Patents

Literature

204results about How to "Reduce erosion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

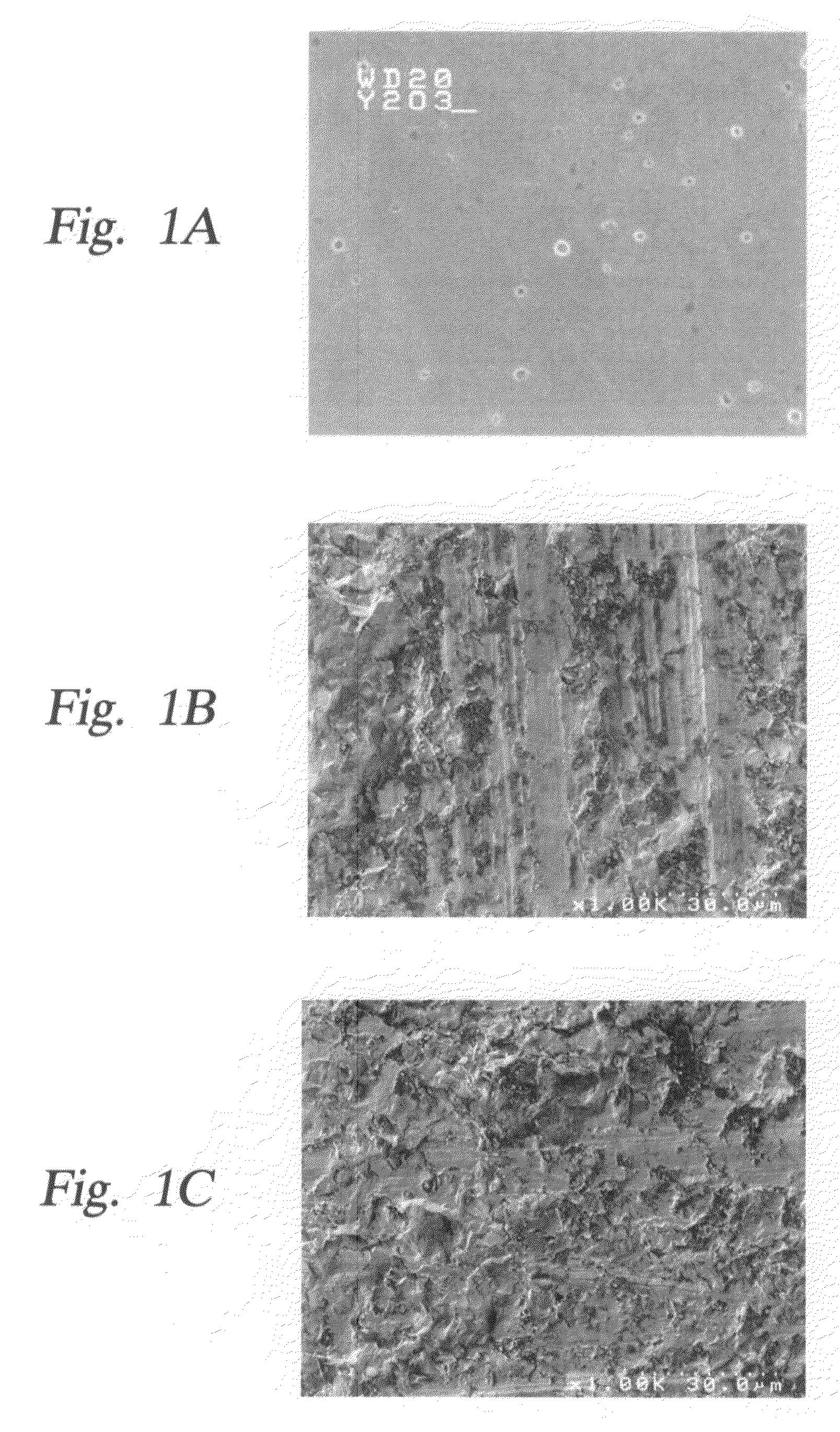

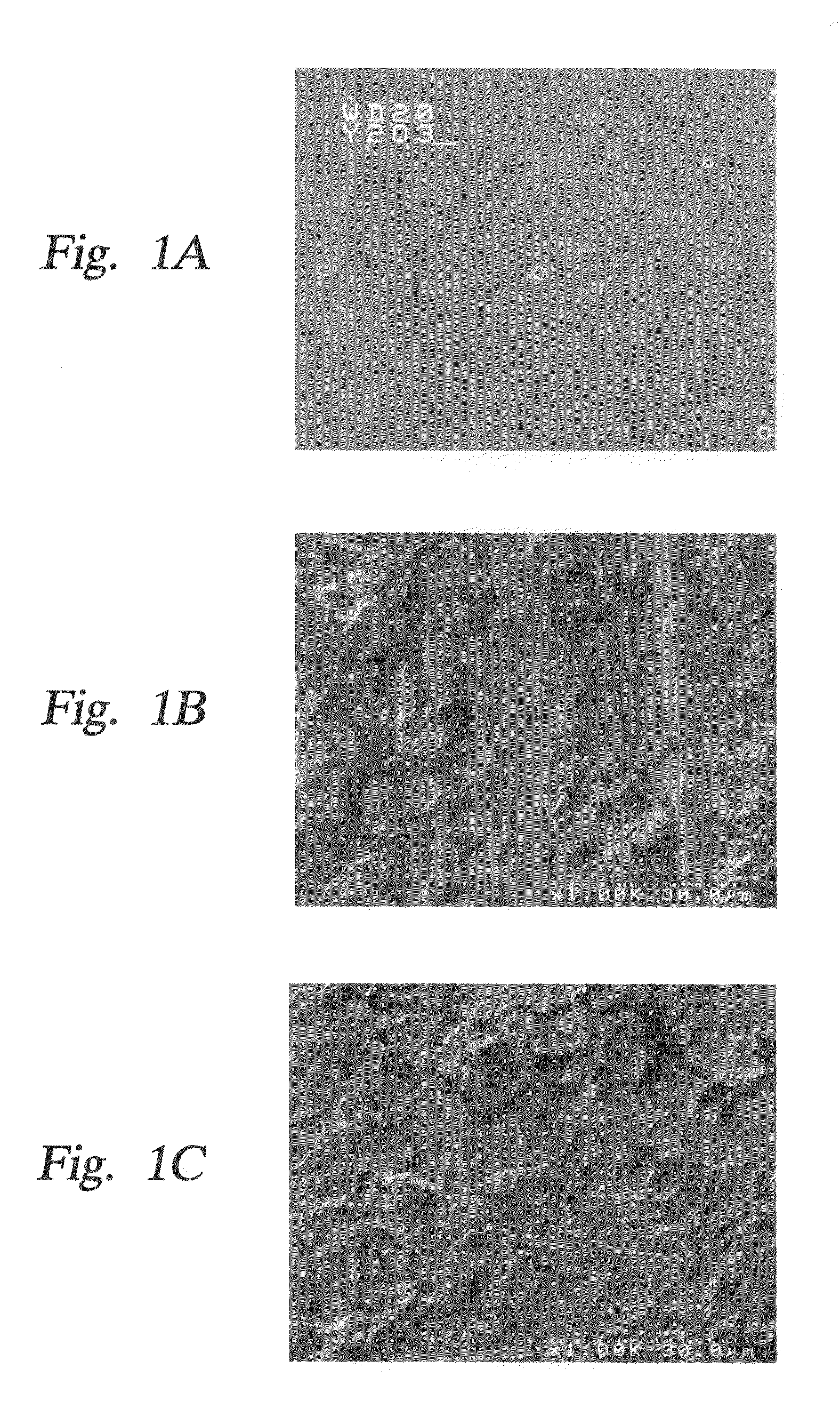

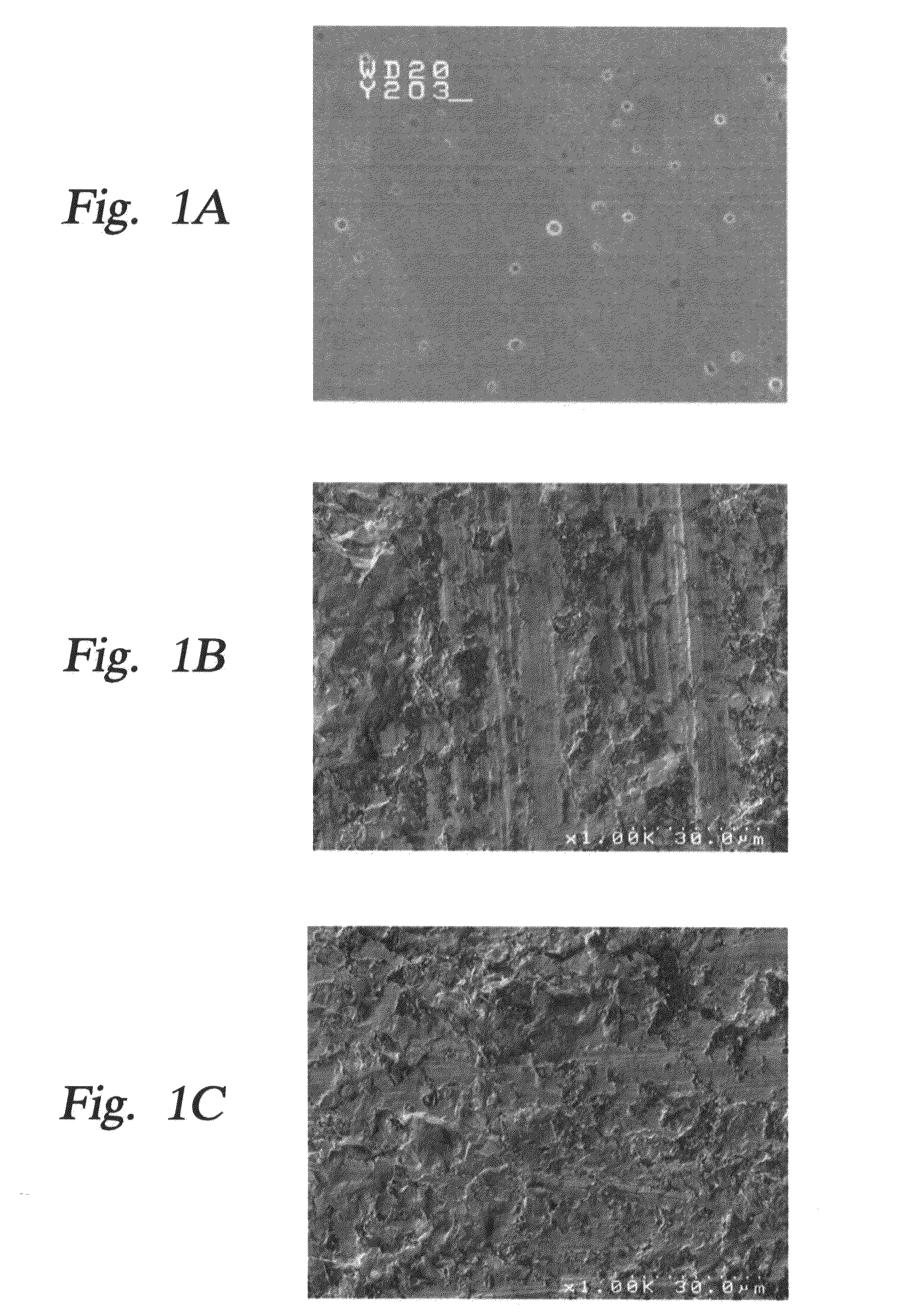

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS20080264565A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingYTTERBIUM OXIDEErosion rate

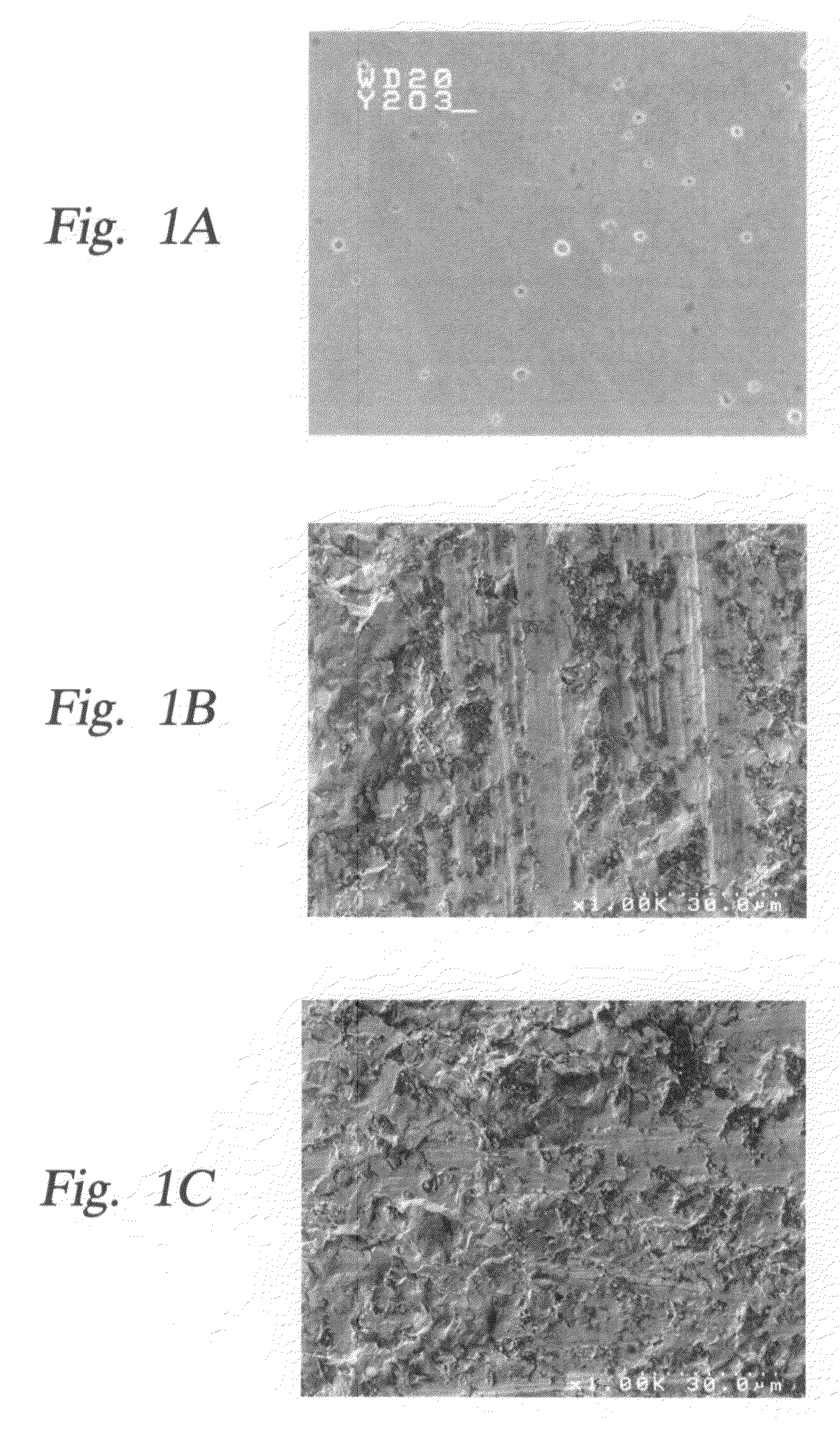

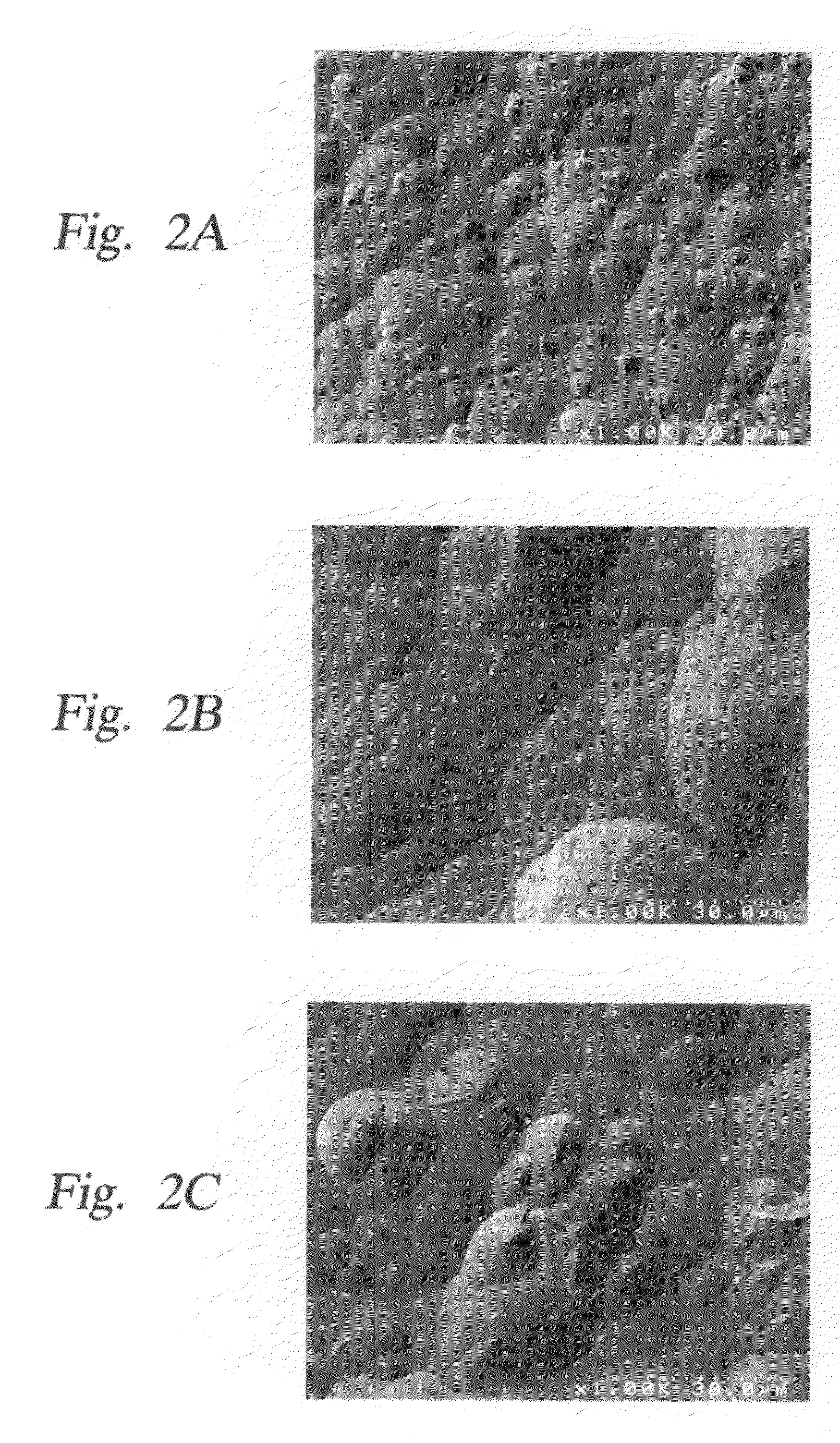

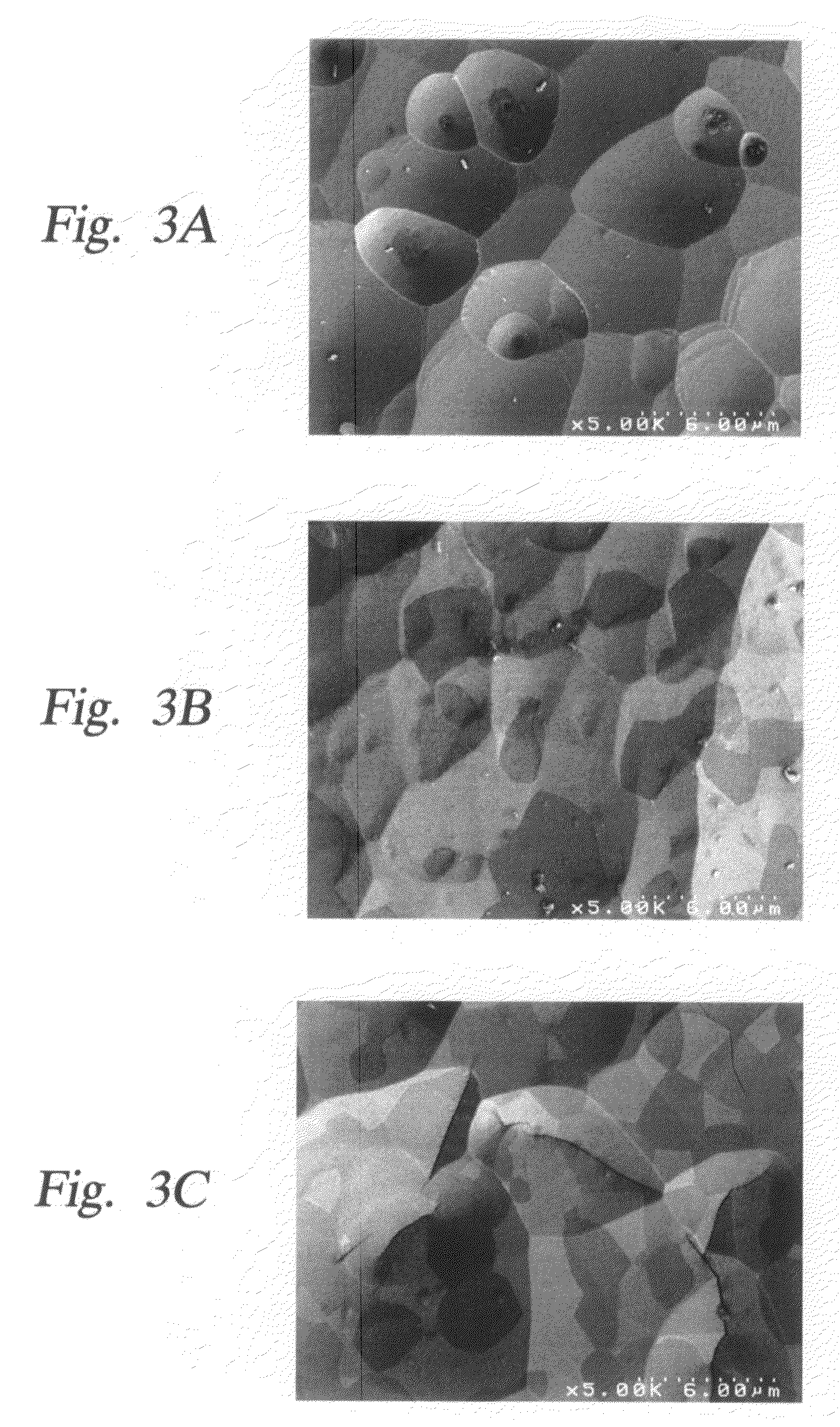

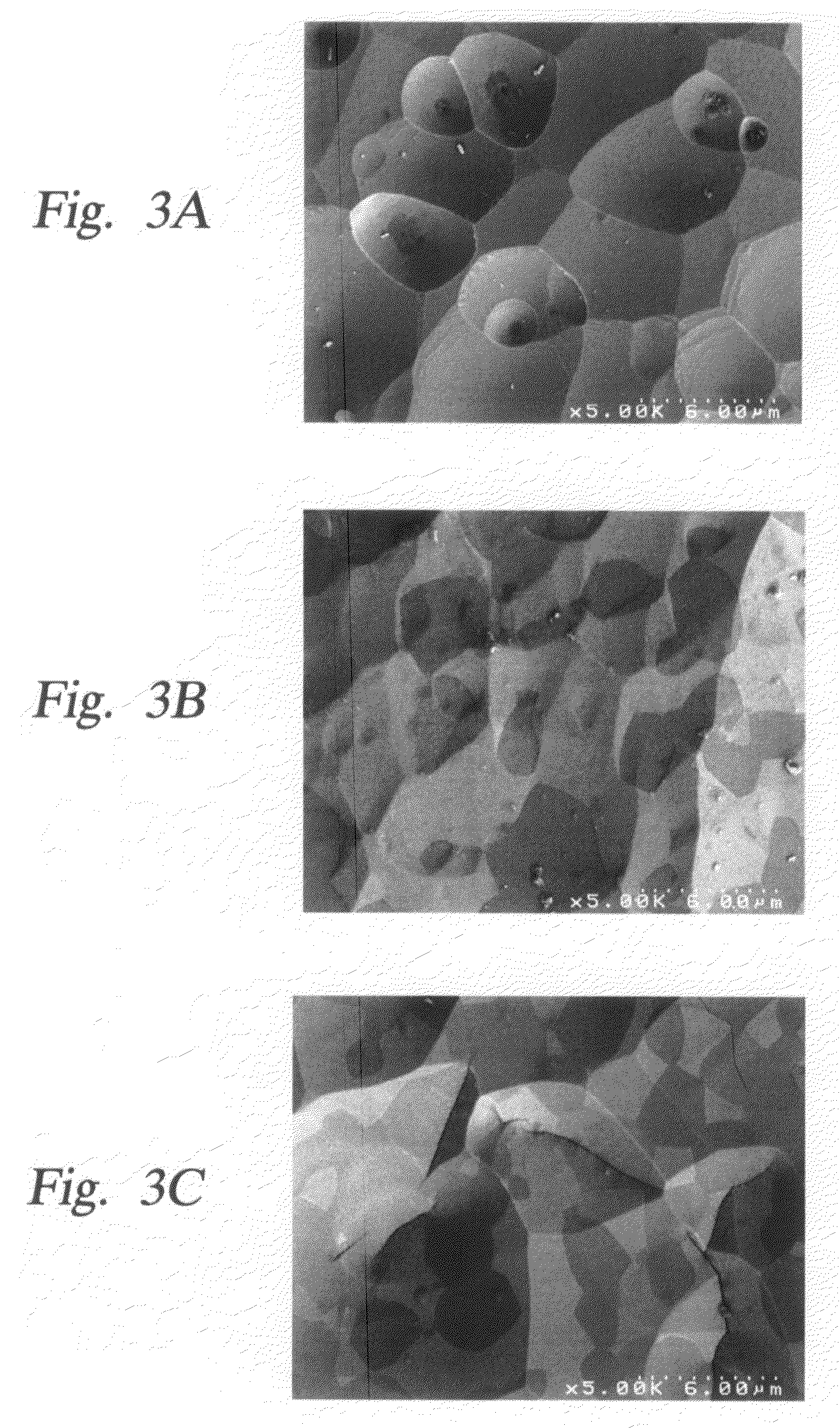

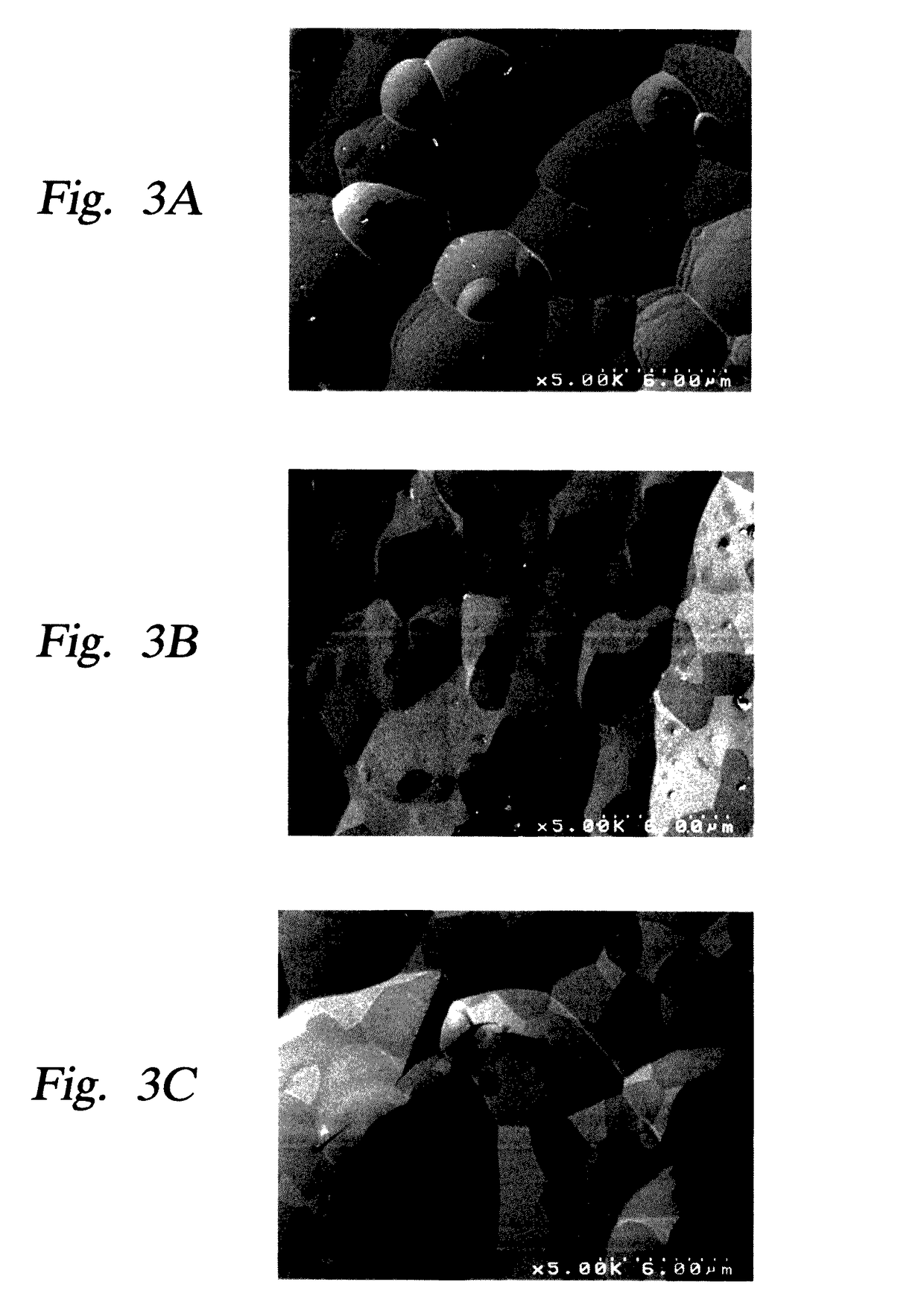

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

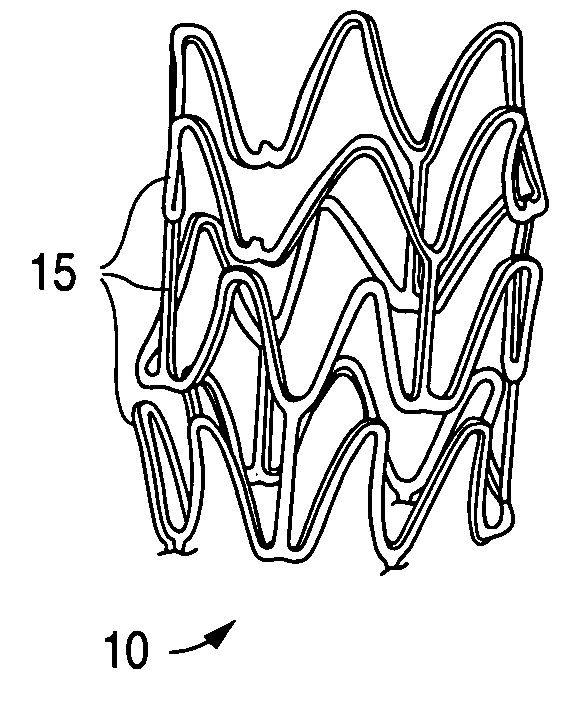

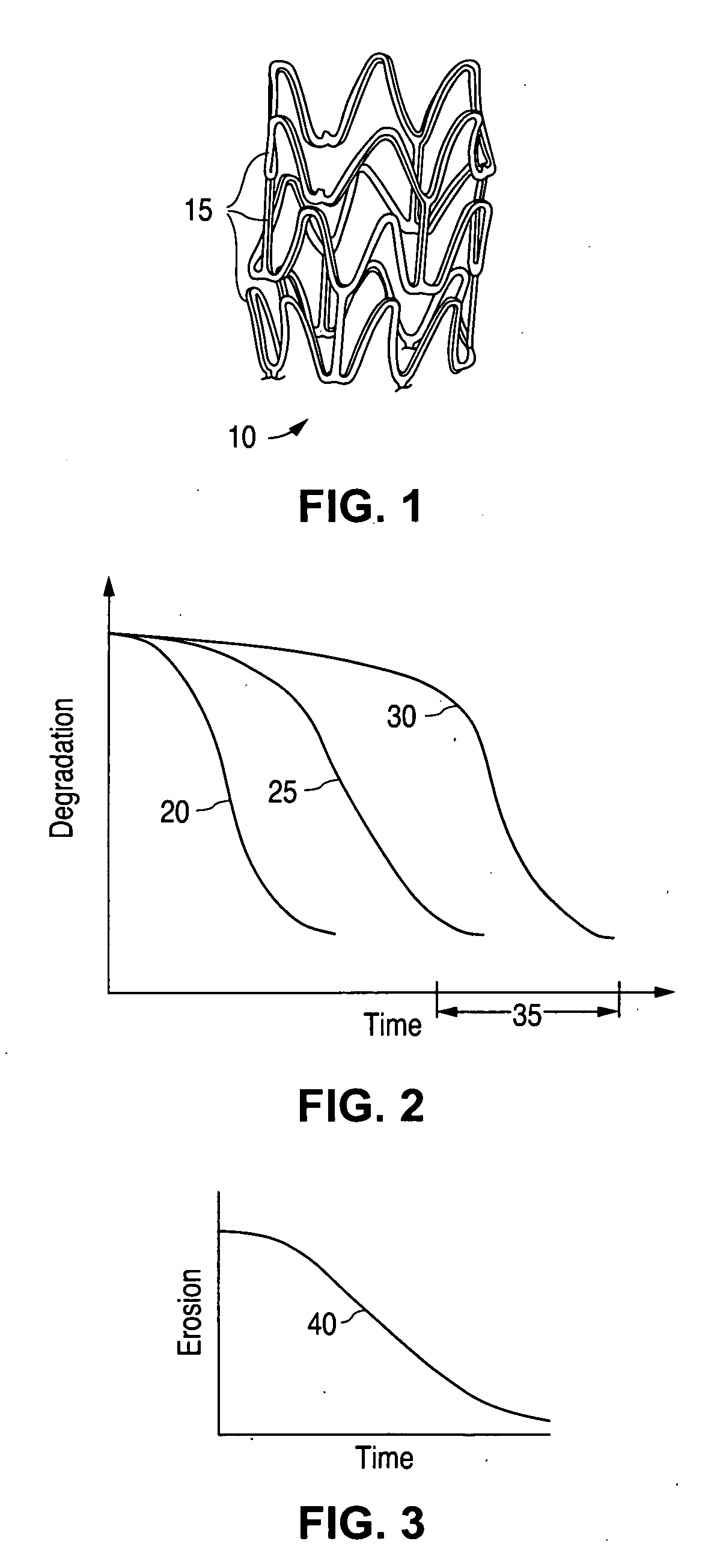

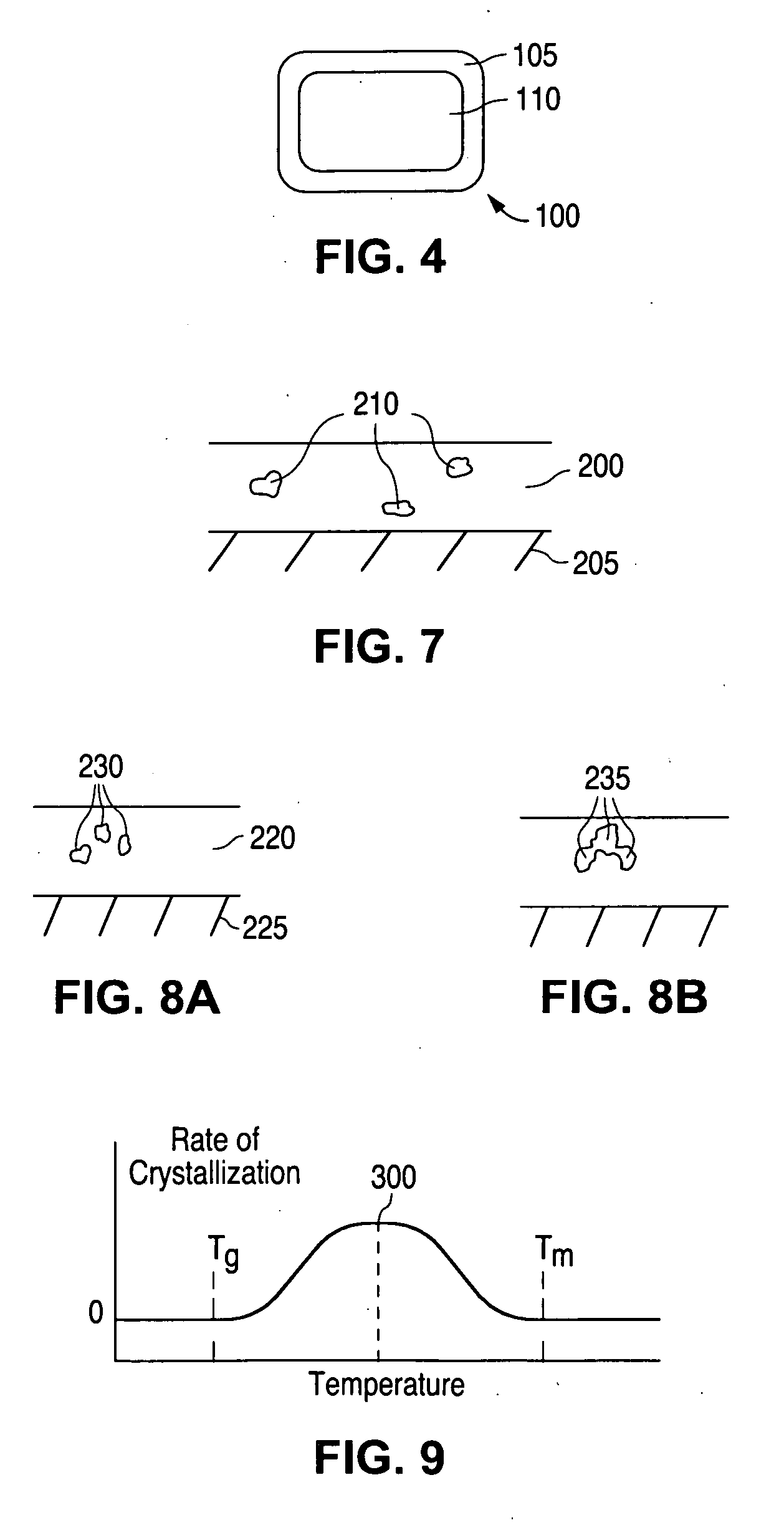

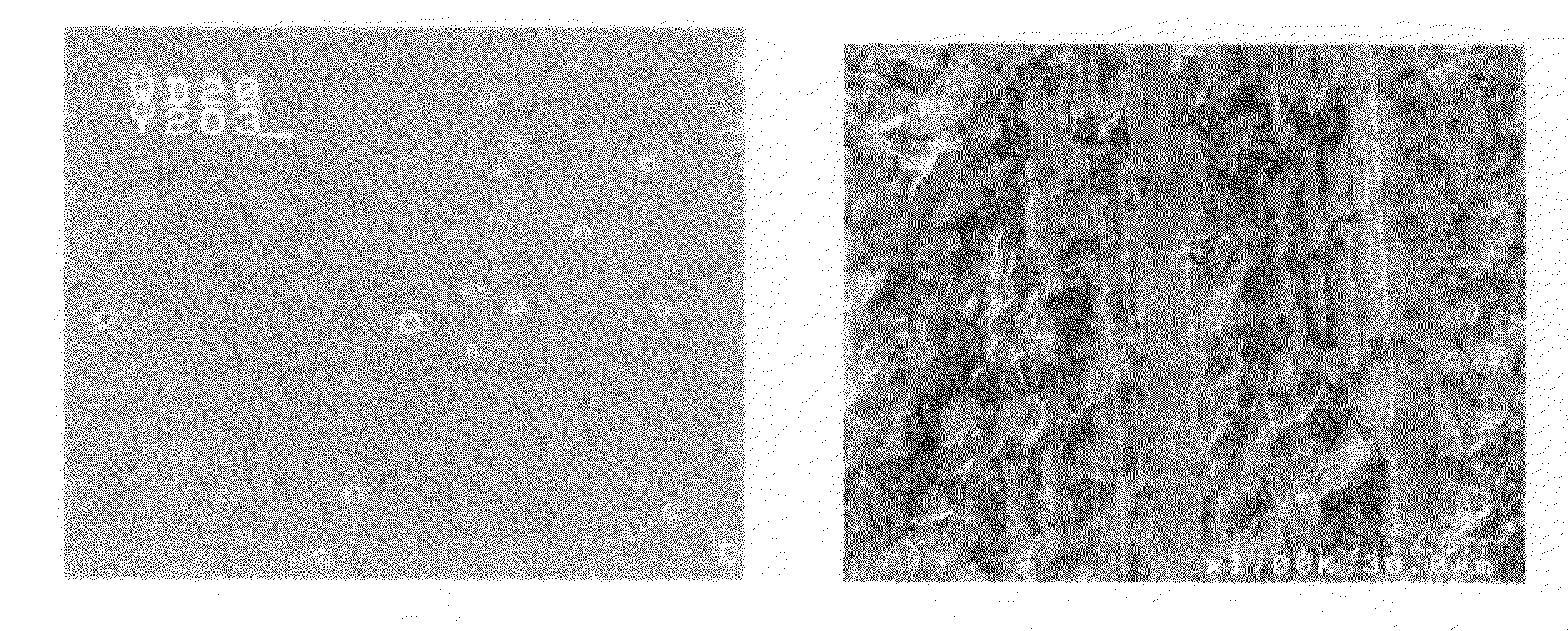

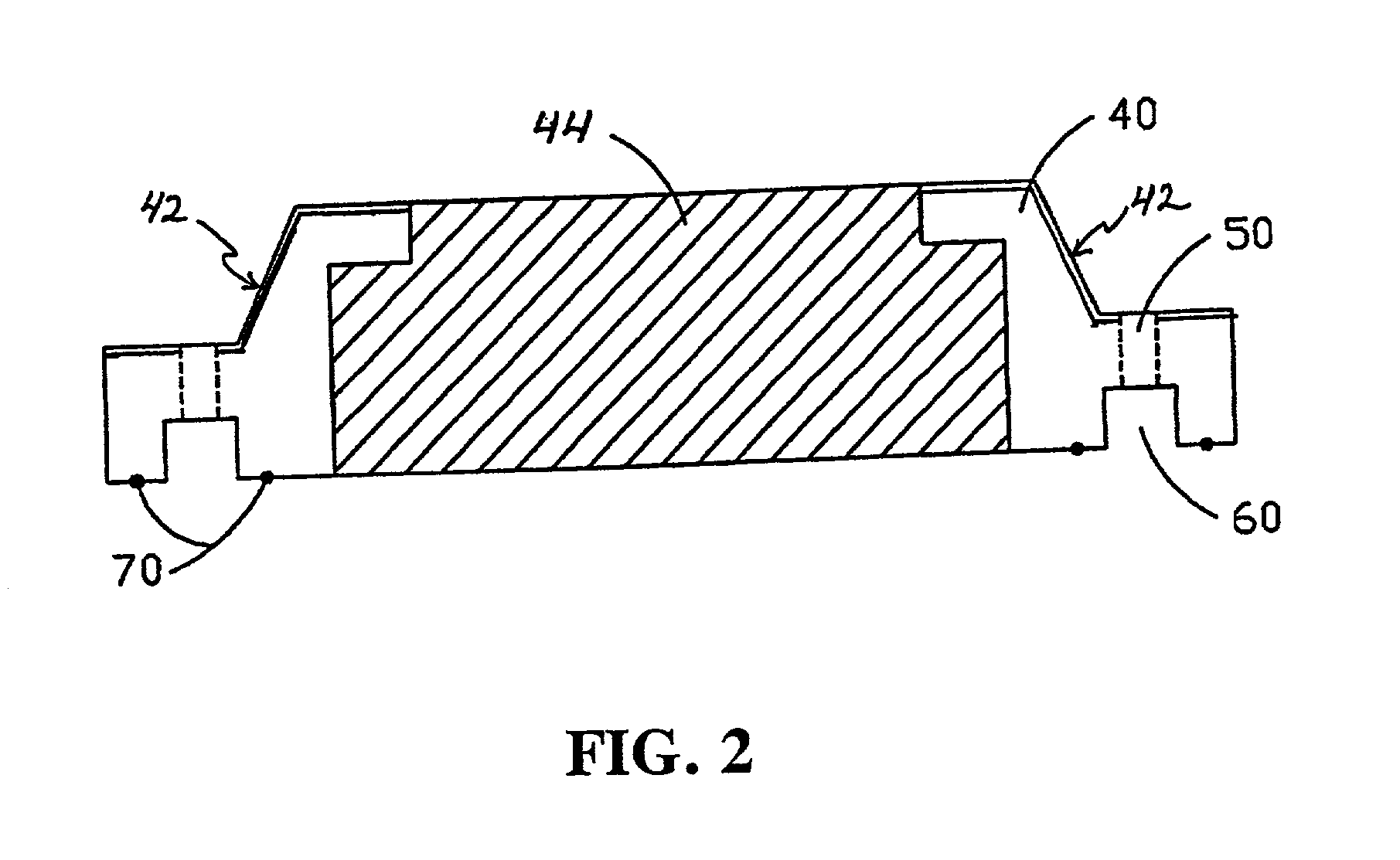

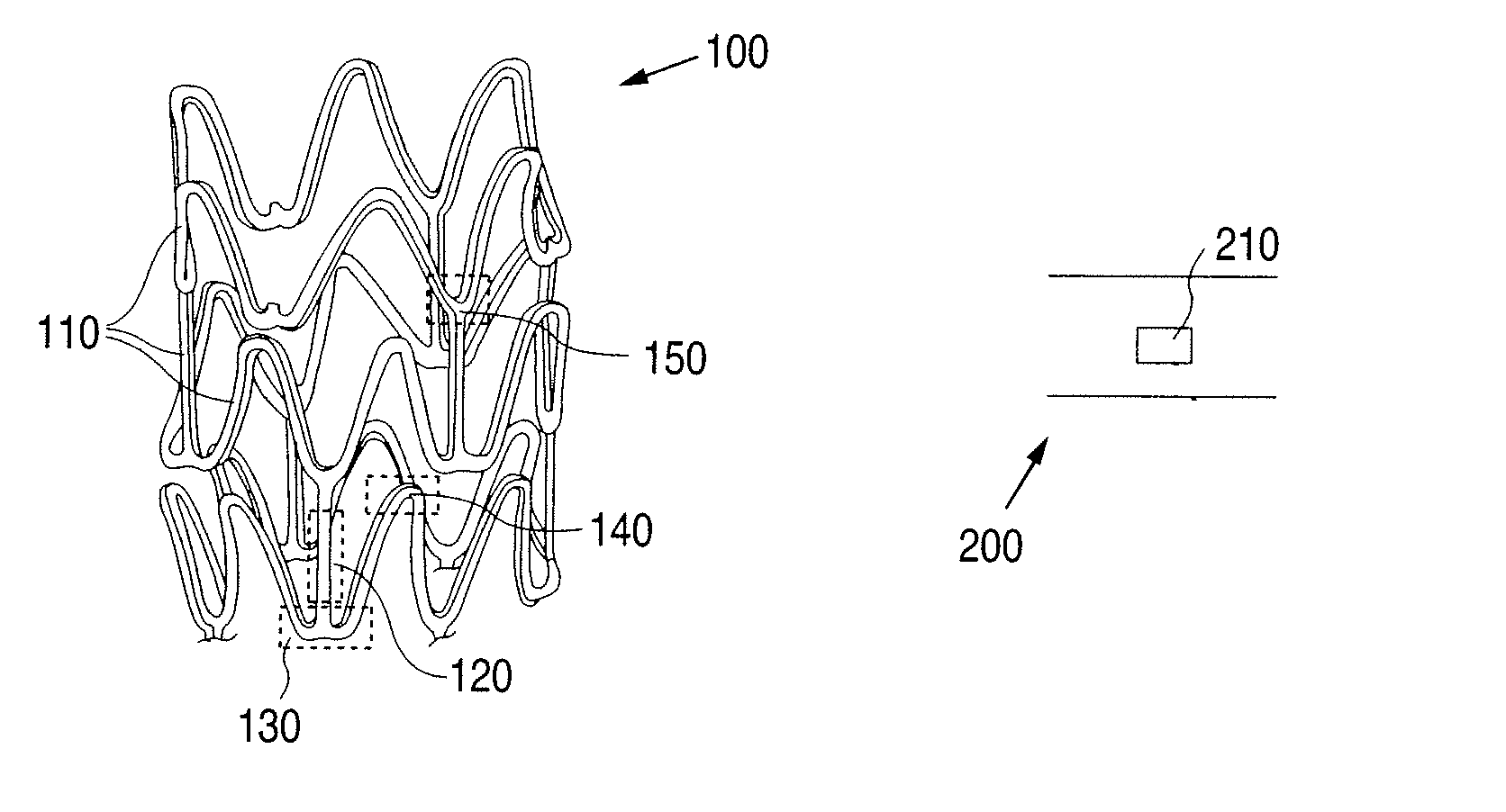

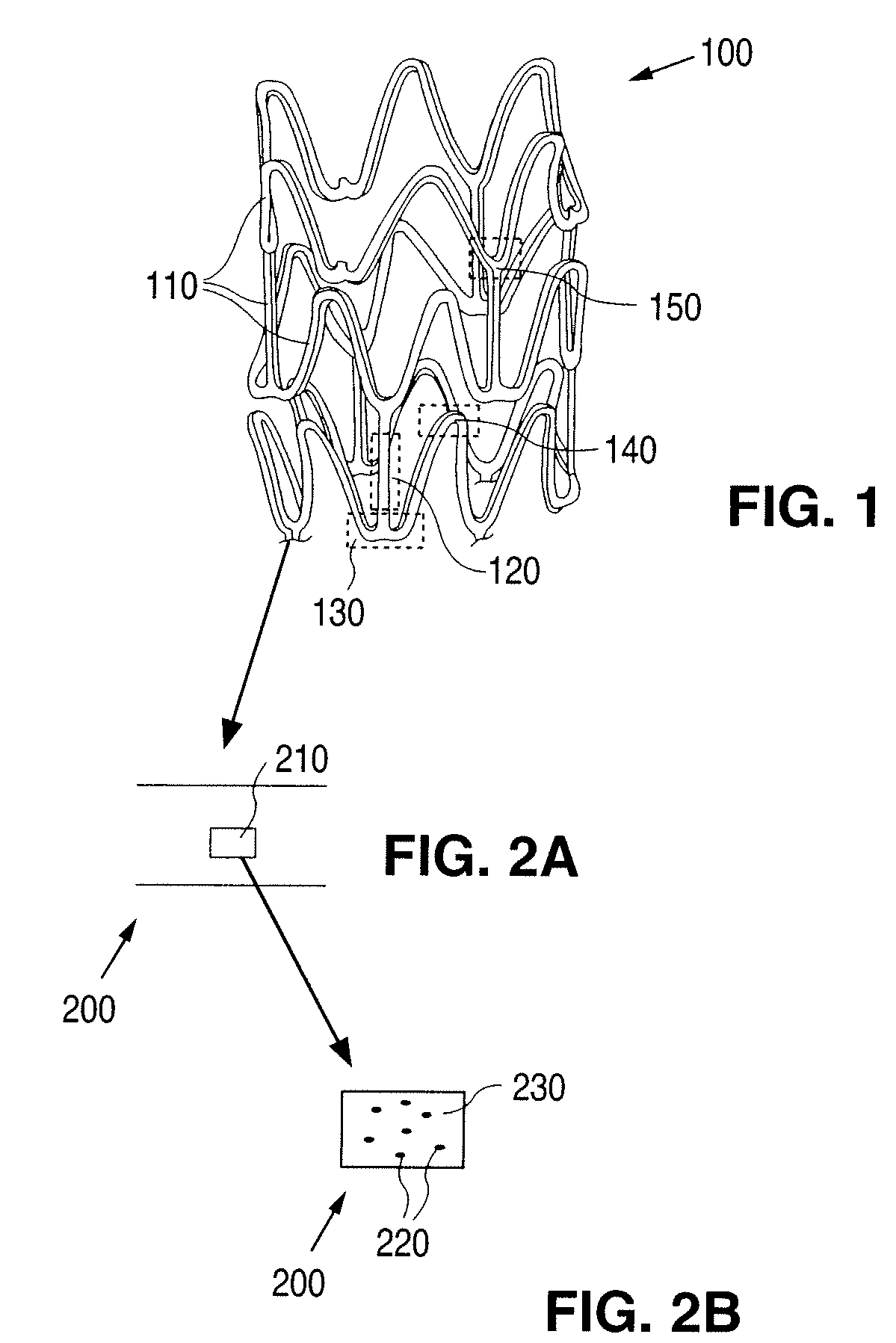

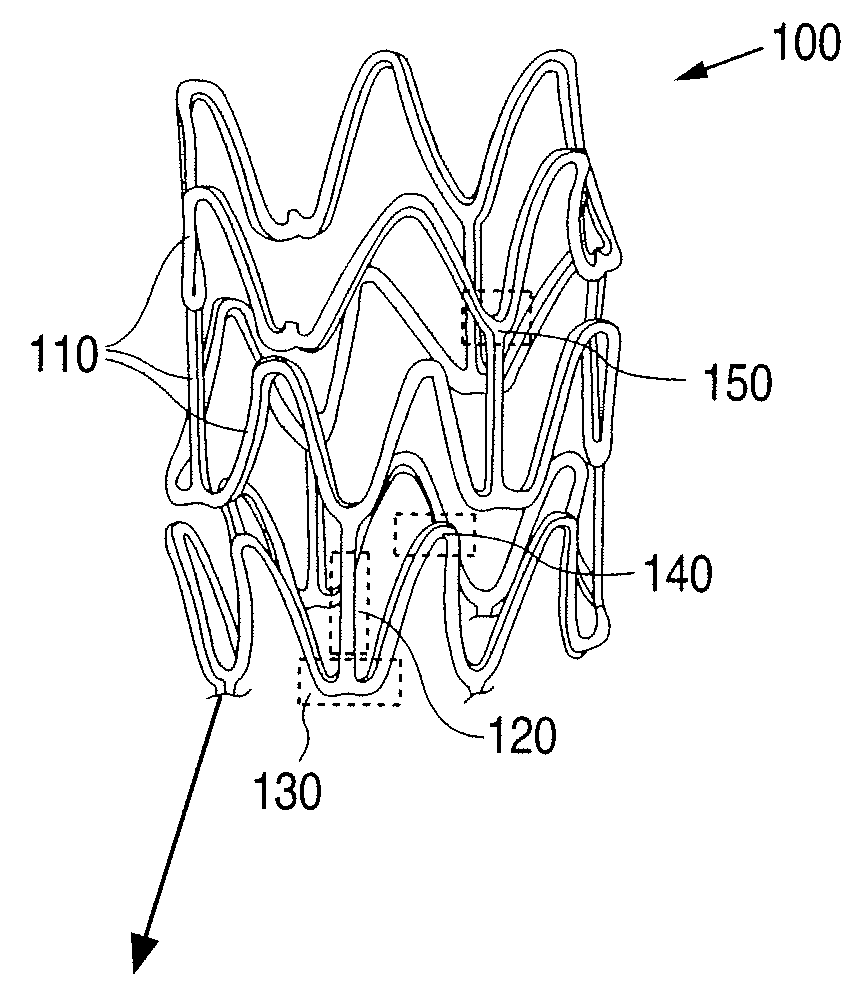

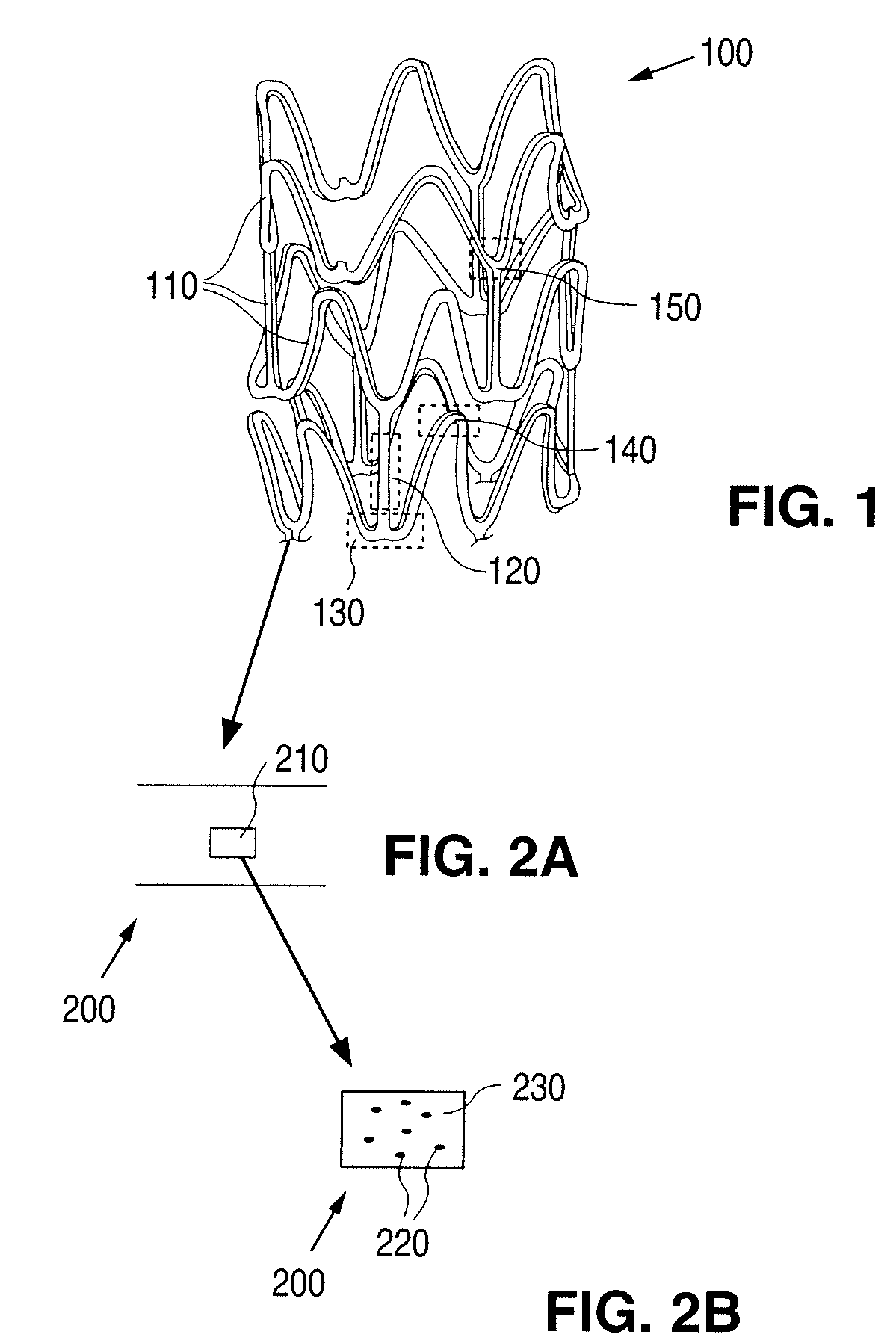

Coatings for controlling erosion of a substrate of an implantable medical device

InactiveUS20050283229A1Reduce and inhibit and delay erosionReduce erosion rateStentsSurgeryInsertion stentMedical device

An implantable medical device, such as a stent, with a coating region for controlling erosion of the substrate region is disclosed.

Owner:ABBOTT CARDIOVASCULAR

Method and apparatus which reduce the erosion rate of surfaces exposed to halogen-containing plasmas

ActiveUS7696117B2Reduce erosion rateImprove mechanical propertiesElectric discharge tubesSemiconductor/solid-state device manufacturingErosion rateYttrium

A ceramic article which is resistant to erosion by halogen-containing plasmas used in semiconductor processing. The ceramic article includes ceramic which is multi-phased, typically including two phase to three phases. The ceramic is formed from yttrium oxide at a molar concentration ranging from about 50 mole % to about 75 mole %; zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %; and at least one other component, selected from the group consisting of aluminum oxide, hafnium oxide, scandium oxide, neodymium oxide, niobium oxide, samarium oxide, ytterbium oxide, erbium oxide, cerium oxide, and combinations thereof, at a molar concentration ranging from about 10 mole % to about 30 mole %.

Owner:APPLIED MATERIALS INC

Method of reducing the erosion rate of semiconductor processing apparatus exposed to halogen-containing plasmas

InactiveUS20080264564A1Improve plasma resistanceImprove corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingErosion rateYttrium

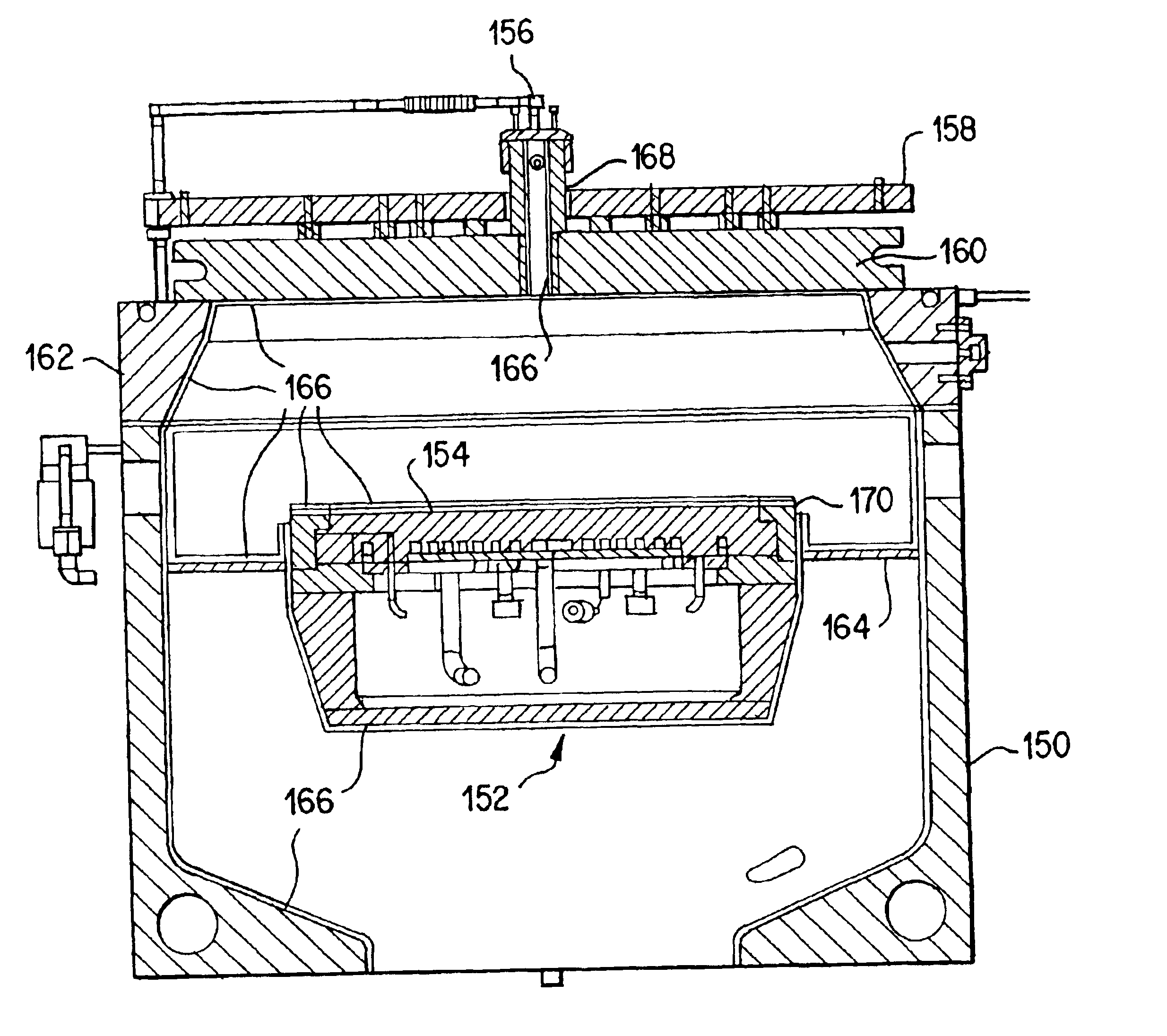

A ceramic article useful in semiconductor processing, which is resistant to erosion by halogen-containing plasmas. The ceramic article is formed from a combination of yttrium oxide and zirconium oxide. In a first embodiment, the ceramic article includes ceramic which is formed from yttrium oxide at a molar concentration ranging from about 90 mole % to about 70 mole %, and zirconium oxide at a molar concentration ranging from about 10 mole % to about 30 mole %. In a second embodiment, the ceramic article includes ceramic which is formed from zirconium oxide at a molar concentration ranging from about 96 mole % to about 94 mole %, and yttrium oxide at a molar concentration ranging from about 4 mole % to about 6 mole %.

Owner:APPLIED MATERIALS INC

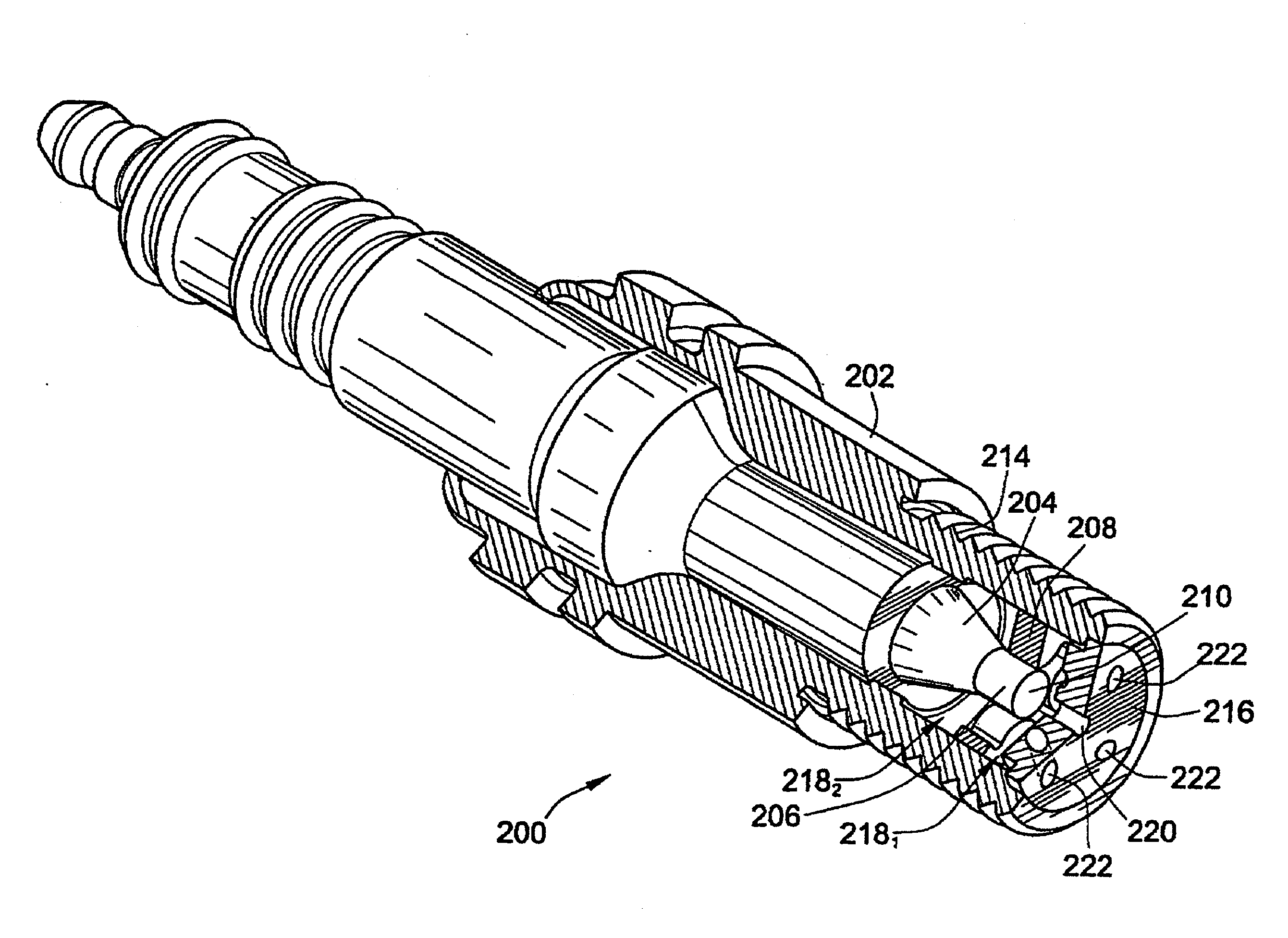

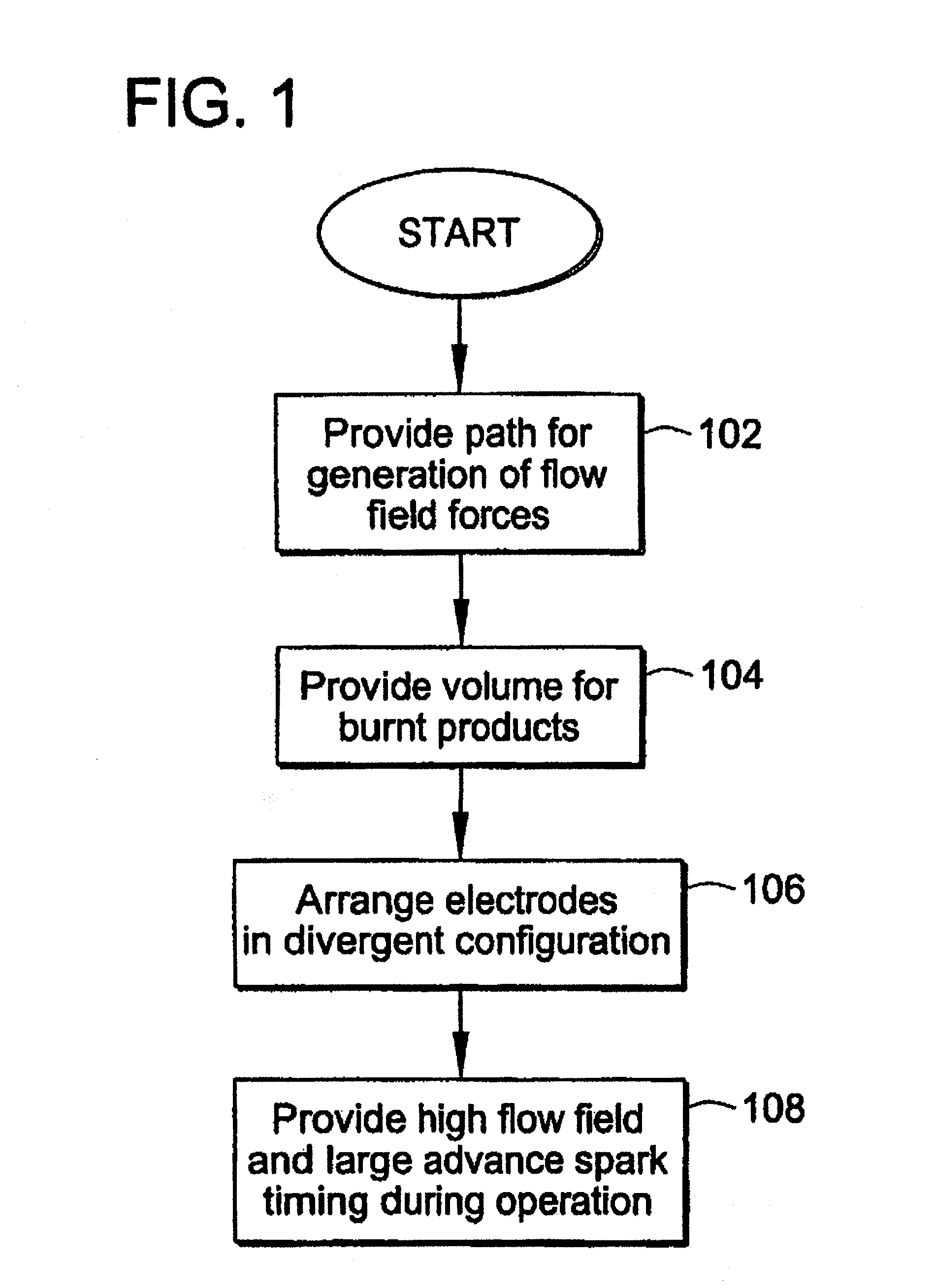

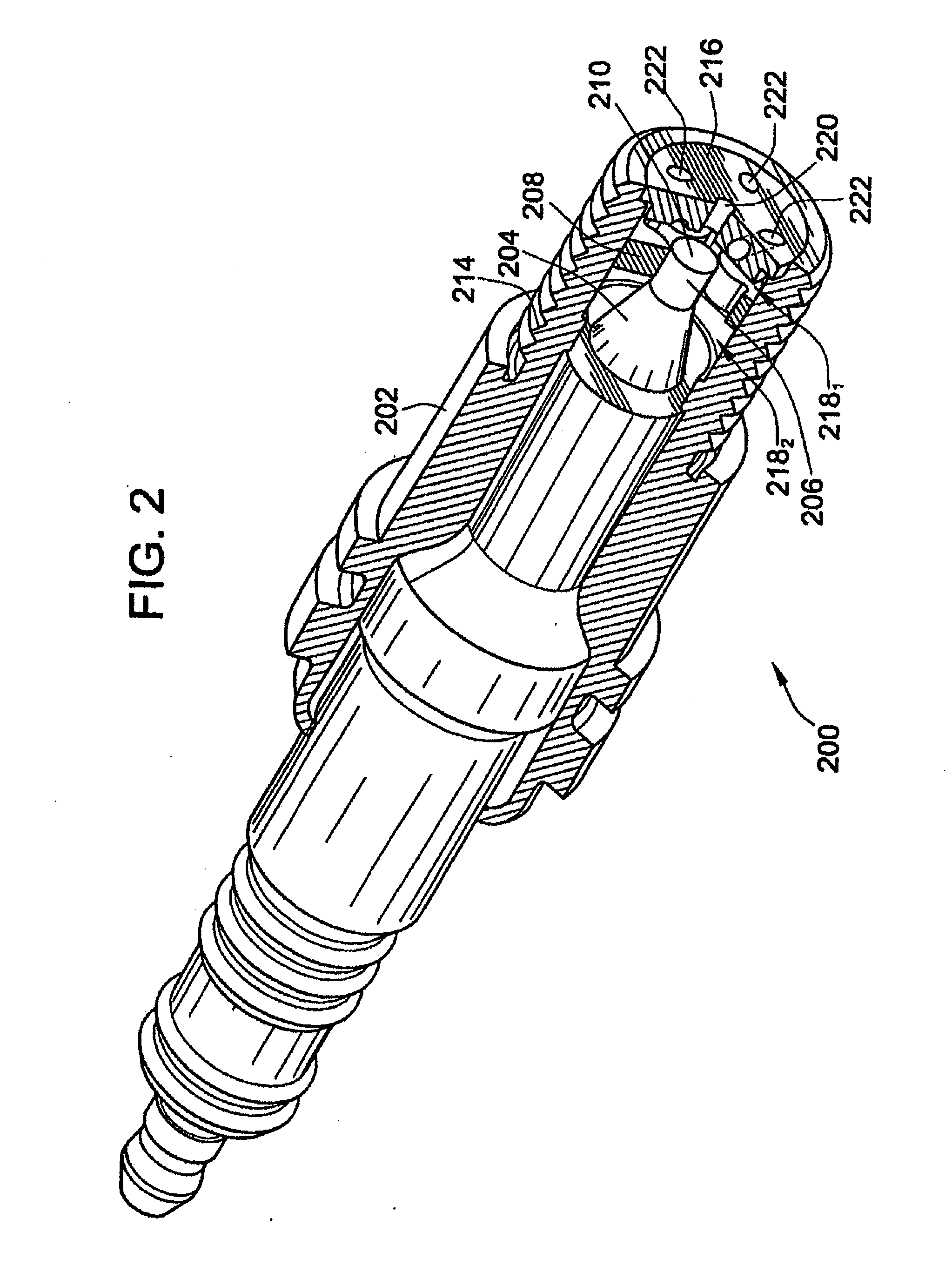

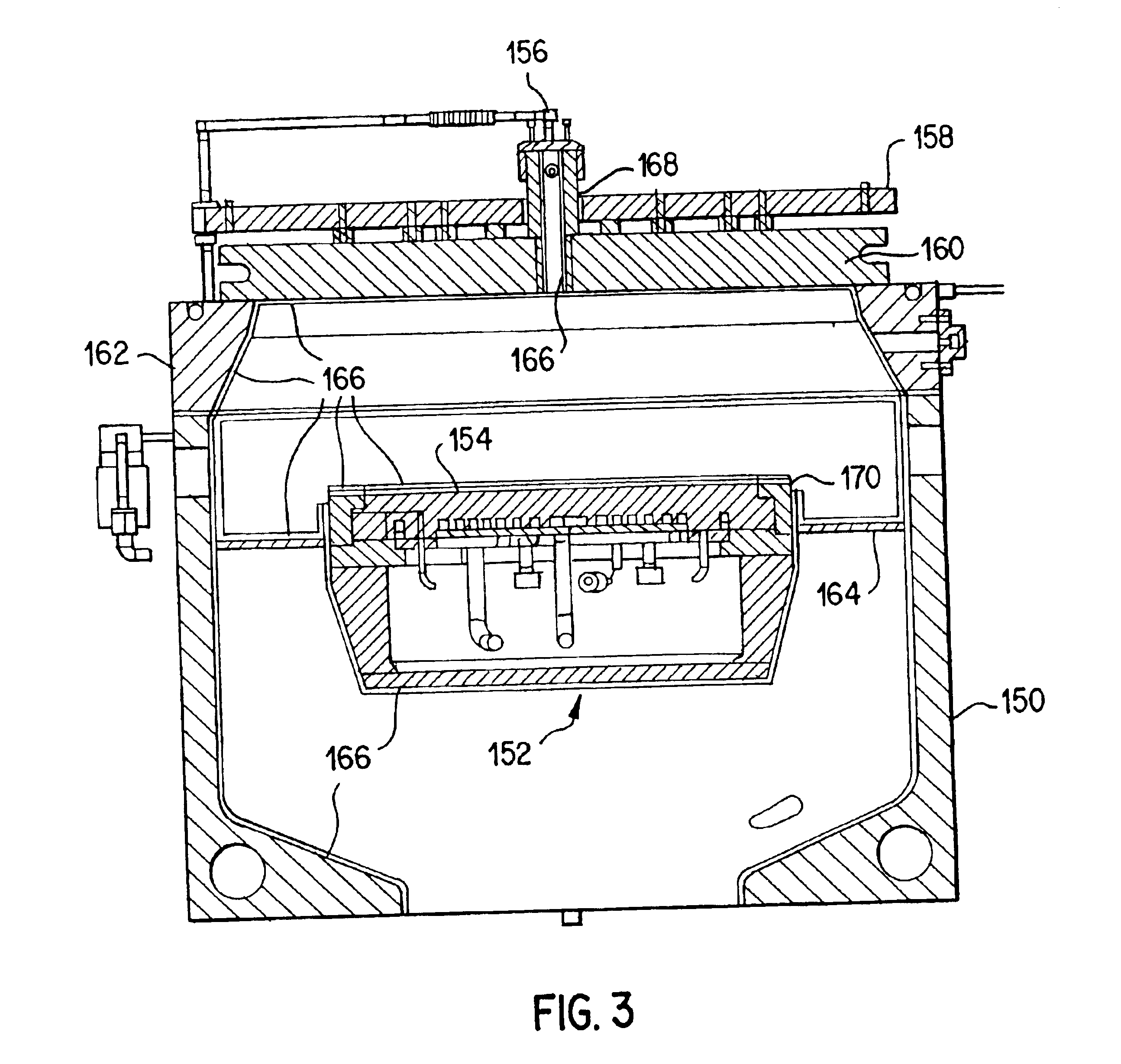

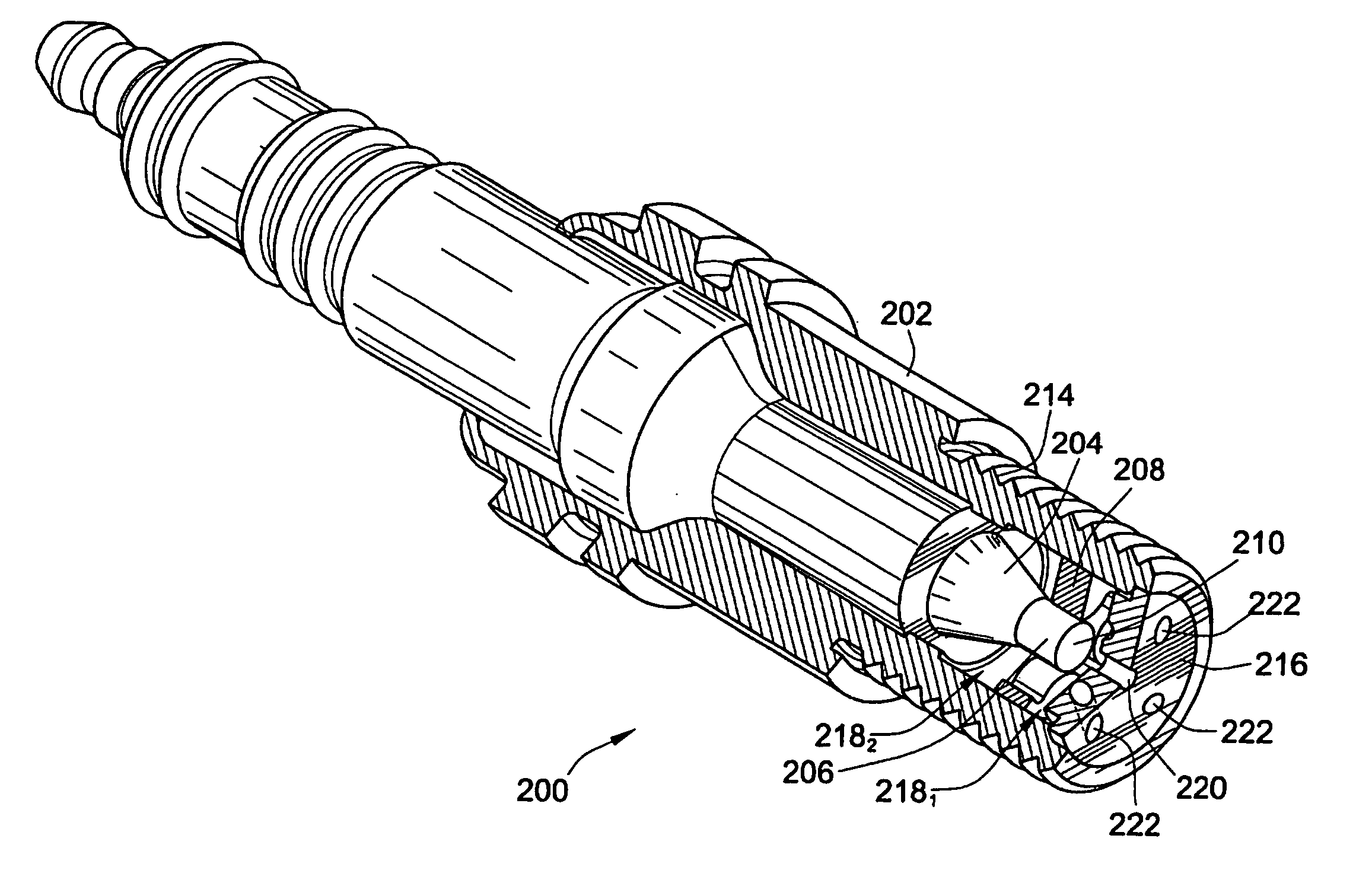

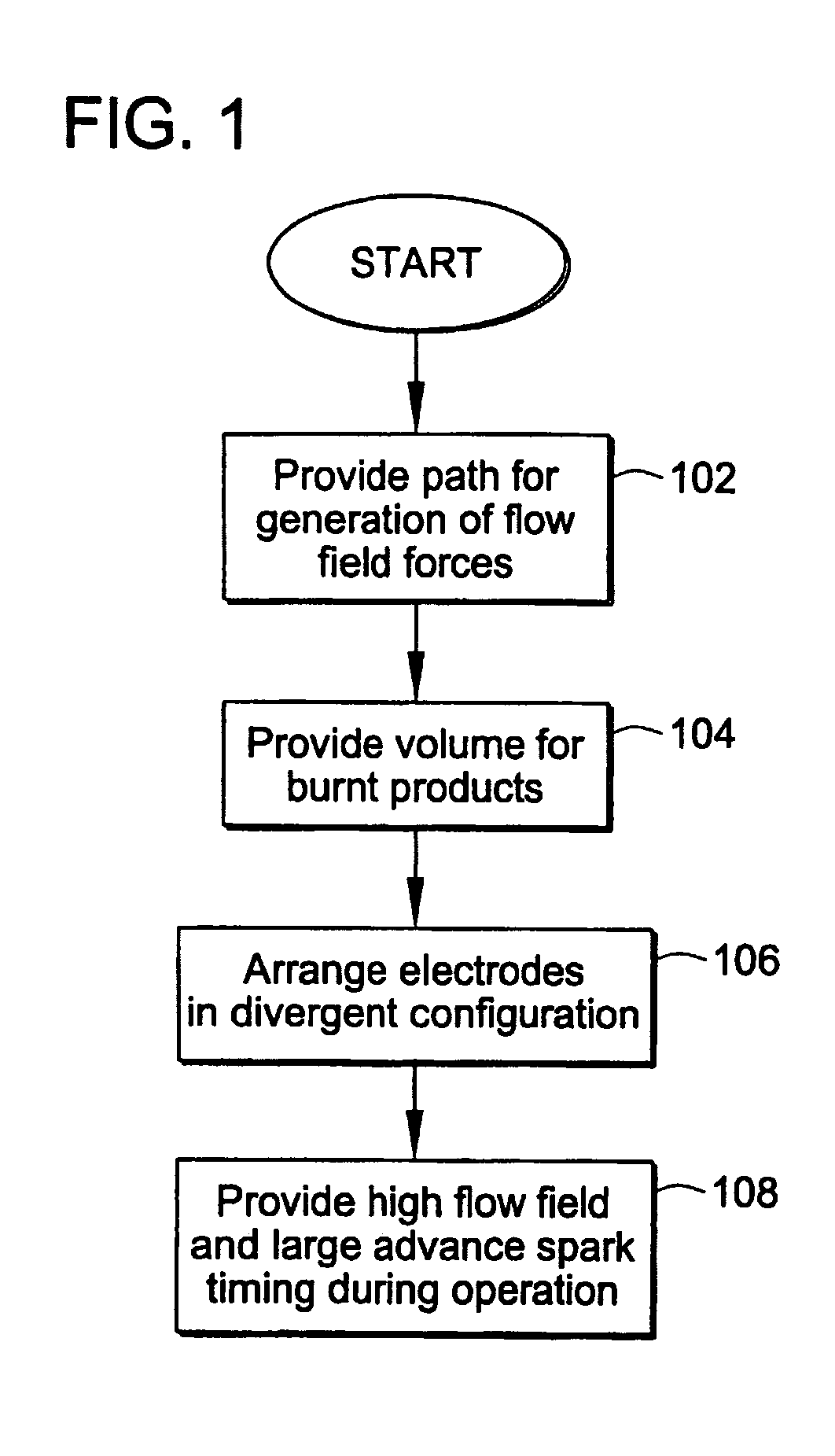

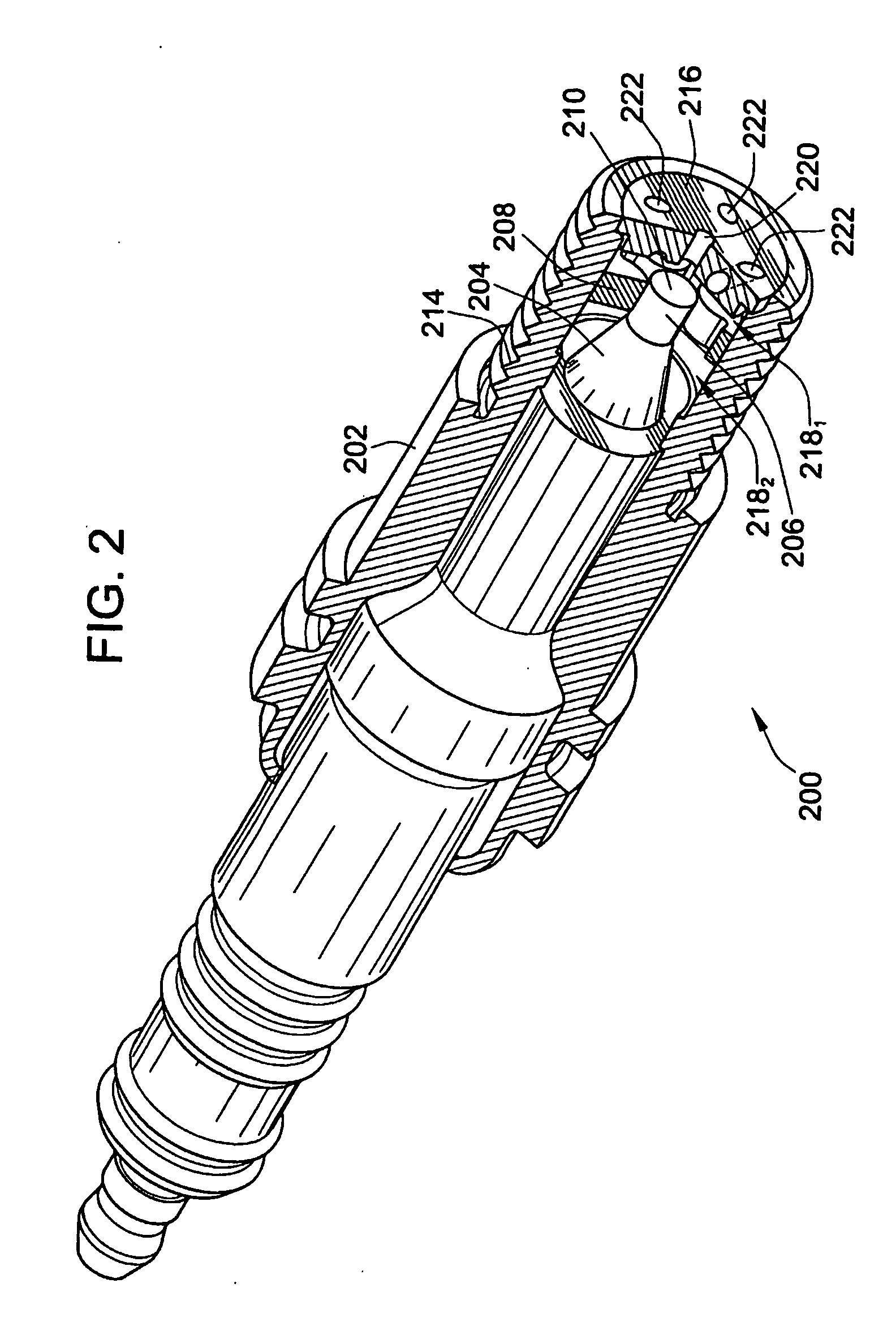

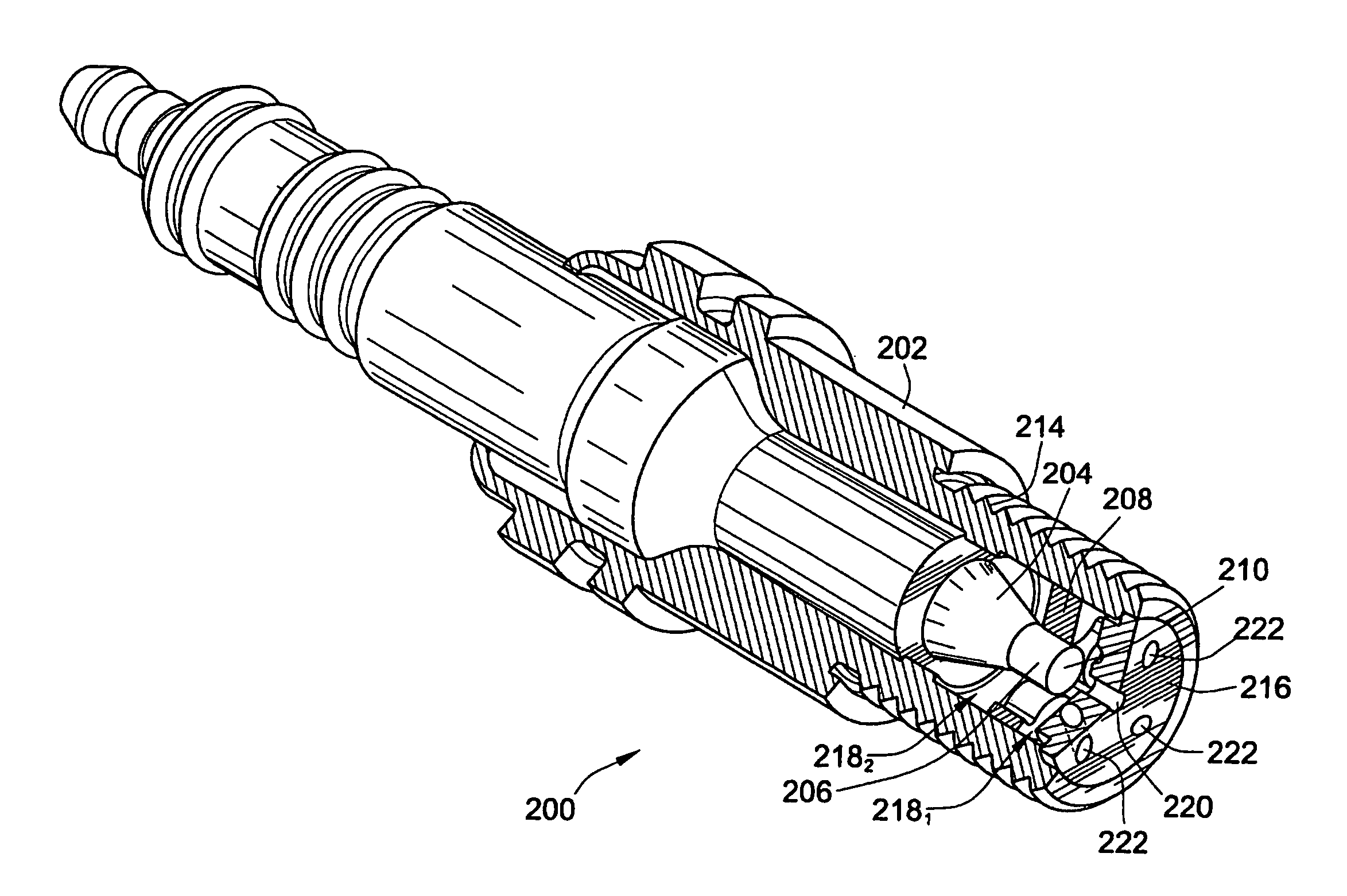

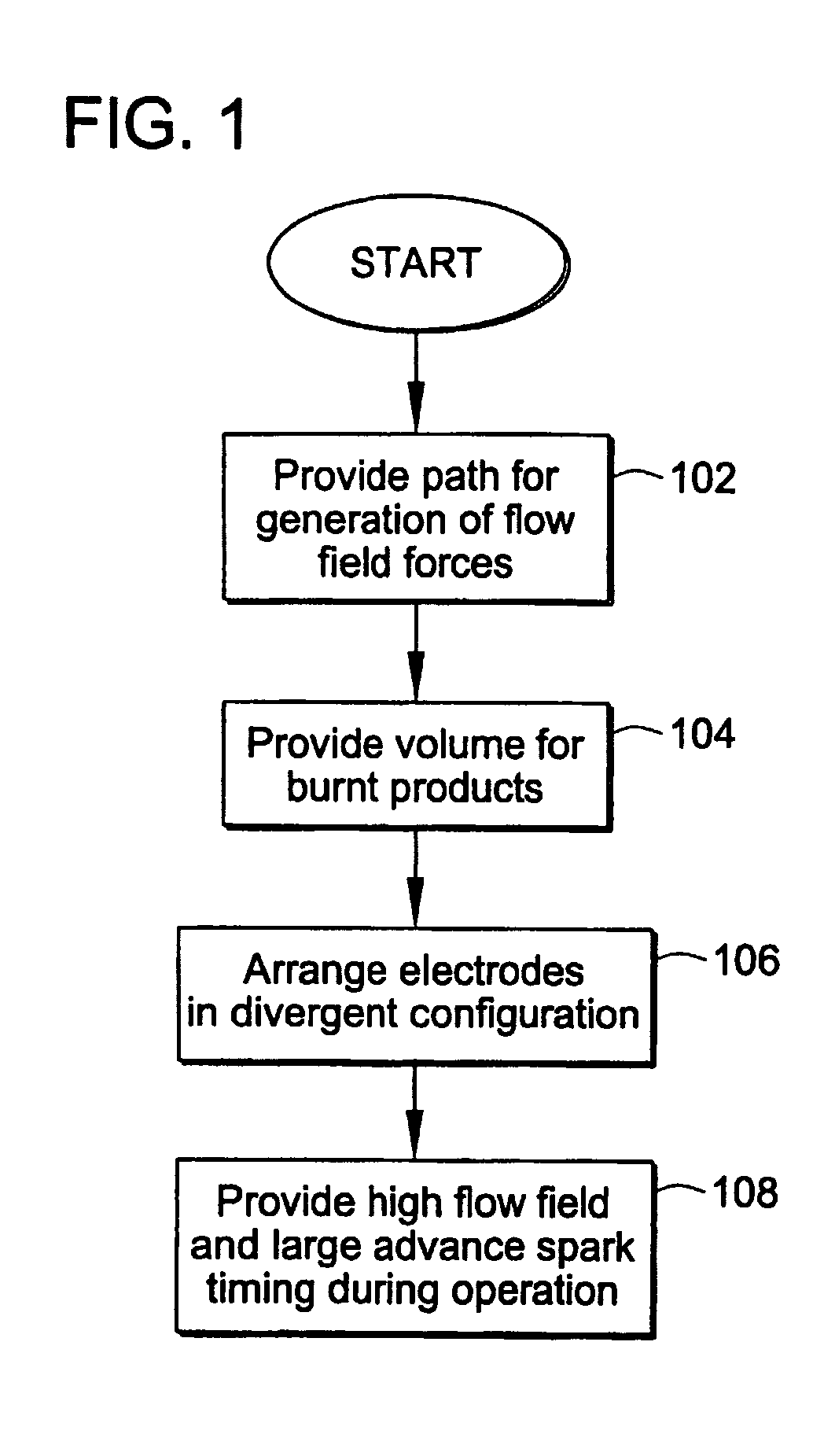

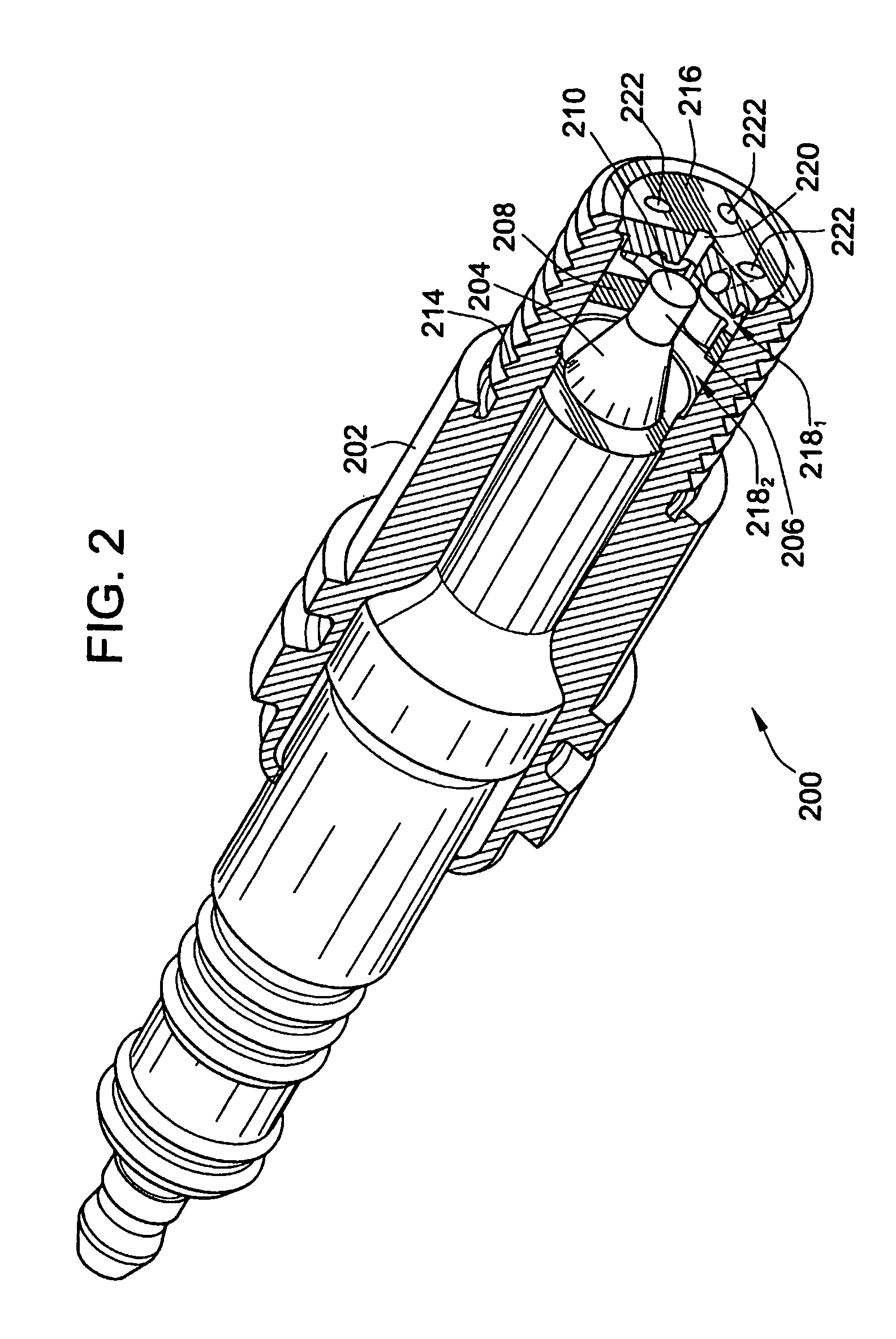

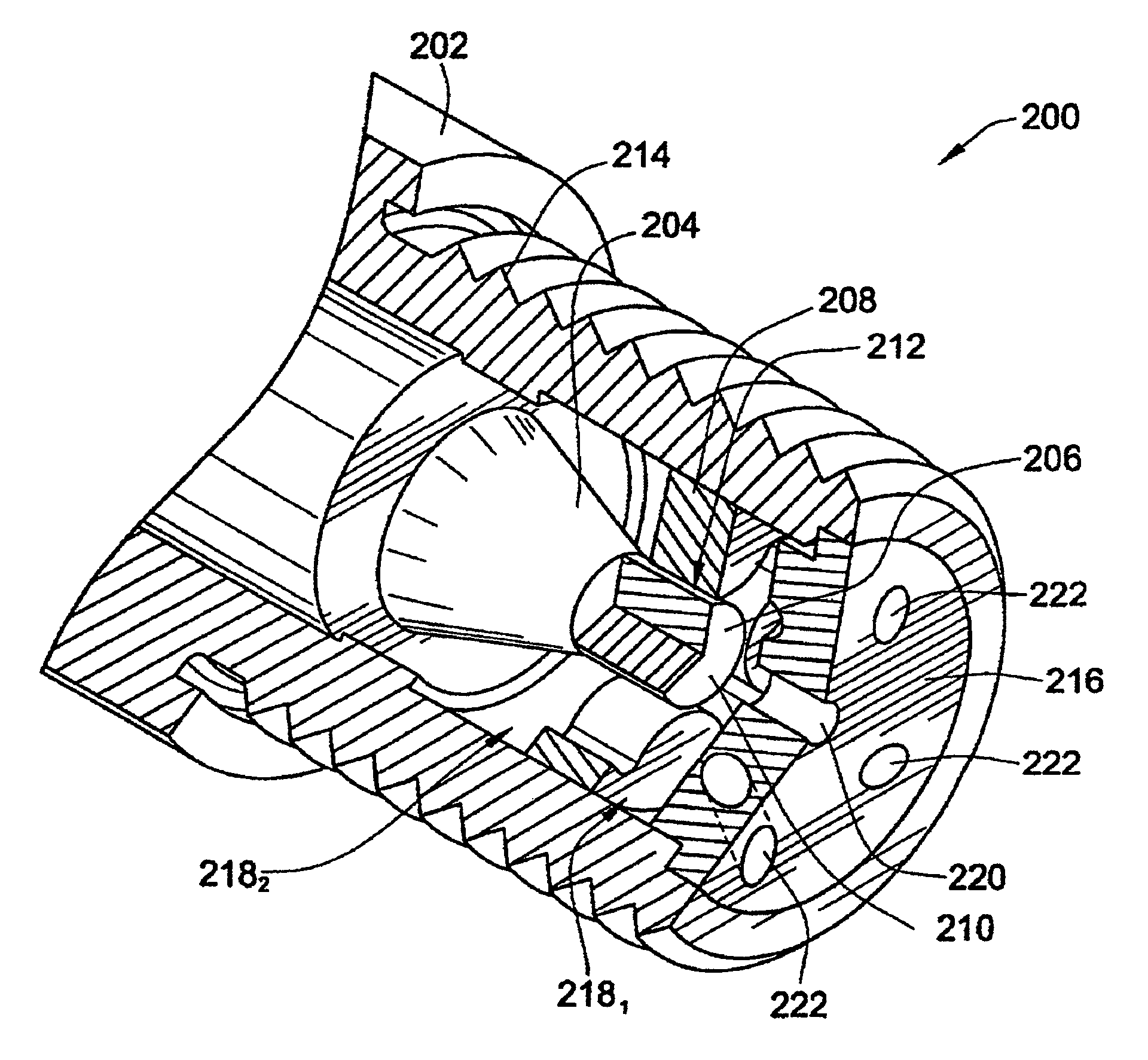

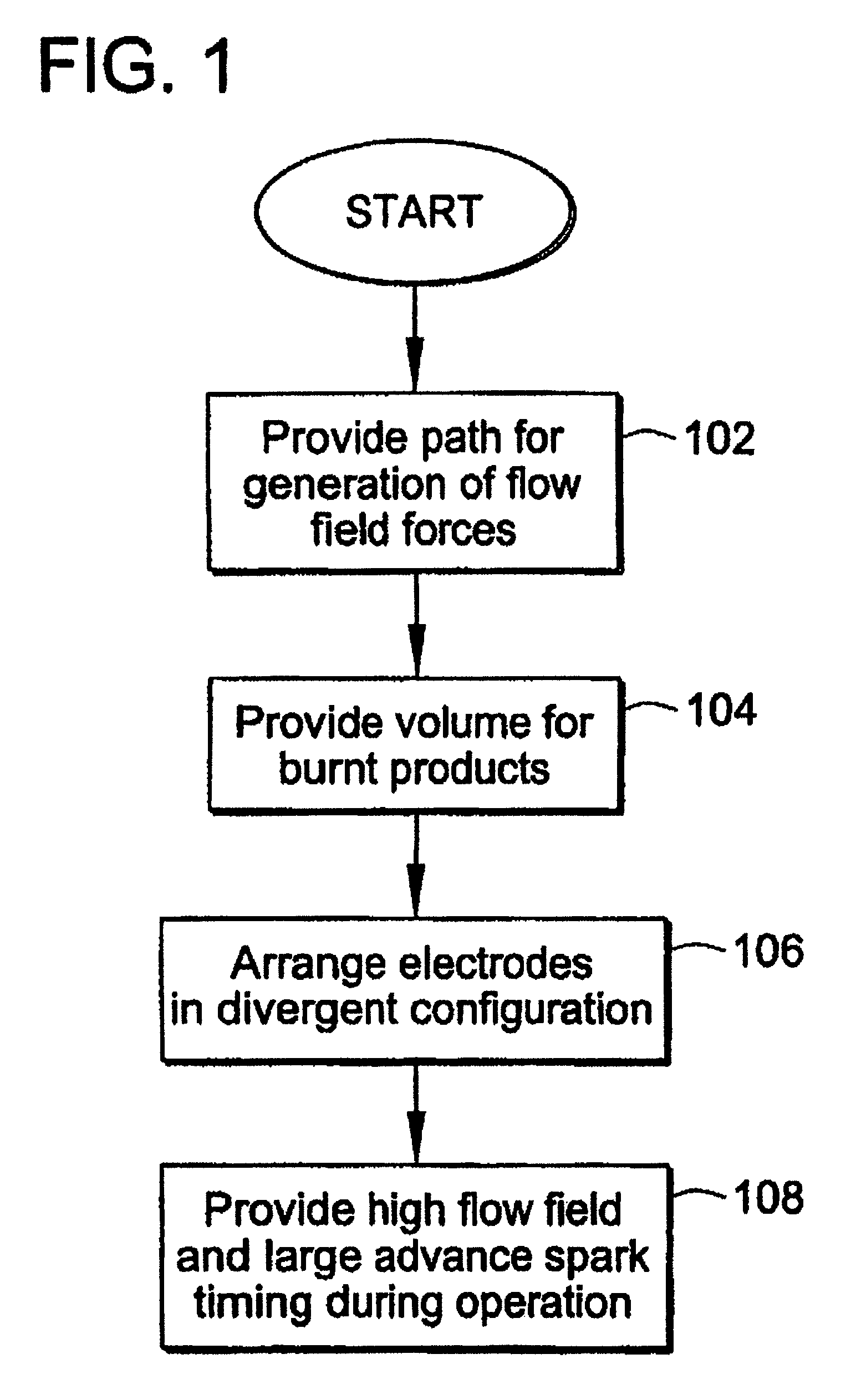

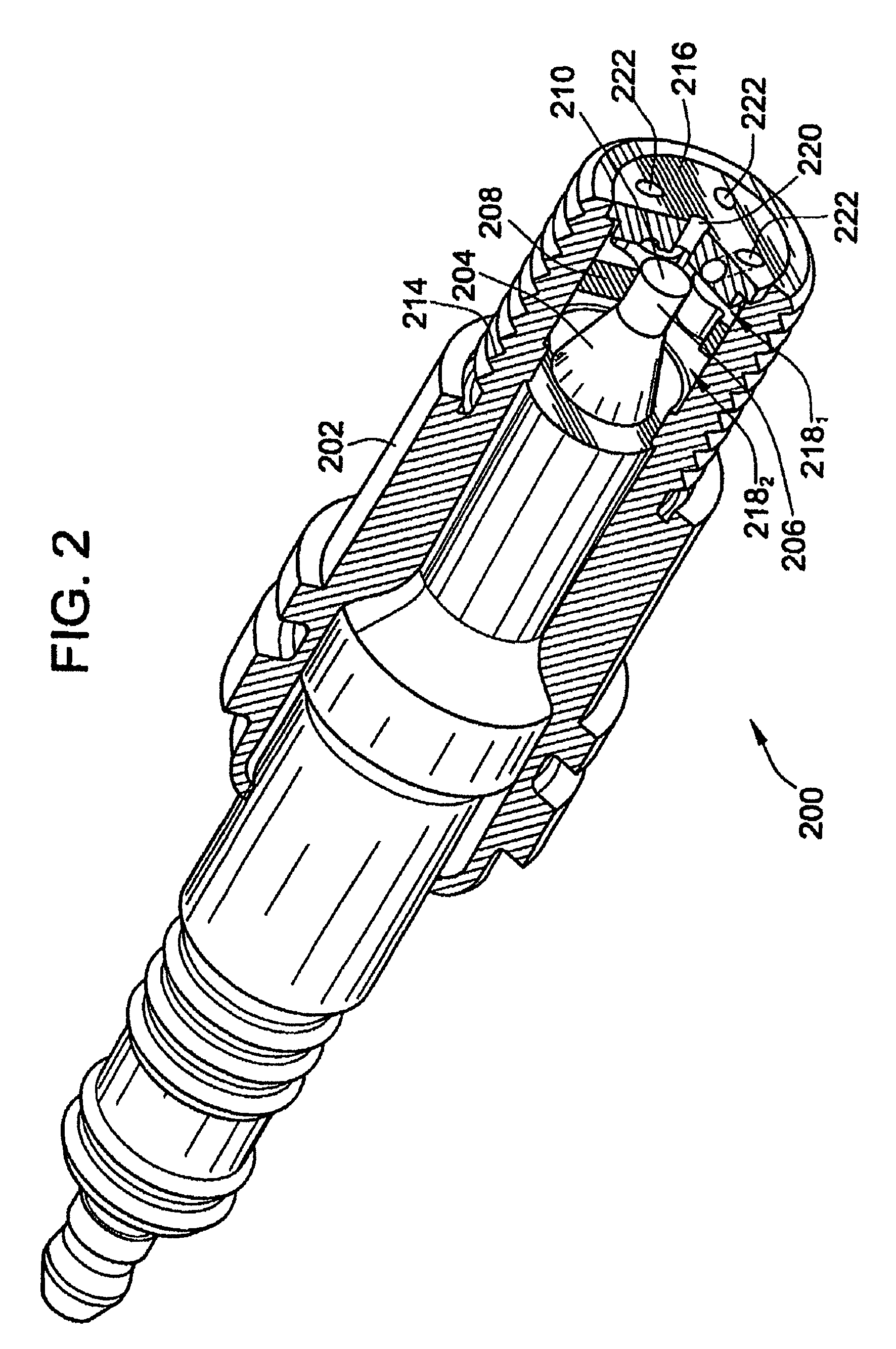

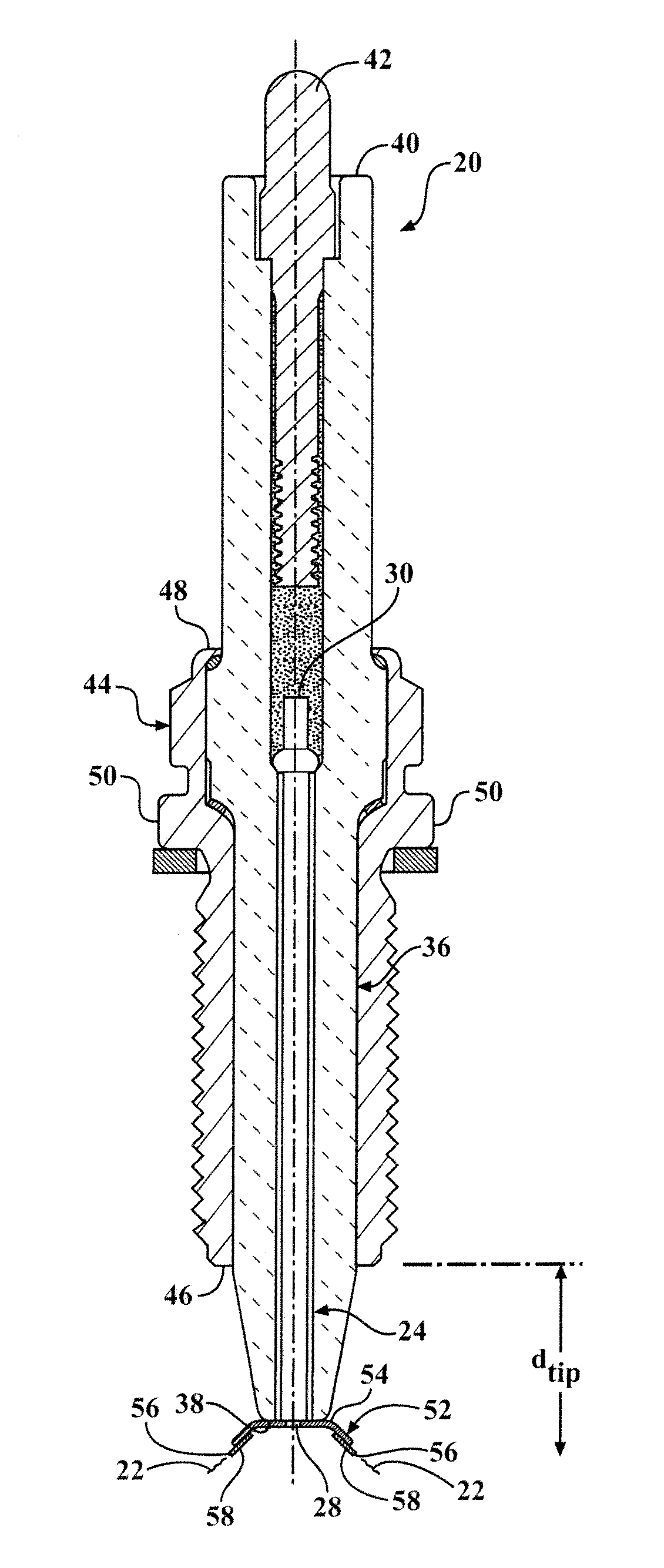

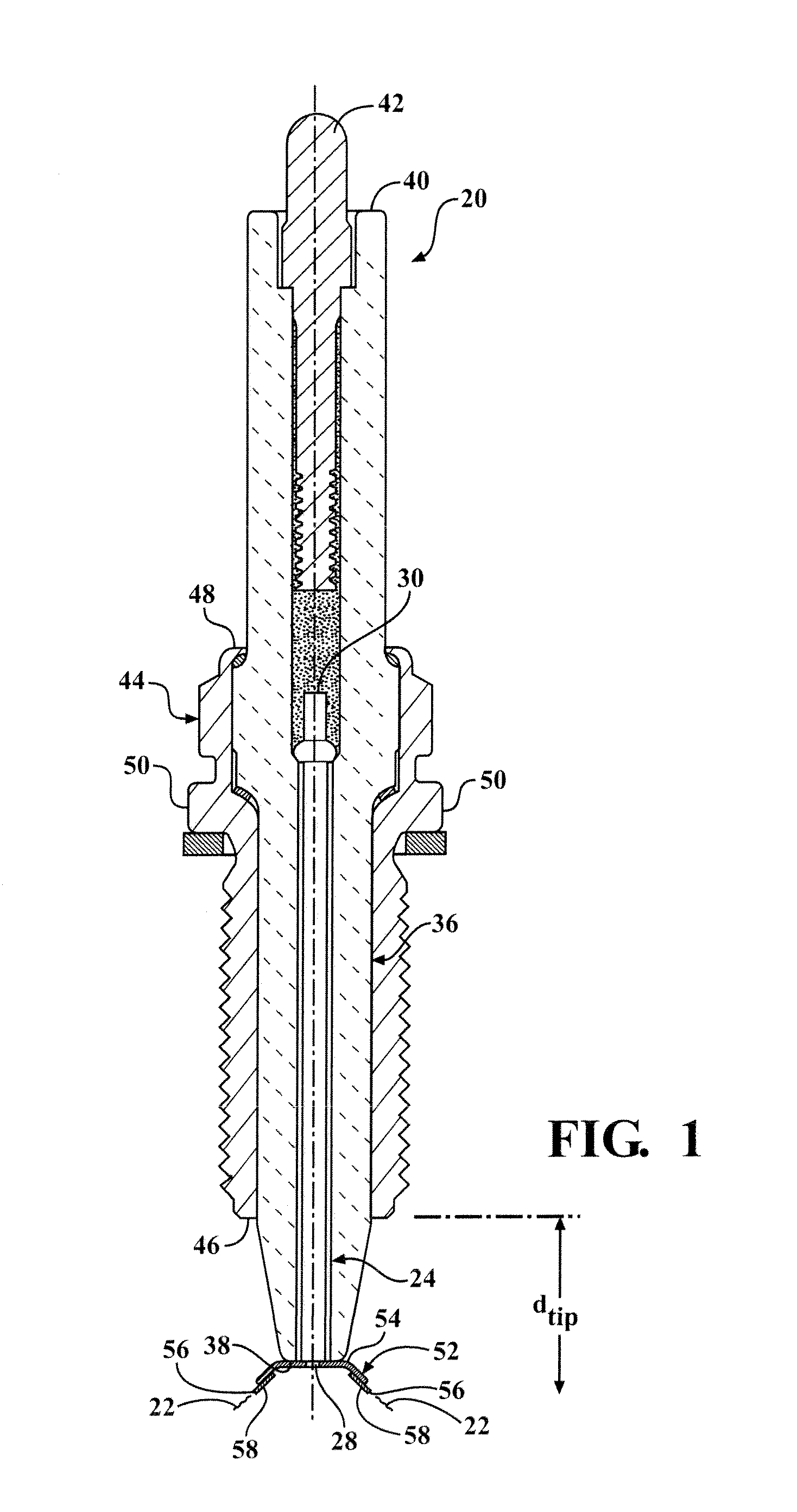

Pre-Chamber Spark Plug

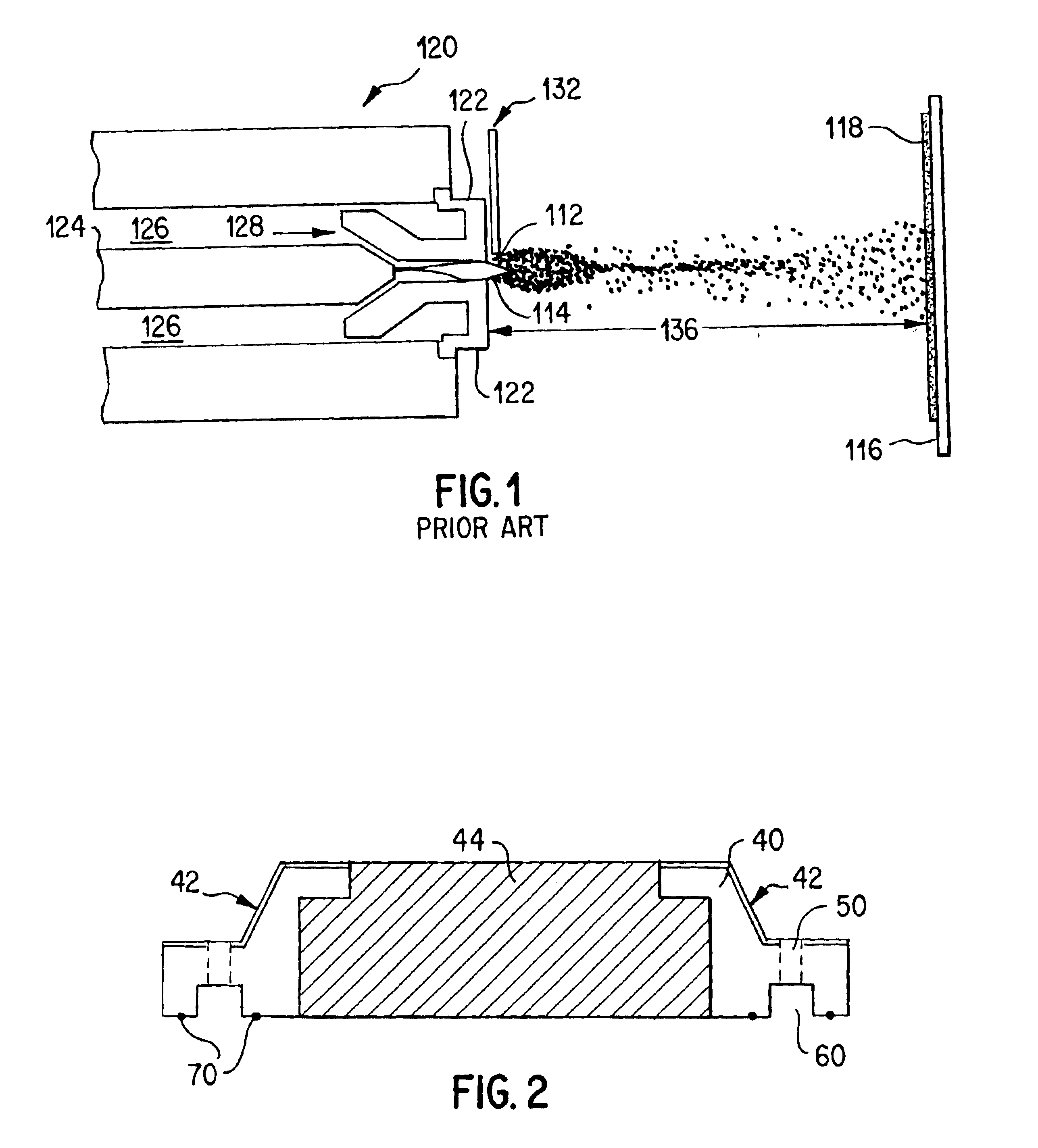

ActiveUS20090309475A1Maximize spark plug lifeReduce erosionSpark gapsInternal combustion piston enginesElectricityElectrode erosion

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and pre-ignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

Semiconductor processing apparatus comprising a solid solution ceramic of yttrium oxide and zirconium oxide

ActiveUS20100160143A1Reduce erosion rateImprove mechanical propertiesElectric discharge tubesSemiconductor/solid-state device manufacturingHalogenSolid solution

Owner:APPLIED MATERIALS INC

Cerium oxide containing ceramic components and coatings in semiconductor processing equipment and methods of manufacture thereof

InactiveUS6830622B2Reduce corrosionReduce erosion rateLiquid surface applicatorsMolten spray coatingCeramic coatingCerium

Owner:LAM RES CORP

Pre-chamber spark plug

ActiveUS20070069617A1Maximize spark plug lifeReduce erosionSparking plugsInternal combustion piston enginesSpecific energyElectricity

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and preignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

Pre-chamber spark plug

ActiveUS7659655B2Life maximizationReduce erosionSparking plugsInternal combustion piston enginesElectricityElectrode erosion

Owner:WOODWARD GOVERNOR CO

Cerium oxide containing ceramic components and coatings in semiconductor processing equipment and methods of manufacture thereof

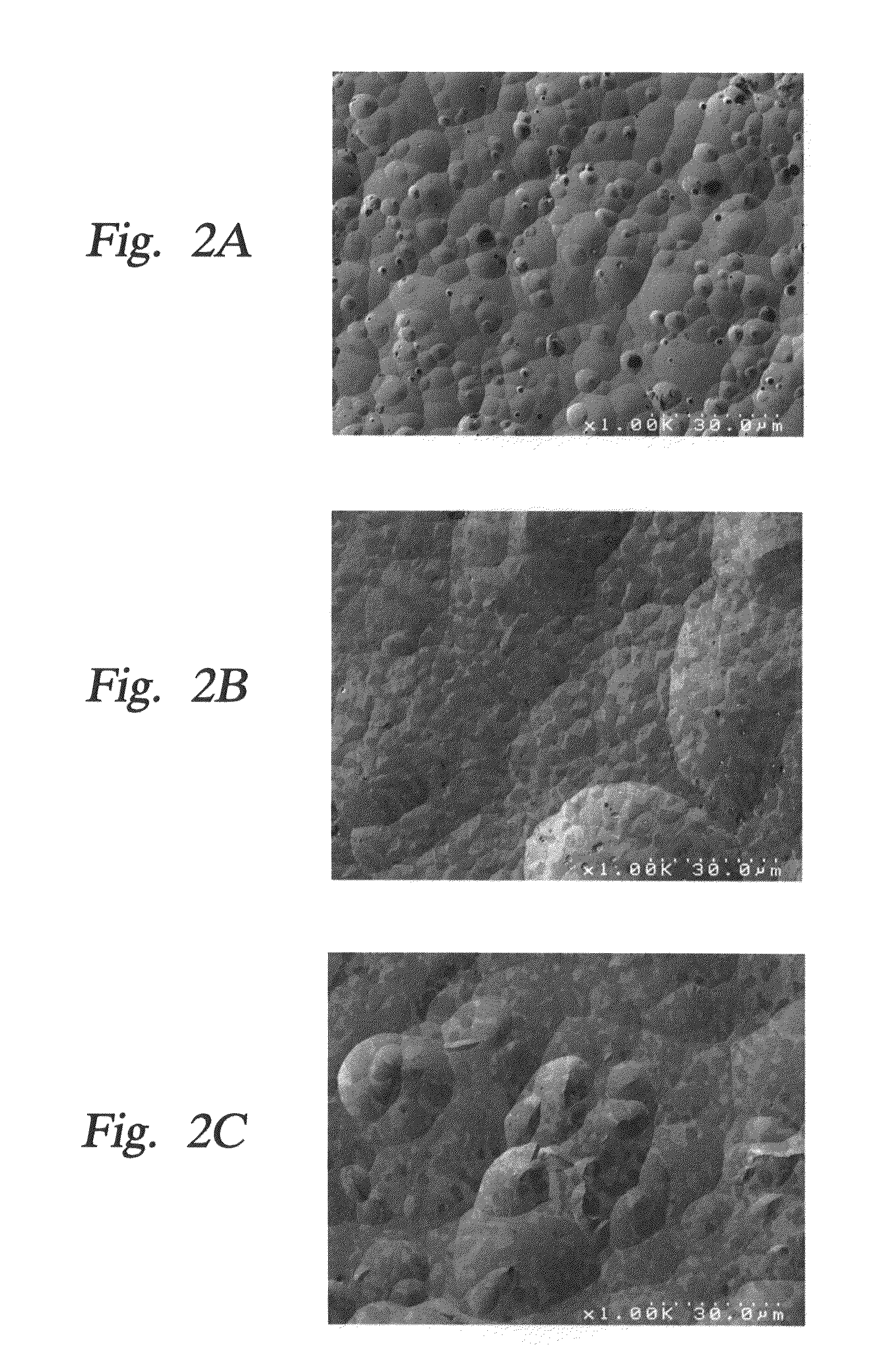

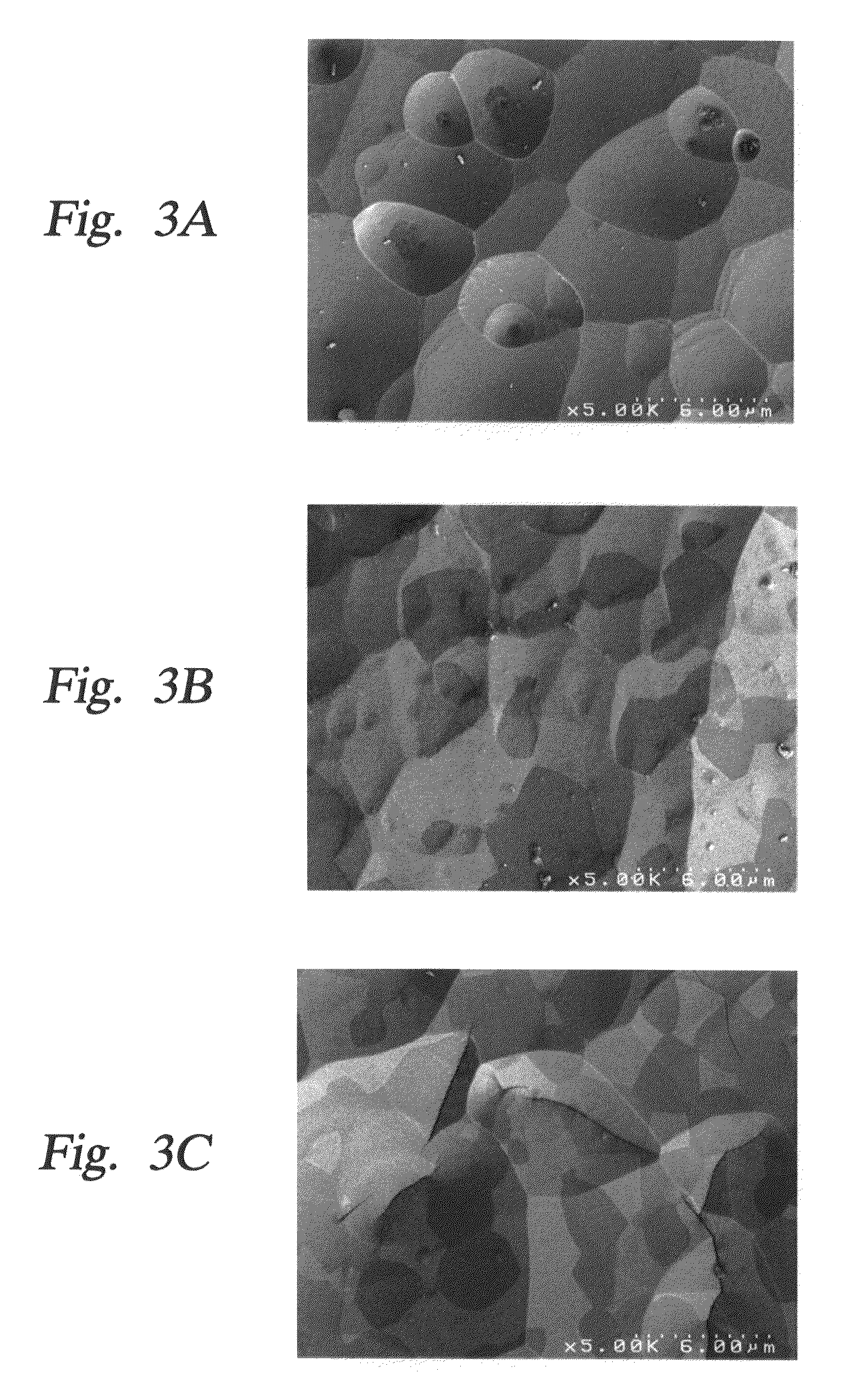

InactiveUS20020142611A1Reduce corrosionReduce erosion rateLiquid surface applicatorsMolten spray coatingCeramic coatingCerium

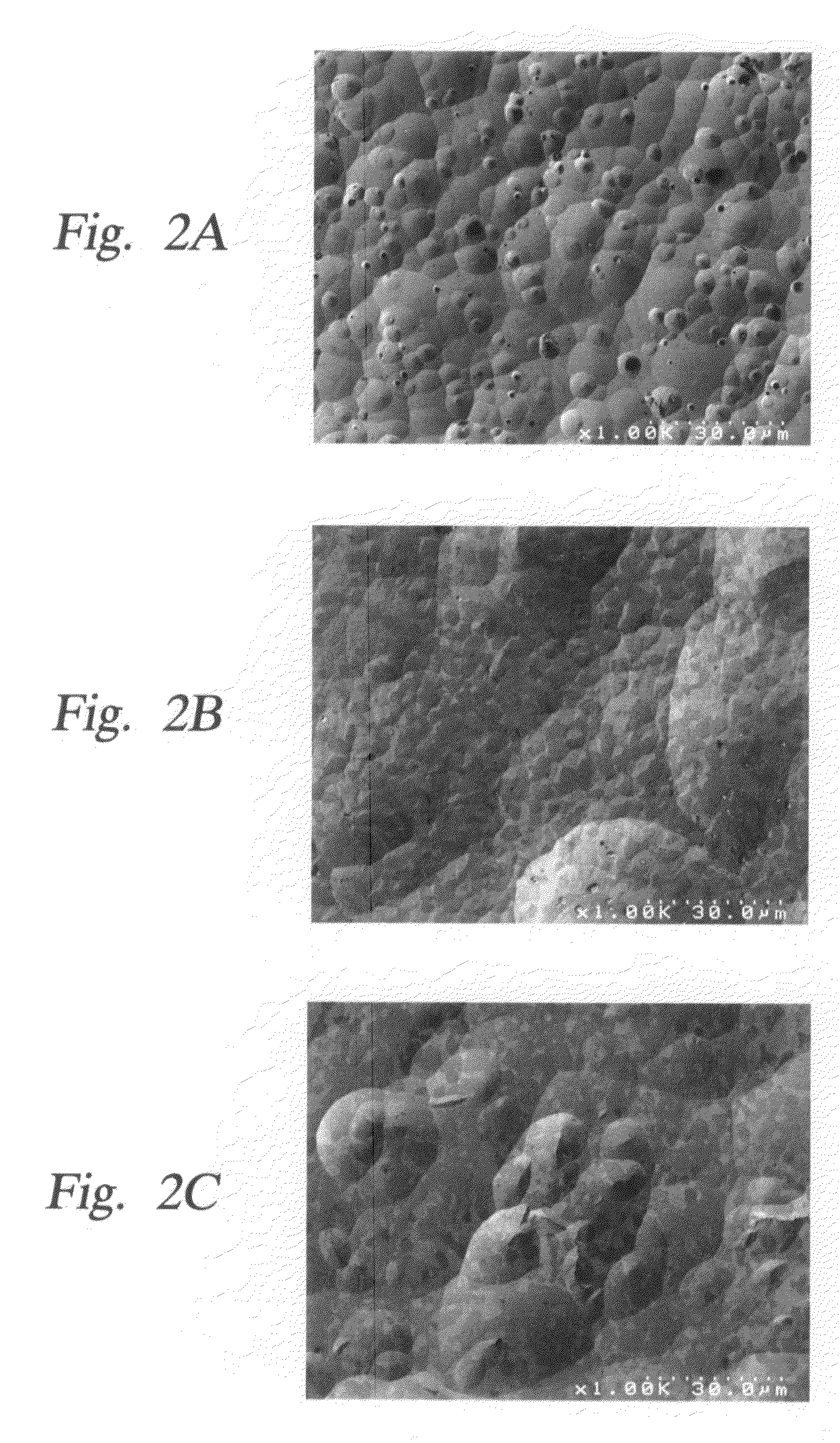

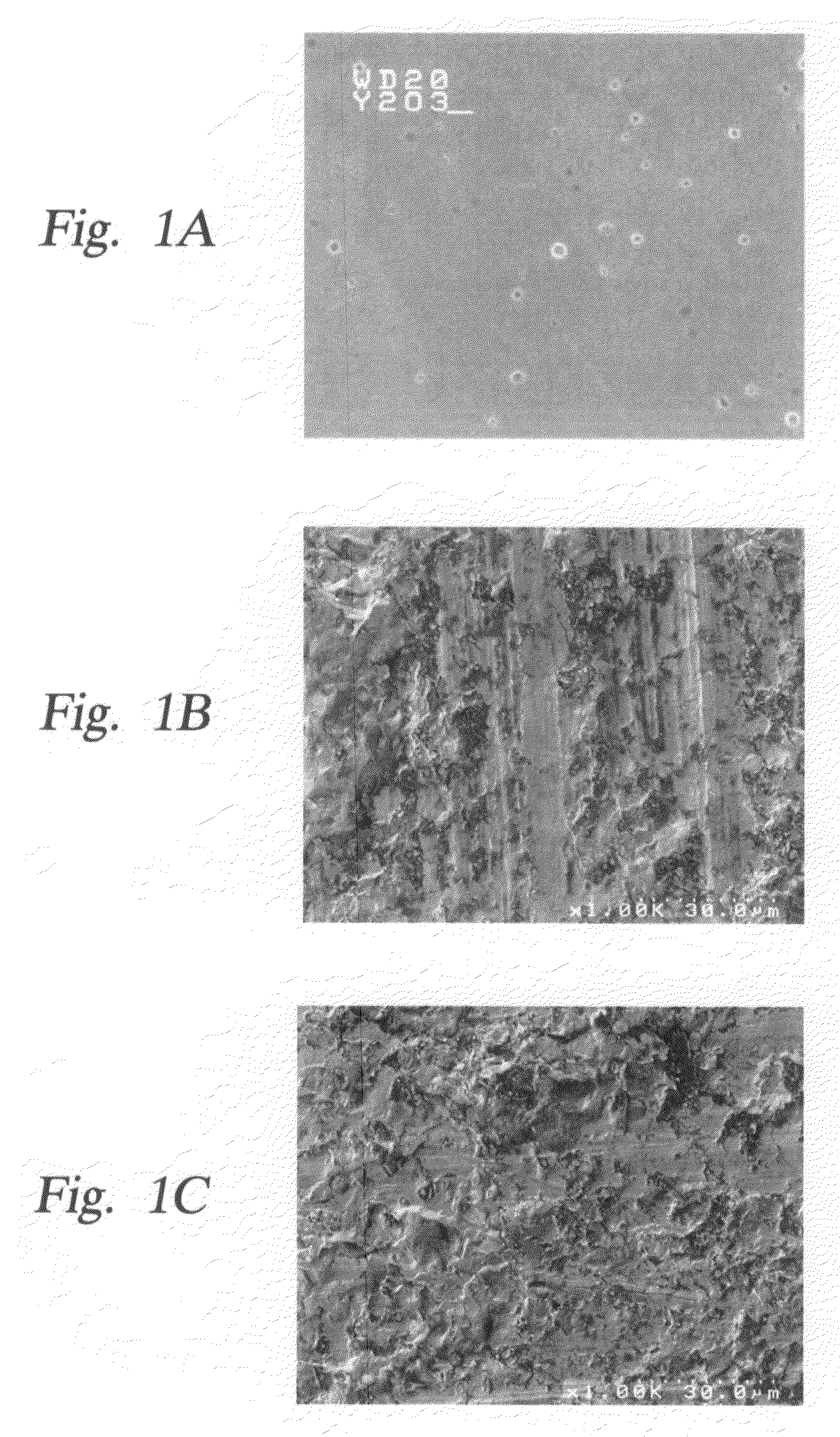

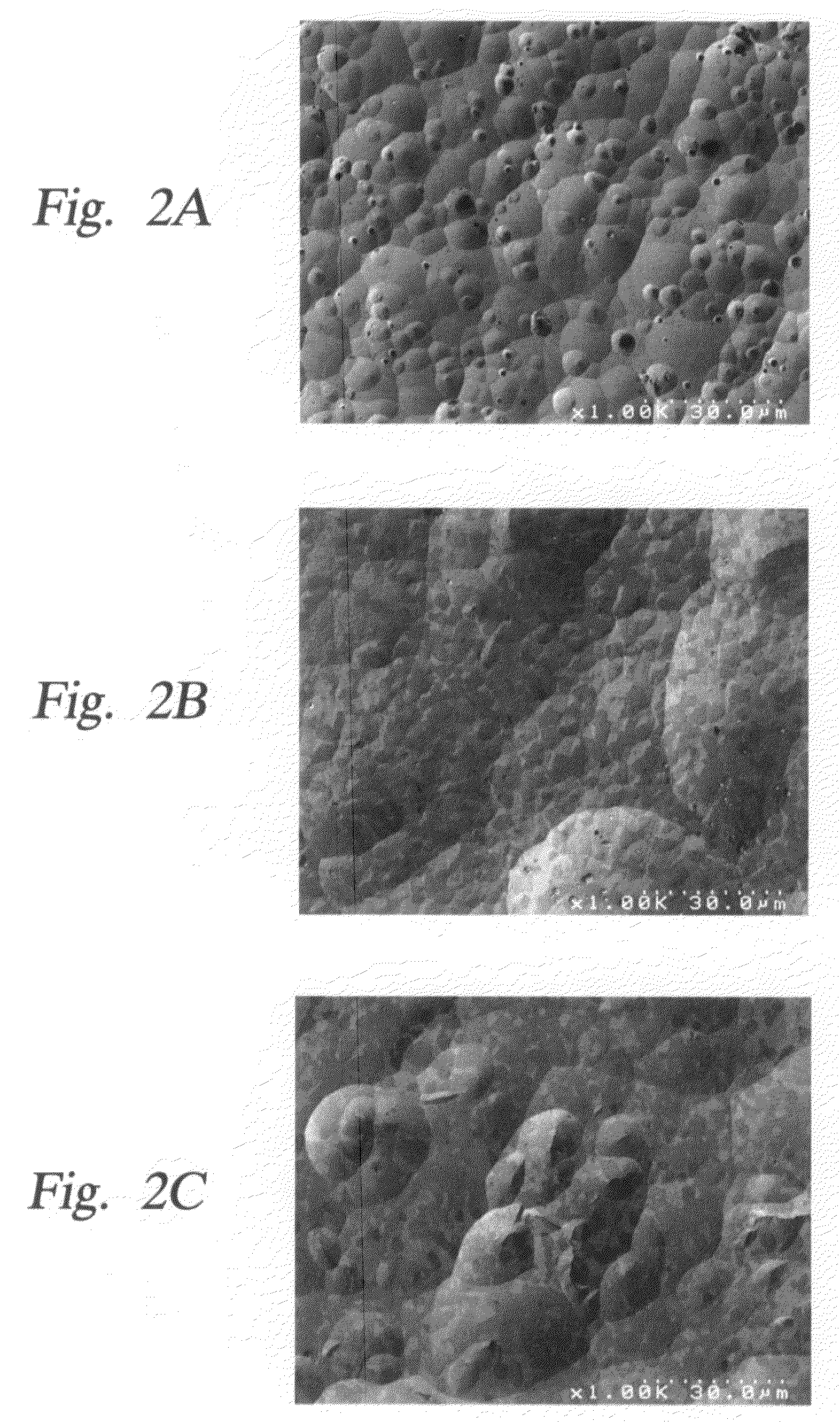

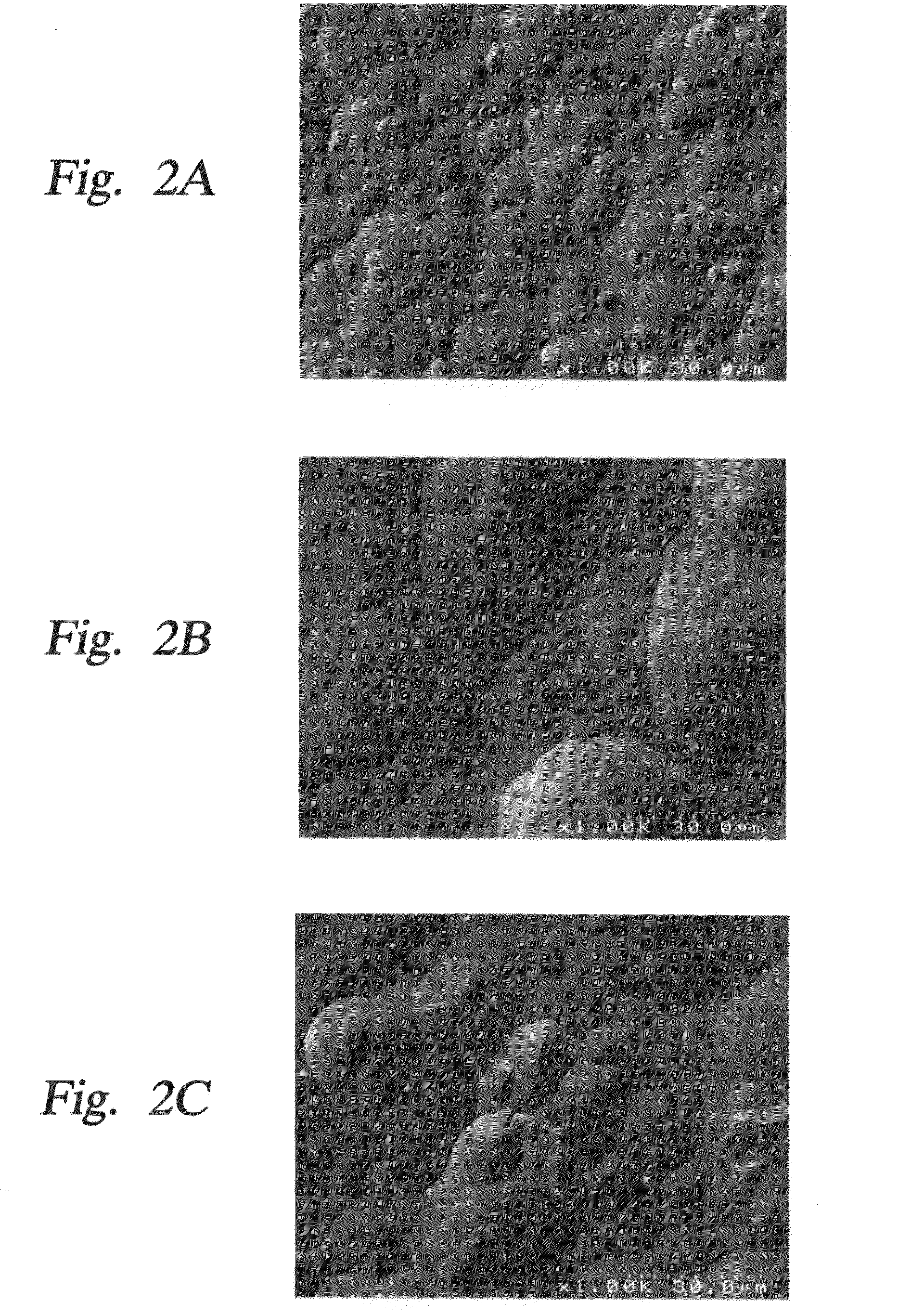

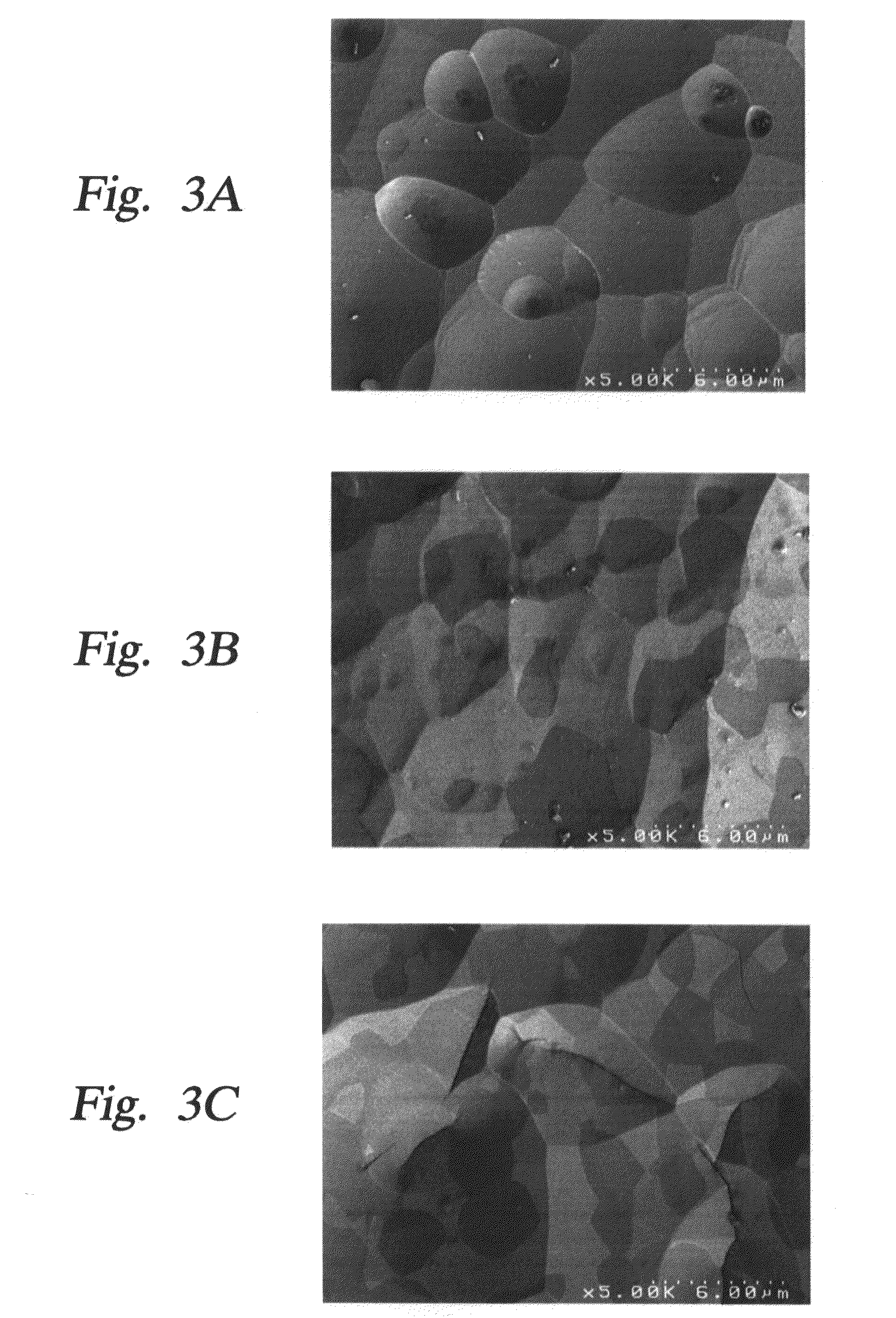

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises a cerium oxide containing ceramic material as an outermost surface of the component. The cerium oxide containing ceramic material comprises one or more cerium oxides as the single largest constituent thereof. The component can be made entirely of the cerium oxide containing ceramic material or, alternatively, the cerium oxide containing ceramic can be provided as a layer on a substrate such as aluminum or an aluminum alloy, a ceramic material, stainless steel, or a refractory metal. The cerium oxide containing ceramic layer can be provided as a coating by a technique such as plasma spraying. One or more intermediate layers may be provided between the component and the cerium oxide containing ceramic coating. To promote adhesion of the cerium oxide containing ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the cerium oxide containing ceramic coating.

Owner:LAM RES CORP

Stent formed from bioerodible metal-bioceramic composite

InactiveUS8998978B2Improve mechanical propertiesReduce erosion rateSurgeryBlood vesselsInsertion stentMetal matrix composite

Medical devices and methods of fabricating such medical devices, such as stents, formed at least in part from a metal matrix composite including bioceramic particles dispersed within an erodible metal are disclosed.

Owner:ABBOTT CARDIOVASCULAR

Stent formed from bioerodible metal-bioceramic composite

InactiveUS20090088834A1Improve mechanical propertiesReduce erosion rateStentsSurgeryCeramic compositeInsertion stent

Medical devices and methods of fabricating such medical devices, such as stents, formed at least in part from a metal matrix composite including bioceramic particles dispersed within an erodible metal are disclosed.

Owner:ABBOTT CARDIOVASCULAR

Pre-chamber spark plug

ActiveUS7922551B2Life maximizationReduce erosionSpark gap detailsInternal combustion piston enginesElectricityElectrode erosion

A method and apparatus to maximize spark plug life in pre-chamber spark plugs operating with ultra-lean mixtures and / or elevated engine BMEP is presented. Electrode erosion is reduced by spreading discharge energy over a wider surface area, maintaining fuel concentration in the spark gap, controlling gas static pressure during discharge, and maintaining safe electrode temperature. Energy is spread via a swirling effect created by periphery holes in an end cap, resulting in a lower specific energy discharge at the electrodes. Divergently configured electrodes reduce the spark voltage at high operating pressures and the energy required for ignition. The flow field generated at the electrodes prevents electrical shorts due to water condensation and avoids misfire. The center electrode insulation provides an effective heat transfer path to prevent electrode overheating and pre-ignition. The volume behind the electrodes provides a volume for burnt products from previous combustion cycles and leads to more reliable ignition.

Owner:WOODWARD GOVERNOR CO

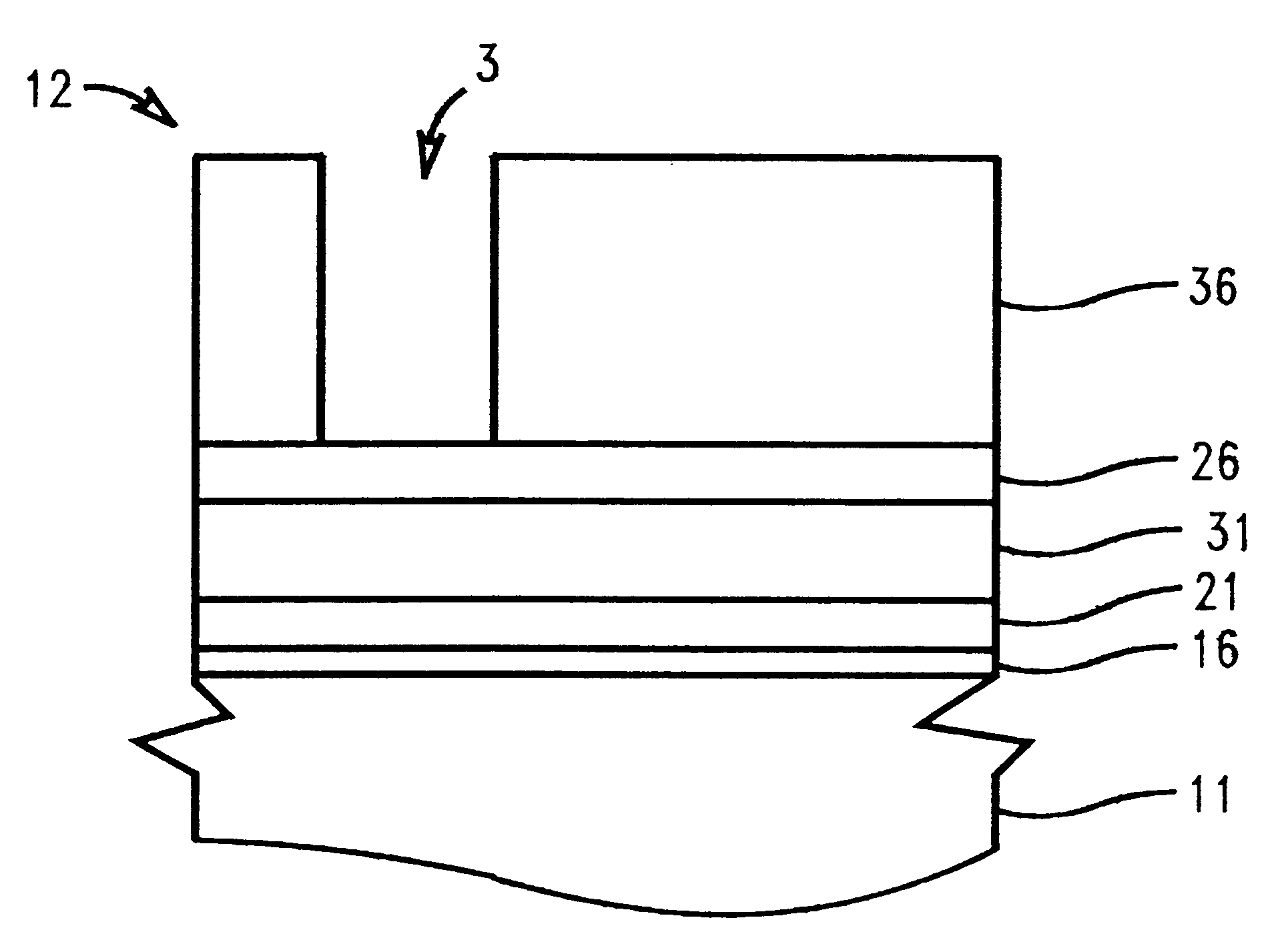

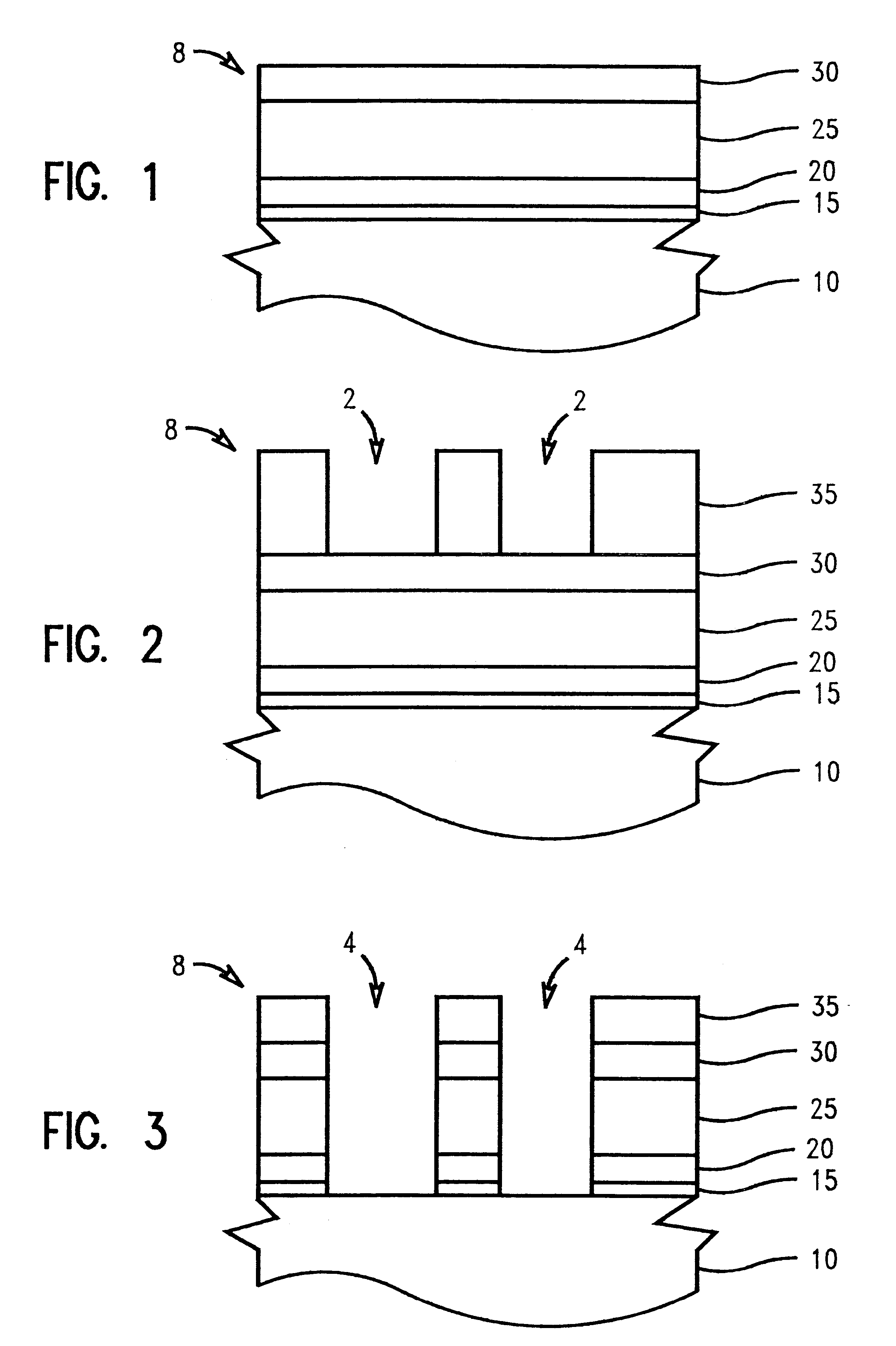

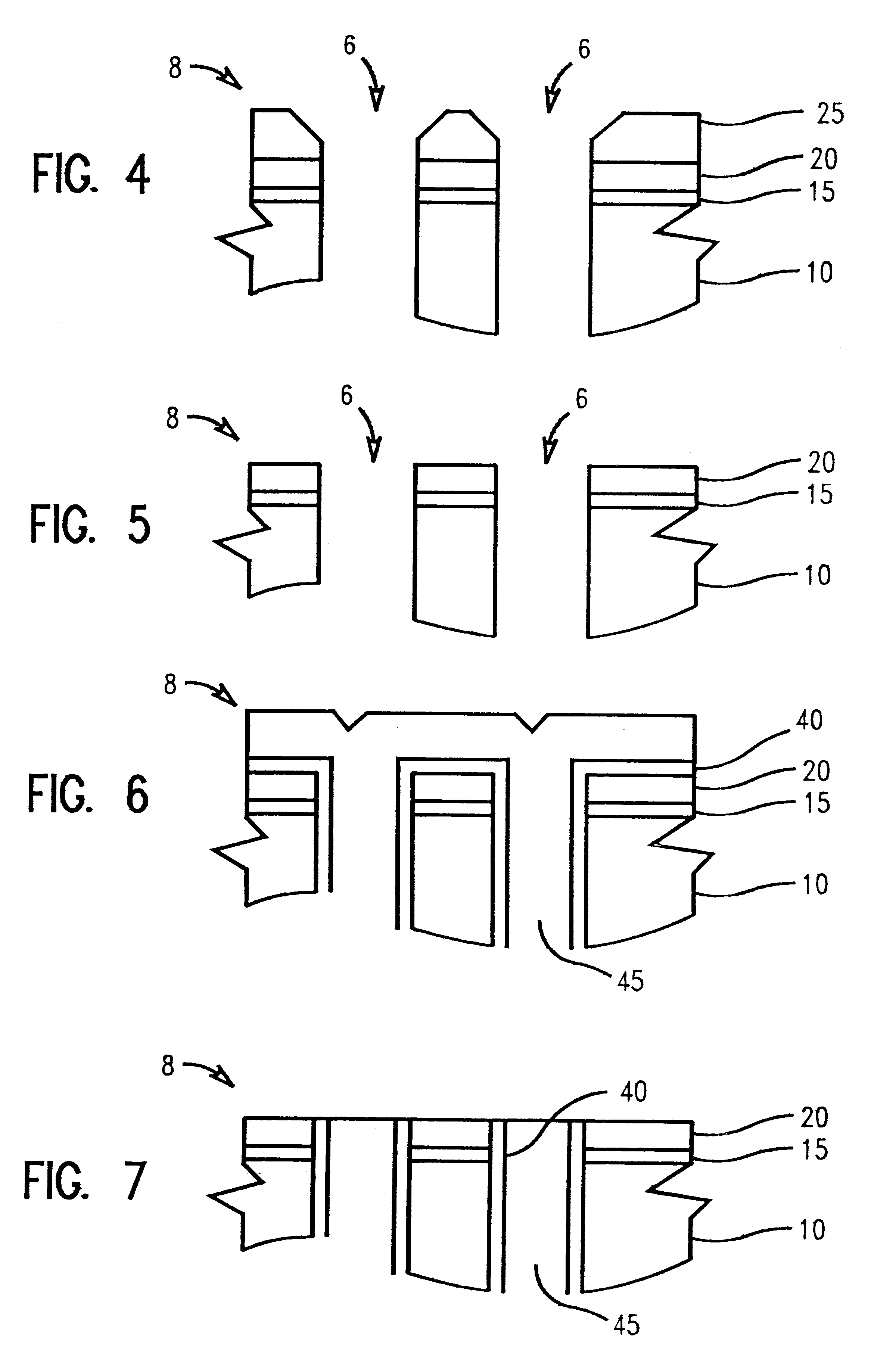

Multi-layer hard mask for deep trench silicon etch

InactiveUS6440858B1Minimize moisture sensitivityEnhanced vapor depositionSolid-state devicesSemiconductor/solid-state device manufacturingDielectricBi layer

A method of etching multiple films with a dual layer hard mask wherein one layer is totally removed and the other layer partially removed during deep trench etching of the silicon substrate. In particular, a method of deep trench etching silicon substrates comprising the steps of providing a semiconductor substrate capable of being etched, with HBr / NF3 / He / O2, having a layer of pad dielectric disposed depositing a layer of material capable of selective removability with respect to the pad dielectric, preferably BSG; depositing a layer of material having a slower etch rate than the semiconductor substrate and the layer of material capable of selective removability with respect to the pad dielectric, preferably, silicon oxide deposited by PECVD; patterning at least one of the layers, and etching the semiconductor substrate to form a trench and removing the layer of material having a slower etch rate than the semiconductor substrate, wherein trenches are of close proximity to each other.

Owner:IBM CORP

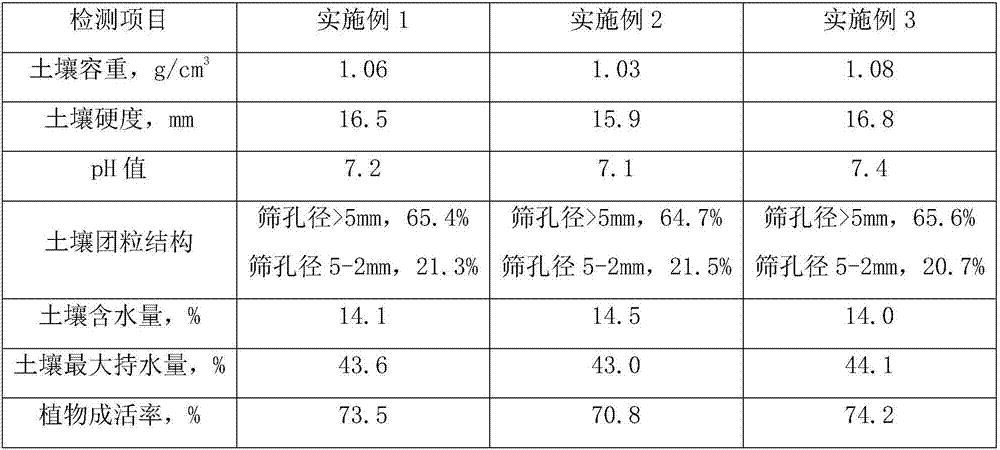

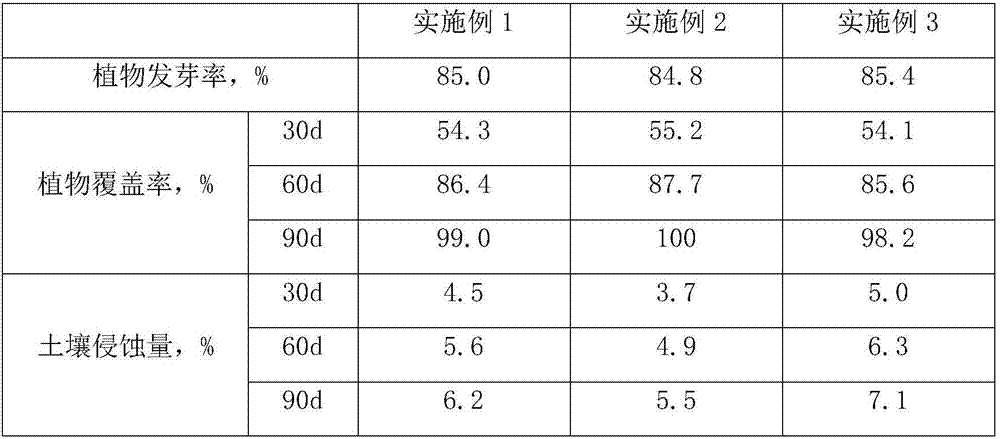

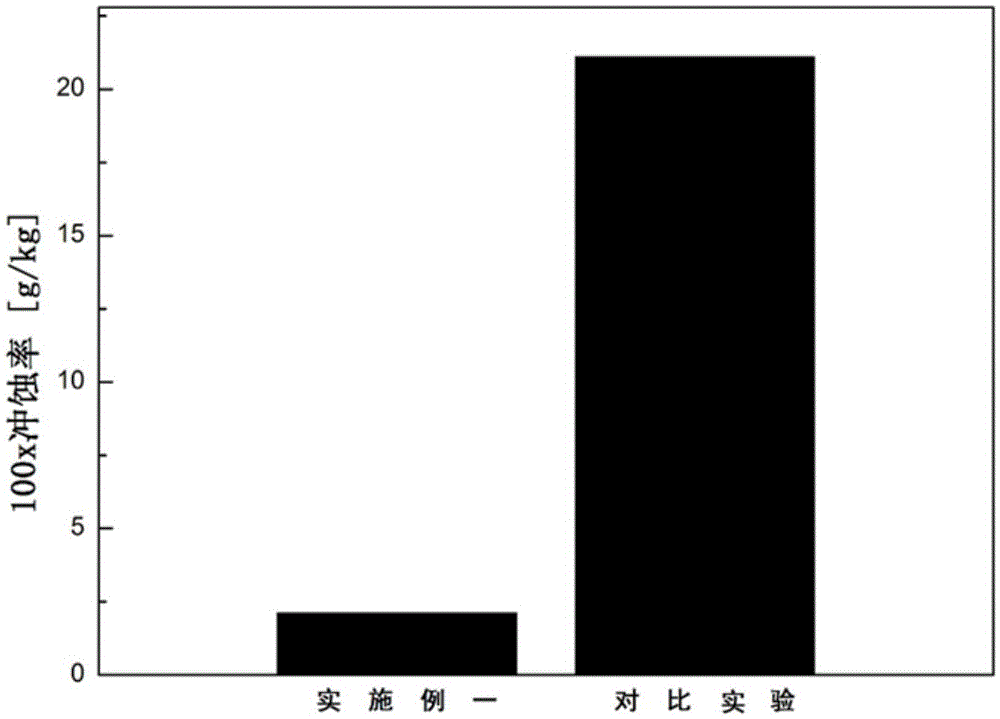

Borrowed soil spraying and seeding base material and road side slope ecological protection constructing method

ActiveCN107268645AIncrease resistanceReduce erosion rateExcavationsCultivating equipmentsFiberLoss rate

The invention relates to a borrowed soil spraying and seeding base material and a road side slope ecological protection constructing method. The borrowed soil spraying and seeding base material comprises a slope face base material and a plant-growing base material. The slope face base material comprises water and the following constituents of, by weight, 100 parts of planting soil, 90-110 parts of plant fiber, 1.0-1.5 parts of papermaking black liquid concentrated modified fluid, and 2.0-4.0 parts of organic fertilizer; and the plant-growing base material comprises water, plant seeds and the following constituents of, by weight, 50 parts of planting soil, 50 parts of peat soil, 45-55 parts of plant fiber, 0.5-0.8 part of papermaking black liquid concentrated modified fluid, and 1.0-2.0 parts of organic fertilizer. The borrowed soil spreading and seeding base material has the suitable granular structure, porosity and pH value and long-lasting water keeping and holding ability, suitable and stable environment and fertilizing effects are provided for growing of side slope plants, and slope face attachment is firm, the loss rate is low, hardening does not occur after long term use, and the borrowed soil is suitable for ecological protecting of the road side slope stone or hard soil slope face.

Owner:陕西省三和建设工程有限公司

Bulk sintered solid solution ceramic which exhibits fracture toughness and halogen plasma resistance

ActiveUS20170110293A1Excellent plasma resistanceGood erosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingCeramicMolar concentration

A bulk, sintered solid solution-comprising ceramic article useful in semiconductor processing, which is resistant to erosion by halogen-containing plasmas and provides advantageous mechanical properties. The solid solution-comprising ceramic article is formed from a combination of yttrium oxide and zirconium oxide. The bulk, sintered solid solution-comprising article is formed from zirconium oxide at a molar concentration ranging from about 96 mole % to about 94 mole %, and yttrium oxide at a molar concentration ranging from about 4 mole % to about 6 mole %.

Owner:APPLIED MATERIALS INC

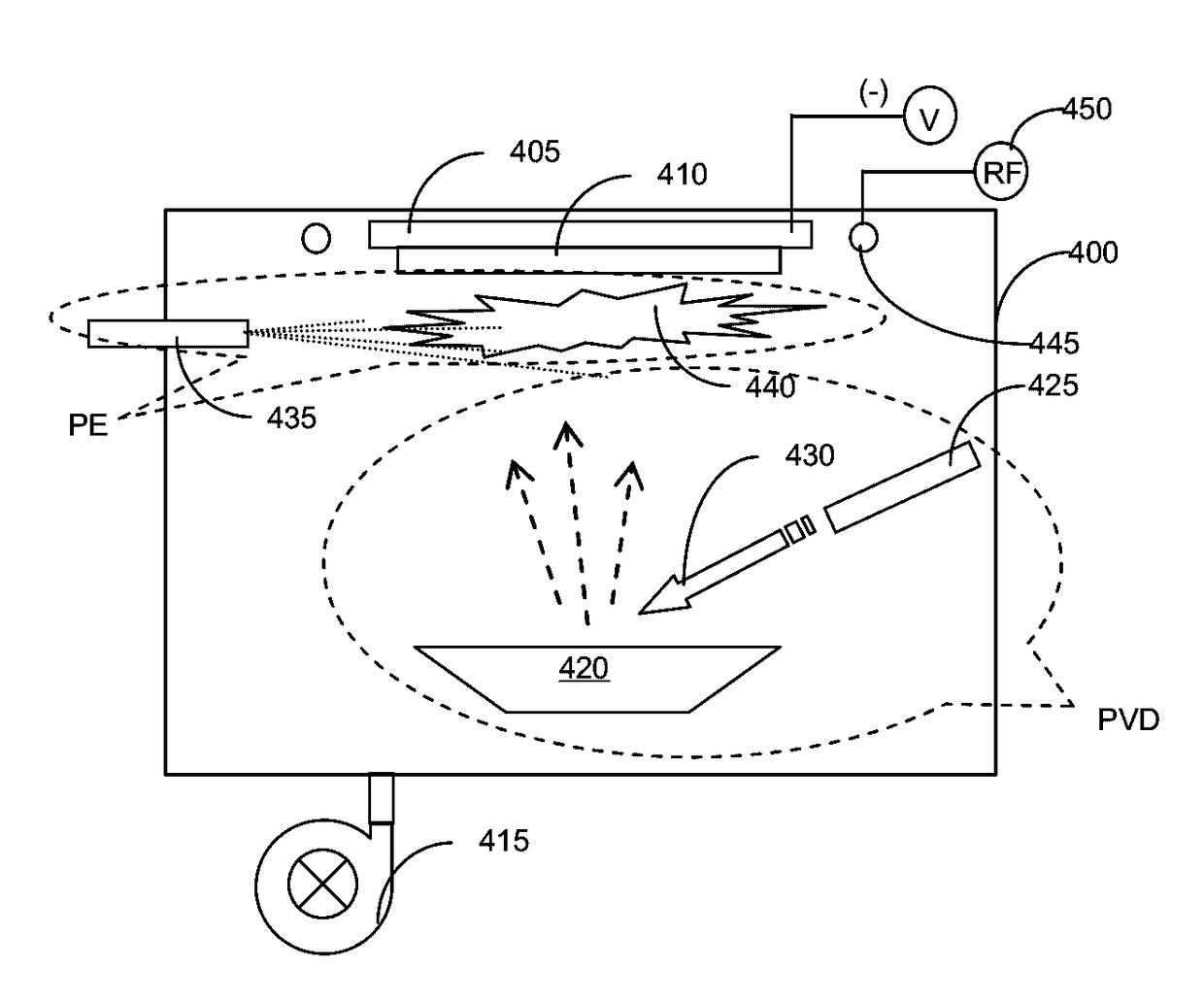

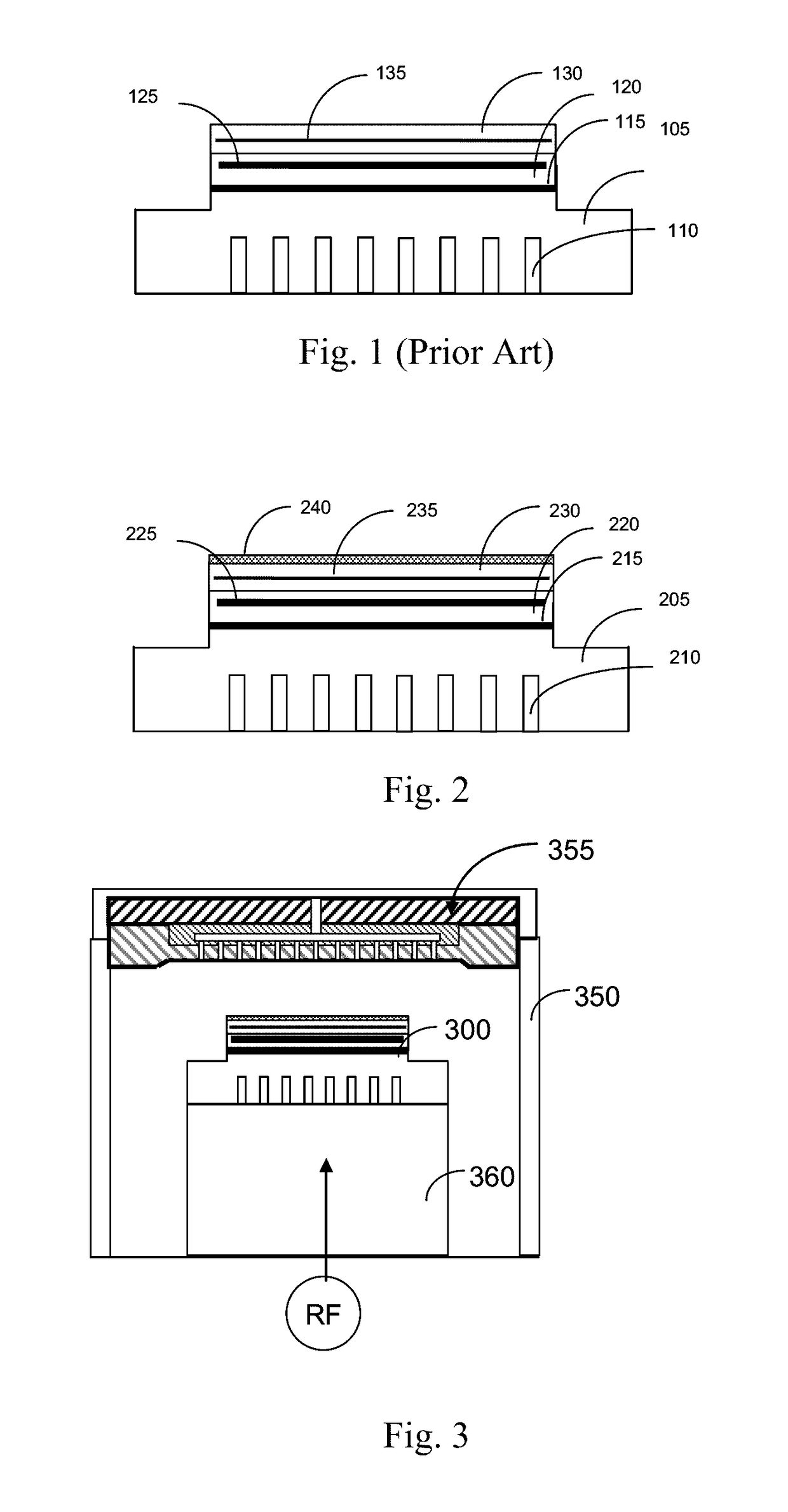

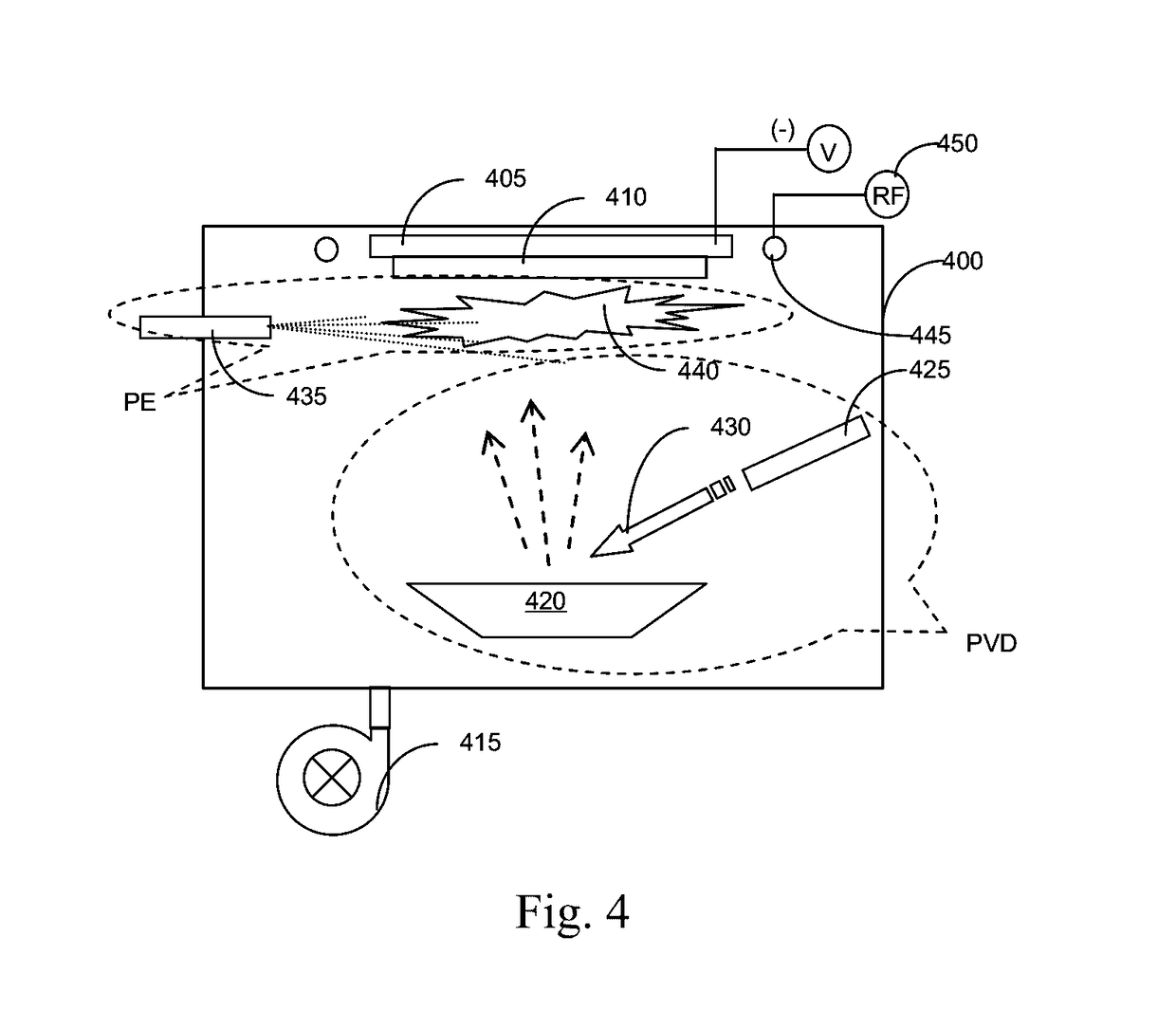

Performance enhancement of coating packaged ESC for semiconductor apparatus

ActiveUS9633884B2Improve service performanceImprove processing qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingPerformance enhancementGas phase

An advanced coating for electrostatic chuck used in plasma processing chamber is provided. The advanced coating is formed using plasma enhanced physical vapor deposition. The coating is generally of Y2O3 / Al2O3, although other material combinations can be used. Also, a multi-layered coating can be formed, such that an intermediate coating layer can be formed using standard plasma spray, and a top coating can be formed using PEPVD. The entire ESC assembly can be “packaged” by the coating.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

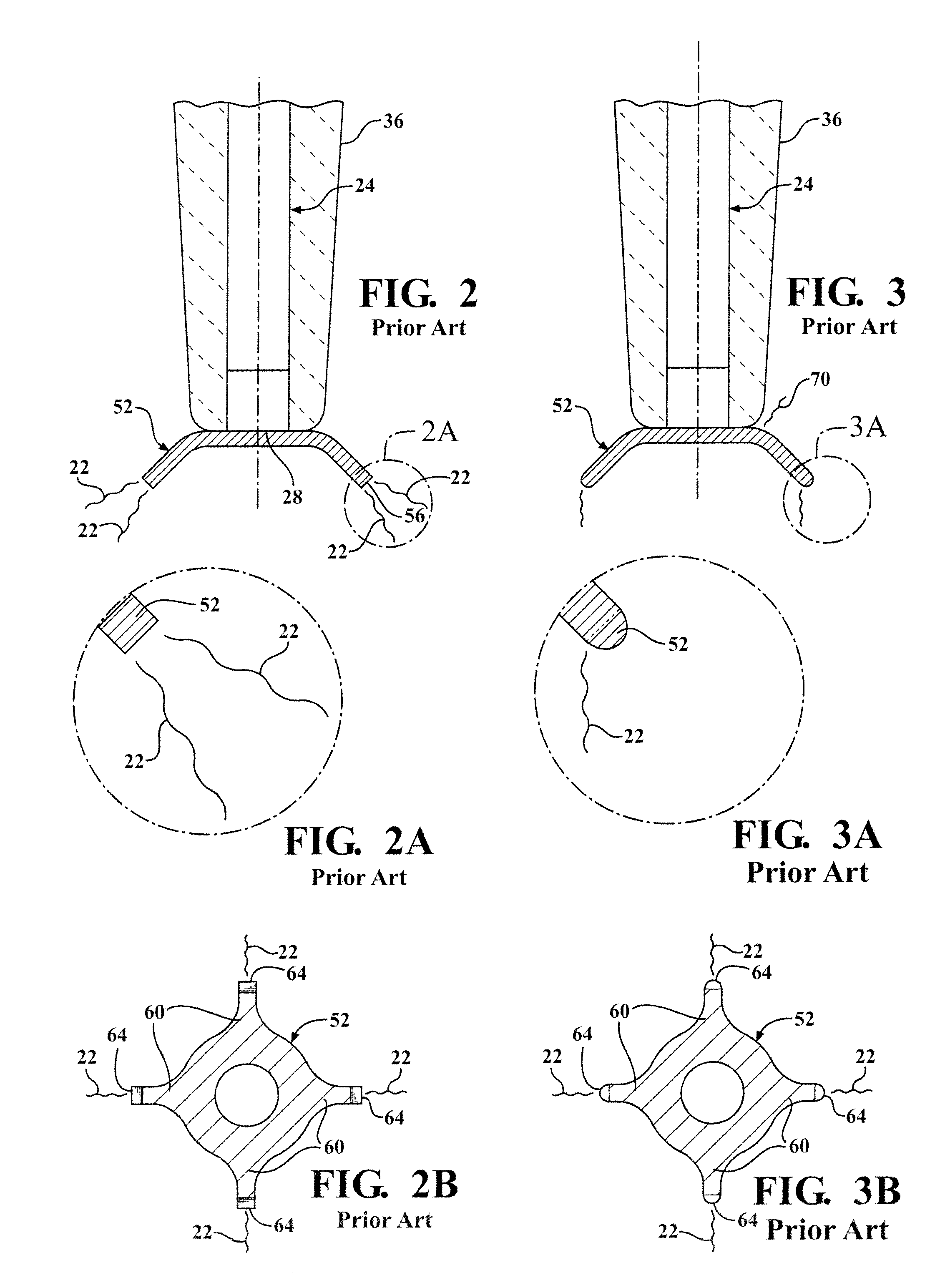

Igniter including a corona enhancing electrode tip

ActiveUS20110247579A1Reduce erosion rateStrong electrical fieldWave amplification devicesAnti-theft devicesElectrical field strengthPrecious metal

An igniter (20) emitting an electrical field including a plurality of streamers forming a corona includes a corona enhancing tip (52) at an electrode firing end (28). The corona enhancing tip (52) includes an emitting member (58) such as a wire, layer, or sintered mass, formed of a precious metal and disposed on a base member (54). The base member (54) is formed of a nickel alloy. The emitting member (58) has a lower electrical erosion rate and chemical corrosion rate than the base member (54). The emitting member (58) presents the smallest spherical radius of the corona enhancing tip (52) at the outermost radial point (56) to concentrate the electrical field emissions and provide a consistently strong electrical field strength over time.

Owner:FEDERAL MOGUL IGNITION

Semiconductor processing apparatus with a ceramic-comprising surface which exhibits fracture toughness and halogen plasma resistance

ActiveUS20150143677A1Improve plasma resistanceImprove corrosion resistanceSemiconductor/solid-state device manufacturingYttriumCeramic coating

A solid solution-comprising ceramic article useful in semiconductor processing, which article may be in the form of a solid, bulk ceramic, or may be in the form of a substrate having a ceramic coating of the same composition as the bulk ceramic material on at least one outer surface. The ceramic article is resistant to erosion by halogen-containing plasmas and provides advantageous mechanical properties. The solid solution-comprising ceramic article is formed from a combination of yttrium oxide and zirconium oxide. The ceramic-comprising article includes ceramic which is formed from zirconium oxide at a molar concentration ranging from about 96 mole % to about 91 mole %, and yttrium oxide at a molar concentration ranging from about 4 mole % to about 9 mole %.

Owner:APPLIED MATERIALS INC

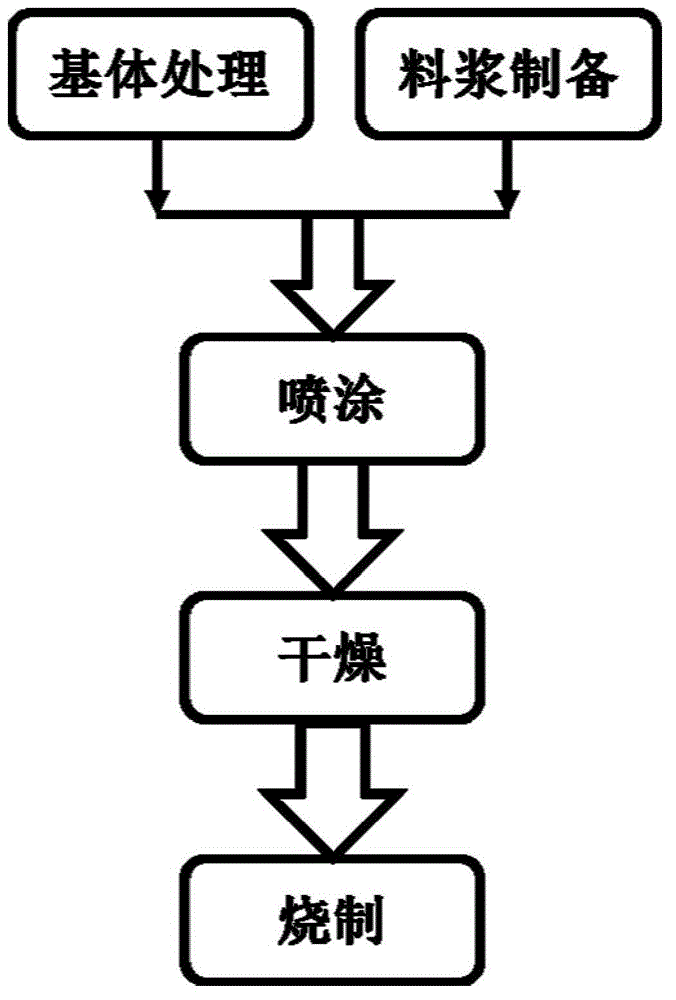

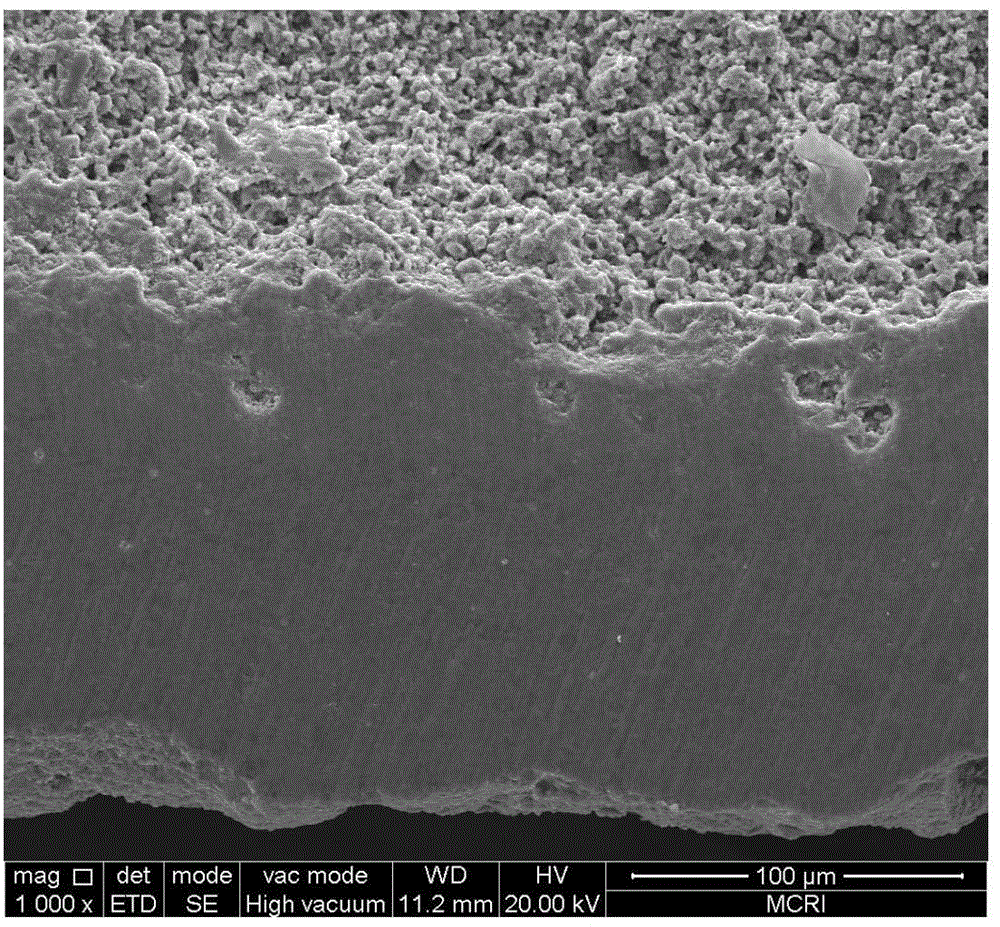

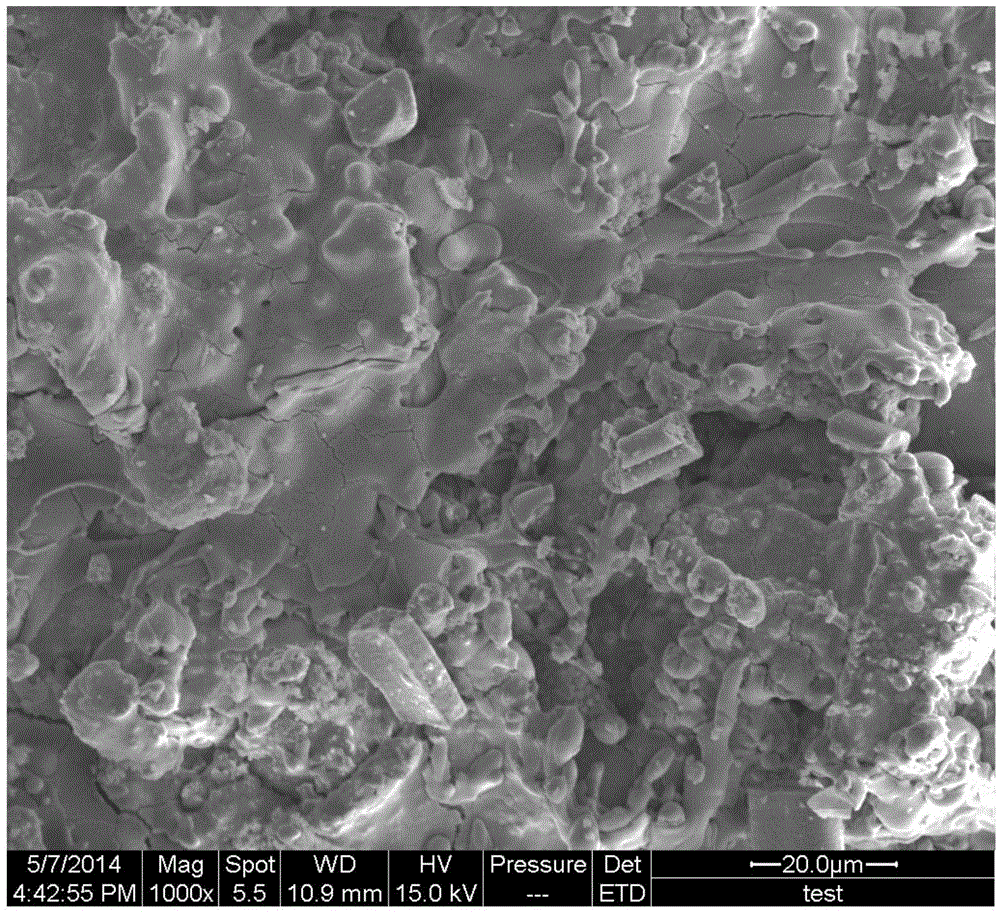

Method for preparing ceramic coating on surface of porous ceramic matrix by slurry spraying

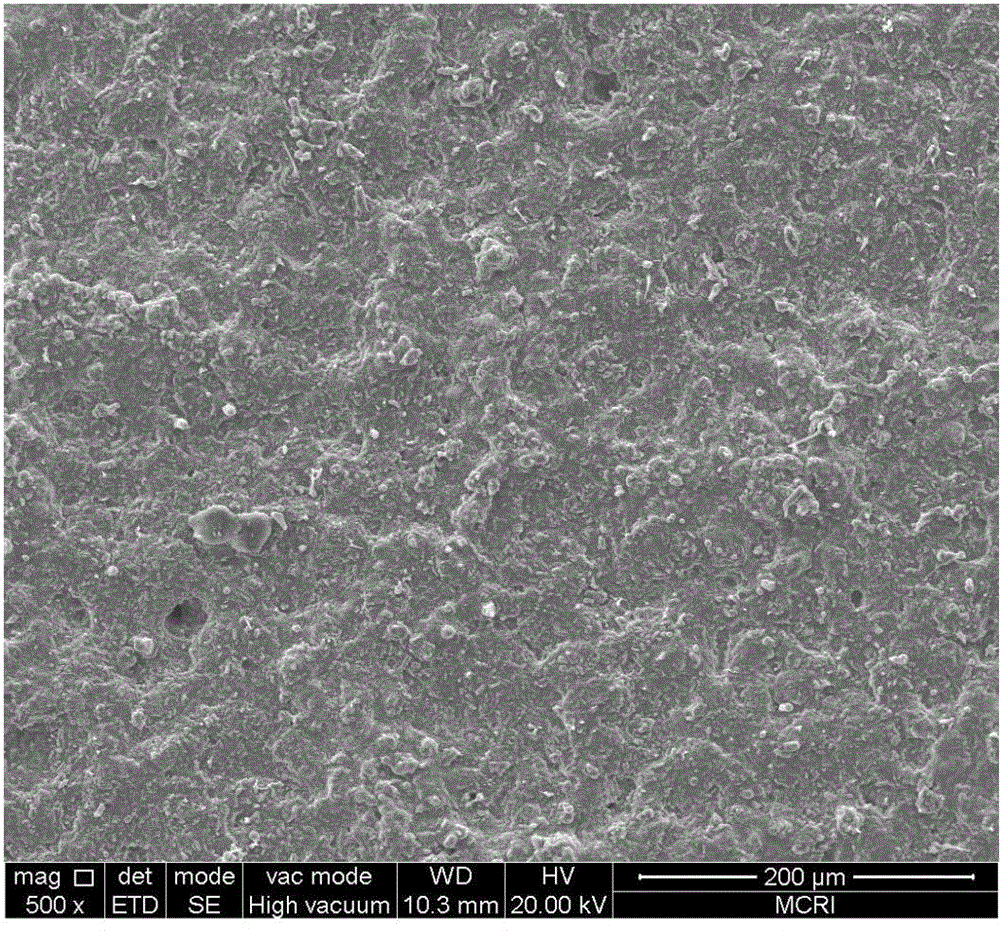

The invention discloses a method for preparing a ceramic coating on the surface of a porous ceramic matrix by slurry spraying. The method comprises the processes of matrix treatment, slurry preparation, spraying, drying, and sintering. The uniform coating samples can be obtained in batch by spraying slurry by an air atomization spray gun. The obtained coating after being sintered is uniform and compact, has good combination with the porous ceramic matrix, and has clear interface. The coating does not infiltrate to the porous matrix severely. The coating can significantly decrease water absorption of the porous ceramic matrix, increases surface hardness, and reduces erosion rate of the matrix. Compared with a conventional method, the method has the advantages of simple process, high production efficiency, low cost and the like, and is easy for large-scale production and industrialized application.

Owner:XI AN JIAOTONG UNIV

Method for maintaining converter

InactiveCN1796576AEffective maintenanceAvoid problems such as easy to block bottom blowing and ventilating componentsManufacturing convertersSlagNitrogen gas

This invention relates to a lining protection method for converter with detailed process as follows: investigate the circumstance of slag after tapping of converter and add some slag coordinating materials into high-temperature and high-oxidative slag so as to keep the MgO content in the slag above 8%; tilt the converter back and forth so as to enhance the fusion of the slag and make partial slag coherent to the converter wall; set the bottom blowing flux and split the quenched and tempered slag onto the wall surface by bottom blowing ventilating components; the control of bottom blowing flux can be modulated according to the lining corrosion and slag circumstances. In this invention, bottom blowing ventilating components are employed and nitrogen and argon are blowing for slag splitting and deposition. Therefore, the line slag, molten pool and ear-axis areas, which are usually corroded most seriously, can be effectively protected. Difficult issues such as sticking lances and burning lances of oxygen lances and bottom rising in the lining protection process of top blowing slag splitting and flow blockage of bottom blowing ventilating components in top and bottom blowing converter are completely avoided. Besides, it also significantly weakens the corrosion of feeble sites of lining and displays considerable lining protection effect.

Owner:SHANGHAI NO 1 IRON & STEEL CO LTD BAOGANG GRP

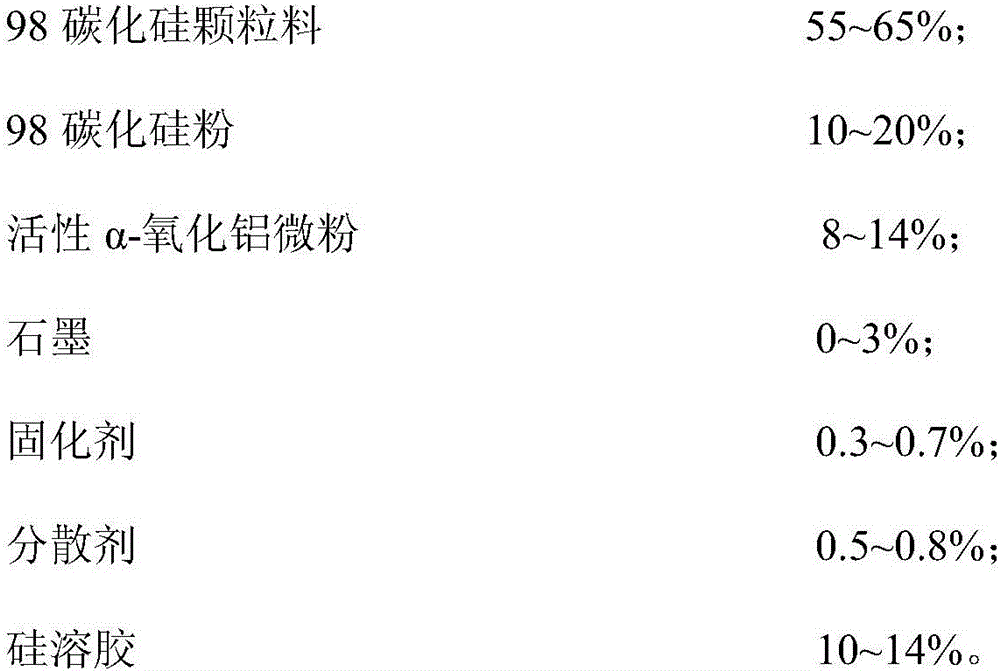

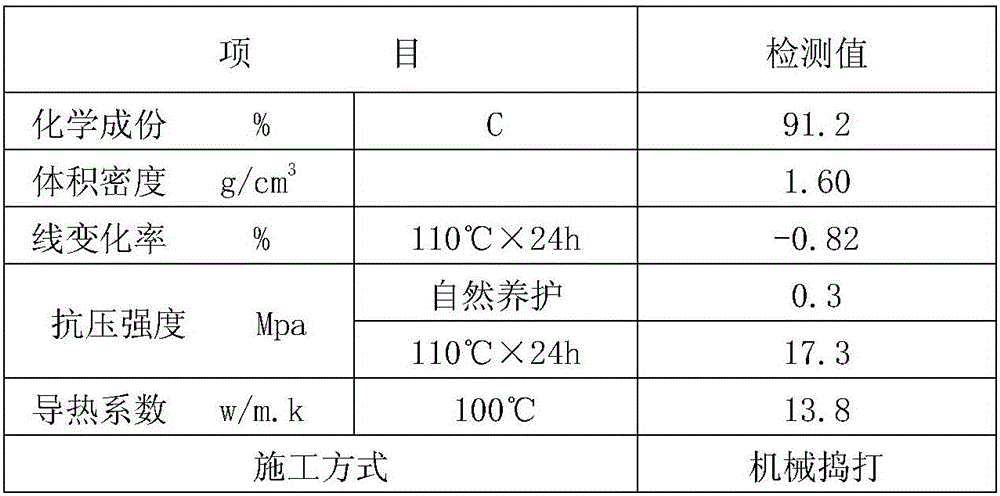

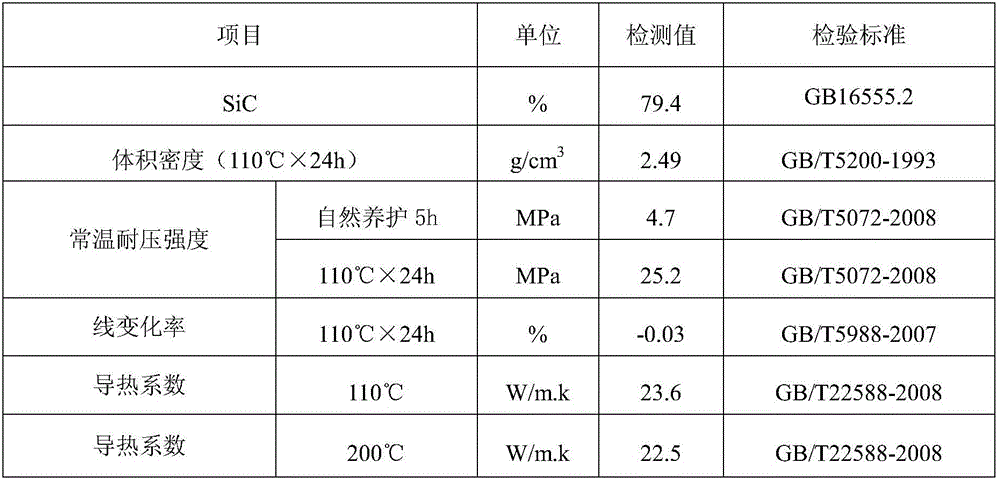

High thermal conductivity silicon carbide grouting material combined with sol used for bottom leveling of blast furnace

This invention belongs to refractory material field. It is concerned with a kind of high thermal conductivity silicon carbide grouting material combined with sol used for bottom leveling of blast furnace. The raw material component proportion of high thermal conductivity silicon carbide grouting material combined with sol is that 55-65% of 98 silicon carbide particle,10-20% of 98 silicon carbide powder, active a The invention discloses a novel coating material to be applied at the bottom of blast furnace with ingredients as follow: 8 to 14 percent of alumina powder, 0 to 3 percent of graphite, , 0.3 to 0.7 percent of curing agent, 0.5 to 0.8 percent of dispersing agent, and 10 to 14 percent of silica solution. The high-thermal conductivity silicon carbide pouring material described in this invention is easy to be constructed with short construction period, high thermal conductivity, high flatness, and long volume stability. Also the novel coating material is difficult to deform with strong anti-corrosion ability and without environment pollution, which is a novel coating material to be applied at the bottom of blast furnace.

Owner:中冶武汉冶金建筑研究院有限公司

Preparation method of thermal barrier coating of lanthanum zirconate fiber doped lanthanum zirconate

ActiveCN105483597AReduce erosion rateStrong erosion resistanceMolten spray coatingEfficient propulsion technologiesFiberWear resistance

The invention discloses a preparation method of a thermal barrier coating of lanthanum zirconate fiber doped lanthanum zirconate, and relates to a preparation method of a thermal barrier coating. The technical problems that a novel lanthanum zirconate thermal carrier coating is poor in erosive wear resistance and is likely to lose efficacy when impacted by external particles are solved. The preparation method comprises the steps that a composite lanthanum zirconate ceramic layer spraying powder material is prepared; a bonding layer spraying material is sprayed to the surface of preprocessed matrix metal; a layer of composite lanthanum zirconate ceramic layer spraying material is sprayed to a bonding layer. Compared with a traditional thermal barrier coating which is not reinforced by fiber, the erosive wear resistance of the thermal barrier coating system is higher. The preparation method is applied to the field of composite materials.

Owner:HARBIN ENG UNIV

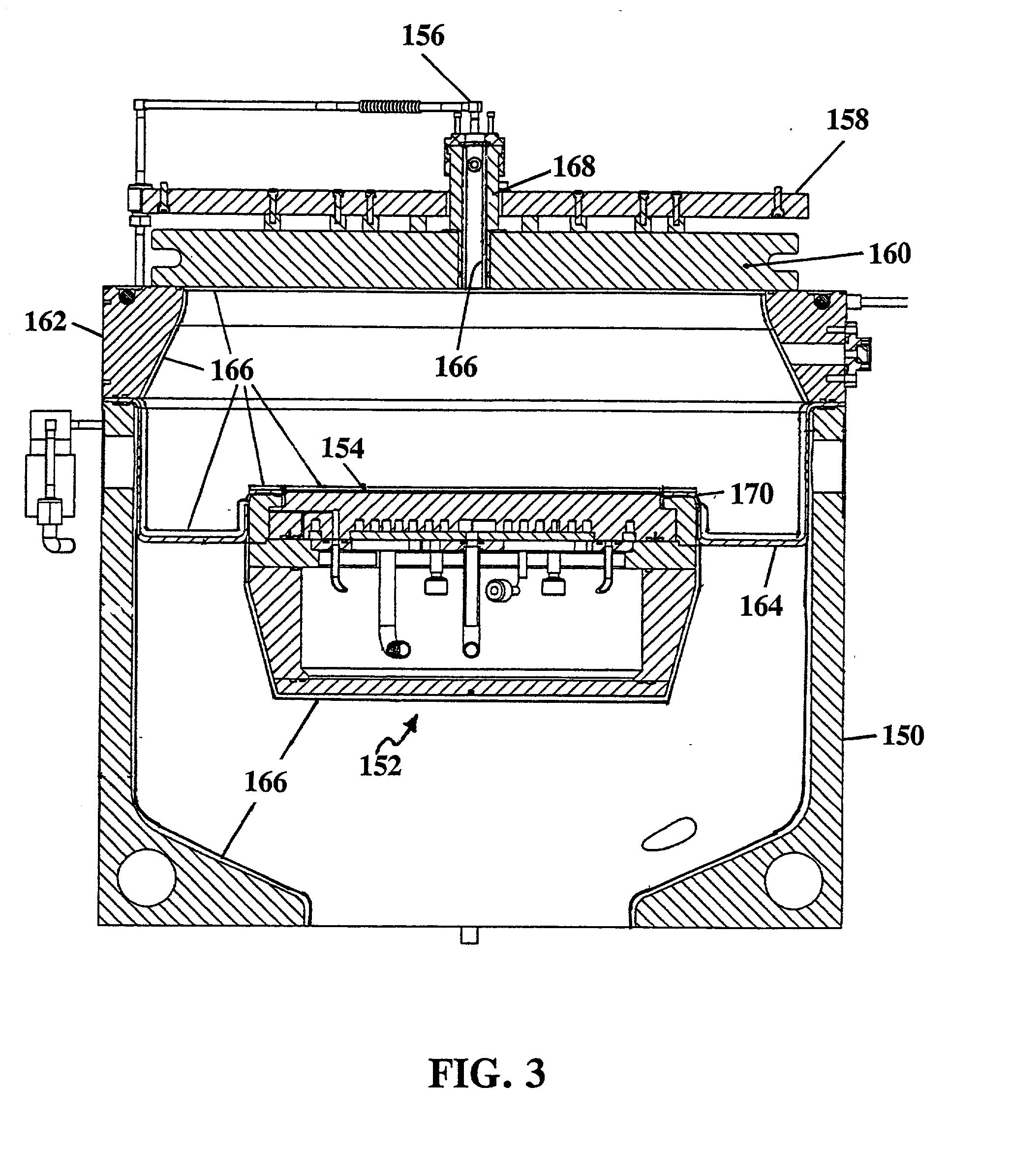

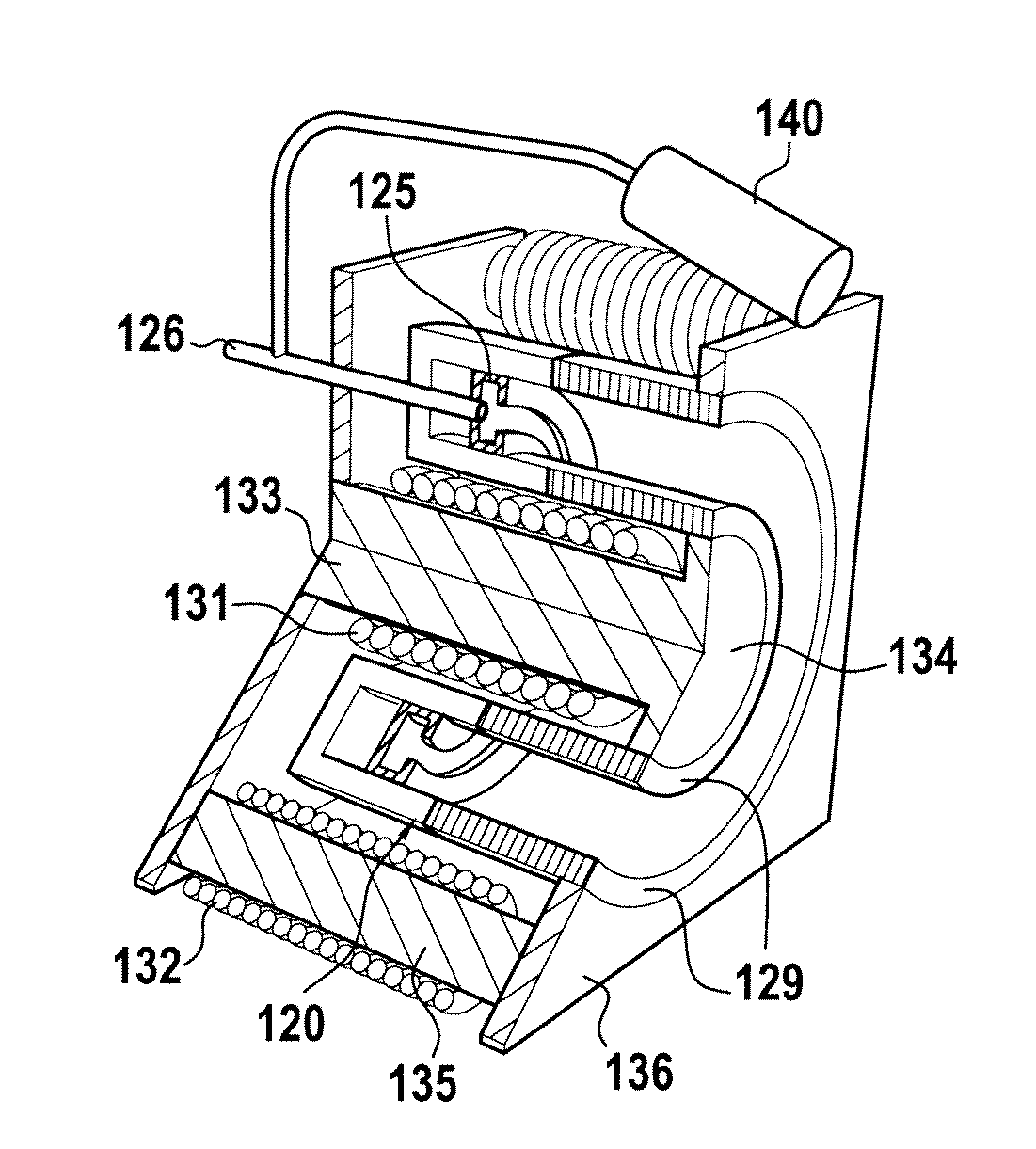

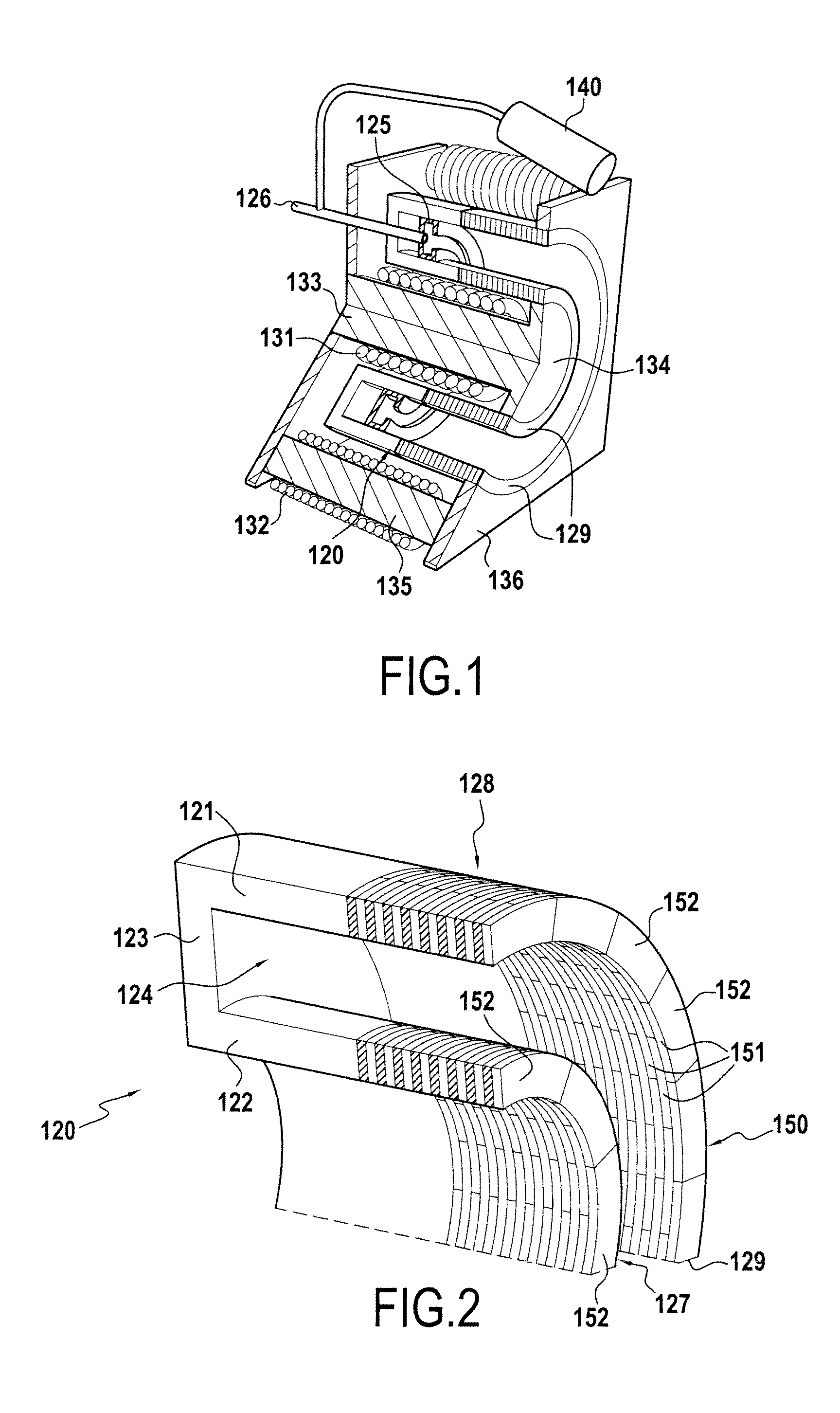

Hall effect plasma thruster

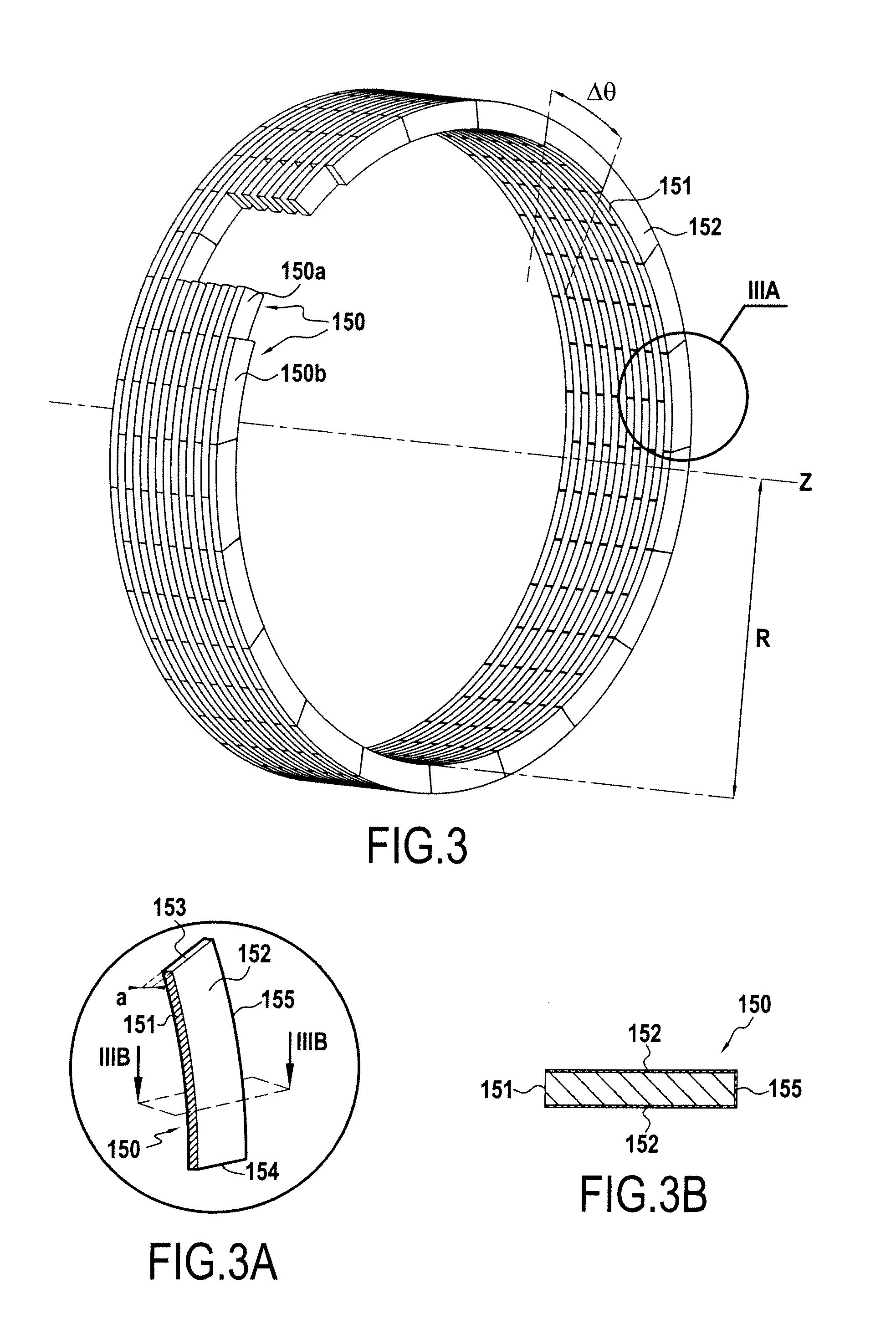

ActiveUS20120117938A1Extended service lifeImprove energy efficiencyMachines/enginesIon beam tubesIonizationAcceleration Unit

The Hall effect plasma thruster comprises a main annular channel (120) for ionization and acceleration that presents an open downstream end (129), at least one cathode, an annular anode concentric with the main annular channel (120), a pipe and a manifold for feeding the channel (120) with ionizable gas, and a magnetic circuit for creating a magnetic field in said main annular channel (120). The main annular channel (120) comprises inner and outer annular wall portions (127,128) situated in the vicinity of said open end (129), each of which comprises an assembly of juxtaposed conductive or semi-conductive rings (150) in the form of laminations separated by fine layers of insulation (152).

Owner:INST OF FUNDAMENTAL TECHNOLOGICAL RES POLISH ACAD OF SCI +3

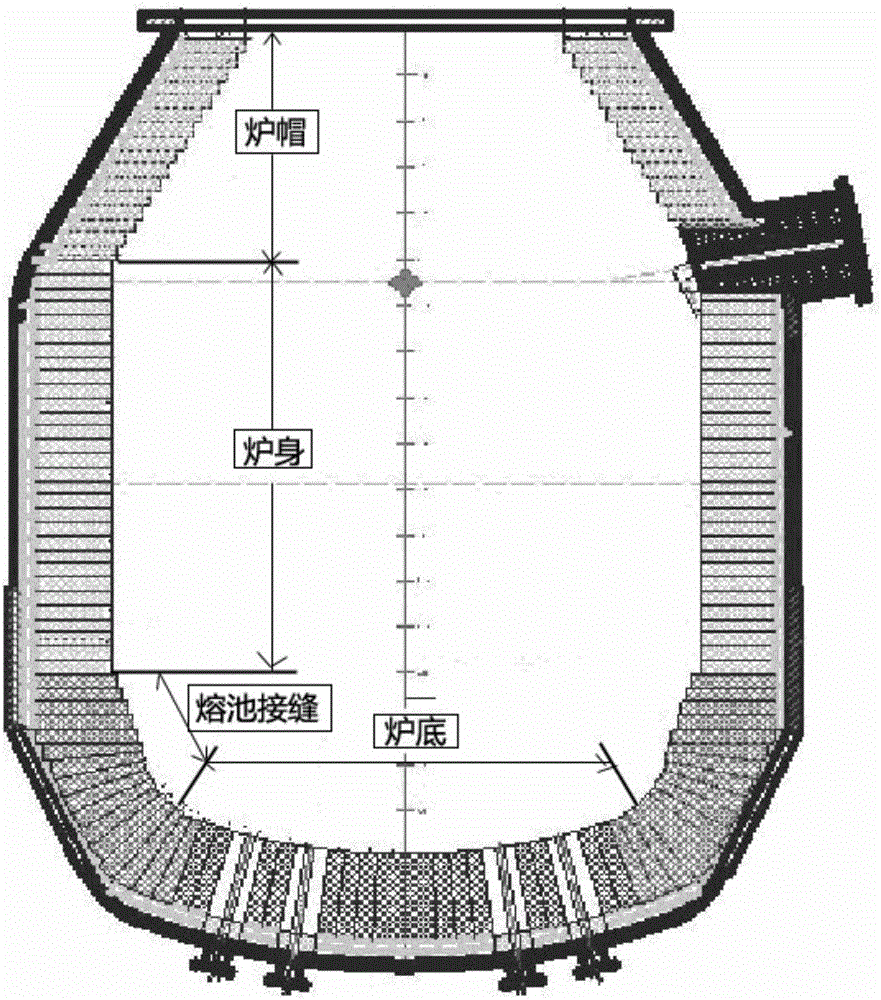

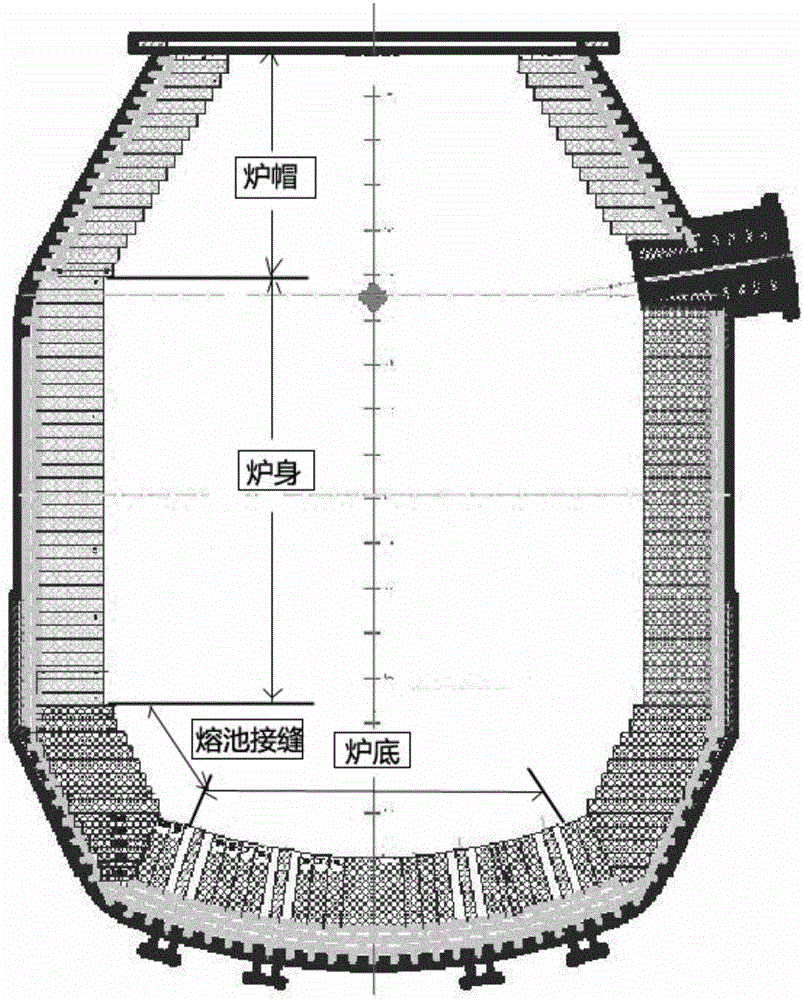

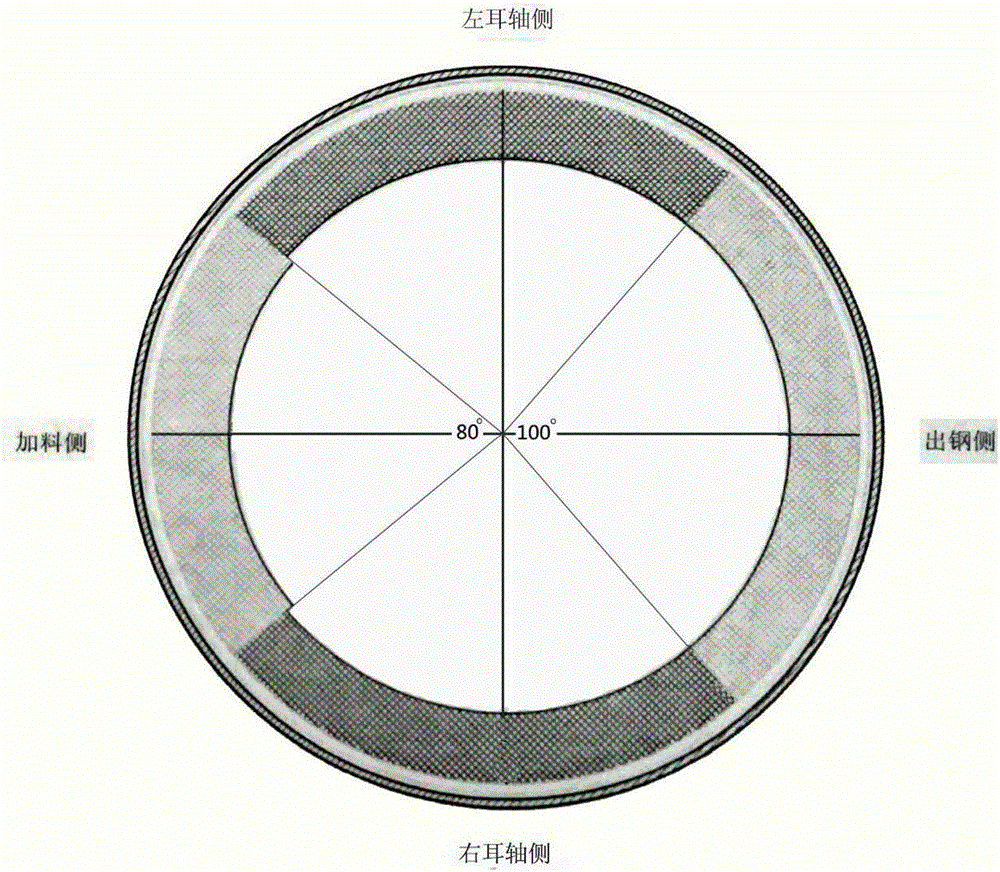

Mammoth converter lining and construction method thereof

InactiveCN106282480AIncreasing the thicknessUniform strengthManufacturing convertersBrickEngineering

The invention discloses a mammoth converter lining and a construction method thereof. The mammoth converter lining comprises a converter bottom part, a melting bath joint seam part, a converter body part and a converter cap part, wherein the converter bottom part, the melting bath joint seam part, the converter body part and the converter cap part comprise permanent layers, middle padding layers and working layers; the working layer at the melting bath joint seam part on a left lug shaft side and a right lug shaft side is manufactured from MT-18A marked magnesium carbon bricks; and the MT-18A marked magnesium carbon bricks have same length and are constructed into an arc-shaped transitional surface with a smooth inner side. A wedge brick is embedded into a seal part of the converter cap and a ramming material completely fills the seal part. The method comprises the following steps of: step 1) setting a lining brick construction sequence; step 2) constructing all the bricks according to a preset construction sequence during a construction sequence; step 3) measuring the inclination angle of the upper plane of the lining bricks after one layer is constructed so as to ensure that the inclination angles of all the parts are same; 4) measuring the lining brick levelness after the last layer of the arc-shaped transitional surface part is constructed; and 5) performing full-process monitoring during the construction process, and baking the converter after achieving acceptance.

Owner:SHANDONG IRON & STEEL CO LTD

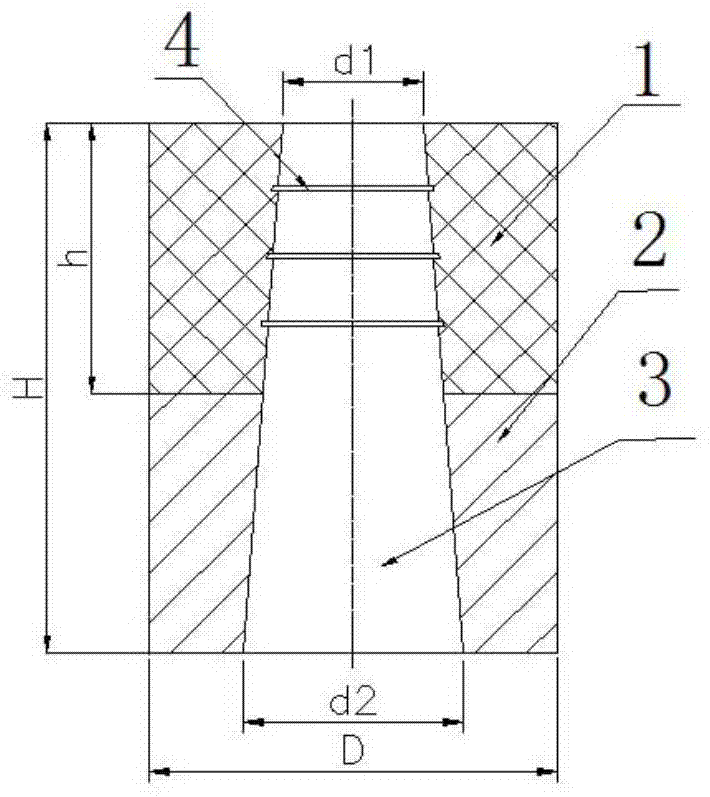

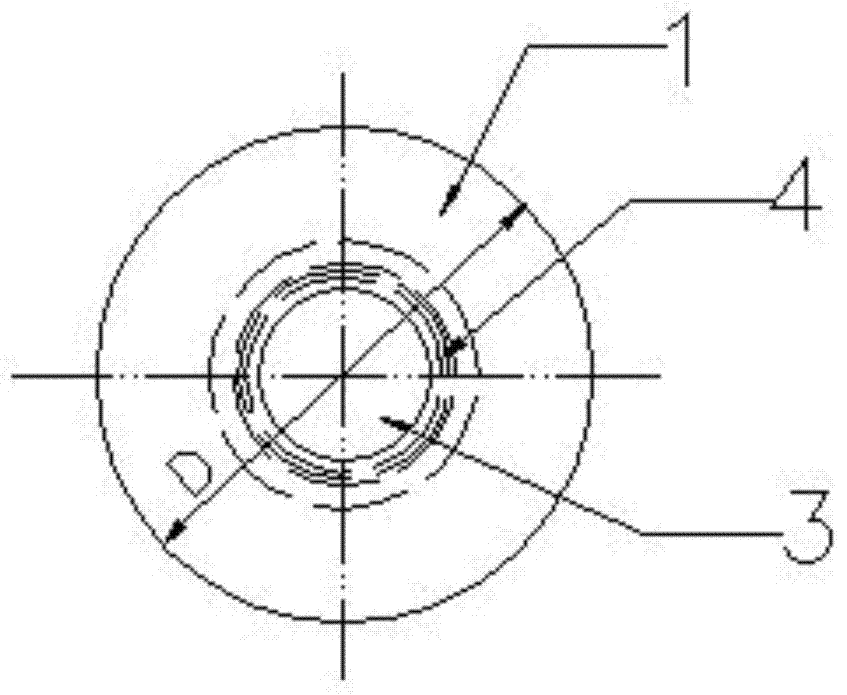

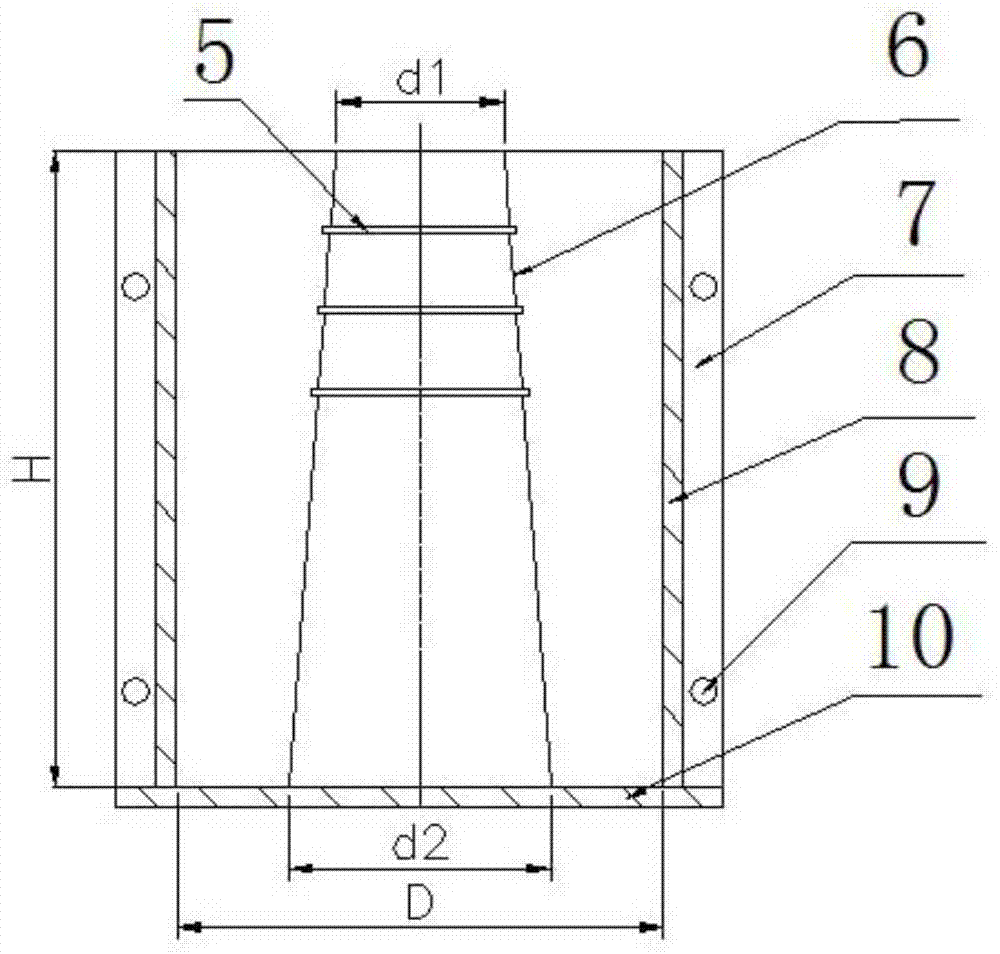

Composite long-life low-cost steel ladle air brick base brick and manufacturing method thereof

The invention relates to a composite long-life low-cost steel ladle air brick base brick. The composite long-life low-cost steel ladle air brick base brick comprises a base brick body, the base brick body comprises an upper body and a lower body which are molded by once casting of different cast materials. The upper body is 260 to 300 mm high, and the inner wall of the upper body is circumferentially provided with grooves uniformly distributed along the height direction. By the composite long-life low-cost steel ladle air brick base brick, cost performance is superior to that of an existing composite air brick base brick, corrosion speed is lower to more than 0.5 mm per furnace year on year, and service life is prolonged by more than ten times.

Owner:SHANDONG IRON & STEEL CO LTD

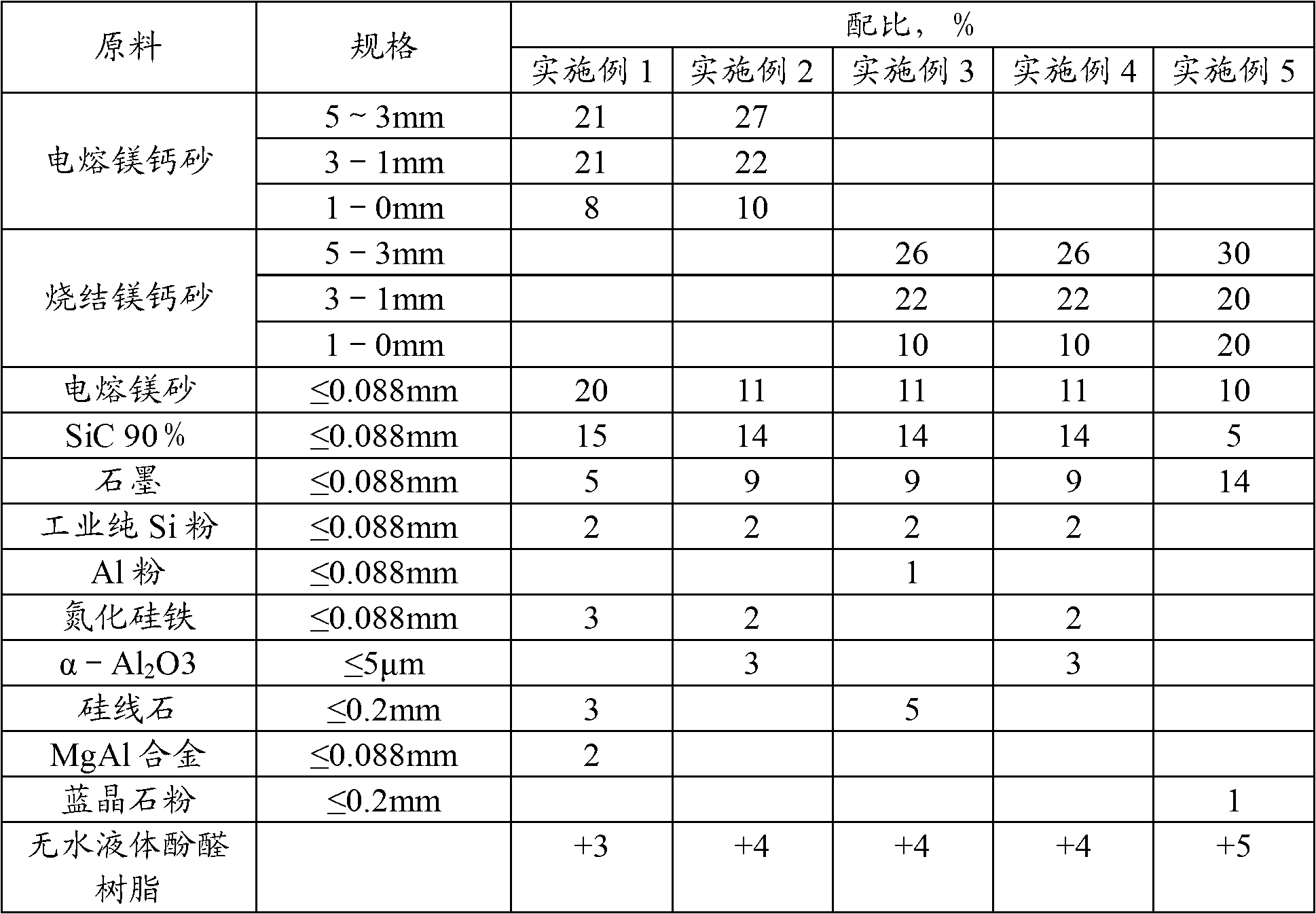

MgCa-SiC-C fireproof material and preparation method thereof

The invention discloses an MgCa-SiC-C fireproof material, belonging to the technical field of fireproof materials. The MgCa-SiC-C fireproof material comprises the following components by mass: 50-70% of electrically molten or sintered magnesium-calcium sand or magnesium-domolite sand granule, 10-20% of electrically molten or sintered magnesium sand fine powder, 5-17% of silicon carbonate, 5-15% of graphite, 1-10% of additive, and anhydrous resin bonder accounting for 3-5% of total mass percent of the electrically molten or sintered magnesium-calcium sand or magnesium-domolite sand granule, the electrically molten or sintered magnesium sand fine powder, the silicon carbonate, the graphite and the additive. The invention further discloses a preparation method of the MgCa-SiC-C fireproof material. The MgCa-SiC-C fireproof material can be applied to a high-temperature steel and iron metallurgy container, especially as an inner lining of a hot metal ladle for iron making, and can meet smelting requirements of the preprocessed hot metal ladle.

Owner:SHOUGANG CORPORATION

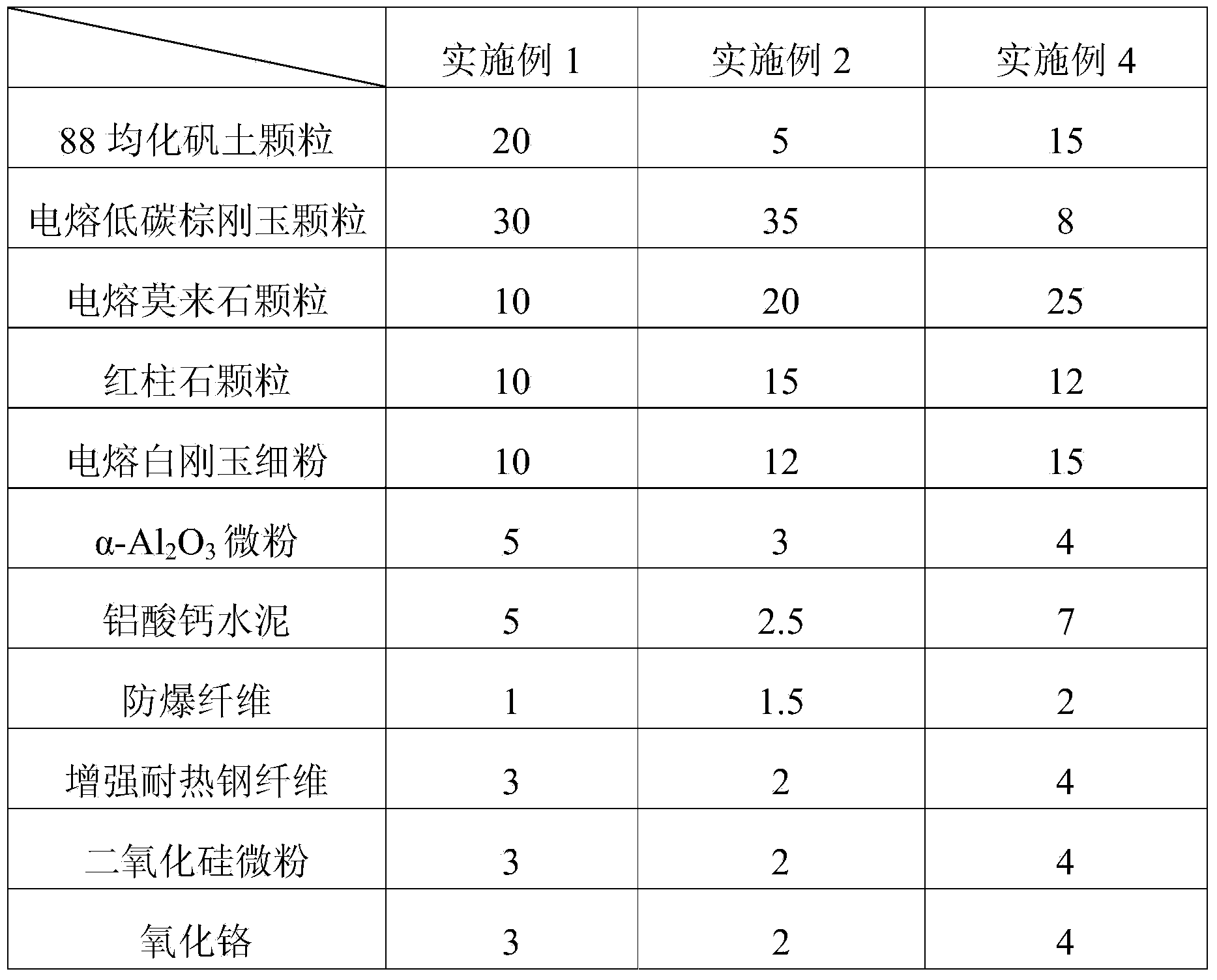

Alumina electric furnace cover and preparation method thereof

The invention aims to provide an alumina electric furnace cover, which is high in thermal shock resistance, density and iron slag erosion resistance and long in service life. The alumina electric furnace cover comprises the following components in percentage by weight: 5 to 20 percent of 88 homogenized alumina particles, 8 to 35 percent of electrofused low-carbon brown aluminum oxide particles, 10 to 25 percent of electrofused mullite particles, 10 to 15 percent of andalusite particles, 10 to 15 percent of electrofused white corundum fine powder, 3 to 5 percent of alpha-Al2O3 micro powder, 2.5 to 7 percent of calcium aluminate cement, 1 to 2 percent of explosion-proof fibers, 2 to 4 percent of reinforced heat-resistant steel fibers, 2 to 4 percent of silicon dioxide micro powder and 2 to 5 percent of chromium oxide. A preparation method comprises the following steps of uniformly mixing the electrofused white corundum fine powder, the alpha-Al2O3 micro powder, the silicon dioxide micro powder and the explosion-proof fibers; adding the electrofused mullite particles and the andalusite particles, stirring the mixture for at least 3min, adding the other raw materials, and stirring the mixture for at least 8min; adding water and a water reducing agent, performing stirring and casting molding, and performing natural curing, de-molding and drying.

Owner:北京利尔高温材料股份有限公司

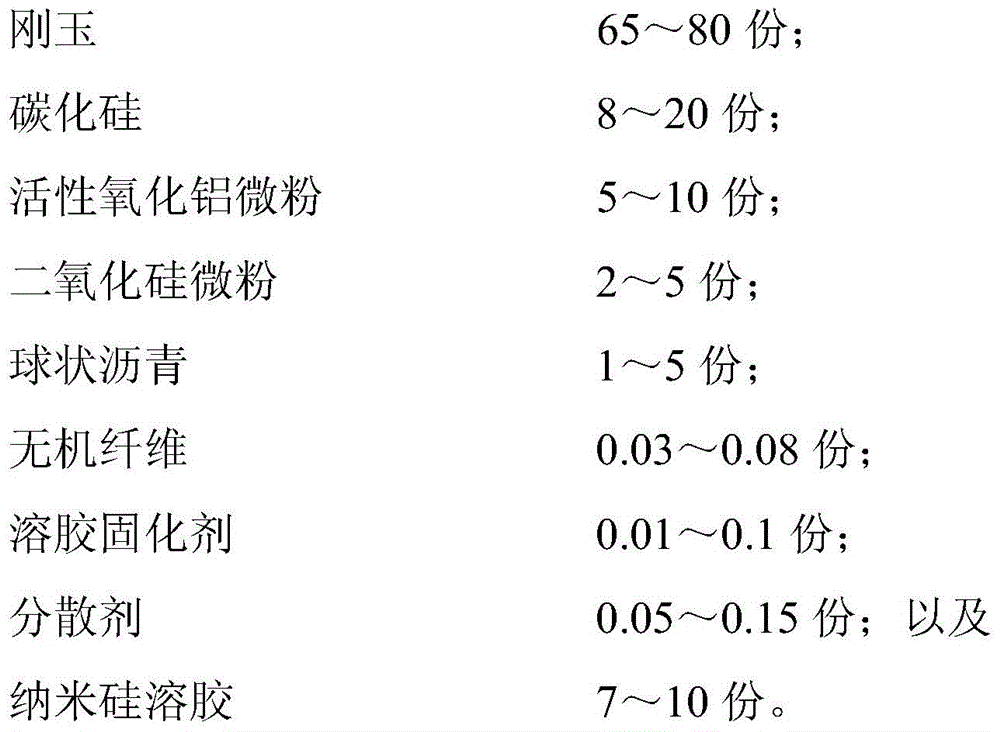

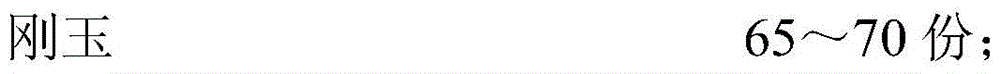

Nano silica sol combination hearth self-flowing material and preparation method thereof

The invention belongs to the technical field of fireproof materials, and relates to a nano silica sol combination hearth self-flowing material and a preparation method thereof. The nano silica sol combination hearth self-flowing material comprises the following components in parts by weight: 65 to 80 parts of corundum, 8 to 20 parts of silicon carbide, 5 to 10 parts of active alumina micropowder, 2 to 5 parts of silica micropowder, 1 to 5 parts of spherical asphalt, 0.03 to 0.08 part of inorganic fiber, 0.01 to 0.1 part of sol curing agent, 0.05 to 0.15 part of dispersant, and 7 to 10 parts of nano silica sol. The provided nano silica soil combination hearth self-flowing material is an advanced self-flowing material for building or maintenance of blast furnace. The self-flowing material is casted and moulded through a framework and pump-delivering so as to build or repair a hearth. Compared with the conventional brick building method, the self-flowing material method has the characteristics of strong integral property, convenience for construction, little construction time, quick production, long service life, and little environmental pollution. Compared with the conventional ceramic cups, SiC and nano silica sol are combined to enhance the matrix, and the performance on resisting molten iron erosion is greatly improved.

Owner:CHINA JINGYE ENG +2

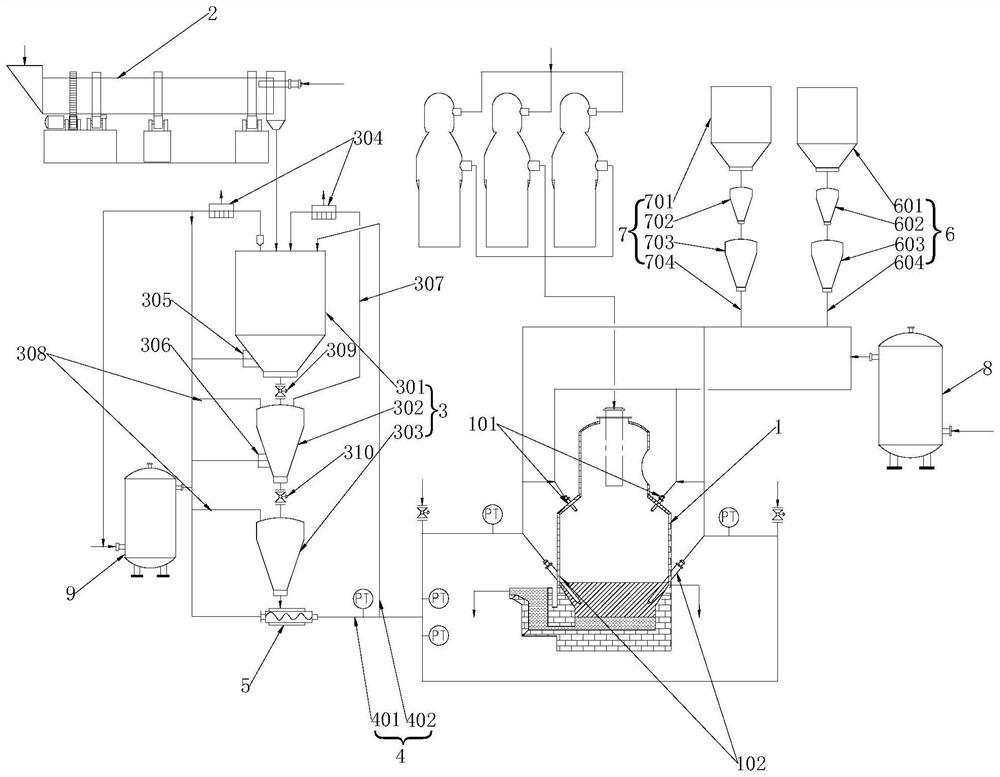

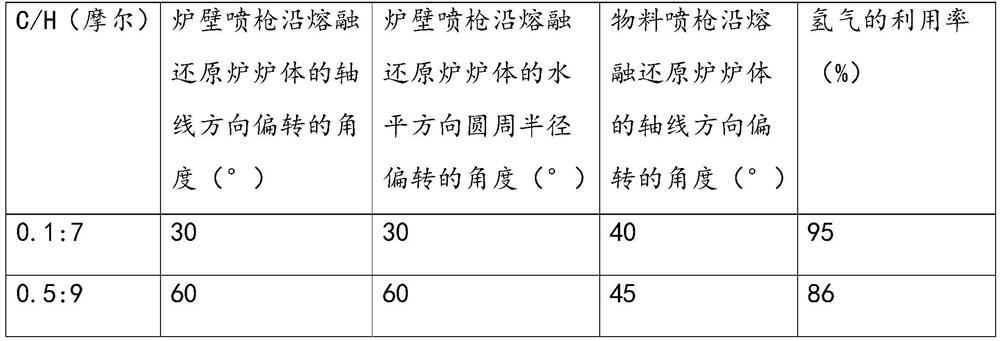

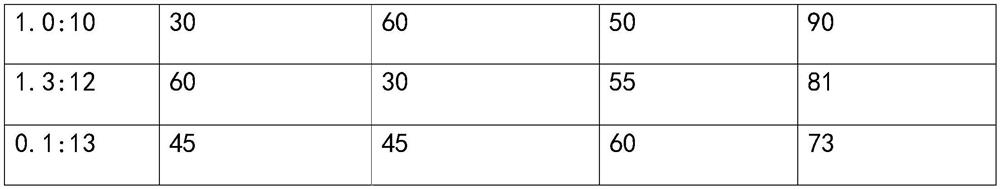

Smelting reduction hydrogen metallurgy process and device

The invention discloses a smelting reduction hydrogen metallurgy process and device. The smelting reduction hydrogen metallurgy process includes the steps that hydrogen is injected into a combustion area of a smelting reduction furnace to form high-pressure rotational flow in the combustion area; and a mixture of an iron-containing material and a magnesium-containing flux, a first carburant and first lime are blown into an iron bath area of the smelting reduction furnace by taking the hydrogen as a carrier gas. According to the smelting reduction hydrogen metallurgy process, the high-pressurerotational flow is formed in the combustion area, so that the retention time of the hydrogen in the smelting reduction furnace and the contact time of the hydrogen and iron-containing materials are prolonged, the amount of the hydrogen entering the combustion area discharged out of the smelting reduction furnace along with flue gas is reduced, the reduction reaction of the iron bath area is enhanced, the content of FeO in slag is reduced, the refractory material erosion speed is reduced, and the hydrogen utilization rate is increased; and the hydrogen is used as the carrier gas, so that the injection depth of a reducing agent can be effectively increased, the fountain effect in the smelting reduction furnace is enhanced, the reduction efficiency in the smelting reduction furnace is improved, and carbon emission in the metallurgical process is reduced.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com