Patents

Literature

228results about How to "Facilitate the reduction reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

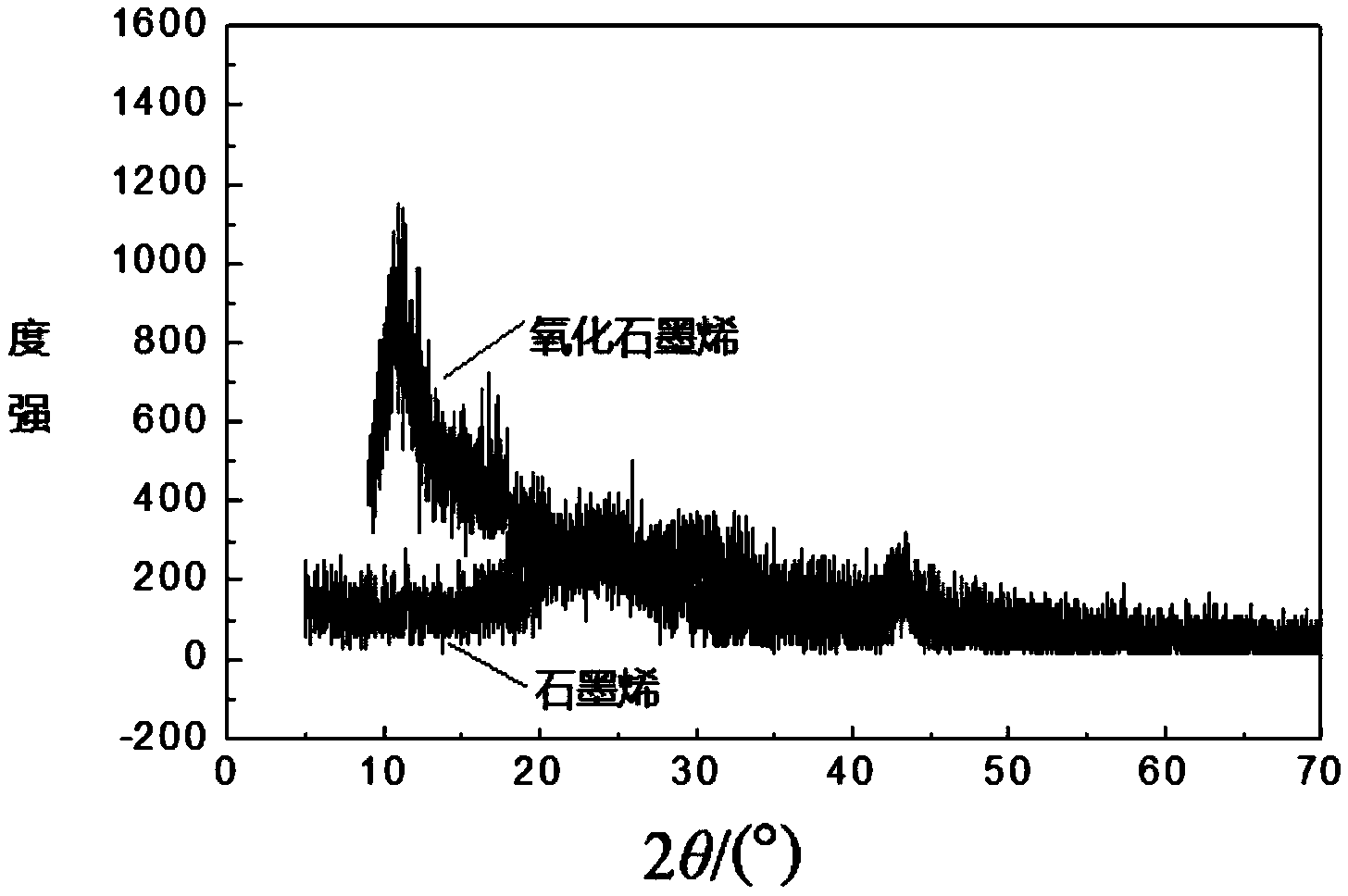

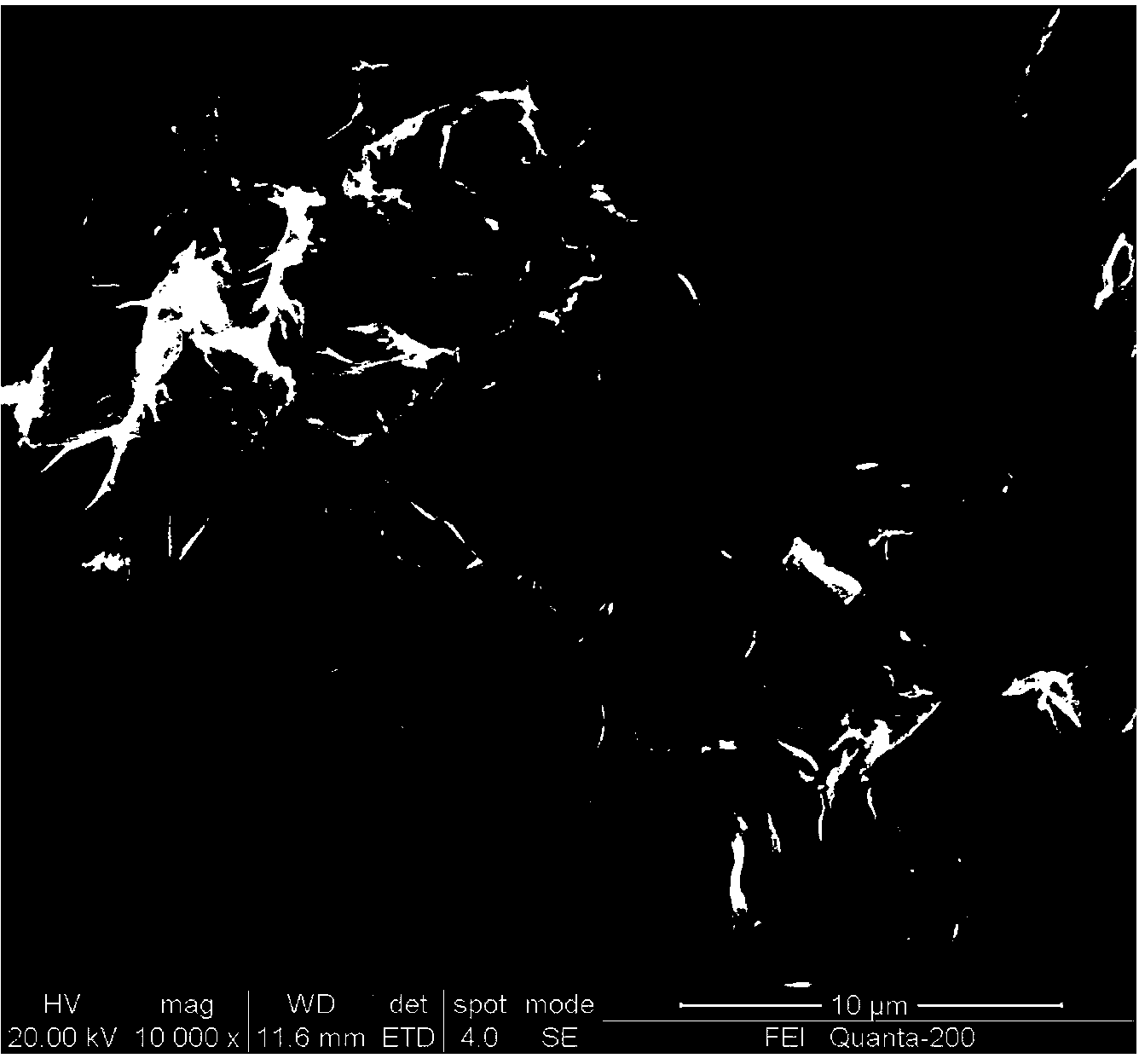

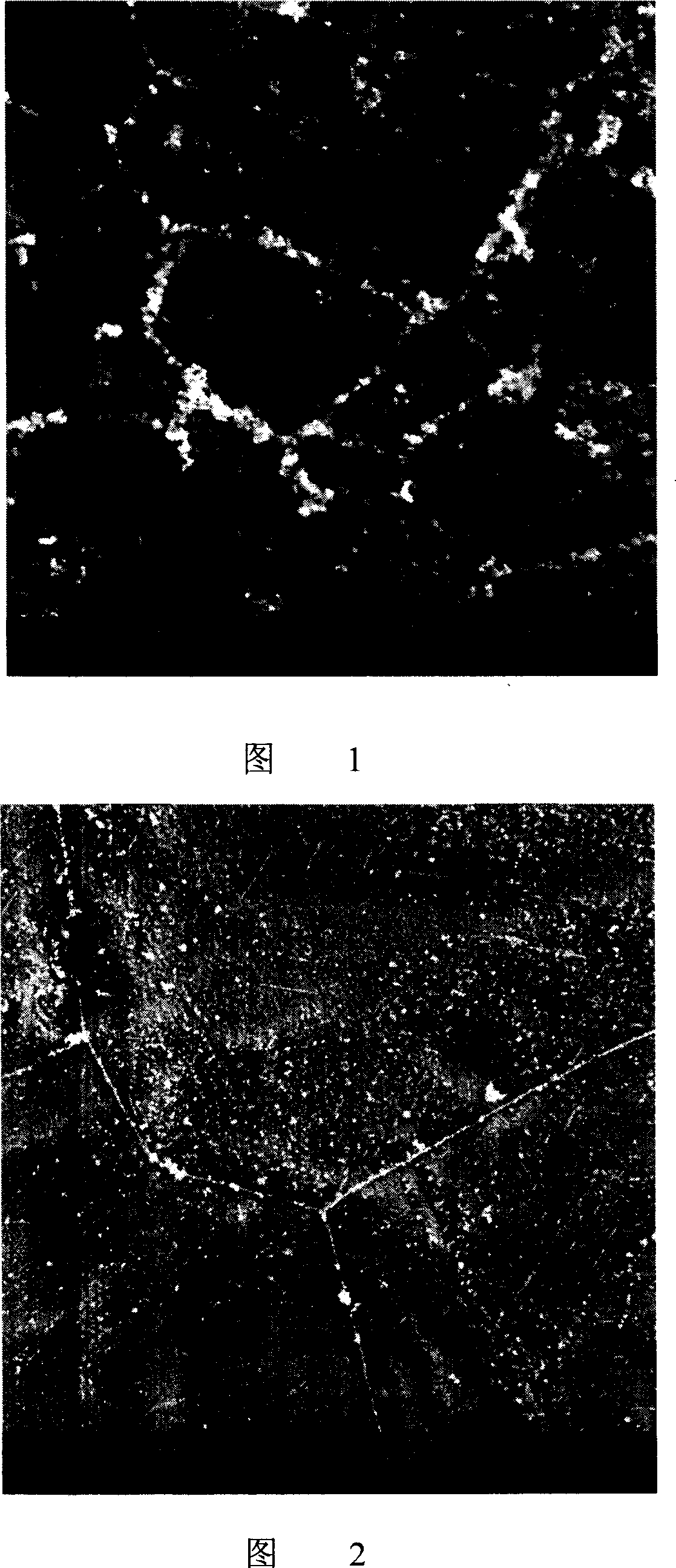

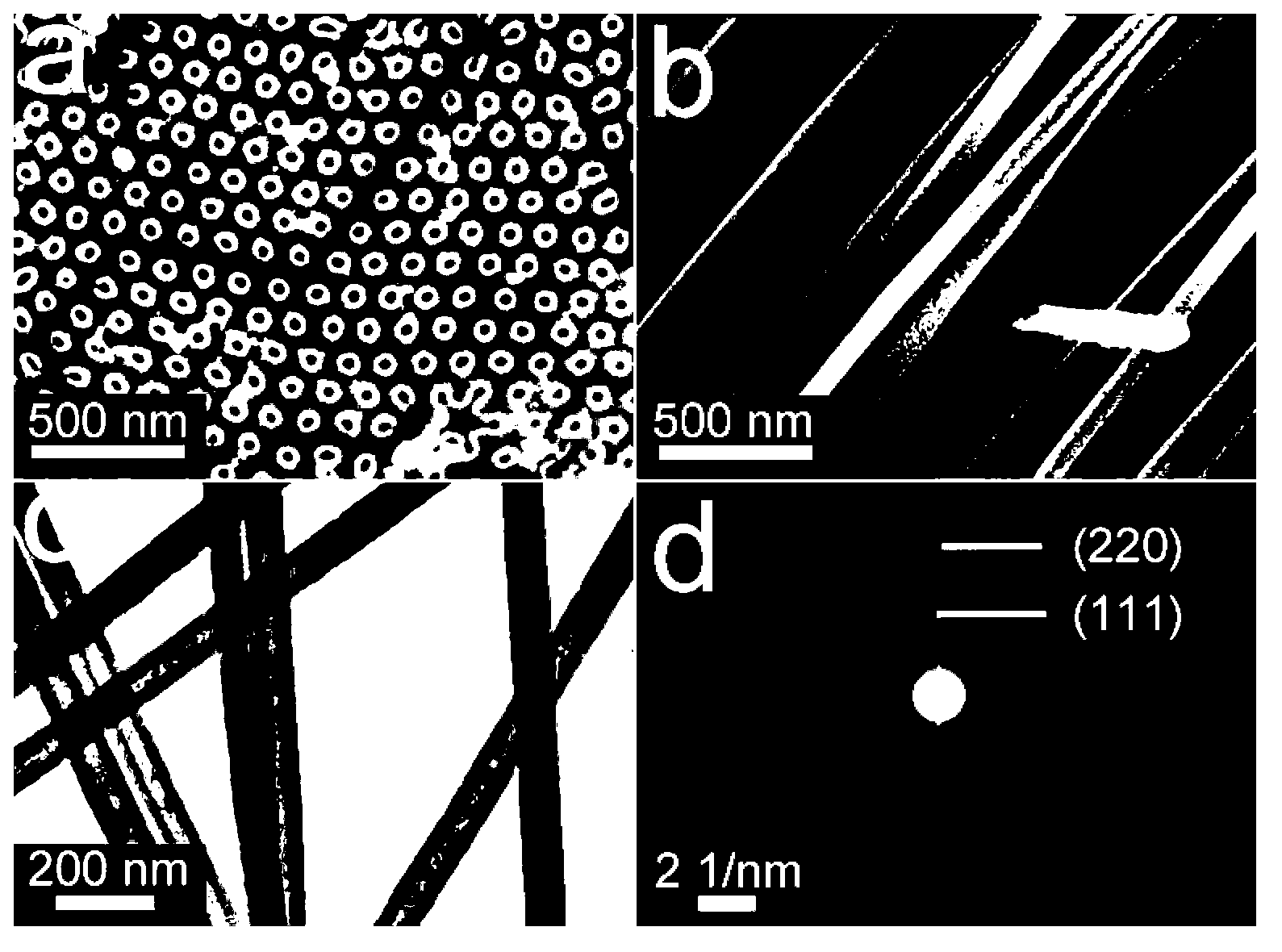

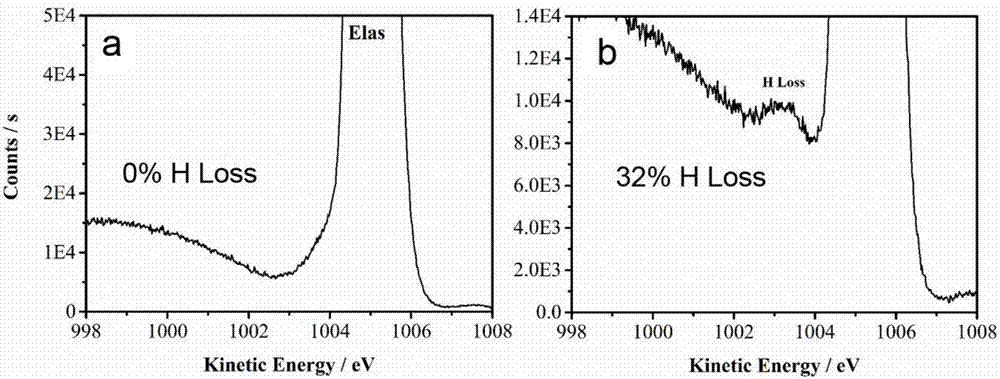

Preparation method of high purity and high concentration graphene suspension

InactiveCN101830458AFacilitate the reduction reactionInhibition of agglomerationHigh concentrationUltrasonic radiation

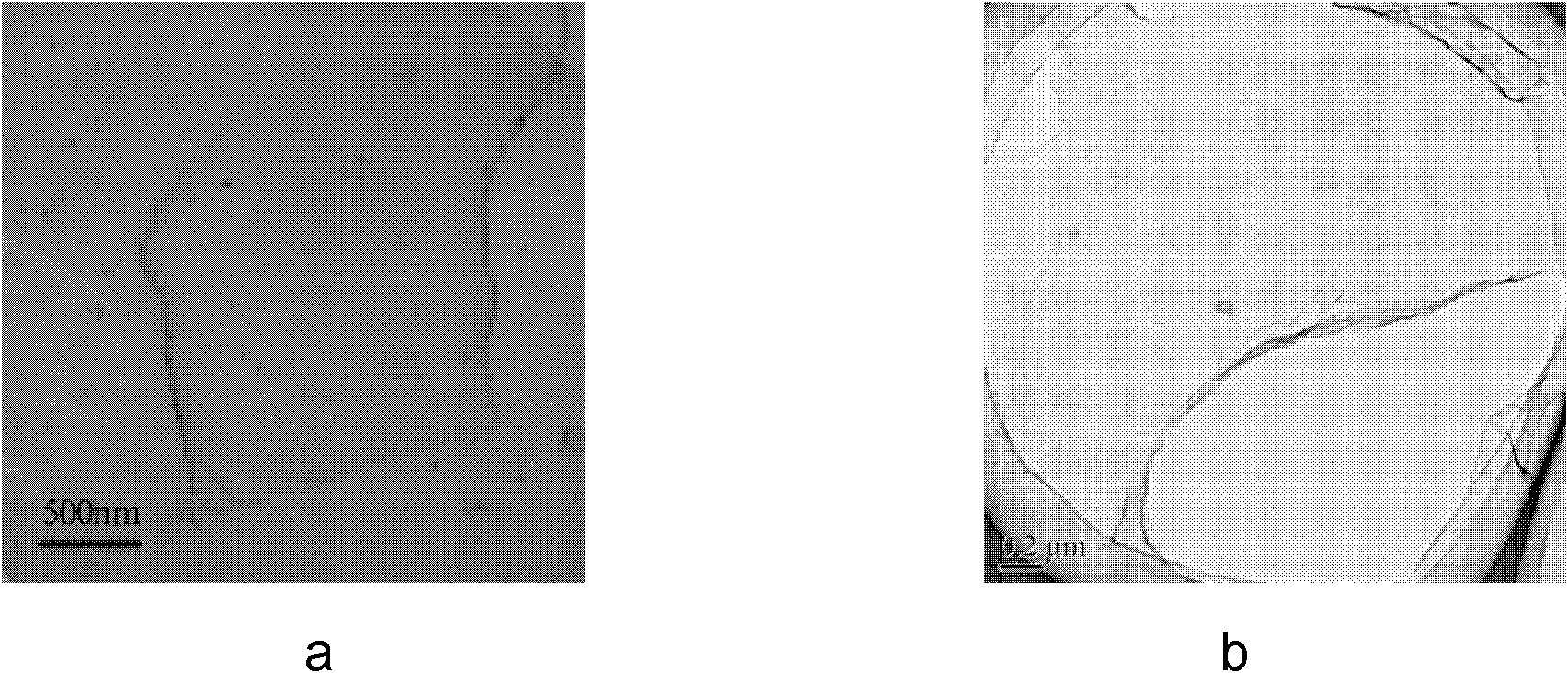

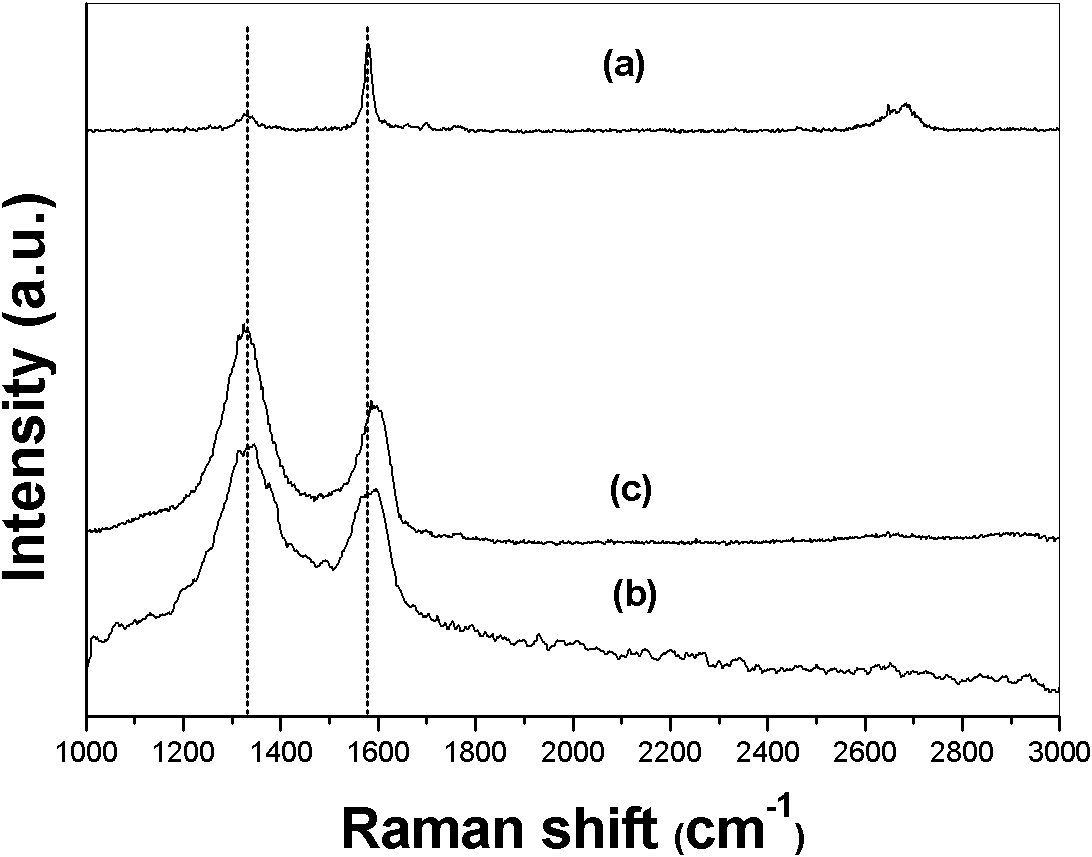

The invention relates to a preparation method of a high purity and high concentration graphene suspension, which comprises the following steps of: reacting natural crystalline flake graphite with a strong oxidizer to obtain graphite oxide; spreading the graphite oxide into a dispersing agent, and obtaining a graphene oxide suspension by ultrasonic dispersion; mixing the graphene oxide suspension with hydrazine hydrate under the protection of nitrogen and reacting at constant temperature under ultrasonic radiation to prepare stable graphene suspension. Compared with the traditional method for preparing the graphene suspension, the method introduces ultrasonic in the reduction process of the graphite oxide. The invention has the following advantages that the prepared graphene suspension has high concentration (higher than 1 mg.mL<-1>), high purity (without influence of surface active agents and other impurities), high dispersionstability (time for stable dispersion is more than 60 days) and the like; the graphene prepared by the method has high electrical conductivity (high than 700 S.m<-1>), less number of layers, is simple and easy to implement, and is very suitable for large scale production in industy.

Owner:XI AN JIAOTONG UNIV

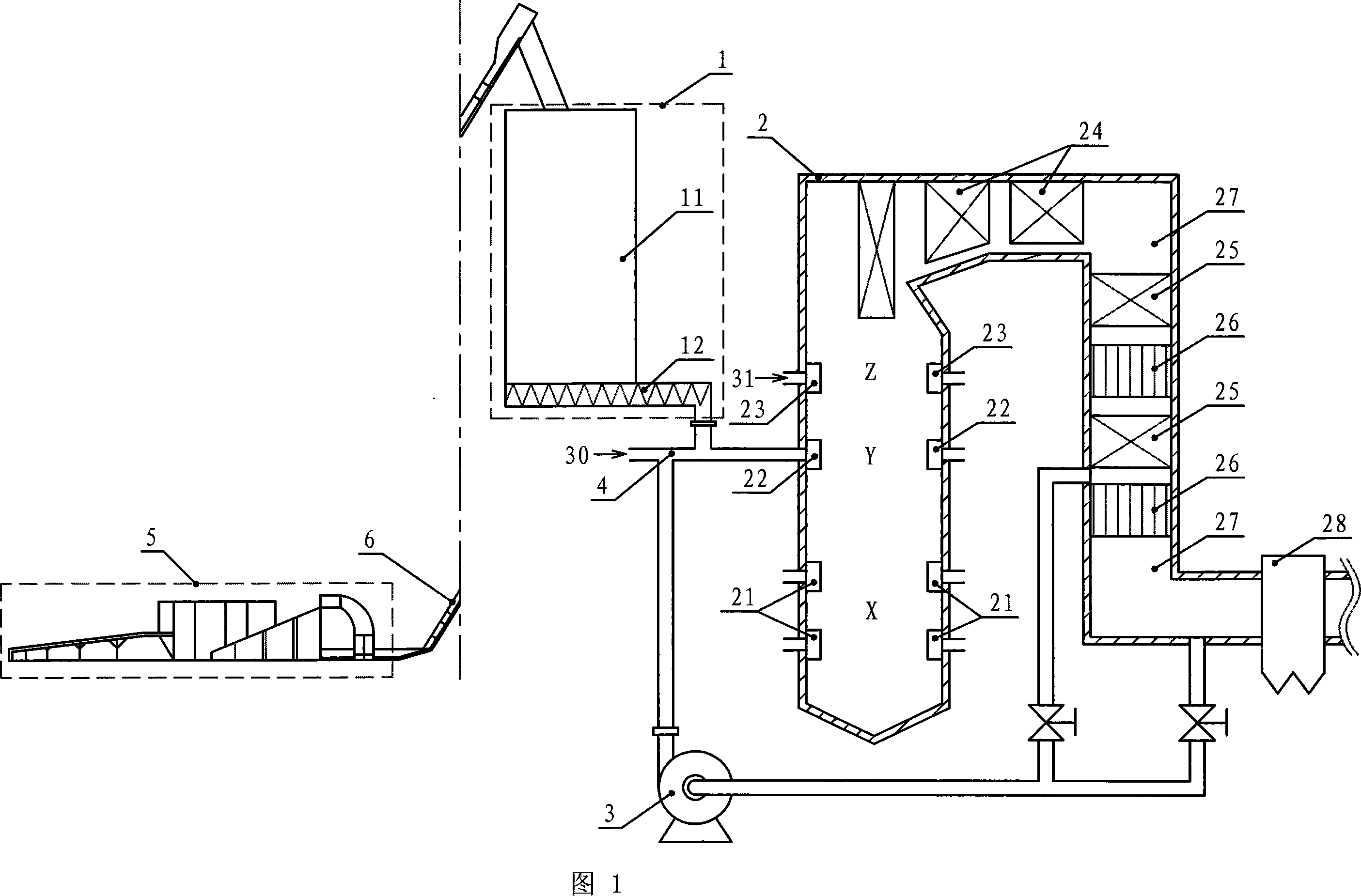

Method and device of denitration utilizing biomass direct burning and re-burning as well as smoke gas recirculating technology

InactiveCN101021316AReduce technical riskLow technical costCombustion apparatusCombustorDirect combustion

The present invention belongs to a denitration method by utilizing biomass direct combustion and secondary combustion and flue gas recirculating process and its equipment, and relates to a coal powder boiler low NOx combustion process and its equipment. The invented method includes the following steps: making coal powder be passed through the combustor of coal powder boiler and fed into main combustion zone to make combustion and form the flue gas containing NOx; utilizing the mixture of once air and recirculating tail portion flue gas to spray biomass particles into secondary combustion reduction zone and make NOx formed in the main combustion zone be reacted and formed into N2; at the same time make the biomass coke ad NOx produce isophase reduction reaction to form Nz; spraying burning air from upper portion of secondary combustion reduction zone to make non-burnt combustible material be burnt up.

Owner:HARBIN INST OF TECH

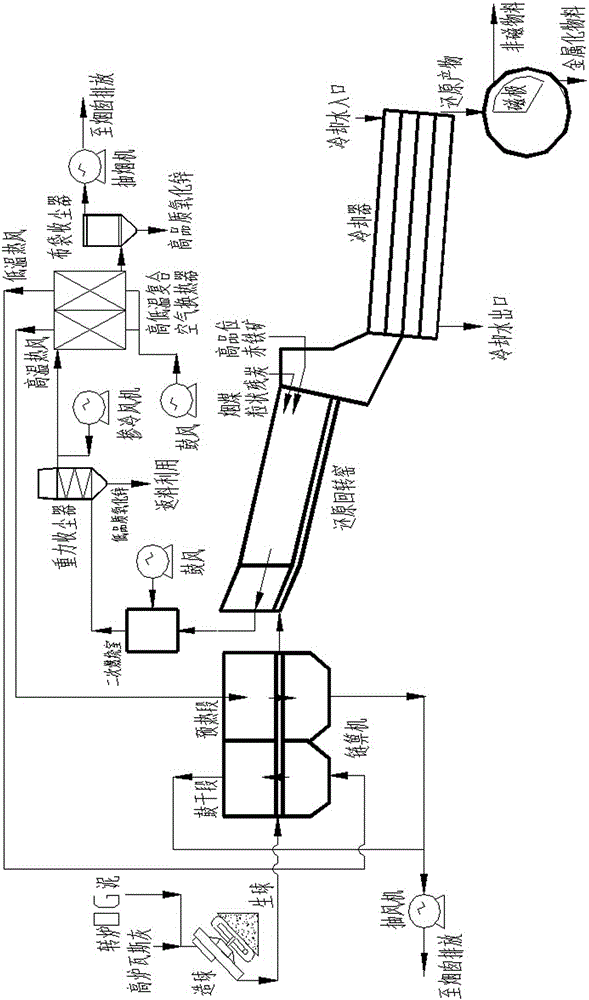

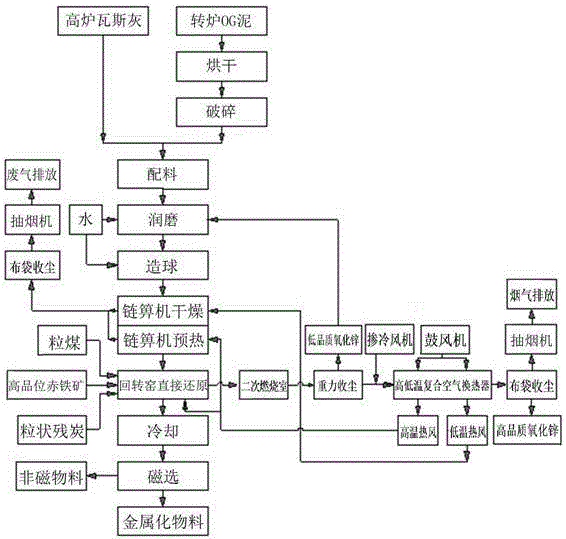

Method for treating high-zinc iron-containing slime through utilizing rotary kiln

ActiveCN106367600AEfficient use ofReduce loadRotary drum furnacesProcess efficiency improvementLarge particleMagnetic separation

The invention relates to a method for treating high-zinc iron-containing slime through utilizing a rotary kiln. The method comprises the steps that blast furnace gas ash and converter OG mud are mixed and pelletized; wet pellets are dried and preheated, and a drying and preheating heat source is hot air generated by high-temperature flue gas of the rotary kiln after passing through a high-low temperature composite air heat exchanger; a pea coal spray gun, a carbon residue spray gun and an ore grain spray gun are arranged at a kiln head of the rotary kiln, and high-volatile matter coal, residual carbon and high-grade iron ore are sprayed into the kiln; the dried pellets are fed into the rotary kiln, and high-temperature metallized pellets are obtained after the dried pellets are subjected to direct reduction and high-temperature solidification in the rotary kiln; after being cooled to the normal temperature, materials like the metallized pellets and excess carbon residue are subjected to magnetic separation, and metallized pellets are obtained; and large-particle dust is removed from the high-temperature flue gas of the rotary kiln, the high-temperature flue gas enters the high-low temperature composite air heat exchanger to be cooled, the cooled flue gas enters a bag-type dust collector, and zinc oxide powder is recycled. According to the method, the high-zinc iron-containing slime generated by iron and steel enterprises is efficiently utilized, and environmental pollution caused by stacking of the high-zinc iron-containing slime is solved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

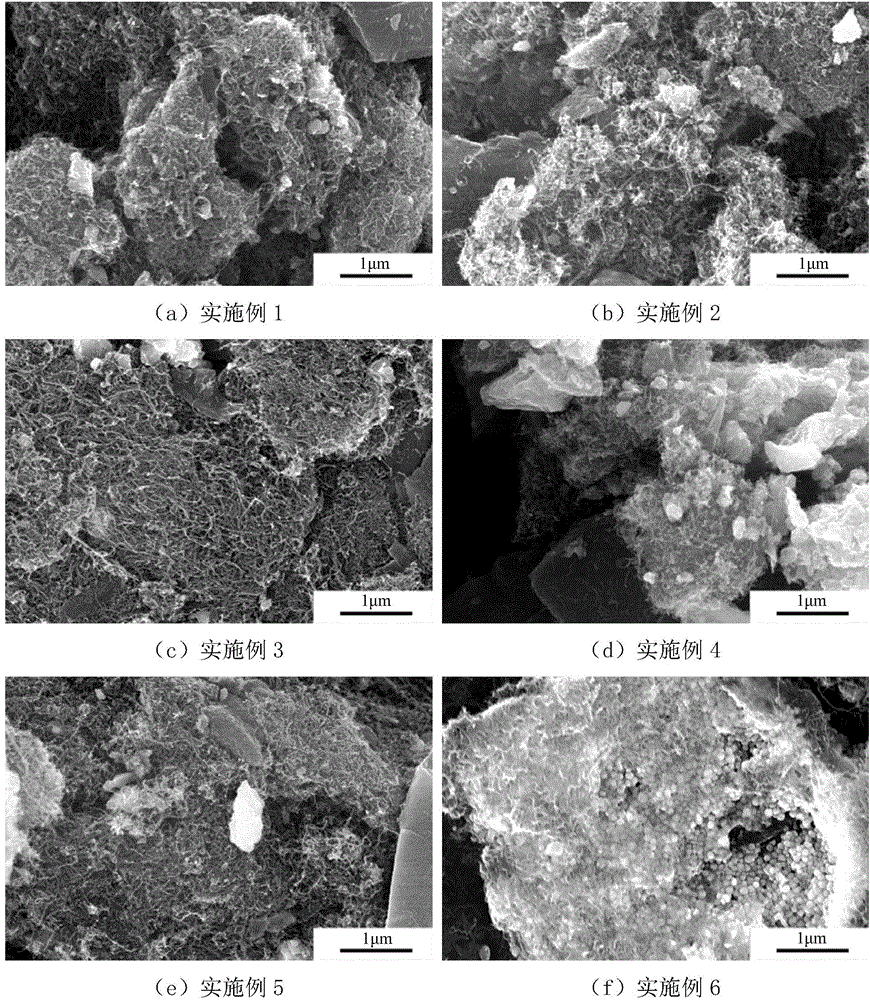

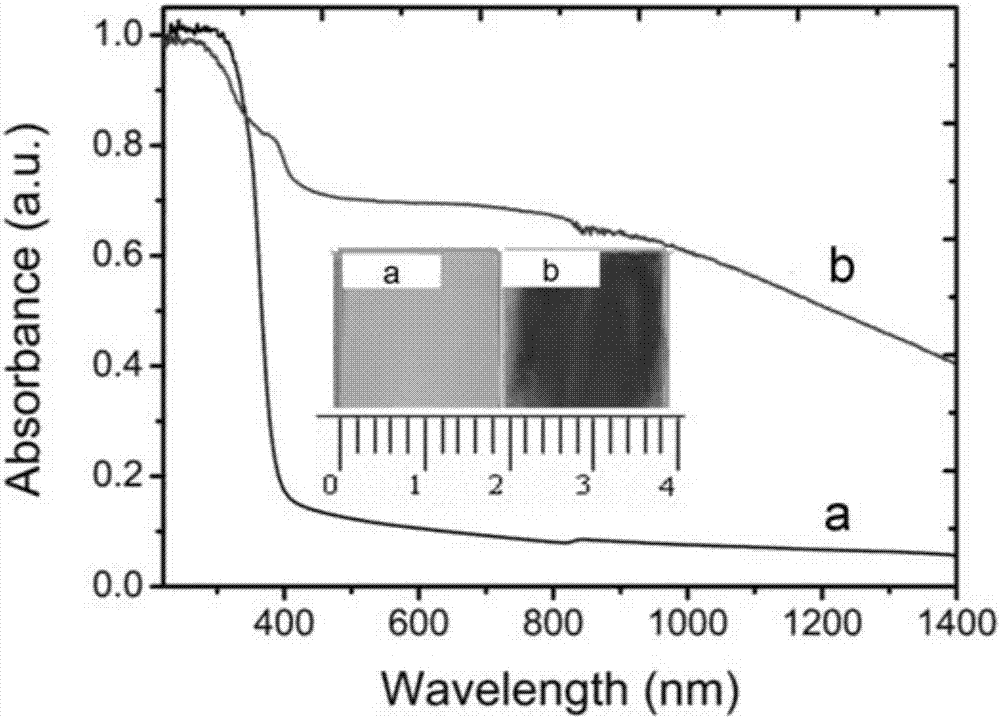

Method for preparing graphene through reduction of oxidized graphene

The invention discloses a method for preparing graphene through reduction of oxidized graphene. The method comprises the steps of under ultrasonic-assisted stirring, reducing the oxidized graphene with alkali metal or alkaline earth metal as a reducing agent and iodine as an initiator, and separating and purifying to obtain the graphene. The method has the advantages of short reaction cycle, simple operation, high efficiency, no pollution, low cost, good product quality and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Porous silicon monoxide composite material and preparation and application thereof

ActiveCN110854377AControl contentThe pre-processing process is simpleMagnesium silicatesSilicaCarbon coatingComposite material

The invention belongs to the field of lithium ion battery materials, and particularly discloses a porous silicon monoxide composite material. The composite material comprises an inner core, a middle layer compounded on the surface of the inner core and an outer layer compounded on the surface of the middle layer, wherein the inner core is silicon, the middle layer is silicon monoxide and silicateof metal M dispersed in the silicon monoxide, the outer layer is a carbon coating layer, and the metal M is a metal element capable of reducing silicon oxide. The invention also provides a preparationmethod of the composite material and an application of the composite material as a negative electrode active material of a lithium ion secondary battery. Research finds that the composite material has the characteristics of long cycle life, high initial efficiency and the like.

Owner:CENT SOUTH UNIV +1

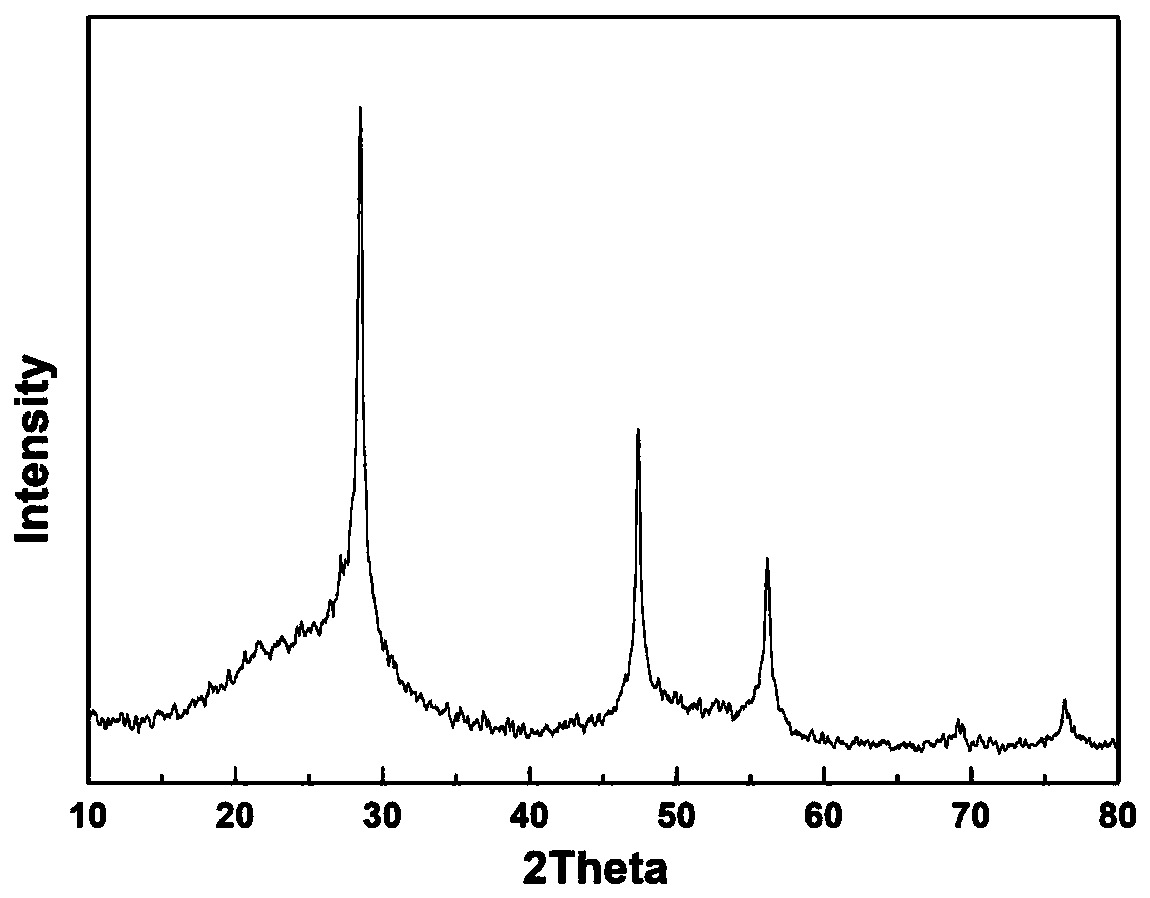

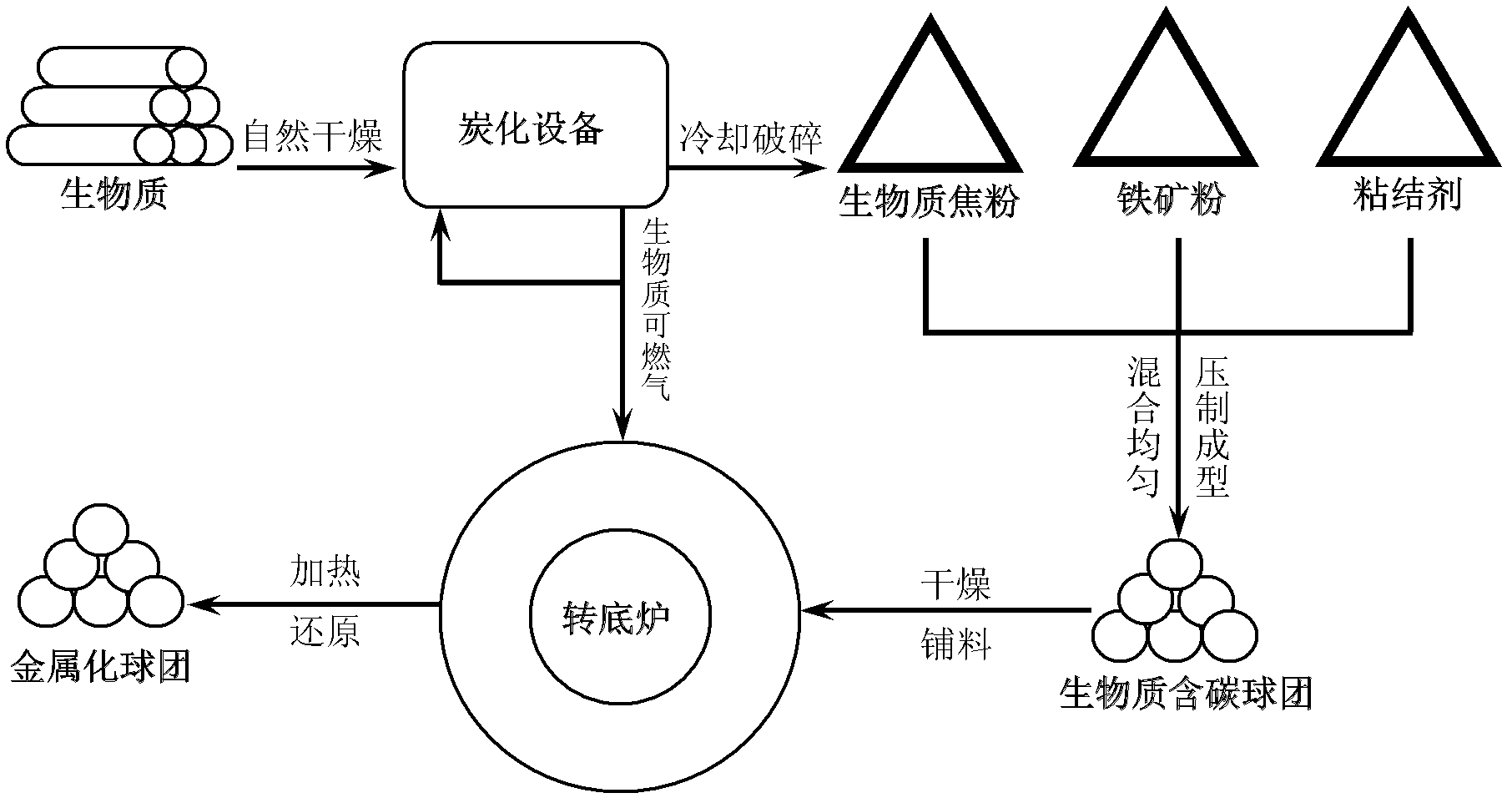

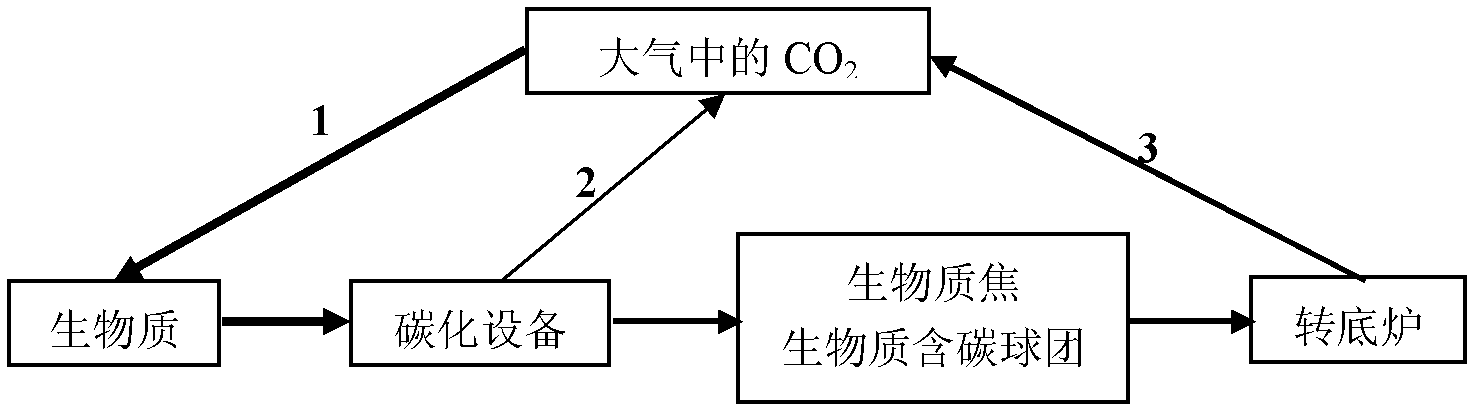

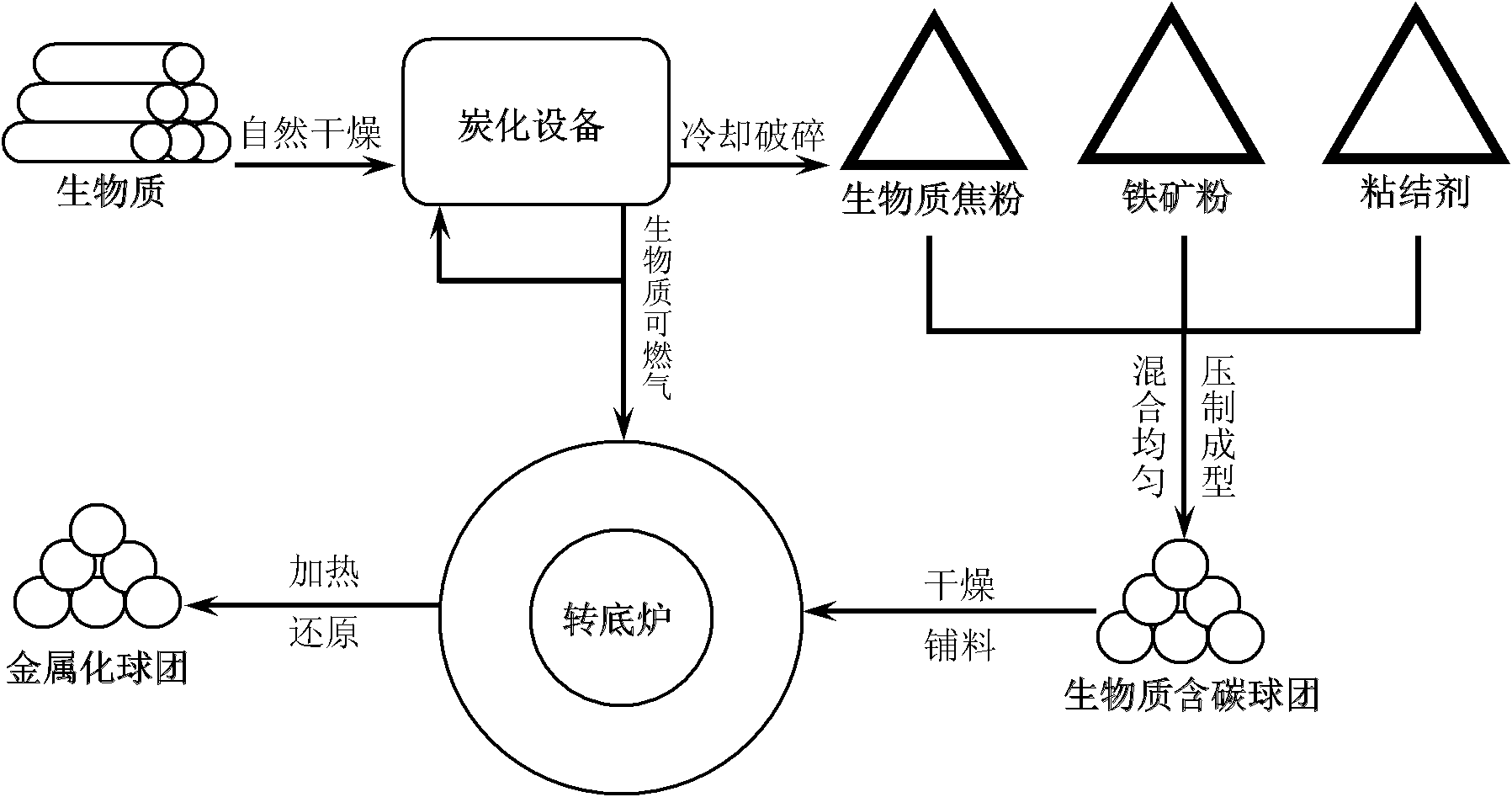

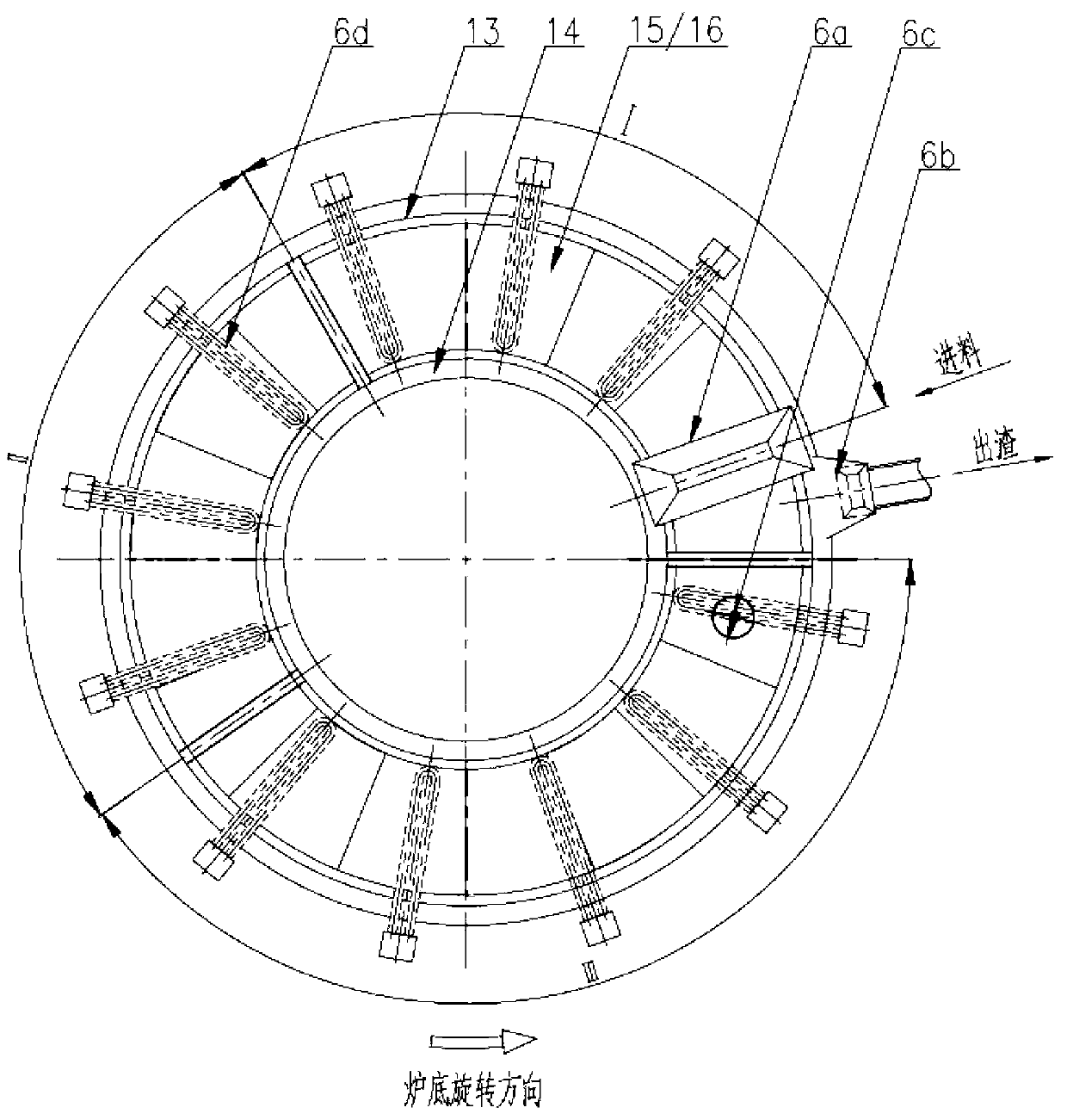

Rotary hearth furnace iron-making method utilizing biomass carbon-containing pellet to serve as raw material

InactiveCN102586529ARealize rational utilizationLarge reservesFluidised-bed furnacesBiomass carbonCoke

A rotary hearth furnace iron-making method utilizing biomass carbon-containing pellets to serve as a raw material belongs to the field of ferrous metallurgy and relates to a rotary hearth furnace iron-making process using the biomass to serve as iron-making fuel and a reducing agent. The process comprises the steps, utilizing reproducible carbon neutral biomass coke powder to replace pulverized coal, enabling the biomass coke powder and the iron ore powder to be matched with each other according to C / O=1.1-1.4, adding an appropriate binder, evenly mixing to make pellets, and enabling the pellets to enter a rotary hearth furnace to be heated and undergo reduction so that a metalized pellet is obtained. The biomass coke has carbon neutral and can fundamentally reduce discharge of pollutantssuch as CO2 caused by coal consumption. The impurity content of the biomass coke is little, the problem that sulphur content of products caused by coal using is too high is solved, and the comprehensive quality of the products is improved. The energy in the preparation process of the biomass coke can be supplied by biomass itself, and green circulating production is substantially achieved. The rotary hearth furnace iron-making method expands energy sources for rotary hearth furnace iron making, reduces production cost, improves product quality and production efficiency and reduces environmental pollution.

Owner:UNIV OF SCI & TECH BEIJING

Method for rapidly and directly reducing haematite or limonite into ferrous powder

The invention relates to a method in which hematite or limonite are quickly reduced and made into iron powder, which aims to use iron ore difficult to be magnetically separated as a raw material to reduce the cost. The method is characterized in that hematite ore or limonite ore are crushed and then washed and magnetically separated; iron ore powder, coal powder and lime powder are mixed according to the proportion, and calcium fluoride and adhesive are added to be pressed into flans with pores, and the flans are dried; the structure of a kiln car surface is improved, and a sagger is made; the pressed and dried flans are hoisted to the kiln car surface after being put orderly, and the sagger is covered outside the flans; a tunnel kiln is used for calcinating the flans, and two ends of the tunnel kiln are covered with air sealing machines; after the kiln car travels out of the tunnel kiln, a motor hoist is used to hoist the sagger, calcinating blocks are pushed into a water pool to be quickly cooled and automatically ground, and the iron powder and dregs are fished out to directly enter a ball mill to be wetly milled and be pressed into blocks or bagged after the separation of a magnetic separator and the drying.

Owner:王号德

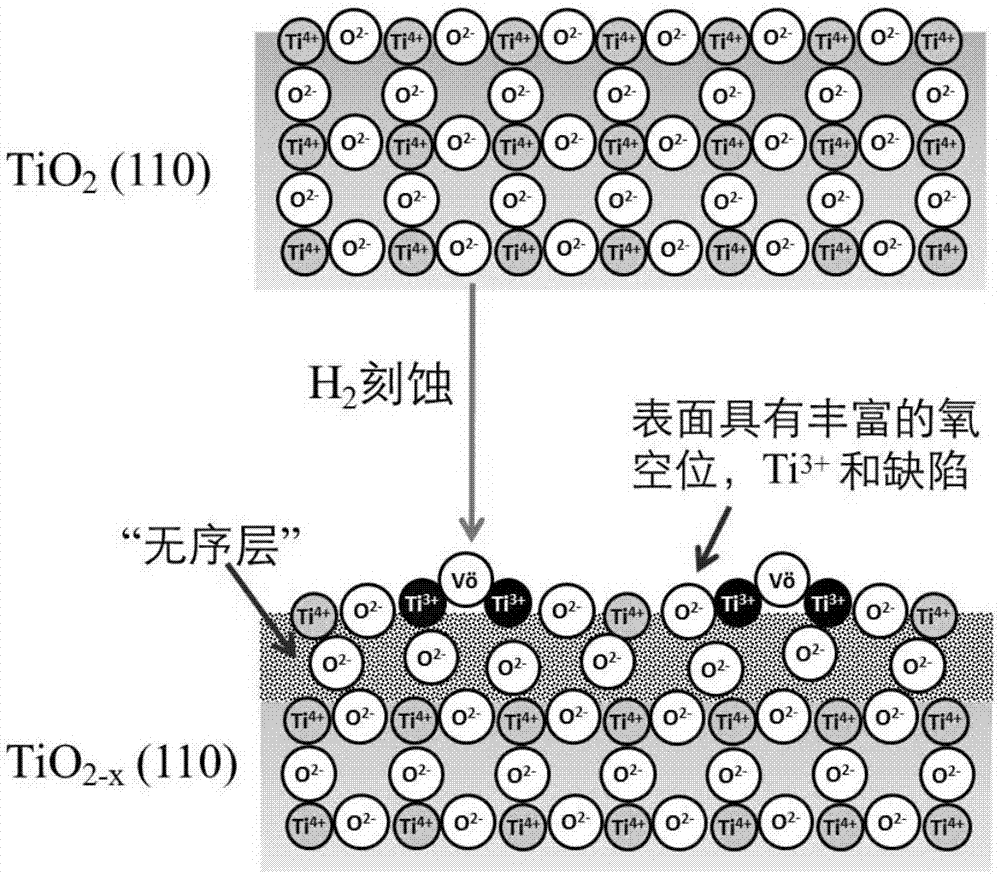

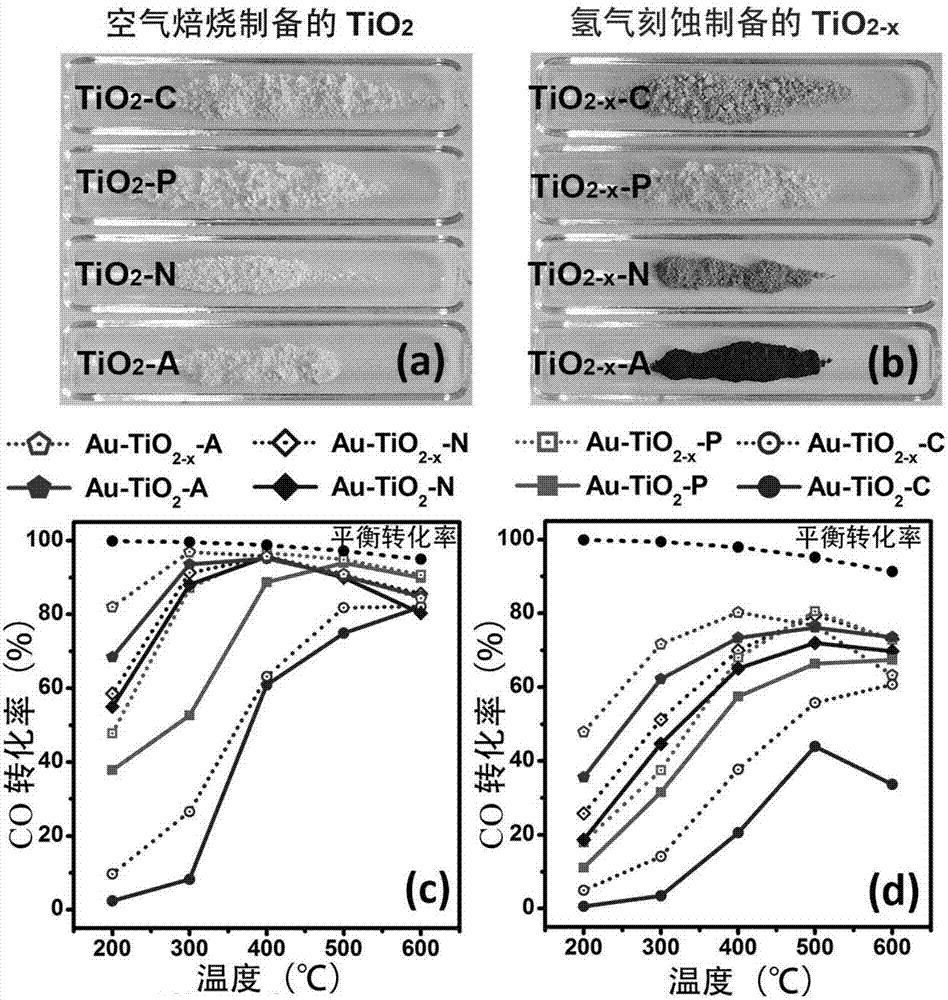

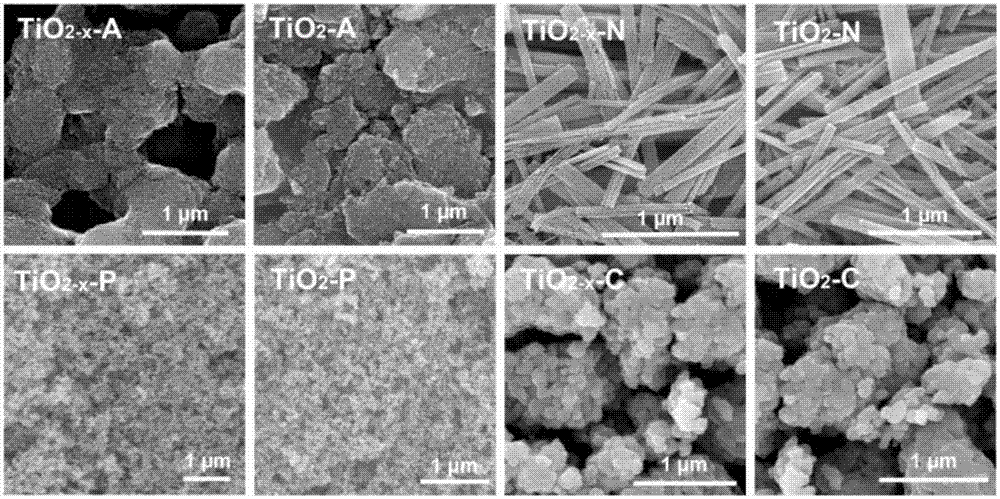

Au-TiO(2-x) catalyst and application thereof

ActiveCN107115861AFacilitate the reduction reactionImprove conversion rateCatalyst carriersHydrogen separation using solid contactAir atmospherePower flow

The invention discloses a Au-Ti(2-x) catalyst and application thereof. The Au-Ti(2-x) catalyst comprises a carrier and an active component, wherein the carrier is obtained through forging anatase-phase TiO2 nano-particles or TiO2 nano-belts under a hydrogen atmosphere. According to the Au-Ti(2-x) catalyst, the anatase-phase TiO2 nano-particles or TiO2 nano-belts are placed in the hydrogen atmosphere to be forged, compared with a TiO2 carrier obtained through forging under the conventional air atmosphere, the carrier provided by the invention has rich oxygen vacancy, Ti<3+> and defective bits, and a surface 'disordered layer' is formed, so that Ohm energy barriers of the Au-Ti(2-x) catalyst are reduced, electron recombination is inhibited, the thermocurrent transmission efficiency is improved, reduction reaction of H2O is promoted, and the CO conversion rate in water gas shift reaction is improved.

Owner:JIAXING UNIV

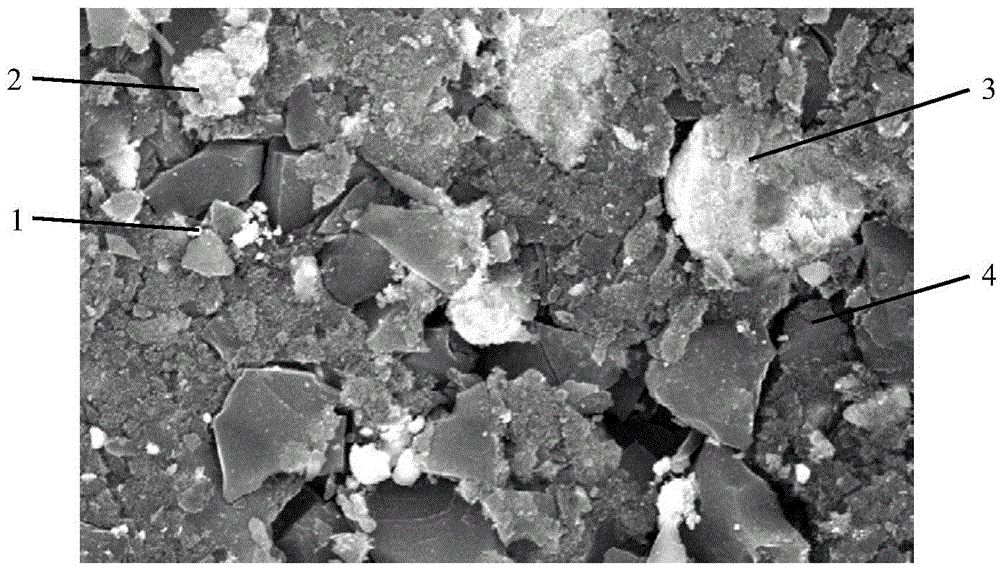

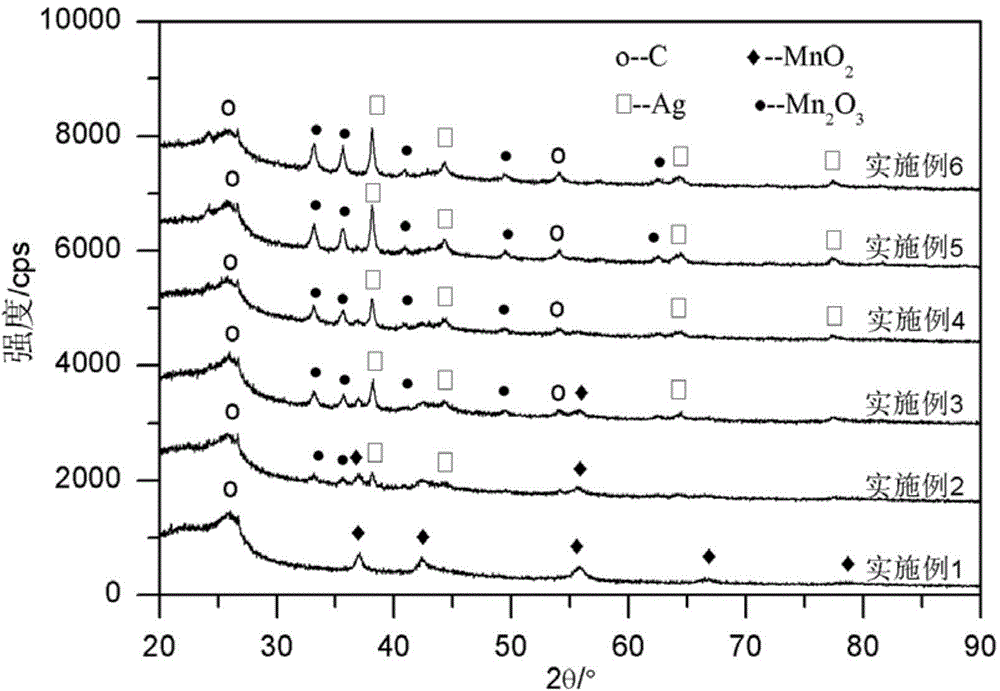

Nano-composite air electrode catalyst for zinc-air battery and preparation method of nano-composite air electrode catalyst

InactiveCN104900890AImprove wettabilityImprove oxygen reduction performanceCell electrodesCarbon nanotubeThree-phase

The invention relates to a nano-composite air electrode catalyst for a zinc-air battery and a preparation method of the nano-composite catalyst, belonging to the technical field of zinc-air batteries. The nano-composite catalyst is composed of manganese dioxide, nano-silver, a carbon nano tube and a carbon material in the mass ratio of (0-0.5) to (0-0.5) to 1 to (1.75-2.75), wherein the mass of manganese dioxide and the mass of nano-silver cannot be zero at the same time. Due to the addition of nanometer materials such as nano-silver and the carbon nano tube, the wettability of the nano-composite catalyst is improved, and the reduction reaction of oxygen in a three-phase boundary formed by electrolyte, catalyst material and oxygen is facilitated; meanwhile, the composite catalyst formed by manganese dioxide and nano-silver has oxygen reduction effect higher than that of a single catalyst. The nano-composite catalyst adopts the preparation technology comprising the steps of pretreatment, granulation, ultrasonic dispersion and ball-milling treatment, the operation is simple and efficient, and the application prospect is good.

Owner:TSINGHUA UNIV

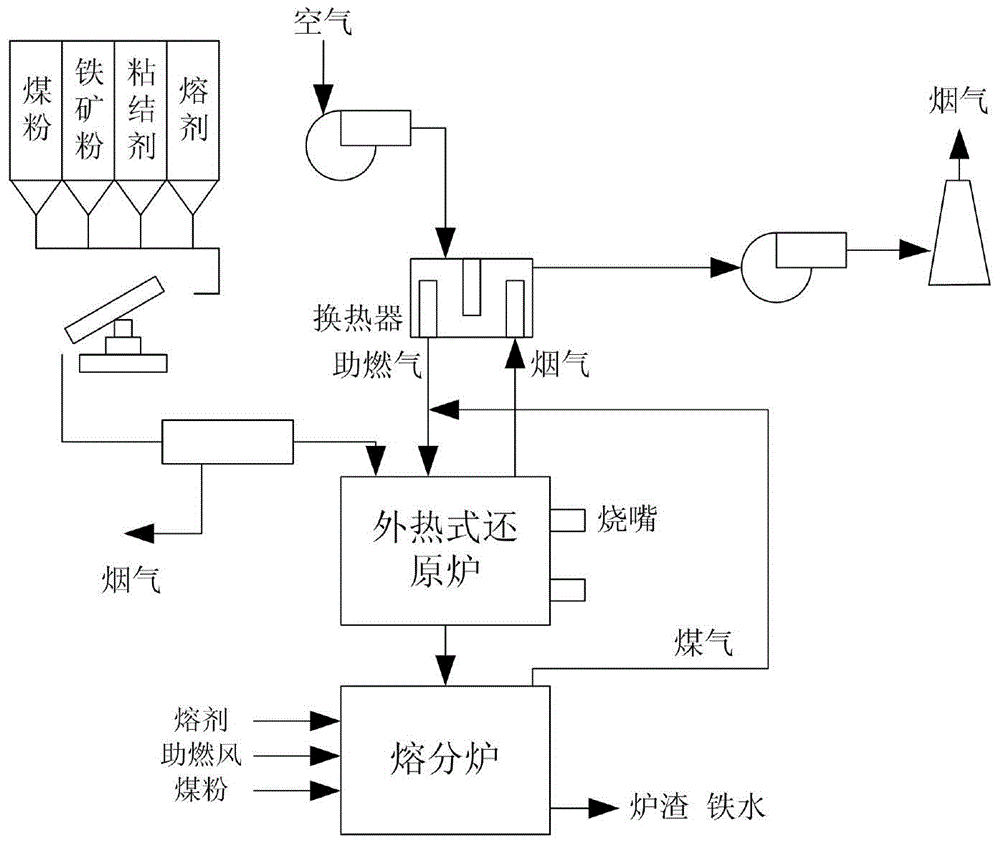

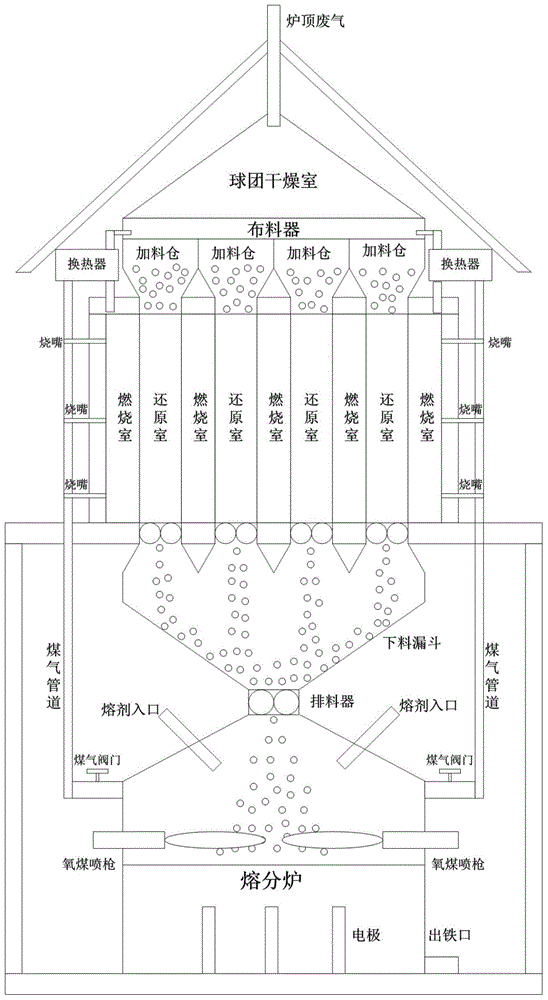

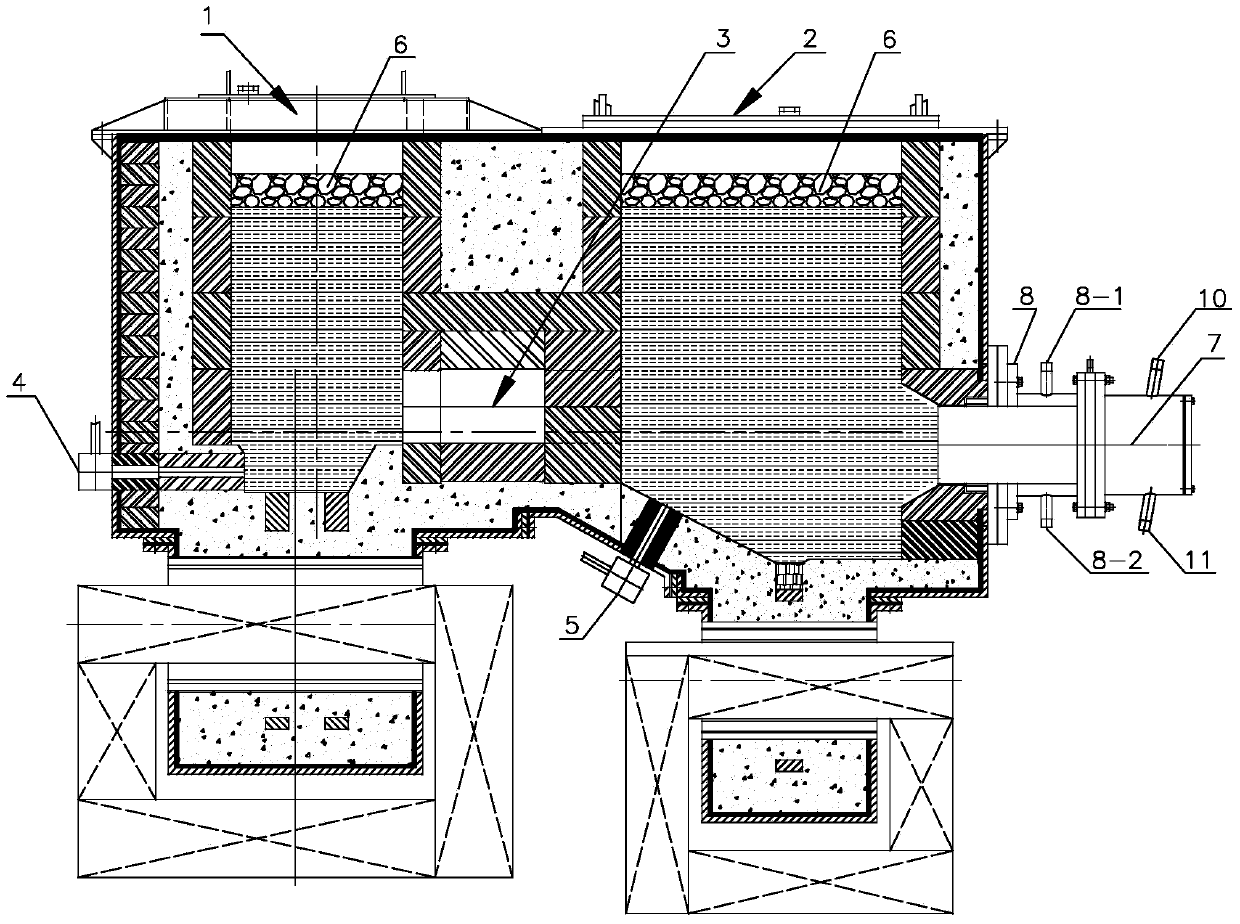

Coal-based direct reduction-melt separation furnace smelting reduction iron-making process using external heating mode

The invention relates to a coal-based direct reduction-melt separation furnace smelting reduction iron-making process using an external heating mode. Equipment used in the process comprises a pellet drying chamber, a distributing device, an external heating type reduction furnace and a melt separation furnace which are arranged from top to bottom. The process includes the steps that S1, carbon-bearing pellets are preheated and dried in the pellet drying chamber; S2, the carbon-bearing pellets in a reduction chamber are continuously and evenly heated, and the carbon-bearing pellets are quickly reduced in the reduction chamber; S3, high-temperature metallized pellets are obtained after the carbon-bearing pellets in the reduction chamber are reduced, and the high-temperature metallized pellets are charged into the melt separation furnace in a hot-delivery and hot-charging mode to be subjected to reduction smelting; S4, after the metallized pellets enter the melt separation furnace, the melting point, the viscosity and the separating effect of slag iron are controlled through the content of added flux and pulverized coal, reduction smelting of the metallized pellets is completed, and accordingly high-quality molten iron and high-temperature furnace slag are obtained. By the adoption of the process, iron ore which is low in grade and difficult to reduce is utilized comprehensively, the technological process is shortened, production cost is lowered, product quality is improved, and production efficiency is effectively improved.

Owner:CHONGQING UNIV

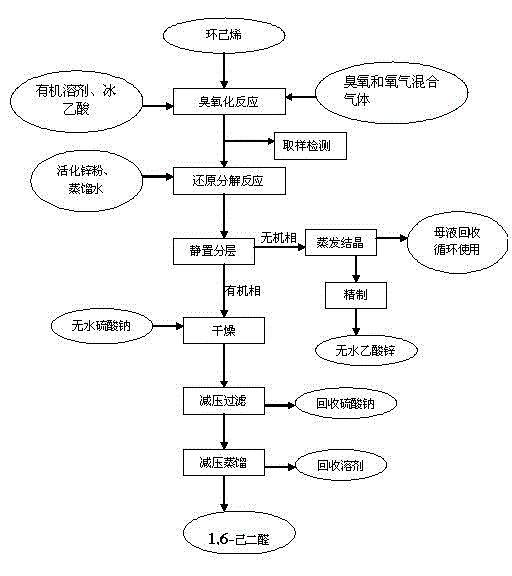

Method for preparing 1,6-adipaldehyde

InactiveCN102746127AHigh activityGood choicePreparation by ozonolysisCarboxylic acid salt preparationCyclohexeneReaction temperature

The invention belongs to the field of synthesis of fine chemicals, and discloses a method for preparing 1,6-adipaldehyde. The method comprises the following steps of: performing an ozonization reaction on cyclohexene serving as a raw material by taking ozone as an oxidant and taking an organic solvent and glacial acetic acid as mixed solvents at the reaction temperature of between 20 DEG C below zero and 10 DEG C to obtain an ozonized reaction liquid, and directly performing a reducing reaction on an ozonide without separating; and reducing and decomposing by adopting zinc powder, and reacting under the protection of nitrogen gas at the room temperature for 0.5-1.5 hours to obtain 1,6-adipaldehyde. Compared with the conventional method, the method has the advantages: ozone is taken as an oxidant, so that high oxidizing capacity and high selectivity are realized, the environmental pollution is low, the requirement of ozonization reaction temperature is low, energy is saved, and consumption is lowered. After reacting, a product is easy and convenient to separate; and zinc acetate is recovered from a water phase by concentrating and crystalizing, so that production cost is lowered, and industrial production is facilitated.

Owner:中国平煤神马控股集团有限公司 +1

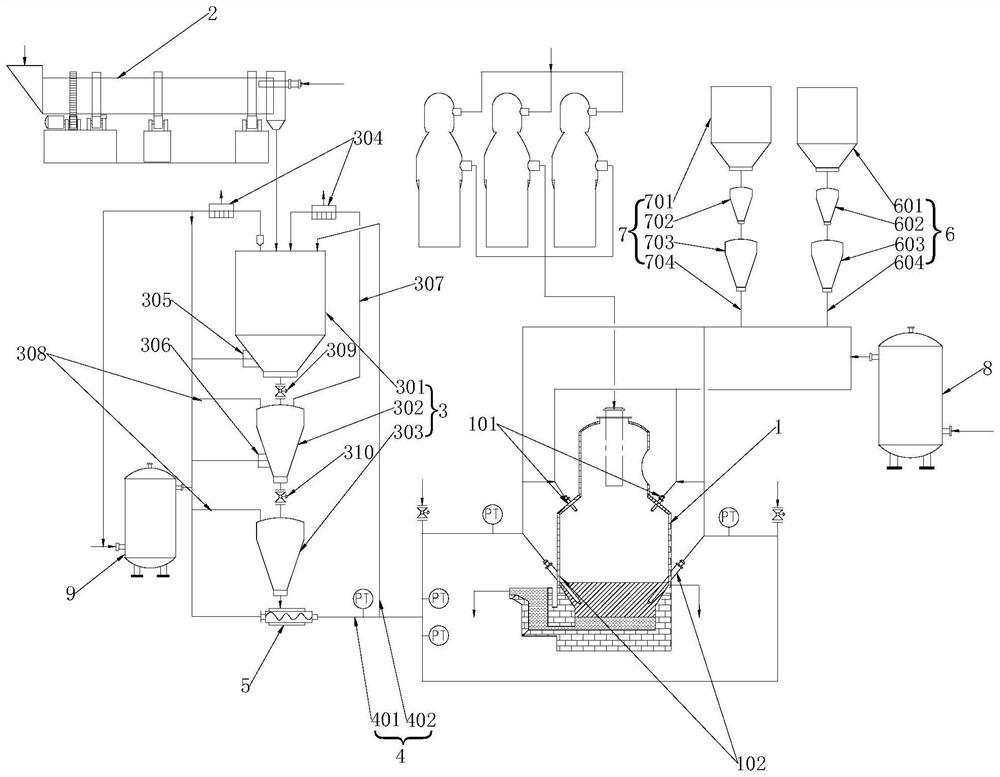

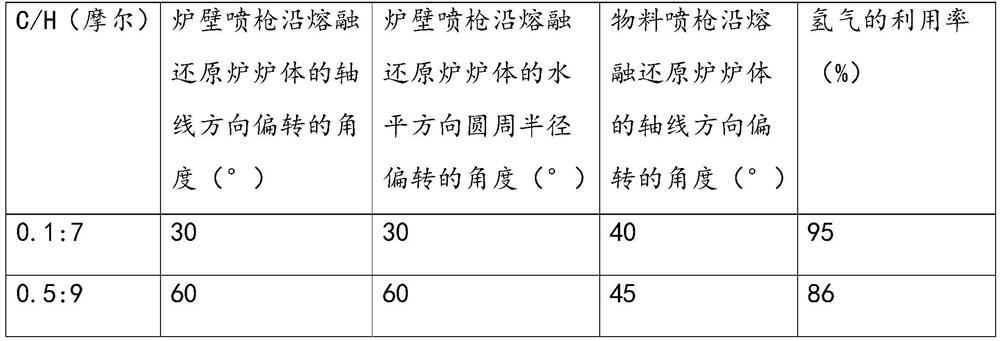

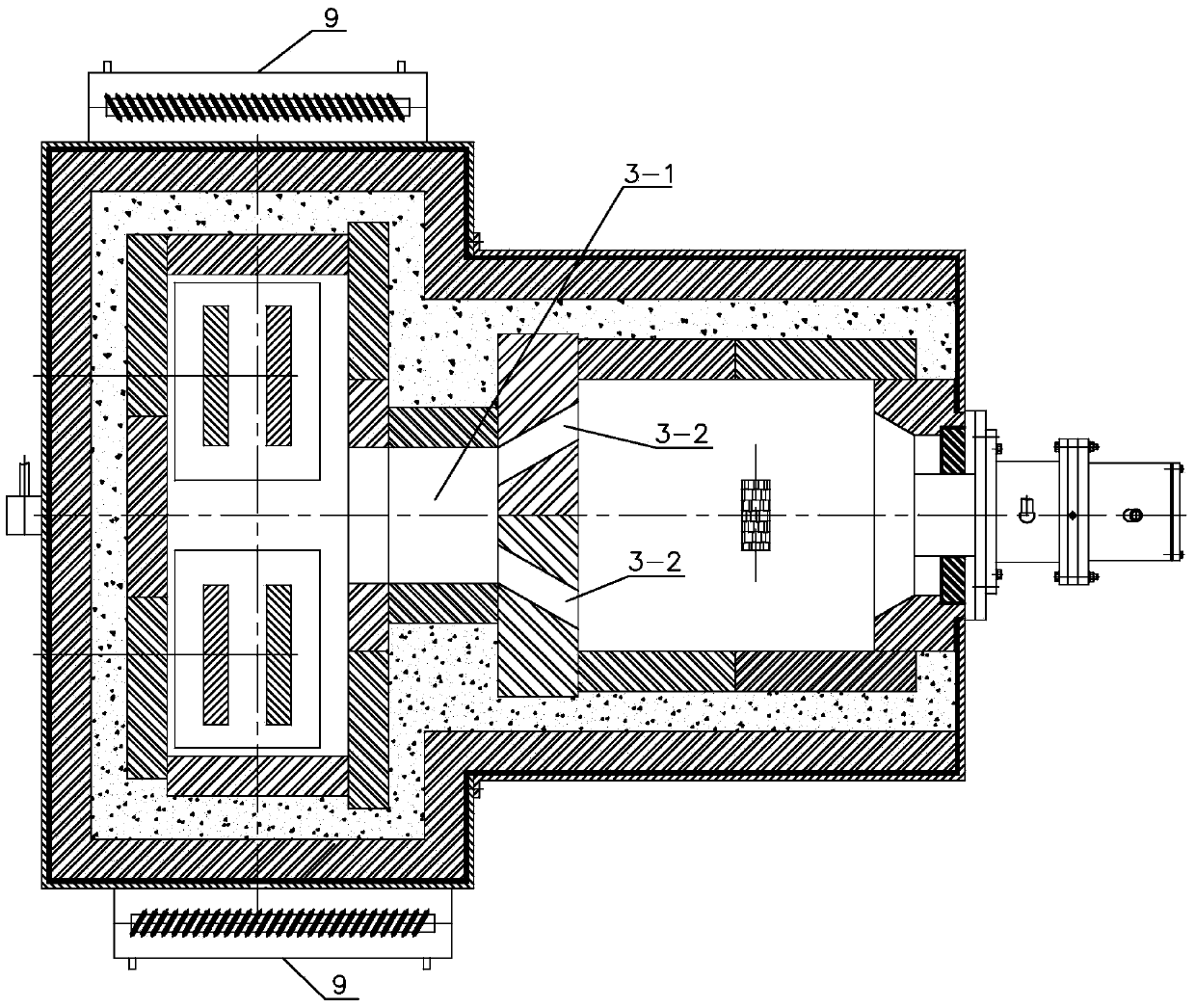

Smelting reduction hydrogen metallurgy process and device

The invention discloses a smelting reduction hydrogen metallurgy process and device. The smelting reduction hydrogen metallurgy process includes the steps that hydrogen is injected into a combustion area of a smelting reduction furnace to form high-pressure rotational flow in the combustion area; and a mixture of an iron-containing material and a magnesium-containing flux, a first carburant and first lime are blown into an iron bath area of the smelting reduction furnace by taking the hydrogen as a carrier gas. According to the smelting reduction hydrogen metallurgy process, the high-pressurerotational flow is formed in the combustion area, so that the retention time of the hydrogen in the smelting reduction furnace and the contact time of the hydrogen and iron-containing materials are prolonged, the amount of the hydrogen entering the combustion area discharged out of the smelting reduction furnace along with flue gas is reduced, the reduction reaction of the iron bath area is enhanced, the content of FeO in slag is reduced, the refractory material erosion speed is reduced, and the hydrogen utilization rate is increased; and the hydrogen is used as the carrier gas, so that the injection depth of a reducing agent can be effectively increased, the fountain effect in the smelting reduction furnace is enhanced, the reduction efficiency in the smelting reduction furnace is improved, and carbon emission in the metallurgical process is reduced.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

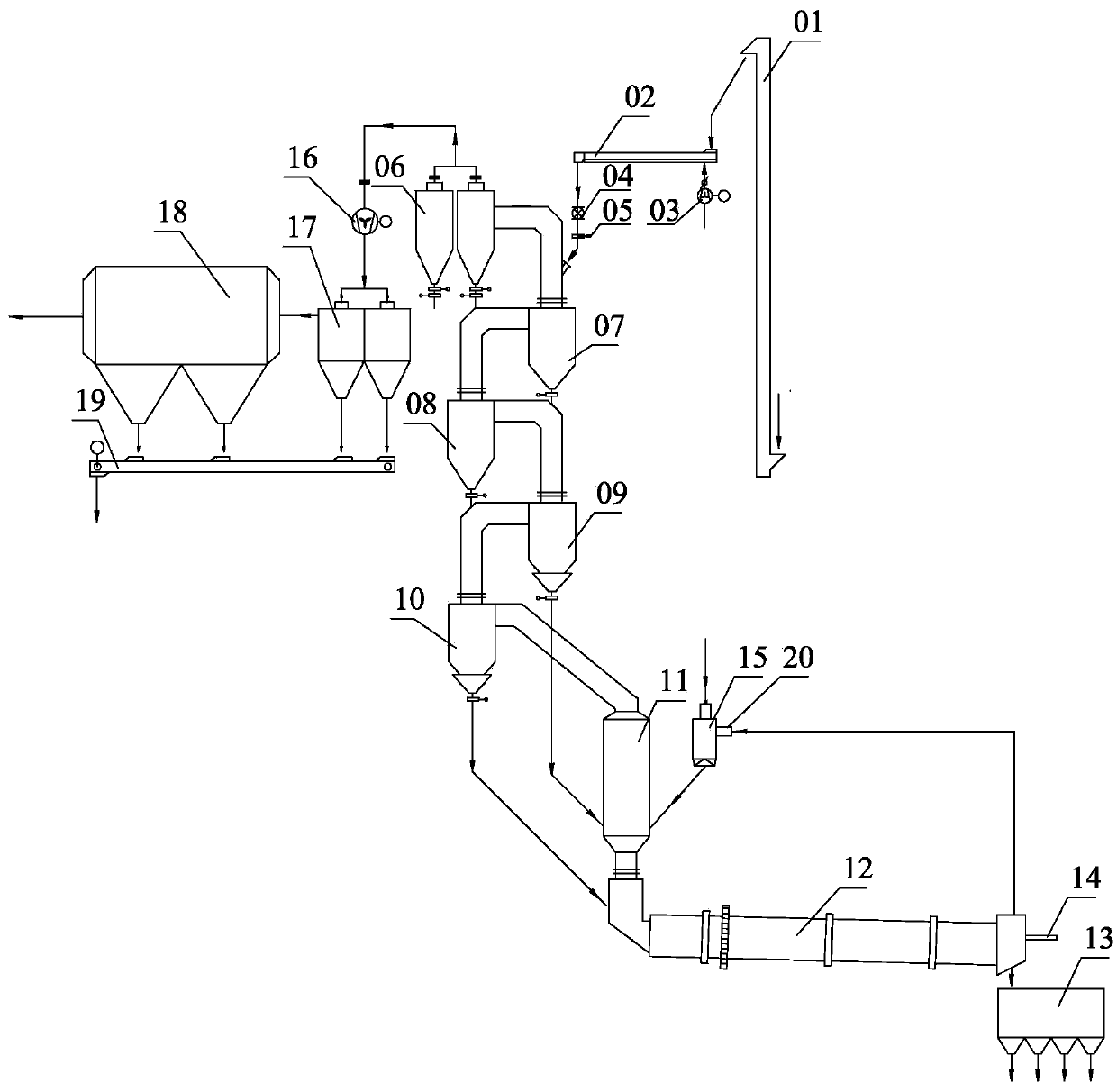

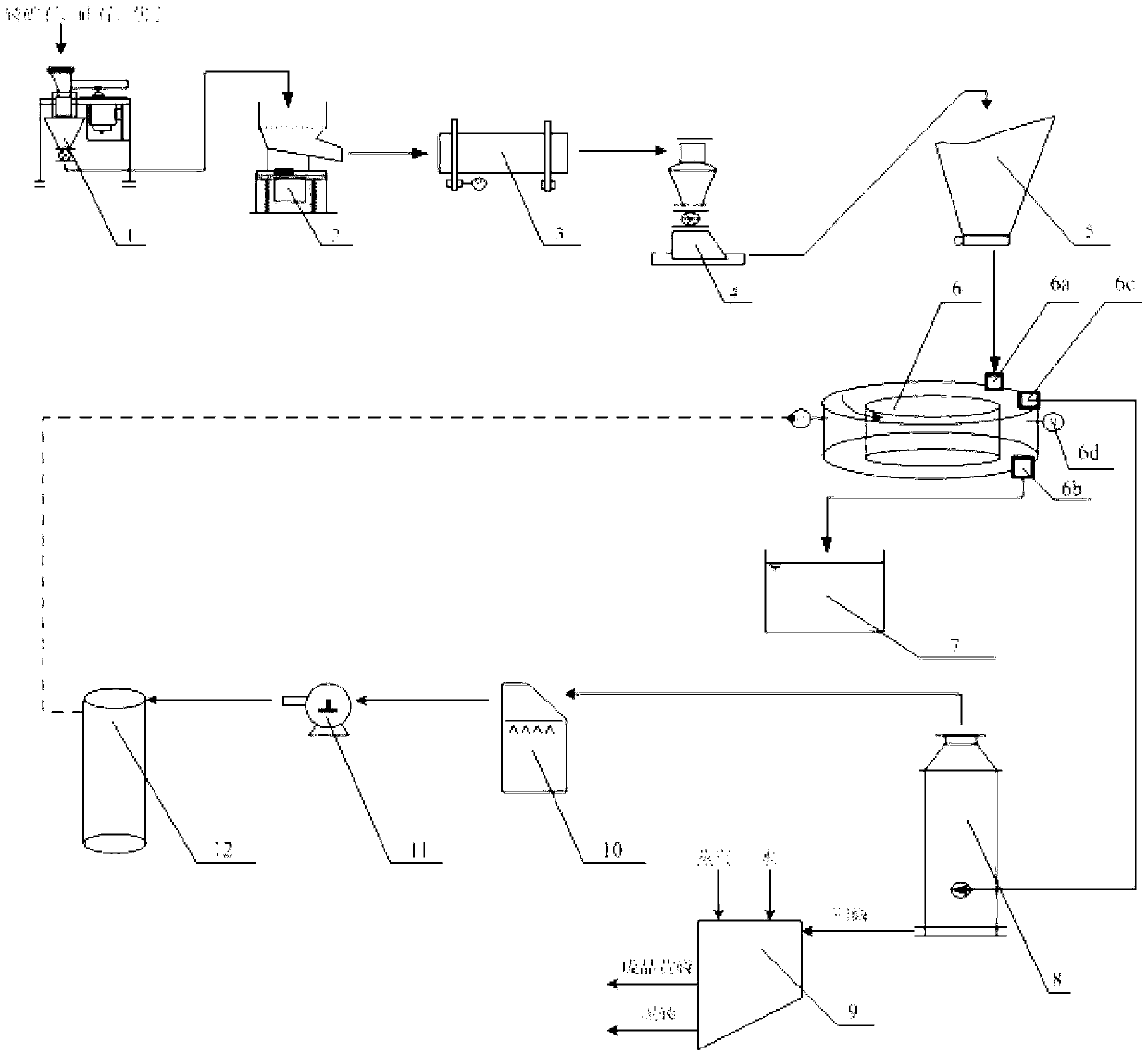

Method and device for preparing nickel iron roasted ore by utilizing lateritic nickel ore

ActiveCN103468930AFast heat and mass transferShorten decrystallization wateChemical reactionLaterite

The invention discloses a method and a device for preparing a nickel iron roasted ore by utilizing a lateritic nickel ore. The method comprises the following steps: firstly, grinding the lateritic nickel ore into an ore powder, then carrying out high-temperature roasting of the obtained ore powder, during the high-temperature roasting process, allowing the ore powder to be in a pre-reduction system and carry out a high-temperature preheating reduction reaction, followed by allowing the high-temperature roasted ore to go into a rotary kiln for high-temperature calcination, thus obtaining a roasted ore containing nickel pig iron after completing high-temperature calcination, and then after dipping the roasted ore into water for cooling, separating to obtain the nickel iron roasted ore. The device comprises a hopper-type elevator, an air chute, a chute draught fan, a rotary feeder, a sluice valve, a rotary kiln, a water-cooling stirring tank, a burner, a hot wind mixing chamber, a high-temperature draught fan, a cyclone dust remover, a bag-type dust remover, a chain-type conveyor, a burner and a pre-reduction system. The preparation method and the device allow the heat transfer area of the ore powder to be large, enable each particle to be uniformly and fully subjected to a chemical reaction, have short reaction time, and have high utilization rate of the lateritic nickel ore.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

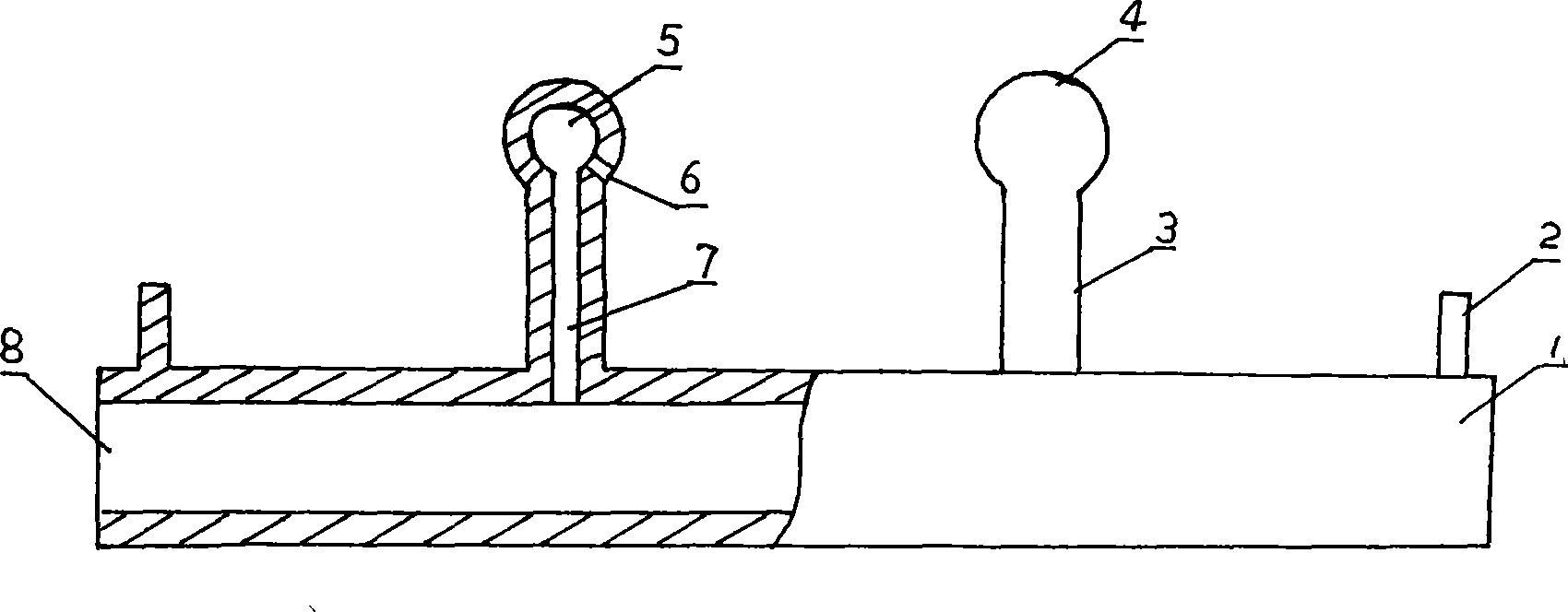

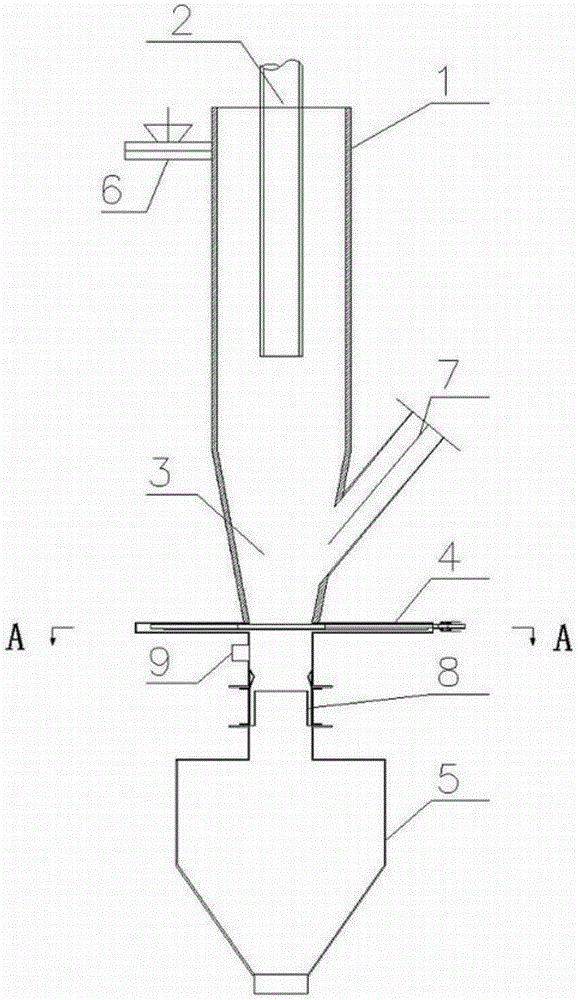

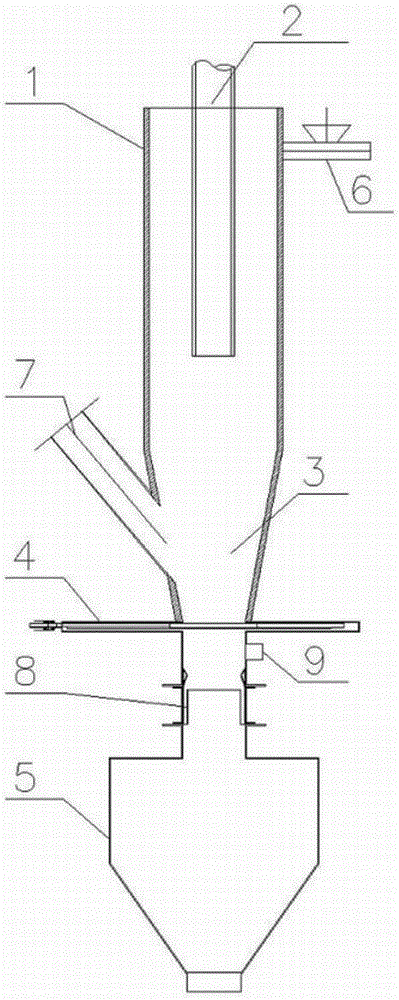

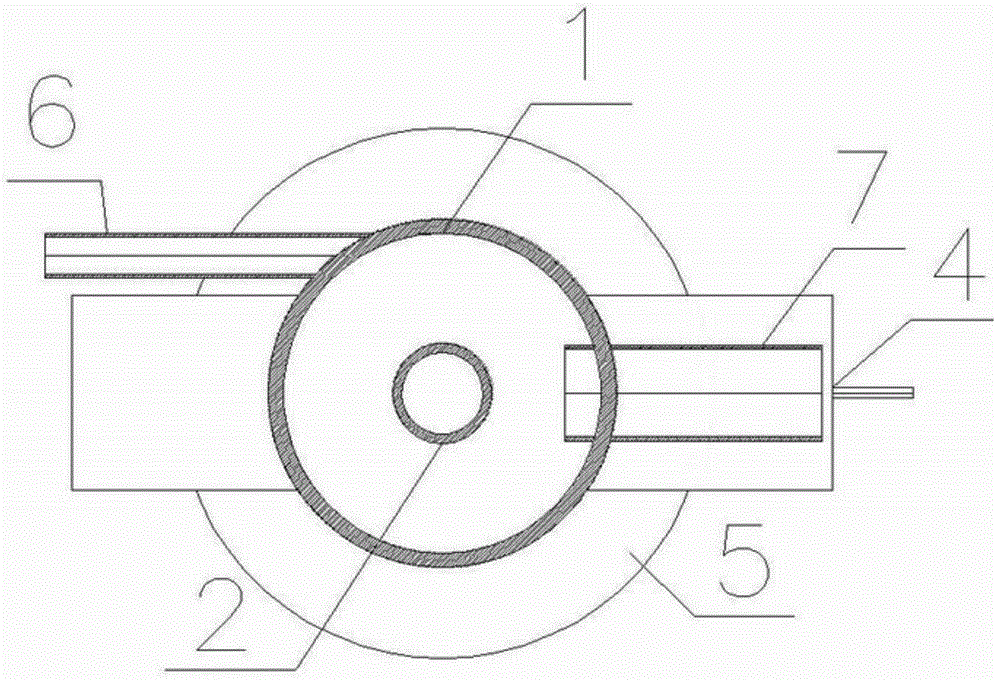

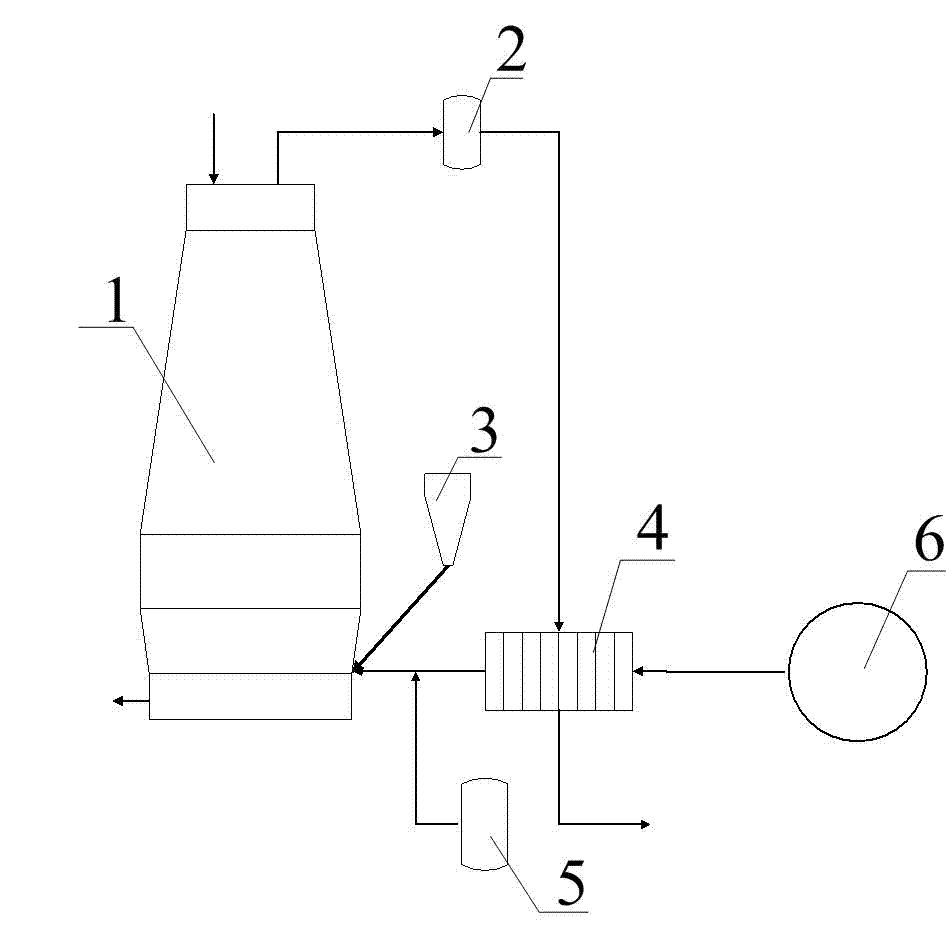

Biomass cyclone pyrolysis-suspension combustion composite gasification device and gasification method thereof

ActiveCN104152184AFacilitate the reduction reactionImprove conversion rateGranular/pulverulent flues gasificationCycloneCombustion chamber

The invention relates to a biomass cyclone pyrolysis-suspension combustion composite gasification device and a gasification method thereof. An existing cyclone gasification furnace has the defects of low biomass fuel conversion rate and low biomass gasification fuel gas heat value. The device provided by the invention has the following components: a central exhaust pipe (2) is concentrically suspended in a cyclone pyrolysis chamber (1); the cyclone pyrolysis chamber (1), a suspension combustion chamber (3), a switch grate (4), an air ring (8) and an ash hopper (5) are connected sequentially; an ignition hole (9) is arranged between the switch grate (4) and the air ring (8). A set of biomass fuel feeding pipes (6) is inserted on a tangential direction on the upper part of the cyclone pyrolysis chamber (1); an ignition fuel feeding pipe (7) is inserted on the lower part of the suspension combustion chamber (3). The gasification method comprises the following steps: a biomass fuel is sprayed into the cyclone pyrolysis chamber (1) along a tangential direction, and rotates downwards, such that a pyrolysis reaction is carried out; biomass coke particles in a pyrolysis reaction product enter the suspension combustion chamber (3), and is subjected to a combustion reaction with a main air flow from the air ring (8); and produced carbon dioxide moves upwards and is subjected to a reduction reaction with the biomass coke particles moving downwards from the suspension combustion chamber (3). The technical scheme provided by the invention is applied to the biomass gasification device and method.

Owner:HARBIN INST OF TECH

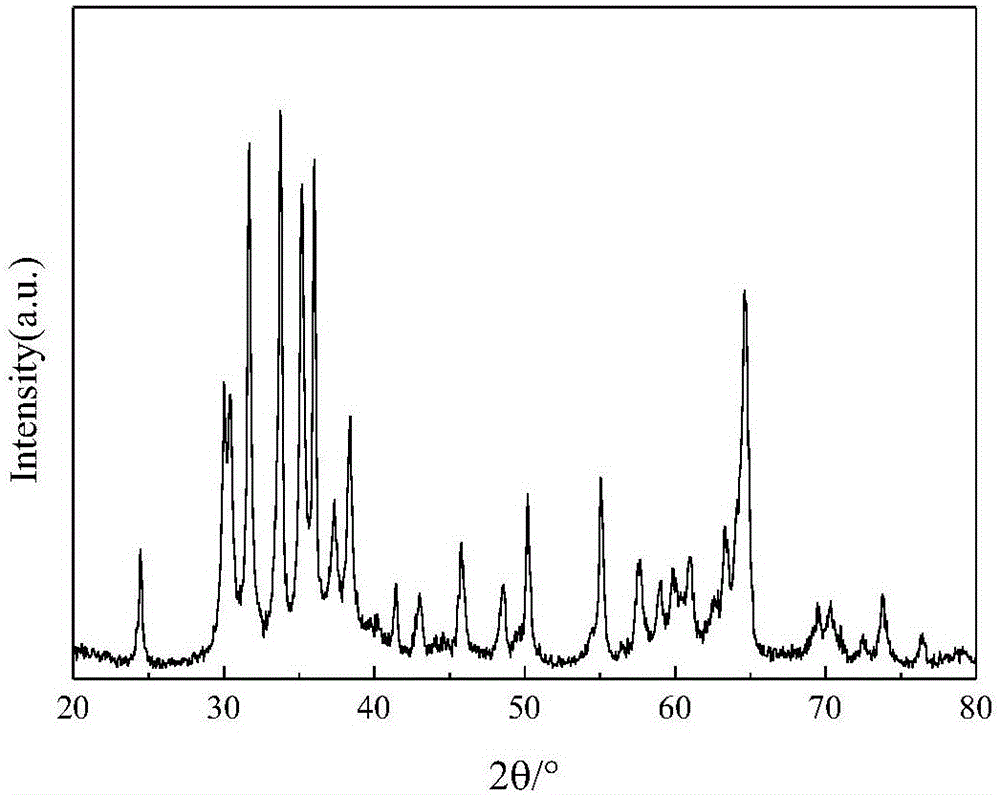

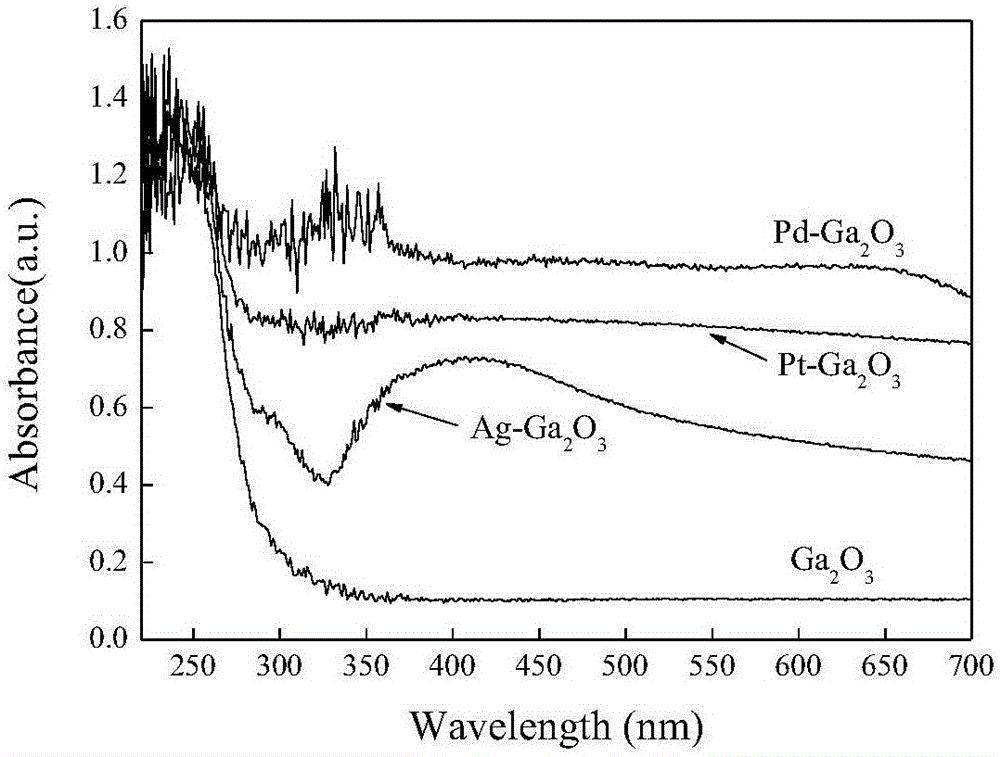

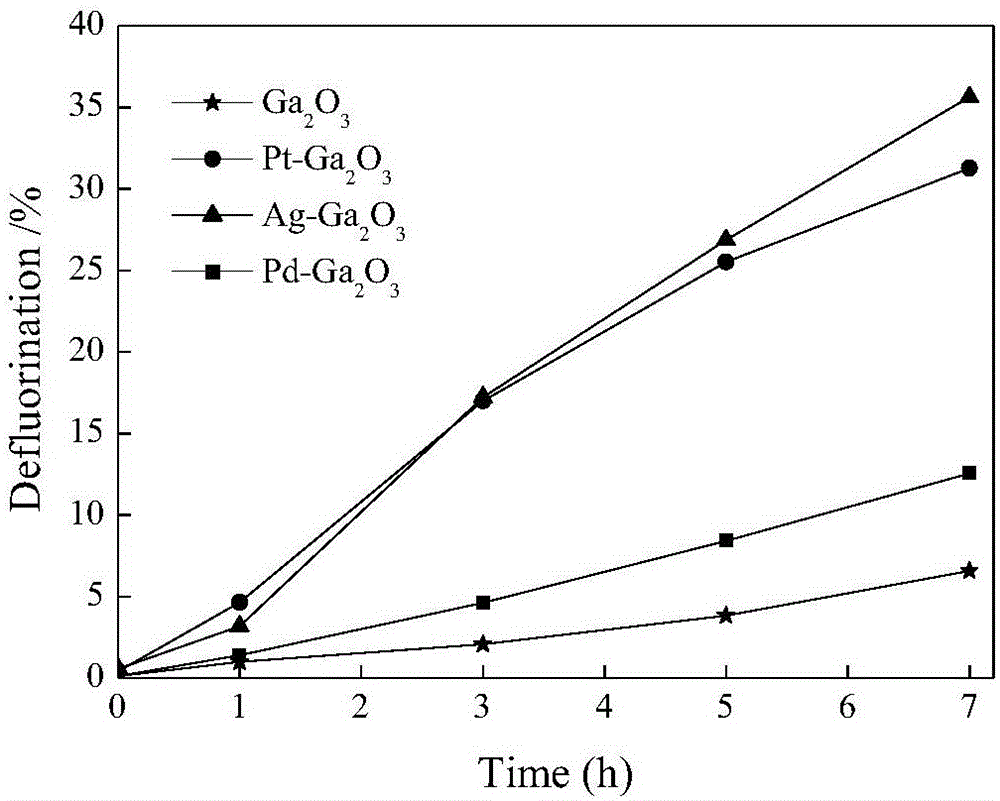

Method for photocatalytic degradation of PFOA (perfluorooctanoic acid) in water through noble-metal-doped gallium oxide

ActiveCN105060389AHigh defluorination efficiencyImprove light absorption abilityWater/sewage treatment by irradiationWater contaminantsPhotocatalytic degradationChemistry

The invention belongs to the technical field of water treatment, and particularly relates to a method for photocatalytic degradation of PFOA (perfluorooctanoic acid) in water through noble-metal-doped gallium oxide. The method comprises steps as follows: preparation of a noble-metal-doped gallium oxide catalyst and photocatalytic degradation of the PFOA through the noble-metal-doped gallium oxide catalyst. Specifically, a noble metal salt solution is added to a gallium oxide suspension for full and even mixing, then a reducing salt solution is added dropwise, metal particles are reduced and loaded onto the surface of gallium oxide, the noble-metal-doped gallium oxide photocatalyst is prepared, and then the PFOA is degraded in the presence of ultraviolet light by the aid of the photocatalyst, so that the PFOA in the water is removed. The method has the advantages that the photocatalyst preparation method is simple, the PFOA is degraded under normal temperature and normal pressure conditions, no complex device is required, and the degradation efficiency is high.

Owner:GUANGXI UNIV

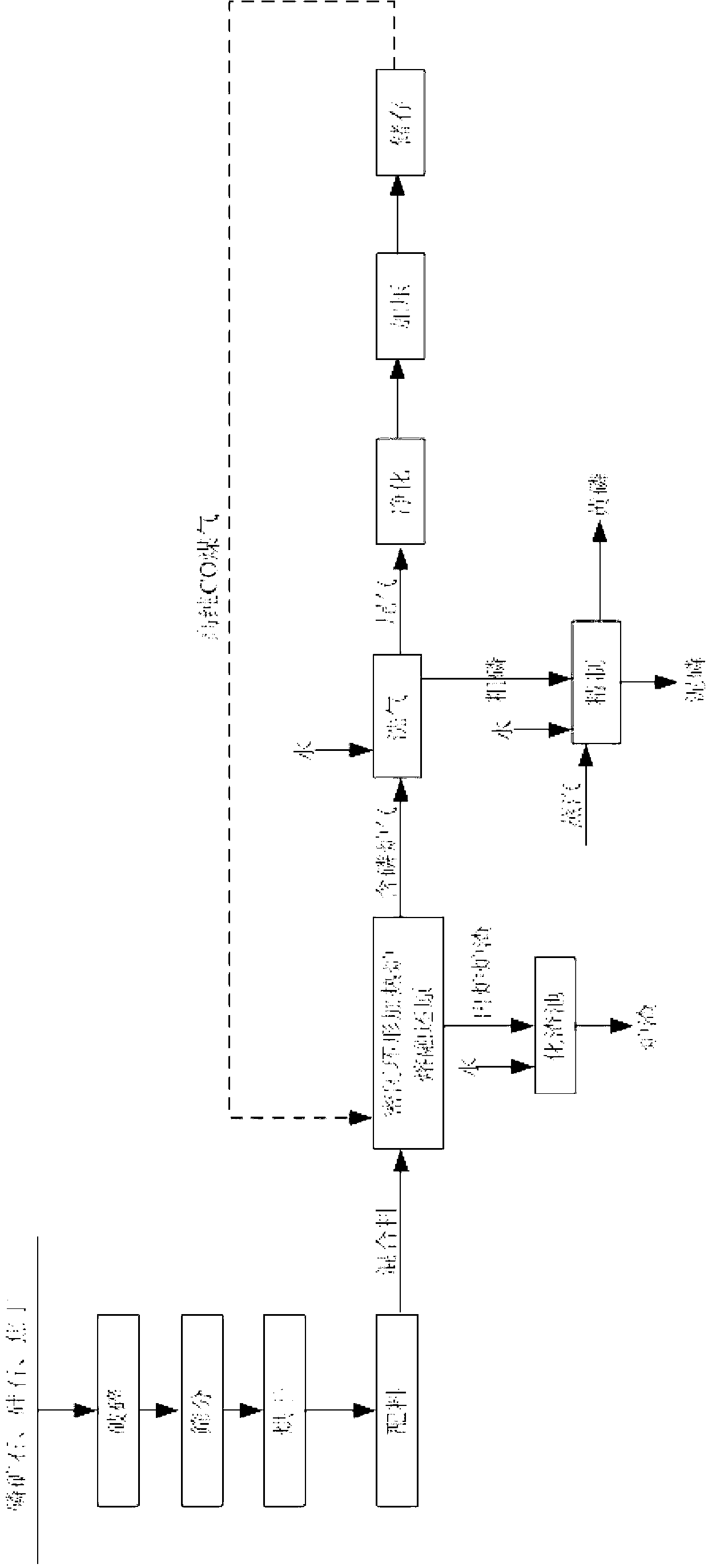

Method and equipment for producing yellow phosphorus by utilizing closed annular heating furnace

InactiveCN102992285AReduce production energy consumptionReduce manufacturing costPhosphorus compoundsExtension setSlag

The invention discloses a method and equipment for producing yellow phosphorus by utilizing a closed annular heating furnace. The equipment comprises a raw material crusher, a vibrating screen extension set, a drying machine, a metering device, a mixed storage bin and the closed annular heating furnace which are sequentially connected, wherein the closed annular heating furnace is respectively connected with a furnace gas treatment tail gas recovery mechanism and a slag collecting tank; and the furnace gas treatment tail gas recovery mechanism is connected with the closed annular heating furnace through a tail gas recovery pipeline. The method comprises the following steps of: raw material pretreatment, material proportioning, carrying out a reaction in furnace, discharging and performing a tail gas comprehensive utilization process. The equipment is low in power consumption, low in operating cost, low in investment strength and easy to maintain and has good industrial application prospect; and moreover, mature process conditions of yellow phosphorus production are by utilizing the equipment are realized, the yellow phosphorus tail gas heat value can be fully utilized, consumable graphite electrodes and carbon electrodes are not consumed, and the production energy consumption and cost are greatly reduced.

Owner:XIAN RICH ENERGY ENG

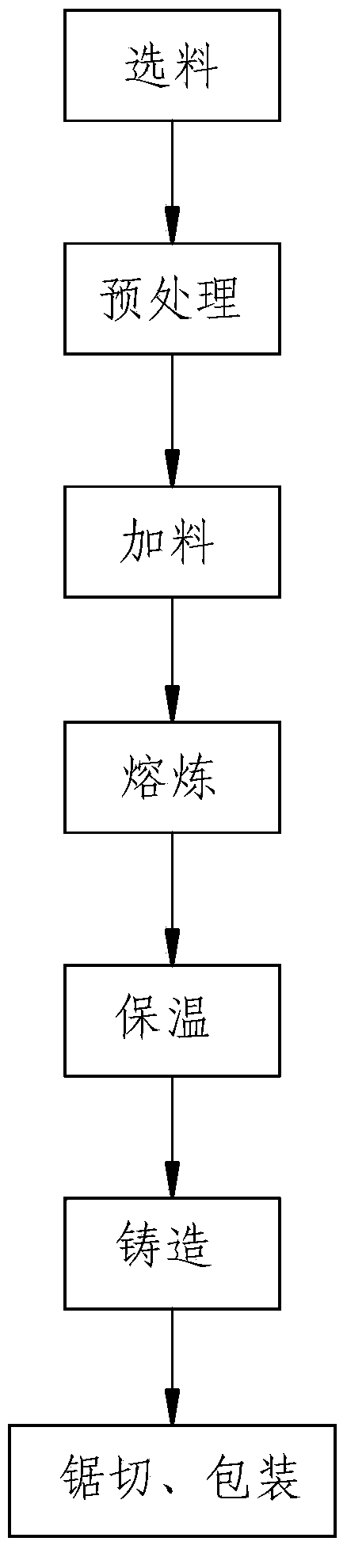

Large-diameter high-purity oxygen-free copper cast blank horizontal continuous casting process and connected furnace

The invention relates to a large-diameter high-purity oxygen-free copper cast blank horizontal continuous casting process. An oxide layer and particles are removed from the standby cathode copper surface, in addition, preheating treatment is carried out, and the preheating temperature is controlled to be 280 DEG C to 300 DEG C; pretreated cathode copper is placed into a smelting furnace to be smelted, the smelting temperature is controlled to be 1180 to 1230 DEG C, inert gas is introduced into the bottom of the smelting furnace, a calcined charcoal layer floats above molten copper to be used as the coverage, and the molten copper is stirred through electromagnetic stirring; then, the smelted molten copper flows into a heat insulation furnace, inert gas is introduced into the bottom of the heat insulation furnace, the calcined charcoal layer floats above molten copper to be used as the coverage, and the temperature inside the heat insulation furnace is controlled to be 1180 to 1230 DEG C; the molten copper in the heat insulation furnace is guided out, a graphite crystallizer is subjected to water cooling, and high-purity oxygen-free copper cast blanks are obtained. The process has the advantages that the oxygen content of the cast blanks can be effectively controlled, the production cost is reduced, products can completely reach TU1 standards, and the yield can reach more than 90 percent.

Owner:JIANGSU XINGRONG MEILE COPPER IND

Chemical nickel plating front activating process for titanium and titanium alloy surface

InactiveCN101016626AIncrease the amount of dissolutionReduce the amount of dissolutionLiquid/solution decomposition chemical coatingSupersonic wavesActive component

The invention discloses a disposing method of titanium and titanium alloy surface, which is characterized by the following: introducing supersonic wave to available activating craft; finishing the activation under the condition of ultrasonication; decreasing the usage of malignancy noxious pests HF in activating liquid; shorting the time of activating time; decreasing the quantity of dissolvable; extending the period of usage of activating liquid; simplifying the craft; increasing the mass transfer coefficient of buffer zinc layer; improving the arrangement of active component zinc layer; improving the deposition rate of coating; enhancing the cohesion of coating and basal body.

Owner:DAQING GASOLINEEUM INST

Alkaline chromium-contaminated soil solidifying, stabilizing and repairing method

ActiveCN105499262AHigh strengthReduce dosageContaminated soil reclamationReduction treatmentResource utilization

The invention relates to an alkaline chromium-contaminated soil solidifying, stabilizing and repairing method, and belongs to the technical field of environmental engineering. Hexavalent chromium in chromium-contaminated soil is separated into water by adopting water-washing pretreatment; hexavalent chromium-contaminated water is adjusted to be acid by adopting sulfuric acid as an acidifying or alkalizing agent, therefore, a reduction reaction of hexavalent chromium is facilitated, sulfuric acid can participate in a later curing reaction, and high-valued application of sulfuric acid is achieved; the efficiency of reducing hexavalent chromium in the contaminated water into trivalent chromium is improved by adopting CaS5 as a reducing agent, and water-washed soil and water after the reduction treatment are mixed for solidification and stabilization treatment; resource utilization of blast furnace slag is achieved by adopting the blast furnace slag and active magnesium oxide as solidification materials, enhancing of the strength of the solidified soil and wrapping of contaminants can be quickly achieved, and the long-term stability of the treated chromium-contaminated soil is good. The method has the advantages of being low in treatment cost, good in effect, free of secondary pollution, convenient to operate, good in long-term stability, high in resource utilization and the like.

Owner:海南碧天环境工程技术有限公司

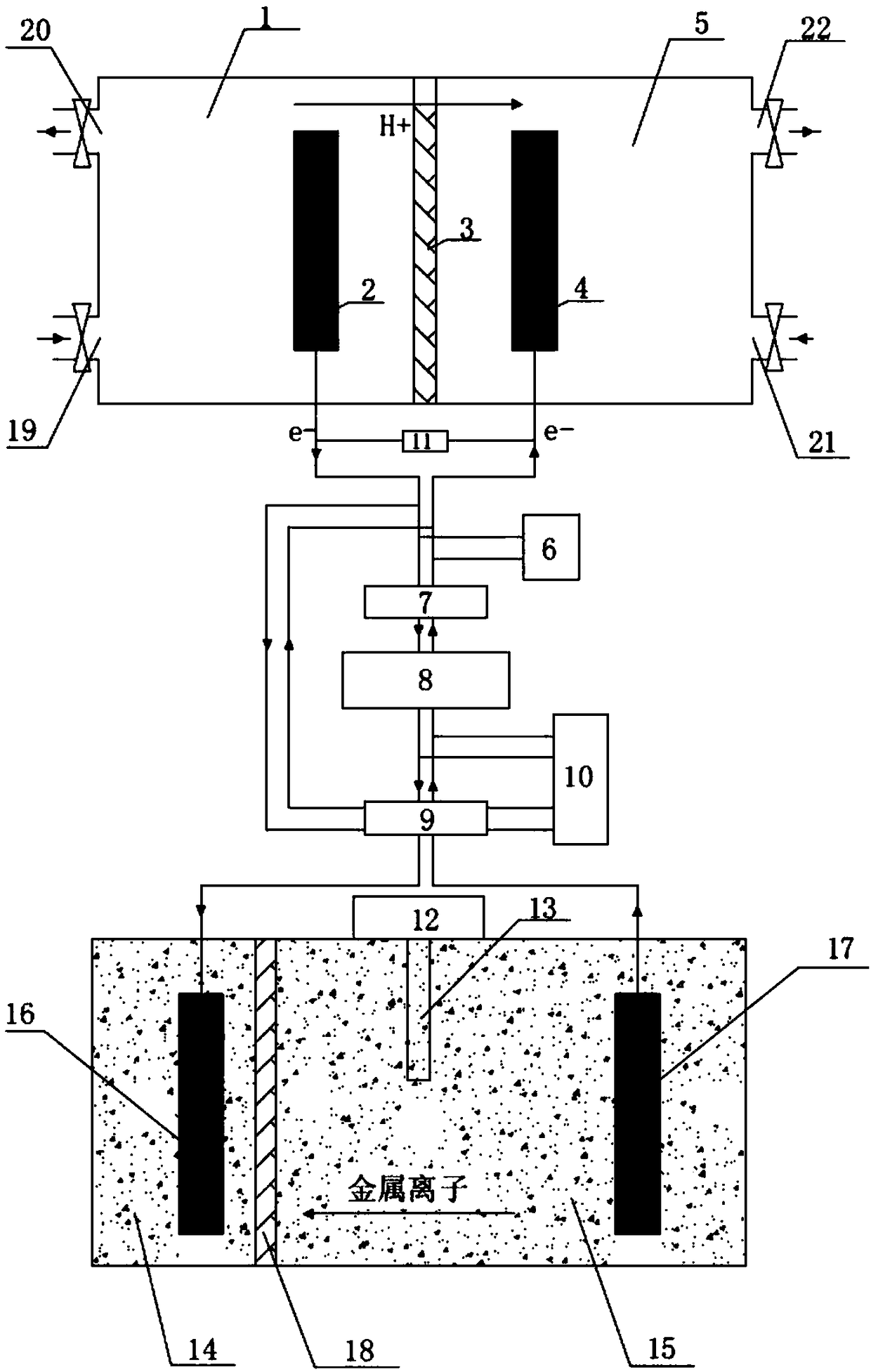

System and method by utilizing fuel cell to treat organic wastewater and synchronously repair soil heavy metal

PendingCN108339846AMaintain fertilityWon't happenWater contaminantsContaminated soil reclamationData acquisitionSoil heavy metals

The invention discloses a system and a method by utilizing a fuel cell to treat organic wastewater and synchronously repair heavy metal in soil. The system comprises a microbiological fuel cell, a data acquisition regulation and control device and a soil electrodynamic remediation device. One end of the data acquisition regulation and control device is connected with an anode unit and a cathode unit through lead wires correspondingly; the other end of the data acquisition regulation and control device is connected with a negative electron and a positive electrode through lead wires correspondingly; and the data acquisition regulation and control device is used for acquiring a voltage signal generated by the microbiological fuel cell and for regulating and controlling the magnitude of electric current received by the soil electrodynamic remediation device. By utilizing the microbiological fuel cell to treat organic wastewater, wastewater is treated, and electric energy is generated to remove the heavy metal in the soil; the system and the method do not damage a soil structure and the organic content in the soil is not affected; and at the same time, the data acquisition regulation and control device is adopted, so that the electric energy utilization efficiency of the microbiological fuel cell is improved effectively and the removal rate of the heavy metal in the soil is reduced.

Owner:QINGDAO UNIV OF SCI & TECH

Method for preventing directly reduced metallic pellets from bonding

Belonging to the technical field of metallurgy, the invention relates to a method for preventing directly reduced metallic pellets from bonding. The method comprises the steps of: (1) mixing anthracite carbon powder, lime powder, clay and bentonite uniformly so as to prepare peritoneal powder; (2) making a material to be reduced into mineral powder pellets; (3) placing the peritoneal powder into the pelletizing disc of a pelletizer, then putting the mineral powder pellets to be reduced on the peritoneal powder in the pelletizing disc, and initiating the pelletizer so as to prepare composite pellets; (4) subjecting the composite pellets and a pulverized coal reducing agent to a reduction reaction at a temperature of 1180-1220DEG C for 3-4h, thus obtaining metallic iron pellets. The method of the invention solves the bonding problem of directly reduced metallic pellets, and is especially suitable for producing high density metallic pellets, and also especially suitable for production of metallic pellets with high grade iron ore powder.

Owner:辽宁博联特冶金科技有限公司

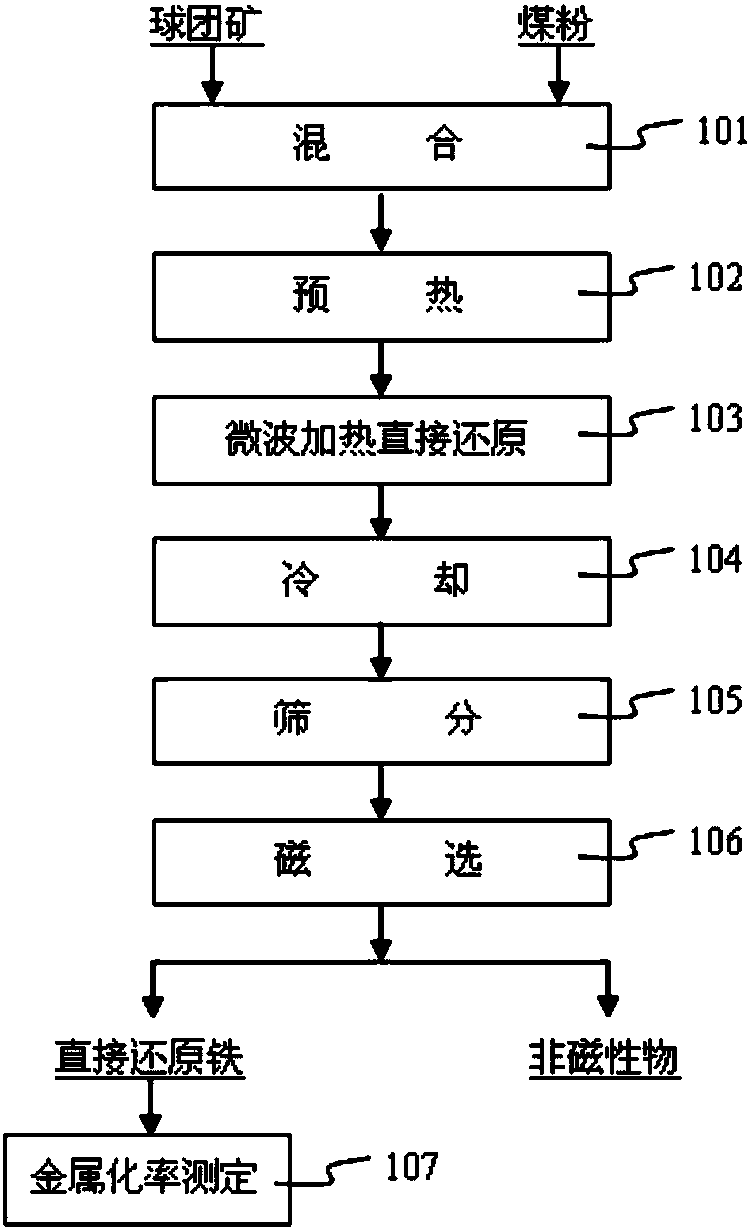

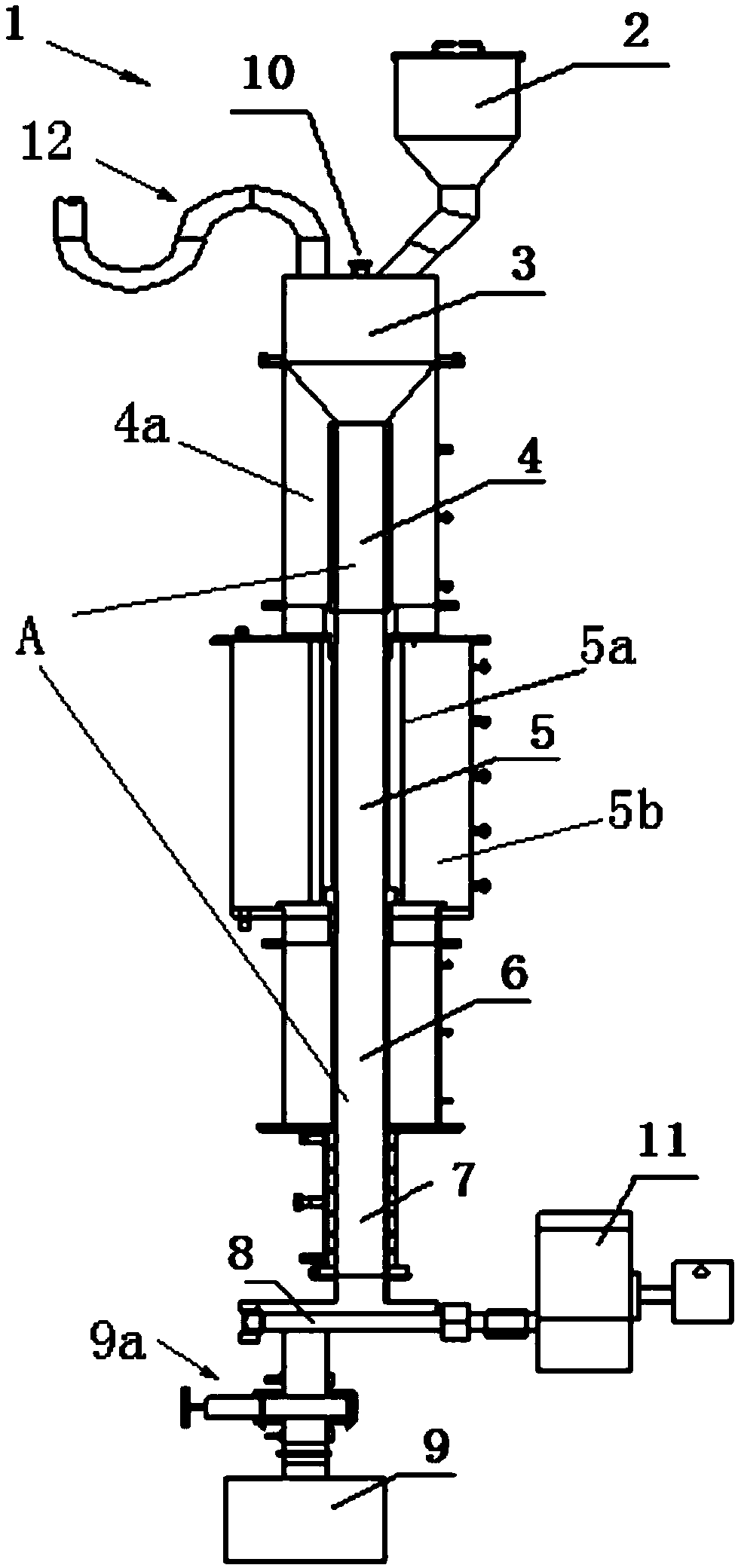

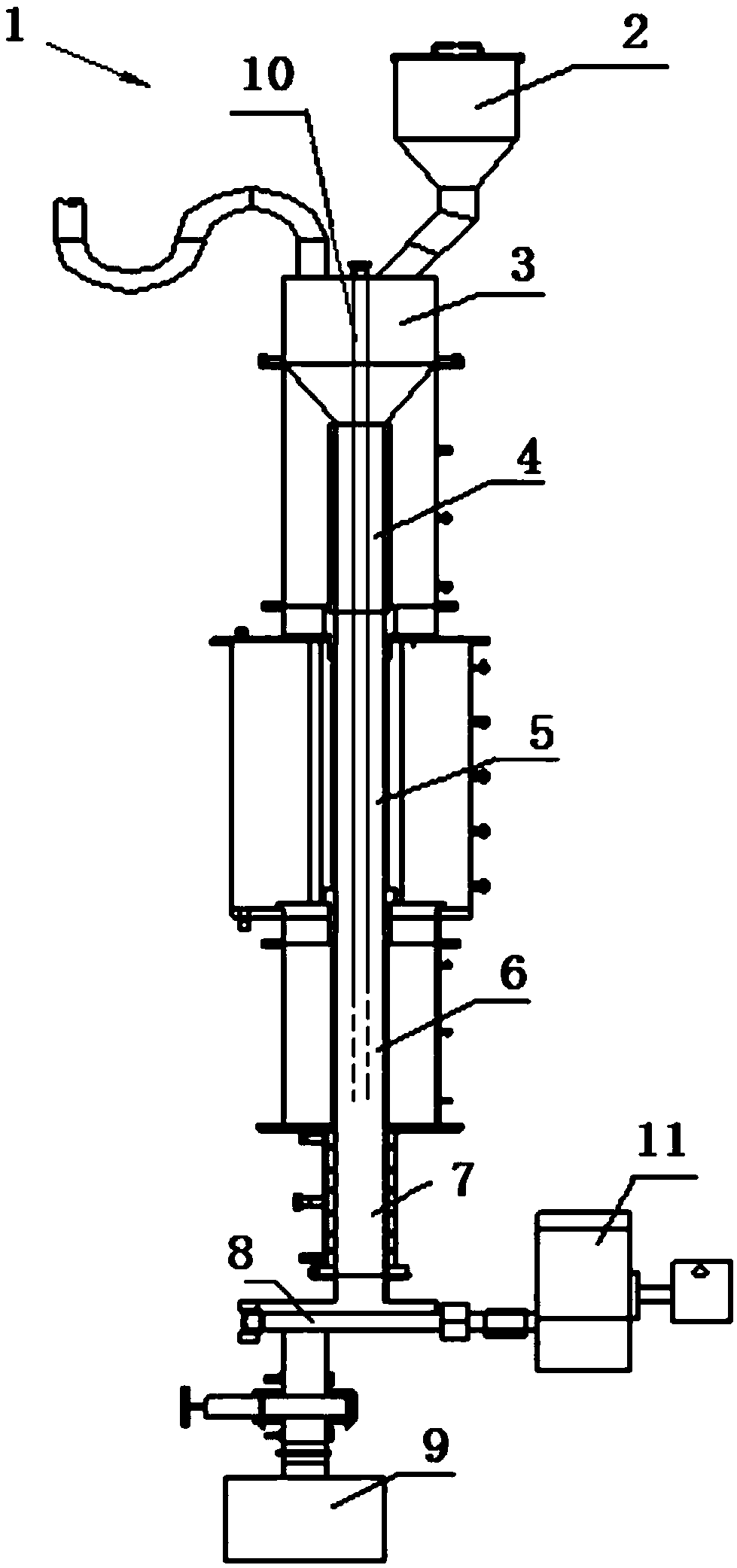

Direct reduced iron production method and device

ActiveCN107779536AImprove use valueQuick restoreShaft furnaceProcess efficiency improvementChemical reactionReaction temperature

The invention relates to a microwave shaft furnace direct reduction process adopting pellets and coal powder. According to the process, direct reduced iron is produced from raw material pellets and external matched material coal powder in a continuous microwave shaft furnace, selection heating, rapid heating, volume heating, activated metallurgical chemical reaction and other features of the microwave are fully utilized, gasification of fixed carbon is accelerated, and iron oxide is further reduced, so that the reduction temperature is lowered and the reaction time is shortened. The coal powder can serve as both a reducing agent and a heating element in the process, a gas-solid-heat exchange step is simplified, energy is saved and emission is reduced. The process contains low free oxygen content, and can produce CO with high purity of 95% or above; and the process is compact in structure, high in metallization degree, which is 94-98%, low in carbon content, which is less than 0.2%, andis low in quality requirements on coal powder, thereby being an environment-friendly iron making process.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

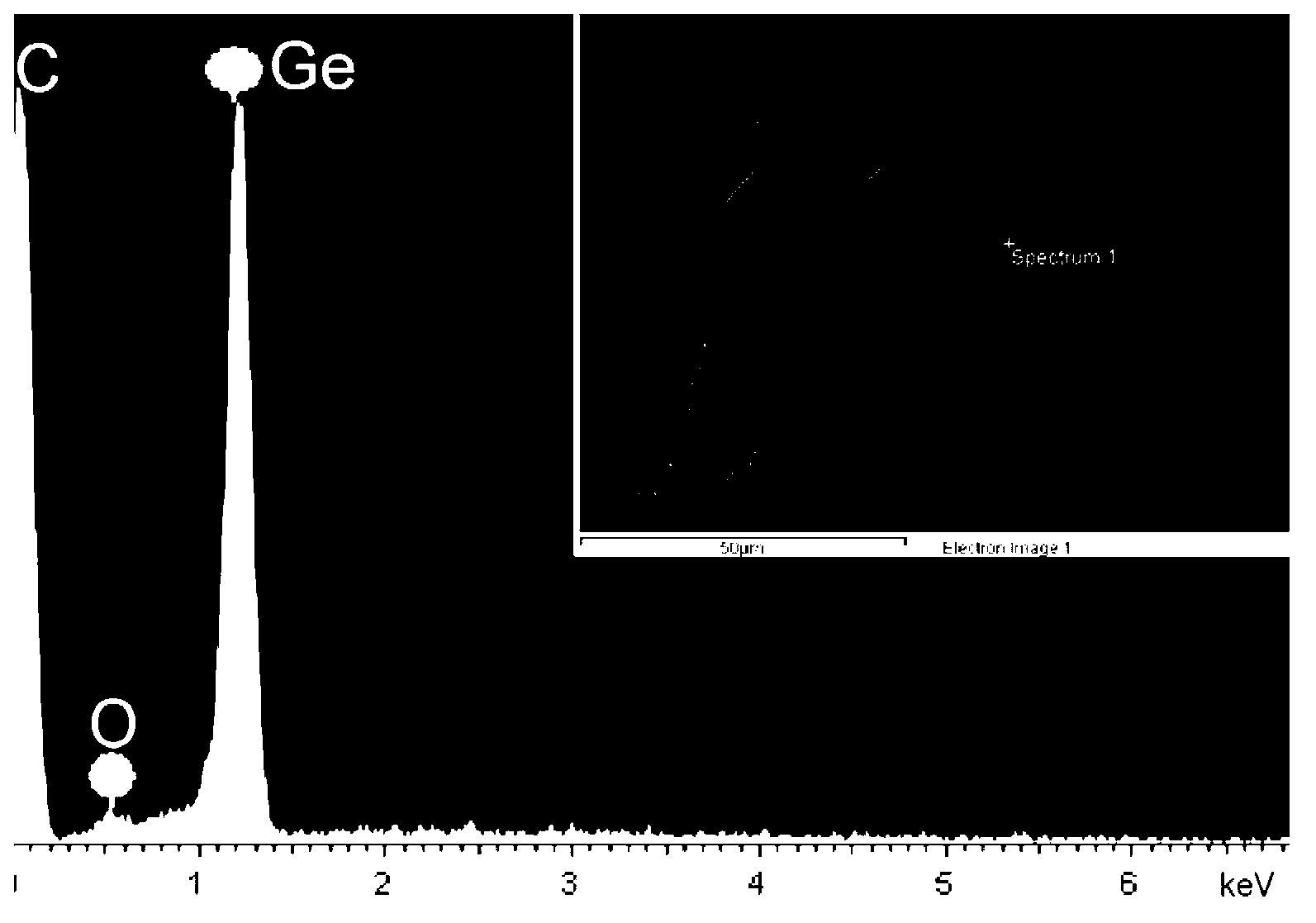

Method for preparing germanium nanotubes

The invention discloses a method for preparing germanium nanotubes. The method includes the steps of firstly, adopting secondary anodic oxidation process to obtain a thorough-hole alumina template, soaking the through-hole alumina template in nickel nitrate solution to remove nickel nitrate from the surface of the template so as to obtain the thorough-hole alumina template with nickel nitrate deposited in holes; secondly, placing the thorough-hole alumina template with nickel nitrate deposited in the holes into a mixed atmosphere of hydrogen argon to be subjected to reduction reaction at the temperature of from 300 DEG C to 380 DEG C for 10-30 minutes, then placing the thorough-hole alumina template with nickel nitrate deposited in the holes into the mixed atmosphere of germane hydrogen argon to be subjected to vapor deposition at the temperature of from 300 DEG C to 380 DEG C for 10-30 minutes to obtain the alumina template with the germanium nanotubes deposited inside the holes; and finally, placing the alumina template with the germanium nanotubes deposited inside the holes into aqueous alkali to remove the alumna template to obtain the germanium nanotubes composed of nickel diffusing evenly in amorphous germanium which has the ratio of germanium to nickel being (95.05-99.95%):(0.05-4.95%). By the method, possibility is provided to a research of characteristics of light, electricity and the like of the germanium nanotubes and an application thereof. Hopefully, the method for preparing the germanium nanotubes can be widely used in the fields of light, electronic device and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

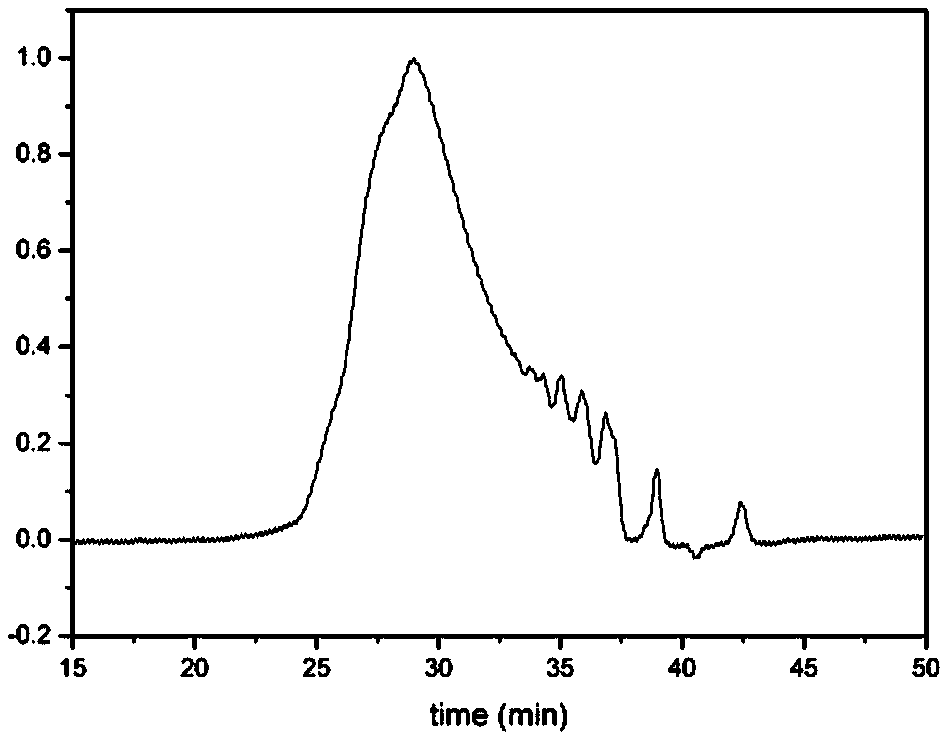

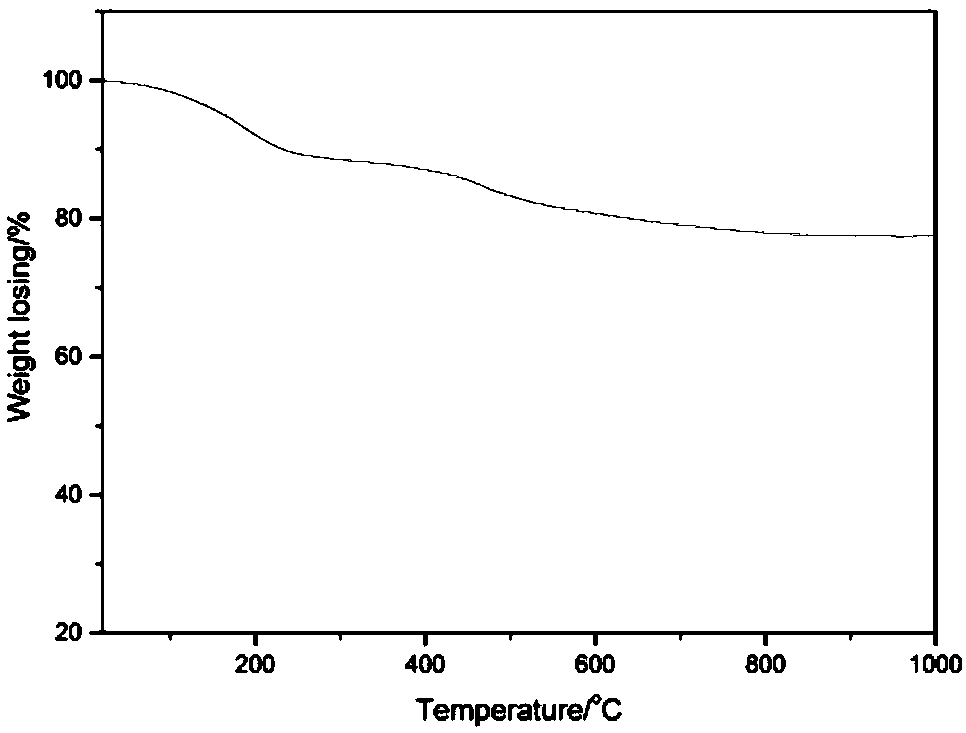

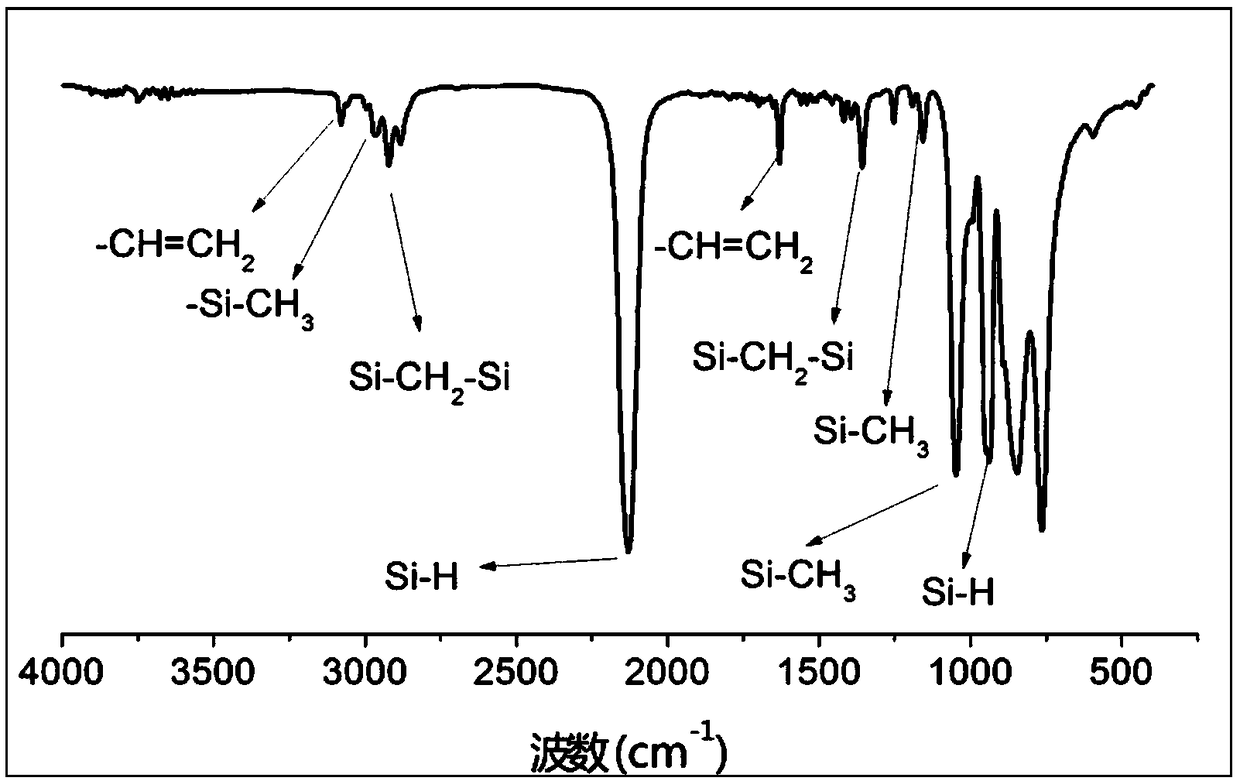

Preparation method of liquid-state polycarbosilane

The invention relates to a preparation method of liquid-state polycarbosilane. The preparation method includes: subjecting hexamethyl disilazane and chloromethyl trichlorosilane to partial ammonolysis, being in format coupling reaction with unsaturated chloroalkane and chloromethyl chlorosilane, adding a certain amount of NaBH4 (sodium borohydride) reductant for reduction after reaction is completed, adding petroleum ether, deionized water and concentrated hydrochloric acid into an obtained material for acid pickling and extraction, adopting NaOH to dry an obtained petroleum ether solution, filtering, and adopting a method of reduced pressure distillation to evaporate the petroleum ether out to obtain flavescent thick liquid which is liquid-state polycarbosilane. Liquid-state polycarbosilane prepared by the method is high in fluidity and processability and can be directly in thermal polymerization, and ceramic yield is higher than 70%. Content of free carbon in ceramic is low, SiC ceramic phase is high in purity, and liquid-state polycarbosilane is suitable for serving as a high-performance SiC ceramic precursor, can be used for ultrahigh-temperature ceramic based composite material soaking substrates and can also be used for preparing high-performance materials like SiC ceramic coatings and fiber.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Full-oxygen humidifying and blasting device and technology for blast furnace

InactiveCN102888475AFacilitate the reduction reactionChange the energy structureBlast furnace componentsBlast furnace detailsWater vaporEngineering

The invention provides a full-oxygen humidifying and blasting device for a blast furnace and a full-oxygen humidifying and blasting technology for the blast furnace. The technology is to blow the mixture of oxygen and steam by virtue of an air port of the blast furnace, wherein the blown oxygen is at temperature of 100-700 DEG C; and the mixture is of 5-20% based on the humidity. The device comprises an oxygen supplying device, a heat exchange device and a steam pocket; the heat exchange device is used for supplying the afterheat from the dust-removed gas of the blast furnace to the oxygen output by the oxygen supplying device for heating; and the heated oxygen from the heat exchange is mixed with the steam output by the steam pocket and then is blown into the air port of the blast furnace. According to the full-oxygen humidifying and blasting device and technology for the blast furnace provided by the invention, the full-oxygen humidifying and blasting is carried out to the blast furnace, so that the theoretical burning temperature of the air port of the full-oxygen blast furnace is beneficially improved, an oxygen-coal gun and the air port can be effectively prevented from being burnt, and the blast furnace can be directly operated; and after humidifying and blasting, the steam generated by blasting is decomposed and generates reducing gas which is beneficial for improving the reduction reaction in the blast furnace.

Owner:WISDRI ENG & RES INC LTD

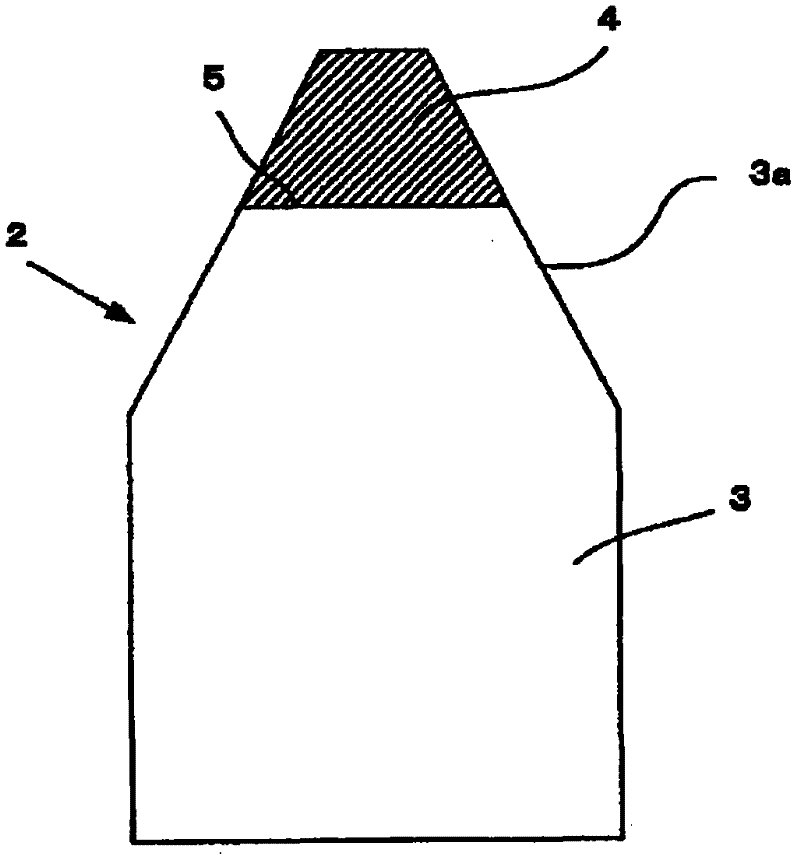

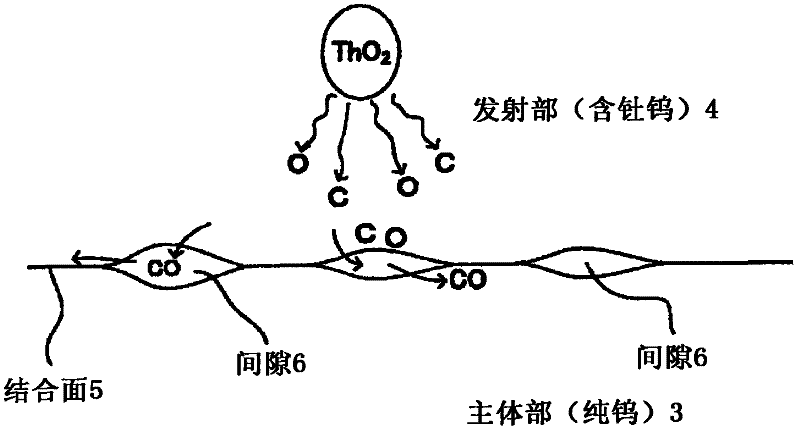

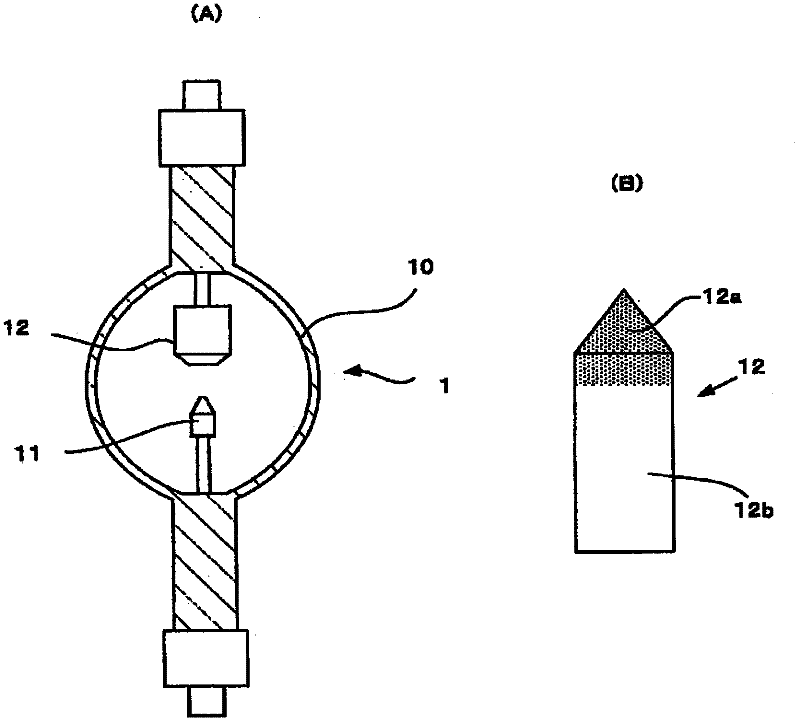

Short arc type discharge lamp

ActiveCN102315078AEfficient use ofNo depletionHigh-pressure discharge lampsThorium oxideOptoelectronics

A short arc type discharge lamp wherein a cathode and an anode are arranged opposite to each other in an interior of a light emitting tube and said cathode comprises a main part made from tungsten and an emitter part made from thoriated tungsten. The cathode effectively utilize thorium oxide contained in the emitter part, and provides a configuration preventing exhaustion of the thorium oxide on the surface of the emitter part.The short arc type discharge lamp is characterized in that gaps are formed locally at a joint face of said main part and the emitter part, and carbonic oxide produced by a reduction reaction of the thorium oxide contained in the emitter part is emitted to the outside.

Owner:USHIO DENKI KK

Preparation method of aluminum-scandium intermediate alloy, aluminum-scandium intermediate alloy and aluminum-scandium alloy

The invention provides a preparation method of an aluminum-scandium intermediate alloy, an aluminum-scandium intermediate alloy and an aluminum-scandium alloy. The preparation method comprises that a scandium-containing compound and an aluminum-containing raw material are added into a first reactor and undergo a thermal reduction reaction to produce a liquid aluminum-scandium intermediate alloy, wherein the aluminum-containing raw material contains aluminum and / or an aluminum alloy, the liquid aluminum-scandium intermediate alloy is added into a second reactor with melt salt and is subjected to slag extraction treatment, wherein the density of the melt salt is less than density of the liquid aluminum-scandium intermediate alloy, and the liquid aluminum-scandium intermediate alloy subjected to slag extraction treatment is cooled and cured so that an aluminum-scandium intermediate alloy cast ingot is obtained. The preparation method realizes a thermal reduction reaction and a slag extraction treatment process in different reactors, realizes semi-continuous production of the aluminum-scandium intermediate alloy, improves aluminum-scandium intermediate alloy production efficiency and improves aluminum-scandium intermediate alloy uniformity.

Owner:GRIREM ADVANCED MATERIALS CO LTD

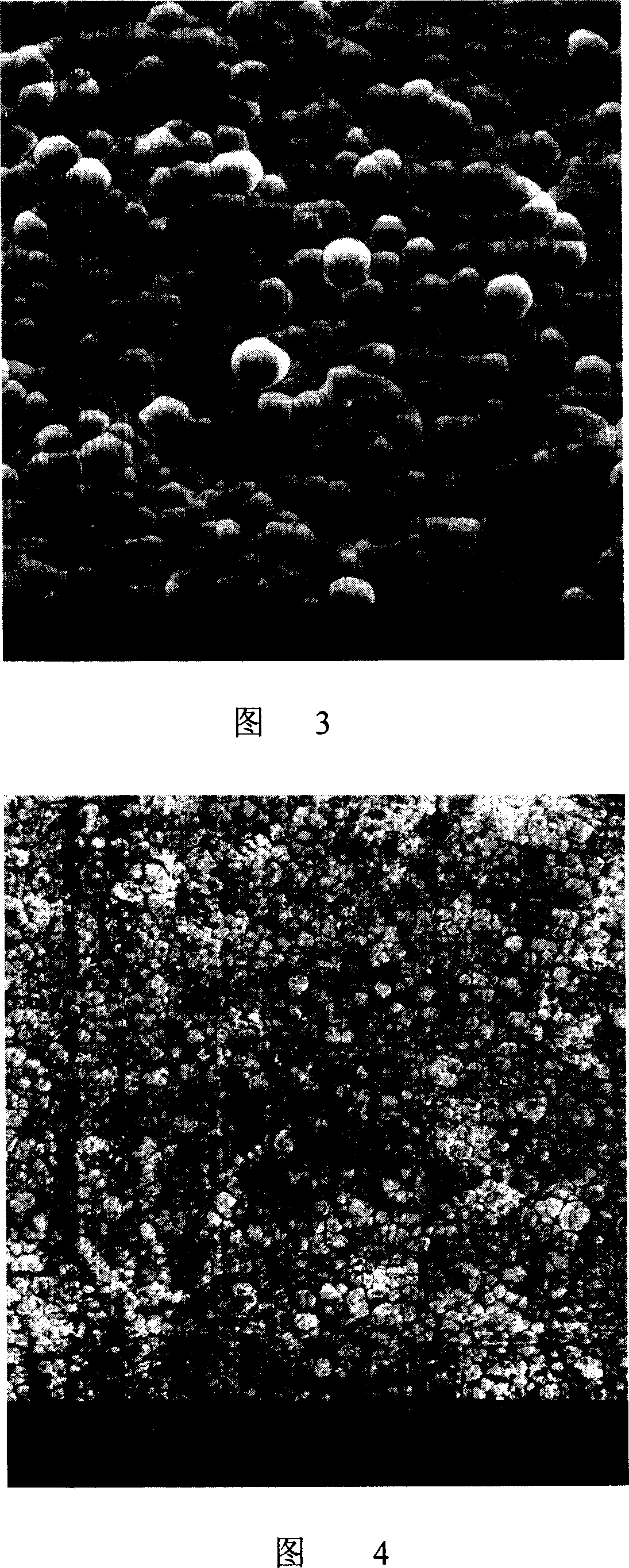

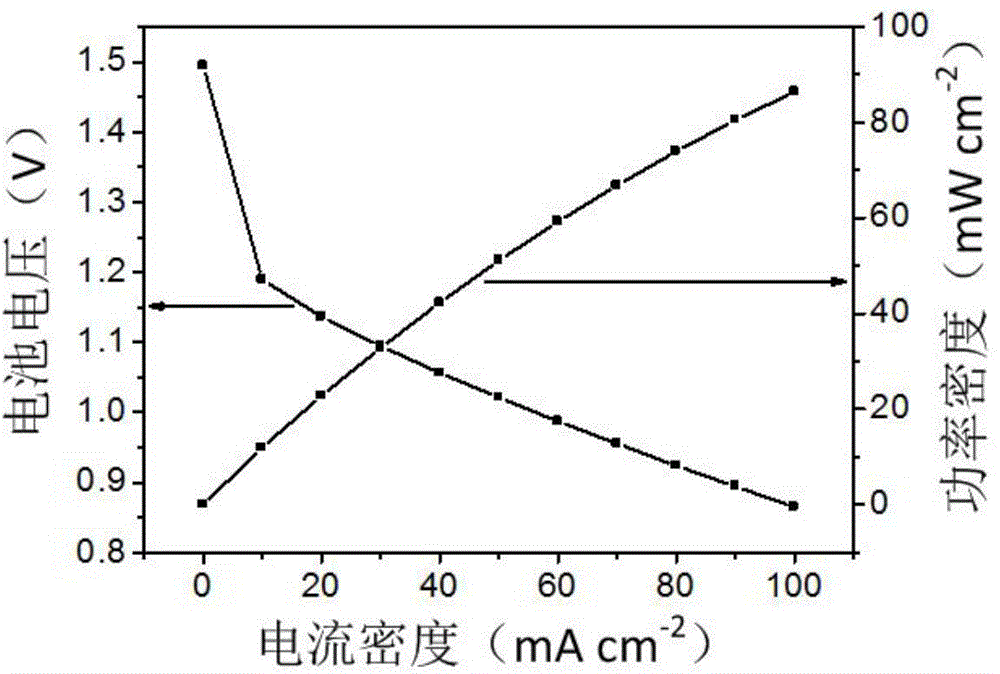

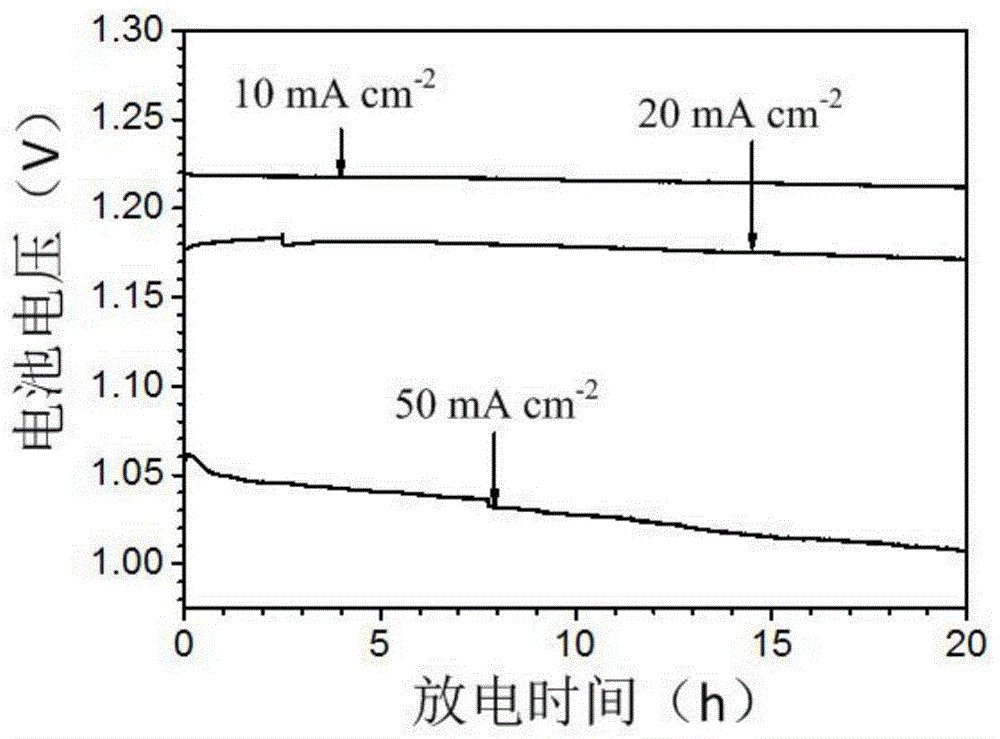

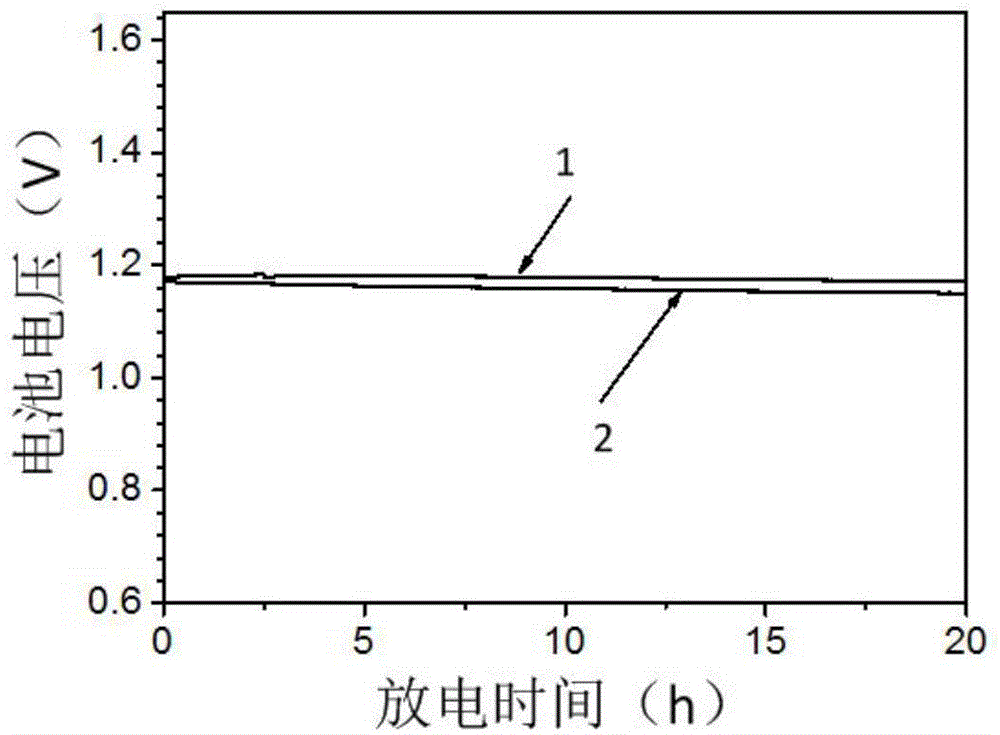

Metal-air battery based on silver-copper catalysis and preparation method thereof

ActiveCN104538709AIncrease discharge voltageAccelerated corrosionFuel and primary cellsCell electrodesAdhesiveSilver copper

The invention discloses a metal-air battery based on silver-copper catalysis and a preparation method thereof. The metal-air battery comprises a metal anode, an air electrode, electrolyte, a glass fiber diaphragm and a battery shell and is assembled according to a conventional method. The catalyst layer in the air electrode consists of a carbon-free adhesive-free Ag-Cu nano-alloy; the catalyst layer is formed by directly performing electro-deposition of an Ag-Cu alloy layer on foamed nickel; the microstructure of the Ag-Cu alloy refers to spherical nanoparticles; the diameter of the spherical nanoparticles is 200-600 nanometers; small particles which are uniformly distributed are attached to the spherical surface; the atomic ratio of Ag to Cu in the Ag-Cu alloy is (25-75):(75-25); the constituent elements of the Ag-Cu alloy refer to zero-valent Ag and Cu; and the Ag-Cu alloy is a solid solution phase or an L12 phase. The metal-air battery disclosed by the invention can achieve high discharge voltage, good carbon dioxide and seawater corrosion resistance and excellent charge and discharge reciprocating circulation efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

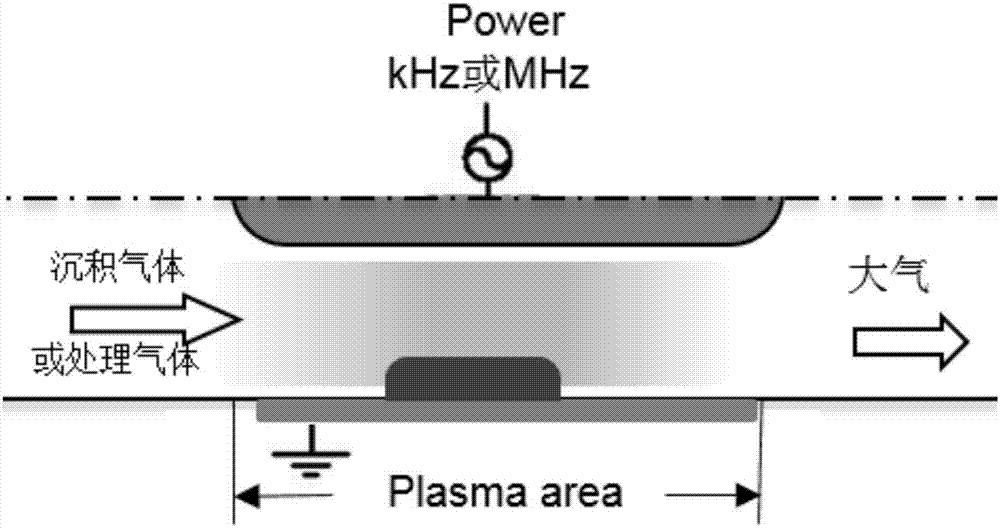

Preparation method of black TiO2 coating

InactiveCN107497413AHigh UVImprove featuresCatalyst activation/preparationChemical vapor deposition coatingEngineeringRadio frequency

The invention relates to a preparation method of a black TiO2 coating, which includes the steps of: 1) under normal pressure and at from room temperature to 200 DEG C, feeding a mixed gas of TiCl4, O2 and a discharging gas into a reaction chamber, and switching on a normal-pressure kHz radio frequency plasma power supply to deposit a TiO2 coating; 2) changing the power supply by a normal-pressure MHz radio frequency plasma power supply, feeding a mixed gas of He and H2, switching on the radio frequency power supply to generate hydrogen plasma, and treating the TiO2 coating at normal temperature to form the black TiO2 coating. The method greatly changes the energy band and photo-response range of the TiO2 material. The black TiO2 coating is improved in absorption in visible light and infrared light zones and is greatly improved in photocatalytic activity under visible light and infrared light. Meanwhile, the black TiO2 coating can be deposited on and coat the surface of materials, such as polymers, so that the black TiO2 coating has important value in practical applications such as dye-sensitized solar cells, hydrogen production with visible light, and environment management, etc.

Owner:DONGHUA UNIV

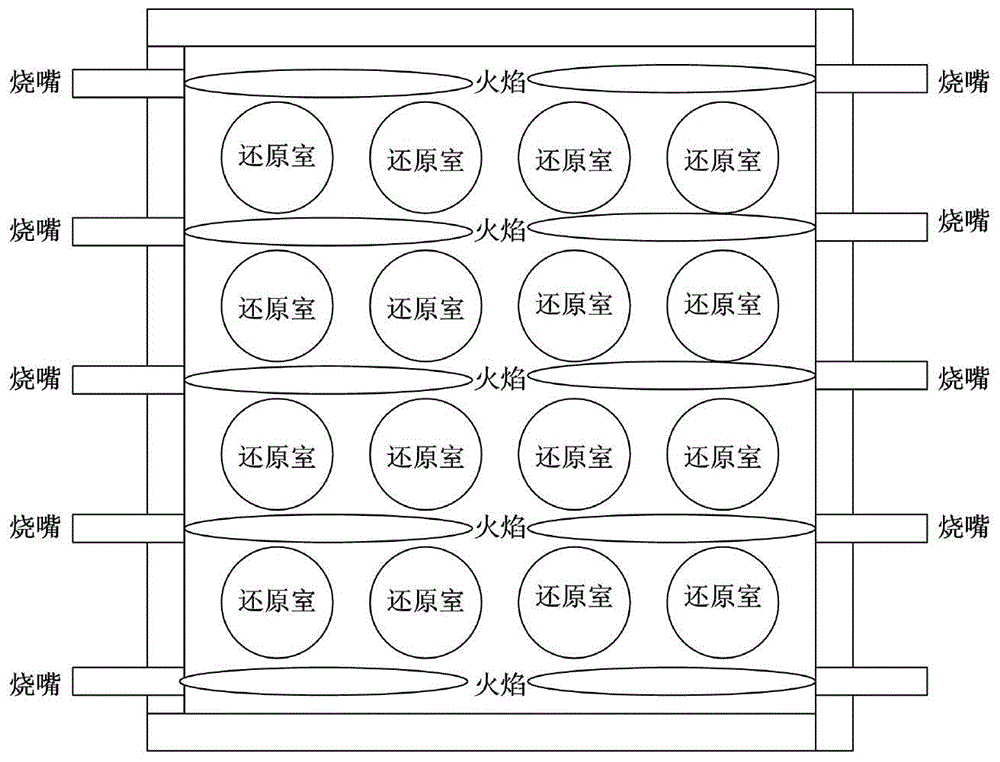

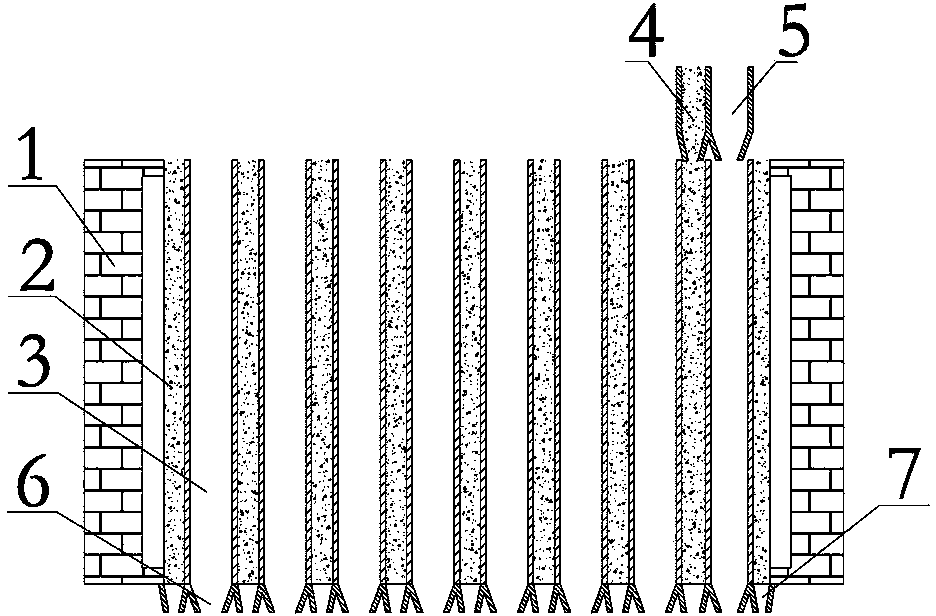

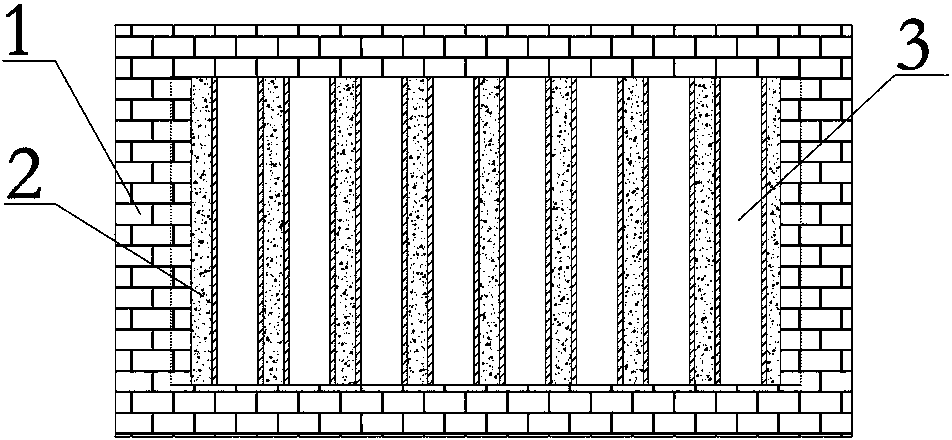

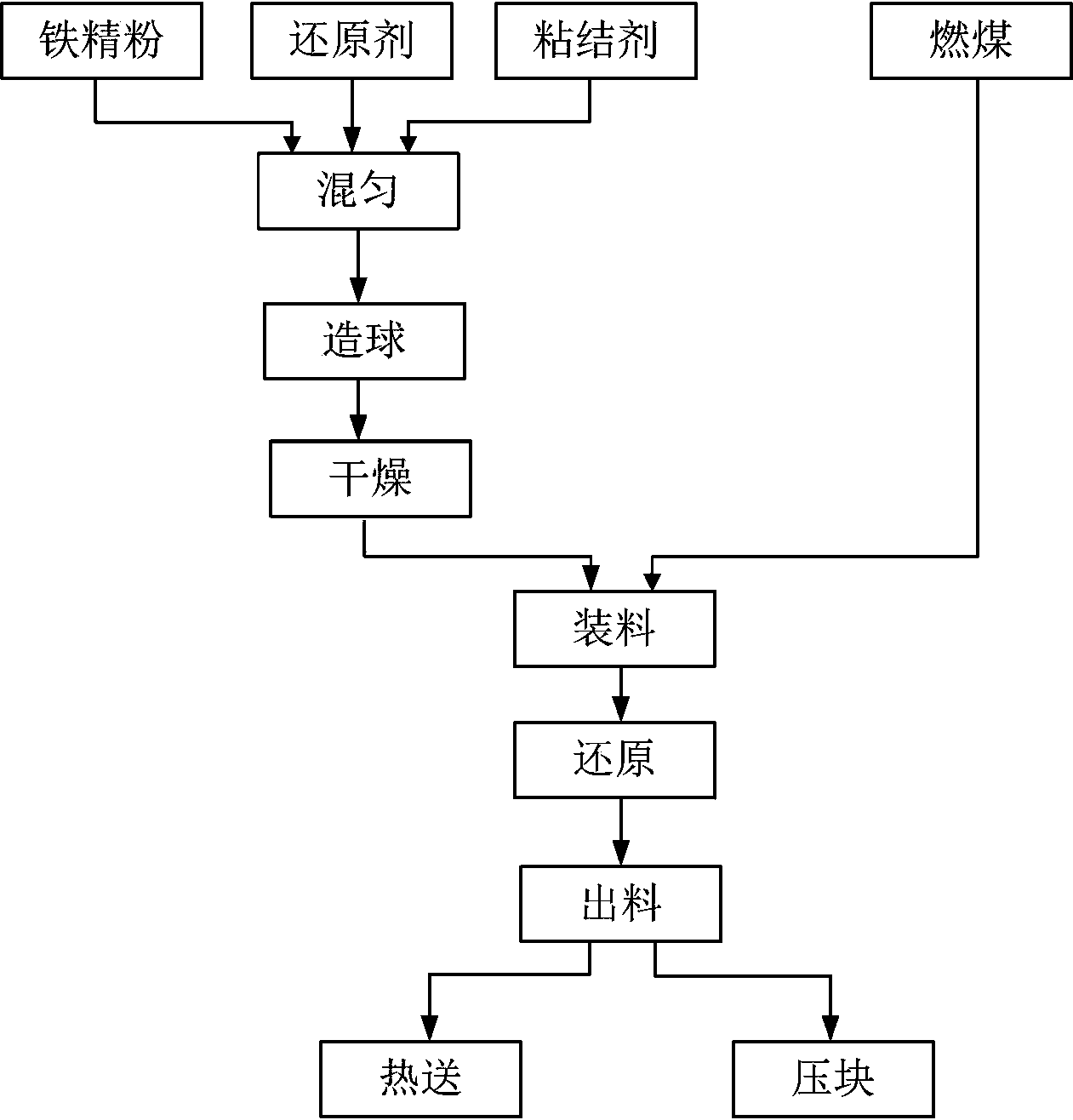

Reducing furnace, and technology for directly reducing coal-containing pellets through preheating outside coal base

InactiveCN103352097AAvoid the fatal flaw of small restoration capacityEvenly heatedFluidised-bed furnacesSteelmakingThermodynamics

The invention provides a reducing furnace. The reducing furnace comprises a furnace wall, at least one reducing tank and at least one combustion tank, and the at least one reducing tank and the at least one combustion tank are alternately arranged. The top of each reducing tank is connected with a raw material feeding device, and the bottom of each reducing tank is provided with a material outlet. The top of each combustion tank is connected with a fuel feeding device, and the bottom of each combustion tank is provided with an ash outlet. The invention also provides a technology for directly heating coal-containing pellets through preheating outside a coal base. The technology comprises the following steps: 1, mixing and pelletizing an iron-containing raw material, coal dust and a binder to obtain coal pellets; and 2, providing the reducing furnace, adding the pellets to the reducing tank(s) through the raw material feeding device(s), adding fire coal to the combustion tank(s) through the fuel feeding device(s), allowing the pellets and the fire coal to independently move from top to bottom, heating and reducing the pellets to form spongy iron, and discharging the spongy iron. The reducing furnace and the reducing technology have the advantages of high shaft furnace productivity, adoption of non-coking coal as a reducing agent in coal base reduction, adoption of cheap coal as a heat source, and production of the direct reduction iron for steel making.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com