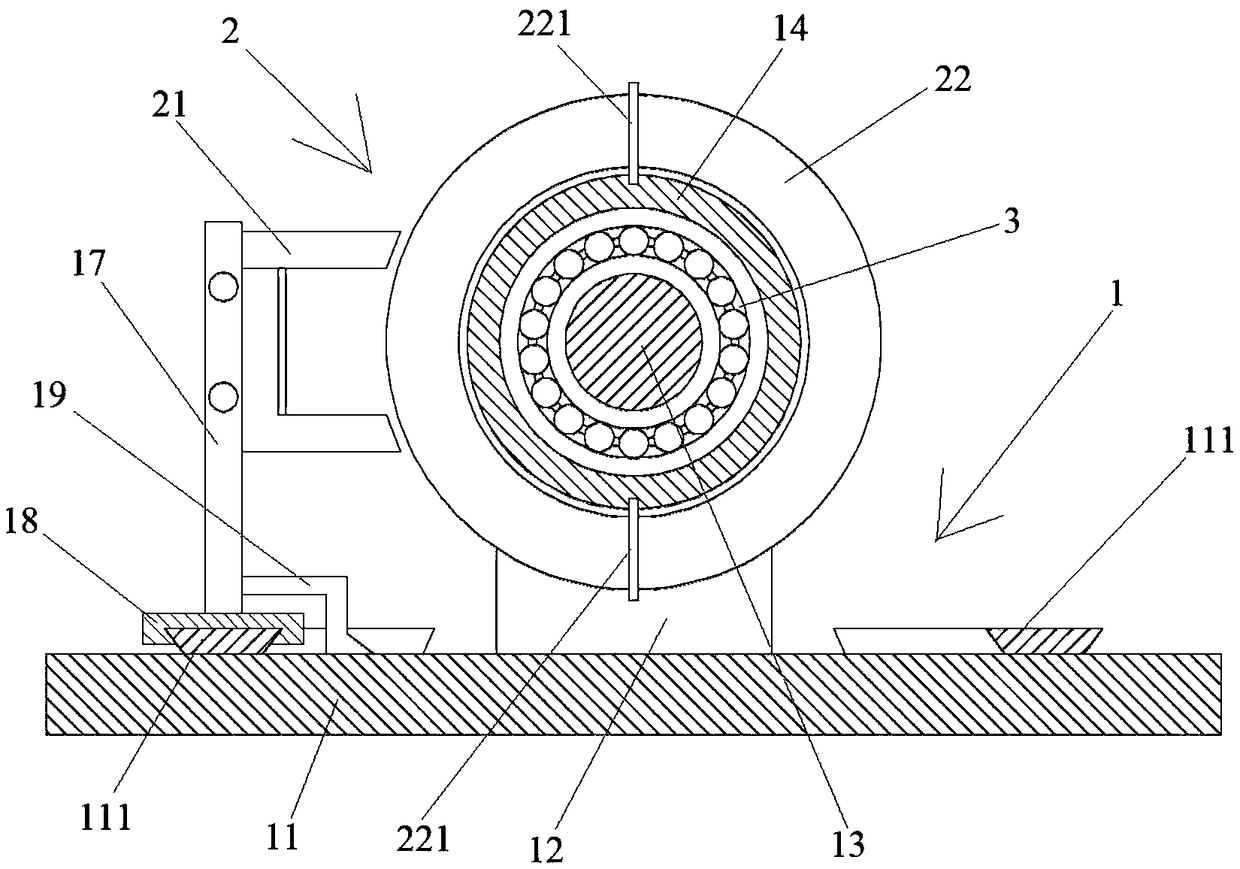

Load loading device for rolling bearing tribological test

InactiveCN106969917AAvoid affecting test accuracyEasy to operateMachine bearings testingBearing componentsRolling-element bearingMagnetic poles

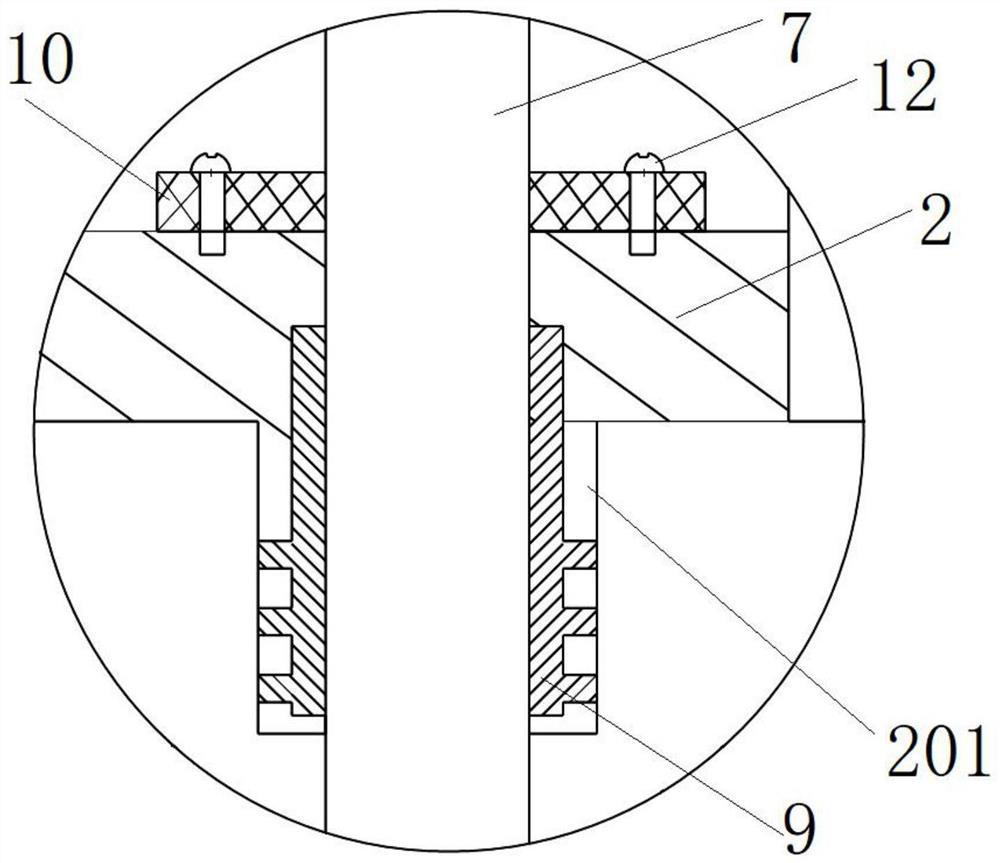

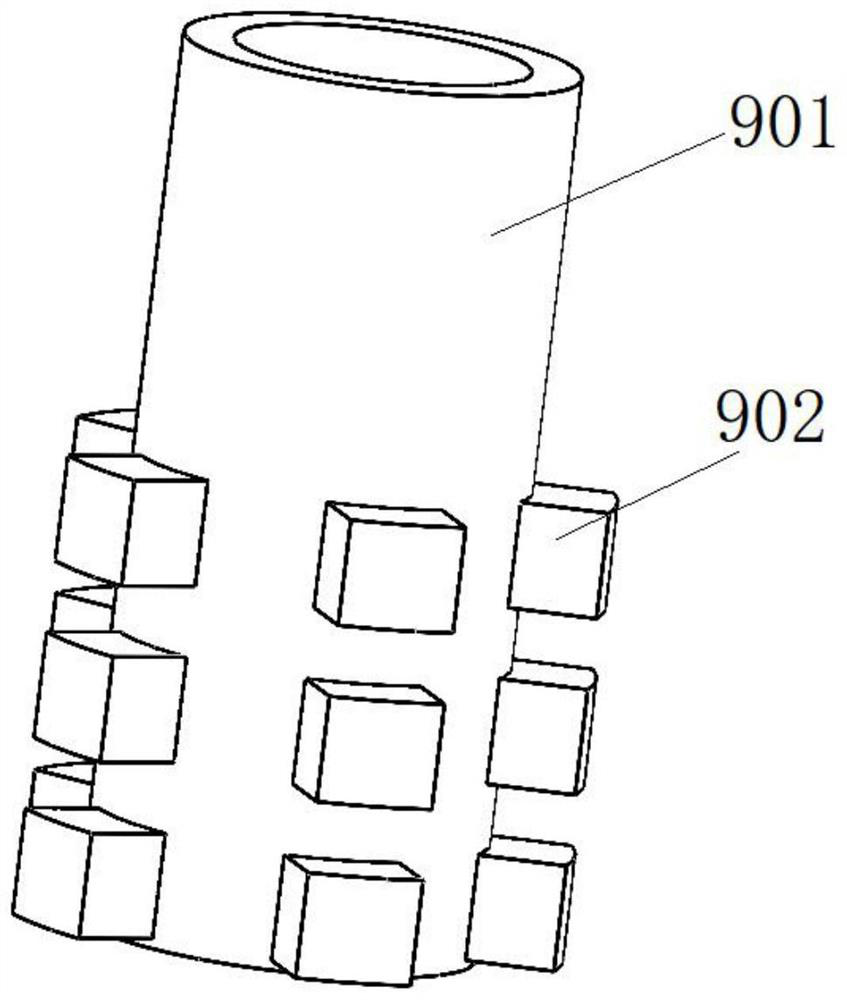

The present invention relates to the field of tribological tests. In order to improve the tribological test precision of a rolling bearing, the invention provides a load loading device for a rolling bearing tribological test. The device comprises a support device and a loading mechanism. The support device comprises a base, a rotation shaft support, and a support rotation shaft. The support rotation shaft is installed on the rotation shaft support and is sleeved by a T-shaped support ring and locking nuts. In a test, a rolling bearing is pressed and buckled by the T-shaped support ring, and the locking nuts are locked and fixed at two sides of the rolling bearing. The loading mechanism comprises an electromagnetic iron core and a magnetic conducting ring in a same plane. Two magnetic poles of the electromagnetic iron core face the support rotation shaft from side directions and are in a vertical symmetry at the horizontal diameter of the rolling bearing, magnetic pole end faces are an arc surfaces, and the arc surfaces and the support rotation shaft are concentric. The magnetic conducting ring sleeves the T-shaped support ring, and air gaps are arranged between the magnetic conducting ring and the magnetic pole end faces of the electromagnetic iron core. When the load loading device for a rolling bearing tribological test is used to carry out a rolling bearing friction test, the test precision is high.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

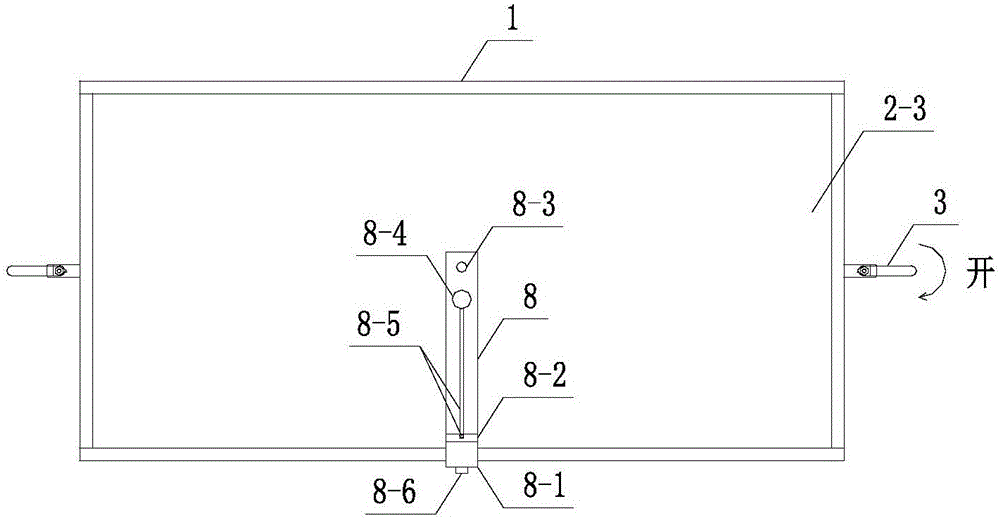

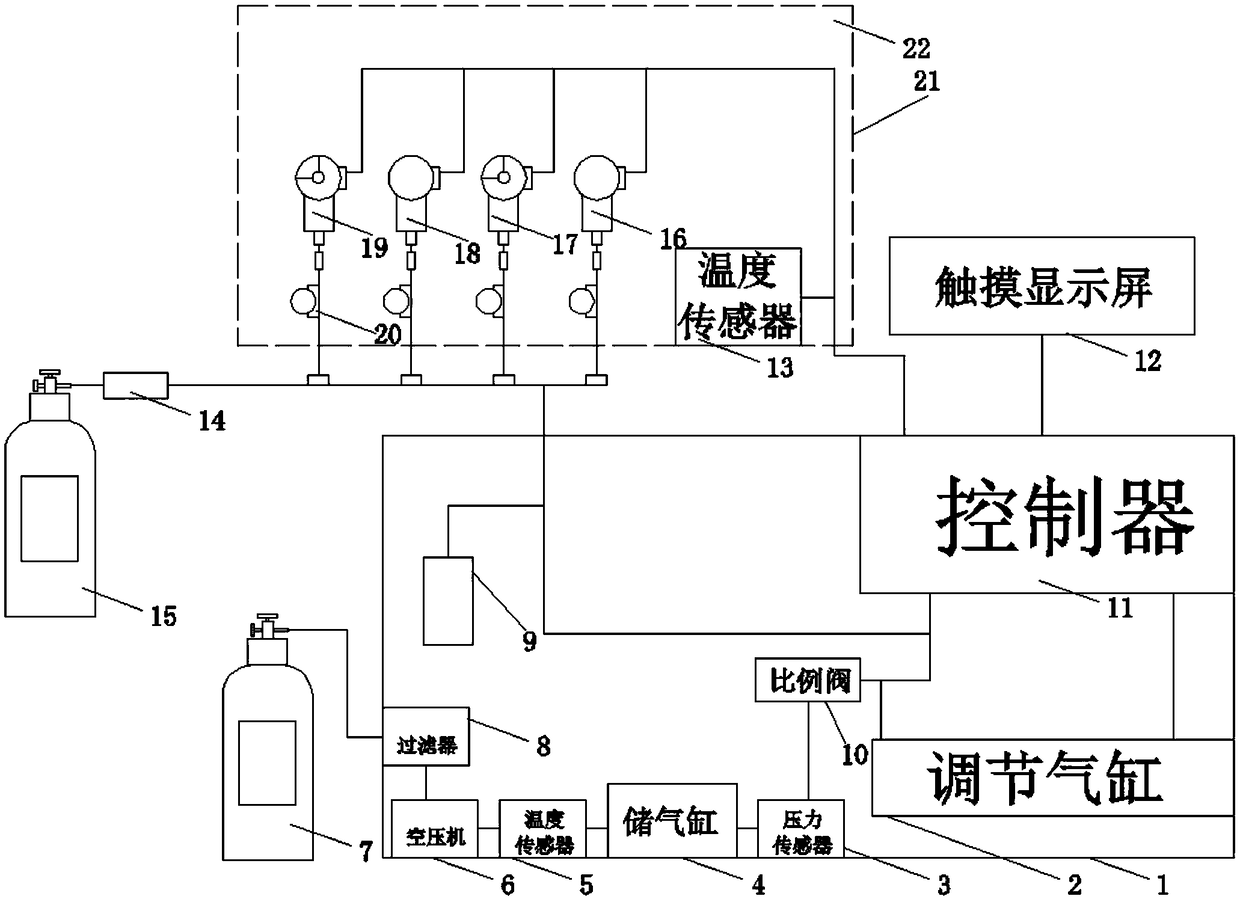

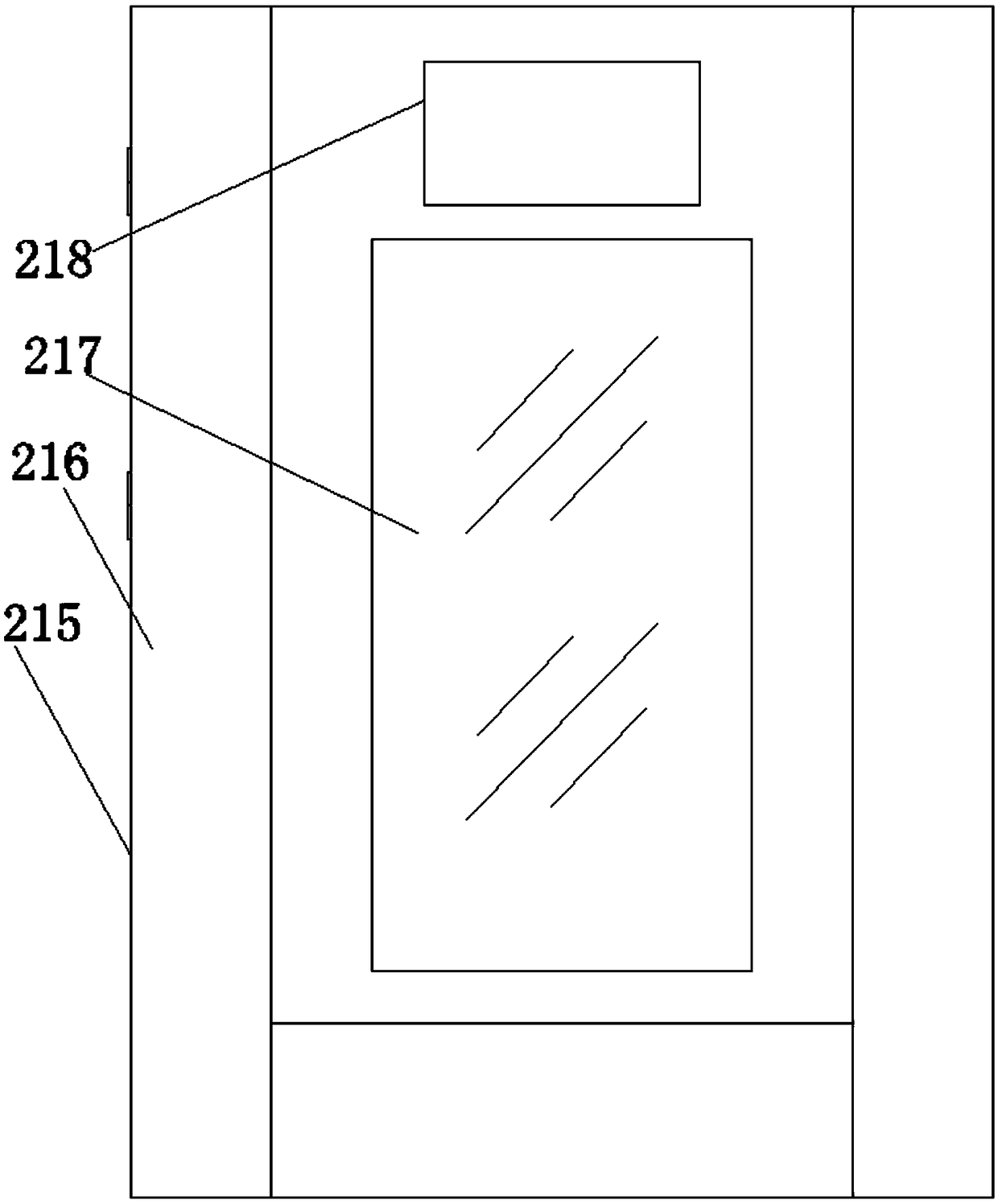

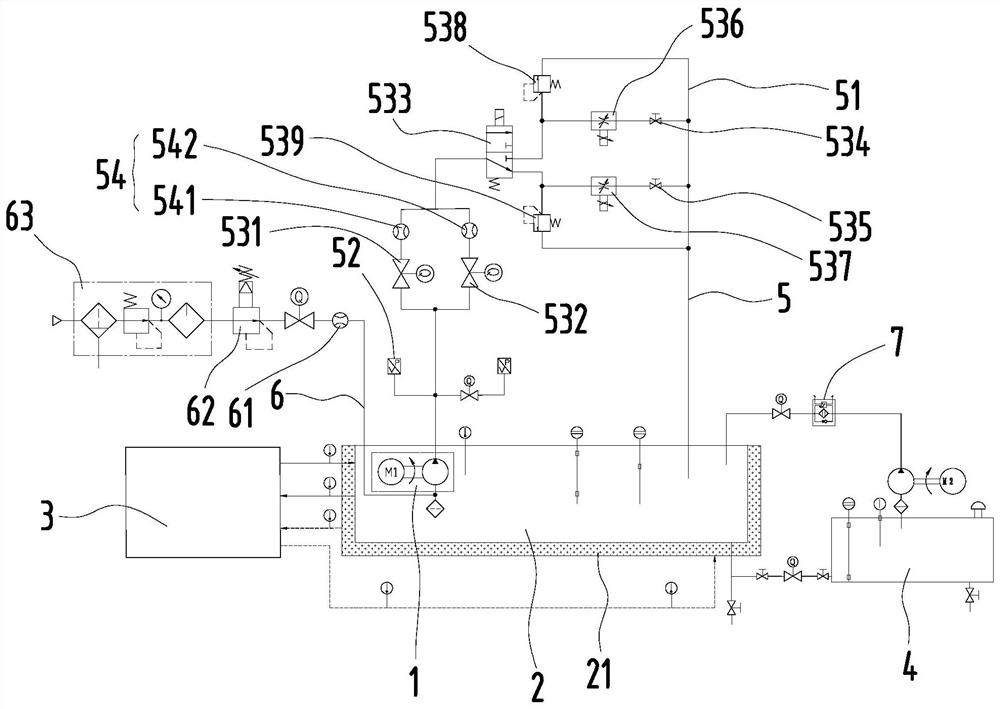

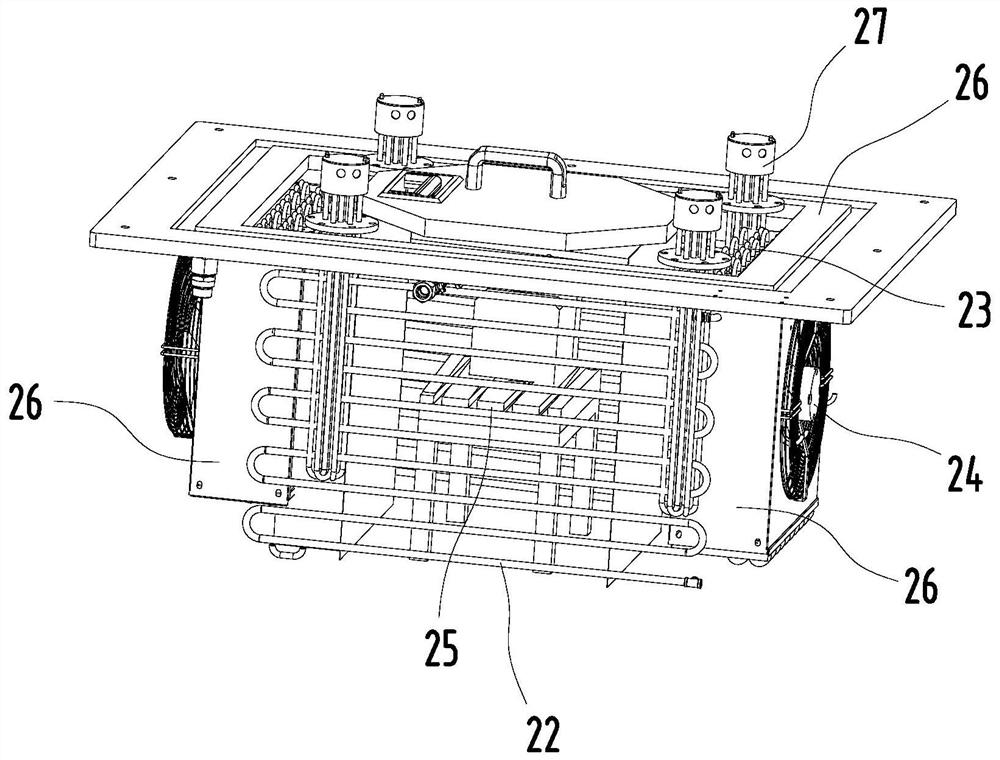

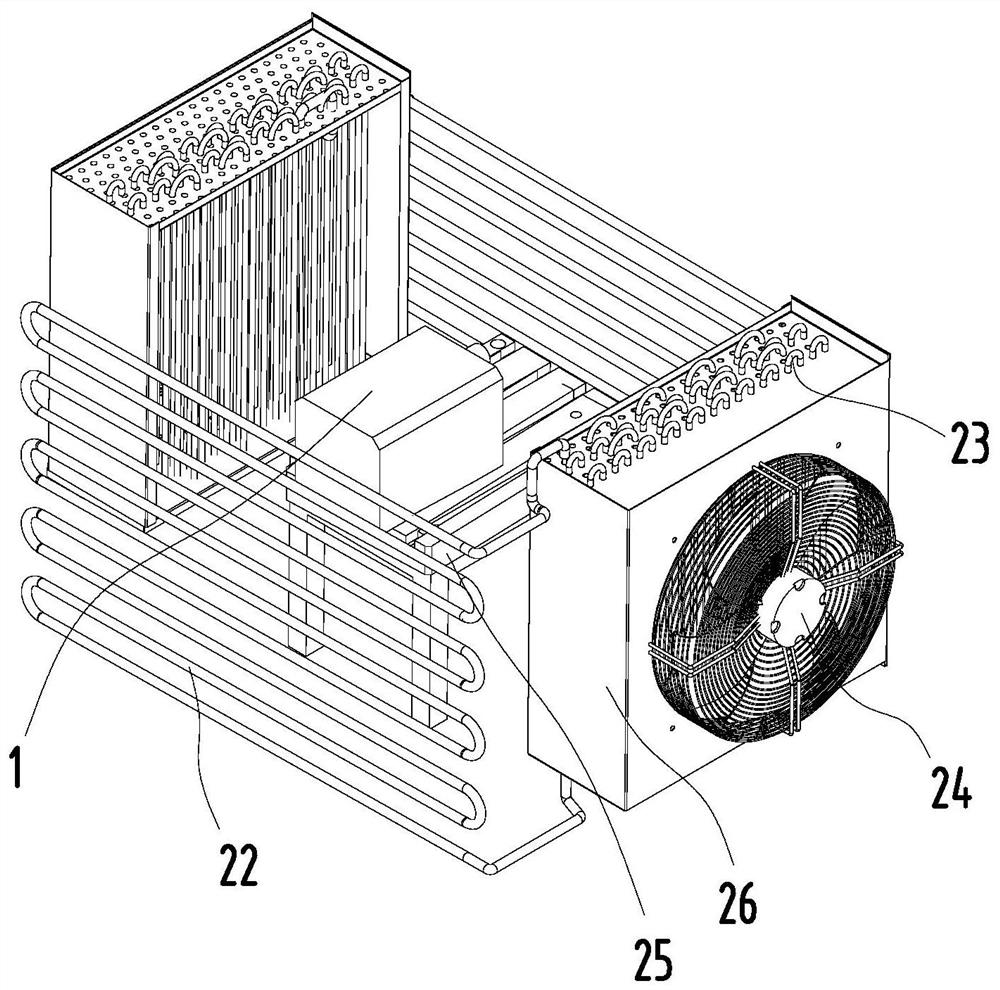

Detection system of sulfur hexafluoride density relay

InactiveCN108872847AAvoid affecting test accuracyIncrease the number of testsMachine part testingCircuit interrupters testingEngineeringTest chamber

The invention discloses a detection system of a sulfur hexafluoride density relay. The detection system having the precise calibration function is capable of calibrating temperature compensation values of multiple groups of density relays once and is capable of recycling sulfur hexafluoride gas. The detection system is composed of a calibration assembly and a high-and-low-temperature test box. Thehigh-and-low-temperature test box consists of a box body, a refrigeration system, a refrigeration system box, a compressor, a control module and an electrical cabinet; the electrical cabinet is arranged at one side of the box body; a control module and a memory are arranged in the electrical cabinet; and a compressor and a refrigeration system are arranged in the refrigeration system box. The boxbody is divided into a test chamber, a return air passage and a refrigeration system box by a lower chamber bottom plate and a test chamber sidewall; a condenser, a heater and a centrifugal fan are arranged in the return air passage; and an air outlet and a return air outlet are formed in the test chamber sidewall. A test frame for supporting density relays and a standard pressure gauge are arranged at a test rack. The calibration assembly includes a controller.

Owner:国网新疆电力有限公司和田供电公司 +1

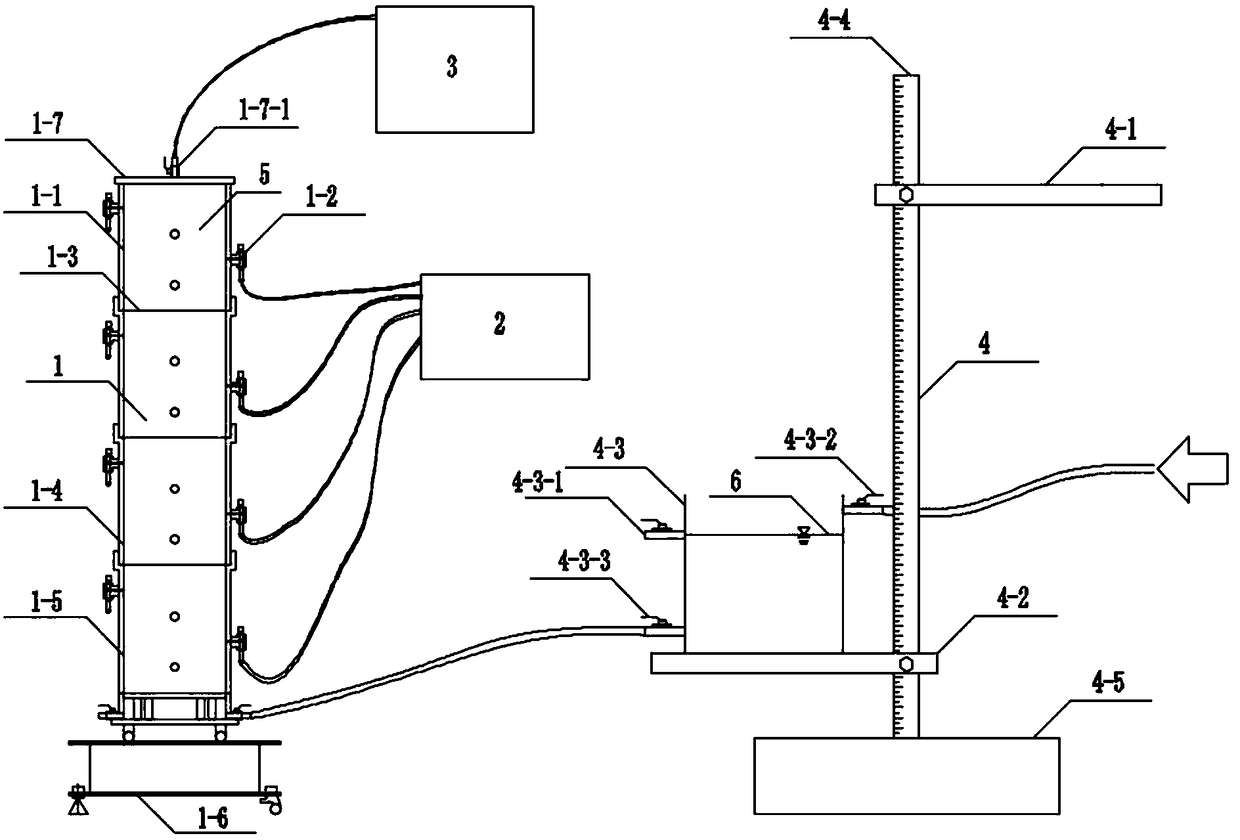

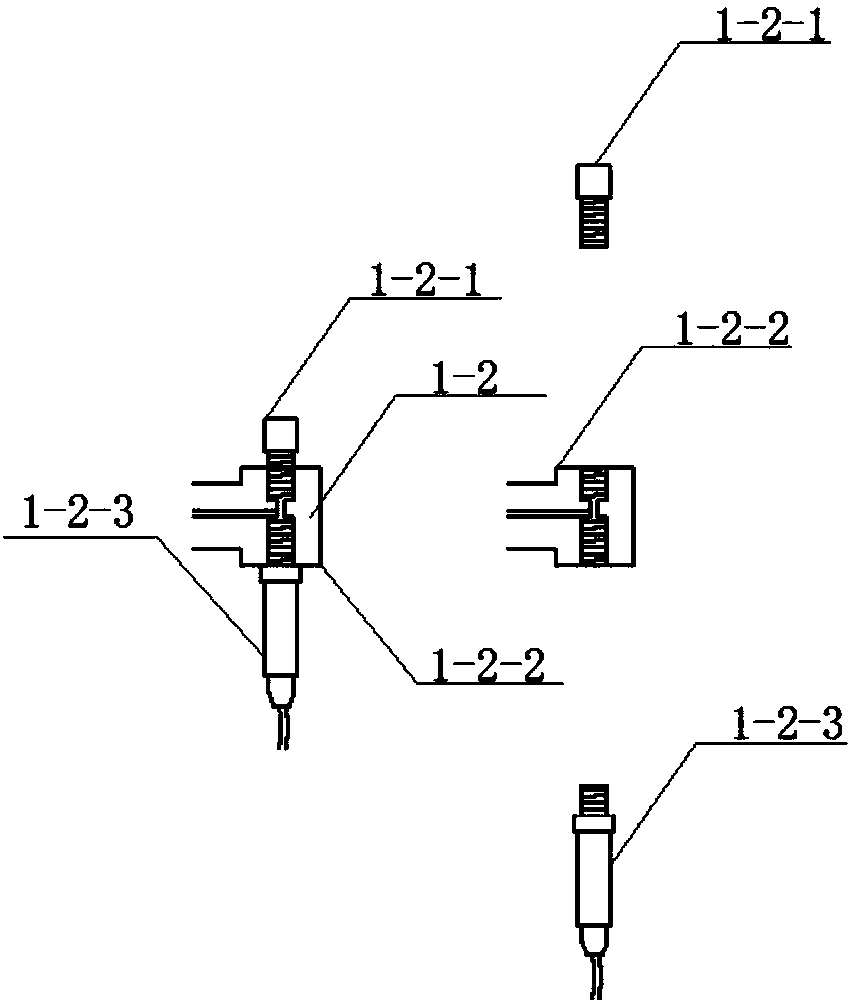

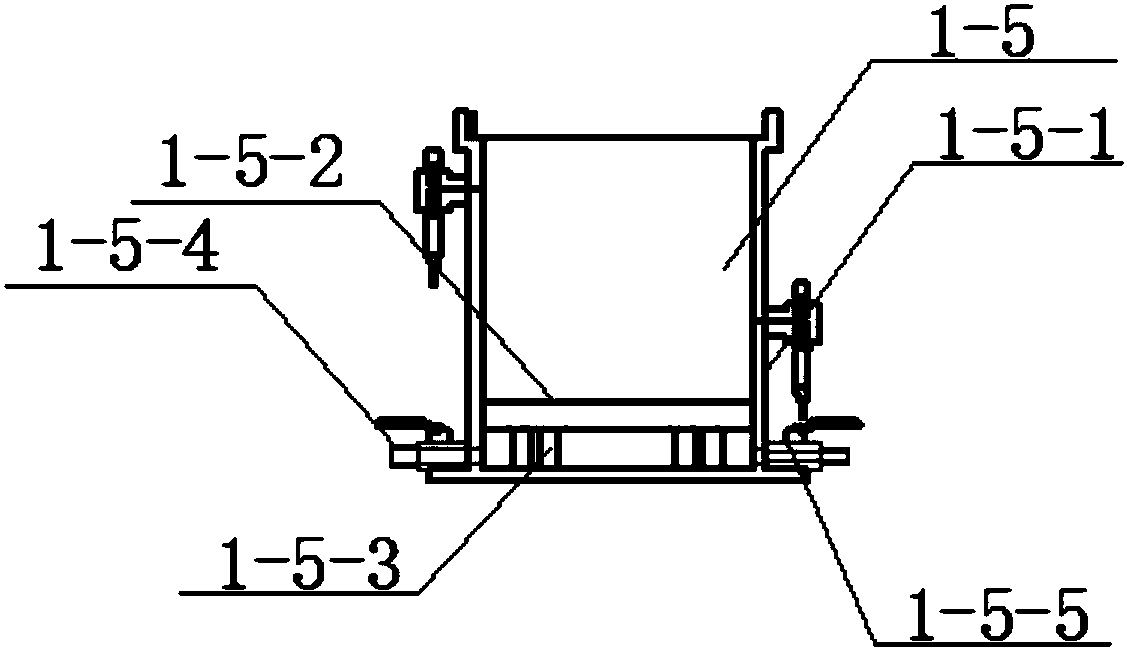

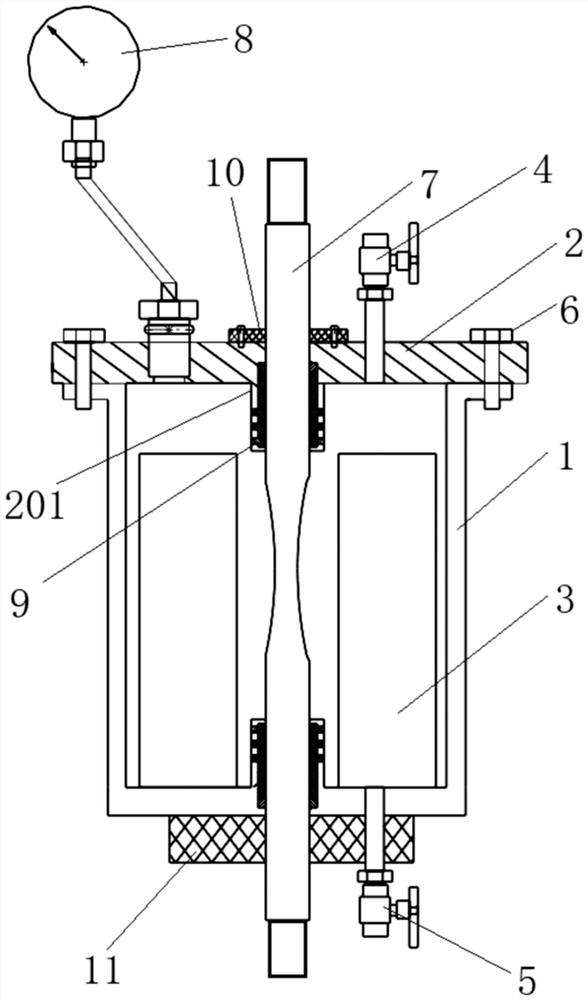

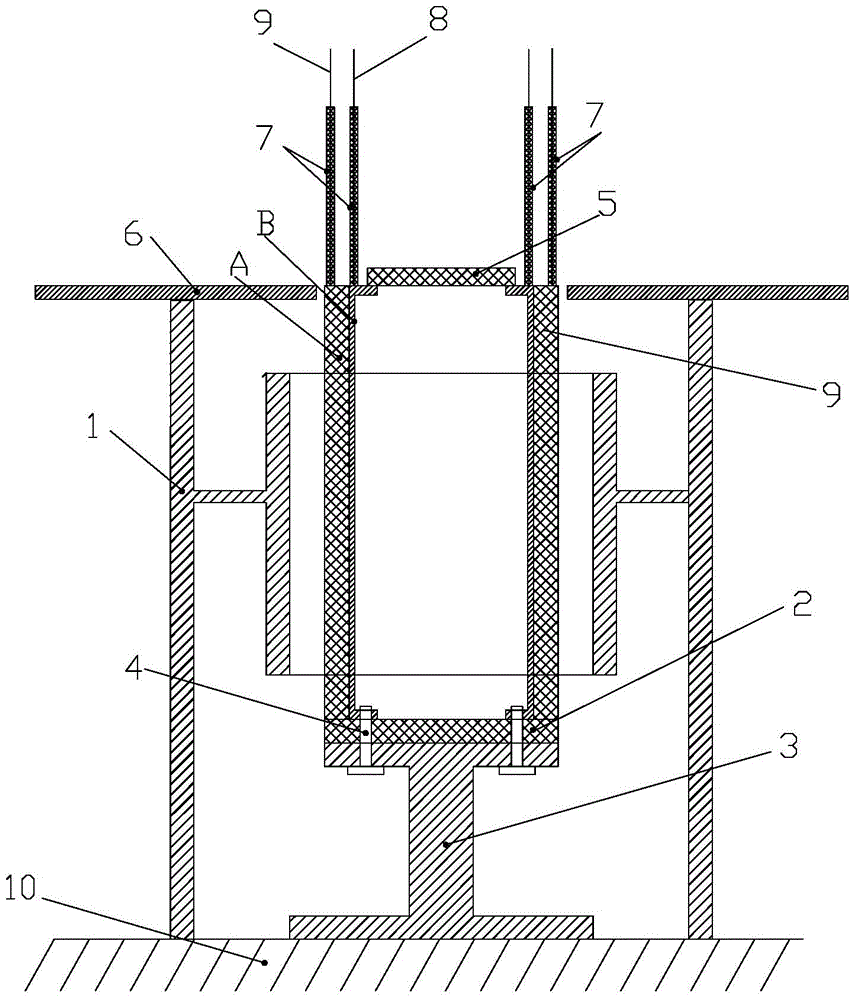

Test device and test method for simulating rectangular water head boundary to act on soil

PendingCN108387710AAvoid forceMutations to Avoid DeformationEarth material testingControl systemConfined water

The invention discloses a test device and a test method for simulating a rectangular water head boundary to act on soil. The device comprises a main body cylinder, a data acquirer, a vacuum pump and arectangular water head control system; the main body cylinder comprises a cover plate, a top cylinder segment, a plurality of middle cylinder segments, a bottom cylinder segment and a dolly; and porewater pressure fixers are mounted on the main body cylinder at different heights. The device and the method can be used to simulate the rectangular dynamic continuous change process of confined waterin a foundation, measure and calculate the water and soil pressure and deformation under the action of the rectangular dynamic confined water, dispose relevant test data and determine the bearing, the deformation development rule and other problems of the foundation; and the device and the method can be used to study the influences of the mean value and the amplitude of the change of the rectangular dynamic confined water, provide an effective test data support for studying the foundation problems caused by the rectangular dynamic confined water, and provides a basis for a theoretic analysismodel.

Owner:ZHEJIANG UNIV

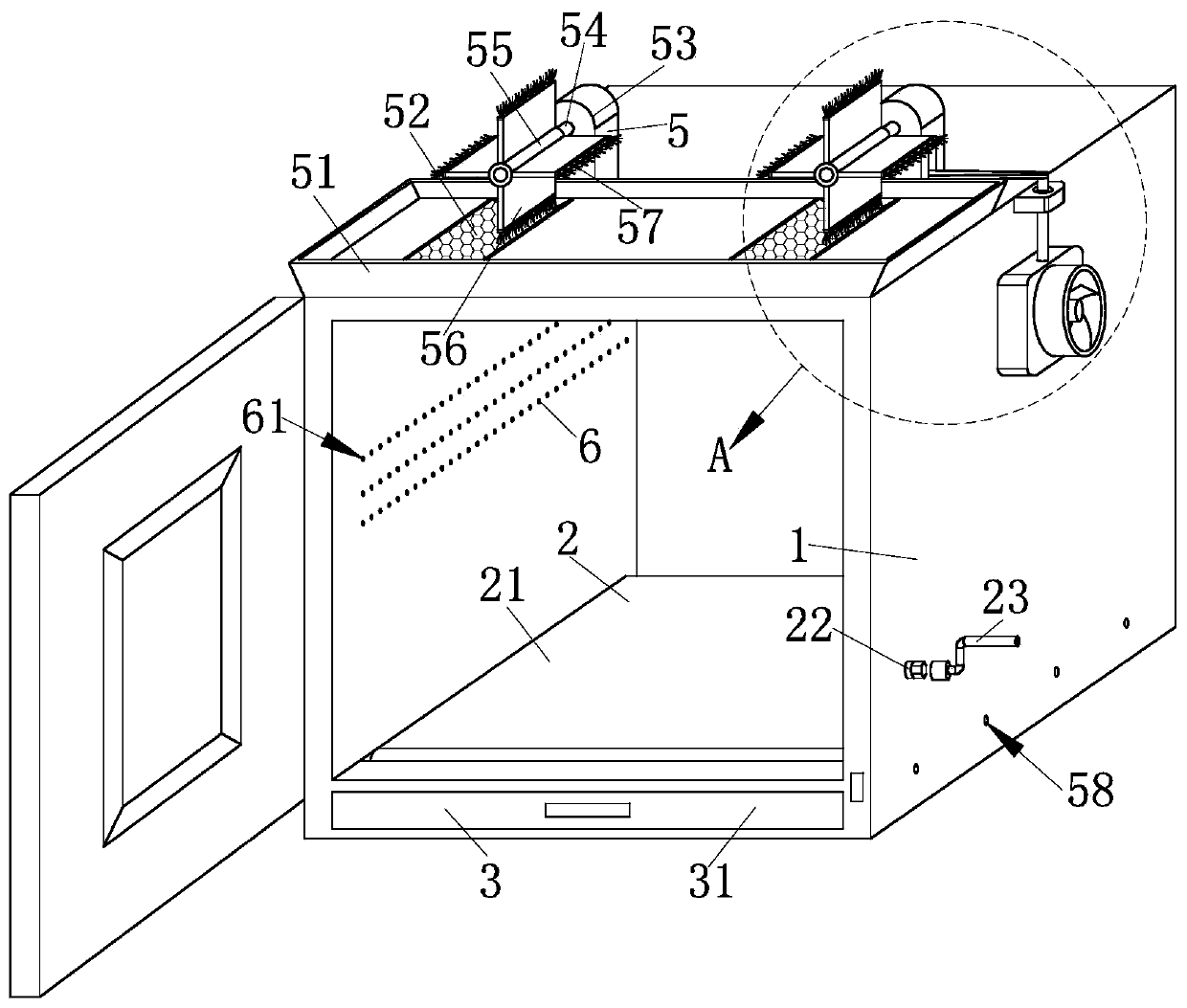

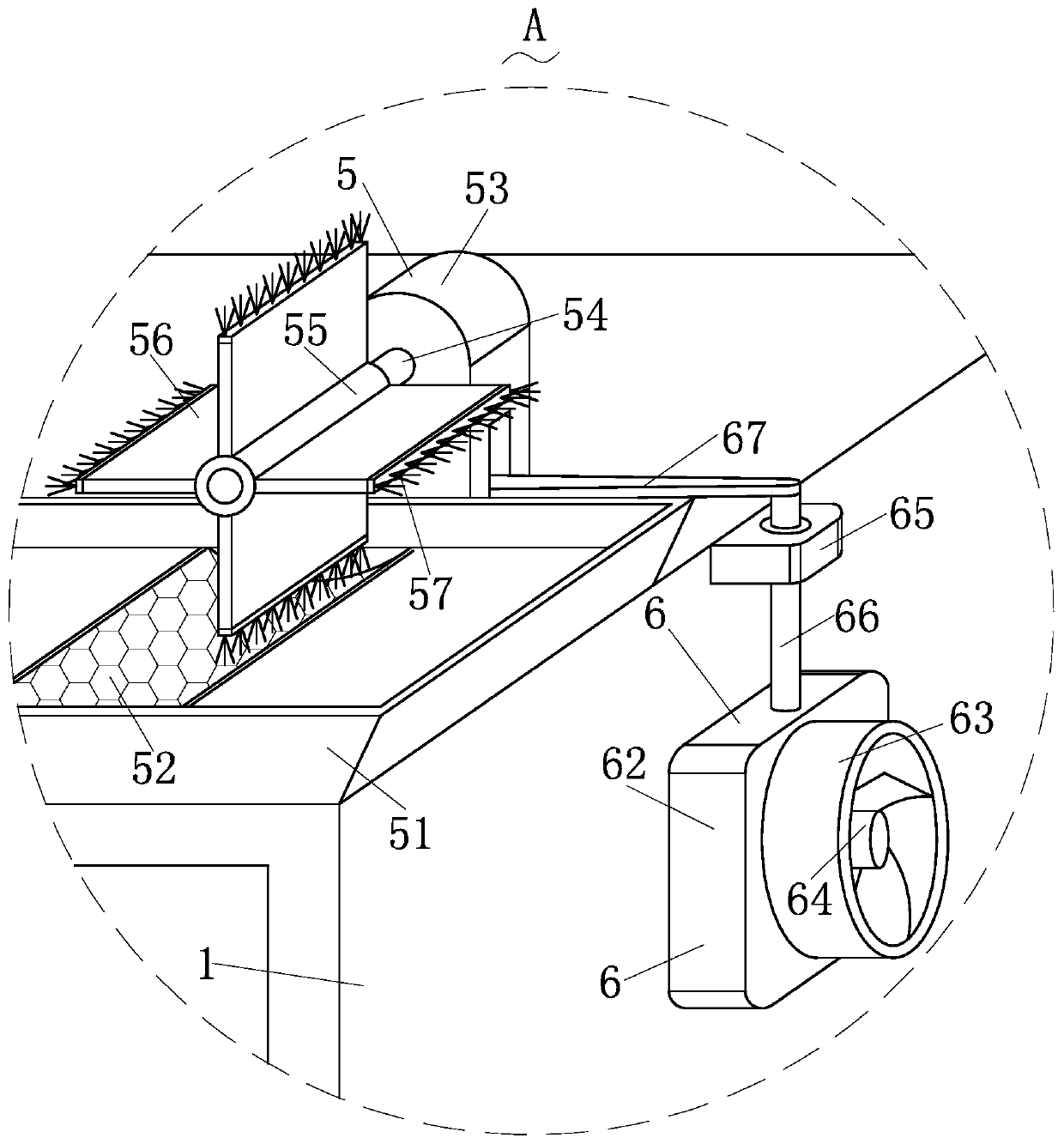

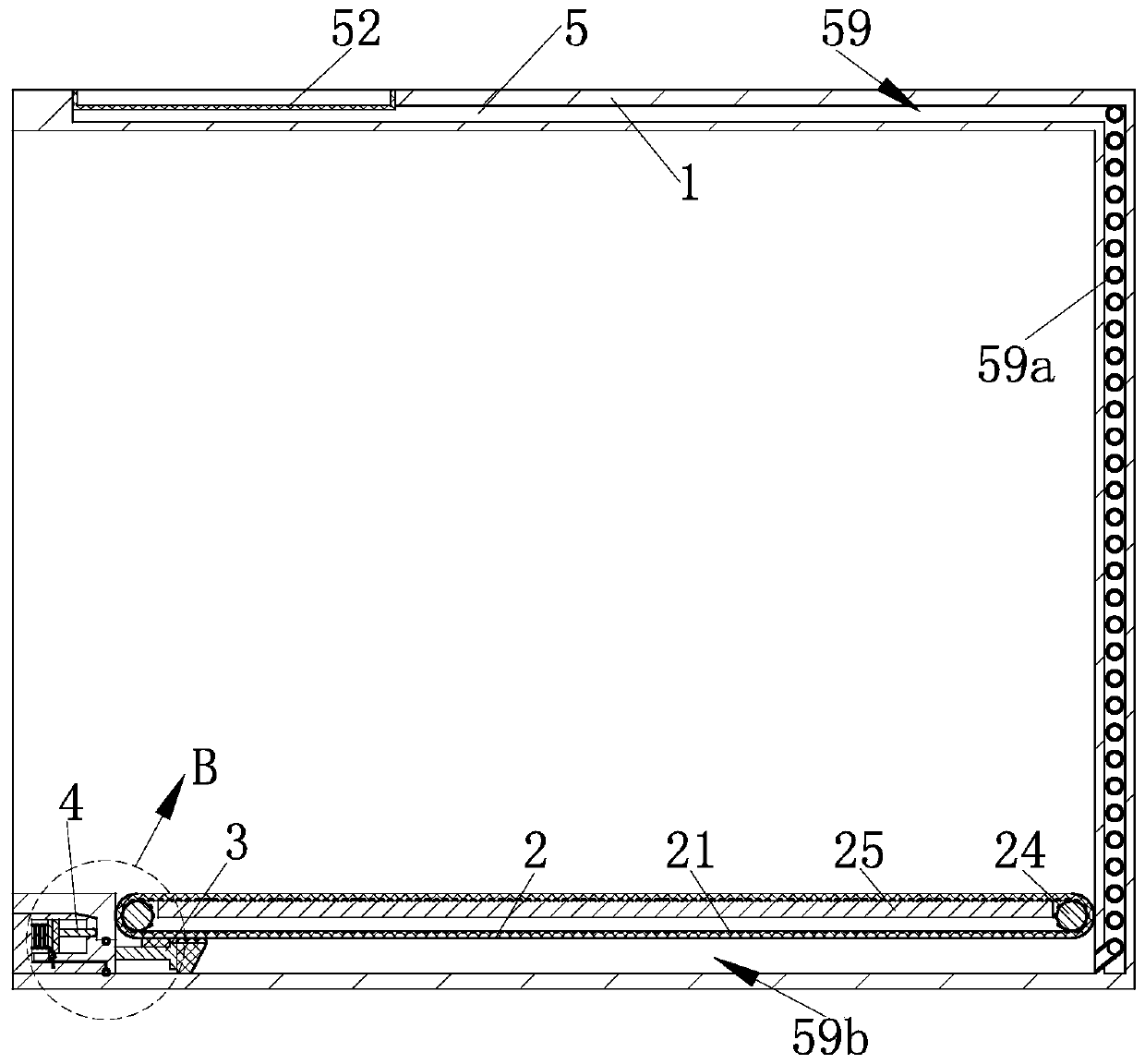

5G test shielding box

InactiveCN111257657AClean and comprehensivePlay a supporting roleElectromagentic field characteristicsStructural waterWater flow

The invention relates to the field of 5G test shielding devices, in particular to a 5G test shielding box which comprises a box body, a rotating structure, a cleaning structure, a sealing structure, awater cooling structure and an anti-blocking structure. By arranging the rotating structure, the ground in the box body can be moved, a cleaning structure is arranged, the ground in the box body canbe comprehensively cleaned, and therefore, dust on the ground in the box body is prevented from influencing the test precision, the cleaning structure can also act on the sealing structure while performing installation work, by adopting seal arrangement, a gap between the cleaning structure and the bottom end of the box body can be filled to increase the sealing effect, the situation that water atthe bottom end of the box body flows out is avoided, normal work of the cleaning structure is guaranteed, it can be kept that water exists at the bottom end of the box body all the time to cool the interior of the box body, and rainwater can be collected and cool the interior of the box body by installing the water cooling structure at the top end of the box body.

Owner:浙江新铭智能科技有限公司

Anode-cathode connector and connector device for battery or capacitor

InactiveCN103969473AAvoid damageGuarantee product qualityMeasurement instrument housingTest batteryElectrical battery

The invention belongs to the technical field of electronic component test, and particularly relates to an anode-cathode connector and a connector device for a battery or a capacitor. The connector comprises a metal portion for on detection of an anode and a cathode of the battery or the capacitor, the metal portion is provided with a heat sensor used for detecting heating temperature of the connector, and the heat sensor is embedded, integrated or attached onto the connector. The connector device comprises a fixed frame and a moving frame spaced from the fixed frame, and the battery or capacitor anode-cathode connectors matched mutually are disposed on the fixed frame and the moving frame respectively. By the aid of the heat sensor arranged on the connector, when the battery or the capacitor is tested by test equipment, heat value on the connector can be monitored constantly, and accordingly the connector can be avoided from transferring heat to the battery or the capacitor to affect test precision; moreover, the battery or the capacitor can be protected from damage due to overheating, and product quality of the battery or the capacitor is guaranteed.

Owner:REPOWER TECH CO LTD

Lamp radiation intensity testing equipment

The invention discloses lamp radiation intensity test equipment, which comprises a fixed base, the upper end of the fixed base is fixedly connected with two symmetrically arranged telescopic rods, the telescopic ends of the two telescopic rods are jointly and fixedly connected with a movable plate, the upper end of the movable plate is provided with a protective cover, and the protective cover is internally provided with a test device. A cavity is formed in the protective cover, and a fixing plate is arranged above the fixing base. The device is reasonable in structure, light of the lamp is absorbed by arranging the liquid pumping mechanism, light dazzling is avoided, the situation that a worker observes the state of the lamp is affected, when light is weak, a potassium permanganate solution cannot be pumped into the cavity, the protective cover has good light transmission, a detector clearly observes the internal detection condition, next operation is facilitated, and the working efficiency is improved. By arranging the telescopic rod, the content of carbon dioxide in the protective cover during detection is reduced, and the accuracy of detection data is improved.

Owner:敦吉电子(上海)有限公司

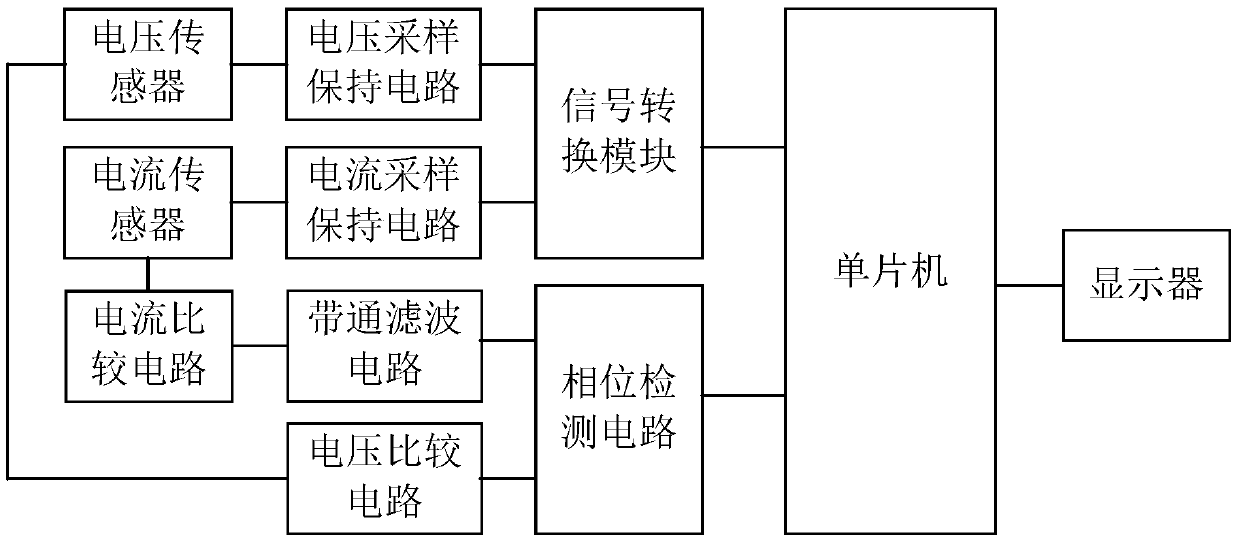

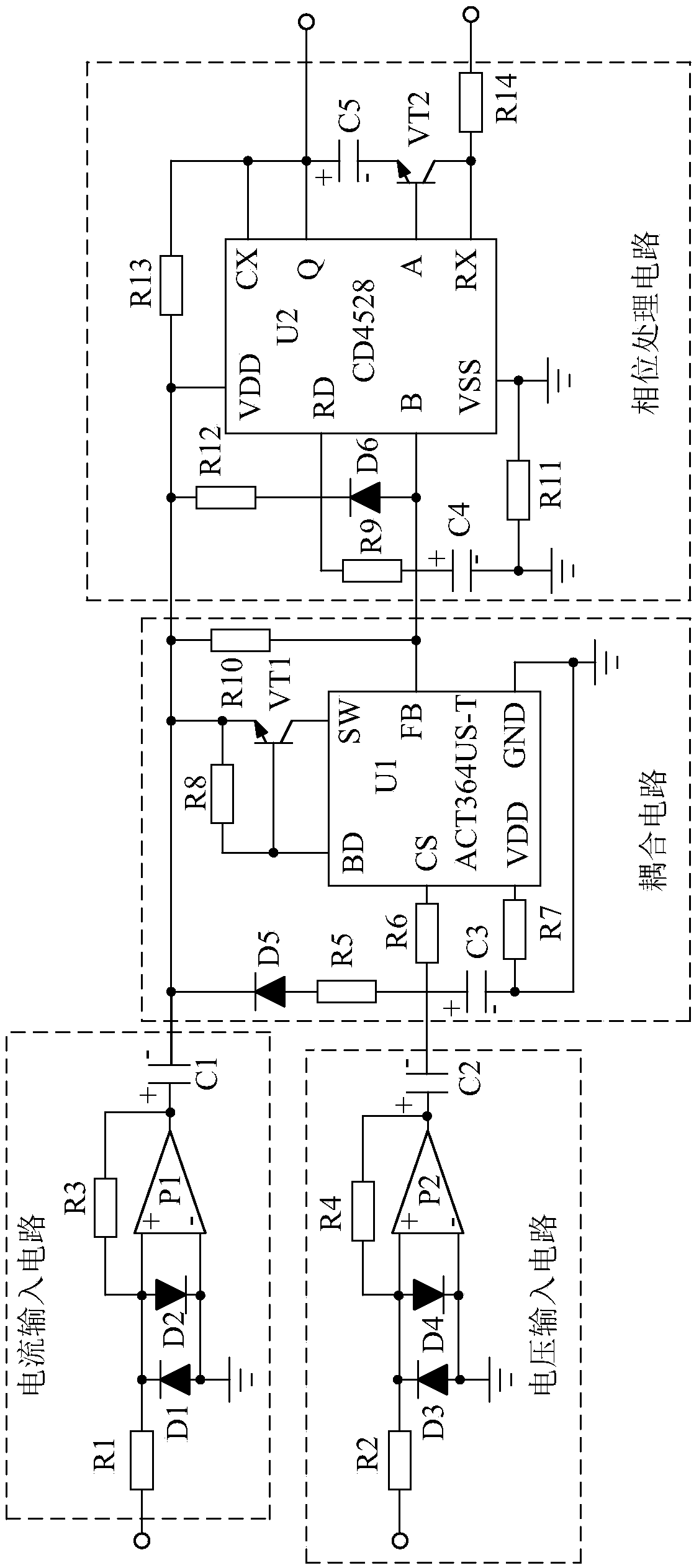

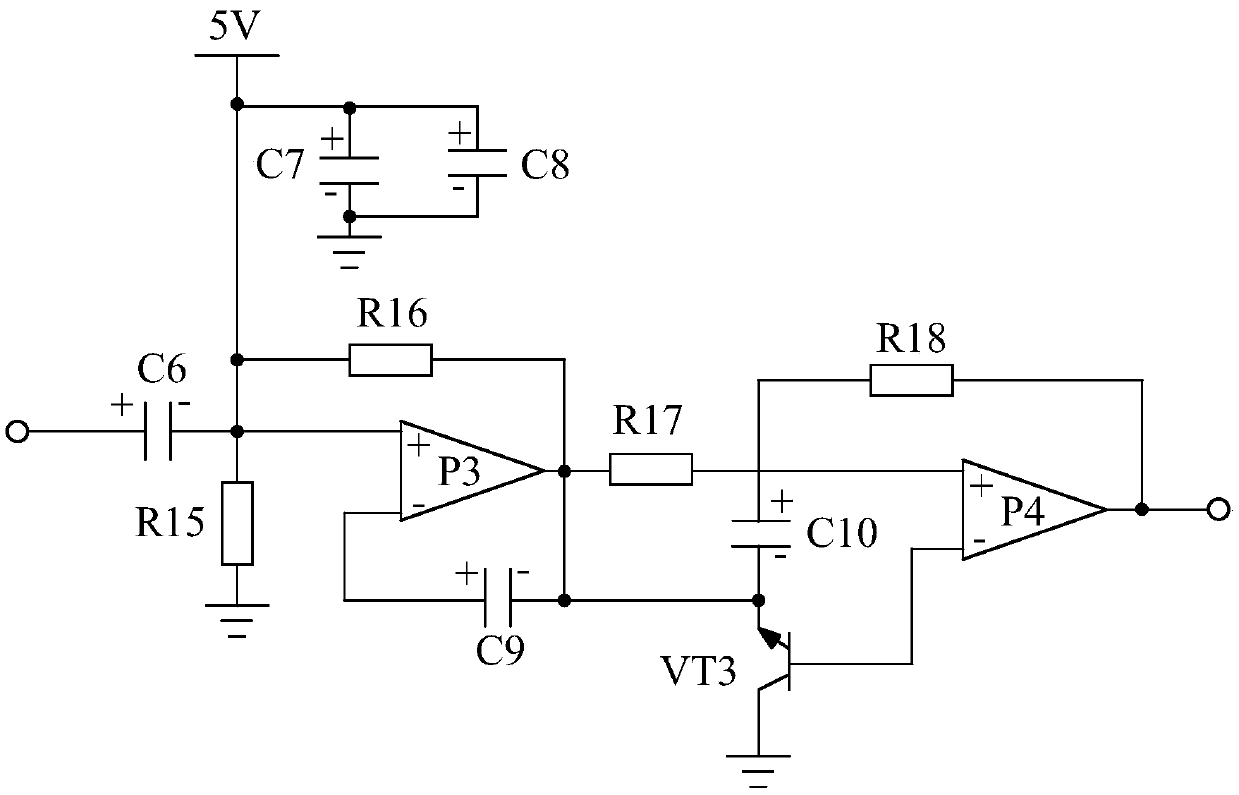

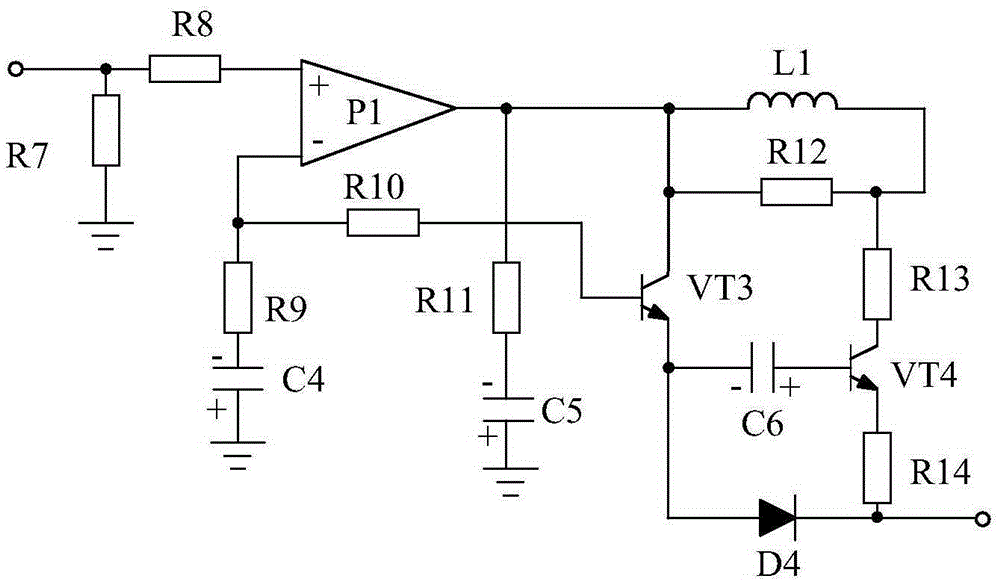

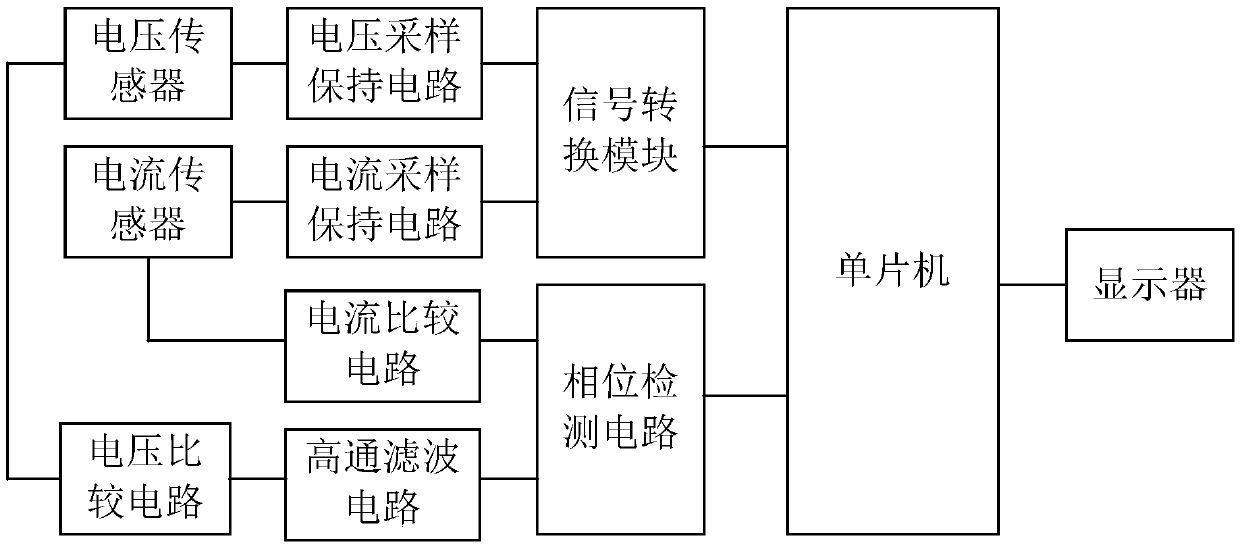

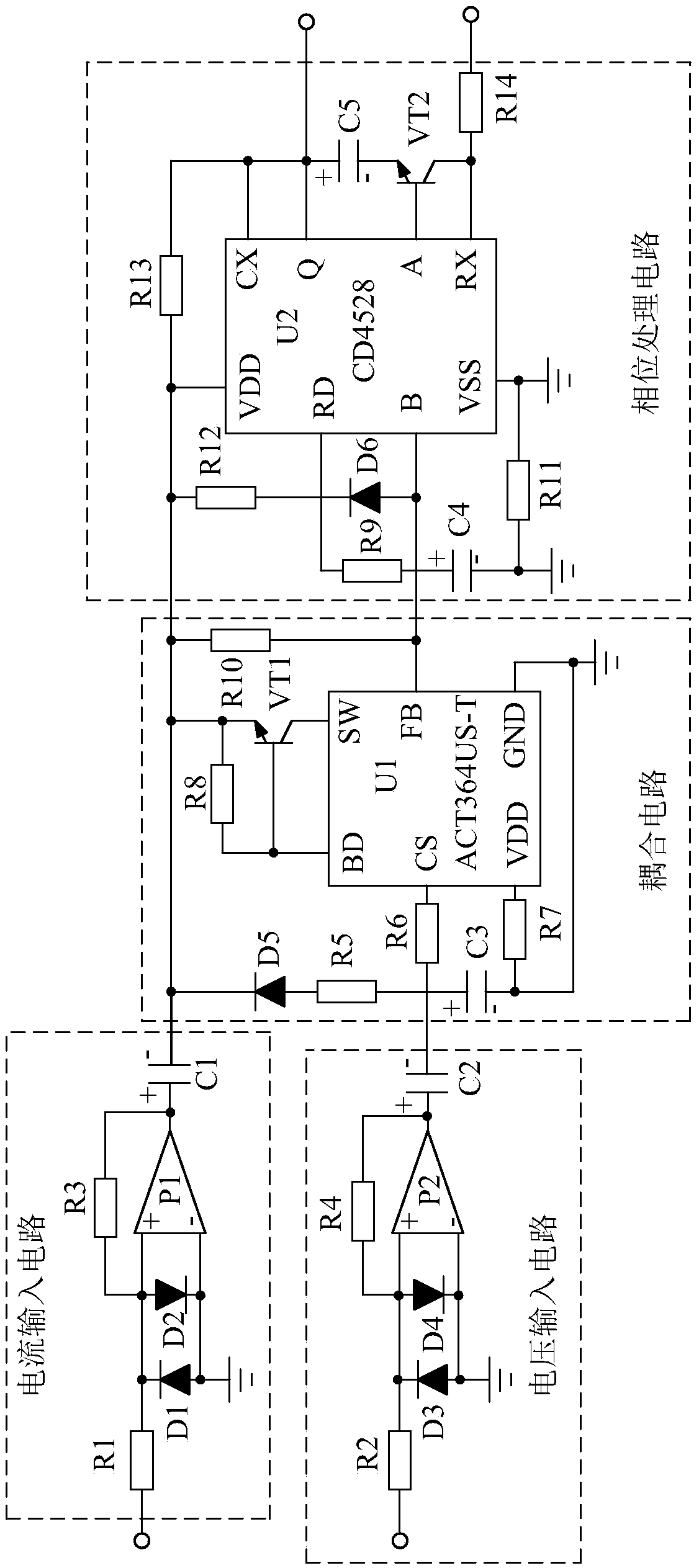

Bandpass filtering type multifunctional power tester based on voltage comparison circuit

InactiveCN105510701ALearn about the operationHigh precisionCurrent/voltage measurementElectrical measurement instrument detailsBandpass filteringCurrent transducer

The invention discloses a bandpass filtering type multifunctional power tester based on a voltage comparison circuit. The bandpass filtering type multifunctional power tester is mainly composed of a single-chip microcomputer, a voltage transducer and a current transducer. The power tester is further composed of a signal conversion module, a phase detection circuit and a display which are respectively connected with the single-chip microcomputer, a voltage sampling maintaining circuit and a current sampling maintaining circuit which are respectively connected with the signal conversion module, a current comparison circuit and the voltage comparison circuit which are respectively connected with the phase detection circuit, and a bandpass filtering circuit which is connected in series between the current comparison circuit and the phase detection circuit. The bandpass filtering type multifunctional power tester provided by the invention can simultaneously test voltages, currents and power parameter signals of equipment, and enables test personnel to more comprehensively understand the operation condition of the equipment. The voltage comparison circuit can convert voltage signals acquired by the voltage transducer into corresponding square wave signals, the conversion efficiency is high, and the test efficiency is improved accordingly.

Owner:CHENGDU HONGKAIRUI TECH CO LTD

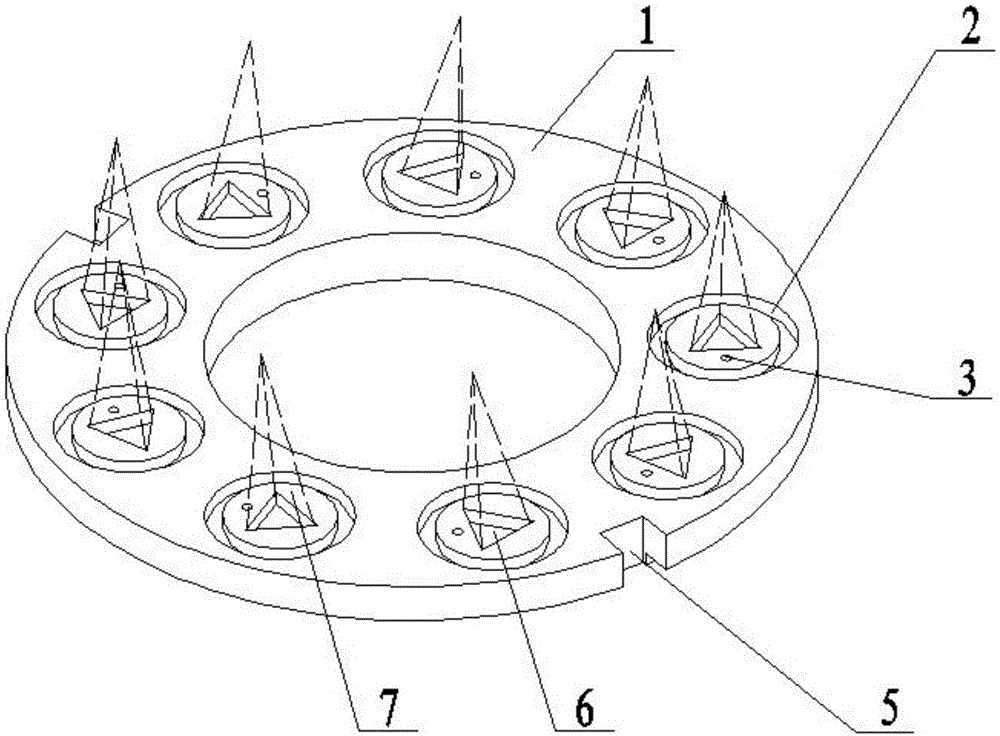

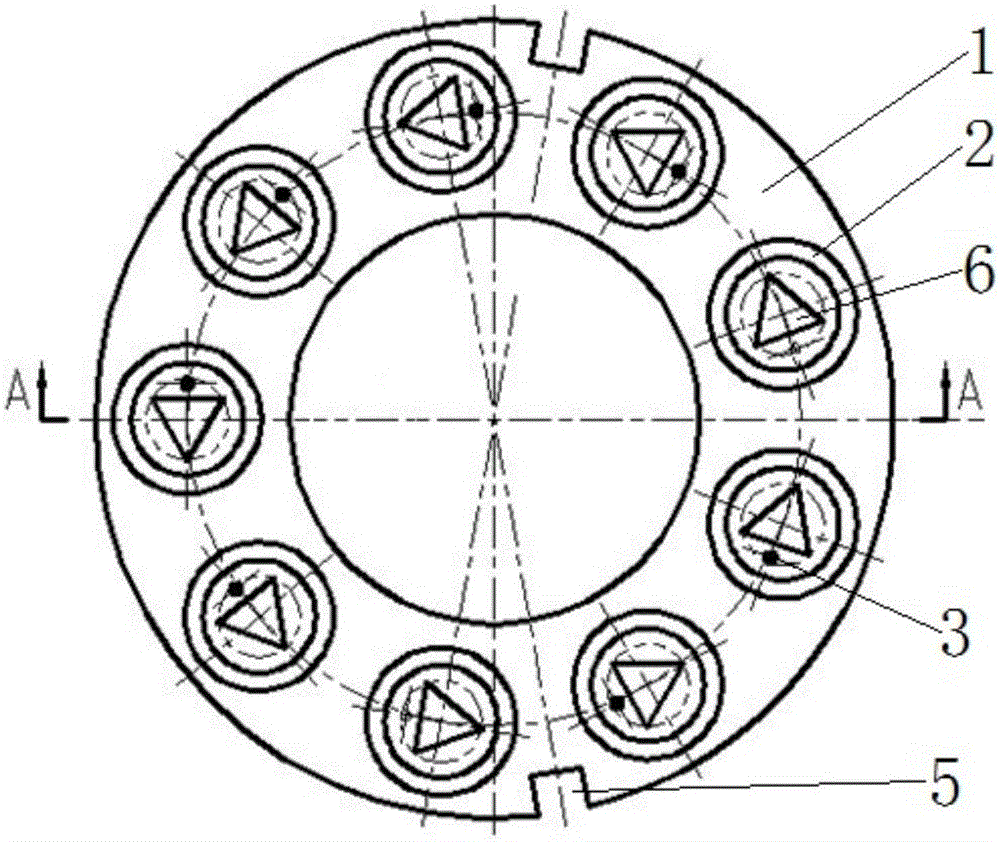

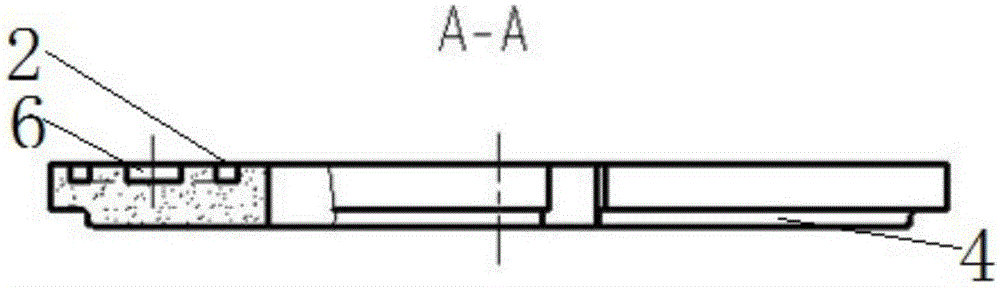

Ash fusibility tester and standard indicating supporting plate thereof

InactiveCN105092633AImprove accuracyEasy to calculateInvestigating phase/state changeVertical planeEngineering

The invention relates to the technical field of test equipment, in particular to an ash fusibility tester and a standard indicating supporting plate thereof. The standard indicating supporting plate comprises a supporting plate body and a plurality of ash taper holes formed in the front surface of the supporting plate body, wherein the supporting plate body is disc-shaped; the ash taper holes are blind holes in the shapes of regular triangles; the ash taper holes are distributed in the circumference of the supporting plate body in an array manner; at least one position indicating point is arranged on the outer side of one corresponding edge of each ash taper hole, and used for indicating the vertical plane position of one corresponding ash taper to be tested, so that images, of the ash tapers to be tested, shot by a camera device in the testing process can be in consistent with an image preset in a picture recognition system. The accuracy of ash fusibility testing results is improved.

Owner:CHANGSHA KAIYUAN INSTR

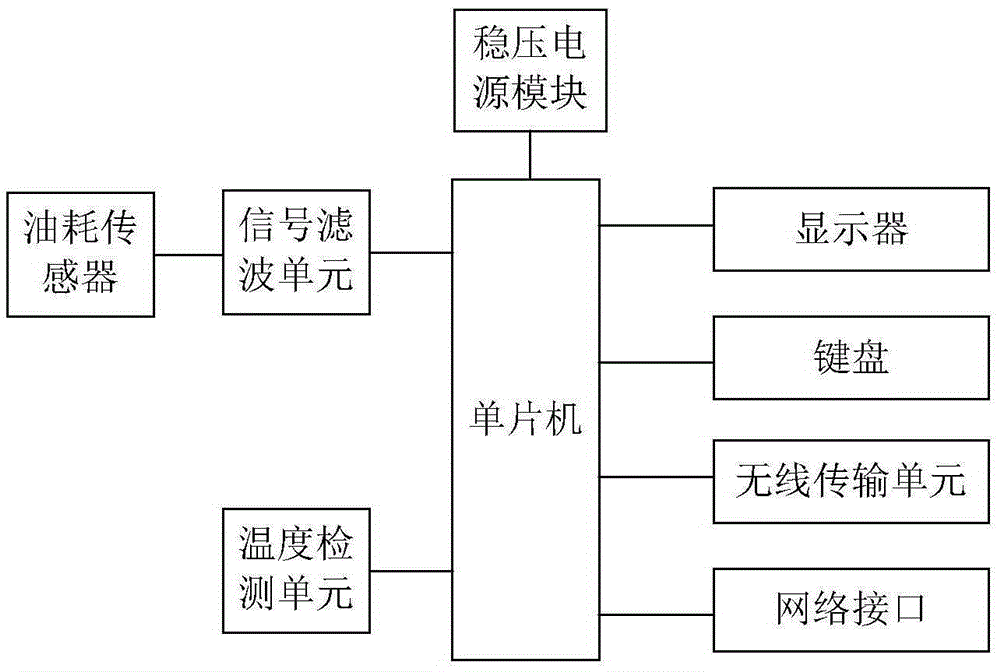

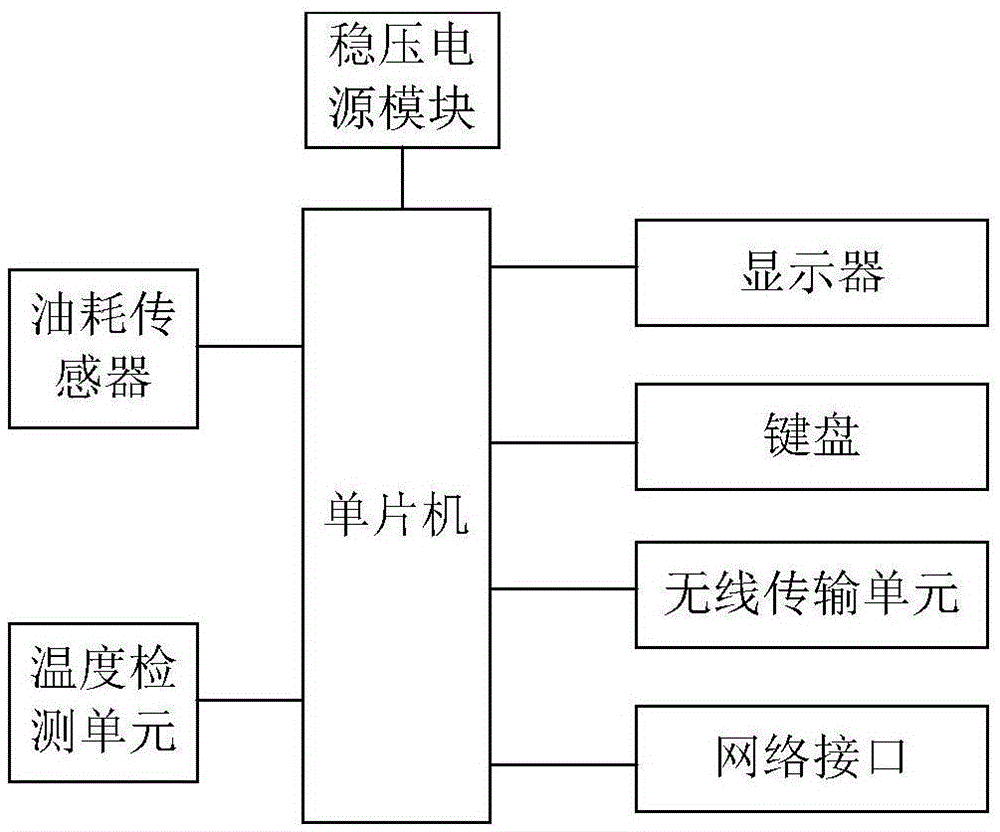

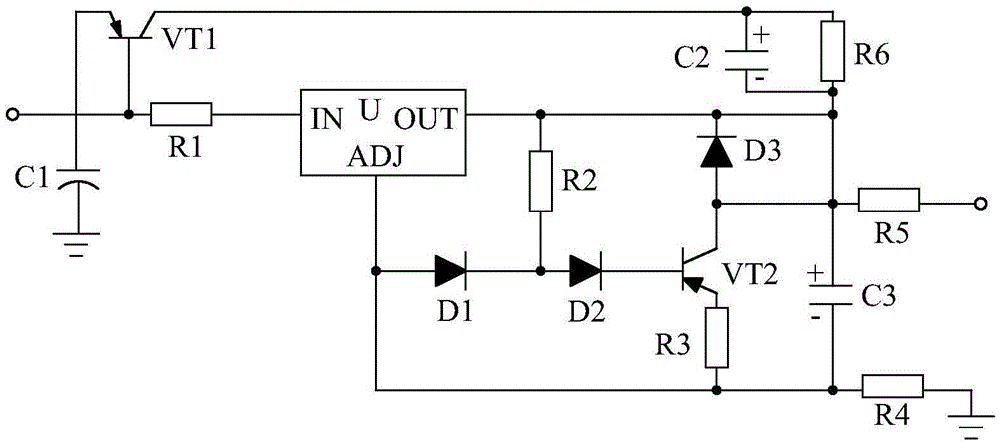

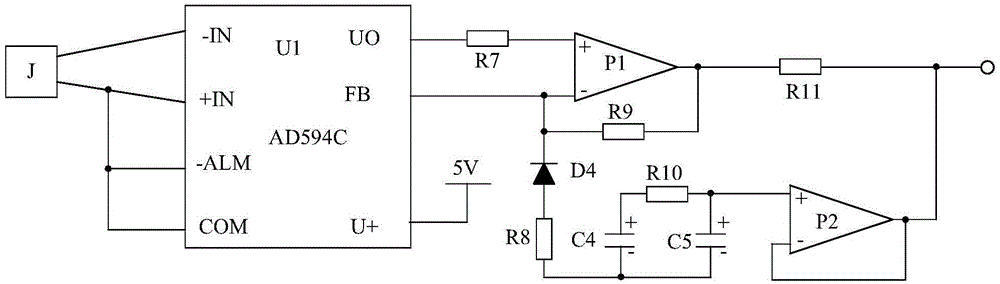

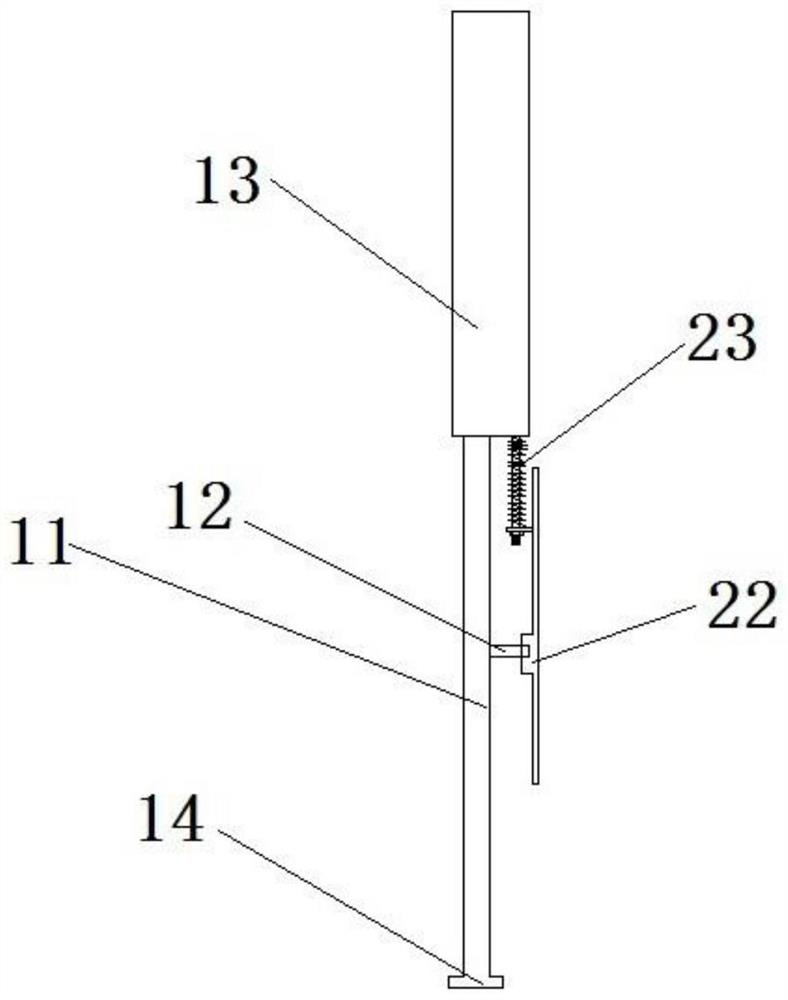

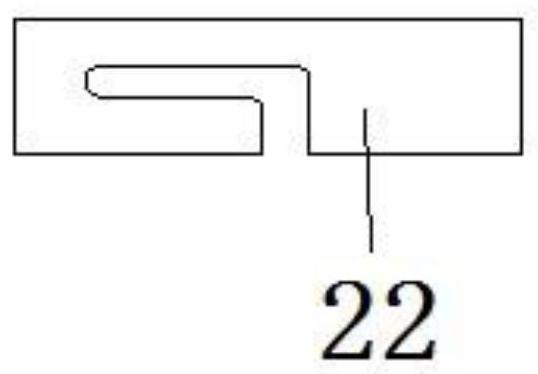

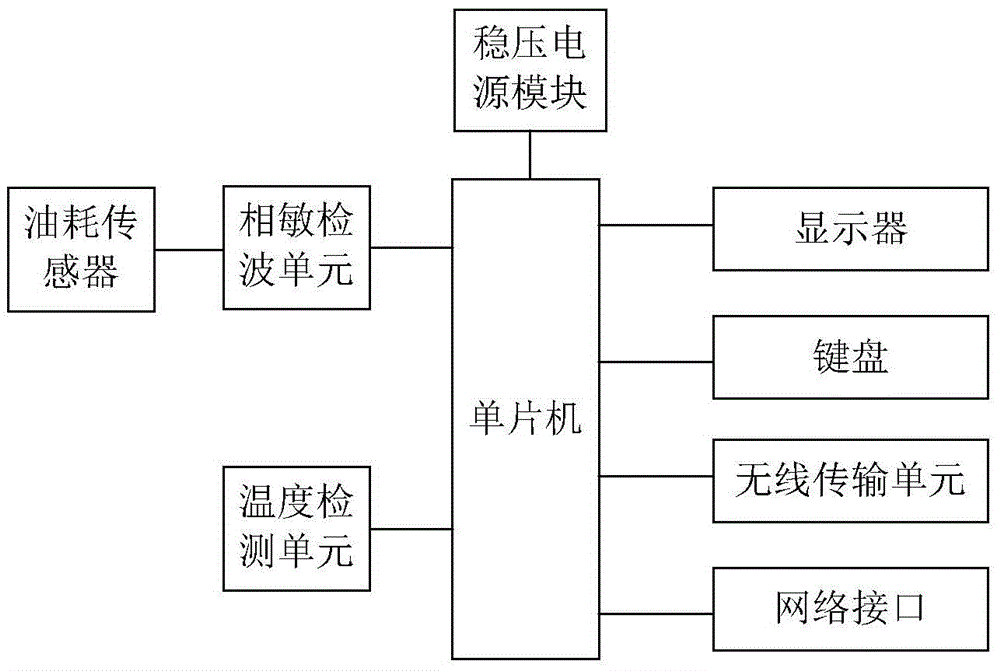

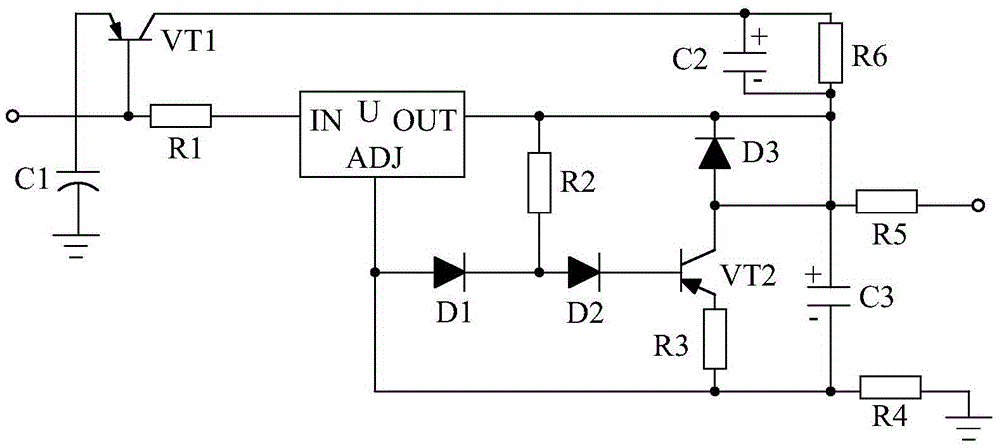

Simple oil consumption tester based on temperature detecting and signal filtering

InactiveCN105241517AAvoid complexityAvoid limitationsRelative volume flow measurementsMicrocontrollerMicrocomputer

The invention discloses a simple oil consumption tester based on temperature detecting and signal filtering. The simple oil consumption tester is characterized by being composed of a single-chip microcomputer, a voltage-stabilized power supply module, a display, a key board, a wireless transmission unit, a signal filtering unit, a network interface, a temperature detecting unit and an oil consumption sensor connected with signal filtering unit, wherein the voltage-stabilized power supply module, the display, the key board, the wireless transmission unit, the signal filtering unit, the network interface and the temperature detecting unit are connected with the single-chip microcomputer. According to the simple oil consumption tester, external interference signals can be removed through the signal filtering unit, and therefore the influence brought by the interference signals on the detecting precision of the tester are avoided; the machine oil temperature can be detected, and therefore the oil consumption tester can be prevented from being damaged due to the fact that the machine oil temperature is too high.

Owner:CHENGDU KERUIXIN TECH CO LTD

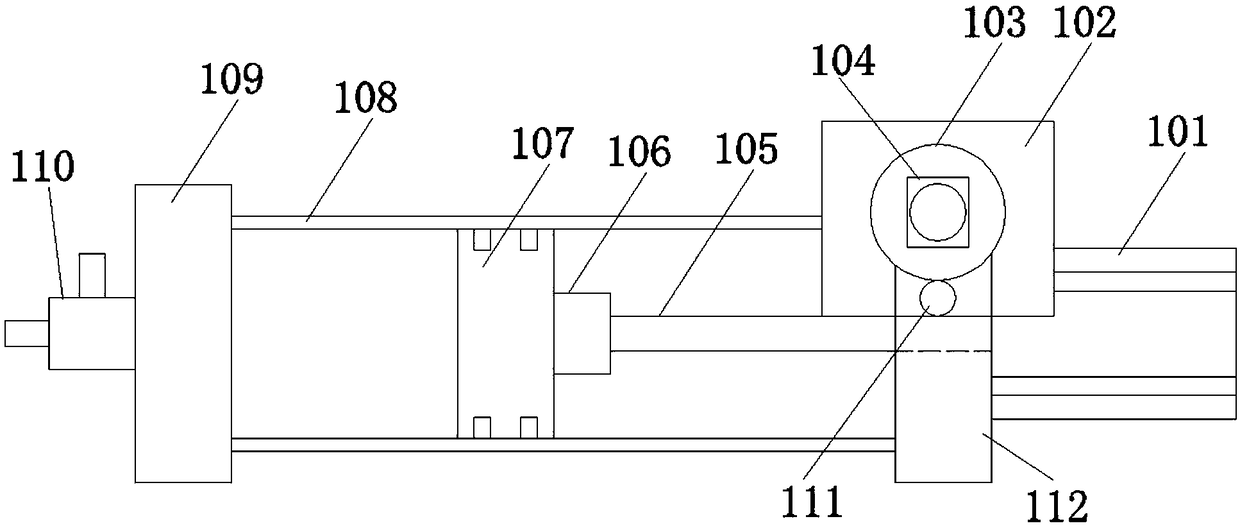

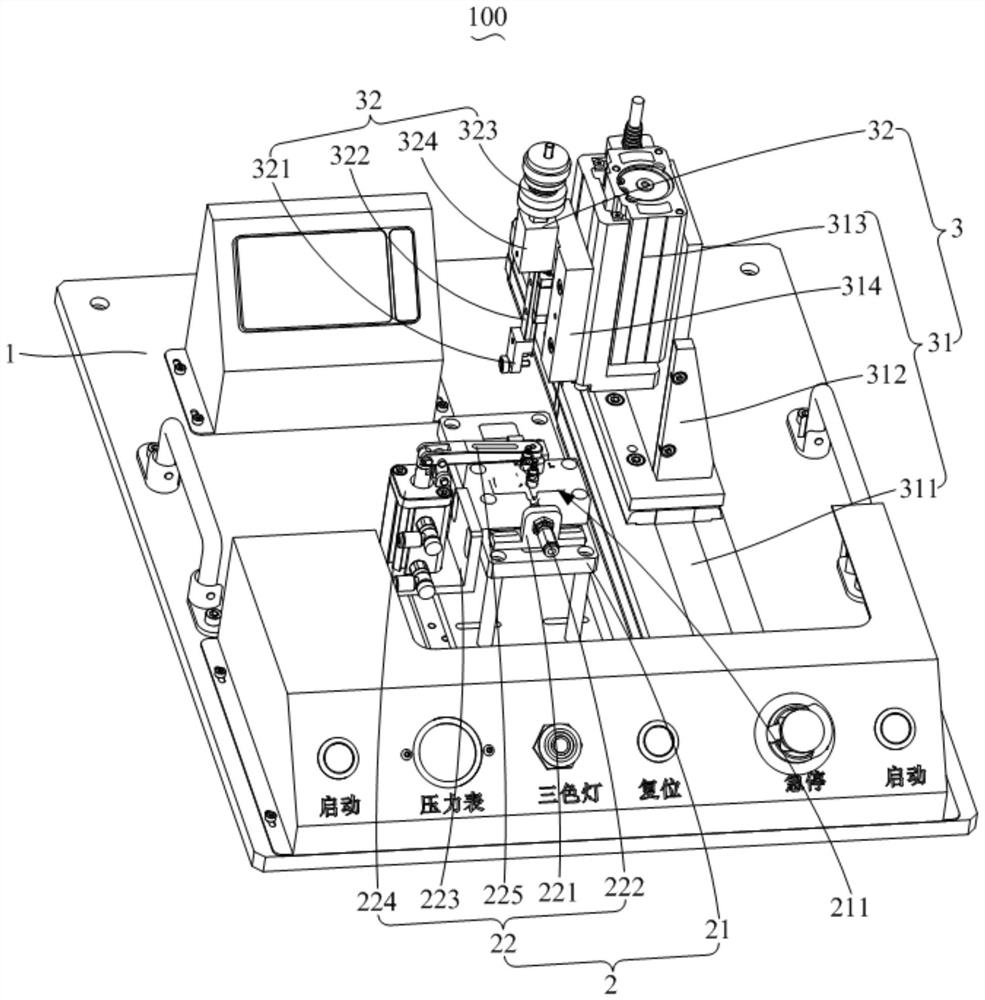

Test tool and detection equipment

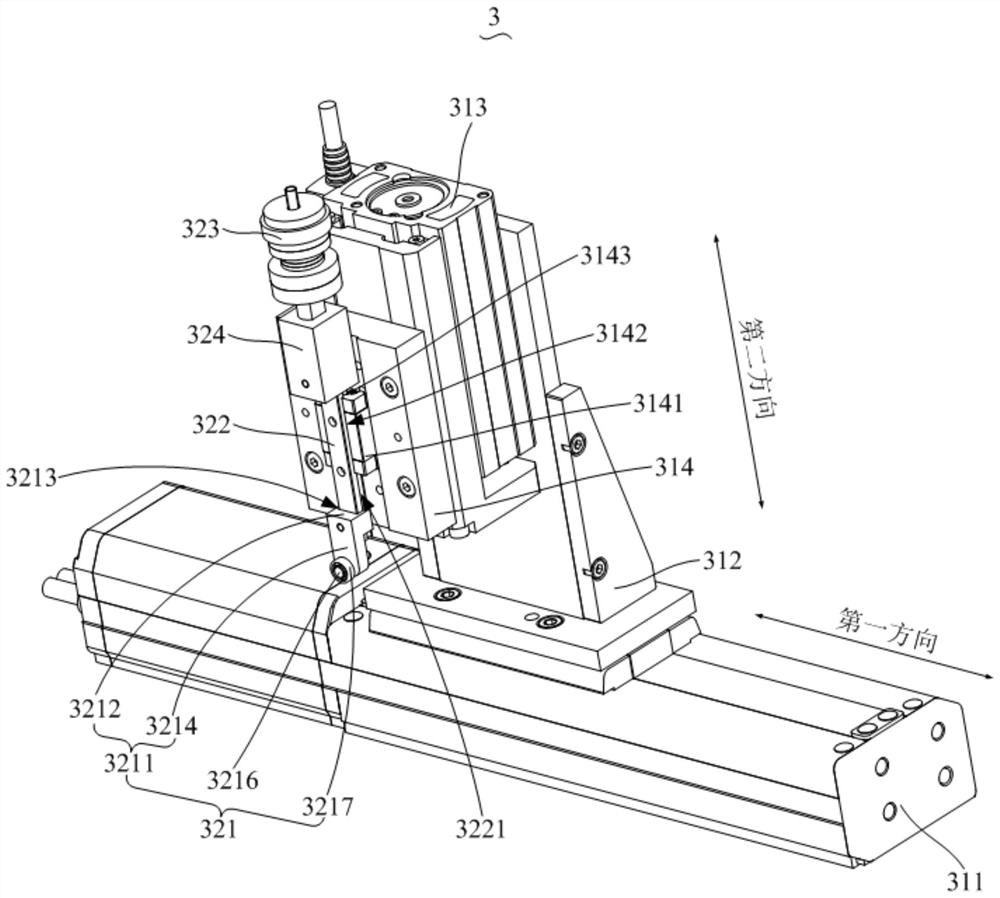

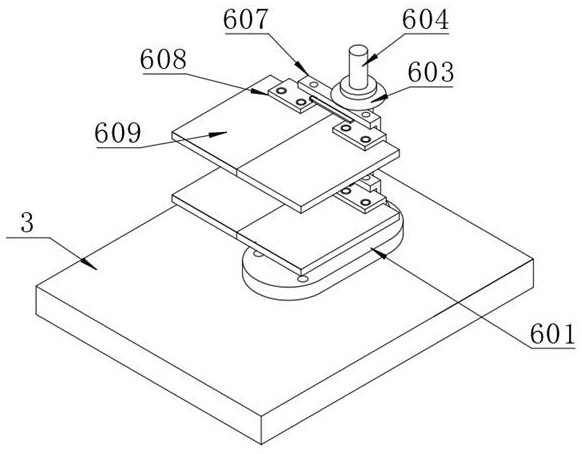

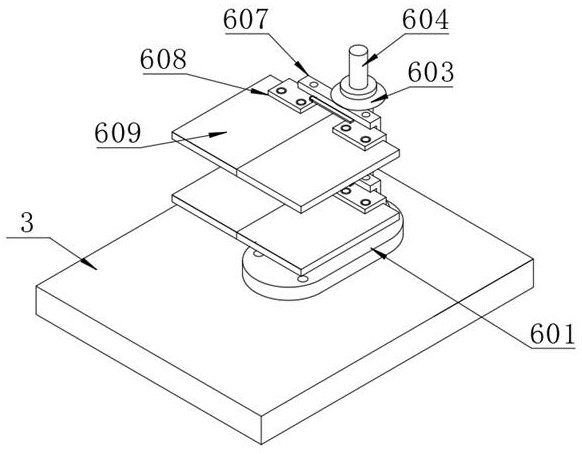

ActiveCN112738702ANo movementAvoid affecting test accuracyEarpiece/earphone attachmentsStructural engineeringMechanical engineering

The invention discloses a test tool and detection equipment. The test tool comprises a base, a fixing structure and a test module, wherein the fixing structure comprises a fixing base and a pressing assembly which are arranged on the base, a placement groove is formed in the fixing base, the placement groove is used for placing a workpiece, the pressing assembly is arranged on the fixing base, and the pressing plate is used for pressing the workpiece in the placing groove; and the test module comprises a driving assembly arranged on the base and a pressure assembly movably arranged on the driving assembly, the pressure assembly is provided with a pressing wheel, and the driving assembly drives the pressure assembly to be close to or far away from the workpiece in the placement groove, so that the pressing wheel slides to press the workpiece. The invention aims to provide the test tool which is not influenced by product taking and placing and shape errors and realizes sliding of the product with constant pressure, and the test tool not only ensures sliding of the product with constant pressure, but also ensures test precision.

Owner:GEER TECH CO LTD

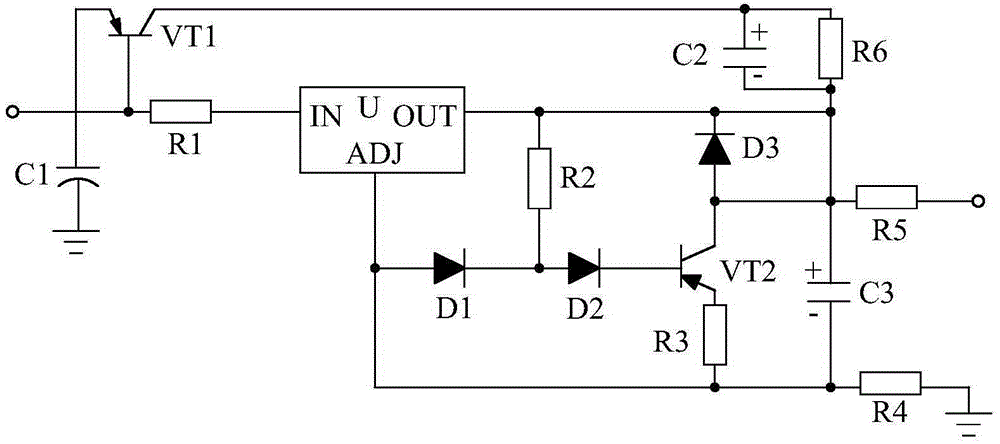

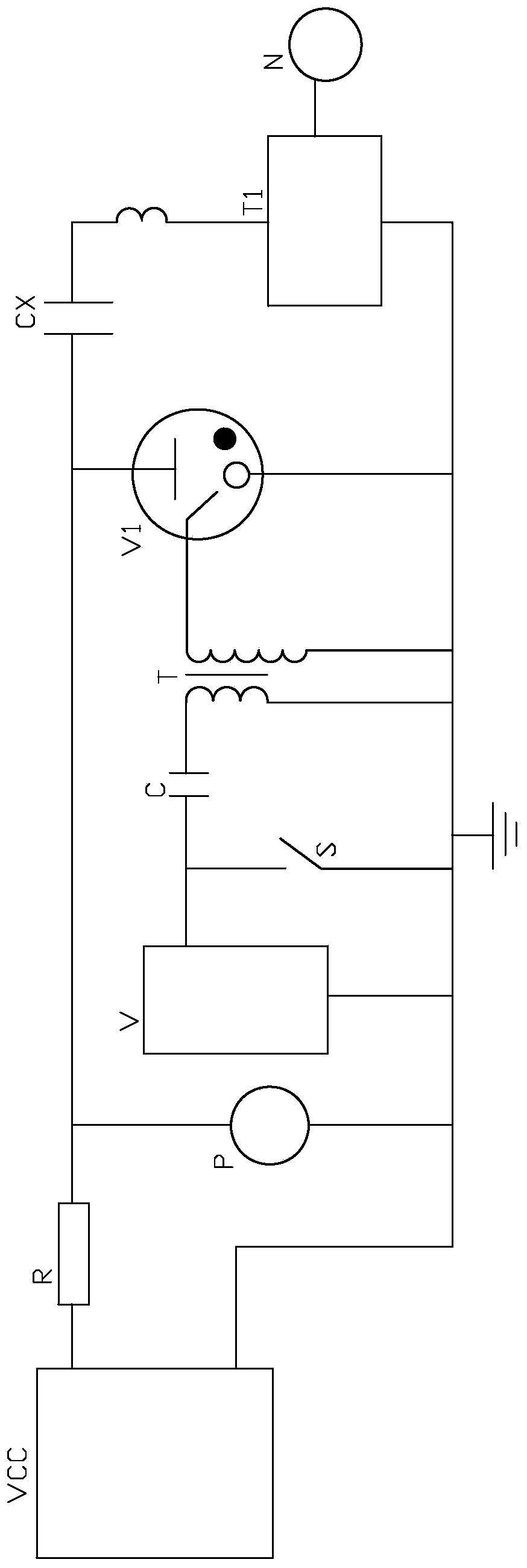

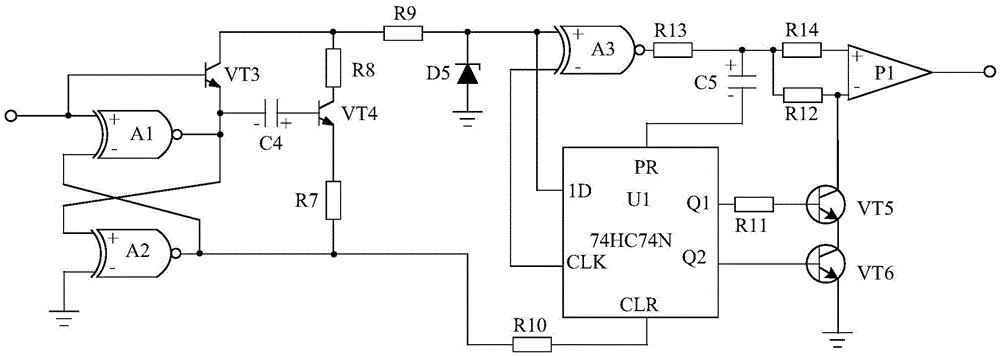

Discharge current testing circuit of pulse capacitor, testing device and testing way

PendingCN110531185AAvoid affecting test accuracyThe test result is accurateElectrical testingCurrent measurements onlyDisplay deviceEngineering

The invention provides a discharge current testing circuit of a pulse capacitor, a testing device and a testing way. The testing circuit comprises a detection loop and a trigger loop; the detection loop comprises a power supply source for supplying power for a tested capacitor, a trigger tube in parallel connection with the tested capacitor, a current transformer for collecting the discharge current of the tested capacitor, and a current display device connected with the current transformer and used for displaying the current; the trigger loop is connected with the trigger tube, the trigger loop is used for controlling the on-off of the trigger tube, thereby controlling the charging and discharging of the tested capacitor. The charging and discharging of the tested capacitor are controlledby arranging the trigger loop, the current transformer is used for collecting the sensing current, thereby preventing the arc phenomenon from occurring to influence the testing precision; the testingresult is more accurate; and the charging time of the tested capacitor and the number of charging and discharging can be set and monitored by arranging the control panel; the testing circuit is safeand stable, the testing is accurate, and the loop is simple.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

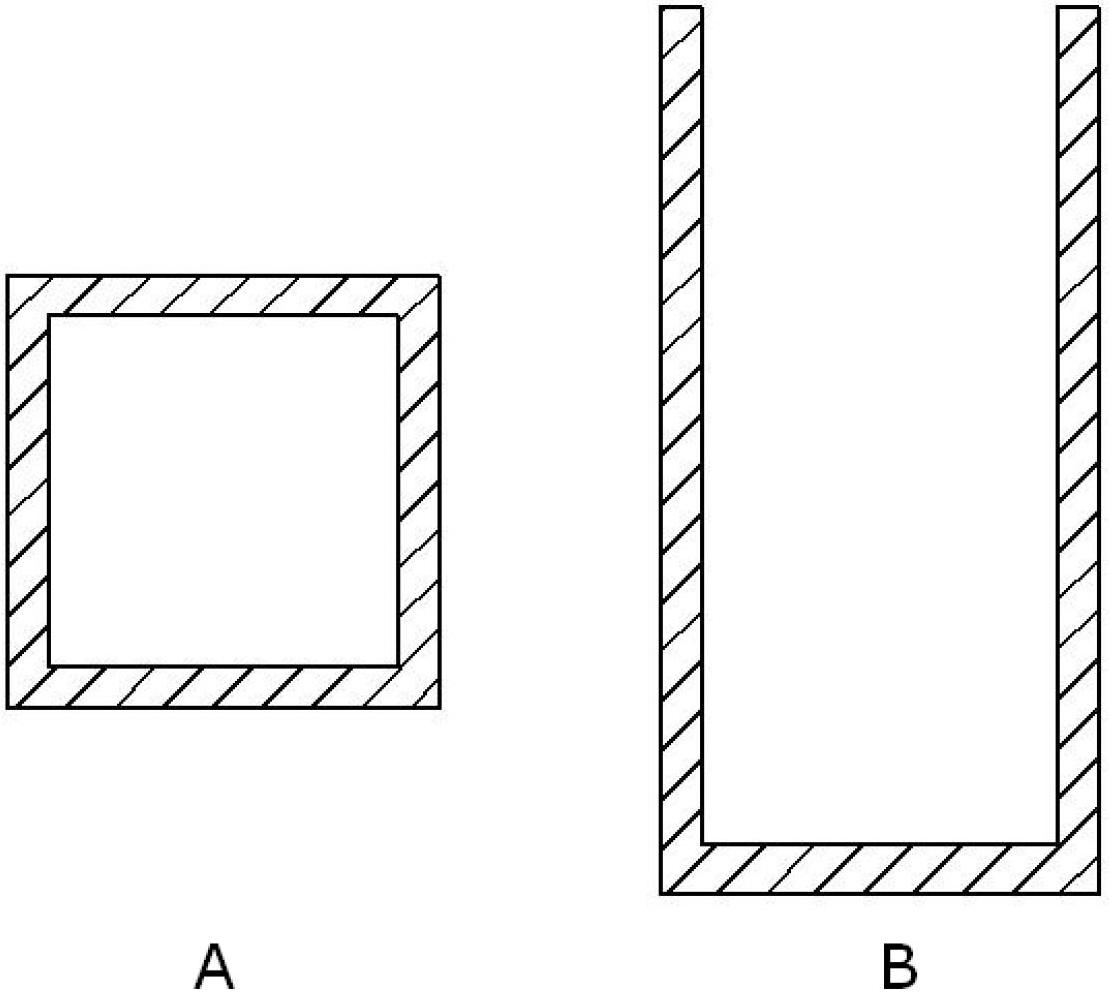

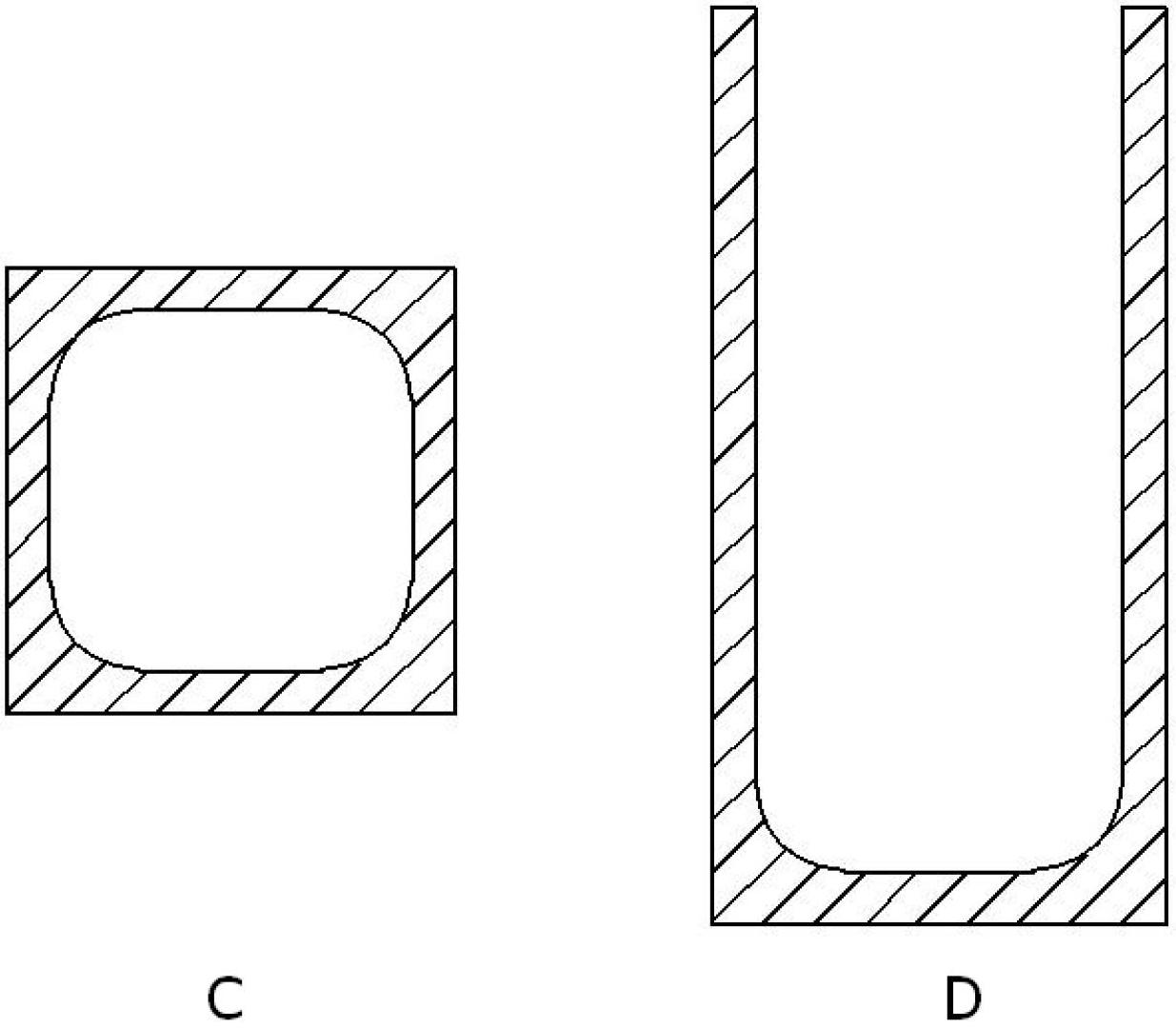

Glass biochemical cup and preparation method thereof

InactiveCN102692381AAvoid affecting test accuracyEasy to cleanMaterial analysis by optical meansTest solutionContamination

The invention discloses a glass biochemical cup and a preparation method thereof. The corners of every two adjacent side faces of the inner wall of the glass biochemical cup and the corners between the side faces and the bottom are shaped like an arc. As the corners in the glass biochemical cup are shaped like an arc, no cleaning blind corners exist and the glass biochemical cup is convenient for cleaning without any test solution residue, thereby avoiding cross contamination to influence test accuracy and avoiding liquid siphon caused by right-angle corners to affect the test accuracy. The existing biochemical cups are produced by bonding a plurality of glass pieces, thus the production efficiency is low and the possibility of errors is high. In the preparation method of the glass biochemical cup, glass tubes are adopted as dies for raw materials, thus the method is simple and easy to operate.

Owner:YIXING JINGKE OPTICAL INSTR

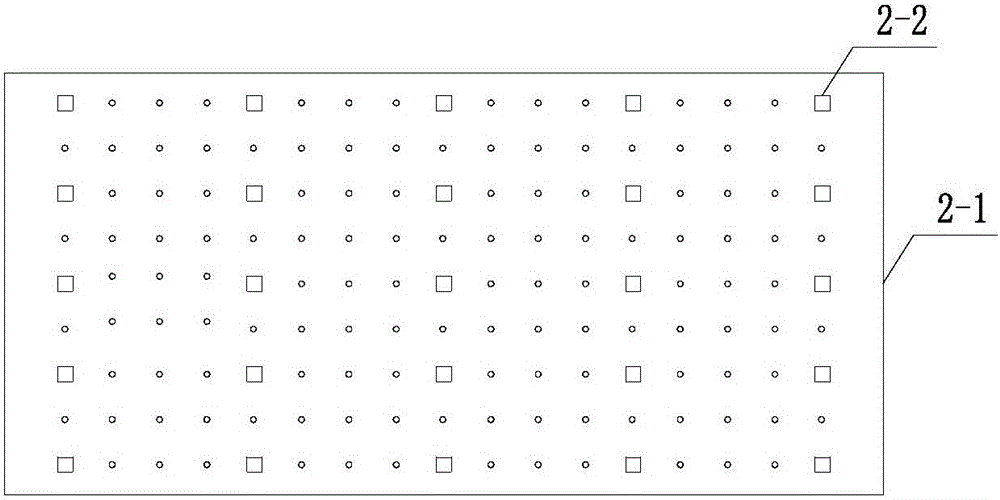

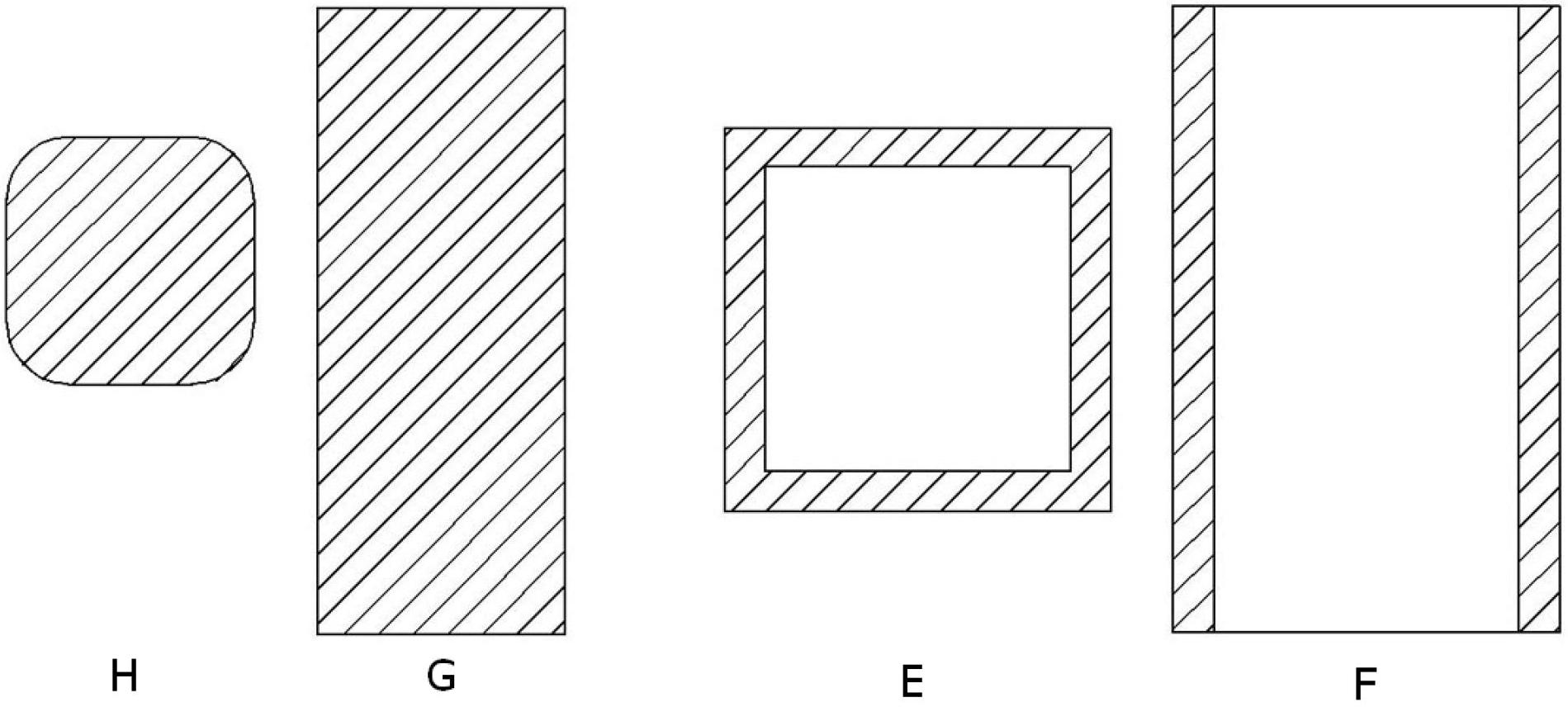

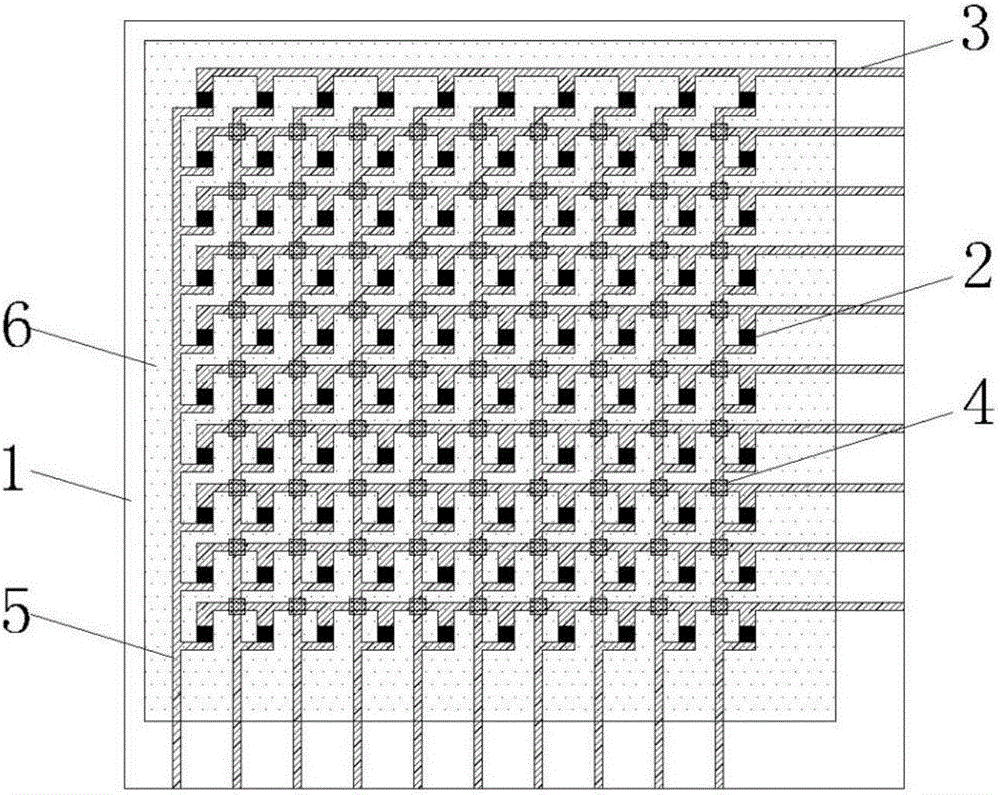

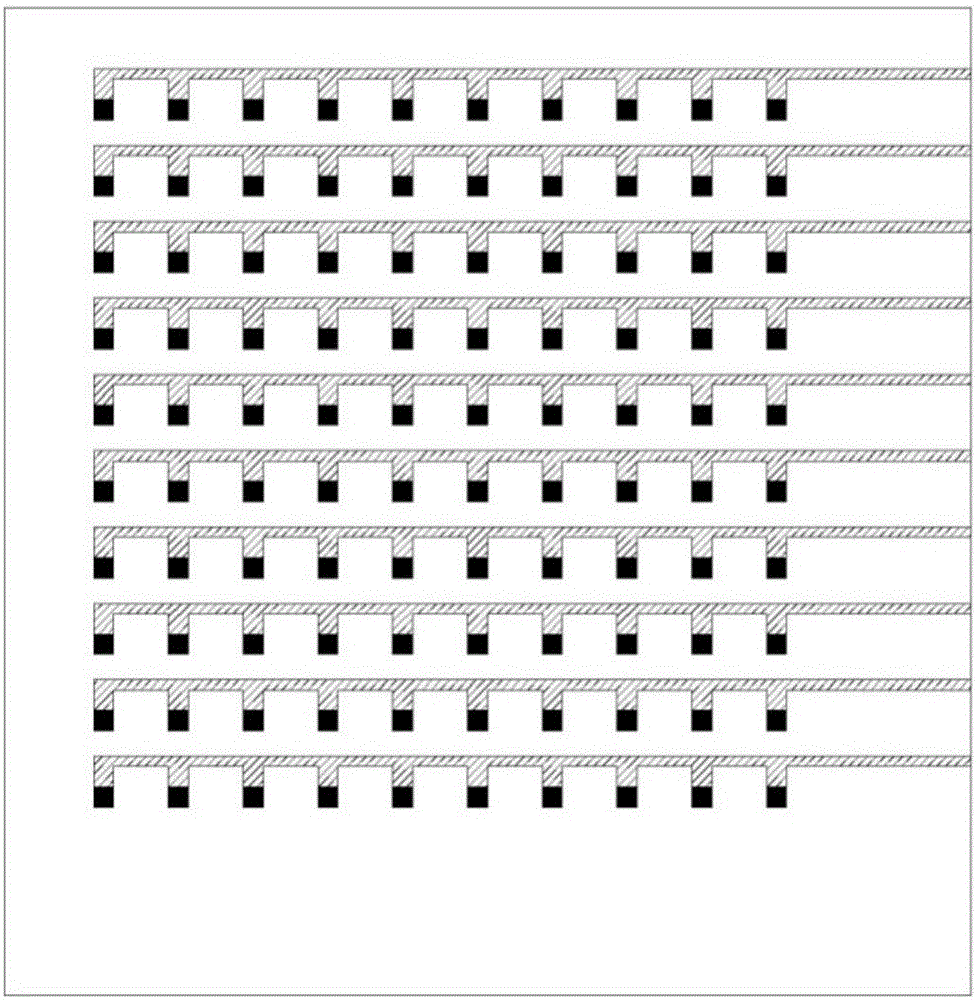

Two-dimensional planar temperature field test sensing element and manufacturing method thereof

InactiveCN104990641ARealization of two-dimensional plane temperature field testSimple structureThermometers using electric/magnetic elementsUsing electrical meansConductive polymer compositeField tests

A two-dimensional planar temperature field test sensing element and a manufacturing method thereof belong to the field of sensing element manufacturing methods and test methods. The two-dimensional planar temperature field test sensing element is composed of a film in a first layer, a sensitive element array and transverse electrodes in a second layer, an insulated thin layer in a third layer, longitudinal electrodes in a fourth layer, and an insulated protective film in a fifth layer. The film in the first layer is made of a plastic film material. The second layer includes the sensitive element array and the transverse electrodes which are printed on the film in the first layer by a printing method, wherein the sensitive element array is printed with a conductive polymer composite material, and the transverse electrodes are printed with conductive silver pulp. The insulated thin layer in the third layer is printed with resin. The longitudinal electrodes in the fourth layer are also made by printing. The insulated protective film in the fifth layer is printed with resin. The test sensing element can test a two-dimensional planar temperature field, the test method is simple, the precision is high, and the range of test is met. Meanwhile, the test sensing element can be mass-produced under printing process conditions, is low in cost, and has a good effect.

Owner:CHINA UNIV OF MINING & TECH

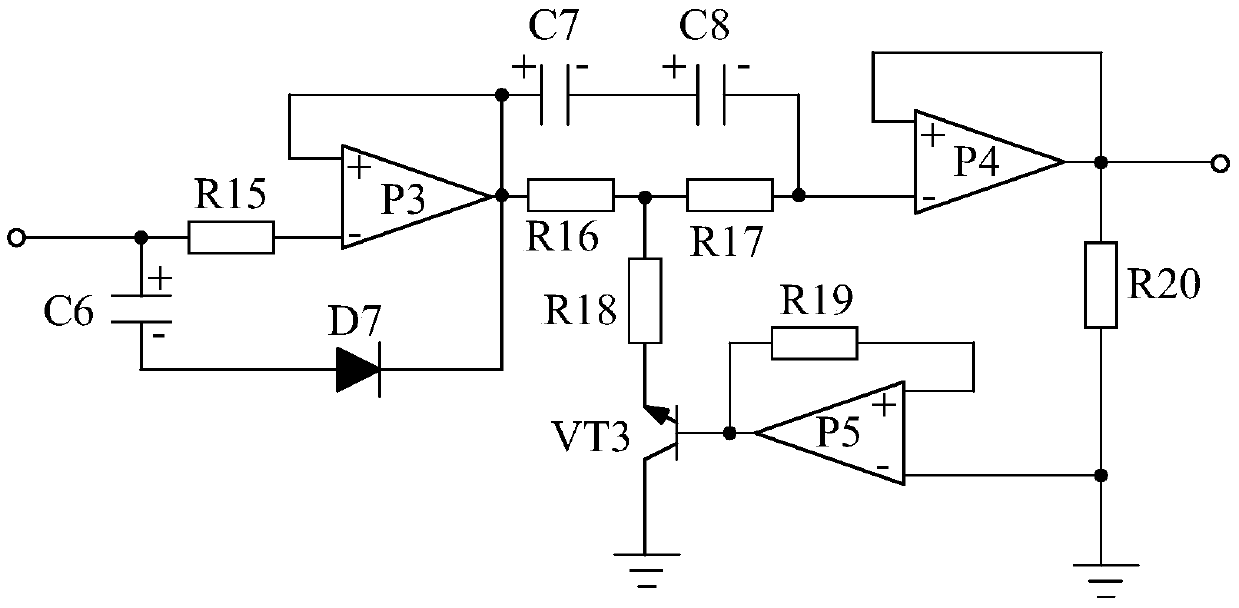

Multifunctional power tester based on high-pass filter circuit

InactiveCN105510699ALearn about the operationHigh precisionCurrent/voltage measurementElectrical measurement instrument detailsCurrent transducerDisplay device

The invention discloses a multifunctional power tester based on a high-pass filter circuit. The multifunctional power tester is mainly composed of a single-chip microcomputer, a voltage transducer and a current transducer. The multifunctional power tester is further composed of a signal conversion module, a phase detection circuit and a display which are respectively connected with the single-chip microcomputer, a voltage sampling maintaining circuit and a current sampling maintaining circuit which are respectively connected with the signal conversion module, and a current comparison circuit and a voltage comparison circuit which are respectively connected with the phase detection circuit, wherein the voltage transducer is connected in series between voltage sampling maintaining circuit and the voltage comparison circuit, and the current transducer is connected in series between the current sampling maintaining circuit and the current comparison circuit. The multifunctional power tester is characterized in that the high-pass filter circuit is also connected in series between the voltage comparison circuit and the phase detection circuit. According to the invention, through arrangement of the high-pass filter circuit, the high-pass filter circuit can filter interference signals mingled in square wave signals and prevent the interference signals from affecting the test precision of the multifunctional power tester.

Owner:CHENGDU HONGKAIRUI TECH CO LTD

Slow tensile test method of pipeline steel in hydrogen environment

PendingCN113933153AThe test method is safe and reliableAccurately know the mechanical propertiesMaterial strength using tensile/compressive forcesFluid pressure measurementLine tubingHigh pressure hydrogen

The invention relates to a slow tensile test method of pipeline steel in a hydrogen environment, belongs to the technical field of pipeline steel testing, and solves the problem that performance testing of the pipeline steel in a high-pressure hydrogen environment is difficult to realize in the prior art. The method comprises the following steps: S1, mounting pipeline steel of a test sample into a hydrogen environment box; S2, filling the pipeline steel in the hydrogen environment box with hydrogen; and S3, connecting the pipeline steel filled with hydrogen into a slow stretching instrument, and carrying out a slow stretching test. Performance testing of the pipeline steel under different hydrogen partial pressure conditions is achieved, the pipeline steel is always in a hydrogen environment in the testing process, and then the testing accuracy is guaranteed.

Owner:SINOPEC PETROLEUM ENG DESIGN +1

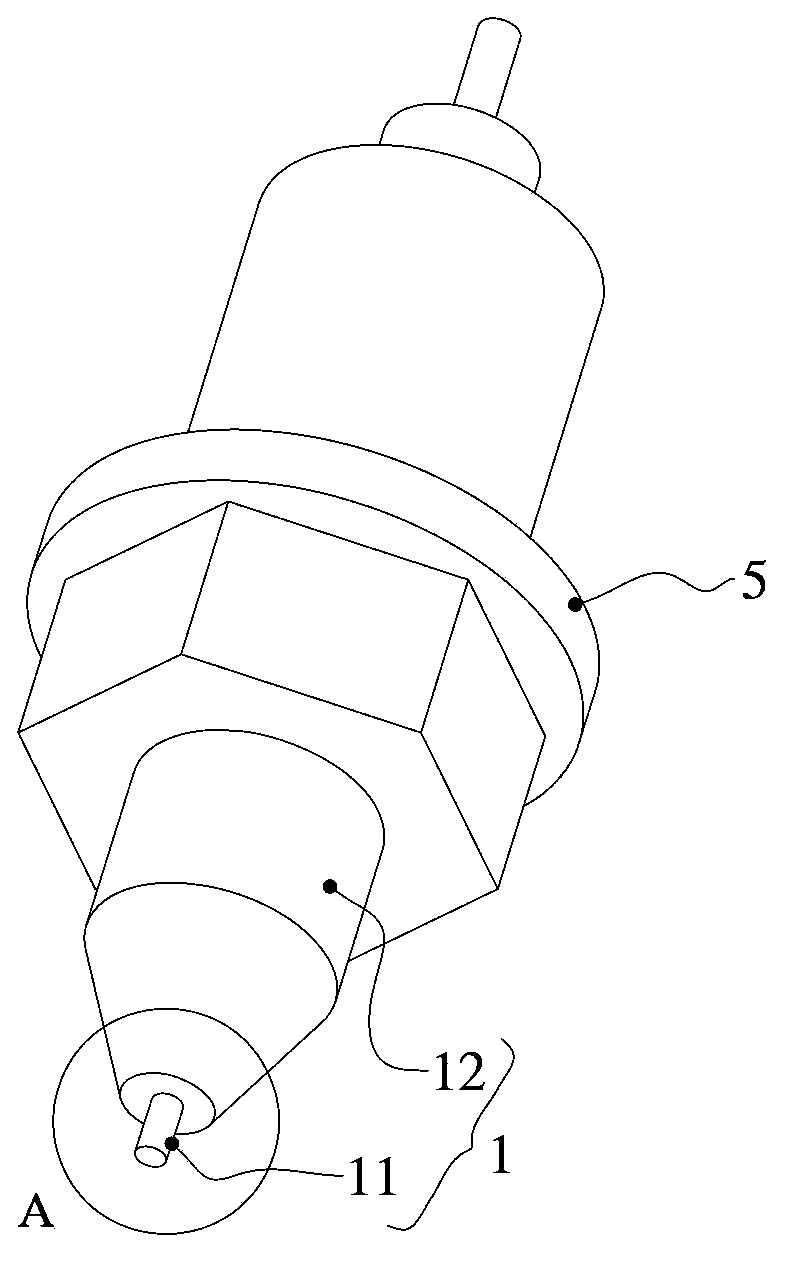

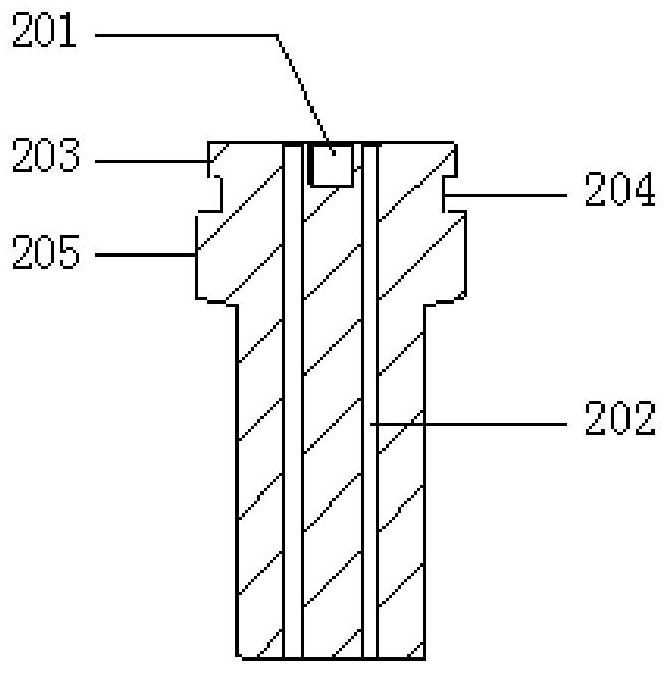

High-temperature-resistant gas sensor and packaging method thereof

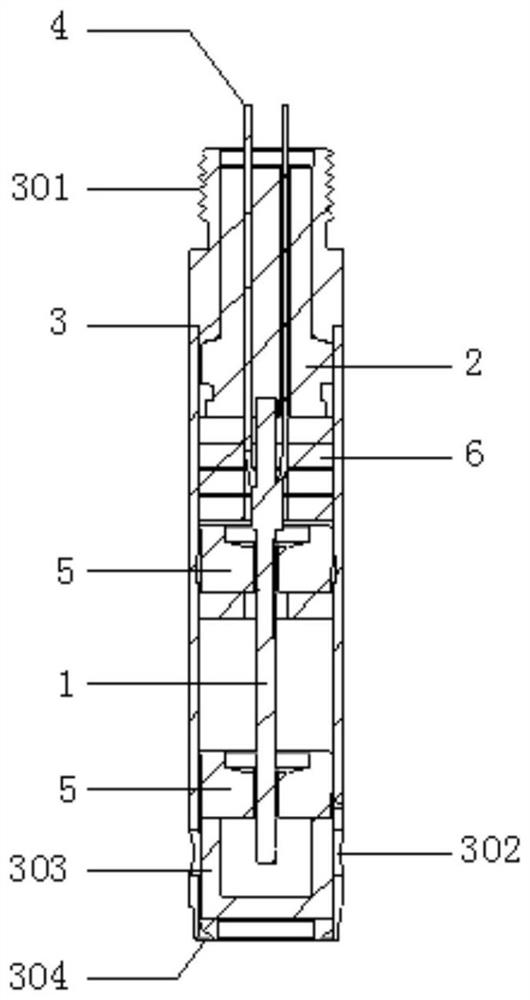

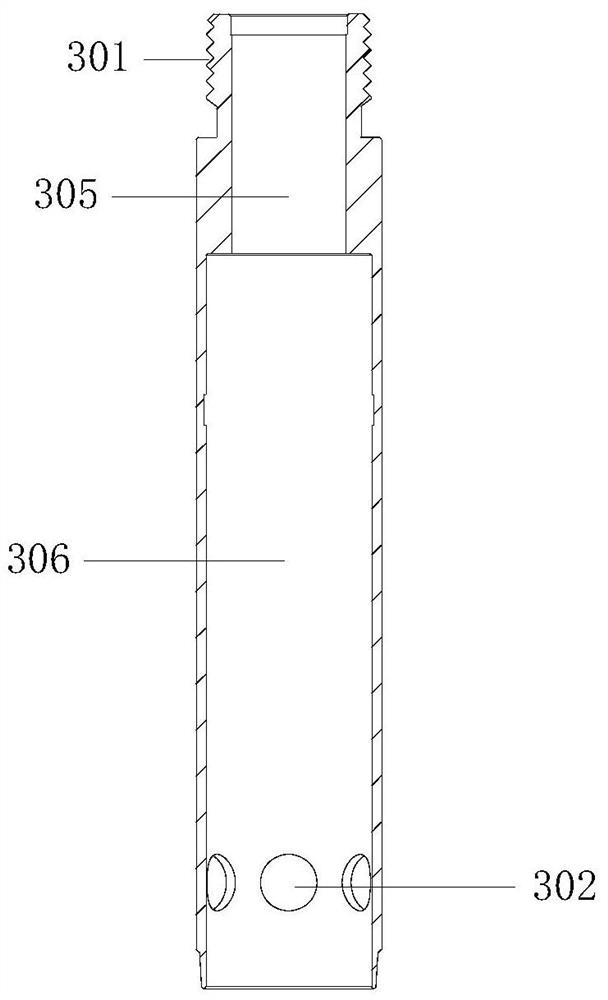

PendingCN111638248AHigh temperature resistanceGood temperature toleranceSoldering apparatusMaterial analysis by electric/magnetic meansEngineeringMechanical engineering

The invention relates to the technical field of gas sensors, in particular to a high-temperature-resistant gas sensor and a packaging method thereof. The sensor comprises a sensor element and a sleeve, the sensor element is arranged in sleeve, the sensor element comprises a detection end and an electrode end; the detection end of the sensor element is used for gas detection; the electrode end of the sensor element is connected with a wire; a first cavity and a second cavity are formed in the sleeve; a lead device is fixed in the first cavity; the electrode end of the sensor element is in buttjoint with the lead device. A lead connected with the electrode end is led out of the lead device, the second cavity is used for containing the sensor element, a ceramic cake and a ceramic pressing ring are further arranged in the second cavity, the ceramic cake fixes the electrode end of the sensor element in the second cavity, and the ceramic pressing ring fixes the detection end of the sensor element in the second cavity. According to the invention, the sensor element can be fixed, insulated and sealed, has higher high-temperature resistance, and can be used in a high-temperature environment.

Owner:成都昶艾电子科技有限公司

Simple oil consumption tester base on temperature detection

InactiveCN105486367AAvoid complexityAvoid limitationsRelative volume flow measurementsWireless transmissionDisplay device

The invention discloses a simple oil consumption tester base on temperature detection, and is characterized in that the simple oil consumption tester base on the temperature detection comprises a single chip microcomputer, an oil consumption sensor, a voltage-stabilized power supply module, a display, a keyboard, a wireless transmission unit, a network interface, and a temperature detection unit. The oil consumption sensor, the voltage-stabilized power supply module, the display, the keyboard, the wireless transmission unit, the network interface, and the temperature detection unit are all connected to the single chip microcomputer. The simple oil consumption tester based on the temperature detection can detect the machine oil temperature and prevent the machine oil temperature from becoming over high so as to damage the oil consumption tester.

Owner:CHENGDU KERUIXIN TECH CO LTD

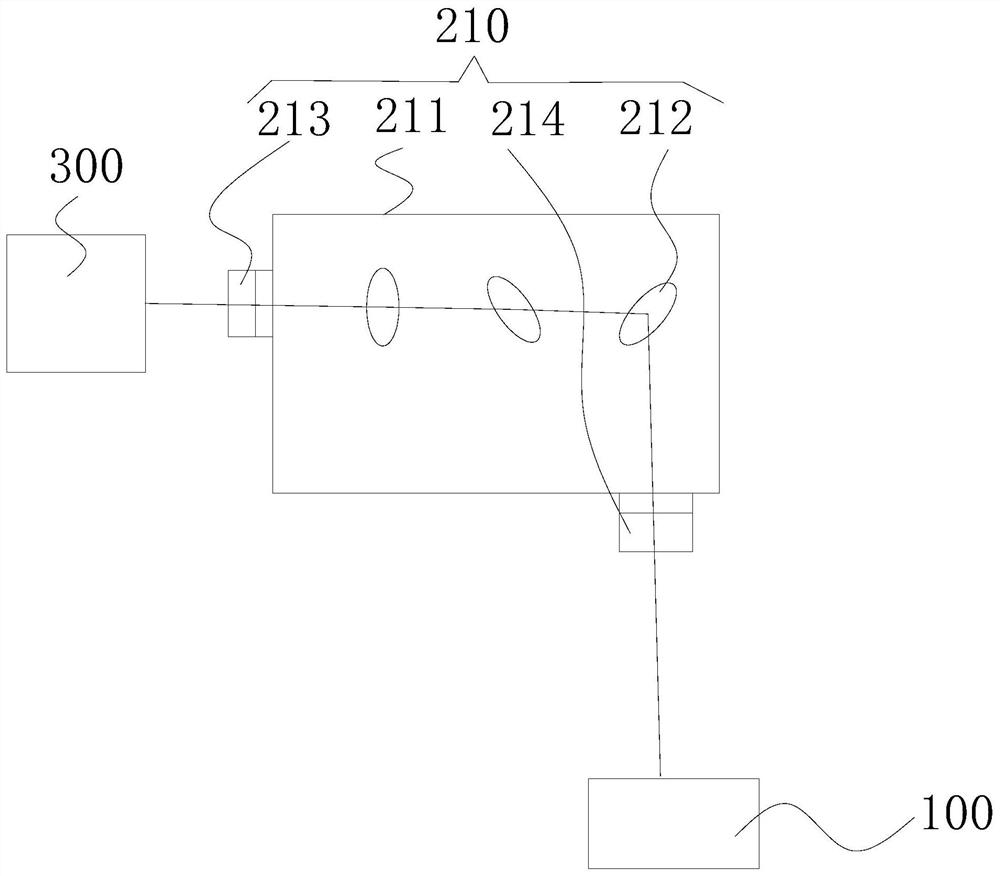

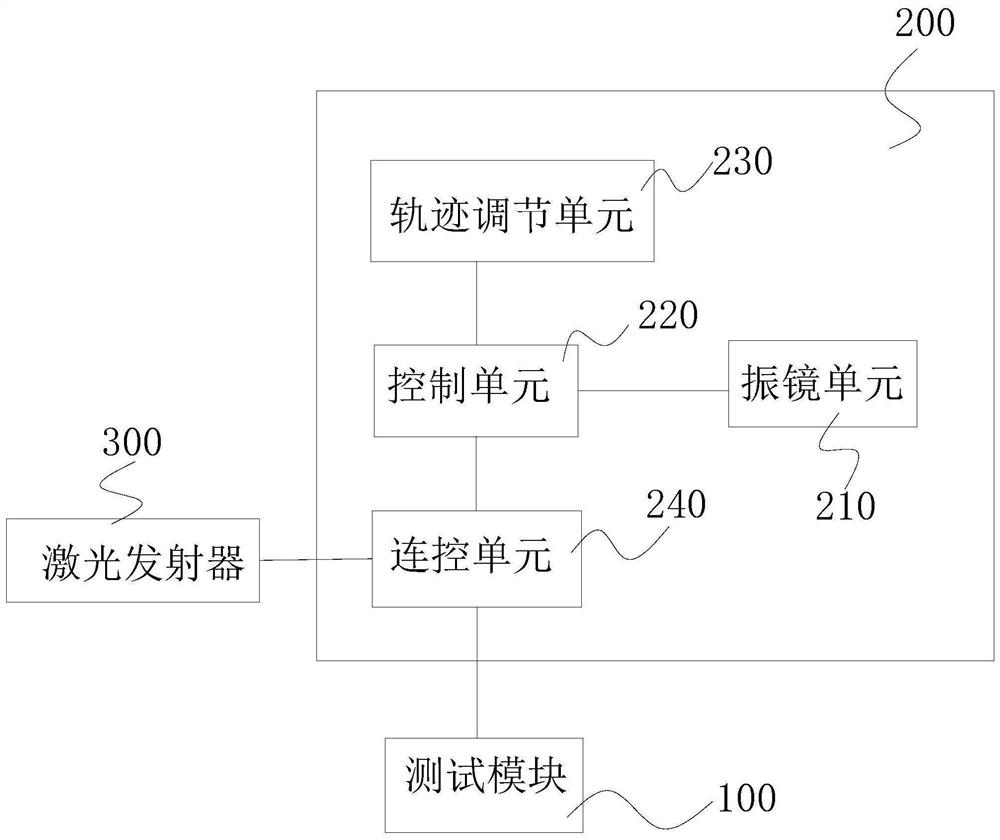

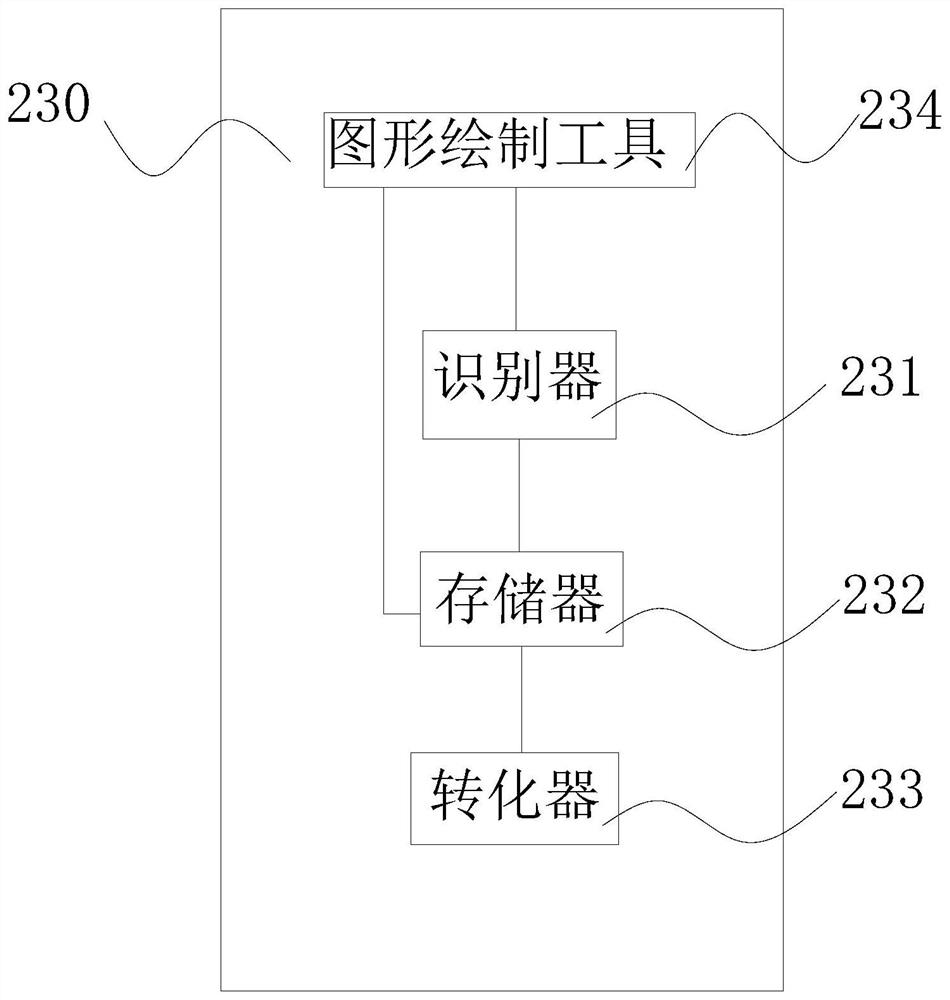

Laser power test system and test method

PendingCN113720443APower Fast and PrecisePower testing is fast and accuratePhotometryTesting optical propertiesLaser transmitterLaser technology

The invention belongs to the technical field of laser, and relates to a laser power test system and a test method. The laser power test system comprises a test module and a regulation and control module, the regulation and control module is used for receiving a test instruction for carrying out power test on a laser emitter to be tested, according to the test instruction, the focus of the laser emitted by the laser emitter to be tested is controlled to move on the test module; the test module is used for detecting the power of the received laser; the regulation and control module comprises a galvanometer unit and a control unit, the control unit is used for controlling the reflection angle of the galvanometer unit, and the control unit is in communication connection with the test module and is used for controlling movement of the test module. According to the laser power test system, the laser focus of the laser emitter moves on the test module so that the laser focus is prevented from staying at the fixed position of the test module for a long time to influence the test precision and even burn out the test module; according to the invention, the power of the laser emitter can be rapidly and accurately tested.

Owner:HANS CNC SCI & TECH

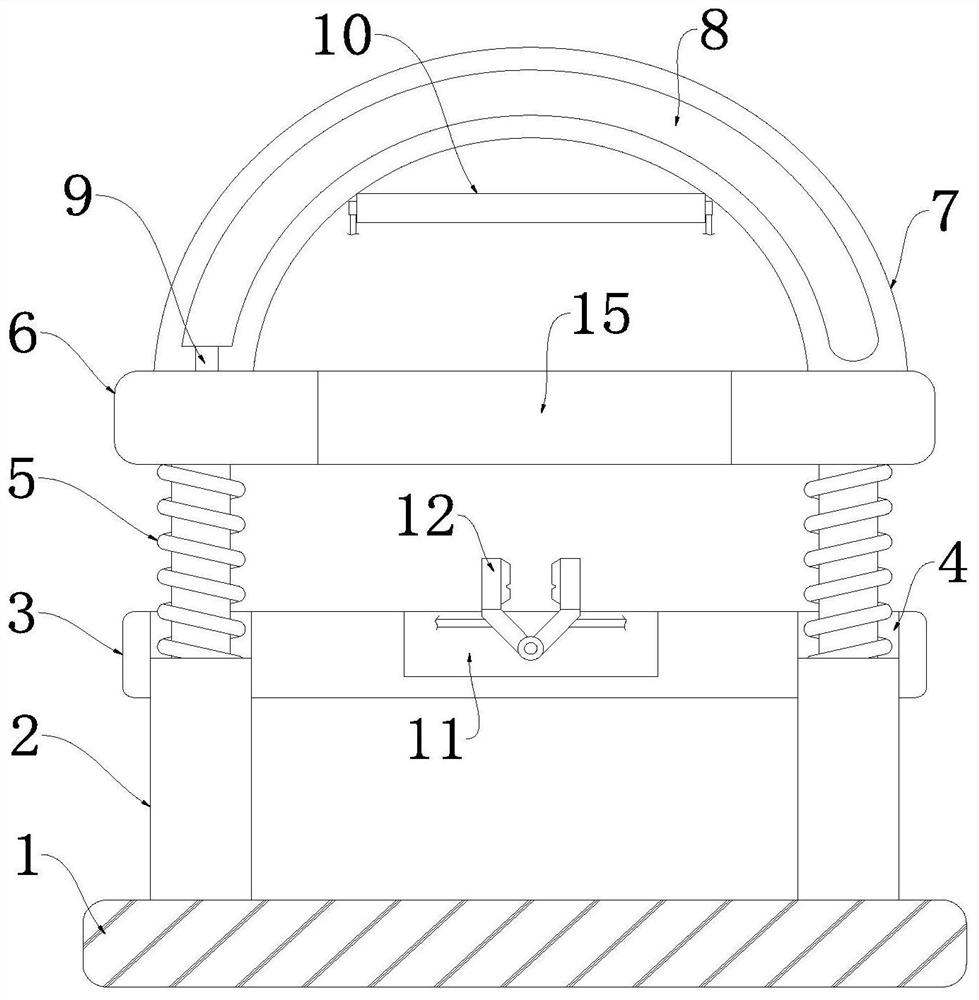

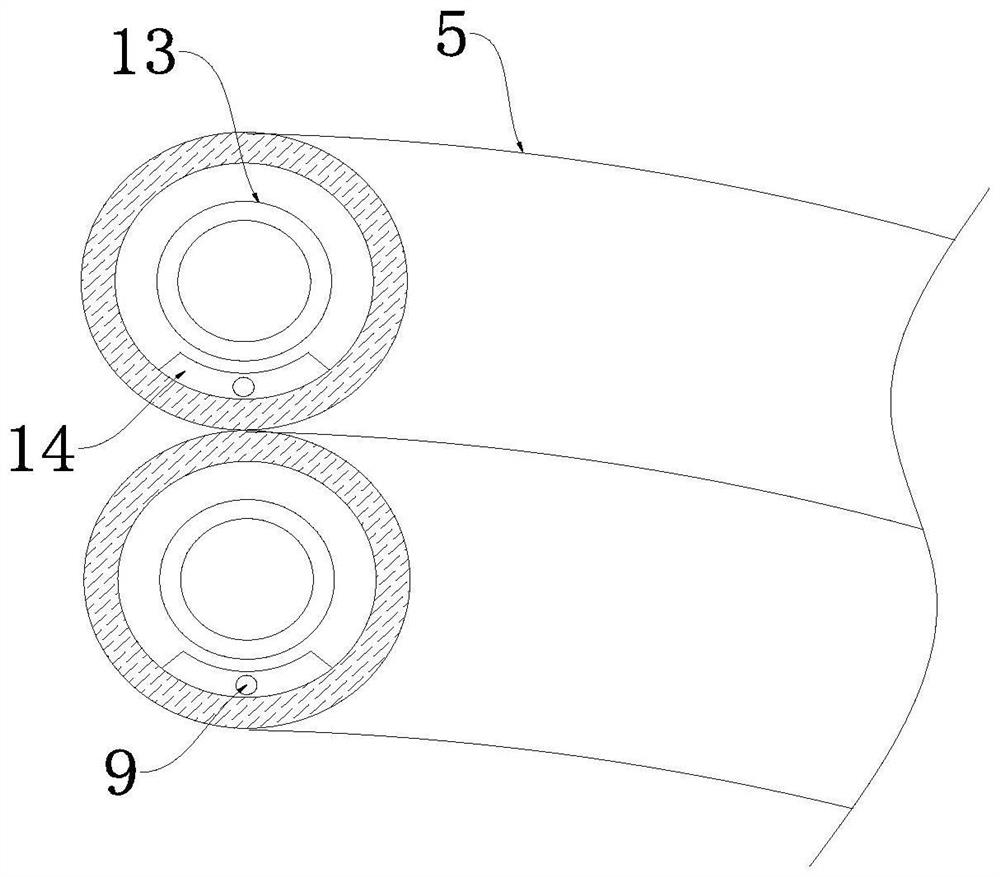

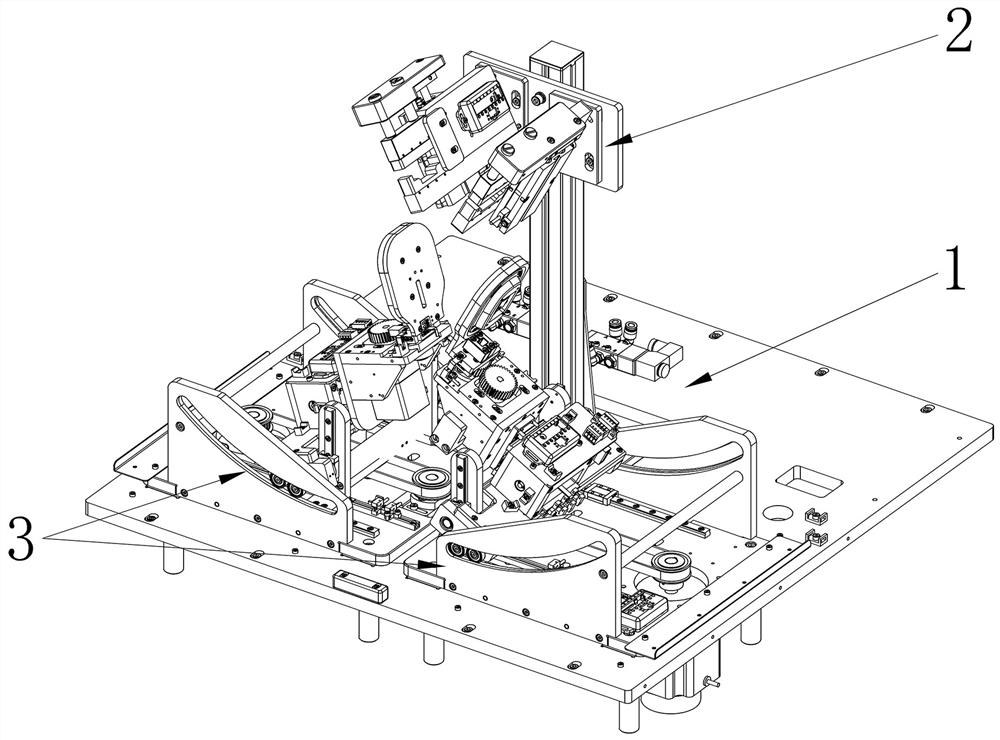

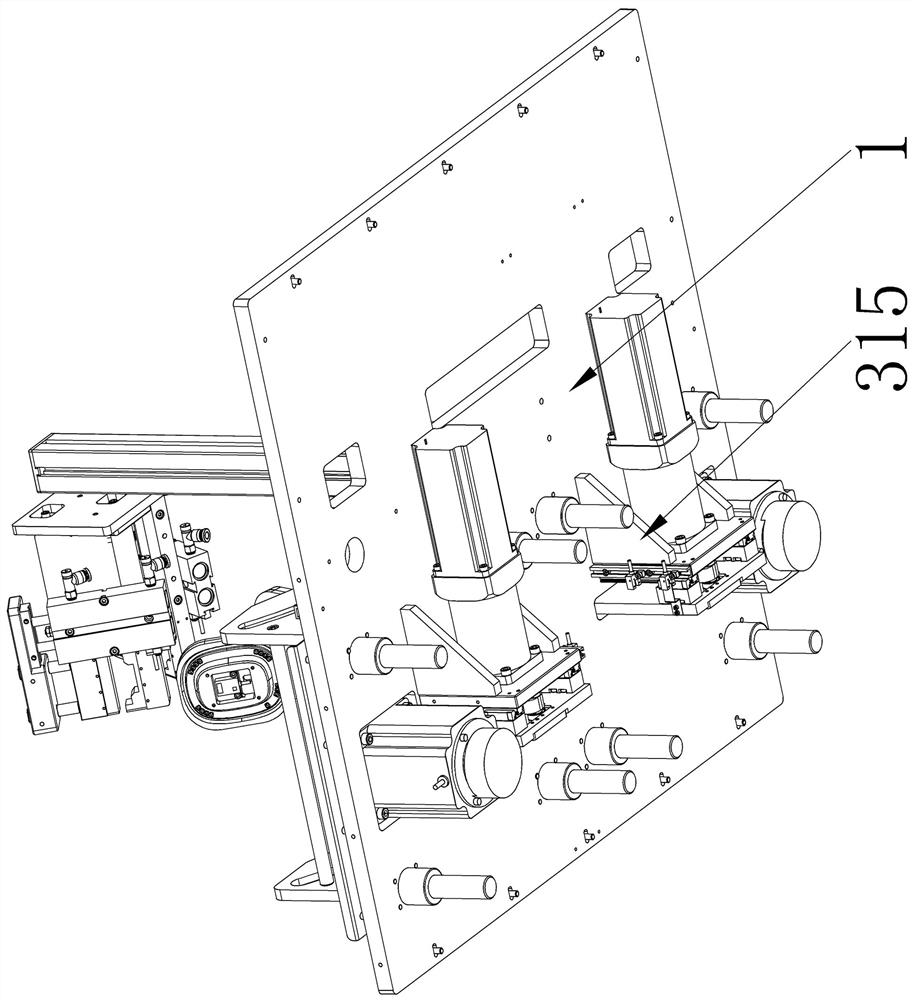

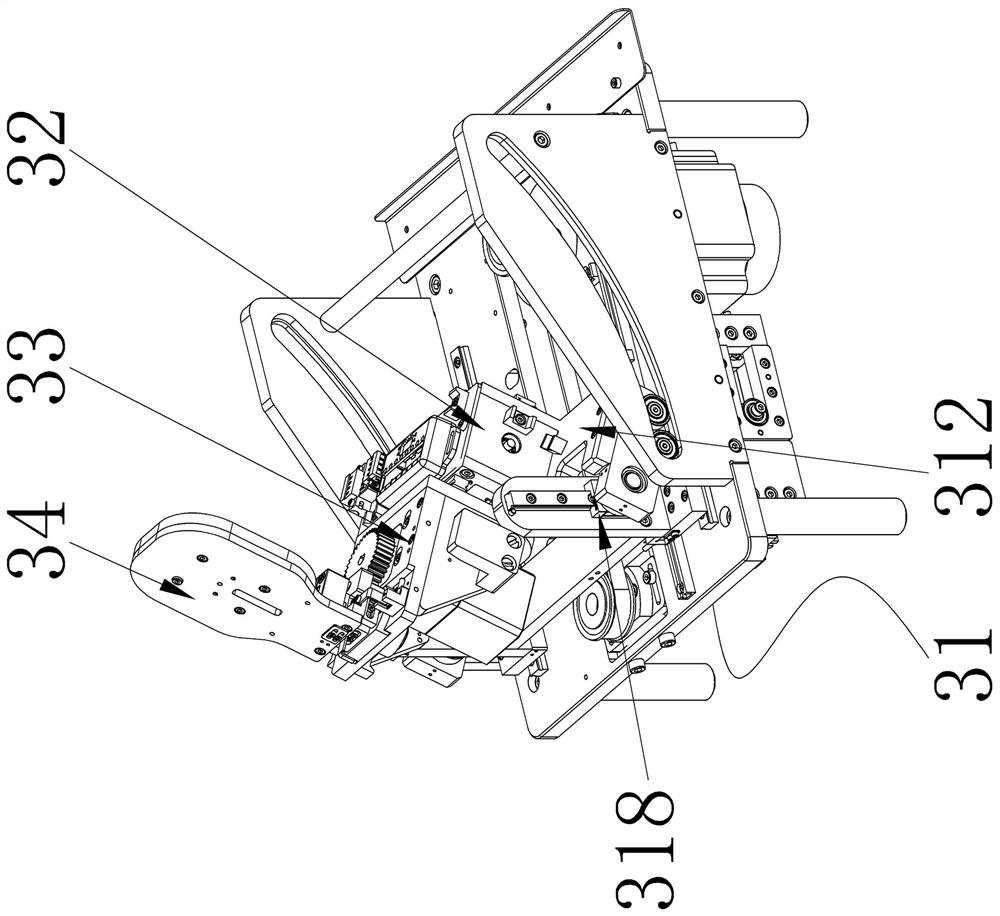

Headphone deformation simulation detection equipment

PendingCN113965867AAvoid damageMeet deformation requirementsMicrophonesLoudspeakersEarmuffsControl theory

The invention aims to provide the headset deformation simulation detection equipment which is wide in simulation bending test range and capable of performing positioning compensation during earmuff expansion. The device comprises a rack, a connecting rod fixing module and two sets of earmuff deformation driving modules are arranged on the rack, the two sets of earmuff deformation driving modules are arranged on the two sides of the connecting rod fixing module correspondingly, and each earmuff deformation driving module comprises a floating outward pulling module, a front-back deformation module, a fixed-axis rotating module and an earmuff limiting piece which are connected in sequence; a test data line is arranged on the fixed-axis rotating module of one earmuff deformation driving assembly, the floating outward-pulling module drives the earmuff limiting piece to conduct pitch angle and displacement adjustment, and the front-back deformation module drives the earmuff limiting piece to conduct displacement in the direction perpendicular to the movement direction of the floating outward-pulling module. The fixed-axis rotation module drives the earmuff limiting member to perform fixed-axis rotation, and the test data line is connected with the earphone interface. The invention is applied to the technical field of deformation test equipment.

Owner:ZHUHAI BOJAY ELECTRONICS

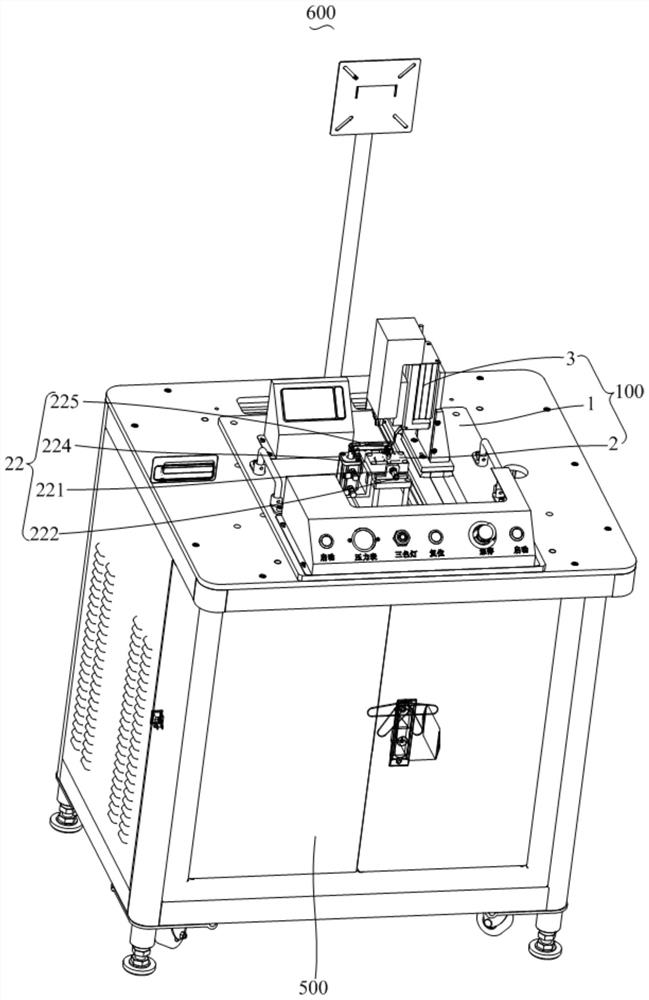

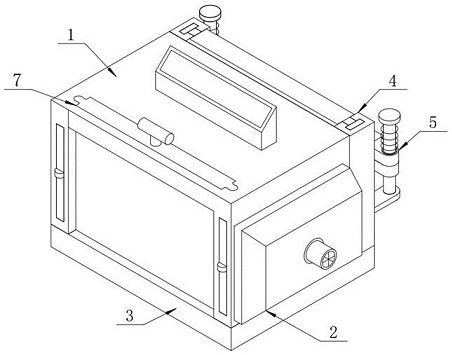

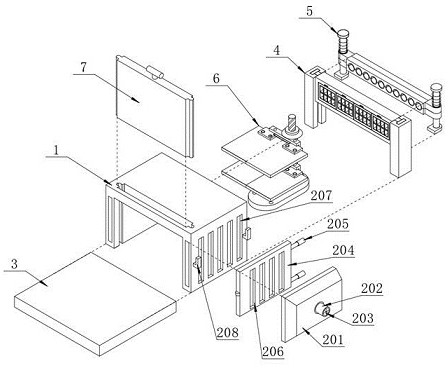

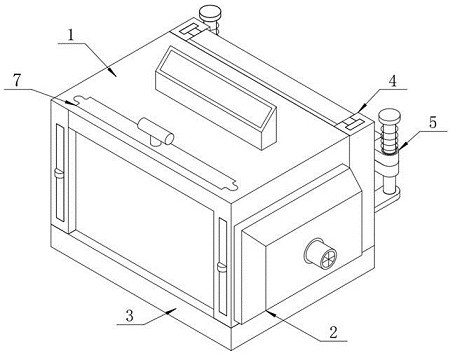

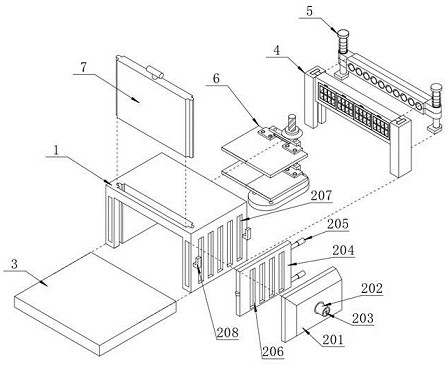

A power aging test equipment

ActiveCN113640698BFacilitate monitoring and acquisition processingImprove securityPower supply testingMeasurement instrument housingTemperature controlElectric machinery

The invention discloses a power supply aging test device, which belongs to the technical field of power supply circuit testing, and comprises a test box, the top of the test box is fixedly equipped with test circuit elements and display instruments, and the bottom of the test box is fixedly equipped with a base. A heating limit mechanism is fixedly installed on the top of the base, and a temperature control mechanism is provided on one side of the test box. In the present invention, it can adapt to the heating processing capacity of power supplies with different thicknesses, and the heating seat can simulate the influence of heat conduction of other circuit elements when the power supply is working by heating the heat transfer plate, which is beneficial to test the box test components for power supplies under different temperature states. Monitoring and acquisition of aging test data, the heat transfer plate fixes the position of the motor through the cooperation of the rear side fixing sleeve and the limit nut, which improves the safety and stability of the test and avoids the impact of external shaking on the data, effectively Improve test security and accuracy.

Owner:南通腾颢电子有限公司

Power supply aging test equipment

ActiveCN113640698AFacilitate monitoring and acquisition processingImprove securityPower supply testingMeasurement instrument housingTemperature controlElectric machinery

The invention discloses power supply aging test equipment, and belongs to the technical field of power supply circuit testing. Thepower supply aging test equipment comprises a test box body, a test circuit element and a display instrument are fixedly assembled at the top of the test box body, a base is fixedly assembled at the bottom of the test box body, and a heating limiting mechanism is fixedly mounted at the top of the base; and a temperature control mechanism is arranged on one side of the test box body. According to the invention, the equipment can adapt to the heating processing capability of power supplies with different thicknesses, and a heating seat can simulate the heat conduction influence of other circuit elements when the power supplies work through heating the heat transfer plate, thereby facilitating the monitoring, obtaining and processing of power supply aging test data under different temperature states by the test elements of the test box body. The heat transfer plate limits and fixes the motor through the cooperation of a rear side fixing sleeve and a limiting nut, the test safety and stability are improved, the influence of test external shaking on data is avoided, and the test safety and accuracy are effectively improved.

Owner:南通腾颢电子有限公司

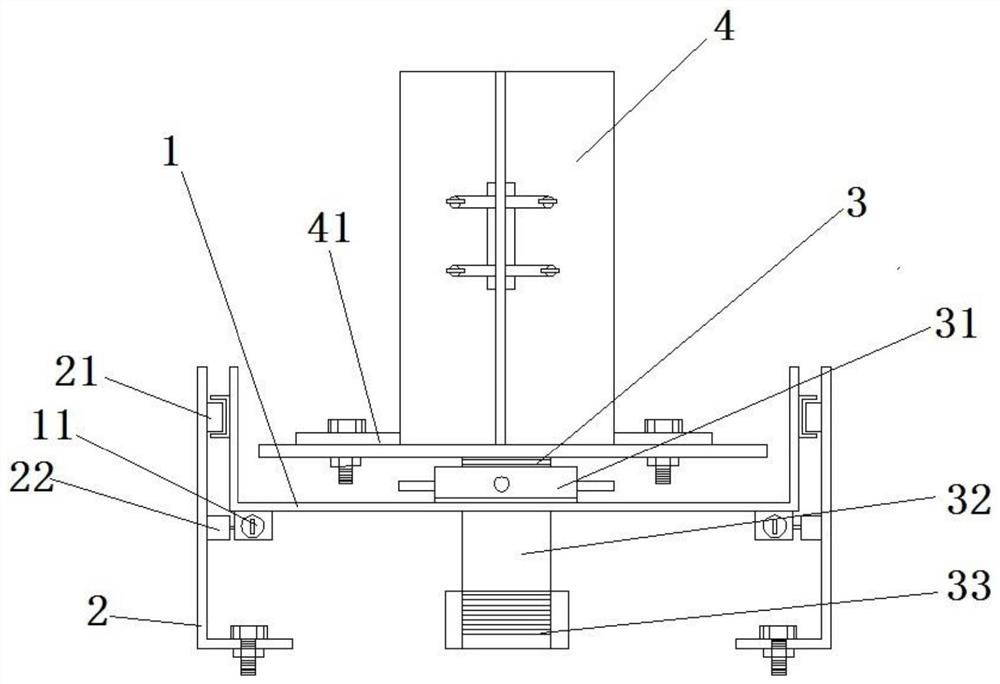

Electronic pump assembly high and low temperature comprehensive performance test bench

PendingCN113719445AAvoid explosionAvoid burnsPump testingPositive-displacement liquid enginesTest efficiencyThermodynamics

The invention discloses an electronic pump assembly high and low temperature comprehensive performance test bench. The test bench comprises a to-be-tested pump body, a test oil tank, an oil temperature machine, an oil storage tank, a detection oil path and a detection gas path, the to-be-tested pump body is mounted in the test oil tank, the oil temperature machine and the oil storage tank are respectively connected with the test oil tank, and the detection oil path and the detection gas path are respectively connected with the to-be-detected pump body and are used for detecting the to-be-detected pump body. A constant-temperature interlayer is arranged in the test oil tank of the test bench, low-temperature and high-temperature setting of oil liquid is achieved, and therefore the test efficiency and accuracy are improved.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

Extensometer base and tensile testing machine with same

PendingCN114087475AEasy to movePrevent affecting test accuracyMaterial strength using tensile/compressive forcesStands/trestlesMachineTensile testing

The invention discloses an extensometer base and a tensile testing machine with the same. The extensometer base comprises a base and supporting plates connected to the two sides of the base through sliding rails. The base can slide back and forth between the supporting plates on the two sides through the sliding rails. A threaded rod is vertically arranged on the bottom face of the base in a penetrating mode, and the top of the threaded rod is connected with a full-automatic extensometer. The part, between the base and the full-automatic extensometer, of the threaded rod is sleeved with an adjusting knob, the adjusting knob can drive the threaded rod to ascend and descend in the vertical direction so as to drive the full-automatic extensometer connected to the upper portion of the threaded rod to ascend and descend, and the lower portions of the supporting plates are supported on a tensile testing machine. Operating rods used for driving the base to slide are arranged on the two sides of the bottom face of the base, locking clamping grooves are formed in the side faces of the supporting plates, and the operating rods can be clamped to the locking clamping grooves to limit the position of the full-automatic extensometer. Therefore, multi-directional adjustment of the position of the extensometer is realized, the influence of space limitation on the test precision is avoided, and the extensometer is convenient to move.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Phase sensitive detecting type oil consumption tester based on temperature detection

InactiveCN105486368AAvoid complexityAvoid limitationsRelative volume flow measurementsWireless transmissionSignal on

The invention discloses a phase sensitive detecting type oil consumption tester based on temperature detection, and is characterized in that the phase sensitive detecting type oil consumption tester comprises a single chip microcomputer, a voltage-stabilized power supply module, a display, a keyboard, a wireless transmission unit, a network interface, a phase sensitive detecting unit, a temperature detecting unit, and an oil consumption sensor. The voltage-stabilized power supply module, the display, the keyboard, the wireless transmission unit, the network interface, the phase sensitive detecting unit, and the temperature detecting unit are all connected to the single chip microcomputer, and the oil consumption sensor is connected to the phase sensitive detecting unit. The phase sensitive detecting type oil consumption tester has the phase sensitive detecting unit which can judge oil consumption signals and inhibit other interference signals. The influence of the interference signals on the phase sensitive detecting type oil consumption tester based on the temperature detection is eliminated, and the detection accuracy of the phase sensitive detecting type oil consumption tester based on the temperature detection is improved. The phase sensitive detecting type oil consumption tester based on the temperature detection can detect the machine oil temperature and prevent the machine oil temperature from becoming over high so as to damage the oil consumption tester.

Owner:CHENGDU KERUIXIN TECH CO LTD

Thermal matching performance measurement device of multi-layer composite thermal protection structure

ActiveCN104165897BAvoid influence of test resultsGuaranteed closeMaterial thermal analysisRelative displacementEngineering

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

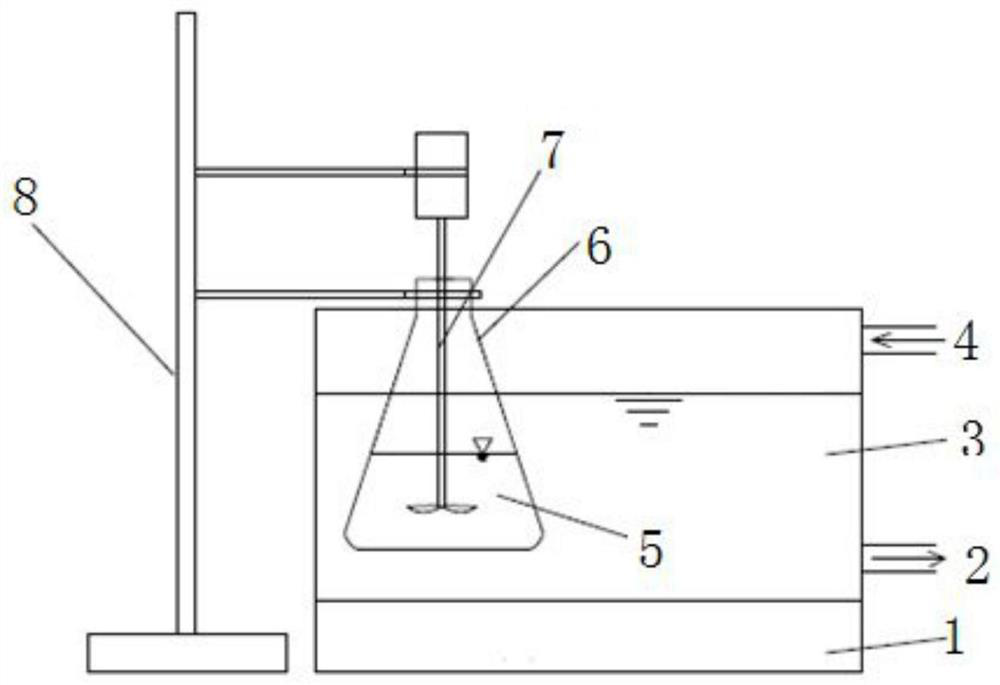

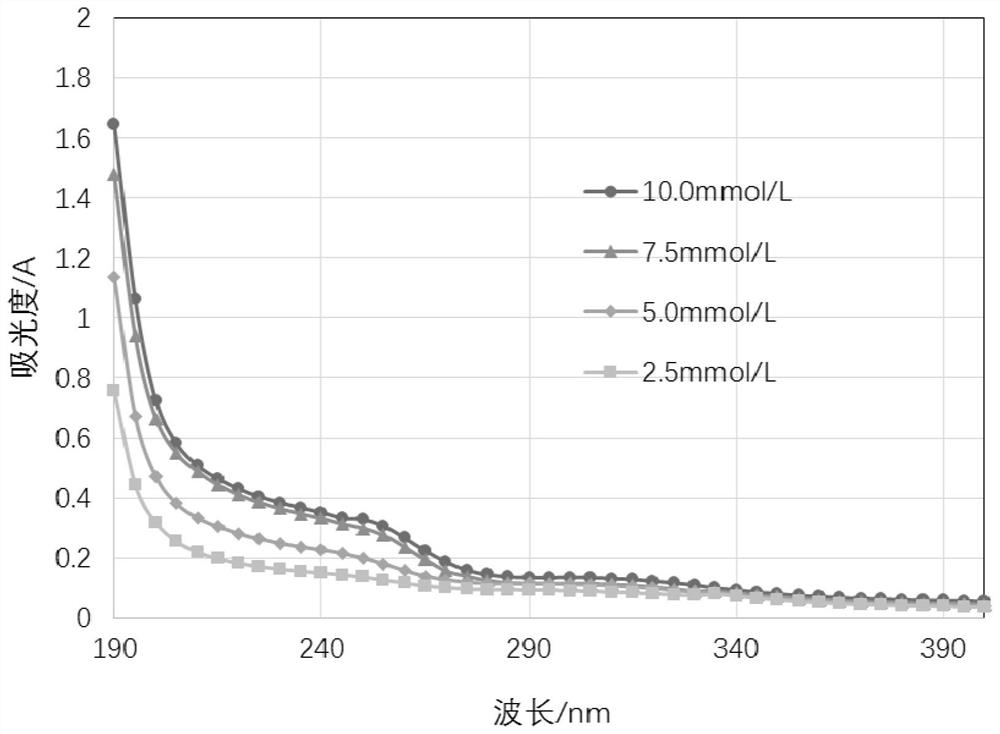

A method and device for quantitatively measuring cavitation strength in clear water or sandy water

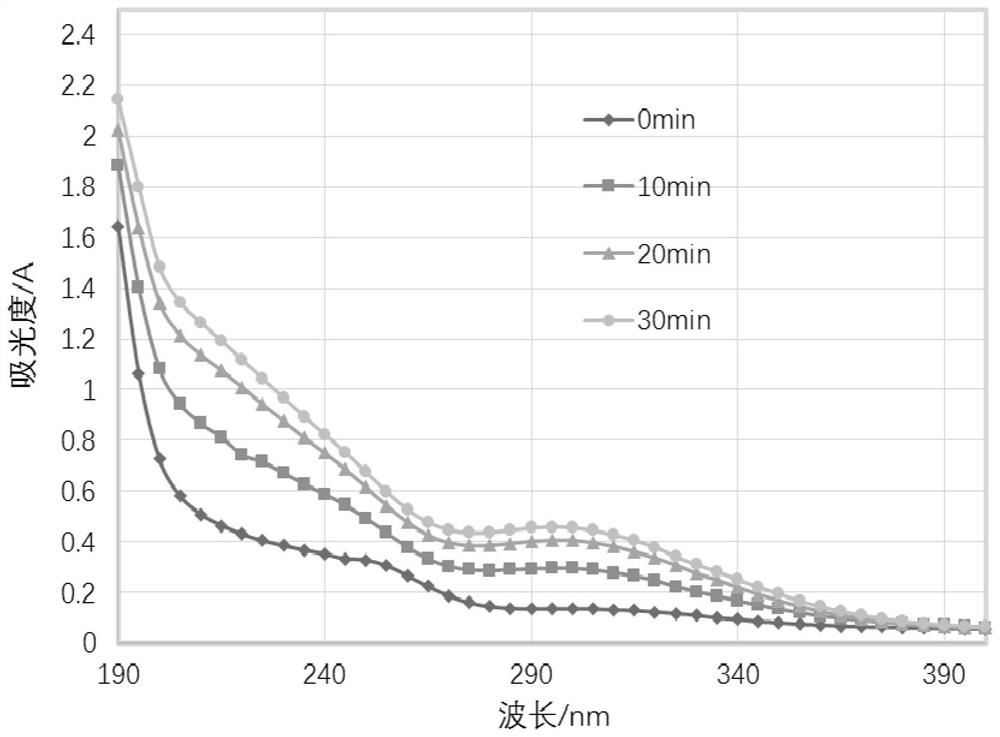

ActiveCN112577919BHigh sensitivityHigh precisionPreparing sample for investigationColor/spectral properties measurementsSoil scienceQuantitative determination

The invention relates to a method and a device for quantitatively measuring cavitation strength in clear water or sandy water. The scheme utilizes FeSO 4 Capture OH and Fe produced by cavitation in water 2+ oxidized to Fe 3+ , under certain conditions · OH concentration and Fe 3+ The concentration has a positive response relationship, and the absorbance of the solution is related to the Fe 3+ The concentration satisfies Lambert-Beer's law, and detecting the absorbance in the solution can quantitatively characterize the cavitation intensity of clear water or sandy water. The method and device provided by the invention can not only quantitatively measure the cavitation intensity in clear water, but also quantitatively measure the cavitation intensity in sandy water, and the agitating device provided can prevent sedimentation during the test and ensure that the reaction is fully carried out. Compared with the existing similar methods, the method of the present invention has many advantages such as high sensitivity, good accuracy, simplicity and ease of operation.

Owner:WUHAN UNIV

Loading device for tribological testing of rolling bearings

InactiveCN106969917BAvoid affecting test accuracyEasy to operateMachine bearings testingBearing componentsRolling-element bearingMagnetic poles

The present invention relates to the field of tribological tests. In order to improve the tribological test precision of a rolling bearing, the invention provides a load loading device for a rolling bearing tribological test. The device comprises a support device and a loading mechanism. The support device comprises a base, a rotation shaft support, and a support rotation shaft. The support rotation shaft is installed on the rotation shaft support and is sleeved by a T-shaped support ring and locking nuts. In a test, a rolling bearing is pressed and buckled by the T-shaped support ring, and the locking nuts are locked and fixed at two sides of the rolling bearing. The loading mechanism comprises an electromagnetic iron core and a magnetic conducting ring in a same plane. Two magnetic poles of the electromagnetic iron core face the support rotation shaft from side directions and are in a vertical symmetry at the horizontal diameter of the rolling bearing, magnetic pole end faces are an arc surfaces, and the arc surfaces and the support rotation shaft are concentric. The magnetic conducting ring sleeves the T-shaped support ring, and air gaps are arranged between the magnetic conducting ring and the magnetic pole end faces of the electromagnetic iron core. When the load loading device for a rolling bearing tribological test is used to carry out a rolling bearing friction test, the test precision is high.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com