Building site guardrail fast to mount and demount

A technology for construction sites and protective railings, which is applied in the processing of building materials, construction, building construction, etc., and can solve the problems of not being able to meet the requirements of construction work efficiency, difficulty in meeting construction safety requirements, time-consuming and laborious installation and disassembly, etc. , to achieve the effect of improving the image of safe and civilized construction, good appearance and image, and highly uniform installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

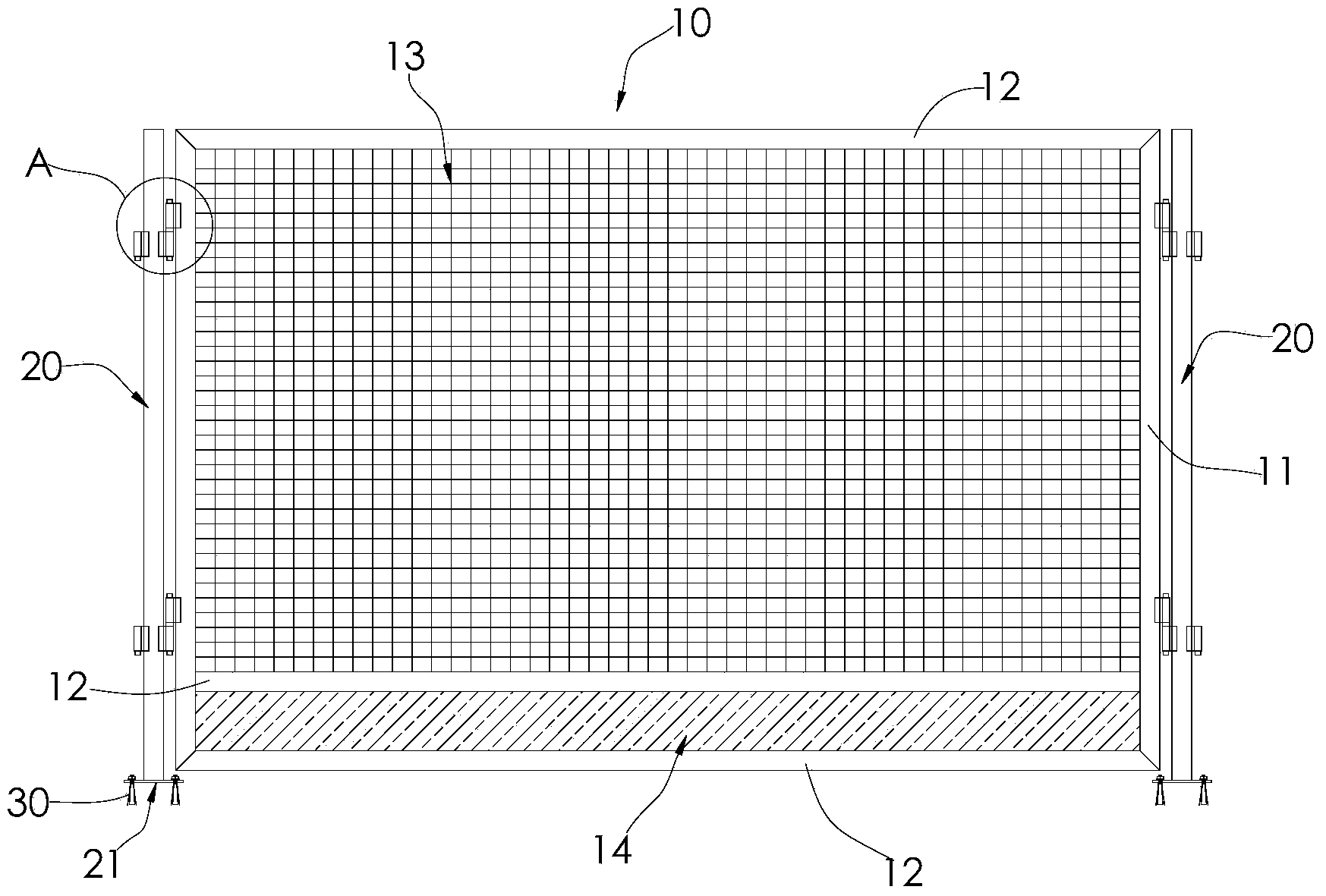

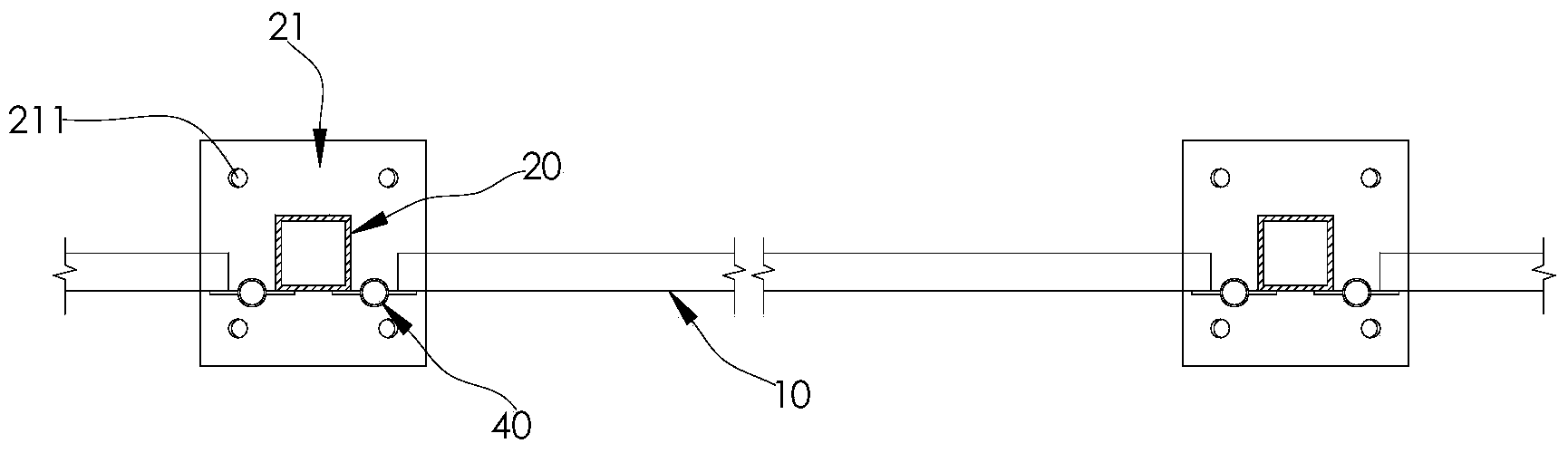

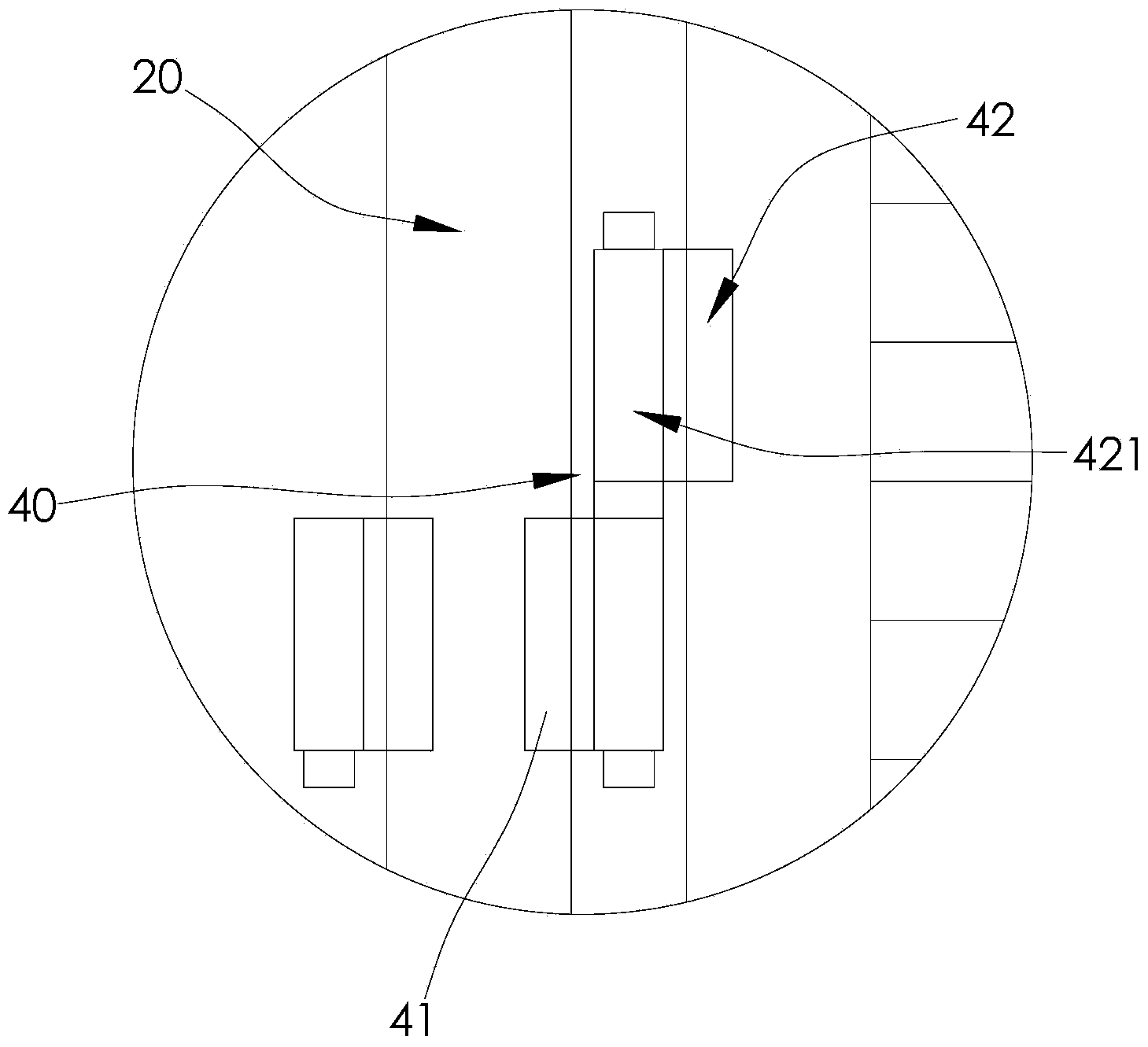

[0023] like Figure 1-3 As shown, it is a quick-detachable protective railing for a construction site of the present invention, which includes a plurality of columns 20 arranged side by side and arranged at equal intervals, and guardrail units 10 with completely uniform shapes and sizes, each of which The bottom of the column 20 is welded with a base plate 21, the base plate 21 is square, and its four end corners are respectively provided with a mounting hole 211, and the expansion bolts 30 are connected in the mounting holes 211, and the four expansion bolts 30 penetrate into the The base plate 21 is fixed on the ground in the installation hole 211, and then the column 20 is firmly fixed to the ground. The above-mentioned base plate 21 is not limited to a square, it can also be set to other shapes according to the installation requirements, and the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com