Patents

Literature

86results about How to "Meet deformation requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

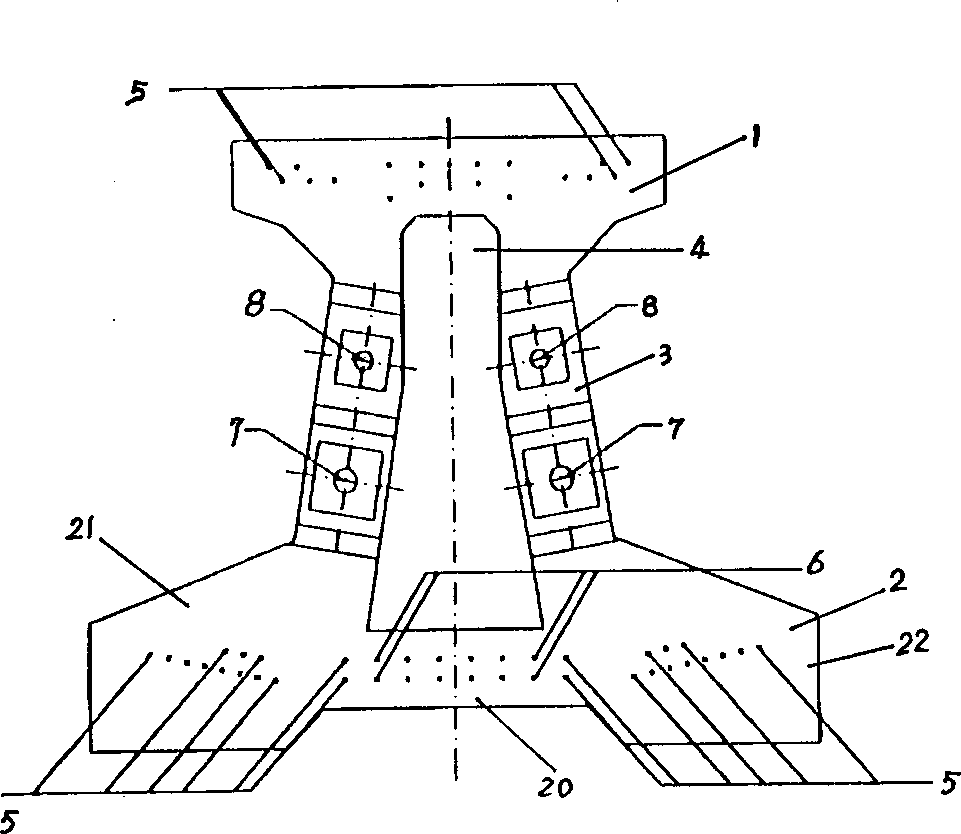

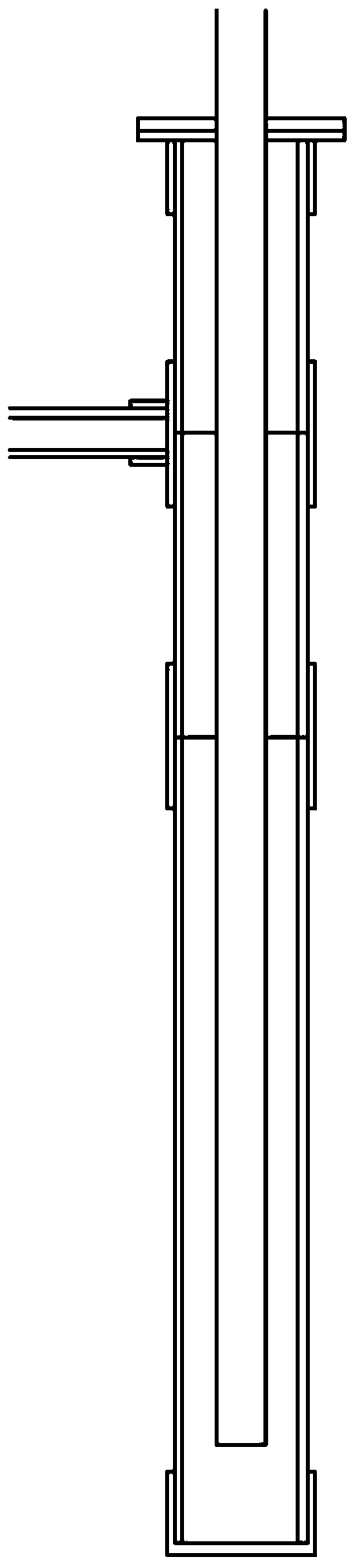

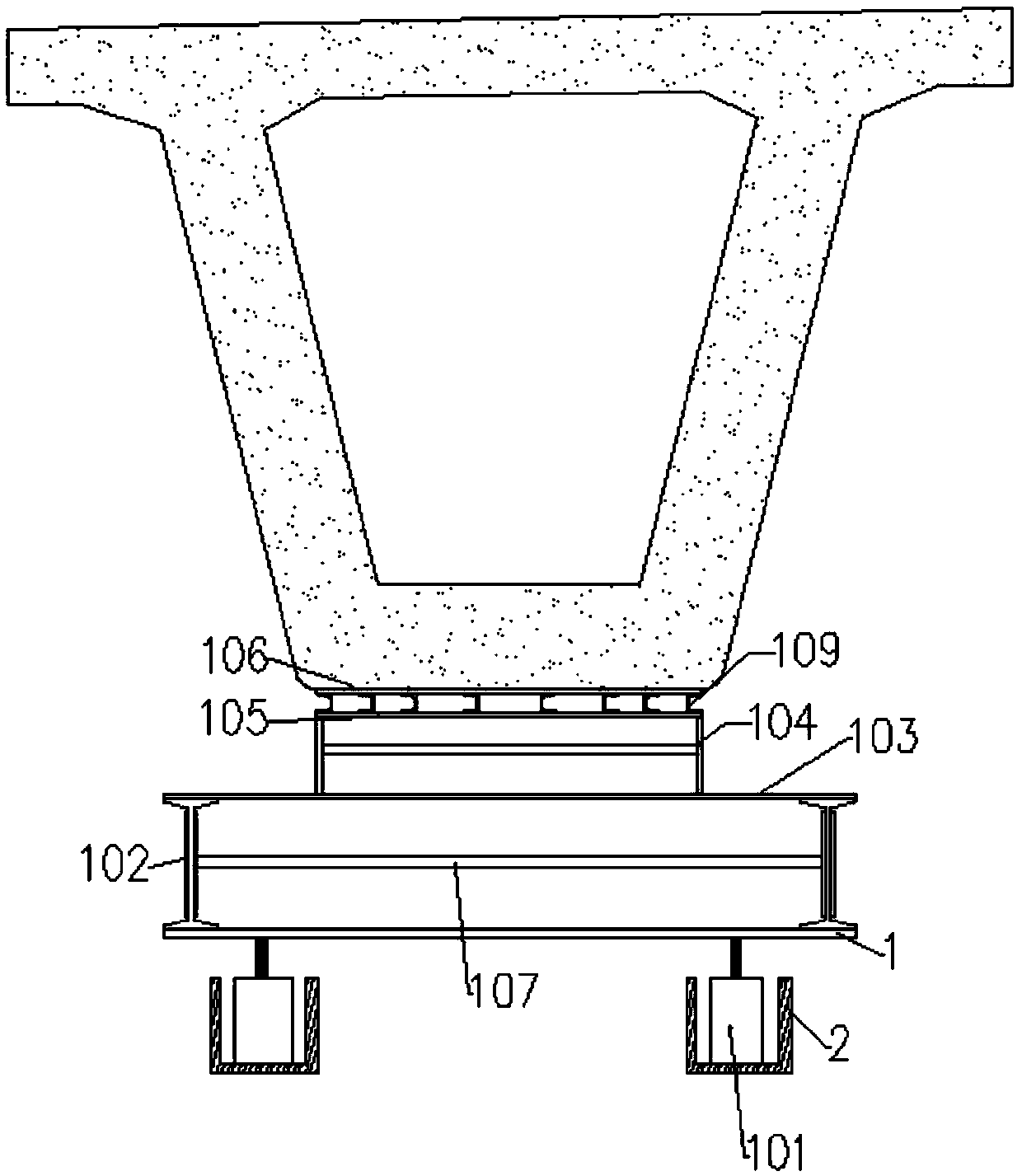

Medium-and-low speed magnetic levitation railway low route continuous arched supporting rail beam structure and construction method

ActiveCN104480803AMeet stability requirementsMeet strength requirementsBallastwayLow speedReinforced concrete

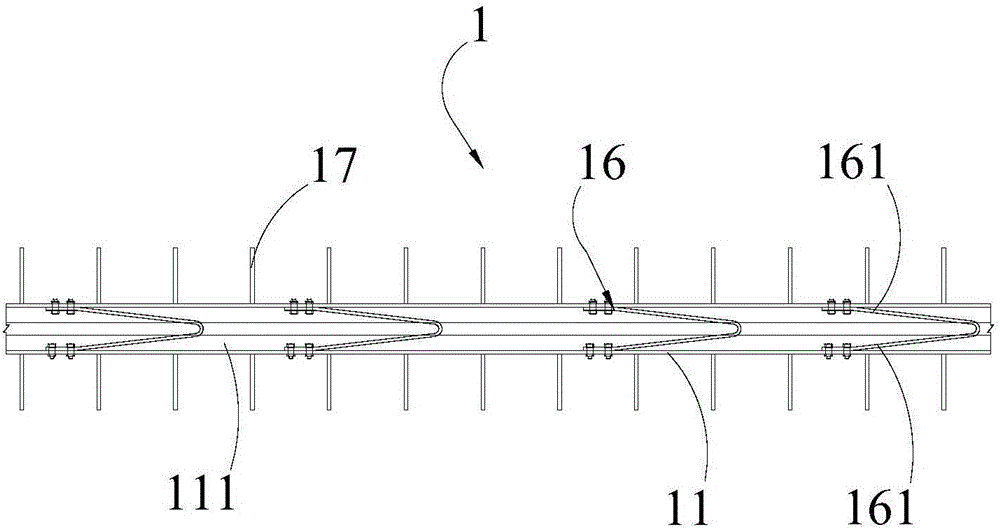

The invention discloses a medium-and-low speed magnetic levitation railway low route continuous arched supporting rail beam structure. The structure comprises a reinforced concrete bottom plate, a rail row, a plurality of rows of track rail supporting tables, a reinforced concrete top plate, flow guide rail brackets and a plurality of reinforced concrete arched posts, wherein a transponder mounting position is arranged between a left track rail supporting table and a right track rail supporting table in each row of track rail supporting tables; the flow guide rail brackets are arranged on the two sides of the reinforced concrete top plate; the reinforced concrete arched posts are arranged on the reinforced concrete bottom plate along the track line direction at equal intervals; the bottom of the reinforced concrete top plate is fixedly connected with the top of each reinforced concrete arched post; the rail row is arranged at the top of the reinforced concrete top plate through the track rail supporting tables; a transverse arch is arranged in each reinforced concrete arched post; a longitudinal arch is formed between every two adjacent reinforced concrete arched posts. The transverse drainage requirement on a low route at a dual-line road section is convenient to meet, and the difficulty on construction of a rail structure on the upper part can be reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

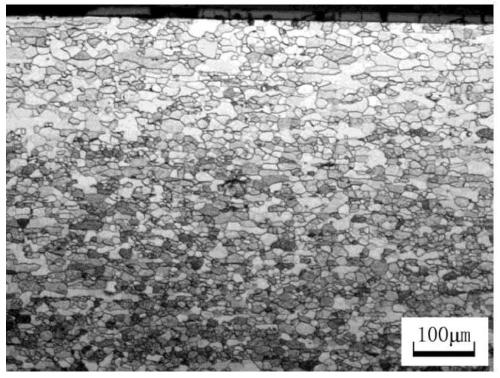

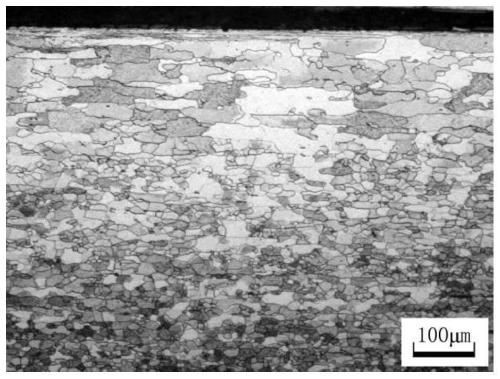

Super deep-draw fingerprint resistant electro-galvanized plate and manufacturing method thereof

InactiveCN104862592AExcellent deep drawing performanceSolve the technical problems of assembly difficultiesReduction rateChemical composition

The invention discloses a super deep-draw fingerprint resistant electro-galvanized plate and a manufacturing method thereof. The super deep-draw fingerprint resistant electro-galvanized plate comprises the following chemical components in percentage by weight: less than or equal to 0.002 percent of C, less than or equal to 0.01 percent of Si, 0.06-0.12 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.009 percent of S, 0.065-0.085 percent of Ti, 0.02-0.05 percent of sol Al, less than or equal to 0.003 percent of N, and the balance of Fe and inevitable impurities. The manufacturing method comprises the steps of molten iron desulphurization, smelting in a converter, vacuum treatment, continuous casting, hot rolling, cold rolling, continuous annealing and reeling, wherein the heating temperature of the hot rolling is 1,000-1,200 DEG C, the temperature of the final rolling is 800-1,000 DEG C, five times of cold rolling is conducted after the continuous hot rolling, the reduction rate of the cold rolling is controlled to be 73-83%, the temperature of continuous annealing is 810-860 DEG C, the time of the continuous annealing is 15-80 s, and then the electrogalvanizing and fingerprint resisting treatment is conducted after leveling and withdrawal straightening. The electro-galvanized plate has excellent stamping processing and fingerprint resisting performance, and the manufacturing method of steel is simple in process flow and low in production cost.

Owner:武钢集团有限公司

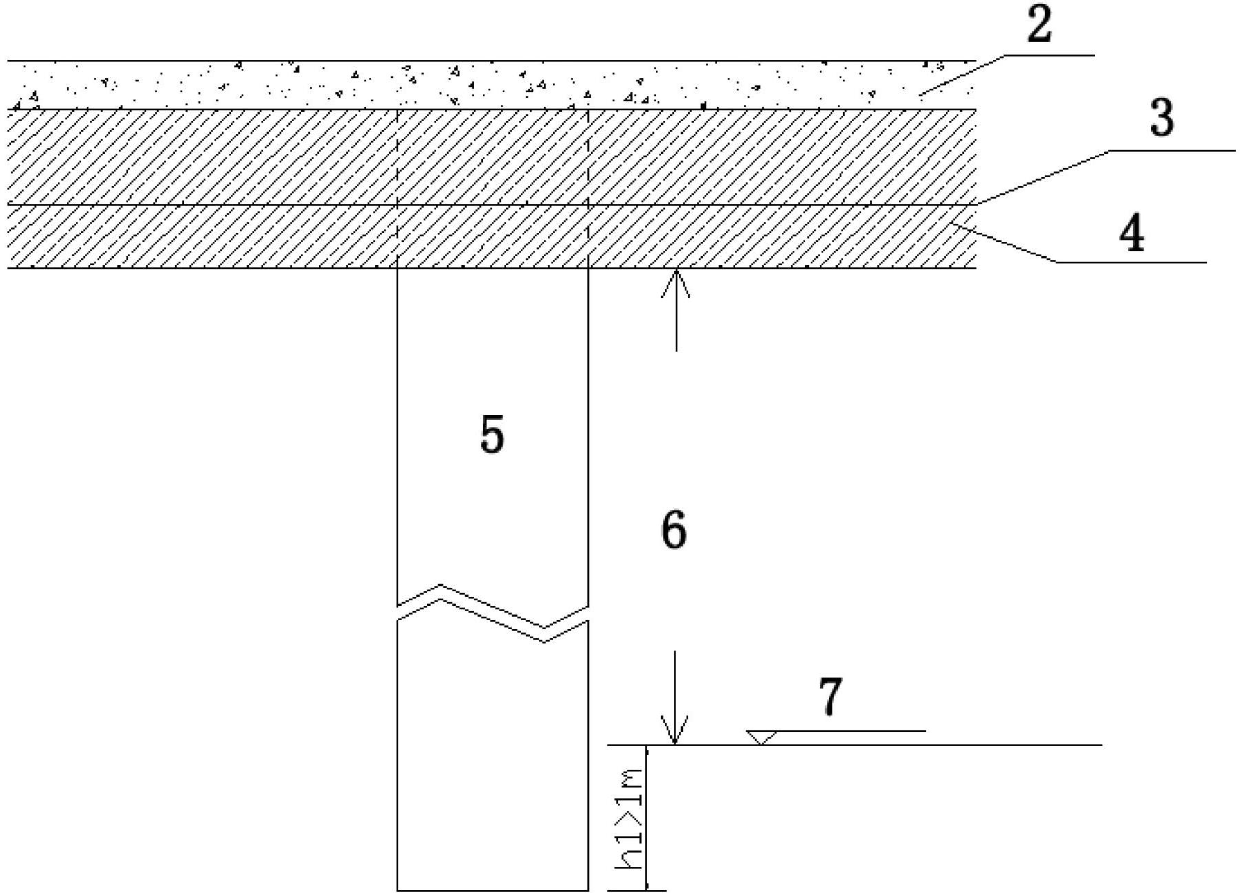

Reinforcement method for foundation of silt soft-based cast-in-place box girder support

InactiveCN102677661AMeet deformation requirementsImprove the combined methodBulkheads/pilesSoil preservationCrushed stoneHigh pressure

The invention relates o the technical field of civil engineering and building construction, in particular to a reinforcement method for a foundation of a silt soft-based cast-in-place box girder support. The reinforcement method is characterized by comprising the following steps of: determining parameters->clearing and leveling a ground->measuring the position of an upper structure and laying off a pile position->carrying out high-pressure rotary jet grouting pile construction->curing->carrying out secondary leveling and compacting->chiseling away the top of the pipe by 50cm and rejecting an unoccupied pile head->paving 20cm grading gravels, flattening and compacting->laying steel-plastic grilles->paving a 30cm grading gravel mattress layer->flattening and compacting->pouring a concrete cushion layer. Compared with the prior art, the reinforcement method has the advantages that the respective principle of a combined process is exerted, the cast-in-place beam deformation requirement is satisfied, the construction process is simple and rapid, the cost is low, the safety risk is small, the permanent and temporary combination is realized, and the follow-up input is saved.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD

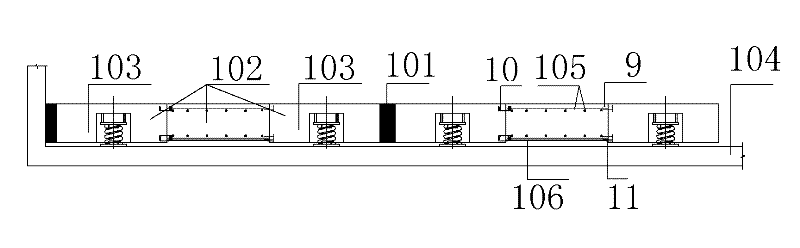

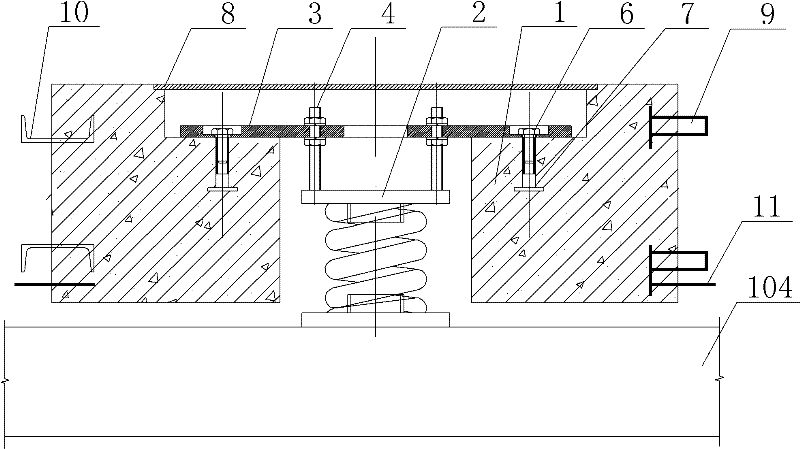

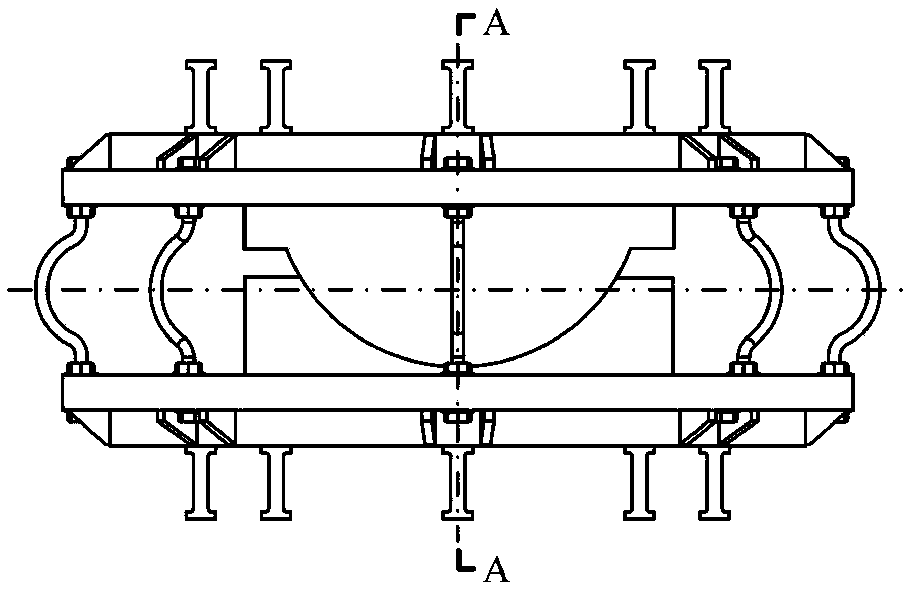

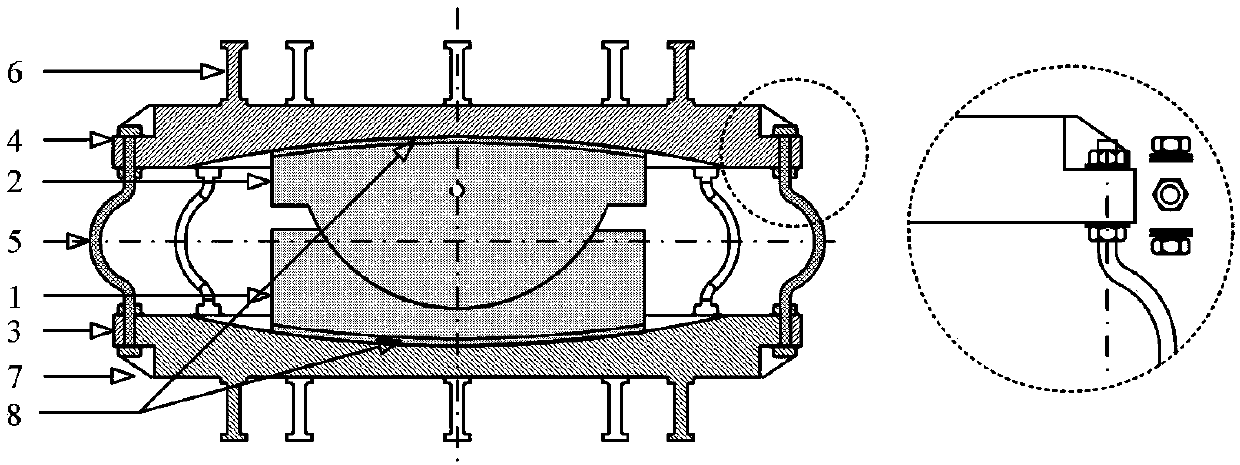

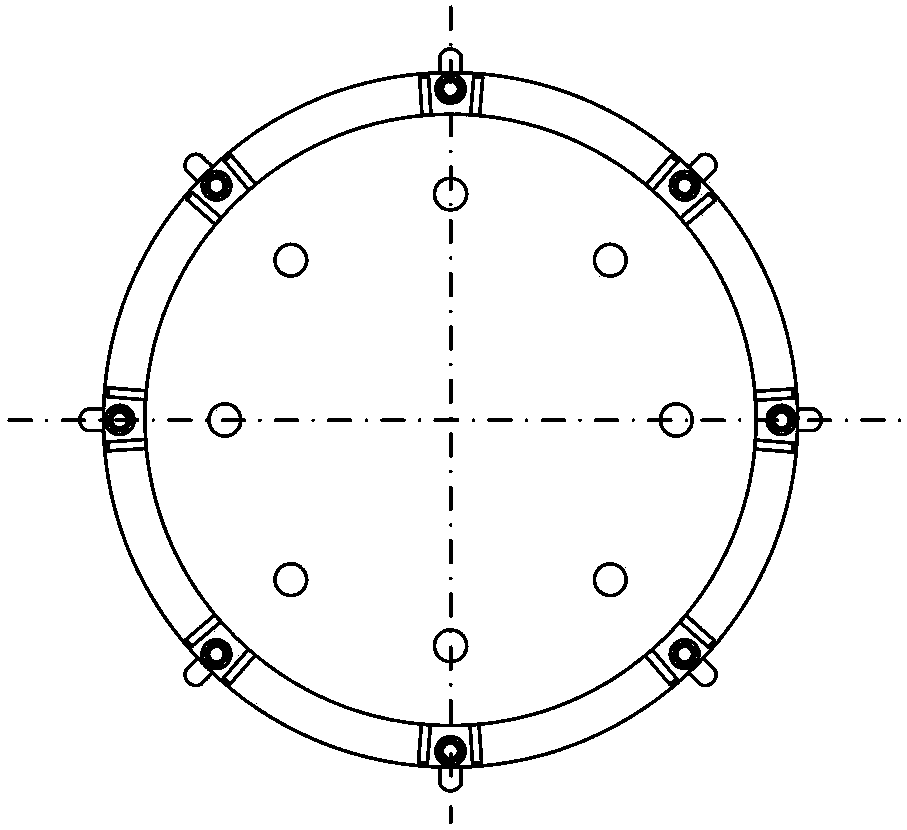

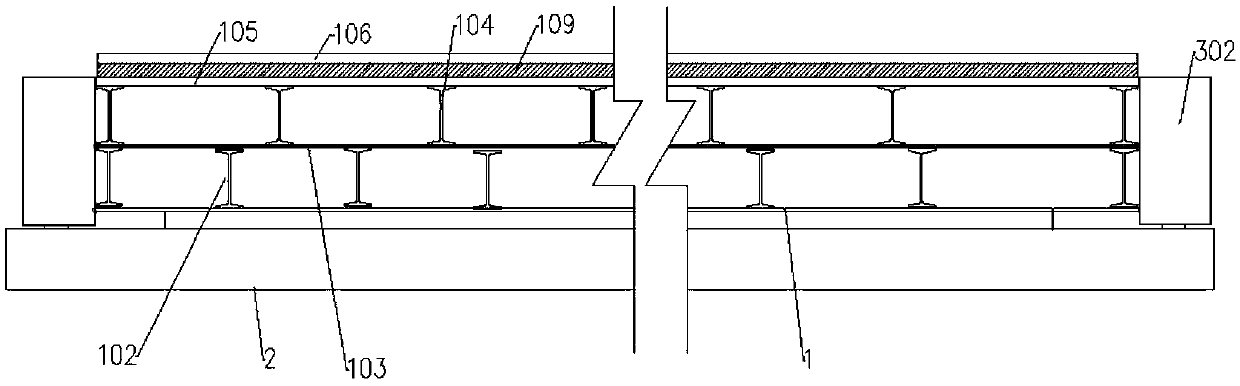

Suspension type floating plate vibration isolation system

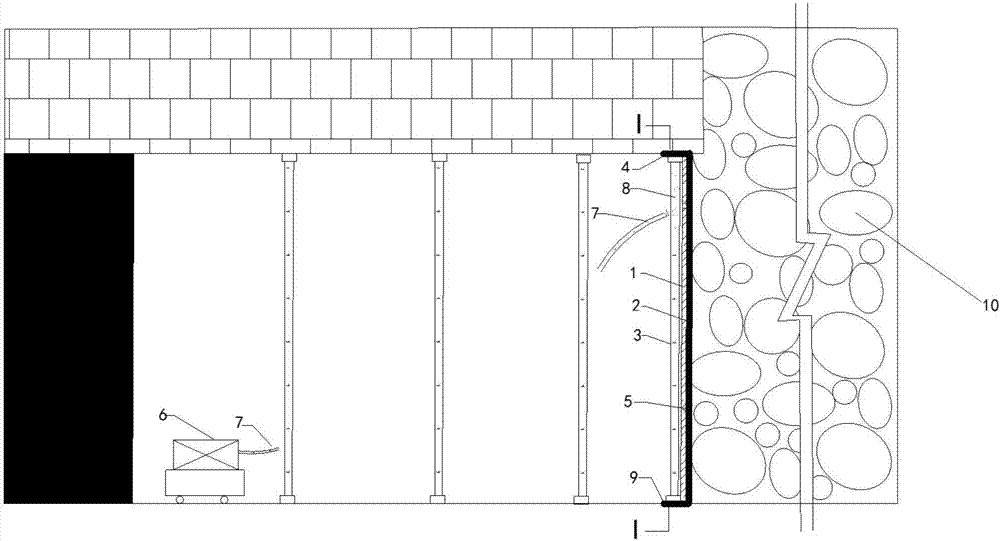

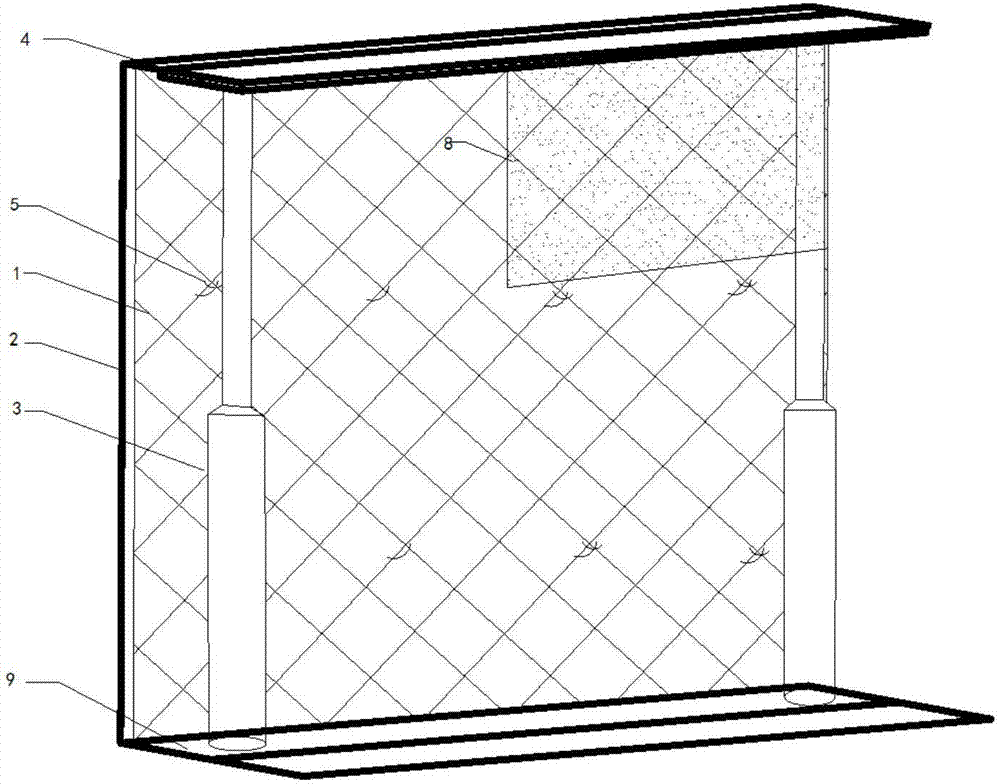

InactiveCN102220789AImprove sound insulationBig vibrationRailway tracksShock proofingFloor slabVibration isolation

The invention discloses a suspension type floating plate vibration isolation system, which comprises area floating plates, rubber vibration damping belts and a plurality of precast vibration isolation units, wherein the plurality of precast vibration isolation units are arranged on floor slabs or the ground, and are cast on site to form the area floating plates; the area floating plates are supported on the floor slabs or the ground by vibration isolators in the precast vibration isolation units and form gaps with the ground or floors to isolate vibration and noise; a plurality of area floating plates are arranged; and the rubber vibration damping belts are arranged among different area floating plates to limit the transmission of vibration in the horizontal direction. The suspension type floating plate vibration isolation system can isolate the vibration of machines from the floor slabs, is not needed to be jacked in the construction process and is easy to maintain and replace in the using process.

Owner:SHANGHAI ZHAORUI DAMPING TECH

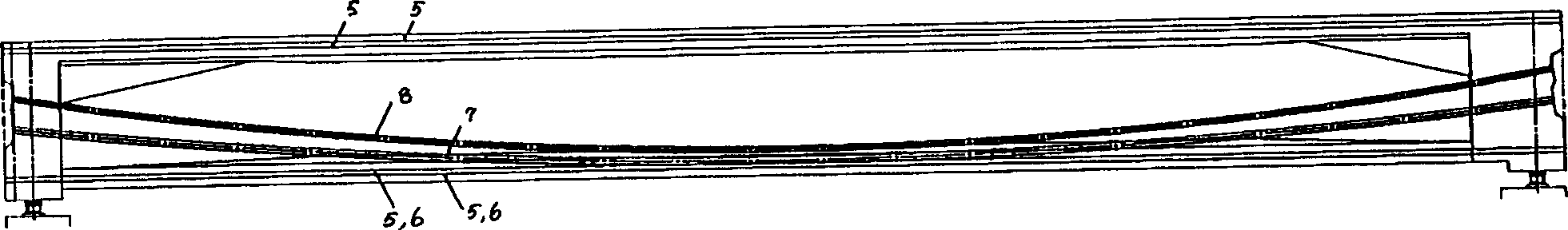

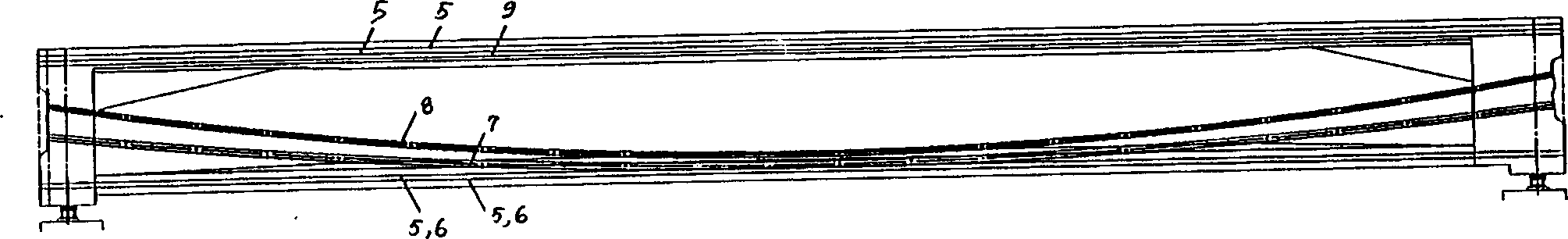

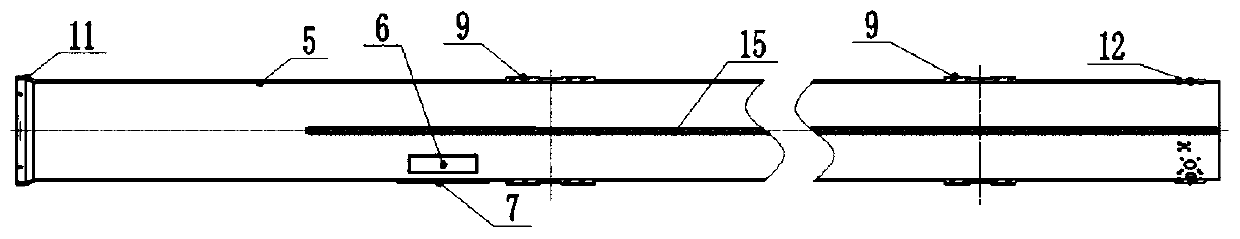

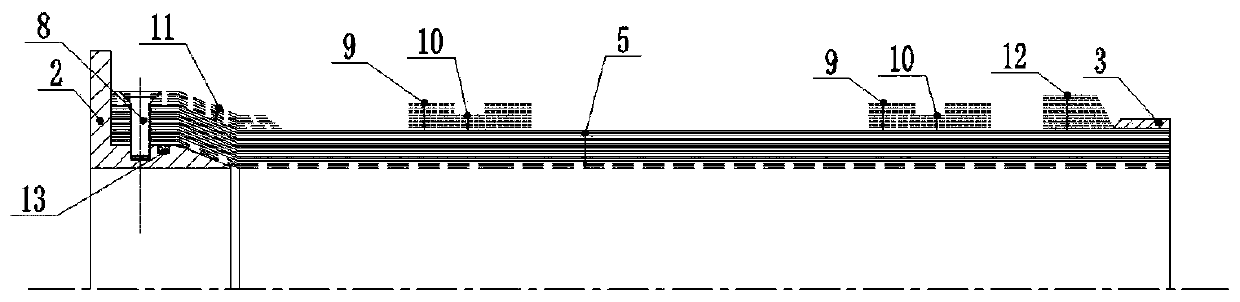

Prestressed rail beam and its manufacture

The prestressed rail beam suitable for use in high speed urban rail transportation includes top plate, bottom plate and web plate. It is featured by that several eccentric pretensioning type prestressed beams set in the right and left parts of the top plate and the bottom plate; several eccentric pretensioning type prestressed beams set in the middle part of the bottom plate; two quadratic parabolic first post tensioning type prestressed beams on two sides of the web separately; two quadratic parabolic second post tensinoing type prestressed beams on two sides of the web separately; and outside prestressed beams in cavity and top plate. Controlling the prestressed rail beam always in prestressed axle state for one deformation keeps within 1 mm.

Owner:SHANGHAI MAGLEV TRANSPORTATION DEVELOPMENT CO LTD

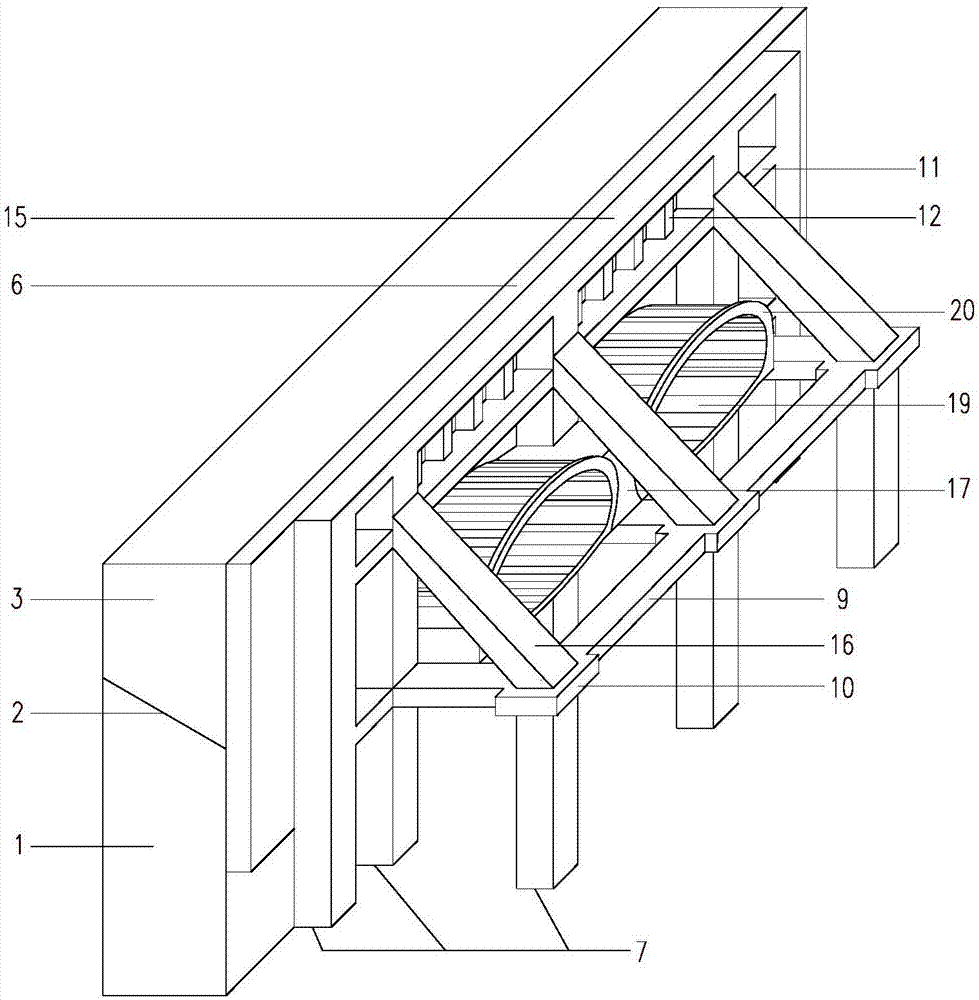

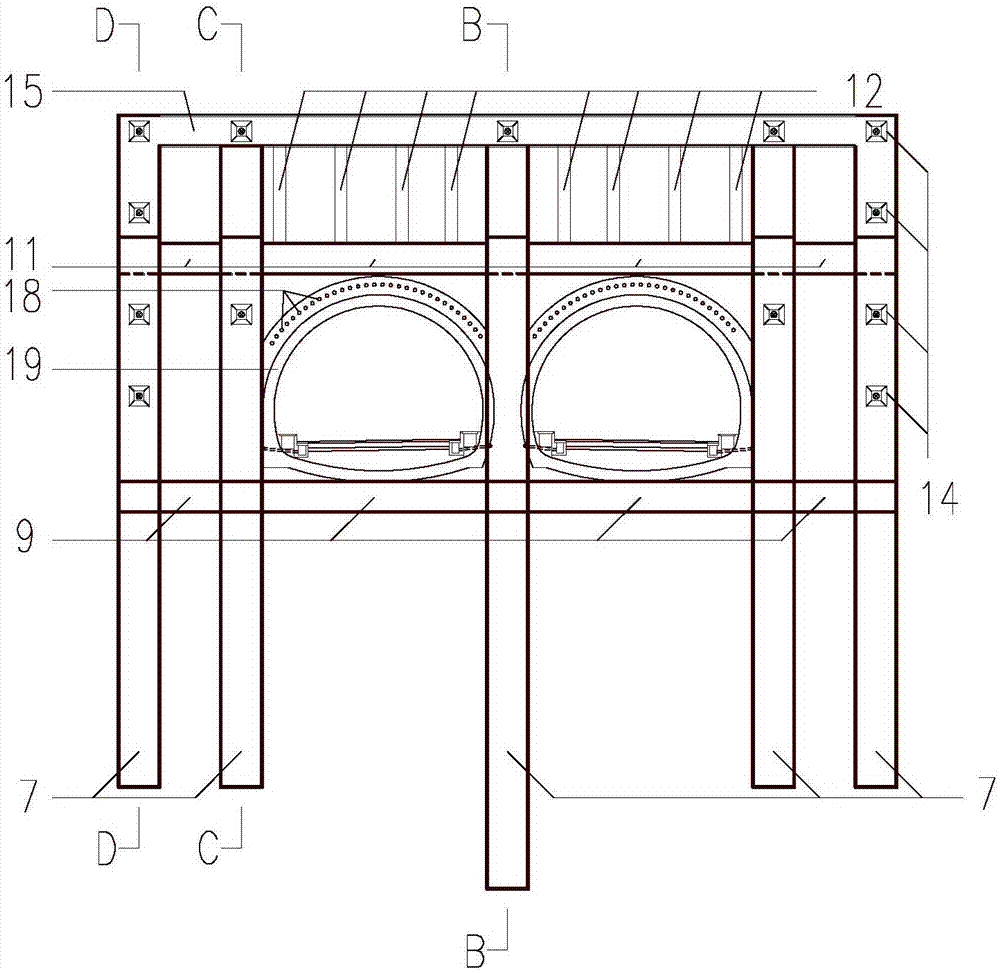

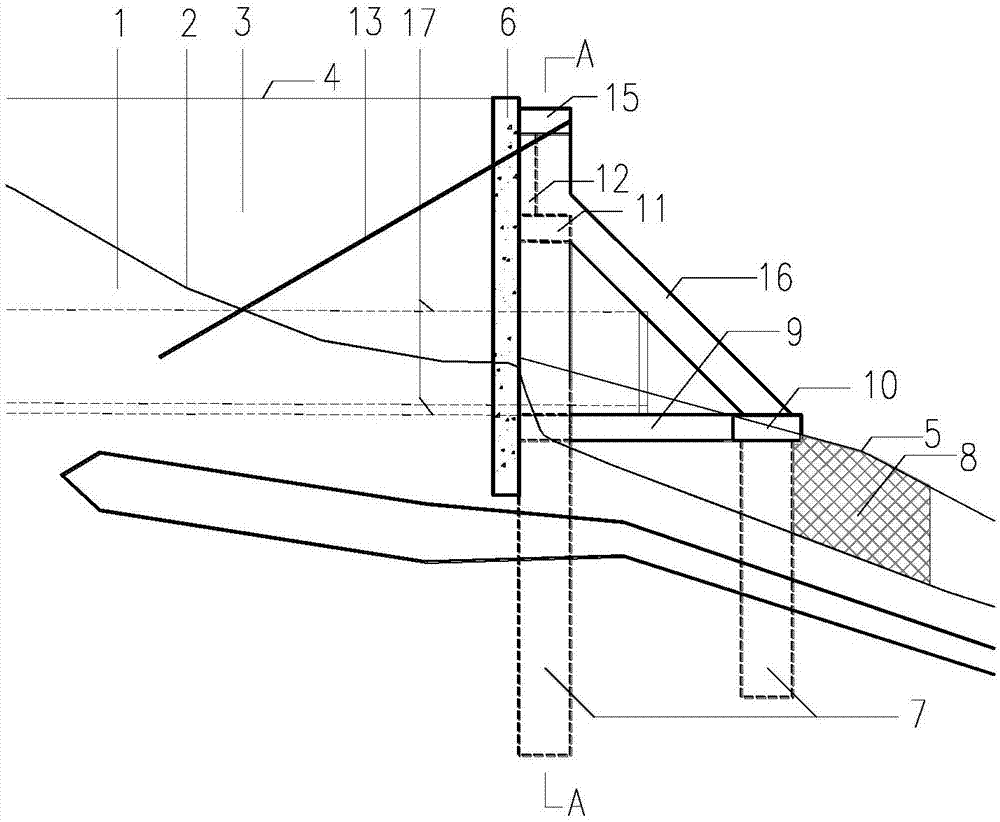

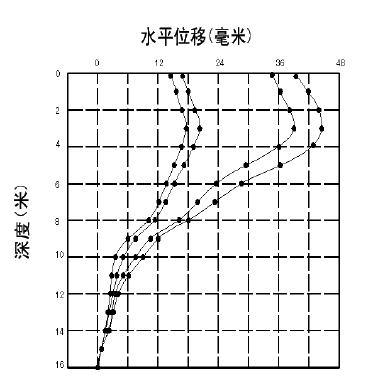

Supporting and retaining structure of existing retaining wall straight penetrated by large-span tunnel and construction method thereof

ActiveCN107130613AReduce distortionImprove reinforcement effectExcavationsBulkheads/pilesEngineeringCoupling beam

The invention belongs to the technical field of tunnel engineering and particularly relates to a supporting and retaining structure of an existing retaining wall straight penetrated by a large-span tunnel and a construction method thereof. The supporting and retaining structure comprises two rows of anti-skid piles, a ground coupling beam, coupling beams, a top beam, inclined struts, an anchor stay cable structure and a grouting reinforcement body. The two rows of anti-skid piles are mounted on the outer side of the supporting and retaining structure. The front row of anti-skid piles are at a certain distance from the supporting and retaining structure and are connected with one another through the ground coupling beam. The rear row of anti-skid piles are tightly attached to the supporting and retaining structure and connected with one another through the top beam, the coupling beams and the ground coupling beam. The two rows of the anti-skid piles are connected through the ground coupling beam and the inclined struts to form an overall frame structure. The rear row of anti-skid piles are provided with opposite-pull anchor stay cables. Rock and soil masses on the stressed sides of the peripheries of the anti-skid piles are subjected to grouting reinforcement, and the bearing capacities of the rock and soil masses and the supporting and retaining structure are improved. The supporting and retaining structure is applicable to an entrance and an exit of the large-span tunnel and a tunnel entrance heading slop with the requirement of small deformation, the reinforcing effect is guaranteed, and traffic operation is not blocked.

Owner:CHONGQING UNIV +1

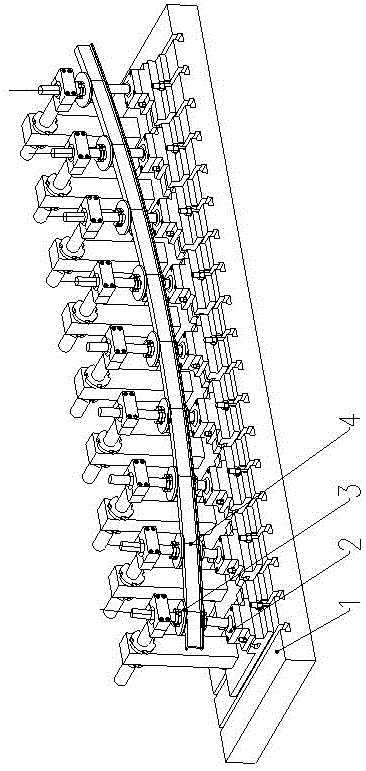

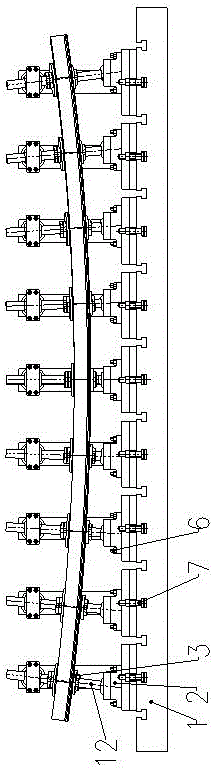

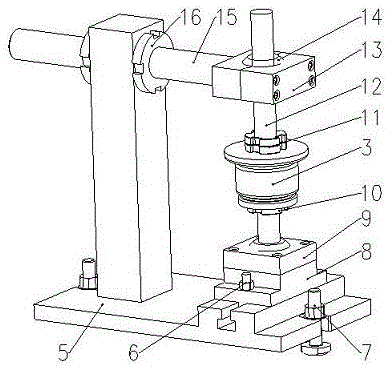

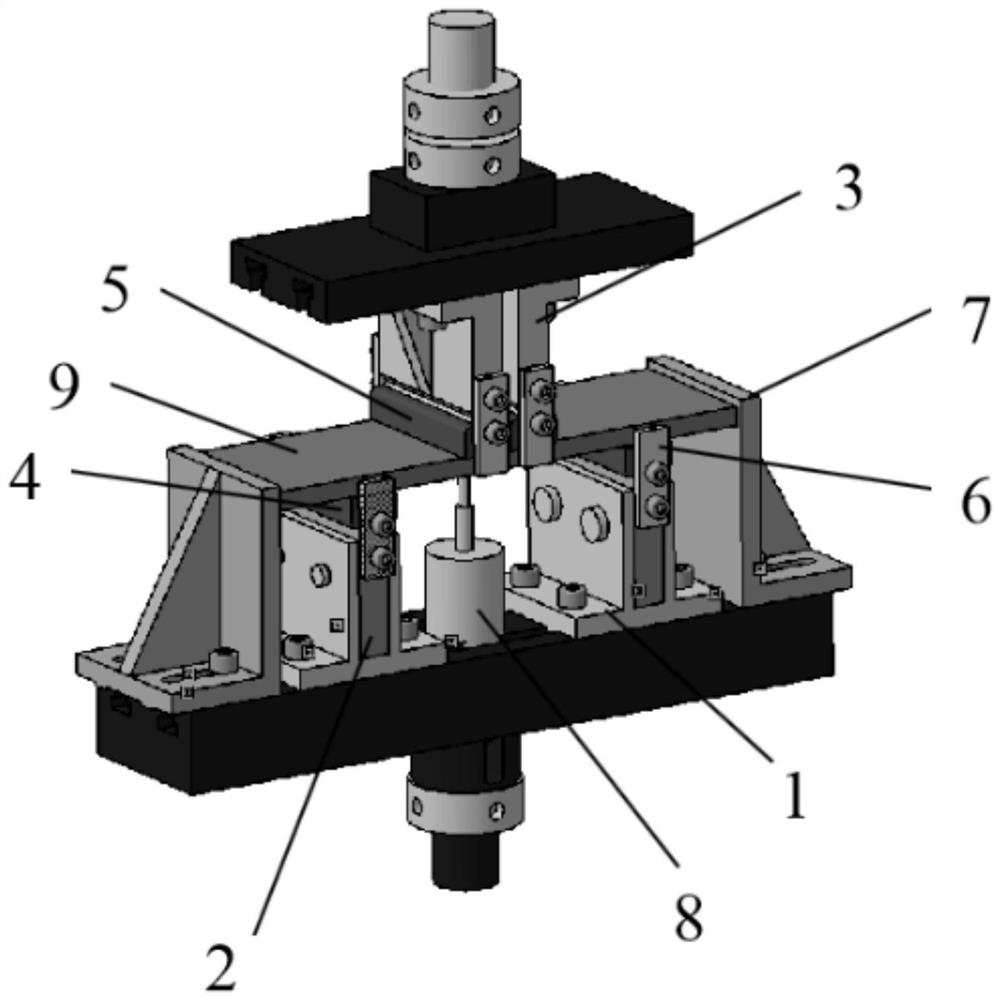

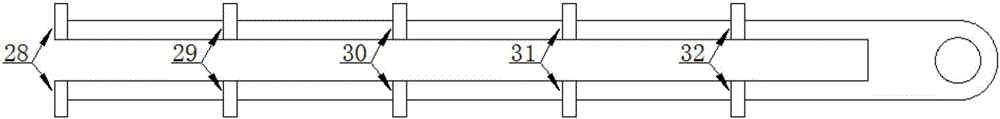

A roller type multi-section control section bar three-dimensional stretch-bending dieless forming device

The invention provides a roller type multi-section control section bar three-dimensional stretch-bending dieless forming device and belongs to the technical field of metal section bar stretch-bending forming. The device is mainly applied to part manufacture of three-dimensional bending and twisting composite deformation of metal section bars. Multiple rollers are used and the positions and angles of the normal sections on the space of three-dimensional bending and twisting formed parts of section bars are subjected to section control, so that linear section bars are bent and twisted according to a preset trajectory to finish composite forming. One roller controls the spatial position and angle of one normal section of one formed part. The device consists of such parts as a machine base, a plurality of universal angle-adjustable supports and a group of forming rollers. One universal angle-adjustable support is provided with and controls one roller, so that the spatial position and the axial direction thereof can meet the deformation requirements. The machine base and the universal angle-adjustable supports are common parts; the group of forming rollers can be applied to formed parts with different bending curvatures of sections bars with the same section.

Owner:JILIN UNIV

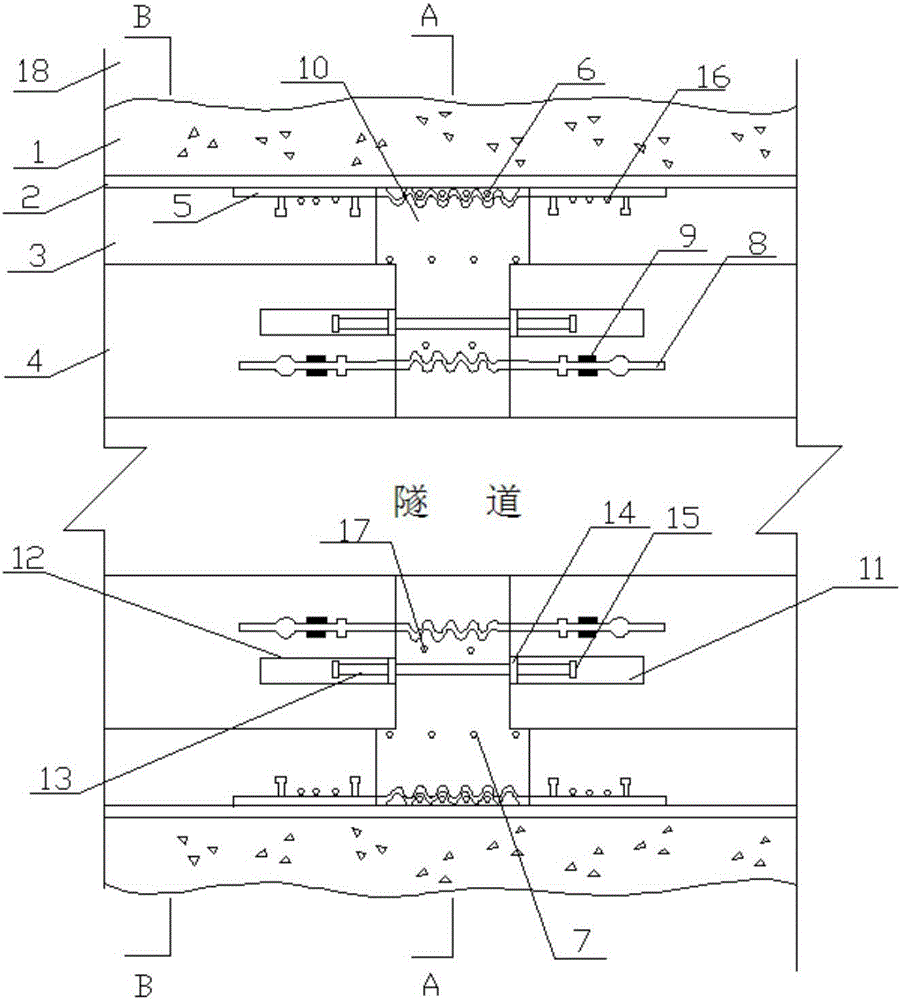

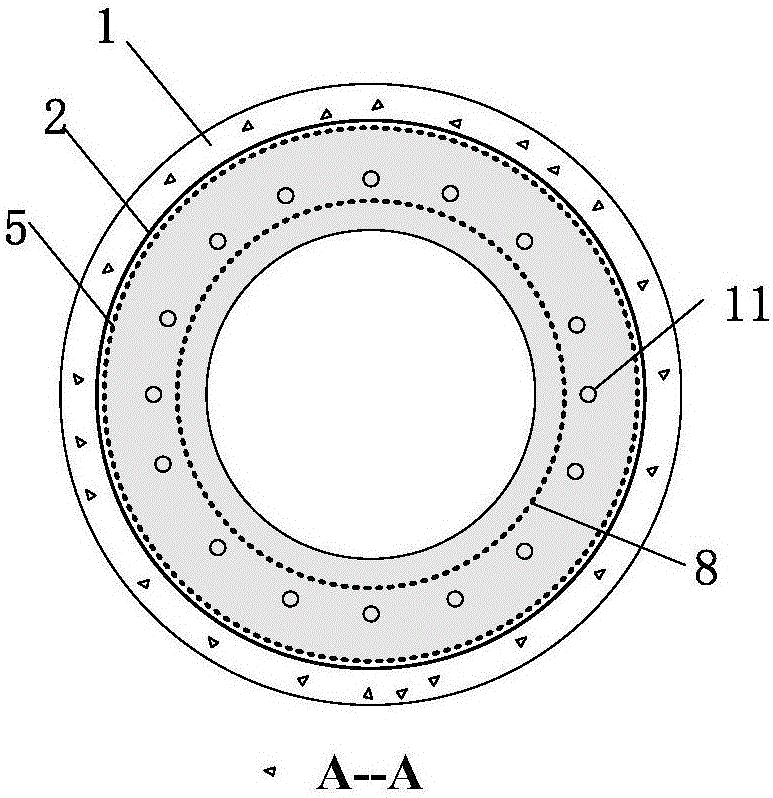

Tunnel lining waterproof joint

ActiveCN106437789AHigh deformation requirementsLow permeability coefficientUnderground chambersTunnel liningFilling materialsPlastic property

The invention relates to a tunnel lining waterproof joint. The tunnel lining waterproof joint comprises a primary lining layer, a waterproof layer, a deformation layer and a secondary lining layer which are sequentially distributed from outside to inside along the section of a tunnel. A flexible joint body is arranged in the annular direction of the tunnel and divides the deformation layer and the secondary lining layer into two adjacent parts in the longitudinal direction of the tunnel. The section of the flexible joint body is in a T shape. The first width of the portion, located in the deformation layer, of the flexible joint body is larger than the second width of the portion, located in the secondary lining layer, of the flexible joint body. The flexible joint body is filled with plastic concrete material. The plastic concrete material is prepared from, by weight, 10-20 parts of cement, 70-80 parts of sand, 20-30 parts of water, 70-90 parts of stone, 2-4 parts of additive, 2-4 parts of bentonite and 6-9 parts of clay. Plastic concrete is adopted as the filling material of a T-shaped deformation joint, the seepage path of seepage water can be prolonged, anti-seepage performance is improved, and the breakage probability of a boundary is reduced.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

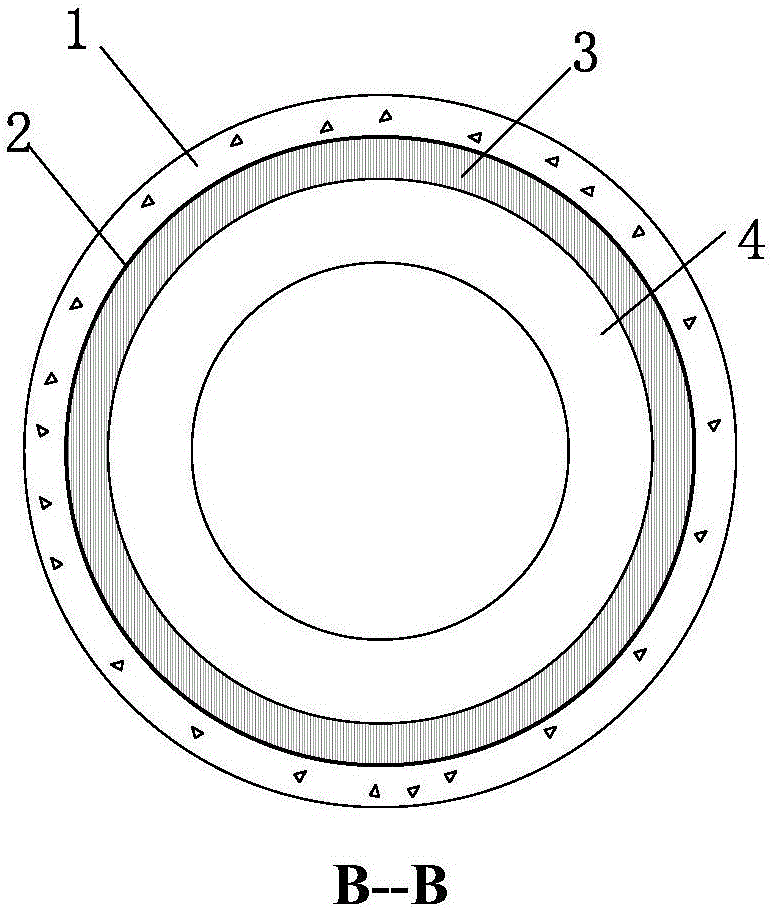

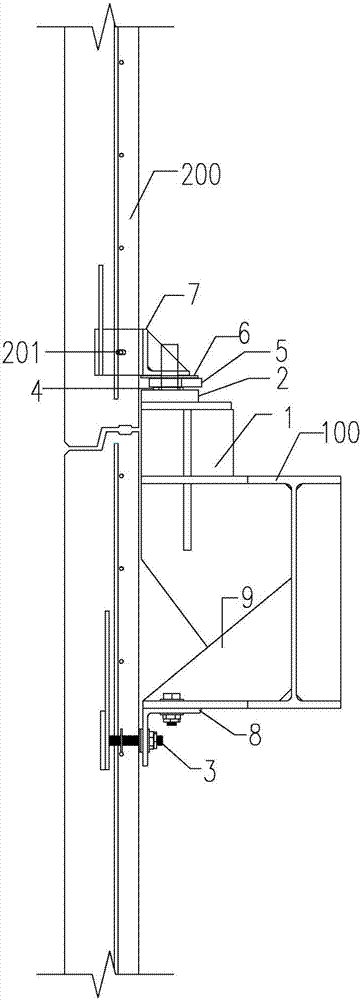

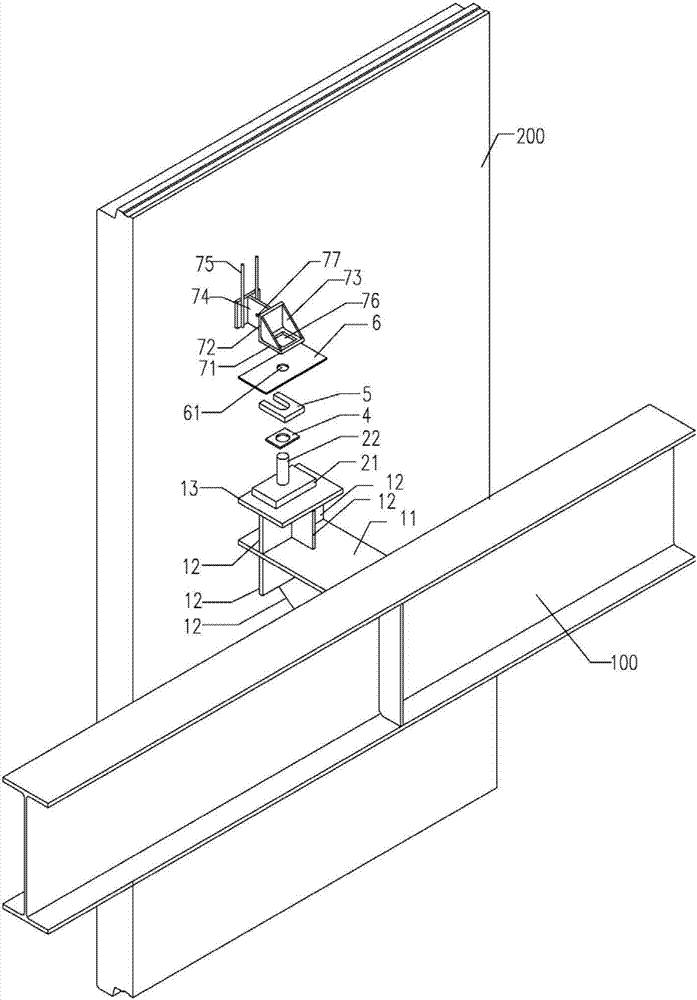

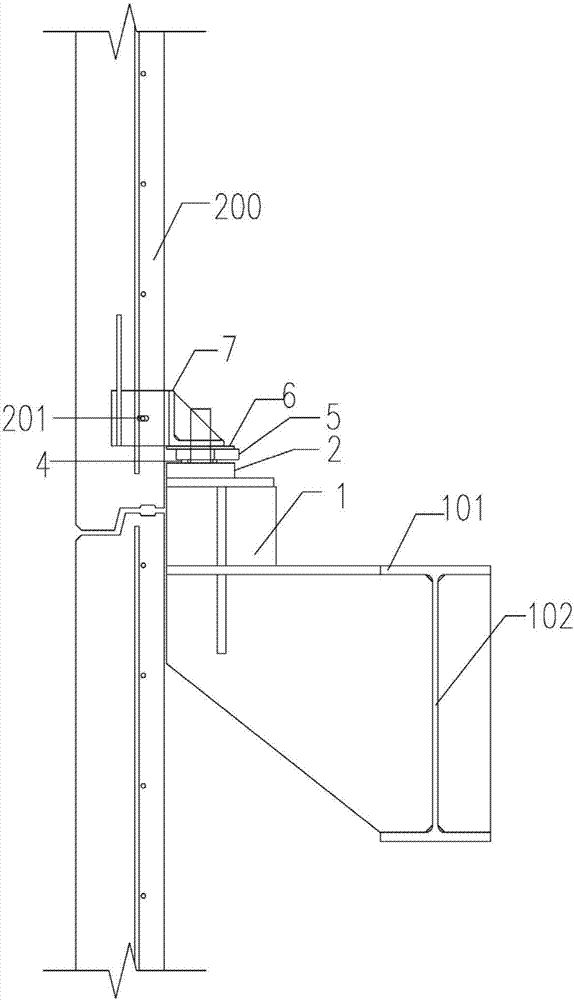

Upper-and-down two-point type connecting joint of steel structure and polycarbonate (PC) outer wall

PendingCN107190865AEffective adjustment of direction installation errorRealize three-dimensional adjustmentBuilding constructionsPre embeddingPolycarbonate

The invention relates to an upper-and-down two-point type connecting joint of a steel structure and a polycarbonate (PC) outer wall. The PC outer wall is assembled vertically. A steel structure boundary beam is arranged on one side of the vertically-assembled PC outer wall. A first bracket is welded to one side of the steel structure boundary beam and located between the steel structure boundary beam and the PC outer wall. A connecting base is welded to the bracket and welded by a bearing plate and round steel, and the round steel is arranged vertically. A welding-stopping plate, a heel block, a positioning plate are inserted in the round steel in sequence from bottom to top, and the round steel is welded to the positioning plate. A pre-embedded part is pre-embedded at the lower part of the PC outer wall on the upper portion and welded to the positioning plate. A pre-embedded bolt is pre-embedded at the upper part of the PC outer wall on the lower portion. Connecting angle steel is correspondingly connected with the pre-embedded bolt and a second bracket. The second bracket is welded to one side of the steel structure boundary beam. According to the upper-and-down two-point type connecting joint of the steel structure and the PC outer wall, the firmness and safety of wall plate installing can be ensured, on-site installation construction errors can be adjusted as much as possible, and on-site actual construction requirements can be met.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

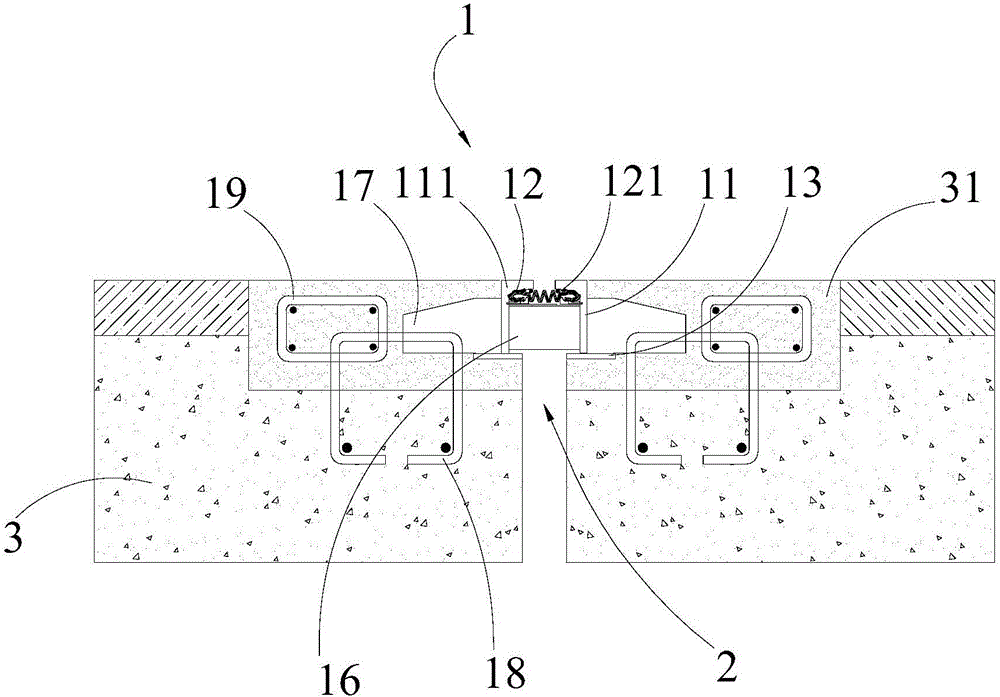

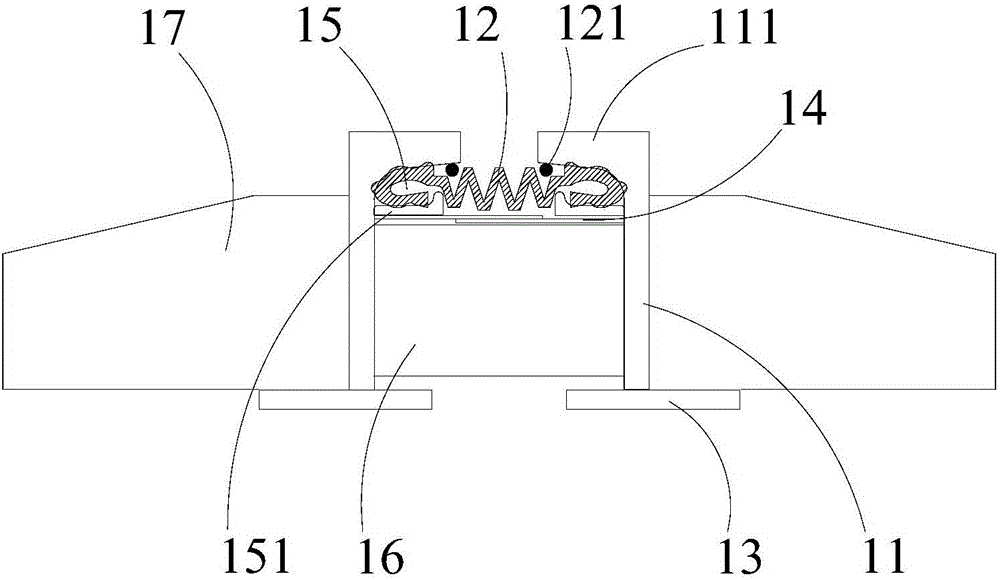

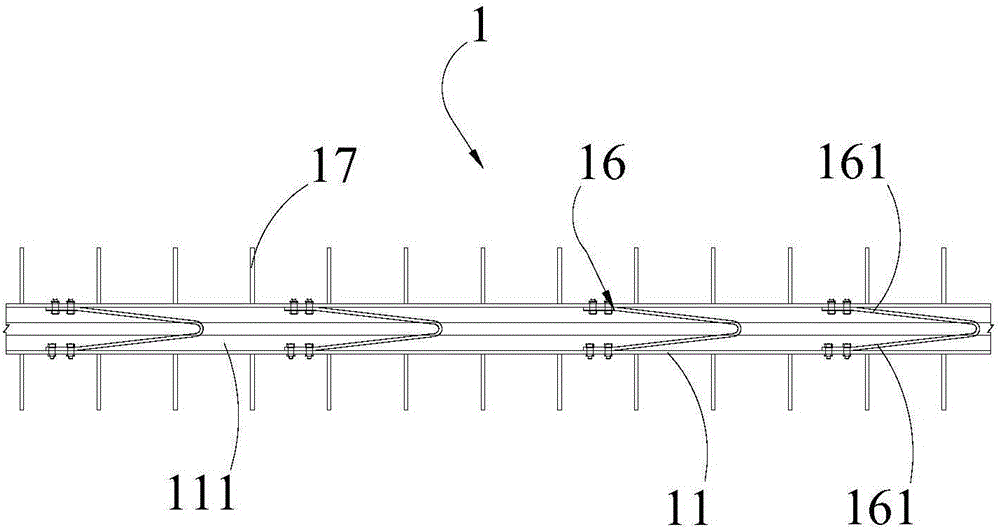

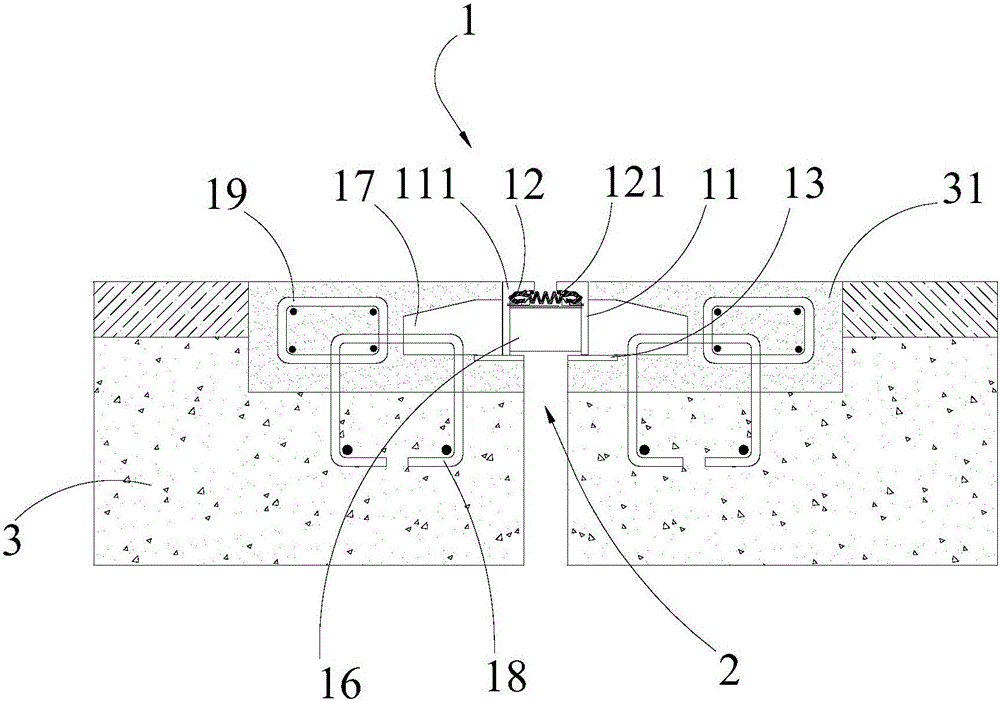

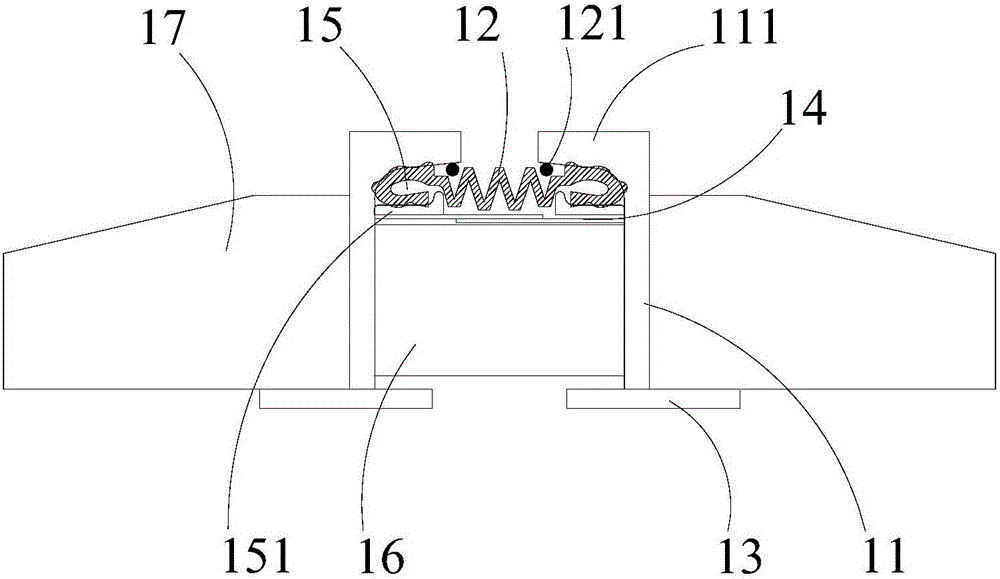

Expansion and contraction device with arch elastic connection function

ActiveCN105887672AImprove structural integrityMeet deformation requirementsBridge structural detailsEngineeringExpansion joint

The invention relates to a building expansion and retraction device, and provides an expansion and contraction device with an arch elastic connection function. The expansion and contraction device comprises two edge beams located on the two sides of an expansion joint and arranged oppositely, and further comprises a rubber strip which is clamped between the two edge beams and stretches across the expansion joint. At least one elastic connecting plate is further arranged below the rubber strip, the elastic connecting plates are sequentially arranged at intervals in the length direction parallel to the expansion joint and fixedly connected to the two edge beams through anchor bolts, and each elastic connecting plate stretches across the expansion joint and vertically supports the rubber strip. According to the expansion and retraction device, the rubber strip is adopted for waterproof sealing between the two edge beams, the elastic connecting plates located below the rubber strip are used for supporting the rubber strip, a certain reverse acting force can be provided for the rubber strip, the reliability of the rubber strip can be improved, and the rubber strip is not likely to disengage from the edge beams; besides, the elastic connecting plates can play a role similar to that of elastic connecting hinges, so that the left edge beam and the right edge beam bear force cooperatively, and the structural integrity of the expansion and retraction device is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

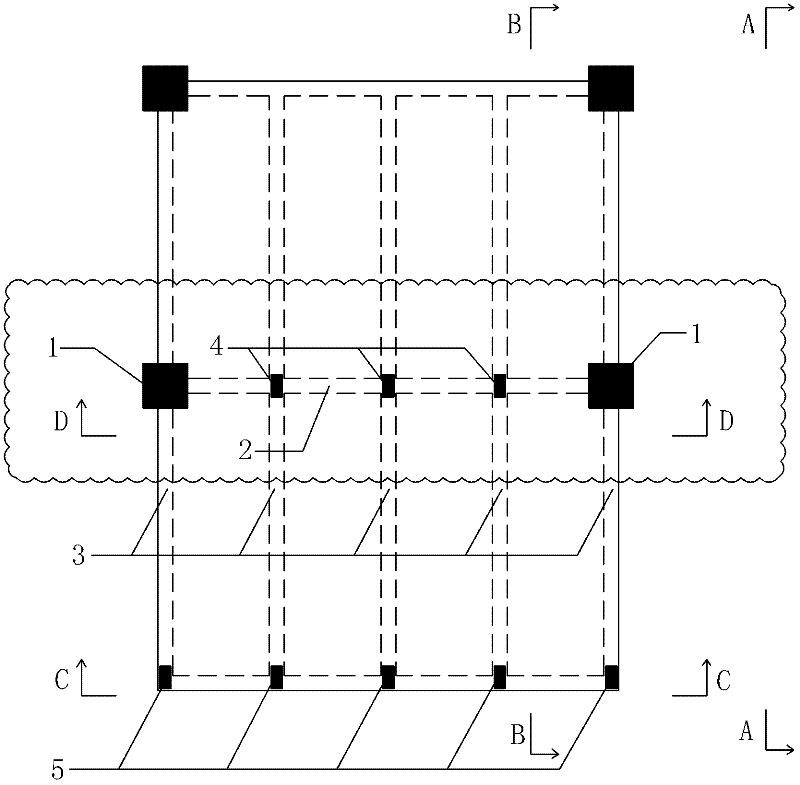

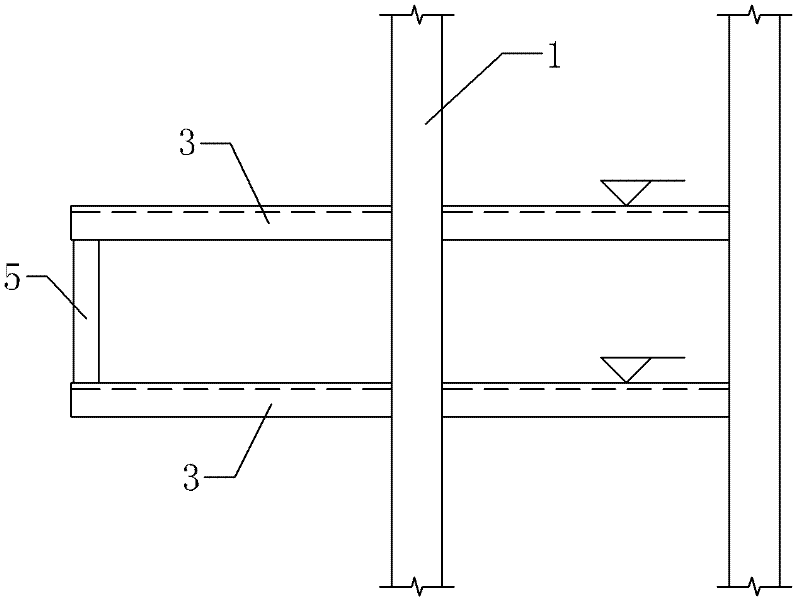

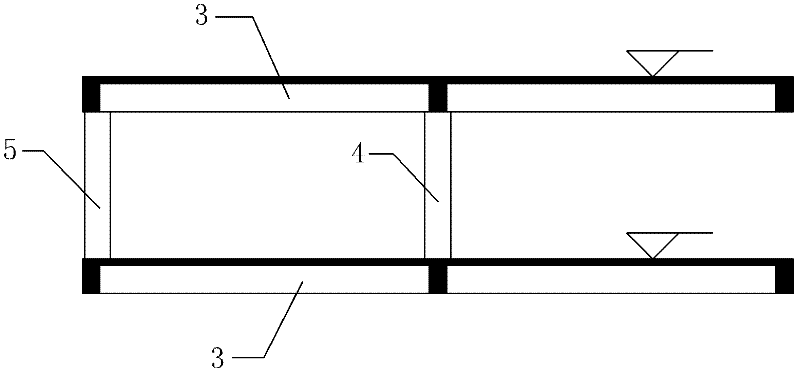

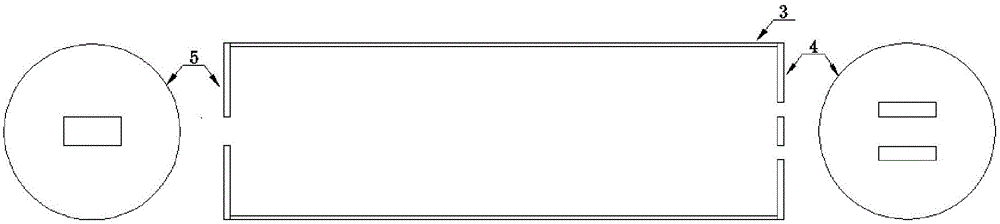

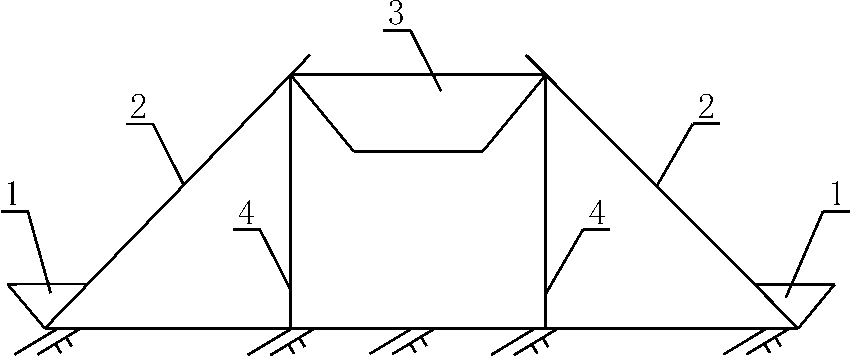

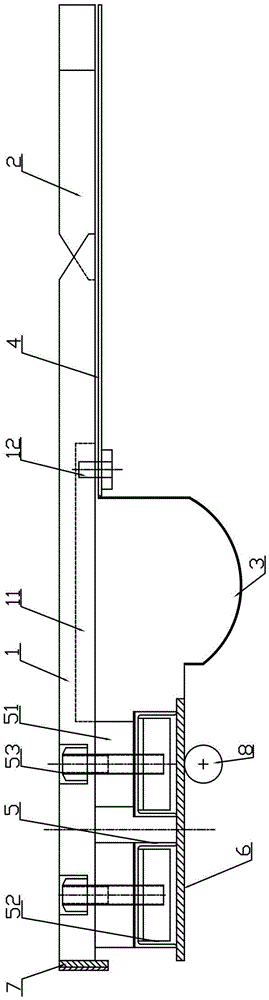

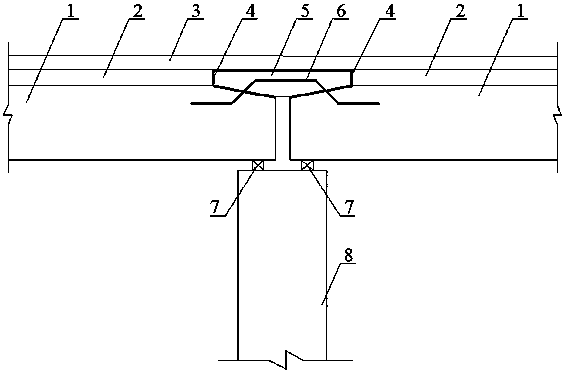

Double-layer vierendeel truss structure system of large cantilever structure

The invention discloses a double-layer vierendeel truss structure system of a large cantilever structure, comprising a floor frame. The floor frame comprises frame columns (1), frame beams (2) and cantilever beams (3). The double-layer vierendeel truss structure system of the large cantilever structure is characterized in that a plurality of main truss columns (4) are arranged between the upper and lower frame beams (2) of the floor, the upper and lower frame beams (2) of the floor are connected with the main truss columns (4) to form a first-layer vierendeel truss structure, a plurality of auxiliary truss columns (5) are arranged between the upper and lower cantilever beams (3) of the floor, the upper and lower cantilever beams (3) of the floor are connected with the auxiliary truss columns (5) to form a second-layer vierendeel truss structure, and the first-layer vierendeel truss structure and the second-layer vierendeel truss structure are connected to form the double-layer vierendeel truss structure system of the large cantilever structure. The double-layer vierendeel truss structure system of the large cantilever structure has a simple structure and is convenient to construct. A space frame structure system is formed by two layers of vierendeel trusses. The double-layer vierendeel truss structure system of the large cantilever structure can meet the structure stress and deformation requirement under the condition of adopting the small beams.

Owner:广州市设计院集团有限公司

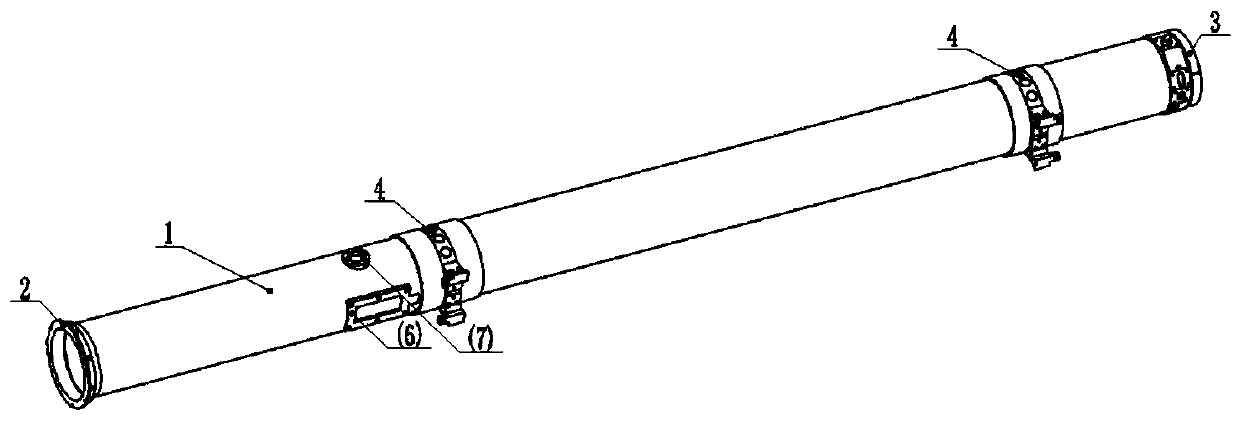

PVC freezing pipe for shield tunneling freeze-consolidation

A PVC freezing pipe for shield tunneling freeze-consolidation is used in a freeze-consolidation area. A shield tunneling machine penetrates through the freeze-consolidation area along the axis. The PVC freezing pipe comprises a pipe body, wherein the pipe body is made of PVC, the bottom end of the pipe body is sealed by a PVC pipe choke plug, a flange assembly is arranged at the other end of the pipe body, the flange assembly comprises a steel flange plate on the outer side and a PVC flange plate on the inner side, the steel flange plate is connected with the PVC flange plate, a liquid inlet pipe passes through the flange assembly and then stretches into the pipe body, and a liquid outlet pipe is further arranged on the pipe body. The PVC freezing pipe for shield tunneling freeze-consolidation is simple in structure, convenient to operate, and capable of meeting engineering strength and deformation requirements in shield tunneling saline water freezing design. Meanwhile, the freezing pipe can be directly cut off during shield tunneling and does not need to be pulled out after freezing is achieved, and therefore safety of shield tunneling is improved.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

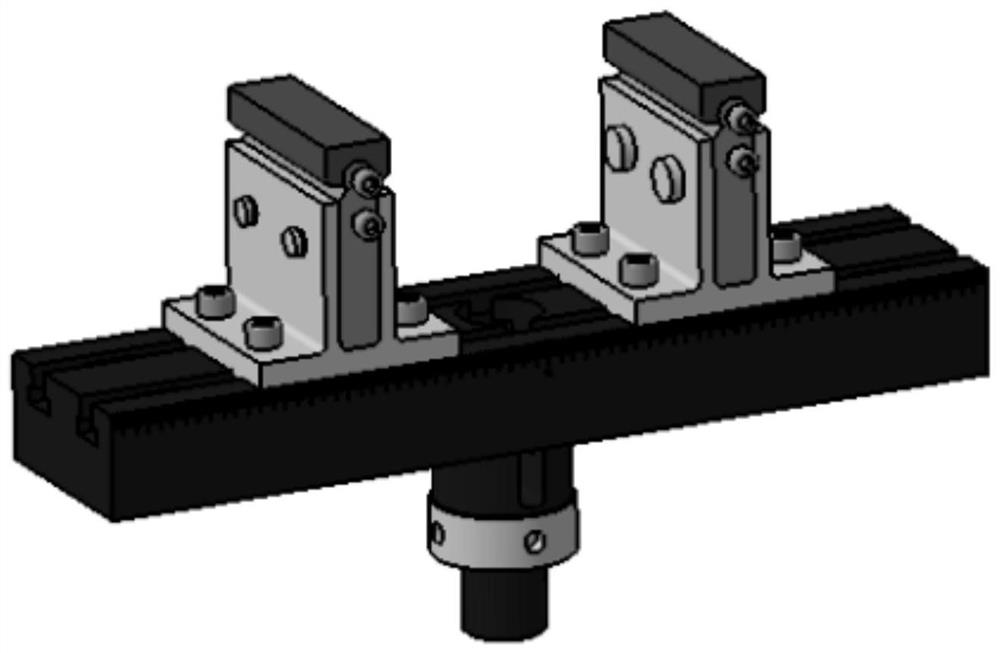

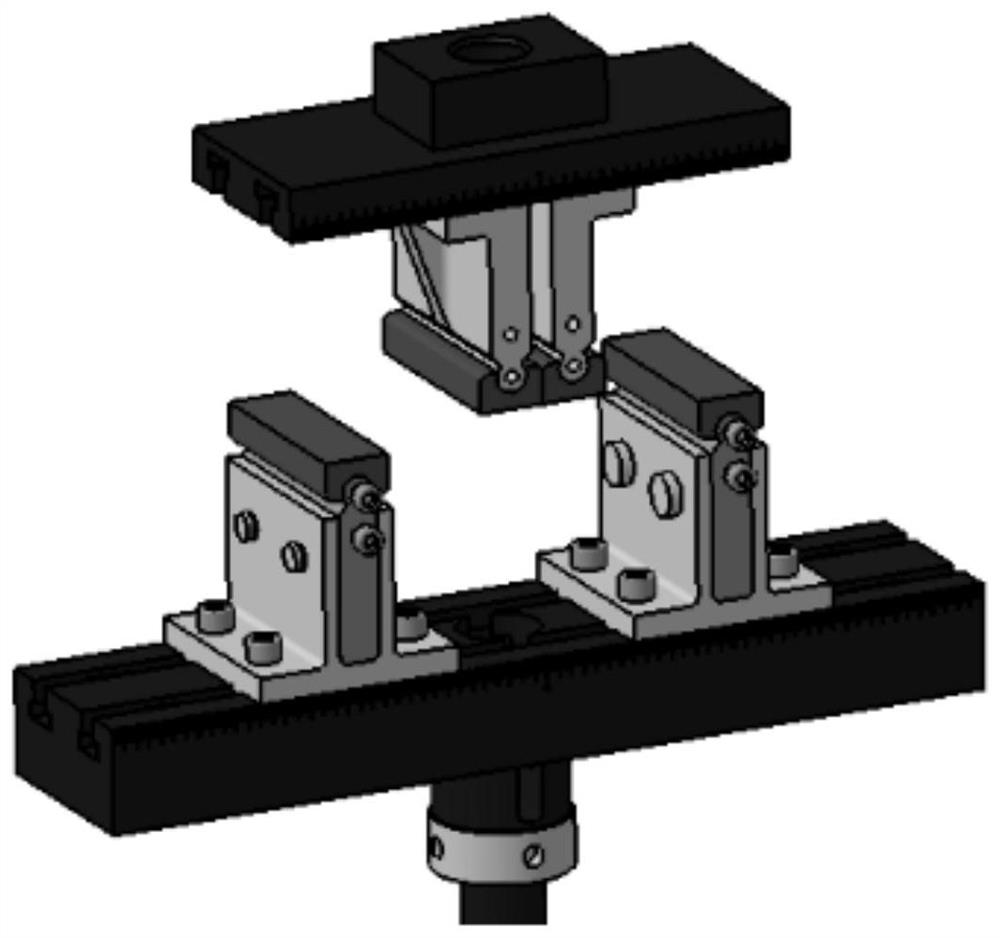

Three-point/four-point bending fatigue test method and device for composite material

PendingCN112378780ANo offsetNo change in external forceMaterial strength using steady bending forcesEngineeringStructural engineering

The invention provides a three-point / four-point bending fatigue test method and device for a composite material. The device comprises an upper loading roller which is used for restraining the verticalupward normal deviation of a test piece in a loading direction, a lower supporting roller which is used for constraining the vertical downward normal deviation of the test piece in the loading direction, a transverse baffle which is used for restraining transverse deviation of the test piece in the length direction, a side baffle plate which is used for restraining the longitudinal deviation of the test piece along the width direction and fixing the upper loading roller and the lower supporting roller at the same time, a lower supporting base which is used for supporting the lower supportingroller, a lower supporting block which is arranged between the lower supporting base and the lower supporting roller, and is used for changing the distance between the lower supporting roller and theupper loading roller by changing the size of the lower supporting block, a lower bottom plate which is used for supporting the lower supporting base and the transverse baffle, and a displacement meterwhich is fixedly connected to the lower bottom plate. The bending deformation of the test piece is measured through the displacement meter.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

Energy-dissipating limiting sliding-friction isolation bearing

InactiveCN107916619AMeet deformation requirementsExtend the natural vibration periodBridge structural detailsBridge engineeringStress concentration

The invention discloses an energy-dissipating limiting sliding-friction isolation bearing which is a bridge friction isolation bearing having limiting capacity applicable to the field of bridge engineering. The energy-dissipating limiting sliding-friction isolation bearing comprises an upper bearing plate, a lower bearing plate, an upper slider, a lower slider, a sliding plate and C-shaped metal bars; under a designed earthquake, sliding friction of the sliders between spherical faces of the bearing plates extend self-vibrating period of a structure, and earthquake energy is dissipated throughthe friction in cooperation with the C-shaped metal bars; under the action of a great earthquake, the C-shaped metal bars can provide certain limiting effect. The shape of the C-shaped metal bars provided herein meets the deformation requirement of the bearing during sliding and can avoid stress concentration. The bearing of the invention is simple in structure, has no need for extra damping andlimiting devices and is particularly applicable to bridge structures having limited pier-top space.

Owner:BEIJING UNIV OF TECH

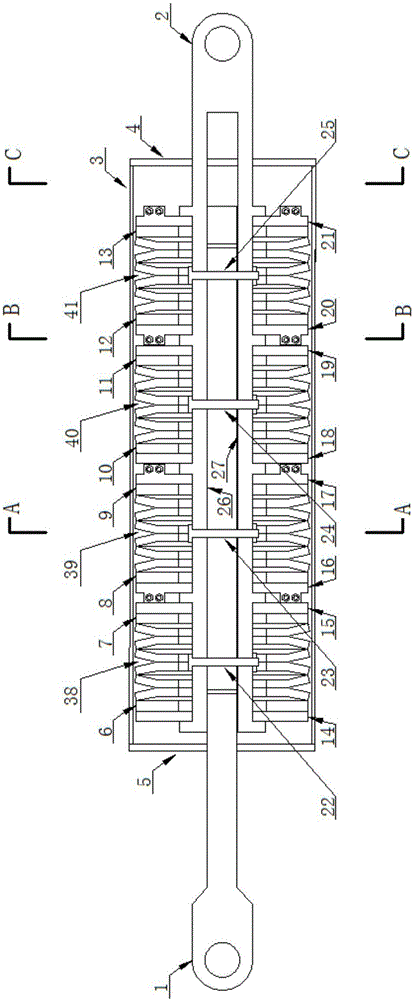

Assembly internal folding type self-reset energy dissipation bracing

ActiveCN106193747AEasy to processEasy to installProtective buildings/sheltersShock proofingWelding residual stressAssembly line

The invention discloses an assembly internal folding type self-reset energy dissipation bracing which comprises an outer pipe, a linear rod and a guide rod. A hollow groove is formed in the middle of the guide rod, the linear rod is inserted into the hollow groove of the guide rod, the linear rod and the guide rod are fixedly connected through a high-strength bolt, and a friction plate is arranged between the linear rod and the guide rod. A first spring, a second spring, a third spring and a fourth spring are arranged between the adjacent check blocks on the guide rod in a sleeving mode, the guide rod is sleeved with the outer pipe, an outer pipe right end plate and an outer pipe left end plate are fixedly arranged at the two ends of the outer pipe, the left end of the linear rod penetrates out of the outer pipe left end plate, and the right end of the guide rod penetrates out of the outer pipe right end plate. A main force bearing and force transferring part of the bracing is a whole, it is avoided that due to welding, the metallographic structure and performance of steel change, and welding residual stress is generated, the stress performance is more stable, a main reset device and a friction device are clear, the structure is simple in integral construction, and machining and mounting are convenient.

Owner:BEIJING JIAOTONG UNIV

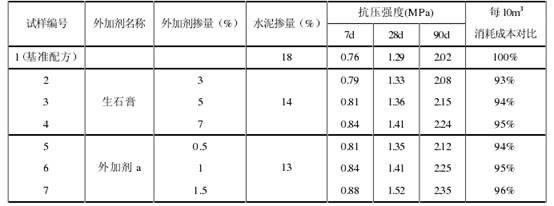

Supporting process of portal frame type anchor pipe soil nail spraying net and modified reinforcing cement mortar employed by same

ActiveCN101906779AImprove early strengthIncreased unconfined compressive strengthExcavationsBulkheads/pilesSocial benefitsExperimental research

The invention discloses a supporting process of portal frame type anchor pipe soil nail spraying net and a modified reinforcing cement mortar employed by the same, which can greatly change the compression resistance and the shearing resistance of soft cement soil. In the novel supporting process of the portal frame type anchor pipe soil nail spraying net, a vertical large-diameter anchor pipe soil nail is added on the basis of the existing supporting technique of the conventional soil nail spraying net, a new formula of a 'modified' curing admixture is adopted to perform cement mortar blowing, and when the cross section of a foundation pit has large changes, theoretical and experimental researches are performed on a failure mode and deformation characteristics of the cross section of the foundation pit. Simultaneously, the supporting process is combined with actual projects to prove that the new type foundation pit support form can be adopted to excavate a foundation pit with the depth of 4 to 6 meters in Wenzhou, so not only the technical problem that a conventional soil nail spraying net support cannot be adopted when the excavation depth of the foundation pit in an urban area of Wenzhou is more than 4 meters is solved, but also compared with other available supports, the supporting process is money-saving and time-saving, reduces risks, and has good economic and social benefits.

Owner:SANJIAN CONSTR ENG GROUP

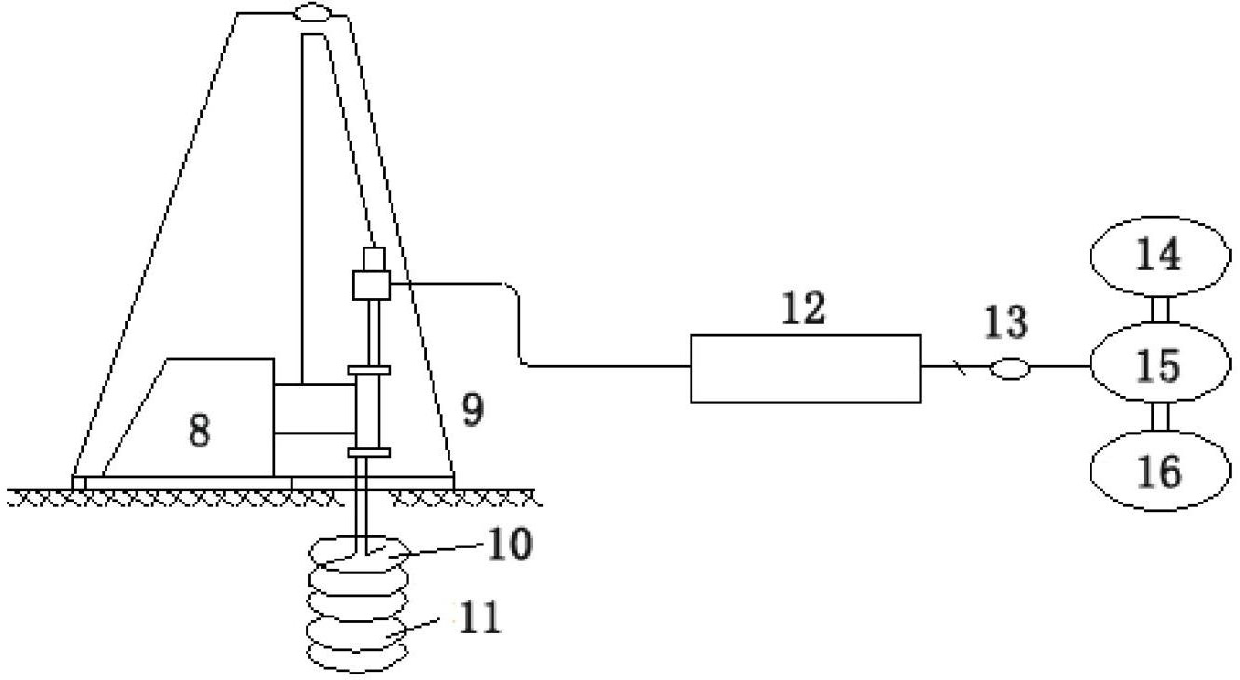

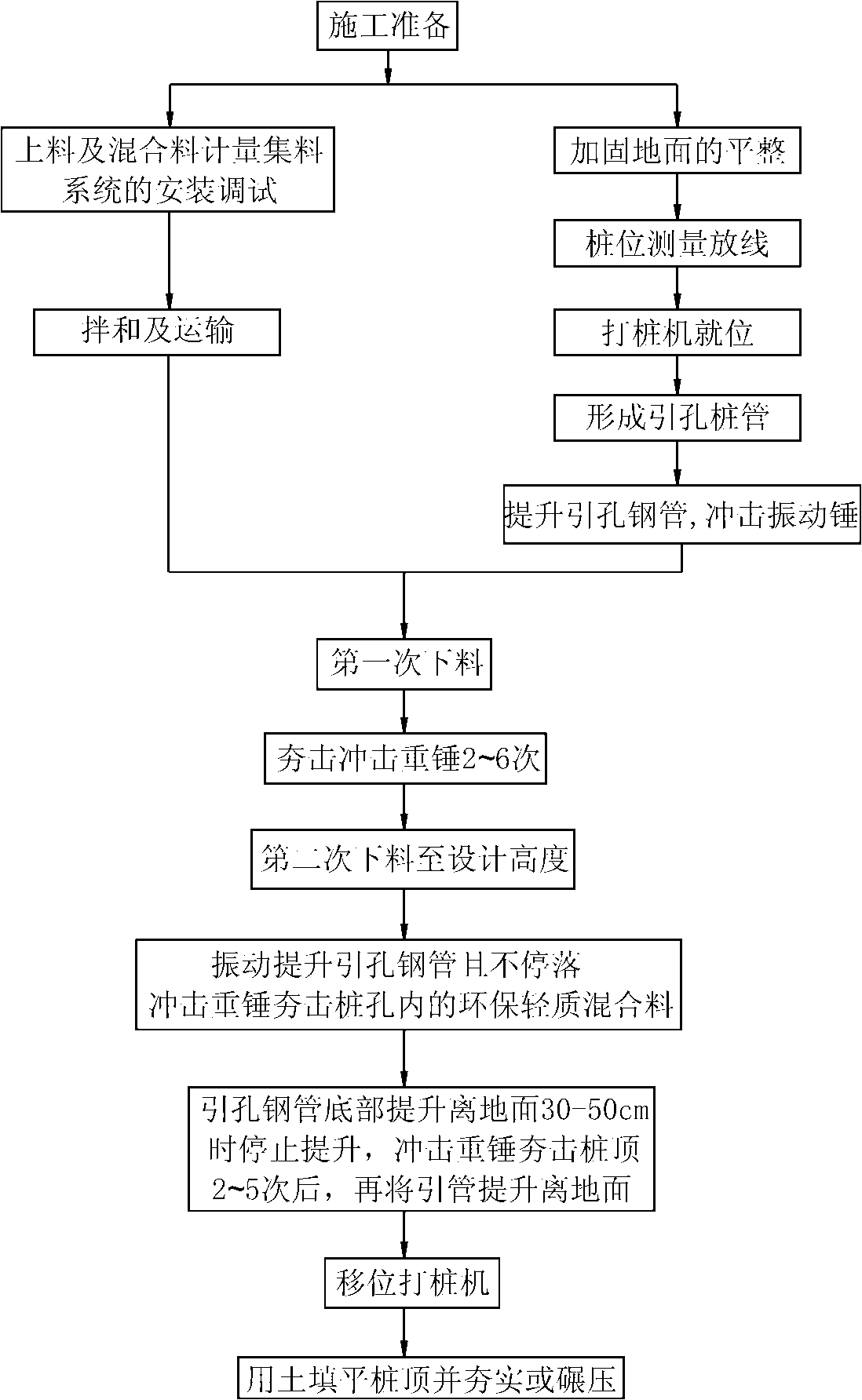

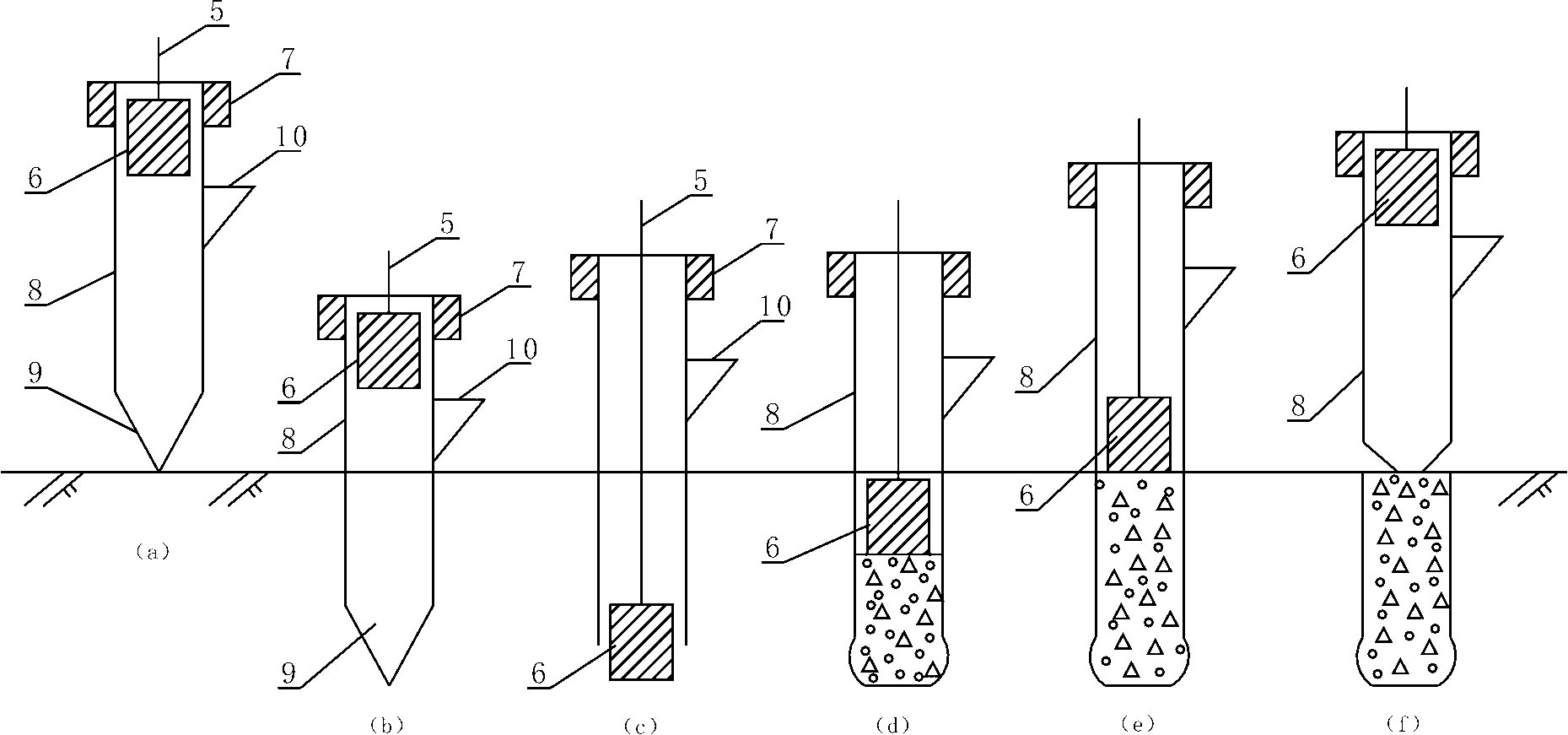

Method for processing soft soil foundation with environment-friendly light pile

ActiveCN103306278AChemical reaction is slowGuarantee the original ecological environmentBulkheads/pilesMaterials preparationEngineering

The invention provides a method for processing a soft soil foundation with an environment-friendly light pile. The method comprises the following steps: 1) preparing materials for the environment-friendly light pile; 2) preparing pile forming equipment for the environment-friendly light pile; 3) preparing a piling machine, and starting a vibration hammer for piling a guide hole pile pipe to a design depth; 4) upwardly pulling the guide hole pile pipe to guarantee that a movable bottom door pile tip is completely opened; 5) feeding a prepared environment-friendly light mixture to a feeding hole of the guide hole pile pipe for the first time; 6) starting an impact heavy hammer for continuously impacting the environment-friendly light mixture in the guide hole pile pipe for 2-6 times to form a dense expanded pile body; 7) feeding for the second time and tamping a pile top for 2-5 times by the impact heavy hammer; 8) continuously lifting the guide hole pile pipe until the distance from the bottom of the guide hole pile pipe to the ground is 30-50 cm, shifting the piling machine, filling up the pile top with soil and tamping or rolling the pile top; and 9) repeating the steps 3) to 8) until the reinforcement treatment of the soft soil foundation is finished. The method has the benefits as follows: the reinforcement effect is good, waste materials are turned into wealth, the cost is low, and the environment is protected.

Owner:WUHAN GUANGYI ENG CONSULTING

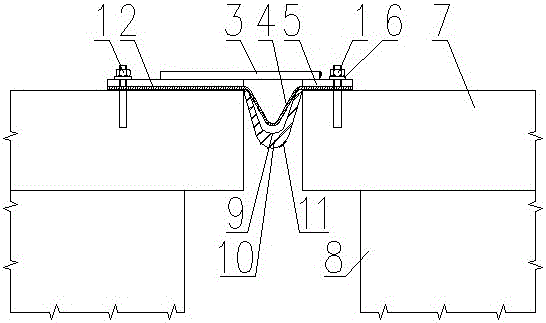

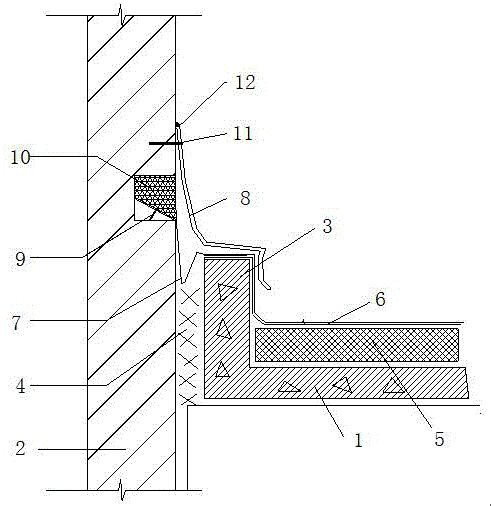

Deformation joint structure for light rail elevated station and construction method thereof

InactiveCN106013473AHigh fire performance requirementsSimple structureBuilding insulationsFire proofingSheet steelFloor slab

The invention discloses a deformation joint structure for a light rail elevated station and a construction method thereof. The deformation joint structure is arranged between floor slabs arranged at two sides of a deformation joint, and comprises a water stop, a fireproof plate and multiple stainless steel plates, wherein the fireproof plate and the water stop are fixed to the floor slabs at the two sides through bolts which are arranged at intervals by pressing the stainless steel plates; the fireproof plate is formed by a fireproof upper plate, a fireproof lower plate and a fireproof material filled between the fireproof upper plate and the fireproof lower plate. According to the deformation joint structure for the light rail elevated station, disclosed by the invention, under the action of various deformation influence factors, not only is the requirement of expansion deformation of the deformation joint met, but also the requirements of fire prevention, heat preservation and water prevention of the deformation joint are considered; the deformation joint structure is simple in structure and construction technology, reliable in performance, convenient in construction and easy in overhauling and replacement, and can be widely applied to a large-area floor deformation joint in a public place which has higher requirement on fireproof performance and is always in larger temperature difference.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

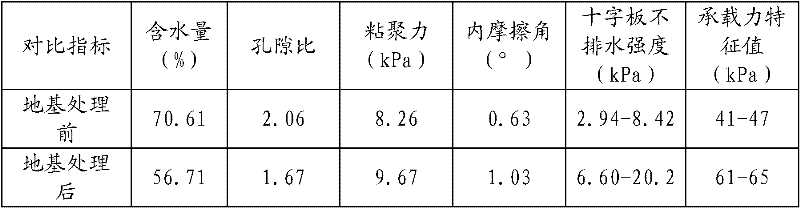

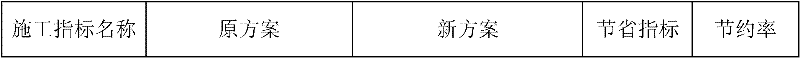

A rapid drainage consolidation treatment method for soft soil foundation

InactiveCN102296591AReduce differential settlementImprove bearing capacitySoil preservationMedicineCushion

The invention discloses a rapid drainage and consolidation treatment method for soft soil foundations, which comprises the following steps: (1) digging the silt to 2-3m below the delivery elevation, and backfilling the first layer of sand to 0.8-3m below the delivery elevation while digging 1.2m, insert the plastic drainage board to a depth of 8m below the handover elevation, cover the second sand cushion to 0.5-1.5m above the handover elevation, set up a drainage system to pump water continuously; (2) start the first dynamic load after 12-18 days after the backfill is in place , the energy is 500-650 kJ, and the depth of the ramming pit does not exceed 1.5m; (3) The second dynamic load after 5-8 days, the energy is 700-900 kJ, and the depth of the ramming pit does not exceed 1.5m, (4) 5-8 Start the third dynamic load after 5-8 days, the energy is 1100-1500 kJ, and the depth of the ramming pit does not exceed 1.5m; m; (6) After 5-8 days, excavate excess filler, perform 600 kilojoule full-field dynamic load once, and level and hand over the work twice. The invention can reduce the cost by 75%, and shorten the construction period from more than 360 days to about 90 days.

Owner:厦门地山建设发展有限公司

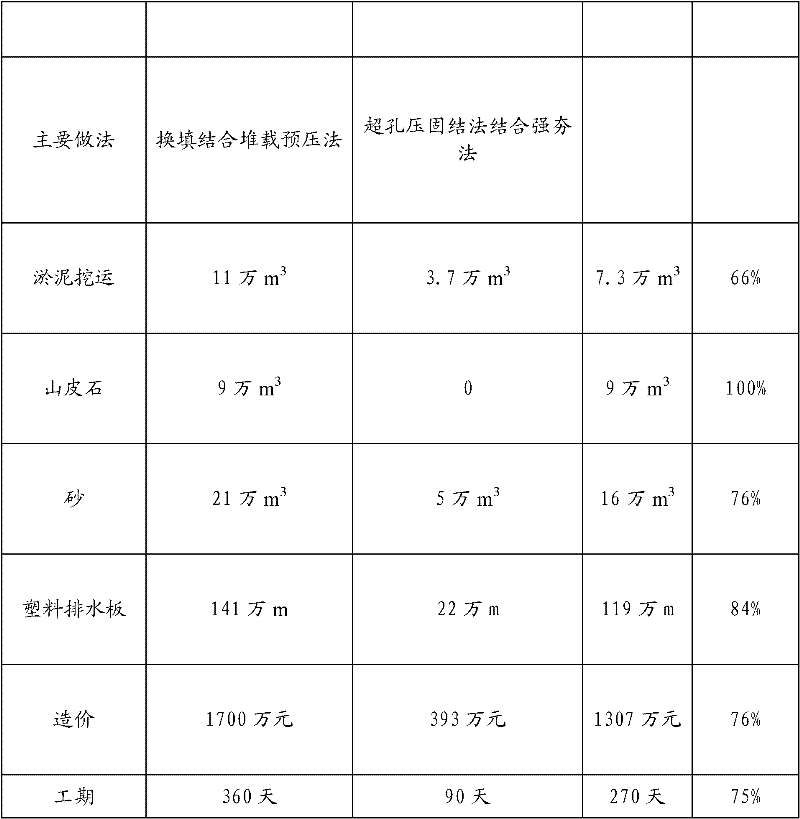

Connecting device capable of being used for deepwater combination foundations and coordinating deformation

ActiveCN104005427ASmall sizeGive full play to carrying capacityArtificial islandsUnderwater structuresEngineeringSteel tube

The invention provides a connecting device capable of being used for deepwater combination foundations and coordinating deformation. According to the connecting device, a steel tube sleeve (3) is arranged in a preformed hole in the center of an open caisson bottom plate (2), a rigid base plate (7) is arranged on the lower portion of the steel tube sleeve (3), a shear key (8) is arranged in the steel tube sleeve (3), a flexible cushion layer (6) is arranged on the lower portion of the rigid base plate (7), a rigid limit plate (5) is arranged on the lower portion of the flexible cushion layer (6), a pile foundation (1) penetrates through the rigid limit plate (5), the flexible cushion layer (6) capable of stretching and retracting for deformation, the rigid base plate (7) and the shear key (8), and pile sealing concrete (9) is located on the upper portion of the open caisson bottom plate (2) and the upper portion of the pile foundation (1). By means of the connecting device, connection between an open caisson (caisson) foundation and the pile foundation can be achieved, relative positions of the open caisson (caisson) foundation and the pile foundation can also be changed according to the loading conditions on the upper portion; as a result, the foundations and a soil body can deform in a coordinating mode, the supporting rigidity of the soil body is changed, the bearing capacity of the soil body at the bottoms of the foundations is given to full play, the sizes of the foundations are reduced, and construction cost is lowered.

Owner:SOUTHEAST UNIV

Six-direction deflection comb plate retractor device

ActiveCN105239503ASimple structureEasy to installBridge structural detailsAbsorption capacitySlide plate

The invention discloses a six-direction deflection comb plate retractor device. The six-direction deflection comb plate retractor device is characterized in that five-direction deflection support sets are fixedly arranged at the rear end of a movable comb plate, the bottom face of the front end of the movable comb plate is provided with sliding grooves and steel pins, and the five-direction deflection support sets are two elastic support bodies which are arranged on an anchor plate and both consist of teflon plate rubber bases, steel channels and teflon sliding plates; the steel channels are provided with axial sliding grooves, and the two steel channels are buckled on the anchor plate and welded with the anchor plate. Compared with the prior art, the six-direction deflection comb plate retractor device has the three-dimensional deformation functions of planar rotation, vertical rotation and transverse displacement, various deformation requirements during everyday operation can be met, and the requirement for longitudinal and transverse extremely-large displacement deformation generated by bridges during an earthquake can be met as well. The device is simple in structure, convenient to construct and mount, high in shock absorption capacity, low in noise and particularly suitable for high-grade highway bridges, viaduct bridges and extremely-long flexible bridges.

Owner:SHANGHAI HUICHENG ARCHITECTURE DECORATION +1

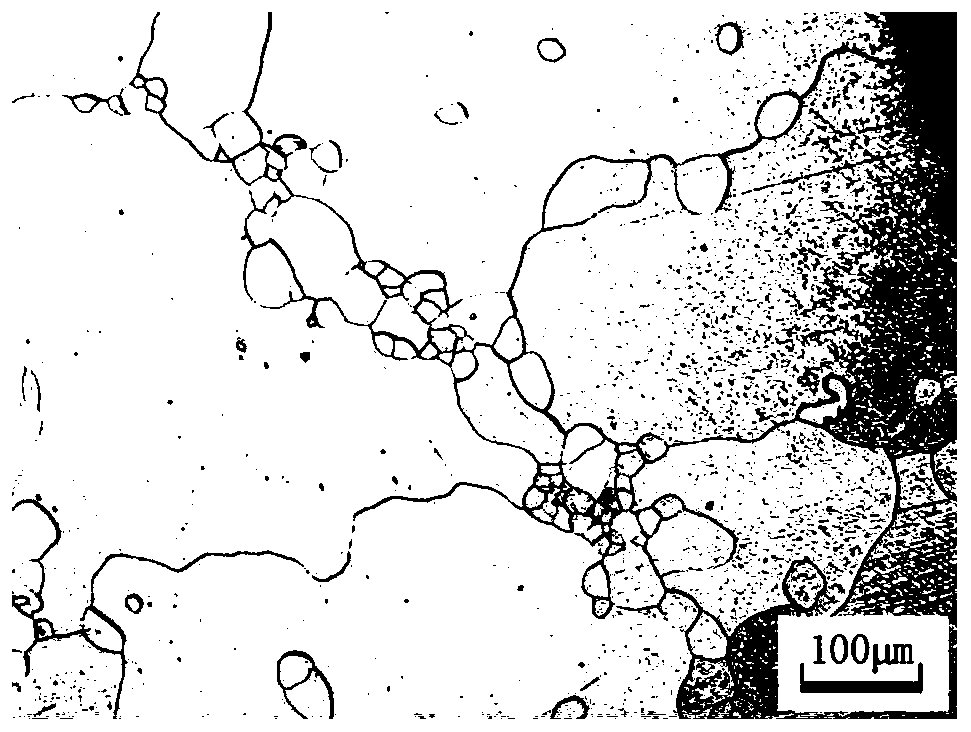

Ultra-low carbon steel, and preparation method and application thereof

The invention discloses ultra-low carbon steel, and a preparation method and application thereof. The ultra-low carbon steel is prepared from the chemical components in percentage by mass: 0.001% to 0.002% of C, 0.03% to 0.05% of Mn, less than or equal to 0.005% of Si, less than or equal to 0.003% of Al, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.01% to 0.05% of Zr, and the balance of Fe and unavoidable impurities. The ultra-low carbon steel has good tensile strength and elongation, the tensile strength is 260 to 280 MPa, and the elongation is 45% to 55%. The ultra-low carbon steel also has good conductance and the conductance is up to 16.5% to 17.5%.

Owner:武汉钢铁有限公司

Single-joint extensible device and bridge

ActiveCN105951588AExtended service lifeImprove flexibilityBridge structural detailsEngineeringContraction joint

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Non-pillar mining roadway sidewall closing device and construction method thereof

InactiveCN107387164ASimple processImprove labor efficiencyMining devicesStructural engineeringPlastic property

The invention discloses a non-pillar mining roadway sidewall closing device and a construction method thereof; the non-pillar mining roadway sidewall closing device comprises a plurality of gangue retaining pillars arranged at intervals; an upper steel beam and a lower steel band are arranged at the upper and lower ends of the gangue retaining pillars respectively; a gangue retaining mesh is arranged on the sides of the gangue retaining pillars close to a gob; flexible cloth is arranged on the gangue retaining mesh; the upper end of the flexible cloth is fixed to a crossheading roof through the gangue retaining pillars and the upper steel beam; the lower end of the flexible cloth is fixed to a crossheading floor through the gangue retaining pillars and the lower steel band. The non-pillar mining roadway sidewall closing device is high in overall structural plasticity and meets the requirement on deformation of a roof; the existing gangue retaining mesh is used directly, the gangue retaining pillars are recyclable, and accordingly the cost is greatly reduced.

Owner:SHAANXI COAL & CHEM TECH INST

Launch canister based on carbon fiber composite base material and manufacturing method

PendingCN111442693AImprove the ability to withstand internal pressureGuaranteed stiffnessLaunching weaponsGlass fiberFiber

The invention discloses a launch canister based on a carbon fiber composite base material and a manufacturing method. The launch canister comprises a launch canister body, wherein the launch canisterbody comprises an ablation resistance preimpregnated layer, an ablation resistance layer, a first flame-retardant toughening layer and a second flame-retardant toughening layer which are arranged in sequence from inside to outside; and a guide plate is paved between the ablation resistance preimpregnated layer and the ablation resistance layer in the length direction of the launch canister body. The manufacturing method of the launch canister is simple, is easy to implement, has strong process operability, and fully utilizes different types of carbon fibers. By adopting the manufacturing method, even if the body of the launch canister is made of carbon fibers having the common strength, the body of the launch canister still has excellent mechanical properties, and the cost can be reduced.Compared with an existing metal multi-layer structure and other multi-layer structures made of mixed carbon fibers, glass fibers and the like, the launch canister based on the carbon fiber composite base material has the advantages that the weight of the launch canister based on the carbon fiber composite base material is reduced, and the launch canister based on the carbon fiber composite base material has good interface continuity and excellent mechanical properties, and meets the requirements for axial stiffness and stability.

Owner:HENGSHEN

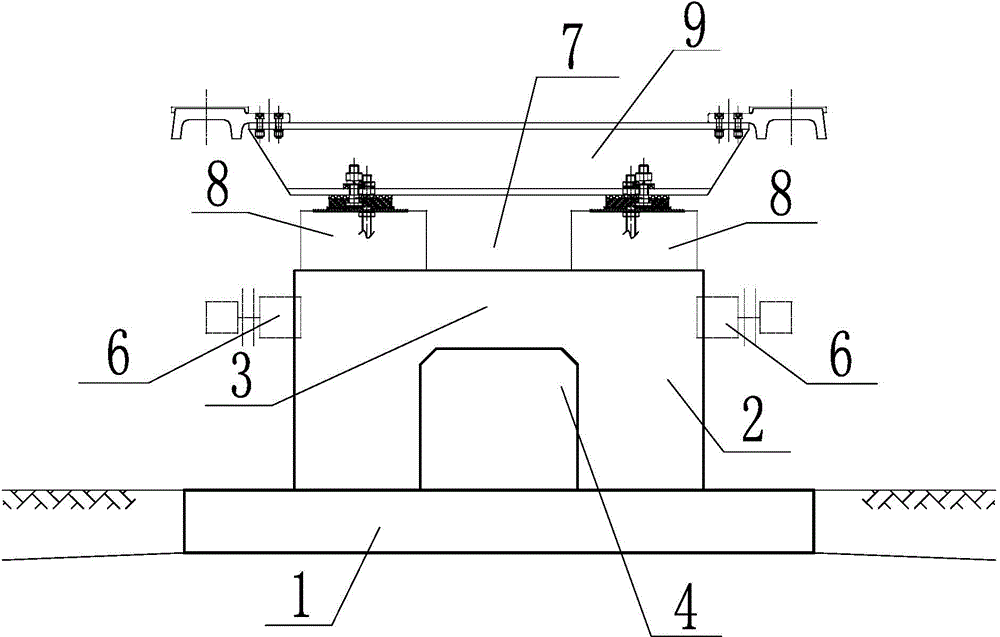

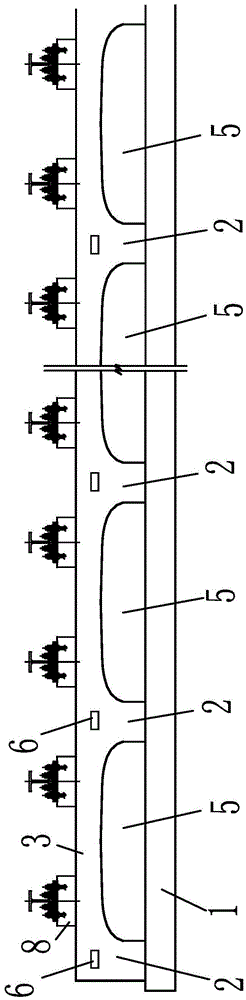

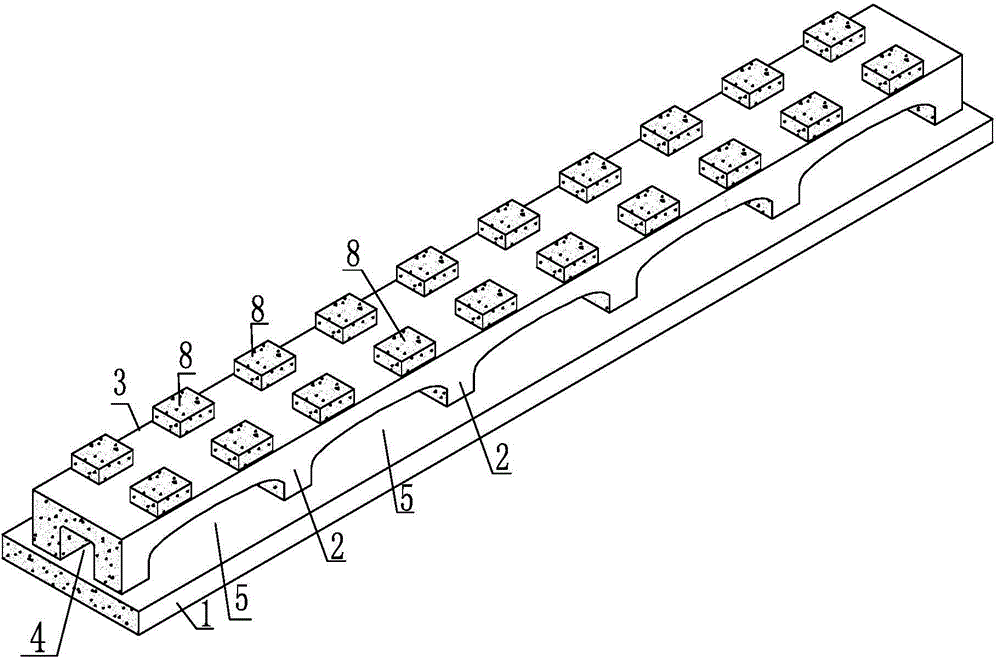

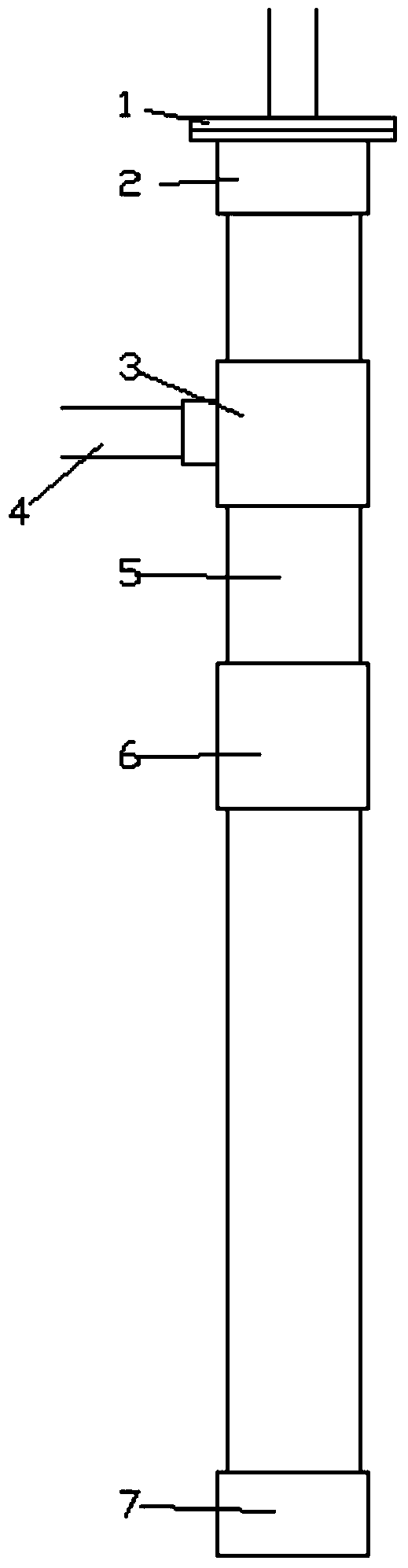

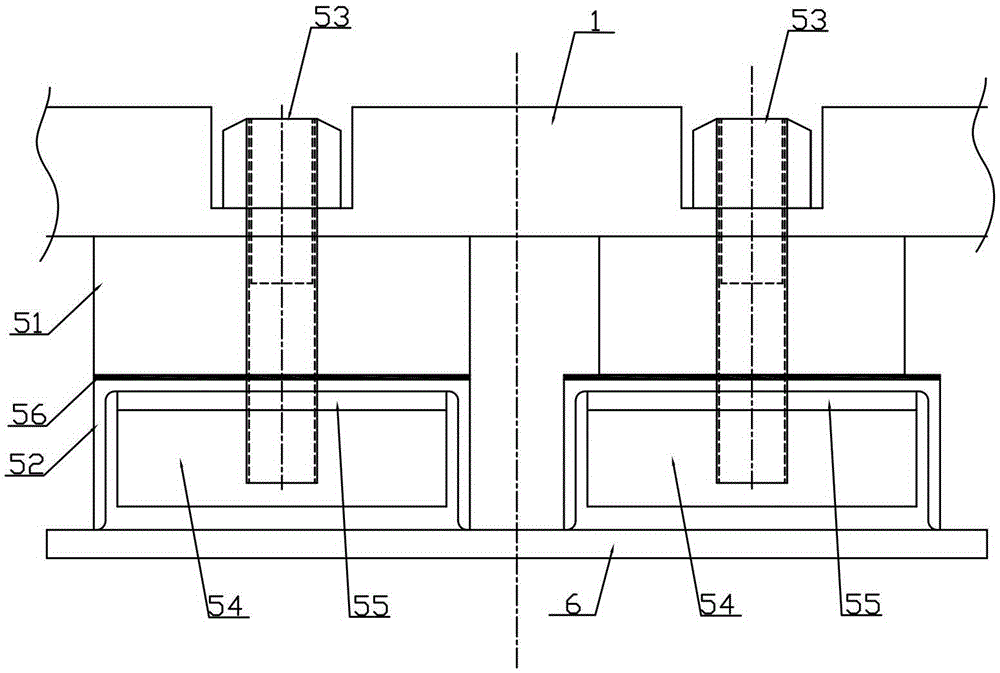

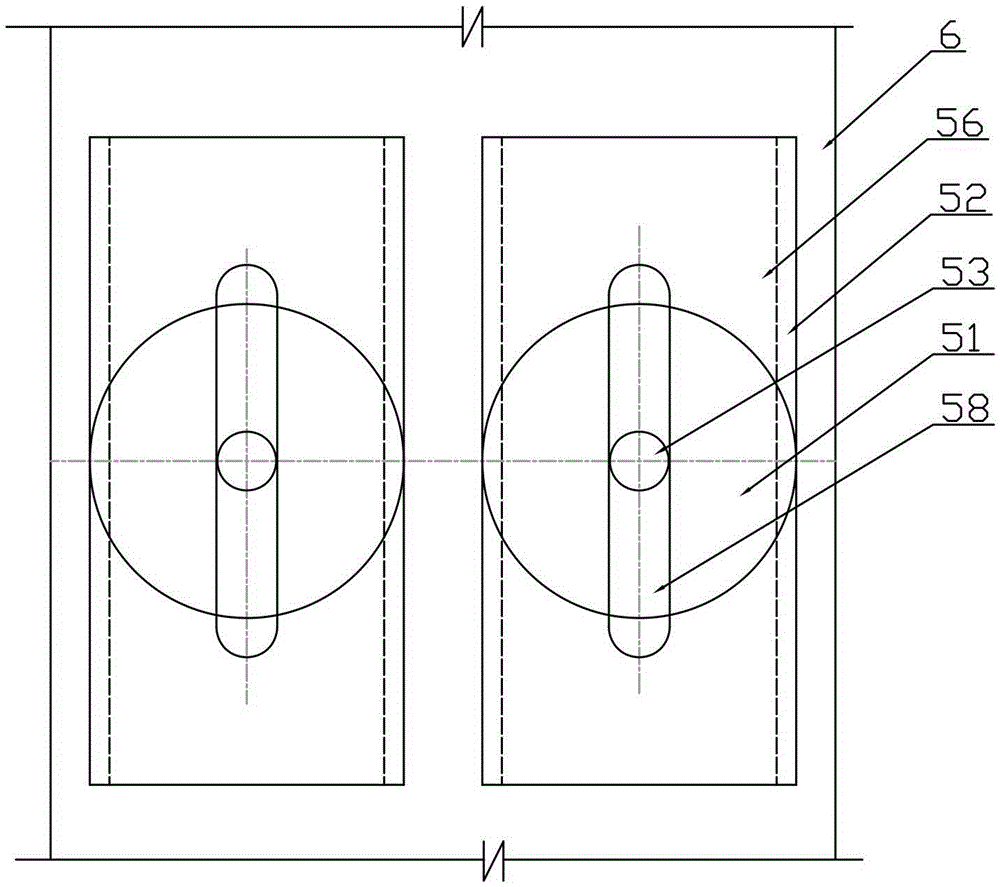

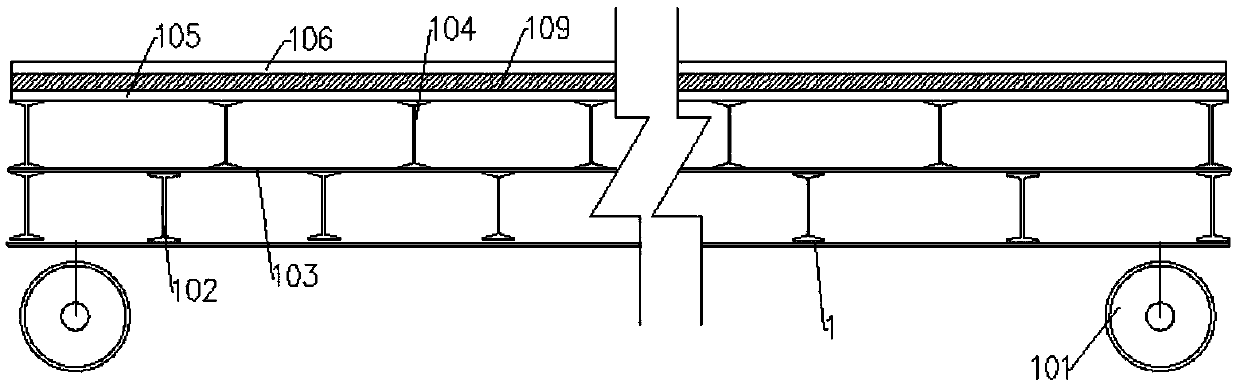

Intelligent prefabricated beam pedestal

ActiveCN109624053ATake advantage ofAddress adverse impacts on productivityCeramic shaping plantsAuxillary shaping apparatusThree stageMechanical equipment

The invention discloses an intelligent prefabricated beam pedestal. The intelligent prefabricated beam pedestal comprises two tracks, the two tracks are arranged in parallel, and arranged in the direction of the prefabricated beam construction process; a pedestal body comprises a first-stage supporting box, a second-stage supporting box and a three-stage supporting box, wherein the first-stage supporting box, the second-stage supporting box and the three-stage supporting box are fixedly arranged in sequence from bottom to top. The first-stage supporting box is slidably arranged on the two tracks, a plurality of cross beams are arranged in the first-stage supporting box and the second-stage supporting box at intervals in the length direction of the prefabricated beam, and the cross beams are arranged in the width direction of the prefabricated beam. The three-stage supporting box comprises a plurality of channel steel fixedly arranged at the top end of the three-stage supporting box atintervals in the width direction of the prefabricated beam and top surface steel plates horizontally arranged on the top surface of the multiple channel steel to support the prefabricated beam, and the channel steel is arranged in the length direction of the prefabricated beam. According to the intelligent prefabricated beam pedestal, the free movement in each area of the pedestal body is realizedthrough the sliding of the pedestal body on the tracks, the construction of the prefabricated beam in different positions and transport beam bodies are met, so that mechanical equipment is fully utilized, the site is saved, and the production efficiency is improved.

Owner:中铁隧道局集团建设有限公司 +1

Novel bridge connecting plate structure and construction method

PendingCN109356020AAvoid destructionImprove full cycle lifeBridge structural detailsBridge erection/assemblyRebarDriving safety

The invention provides a novel bridge connecting plate structure and construction method. The structure comprises main beams and connecting plates, the main beams are adjacently arranged, the connecting plates are arranged between the main beams, piers are arranged on the lower portion between the upper adjacent main beams, the adjacent main beams are connected through the connecting plates, the vertical cross section of each connecting plate is in a wedge shape, and connecting reinforcing steel bars are arranged in the connecting plates and extend into the adjacent main beams. According to the structure, displacement and corners of the main beams in a vertical bridge direction can be effectively absorbed, horizontal deformation between the main beams is converted into vertical deformationof the connecting plates, the deformation amount is greatly decreased, the horizontal deformation amount between the main beams is dispersed into two ends of each connecting plate, deformation requirements can be met, good waterproof performance is achieved, driving safety and smoothness is ensured, cracking of the connecting plates between the main beams is prevented, defects such as bumping atconnecting sections of the main beams is removed, the life cycle of a bridge can be prolonged, the passing capability of the bridge is improved, the structure has the advantages of simple structure, high universality, convenience in construction and the like, and the structure has great engineering significance and practical values.

Owner:FUZHOU UNIV

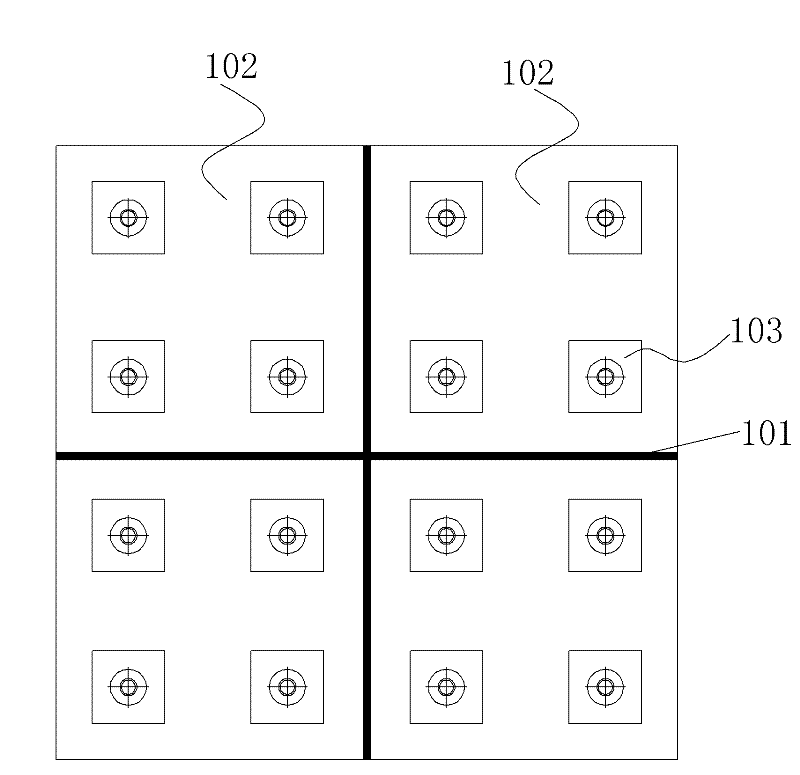

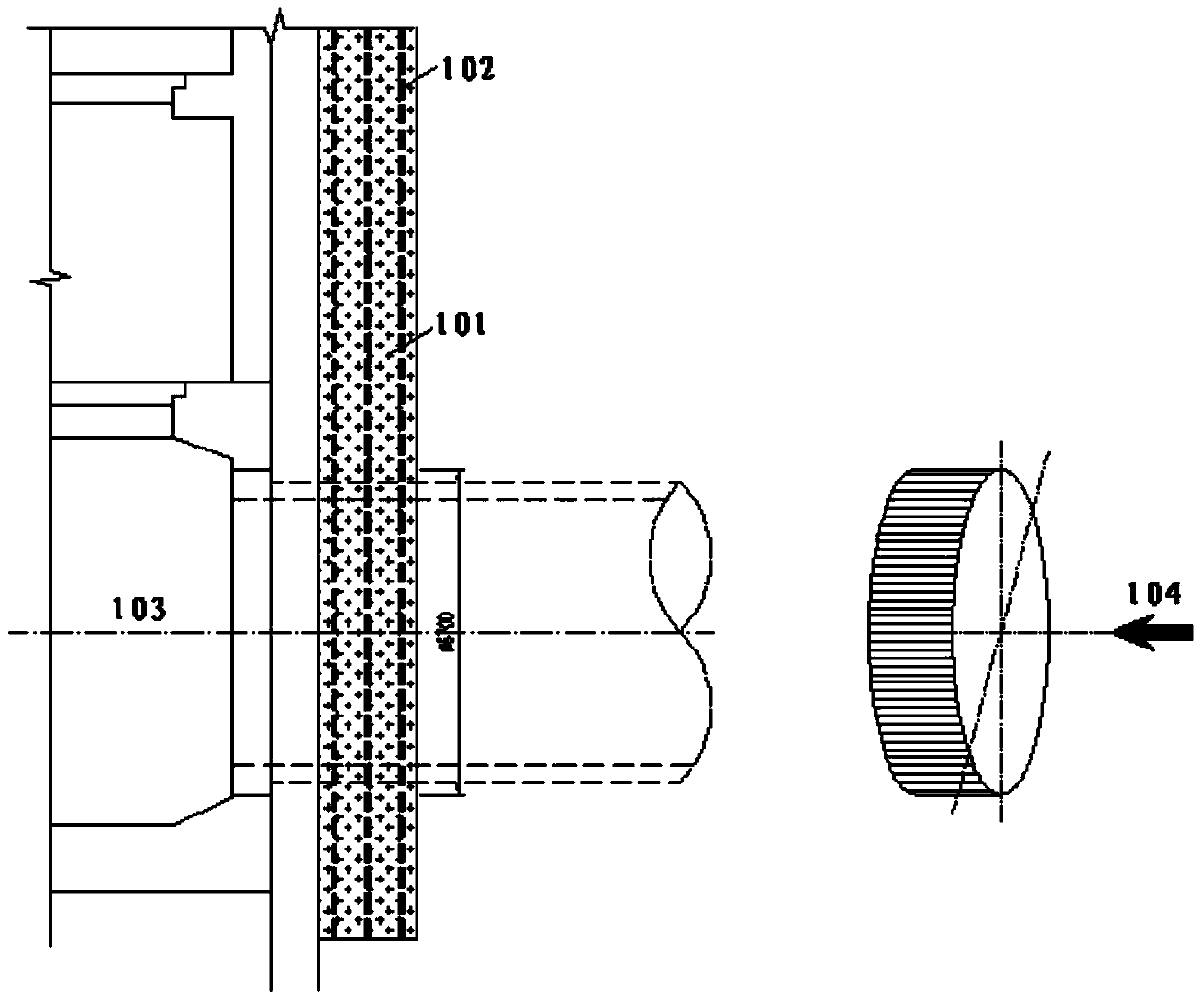

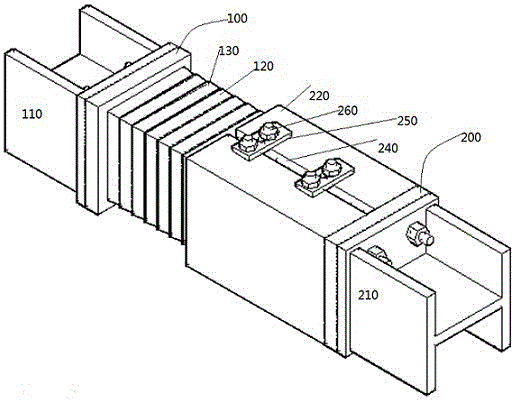

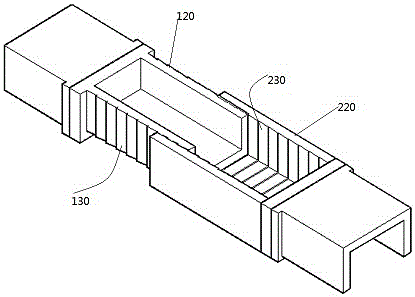

Telescopic steel frame joint suitable for large tunnel deformation

ActiveCN105888700AMeet deformation requirementsIncrease stiffnessUnderground chambersTunnel liningCouplingEngineering

The invention discloses a telescopic steel frame joint suitable for large tunnel deformation. The joint consists of two parts, namely an upper part (100) and a lower part (200) which are coupled with each other; both the upper part (100) and the lower part (200) are provided with coupling heads connected with a steel frame, namely an upper coupling head (110) and a lower coupling head (210); the upper part (100) is provided with a convex body end (120), and barbed inverted teeth (130) are arranged on the outer surface of the convex body end; the lower part (200) is provided with a sheathing cavity (220) capable of being sheathed with the convex body end (120) of the upper part, and barbed reverse inverted teeth (230) are arranged on the inner surface of the sheathing cavity; a gap (240) is formed in the sheathing cavity (220); each of connecting steel plates (250) transversely spans the two sides of the gap and is connected with the sheathing cavity through a bolt. The telescopic steel frame joint disclosed by the invention is suitable for various forms of excavation methods and can be processed and mounted with the finished steel frame on site, the length of the steel frame is automatically adjusted according to the stress situations, the telescopic amount and the ultimate bearing capacity of the steel frame can also be manually set at the beginning, the telescopic amount can be locked during construction, and the stress of the steel frame and the deformation of surrounding rocks can be effectively controlled to ensure the safety and the stability of a tunnel structure.

Owner:CCCC FOURTH HARBOR ENG CO LTD +2

Cover plate structure for deformation joint of pitched roof

InactiveCN106760263AGuarantee the construction qualityMeet deformation requirementsRoof covering insulationsSnow trapsBuilding construction

The invention discloses a cover plate structure for a deformation joint of a pitched roof. The cover plate structure comprises a roof and a high-span wall body adjacently connected with the roof. A low-span wall is arranged between the roof and an adjacent side of the high-span wall body. A gap is kept between the low-span wall and a high-span wall and filled with foam plastics. The surface of the low-span wall is adhered to 1-2 coiled material additional layers, on which water-proof coiled material is laid. The inside of the water-proof coiled material is laid to a wall top of the low-span wall. A coiled material sealing cover covers the top position of the gap. One end of the coiled material sealing cover is laid to the wall top of the low-span wall and adhered to the water-proof coiled material as a whole. The other end of the coiled material sealing cover is fixed in a wall body of the high-span wall body. The position where the top of the gap is located above the coiled material sealing cover is provided with a cover plate in a buckling manner. The cover plate structure for the deformation joint of the pitched roof has following beneficial effects: a construction method for the deformation joint of the roof is improved so that construction quality of the deformation joint is ensured and the deformation requirement for the deformation joint is satisfied; construction is conveniently carried out; and the water-proof effect is obvious so that the long-term water-proof requirement is satisfied.

Owner:ANHUI SHUIAN CONSTR GRP CO LTD

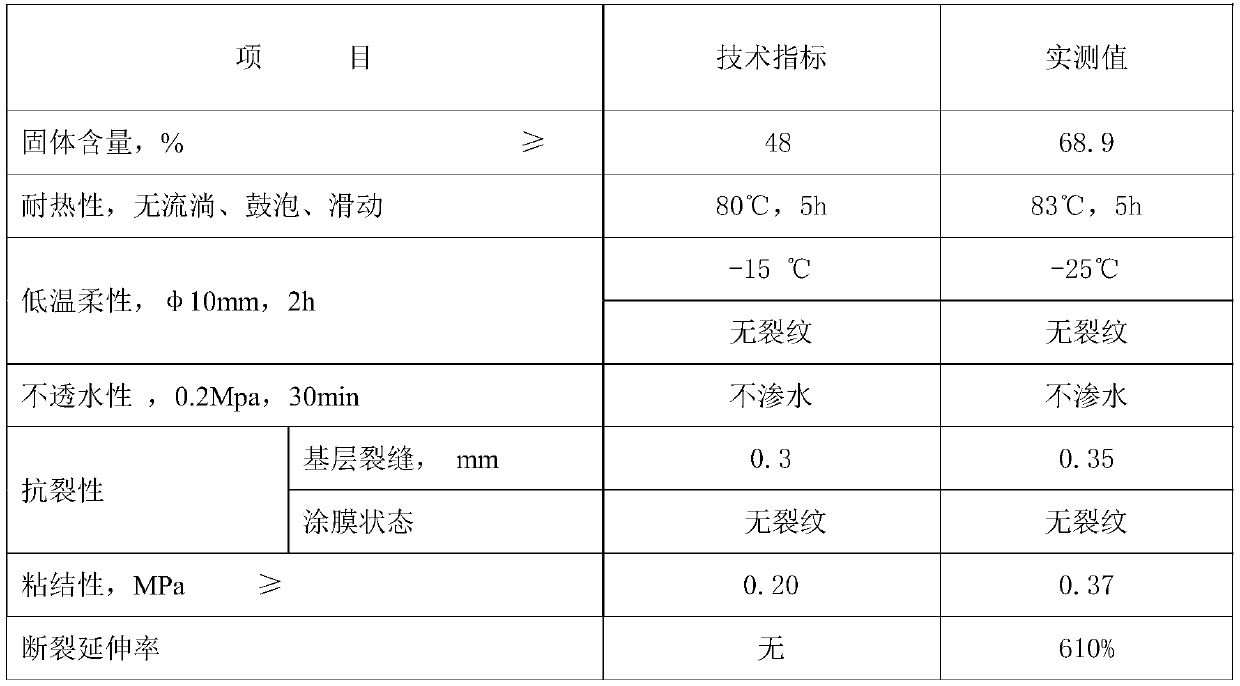

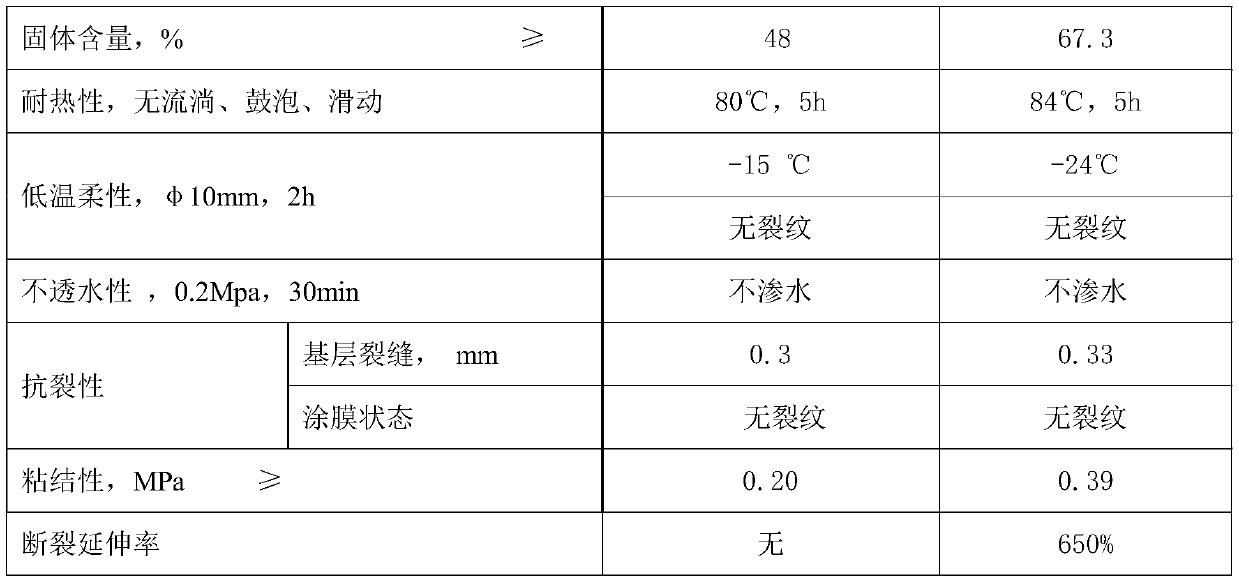

A kind of solvent type rubber asphalt waterproof coating and preparation method thereof

ActiveCN107474740BReduce risk of bumpingGood high and low temperature performanceBituminous coatingsPolymer scienceBituminous waterproofing

The invention discloses a solvent type rubber asphalt waterproof coating and a preparation method thereof and relates to the field of a waterproof coating. The preparation method disclosed by the invention comprises the following steps: mixing asphalt and an organic solvent and heating to the first temperature, thereby forming a first product; adding styrene-butadiene-styrene segmented copolymer into the first product, controlling the temperature under the second temperature, fusing and shearing till fully dissolving styrene-butadiene-styrene, thereby forming a second product; adding amorphous state alpha olefin copolymer into the second product, controlling the temperature under the third temperature and stirring, thereby forming a third product; and adding filler into the third product, controlling the temperature under the fourth temperature and then stirring, thereby forming a fourth product, namely, the solvent type rubber asphalt waterproof coating. According to the method disclosed by the invention, the modifying temperature is greatly lowered, the modifying time is shortened and the elongation at break of the product is increased.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com