Cover plate structure for deformation joint of pitched roof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

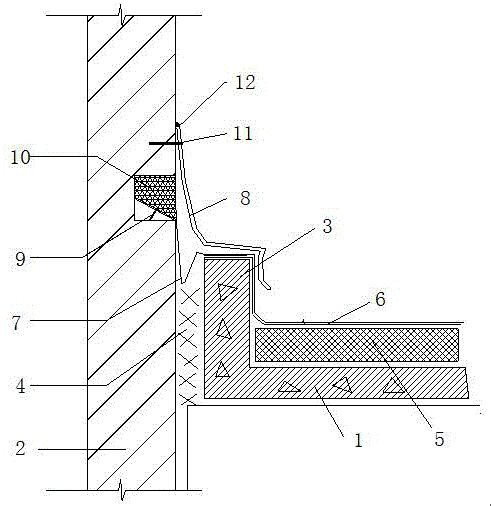

[0028] A roof deformation joint slope cover structure, including a roof 1 and a high-span wall 2 adjacent to it, a low-span wall 3 is provided on the adjacent side of the roof 1 and the high-span wall 2, the low-span wall 3 and the high-span wall There are gaps between the cross walls 2, and the gaps are filled with foam plastics 4; the surface of the low cross wall is glued with 1-2 layers of additional coiled material layers 5, and waterproof coiled materials 6 are laid on the additional coiled material layers 5, waterproof rolls The inner side of the material 6 is laid to the top of the low-span wall; the top part of the gap is covered with a coiled material cover 7, and one end of the coiled material cover 7 is laid to the top of the low-span wall and bonded with the waterproof coiled material 6 as a whole, and the other end is fixed In the wall of the high-span wall body 2 ; the top of the gap is located above the coiled material cover, and a cover plate 8 is fastened ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com