Patents

Literature

4524results about How to "Improve transportation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

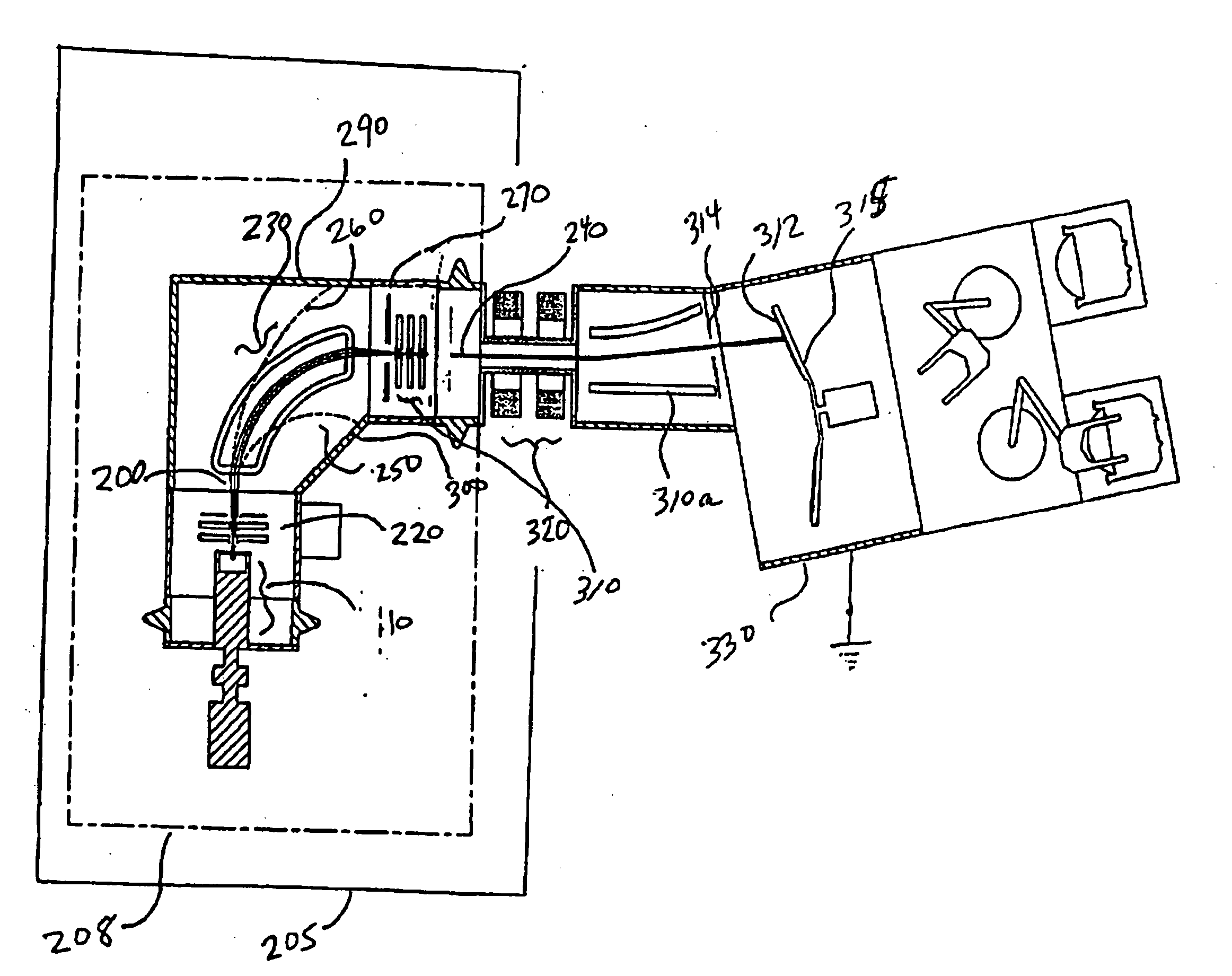

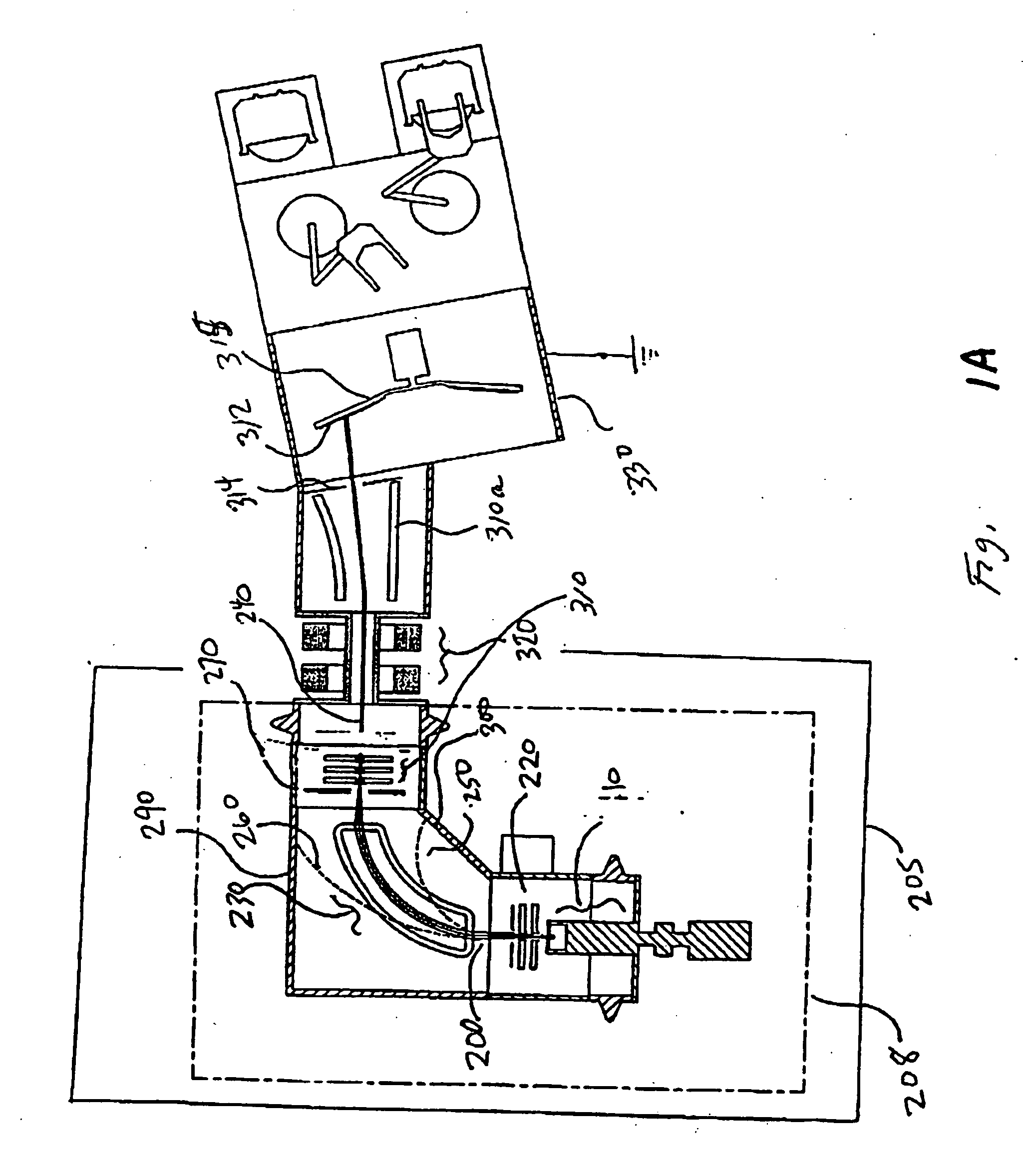

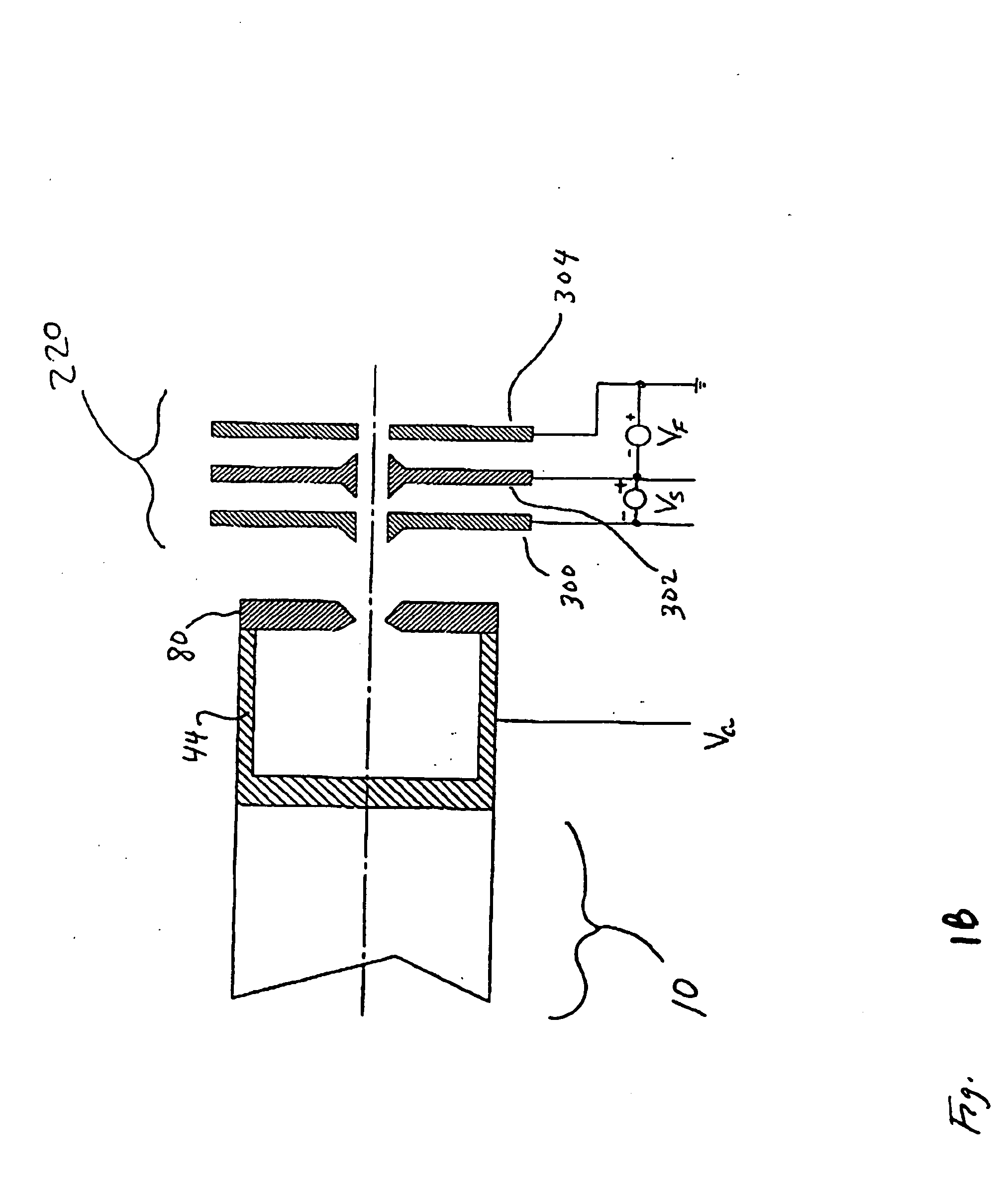

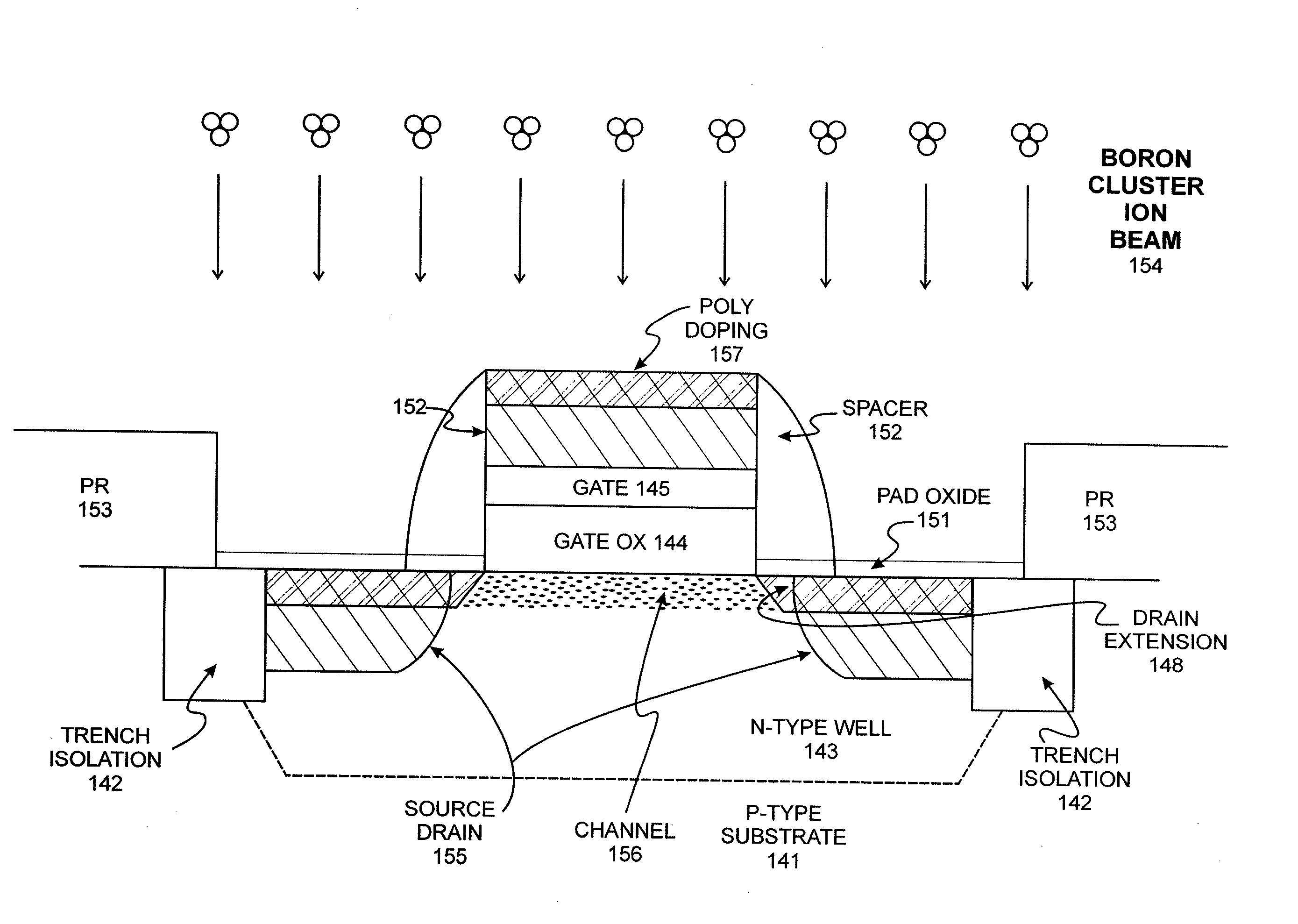

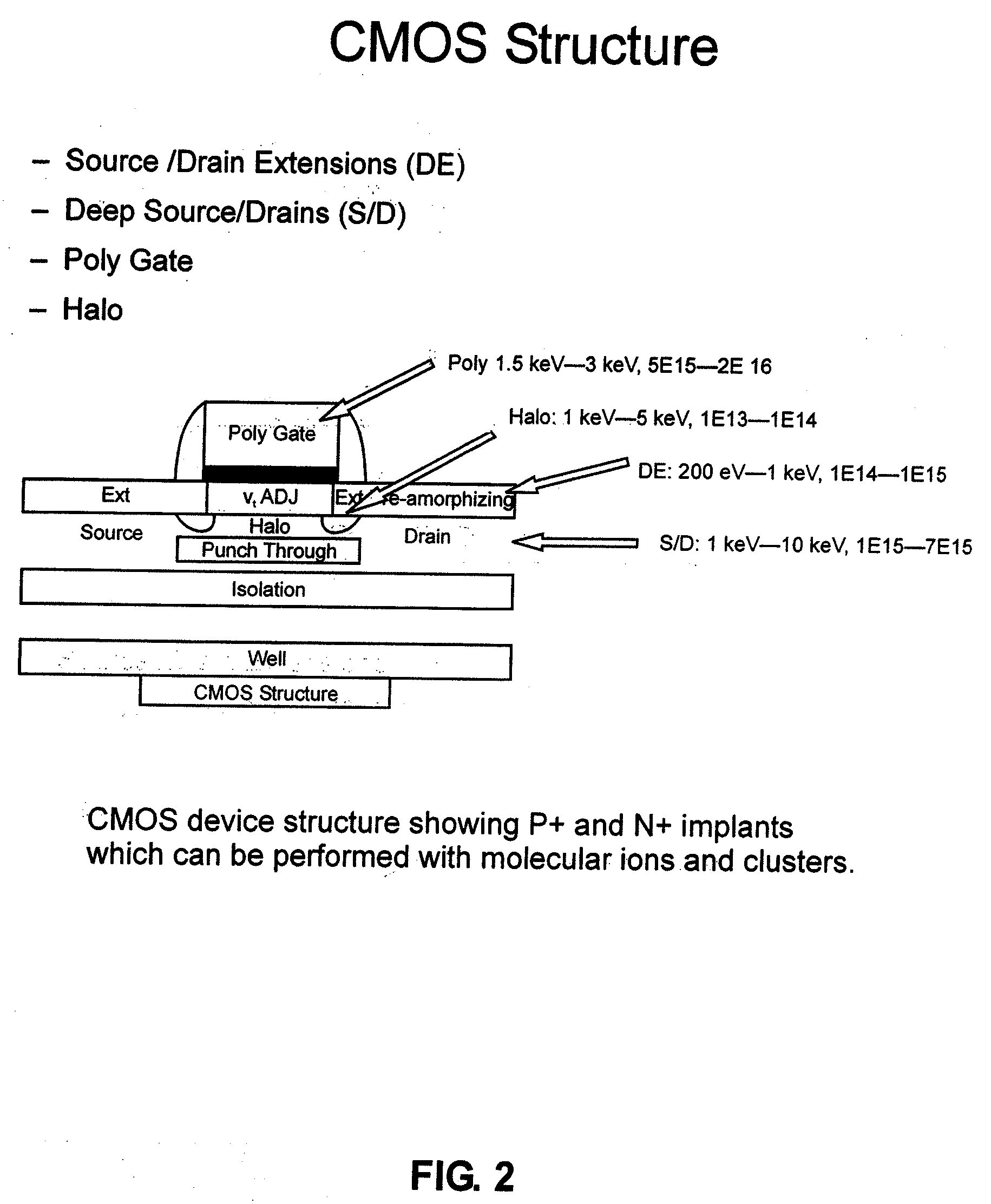

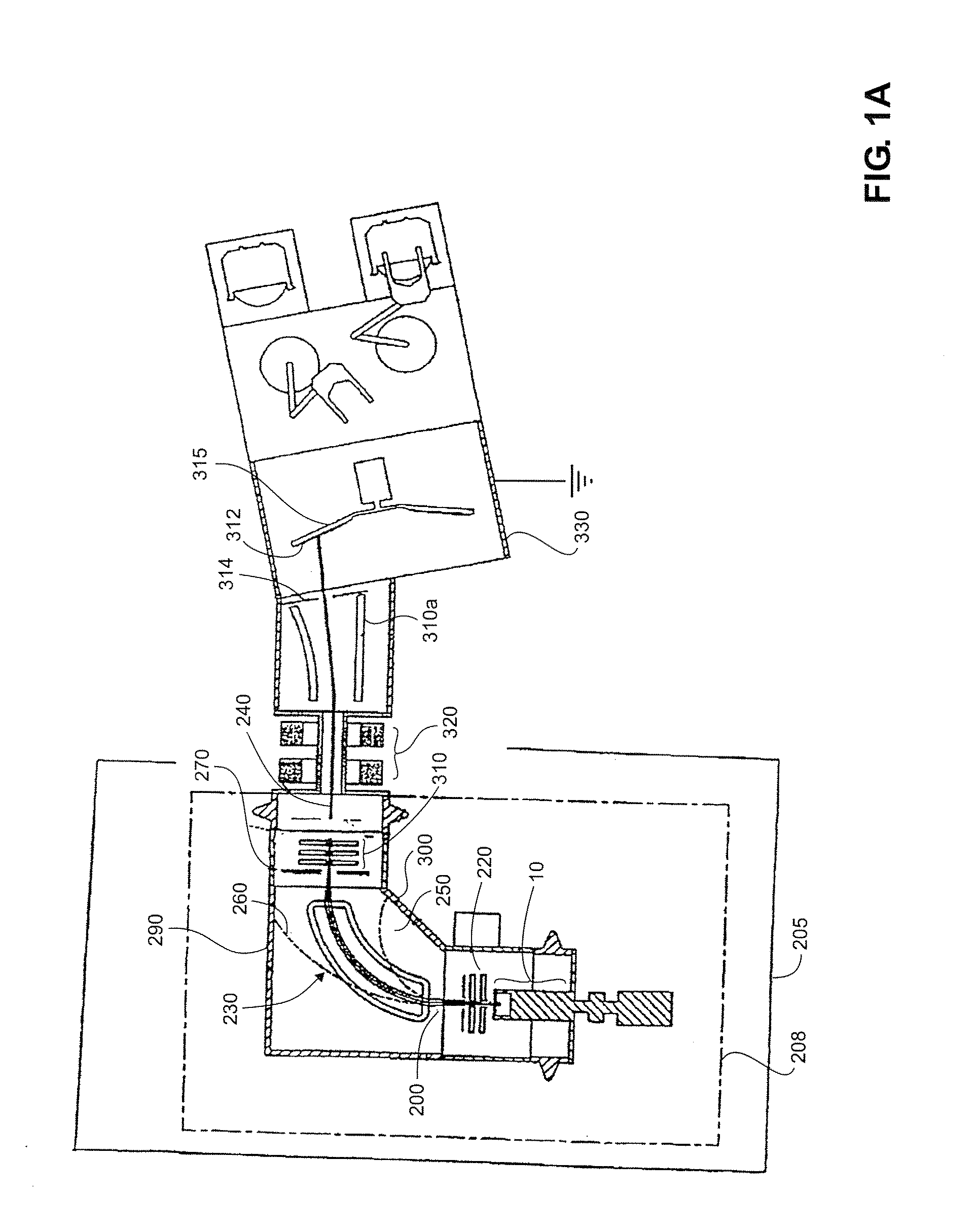

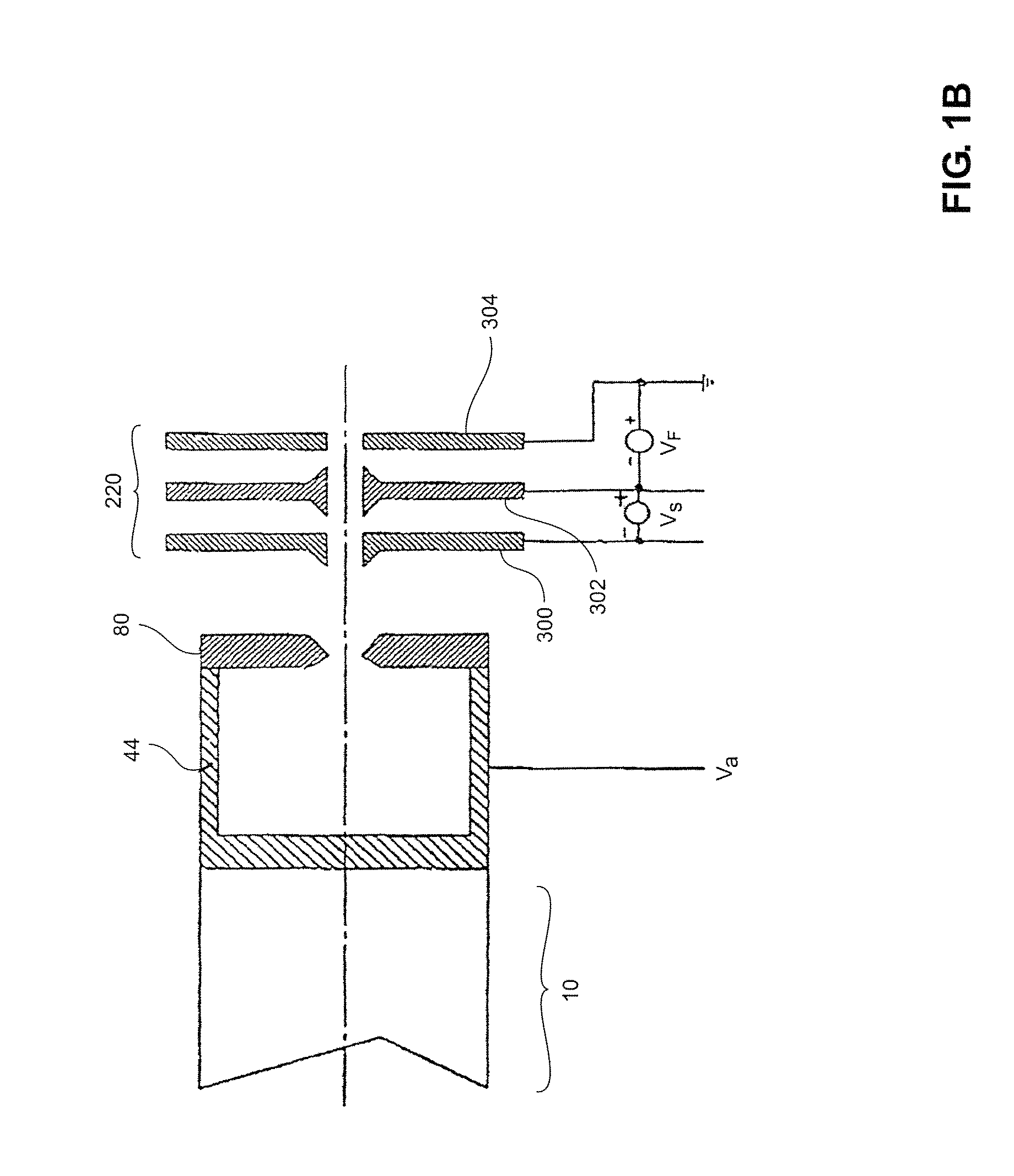

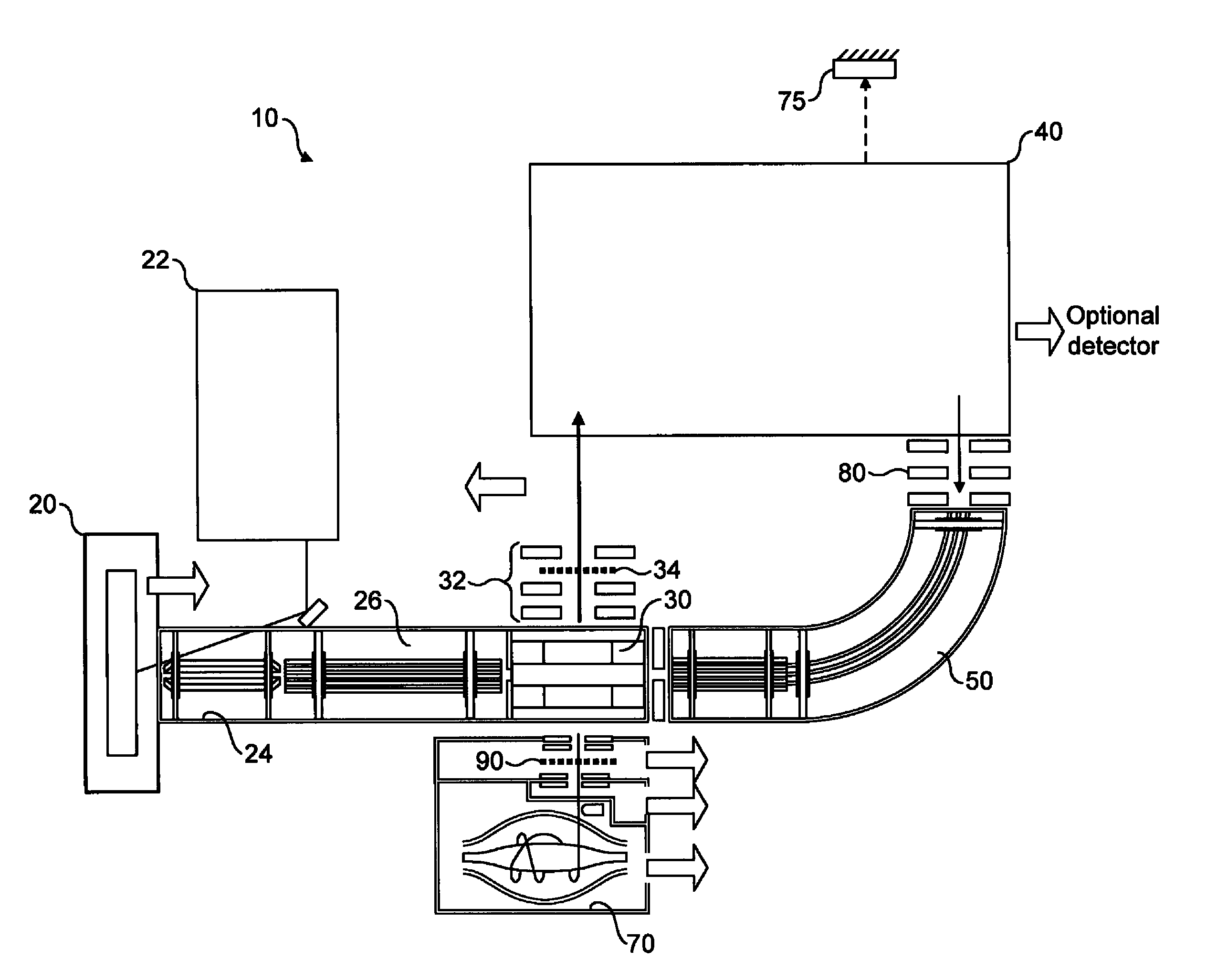

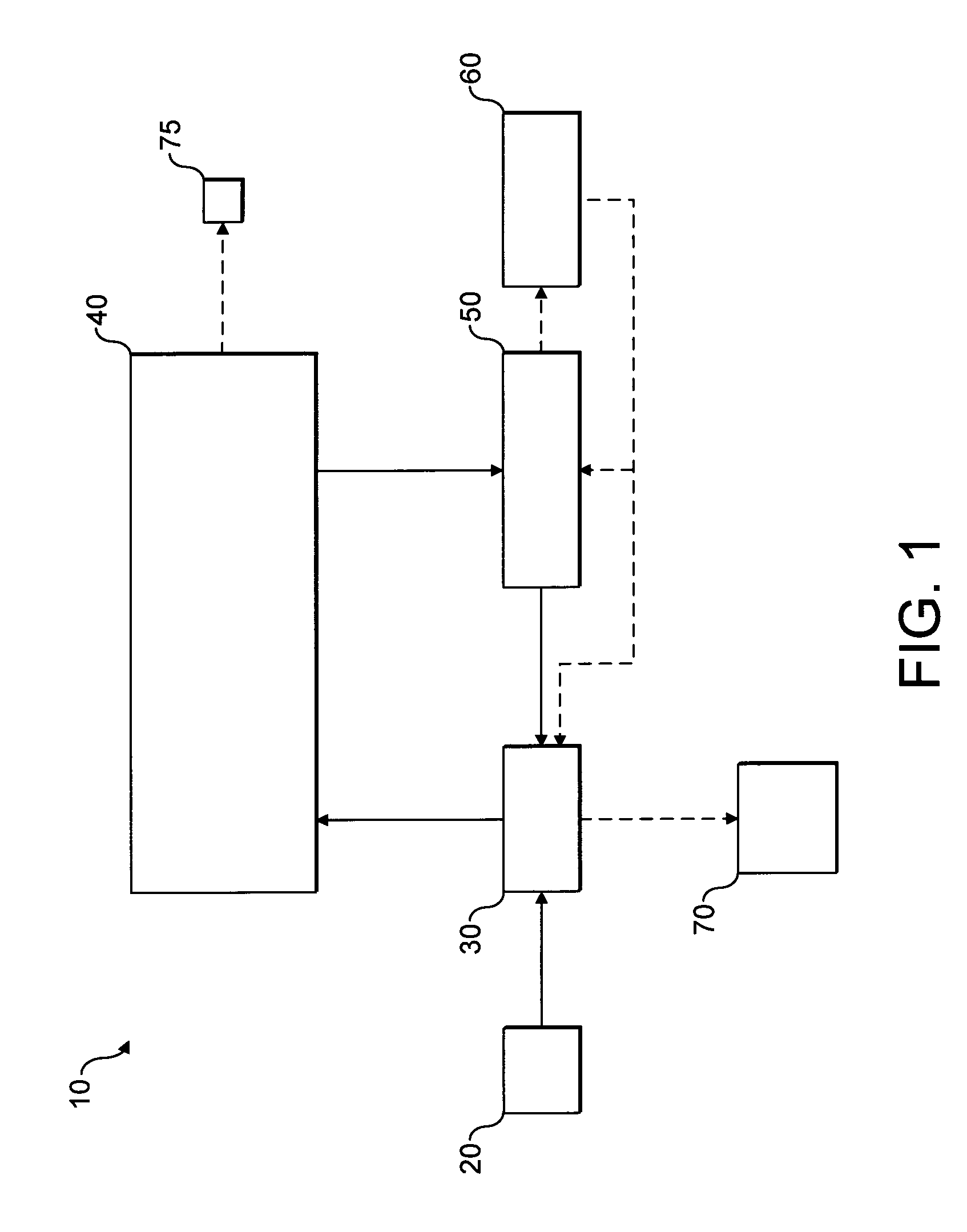

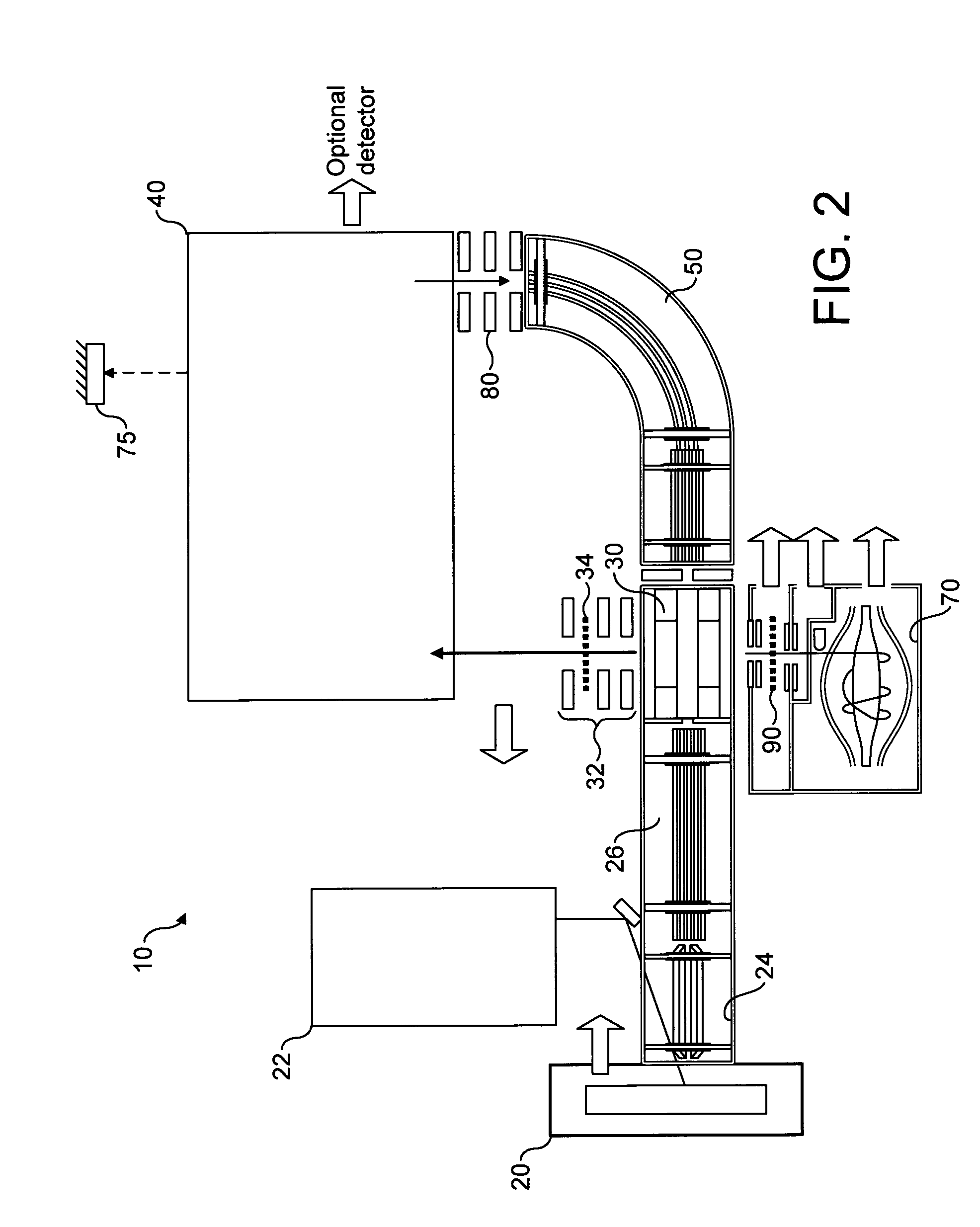

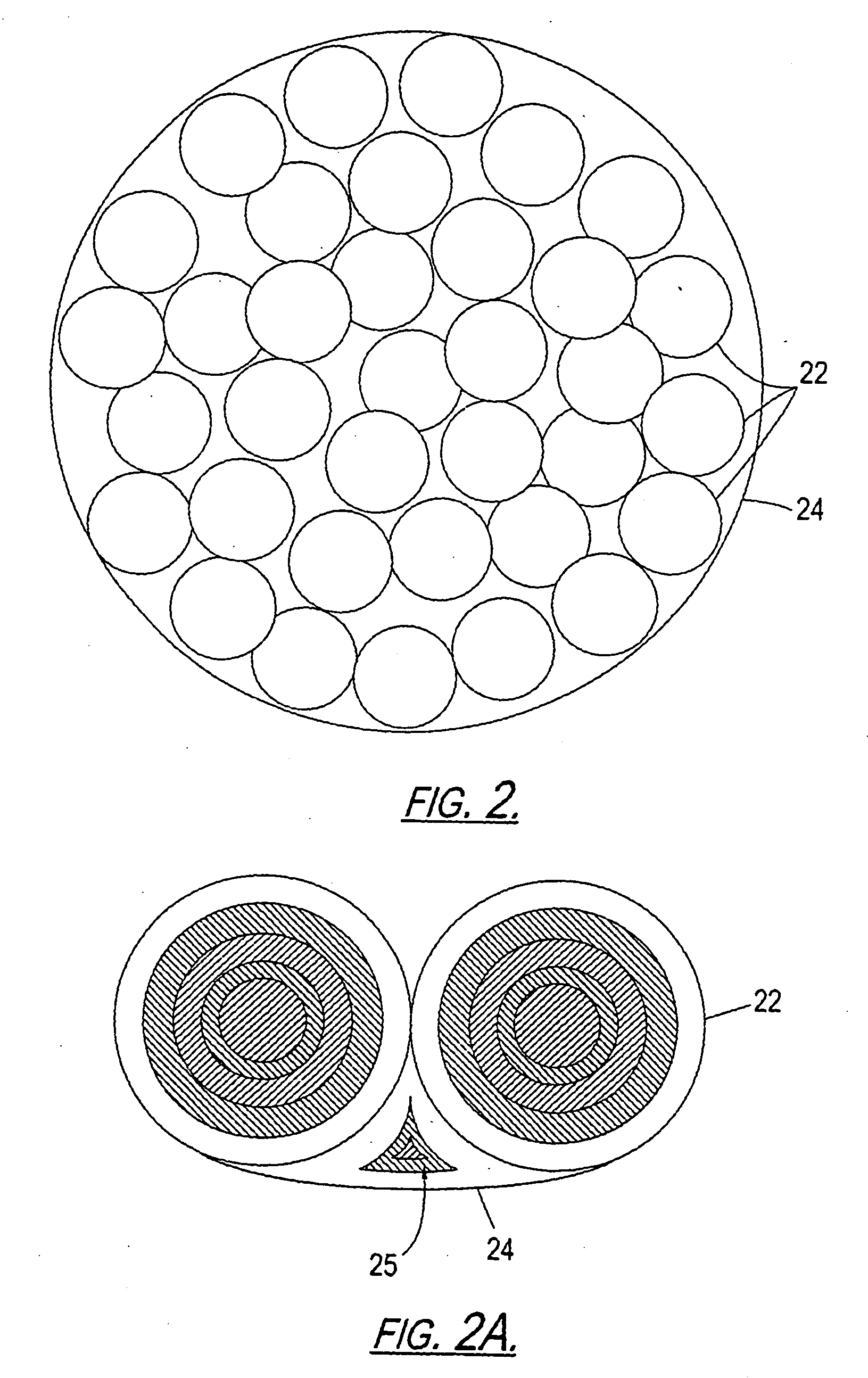

Ion implantation device and a method of semiconductor manufacturing by the implantation of boron hydride cluster ions

InactiveUS20060097193A1Improve productivityLow costTransistorSemiconductor/solid-state device manufacturingMolecular clusterDevice material

An ion implantation device and a method of manufacturing a semiconductor device is described, wherein ionized boron hydride molecular clusters are implanted to form P-type transistor structures. For example, in the fabrication of Complementary Metal-Oxide Semiconductor (CMOS) devices, the clusters are implanted to provide P-type doping for Source and Drain structures and for Polygates; these doping steps are critical to the formation of PMOS transistors. The molecular cluster ions have the chemical form BnHx+ and BnHx− where 10

Owner:SEMEQUIP

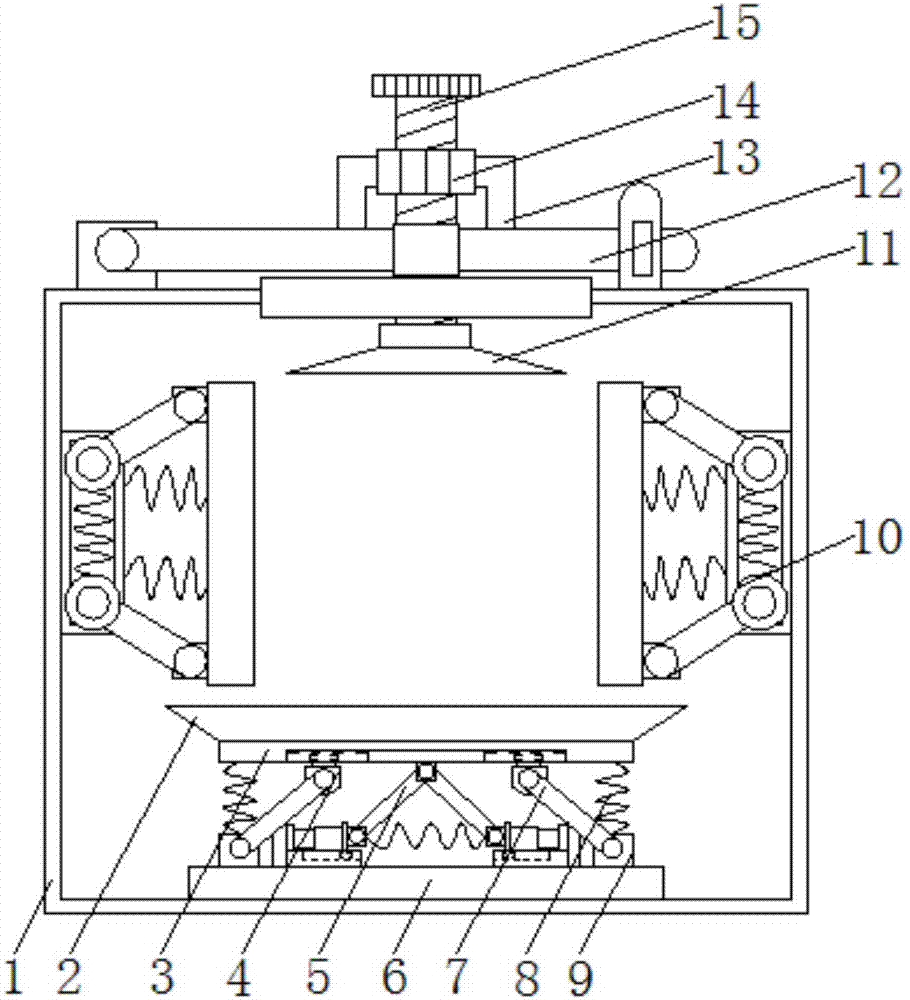

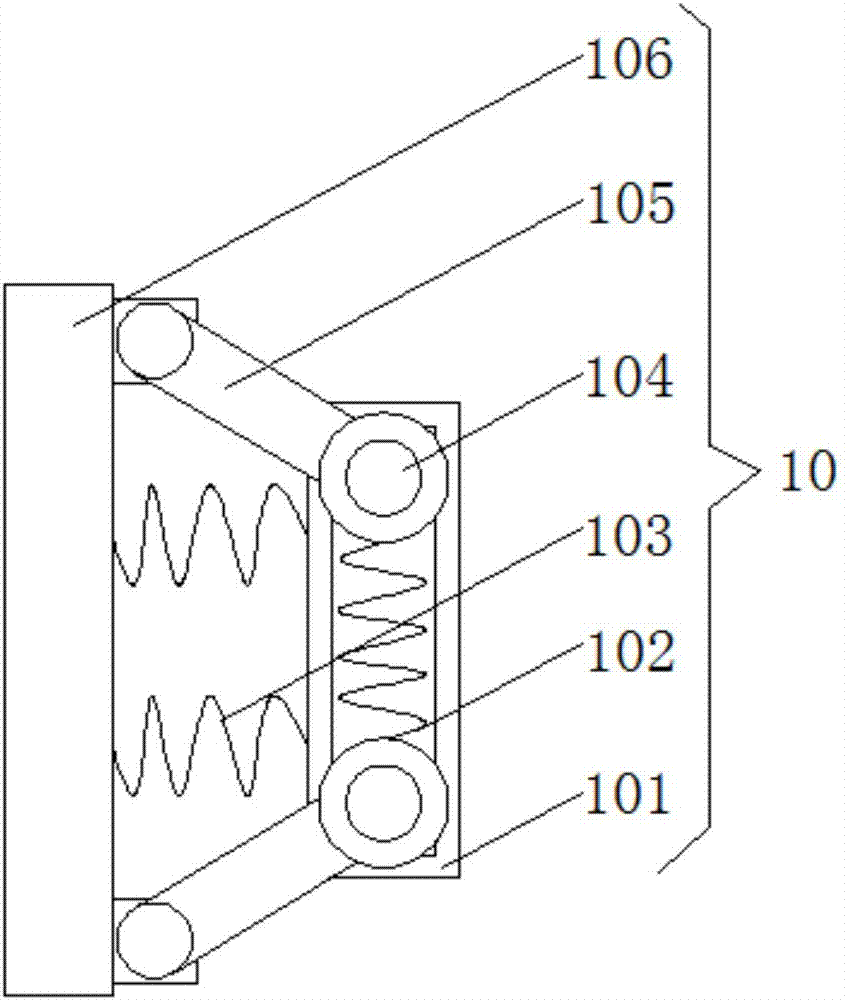

Transportation fixing device for electricity meter

InactiveCN107161524AAvoid property lossImprove transportation efficiencyContainers to prevent mechanical damageDamagable goods packagingElectricity meterAccuracy and precision

The invention discloses a transportation fixing device for an electricity meter and relates to the technical field of electric equipment. The transportation fixing device comprises an outer frame. A bottom plate is fixedly connected to the bottom of the inner wall of the outer frame. Bases are fixedly connected to the two sides of the top of the bottom plate. One sides of the two bases are rotationally connected with connecting rods. Top seats are fixedly connected to the top ends of the connecting rods. A top plate is connected to the tops of the top seats in a sliding manner. By means of the transportation fixing device for the electricity meter, the purpose of buffering the bottom of the electricity meter is achieved, the phenomenon that the electricity meter is damaged due to vibration in the transportation process is prevented, property losses are avoided, the electricity meter is better protected, the transporting efficiency is improved, the transporting cost is saved, the phenomenon that the electricity meter is impacted in the re-transportation process is avoided, damage to the electricity meter is avoided, the measuring precision of the electricity meter is ensured, later-period use is facilitated, and the phenomenon that the precision of the electricity meter goes wrong due to errors is avoided.

Owner:方敏

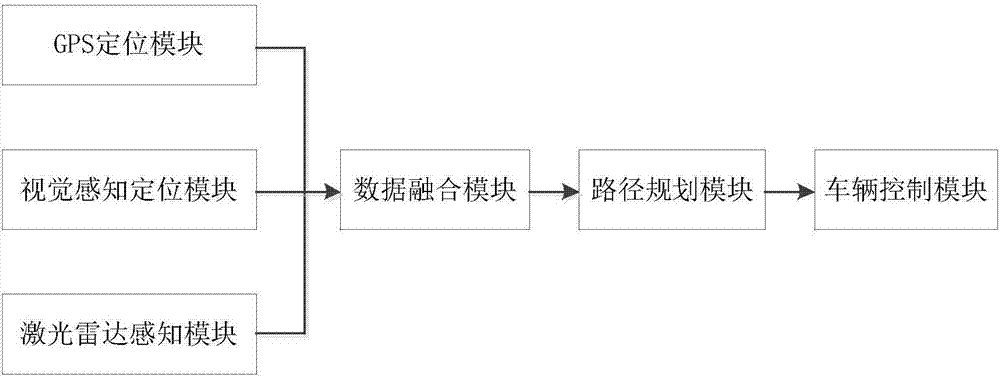

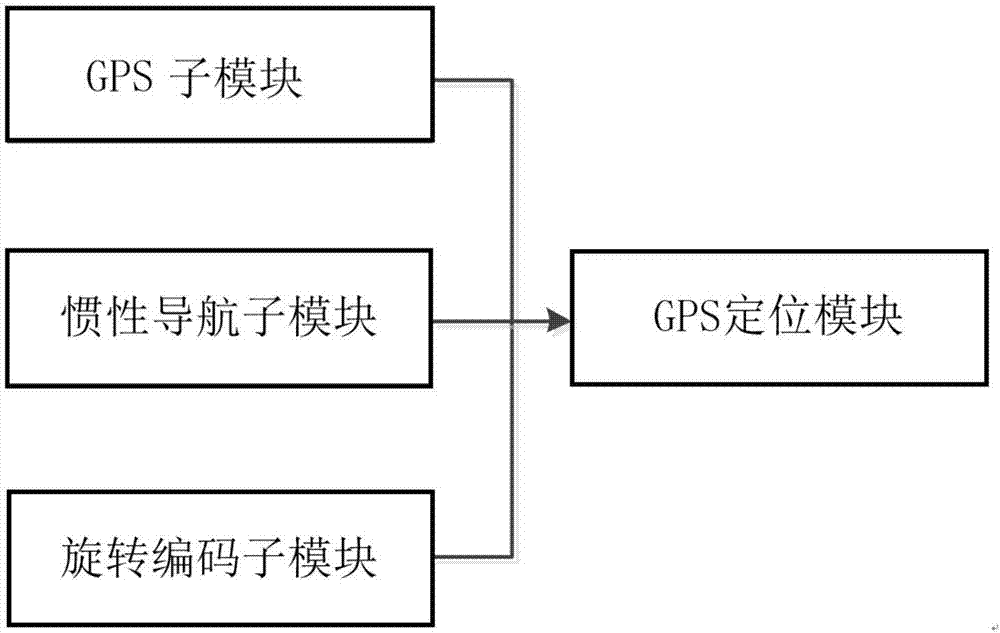

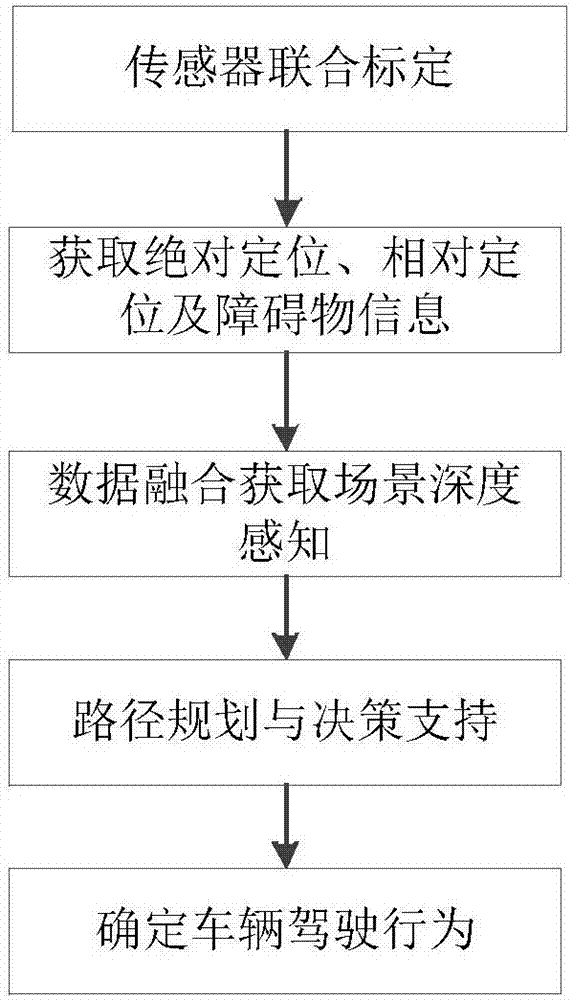

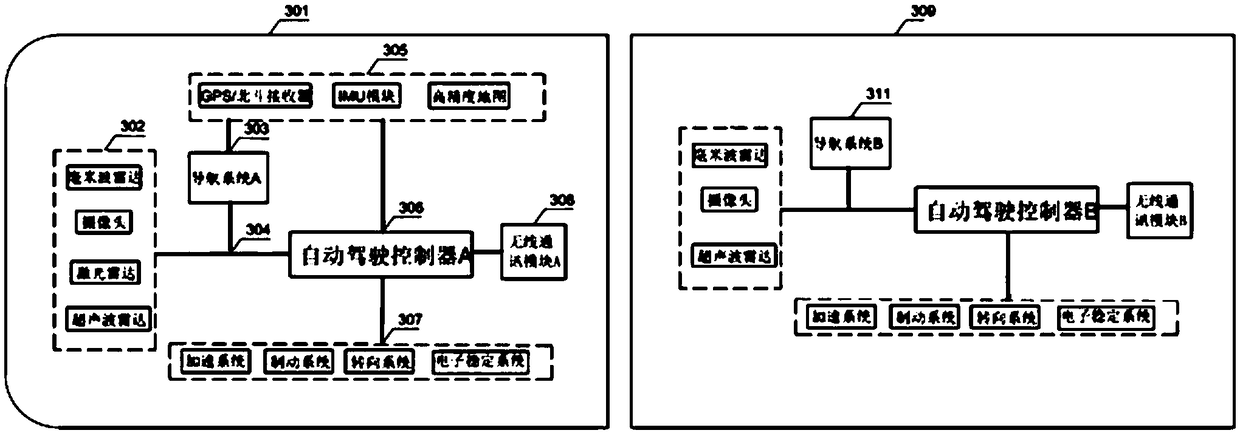

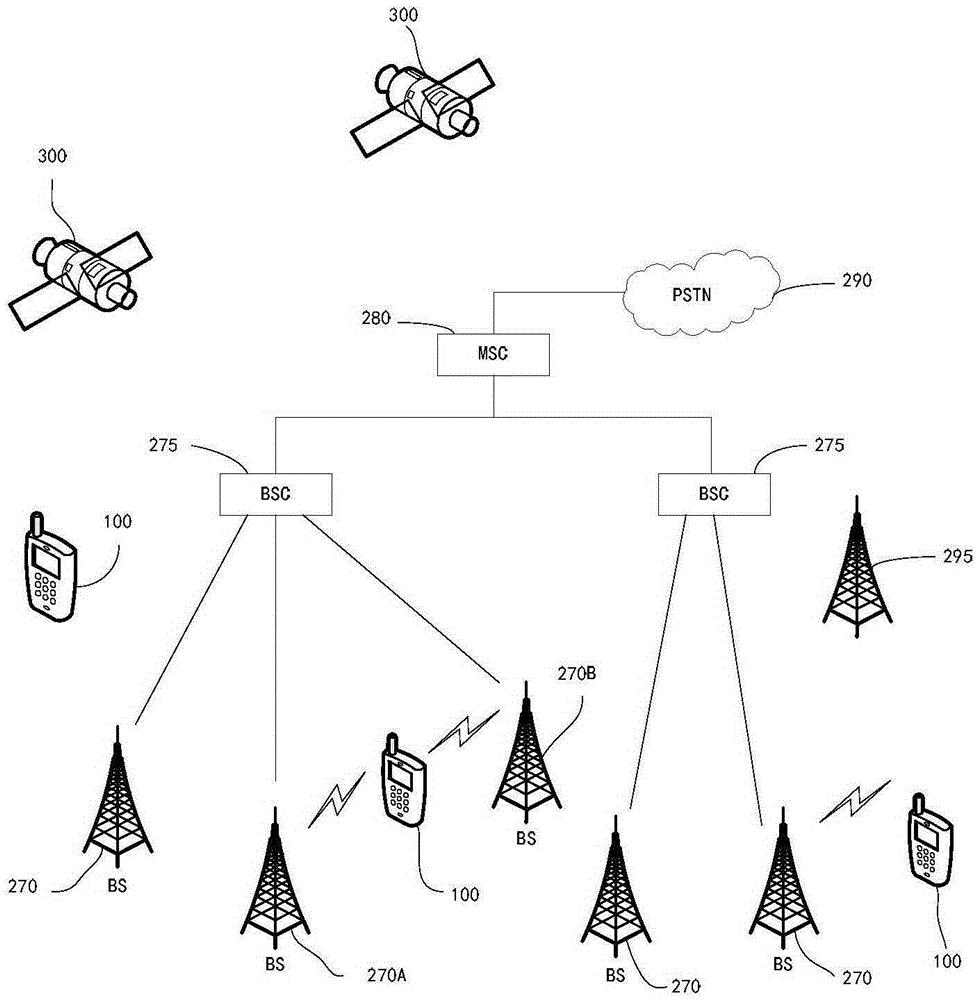

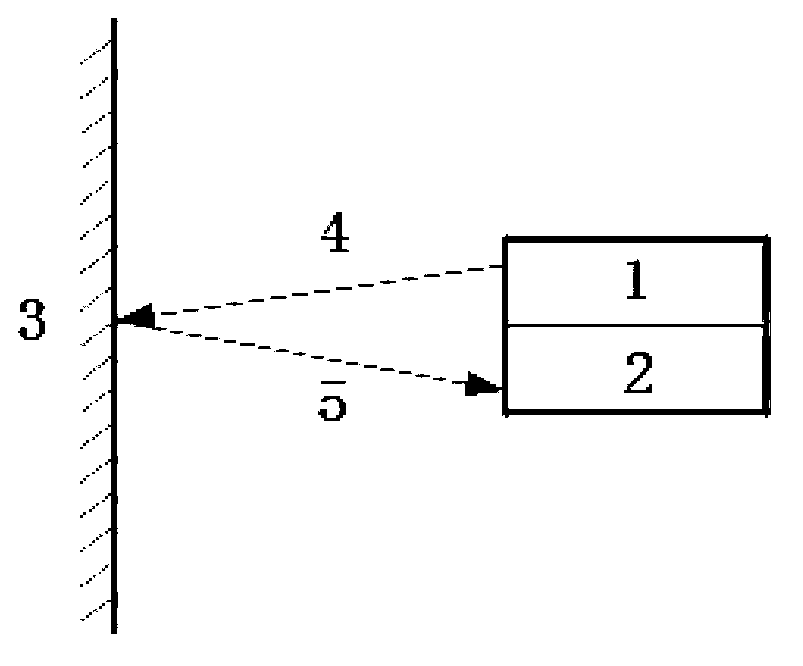

AGV transport system based on vision guidance and driving control method thereof

InactiveCN107422730AEasy to install and maintainLow costPosition/course control in two dimensionsVehiclesElectronic mapRoute planning

The invention discloses an AGV transport system based on vision guidance and a driving control method thereof. The AGV transport system comprises a GPS positioning module used for obtaining the absolute position and course information of an AGV; a visual perception positioning module used for recognizing ground lane lines and laid visual markers and obtaining the spatial position relations of the lane lines and the visual markers relative to a visual sensor and high-precision positioning information of the AGV; a laser radar perception module used for recognizing the position, the motion state and shape information of an obstacle in a short distance range in front of the AGV; a data fusion module used for obtaining fusion data; and a route planning module used for performing positioning and route planning on the AGV according to the fusion data and a known navigation electronic map and providing a positioning and route planning result to a vehicle control system. According to the system and the driving control method thereof, the cost is low, the precision is high, stability, safety and reliability are achieved, and the automation of the transport of port containers can be realized.

Owner:武汉市众向科技有限公司

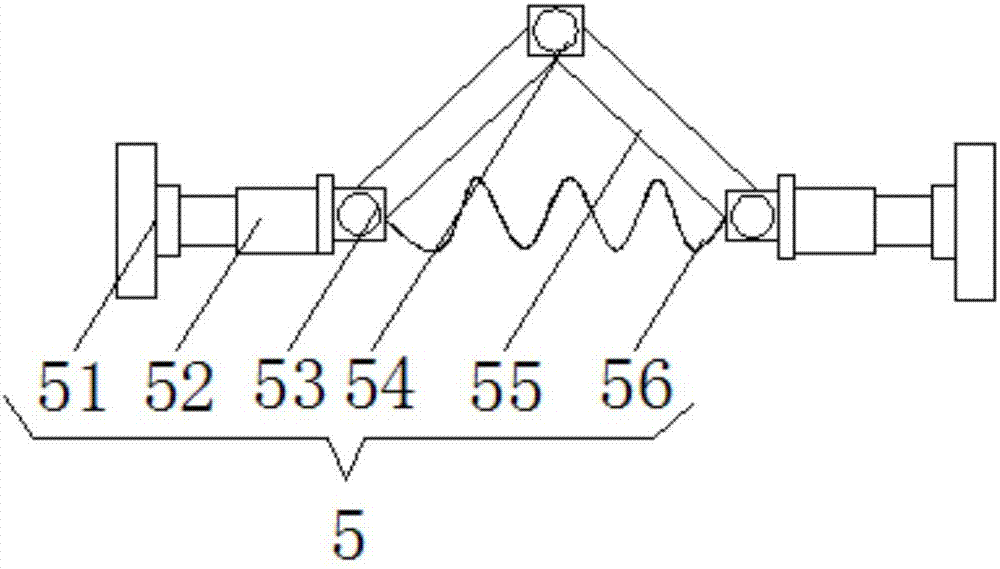

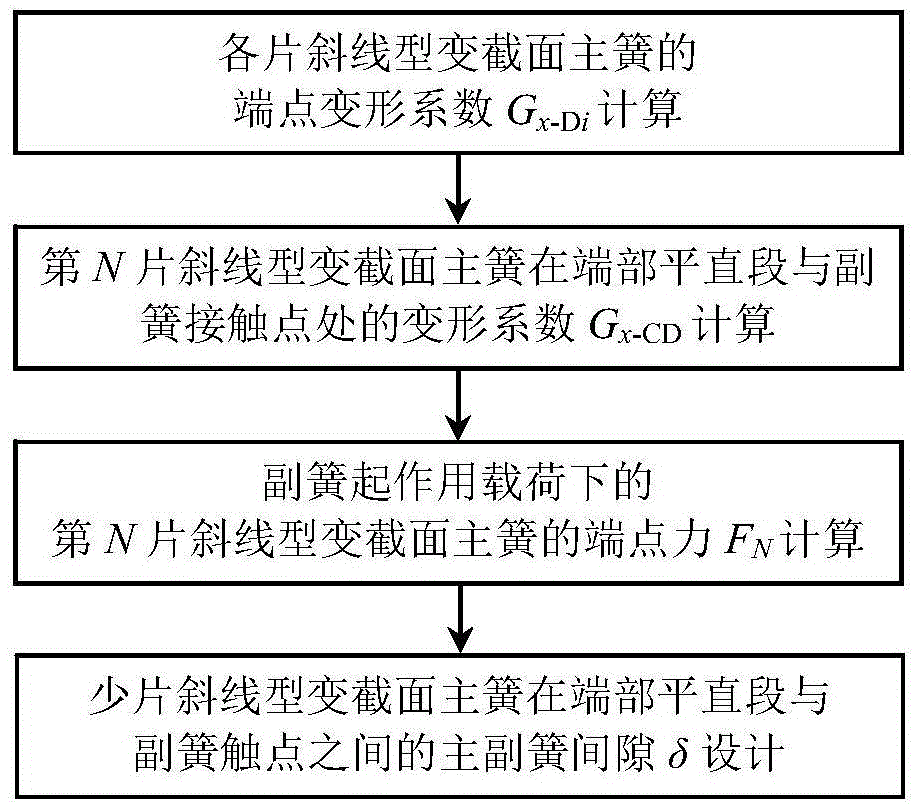

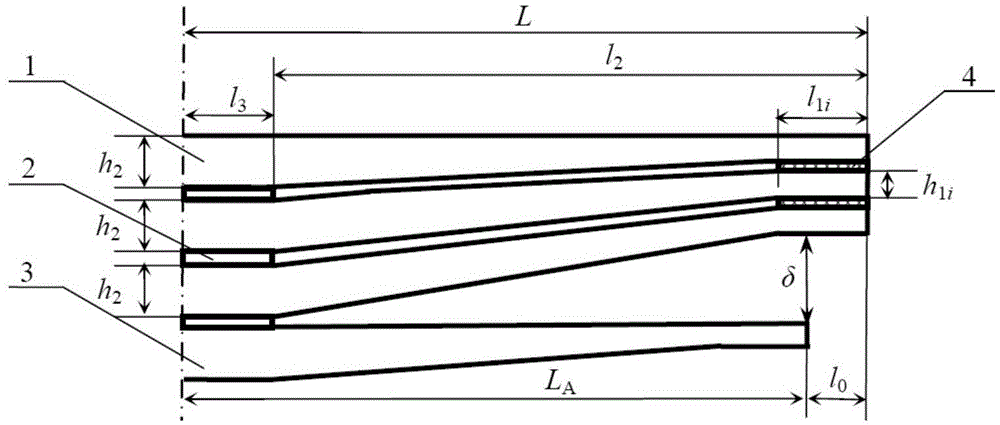

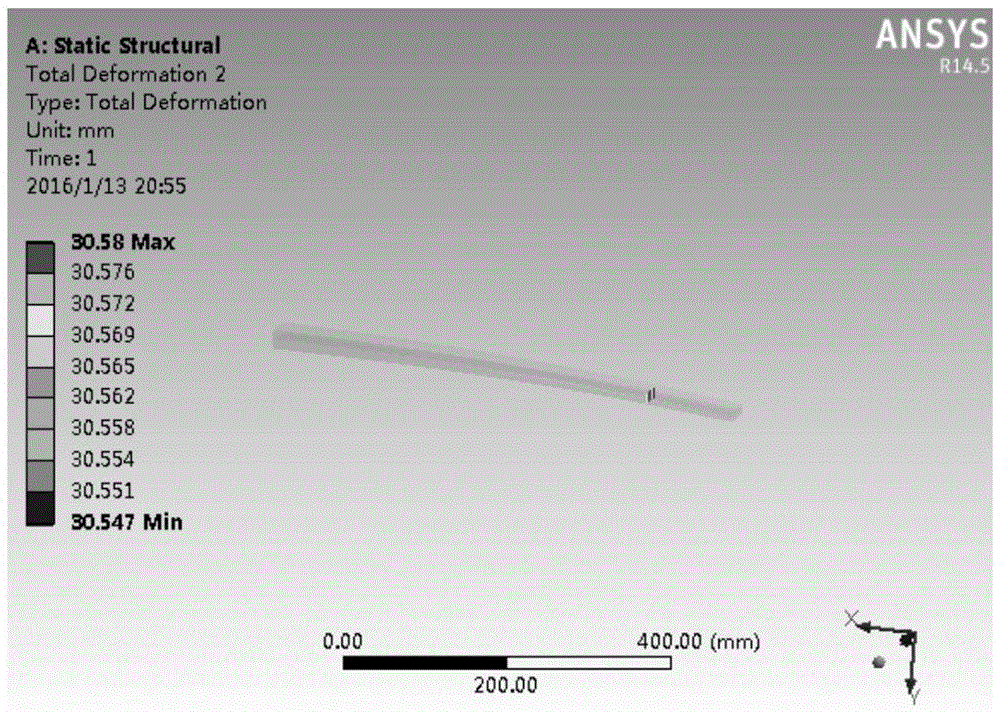

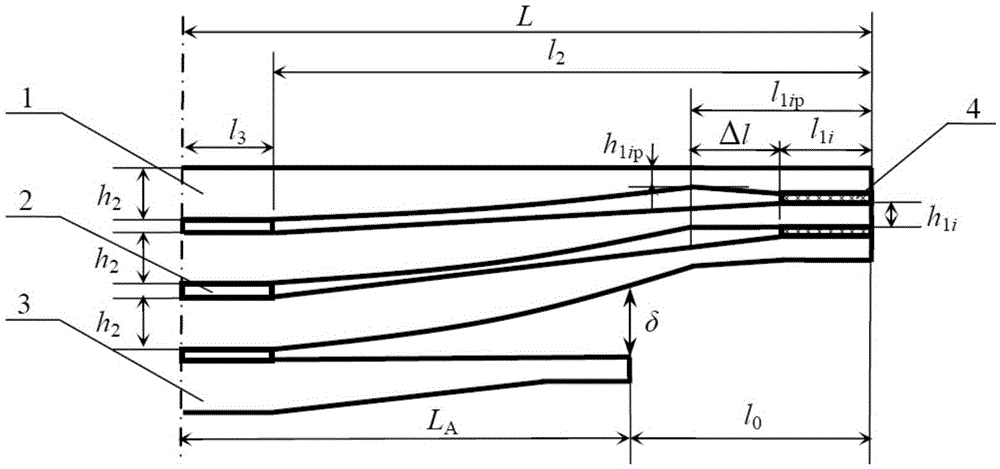

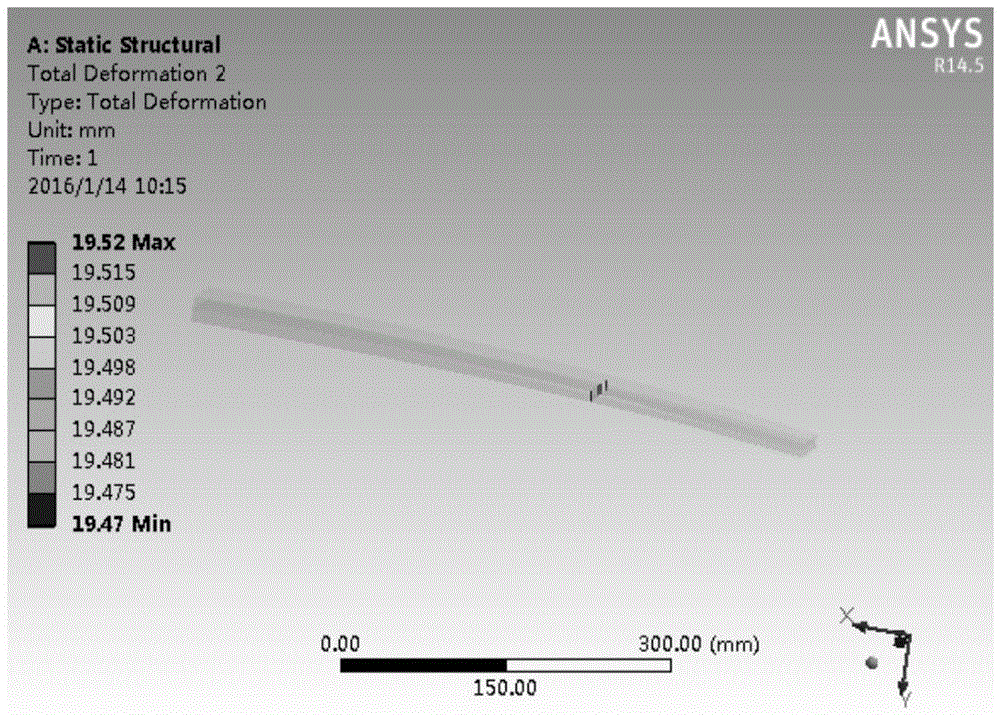

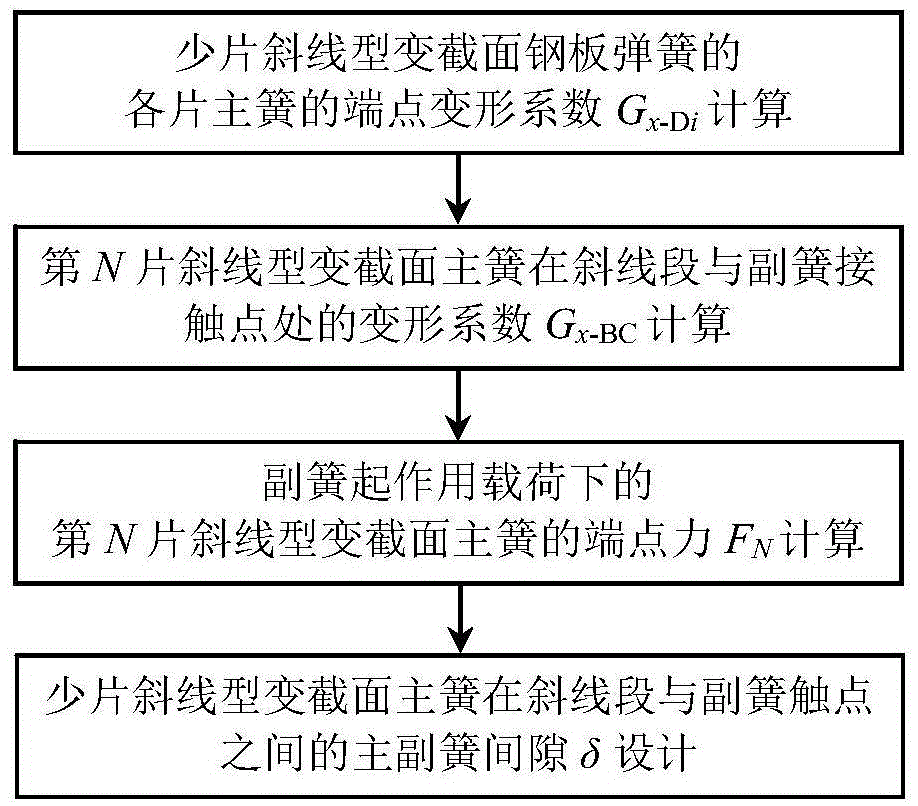

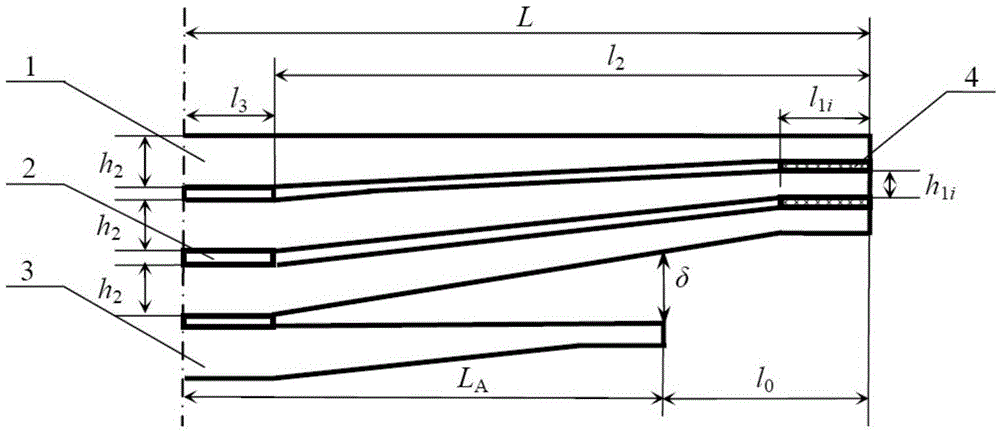

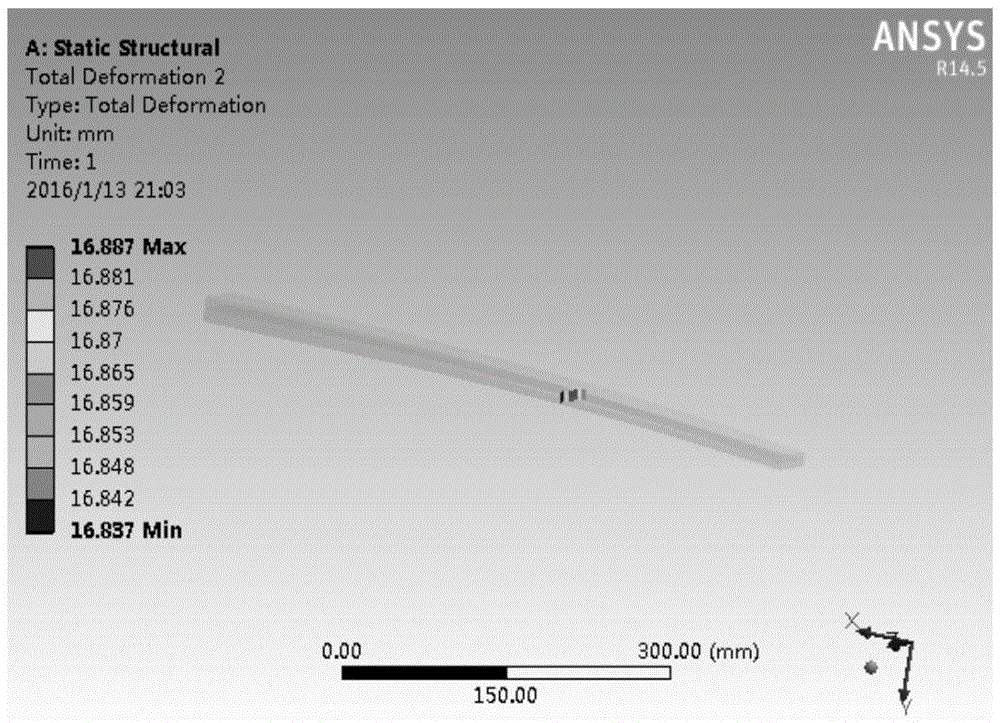

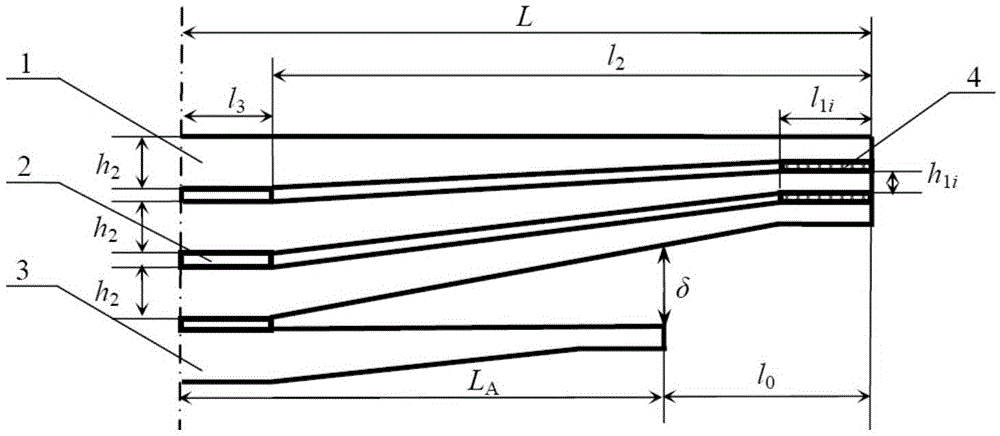

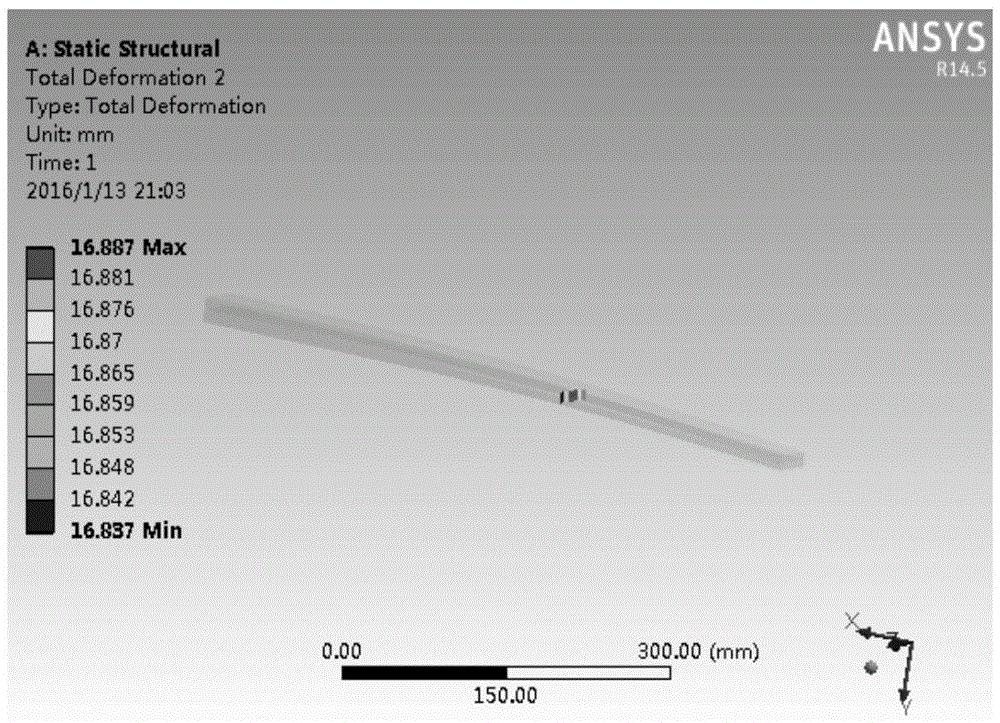

Method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs

ActiveCN105526290AExact design valueReliable design valueGeometric CADLeaf springsEngineeringDesign values

The invention relates to a method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs, and belongs to the technical field of suspension steel plate springs. The method includes determining endpoint deformation coefficients of the various main springs and deformation coefficients G<x-CD> of contact points of the end straight sections of the N main springs and the auxiliary springs according to structure sizes and elastic modulus of the various diagonal variable-section main springs; acquiring endpoint force F<N> of the N main springs according to acting load of the auxiliary springs and the endpoint deformation coefficients of the various main springs; designing the main and auxiliary spring gaps between contact points of the end straight sections of the main springs and the auxiliary springs according to the thicknesses h<2> of roots of the N main springs, the endpoint force F<N> and the deformation coefficients G<x-CD>. The method has the advantages that as known from simulation verification, design values of the gaps of the end straight sections of the diagonal few-leaf variable-section main springs and the auxiliary springs can be accurately and reliably obtained by the aid of the method, and accordingly the product design level and performance and the vehicle ride comfort can be improved; the design and experiment costs can be reduced, and the product development speeds can be increased.

Owner:山东恒日悬架弹簧股份有限公司

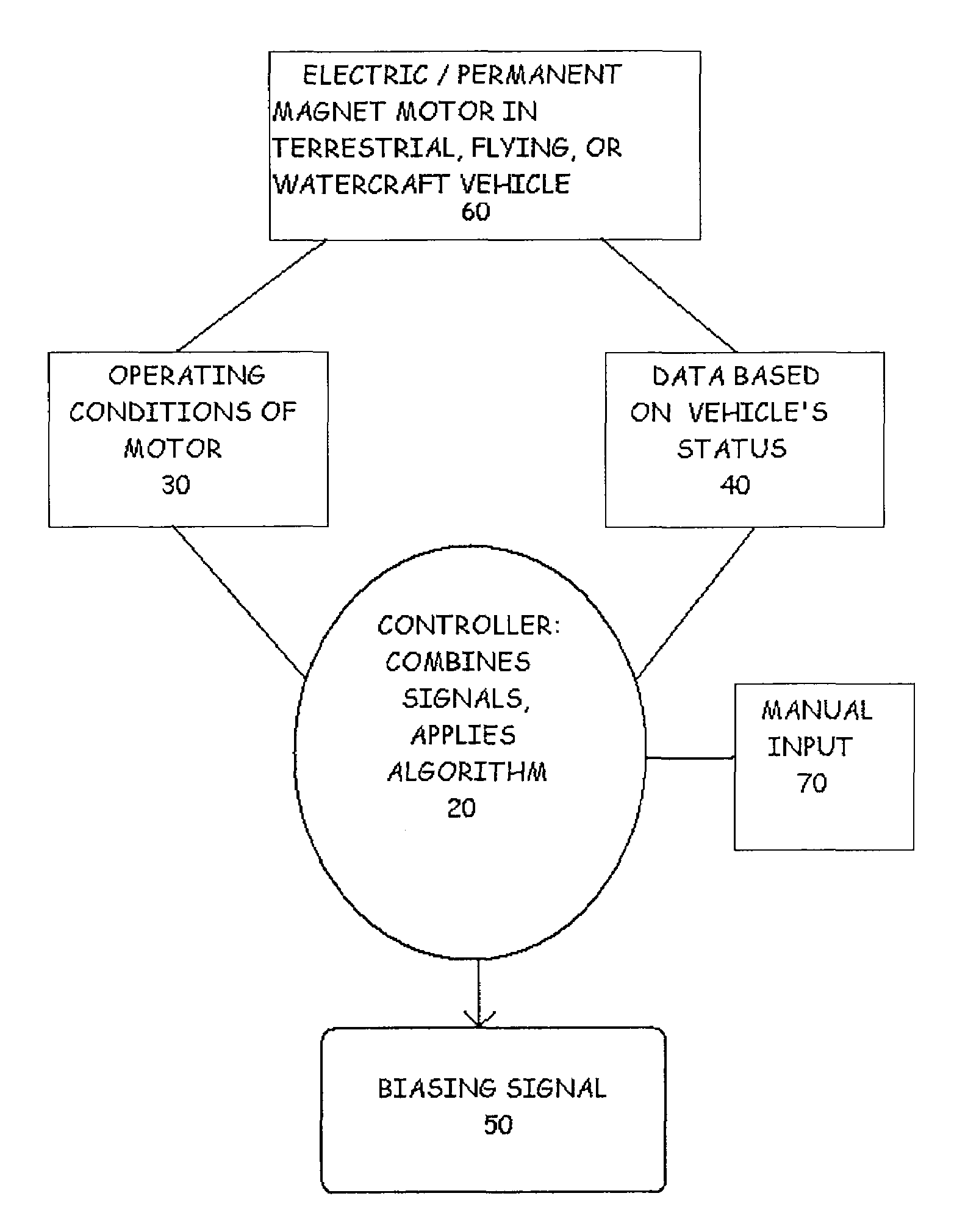

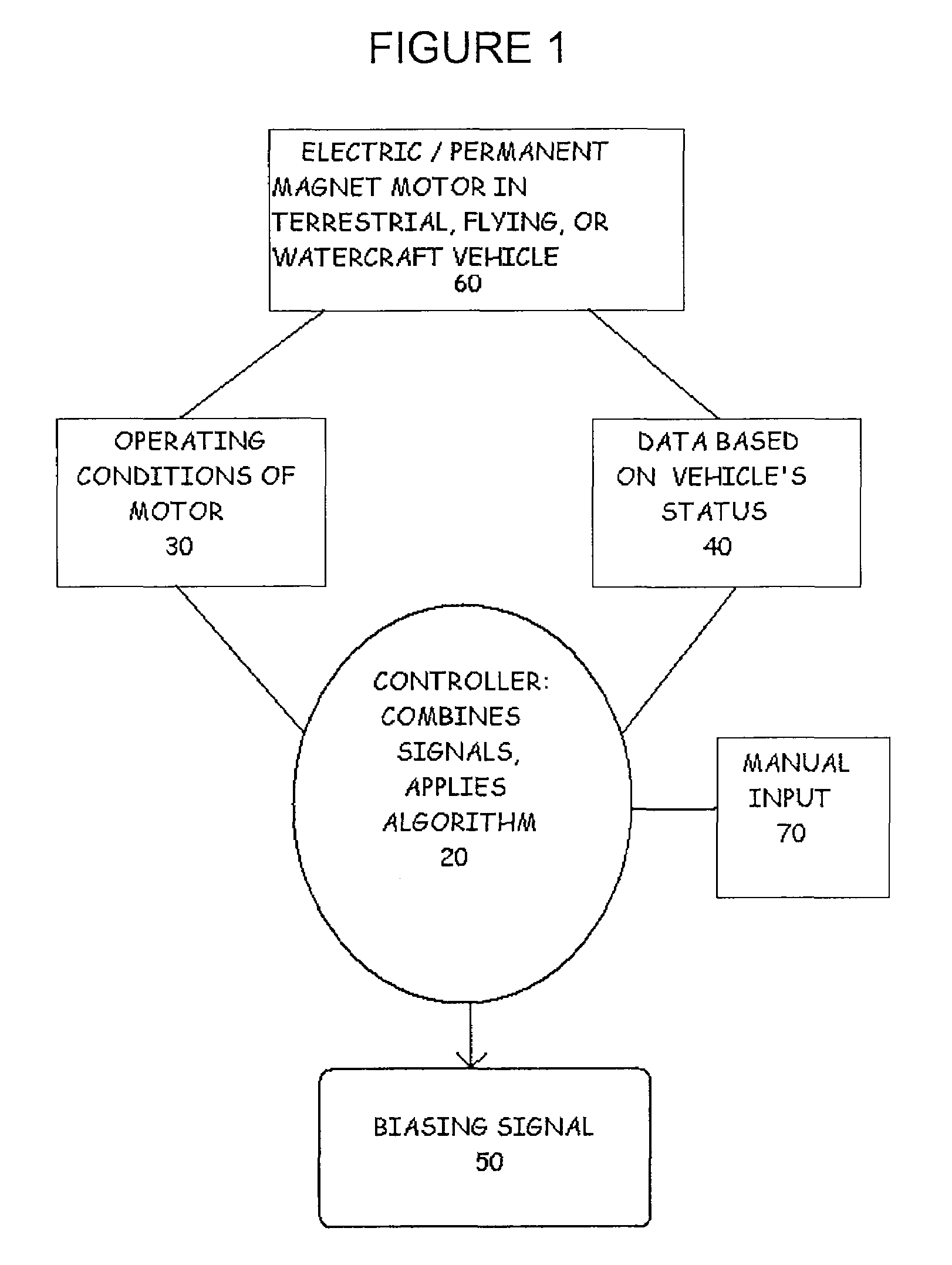

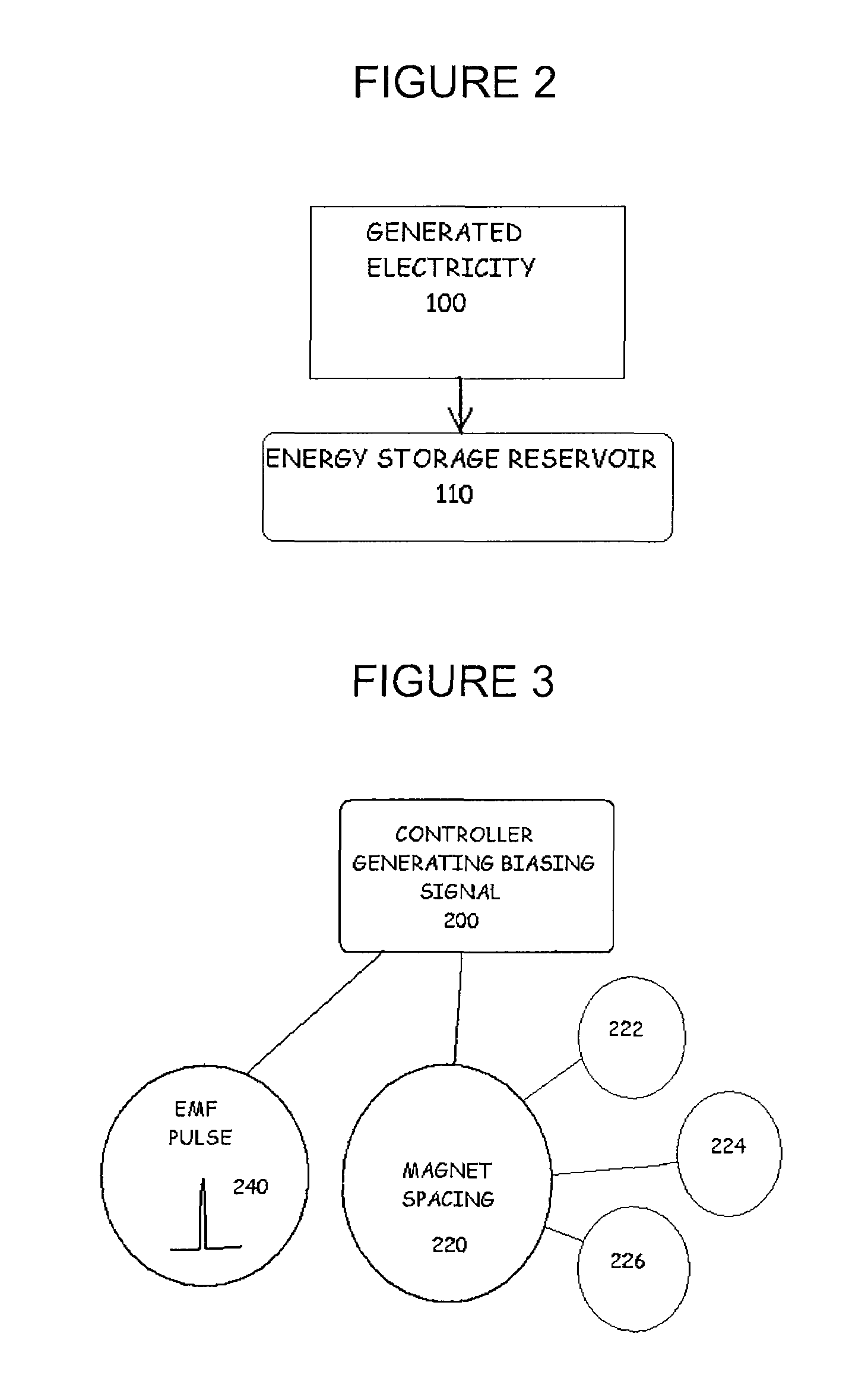

Regenerative motor propulsion systems

InactiveUS7482767B2Improve transportation efficiencyImprove fuel economyDC motor speed/torque controlSynchronous machinesElectricityElectrolysis

A vehicle or watercraft regeneration system includes at least one electric motor capable of generating electricity and a controller for the at least one motor; wherein the controller to optimize the efficiency of the regeneration. The controller can optimize efficiency by including comprises circuitry for biasing the electric motor during regeneration. Also provided is a regeneration system that further comprises an electricity storage device such as a battery, a capacitor, an electrolysis unit that generates hydrogen from water, and a flywheel. In addition, an efficiency enhancing system for a watercraft or vehicle includes at least one electric motor capable of generating electricity; a controller for the at least one motor; and an electrical connection between the at least one motor and the controller, where in the controller adjust one or more magnetic fields of the electric motor during regeneration to optimize the efficiency of the regeneration. Methods for increasing efficiency of regeneration of a watercraft of vehicle powered by at least one electric motor are also disclosed.

Owner:TECHNIPOWER SYST INC

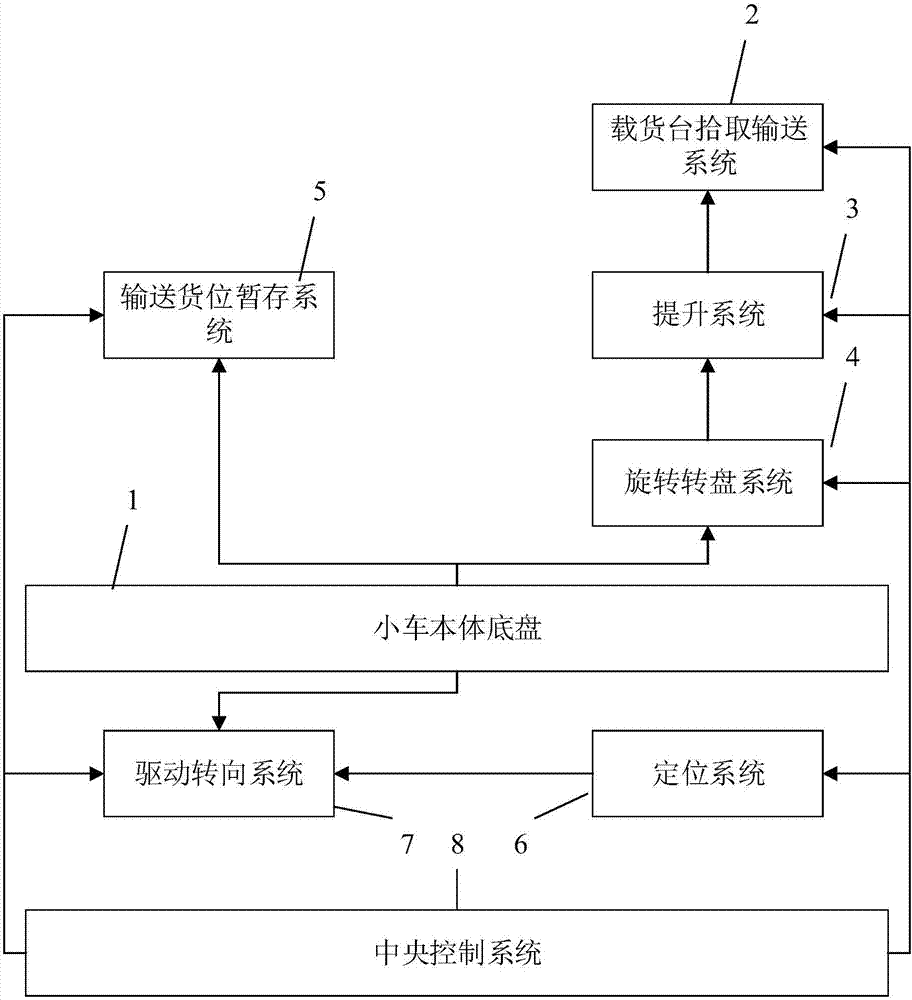

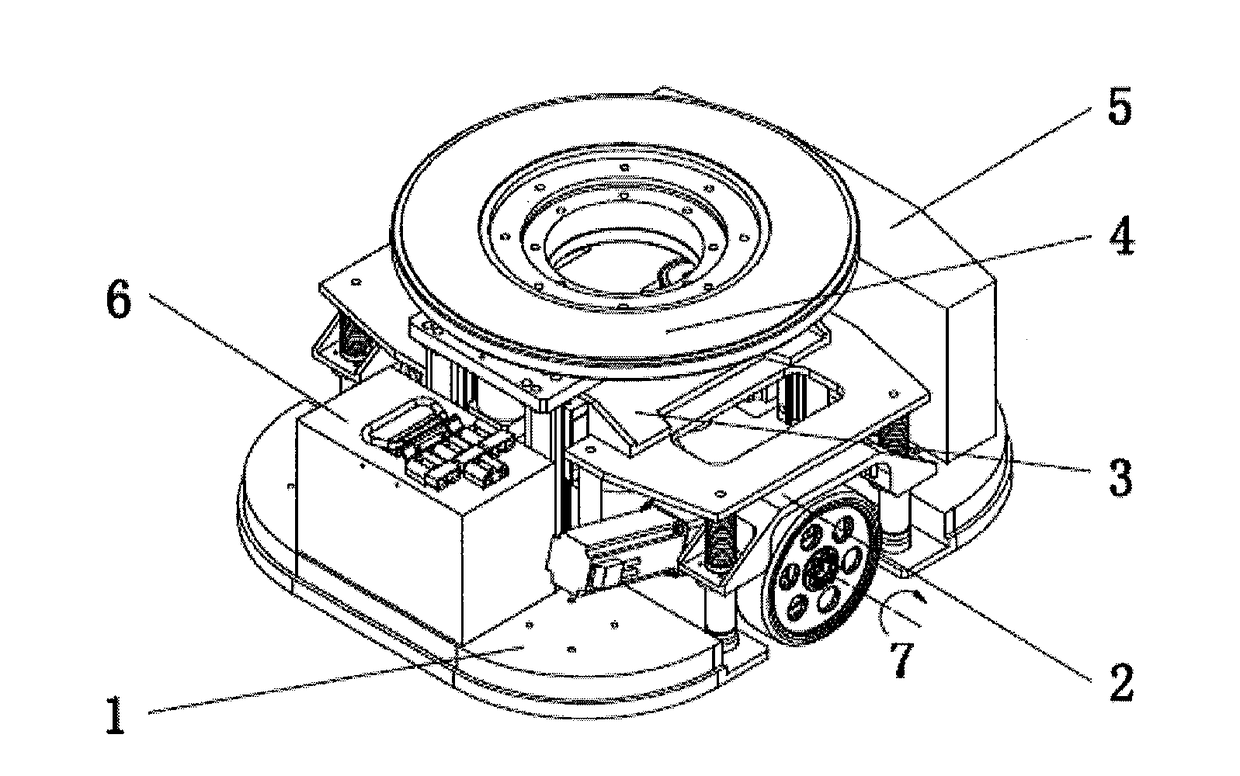

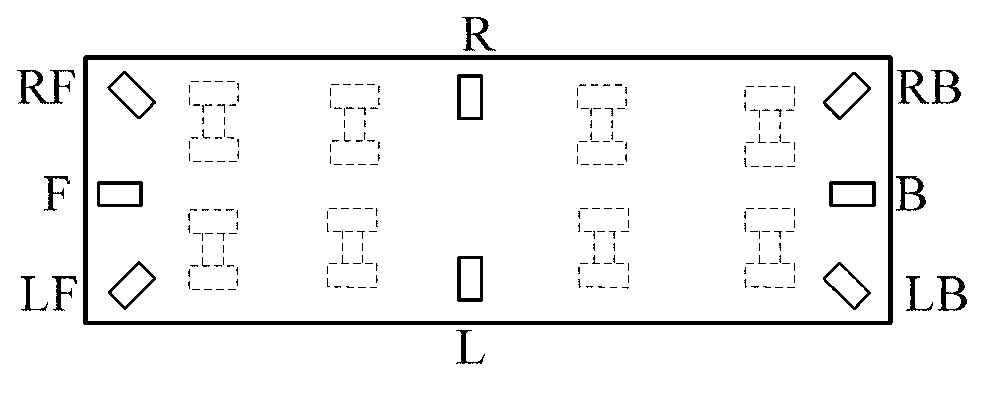

AGV (Automatic Guided Vehicle) and method

PendingCN107226310AImprove picking efficiencyImprove accuracyControl devices for conveyorsStorage devicesEngineeringTemporary storage

The invention discloses an AGV (Automatic Guided Vehicle) and a method. The AGV (Automatic Guided Vehicle) comprises a vehicle body chassis, a cargo bearing platform picking-up and conveying system, a lifting system, a rotary rotary-table system and a delivered cargo temporary storage system; the rotary rotary-table system and the delivered cargo temporary storage system are fixed to the two sides of the upper portion of the vehicle body chassis correspondingly; the lifting system is fixed to the upper portion of the rotary rotary-table system, and the control end of the lifting system is connected with the cargo bearing platform picking-up and conveying system; the delivered cargo temporary storage system comprises a plurality of layers of temporary storage racks, and each layer of the temporary storage racks is provided with a plurality of temporary storage cargo positions; and the lifting system is used for controlling the sliding height of the cargo bearing platform picking-up and conveying system, and the rotary rotary-table system is used for controlling the rotation angle of the lifting system. By means of the AGV (Automatic Guided Vehicle) and the method, operation of manual picking-up of workbins is omitted, manpower and time are saved, and meanwhile workbin picking-up efficiency and accuracy are also improved.

Owner:湖北九州云仓科技发展有限公司

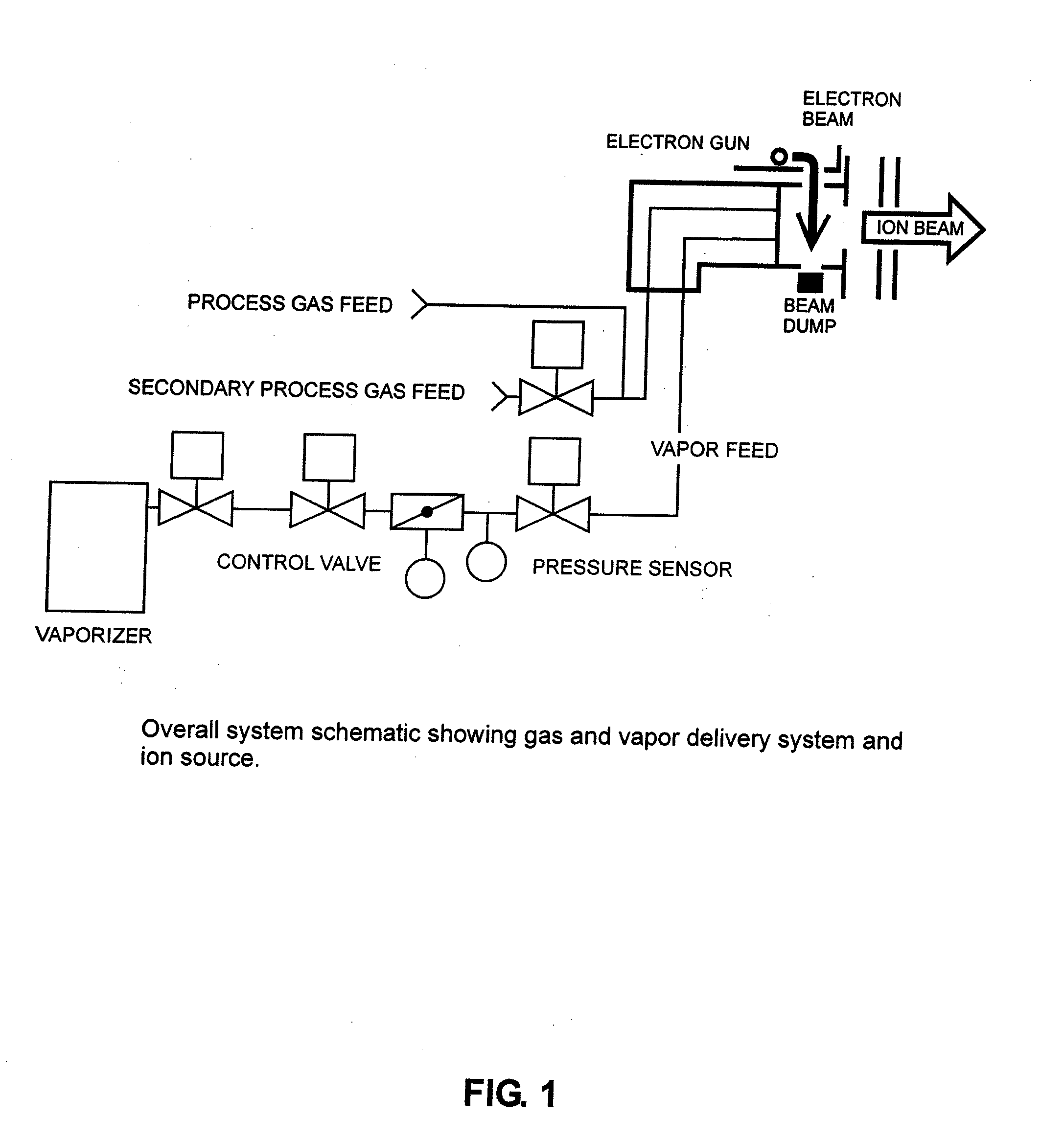

Ion implantation device and a method of semiconductor manufacturing by the implantation of ions derived from carborane molecular species

InactiveUS20080305598A1High doseLow-energy implantTransistorElectric discharge tubesImpact ionizationHigh doses

An ion implantation device and a method of manufacturing a semiconductor device is described, wherein ionized carborane cluster ions are implanted into semiconductor substrates to perform doping of the substrate. The carborane cluster ions have the chemical form C2B10Hx+, C2B8Hx+ and C4B18Hx+and are formed from carborane cluster molecules of the form C2B10H12 ,C2B8H10 and C4B18H22 The use of such carborane molecular clusters results in higher doping concentrations at lower implant energy to provide high dose low energy implants. In accordance with one aspect of the invention, the carborane cluster molecules may be ionized by direct electron impact ionization or by way of a plasma.

Owner:SEMEQUIP

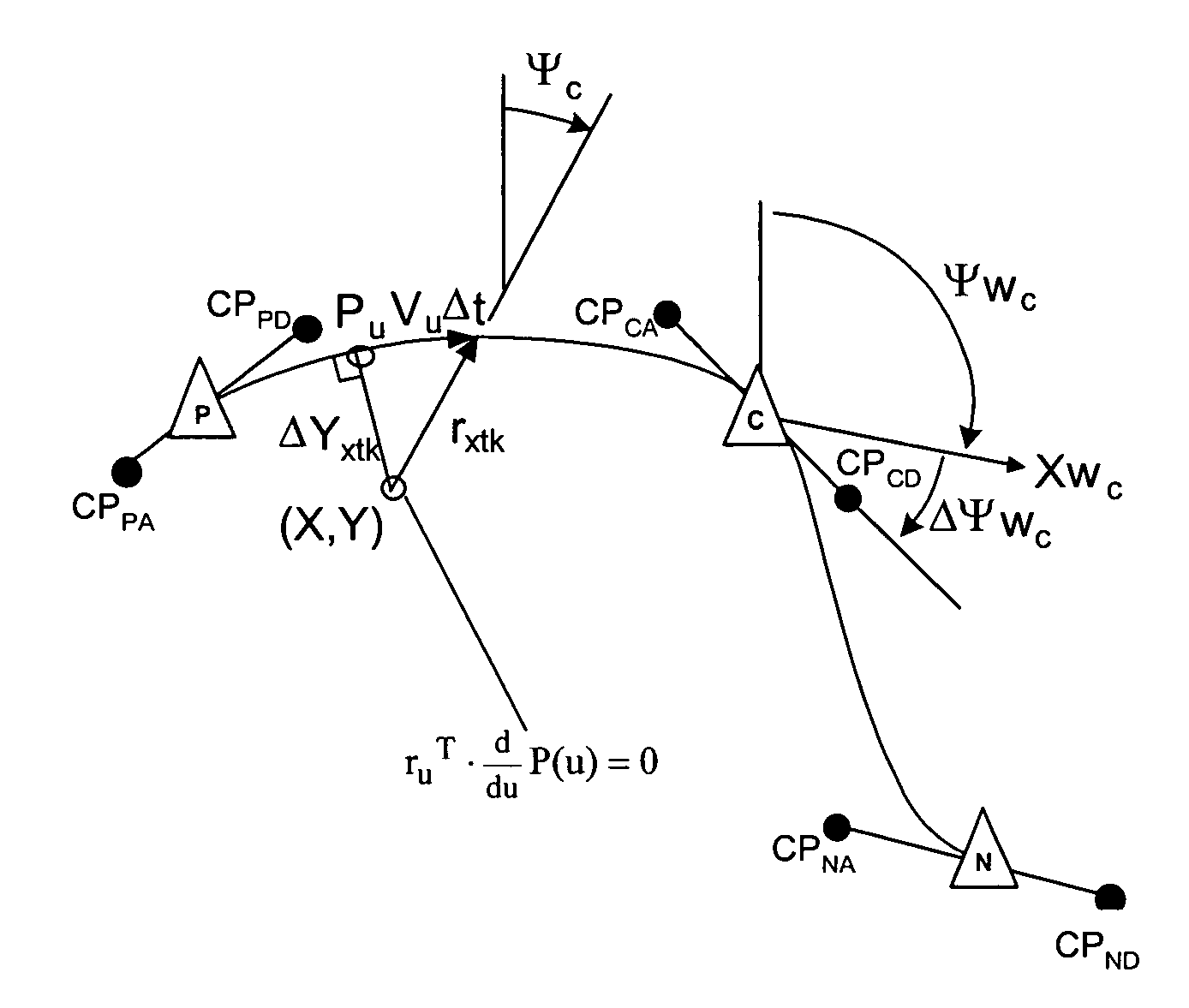

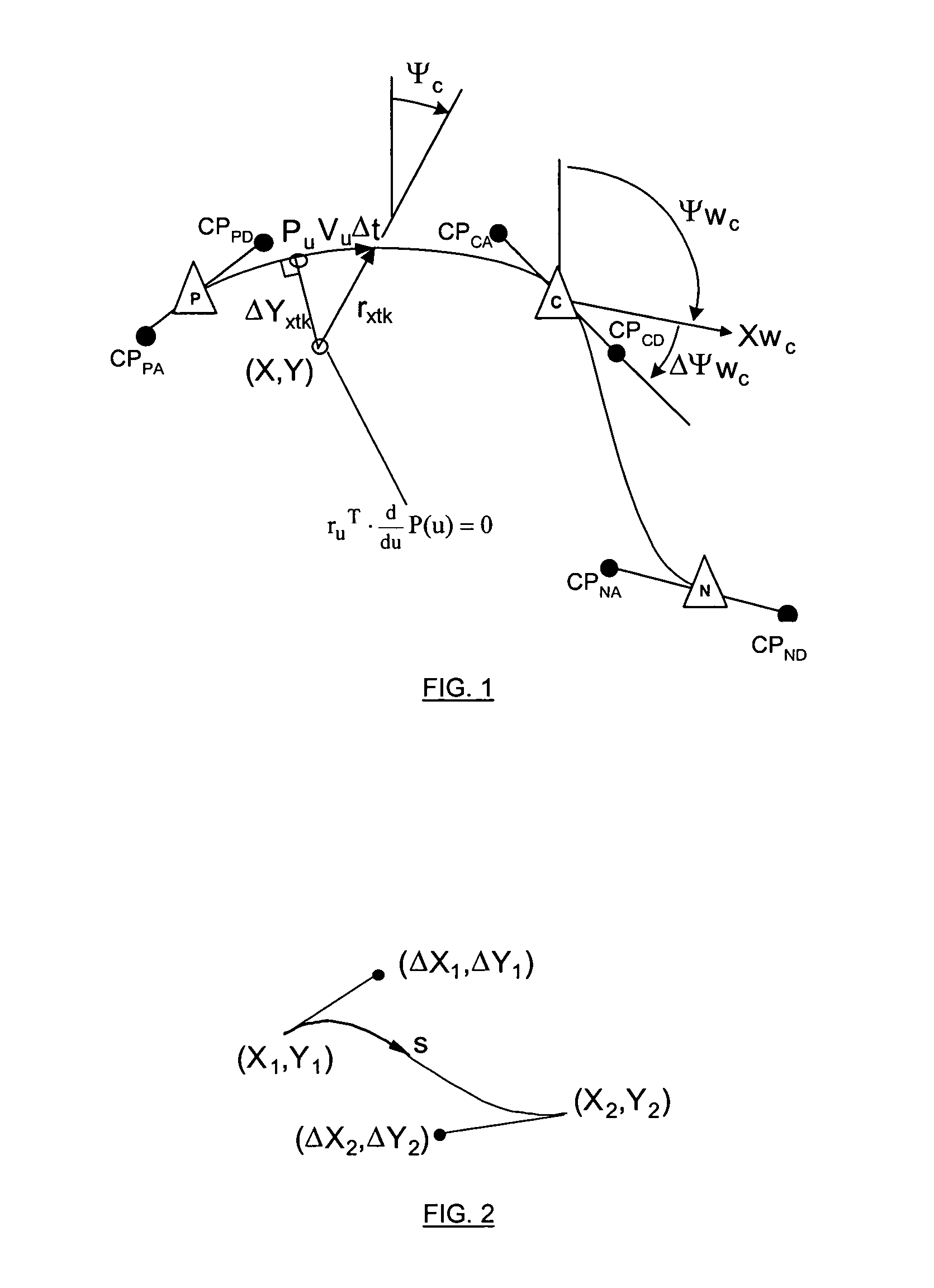

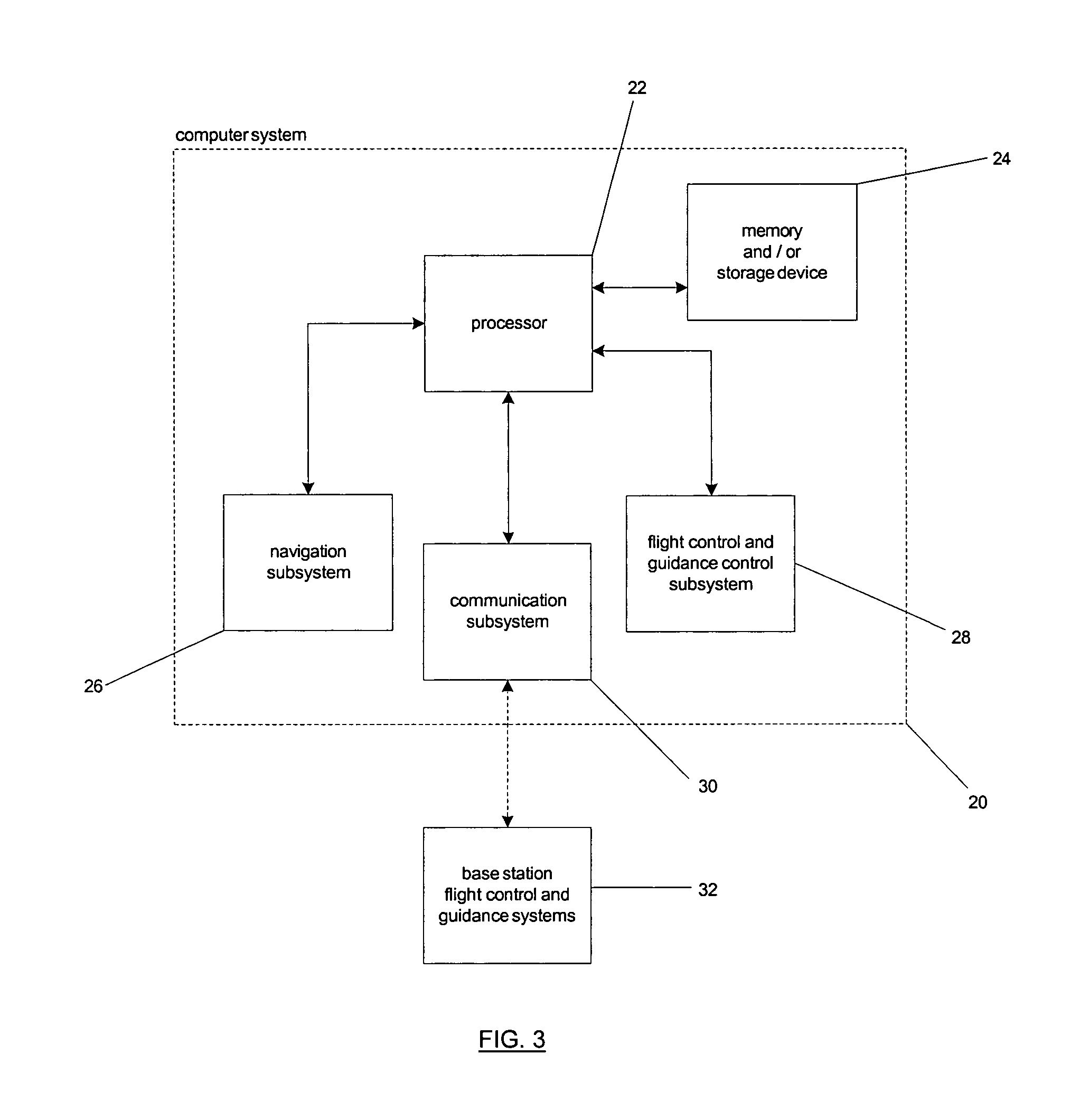

Bezier curve flightpath guidance using moving waypoints

InactiveUS7228227B2Shorten cycle timeEasy to separateUnmanned aerial vehiclesRoad vehicles traffic controlGuidance systemAir traffic control

A flightpath guidance system and method is disclosed for using moving waypoints for a curved route plan such as a Bezier curve. The actual location of a vehicle and a leading target point along the path are used to provide commanded guidance of the vehicle along the path and to correct for disturbances from the intended route. Waypoints along the path may be moving with respect to the reference frame in which the vehicle is measured. Curved flightpath guidance using moving waypoints may be used for aerial rendezvous and refueling, multiple vehicle applications such as formation flying and battlefield formation grouping, and carrier landing. Further application includes air traffic control and commercial flight guidance systems.

Owner:THE BOEING CO

Ion implantation device and a method of semiconductor manufacturing by the implantation of boron hydride cluster ions

InactiveUS20070194252A1Improve productivityLow costTransistorSemiconductor/solid-state device manufacturingMolecular clusterDevice material

An ion implantation device and a method of manufacturing a semiconductor device is described, wherein ionized boron hydride molecular clusters are implanted to form P-type transistor structures. The molecular cluster ions have the chemical form BnHx+and BnHx−, where 10<n<100 and 0≦x≦n+4. The use of such boron hydride clusters results in a dramatic increase in wafer throughput, as well as improved device yields through the reduction of wafer charging. A method of manufacturing a semiconductor device is further described, comprising the steps of: providing a supply of molecules containing a plurality of dopant atoms into an ionization chamber, ionizing said molecules into dopant cluster ions, extracting and accelerating the dopant cluster ions with an electric field, selecting the desired cluster ions by mass analysis, modifying the final implant energy of the cluster ion through post-analysis ion optics, and implanting the dopant cluster ions into a semiconductor substrate.

Owner:SEMEQUIP

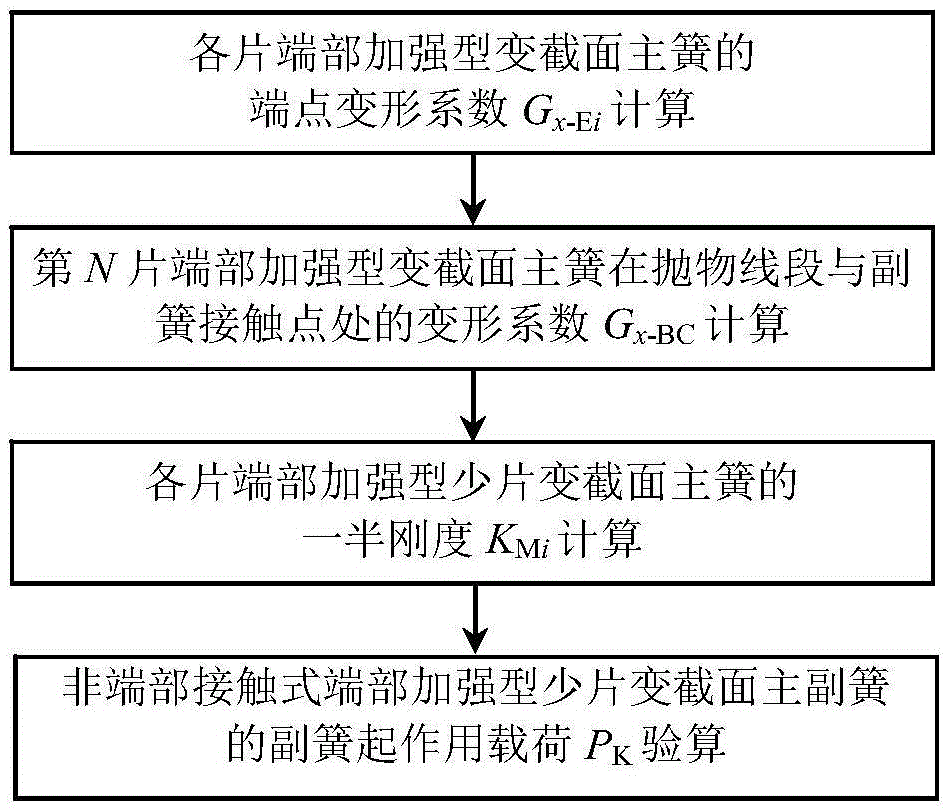

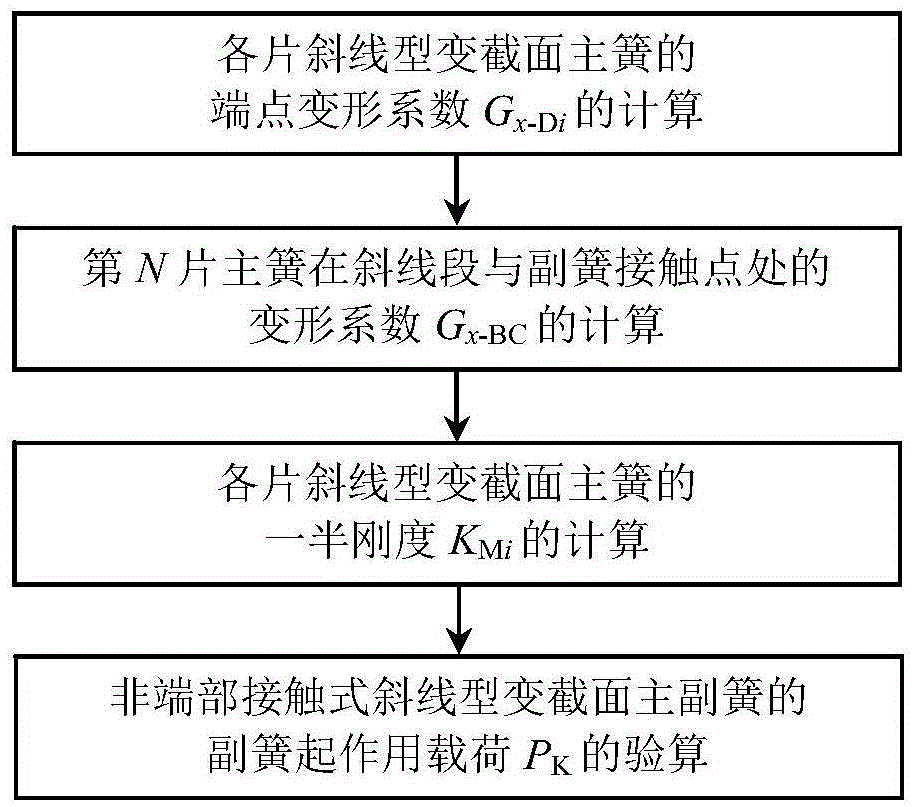

Auxiliary spring work load checking method of non end part contact type end part strengthened few-leaf main and auxiliary springs

ActiveCN105590009AImprove the design levelThe checking method is reliableDesign optimisation/simulationSpecial data processing applicationsContact typeEngineering

The invention relates to an auxiliary spring work load checking method of a non end part contact type end part strengthened few-leaf main and auxiliary springs belonging to the suspension steel plate spring technical field. According to the method of the invention, firstly, according to the structure size and the elastic modulus of each end part strengthened few-leaf cross-section variable main spring, the end point deformation coefficient Gx-Ei and the half rigidity KMi of each main spring, and the deformation coefficient Gx-BC at the contact point of the Nth main spring and an auxiliary spring on a parabolic segment can be determined; then, according to the half rigidity KMi of each main spring, the thickness h2 of a root straight section, the Gx-BC of the Nth main spring and a main and auxiliary spring interval Delta design value, the auxiliary spring work load of the non end part contact type end part strengthened few-leaf cross-section variable main and auxiliary springs is checked. Through the emulation proof, in adoption of the method of the invention, the accurate and reliable auxiliary spring work load checking value can be obtained; therefore, the design levels and performances of the few-leaf cross-section variable main and auxiliary springs and the smoothness of a vehicle are improved; moreover, the design and test cost is saved; and the product development speed is accelerated.

Owner:SHANDONG AUTOMOBILE SPRING FACTORY ZIBO CO LTD

Method for designing few-leaf oblique line type variable-section main springs in gaps between oblique line segments and auxiliary spring

ActiveCN105550487AImprove the design levelQuality improvementGeometric CADDesign optimisation/simulationLine segmentOblique line

The invention relates to a method for designing few-leaf oblique line type variable-section main springs in the gaps between oblique line segments and an auxiliary spring, and belongs to the technical field of suspension steel plate springs. According to the structural sizes and the elasticity moduli of the oblique line type variable-section main springs, the endpoint deformation coefficient Gx-Di of each main spring and the deformation coefficient Gx-BC of the Nth main spring at the contact point of the corresponding oblique line segment and the auxiliary spring are determined first; then, according to the required auxiliary spring acting load design value and the endpoint deformation coefficient Gx-Di of each main spring, endpoint force FN of the Nth main spring is obtained; then, according to the thickness h of the root straight section of the Nth main spring, the Gx-BC and the FN, main spring and auxiliary spring gaps between the oblique line segment of the main springs and the contact point of the auxiliary spring are designed. Through simulation verification, it can be known that the main and auxiliary spring gap design value meeting the auxiliary spring acting load requirement can be obtained by means of the method, and the product design level, product performance and vehicle smoothness are improved. Meanwhile, design and testing cost is reduced, and product development speed is increased.

Owner:JIANGSU HAIHONG MACHINERY MFG

Mass spectrometer arrangement with fragmentation cell and ion selection device

ActiveUS7829842B2Increase rangeHigh resolutionStability-of-path spectrometersIsotope separationMass Spectrometry-Mass SpectrometryMass analyzer

A method of mass spectrometry having the steps of, in a first cycle: storing sample ions in a first ion storage device; ejecting the stored ions out of the first ion storage device into a separate ion selection device; selecting a subset of the ions in the ion selection device; ejecting the subset of ions selected within the ion selection device to a fragmentation device; directing ions from the fragmentation device back to the first ion storage device without passing them through the said ion selection device; receiving at least some of the ions ejected from the first ion storage device, or their derivatives, back into the first ion storage device; and storing the received ions in the first ion storage device.

Owner:THERMO FISHER SCI BREMEN

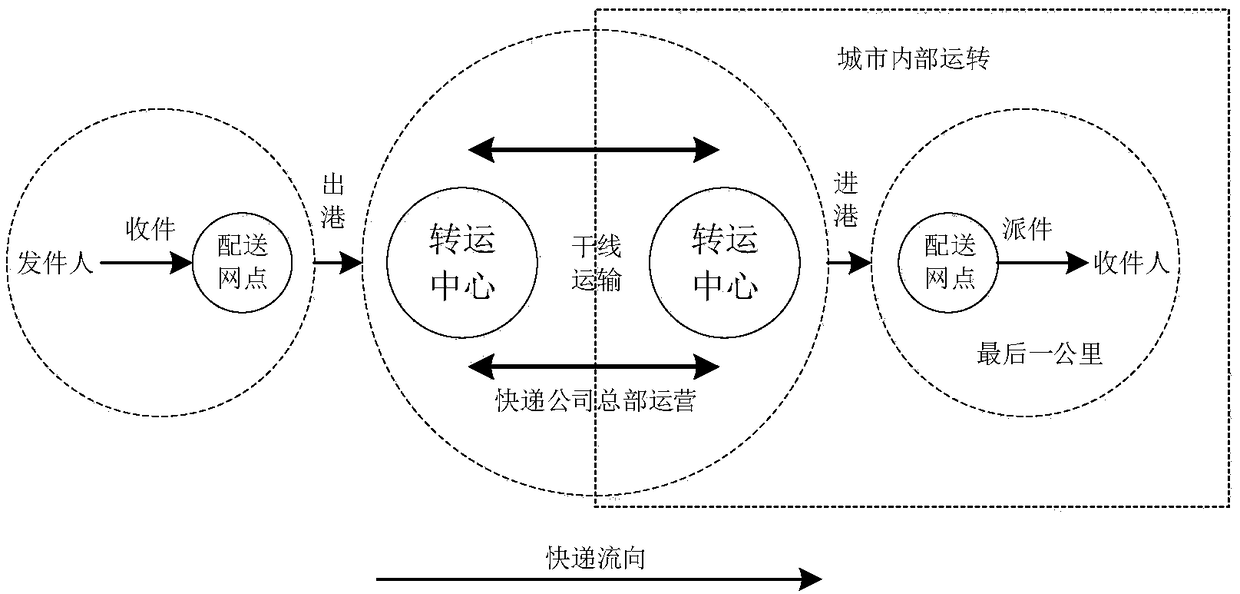

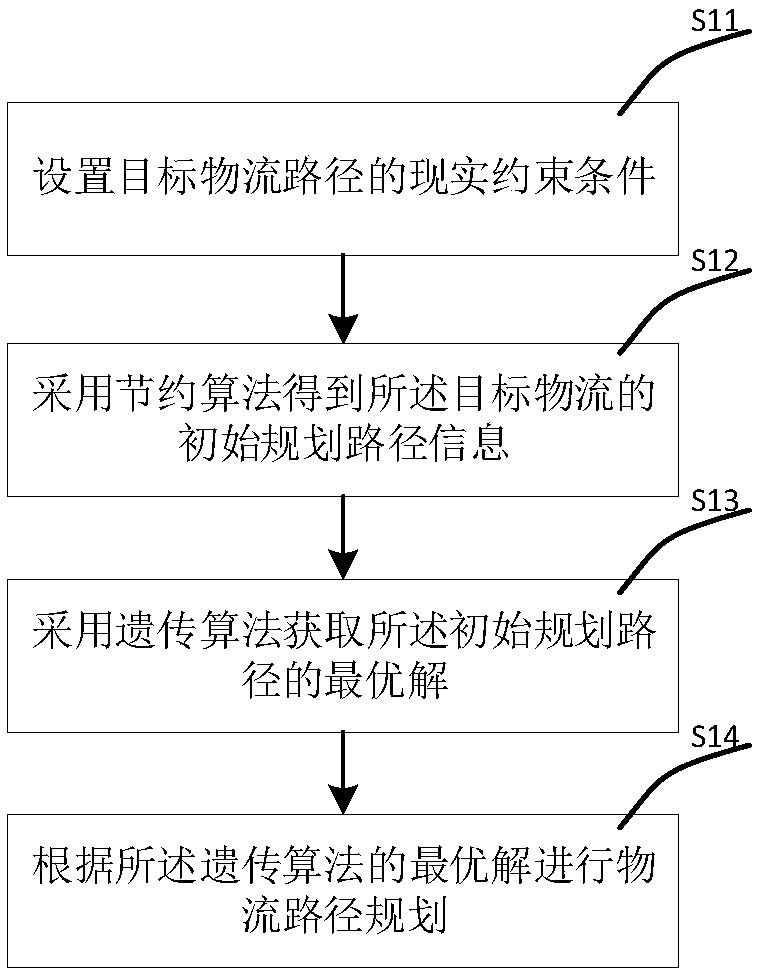

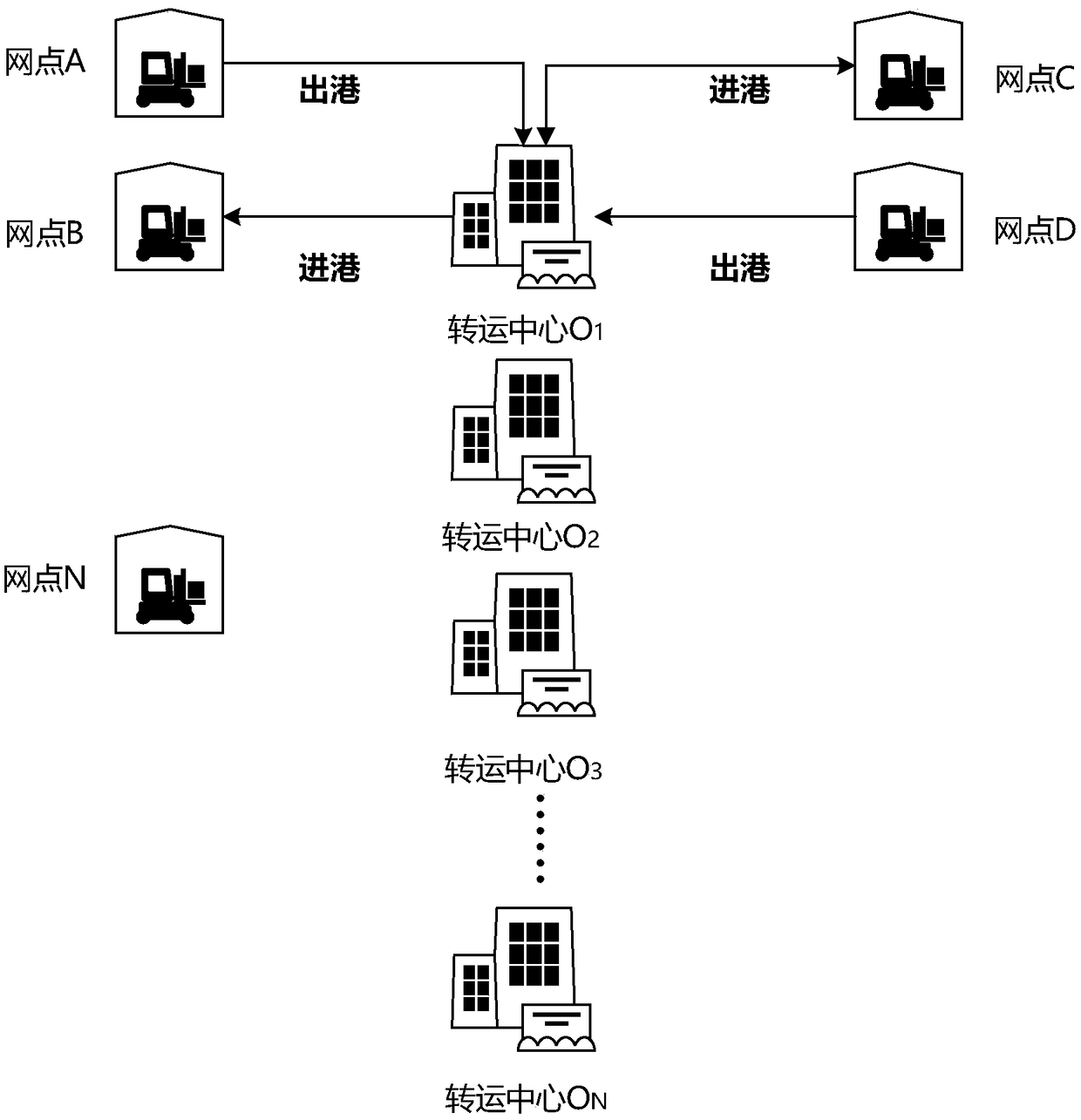

Logistics path planning method and device and driver scheduling method and device

InactiveCN108921483AReduce shipping costsReduce labor costsResourcesLogisticsLogistics managementPlanning approach

The invention discloses a logistics path planning method. The method comprises the steps of setting realistic constraint conditions of a target logistics path; obtaining initial planning path information of target logistics by adopting a saving algorithm; obtaining an optimal solution of the initial planning path by adopting a genetic algorithm; and planning a logistics path according to the optimal solution of the logistics path. The invention also discloses a driver scheduling method. By applying the logistics path planning method, the driver scheduling method comprises the following steps of: obtaining preset driver constraint conditions and planning the driver scheduling according to the genetic algorithm by combining with the obtained optimal logistics path; and generating driver scheduling information. The invention also discloses a logistics path planning device and a driver scheduling device. Through the realistic constraint condition-considered logistics path planning method and driver scheduling method, the established model is more accurate and closer to the actual situation; the operability is stronger; and the transportation cost, the labor cost and the time cost, which are caused by model deviation, of enterprises are reduced.

Owner:深圳北斗应用技术研究院有限公司

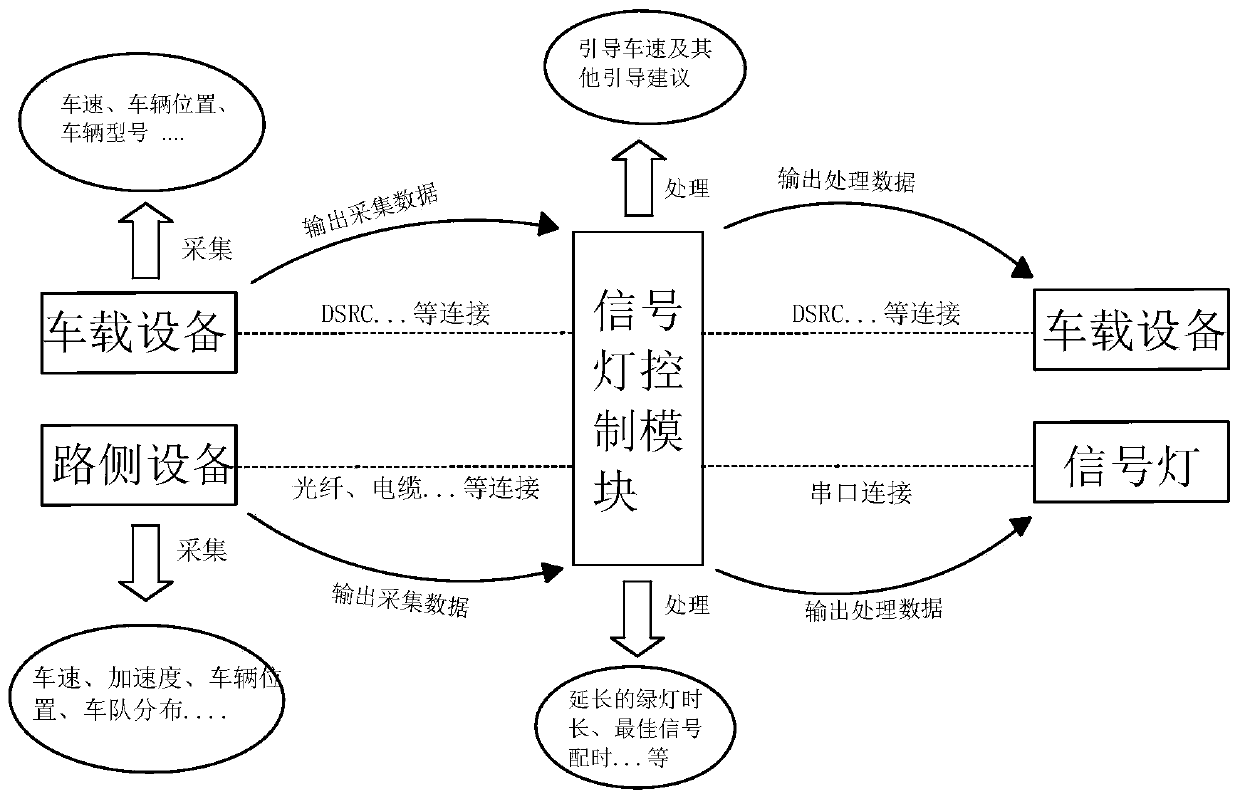

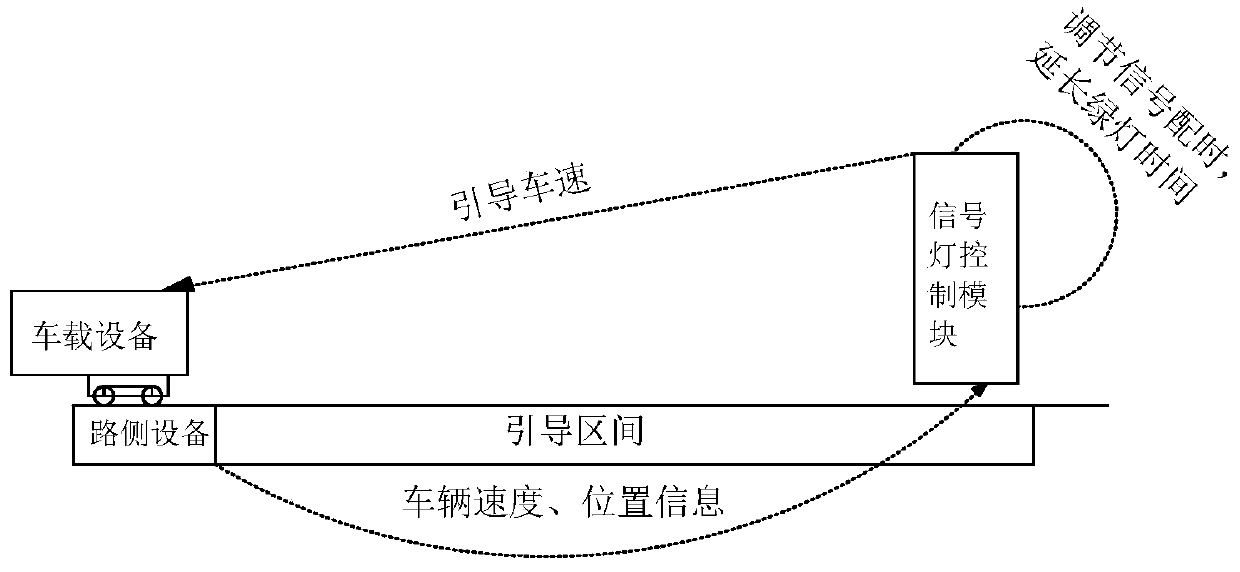

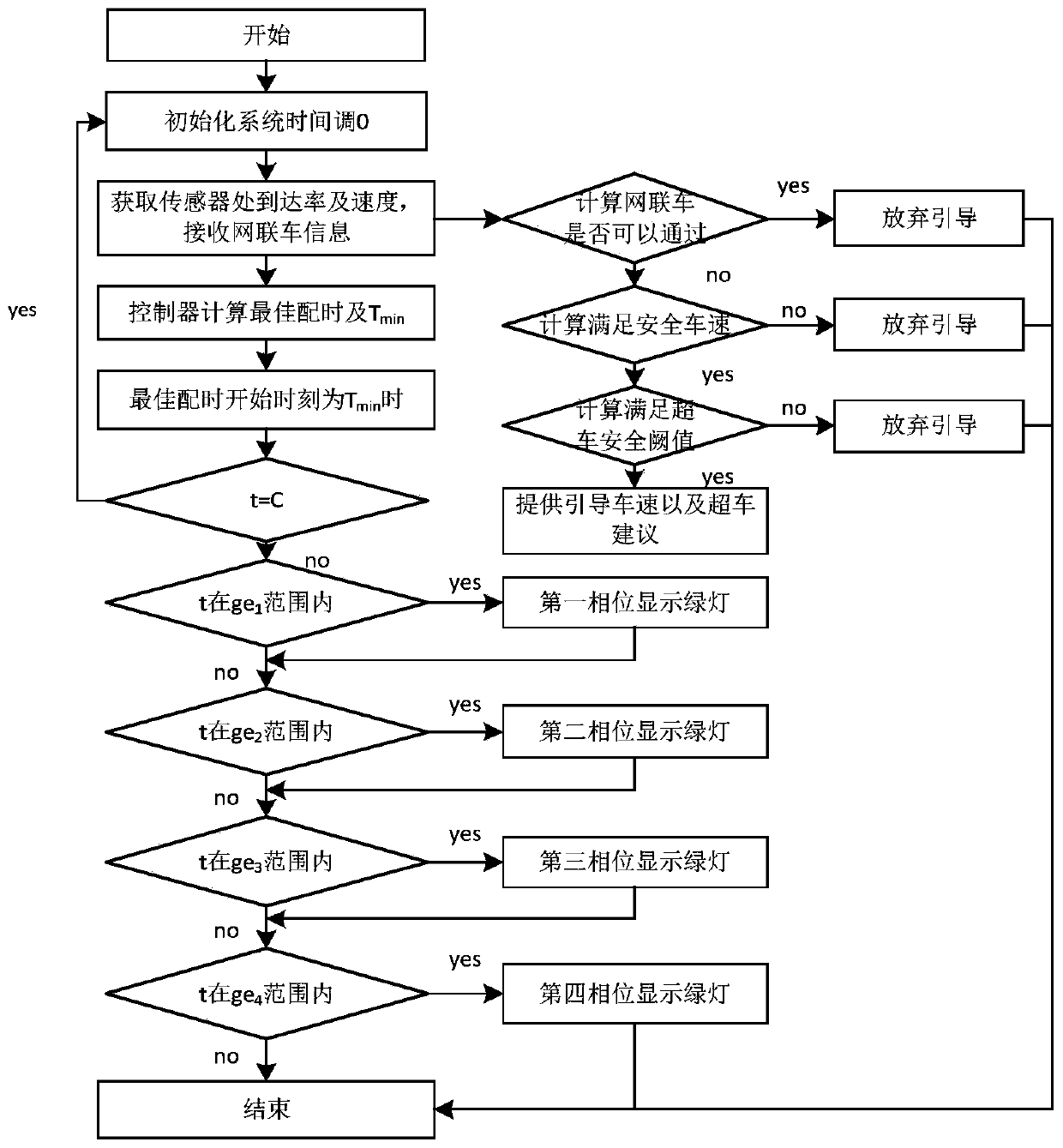

Intersection signal control and speed guidance system in cooperative vehicle infrastructure environment

ActiveCN110085037ARealize green wave traffic travelReduce delaysControlling traffic signalsTransmission systemsGuidance systemInformation transmission

The invention discloses an intersection signal control and speed guidance system in a cooperative vehicle infrastructure environment. The system comprises on-board units, a road side unit and a signallight control module, wherein an on-board information transmission module in each on-board unit acquires vehicle information and transmits the vehicle information to the signal light control module,and the information fed back by the signal light control module is sent to an information acquisition module; a road side information acquisition module in the road side unit acquires road side information and stores the road side information into an intersection basic information storage module, the intersection basic information storage module pre-stores intersection information and historical data, and a wireless communication module wirelessly transmits the road side information, the intersection information and the historical data to the signal light control module; and in the signal light control module, optimal timing scheme information and travel advice information are obtained through calculation by use of a program model in the signal light control module based on the vehicle information, the road side information, the intersection information and the historical data, and the travel advice information is fed back to the on-board units.

Owner:HEFEI UNIV OF TECH

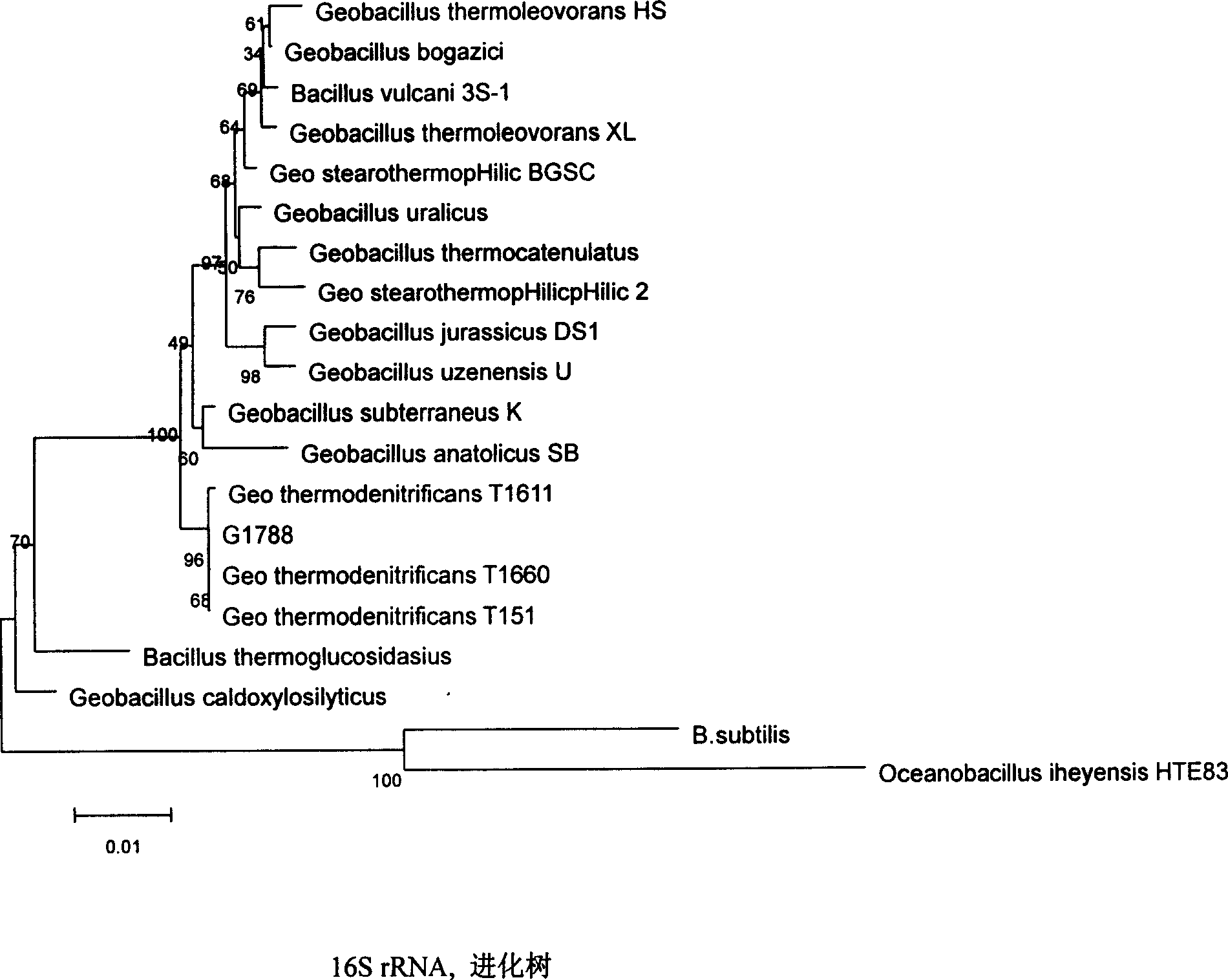

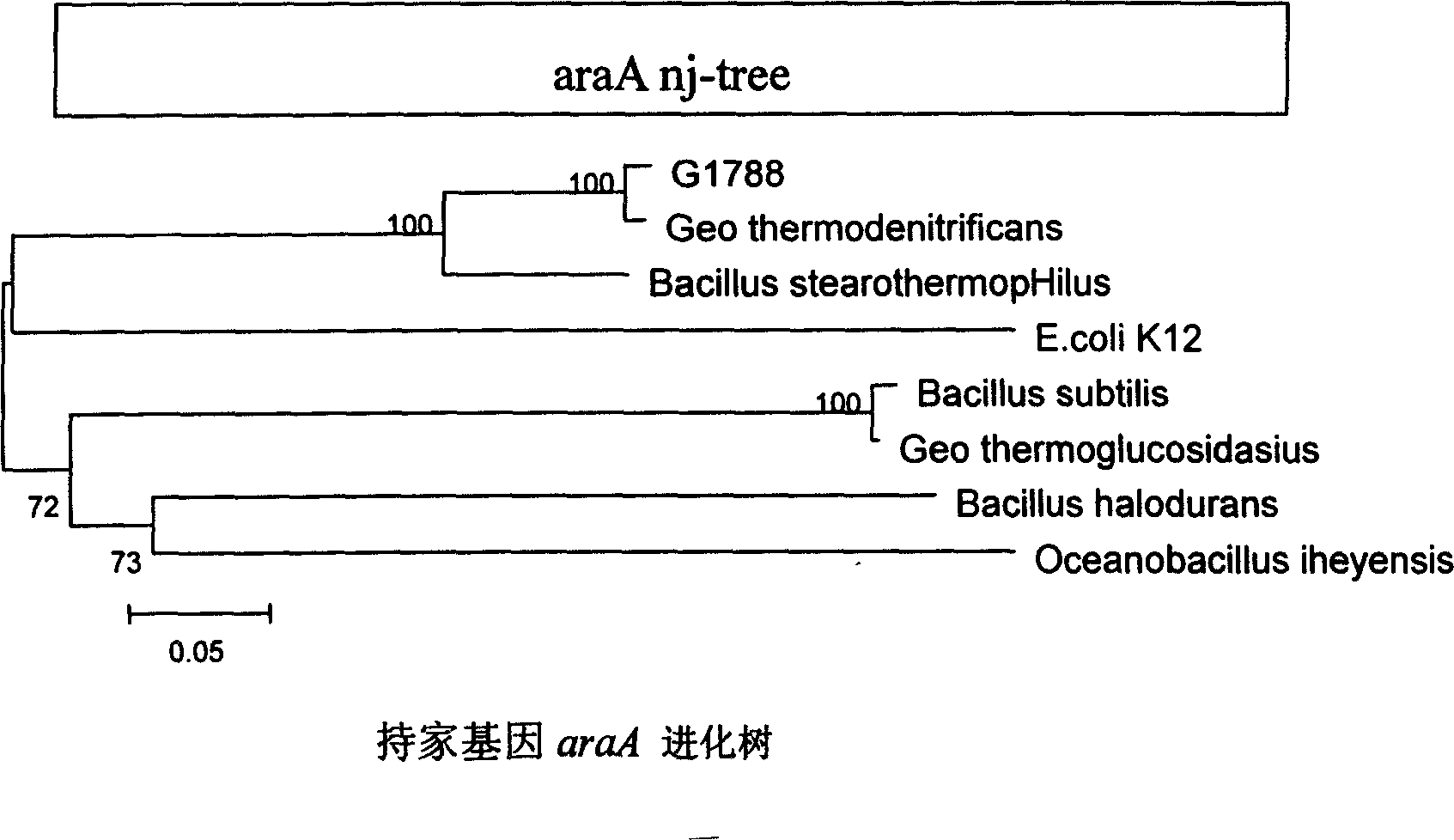

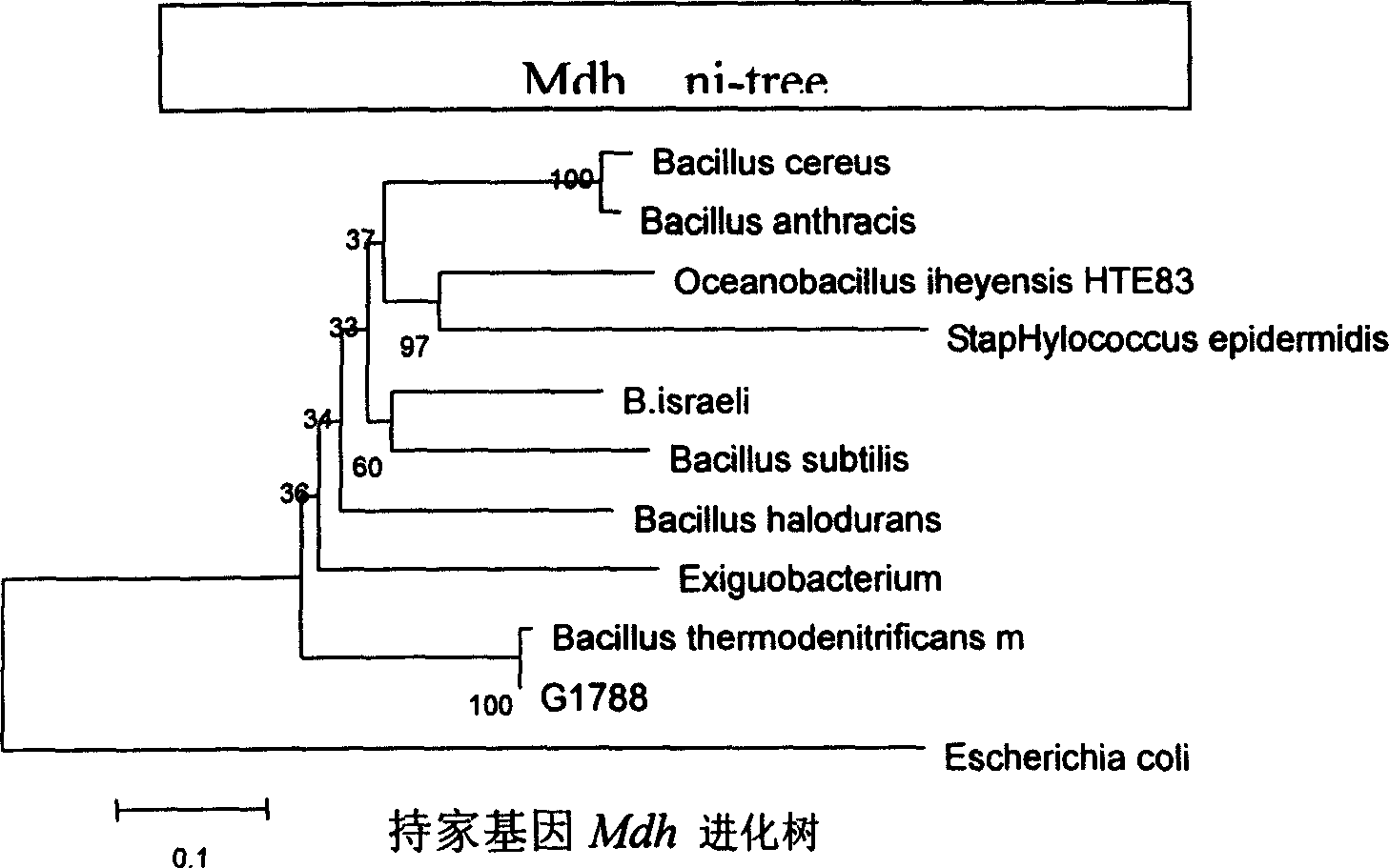

Thermophilic denitrifying bacillocin, screening and use thereof

InactiveCN1614006AImprove propertiesReduce viscosityOrganic detergent compounding agentsBacteriaActive agentThermostable enzymes

This invention relates to selection and application of thermophil denitriding Bacillales,of which conservation number is CGMCC-1228. Initial strain is from water of oil field. The strain is obtained by selection, inoculation, and domestication with good thermal stability. It belongs to soil Bacillales and can be used in fermented industry, which needs thermally stable enzyme. It grows well in the oil field and can degrade paraffin and decrease viscosity to improve liquidity. All of this can increase recovery and carriage efficiently. It can be used to control pollution and prepare surfactant.

Owner:NANKAI UNIV

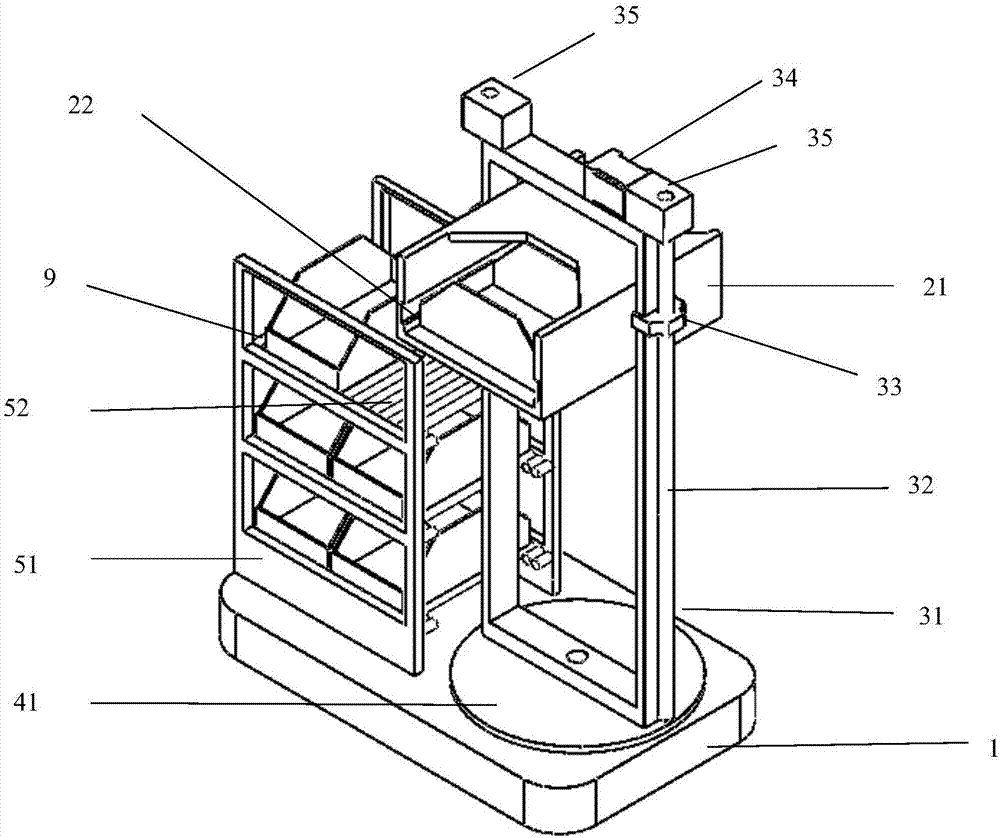

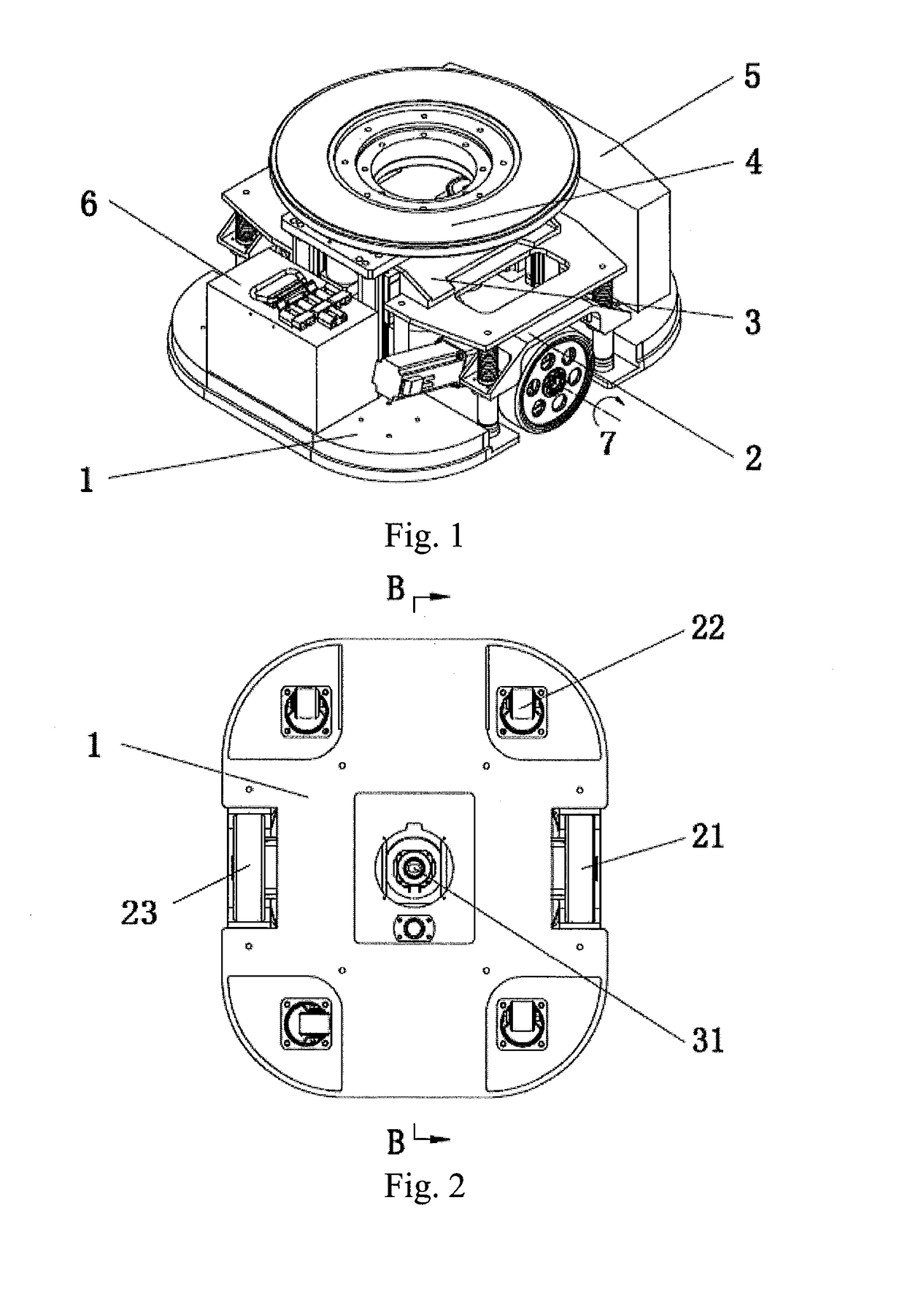

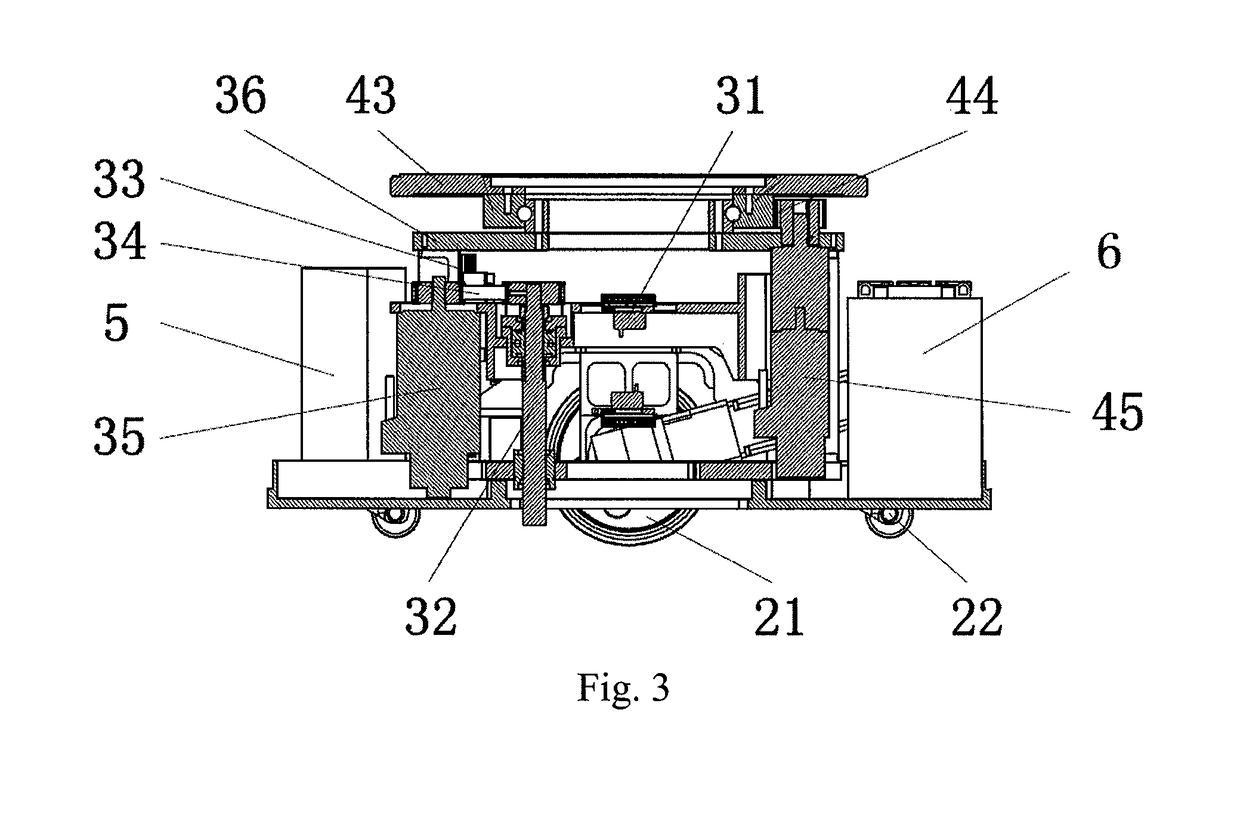

Inventory item management system, transporting robots and the method for transporting inventory holder

ActiveUS20180099811A1Improve transportation efficiencyLifting framesStorage devicesInventory managementManagement efficiency

The present invention discloses an inventory item management system, transporting robots and the method for transporting inventory holder, wherein the transporting robot comprises a lifting unit and a horizontal rotation unit, the lifting unit comprises a first power unit, a lifting shaft and a first supporting part, and the first power unit configured to drive the first supporting part to move along the lifting shaft; the horizontal rotation unit comprises a second supporting part and a second power unit which drives the second supporting part, and the second supporting part and the first supporting part are connected rotatably. The lifting unit has a hollow hole which is disposed in vertical direction internal to the lifting unit, and the lifting shaft is located on one side of the hollow hole. The inventory item management system of the present invention transports the inventory holder with required items to the manual picking table automatically via the transporting robots, and the transporting robots again carry the inventory holders they transported back to the designated positions after manual picking. The present invention increases the transport efficiency of the transporting robots and the management efficiency of the entire inventory item management system, and reduces the costs.

Owner:ZHEJIANG GUOZI ROBOT TECH

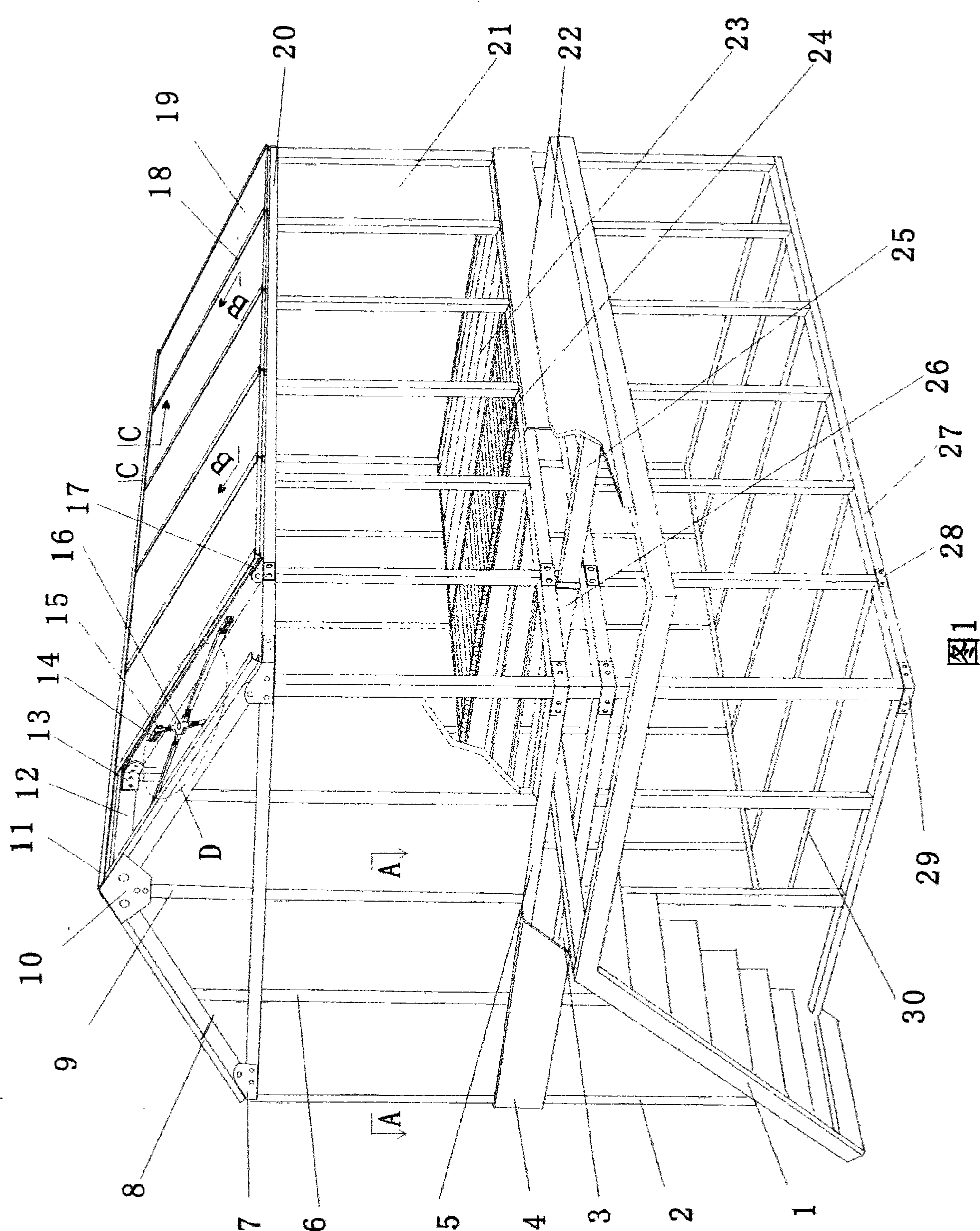

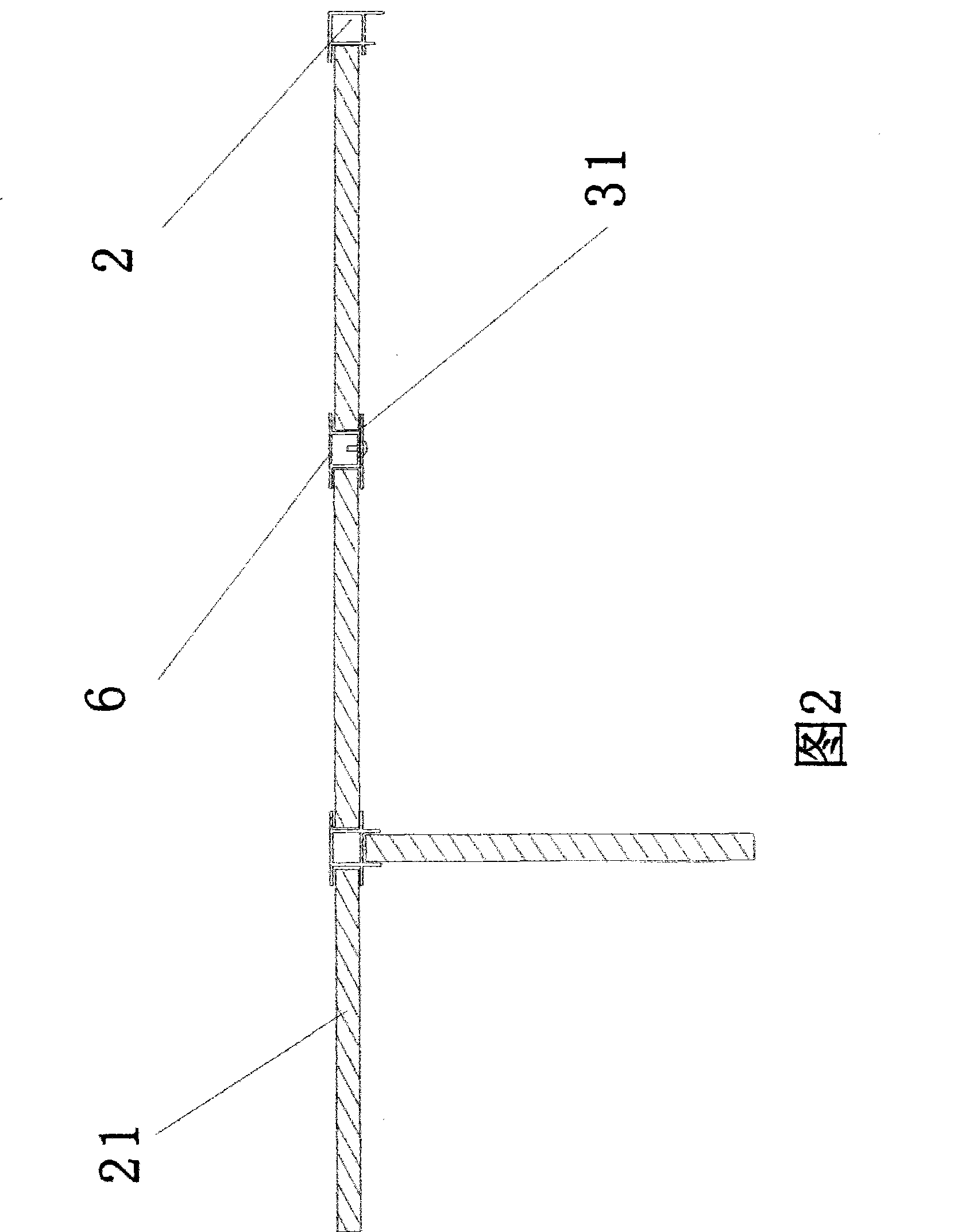

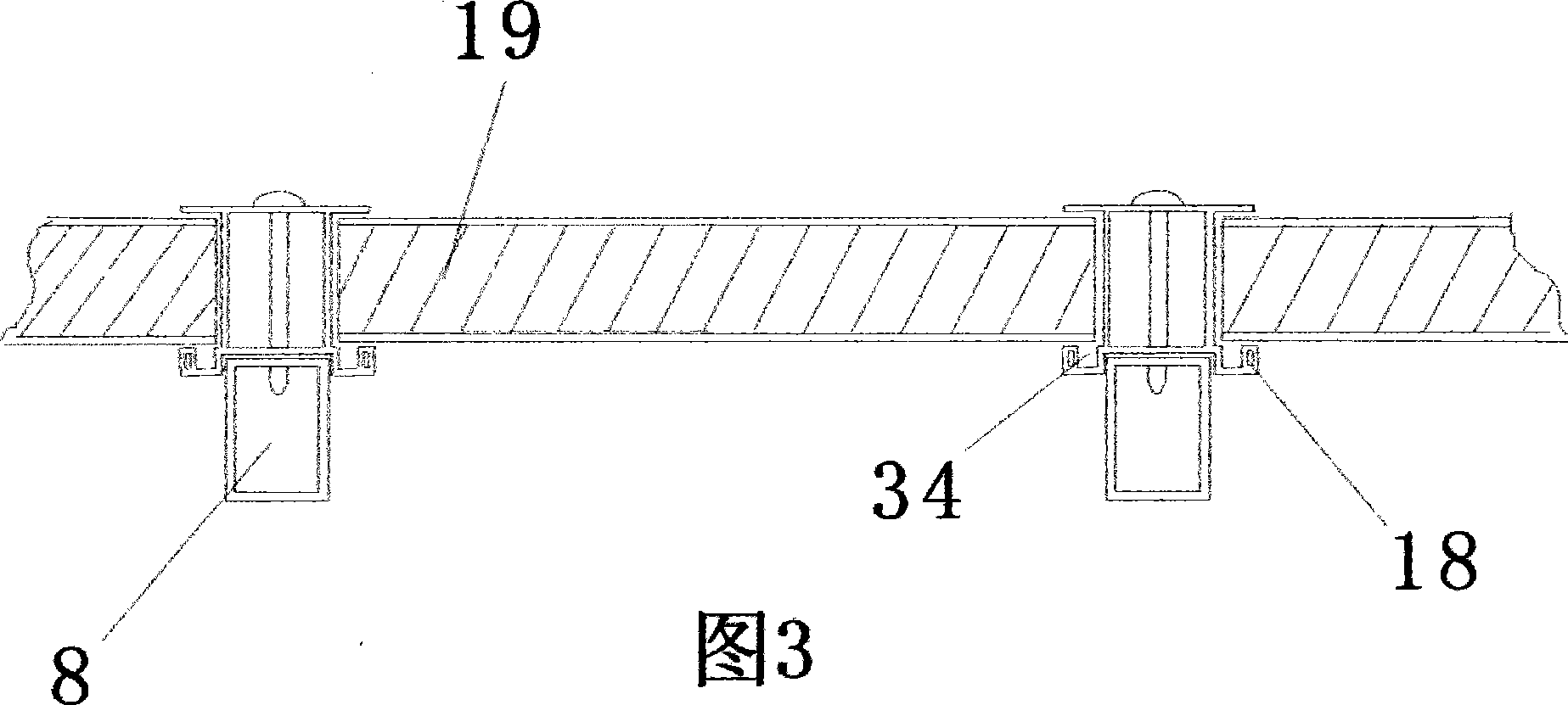

Combined light steel structure house and mounting method thereof

InactiveCN101418592AHigh degree of factoryReduce the ratio of output value to energy consumptionBuilding constructionsFloor slabSandwich panel

The invention relates to a combined lightweight steel structure building and an assembling method thereof. The combined lightweight steel structure building comprises ground beams, angular upright posts, upright posts, ring beams, sandwich panels, a roof, staircases, doors and windows. The key technical points of the combined lightweight steel structure building are as follows: a plurality of floor bottom girders in parallel are arranged on the ground; four ground beams are arranged on the circumference of each floor bottom girder in turn; bolt fastening sheets which are connected with the ground beams and the ring beams are arranged on joints of upper ends and lower ends of each angular upright post and each upright post respectively; limit baffle plates of wall panels are arranged on angular upright posts and upright posts near the outside of the building; bolt fastening limit treadle bars of the wall panels are arranged on upright posts near the inside of the building; the wall panels comprise wall panels provided with door bodies or wall panels provided with window bodies; metal section supporting layers which are suitable to be connected with balcony bottom girders or / and corridor bottom girders are uniformly distributed between two adjacent floors; metal floor slabs are laid on the metal section supporting layers; and the roof is as follows: a waterproof ridge section is arranged on the upper part of a ridge main girder; the edge of a roof slab is embedded into the ridge section; and a roof slab slot section provided with a drainage channel is arranged on the upper part of a ramp beam of the roof.

Owner:官木喜

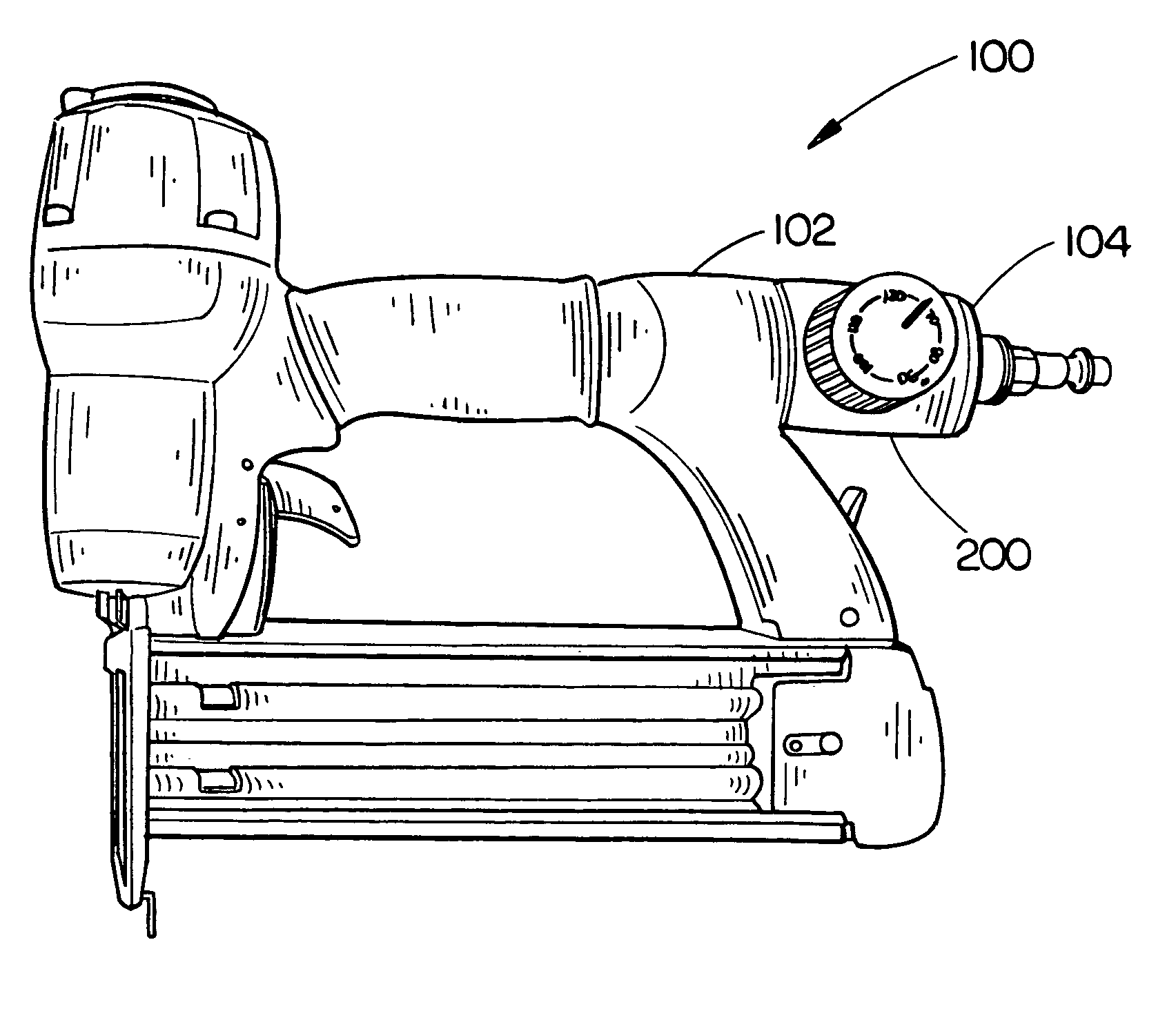

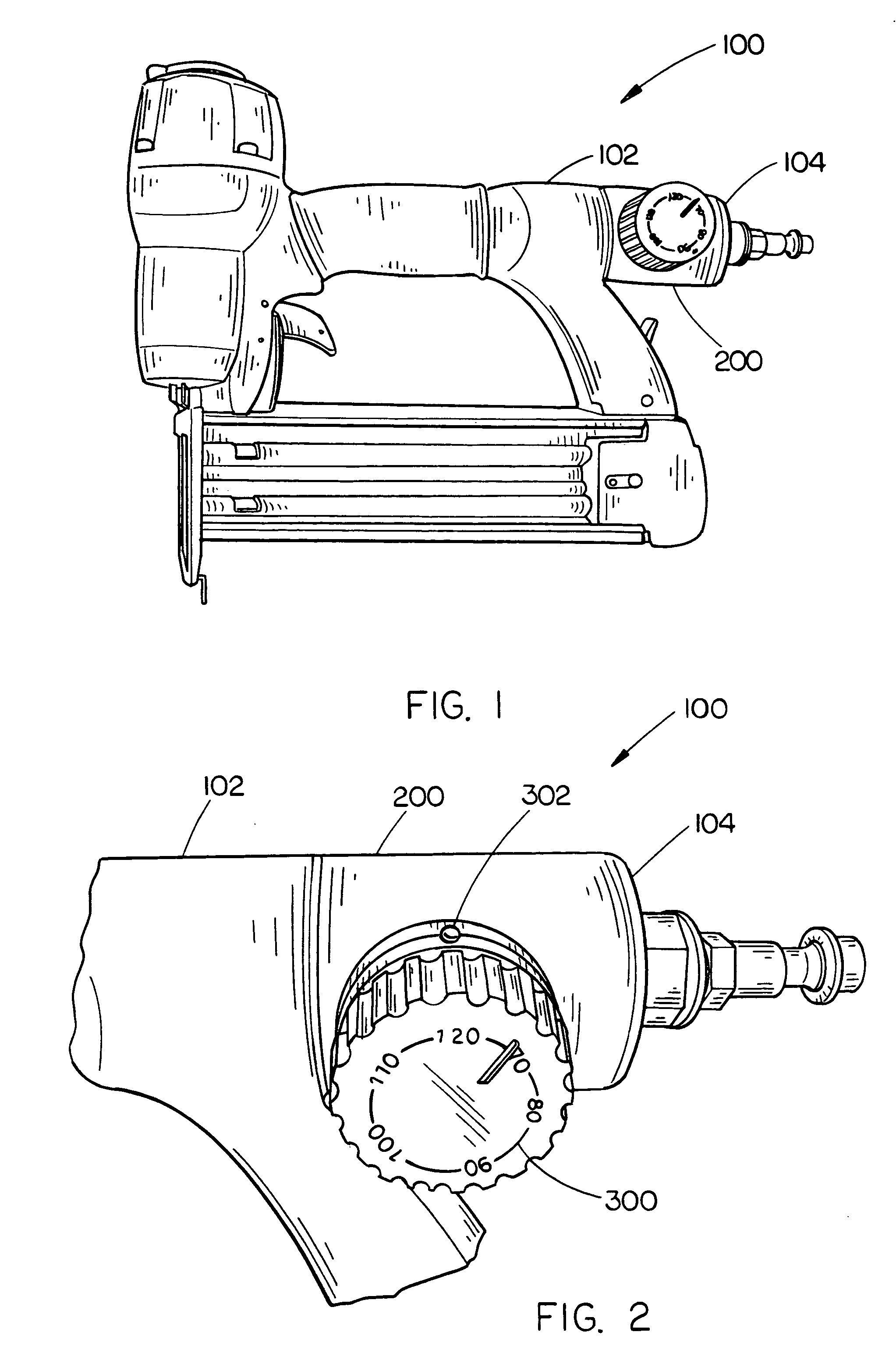

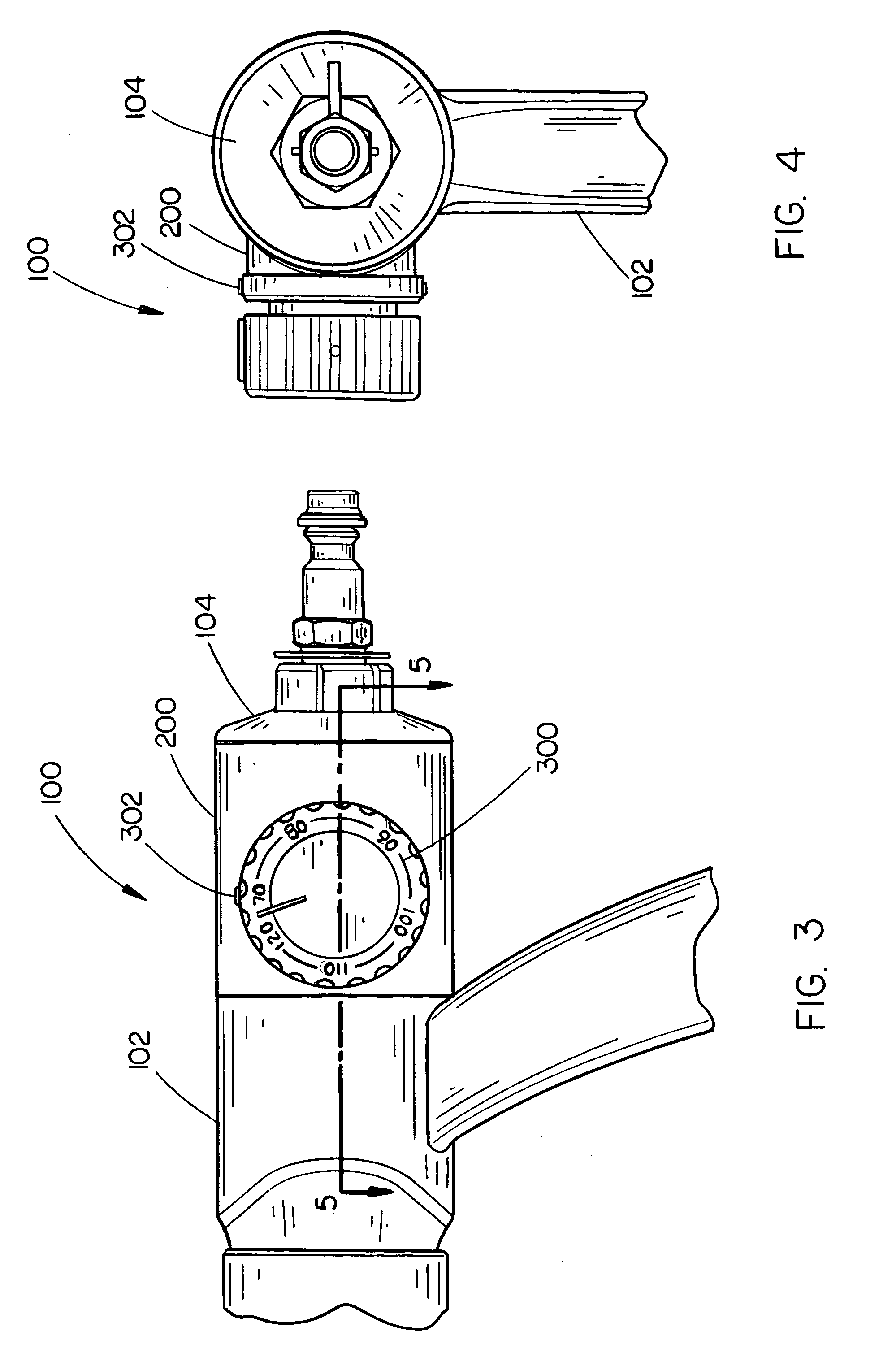

Integrated air tool and pressure regulator

InactiveUS20050247750A1Less pressure lossImprove transportation efficiencyStapling toolsOperator-supported drilling machinesDistribution systemPneumatic tool

The integrated air tool and pressure regulator assembly allows several air tools to operate from a single air compressor, using a simplified air hose distribution system. An operator may independently adjust the regulated pressure of the integrated air tool and pressure regulator assembly to compensate for varying working conditions. A greater air hose supply pressure may be used, as regulation of air pressure is accomplished at the integrated air tool and pressure regulator assembly. The increased air transport efficiency allowed by the integrated air tool and pressure regulator assembly of the present invention may provide for the use of smaller diameter hose, which may be lighter, more flexible, less costly, and the like.

Owner:BLACK & DECKER INC

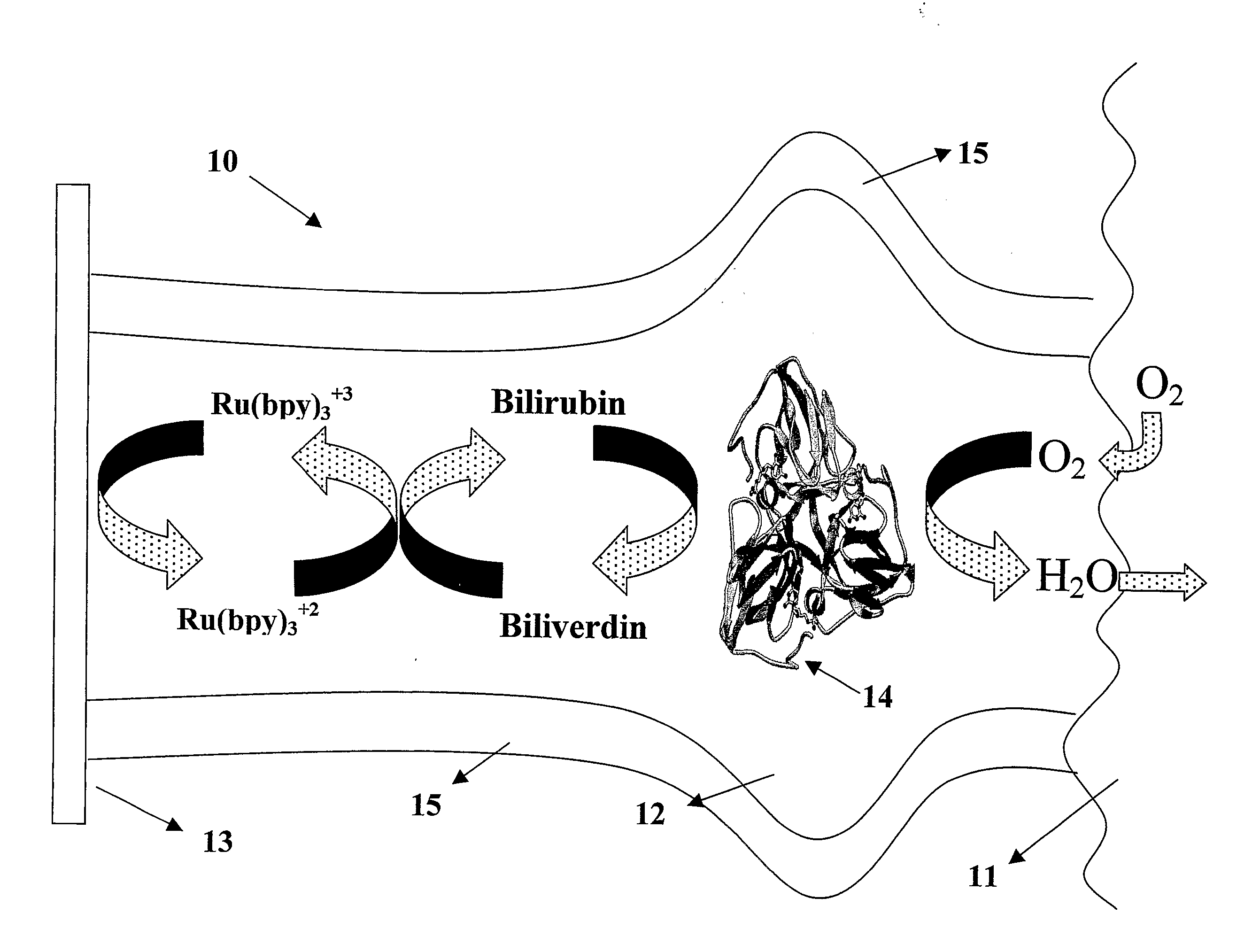

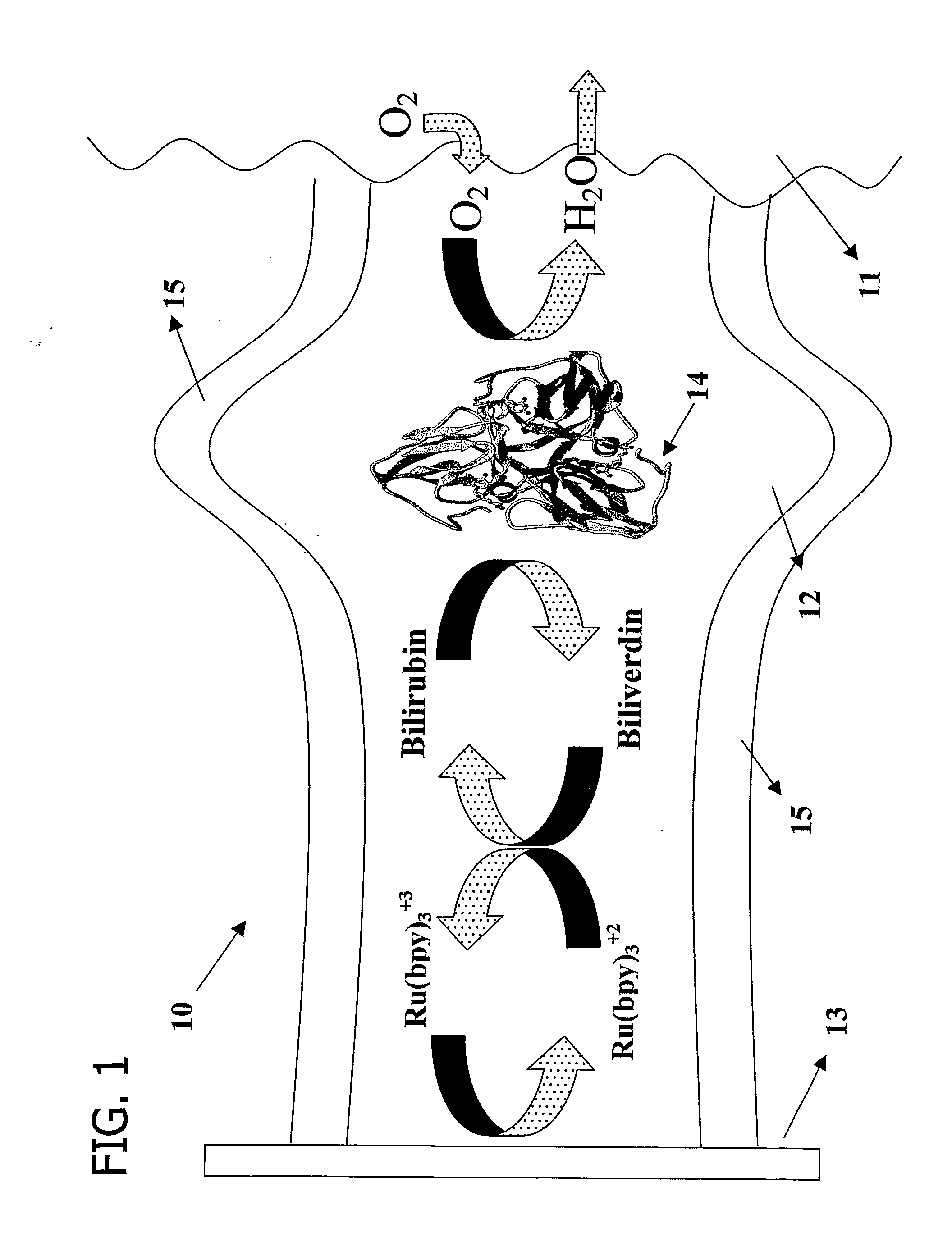

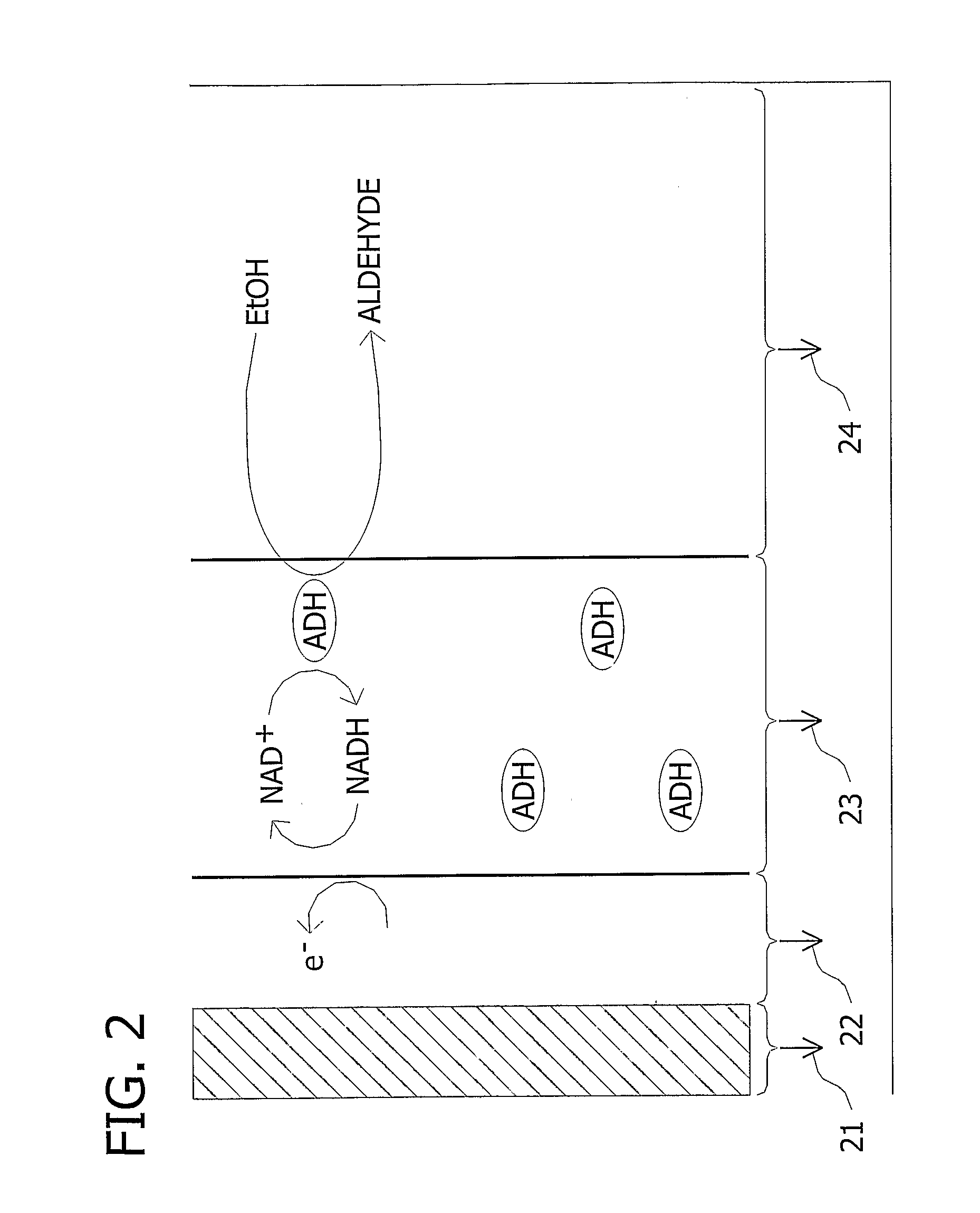

Microfluidic Biofuel Cell

InactiveUS20070287034A1Great current densityIncrease current densityElectrolysis componentsActive material electrodesChemical physicsFuel cells

Microfluidic biofuel cells comprising a bioanode and / or a biocathode are formed using microfluidic principles and soft lithography. The enzymes utilized in the redox reactions at the bioanode and / or the biocathode are stabilized in a micellar or inverted micellar structure. The biofuel cell is used to produce high power densities.

Owner:SAINT LOUIS UNIVERSITY

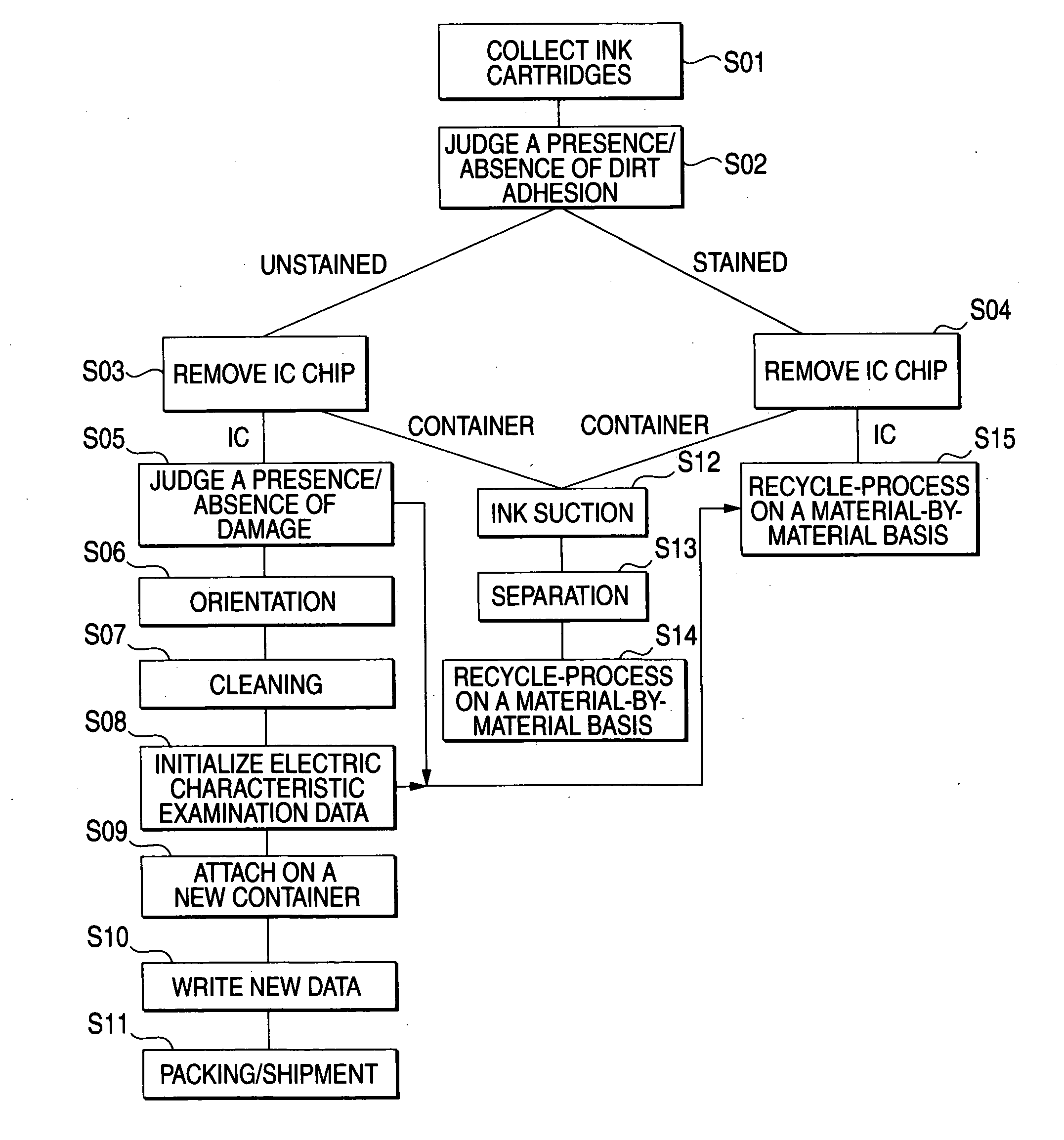

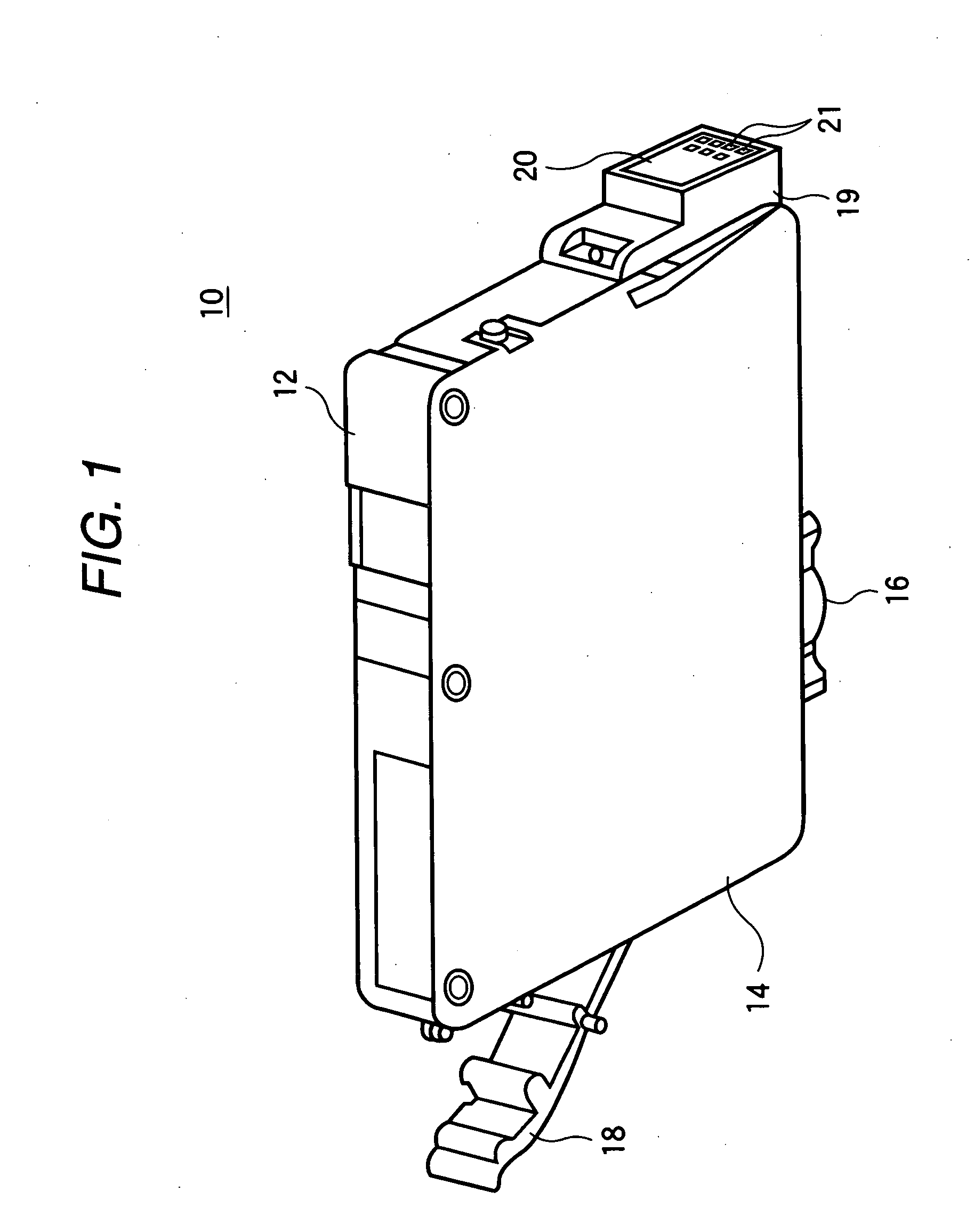

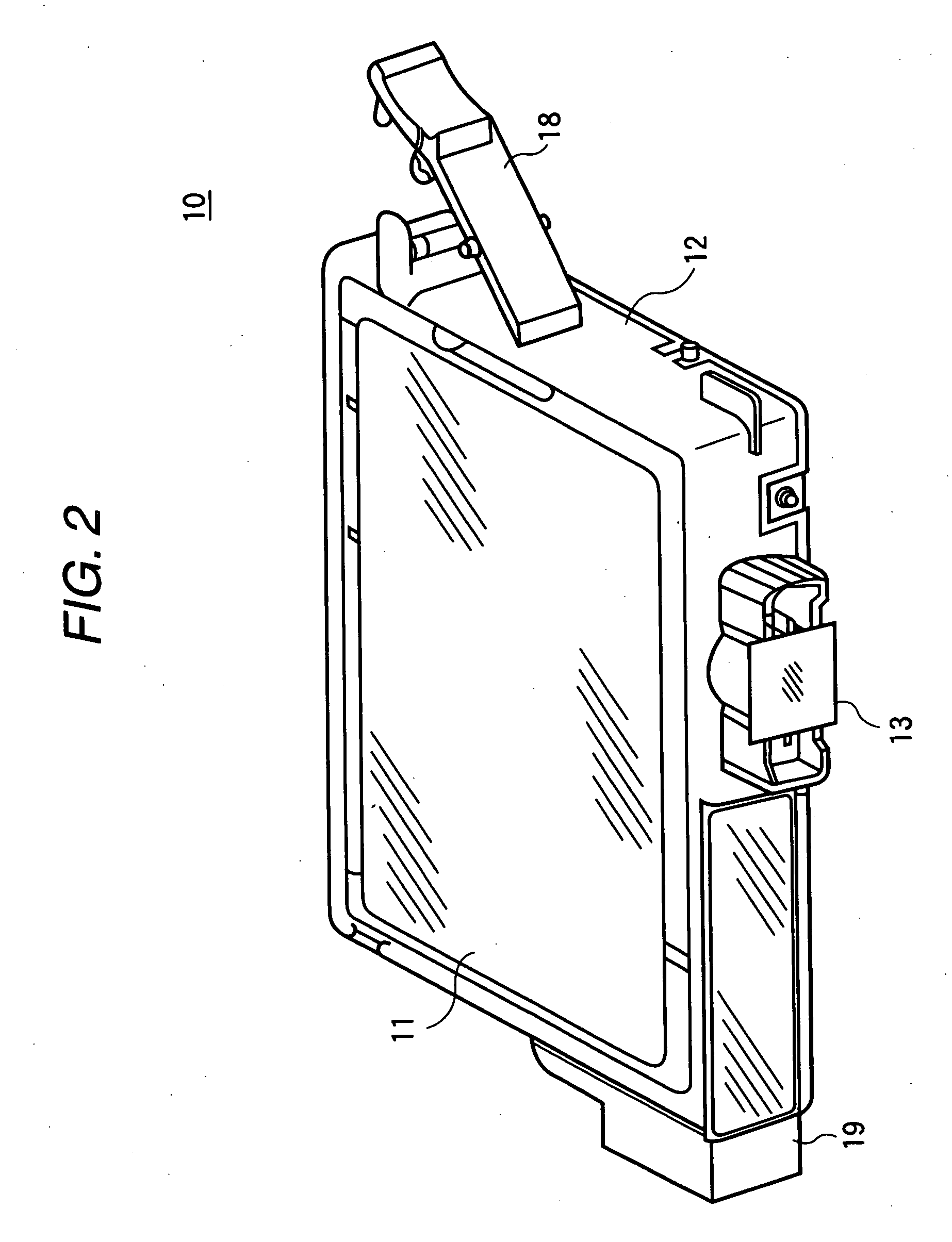

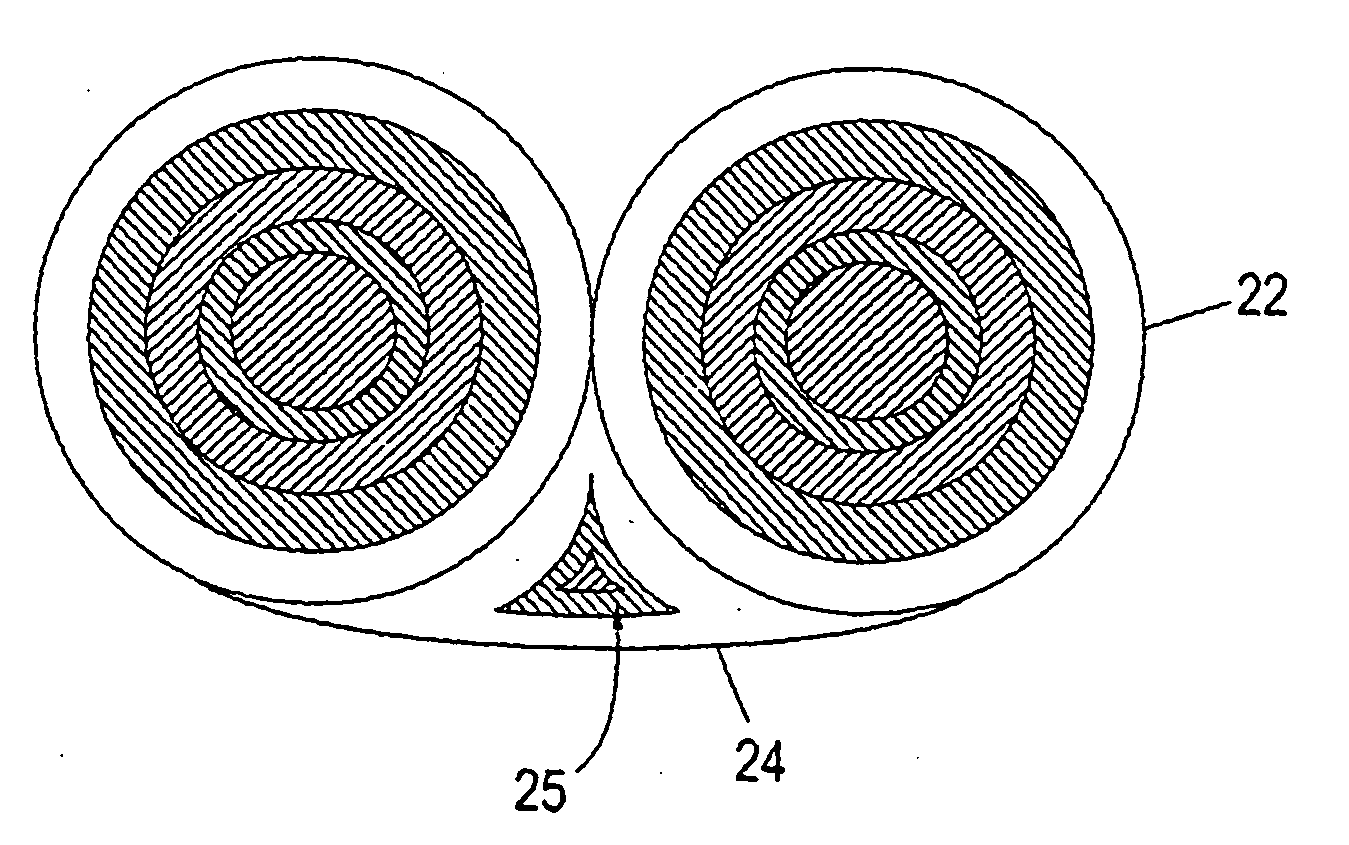

Method of recycling a liquid cartridge

InactiveUS20060053030A1Reduce volumeEfficiently transportData processing applicationsPrintingEngineeringElectronic component

A container is provided with a liquid container for containing a liquid and a liquid supply for discharging the liquid of the liquid container. An electronic component is allowed to store data concerning the liquid contained and exchange data with an external device. A takeout step is to take the electronic component out of the liquid cartridge spent. A screening step is to screen out a reusable electronic component out of the electronic components removed. An attaching step is to attach the electronic component screened, in a new container for the liquid cartridge. A write step is to cause the electronic component to store new information.

Owner:SEIKO EPSON CORP

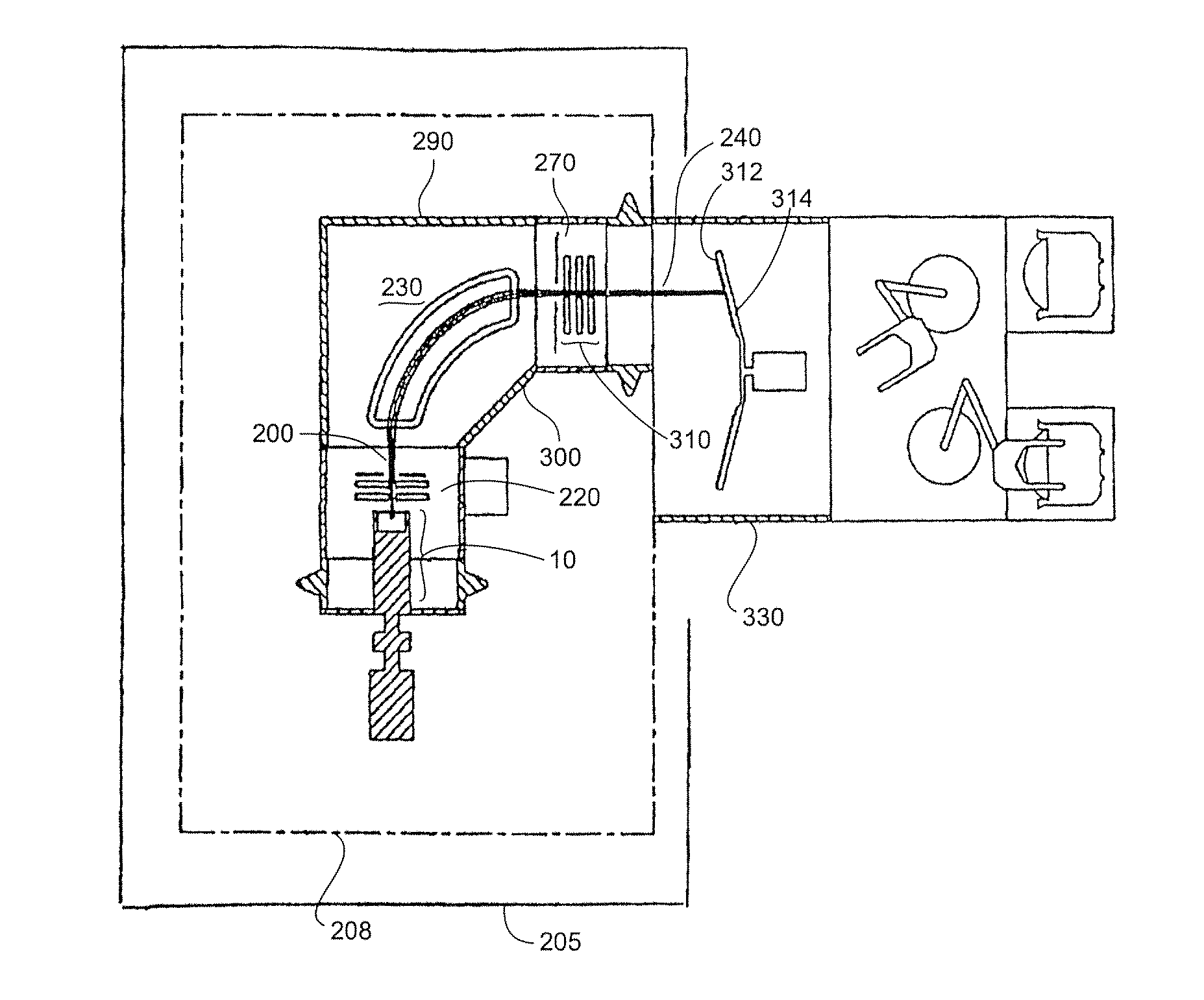

Method and apparatus for treating renal disease with hemodialysis utilizing pulsatile pump

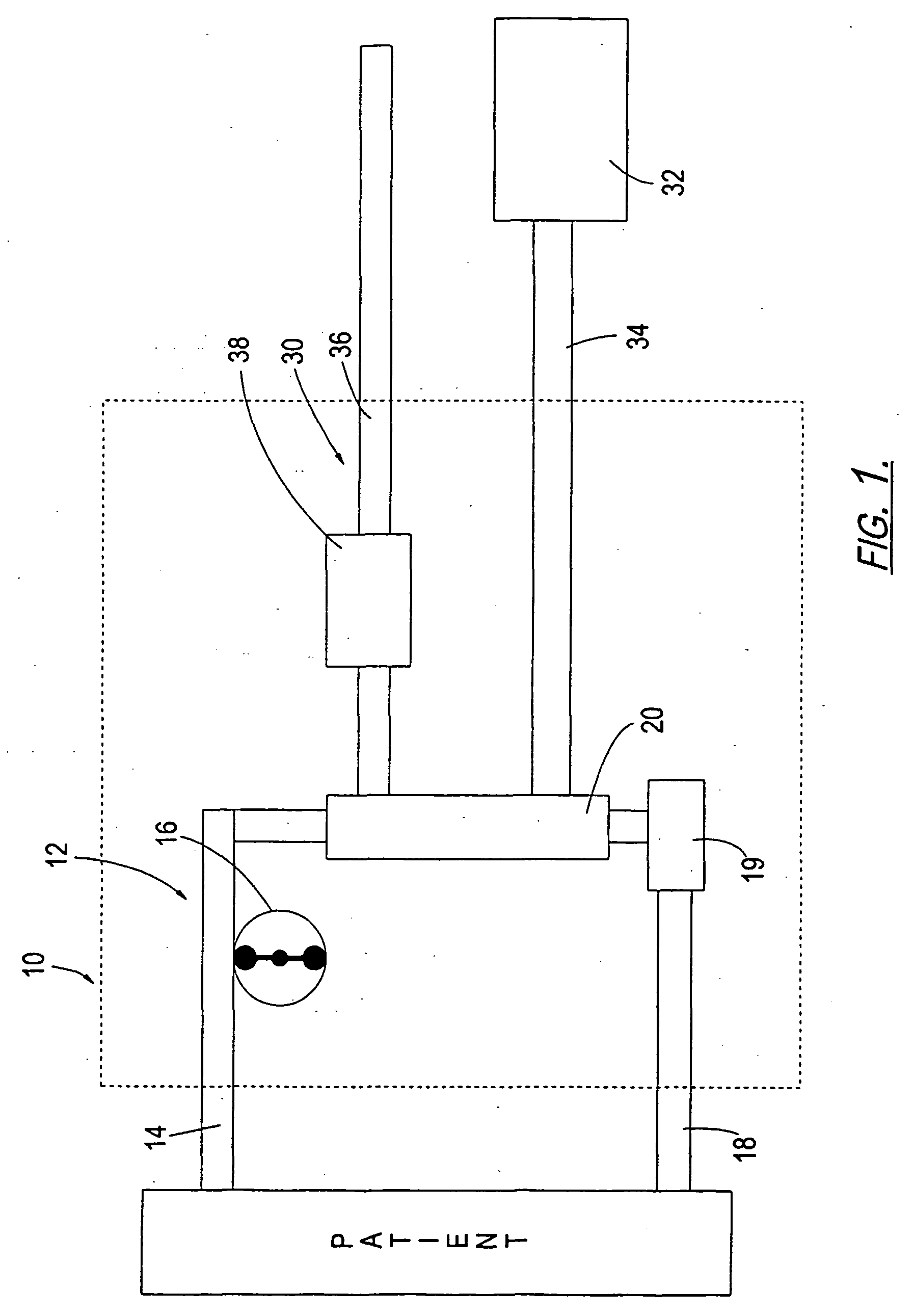

InactiveUS20110098624A1Improve transportation efficiencyDead region can be reducedSemi-permeable membranesControl devicesDiseaseNephrosis

A method of removing toxins from blood from a patient in need of such toxin removal includes: providing a countercurrent dialysis filter (20) having a blood compartment and a dialysate compartment separated from the blood compartment by a semi-permeable membrane; conveying blood from the patient through the blood compartment of a countercurrent filter (20) an back to the patient; and drawing dialysate from a reservoir (32) through the dialysate compartment of the countercurrent filter (20). At least one of the blood or dialysate experiences pulsatile flow. The steps are carried out such that blood toxins are drawn from the blood compartment through the semi-permeable membrane into the dialysate compartment.

Owner:EAST CAROLINA UNIVERISTY

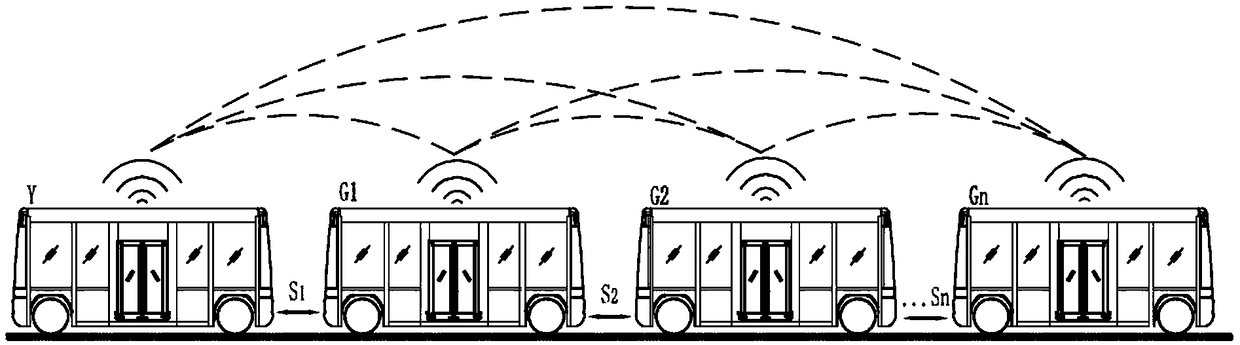

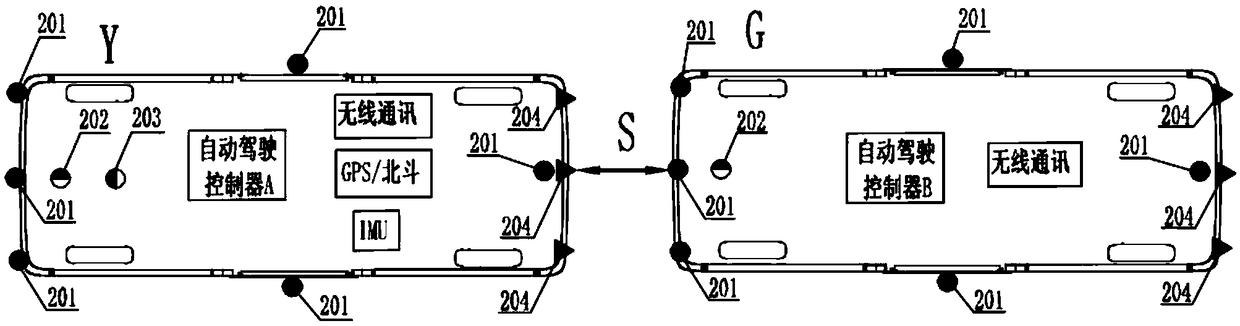

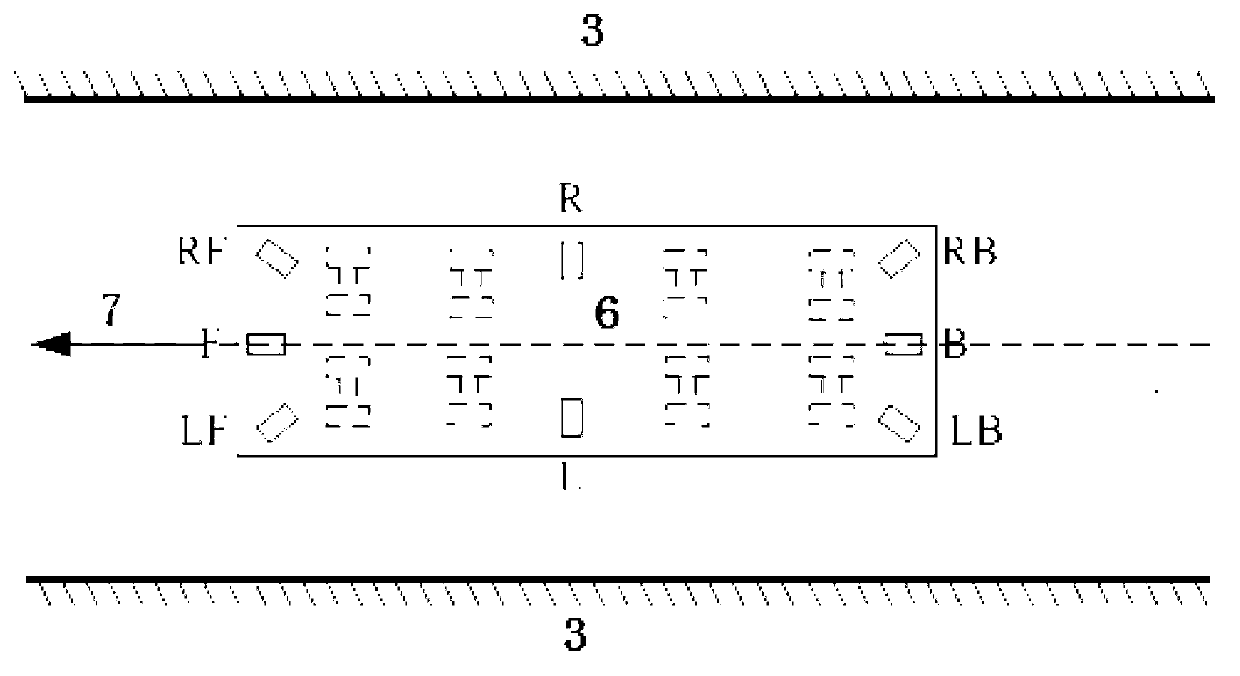

Intelligent grouping vehicle system and control method thereof

PendingCN109062221AFlexible groupingReduce distance between vehiclesPosition/course control in two dimensionsVehiclesE communicationEnergy consumption

The invention discloses an intelligent grouping vehicle system, comprising a guiding vehicle module and following vehicle modules, wherein the number n of the following vehicle modules is determined by the actual traffic demand, wherein n can be 0; the guiding vehicle module of a vehicle queue can at least realize full-automatic driving of L4 level; the following vehicle modules of the vehicle queue can achieve the basic functions of automatic grouping and separation, automatic following and automatic parking; the modules of the vehicle queue realize information interaction and sharing throughwireless communication; and the modules of the vehicle queue can be remotely controlled by a dispatching center, and automatic grouping, automatic separation and automatic parking in a station are performed. The intelligent grouping vehicle system disclosed by the invention comprises one guiding vehicle module and a plurality of following vehicle modules. There is no physical connection among themodules, flexible grouping is achieved, the distance between vehicles can be reduced, the windage is reduced, the energy consumption is reduced, and the transportation efficiency is improved.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

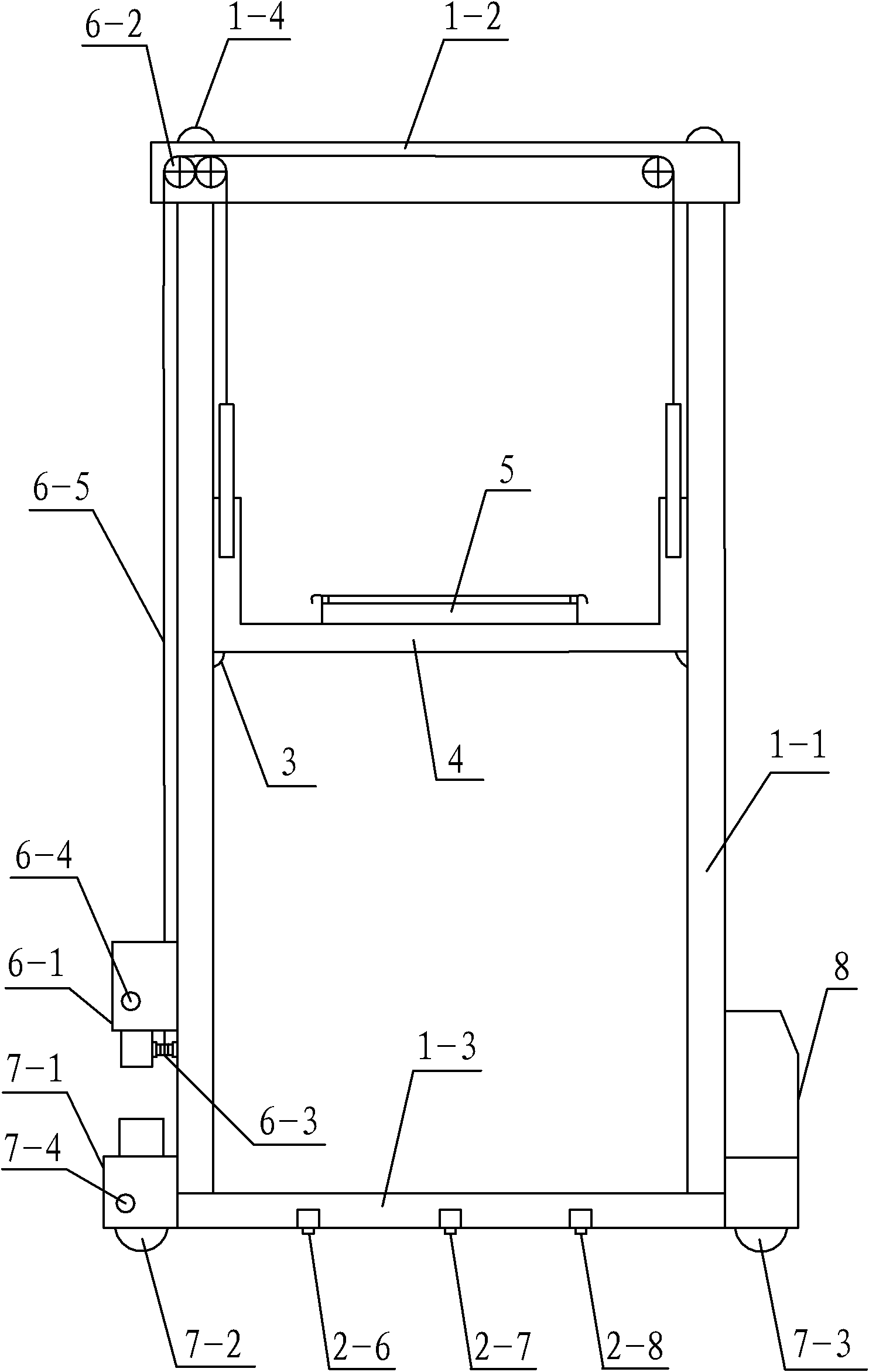

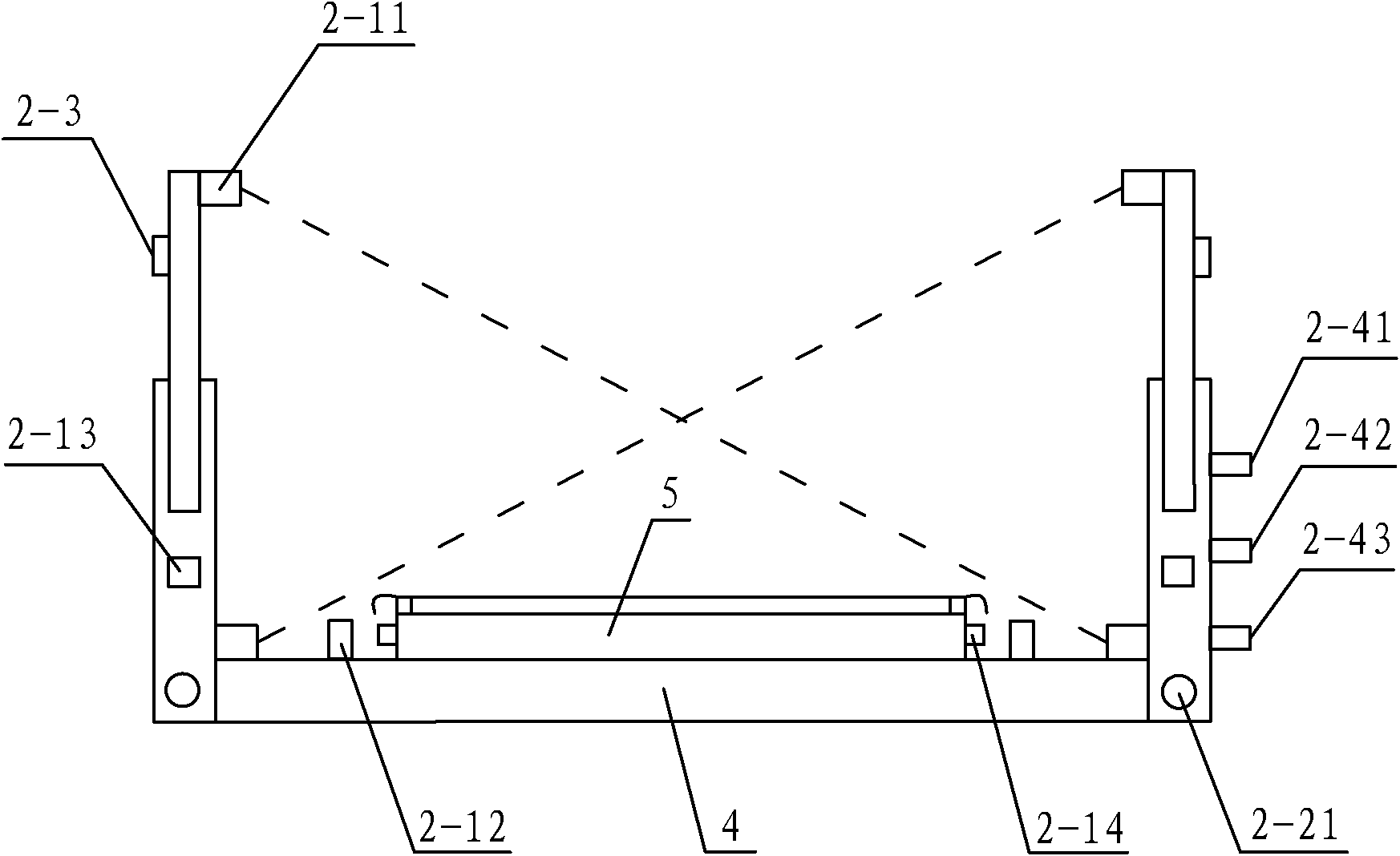

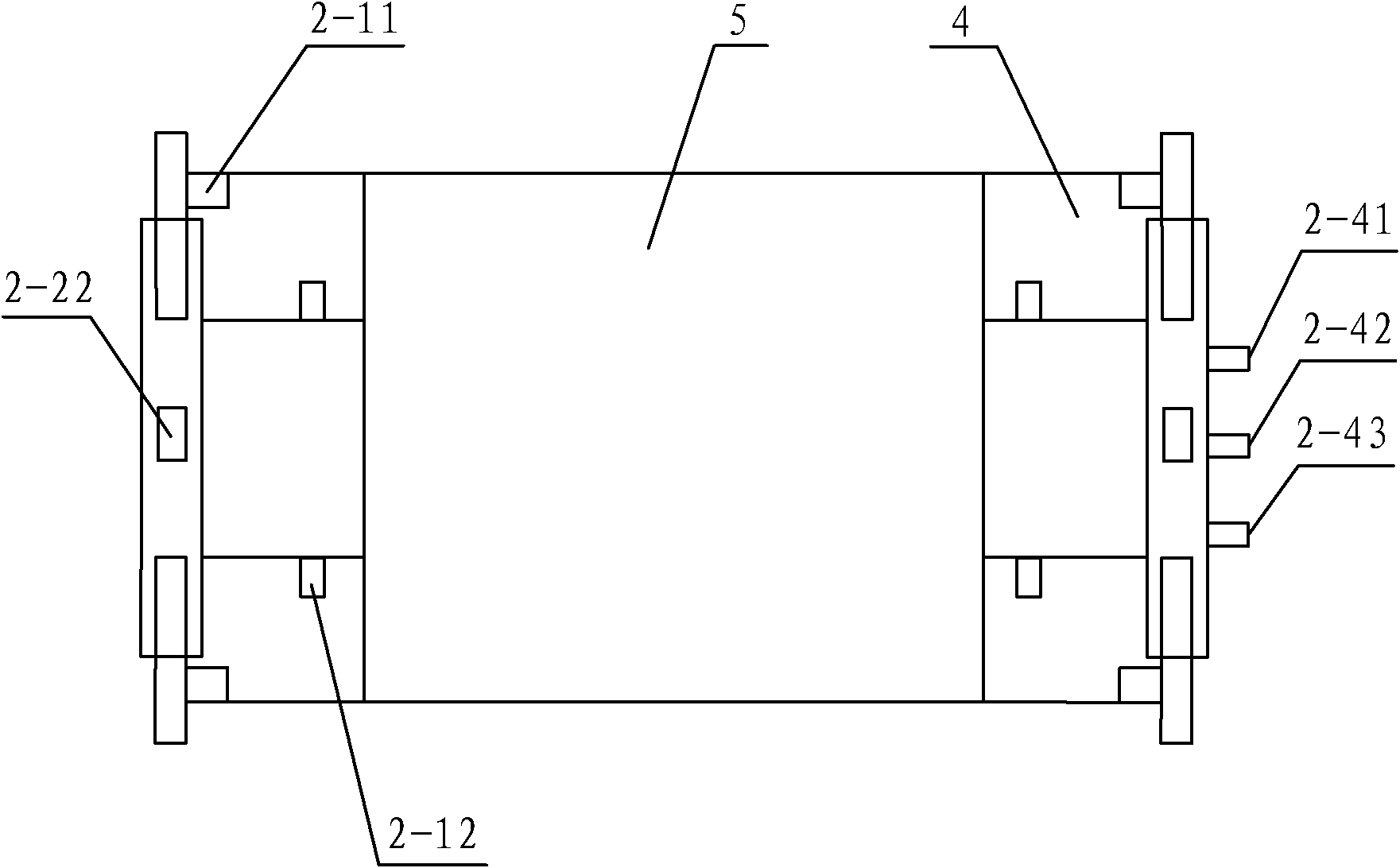

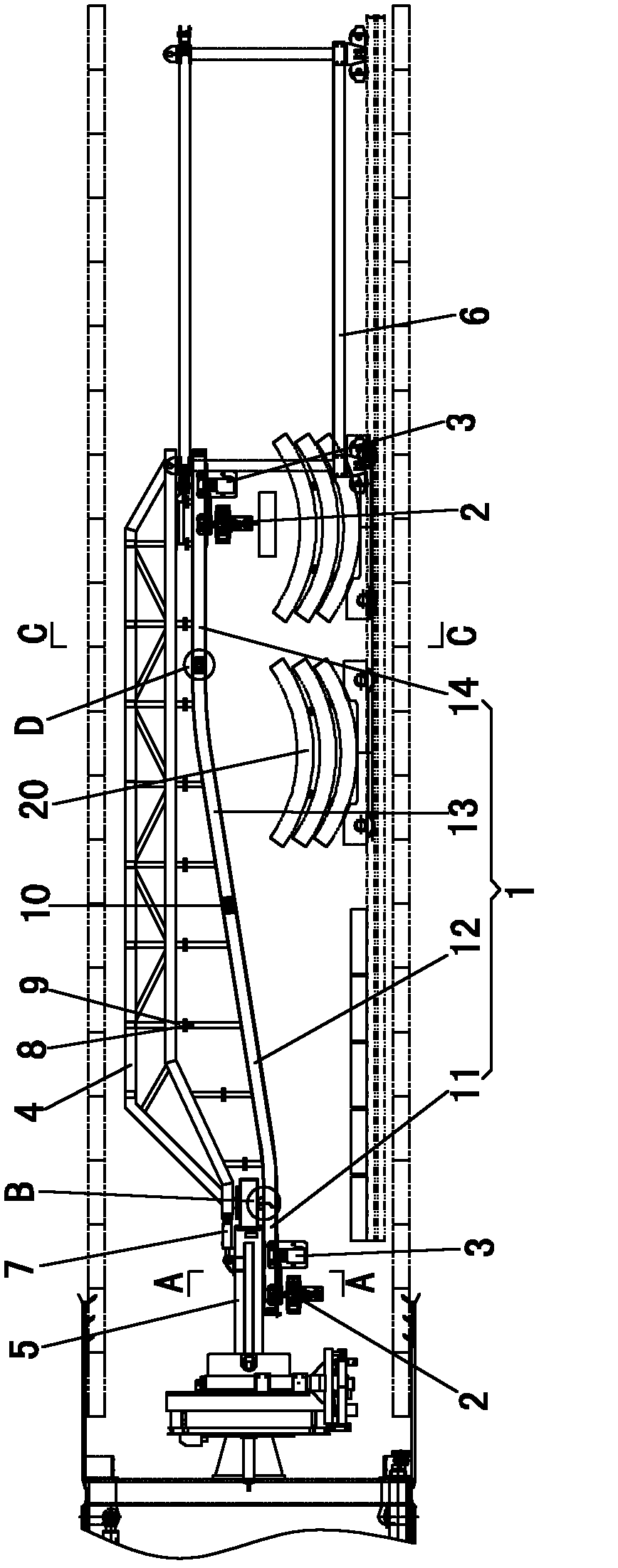

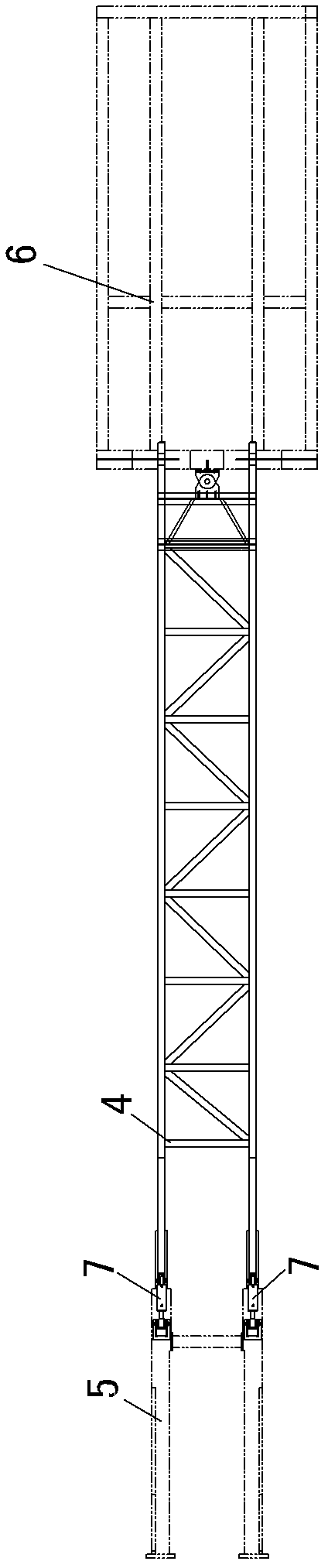

Heavy duty stacker for containers

InactiveCN102040177AReasonable structural designEasy to operateSafety devices for lifting equipmentsDrive wheelOperability

The invention discloses a heavy duty stacker for containers. The heavy duty stacker comprises a stacker frame, a safety protection device, a loading platform, a container hooking and taking device, a lifting device, an operation driving device and an electrical control device, wherein the stacker frame comprises four upright posts, an upper cross beam and a lower cross beam; the safety protection device comprises a cargo state detection device, a broken rope protection device, a power outage protection device, a travel speed-limiting device, a detection and positioning device and a progression speed reduction, walking emergency stop and retreat speed reduction switch; the container hooking and taking device comprises a lower fork, a middle fork, an upper fork and a hooking and taking driving mechanism composed of a normally closed electromagnetic braking motor, a chain wheel and a chain; the lifting device comprises a speed reduction motor, a pulley group, a steel wire rope reel, an encoder and a steel wire rope; and the operation driving device comprises a motor, a driving wheel, a driven wheel and an encoder. The heavy duty stacker is reasonable in structural design, strong in operability, good in safety performance and good in stable performance, and can meet the loading demand of large containers at ports and docks, and be convenient for popularization.

Owner:威仁(西安)仓储设备有限公司

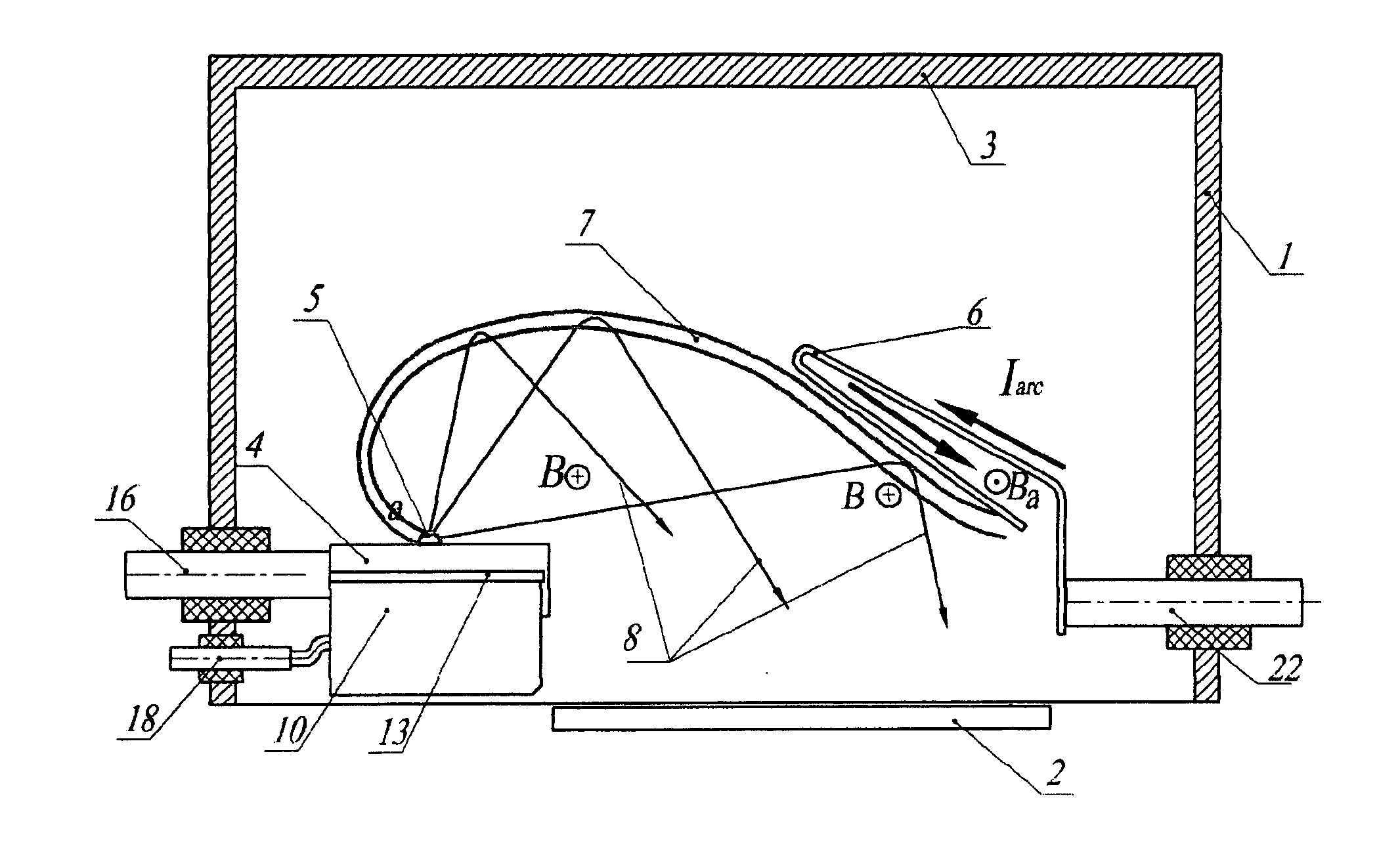

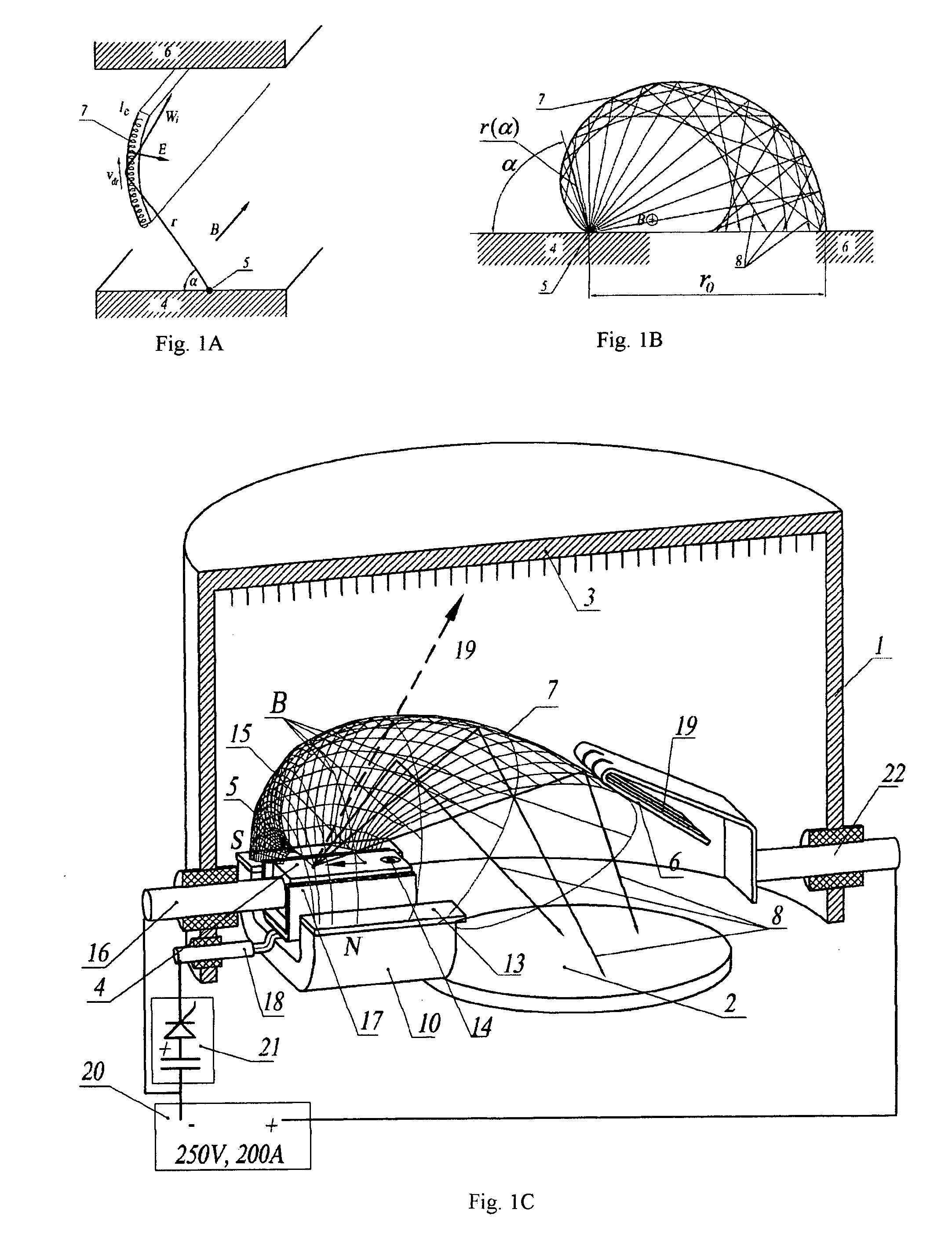

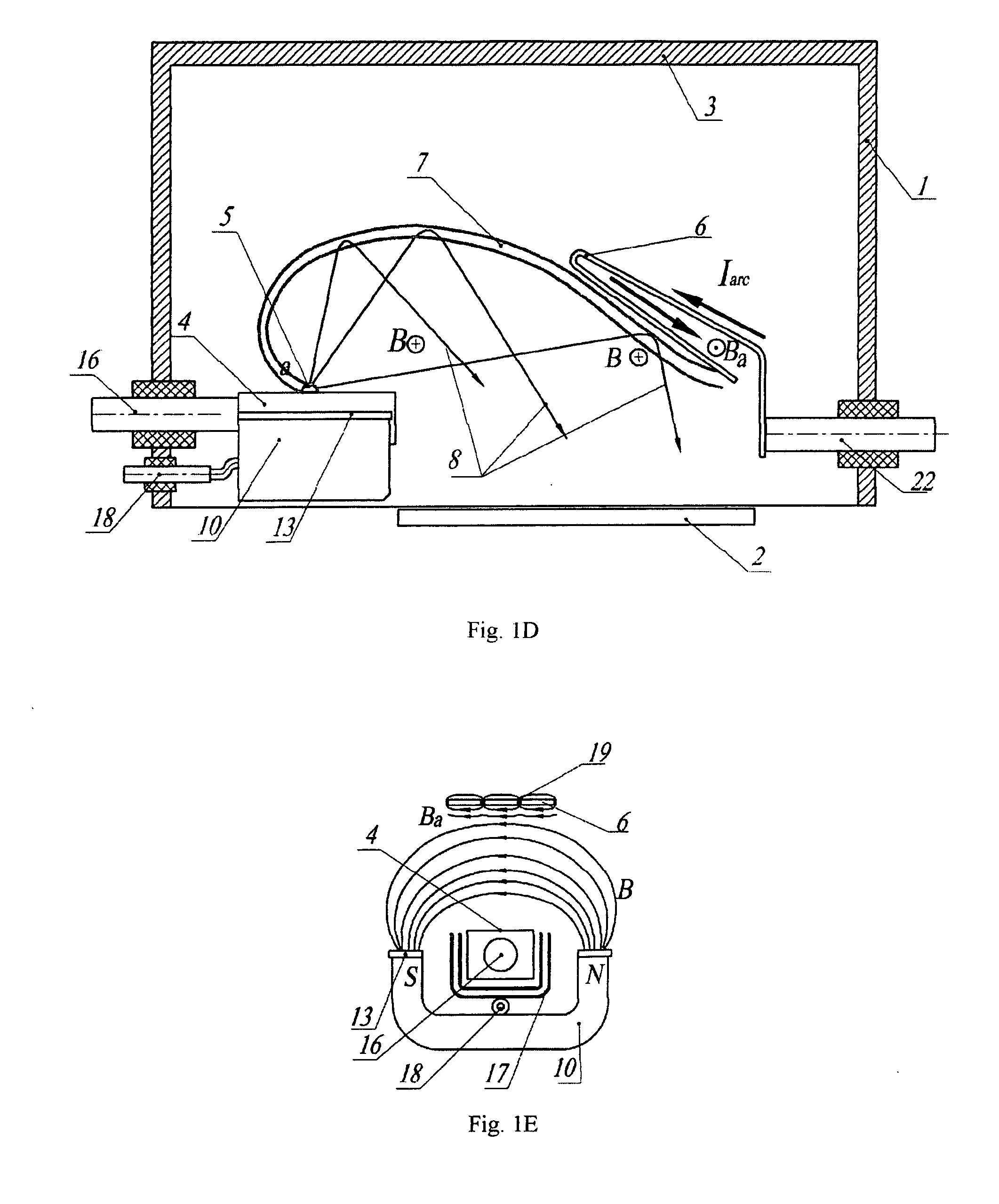

Cathode-arc source of metal/carbon plasma with filtration

InactiveUS20070034501A1Improve transportation efficiencyIncrease the number ofCellsElectric discharge tubesStationary conditionsCurrent sheet

The a cathode-arc source of metal plasma with filtration, used, in particular, for deposition of DLC, utilizes the effect of fast ions reflection from the Hall stratum in a transversal arched magnetic field to filtrate vacuum arc plasma arc from contaminating macroparticles and vapor. Various embodiments for producing maximal plasma flux at the source outlet, in particular, a pulse source with more the one cathode units for deposition of coating inside pipes / cavities, for deposition of coating in a stationary / quasi-stationary condition are offered. The cathode is made of a consumable material and is exposed to poles of magnets on both ends of cathode for creating a transversal magnetic field of an arched configuration in a discharge gap between the cathode and the anode. The anode geometry adequate to the mechanism of the arc current passage through a transversal magnetic field is offered. To avoid longitudinal and transverse short circuits of the current layer, an installation of non-conducting surfaces at ends or sectioned shields under a floating potential at the cathode sides is provided. The method of creating the Hall stratum in said transversal magnetic field of arched configuration is offered.

Owner:BENDER EFIM

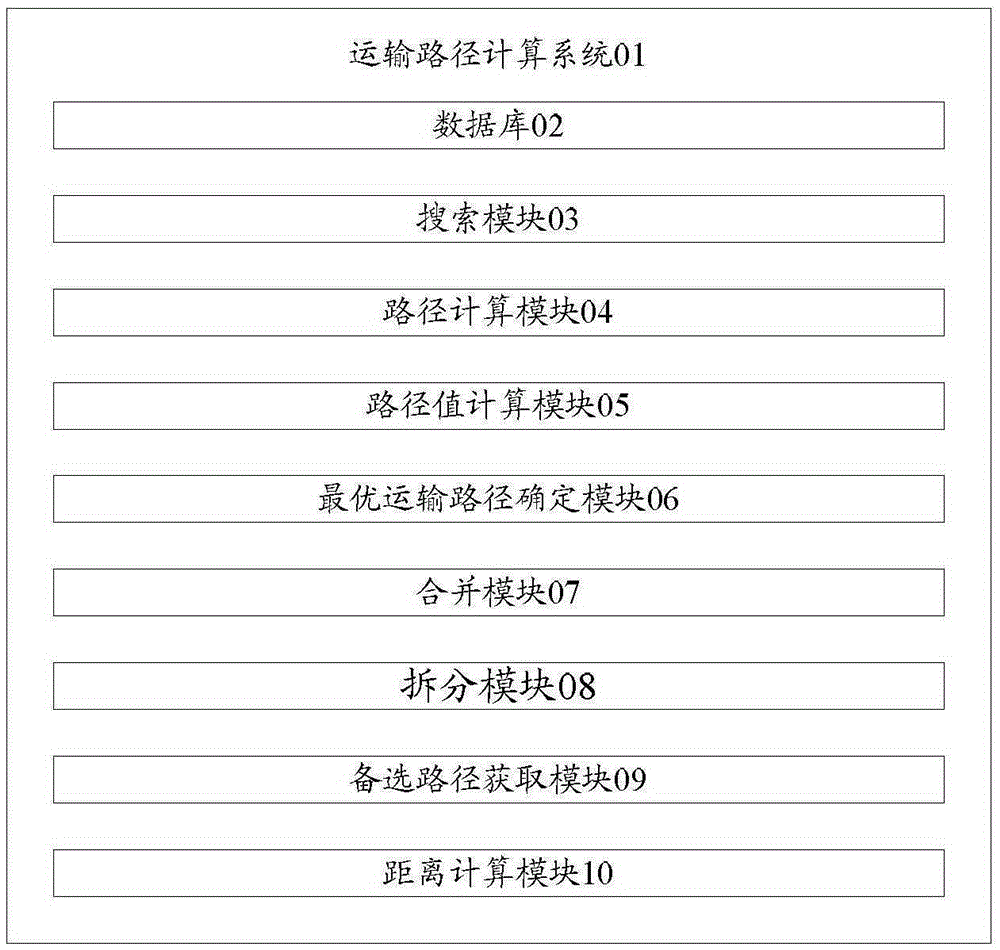

Transportation route calculation system and method

InactiveCN105354633AImprove transportation efficiencyForecastingLogisticsInformation searchingComputing systems

The invention discloses a transportation route calculation system and method. The method comprises: storing location and commodity information of each warehouse in a database; a search module searching all warehouses storing commodities according to the commodity information in an order; a route calculation module taking the searched warehouse location as a transportation starting point, taking a receiving location of the order commodities as a transportation destination, and calculating a transportation route from all transportation starting points to transportation destinations; a route value calculation module calculating a route value of each transportation route according to a preset first weight calculating rule; and an optimal transportation route determination module comparing the route value of each transportation route to determine an optimal transportation route. According to the scheme of the present invention, the commodities can be sent to users in the shortest time, and the transportation efficiency is improved.

Owner:NUBIA TECHNOLOGY CO LTD

Method for checking useful load of auxiliary springs of non-end contact diagonal main and auxiliary spring

ActiveCN105653883AImprove transportation efficiencyImprove securityInformaticsSpecial data processing applicationsEngineeringOblique line

The invention relates to a method for checking a useful load of auxiliary springs of a non-end contact diagonal primary and auxiliary spring, and belongs to the technical field of suspension steel plate springs. The method comprises the following steps: firstly, determining an endpoint deformation coefficient and the half rigidity of each main spring, as well as a deformation coefficient Gx-CB of the contact point between an Nth main spring and the auxiliary spring at an oblique line segment according to a structural dimension and an elastic modulus of the diagonal variable cross-section main spring with non-isostructural end parts; then, checking the useful load of the auxiliary springs of the non-end contact few-leaf diagonal variable cross-section main and auxiliary spring according to the thicknesses of root straight sections of the main springs, Gx-CB of the Nth main spring, the half rigidity of each main spring and a design value of the clearance Delta between the main springs and the auxiliary springs. The simulated verification shows that an accurate checking value of the useful load of the auxiliary springs of the non-end contact diagonal main and auxiliary spring can be obtained by using the method, the design level and performance of products are improved, the vehicle running smoothness is improved, meanwhile, the design, manufacturing and test costs are reduced, and the product development speed is increased.

Owner:平邑经济开发区投资发展有限公司

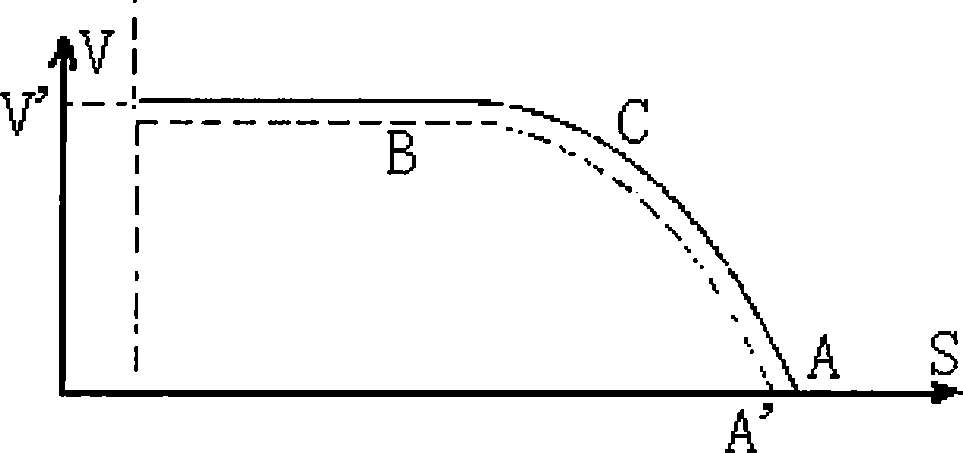

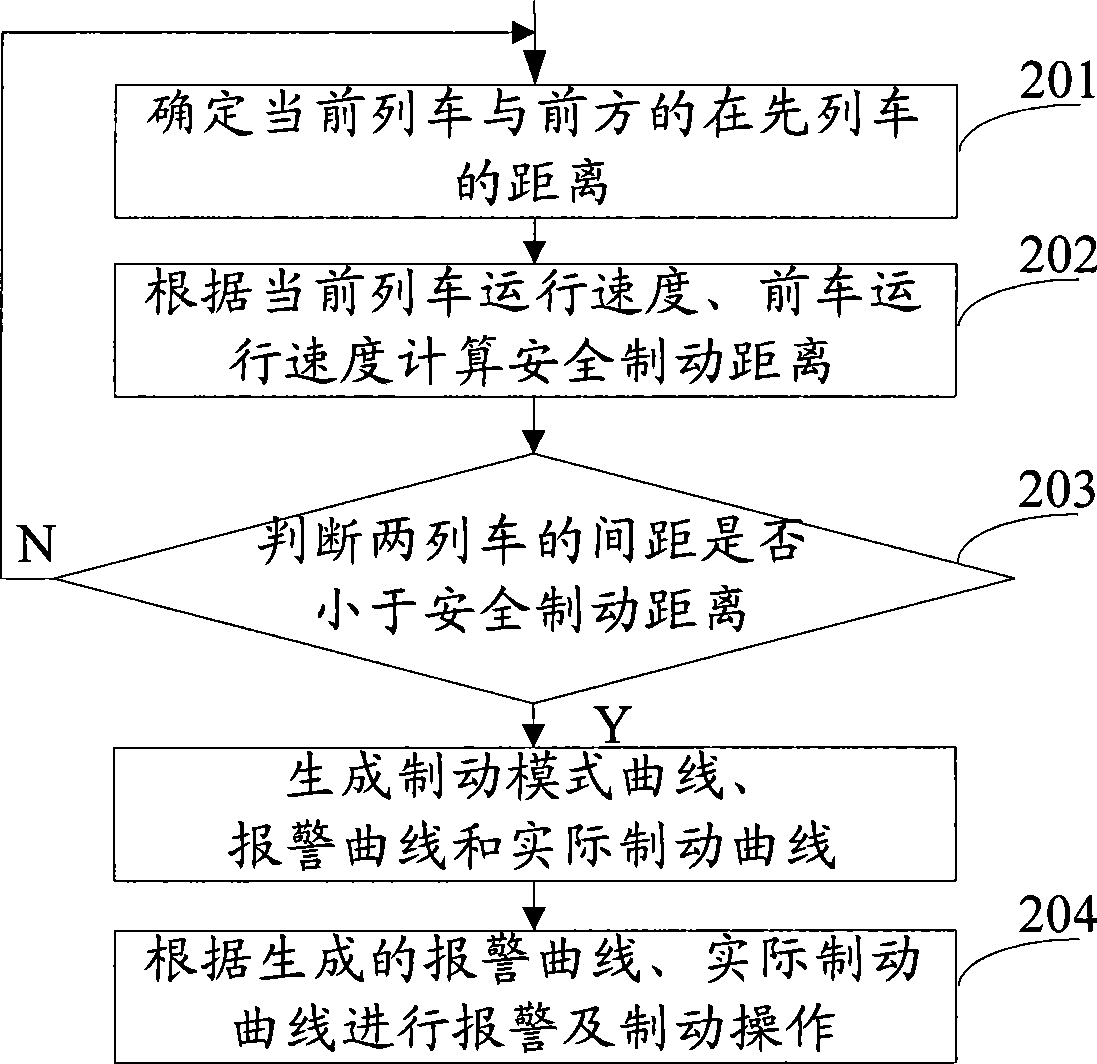

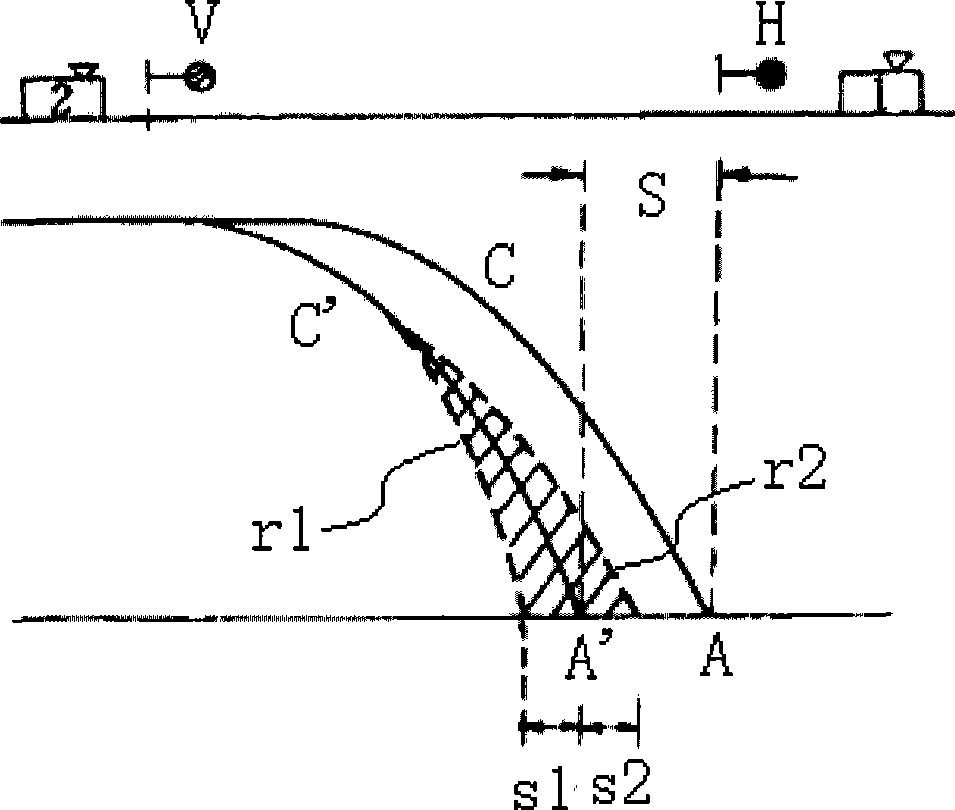

Speed controlling method for running of combined train

ActiveCN101480962ARealize security protectionImprove transportation efficiencyRailway signalling and safetyControl theoryBraking distance

The invention provides a running speed control method of a combined train. The method comprises following steps: A, the present distance between the train and an object is confirmed; B. the present safe braking distance between the train and the object is calculated; C, when the present distance between the train and the object is judged to be smaller than the safe stopping distance, a braking mode curve is generated to perform braking. By adopting the method, the speed of the combined train can be controlled in real time on a whole rail way, and the signaling security of the transportation of the train can be improved.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD +1

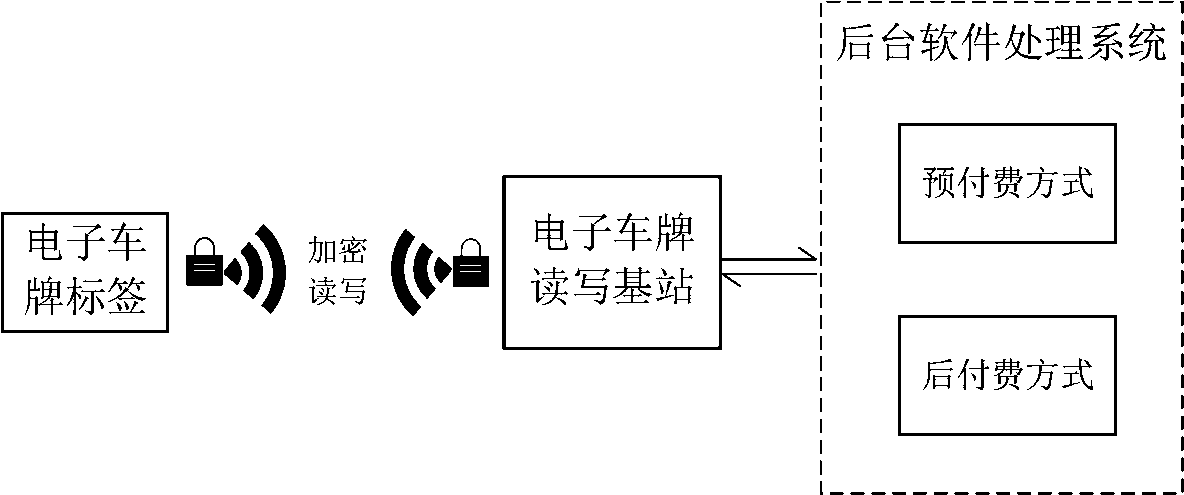

Electronic number plate free flow charge payment method

InactiveCN104112296AImprove transportation efficiencySimplify the payment processTicket-issuing apparatusPaymentEngineering

The invention discloses an electronic number plate free flow charge payment method. The electronic number plate free flow charge payment method is characterized by comprising an electronic number plate tag, an electronic number plate read-write base station and a background software processing system, wherein the electronic number plate tag is installed on a vehicle, the electronic number plate read-write base station is mounted on a charge road, the background software processing system performs information records in a background and operates charge rules, and the free flow charge payment method supports a prepayment method and a post-payment method. The charge payment method relies on support of the background software processing system, a lane where a vehicle is located, front and back positions, passing time or speed is not required to be confirmed, multiple electronic number plate tags can be read simultaneously on multiple lanes, and electronic identity verification and charge payment processes of multiple vehicles can be achieved simultaneously.

Owner:JIANGSU BELLON TECH

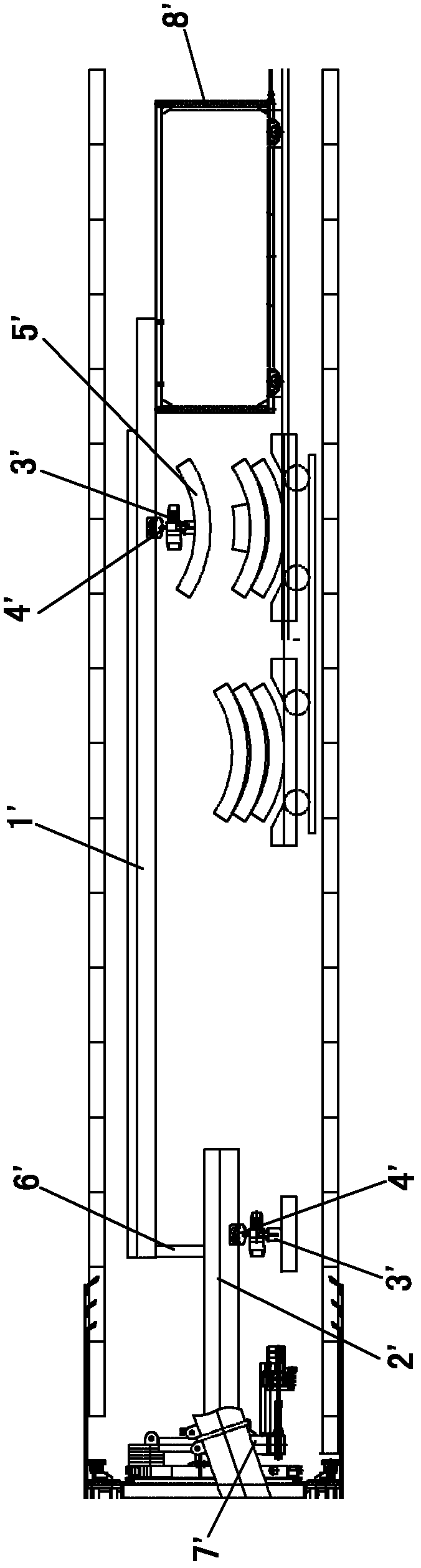

Tube segment shipping and trolley towing integrated device of shield machine

InactiveCN102381635AImprove transportation efficiencyReduce manual labor intensityUnderground chambersTrolley cranesShield machineEngineering

The invention relates to a tube segment shipping and trolley towing integrated device of a shield machine, belonging to the technical field of tunneling equipment. The integrated device comprises a two-track beam, a pair of electric hoists mounted under the two-track beam, a travelling trolley towing the electric hoists to travel and a connecting frame; the connecting frame is mounted on the two-track beam; the two-track beam is mounted between a traveling beam of a tube segment assembling machine and a first-section trolley of a back affiliated system; the front-station working end and the back-station working end of the two-track beam are horizontal beams, and a middle part of the two-track beam is an tilted beam; the front end of the two-track beam is lower than the back end of the two-track beam; the connecting frame is a truss structure; the left side and the right side of the connecting frame are respectively connected with the two beams of the two-track beam; the front end of the connecting frame is movably connected with the traveling beam of the tube segment assembling machine; and the back end of the connecting frame is connected with the first-section trolley of the back affiliated system through a pin shaft. The tube segment shipping and trolley towing integrated device of the shield machine provided by the invention has a simple structure, the bearing strength is enhanced under the premise of not increasing the weight, the shipping efficiency is high, the labor intensity for workers is lowered, and the cost and the failure rate of equipment are lowered.

Owner:BEIJING SANY HEAVY MASCH CO LTD

Control method for implementing coordinated operation of multiple vehicle groups of hydraulic heavy duty truck

InactiveCN103217978ACoordinated controlEasy to correctPosition/course control in two dimensionsArea networkSteering angle

The invention relates to a control method for implementing coordinated operation of multiple vehicle groups of a hydraulic heavy duty truck, which can be used for implementing unmanned automatic driving of a roadway trackless wheel-type hydraulic heavy duty truck. Positions between vehicle bodies and a roadway are determined by applying an ultrasonic distance measurement principle; various information of the truck, which is measured by ultrasonic distance measurement sensors, is transmitted to a central processor; information of the truck relative to the roadway, such as a vehicle body speed, a steering angle, a traveling track and a path, is calculated by the processor according to a set program; the position information is uploaded to a CAN (Controller Area Network) bus system for being called by a next truck; a next truck processor downloads posture information of a previous truck from a CAN bus; according to the posture information of the previous truck, the processor operates geometrical parameters required for tracking the movement track of the previous truck according to a control program so as to determine the movement track of the next truck and fulfill the aim that the next trunk automatically tracks the previous truck, thereby implementing steering control of the split heavy duty transportation truck.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com