Patents

Literature

607results about How to "Quick export" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

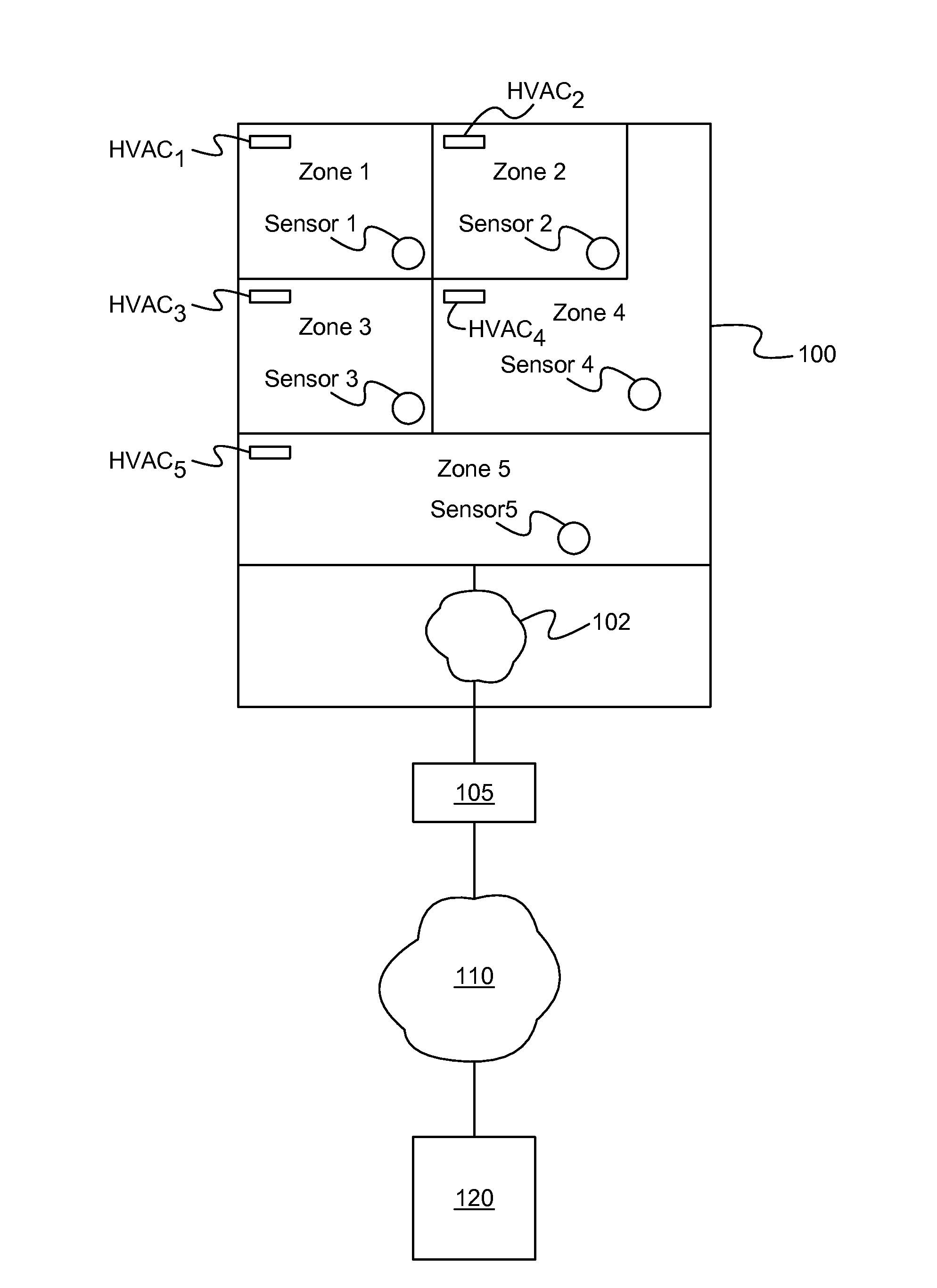

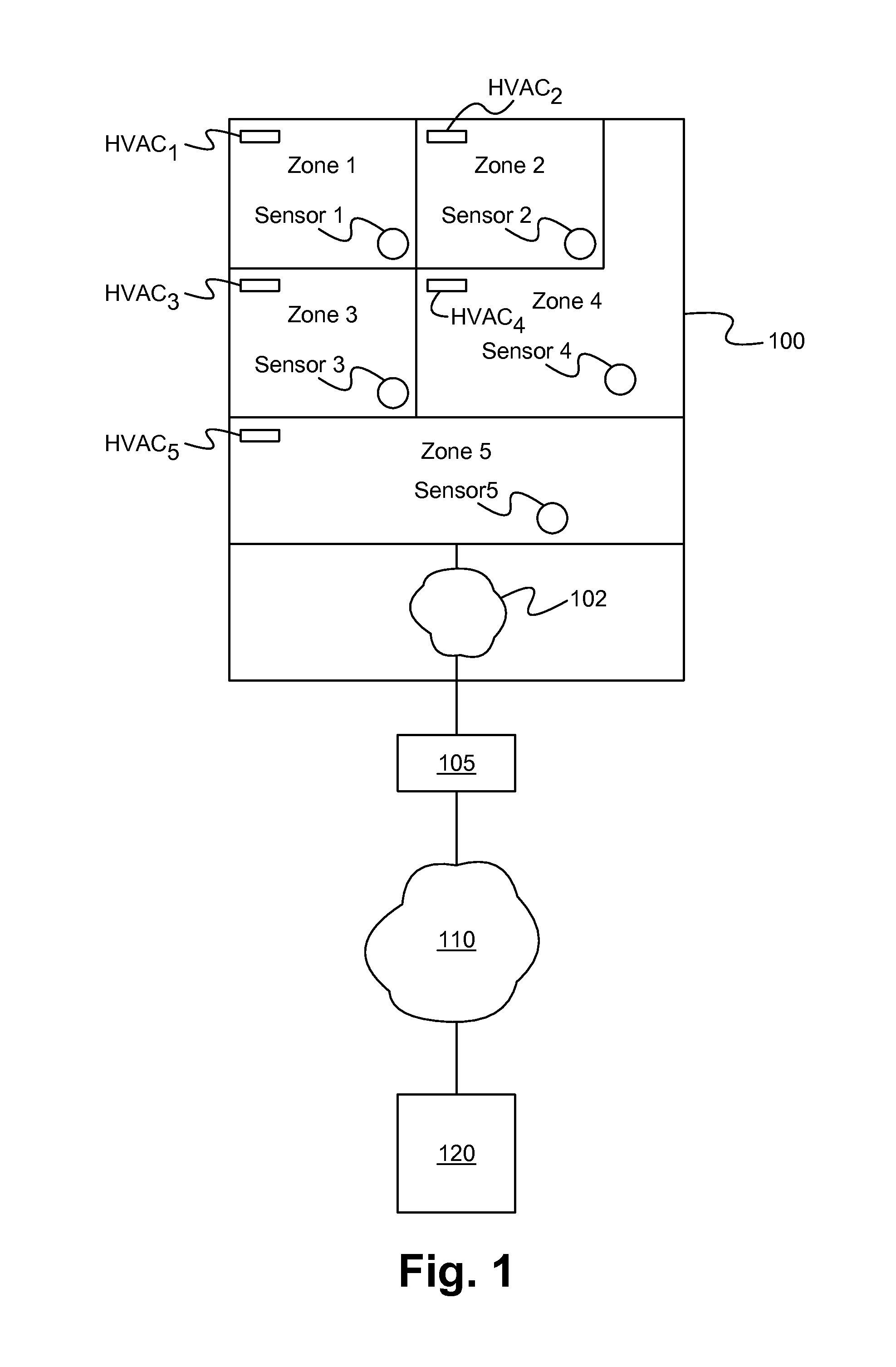

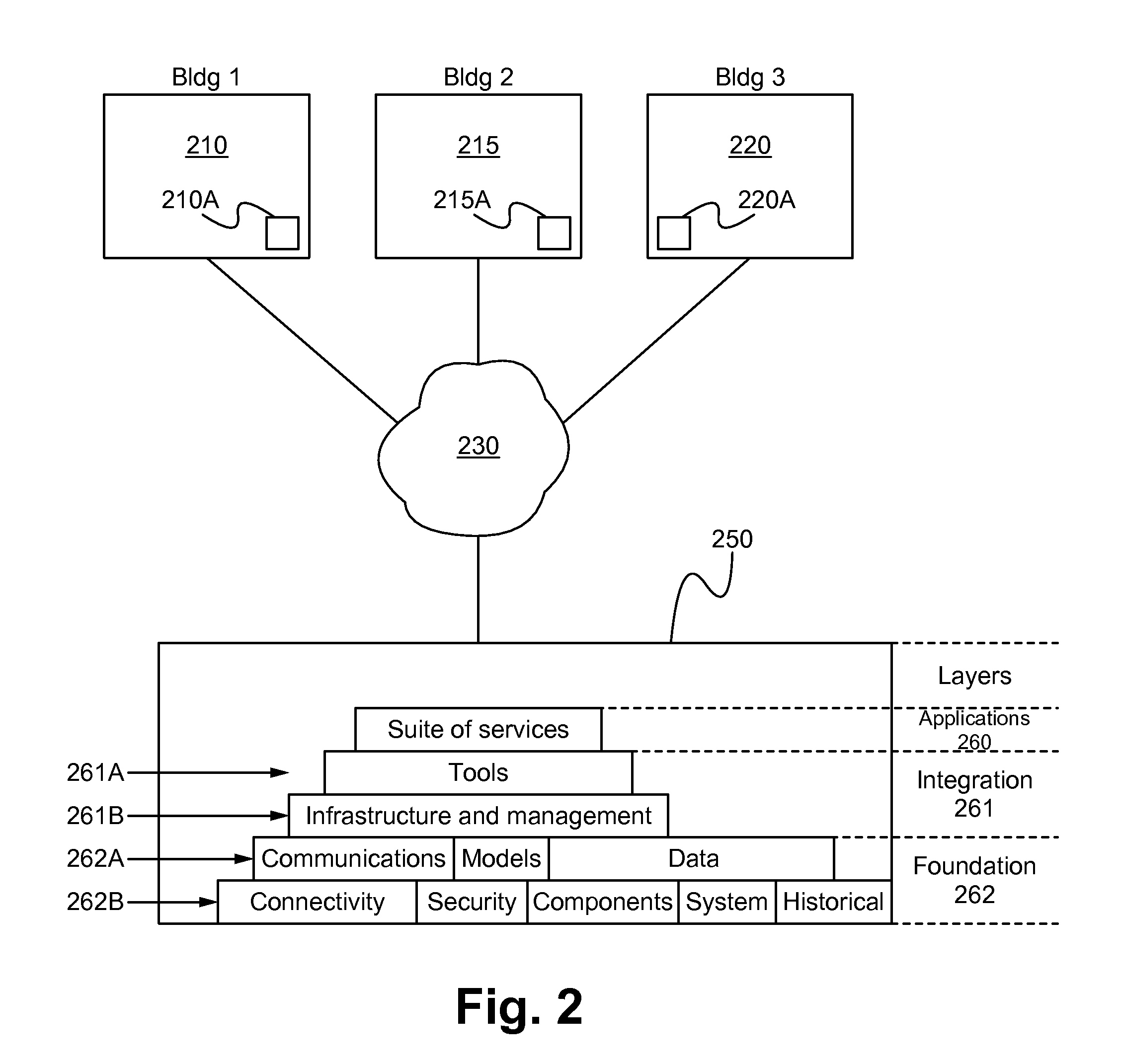

Systems for and methods of modeling, step-testing, and adaptively controlling in-situ building components

InactiveUS20150178421A1Efficient and accurateQuick exportGeometric CADSpace heating and ventilation safety systemsEnvironmental SettingMeasuring output

A system for and method of modeling thermal performance characteristics of HVAC components in a building uses the building power or other meter to measure power consumed by the components. The models are used to test the components, preferably during off hours, to ensure proper and efficient operation. Preferably, the testing software is written in a high-level interpretive language that is independent of the HVAC component being modeled. The models are adaptively maintained by periodically ensuring that their measured output matches the predicted output. When the two do not match, the model parameters are updated. These models can also be used to generate reports comparing costs and cost savings for different temperature and other environmental settings within selected zones in the building.

Owner:NEXTRACKER LLC

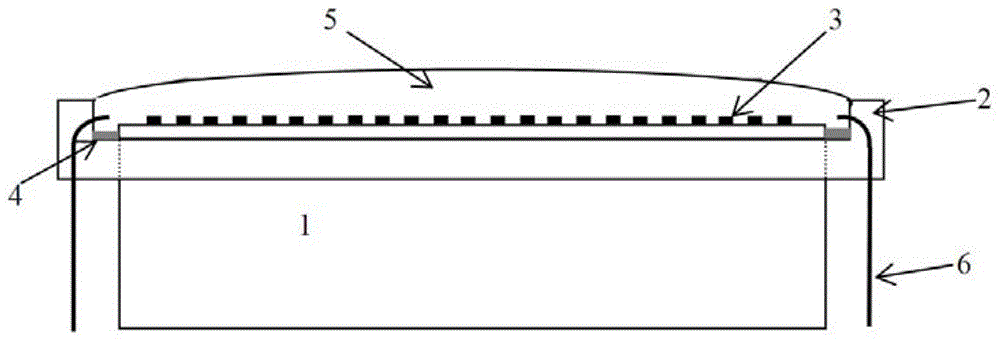

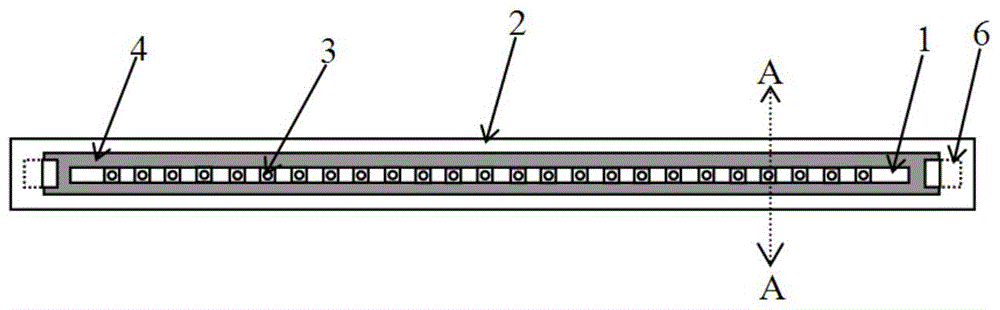

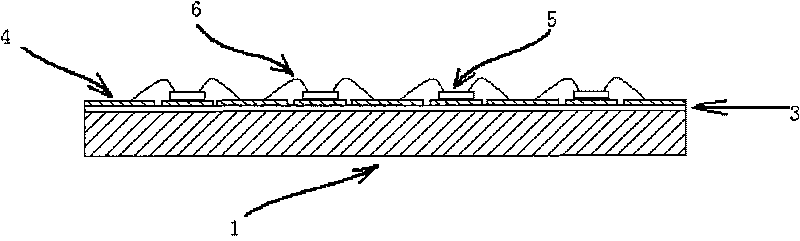

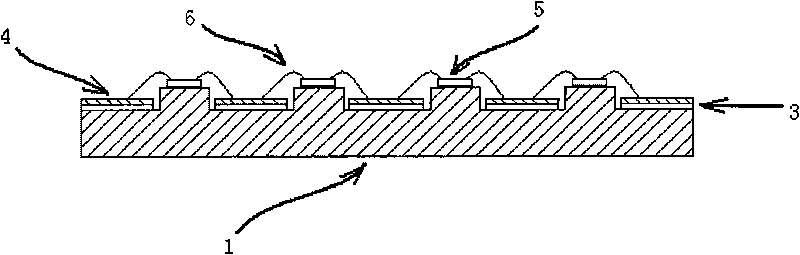

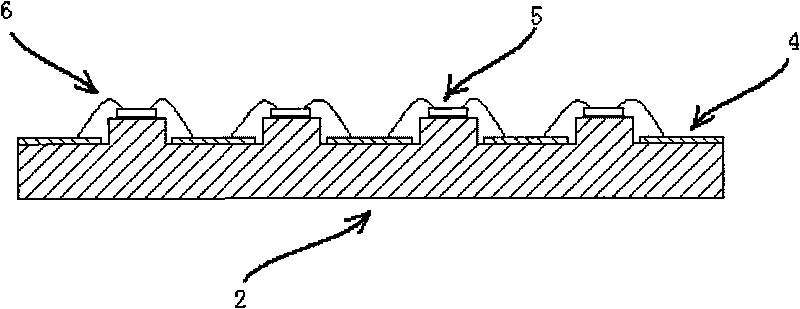

LED (Light Emitting Diode) lamp filament and manufacturing method thereof

ActiveCN104600174AImprove thermal reliabilityMaximum Thermal ReliabilitySemiconductor devicesFluorescenceConductive coating

The invention provides an LED (Light Emitting Diode) lamp filament and a manufacturing method thereof. An LED chip is encapsulated on the edge top surface of a thin and long sheet metal support of the LED filament innovatively, meanwhile the sheet metal is inserted into a preformed transparent plastic model frame to produce a light source, and accordingly the automated continuous production of the LED lamp filament is implemented and the problem of the facing direction strength caused by the too thin and too long metal support is solved due to the transparent plastic model frame; meanwhile the lateral direction strength of the metal support is effectively utilized and accordingly the integral mechanical strength of the LED lamp filament is ensured; the heat dissipation characteristics of the metal is directly utilized, meanwhile the heat dissipation efficiency of the LED chip is maximized through the innovative encapsulation of thermal conductive coatings, and accordingly the problem of a heat dissipation bottleneck of the LED lamp filament is effectively solved, the LED lamp filament can work at the rated power for a long time, and the cost is reduced; the LED light extraction efficiency is improved, the light attenuation is reduced, the high lighting effect and ambient light of lamp filament light emission is implemented, and the market vacancy of the existing LED lamp filament is filled through innovative fluorescence encapsulation materials.

Owner:DONGGUAN RIWEI ELECTRONICS

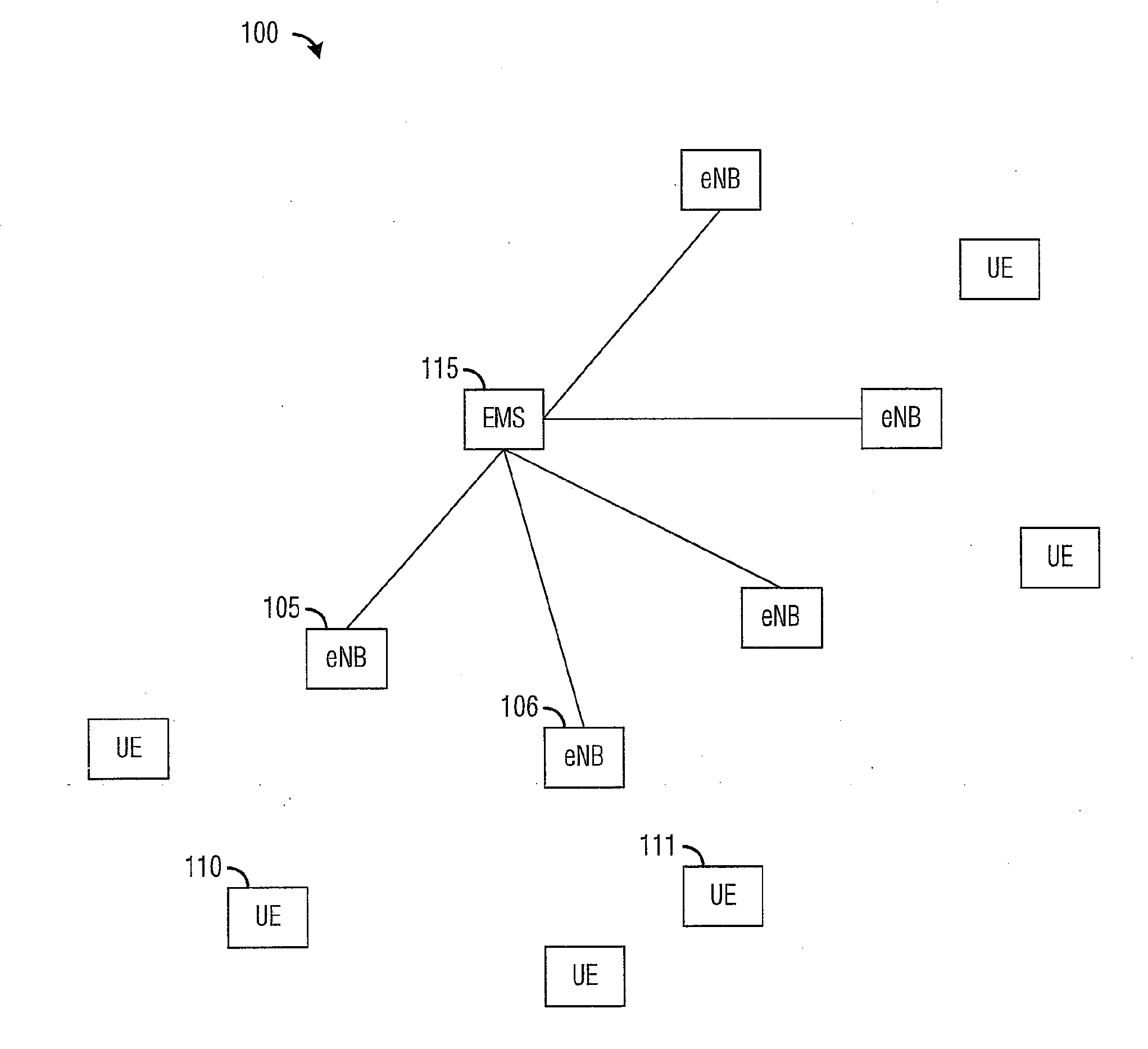

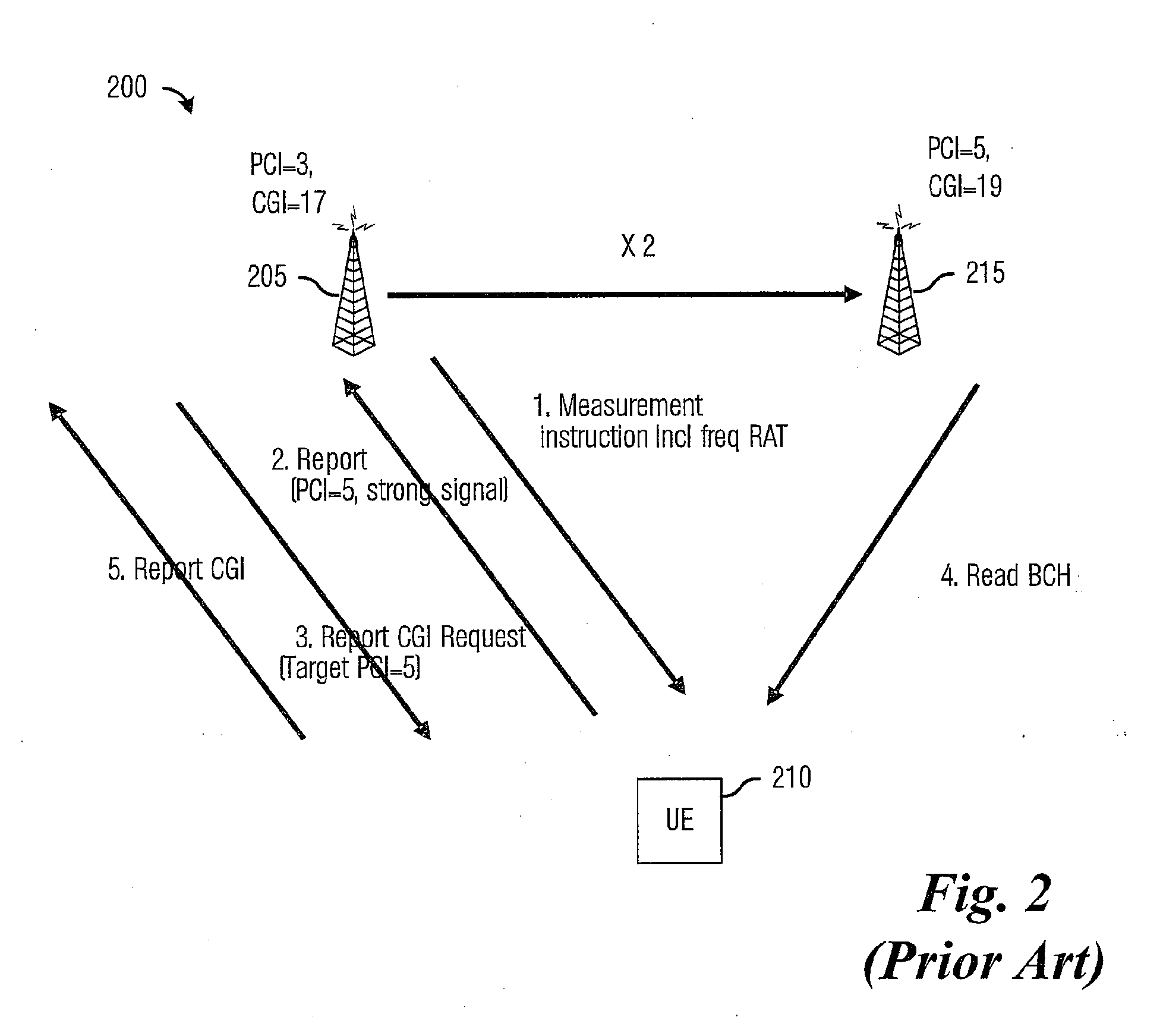

System and Method for Deriving Cell Global Identity Information

ActiveUS20110070897A1Negatively impact performanceQuick determinationAssess restrictionMessaging/mailboxes/announcementsCell basedGlobal information

A system and method for deriving cell global identity information are provided. A method for deriving cell global information includes receiving, at a first cell, a measurement report, determining a second identifier for the second cell based on a first identifier and information about the first cell, and adding the second cell to a cell list. The measurement report includes the first identifier of a second cell, and the second identifier is used to reference the second cell.

Owner:FUTUREWEI TECH INC

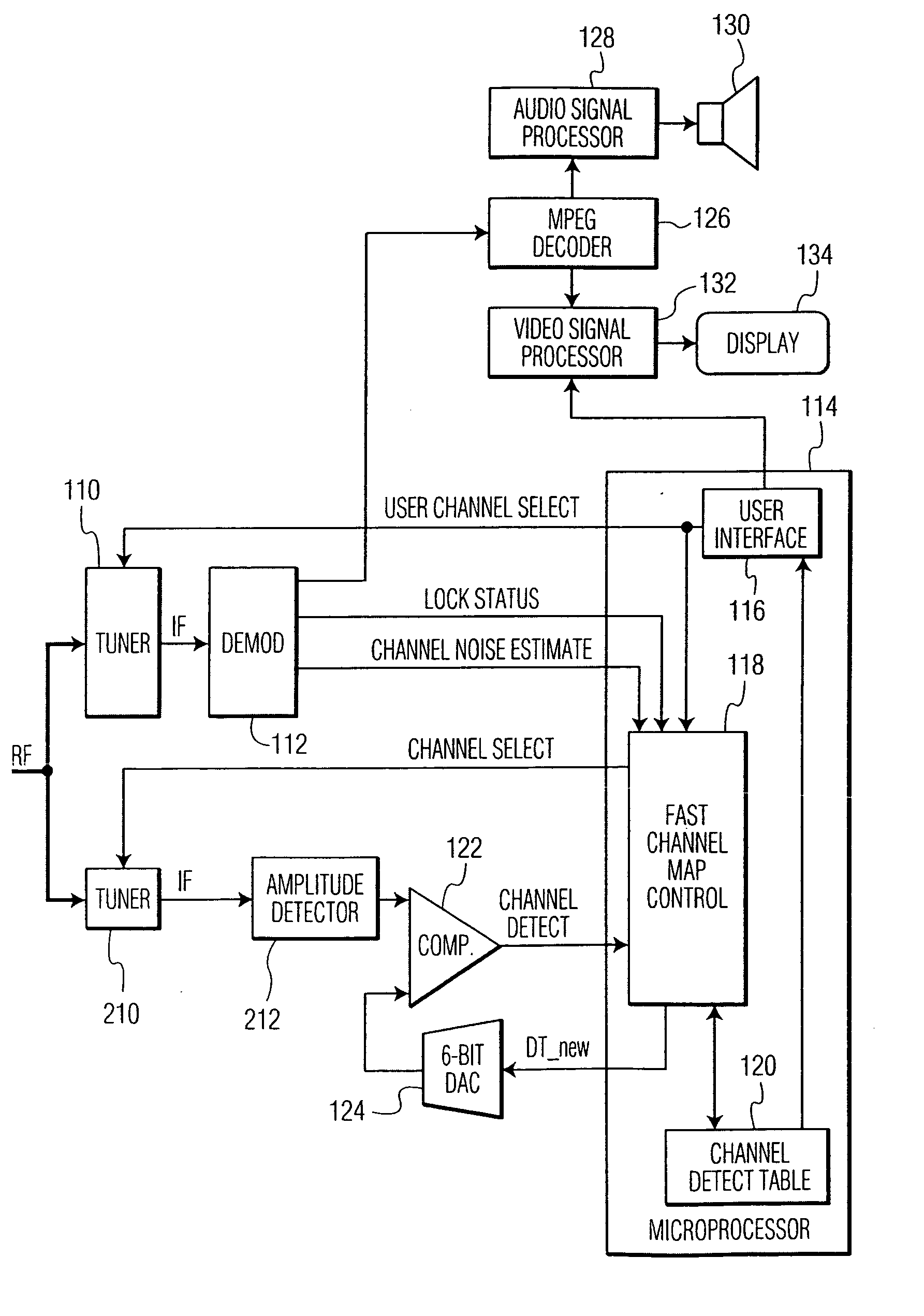

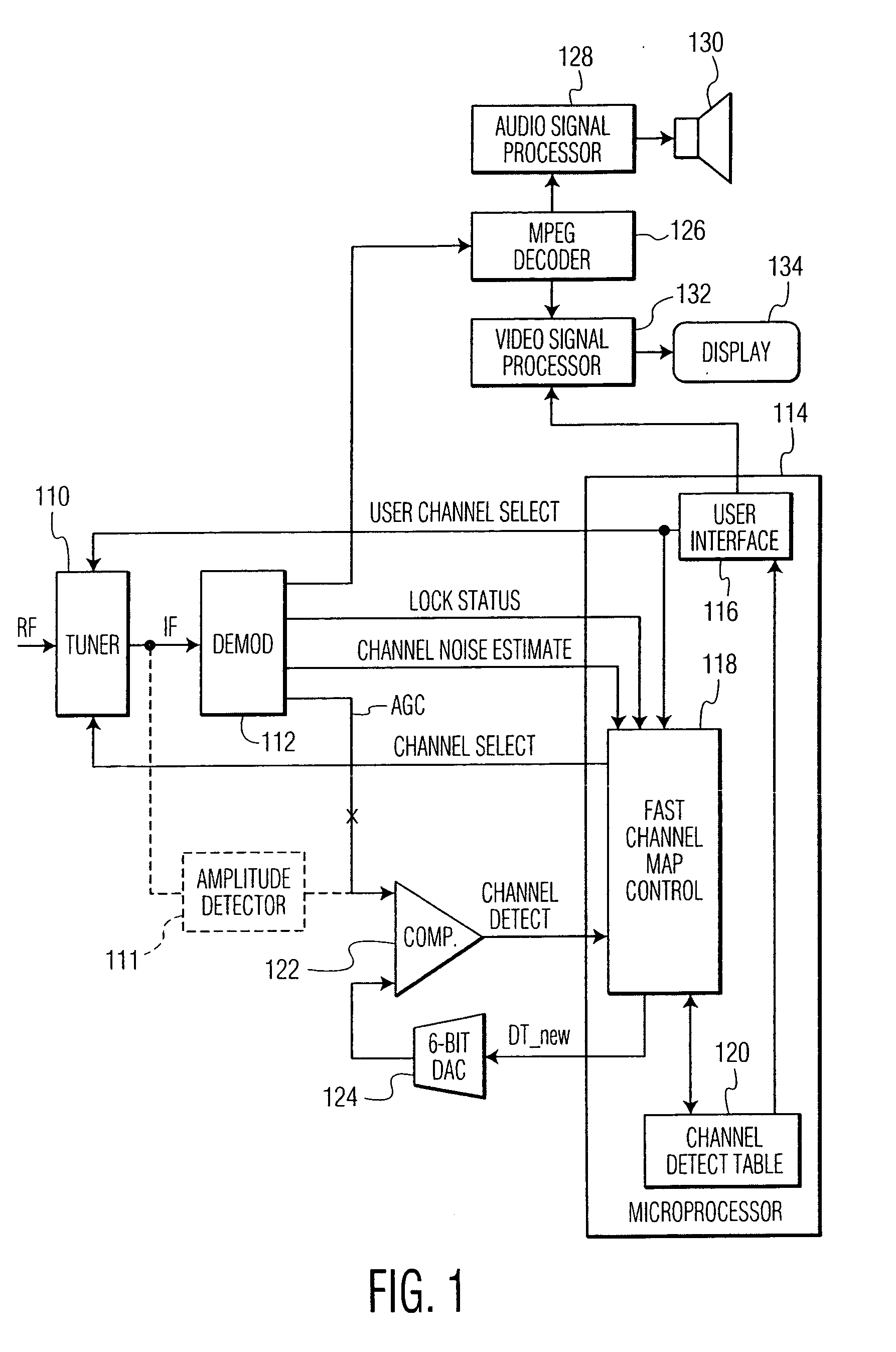

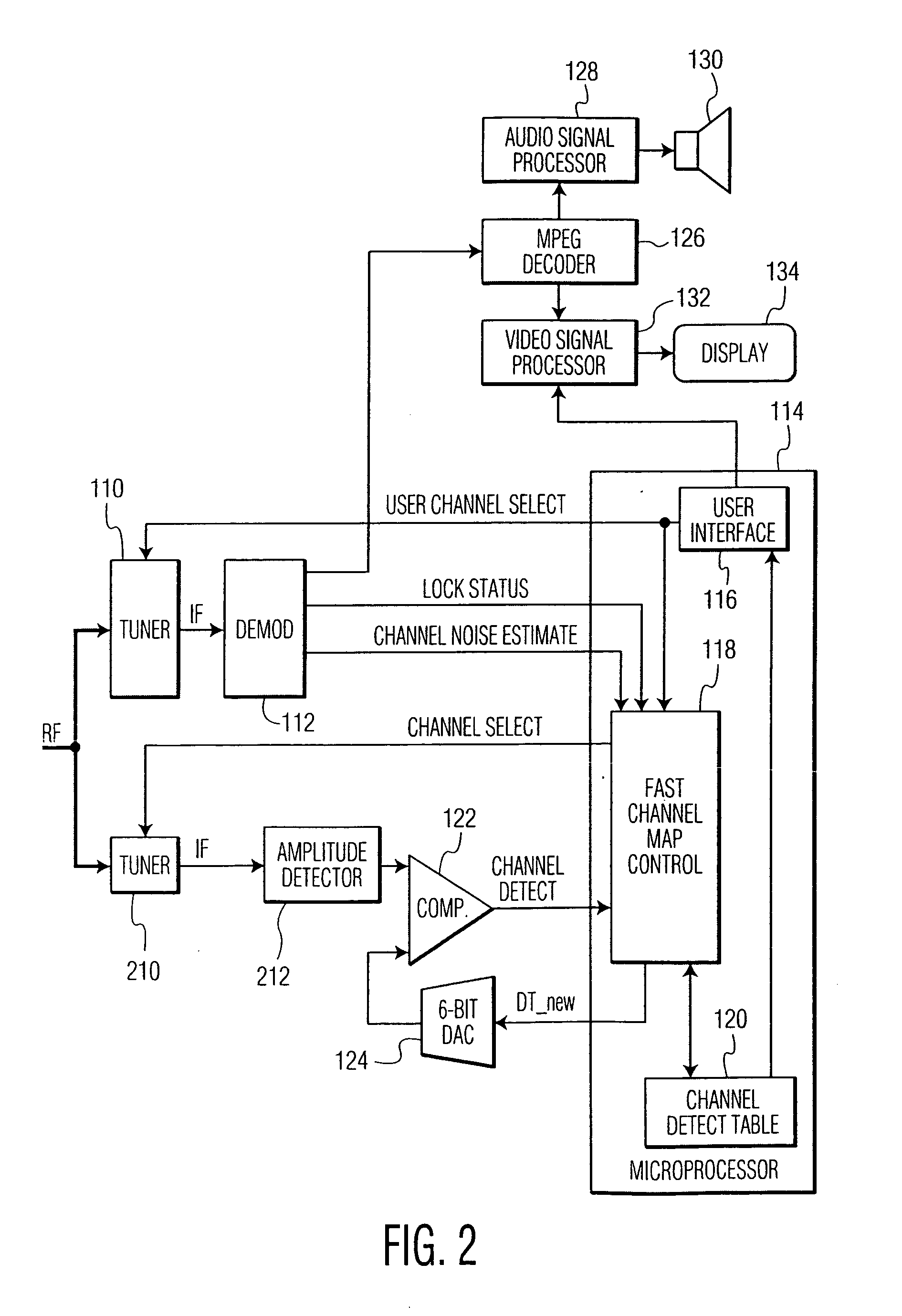

Method and apparatus for deriving a channel map for a digital television receiver

InactiveUS7113230B1Quick exportTelevision system detailsAnalogue secracy/subscription systemsTelevision receiversNoise level

A television receiver includes circuitry that quickly derives a channel map for a DTV receiver. The apparatus includes tuner that is controlled by a processor in the television receiver to periodically test each channel frequency to determine the strength of the signal at that frequency. If the signal strength exceeds a threshold value, the channel map is updated to indicate that a channel exists at that frequency. The processor monitors the signal recovered by the tuner during normal television viewing for valid program information. If the processor does not detect valid program information for a channel in the program map, the threshold value used by the processor to build the channel map is raised. If the processor detects valid program information then information on the estimated noise level in the received DTV signal is used to update the threshold value. In one embodiment of the invention, the television receiver includes both a main tuner and an auxiliary tuner. The auxiliary tuner is controlled to periodically scan the television channel frequencies to update the channel map, even when the main tuner is being used by a viewer who is watching television.

Owner:PANASONIC CORP

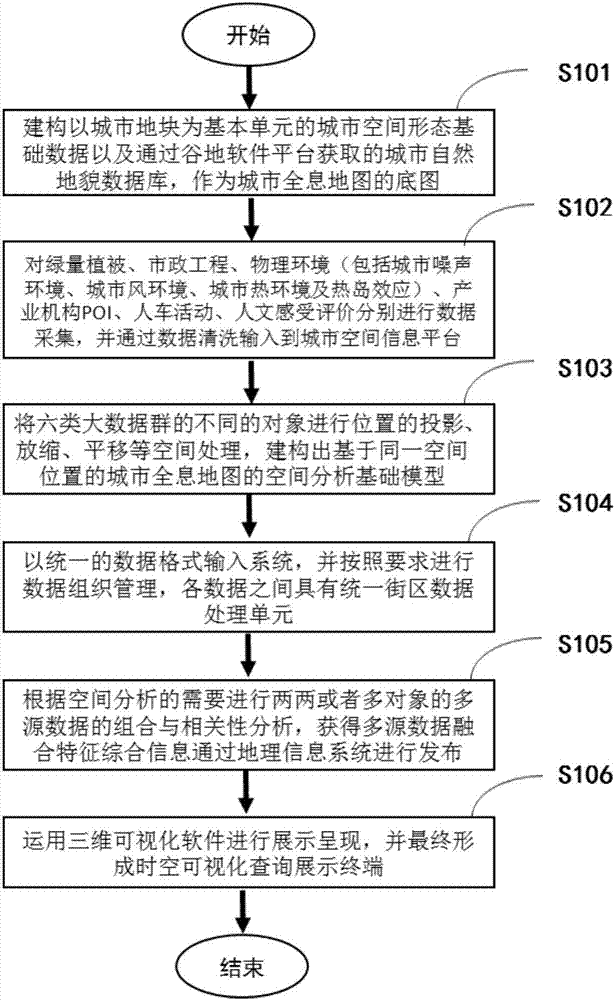

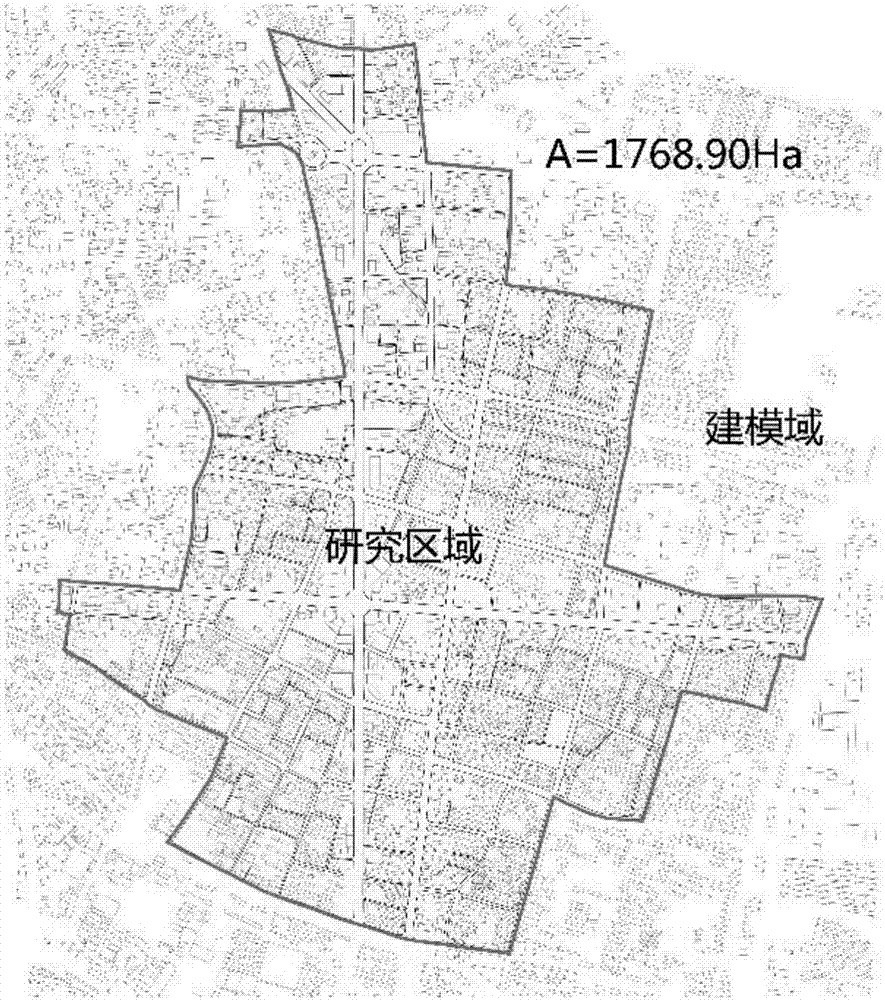

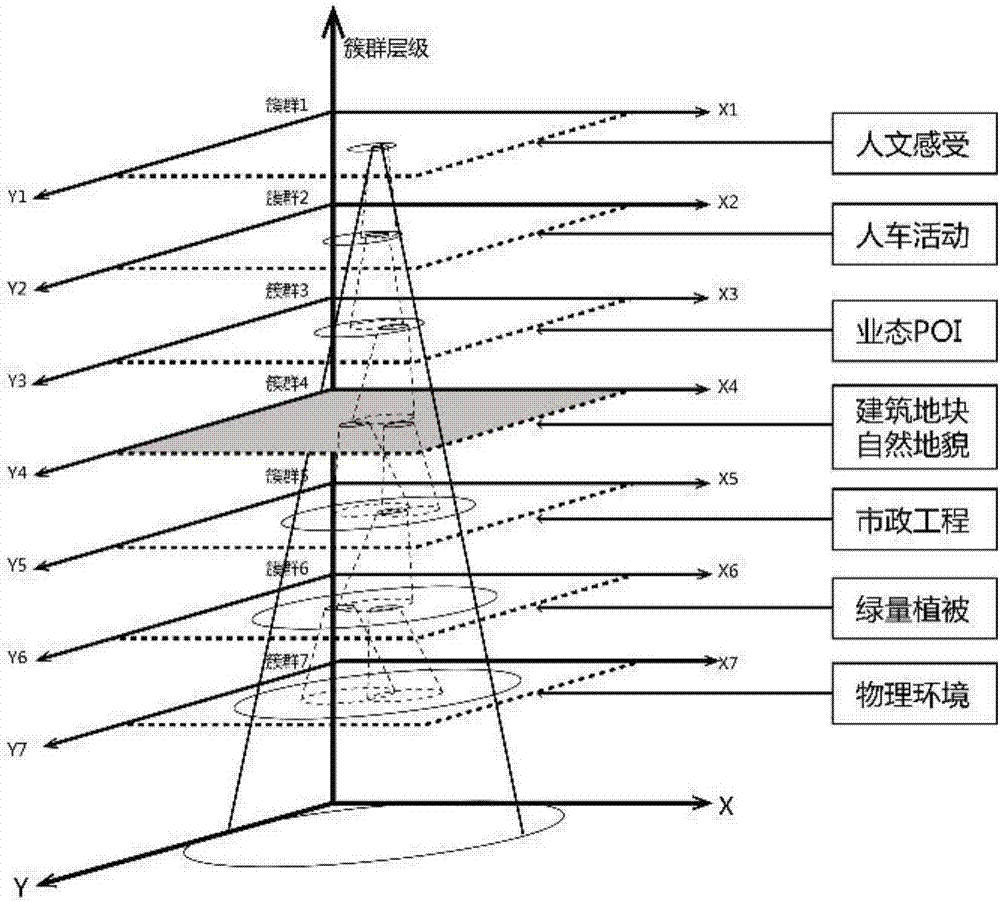

Multisource big data fusion-based city space holographic map establishment method

ActiveCN106897417ARealize the simulation dynamic displayQuick query showsClimate change adaptationGeographical information databasesVegetationData space

The invention discloses a multisource big data fusion-based city space holographic map establishment method. The method comprises the steps of mapping green quantity vegetations, municipal engineering, physical environments (including a city noise environment, a city wind environment, a city heat environment and a heat island effect), industry organization POI, people-vehicle activities and humanistic feeling evaluations in a city full-space coverage range to a cloud database through different graphic layers; and intuitively and dynamically displaying and outputting different types of data space features in combination with city space forms, so that city systems can perform real-time detection, and city plan design engineering practice is facilitated. Based on a cloud data end, massive data can be processed, and real-time quick query and display can be carried out; and by superposing multisource big data and city space form data in a same digital map system, city coordinate system-based seamless connection collection of multisource data interfaces and simulated dynamic display of space features are realized.

Owner:SOUTHEAST UNIV

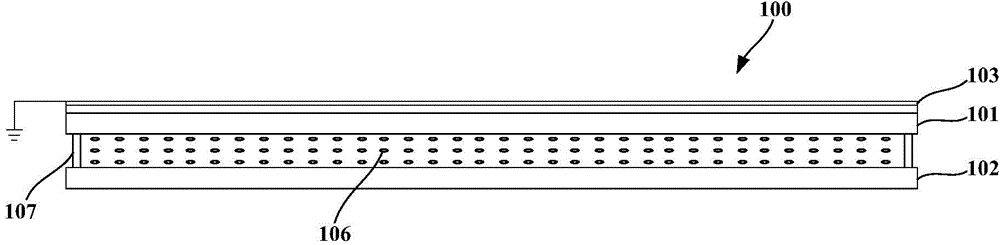

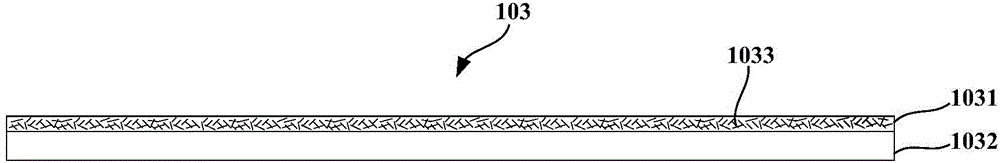

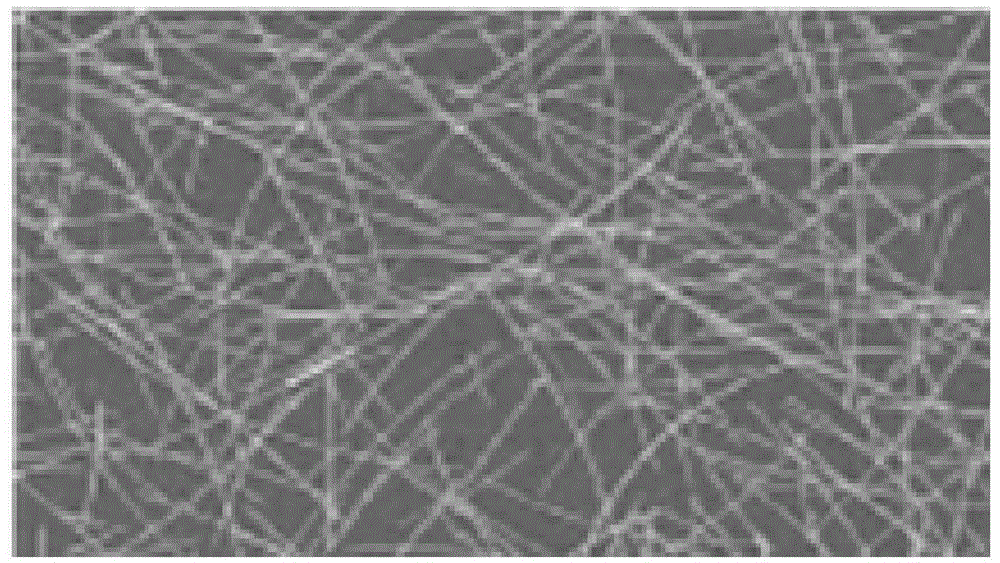

Display panel and display device

InactiveCN104536184AGood flexibilityQuick exportNon-linear opticsElectrostatic chargesDisplay deviceEngineering

The invention discloses a display panel and a display device. The display panel has the good anti-static-damage effect. Meanwhile, the production technology of the display panel is simplified, and production cost is reduced. The display panel comprises a first substrate, a second substrate and a conductive layer, wherein the first substrate and the second substrate are oppositely arranged, and the conductive layer is arranged on the side, opposite to the second substrate, of the first substrate. The conductive layer is grounded and comprises a base layer and a nano conductive material arranged in the base layer. Due to the fact that the conductive layer has the electric conductibility and is grounded, static charges on the display panel can be rapidly led out and led into the ground, and the display panel has the good anti-static-damage effect. Due to the good flexibility of the conductive layer, the conductive layer can be directly attached to the surface of the side, opposite to the second substrate, of the first substrate; in this way, the production technology of the display panel can be greatly simplified, production cost is reduced, and the anti-static-damage capacity of the display panel can be greatly improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

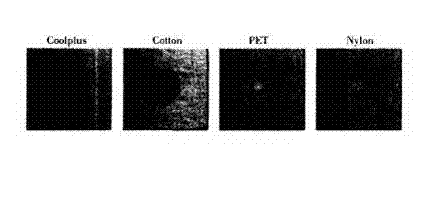

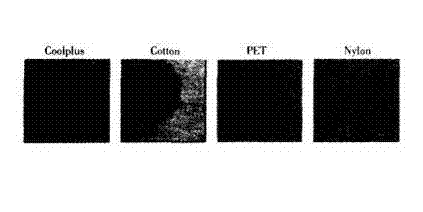

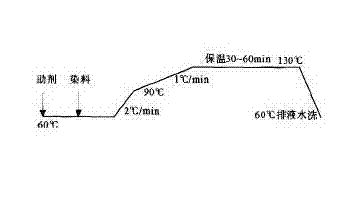

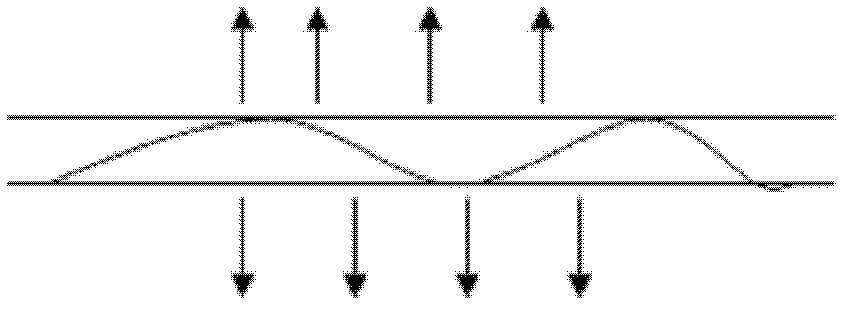

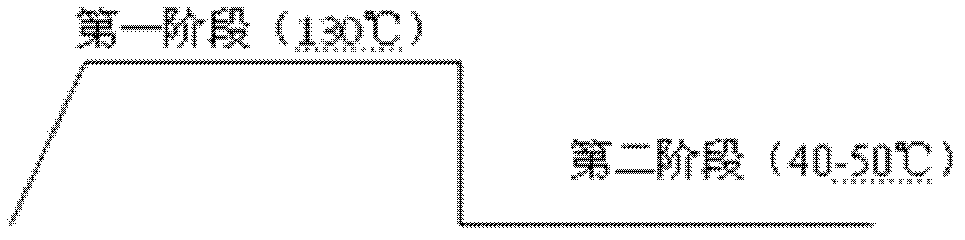

Production process for single-direction rapid moisture guide composite knitted fabric

InactiveCN102733056ASignificant differential effectHas the effect of one-way quick moisture conductionWeft knittingDyeing processFiberAfter treatment

The invention discloses a production process for single-direction rapid moisture guide composite knitted fabric, belonging to the technical field of the single-direction rapid moisture guide fabric. The single-direction rapid moisture guide composite knitted fabric provided by the invention is characterized by using a multilayer composite structure, wherein an outer layer of the fabric is weaved by hydrophilic fibers, and an inner layer is weaved by hydrophobic fibers; the inner layer and the outer layer of the fabric are connected by using hydrophobic moisture guide fibers, so as to form a wicking effect; and meanwhile, the moisture guide property and the comfort sense of the fabric can be further improved through an optimal dying and after-treatment process. With the adoption of the single-direction rapid moisture guide composite knitted fabric, sweat can be rapidly conducted to the outer layer of the fabric from the inner layer of the fabric in a single-direction manner, and rapidly evaporated on the outer layer; the single-direction moisture guide rate is within 30 seconds, so that the warm balance between the inner layer of the fabric and human skin can be kept to improve the thermohumid comfort when the fabric is worn; and furthermore, the fabric provided by the invention is dry, cool and comfortable to wear and is not adhered to a human body when a user sweats.

Owner:ZHEJIANG GANGLONG WEAVING TECH

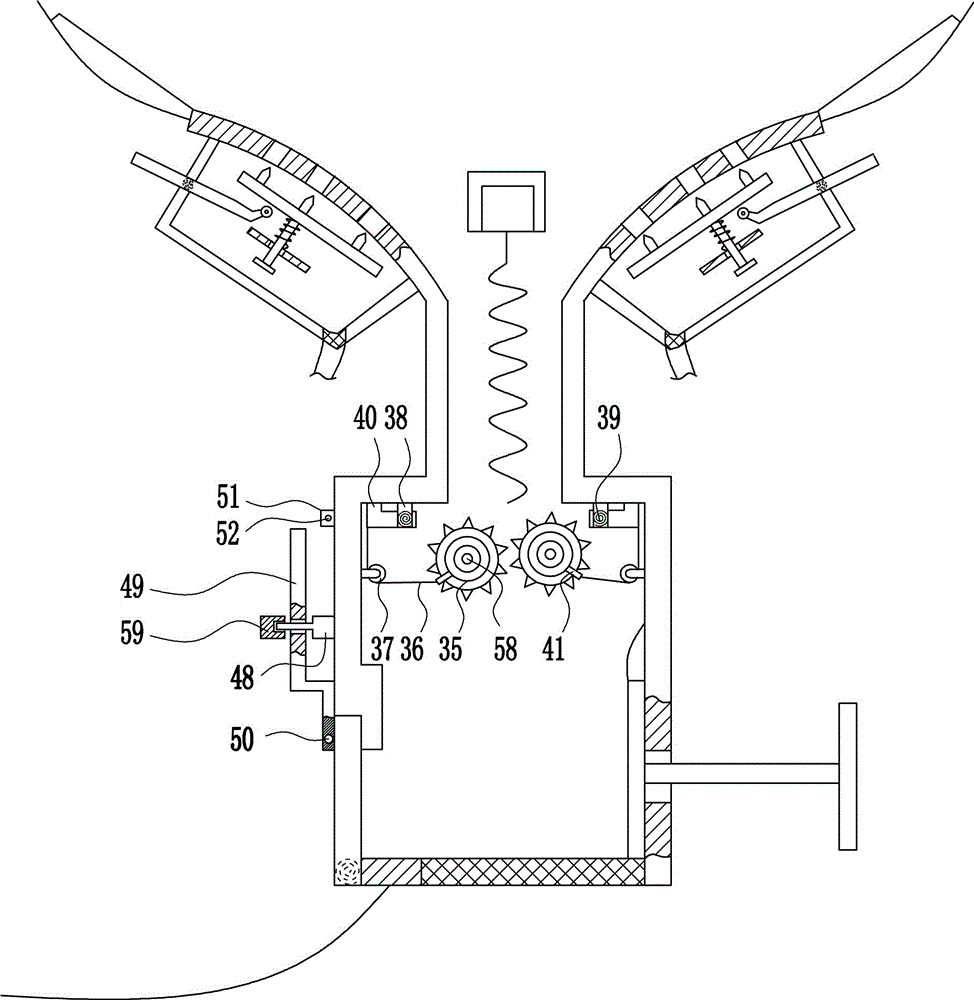

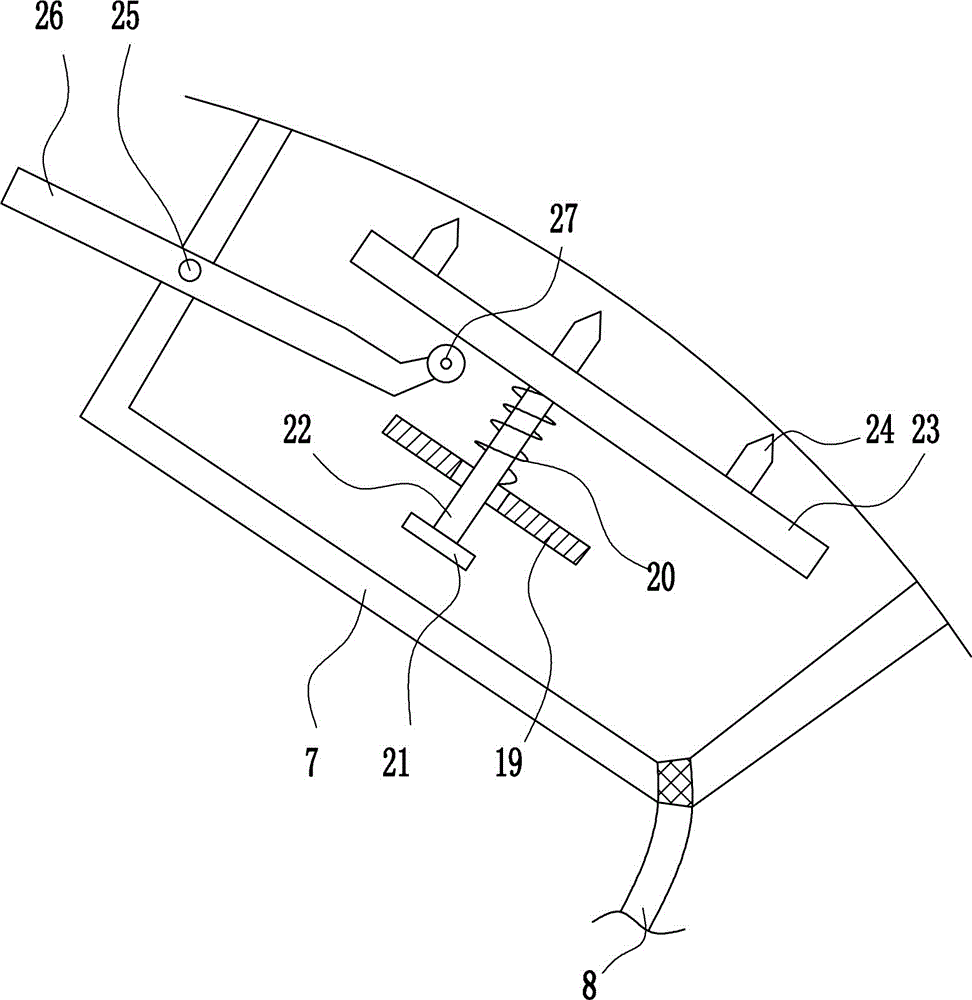

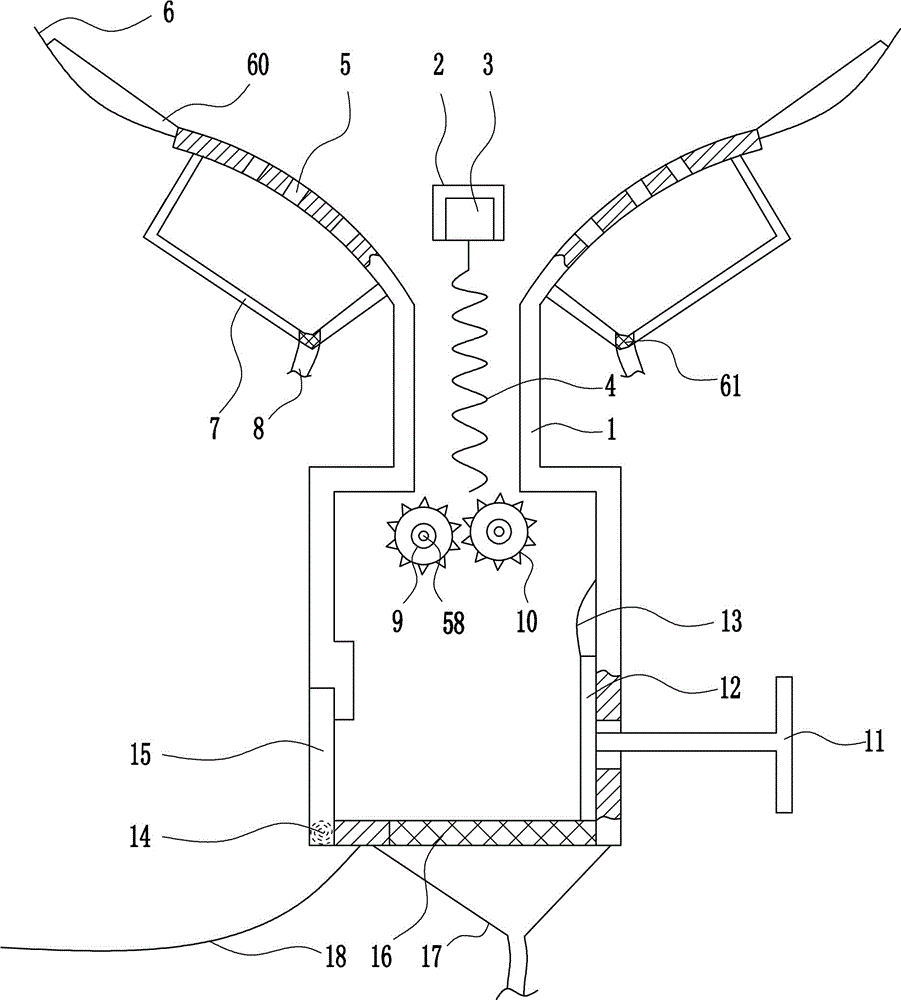

Garbage water separation equipment

The invention relates to separation equipment, in particular to garbage water separation equipment. The technical problem to be solved by the invention is to provide the active garbage water separation equipment provided with a cleaning device and having good compression effect. In order to solve the technical problem, the invention provides the garbage water separation equipment. The garbage water separation equipment comprises a treatment box, a protective cover, a first motor, a spiral rod, a first guide plate, a collecting box, a water outlet pipe, a second motor, crushing rollers, a push rod, a push plate and the like; the upper part of the treatment box is cone-shaped; the back wall of the upper part in the treatment box is connected with the protective cover through a screw connecting mode; the first motor is arranged in the protective cover; an output shaft of the first motor is connected with the spiral rod through a coupling; and first through holes are uniformly formed in the left and right two sides of the upper part of the treatment box. The garbage water separation equipment is provided with the rotating spiral rod, so that garbage can be quickly leaded between the crushing rollers, and can be stirred to a certain extent.

Owner:赣州科源甬致科技有限公司

Cryptographic token with leak-resistant key derivation

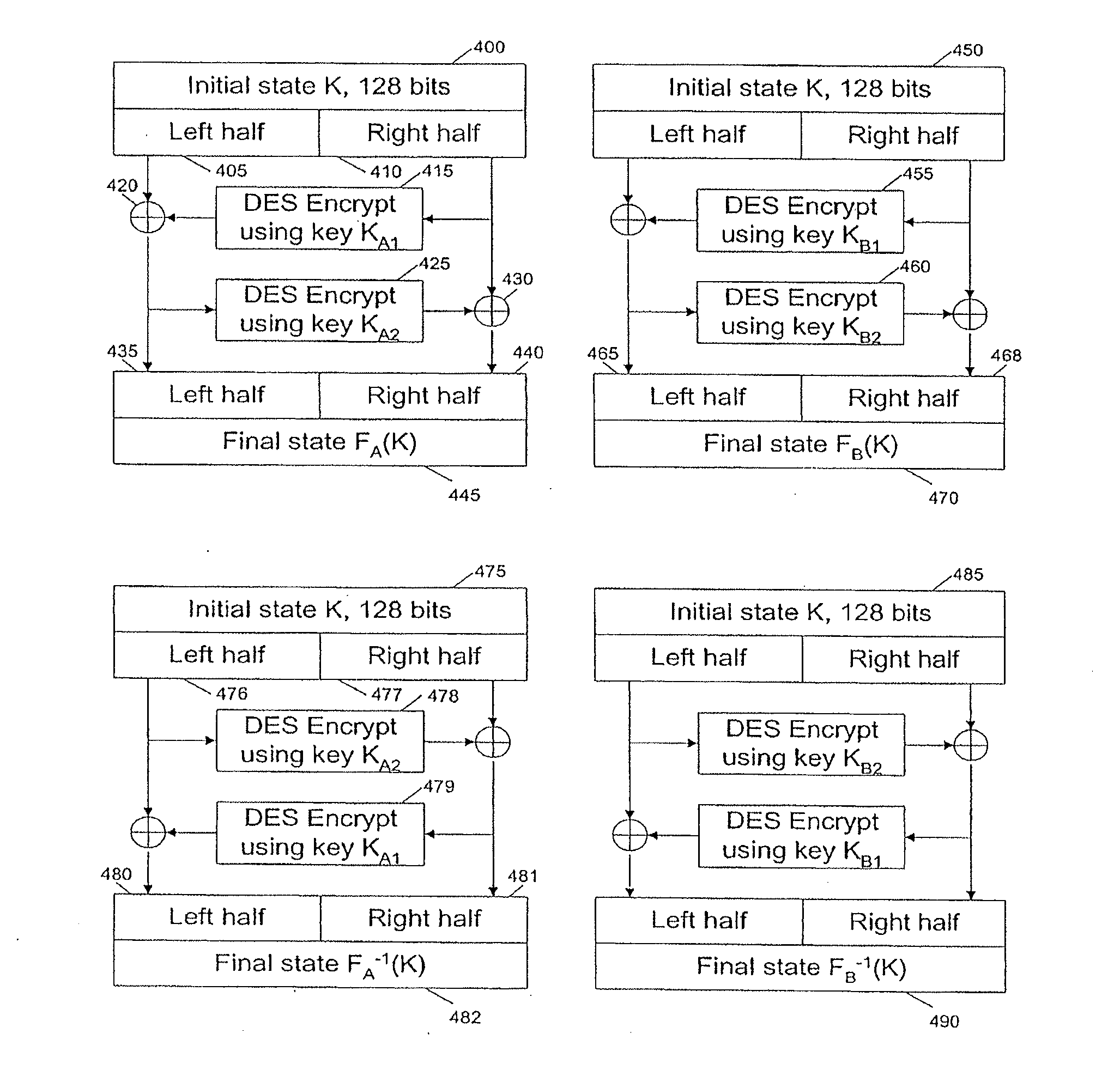

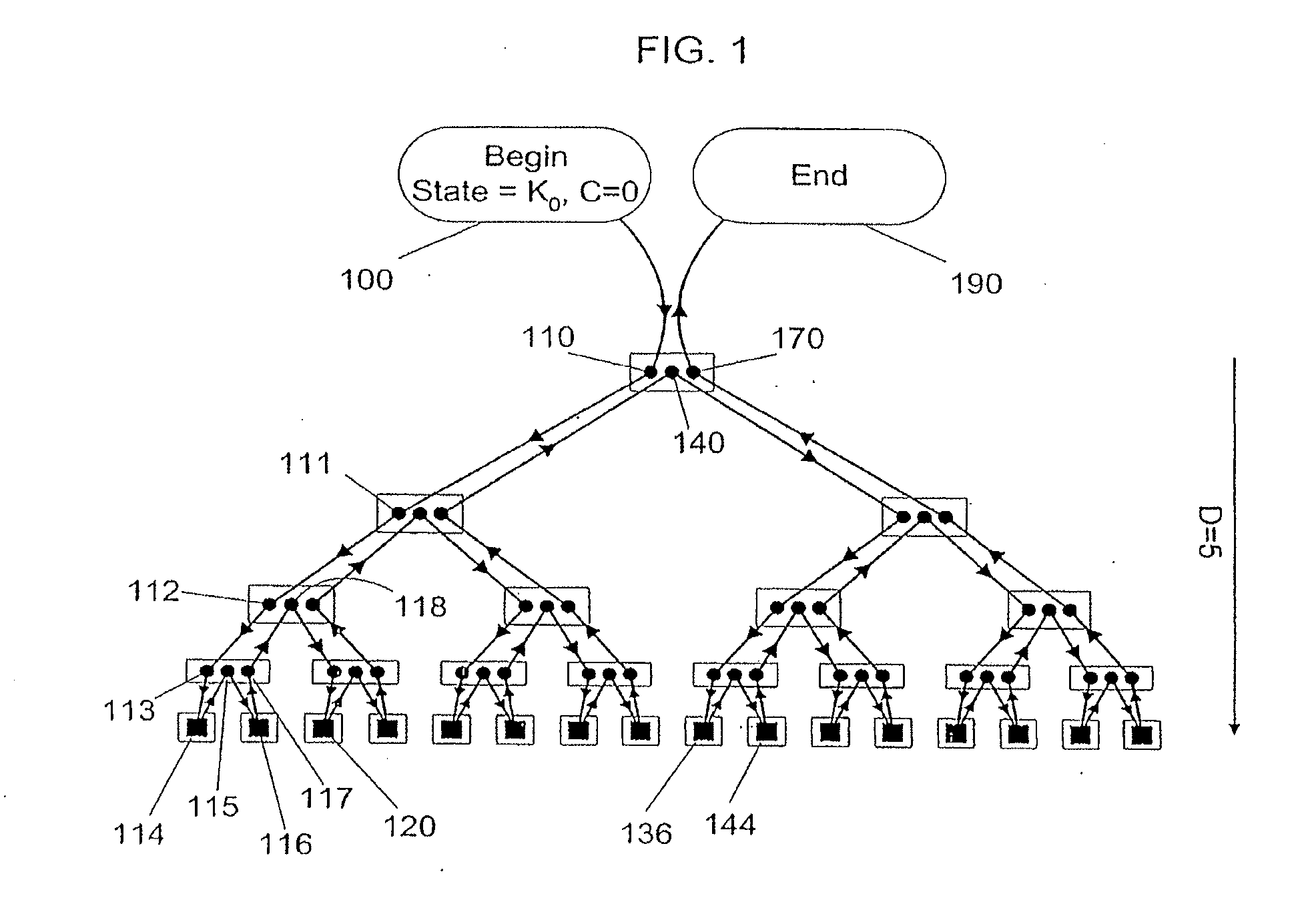

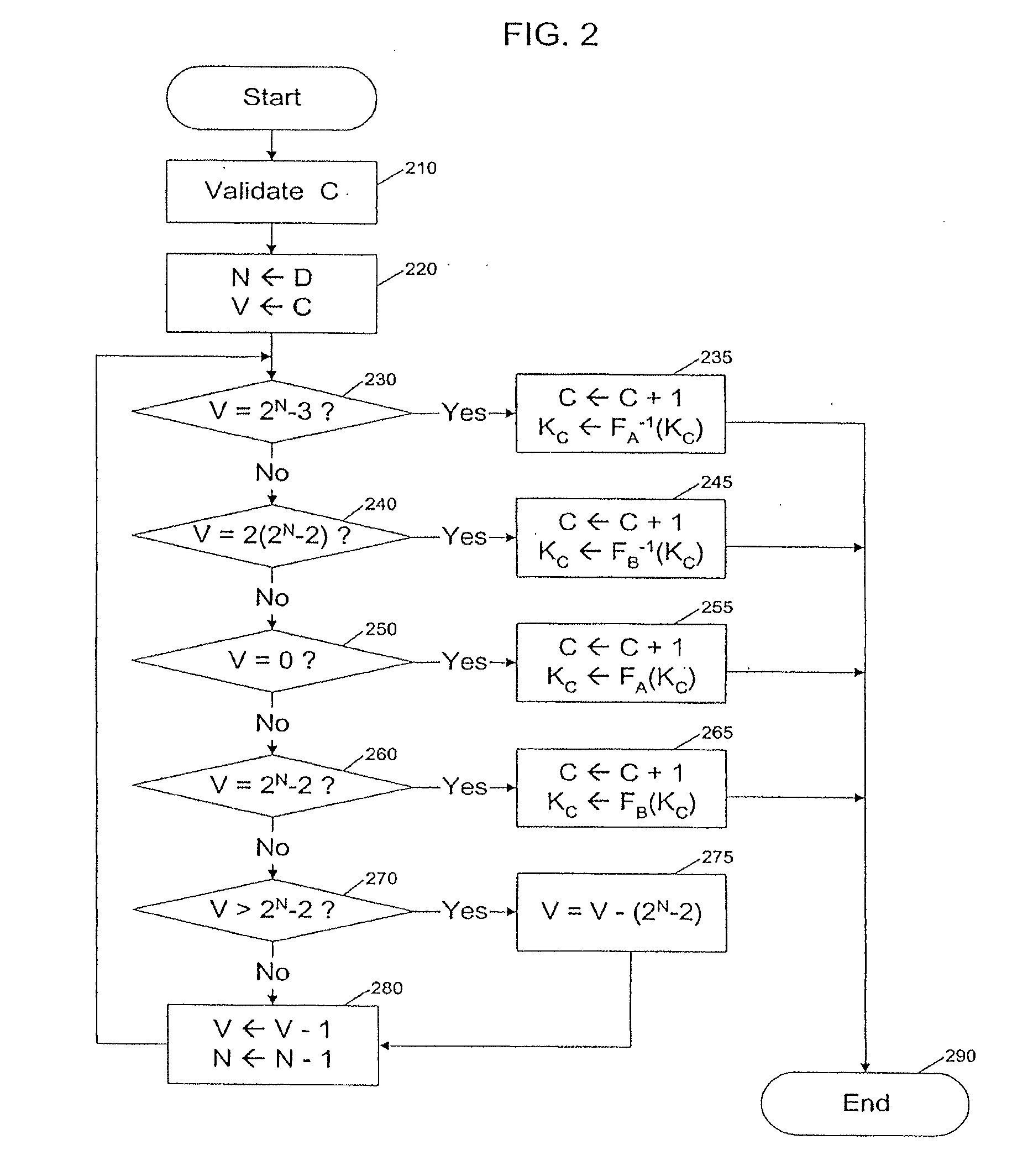

InactiveUS20120017089A1Improve performanceMaintaining leak-resistant and leak-proof security characteristicKey distribution for secure communicationUser identity/authority verificationCryptographic protocolCryptographic nonce

Owner:CRYPTOGRAPHY RESEARCH INC

A composite fabric containing liquid metal

ActiveCN102296405AQuick exportImprove thermal conductivityFibre treatmentWoven fabricsTextile fiberYarn

The invention relates to a compound-type fabric containing liquid metal. The fabric can be completely woven by blended fiber yarn of a liquid-metal-containing fiber, and can also be woven by mixing a natural fiber yarn and blended fiber yarn of the liquid-metal-containing fiber, wherein the liquid-metal-containing fiber is a textile fiber the surface of which is adhered with liquid metal nanoparticles, a tubular textile fiber the pipe of which is filled with liquid metal, or a reticular casing-pipe-type textile fiber which is woven by nanowires and the reticular casing pipe of which is filledwith liquid metal; and the liquid metal is gallium metal, gallium-based alloy, Na-K alloy or wood metal containing indium. The compound-type fabric can be made into a single layer, two layers or three layers according to requirements, can be used as a basic fabric for manufacturing articles such as clothes, trousers, shoes and hats, gloves, stockings, bedclothes and pillowcases and the like, can endow clothing and household articles with temperature adjusting, radiation proofing, electrostatic resisting and sterilizing and antimicrobial functions, has stable performance and high reliability, needs not to be added with other organic components, and can be used for making up the defect of the property singleness of the traditional fabric.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

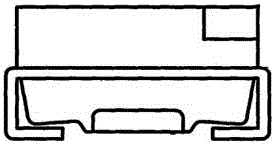

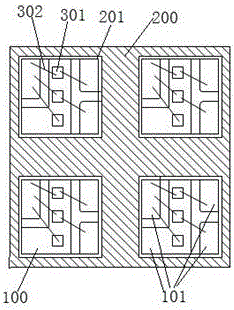

QFN surface-mounted RGB-LED encapsulation module and manufacturing method thereof

PendingCN106847800AQuick exportHigh resolutionSolid-state devicesIdentification meansSurface mountingEngineering

The invention provides a QFN surface-mounted RGB-LED encapsulation module and a manufacturing method thereof. The RGB-LED encapsulation module comprises an encapsulation bracket and light-emitting units arranged on the encapsulation bracket, wherein the number of the light-emitting units is at least two; the encapsulation bracket comprises a metal baseplate and an insulating frame; a bracket electrode for fixing crystal and bonding a wire is arranged at a region, where each light-emitting unit is located, by the metal baseplate; each light-emitting unit comprises an RGB-LED chip fixed on the metal baseplate and a bond and a wire for connecting the RGB-LED chip and a bracket electrode; a protective layer is arranged on each light-emitting unit; the bracket electrode is connected with an external circuit through a bonding pad arranged on the back of the metal baseplate. The encapsulation module is in direct contact with a PCB through the metal baseplate, so that chip heat can be quickly led out; a bowl-cup structure is formed on the front, so that a light-emitting surface is unique; the multiple light-emitting units are integrated on the one encapsulation module, so that the production efficiency is further improved.

Owner:SHANDONG JIERUNHONG OPTOELECTRONICS CO LTD

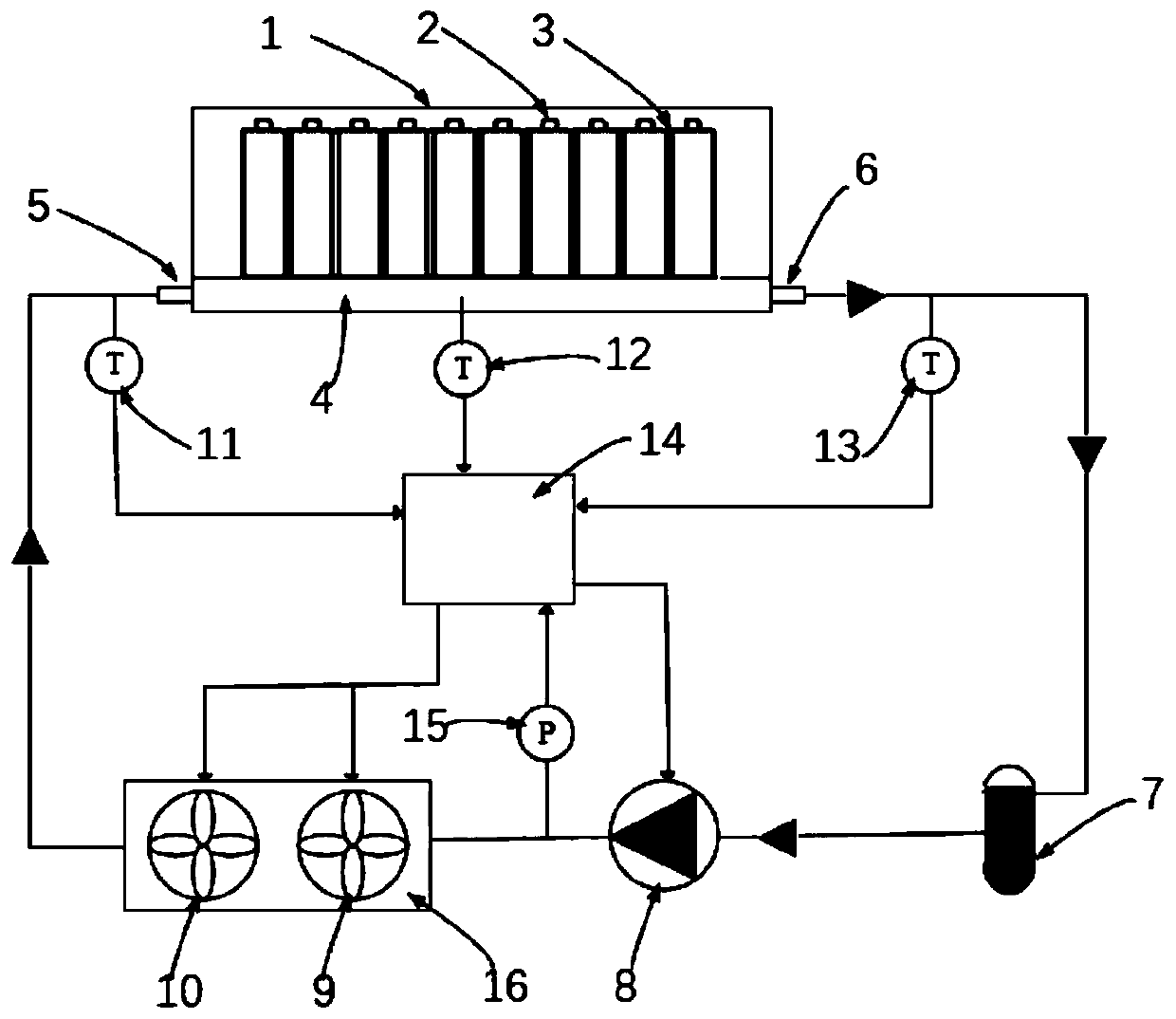

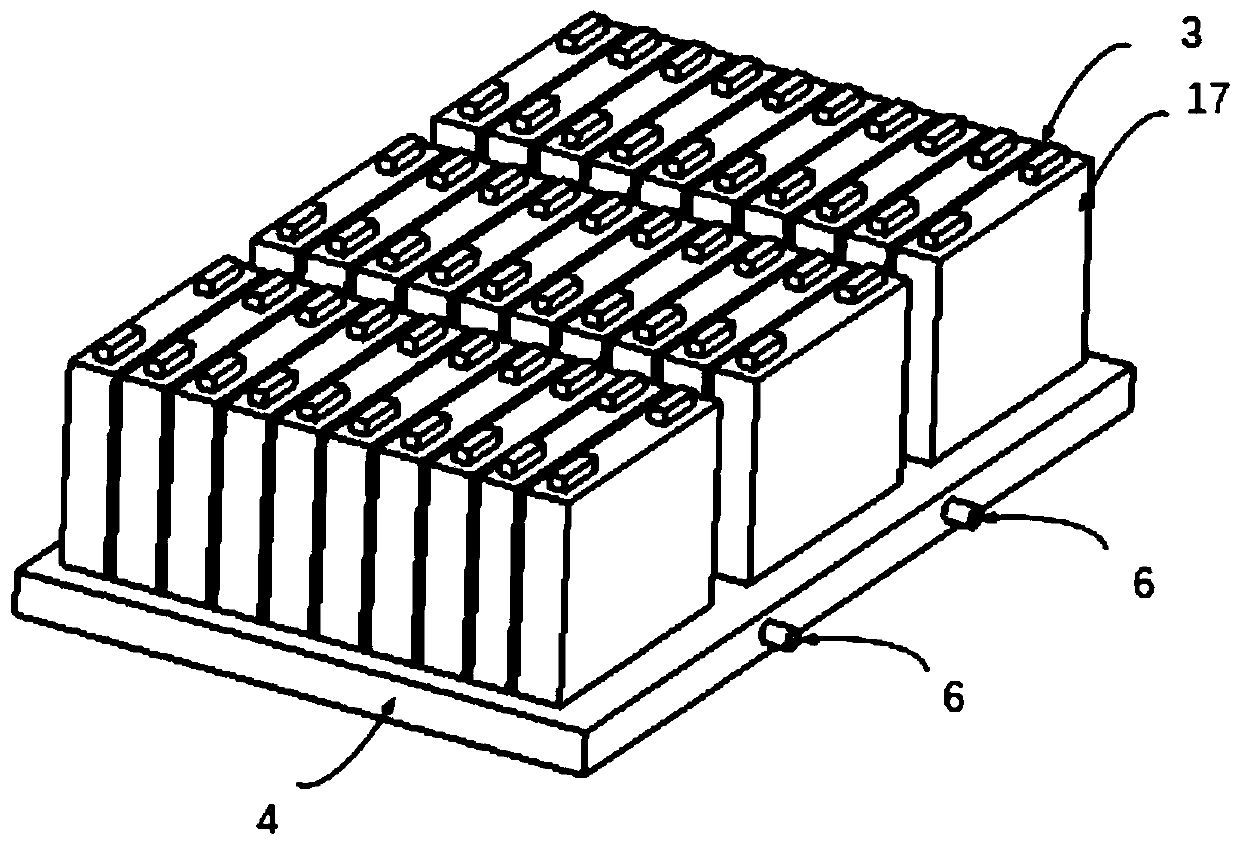

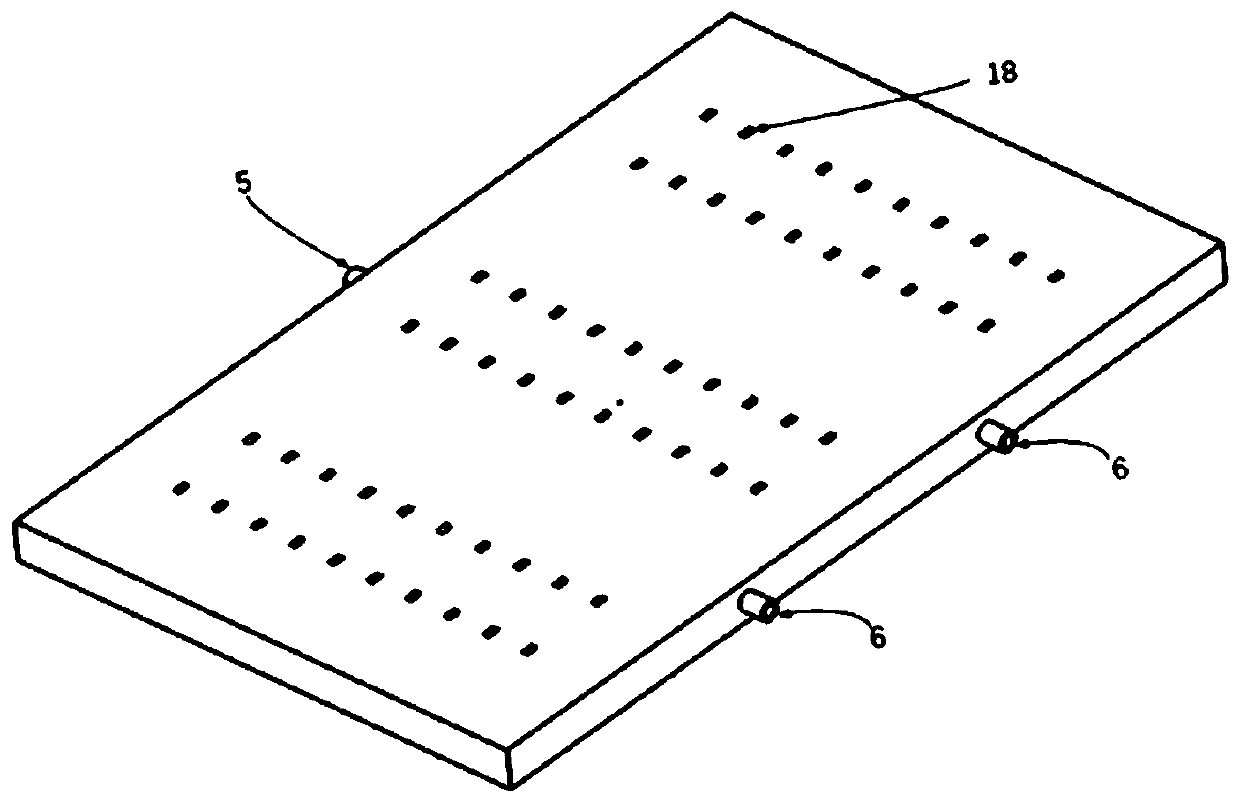

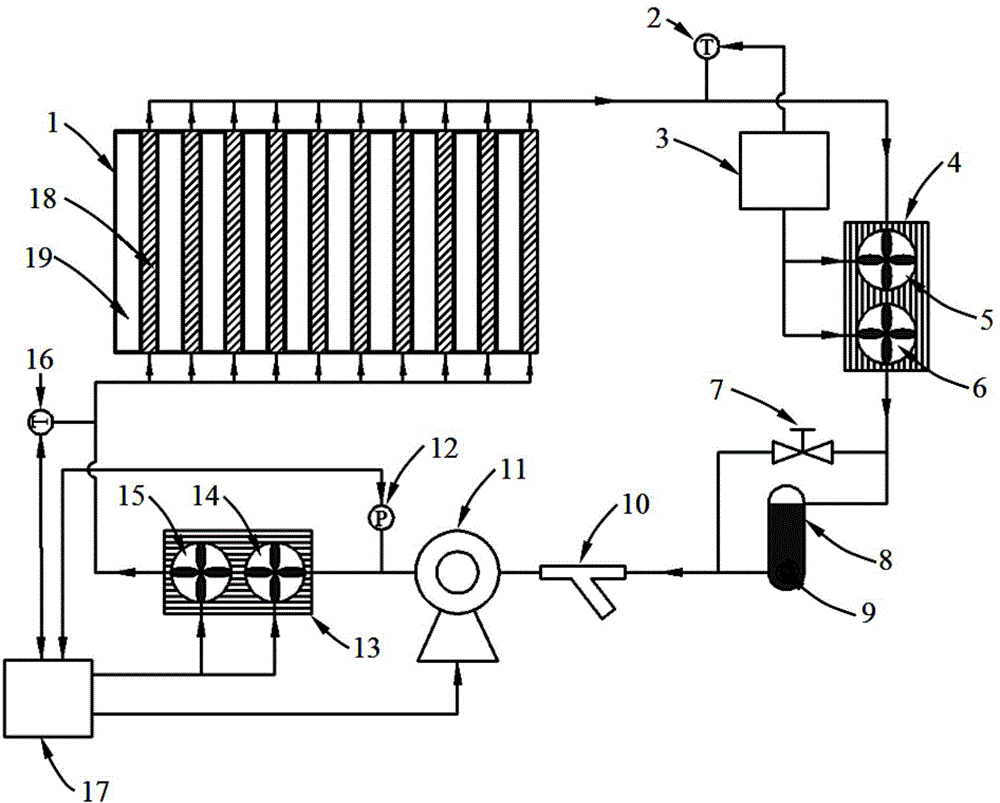

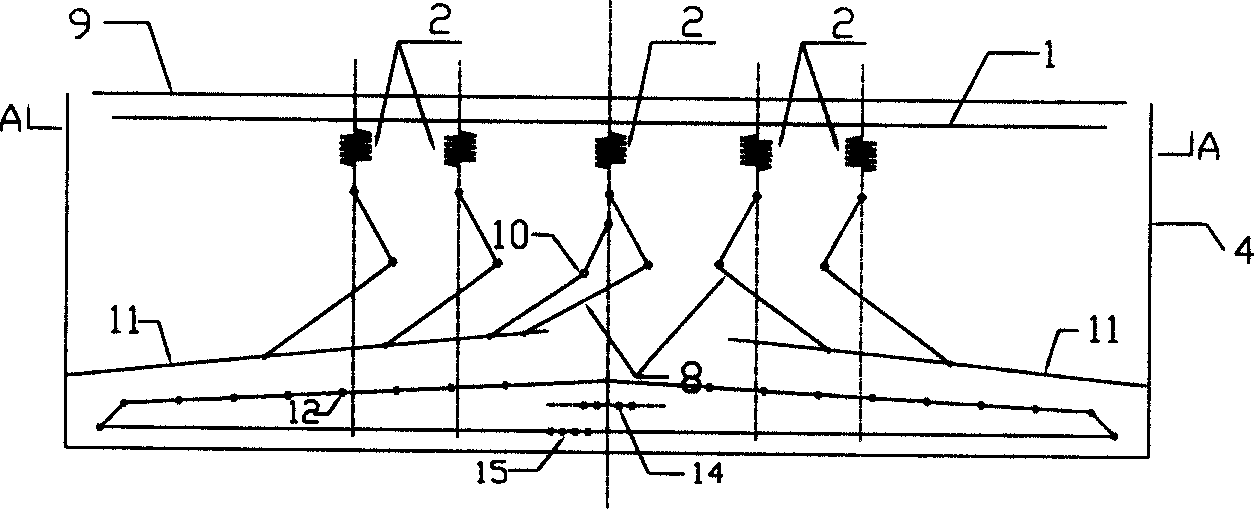

Power battery thermal management system

InactiveCN110289460AQuick exportImprove cooling efficiencySecondary cellsHeat conductingCoolant flow

The invention discloses a power battery thermal management system, which mainly comprises power batteries, heat conducting devices, a liquid cooling plate, a control system and a heat dissipating device, wherein at least one group of heat conducting devices are arranged between the power batteries; each heat conducting device comprises a heat conducting graphite plate, a heat pipe embedded in the liquid cooling plate and fins; a heat conducting device mounting hole is disposed on the liquid cooling plate; a coolant flow channel is disposed in the liquid cooling plate; the rest part of the liquid cooling plate is filled with a phase change material; the liquid cooling plate is in communication with the heat dissipating device to form a heat dissipating circuit; the control system is configured to drive the coolant and control the circuit in which the coolant is located. The power battery thermal management system has high heat storage and heat dissipation efficiency, saves energy, improves the energy density of the battery pack, ensures that the power batteries are in a suitable temperature range in operation, and achieves the temperature consistency of the power batteries.

Owner:JIANGSU UNIV

Anti-electrostatic ceramic material, preparation method thereof and firecrackers lead knitting needle made of material

ActiveCN101786878ALow resistivityImprove flexural strengthCeramic shaping apparatusFuse manufactureFirecrackerMass ratio

The invention discloses an anti-electrostatic ceramic material which comprises the following components in percentage by weight: 68-80 percent of yttria stabilized zirconia, 1-3 percent of silicon dioxide, 10-14 percent of tin oxide, 7-11 percent of zinc oxide, 1-2.5 percent of silicon 1-2.5 percent of silicon carbide. The preparation method of the ceramic material comprises the following steps of: firstly, mixing various raw materials in ultrathin powder state by a ball mill; then drying; melting and blending the dried mixed raw materials with an organic binder according to a mass ratio of (4-9):1; injecting and forming particles obtained by melting and blending to obtain a ceramic blank; and degreasing and sintering to obtain an anti-electrostatic ceramic material. In the method, the firecrackers lead knitting needle is injected and formed by a die. The anti-electrostatic ceramic material and the firecrackers lead knitting needle thereof have the advantages of electrostatic resistance, abrasion resistance, good anti-bending performance, simple preparation process, lower cost, and accurate size of a prepared ceramic product without post-processing.

Owner:JIANGSU JINSHENG CERAMIC TECH

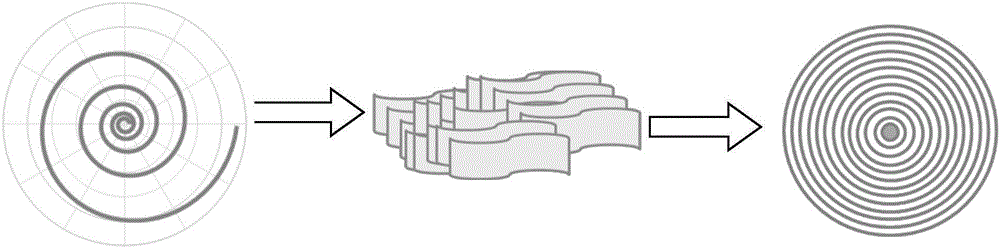

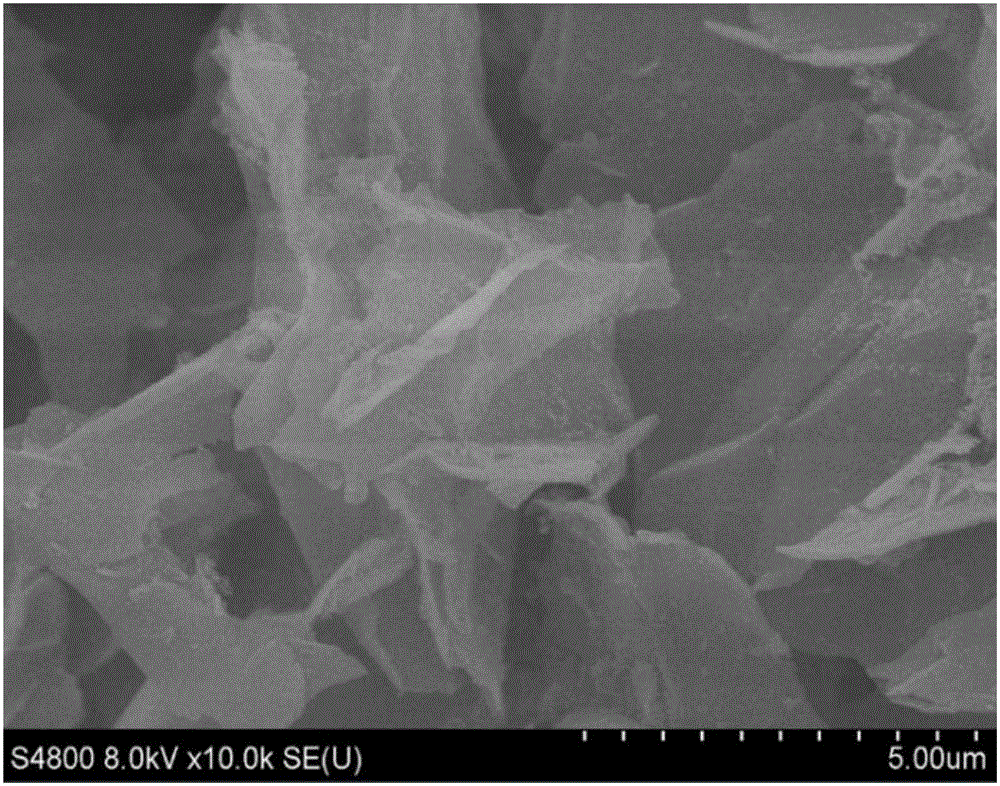

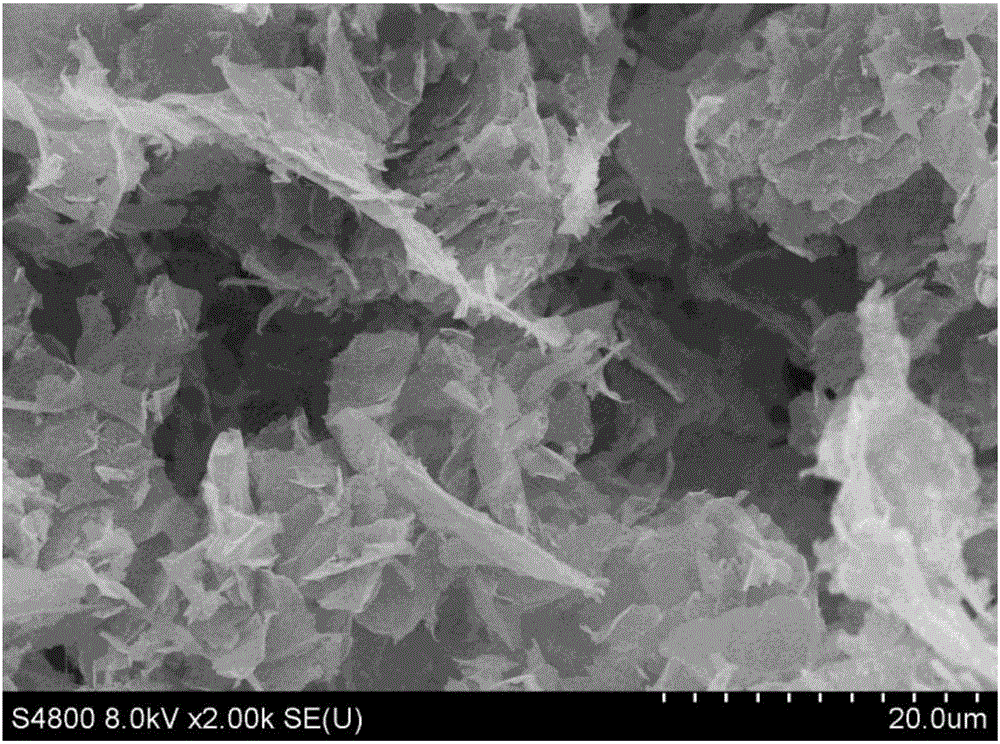

Graphene based heat-conducting interface material and preparation method thereof

ActiveCN106633916AImprove longitudinal thermal conductivityFacilitate rapid heat dissipationHeat-exchange elementsCvd grapheneSilane coupling

The invention provides a preparation method for a graphene based heat-conducting interface material. The preparation method comprises the following steps: A) mixing a graphene material, vinyl silicone rubber, hexagonal boron nitride, flake graphite, hydroxy-terminated silicone oil, vinyl silicone oil and a first silane coupling agent, and carrying out stirring so as to obtain a rubber material, wherein the graphene material is one or more selected from the group consisting of graphene, graphene / silica composite powder and a graphene / silica composite sheet material; and B) subjecting the rubber material to pull-pressing, rolling and cutting so as to obtain the graphene based heat-conducting interface material.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

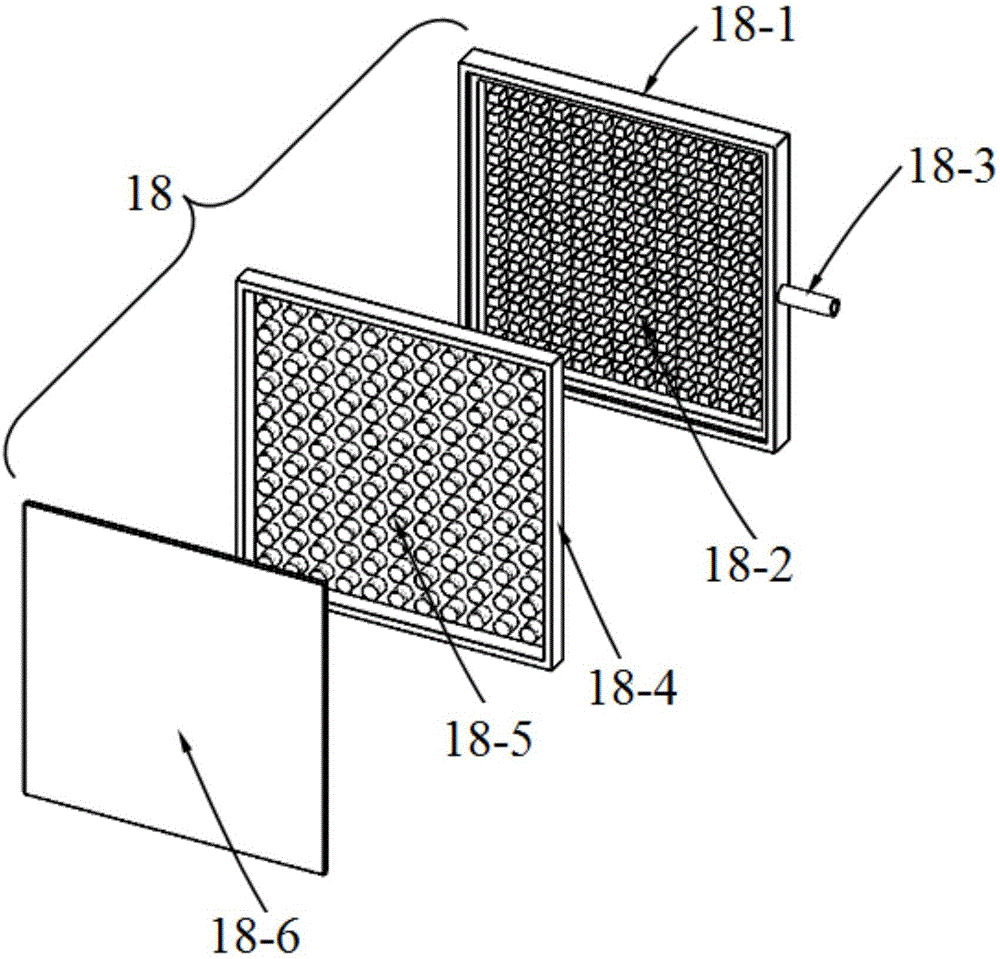

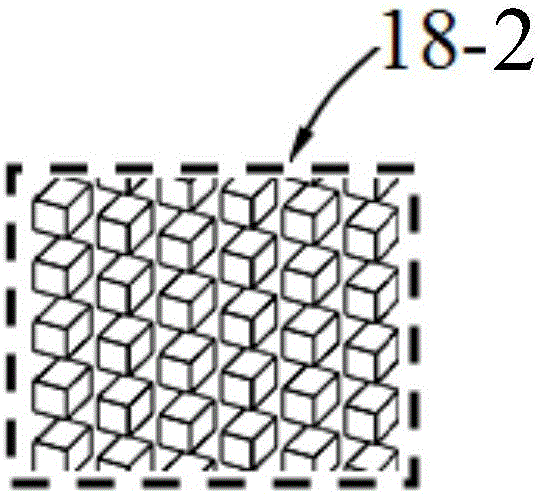

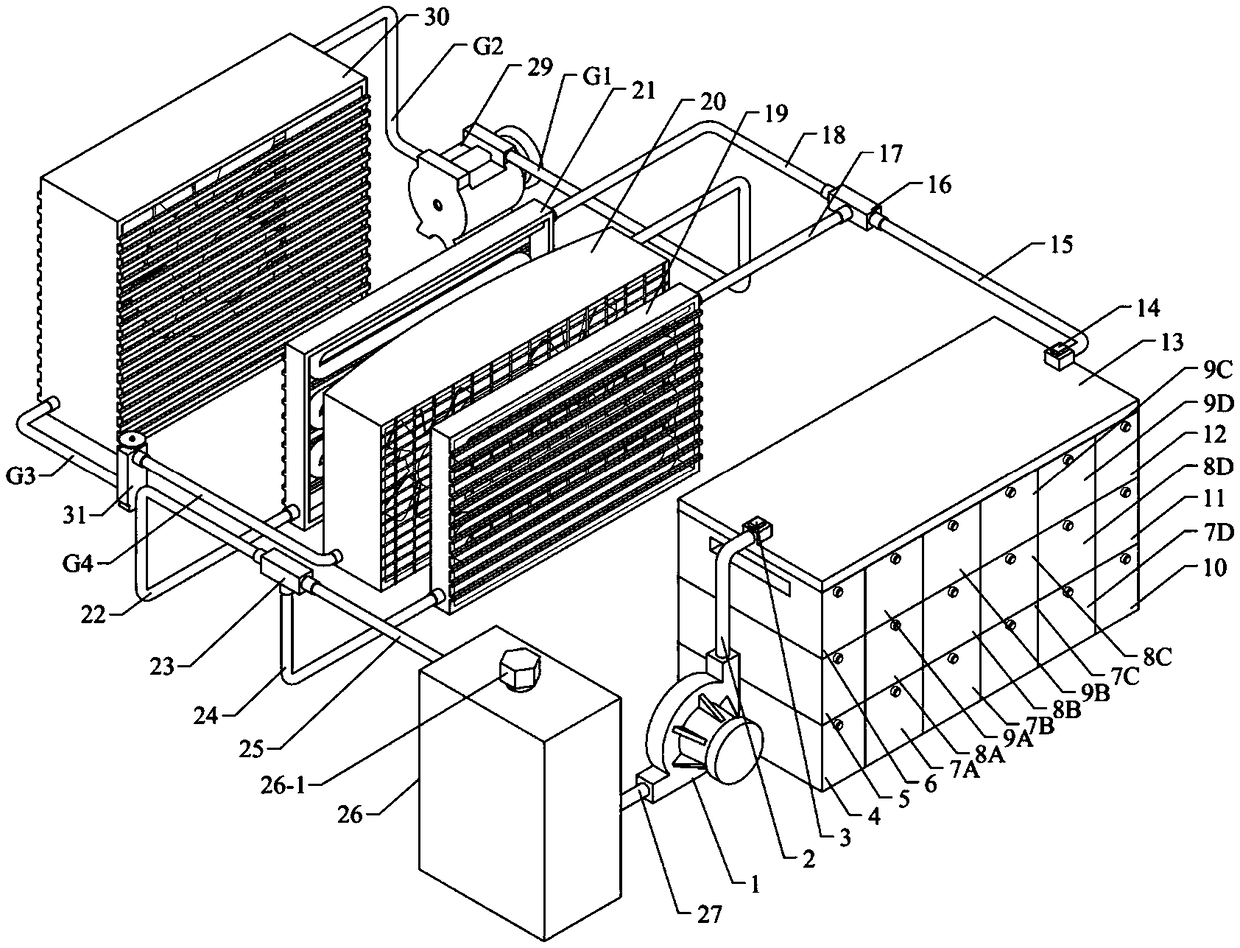

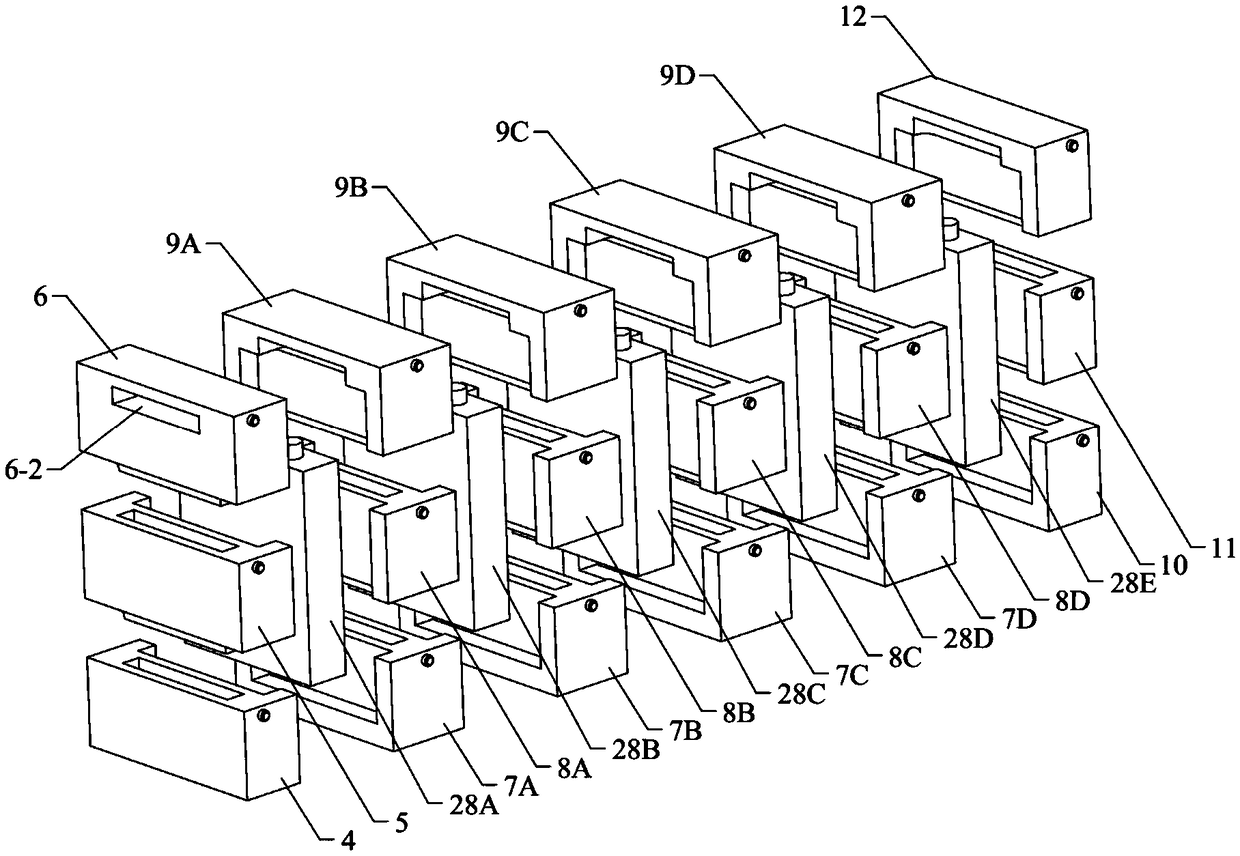

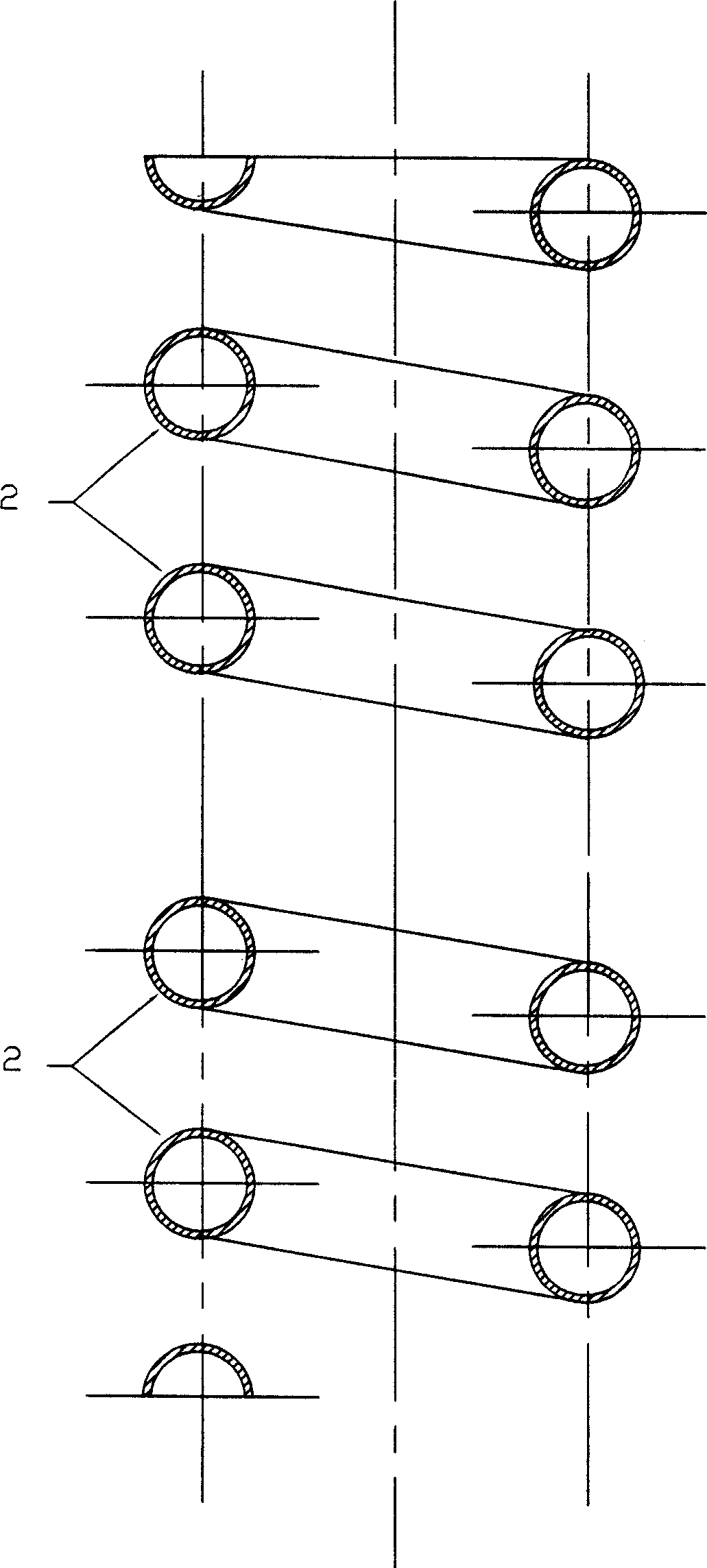

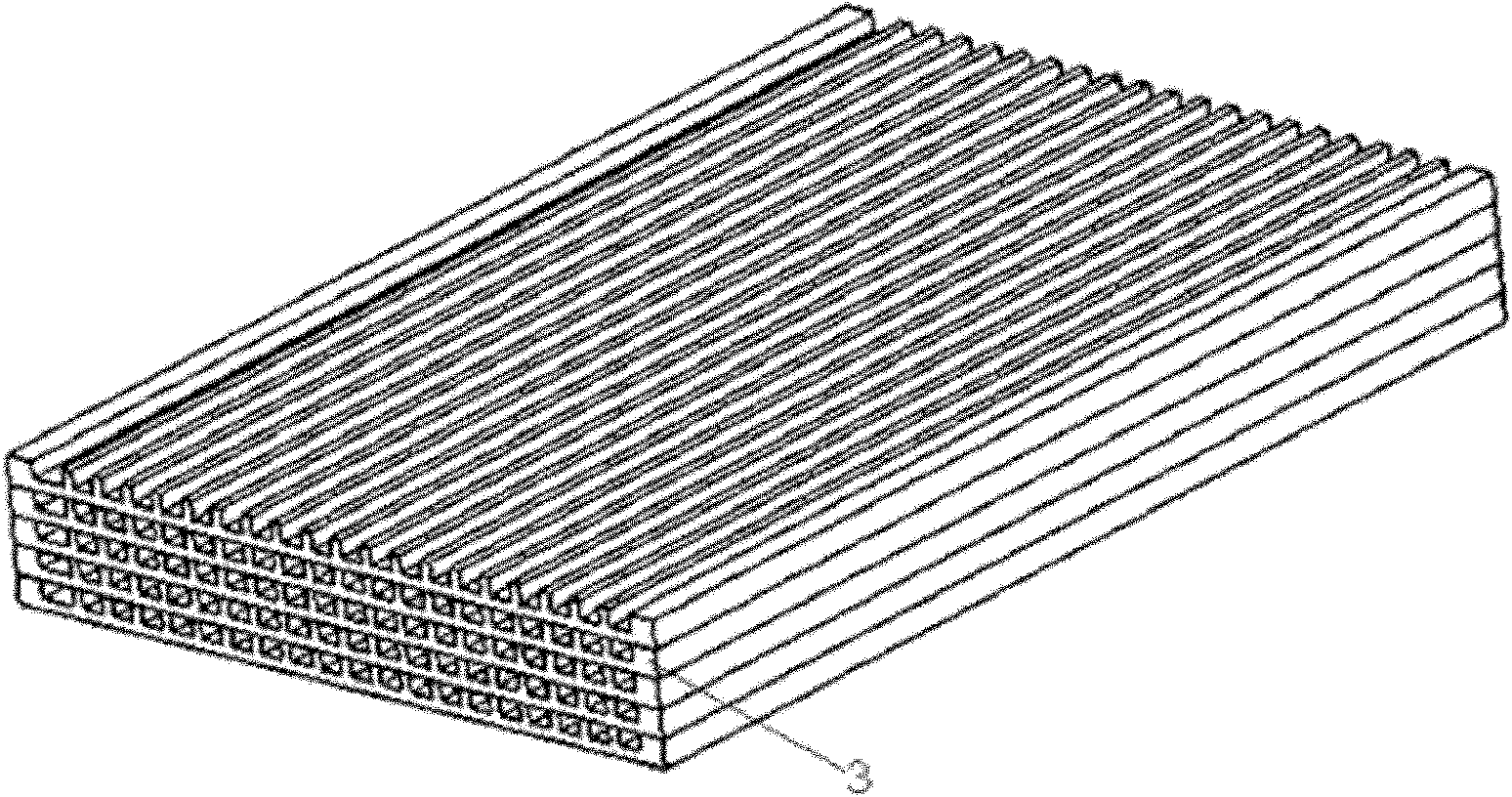

Thermal management system of proton exchange membrane fuel cell

ActiveCN106602105AImprove cooling efficiencyIncrease cooling areaFuel cell heat exchangeControl systemEvaporation

The invention discloses a thermal management system of a proton exchange membrane fuel cell. The thermal management system comprises heat dissipation devices, a fuel cell stack, a cooling liquid distribution pipe, a cooling liquid collection pip and a control system, wherein each heat dissipation device comprises a microchannel heat sink, an ultrathin uniform temperate plate evaporation cavity assembly and a sealing plate, the microchannel heat sink comprises a shell and a heat dissipation fin array, the ultrathin uniform temperate plate evaporation cavity assembly comprises a bottom plate and a capillary core, one end of the capillary core is in direct contact with a base part of the microchannel heat sink, an evaporation cavity is formed between the bottom plate and the base part, the ultrathin uniform temperate plate evaporation cavity assembly and the sealing plate are respectively connected with two ends of the microchannel heat sink, the fuel cell stack is formed by laminating and combining at least two single cells in a series mode, the heat dissipation device is correspondingly arranged at one side of each single cell, the single cells and the heat dissipation devices are arranged in a lamination way at intervals, and the control system is used for supplying a cooling liquid and controlling the cooling liquid to flow. By the thermal management system of the proton exchange membrane fuel cell, the fuel cell can be enabled to be in an appropriate temperature range during the operation process, and the temperature uniformity in the fuel cell can be ensured.

Owner:淳华氢能源科技(湖南)有限公司

Battery thermal management and in-vehicle heating system for electric vehicles based on ultra-fast charge-discharge technology

PendingCN109244593AImprove cooling effectAvoid direct contactSecondary cellsCell component detailsIn vehicleHeating system

The invention relates to the technical field of thermal management of electric vehicle power battery, in particular to an electric vehicle battery thermal management and in-vehicle heating system applied to ultra-fast charging and discharging technology. The invention is installed on an automobile and connected with an ECU of the automobile, and is composed of a battery pack module, a cooling circulation module and a heat pump air conditioning module. A temperature control loop is composed of an inlet water temperature sensor, an outlet water temperature sensor, an in-vehicle temperature sensor, an inlet reversing valve, an outlet reversing valve, a water pump, an air condition heat exchanger and a compressor and an automobile electronic control unit ECU. By utilizing the phase change endothermic property of phase change material to absorb fully and fill rapidly, the amount of heat emitted by a battery during discharge, The heat dissipation effect of the battery cell and the battery pack is improved, the heat generated in the charging and discharging process of the battery is brought into the vehicle through the air conditioner heat exchanger in winter, the battery pack can be cooled by the heat pump air conditioner in summer, the energy consumption is reduced, and the efficient heat dissipation of the battery pack and the cooling of the vehicle compartment are realized.

Owner:SHANDONG UNIV

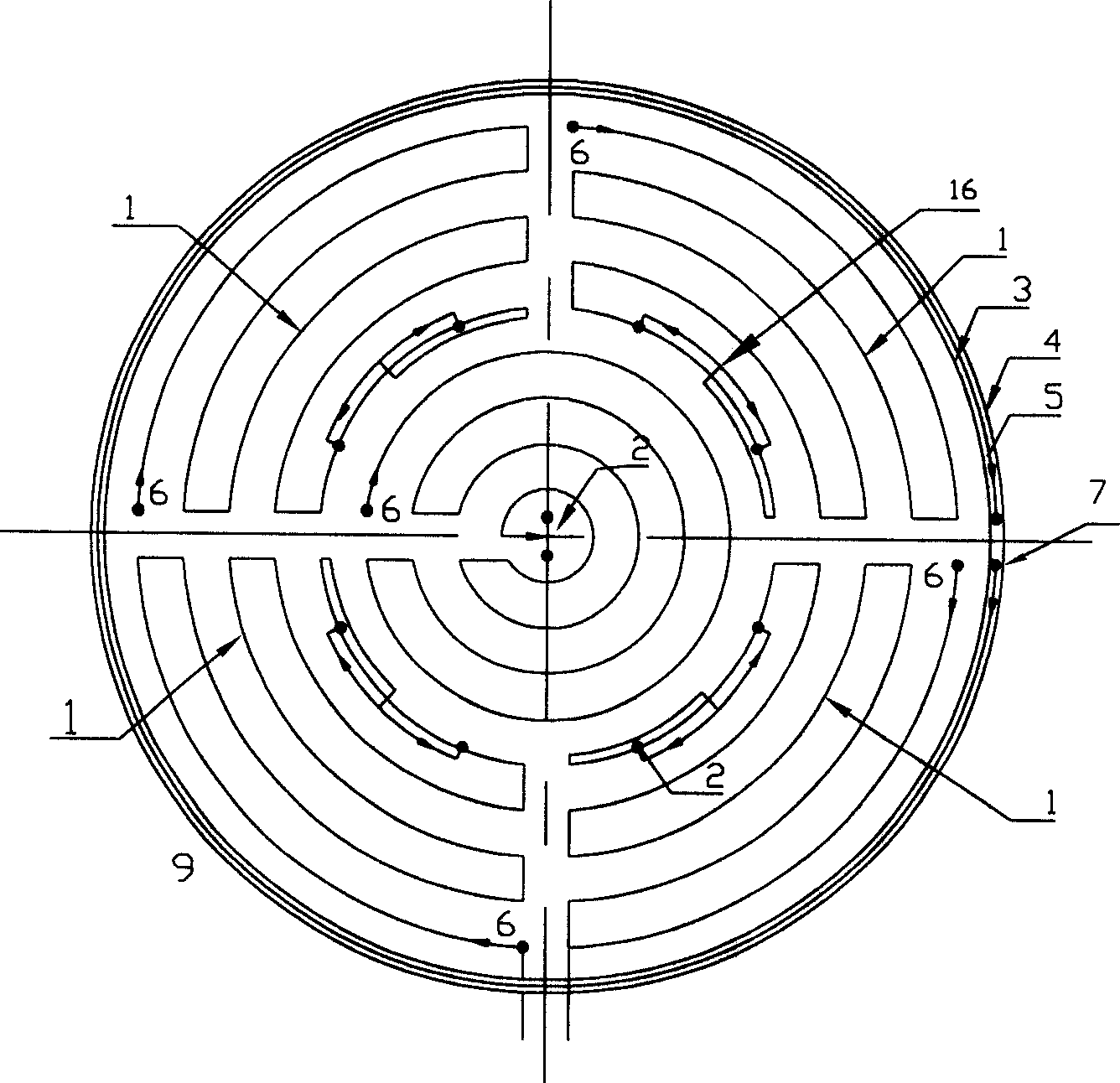

High-solidified oil floating-roof oil tank space heating device

The present invention relates to a high solidification high-viscosity wax-containing petroleum product floating-roof-tank low-temp. stored space heating equipment. It is characterized by that on the tank bottom a bottom portion steam tube heater is mounted, under the floating roof a top horizontal steam tube heater is mounted, and is connected with 9-13 vertical helical steam tube heaters which are uniformly distributed in the oil tank, and the lower portion of vertical helical steam tube is connected with metal hose, then is connected to the water-discharging header of bottom portion.

Owner:PIPECHINA SOUTH CHINA CO

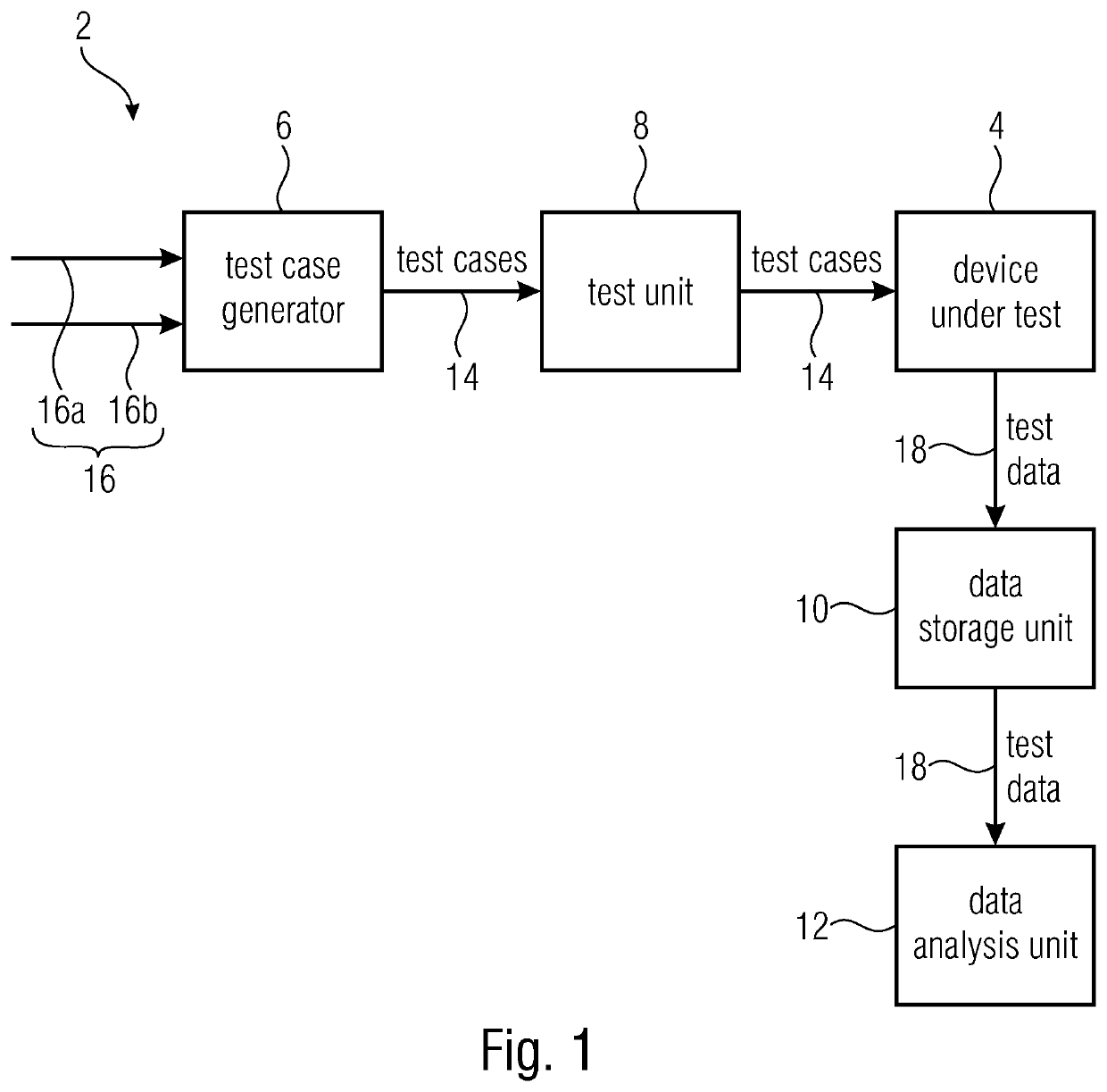

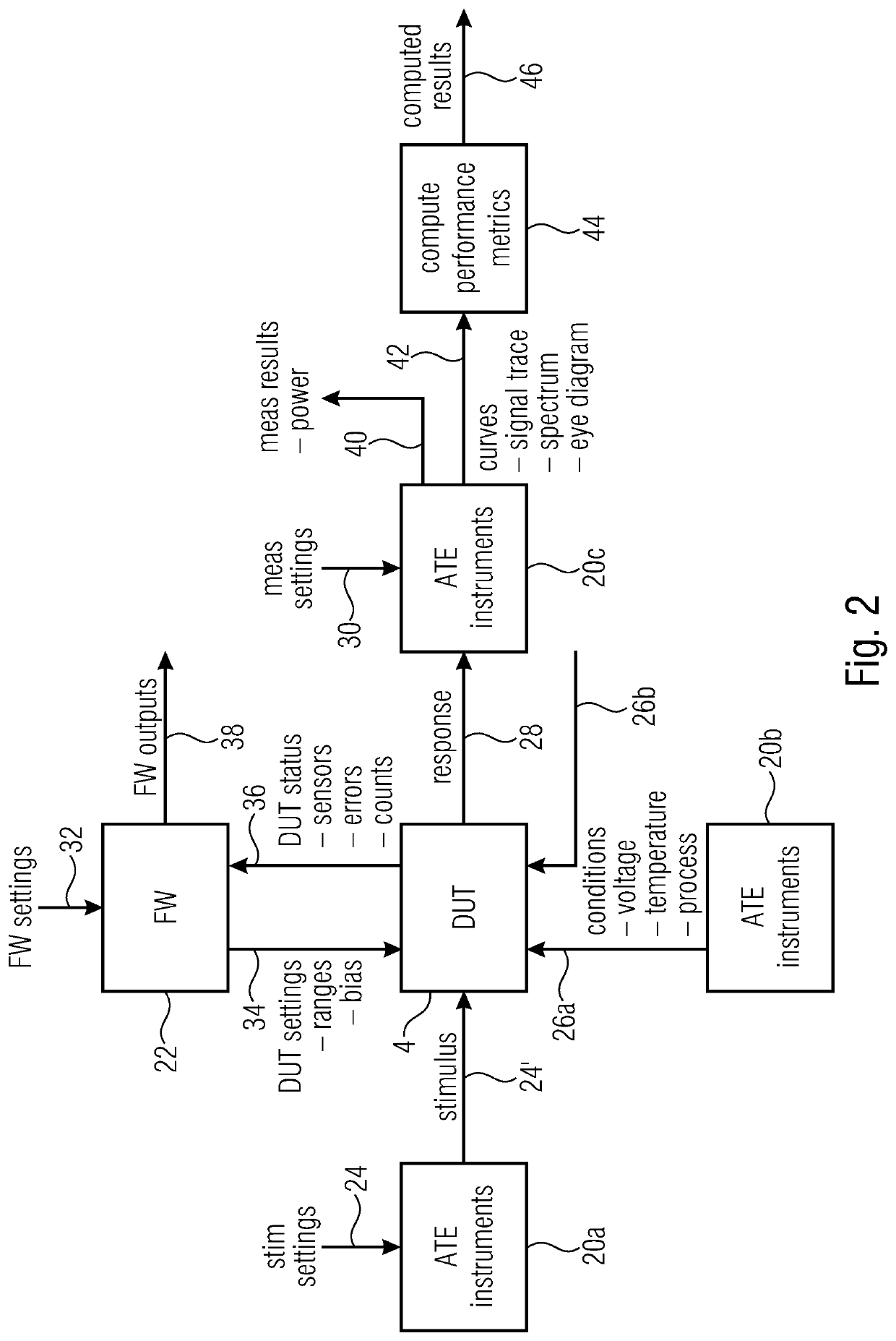

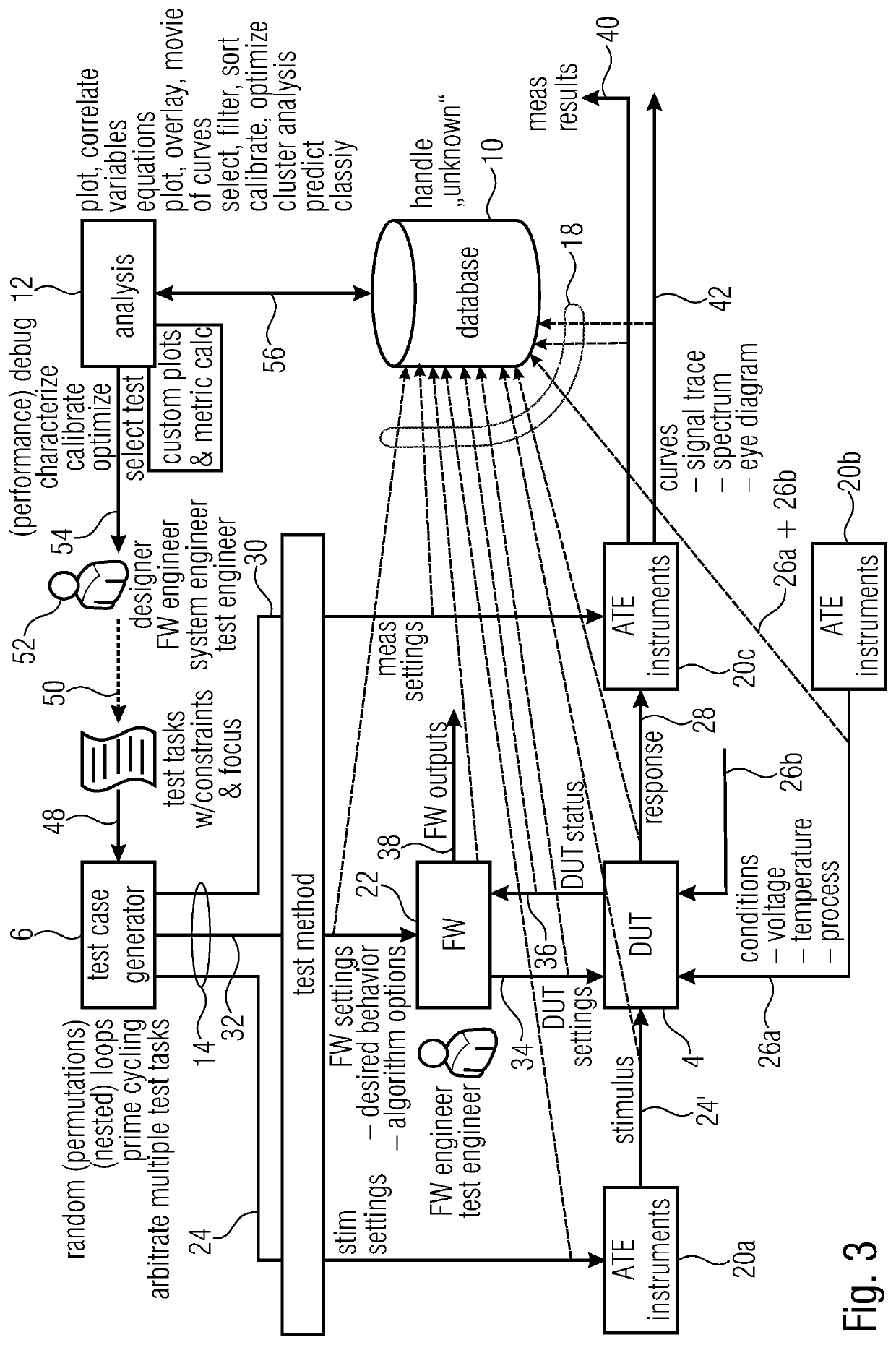

Test apparatus and method for characterizing a device under test

ActiveUS20190370158A1High practical relevanceIncrease probabilityDetecting faulty computer hardwareSoftware testing/debuggingEquipment under testTest case generator

A test apparatus for characterizing a device under test includes a test case generator, a test unit, a data storage unit, and a data analysis unit. The test case generator is configured to randomly generate a plurality of test cases, which include values of one or more input variables of a set of input variables. The test unit is configured to perform the plurality of test cases on the device under test. The data storage unit may store sets of test data, which are associated to the test cases and include values of input variables of a respective test case and corresponding values of output variables of the device under test related to the respective test case. The data analysis unit may further analyze the test data and is further configured to determine dependencies within a subset of variables of the test data to characterize the device under test.

Owner:ADVANTEST CORP

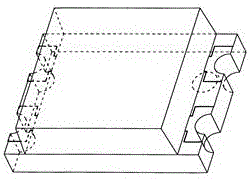

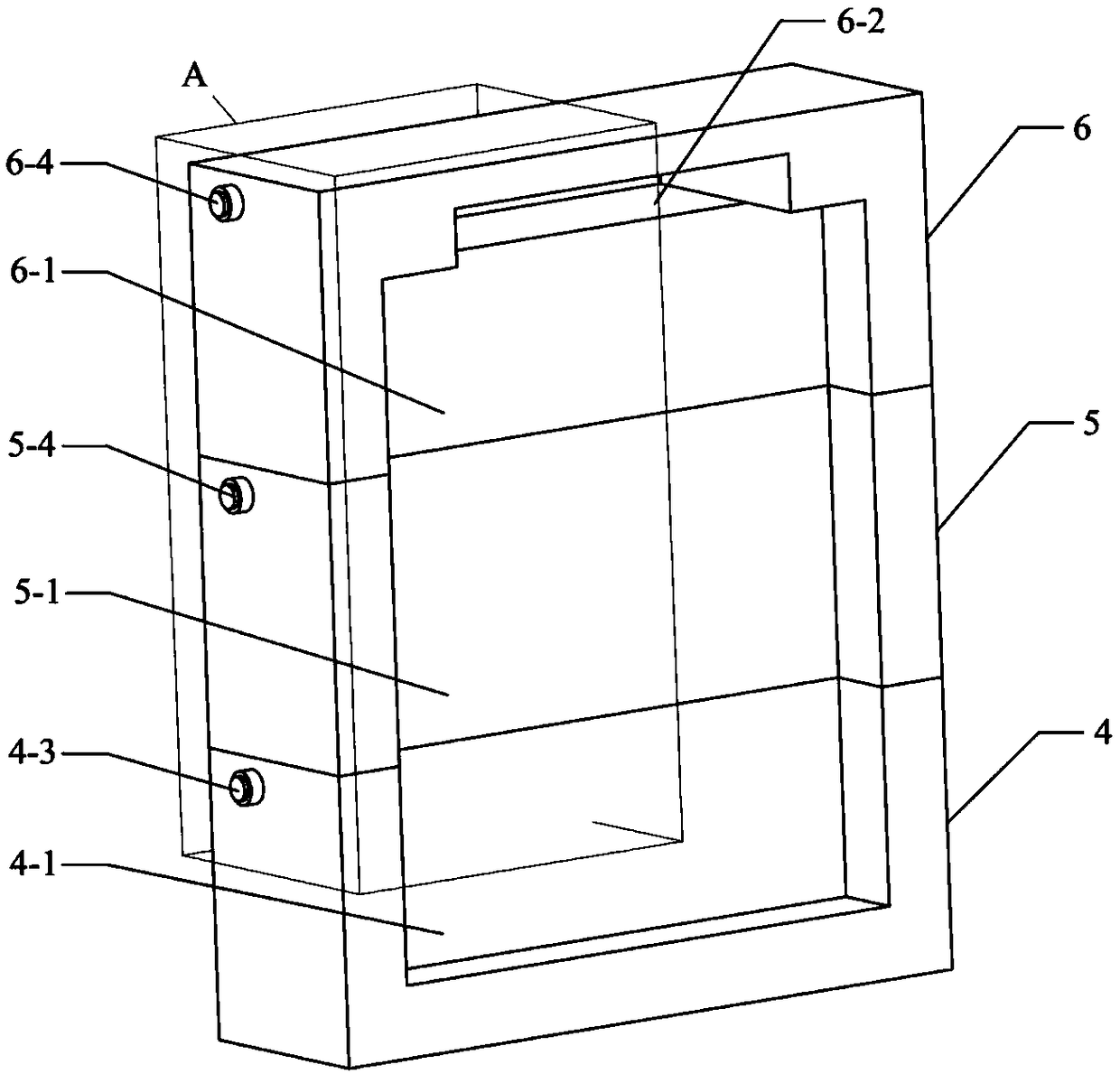

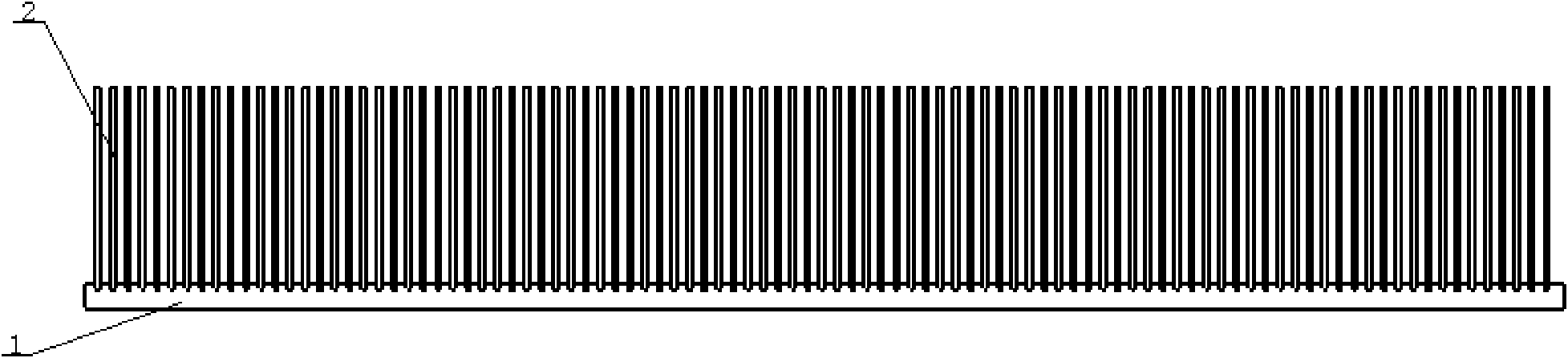

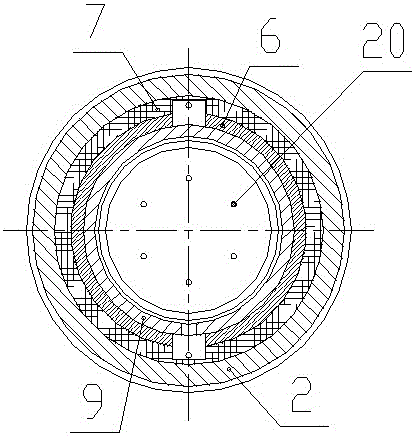

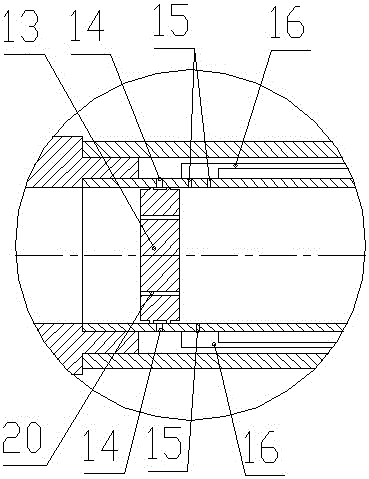

Metal and conductive plastic composite micro heat exchanger

ActiveCN102109291AImprove machinabilityQuick exportSemiconductor/solid-state device detailsSolid-state devicesMicro structureEngineering

The invention discloses a metal and conductive plastic composite micro heat exchanger, belonging to the technical field of heat exchangers. In the heat micro-exchanger, a shell with heat insulating function is sleeved outside the heat exchanger to protect internal panels; a seal head for distributing or collecting fluid is welded on the shell, and mouths of cold and heat fluid inlet and outlet pipes are welded on the seal head; and particular structures can be arranged according to requirements. The heat micro-exchanger is characterized in that the internal panels comprise a metal substrate and a plastic micro-structure, wherein metal is used as a conductive substrate, and the conductive plastic of a micro-structure is compounded on the metal substrate. By the metal and conductive plastic composite heat micro-exchanger, the processing cost is greatly reduced, and the micro-channel made of plastic is difficult to scale compared with that made of metal materials.

Owner:BEIJING UNIV OF CHEM TECH

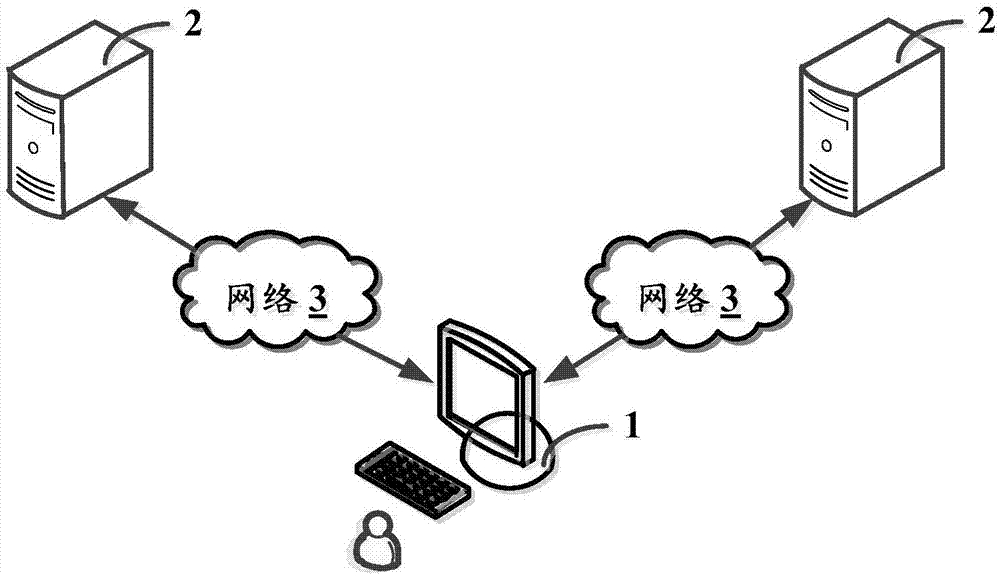

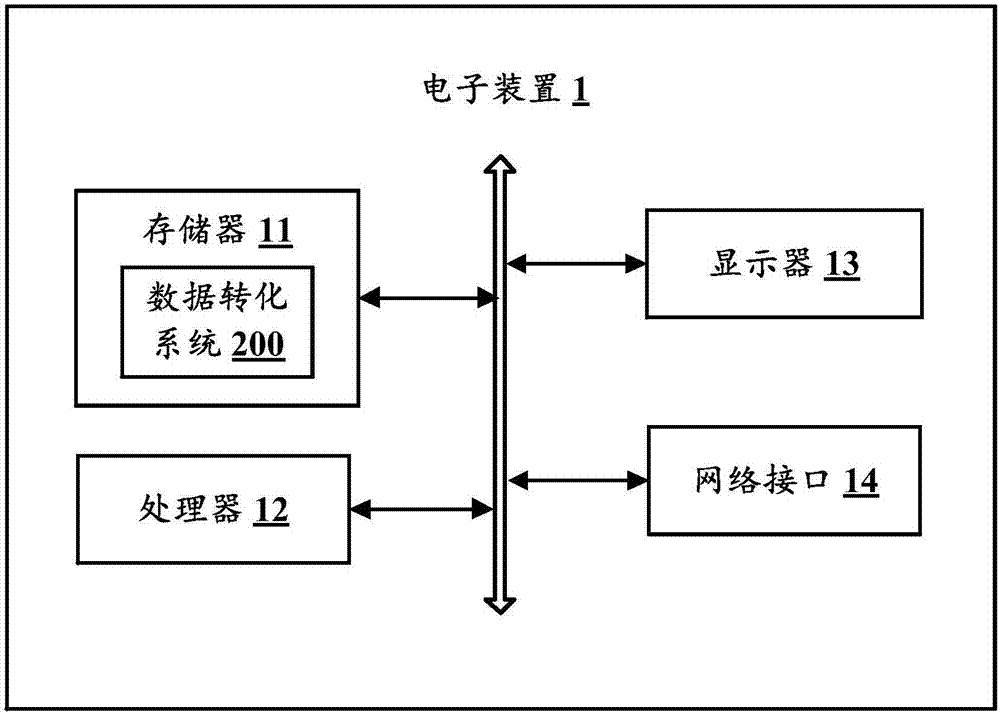

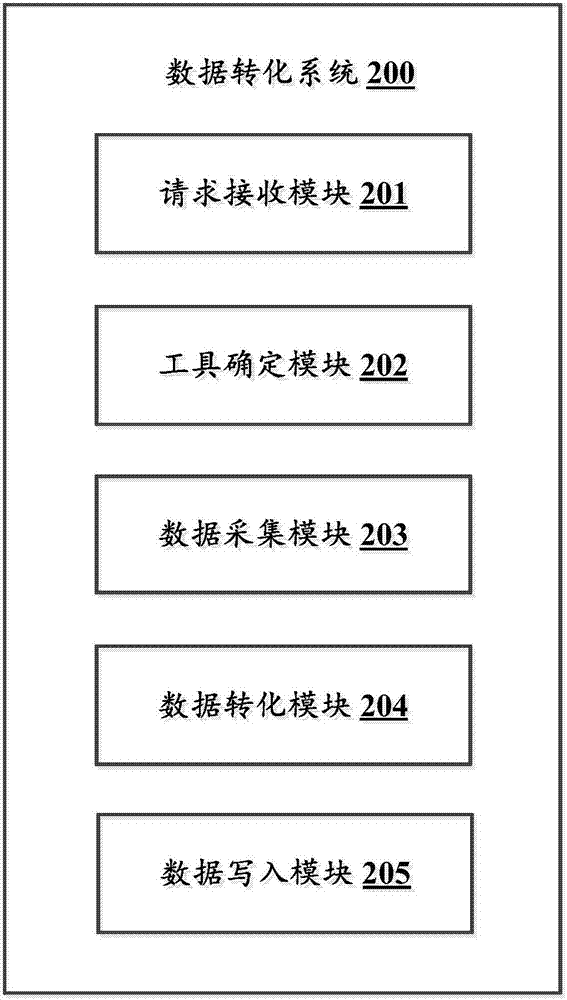

Data conversion method and system

InactiveCN106951536AQuick importAccelerateDatabase distribution/replicationSpecial data processing applicationsData conversionCollections data

The invention discloses a data conversion system. The system comprises a request receiving module used for receiving a data conversion request, a tool determination module used for determining a reading tool for reading data from a source database according to a type and a data format of the source database and determining a writing tool for writing data in a destination database according to a type and a data format of the destination database, a data collection module used for reading to-be-converted data from the source database by utilizing the reading tool, a data conversion module used for converting the to-be-converted data into data corresponding to the data format of the destination database, and a data writing module used for obtaining the data after conversion and writing the data after conversion in the destination database by utilizing the writing tool. By utilizing the system, the conversion of the data between the databases can be carried out more flexibly.

Owner:NUBIA TECHNOLOGY CO LTD

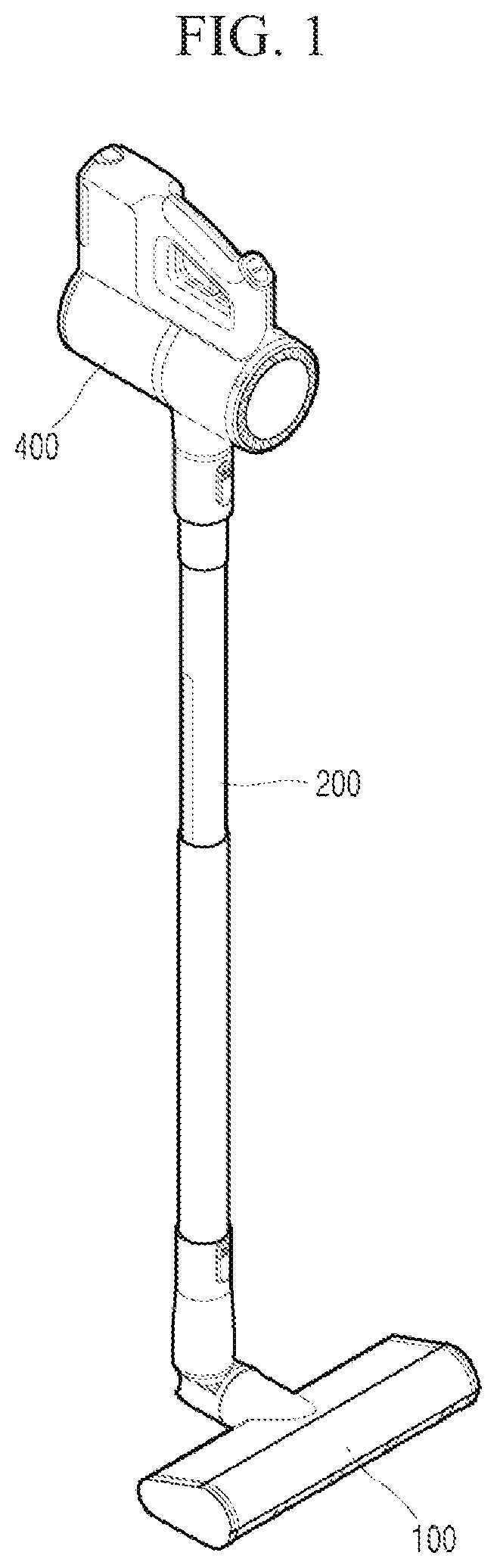

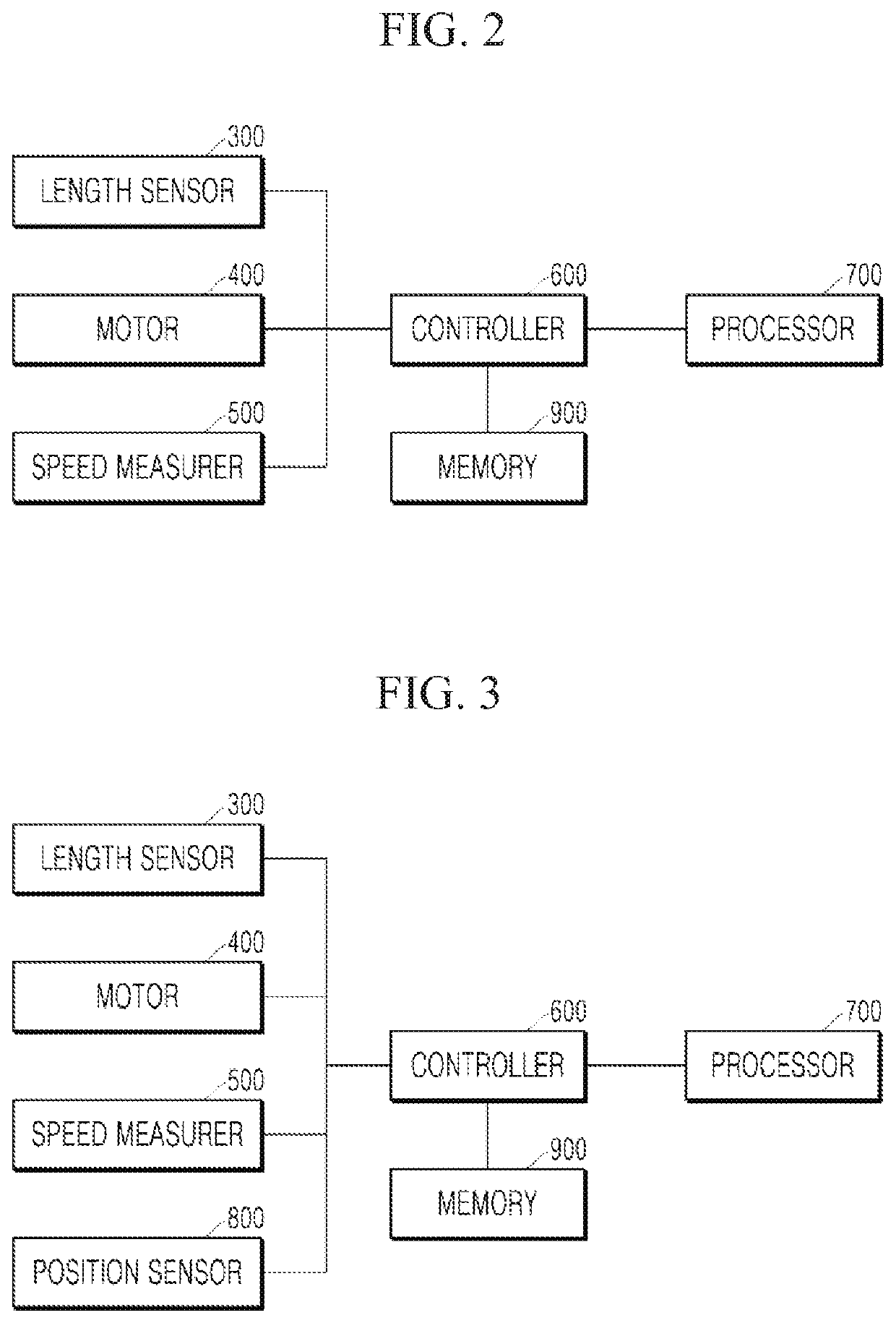

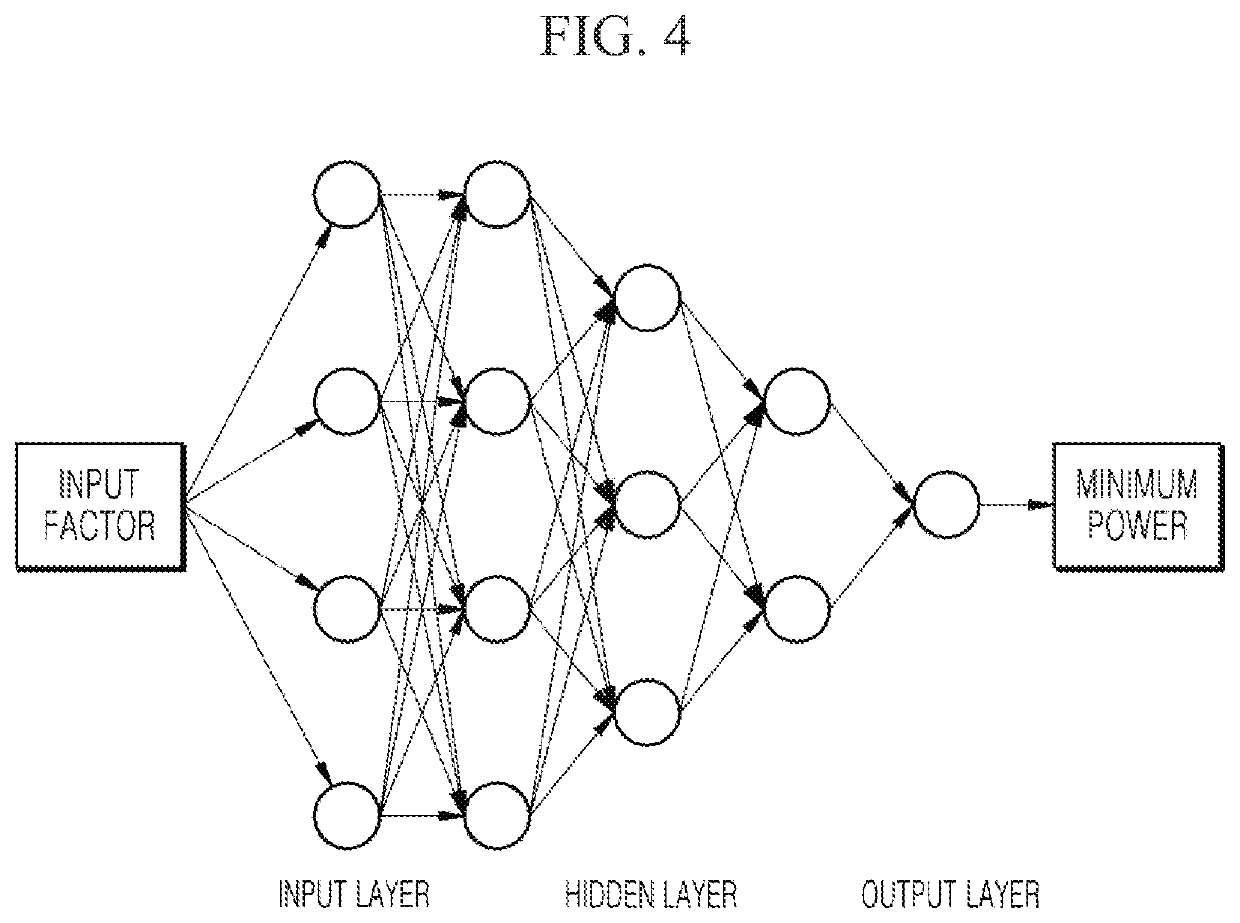

Cleaner capable of controlling motor power and control method thereof

ActiveUS20190387943A1Longer stickIncrease movement speedDC motor speed/torque controlKernel methodsControl powerElectric machinery

A cleaner capable of controlling motor power and a control method thereof are disclosed. The cleaner may include a head suctioning external dirt, a stick communicating with the head, being adjustable in length, and providing a passage through which dirt that is suctioned moves, a length sensor mounted on the stick and sensing a length change of the stick, a motor providing dirt suction power to the head, a speed measurer measuring a movement speed and a movement direction of the head, and a controller controlling power of the motor. The controller may select minimum power for dirt suction of the motor on the basis of at least one of information about the length change of the stick, the movement speed of the head, and the movement direction of the head, and may control the motor to have the selected minimum power. The cleaner can transmit / receive wireless signals on a mobile communication network established in accordance with 5G (Generation) communication.

Owner:LG ELECTRONICS INC

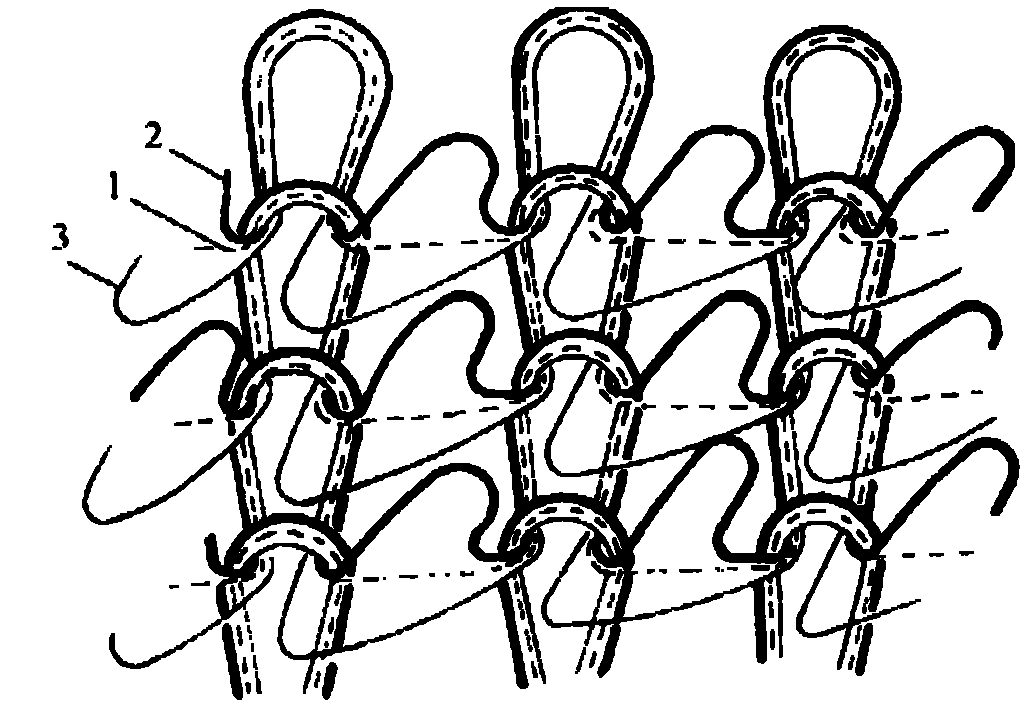

Bamboo fiber knitted terry fabric and preparation method thereof

ActiveCN102418225AImprove comfortGood lookingFabric breaking/softeningWeft knittingMoisture permeabilityMoisture absorption

The invention relates to a preparation method of a bamboo fiber knitted terry fabric. The preparation method comprises the following steps of: preparing raw materials; knitting on a machine; inspecting; performing mechanical softening treatment; presetting; performing pretreatment; dyeing; performing softening treatment; drying; shearing; and opening width for setting. A unique interwoven terry texture structure is adopted, bamboo fibers and the special polyester filament yarns have high moisture absorption and moisture permeability, and the special polyester filament yarns have high wicking capacity; and in the preparation method, a physical and chemical double softening finishing technology is adopted, the hand feel and luster of the fabric are improved, polluting reagents are not used in the treatment process, and the preparation method has a good application prospect.

Owner:NINGBO DAQIAN TEXTILE

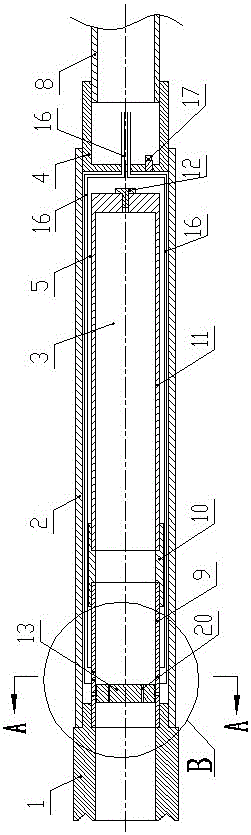

Coal seam low-temperature fixed-point frozen sampling device and use method thereof

ActiveCN106194168AGuaranteed preservationRealize the cooling effectBorehole/well accessoriesCore removalDry iceEngineering

The invention discloses a coal seam low-temperature fixed-point frozen sampling device and a use method thereof. The coal seam low-temperature fixed-point frozen sampling device comprises a through hole coring bit. The outer wall and the inner wall of the right end of the through hole coring bit are connected with a sampling drill pipe and a frozen low-temperature sample storing device correspondingly. The right end of the sampling drill pipe is connected with a drill pipe adapter. A dry ice cooling layer and a heat-insulation heat-preservation layer are arranged between the sampling drill pipe and the frozen low-temperature sample storing device. According to the sampling method, a drilled hole is constructed to the designed depth, the coal seam low-temperature fixed-point frozen sampling device is put into the bottom of the drilled hole and pushed towards a coal seam, a collected coal sample pushes a round baffle to enter an inner cavity of a low-temperature sample storing barrel and is cooled rapidly, meanwhile, water is supplied into a frozen sealed barrel, the coal sample mixed with water in the frozen sealed barrel is frozen rapidly in a low-temperature environment, dissipation of gas is lowered, a sealing bolt is detached after a drill is retreated, the internal coal sample is rapidly poured out by pushing the round baffle with a metal guide rod, and the coal sample is transferred into a coal sample tank to be sealed and stored. The coal seam low-temperature fixed-point frozen sampling device and the use method thereof realize low-temperature fixed-point frozen sampling, can effectively reduce the loss of gas in the sampling process, and are beneficial to improving the accuracy of the measured gas content of the coal seam.

Owner:HENAN POLYTECHNIC UNIV

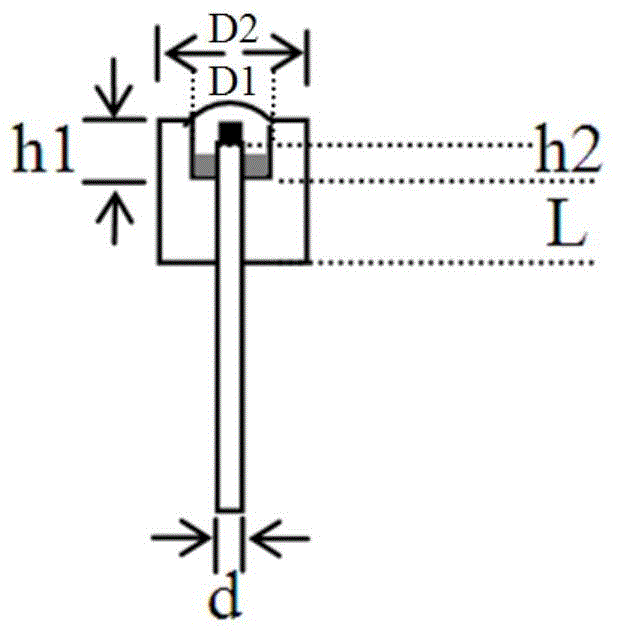

Packaging substrate structure for LED and production method thereof

InactiveCN101752354AEase of lightImprove light color distributionSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

The invention discloses a packaging substrate structure for an LED and a production method thereof. An LED substrate of the invention is characterized in that a boss with the specific size, shape and height is formed on a die bonding or eutectic position of a common LED substrate; and the boss is directly connected with the substrate. The substrate outside the boss is paved with a circuit connection layer. An LED chip is bonded on the boss in a die bonding or eutectic mode. Compared with the common metal PCB, the LED substrate on the boss position reduces an insulating material layer with bad heat-conducting property so that the heat generated by the high-power LED chip can be better dissipated through the substrate from the bottom. The boss structure increases the utilization of the emitted light on the lateral surface of the LED chip, improves the light-extraction efficiency, reduces the influence of the reflector cup, increases the light emergent angle, and greatly improves the light color distribution of the LED.

Owner:SUN YAT SEN UNIV

Reflective type high-power light-emitting diode (LED) packaging structure

The invention relates to a light-emitting diode (LED) packaging structure, in particular to a reflective type LED packaging structure. The structure comprises a reflecting base plate and an LED light-emitting chip, wherein the LED light-emitting chip is positioned on the reflecting base plate; the reflecting base plate is provided with a reflecting groove corresponding to the lower end for placing the LED light-emitting chip and totally reflects light projected to the reflecting base plate on the surface for placing the LED light-emitting chip by the reflecting groove at the end part and side walls at both sides of the reflecting groove; the left end and the right end of the reflecting base plate are both provided with fixed brackets, and the fixed brackets are fixedly connected with the reflecting base plate; conducting electrodes which are fixedly connected are arranged in the fixed brackets and electrically connected with the LED light-emitting chip; conducting pins are arranged on the fixed brackets and electrically connected with the conducting electrodes. The invention has simple structure, is safe and reliable, and improves the luminance of an LED light source and the utilization ratio of the light emission of the LED.

Owner:王海军

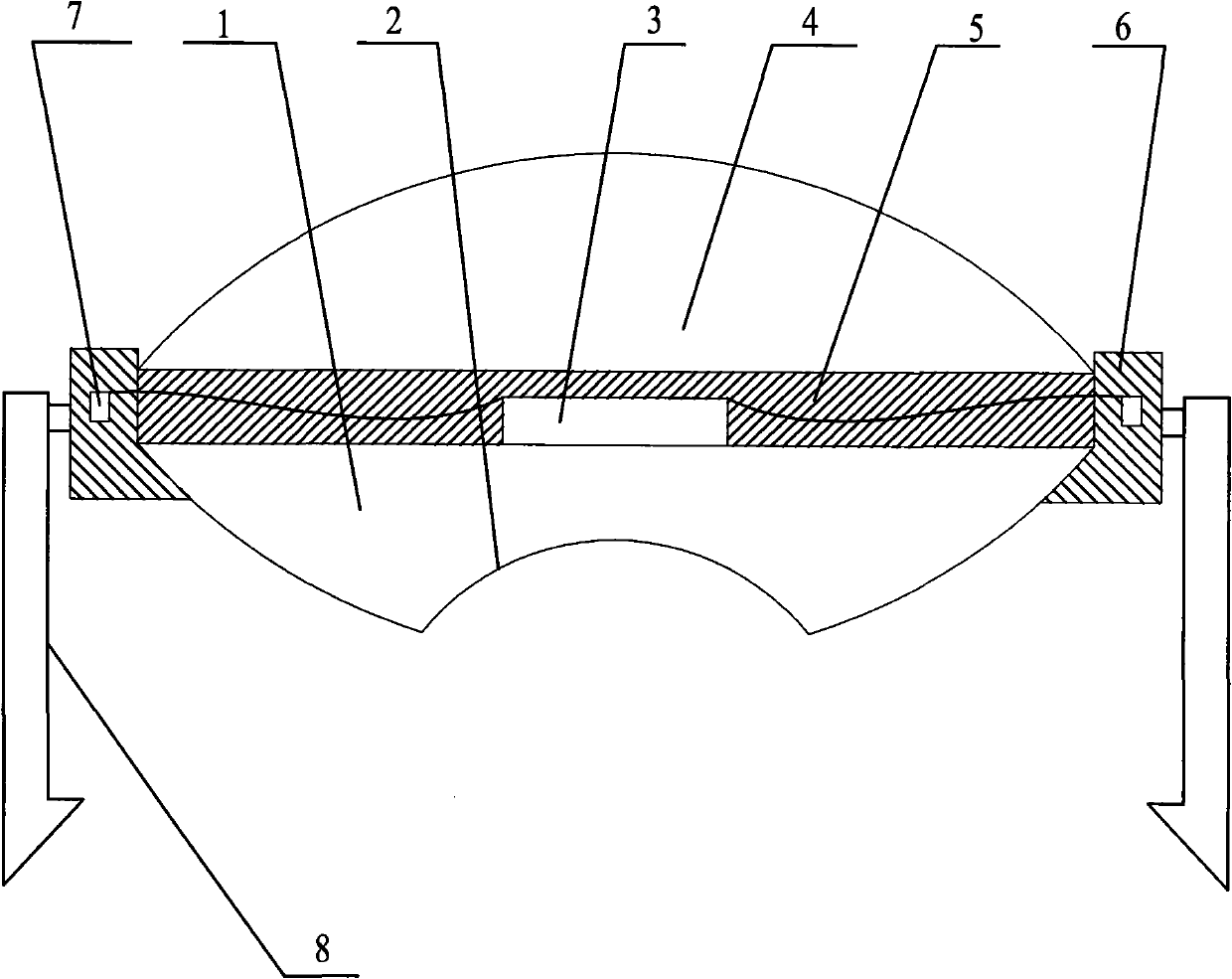

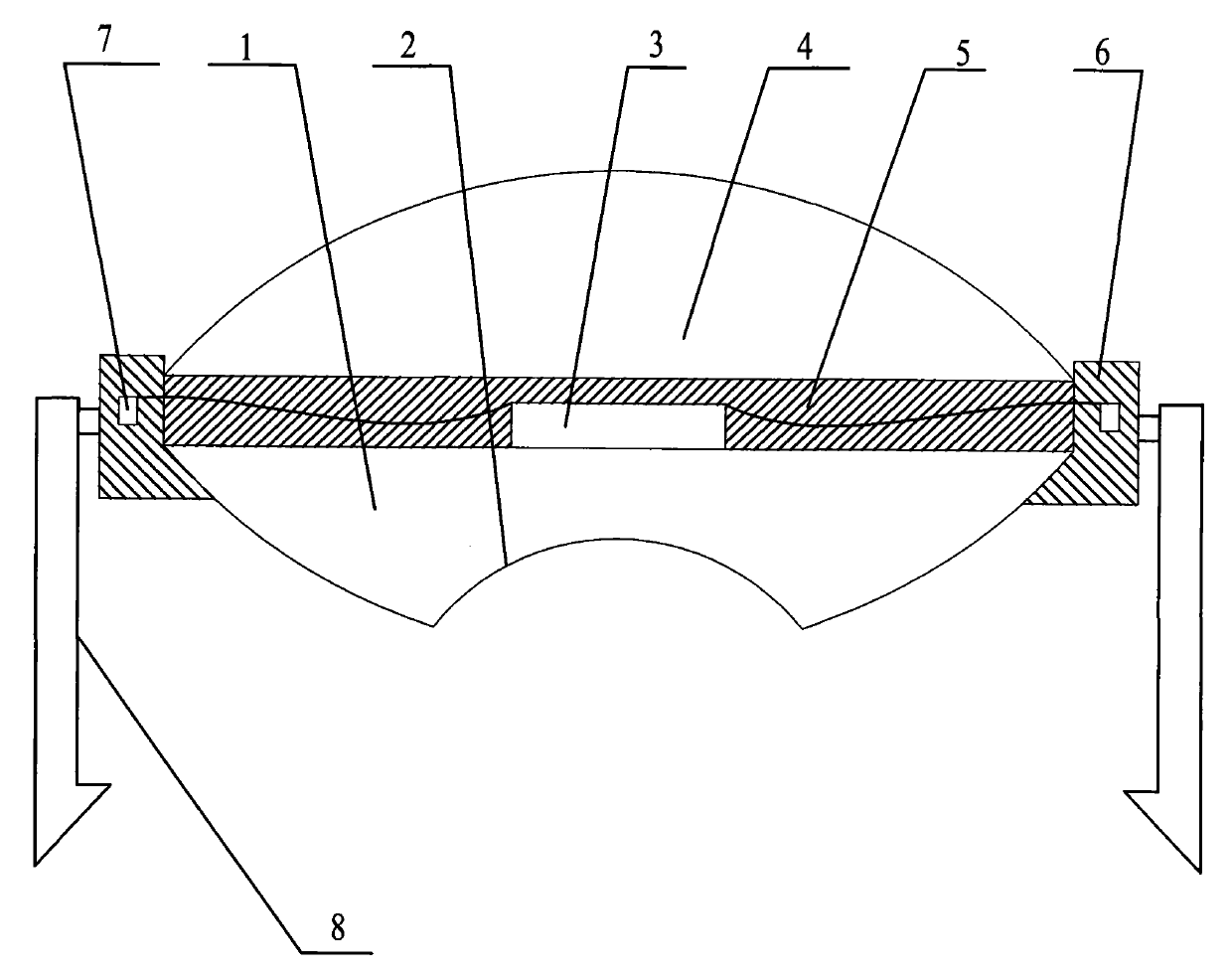

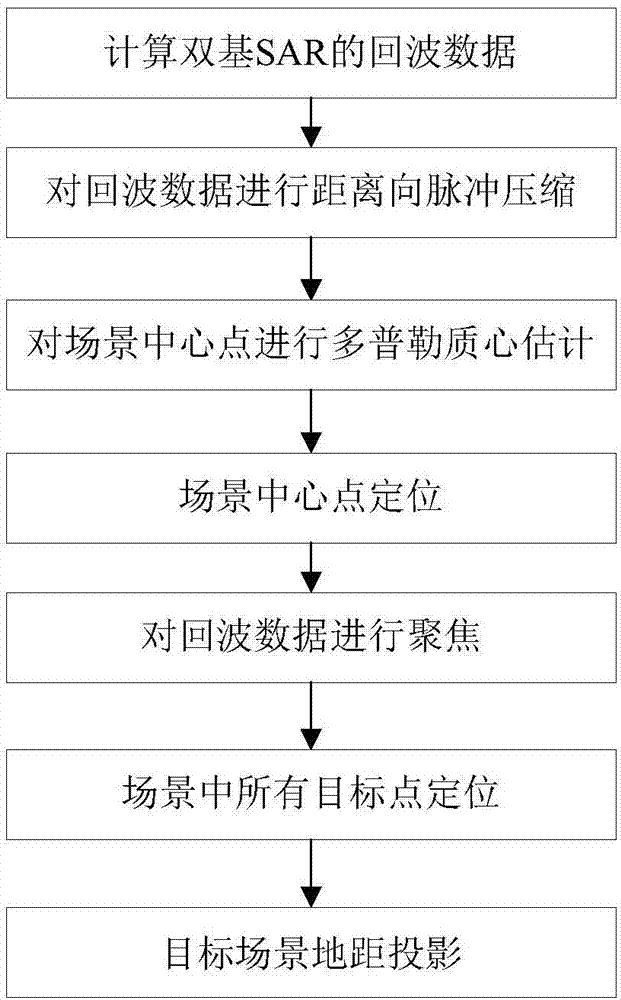

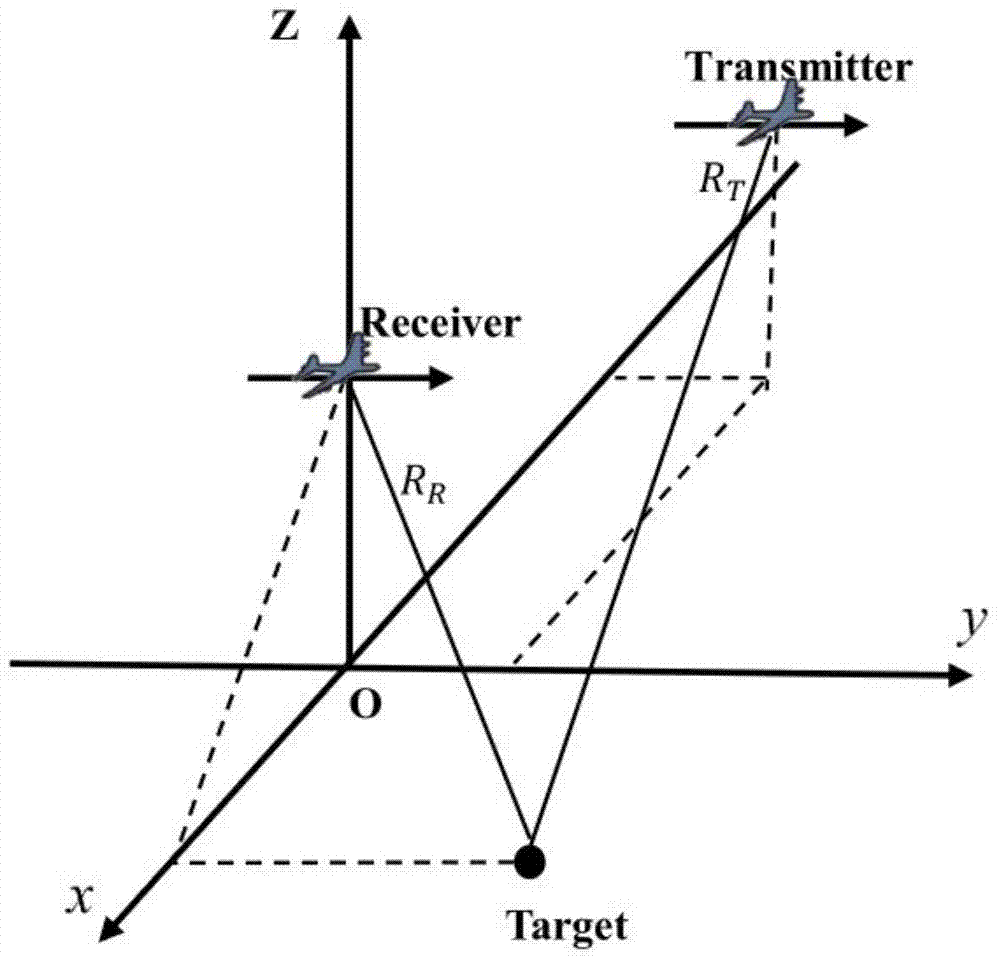

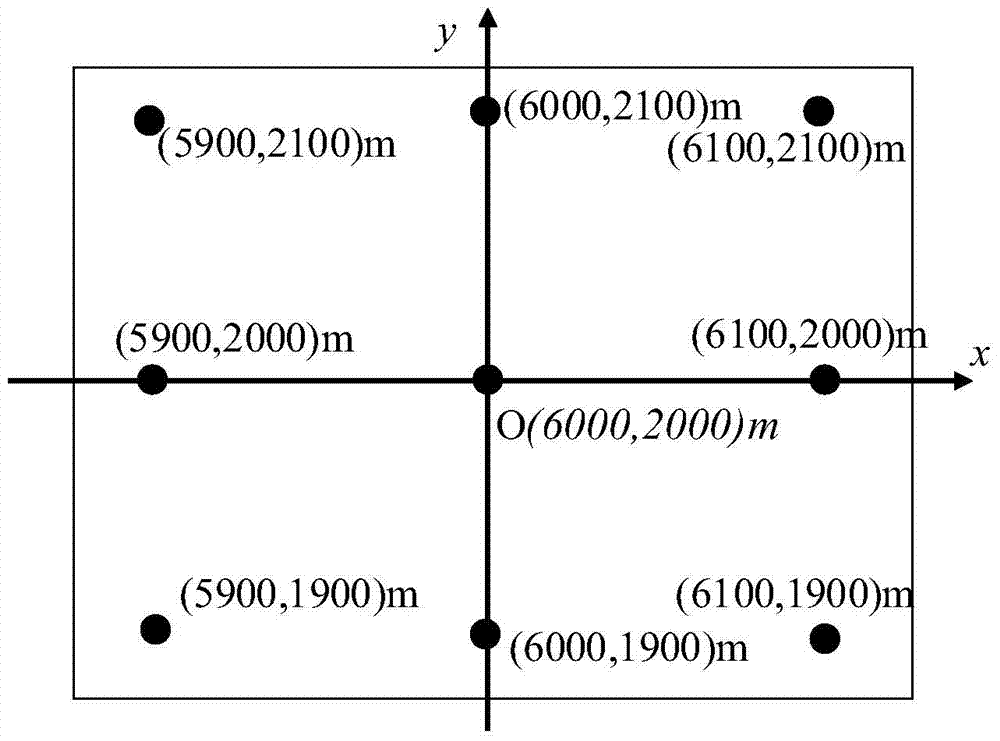

Shift invariant airborne bistatic synthetic aperture radar target positioning method

ActiveCN104749570AQuick exportSmall amount of calculationSpecial data processing applicationsRadio wave reradiation/reflectionSynthetic aperture radarGeographic coordinate system

The invention discloses a shift invariant airborne bistatic synthetic aperture radar target positioning method. The method includes the following steps: S1, calculating echo data of bistatic SAR; S2, performing distance-to-pulse compression on the echo data; S3, performing Doppler center-of-mass estimation on a scene center point; S4, positioning the scene center point; S5, focusing the echo data; S6, positioning all target points in a scene; S7, performing ground scene projection on a target scene. By the method, accurate positioning of imaging target points under the bistatic SAR is realized, and geographic position of a whole image is quickly guided out by utilizing a relation expression of adjacent pixel points and projected into a geographic coordinate system, so that calculation quantity is reduced greatly; the method can be widely applied in the fields of geometric correction, target positioning, moving target detection of the bistatic SAR image.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

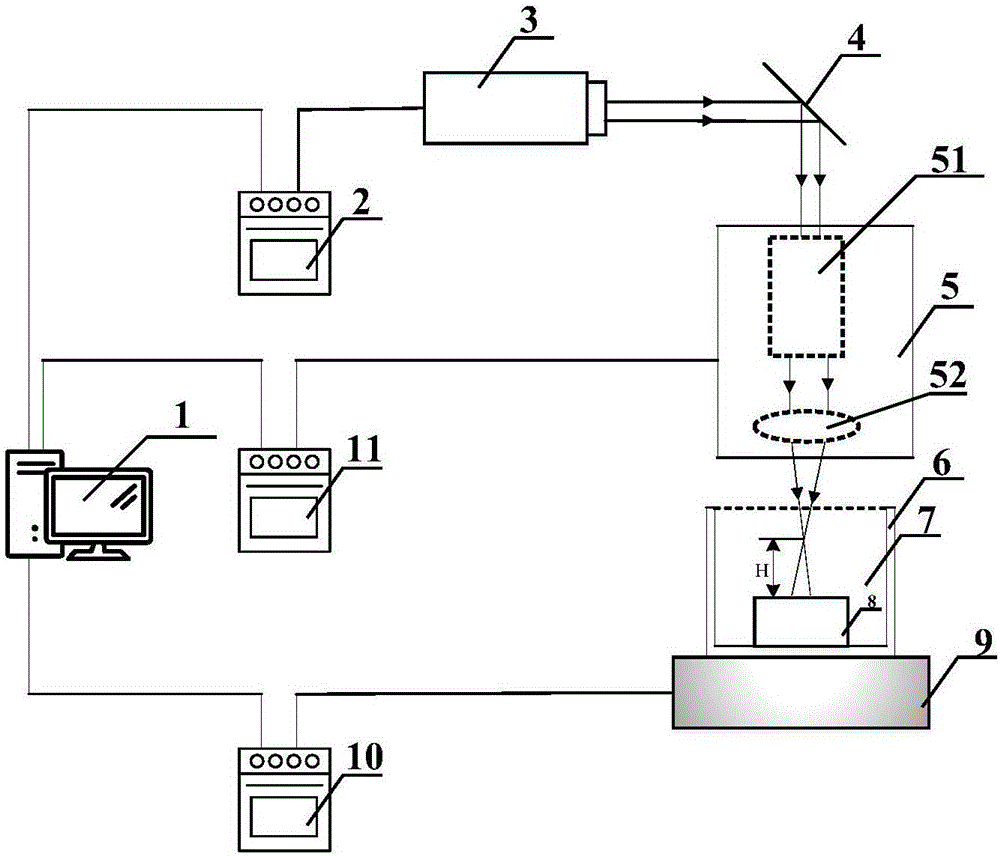

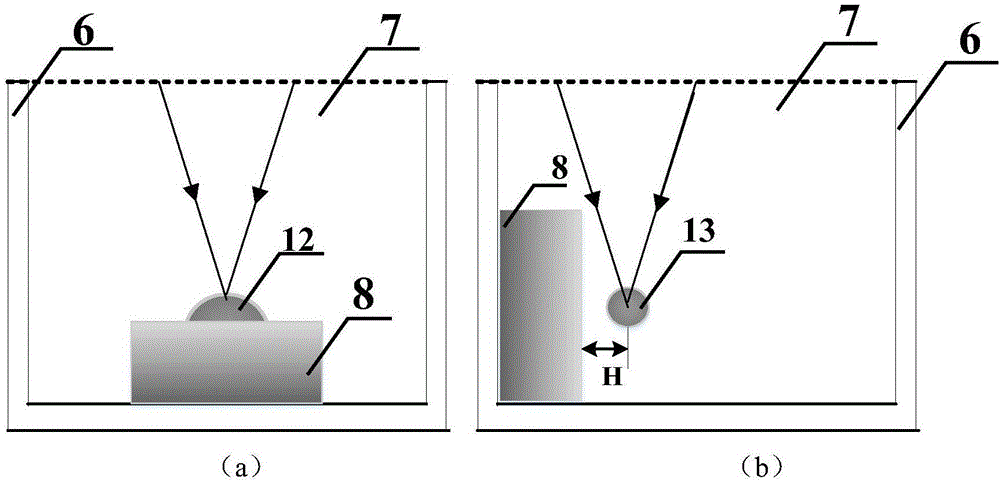

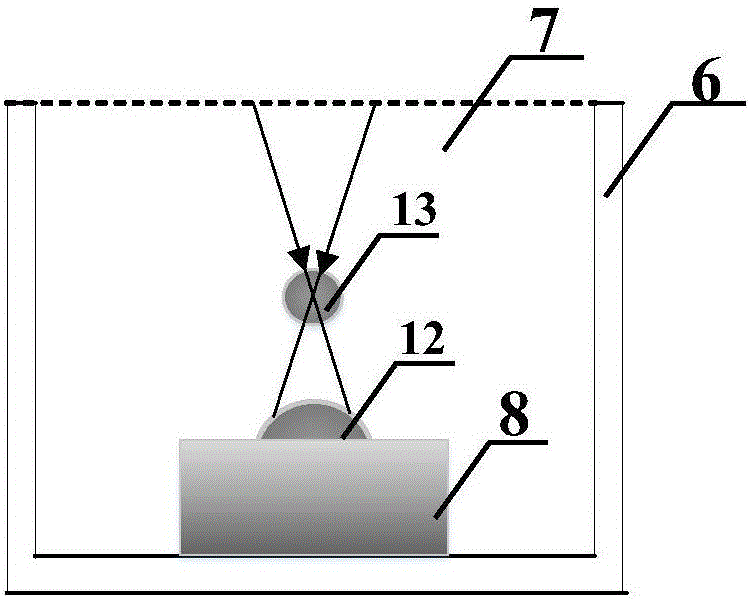

Method and device using laser to induce double cavitations

ActiveCN106271063AComposite processing effect is goodIncrease the strength of the actionLaser beam welding apparatusShock waveLiquid medium

The invention discloses a method and a device using laser to induce double cavitations. The method and the device using the laser to induce the double cavitations have the advantages that when liquid medium is radiated by a laser beam, the cavitations are simultaneously produced on the laser focusing part and the surface of to-be-processed material, so that the cavitation inducing strong shock wave in the liquid medium and the strong shock wave produced by the cavitation inducing at the surface of the to-be-processed material are overlapped, repeated, or simultaneously acted on the surface of the to-be-processed material; the surface intensity of the material is improved; the impact pressure is high, the oxidizing degree of material is low, and the like; the application prospect is wide.

Owner:JIANGSU UNIV

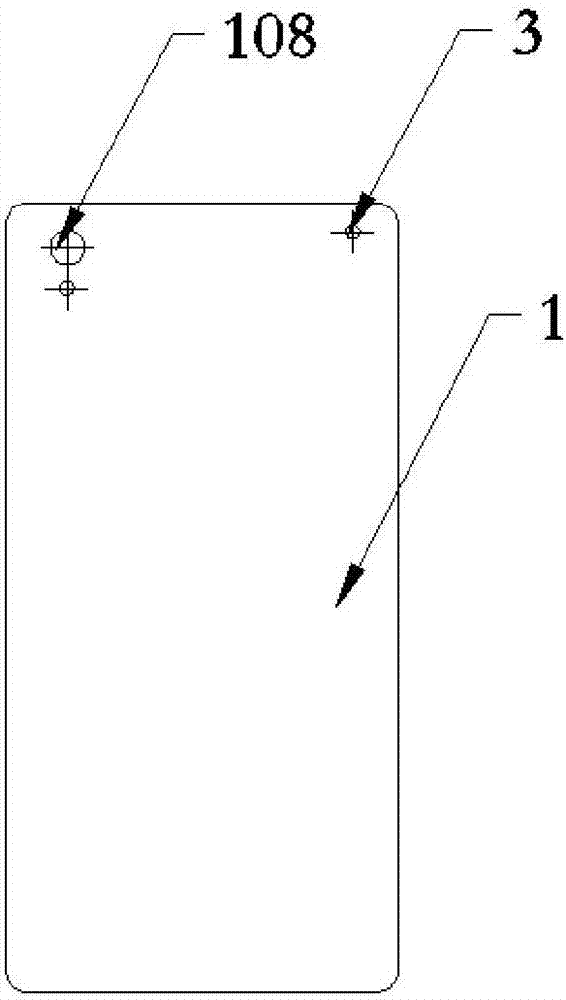

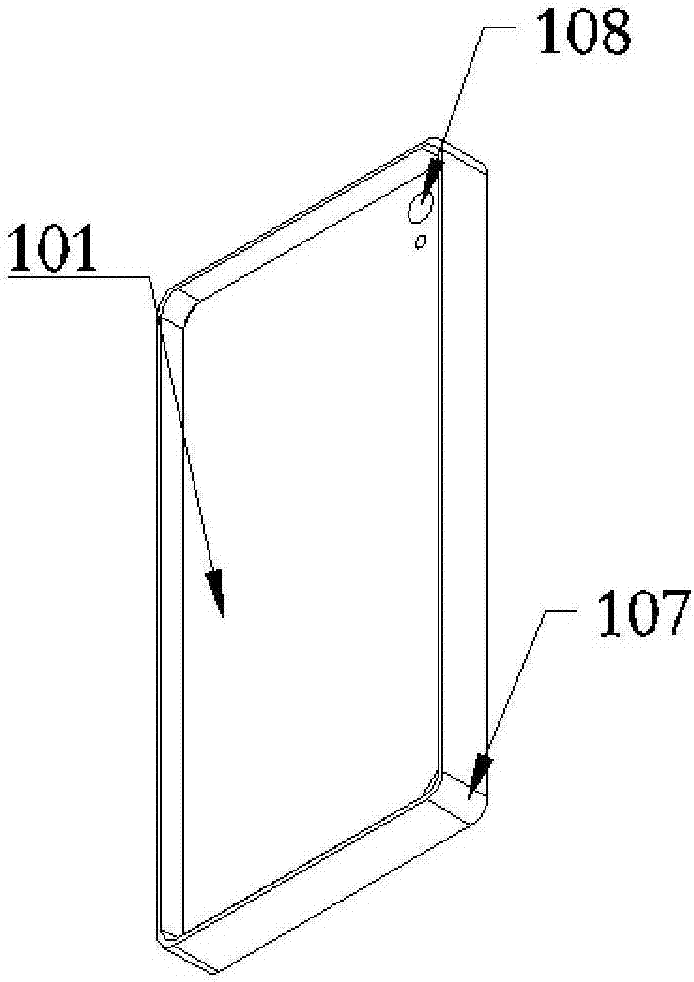

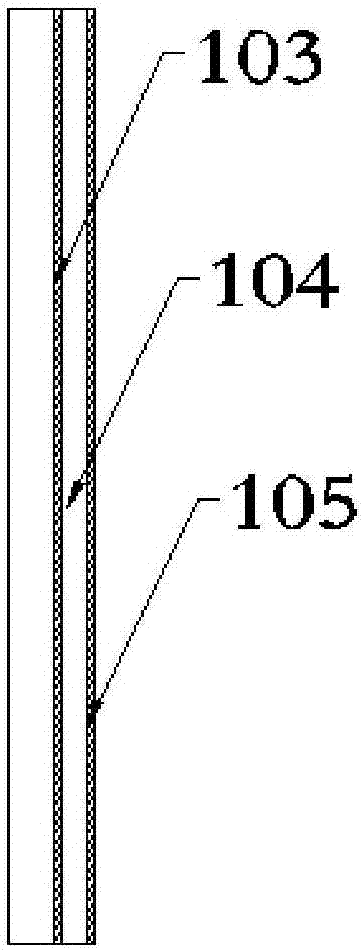

Electronic device housing and preparation method for the same

InactiveCN107172868AImprove cooling effectQuick exportDomestic articlesCooling/ventilation/heating modificationsTablet computerHeat conducting

The invention belongs to electronic device technology field and particularly relates to an electronic device housing and a preparation method for the same. The electronic device housing of the invention comprises a housing main body; the housing main body comprises a heat radiation sheet, a heat conducting sheet, a housing main body inner layer, a vacuum chamber and a housing main body outer layer which are arranged from the inside to the outside; the vacuum chamber is filled with a phase transition material; the phase transition material comprises a capric acid-lauric acid binary complex phase transition material; the housing of the electronic device has excellent performances of heat conducting and heat radiation, which does not affect normal working of the electronic device; the electronic device housing is small in volume, easy to carry, low in manufacture cost and safe in usage, can be widely applied to the mobile phone, the flat computer, the personal digital assistant, etc, and achieves a goal of controlling temperature and protecting the electronic device.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

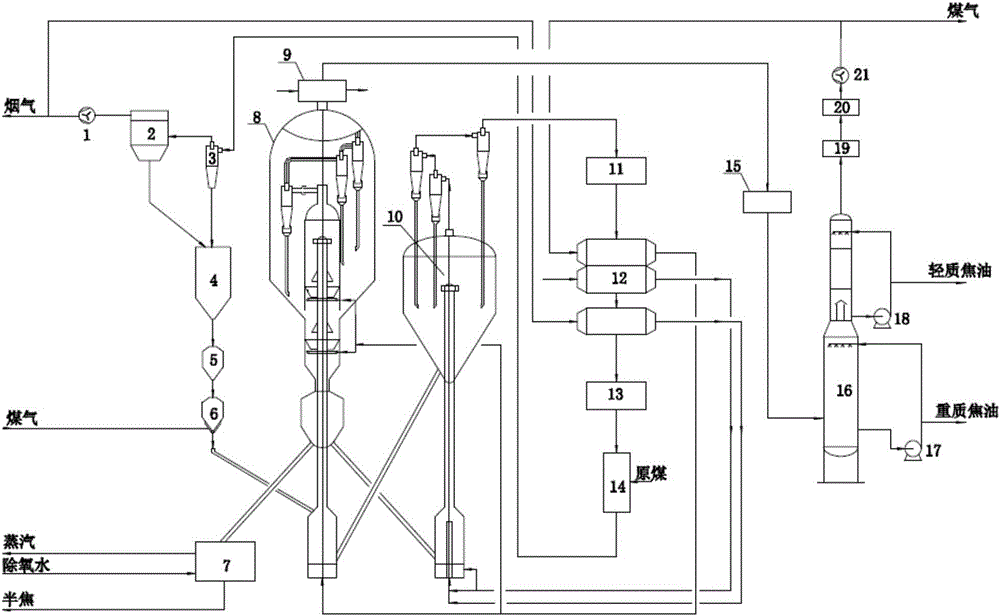

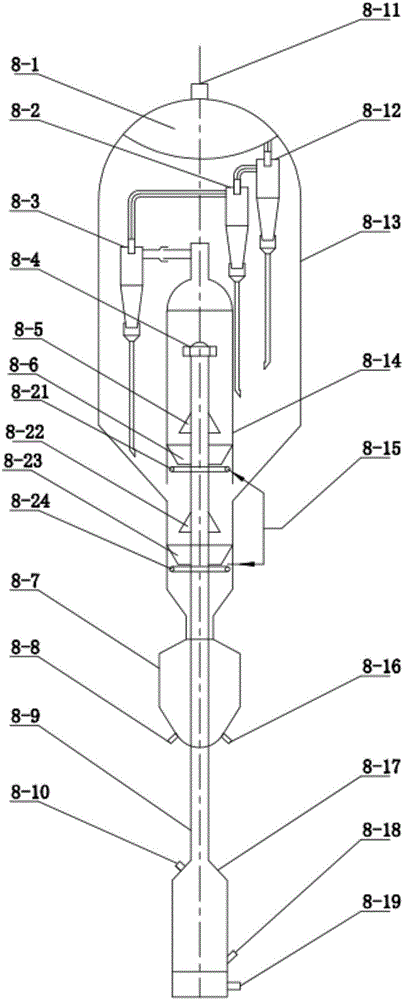

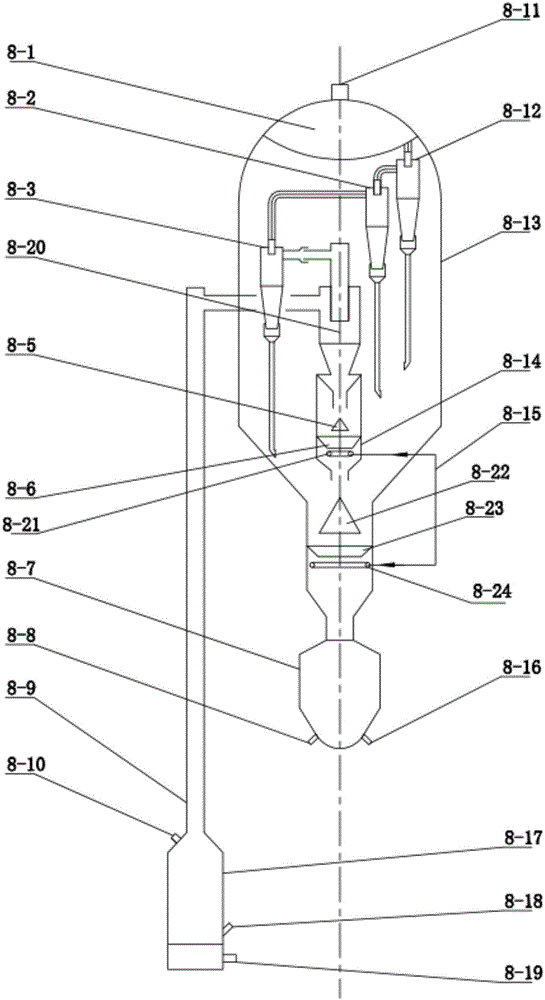

System and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with solid heat carrier

ActiveCN106753491AHigh yieldShort stayDirect heating destructive distillationSpecial form destructive distillationHeat carrierHigh energy

The invention relates to a system and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with a solid heat carrier. The system comprises a raw coal primary processing apparatus, a pyrolytic reaction separator, a semi-coke heating separator, a recycling apparatus, a coak tar recovering apparatus and a semi-coke cooling apparatus; a part of semi-coke powder discharged from the pyrolytic reaction separator enters the semi-coke heating separator, high-temperature smoke discharged from the semi-coke heating separator enters the recycling apparatus, the coal tar recovering apparatus produces coal tar and coal gas, and the semi-coke cooling apparatus produces semi-coke. In the existing coal tar preparation method, the coal pyrolytic optimization of the coal is not good, so that the existing coat tar preparation method has the technical problems of low oil yield, high investment and high energy consumption. The system for preparing the coal tar, gas and semi-coke by activating the coal gas and flash pyrolysing the coal with the solid heat carrier is rapid in pyrolysis, rapid in output and rapid in cooling.

Owner:陕西凯德利能源科技有限公司

Double-layer single-side moisture transporting fabric and application thereof

InactiveCN106827730AGood moisture absorption and releaseReach the function of one-way moisture guideWeft knittingSynthetic resin layered productsYarnSingle fiber

The invention discloses a double-layer single-side moisture transporting fabric and an application thereof. The double-layer single-side moisture transporting fabric is formed by compounding two layers of fabric, namely an inner skin-friendly fabric layer and an outer fabric layer, wherein the inner skin-friendly fabric layer is a polypropylene fiber knitted fabric; the outer fabric layer is a modal fiber knitted fabric; the single fiber density of the inner skin-friendly fabric layer is greater than that of the outer fabric layer; the double-layer single-side moisture transporting fabric can be used for preparing an underwear fabric and a sportswear fabric. Through the design of the fabric texture structure, a double-sided isomeric knitted fabric is constructed by yarns with permanent functionality, thereby achieving single-side moisture transporting effect of the fabric.

Owner:LILANG CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com