Saltpeter mixing and lead preparing integrated machine and saltpeter mixing and lead preparing process

An all-in-one machine and mixed nitrate technology, applied in the direction of fuse manufacturing, etc., can solve problems that are not conducive to safety production, production efficiency, and saving of factory area, so as to improve labor production efficiency, avoid storage and transshipment operations, and prevent The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

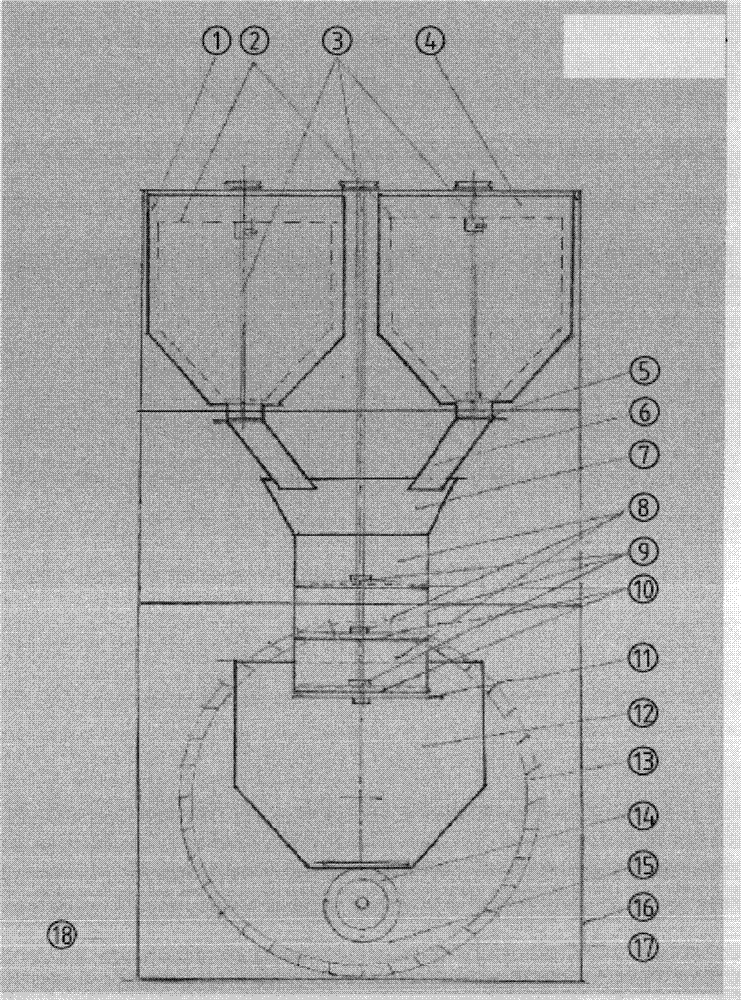

[0053] like figure 1 As shown, a kind of mixed nitrate making and leading machine of the present invention, its structure mainly comprises frame 16, drug hopper 1 and 4, mixed nitrate hopper 6, nitrate cup 12, inner ring recovery ring 13, winding machine 19 and the motor 18.

[0054] The medicine hopper 1 is used for feeding the oxidant, and the medicine hopper 4 is used for feeding the reducing agent. The medicine hopper is equipped with an agitating member 2 and an agitating shaft 3. The agitating member 2 is driven by the agitating shaft 3 to stir the raw materials to prevent powdery The flow regulating valve 5 of the raw material blockage hopper is used to control the flow of oxidizing agent and reducing agent. The oxidizing agent and the reducing agent are respectively added to the medicine hopper 1 and 4 according to the ratio required for production, and they will enter the mixing nitrate hopper 7 through the lower feeding cylinder 6 below the medicine hopper.

[0055...

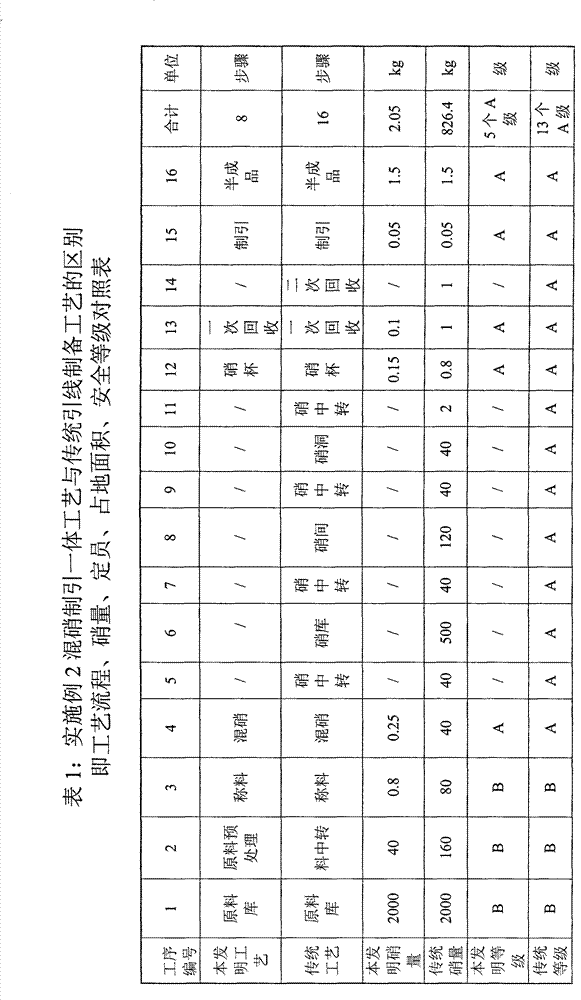

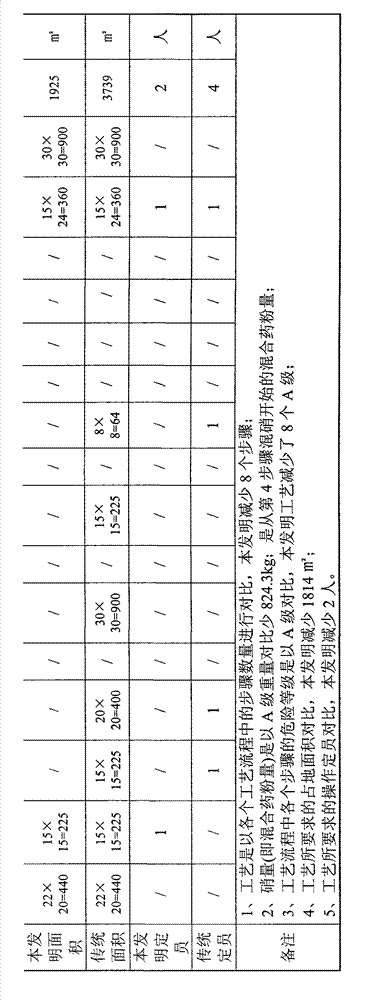

Embodiment 2

[0059] The method for preparing a lead wire by using the mixed nitrate making lead integrated machine of embodiment 1 mainly includes the following steps:

[0060] a. Potassium perchlorate and charcoal raw materials are pretreated to remove impurities in the raw materials and make the raw material particles uniform and conducive to stirring and mixing;

[0061] B. Weigh pretreated potassium perchlorate and charcoal by weight ratio 5: 3, and add respectively in the medicine hopper 1 and 4 of the mixed nitrate making and drawing all-in-one machine described in embodiment 1;

[0062] c. carry out the mixing of potassium perchlorate and charcoal in the mixed nitric hopper 7;

[0063] d. The mixed medicinal powder spreads on the drawing paper through the nitre cup 12;

[0064] e. Utilize the inner ring recovery circle 13 to recover the scattered mixed powder;

[0065] f. Utilize the winding machine 19 to wind the lead paper spread with the powdered paper into a spiral lead wire f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com