A roller type multi-section control section bar three-dimensional stretch-bending dieless forming device

A stretch-bending, multi-section technology, applied in the field of roll-type multi-section control profile three-dimensional stretch-bending dieless forming devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

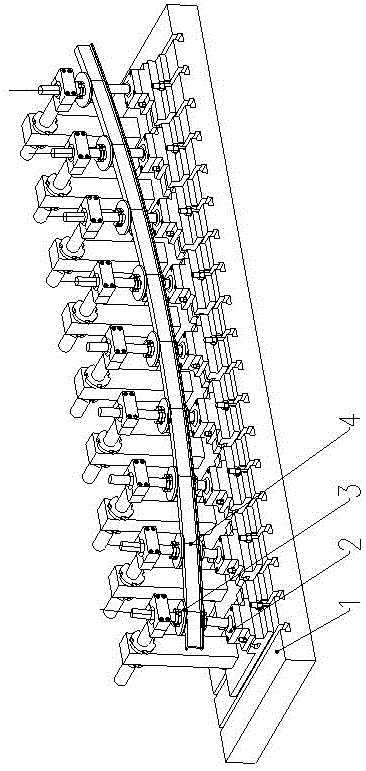

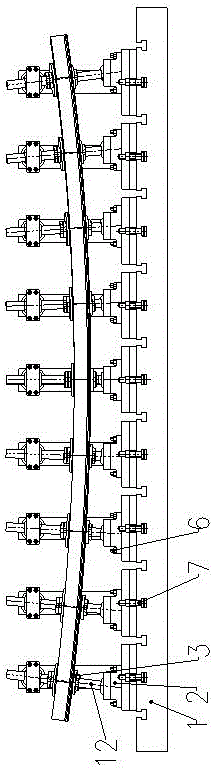

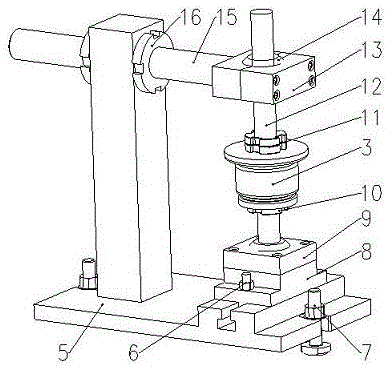

[0024] See attached picture, Figure 1~Figure 5 Shown in is a set of 9 roller wheels 3 and 9 universal angle adjustable brackets 2 to construct the device of the present invention. Among them, the machine base 1 and the universal angle adjustable bracket 2 are general parts, which should be designed according to the production program of the product and the structural parameters of the three-dimensional stretch bending machine so that they can adapt to the processing of various stretch bending parts as much as possible; The universal angle adjustable bracket can be designed as a series of common or standard parts with different specifications and angle adjustment ranges, and should match the T-shaped groove opened on the base; the outer contour groove of the roller should be designed according to the section contour of the profile, and The necessary avoidance gap should be set on the non-stressed surface. The axis direction of the roller should be set according to the bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com