Patents

Literature

306results about How to "Quick import" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expert-system-based AID (Automated Incident Detection) system of road traffic

InactiveCN103247176AQuick importReduce the degree of impactDetection of traffic movementEvent typeManagement unit

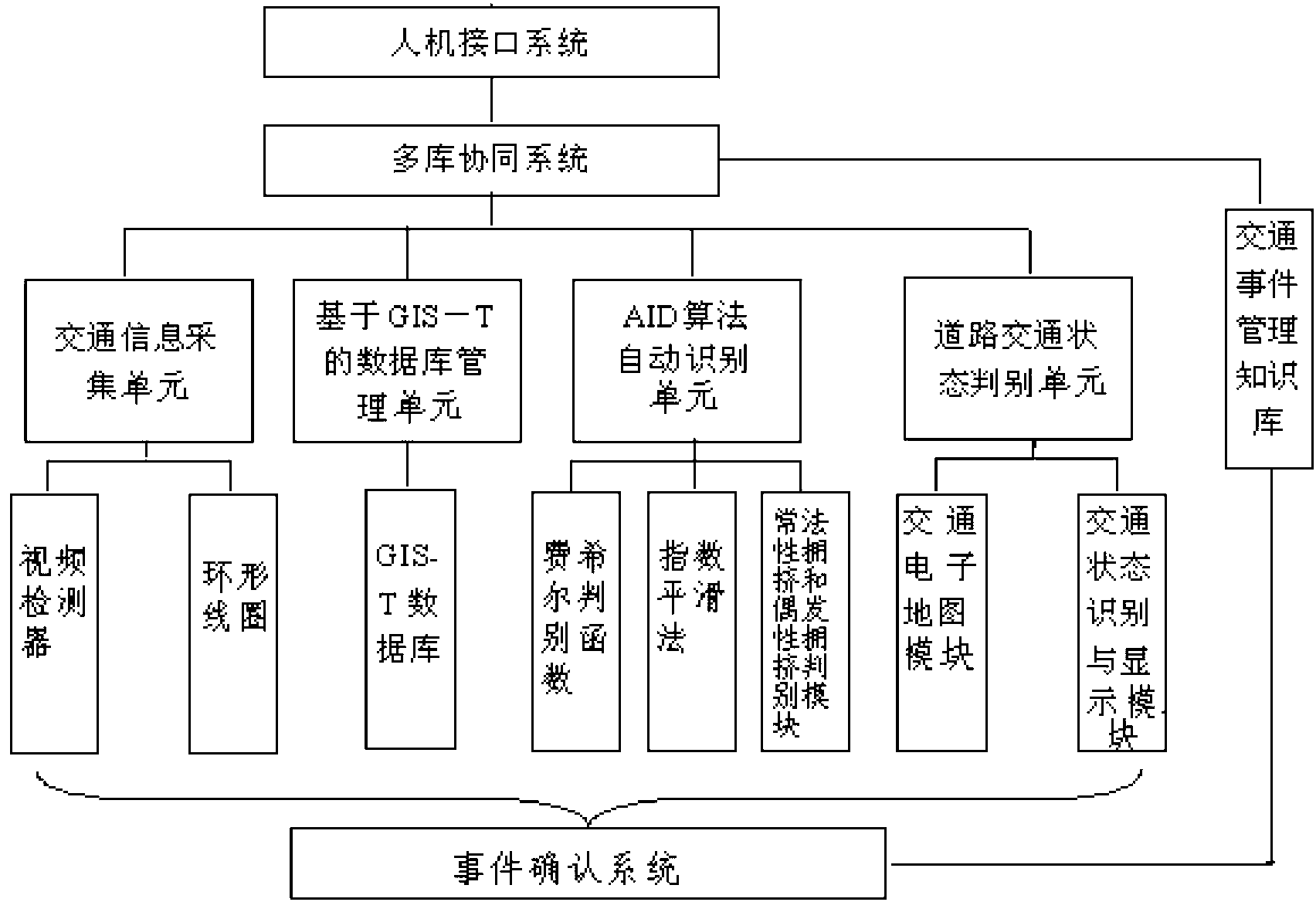

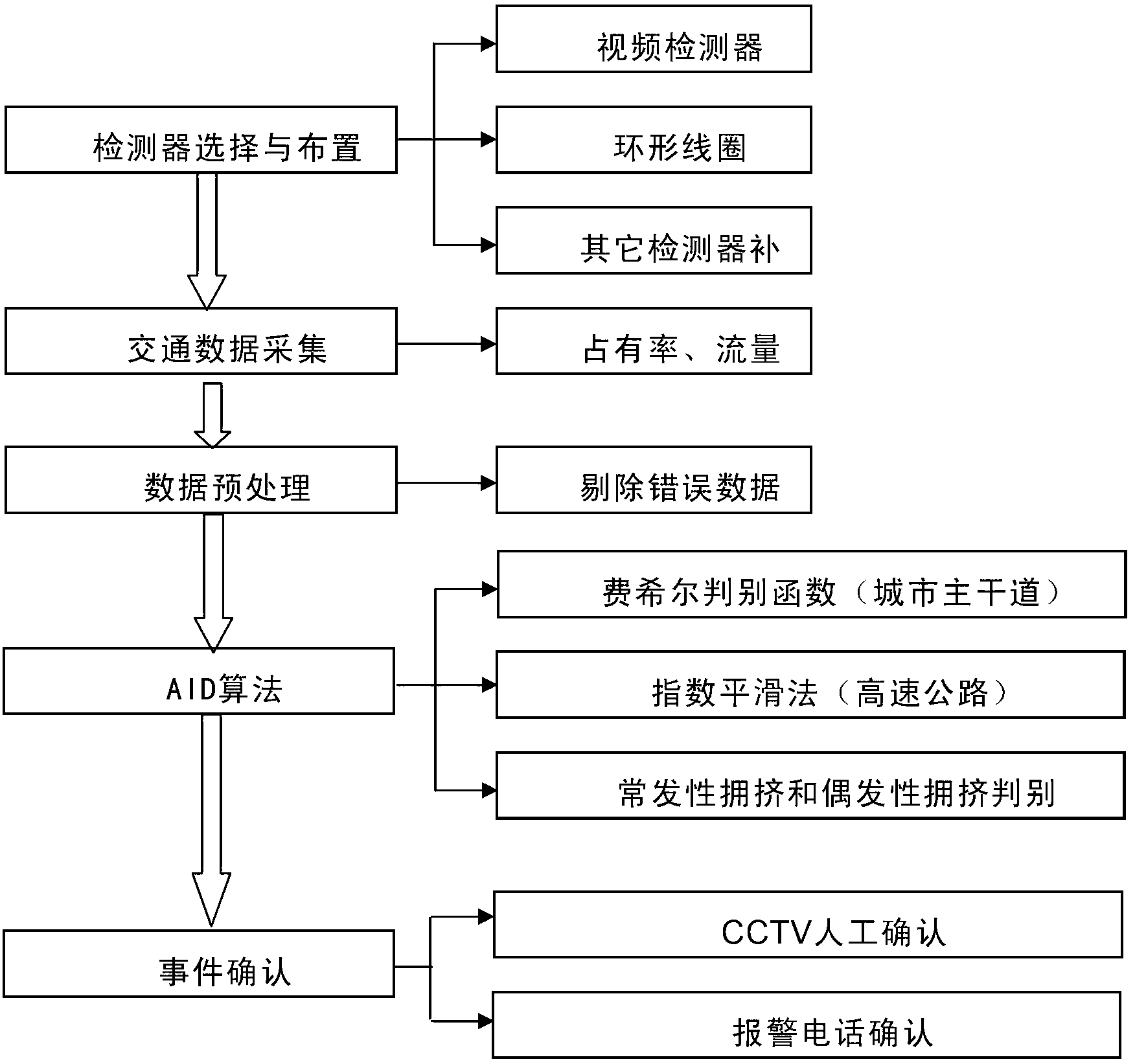

The invention discloses an expert-system-based AID (Automated Incident Detection) system of road traffic. The system comprises a man-machine interface system, a multi-base cooperative system and an incident verification system. The multi-base cooperative system comprises a traffic information collection unit, a GIS-T (Geographic Information System for Transportation)-based database management unit, an AID algorithm automatic recognition unit, a road traffic state judgment unit and a traffic incident management knowledge base which are connected with the man-machine interface system respectively. The traffic information collection unit, the GIS-T-based database management unit, the AID algorithm automatic recognition unit, the road traffic state judgment unit and the traffic incident management knowledge base are connected with the incident verification system respectively. The invention discloses the expert-system-based AID system of road traffic, which can be used for carrying out information interaction with a driver, fast importing traffic information, further judging and verifying types and duration of incidents, and the like.

Owner:ZEYI INFORMATION TECH SHANGHAI

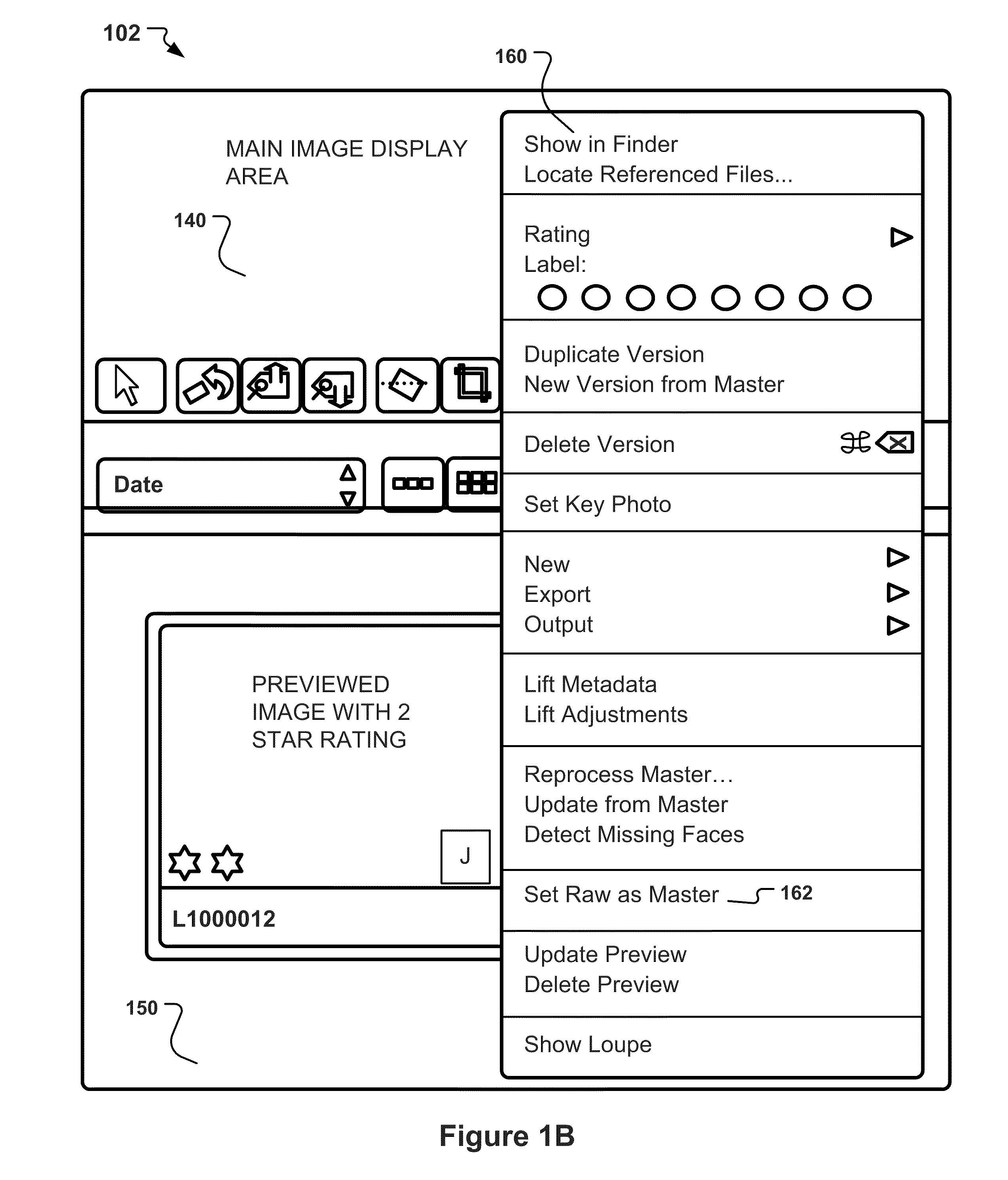

Managing Raw and Processed Image File Pairs

ActiveUS20110103684A1Small sizeEasy to adjustStill image data indexingCharacter and pattern recognitionComputer graphics (images)Single image

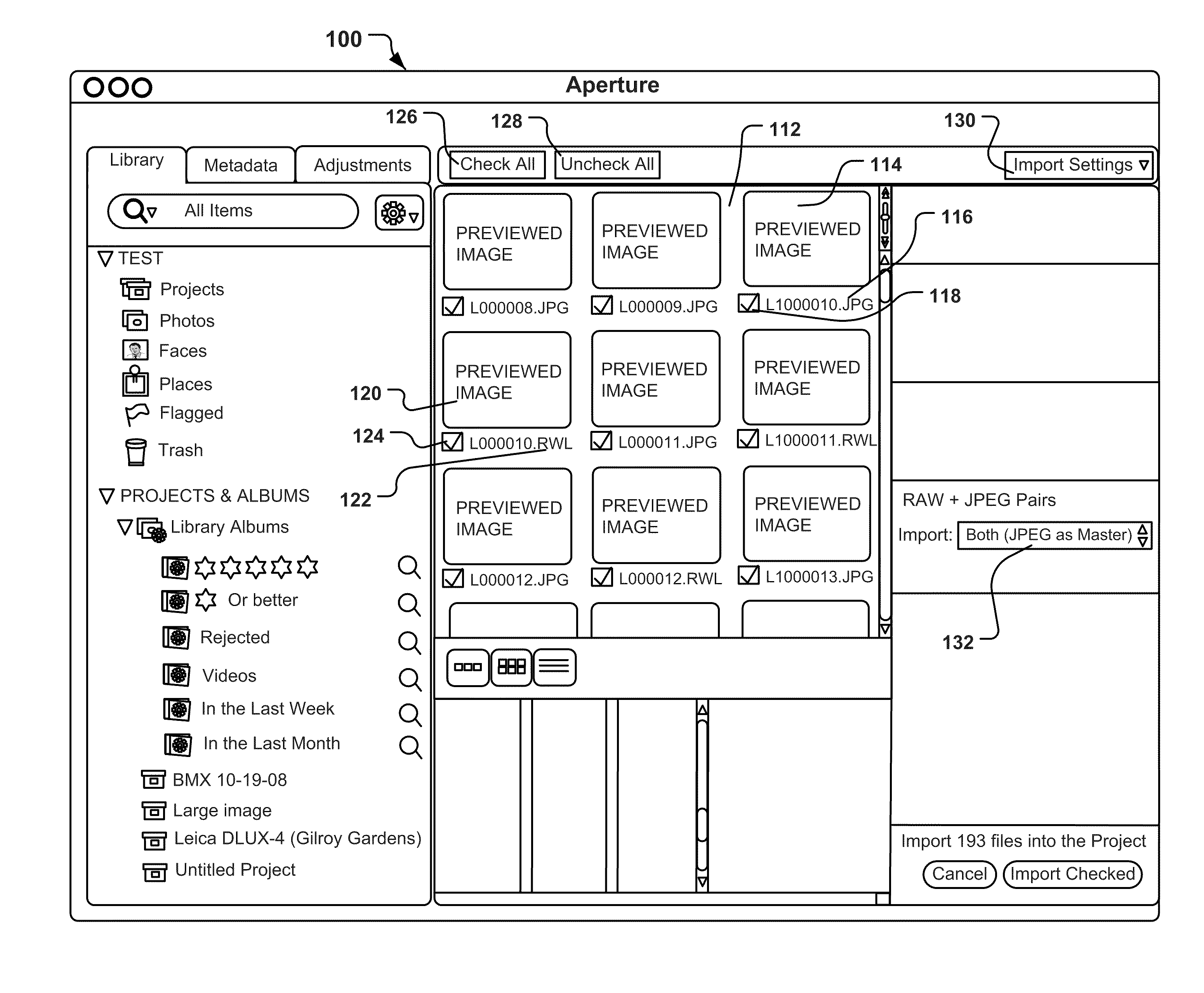

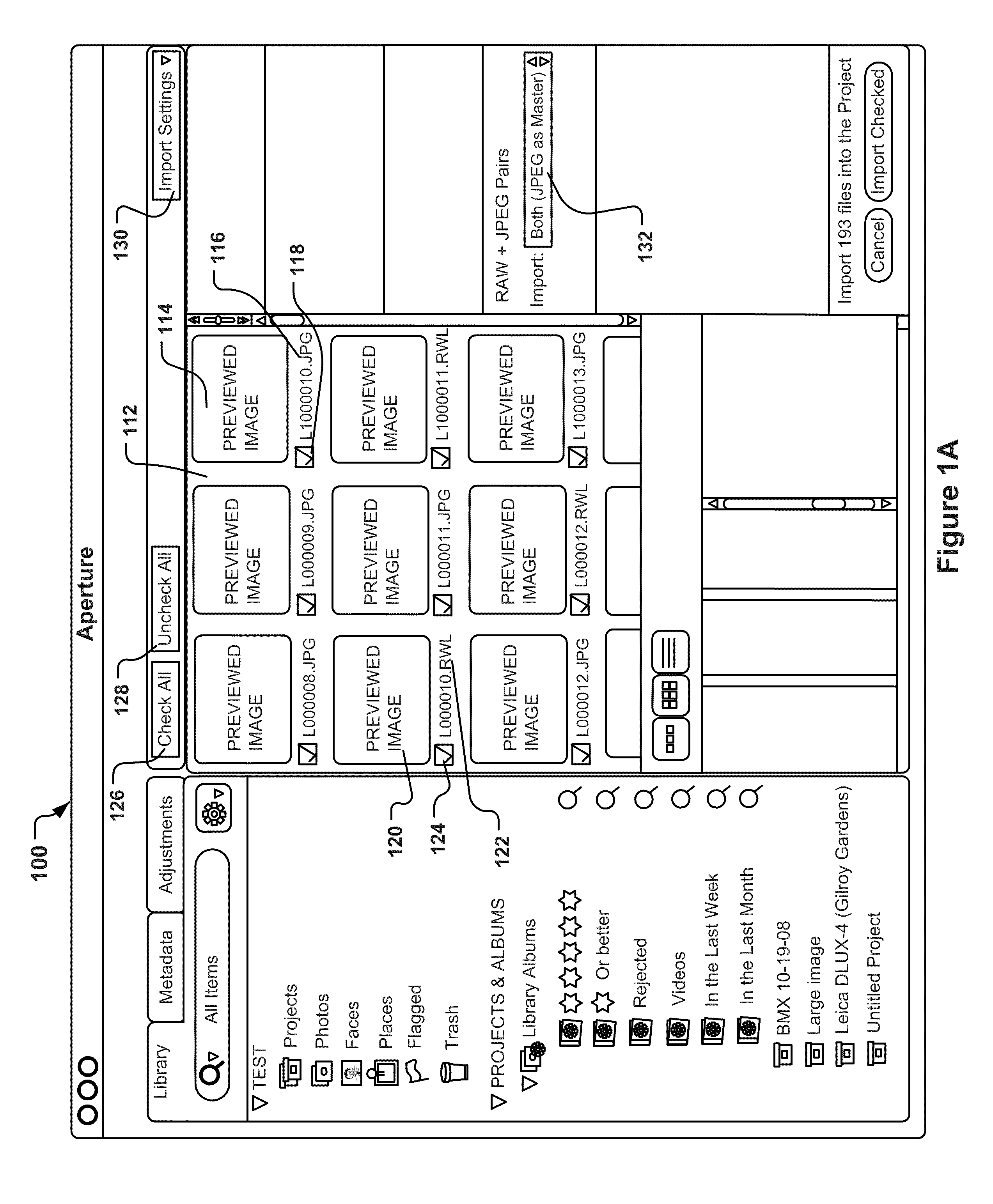

Among other things, methods, systems and computer program products are disclosed for managing image files. In one aspect, a method includes displaying, at a data processing device, a preview of images available for import from a storage device, wherein each image is associated with a pair of corresponding image files comprising a compressed image file and a raw image file obtained from a single image capture. At the data processing device, both the raw image file and the compressed image file of the pair associated with at least one of the images are imported. At the data processing device, at least one of the pair of corresponding image files is identified as a master image file for the associated image. At the data processing device, the identified master image file for the associated captured image is displayed.

Owner:APPLE INC

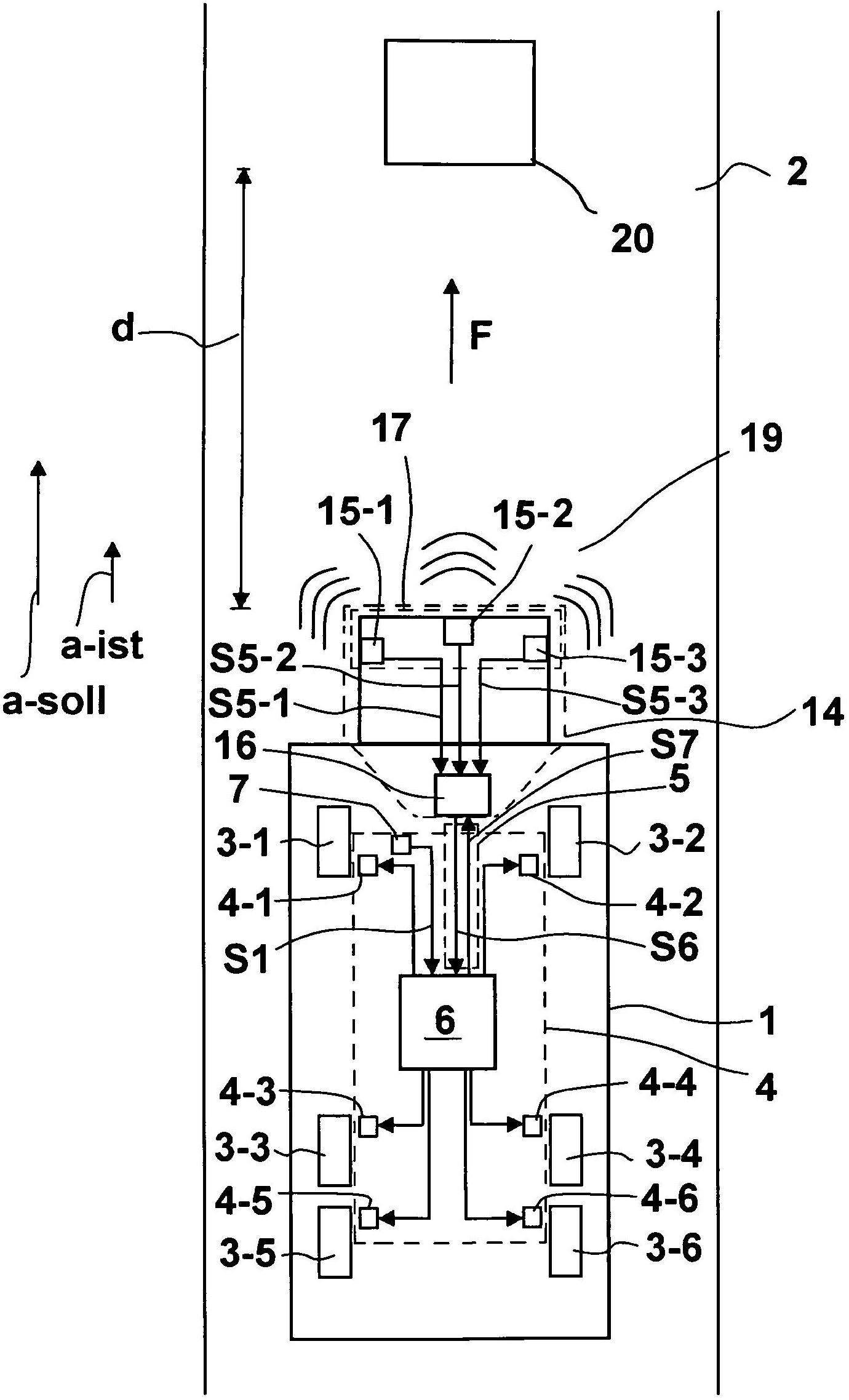

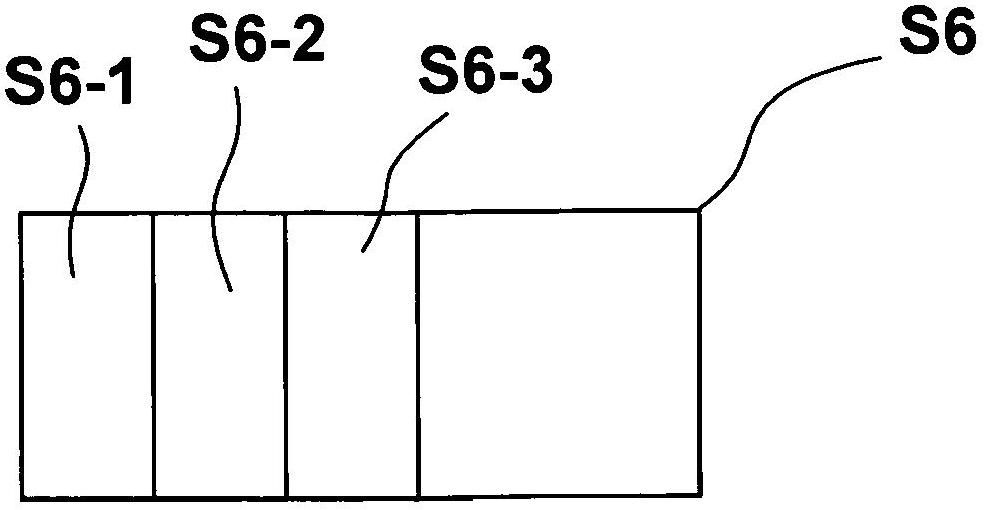

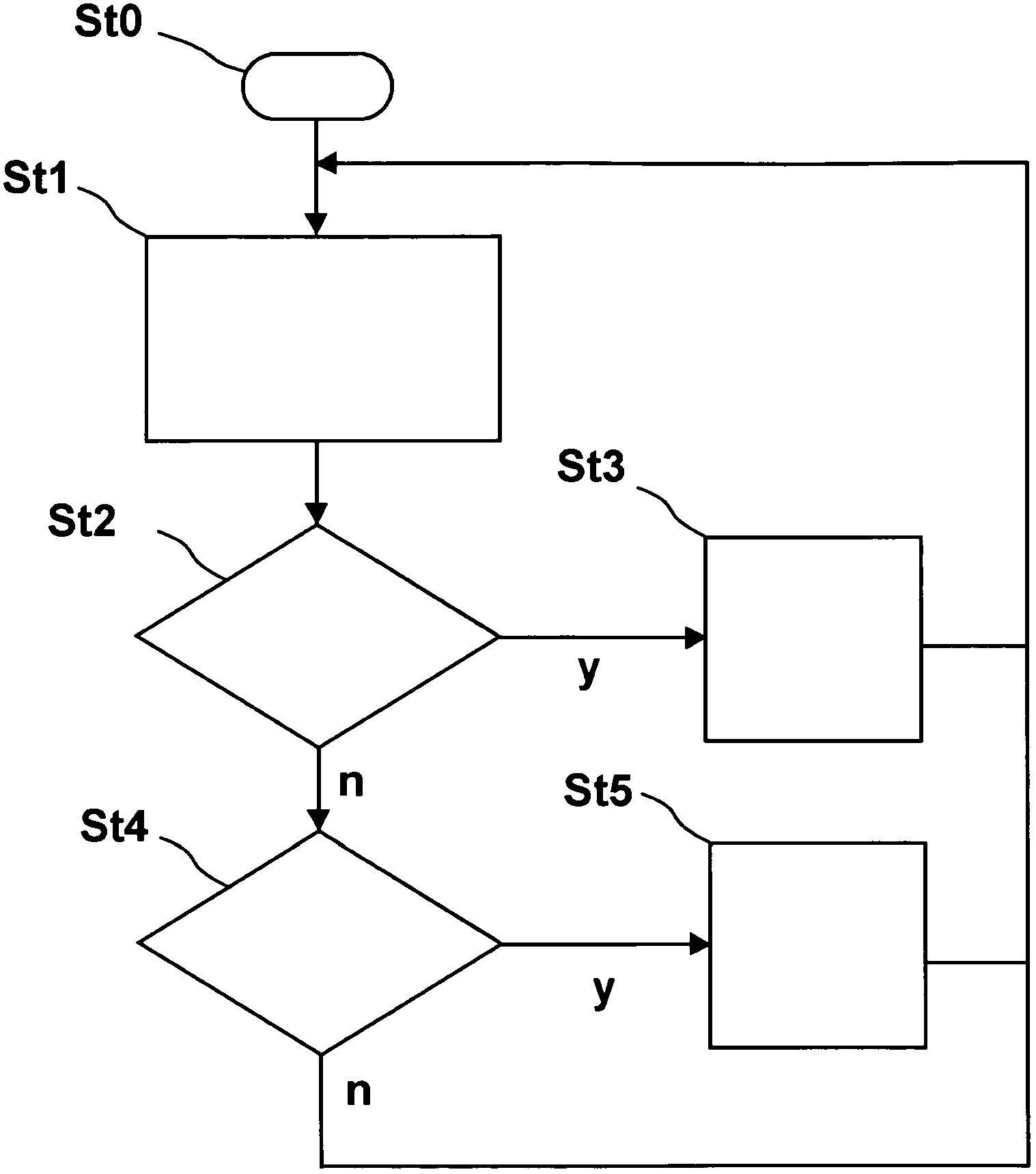

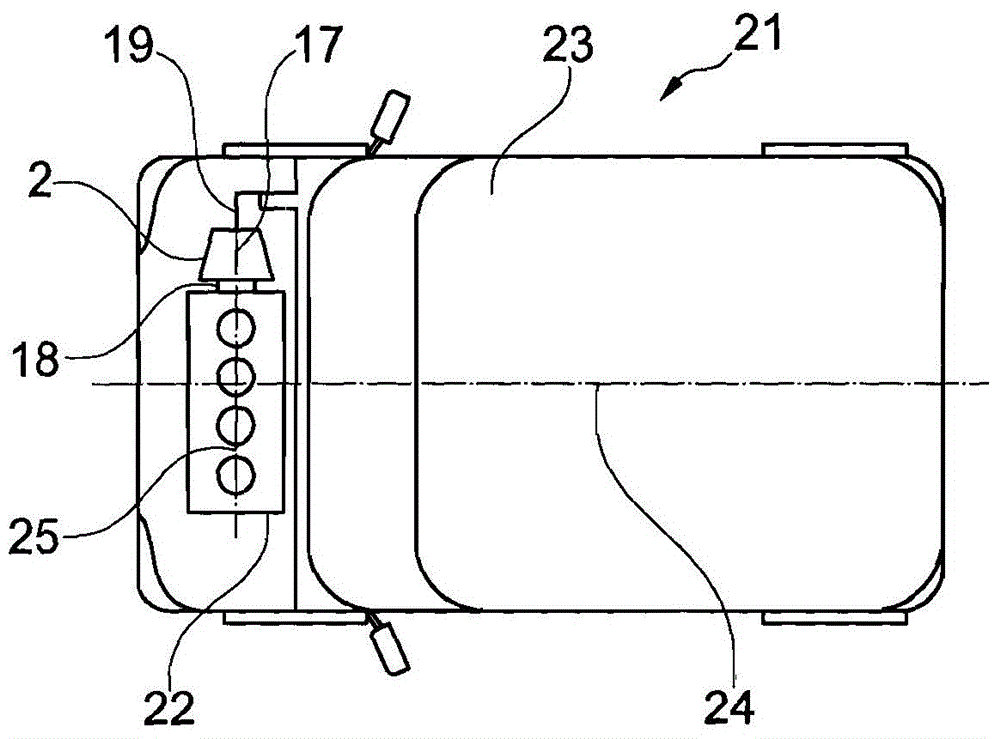

Driver assistance system for vehicle, in particular commercial vehicle, and method for controlling brake system

ActiveCN102652084AQuick importHigh quality inertiaPedestrian/occupant safety arrangementAutomatic initiationsDriver/operatorControl engineering

The invention relates to a driver assistance system for a vehicle, in particular a commercial vehicle, wherein the driver assistance system (14) has: a detection system which has at least one sensor (15-1, 15-2, 15-3) for issuing measuring signals (S5-1, S5-2, S5-3), a control unit (16) for receiving the measuring signals (S5-1, S5-2, S5-3) and for determining the probability of a critical situation or critical state of the vehicle (1), wherein, when a critical state or sufficient probability of a critical state is identified, the control unit (16) of the driver assistance system (14) outputs a signal (S6) for priming a brake system (4) to a brake control device (6) of the brake system (4) of the vehicle (1), and wherein the control unit (16) outputs an external brake request signal (S6) for initiating braking operations to the brake control device (6) of the brake system (4). According to the invention, in order to prime the brake system (4), the control unit (16) outputs an external brake request signal (S6) which has a desired acceleration value signal (S6-3) with a higher desired acceleration value (a-soll) than a current actual acceleration value (a-ist).

Owner:ZF CV SYST EURO BV

Individual line user smart access method

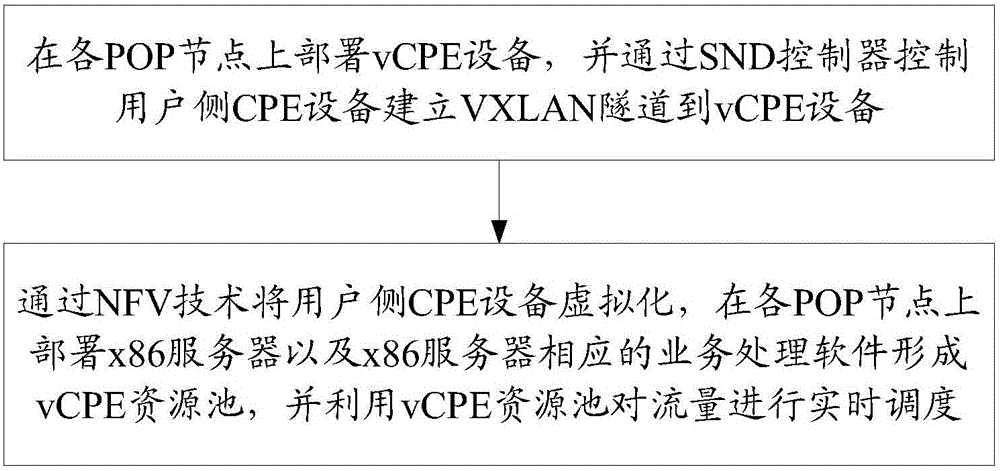

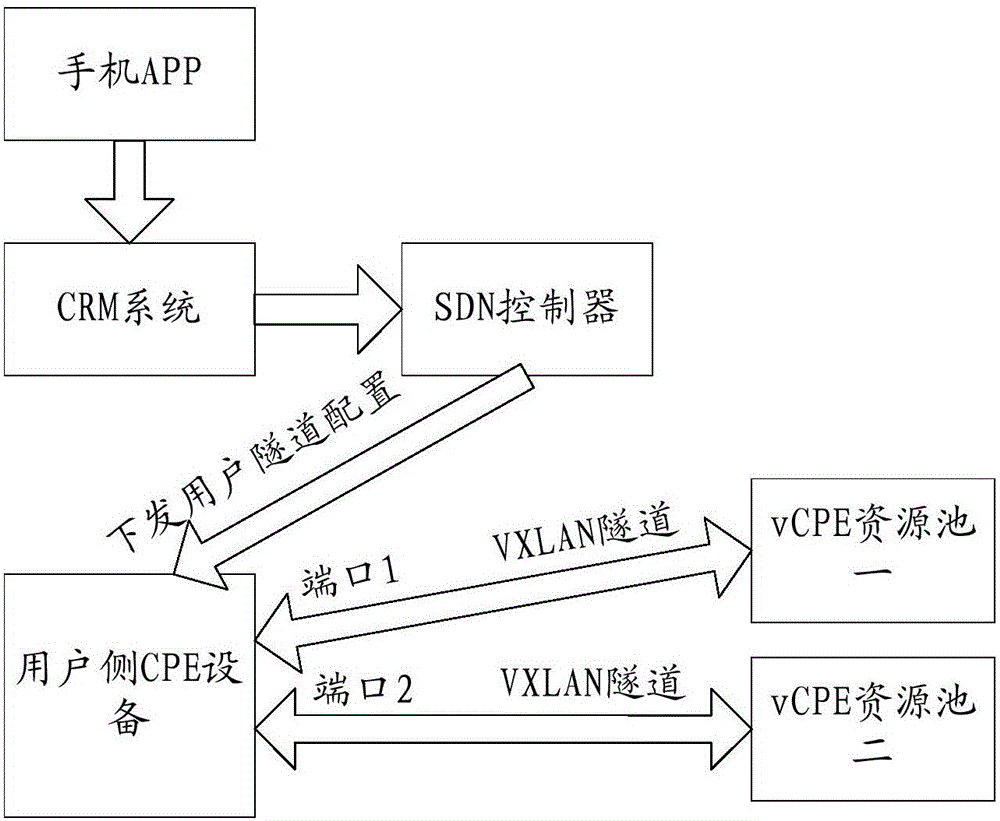

ActiveCN106130850AIntelligent Scheduling SeparationEasy to manage centrallyNetworks interconnectionTraffic capacityVirtualization

The invention provides an individual line user smart access method. The method comprises the steps of 1, deploying vCPE devices on various POP nodes, and controlling to establish VXLAN tunnels from user side CPE devices to vCPE devices through an SND controller; and 2, virtualizing the user side CPE devices through an NFV technology, deploying x86 servers and service processing software corresponding to the x86 servers on the POP nodes, thereby forming vCPE resource pools, and carrying out real-time scheduling on traffic by employing the vCPE resource pools. The method has the advantages that the VXLAN tunnels are established between the user side CPE devices and the vCPE devices through a VXLAN tunnel technology, smart scheduling separation can be carried out on the user traffic, and the individual service business of the user traffic can be customized.

Owner:中电福富信息科技有限公司

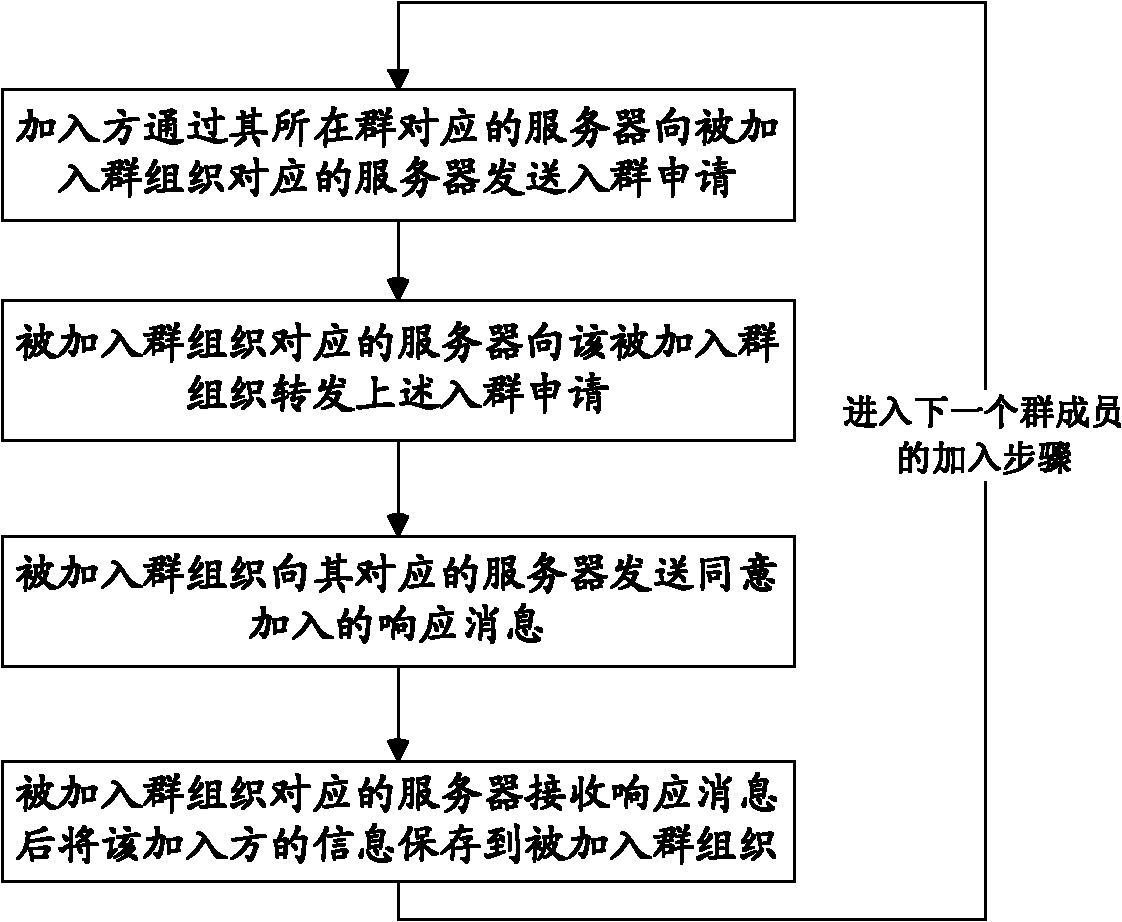

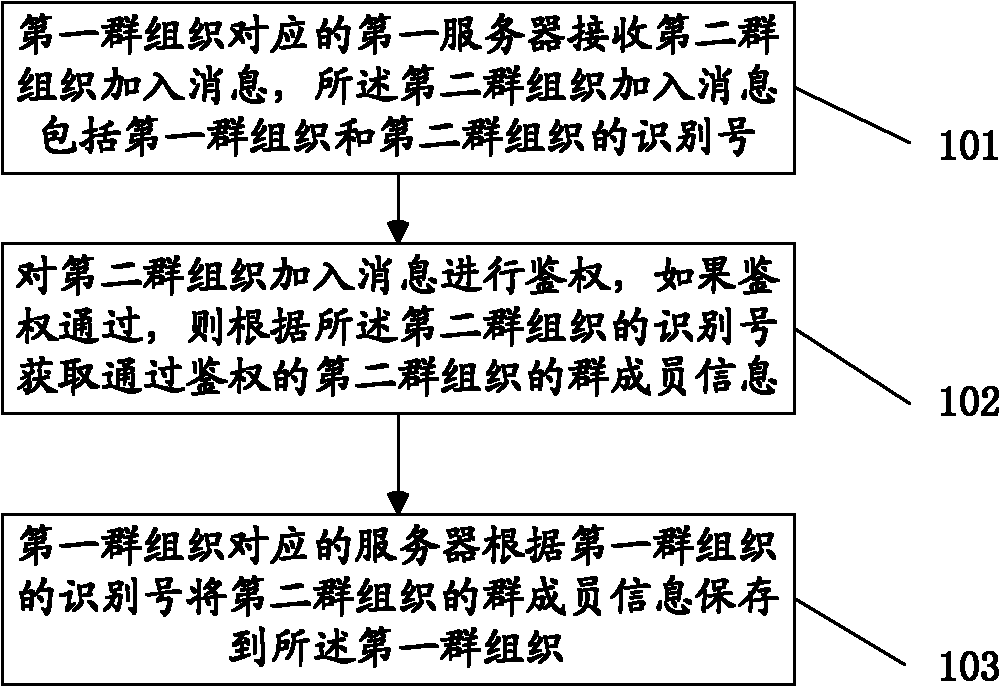

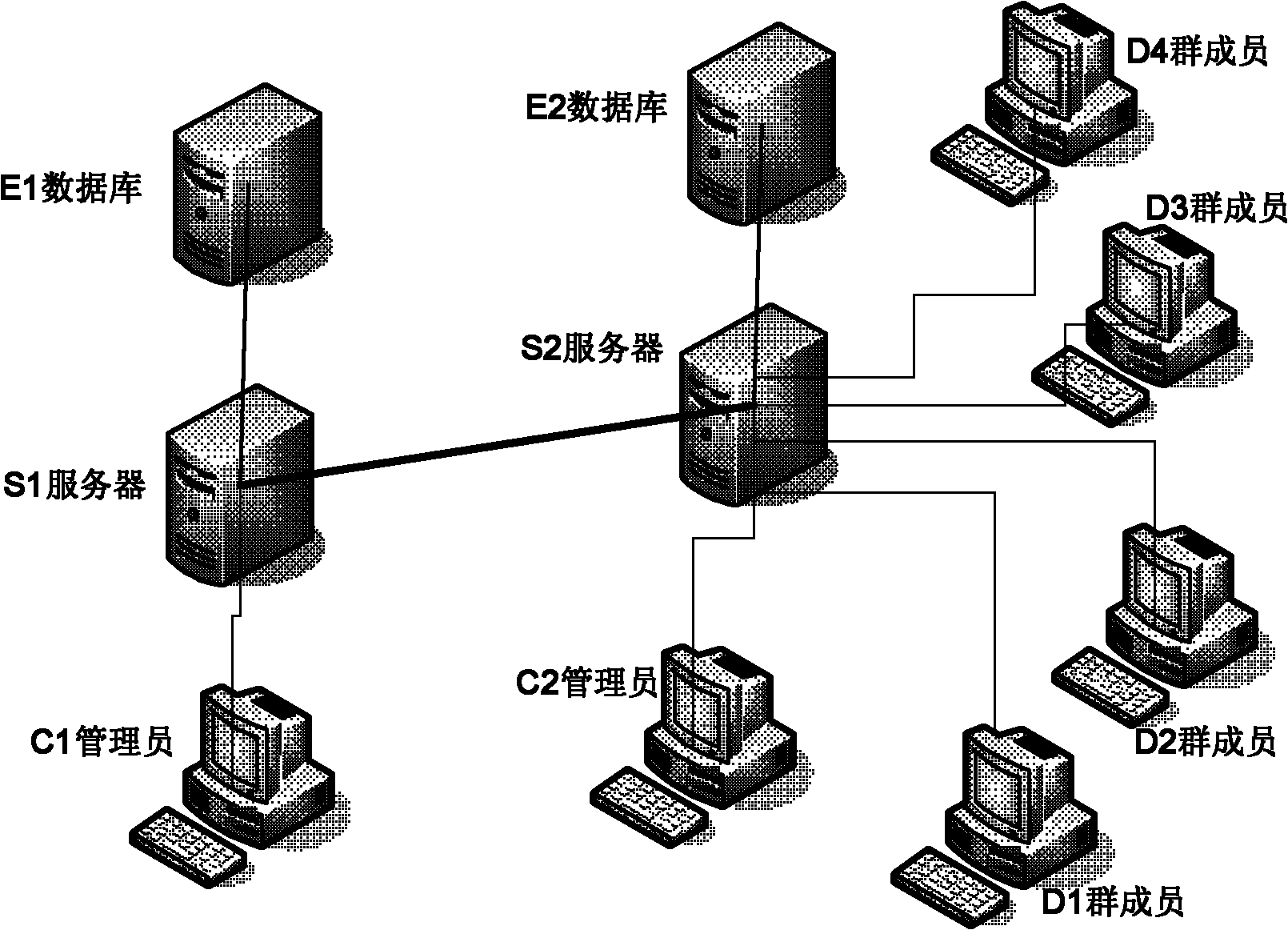

Method for importing group members

ActiveCN102202060AImport implementationQuick importData switching networksComputer scienceGroup member type

The invention provides a method for importing group members. The method comprises the following steps: the server of a first group organization receives the join message of a second group organization, and the join message of the second group organization comprises identification numbers of the first group organization and the second group organization; the join message of the second group organization is authenticated, if the authentication succeeds, the group member information of the second group organization which passes the authentication can be acquired according to the identification number of the second group organization; a server corresponding to the first group organization stores the group number information of the second group organization to the first group organization according to the identification number of the first group organization. By the method, the mode of one-by-one application / invitation, one-by-one approval and one-by-one import in the prior art can be avoided, a large number of group members can be imported quickly, thereby improving the work efficiency of group member import.

Owner:广州方硅信息技术有限公司

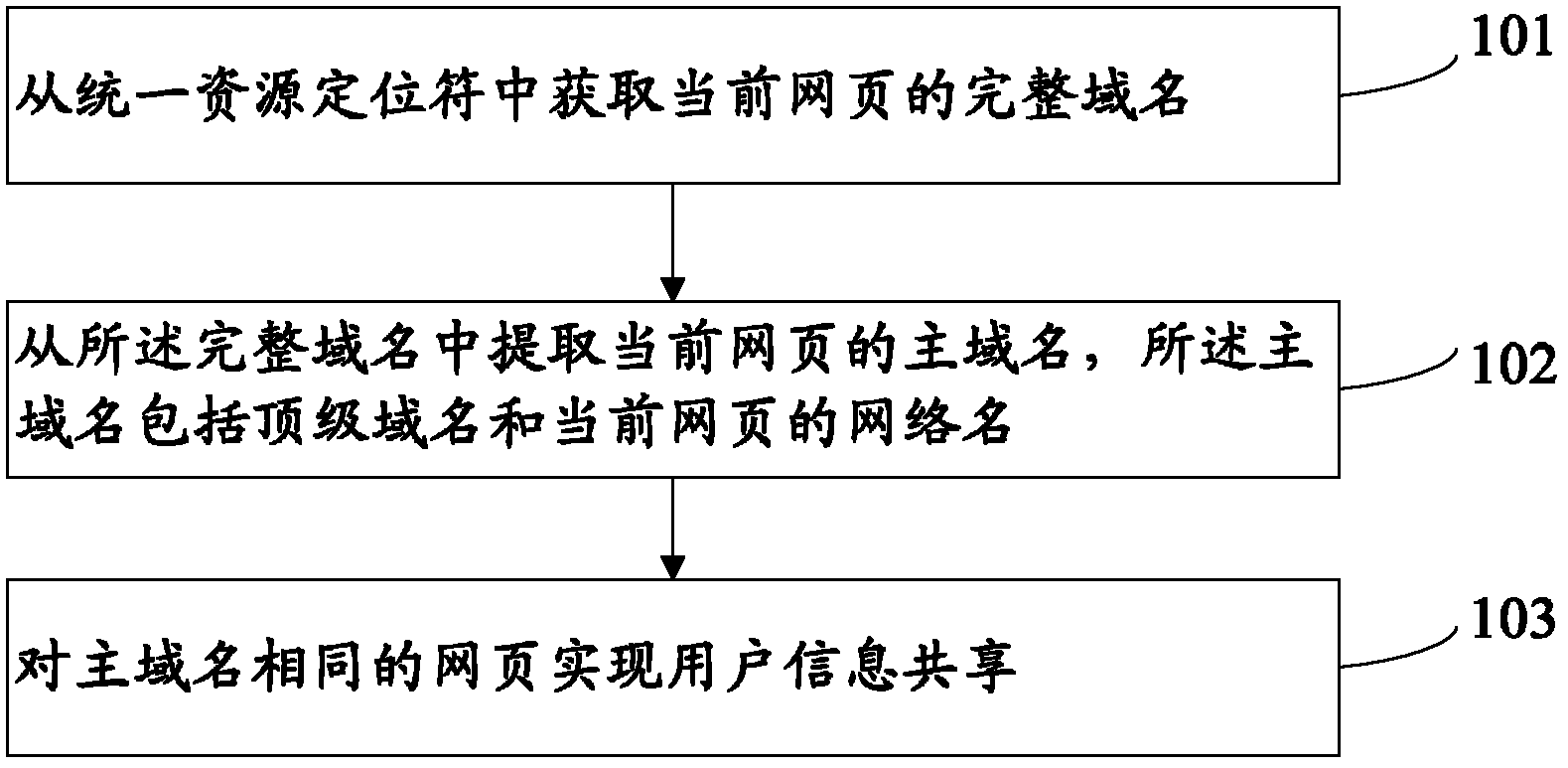

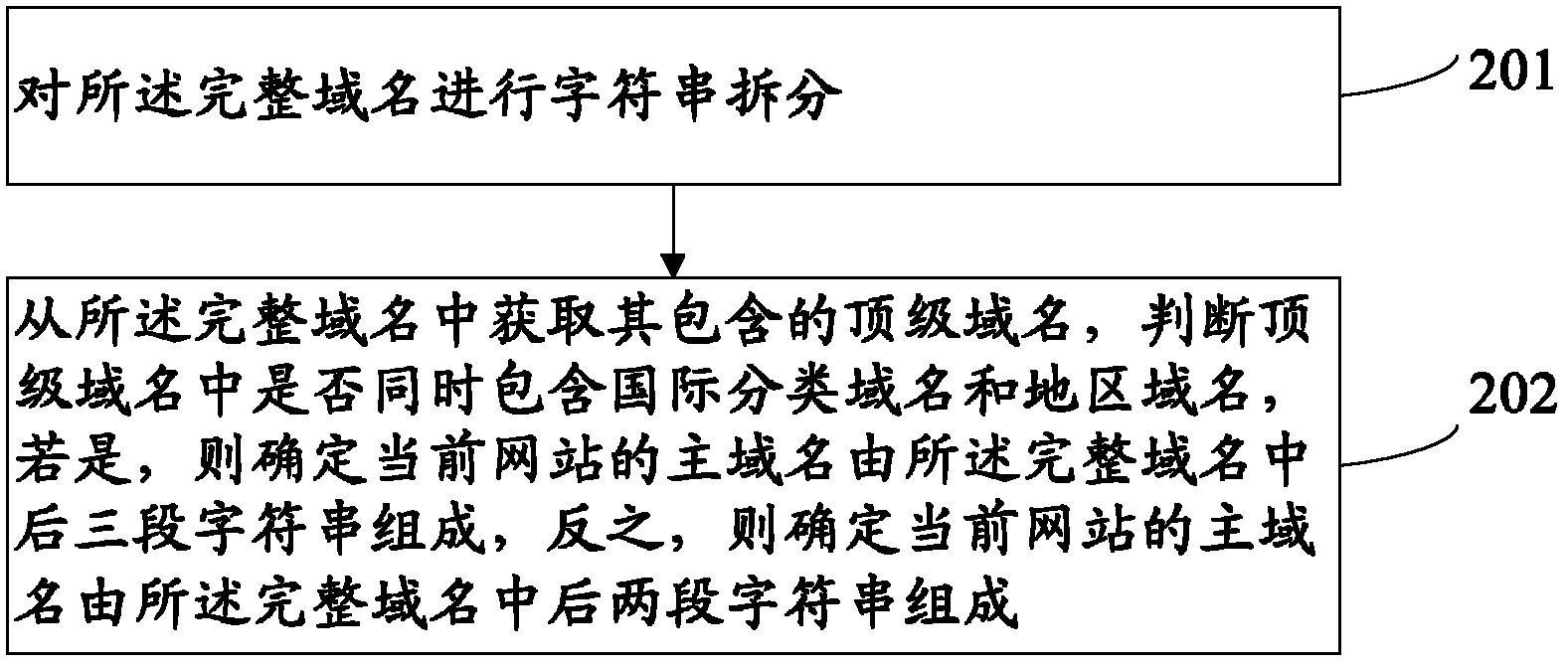

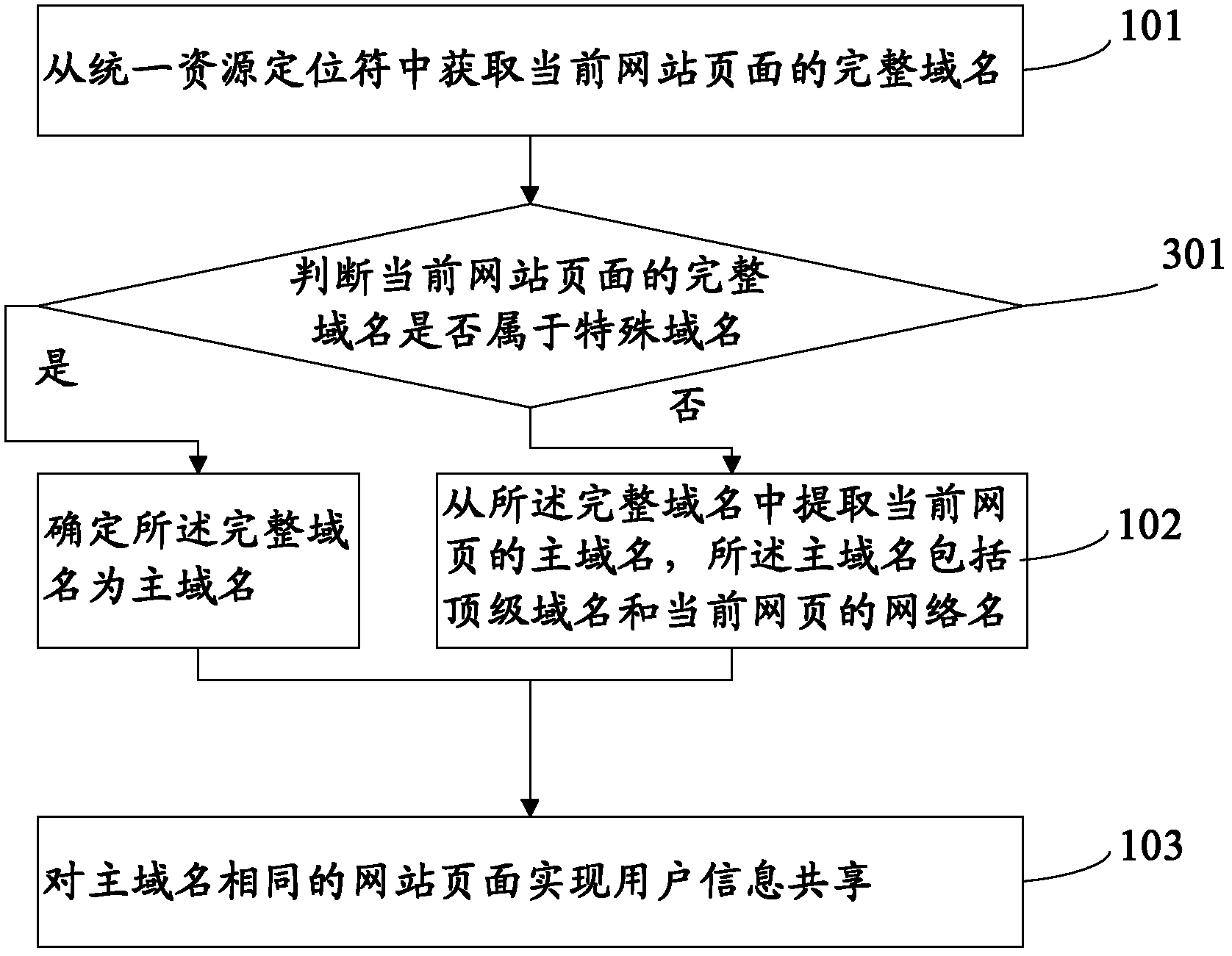

Method and system for user information sharing

ActiveCN102664926AAchieve sharingReduce storageTransmissionInformation sharingFully qualified domain name

The application provides a user information sharing method, comprising the following steps: obtaining a complete domain name of a current webpage from a uniform resource locator; extracting a main domain name of the current webpage from the complete domain name, wherein the main domain name includes a top level domain name and a network name of the current webpage; and realizing user information sharing for webpages with same main domain names. In addition, the application also discloses a user information sharing system for realizing the method. According to the method and the system for user information sharing, occupation of system resources by user information records can be reduced; and sharing of user information can be realized.

Owner:BEIJING QIHOO TECH CO LTD

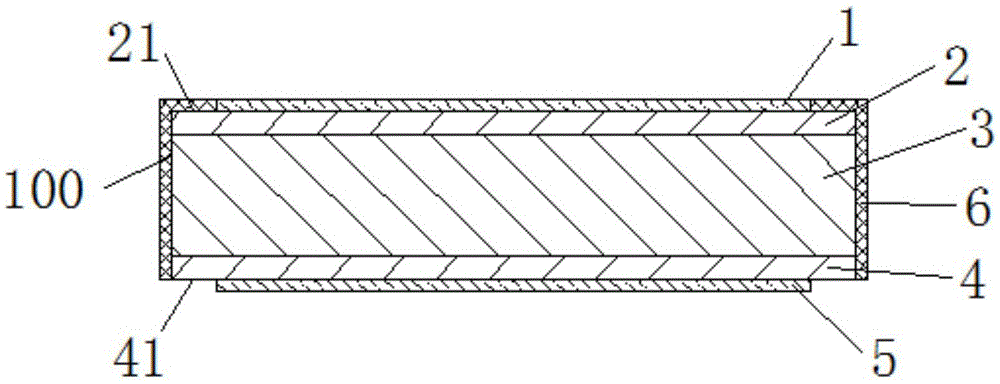

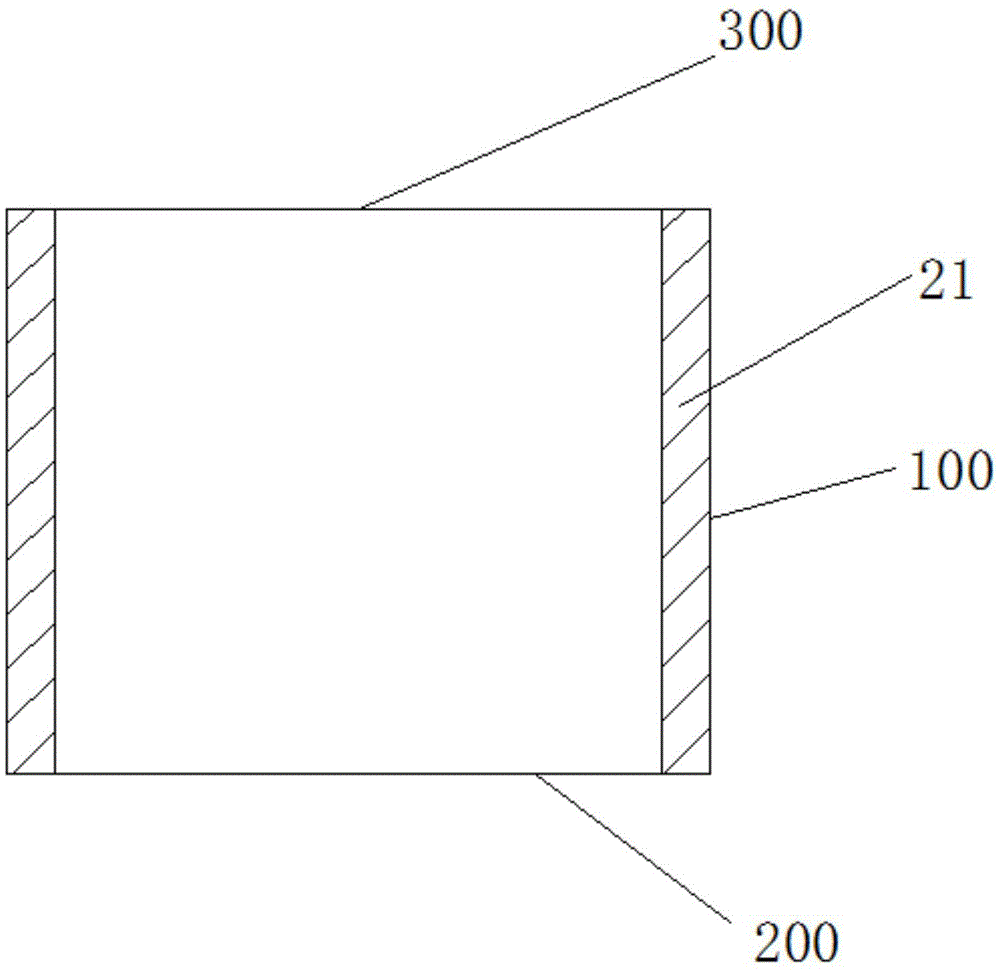

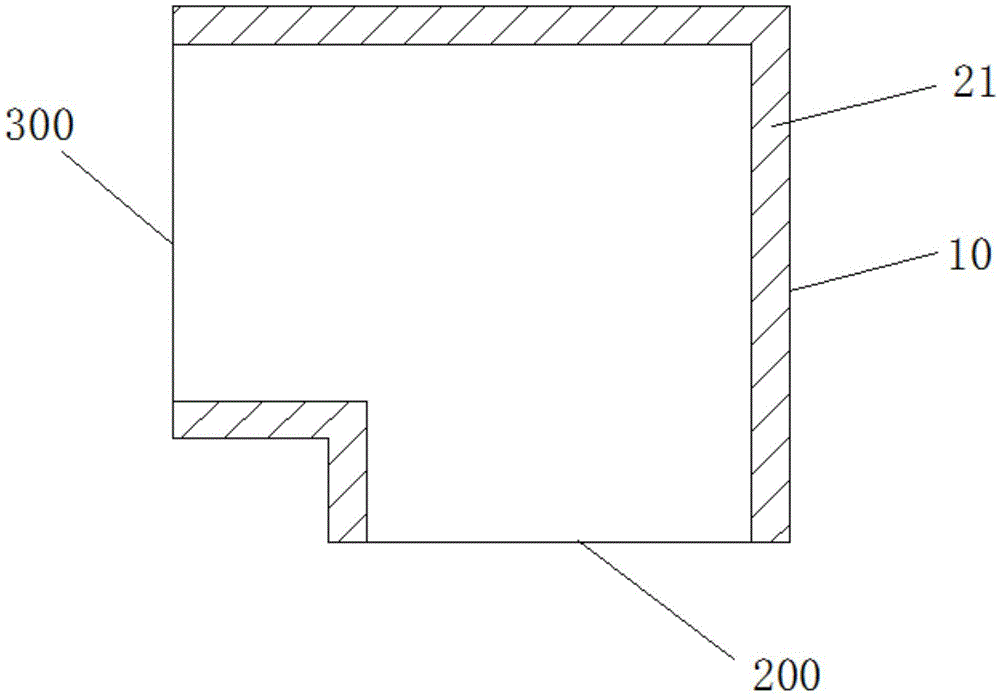

Advertising board installing device capable of completing installation rapidly

InactiveCN104896282AImport smoothlyQuick importMachine supportsRear quarterArchitectural engineering

Owner:江苏支点传媒集团有限公司

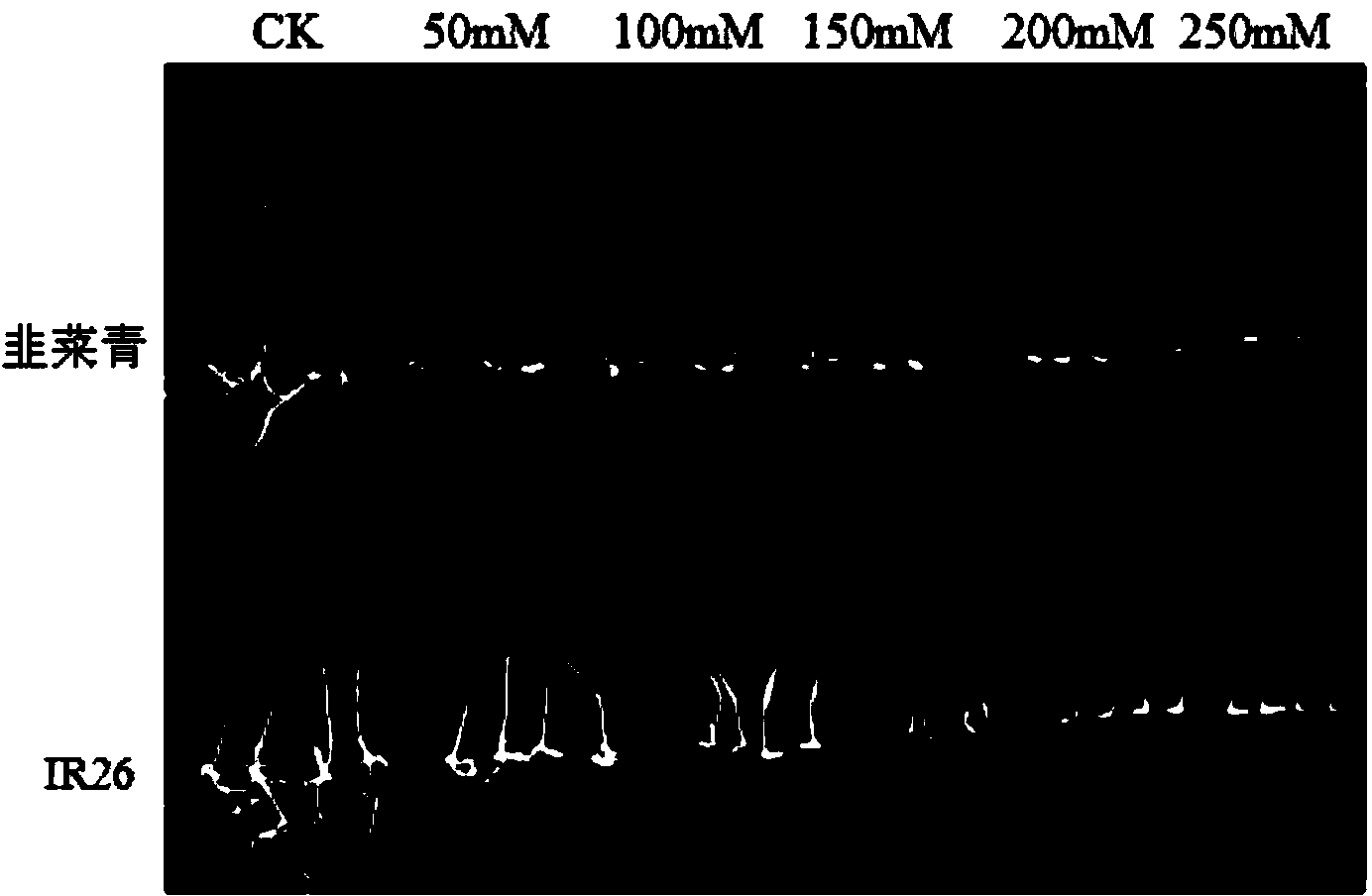

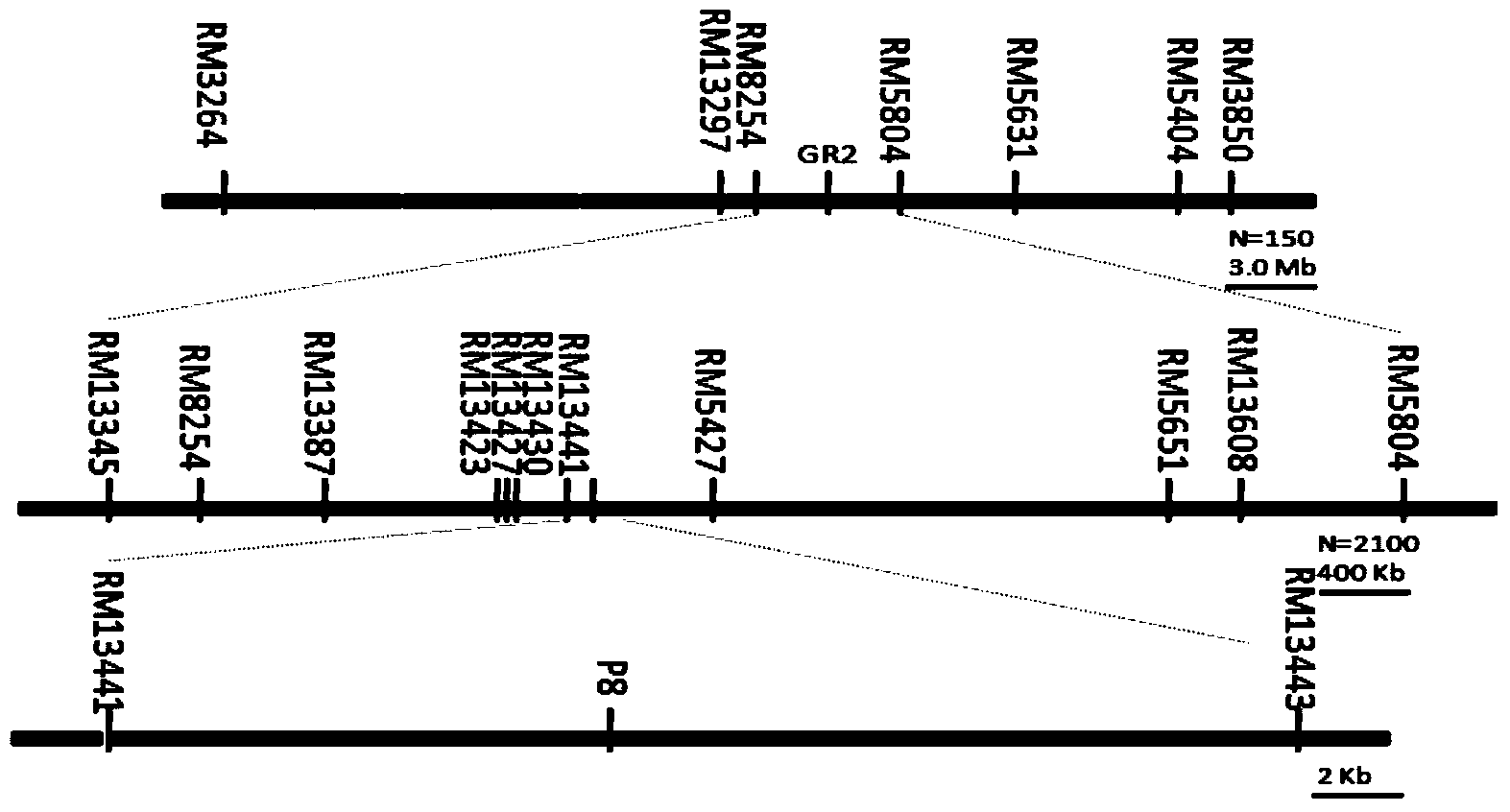

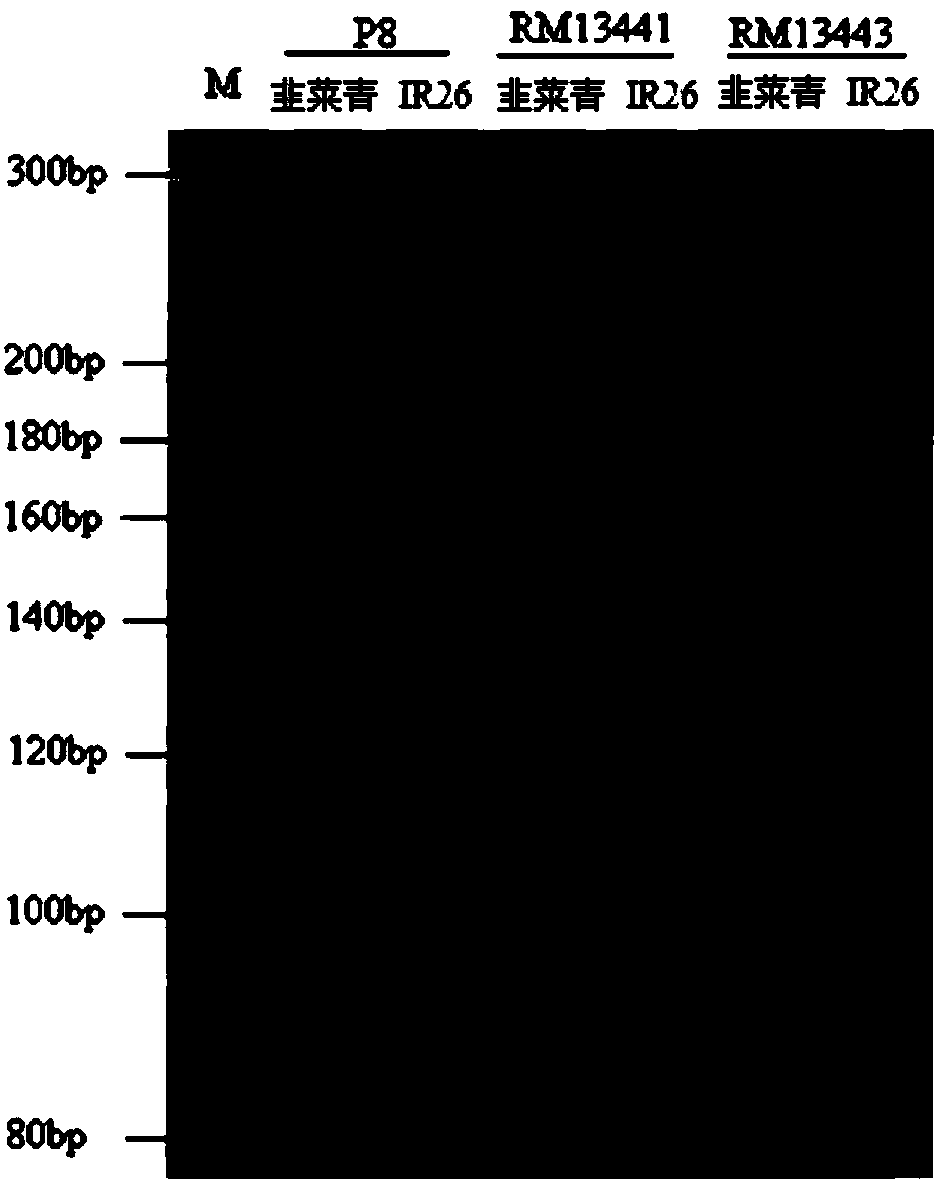

Molecular marker of rice seed salt tolerant germination major QTL qGR2 and its application

ActiveCN103642801AQuick filterClear locationMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceElectrophoresis

Belonging to the fields seed science and technology application, the invention relates to a molecular marker of a rice seed salt tolerant germination major QTL qGR2 and its application. One or more pairs of rice genome DNA in SSR marked primers are employed to conduct PCR amplification, and the PCR amplification product is subjected to electrophoresis detection on 8% non-denaturing polyacrylamide gel. If a DNA fragment with a corresponding size is amplified, major QTL qGR2 synergetic allele for controlling rice seed salt tolerant germination can exist. By means of a molecular marker method in coseparation and close linkage with the seed salt tolerant germination gene qGR2, the salt tolerance level during rice germination can be predicted, and the salt rice variety in a rice germination period can be screened out rapidly.

Owner:NANJING AGRICULTURAL UNIVERSITY

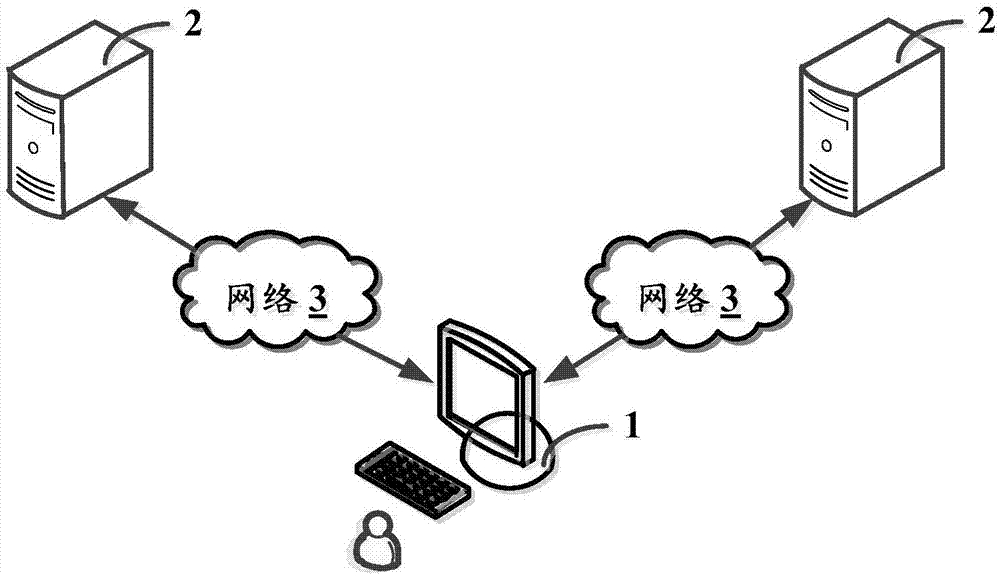

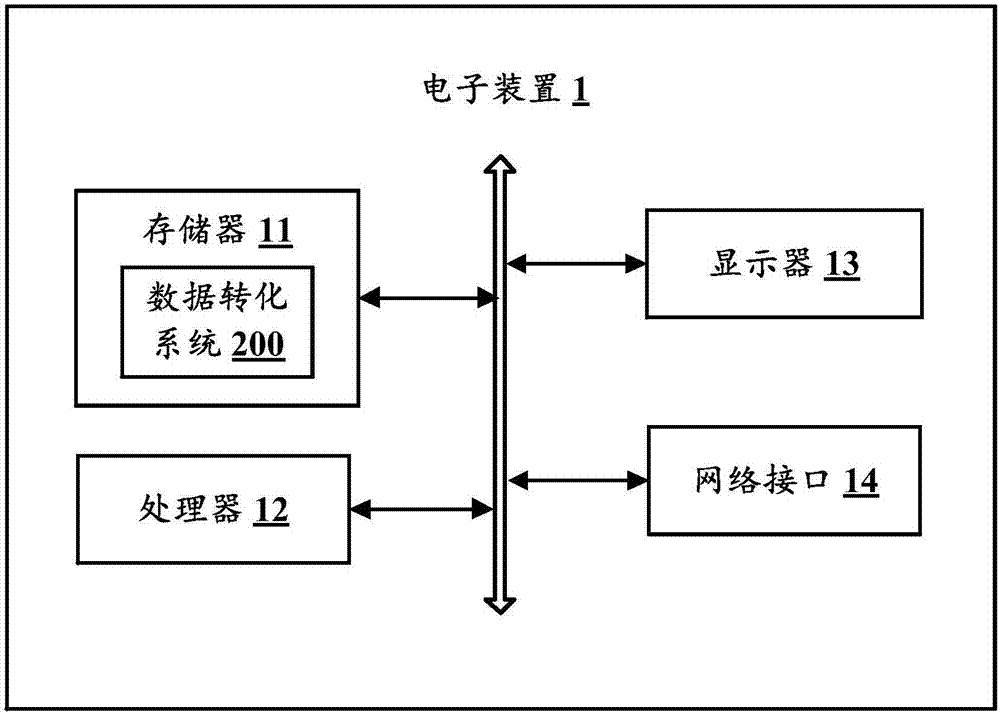

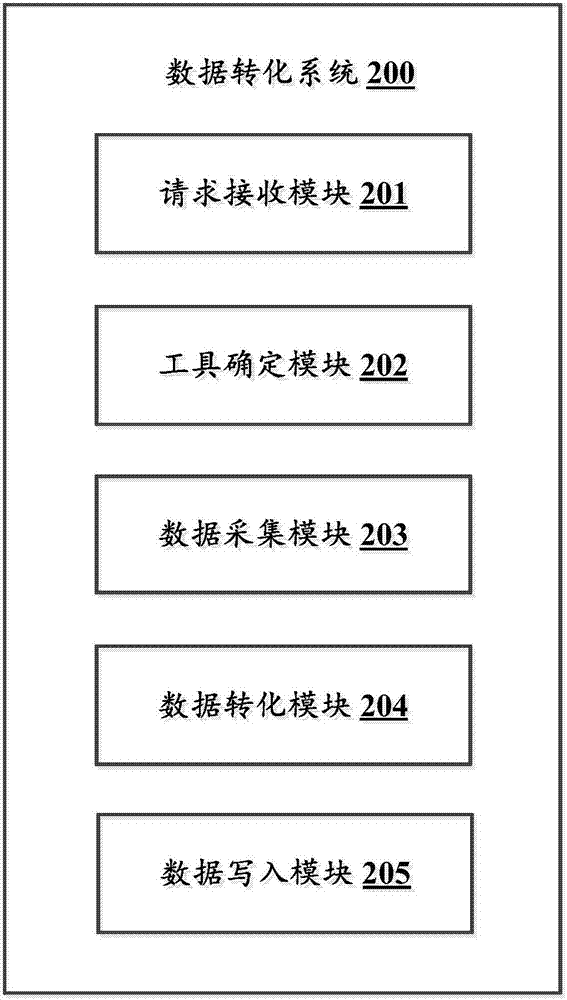

Data conversion method and system

InactiveCN106951536AQuick importAccelerateDatabase distribution/replicationSpecial data processing applicationsData conversionCollections data

The invention discloses a data conversion system. The system comprises a request receiving module used for receiving a data conversion request, a tool determination module used for determining a reading tool for reading data from a source database according to a type and a data format of the source database and determining a writing tool for writing data in a destination database according to a type and a data format of the destination database, a data collection module used for reading to-be-converted data from the source database by utilizing the reading tool, a data conversion module used for converting the to-be-converted data into data corresponding to the data format of the destination database, and a data writing module used for obtaining the data after conversion and writing the data after conversion in the destination database by utilizing the writing tool. By utilizing the system, the conversion of the data between the databases can be carried out more flexibly.

Owner:NUBIA TECHNOLOGY CO LTD

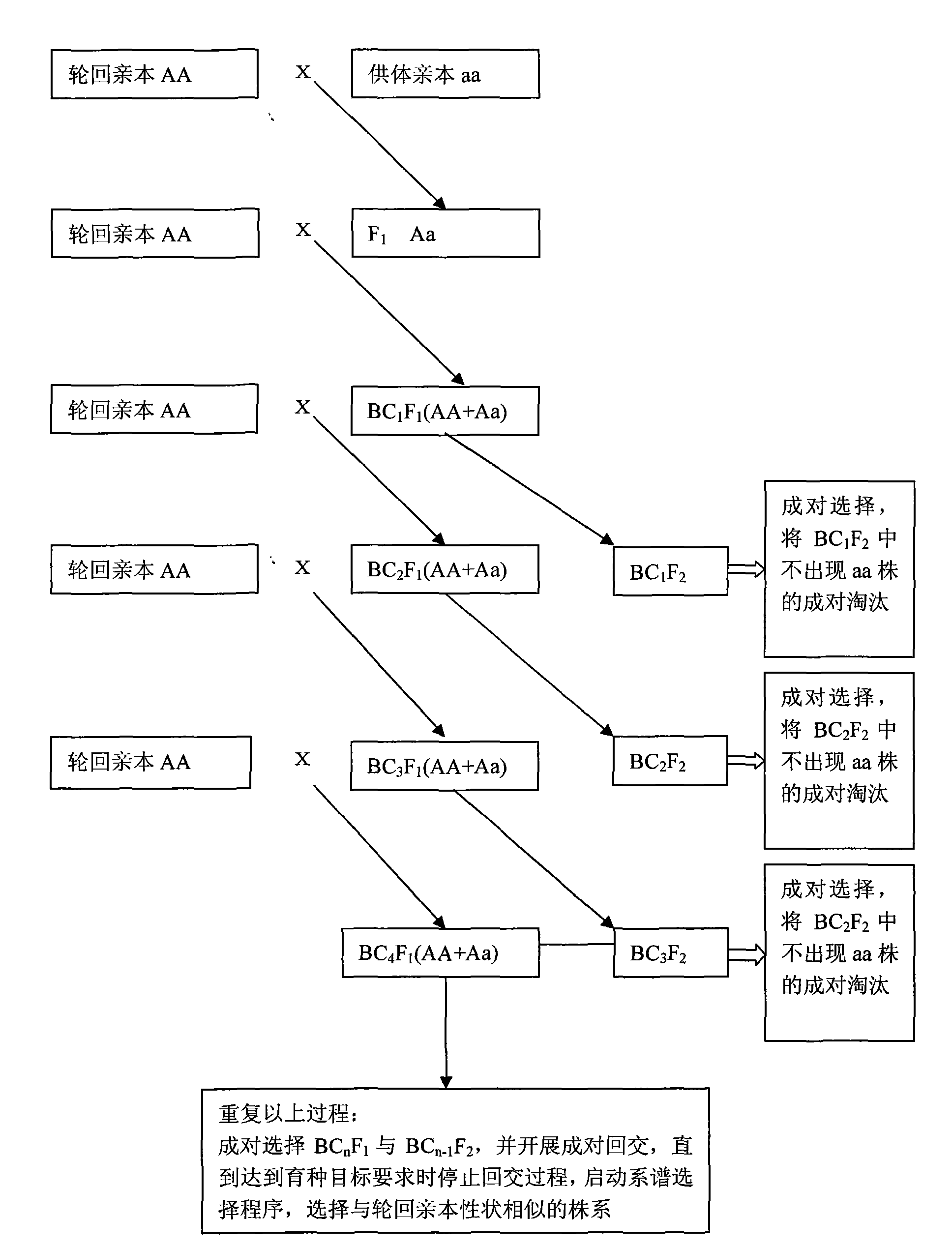

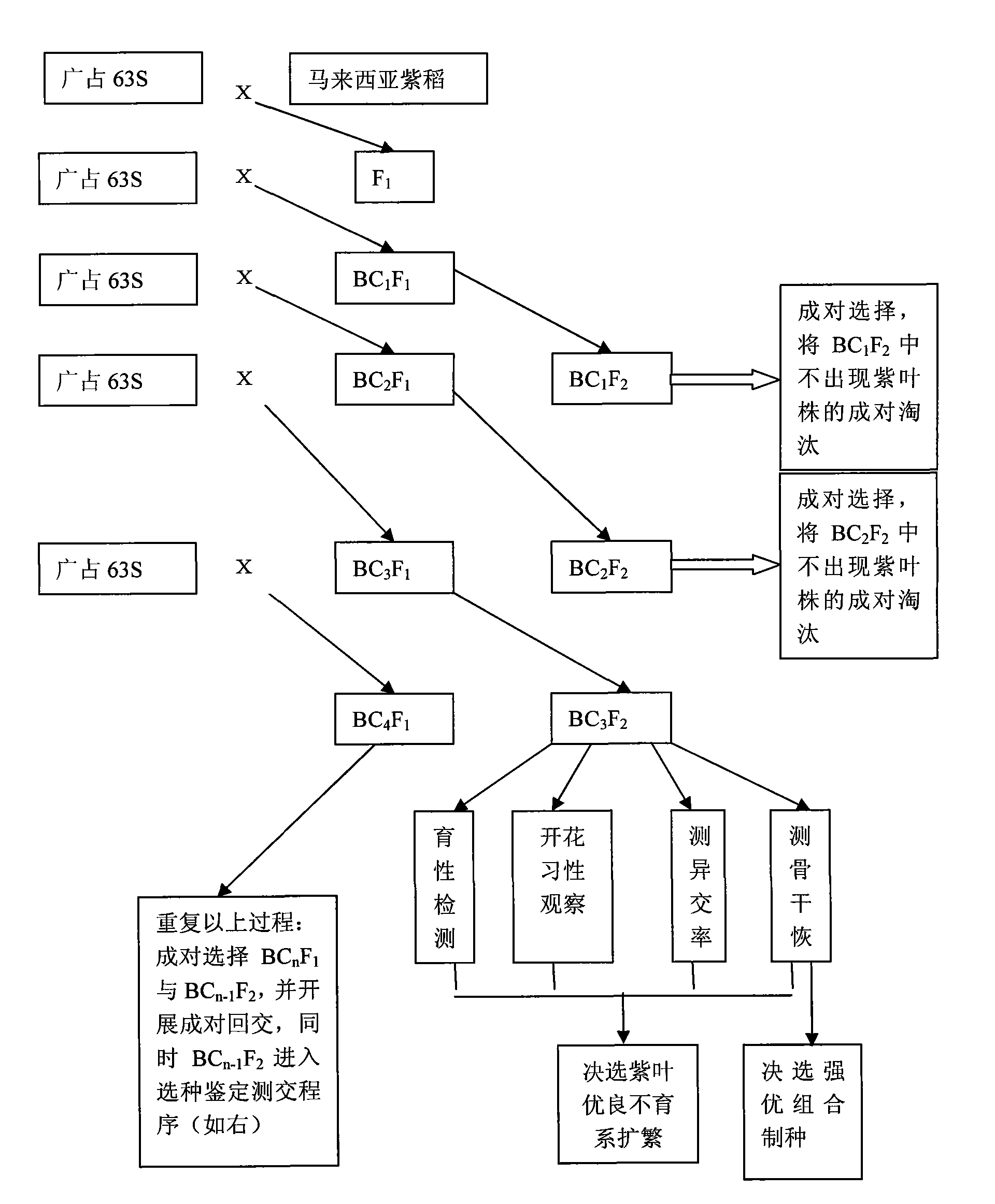

Continuous recessive character backcrossing technology

InactiveCN101637119AShorten breeding timeImprove time and efficiencyPlant genotype modificationHybrid seedTyping

The invention discloses a continuous recessive character backcrossing technology which is characterized by taking a material which contains no target recessive genes and is ready to be improved as a recurrent parent, and taking a material which contains the target recessive genes as a donor parent; taking the recurrent parent as the parent to be hybridized with the donor parent and harvesting hybrid seeds of the first generation F1 and recurrent parent seeds; and planting the hybrid seeds of the first generation F1 and the recurrent parent seeds till the planting of a group containing backcross hybrid seeds of the second of n generations BCn F2 and till the typing into a target recessive gene isogenic line of the recurrent parent. The invention also discloses a method for creating a purpleleaf marker isogenic line by applying the continuous recessive character backcrossing technology and also a method for transferring new purple leaf marker nucleus sterile line by taking the purple leaf marker isogenic line as an intermediate material. In the methods, a selfing process is combined with a next backcrossing process for the treatment in one season, therefore, the time efficiency is improved by about 50 percent, a small number of dominant-gene-controlled unsuitable characters of existing fine-quality parents can be fast improved, and useful recessive characters can be fast imported to the present high-level heredity background.

Owner:LIANYUNGANG ACAD OF AGRI SCI

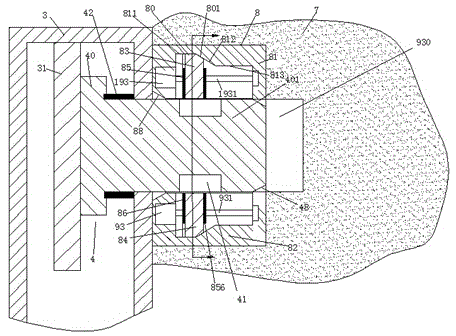

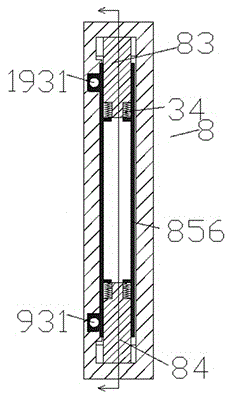

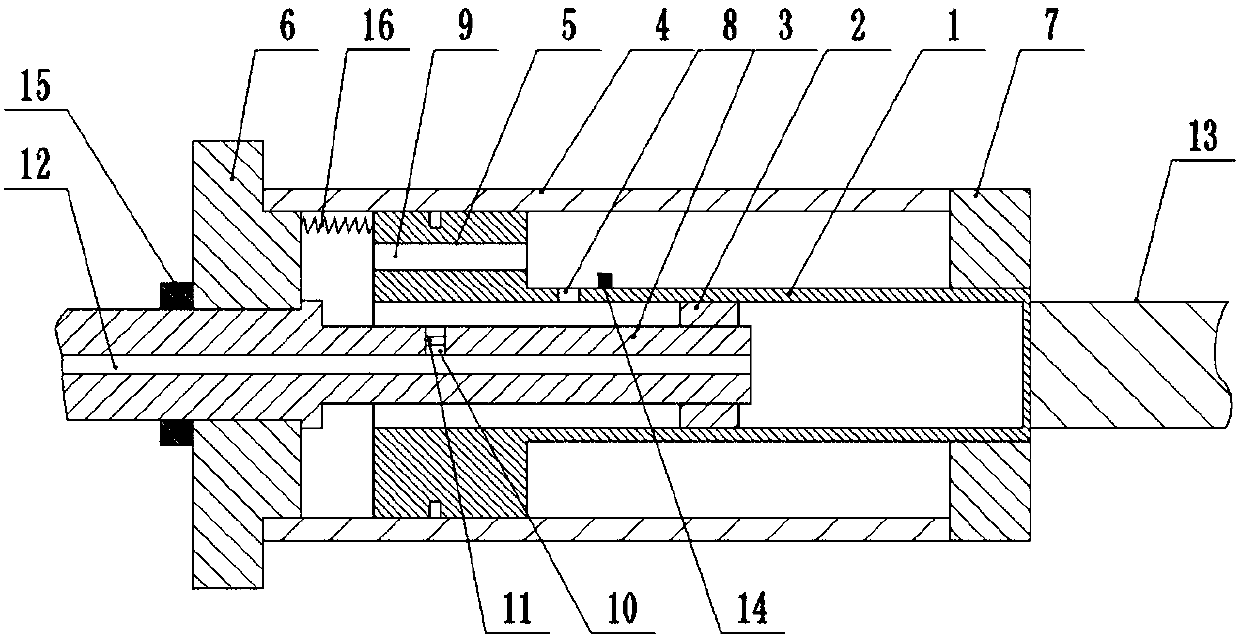

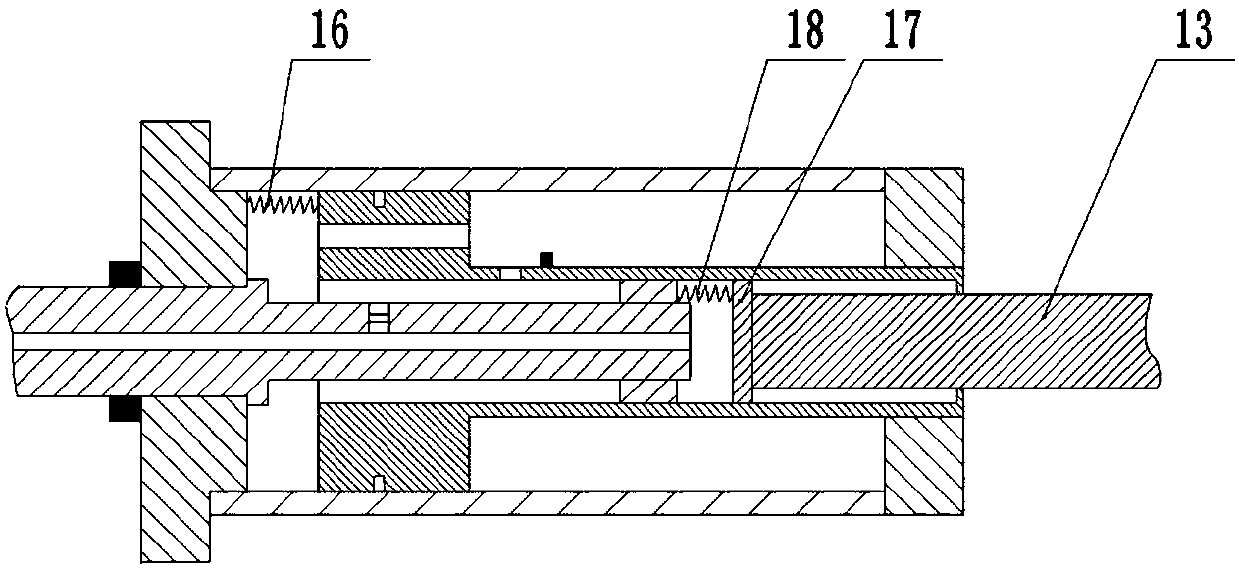

Two-way quick hydraulic cylinder

ActiveCN108050123AStrong pullSlow down scalingFluid-pressure actuatorsHydraulic cylinderPulp and paper industry

The invention belongs to the technical field of hydraulic equipment, and specifically discloses a two-way quick hydraulic cylinder. The two-way quick hydraulic cylinder comprises a cylinder barrel, apiston and a piston rod, wherein a sleeve is arranged at the outer side of the cylinder barrel; one end of the cylinder barrel is connected with a pushing rod; the other end of the cylinder barrel isconnected with a sealing disc; the sealing disc is in sliding and sealing connection with the sleeve; a plurality of oil conducting holes are formed in the sealing disc; one end of the sleeve is connected with a bottom disc; a plurality of first elastic pieces are connected on the bottom disc of the sealing disc; a central hole is formed in the shaft center of the bottom disc; the piston rod is fixedly connected with the bottom disc through the central hole; one end, connected with the pushing rod, of the cylinder barrel is in sliding and sealing connection with a fixed ring; the piston rod isin sliding and sealing connection with the central hole of the bottom disc; an oil outlet hole is formed in the cylinder barrel; and a through oil inlet hole is formed in the piston rod in the axialdirection. The two-way quick hydraulic cylinder is mainly used on hydraulic equipment, and solves the problem that telescopic length is inaccurate as a result of high telescopic speed at the last telescopic stage of the hydraulic cylinder.

Owner:CHONGQING WEIQING HYDRAULIC MACHINERY CO LTD

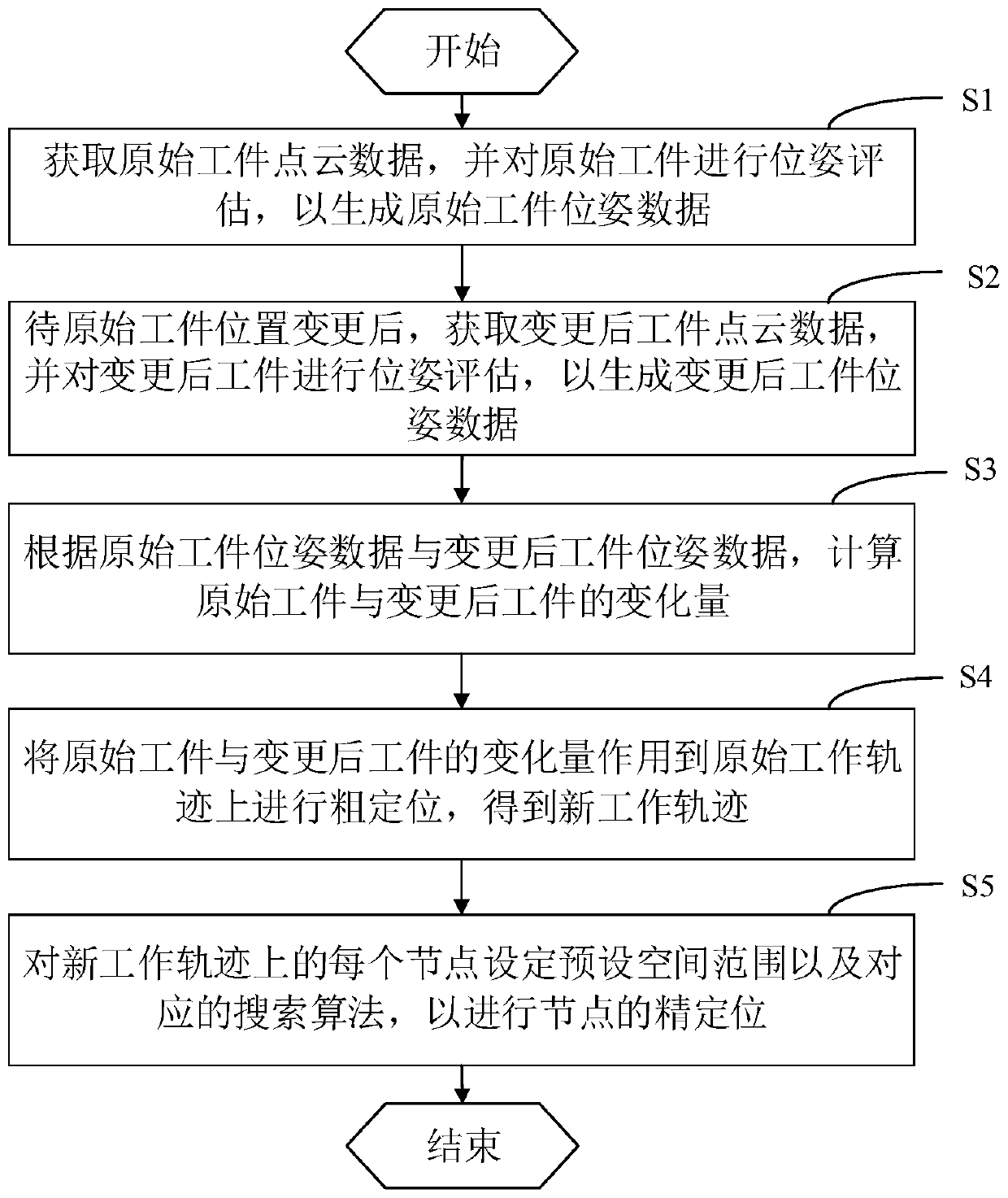

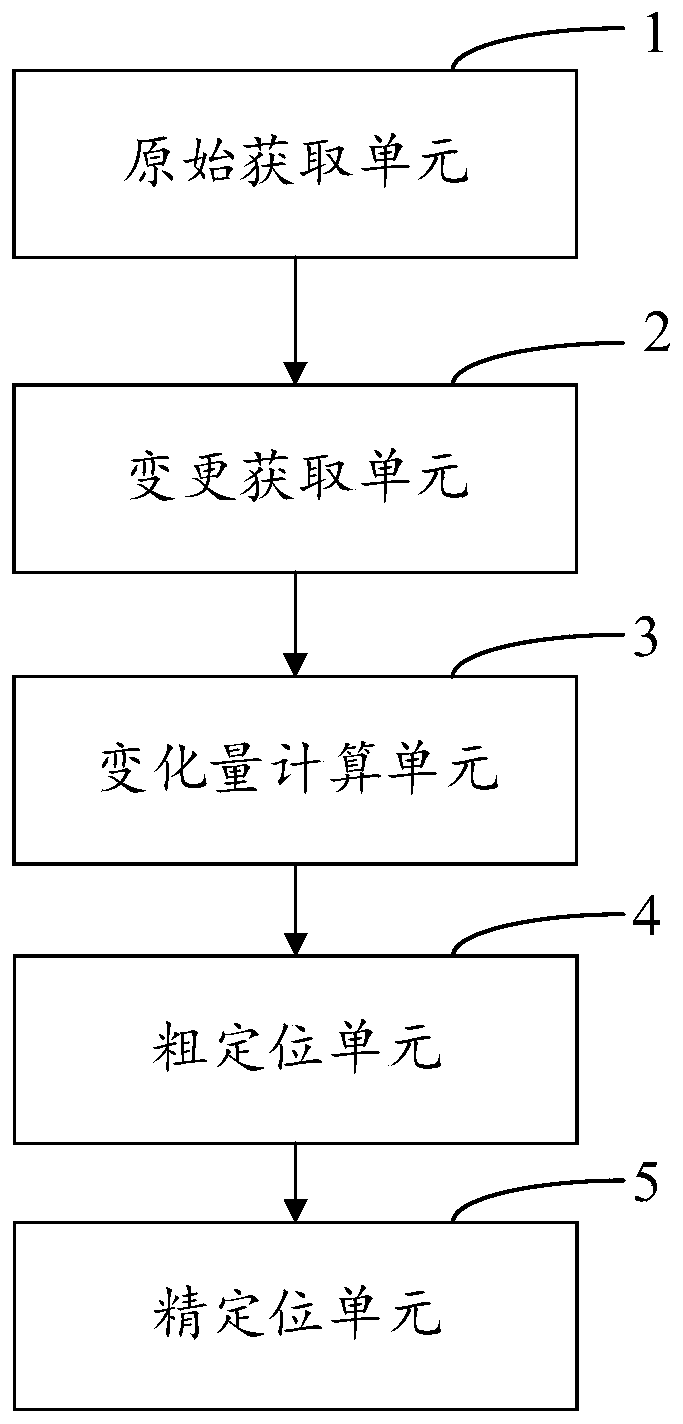

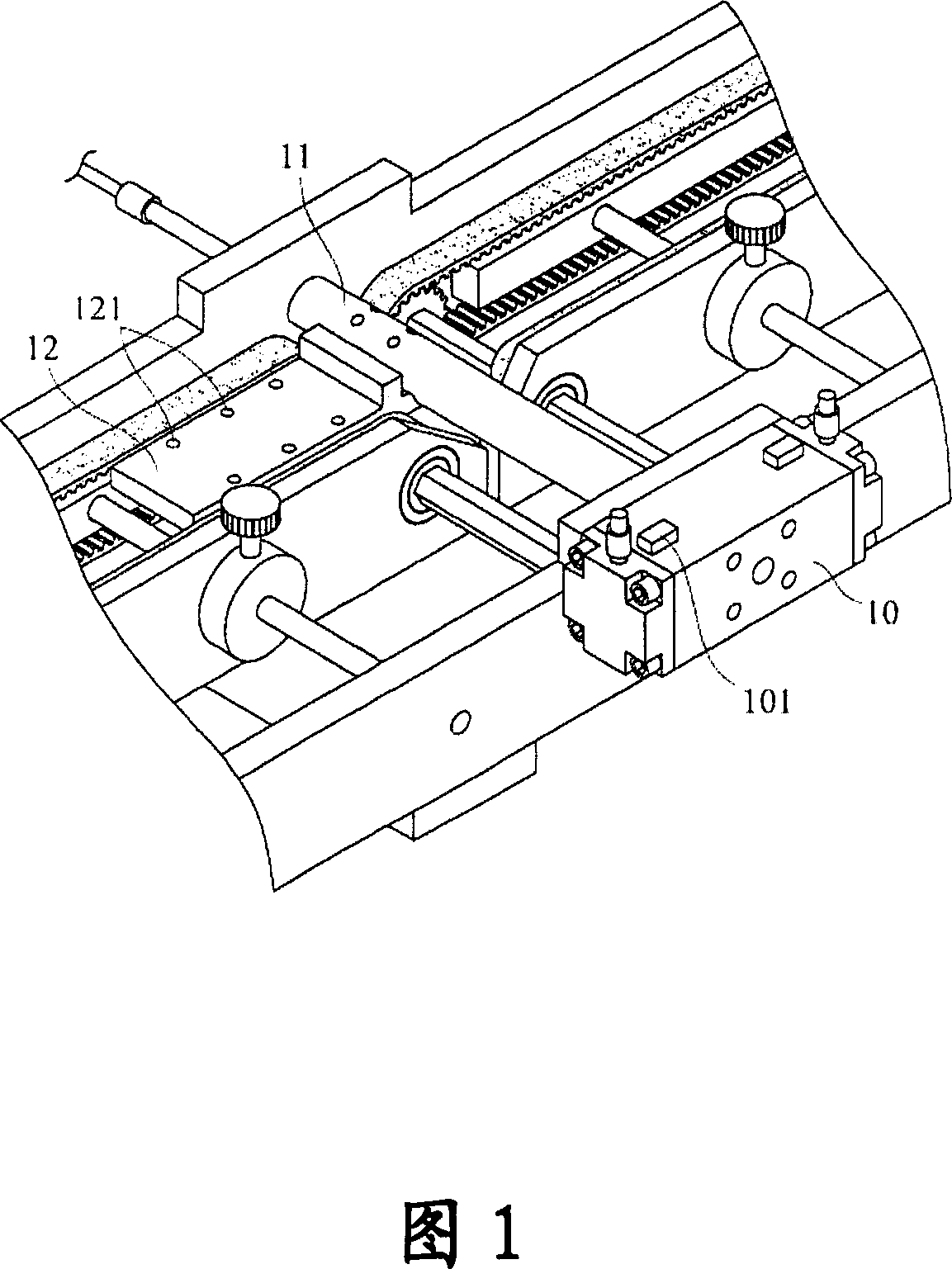

Manipulator guide method and device based on 3D machine vision

ActiveCN111152229AQuick importSimple processProgramme-controlled manipulatorManufacturing computing systemsPoint cloudMachine vision

The invention provides a manipulator guide method and device based on 3D machine vision, and is applied to the technical field of manipulator control. The method comprises the steps that point cloud data of an original workpiece are obtained, and the original workpiece is subjected to pose evaluation so that pose data of the original workpiece can be generated; after the position of the original workpiece is changed, point cloud data of the workpiece after change are obtained, and the changed workpiece is subjected to pose evaluation so that pose data of the workpiece after change can be obtained; and the pose variable quantity before and after change is calculated and acts on an original working track planned on the original workpiece to obtain a coarse positioning track, and then, a track after precise positioning is obtained through a preset spatial range and a point position search algorithm for each track point of the coarse positioning track. Thus, the working track of a manipulator can be quickly guided into a system, a quick track switching working mode is included, the process of conducting track guide on the manipulator through machine vision is simplified, and the work amount for switching different operation tracks is decreased.

Owner:群滨智造科技(苏州)有限公司

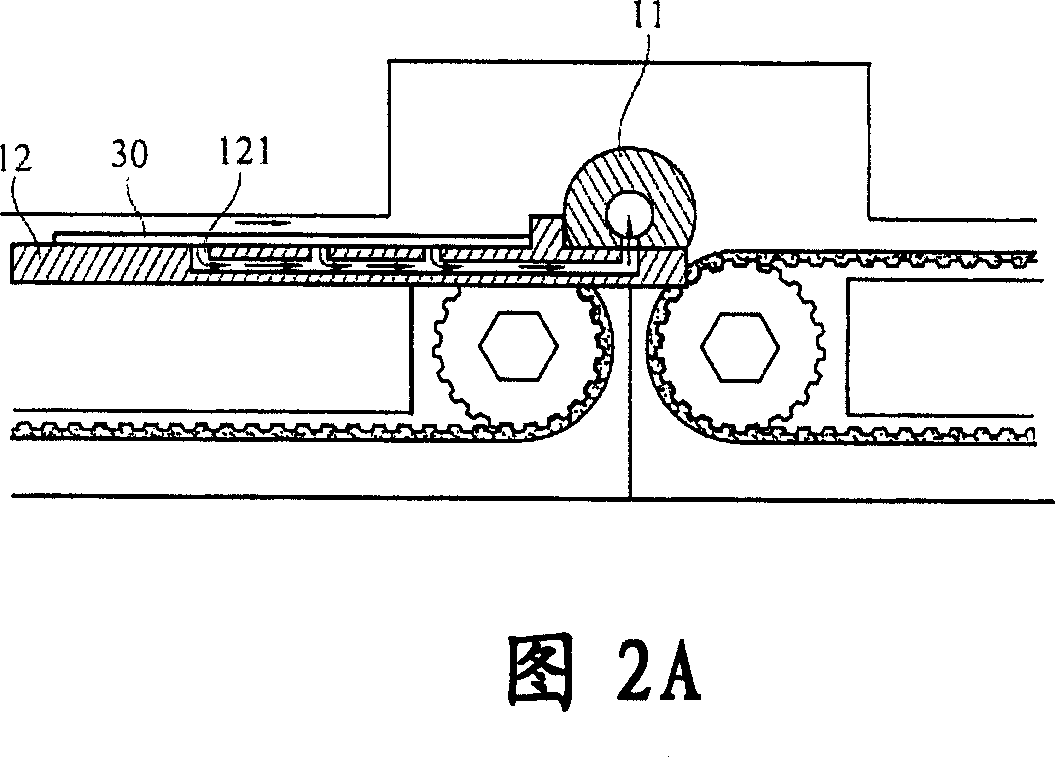

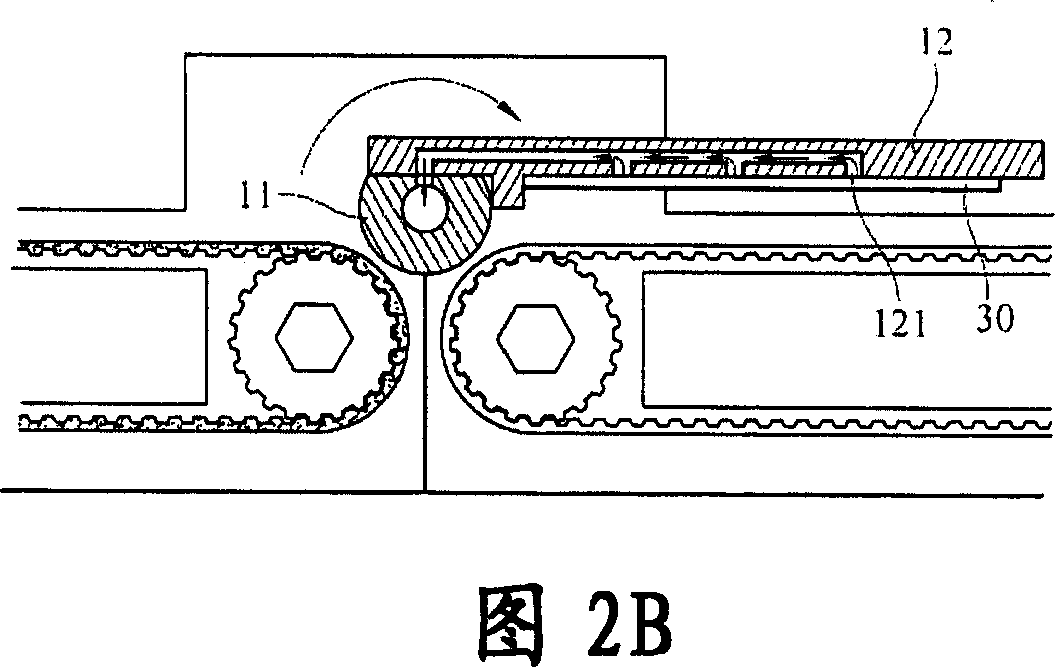

Turnover device and method

InactiveCN1945394AReduce the rate of flipping fragmentsShorten working timeNon-linear opticsHuman–machine interfaceMan machine

A tilting device includes a support, a number of gripper arms, a gripping unit, a drive unit and an overturn unit and a control unit with a man-machine interface, in which, at least one point of positioning-information is input, and then the device can drive the support and the machine to move for gripping according to the positioning information. A kind of overturning method includes the following steps: it loads one positioning-information into the controlling unit, then it drives one support and the transmission unit, then it drives a number of gripper arms to a lower location, then it moves the arm in a horizontal direction to the side of an item, then the transmission unit drives a number of fixed gripping units to gripe the item, then it drives a number of gripper arms to the higher location, then a turning machine drives the gripping unit overturns around an axis, then it drives the gripper arm to the lower location, and the gripping unit looses the panel.

Owner:AU OPTRONICS CORP

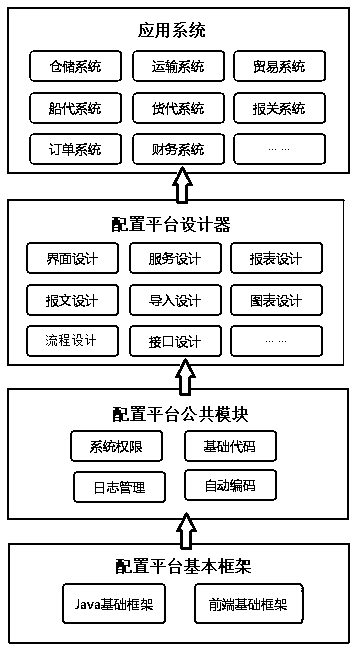

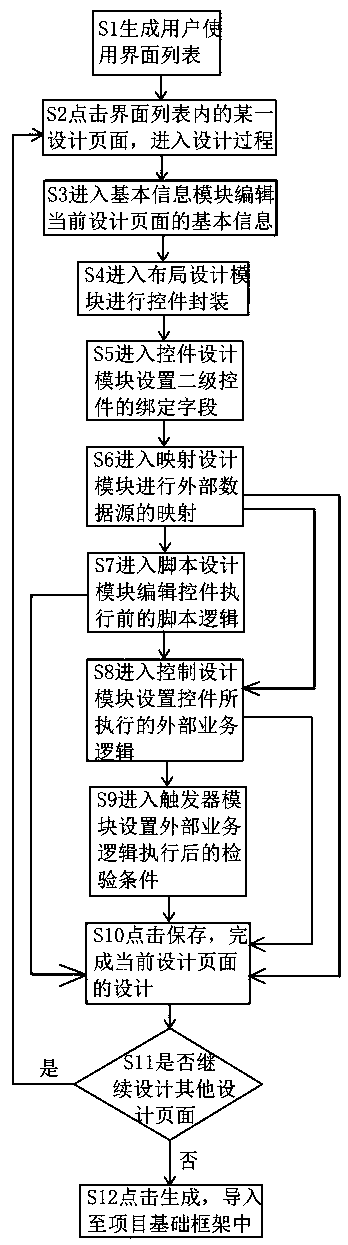

Enterprise information management system configuration platform based on JavaWeb

ActiveCN110673848AShorten development timeReduce the amount of source codeDatabase management systemsSoftware designData displaySystem configuration

The invention provides an enterprise information management system configuration platform based on JavaWeb. The platform comprises a service designer which is used for the definition, execution and monitoring of the external business logic; an interface designer used for reading a data source or an external data report designer and generating a report through an Excel template, a data display control and the data source; a chart designer used for performing chart design in combination with the data source in a visual form; a process designer used for supporting the complex business process definition; an interface designer used for butting with an external system in an interface manner through the data source; and an import designer used for designing the Excel template according to the business requirements and executing the data source to import the Excel data into the system. The enterprise information management system configuration platform based on JavaWeb is low in developmentcost, customizable in function selection and high in development efficiency.

Owner:厦门荆艺软件股份有限公司

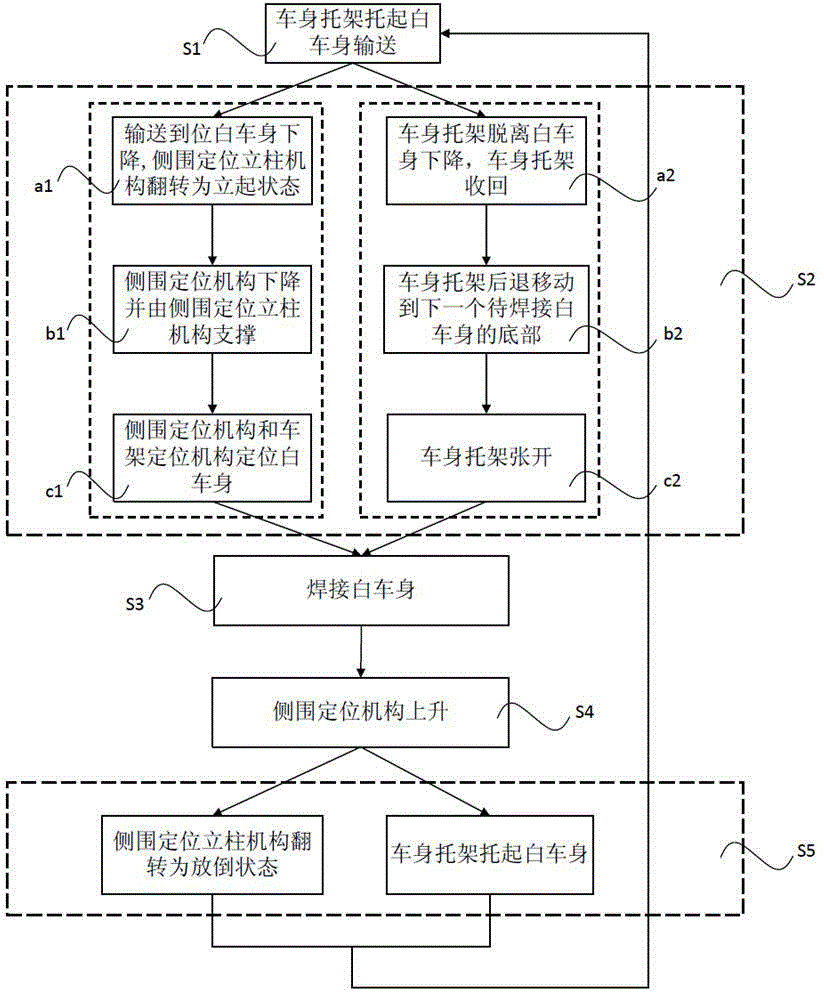

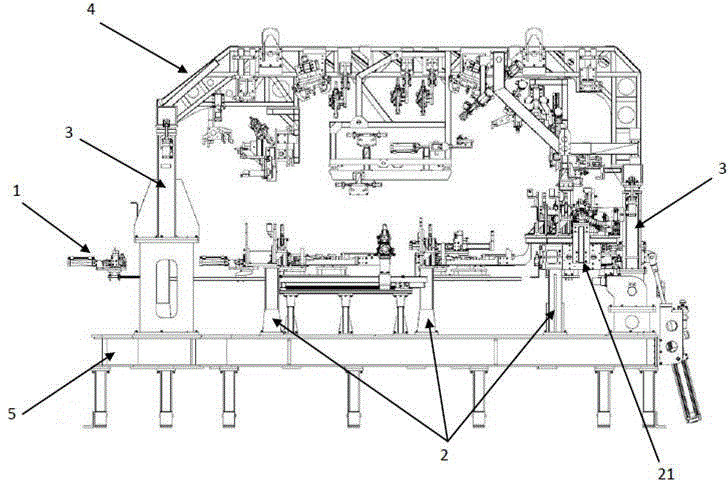

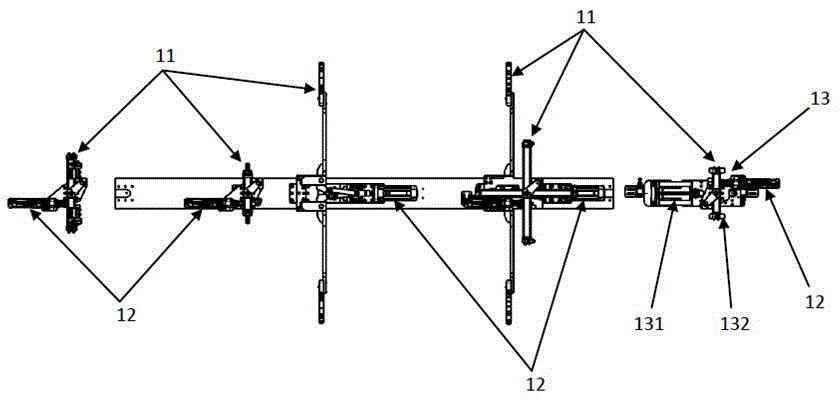

Method for conveying vehicle body between welding production lines and welding device

ActiveCN103949811AReduce manufacturing costQuick importWelding/cutting auxillary devicesAuxillary welding devicesProduction lineVehicle frame

The invention relates to technical field of vehicle body manufacture, in particular to a method for conveying a vehicle body between welding production lines, and further relates to a welding device. The method for conveying the vehicle body between the welding production lines comprises the following steps: S1, conveying a body-in-white to the upper end of a welding station through a vehicle body conveying mechanism; S2, conveying the body-in-white to the welding station, and positioning the body-in-white, wherein the step S2 comprises the following steps that a1, an elevating guide rail of the vehicle body conveying mechanism drives the body-in-white to descend to the welding station, and positioning upright columns of a side surrounding positioning upright column mechanism are in erected states, b1, a side surrounding positioning mechanism descends and is supported by the side surrounding positioning upright column mechanism, and c1, the body-in-white is clamped by fixtures of the side surrounding positioning mechanism and a frame positioning mechanism; S3, welding the body-in-white to be welded at the welding station. The invention further provides the welding device. The vehicle body conveying method disclosed by the invention is better adapted to the production rhythms, and improves the production efficiency. Meanwhile, the welding device further meets the requirements of the vehicle body conveying method on adapting to the production rhythms and improving the production efficiency.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

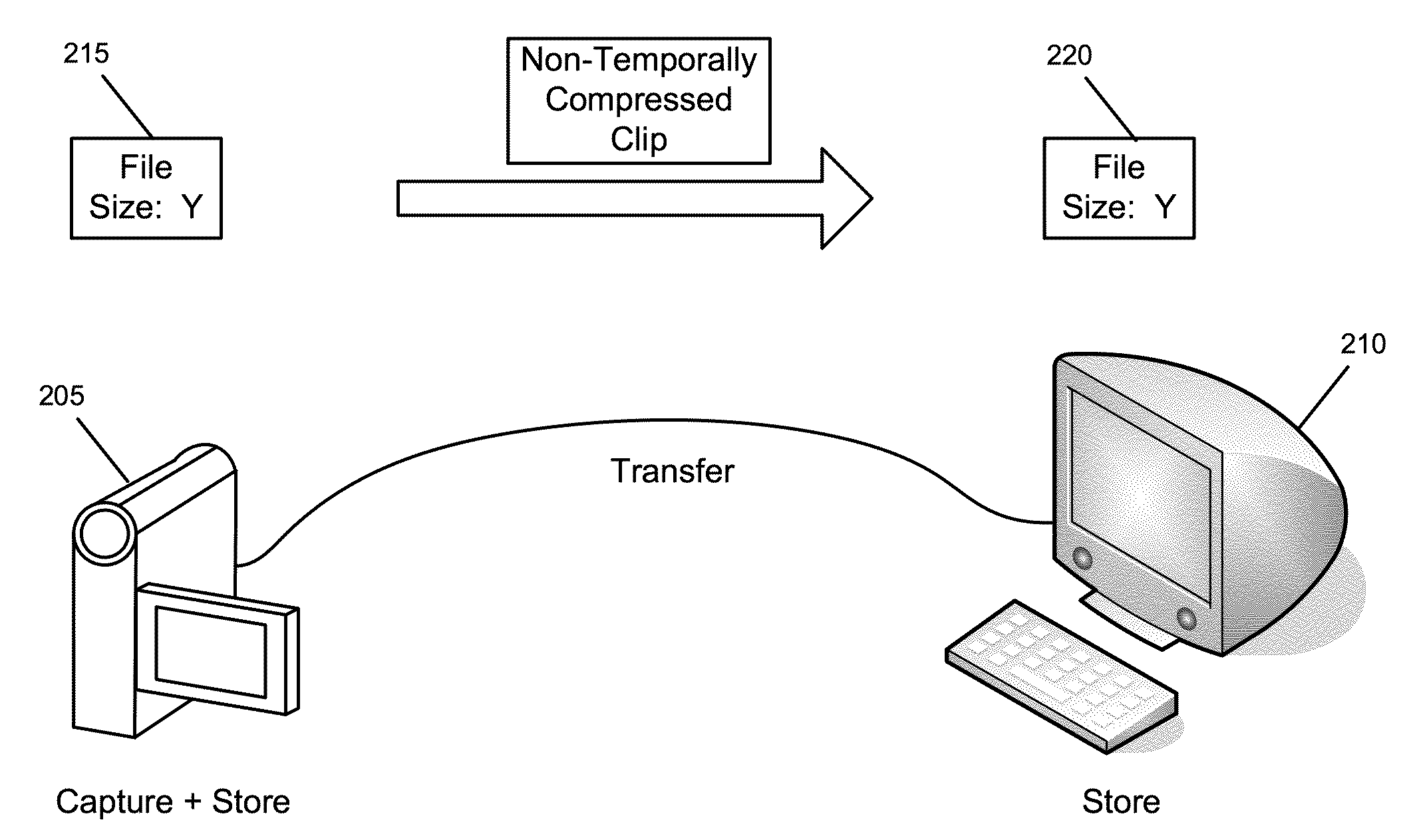

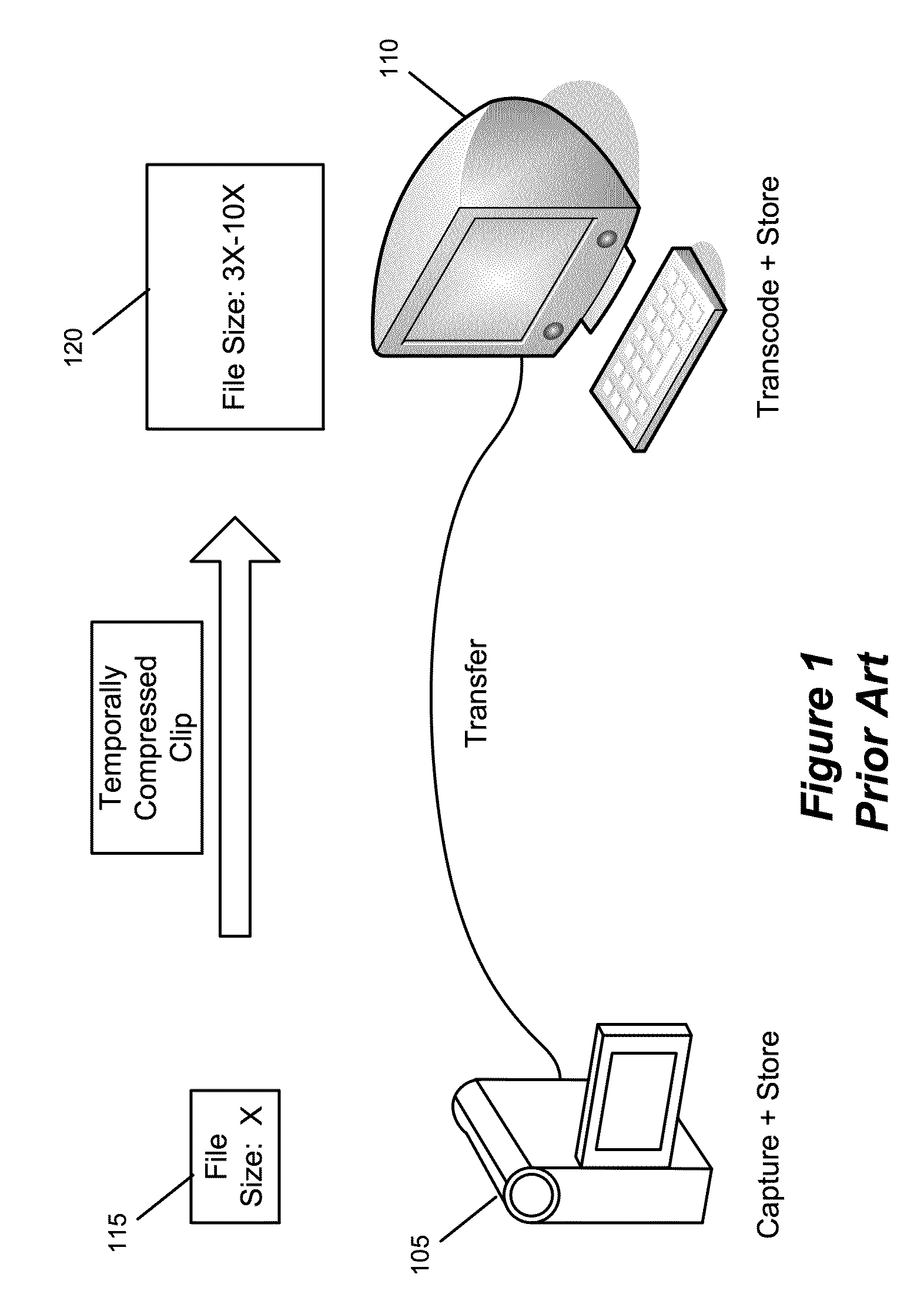

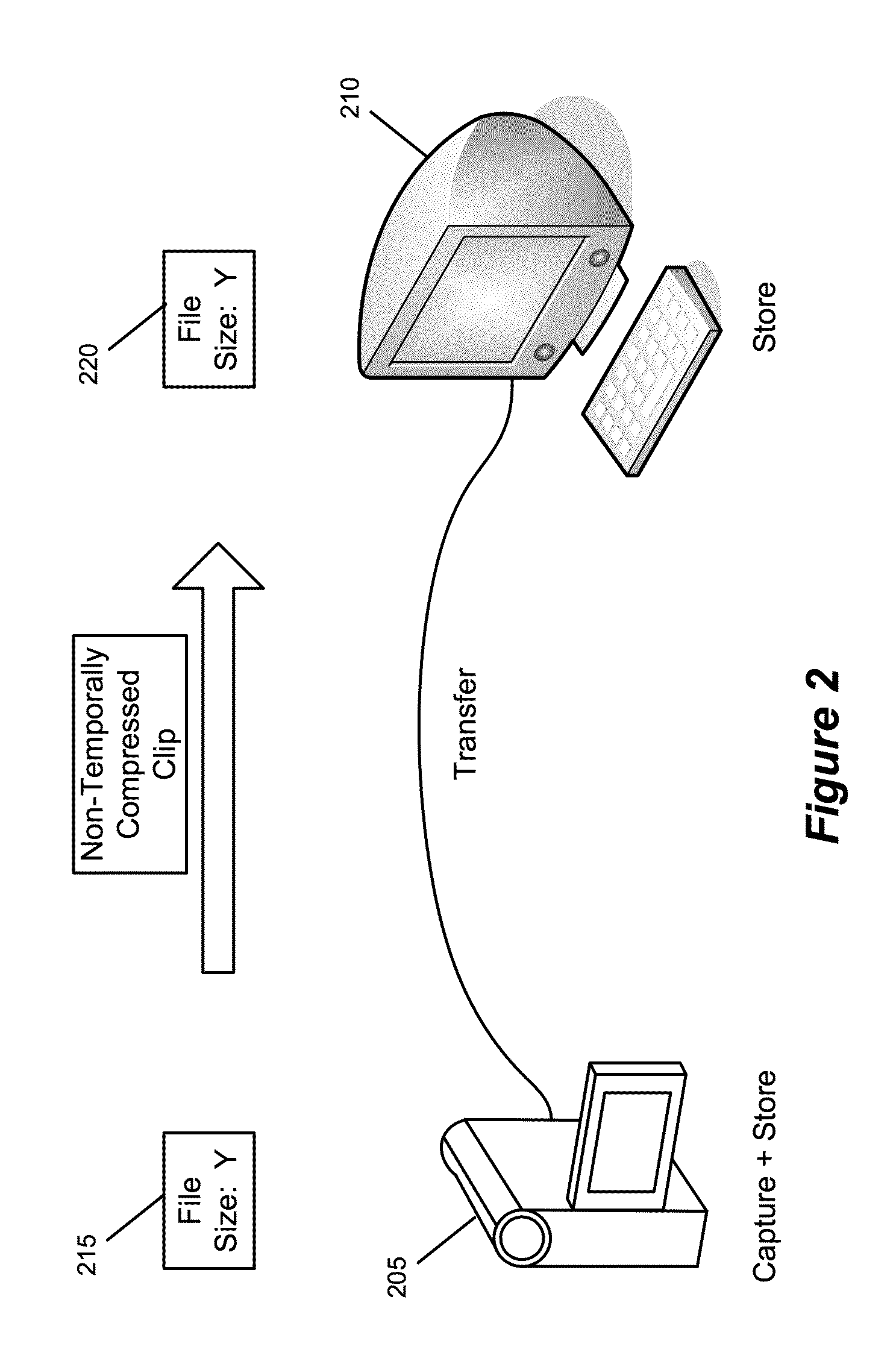

Video Format for Digital Video Recorder

ActiveUS20110058793A1Fast transferQuick importTelevision system detailsElectronic editing digitised analogue information signalsDigital videoVideocassette recorder

Some embodiments provide a video camera. The video camera includes image sensing circuitry for capturing a sequence of video pictures, a user interface for allowing a user to select a video encoding format from a temporally compressed encoding format and non-temporally compressed encoding format, encoding circuitry for encoding the video pictures according to the format selected by the user, and random access storage for storing video clips.Some embodiments provide a video editing application for a computer. The application includes a first module for (i) receiving video clips stored on the video camera and (ii) storing a first set of video clips that are non-temporally compressed on the video camera in a storage of the computer, and a second module for (i) transcoding a second set of video clips that are temporally compressed on the video camera and (ii) storing the transcoded second set of video clips in the storage.

Owner:APPLE INC

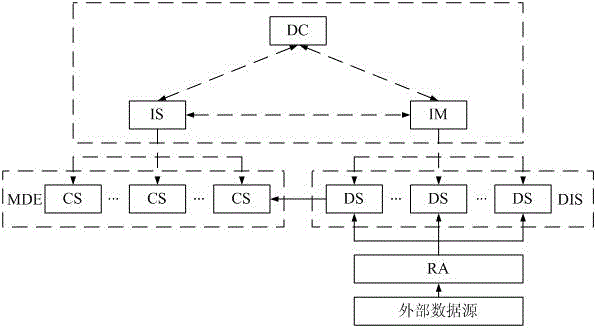

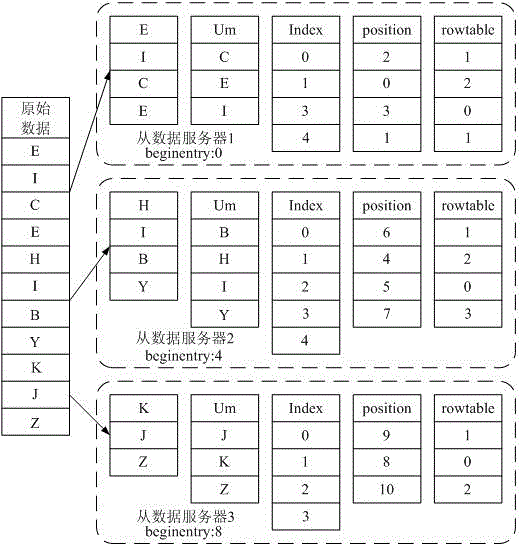

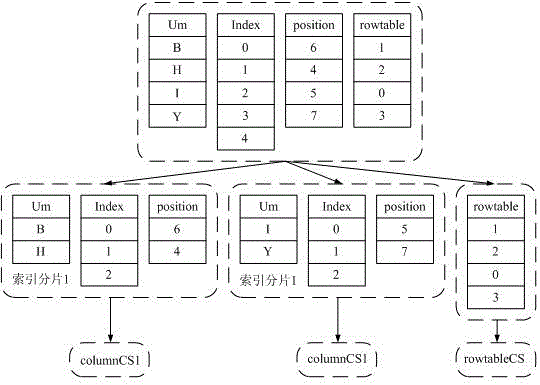

Index building method for distributed memory columnar database

ActiveCN105843933AQuick buildQuick importSpecial data processing applicationsDistributed memoryDatabase

The invention discloses an index building method for a distributed memory columnar database. The method comprises the following steps: segmenting a single column of data into at least two data fragments; computing intermediate data of columnar compression indexes of the data fragments and intermediate data of row table vectors in parallel, wherein the columnar compression indexes include dictionary vectors, index vectors and position vectors; and sequentially storing and updating the intermediate data of the columnar compression indexes of the data fragments and the intermediate data of the row table vectors in order to form the columnar compression indexes and the row table vectors. Through adoption of the index building method for the distributed memory columnar database provided by the invention, an excessively large memory is not required for import computing nodes of a huge table, so that the hardware cost can be reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

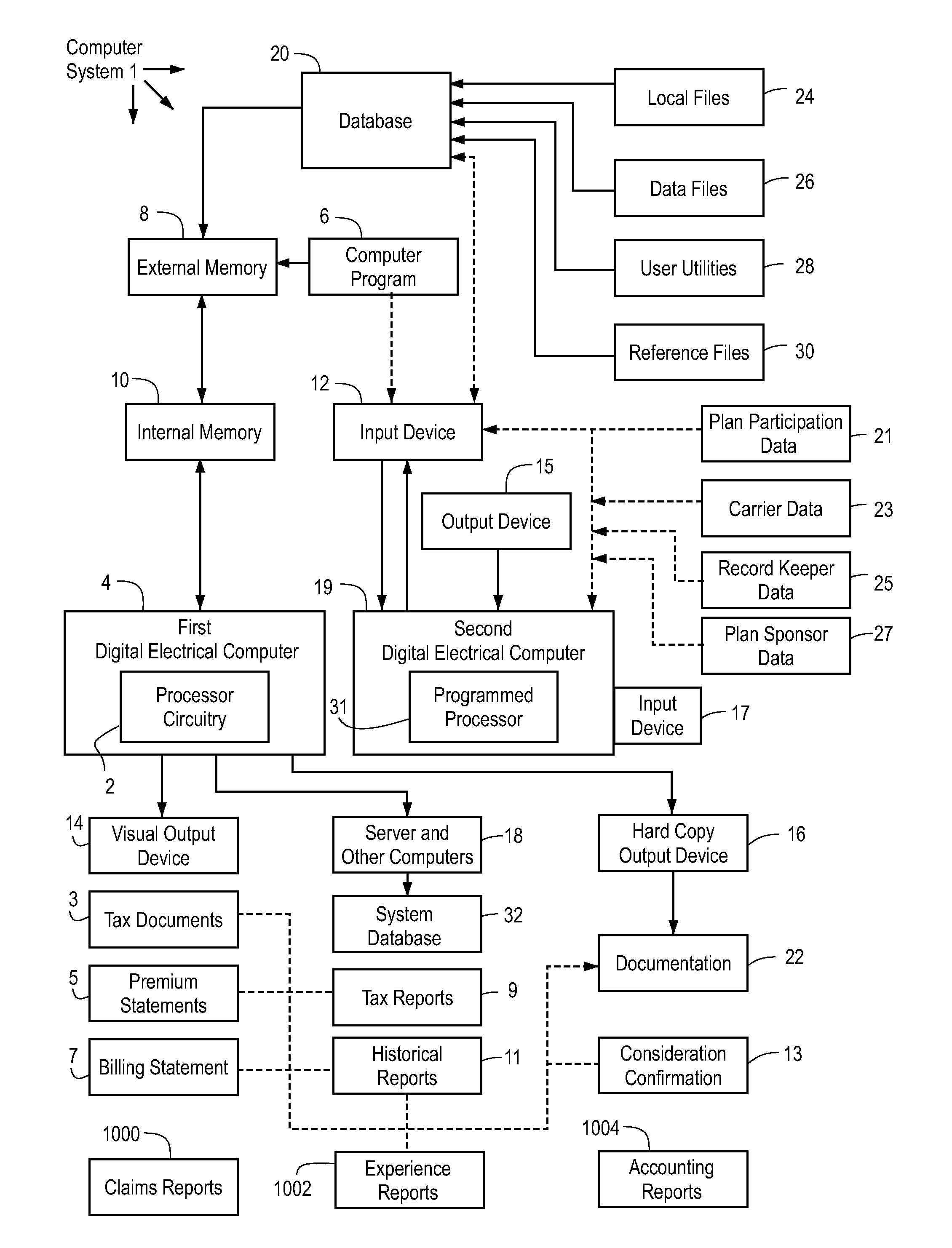

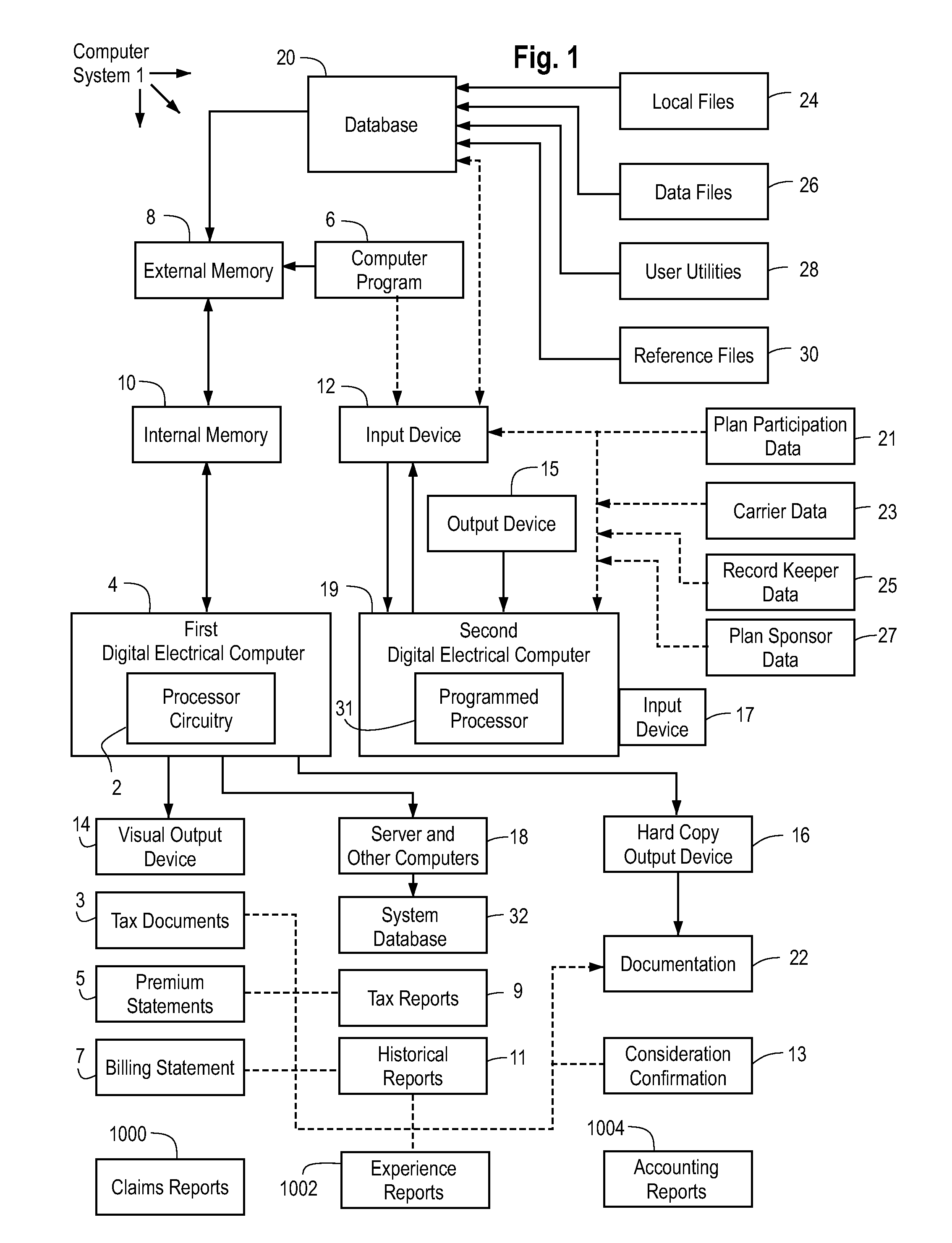

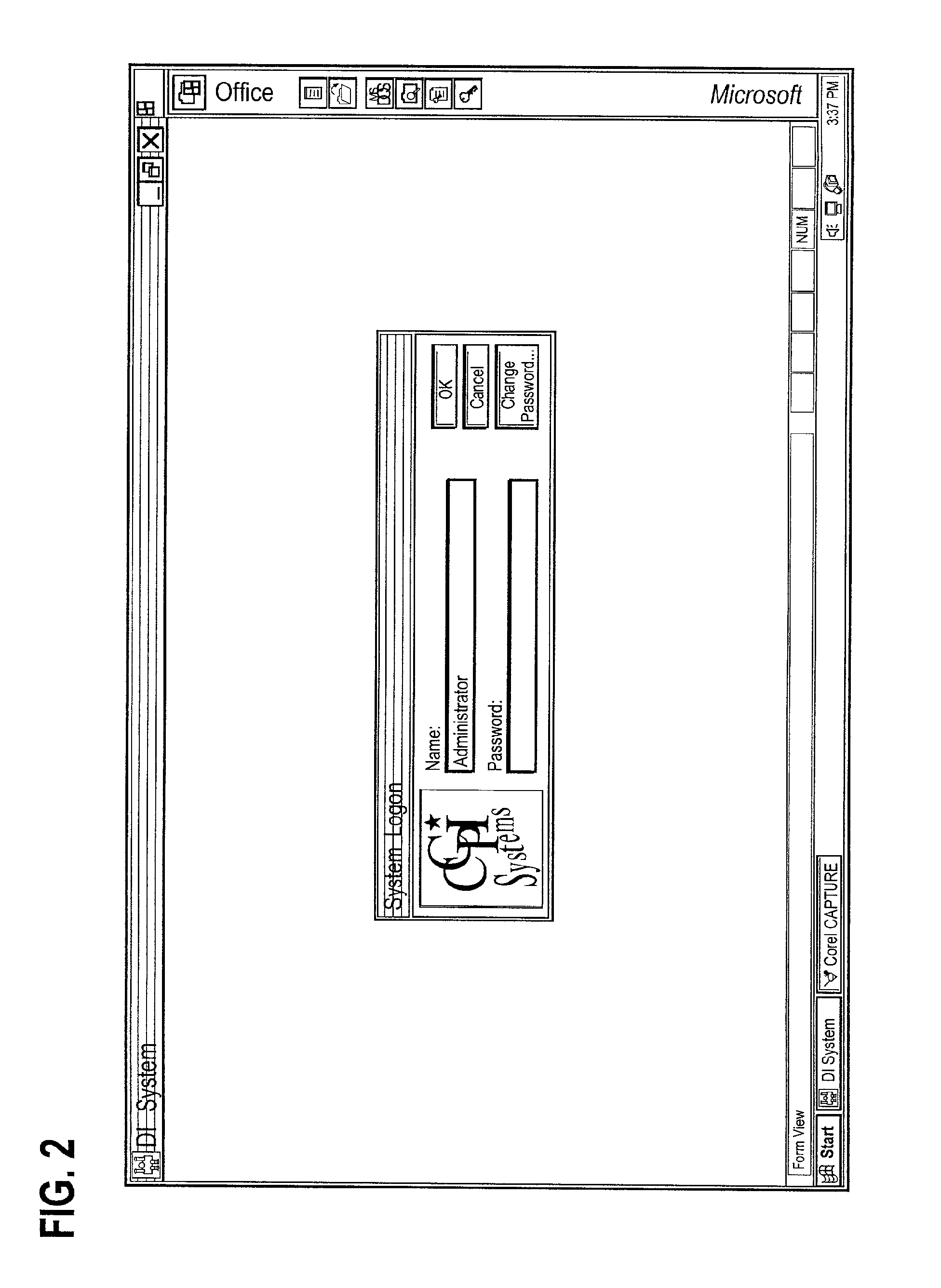

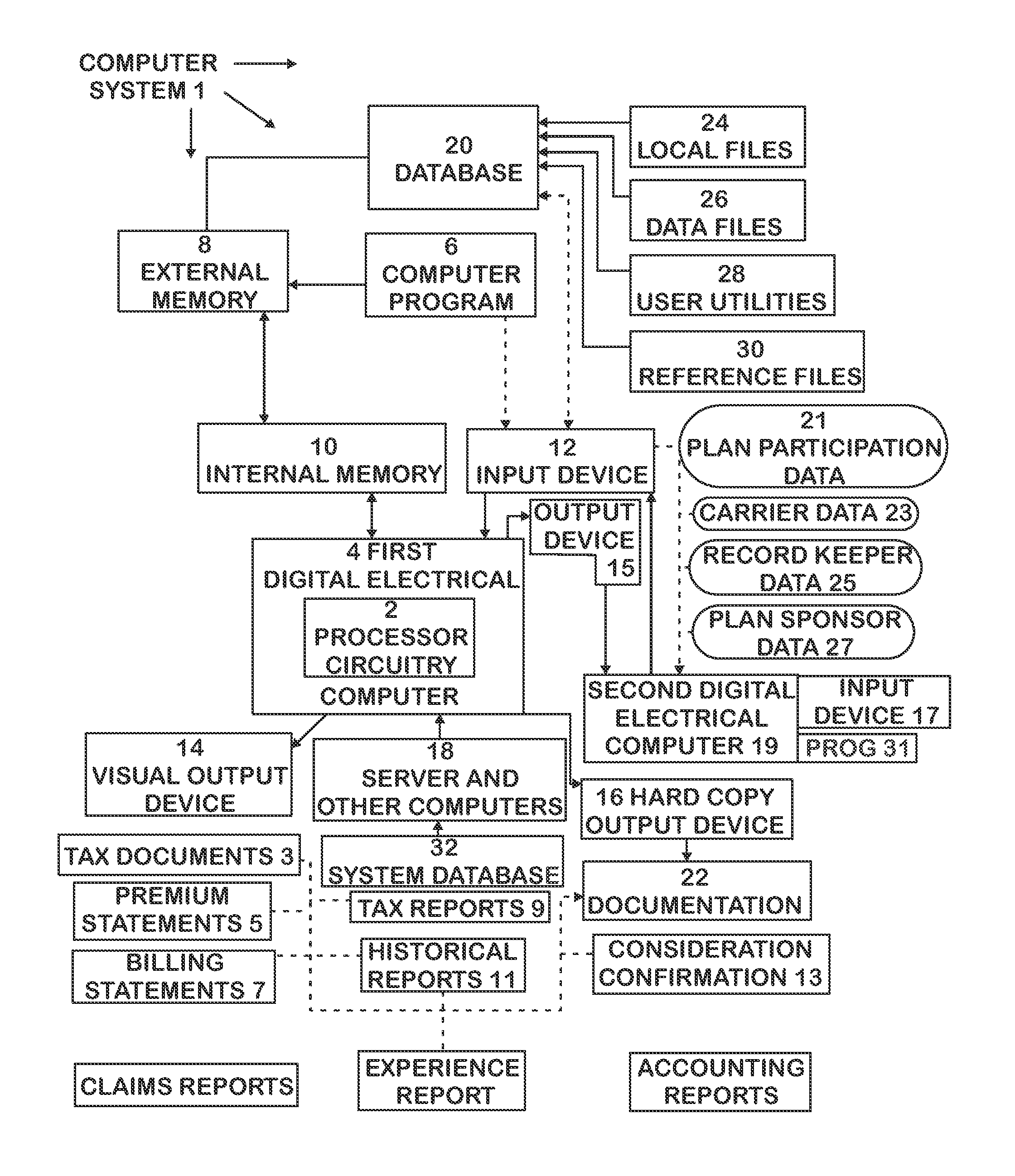

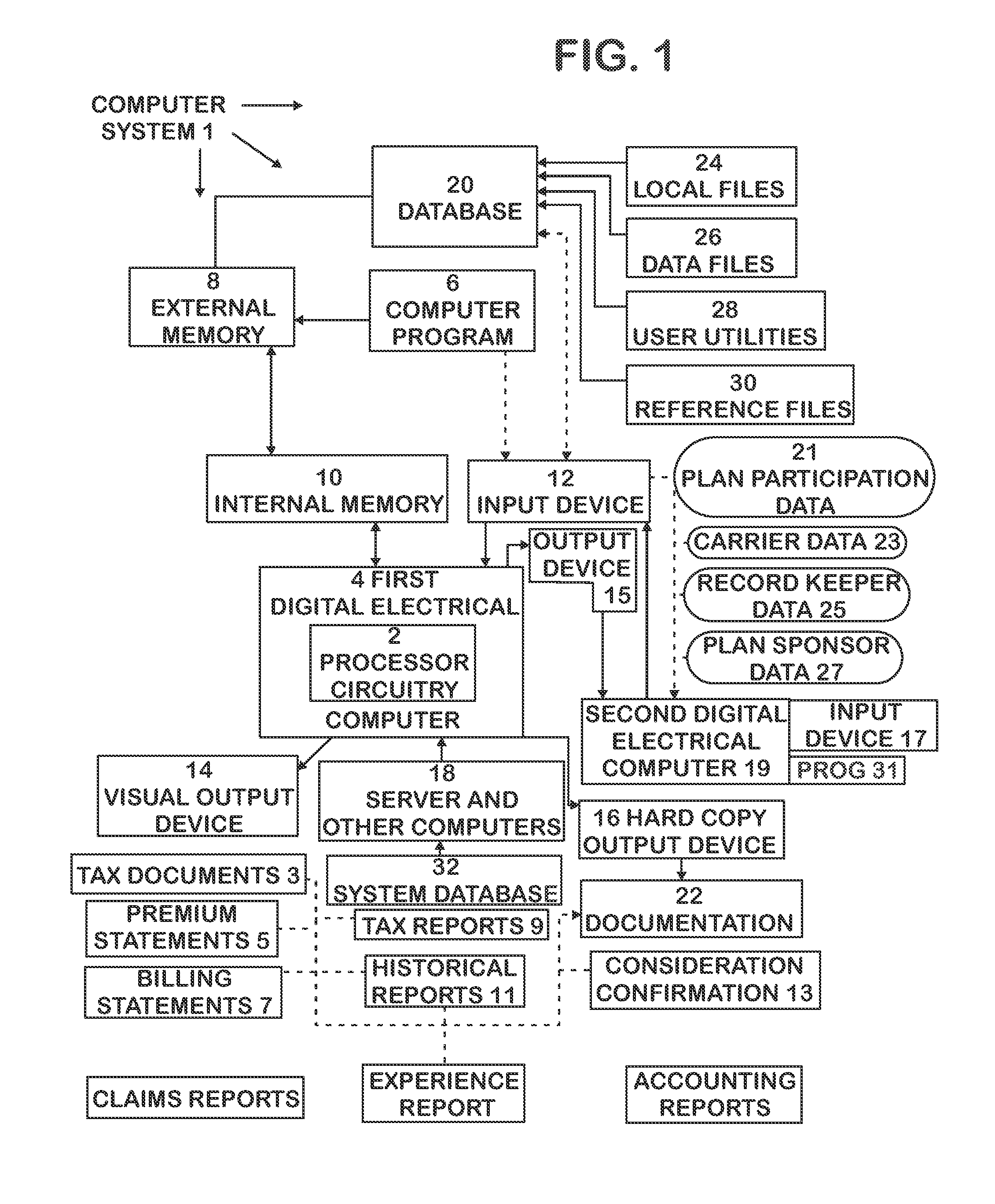

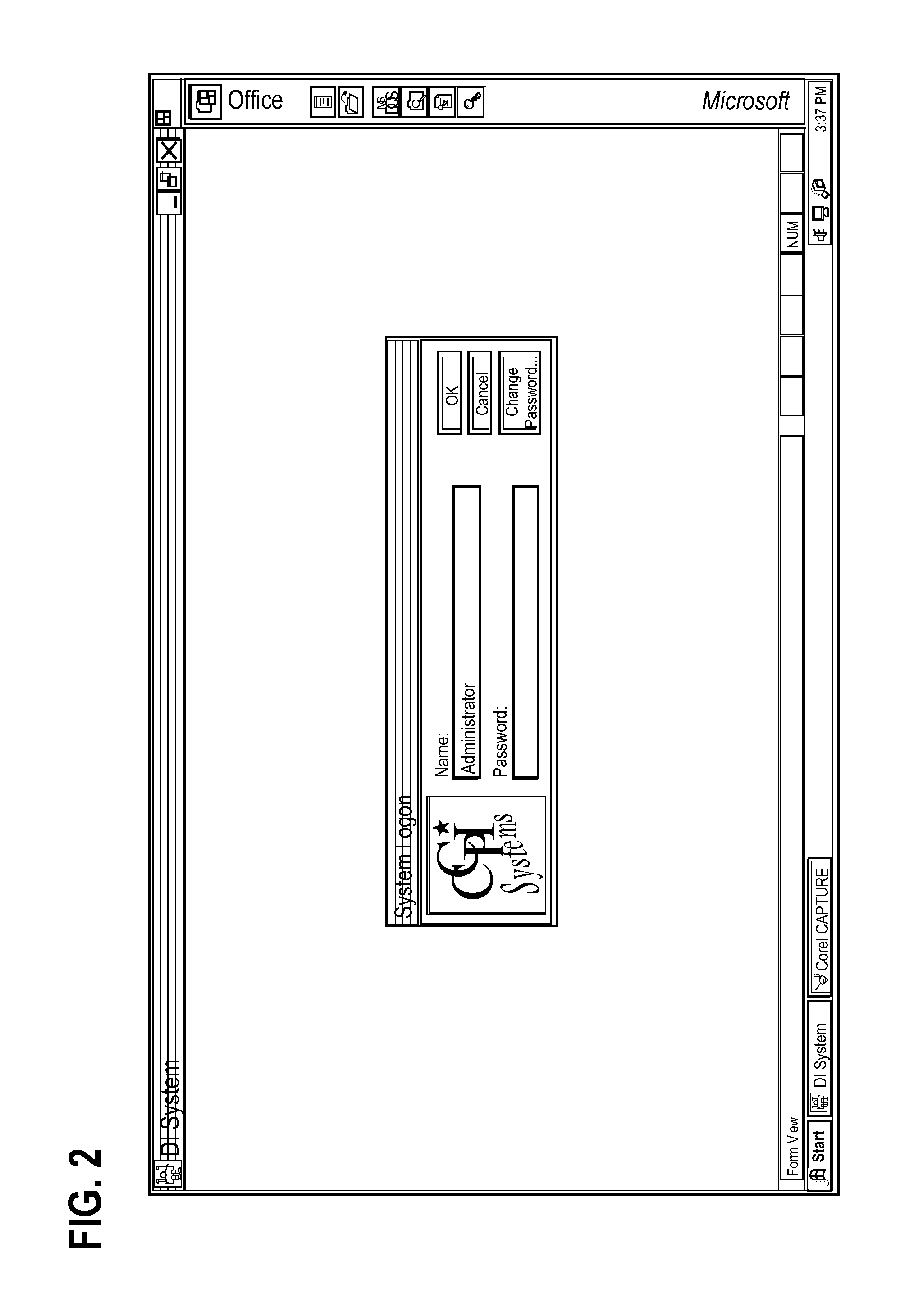

Computer apparatus and method for illustrating, issuing, and managing disability coverage for retirement plans with individual accounts

A system and method for providing insurance protection against loss of contributions to tax favored defined contribution plans should an active employee / participant become disabled. The invention manages the administration of a disability insurance policy held inside the plan that continues contributions to the plan during a period of disability, where the coverage amount for each participant is determined by the level of contributions made by or for each participant.

Owner:CYARCH

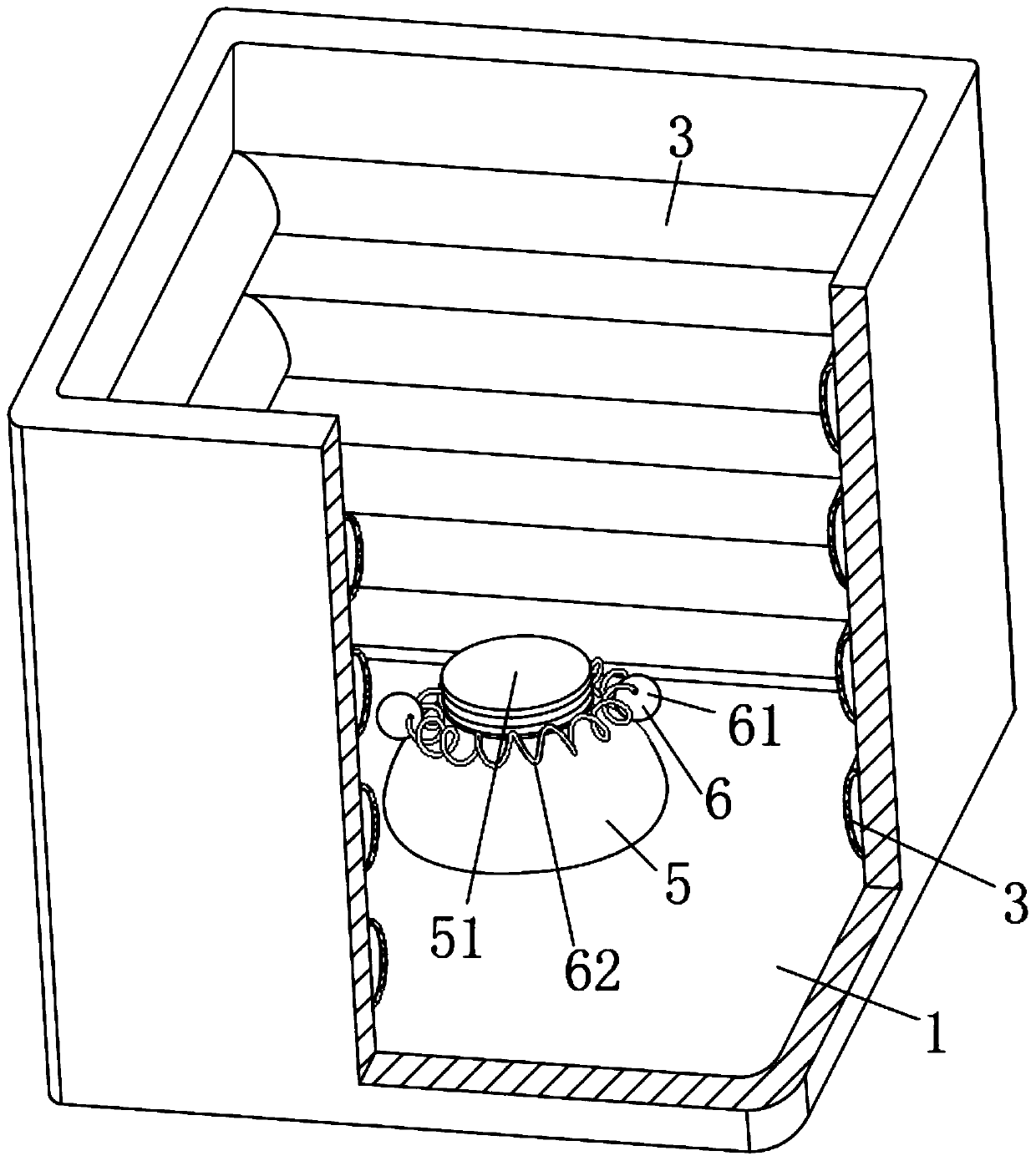

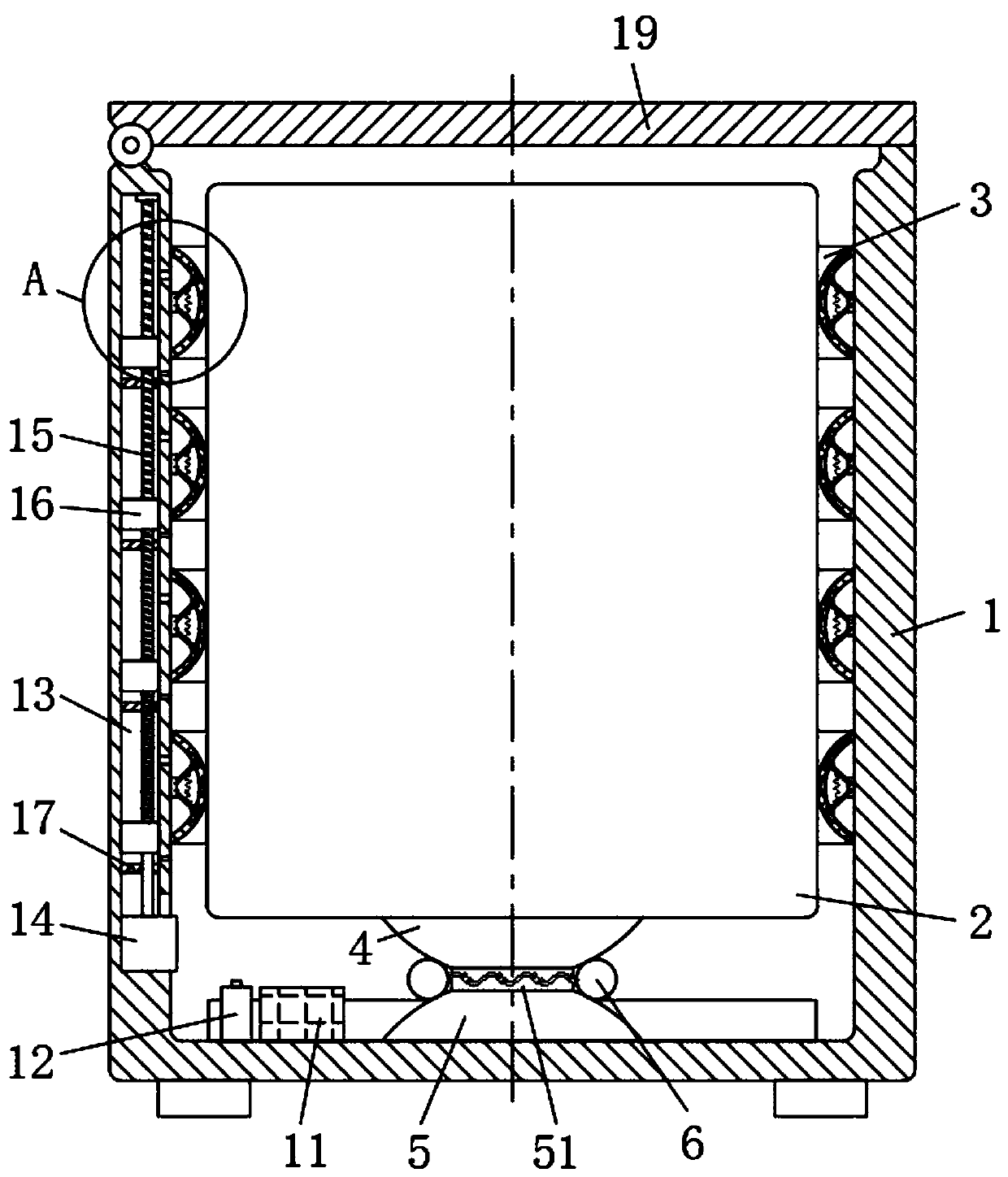

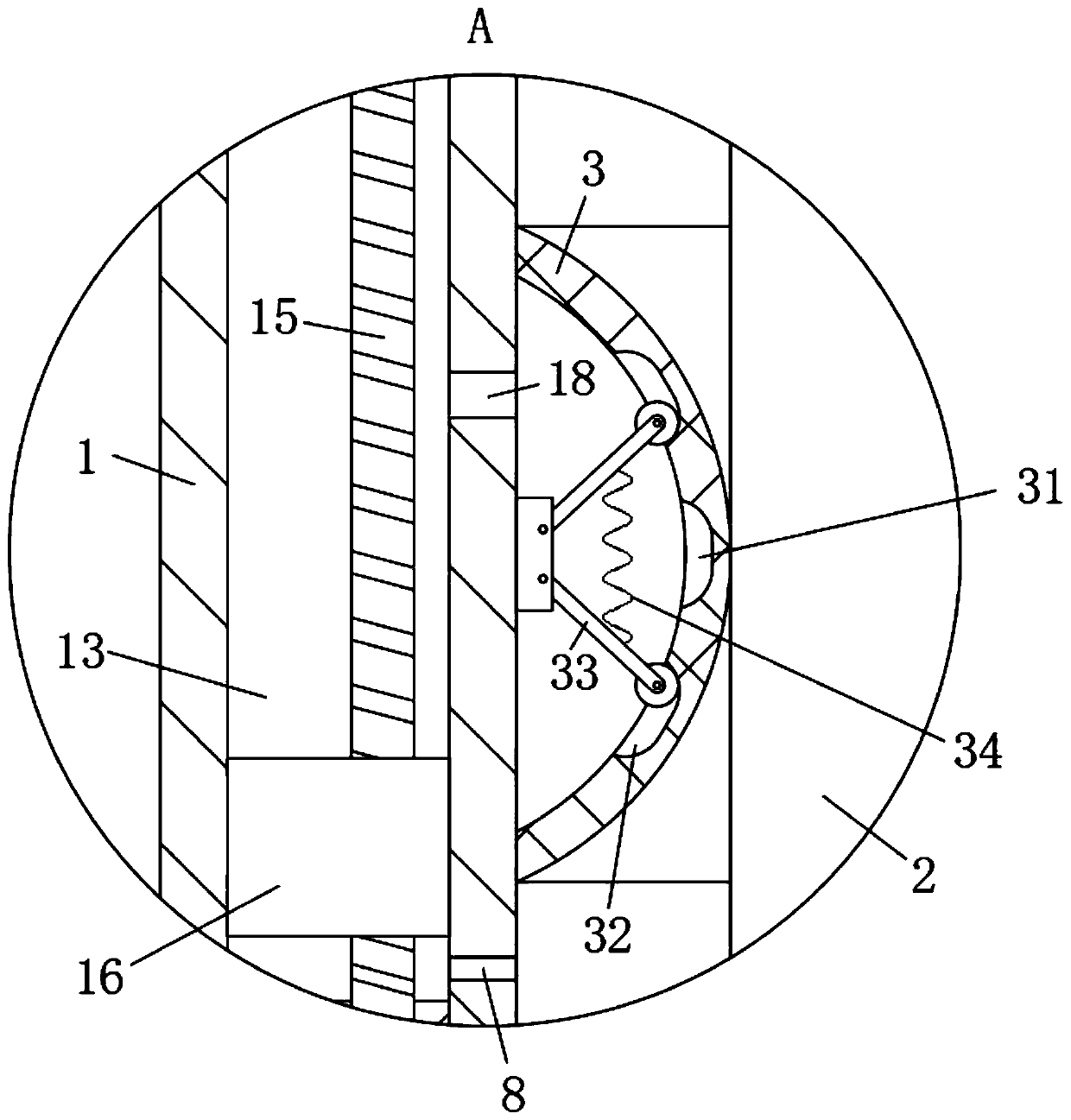

Anti-collision computer transportation device for mountainous areas

ActiveCN110356675AReduce the chance of collisionImprove stabilityPackaging vehiclesContainers for machinesEngineering

Owner:临沂高新区人才职业培训学校有限公司

Sealing element for a hydraulically-actuated friction clutch

ActiveCN104343844AQuick importEasy to assembleEngine sealsMechanical actuated clutchesEngineeringPiston

The invention relates to a sealing element for a hydraulically-actuated friction clutch, wherein the sealing element is separately positionable between an actuating piston of a friction clutch and a pressure chamber for actuating said actuating piston and has a first axially-oriented sliding surface for a first axial sealing means. With the seal member proposed here, it is possible to implement different functions with simple means in a complex friction clutch, in particular a double clutch with simple means and at low cost.

Owner:SCHAEFFLER TECH AG & CO KG

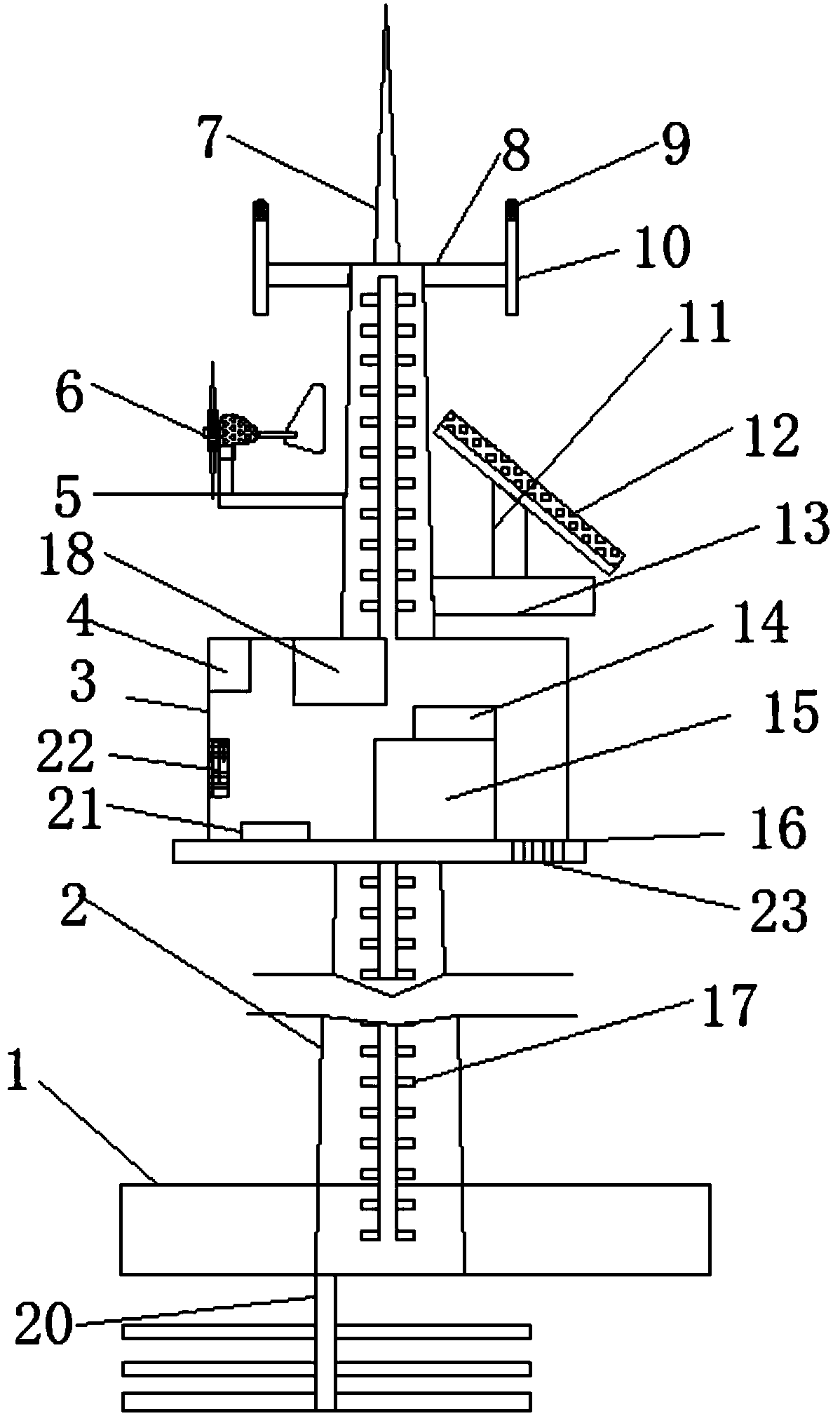

Outdoor signal transmitting base station based on network technology service

InactiveCN108770083AMonitor temperature in real timeAvoid damageHigh level techniquesWireless communicationElectricityEngineering

The invention discloses an outdoor signal transmitting base station based on network technology service. The outdoor signal transmitting base station comprises a tower body, a base is connected to thebottom of the tower body through bolts, a mounting platform is connected to an outer wall of the tower body through bolts, a box body is connected to the top of the mounting platform through bolts, acontroller is connected to a lower top in the box body through bolts, a temperature sensor is connected to an inner wall of the box body through bolts, a storage battery is connected to the top of the mounting platform through bolts, and an inverter is connected to the top of the storage battery through bolts. The outdoor signal transmitting base station disclosed by the invention is provided with a solar panel, a wind power generator, the storage battery, the inverter and a first crossbar, the solar panel converts luminous energy into an electric energy source through the inverter, the windpower generator installed on the first crossbar converts the wind energy into electric energy and stores the electric energy in the storage battery, the two energy supply mechanisms ensure that the outdoor signal transmitting base station adapts to various weathers, and furthermore, the outdoor signal transmitting base station is suitable for fields, is economical, environmentally friendly and energy-saving.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

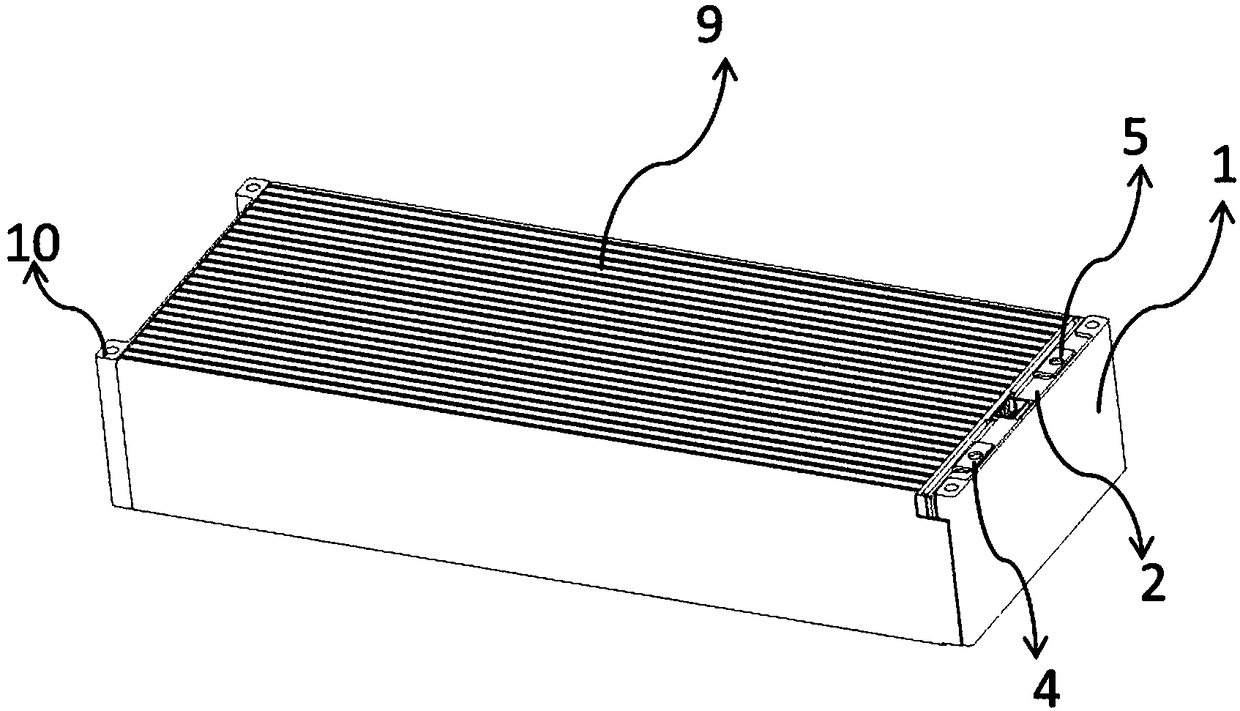

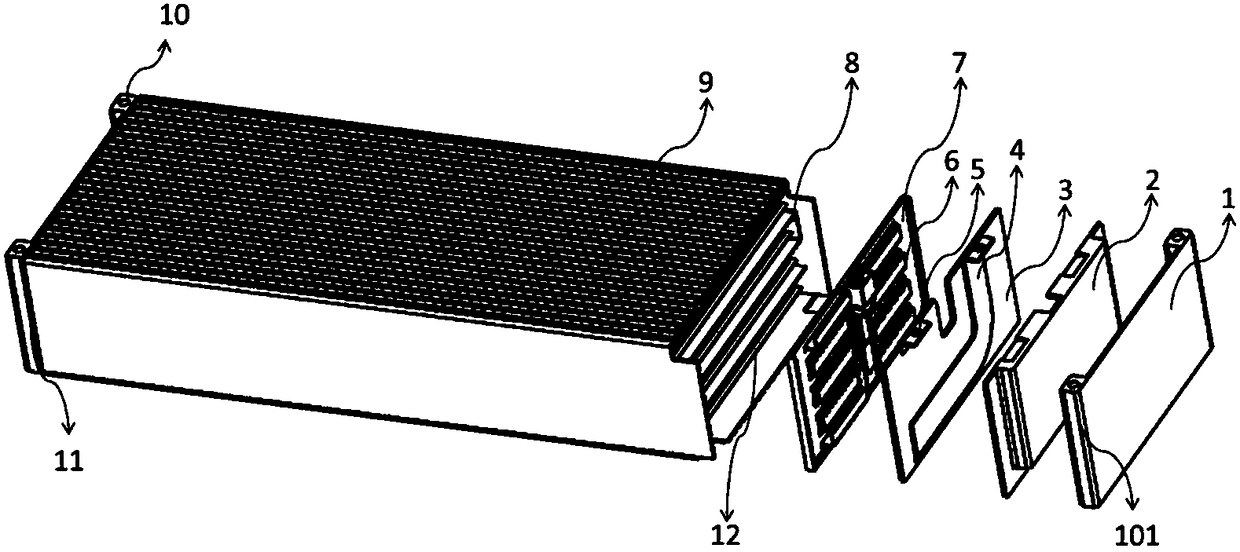

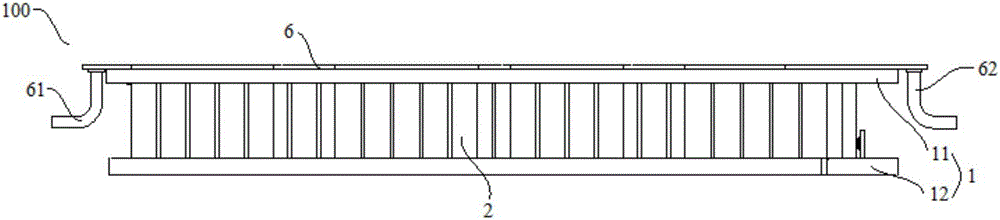

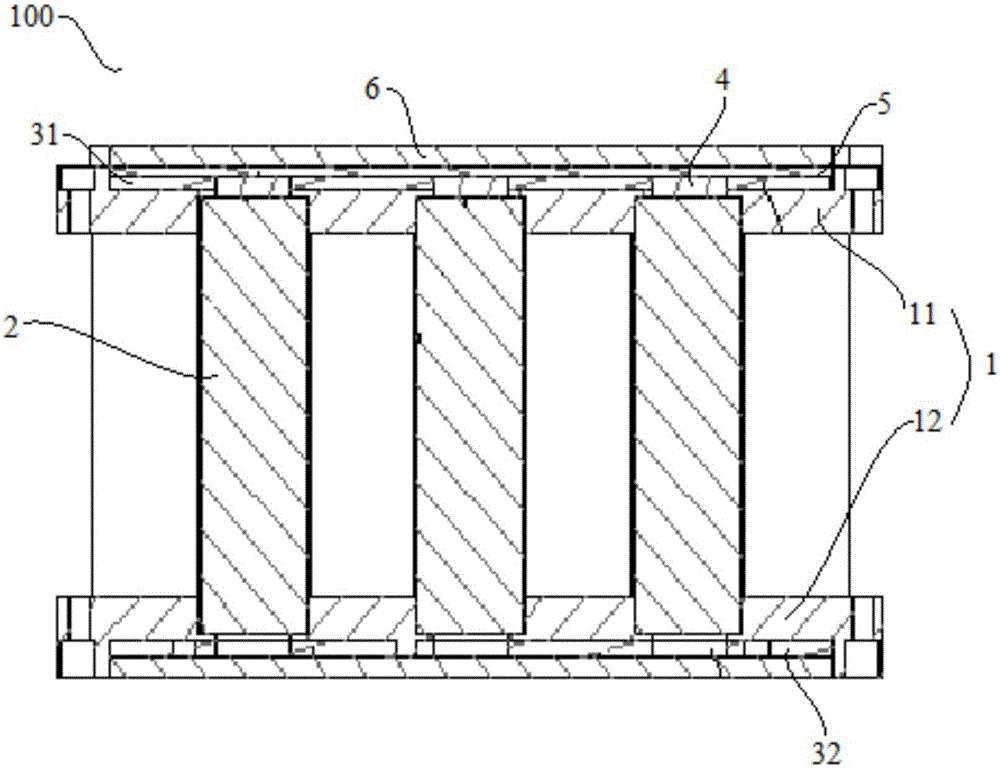

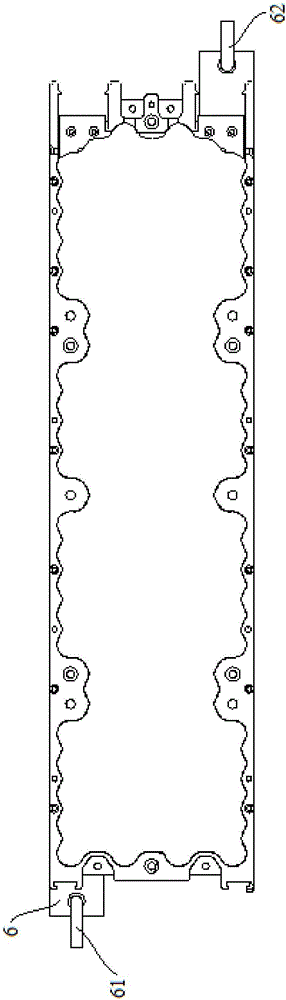

Soft pack battery module structure and power battery

InactiveCN109346630AImprove cooling effectGood thermal consistencySecondary cellsCell component detailsPower batteryAgricultural engineering

The invention provides a soft pack battery module structure and a power battery, and relates to the technical field of batteries. The soft pack battery module structure comprises an aluminum shell outer frame, and a reverse S-shaped aluminum plate for the placement of soft pack cells, wherein every two soft pack cells in a group are placed in the reverse S-shaped aluminum plate, and the soft packcells and the reverse S-shaped aluminum plate are bundled with a tape and then integrally inserted into the aluminum shell outer frame; an integrated cover plate is arranged at one end of the aluminumshell outer frame, and lugs of the soft pack cells are embedded into the integrated cover plate and led out through an insulating plate, and then are fixed and sealed by a right insulating cover plate and a right fixed end plate; the other end of the aluminum shell outer frame is fixed and sealed by a left insulating cover plate and a left fixed end plate; the aluminum shell outer frame and the reverse S-shaped aluminum plate are integrally formed. The soft pack battery assembly process is simple and easy to operate, and improves the production efficiency of products.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

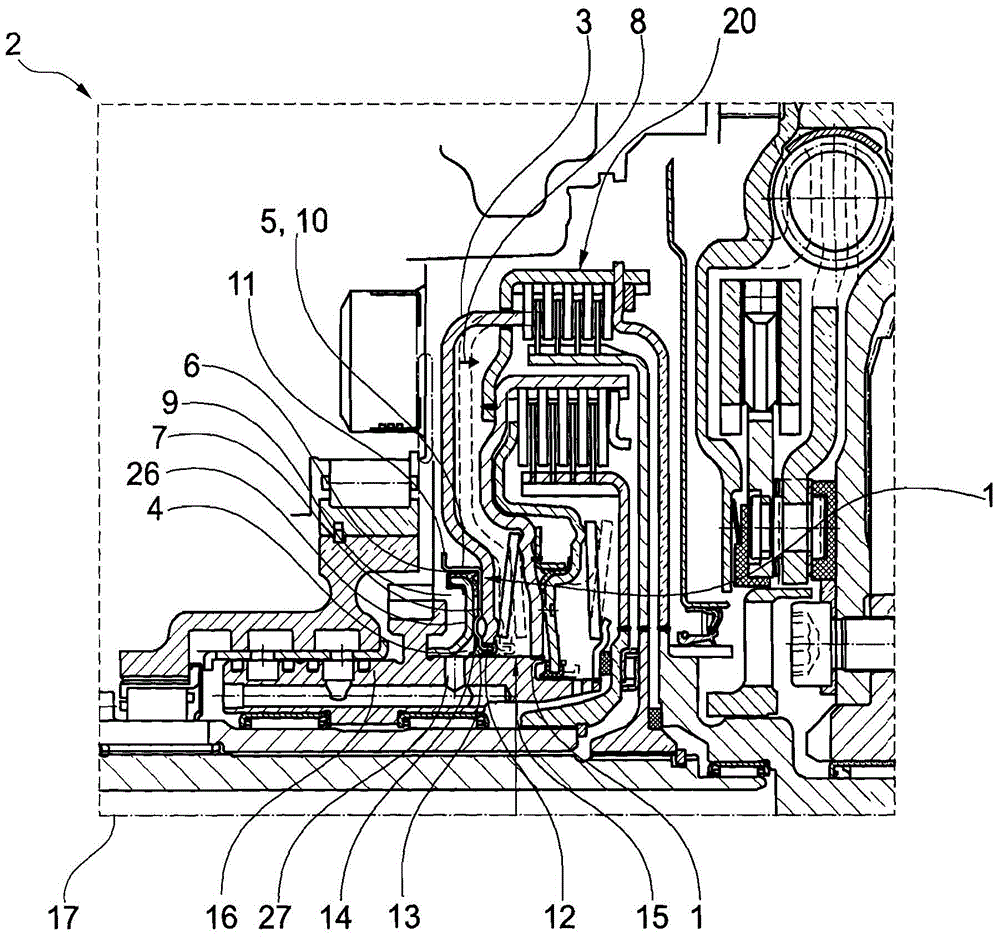

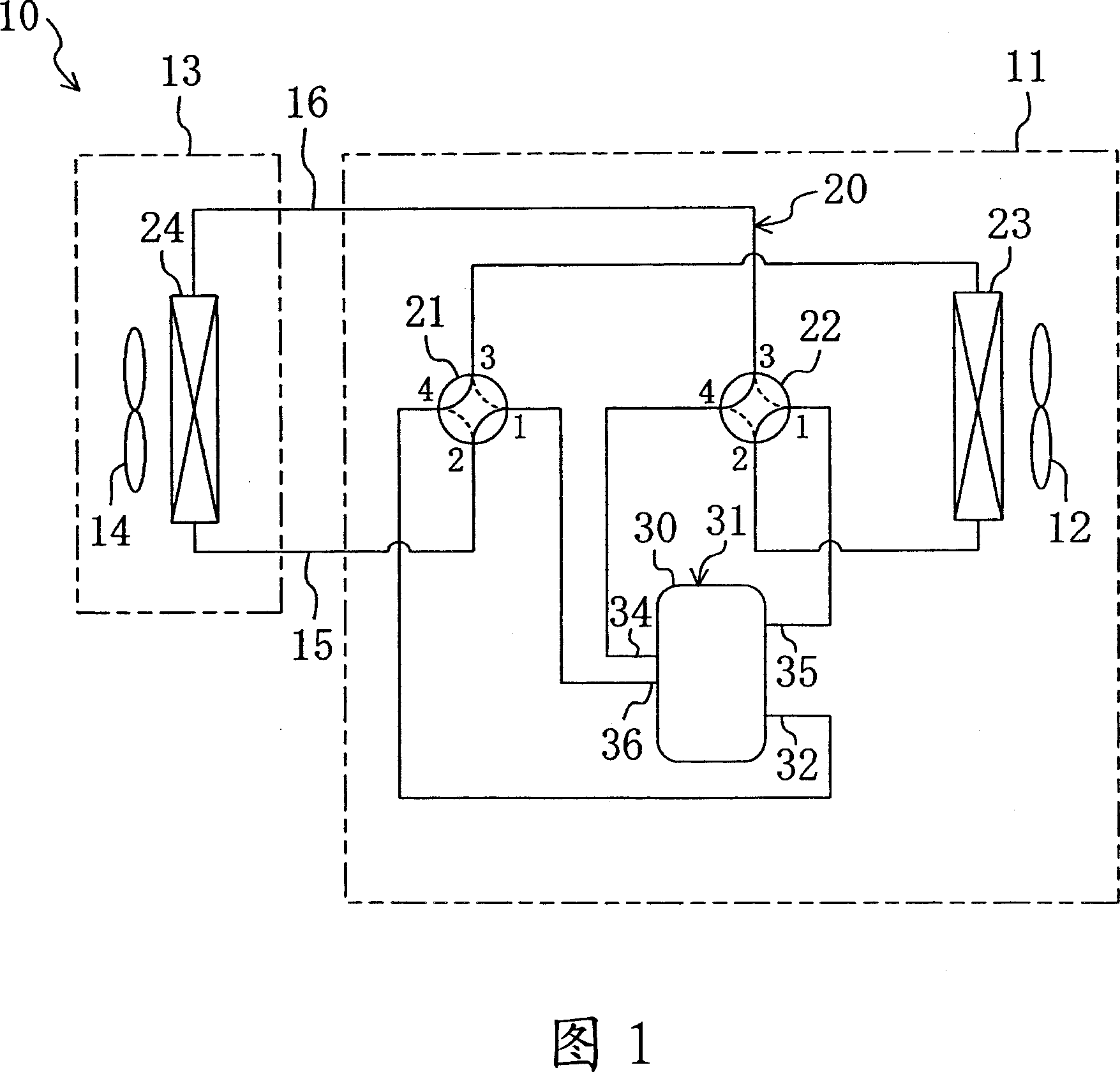

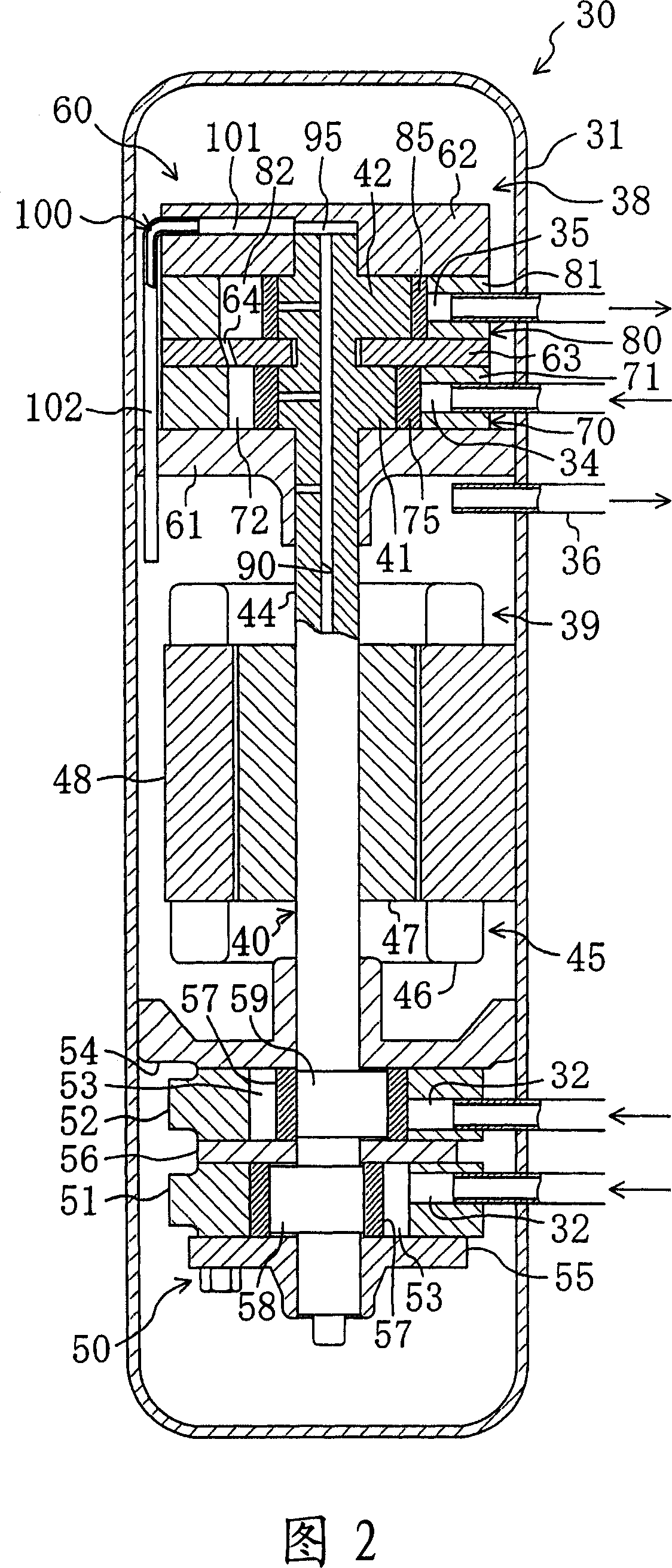

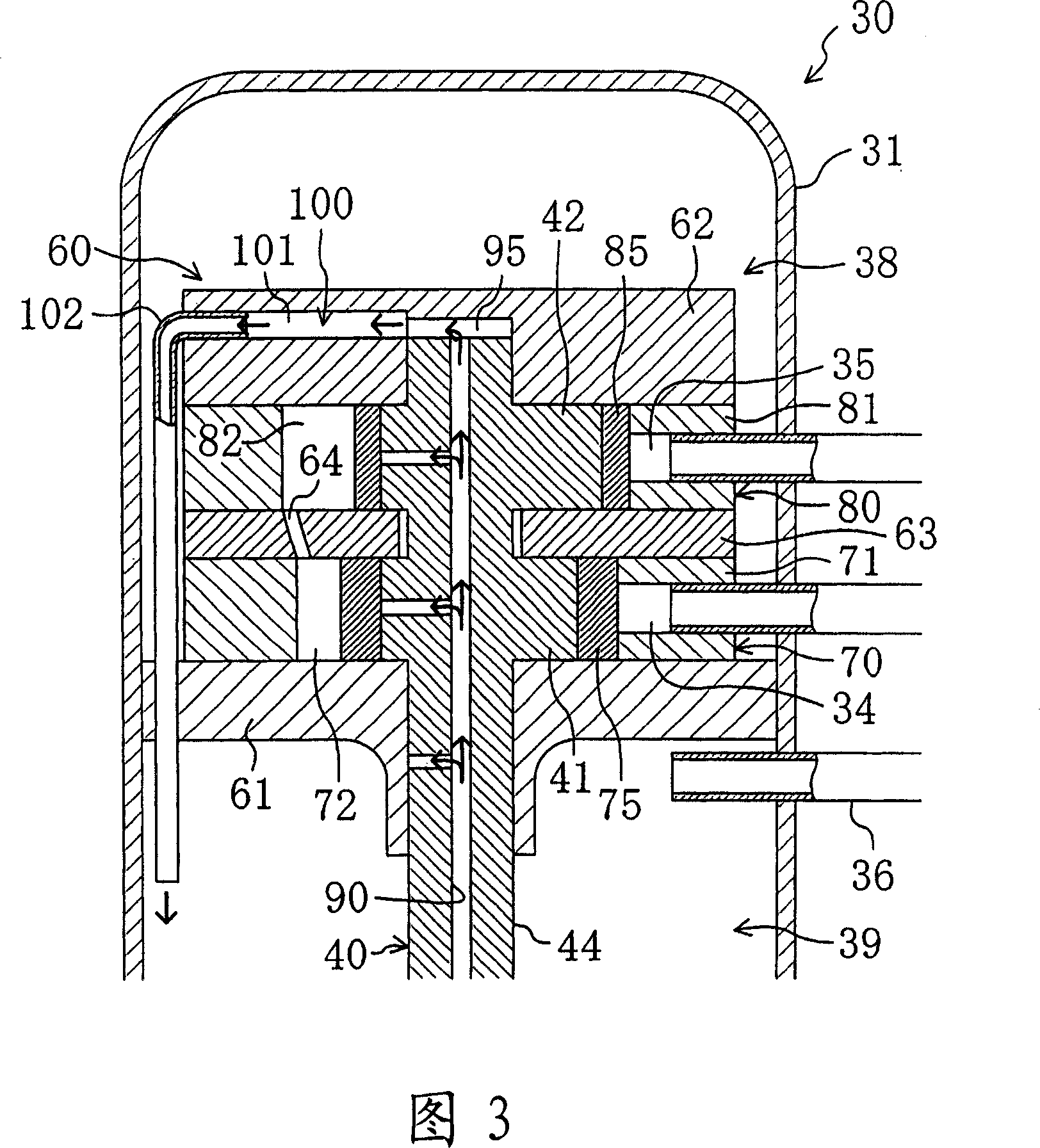

Fluid machine

ActiveCN1930373AQuick importFast deliveryRotary/oscillating piston combinations for elastic fluidsCombination enginesExpansion jointRefrigeration

In a compression / expansion unit (30) serving as a fluid machine, both a compression mechanism (50) and an expansion mechanism (60) are housed in a single casing (31). An oil supply passageway (90) is formed in a shaft (40) by which the compression mechanism (50) and the expansion mechanism (60) are coupled together. Refrigeration oil accumulated in the bottom of the casing (31) is drawn up into the oil supply passageway (90) and is supplied to the compression mechanism (50) and to the expansion mechanism (60). Surplus refrigeration oil, which is supplied to neither of the compression and expansion mechanisms (50) and (60), is discharged out of the terminating end of the oil supply passageway (90) which opens at the upper end of the shaft (40). Thereafter, the surplus refrigeration oil flows into an oil return pipe (102) from a lead-out hole (101) and is returned back towards a second space (39). This reduces the amount of heat input to the fluid flowing through the expansion mechanism from the surplus refrigeration oil which has not been utilized to lubricate the compression and expansion mechanisms.

Owner:DAIKIN IND LTD

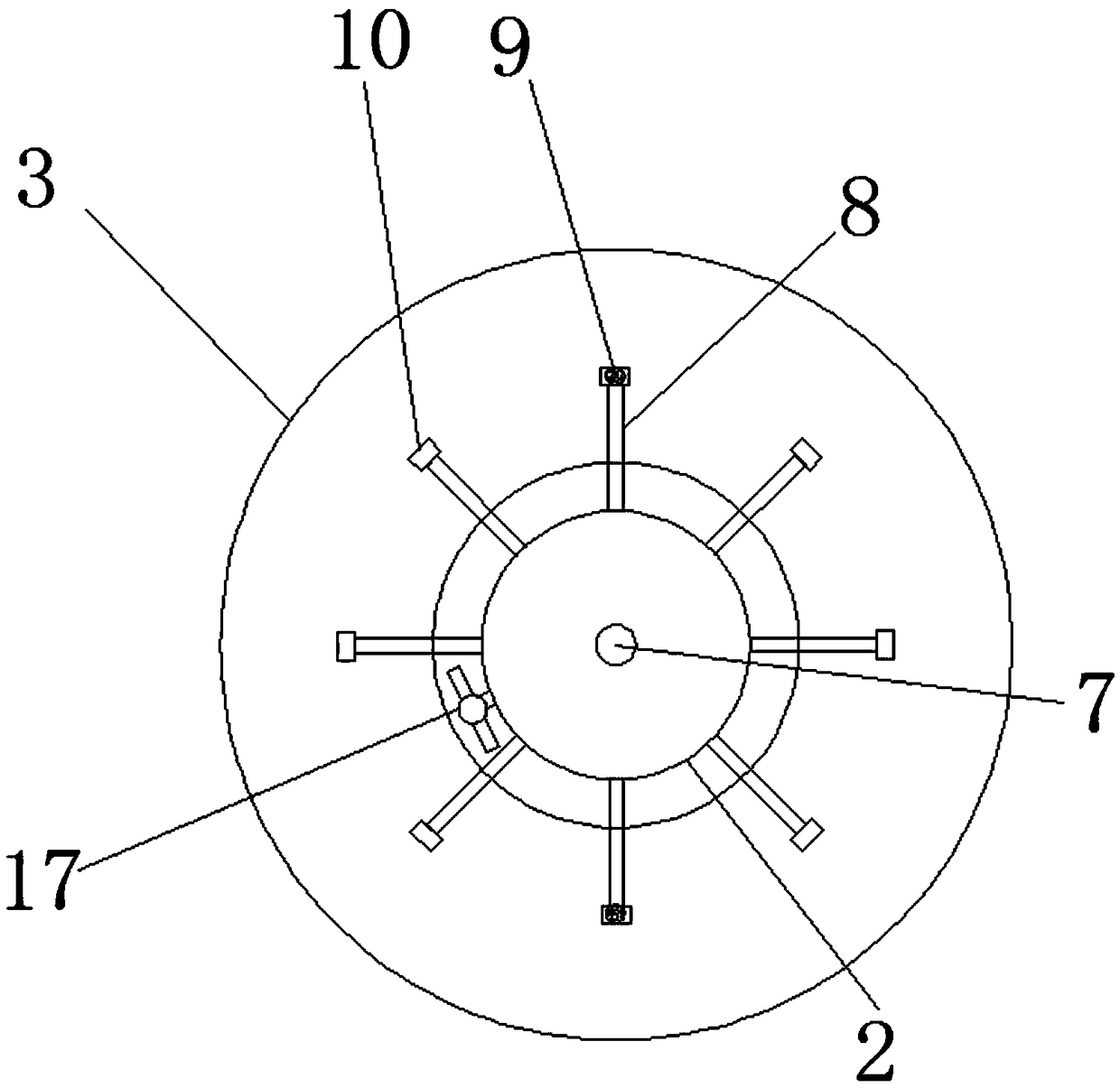

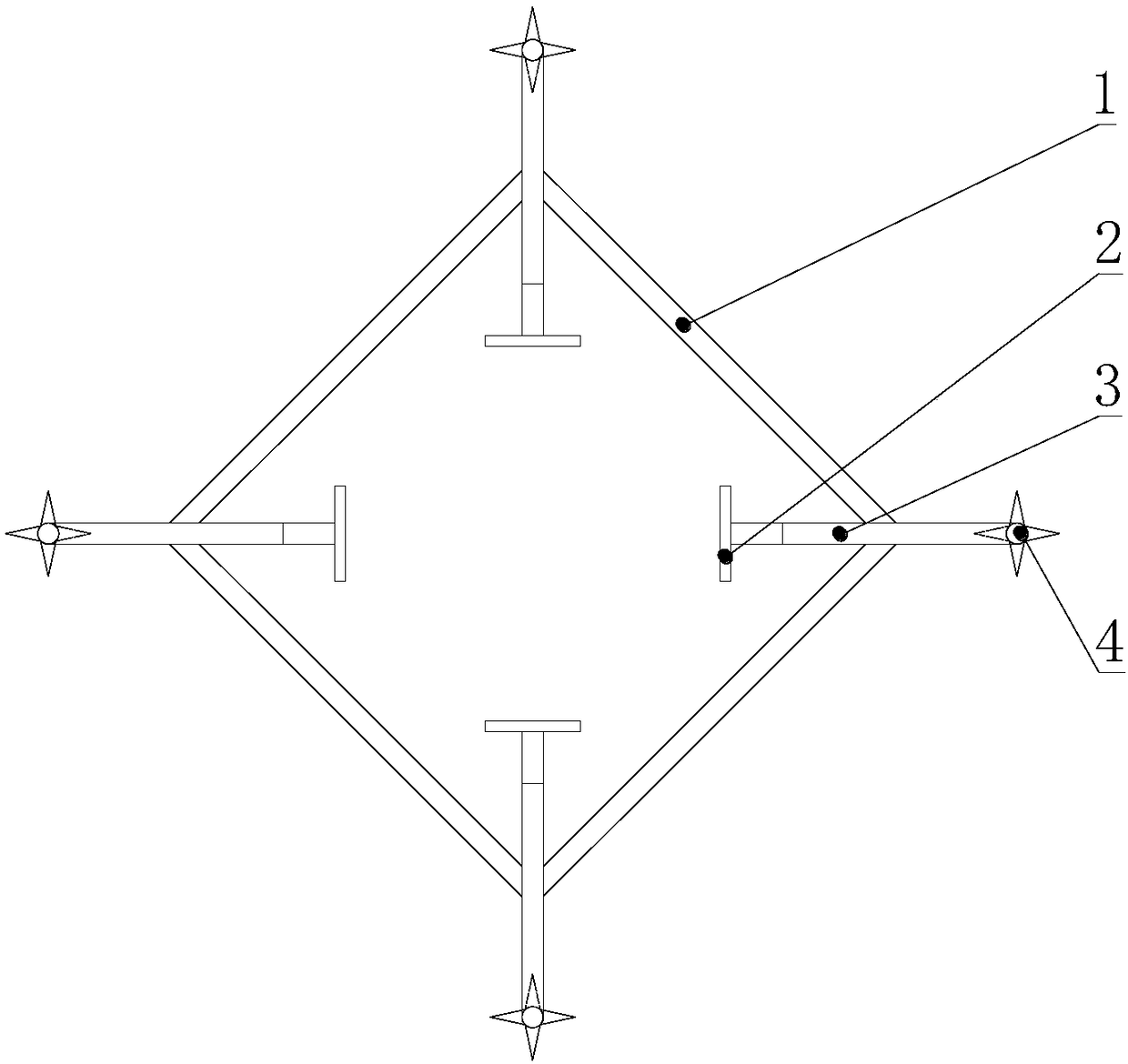

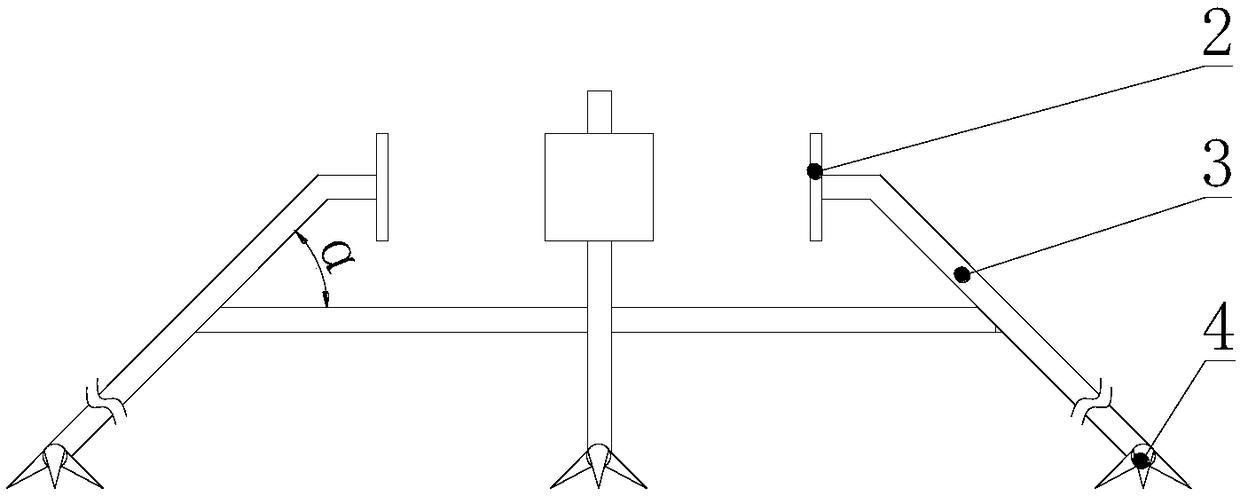

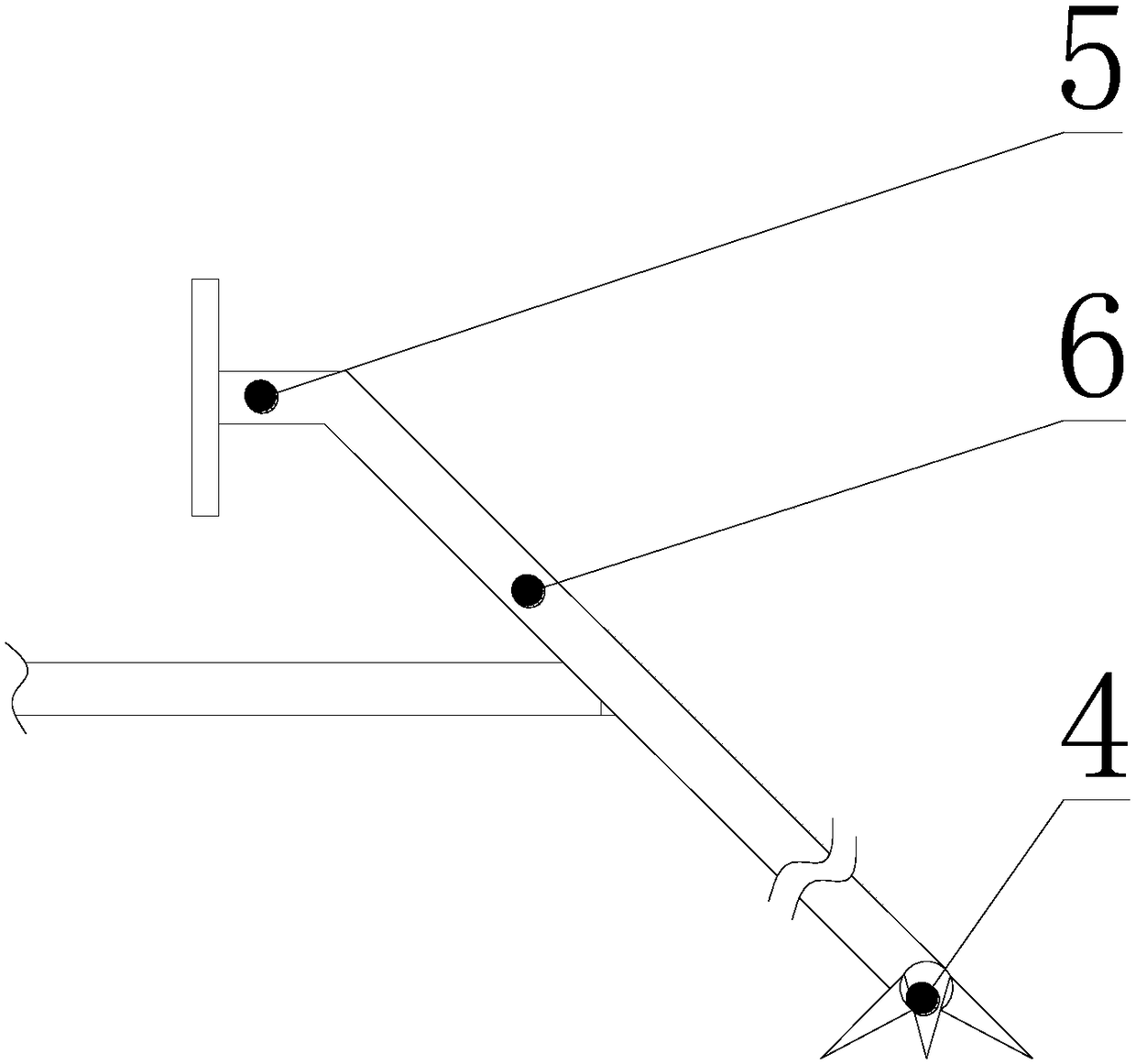

Pole and tower grounding device

ActiveCN108521031AImprove current spreading abilityQuick importConnection contact member materialPower flowClosed loop

The invention provides a pole and tower grounding device. The pole and tower grounding device comprises first connecting beams, second connecting beams, a grounding plate and a grounding fringing ball, wherein multiple first connecting beams are arranged, the first connecting beams are connected end to end and define a closed loop, the second connecting beams are arranged at joints of the first connecting beams, one end of each second connecting beam is located inside the closed loop, the other end of each second connecting beam is located outside the closed loop, the grounding plate is arranged at one end, located in the closed loop, of each second connecting beam, the grounding fringing ball is arranged at one end, located outside the closed loop, of each second connecting beam, and an acupuncture is arranged on each second connecting beam. The acupuncture is arranged on each second connecting beam, shunt acupunctures can be increased, current can be beneficially and rapidly guided into soil, and current fringing capability of the grounding device also can be improved.

Owner:国网山东省电力公司惠民县供电公司

Printed circuit board and mobile terminal

ActiveCN105636336AQuick importPrevent Static InterferenceCross-talk/noise/interference reductionPrinted circuit aspectsPrinted circuit boardSignal lines

The invention discloses a printed circuit board. The printed circuit board comprises a first protection layer, a first shielding layer, a circuit layer, a second shielding layer and a second protection layer, which are successively laminated. The circuit layer comprises a data signal line and a grounding line. The grounding line is electrically connected with the first shielding layer and the second shielding layer. The peripheral side faces of the printed circuit board comprise an input face, an output face and a non connection face. A first shielding region which is not covered by the first protection layer is formed in a position near the non connection face of the first shielding layer. A second shielding region which is not covered by the second protection layer is formed in a position near the non connection face of the second shielding layer. The printed circuit board comprises a shielding support which is electrically connected with the first shielding region or / and the second shielding region and covers the non connection face. The printed circuit board is capable of preventing static interference. The invention also discloses a mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

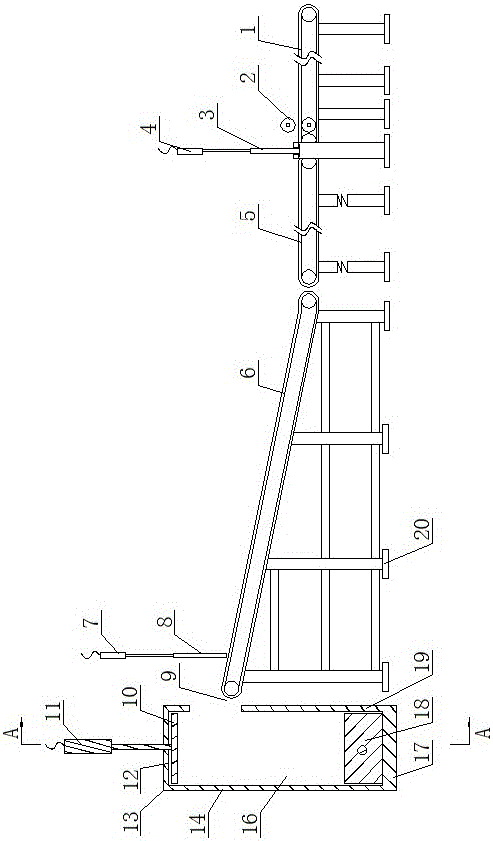

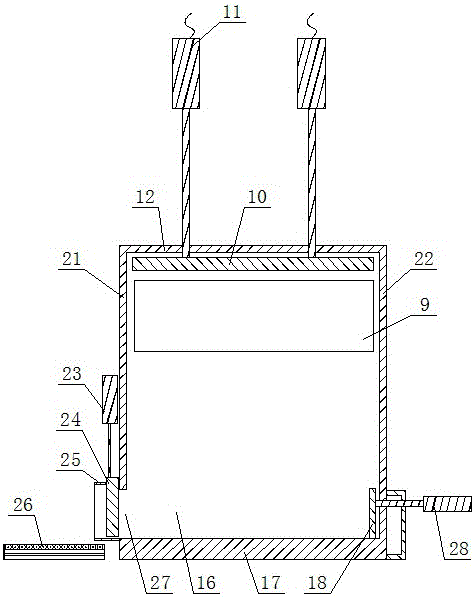

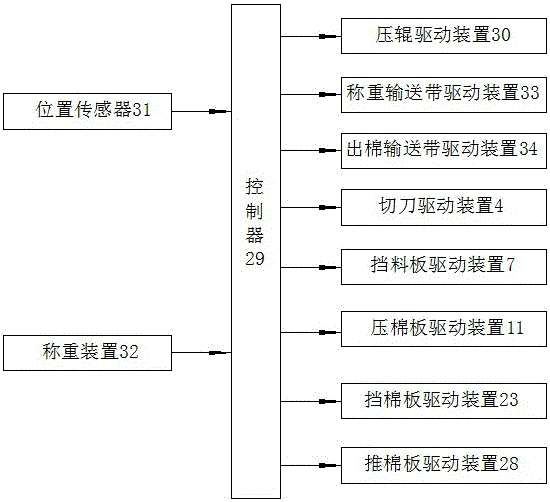

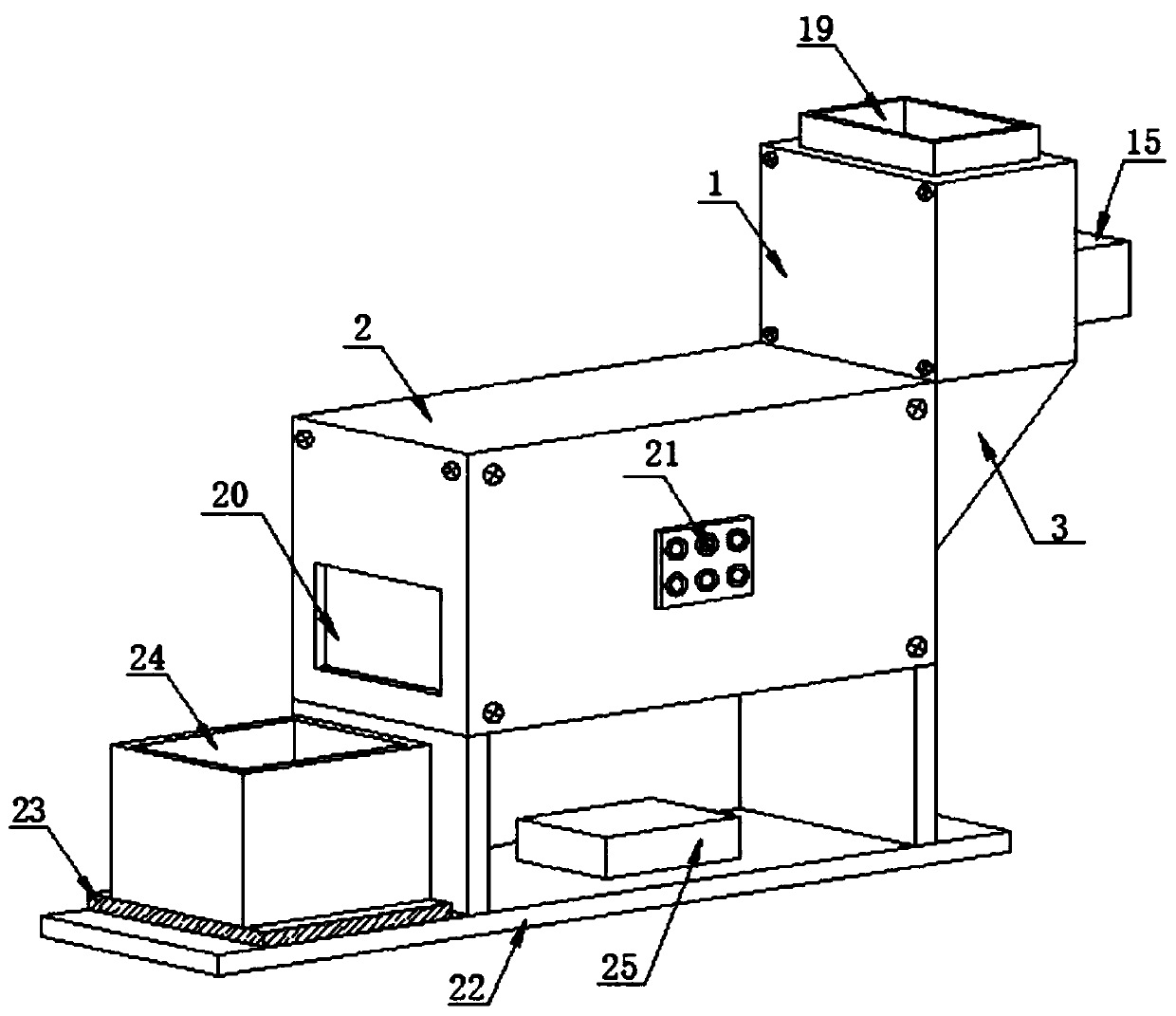

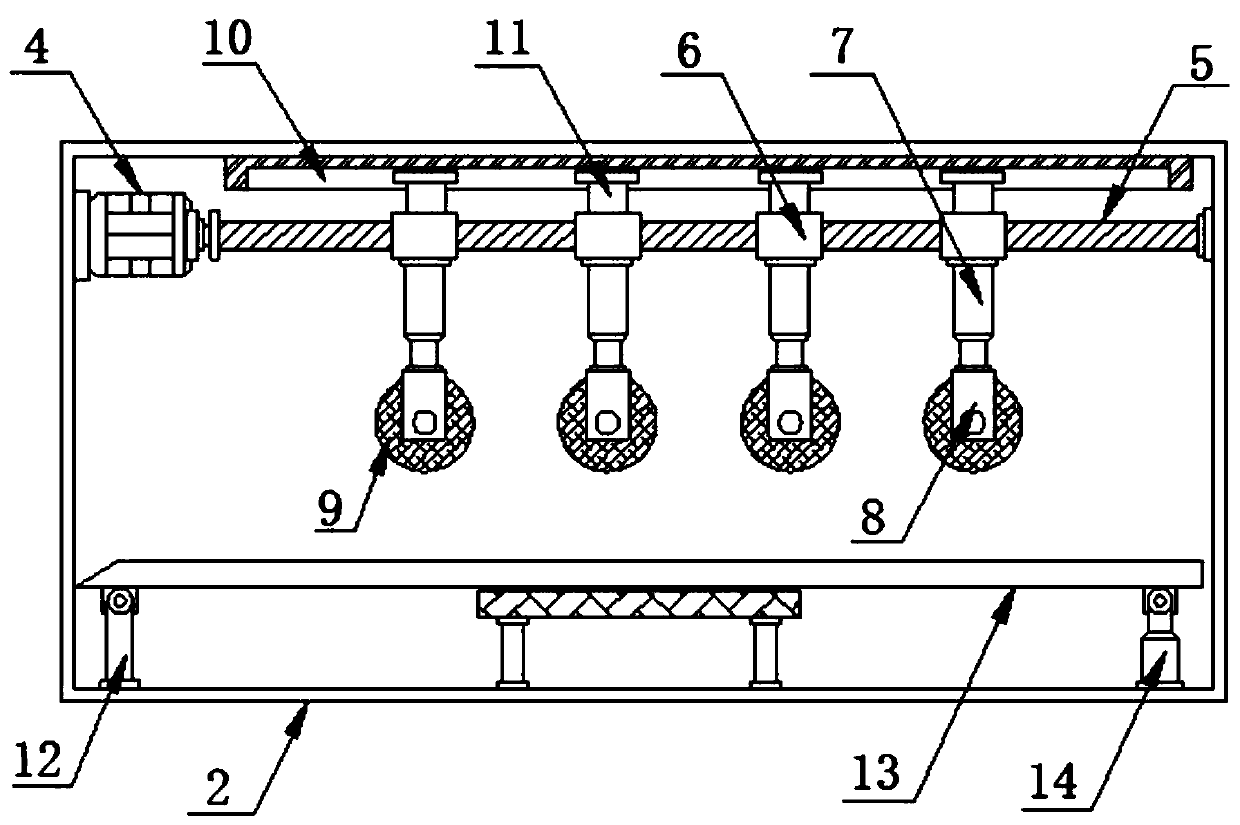

Ceramic fiber blowing cotton packing device and method

ActiveCN106628434ASave human effortImprove work efficiencyTextile disintegration and recoveryIndividual articlesFiberWork flow

The invention discloses a ceramic fiber blowing cotton packing device, and belongs to a device for a ceramic fiber cotton production line, which can solve the technical problem that manual packing of the ceramic fiber cotton takes lots of time, is uncontrollable in weight, and is large in size. The ceramic fiber blowing cotton packing device includes a controller, a packing device, a conveying belt rack, a cotton feeding conveying belt, a weighing conveying belt, and a cotton discharging conveying belt, wherein the cotton feeding conveying belt, the weighing conveying belt, and the cotton discharging conveying belt are arranged on the conveying belt rack; a weighing device is correspondingly arranged on the weighting conveying device; a cutter is arranged between the cotton feeding conveying belt and the weighing conveying belt; The cutter is connected to a cutter driving device; and the packing device includes a box, a cotton compressing device and a cotton pushing device, wherein the box is positioned on an output end of the cotton discharging conveying belt. The ceramic fiber blowing cotton packing method includes the following working flows: importing ceramic fiber blowing cotton; acquiring a ceramic fiber blowing cotton block having a preset weight; putting the ceramic fiber blowing cotton block in the box; and packing the ceramic fiber blowing cotton block. The ceramic fiber blowing cotton packing device and method can acquire the ceramic fiber blowing cotton block having the preset weight and size.

Owner:山东红阳高温节能材料股份有限公司

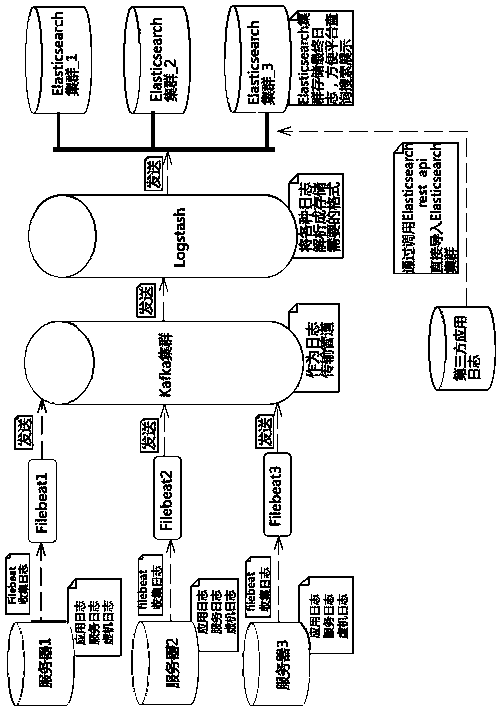

A cloud log collection method based on distributed architecture

The invention provides a cloud log collection method based on a distributed architecture, The invention belongs to the field of information technology. According to the characteristics of the components, the invention needs to deploy Kafka cluster, Elasticsearch cluster, Logstash, each server installs FileBeat component, and finally builds a log system framework. Realize the automatic collection and real-time query analysis of various logs and the fast import of the third-party logs.

Owner:INSPUR SOFTWARE CO LTD

Battery module and vehicle provided with same

ActiveCN106450570ARealize heat conductionIncrease battery temperatureSecondary cellsBusbarEngineering

The invention discloses a battery module and a vehicle provided with the same. The battery module comprises a battery fixing support frame, a series-connection busbar, axial heat conduction structures, an average-temperature heat conduction pad and a heat exchange plate, wherein multiple cylindrical battery cells are arranged on the battery fixing support frame; the series-connection busbar is arranged at one side of the battery fixing support frame and is used for connecting the multiple cylindrical battery cells in series, and an end face of the series-connection busbar, opposite to the cylindrical battery cells, protrudes outwards so as to form grooves between end faces of the cylindrical battery cells and the series-connection busbar; the axial heat conduction structures are arranged in the grooves; the average-temperature heat conduction pad is pasted on the series-connection busbar and are laminated with the multiple axial heat conduction structures; and the heat exchange plate and the average-temperature heat conduction pad are arranged by laminating. According to the battery module disclosed by the invention, efficient balanced heat management of the battery cell temperature can be achieved.

Owner:BEIJING ELECTRIC VEHICLE

Waste crushing device for construction engineering

The invention discloses a waste crushing device for construction engineering, and relates to the technical field of construction waste processing. The device comprises a crushing box and a fine crushing box, wherein the bottom of the crushing box communicates with a material guide frame, the left side of the material guide frame communicates with the right side of the fine crushing box, the top ofone side of an inner cavity of the fine crushing box is connected with a first driving motor through a connecting plate, an output shaft of the first driving motor is fixedly connected with a rotating screw rod, and one end of the rotating screw rod is rotatably connected with one side of the inner cavity of the fine crushing box through a bearing. According to the waste crushing device for construction engineering, construction waste is preliminarily crushed firstly, after preliminary crushing is completed, the construction waste is finely crushed, the construction waste is subjected to double crushing, so that the construction waste can be crushed uniformly, the crushing quality is improved to a great extent, the material discharging amount can be accurately controlled, material receiving can be automatically stopped without manual control when a material receiving box is full, the automation degree is high, and the use by operators is facilitated to a great extent.

Owner:程志求

Computer apparatus and method for illustrating, issuing, and managing disability coverage for retirement plans with individual accounts

A computer-aided method of computing coverage benefit costs for a retirement plan having respective accounts for individuals, the method including the steps of converting input plan contribution data for at least one of said accounts of said retirement plan into corresponding input digital electrical signals, manipulating the input digital electrical signals in computing the coverage benefit costs for the at least one of said accounts according to said retirement plan, and producing output at an output device. The output including the computed coverage benefit costs for the at least one of said accounts of said retirement plan. The method is suitable for IRS Sec. 401, 408, 457, in cases such as an IRA, ROTH IRA, individual social security accounts of whatever country may be at issue, and the like. Input plan contribution data can include data such as FICA tax, Federal Old Age, Survivors, and Disability Insurance tax data.

Owner:CYARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com