Process for producing activated carbon by physical activation method

A technology for the production of activated carbon and physical activation, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., and can solve problems such as inability to use, environmental pollution, and poor adsorption capacity of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

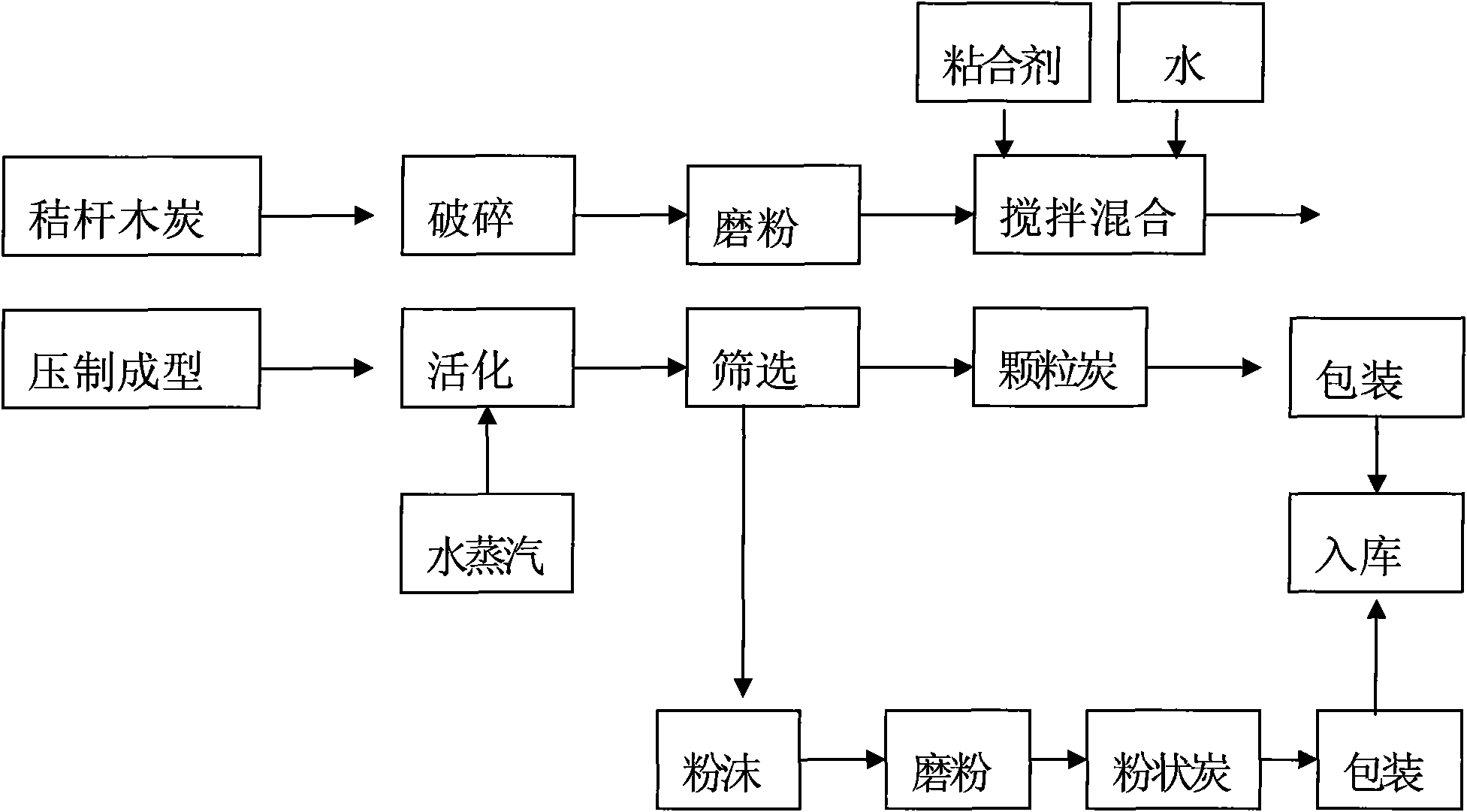

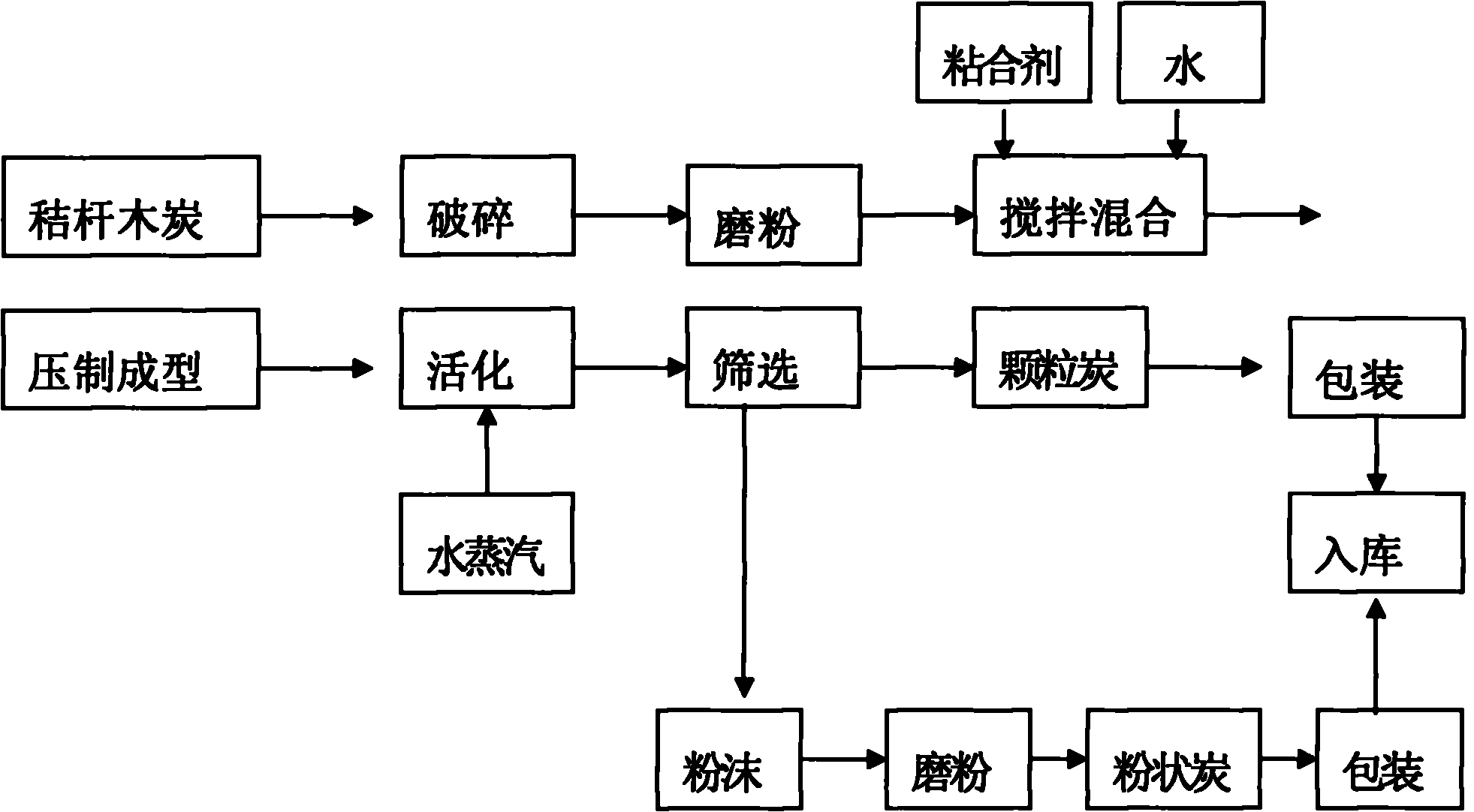

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] 1. Raw materials: straw mechanism charcoal is used as raw material for production.

[0028] 2. Crushing: Crushing rod-shaped or coarse-grained straw charcoal into unshaped particles with a roller crusher.

[0029] 3. Grinding: Send the granular charcoal to a ball mill or Raymond mill for grinding, and the particle size should be 140-180 mesh.

[0030] 4. Stirring and mixing: In order to increase the density and strength of activated carbon, add an appropriate amount of wood tar or coal tar pitch to the charcoal powder as a binder, fully stir in a mixer, and mix well to a degree.

[0031] 5. Compression molding: The mixed charcoal wet material is extruded in a batch punching machine, or continuously extruded in a screw extruder. The aperture of the steel flower plate at the exit of the extruder is generally 1.5-8mm (selected according to the needs). The extruded str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com