Patents

Literature

64results about "Fuse manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

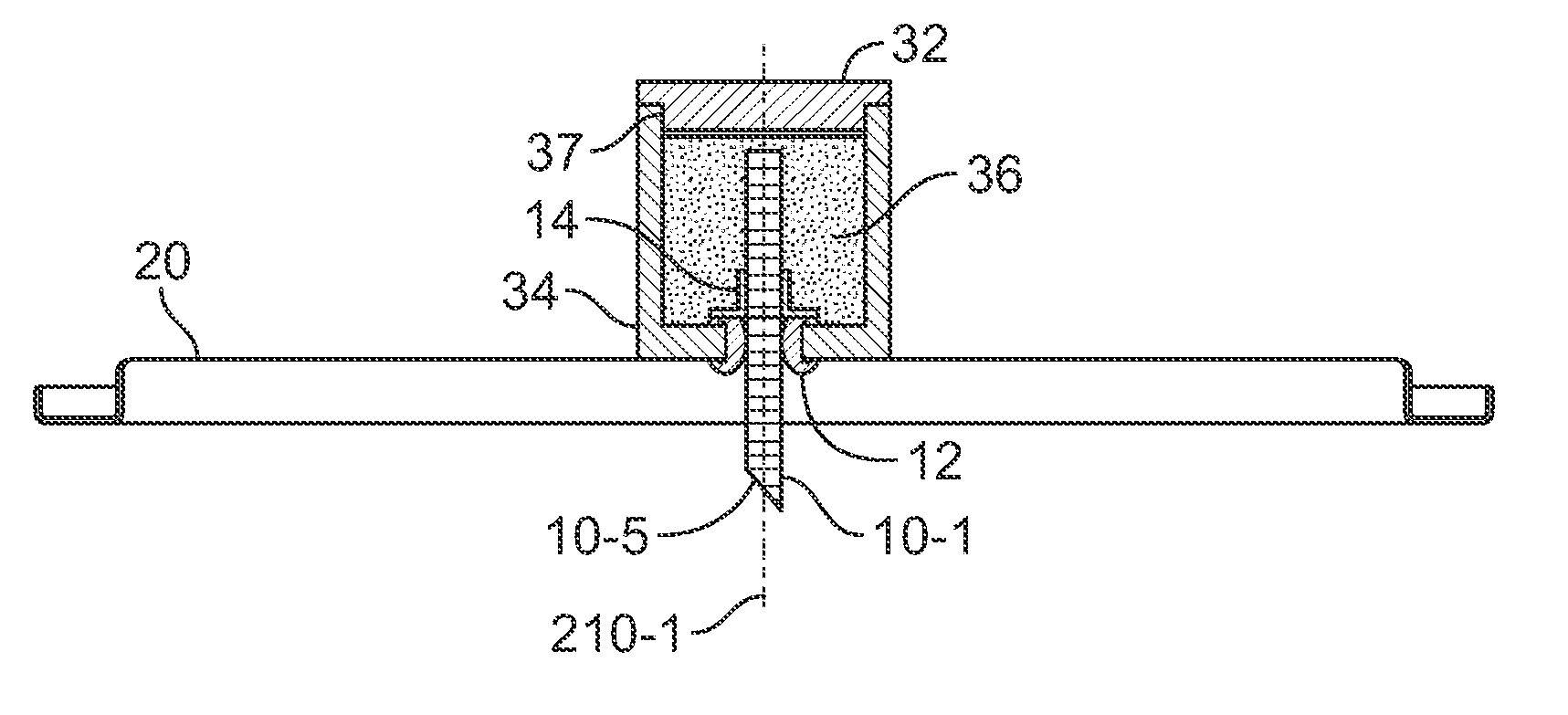

Method of making a signal transmission fuse

InactiveUS6347566B1Avoid less flexibilityEasy loadingBlasting cartridgesExplosive working-up apparatusEngineeringMechanical engineering

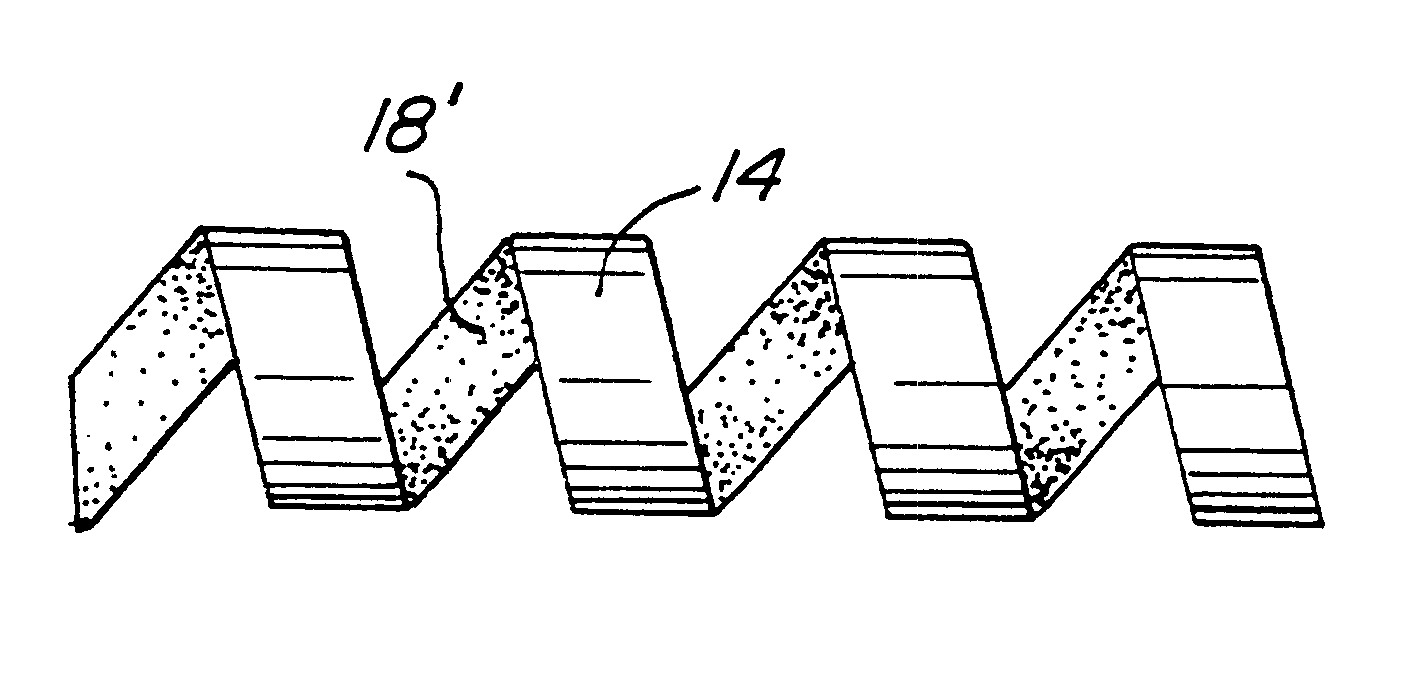

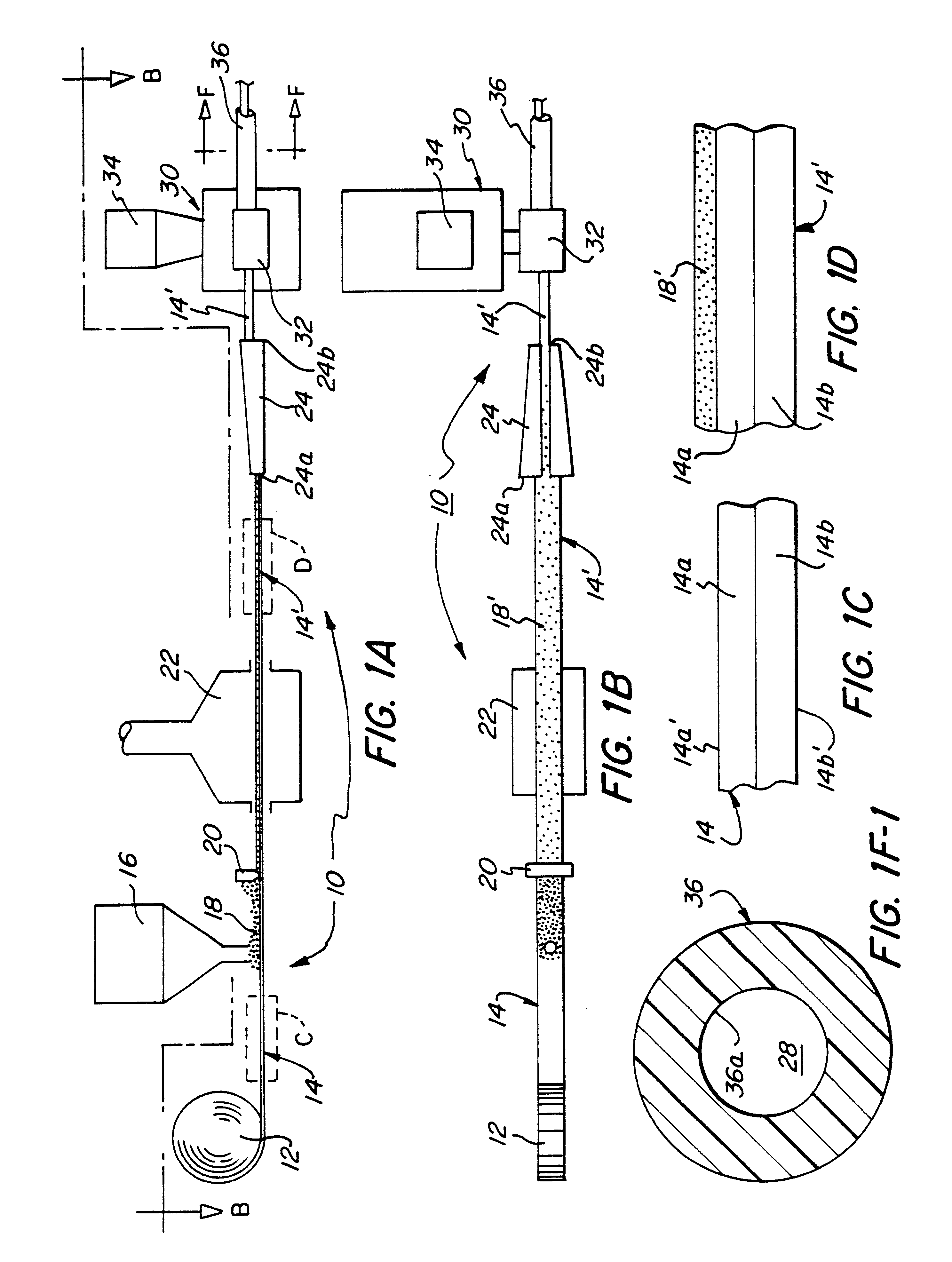

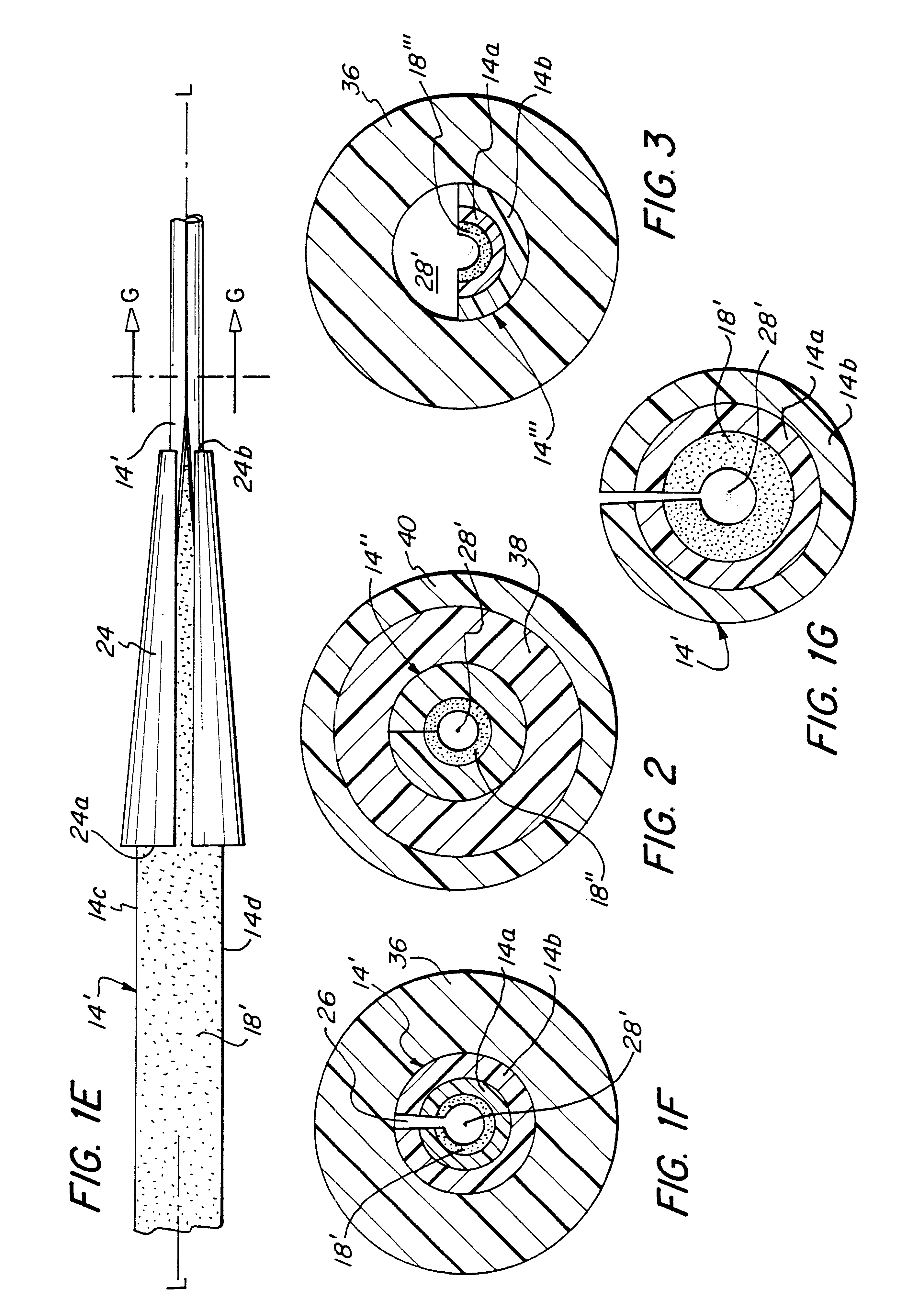

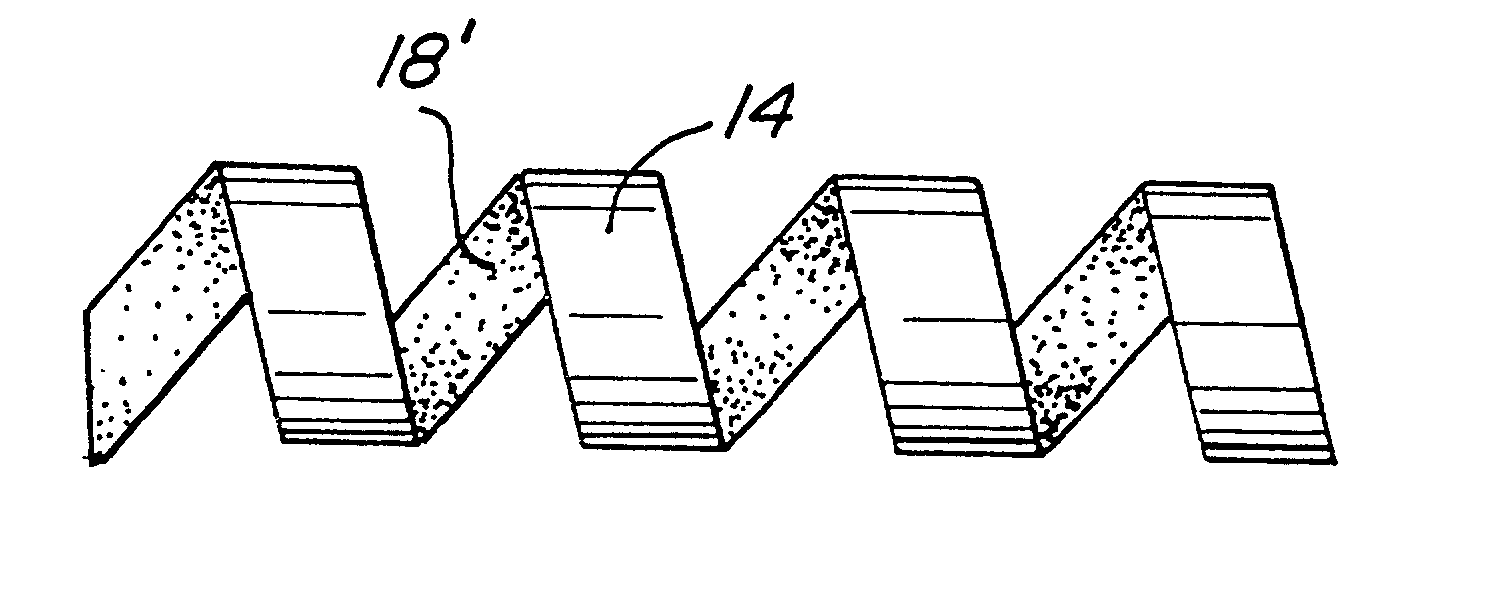

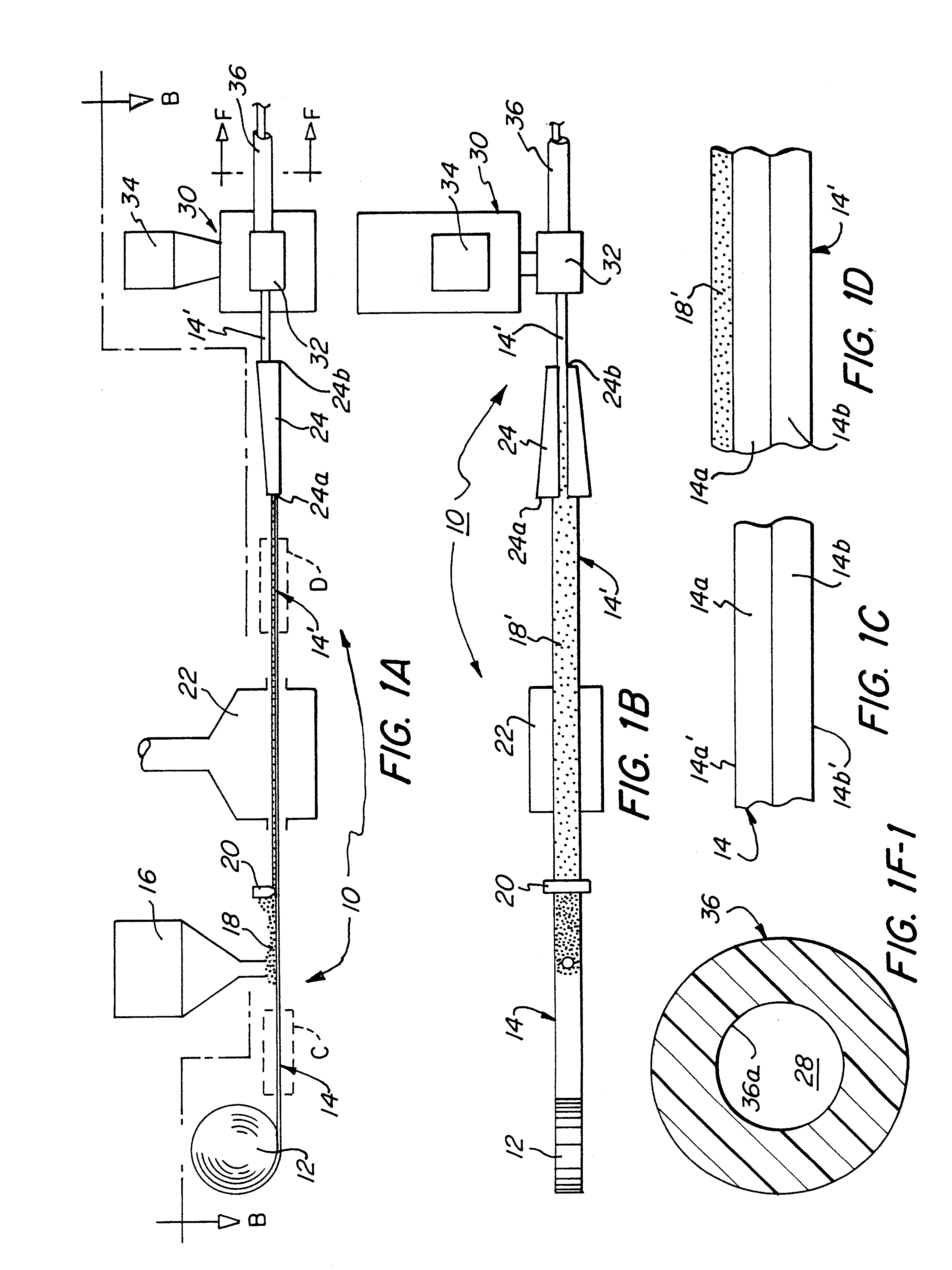

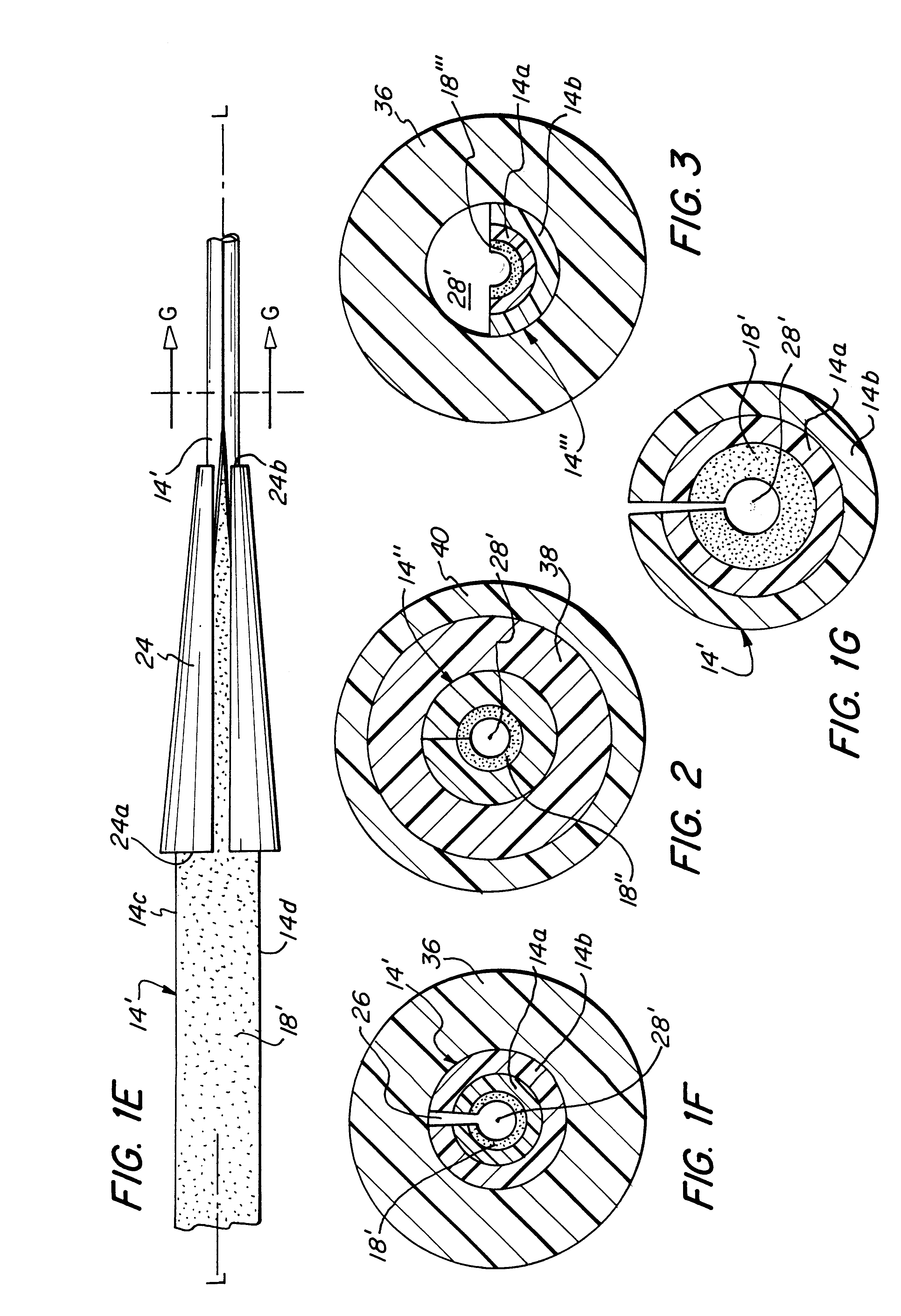

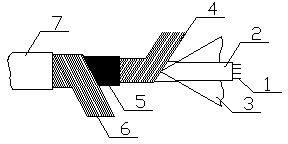

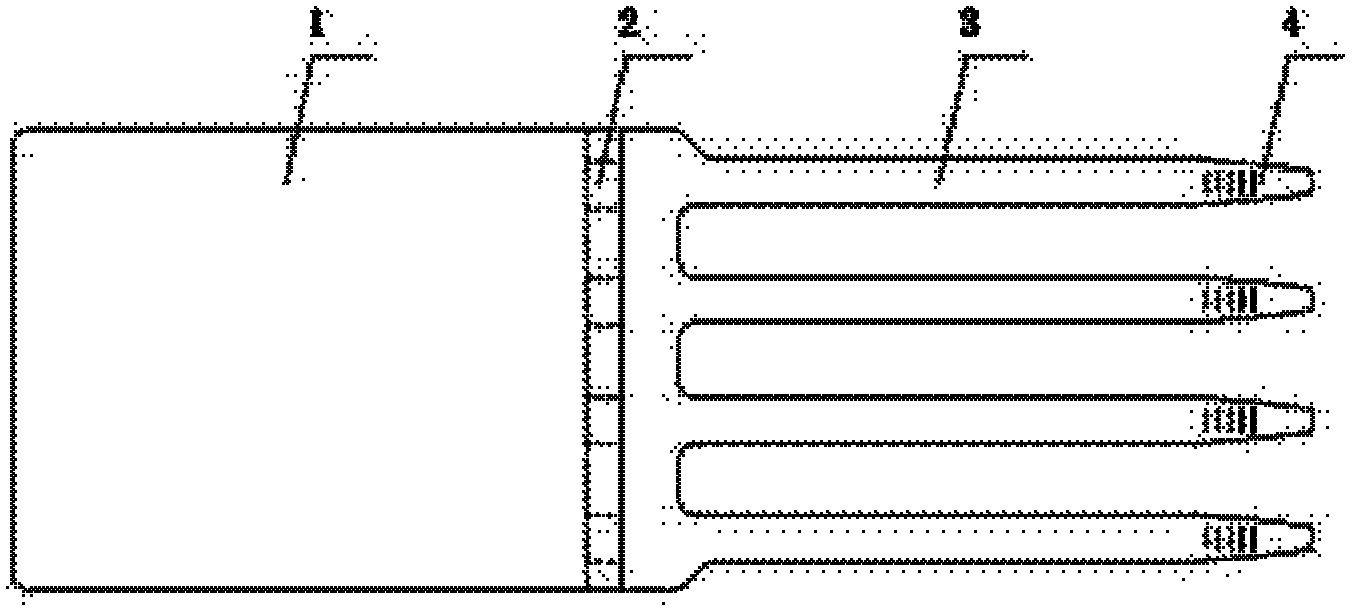

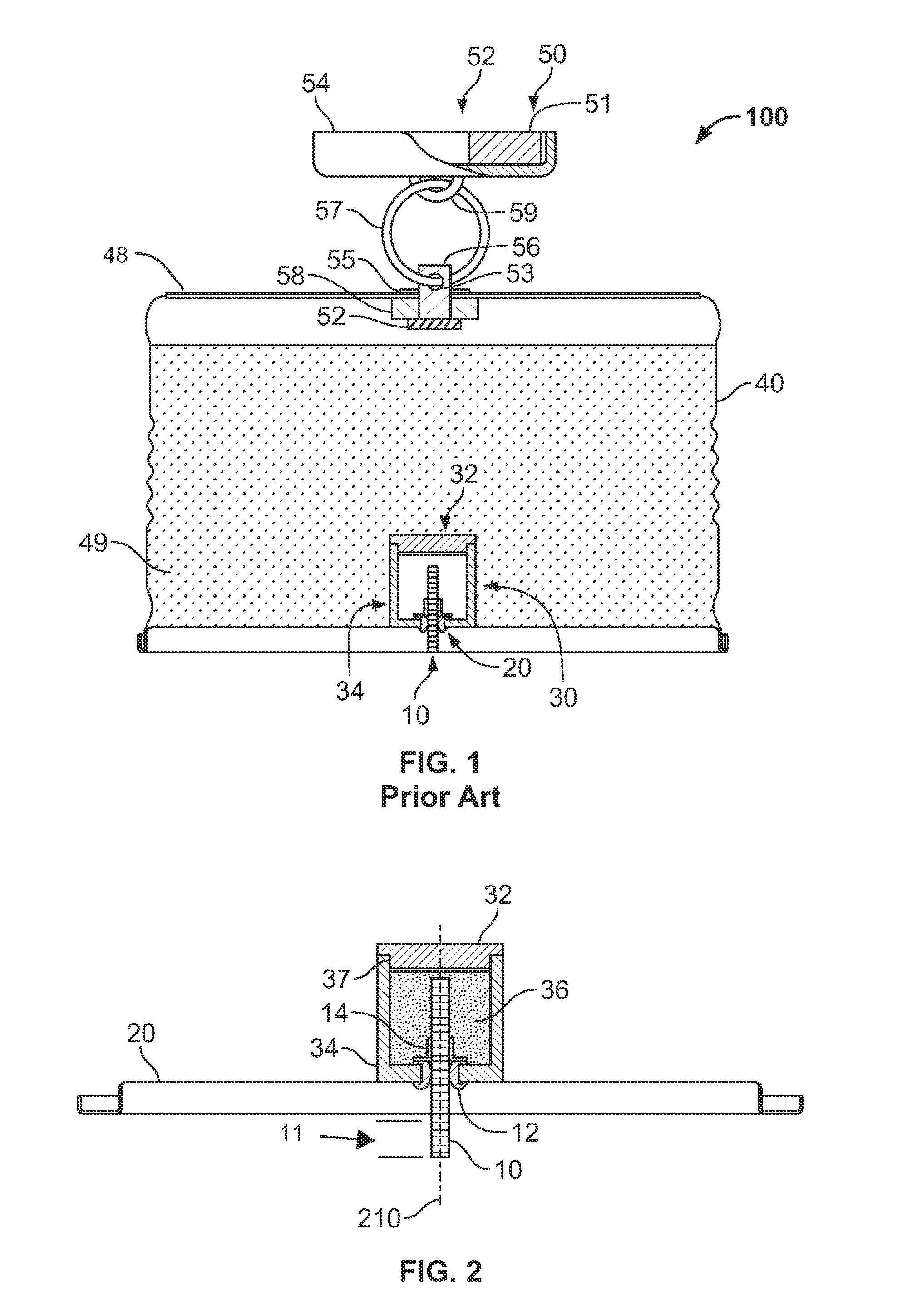

A signal transmission fuse is made of a tube (36) which encases a support tape (14) having a reactive coating (18') which is adhered to one side of the tape by a binder. A method of making the signal transmission fuse includes depositing on the support tape (14) a reactive paint (18) including a binder, which paint dries to form a reactive coating (18'). The coated support tape (14') is then folded, i.e., formed into a channel configuration, to provide an inner concave side of the tape on which the reactive coating (18') has been disposed. The coated support tape is then enclosed, e.g., within an extruded plastic tube (36). One side of the support tape may be made of a first material (14a) to which the reactive coating adheres, and a second side may be made of a second material (14b) which bonds or adheres to the inner surface (36a) of the plastic tube (36) enclosing the coated support tape (14'). The binder causes even high loadings of the reactive coating (18') to adhere to the coated support tape (14') to prevent reactive material migration. The support tape also shields the reactive material from the hot, freshly extruded surrounding plastic tube (36) during manufacture.

Owner:DYNO NOBEL INC

Signal transmission fuse

InactiveUS6170398B1Avoid less flexibilityEasy loadingBlasting cartridgesFuse manufactureEngineeringReactive material

A signal transmission fuse is made of a tube (36) which encases a support tape (14) having a reactive coating (18') which is adhered to one side of the tape by a binder. A method of making the signal transmission fuse includes depositing on the support tape (14) a reactive paint (18) including a binder, which paint dries to form a reactive coating (18'). The coated support tape (14') is then folded, i.e., formed into a channel configuration, to provide an inner concave side of the tape on which the reactive coating (18') has been disposed. The coated support tape is then enclosed, e.g., within an extruded plastic tube (36). One side of the support tape may be made of a first material (14a) to which the reactive coating adheres, and a second side may be made of a second material (14b) which bonds or adheres to the inner surface (36a) of the plastic tube (36) enclosing the coated support tape (14'). The binder causes even high loadings of the reactive coating (18') to adhere to the coated support tape (14') to prevent reactive material migration. The support tape also shields the reactive material from the hot, freshly extruded surrounding plastic tube (36) during manufacture.

Owner:DYNO NOBEL INC

Anti-electrostatic ceramic material, preparation method thereof and firecrackers lead knitting needle made of material

ActiveCN101786878ALow resistivityImprove flexural strengthCeramic shaping apparatusFuse manufactureFirecrackerMass ratio

The invention discloses an anti-electrostatic ceramic material which comprises the following components in percentage by weight: 68-80 percent of yttria stabilized zirconia, 1-3 percent of silicon dioxide, 10-14 percent of tin oxide, 7-11 percent of zinc oxide, 1-2.5 percent of silicon 1-2.5 percent of silicon carbide. The preparation method of the ceramic material comprises the following steps of: firstly, mixing various raw materials in ultrathin powder state by a ball mill; then drying; melting and blending the dried mixed raw materials with an organic binder according to a mass ratio of (4-9):1; injecting and forming particles obtained by melting and blending to obtain a ceramic blank; and degreasing and sintering to obtain an anti-electrostatic ceramic material. In the method, the firecrackers lead knitting needle is injected and formed by a die. The anti-electrostatic ceramic material and the firecrackers lead knitting needle thereof have the advantages of electrostatic resistance, abrasion resistance, good anti-bending performance, simple preparation process, lower cost, and accurate size of a prepared ceramic product without post-processing.

Owner:JIANGSU JINSHENG CERAMIC TECH

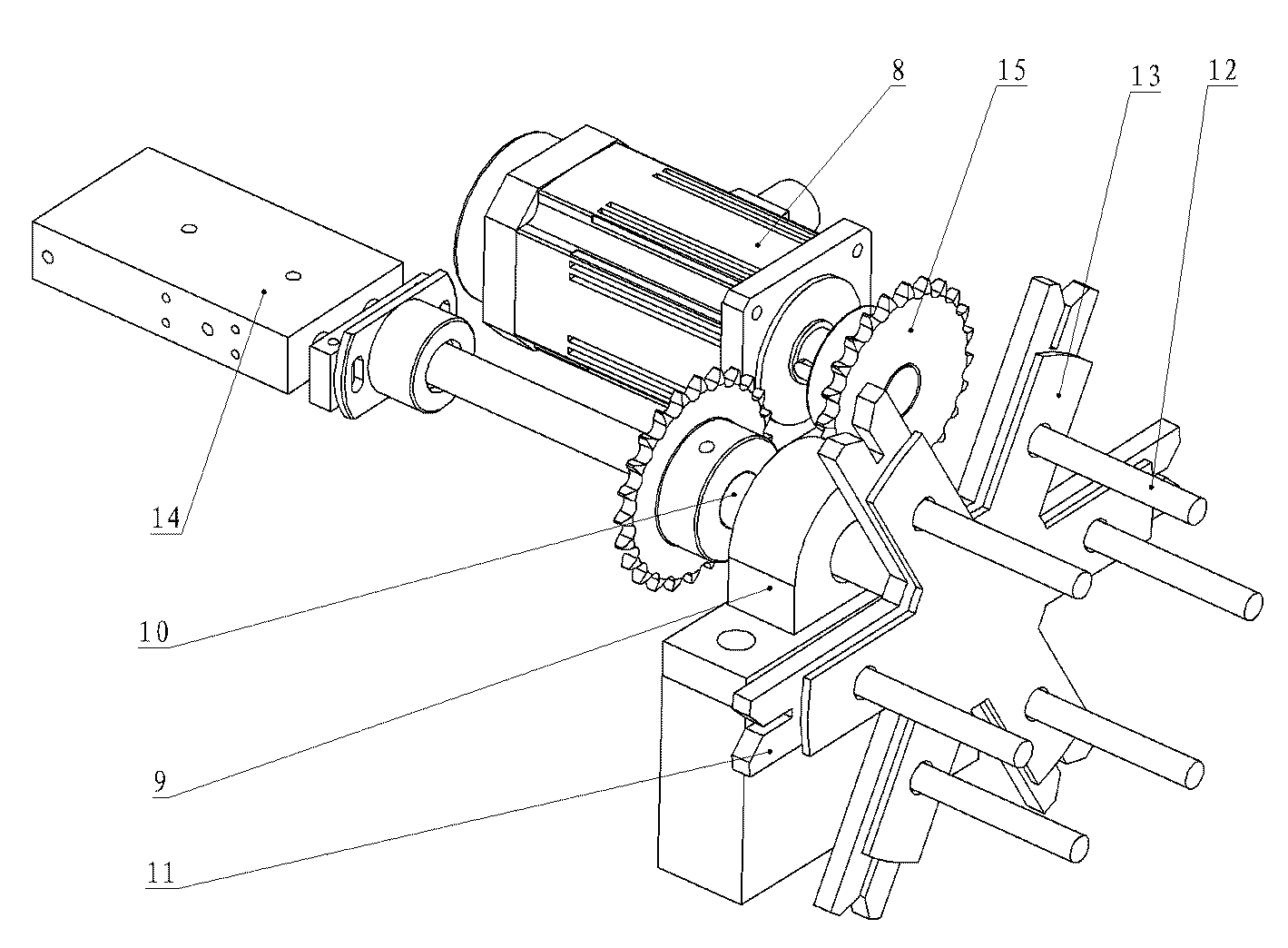

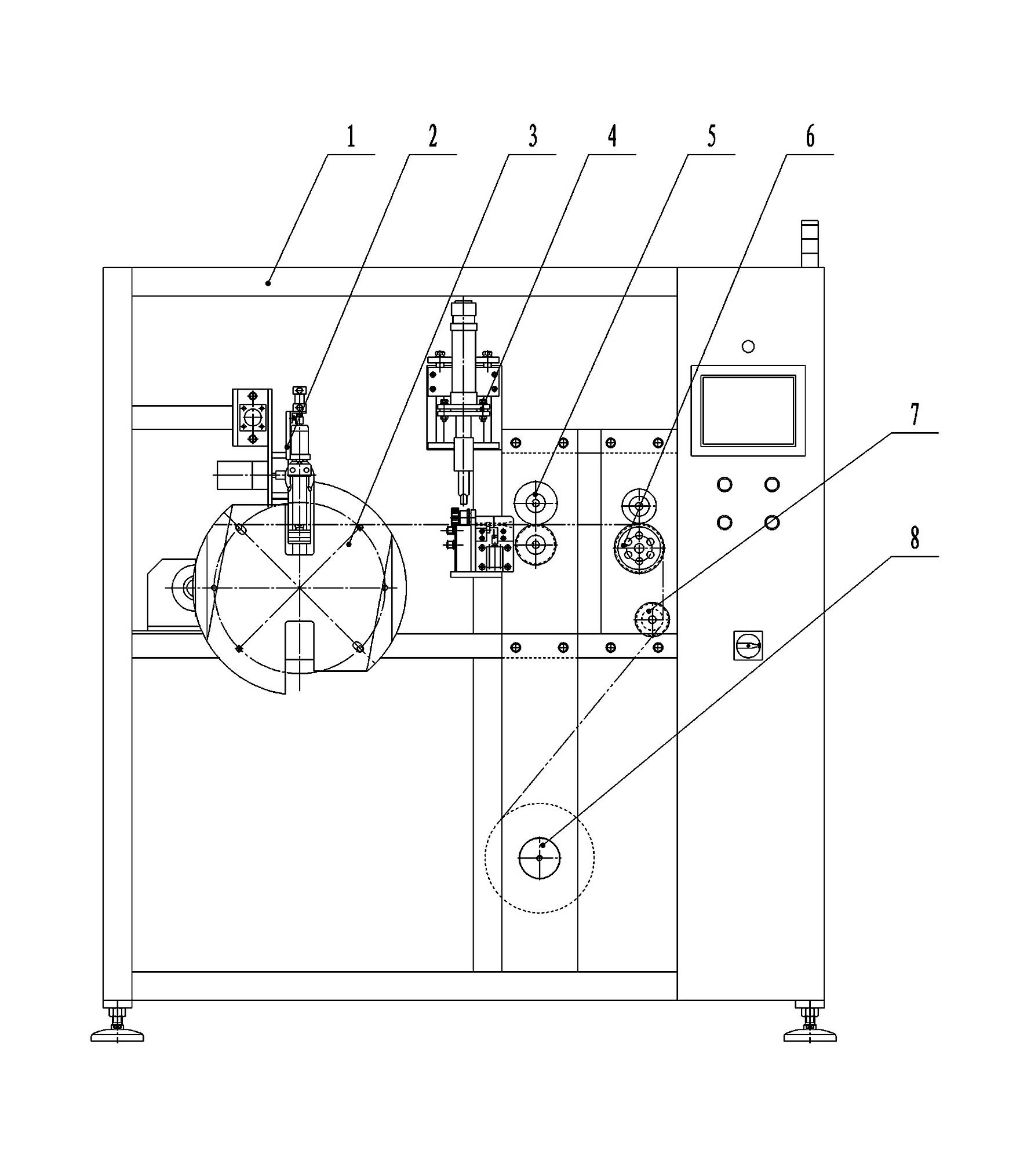

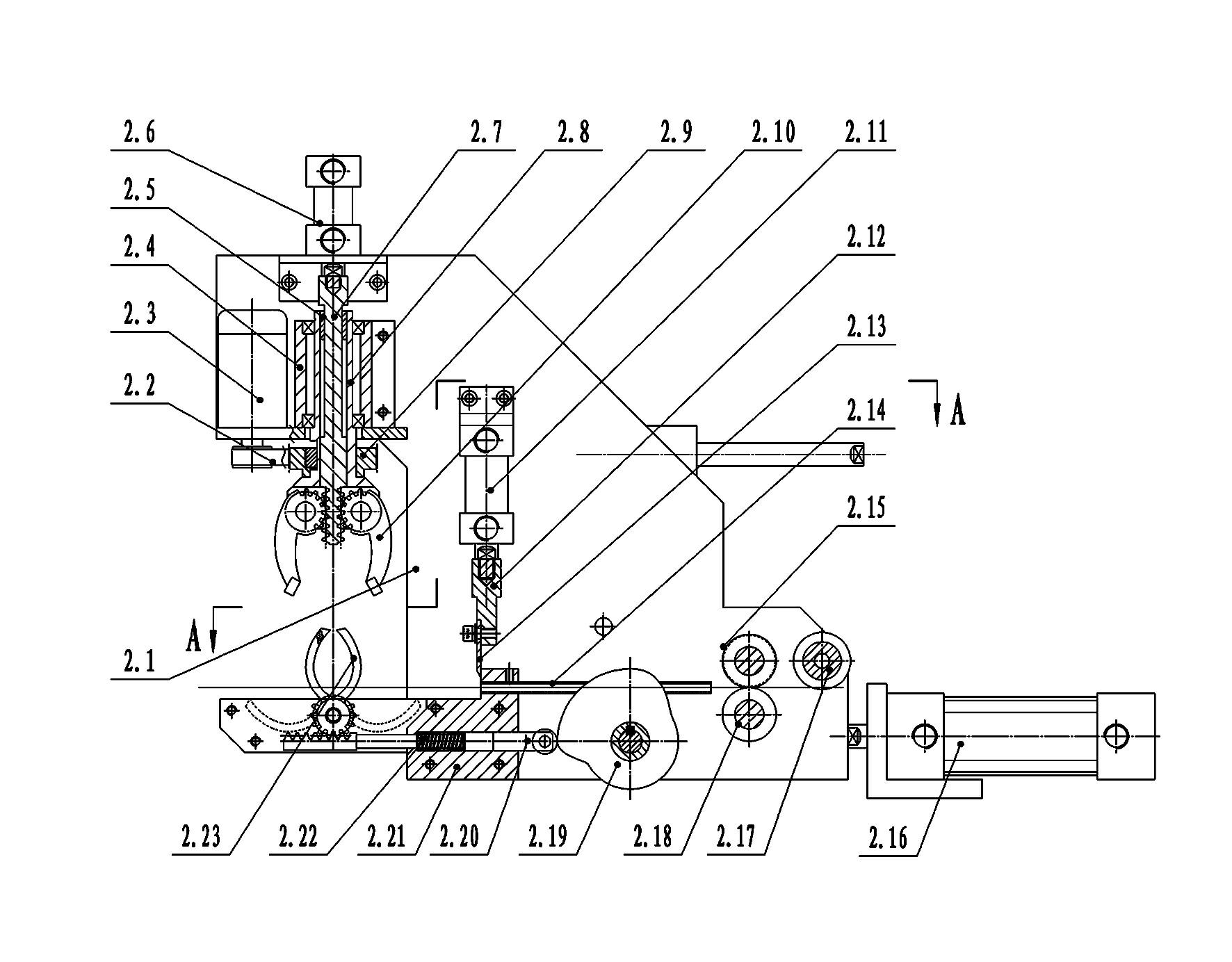

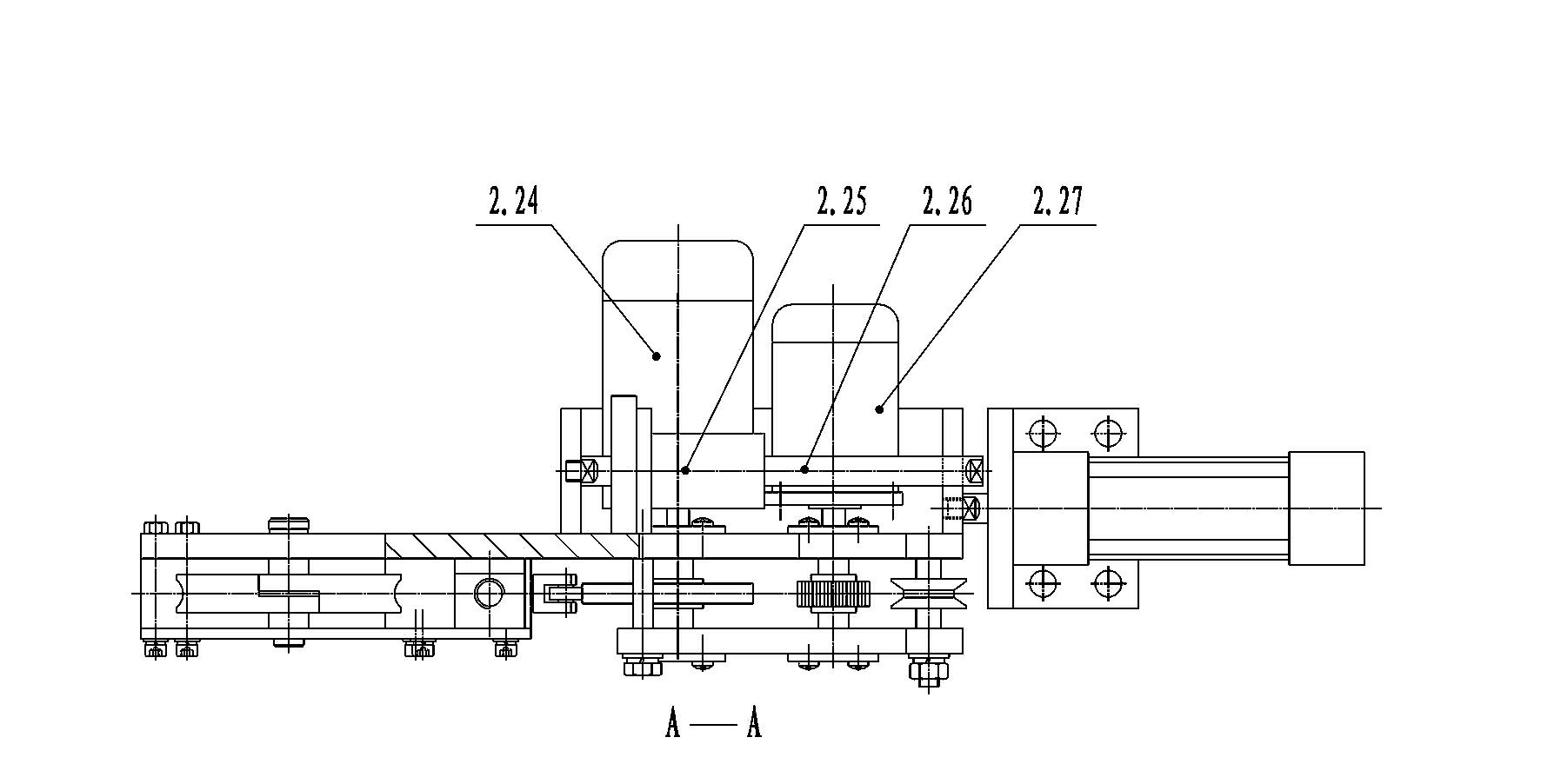

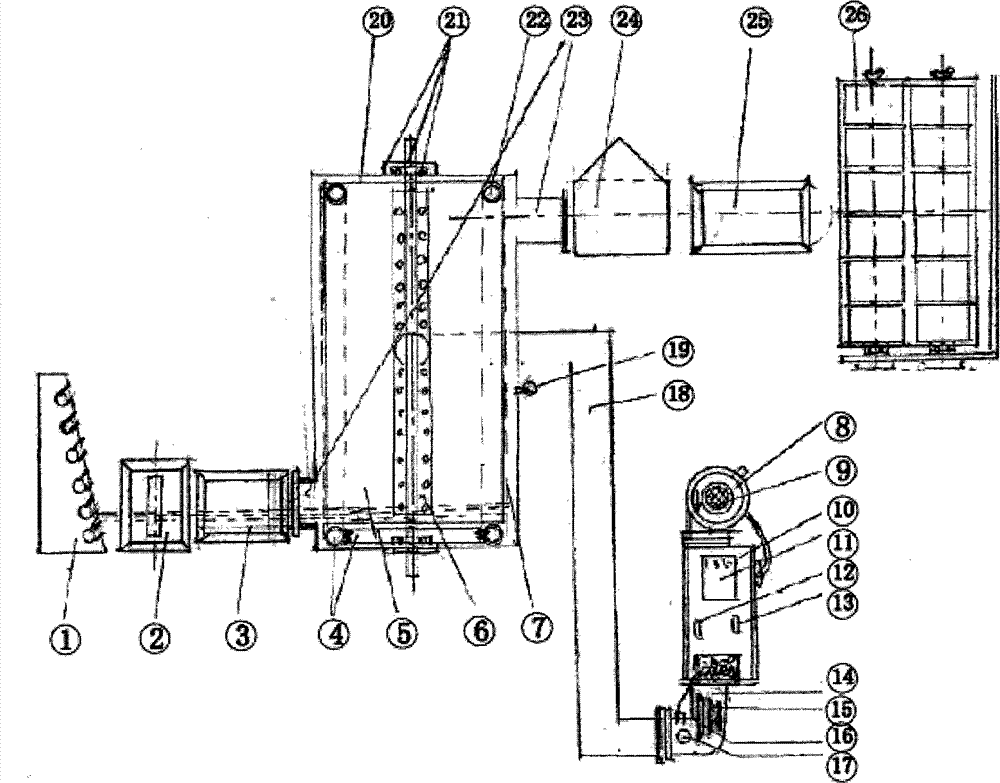

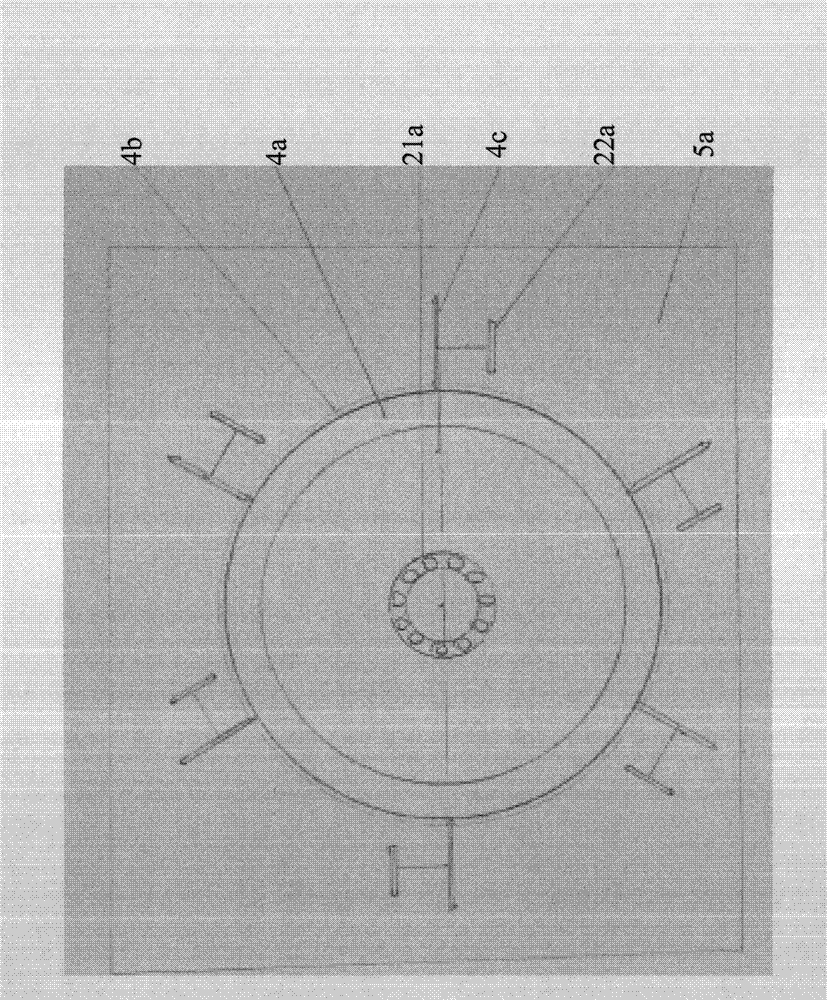

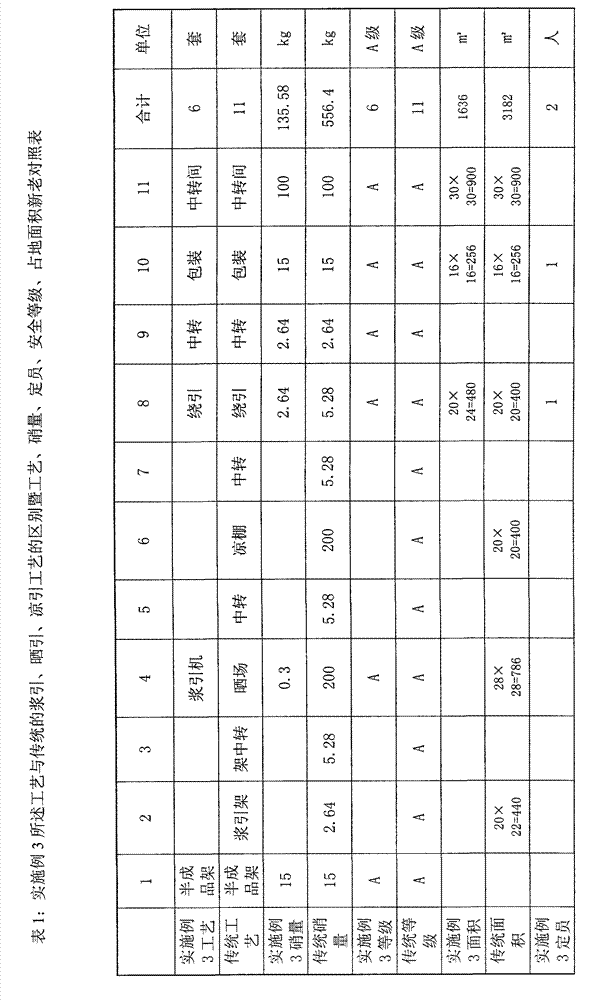

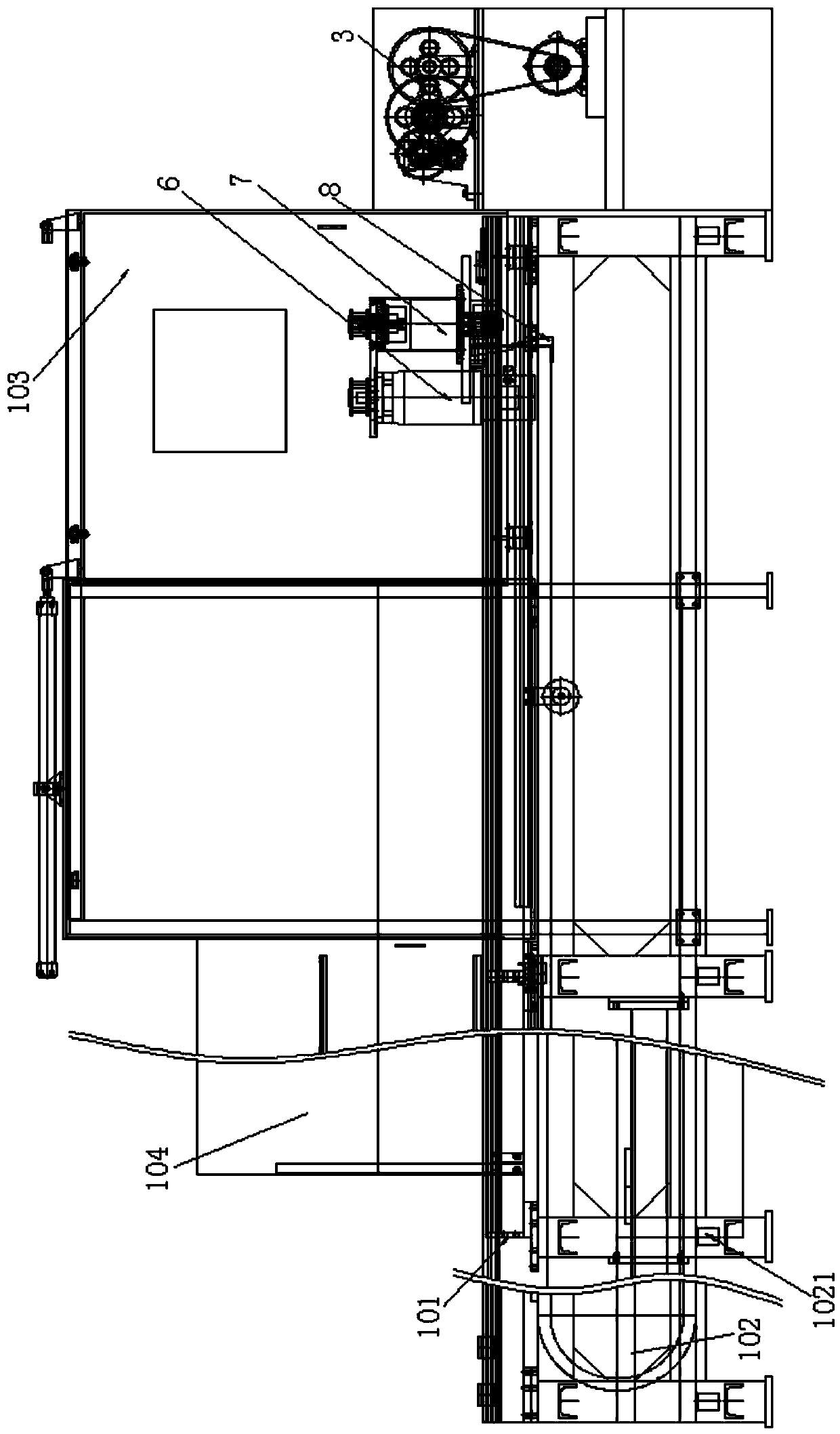

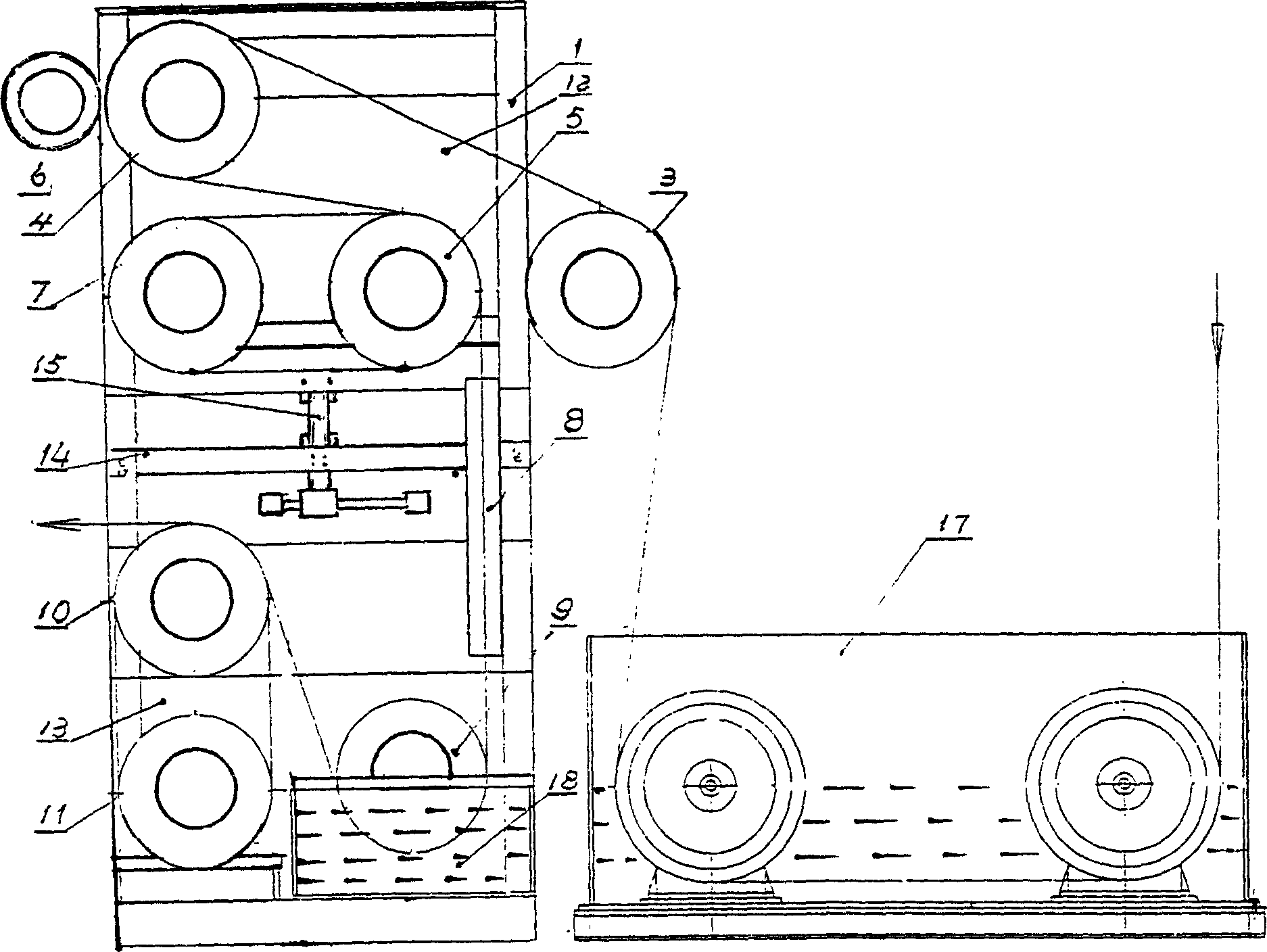

Full-automatic nonel tube machine

InactiveCN103641672AReduce labor intensityIncrease productivityFuse manufactureWinding machineMachine

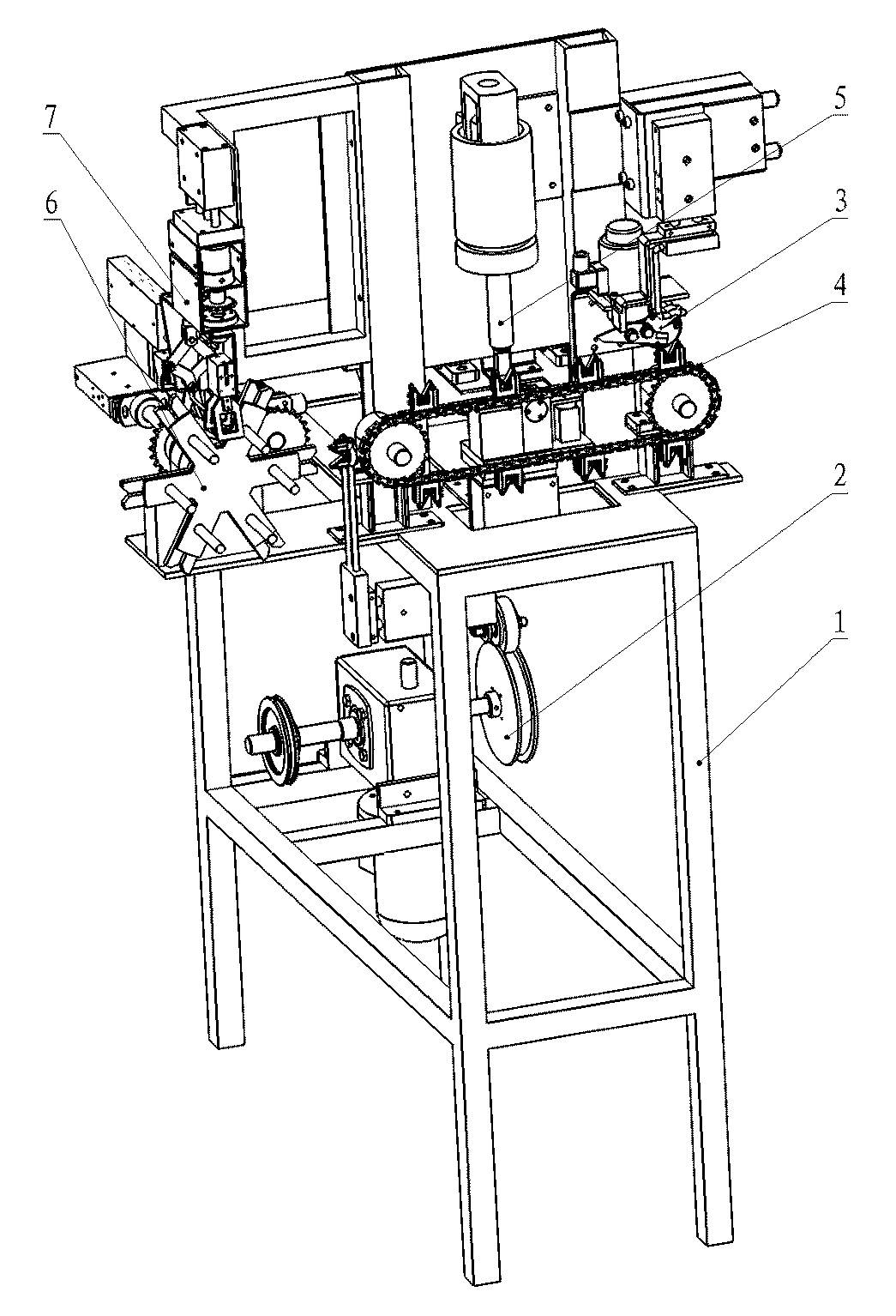

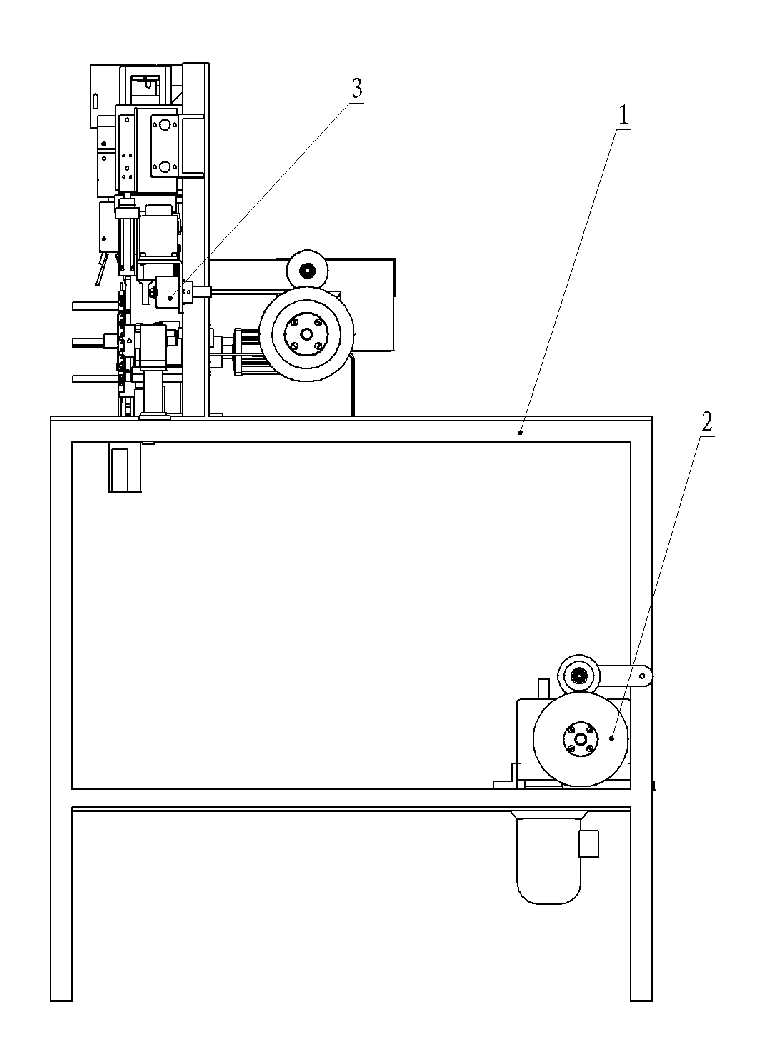

The invention relates to a full-automatic nonel tube machine which comprises a stand, a drawing mechanism, a cut-off mechanism, a conveying mechanism, an endcapping and labeling mechanism, a winding mechanism and a binding mechanism, wherein the drawing mechanism is arranged under a position in back of the stand; the cut-off mechanism, the conveying mechanism, the endcapping and labeling mechanism and the winding mechanism are arranged on a face plate of the stand; the cut-off mechanism and the winding mechanism are respectively arranged at the two ends of the conveying mechanism; the endcapping and labeling mechanism is arranged in the middle of the conveying mechanism; the binding mechanism is arranged above the winding mechanism. After the full-automatic nonel tube machine is adopted, the automation of working procedures including blanking with the fixed length, endcapping and labeling, winding and binding in the nonel tube production can be realized, so that the production efficiency is improved.

Owner:柳昶明

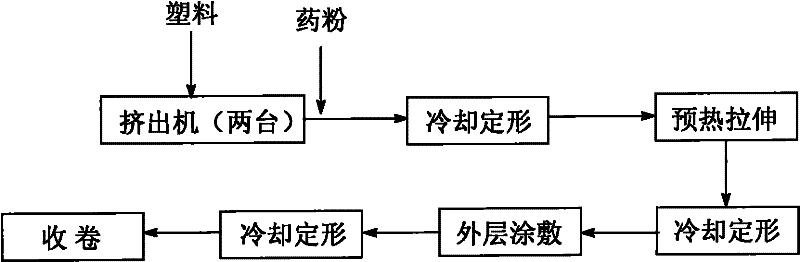

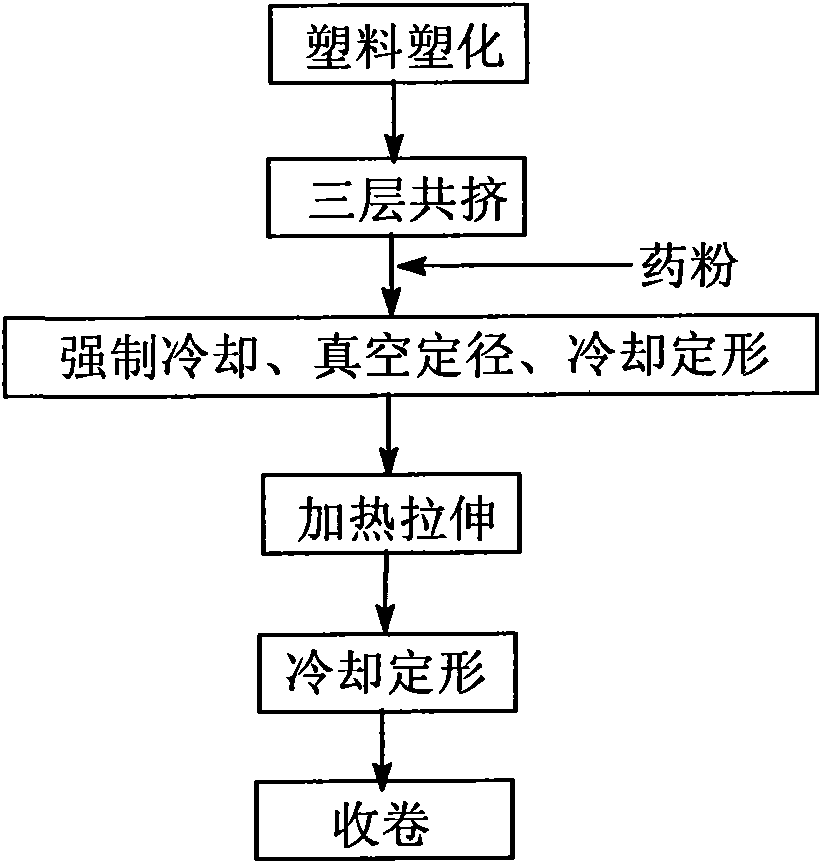

Production method and production line of conducting tube

The invention discloses a production method and a production line of a low-cost and high-intensity conducting tube prepared by a 'double-layer coextrusion-tensile reinforcement-billet tube coating' process. The production method comprises the following steps of: plastifying two different kinds of blended plastic; extruding the plastified plastic into a double-layer coextruded composite die head to form a double-layer coextruded composite billet tube; adhering the explosive fine powder to the inner wall of the billet tube uniformly through a die head mandril inner hole; cooling and shaping the composite billet tube; allowing the billet tube to enter a high-temperature heating box to perform preheating and drawing and then enter a cooling water tank to cool and shape; coating by using the die head of an extruder; cooling and removing water; rolling to form a finished product by using a rolling machine. The high-intensity conducting tube manufactured by a blended material and a new process can guarantee the advantages of the conventional conducting tube and can solve the problems of low tension intensity, inconvenience in construction due to softness of the tube, low yield, high energy consumption and the like of the conventional conducting tube. Special conducting tubes with special properties can be manufactured by changing the formula of inner and outer layers or the quality of the raw materials.

Owner:NANJING UNIV OF SCI & TECH +1

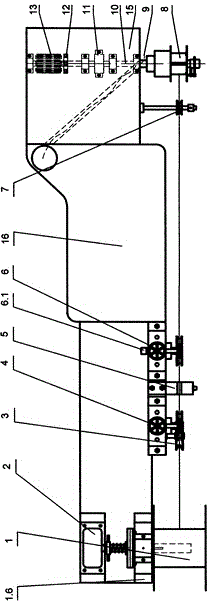

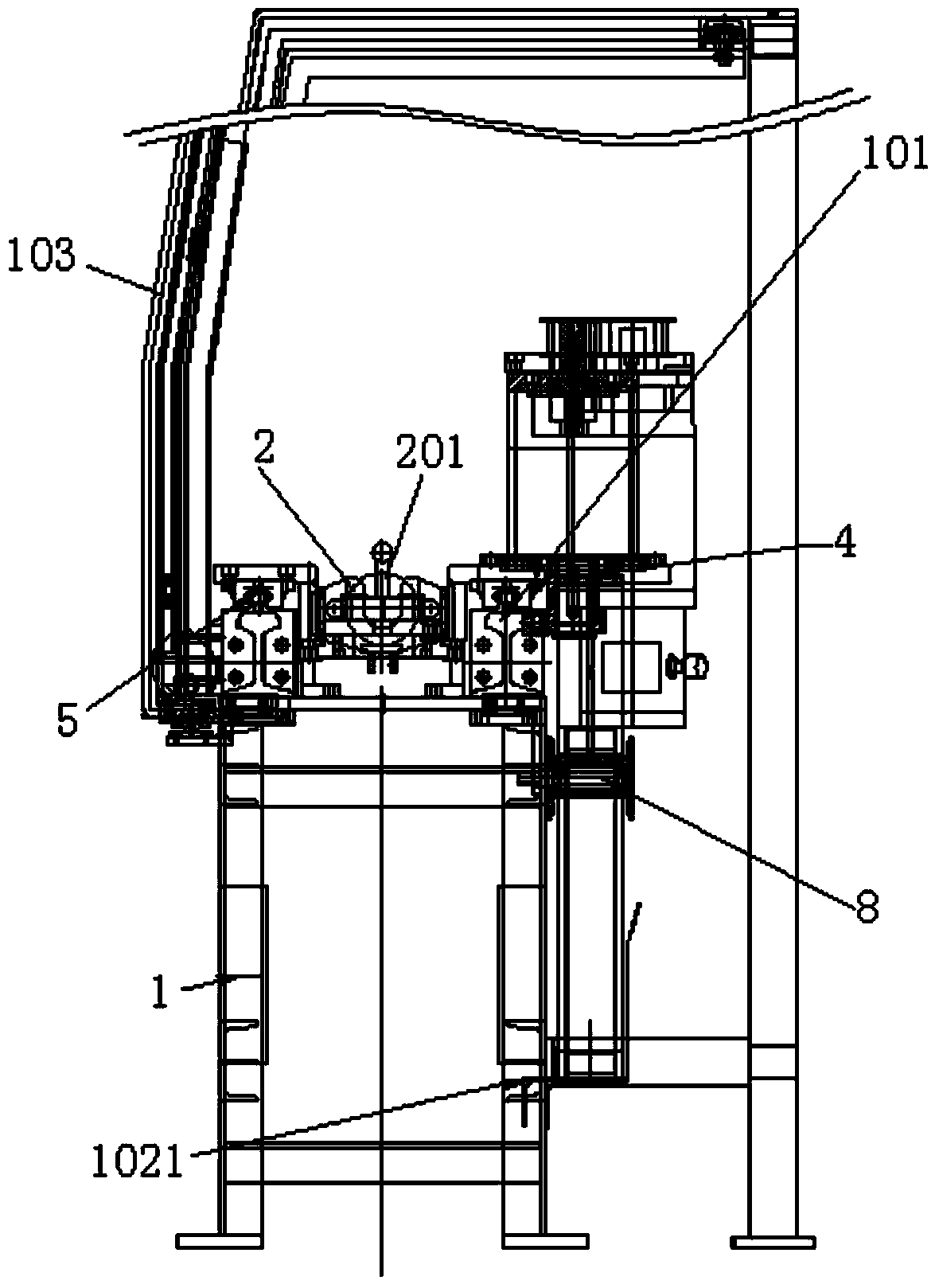

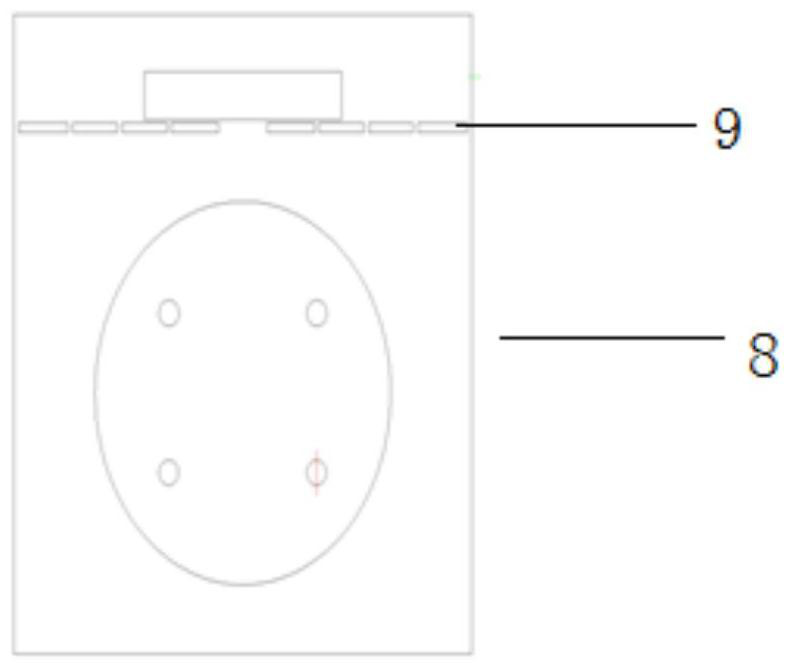

Automatic segmentation sealing and bundling device for plastic detonating tubes

The invention discloses an automatic segmentation sealing and bundling device for plastic detonating tubes. The automatic segmentation sealing and bundling device for the plastic detonating tubes is characterized by comprising a machine frame (1), a bundling system (2), a wire-winding withdrawing system (3), an ultrasonic sealing system (4), a wire feeding mechanism (5), a metering mechanism (6), a wire guide wheel (7) and a wire coil main shaft (8), wherein the bundling system (2) is arranged on the upper part of the machine frame (1); the wire coil main shaft (8) is arranged on the lower part of the machine frame (1); the bundling system (2) is arranged above the wire-winding withdrawing system (3); the mounting centers of the ultrasonic sealing system (4), the wire feeding mechanism (5) and the metering mechanism (6) are positioned on the same plane; and the wire guide wheel (7) is arranged below the metering mechanism (6). The equipment is high in production efficiency, safe and reliable, can automatically finish the procedures of length metering, handle winding, tail sealing, labeling, cutting, bundling, handle withdrawing and the like of the plastic detonating tubes, and realizes mechanization and automation.

Owner:CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST +2

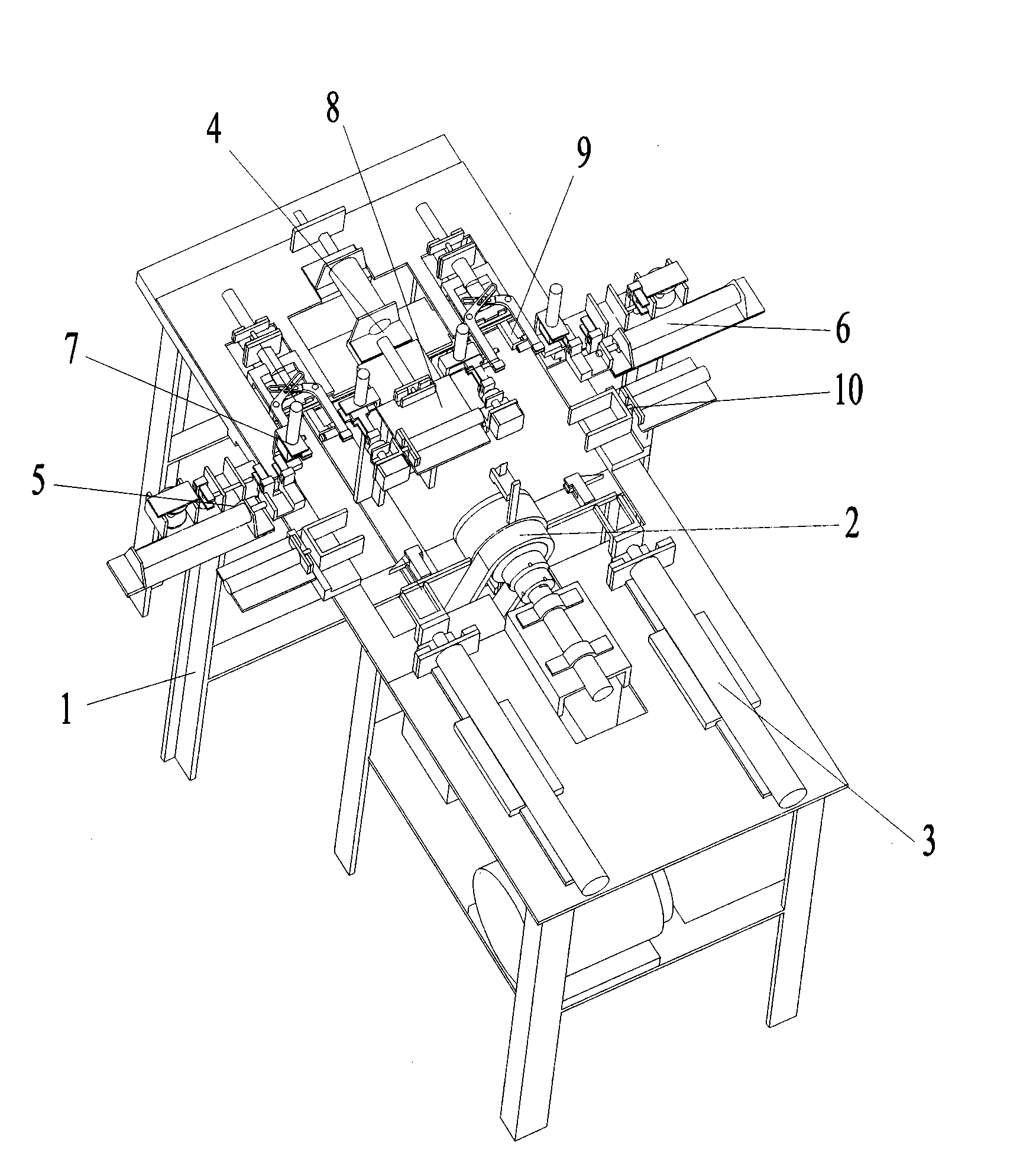

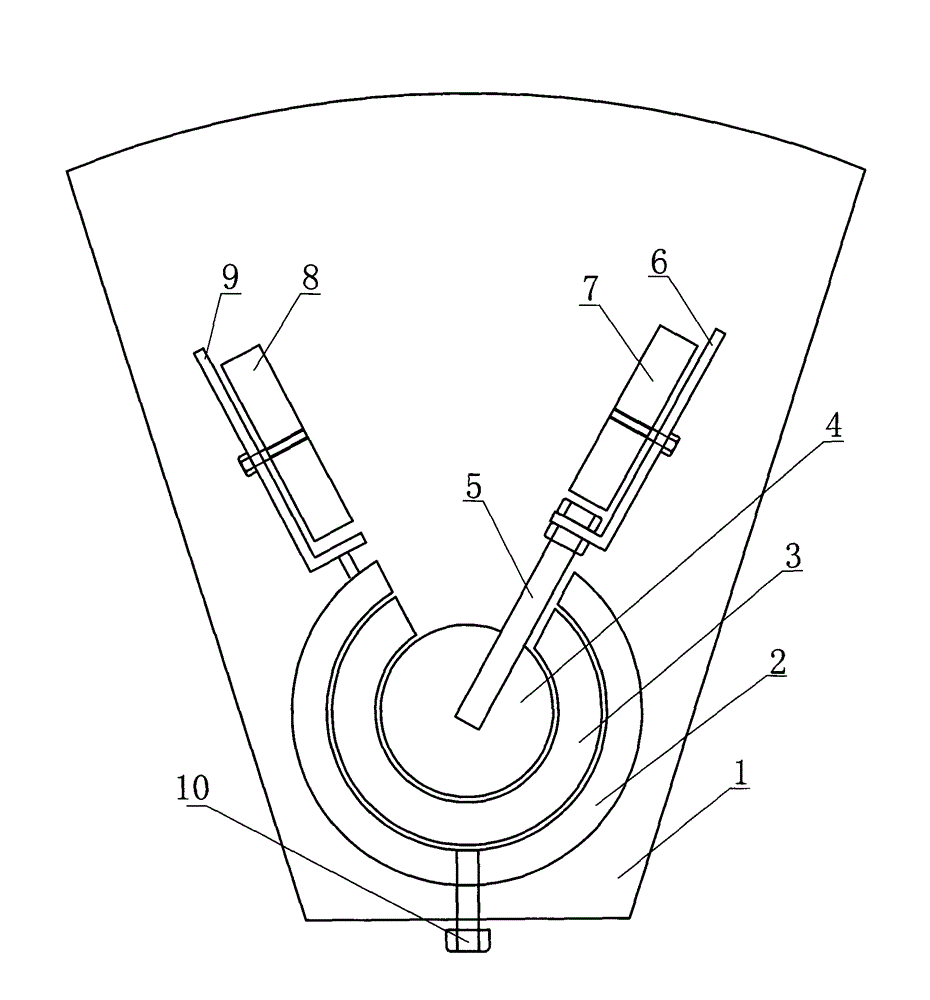

Nonel tube automatic bander

InactiveCN102120712AReduce labor intensityCons of Avoiding KnotsFuse manufactureEngineeringUltimate tensile strength

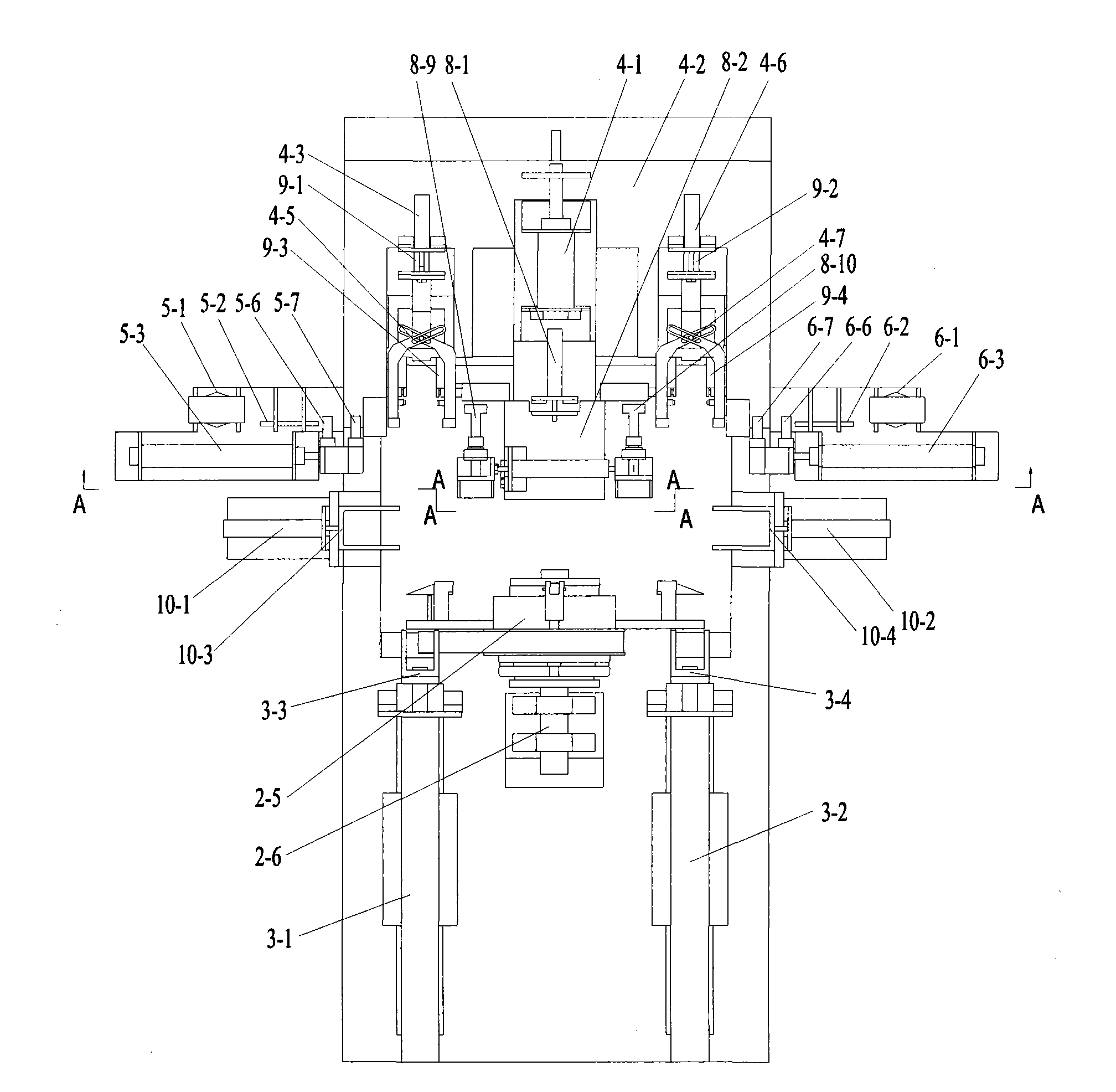

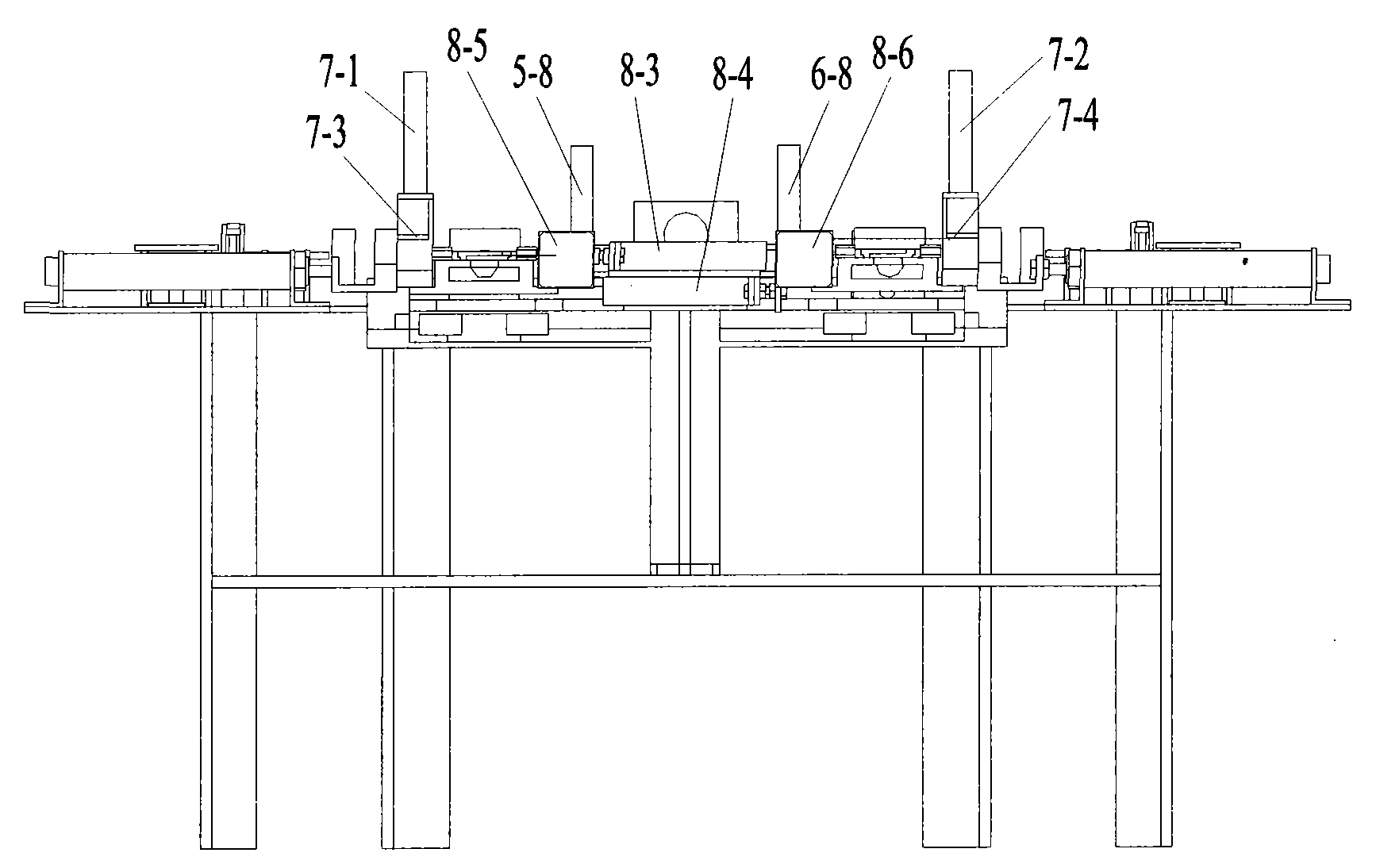

A plastic nonel tube automatic bander contains a frame (1), a winding part (2), a material-pushing part (3), a material-clamping part (4), wire-sending parts (5, 6), a cut-off part (7), a knotting part (8), a discharging part (9) and an auxiliary discharging part (10). By adopting the device of the invention, the labor productivity can be greatly increased and the labor intensity of workers can be reduced; thin iron wires are used for knotting in the knotting process, thus avoiding the defect that when adhesive tapes are used for knotting, the knots are not firm and the storage time is short; and an air cylinder is used as the power source, which is more environmentally friendly.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Device for manufacturing safe fireworks fuse

InactiveCN102079683AMeet the needs of wet induction processConsistent thickness specificationsFuse manufactureFireworksEngineering

The invention discloses a device for manufacturing a safe fireworks fuse, which comprises a powder hopper arranged on a rack, a weaving mechanism, a coiling mechanism and a driving and transmitting mechanism. The device is characterized in that the discharging hole of the power hopper is connected with a powder applying pressure tank via a screw rod powder-extruding cylinder, the upper end surface of the powder applying pressure tank is provided with at least one line hole, the corresponding position at the lower end surface is provided with at least one line hole, and a screw rod of the screw rod powder-extruding cylinder is connected with the driving and transmitting mechanism. According to the device, the requirements on a wet processing technology for manufacturing the fuse can be satisfied, the consistent specification of a product is realized, the powder density of the fuse is substantially strengthened, higher uniformity and stable burning rate are realized, and the occurrence of a cutoff phenomenon can be completely stopped. The device has the advantages of high automation degree, coordination in system operation and higher production efficiency. Moreover, all performance data of the fuse product meet or exceed the requirements on the national standard, and the storage time of the fuse product is prolonged by more than four years compared with the original product.

Owner:鲁向华

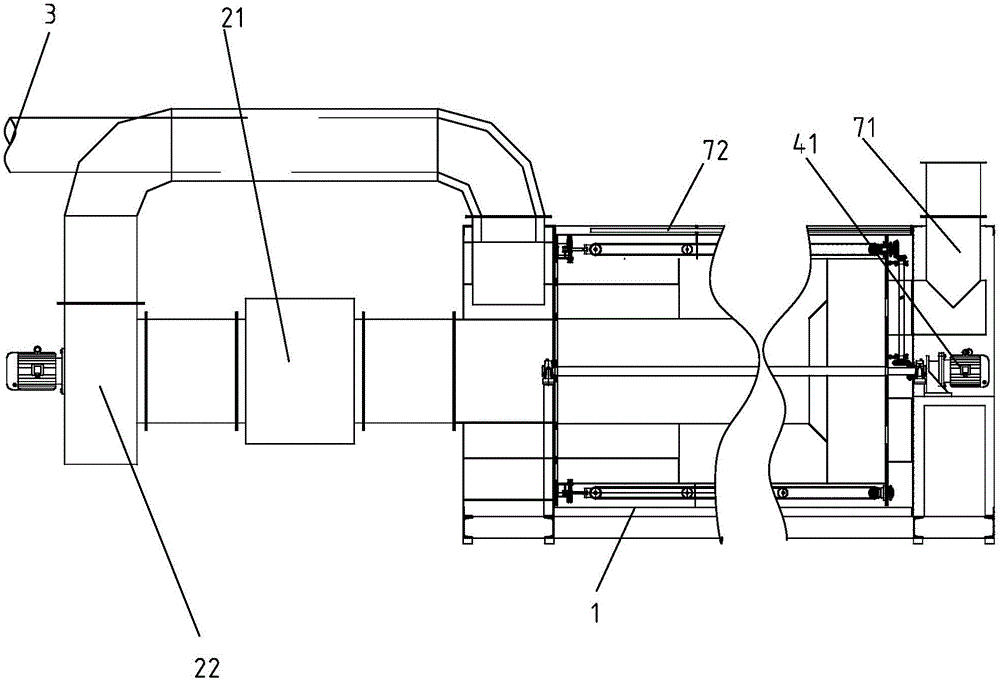

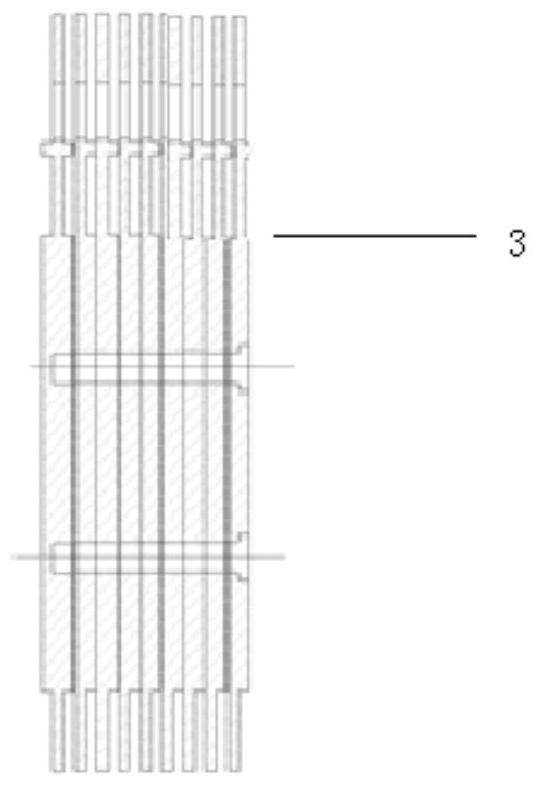

Leading wire drying device and leading wire treatment equipment using thereof

ActiveCN106083502AImprove mechanical propertiesImprove product qualityDrying gas arrangementsEnergy inputEngineeringProduction quality

The invention discloses a leading wire drying device and leading wire treatment equipment using thereof. The leading wire drying device comprises a casing, an inner cylinder and a driving mechanism, wherein the casing is provided with an inner cavity, and is provided with a leading wire inlet and a leading wire outlet which are respectively communicated with the inner cavity; the inner cylinder is positioned in the inner cylinder, and is rotationally supported on the casing, a plurality of leading wire axial translation mechanisms are arranged on the inner cylinder along the peripheral direction, the interior of the casing is sequentially provided with a temperature rise area and a cooling area along the axial direction of the inner cylinder, and a leading wire entering from the leading wire inlet is firstly wound on the inner cylinder and the leading wire axial translation mechanisms; the driving mechanism is in transmission connection with the inner cylinder, and is also in transmission connection with the leading wire axial translation mechanisms, so as to enable the driving mechanism to drive the inner cylinder to rotate and also drive the leading wire axial translation mechanisms to act. The leading wire drying device has the advantages that the production quality and efficiency of leading wire drying are improved, the labor intensity is decreased, and the safety property is improved.

Owner:谢启云 +2

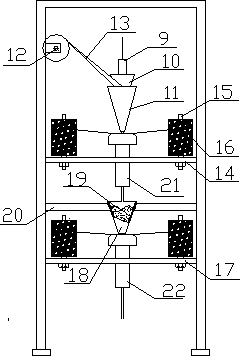

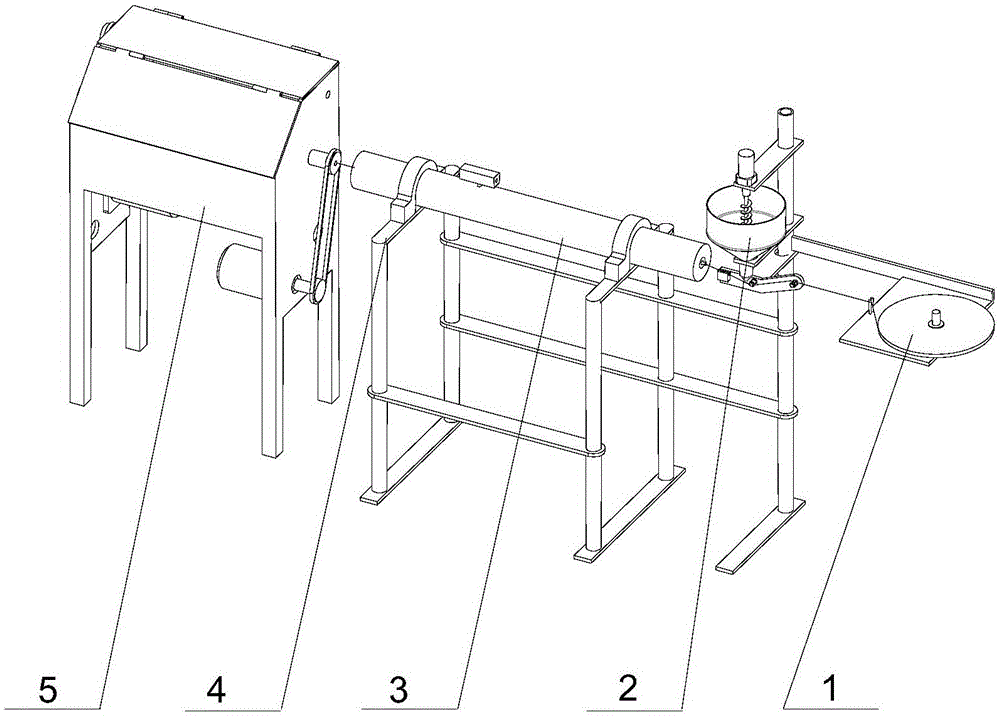

Permissible detonating cord for coal mine, and cord maker thereof

InactiveCN103772079ALower explosion temperatureLow mechanical sensitivityFuse manufactureFuse detonationFiberPentaerythritol tetranitrate

The invention relates to a permissible detonating cord for a coal mine. The core of the detonating cord is mixed type explosive and comprises the following formulas in percentage by weight: 93%-97% of PETN (pentaerythritol tetranitrate) or RDX and 3%-7% of flame inhibitor A; the core is coated with a flame inhibitor B, the formula of the flame inhibitor B is as follows in percentage by weight: 60%-80% of alkaline metal halide, and 20-40% of halogenated hydrocarbon. A cord production machine for producing the detonating cord comprises a rack, a first coil and a second coil are arranged on the rack and are respectively provided with a forming die and a fibrous scaffold, and an explosive feeding device is arranged on the forming die of the second coil. The flame inhibitor is added in the core and the core is coated with the flame inhibitor, so as to omit the asphalt coating, so that the detonating cord is safe and reliable, and the hidden safety hazard of the coal mine can be eliminated; the flame inhibitor feeding device is additionally arranged on the basis of the existing detonating cord production machine, so that the mass production of the detonating cord can be realized.

Owner:云南燃二化工有限公司

Bundling device for ignition and detonation tube bundle and using method thereof

The invention discloses a bundling device for an ignition and detonation tube bundle and a using method thereof, belonging to the technical field of blasting. The device comprises a wrapping plate, a bayonet binding tape is fixedly arranged at the front end of the wrapping plate, the bayonet binding tape and the wrapping plate are connected into a whole, a self-locking device of the binding tape is fixed at the back end of the bayonet binding tape, and a drawing head of the binding tape is fixed at the front end of the bayonet binding tape. The ignition and detonation tube bundle is bundled through the device, so that the operation is simple, the consumed time is short, the working efficiency is high, the bundling is firm and the ignition is reliable.

Owner:WUHAN BLASTING ENG

Palladium-ruthenium/aluminum-magnesium composite metal wire and preparation method thereof

The invention provides a palladium-ruthenium / aluminum-magnesium composite metal wire and a preparation method thereof. The composite metal wire takes a palladium-ruthenium alloy as a clad material and takes an aluminum-magnesium alloy as an inner core material. A preparation process comprises the following steps of: I, smelting the palladium-ruthenium alloy, and performing ingot casting to obtain a pipe blank; II, smelting the aluminum-magnesium alloy, and performing ingot casting to obtain a bar material; III, performing cold rolling and cold drawing on the pipe blank to obtain a palladium-ruthenium alloy pipe; IV, preparing aluminum-magnesium alloy filaments by cold drawing; V, continuously introducing the aluminum-magnesium alloy filaments into the palladium-ruthenium alloy pipe to obtain a blank piece; VI, swaging the blank piece to obtain a composite metal wire; and VII, performing cold drawing on the composite metal wire to obtain the palladium-ruthenium / aluminum-magnesium composite metal wire of a required size. The prepared palladium-ruthenium / aluminum-magnesium composite metal wire has high alloy reaction performance, and can be applied to a detonating cord of a detonator or an ignition device of an engine.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

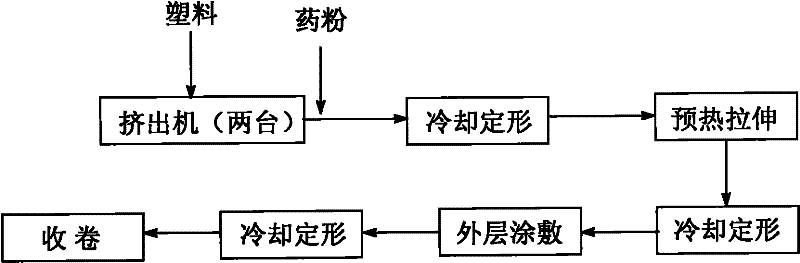

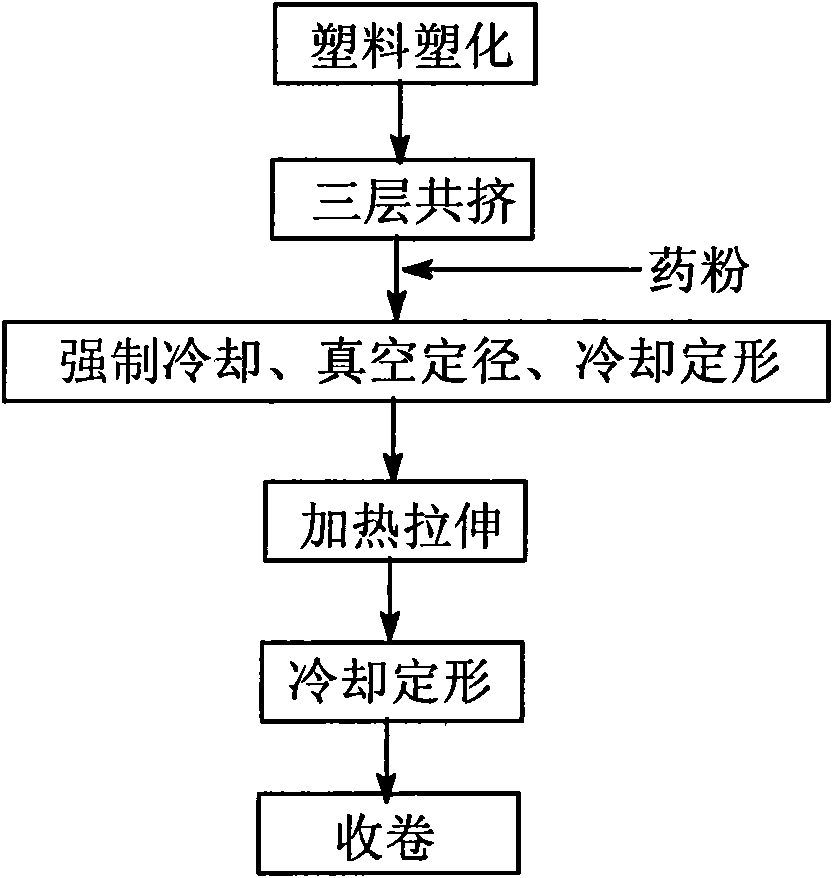

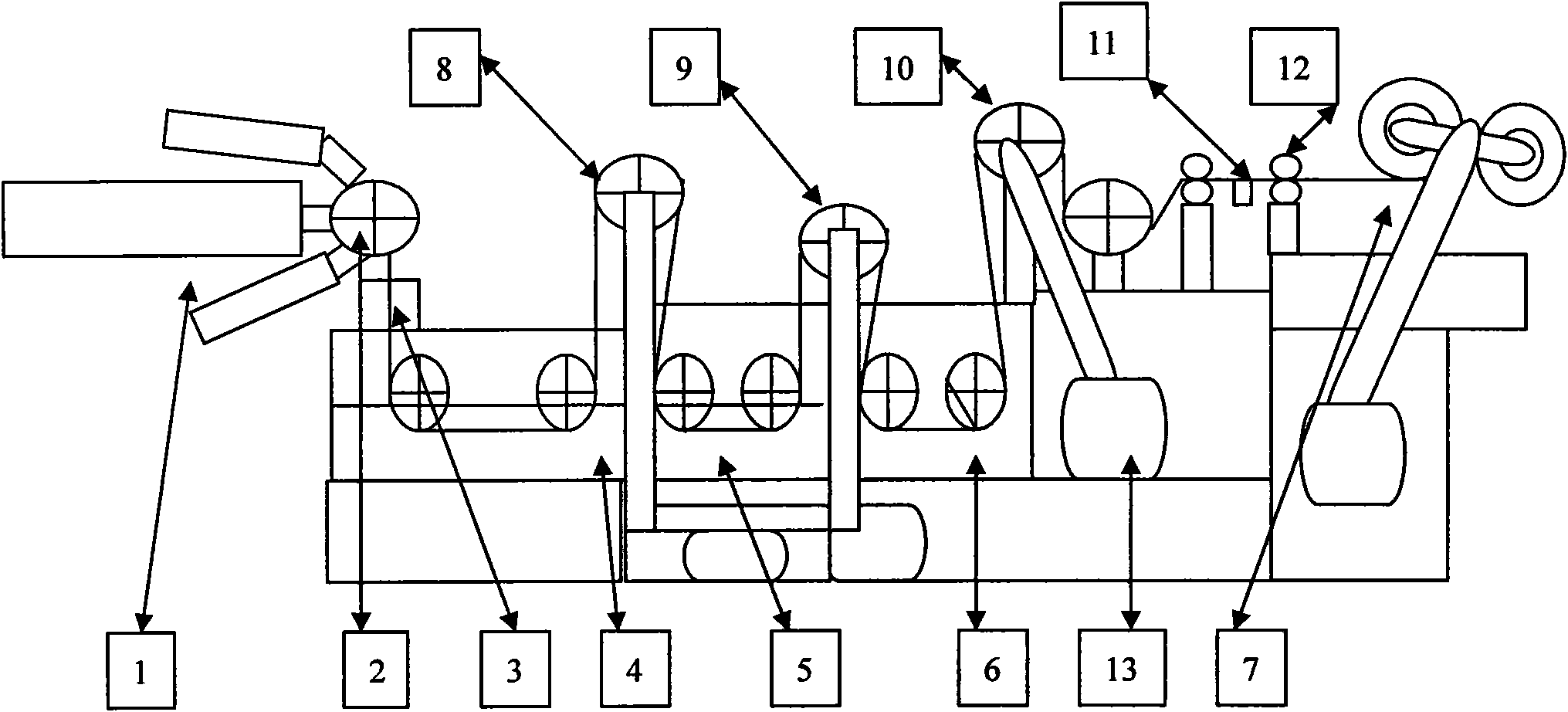

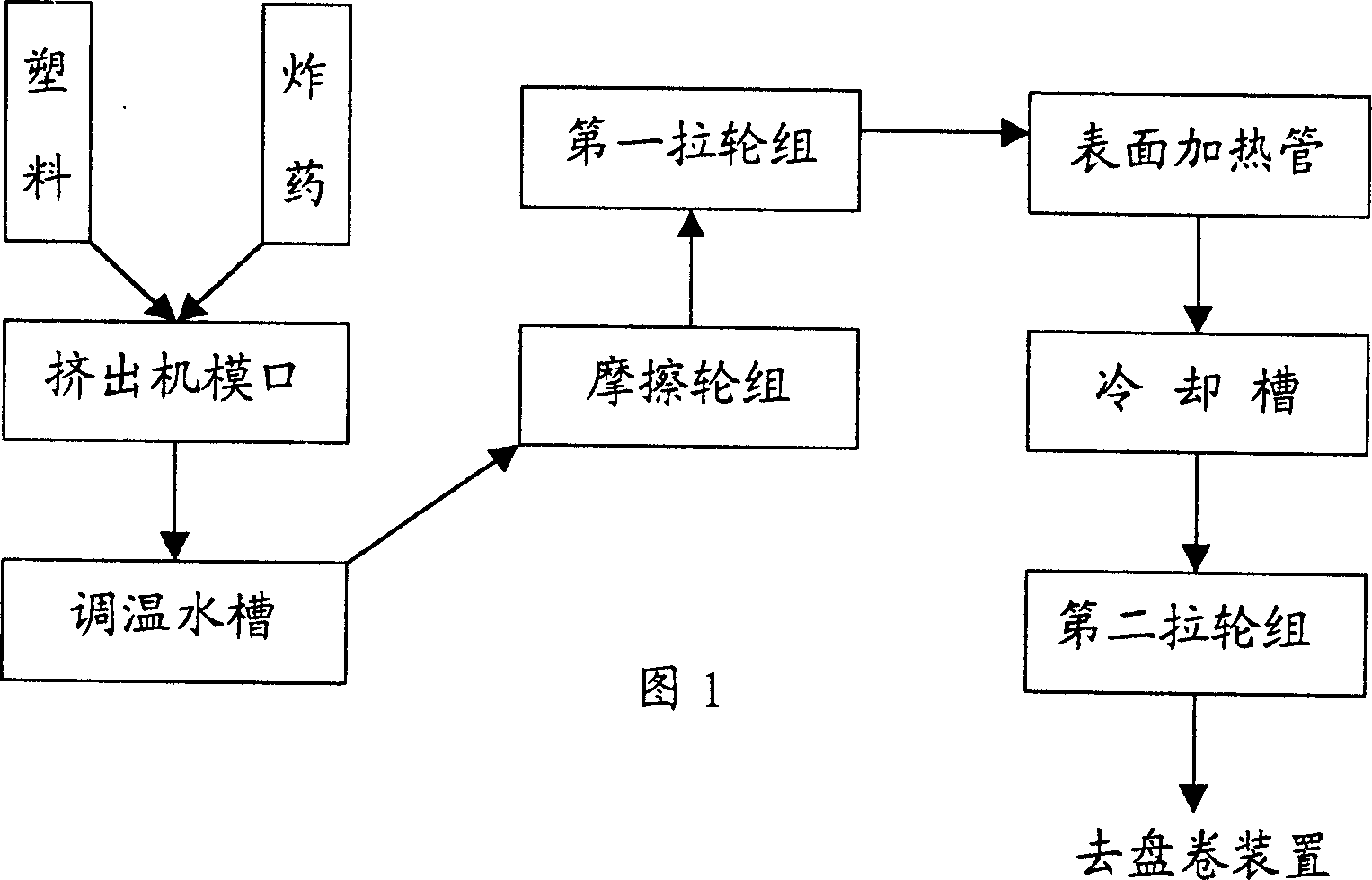

Production method for preparing detonating tube with low cost and high strength through three-layer co-extrusion and production line thereof

InactiveCN101891567AOvercome strengthOvercoming the inconvenience of soft tube constructionFuse manufactureProduction linePlastic materials

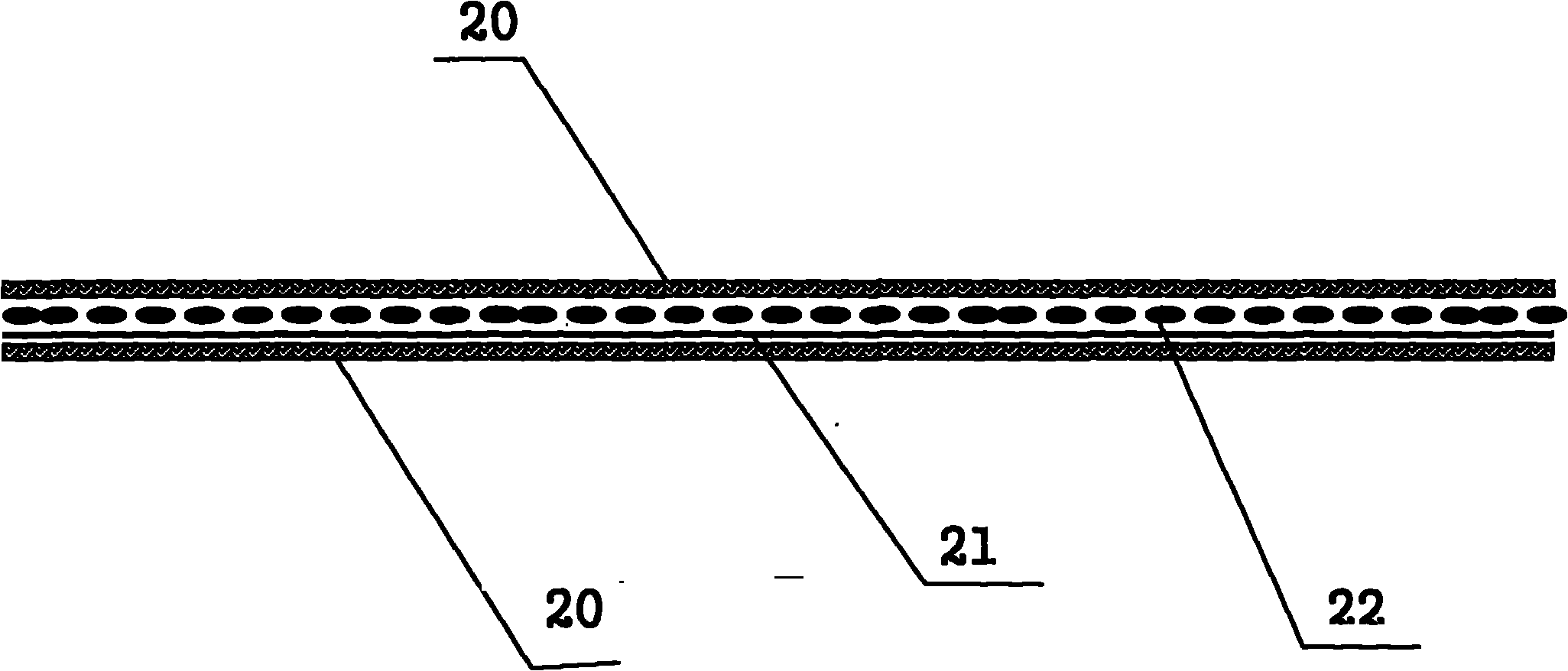

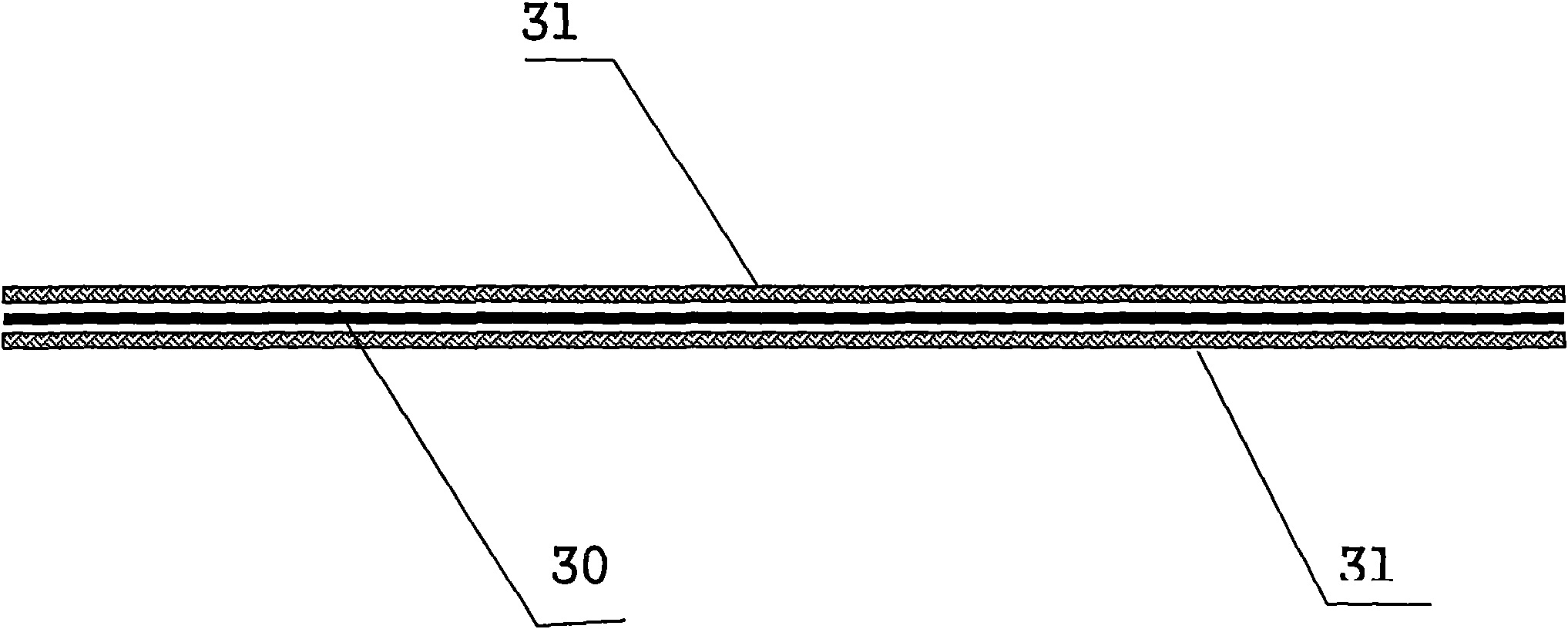

The invention discloses a production method for preparing a detonating tube with low cost and high strength through three-layer co-extrusion and a production line thereof. The production method comprises the following steps: firstly, plasticizing plastics; then, squeezing the plasticized plastic materials into a three-layer co-extrusion compound die head to form a three-layer co-extrusion compound billet tube; uniformly sticking fine explosive powder on the inner wall of the billet tube through the inner hole of the core rod of the die head, forcibly cooling the compound billet tube, sizing the compound billet tube in a vacuum mode, and then, cooling and forming the compound billet tube; heating and stretching the compound billet tube; cooling and forming the stretched compound billet tube to form the detonating tube; and finally, winding the formed detonating tube. By using the three-layer co-extrusion compound method for manufacturing a new detonating tube, the invention can ensure the advantages of the existing detonating tube and simultaneously can overcome the defects of small tension strength, inconvenient tube flexible construction, low yield, high energy consumption and the like of the existing detonating tube; and by changing formulas or raw materials of inner and outer layers, the invention can be used for preparing special detonating tubes with special performance.

Owner:NANJING UNIV OF SCI & TECH

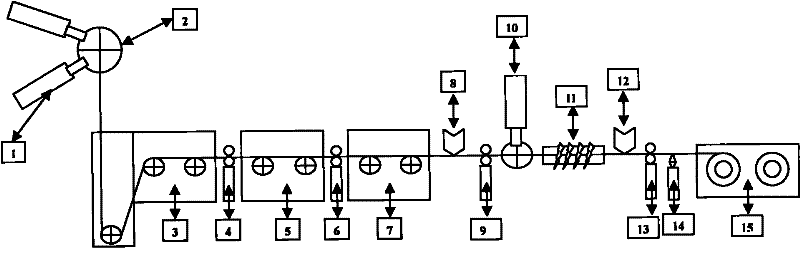

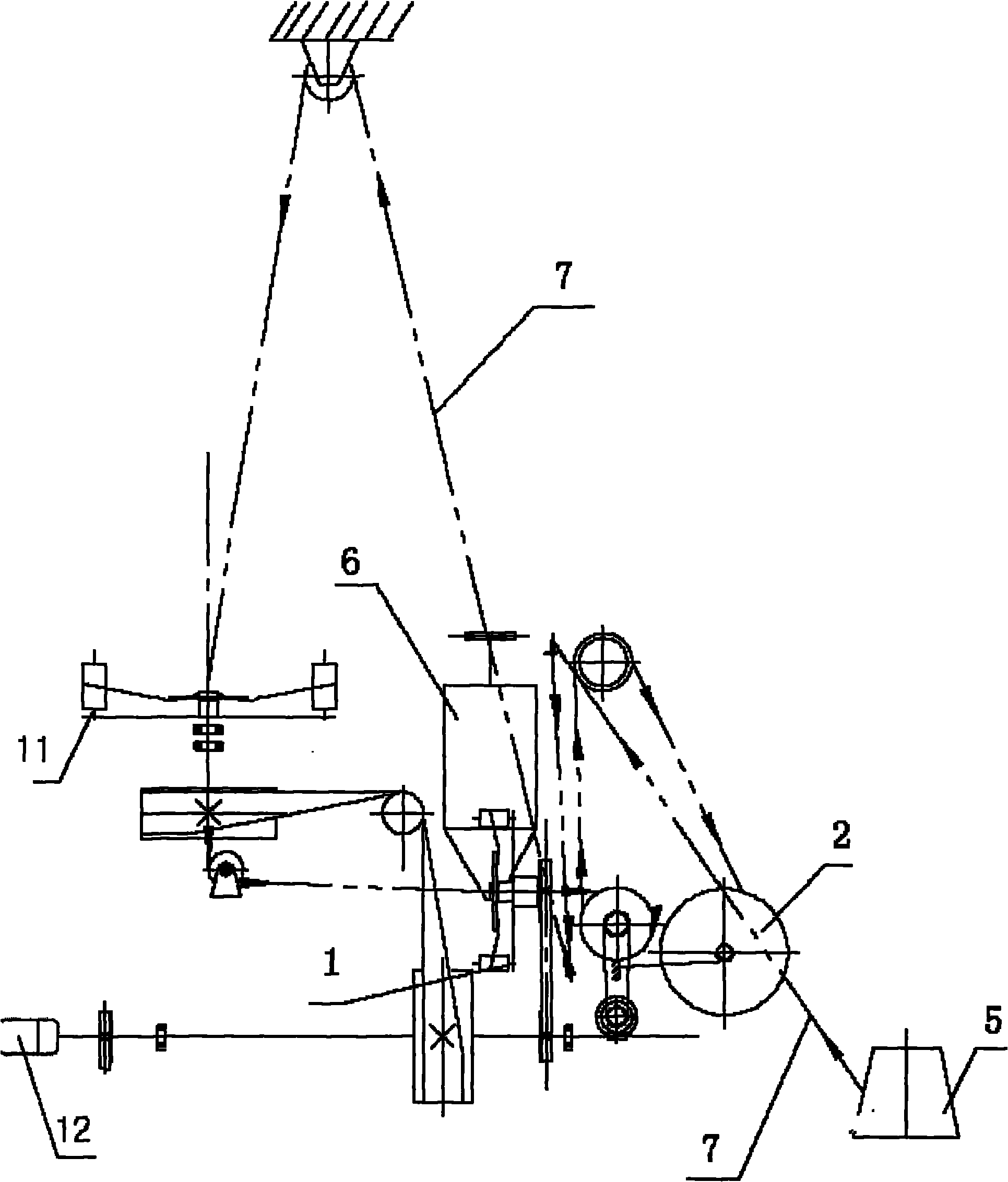

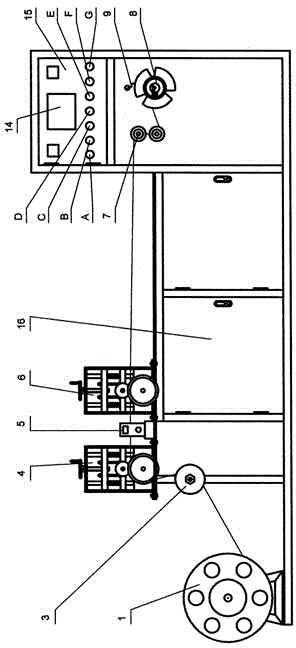

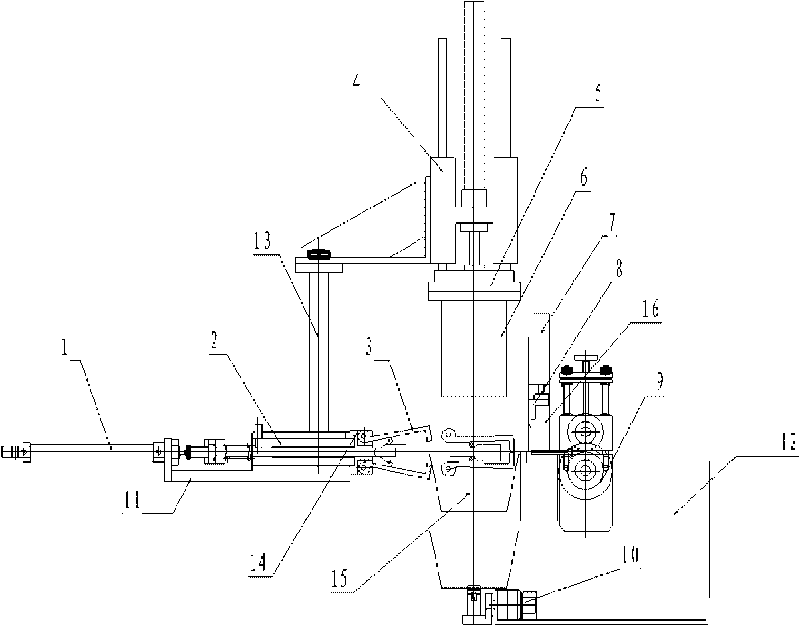

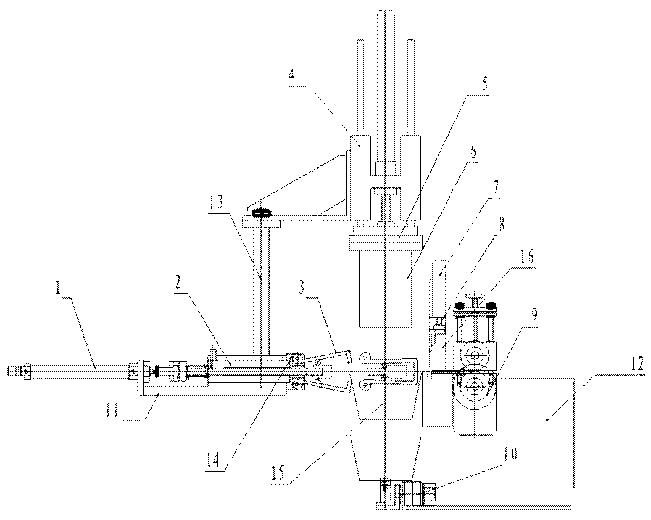

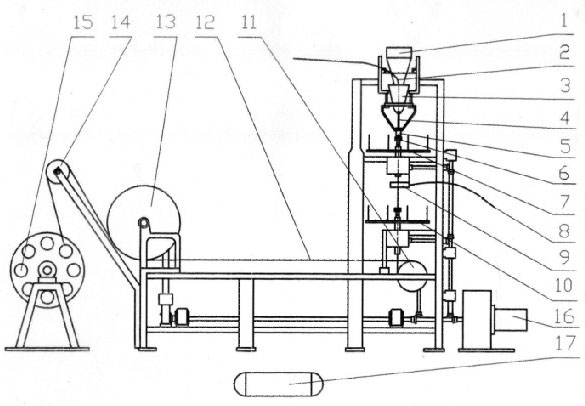

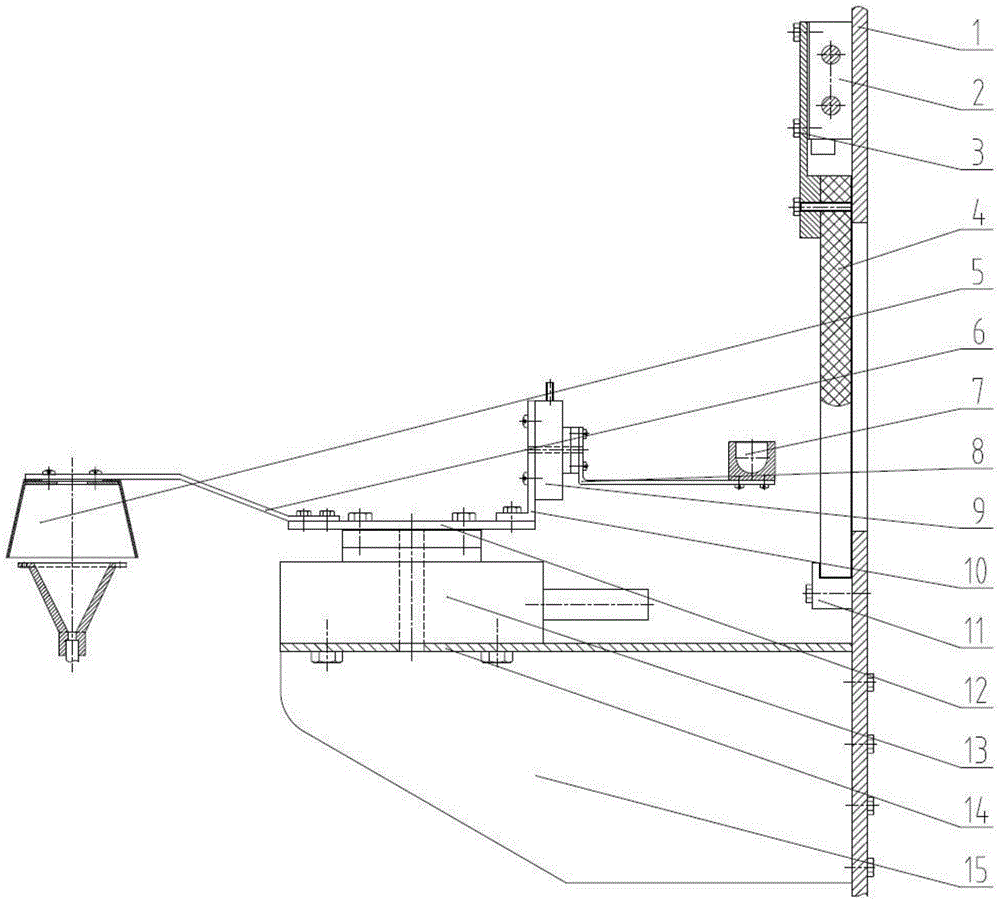

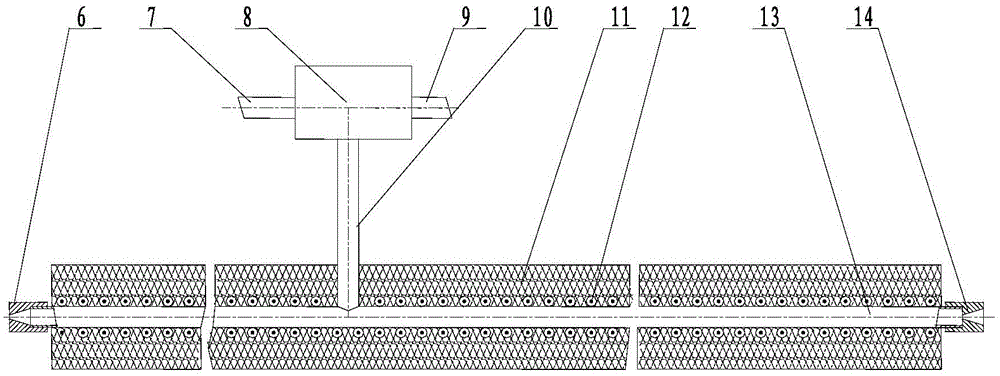

Industrial detonating fuse automatic curler

ActiveCN104058907AGuarantee product qualityBeautiful lineFuse manufactureAutomatic controlConductor Coil

The invention discloses an industrial detonating fuse automatic curler and relates to the technical field of detonating fuses. The curler comprises an adjustable tension stringing wheel device 1, an electromagnetic power-off brake 2, a guide roller 3, a first line pressing device 4, a detonating fuse surface blemish automatic detection device 5, a second line pressing device 6, a winding wheel 7, a third locking reel device 8, a banding rope 9, a transmission shaft 10, an electromagnetic clutch 11, a reducing belt pulley 12, an explosion-proof electric machine 13, a PLC (Programmable Logic Controller) control panel 14, an electronic control cabinet 15 and a worktable 16. The industrial detonating fuse is automatically wound, automatically controls the specified lengths and monitors off-explosive and thin explosive of the industrial detonating fuse as well as surface blemishes of the coating layer, and automatically alarms, stops and removes defected products if problems are found, so that the product quality is strictly guaranteed. The curler disclosed by the invention is high in degree of automation, improves the product quality, alleviates the labor intensity and improves the production efficiency, and is remarkable in comprehensive economic benefit. The curler disclosed by the invention can be popularized and applied to all detonating fuse production enterprises and electric wire and cable, blasting fuse and rope production enterprises.

Owner:HUBEI SHUAILI CHEM

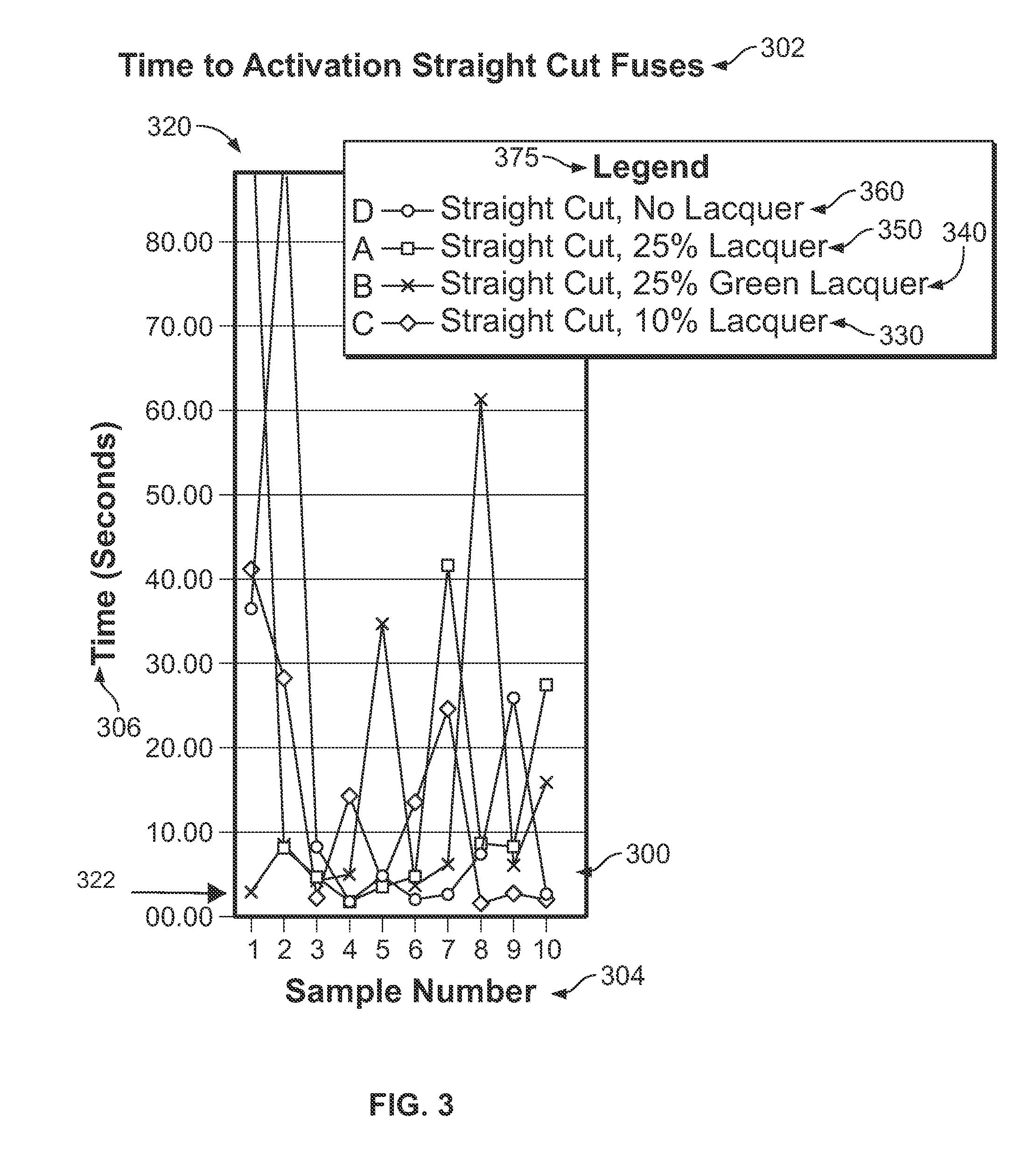

Stovetop fire extinguisher initiator with fuse device and method

ActiveUS9421405B1Minimum heating timeAdditional manufacturing stepFuse device manufactureFire rescueComparative testSuppressor

An initiator with fuse device for an automatic self-contained fire suppressor and method are provided herein. Stovetop fires are a well-known residential and commercial hazard. The initiator with fuse device for an automatic stovetop fire suppressor has a rapid light time in the presence of flames. The time to light is consistent and reliable for the fuse described herein. Comparative tests show a shorter light time for the present fuse as compared to conventional fuses. Further, the variability in lighting times is shortened when the herein described configuration is employed. Deployment of an automatic stovetop fire suppressor can be safer than manual extinguishing means and via the initiator with fuse described herein, the time to deployment is greatly improved. Manufacturing of the initiator with fuse is readily adapted to existing processes.

Owner:WILLIAMSRDM

Smokeless firework lead powder and firing line thereof

ActiveCN103980074AEasy to viewImprove moisture resistanceFuse manufactureAmmonium perchlorate explosive compositionsAlcoholCelluloid

The invention relates to smokeless firework lead powder and a firing line thereof. The smokeless firework lead powder comprises the following compositions in parts by weight: (A) 40-65 parts of monomer powder, (B) ammonium perchlorate, (C) 10-20 parts of carbon powder and (D) 10-30 parts of rare earth, wherein the ammonium perchlorate is obtained by adopting the following methods: evenly spraying celluloid nitrate dissolution liquor onto 20-40 parts of ammonium perchlorate and evenly mixing, wherein the celluloid nitrate dissolution liquor is obtained by dissolving celluloid nitrate through an acetone and alcohol mixing solvent; the carbon powder is obtained by adopting the methods: mixing carbon powder and nitric acid, filtering off acid liquor and drying. In burning, the smokeless firework lead powder is smokeless and has no sulfur flavor, the ornamental effect of fireworks can be improved, no sulfur dioxide is generated, the dampness-proof effect of a lead is good, and the safety performance is good.

Owner:浏阳市吉祥环保材料开发有限公司

Angle line automatic forming device for nonel tube bundling

InactiveCN101717319ARealize automatic formingRealize automatic tractionFuse manufactureEngineeringManipulator

The invention provides an angle line automatic forming device for nonel tube bundling. A traction air cylinder, a movement limiting block and a forming opening are arranged on a horizontal installation bench surface of the angle line automatic forming device. A vertical installation surface is vertically connected with the horizontal installation bench surface and is provided with a support rack II and a dynamic traction mechanism. An installation support rack I is fixed on the horizontal installation bench surface, the forming air cylinder is fixedly connected with the installation support rack I, and a forming mould is arranged under a forming mechanism. A conveying mechanical arm is fixedly arranged under the left lower part of the vertical installation surface. The invention can realize the automatic traction, the automatic forming, the separate cutting and the automatic transfer of angle lines.

Owner:NO 70 INST OF CHINA NORTH IND GRP

Micro-smoke lead formula and preparation process thereof

InactiveCN111689823ASatisfy the characteristic requirements of combustionSmall loosenessExplosivesFuse manufactureCelluloseNitrocellulose

A micro-smoke lead formula comprises the components in percentage by mass: 20%-80% of smokeless gunpowder, 10%-40% of an oxidizing agent, 0%-40% of metal powder and 0%-40% of inorganic salt. The preparation process of a lead comprises the steps: preparing chemicals of the micro-smoke lead, dissolving the chemicals of the lead into an organic solvent, feeding, forming and airing the lead. Comparedwith the prior art, the smokeless powder based on nitrocellulose is used for replacing black powder in a lead formula, so that the problem of environmental pollution is solved, or single and double base powder in the lead formula is replaced, and the problems that the performance of the single and double base powder is uncontrollable and the supply amount of the single and double base powder is limited are solved. Meanwhile, the lead formula is composed of smokeless gunpowder, an oxidizing agent, metal powder and inorganic salt, and smoke generated by combustion is reduced to the maximum extent. Besides, the preparation process for producing the lead by the wet mixing method provided by the invention not only meets the characteristic requirement of lead combustion, but also solves a plurality of defects of lead production by a dry mixing method.

Owner:湖南坤普科技有限公司

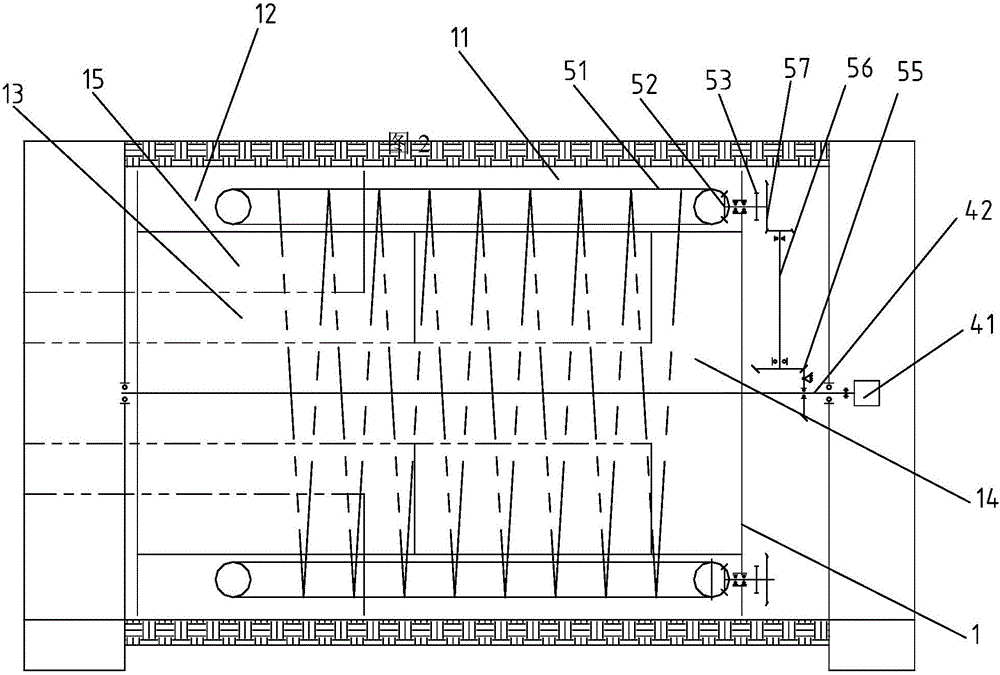

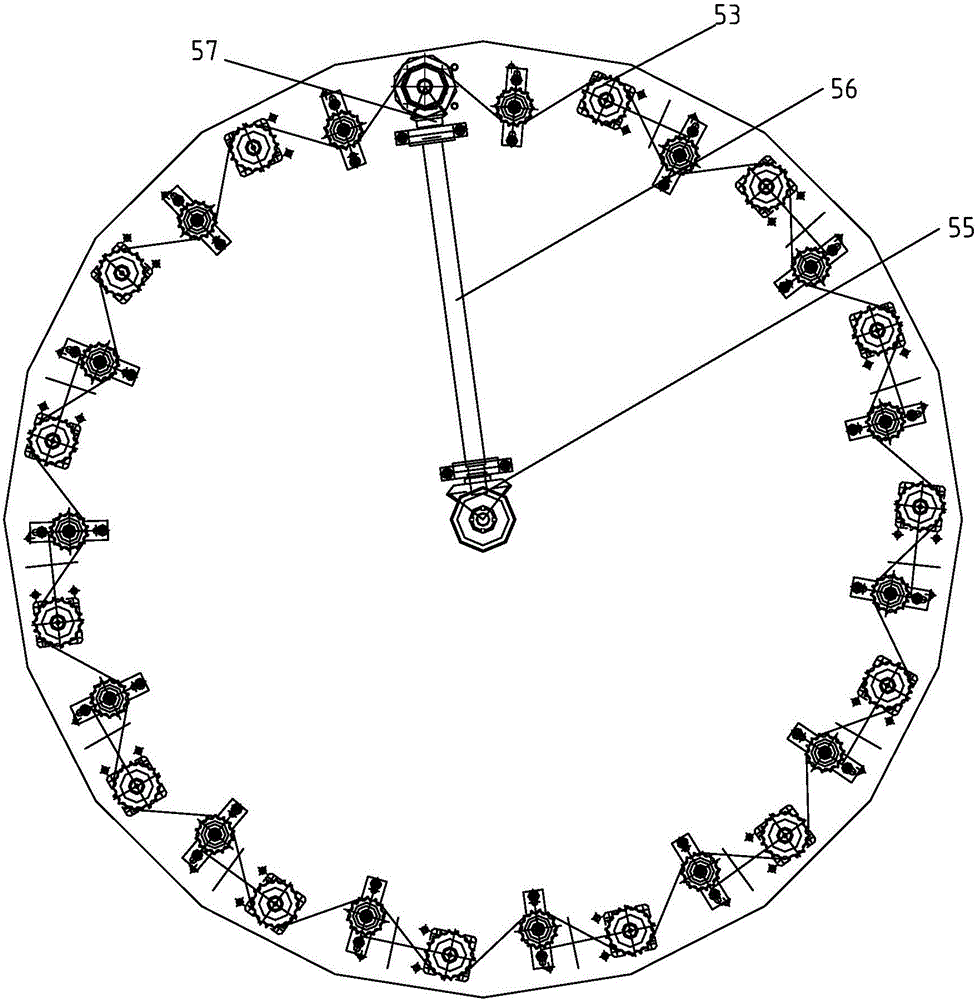

Drying drum and starch guiding machine containing the same

ActiveCN102924197AOperational securityHigh sizing drying efficiencyFuse manufactureFirecrackerFireworks

The invention provides a drying drum which is reasonable in structure. The drying drum comprises a drum body, an inner ring support, a turbine worm, a transport belt, a belt wheel, a hot air dispersing pipe and a hot air machine. The invention further provides a starching drying device for leading wires of firework and firecrackers, namely, the starch guiding machine which is safe and reliable in operation, and high in starching and drying efficiency. The starch guiding machine mainly comprises a starching box, the drying drum, and a winding guide machine. The drying drum in the starch guiding machine adopts a turbine worm structure, can provide spiral upward drying routes for the leading wires so that the drying drum is enabled to have a reasonable volume size and provide a proper drying method for the leading wires.

Owner:邓卫科

Detonating cord machine

The invention discloses a detonating cord machine which comprises a framework, a traveling car and a pinching and rolling mechanism, wherein the pinching and rolling mechanism is arranged at the operation end of the framework; both sides of the upper end surface of the framework are provided with light rails, the light rail on one side is provided with a rolling support, and the light rail on the other side is provided with a straight guide rail; the rolling support is fixedly provided with a servo motor and a reducer, and the lower end is provided with a supporting roller assembly; the traveling car is arranged between the light rails on the two sides; both ends of the traveling car are mounted on the light rails through a linear slide rail; the traveling car is provided with a drawing die; the lower end of the middle position of the framework is provided with a wire casing; and the wire casing is mounted on the framework through a wire casing bracket. According to the invention, the defects of the prior art are overcome; the designed mechanism is reasonable in layout; and the rolling of the precise straight guide rail is used instead of sliding friction of the existing equipment, thereby improving the motion stability of the car and simultaneously reducing the noise.

Owner:HEFEI YACHEN MACHINERY MFG

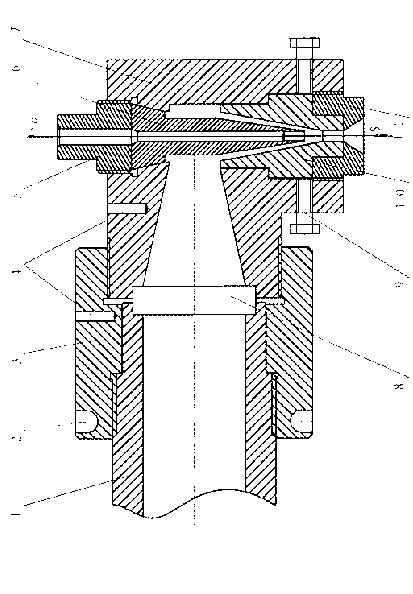

Adjustable nose for plastic detonating cord plastic coating and extruding machine

The invention relates to a plastic detonating cord, in particular to an adjustable nose for a plastic detonating cord plastic coating and extruding machine. The adjustable nose comprises an extruding machine delivery rod, an electric heating ring, an extruding machine nose connecting sleeve, a thermocouple, a core mold fixing bolt, a core mold, an extruding machine mold body, a filter board, a gate mold adjusting bolt, a gate mold and a gate mold fixing bolt. Fixed connection of the extruding machine mold body and the gate mold of the plastic detonating cord plastic coating and extruding machine is changed to floating connection, the thickness of a plastic layer coated on an outer surface of a semi-finished detonating cord product penetrating through the core mold and the gate mold is even, thickness difference can be controlled from 0mm to 0.02mm and the product quality requirement for plastic detonating cord plastic coating is strictly guaranteed. The adjustable nose for the plastic detonating cord plastic coating and extruding machine is compact in structure, reliable in operation, convenient to use, automatic in coating, capable of reducing a failure rate, even in a coating layer, high in accuracy and capable of strictly guaranteeing product quality, remarkably improving economic benefit and being popularized and applied to all plastic detonating cord production enterprises and suitable for electric wire and electric cable production enterprises.

Owner:HUBEI SHUAILI CHEM

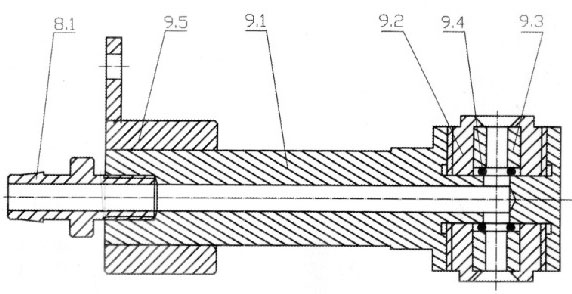

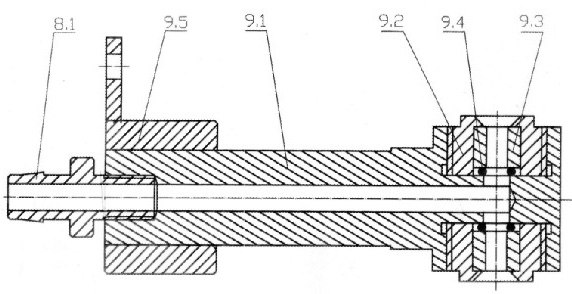

Convenient probe of detonating fuse manufacturing machine

InactiveCN102675013AImprove detection accuracyExtended service lifeFuse manufactureEngineeringWasher

a convenient probe of a detonating fuse manufacturing machine relates to an automatic explosive interruption or shortage detection probe of the detonating fuse manufacturing machine, adopts a separated structure instead of an integral structure and comprises a probe main body, a probe clamp pipe sleeve, a probe clamp pipe, sealing washers and a probe support, wherein a through hole passing through and perpendicular to the axial lead of the probe and countersunk threaded holes concentric with the two ends of the through hole are formed in the outer circumference of the probe main body; the probe clamp pipe sleeve and the sealing washers are mounted in the countersunk threaded holes; and the probe clamp pipe is made of high-hardness wear-resistant material. The convenient probe has the advantages that the service life of the probe is prolonged, the detection accuracy is improved, the product quality is stabilized and guaranteed, the replacement cycle of the probe is prolonged, the loss in downtime is reduced, and the yield is increased; and when the abrasion of the probe reaches the set value, all that is needed to do is conveniently and fast replace the probe clamp pipe by unscrewing the probe clamp pipe sleeve rather than disassemble and replace the whole probe, so as to save material cost and cost of unit production time and achieve remarkable comprehensive economic benefits. The convenient probe can be popularized in and applied to all detonating fuse manufacturers.

Owner:HUBEI SHUAILI CHEM

Thermosensitive wire and preparation method thereof

InactiveCN111689824AImprove moisture resistanceImprove flammabilityFire rescueFuse manufacturePhysical chemistryMoisture resistance

The invention provides a thermosensitive wire and a preparation method thereof. The preparation method comprises the steps that a temperature-sensitive combustible agent, a stabilizing agent, a flameinhibitor, a performance modifier and a solvent are mixed and plasticized, the mixture is pressed into a medicine strip after being plasticized, and the medicine strip is cut and dried after being dried in the air. The thermosensitive wire prepared by the invention can be started in a rated temperature range; when the temperature of the surface of the thermosensitive wire reaches 170-180 DEG C andthe heating duration exceeds 10 seconds, the thermosensitive wire can be automatically started, the false touch rate is low under normal conditions, and the thermosensitive wire has excellent moisture resistance, small combustion smoke and small flame, belongs to an environment-friendly moisture-proof lead, and is simple and convenient in production process.

Owner:LUZHOU NORTH CHEM IND

Automatic door control device assembled and used on explosive mixing machine

InactiveCN102910993ASimple structureEasy to assemble and connectExplosive working-up apparatusFuse manufactureAutomatic controlEngineering

The invention discloses an automatic door control device assembled and used on an explosive mixing machine. The automatic door control device comprises an outer drive shaft, an inner drive shaft, an explosive mixing barrel, a connecting shaft sleeve and an automatic explosive barrel door, wherein the explosive mixing barrel is fixedly connected with a barrel bottom through the connecting shaft sleeve. The technical solution adopted by the invention is that the automatic door control device further comprises shift lever screw bolts, a connecting screw rod, a support shaft sleeve and a connecting rod, wherein the shift lever screw bolts and the connecting screw rod are arranged on the inner drive shaft; the support shaft sleeve is arranged on the outer drive shaft in a sleeving manner; the automatic explosive barrel door is connected with the connecting screw rod through the connecting rod; a V-shaped open slot is formed in the middle connection part of the support shaft sleeve and the outer drive shaft; a V-shaped open slot is also formed in the connection part of the outer drive shaft and the connecting shaft sleeve; the inner drive shaft is connected with a drive structure through a connecting element and an external drive power device; and the automatic door control device is a connection structure automatically controlling the opening and the closing of the door through programmable control that is set according to explosive mixing time. The automatic door control device better solves the problem in remote programmable control of the opening and the closing of the automatic explosive barrel door for automatic explosive feeding, has the advantages of simple structure, convenience in assembly and connection, high degree of automation, no potential safety hazard and the like, and is suitable to be assembled and used on various explosive mixing machines.

Owner:黄蒲昌 +2

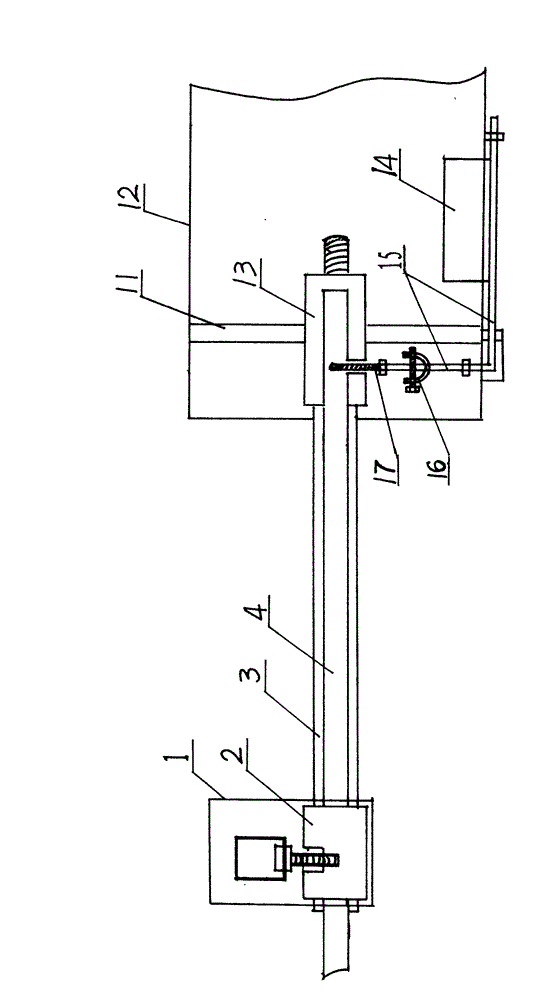

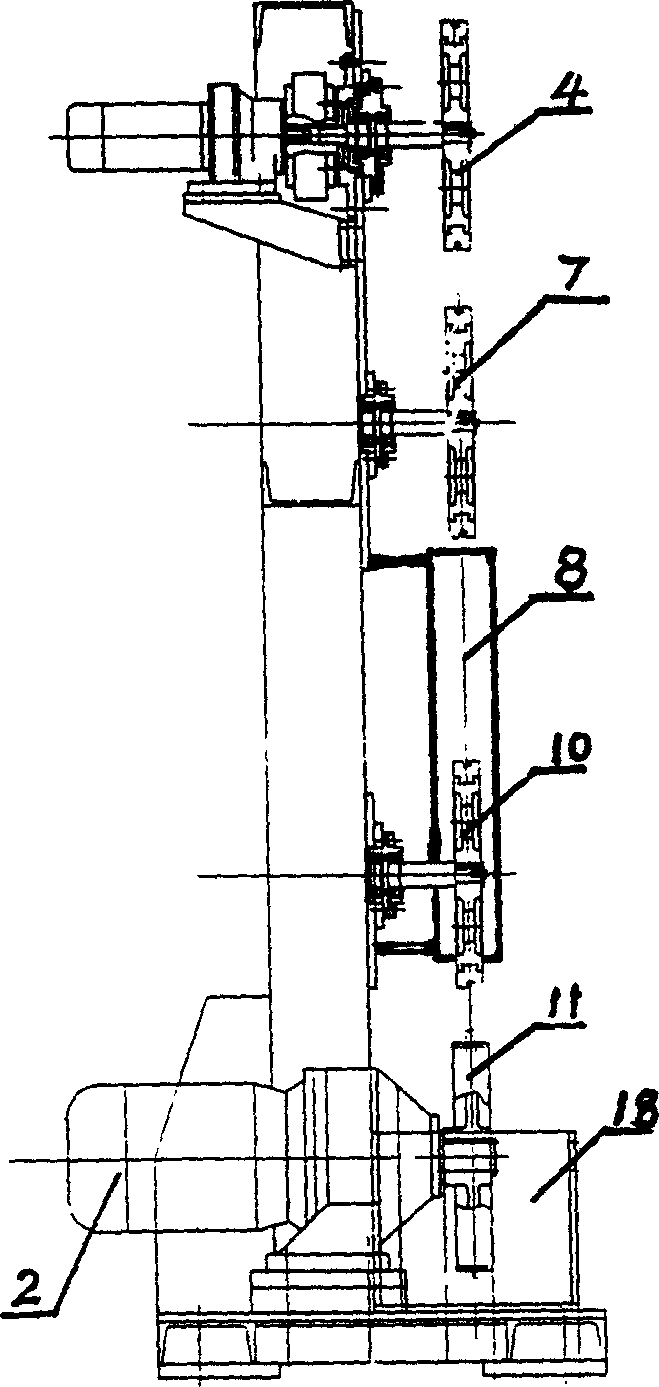

Detonator modify process and modify reinforcing means

The present invention relates to detonating tube production process and apparatus in explosion technology. The detonating tube modifying process in a modifying intensifier includes the following steps: properly cooling the detonating tube to 2-30 deg.c; compacting and stretching cooled detonating tube with one group of friction wheels and stretching wheels; heating the detonating tube surface under stretching at 100-500 deg.c; and re-cooling to 2-30 deg.c and stetching. The said process can improve the molecule orientation of detonating plastic tube and raise the tensile strength and oil resistance, and the present invention makes it possible to produce detonating tube of high strength in low cost.

Owner:中钢集团武汉安全环保研究院有限公司

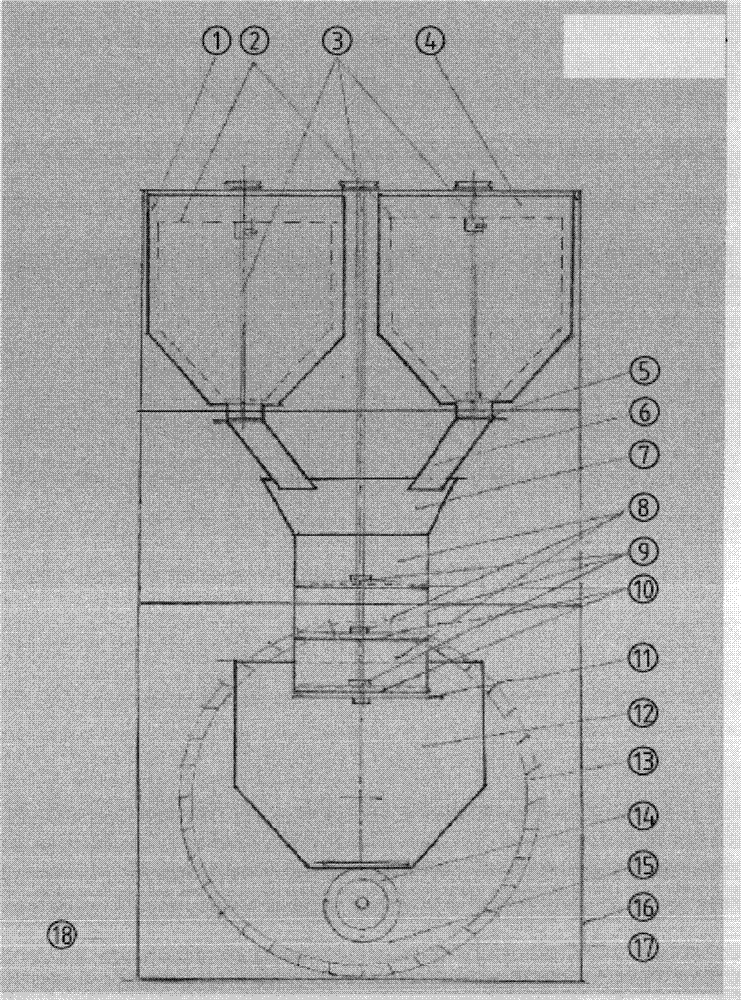

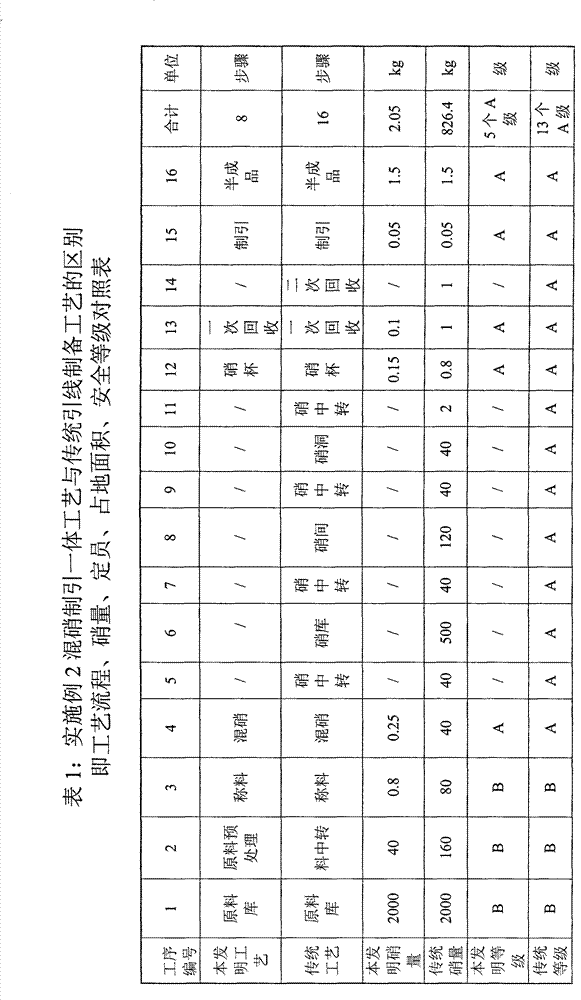

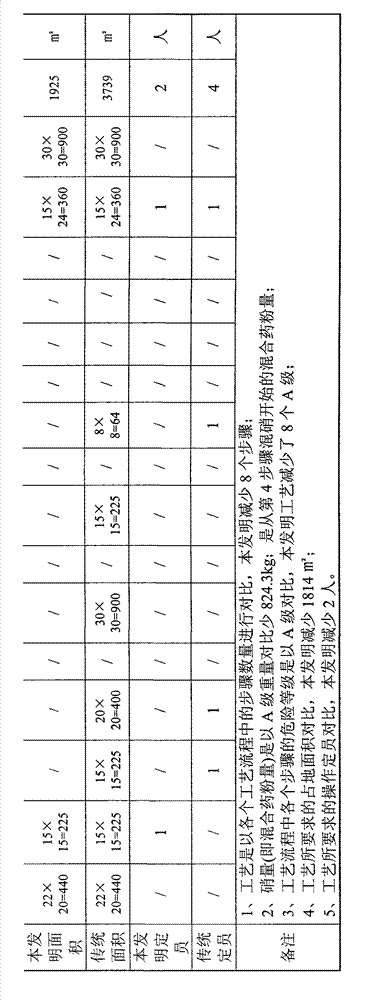

Saltpeter mixing and lead preparing integrated machine and saltpeter mixing and lead preparing process

InactiveCN102924198AAvoid storage problemsAvoid operabilityFuse manufactureEngineeringProcess design

The invention provides a saltpeter mixing and lead preparing integrated machine, which mainly comprises a chassis, a saltpeter feeding device, a lead reeling machine and an electric motor, wherein the saltpeter feeding device comprises two chemical hoppers for adding oxidant and reductant, and a saltpeter mixing hopper connected with outlets of the chemical hoppers; the saltpeter mixing hopper is provided with three layers of sieve structure; the sieve surface on each layer is provided with a rotary blade; and three rotary blades are driven by the electric motor to rotate; the outlet of a saltpeter cup is directed at a piece of lead paper. The saltpeter mixing and lead preparing integrated machine provided by the invention realizes integration of saltpeter mixing and lead preparing. The real-time saltpeter mixing process design avoids storage and transport of large amounts of mixed chemical powder in the existing process, and can achieve purposes of effectively preventing accident occurrence, guaranteeing public, personal and property safety and increasing labor productivity at the same time.

Owner:邓卫科

Explosive-proof powder-dust-preventing powder conveying mechanism for automatic metal cord powder loading

InactiveCN105541524AImprove intrinsic safetyReduce the scattering rangeFuse manufactureEngineeringMetal

The invention provides an explosive-proof powder-dust-preventing powder conveying mechanism for automatic metal cord powder loading. A powder conveying rotary cylinder is fixed on an explosive-proof steel plate through a powder conveying rotary cylinder mounting plate; a powder conveying window is formed in the explosive-proof steel plate; a protection plate is used for closing or opening the powder conveying window under the action of a protection plate sliding table cylinder; a powder feeding rotary cylinder and a dust prevention cover are fixed on the two sides of a powder conveying rotary cylinder cover plate, and rotate by winding an output shaft of the powder conveying rotary cylinder in the horizontal plane; a powder cup is connected with an output shaft of the powder feeding rotary cylinder. When the powder cup moves above a powder funnel, the powder feeding rotary cylinder drives the powder cup to move downwards perpendicularly, and the protection plate closes the powder conveying window; when the powder cup moves to the powder conveying window, the powder feeding rotary cylinder drives the powder cup to move upwards perpendicularly, then the dust prevention cover covers the upper part of the powder funnel, and the powder conveying window is opened. According to the mechanism, the automation level and safety of conveying and feeding of metal cord powder loading can be improved.

Owner:中国兵器工业第二一三研究所

Combined mold and method for preparing casting type explosives and powders

ActiveCN112759494AImprove production efficiencyImprove securityExplosive working-up apparatusFuse manufactureTEX-explosiveSlurry

The invention discloses a combined mold for preparing casting type explosives and powders, which comprises a reverse flow forming mold and a cartridge type mold, the reverse flow forming mold comprises a hollow shell and a bottom opening arranged at the bottom of the shell, and the reverse flow forming mold can be directly a combined body of the cartridge type mold; the explosive type mold is provided with a hollow mold cavity and openings formed in the two ends of the mold cavity; one or more explosive-shaped section molds are contained in a shell of the countercurrent forming mold, and an opening in one end of each explosive-shaped section mold is in butt joint with an opening in the bottom of the countercurrent forming mold; and under the action of external pressure, slurry without gas in advance under a vacuum condition is upwards injected into a cavity of the explosive type mold through an opening in the bottom of the countercurrent forming mold, and the cavity of the explosive type mold is filled with the slurry. The combined mold is suitable for batch pouring of explosives and powders of various complex fine types.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

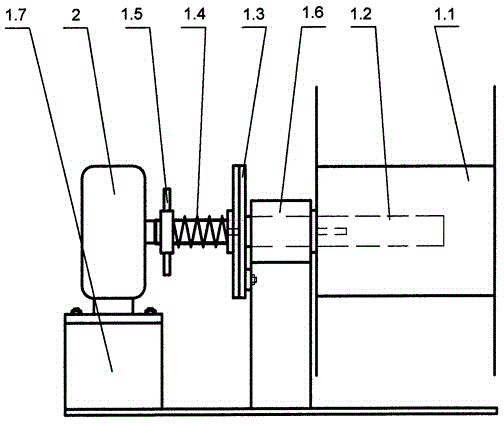

Wet lead wire preparing and drying integrated machine and wet lead wire preparing and drying integrated method

InactiveCN105016936ASmall footprintImprove intrinsic safetyEnergy inputDrying machines with progressive movementsFireworksEngineering

The present invention discloses a wet lead wire preparing and drying integrated machine and a wet lead wire preparing and drying integrated method, the wet lead wire preparing and drying integrated machine is mainly composed of a lead wire paper tray (1), a quantitative dosing device (2), a drying device (3), a rack (4) and a lead wire twisting and collecting device (5); firstly, the lead wire paper tray (1) is put on the rack, lead wire paper artificially passes through a dosing site of the quantitative dosing device (2), passes through the drying device (3), and then enters into the lead wire twisting and collecting device (5) for well fixing; secondly, an artificially mixed wet chemical agent is added into a chemical agent hopper of the quantitative dosing device (2); then the drying device (3) works, and when the temperature reaches the set temperature, the lead wire twisting and collecting device (5) is started automatically for lead wire preparing production. The wet lead wire preparing and drying integrated machine is applicable to the production of lead wire preparing production in fireworks industry, lead wires are directly dried on line, and directly coiled and packed into a finished product for storage without backwinding, sun-drying, and re-backwinding, and the production process is no longer limited by environmental conditions.

Owner:CHINA WUZHOU ENG GRP +1

Method for producing blasting wire in dry-wet way

ActiveCN101863724AEliminate winding processFacilitate automated productionFuse manufactureEngineeringConductor Coil

The invention discloses a method for producing a blasting wire in a dry-wet way, which is characterized in that: clearcole is firstly adhered onto a wire, initiator is adhered onto the clearcole, surface sizing is adhered onto the initiator to complete the formation of the blasting wire or paper is used for wrapping the initiator to be sealed with glue to complete the formation of the blasting wire, and then the formed blasting wire is dried to form the blasting wire. The method has the advantages that: the winding procedure of the prior art for producing the blasting wire is saved, and the blasting wire is directly used after being dried, so not only the quality of the blasting wire and the production safety can be ensured, but also the blasting wire can be produced when in use, the production procedure is simplified, the working hour and the material cost are reduced, and the automatic mass production can be realized; and at the same time, the complex process flow problem of the present wet-method that the initiator is arranged inside a production device after being wetted by the initiator pulp can be solved.

Owner:浏阳市中洲机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com