Method and device for preparing nickel iron roasted ore by utilizing lateritic nickel ore

A laterite nickel ore and roasting technology is applied in the field of preparing nickel-iron roasting ore, which can solve problems such as immaturity of low-Ni nickel-iron ore, and achieve the effects of saving energy, reducing residence time and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

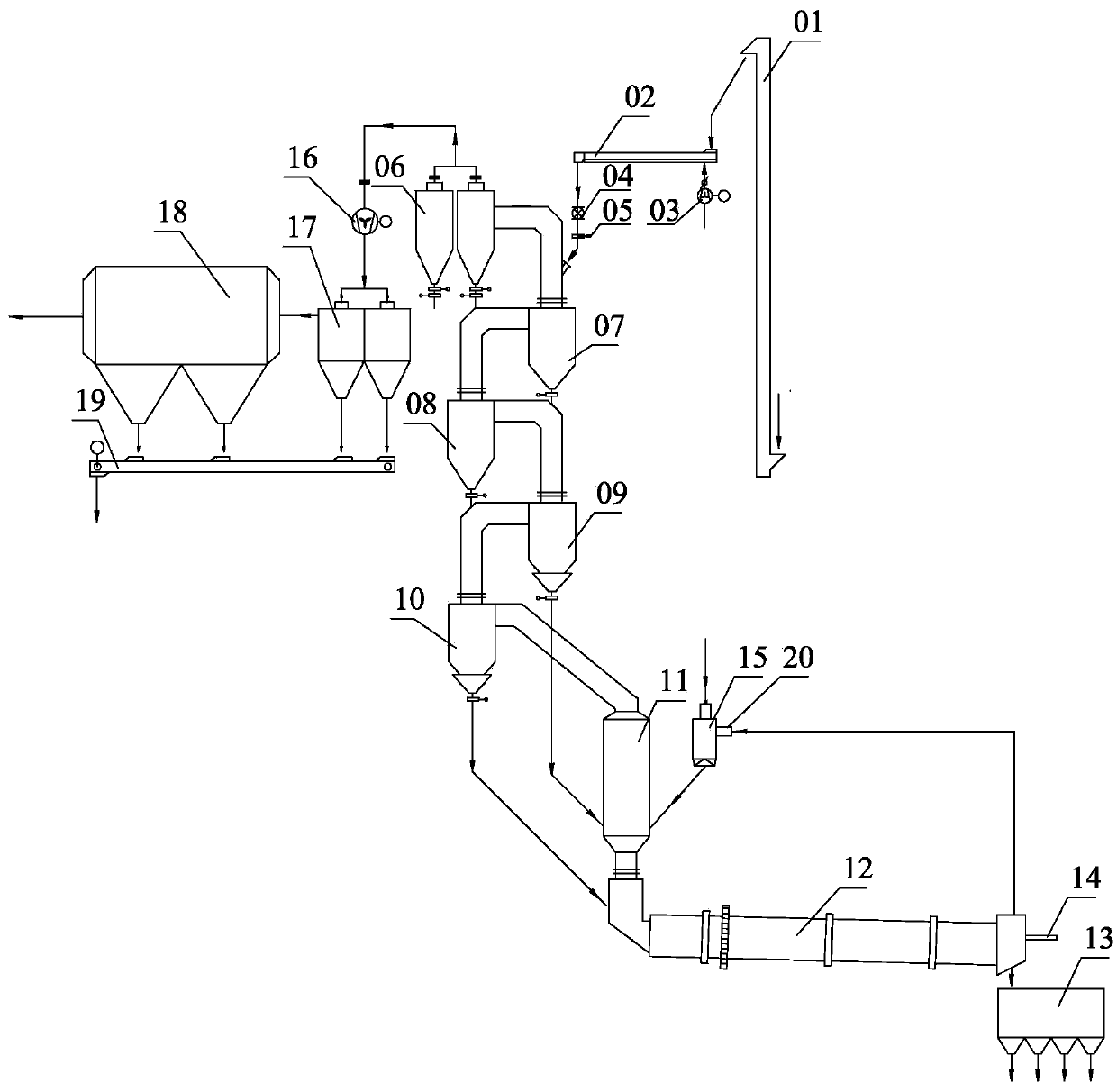

[0035] Embodiment 1: as figure 1 Shown, the present invention provides a kind of method utilizing laterite nickel ore to prepare ferronickel roasted ore, comprises the following steps:

[0036] (1) Grinding: finely grind the laterite nickel ore to make ore powder and send it to the bucket elevator 01 after metering. The particle fineness is between 0.075mm~1.0mm. The water content is less than 3wt%.

[0037](2) Preheating reduction: The material first enters the bucket elevator 01, and then enters the air chute 02 through the feeding chute (the chute fan 03 supplies air to the air chute 02 through the air supply duct, and passes through the air chute 02 The air distribution plate sends the material out), and then transports it to the double-barreled primary cyclone preheater 06, secondary cyclone preheater 07, and tertiary cyclone preheater 06, secondary cyclone preheater 07, and tertiary cyclone preheater in the pre-reduction system In the preheater 08, the four-stage cyclo...

Embodiment 2

[0041] Embodiment 2: as figure 1 As shown, the present invention also provides a device for preparing nickel-iron roasted ore by using laterite nickel ore, including a bucket elevator 01, an air chute 02, a chute fan 03, a rotary feeder 04, a gate valve 05, a rotary Kiln 12, water-cooled mixing tank 13, burner 14, hot air mixing chamber 15, high-temperature fan 16, cyclone dust collector 17, bag filter 18, chain conveyor 19, burner 20; the bucket elevator 01 The chute fan 03 is connected to the air chute 02 through the feeding chute, the air chute 02 is connected to the rotary feeder 04 through the feeder chute, and the rotary feeder 04 passes through the The feeder is connected to the gate valve 05, the rotary kiln 12 is fixed on a frame through the sealing device and the water-cooled mixing tank 13, the burner 14 is extended into the rotary kiln 12 through the hanger, and the hot air mixing chamber 15 is fixed on the frame Inside, the burner 20 is directly fixed on the hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com