Patents

Literature

76results about How to "Less pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

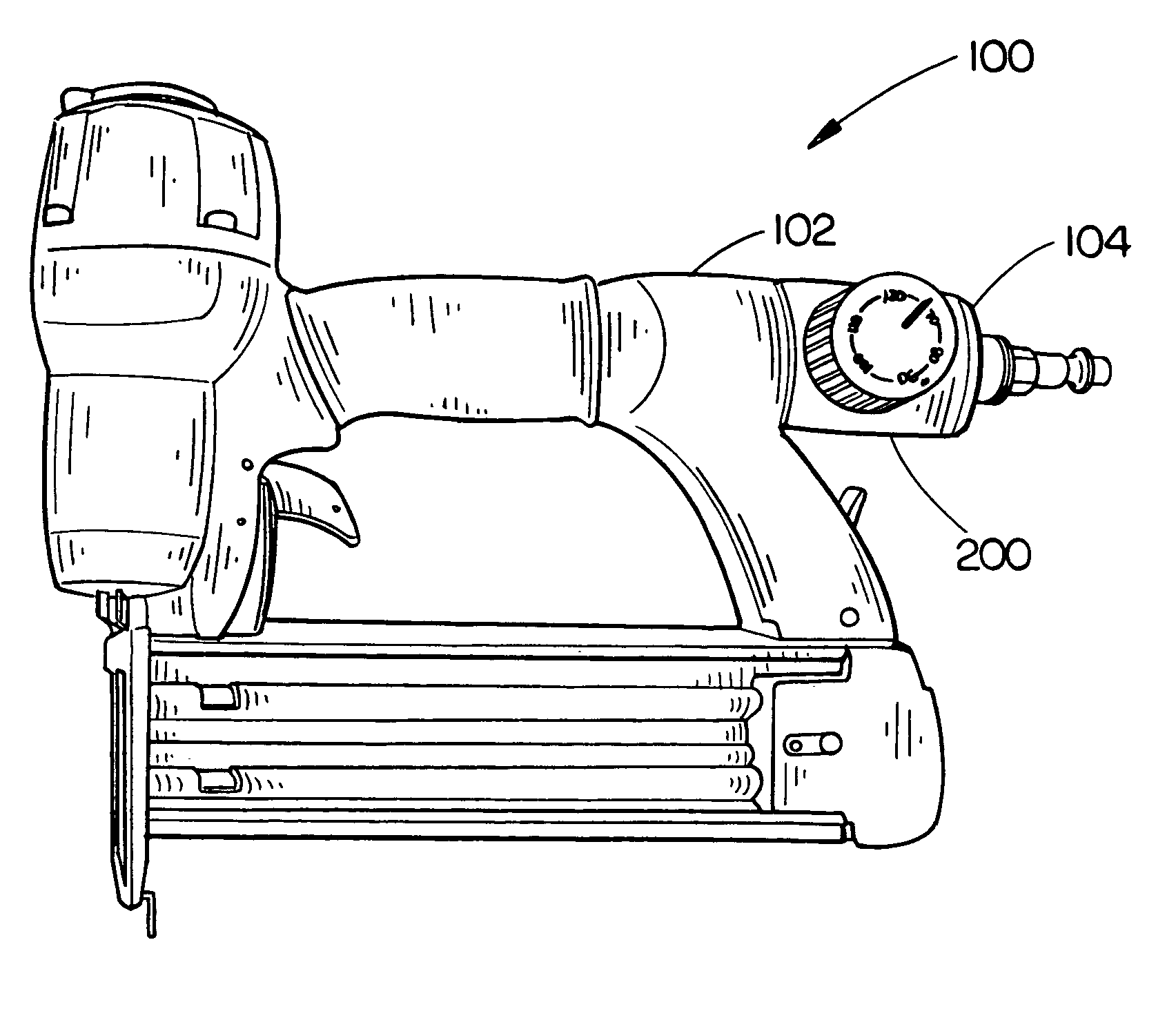

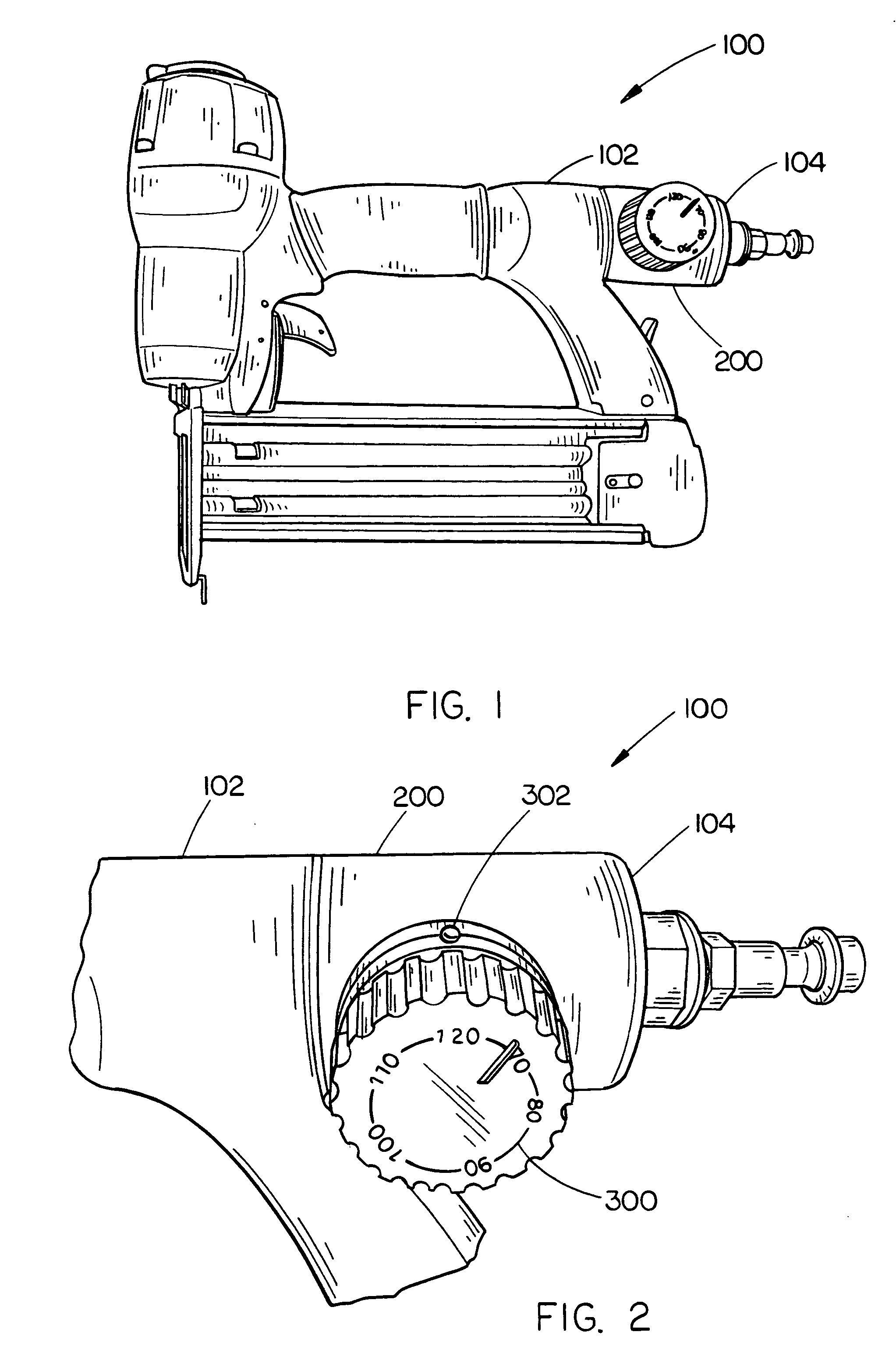

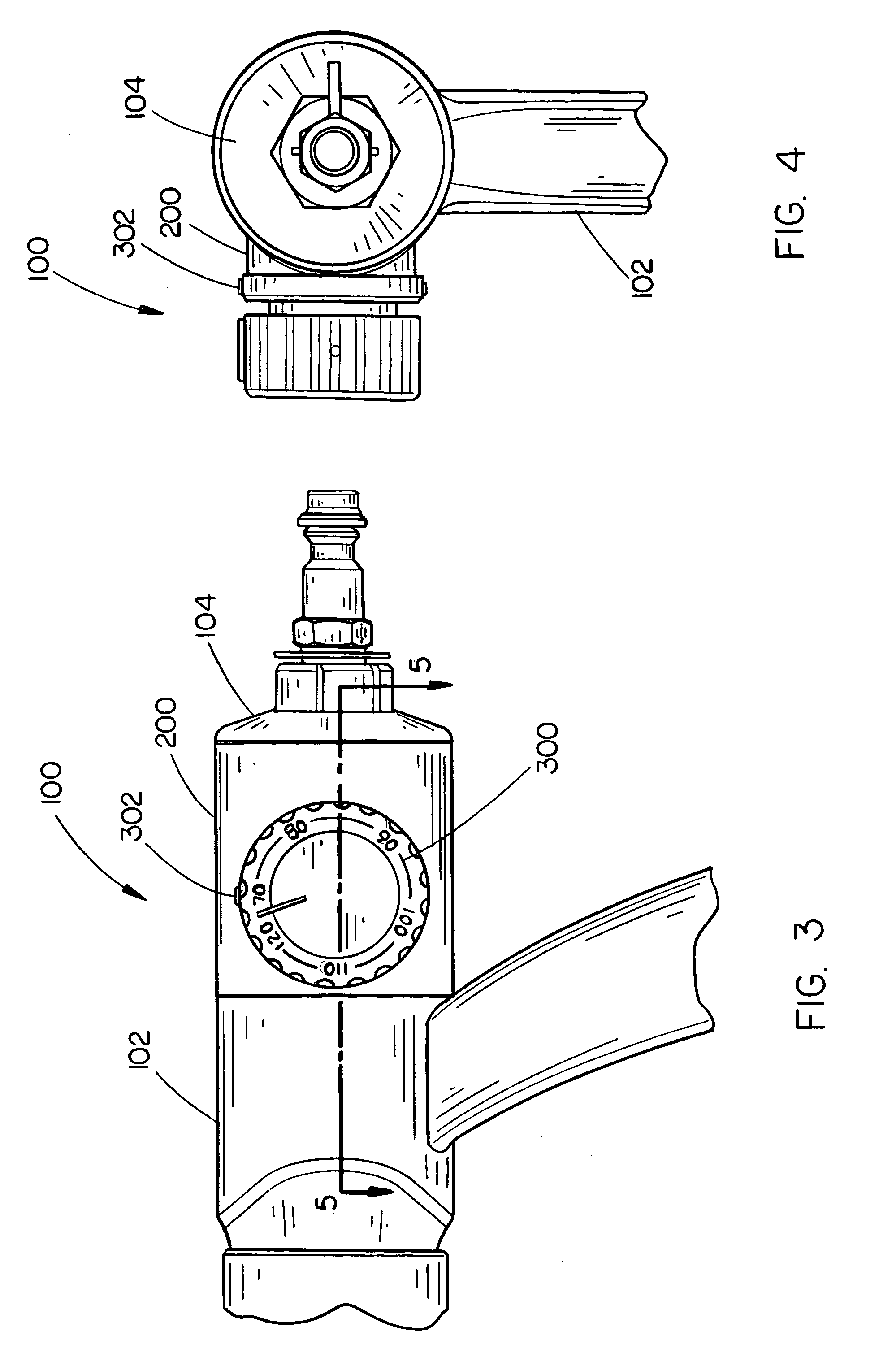

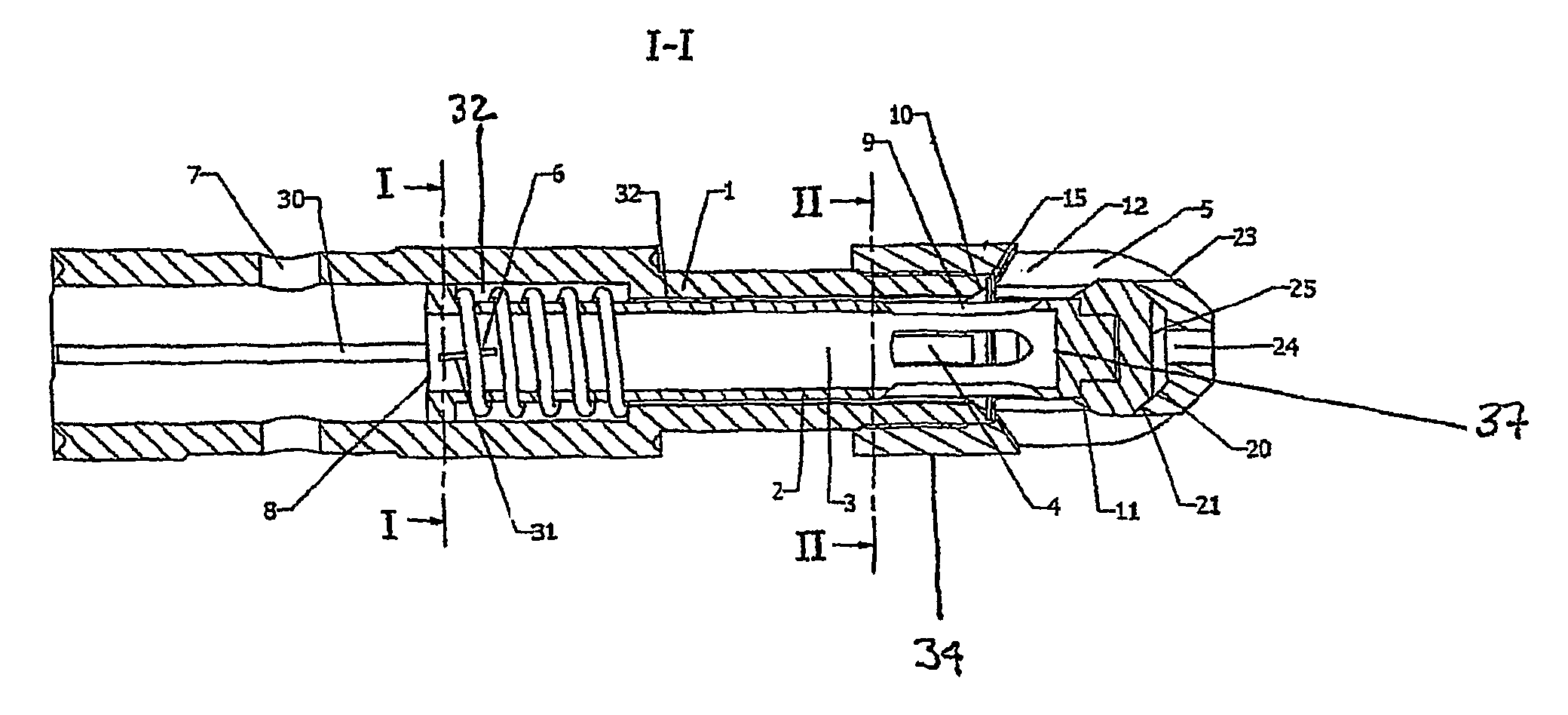

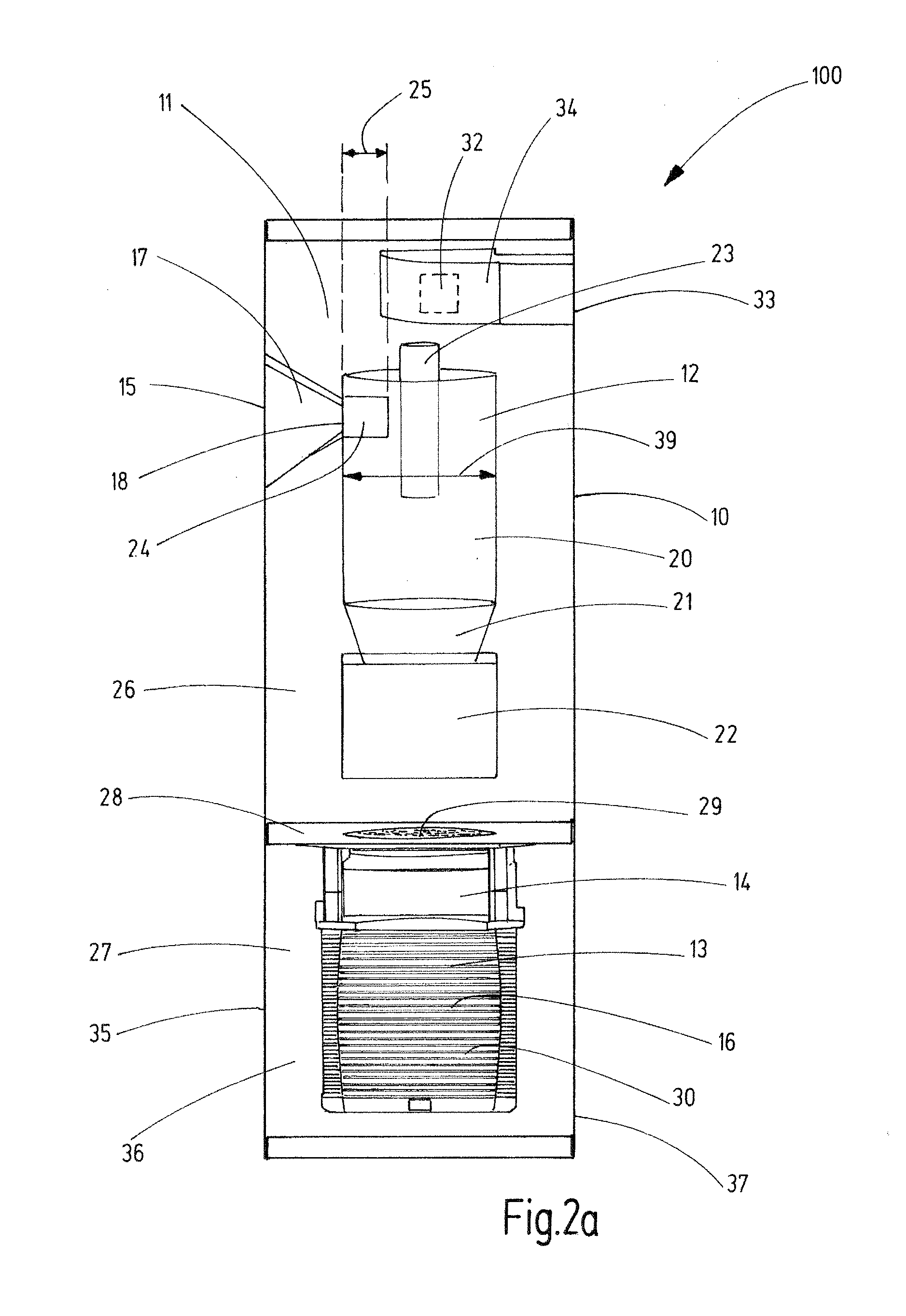

Integrated air tool and pressure regulator

InactiveUS20050247750A1Less pressure lossImprove transportation efficiencyStapling toolsOperator-supported drilling machinesDistribution systemPneumatic tool

The integrated air tool and pressure regulator assembly allows several air tools to operate from a single air compressor, using a simplified air hose distribution system. An operator may independently adjust the regulated pressure of the integrated air tool and pressure regulator assembly to compensate for varying working conditions. A greater air hose supply pressure may be used, as regulation of air pressure is accomplished at the integrated air tool and pressure regulator assembly. The increased air transport efficiency allowed by the integrated air tool and pressure regulator assembly of the present invention may provide for the use of smaller diameter hose, which may be lighter, more flexible, less costly, and the like.

Owner:BLACK & DECKER INC

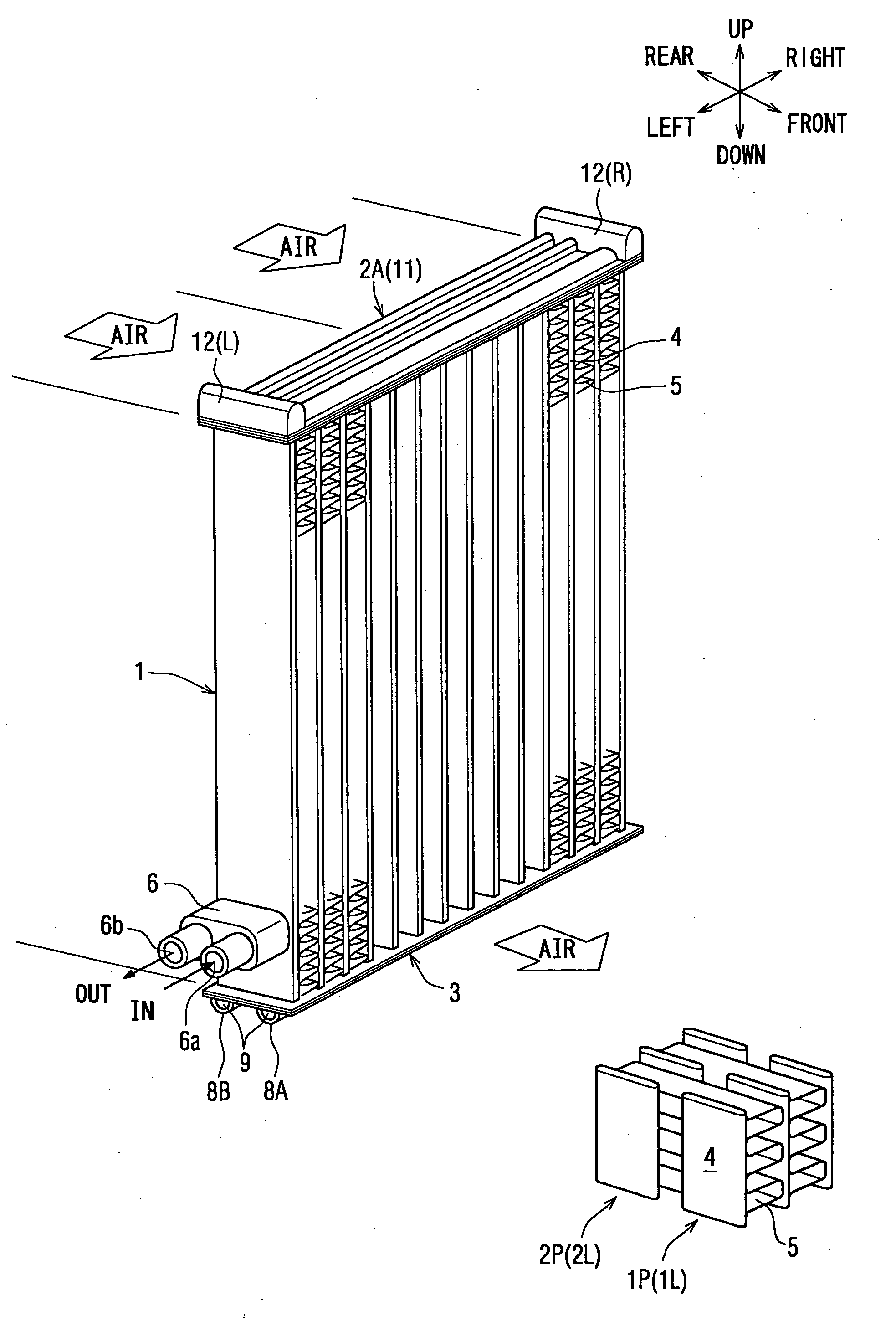

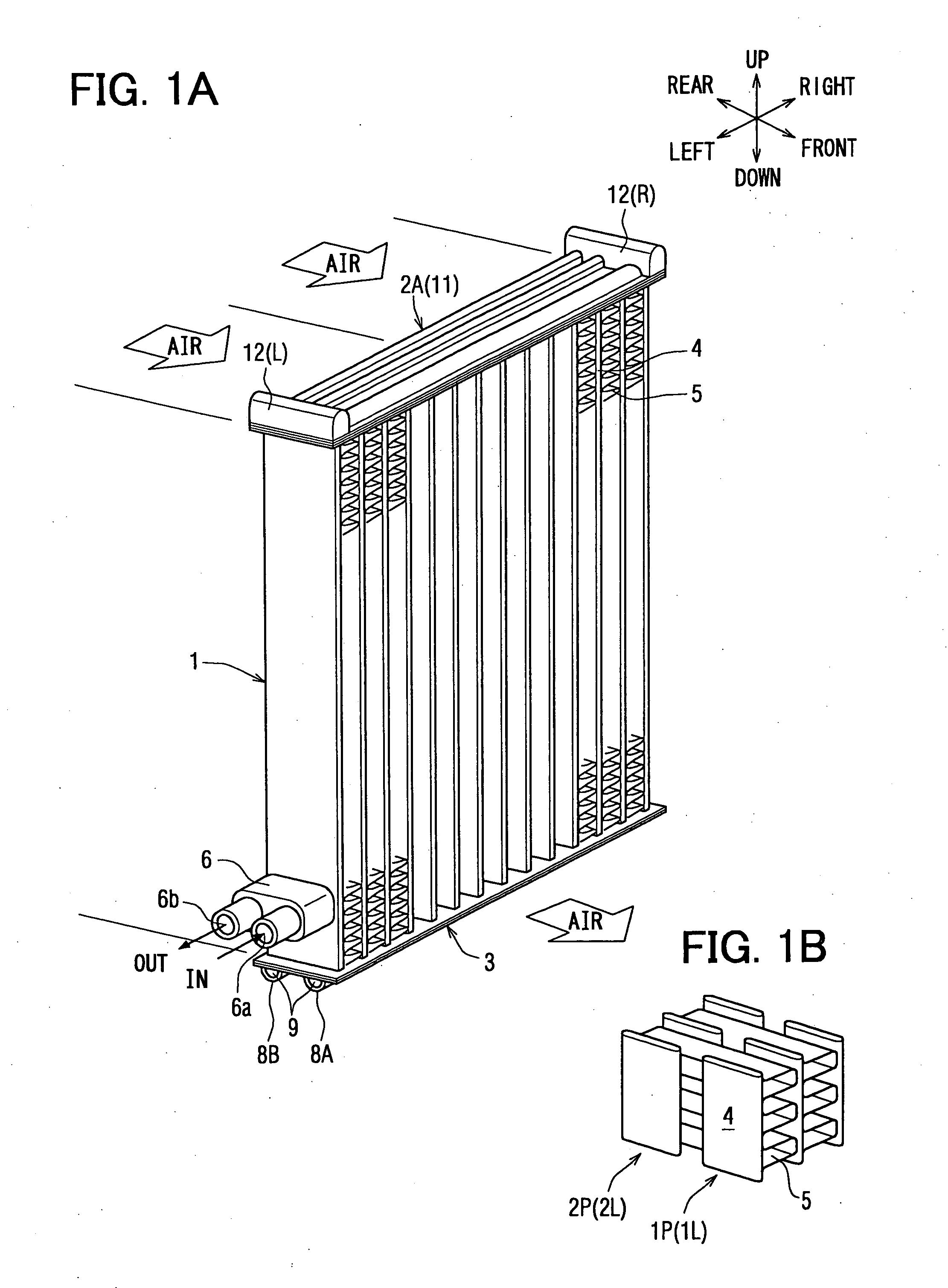

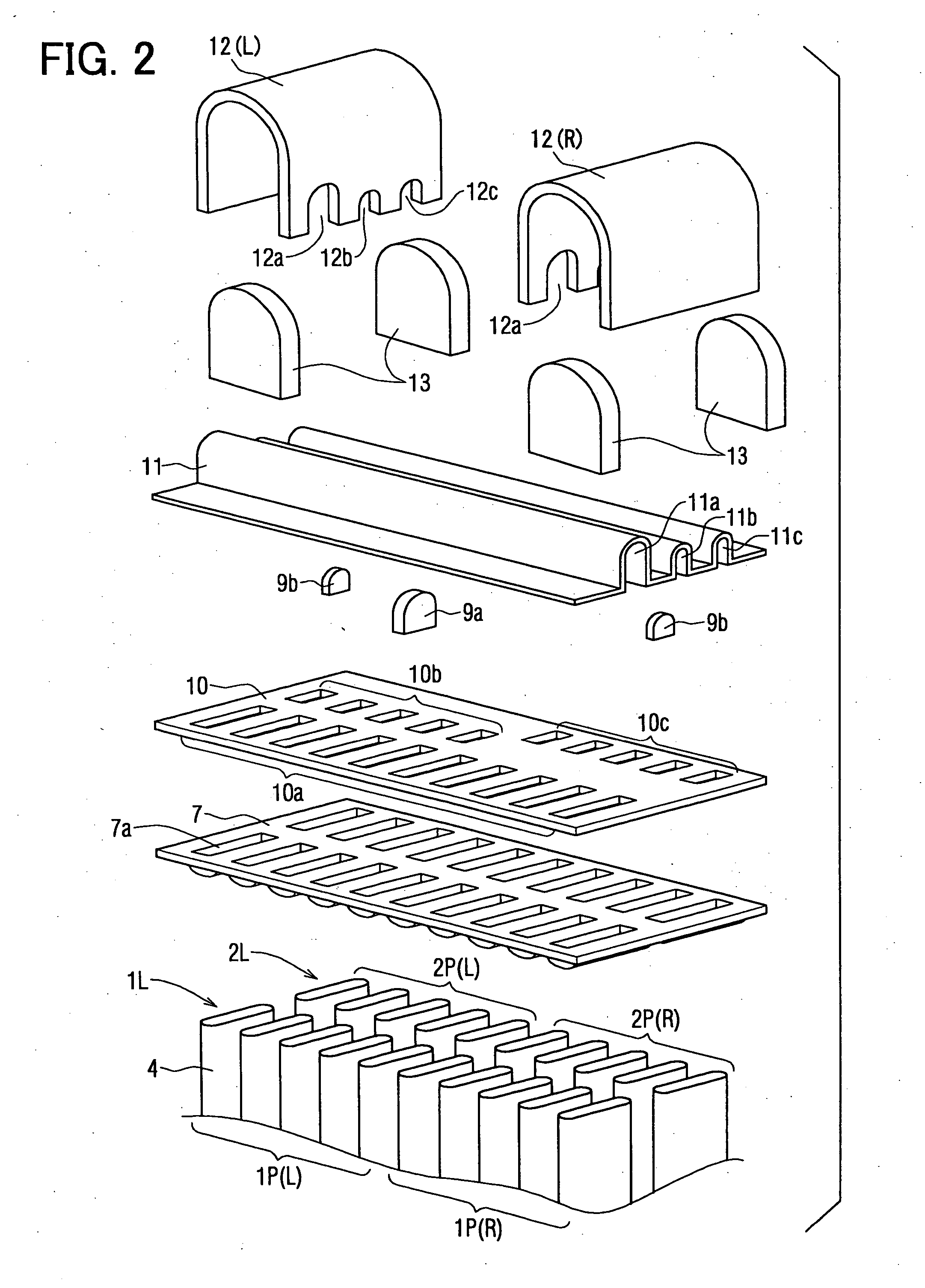

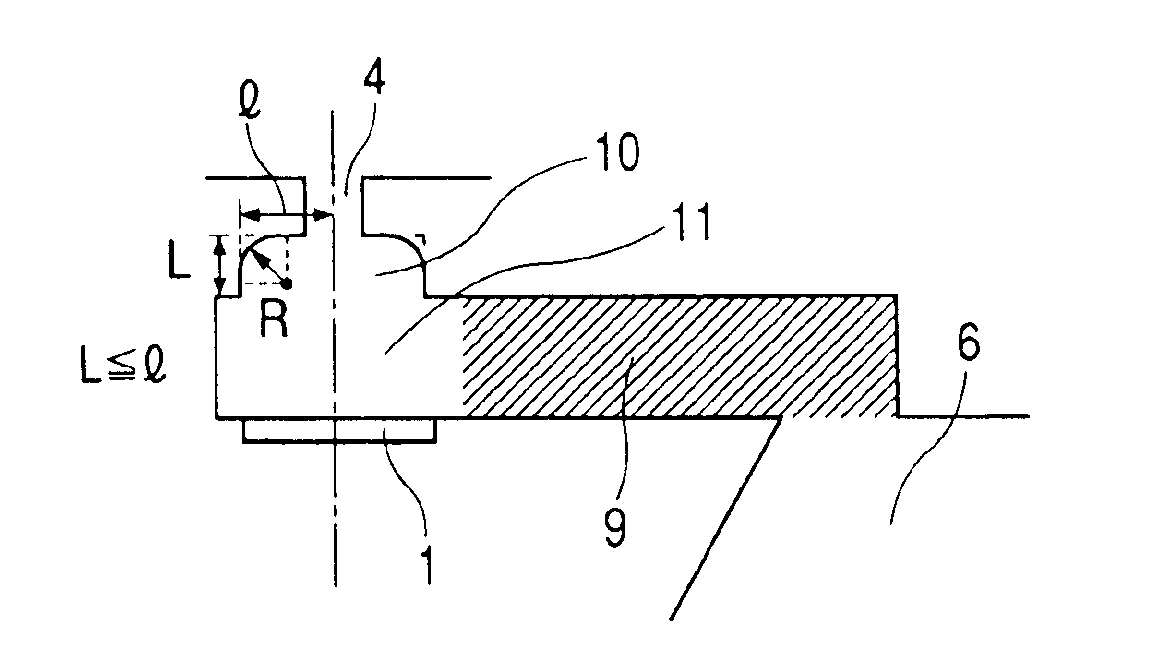

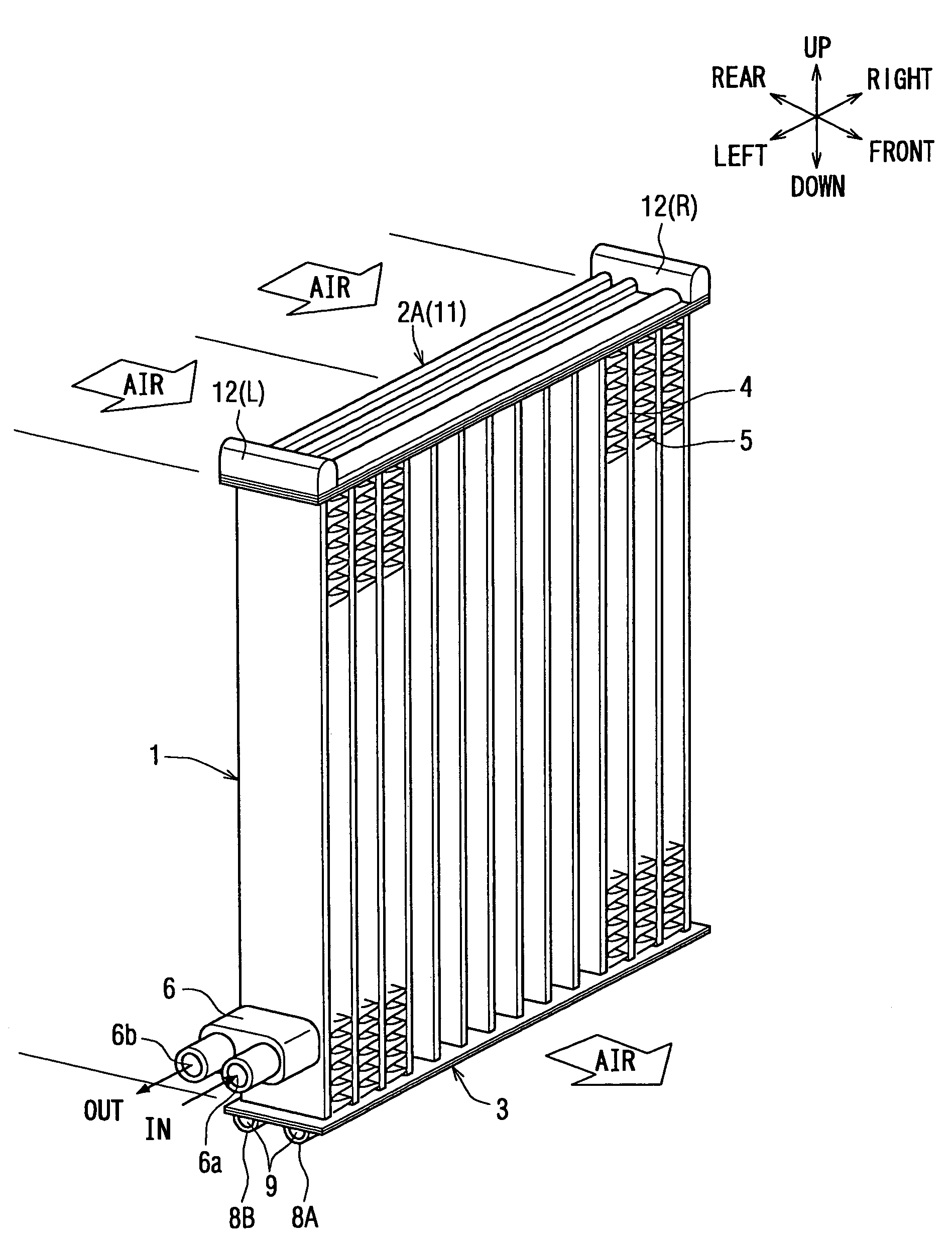

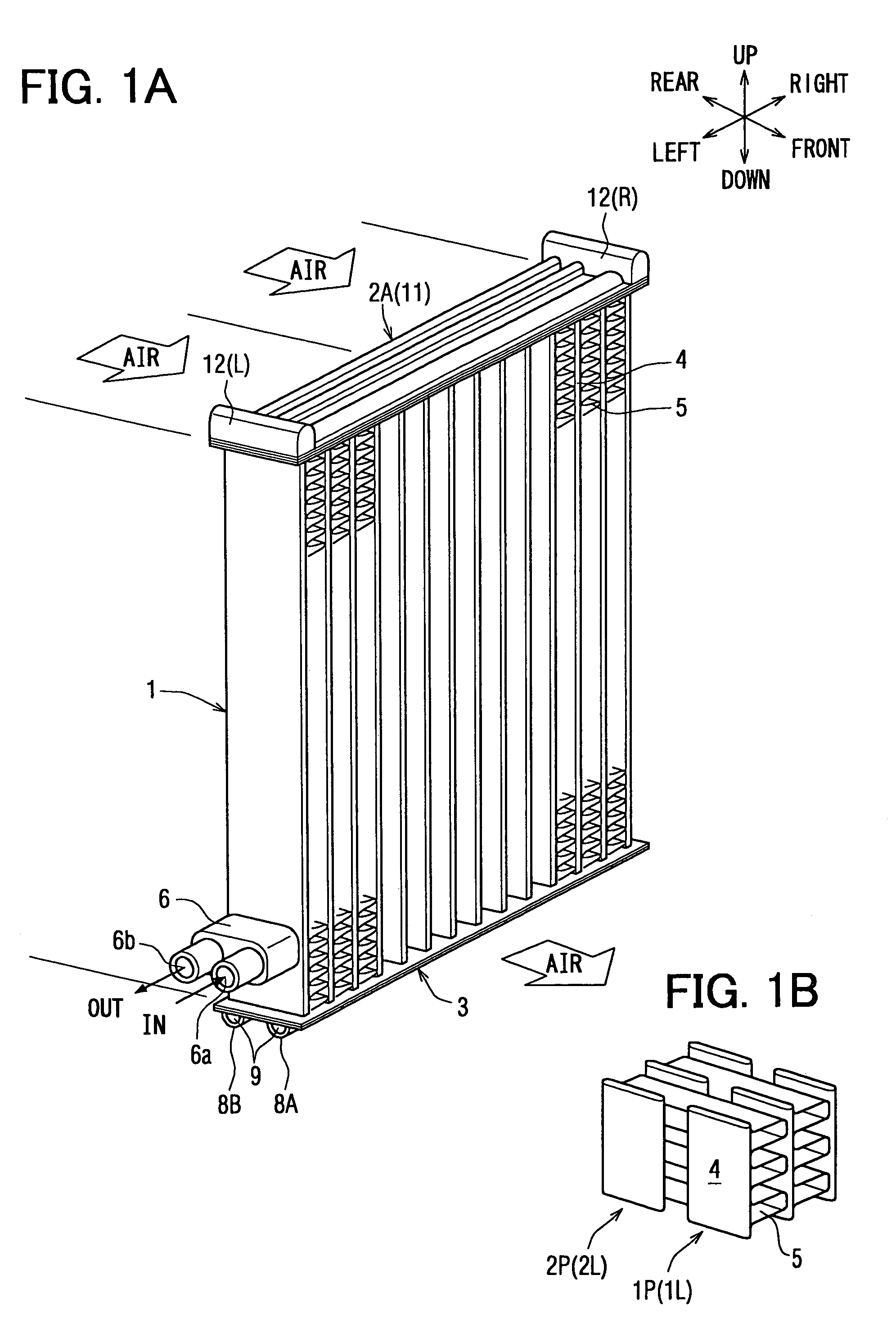

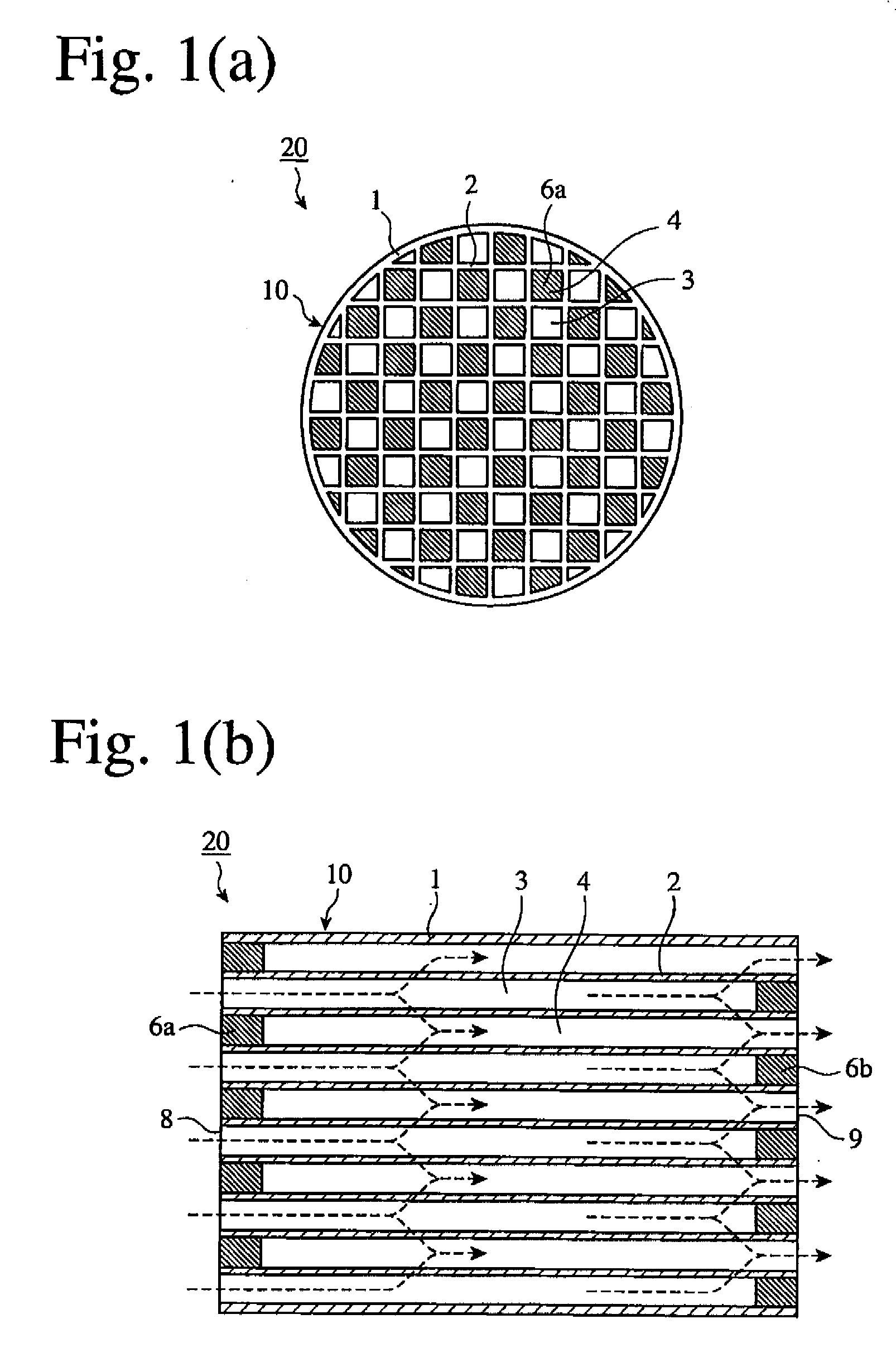

Refrigerant evaporator

ActiveUS20050235691A1Simplified tank structureLess pressure lossDomestic cooling apparatusEvaporators/condensersRefrigerant distributionLeft direction

A refrigerant evaporator includes a tank constituted by a tank portion and a header plate. The tank portion includes refrigerant collecting portions for guiding the refrigerant passed through a first path to the ends of the tank in the right-and-left direction and refrigerant distributing portions for guiding the refrigerant to the tubes forming a second pass. The header plate has refrigerant collecting / distributing space for the tubes. Side tanks are arranged to cover open portions at the ends of the tank in the right-and-left direction, and to spatially connect the flow passages. Separators are provided at portions where the flow passages are to be spatially blocked to constitute a front-and-rear right-and-left cross path. An increased sectional area of flow passages is obtained at the refrigerant flow corner portions relying upon a simple constitution, to decrease the pressure loss on the refrigerant side in the tank and to enhance performance.

Owner:DENSO CORP

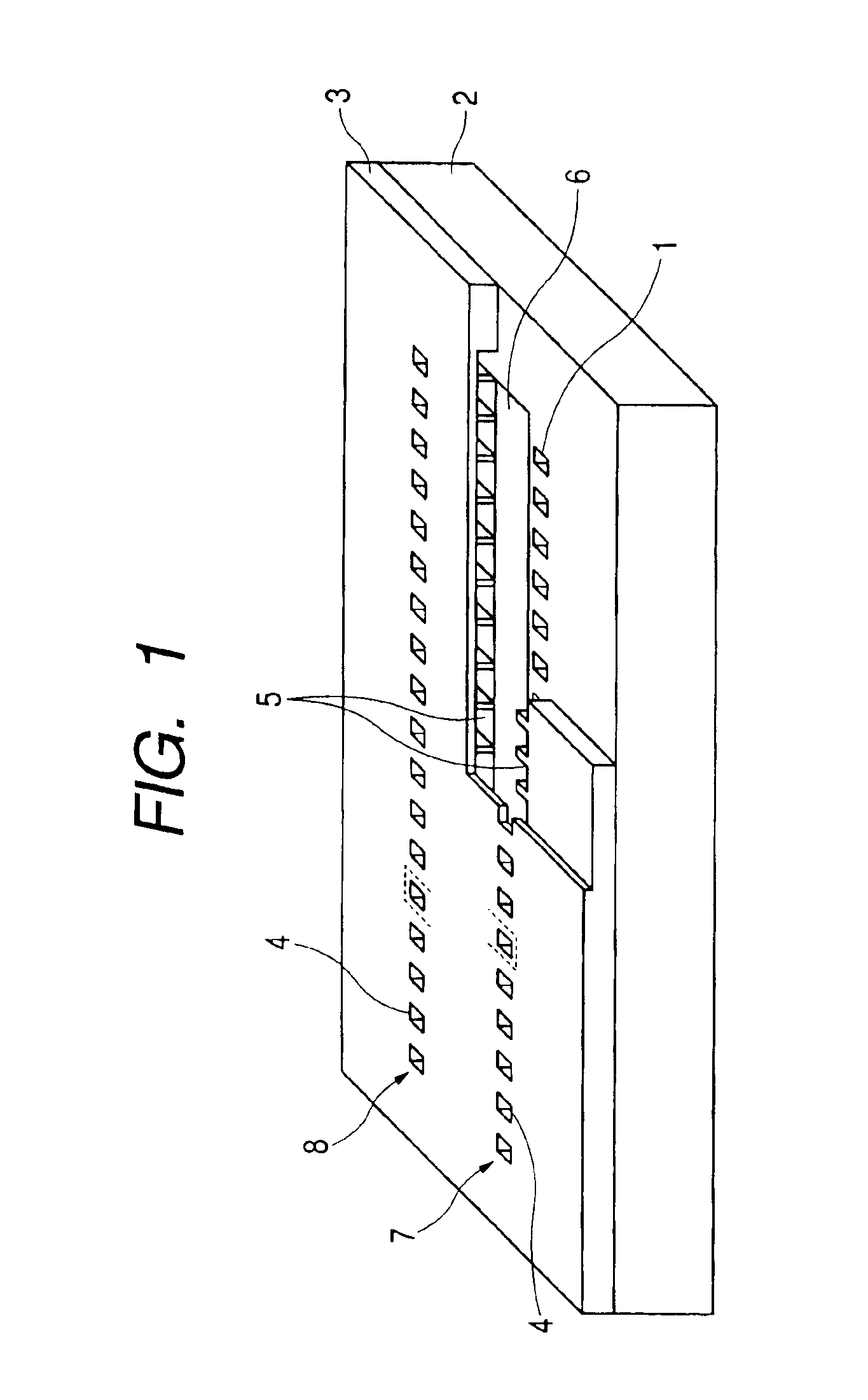

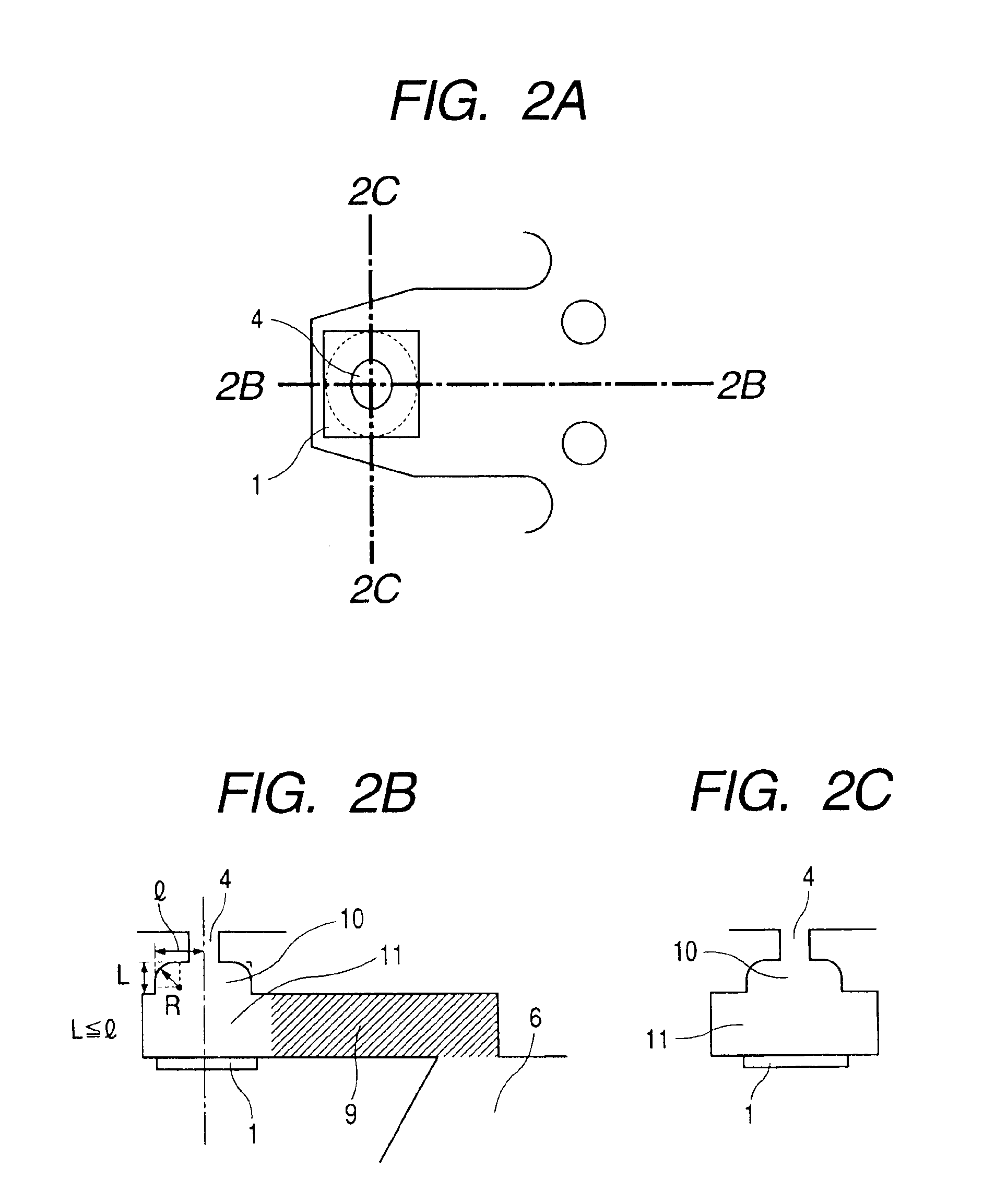

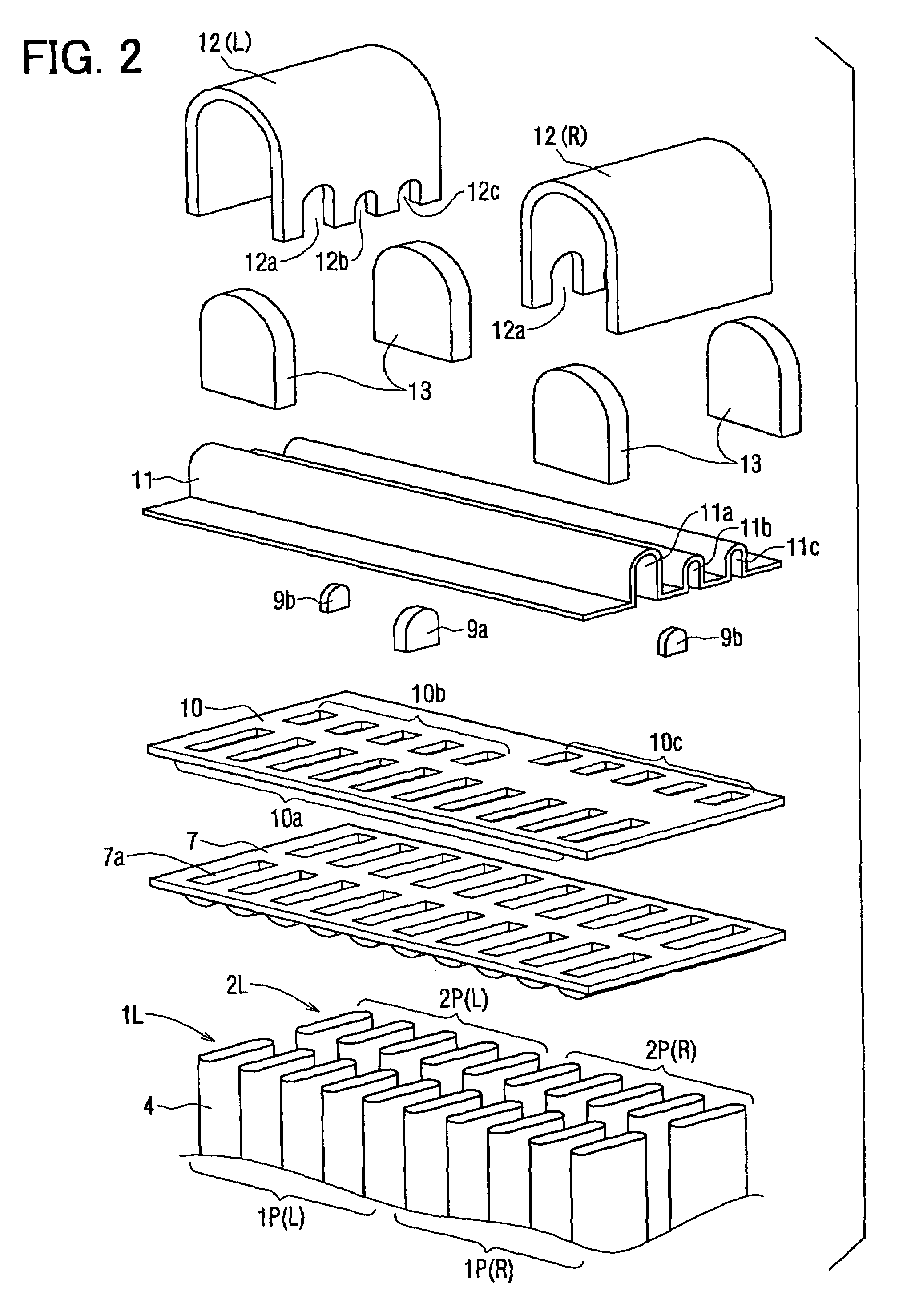

Ink jet record head

To provide an ink jet record head having a nozzle shape capable of promptly curbing meniscus vibrations occurring on refilling and stably performing discharge.A second discharge port portion 10 has a form in which, with a lower side of a square on a bubbling chamber 8 side, angles on an upper side of the square are curved respectively on any cross section vertical to a principal surface of an element substrate on which heaters 1 are formed and going through the center of a discharge port 4, and these curves are shaped as arcs of circles of a radius R inscribed in the angles on the upper side of the square respectively.

Owner:CANON KK

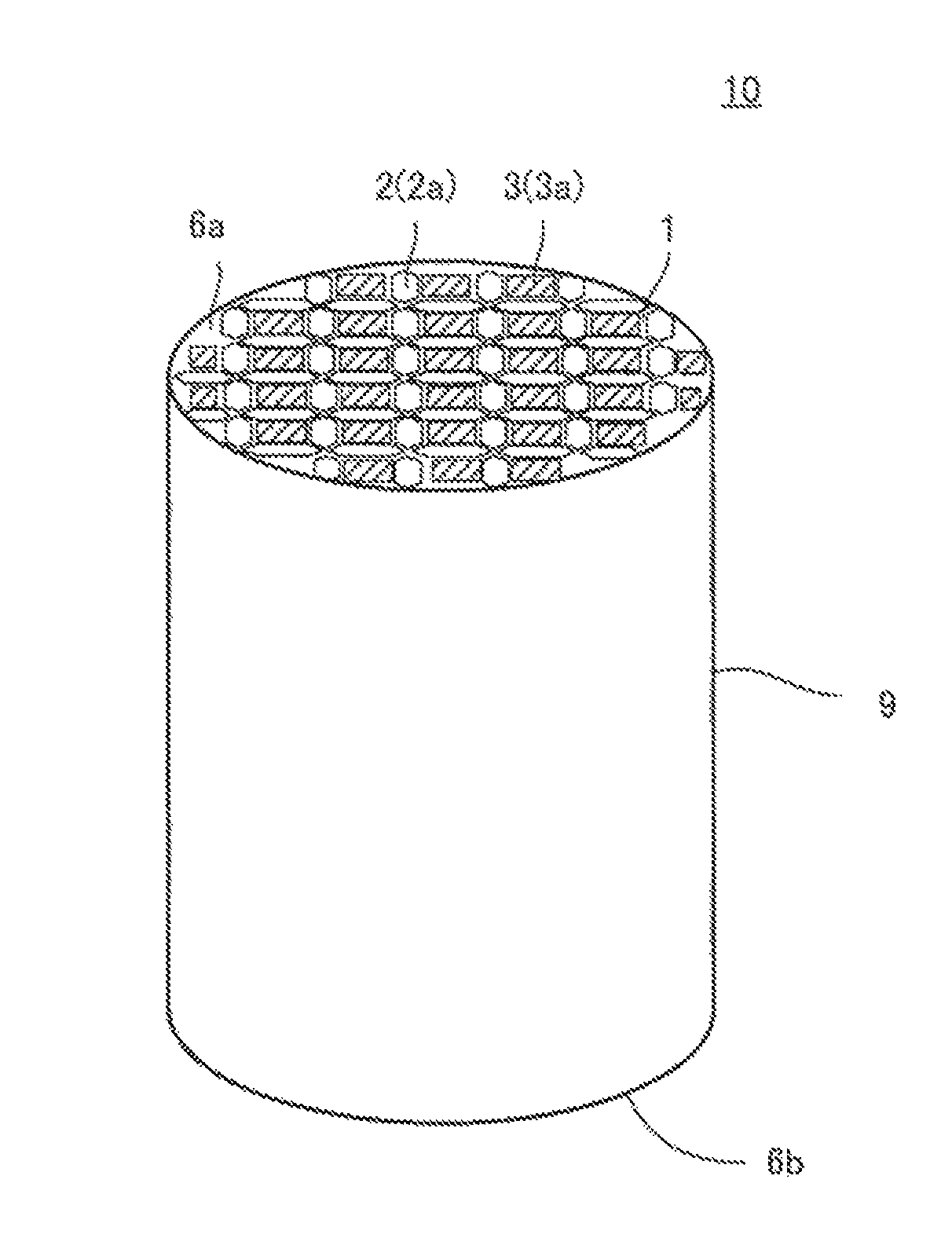

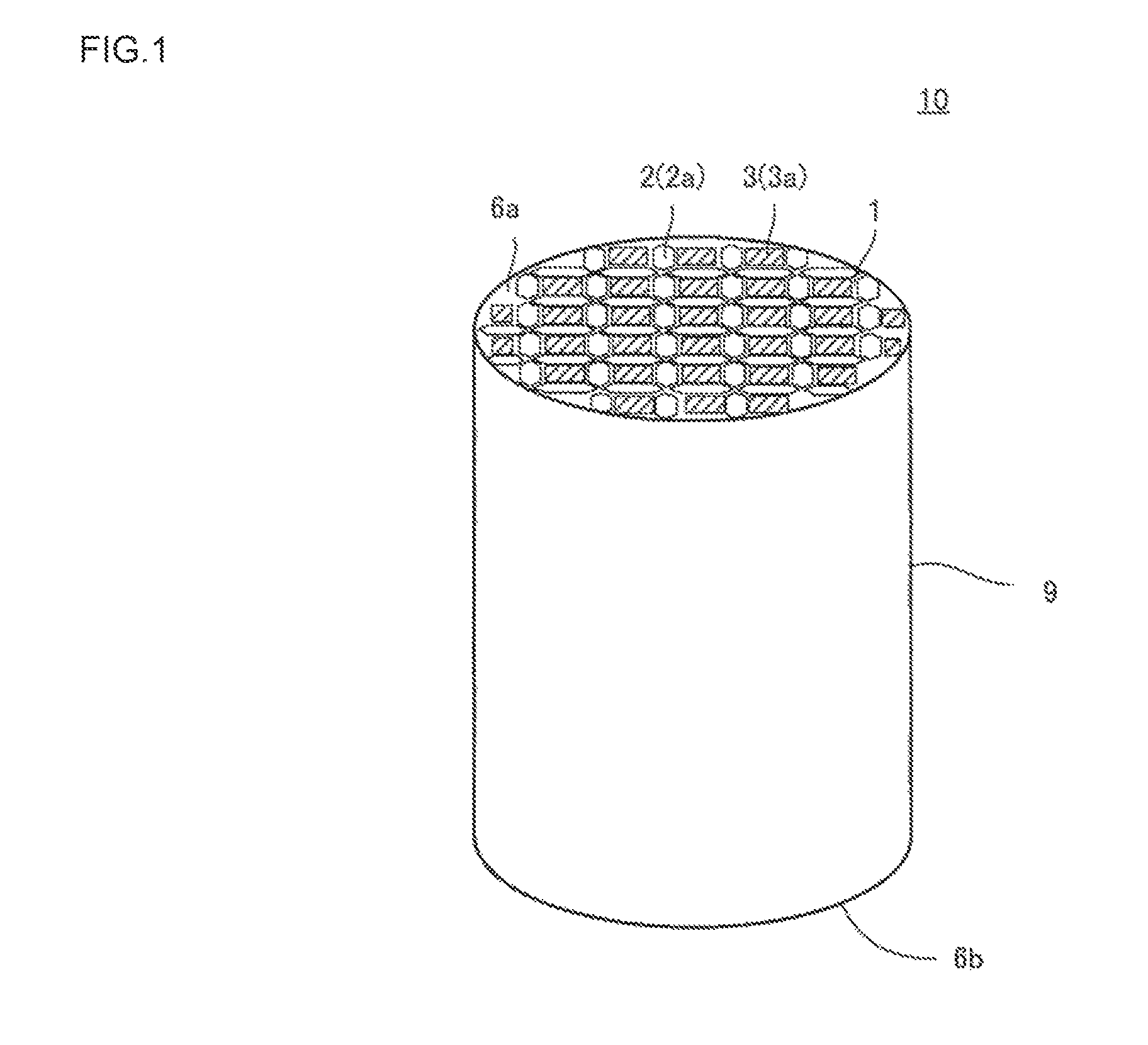

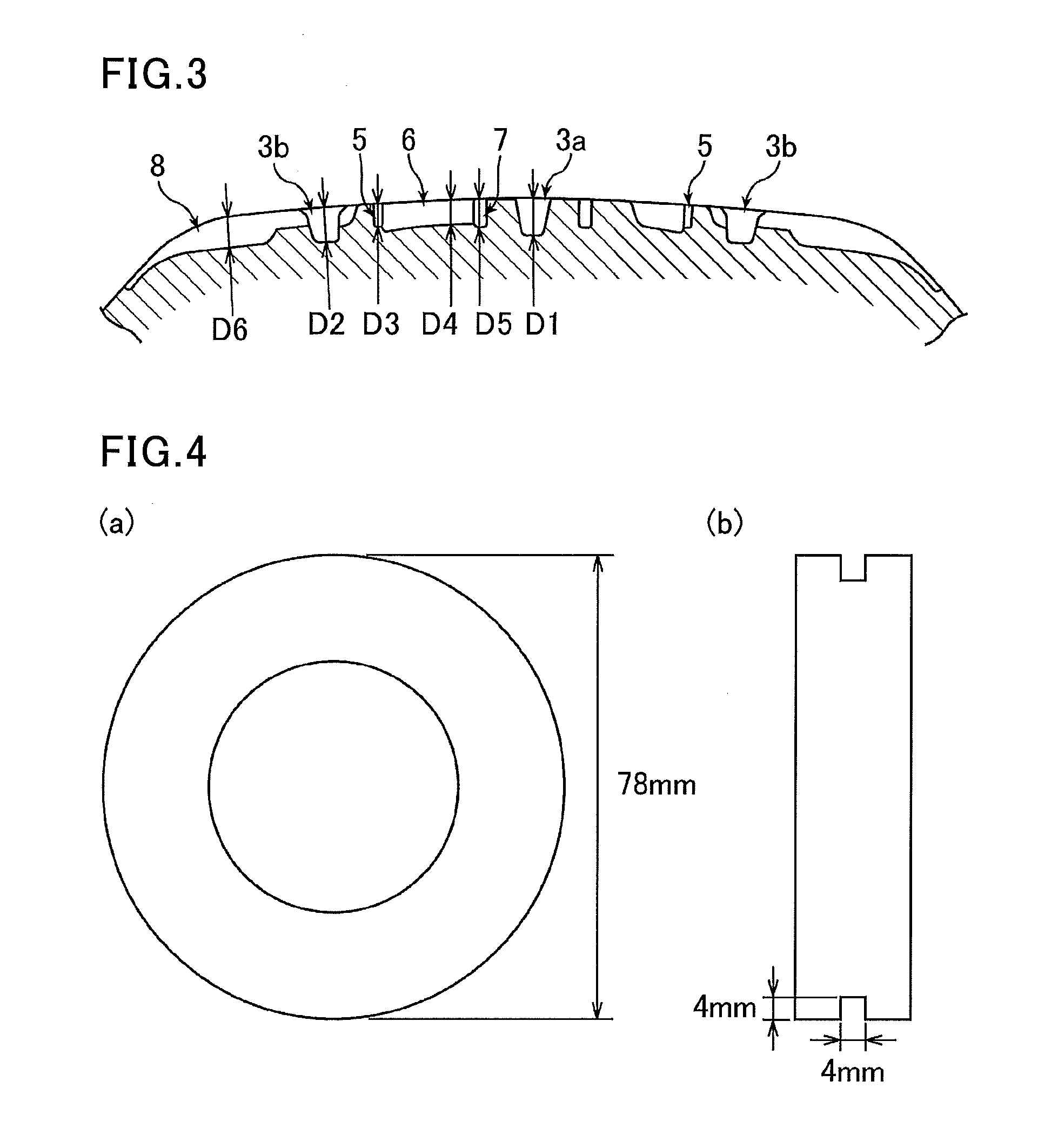

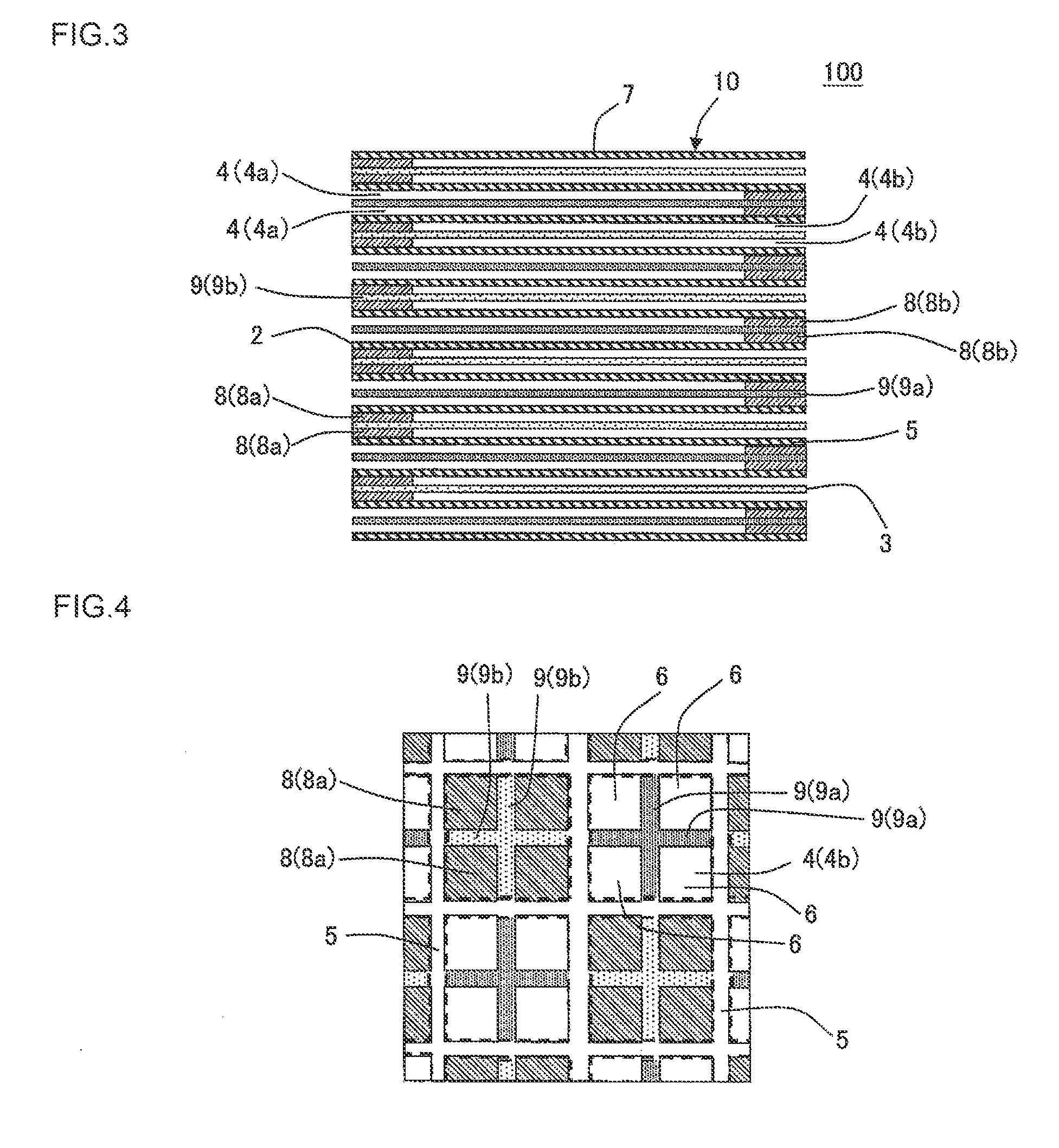

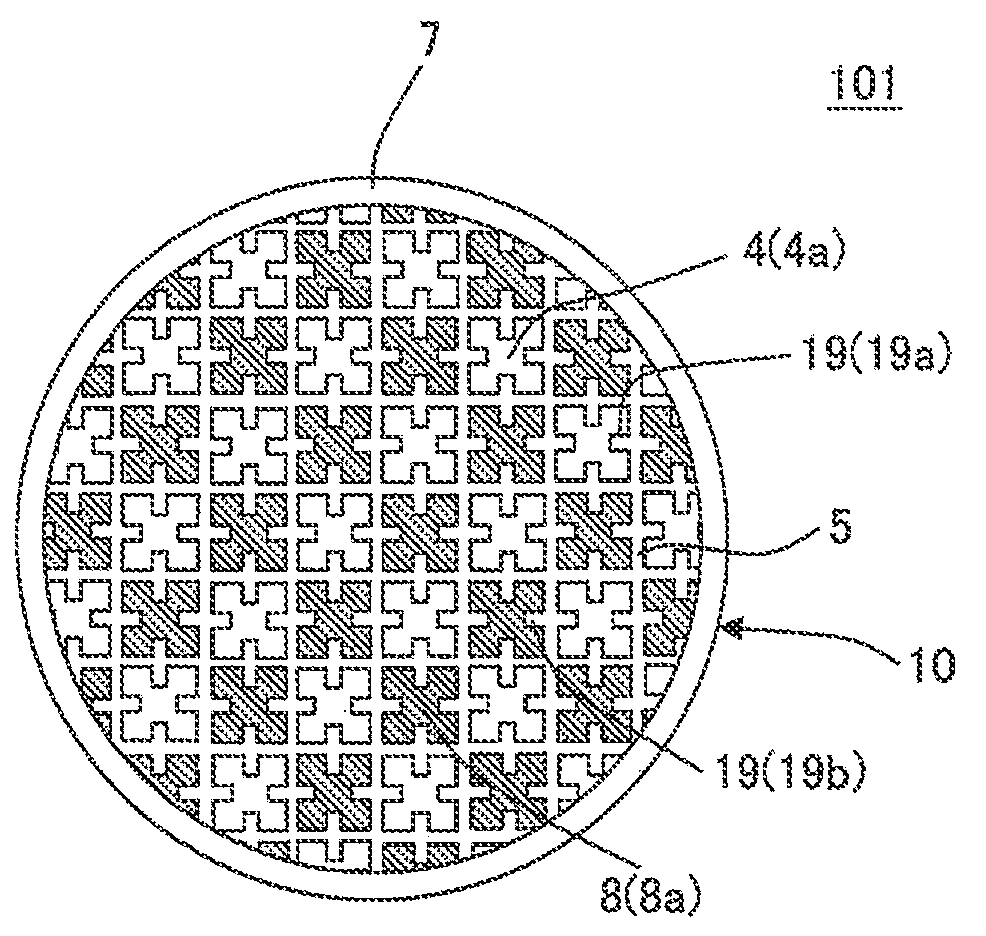

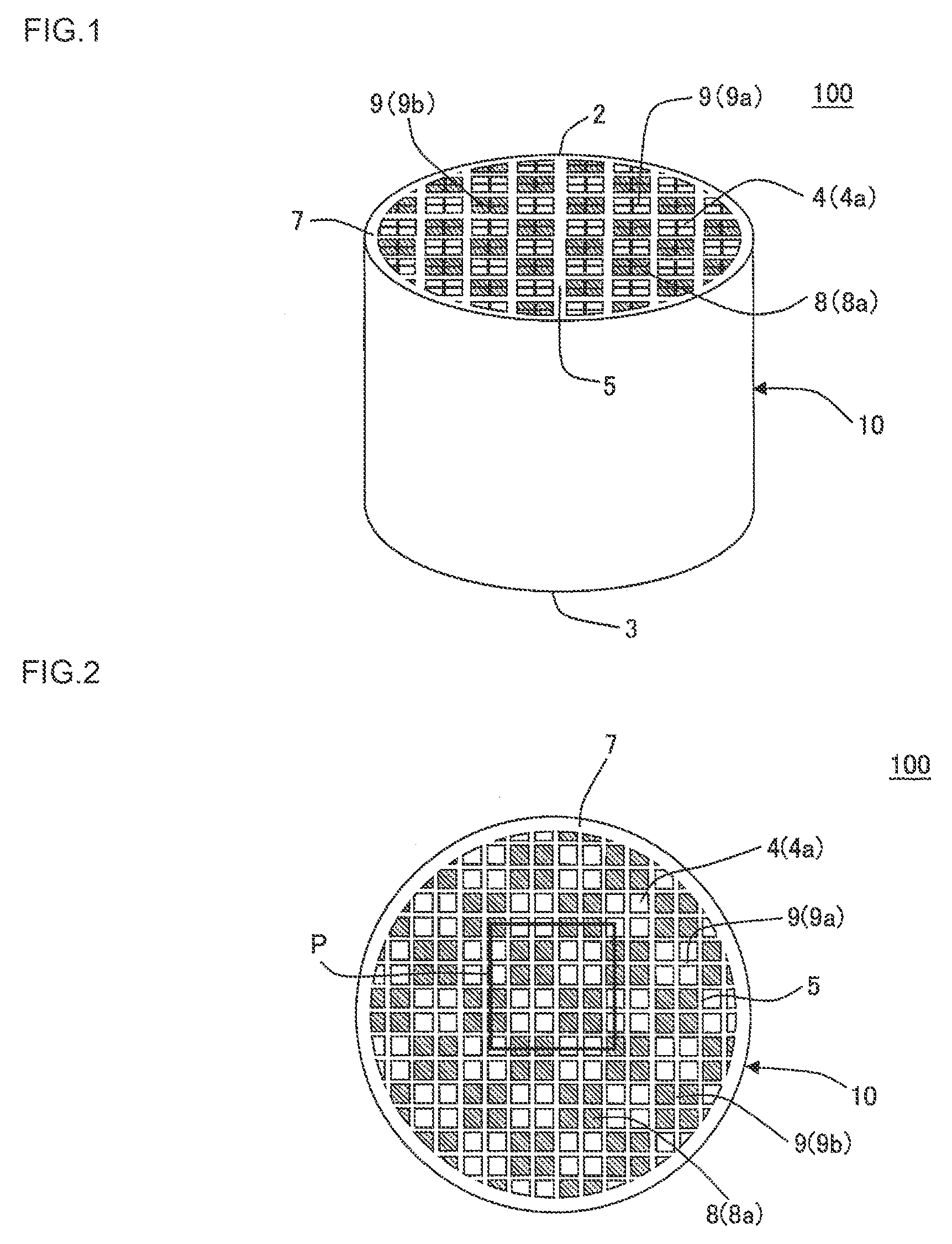

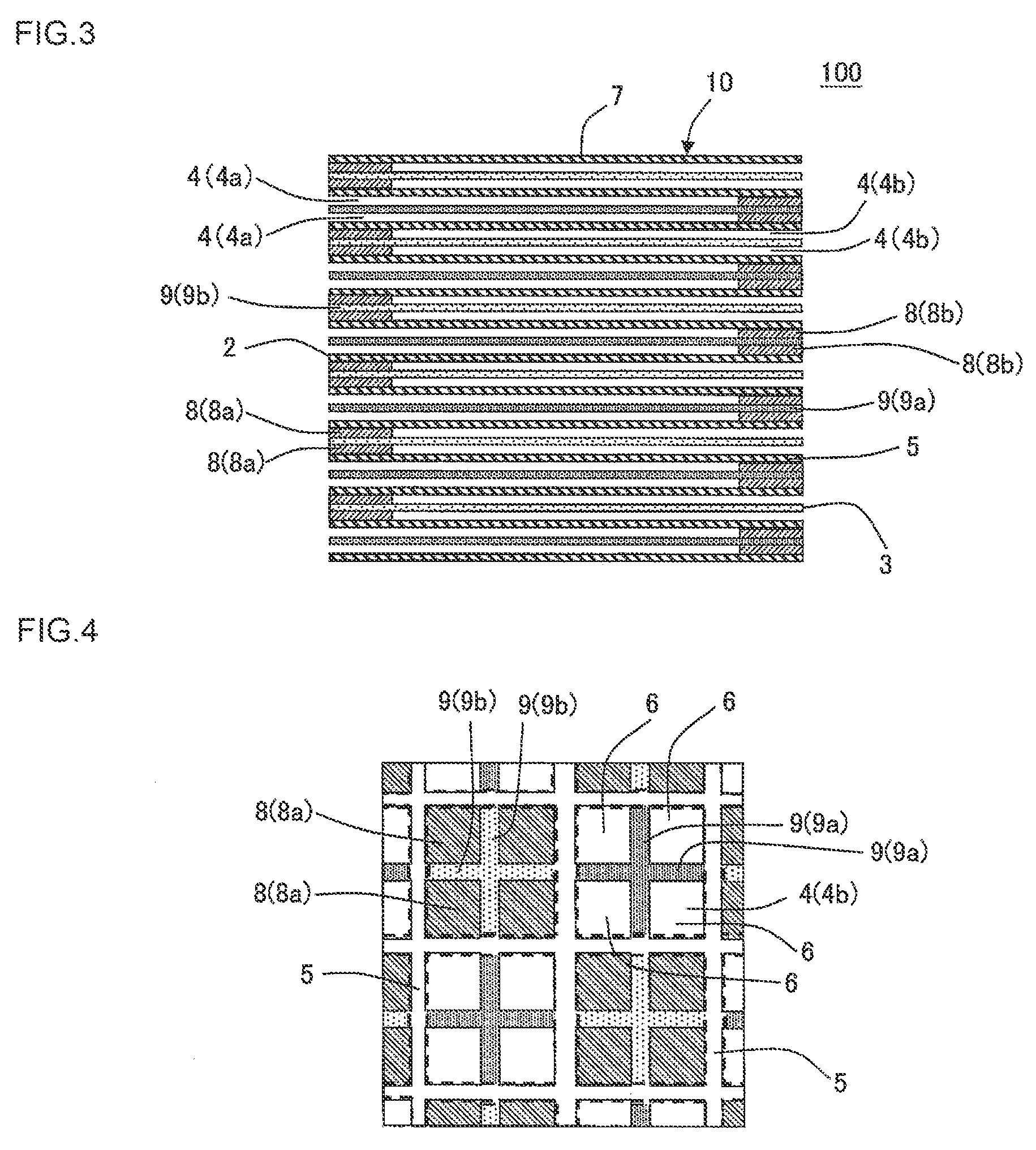

Wall flow type exhaust gas purification filter

ActiveUS9080484B2Avoid high local temperaturesSuppress pressure lossSilencing apparatusMachines/enginesEngineeringMechanical engineering

Owner:NGK INSULATORS LTD

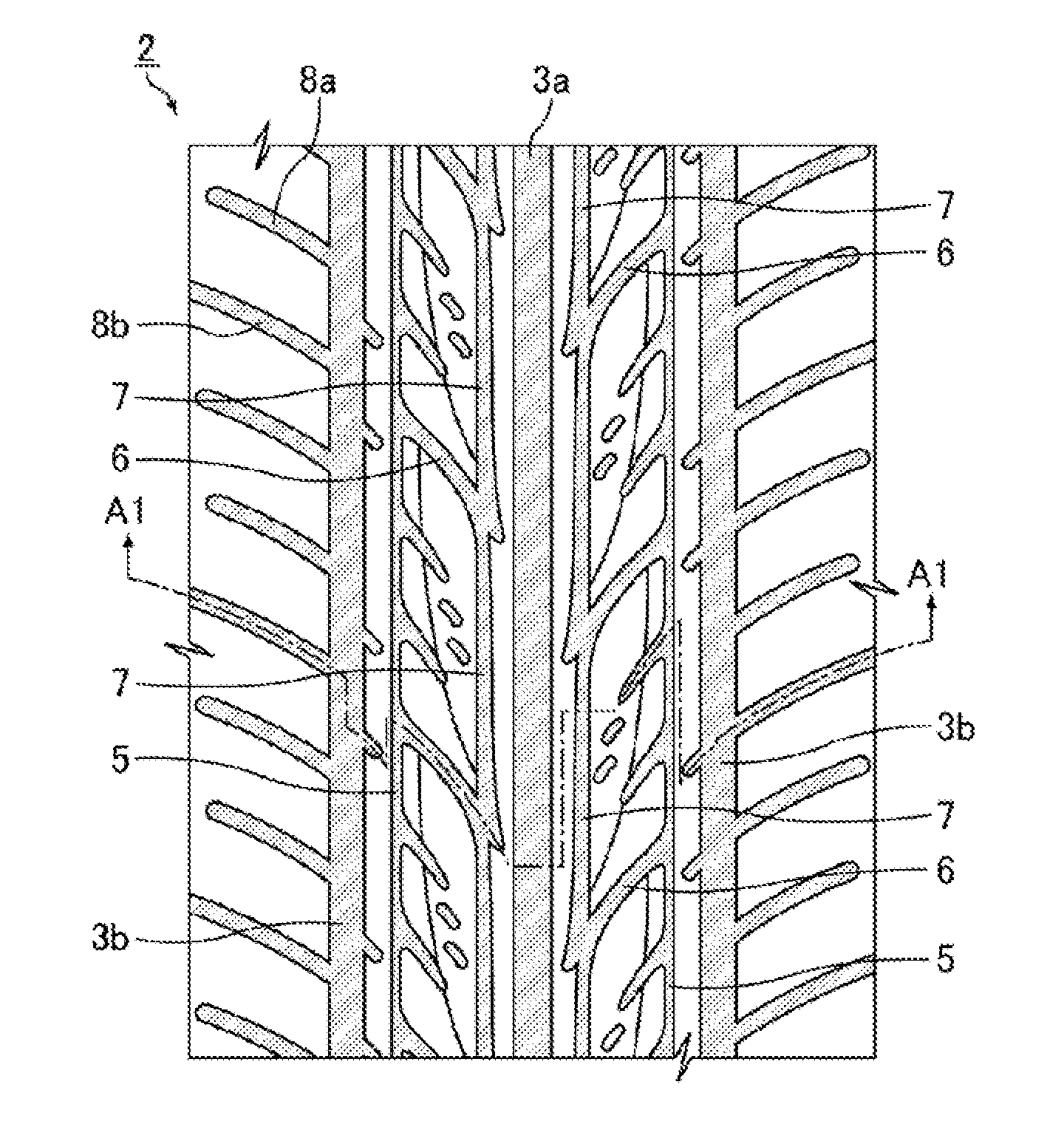

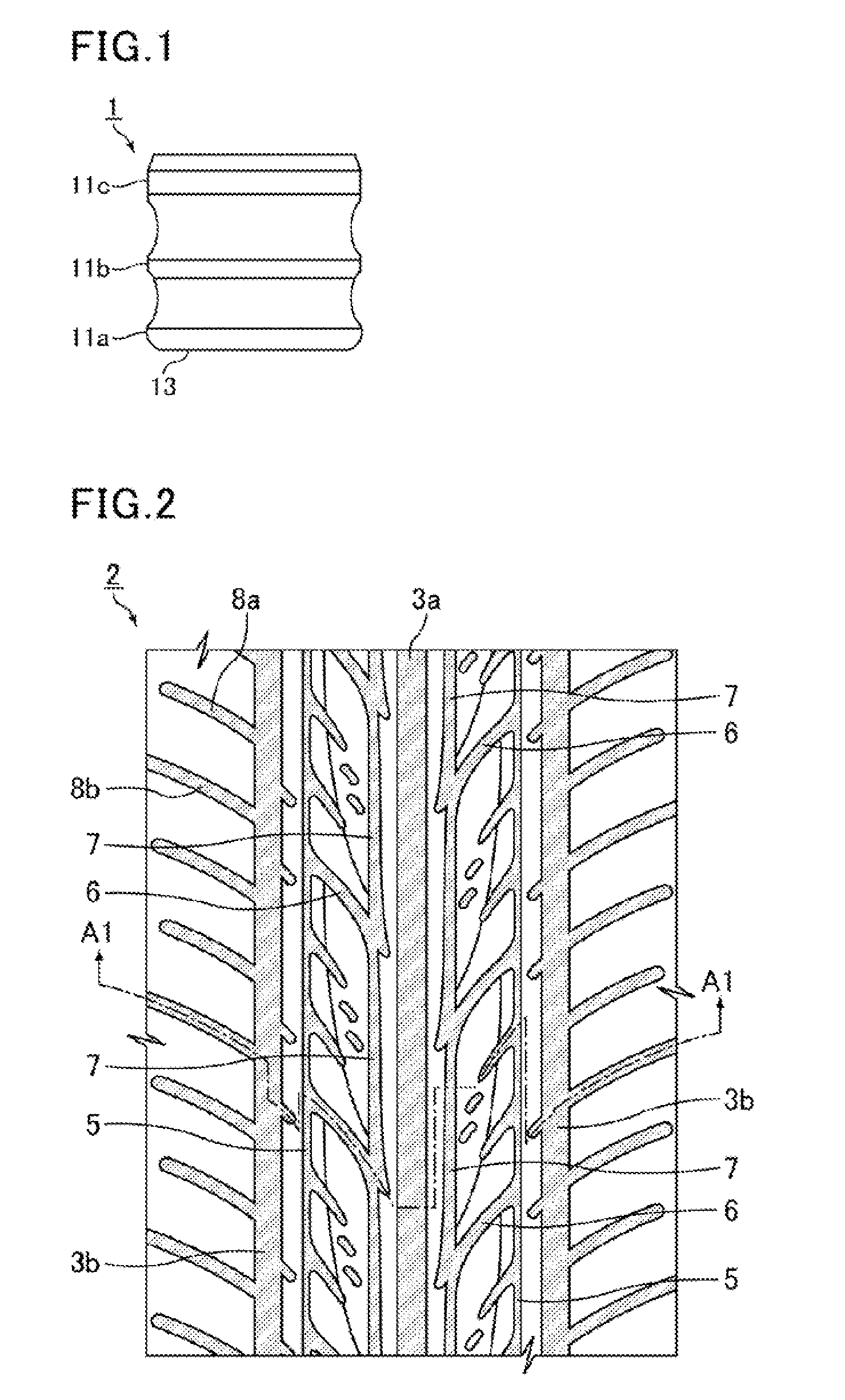

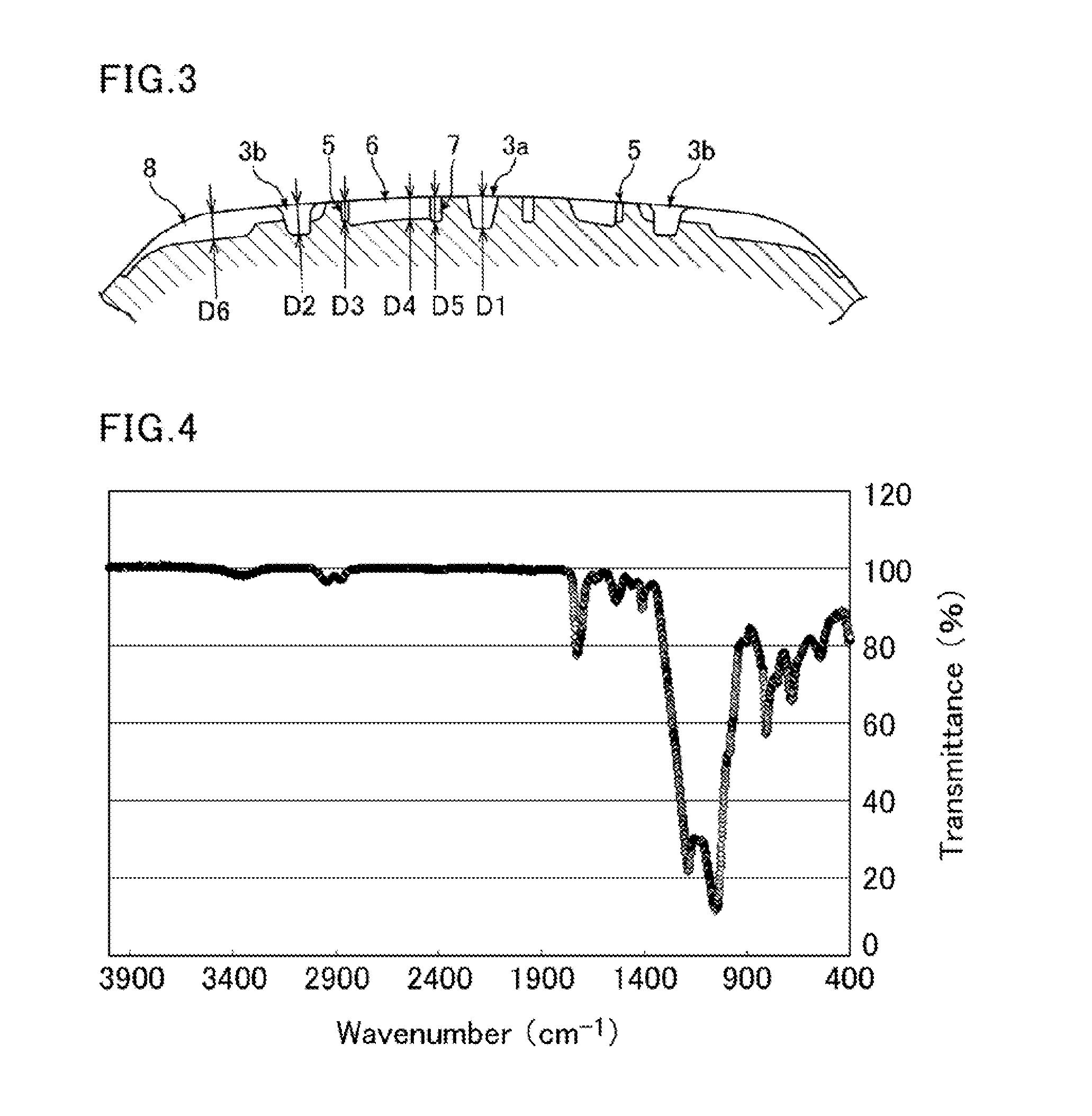

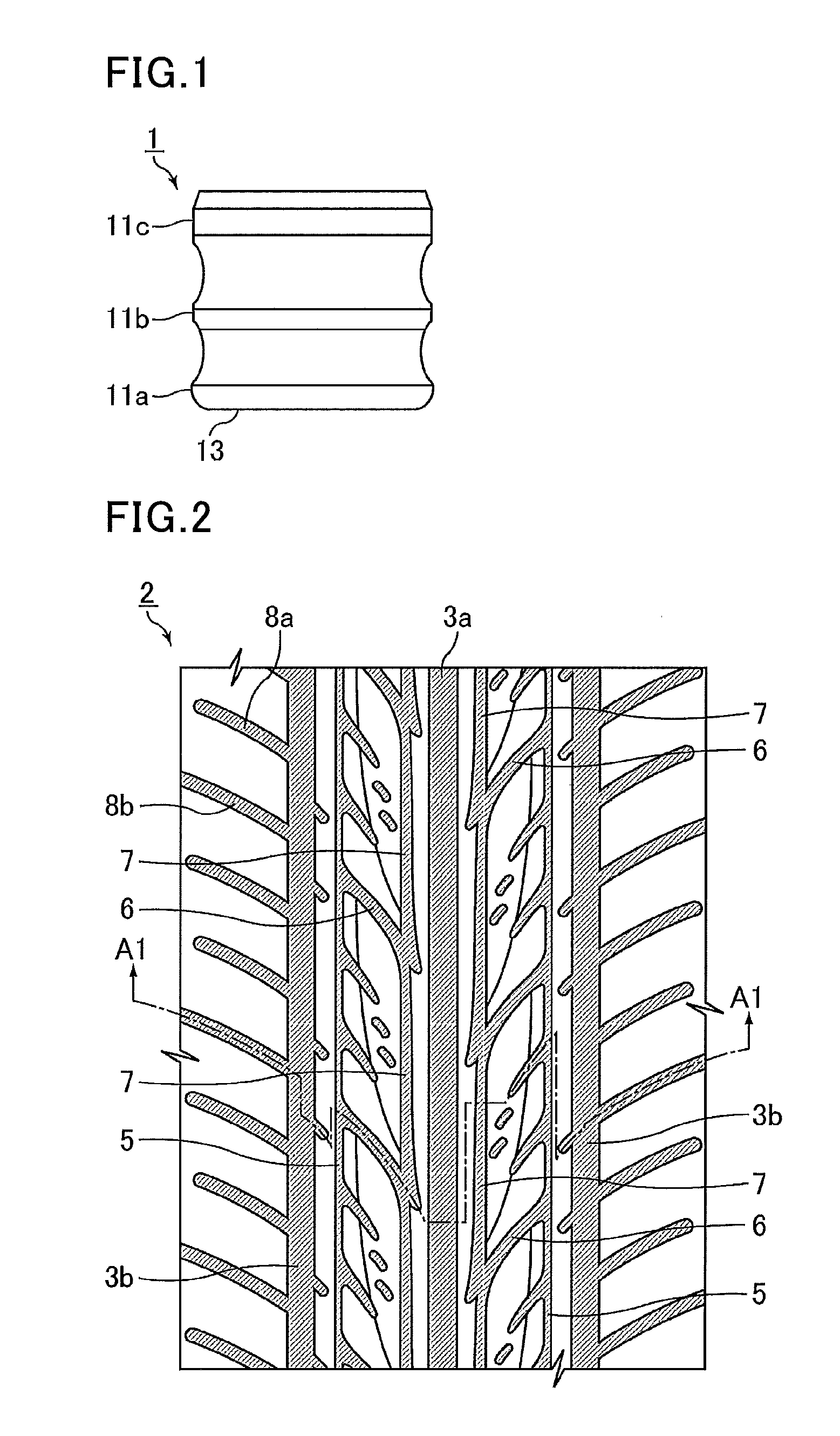

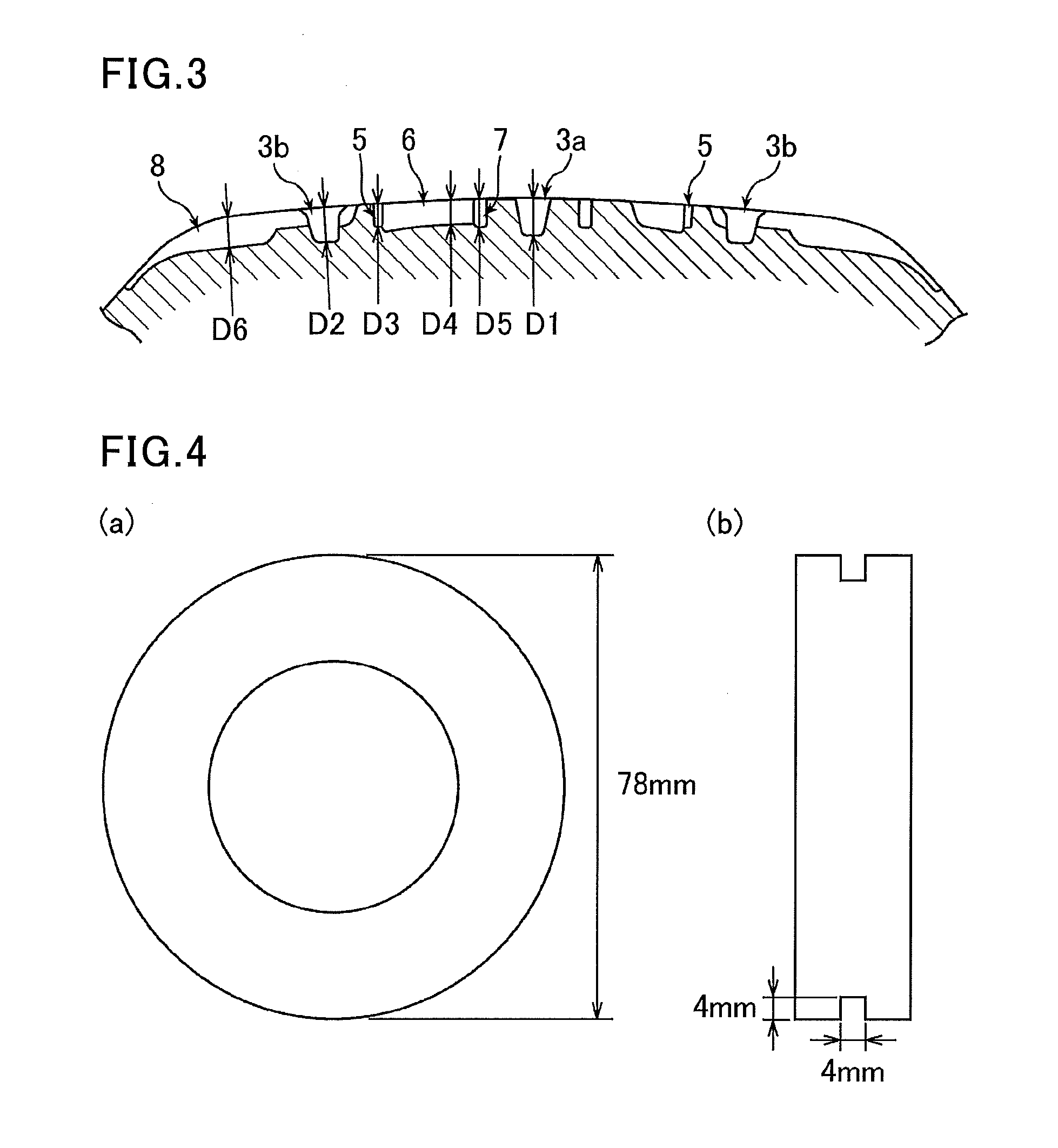

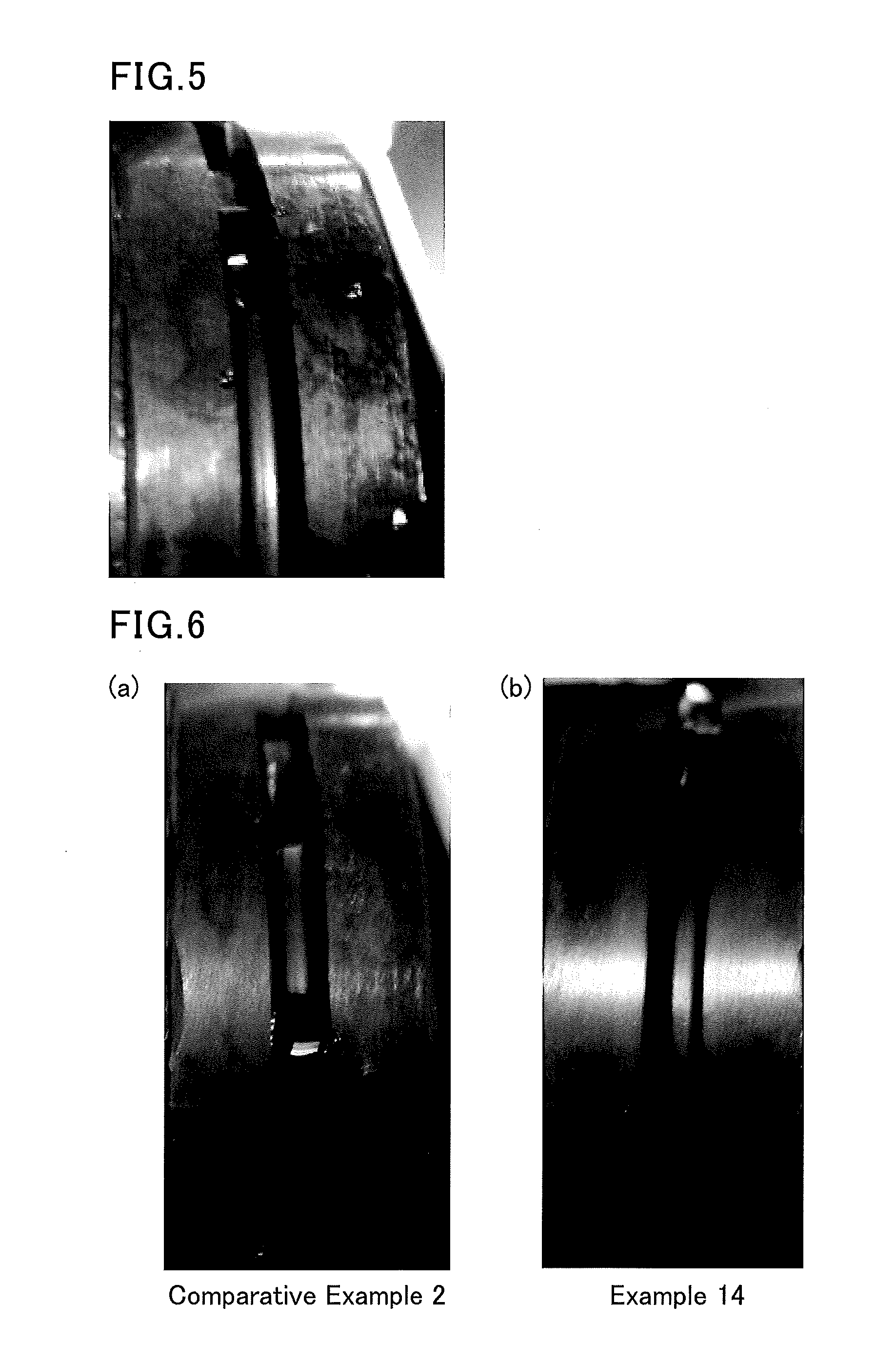

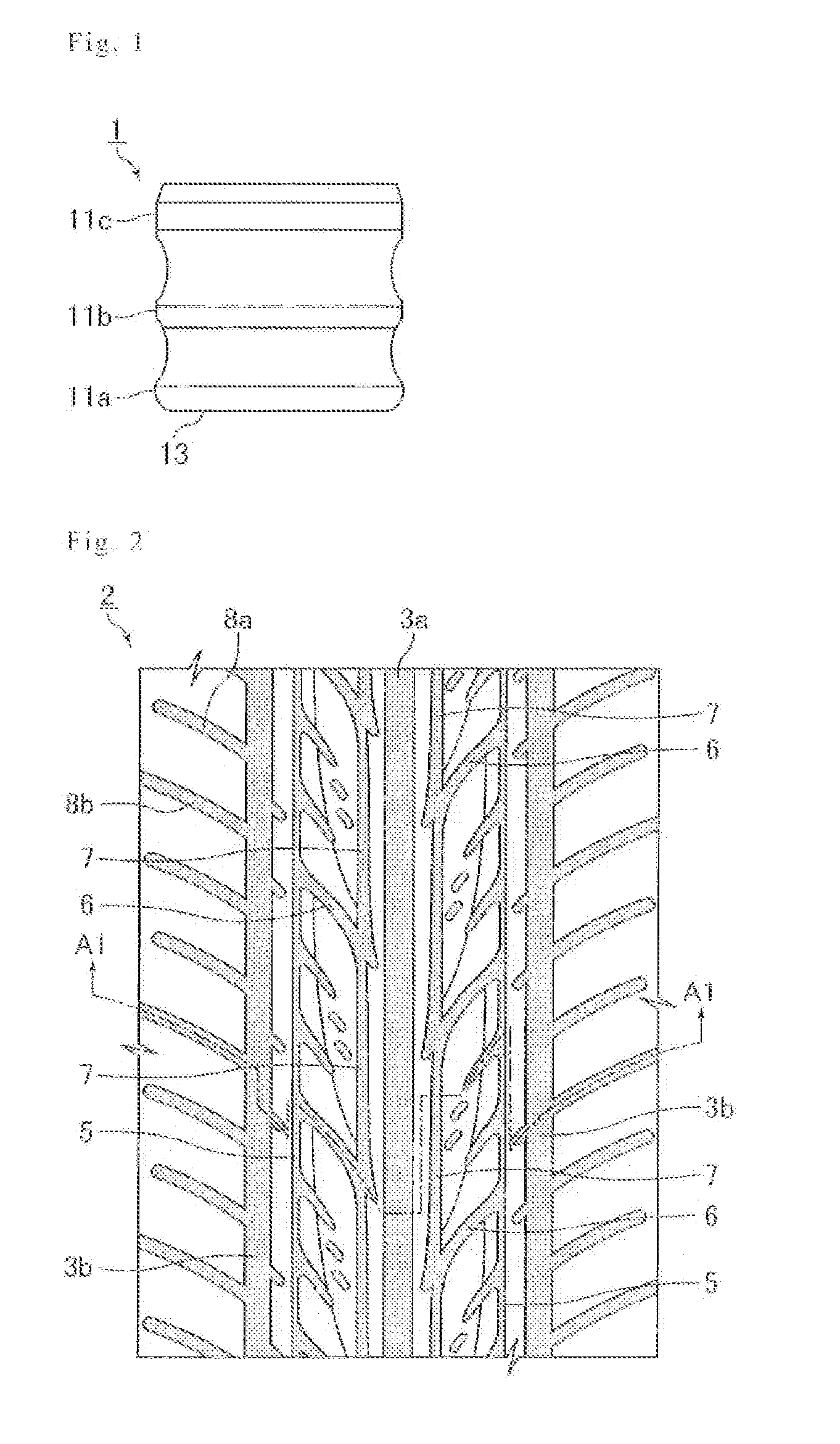

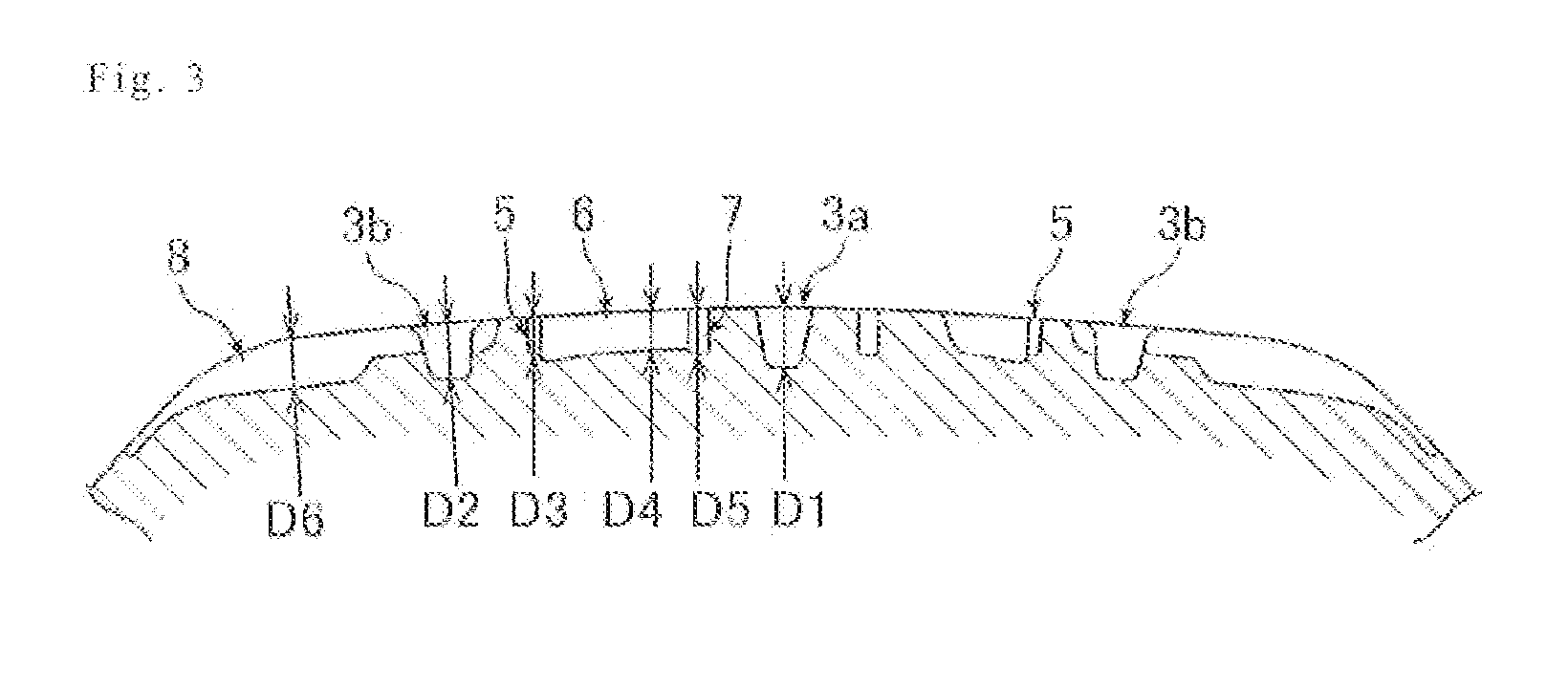

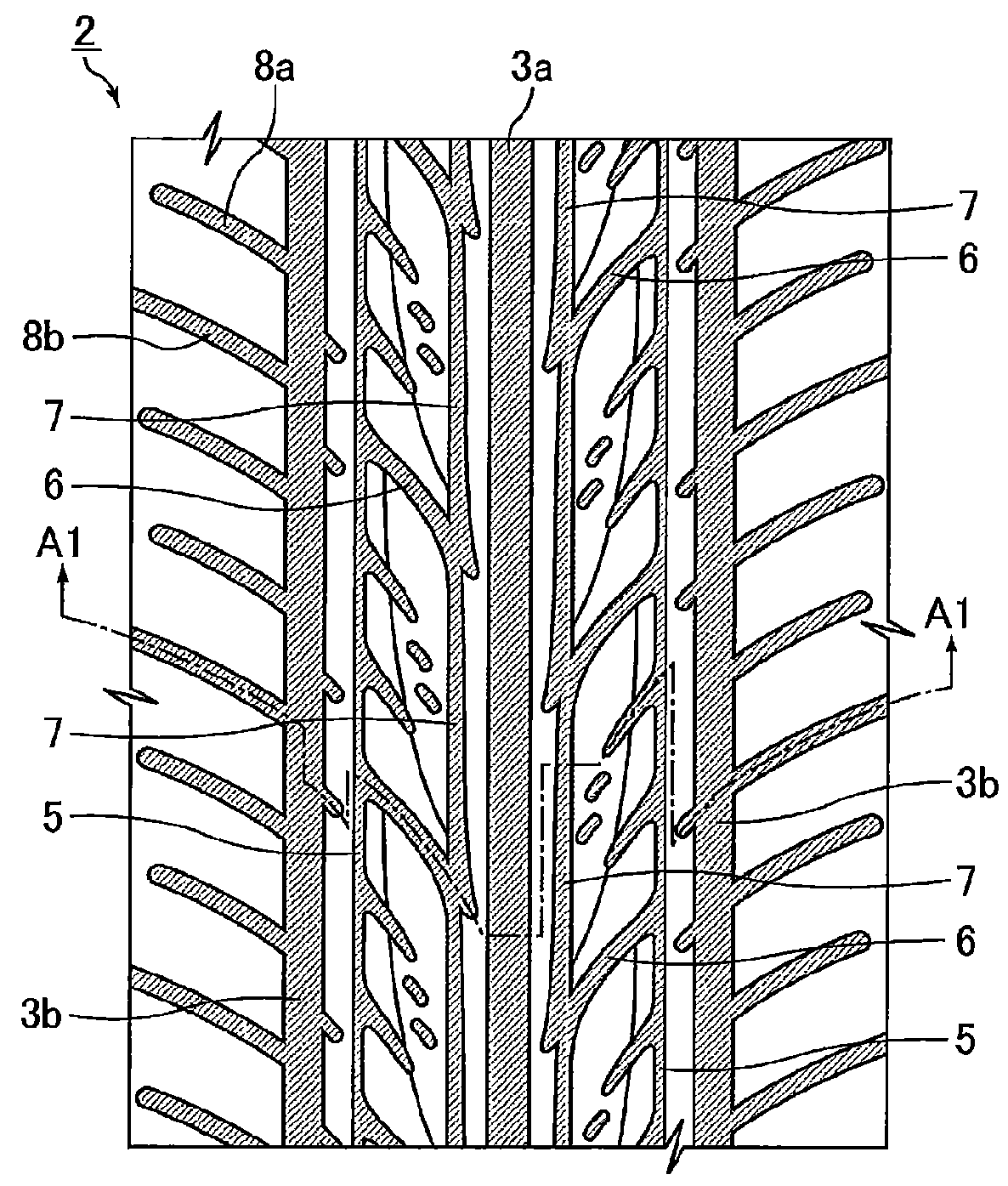

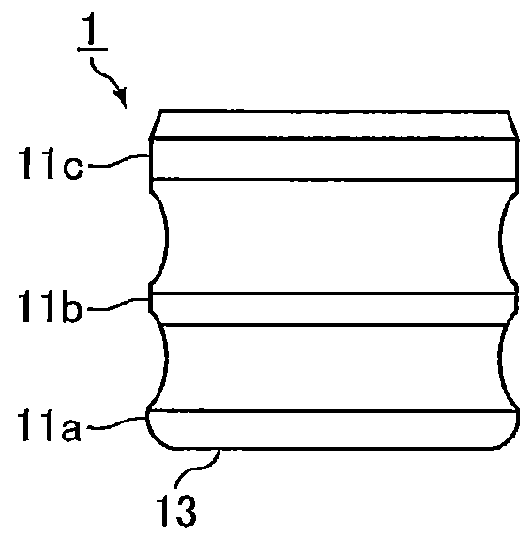

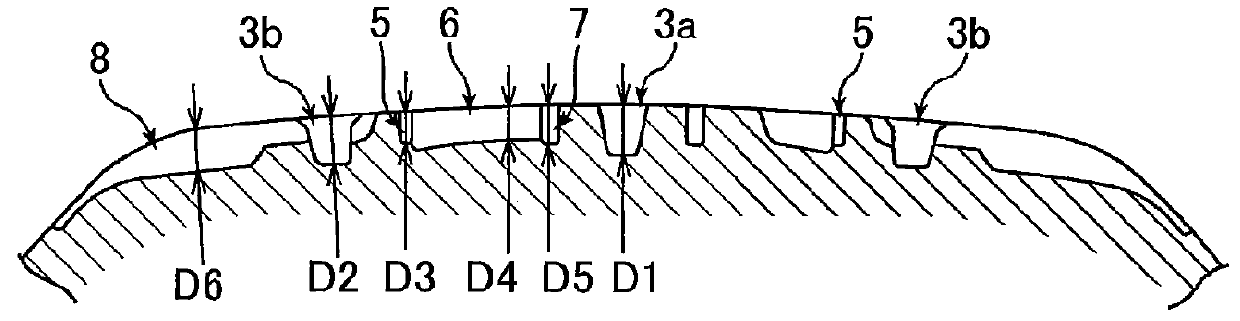

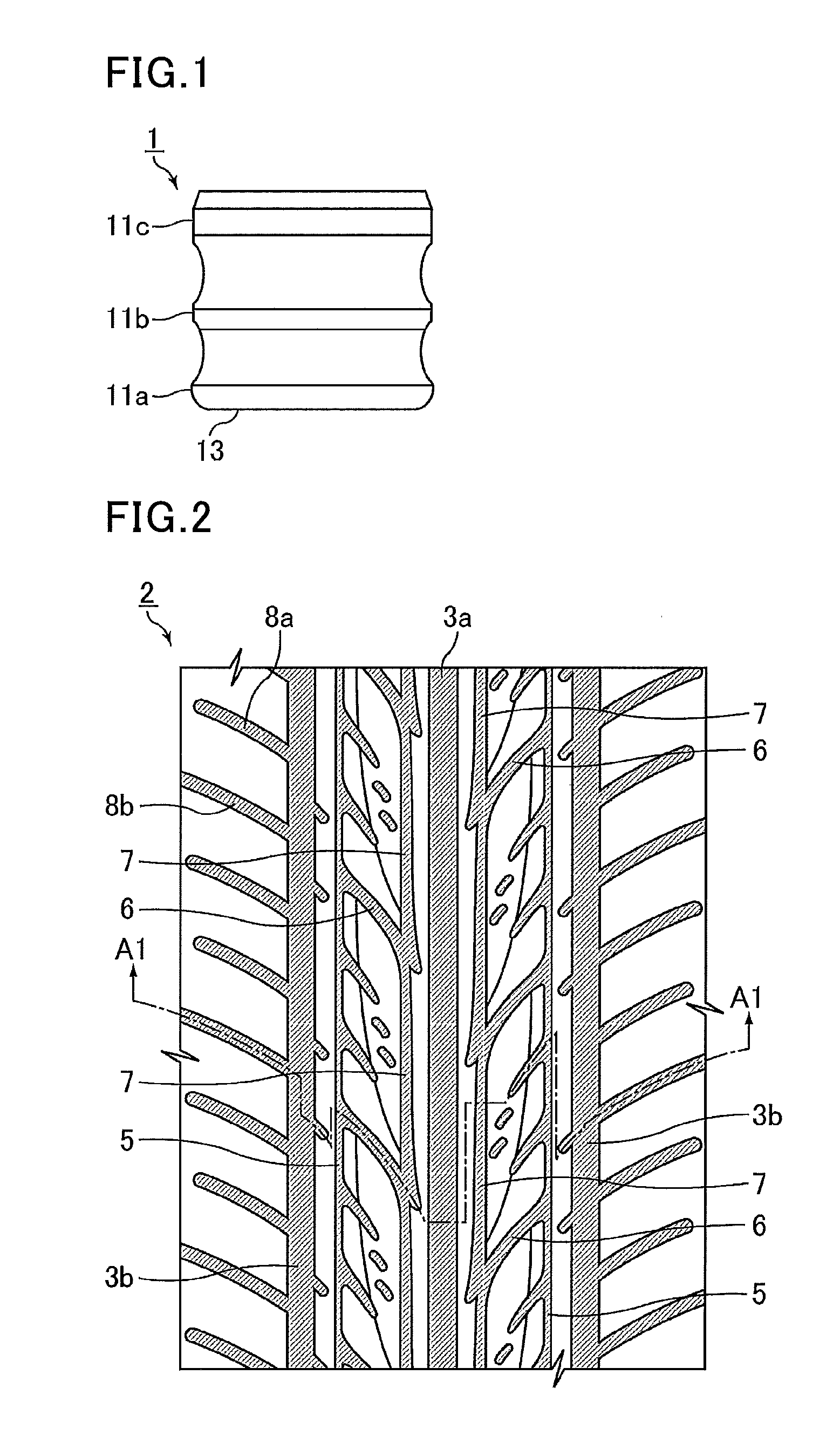

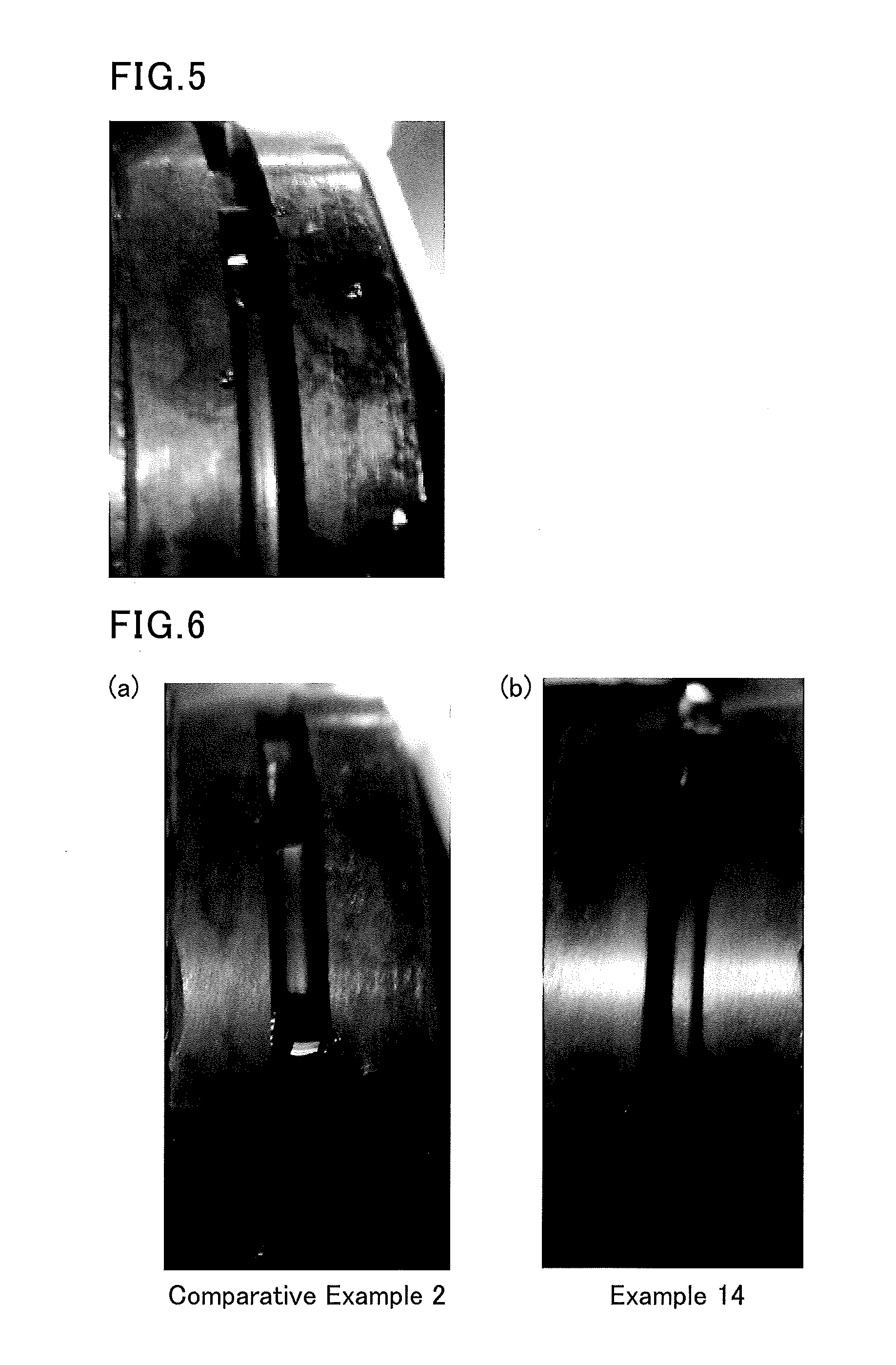

Surface modification method and surface-modified elastic body

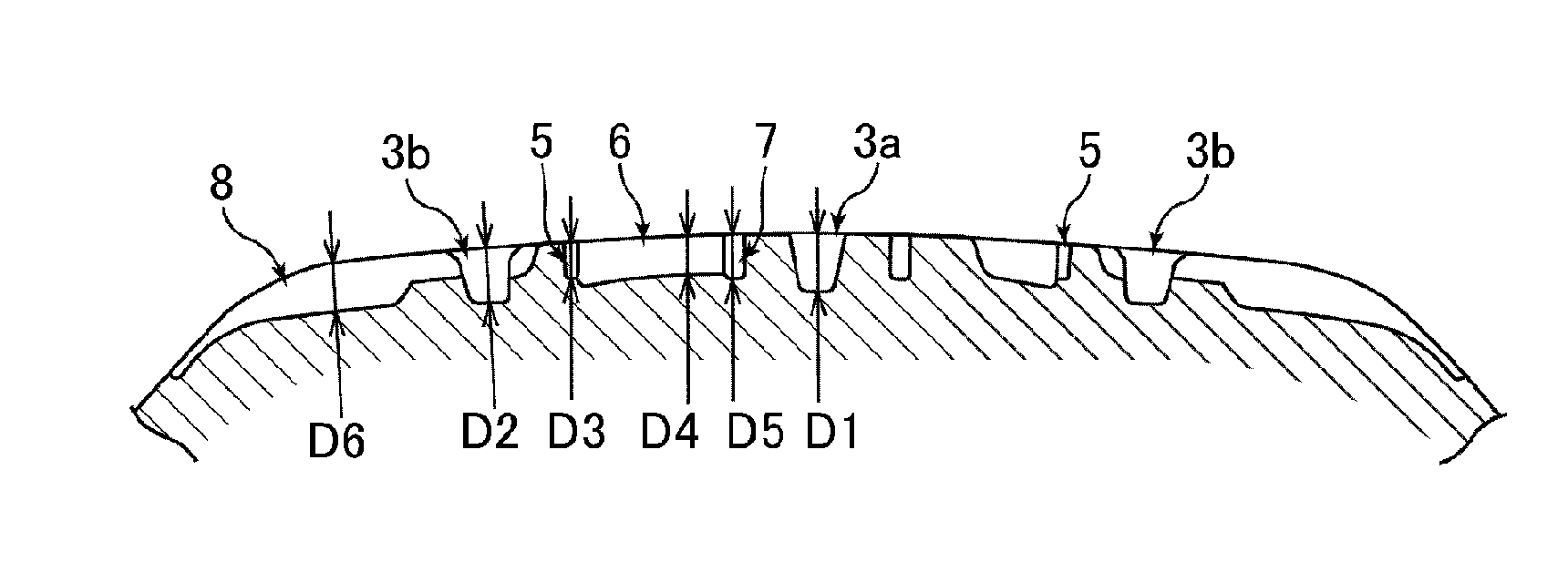

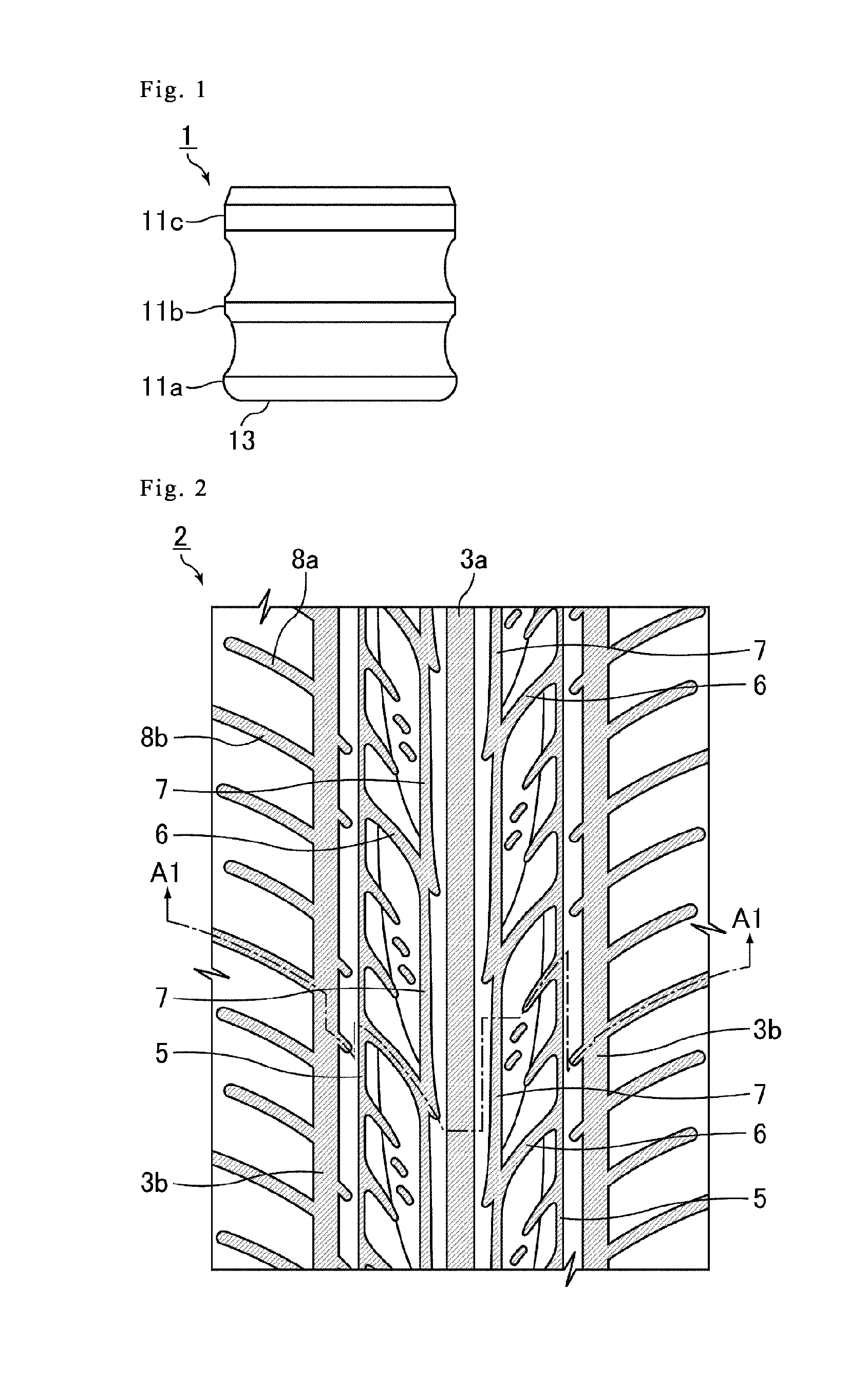

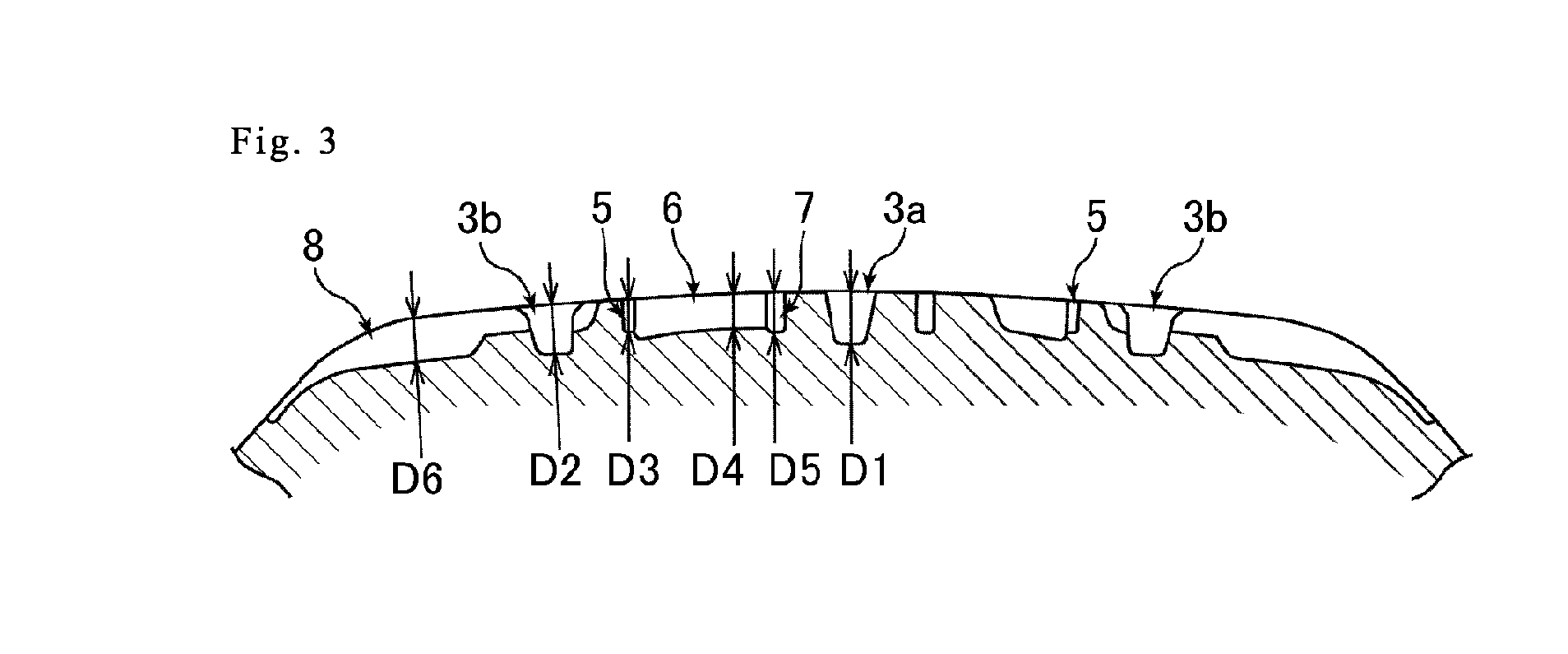

ActiveUS20130203883A1Less pressure lossEasy to slidePharmaceutical delivery mechanismSpecial tyresSurface modificationMonomer

The present invention aims to provide a surface modification method for a rubber vulcanizate or a thermoplastic elastomer, which can impart various functions such as sliding properties and biocompatibility according to its use. The present invention relates to a surface modification method for modifying a rubber vulcanizate or a thermoplastic elastomer as an object to be modified, the method including: Step 1 of forming polymerization initiation points on a surface of the object to be modified; Step 2 of radical polymerizing monomers starting from the polymerization initiation points to grow polymer chains on the surface of the object to be modified; and Step 3 of functionalizing the polymer chains.

Owner:SUMITOMO RUBBER IND LTD

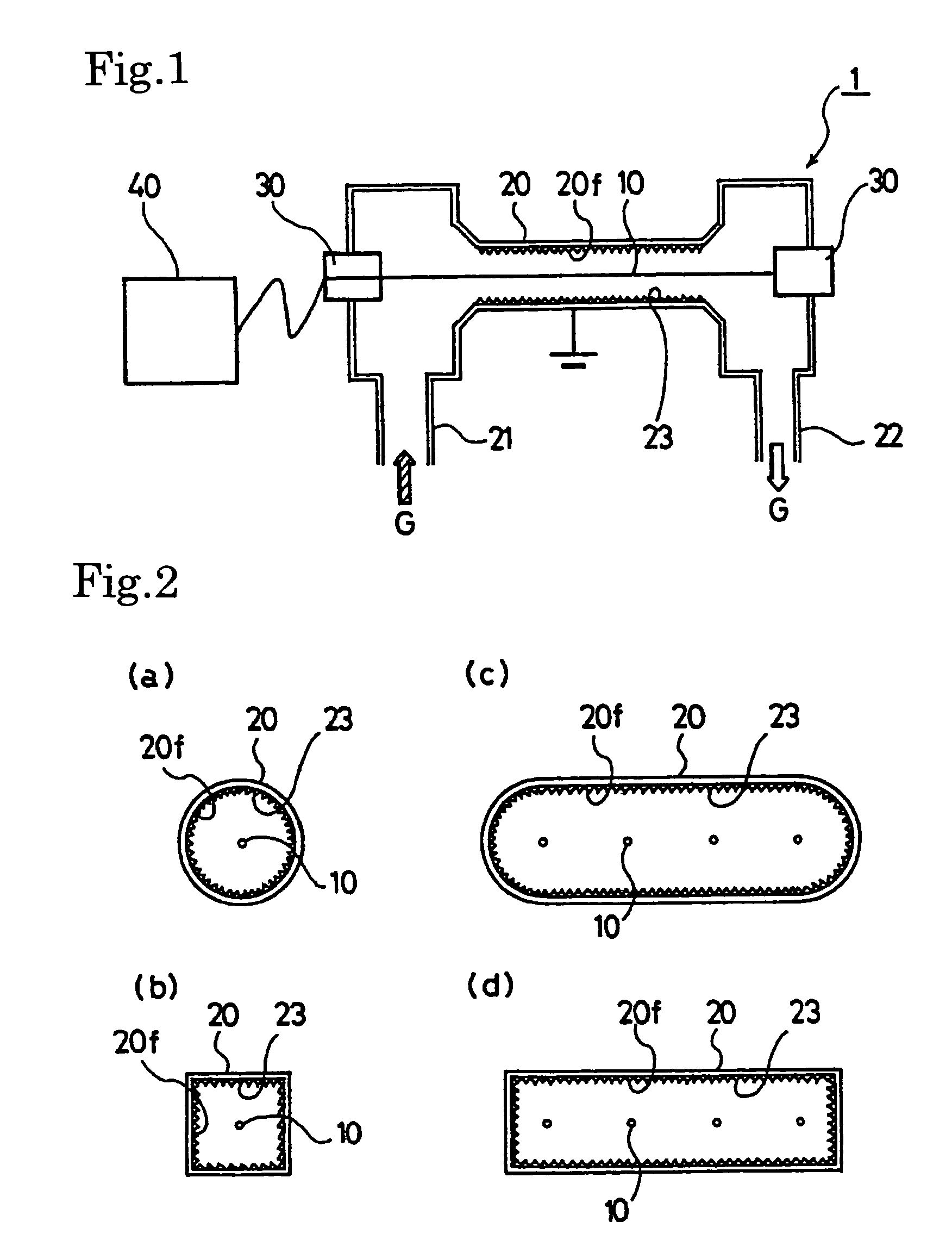

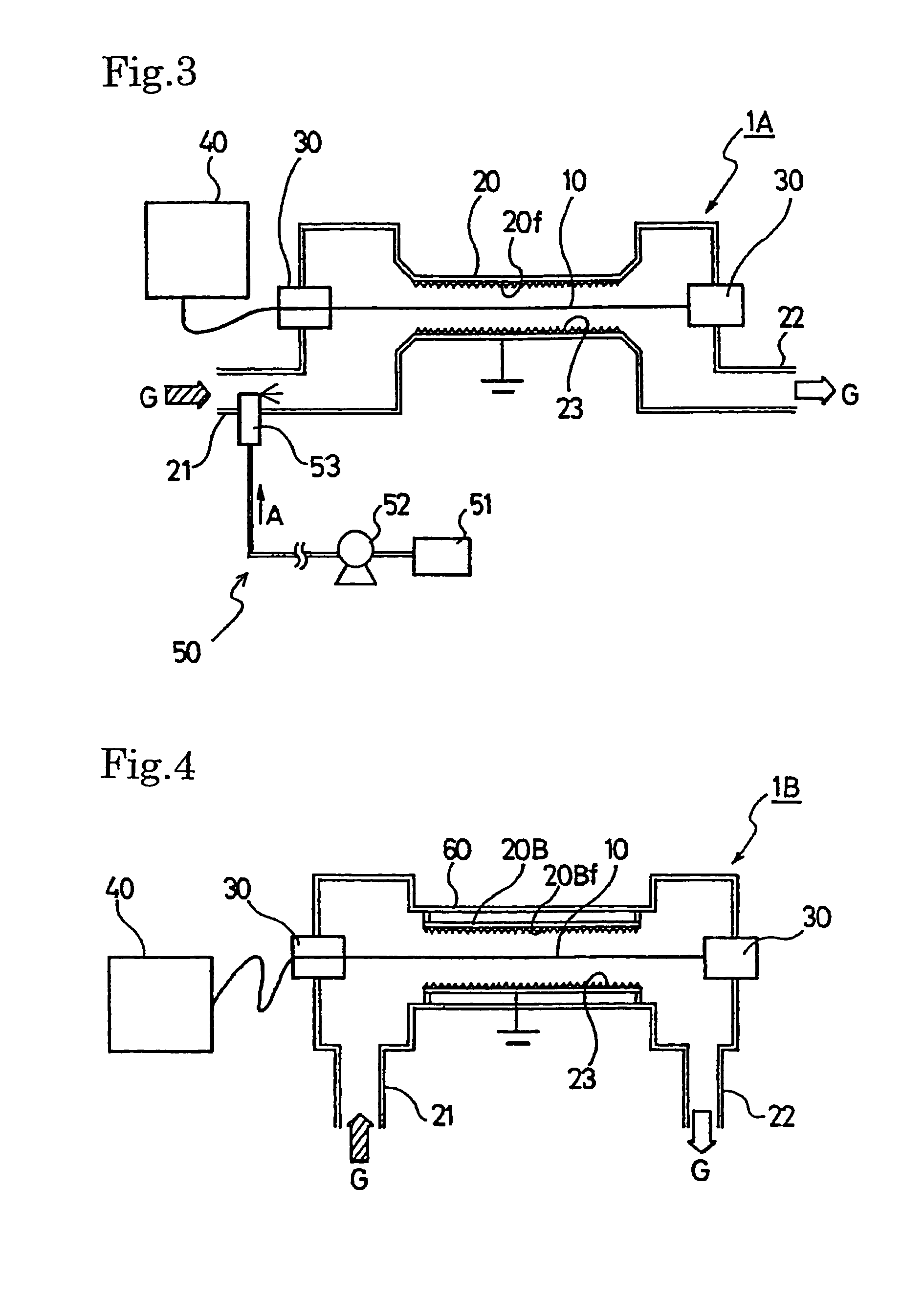

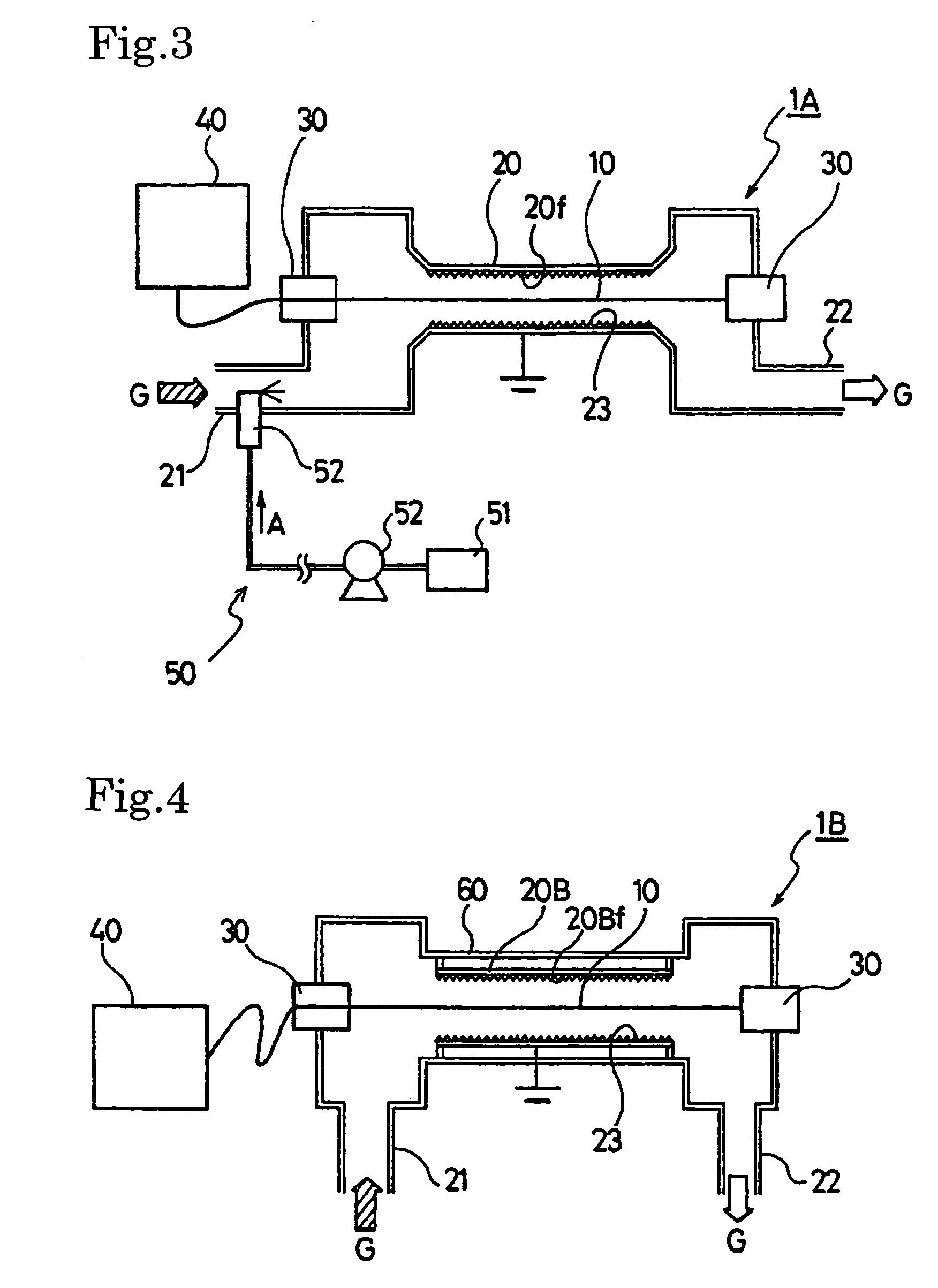

Gas treatment device

InactiveUS7758675B2Improve performanceLess pressure lossGas treatmentInternal combustion piston enginesGas passingCorona discharge

Owner:AKIRA MIZUNO +1

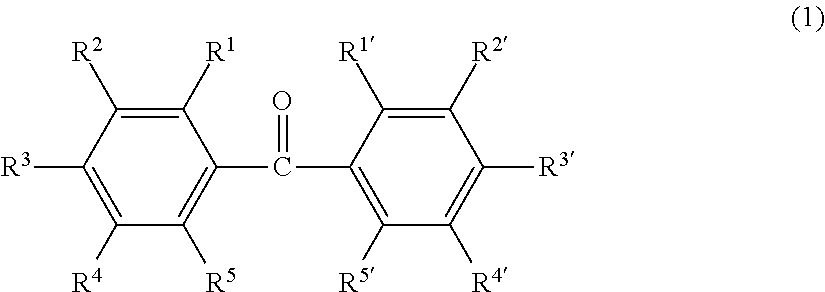

Surface modification method and surface-modified elastic body

InactiveUS20150203612A1Less pressure lossEasy to slideMedical devicesSpecial tyresInitiation pointFunctional monomer

The present invention aims to provide methods for surface-modifying a rubber vulcanizate or a thermoplastic elastomer, which can cost-effectively impart a variety of functions, such as sliding properties or biocompatibility, according to the application. The present invention relates to a method for surface-modifying an object of a rubber vulcanizate or a thermoplastic elastomer, the method including: step 1 of forming polymerization initiation points A on the surface of the object; and step 2 of radically polymerizing a non-functional monomer, starting from the polymerization initiation points A, to grow non-functional polymer chains, and further radically polymerizing a fluorine-containing functional monomer to grow fluorine-containing functional polymer chains.

Owner:SUMITOMO RUBBER IND LTD

Surface-modifying method and elastic body with modified surface

The present invention aims to provide a method for modifying a surface of a rubber vulcanizate or a thermoplastic elastomer, which can impart excellent sliding properties and excellent durability against repeated sliding motion, and allow the surface to maintain the sealing properties, without using expensive self-lubricating resins. The present invention relates to a method for modifying a surface of an object of a rubber vulcanizate or a thermoplastic elastomer, the method including: Step 1 of forming polymerization initiation points on the surface of the object; and Step 2 of radical-polymerizing a monomer starting from the polymerization initiation points to grow polymer chains on the surface of the object.

Owner:SUMITOMO RUBBER IND LTD

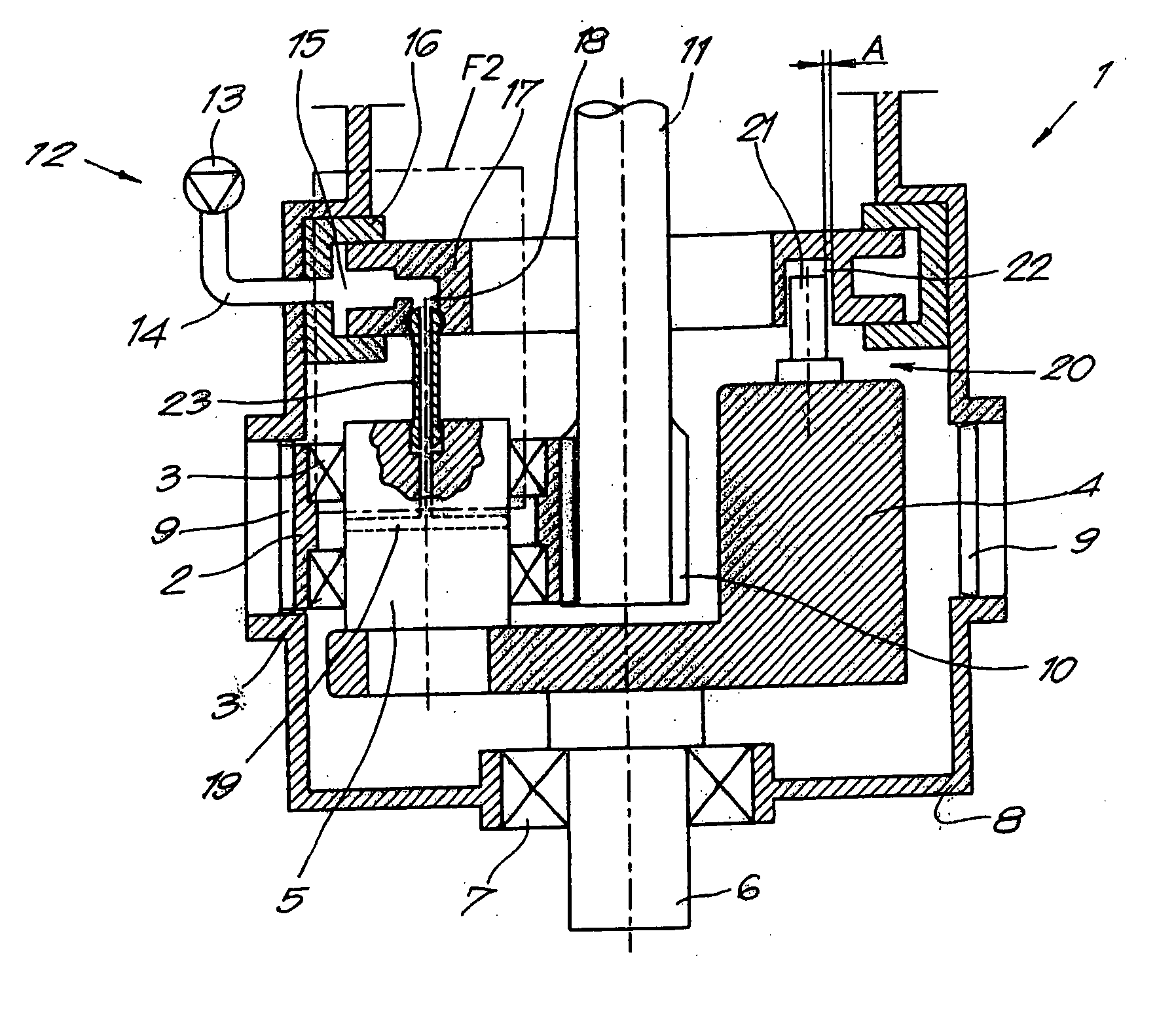

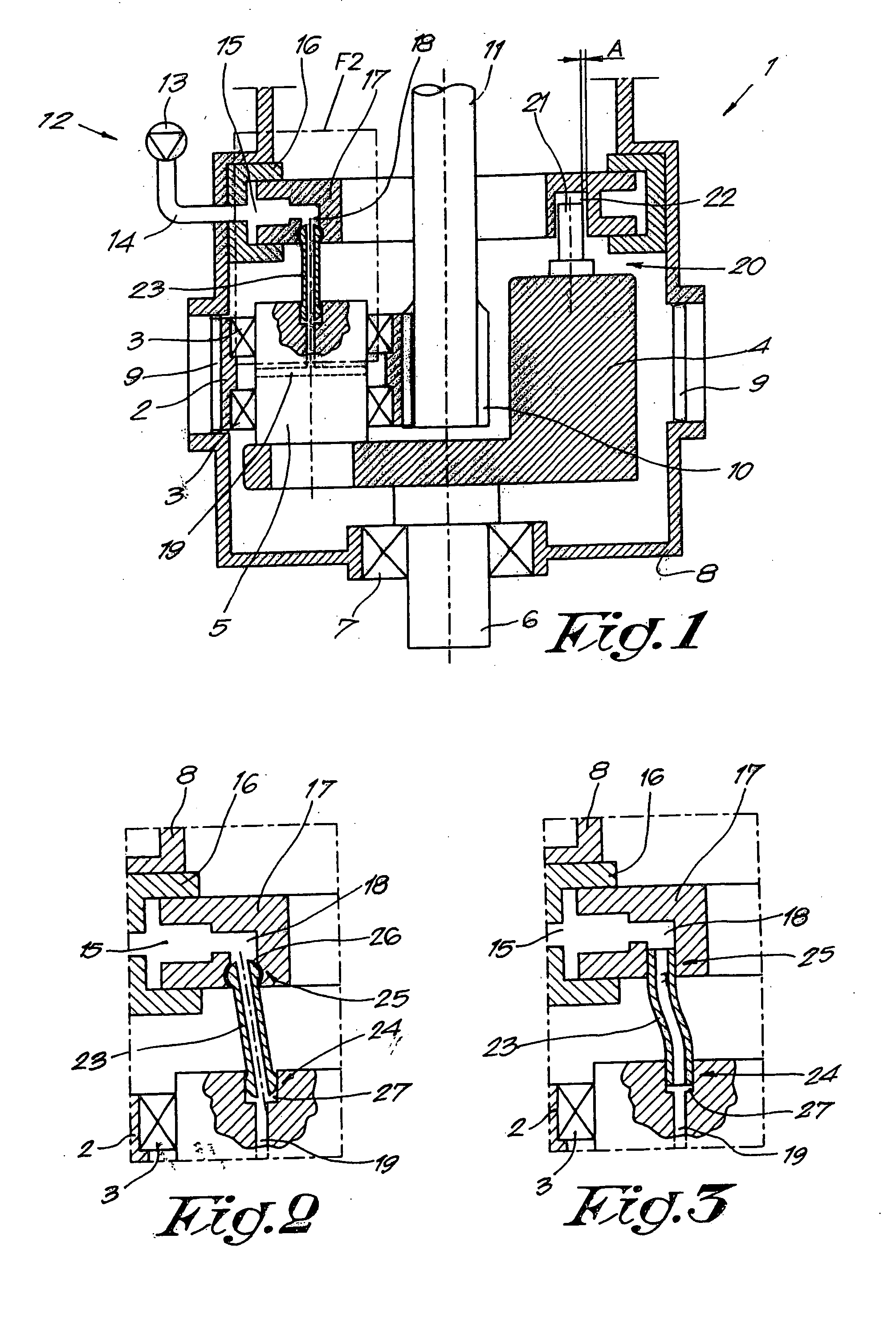

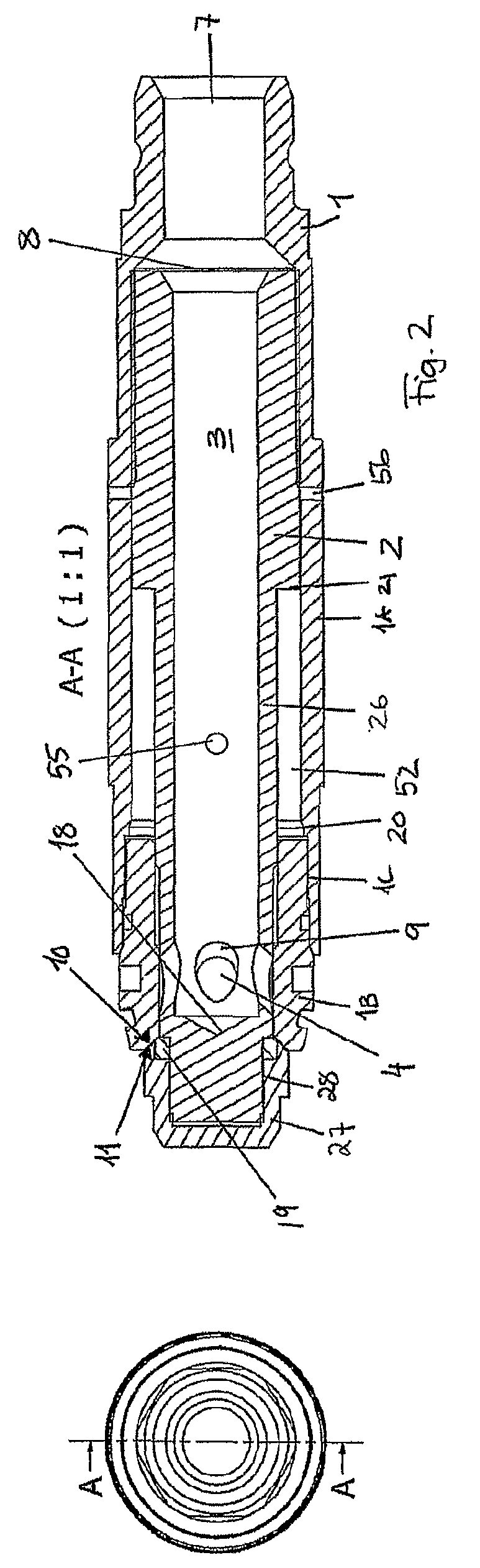

Planetary gear wheel construction

A planetary gear wheel construction with one or several planet wheels which are bearing-mounted on a planet carrier, which is provided in a rotating manner in a housing, and an oil lubrication which is formed of an oil supply via a ring-shaped channel in the housing formed of a ring-shaped groove and a distribution element turning along with the planet carrier which is held in said groove such that it can rotate, and which is provided with a passage to connect said oil channel to an oil channel in the planet carrier which opens at a planet wheel, wherein the distribution element is coupled to the planet carrier by means of a loose connection which makes it possible to transmit the rotational movement of the planet carrier to the distribution element, and in that the oil channel in the planet carrier is connected to the passage in the distribution element by means of a flexible or moving oil pipe.

Owner:HANSEN TRANSMISSIONS INT NV

Refrigerant evaporator

ActiveUS7367203B2Simplified tank structureLess pressure lossDomestic cooling apparatusEvaporators/condensersRefrigerant distributionLeft direction

A refrigerant evaporator includes a tank constituted by a tank portion and a header plate. The tank portion includes refrigerant collecting portions for guiding the refrigerant passed through a first path to the ends of the tank in the right-and-left direction and refrigerant distributing portions for guiding the refrigerant to the tubes forming a second pass. The header plate has refrigerant collecting / distributing space for the tubes. Side tanks are arranged to cover open portions at the ends of the tank in the right-and-left direction, and to spatially connect the flow passages. Separators are provided at portions where the flow passages are to be spatially blocked to constitute a front-and-rear right-and-left cross path. An increased sectional area of flow passages is obtained at the refrigerant flow corner portions relying upon a simple constitution, to decrease the pressure loss on the refrigerant side in the tank and to enhance performance.

Owner:DENSO CORP

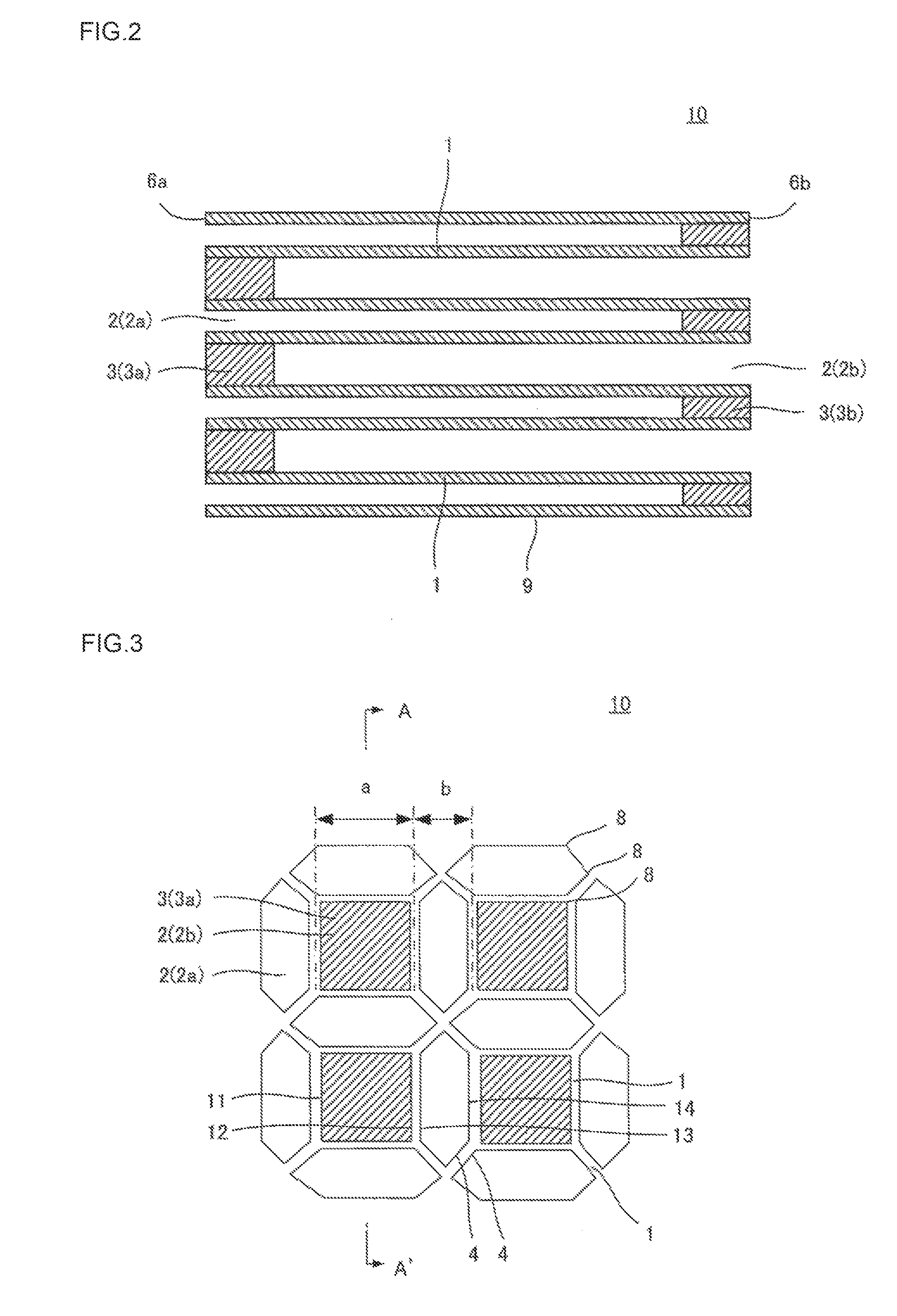

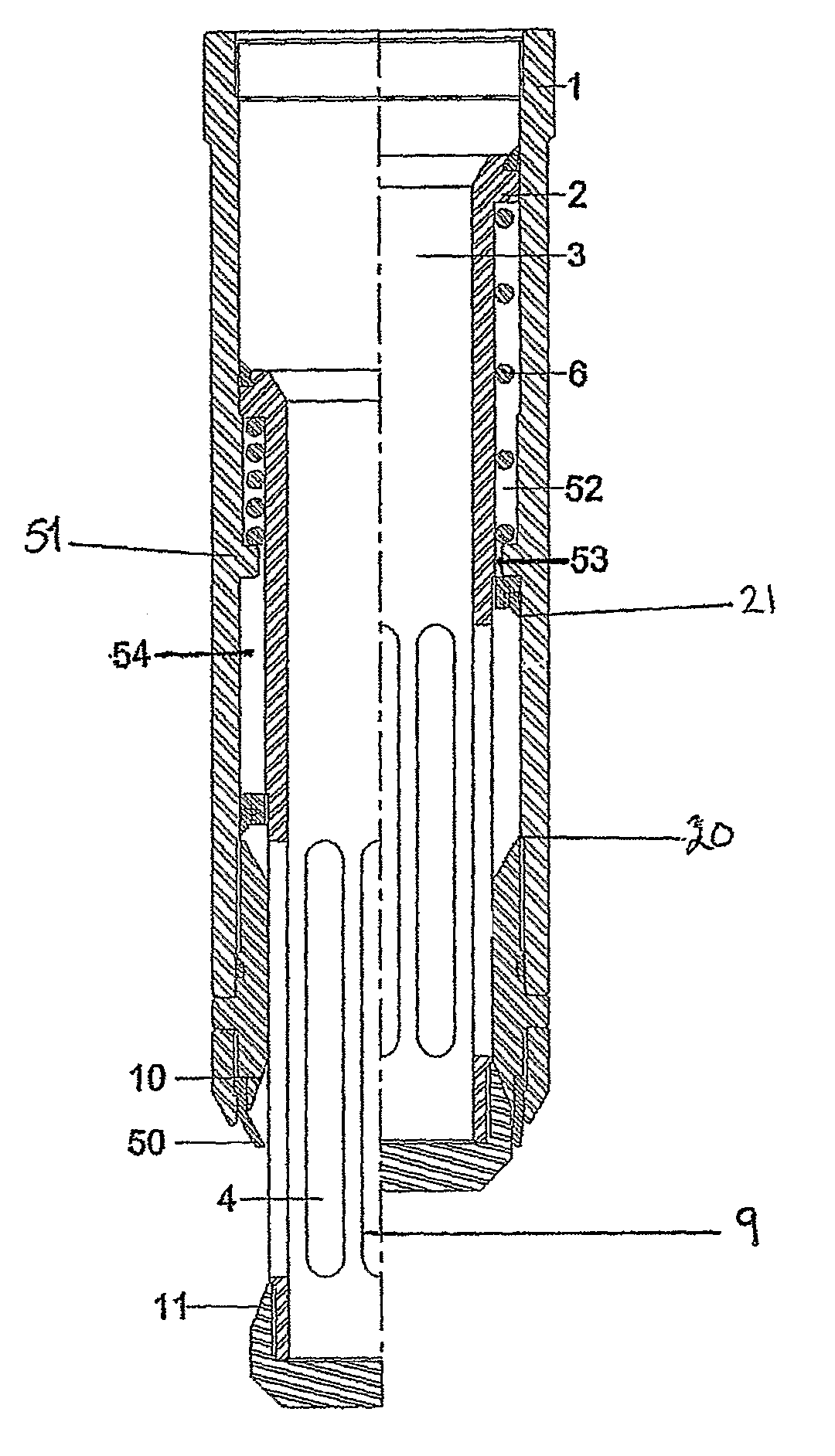

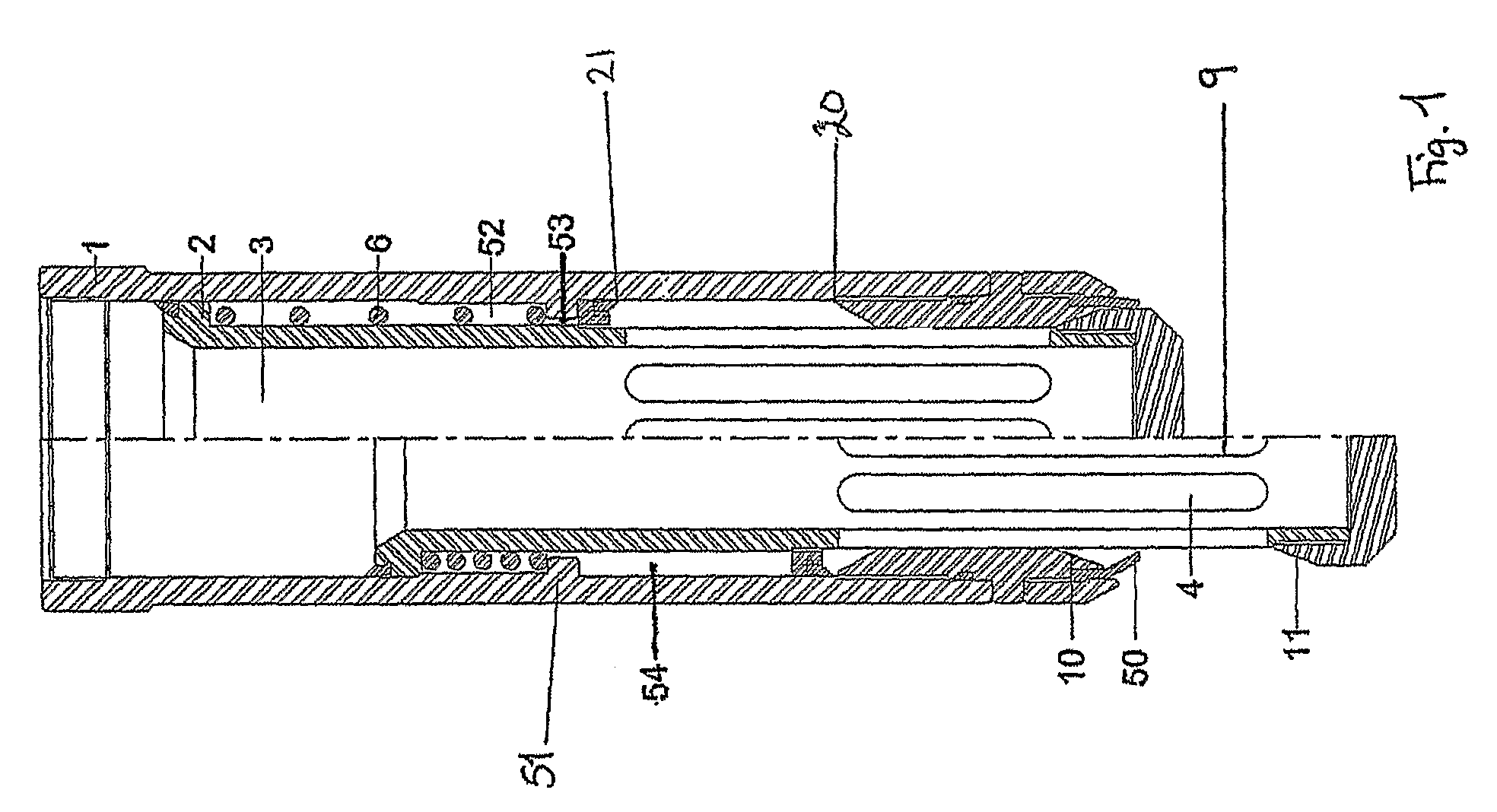

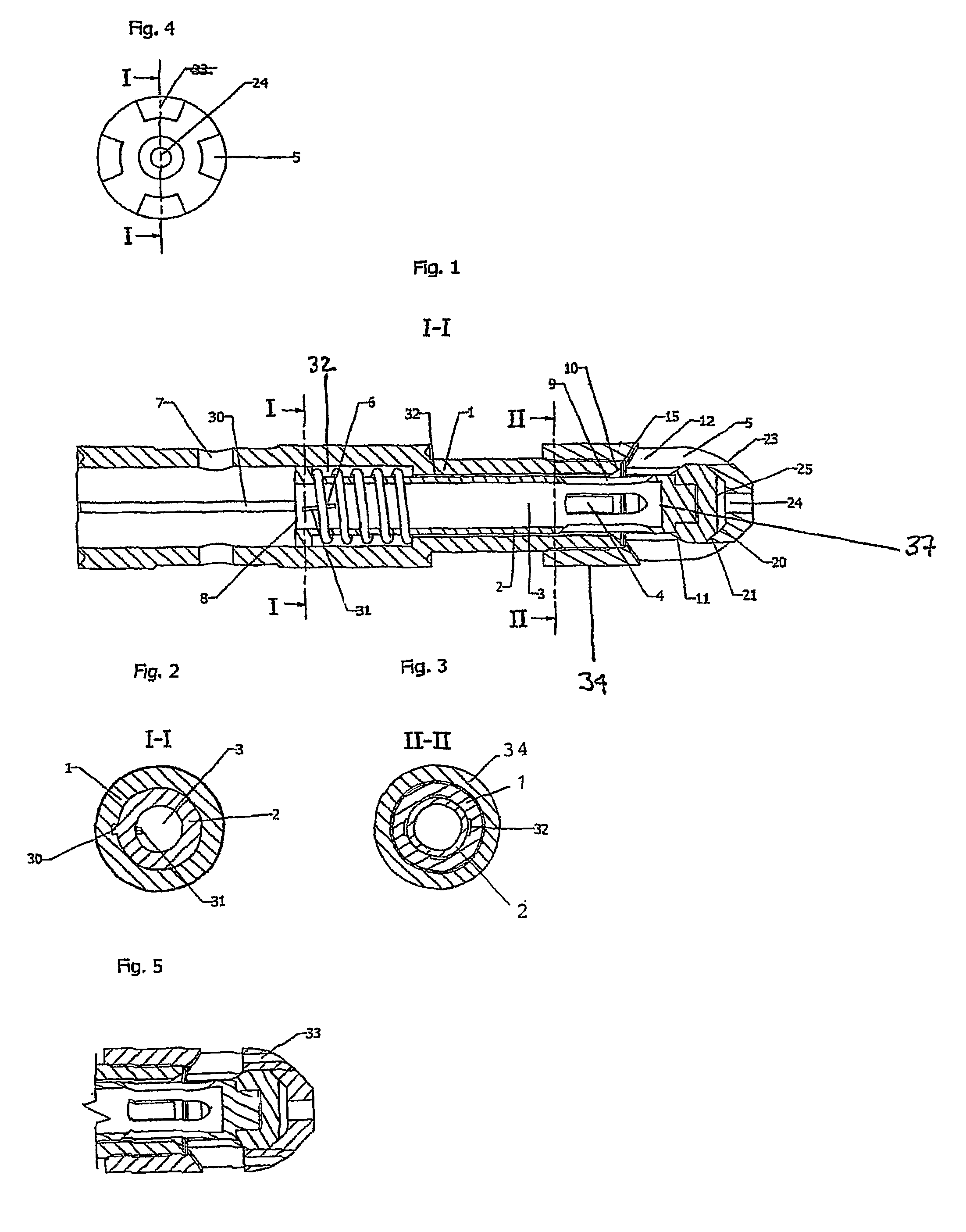

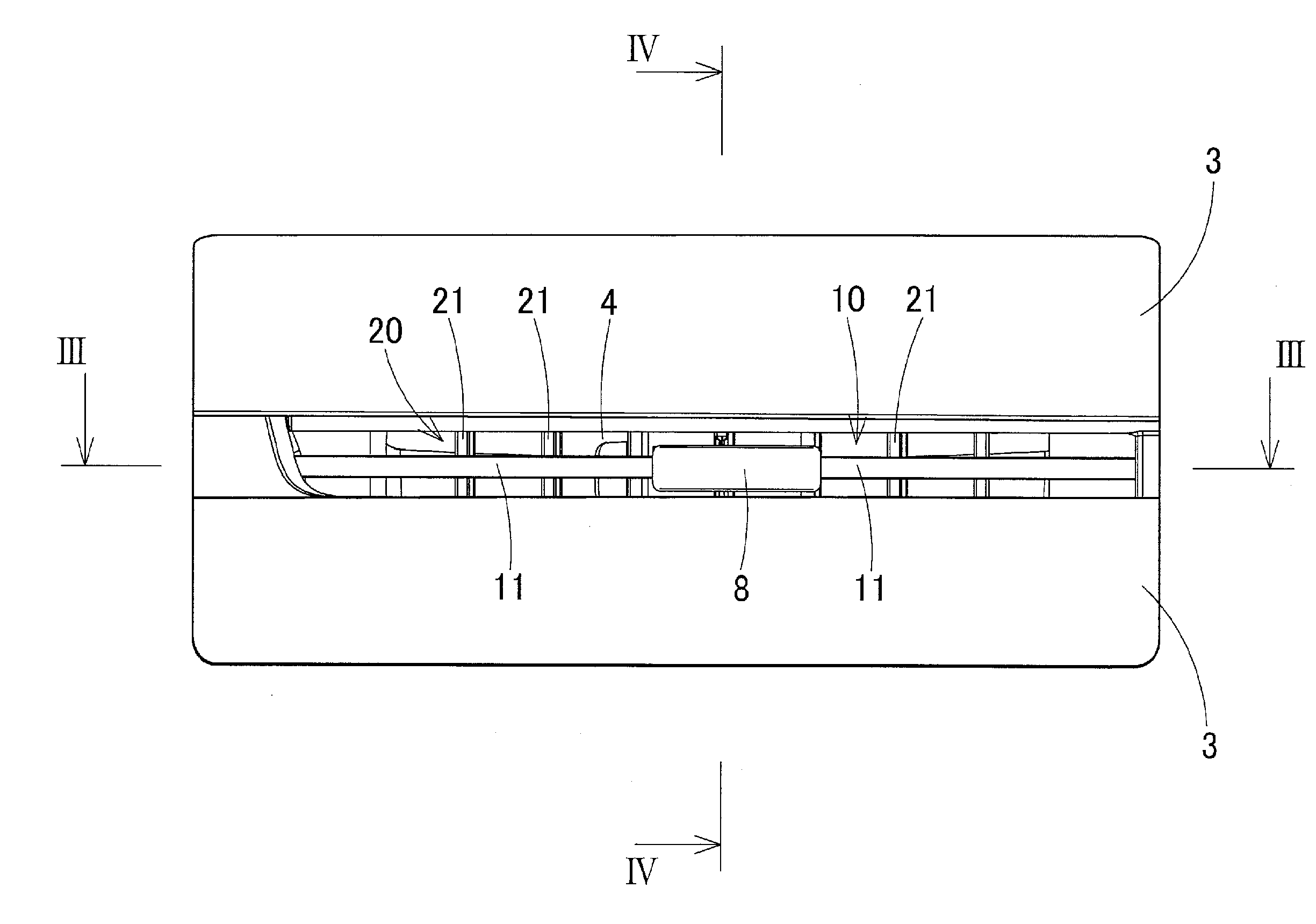

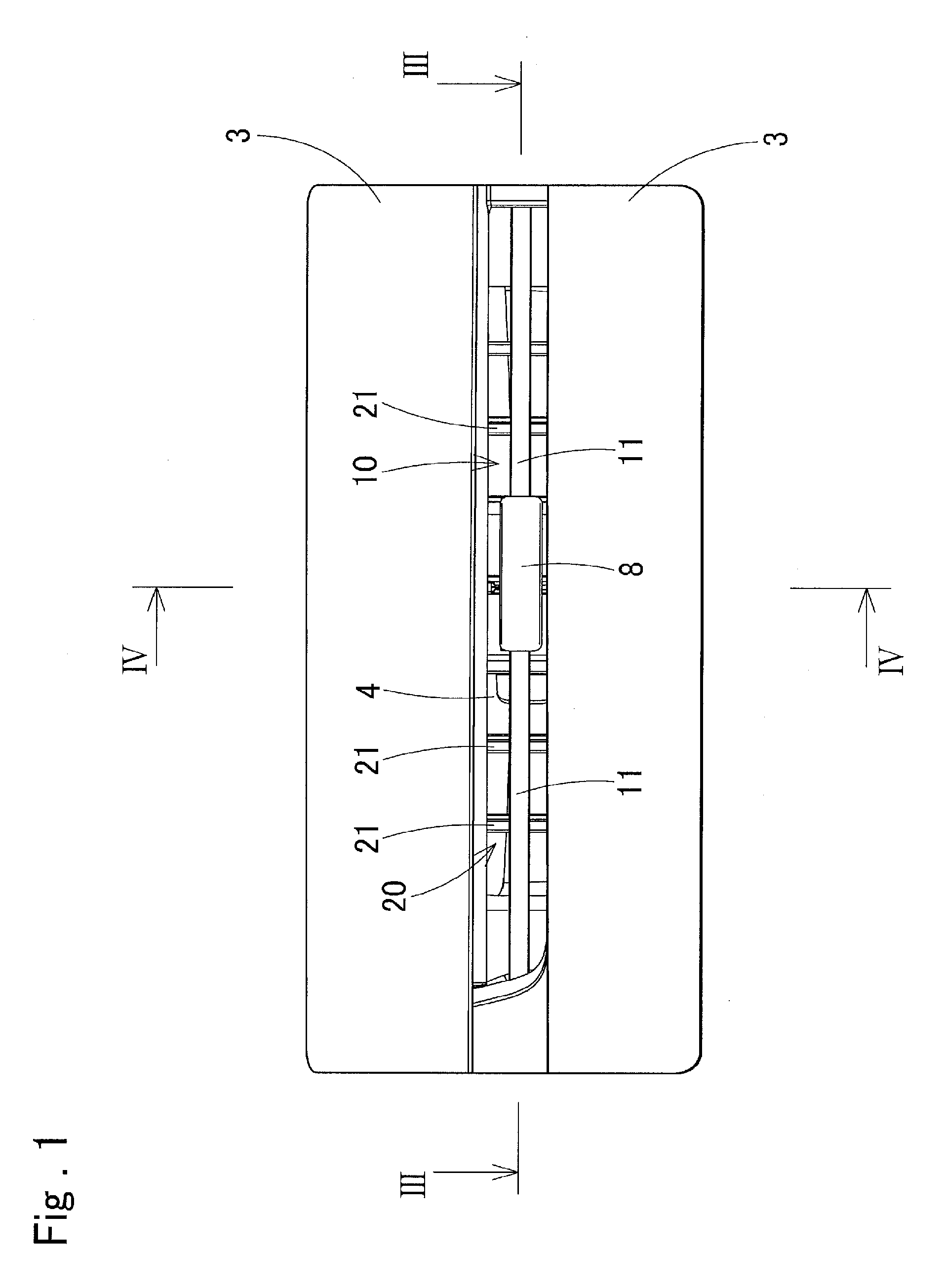

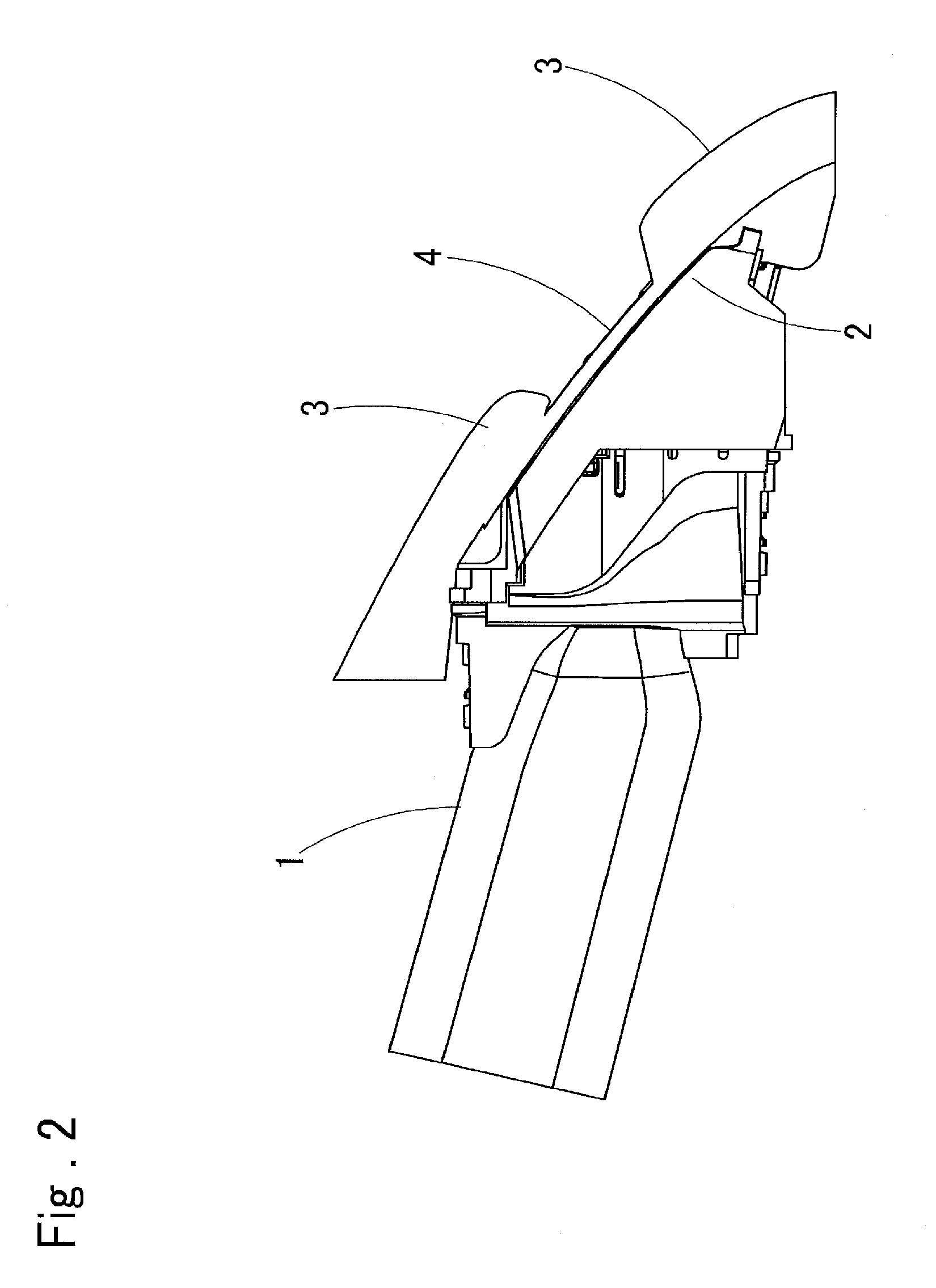

Fluid injection device

ActiveUS8186440B2Large flow areaLess pressure lossCheck valvesFluid removalEngineeringPressure difference

The present invention regards a device designed for injection of fluids in a well bore, typically an offshore well bore for petroleum production and gas injection / gas lift system for fluid injection. The device comprises a outer hollow housing (1) with an internal body (2) moveable within the outer housing (1) with an internal bore (3) which in a first closed position is closed with a metal to metal seal system between the outer housing (1) and the internal body (2), which internal body (2) is operated by pressure differential across the internal body (2), where the internal body (2) is designed with slots (4) forming outlets of the internal bore (3) which in an open position of the device is positioned outside of the outer housing (1).

Owner:GASOLINEEUM TECH

Surface modification method and surface-modified elastic body

The present invention aims to provide a surface modification method for a rubber vulcanizate or a thermoplastic elastomer, which can impart excellent sliding properties and excellent durability against repeated sliding motion and can allow the surface to maintain the sealing properties, without using expensive self-lubricating plastics. The present invention relates to a surface modification method for modifying a rubber vulcanizate or a thermoplastic elastomer as an object to be modified, the method including: step 1 of forming polymerization initiation points on the object to be modified; step 2 of radically polymerizing a monomer, starting from the polymerization initiation points, by irradiation with LED light at 300 nm to 400 nm to grow polymer chains on a surface of the object to be modified; and step 3 of esterifying, transesterifying or amidating side chains of the polymer chains.

Owner:SUMITOMO RUBBER IND LTD

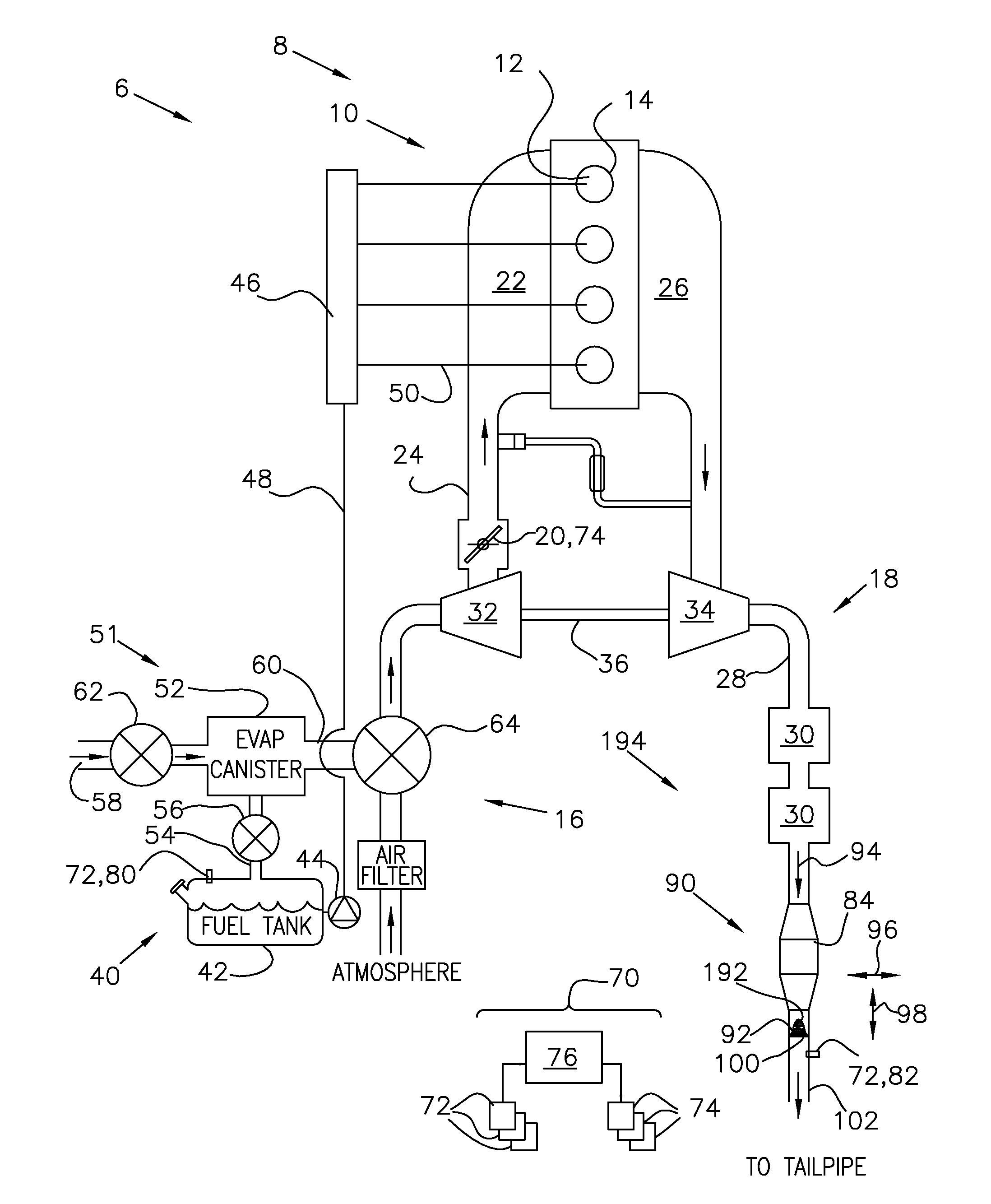

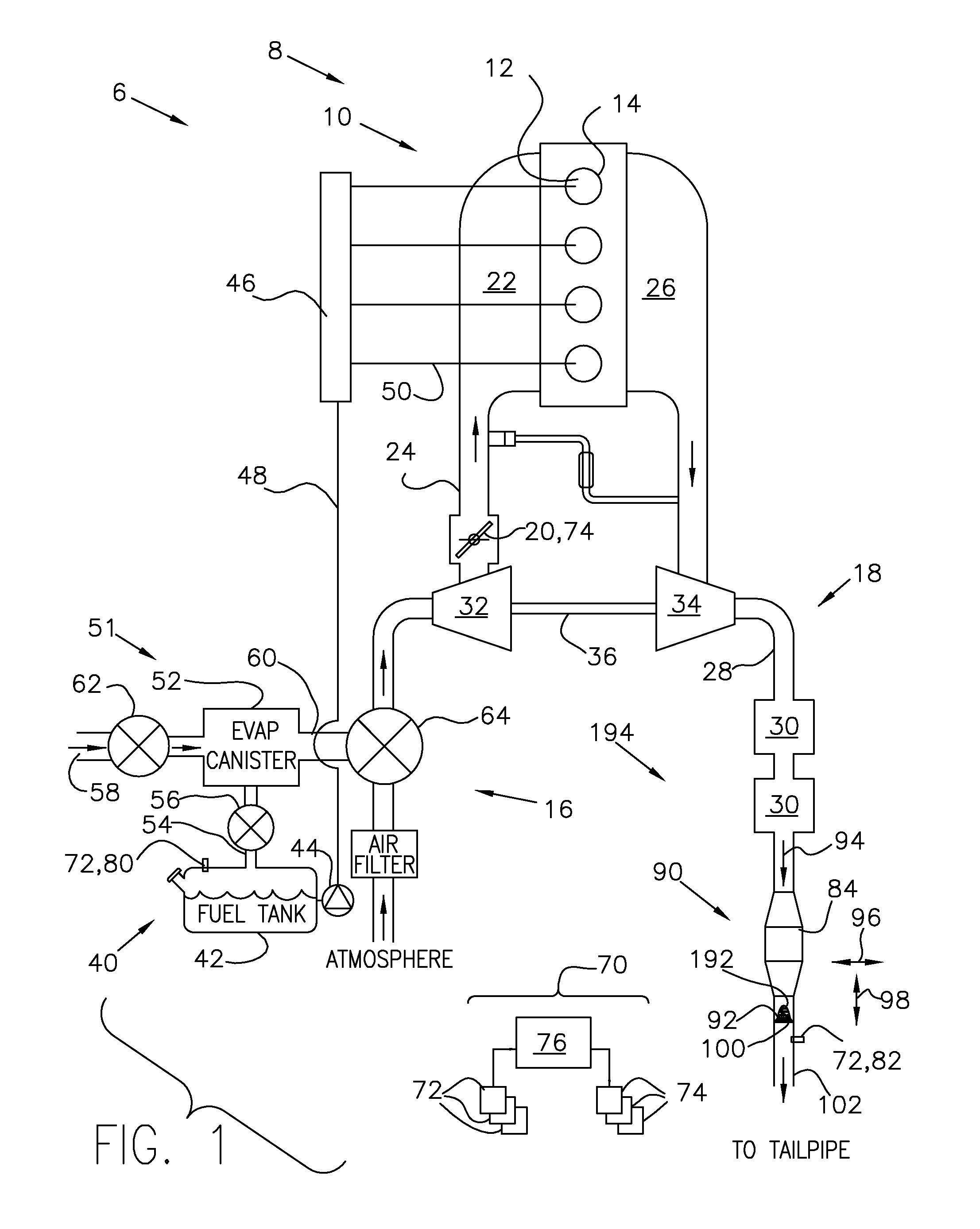

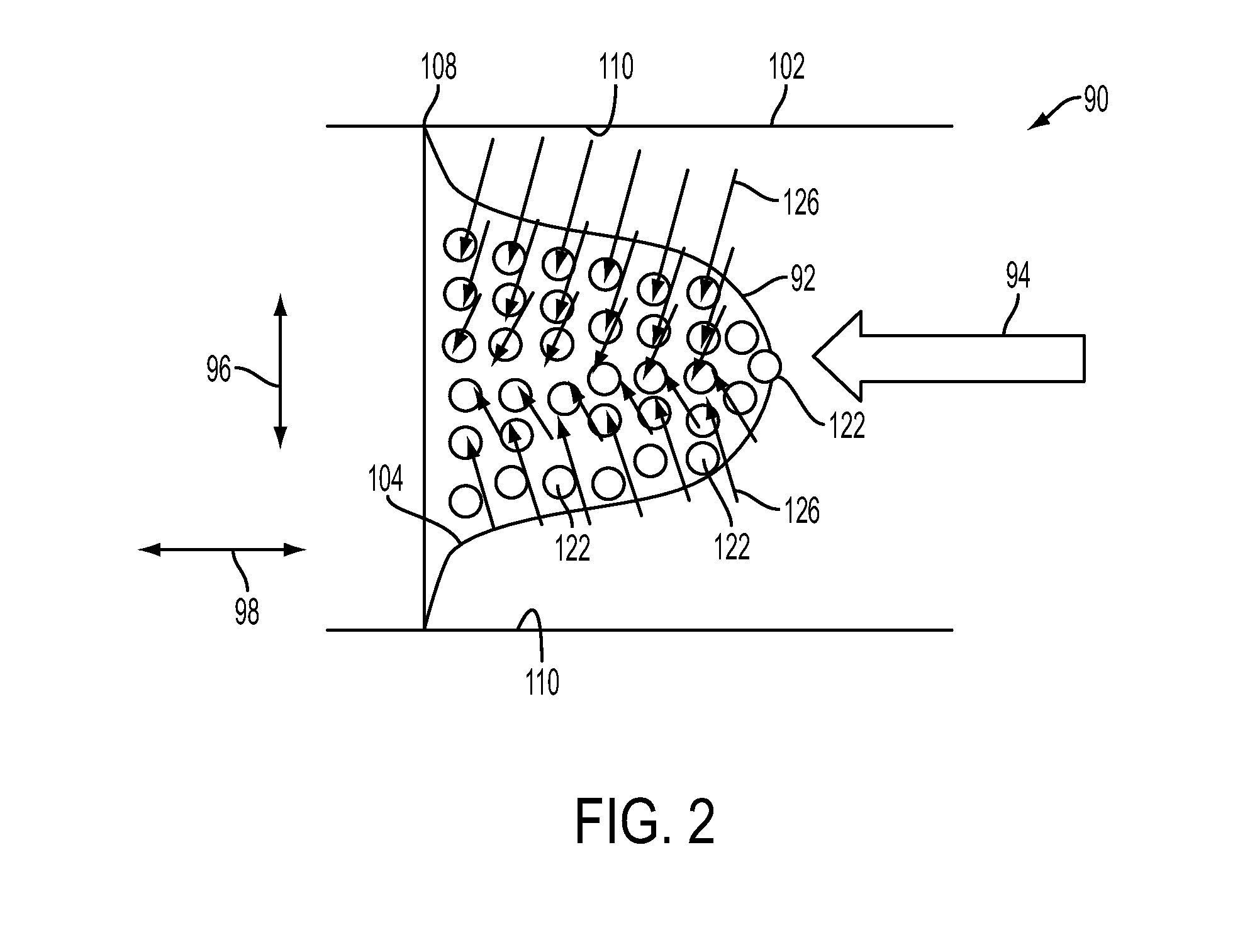

Exhaust gas mixer and system

InactiveUS20150047330A1Accurate readingWell mixedInternal combustion piston enginesExhaust apparatusCombustion chamberExhaust fumes

A device and a system are provided. The system may include a perforated barrier disposed within an exhaust stream downstream from the combustion chamber(s). The barrier may divide the exhaust stream radially and longitudinally. A mixing surface may be coupled with the perforated barrier which may define a path within the exhaust stream to impart a swirl to the exhaust stream.

Owner:FORD GLOBAL TECH LLC

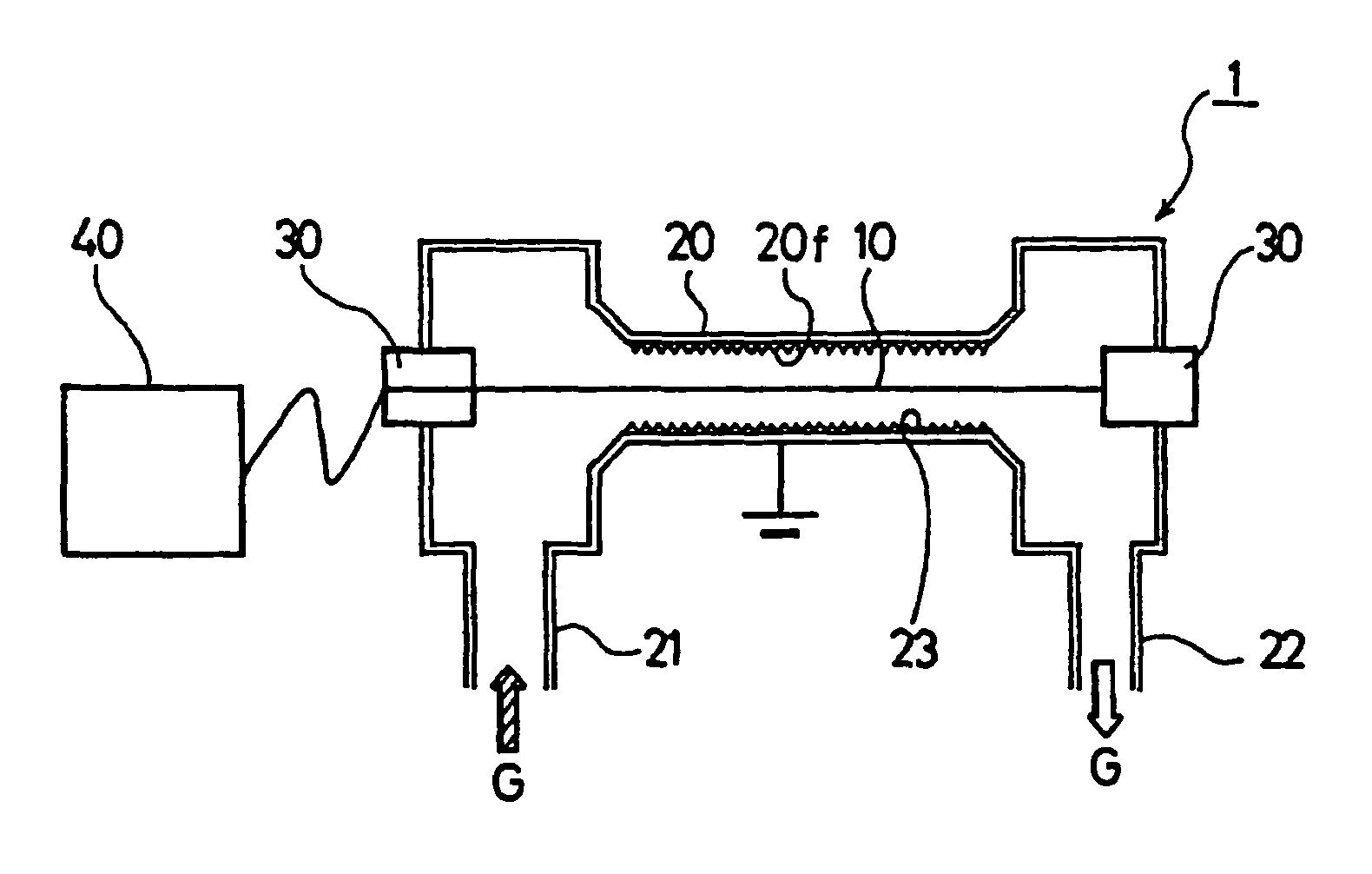

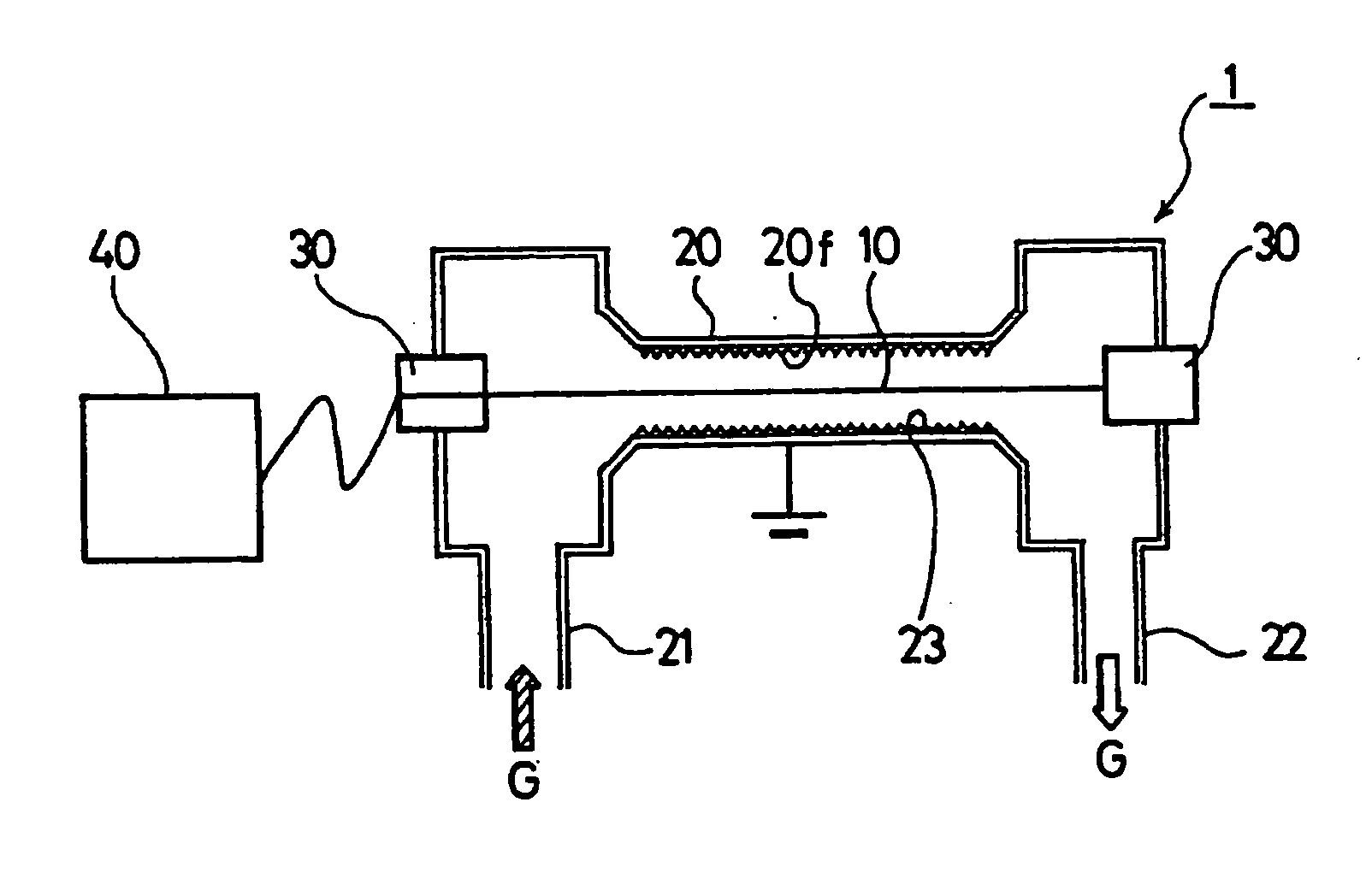

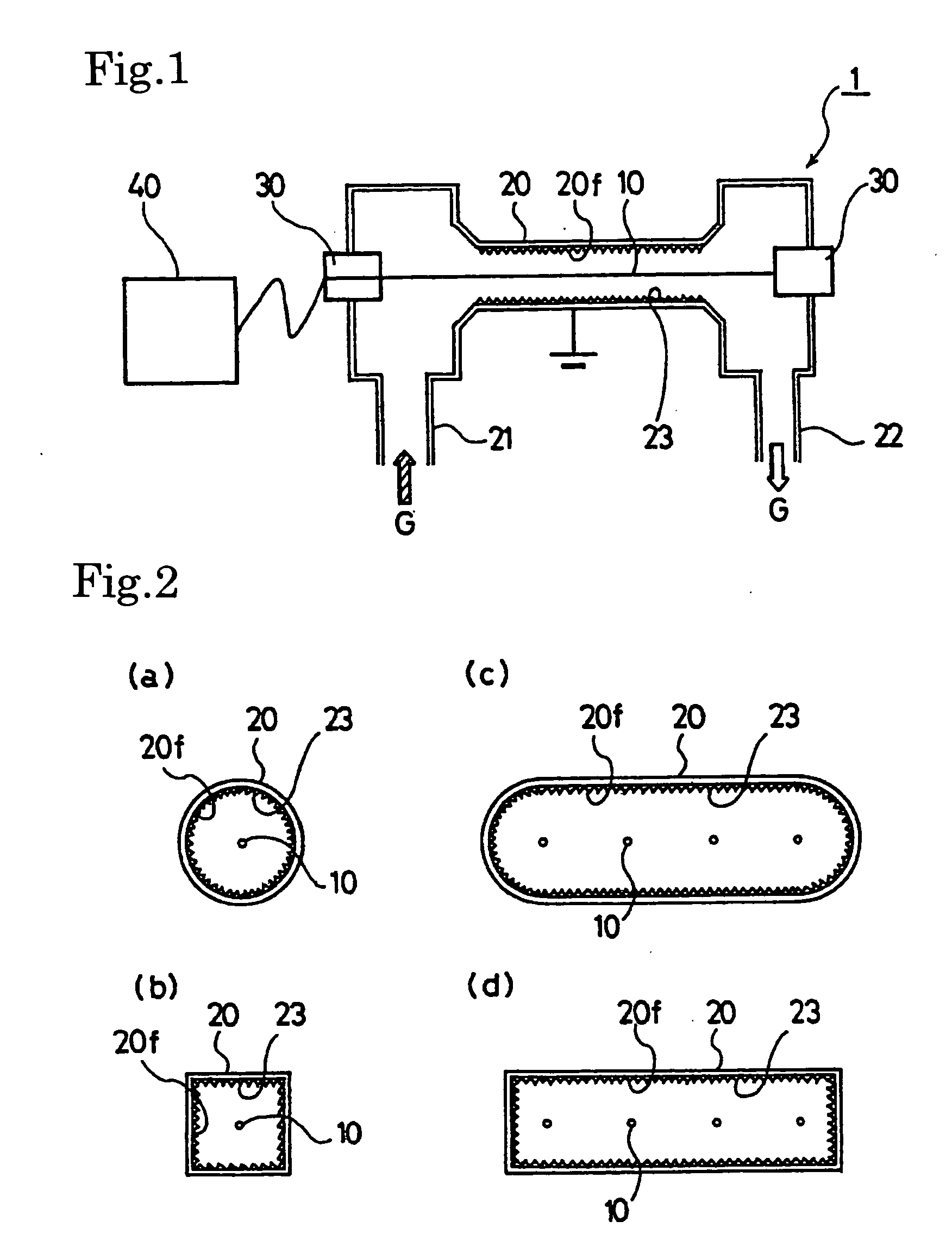

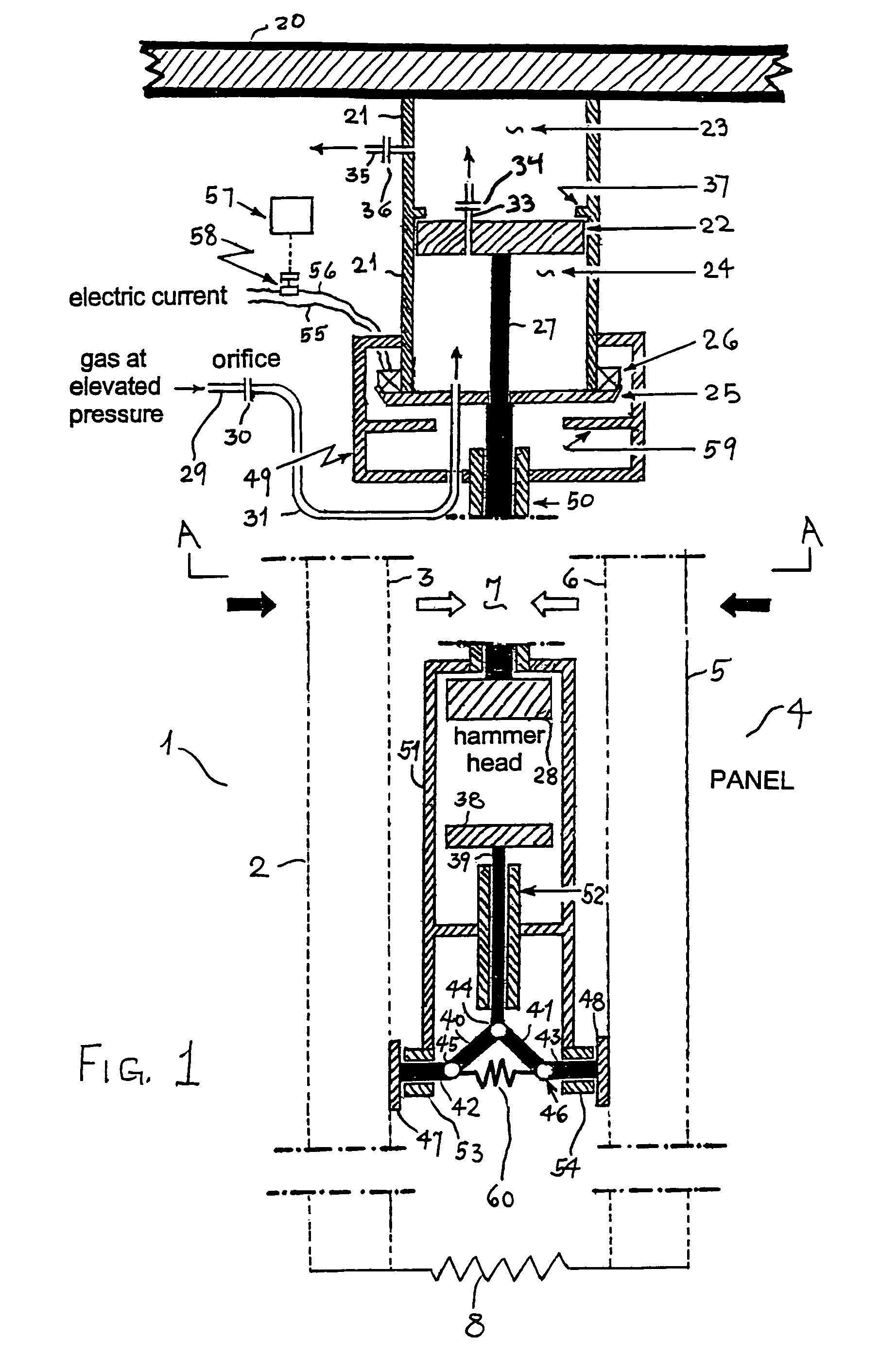

Gas Treatment Device

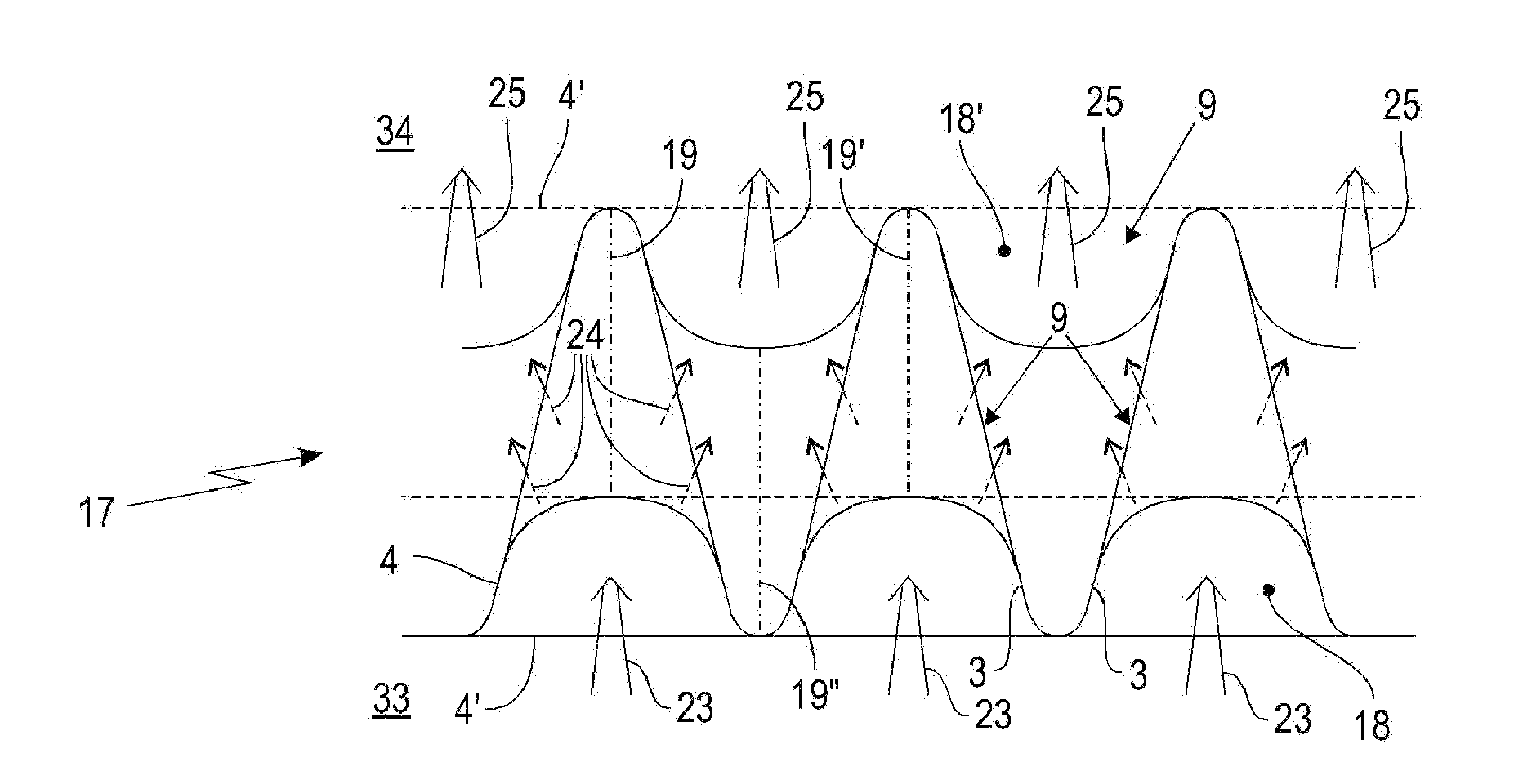

InactiveUS20070245898A1Good effectShorten the time periodGas treatmentInternal combustion piston enginesCorona dischargeEngineering

Gas treatment equipment (1) comprising a corona electrode (10) and a dust-collection electrode (20) facing the corona electrode (10), and forming corona discharge in gas (G) passing between the corona electrode (10) and the dust-collection electrode (20) by applying a high voltage between them to thereby agglomerate or collect components in the gas (G), wherein a means (23) for accelerating turbulence of the gas (G) in the vicinity of the surface (200 of the dust-collection electrode (20) facing the corona electrode (10) is provided on the opposing surface (20f) or in the vicinity thereof.

Owner:AKIRA MIZUNO +1

Surface modification method and surface-modified elastic body

ActiveUS9339845B2Less pressure lossEasy to slidePharmaceutical delivery mechanismRecord information storageThermoplastic elastomerLength wave

The present invention aims to provide a surface modification method for a rubber vulcanizate or a thermoplastic elastomer, which can impart excellent sliding properties and durability against repeated sliding motion and can allow the surface to maintain the sealing properties, without using expensive self-lubricating plastics. The present invention relates to a surface modification method for modifying a rubber vulcanizate or a thermoplastic elastomer as an object to be modified, the method including: Step 1 of allowing a photopolymerization initiator to be adsorbed on a surface of the object to be modified; and Step 2 of radical polymerizing monomers, starting from the adsorbed photopolymerization initiator, by irradiation with UV light at a wavelength of 300 nm to 400 nm to grow polymer chains on the surface of the object to be modified.

Owner:SUMITOMO RUBBER IND LTD

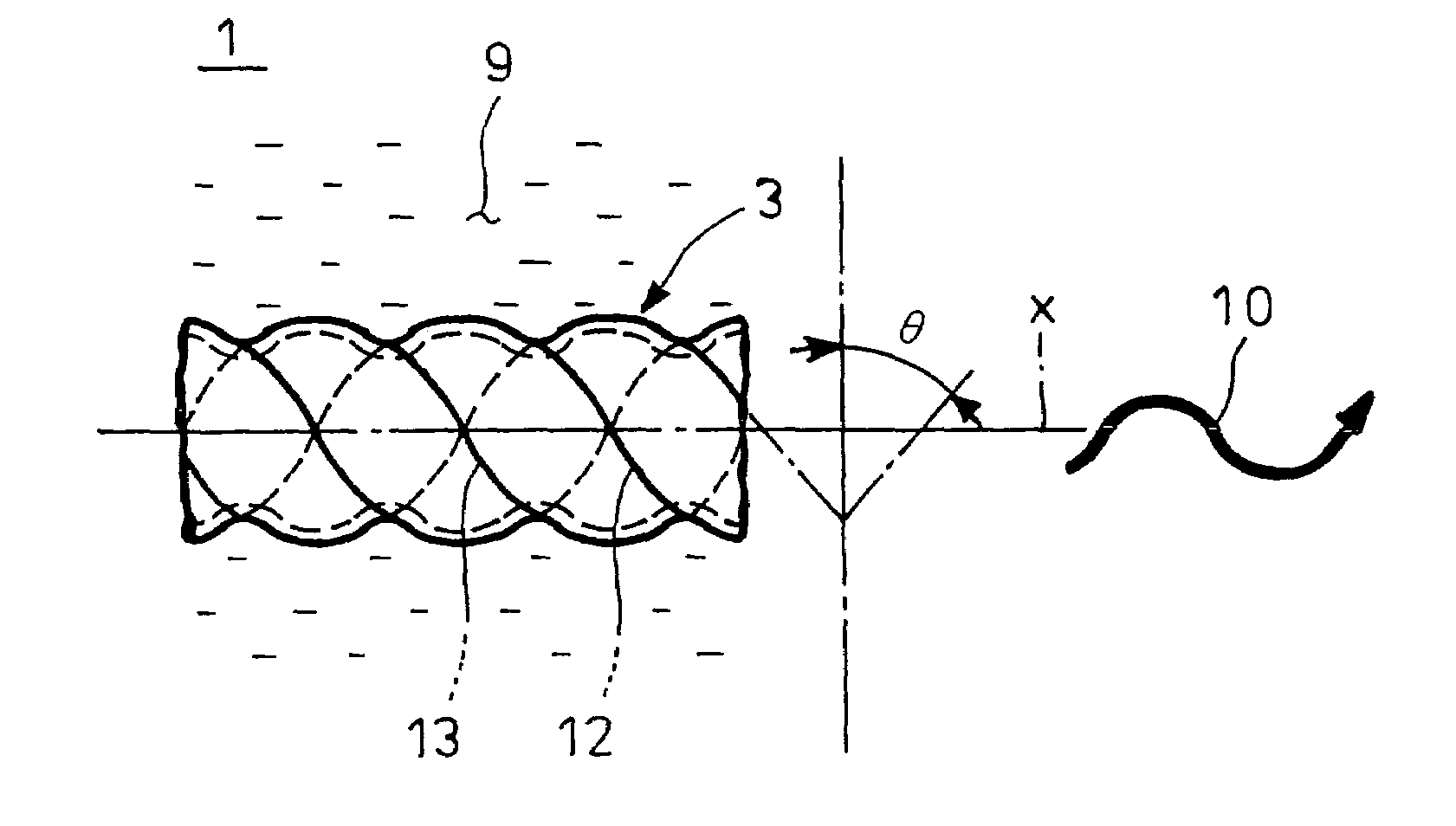

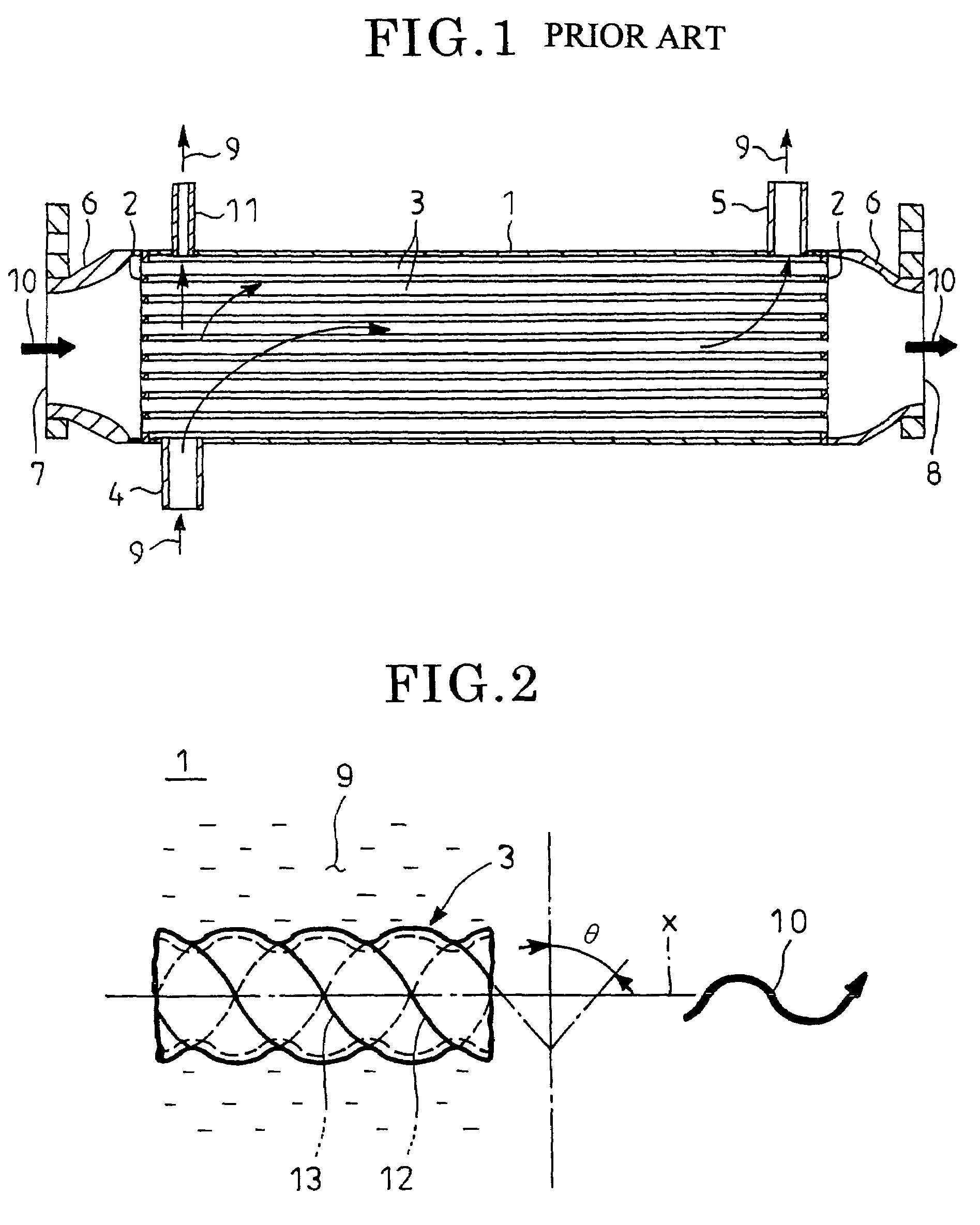

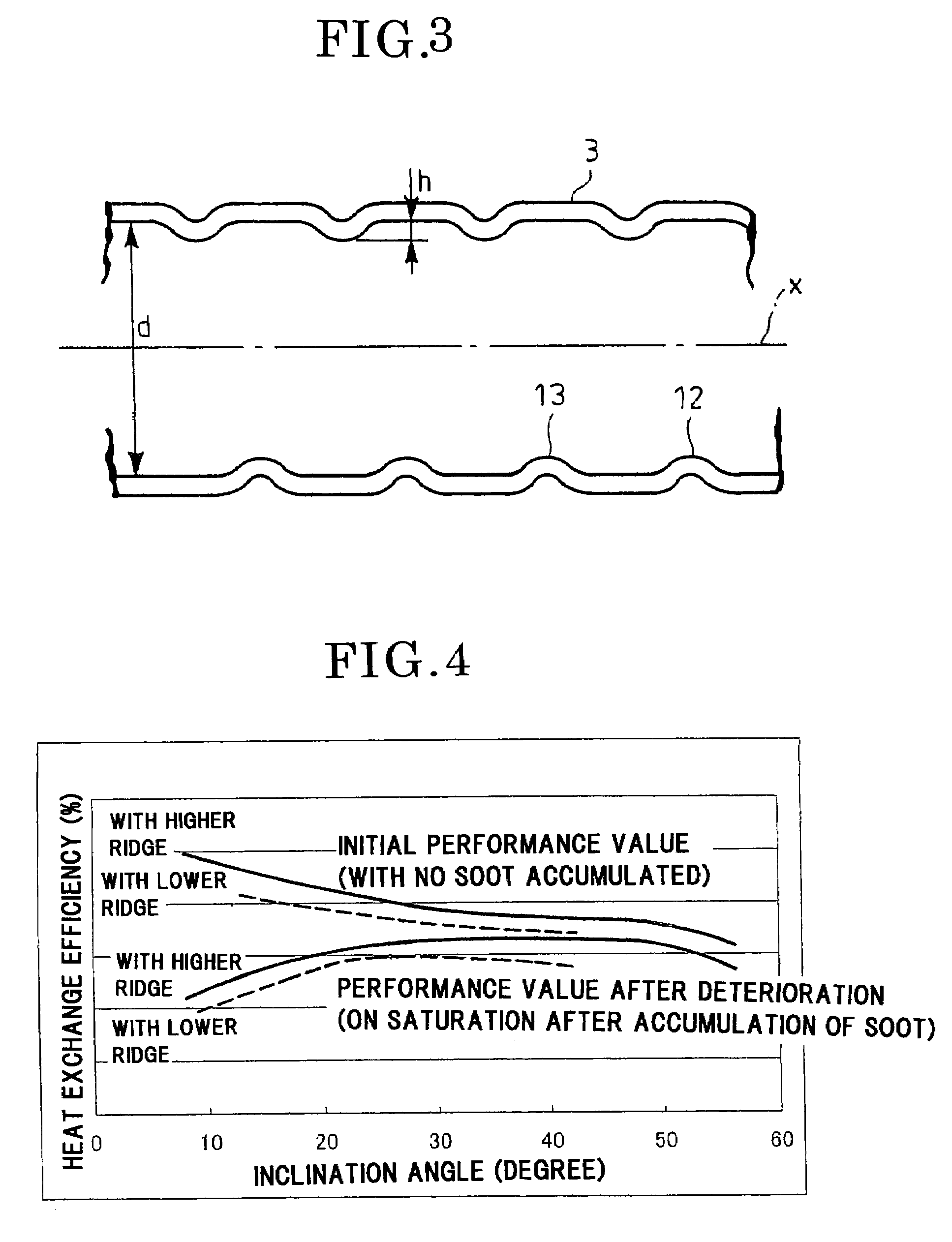

EGR cooler

InactiveUS7080634B2Inferior performanceLess pressure lossInternal combustion piston enginesNon-fuel substance addition to fuelDiesel engineChiller

An EGR cooler has tubes and a shell for enclosing the tubes. Cooling water is supplied into and discharged from the shell and exhaust gas from a diesel engine is guided into each of the tubes so as to conduct heat exchange of the exhaust gas with the cooling water. An inner periphery of each of the tubes is formed with spiral protrusions each having an inclination angle in a range of 26°–50° to a plane perpendicular to an axis of the tube.

Owner:HINO MOTORS LTD +1

Fluid injection device

ActiveUS8181705B2Reduce erosion rateIncrease the circulation areaCheck valvesEqualizing valvesEngineeringPressure difference

The present invention regards a device designed for injection of fluids in a well bore, typically an offshore well bore for petroleum production and gas injection / gas lift system for fluid injection. The device comprises a outer hollow housing (1) with an internal body (2) moveable within the outer housing (1) with an internal bore (3) which in a first closed position is closed with a metal to metal seal system between the outer housing (1) and the internal body (2), which internal body (2) is operated by pressure differential across the internal body (2), where the internal body (2) is designed with slots (4) forming outlets of the internal bore (3) which in an open position of the device leads to the outside of the outer housing (1).

Owner:GASOLINEEUM TECH

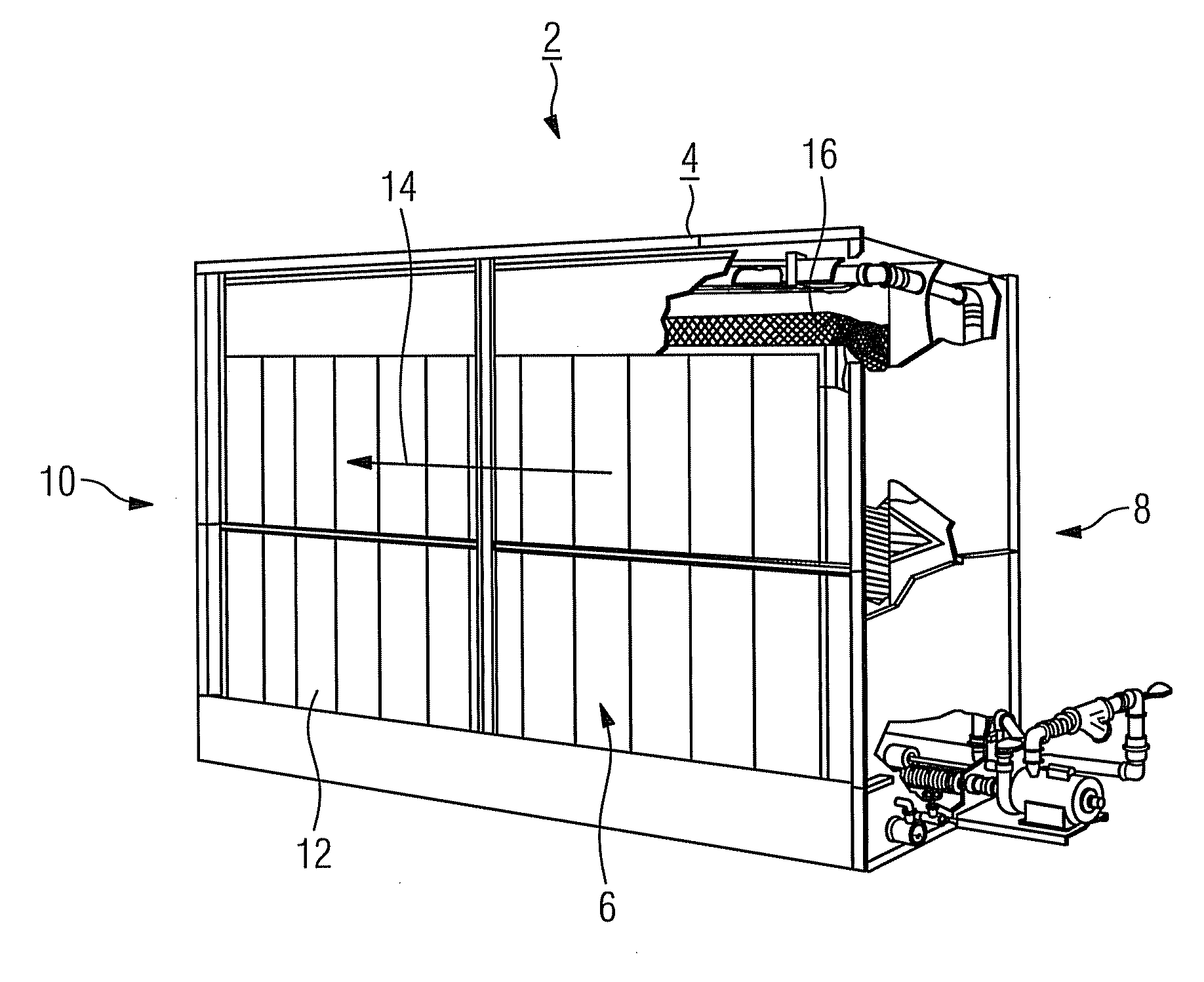

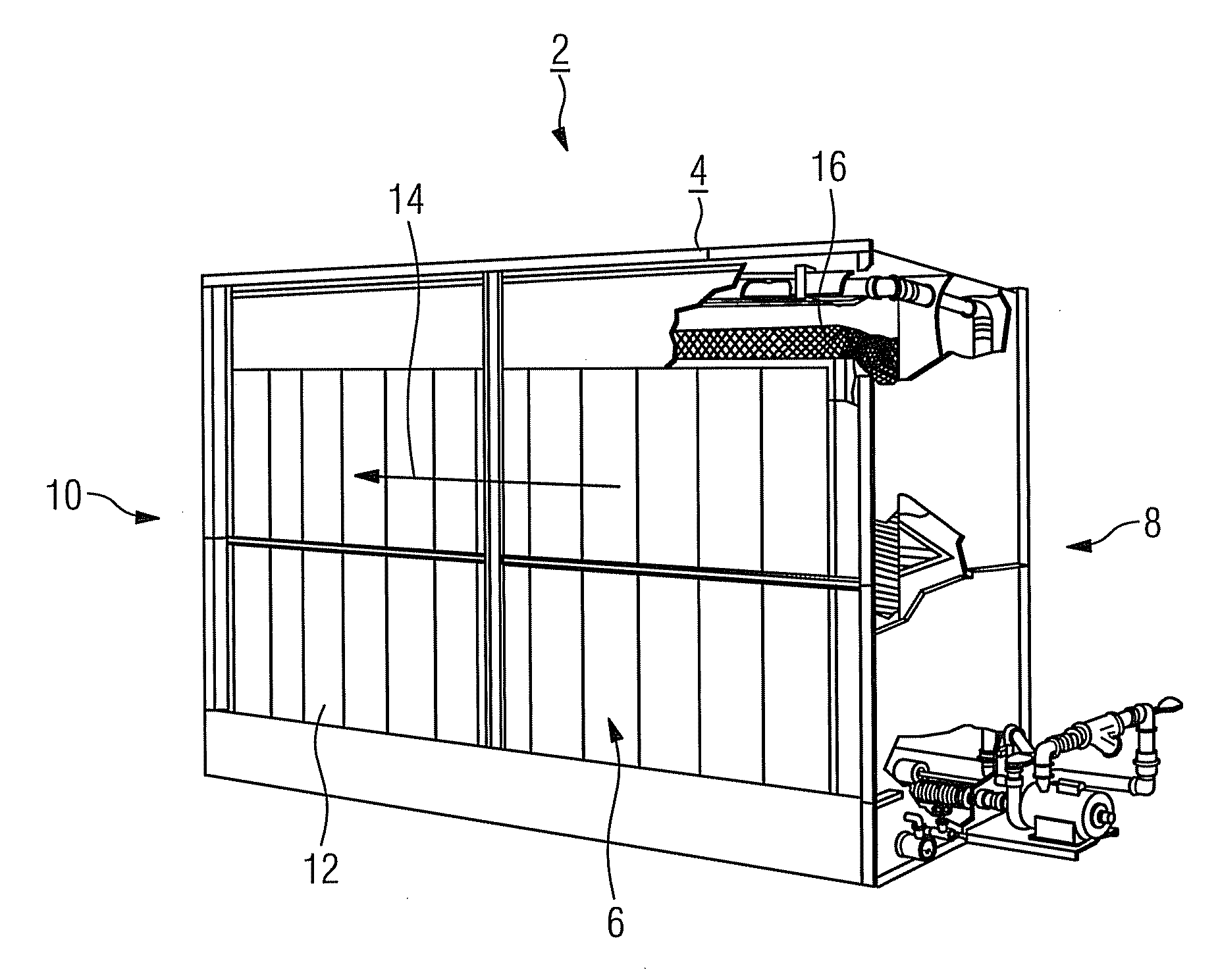

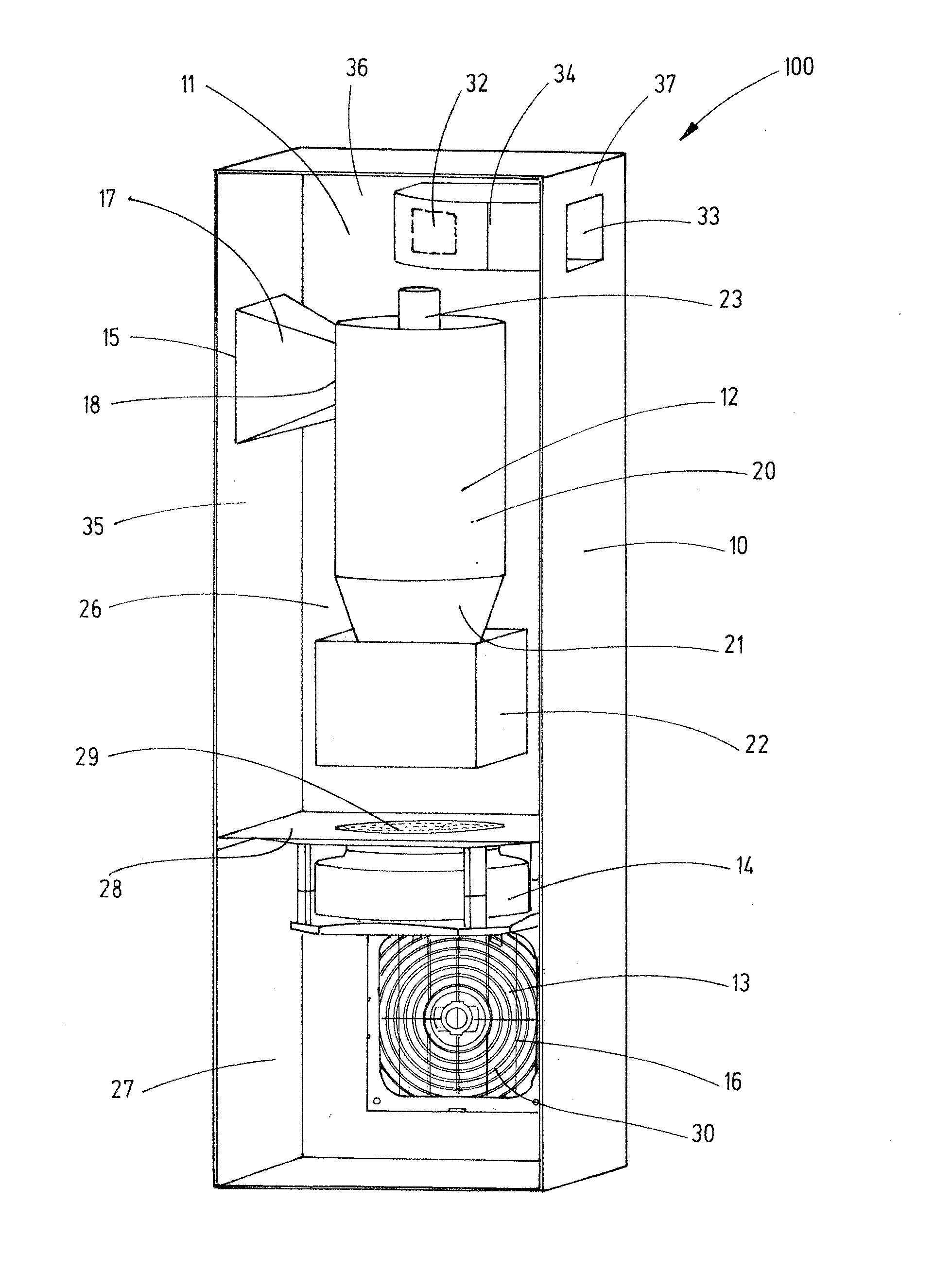

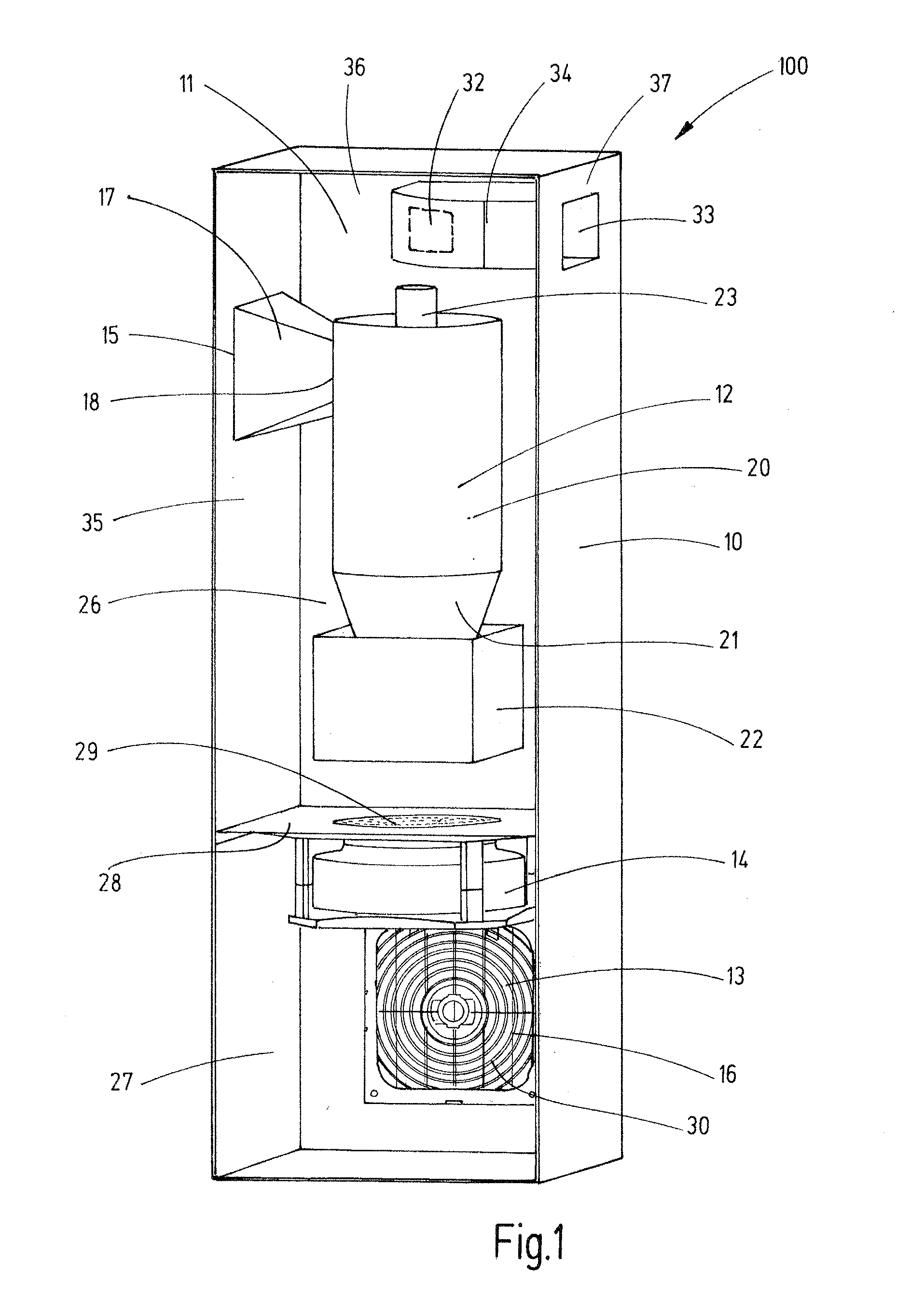

Evaporative Cooler and Use Thereof and Gas Turbine System Featuring an Evaporative Cooler

InactiveUS20100101234A1Improve cooling effectImprove wettabilityAnodisationTurbine/propulsion engine coolingEvaporative coolerGas turbines

An evaporative cooler for cooling a gas stream, in particular an air stream, including a number of cooling elements located in a flow channel, is provided. A liquid, preferably water, is supplied by a feed device and will be vaporized or evaporated. In one aspect, the surface of at least one of the cooling elements has hydrophilic properties, at least in one sub-region designed to form a liquid film.

Owner:SIEMENS AG

Surface-modifying method and elastic body with modified surface

The present invention aims to provide a method for modifying a surface of a rubber vulcanizate or a thermoplastic elastomer, which can impart excellent sliding properties and excellent durability against repeated sliding motion, and allow the surface to maintain the sealing properties, without using expensive self-lubricating resins. The present invention relates to a method for modifying a surface of an object of a rubber vulcanizate or a thermoplastic elastomer, the method including: Step 1 of forming polymerization initiation points on the surface of the object; and Step 2 of radical-polymerizing a monomer starting from the polymerization initiation points to grow polymer chains on the surface of the object.

Owner:SUMITOMO RUBBER IND LTD

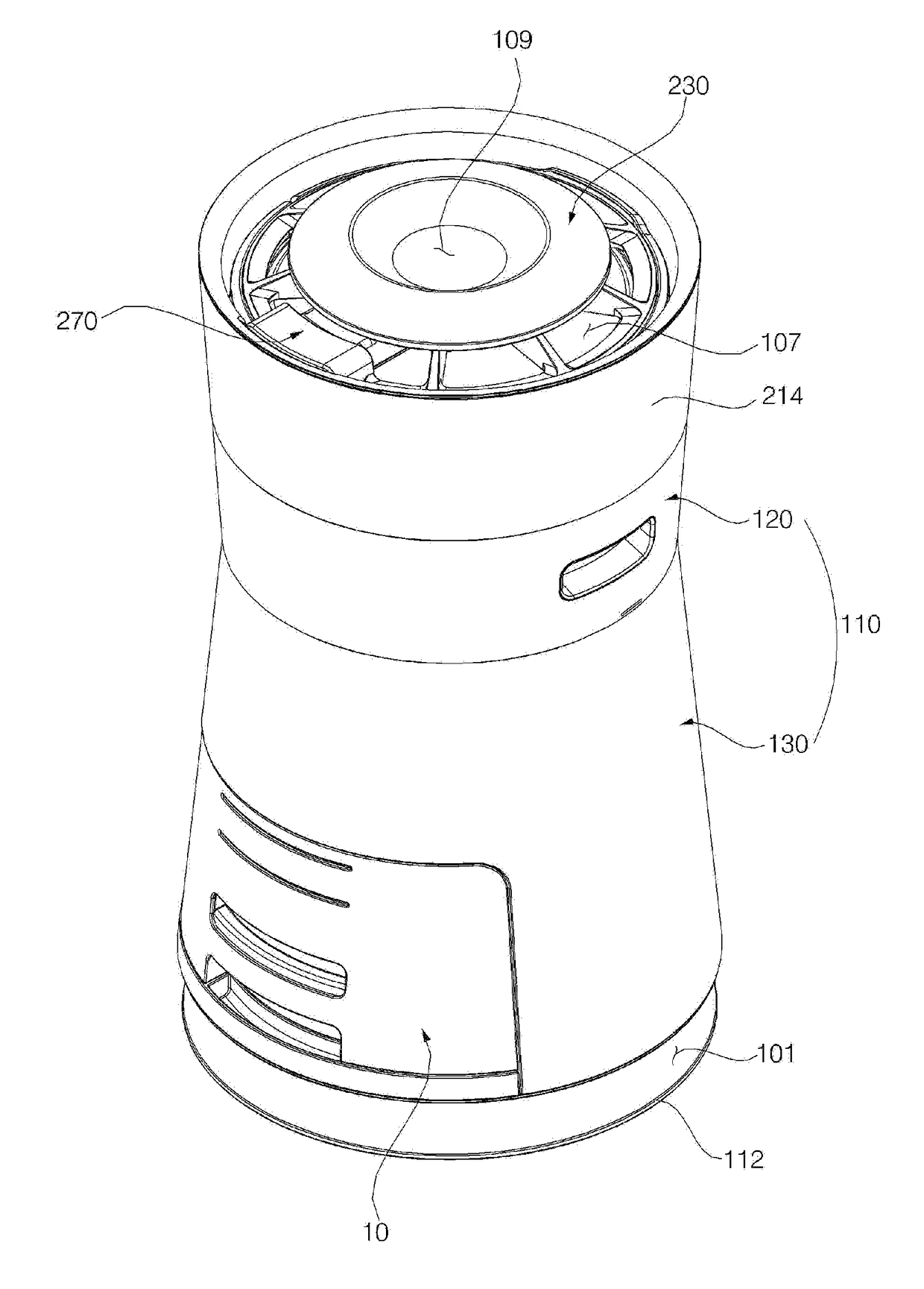

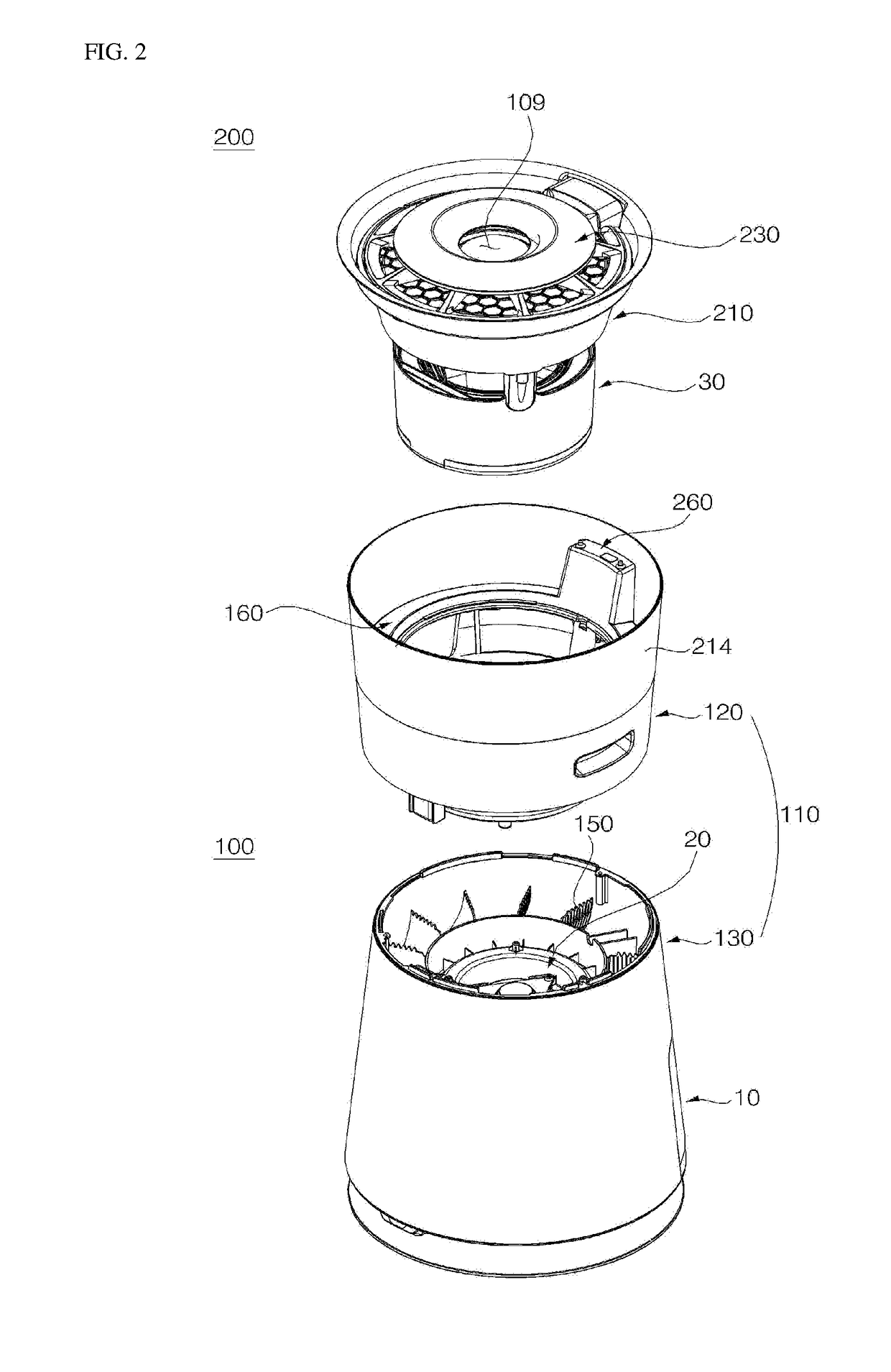

Humidification and air cleaning apparatus

ActiveUS20170122597A1Improve the humidification effectReduce noiseMechanical apparatusGas treatmentAir cleaningEngineering

Provided is a humidification and air cleaning apparatus. The humidification and air cleaning apparatus includes an intake flow passage suctioning external air, a discharge flow passage discharging internal air, a blower unit flowing air flowing to the intake flow passage to the discharge flow passage, a discharge humidification medium disposed on the discharge flow passage to additionally humidify flowing air, a water tank humidification medium disposed between the blower unit and the discharge humidification medium to humidify flowing air, and a watering unit spraying water between the water tank humidification medium and the discharge humidification medium.

Owner:LG ELECTRONICS INC

Thin register

InactiveUS20170057327A1Prevent appearance deteriorationImprove directionalityAir-treating devicesVehicle heating/cooling devicesEngineeringLouver

A front fin of a front movable louver is axially supported immediately inside of an air outlet, and an auxiliary fin is axially supported in a recessed portion under the front fin. The front fin and the auxiliary fin are joined via a link member, and opposite side end portions at an upstream side of the auxiliary fin are axially supported via pivots. An inclined surface is provided on a distal end portion at a downstream side of the auxiliary fin. A recessed portion cover to overlay the recessed portion is attached to the recessed portion. When the front movable louver is operated so as to turn, the auxiliary fin turns so as to project its distal end portion upward through an opening in a front portion of the recessed portion cover and make the inclined surface of its distal end portion hit against an air flow flowing under the front fin.

Owner:HOWA PLASTICS CO LTD

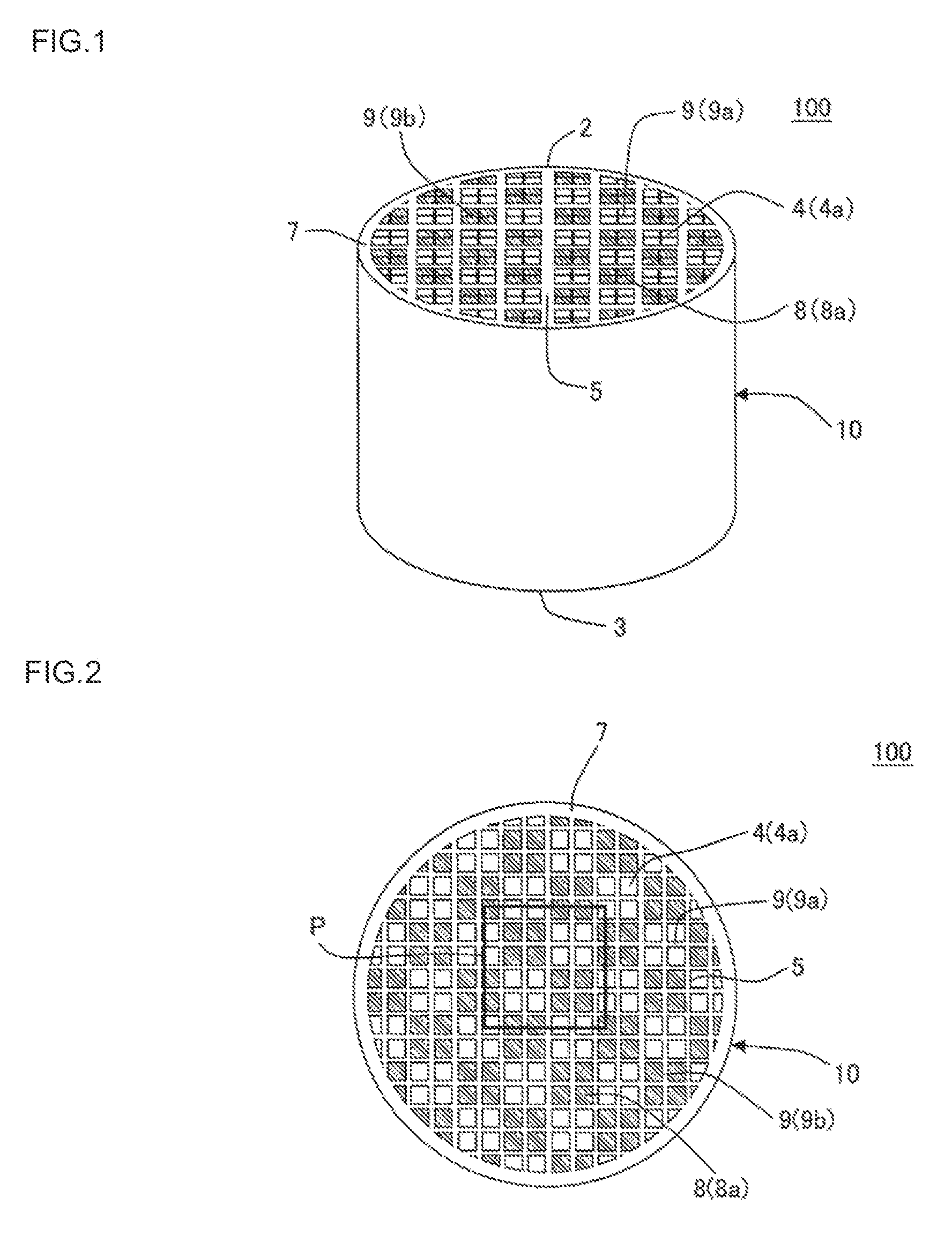

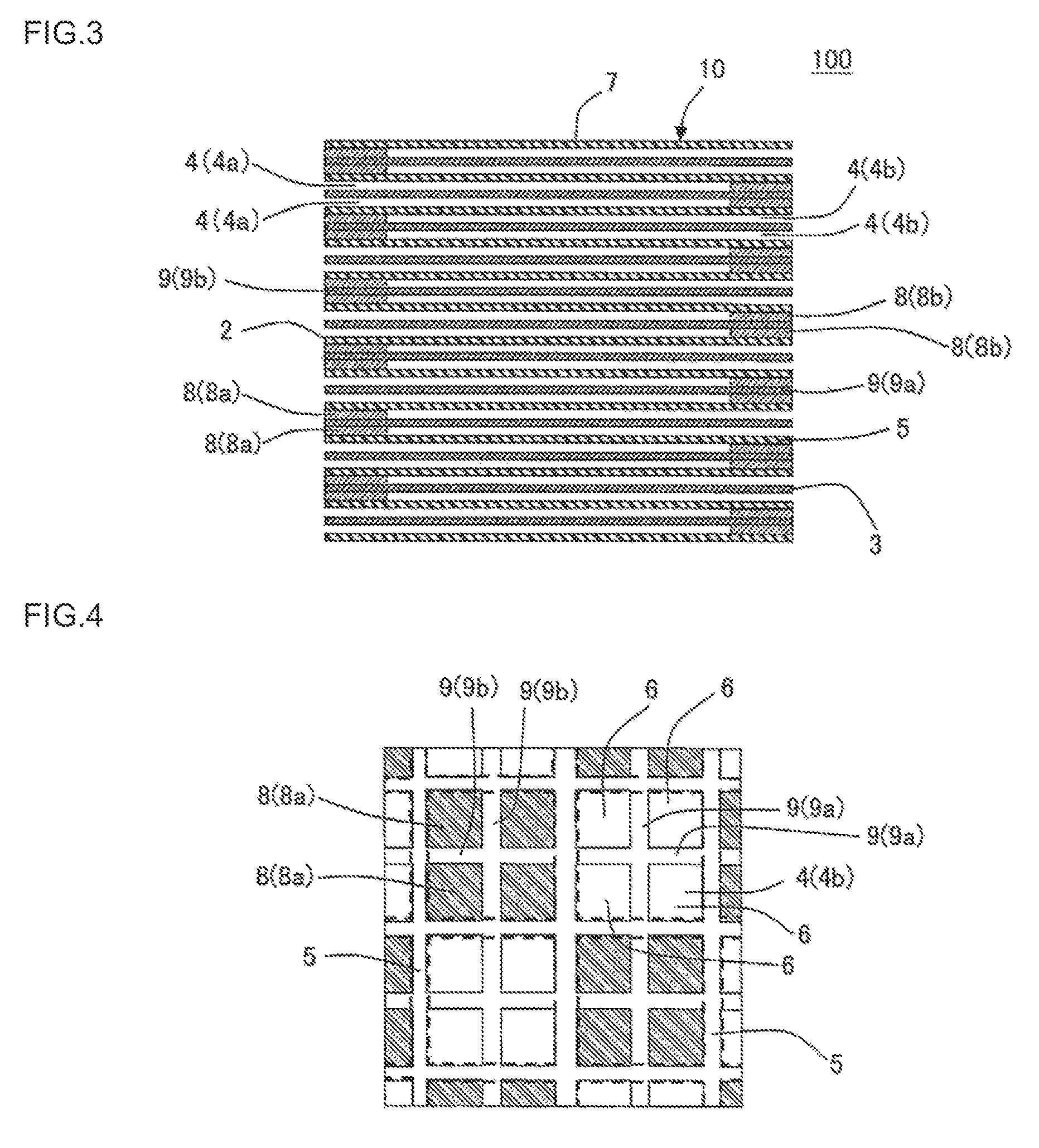

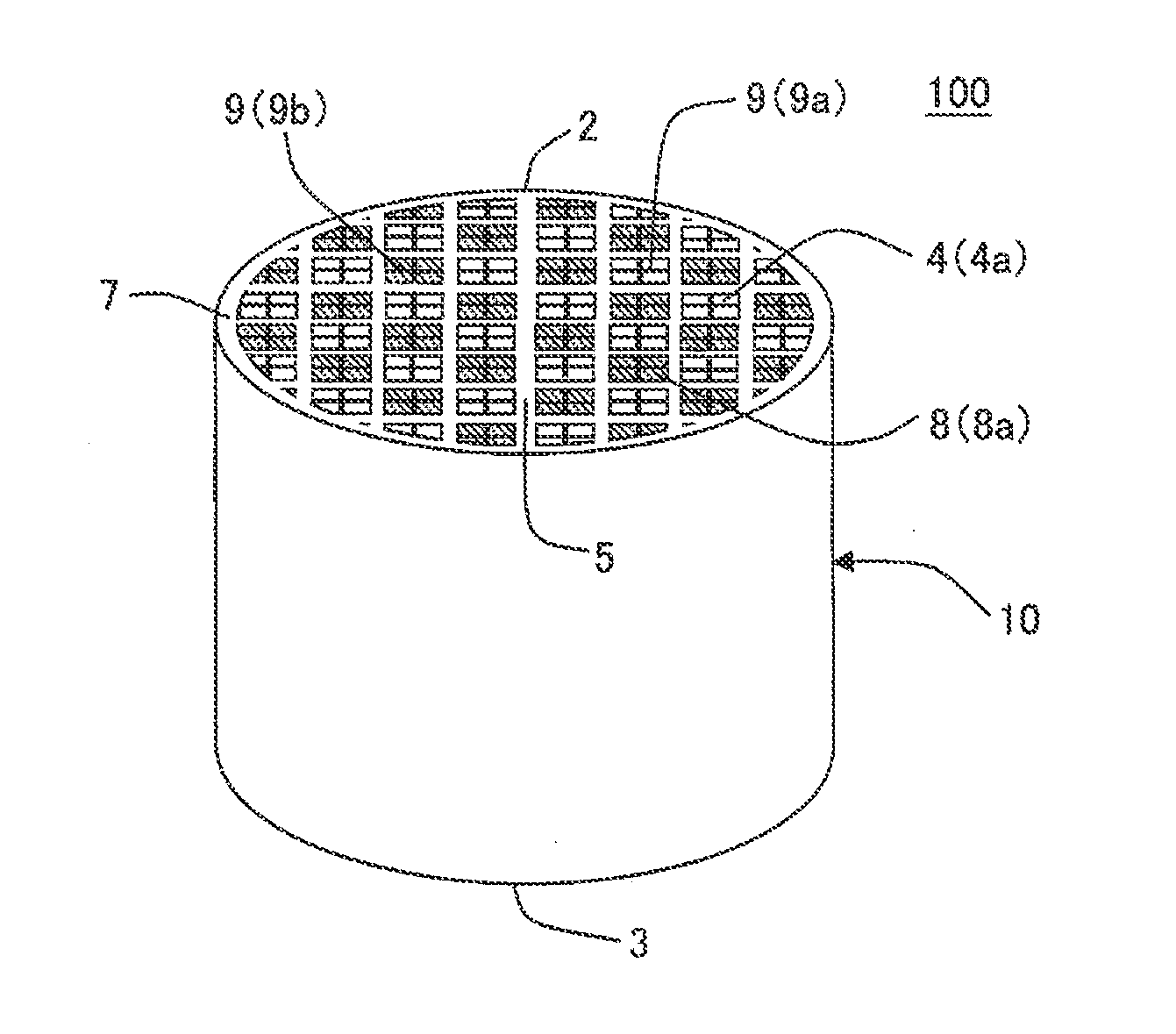

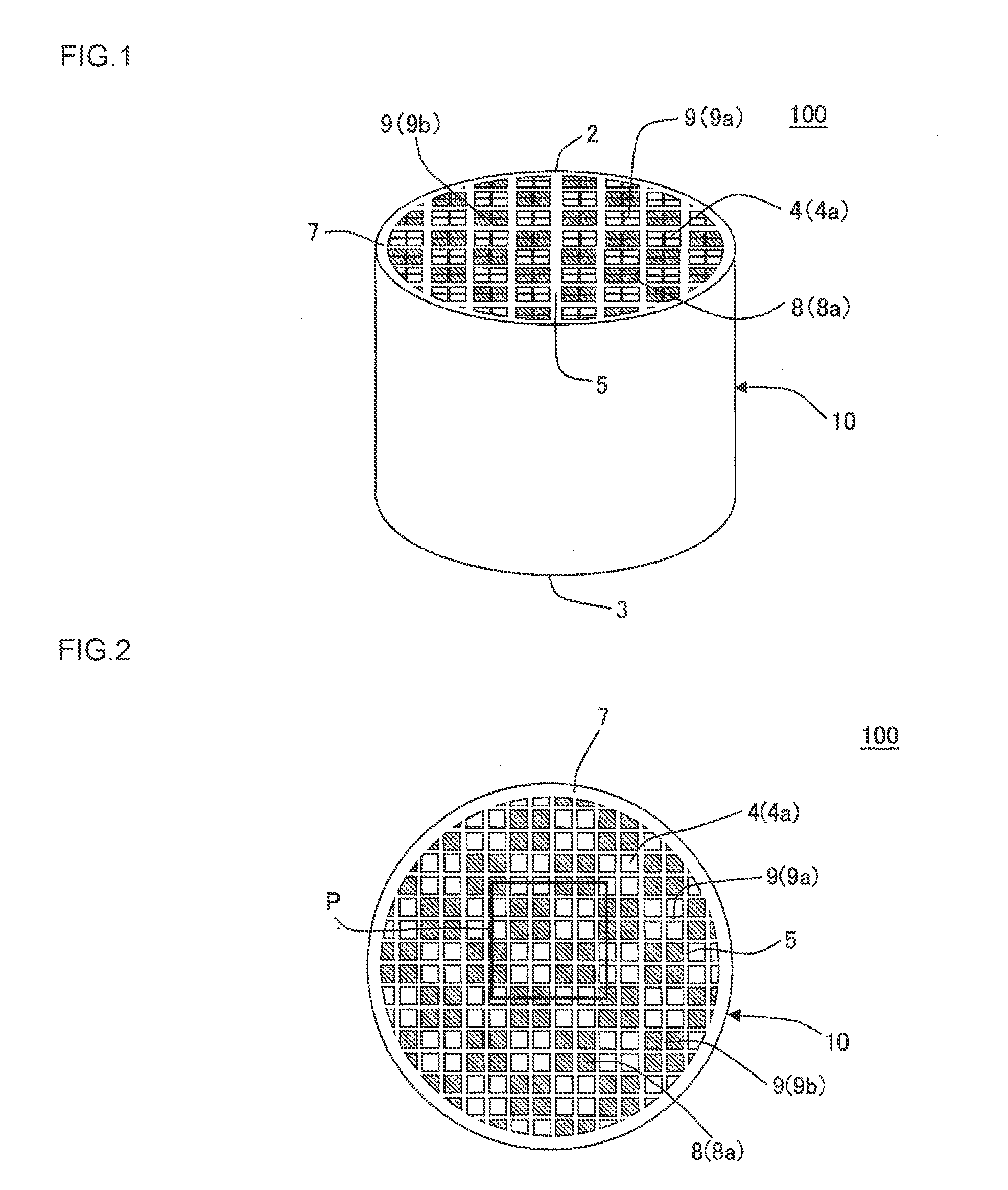

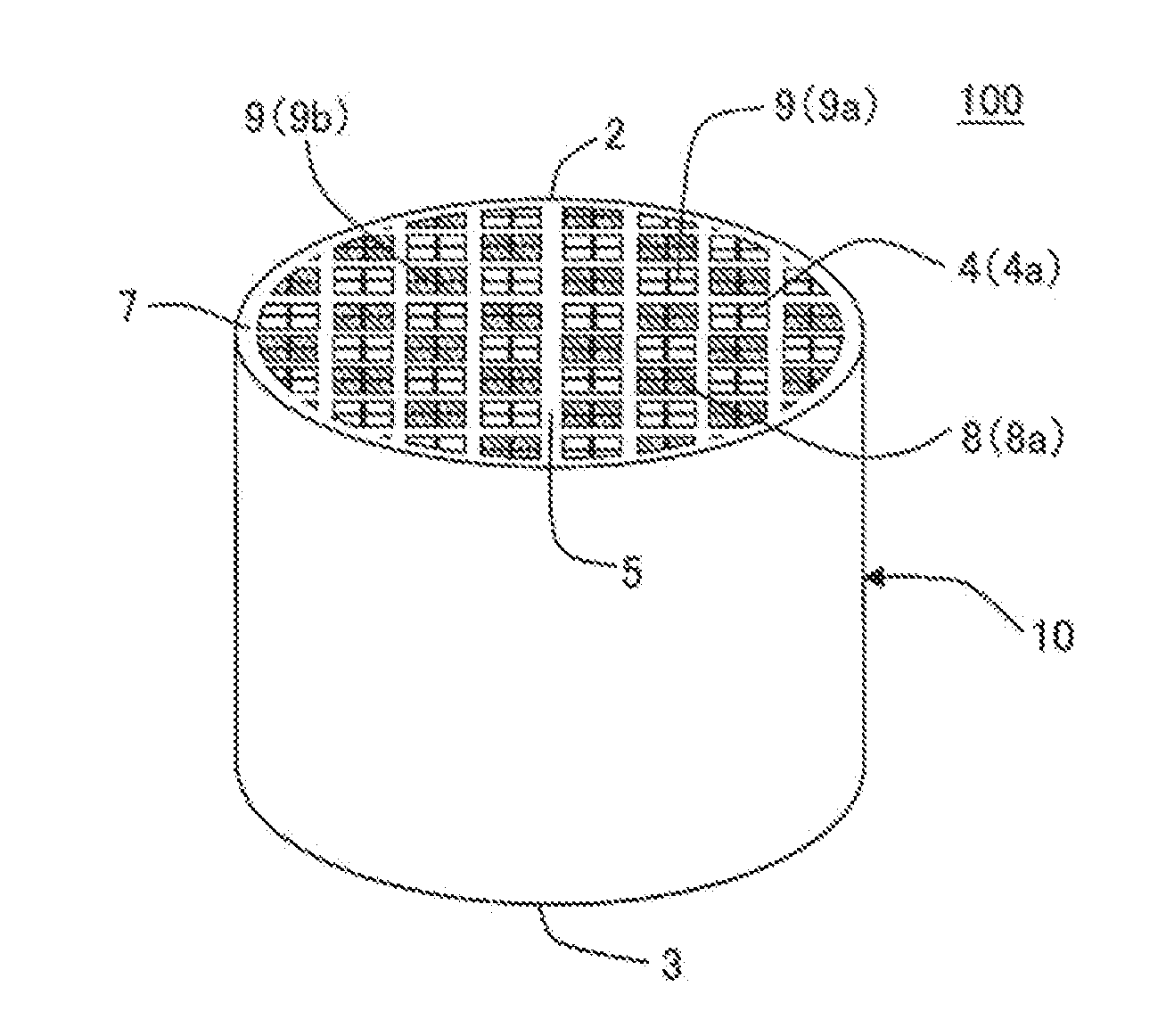

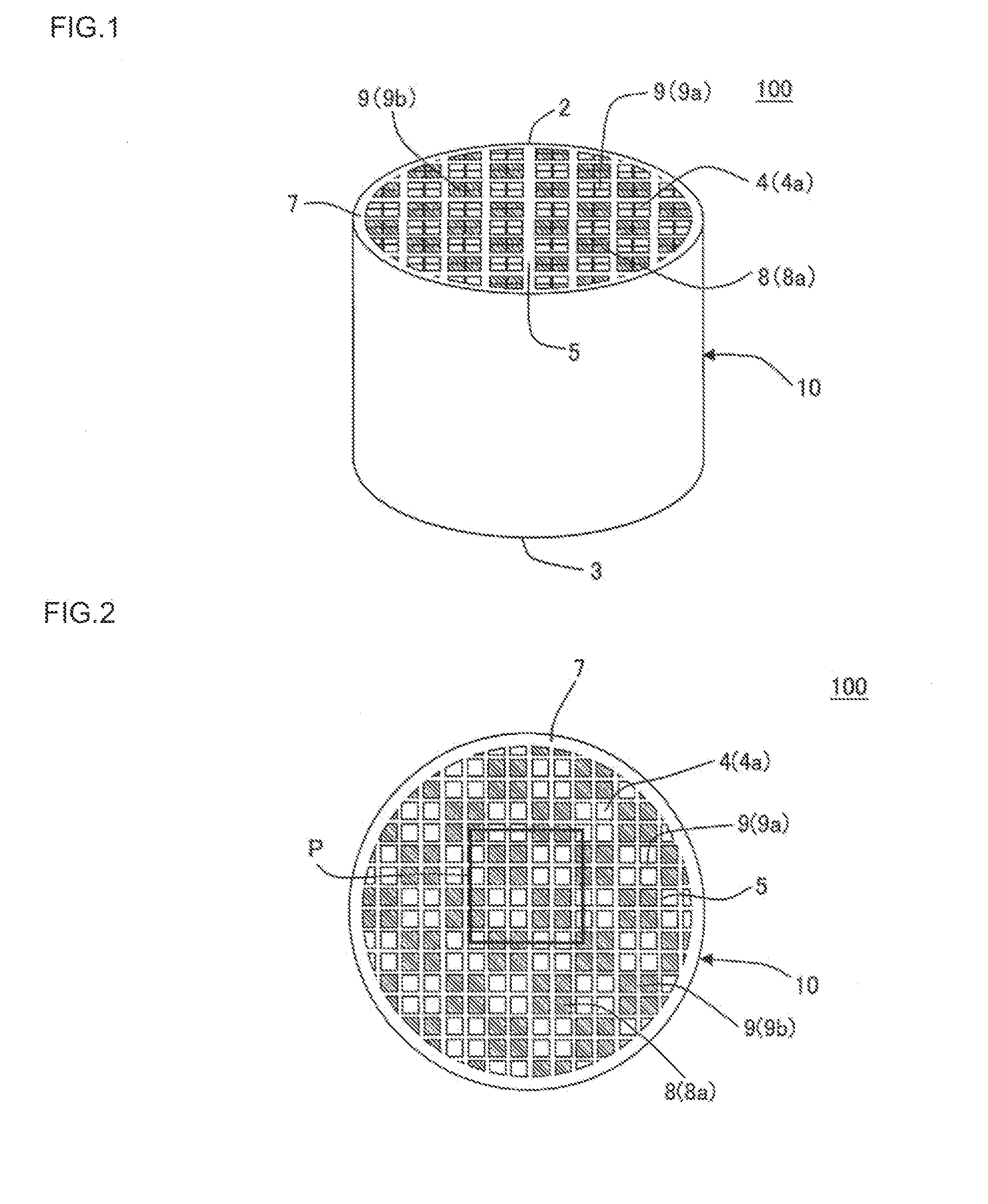

Honeycomb catalyst body

ActiveUS9303543B2High mechanical strengthLess pressure lossCombination devicesExhaust apparatusPorosityEngineering

A honeycomb catalyst body having high mechanical strength, less pressure loss, and suitable purification performance is provided, and includes a plugged honeycomb structure having porous partition walls defining cells extending from one end face to another end face, inflow side plugged portions provided at one ends of the predetermined cells, outflow side plugged portions provided at another ends of the remaining cells, and porous projecting portions projecting so as to extend from the partition walls into the cells and being formed integrally with the partition walls; and a catalyst loaded onto the projecting portions of the plugged honeycomb structure, wherein porosities of the partition walls are 40% or more and smaller than 60%, thicknesses of the projecting portions are from 30 to 140% of thicknesses of the partition walls, and a catalyst amount loaded onto the partition walls thereof is smaller than a catalyst amount loaded onto the projecting portions.

Owner:NGK INSULATORS LTD

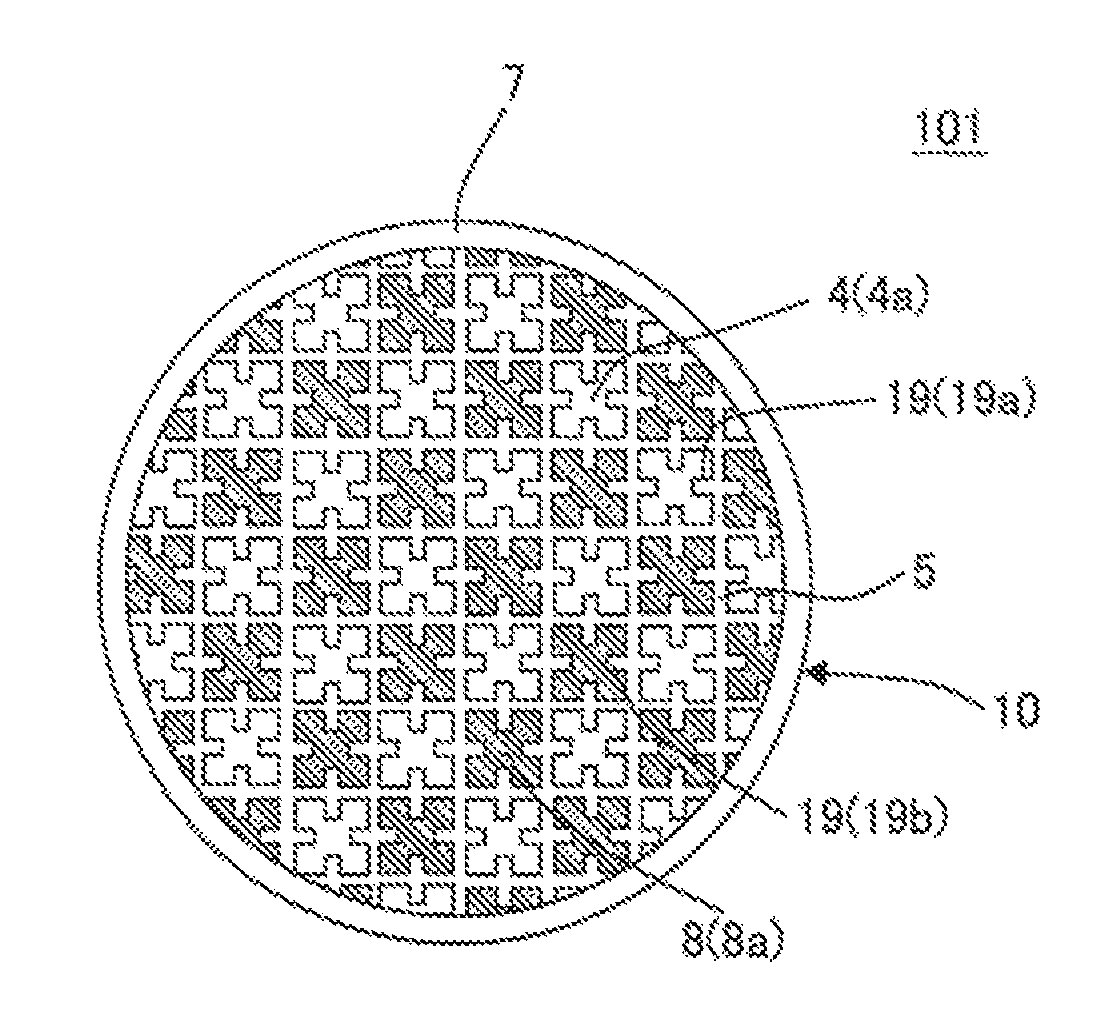

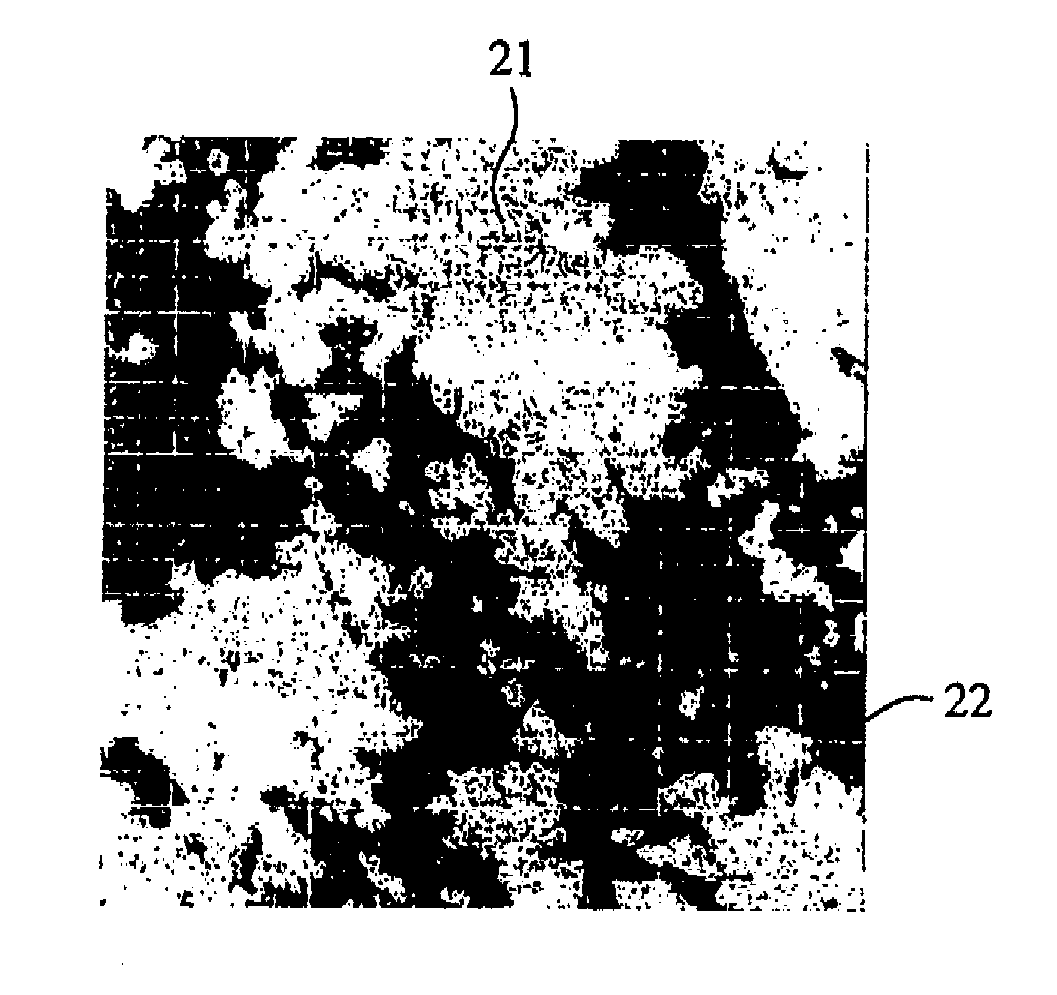

Ceramic honeycomb structure and method for producing ceramic honeycomb structure

ActiveUS20090142543A1Extended capture timeLess pressure loss increaseInternal combustion piston enginesDispersed particle filtrationProject areaSurface roughness

A ceramic honeycomb structure having porous cell walls defining large numbers of flow paths, the cell walls having porosity of 55-70%, an average pore diameter of 10-40 μm, a concave area ratio CR (projected area ratio of portions lower than an average surface determined from cell wall surface roughness by a least square method) of 0.32-0.6, and an average concave depth Hconcave (average depth of portions lower than the average surface) of 0.02-0.1 mm.

Owner:HITACHI METALS LTD

Honeycomb catalyst body

ActiveUS20140154144A1High mechanical strengthLess pressure lossCombination devicesExhaust apparatusPorosityEngineering

A honeycomb catalyst body capable of containing in a limited space, having high mechanical strength, less pressure loss, and suitable purification performance is provided, and it includes a plugged honeycomb structure having porous partition walls defining cells, plugged portions, and porous projecting portions projecting so as to extend from the partition walls into the cells and being formed integrally with the partition walls; and catalysts loaded onto the projecting portions, wherein a porosity of the partition walls is 40 to 70%, thicknesses of the projecting portions is from 30 to 140% of thicknesses of the partition wall, an amount of the catalyst loaded onto the partition walls thereof is smaller than an amount of the catalyst loaded onto the projecting portions, one catalyst loaded onto projecting portions is a selective reduction catalyst, and another catalyst loaded onto projecting portions is an ammonia slip preventing catalyst.

Owner:NGK INSULATORS LTD

Honeycomb catalyst body

ActiveUS9303542B2High mechanical strengthLess pressure lossCombination devicesExhaust apparatusPorosityEngineering

A honeycomb catalyst body capable of containing in a limited space, having high mechanical strength, less pressure loss, and suitable purification performance is provided, and it includes a plugged honeycomb structure having porous partition walls defining cells, plugged portions, and porous projecting portions projecting so as to extend from the partition walls into the cells and being formed integrally with the partition walls; and catalysts loaded onto the projecting portions, wherein a porosity of the partition walls is 40 to 70%, thicknesses of the projecting portions is from 30 to 140% of thicknesses of the partition wall, an amount of the catalyst loaded onto the partition walls thereof is smaller than an amount of the catalyst loaded onto the projecting portions, one catalyst loaded onto projecting portions is a selective reduction catalyst, and another catalyst loaded onto projecting portions is an ammonia slip preventing catalyst.

Owner:NGK INSULATORS LTD

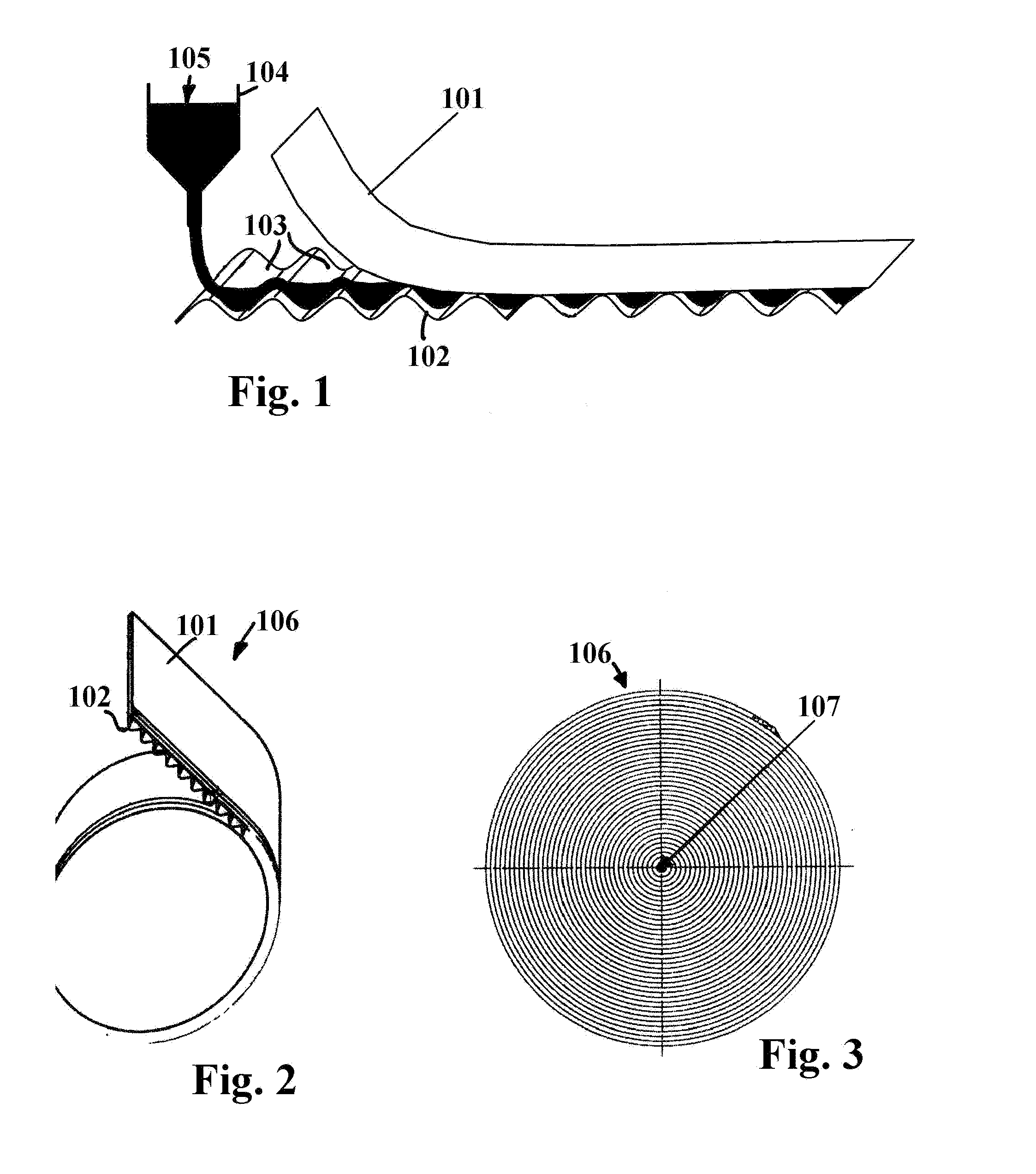

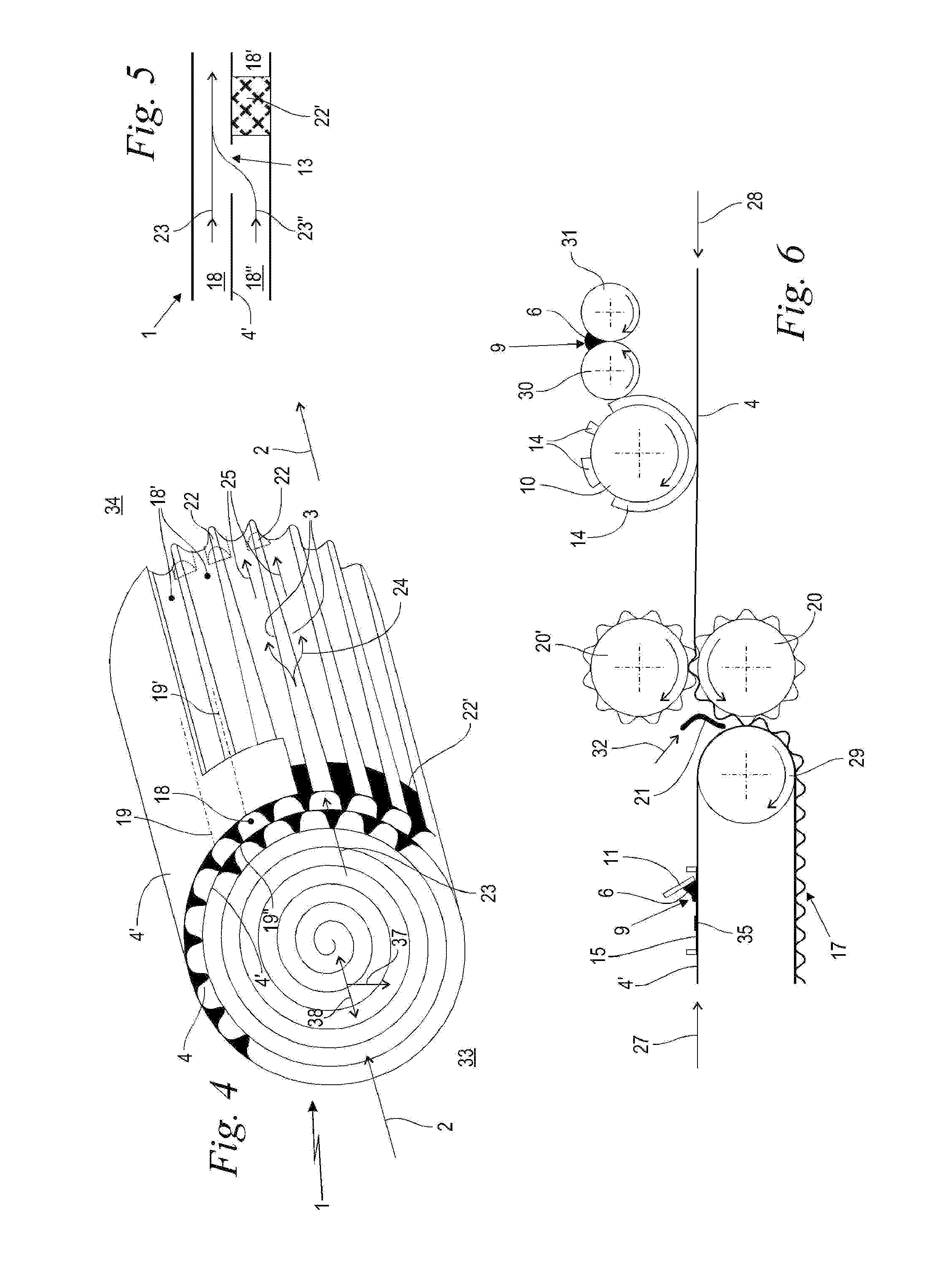

Ceramic filter element and method of manufacture

A method of manufacturing a ceramic diesel particle filter (DPF) and a DPF manufactured by the method, the DPF having a ceramic filter body (1) including gas channels (18, 18′) with planar and porous filter segments (3), which are provided for the exhaust gas stream (2) to flow through them transversely to the face of the filter segments (3). The filter body (1) is formed by sintering at least one ceramic-impregnated fiber web (4) in a firing step under heat such that fibers (5) of the fiber material are burned off and the ceramic material (6) is sintered together to form the porous filter segment (3) between its two surfaces (7, 8). At least one fiber web (4) is corrugated to form the gas channels (18, 18′) and rolled up to form the filter body (1), and the cross section of at least a portion of the gas channels (18, 18′) changes from an inlet end (33) to a discharge end (34).

Owner:MANN HUMMEL GMBH

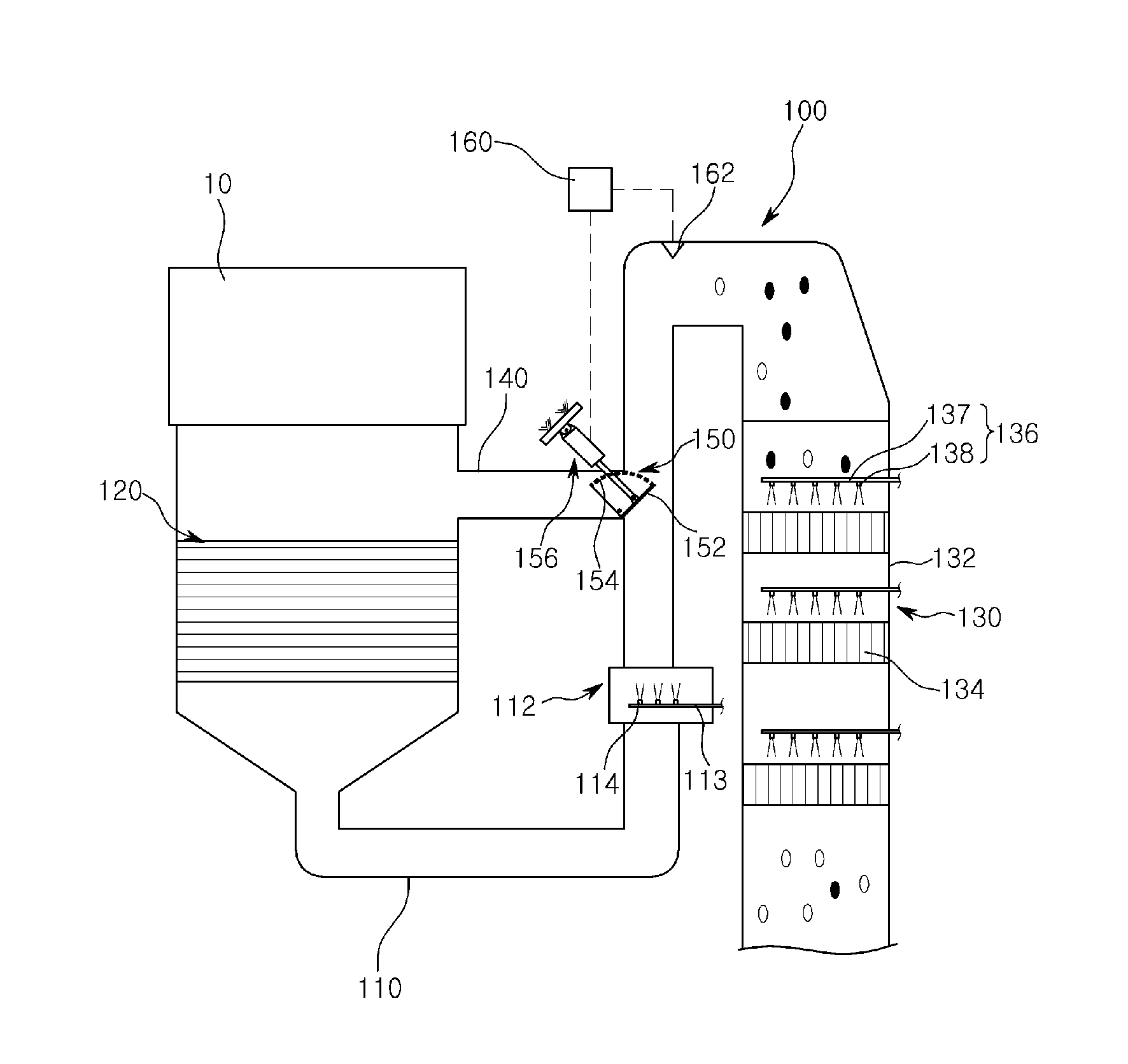

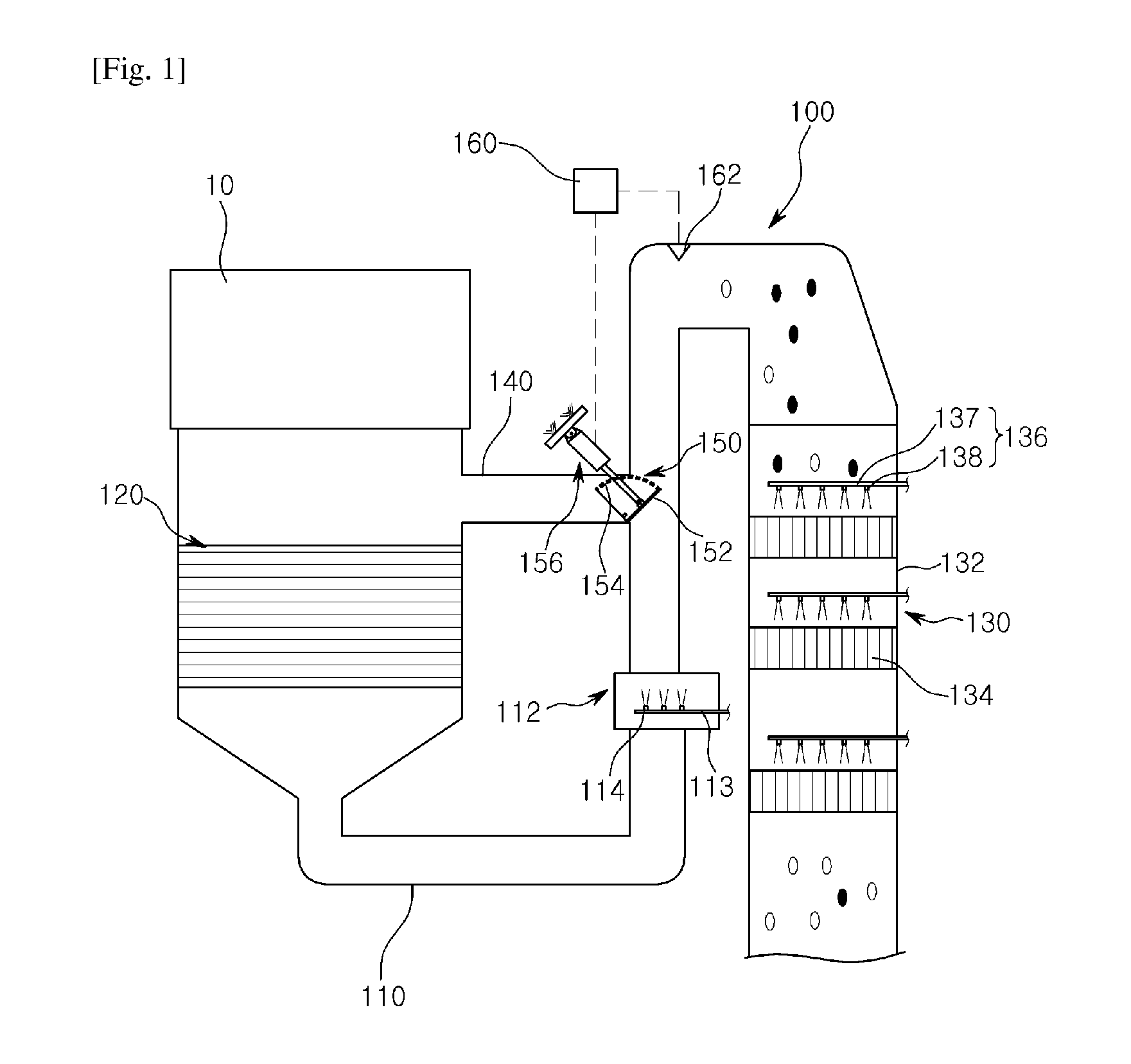

Exhaust gas treatment apparatus

ActiveUS20150202571A1Improve denitrification efficiencyReduce nitrogen oxide emissionsExhaust apparatusTemperatue controlCombustionNitrogen oxides

There is provided an exhaust gas treatment apparatus. The exhaust gas treatment apparatus includes: a main discharge passage through which exhaust gas of combustion equipment is discharged; an heat exchanger between the combustion equipment and the main discharge passage; a nitrogen oxide decreasing device connected to the main discharge passage to decrease nitrogen oxides of exhaust gas; a bypass connected from the combustion equipment to the main discharge passage as a passage bypassing the heat exchanger to supply high temperature exhaust gas from the combustion equipment to the nitrogen oxide decreasing device; and a variable exhaust regulator disposed between the bypass and the main discharge passage to vary the amount of relatively high temperature exhaust gas flowing in the bypass and the amount of exhaust gas flowing in the main discharge passage in a correlated manner.

Owner:GSCO

Air passage device for admitting purified air into an interior of a control cabinet

InactiveUS20150147952A1Avoid replacementCost-effectiveModifications using gaseous coolantsElectrical apparatus casings/cabinets/drawersEngineeringAmbient air

In order to arrange an air passage device for the admission and purification of air, in particular ambient air, into the interior of a control cabinet or computer housing in such a way that the device can be used also in an environment which is subject to an increased degree of pollution, a first purifying includes a centrifugal separator.

Owner:PFANNENBERG GMBH

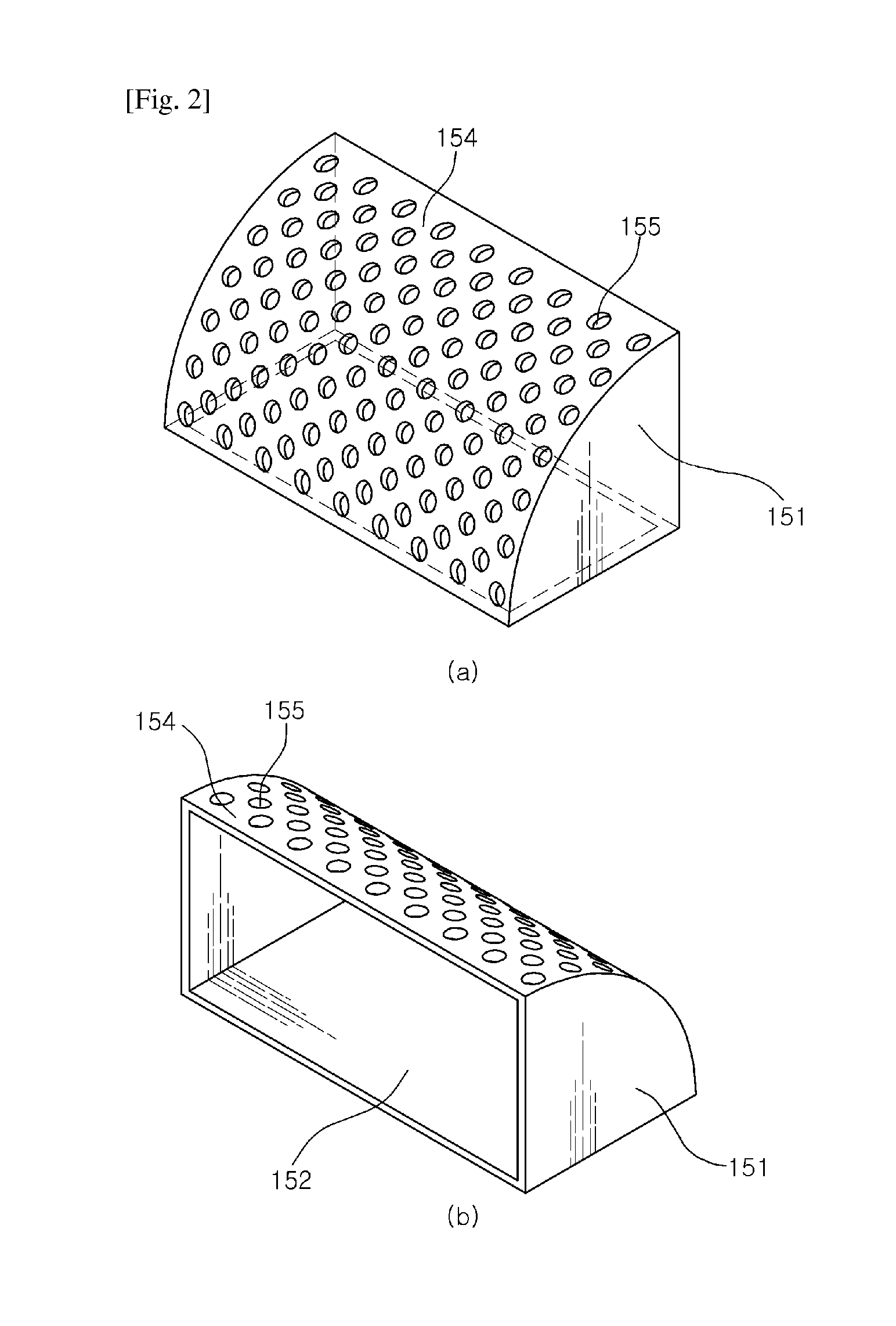

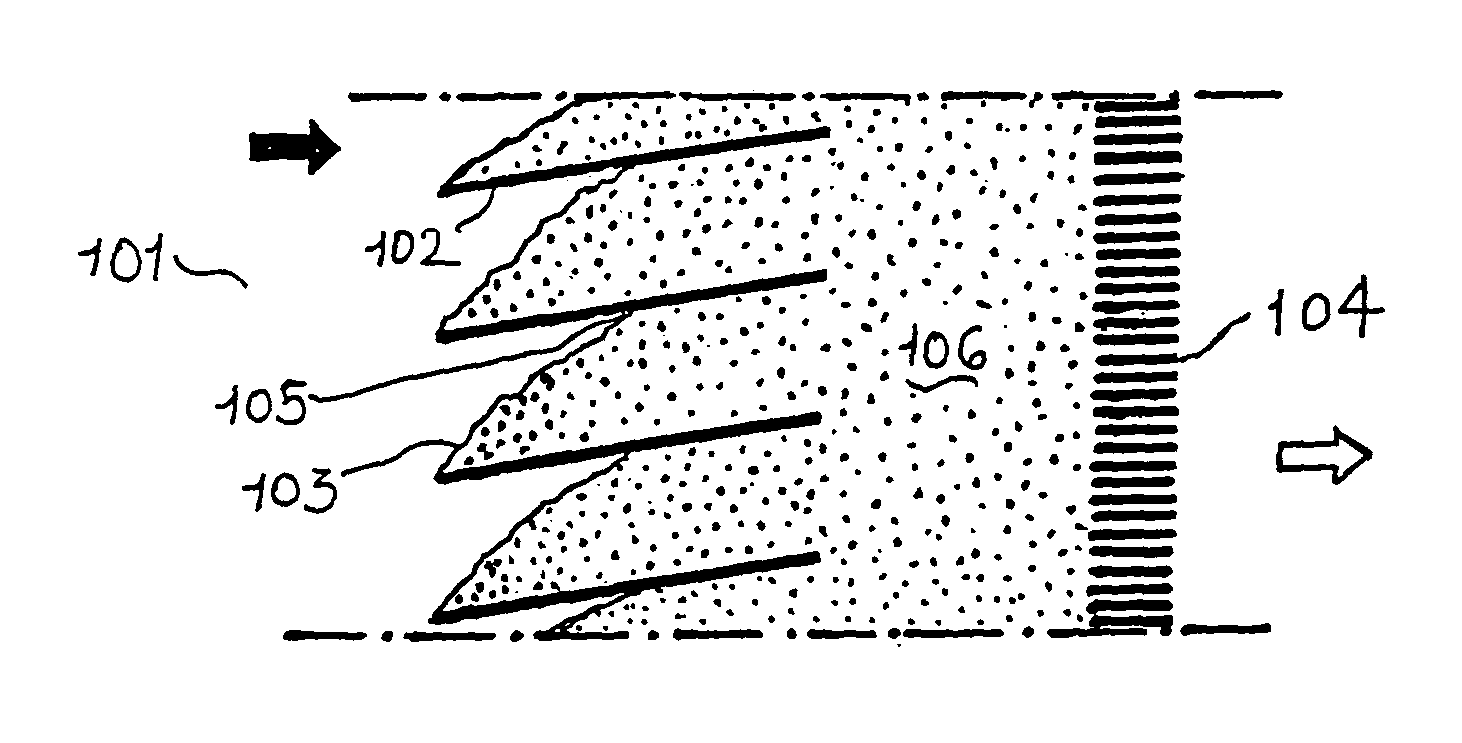

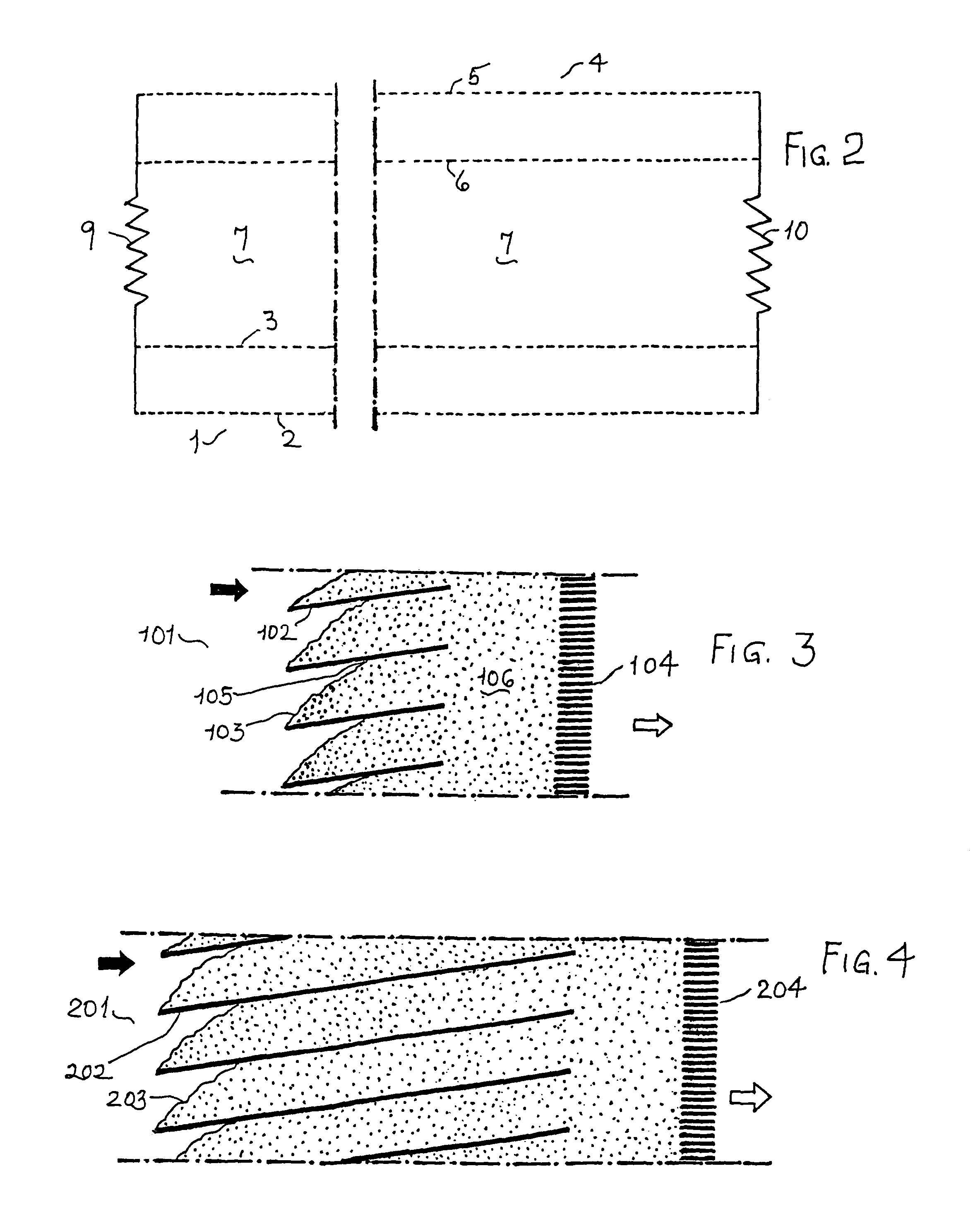

Method and apparatus for renewing gas-entry faces of a panel for gas and granular material contacting

InactiveUS7815717B1Less pressure lossLow costDispersed particle filtrationIsotope separationChemical treatmentProduct gas

There is provided an improved method and apparatus for renewal of a plurality of faces across which gas enters a panel of a granular material. The panel is for contacting the gas and granular material with each other to effect physical or chemical treatment of at least one of them (for example, to filter dust from a gas or to remove a constituent from a gas by means of adsorption or absorption). In the panel, gas-entry faces are transversely disposed, upwardly spaced, and held in place by supporting members. These supporting members are subjected to a sharp motion in a direction toward the gas-entry faces, causing body movement of the granular material toward the faces, thereby causing moieties of granular material to fall away therefrom. Removal of these moieties and exposure of previously underlying granular material renew the faces. Flat-plate louvers are preferred supporting members.

Owner:ARTHUR M SQUIRES IRREVOCABLE TRUST

Honeycomb catalyst body

ActiveUS20140154146A1High mechanical strengthGuaranteed StrengthCombination devicesExhaust apparatusPorosityEngineering

A honeycomb catalyst body having high mechanical strength, less pressure loss, and suitable purification performance is provided, and includes a plugged honeycomb structure having porous partition walls defining cells extending from one end face to another end face, inflow side plugged portions provided at one ends of the predetermined cells, outflow side plugged portions provided at another ends of the remaining cells, and porous projecting portions projecting so as to extend from the partition walls into the cells and being formed integrally with the partition walls; and a catalyst loaded onto the projecting portions of the plugged honeycomb structure, wherein porosities of the partition walls are 40% or more and smaller than 60%, thicknesses of the projecting portions are from 30 to 140% of thicknesses of the partition walls, and a catalyst amount loaded onto the partition walls thereof is smaller than a catalyst amount loaded onto the projecting portions.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com