Battery thermal management and in-vehicle heating system for electric vehicles based on ultra-fast charge-discharge technology

A technology for battery thermal management and electric vehicles, which is applied in electric vehicles, secondary batteries, battery pack components, etc., and can solve problems such as uncontrollable battery cell temperature, low efficiency, and small battery cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

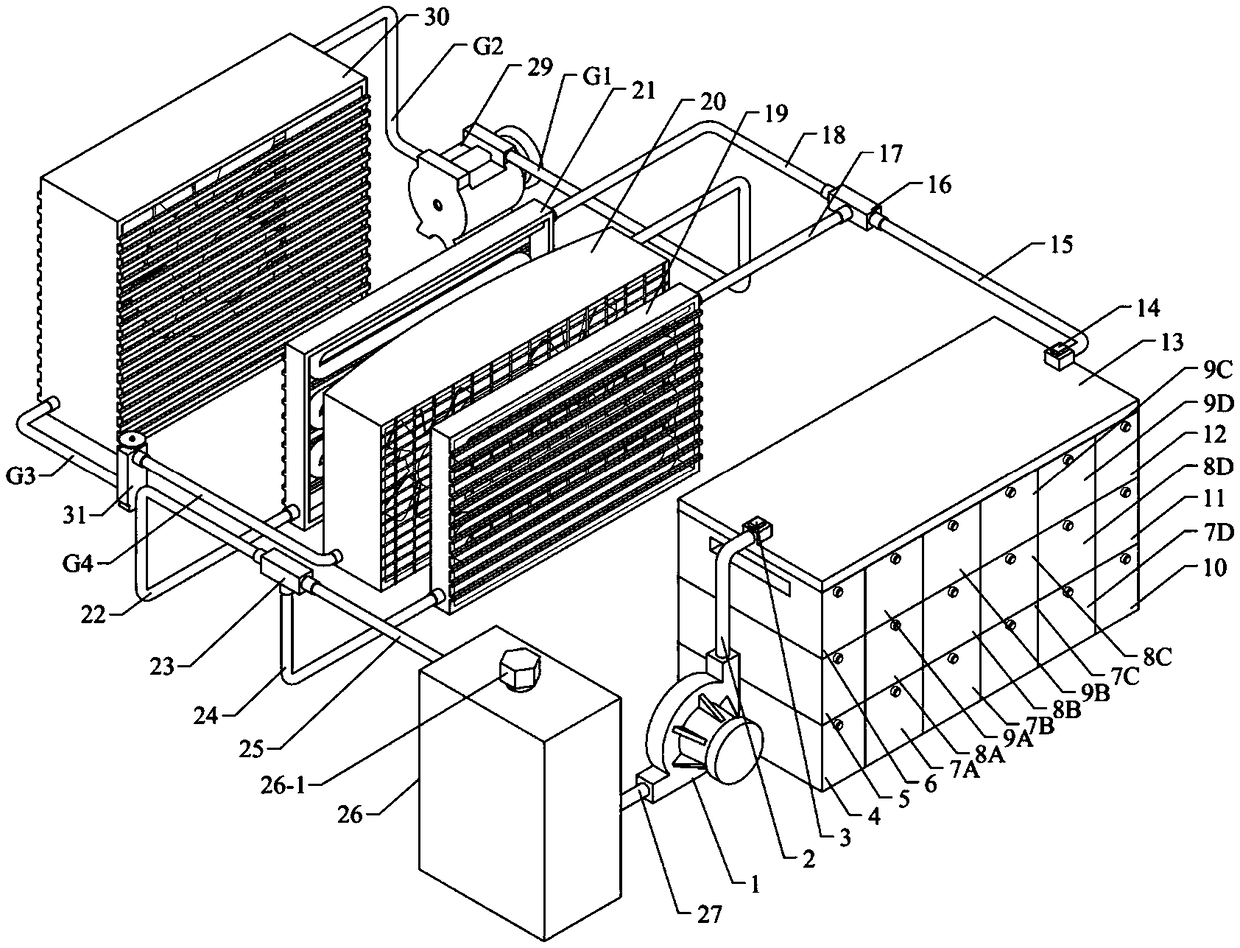

[0056] The invention is installed on the automobile and connected with the ECU of the automobile, and consists of a battery pack module, a cooling cycle module and a heat pump air-conditioning module;

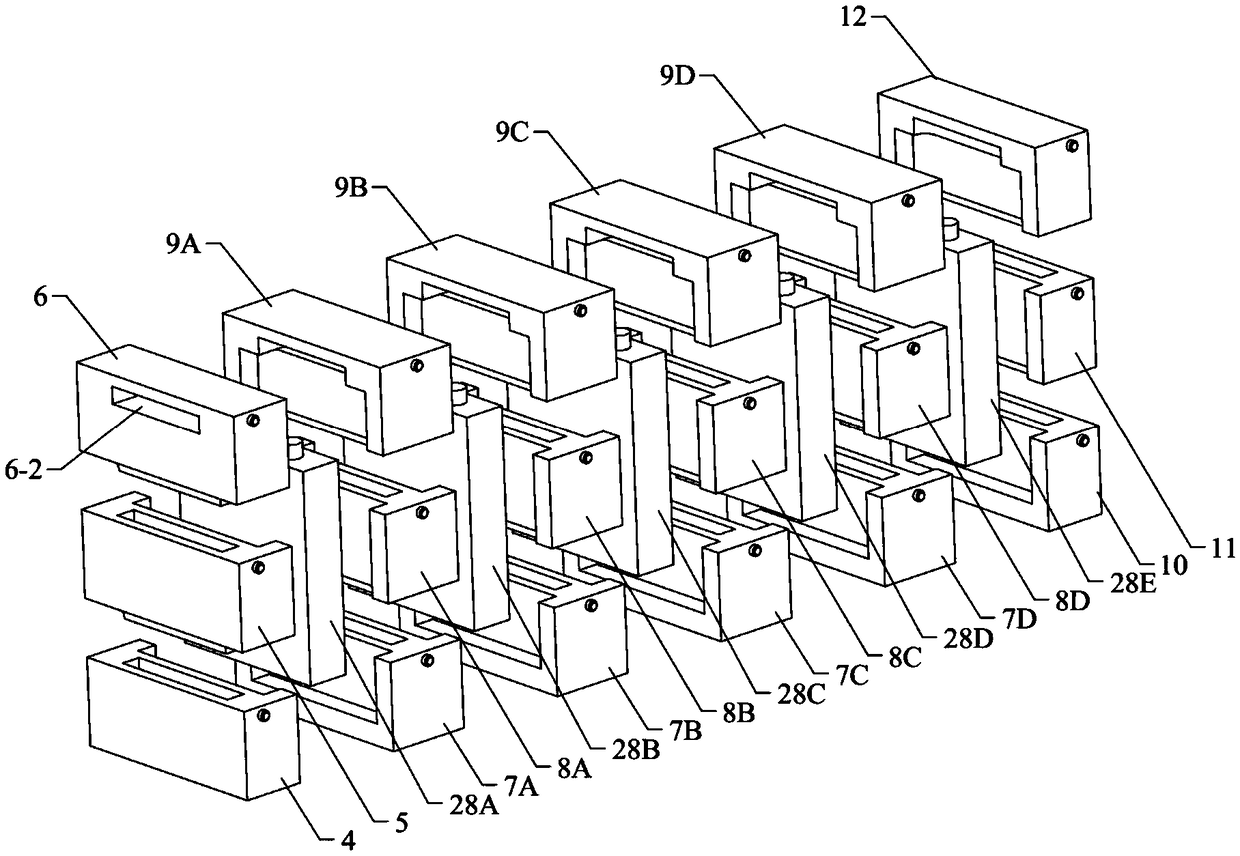

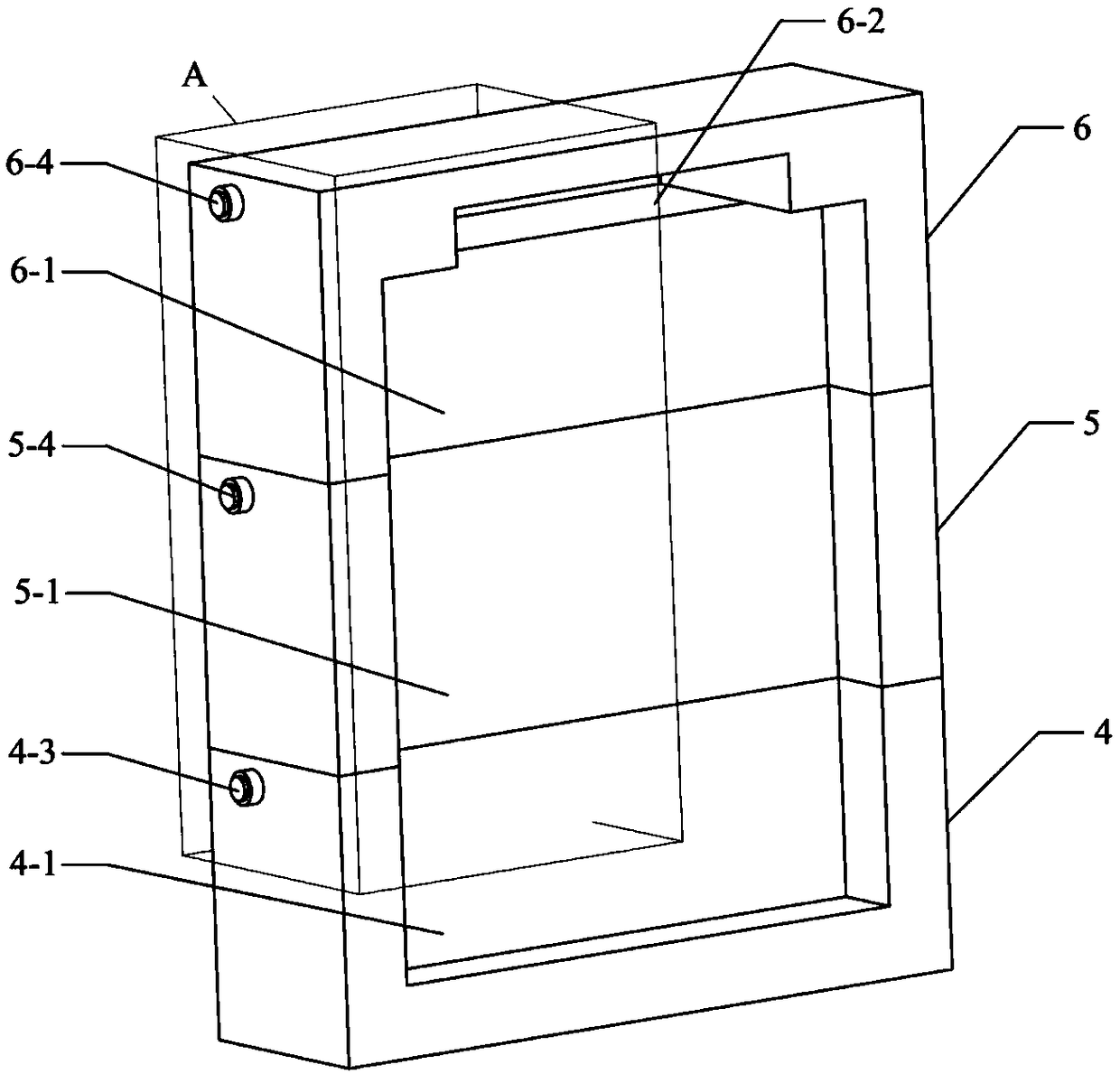

[0057] Such as Figure 2-11 As shown, the battery pack module is composed of vehicle-mounted battery cells 28A, 28B, 28C, 28D, and 28E, respectively connected to the phase-change material box LX4 in the lower left corner, the middle phase-change material box LZ5 in the left side, and the phase-change material box LS6 in the upper left corner. , A phase-change material box MX7A in the middle of the bottom, MZ8A in the middle A phase-change material box, MS9A in the middle A phase-change material box in the upper side, MX7B in the middle B phase-change material box in the lower side, MZ8B in the middle B phase-change material box, and B phase-change material box in the upper side Box MS9B, lower middle C phase change material box MX7C, middle C phase change material box MZ8C, upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com