Smelting reduction hydrogen metallurgy process and device

A technology of hydrogen metallurgy and technology, which is applied in the field of smelting reduction hydrogen metallurgy technology and equipment, can solve the problems of low hydrogen utilization rate, hydrogen waste, and increased hydrogen use cost, so as to improve hydrogen utilization efficiency, improve purity, and save The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

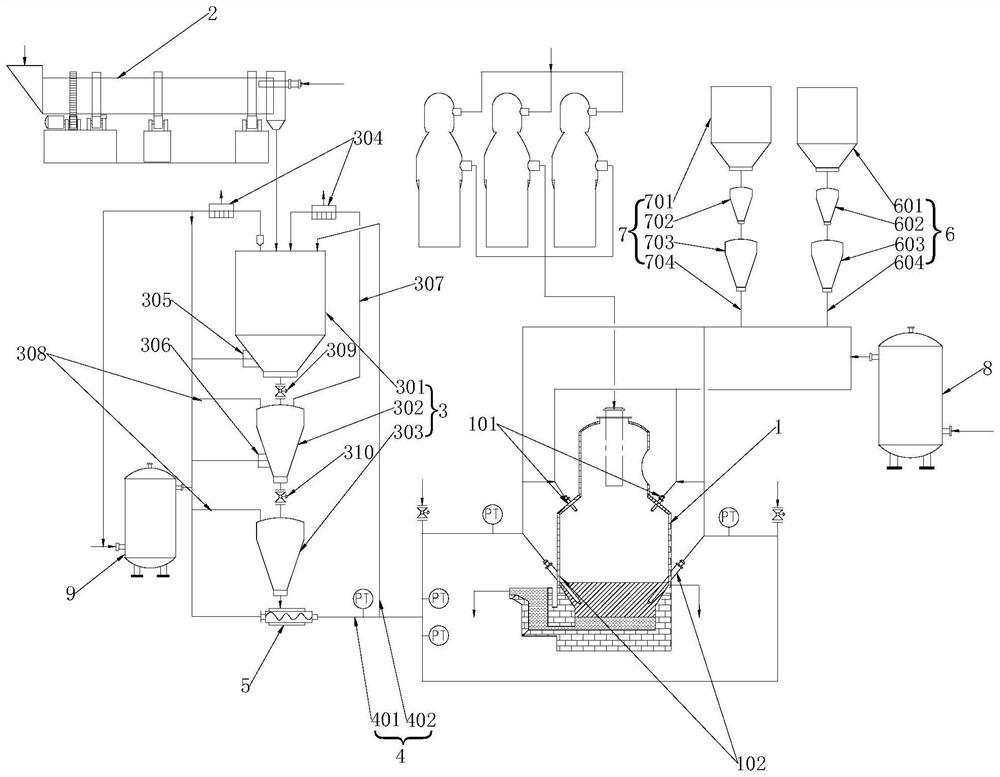

[0058] According to a typical embodiment of the present invention, a smelting reduction hydrogen metallurgy process is provided, the smelting reduction hydrogen metallurgy process includes: injecting hydrogen gas into the combustion zone of the smelting reduction furnace to form a high-pressure swirl in the combustion zone; Gas is injected into the iron bath area of the smelting reduction furnace to inject the mixture of iron-containing material and magnesium-containing flux, the first recarburizer and the first lime.

[0059] Applying the technical scheme of the present invention, hydrogen is injected into different areas of the smelting reduction furnace respectively, one is injected into the combustion area to form a high-pressure swirl, the other is injected as a carrier gas into the iron bath area to reduce iron-containing materials, When the hydrogen gas injected into the iron bath area enters the combustion area along with the splashed slag, the high-pressure swirl for...

Embodiment 1

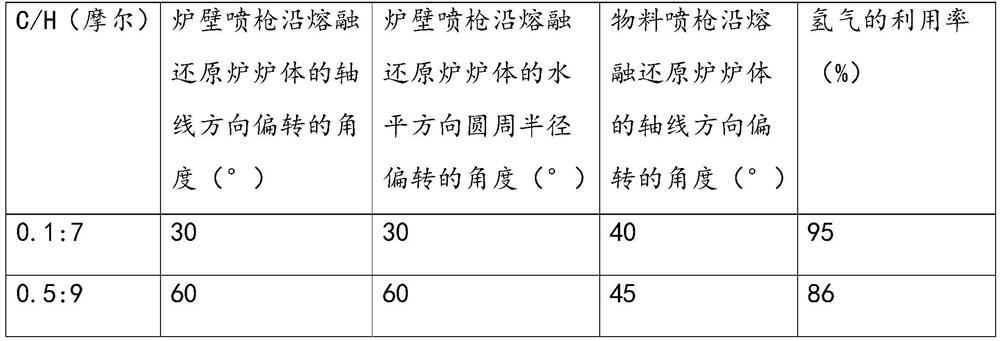

[0089] Using the above-mentioned smelting reduction hydrogen metallurgy process, when the ratio of materials entering the smelting reduction furnace (the molar ratio of C in the carburant to H in the hydrogen) is different, the angles of the furnace wall spray guns are different, and the angles of the material spray guns are different, The utilization rate of the obtained hydrogen is shown in Table 1.

[0090] Table 1

[0091]

[0092]

[0093] From Table 1, it can be seen that using the smelting reduction hydrogen metallurgy process provided by the present application, the utilization rate of hydrogen can reach up to 95%, which shows that the utilization rate of hydrogen can be significantly improved. It can also be seen from Table 1 that the utilization rate of hydrogen can be changed by adjusting the parameters of the device, and the utilization rate of hydrogen can meet different customer needs. When customers need to use reducing gas, the parameters of the device can ...

Embodiment 2

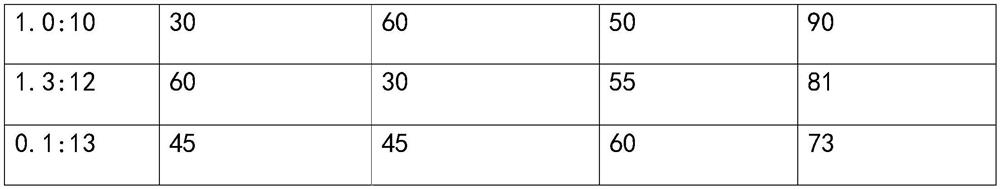

[0095] By pre-reducing the iron-containing material before entering the smelting reduction furnace, the pre-reduction degree of the iron-containing material under different parameters is shown in Table 2.

[0096] Table 2

[0097]

[0098] Iron-containing materials enter the smelting reduction furnace after three-stage pre-reduction treatment, which is conducive to improving the reduction efficiency of iron-containing materials in the smelting reduction furnace, saving hydrogen consumption, improving hydrogen utilization efficiency, and further increasing production capacity and improving melting Technical and economic indicators of reduction smelting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com