Patents

Literature

602results about How to "Unified specifications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Assembled integral building and construction method thereof

ActiveCN101818539AGuarantee the construction qualityLow costBuilding componentsBuilding material handlingFloor slabReinforced concrete

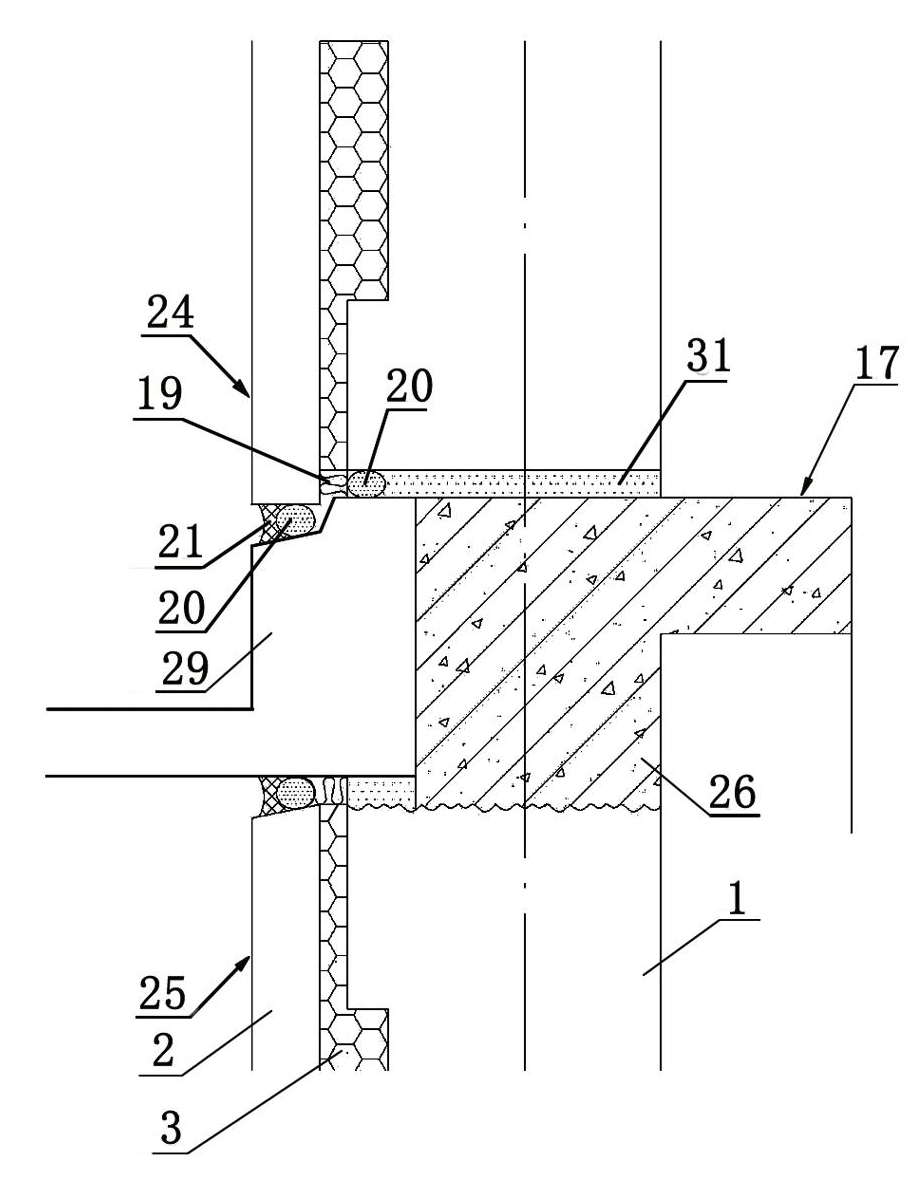

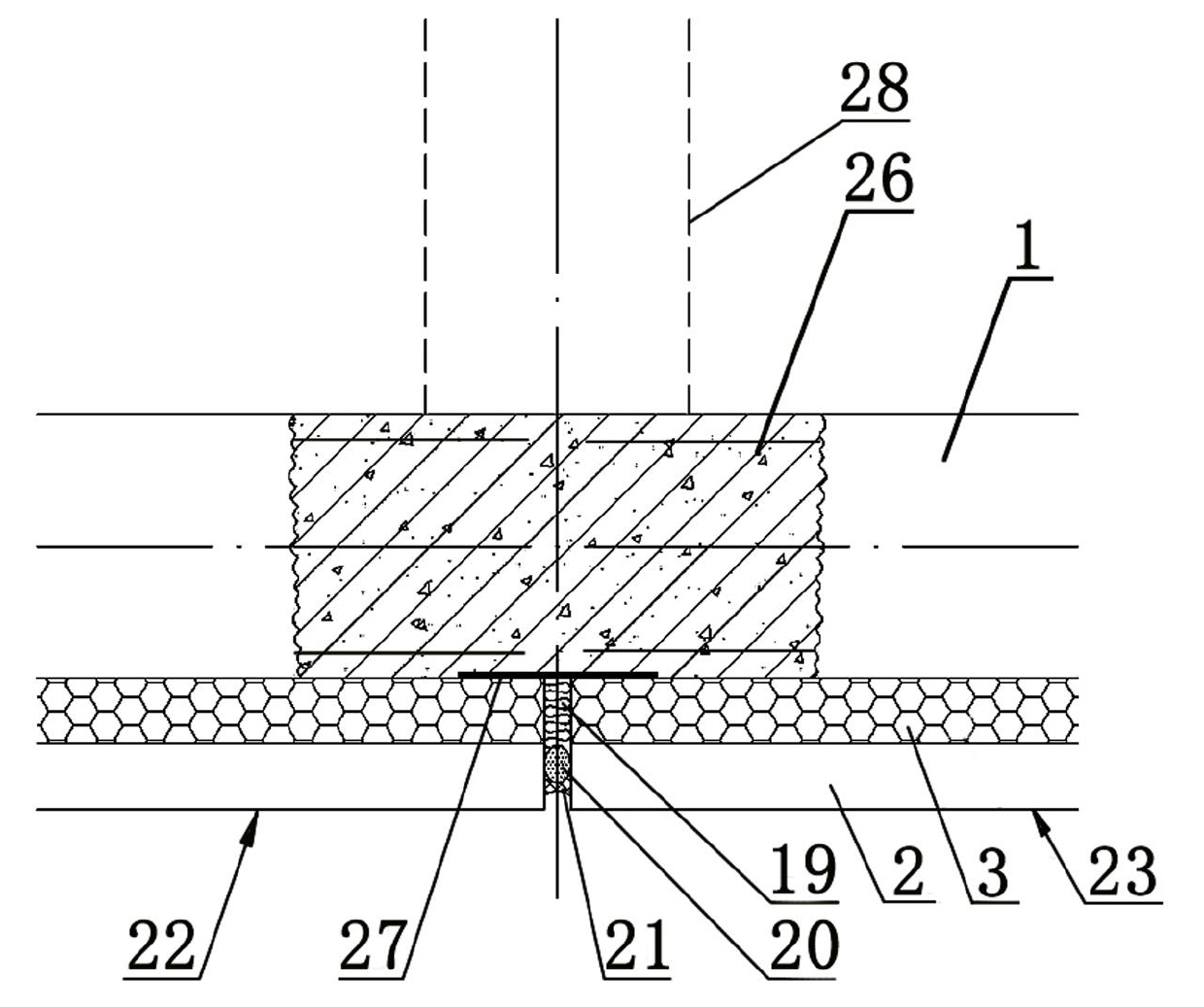

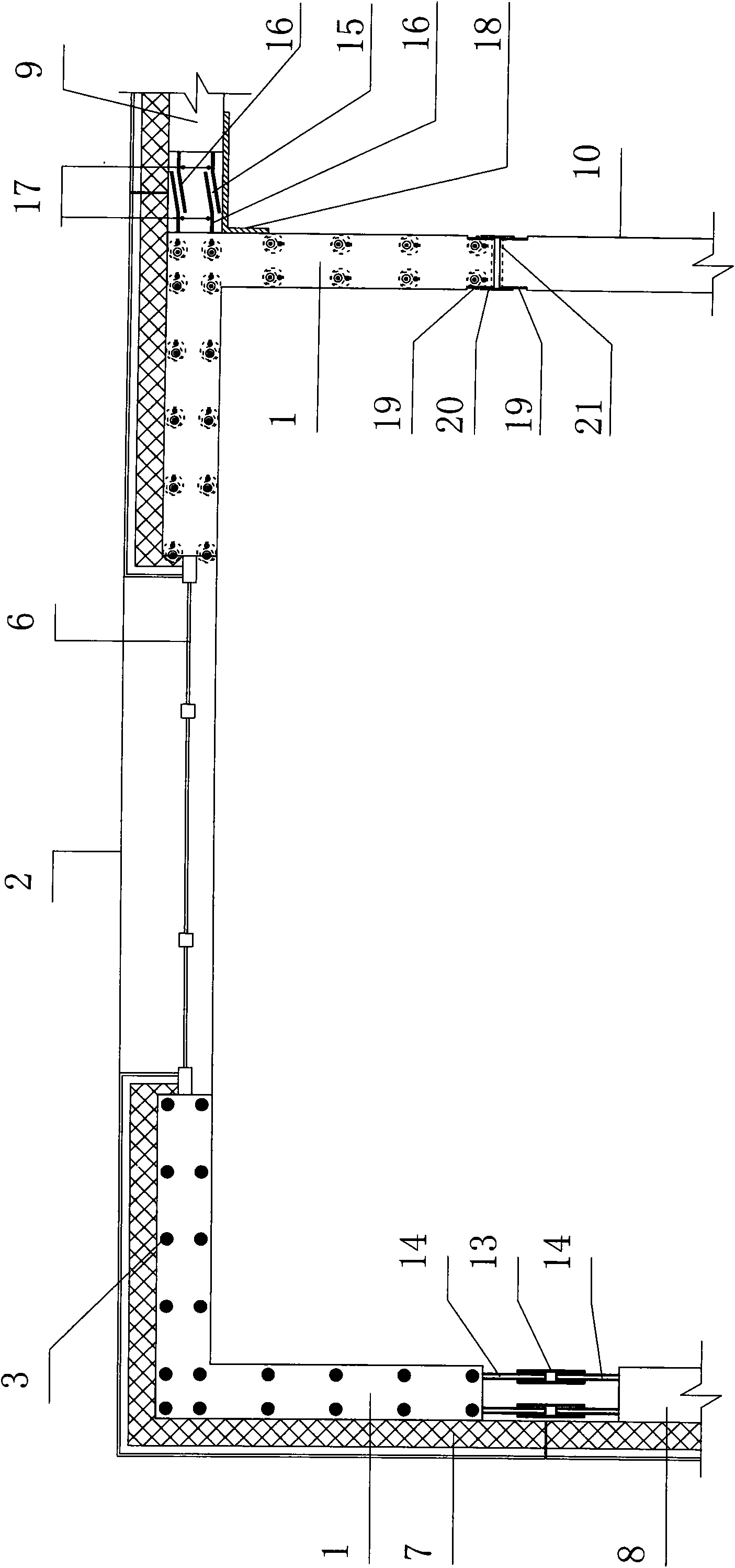

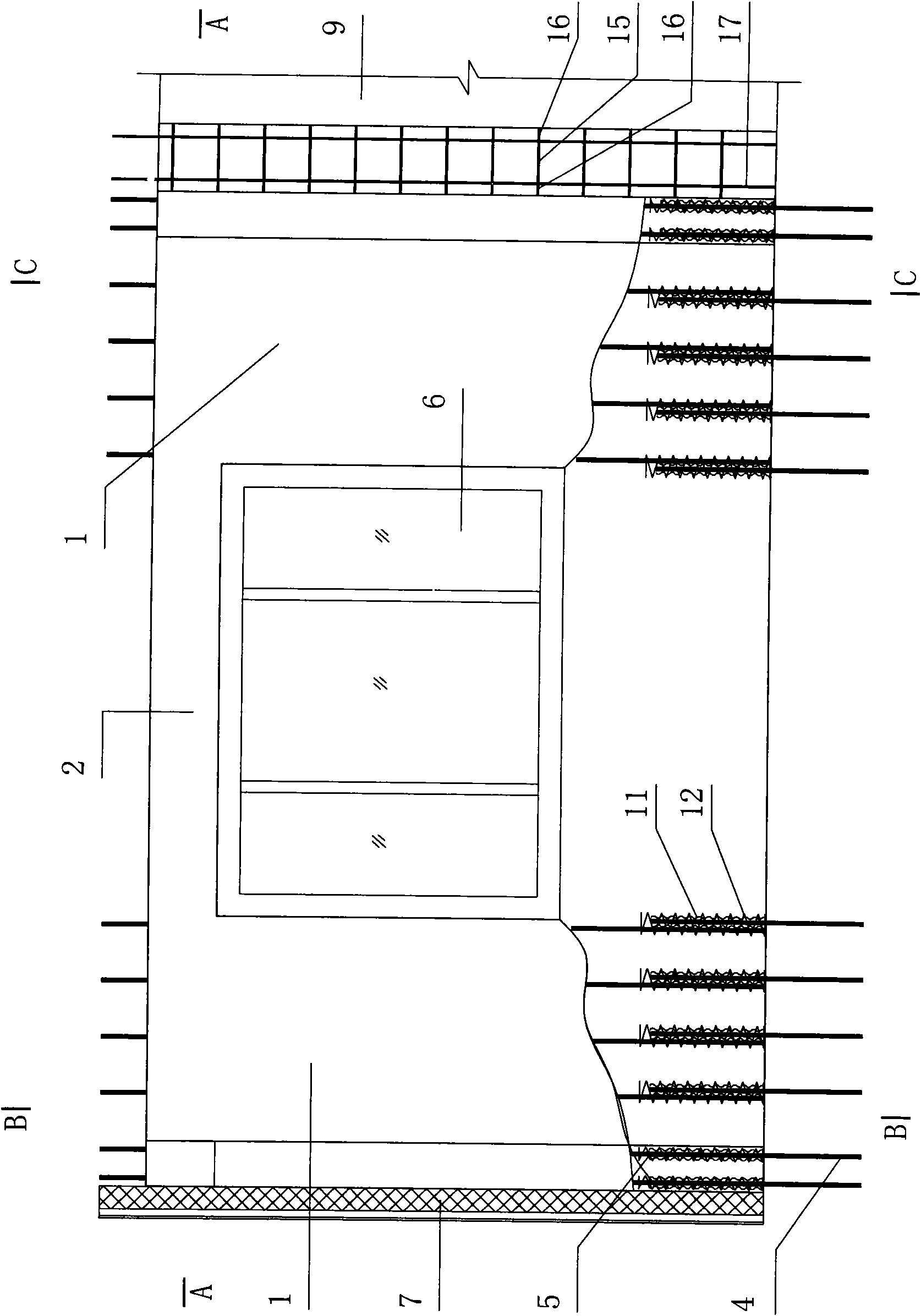

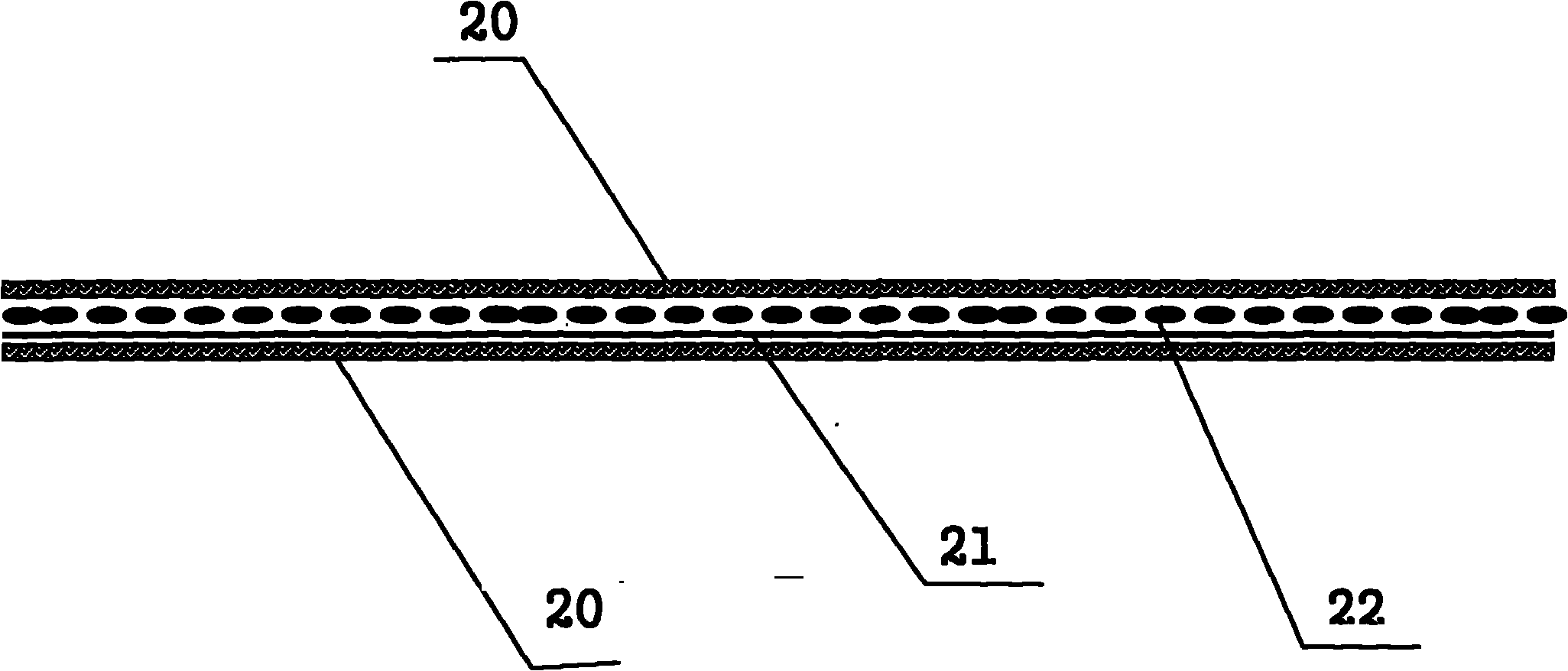

The invention discloses an assembled integral building and a construction method thereof. The assembled integral building comprises a reinforced concrete wall and floor slabs, wherein the reinforced concrete wall is formed by hoisting and assembling prefabricated composite insulating wallboards integrally at a construction site; a board body of each prefabricated composite insulating wallboard comprises a structure layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; steel meshes are arranged in the concrete of the protective layer; the structural layer, the insulating layer and the protective layer are anchored together by inserting connecting members in a dotted distribution; the left and right edges of the protective layer and the insulating layer protrude out of the structural layer; a lower edge of the protective layer extends downward to form a bulged opening; the top parts of the protective layer and the insulating layer upward protrude out of the structural layer; and an upper edge of the protective layer is provided with a notch which corresponds to the bulged opening of the prefabricated composite insulating wallboard adjacent to an upper layer. The building overcomes the defects of erecting shuttering on site, binding steel bars and concreting in a traditional construction method, speeds up the construction, and lowers the construction cost; and the construction quality of the building structure can be sufficiently guaranteed.

Owner:雄安万科绿色研发有限公司

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527ALow costGuarantee the construction qualityWallsBuilding material handlingReinforced concretePolystyrene

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Owner:华筑(辽宁)建筑工程设计有限公司

Method and apparatus for uniformly stretching thermoplastic film and products produced thereby

ActiveUS7442332B2Improve mechanical propertiesUnified specificationsLayered productsHollow filament manufactureEngineeringMechanical property

Thermoplastic films and laminates are made by extrusion and stretching using differential speed rollers employing a short stretching gap of no more than one inch immediately after the extruded film product is formed. The method and apparatus control the thickness of the stretched film and impart desirable mechanical properties thereto such as film products with a high modulus for handling and suitable tensile for softness.

Owner:BERRY FILM PROD CO INC

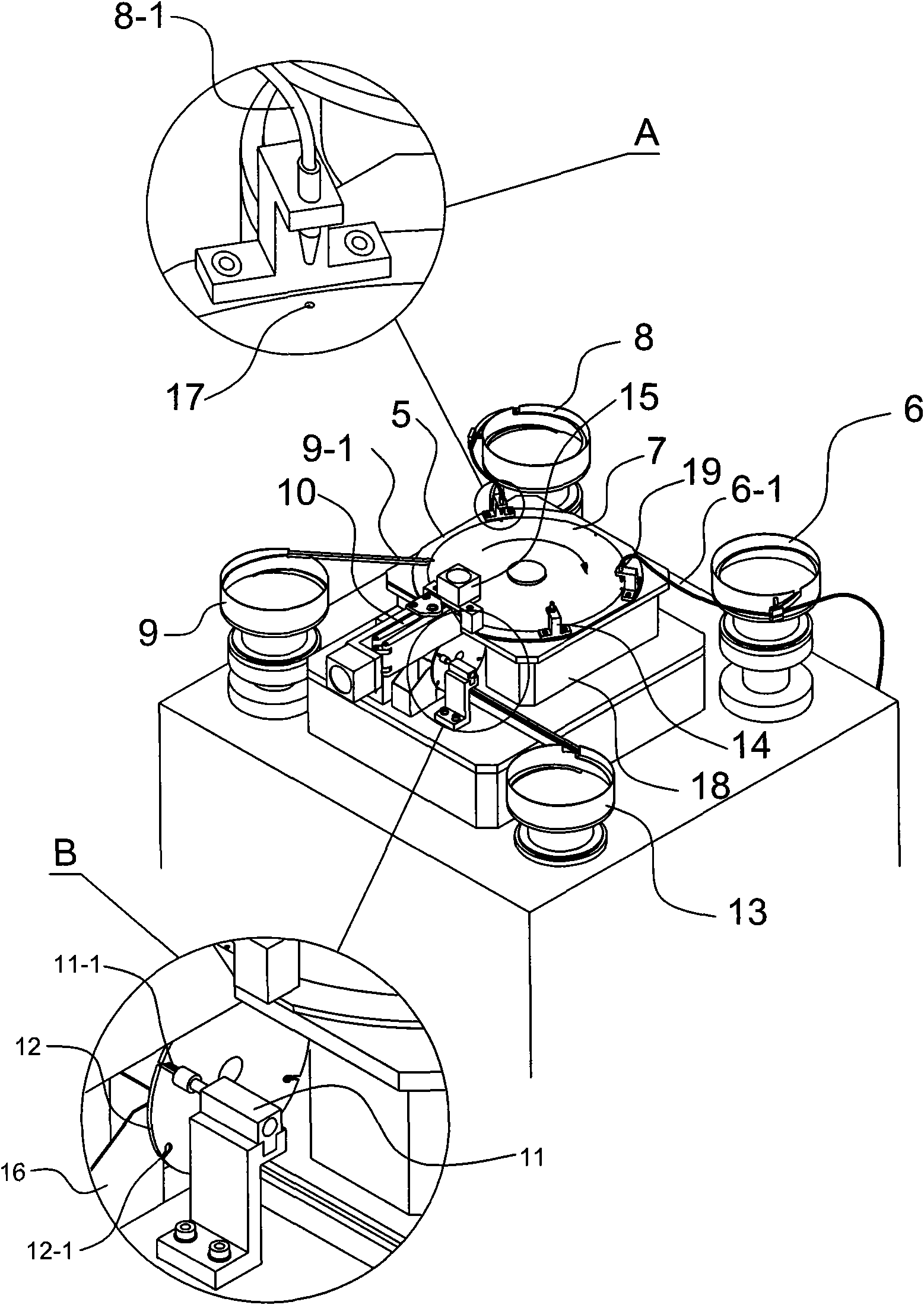

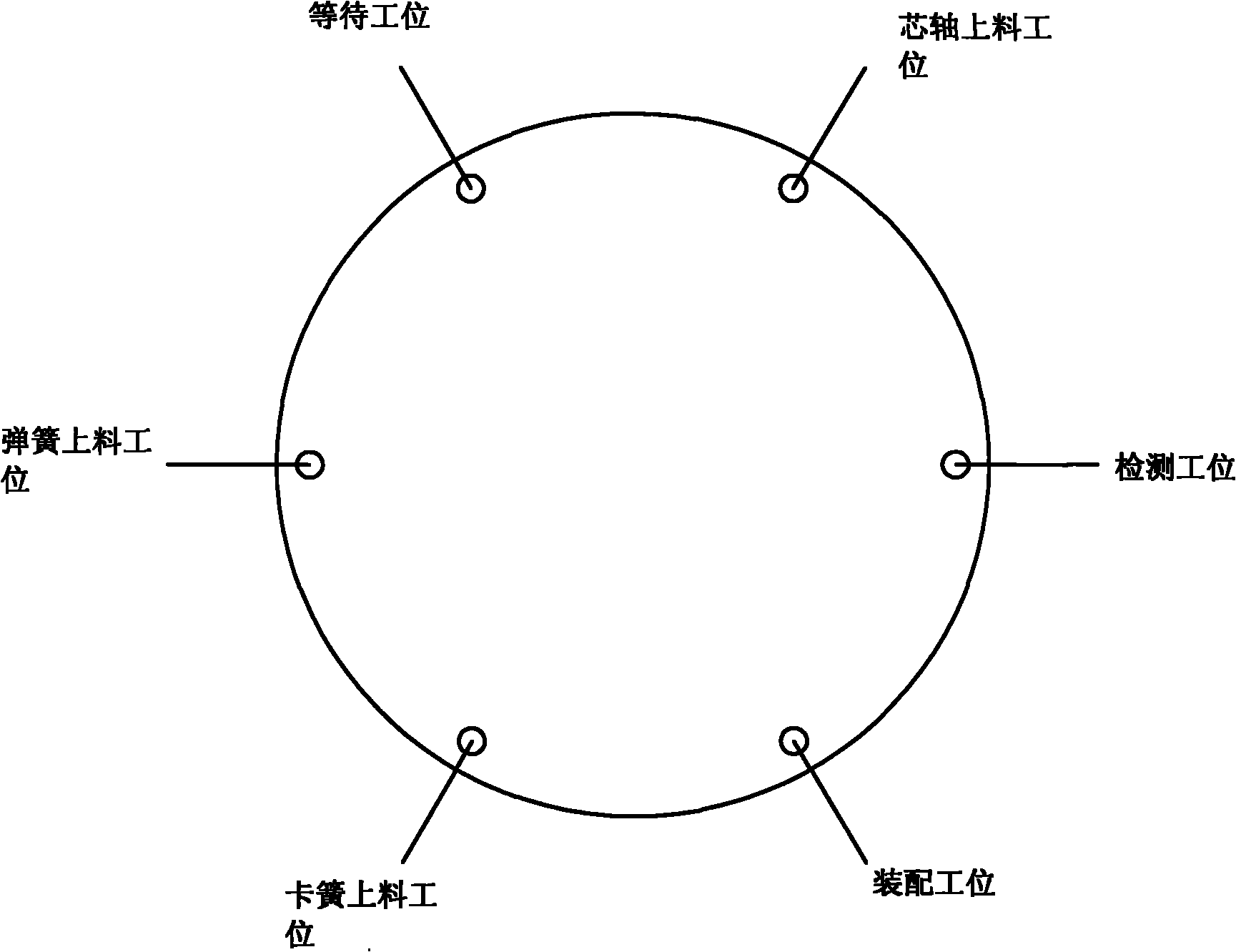

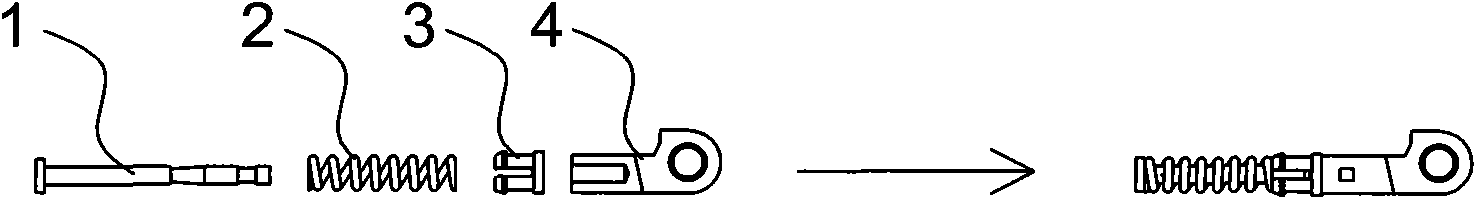

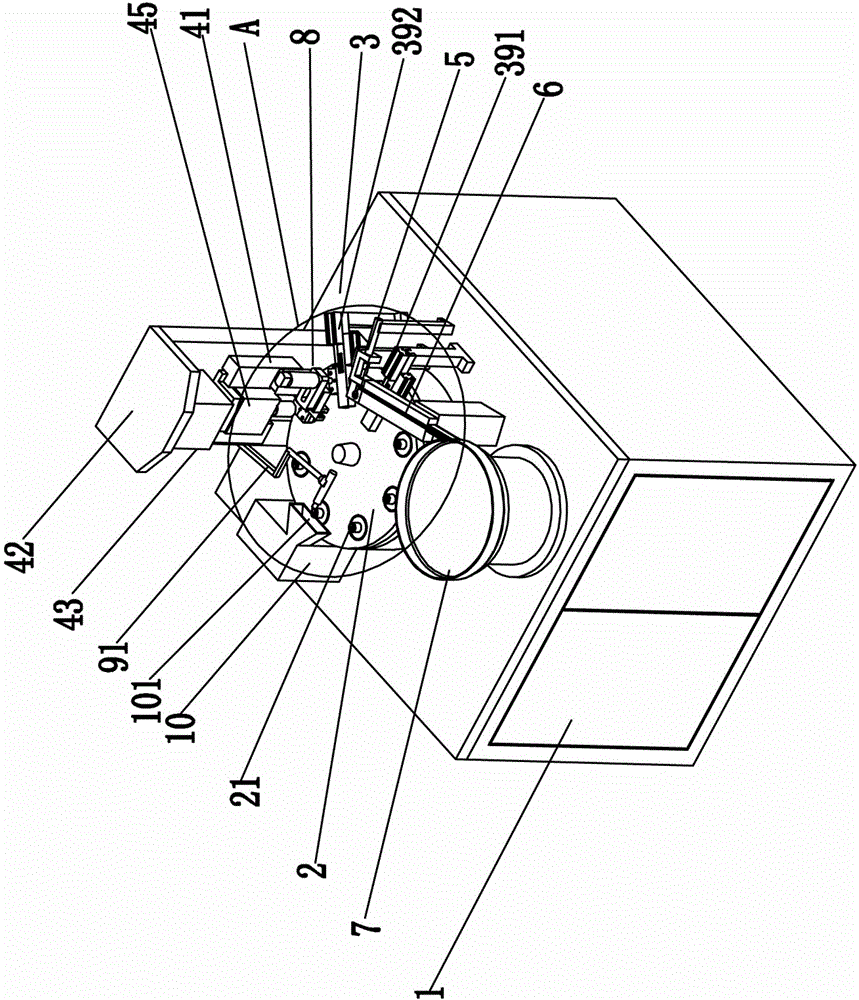

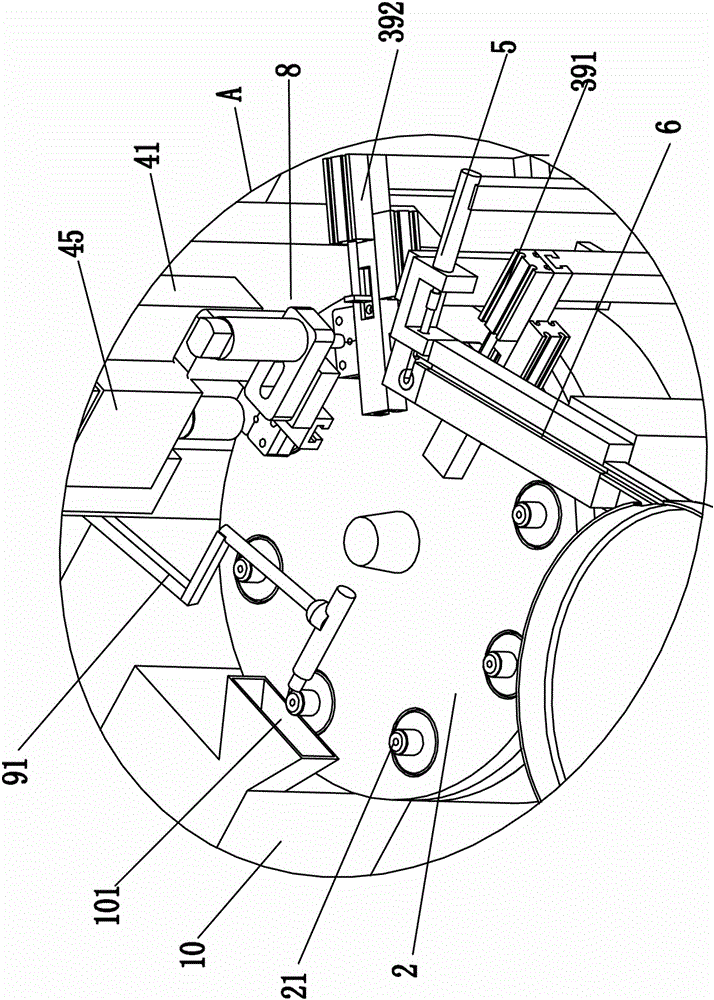

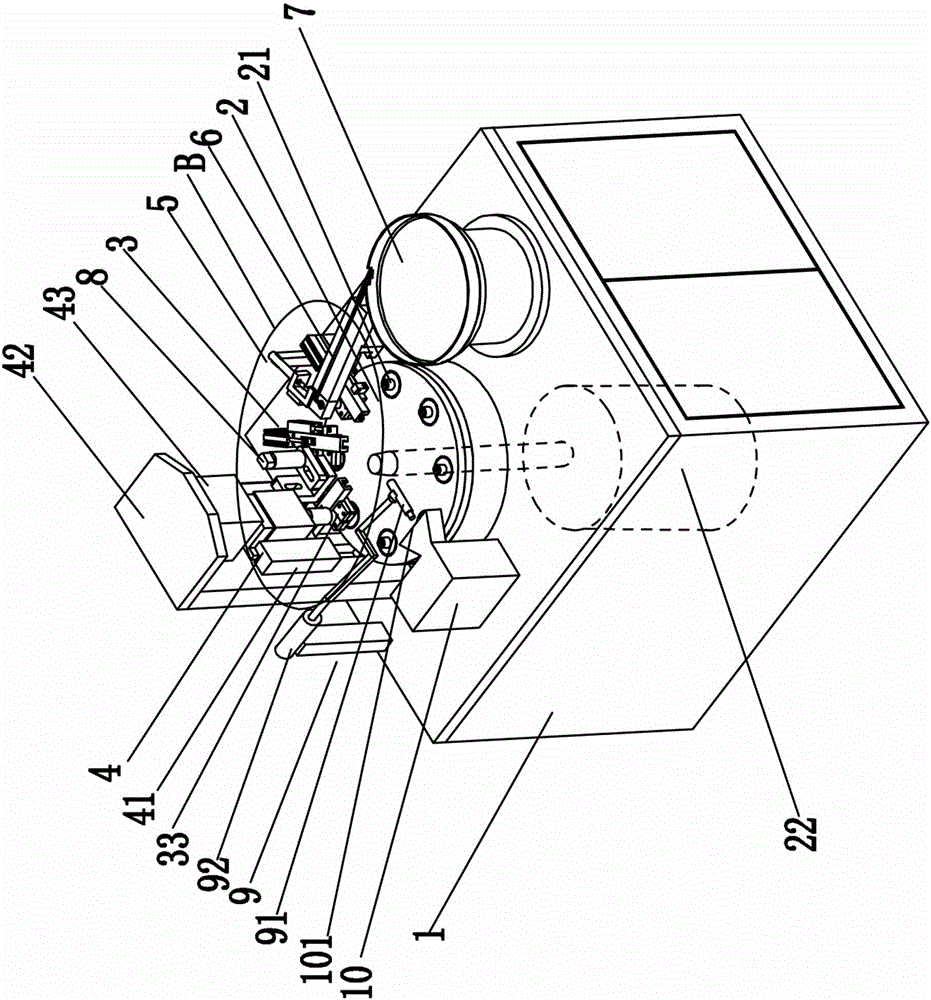

Automatic assembling machine of hinge spring shafts

InactiveCN101875167AReduce the differenceUnified specificationsAssembly machinesNon-optical partsEngineeringAssembly machine

The invention belongs to an assembling machine for manufacturing spectacle frames, in particular to an automatic assembling machine of hinge spring shafts, which can continuously and automatically complete the integral assembly of spectacle hinge spring shafts. The traditional assembly of the spectacle hinge spring shafts completely depends on manual operation of workers and has the defects of low assembly speed, long period and low production efficiency due to one-by-one serial connection, and the assembled spectacle hinge spring shafts have great difference and unstable quality due to the limitations of the technical level of the workers, which greatly influences the later actual use of the spectacle frames. Aiming at the defects, the invention provides an automatic assembling machine of hinge spring shafts, which has the technical characteristic that one large rotary table and one small rotary table which are mutually perpendicular are arranged, the rotary tables are provided with a plurality of corresponding through holes and card slots for installing corresponding parts, and the two rotary tables rotate and are mutually matched according to a set beat so as to continuously and automatically assemble the hinge spring shafts. Compared with the traditional manual operation, the invention has high speed and high efficiency, and the finished hinge spring shafts assembled by the machine have uniform specifications, small difference and stable quality.

Owner:浙江康华眼镜有限公司 +1

Precast concrete wallboard and preparation method thereof

ActiveCN101831985ALow costGuarantee the construction qualityConstruction materialForms/shuttering/falseworksReinforced concreteArchitectural engineering

The invention relates to a precast concrete wallboard and a preparation method thereof. A wall body has a structural layer and a protection layer from inside to outside, wherein the structural layer is internally provided with a reinforcement cage, and a reinforcement fabric is arranged in the concrete of the protection layer; the protection layer is connected with the structural layer through a transverse connecting reinforcement connected to the reinforcement fabric; the left edge and the right edge of the protection layer protrude out of the structural layer; the lower edge of the protection layer downwards extends out of a protruded port; and the top of the protection layer upwards protrudes out of the structural layer; the upper edge of the protection layer has a dent corresponding to the protruded port of the adjacent precast concrete wallboard on the upper layer; and the two ends of a transverse bar of the reinforcement cage protrudes out of the left side surface and the right side surface of the structural layer of the wall body and form two rows of transverse steel ties bending inwards. The wallboard has the advantages that the construction process is simplified, the construction speed is accelerated, and the construction cost is reduced. Meanwhile, products precast by a factory have uniform specification and quality, and thus, the construction quality of a building structure can be guaranteed sufficiently. The precast concrete wallboard can be widely applied to construction of concrete steel buildings in building industry.

Owner:华筑(辽宁)建筑工程设计有限公司

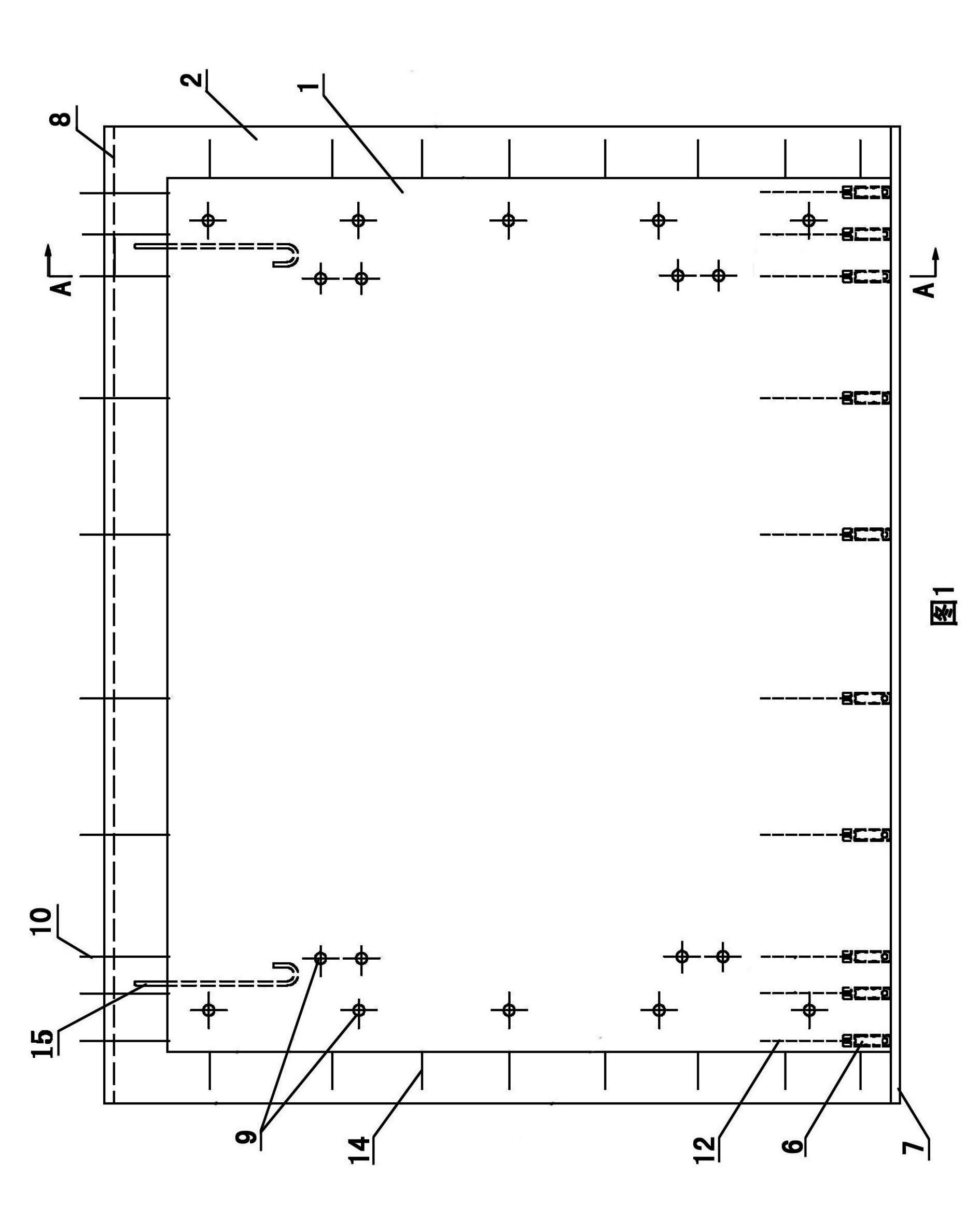

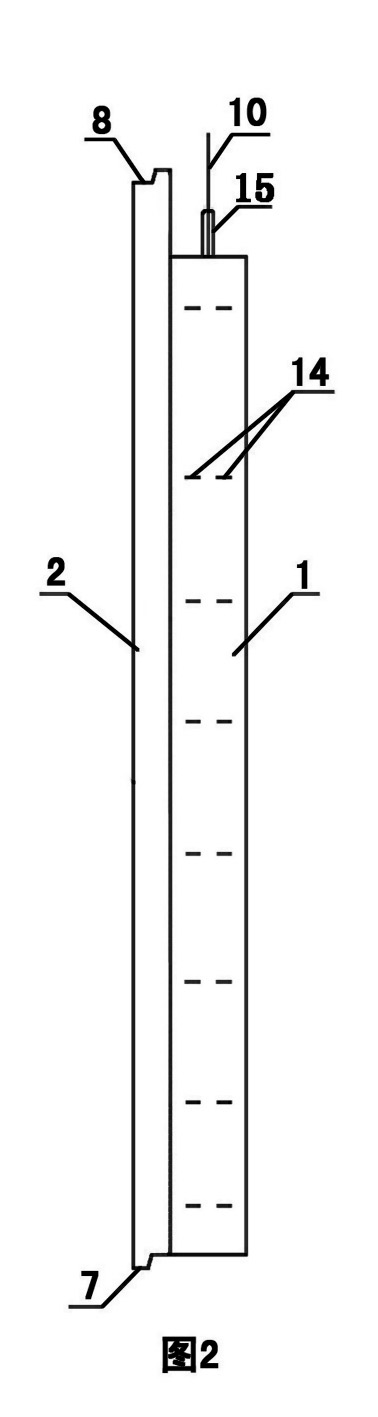

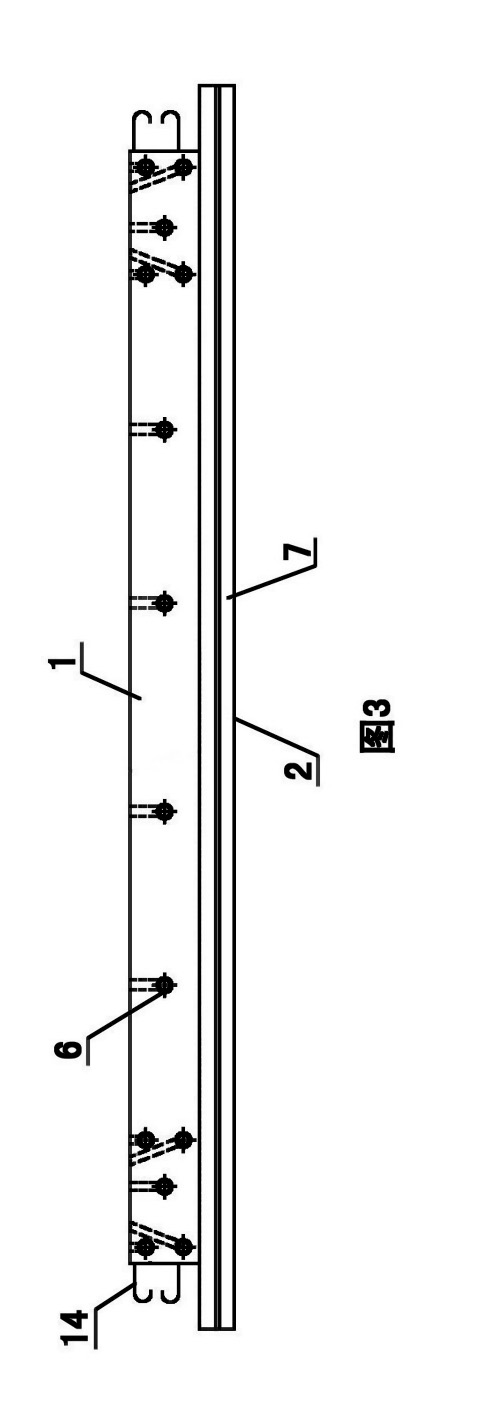

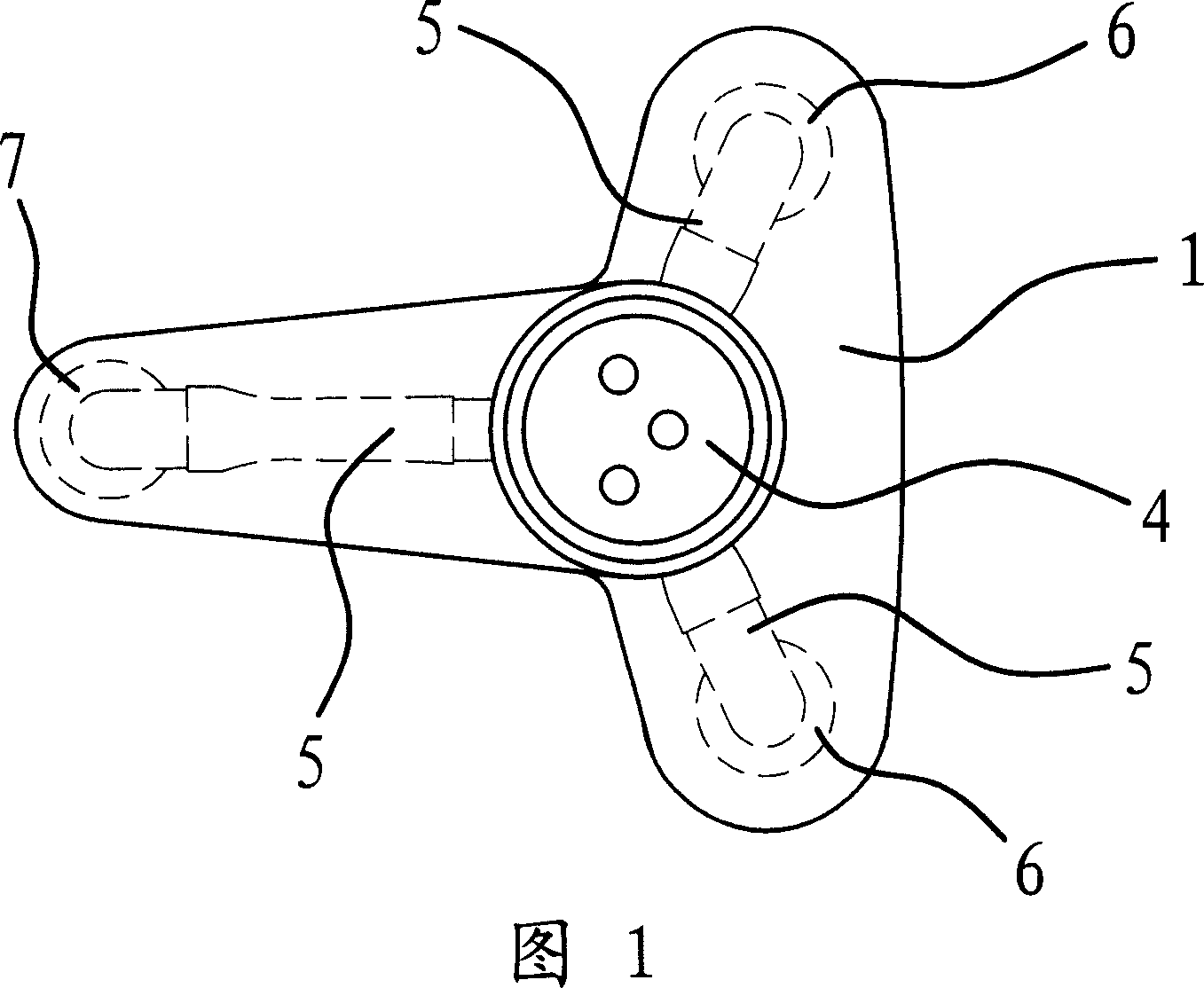

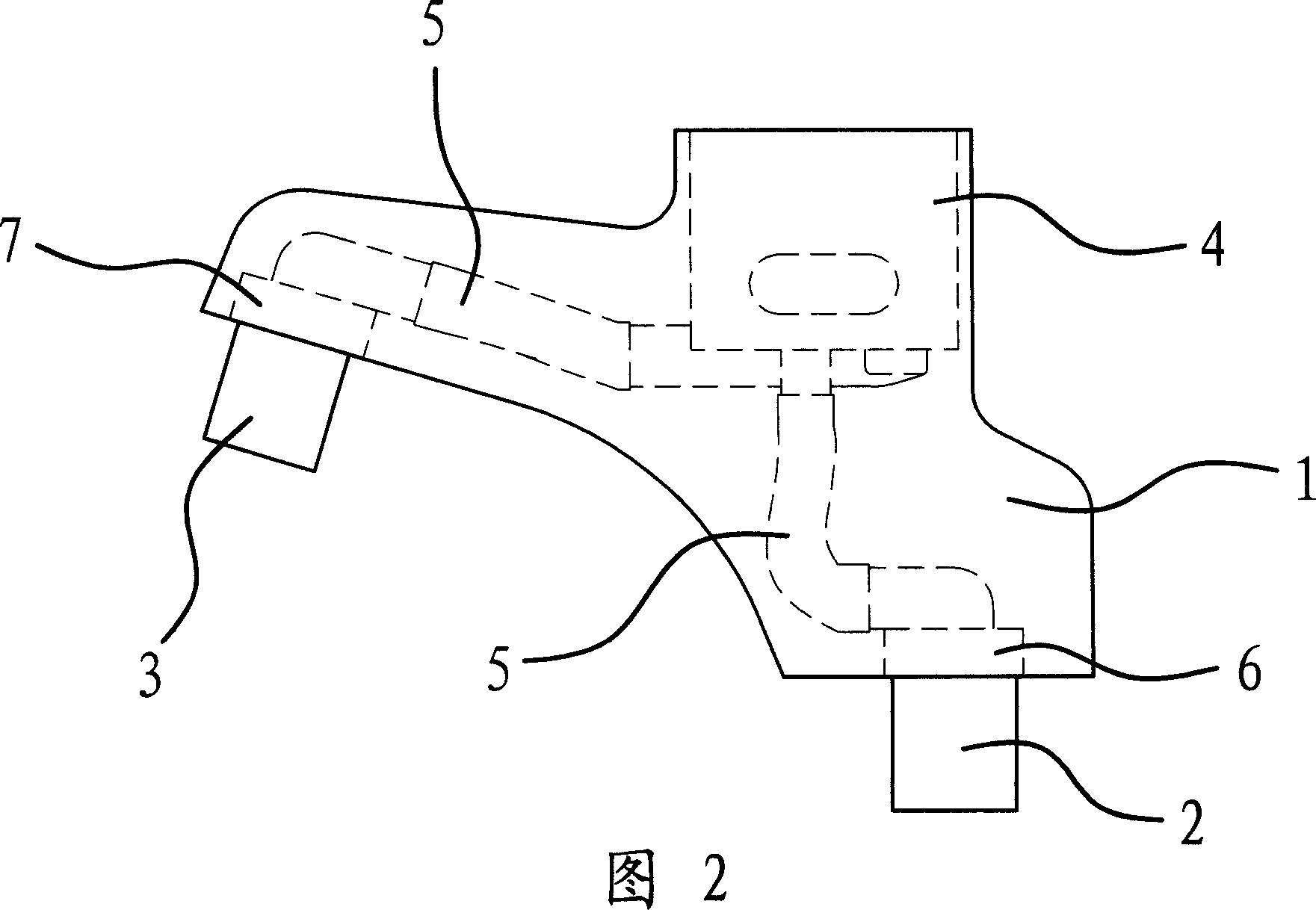

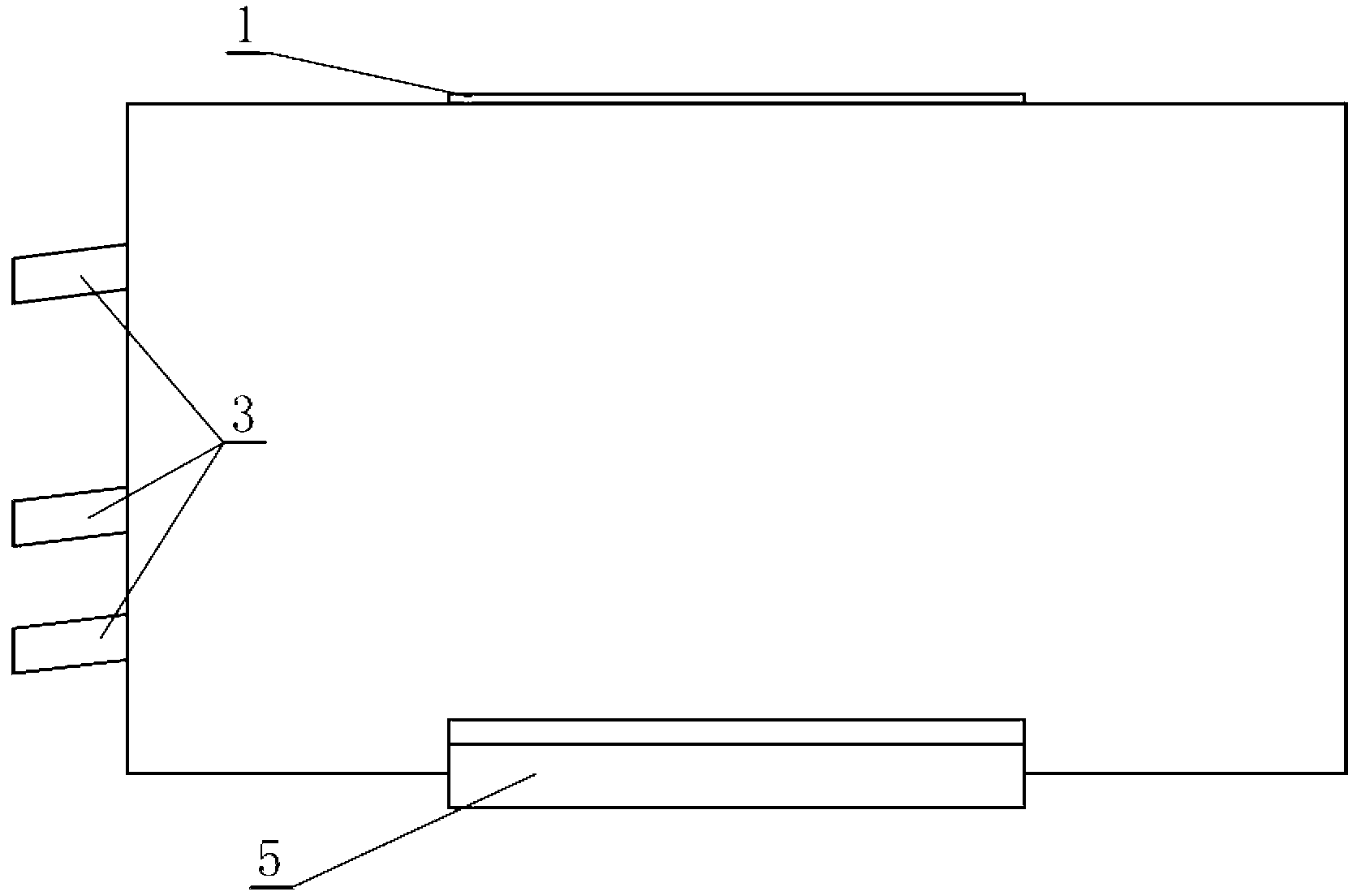

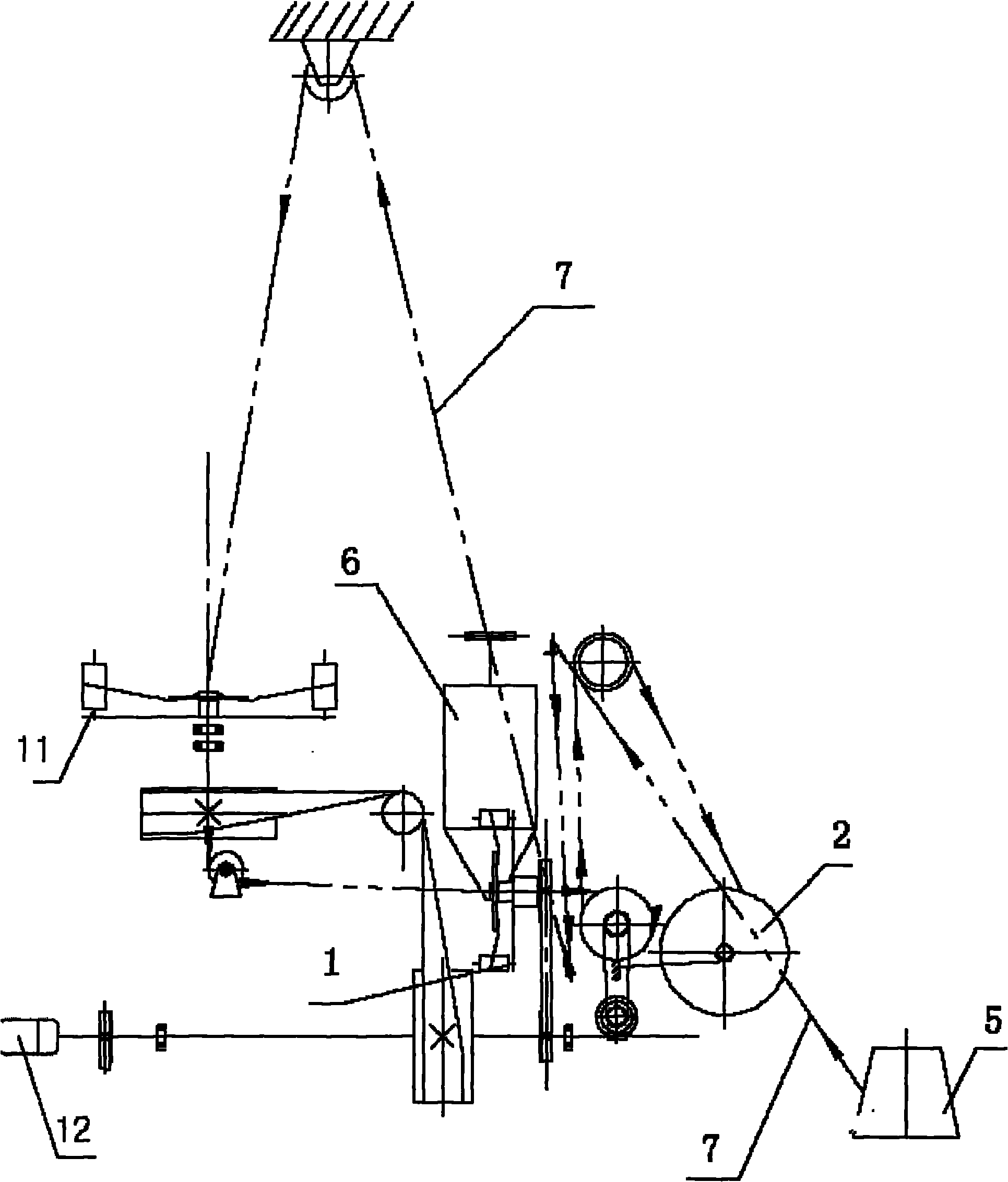

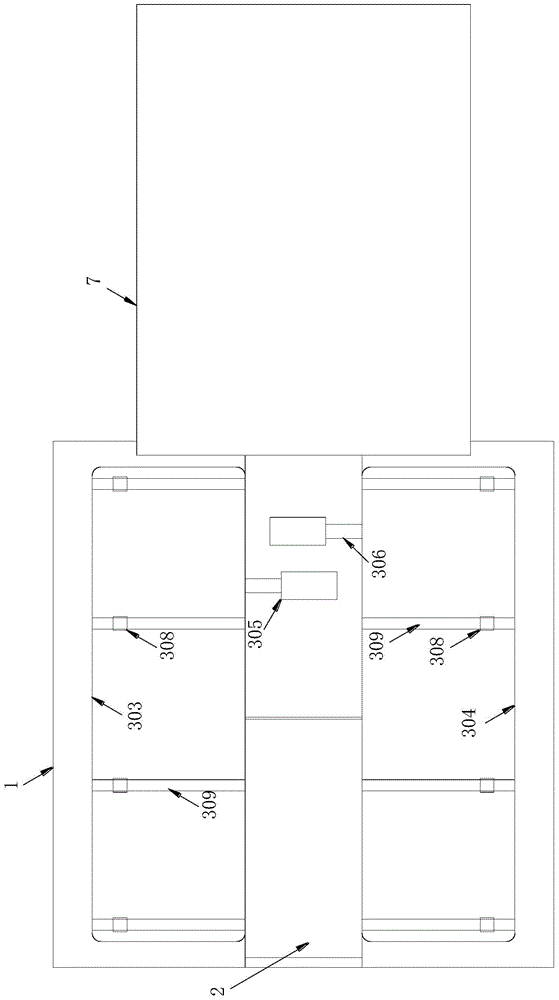

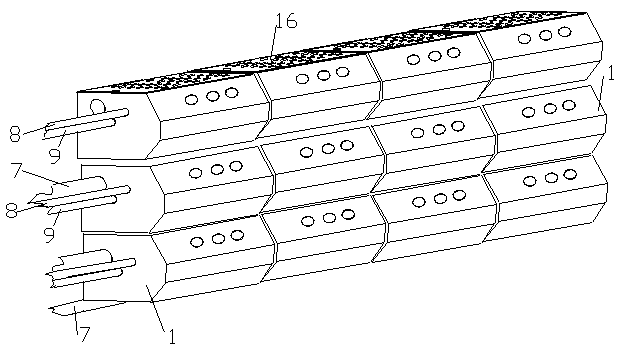

Precast concrete short-limb shear wall provided with door windows and manufacturing method thereof

The invention relates to a precast concrete short-limb shear wall provided with door windows and a manufacturing method thereof. The concrete short-limb shear wall refers to a shock-resistant wall of which the ratio of the wall limb cross section height to the thickness is between 5 and 8, and according to the active code requirement in China, the cross section thickness of a wall body is not less than 200 millimeters, and the stress performance of the structure of the concrete short-limb shear wall is between a specially-shaped column and a common shear wall structure. Because of the good performances in various aspects of construction, structure, construction cost, energy conservation and environmental protection and the like, the structural system becomes the structural form which is most suitable for residential constructions. The precast concrete short-limb shear wall comprises precast concrete wall limbs (1), wherein the wall limbs (1) are connected with connecting beams (2), are provided with door windows (6), and are connected with an external wall heat insulation layer and an architectural surface (7), and the wall limbs are connected with each other by assembling steel bars. The precast concrete short-limb shear wall is applied to industrialized fully-assembled shear walls for residential buildings.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

Oriented cook-in film with good interply adhesion

InactiveUS6294264B1High bonding strengthUnified specificationsFlexible coversWrappersAcetic acidFatty food

A multilayer film suitable for cook-in end use includes an outer layer that includes a homo- or co-polymer of propylene and, directly adhered to the outer layer, a layer that includes at least one of: (a) an ethylene / alkyl acrylate copolymer having a high melting point, (b) propylene / alpha-olefin copolymer having a lower propylene mer content than the outer layer and having a high Vicat softening point, and (c) an ethylene / vinyl acetate copolymer with at least 15% vinyl acetate mer content. The film exhibits good seal strength and good adhesion between the two layers, even in areas where the film is sealed, even after the film is oriented, even when the film is subjected to the elevated temperatures involved in cook-in procedures, and even where the film is subjected to, e.g., grease from fatty foods. The film also can include one or more other layers including, for example, bulk layers, O2-barrier layers, and / or abuse layers.

Owner:CRYOVAC ILLC

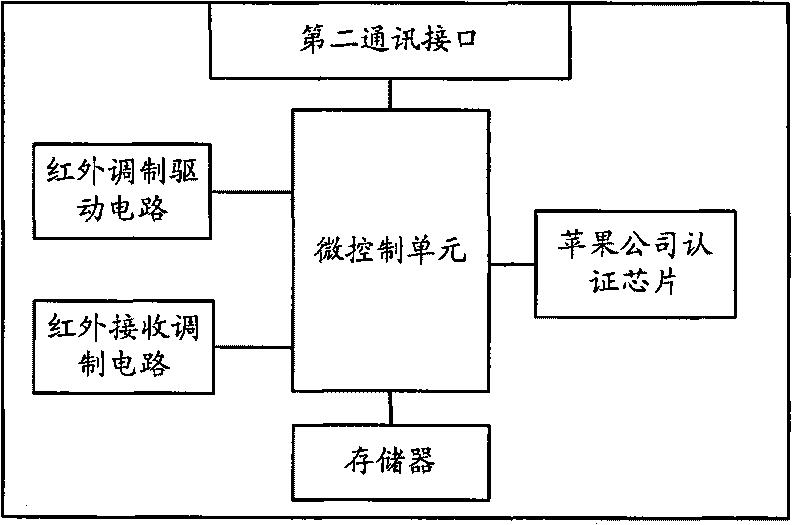

Electronic equipment, mobile communication equipment and remote control device

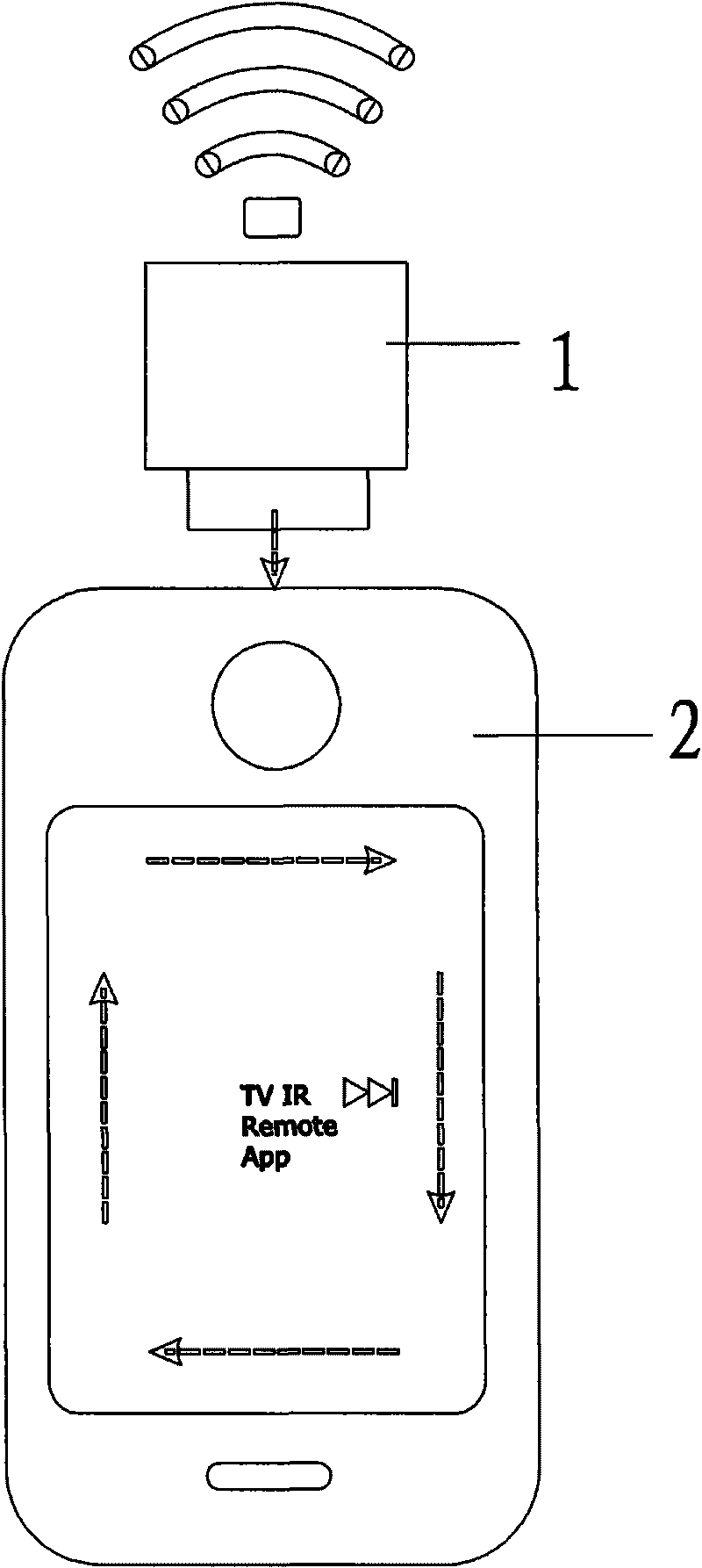

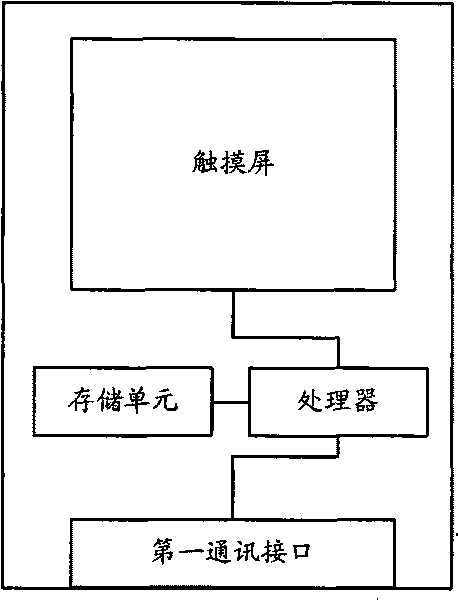

InactiveCN101707662AEasy remote controlTransmitting power is sufficientTelephonic communicationWireless communicationCommunication interfaceRemote control

The invention discloses electronic equipment, mobile communication equipment and a remote control device. The electronic equipment comprises a mobile communication equipment main body and the remote control device, and the equipment main body comprises a multi-contact touch screen, a first communication interface and a remote control unit, wherein the multi-contact touch screen is used for displaying information and inputting signals including touch signals; the first communication interface is positioned on the lateral surface of the equipment main body, and the first communication interface and the remote control device are connected by insertion; and the remote control unit is connected with a display unit, an input unit and the first communication interface and used for generating or finding remote control coded data corresponding to the input touch signals, sending the remote control coded data to the remote control device through the first communication interface and controlling the remote control device to send remote control coded signals corresponding to the input touch signals to controlled external equipment. The cost can be lower, and the mobile communication equipment can be more conveniently and effectively used for carrying out wireless remote control on the controlled external equipment.

Owner:郭治华

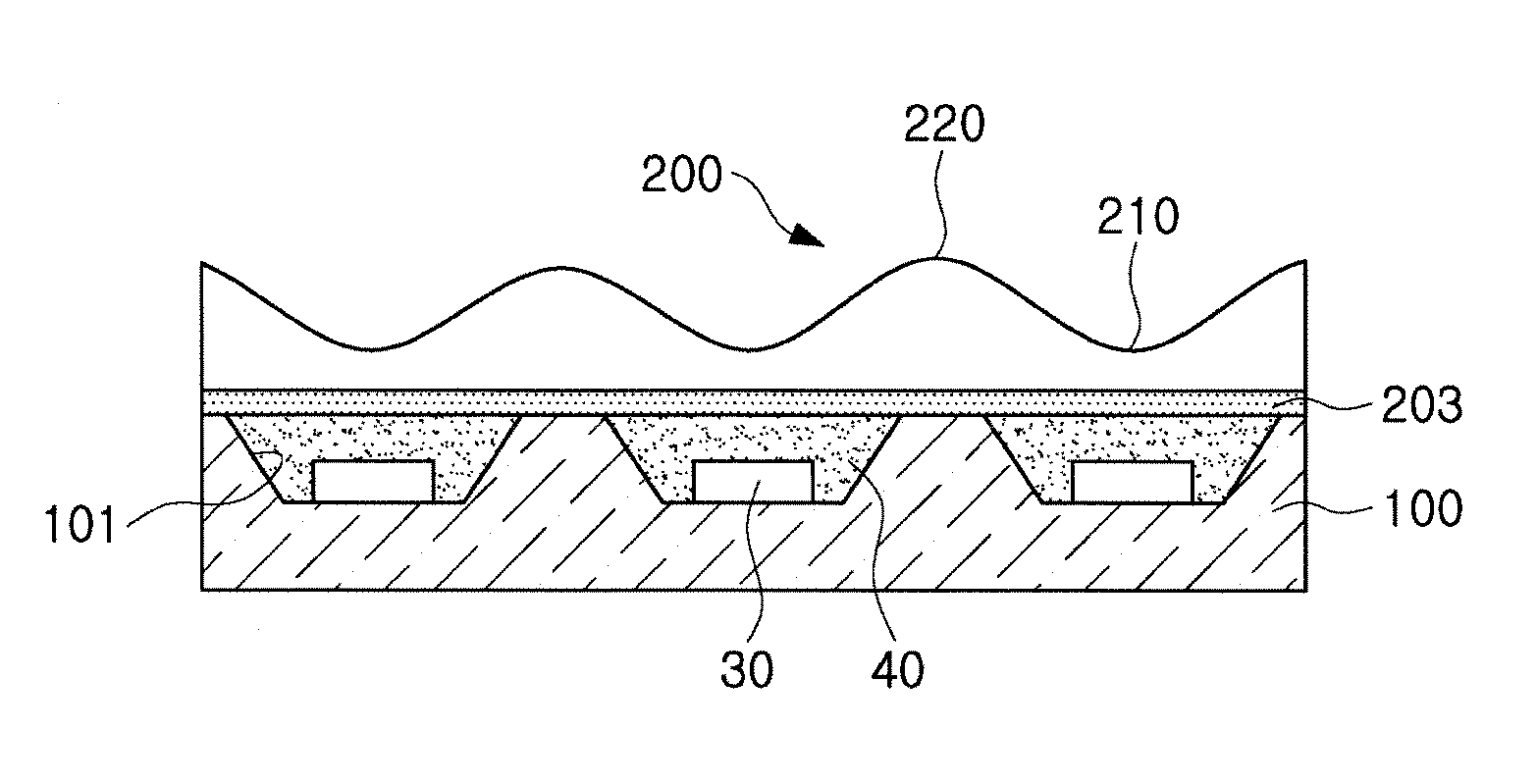

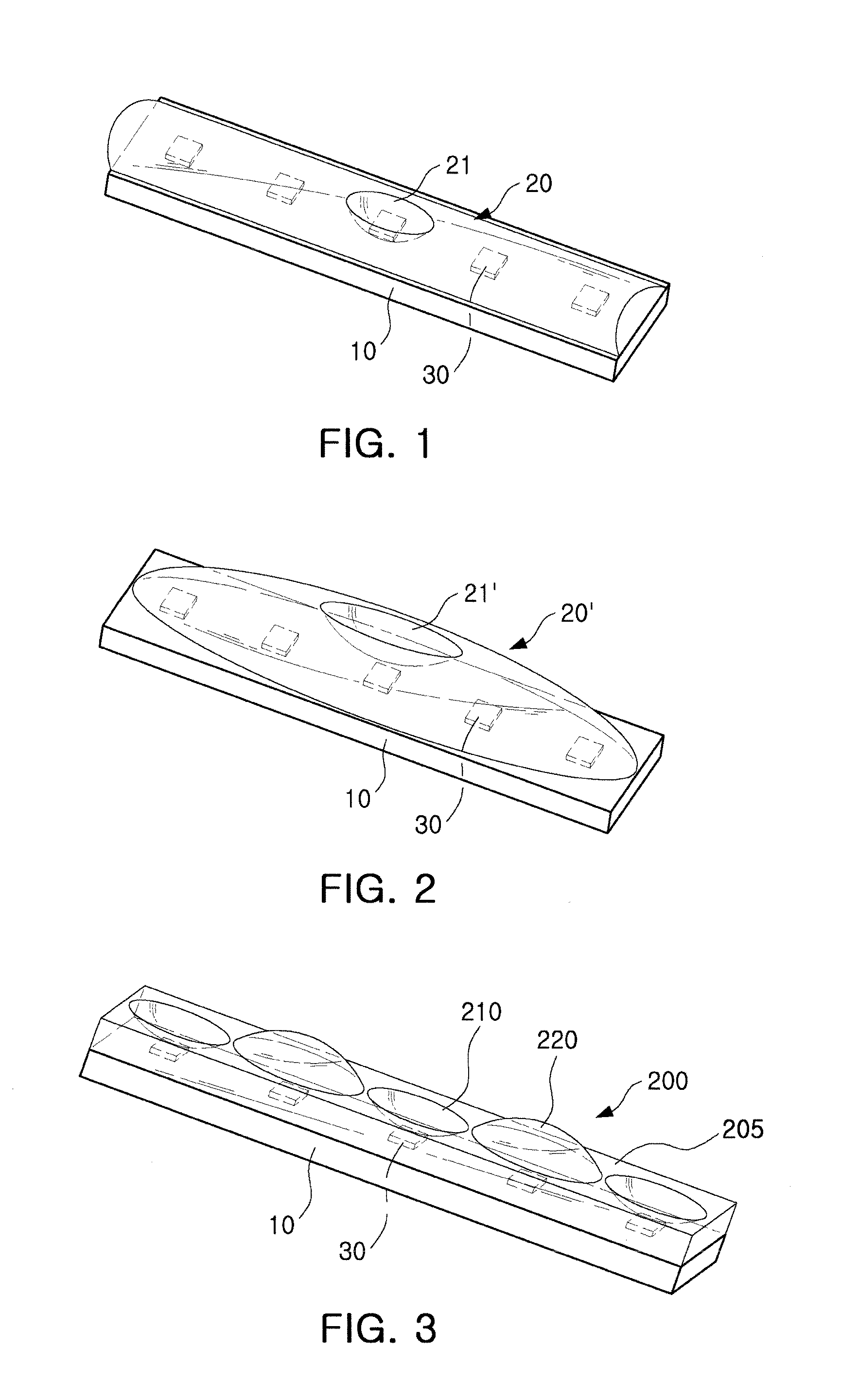

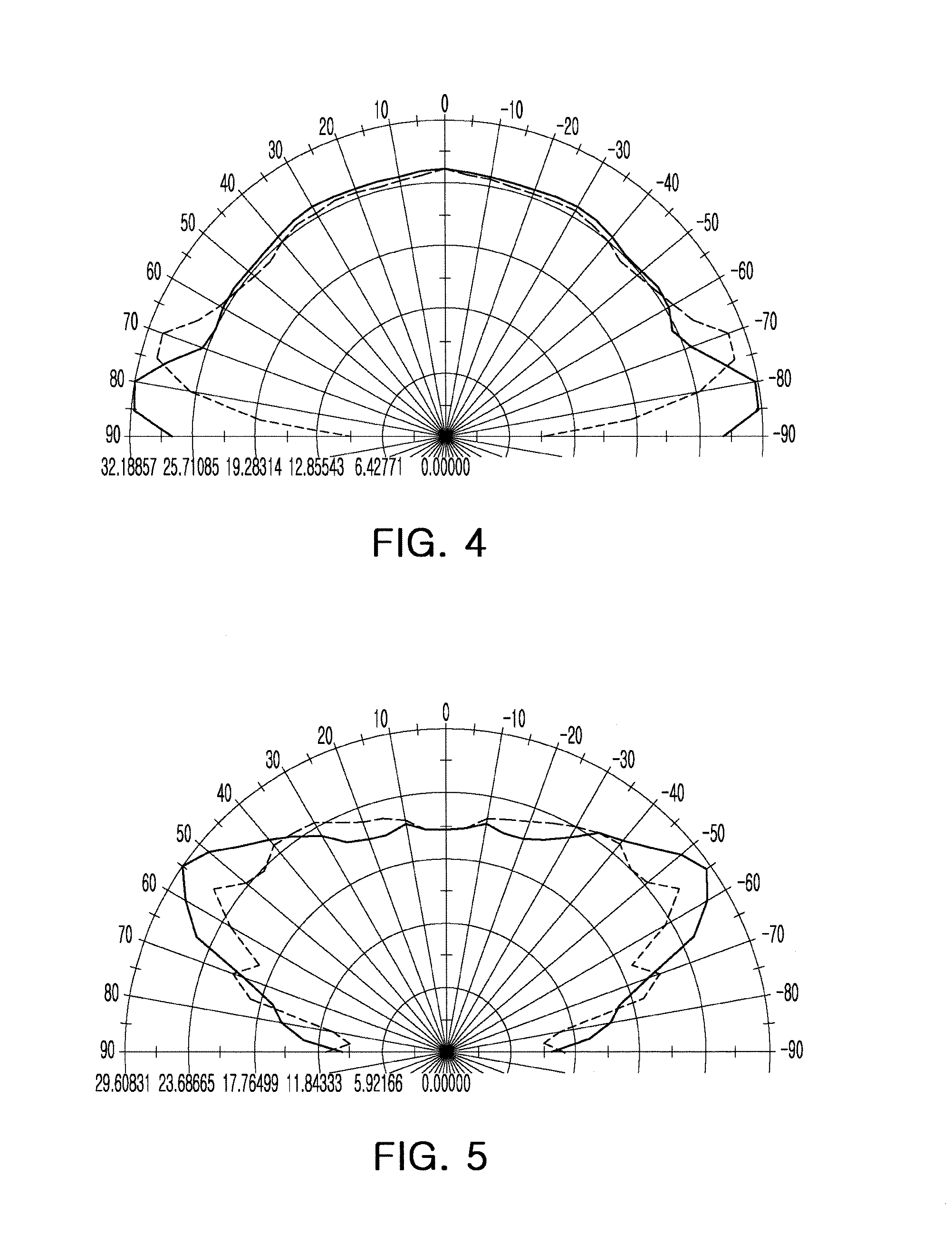

Light emitting device

ActiveUS20120300431A1Low costShorten the timeNon-electric lightingLighting support devicesEngineeringLight emitting device

A light emitting device includes: a substrate having a bar shape; a plurality of light emitting elements separately mounted in a lengthwise direction of the substrate on an upper surface of the substrate; and a light-transmissive cover formed to be upwardly convex, having one or more localized concave portions, and installed on the substrate to cover at least two of the plurality of light emitting elements together.

Owner:SAMSUNG ELECTRONICS CO LTD

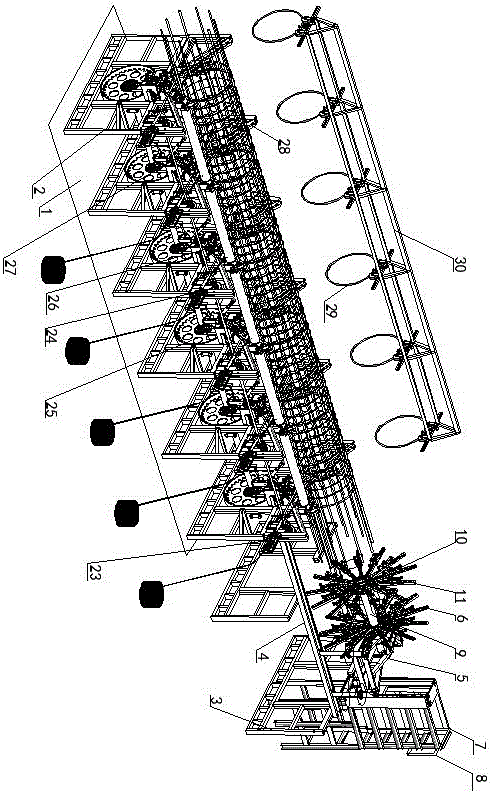

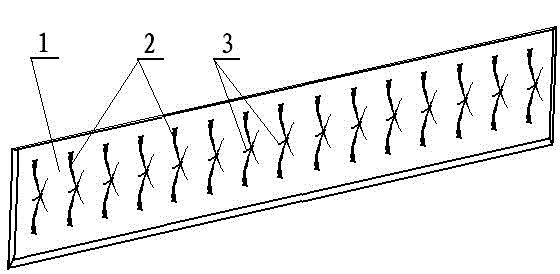

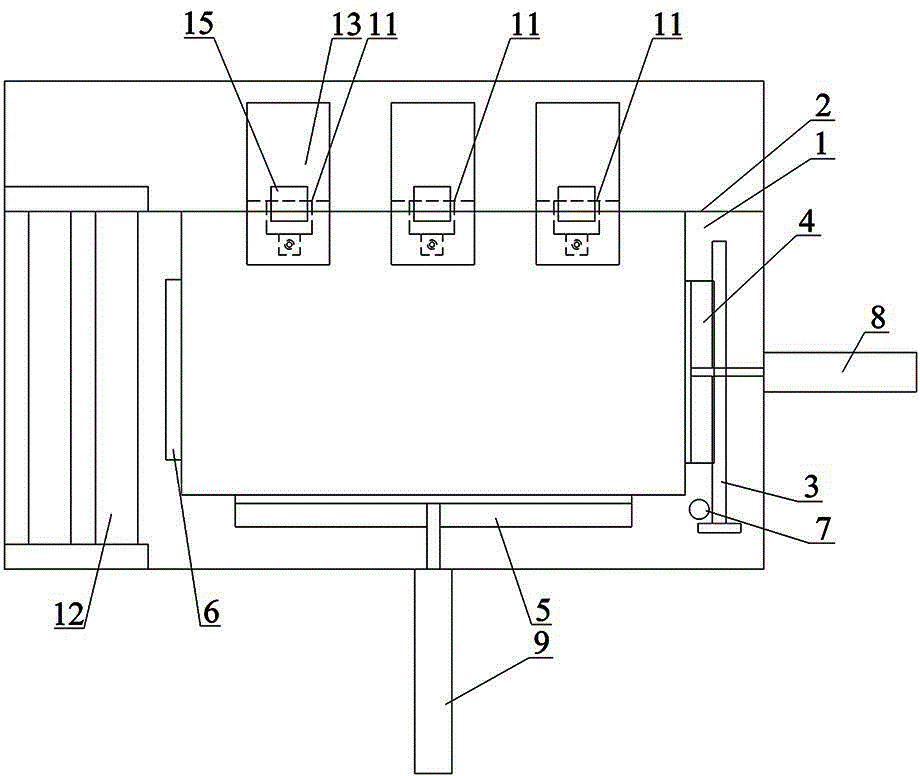

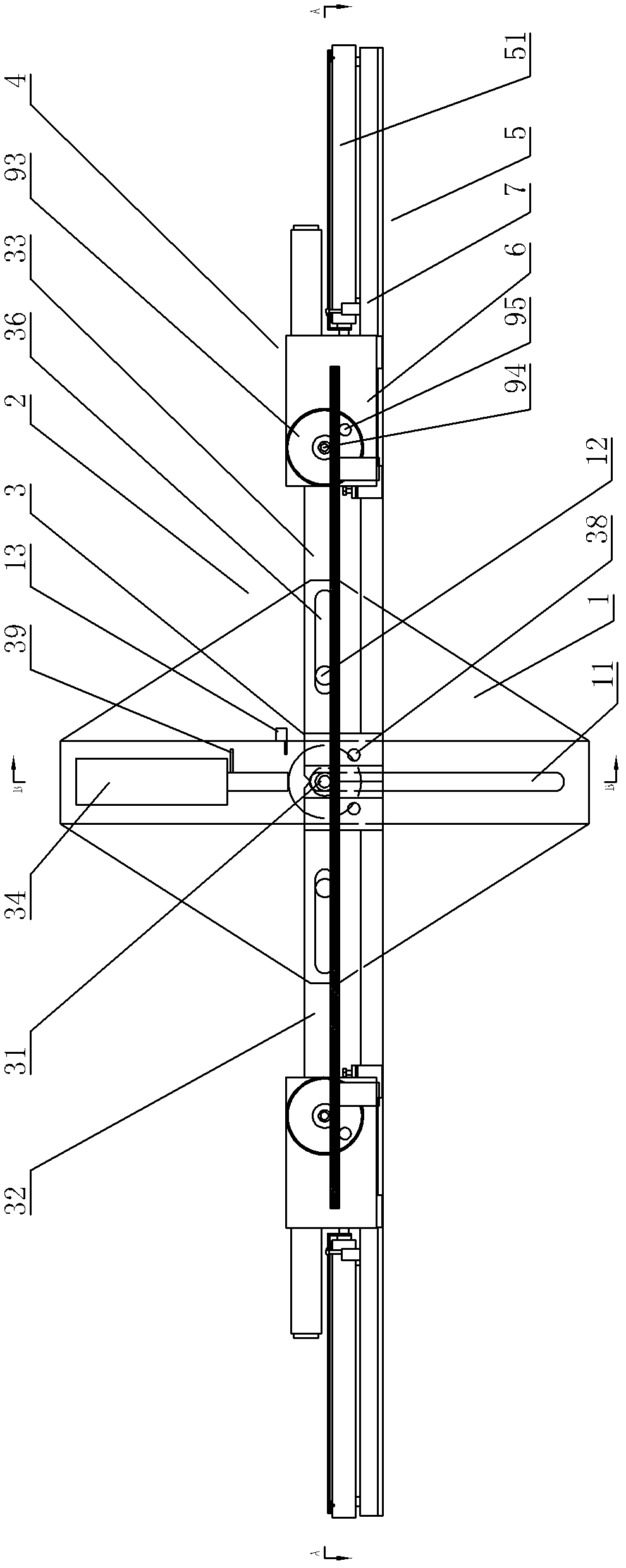

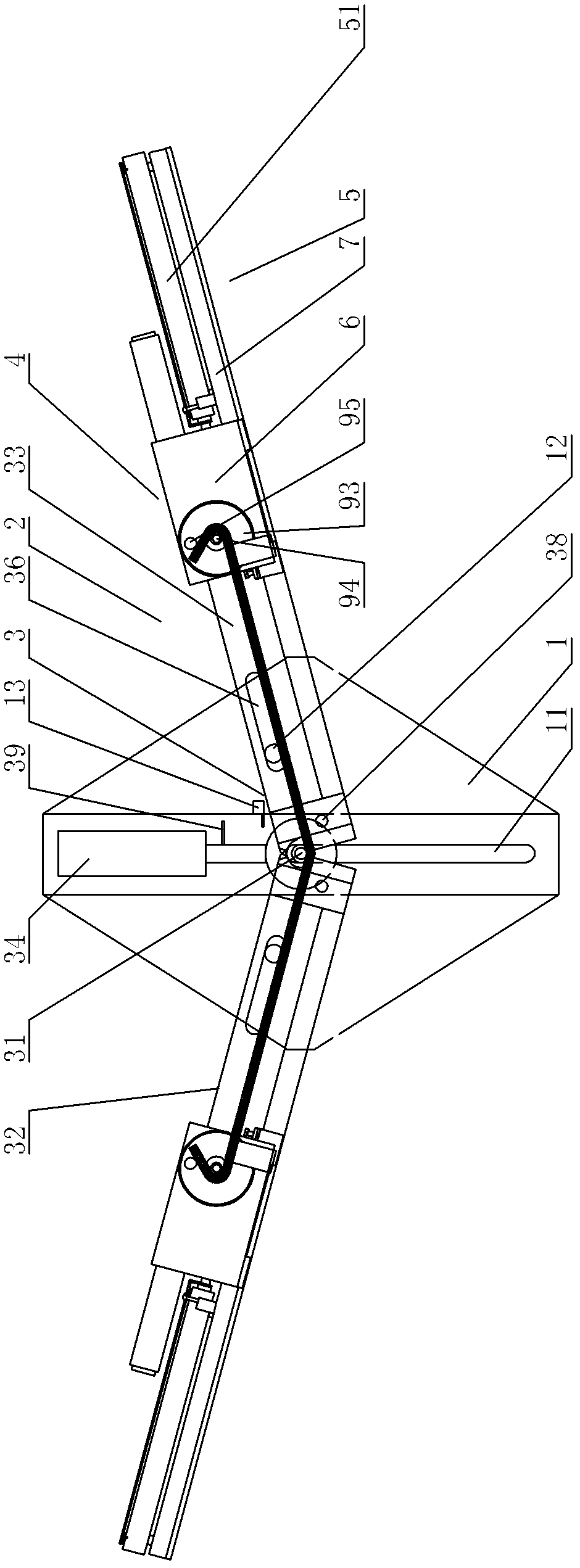

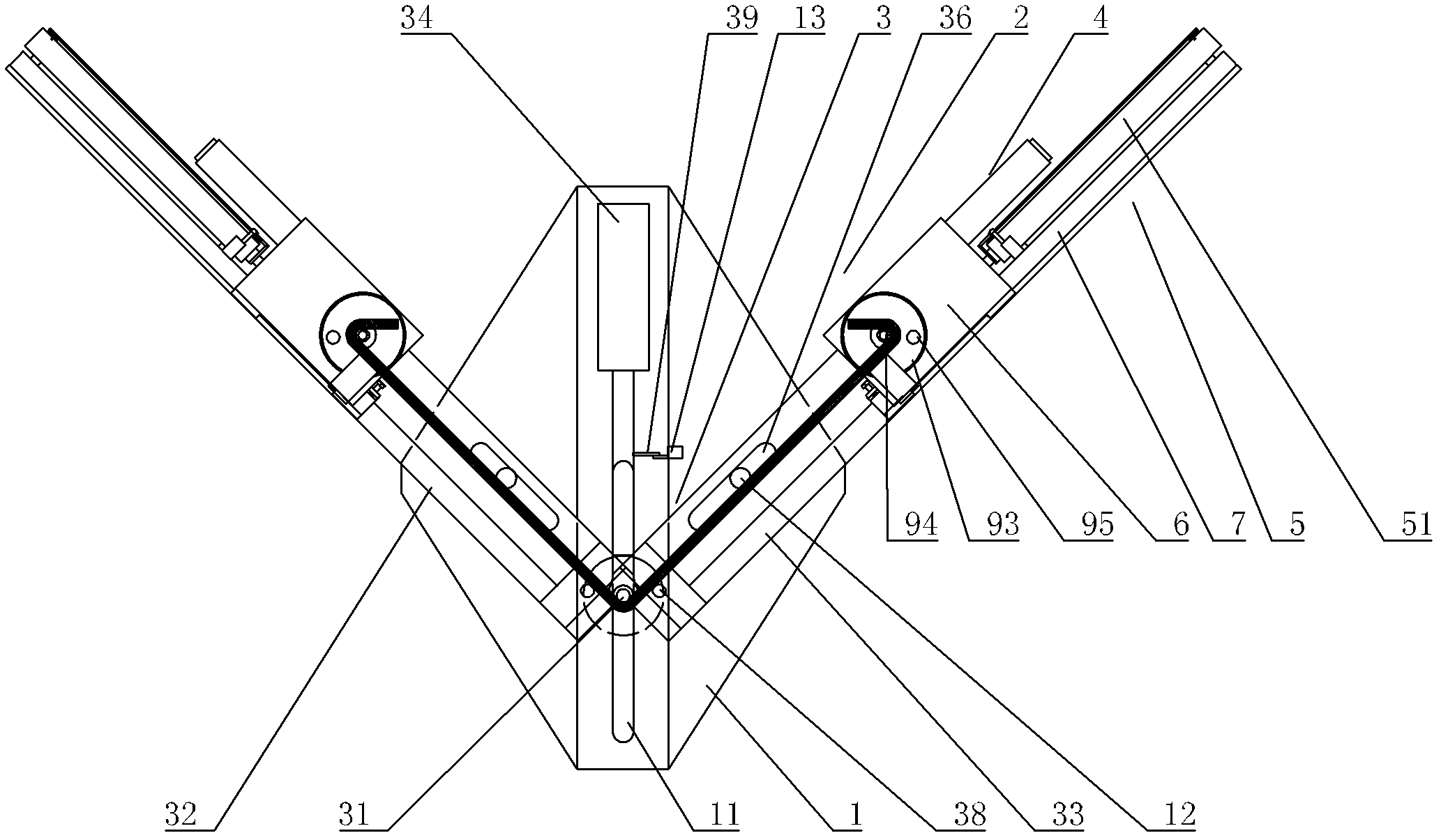

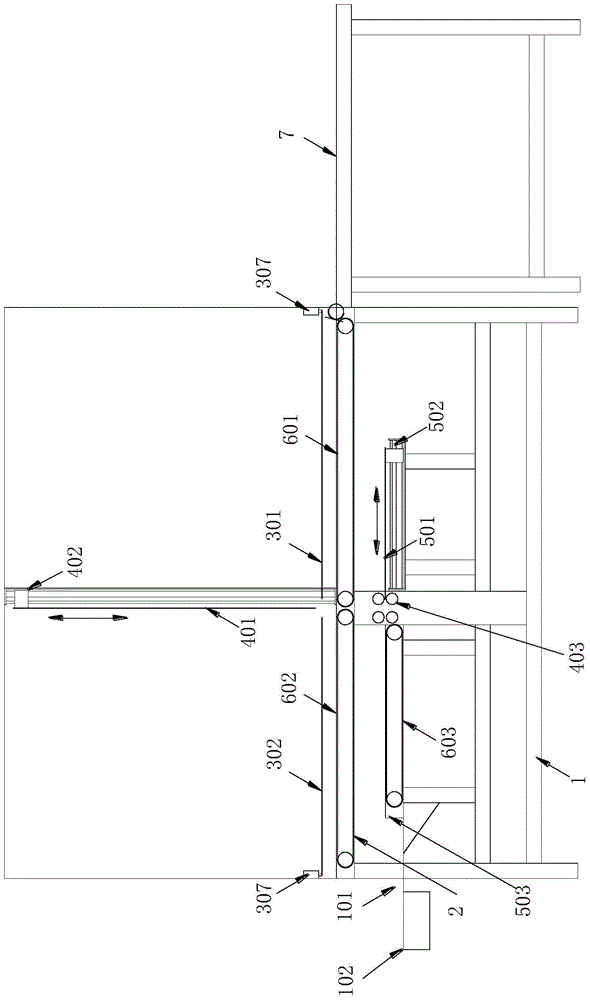

Reinforcement cage seam welder

ActiveCN106735812ASimple structureEasy maintenance and operationWelding with roller electrodesStirrupManipulator

The invention discloses a reinforcement cage seam welder. The reinforcement cage seam welder comprises a base; the base is provided with a bracket with a rail at the upper part and at least one U-shaped reinforcement cage welding frame body; a mobile frame is arranged on the rail of the bracket; a main stirrup fixed clamping device is arranged in the center position of the mobile frame; a fixed frame is arranged at the upper part of the right side of the bracket, and a lead screw traction device is arranged in the center position thereof; an outer stirrup conveying device is arranged at the middle part of one side of the reinforcement cage welding frame body, and a main rib push rotating device is arranged at the upper part of the same one side thereof; a support main rib device is arranged at the middle part of the reinforcement cage welding frame body; an outer stirrup welding manipulator and an inner stirrup welding manipulator are respectively arranged on the reinforcement cage welding frame body and at the upper part of the support main rib device; and main rib fixed adjusting devices are arranged at the upper parts of the outer stirrup welding manipulator and the inner stirrup welding manipulator on the reinforcement cage welding frame body. The reinforcement cage seam welder is adopted to realize the effects of simple structure, convenience to operate and maintain, good quality, high efficiency, low cost, unified specification and high automation degree.

Owner:山东五岭智能机械有限公司

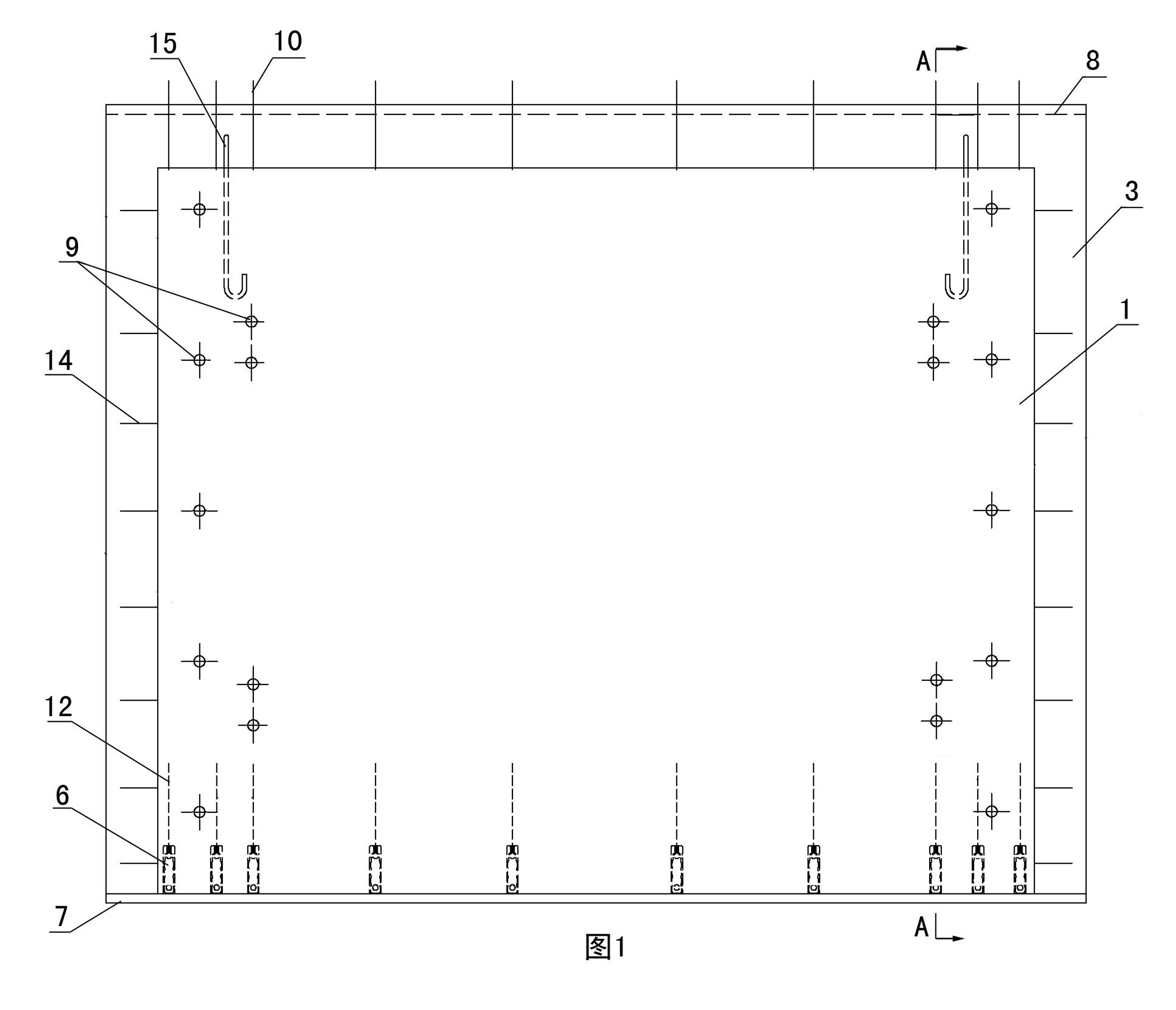

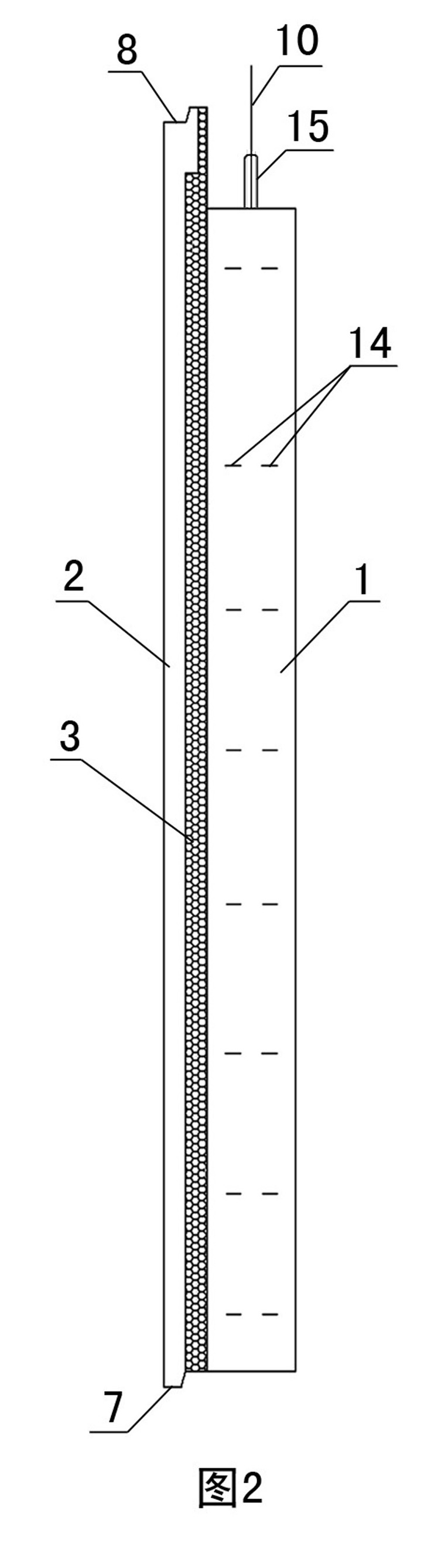

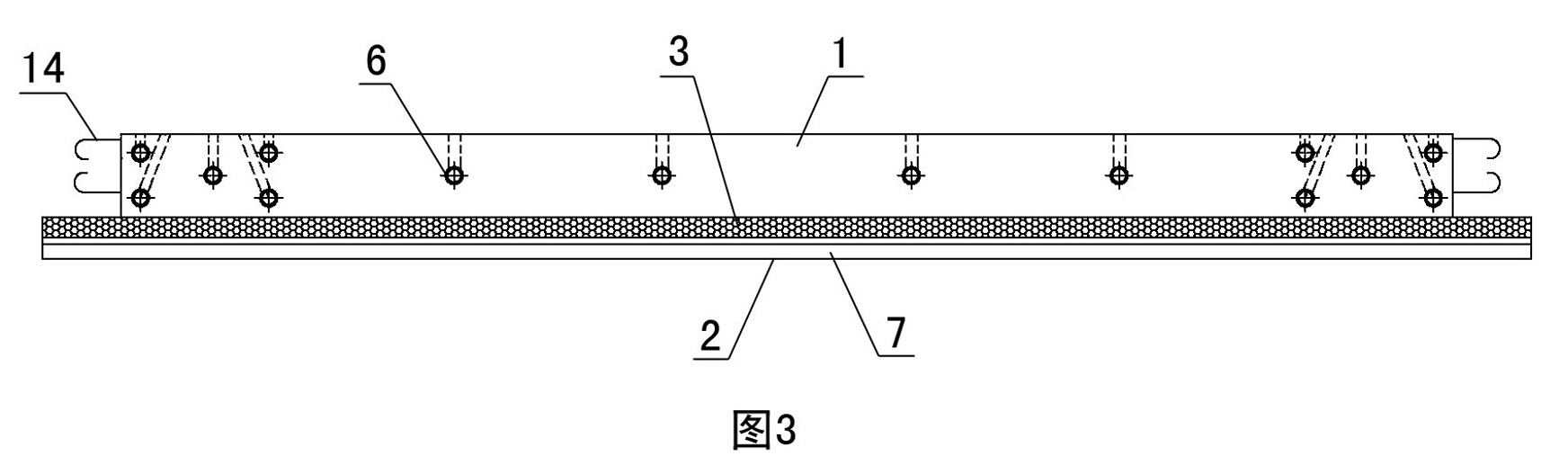

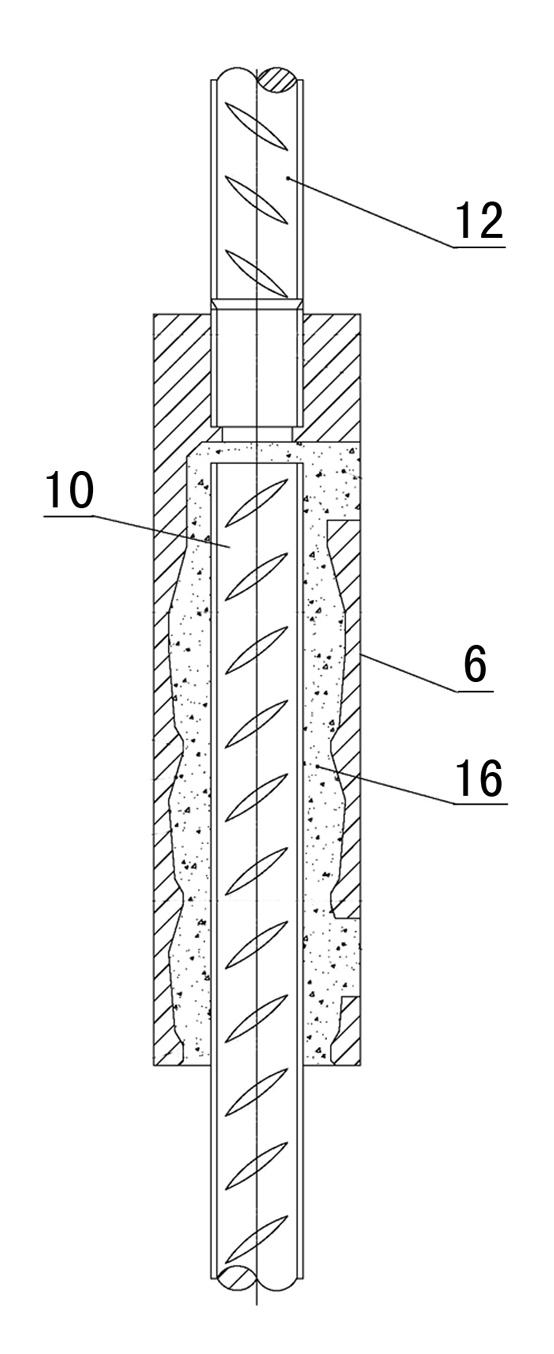

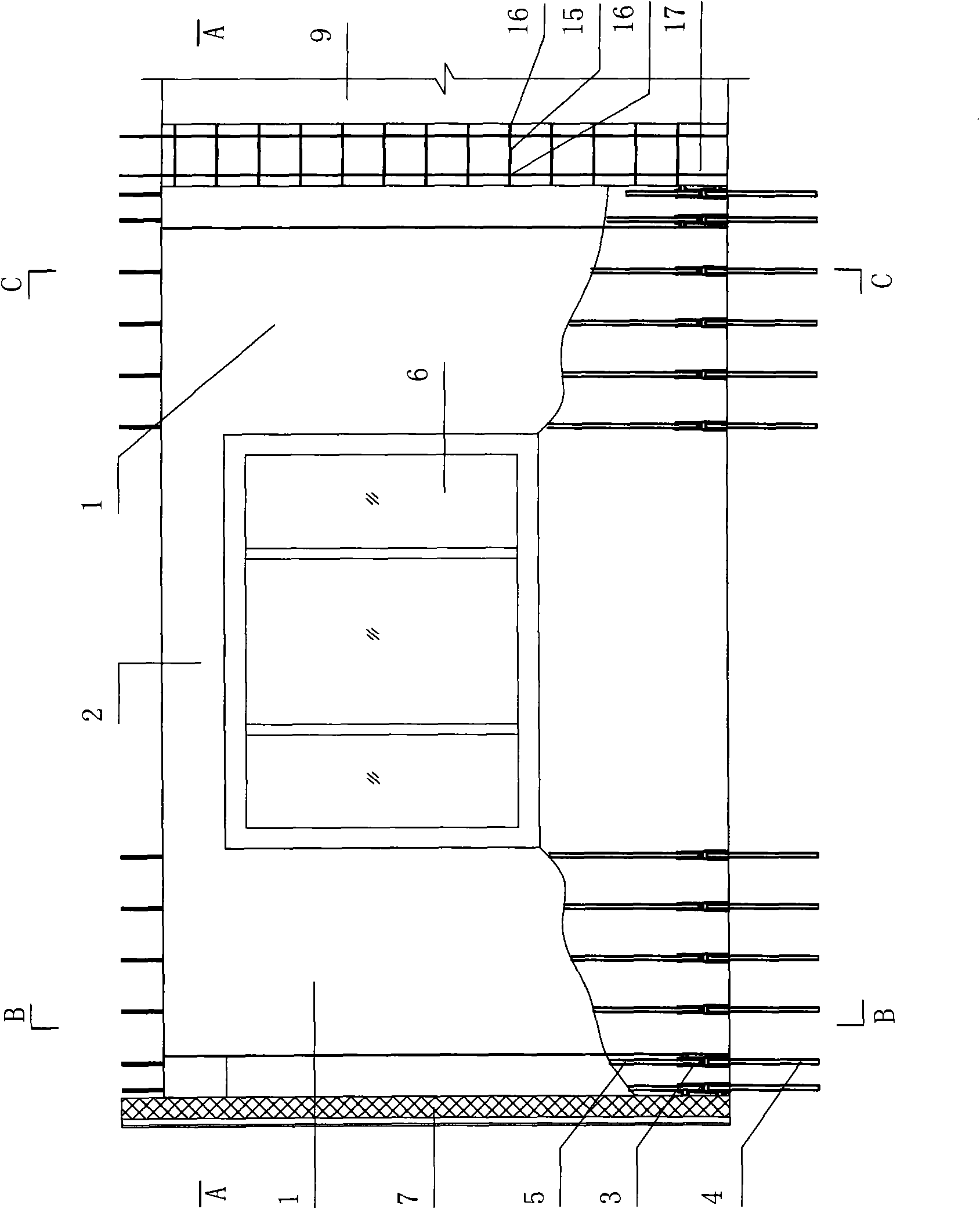

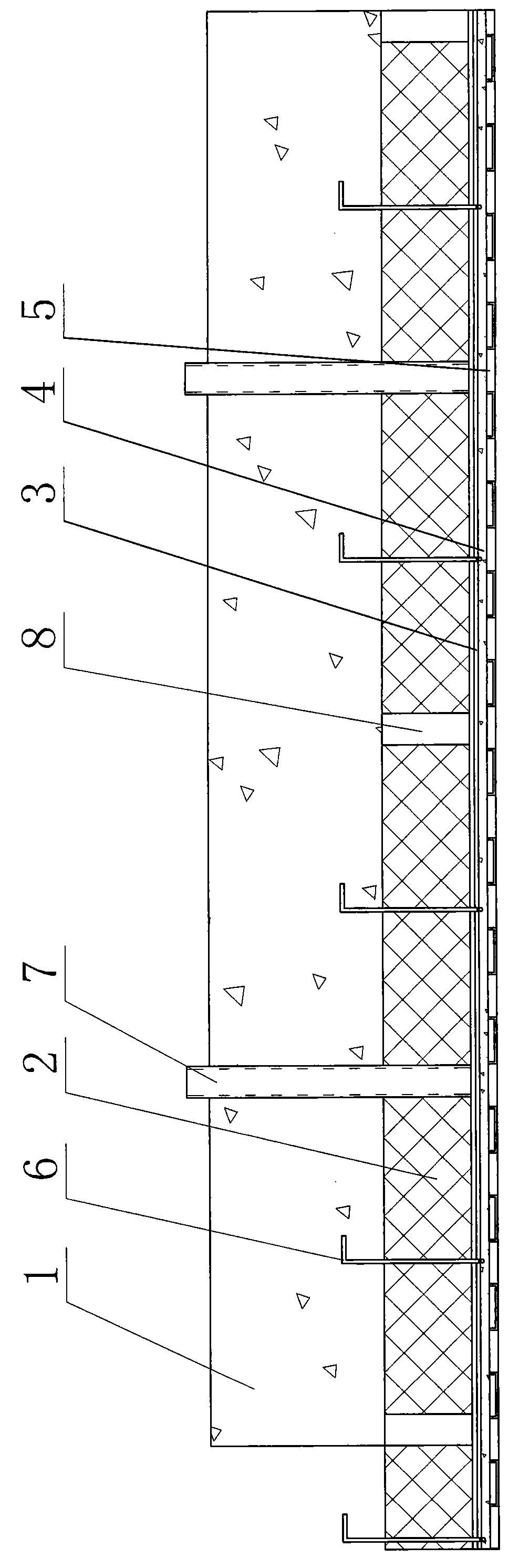

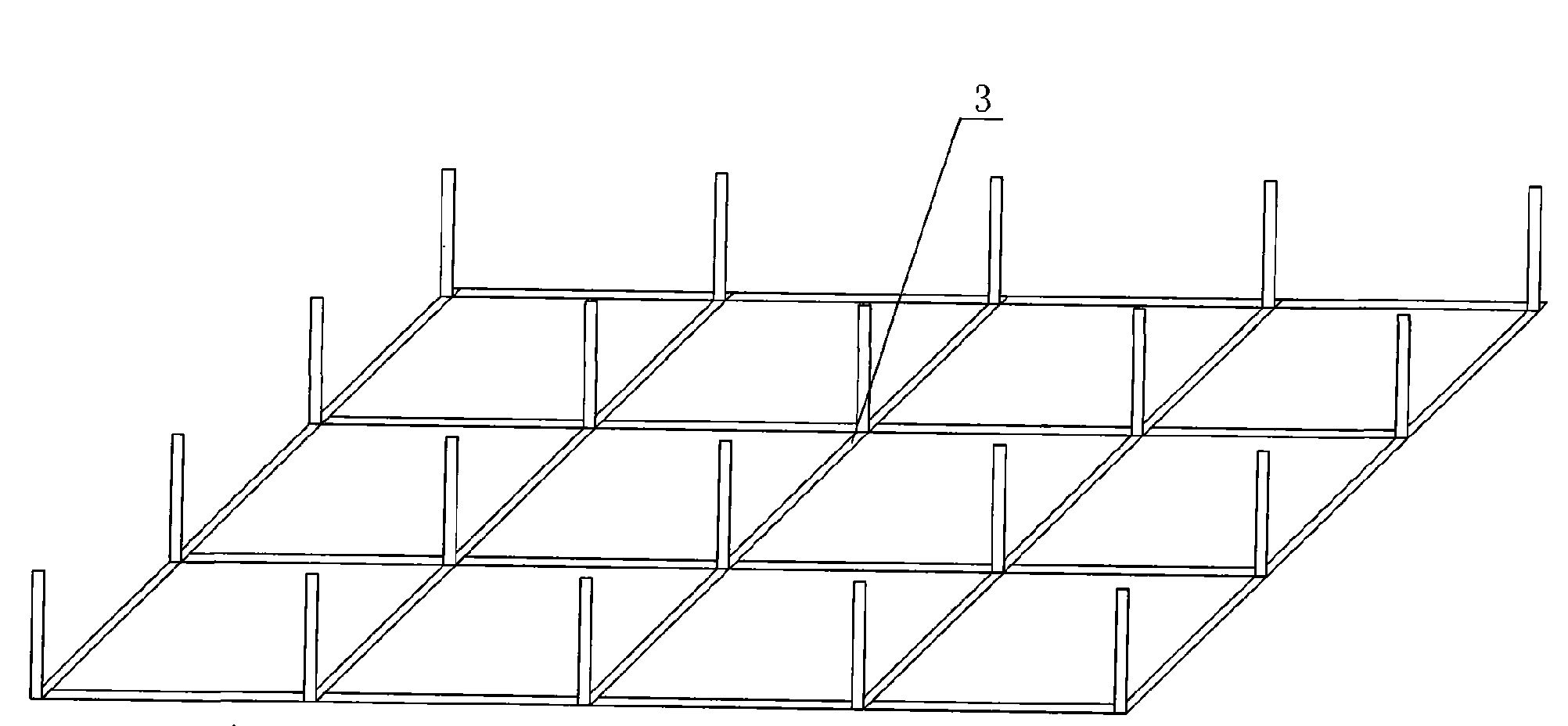

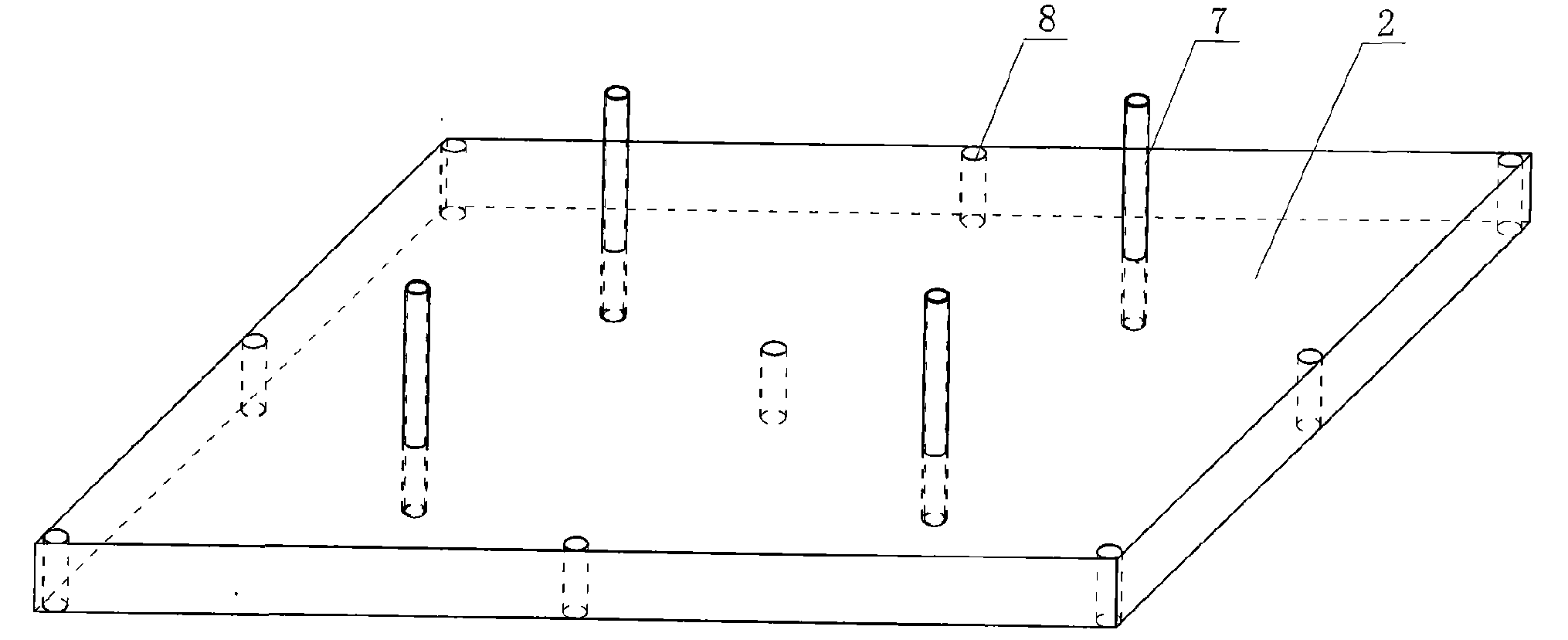

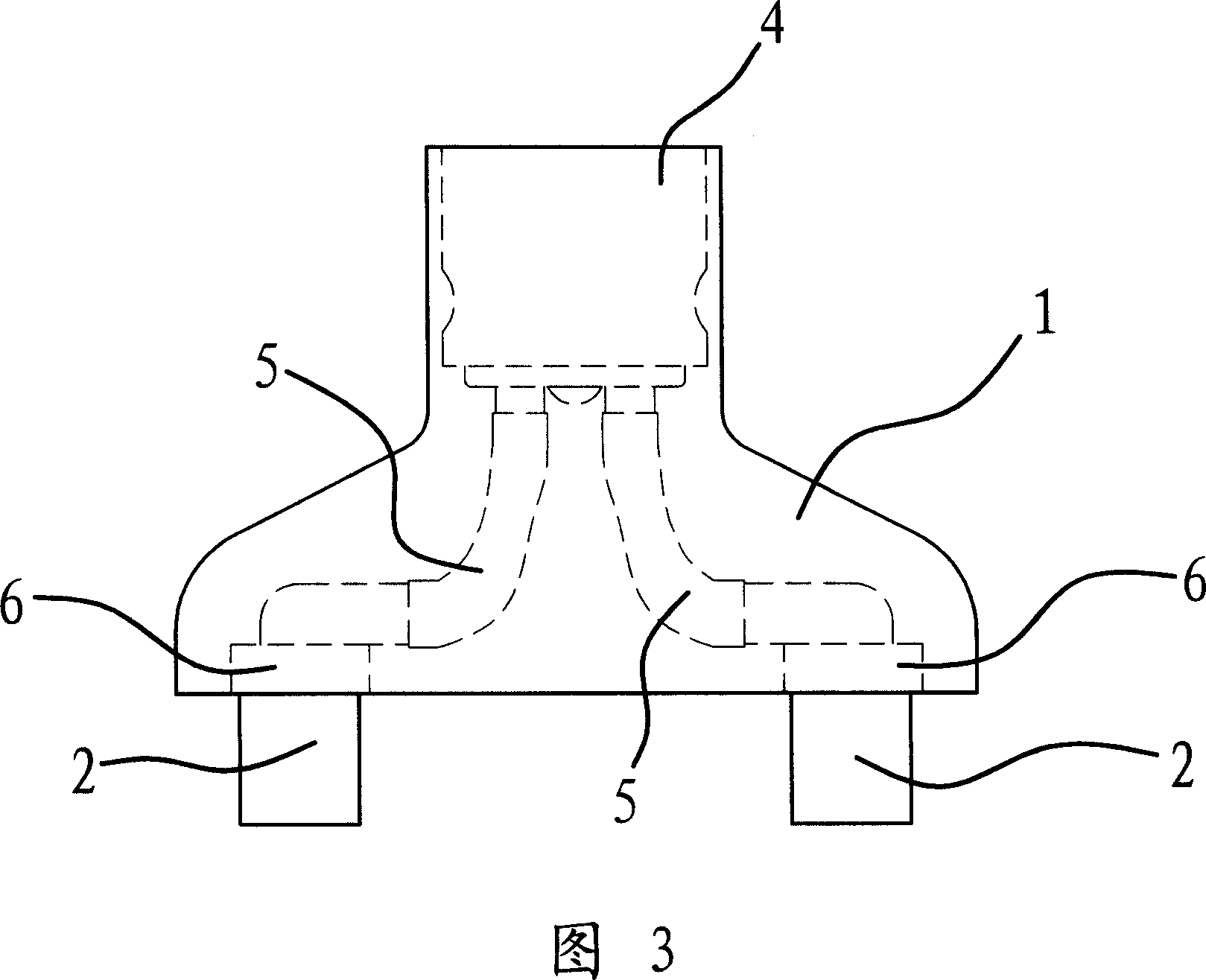

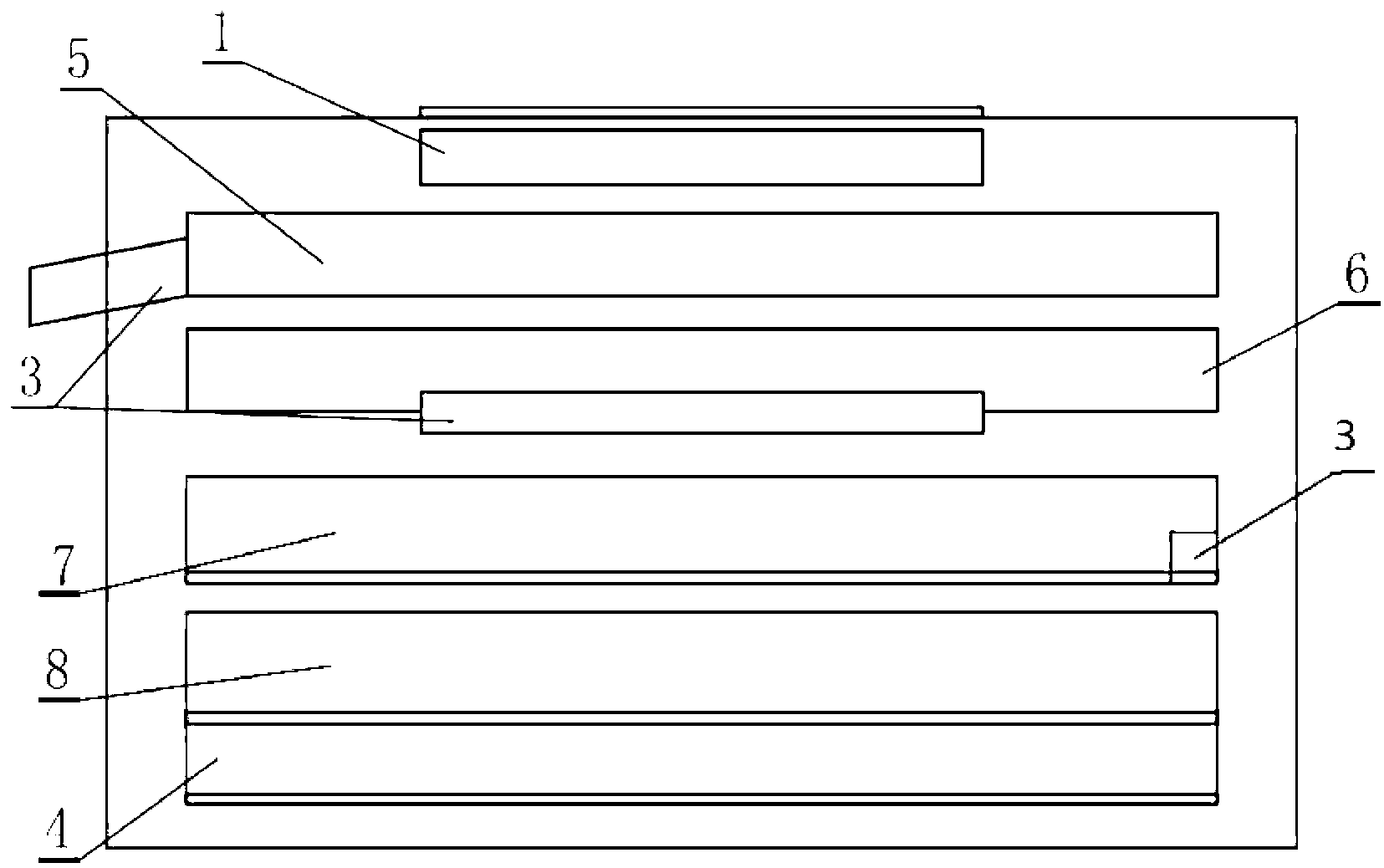

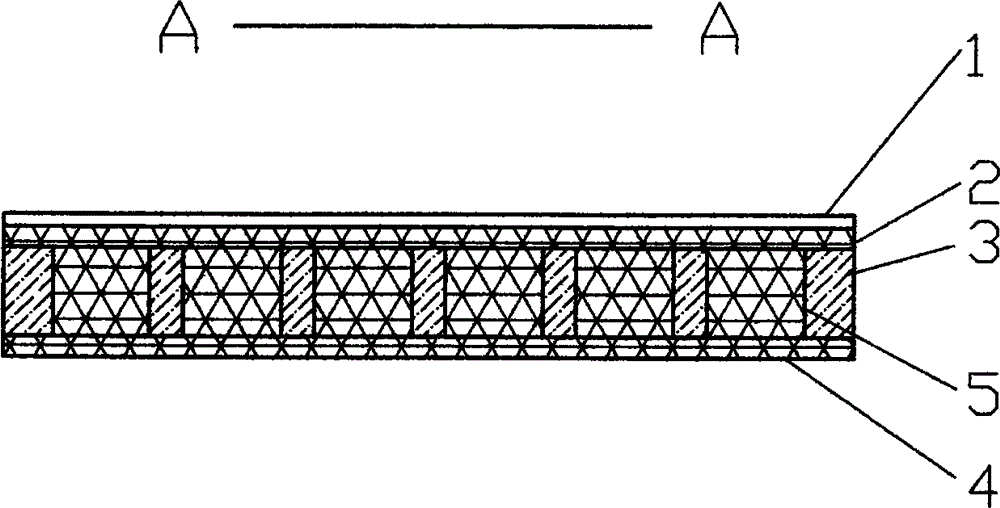

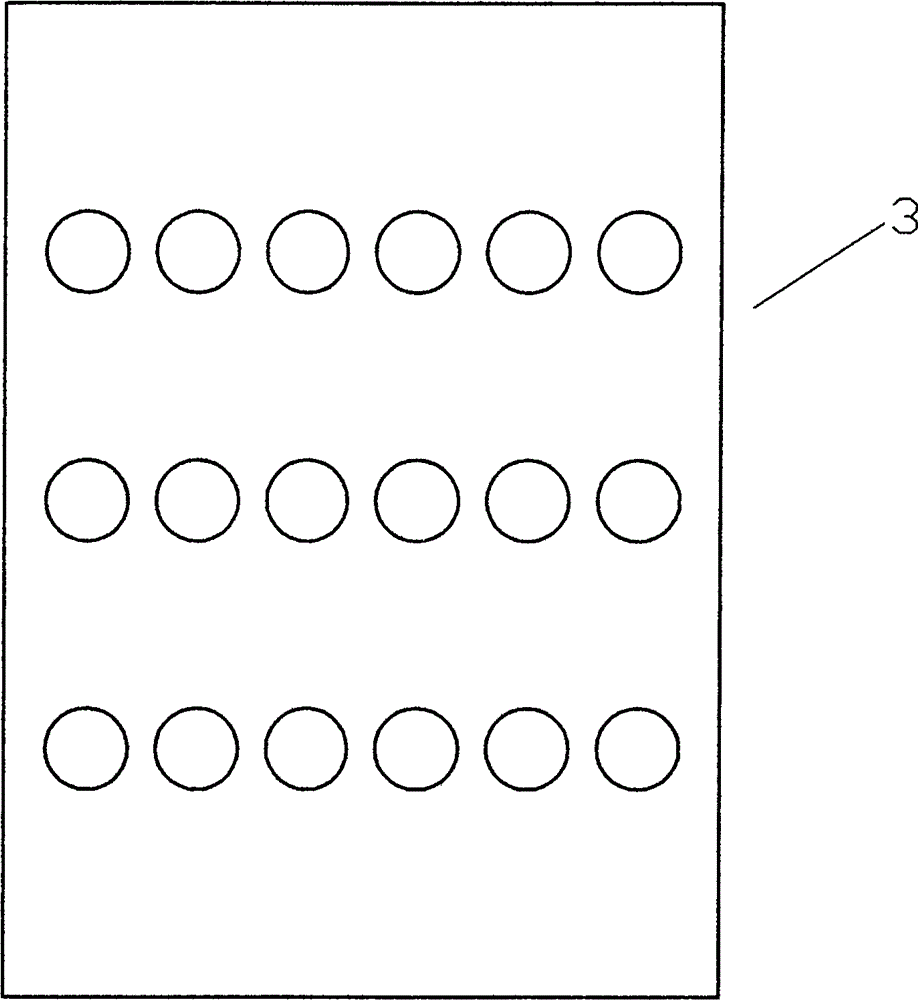

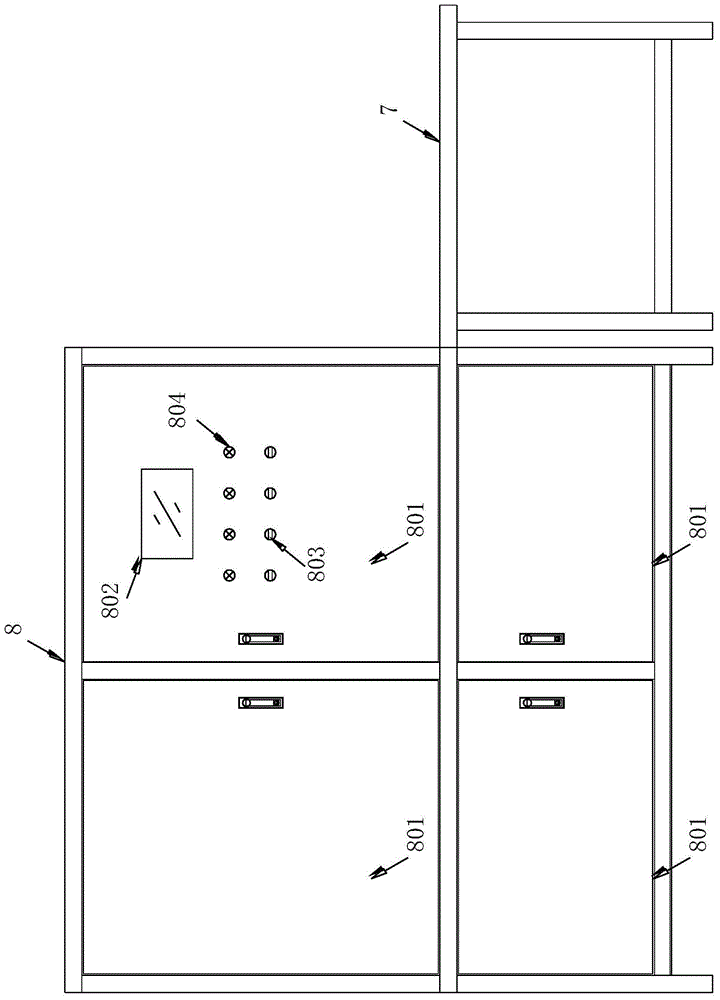

Once formed precast concrete shear wall with heat preserving veneer and production method thereof

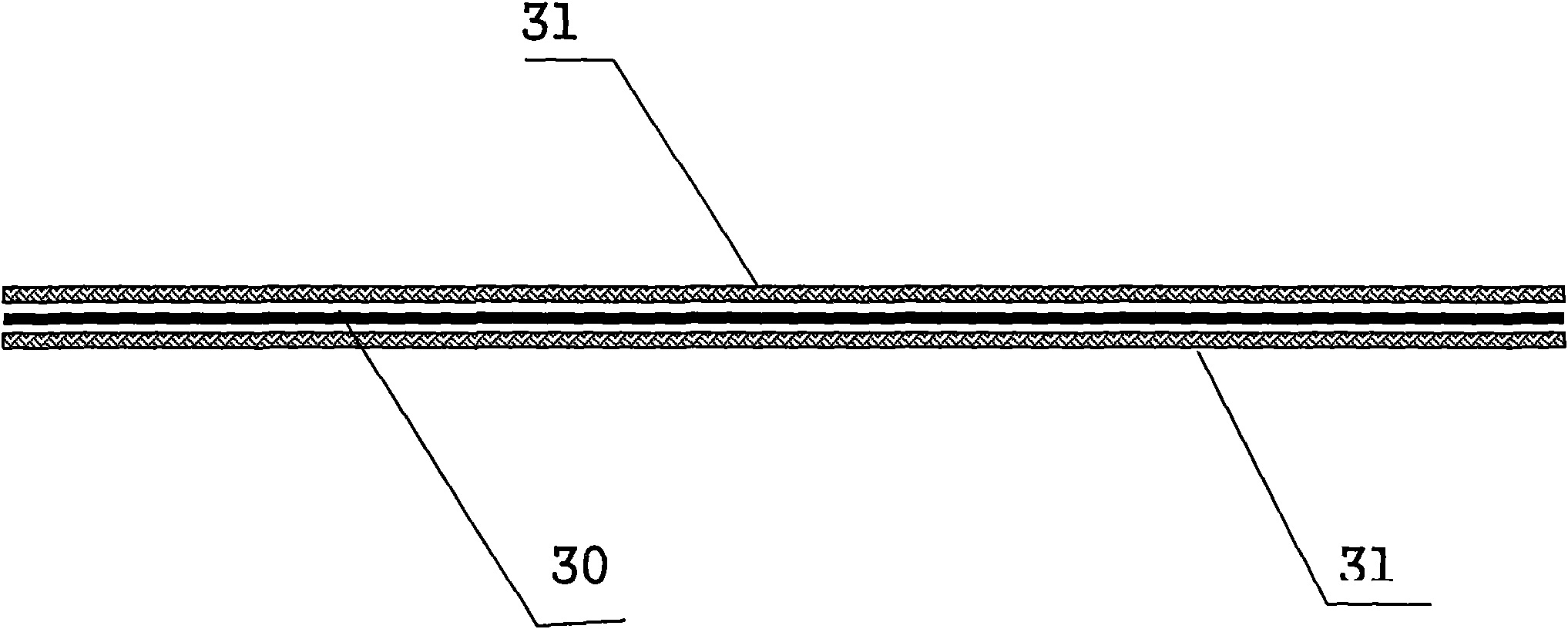

InactiveCN101603335AUnified specificationsUniform qualityWallsClimate change adaptationResidenceRebar

The invention relates to a once formed precast concrete shear wall with a heat preserving veneer and a production method thereof. A building structure with an original construction way has higher comprehensive energy consumption and is not beneficial to the environment and energy saving in the construction way. The once formed precast concrete shear wall with a heat preserving veneer comprises a wall body (1) which is connected with an insulating layer (2), a welding reinforcing mesh (3), a sand pulp bonding layer (4) and an architectural surface (5) in sequence, wherein a binding bar is bound with the wall body; the sand pulp bonding layer is connected with a pulp filling pipe (7) passing through the wall body; and the sand pulp bonding layer is provided with an air exit hole (8). The invention is used as a residence industrial all-assembled type construction wall body and a production method thereof.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

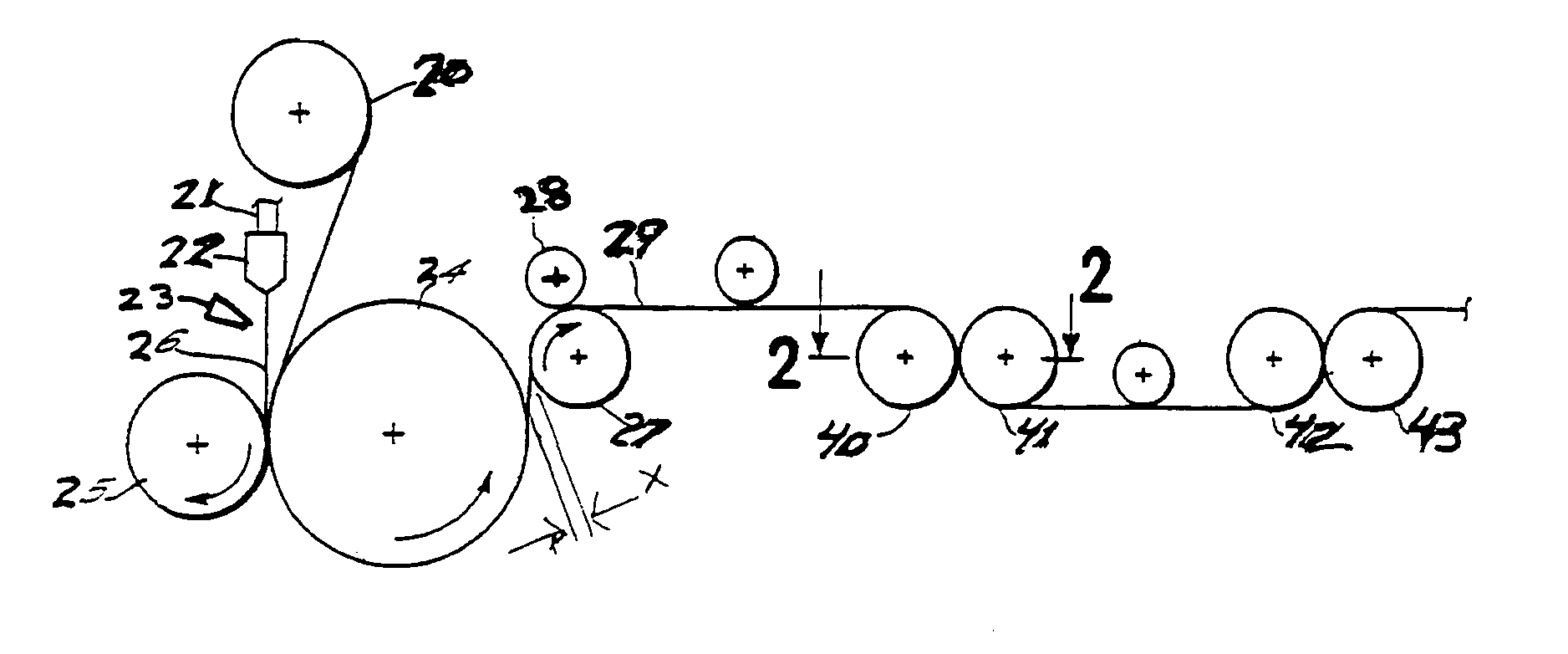

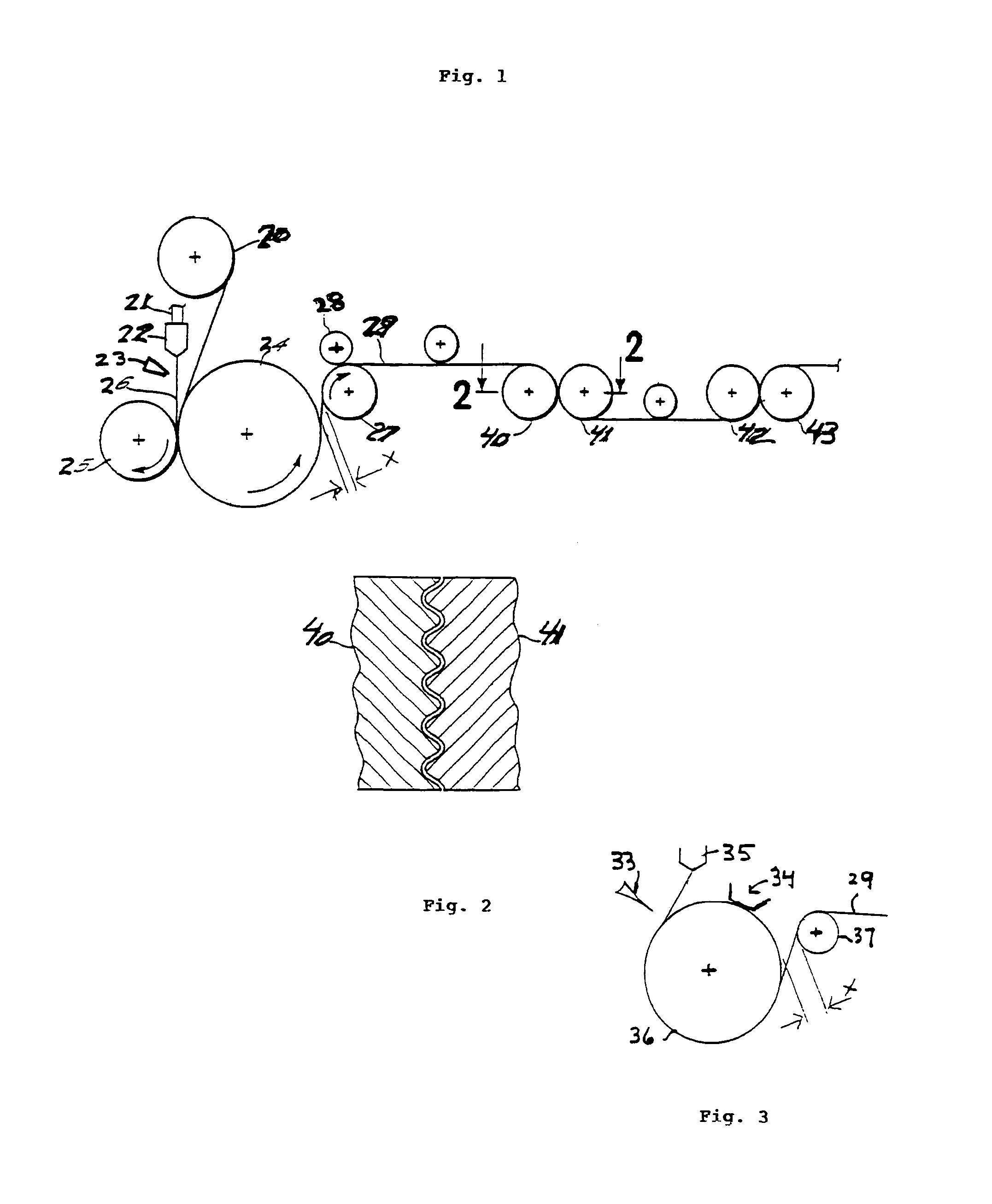

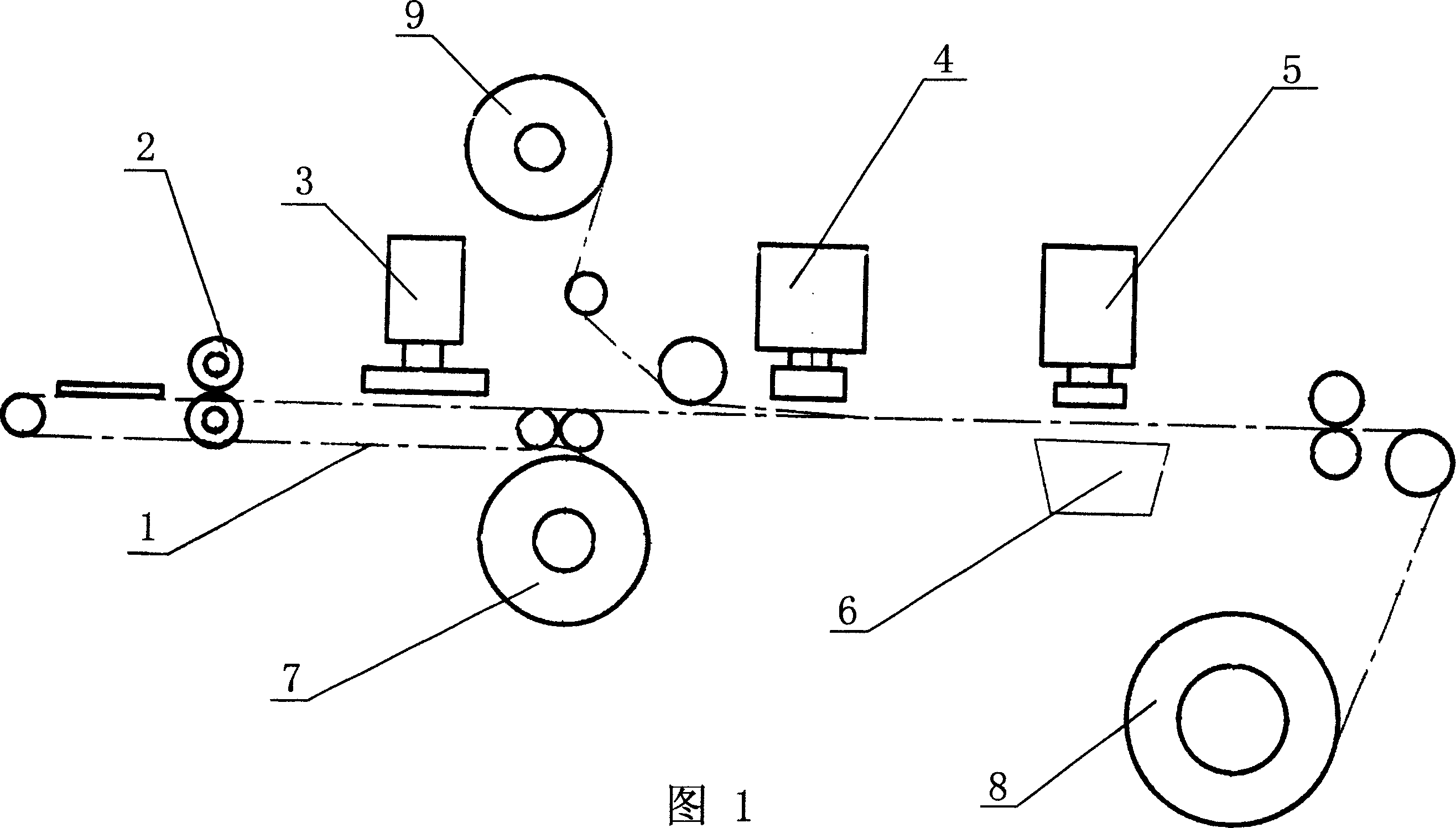

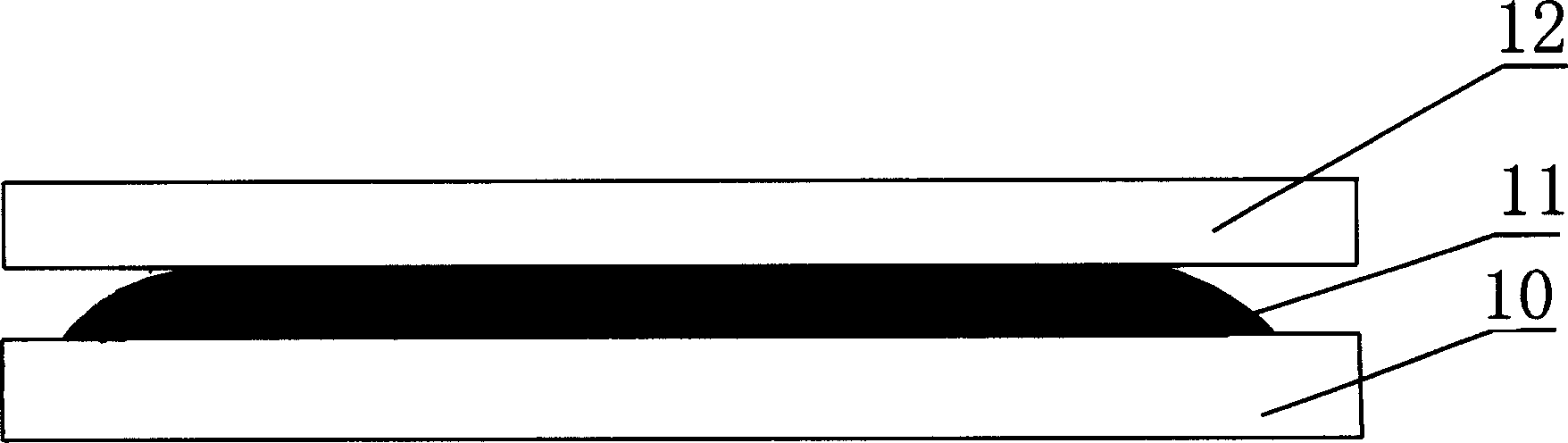

Thin plaster, plaster thinning making method and apparatus

InactiveCN1839798AUnified specificationsThin and lightAerosol deliveryOintment deliveryTemperature controlWood veneer

This invention relates to thin black plaster comprising back-up material layer and plaster layer adhered on the back-up material layer. The black plaster thickness is 0.1-0.9mm, and its processing steps contains: 1) Process boiled plaster into plaster blank; 2) heating compress the plaster blank to thin piece whose thickness maintains between 0.1-0.9mm; 3) Cut the molded thin piece to some shape and package to obtain finished product. The thin black plaster equipment comprises delivery mechanism, at the front end of the delivery mechanism a temperature controlling and piece compressing device is arranged for heating and compress the plaster stuff; behind the temperature controlling and piece compressing device, a blank shaping device is arranged for strike the lamellar plaster stuff into wafer shape; a heating and compressing device is arranged behind the blank shaping device for compressing the plaster blank into flakes. The black plaster can be directly pasted on affected part without heating and can be pasted for many times. The shaping machine has simple structure and is convenient to handle; it achieves mechanization continuous production of black plaster molding.

Owner:莫有双 +1

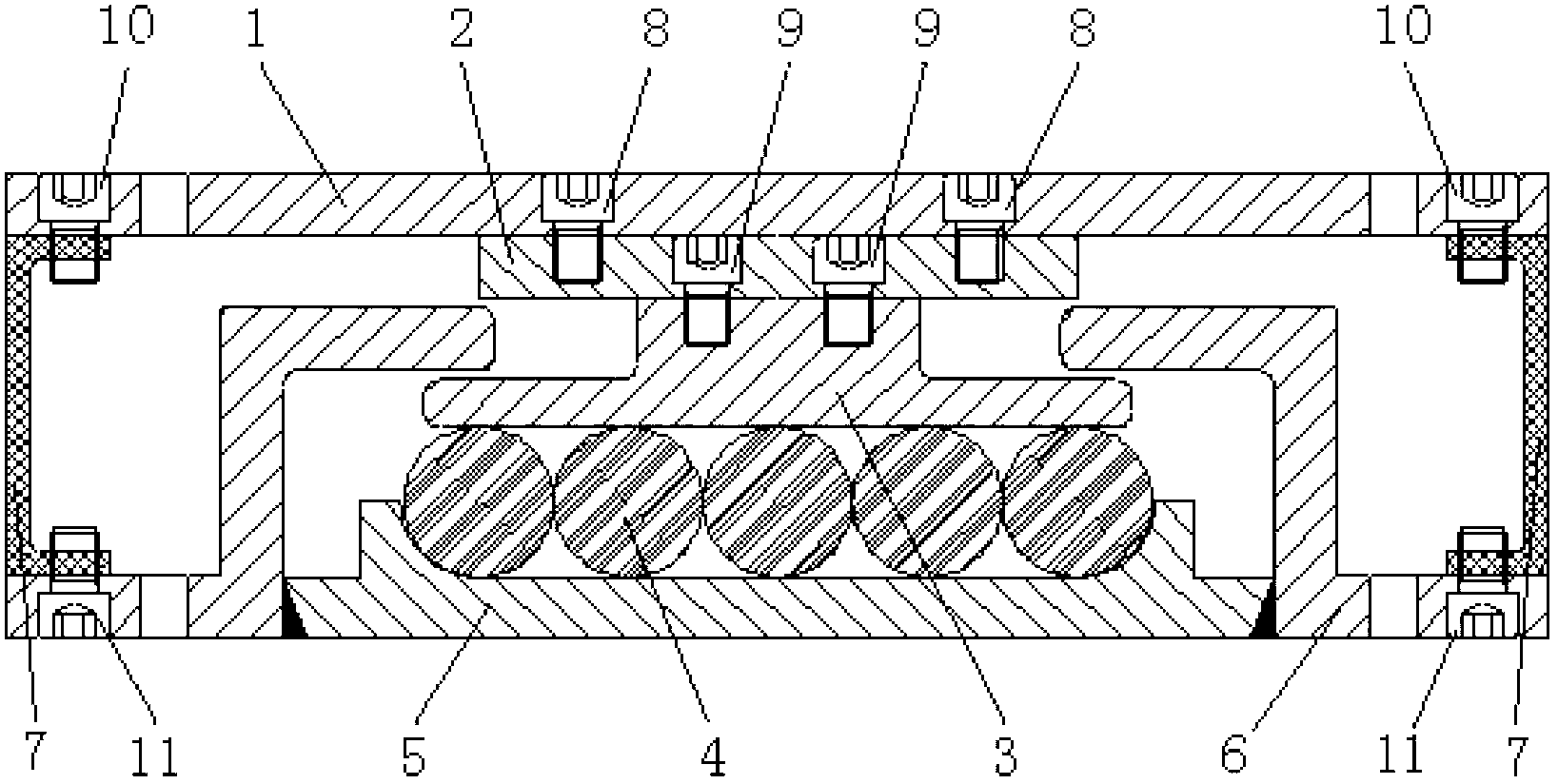

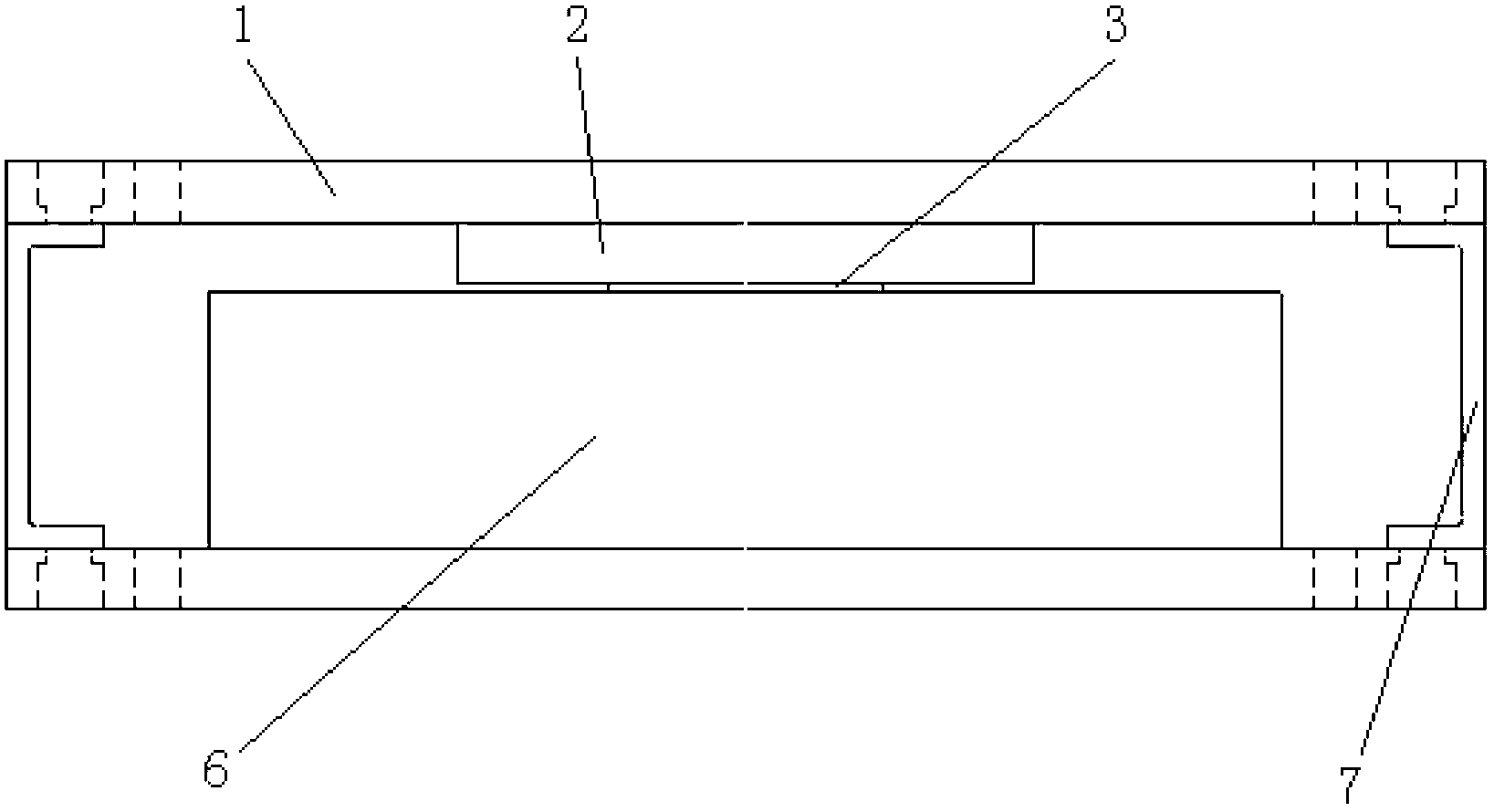

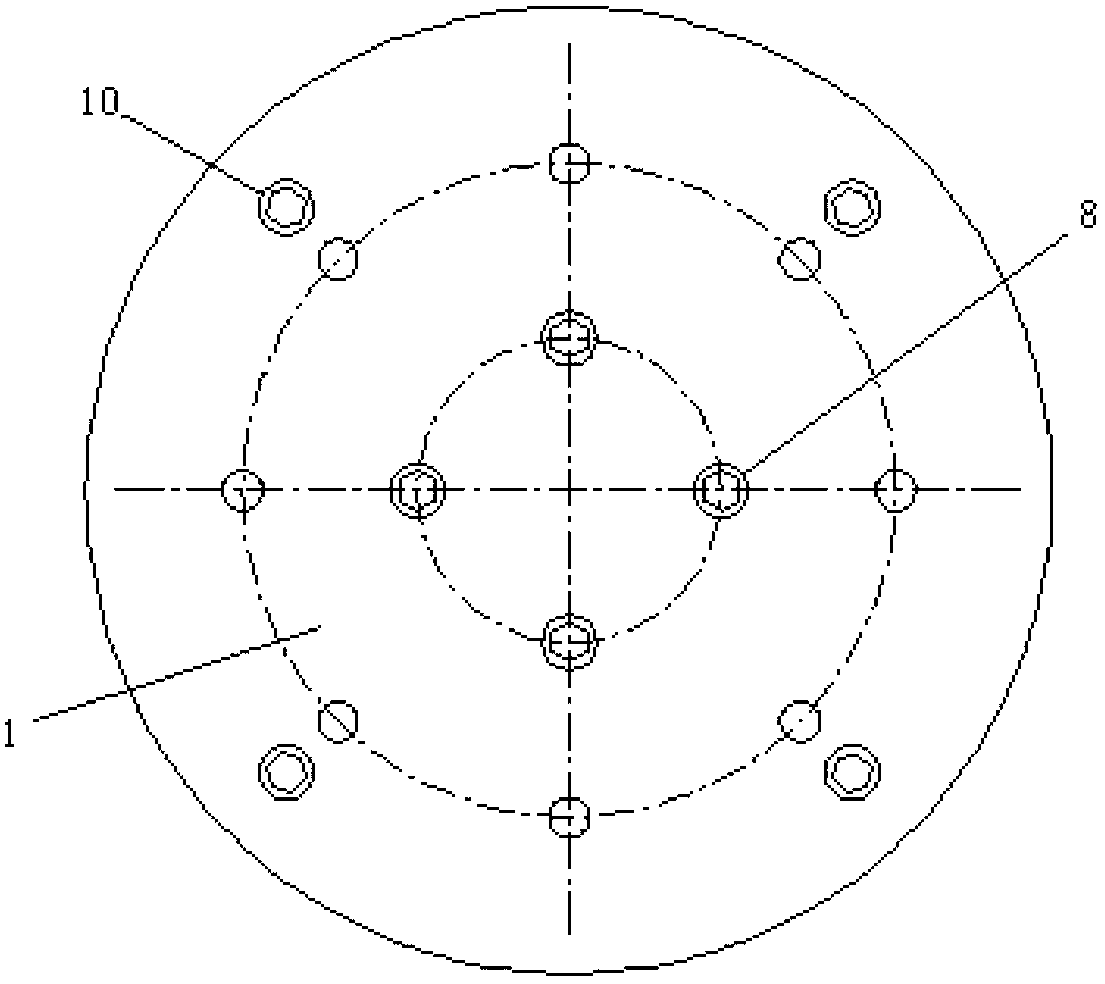

Soft steel-rolling seismic isolation bearing

InactiveCN102839750ASimple structurePower transmission is clear and reasonableShock proofingSpatial structureEngineering

The invention provides a soft steel-rolling seismic isolation bearing and belongs to the field of seismic isolation and shock absorption control for a building structure. The upper part of the support is a cover plate structure, wherein an upper connecting plate is connected with an upper seat plate and the upper seat plate is connected with an upright post part of a rolling plate to form the cover plate structure. The rolling plate is supported on balls which are arranged in a seat groove at the bottom, the seat groove provides a rolling space for the balls so that the balls can roll freely in the seat groove at the bottom. A through cavity is formed between the upper seat plate and the rolling plate, an upper plate of an uplift cover plate can be inserted into the through cavity when horizontally moving, and a lower plate of the uplift cover plate is fixedly connected with the seat groove. The seat groove is arranged in a cavity formed at the lower part of the uplift cover plate. A soft steel rod is arranged at each corner of four corners of each of the upper connecting plate and the uplift cover plate. The bearing is simple in structure and definite and reasonable in force transfer; the performances of materials are given a pull play, the specification is uniform, the stability of all performances is high; moreover, the bearing is good in applicability, convenient to manufacture and install and high in practicability and is suitable for seismic isolation of a large-span space structure.

Owner:BEIJING UNIV OF TECH

Plastic tap and mould and process for its production

This invention provides one plastic piston and its process method and mode, which is made by plastic materials with several connection tubes, wherein, each connection tube inner end is connected to valve chip socket; each connection tube outer end is connected to water-in tube or exit tube. This invention process method comprises the following steps: a, parts processing; b, parts assembling; c, mode fixing; d, mode integrating; e plastic injection; f, surface processing; g, assembling product.

Owner:汤万德 +1

Seedling-to-seedling method using tissue culture seedlings of cunninghamia lanceolata

Owner:GUANGXI FORESTRY RES INST

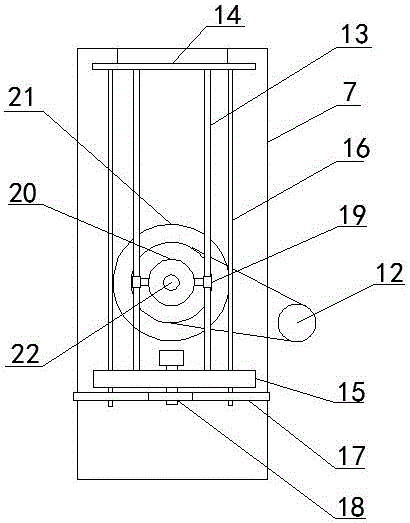

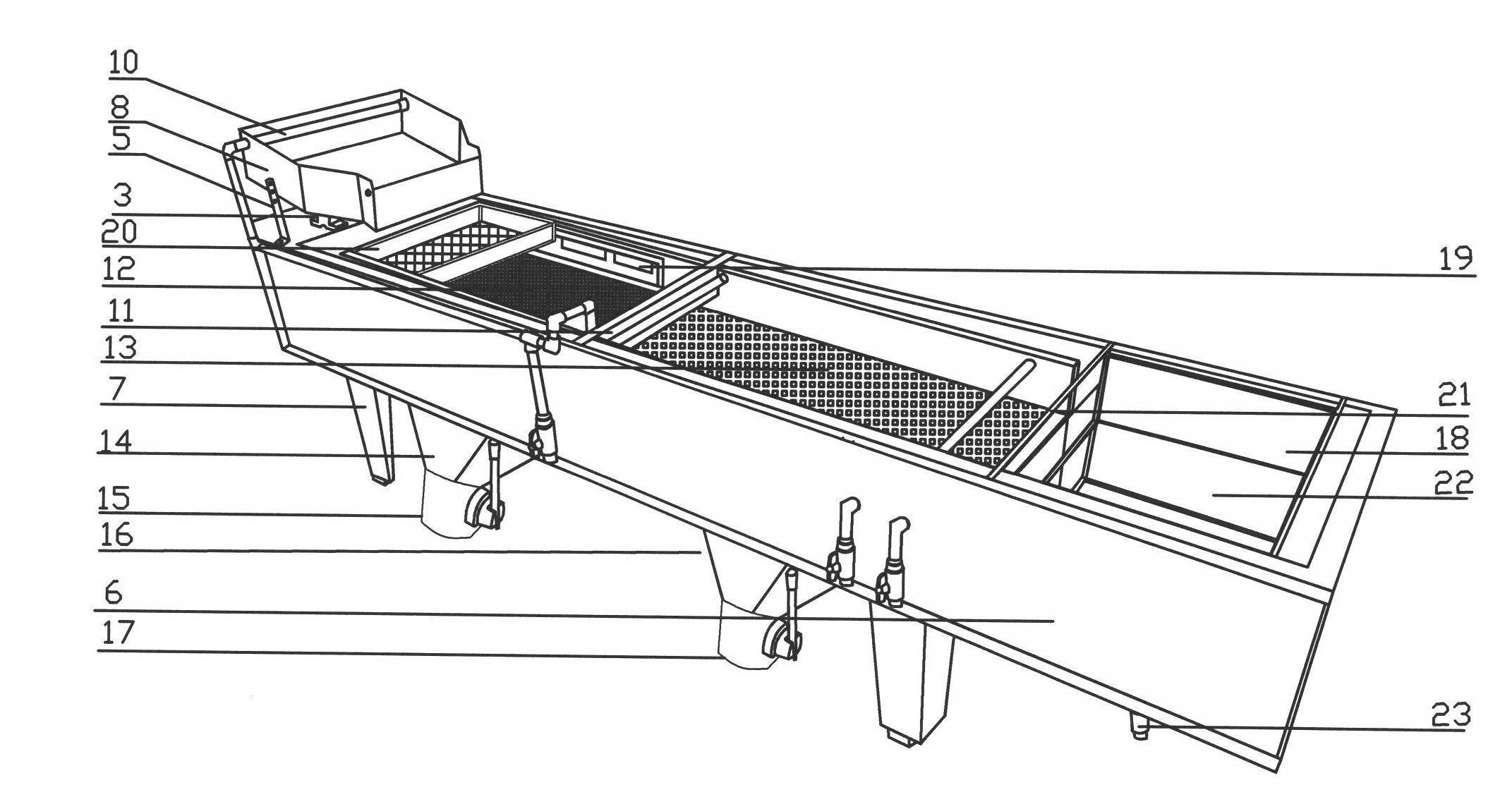

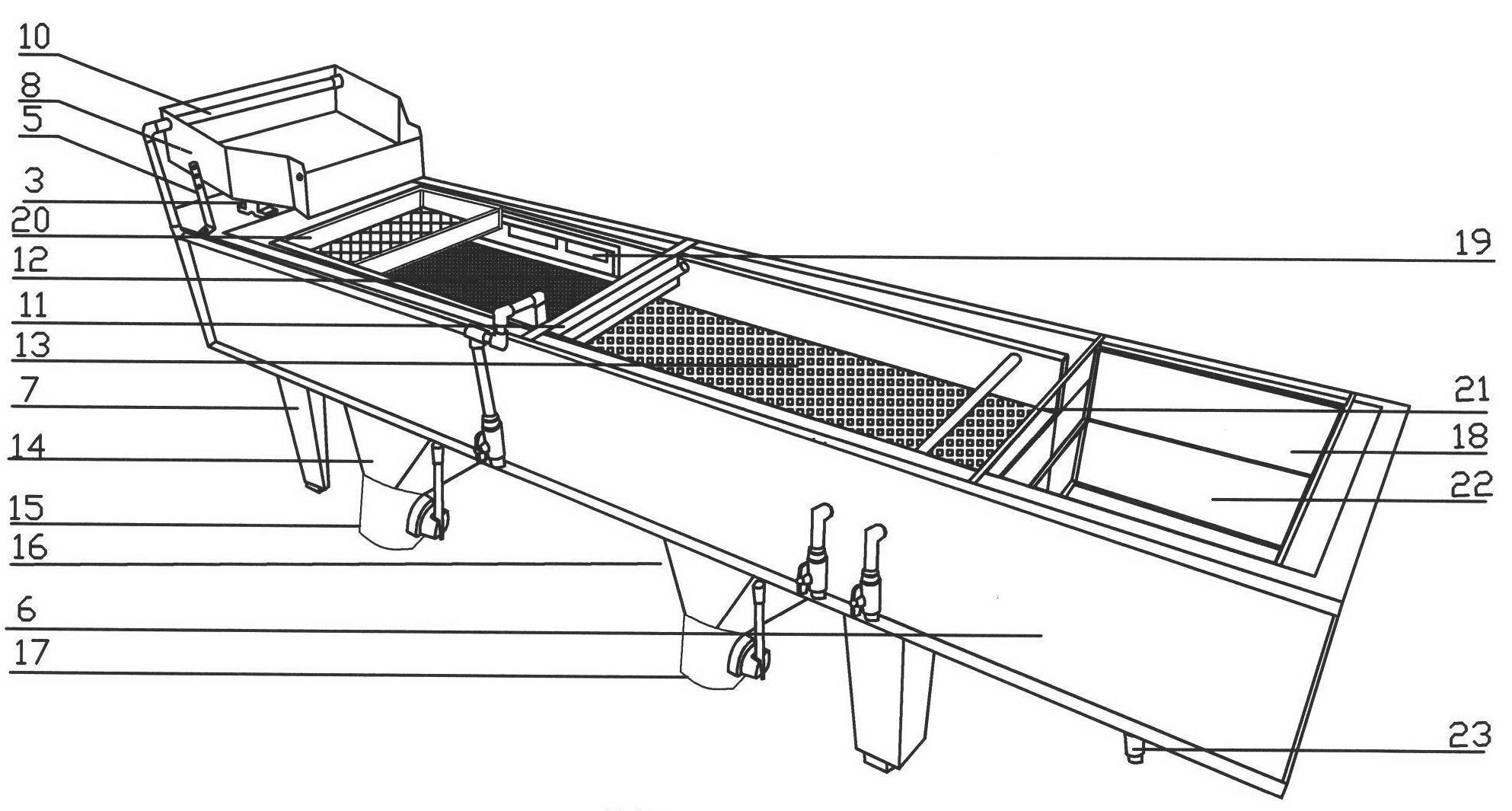

Scallop seed screening device

ActiveCN102273420AGuaranteed survival rateUnified specificationsClimate change adaptationPisciculture and aquariaFrequency conversionEngineering

The invention relates to the field of aquaculture, in particular to a device for screening scallop seedlings. The device for screening the scallop seedlings comprises a power device, a frequency conversion device, an eccentric crank arm mechanism, a connecting rod, an adjusting support, a machine body, a machine body support, a seedling feeding tank, a screen support, a water spraying pipe, a barrier, a primary screen, a secondary screen, a primary screen collection box, a collection box discharge outlet, a secondary screen storage box, a storage box discharge outlet, a seedling collection tank and an overflow port. In the invention, a mechanical device is used for substituting the traditional manual seedling screening operation, so that a large amount of labor force is saved, the labor intensity of employees is greatly reduced, and the work efficiency is greatly improved at the same time; moreover, the whole process of the screening of scallop seedlings is performed in water in the operation process, so the survival rate of the seedlings is ensured, and the screened seedlings have good quality and consistent specification; and seedling washing and screening are finished at one time, the operation link of seedling washing is saved, and pollution can be removed and two grades of scallop seedlings can be sorted through once-through operation.

Owner:ZHANGZIDAO GRP

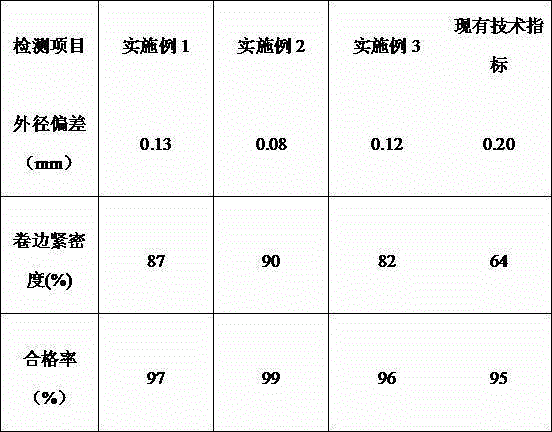

Production process of electric rice cooker

The invention discloses a production process of an electric rice cooker. The production process is characterized in that lubricating oil is added based on the mixing ratio to lubricate during the stretching process, and thus a strip-shaped stainless steel plate and a die can be sped up to slide. The production process has the advantages of inhibiting the thinning speed and preventing temperature from increasing. The heat sealing area of a rim-crimping machine can be controlled so as to control the size of a crimped circular arc; the temperature and humidity in rim crimping can be controlled, thereby reducing the phenomenon of poor rim crimping effect due to the deformation of the strip-shaped stainless steel plate; the temperature of a punch can be controlled during punching, thus the aperture of a formed hole meets the standard, and as a result, pressed ribs can be conveniently formed in the next step; the ribs are pressed in a combination manner, so that the problem of low working efficiency can be solved. The production process has the advantages of being consistent in product specification, high in working efficiency, huge in market potential and broad in prospect.

Owner:HUIZHOU UNIV

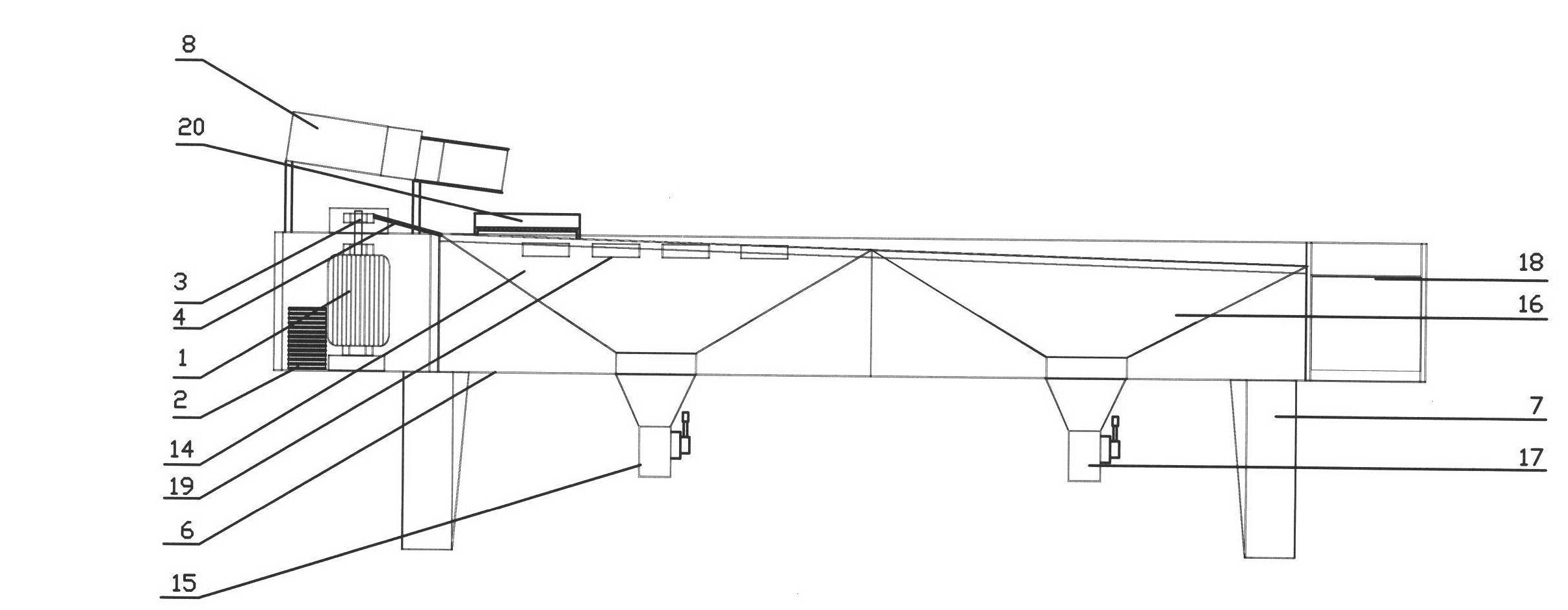

Multi-level thinning screen separation device for caboes

InactiveCN103302023AImprove screening efficiencyUnified specificationsSievingScreeningEngineeringSquare mesh

The invention discloses a multi-level thinning screen separation device for caboes, which comprises a screen separation driving device, a feed opening, a crushed cabo outlet and sieves, wherein the screen separation driving device drives the sieves; the sieves include a bar grate-shaped sieve, a square-mesh sieve, an elliptical slot hole sieve and a round hole sieve from high to low sequentially; each sieve comprises a baffle, a screen mesh and an oversize outlet; the feed opening corresponds to the screen mesh of the bar grate-shaped sieve; and the screen mesh of the bar grate-shaped sieve also corresponds to the that of the square-mesh sieve; the screen mesh of the square-mesh sieve corresponds to a crushed cabo collecting tank; the oversize outlet of the square-mesh sieve corresponds to the screen mesh of the elliptical slot hole sieve; the screen mesh of the elliptical slot hole sieve corresponds to that of the round hole sieve; and the screen mesh of the round hole sieve also corresponds to the crushed cabo collecting tank. According to the invention, the different sieves at different layers are used for effectively separating cabo heads, overlong stems, long stems, short stems, crushed stems and smashed pieces of the stemmed caboes subjected to threshing and redrying, and accordingly, the cabo specification is uniform, which can more meet the requirements of tobacco primary process procedures, and facilitate classification packaging, storage and transportation of the caboes.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Preparation method of braised pork cubes

InactiveCN101664194ARealize industrial productionReduce consumptionMeat/fish preservation by freezing/coolingFood preparationWhole eggFood flavor

The invention discloses a traditional food, in particular to a preparation method of braised pork cubes using chicken and pork as main materials. The braised pork cubes have the following formula: using 100g of raw material pork as the reference: 100g of raw material pork, 1g of cooking wine, 1g of dark soy sauce, 8g of flour, 20g of starch, 5g of salad oil, 25g of water, 2g of salt, 5g of whole egg liquid, 0.5g of peppery powder, 0.5g of little pepper powder, 0.8g of chicken crease flavor and 0.4g of white pepper powder. The industrial preparation method comprises the steps of checking and accepting the raw materials, processing the raw materials and stirring syrup, pre-frying, quickly freezing, packaging and storing. The invention realizes the industrial and standard production of the traditional food by adopting a scientific and reasonable process, prolongs the refreshing time by adopting a modern refreshing and packaging technology, ensures the specification consistency of the product, is reliable, safe and reliable in quality, lowers the production cost by comprehensively utilizing the raw materials and is convenient for customers.

Owner:HENAN DAYONG INDUSTRIAL CO LTD

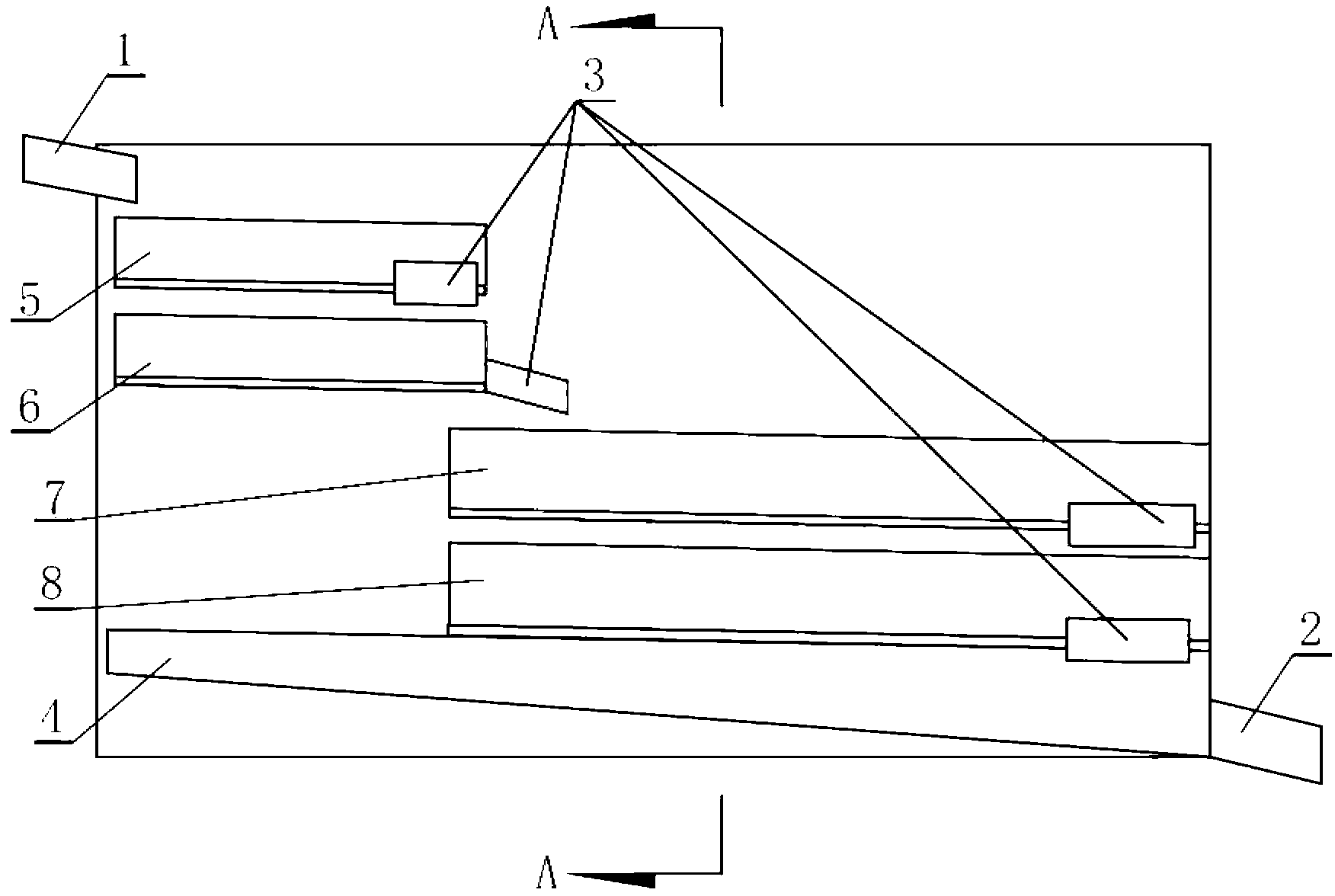

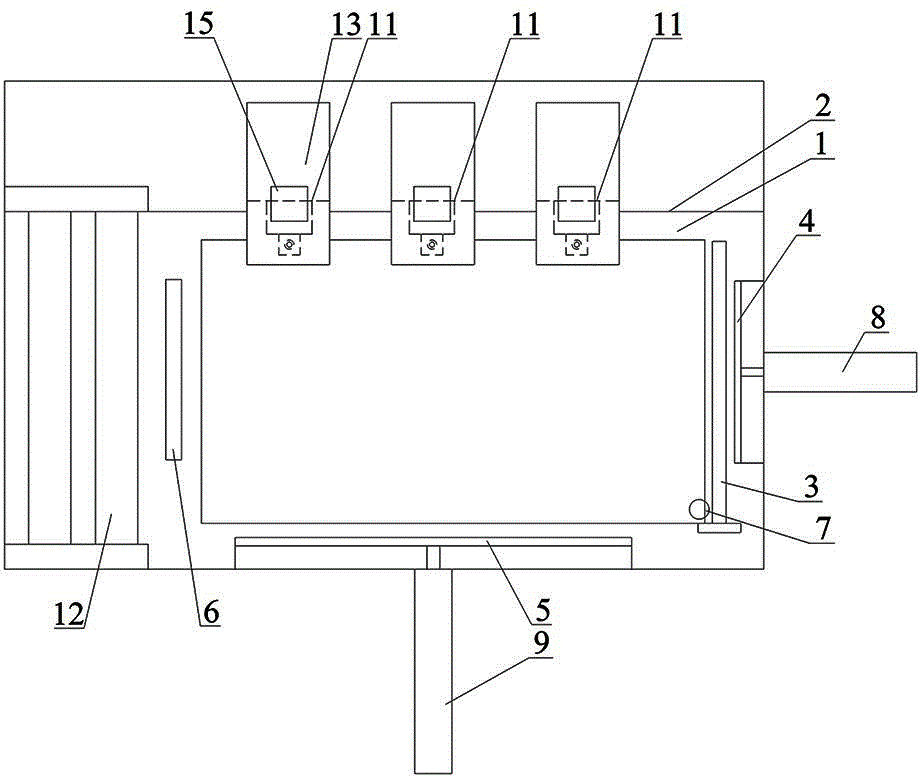

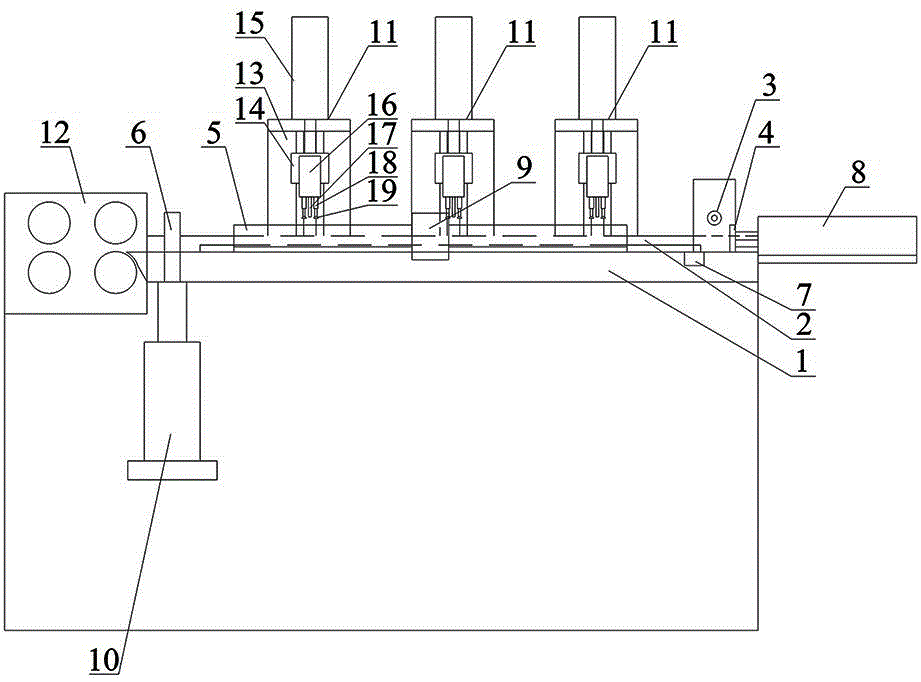

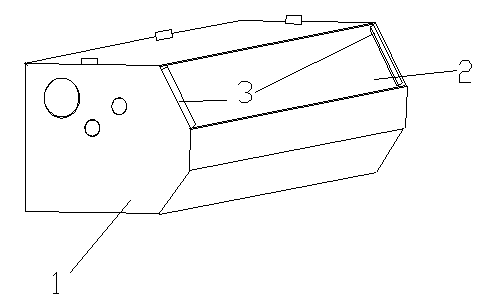

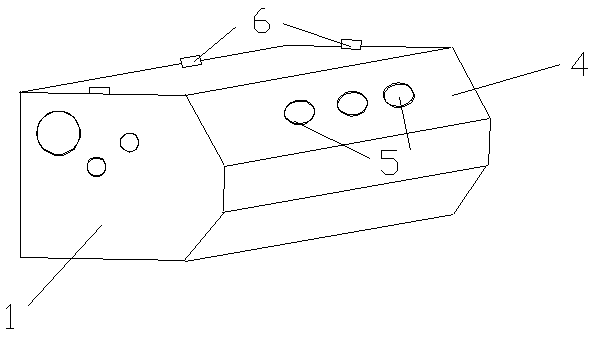

High-precision automatic drilling device

ActiveCN104626283AEliminate timeHigh degree of automationStationary drilling machinesBiochemical engineeringVertical cylinder

The invention discloses a high-precision automatic drilling device which comprises a worktable (1), wherein a rear-side stop surface (2) is formed in the rear side of the worktable (1); a feeding guide roller (3) and a left ejector plate (4) are arranged on the right side of the worktable (1); a proximity switch (7) is arranged on the part, positioned on the left side of the feeding guide roller (3), of the worktable (1); a rear ejector plate (5) is arranged on the front side of the worktable (1); a left-side limiting plate (6) is arranged on the left side of the worktable (1); the bottom of the left-side limiting plate (6) is connected with a vertical cylinder (10); and multiple drilling machines (11) and a wooden board conveying device (12) are arranged on the worktable (1). The high-precision automatic drilling device disclosed by the invention has the beneficial effects that the total process of feeding, positioning, drilling and discharging of wood boards is continuous, the degree of automation is high, the positioning accuracy is high, the processing efficiency and yield are improved, the product specification is unified, and the machining quality is high.

Owner:CHINA FORGING MACHINERY

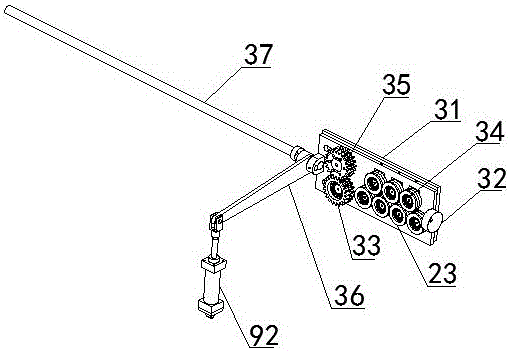

Arm type automatic reinforcing steel bar molding machine

ActiveCN102632165ARealize one-time automatic moldingSpecificationsMolding machineClassical mechanics

The invention discloses an arm type automatic reinforcing steel bar molding machine, which comprises a support provided with a horizontal guide groove. An automatic molding device is arranged on the support and consists of a hinge type bending mechanism and movable bending mechanisms, the hinge type bending mechanism is disposed on the support, the movable bending mechanisms are positioned on two sides of the support, the hinge type bending mechanism consists of a left swing arm, a right swing arm and a power device, the left swing arm and the right swing arm are symmetrically hinged together by a hinge shaft, the bottom of the hinge shaft is arranged in the guide groove and can be driven by the power device to slide along the guide groove so as to drive the left swing arm and the right swing arm to swing, each movable bending mechanism consists of driving devices which are symmetrically fixed onto the left swing arm and the right swing arm around the hinge shaft, and the driving devices are connected with the bending mechanisms and drive the bending mechanisms to reciprocate on the swing arms. After the hinge type bending mechanism and the movable bending mechanisms are used together, an operator only needs to place a reinforcing steel bar into the automatic molding machine so that the reinforcing steel bar can be automatically molded at one step.

Owner:冯广建

Compound type decorating thermal insulation panel with cement polymer at double surfaces and preparation method thereof

InactiveCN104563428ANot affected by the weatherNice appearanceCovering/liningsWater-setting substance layered productEpoxyPolymer science

The invention relates to a compound type decorating thermal insulation panel with cement polymer at double surfaces and a preparation method thereof. The thermal insulation panel comprises a surface layer, a cover surface layer coated on the surface layer surface, a bottom layer connected with the surface layer through a connecting post, and a thermal insulating layer clamped between the surface layer and bottom panel layer. The surface layer is made of cement polymer composed of special cement, surface layer padding and acrylic elastic emulsion or epoxy resin emulsion, and the bottom layer is made of cement polymer composed of cement and bottom layer padding. The compound type decorating thermal insulation panel with the cement polymer at double surfaces is mechanically produced in a factory, the labor cost is saved, the appearance is beautiful, the size is uniform, and the quality is guaranteed; the construction is not influenced by weather; the surface of the thermal insulation panel bonded with the wall surface is cement polymer, and the problem of thermal insulation panel detachment from the wall surface due to the fact that the surface of the thermal insulation panel bonded with the wall surface is inconsistent with the interface of the wall surface in coefficients is avoided; crack is avoided, the outer surface is smooth and clean, and the service life is long.

Owner:四川安美达节能科技有限公司

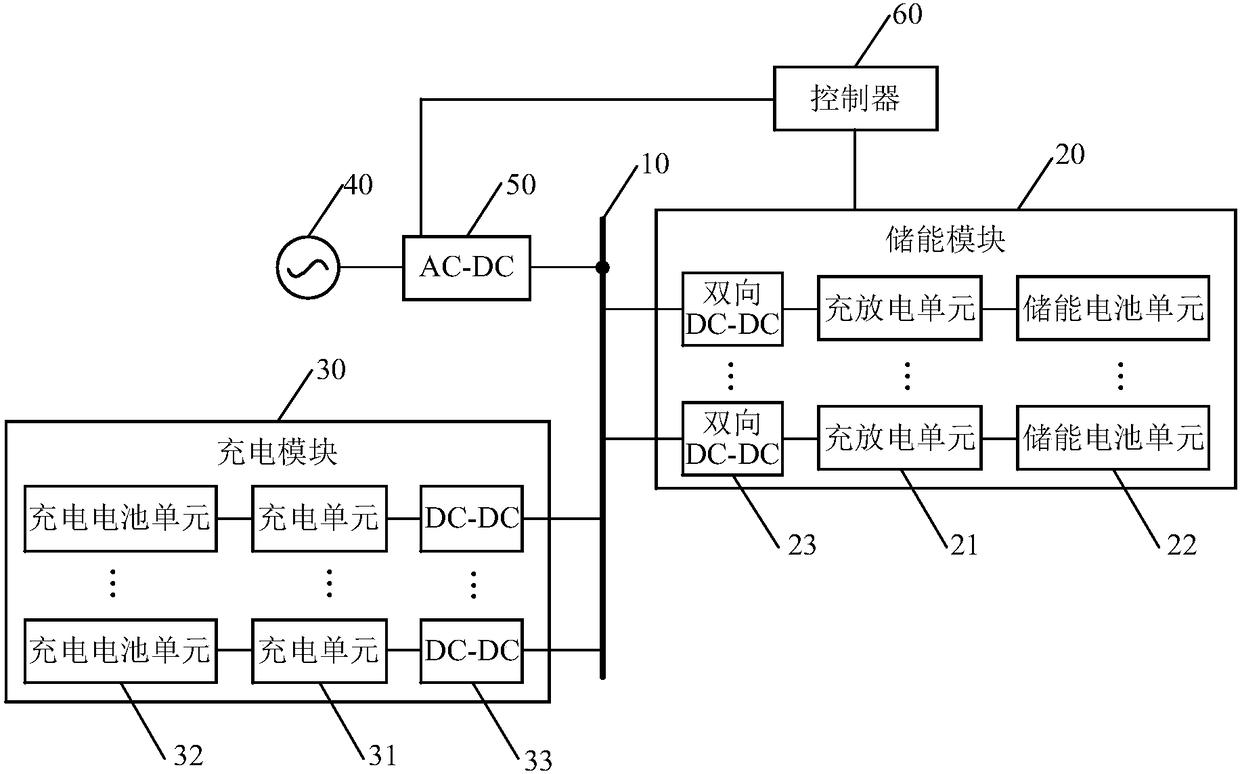

Power transmission system for electromobile power conversion and energy storage station

PendingCN108365623AUnified specificationsImprove stabilityCharging stationsMobile unit charging stationsElectric power transmissionElectricity

The invention discloses a power transmission system for an electromobile power conversion and energy storage station. The power transmission system comprises a power grid, a two-way AC-DC conversion module, a direct current bus, an energy storage module, a charge module and a controller, the two-way AC-DC conversion module is connected between the direct current bus and the power grid, the energystorage module is connected with the direct current bus, the charge module is connected with the direct current bus, the charge module and the two-way AC-DC conversion module are both connected with the controller, and the controller is used for controlling the conversion direction of the two-way AC-DC conversion module and controlling a charge and discharge unit to charge or discharge. The two-way power transmission and conversion between the energy storage module and the power grid is realized, an electromobile is also stably charged under the condition of grid failure, the stored electric energy is fed back to the power grid to respond to the failure of the power grid; and in addition, the operation cost of an electromobile power conversion station is reduced by means of peak load shifting, and the stability of the power supply order of the power grid is improved.

Owner:宁波利维能储能系统有限公司

Preparation method for rooting of test-tube plantlet of ample flow pear

InactiveCN103444522APromote growthGood characterHorticulture methodsPlant tissue culturePEARAxillary bud

The invention discloses a preparation method for rooting of a test-tube plantlet of an ample flow pear. The preparation method comprises the following steps of A, carrying out sterile test-tube plantlet cultivation on annual branches and stems of the ample flow pear, namely cutting the sterile test-tube plantlet into branches and stems with axillary buds for disinfection treatment, and cutting a root into an inclined surface to be inserted into an axillary bud medium for cyclic cultivation through day and night illumination; B, carrying out subculture proliferation on the sterile test-tube plantlet, namely cutting axillary bud seedlings which are sterile and robustly grow from the branches and the stems to be inoculated into a subculture medium for cyclic cultivation through the day and night illumination; C, transferring the test-tube plantlet of the ample flow pear into a rooting medium to induce the rooting, namely inoculating the test-tube plantlet of the ample flow pear to a first rooting medium for dark cultivation and then transferring to a second rooting medium for light cultivation to obtain a rooted plant, and carrying out cyclic cultivation through the day and night illumination; D, carrying out transplanting and domestication on the rooted seedlings in an illumination incubator, transferring the survived seedlings into a pot for cultivation. The preparation method is easy to carry out and easy to operate and solves the problem that the test-tube plantlet of the ample flow pear is difficult to root in the process of tissue cultivation; the rooting rate is high, a root system is developed, and the survival rate of transplanting is high.

Owner:HUAZHONG AGRI UNIV

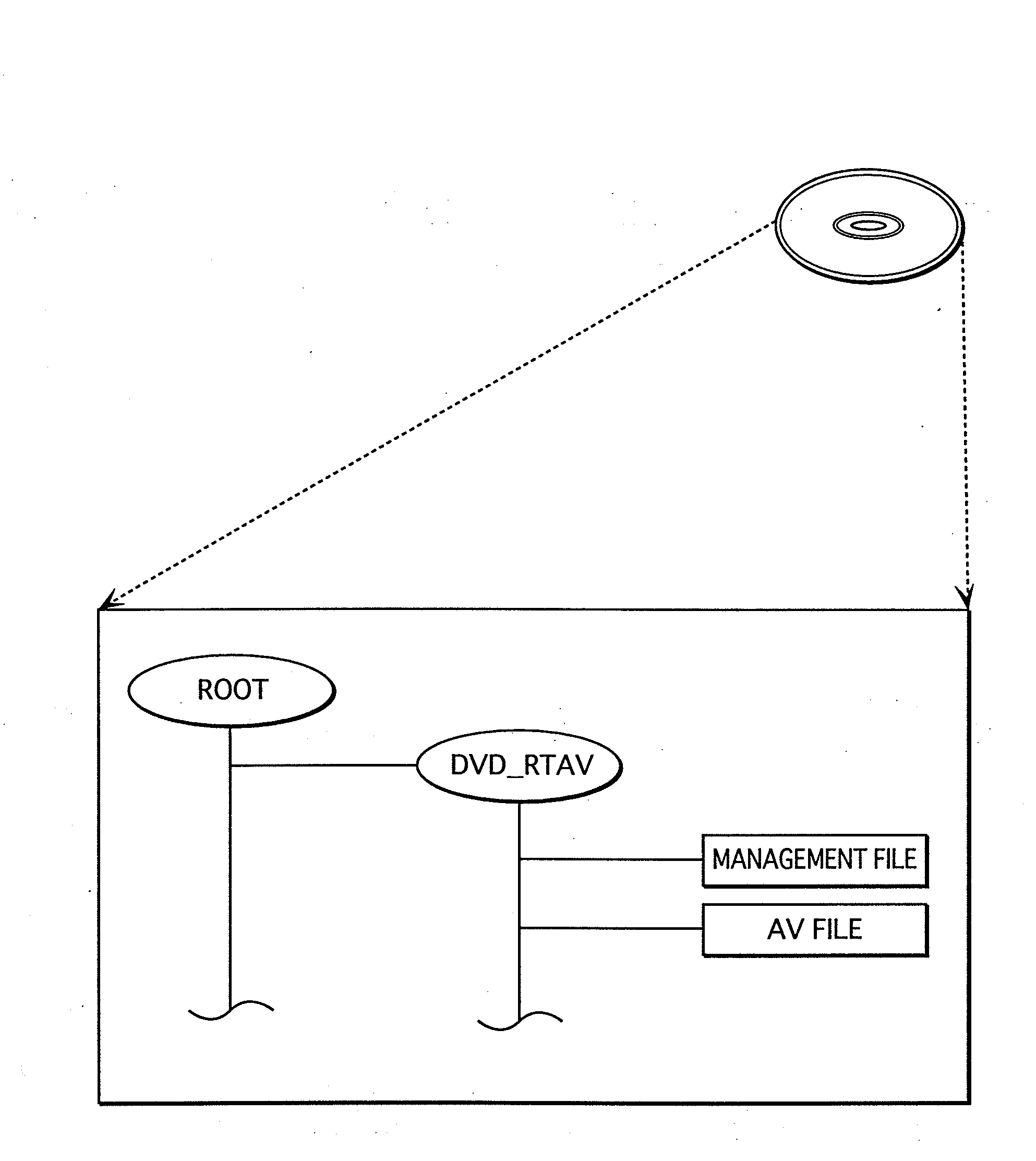

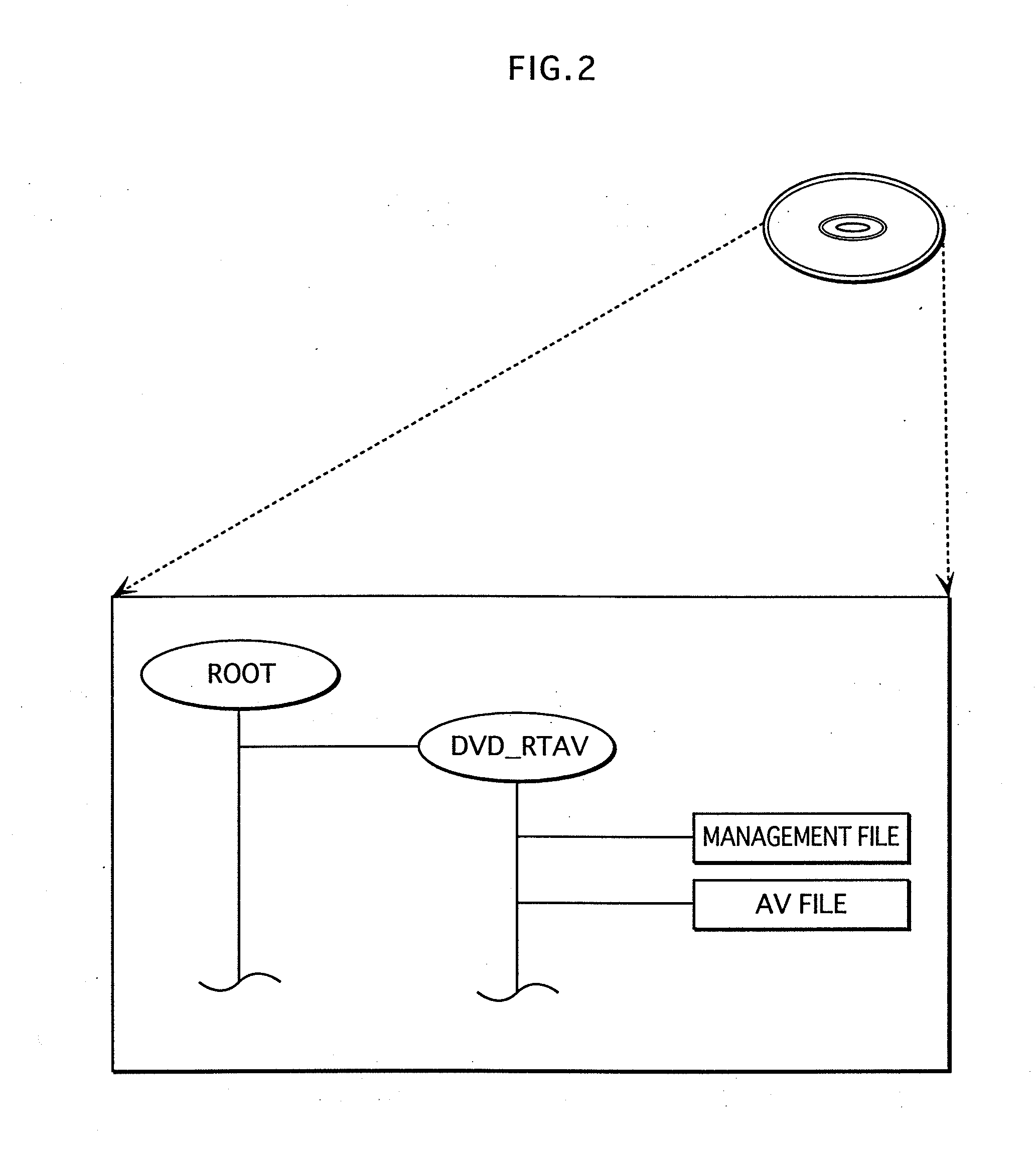

Recording apparatus, recording medium, playback apparatus, program, and method

InactiveUS20090087169A1Reduce the burden onHigh user needTelevision system detailsElectronic editing digitised analogue information signalsComputer architectureRecording media

Owner:NAKANISHI NOBUO +3

Automatic hollow bead forming machine

ActiveCN105105434AImprove work efficiencyImprove product qualification rateJewelleryPunchingMolding machine

The invention relates to an automatic hollow bead forming machine. According to the automatic hollow bead forming machine, a metal pipe blank is conveyed to a lower forming die of a turntable through a vibration feeding plate, a material guide slot and a material pushing mechanism, and is corrected by a correction mechanism; then the turntable rotates to convey the metal pipe blank on the lower forming die, so that the metal pipe blank is punched by an upper forming die mechanism to form thin-wall hollow beads; therefore, the automatic hollow bead forming machine realizes full automation of material screening, material conveying, material swinging and punching, and the specifications of the thin-wall spherical hollow beads punched by the automatic hollow bead forming machine are uniform; meanwhile, the potential safety hazard is eliminated; compared with the conventional hollow bead forming machine, the automatic hollow bead forming machine disclosed by the invention is high in automation degree, and the technical problems of large artificial operation error and low efficiency are solved; and the labor intensity of a worker and the production cost are effectively reduced, and the working efficiency and the product yield are improved, so that full automatic production of the thin-wall hollow beads is realized.

Owner:佛山市顺德区汇伦生产力促进服务中心有限公司 +1

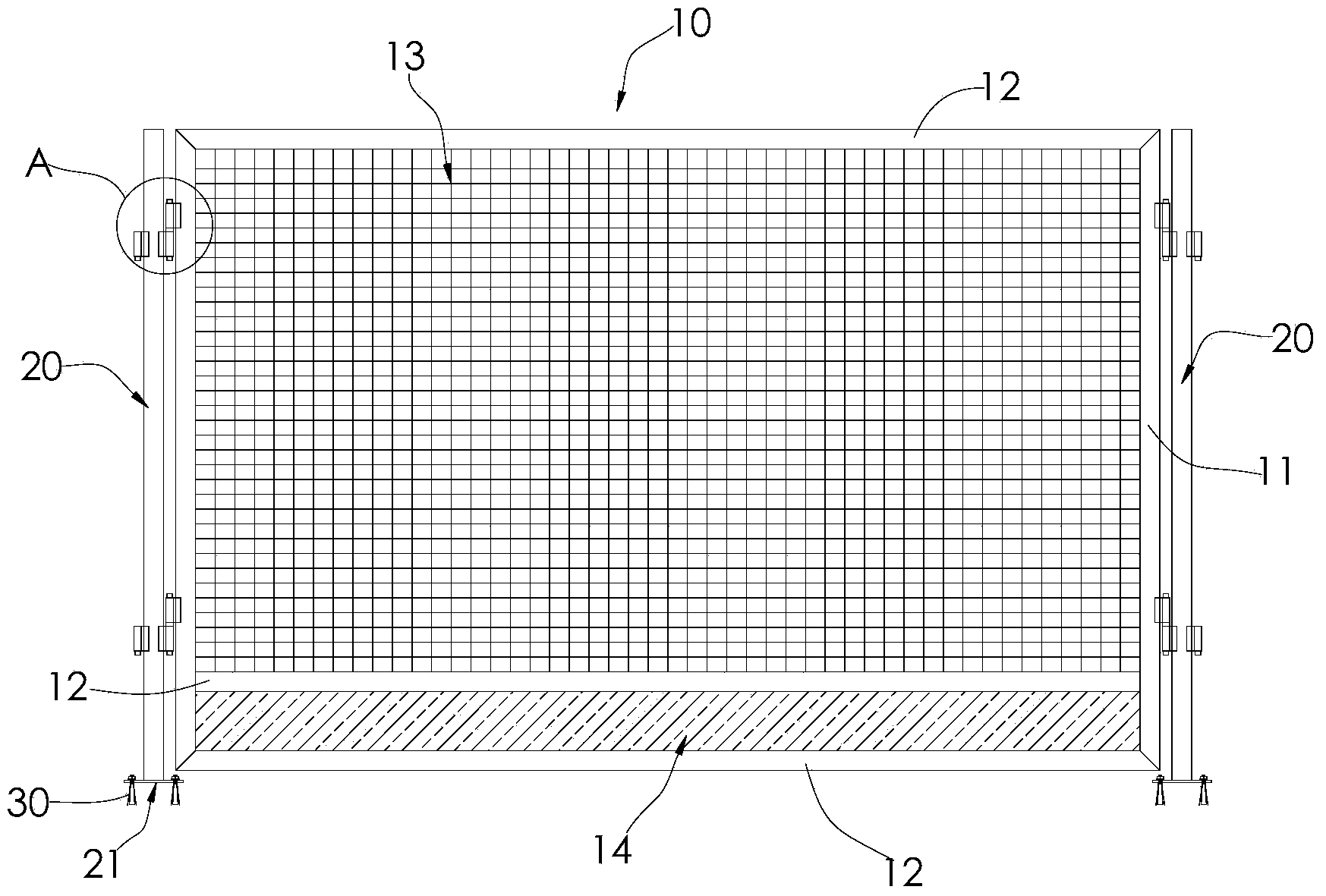

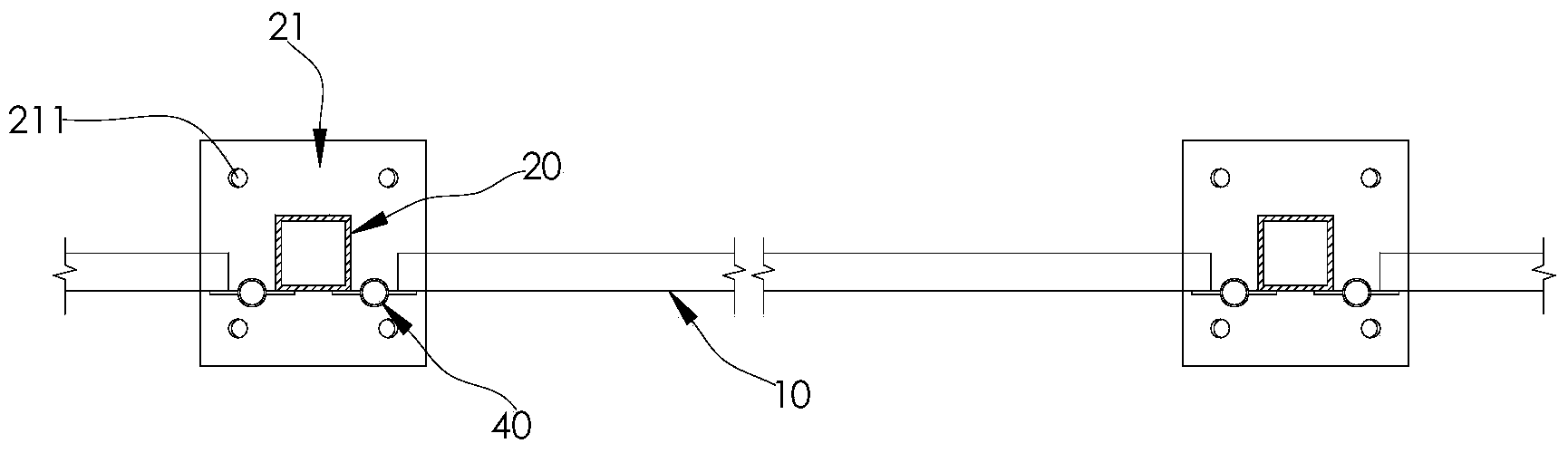

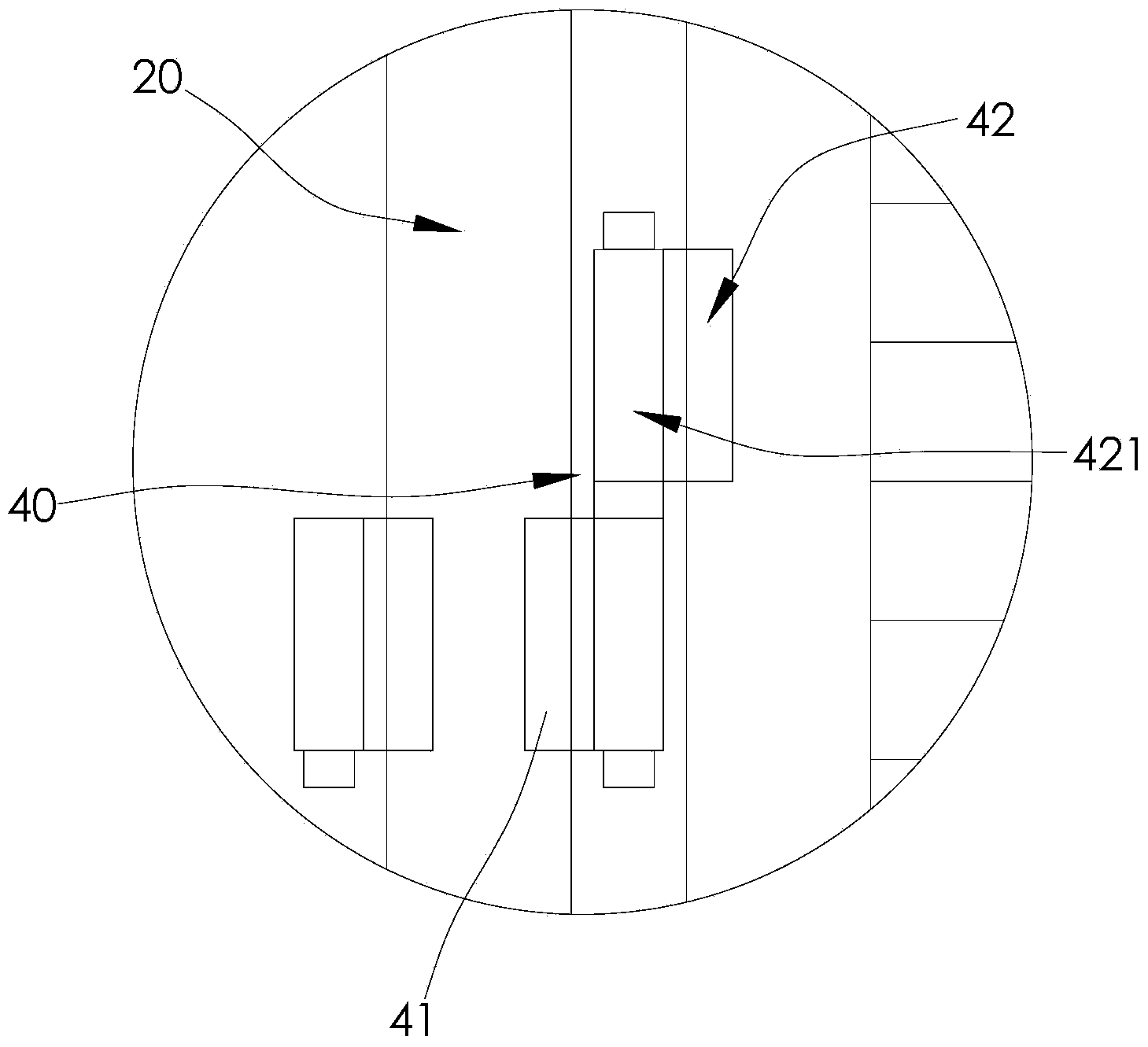

Building site guardrail fast to mount and demount

InactiveCN104179362AReduce wasteSimple structureBuilding material handlingUniform designArchitectural engineering

A building site guardrail fast to mount and demount comprises a plurality of standing columns parallelly arranged and a plurality of guardrail units. A base plate is welded to the bottom of each standing column and provided with at least three mounting holes, and an expansion bolt for fixing the base plate on the ground penetrates each mounting hole. Each guardrail unit comprises two vertical beams located on two sides of the guardrail unit, a steel plate mesh located between the two vertical beams, and crossbeams which are transversely disposed and used for fixedly connecting the two vertical beams. Each guardrail unit is disposed every two adjacent standing columns, and the vertical beams of the guardrail unit are fixedly connected with the corresponding standing columns in an inserted manner. The building site guardrail has the advantages that the guardrail is simple in structure, uniform in specification and capable of achieve unit type assembling; the specification of each guardrail unit is designed uniformly, circulation in different building sites is achieved, material waste is reduced, and building cost is lowered; the connecting parts are in socket and spigot joint, fast mounting and demounting can be achieved, and time and labor are saved.

Owner:中国建筑第五工程局有限公司东莞分公司 +1

Device for manufacturing safe fireworks fuse

InactiveCN102079683AMeet the needs of wet induction processConsistent thickness specificationsFuse manufactureFireworksEngineering

The invention discloses a device for manufacturing a safe fireworks fuse, which comprises a powder hopper arranged on a rack, a weaving mechanism, a coiling mechanism and a driving and transmitting mechanism. The device is characterized in that the discharging hole of the power hopper is connected with a powder applying pressure tank via a screw rod powder-extruding cylinder, the upper end surface of the powder applying pressure tank is provided with at least one line hole, the corresponding position at the lower end surface is provided with at least one line hole, and a screw rod of the screw rod powder-extruding cylinder is connected with the driving and transmitting mechanism. According to the device, the requirements on a wet processing technology for manufacturing the fuse can be satisfied, the consistent specification of a product is realized, the powder density of the fuse is substantially strengthened, higher uniformity and stable burning rate are realized, and the occurrence of a cutoff phenomenon can be completely stopped. The device has the advantages of high automation degree, coordination in system operation and higher production efficiency. Moreover, all performance data of the fuse product meet or exceed the requirements on the national standard, and the storage time of the fuse product is prolonged by more than four years compared with the original product.

Owner:鲁向华

Automatic dress material folding machine

InactiveCN104444554AFold applicableUnified specificationsFolding thin materialsControl systemAgricultural engineering

The invention provides an automatic dress material folding machine. The automatic dress material folding machine comprises a panel, a position sensor, horizontal folding mechanisms, a vertical folding mechanism and a control system; a vertical folding groove is formed in the panel, and the horizontal folding mechanisms are fixed to the two sides of the panel; the vertical folding mechanism comprises a vertical insertion plate and a guide roller set, the vertical insertion plate is correspondingly arranged at the position, above the vertical folding groove, of the panel, and the guide roller set is fixed to the position, below the vertical folding groove, of the panel; the input end of the control system is connected with the output end of a position sensor, the output end of the control system is connected with the control ends of the horizontal folding mechanisms and the control end of the vertical folding mechanism, and the control system receives signals of the position sensor, starts to control the horizontal folding mechanisms to complete longitudinal folding of dress materials, and then controls the vertical folding mechanism to complete transverse folding of the dress materials. The automatic dress material folding machine is simple and rapid in folding movement, folding of the dress materials can be automatically and rapidly completed, and the time spent in the overall folding process is shorter than or equal to 8 minutes per piece. The labor cost is reduced. The automatic dress material folding machine is particularly suitable for folding the light, thin and soft dress materials.

Owner:WUHAN HENGFEI ELECTRICAL TECH CO LTD

Land-based crab breeding device and crab breeding method

InactiveCN102696513AImprove survival rateEasy harvestClimate change adaptationPisciculture and aquariaFisheryOceanography

The invention relates to a land-based crab breeding device. The land-based crab breeding device consists of one layer of row cages or is formed by overlapping more than two layers of row cages, wherein each layer of raw cages consists of one crab cage or is formed by connecting more than two crab cages in series through the sides; run-through holes at the corresponding position of the side of each layer of crab cages are positioned on the same straight line; three groups of run-through holes for connecting a water supply pipe, an air supply pipe and a blowdown pipe are formed on the sides of the crab cages; discharge holes are formed on the bottom surfaces of the crab cages; the water supply pipe, the air supply pipe and the discharge pipe transversely pass through the three groups of run-through holes of each layer of crab cages below the top layer of crab cages correspondingly; the water supply pipe and the air supply pipe are communicated with each crab cage through a three-way connector; the discharge pipe in each crab cage is communicated with the discharge hole at the bottom of the previous layer of crab cages through the vertical end of a T-shaped three-way connector; control valves are arranged on the water supply pipes, the air supply pipes and the discharge pipes; and airflow and water circulation in the crab breeding device is controlled by adjusting the control valves arranged on the water supply pipes, the air supply pipes and the discharge pipes.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com