Patents

Literature

859 results about "Firecracker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A firecracker (cracker, noise maker, banger, or bunger) is a small explosive device primarily designed to produce a large amount of noise, especially in the form of a loud bang; any visual effect is incidental to this goal. They have fuses, and are wrapped in a heavy paper casing to contain the explosive compound. Firecrackers, along with fireworks, originated in China.

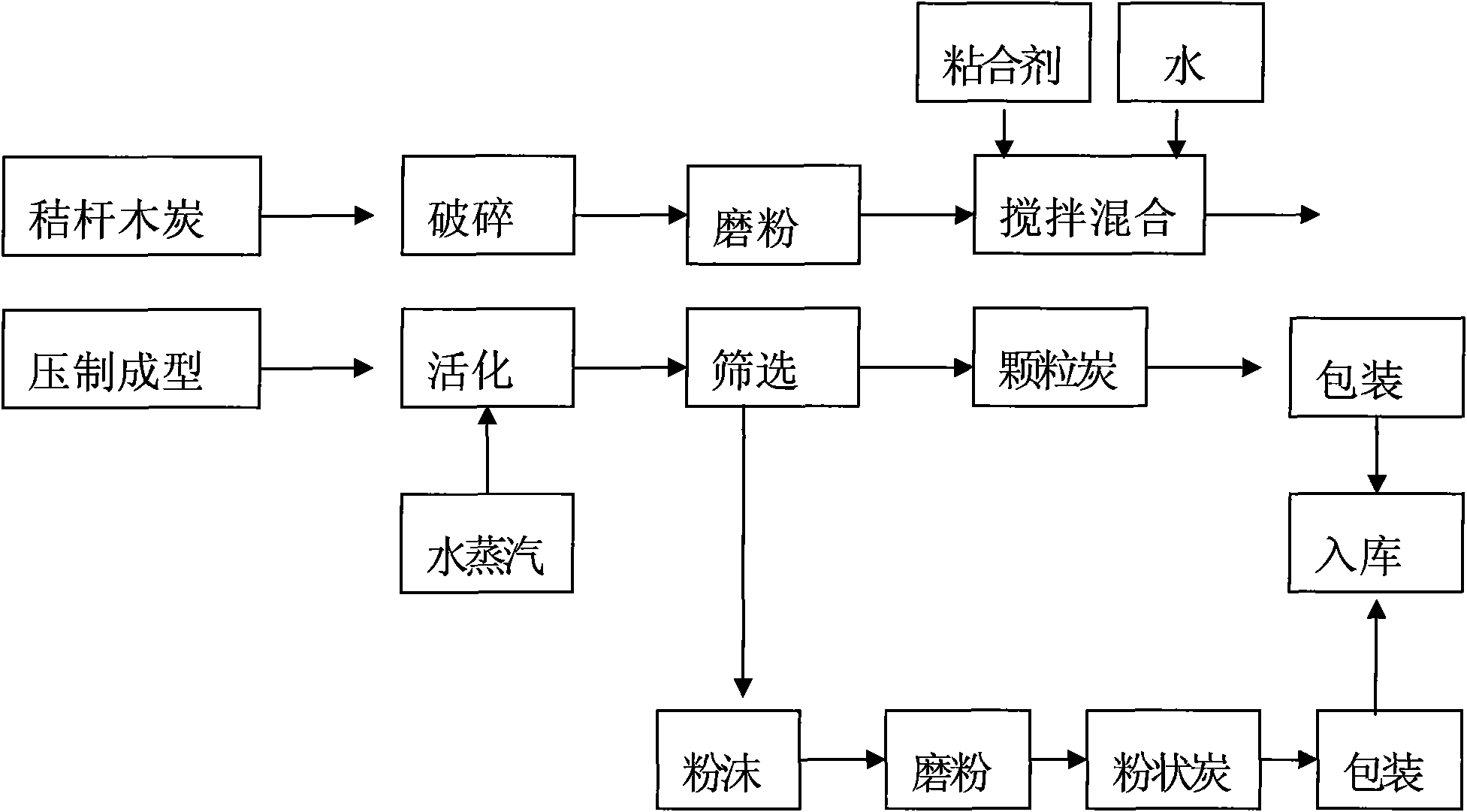

Process for producing activated carbon by physical activation method

The invention discloses a process for producing activated carbon by a physical activation method. The process is characterized in that an activation process is added on the basis of machine-made straw charcoal, and comprises the following steps of: crushing and grinding the straw charcoal into powder and pressing the powder again to form grains; and feeding the grains into a special externally heated rotary activating furnace and performing activation by taking a gas as an active agent to obtain a finished product. The activation principle of the process is that: the activated carbon has strong adsorption capacity due to a special microcrystalline structure, well-developed micropores and great specific surface area thereof, and is produced by making the carbon form the porous microcrystalline structure and the straw carbon have a well-developed specific surface area. The machine-made straw charcoal produced by the process has high quality and high adsorption capacity, can be used for the production of firecrackers and fireworks, also can be widely used for the water purification for drinking water, alcoholic beverages and various cooling beverages and the advanced purification of industrial waste sewage and domestic sewage, and is also suitable for the purification of indoor air.

Owner:卞奎友

Mixing fireworks and producing method thereof

A mixed 'firecracker-fireworks' having the effects of firecracker and fireworks and generating 5 colors is prepared from potassium perchlorate, Mg-Al alloy powder, strontium carbonate, phenolic resin, polyvinyl chloride, strontium nitrate, sulfur, glutinous rice flour, etc. Its advantages are simple preparing process, dual effect, multiple color and long perdurability.

Owner:黄远清 +1

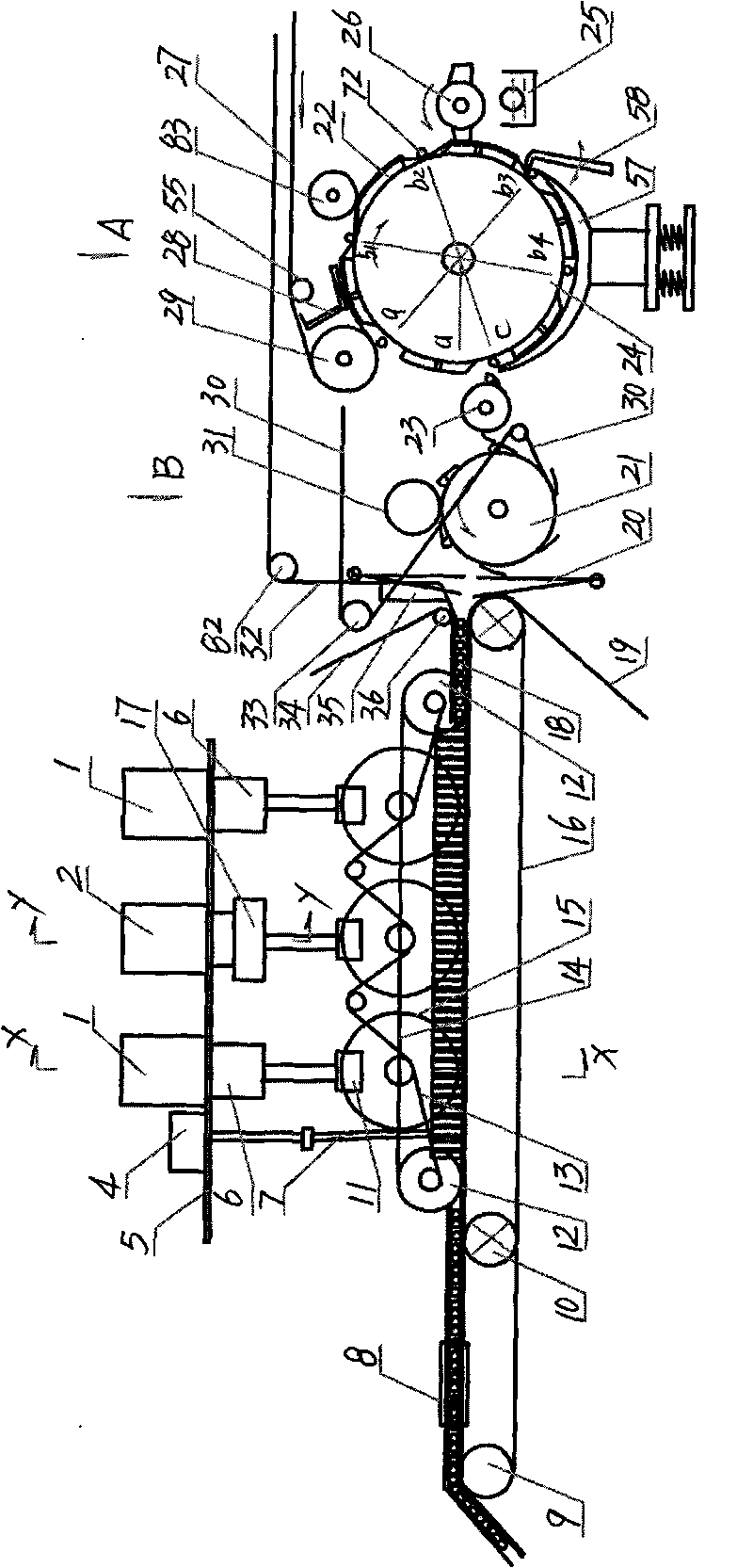

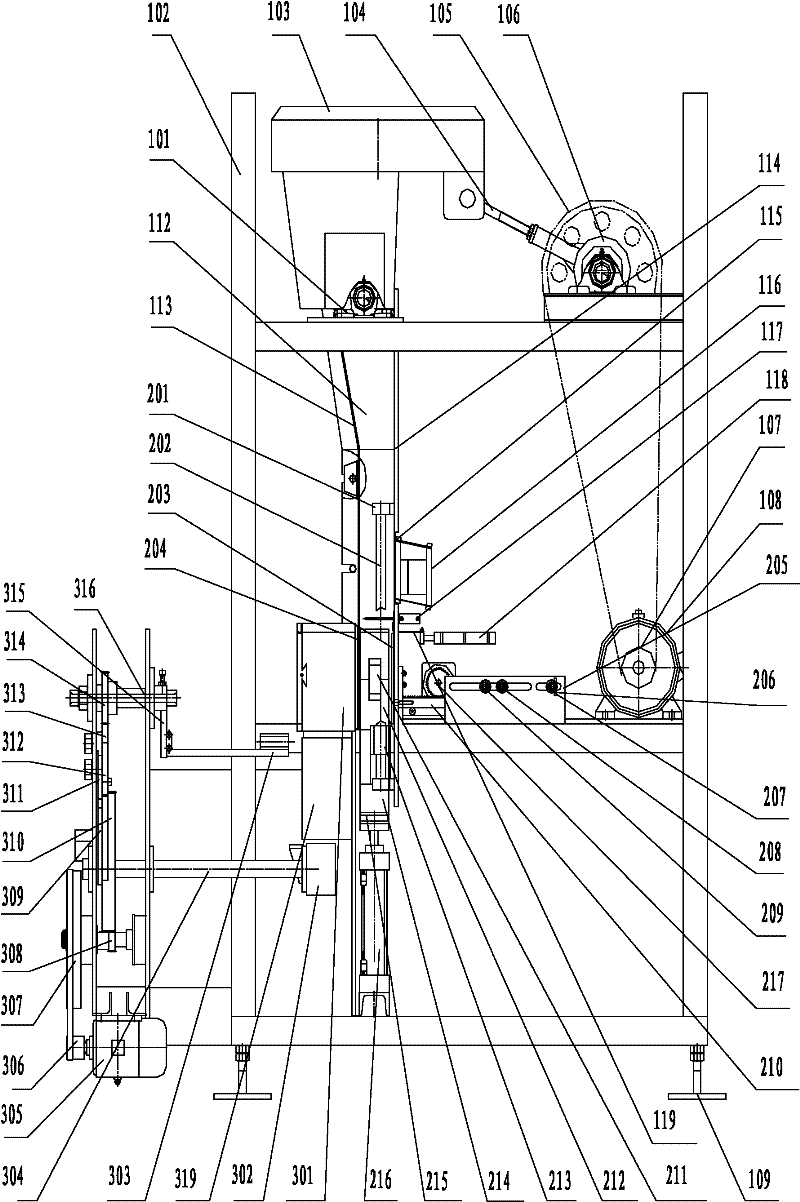

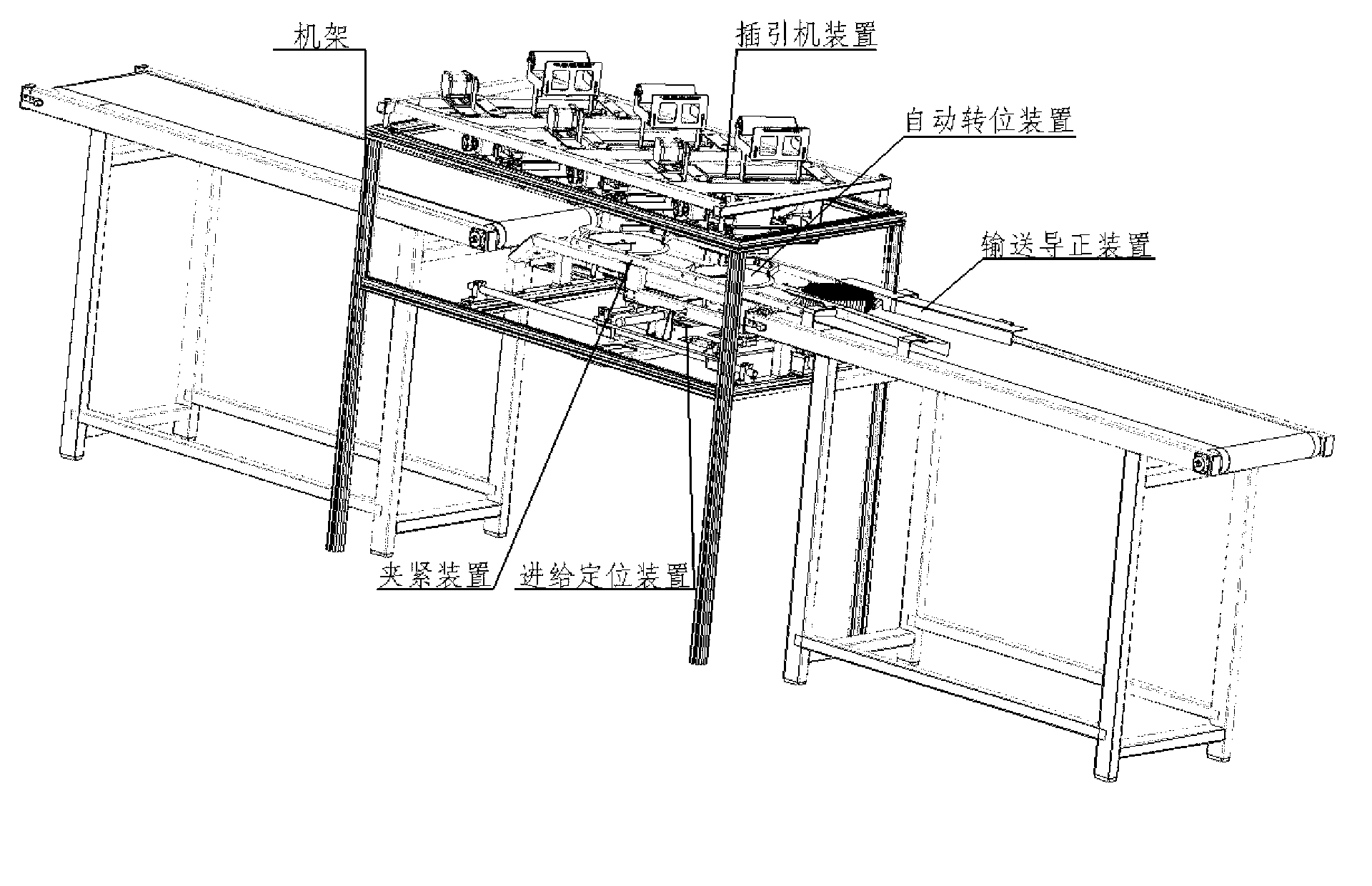

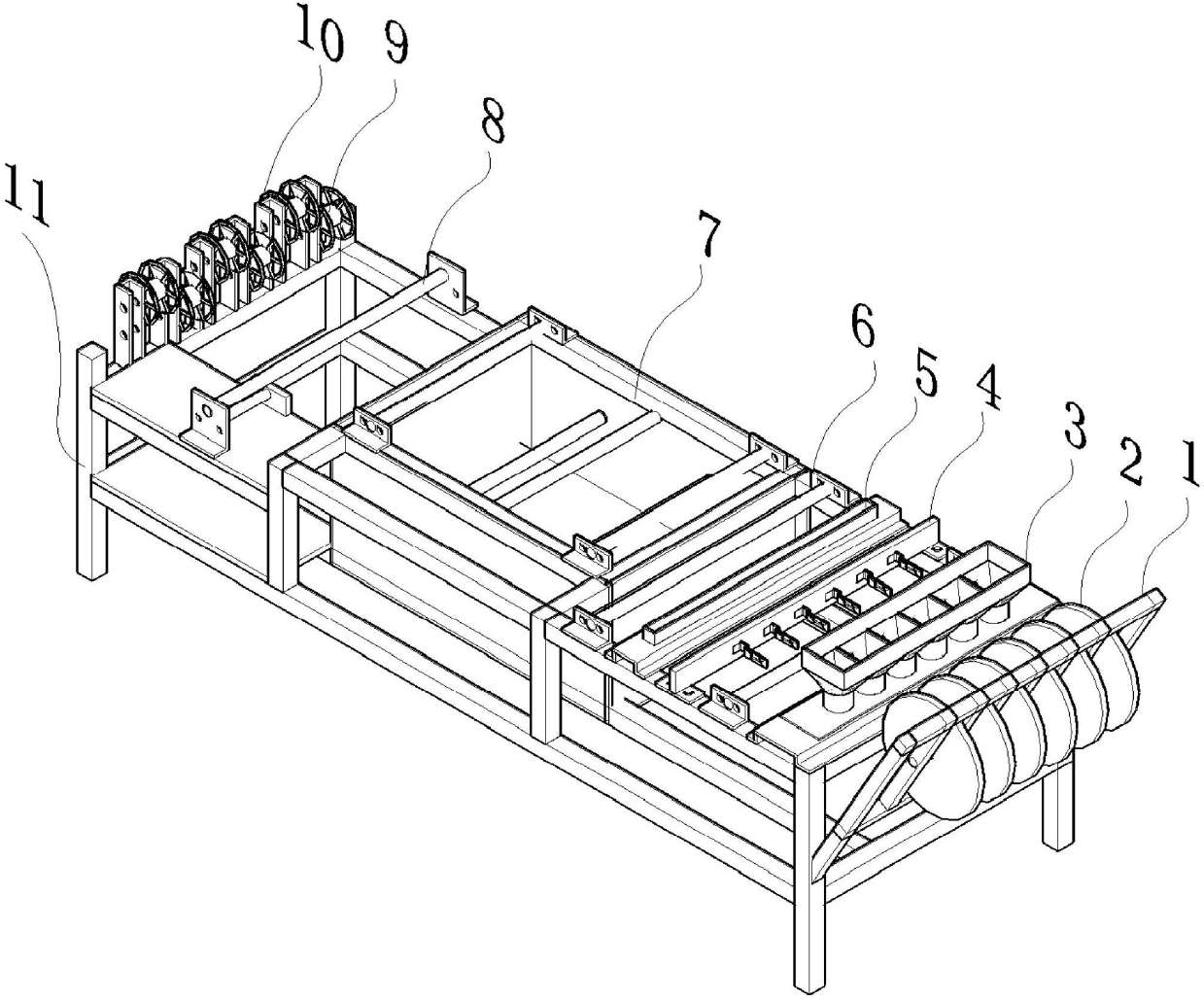

Firecracker manufacturing all-in-one machine

InactiveCN101713622AImprove production and processing efficiencyImprove processing qualityFireworksFirecrackerDistributor

The invention discloses a firecracker manufacturing all-in-one machine comprising a reel mechanism, a fuse inserting mechanism, a firecracker connecting mechanism, a conveying mechanism, a powder charging mechanism and an encapsulating mechanism, wherein the reel mechanism comprises a center wheel (24), and at least four tiles and rollers, wherein the tiles and the rollers are evenly arranged in the middle of the axial direction of the excircle of the center wheel at intervals; the fuse inserting mechanism comprises a fuse inserting wheel (21), and at least four pairs of shuttle needle pipes (65) and shuttle needles (66), wherein the shuttle needle pipes (65) and the shuttle needles (66) are evenly arranged on one end of the fuse inserting wheel at intervals; a transition wheel (23) and a clamping hook (44) are arranged between the fuse inserting wheel and the center wheel; a swing flask conveying device (20) on the conveying mechanism is arranged between the fuse inserting wheel and a delivery wheel (10); the powder charging mechanism comprises a spiral conveyor (17) and distributors (11), wherein the distributors on both ends are respectively connected with an agitating vessel; the distributor in the middle is connected with the spiral conveyor; and the spiral conveyor is connected with the distributors. The invention greatly increases the firecracker producing and processing efficiency, improves the firecracker processing quality, and can ensure the firecracker processing safety, thereby being beneficial to organizing scale production and processing of firecrackers, and lowering the firecracker processing cost.

Owner:黎高明 +4

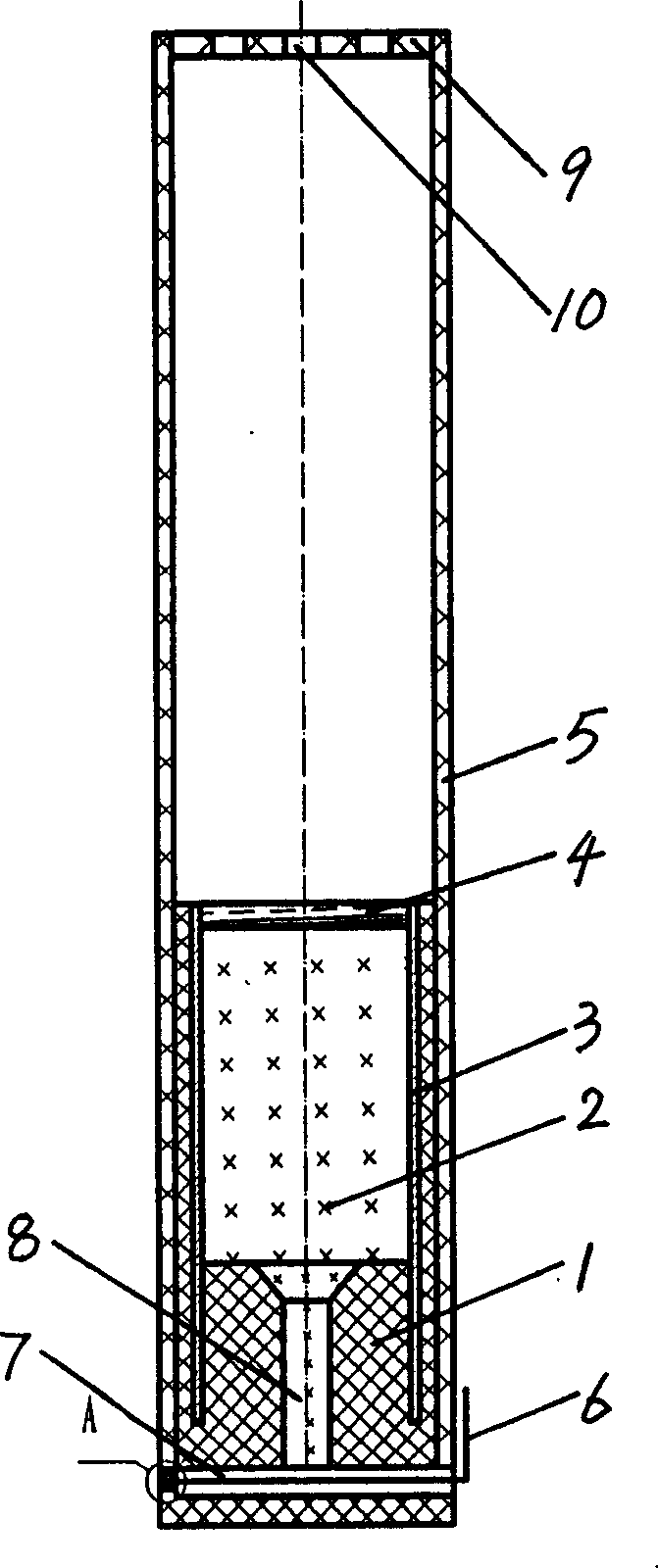

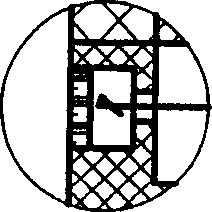

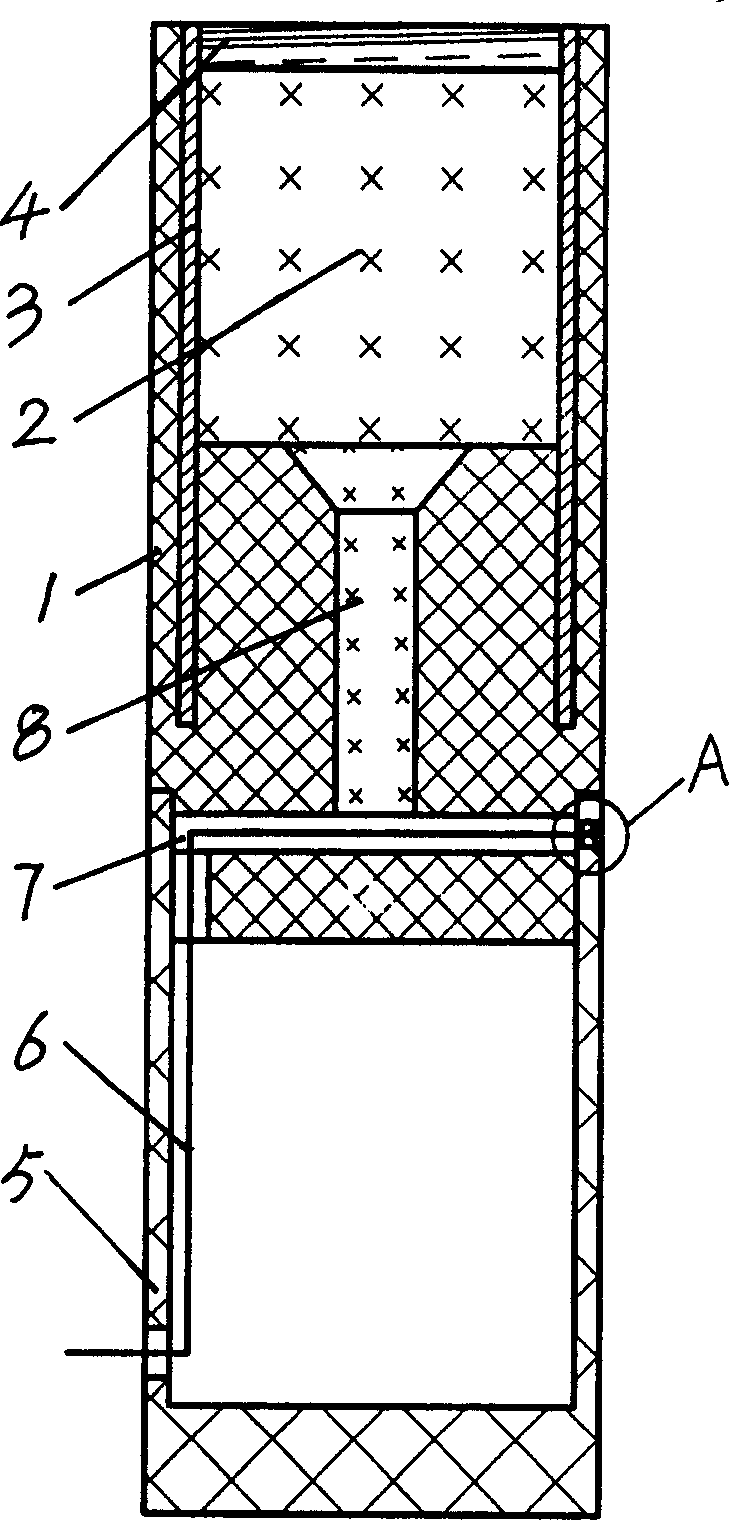

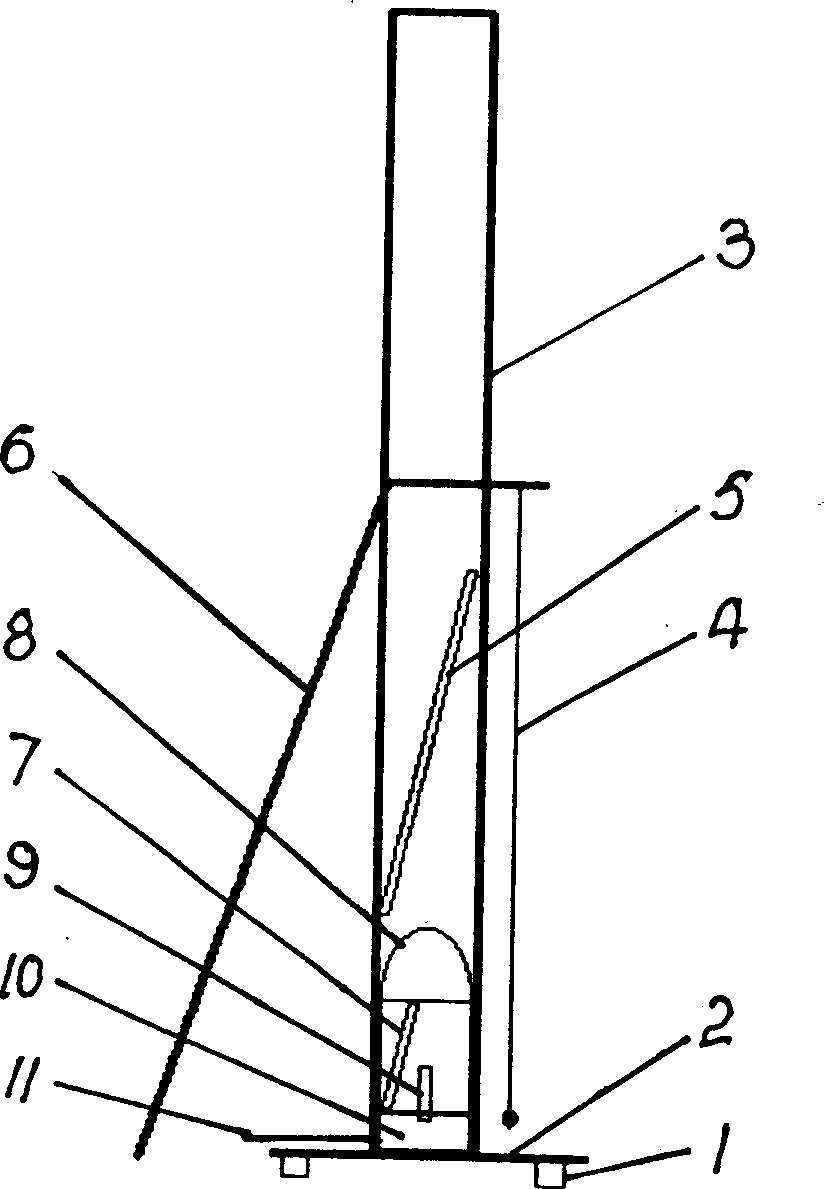

Safe environment-friendly energy-saving type built-in firecrackers

The invention relates to a safe, environment-friendly and energy-saving internal firecracker, which can solve the defects of present product which is not safe. The invention comprises a base for stuffing medicine, a sealing cut above the medicine, and lead wire. A metallic sheath is arranged between the inner wall of cylinder base and the medicine, whose lower end is embedded into base; the base is sheathed with a protective frame whose upper part has a dustproof cover with ventilating holes. Compared to present technique, the invention has the advantages that: 1, high safety without injecting high-speed matters; 2, environment protection without left matters; 3, lower cost and the application for batch production, with controllable producing process.

Owner:赵子刚 +1

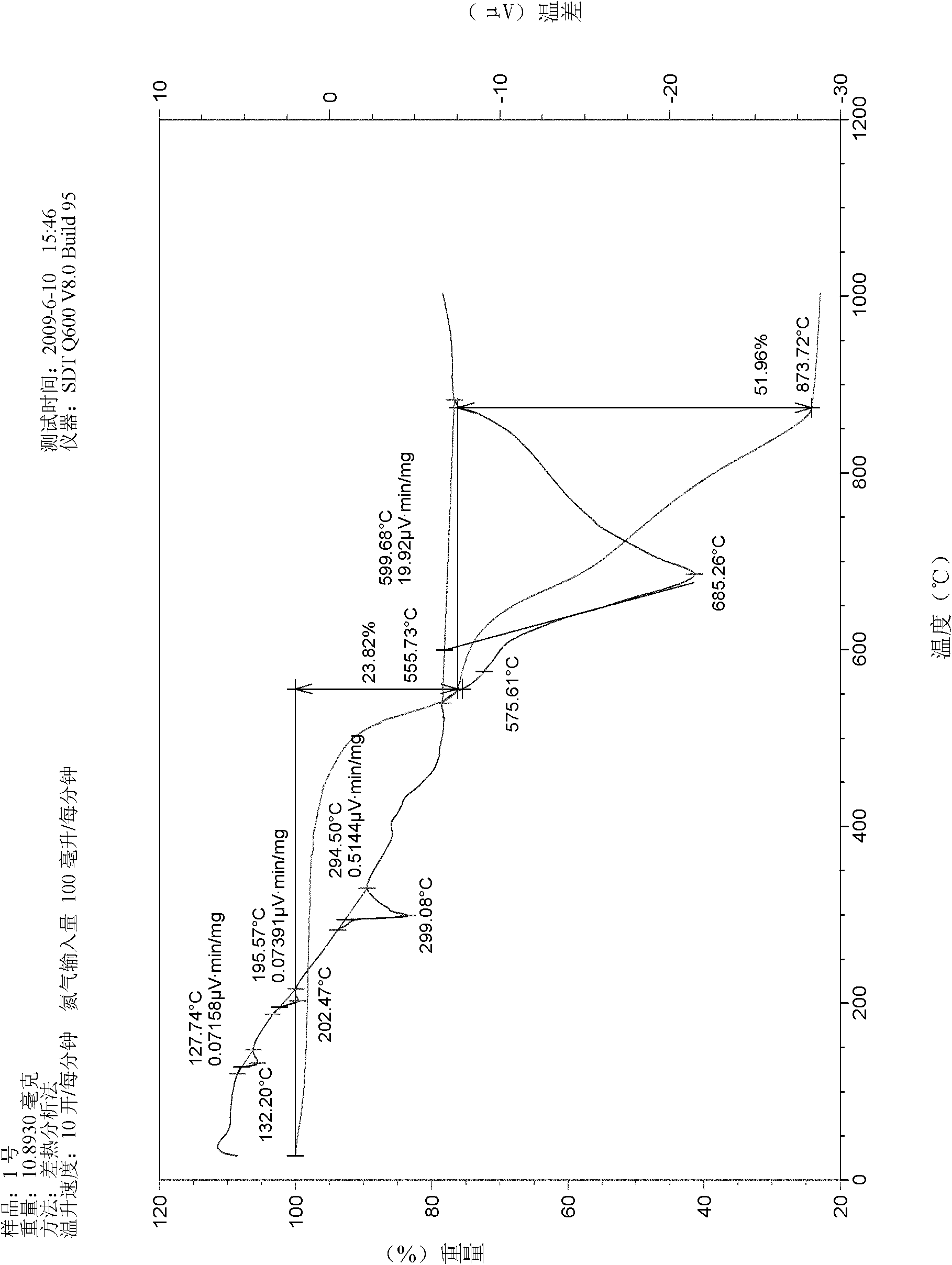

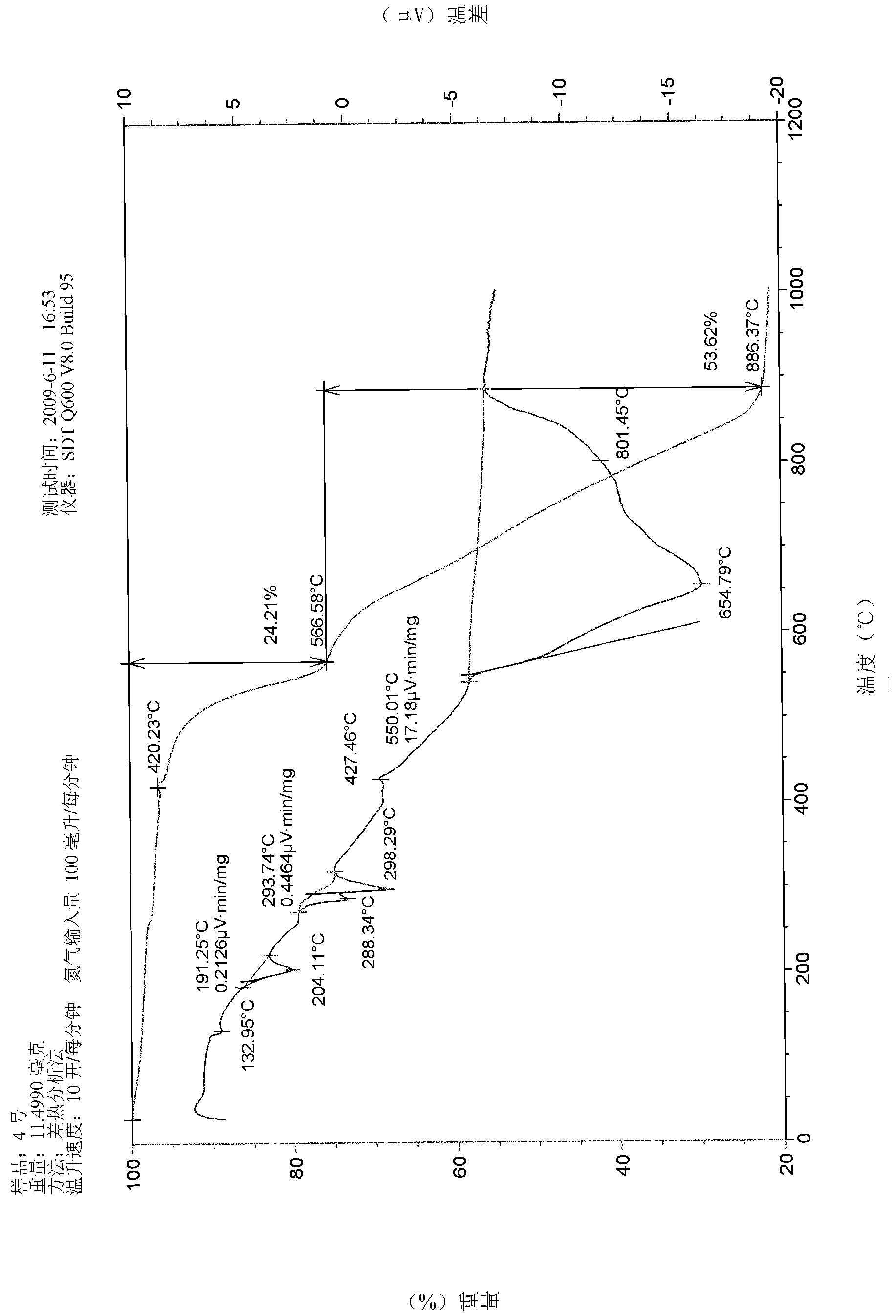

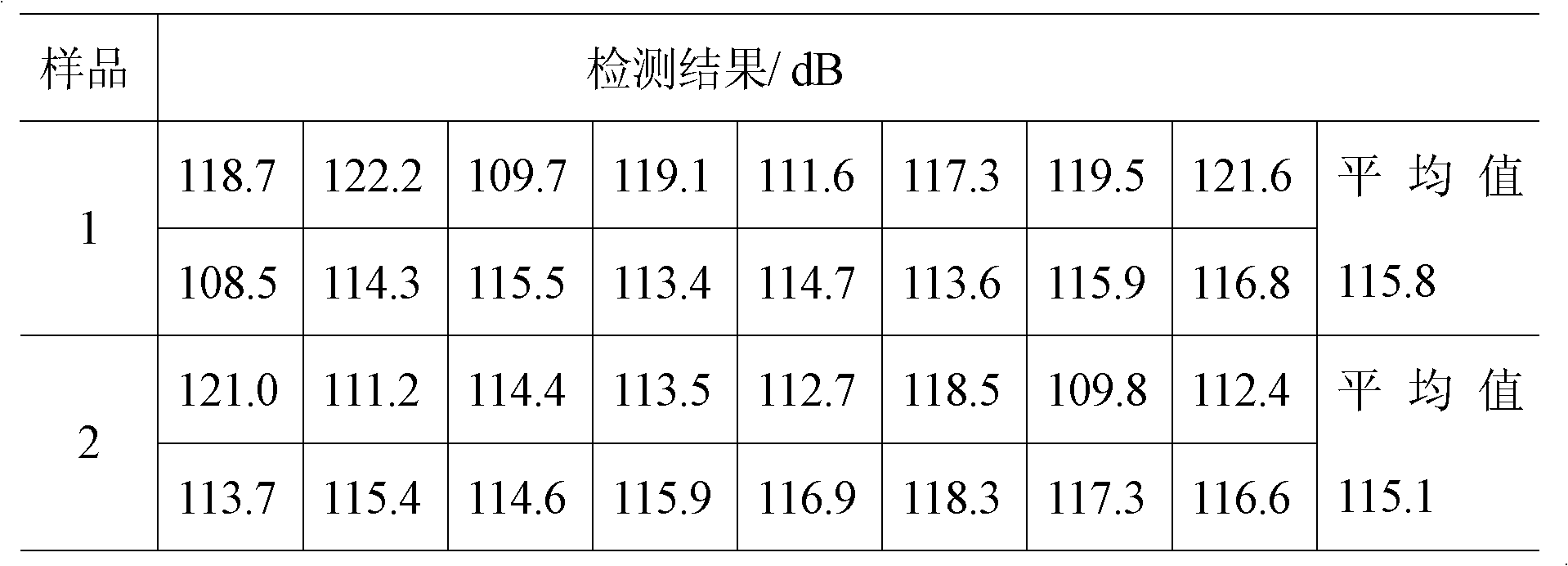

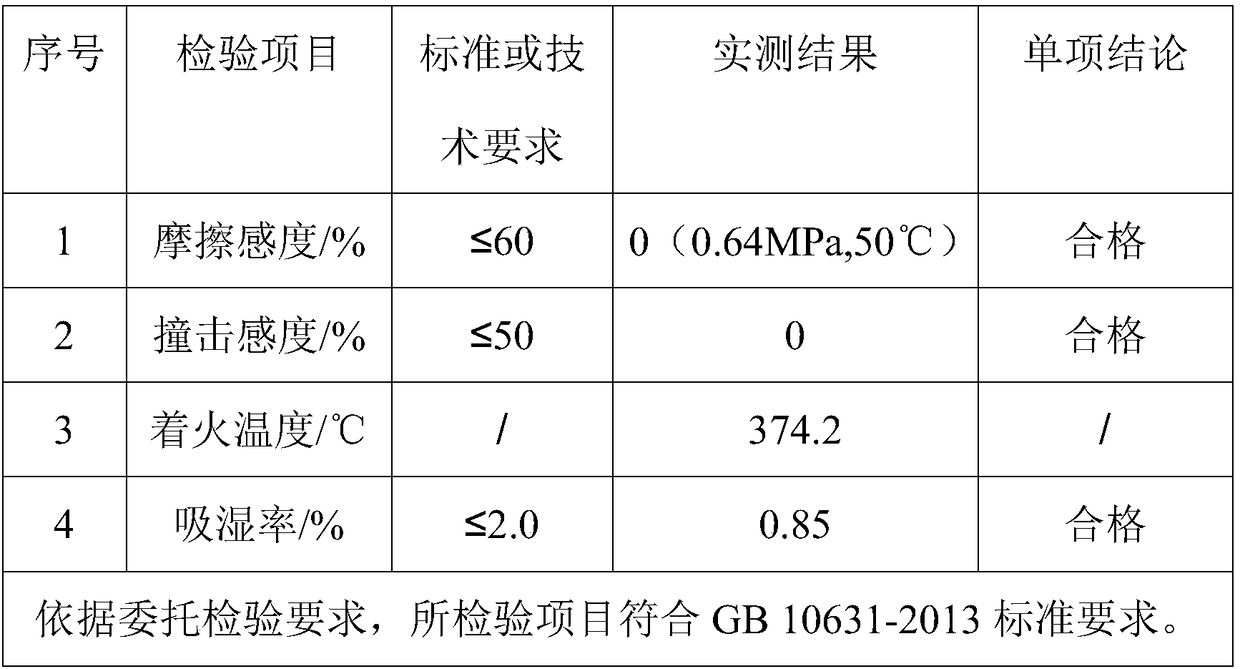

Sulfur-free and pearlite-free firecracker reagent and preparation method thereof

The invention discloses a sulfur-free and pearlite-free firecracker reagent and a preparation method thereof. The reagent comprises the following mass components: 35-65 percent of A component and 35-65 percent of B component, wherein the A component comprises the mass compositions: a mixture formed by 20-50 percent of potassium perchlorate, 0-30 percent of potassium nitrate and 30-50 percent of barium nitrate and a complexing agent occupying 1-5 percent of the mixture, and the B component comprises the mass compositions: 50-80 percent of aluminum powder, 10-25 percent of charcoal powder and 10-25 percent of organic foaming powder. The burning rate of a firecracker prepared from the reagent is more than 98 percent, the sound level value is no less than 100dB and is no more than 140dB, the time the gas product pressure rises from 0.69MPa to 2.07MPa is 1.74ms, a pH value of the pyrotechnic composition is 5-9, the moisture is no more than 1.5 percent, the hygroscopicity is no more than 2.0 percent, the thermal stability is 75 DEG C plus / minus 2 DEG C, the firecracker has no decomposition phenomenon under the condition of 48h, the friction sensitivity is no more than 40 percent, and the impact sensitivity of the pyrotechnic composition is no more than 0 percent. The key is that the reagent reduces the environmental pollution without harm to human bodies and has great application prospect.

Owner:HUNAN VOCATIONAL INST OF SAFETY TECH +1

Anti-electrostatic ceramic material, preparation method thereof and firecrackers lead knitting needle made of material

ActiveCN101786878ALow resistivityImprove flexural strengthCeramic shaping apparatusFuse manufactureFirecrackerMass ratio

The invention discloses an anti-electrostatic ceramic material which comprises the following components in percentage by weight: 68-80 percent of yttria stabilized zirconia, 1-3 percent of silicon dioxide, 10-14 percent of tin oxide, 7-11 percent of zinc oxide, 1-2.5 percent of silicon 1-2.5 percent of silicon carbide. The preparation method of the ceramic material comprises the following steps of: firstly, mixing various raw materials in ultrathin powder state by a ball mill; then drying; melting and blending the dried mixed raw materials with an organic binder according to a mass ratio of (4-9):1; injecting and forming particles obtained by melting and blending to obtain a ceramic blank; and degreasing and sintering to obtain an anti-electrostatic ceramic material. In the method, the firecrackers lead knitting needle is injected and formed by a die. The anti-electrostatic ceramic material and the firecrackers lead knitting needle thereof have the advantages of electrostatic resistance, abrasion resistance, good anti-bending performance, simple preparation process, lower cost, and accurate size of a prepared ceramic product without post-processing.

Owner:JIANGSU JINSHENG CERAMIC TECH

Smokeless flameless gunpowder agent

InactiveCN101215211AImprove stabilityImprove moisture resistanceNon-explosive/non-thermic compositionsFirecrackerFireworks

The invention discloses a firework agent with no smoke, which is characterized in that the invention is produced by nickel hydrazine nitrate blending with accessories , wherein, the nicker hydrazine nitrate is generated by mixing and reaction of nickelous nitrate hexahydrate and hydrazine hydrate, The weight ratio of raw materials of the nickel hydrazine nitrate is that nickelous nitrate hexahydrate takes 35-85 portions of weight per percentage, hydrazine hydrate takes 15-65 portions of weight per percentage, the weight ratio of raw materials of the fireworks agent with no smoke is that nickelous nitrate hexahydrate takes 20-62 portions of weight per percentage, excipients takes 40-80 portions of weight per percentage, wherein the excipients are mineral powders with 80-120 orders which are incombustible, such as pearlite powder or sepiolite powder or river sand, two or more of the excipients can be used in manufacture of different firework products. Protocol fireworks with color flowers and firecrackers which are made by the firework agent with no smoke are smokeless and flameless, and are in according with the environment-friendly requirement.

Owner:邹建文

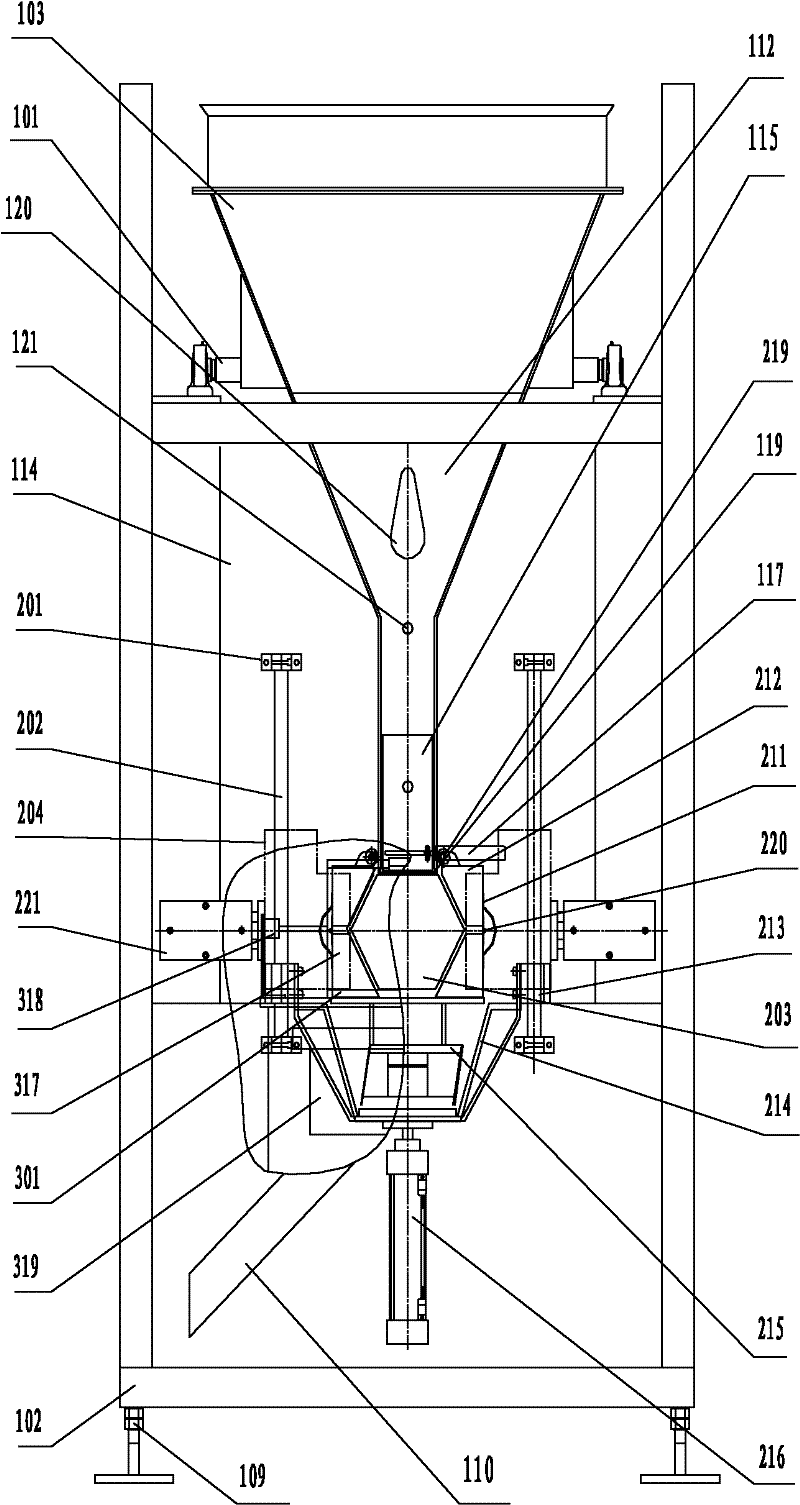

A molding binding device of firecrackers tube cake

The invention discloses a molding binding device of firecrackers tube cake, comprising a vertical feeding system, a loading molding system, a binding system and a control system. The beneficial effects of the molding binding device of firecrackers tube cake are lie in that(1) the arrangement, combination molding and binding of the firecrackers tube cake are completed in full-automation, the molding speed is fast, the binding is tight and the shape of the firecrackers tube cake is regular and beautiful; more than 300 firecrackers tube cakes can be finished per hour, which saves the human resources significantly, improves the work efficiency and solves the problem of labor shortage; (2) each part of the molding binding device is modular designed and installed, the size can be adjusted in accordance with the product, and the operation is convenient and the maintenance is fast; the abrasion of the contact site is low by employing a pneumatic roller structure, so that the device can be used for a long time without worrying about the precision to be effected.

Owner:浏阳市鸿隆综合贸易有限公司

Air firecracker

An air firecracker is formed by parallelly connecting a plurality of air cannons on an air pipe, an air tap is arranged at one end of the air pipe, a one-way valve is arranged in the air tap, a safety valve is arranged at the other end of the air pipe, and an air escape cock is further arranged on the air pipe. Each air cannon is formed by connecting a fixing seat with a sealing sleeve through a connecting column, a slide sleeve is arranged on each sealing sleeve, a stopper is arranged below each slide sleeve, an internal space of each sealing sleeve is divided into an upper air chamber and a lower air chamber, each connecting column is of a hollow structure, an air vent hole is arranged at the position of each upper air chamber, a damping hole is arranged at the position of each lower air chamber, and an explosion opening is arranged at the tail end of the lower air chamber of each sealing sleeve. Sounds similar to those of firecrackers are made by the aid of pressure difference of air, the air firecracker is similar to an explosive firecracker acoustically and visually, environmental pollution and fire can be avoided while personnel risks cannot be caused as air is produced during explosion, a reel of air firecrackers can be recycled for many times, and energy saving, environmental protection and safety are really achieved.

Owner:广州市君尚环保科技有限公司

Non-sulphur firecracker components and preparation thereof

The invention discloses a sulfur-free firecracker medicament and a method for the production thereof, and the medicament constituents are 50 to 70 parts of potassium perchlorate, 20 to 45 parts of aluminum powder, 5 to 20 parts of pearl powder, 10 to 30 parts of modified wood flour, and 0 to 5 parts of a mixture of ferroferric oxide and manganese dioxide or one material thereof. The preparation of the sulfur-free firecracker medicament is mainly characterized in that the wood flour undergoes the imbibitions treatment and the surface treatment by adopting a potassium nitrate and a micro-crystalline wax respectively. The sulfur-free environment-friendly firecracker produced by the sulfur-free firecracker medicament system of the invention has advantages of sonorous sound when setting off the firecracker, high rate of sonority, non discharge of noxious gas of sulfur dioxide, easy obtaining of constituents and materials, rather low cost, not containing prohibited articles such as potassium chlorate and being fully fit to replace the current sulfur-bearing firecracker.

Owner:湖南省浏阳金生花炮有限公司

Blasting fuse of high-safety firecracker and preparation method thereof

InactiveCN101270015AStable chemical propertiesLow mechanical sensitivityInorganic oxygen-halogen salt explosive compositionsFuse detonationYarnDecomposition

The present invention relates to a preparation method of a safe firing cable of firecrackers. In the method, yarn is used as a carrier to infuse the following medicines, which are used raw materials, according to the following steps. The medicines comprise potassium perchlorate, potassium terephthalic acid, ammonium dichromate, polyethylene alcohol, moisture resistant agent, charcoal and sulfur. The method has the following steps: the potassium perchlorate, the potassium terephthalic acid, the ammonium dichromate, the charcoal, the sulfur and the polyethylene alcohol are arranged in a container according to the weight ratio; water with a certain proportion is added into the container; the mixture is stirred so that the medicines can be dissolved in the water; then the moisture resistant agent is added; and the mixture is mixed well; the yarn is infused in the container, taken out and then sent to a drying device to be dried; thus the safe firing cable can be prepared. In the method, the yarn is used as the carrier to infuse the medicines of the firing cable; the production is simple; the amount of the medicines is reduced; the method is safe; and the cost is reduced. The application of the potassium perchlorate has the advantages of low oxygen content, low decomposition temperature, excellent stability and low sensitivity. Thus the application of the potassium perchlorate is superior to the application of potassium chlorate. The firing cable solves the problems of storage, transportation and insecurity in use.

Owner:醴陵神马花炮有限公司

Preparation method of waste paper nitrocellulose blasting powder

InactiveCN103497076AReduce pollutionSimple processNitrated explosive compositionsCelluloseFirecracker

The invention discloses a preparation method of waste paper nitrocellulose blasting powder, and belongs to the field of production of waste paper nitrocellulose blasting powder. The preparation method sequentially comprises the following steps: removing impurities in waste paper; drying cellulose; carrying out esterification reaction; carrying out invariability treatment; dehydrating; carrying out forming treatment; drying and packaging to obtain a finished product of the waste paper nitrocellulose blasting powder. The preparation method is used for preparing the nitrocellulose blasting powder from waste paper and can be used for preparing the blasting powder which is low in cost, high in energy and less in environment pollution after combustion, and black powder greatly used in the current firework and cracker industry is replaced with the blasting powder, so that the environment pollution caused when fireworks and crackers are set off is greatly relieved, and meanwhile, the entertainment and practicability of the fireworks and crackers set off by people are achieved.

Owner:白雪

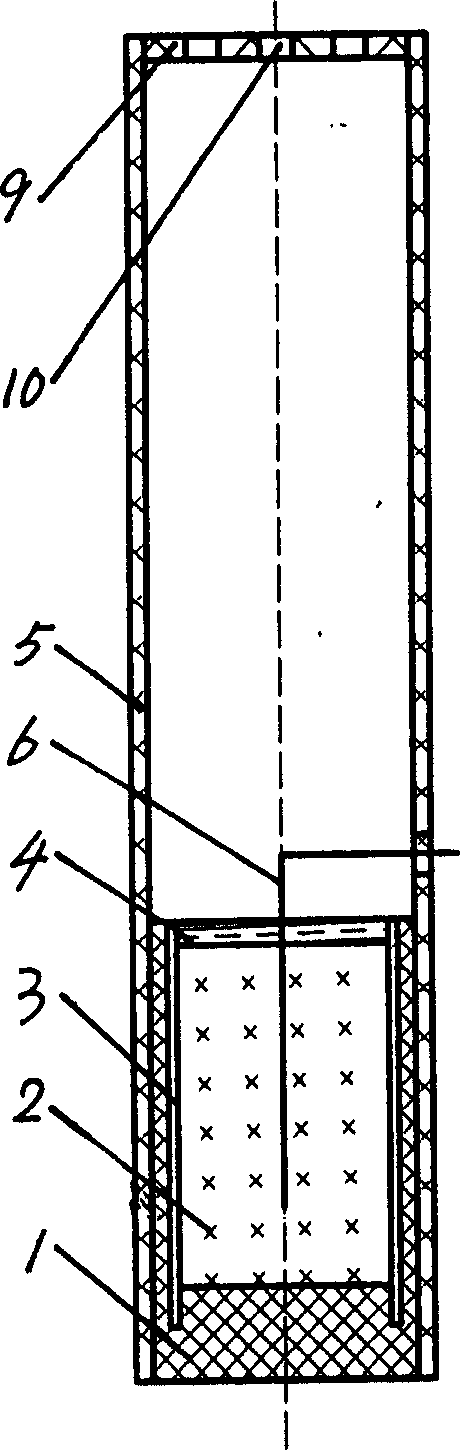

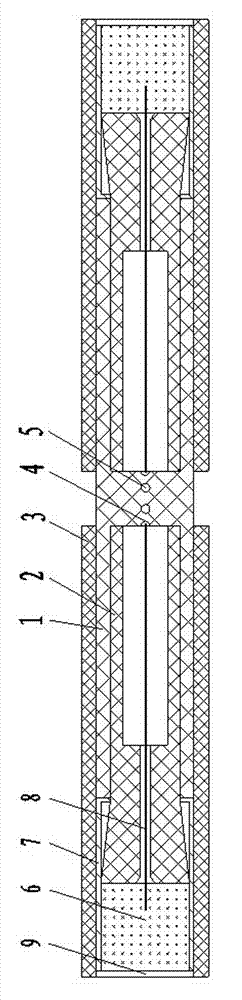

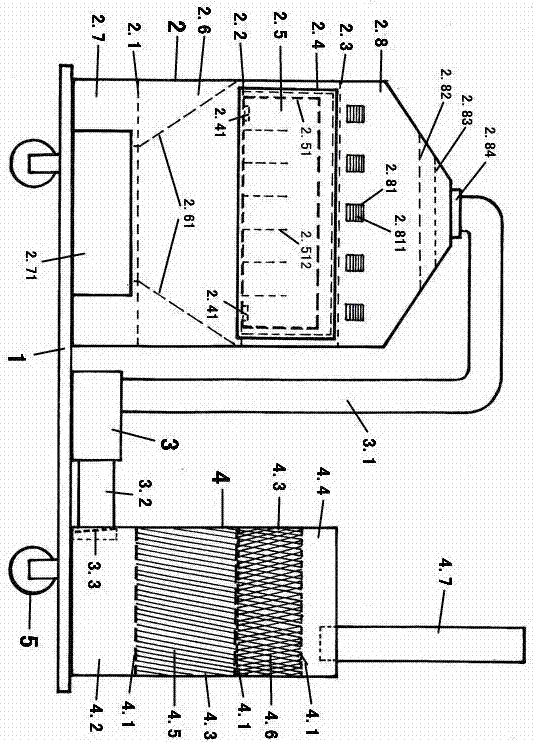

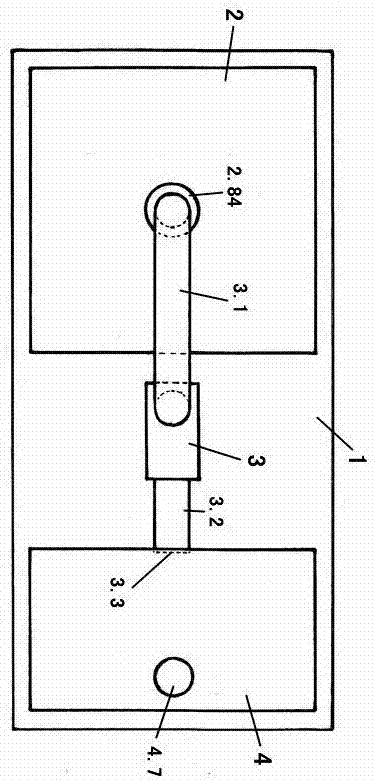

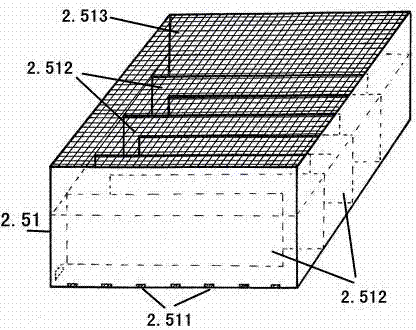

Safe environmentally-friendly firecracker with two serially-connected built-in bodies

ActiveCN103033093AAvoid pollutionOvercoming pollutionFirecrackersFirecrackerEnvironmental resistance

The invention belongs to the technical field of firecrackers and particularly relates to a safe environmentally-friendly firecracker with two serially-connected built-in bodies, and the firecracker is used for solving the problem that an existing safe, environmentally-friendly and energy-saving firecracker has a limited sound number and has difficulty in building festival atmosphere brought by the traditional firecracker. The firecracker comprises a plurality of single bodies, wherein each single body comprises a connecting piece and a fixed leading plug; each connecting piece is of a cylindrical structure with one closed end; each fixed leading plug comprises a table body at one end and a cylinder at the other end, and each cylinder is integrated with the small-diameter end of the corresponding table body; the cylinder part of each leading plug is inserted into the cylindrical structure of each connecting piece; the table body part of each fixed leading plug is inserted into a metal shell respectively; and outer shells are sleeved outside the metal shells and the connecting pieces. The built-in safe environmentally-friendly firecracker has the following beneficial effects: zero discharge is basically realized, air pollution, dust pollution and potential safety hazards caused by the traditional firecracker are overcome to the greatest extent, the advantages of the traditional firecracker and the existing safe and energy-saving firecracker are combined, and safety, environmental friendliness and energy conservation are realized to a greater extent.

Owner:HUNAN HANZHU HIGH NEW SCI & TECH

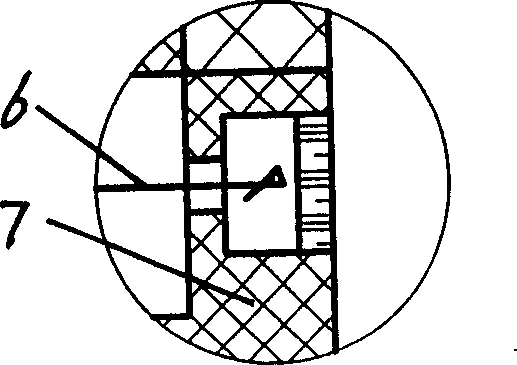

Safe environment-friendly energy-saving type exposed firecrackers

InactiveCN1828214AImprove the sound effectSuitable for industrial mass productionFirecrackersFirecrackerEngineering

The invention relates to a safe, environment-friendly and energy-saving exposed firecracker, which can solve the defects of present product which is not safe. The invention comprises a base for stuffing medicine, a sealing cut above the medicine, and lead wire. A metallic sheath is arranged between the inner wall of cylinder base and the medicine, whose lower end is embedded into base; the lower part of base is inserted into a protective frame with lead wire outlet. Compared to present technique, the invention has the advantages that: 1, high safety without injecting high-speed matters; 2, environment protection without left matters; 3, lower cost and the application for batch production, with controllable producing process.

Owner:SHENZHEN CHUANGYE TECH

Safe and environmentally-friendly firecracker firing device

Owner:芜湖启博知识产权运营有限公司

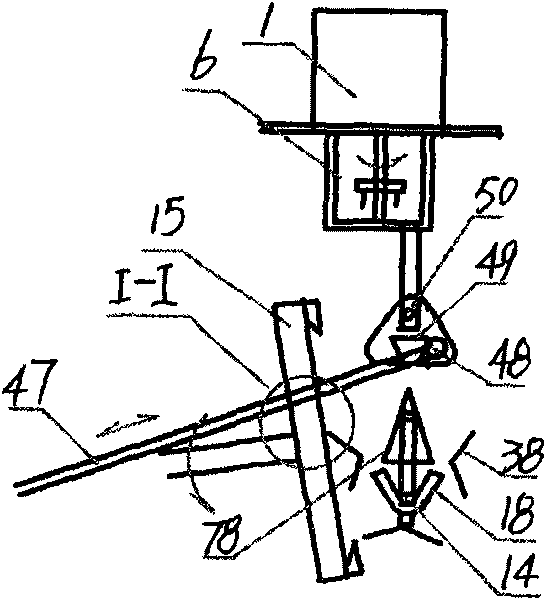

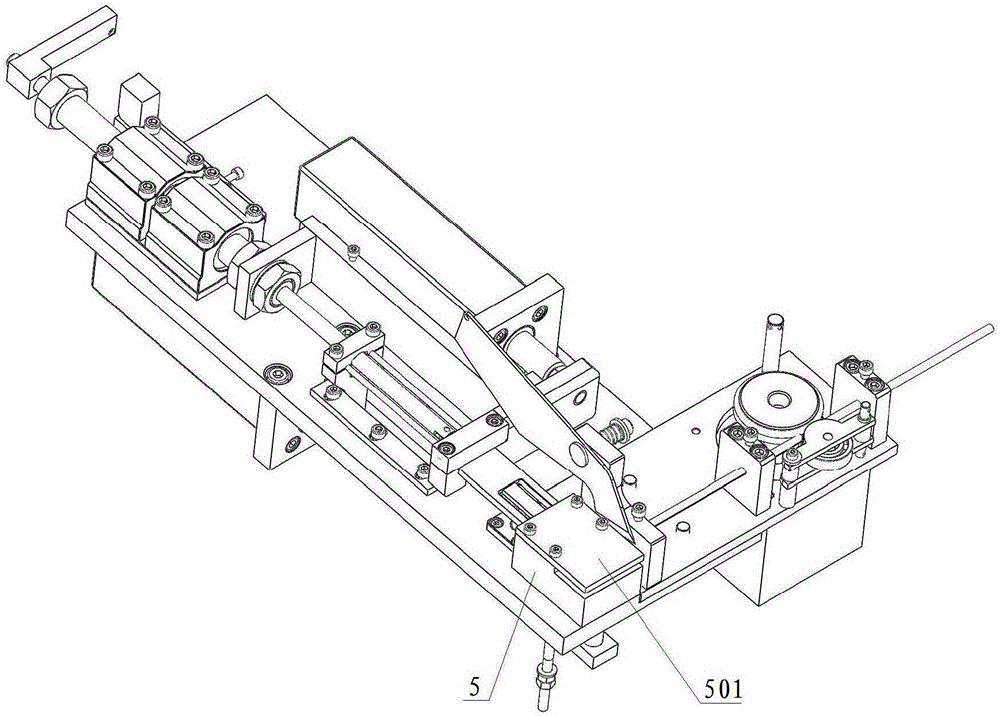

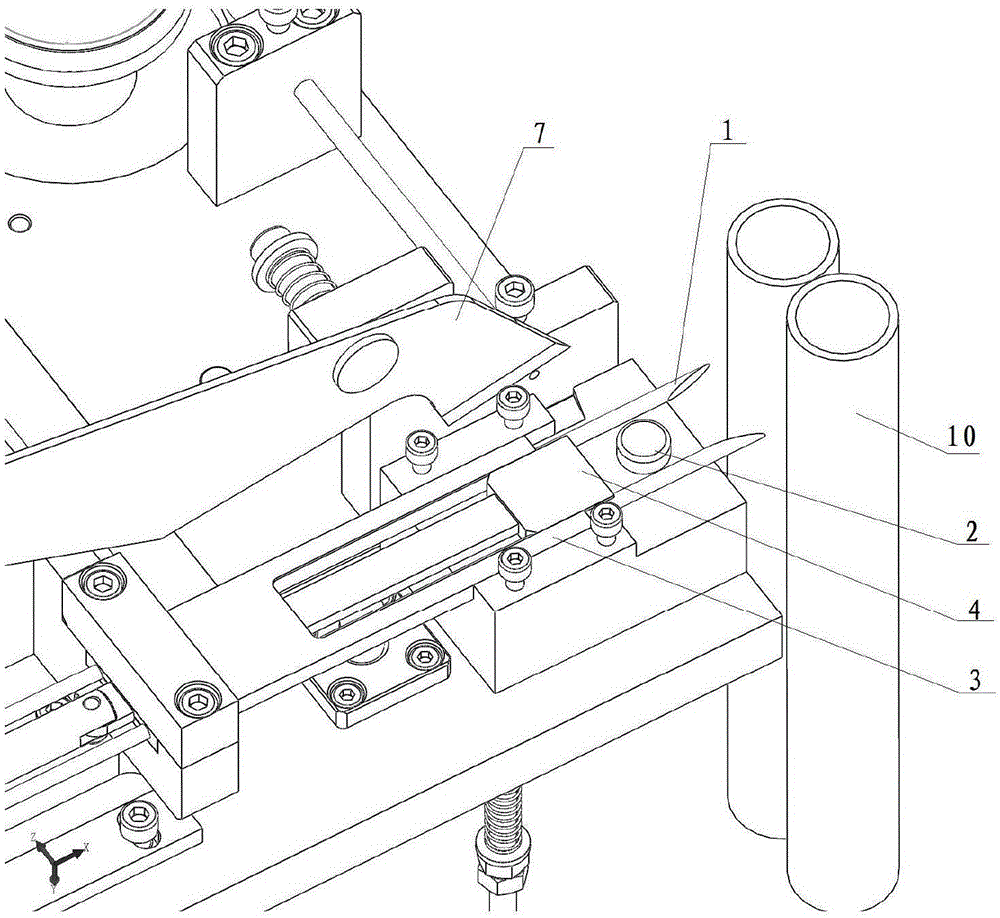

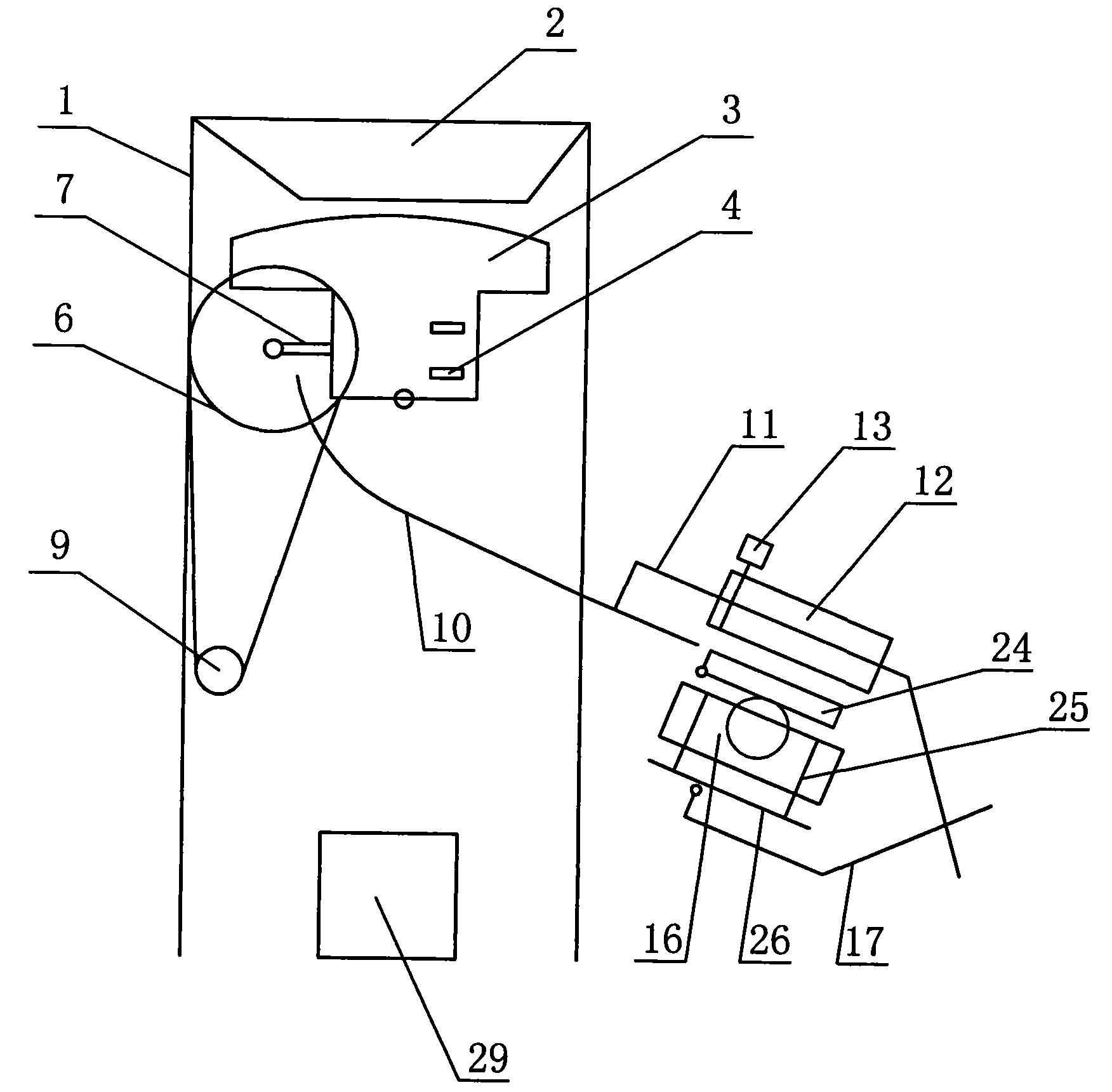

Drilling and insertion guiding mechanism for firecracker assembling

The invention discloses a drilling and insertion guiding mechanism for firecracker assembling. The drilling and insertion guiding mechanism comprises two forming guiding grooves capable of reciprocating up and down. Groove openings of the two forming guiding grooves are opposite. Groove cavities of the two forming guiding grooves are each internally provided with a drilling pin. The drilling pins reciprocate up and down along the groove cavities. A push guiding piece capable of reciprocating up and down is arranged between the two forming guiding grooves. A forming core capable of stretching out and drawing back is arranged between the two forming guiding grooves. The stretching-out forming core blocks the downward movement of the push guiding piece. The mechanism is high in work stability and reliability; firecrackers are not prone to damage; the insertion guiding quality is good; in the insertion guiding process, leads can not be damaged; a drilling mechanism and an insertion guiding mechanism can be integrated at a station so that functional movements of the drilling mechanism and the insertion guiding mechanism can be completed, and the machining quality of pre-drilling and insertion guiding is effectively improved; the troublesome of movable positioning is avoided, machining time is greatly shortened, production efficiency is improved, and possibility of failures is lowered.

Owner:CHONGQING SINYM TECH CO LTD

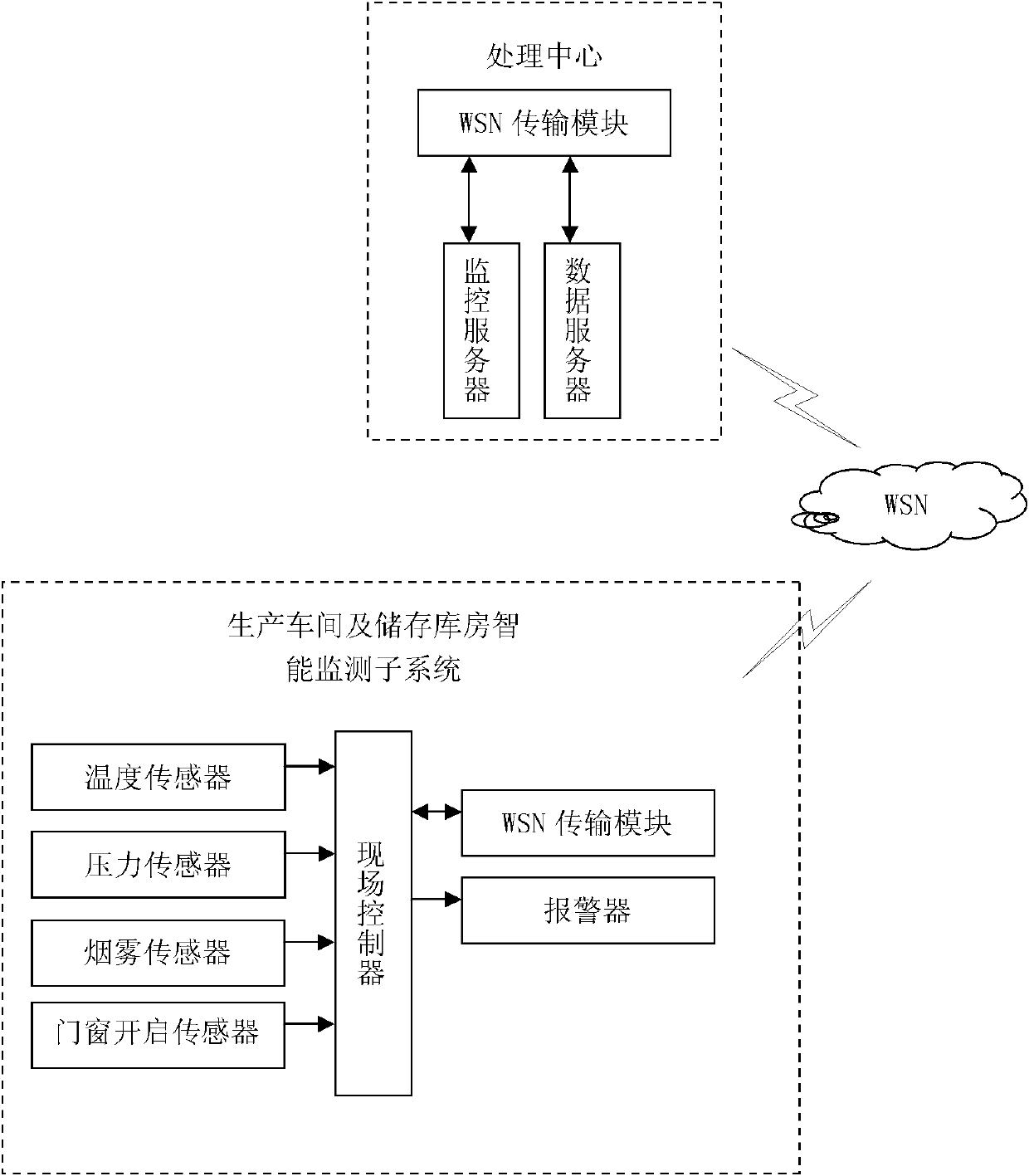

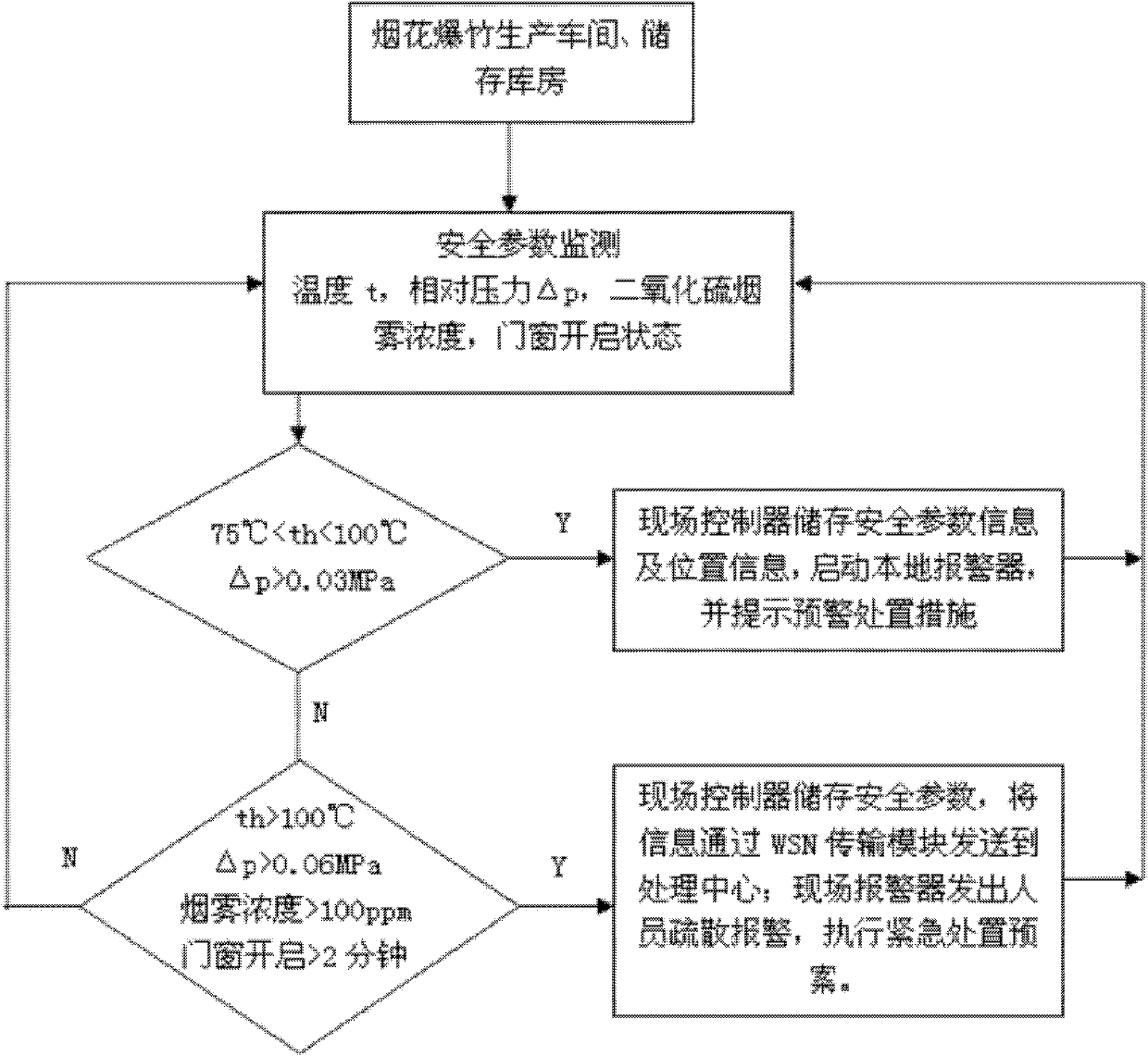

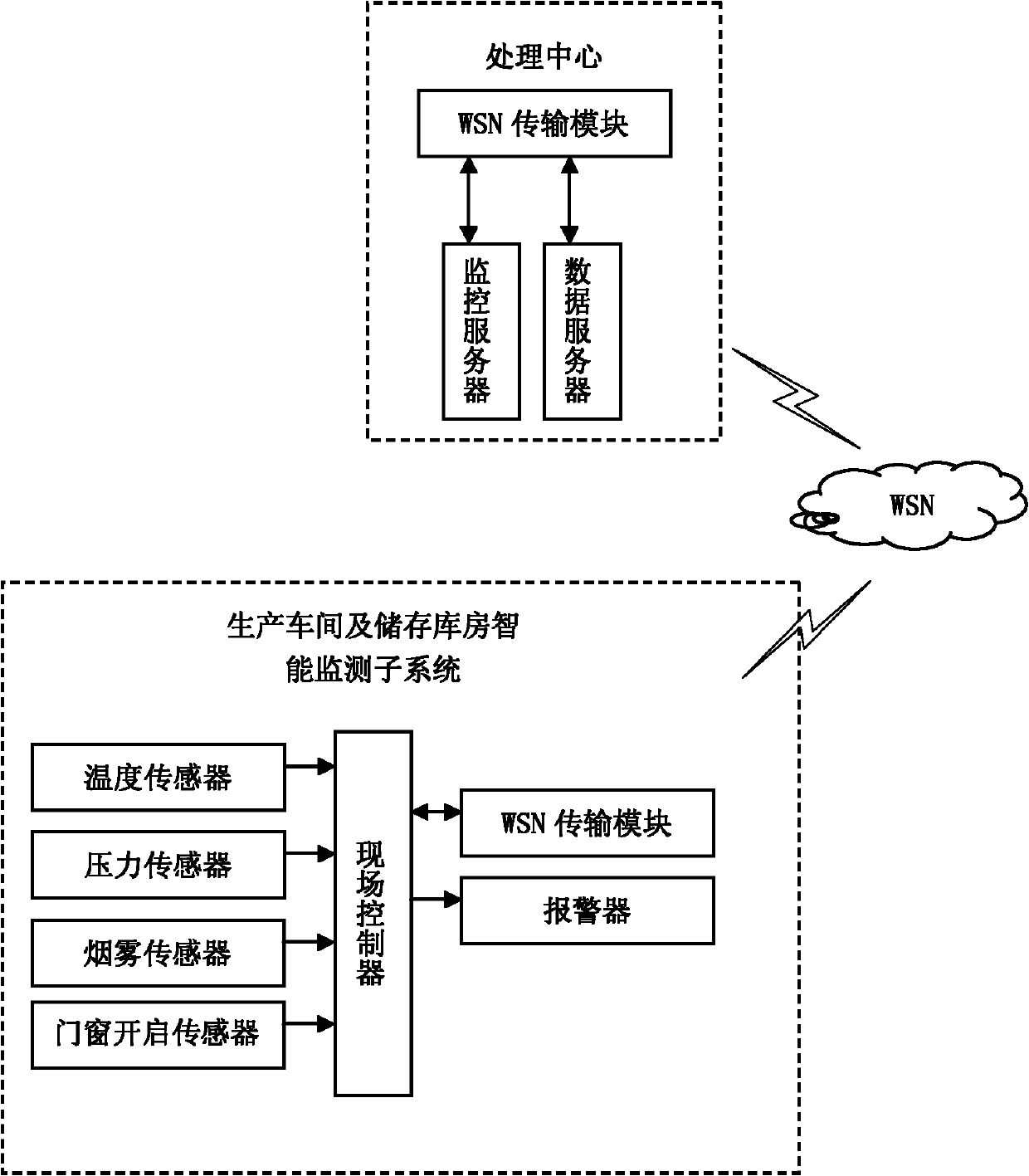

Safety monitoring system and method for firework/cracker manufacturing workshops and storerooms

InactiveCN102183943ARealize security monitoringGuarantee the safety of lifeTotal factory controlProgramme total factory controlFirecrackerStatistical analysis

The invention relates to a safety monitoring system and a safety monitoring method for firework / cracker manufacturing workshops and storerooms. The safety monitoring system comprises an intelligent monitoring subsystem for the manufacturing workshops and storerooms and a processing center which are networked by virtue of a wireless sensor network (WSN); and the safety monitoring method comprises the following steps: acquiring and storing the safety parameters of the firework / cracker manufacturing workshops and storerooms; carrying out graded early warning, alarming and corresponding processing on the firework / cracker manufacturing workshops and storerooms; and carrying out statistical analysis on the safety situations of enterprises. By using the system and method provided by the invention, the overall safety monitoring on the firework / cracker manufacturing workshops and storerooms can be realized, and timely and accurate information can be provided for the graded supervision and accident emergency of the processes of manufacturing and storing fireworks and crackers implemented by management departments, thereby preventing and eliminating the occurrence of big and special vicious accidents in the processes of manufacturing and storing the fireworks and crackers, and better guaranteeing the lives and property of people.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

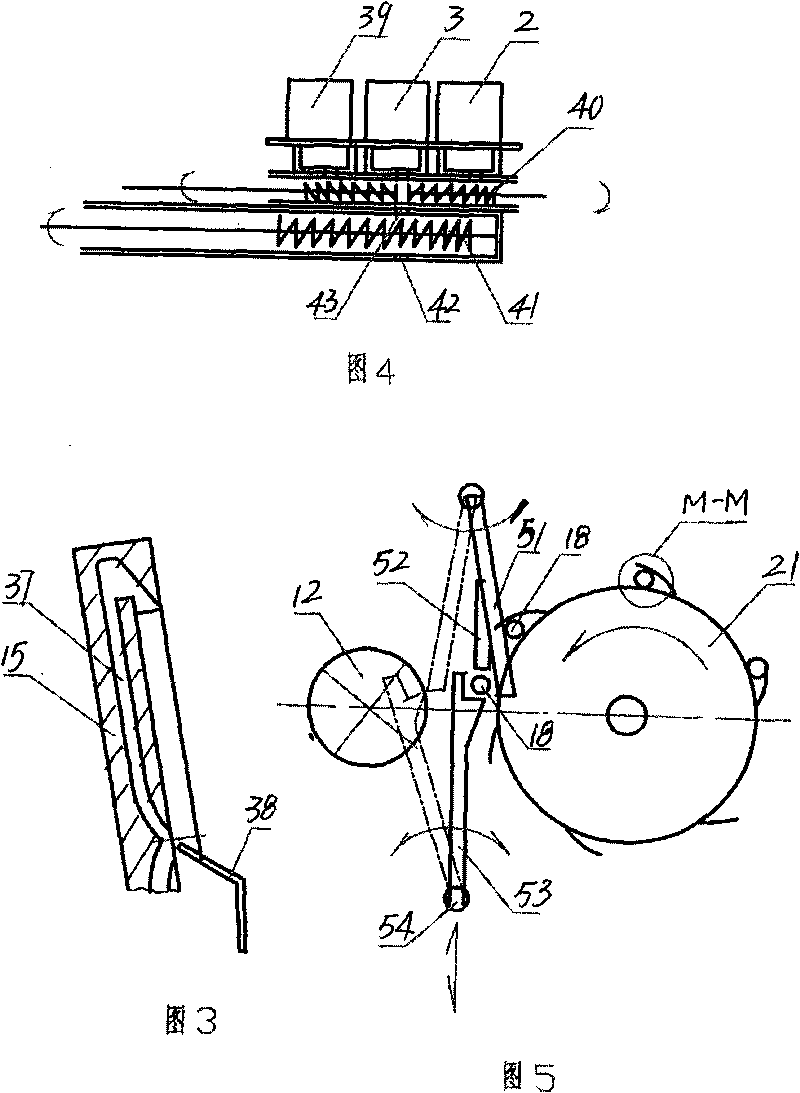

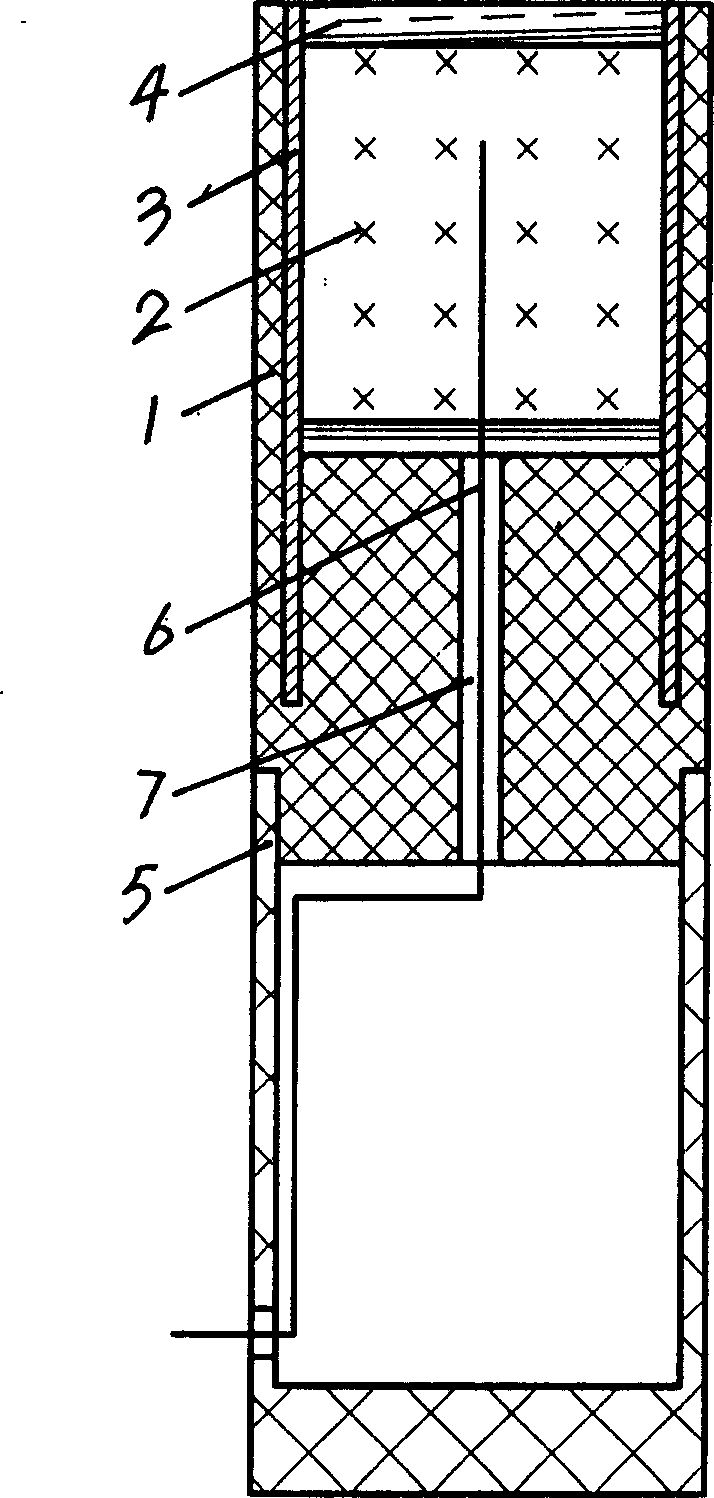

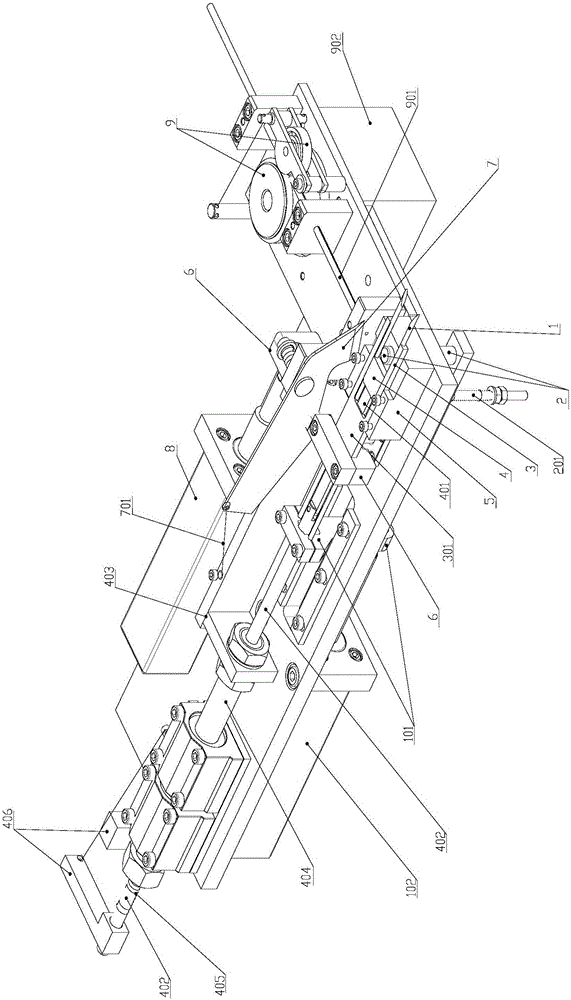

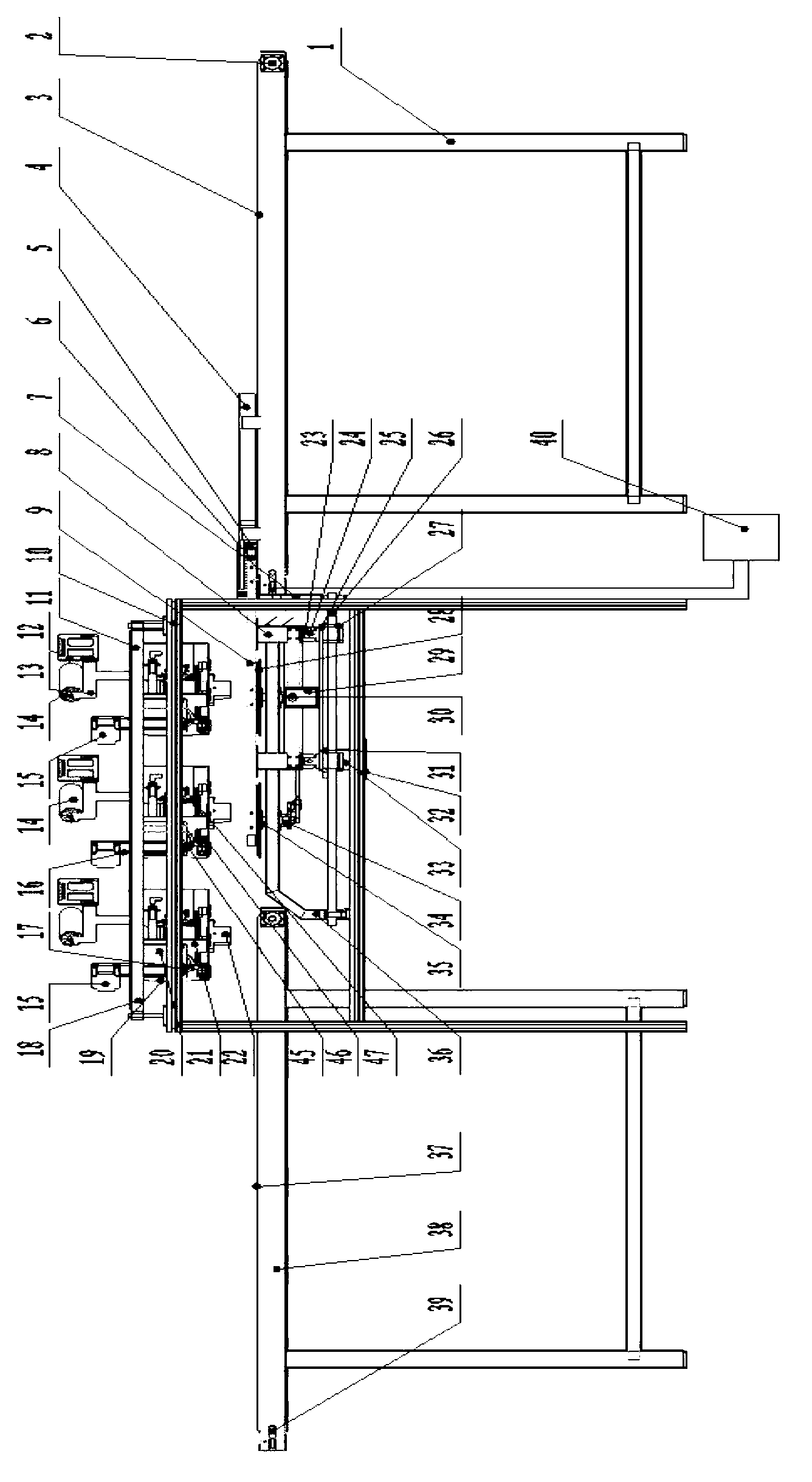

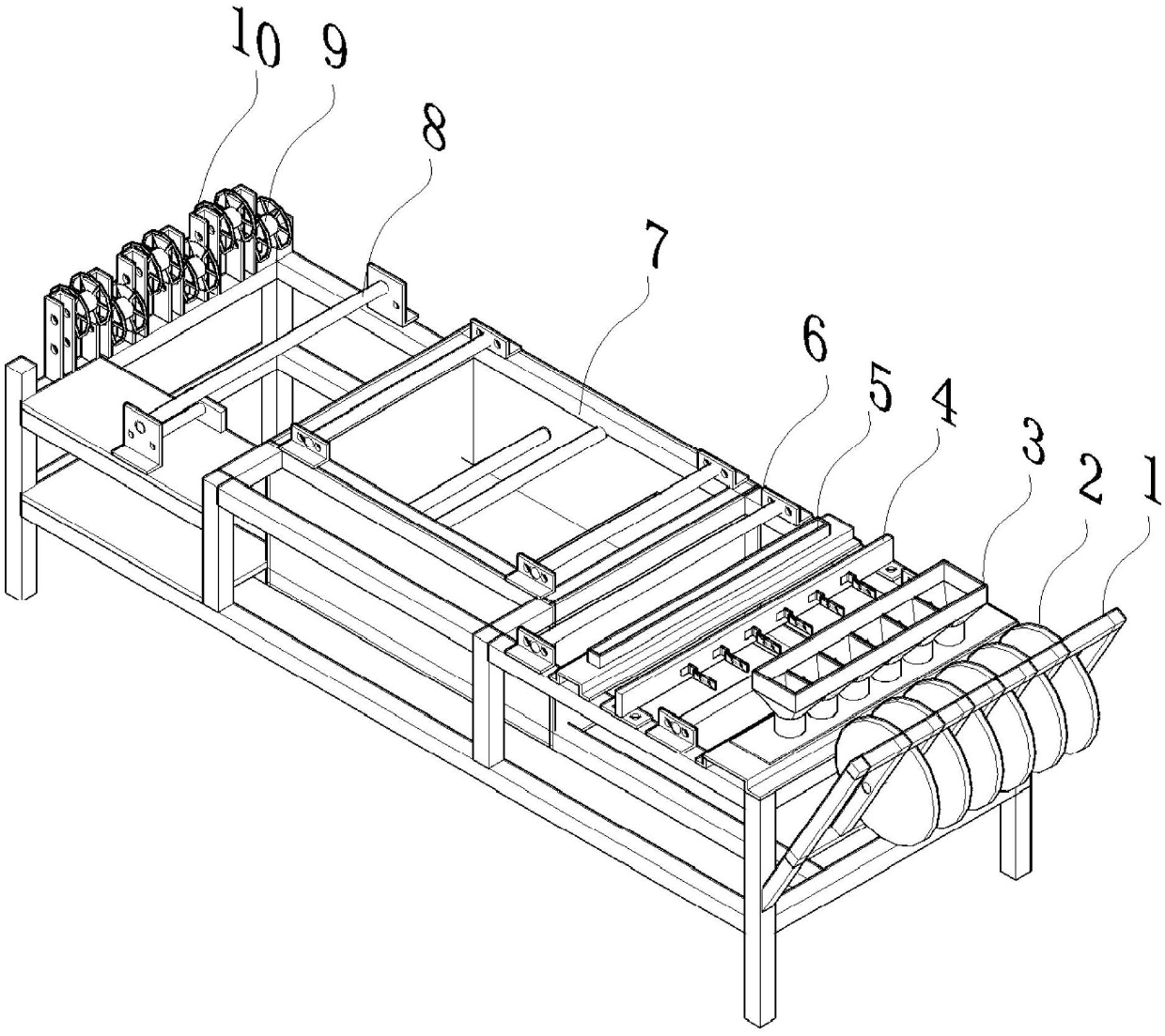

Full-automatic multi-station firecracker insertion and guide machine and working method thereof

The invention relates to a full-automatic multi-station firecracker insertion and guide machine and a working method of the full-automatic multi-station firecracker insertion and guide machine. The firecracker insertion and guide machine comprises a main frame (10), an input unit frame (1) and an output unit frame (38) respectively placed at two ends of the main frame (10), a pie plate correction rail (4), an insertion and guide machine device (19), a transposition device (35), a clamping device (9) and a feed positioning device (31). With the adoption of the scheme of the invention, full-automatic multi-station firecracker insertion and guide is achieved, the whole process of firecracker input, clamping, feeding, transposition and insertion and guide is automatically controlled, and thus the production efficiency is greatly improved.

Owner:HUNAN UNIV

Safe and sulfur-free firework bursting powder and propelling powder and preparing method thereof

The invention discloses safe and sulfur-free firework bursting powder and propelling powder and a preparing method thereof, and relates to the technical field of fireworks. The firework bursting powder is prepared from, by weight, 15-35 parts of carbon powder, 5-60 parts of potassium perchlorate and 15-70 parts of potassium nitrate. The firework propelling powder is prepared from, by weight,15-35parts of carbon powder, 5-60 parts of potassium perchlorate, 15-70 parts of potassium nitrate, 5-10 parts of adhesive and a proper amount of solvent. The firework bursting powder and propelling powderdo not contain sulfur, metal, benzene or the like, have no toxicity, reduce the air pollution, generate less smoke, have zero percussion sensitivity and friction sensitivity, guarantee safety and environmental protection, have a low moisture absorption rate and stable performance, reduce the ignition point properly, have flammability, high safety performance and propelling performance, do not easily cause barrel blasting, and reduce the production cost; the preparing method of the sulfur-free firework bursting powder and propelling powder is simple and safe.

Owner:张宏善

Safety oxidant for firecrackers

The invention is a firecracker safety oxidant, including the following components in weight ratio: barium nitrate, potassium perchlorate and perlite powder. Its advantages: it has better effect than potassium chlorate and potassium perchlorate oxidants; for adopting barium nitrate and adopting perlite powder as flame retardant and dampproofer, its safety is by far the higher than that of potassium chlorate and potassium perchlorate oxidants, and simultaneously its cost is lower than potassium perchlorate oxidant and only 5% higher than potassium chlorat oxidant. It has a wide prospect in market.

Owner:雍和平

Environment protection type micro-fume firecrackers

InactiveCN101275820AIncrease productivityGranulation realizationFirecrackersFirecrackerAdditive ingredient

The invention discloses an environment-friendly minimum smoke firecracker, composed of a high sounder, an igniting wrapped powder on the surface of the high sounder, a lead wire and a casing layer. The high sounder has a lead-free high sounder as a sounder of the firecracker; the igniting wrapped powder has smokeless igniting powder, ingredient and weight proposition of which is as follows: nitrated cellulose 60 to 90 parts; ammonium perchlorate 10 to 40 parts; antiodorant 5 parts; and strong rubber powder 2 parts; the finished product of firecracker is produced by wrapping the lead-free smokeless sounder with smokeless paper and the smokeless lead wire, so as to ensure each step of setting off firecracker is contamination free such as smoke, pungent smell, residue, etc., and implement minimum smoke and even smokeless effect.

Owner:湖南省浏阳金生花炮有限公司

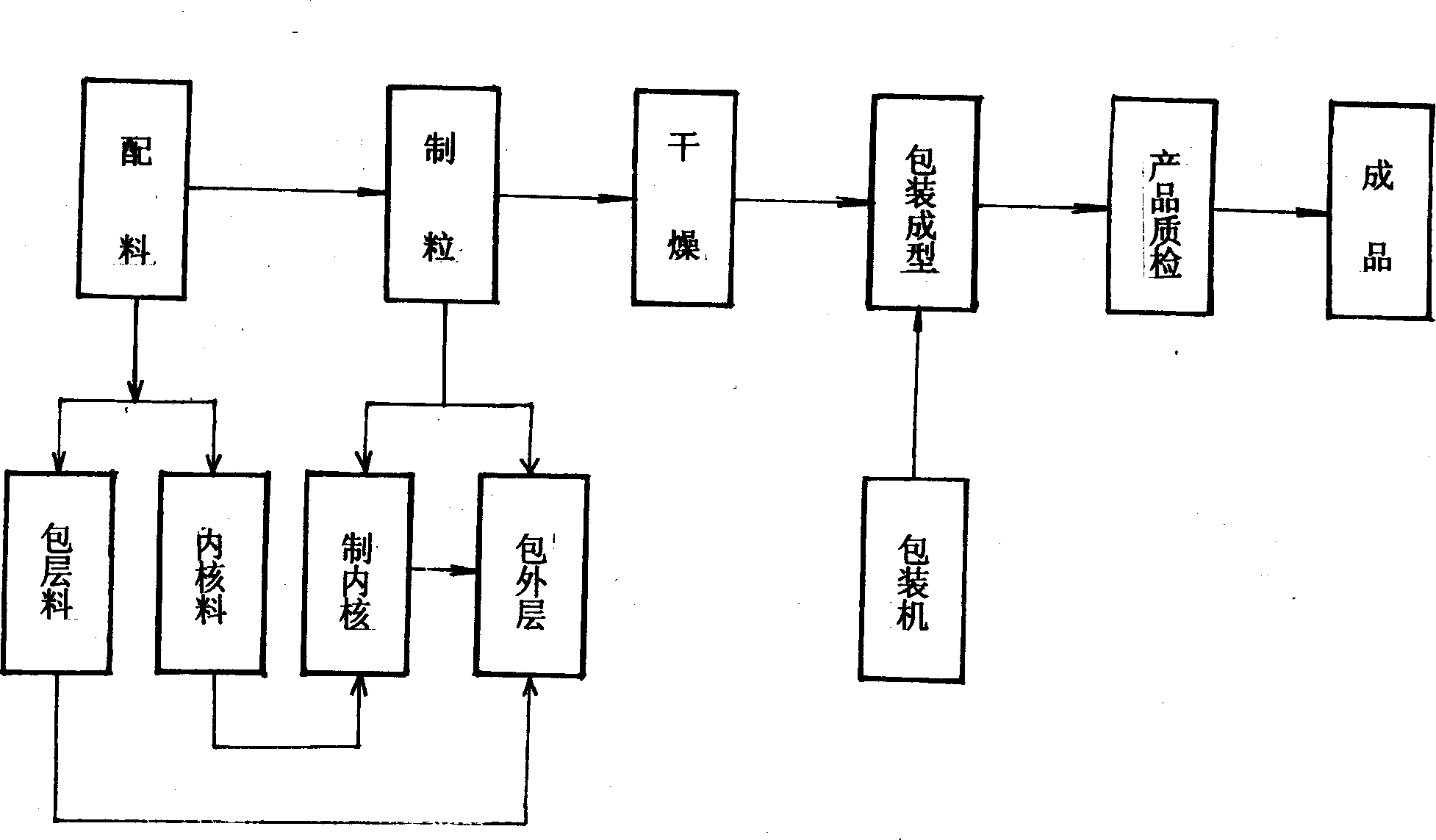

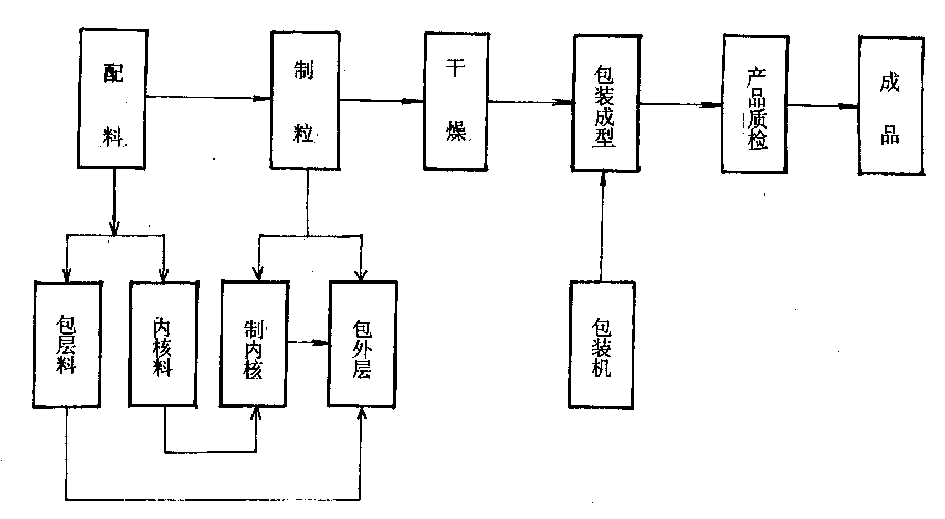

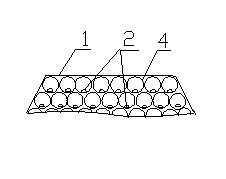

Environment protecting explosive-free safe color-light firecrackers and the production technique

The environment protecting color-liquid firecrackers consists of adhesive casing, internal safe lead and chemical grains and features that the chemical grain consists of inner kernal comprising red lead powder, copper oxide powder, Al-Mg alloy and PVA adhesive; and outer coating comprising potassium nitrate, Al-Mg alloy, charcoal. sulfur, aluminium dregs and phenolic resin. The firecrackers and produced through pelletizing in steel sieve, rolling to form inner kernel, rolling to adhere outer coating to inner kernel and other steps. It is safe in production, storage, transportation and firing and has large sound produced.

Owner:欧定锋

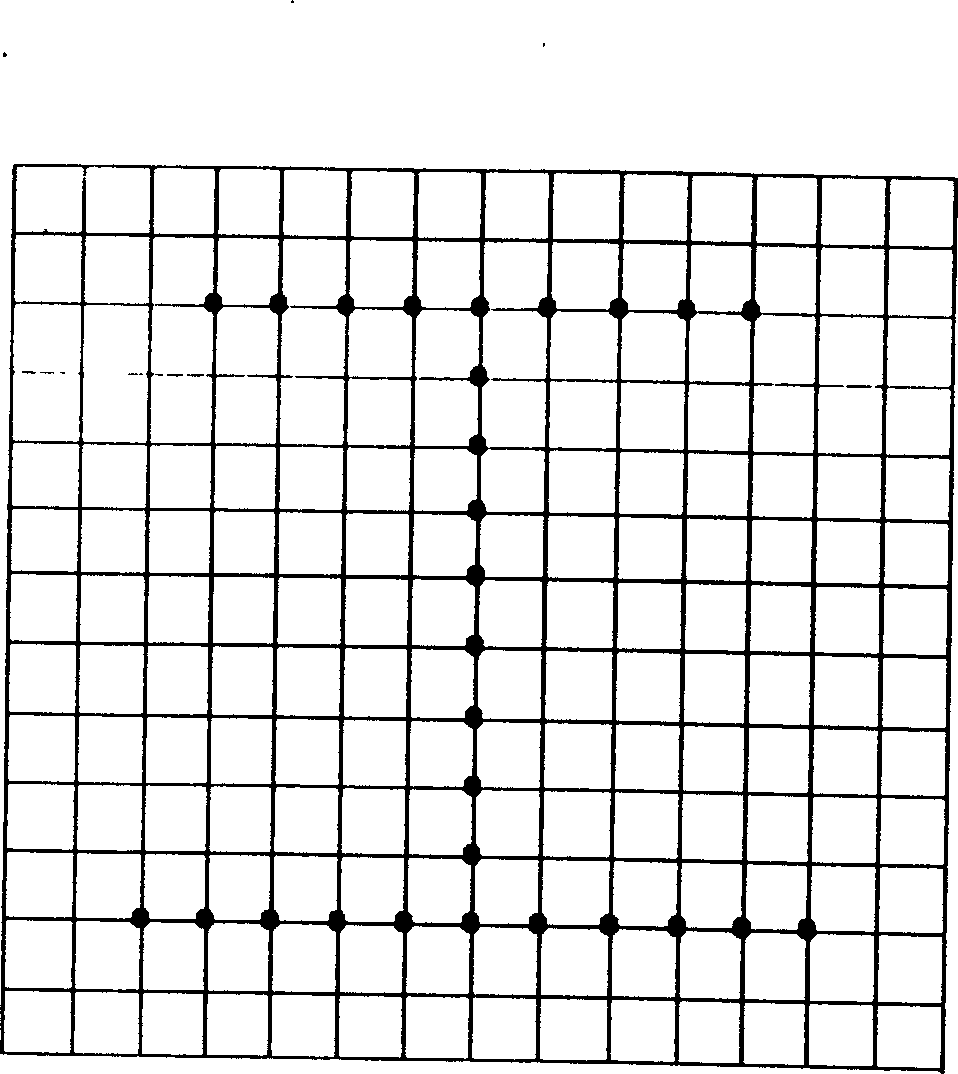

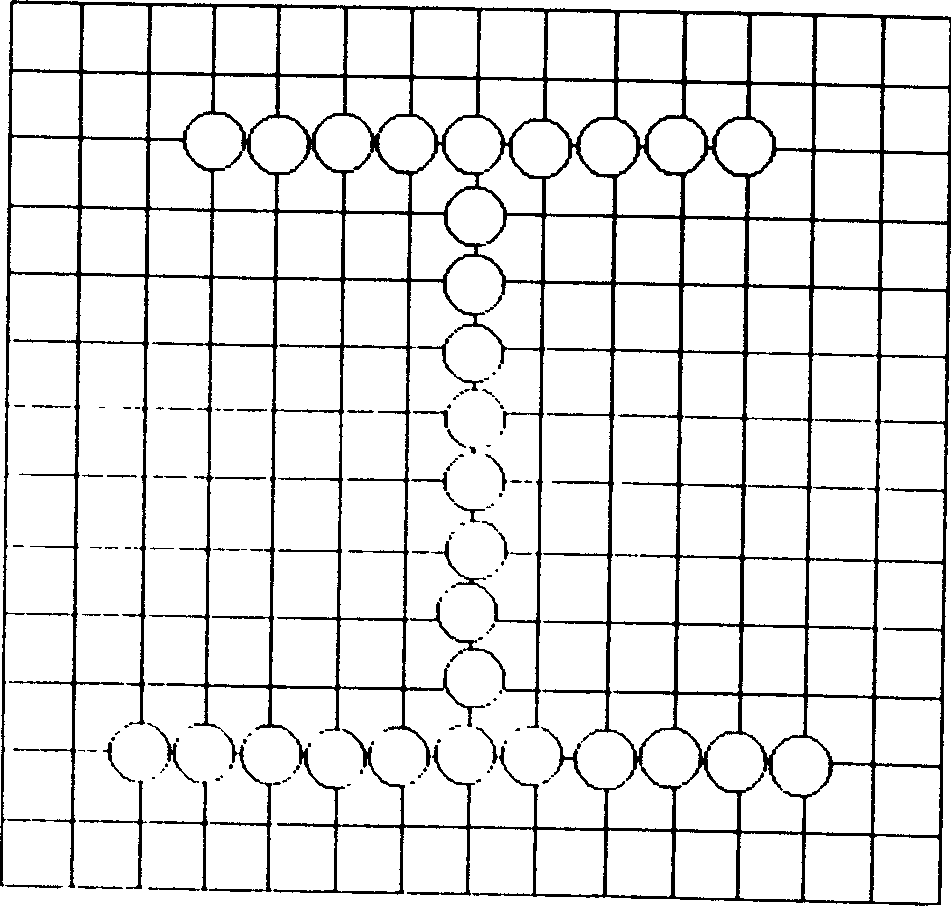

Method for caption displaying by firecracker in the sky and its launching system

The invention discloses a method for caption displaying by fire cracker in the sky and lunching system. The ground lunching fireworks head and forming lattice at the precaptions effect surface displaying captions. The lunching system includes lunching frame, lunching pipe, and display fireworks head. It can display any word or picture in the key.

Owner:陈刚

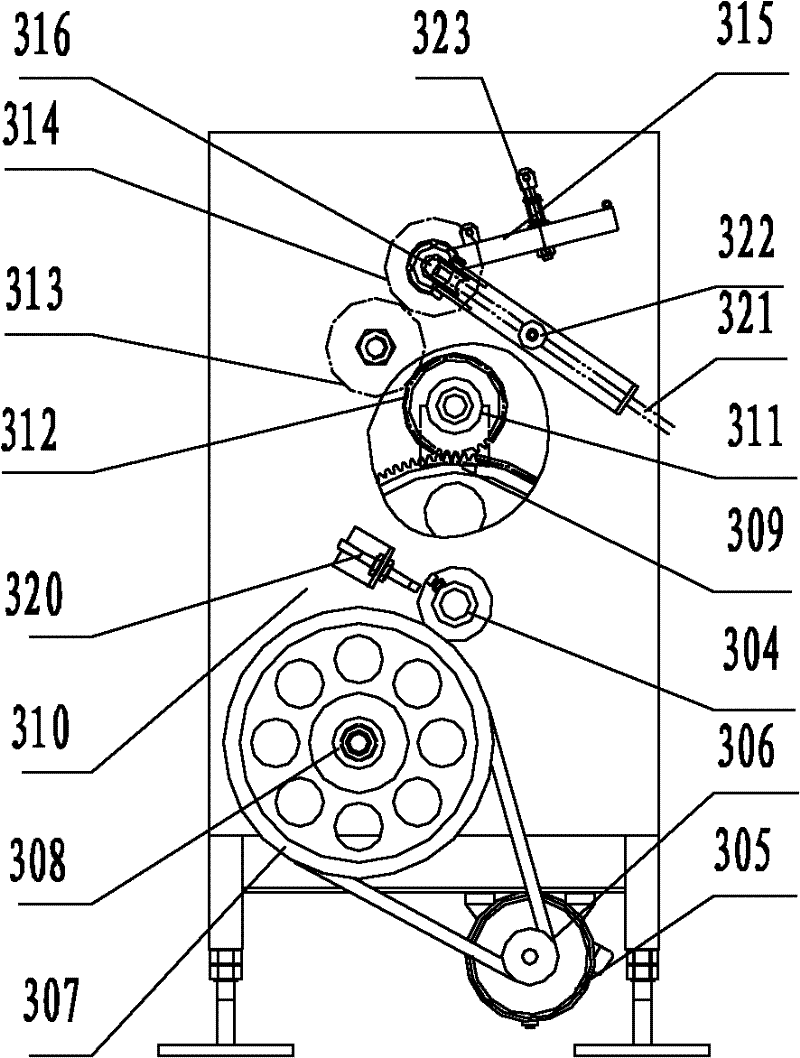

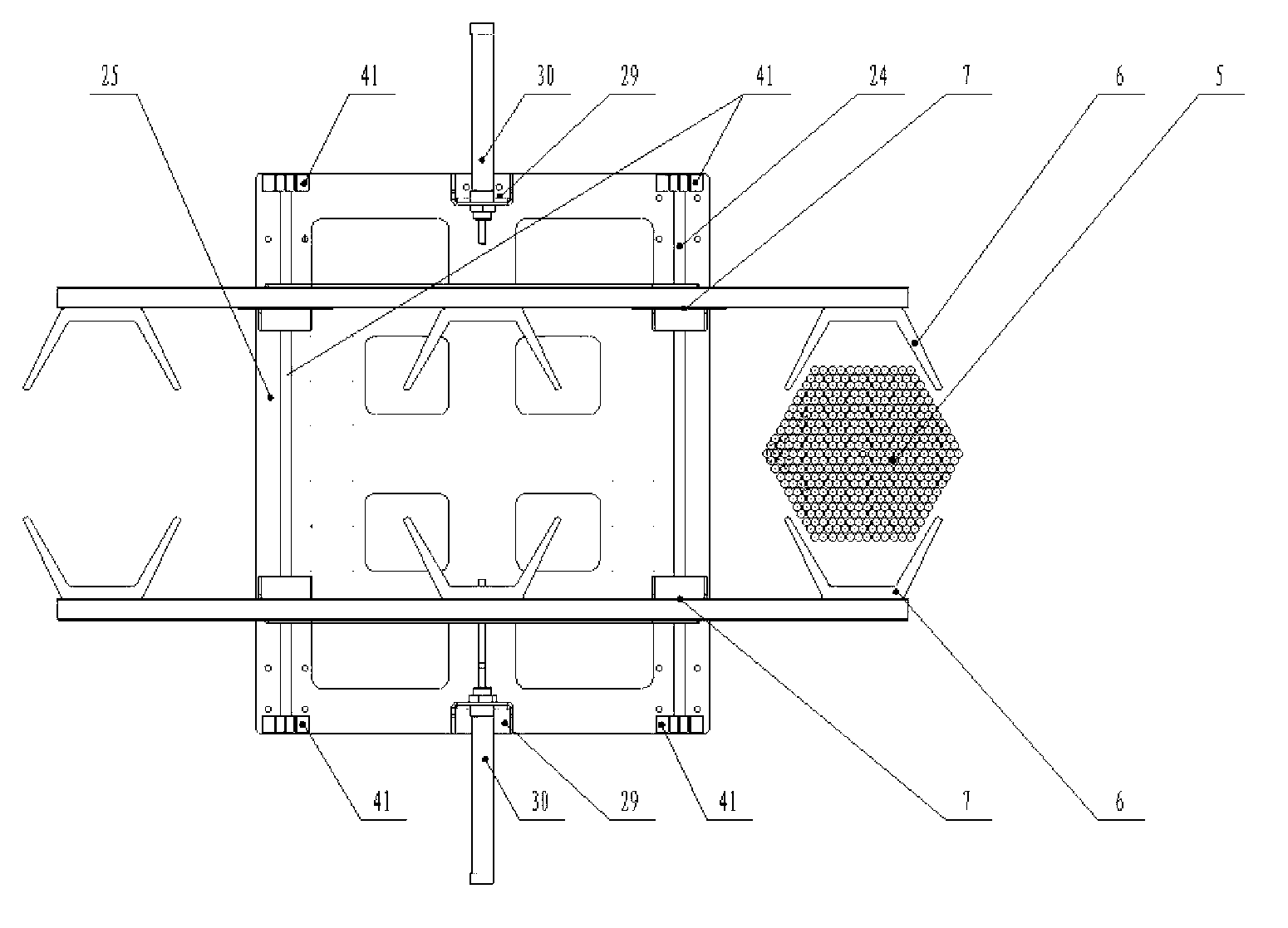

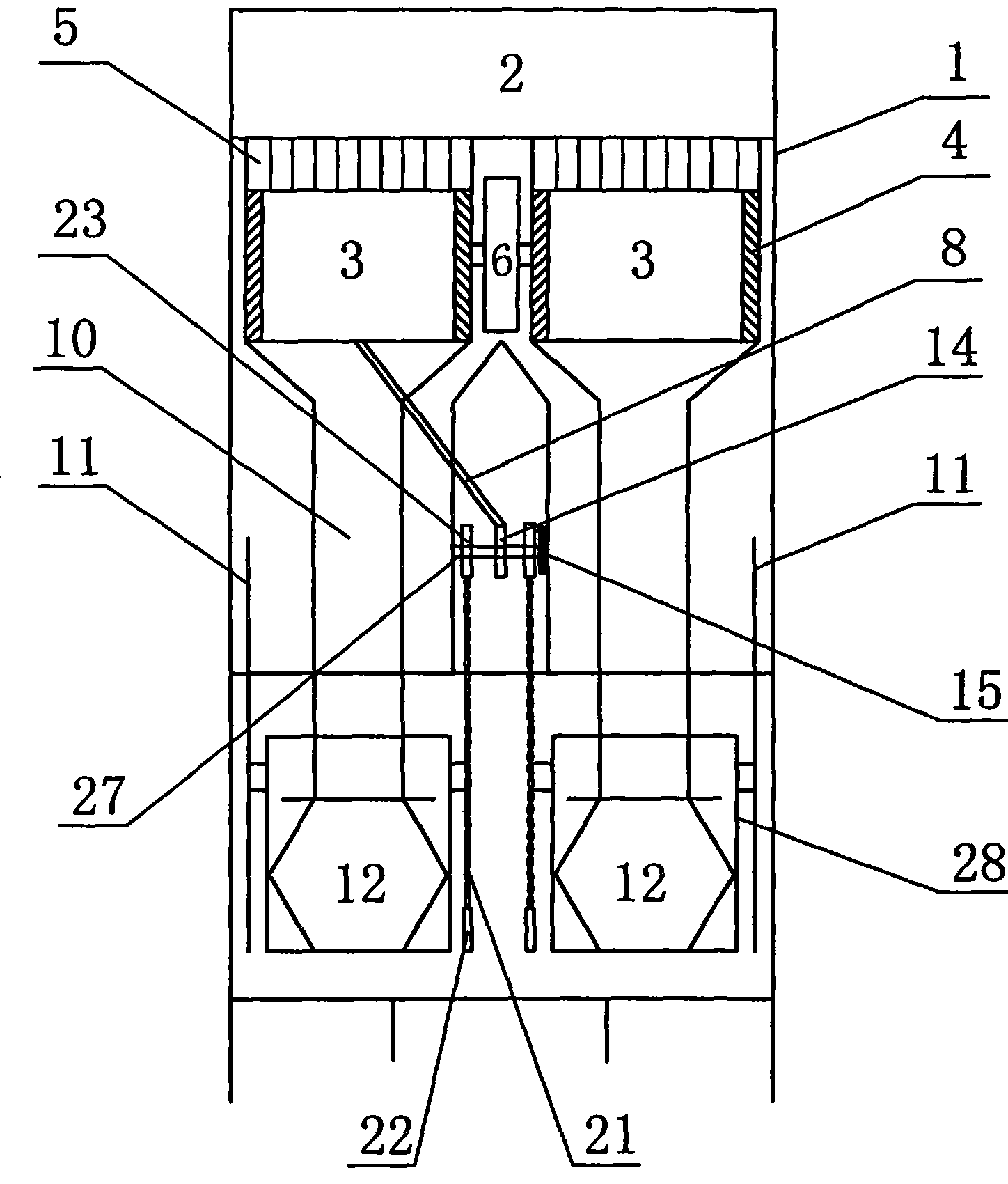

Semi-automatic firecracker drum washing and forming machine

InactiveCN101551216AImprove work efficiencyReduce manufacturing costFireworksFirecrackerMolding machine

The invention discloses a semi-automatic firecracker drum washing and forming machine which has a structure that two swing screen drum devices are arranged below a hopper, lower outlets of the two swing screen drum devices are respectively provided with a discharging passage, both sides of the two discharging passages are respectively provided with a directional guide rail, the middles of the two directional guide rails are respectively provided with a regular hexagon forming die, the bottoms of the regular hexagon forming dies are provided with regular hexagon moulding boards with the side lengths slightly shorter than the side lengths of the regular hexagon forming dies, the lower parts of the regular hexagon moulding boards are provided with oscillators which are connected with rushing boards through push rods, and the rushing boards are connected with foot-pedal type push rods; one of the two swing screen drum devices is connected with a ratchet arranged at the middle of a fixing shaft through a guide gear, and the middle of an annular chain is connected with die carriers of the fixed forming dies. The invention replaces the manual operation, thereby greatly enhancing the work efficiency.

Owner:刘大勇

Agent combination of safe fireworks and fire cracker

InactiveCN1431182AAvoid low temperature decomposition disadvantagesHigh melting pointExplosivesFireworksUrea nitrateFireworks

A high-safety composite charge for firecrackers or fireworks is prepared from oxidant (metallic oxides including Fe2O3, Fe3O4, copper oxide, manganese oxide, etc and organic alkali nitrate including urea nitrate, guanidine nitrate, etc.) sulfate compound, aluminium powder, pearlite powder and charcoal powder. The said sulfate compound is ferrous sulfate as gas expanding agent, which is treated through dewatering, pulverizing, surface treating, and neutralizing. Its advantages are high safety, and high performance in sound, light and colors.

Owner:刘琼吾 +1

Lead coil forming machine for fireworks and crackers

The invention discloses a lead coil forming machine for fireworks and crackers. The lead coil forming machine mainly comprises a paper disc mounting frame, a charge bucket, a lead coil forming device, a glue box, a lead traction rod, a heating region, a reciprocal moving rod, a lead disc bracket and a stand. An electrochemical integrated automatic comprehensive technology is adopted in the lead coil forming machine; the modern advanced manufacturing level of firing line manufacturing equipment for the fireworks and the crackers is represented; the machine is independently controlled and operated by a single wire; and the entire machine can realize full or partial independent work. By applying a wet processing technology, the lead coil forming machine is reasonable in structure and capable of safely discharging static electricity generated by various factors, effectively preventing accidents, guaranteeing the public safety, the personal safety and the property safety, also increasing the labor efficiency and the production efficiency and practically reducing the number of employees on dangerous duties. A produced finished product has a unified standardization, and the market competition of the product is improved. The lead coil forming machine can be widely applied and used in the field of manufacturing of the fireworks and the crackers.

Owner:DONGXING HUAHONG OPTICAL TECH

Smokeless and ammonia smell-free cold-light firework chemical

InactiveCN108299135ASteady and full sprayReduce the temperatureNon-explosive/non-thermic compositionsFirecrackerNitrocellulose

The invention discloses a smokeless and ammonia smell-free cold-light firework chemical, and belongs to the field of fireworks and crackers. The invention solves the technical problems by providing the cold-light firework chemical with very little combustion smoke, even no smoke, strong jetting force, full sparks and no ammonia smell. The cold-light firework chemical comprises the following components in parts by mass: 13-91 parts of nitrocellulose, 0.2-7 parts of ferrocene, 0.5-2.5 parts of a stabilizing agent and 8-80 parts of titanium powder. Through adjustment of a ratio of the nitrocellulose, the stabilizing agent, the ferrocene and the titanium powder, the cold-light firework chemical is free of combustion smoke, stable and full in spark jet, low in temperature, free of irritating ammonia smell after combustion, safe and reliable, and has a wide application range in the field of fireworks and crackers.

Owner:LUZHOU NORTH CHEM IND

Smokeless and quick lead medicament for fireworks and firecrackers

The invention provides a smokeless and quick lead medicament for fireworks and firecrackers. The lead medicament mainly comprises, by mass, 50-90% of a eutectic compound of amine perchlorate, 5-25% of carbon powders, 1-20% of metal powders and 1-7% of an adhesive. The smokeless and quick lead medicament for the fireworks and the firecrackers has obvious advantages of no smoke, environmental protection, quick burning and low hygroscopicity.

Owner:NANJING UNIV OF SCI & TECH

Explosive with aromatic for environmental protection safety firecrackers

InactiveCN1559999AImprove securitySimple recipeAlkali metal salt explosive compositionsFriction sensitivityFirecracker

The invention relates to a potassium chlorate-free and sulfur-free fragrant environmental- protection safety powder of firecrackers and its components are compounded of potassium perchlorate, Al powder, perlite powder and sandalwood powder. It has simple formula, a few components, good chemical stability and safety, no potassium chlorate and no sulfur, eliminates the defects of strong impact and friction sensitivity, high danger, etc, and has the advantages of low mechanical sensitivity and high safety, excellent bang rate of setting off firecrackers and sound level value.

Owner:易显云

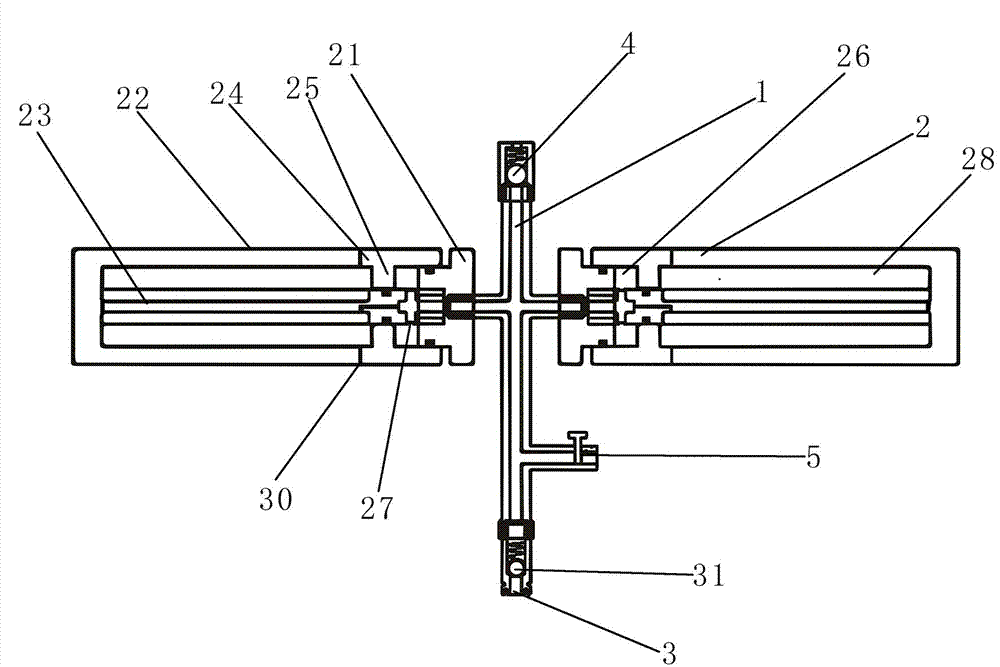

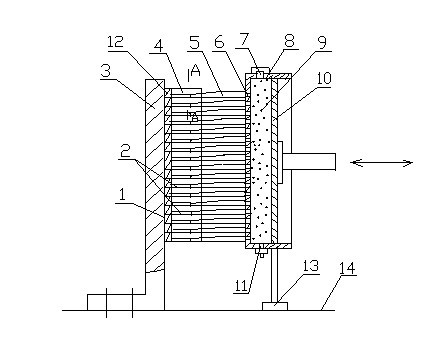

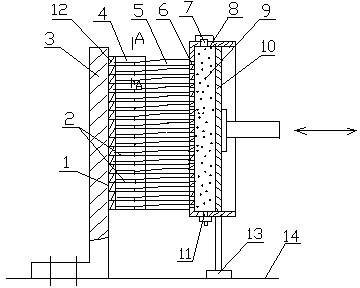

Firecracker pouring leading line technology method

ActiveCN102679822ATo achieve the discharge effectImprove ergonomicsFireworksFirecrackerEconomic benefits

The invention discloses a firecracker pouring leading line technology method that a bottom-sealed firecracker cake (1) is vertically fixed on a mold plate (3); a pouring and leading device is arranged in the axis direction of the firecracker cake; pouring and leading needles (5) correspond with the paper cylinders on the firecracker cake in number and position; the pouring leading line needles (5) can extend into the paper cylinders (4); and when the leading line slurry (9) in the pouring leading line needles flows into the inner walls of the paper cylinders in line shape under the pressure, the pouring leading line needles move from inside to outside till the pouring leading line needles move out of the firecracker cake, and the solidified line-shaped leading line slurry can be fixed on the inner walls of the paper cylinders to serve as the leading lines (2). According to the firecracker pouring leading line technology method, the leading lines are safe to make, the material consumption and waste are reduced, the making cost of the leading lines is reduced; and as the leading lines are uniform in size and correct in position, leading line breaking and splitting are avoided, the fire joining performance is excellent, and all the paper cylinders of the firecracker cake can be simultaneously poured and led once for all, the inserting leading line procedure is reduced, the inserting leading line efficiency of the firecrackers is improved, the inserting leading line cost is reduced, and the economic benefits are improved.

Owner:崔立波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com