Fluid machine

A kind of fluid machinery and fluid technology, applied in the field of expander, can solve problems such as increase in enthalpy and decrease in refrigeration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

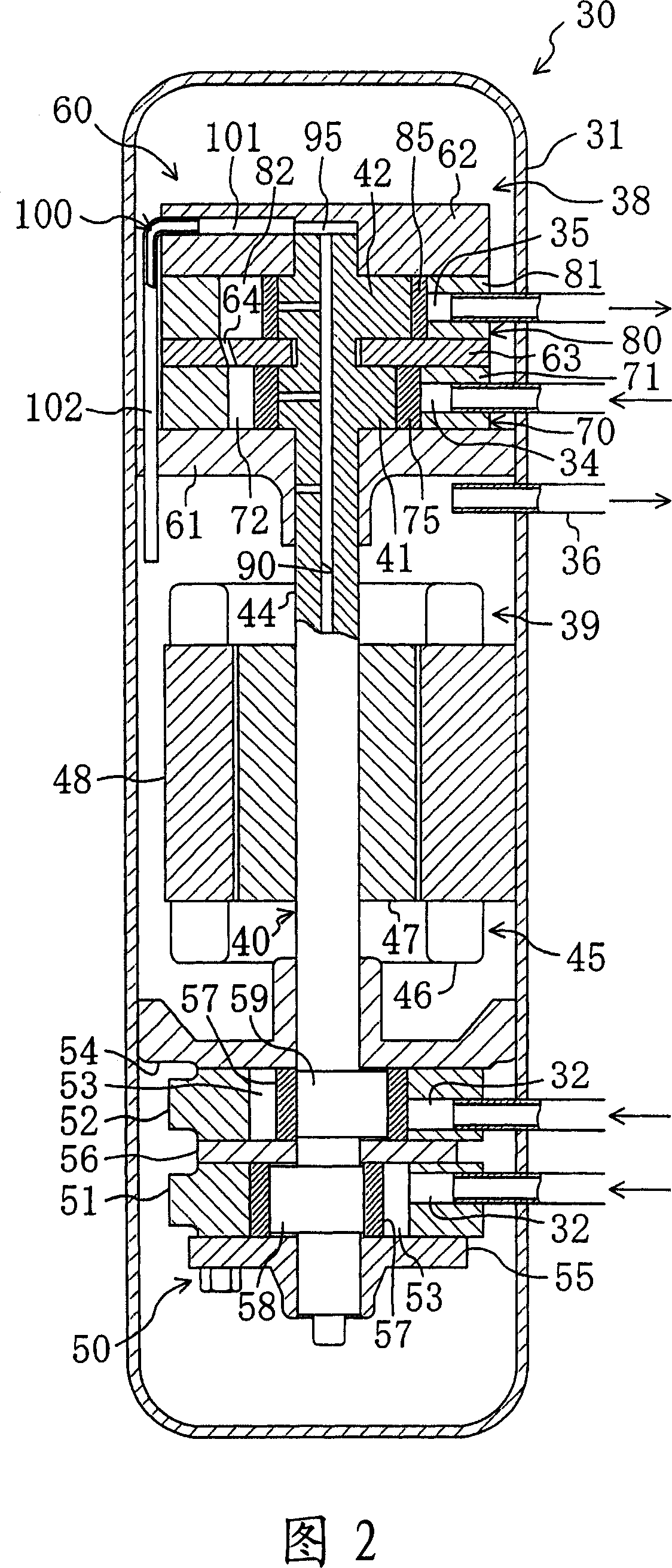

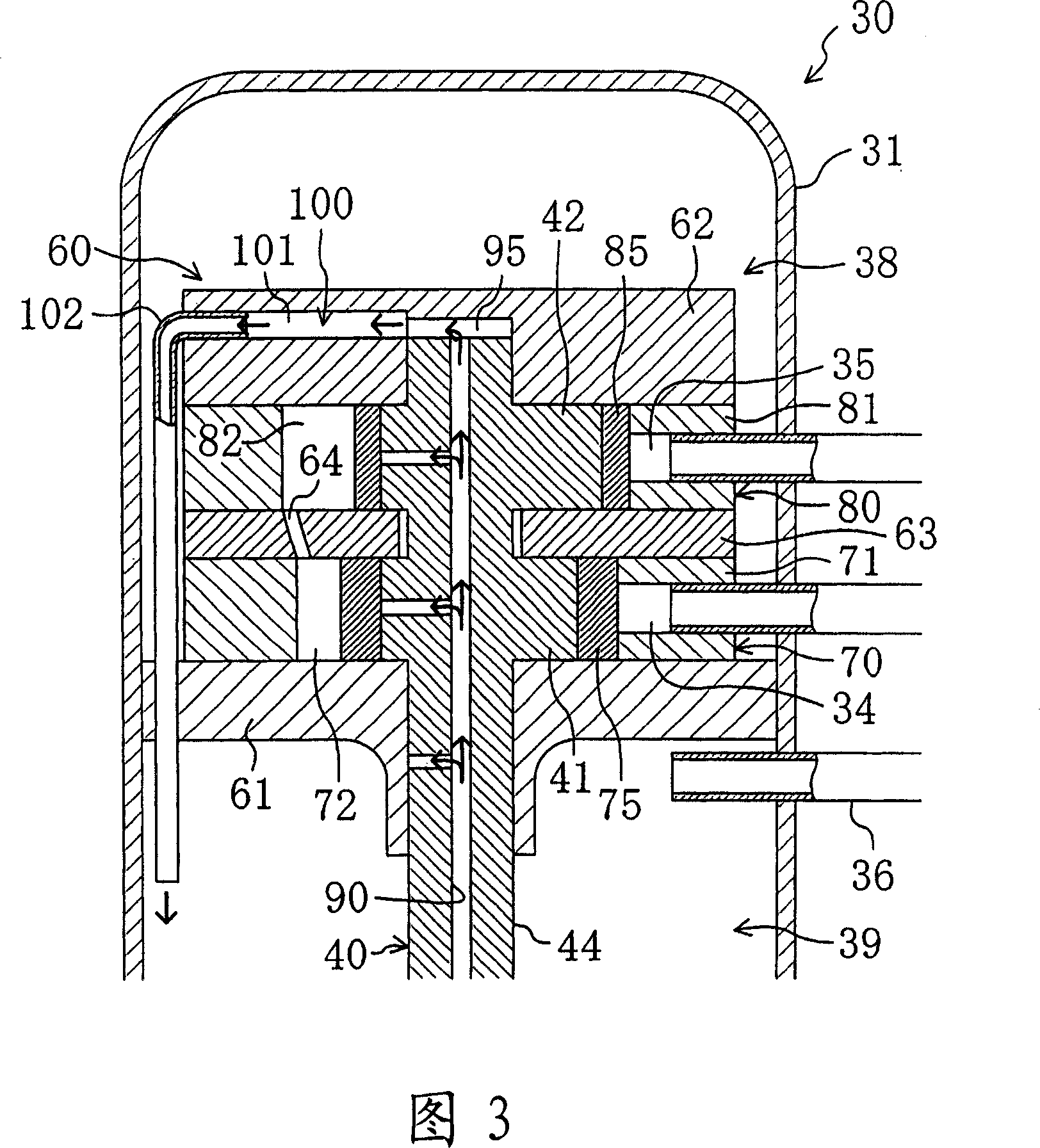

[0060] The first embodiment of the present invention will be described. The air conditioner 10 of this embodiment has a compression / expansion unit 30 as the fluid machine of the present invention.

[0061]

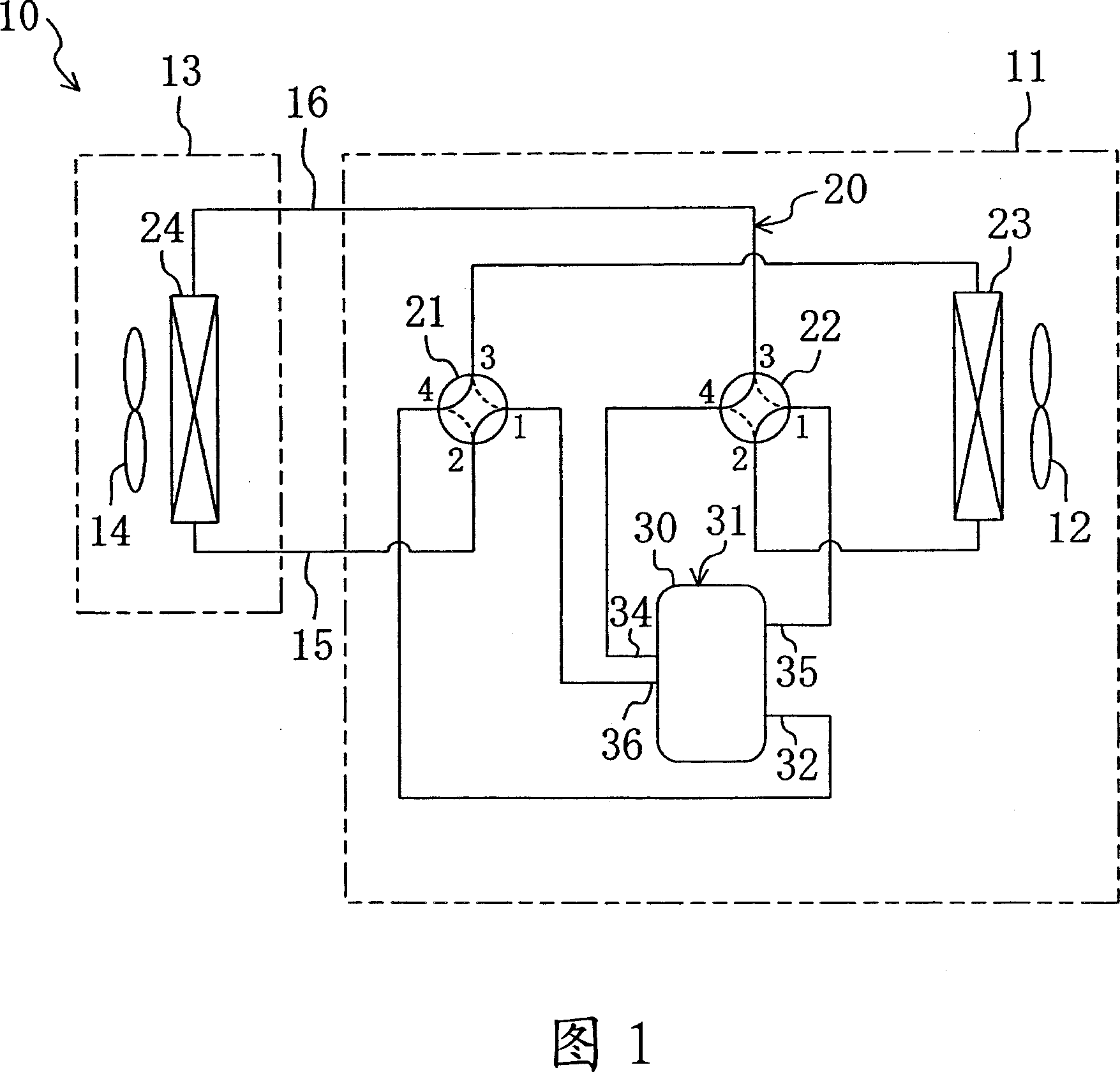

[0062] As shown in FIG. 1, the above-mentioned air conditioner 10 is of a so-called separate type, and includes an outdoor unit 11 and an indoor unit 13. The outdoor unit 11 houses an outdoor fan 12, an outdoor heat exchanger 23, a first four-way switching valve 21, a second four-way switching valve 22, and a compression / expansion unit 30. An indoor fan 14 and an indoor heat exchanger 24 are housed in the indoor unit 13. The outdoor unit 11 is installed outdoors, and the indoor unit 13 is installed indoors. In addition, the outdoor unit 11 and the indoor unit 13 are connected by a pair of connecting pipes 15 and 16. In addition, the details of the compression / expansion unit 30 will be described later.

[0063] The air conditioner 10 is provided with a refrigerant circuit 20. ...

Embodiment approach 2

[0130] The second embodiment of the present invention will be described. The present embodiment is formed by changing the structure of the compression / expansion unit 30 in the first embodiment described above. Here, regarding the compression / expansion unit 30 of the present embodiment, the difference from the above-mentioned first embodiment will be described.

[0131] As shown in FIG. 7, in the expansion mechanism 60 of the present embodiment, a center hole penetrating the rear cylinder head 62 in the thickness direction is formed in the center portion of the rear cylinder head 62. The upper end of the shaft 40 is inserted into the central hole of the rear cylinder head 62.

[0132] The upper plate 110 is provided in the expansion mechanism 60 described above. The upper plate 110 is placed on the upper surface of the rear cylinder head 62, and the center hole of the rear cylinder head 62 and the upper end surface of the shaft 40 together form an end space 95. A lead-out groove 11...

Embodiment approach 3

[0141] The third embodiment of the present invention will be described. This embodiment is formed by changing the structure of the compression / expansion unit 30 in the first embodiment described above. Here, regarding the compression / expansion unit 30 of the present embodiment, the difference from the above-mentioned first embodiment will be described.

[0142] As shown in FIG. 8, in the compression / expansion unit 30 of this embodiment, an oil return passage 100 is formed in the shaft 40, and the lead-out hole 101 and the oil return pipe 102 of the rear cylinder head 62 are omitted. In the shaft 40 described above, an oil return passage 100 is formed along the oil supply passage 90.

[0143] The initial end of the oil return passage 100 is opened on the upper end surface of the shaft 40 and communicates with the end space 95. The end of the oil return passage 100 opens on the outer peripheral surface of the main shaft portion 44 of the shaft 40 and communicates with the second spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com