Patents

Literature

730 results about "Firewood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Firewood is any wooden material that is gathered and used for fuel. Generally, firewood is not highly processed and is in some sort of recognizable log or branch form, compared to other forms of wood fuel like pellets or chips. Firewood can be seasoned (dry) or unseasoned (fresh/wet). It is generally classified as hardwood or softwood.

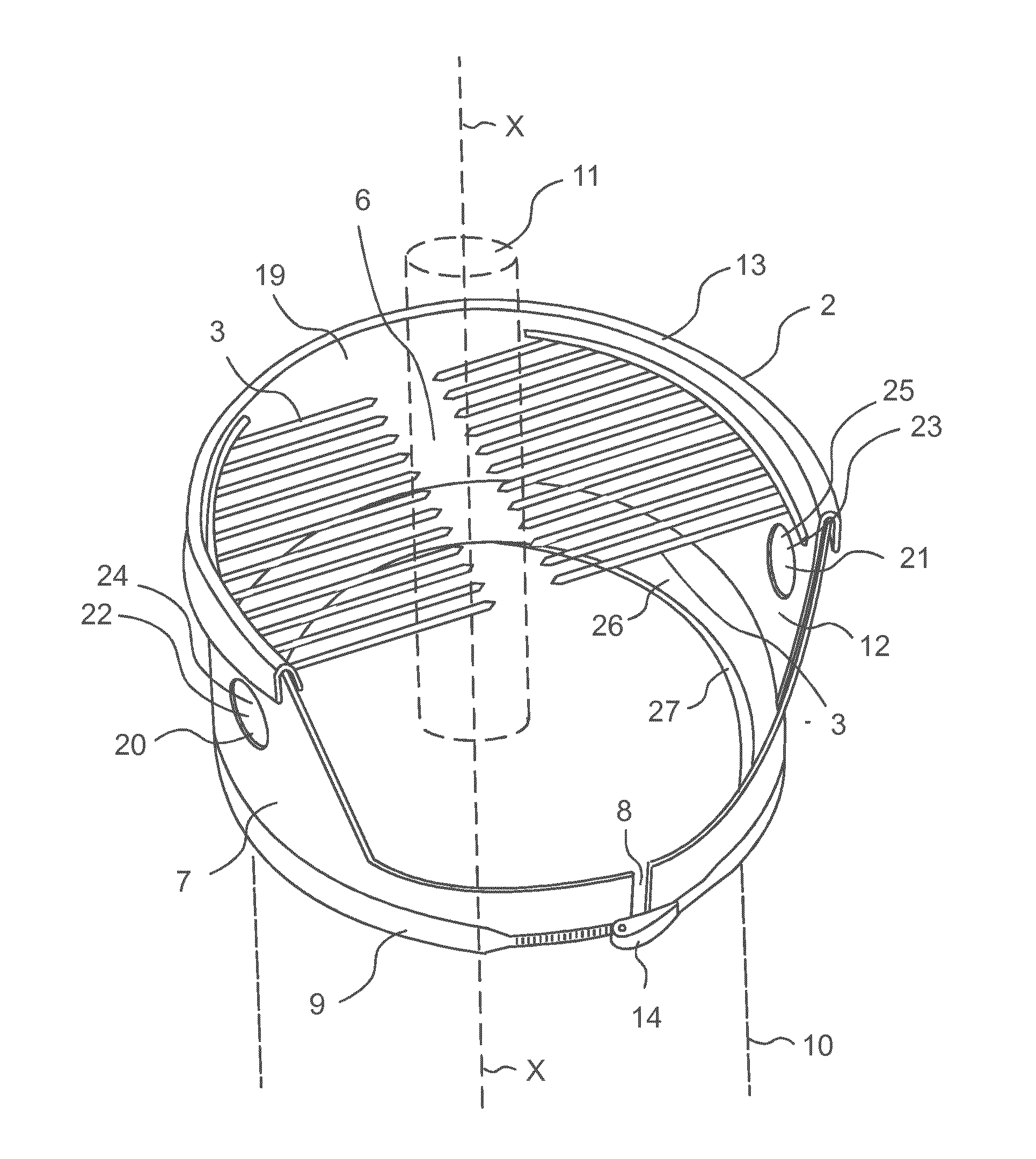

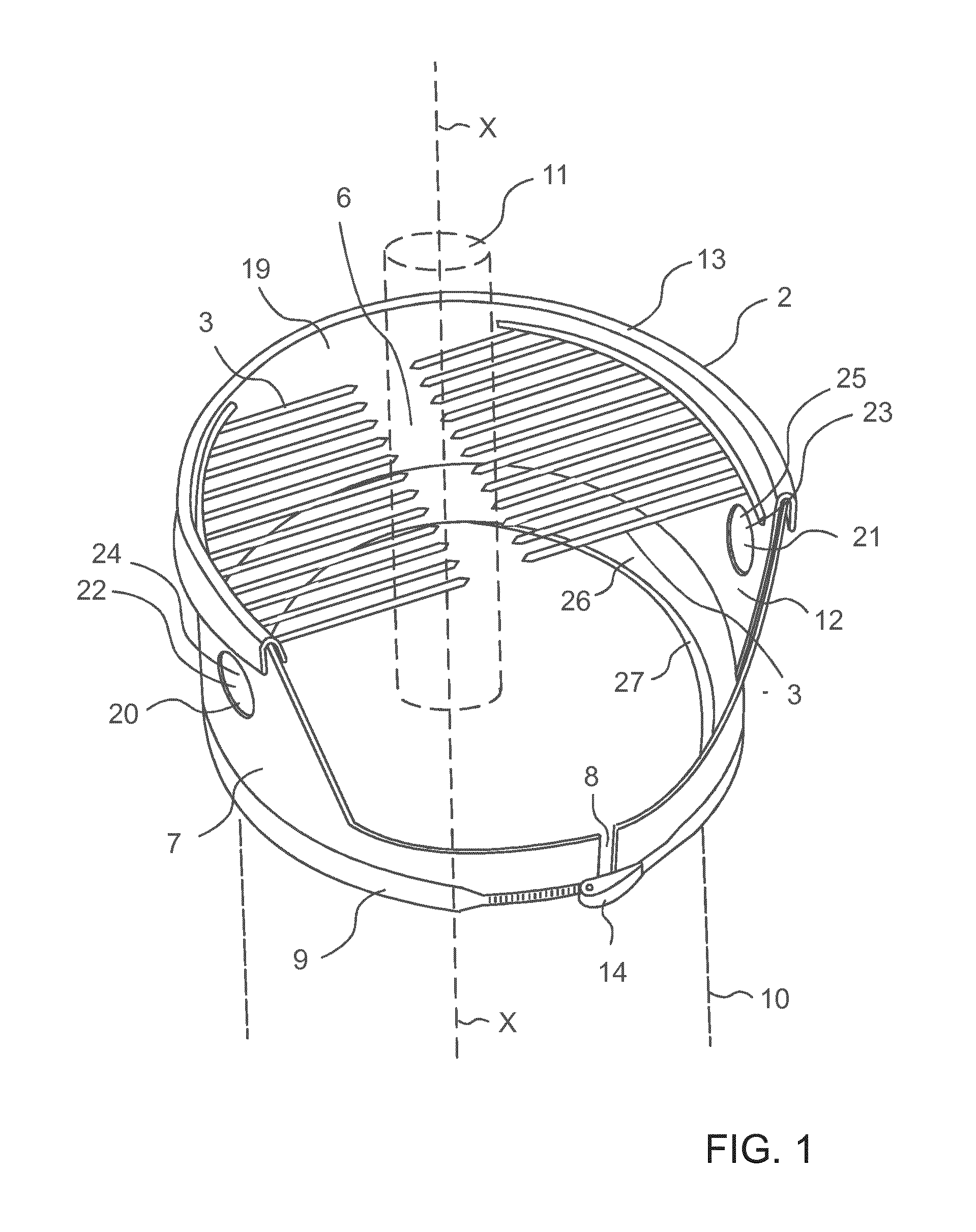

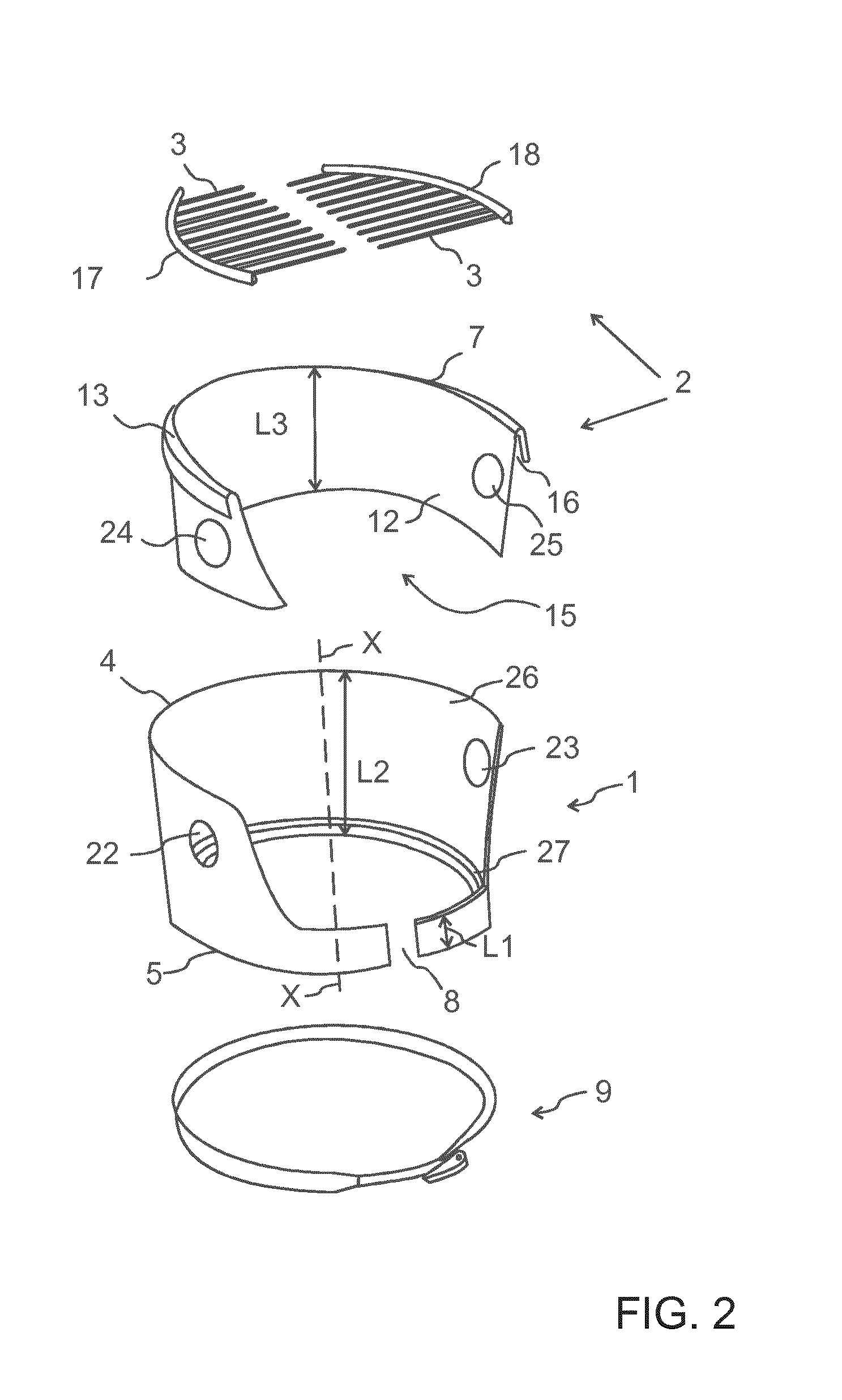

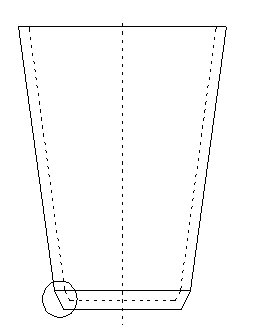

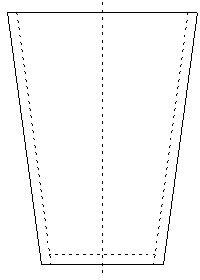

Chopping aid device

ActiveUS20140175724A1Chopping and splitting of logs easier, faster and saferEasy to replaceWood splittingPositioning apparatusFirewoodEngineering

A chopping aid device for use in chopping of firewood includes a frame to pre-vent pieces of wood from spreading into the surroundings outside the chopping aid device during chopping. In order to make chopping of wood easy, fast and safe, the chopping aid device has a support with flexible spikes to keep the firewood in an upright position within the frame.

Owner:FISKARS BRANDS FINLAND

Processing process for anhua black raw tea

InactiveCN102972541ASoup color orange redSoup color orange red translucentPre-extraction tea treatmentCooking & bakingBlack tea

The invention relates to a processing process for anhua black raw tea, and in particular relates to the processing process for the anhua black raw tea. The processing process comprises the following steps of: picking fresh leaves, removing water, primarily rubbing, piling, secondarily rubbing, drying, naturally storing and pre-pressing. According to the processing process provided by the invention, the material selecting is particular, and all black tea raw materials adopt the raw materials in the producing area of liudong tea in jiangnan town; in the process of removing water, the firewood is used as fuel, so that air pollution caused by using coal as fuel is avoided and the tea is prevented from absorbing peculiar smell of sulfur dioxide released by coal combustion, and the original flavor of the tea is greatly ensured. The tea can be kept black and oily through the baking of pine firewood, and the tea color is orange red and bright. After being baked, the tea is naturally stored for over one year before being pressed, fermented in an oxidative manner, and primarily processed; no crushing process is needed before the pressing process; as space inside the tea is bigger due to raw tea-leaf pressing, oxygen needed for microbial activities is provided, and so golden flowers can be seen inside the black tea finished product.

Owner:湖南三十九铺茶业有限公司 +1

Method for preparing biomass lump coal

The invention discloses a method for preparing lump coal by adopting biomass as raw material and relates to the preparation method for the lump coal. The method comprises the following steps: (1) crushing straws into thick-filament straws, and crushing firewood and twigs into sawdust; (2) mixing the thick-filament straws and the sawdust, then, soaking the mixture with an aqueous alkaline solution, then, fermenting the mixture, and then, continuing to ferment under the condition of high-speed stirring; (3) crushing cattle manure and combustible refuse in municipal domestic waste, then, adding the crushed material into a fermentation softening solution, soaking the crushed material, and then, fermenting for 6 to 10 hours; (4) standing the fermented solution, and filtering out moisture, thereby obtaining viscous biomass slurry; (5) crushing barks, then, adding water to the crushed barks, heating, and then adding starch; and (6) uniformly mixing coal slurry, a binder and the biomass slurry which are in the mass ratio of 1 to (2 to 3) to (40 to 45), and then, carrying out compacting molding at molding pressure, thereby obtaining the finished product. The method disclosed by the invention has the advantages that the method is low in cost and easy to operate, and the product is easy to mold, high in mechanical strength, difficult in slag-bonding and little in smoke dust.

Owner:SHANXI TIANRUNFENG AGRI TECH DEV CO LTD

Wet process for building 3t intermediate frequency electric furnace

The invention relates to a wet process for building a 3t intermediate frequency electric furnace. By the process, 3t of materials can be melted, and the service life is prolonged. The process comprises the following steps of: (1) manufacturing a steel crucible die which has a shape of a truncated hollow cone; (2) paving an insulation layer and a thermal insulation layer by using two layers of asbestos cloth; (3) paving a furnace bottom, namely paving two layers of asbestos cloth at the furnace bottom in a staggered mode; (4) paving a furnace wall, namely paving two layers of asbestos cloth next to the inner wall of an induction coil from top to bottom, ensuring that each layer is flat and does not have any wrinkle, adhering longitudinal joints for lapping by using water glass, staggering joints of two adjacent layers, and adhering the asbestos cloth which stretches out of the upper plane to a fireproof brick plane at an upper opening of the furnace by using the water glass; (5) preparing a furnace lining material from refined quartz sand; (6) manually knotting a furnace lining, brushing a layer of water glass before filling, and tamping a filler; and (7) baking the furnace and sintering, namely baking only by using firewood after the furnace is built by the wet process, adding 50 to 60kg of firewood into a hearth for several times, and completely combusting to bake the furnace lining.

Owner:HANGZHOU ZHONGQIANG ROLLER

Earlier-stage treatment method adopting cotton straw to prepare pleurotus edible mushroom cultivation raw material

InactiveCN102219574ABio-organic fraction processingOrganic fertiliser preparationFirewoodAgricultural science

The invention discloses an earlier-stage treatment method adopting cotton straw to prepare pleurotus edible mushroom cultivation raw material. The method comprises the step of fermenting the raw material including cotton and firewood powder dust to obtain an edible mushroom cultivation substrate. The core of the method is that fermentation treatment is conducted after the cotton straw is smashed to improve the physical and chemical properties of the cotton straw, so that the cotton straw becomes a main cultivation material suitable for edible mushroom cultivation. The species of mushroom suitable for the obtained cultivation substrate include oyster mushroom, pleurotus eryngii, pleurotus nebrodensis, pleurotus geesteranus, pleurotus cornucopiae and other pleurotus edible mushrooms.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

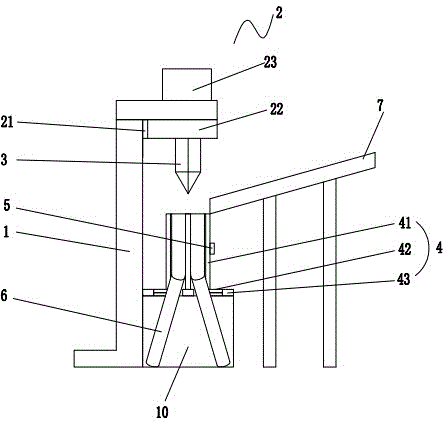

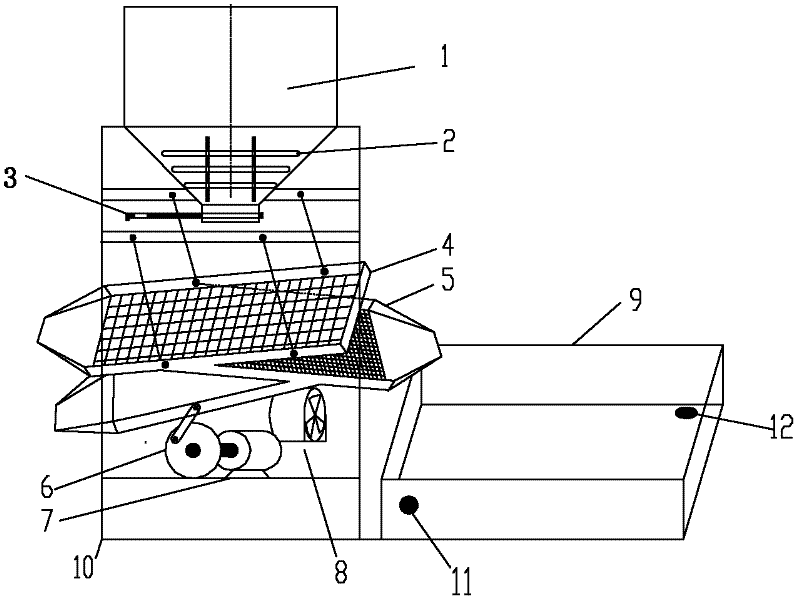

Automatic firewood chopping equipment

The invention relates to automatic firewood chopping equipment. The automatic firewood chopping equipment comprises a frame, a driving mechanism arranged on the frame, and a chopper mounted on the driving mechanism, wherein a positioning device for positioning logs is arranged rightly below the chopper, and comprises four vertical stoppers; each of the stoppers is connected with a horizontal slide rail; the horizontal slide rails are respectively connected with push cylinders; and inductors for inducing the existence of the logs in the stoppers are arranged at the outer sides of the stoppers. The automatic firewood chopping equipment is reasonable in structural design, realizes the positioning of the logs and automatic firewood chopping, largely improves the firewood chopping efficiency, largely saves the labor cost, and reduces the labor intensity.

Owner:张丽花

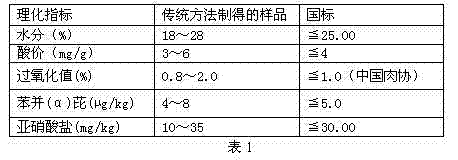

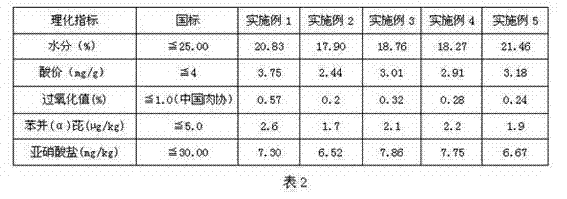

Method for processing Tujia smoked bacon

A novel method for processing Tujia smoked bacon comprises the following steps of: 1) washing and cutting the fresh meat into strips; 2) adding a natural antioxidant into the traditional pickling seasoning for uniformly mixing, and then uniformly daubing the seasoning on the strip-shaped fresh meat, and pickling for 7 to 15 days; 3) hanging and smoking the pickled meat for 20 to 30 days through firewood, controlling the temperature of the bacon layers to 20 to 50 EDG C, and installing a smoke separating and purifying layer between the meat and the firewood when the meat is smoked; and obtaining the Tujia smoked bacon by the steps. The method provided by the invention is simple to operate and convenient to realize, and the Tujia smoked bacon provided by the method has various indexes according with the relevant national rules, delicious in taste and liable to popularize.

Owner:宜昌神头岩农业开发有限公司

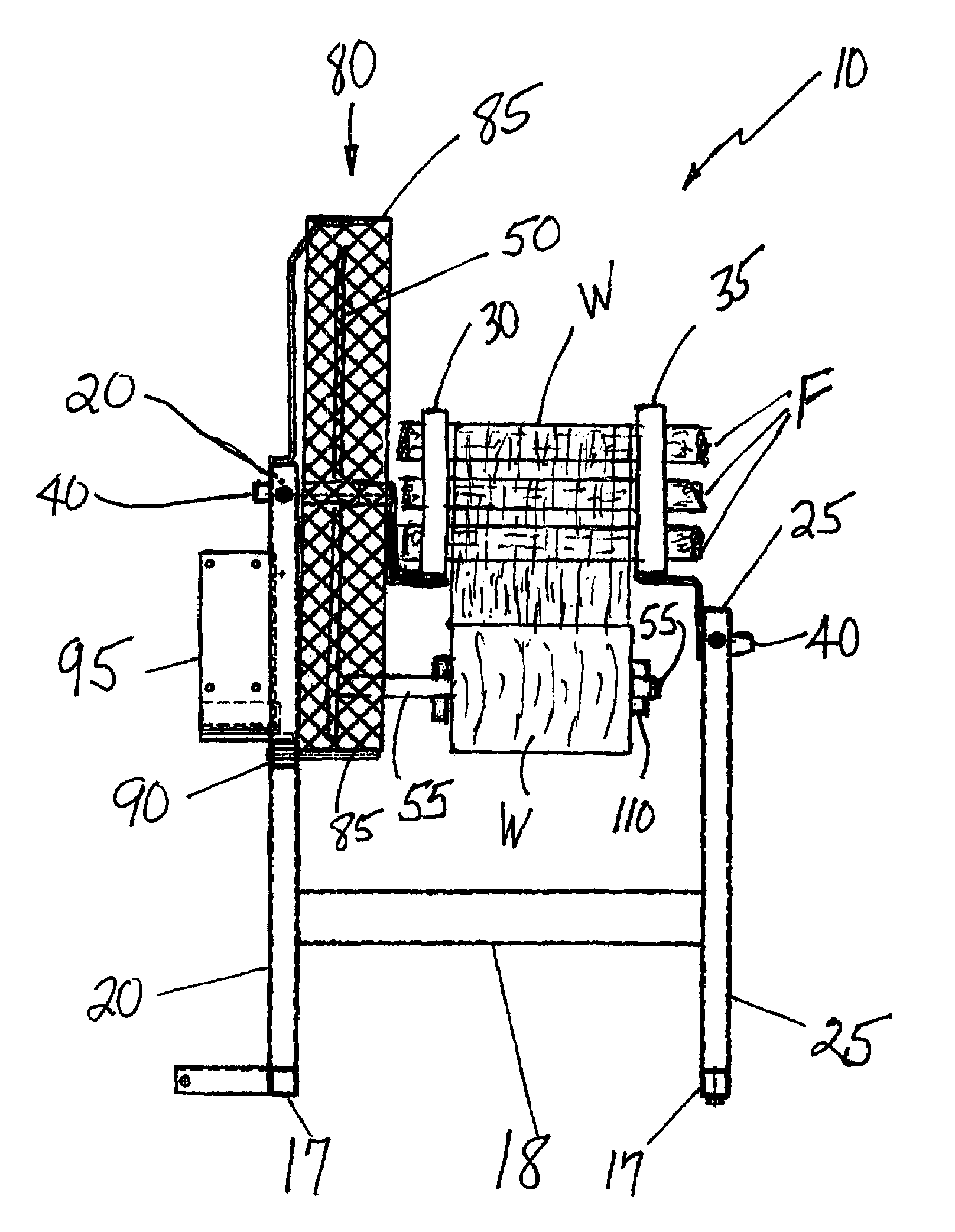

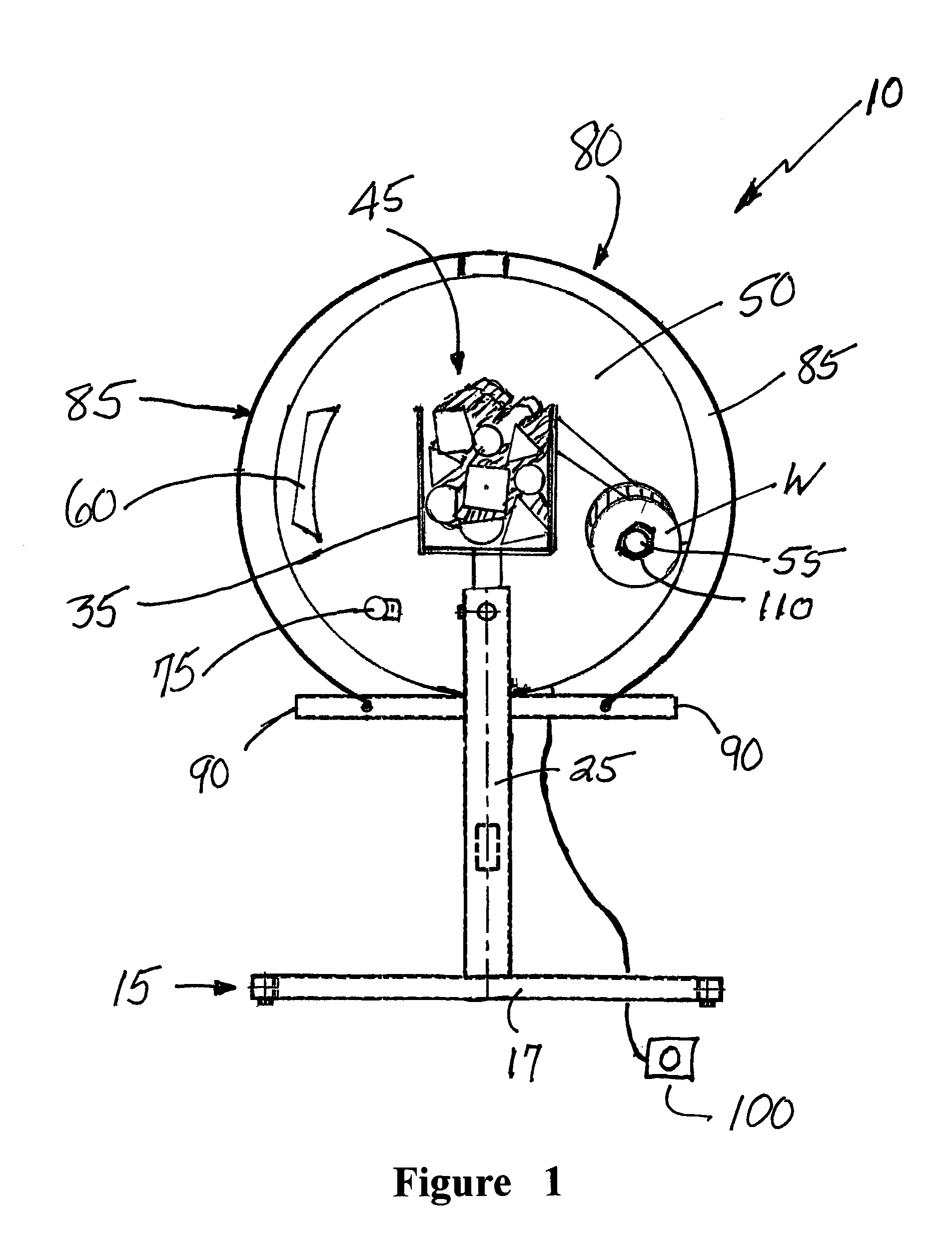

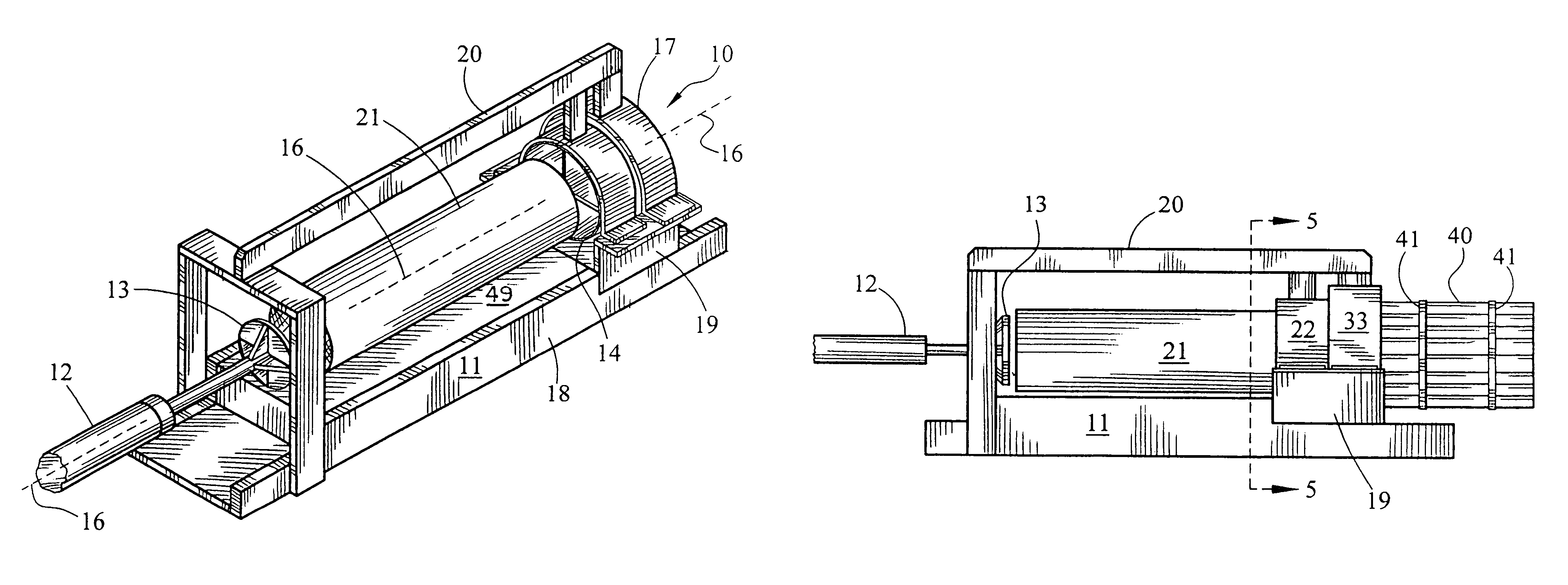

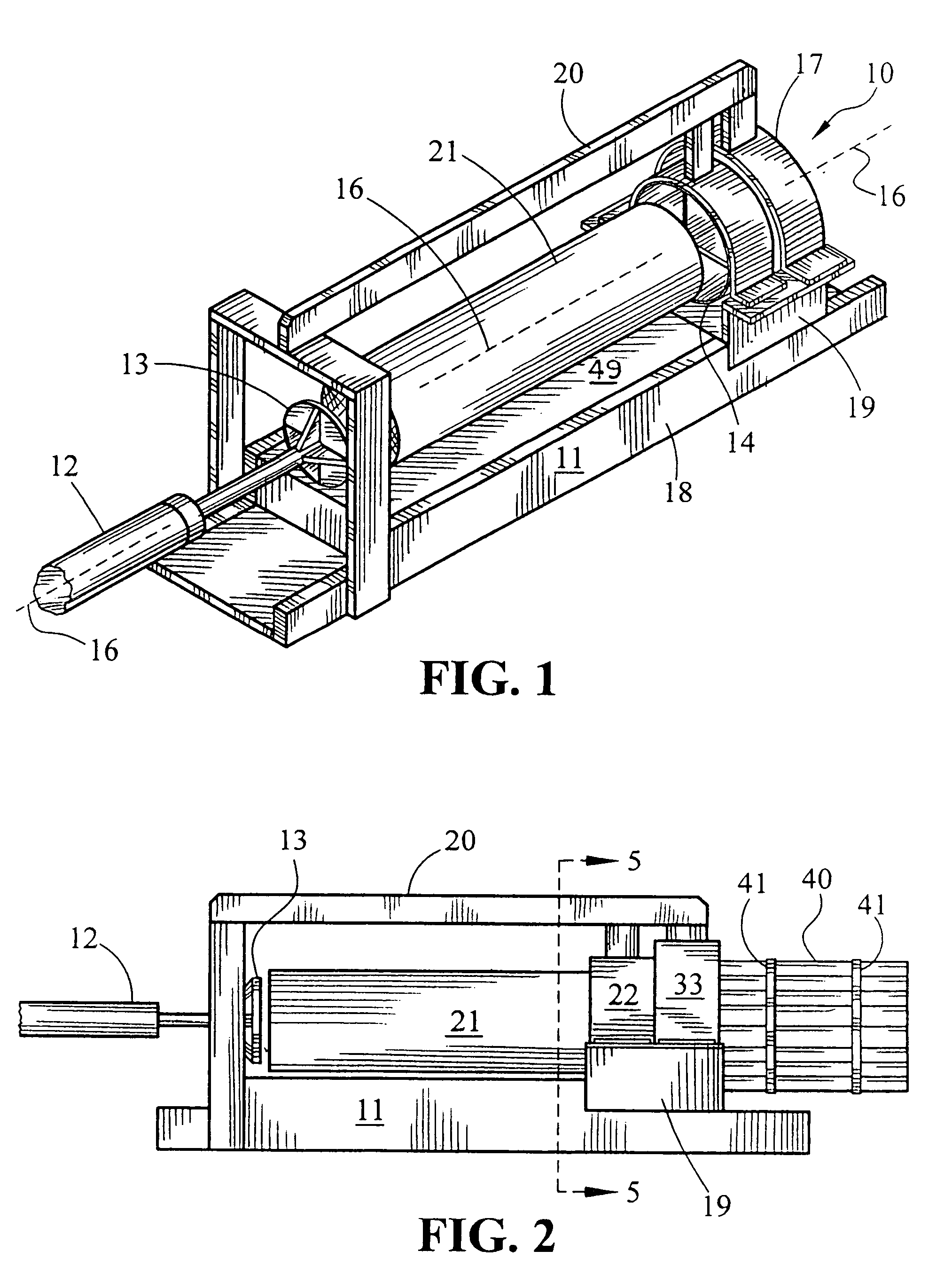

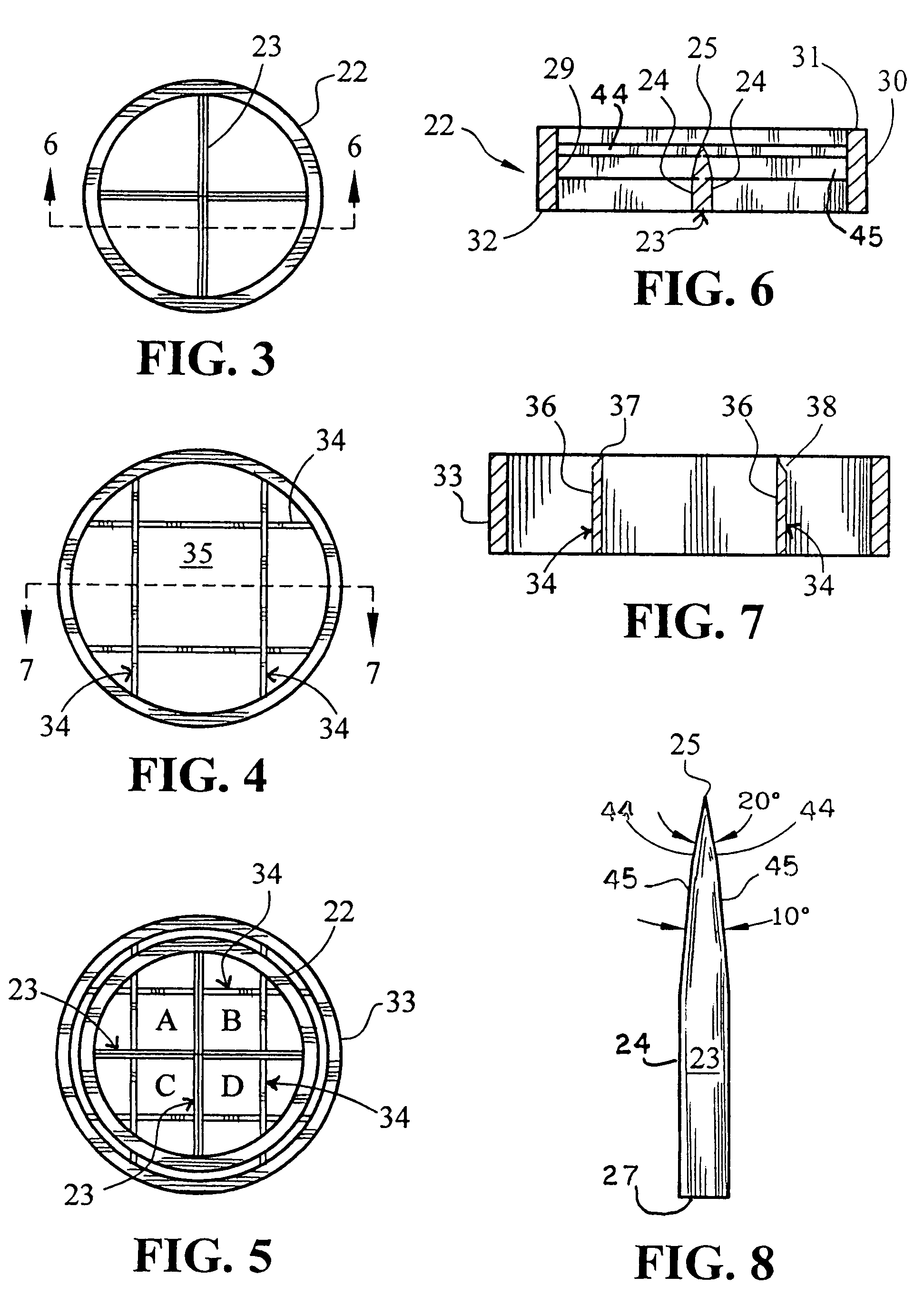

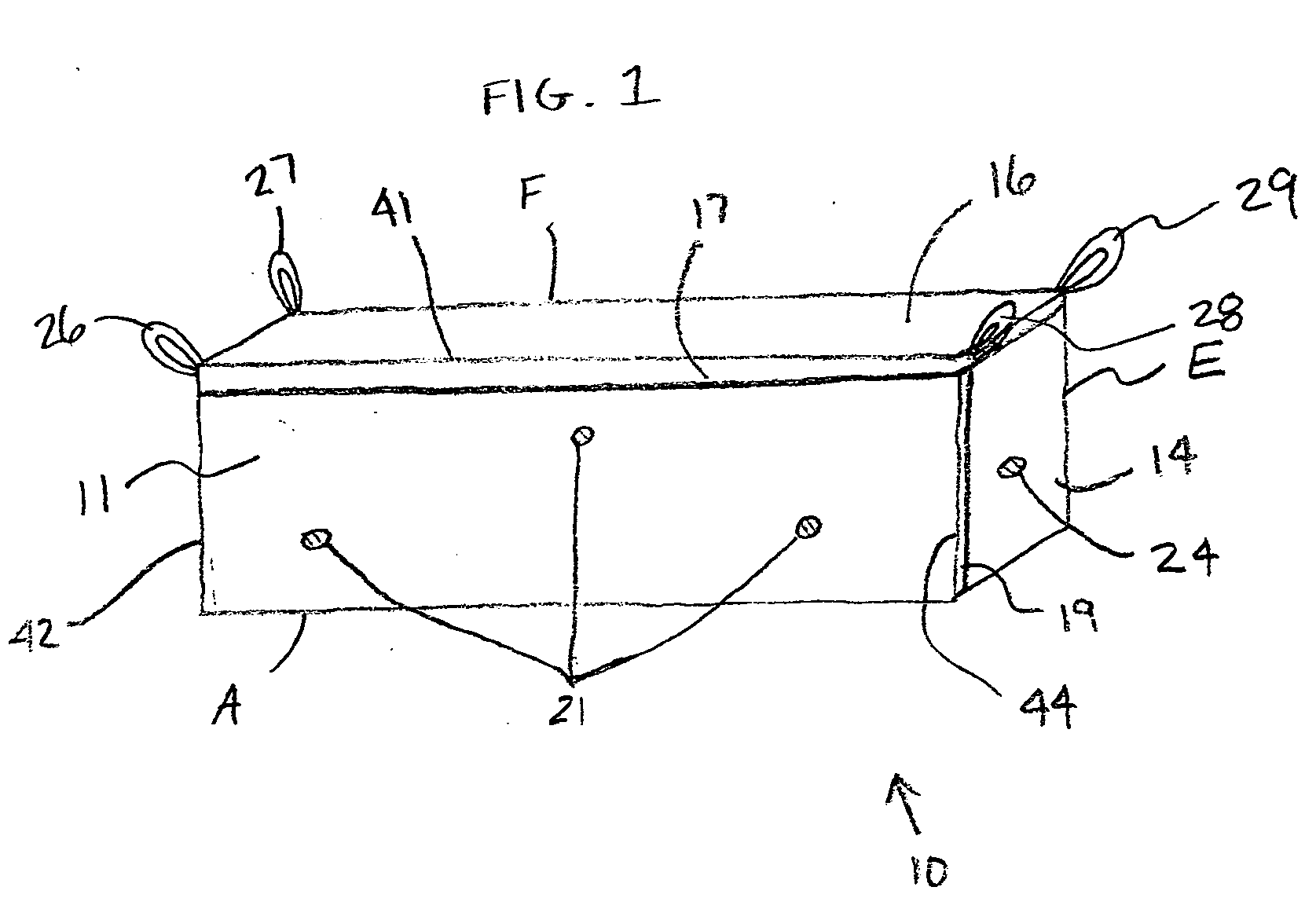

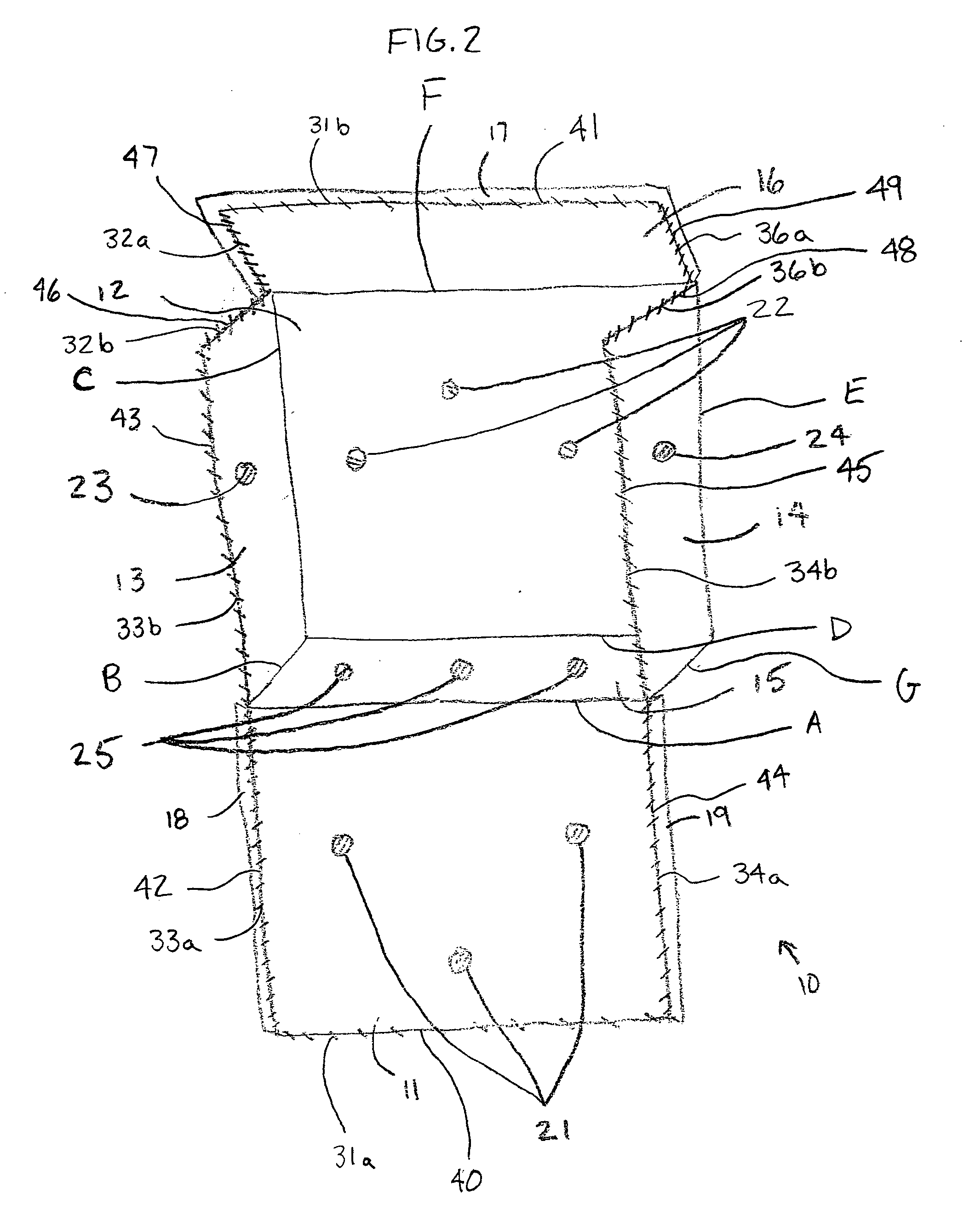

Firewood bundler device

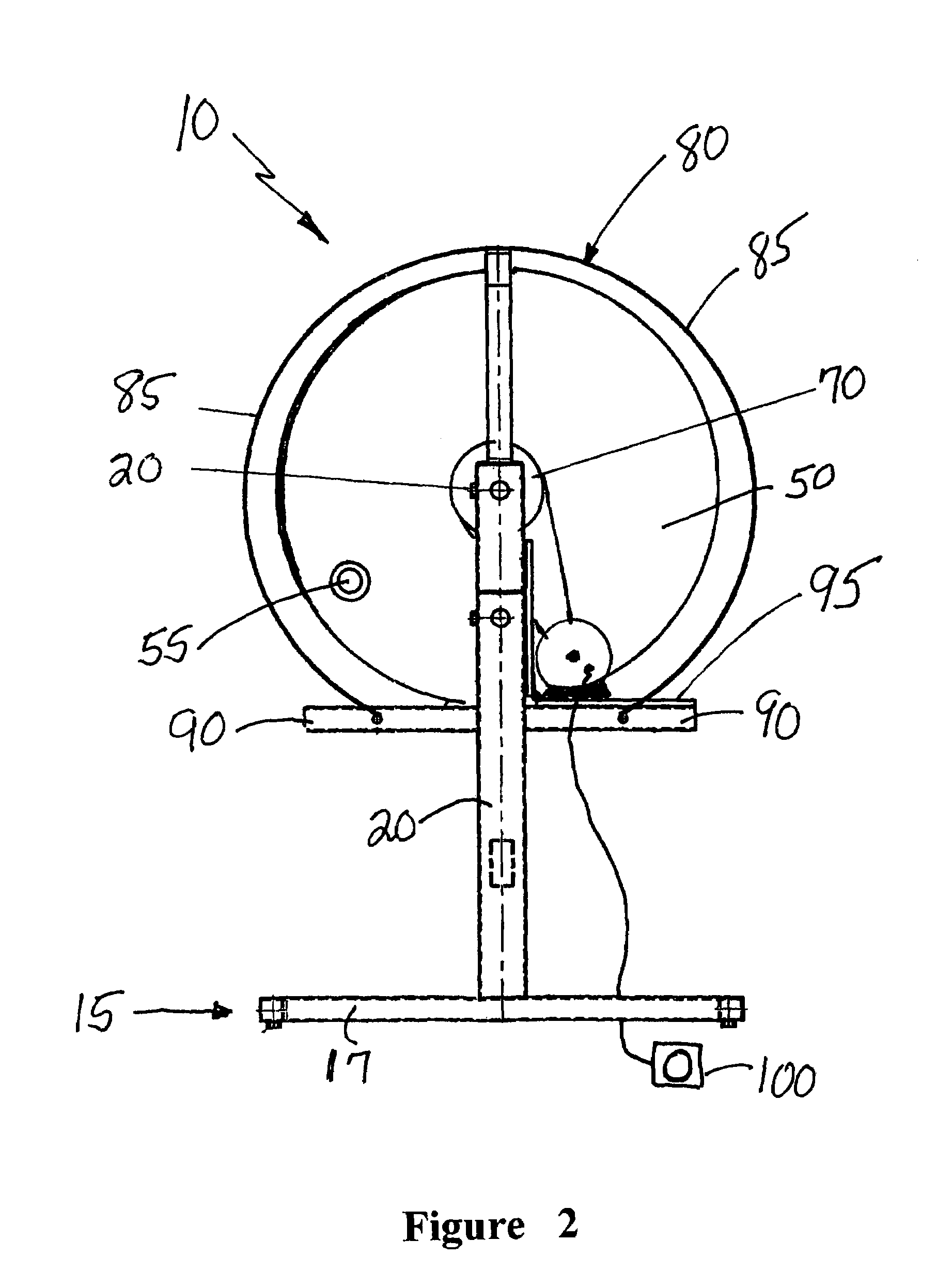

InactiveUS7516694B1Impart tensionWrappers shrinkageWrapper folding/bending apparatusFirewoodEngineering

A firewood bundler device includes a base member having first and second opposed, vertical arm members extending from the base member. A U-shaped, wood support member is attached at an end of each arm member, with an open end opposite the base member. A wrapping support member is rotatably attached to an end of one arm member and includes a spindle section extending therefrom, the spindle section movable in a circular path around the wood support members upon rotation of the wrapping support member. The spindle section holds a roll of wrapping material. A rotation device is operatively connected to the wrapping support member for imparting rotational movement thereto and to the spindle section. Multiple pieces of firewood placed in the U-shaped supports are encircled with wrapping material by rotation of the wrapping support member holding a roll of wrapping material.

Owner:EIFLER SCOTT M

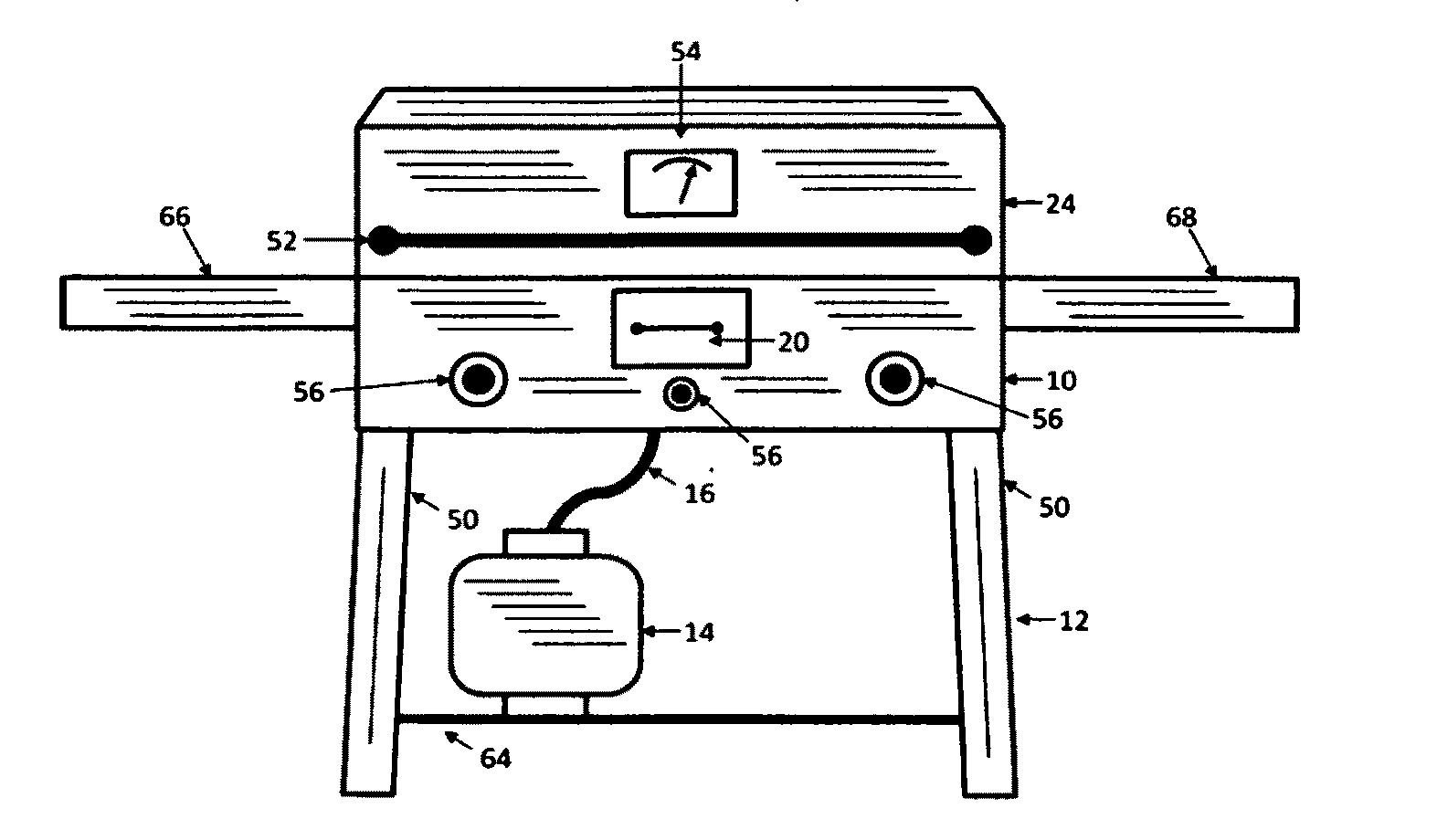

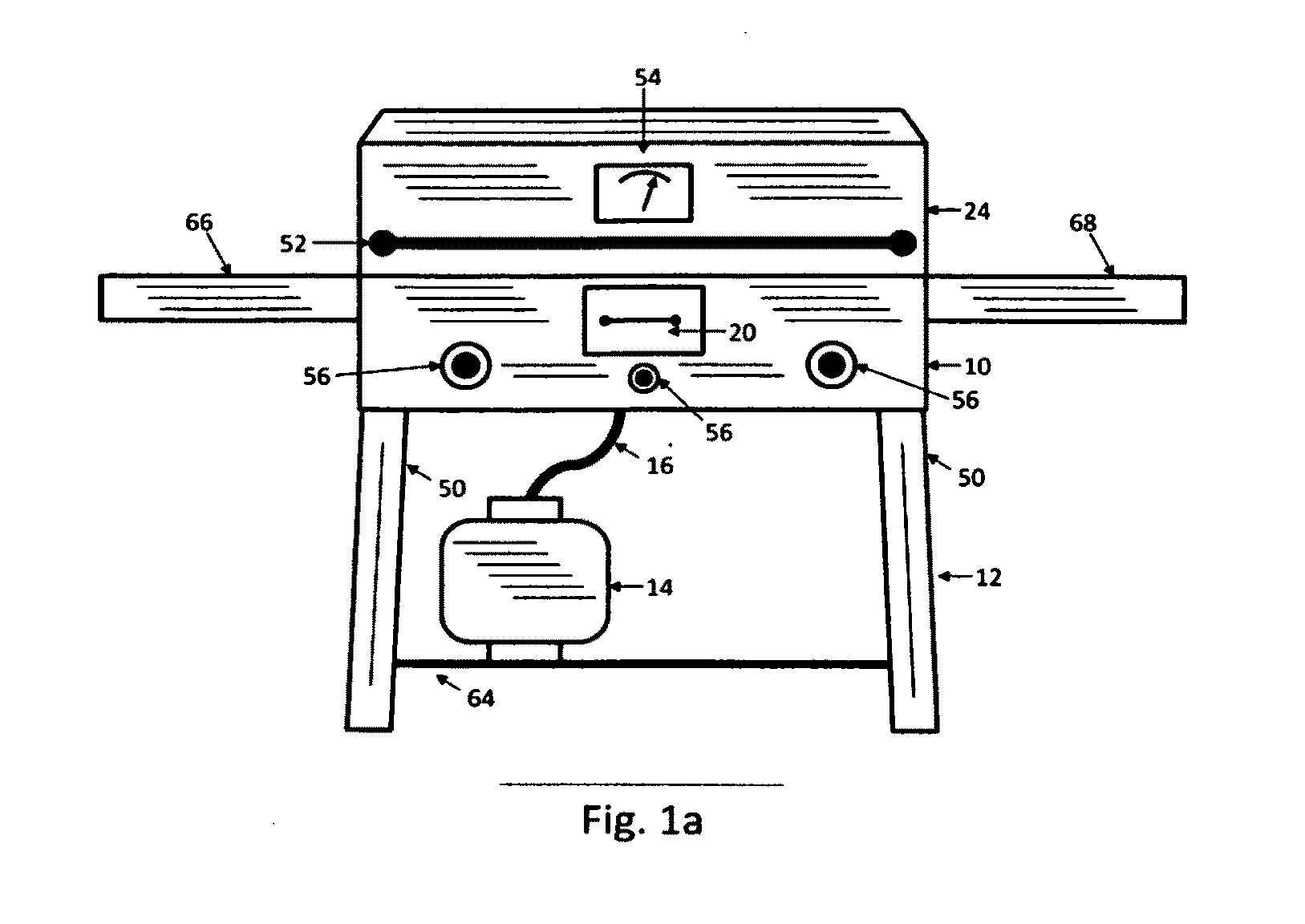

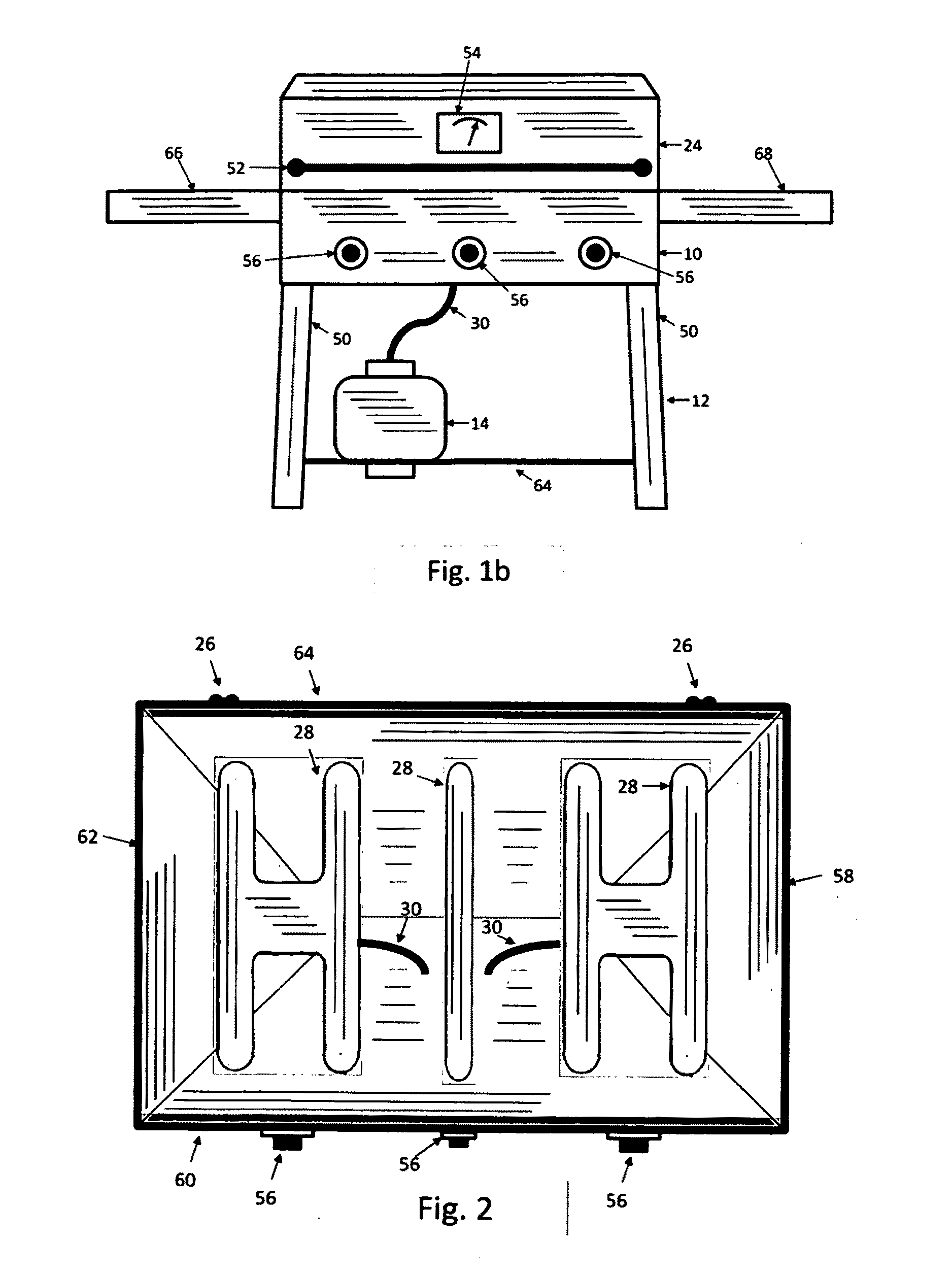

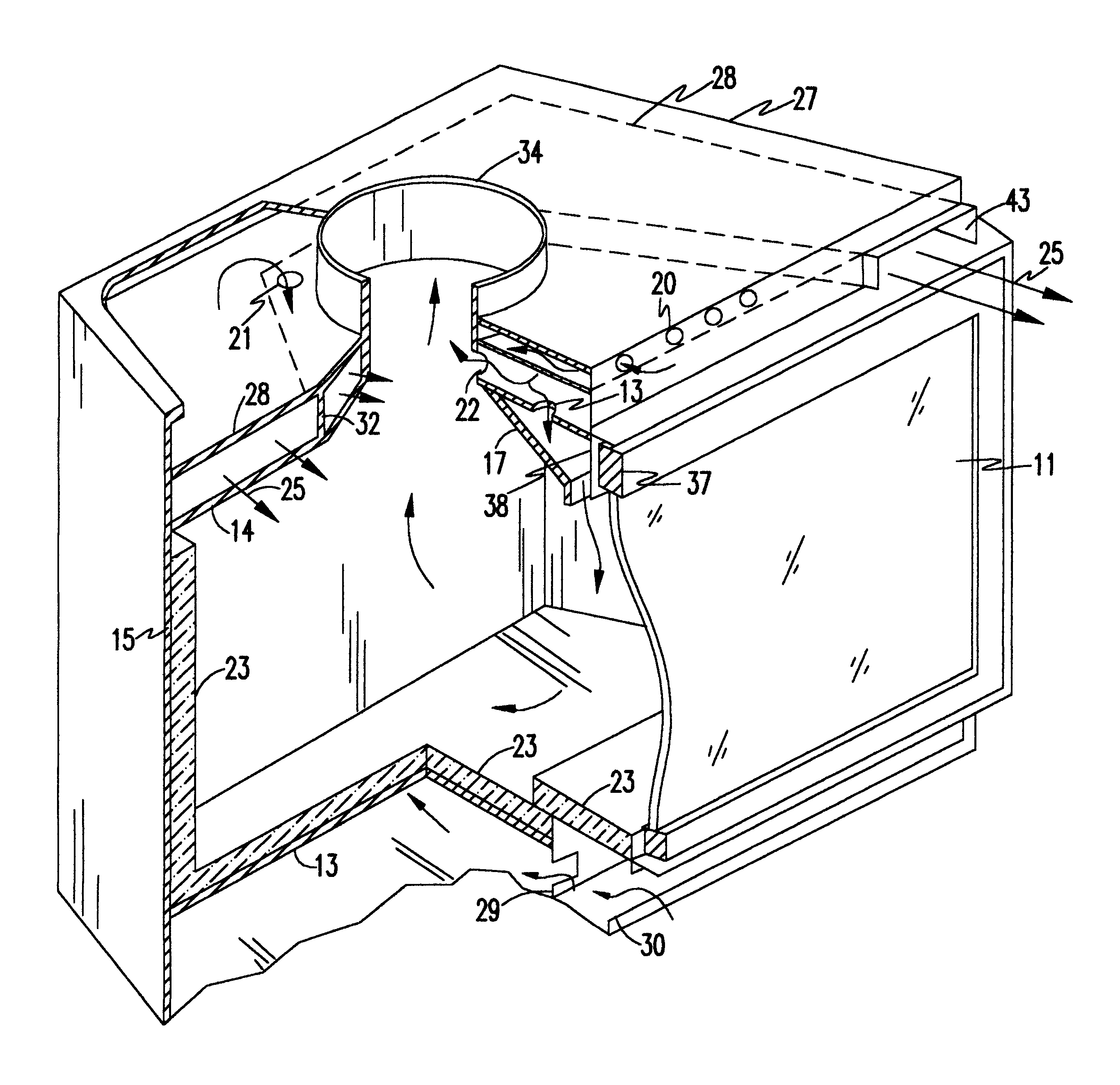

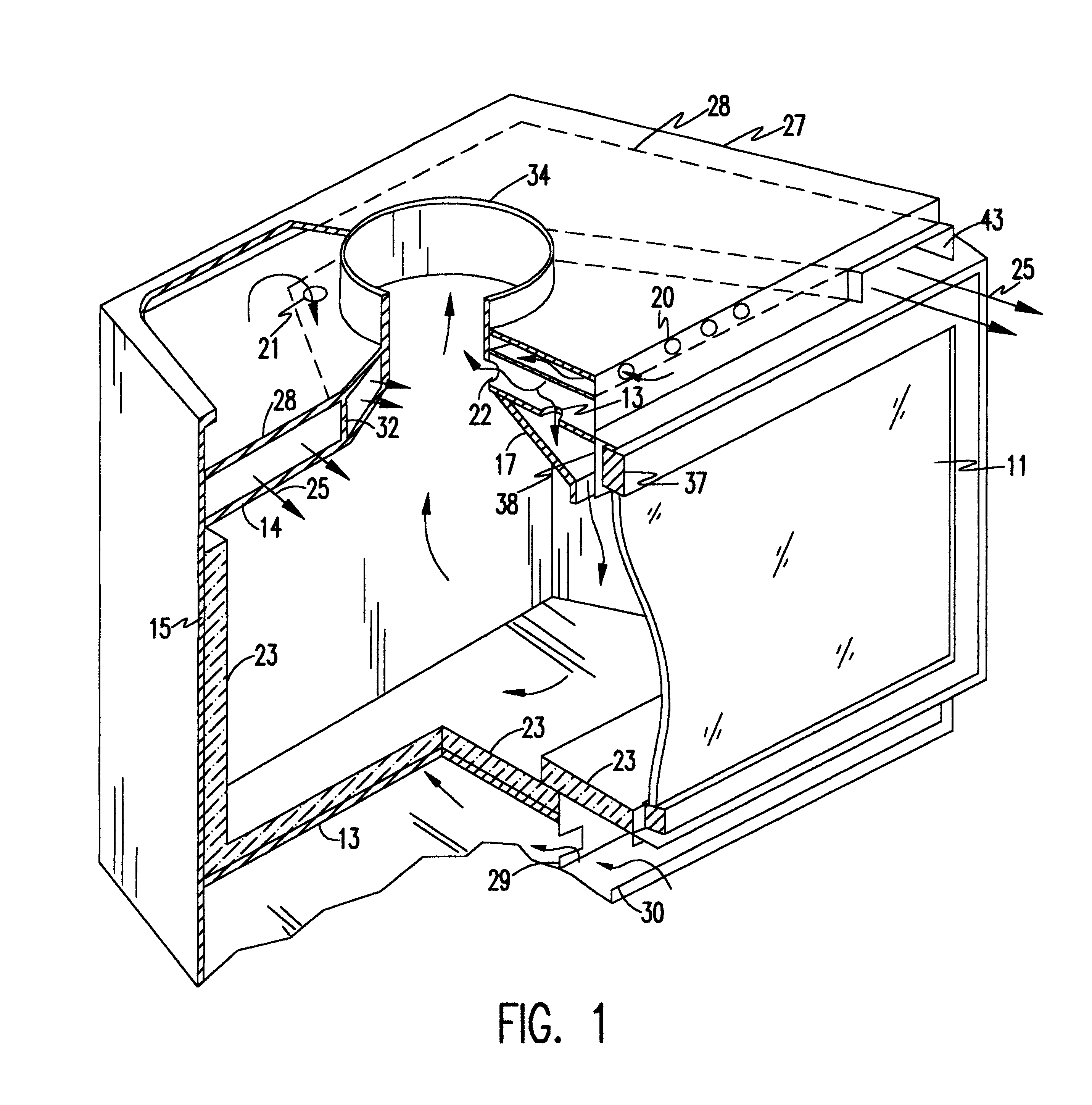

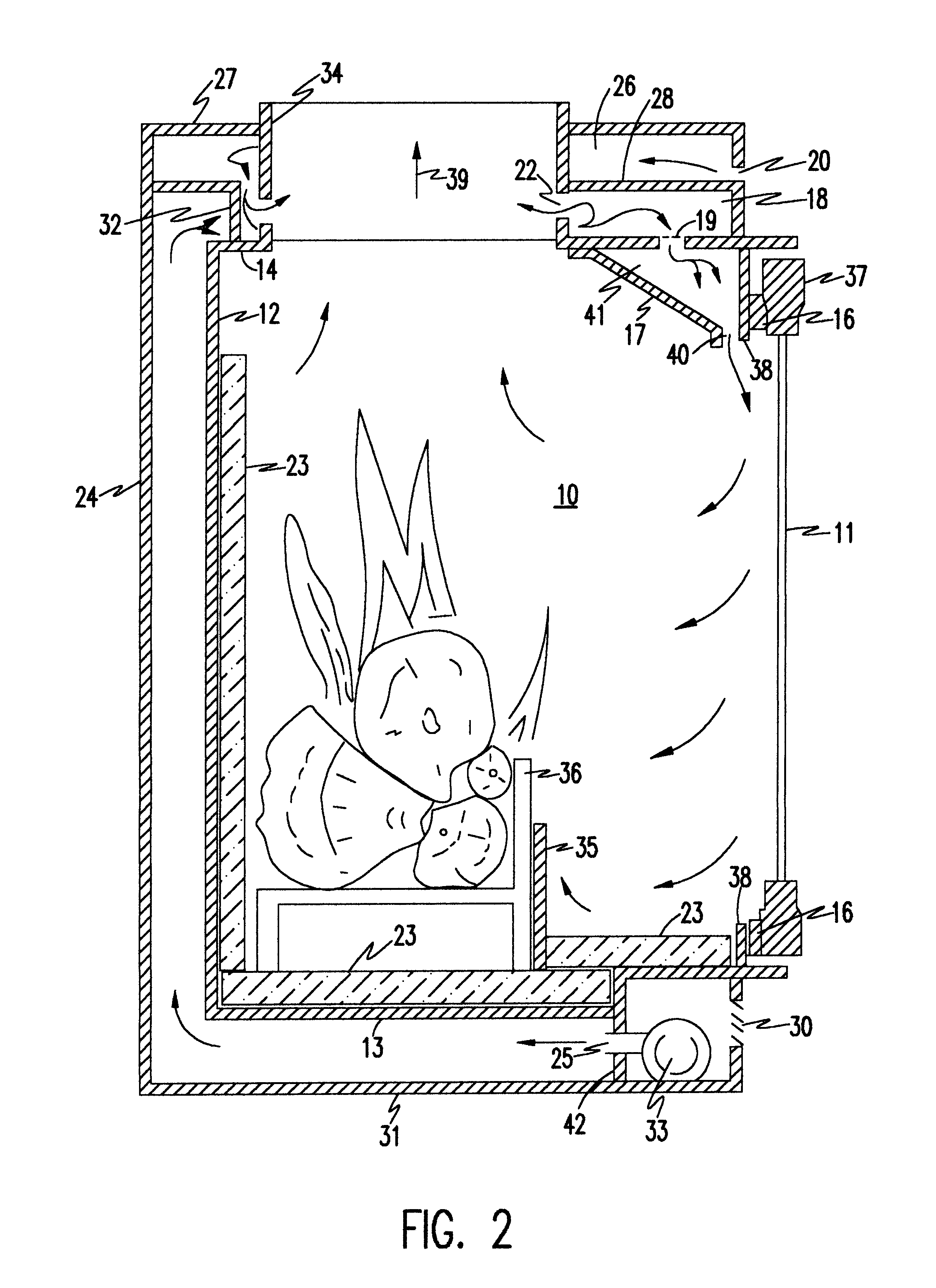

Barbecue Grill and Smoker

InactiveUS20110120442A1Minimal amountLess skillDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke

A barbecue grill, have an enclosed cooking container resting upon a support structure, the cooking enclosure having walls that enclose the cooking area and a clamshell lid for access, heating elements in the lower portion of the enclosure, connected to a fuel source, and containing within the cooking enclosure heating elements in the lower portion, grills for holding food and exposing it to the circulating air in the superior portion, and a drawer or drawers for wood, water, or other substances, which can be exposed to heat for the creation of smoke, steam or other result, consequently enabling the standard grilling process, but also providing a low skill, low effort means of enabling the slow smoking process as well as the simulated cooking of food over a wood fire.

Owner:DUNCAN DARIN JASON

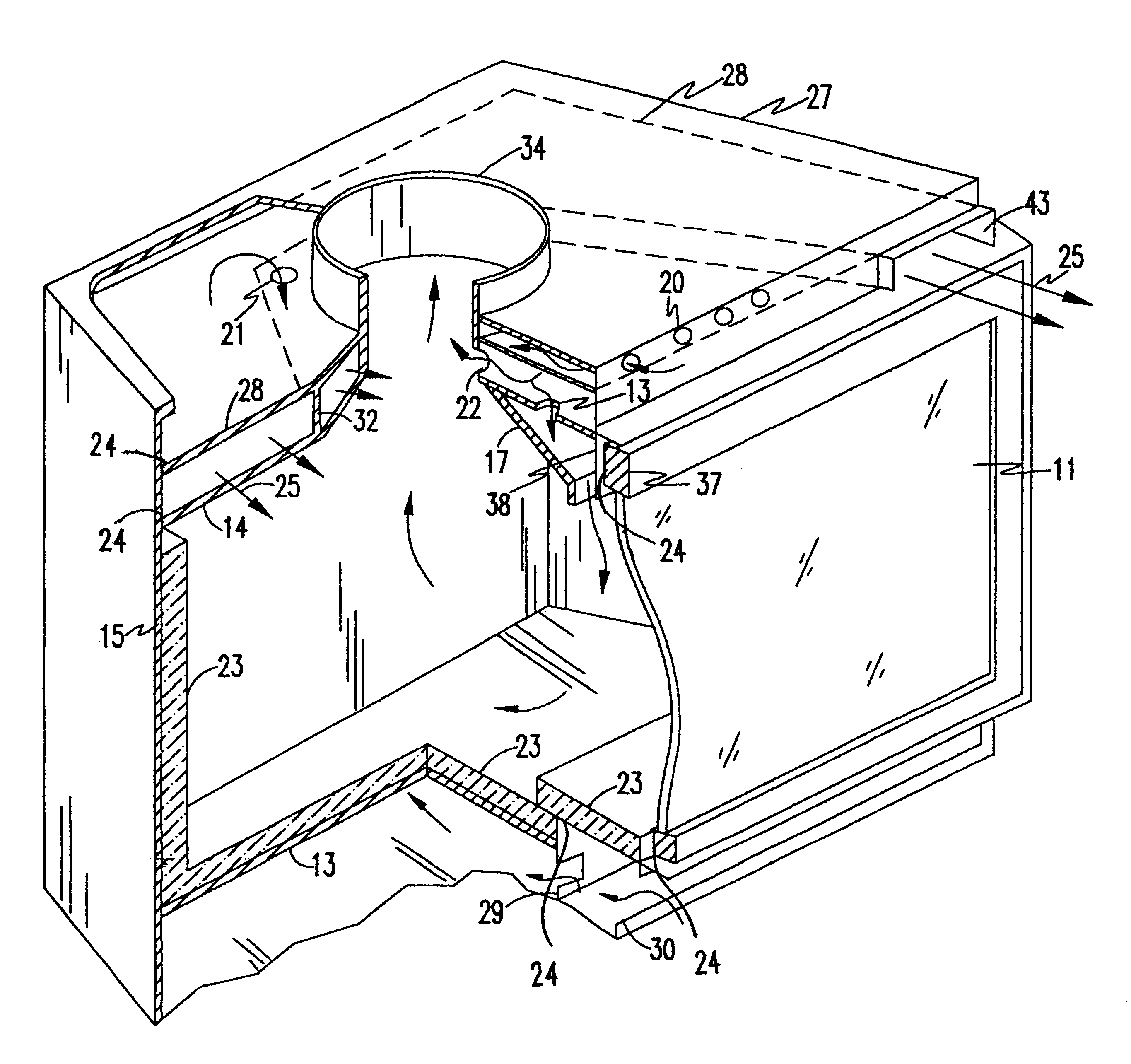

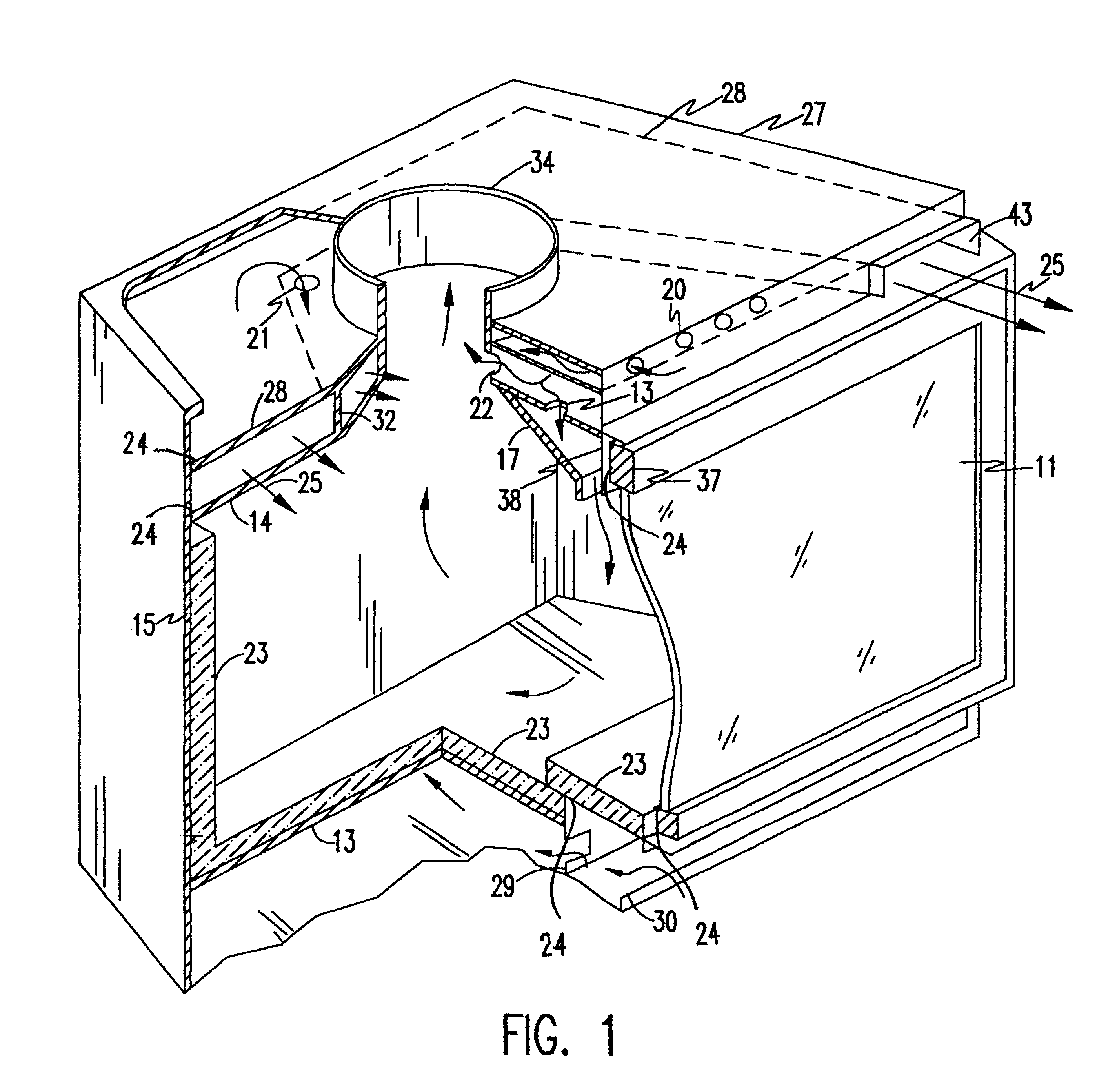

Flame imitation device for wall mounted heater

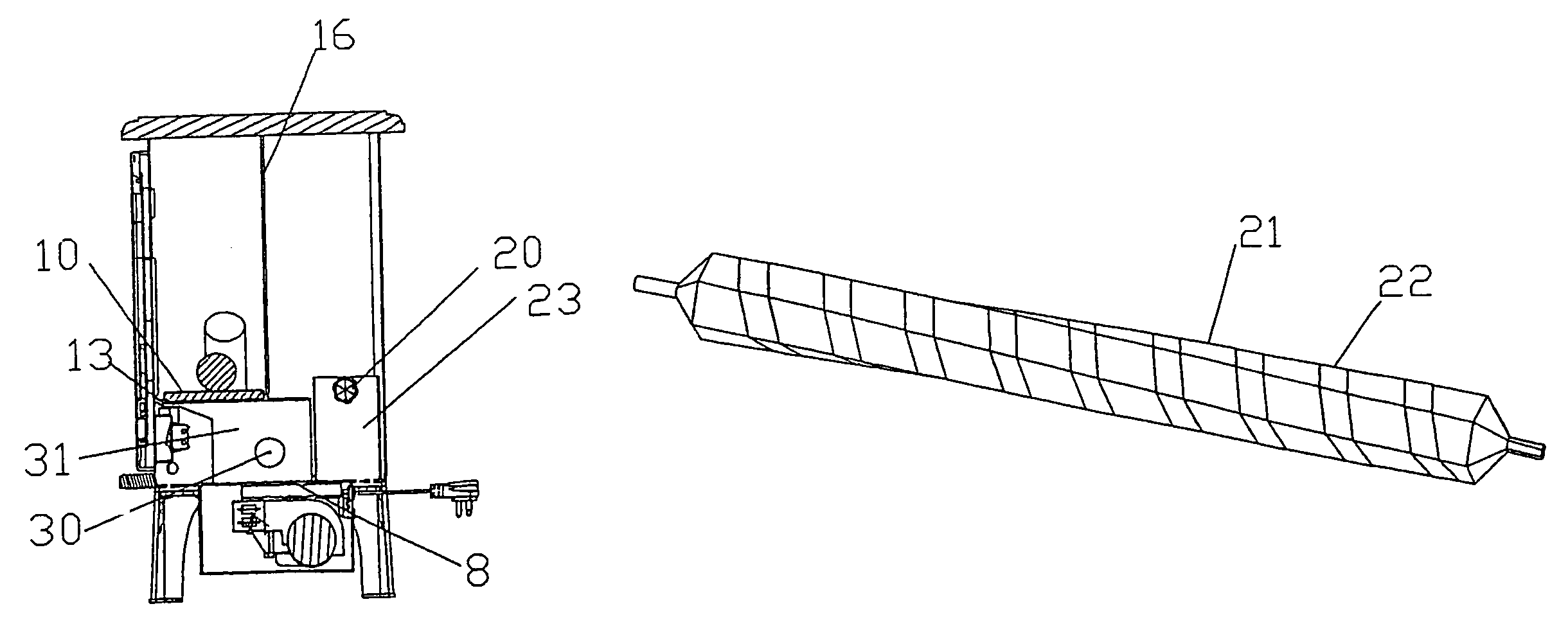

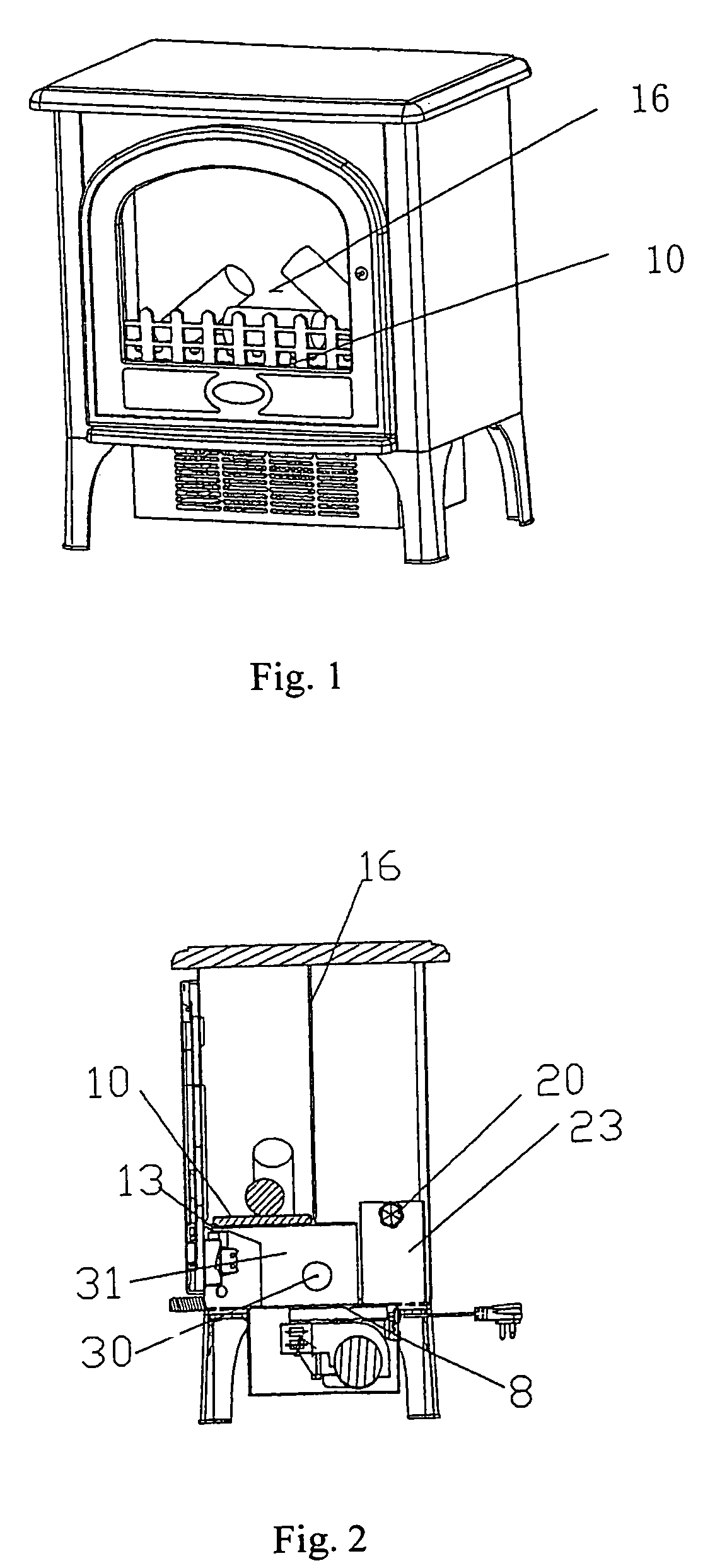

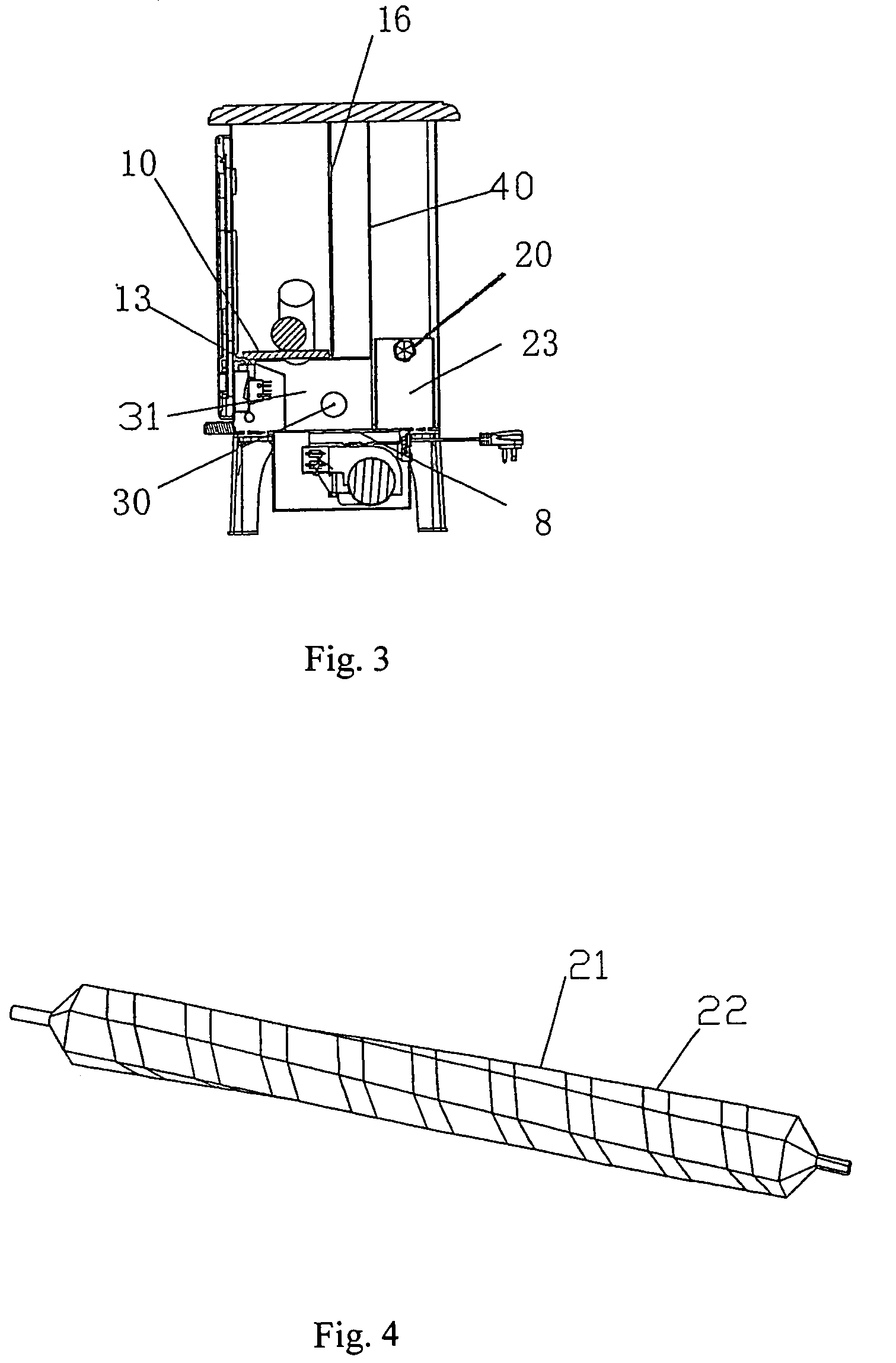

InactiveUS7234255B2Imitation effect is moreSimple processDomestic stoves or rangesFuel lightersFirewoodEmber

The invention relates to a flame imitation device for a wall-mounted heater. The flame imitation device comprises a light source, a combustion bed including imitated firewood and embers, and a vertical translucent screen located closely adjacent to the back edge of the combustion bed. The light source is located under the combustion bed. A glittering member is rotatably provided behind the translucent screen. The main body of the glittering member comprises a polyhedron with a polygonal cross section. A reflector is provided on the polyhedron. The glittering member is connected to a rotational driver. Light irradiated from the light source partially transmits upward onto the combustion bed for imitating firewood and embers. Light irradiated from the light source partially transmitted rearward to the glittering member positioned at the back portion of the heater, and reflects the light to the translucent screen. With the rotation of the glittering member, a dynamic flame image presents on the translucent screen. The structure and manufacturing process of the flame imitation device of the invention are simple. Moreover, the reflectors are arranged over the whole polyhedron which results in that the flame images produced by reflecting lights are continuous and the imitation effects are more vivid.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

Process for preparing biological diesel by repeseed fermenting method

This invention has disclosed a kind of production technology of utilizing fermented legal system of the rape seed to fetch the biological diesel oil. Compared with diesel oil drawn the diesel oil made and is fetched in the petroleum, the burning that the biological diesel oil can not merely be more abundant, and the harmful gas dicharged in the air is much fewer. Ferment kinds of fungus, rape seed powder gone mouldy to stem from have, fermented course steady performance have, easy to control, it is high to transform the diesel oil rate, does not porph under the corresphonding save condition. This invention production technology is divided into five stages, raw materials pretreament, bacterial cultivation, neutralization, then wash dry fractional distillation, the production equipment used is like making oil equipment of one share, produce biological diesel oil have high economic benefits very, average each ton of rape seed can be made and fetched 245 kilograms of biological diesel oil, and will also produce 10% of the by products-glycerine and odder yeast during the process of producing biological firewood.

Owner:曹建国 +2

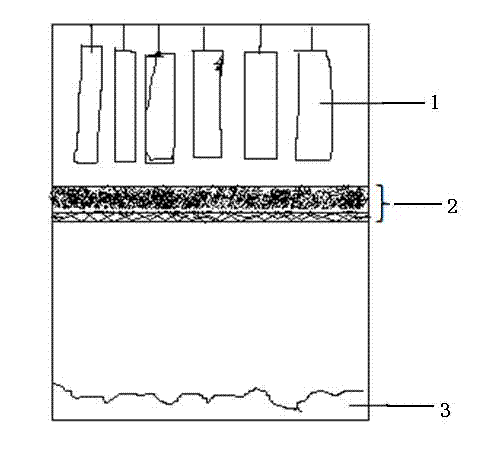

Method for producing module timber using small firewood material

InactiveCN101279461AHigh hardnessImprove stress resistanceWood treatment detailsFlat articlesFirewoodCompression molding

The invention discloses a method for replacing log with second smallest fuelwood to produce module wood. After the steps of crushing, degradation, drying, dipping, drying, compression molding, curing, etc., the second smallest fuelwood is glued into the module wood or profile. The module wood made in the method has the advantages of keeping original fibrous tissue, texture and performance, having ultrahigh hardness, compressive strength, shock resistance, and anti-distortion capacity, eliminating the need for corrosion, insect and water prevention directly and being directly made into floors, furniture, building equipments, etc. In the method, the second smallest fuelwood such as small branches, small woods, etc., are utilized and processed to make the module wood so as to save resources and changes waste into valuables, thus being an ideal substitute of the log.

Owner:浙江仕强竹业有限公司

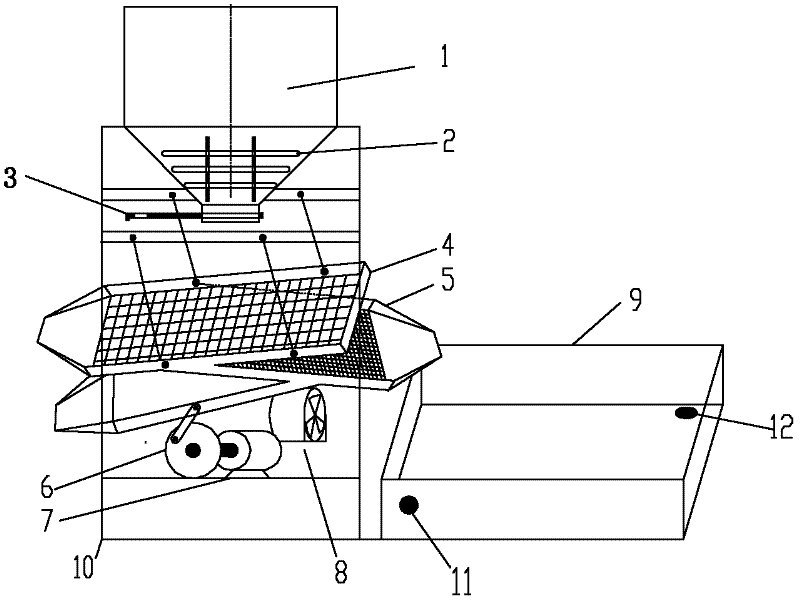

Polyethylene pipe broken material or drop material sorting and separating device

InactiveCN102328360AReach the purpose of sorting and recyclingImprove the blockage of the feeding portGas current separationPlastic recyclingFirewoodFiltration

The invention relates to a polyethylene pipe broken material or drop material sorting and separating device. The device comprises a machine frame and a flow filtration water tank, and is characterized in that: a discharging hopper, a primary screen and a secondary screen are arranged on the machine frame from the top to the bottom in turn; the flow filtration water tank is arranged below an outlet on one side of the secondary screen; both the primary screen and the secondary screen are connected with an eccentric shaft which is connected with a motor; and a magnetic frame is arranged in the discharging hopper. The device has the advantages that: by using the device, iron scraps, stones, sand and firewood in drop materials or the iron scraps, powder cutting scraps, and irregular broken materials such as strip-shaped broken materials, thread-like broken material and the like in broken materials can be separated from regular broken materials effectively to fulfill the aims of sorting and recycling; when the sorted drop materials and the broken materials are subjected to extrusion manufacturing after being dried and recycled, the phenomena of bridging, feed opening blockage, unstable wall thickness and the like are improved obviously; energy is saved; consumption is reduced; and production cost is remarkably reduced.

Owner:宁夏青龙塑料管材有限公司

Method for preparing preserved meat

The invention relates to a method for preparing preserved meat, which comprises the following processing steps of: selecting streaky pork, salting for 3 to 6 days, smoking and packaging to obtain preserved meat products. In the method, meat is smoked by flue gas produced by combusting high mountain firewood, fish bones and the like, dust is isolated by a mesh, and a house is preheated and dehumidified by a flue in the low-temperature wet weather. The invention has the advantages that: the method is simple and practical, is safe and hygienic to operate and is convenient and flexible to use; and the prepared preserved meat products have high quality.

Owner:赵才勇

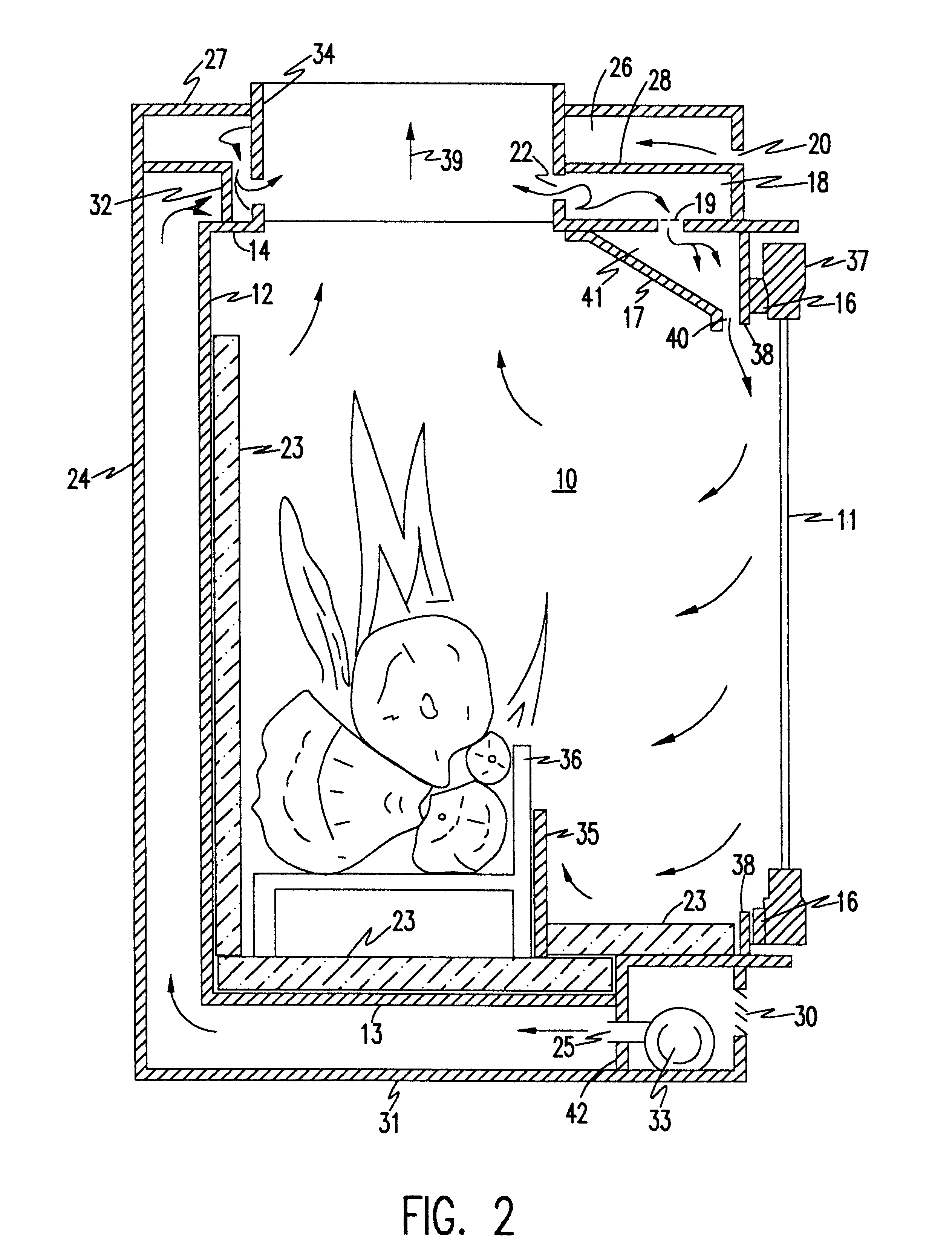

Wood heater

InactiveUS6216684B1Low efficiencyReduce pollutionDoors for stoves/rangesCombustion-air/flue-gas circulation for stovesCombustion systemFirewood

A combustion system for burning firewood including a combustion chamber defined by front, rear and side walls, a ceiling and a bottom. An access door is provided for addition of fuel into the combustion chamber. A substantial amount of combustion air enters the combustion chamber near the top of the fueling doors via apertures and is directed down the face of the fueling doors providing cooling. A geometry of the air metering orifice is either fixed or of limited adjustability such that the minimum flow of combustion air required for flaming combustion of a full load of fuel is maintained at all times. The combustion air flow cannot be reduced beyond a certain point and thus smoldering and very low air / fuel ratios are avoided. Since the air metering is tuned for proper flaming combustion with the largest expected fuel load and cannot be reduced further, fuel loads smaller than the design fuel load will result in higher air / fuel ratios, thus further ensuring that sufficient combustion air is present for sustained flaming. Furthermore, the minimum combustion air setting limits the amount of combustion air entering the combustion chamber such that too much air is not introduced resulting in inefficiency due to sensible heat loss, chemical loss (pollution), quenching of the flames, and undesirably high burn rates. Ideally, the burning rate of a full load of fuel is below 5 kg / hr, however, the maximum bum rate when burning a full load of fuel may be reduced to as low as 2 kg / hr depending on the size of the firebox and the desired maximum heating capacity of the appliance. Heat output is adjustable primarily by the amount of fuel added at each fuel loading.

Owner:CHAMPION MARK

Wood heater

InactiveUS6488024B2Low efficiencyReduce pollutionDoors for stoves/rangesCombustion-air/flue-gas circulation for stovesCombustion systemFirewood

A combustion system for burning firewood including a combustion chamber defined by front, rear and side walls, a ceiling and a bottom. An access door is provided for addition of fuel into the combustion chamber. A substantial amount of combustion air enters the combustion chamber near the top of the fueling doors via apertures and is directed down the face of the fueling doors providing cooling. A geometry of the air metering orifice is either fixed or of limited adjustability such that the minimum flow of combustion air required for flaming combustion of a full load of fuel is maintained at all times. The combustion air flow cannot be reduced beyond a certain point and thus smoldering and very low air / fuel ratios are avoided. Since the air metering is tuned for proper flaming combustion with the largest expected fuel load and cannot be reduced further, fuel loads smaller than the design fuel load will result in higher air / fuel ratios, thus further ensuring that sufficient combustion air is present for sustained flaming. Furthermore, the minimum combustion air setting limits the amount of combustion air entering the combustion chamber such that too much air is not introduced resulting in inefficiency due to sensible heat loss, chemical loss (pollution), quenching of the flames, and undesirably high burn rates. Ideally, the burning rate of a full load of fuel is below 5 kg / hr, however, the maximum burn rate when burning a full load of fuel may be reduced to as low as 2 kg / hr depending on the size of the firebox and the desired maximum heating capacity of the appliance. Heat output is adjustable primarily by the amount of fuel added at each fuel loading.

Owner:CHAMPION MARK

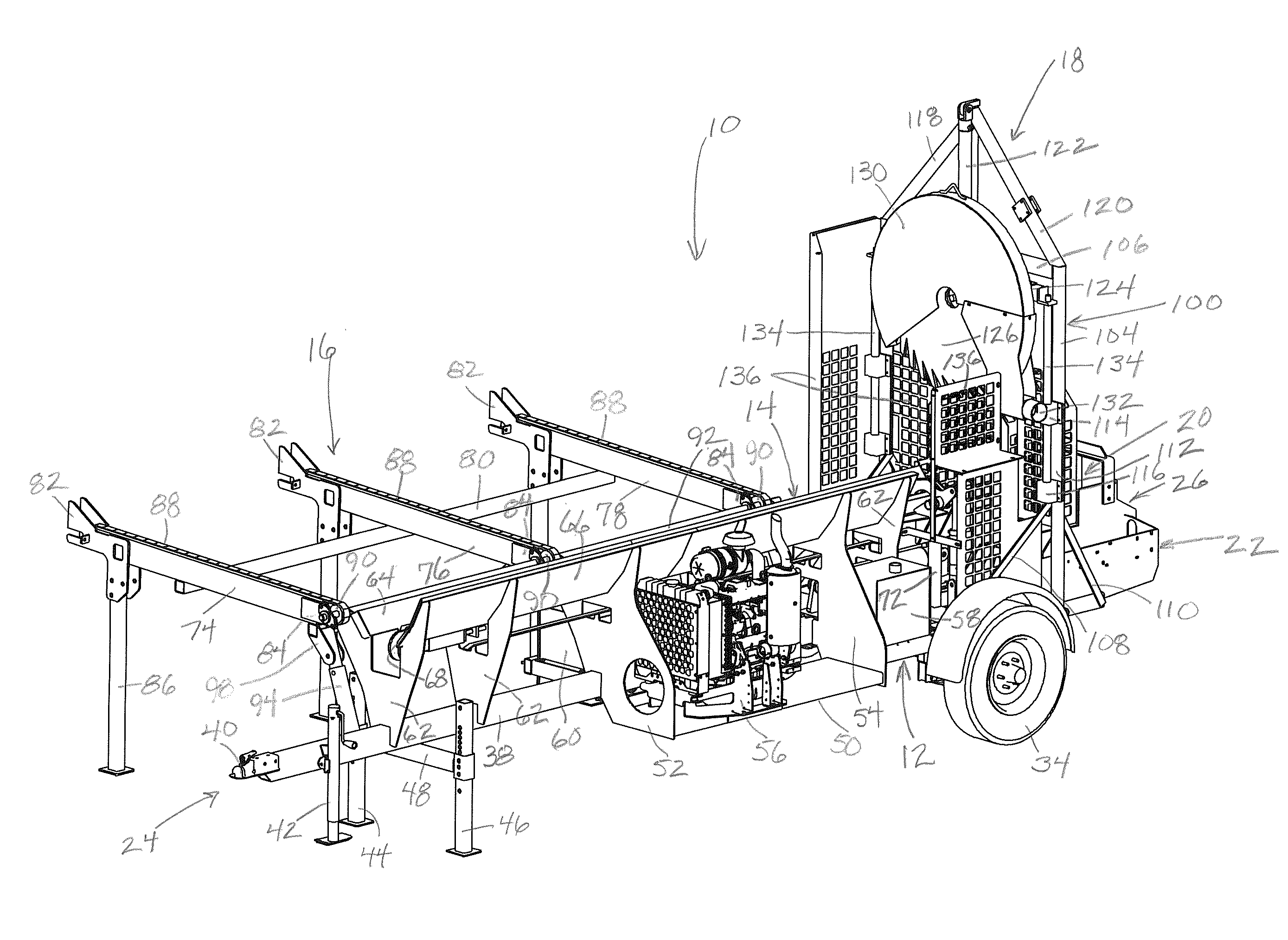

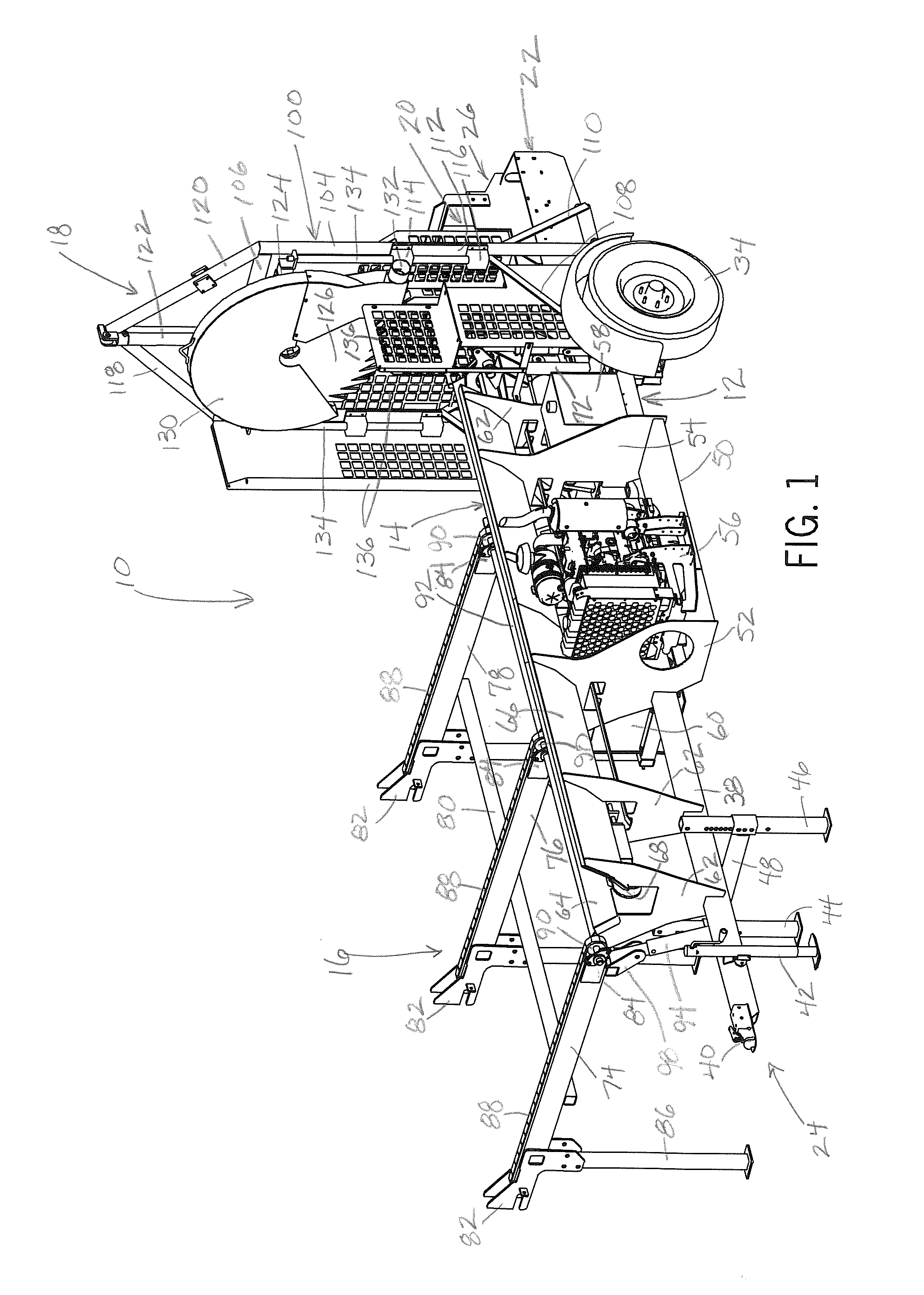

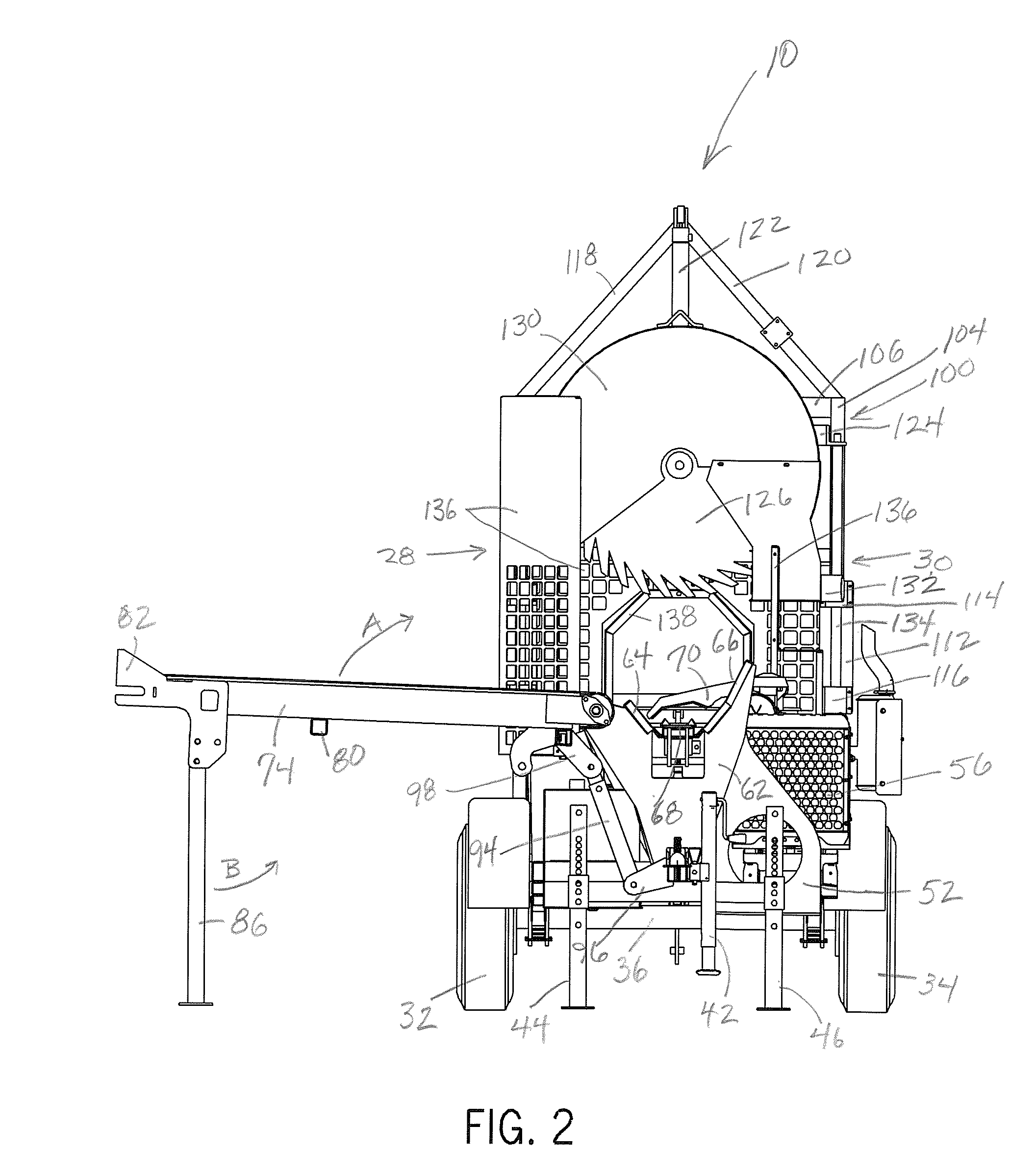

Firewood Processor with Vertically-Displaceable Circular Saw

A firewood processor includes a main framework having a front end, rear end and opposite sides. A log infeed trough is supported on the main framework for advancing a log lengthwise along a longitudinal axis from the front end to the rear end of the main framework to a cutting station extending upwardly from the main framework for selectively cutting a log advanced on the log infeed trough into individual log rounds. An operator control station is positioned on the main framework for selectively controlling the advancing and the cutting of the log. The cutting station includes a rotating blade that is positioned above the log infeed trough and is mounted for upward and downward movement controlled by an operator at the control station in a vertical direction substantially perpendicular to the longitudinal axis of the trough to enable cutting of the log.

Owner:MULTITEK NORTH AMERICA

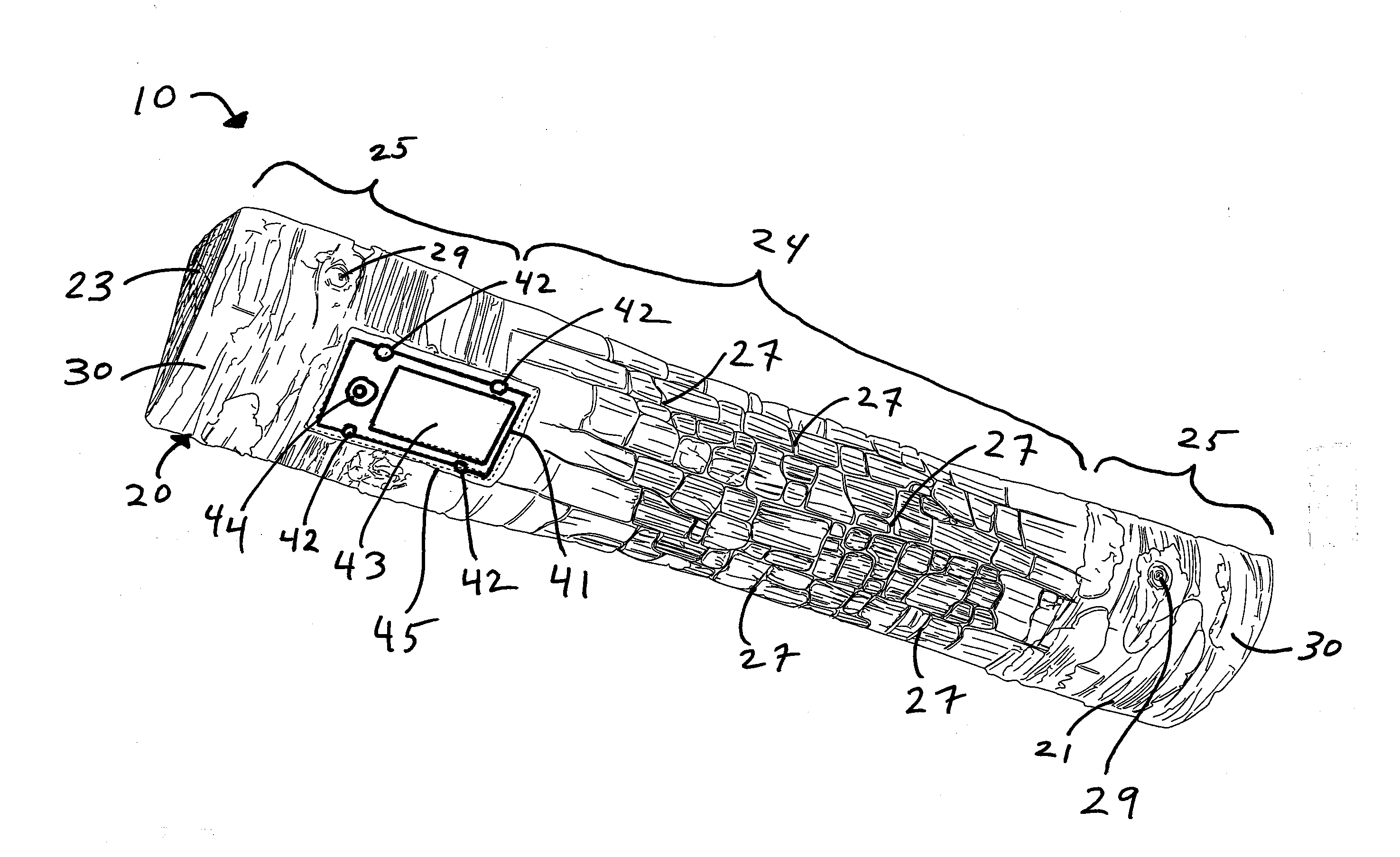

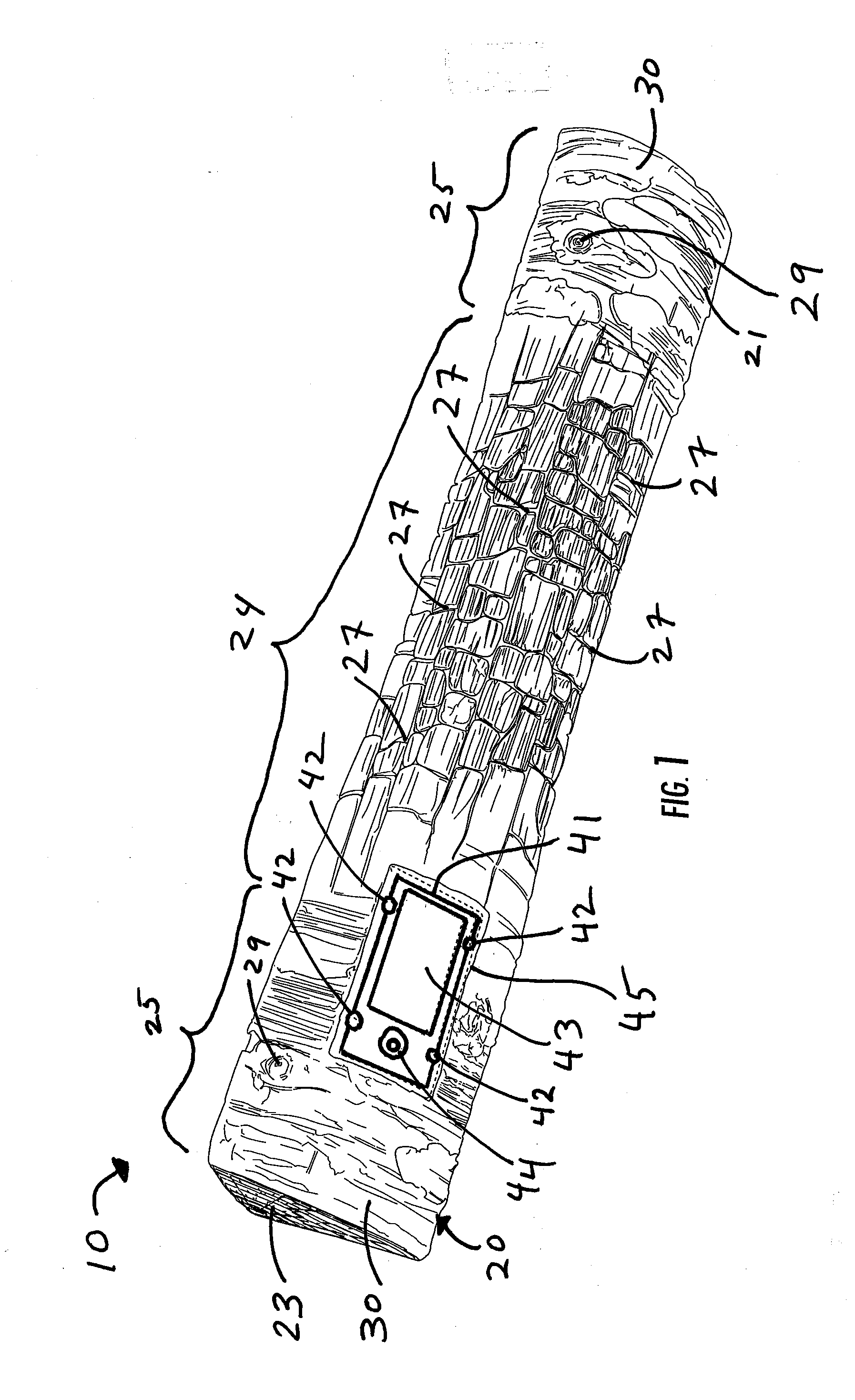

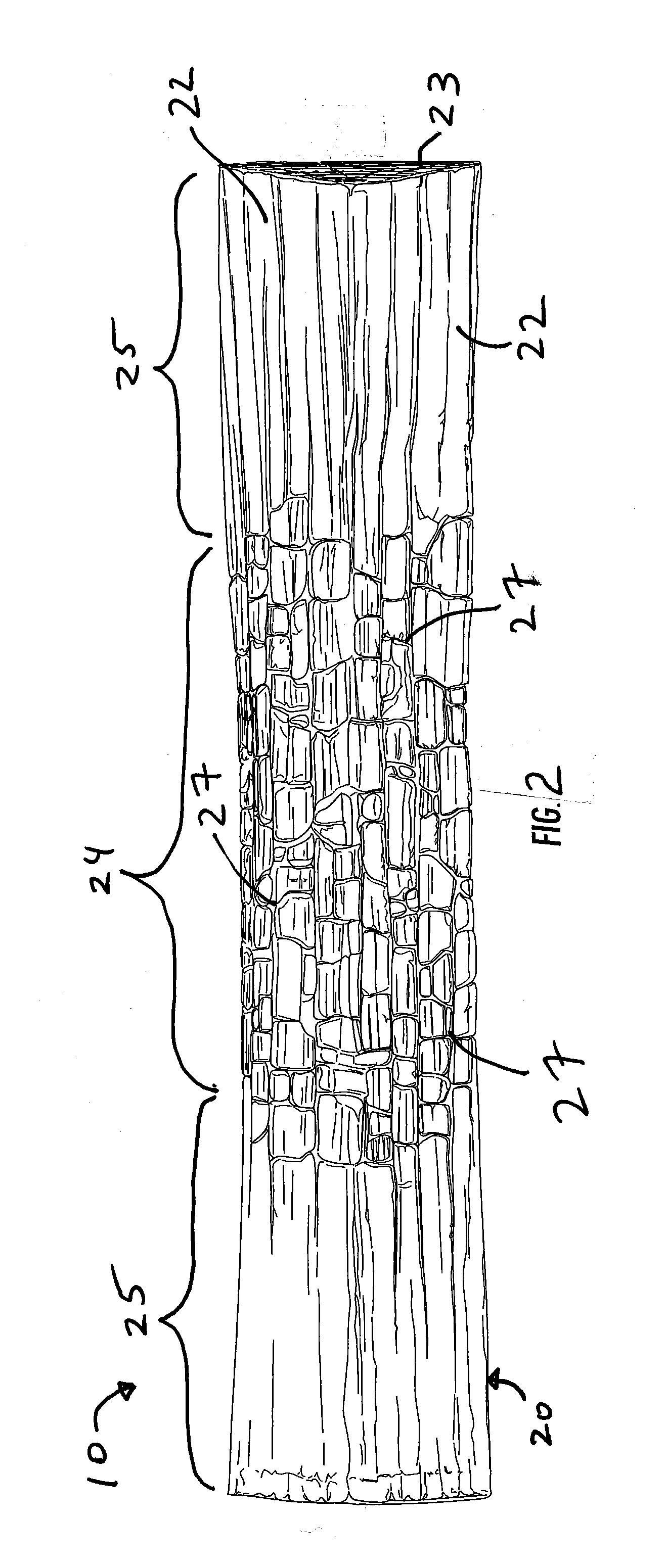

Faux glowing firewood log suitable for outdoor use

ActiveUS20150253013A1Simulating appearanceDomestic stoves or rangesPoint-like light sourceFirewoodRechargeable cell

A faux glowing firewood log has an appearance simulating that of a burning or glowing log of natural firewood, and is suitable for outdoor use. The simulated log includes an integral power source comprising a rechargeable battery and a solar panel for charging the battery. A plurality of light emitting diodes, powered by the integral power source, are disposed in spaced relationship within a body of the simulated log. The faux glowing log's body includes a translucent region, and an outer surface including crevices or grooves, simulated knots, simulated tree rings, and simulated tree bark. Light emitted by the diodes is transmitted through the translucent region, including the crevices, giving the appearance simulating that the log is on fire or glowing with heat.

Owner:FUSION PROD LTD

Hot bean dreg sauce and preparation method thereof

The invention discloses a composition for chili bean dreg sauce and a manufacturing method thereof, belonging to the food industry field. The compositions by weight percentage of the raw materials of the chili bean dreg sauce are: 40 to 50 percent of edible oil, 40 to 50 percent of soybean curb residue and 5 to 10 percent of flavoring substances, wherein, besides edible salt and monosodium glutamate, other flavoring substances are all pungent raw materials, namely chili, pepper, ginger and garlic. The manufacturing method comprises the following steps: firstly, the soybean curb residue is fried in a cooking pot, laid open, cooled, heaped and tightly hit, and then fermented under the environment between 8 and 20 DEG C until the soybean curb residue has aroma; secondly, the fermented soybean curb residue is baked, blown and dried in the sun, and firewood is optimally used for baking; thirdly, the dried fermented soybean curb residue is crushed and added with the flavoring substances for uniform stirring, and then the edible oil between 200 and 300 DEG C is poured into the soybean curb residue for uniform stirring and then naturally cooled; and fourthly, after bottling, the chili bean dreg sauce finished product is obtained. The method is simple and unique in manufacturing; and the manufactured chili bean dreg sauce not only has rich nutrition but also contains a great deal of cellulose, is suitable for being eaten together with rice or bread as a cole in a household, is used for adjusting the taste and adjusting stomach and intestine functions, and is favorable for weight-loss and bodybuilding.

Owner:覃业炬

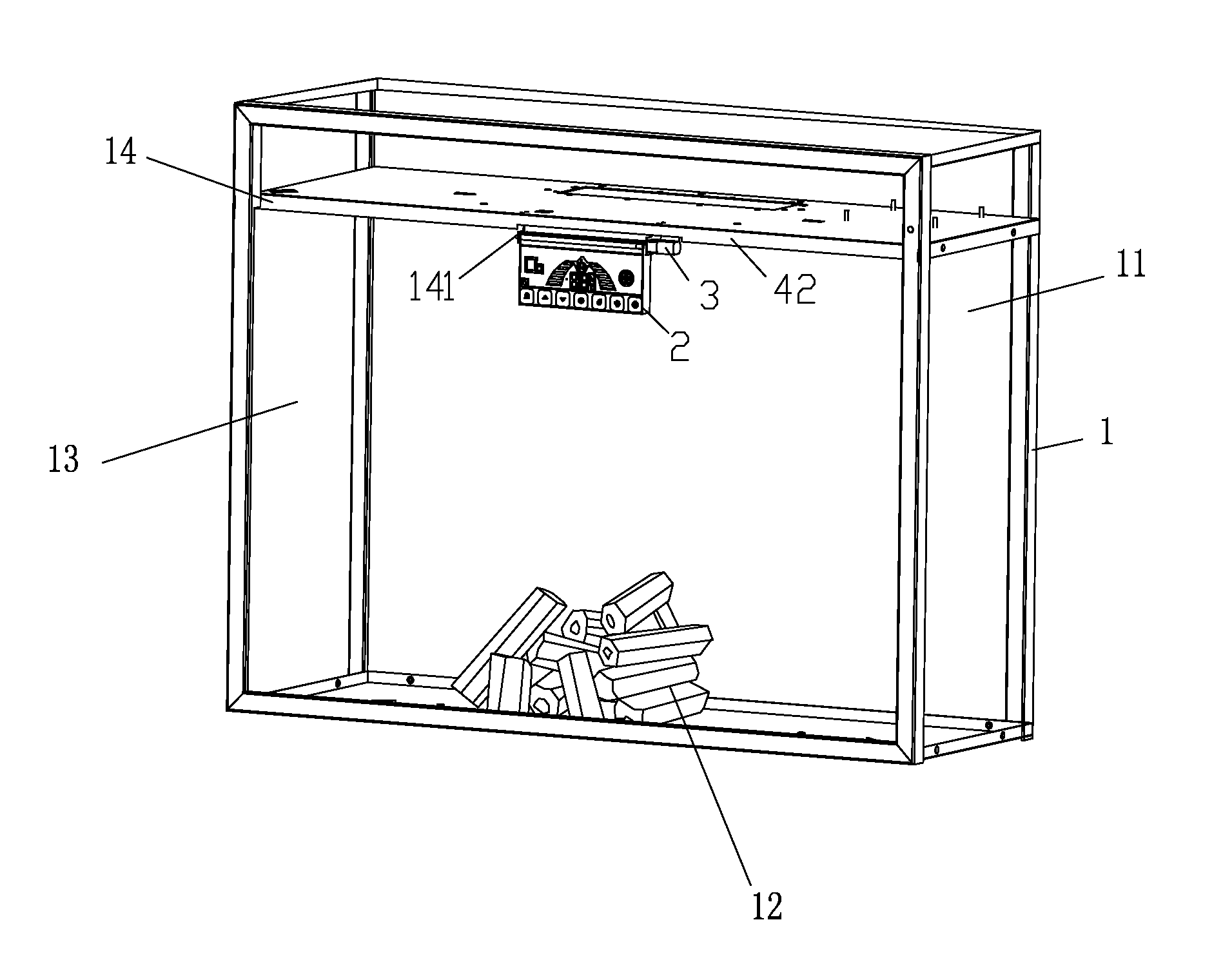

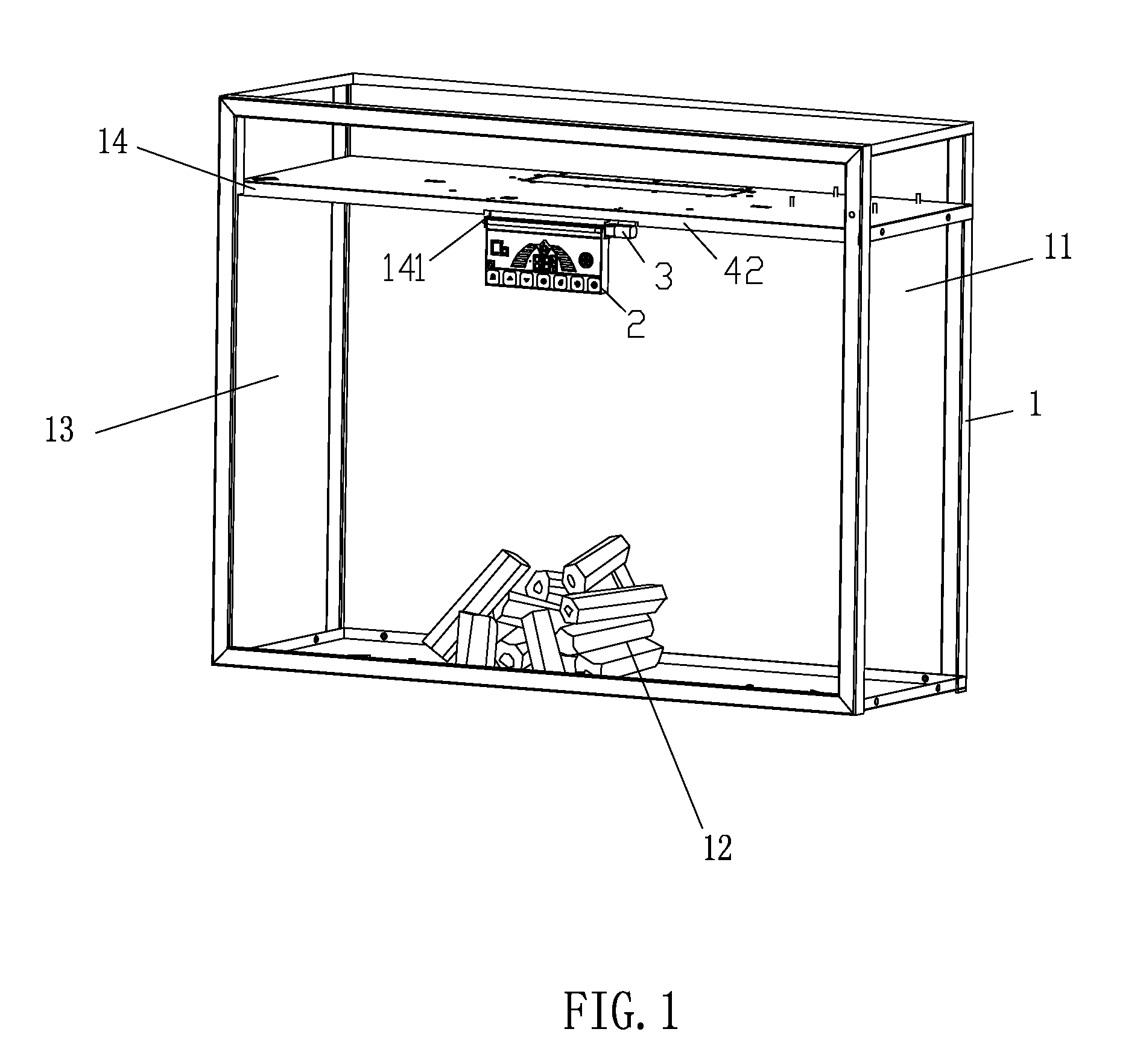

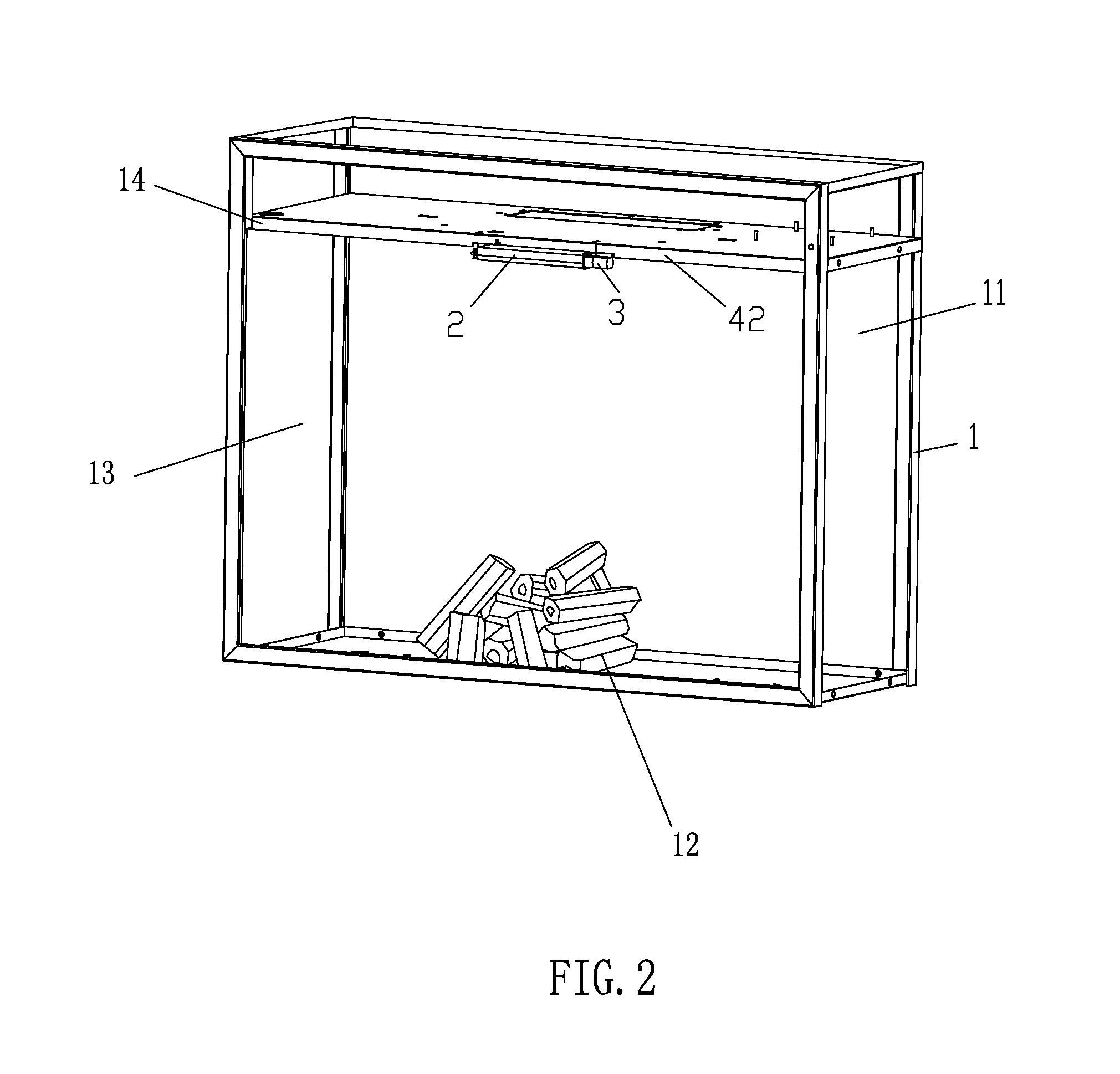

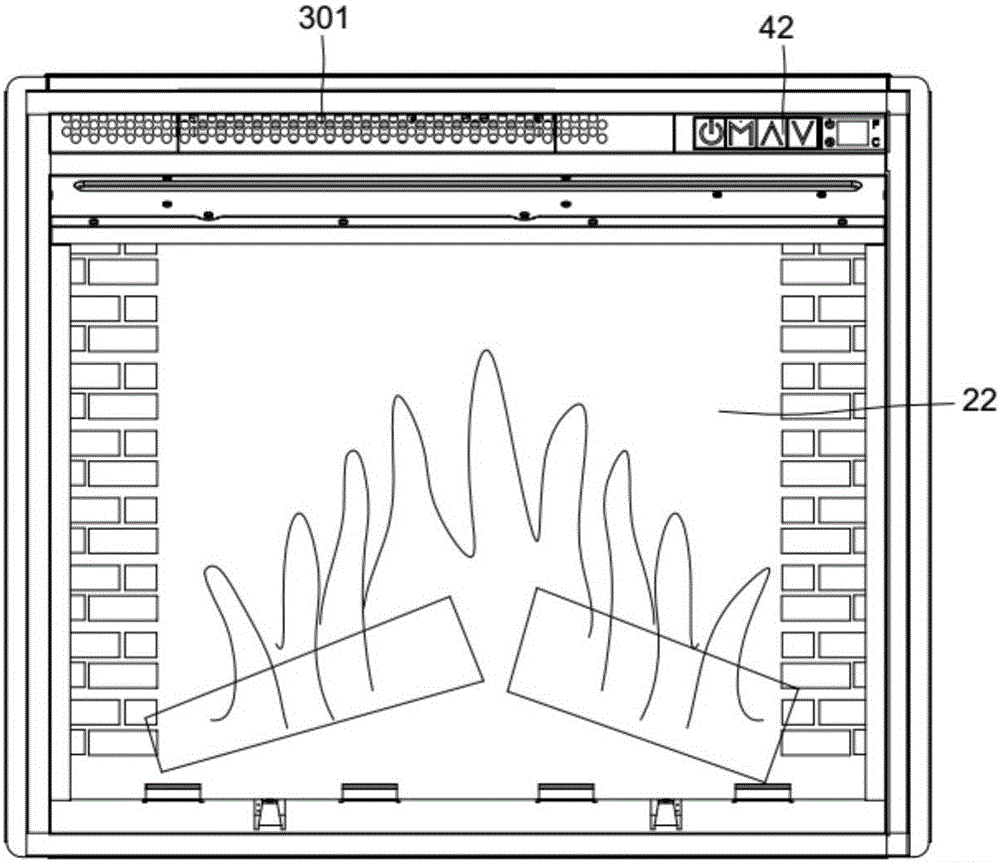

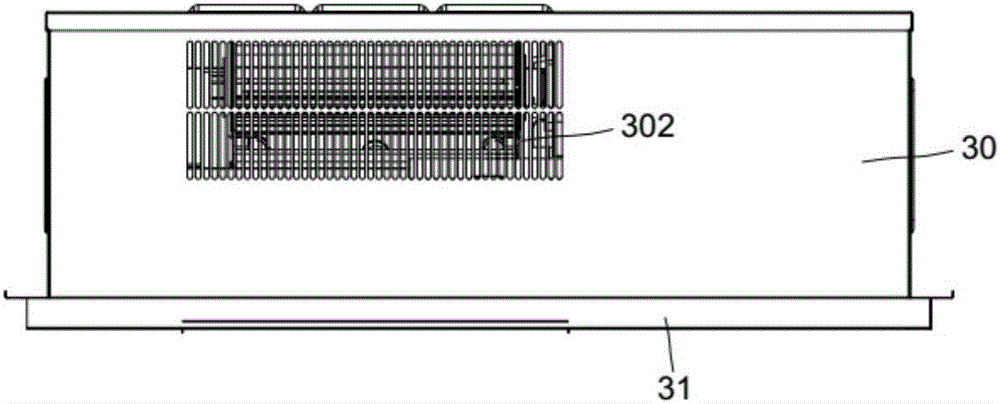

Electric fireplace

InactiveUS20150113840A1Simple structureEasy to manufactureDomestic stoves or rangesElectrical heating fuelFirewoodElectricity

An electric fireplace, comprising a main body, a control panel, a control circuit and a driving mechanism; the main body includes a housing and a simulation device, the simulation device and the control circuit are disposed inside the housing, the simulation device, the control panel, the driving mechanism are respectively electrically connected to the control circuit; the control panel is pivot joint to an edge of the front wall of the housing; the driving mechanism is connected to the control panel to make the control panel with an unfold state and a fold state with respect to the main body, with a concealable control panel, the appearance of the electric fireplace is more like traditional firewood fireplace, and the consumers can get a better view of flame, the present invention is simple structural and easy to manufacture.

Owner:FUJIAN ERLING ELECTRONICS

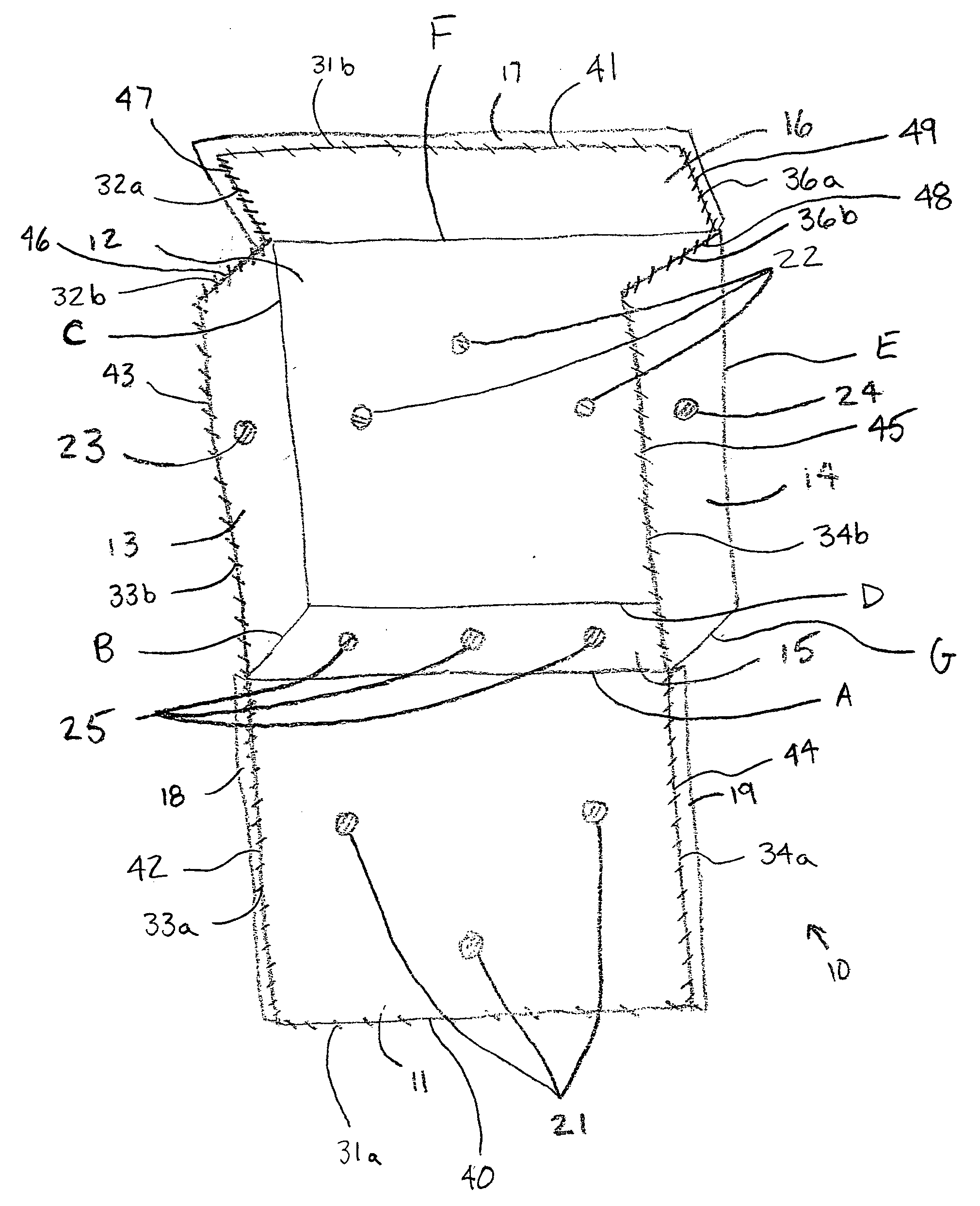

Log splitting head for bundlewood production

A splitting head for a log splitting apparatus includes abutting primary and secondary splitting assemblies, each having a circular securing ring that holds wedge members having cutting edges directed toward the log. The cutting edges of the secondary assembly split into smaller pieces the pieces produced by the primary assembly, producing a bundle of elongated pieces of firewood in parallel array and wherein the center of the bundle has not been compressed.

Owner:SMITH JOHN R

Processing method of preserved meat

InactiveCN107095170AReduces greasy feeling in the mouthDelicate tasteMeat/fish preservationFirewoodSalt content

The invention provides a processing method of preserved meat. The processing method comprises the steps of (1) treatment of raw material meat; (2) soaking and cleaning: putting finished meant strips into rice washing water for ultrasonic treatment for 0.5-1h and taking out the meant strips for airing; (3) pickling of meat: carrying out negative pressure pickling on the raw material meat treated in the step (2); (4) draining of the pickled meat; (5) baking of the meat: baking the meat drained off in the step (4) in a drying room with firewood for 10-12 days, wherein the temperature of the drying room is 50-65 DEG C; and (6) smoking of the meat: carrying out smoking and baking treatment on the baked meat under the conditions that the temperature is 30-40 DEG C and the relative humidity is 55%-60%. The salt content and the benzopyrene content in a preserved meat product processed by the method are significantly reduced.

Owner:合肥绿益食品有限公司

Brown chili sauce and making method thereof

The invention relates to a brown chili sauce and a making method thereof. The brown chili sauce mainly comprises the following raw materials: rapeseed oil, ginger, garlic, fermented chili, brown chili powder, soy sauce, lard, salt and chicken essence. The making method of the brown chili sauce comprises the following steps of: stir-baking dry chili to brown with firewood, then beating the dry chili into brown chili powder for later use; weighing the rapeseed oil, ginger, garlic, fermented chili, the soy sauce, the lard, the salt, the chicken essence and the brown chili powder obtained in the step (1) for later use according to parts by weight in a formula; adding other materials in the rapeseed oil and stewing together; when the stewing temperature is above 100 DEG C, stirring evenly, and sealing and packing after cooling. The making method has the following beneficial effects: the fermented chili and the brown chili powder are stewed together so the brown chili sauce is spicy and unique in taste; by combination of rapeseed oil and lard, the brown chili sauce is unique in flavor; by adding the soy sauce, the brown chili sauce is more mellow after being put into soup; and the making method is simple and convenient, easy in production process control, and high in production efficiency.

Owner:ZUNYI LIUHUZI FOOD

Breeding method for polygonatum cyrtonema seeds

InactiveCN107155591AIncrease productionImprove germination rateSeed and root treatmentHorticultureTemperature controlFirewood

The invention discloses a breeding method for polygonatum cyrtonema seeds. The method comprises the steps: a. seed collection and storage: picking mellow polygonatum cyrtonema fruits, rubbing off coats, carrying out rinsing, and carrying out shade drying; selecting a leeward and shady place, digging a cellar, placing wooden boxes in the cellar, placing fine sand with the thickness of 3cm in each wooden box, then, spreading the polygonatum cyrtonema seeds, and then, laying fine sand with the thickness of 1cm; and then, covering the wooden boxes with sunshade nets, and then, carrying out covering with rice straws; b. seed germination hastening: taking out the cellared seeds, and screening out superficial fine sand; soaking the sterilized seeds with constant-temperature water, then, loading the soaked seeds to the wooden boxes, and possibly using cotton cloth or rice straws as bedding; adopting temperature-changed and temperature-controlled germination hastening, and keeping wet; and carrying out sowing after white spots emerge on seed coats; and c. sowing: digging up sterilized soil to be loose, allowing the soil to be fine, then, applying farmyard manure, then, carrying out sowing, covering the seeds with a layer of fine soil after sowing, and carrying out spray watering according to soil humidity; and then, covering surfaces with a layer of firewood for water retention, heat preservation and weed control. According to the method, by using a seed cellar sand storage and breeding technology, the germination percentage is high; and by adopting indoor temperature-changed germination hastening, the rate of seedling emergence is high.

Owner:新化县绿源农林科技有限公司 +1

Firewood container

A firewood storage device for made of a container having a plurality of panels, wherein at least one said panel having an edge being capable of removably affixing to an edge of at least one other said panel, and at least one said panel having a vent.

Owner:MATERNA RICHARD

Simulation fireplace with 3D stereoscopic effect glass

InactiveCN106091090AImprove the three-dimensional effectElectric heating systemLighting elementsFirewoodLaser processing

The invention discloses a simulation fireplace with 3D stereoscopic effect glass. The simulation fireplace comprises a heating system and a light reflecting system mounted in a shell; the light reflecting system includes a reflecting device, and a projection screen positioned in front of the reflecting device; the projection screen is transparent; and a false wall, false firewood and a flame pattern are arranged on the projection screen. The projection screen is a plane or a convex surface or a concave surface, and is provided with the false firewood and the flame pattern; the false wall, the false firewood and the flame pattern are engraved in the projection screen by laser processing; and the color treatment is performed for the false wall, the false firewood and the flame pattern to achieve a 3D stereoscopic effect.

Owner:东莞首资宝电器制造有限公司

Method for culturing of Armillaria mellea and rapid high-yield cultivation of Gastrodia elata by using wood sheets

InactiveCN105917919AGrow fastSolve outputCalcareous fertilisersBioloigcal waste fertilisersFirewoodWoodchips

The invention provides a method for culturing of Armillaria mellea and rapid high-yield cultivation of Gastrodia elata by using wood sheets. The method comprises the following steps: selection of a mother Armillaria mellea strain, culturing of an Armillaria mellea stock, fabrication and culturing of a three-grade Armillaria mellea cultivar, preparation of new firewood and a cellar bed, and placement of the new firewood and sowing. According to the invention, the Armillaria mellea cultivar is cultured through the following steps: sawing a weed tree applicable to growth of Armillaria mellea into unpeeled wood sheets with a length of 9 to 12 cm and a width of 2 to 4 cm; by weight, preparing weed tree sawdust, wheat bran, white sugar and gypsum into a culture medium, placing the obtained culture medium powder onto the bottom part of a wood sheet bag, then vertically placing the wood sheets of the weed tree into the wood sheet bag, placing the culture medium powder onto the bag, tying the bag mouth, placing the wood sheet bag into a sterilization tank, and carrying out continuous sterilization at a constant temperature of 100 DEG C for 20 hours or above; and after sterilization is completed, placing the Armillaria mellea stock into a culture chamber, and carrying out culturing at about 20 DEG C for 40 days so as to obtain the Armillaria mellea cultivar used for cultivation of Gastrodia elata or Polyporus umbellatus. The method provided by the invention replaces conventional mushroom-sticks for direct co-cultivation of Gastrodia elata or Polyporus umbellatus, achieves that cultivation and harvesting are in a same year, realizes one-time cultivation and harvesting for a plurality of times, has high and stable yield of Gastrodia elata, and fundamentally solves the phenomenon of empty cellar.

Owner:绥宁县博世康天麻科技开发有限责任公司

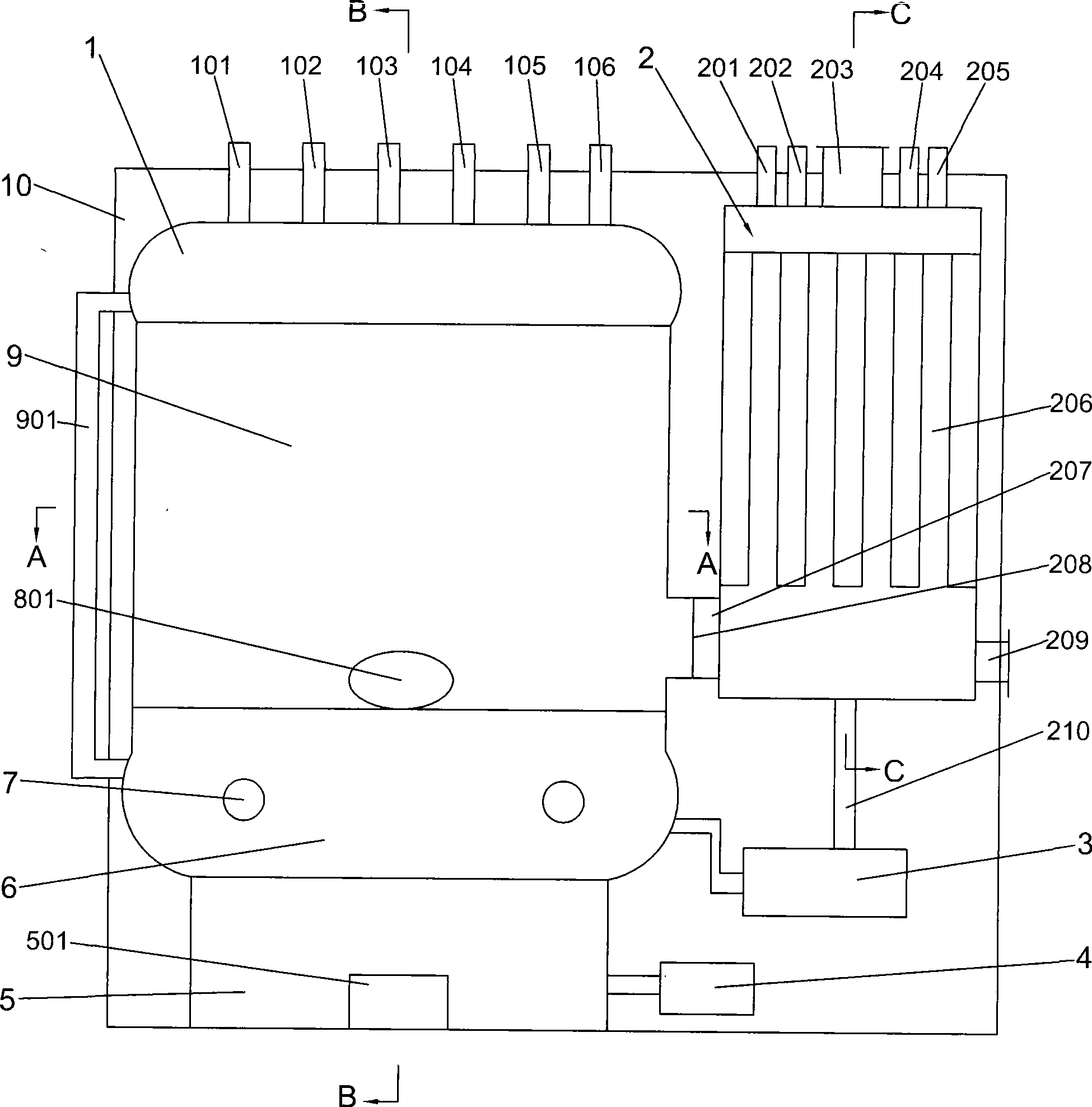

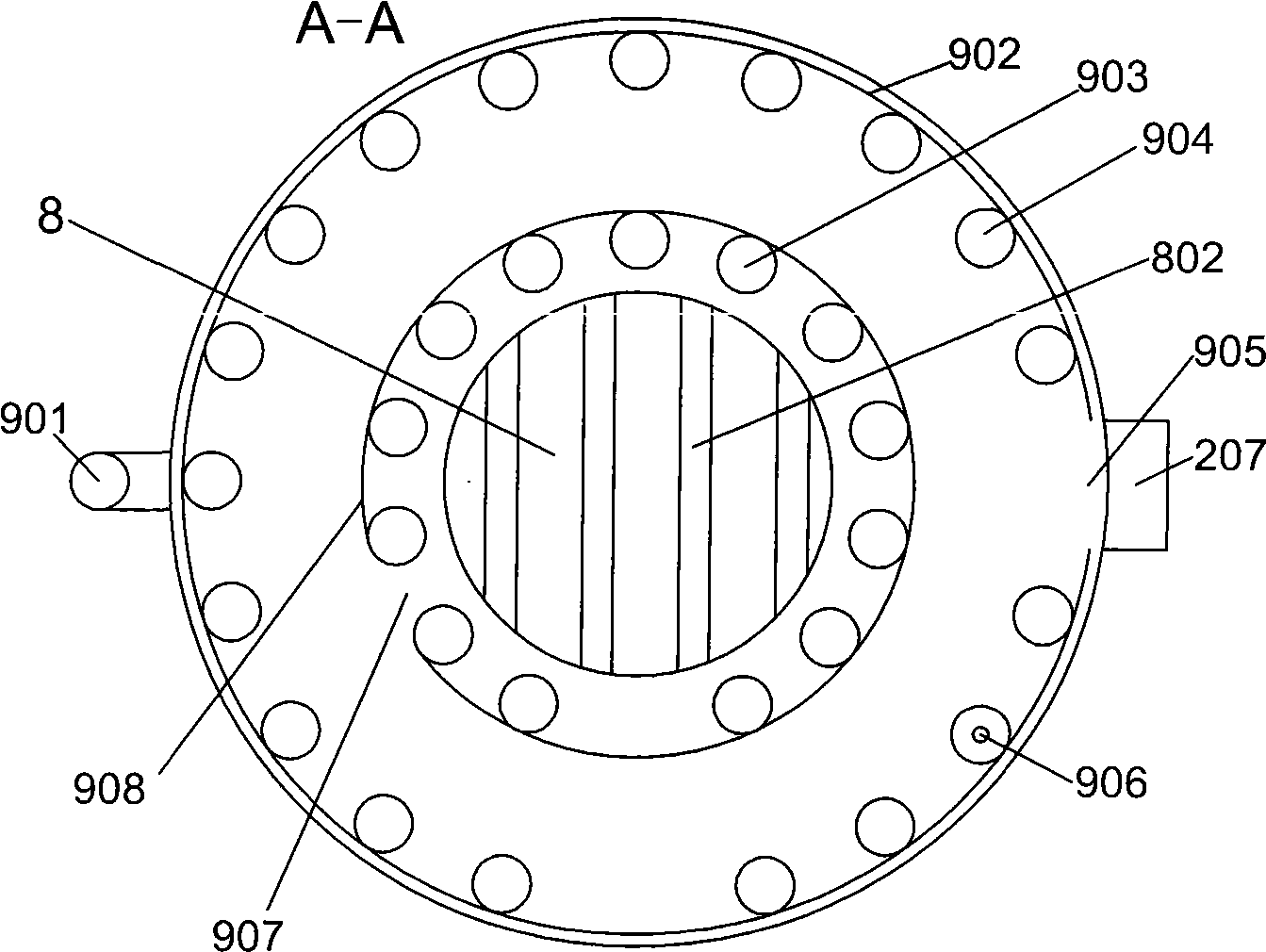

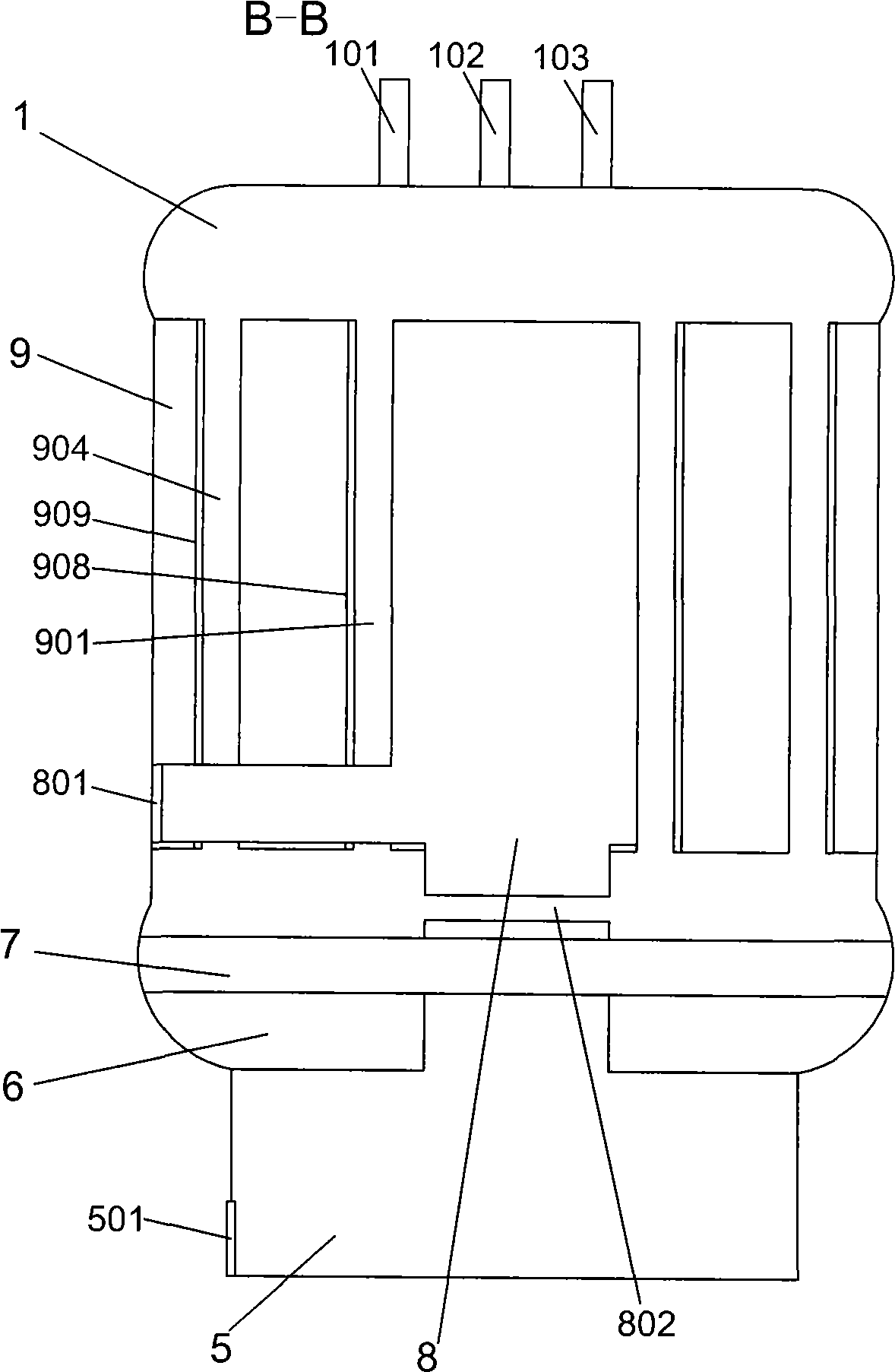

Dual purpose energy-saving boiler for hot water and steam

InactiveCN101532722ASignificant comprehensive benefitsEasy to take outSteam generation heating methodsWater heatersThermal energyCombustion chamber

The invention provides a dual purpose energy-saving boiler for hot water and steam. The boiler comprises an upper water liner, a lower water liner, a main liner body, a subsidiary water tank, a combustion chamber and an electric heating tube, wherein the main liner body comprises an inner circle of a water pipe and an outer circle of a water pipe, and is a pipeline structure, thereby not only increasing the heating area in the main liner body, improving the heat utilization rate of heat energy, but also having strong pressure resistance, preventing occurrence of boiler explosion, and ensuring the safety of the boiler; after the subsidiary water tank heats cold water by residual heat, the water enters the lower water liner, the main liner body and the upper water liner, thereby improving the efficiency of heat energy, and saving energy. The boiler can select different heat modes conveniently according the requirement of different production situations, selects different single fuels or mixture fuels or electric heating, such as coal, firewood, electricity, fuel, gas and the like. The boiler can be used both as a steam boiler and a hot water boiler, is the energy-saving environment-friendly boiler with steam and hot water dual purposes.

Owner:王爱清

Moving cleaning barbecue and catering kitchen

InactiveCN104223961AIncrease profitReplace as soon as possibleKitchen equipmentIncinerator apparatusElectrolysisAutomatic control

The invention discloses moving cleaning barbecue and catering kitchen equipment. The equipment is powered by 110 / 220V alternating current and a 48V direct current battery, has a fixed and moving 48V voltage safe-using function, oily fume and oily gas are automatically cleaned, the PM2.5 quality index of ambient air is sensed, displayed and detected, the cleaning work of a main unit is automatically controlled, a set additive for eliminating oily fume and an oily substance is automatically detected and added, a fume, dust and oily substance filtering system and a hydrolyte circulating spraying cleaning type filtering purification mode are adopted, water electrolysis oxyhydrogen gas for the combined purification of secondary gas of fuel coal, firewood, combustible waste and the like is combined to cyclically eliminate harmful fume, dust and gaseous substances during cyclic full combustion or combustion supporting, emission is eliminated by energy-saving measures, the display of an alarming lamp is detected to prompt a user to change tap water as soon as possible when hydrolyte reaches a certain concentration or certain time, and a set decomposing additive for neutralizing oily fume and oil is automatically added. The equipment is a necessary mechanical product for the healthy life of the user.

Owner:常州市利众环保科技有限公司

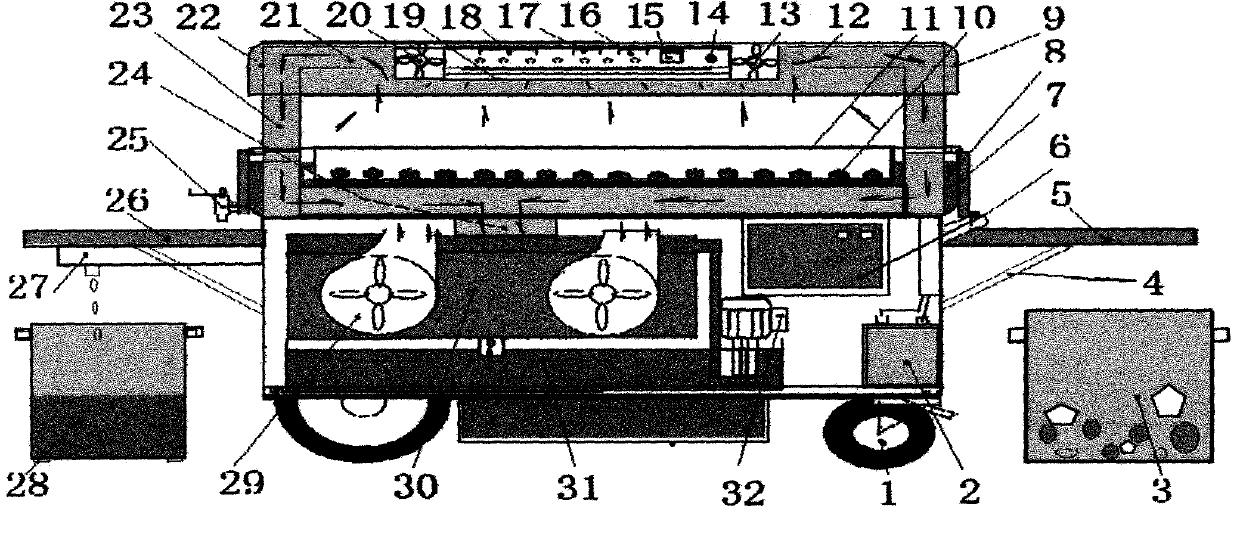

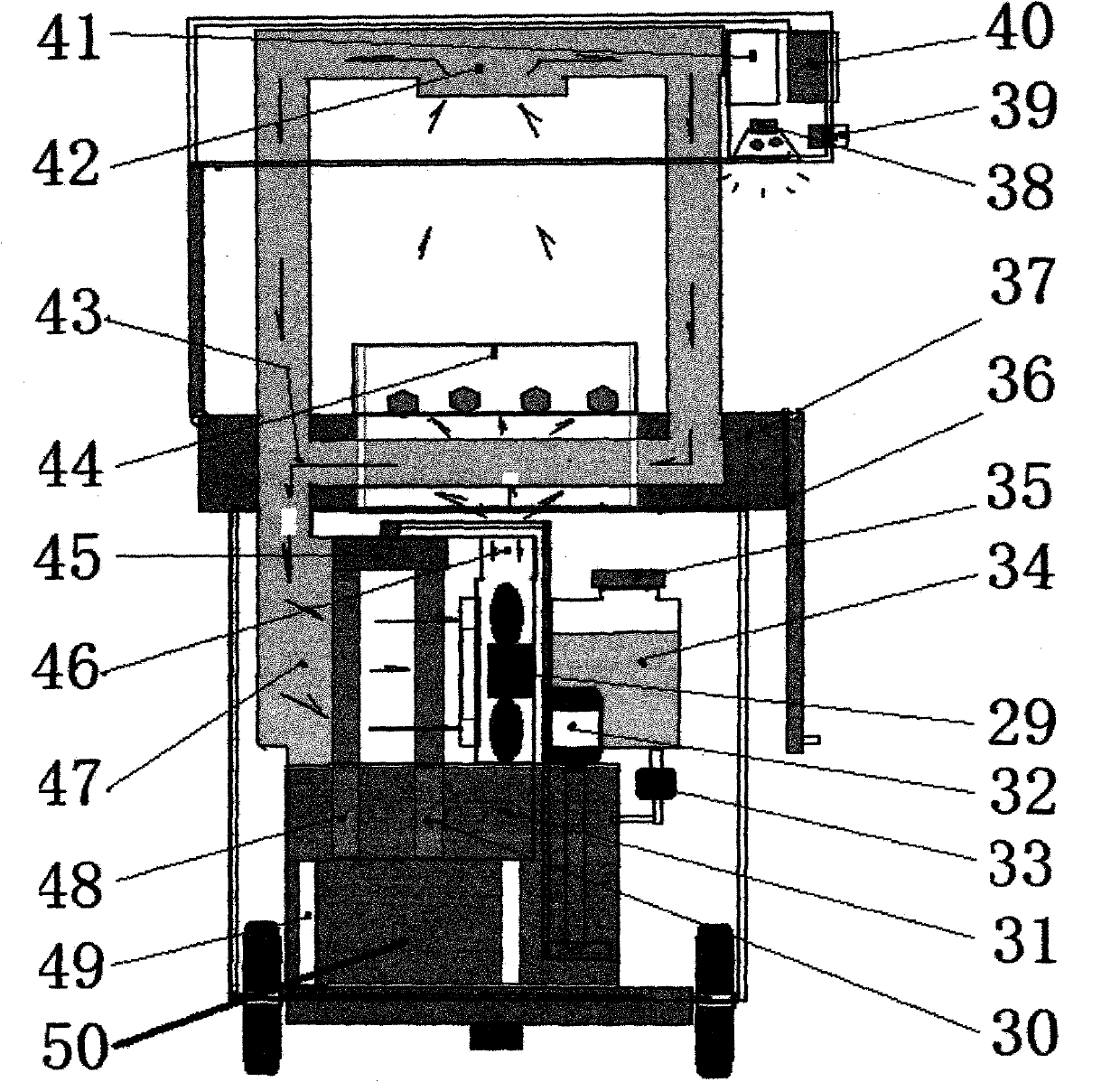

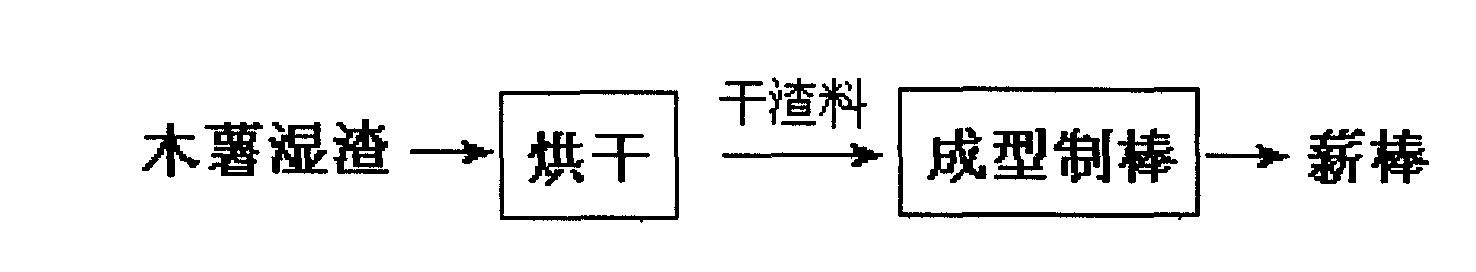

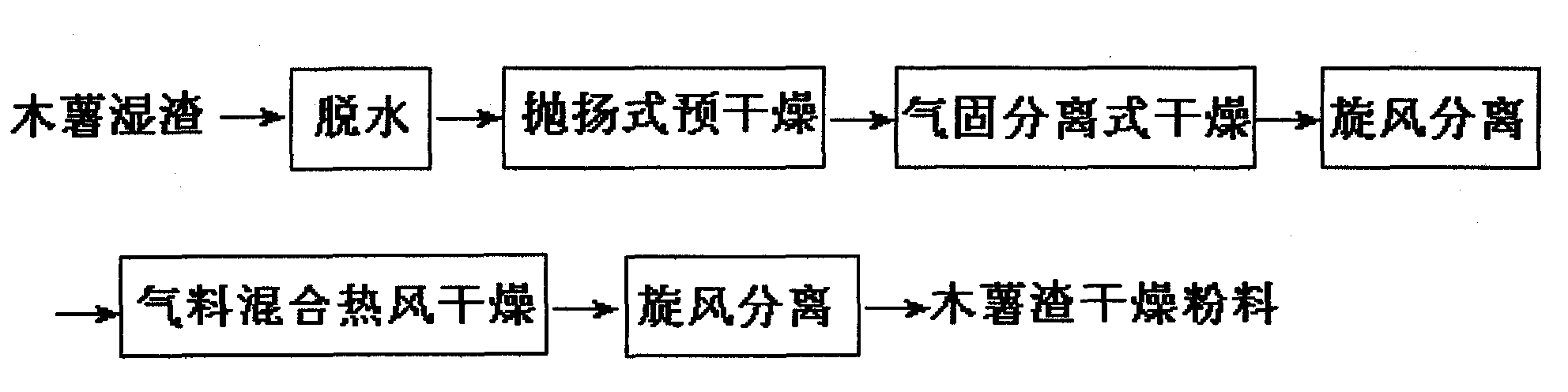

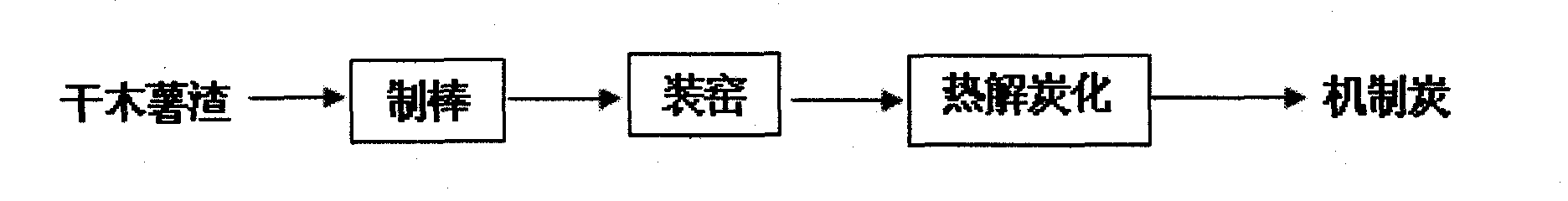

Method for preparing firewood sticks by waste cassava residues and application on charcoal preparation

InactiveCN102220178AIncrease added valueAvoid pollutionBiofuelsSolid fuelsEngineeringManihot esculenta

The invention discloses a method for preparing firewood sticks by waste cassava residues and application on charcoal preparation. The method comprises the following steps of taking the waste cassava residues produced in the production process of cassava starch as raw materials, drying the waste cassava residues to obtain dried residues, and preparing the formed firewood sticks by the dried residues, wherein after the waste cassava residues are dried, the water content rate of the dried residues is controlled to range from 10% to 15%, and the temperature of a mold for preparing the formed firewood sticks by the dried residues is controlled to be 230-280 DEG C. The firewood sticks prepared by the method are further baked into charcoal products which have the advantages of low ash content, low sulphur content, charcoal content, high heat productivity and the like, and are high-quality biomass energy. By the method, the waste cassava residues can be subject to industrial processing to form three levels of products (the dried residues, the firewood sticks and charcoal), so that circulated economic ecological chain of 'cassava-starch-cassava residues-biomass energy' can be formed, simultaneously, the risk that the waste cassava residues pollute environments can be eliminated, the direct energy-saving benefit is obvious, and the indirect emission reduction economic benefit is remarkable.

Owner:南宁市环境保护科学研究所

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com