Precast concrete wallboard and preparation method thereof

A technology of precast concrete and production method, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, and processing of building materials, etc., can solve the problems of unguaranteed construction quality, high construction cost, environmental pollution, etc. To achieve the effect of saving the decoration period, reducing construction waste, and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

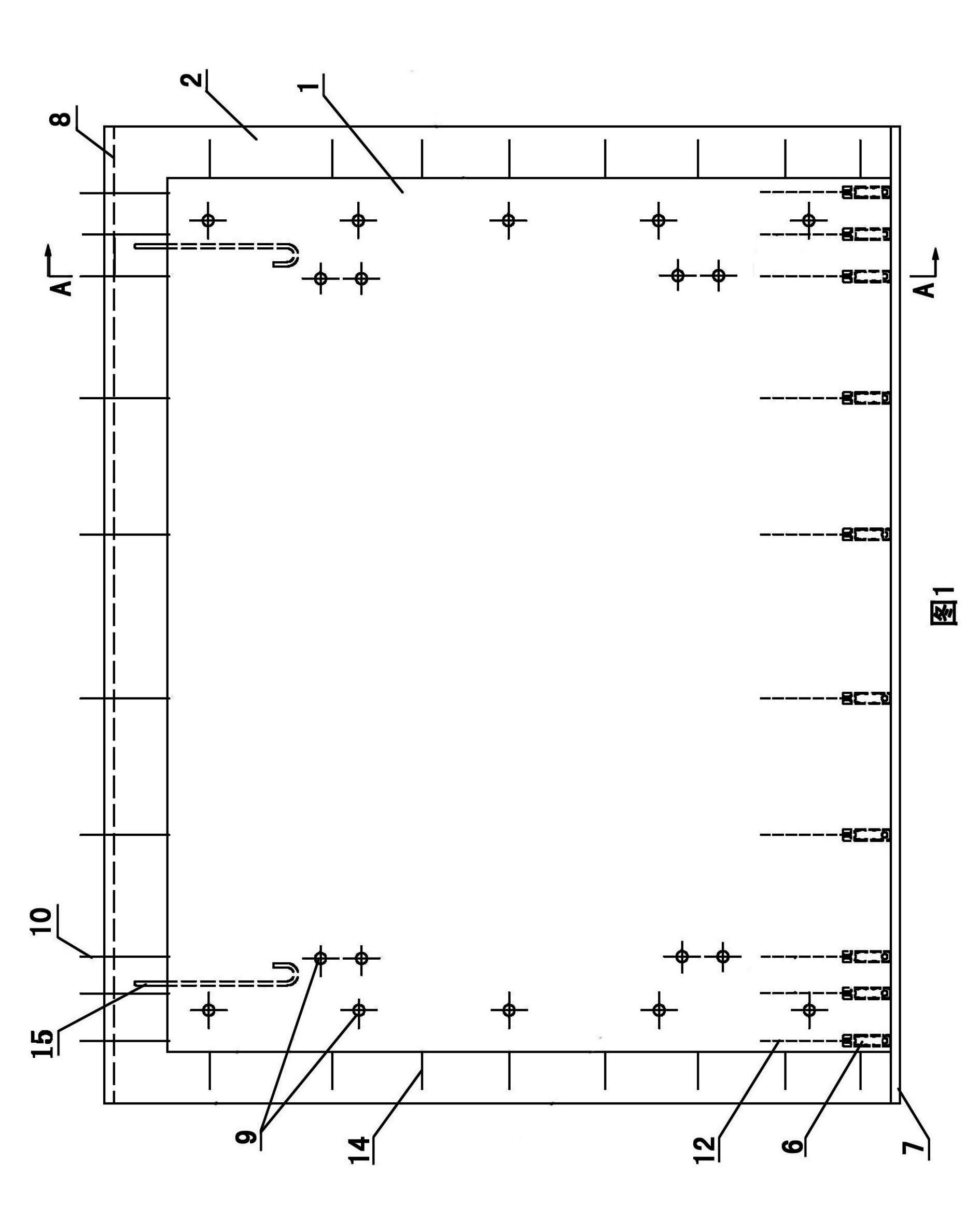

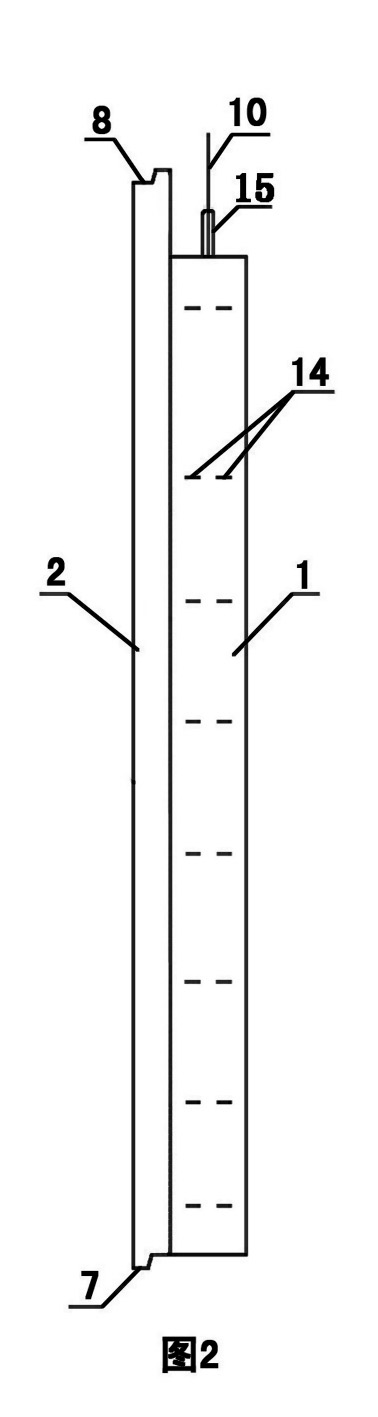

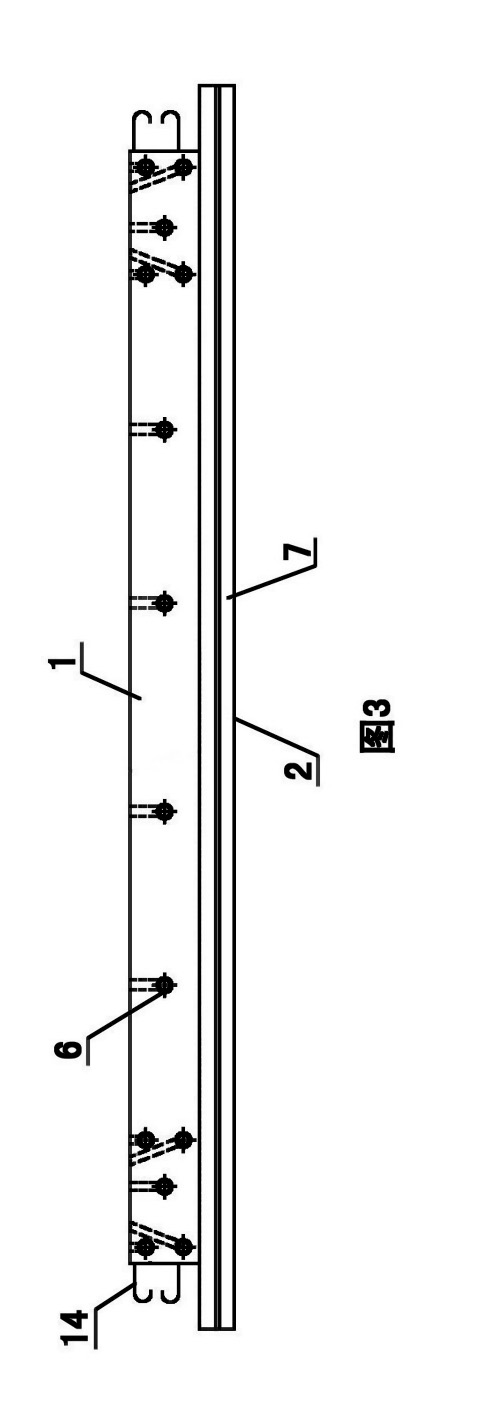

[0055] Embodiment one sees Figure 1-4 As shown, this prefabricated concrete wall panel has a structural layer 1 and a protective layer 2 in sequence from the inside to the outside, the structural layer has a steel cage, the concrete of the protective layer 2 has a steel mesh, and the protective layer 2 The horizontal connecting steel bars 24 connected to the reinforcement mesh are connected to the structural layer 1, the left and right edges of the protective layer 2 protrude from the structural layer 1, the lower edge of the protective layer 2 extends downwards from the protrusion 7, and the top of the protective layer 2 protrudes upwards For the structural layer 1, the upper edge of the protective layer has a notch 8 corresponding to the notch of the adjacent precast concrete wall panel on the upper layer. When concrete is poured at the connecting joint between two adjacent prefabricated concrete wall panels, the protective layer 2 can serve as a template, which simplifies ...

Embodiment 2

[0062] Embodiment two see Figure 5 , the outer surface of the protective layer 2 is connected with an outer decorative layer 4, and the outer decorative layer 4 is a face brick, a paint or a decorative board.

[0063] The manufacture method of this prefabricated concrete wall panel, step 1, assembling bottom formwork; Step 2, place protective layer reinforcement mesh sheet on the bottom formwork, connect horizontal connecting steel bar 24 on reinforcement mesh sheet; Step 3, pour protective layer concrete; Step Four, before the initial setting of the protective layer concrete, insert the transverse connecting reinforcement 24 on the protective layer concrete; step five, integrally vibrate, make the transverse connecting reinforcing bar 24 and the protective layer concrete combine closely; step six, support the side form; step seven, Place reinforcement cages, reinforcement rings 15 and internal thread sleeves 9 on the protective layer. The reinforcement cages include transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com