Patents

Literature

585 results about "Woodchips" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Woodchips are small to medium sized pieces of wood formed by cutting or chipping larger pieces of wood such as trees, branches, logging residues, stumps, roots, and wood waste. Woodchips may be used as a biomass solid fuel and are raw material for producing wood pulp. They may also be used as an organic mulch in gardening, landscaping, restoration ecology, bioreactors for denitrification and as a substrate for mushroom cultivation.

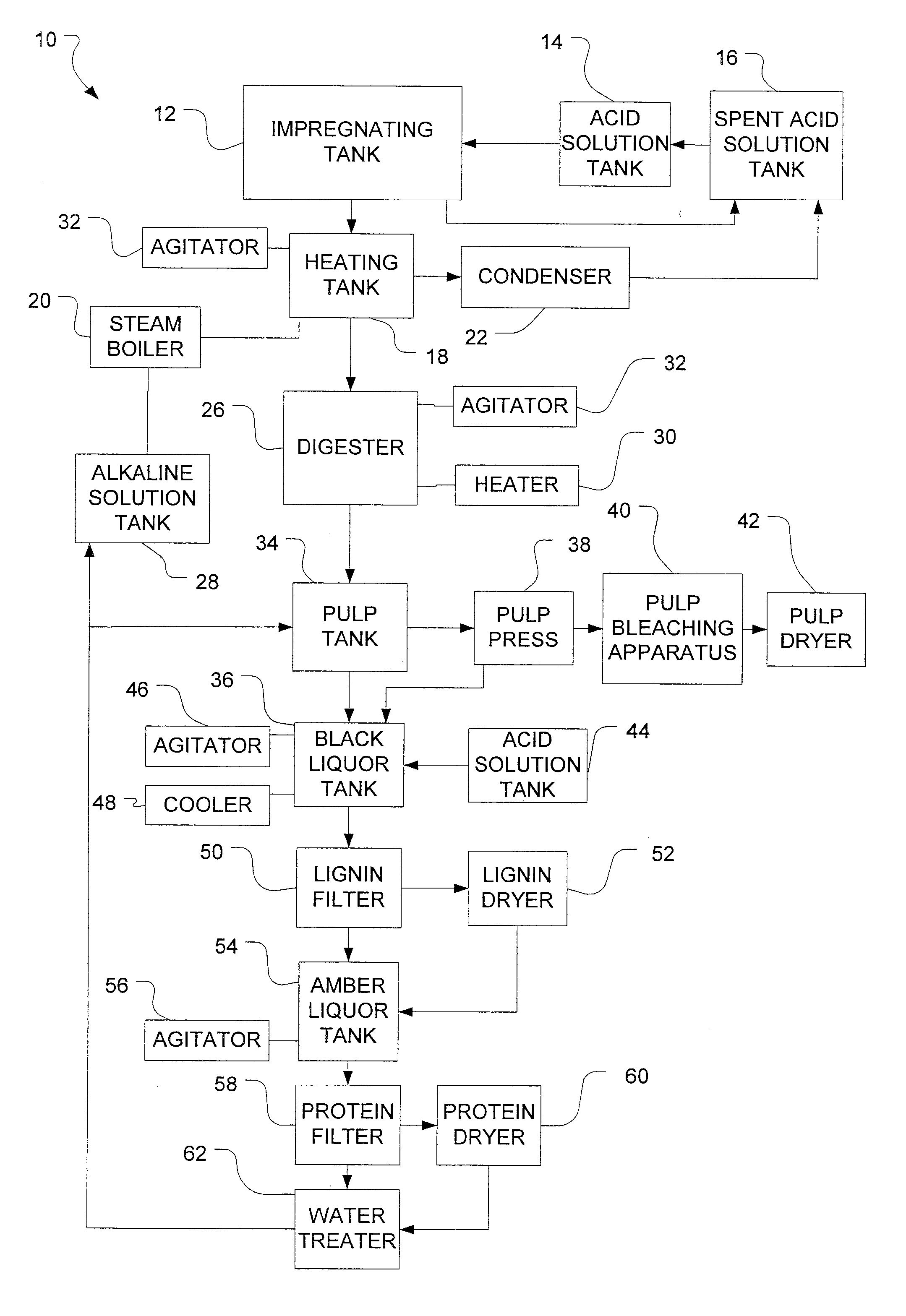

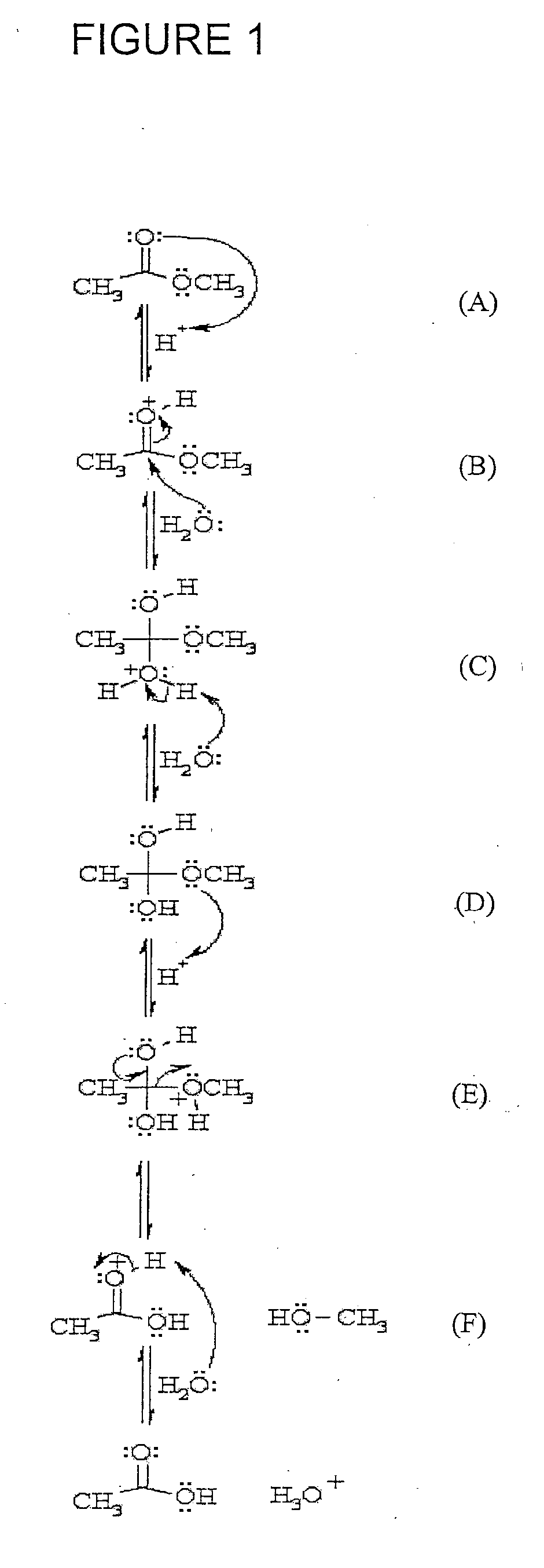

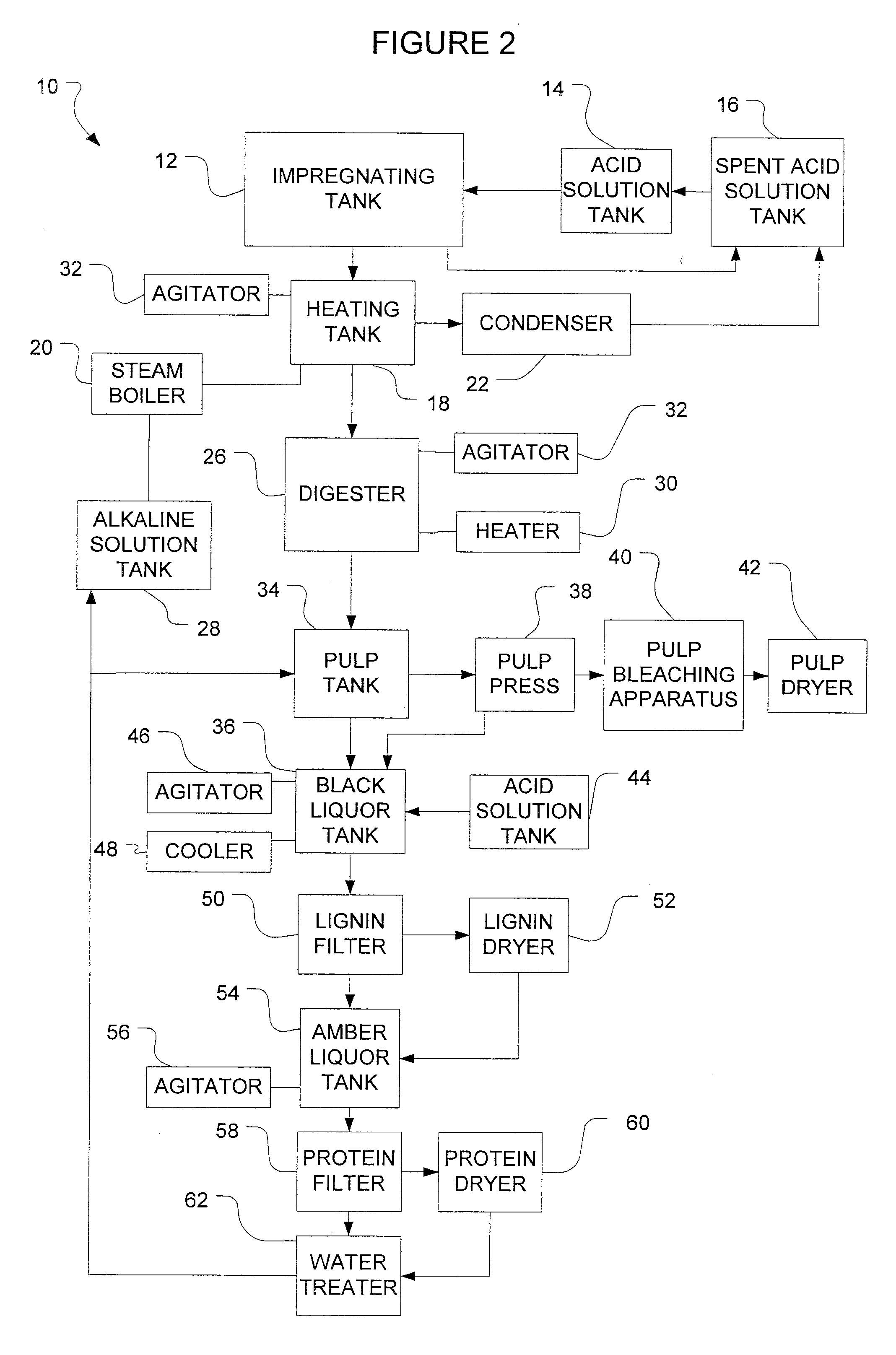

Method for producing pulp and lignin

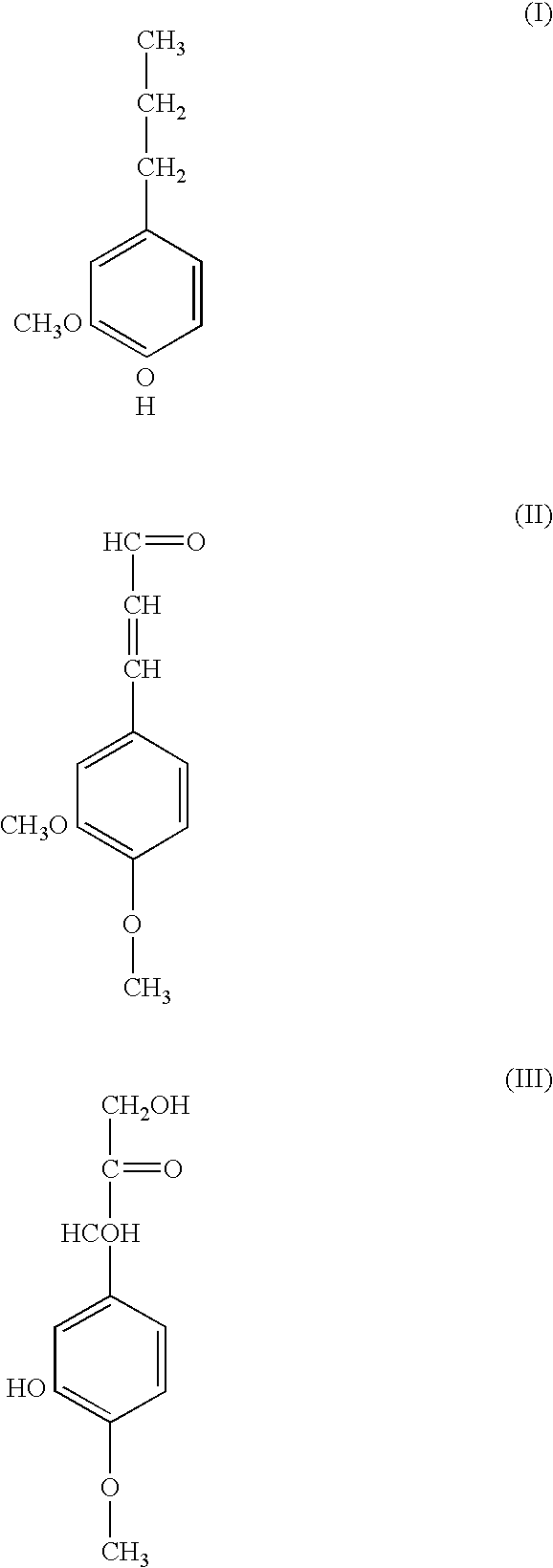

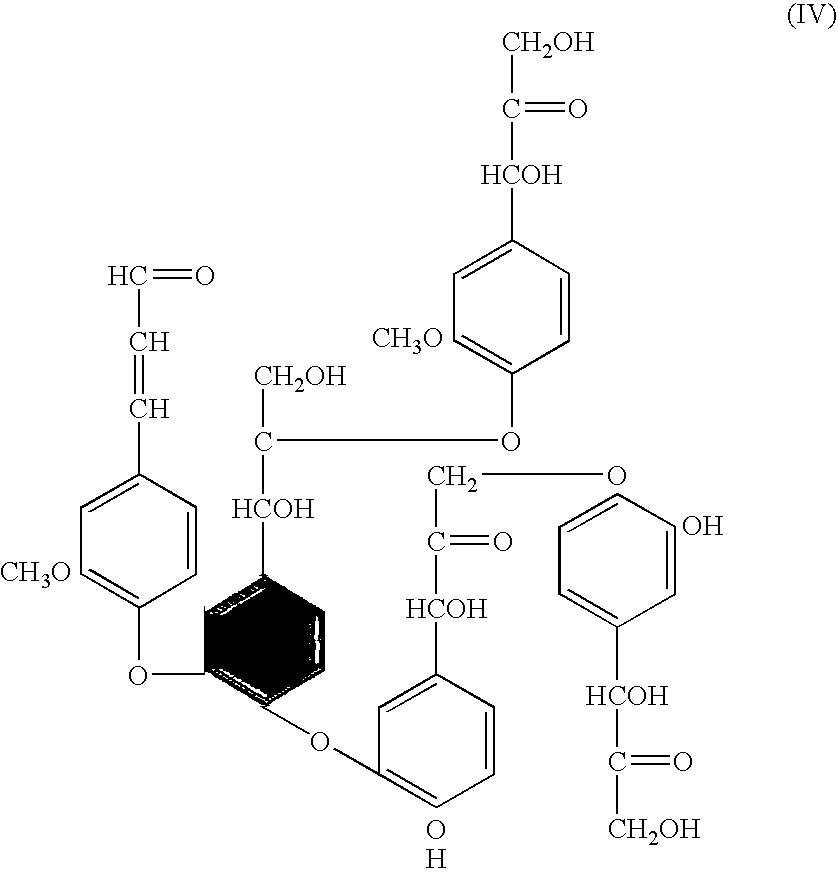

InactiveUS20040244925A1Pretreatment with acid reacting compoundsPulp bleachingCellulosePtru catalyst

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

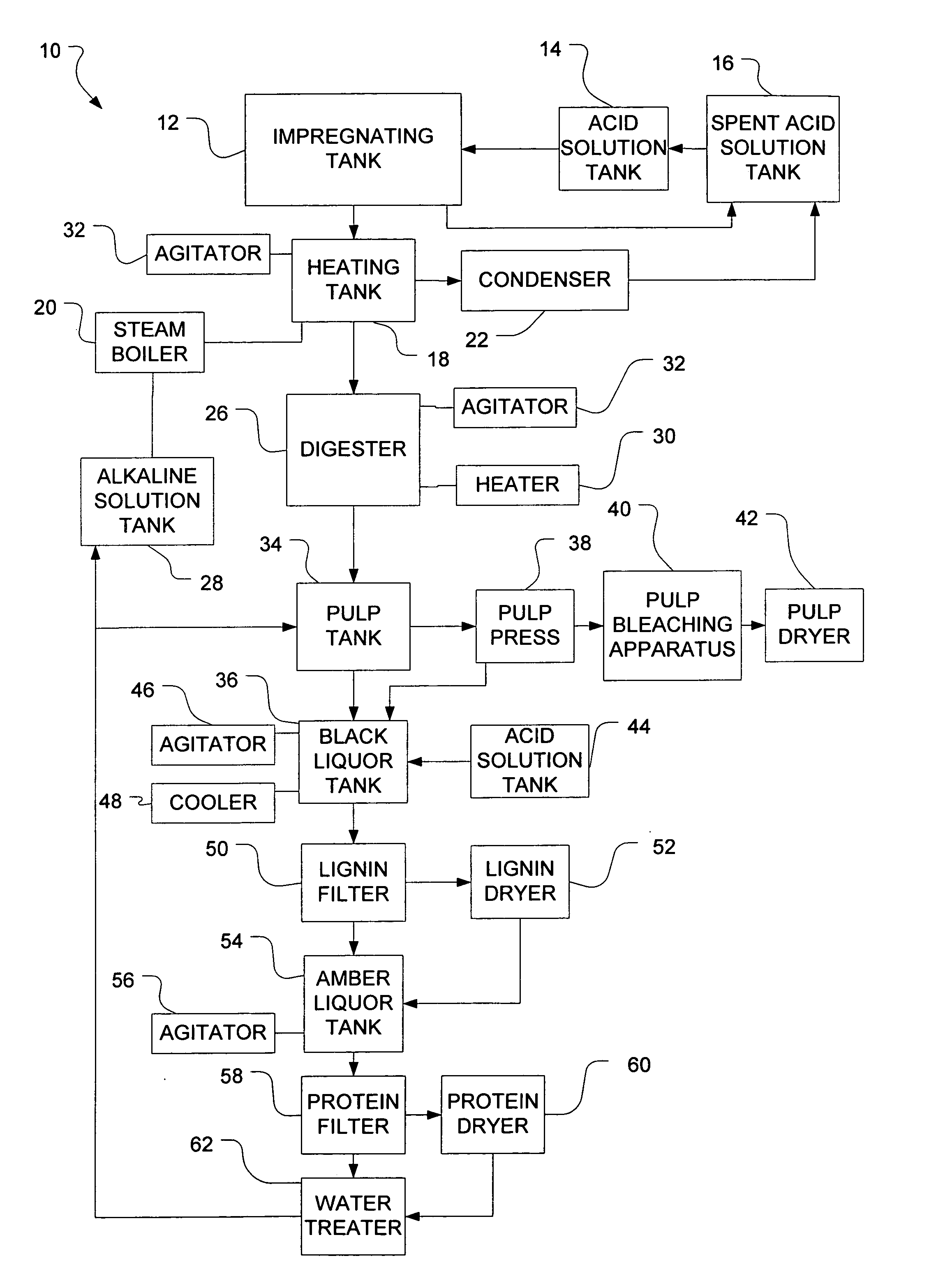

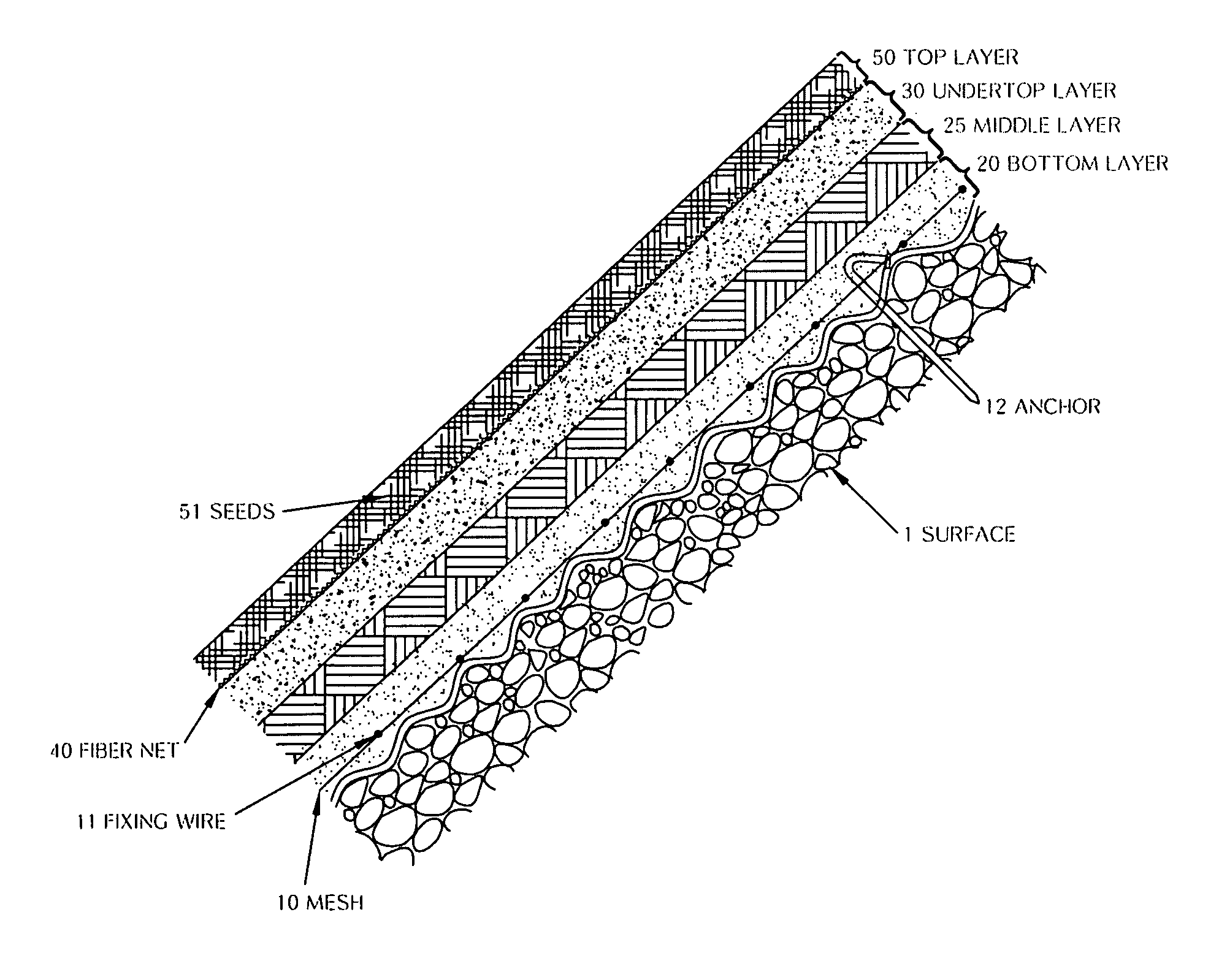

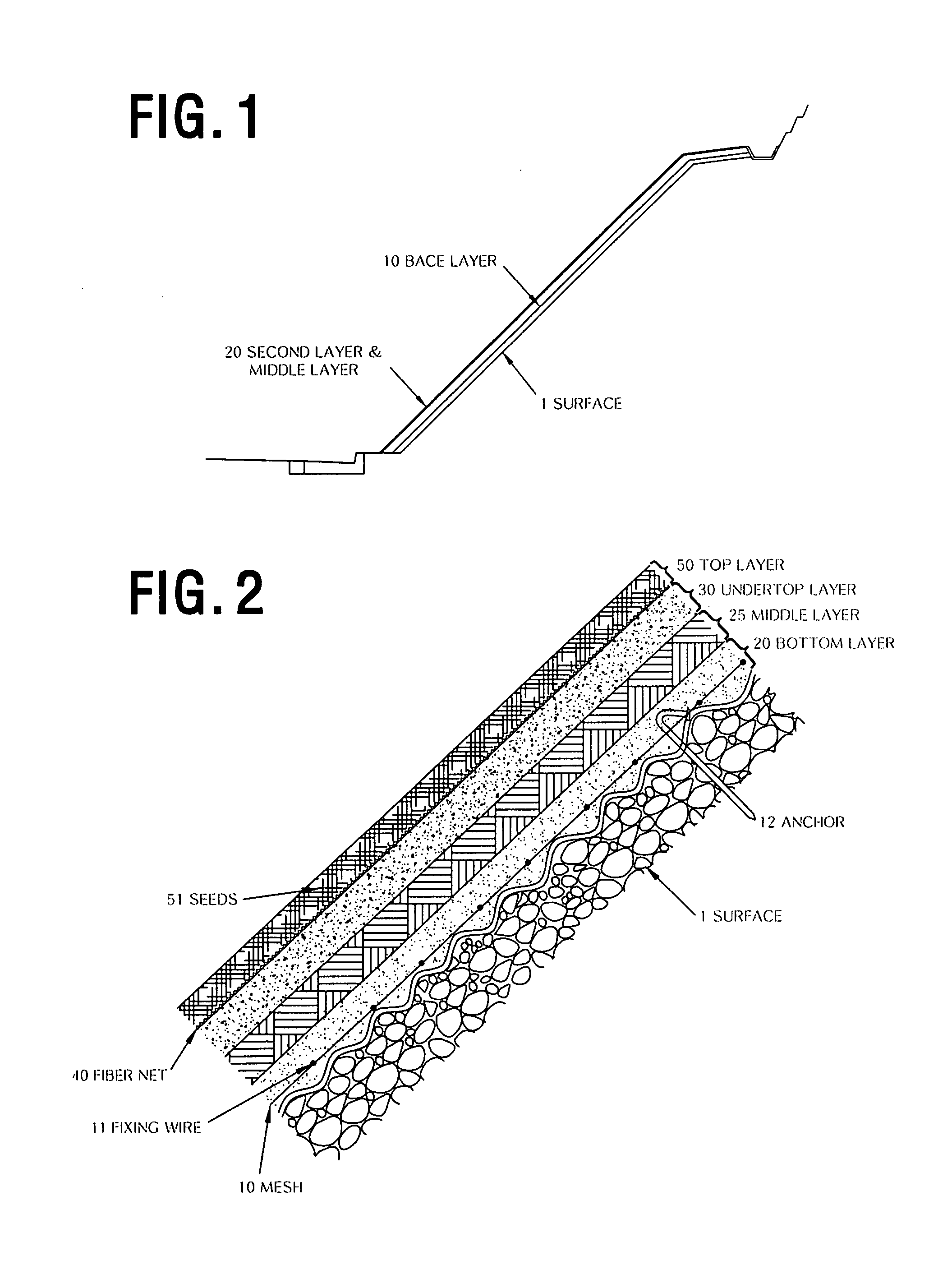

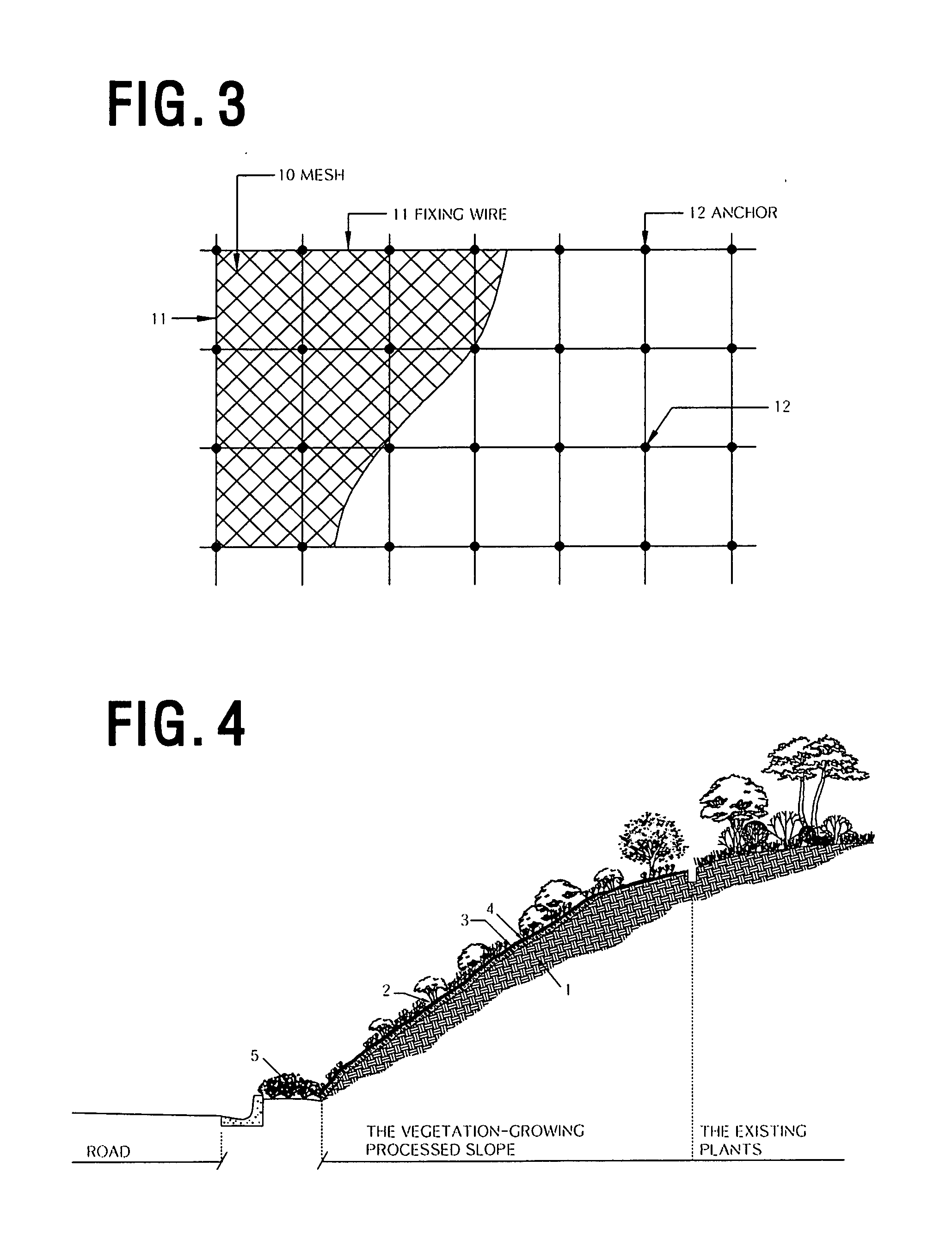

Vegetation base soil and a method for growing vegetation on a sloped surface

InactiveUS20110226169A1Improve adhesionPromote plant growthExcrement fertilisersSowingPeatBiological activation

Slope surfaces of land can be eroded by rain and wind. It is necessary to vegetate a bared slope surface of land for the purpose of erosion control and environmental conservation. The present invention provides a vegetation base soil composition and a method of growing vegetation on a sloped surface for erosion control and vegetating on cut rock slope surface, such as weathered rock surface and barren soil surface. The vegetation base soil includes peat, bio-solids formed by the treatment of urban sewage, for example water treatment plant sediment, woodchip, bark, animal waste compost and clay or loam. The vegetation base soil with a microbes active material, a root activation fertilizer, an adhesive material and seeds are applied over a mesh that is secured over the sloped surface. Plants are grown in the layer of vegetation base soil.

Owner:KIM YOUNG KOO

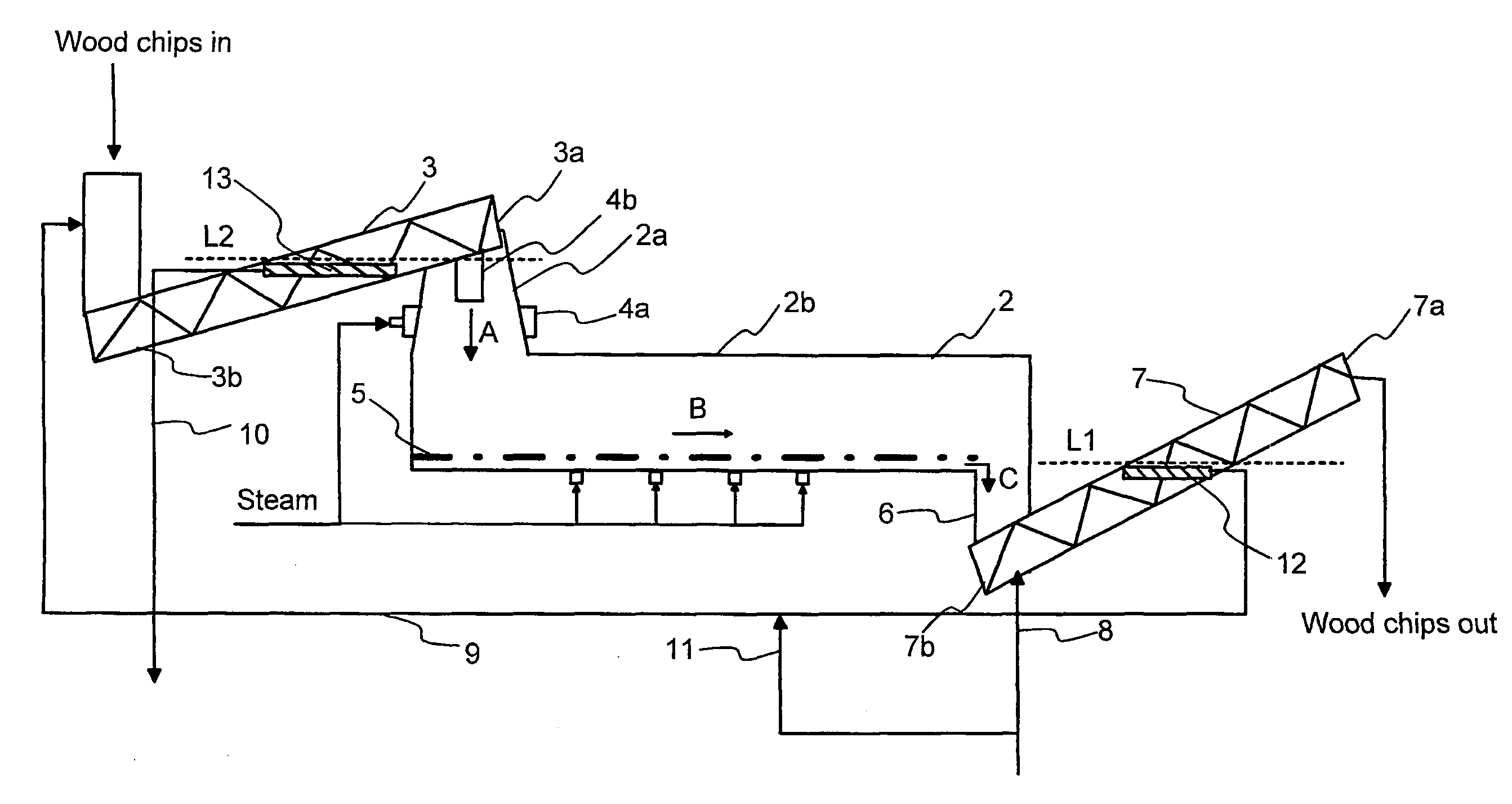

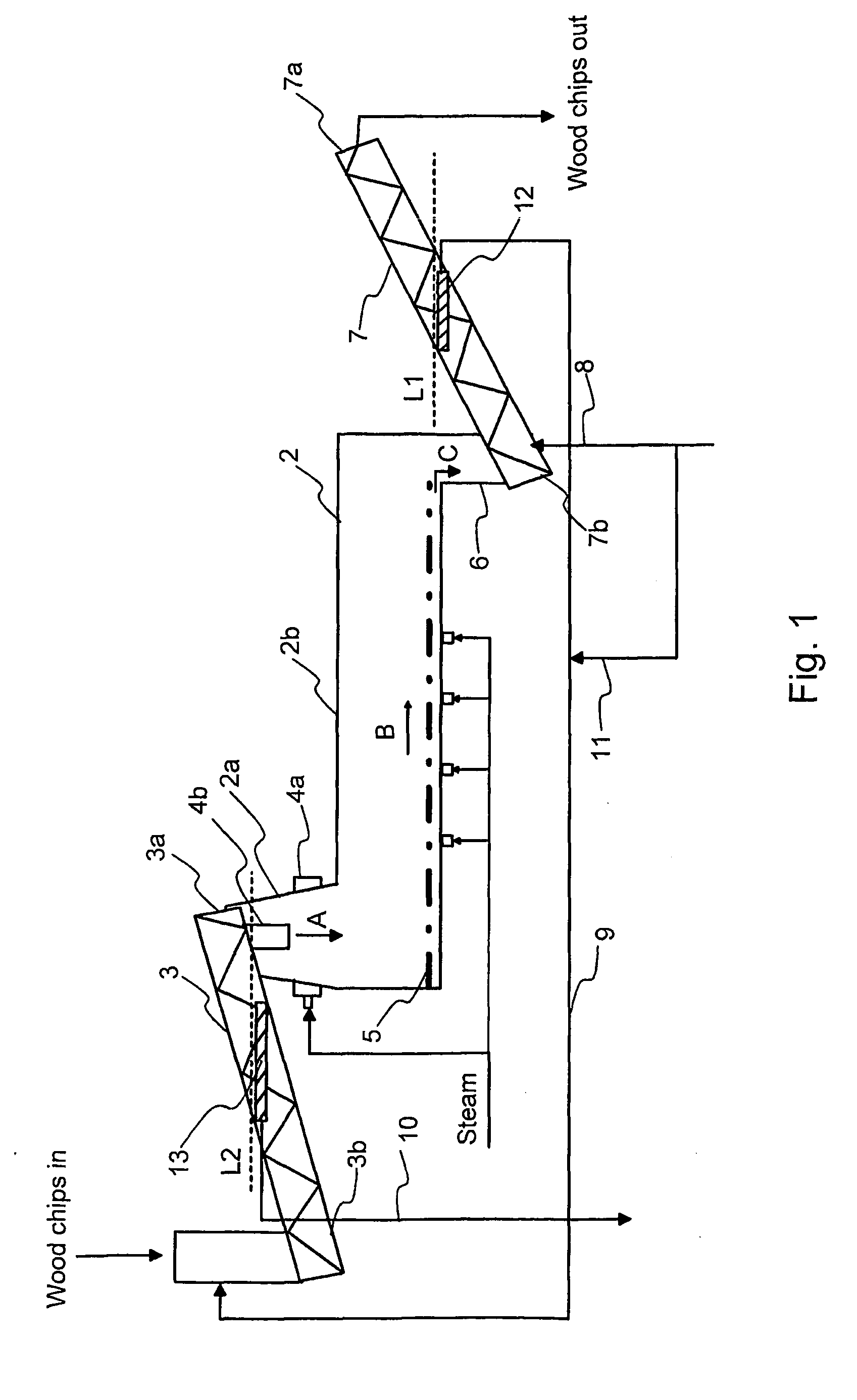

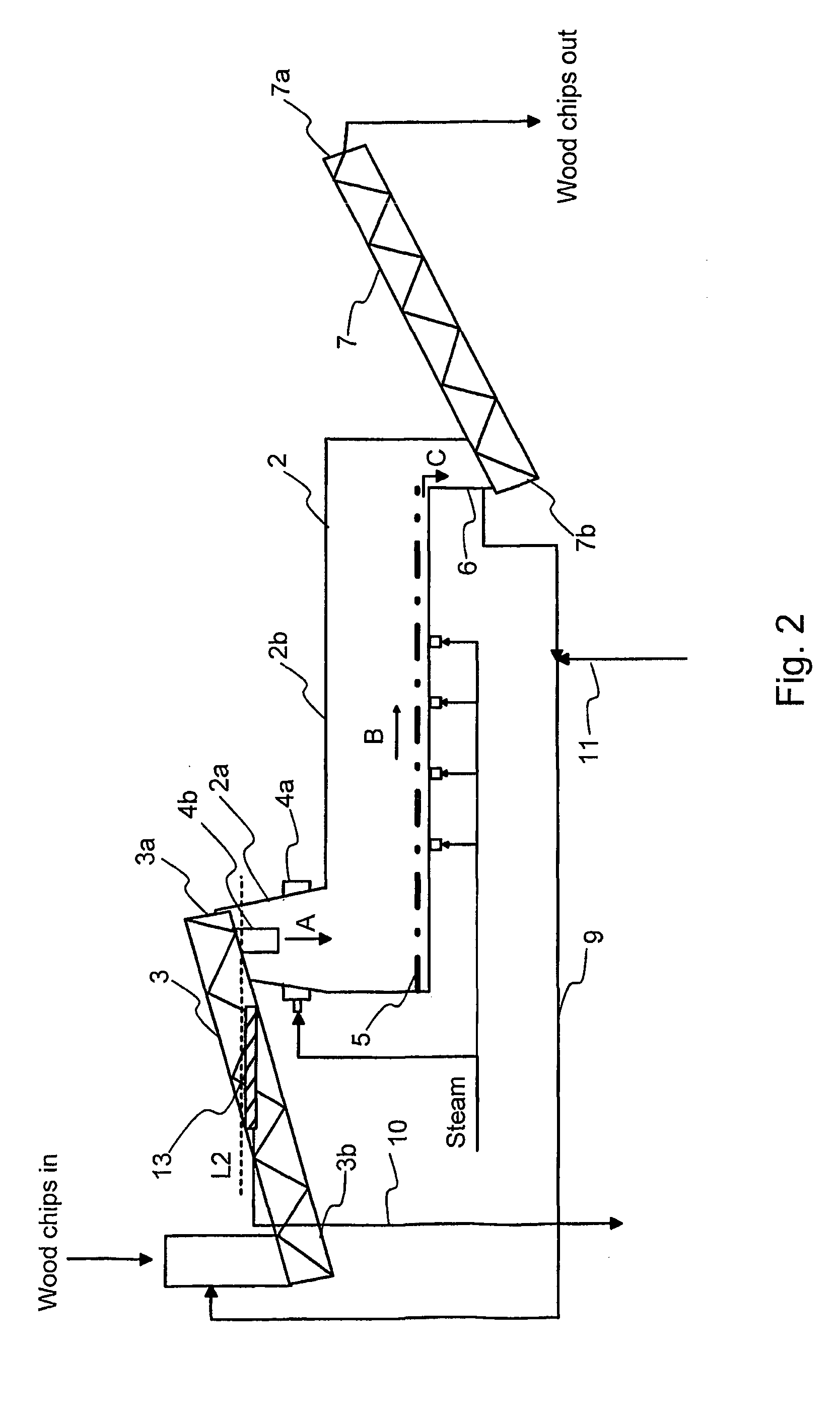

System and method for treatment of cellulose-containing material prior to pulp digestion

The invention relates to a process system and a method for preliminary treatment of disintegrated cellulose-containing material, preferably wood chips, prior to pulp digestion. The process system and the method according to the invention make use of a process vessel intended to function both as a so-called chip bin and as a pre-impregnation vessel. The characteristics of the invention are that a sloping steaming vessel is arranged downstream of the process vessel for the purpose of separating an excess of pre-impregnation liquid from the pre-impregnated cellulose-containing material, that the sloping steaming vessel is arranged for supplying steaming vapor which preferably has been generated by flashing of extraction liquor from a pulp digester, and that the sloping steaming vessel is connected to a chip chute communicating with a condenser for connection to a system for managing foul-smelling process gases. The invention can be applied in the production of pulp which is intended for paper manufacture or other applications where cellulose fibers are used.

Owner:METABO PAPER SWEDEN

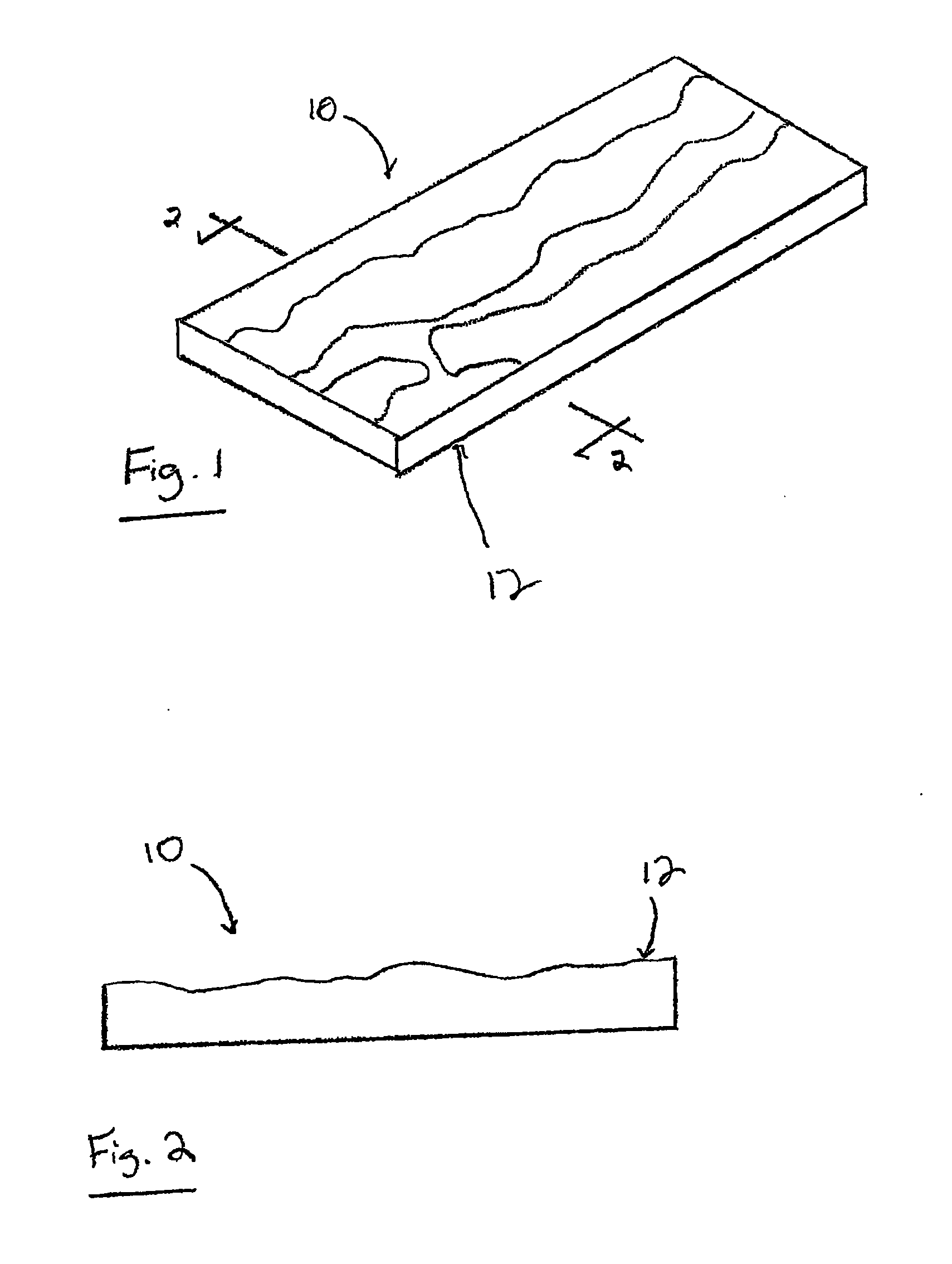

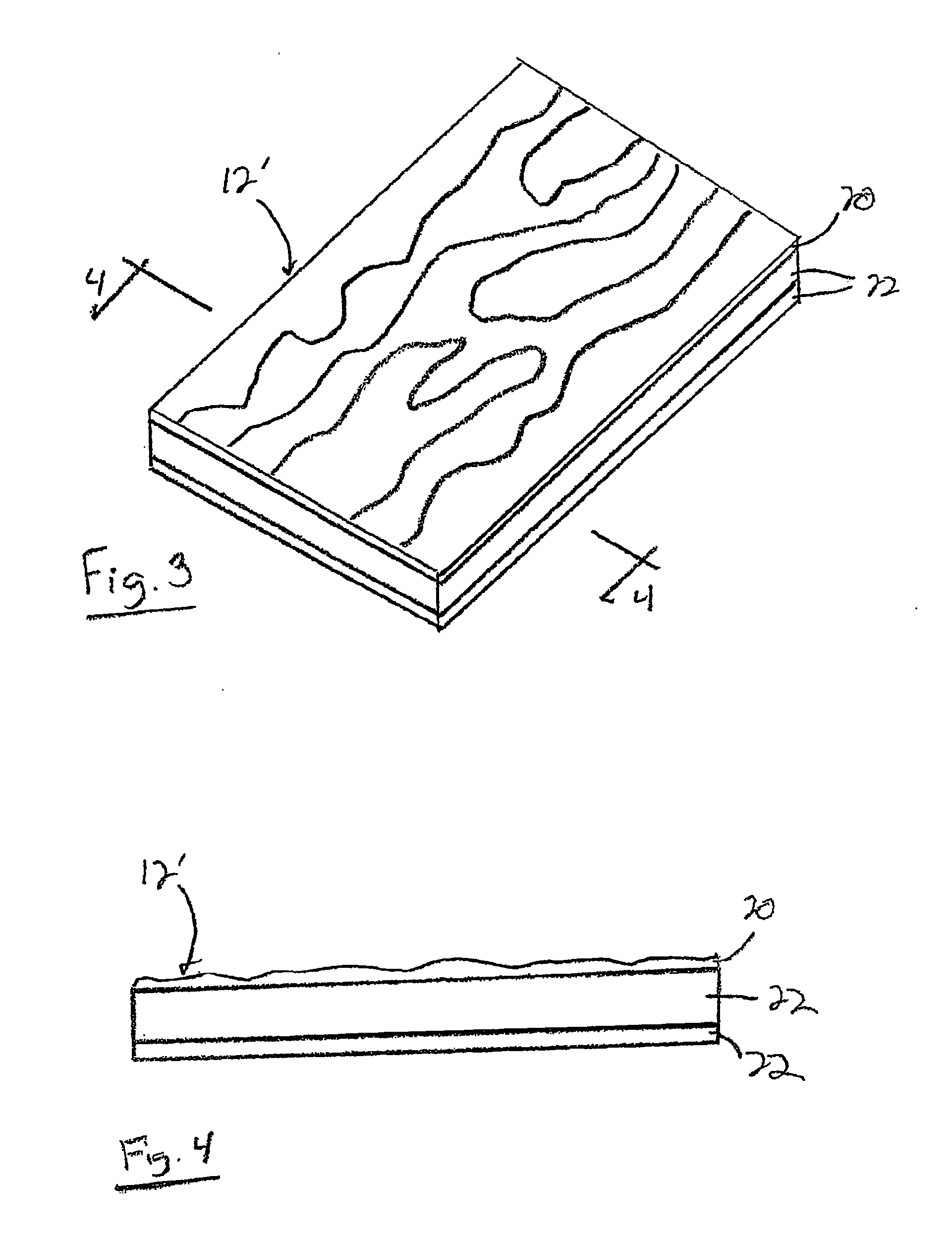

Manufactured Wood Boards Having a Distressed Appearance

InactiveUS20100304089A1Natural appearanceWood compressionMechanical surface treatmentPulp and paper industryWood plank

The present invention is a wood-based product utilized in forming various structures and other items. The product includes a piece of wood disposed on the exposed surface of the product that has been embossed with a desired pattern to give the product a desired appearance, such as a distressed or weathered appearance. The wood piece used in the product is embossed at a sufficient temperature and pressure to create the desired appearance in the wood piece. Additionally the product can be formed completely or only partially from the wood piece.

Owner:SPECTRUM TOWERS

Low glue consumption method for making medium density fiberboard

InactiveCN102514071AGuaranteed mechanical propertiesReduce the amount of sizingWood working apparatusFlat articlesFiberFiberboard

The invention relates to a low glue consumption method for making a medium density fiberboard, which comprises the following steps of: material preparation, i.e. processing the raw materials of small dimension wood, brush wood and the like into wood chips by adopting a drum chipper; fiber preparation, i.e. sending qualified wood chips to a wood chip cooking pot through a belt conveyor, introducing papermaking waste liquid into a boiler to carry out cooking softening treatment after filtering the papermaking waste liquid, sending the wood chips which are cooked and preheated into a thermofiner to carry out mechanical separation through a feeding screw, and filling molten wax before the wood chips enter a grinding chamber body of the thermofiner, so that after the wood chips are separated into the fibers, the wax is uniformly distributed on the surfaces of the fibers; sizing and drying of the fibers, wherein a production process of firstly sizing and then drying is adopted; pavement and formation of a board blank; hot-press forming, i.e. sending the single board blank into a hot press to carry out hot pressing through a loader, so that under the combined action of heat and pressure, moisture in the board blank is gasified and evaporated, the density of the board blank is improved, glue is cured and a waterproof agent is redistributed; and post-processing, i.e. finally, sending the obtained product into a sanding machine to carry out surface processing. The low glue consumption method for making the medium density fiberboard is simple and convenient.

Owner:广西新凯骅实业集团股份有限公司

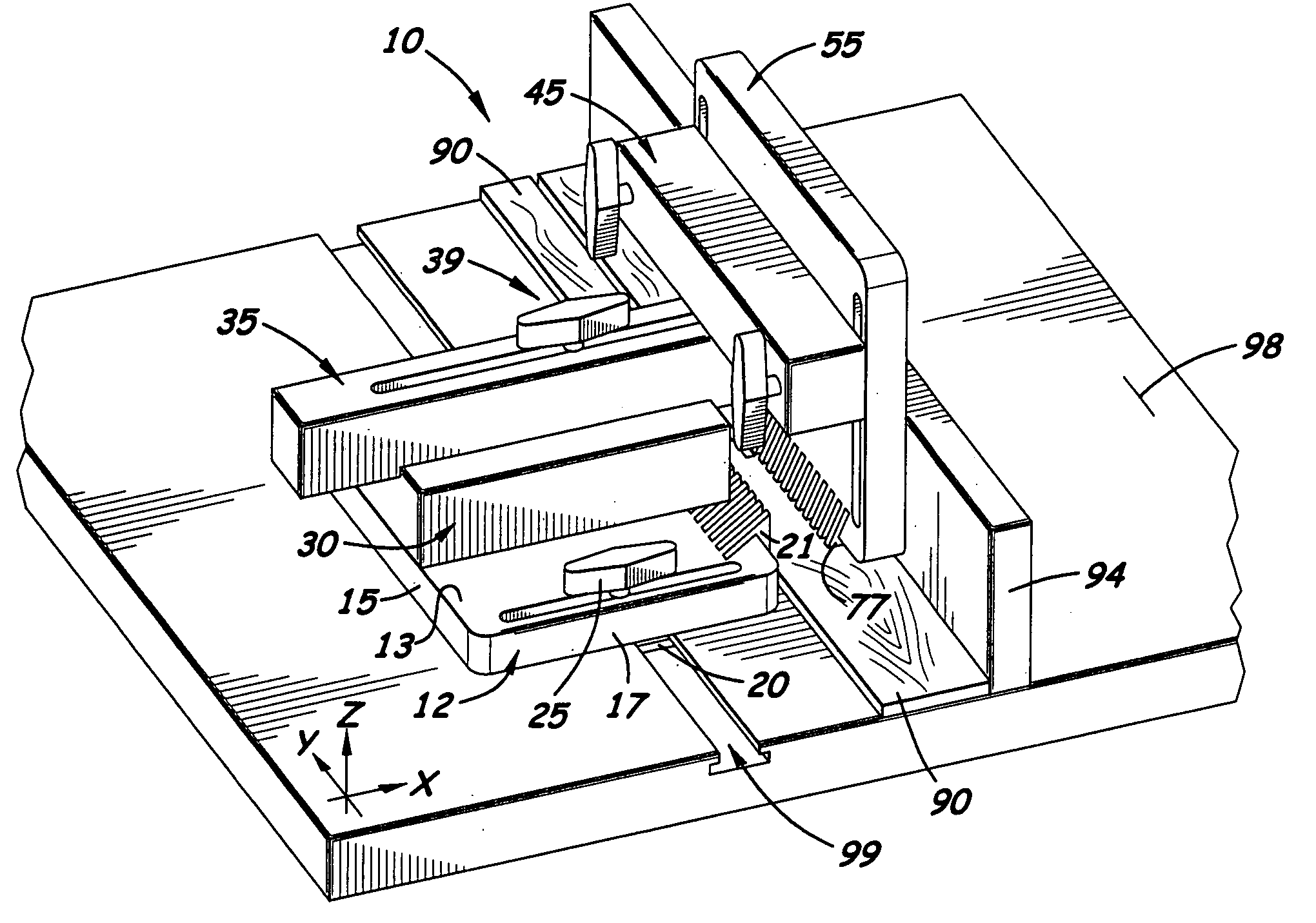

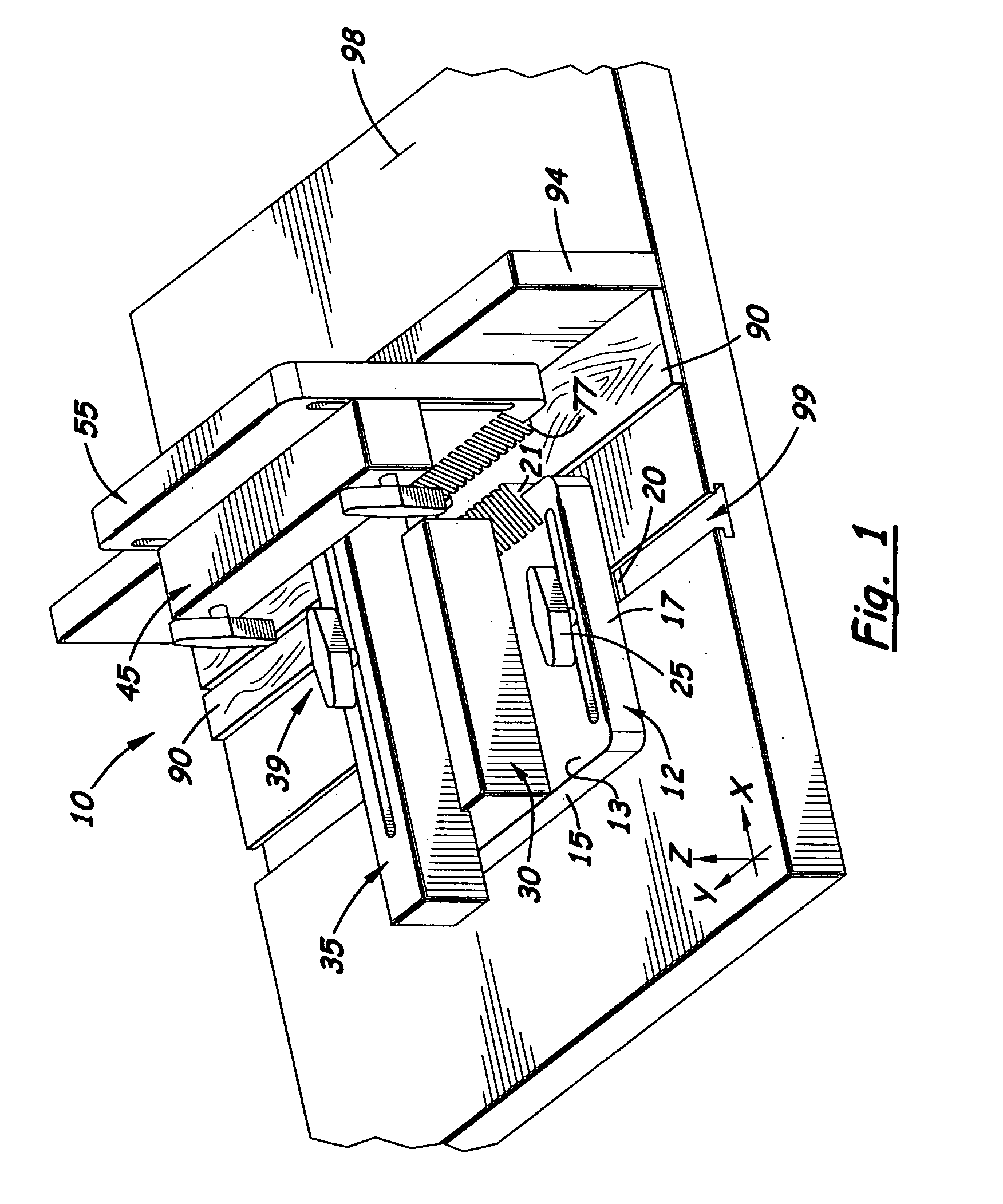

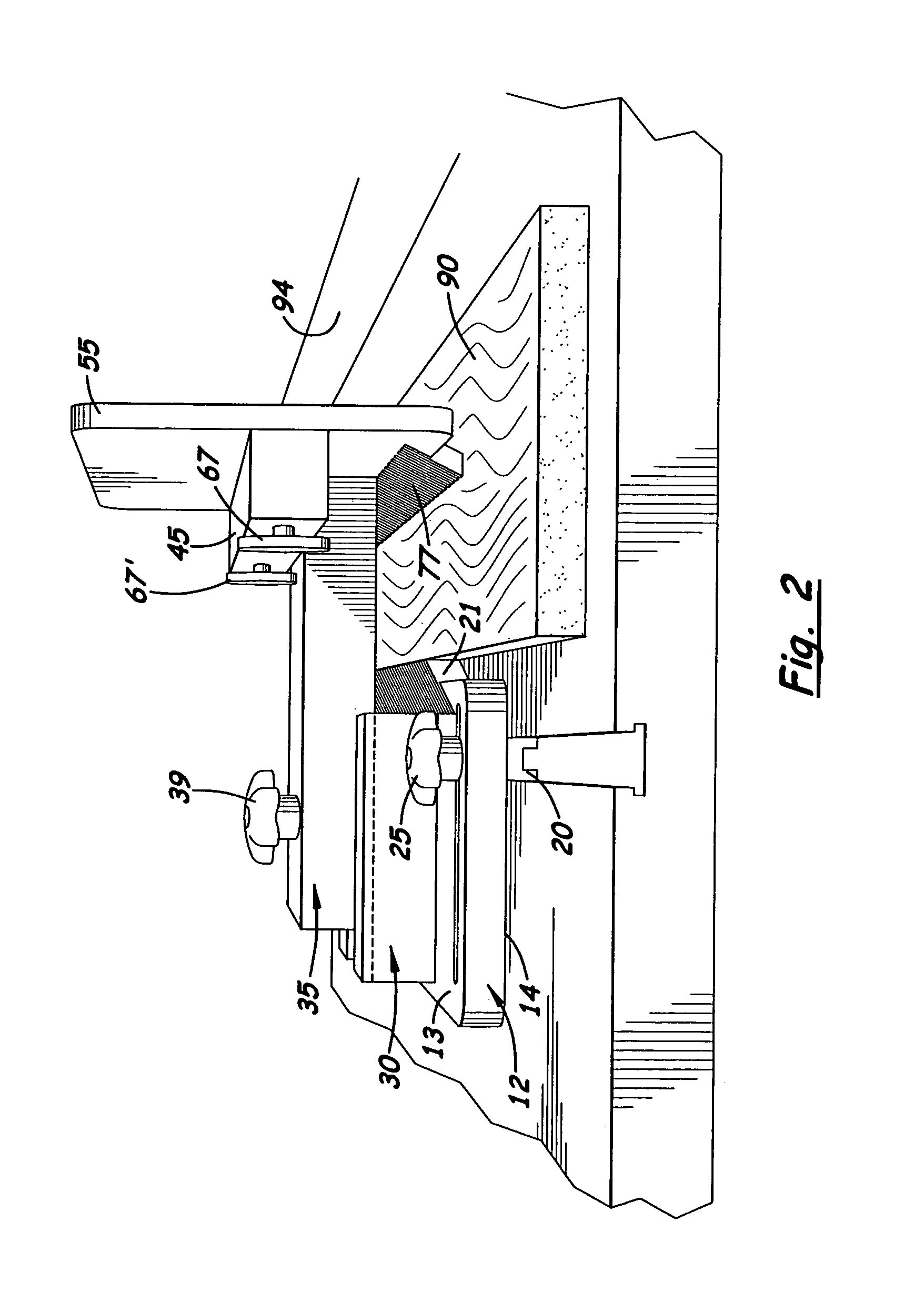

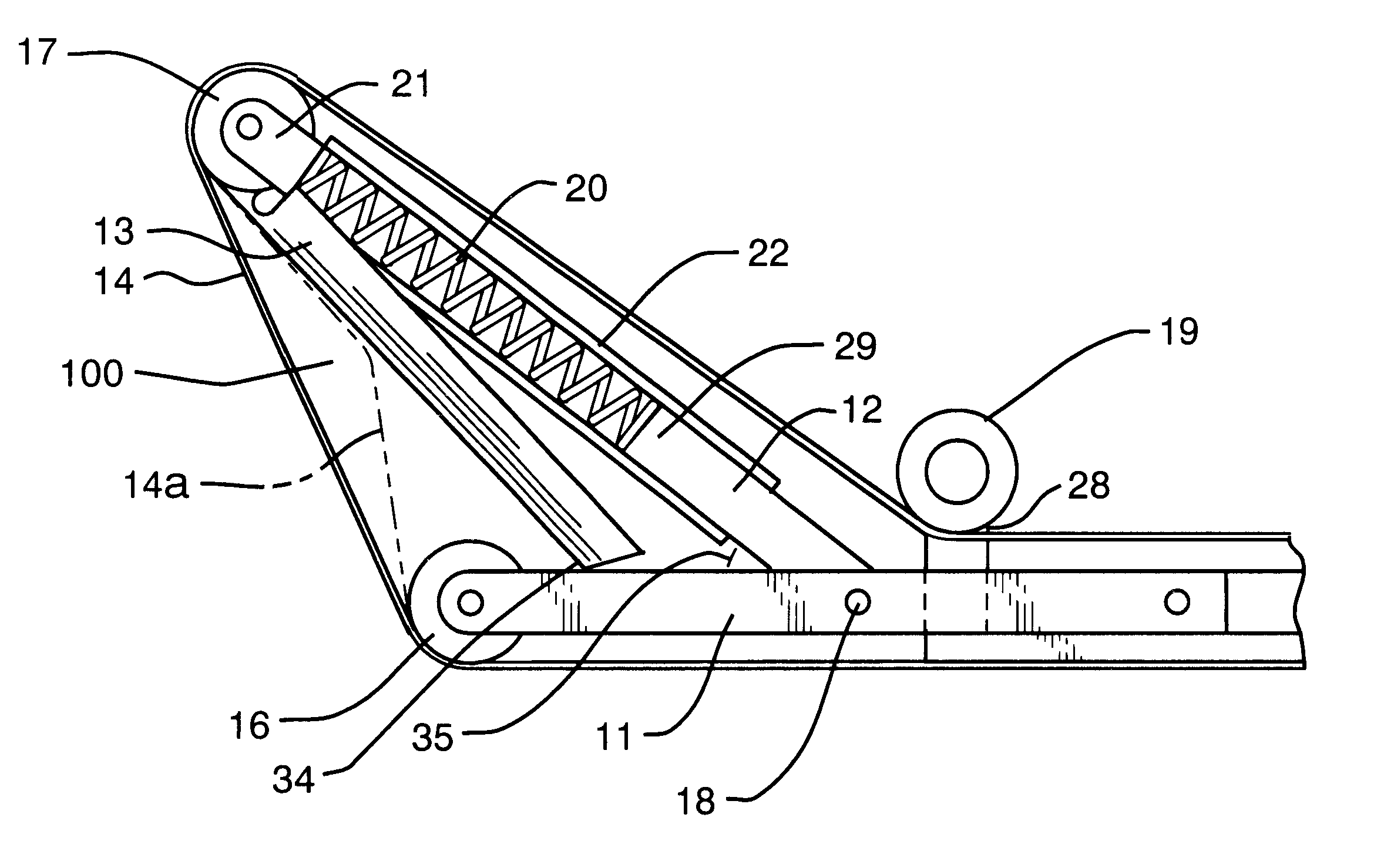

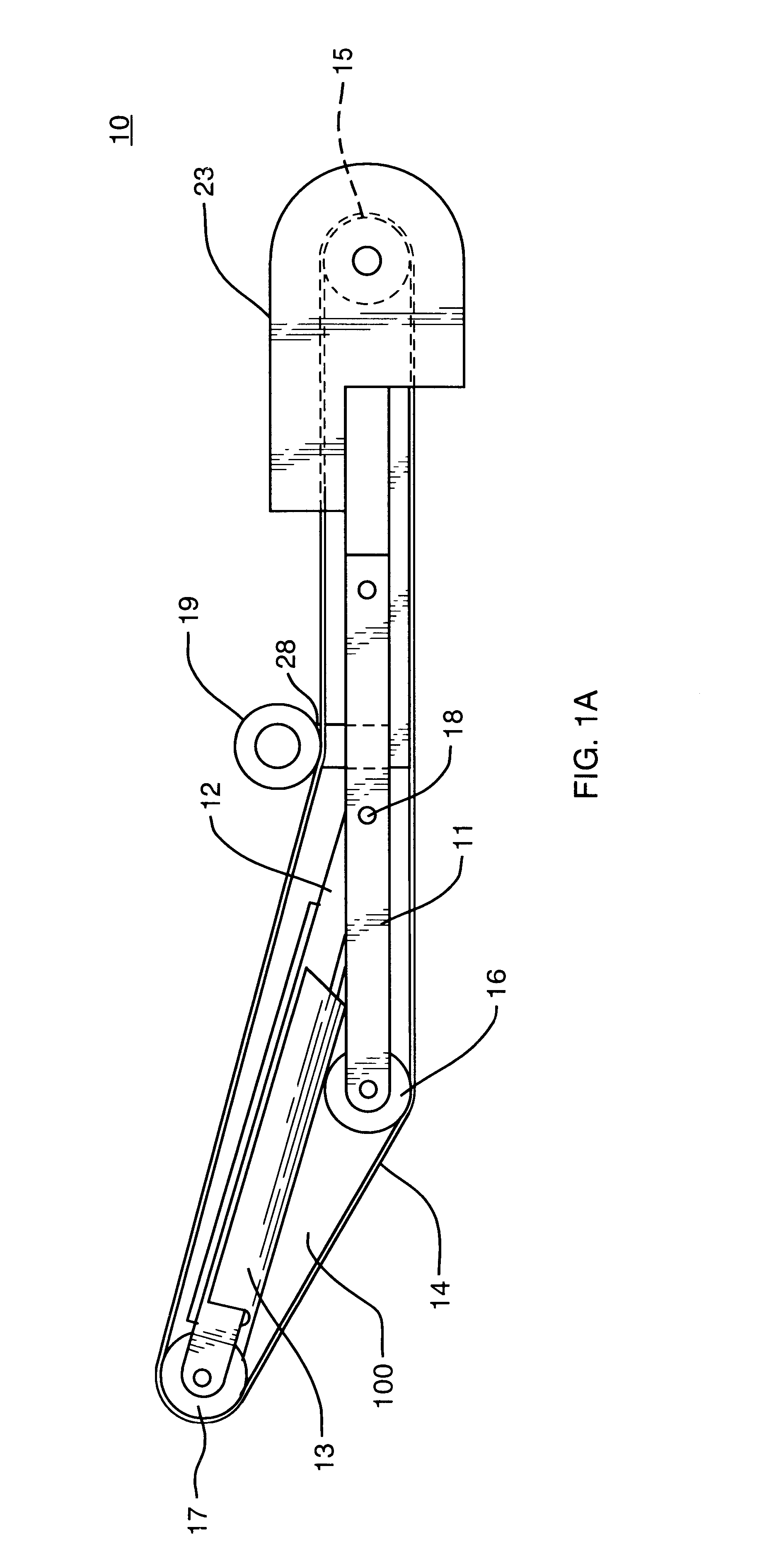

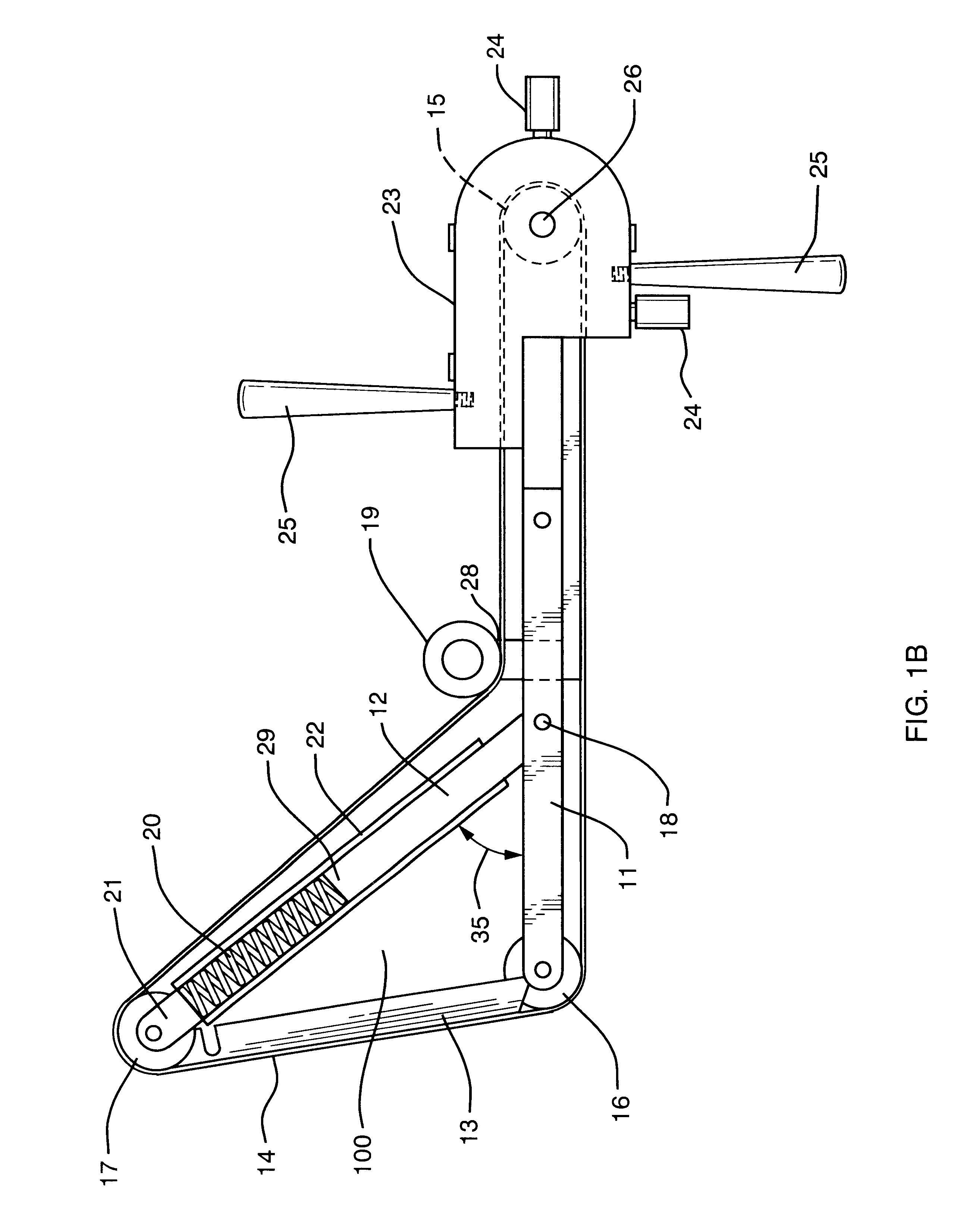

Dual adjustable feather jig

A dual adjustable feather jig for simultaneously holding a piece of wood stock firmly against a stationary rip fence and against the top surface of a worktable. The feather jig includes a lower feather board with a ‘T’ in channel bar adjustably mounted on the bottom surface of the lower feather board to laterally adjust the lower feather board over the worktable. Mounted transversely on the lower feather board is an upper feather board assembly that includes a vertical feather board to hold the wood piece against the worktable. The vertical feather board is connected to a slider arm that slides longitudinally over a riser block securely mounted to the lower feather board. Formed on the lateral and lower edges of the lower and vertical feather boards, respectively, are diagonally aligned fingers that press the wood piece against the rip fence and against the top surface of the worktable.

Owner:SCHWARTZ NEAL K

Method for producing pulp and lignin

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

Special culture material formula capable of remarkably improving content of various amino acids in dictyophora fruit body and cultivation method

InactiveCN102557799ARealize resource reuseHigh in amino acidsHorticultureFertilizer mixturesEngineeringMonopotassium phosphate

The invention discloses a special culture material formula capable of remarkably improving content of various amino acids in dictyophora fruit body and a cultivation method. The special culture material formula is characterized by comprising the following raw materials in parts by weight: 20-30 parts of bamboo, 20-30 parts of wood chips or sawdust or roots of other trees, 20-30 parts of bagasse, 10-20 parts of chaff, 1-3 parts of urea (or 5-10 parts of ammonia bicarbonate), 0.3-0.5 parts of potassium dihydrogen phosphate, 0.2-0.3 parts of magnesium sulfate and 1.0-1.2 parts of calcium carbonate, wherein 20-40kg of swine waste is added into every 100kg of mixed cultivation material. The cultivation method comprises the following steps of: selection of a cultivation place, preparation of materials, stockpile fermentation, blanking and seeding, earthing, spawn running and harvesting. According to the invention, the content of various amino acids in dictyophora fruit body is remarkably improved, the discharge of pollutants in the pig industry can be reduced, the pollutants of the pig industry are reduced, and the resource recycling of the swine waste is realized.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

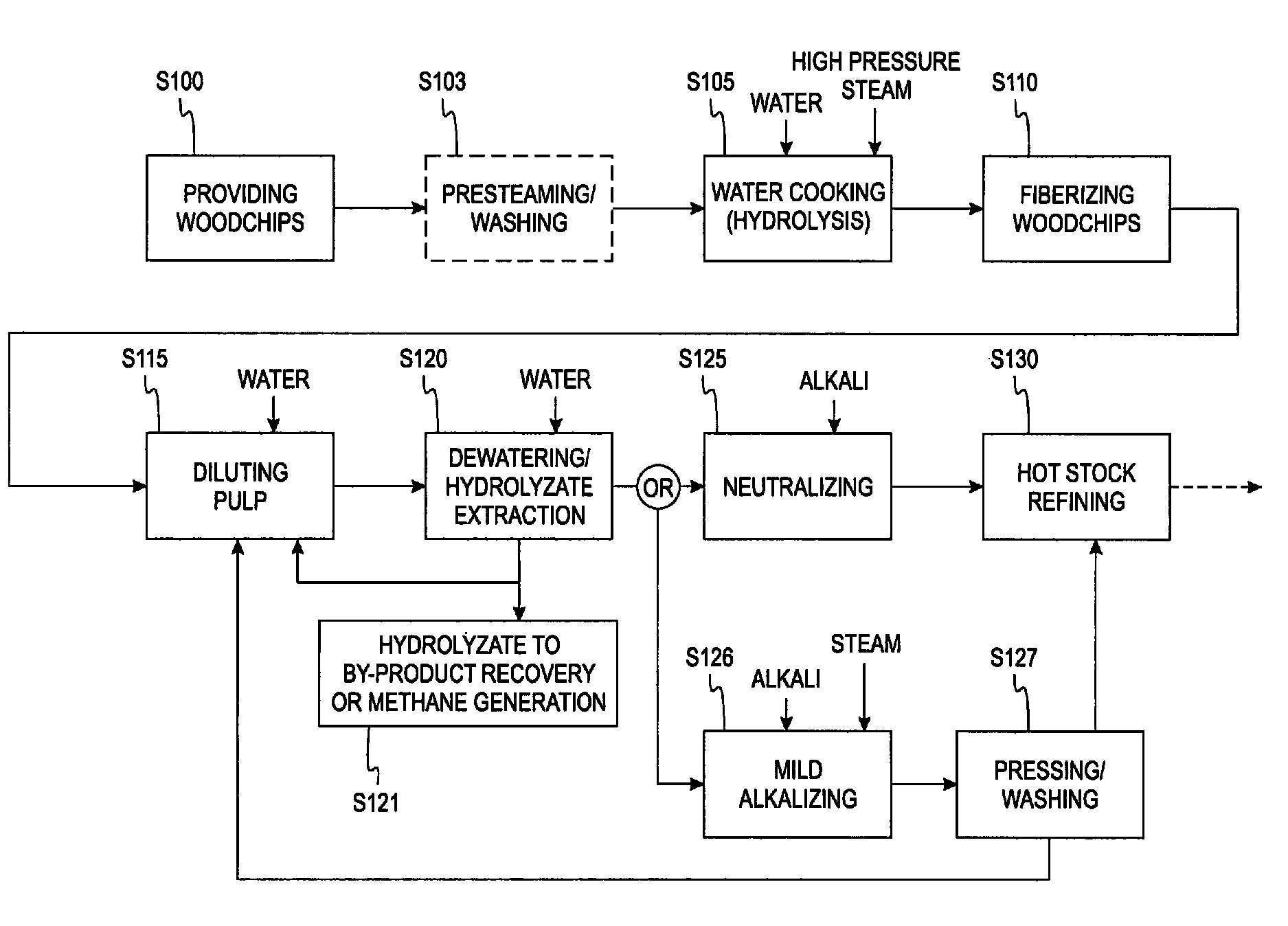

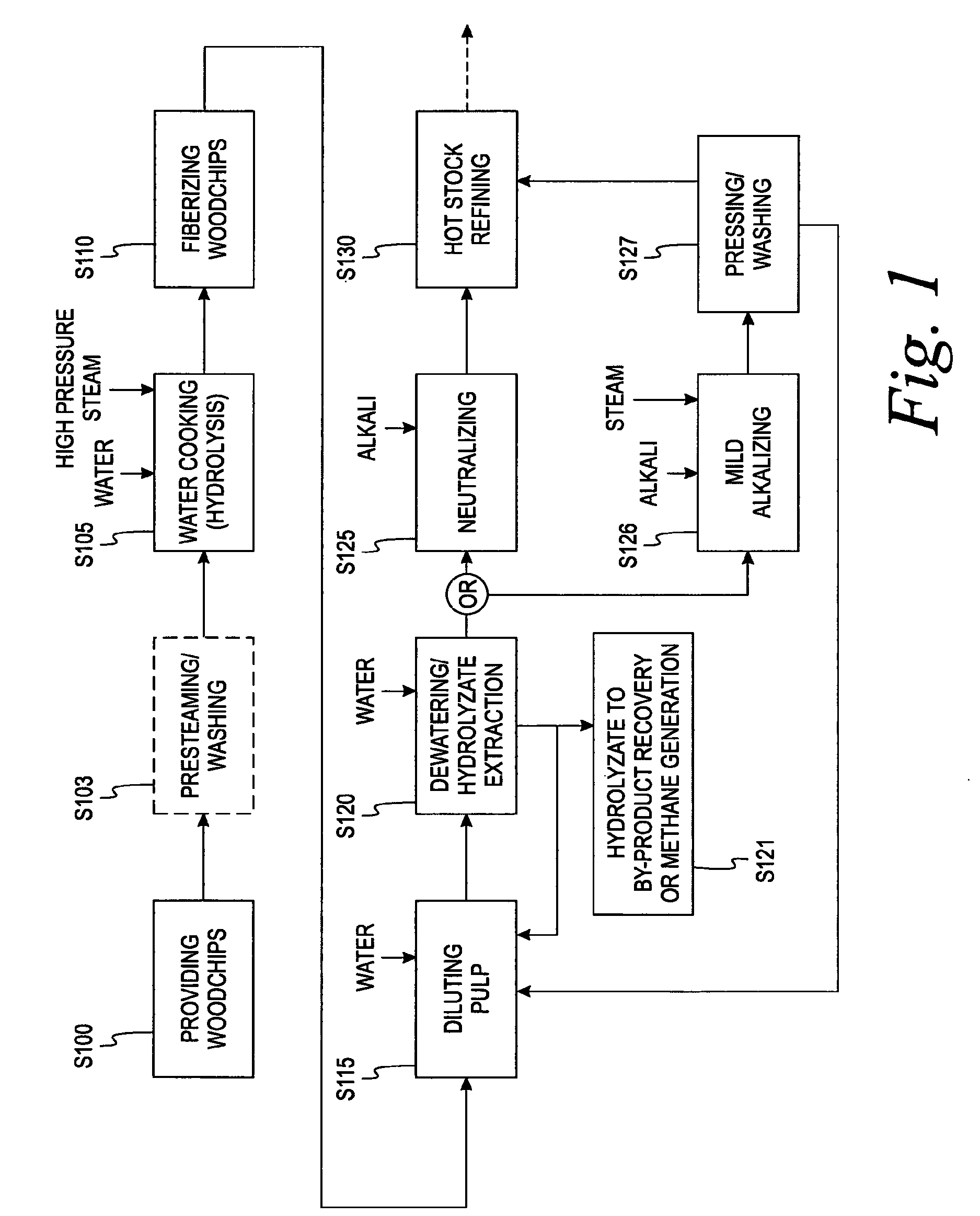

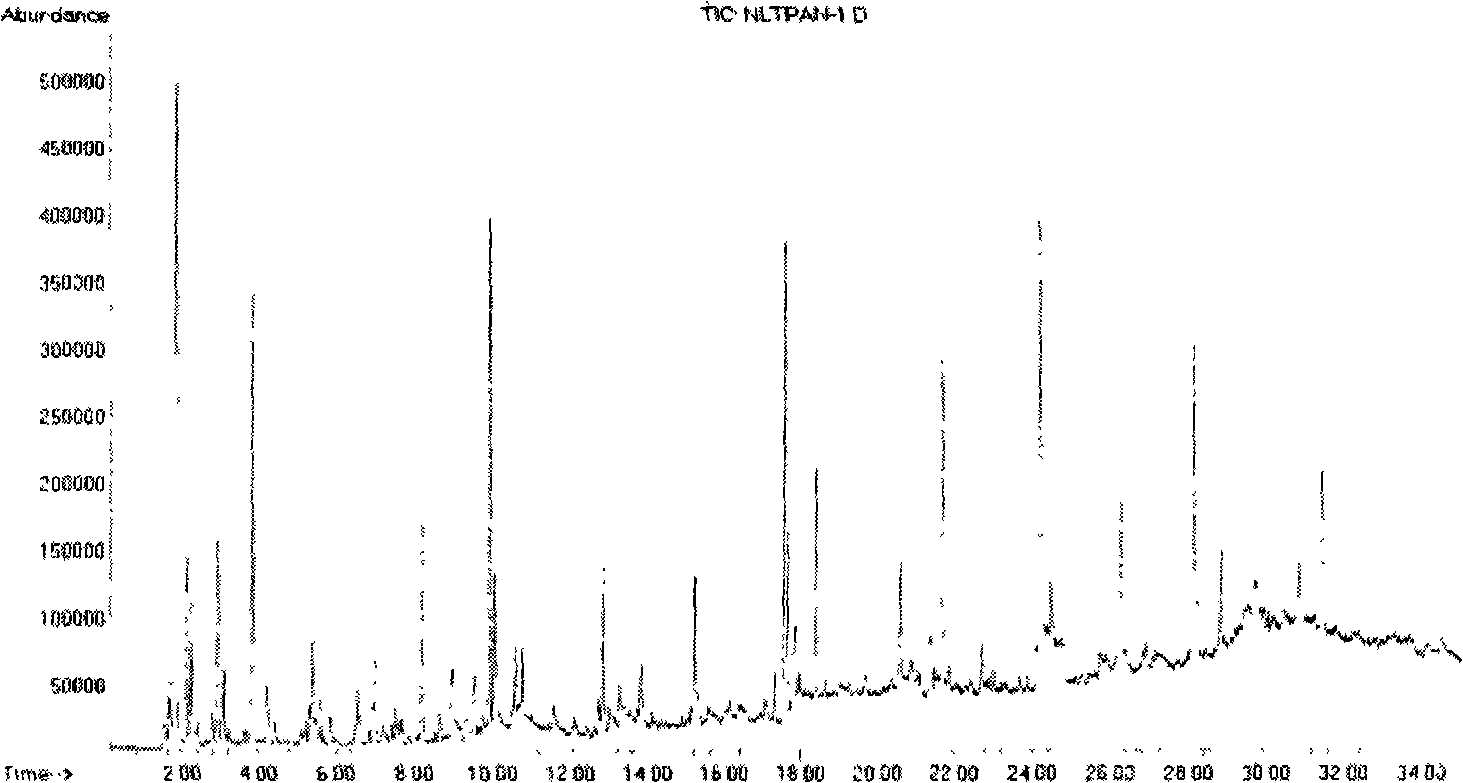

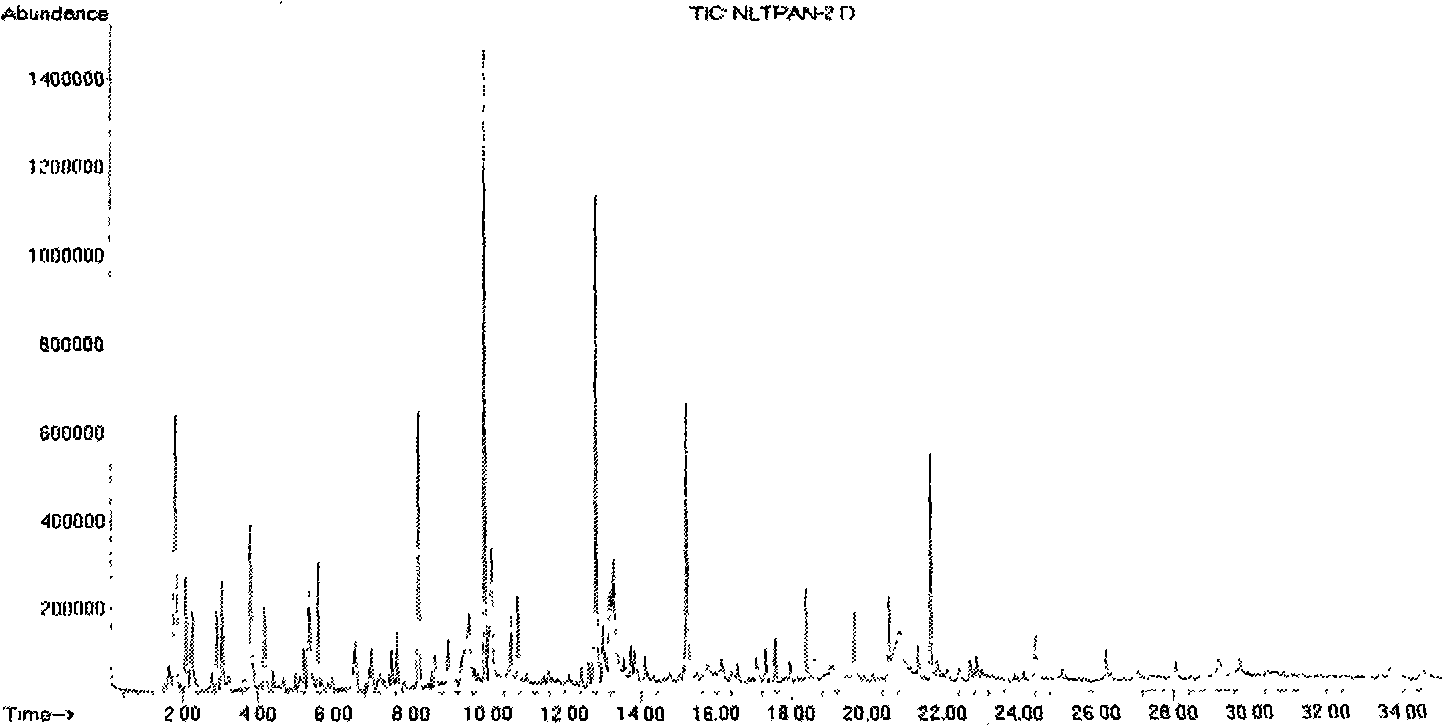

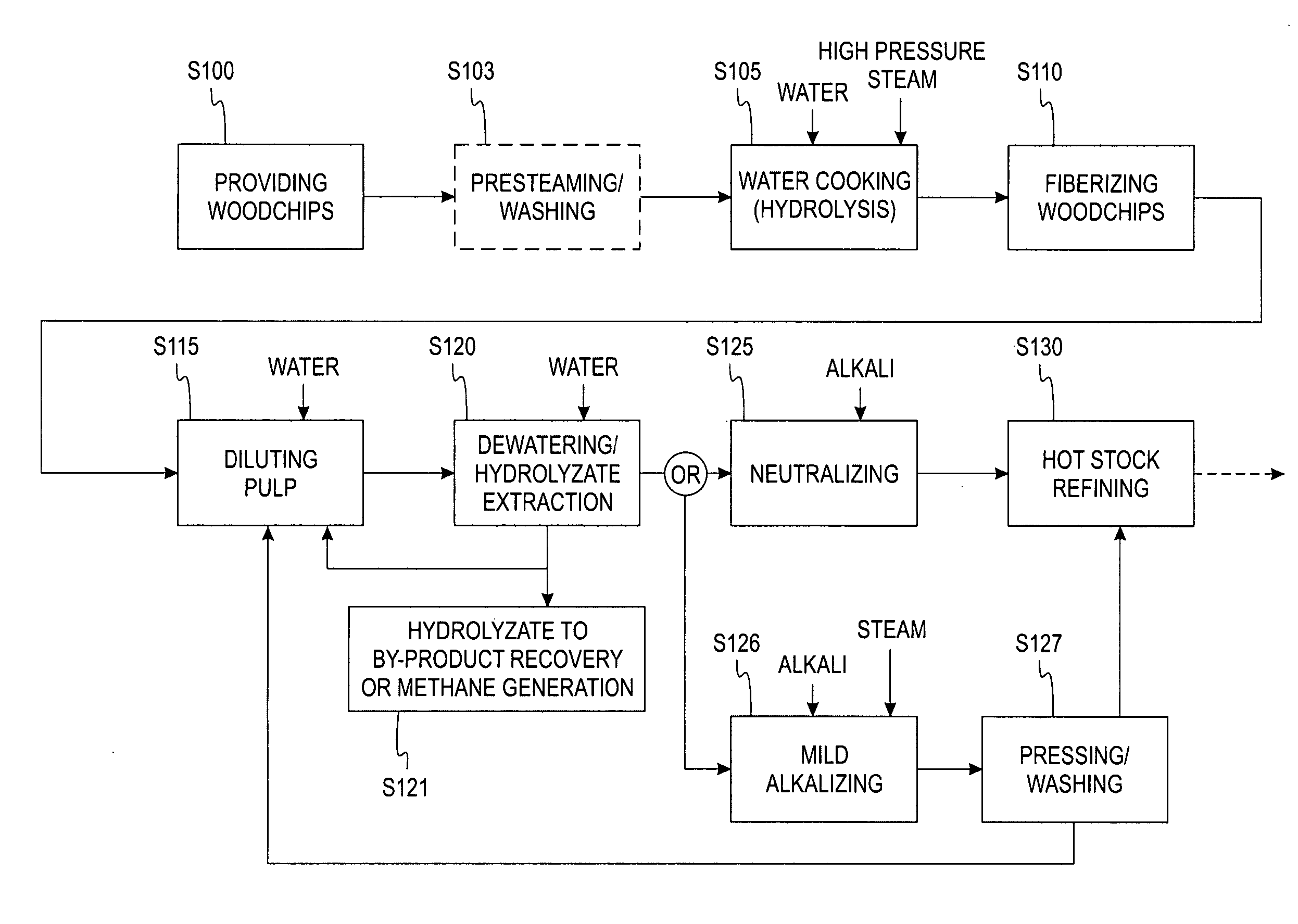

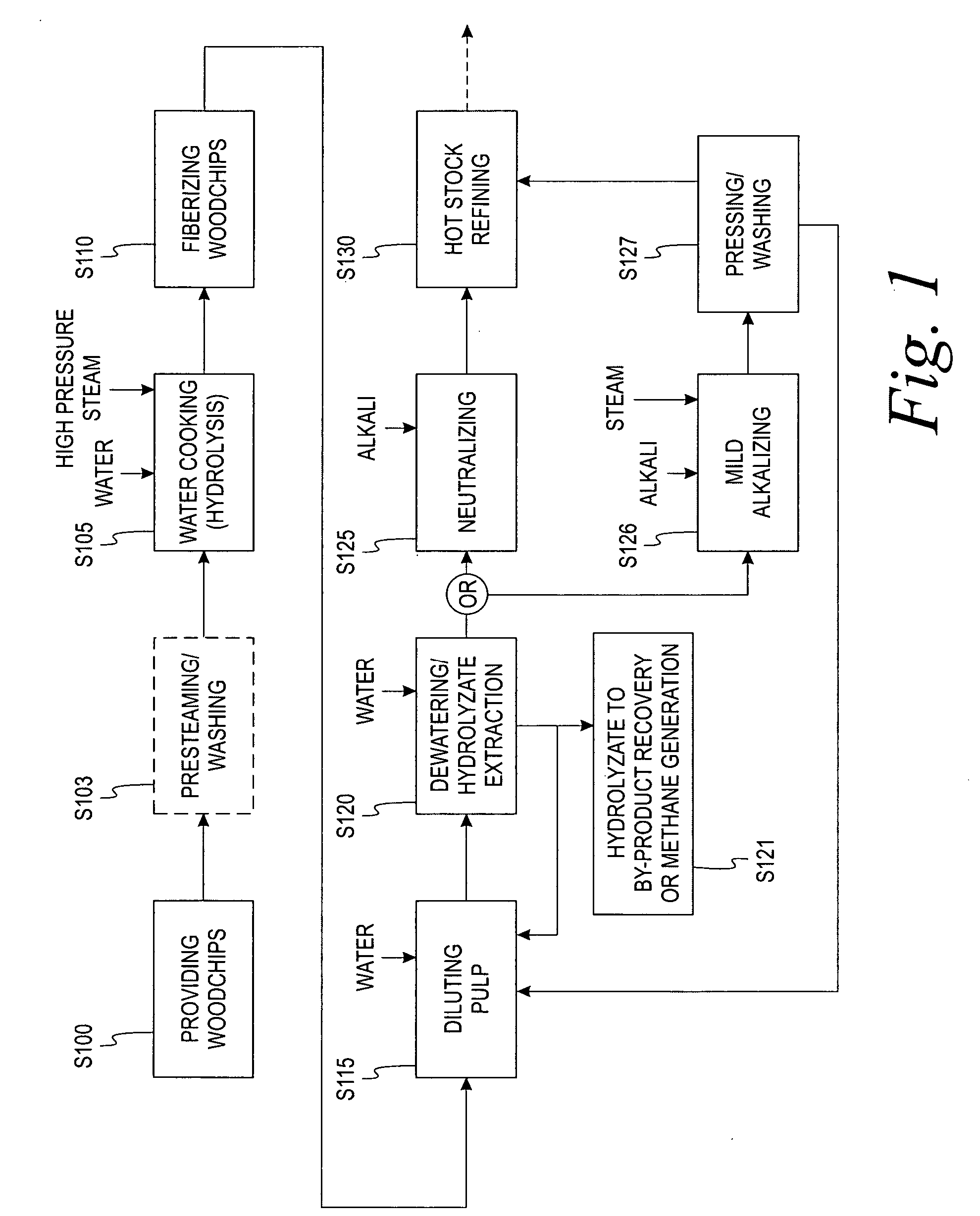

Method of pre-treating woodchips prior to mechanical pulping

ActiveUS7771565B2Pretreatment with water/steamPulping with inorganic basesPulp and paper industryPre treatment

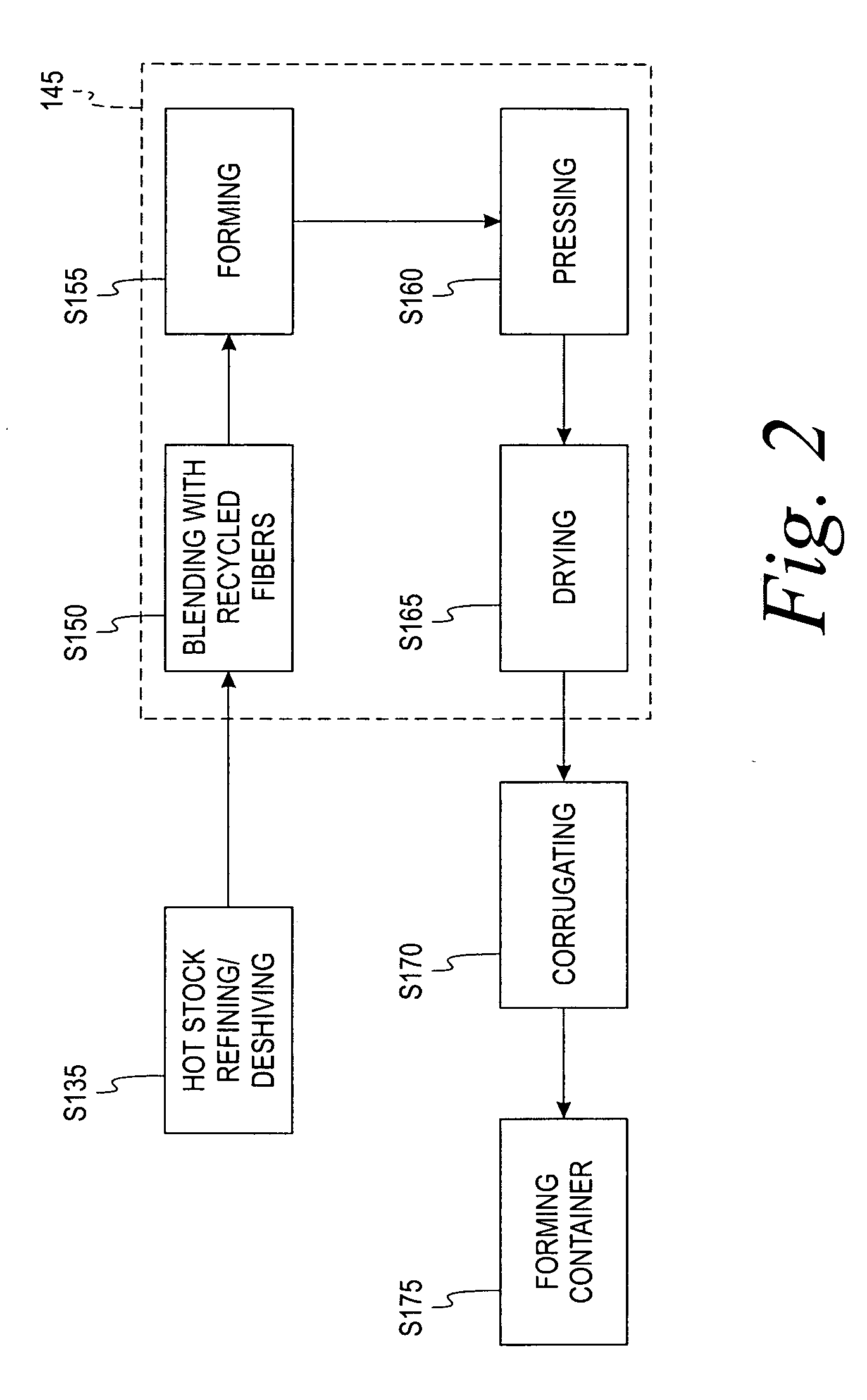

A method of making pulp adapted to be used in forming corrugating medium is disclosed. The method comprises cooking woodchips in a first liquor in the absence of an alkali addition. The method further comprises mechanically fiberizing the woodchips to form a pulp. The method further comprises separating hydrolyzate from the pulp. The method further comprises treating the pulp with a second liquor, the second liquor including at least one alkali. The method further comprises refining the pulp.

Owner:PACKAGING CORPORATION OF AMERICA

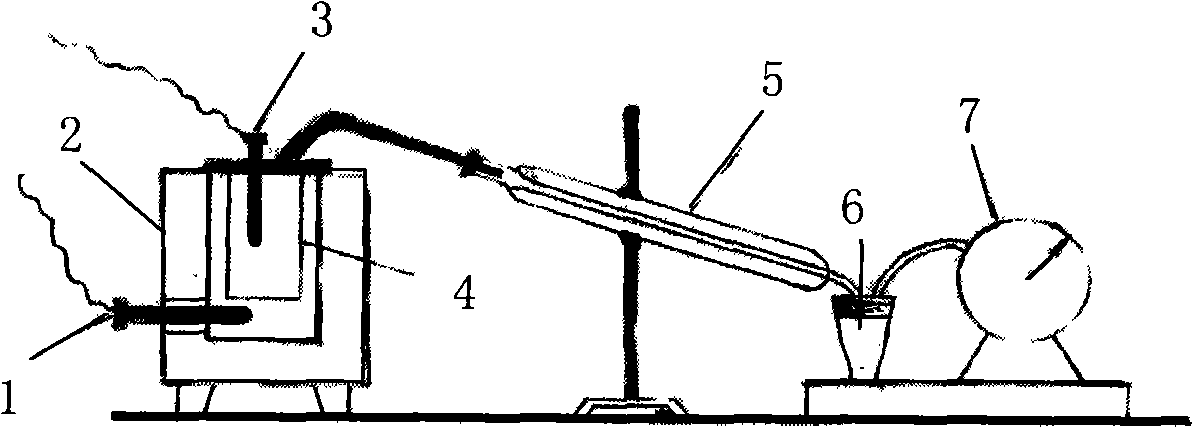

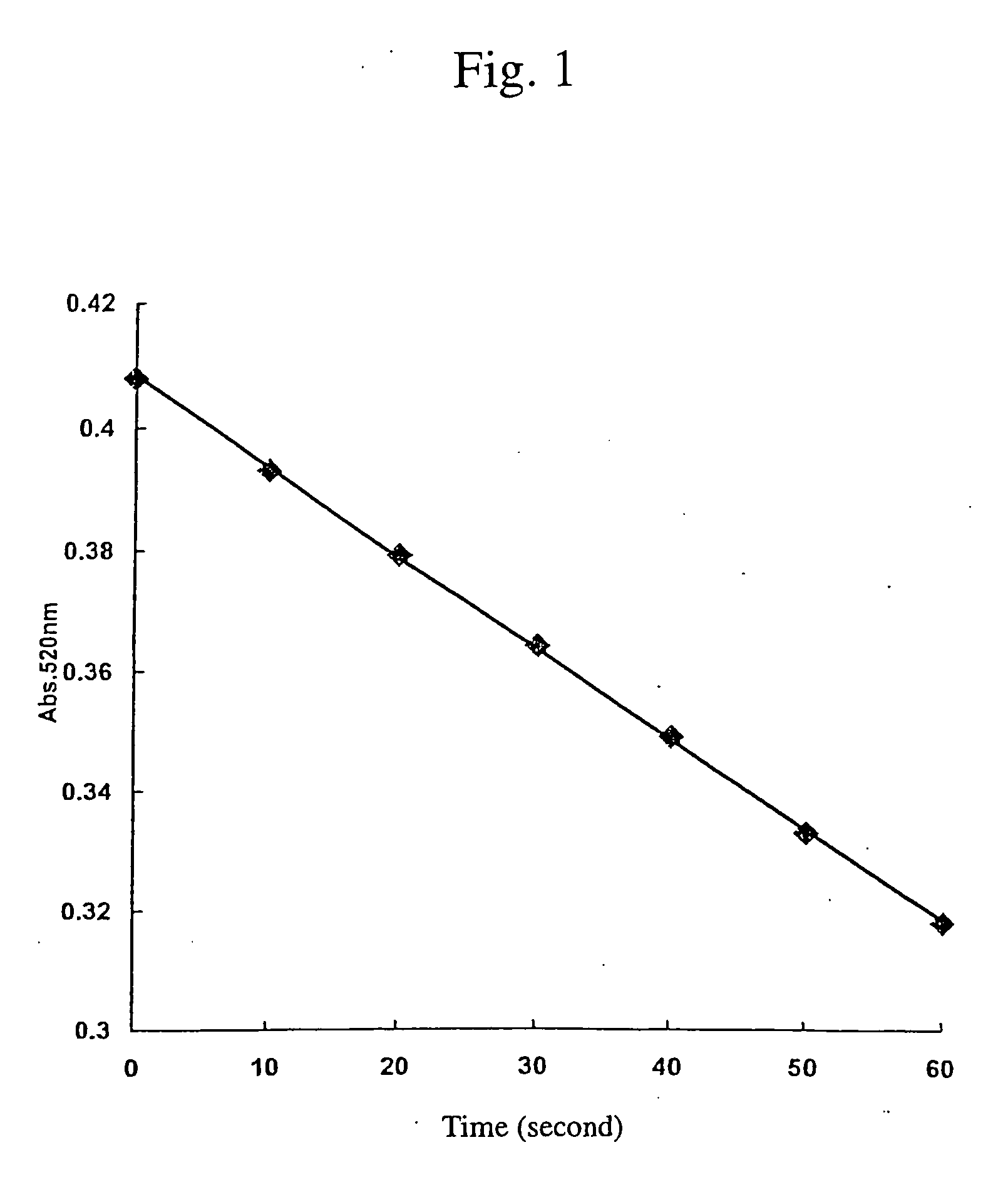

Ginko pyroligneous and its applications in promoting germination of crop seeds and growth of seedlings

InactiveCN101273730AEasy to prepareNo pollution in the processPlant growth regulatorsBiocideHigh densityWoodchips

The invention provides a ginkgo pyroligneous liquor and the application thereof in promoting the seed germination of crops and the growth of seedling, and the ginkgo pyroligneous liquor is prepared according to the following steps: after ginkgo wood is split into wood chips, the charring of ginkgo wood is carried out in a retort, the gas generated in the process of charring is condensed, the liquid after condensation is collected and then is placed still for three months, after that, supernatant liquid is separated, thus obtaining the ginkgo pyroligneous liquor. Proved by experiments, the ginkgo pyroligneous liquor has great promoting function on the seed germination of crops and the growth of seedling. The method for preparing the ginkgo pyroligneous liquor of the invention is simple, the obtained product is a green product of all-natural formulation and has no residue and pollution as a natural agricultural chemical substitute. The ginkgo pyroligneous liquor and the application thereof of the invention opens up a new orientation of the processing and using ginkgo wood, prompts the cultivation mode of ginkgo wood to develop into the orientation of constructing timberland used for high density in large acreage, shortening the felling cycle, solving the fear of troubles in the rear of farmers after planting ginkgo.

Owner:NANJING FORESTRY UNIV

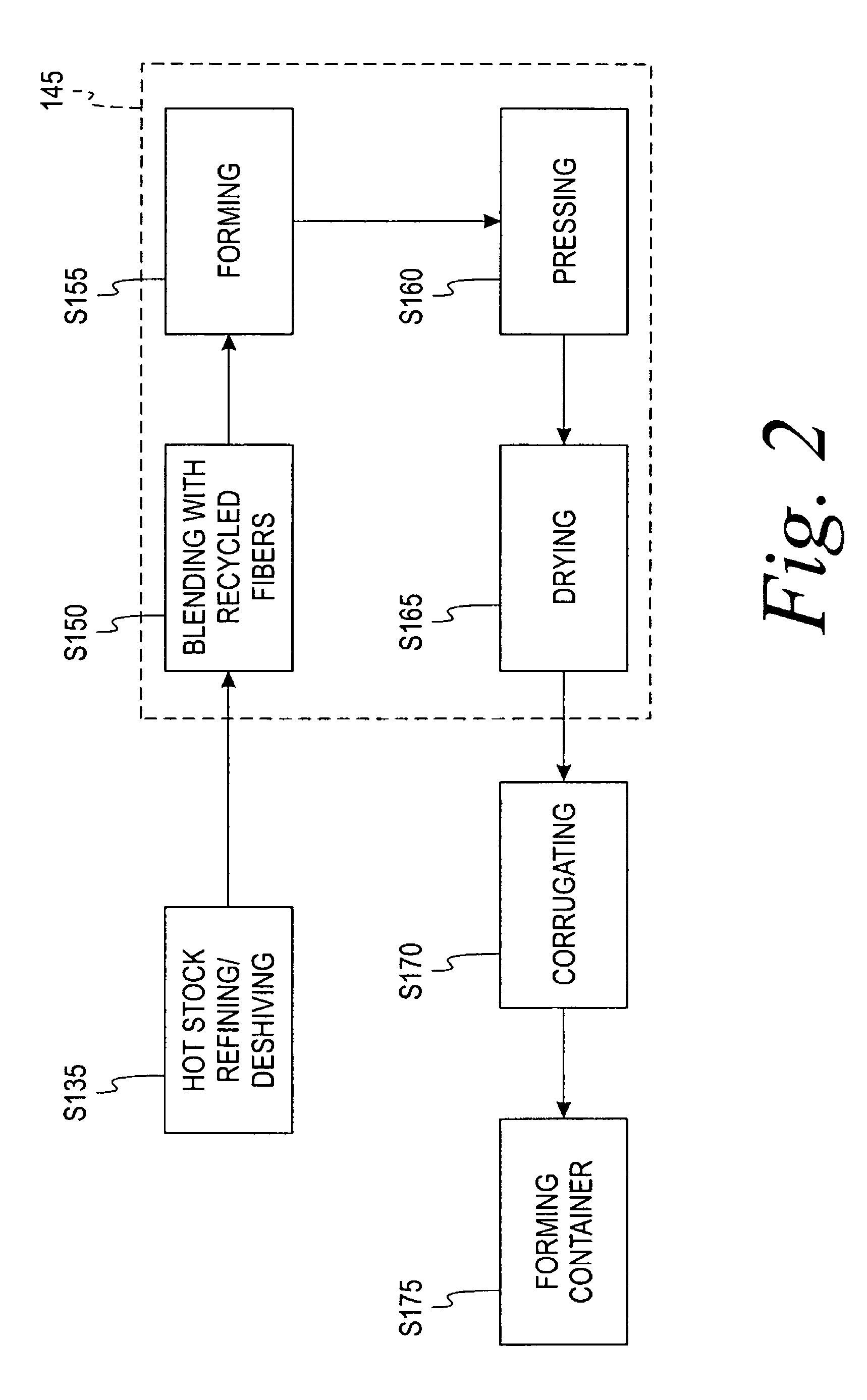

Method of manufacturing pulp and articles made therefrom

ActiveUS20070193706A1Pretreatment with water/steamPulping with inorganic basesEngineeringPulp and paper industry

A method of making pulp adapted to be used in forming corrugating medium is disclosed. The method comprises cooking woodchips in a first liquor in the absence of an alkali addition. The method further comprises mechanically fiberizing the woodchips to form a pulp. The method further comprises separating hydrolyzate from the pulp. The method further comprises treating the pulp with a second liquor, the second liquor including at least one alkali. The method further comprises refining the pulp.

Owner:PACKAGING CORPORATION OF AMERICA

Manufacturing process for ultra light fiber board

ActiveCN102806591AEasy to prepareEasy to operateDigestersAldehyde/ketone condensation polymer adhesivesFiberAdhesive cement

The invention discloses a manufacturing process for an ultra light fiber board. The method comprises the following steps of: peeling wood, cutting to obtain sheets, screening, washing, boiling, separating fibers, mixing and applying adhesive, drying and sorting, paving and forming, prepressing, performing hot-pressing, turning the board and cooling, sanding, inspecting and classifying, and packaging and putting in storage, wherein in the boiling step, the boiling material level is 1.6 to 3m, and the boiling temperature is 165 to 175 DEG C; in the step of separating the fibers, the wood sheets enter a mill through a ribbon spiral conveyor, molten waxes are fed into the mill simultaneously, the application amount is 5.0 to 7.0kg / m<3>, and the gap of an abrasive wheel is 0 to 4mm; and in the step of mixing and applying the adhesive, melamine modified urea resin adhesive is applied, the adhesive application amount is 195 to 210kg / m<3>, the adding amount of a curing agent is 1 to 2.5 percent based on the mass of absolute drying adhesive, and the curing agent is a mixture of ammonium chloride and a (commercially available) HA101 cross-linking agent in a mass ratio of 3:1. Moreover, a method for preparing the melamine modified urea resin adhesive used by manufacturing the ultra light fiber board is correspondingly provided for matching the manufacturing process.

Owner:DAYA WOOD IND JIANGXI +1

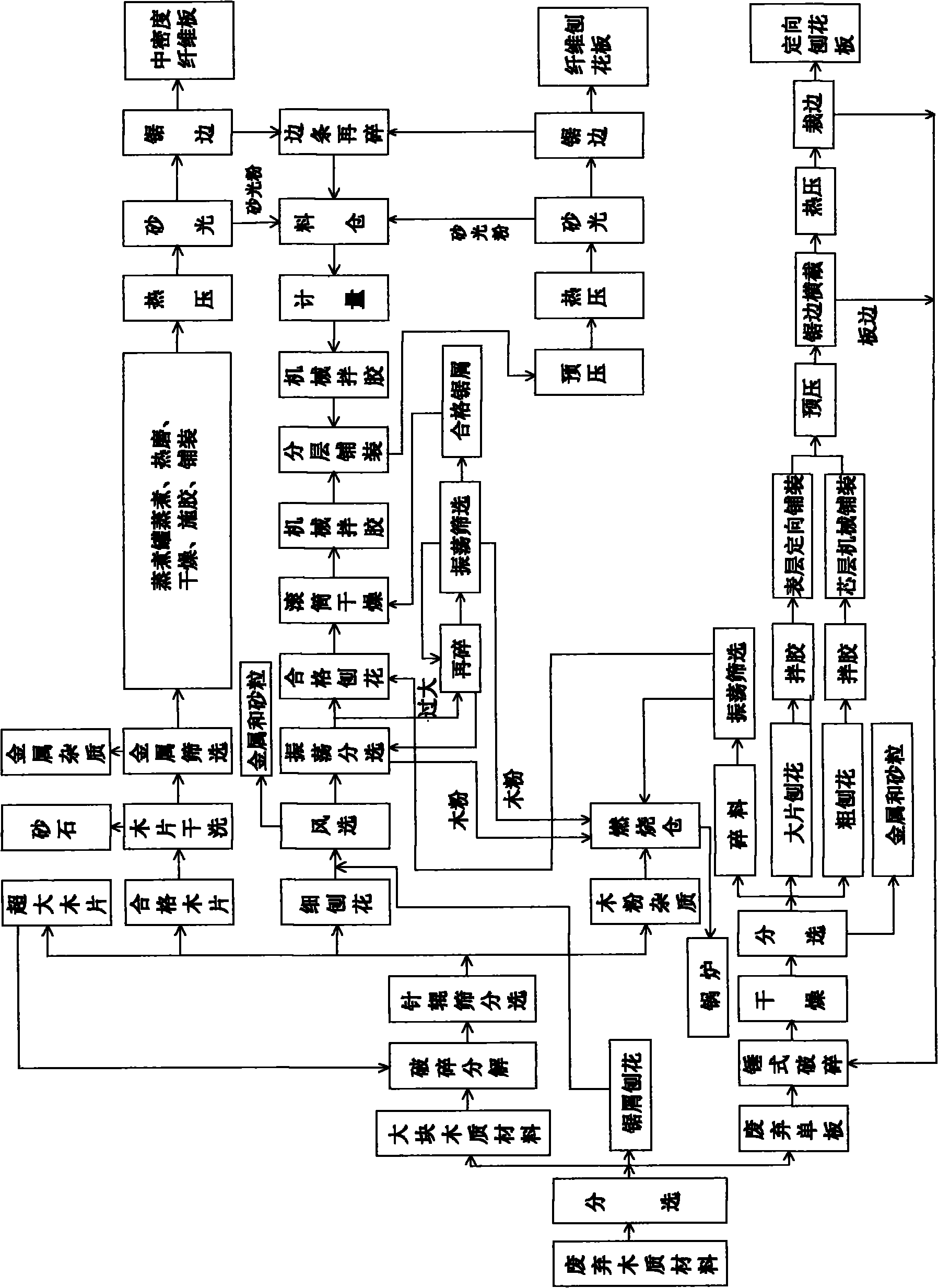

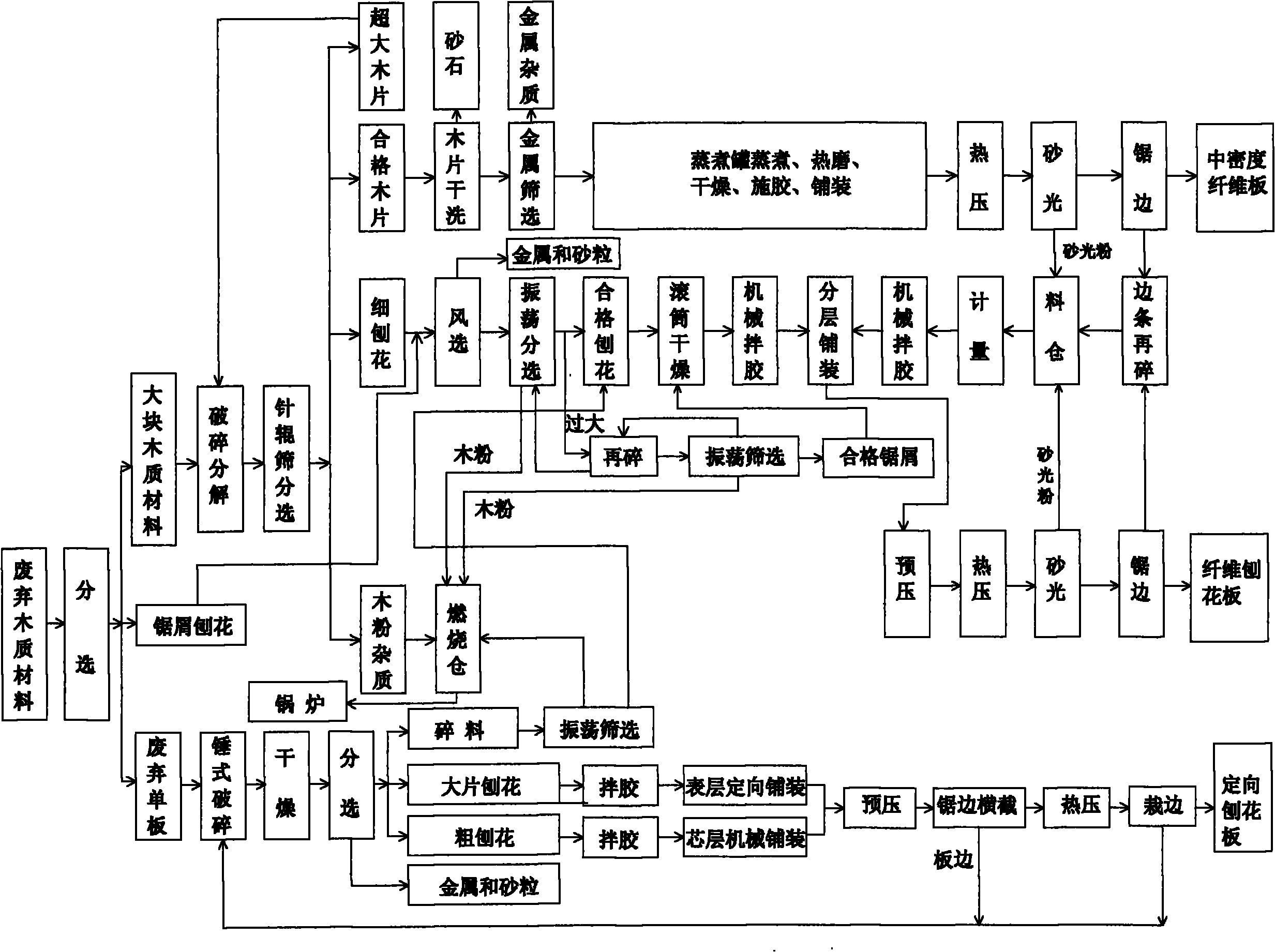

Method for manufacturing regenerated composite boards by using waste wood

InactiveCN102310453AReasonable useMaximize utilizationWood working apparatusDomestic articlesFiberWood shavings

The invention discloses a method for manufacturing regenerated composite boards by using waste wood. The method comprises the following steps of: a, sorting waste wood materials into a massive wood material, sawdust wood shavings and waste veneers; b, crushing and decomposing the massive wood material; c, sorting with a needle roll screen, and obtaining extra large wood chips, qualified wood chips, thin wood shavings and wood meal impurities; d, treating the extra large wood chips according to the step b; e, processing the qualified wood chips into medium density fiber boards by a medium density fiber board manufacturing process; f, removing metal and sand from the thin wood shavings by winnowing, removing powder, gravel and metal impurities from the thin wood shavings by oscillation sorting to form qualified wood shavings, and manufacturing fiber shaving boards by a fiber shaving board production process; g, conveying the wood meal impurities to a fuel bin; h, treating the sawdust wood shavings according to the winnowing process of the step f; i, removing metal and sand from the waste veneers by hammer-type crushing, drying and sorting, and forming crushed materials, big wood shavings and thick wood shavings; and j, producing oriented shaving boards by an oriented shaving board production process.

Owner:JUYE WODESEN PLATE IND

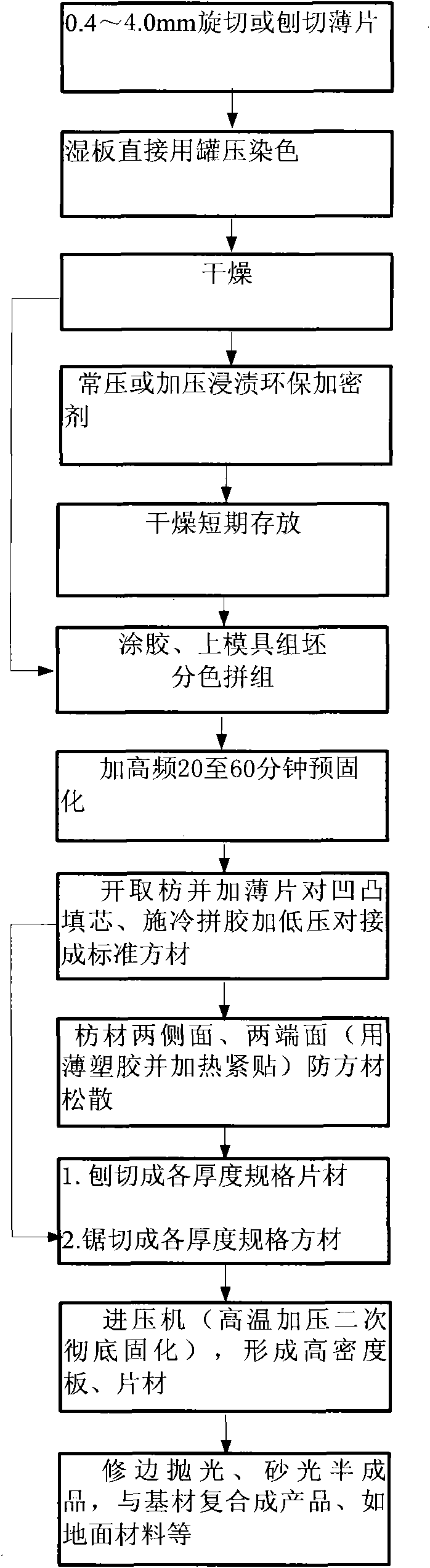

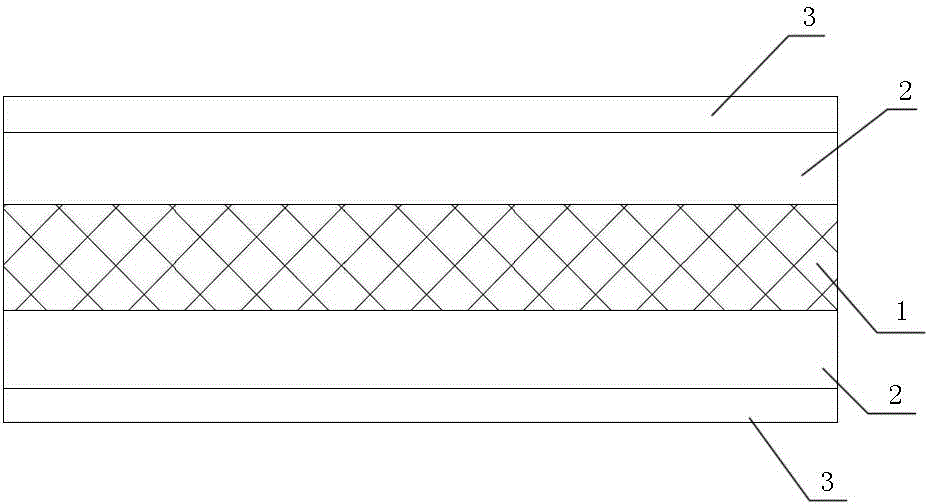

Combined lumber and fabrication technique thereof

The invention discloses a combined lumber and a fabrication technique thereof. The invention needs to solve the technical problem on how to enhance the density and hardness of the lumber and bring imitative natural wood grains to the lumber. The manufacturing method of combined lumber: slicing, dyeing, drying, assembly, pressing and hot precuring; the lumber is longitudinally cut into two parts which are respectively placed on both sides of another lumber, multi-colored filling wood sheets are filled in concave-convex joints and glued, and the lumbers are pressed, so that the combined lumber is obtained. Compared with the prior art, the invention has the following advantages that: the multi-colored, diversified hard lumber or wood sheet with the density of 0.7g / cm<3> to more than 1.0g / cm<3> has imitative natural wood grains or unique colorful grains, and can be applied to furniture, door frames, staircases and square columns, and the sliced or sawed sheet can be combined with other base materials, such as cabinet panels, tabletops, drawers, floorboards and the line, in order to increase the additional value.

Owner:SINO FOREST CHINA INVESTMENTS LTD

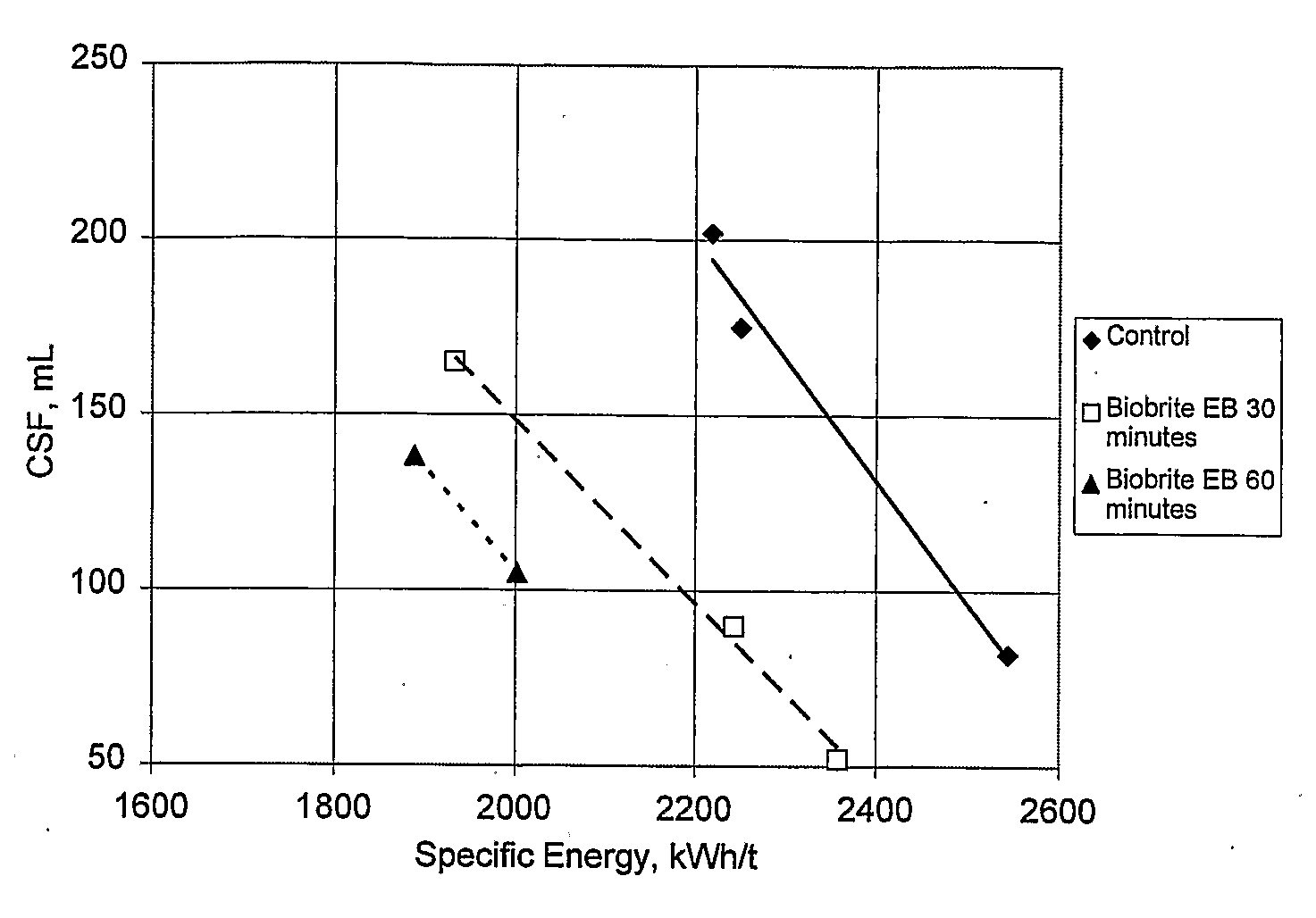

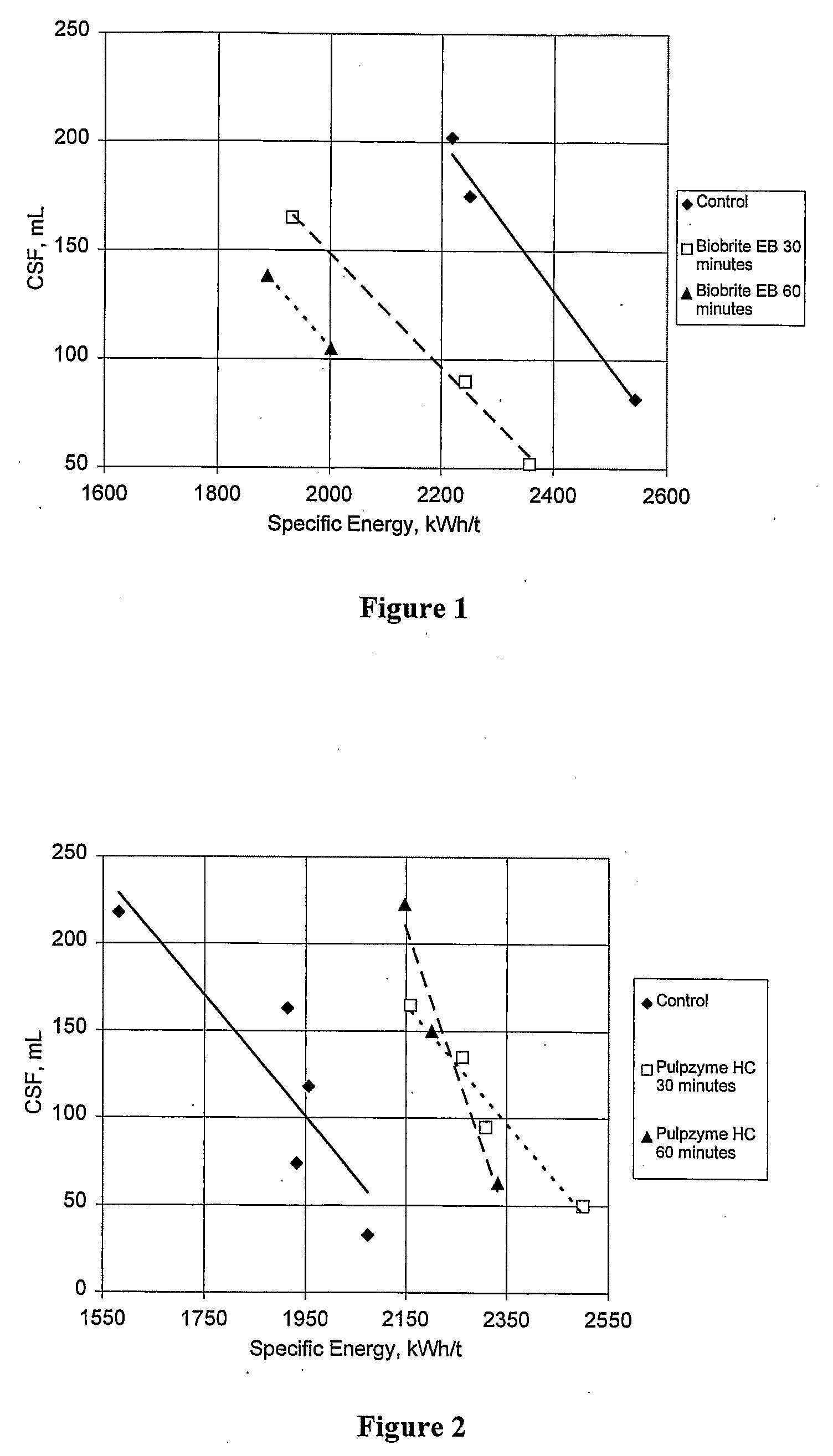

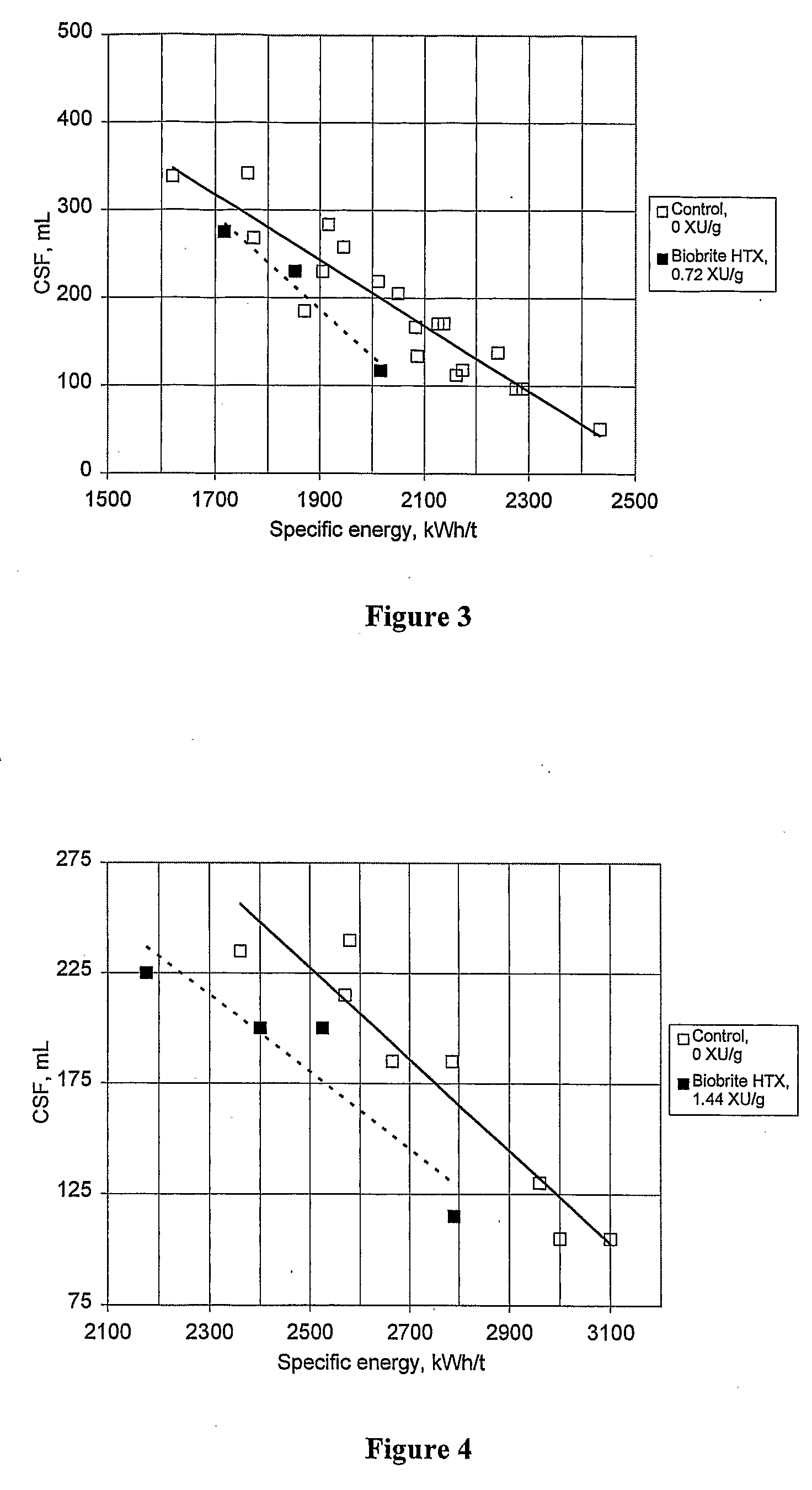

Method For Mechanical Pulp Production

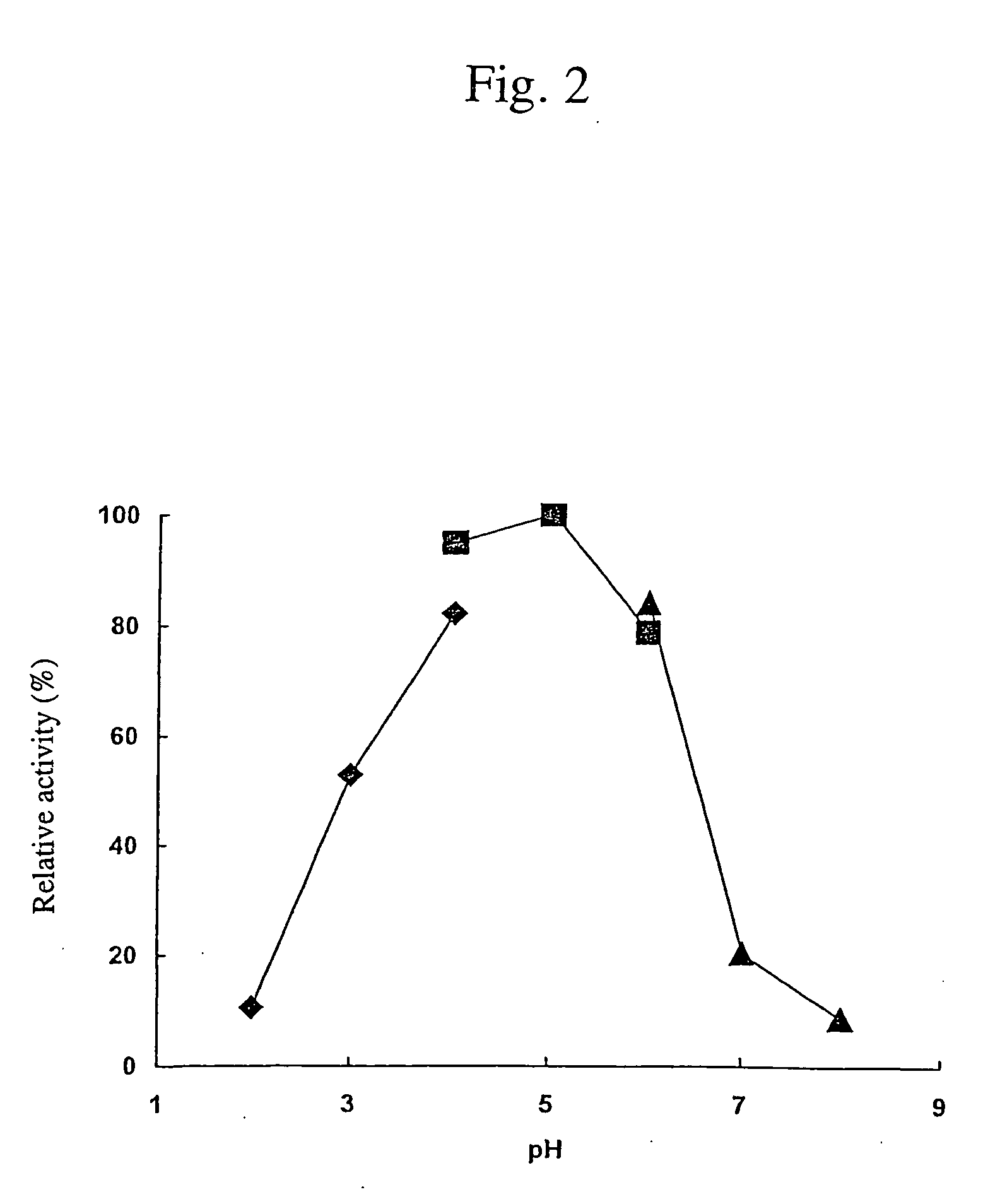

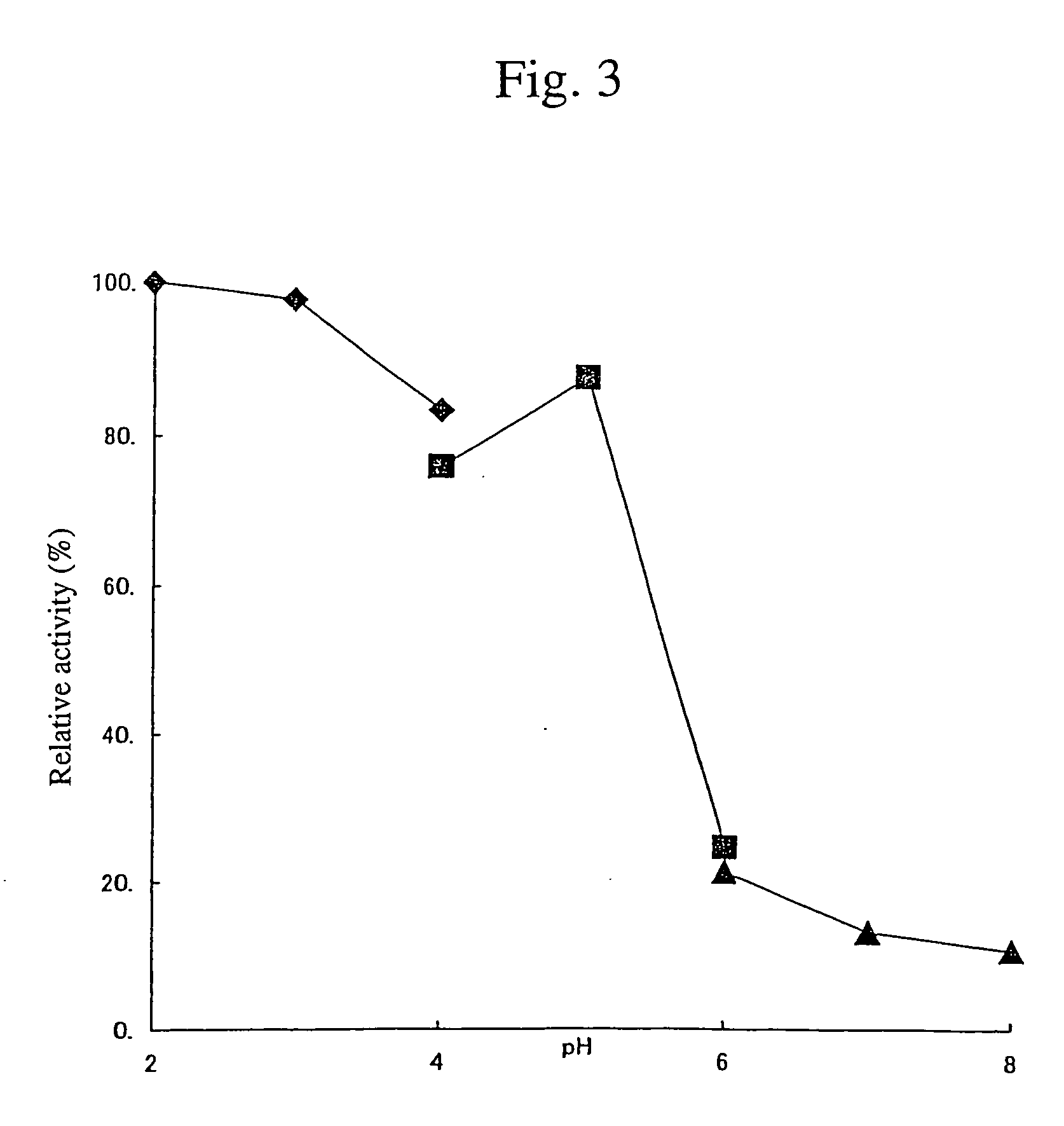

InactiveUS20090107643A1Reduce refiner energyHigh energyPretreatment with water/steamPretreatment with acid reacting compoundsPulp and paper industryOxidative enzyme

A method of producing hardwood pulp is provided. This method comprises treating hardwood chips with one or more than one Family 11 xylanase enzyme in the absence of adding an oxidizing enzyme for about 5 minutes to about 120 minutes, to produce a treated chip mixture. The treated chip mixture is then mechanically refined to produce the hardwood pulp.

Owner:CENT TECHN IND DIT CENT TECHN

Method for preparing bleached pulp by using eucalyptus wood chips

InactiveCN103334328AQuality improvementAvoid damagePretreatment with water/steamWashing/displacing pulp-treating liquorsFiberPapermaking

The invention discloses a method for preparing bleached pulp by using eucalyptus wood chips, and belongs to the fields of pulping and papermaking. The method comprises the following steps: orderly washing, dewatering and presteaming a eucalyptus wood material, carrying out double helix extrusion, chemical impregnation and high-consistency refining, eliminating, washing and the like. A double helix extruder with a variable pitch and a variable diameter is adopted in extrusion and concentration treatment of the material before defibrination; the damage of the traditional extrusion tearing machine to a fiber is avoided; the quality of the prepared pulp is similar to that of the pulp prepared by qualified chips; the bulk of the pulp can achieve over 3.4 cm<3> / g; the whiteness can achieve over 76% ISO (international standardization organization); effective utilization of the eucalyptus wood chips in the fields of pulping and papermaking is achieved; alkaline hydrogen peroxide which is friendly to the environment is adopted in the craft process; a fewer of pollutants are generated in the pulping process and are non-toxic; instant bleaching and subsequent bleaching reaction are achieved by effectively utilizing the heat energy generated in the pulping process; and steam consumption is reduced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

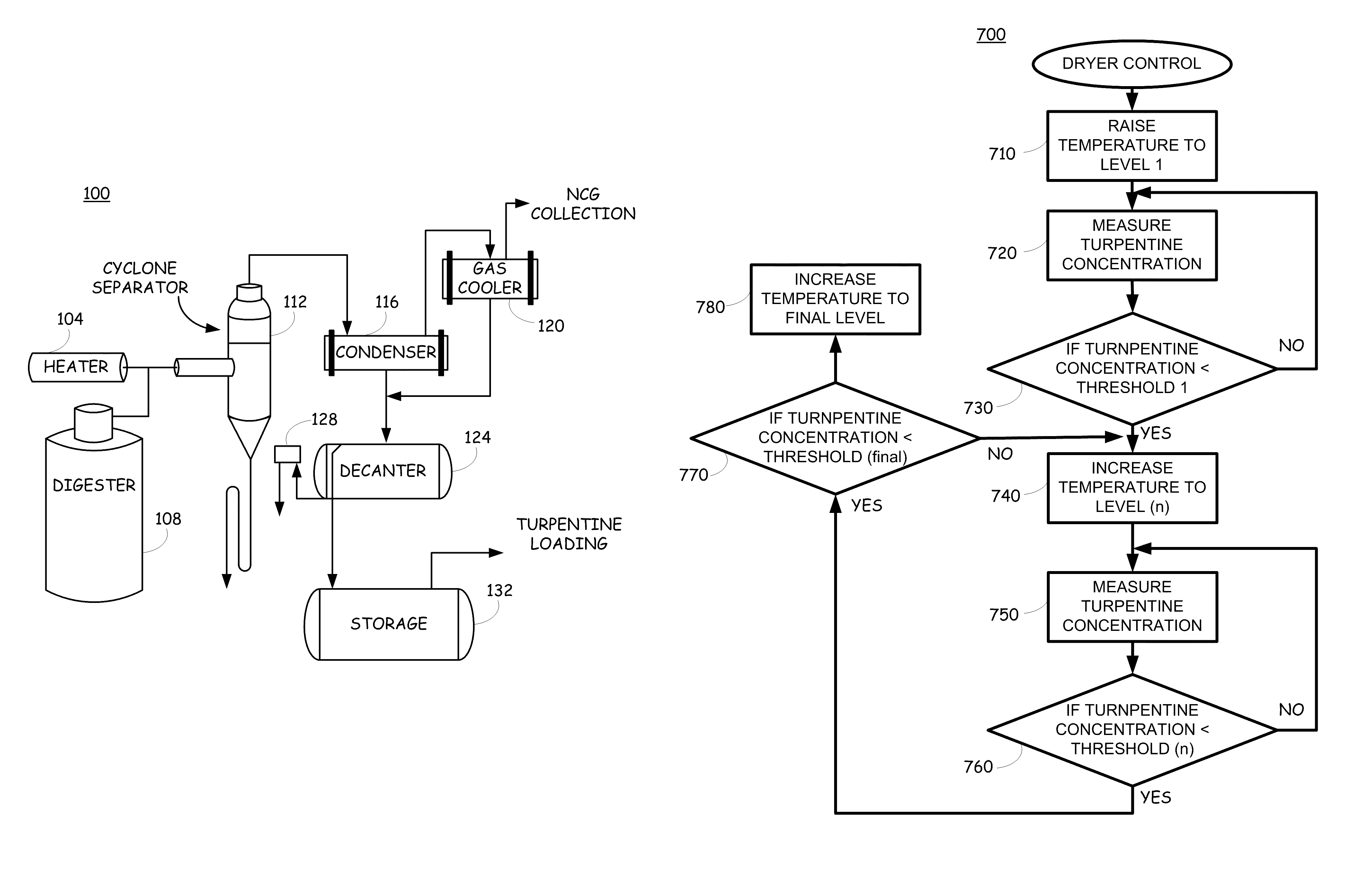

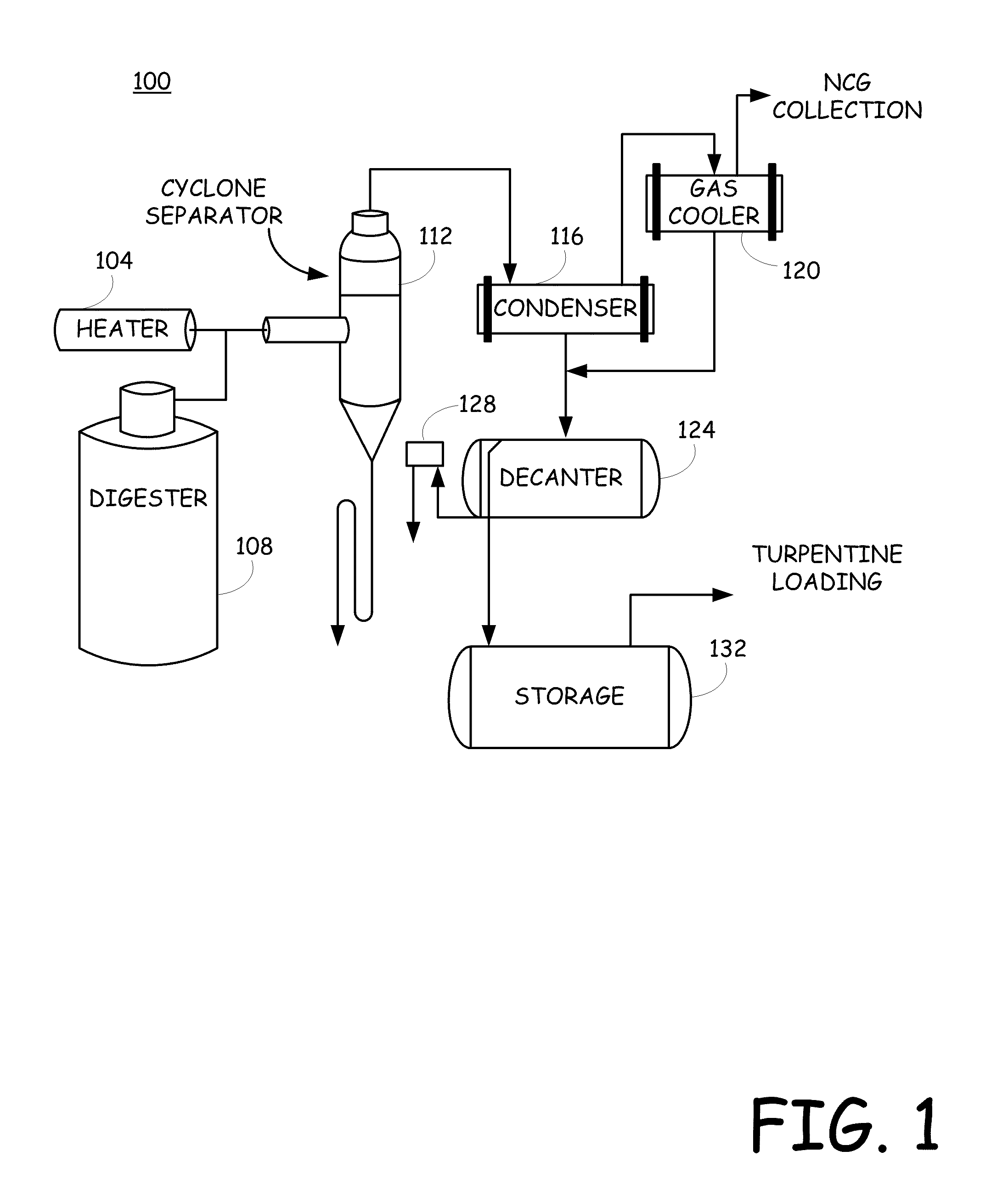

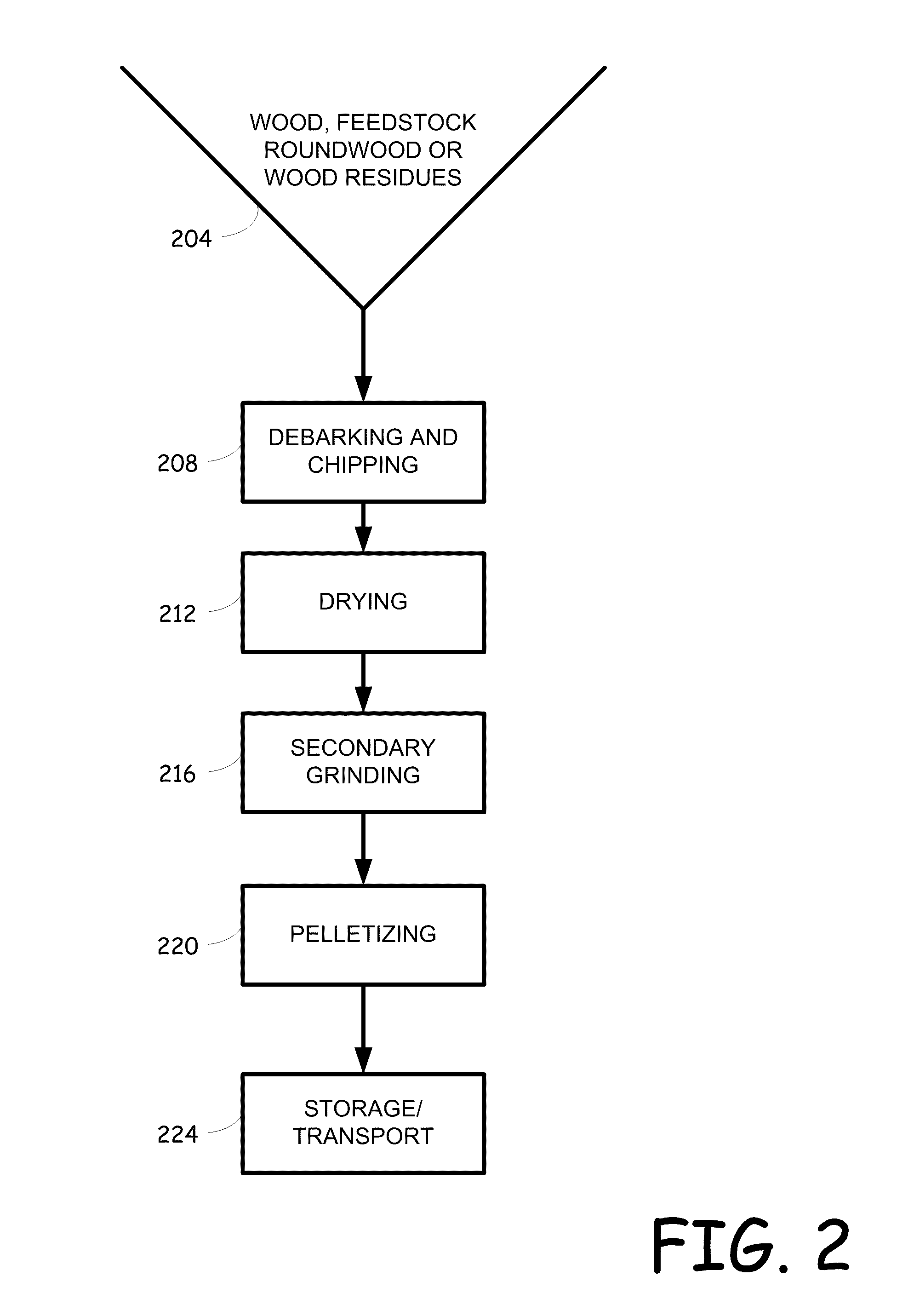

System and method for recovering turpentine during wood material processing

InactiveUS8832964B2Reduction in capital and operation costDrying using combination processesDrying solid materials with heatTurpentinePulp and paper industry

A system, method and configuration for recovering turpentine during the manufacturing of wood chips, wood pellets or other substances that may include turpentine. In general, a turpentine recovery system is used to capture turpentine from exhaust of a dryer as wood chips are being dried. Advantageously, application of the various techniques disclosed herein can result in the recovery of turpentine that can then be sold to generate revenue and, may contribute to a reduction in the capital and operation costs for emission controls for the dryer exhaust.

Owner:FOXEN ROBERT J

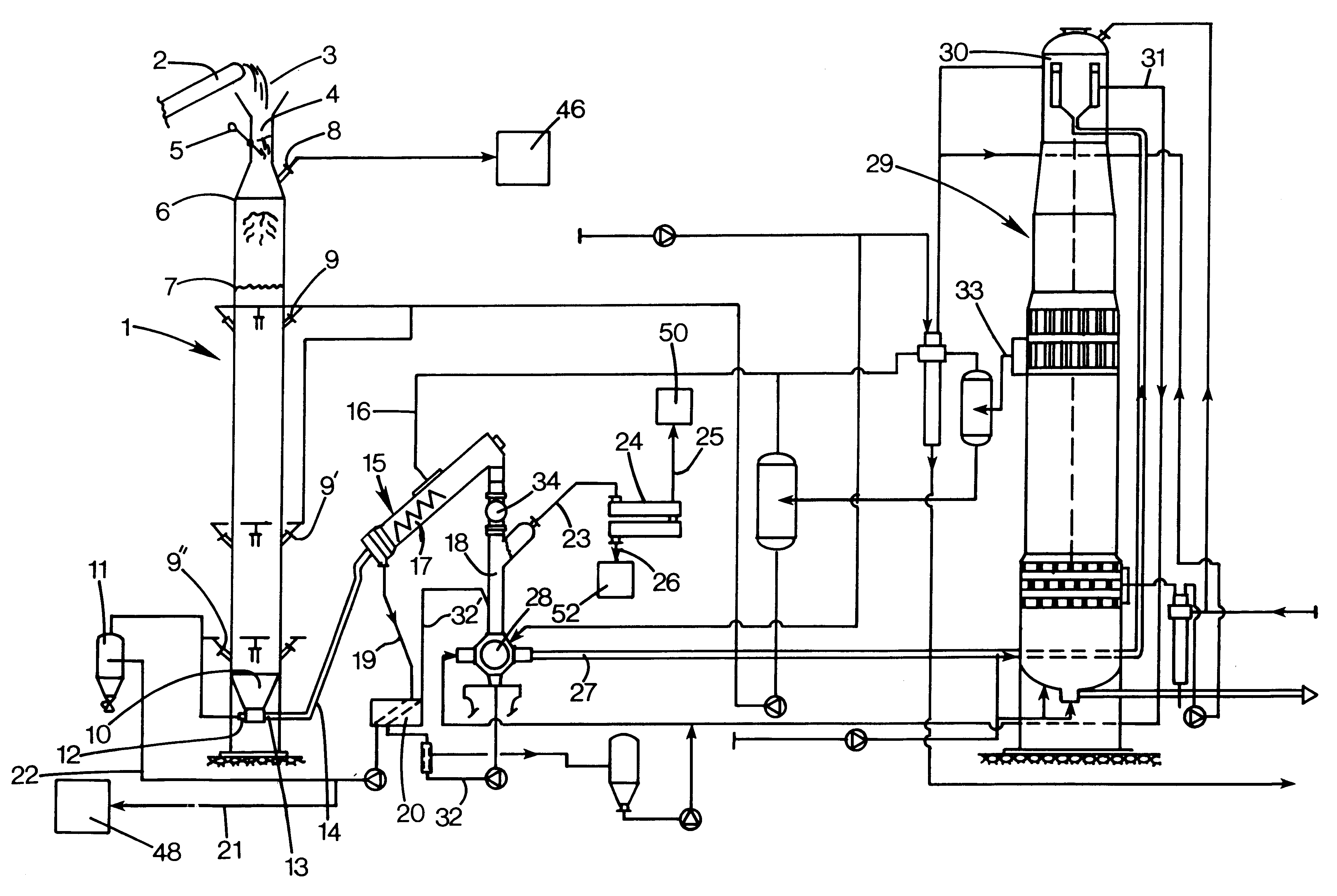

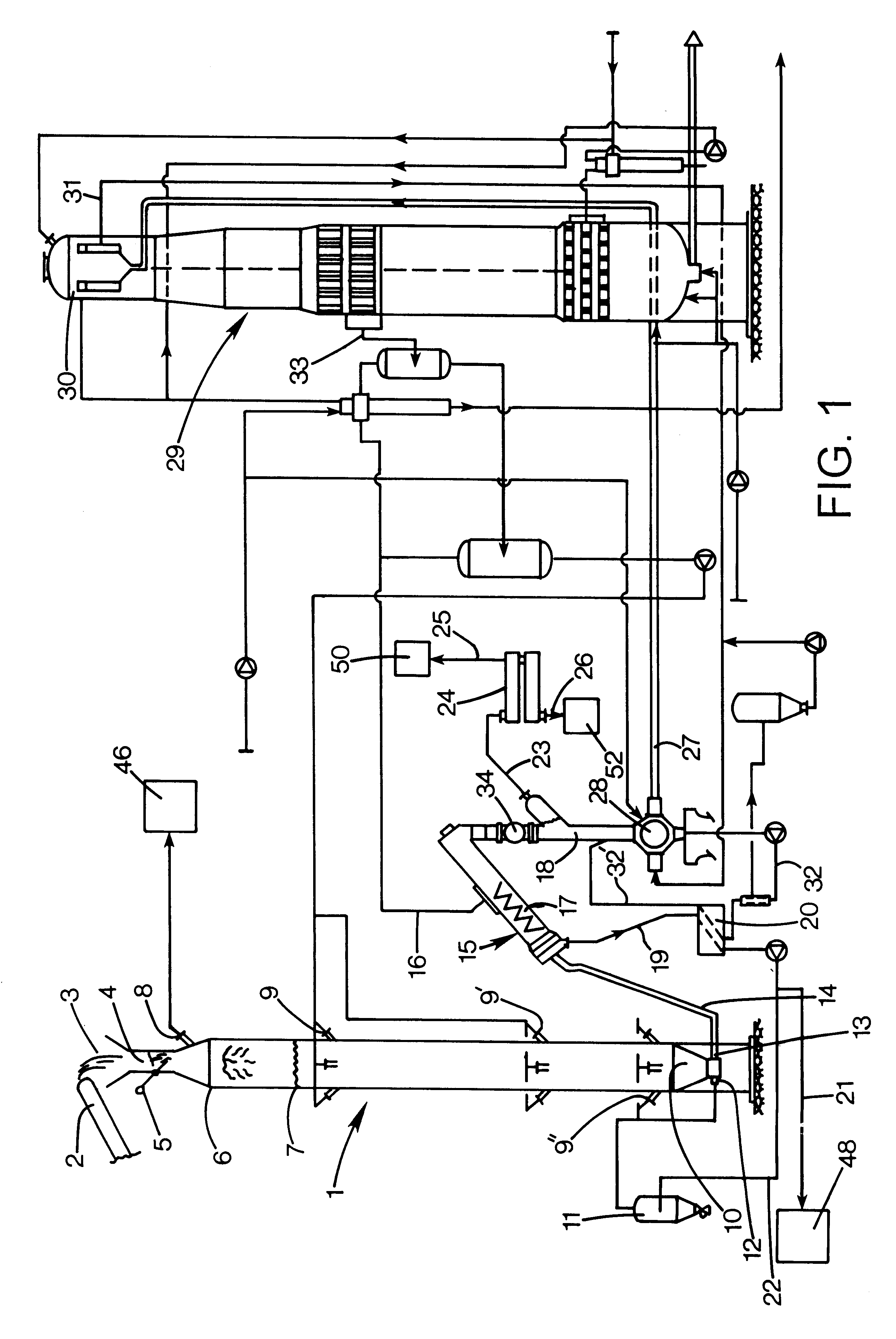

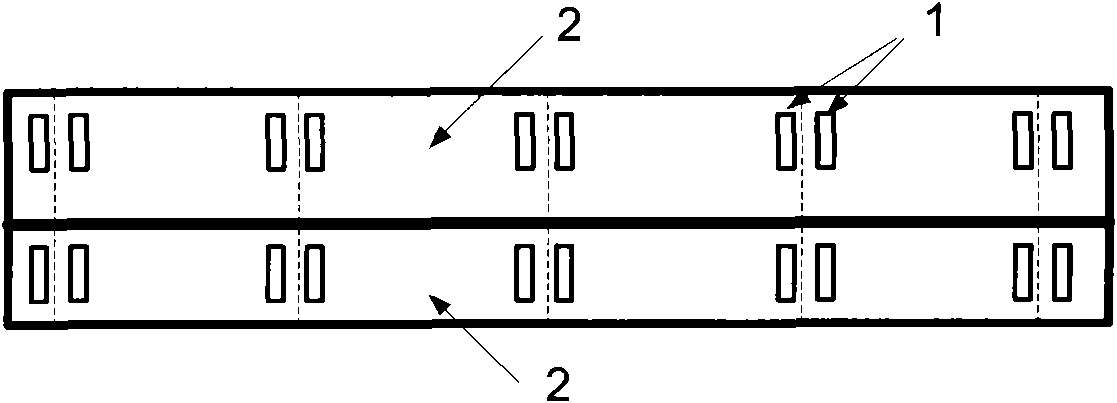

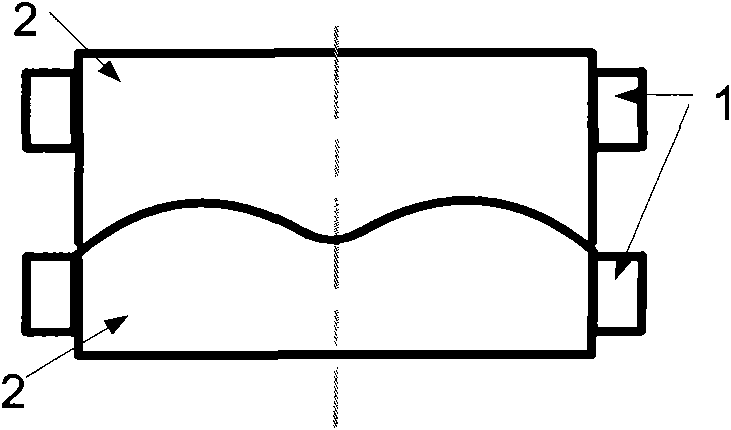

Method and Apparatus for Processing Wood Chips

InactiveUS20090084511A1Simple and easyAvoid problemsPretreatment with water/steamDigestersMetalSolution processed

A method and an apparatus for processing wood chips, wherein the wood chips are treated with steam in a gas removal apparatus. The condensate formed in the gas removal apparatus is removed from the gas removal apparatus and the wood chips are treated with a processing solution in order to remove metal ions from the wood chips. Condensate formed in the gas removal apparatus is used as processing solution.

Owner:VALMET TECH INC

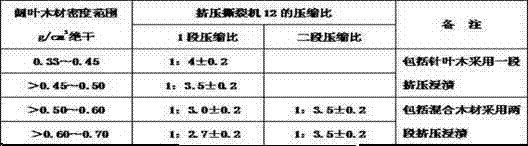

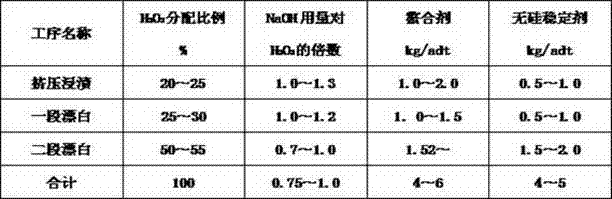

Chemi-mechanical pulp manufacturing technology

ActiveCN104711880AImprove purification qualityIncrease productivityPretreatment with water/steamWashing/displacing pulp-treating liquorsFiberManufacturing technology

The invention discloses a chemi-mechanical pulp manufacturing technology which includes the step of wood chip washing, the step of extruding and dipping, the step of pulp grinding, bleaching and pulp washing, the step of screening, purifying and regrinding of pulp residues, the step of pulp condensation and storage, the step of water circulating use and the step of chemical application and control. In the step of extruding and dipping, the extruding and dipping technology and an extruding and tearing device are used, heated and softened wood chips are evenly squashed in the texture direction, air in the wood chips and extracts affecting bleaching are discharged, it is ensured that the wood chips evenly absorb bleaching chemical liquid to be in a saturated state, fibers are promoted to be in the best moist and expanded state, and accordingly separation of the wood chips and fibrillation of the fibers are facilitated. The chemi-mechanical pulp manufacturing technology is wide in raw material application range and successfully combines the advantages that chemical pulp is high in strength and mechanical pulp is high in yield, produced bleached pulp can be used for newsprint, high-grade toilet paper, facial tissues, high-grade culture and printing paper, coating paper, light paper, white paper boards, food package paper and the like, and development prospects are wide.

Owner:WENRUI MACHINERY SHANDONG

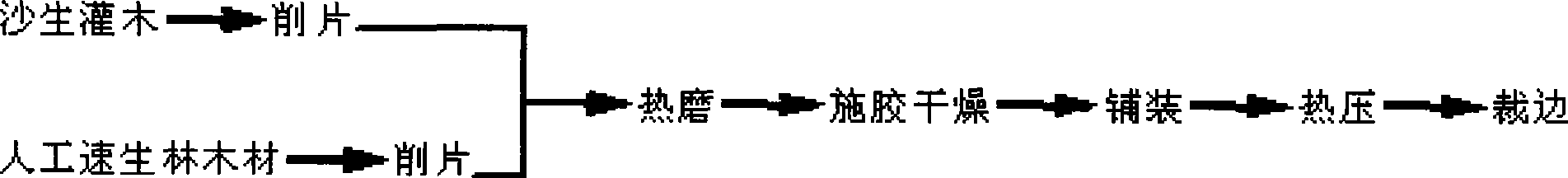

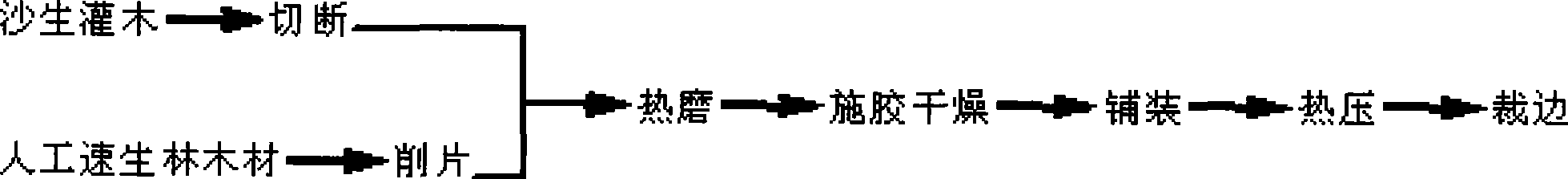

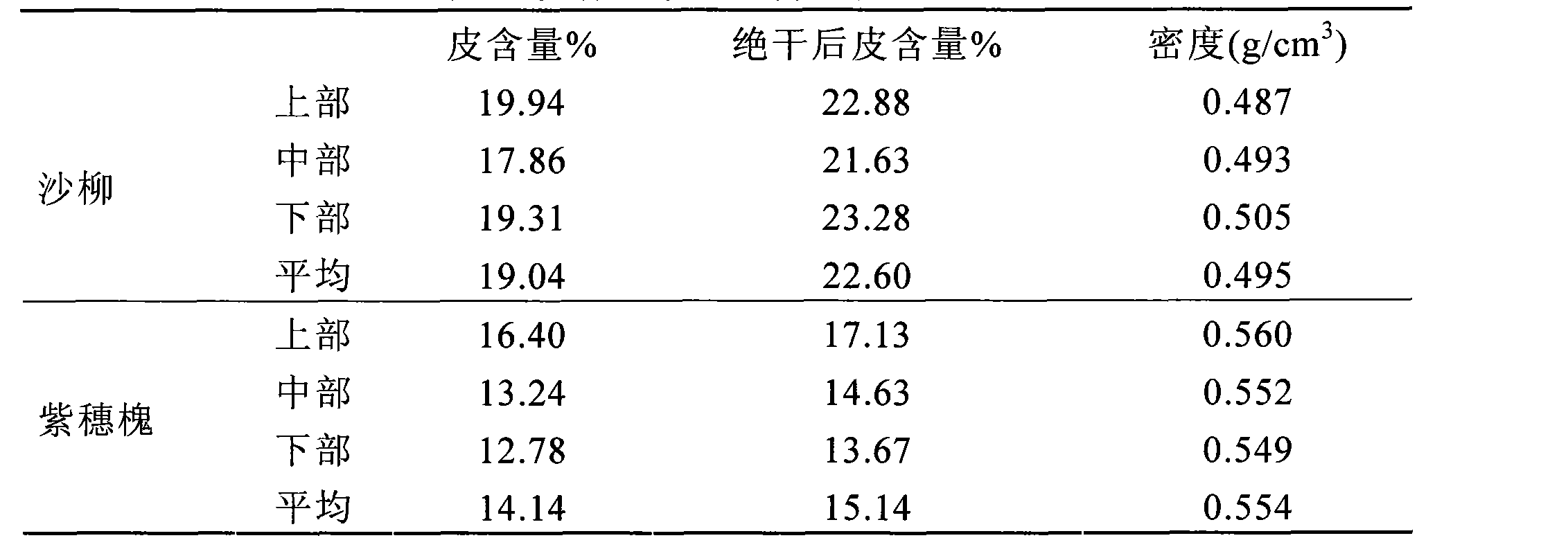

Desert shrub composite fibre board and method of manufacturing the same

InactiveCN101486216AReduce skin contentQuality improvementDomestic articlesFlat articlesFiberMaterials preparation

The invention discloses a composite fibreboard of psammophyte bush. A manual fast-growing forest timber is mixed in the psammophyte bush to prepare mixed fibre by a mixed jordaning method; and the mixed fibre reduces the bark content of the psammophyte bush and improves the fibre quality of the psammophyte bush, thereby improving the quality of the fibreboard. The invention also provides a method for manufacturing the composite fibreboard of the psammophyte bush; the method comprises the main steps: (1) material preparation; (2) hot grinding; (3) adhesive application and drying; (4) pavement; (5) hot pressing; (6) edge trimming, and other working procedures; in the material preparation section, wooden chips of the psammophyte bush with length of more than 10 cm are controlled within 5 percent; or the psammophyte bush is cut into small sections of crabsticks with the length of between 1.5 and 5.0 cm; and the wood chips or the crabsticks and the wood chips of the fast-growing forest timber are mixed to solve the problems that uncut strips of the psammophyte bush wind a cutter wheel of a drum-type chipper and block a tub wheel and a screen, and the like.

Owner:张琪

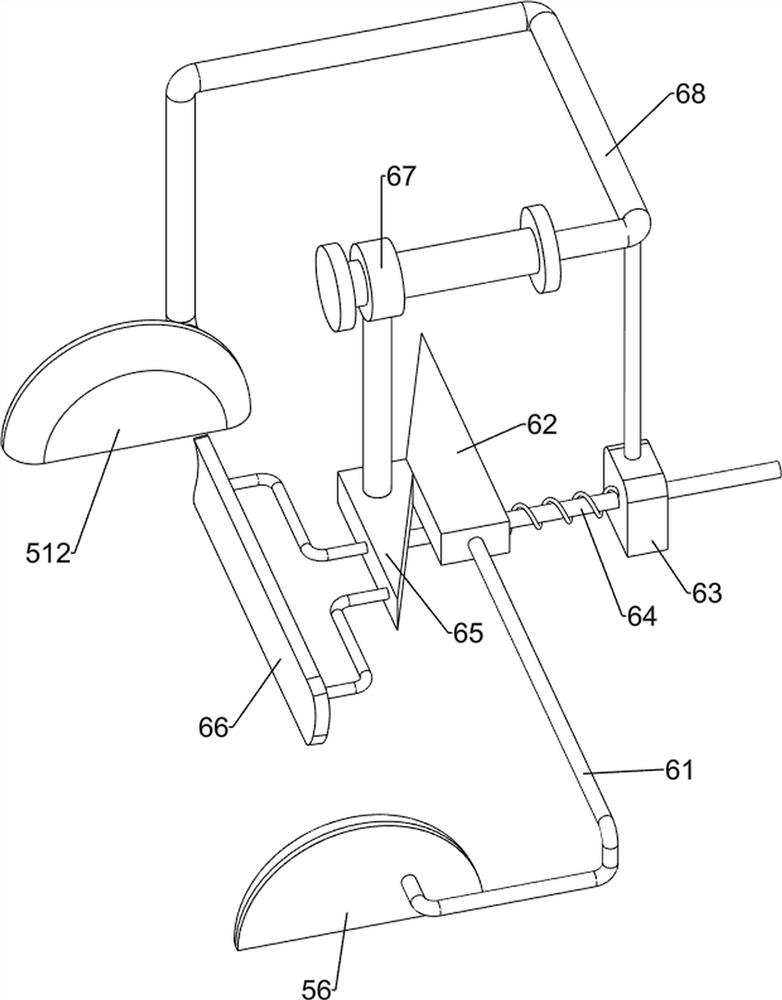

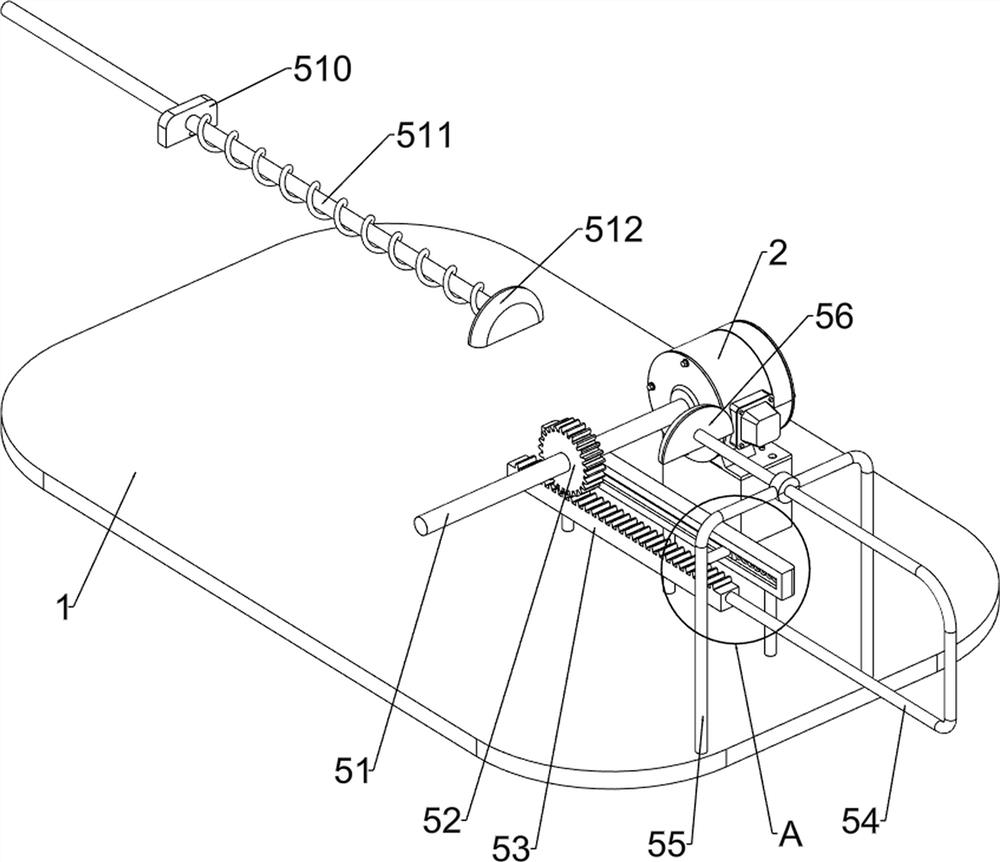

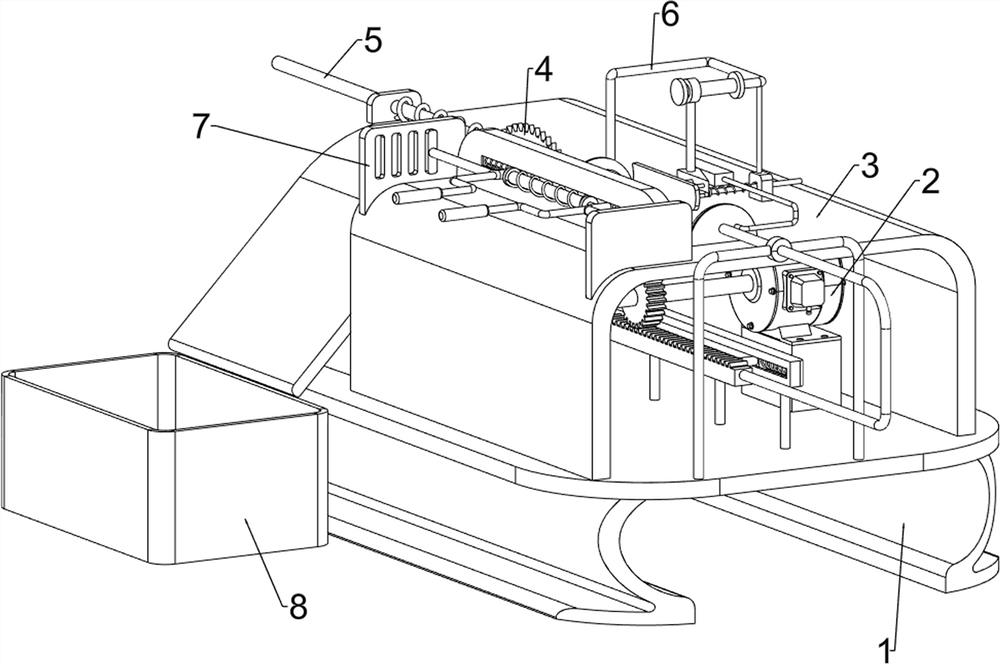

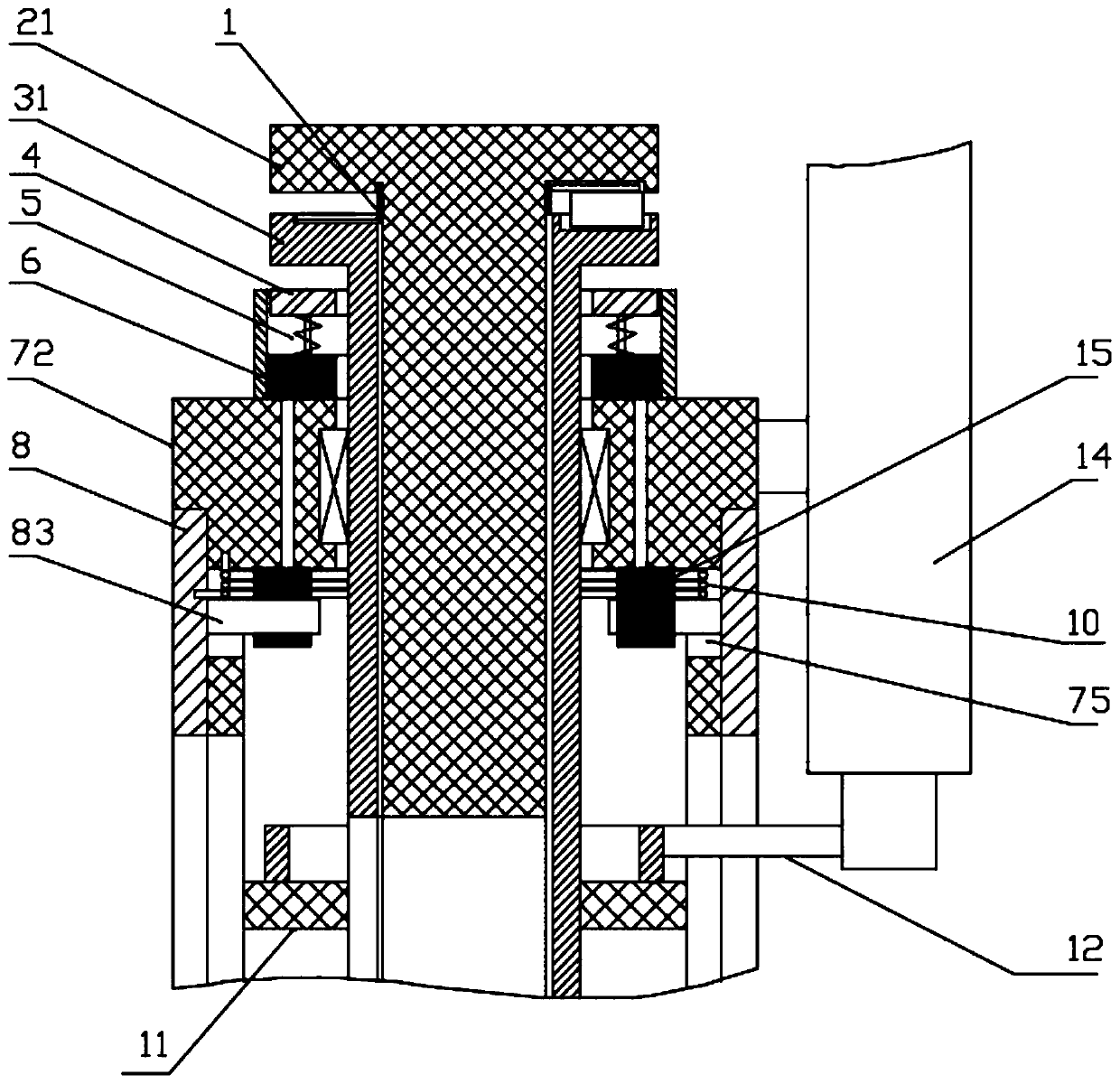

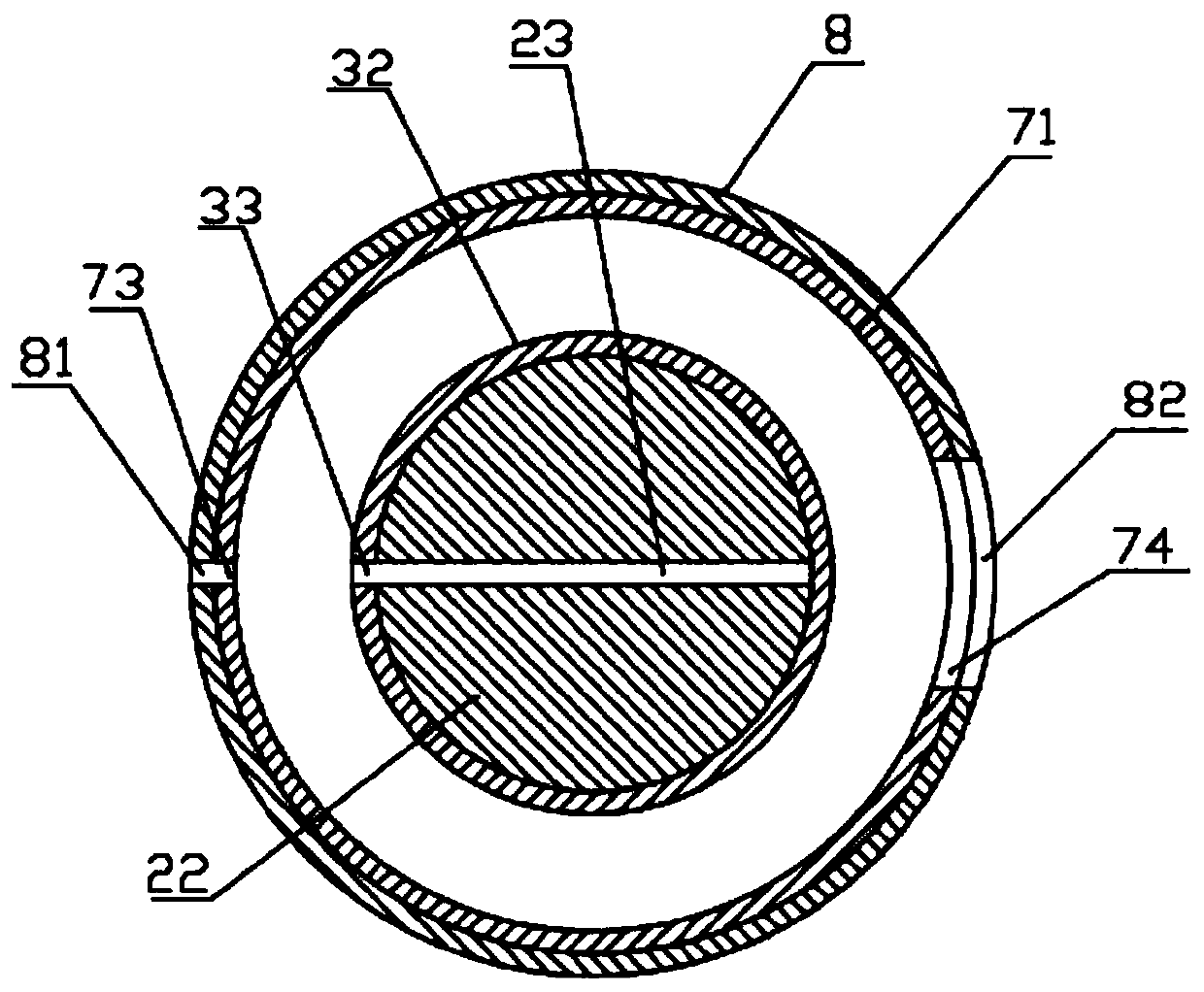

Automatic wood slicing device for building materials

ActiveCN112092099AAvoid unevennessSuit one's needsGuide fencesFeeding devicesAgricultural engineeringElectric machinery

The invention relates to a slicing device, in particular to an automatic wood slicing device for building materials. According to the automatic wood slicing device for the building materials, the efficiency can be improved, the thickness of cut wood blocks can be adjusted, and convenience is achieved. The automatic wood slicing device for building materials comprises a first working table, a second working table, an electric saw, a pushing mechanism and a pressing mechanism. A motor is arranged on the side wall of the upper part of the first working table; the second working table is arrangedon the first working table; the electric saw is rotatably arranged on the second working table; the pushing mechanism is arranged on the first working table; and the pressing mechanism is arranged onthe second working table. The pressing mechanism can stabilize the wood block and prevent the wood block from being unevenly cut due to instability during cutting. After the wood blocks are sliced bythe electric saw, the wood chips can be collected by a collecting box and are convenient to arrange; and a distance adjusting mechanism enables the wood block to be cut thick or thin according to needs, the needs of people can be met, and convenience is achieved.

Owner:蓝山县奔嘉木业有限公司

Contour sanding attachment and method

A grinding attachment for use in conjunction with hand-held grinding or drilling power tools such as are commonly found around the house, and method for using this attachment. The purpose of the invention is to allow the homeowner and the like to have greater facility in performing surface sanding, grinding, or finish work on pieces of wood and the like. In particular, the goal is to provide proficiency in working with surfaces that are not planar or otherwise simple. By providing an appropriate compound support against which an abrasive belt or the like is to run as it works the surface, it is possible to have a variety of backing shapes ranging from a strictly planar backing to one that allows the abrasive material to take the shape of whatever piece is being pressed against it. The invention derives its motive power from a coupling to a power tool, typically by the insertion of a drive axle of the attachment into the chuck of a hand drill. The compound support of the attachment includes a means of spring-loading the abrasive belt so as to maintain tension in it. The intended method of use of the attachment will depend on the particular shape of the piece to be worked. The preferred method utilizes an elastic abrasive belt.

Owner:DEWARE WILLIAM R +1

Cellulose digesting enzyme gene and utilization of the gene

InactiveUS20050181485A1Controlling in paper strengthReduce yieldFungiOxidoreductasesCelluloseAntisense RNA

A method for treating woodchips, comprising the steps of: preparing a DNA encoding an antisense RNA substantially complementary to the whole or a part of a transcription product of a cellulolytic enzyme gene derived from Basidiomycete; preparing a vector comprising (a) the above DNA, or (b) a recombinant DNA comprising the above DNA and a DNA fragment having a promoter activity, wherein the above DNA binds to the above DNA fragment such that an antisense RNA of the cellulolytic enzyme gene is generated as a result of transcription; transforming host cells with the above vector, so as to prepare the host cells having a suppressed cellulolytic enzyme activity; and inoculating the above host cells having a suppressed cellulolytic enzyme activity into woodchips to treat them.

Owner:OJI PAPER CO LTD

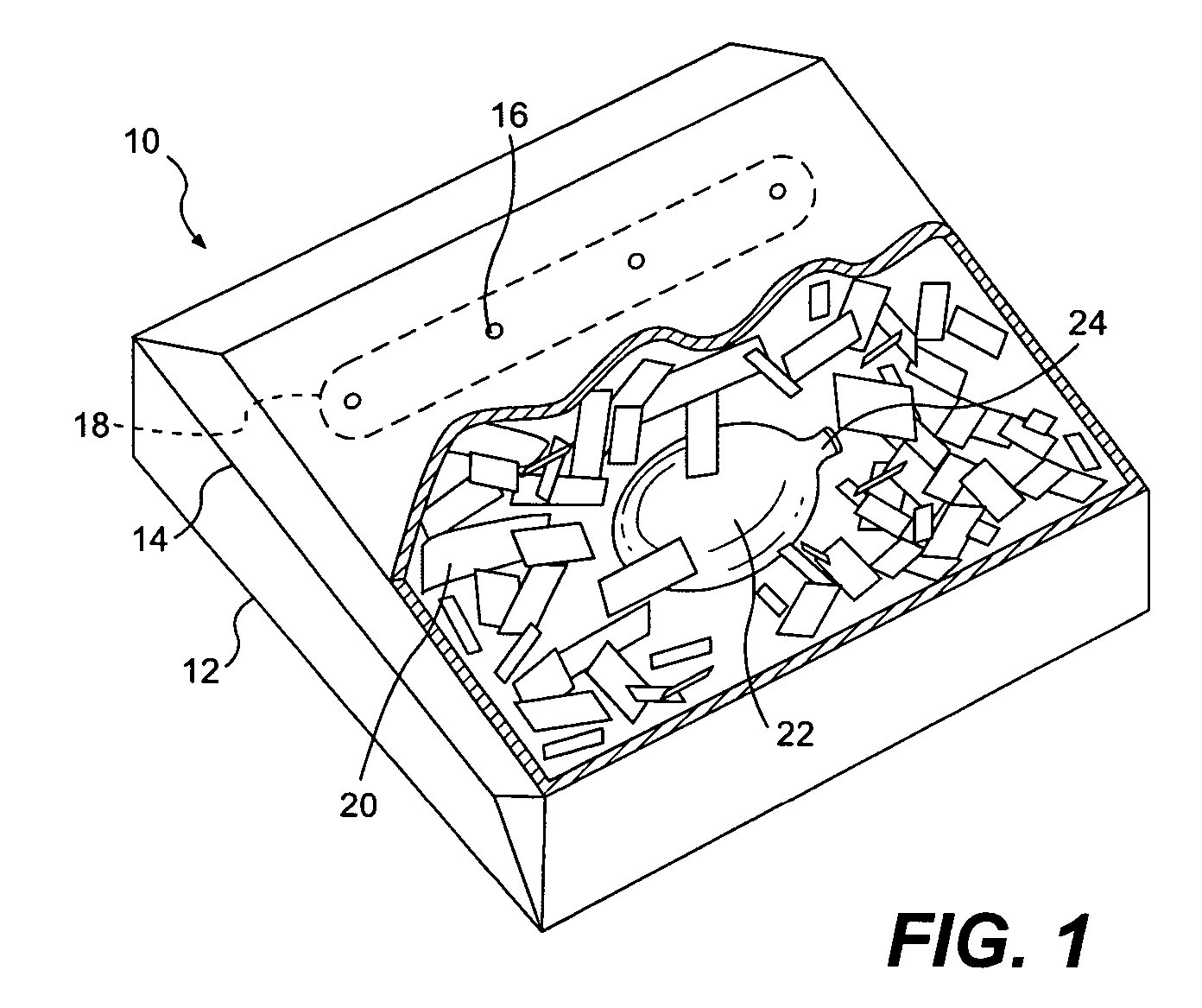

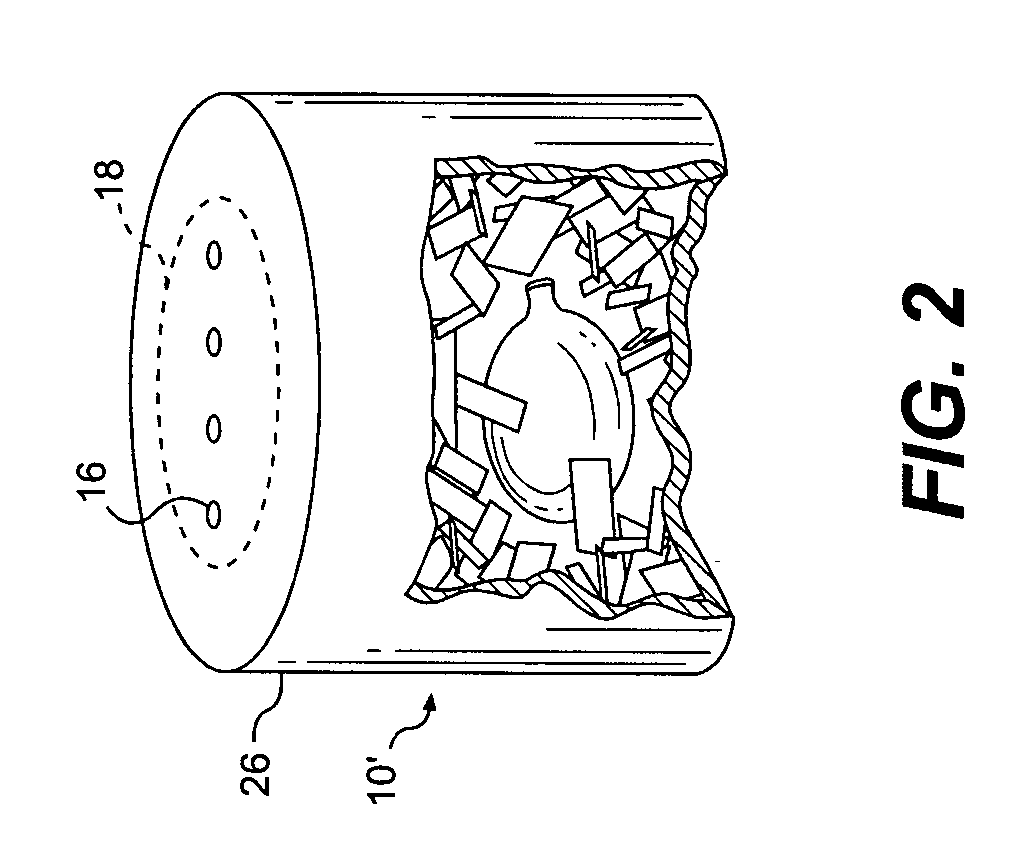

Disposable barbeque smoking box with integrated soaking device

A barbeque smoking box includes a metal container that encloses woodchips. Within the mass of the woodchips is located a frangible liquid container that ruptures when subjected to the heat of a barbeque grill. The liquid then permeates and soaks the woodchips in the frangible container. As the barbeque grill continues to heat the soaked woodchips, smoke is generated and passes in an continuous control manner through a number of small openings formed in the external package so as to smoke food that is being prepared in the grill.

Owner:FEINBERG ANDREW

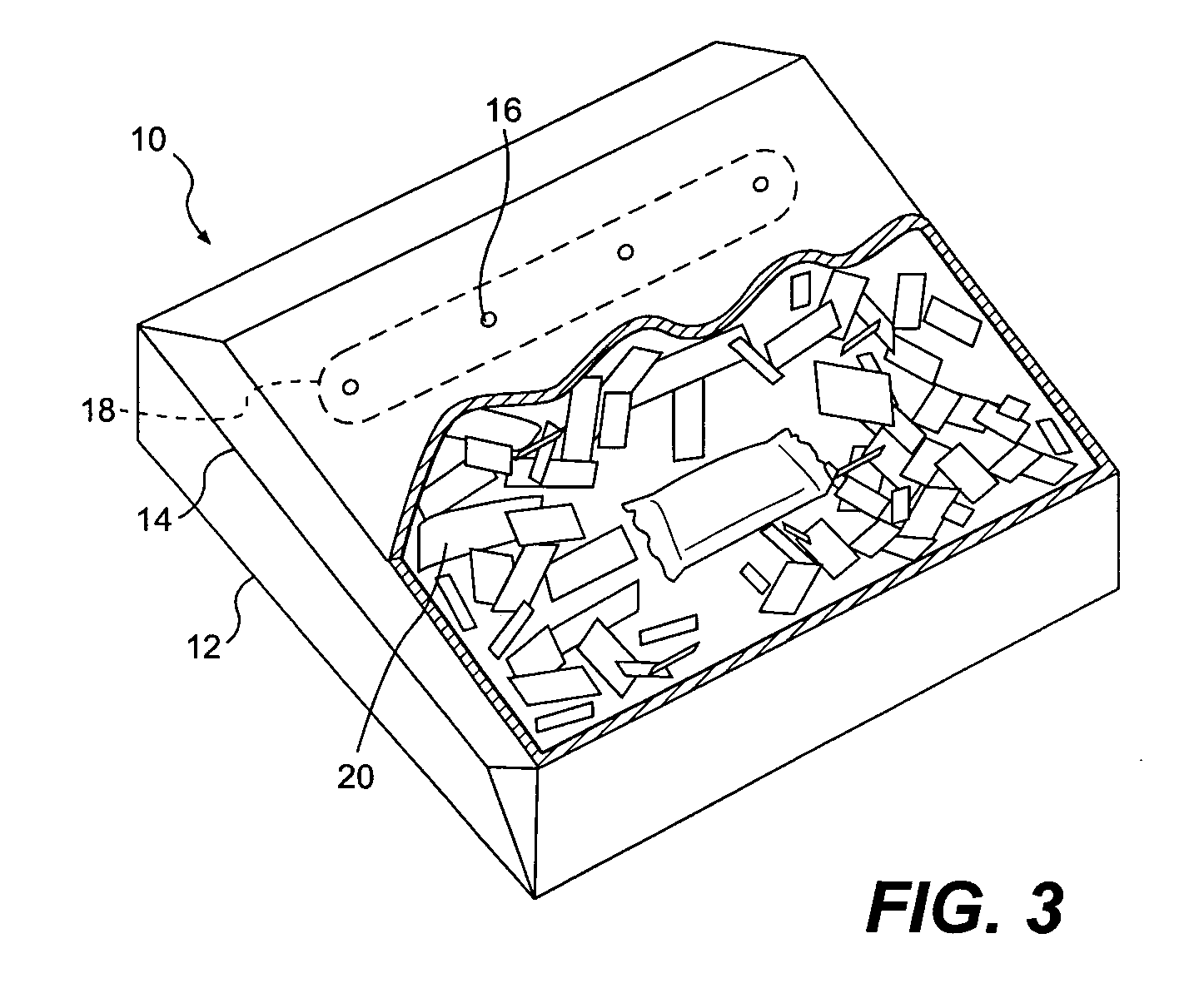

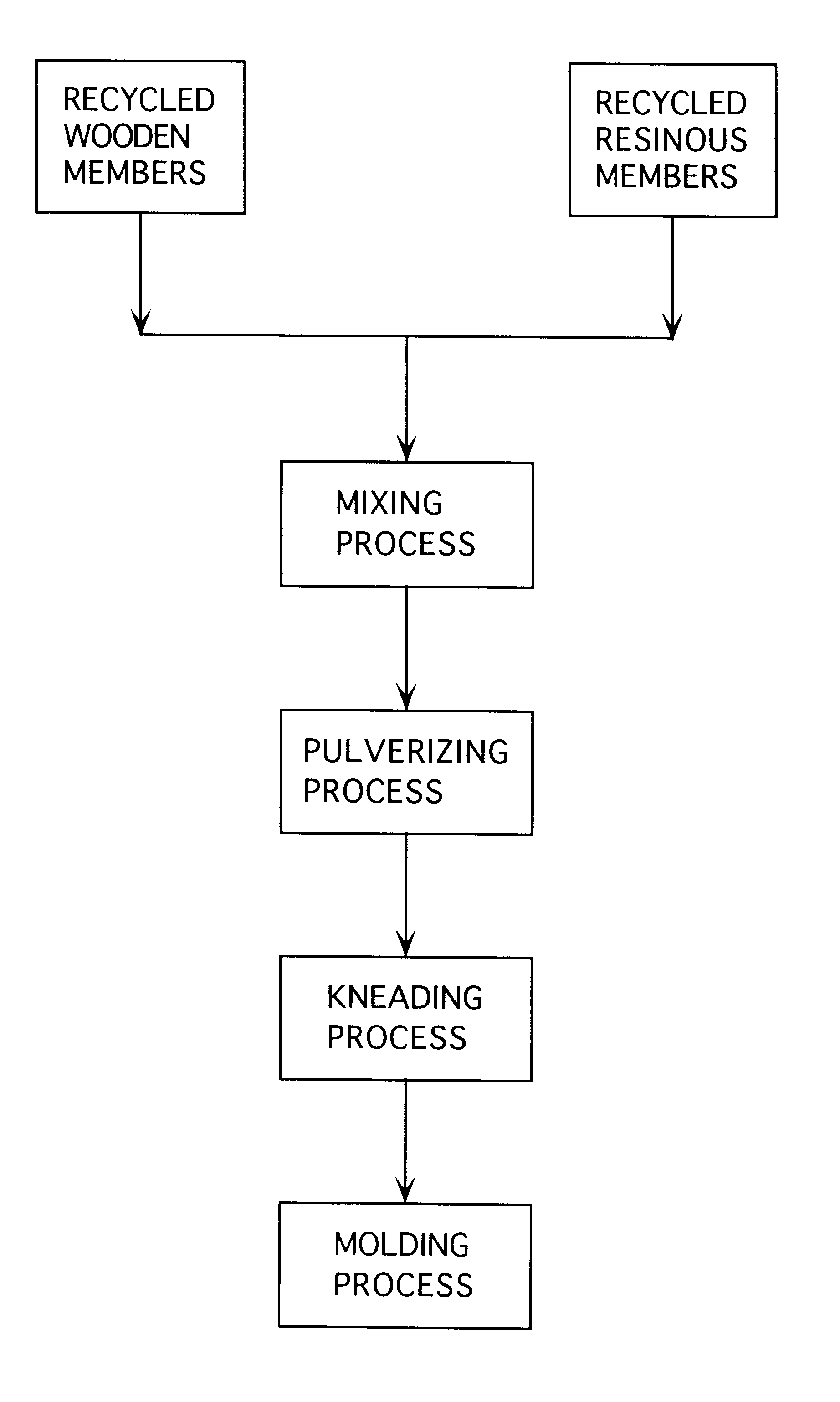

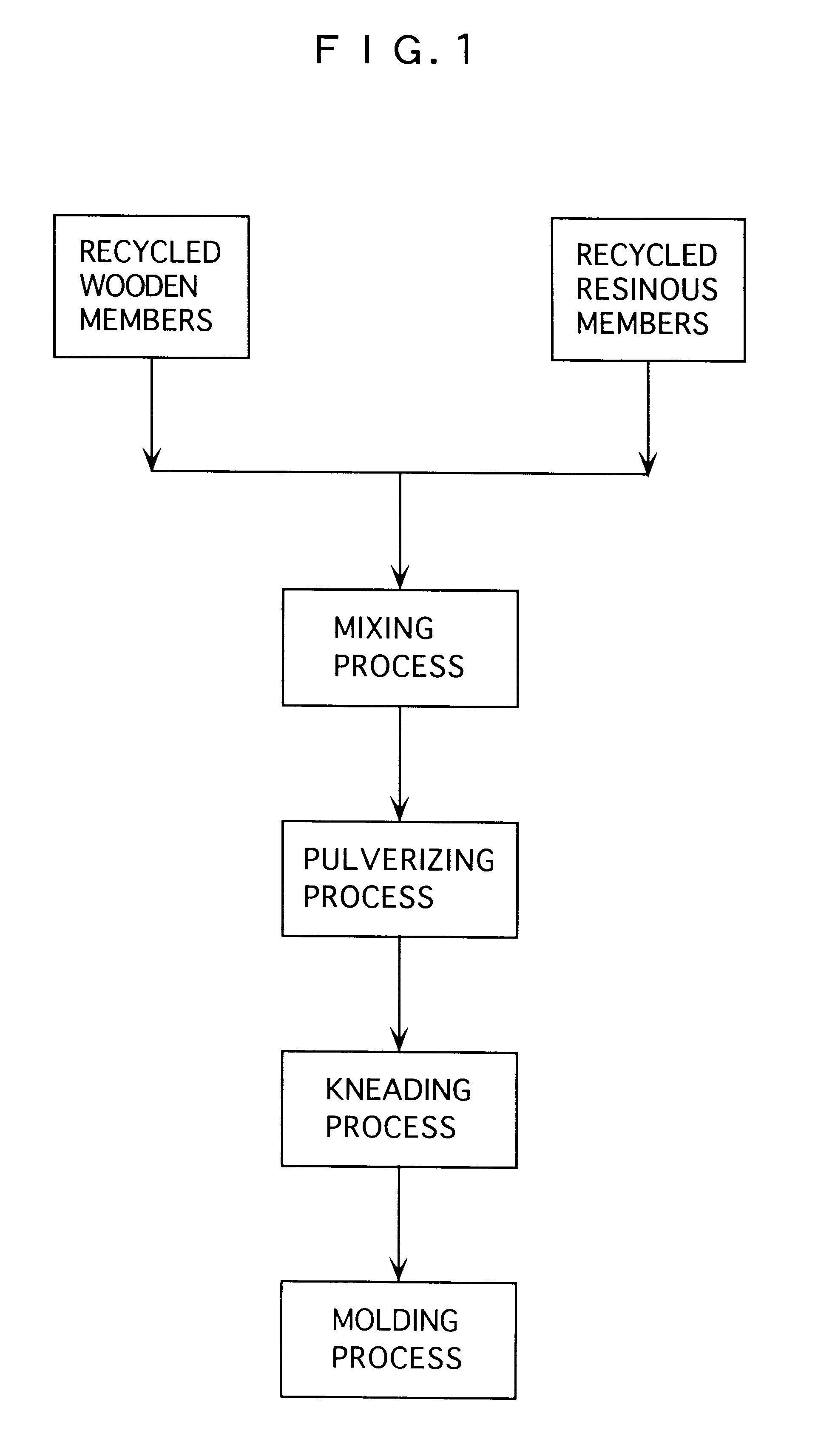

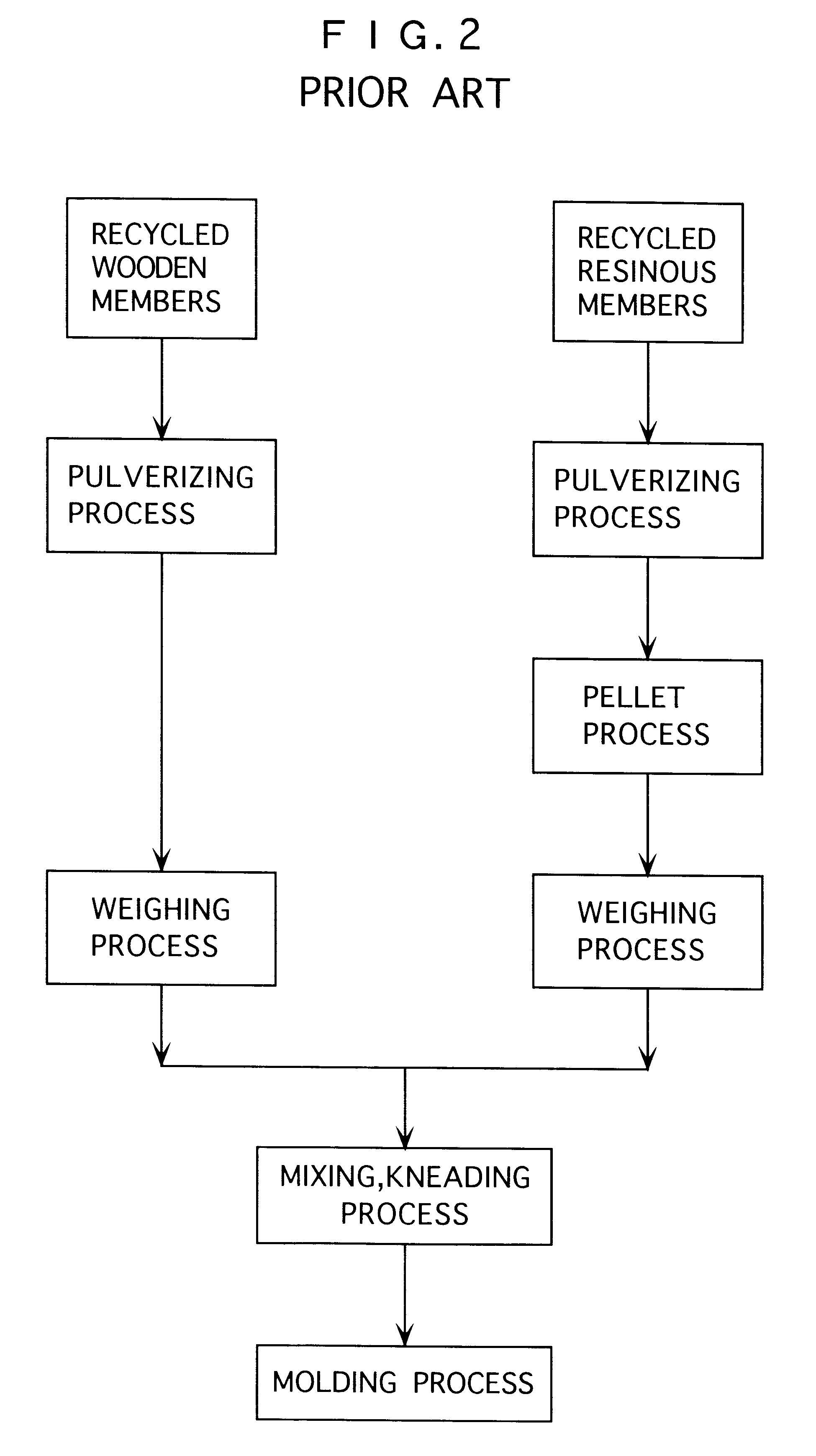

Cement bonded wood chip product, resin bonded wood chip product, simulated wood product and manufacturing method thereof

InactiveUS6228301B1Reduce the numberReduce processFilament/thread formingDomestic articlesShell moldingMixed materials

A manufacturing method of a simulated wood product utilizing pulverized powders obtained from recycled building members as raw material, in which the building members have recycled wooden members made of wooden materials and resinous members made of resinous materials, the manufacturing method further including a mixing process for mixing the recycled wooden members, a pulverization process for pulverizing the mixed materials obtained in the mixing process to form pulverized powder, a kneading process for kneading the pulverized powders obtained by the pulverizing process, and a molding process for molding the kneaded materials obtained in the kneading process either by an extrusion or injection molding.

Owner:MISAWA HOMES CO LTD

OSB ecological painting-free decorative surface furniture plate and preparing method thereof

InactiveCN103978525AStable structureHigh strengthWood veneer joiningWood layered productsPaperboardAdhesive glue

An OSB ecological painting-free decorative surface furniture plate comprises at least one OSB blank plate; a decorative surface layer is composited on at least one surface of the OSB blank plate by at least one buffer balance layer in the middle; the preparing method comprises the following steps of a, manufacturing the OSB blank plate: machining a raw material into a thin long wood chip which is 40-120mm long, 5-20mm wide and 0.3-0.7mm thick along the grain direction, paving a three-layer or four-layer criss-cross structure by gluing, and manufacturing the blank plate by adopting a continuous hot press process; b, compositing by adopting a direct attaching mode: compositing the OSB blank plate and a veneer which is 0.1-3.0mm thick to manufacture an OSB base pate by using E0 glue, then attaching one layer of impregnated paper decorative surface layer on the surface of the OSB base plate; or the step b, compositing by using a repeated attaching mode: compositing the veneer which is 0.1-3.0mm thick and the impregnated paper to manufacture a paper board composite decorative surface layer, and gluing the paper board composite decorative surface layer to the OSB base plate by E0 glue. The furniture plate has a painting-free function, and has the excellent performances of environment friendliness, high stability, high carrying property, high nail keeping capacity and the like.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Class C coated water transfer printing base paper papermaking process

ActiveCN103451990ALow costMeet needsCoatings with pigmentsWater-repelling agents additionFiberPapermaking

The invention discloses a class C coated water transfer printing base paper papermaking process. The class C coated water transfer printing base paper papermaking process comprises the steps of preparing a surface sizing solution, pulping, mixing, papermaking, performing surface sizing, coating, calendering, rewinding and packaging; mixed pulping is performed by using three raw materials, namely long and short fiber wood pulp and wood chip pulp; when pulp kneading is performed, a charge enhancer is added, a wet strength agent is added in the pulping process step, a starch curing agent is added into the surface sizing solution, and a water-resistant agent, a latex, a lubricating agent and a starch sizing agent are added in the coating process step, so that the surface performances of coated water transfer printing base paper are improved, the coated water transfer printing base paper can be used for replacing existing domestic low-grade base paper products, and the production process has the characteristics of low cost, good uniformity of the prepared paper, smooth surface, strong two-sided hygroscopicity, good dry and wet mechanical strength and the like.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

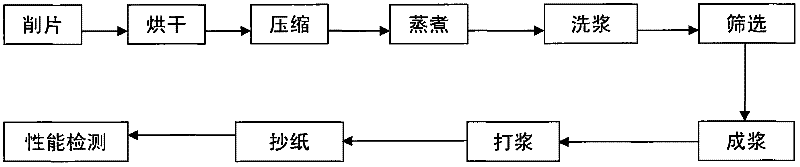

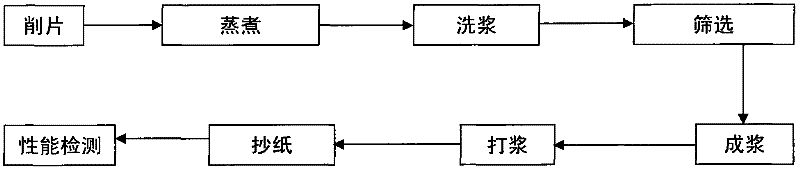

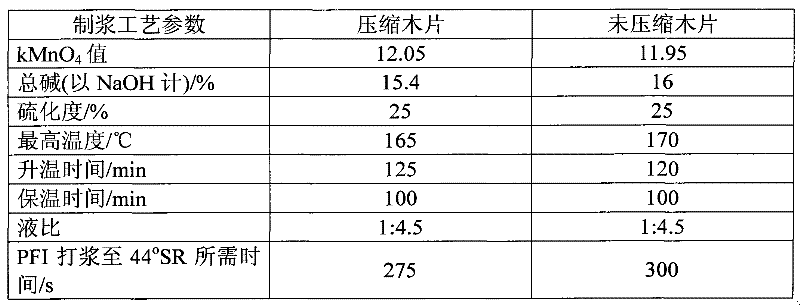

Sulfate pulping method of broadleaf wood compressed wood chip

InactiveCN102535237AReduce storage spaceImprove transportation efficiencyPulping with inorganic basesChemical/chemomechanical pulpSulfateHardness

The invention discloses a sulfate pulping method of a broadleaf wood compressed wood chip, which relates to a drying and compressing method of broadleaf wood chips, and a sulfate pulping process of the compressed wood chips. The method solves the difficult problems that bulked broadleaf wood chips are small in volume weight, low in transmitting efficiency, large in storage space and the like, and provides a targeted sulfate pulping process scheme aiming at the broadleaf wood compressed wood chips. Compared with uncompressed wood chips, after being dried and compressed, the broadleaf wood chips reduces volume by 1 / 3-1 / 4 of natural accumulation, so as to greatly improve the transporting efficiency and reduce the transporting cost; under the same sulfate cooking process conditions, the method reduces the full pulp sieving rate by 20-50%; under the premise of achieving same full pulp hardness indexes, the method reduces chemicals cooking consumption by 2-5%, reduces the pulping cost, and reduces the pollution load of pulping waste liquid; and when under the same pulping degree, the method shortens 8-25% of pulping time and obviously reduces the pulping energy consumption.

Owner:北京晨峰投资控股有限公司

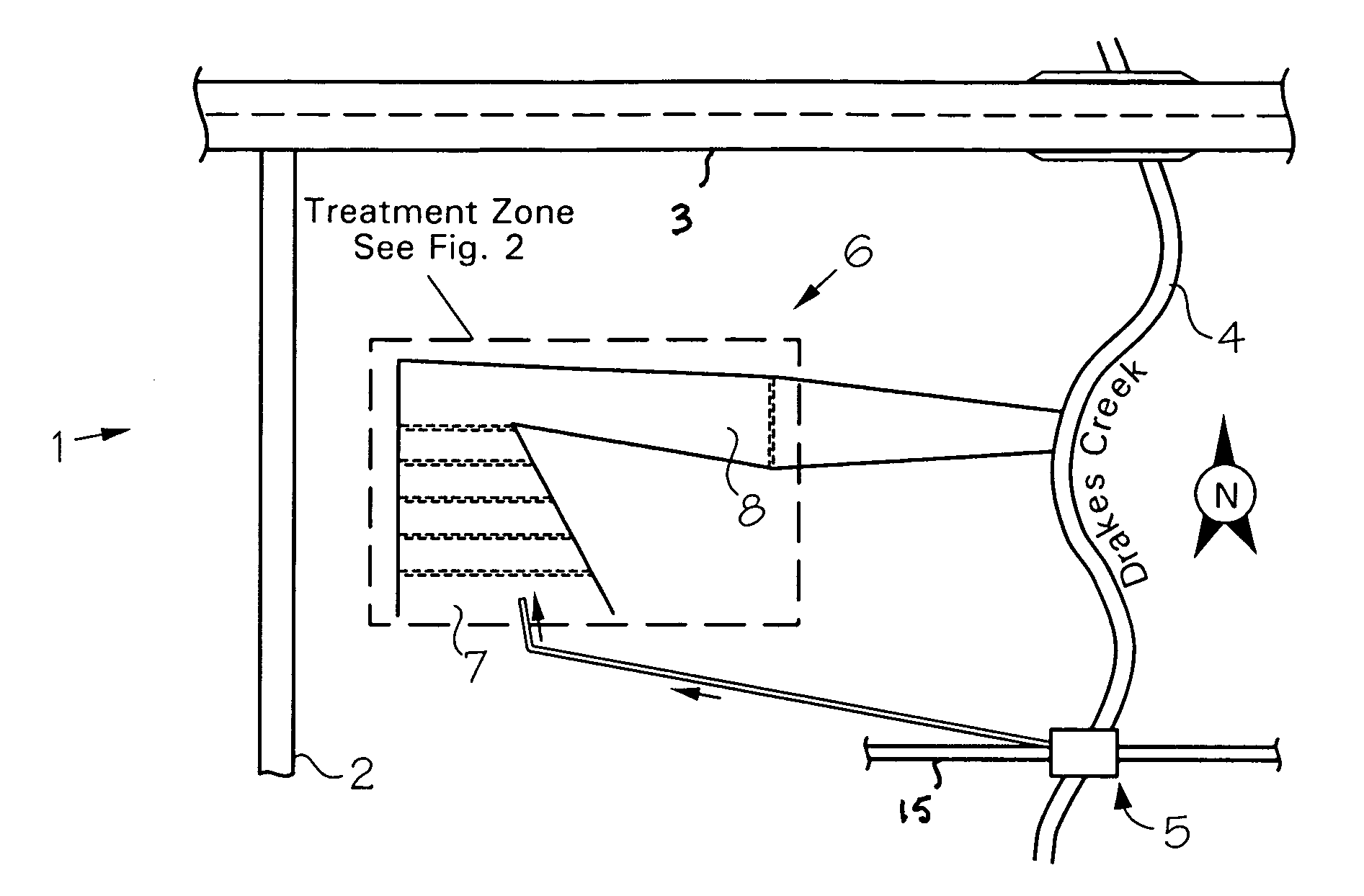

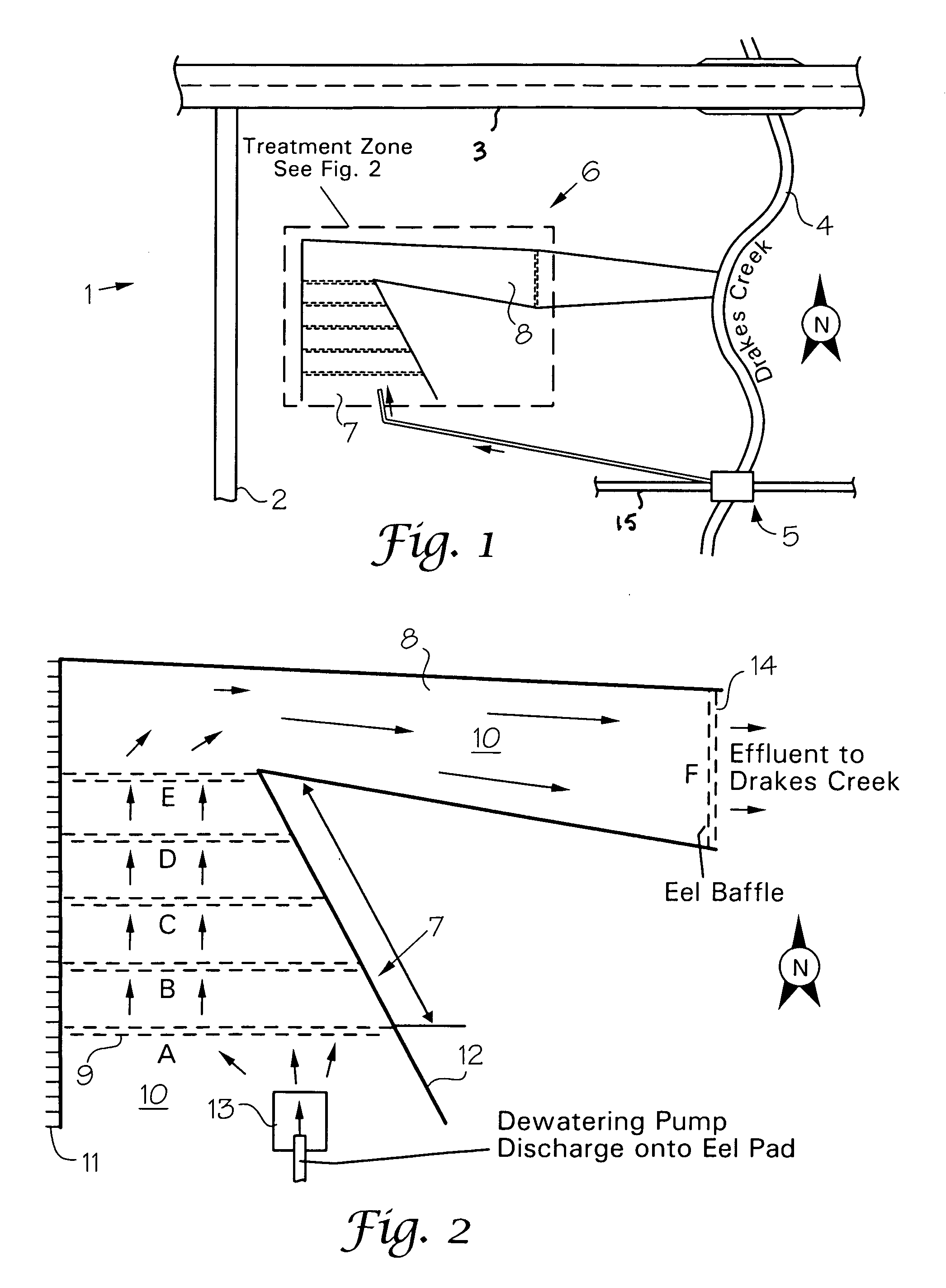

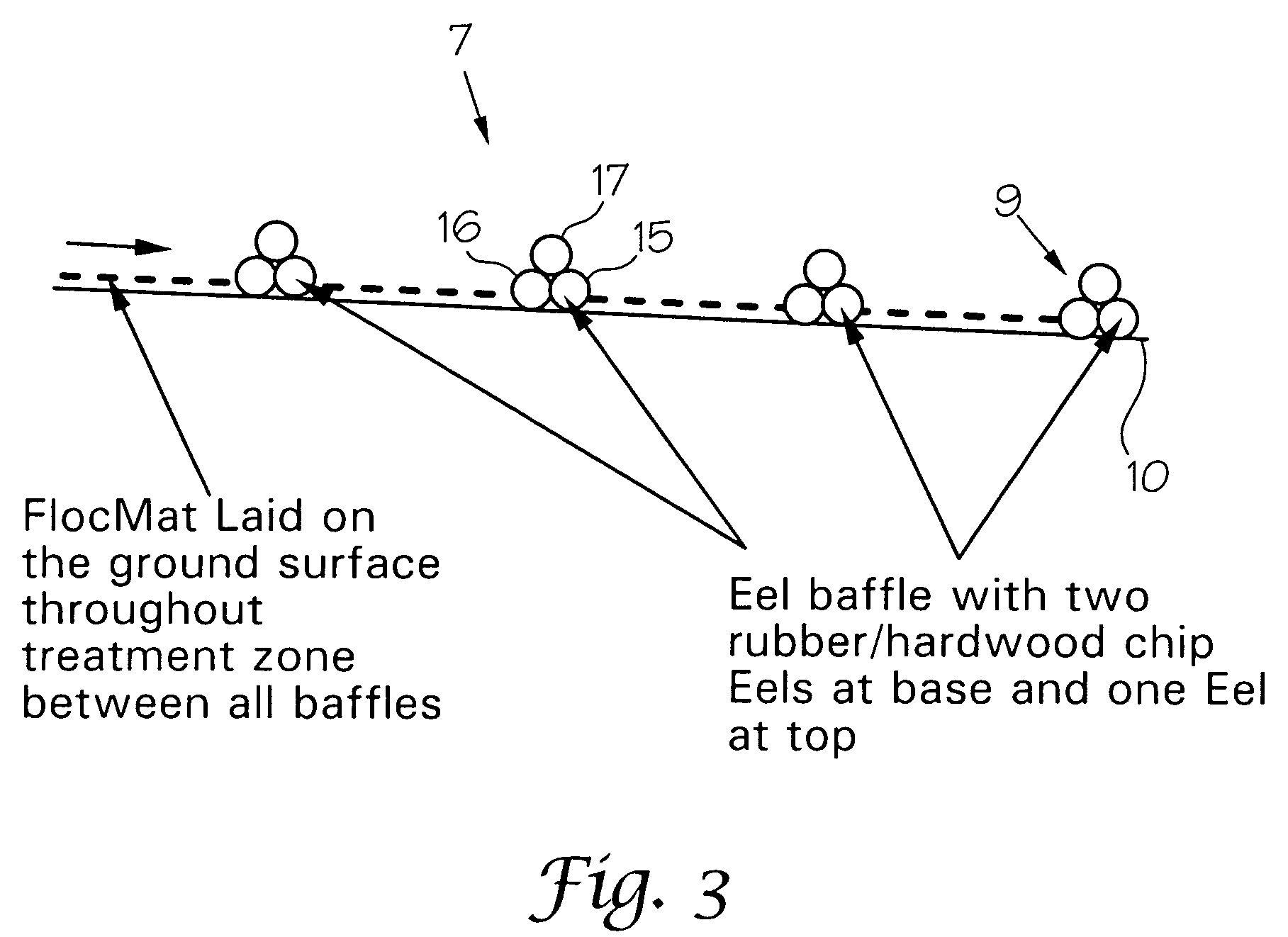

Method for dewatering slurry from construction sites

ActiveUS20090178979A1Promote flocculationIncrease ratingsSludge treatmentWater cleaningSlurryWoodchips

A method of removing solids from the slurry at a construction site located on or near a stream in order to improve the quality of water discharged into the stream by forming treatment zones for receiving slurry, said zones comprising walls of filter bags and floors of filter skirts, said bags and skirts comprising geotextile material and the bags being filled with a shredded rubber and woodchip combination.

Owner:DENNY HASTINGS FLP 14

Rolling type bamboo straw and processing technology and processing device thereof

PendingCN110126050AEliminate consumptionIncrease profitWood working apparatusPulp and paper industryThin sheet

The invention discloses a rolling type bamboo straw and a processing technology and a processing device thereof, and belongs to the technical field of straw production. The bamboo straw is a cylindrical tube formed by rolling thin bamboo sheets soaked and softened in water or wood slices coated with glue in a spiral manner. The processing technology comprises the steps that after bamboo and wood raw materials are cut off and dried in the process, softening treatment is carried out, then the bamboo and wood raw materials are cut into slices, and the slices are rolled and formed by equipment; rolling equipment adopted in the process can realize the rolling of thin sheets and cutting of redundant thin sheets on the inner layer and the outer layer at the same time, and the rolling type bamboostraw is automatically separated after being formed, so that the production efficiency of the rolling type bamboo straw can be greatly improved. Compared with a traditional drilling type bamboo straw,the rolling type bamboo straw has the advantages that the outer wall of the bamboo straw is thinner, the length of the bamboo straw can be longer, and the raw materials are saved.

Owner:怀化市恒裕竹木开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com