Novel low-pollution bubbling bed gasification combustion reaction device and method

A combustion reaction, low-pollution technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of large ash production, large fluctuations in pressure drop in bubbling fluidized bed, and high exhaust gas treatment costs, and achieves high Effects of combustion heat load, rapid heat and mass transfer, NOx reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

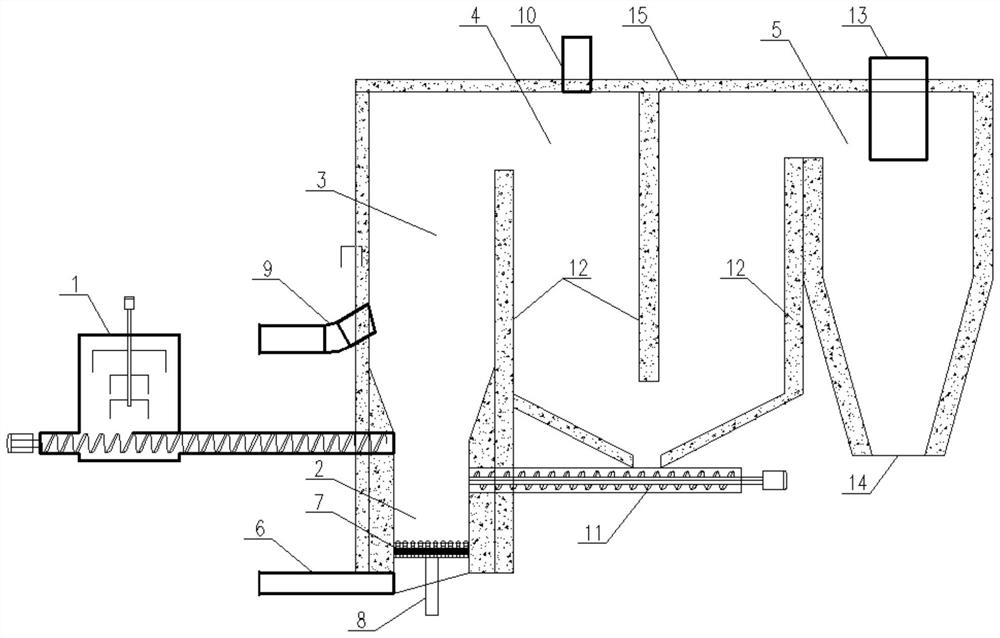

[0028] The organic solid particles and desulfurizer are sent into the bubbling gasification section 2 through the feeding device 1, and gasification reaction occurs after contacting the air from the gasification medium inlet 6 to generate gasification gas and ash, and the gasification gas is sent to the second gasification section. In the combustion section 3, the ash and slag are discharged through the slag discharge device 8; during the whole gasification reaction process, the organic solid particles are in the state of rapid fluidization and bubbling fluidization, and the gasification temperature is maintained between 500-800°C. Most of the sulfur contained in the solid particles will remain in the ash; the gasification gas from the bubbling gasification section 2 and the air from the secondary combustion medium inlet 9 are fully mixed in the secondary combustion section 3, and a low-temperature low-oxygen combustion reaction occurs During the combustion process, the total g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com