Patents

Literature

94results about How to "Realize heat conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

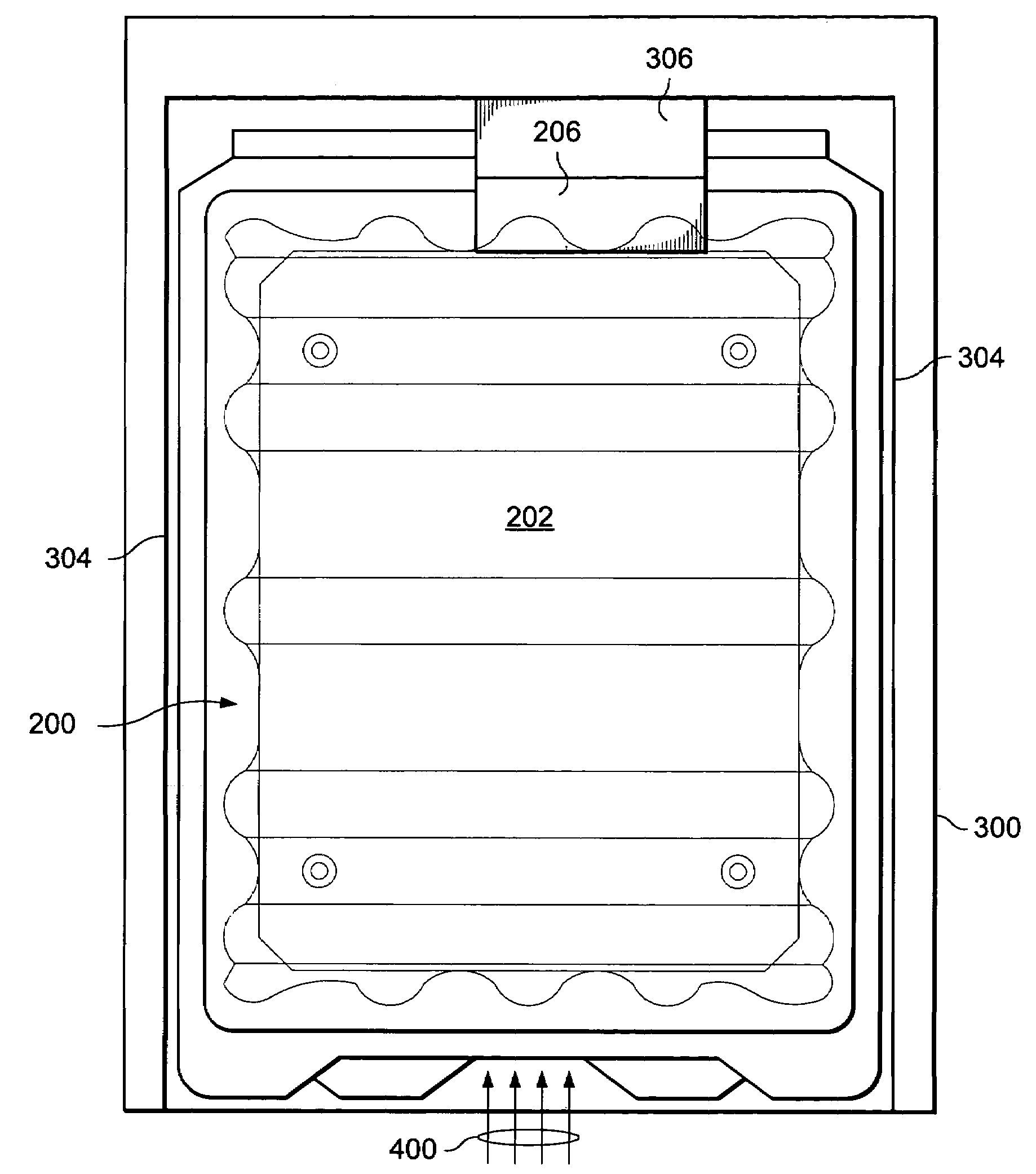

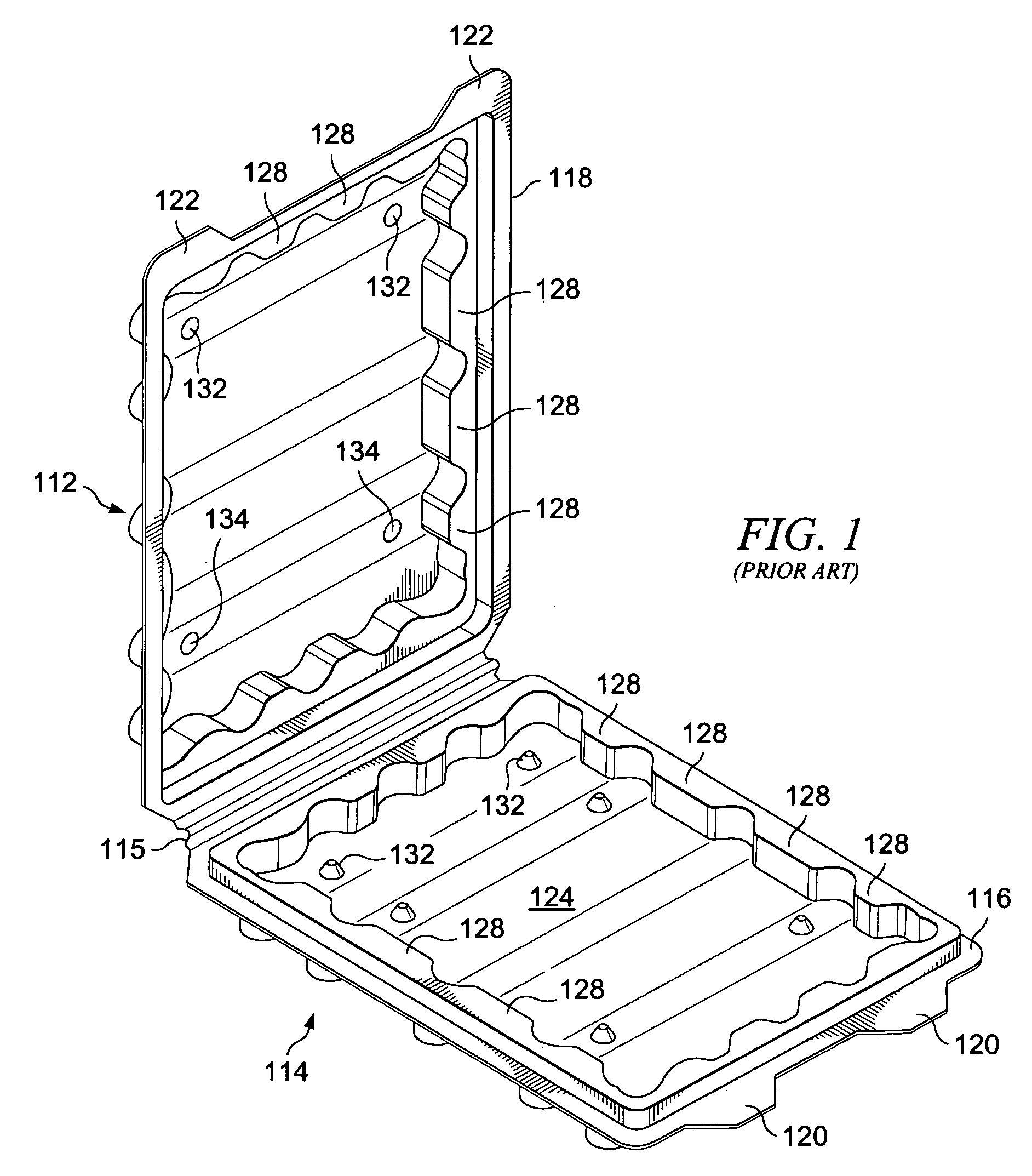

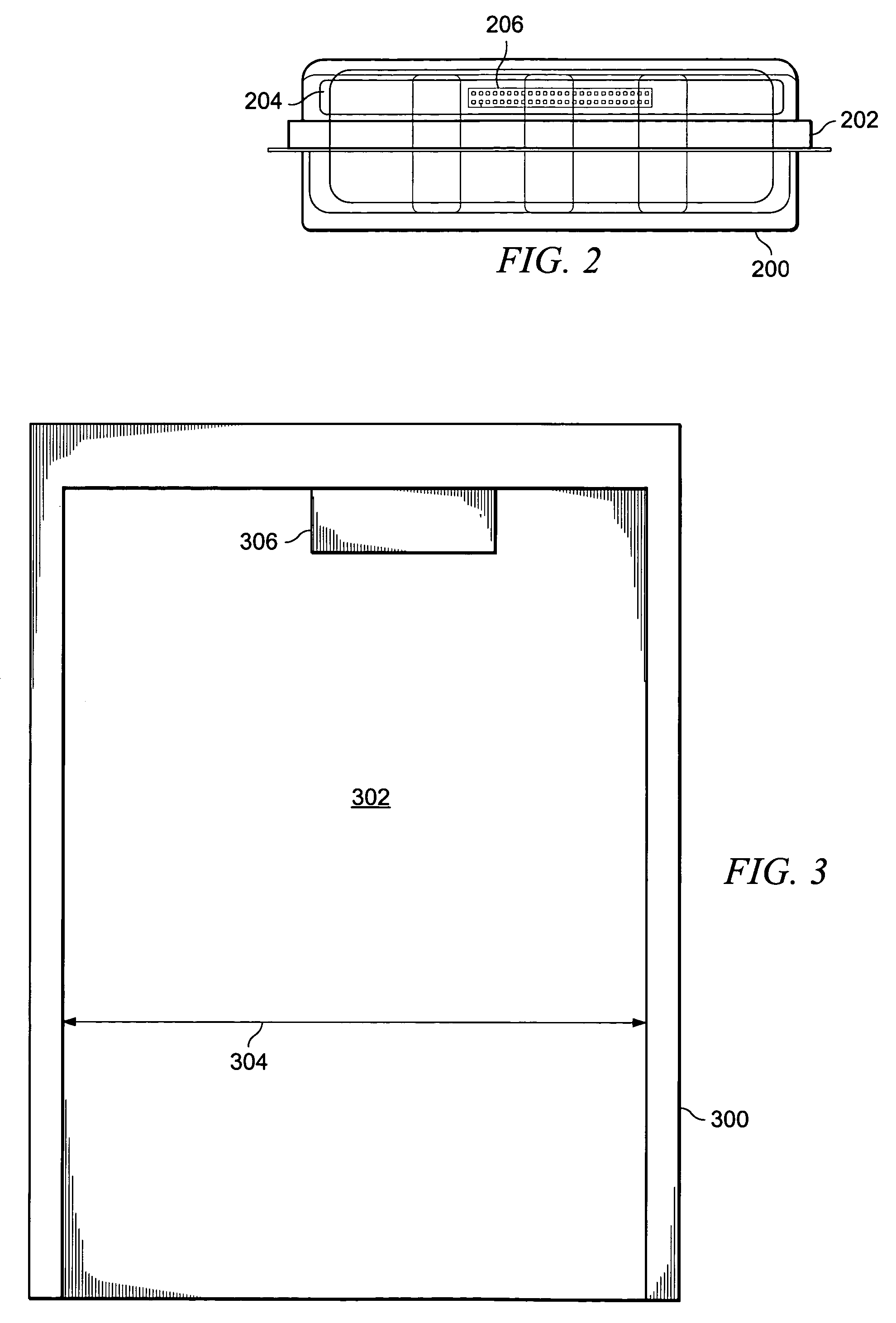

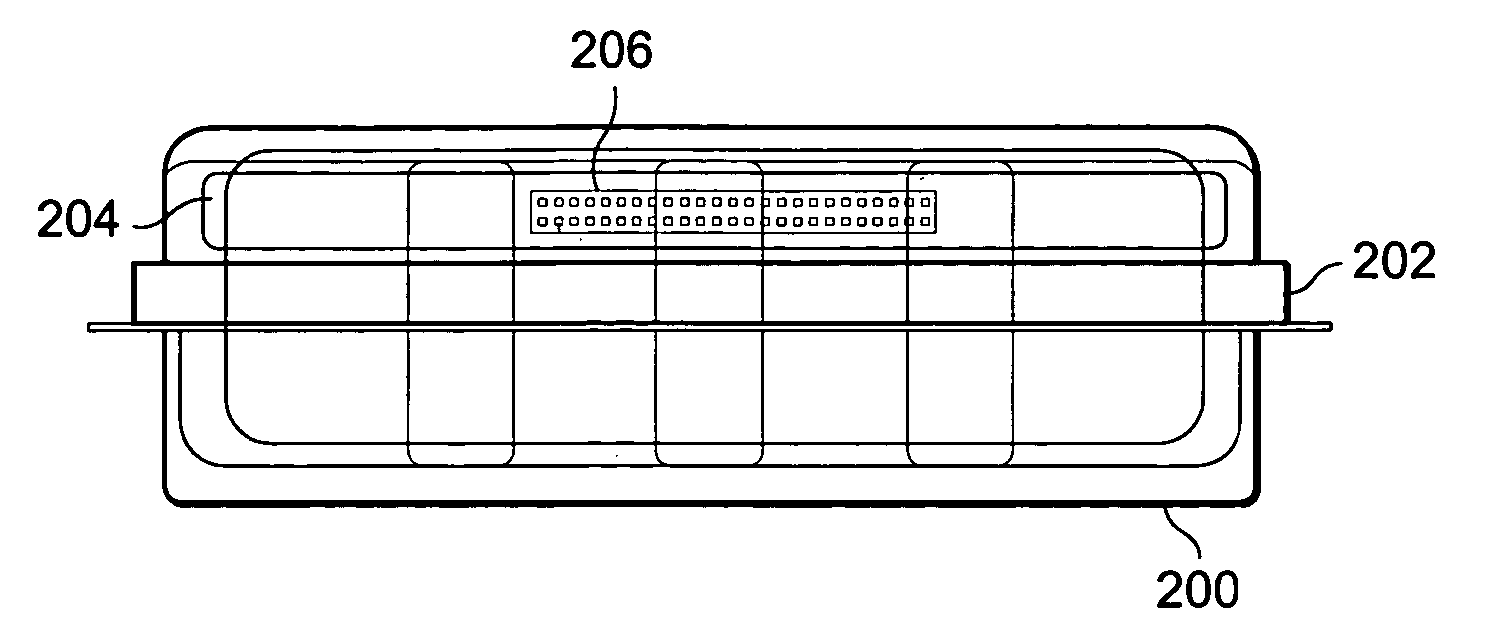

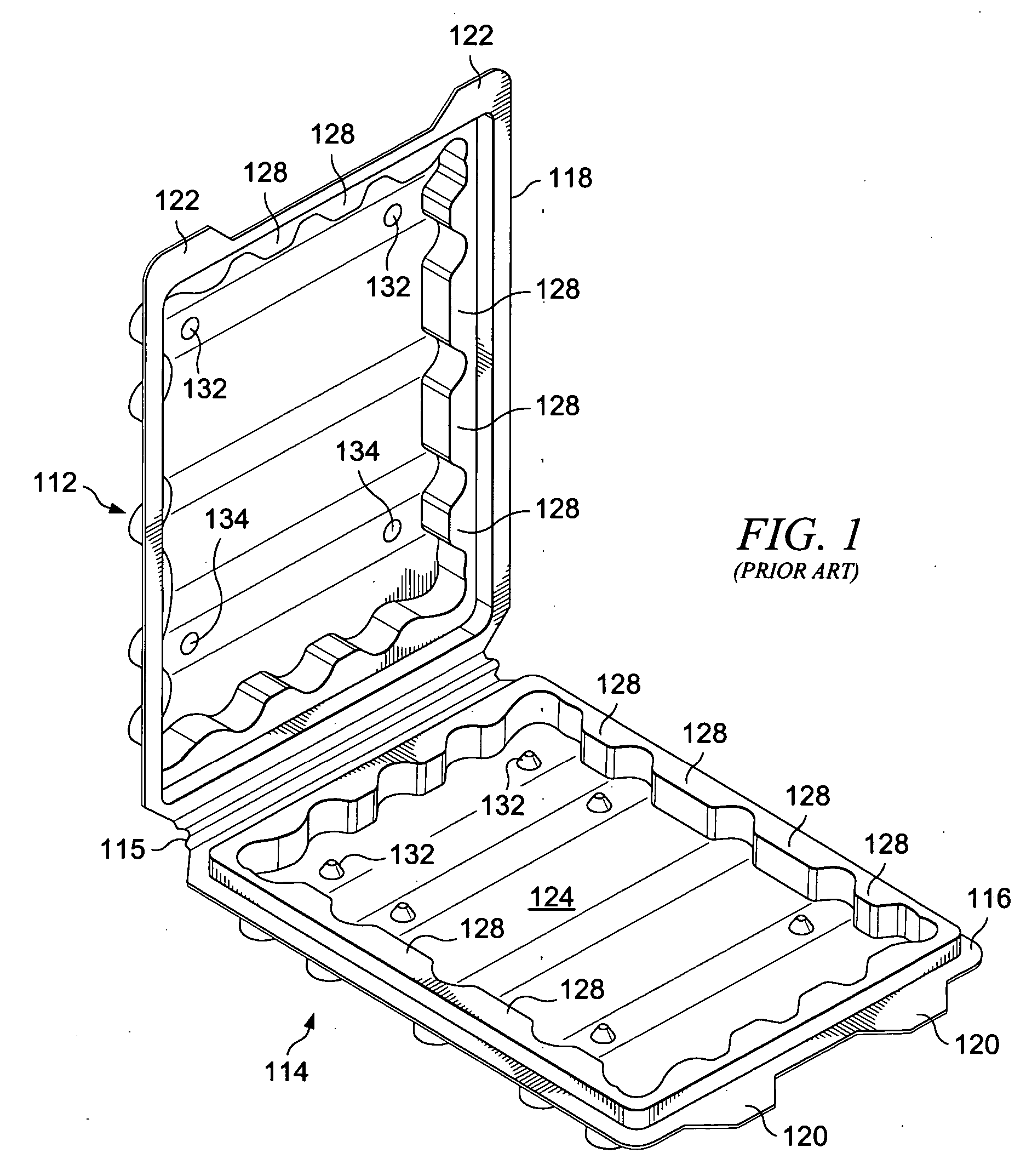

Package structure for soft mounting direct connect storage device

ActiveUS7520389B2Realize heat conductionOther accessoriesContainer/bottle contructionData processing systemInterposer

A method and article of manufacture for protecting a device from damage caused by physical shocks during shipment, handling, and use of the device are disclosed. A shock-absorbing container is provided with a foam material provided around the device when it is placed in the container. An opening in the container is aligned with respect to the device so as to expose a physical interface of a bay to the physical interface of the device in the container. The device and container are proportioned so that when the container, containing the device, is slid into a bay of a device array or data processing system, the physical interface directly connects with a mating physical interface in the bay without requiring an interposer between the physical interface of the device and the physical interface of the array or data processing system.

Owner:SEAGATE TECH LLC

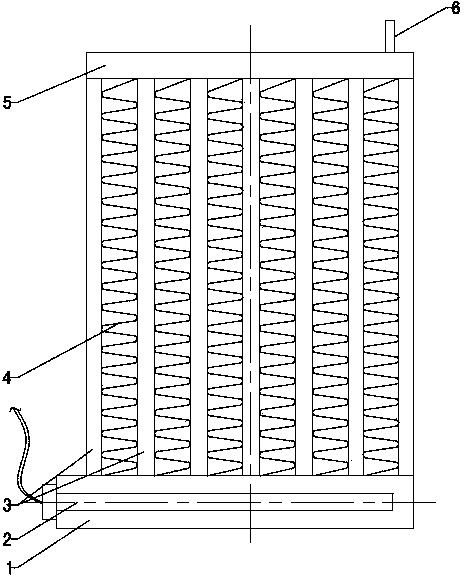

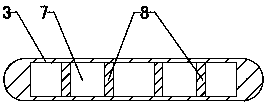

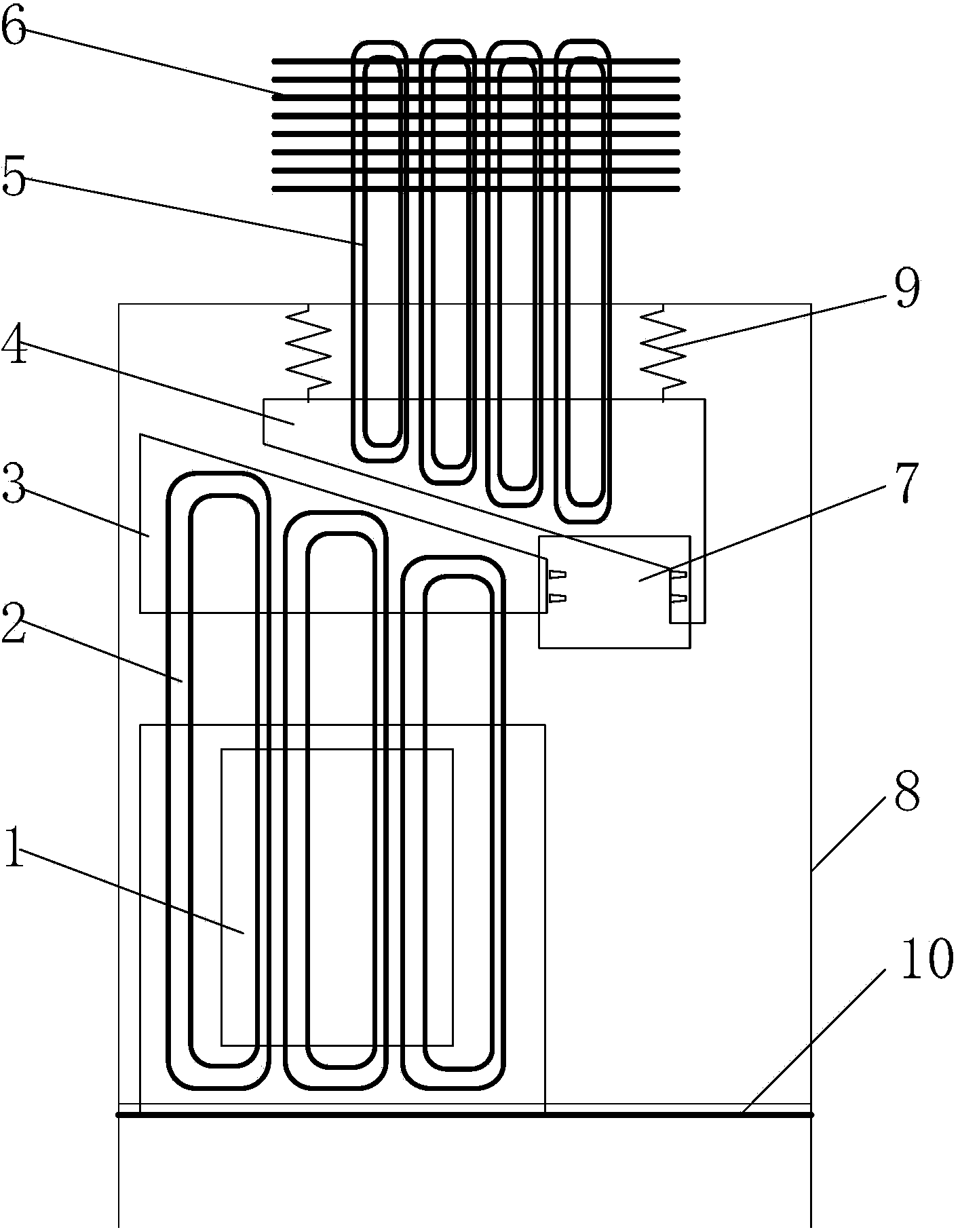

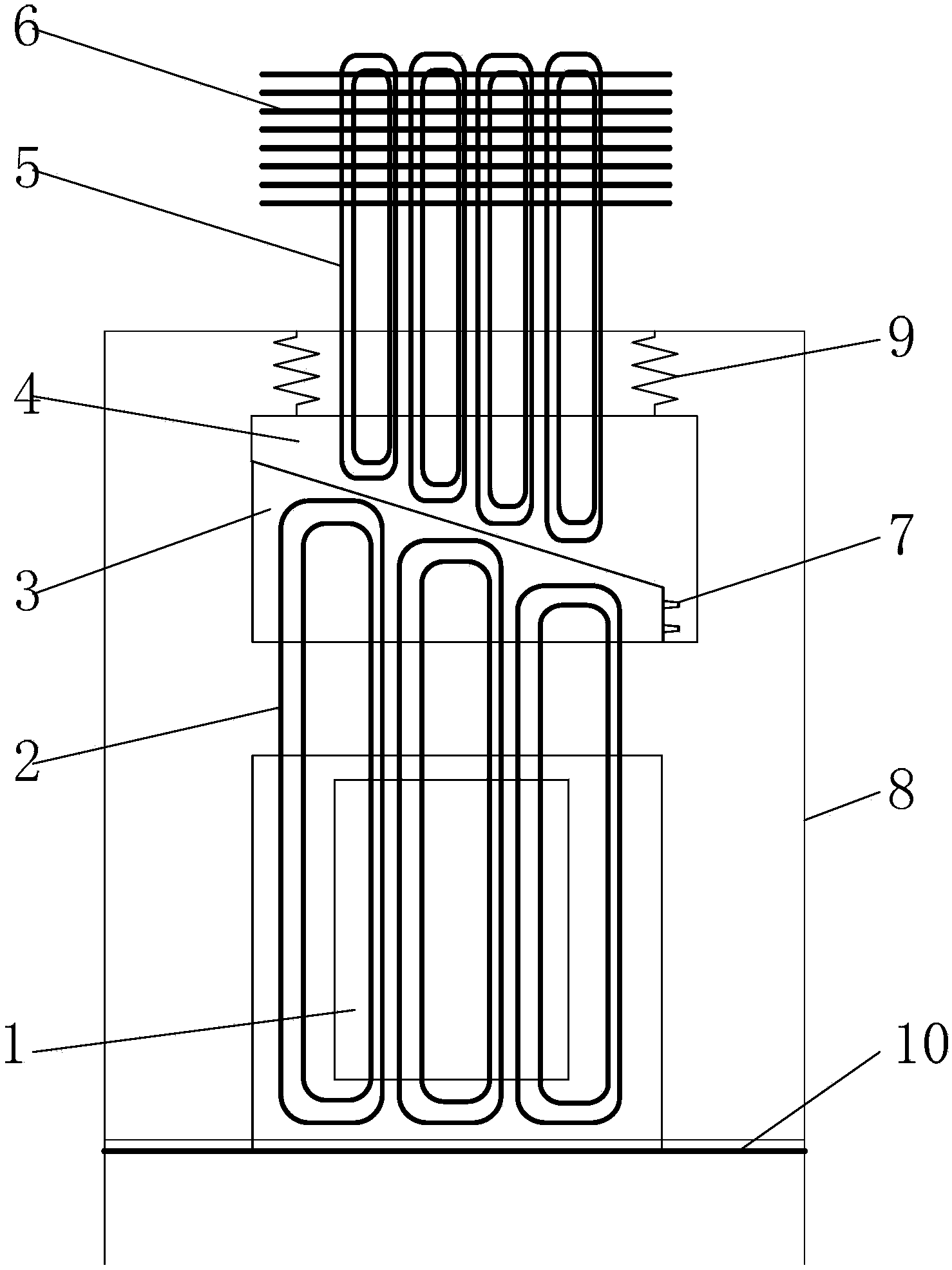

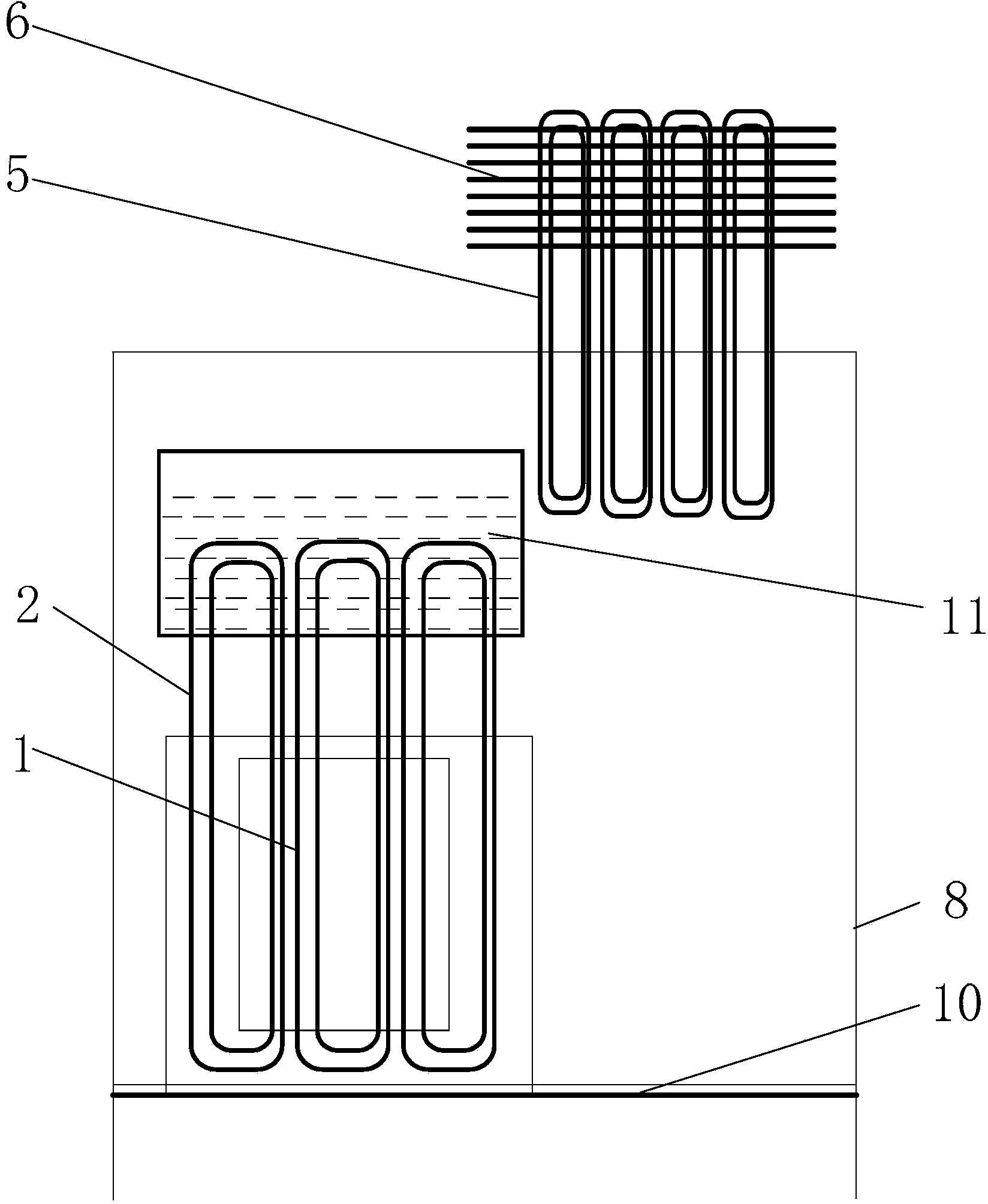

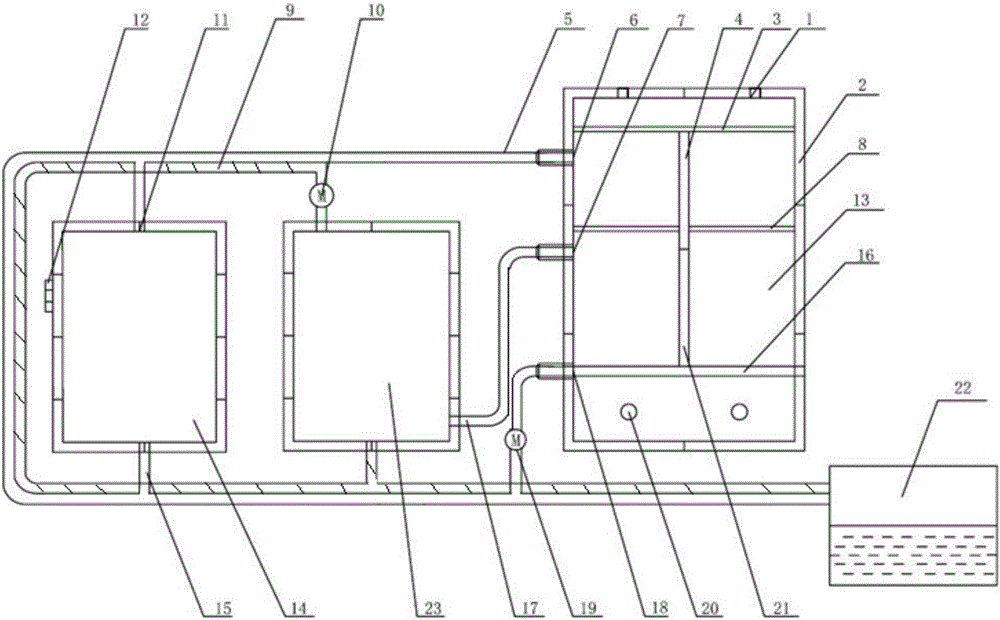

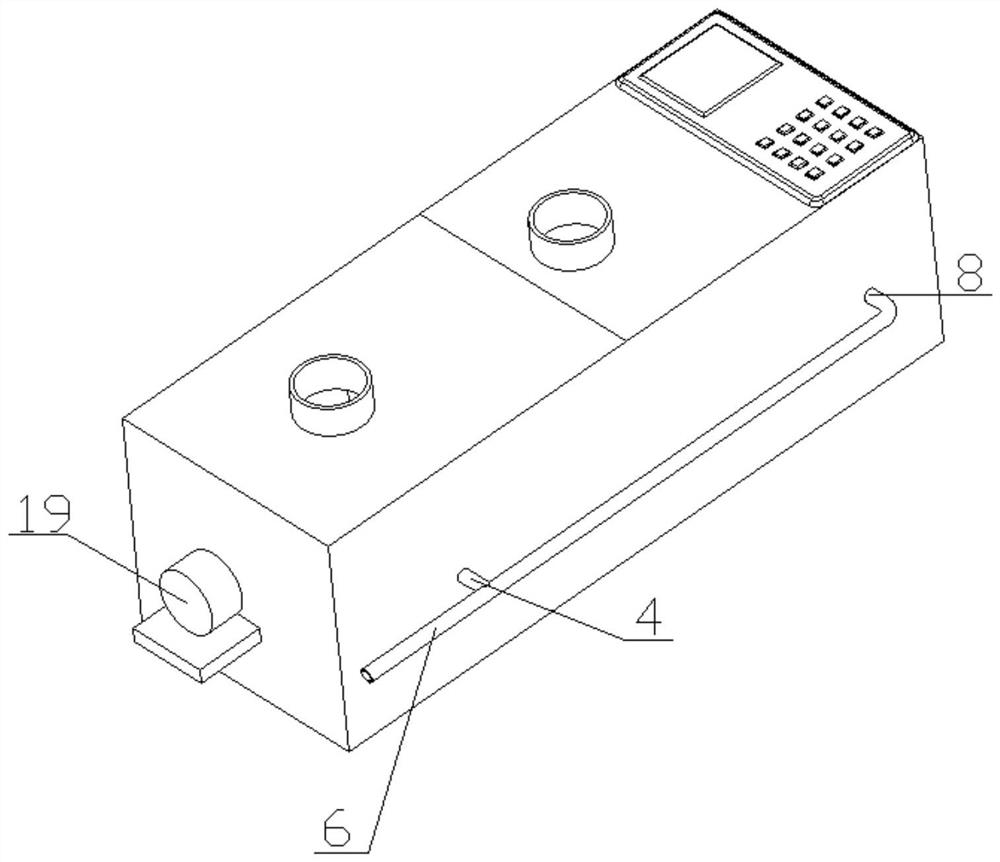

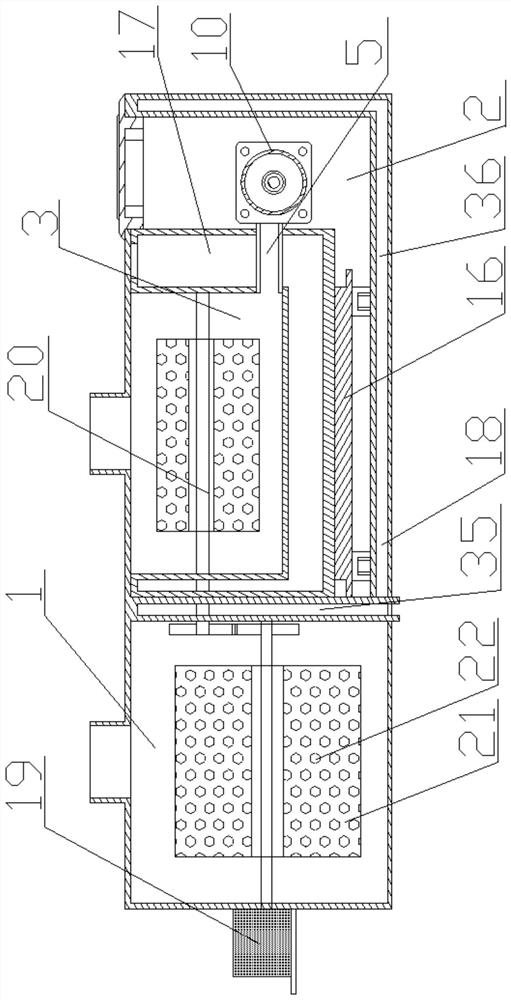

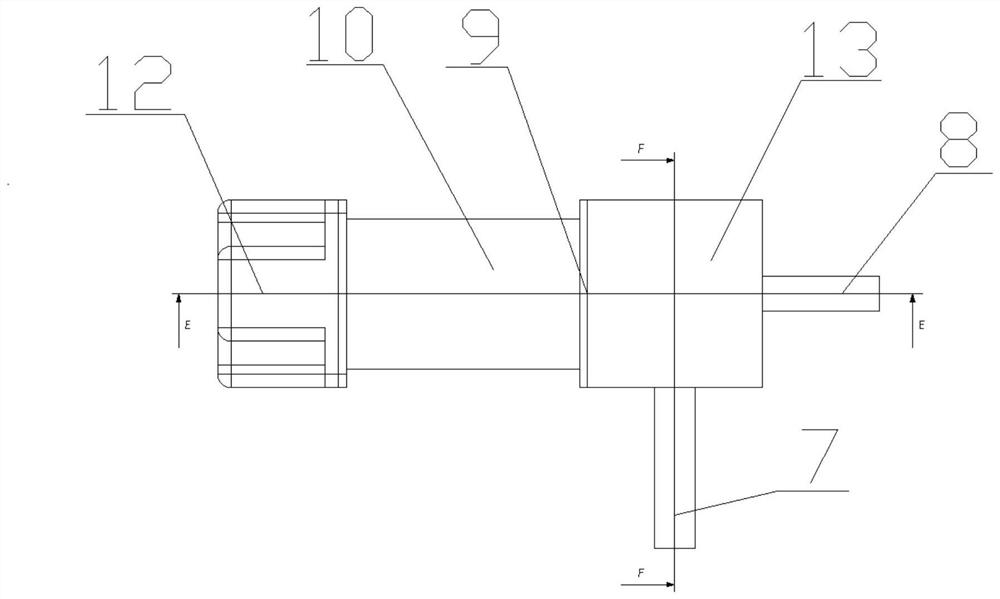

Superconductive heat pipe electric heater

ActiveCN103363571ASimple structureReasonable structureElectric heating systemIndirect heat exchangersHeat conductingEngineering

The invention provides a superconductive heat pipe electric heater, belongs to the field of electrical heating equipment, and particularly relates to an electric heater using a heat pipe as a heat transfer element to dissipate heat. A heat-conducting medium absorbs heat released by a heating element. The heat is dissipated to the air through fins (4). The superconductive heat pipe electric heater is characterized in that a circulation chamber (5) and a heating chamber (1) are installed in a heater shell body (9); the circulation chamber (5) and the heating chamber (1) are communicated through the heat pipe (3) which is used as a heat conduction element; the circulation chamber (5), the heating chamber (1) and the heat pipe (3) form an airtight vacuum space; the circulation chamber (5), the heating chamber (1) and the heat pipe (3) are filled with heat-conducting media respectively; an electrical heating rod (2) is installed in the heating chamber (1). According to the superconductive heat pipe electric heater, the heating method and heat conduction method of a traditional electric heater are changed, superconductive liquid is used as the heat-conducting media, therefore, the temperature rise speed is increased, energy sources are saved, and heat exchange efficiency is improved at the same time.

Owner:山东伟瑞制冷科技有限公司

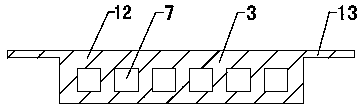

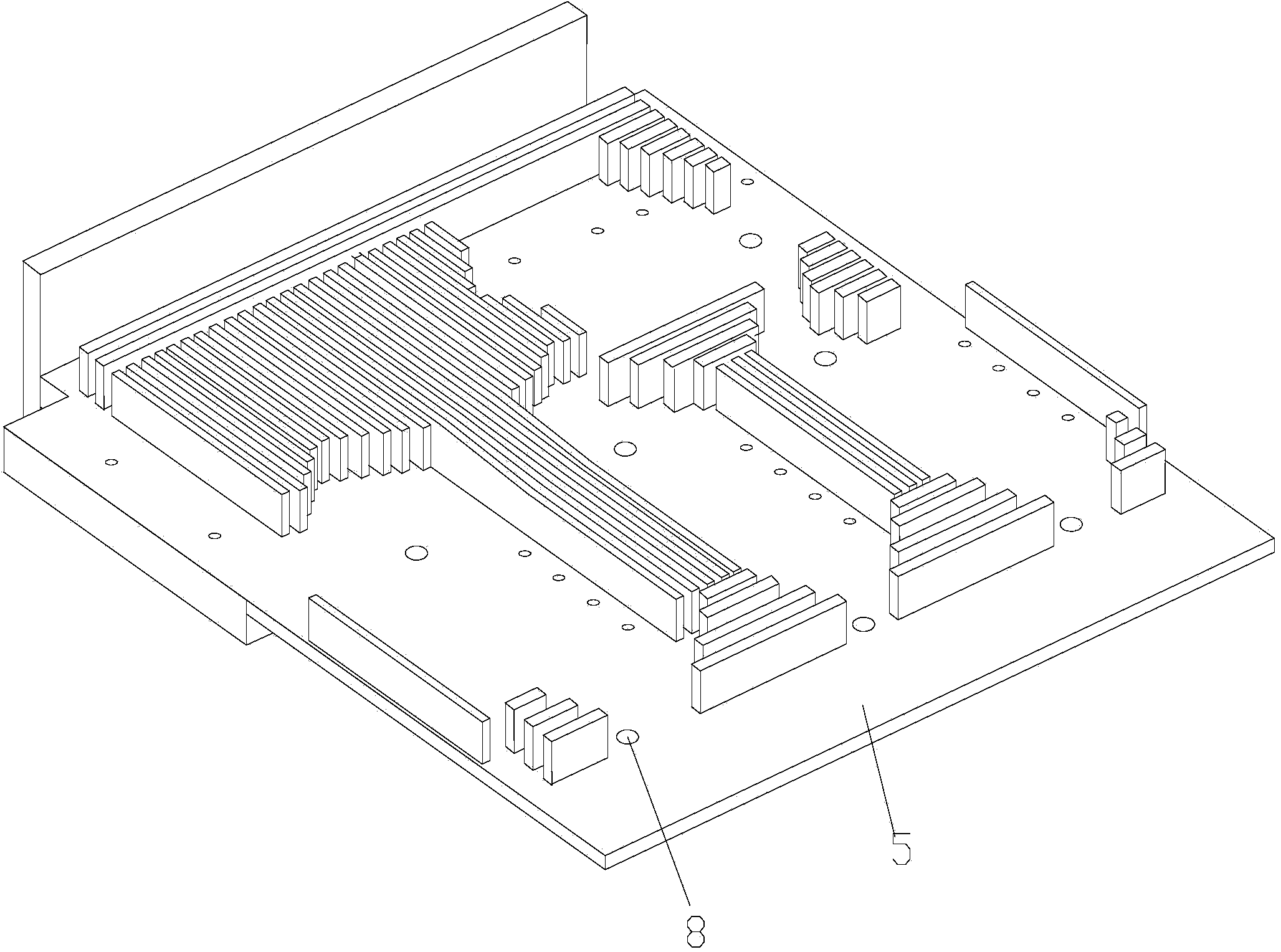

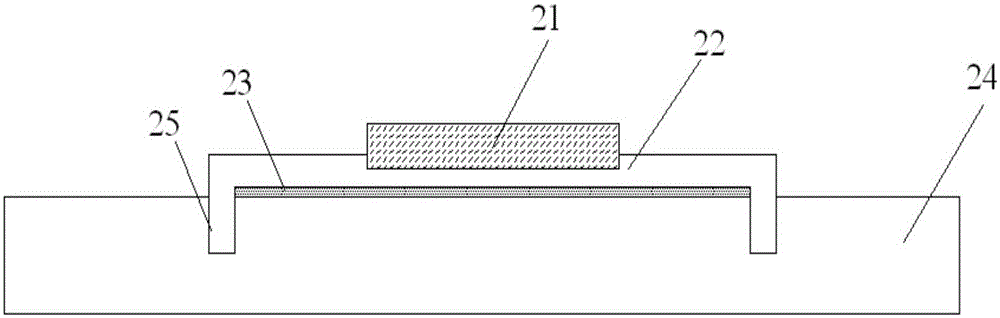

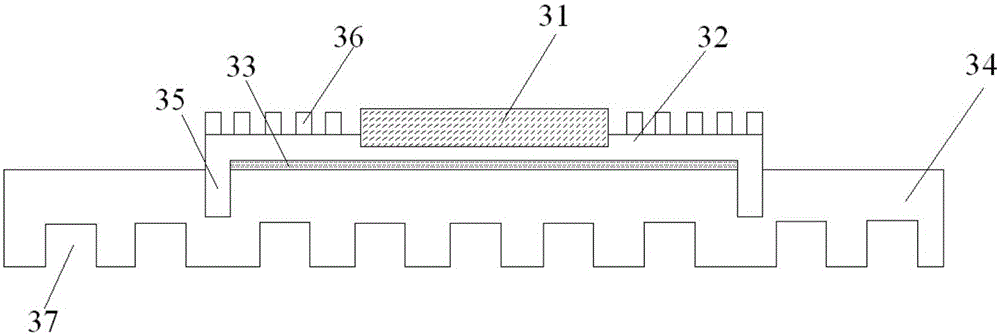

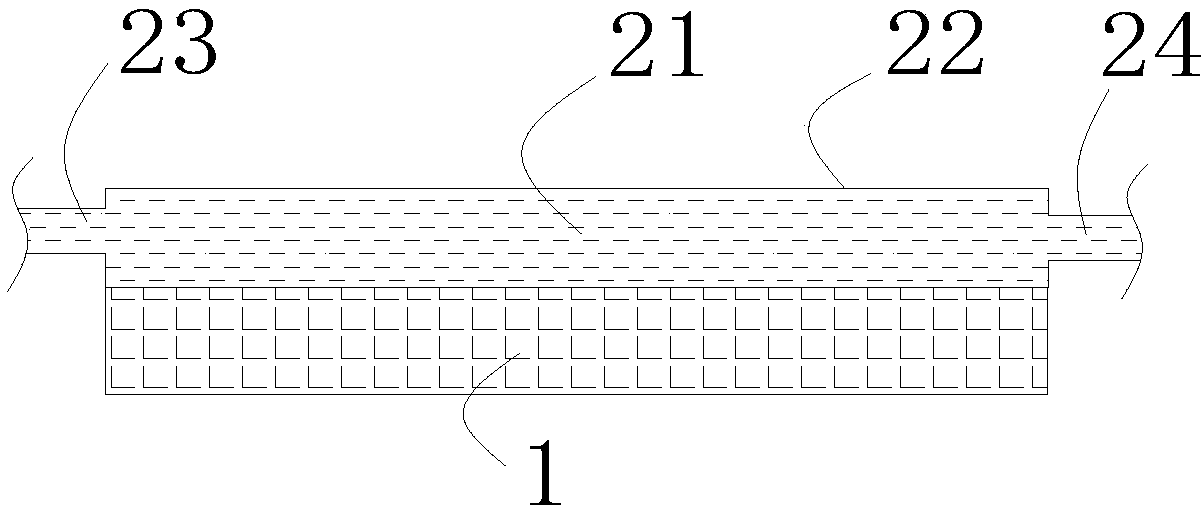

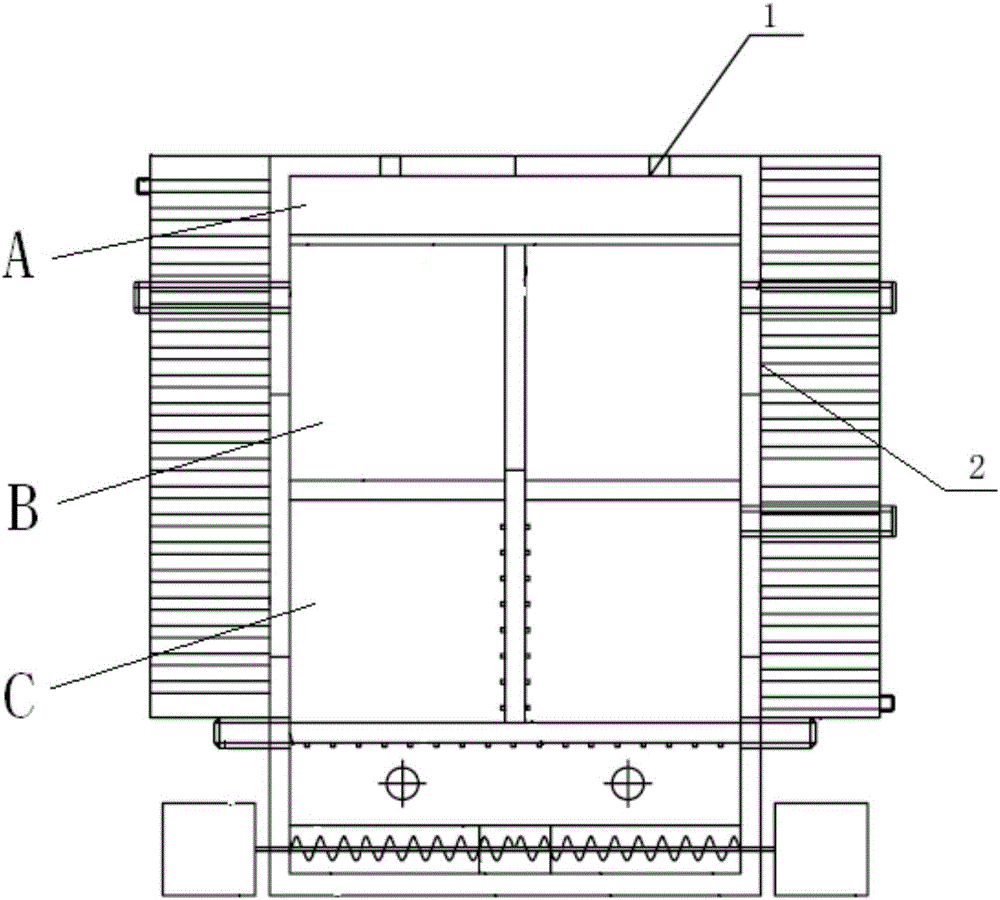

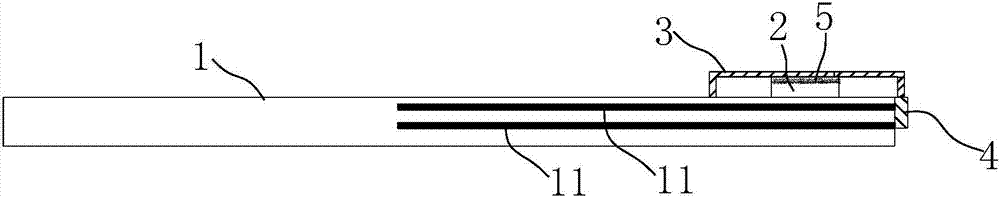

Circuit board heat conduction optimization design structure for onboard aviation product

ActiveCN103687450AIncrease cooling areaReduce thermal contact resistanceCooling/ventilation/heating modificationsAviationSilica gel

The invention provides a circuit board heat conduction optimization design structure for an onboard aviation product. A heat-conductive board is arranged between a high-power highly-heat-radiating device and a PCB. The heat-conductive board is directly and additionally arranged on the PCB, so that the heat dissipation area is greatly increased; meanwhile, a soft silica gel heat-conductive fin is additionally arranged between the high-power highly-heat-radiating device and a heat-conductive aluminum plate so that an air gap can be eliminated, thermal contact resistance between the device and the heat-conductive aluminum plate can be reduced, and heat generated by the device can be rapidly conducted to the heat-conductive aluminum plate. A T-shaped structure of a heat-conductive and radiation heat exchange face is additionally arranged at the top of the heat-conductive aluminum plate. After the soft silica gel heat-conductive fin is additionally arranged on the upper end face of the T-shaped structure, the T-shaped structure is connected with a box body sealing cover into a whole, so that heat is effectively conducted to the surface of a box body, and the heat dissipation area is increased. A wedge-shaped pressing mechanism is adopted, so that the contact area between the heat-conductive aluminum plate and the box body is increased, heat conduction is effectively achieved, the temperature of the surface of an electronic device is rapidly lowered, and the service life of the product is prolonged.

Owner:SHAANXI BAOCHENG AVIATION INSTR

Package structure for soft mounting direct connect storage device

ActiveUS20050257949A1Realize heat conductionOther accessoriesContainer/bottle contructionData processing systemInterposer

A method and article of manufacture for protecting a device from damage caused by physical shocks during shipment, handling, and use of the device are disclosed. A shock-absorbing container is provided with a foam material provided around the device when it is placed in the container. An opening in the container is aligned with respect to the device so as to expose a physical interface of a bay to the physical interface of the device in the container. The device and container are proportioned so that when the container, containing the device, is slid into a bay of a device array or data processing system, the physical interface directly connects with a mating physical interface in the bay without requiring an interposer between the physical interface of the device and the physical interface of the array or data processing system.

Owner:SEAGATE TECH LLC

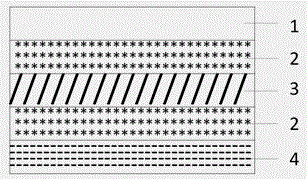

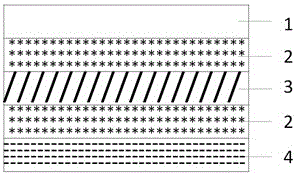

Adhesive tape used as shielding cover and application of adhesive tape

InactiveCN106010338AReduce surface resistancePlay a cooling effectMagnetic/electric field screeningFilm/foil adhesivesConductive coatingOxidation resistant

The invention discloses adhesive tape used as a shielding cover and application of the adhesive tape. When used as the shielding cover, the adhesive tape is excellent in shielding effect, thin and light. The adhesive tape comprises a release layer, a conductive adhesive layer, a fiber layer, a conductive adhesive layer, a conductive base body layer and an anti-oxidization conductive coating which are sequentially connected. The thickness of the adhesive tape is 0.03-0.3 mm. The conductive base body layer is a copper foil layer, an aluminum foil layer, a conductive fabric layer or a stainless steel layer. The thickness of the conductive base body layer is 0.005-0.25 mm. The adhesive tape can achieve electricity conductivity, shielding, grounding, anti-oxidization, heat conductivity and the like at the same time.

Owner:昆山汉品电子有限公司

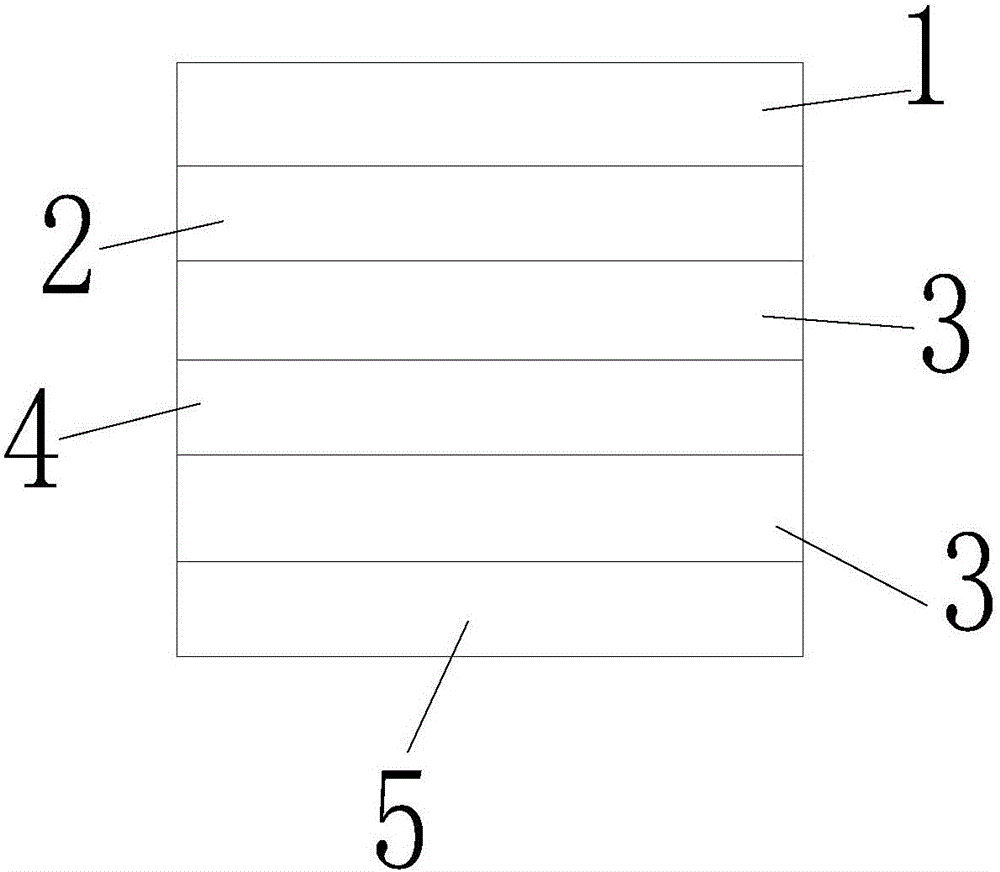

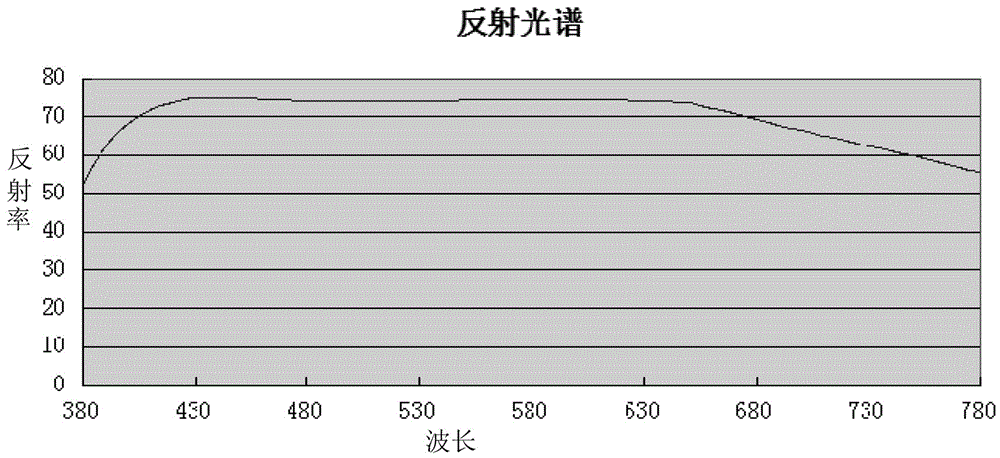

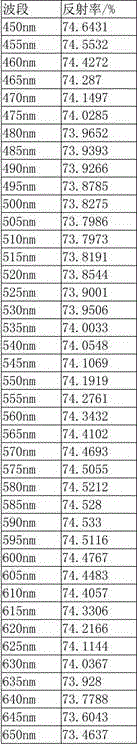

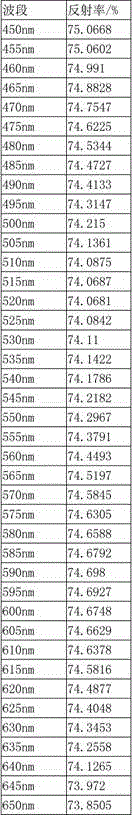

Multi-functional reflective film of on-board exterior mirror and preparation method

The invention discloses a multi-functional reflective film of on-board exterior mirror and the preparation method. The reflective film comprises glass substrates piled in sequence, the first high refractive layer, the first low refractive layer, the second high refractive layer, the second low refractive layer, metal material layer, the third low refractive layer and conducting layer. The first high refractive layer and second high refractive layer are made from Ta2O5, TiO2 and Nb2O5, the first low refractive layer, the second low refractive layer and the third low refractive layer are made from MgF2, SiOxNy and SiO2, the metal material is made from Al and Ag, and the conducting layer is made from ITO and graphene. Inorganic material and conductive material are mixed reasonably. Vacuum magnetron sputtering deposition is used to produce adjustable reflective film used for on-board exterior mirror. Based on this, the film is connected with the heating system through the conductive coating. The mirror will be clean even in the Frost and snow weather, providing safety guarantee during driving.

Owner:YICHANG NANBO DISPLAY

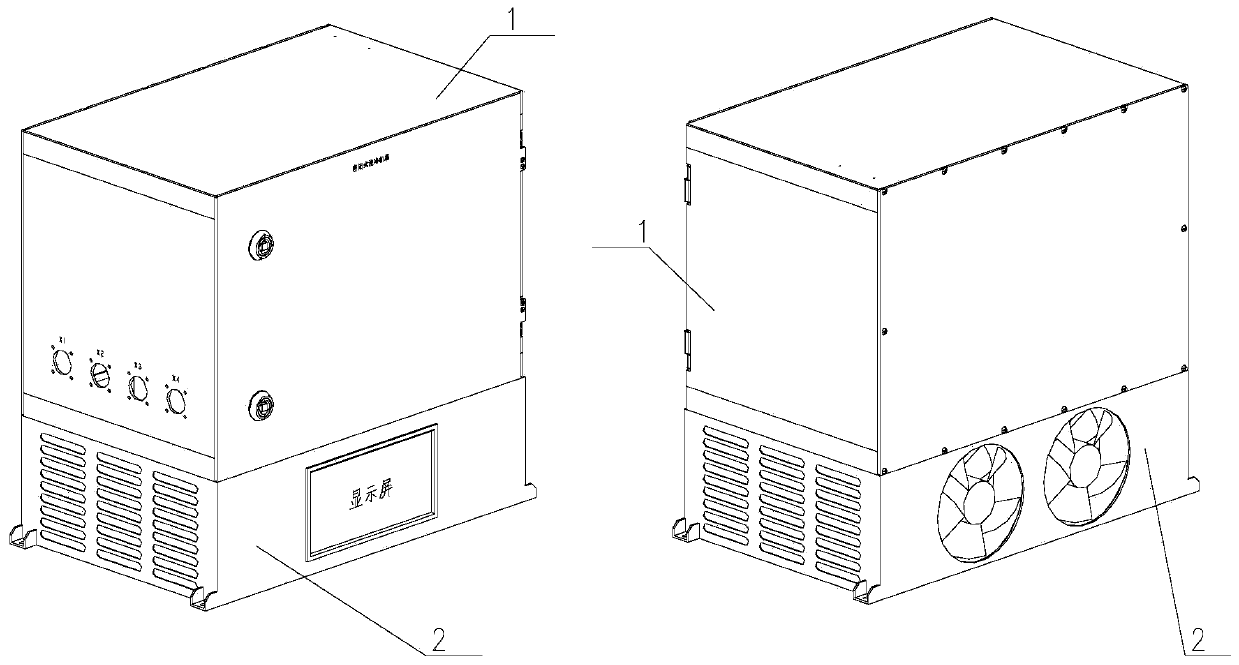

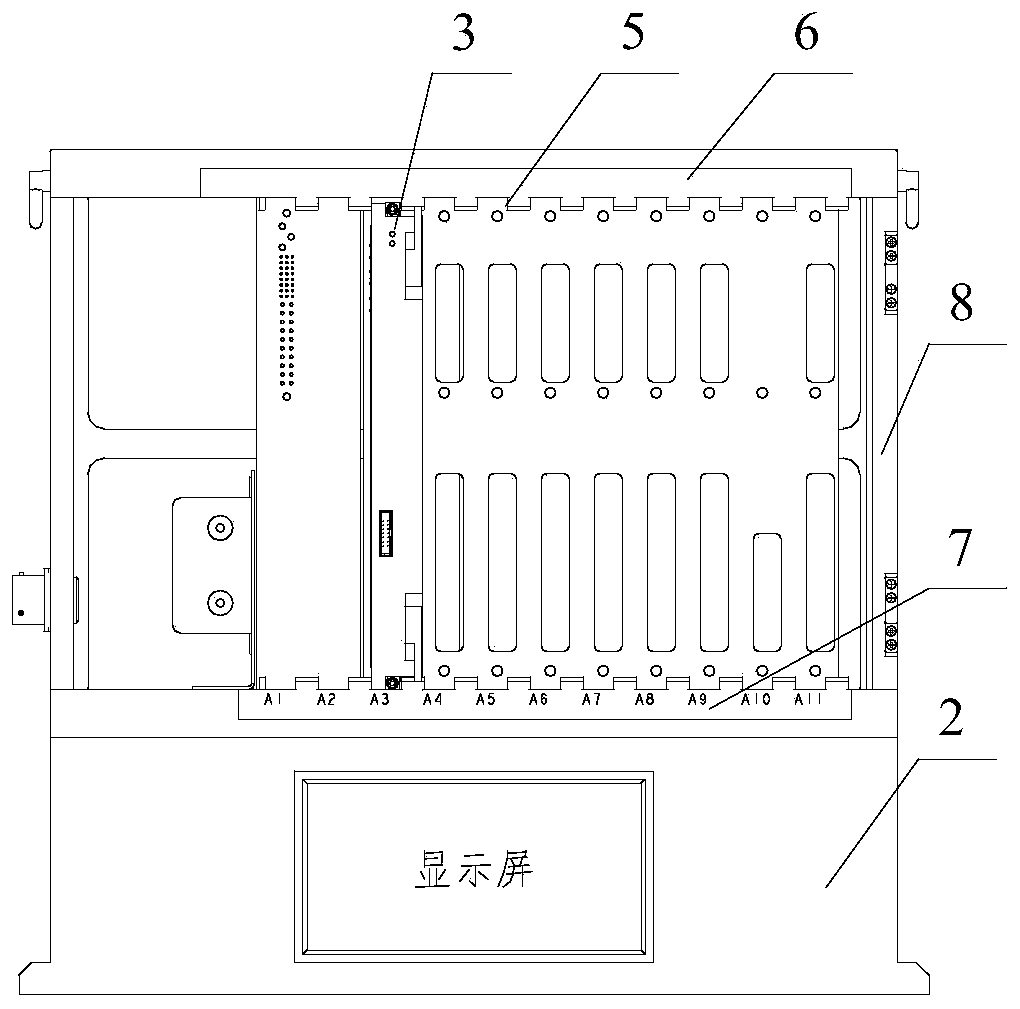

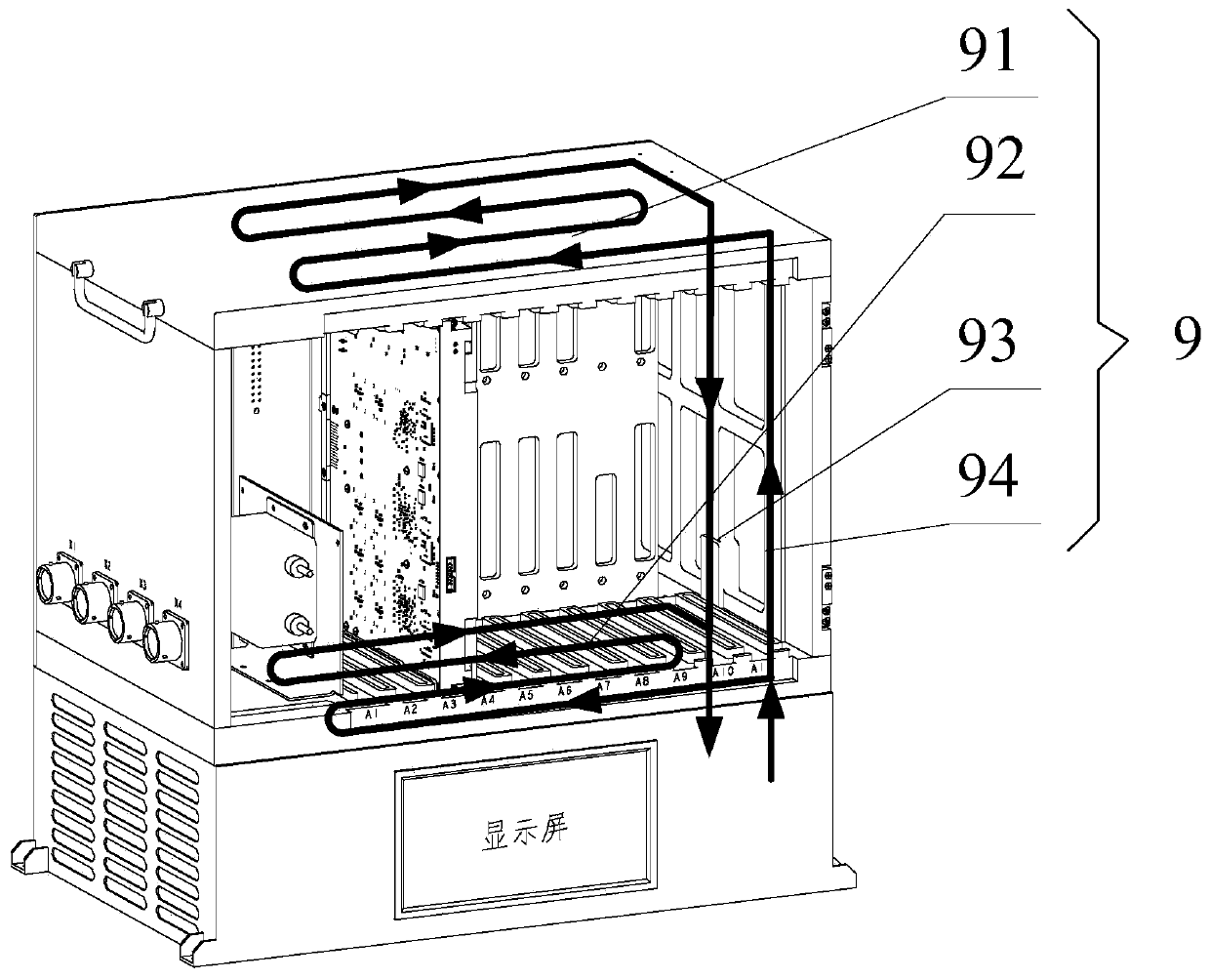

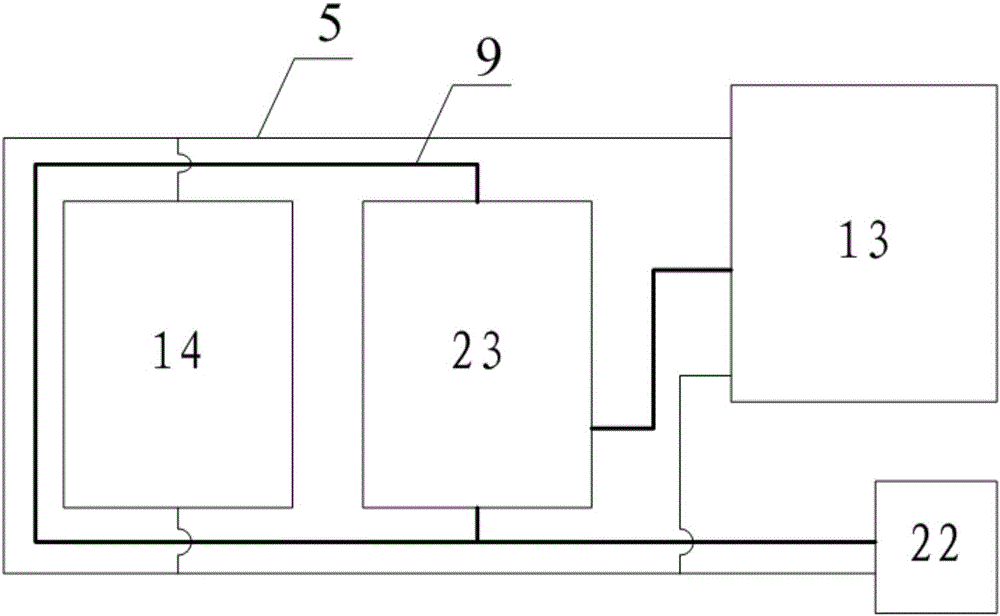

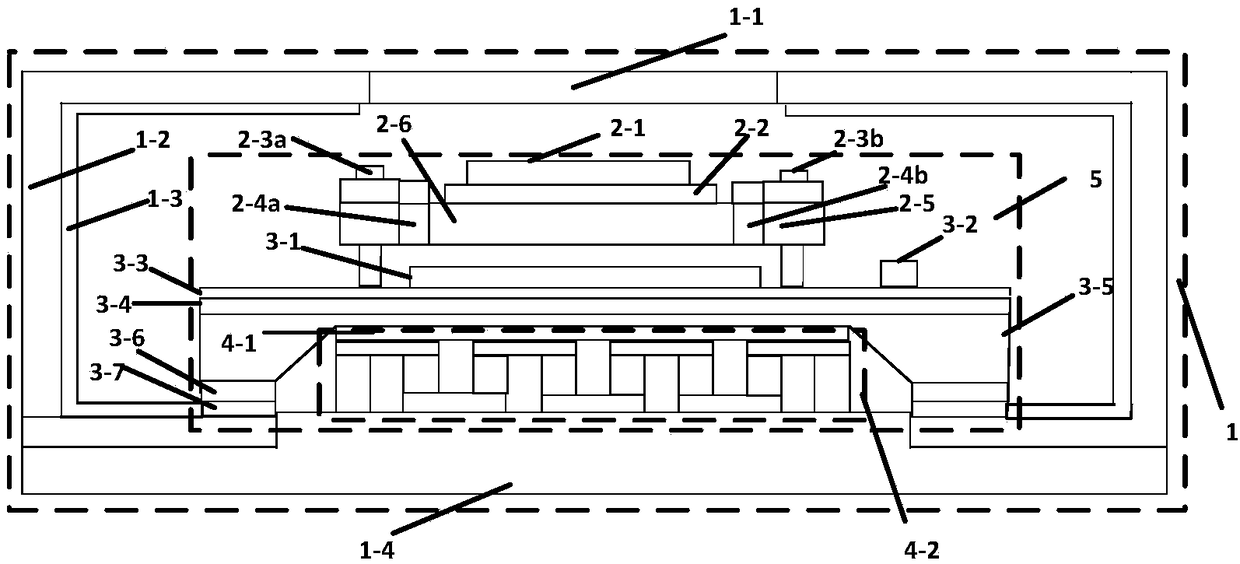

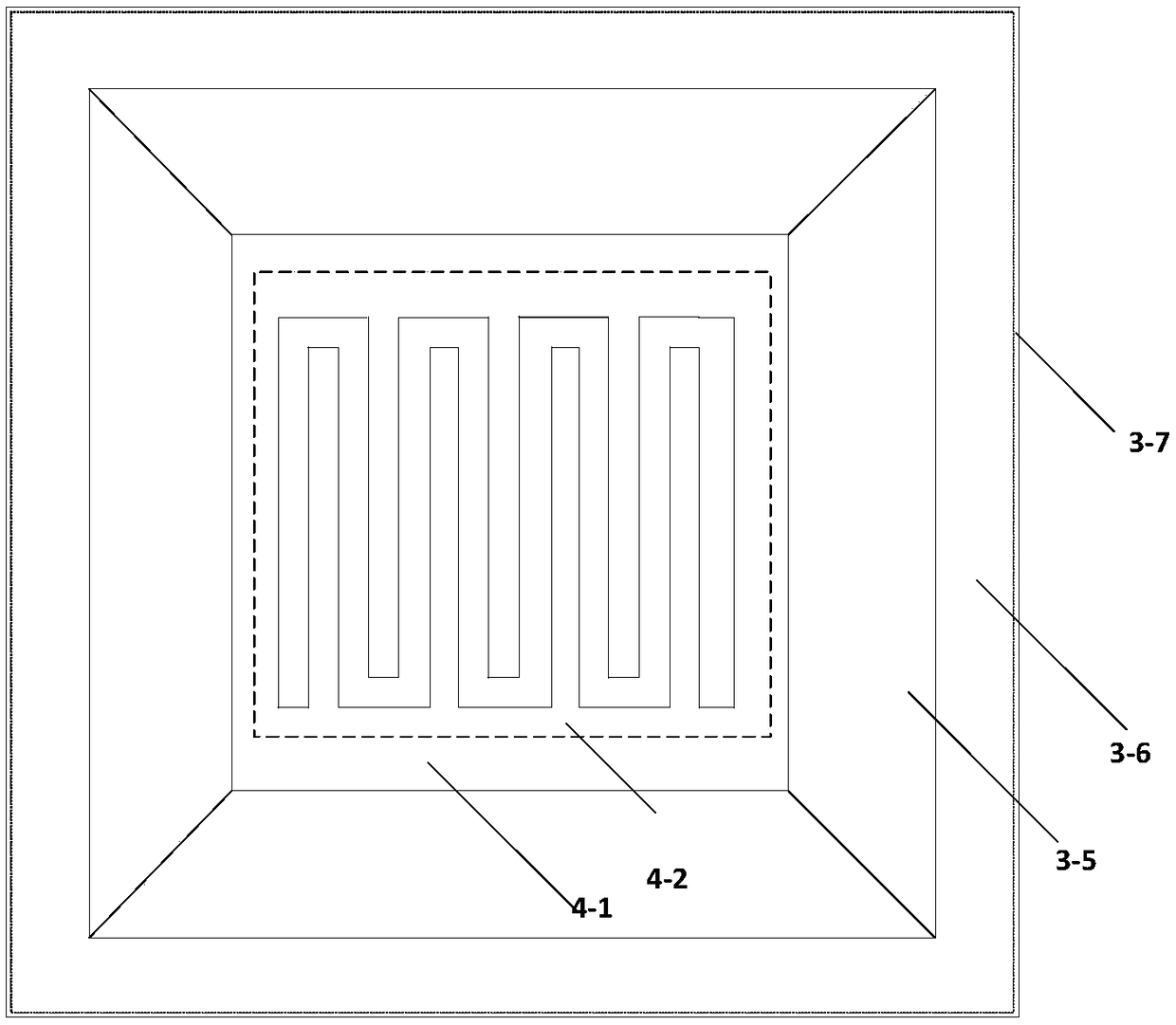

Integrated liquid cooling machine box based on two-phase heat transfer and two-phase heat transfer method thereof

InactiveCN110213942AImprove heat transfer efficiencyGood isothermModifications using liquid coolingSingle phaseIntegrated circuit

The invention relates to an integrated liquid cooling machine box based on two-phase heat transfer and a two-phase heat transfer method thereof. The integrated liquid cooling machine box comprises a machine box shell, a two-phase liquid cooling source and a plug-in cold guide plate, wherein flow channels which are communicated with each other are arranged in the top wall and the bottom wall of themachine box shell; the upper end and the lower end of the plug-in cold guide plate are fixedly connected with the top wall and the bottom wall of the machine box shell respectively, and are used forfixing electronic plug-in components; the two-phase liquid cooling source is fixedly connected with the machine box shell; and each flow channel has a flow channel inlet and a flow channel outlet which are communicated with the two-phase liquid cooling source through pipelines. The two-phase liquid cooling source is fixedly connected with the machine box shell and does not need to depend on an external liquid cooling source. The two-phase liquid cooling source is adopted, and a working medium is subjected to liquid state and gaseous state conversion in a pipeline system; the cooling working medium absorbs the heat of electronic equipment in the flow channels and is changed from the liquid state into the gaseous state, so that heat exchange efficiency is far higher than that of single-phasefluid heat exchange; and the cooling working medium phase change is performed in an isothermal process, so that the isothermal performance of the top wall and the bottom wall of the machine box shellis superior to that of the single-phase fluid heat exchange.

Owner:BEIJING INST OF RADIO MEASUREMENT

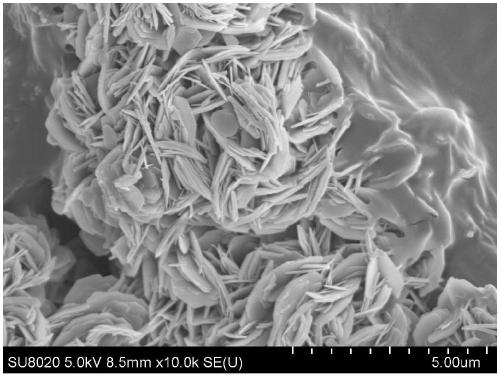

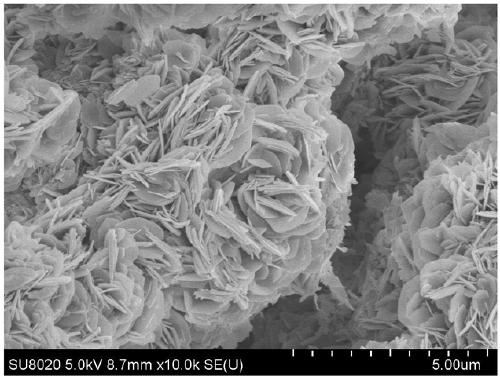

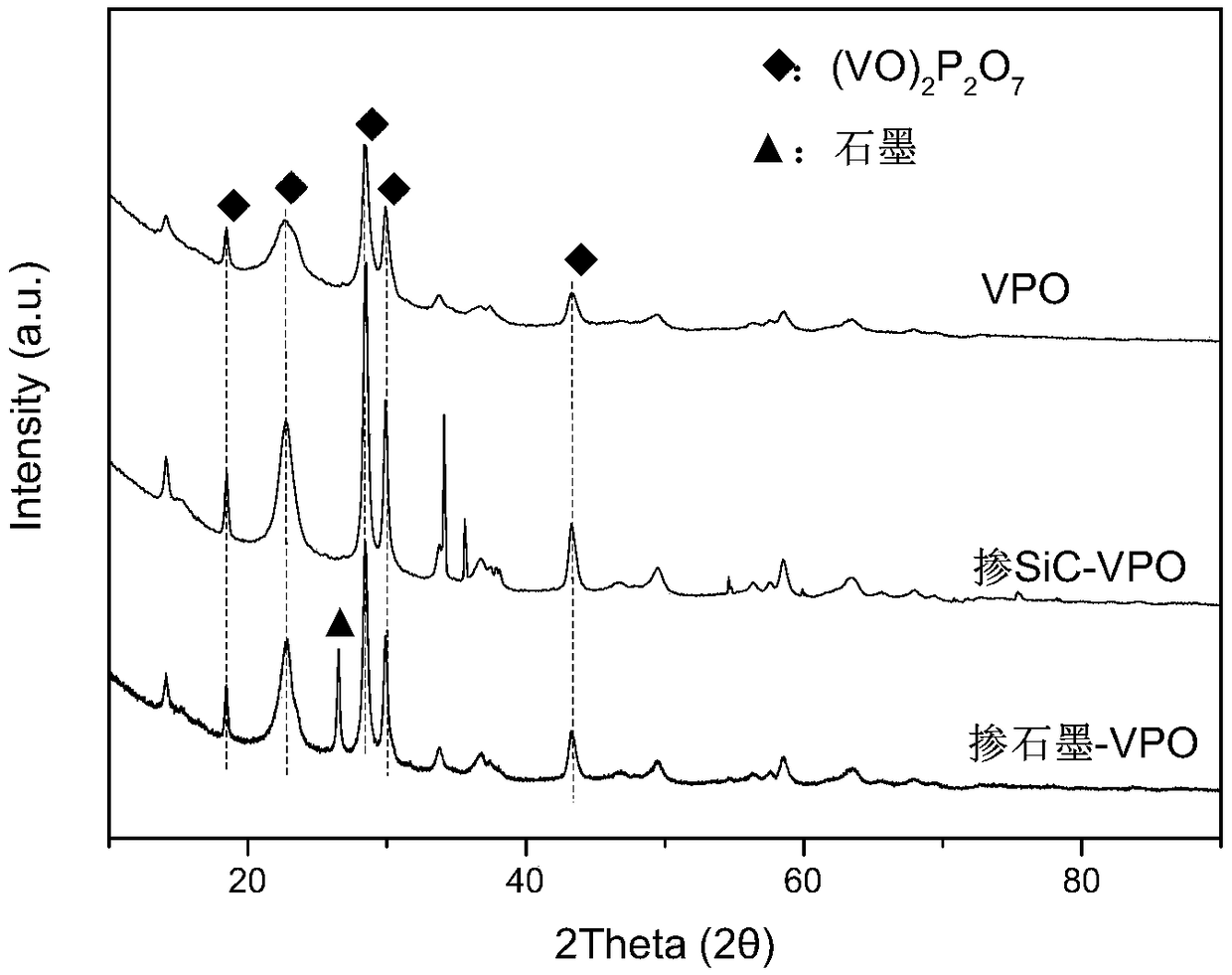

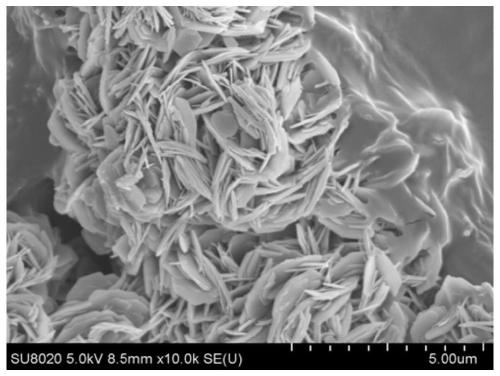

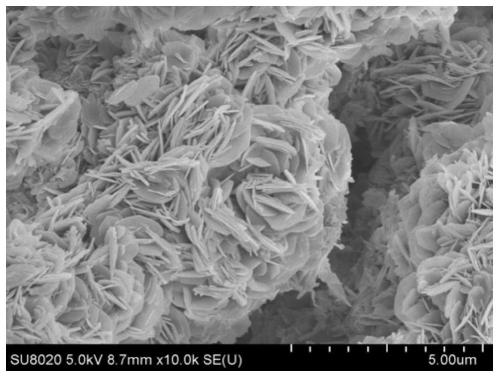

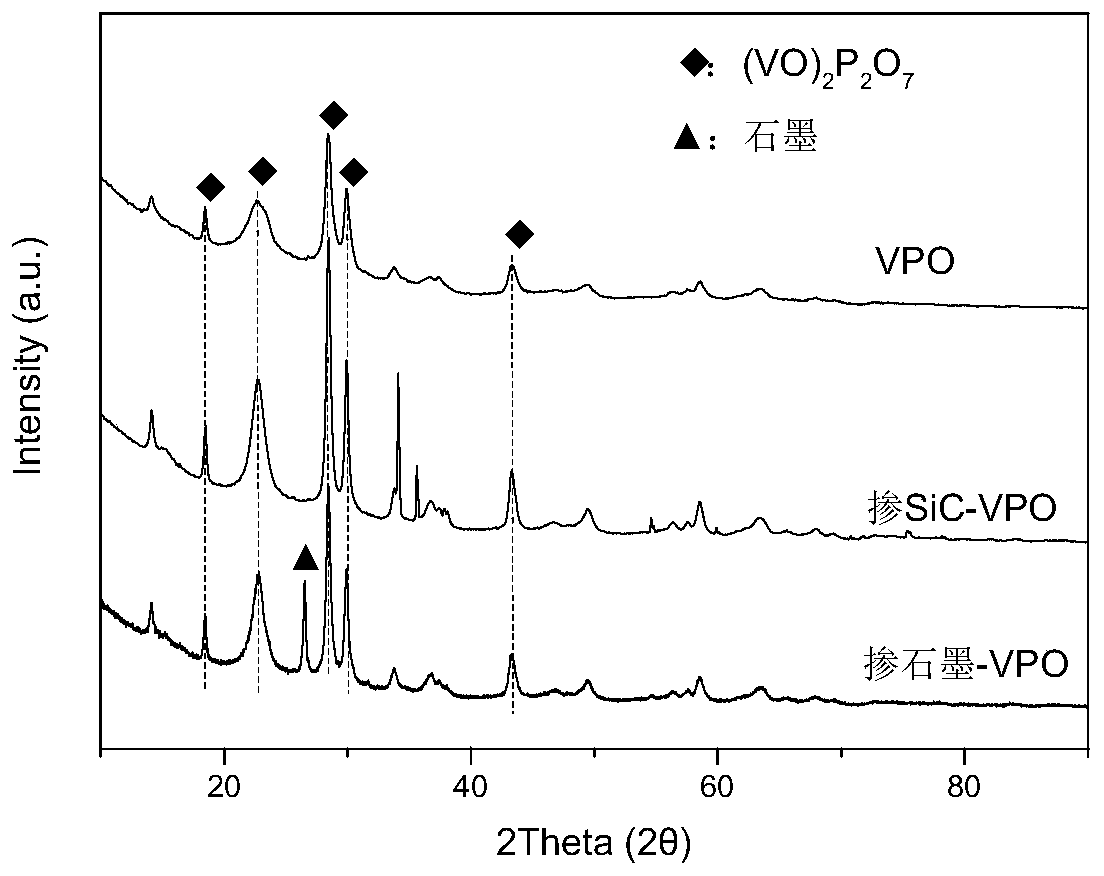

Heat conduction material-doped vanadium phosphorus oxide catalyst, preparation thereof and application thereof to selective catalytic oxidization synthesis of maleic anhydride with n-butane

InactiveCN109395755AHigh selectivityHigh catalytic activityPhysical/chemical process catalystsOrganic chemistryCatalytic oxidationPhosphoric acid

The invention discloses a heat conduction material-doped vanadium phosphorus oxide catalyst, preparation thereof and application thereof to selective catalytic oxidization synthesis of maleic anhydride with n-butane. A preparation method of the catalyst comprises the following steps: placing a vanadium source and a heat conduction material into a fatty alcohol / aromatic alcohol mixed solution for performing a reflux reaction, and adding phosphoric acid for further performing the reflux reaction to obtain a catalyst precursor; placing the catalyst precursor in a protection atmosphere or an n-butane / air mixed atmosphere for activating to obtain the heat conduction material-doped vanadium phosphorus oxide catalyst. The heat conduction material-doped vanadium phosphorus oxide catalyst is dopedwith the heat conduction material, so that the generation of a catalytic active phase is facilitated, the catalyst can be heated uniformly in a catalyzing process, and the catalytic stability, selectivity and activity are improved greatly.

Owner:CENT SOUTH UNIV

LED chip heat dissipation structure

The invention relates to an LED chip heat dissipation structure. The structure includes an LED chip, a heat dissipation cushion and a heat dissipation substrate. The heat dissipation cushion is provided with a groove, and the LED chip is disposed in the groove. Part of the side surface and the bottom of the LED chip are in contact with the heat dissipation cushion. The structure is characterized in that the heat dissipation cushion is at least equipped with a heat dissipation pin, the heat dissipation substrate is equipped with a groove, and the heat dissipation pin is inserted into the groove. Through adoption of the pin and the groove, the heat dissipation cushion and the heat dissipation substrate can be combined together. The pin and the groove achieve fixing and combining effects. Moreover, thermal conduction is achieved when the pin and the groove are in contact, that is to say, heat dissipated from the bottom and the side of the chip is conducted to the heat dissipation substrate through the heat dissipation cushion. Therefore, a heat dissipation function is achieved.

Owner:GOLDEN SCORPION CO LTD

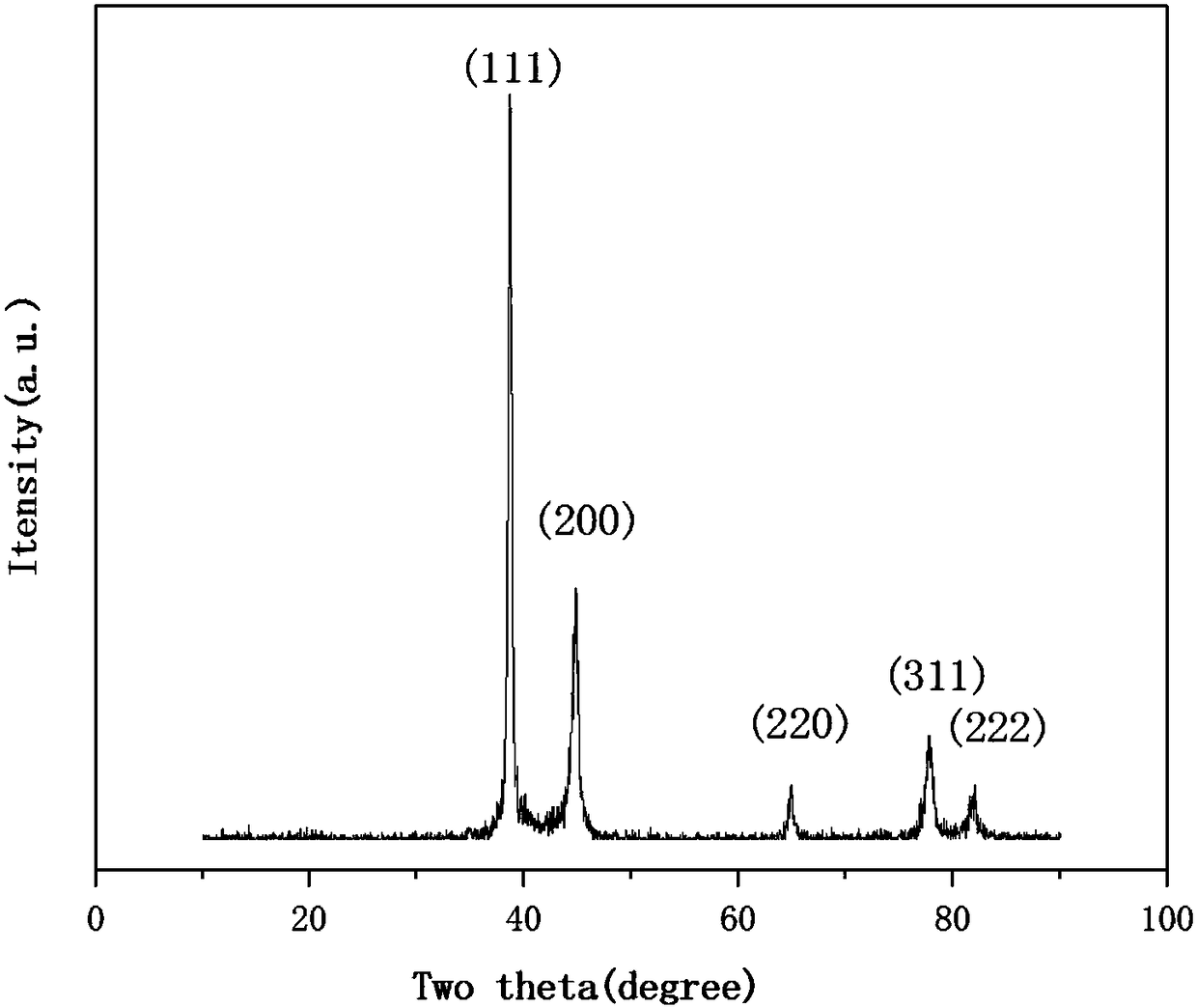

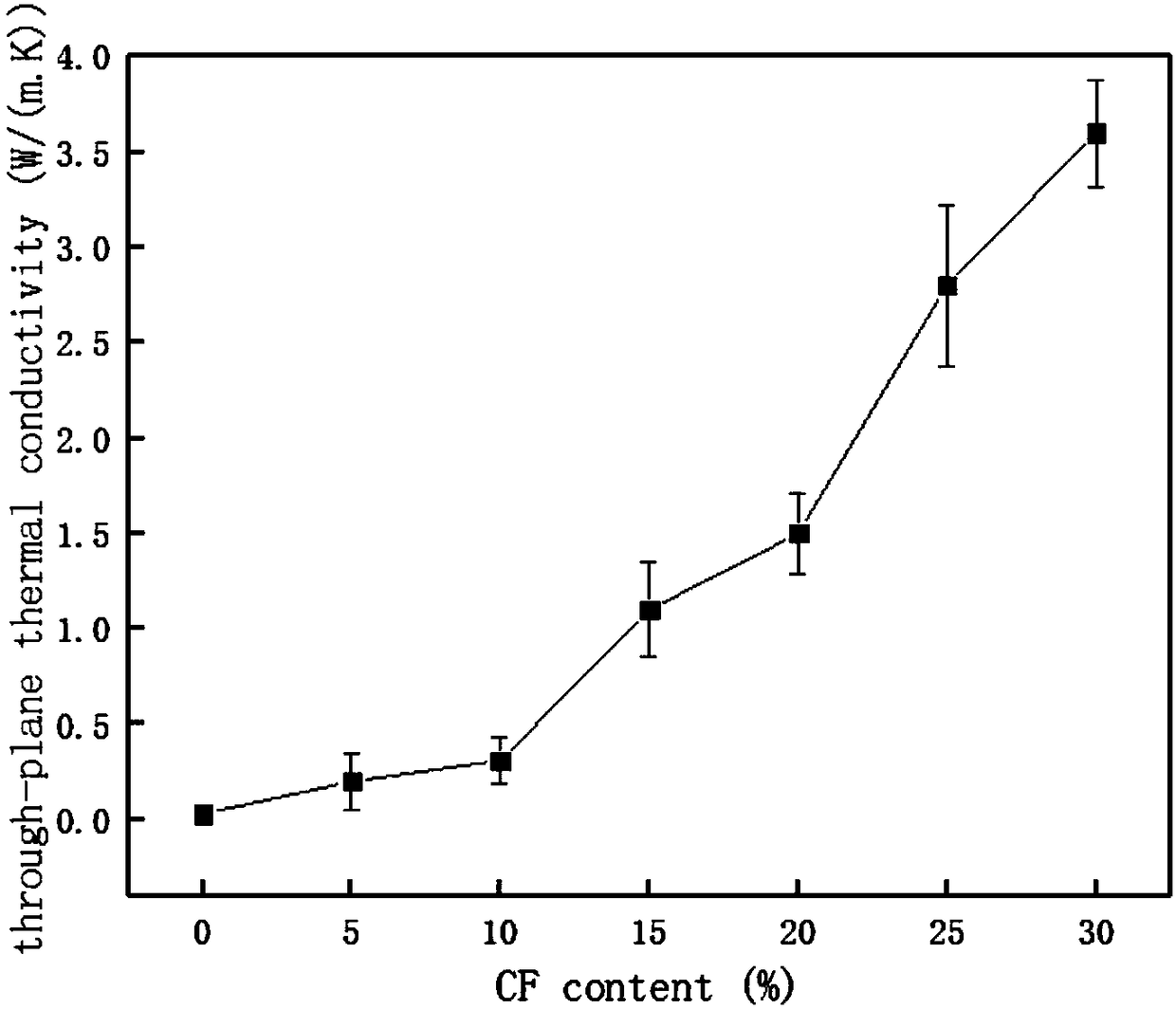

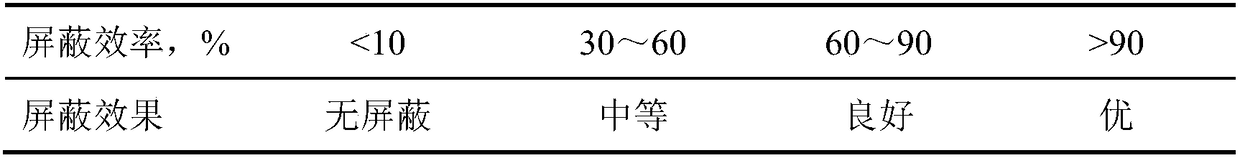

Three-phase double-percolation electromagnetic shielding material and preparation method thereof

The invention discloses an electromagnetic shielding material, which is prepared from the following components in parts by weight: 30 to 50 parts of ABS (Acrylonitrile Butadiene Styrene), 40 to 70 parts of PA66, 7 to 20 parts of silver-plated carbon fiber, 0.5 to 1 part of a plasticizer, 2 to 4 parts of a solubilizer, and 0.5 to 1 part of an antioxygen, wherein the silver-plated carbon fiber is prepared by plating a silver layer with the thickness being 1 to 500nm on the surface of a carbon fiber by adopting an electrodeless silver plating manner. The electromagnetic shielding material provided by the invention breaks through a traditional melt blending process, process parameters, a processing sequence and an extrusion process for preparing a double-percolation structure are designed, anda percolation threshold value of CF is greatly reduced. The method has the advantages of high production efficiency, simpleness in operation, capability of greatly reducing the material cost, and benefit to mass industrial production.

Owner:CHENGDU TECHCAL UNIV

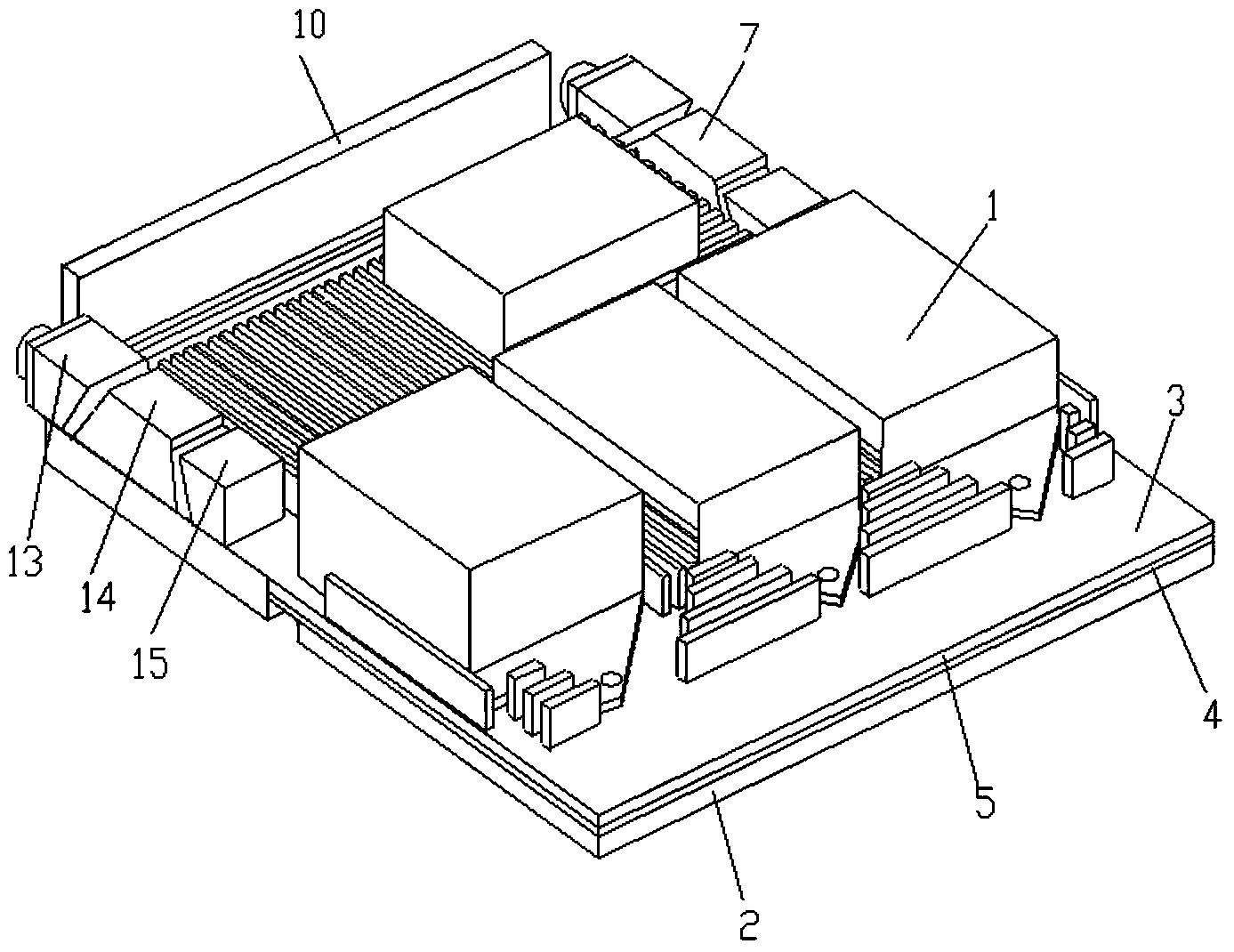

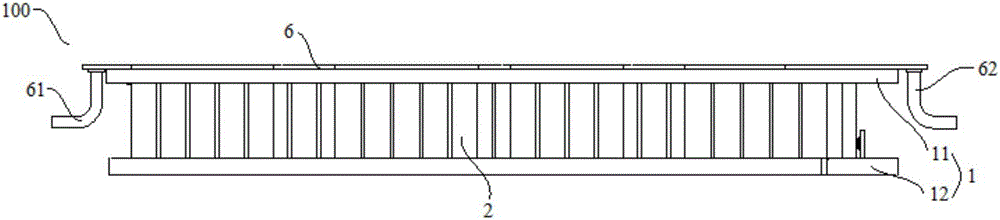

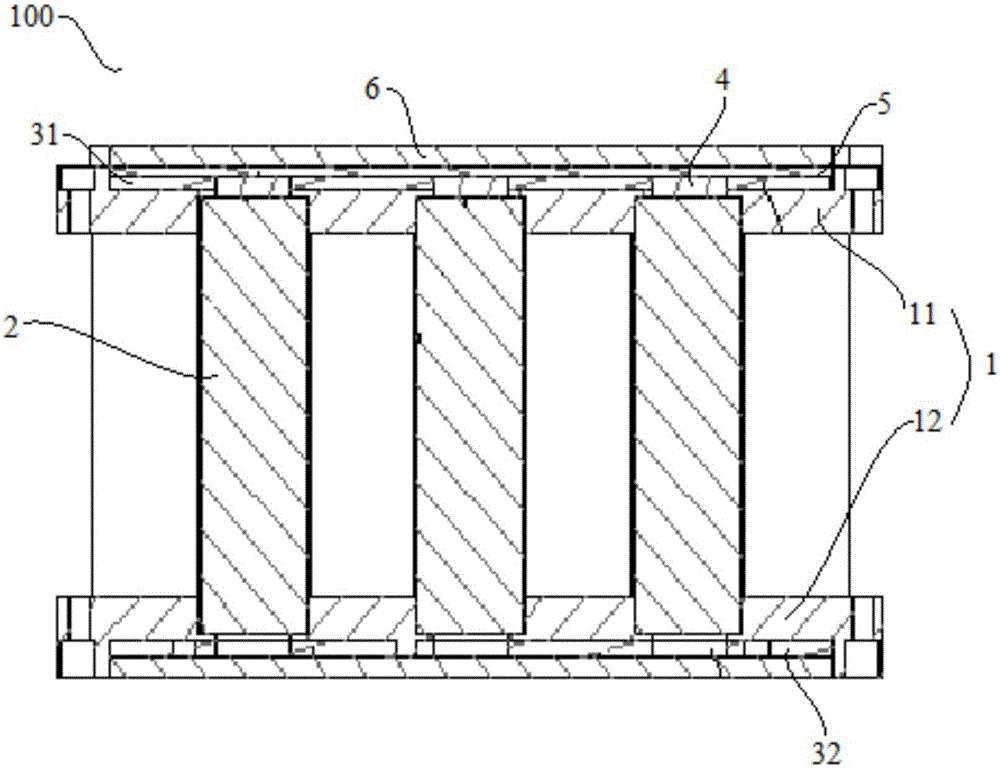

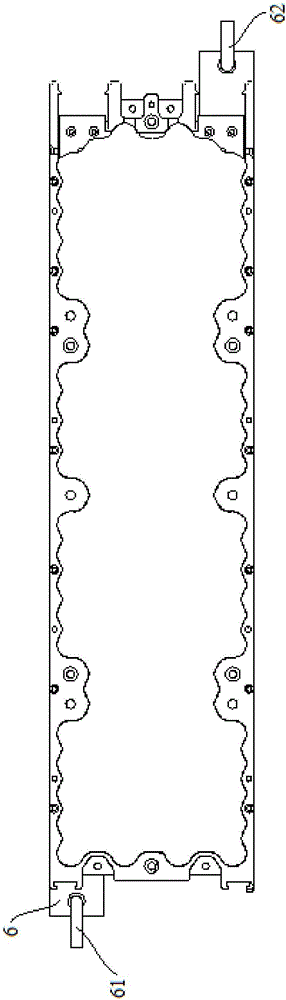

Battery module and vehicle provided with same

ActiveCN106450570ARealize heat conductionIncrease battery temperatureSecondary cellsBusbarEngineering

The invention discloses a battery module and a vehicle provided with the same. The battery module comprises a battery fixing support frame, a series-connection busbar, axial heat conduction structures, an average-temperature heat conduction pad and a heat exchange plate, wherein multiple cylindrical battery cells are arranged on the battery fixing support frame; the series-connection busbar is arranged at one side of the battery fixing support frame and is used for connecting the multiple cylindrical battery cells in series, and an end face of the series-connection busbar, opposite to the cylindrical battery cells, protrudes outwards so as to form grooves between end faces of the cylindrical battery cells and the series-connection busbar; the axial heat conduction structures are arranged in the grooves; the average-temperature heat conduction pad is pasted on the series-connection busbar and are laminated with the multiple axial heat conduction structures; and the heat exchange plate and the average-temperature heat conduction pad are arranged by laminating. According to the battery module disclosed by the invention, efficient balanced heat management of the battery cell temperature can be achieved.

Owner:BEIJING ELECTRIC VEHICLE

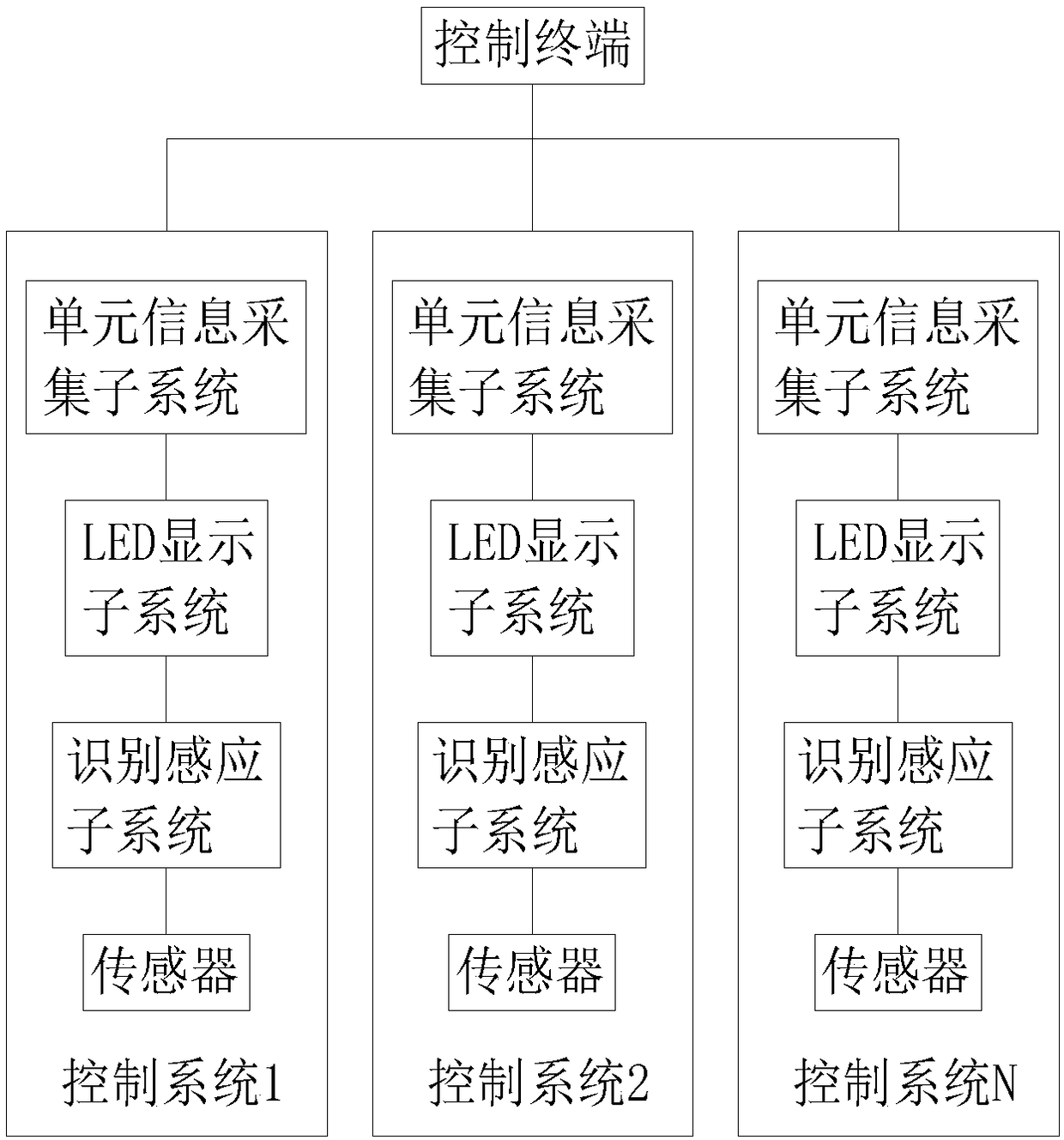

Interactive LED display device and display method thereof

ActiveCN108109581AIncrease diversityAchieve positioningStatic indicating devicesDigital output to display deviceTime responseElectricity

The invention discloses an interactive LED display device, which comprises a control terminal and at least one control system which is connected to the control terminal, wherein the at least one control system comprises a unit information acquisition sub-system, an LED display sub-system and a recognition and induction sub-system which are sequentially electrically connected. According to the interactive LED display device provided by the invention, when a sensor in the LED display device is touched and triggered by a human body, induction signals are returned to the control terminal via the sensor, and the induction signals are located via the control terminal and the unit information acquisition sub-system, so that corresponding playing data can be controlled to play via an LED display screen module, a real-time response effect can be achieved and response-point localization can be implemented; and an always-on-display state is kept or specific videos are played when the LED displayscreen module is not triggered. When the induction signals of the LED module are touched by the human body or an object, corresponding play contents or specific functions of a touch point are startedvia the control terminal. Therefore, the LED display device and display contents can be controlled by a person in a touch mode, and diversity of the functions and display contents of the LED display device can be enhanced.

Owner:深圳鑫亿光科技有限公司

Oxyvanadium phosphate catalyst and preparation method and application thereof

InactiveCN109731594AEvenly heatedUniform and stable heatingOrganic chemistryPhysical/chemical process catalystsAlcoholPhosphate

The invention belongs to the technical field of catalysis and mainly relates to a preparation method of an oxyvanadium phosphate catalyst and application of the oxyvanadium phosphate catalyst in maleic anhydride preparation using selective n-butane oxidation. The preparation method includes the steps of firstly, mixing a vanadium source, benzyl alcohol, C1-C8 monohydric alcohol and a heat-conduction material to obtain a mixture, and performing reaction, wherein the heat-conduction material is at least one of SiC, graphite, graphene and carbon nanotubes; secondly, mixing the reaction product obtained in the first step with a phosphorus source, heating to 100-200 DEG C, and performing reaction to obtain a oxyvanadium phosphate precursor; thirdly, calcining to obtain the oxyvanadium phosphatecatalyst. The preparation method has the advantages that the heat-conduction material is added during the preparation and can effectively achieve heat conduction to solve the problem of local overheat; the uniform and stable formation of active phase is promoted effectively, the catalyst is promoted to be heated evenly during reaction, and catalyst performance is increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing aluminum foil power conductive, heat conductive, shock resistance and shielding adhesive tape

InactiveCN106281080AGood dispersionIncrease stickinessNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveShock resistance

The invention discloses a method for preparing an aluminum foil power conductive, heat conductive, shock resistance and shielding adhesive tape. The method comprises the following steps: S1, selecting an aluminum foil preparation base material layer; S2, mixing 20-30 parts by weight of nano-grade metal powder and 10-15 parts of nano-grade powdered graphite, adding 40-60 parts of methylbenzene, stirring for 5-10 minutes, adding a 10-15wt% power and heat conductive liquid, stirring for 15-20 minutes so as to obtain a power and heat conductive adhesive; S3, preparing a release material layer from a release material, coating the release material layer with the power and heat conductive adhesive by using a coating machine, curing for 5-10 minutes inside an oven of 80-100 DEG C, curing the power and heat conductive adhesive as a power and heat conductive adhesive layer, and transferring to two sides of the base material layer so as to obtain an aluminum foil double-sided adhesive with release material layers on both sides; S4, preparing a shock resistance material layer from all-direction power conductive sponge. The adhesive tape is simple in structure, comprises an all-direction power conductive sponge layer and a power and heat conductive adhesive layer, and is capable of achieving functions of power conduction, heat conduction, shock resistance and shielding.

Owner:斯迪克新型材料(江苏)有限公司

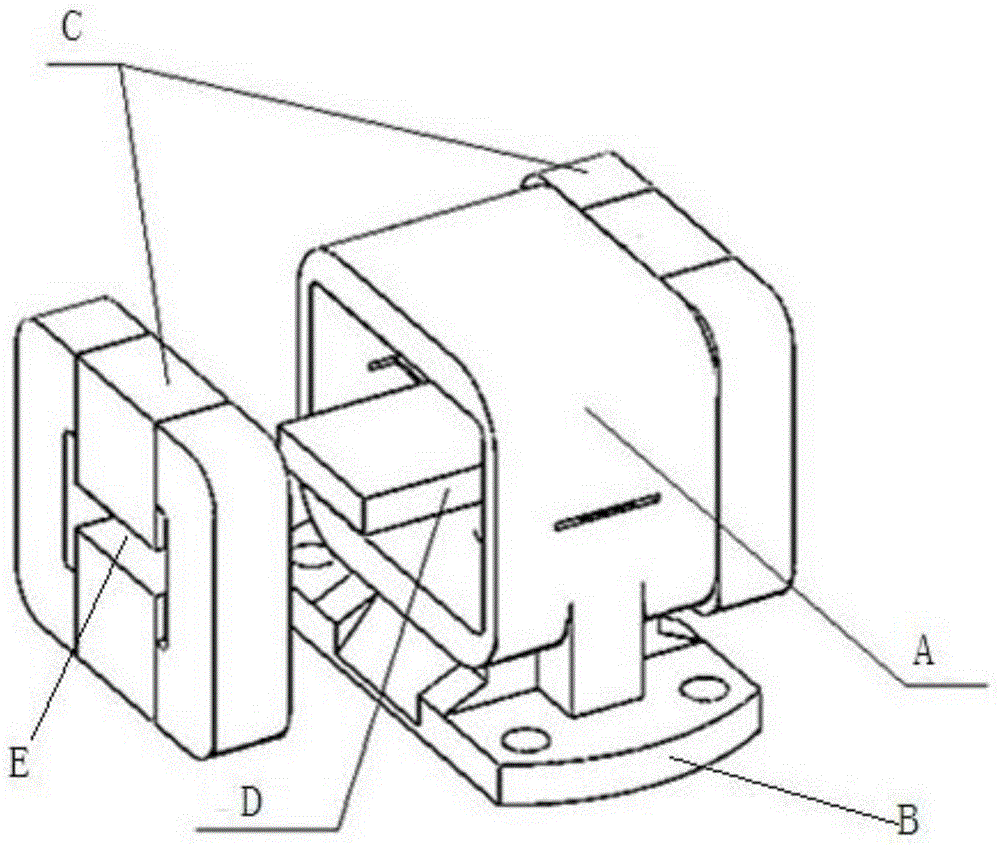

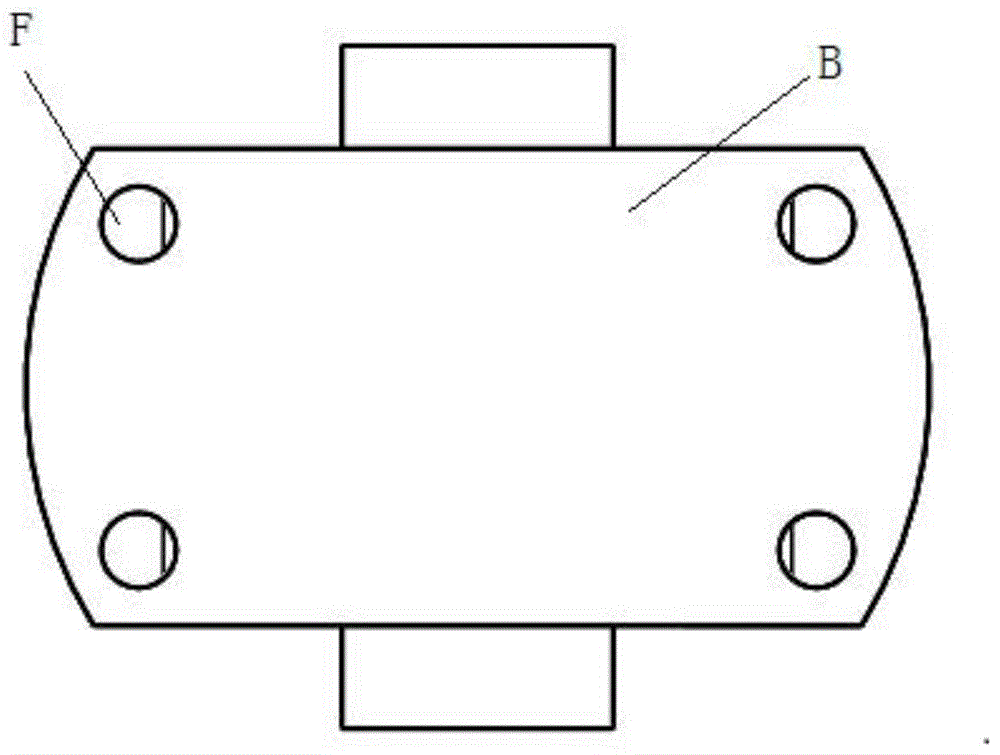

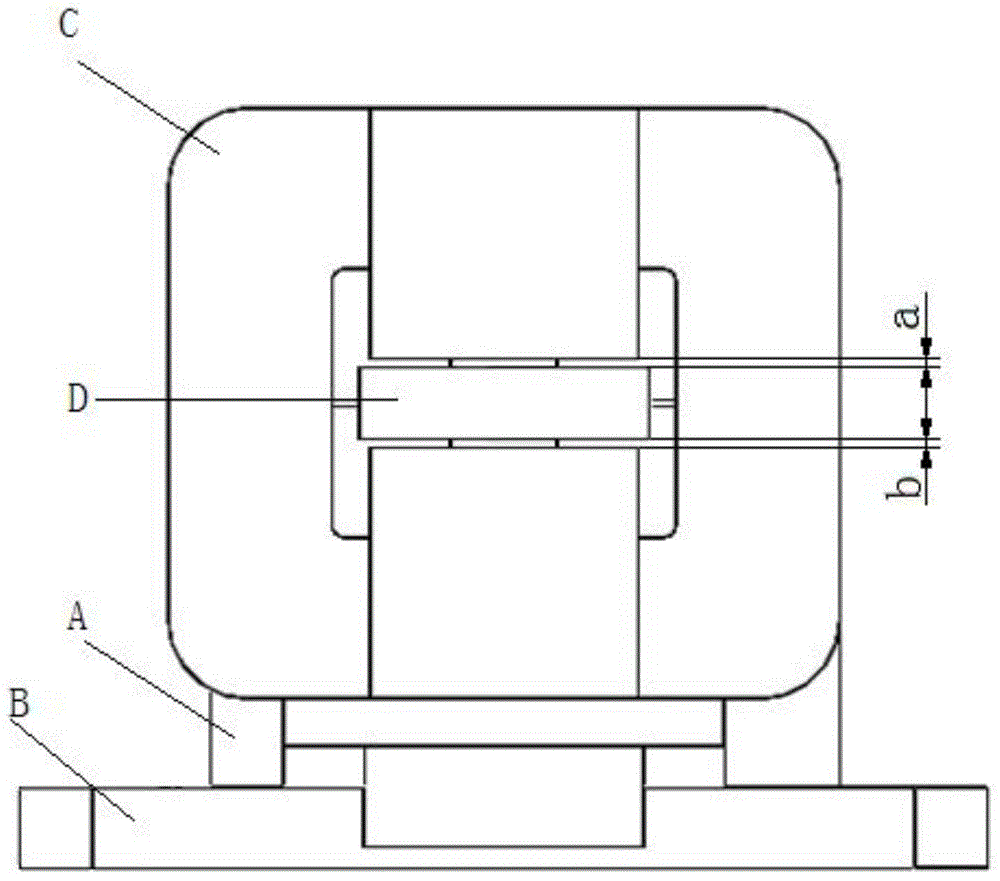

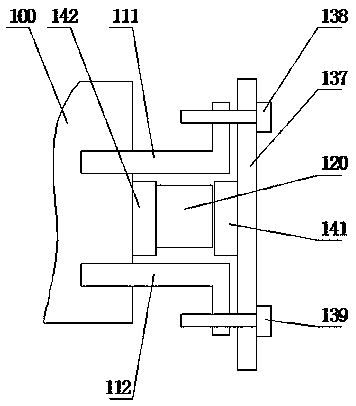

Positioning tool clamp for precision box-shaped sensor welding and using method of positioning tool clamp for precision box-shaped sensor welding

ActiveCN104858593AAvoid damageEasy to observeWelding/cutting auxillary devicesAuxillary welding devicesDirect observationEngineering

The invention discloses a positioning tool clamp for precision box-shaped sensor welding and a using method of the positioning tool clamp for precision box-shaped sensor welding. An observation window is arranged in the center of an upper plate; radiating clamping devices are arranged at the positions, on the periphery of the observation window, on the lower surface of the upper plate, a stand column penetrates through a guide rail sleeve and penetrates through the upper plate, a middle plate and a lower plate, the two ends of the stand column are fixed to the upper plate and the lower plate respectively, and a spring is arranged at the position, between the vertical part of the middle plate and the vertical part of the lower plate, of the stand column. Compared with the prior art, according to the technical scheme, the spring, a rapid clamp and the radiating clamping devices are jointly matched to complete clamping of a box-shaped sensor body and a cover plate assembly, and therefore relative slippage of the box-shaped sensor body and the cover plate assembly can be avoided; the radiating clamping devices are adopted, heat conduction in the welding process can be achieved while the clamping force is used, and therefore damage of welding heat to a box-shaped sensor is avoided; the direct observation window is arranged, the size required by welding is conveniently observed and adjusted.

Owner:TIANJIN UNIV

Preparation method of copper foil electricity-conducting, heat-conducting, anti-shock and shielding adhesive tape

InactiveCN106273790AGood dispersionIncrease stickinessNon-macromolecular adhesive additivesFilm/foil adhesivesElectricityHeat conducting

The invention discloses a preparation method of copper foil electricity-conducting, heat-conducting, anti-shock and shielding adhesive tape. The preparation method includes the following steps that S1, copper foil is selected and prepared into a base material layer; S2, 20-30 parts by weight of nano-scale metal powder and 10-15 parts by weight of nano-scale graphite powder are mixed, then 40-60 parts by weight of methylbenzene is added, after the materials are stirred for 5-10 min, 10 wt% to 15 wt% of electricity-conducting and heat-conducting liquid is added, the materials are stirred for 15-20 min, and an electricity-conducting and heat-conducting adhesive is prepared; S3, a release material is selected and prepared into a release material layer, the release material layer is coated with the electricity-conducting and heat-conducting adhesive through a coating machine, then the release material layer is cured in an oven at the temperature of 80-100 DEG C for 5-10 min, the electricity-conducting and heat-conducting adhesive is cured into electricity-conducting and heat-conducting adhesive layers, the electricity-conducting and heat-conducting adhesive layers are transferred to the two faces of the base material layer, and the copper coil double-faced adhesive tape with the two sides provided with the release material layers is prepared. The structure is simple, an omni-bearing electricity-heating sponge layer and the electricity-conducting and heat-conducting adhesive layers are arranged, and the electricity-conducting, heat-conducting, anti-shock and shielding effects can be achieved.

Owner:斯迪克新型材料(江苏)有限公司

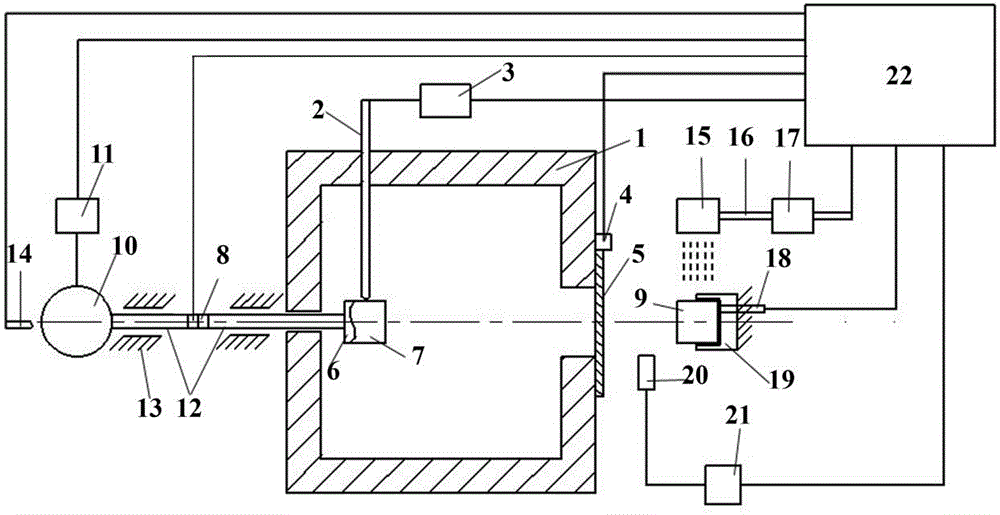

Hot working die thermo-mechanical fatigue tester

ActiveCN106769451AImprove reliabilityImprove stabilityMaterial strength using tensile/compressive forcesStressed stateHeat load

The invention relates to a hot working die thermo-mechanical fatigue tester. The tester comprises a hot working die mounting base and a preform block mounting base. The tester also comprises a power mechanism for driving the hot working die mounting base and the preform block mounting base to carry out motion towards each other in the opposite directions and motion far from each other in the opposite directions. The tester also comprises a heating device for heating a preform block on the preform block mounting base. The heating device is used for heating the preform block and then the power mechanism drives the hot working die to carry out ejection-pressing fit to the preform block so that heat conduction between the hot working die and the preform block is realized and thus the hot working die is heated and the real working condition of the hot working die in a mechanical stress cycle and a temperature cycle is simulated. The tester realizes an alternating mechanical stress state and an alternating heat load state of the hot working die under actual motion conditions and has the characteristics of high reliability, good stability and measured value close to the real value.

Owner:HENAN UNIV OF SCI & TECH

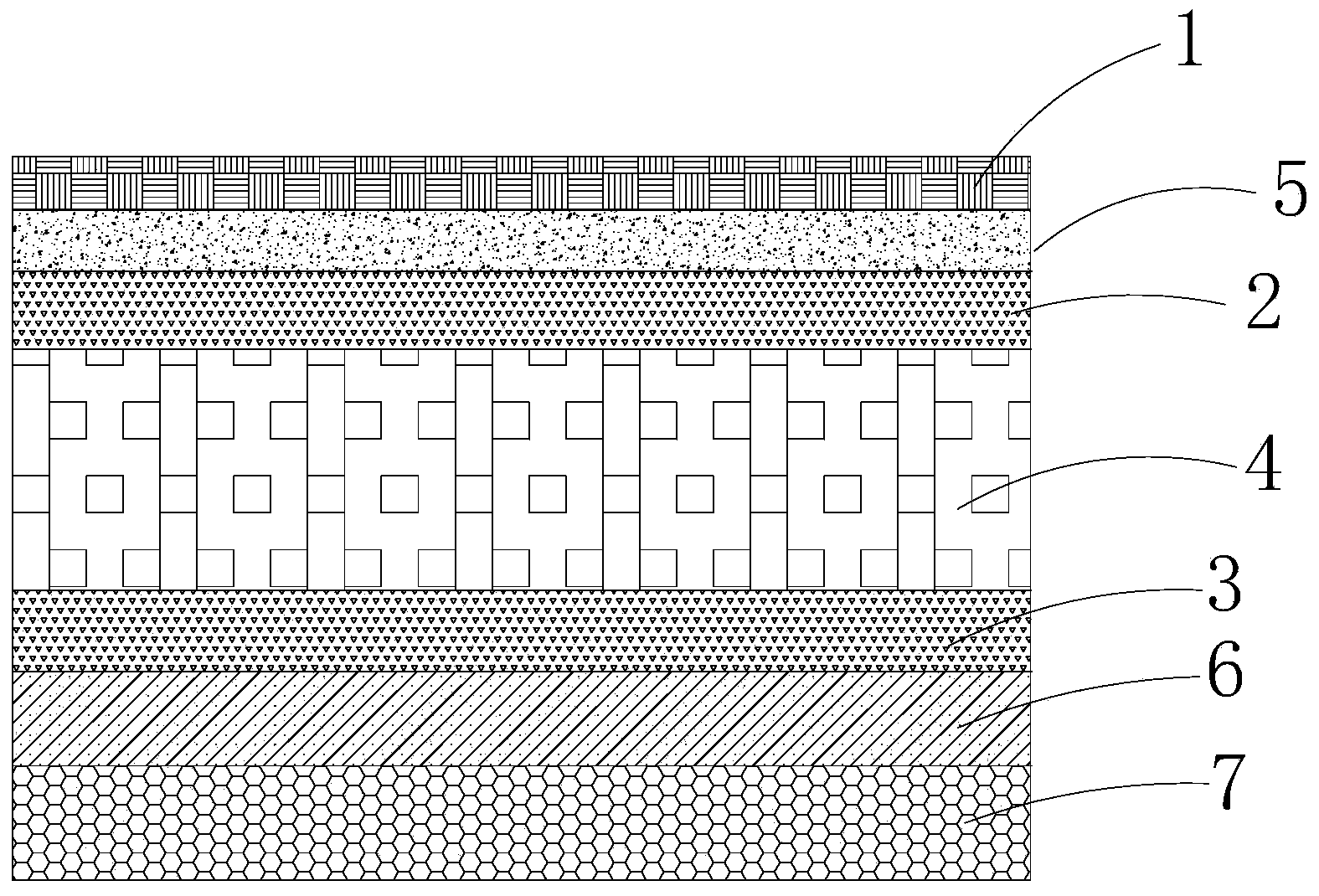

Energy-saving wall with functions of heat preservation and heating

InactiveCN108547399AUniform temperatureImprove insulation effectLighting and heating apparatusWallsInsulation layerReinforced concrete

The invention relates to an energy-saving wall with the functions of heat preservation and heating. The energy-saving wall comprises a composite sandwich steel wire net frame heat-insulation plate, amain body layer formed by a cast-in-place reinforced concrete layer, and an outer protective layer formed by a concrete layer. An inner steel wire net piece and an outer steel wire net piece of the composite sandwich steel wire net frame heat-insulation plate are fixedly bonded in the main body layer and the outer protective layer. An inner heat-insulation layer, a heating bracket, an inner protective plate, a net cloth and a surface coating are arranged on the inner side of the main body layer in sequence. A heating pipeline is mounted in the heating bracket. A heat-insulating pad or a heat-insulating sleeve is arranged between a bracket connecting piece and the heating bracket. The inner protective plate is provided with a plurality of longitudinal through holes. At least part of longitudinal through holes is not shielded by the net cloth. According to the energy-saving wall, the heat-insulation effect of the wall is improved obviously, the heat bridge effect is reduced obviously, the proportion of heat dissipating of heating heat energy to a wall structure and an outdoor space is decreased obviously, the utilization ratio of the heating heat energy is increased obviously, and the good building energy-saving effect is obtained accordingly.

Owner:牛光华

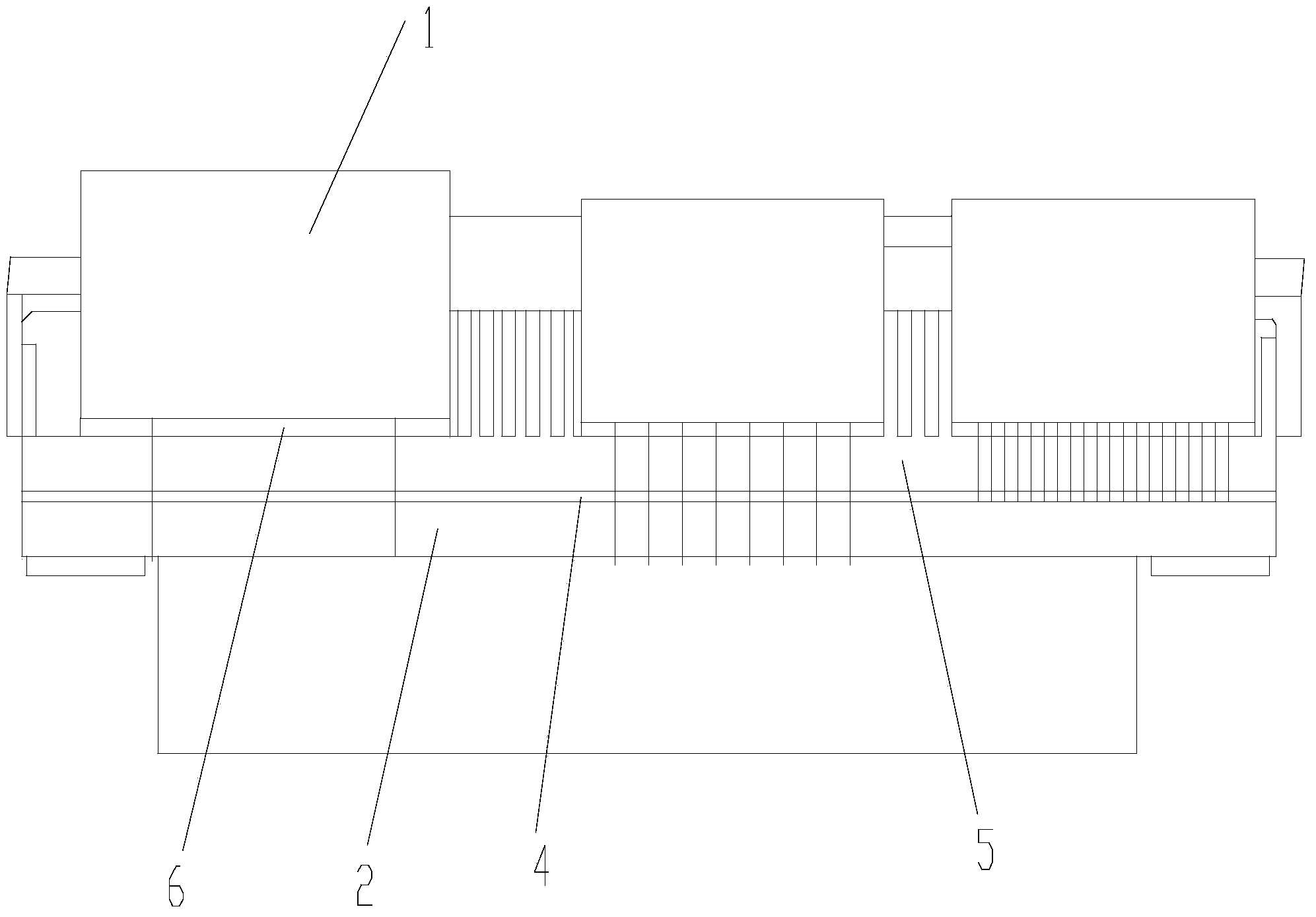

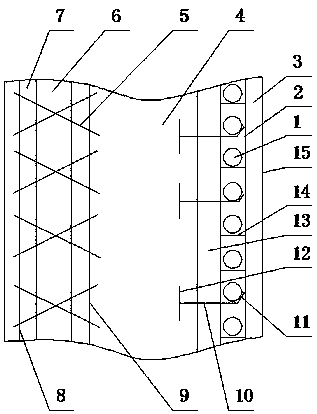

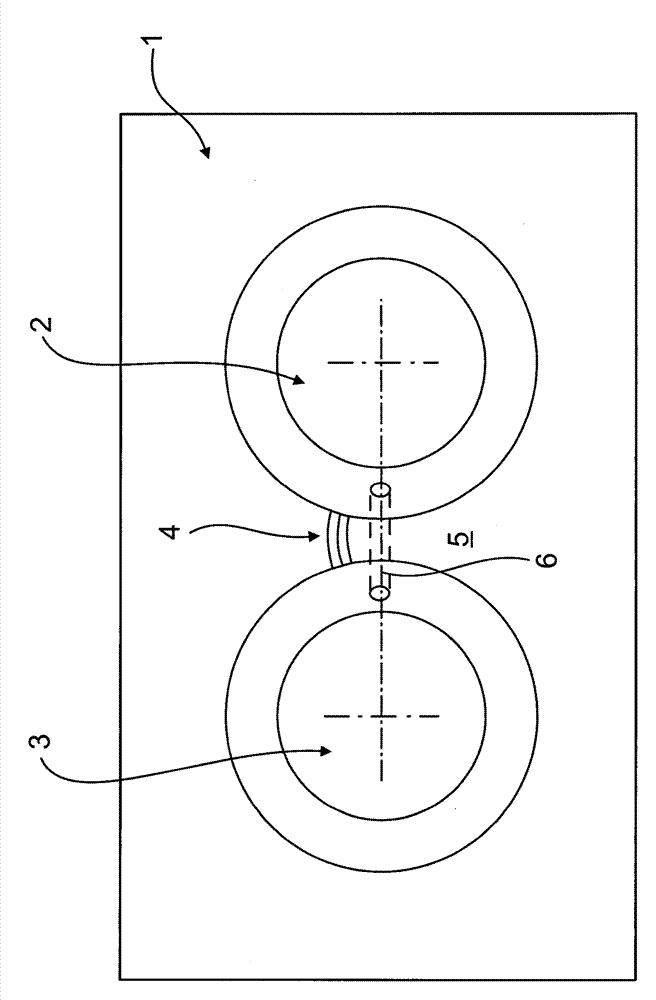

Heat tube cooling system and power equipment

ActiveCN103619150ARealize heat conductionSave spaceIndirect heat exchangersCooling/ventilation/heating modificationsEngineeringPower equipment

The invention discloses a heat tube cooling system and power equipment. The heat tube cooling system comprises first heat exchange tubes, a first heat exchange plate, a second heat exchange plate, second heat exchange tubes and a condensing unit, or the heat tube cooling system comprises the first heat exchange tubes, a heat exchange device with a cavity, the second heat exchange tubes and the condensing unit. In the working process, heat conduction between a heating device and the condensing unit can be achieved, and in the overhauling process, the heating device and the condensing unit can be separated and can be respectively maintained. The power equipment comprises the heat tube cooling system, an equipment cabinet and electronic components. By means of the heat tube cooling system and the power equipment, the heating device and the condensing unit can be mutually detached, the heating device is mounted inside the equipment cabinet, the condensing unit is mounted outside the equipment cabinet, during daily maintenance, the heating device and the condensing unit are separated, the inside of the cabinet and the outside of the cabinet can be respectively maintained, and thus the maintaining and cleaning work can be completed rapidly.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

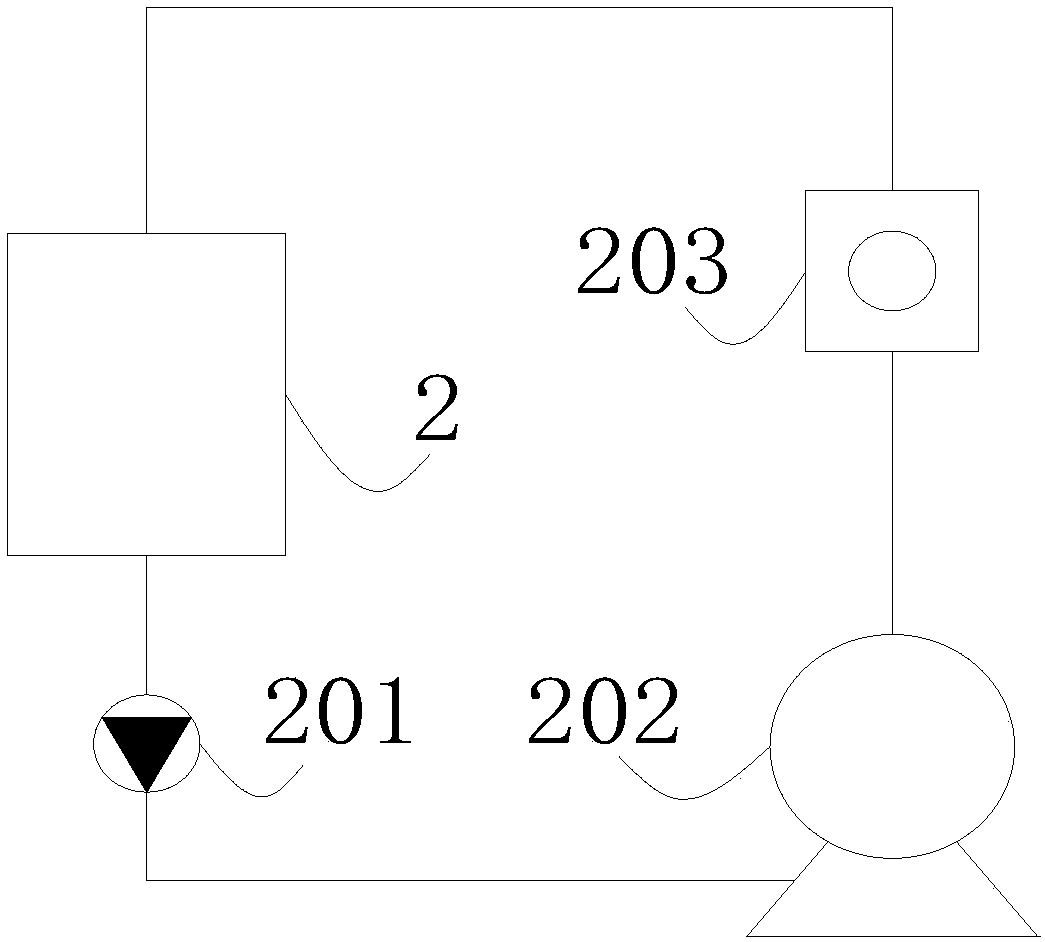

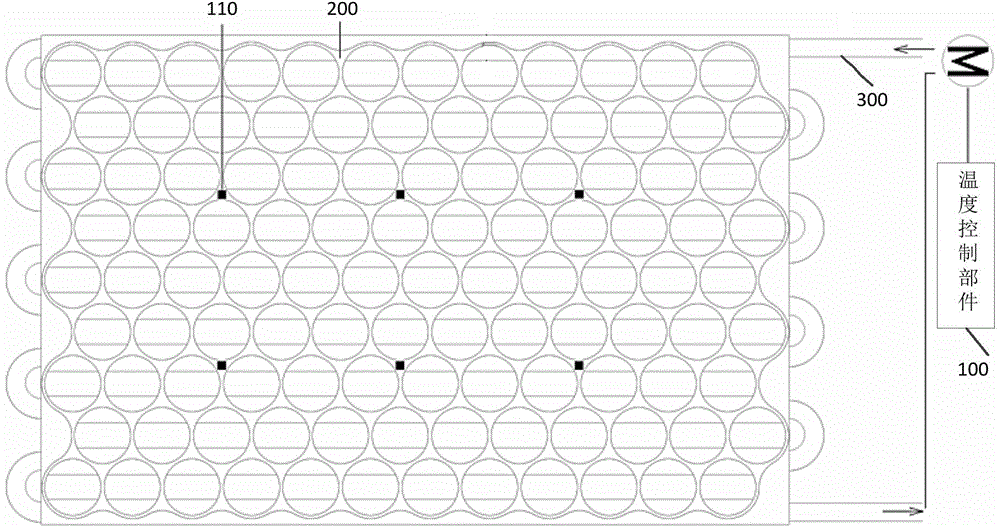

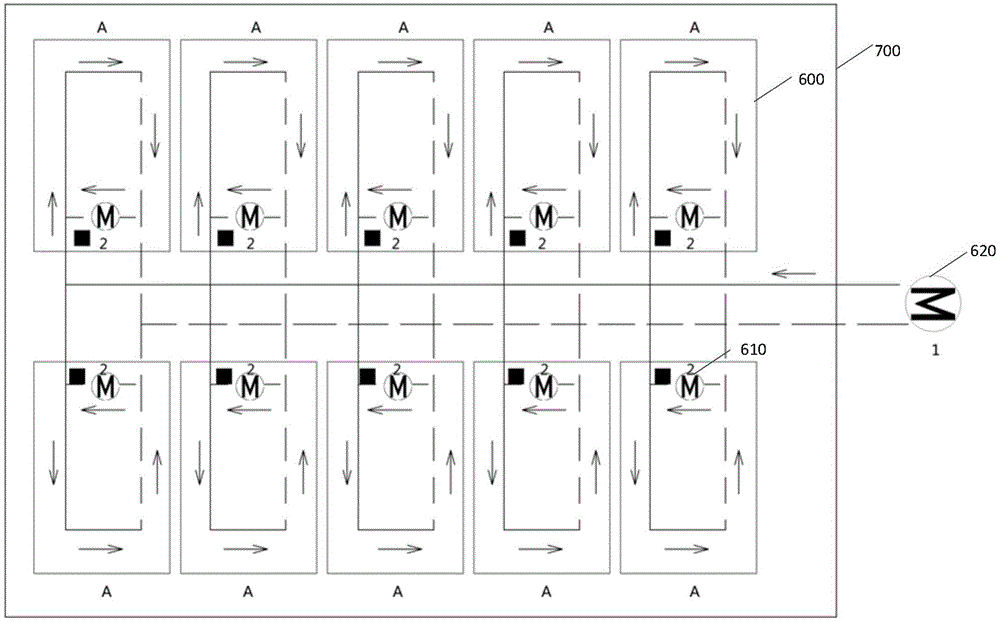

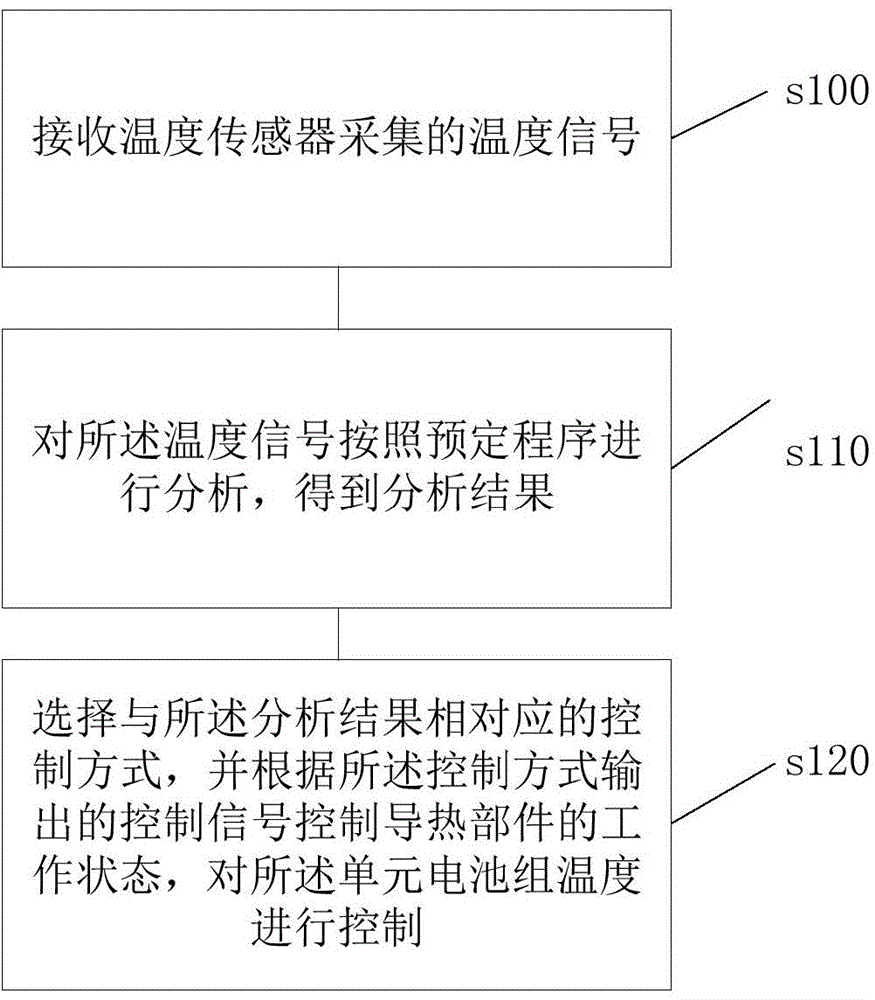

Battery pack temperature control system and battery pack temperature control method

InactiveCN104900940ARealize heat conductionImprove the use environmentCell temperature controlTemperature controlControl manner

The invention discloses a battery pack temperature control system, which comprises a heat conduction and insulation part, a heat conduction part and a temperature control part, wherein the heat conduction and insulation part is used for being filled among monomers in a battery pack to implement the conduction of the heat of the battery pack; the monomers in the battery pack are arranged according to a predetermined arrangement rule; the temperature control part is connected with the heat conduction part, and is used for receiving temperature signals acquired by temperature sensors, analyzing the temperature signals according to a preset program to obtain an analysis result, choosing a control mode corresponding to the analysis result and controlling the operating state of the heat conduction part according to a control signal outputted by the control mode to control the temperature of the battery pack. The system can increase the efficiency, safety and cycle life of the battery pack. The invention also discloses a battery pack temperature control method.

Owner:张哲群

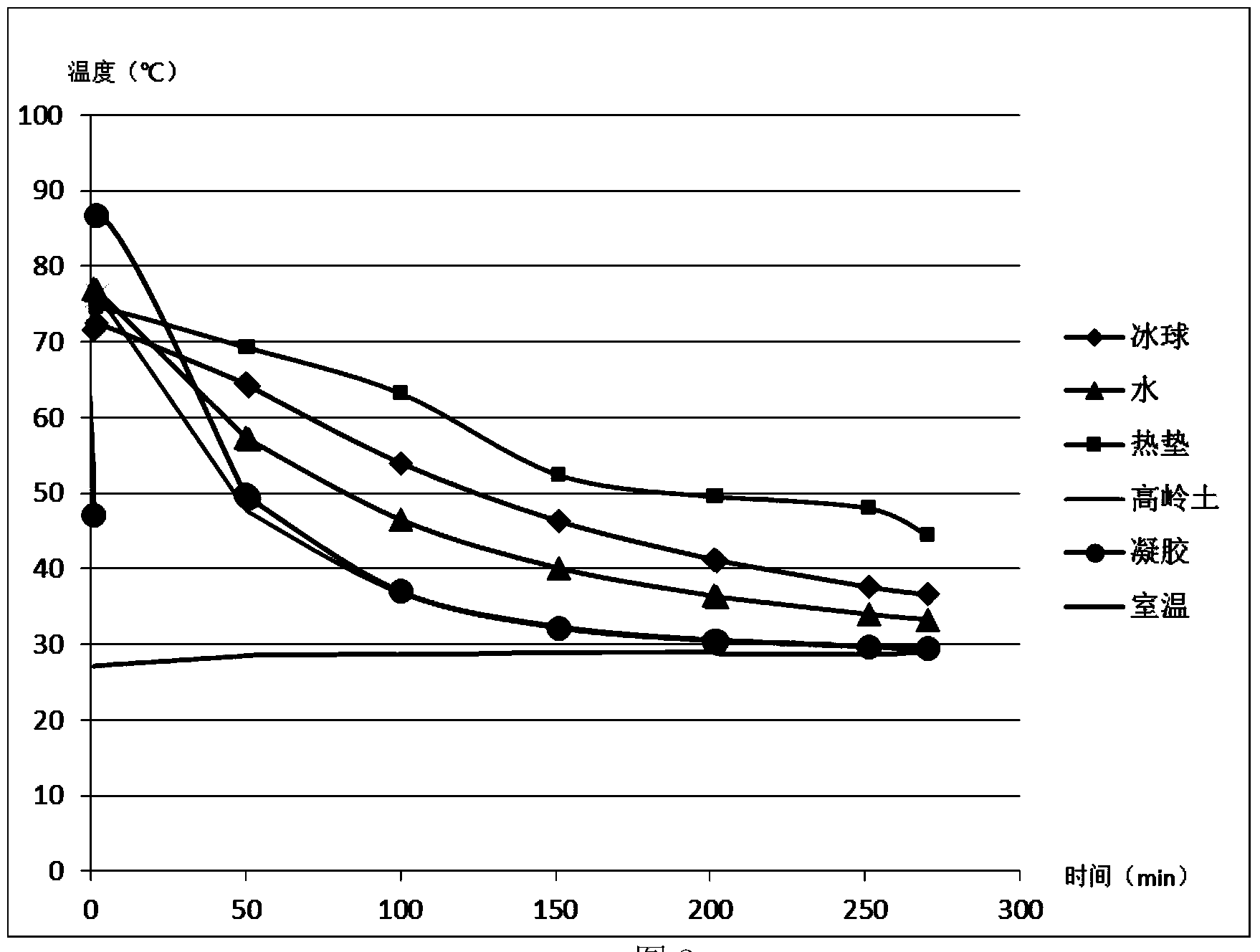

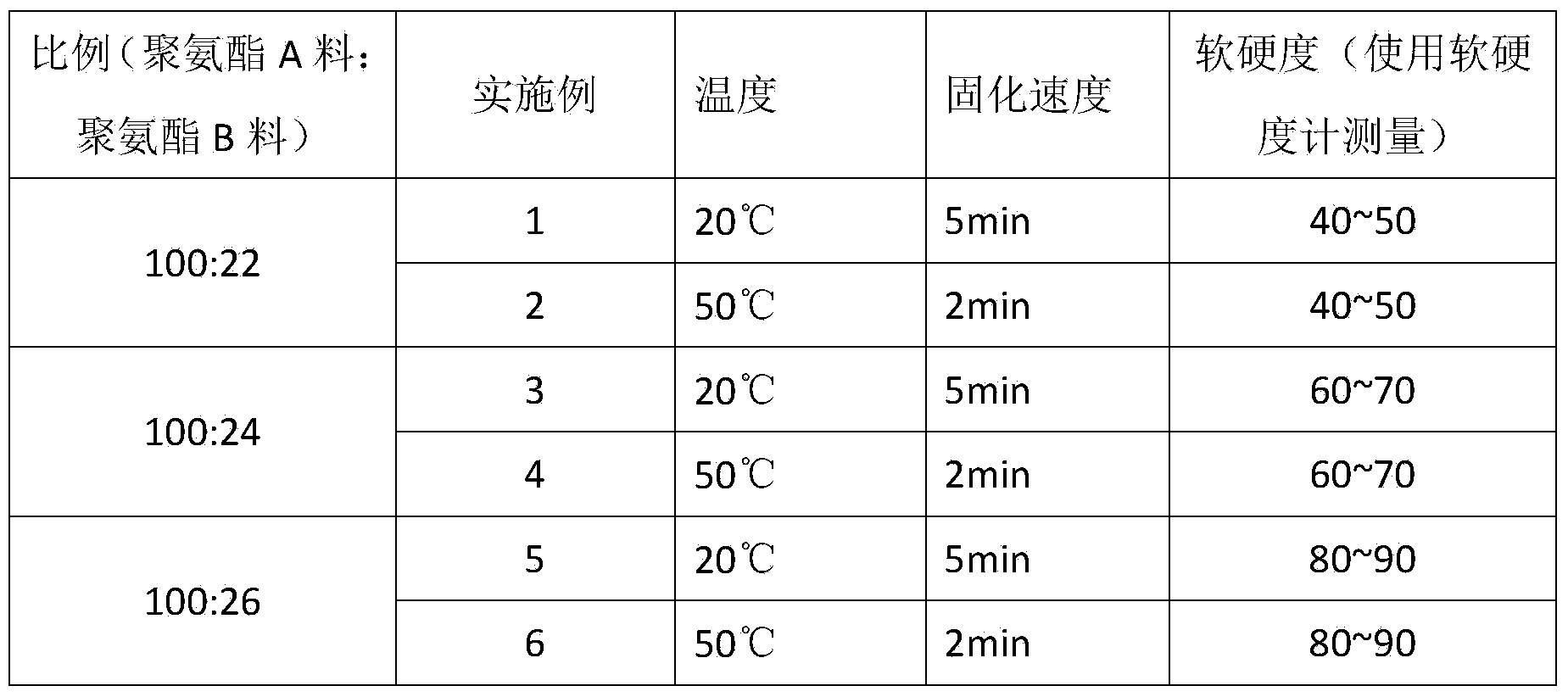

Gel heating pad and method for manufacturing same

The invention discloses a gel heating pad and a method for manufacturing the same. The gel heating pad comprises a fabric layer and at least two heating layers including a first heating layer and a second heating layer; a heat storage layer of phase change materials is arranged between the first heating layer and the second heating layer; an elastic non-glue cotton layer covers the outer side of the first heating layer, and the fabric layer covers the outside of the elastic non-glue cotton layer; a heat-insulation felt is arranged on the outer side of the second heating layer, and an antislip layer is arranged on the outer side of the heat-insulation felt. According to the technical scheme, the gel heating pad and the method have the advantages that the gel heating pad is provided with two layers of carbon fiber heating cloth, accordingly, double-temperature double-control effects can be realized, and the gel heating pad can be utilized after being plugged; a pressure heat conduction effect and a non-pressure heat-insulation effect can be realized by the non-glue cotton layer; heat can be stored for 15-20 minutes under the integral arrangement condition, and the gel heating pad can keep warm for 5-8 hours.

Owner:ZHEJIANG TRIPLE WIN MEDICAL APPLIANCE

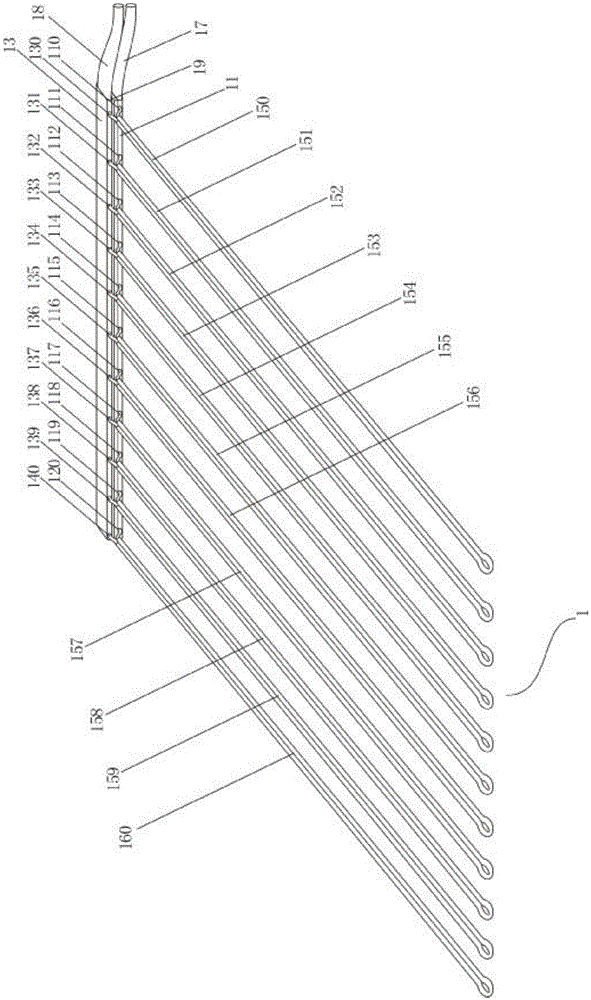

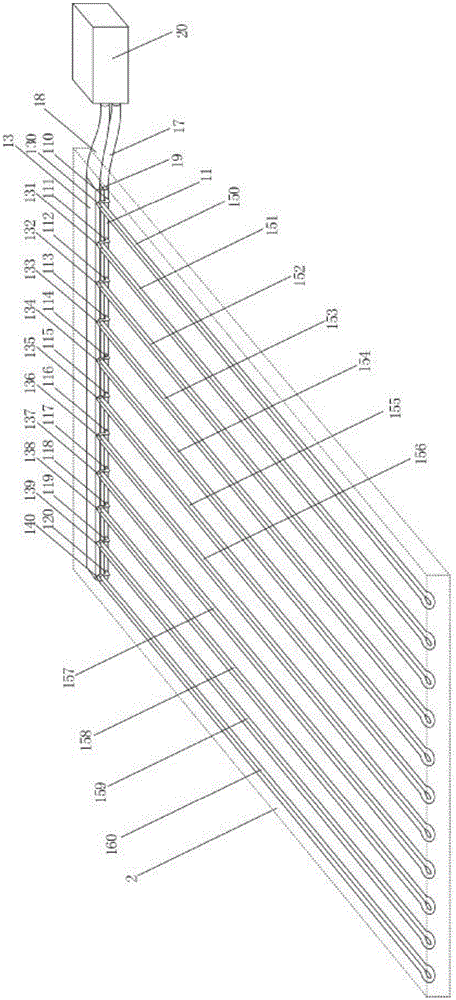

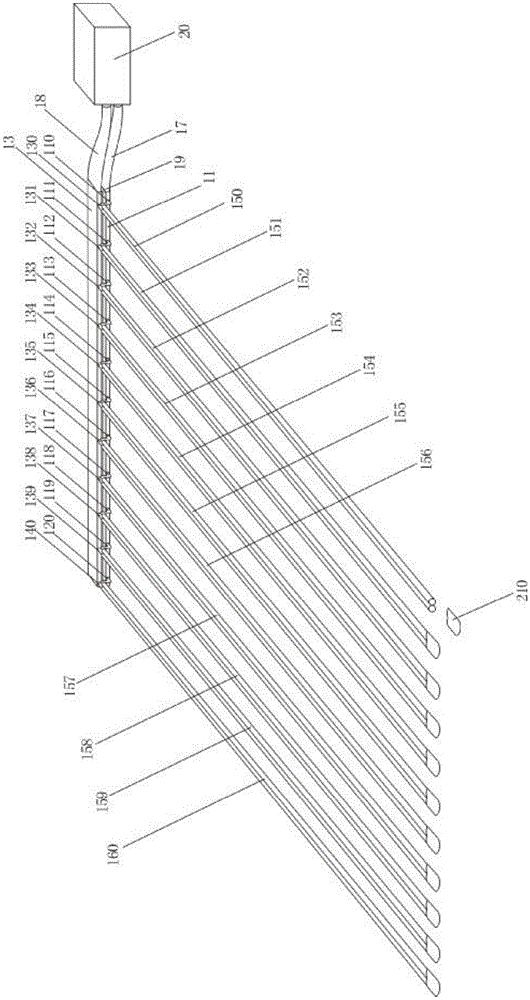

Cold and hot air circulating pad

InactiveCN105534148AImprove securityUniform heat conductionStuffed mattressesHot-air central heatingEngineering

The invention relates to a cold and hot air circulating pad. The cold and hot air circulating pad consists of a cold and hot air circulation pipeline and a pad enclosure wrapping the outside of the cold and hot air circulation pipeline; the cold and hot air circulation pipeline consists of an air supply main pipeline, an air return main pipeline and a plurality of cold and hot air circulation branch pipelines, wherein the air supply main pipeline and the air return main pipeline are arranged in parallel, and the cold and hot air circulation branch pipelines are parallelly connected onto the air supply main pipeline and the air return main pipeline in a spaced manner; a gap is formed between the air supply main pipeline and the air return main pipeline and is filled with a heat preserving and insulating layer; an air inlet end and an air return end of any cold and hot air circulation branch pipeline are adjacent to each other and are separately connected onto the air supply main pipeline and the air return main pipeline, and rest parts of the pipelines are closely fit and extend side by side. The cold and hot air circulating pad has the characteristics that the pad is safe, the heat conduction is uniform, and the pad can be subjected to curled storage.

Owner:朴光哲

Garbage disposal device capable of utilizing self-circulation pyrolysis gas for preheating air

ActiveCN106439834AGuaranteed heat treatment efficiencyRealize heat conductionIndirect carbon-dioxide mitigationIncinerator apparatusDistribution systemPollutant emissions

The invention discloses a garbage disposal device capable of utilizing self-circulation pyrolysis gas for preheating air. The device comprises a feeding opening, a garbage pyrolysis furnace wall, a first horizontal heat conduction plate, a vertical heat conduction plate, a first smoke circular pipeline, a top smoke circular pipeline connection opening, a tail gas pipeline connection opening, a second horizontal heat conduction plate, a second smoke circular pipeline, a first induced draft fan, an air preheating cavity connection opening, a first air inlet, a garbage pyrolysis furnace, an air preheating cavity, an exhaust opening, a horizontal air distribution pipeline, a tail gas treatment pipeline, a bottom smoke circular pipeline connection opening, a second induced draft fan, an observation window, a vertical air distribution pipeline, a settling pond, a tail gas purification device, an air distribution system, a smoke circular system and other structures. According to the disposal device, the reduction reaction efficiency is improved, the garbage heat treatment efficiency is ensured; and meanwhile, the self-circulation pyrolysis gas can be used for preheating the air, it can be ensured that low-heat-value components such as aromatic alcohol and heavy oil can be sufficiently decomposed in the reaction, and pollutant emissions in the tail gas can be reduced.

Owner:湖南省环境保护科学研究院

Phase-change microbial capsule grouting method for seepage prevention of fractured rock mass

PendingCN112324465ATo achieve anti-seepageOvercoming prejudices that cannot be usedUnderground chambersTunnel liningMicroorganismParaffin wax

The invention discloses a phase-change microbial capsule grouting method for seepage prevention of fractured rock mass. The method comprises the following steps of, S1, determining a grouting hole site on a rock mass fracture, and drilling to form a grouting hole; S2, mixing a paraffin capsule with boosting oil to obtain a first mixture; S3, mixing a microbial capsule with water to obtain a secondmixture; S4, heating the first mixture, and keeping the temperature of the first mixture at 35 - 40 DEG C; and S5, continuously injecting the second mixture into the rock mass fractures through a grouting device, and meanwhile, the intermittently injecting the first mixture into the rock mass fractures through the grouting device. The paraffin capsule and the boosting oil are used for storing heat in advance, then the first mixture and the second mixture are simultaneously and continuously injected into the rock mass fracture through the grouting device, liquid-solid phase change can be generated through precooling of the paraffin capsule, and heat is released, so that the effect of increasing the fracture temperature is achieved, a good environment is provided for microorganism growth, and rock mass seepage prevention in the alpine region is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

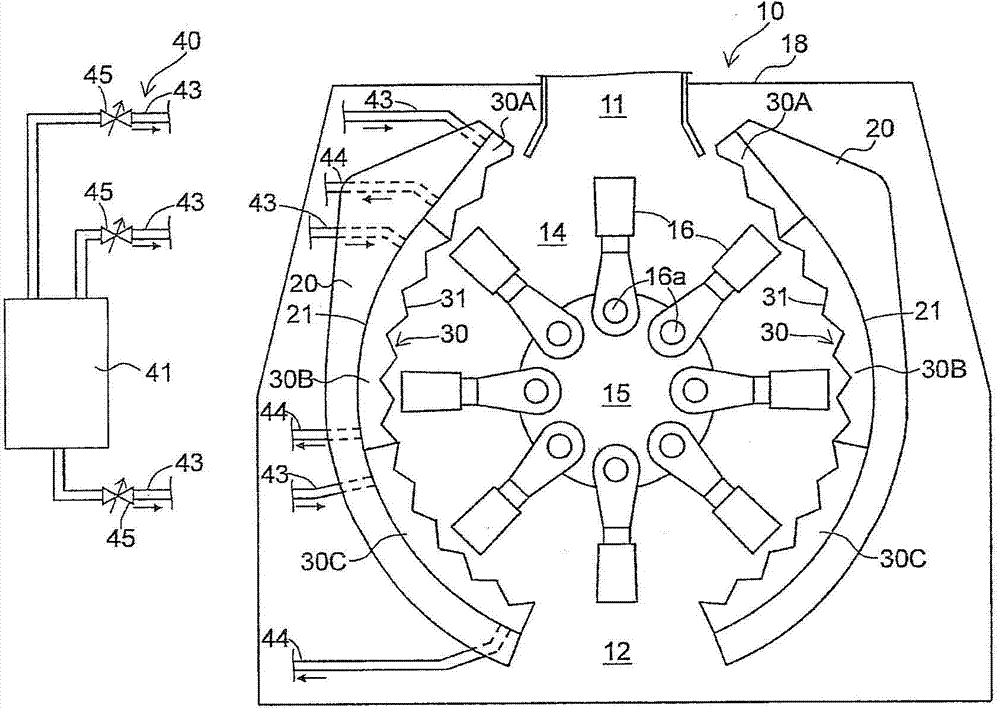

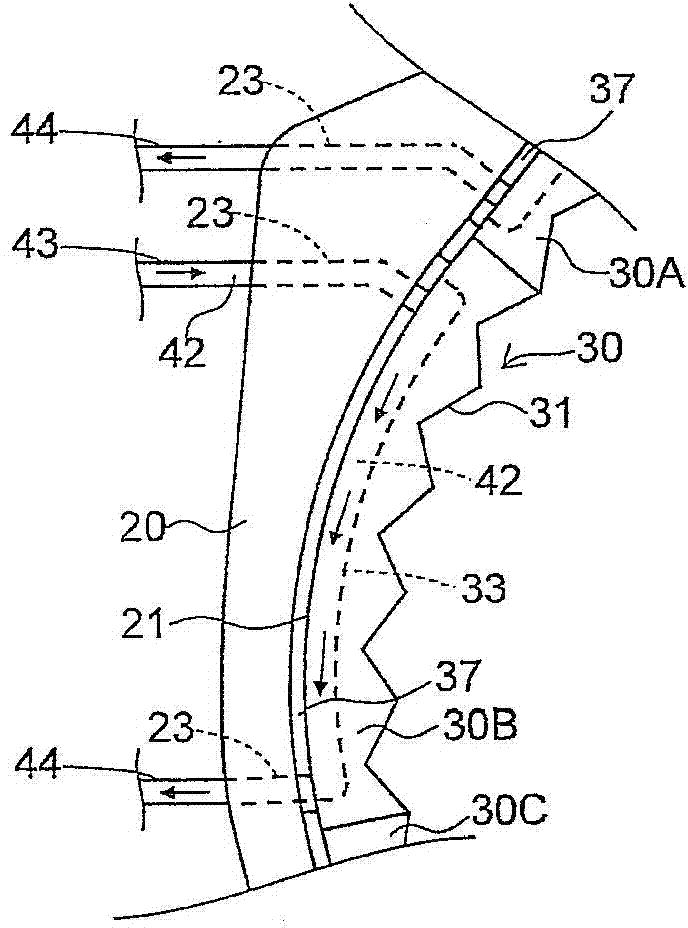

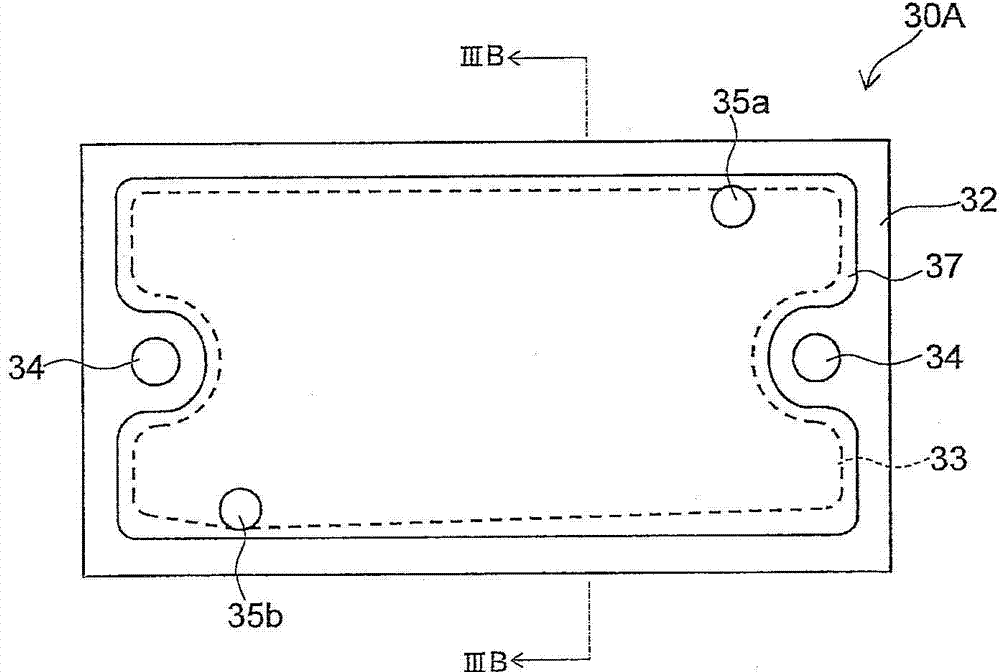

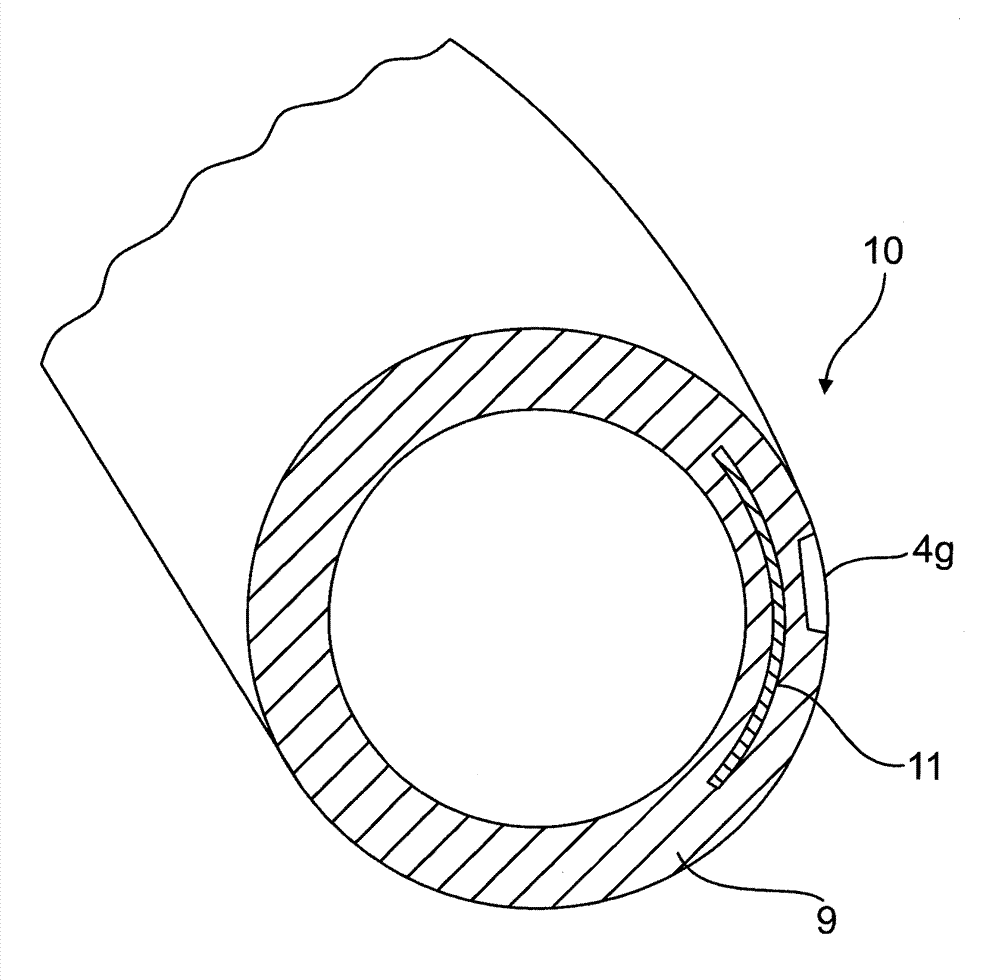

Pulverizer

[Problem] To provide a pulverizer wherein the temperature of the inner surface of the liner can be efficiently adjusted. [Solution] The pulverizer (10) is provided with: a rotator (15); striking members (16) installed on the rotator (15) for colliding with brown coal (13); collision plates (20) disposed around the rotator (15); and liners (30) provided on the inner surfaces (21) of the collision plates (20) and having an inner surface (31) onto which brown coal (13) that has collided with the striking members (16) is thrown. The pulverizer (10) also is provided with a temperature adjustment mechanism (40) for adjusting the temperature of the inner surface (31) of a liner (30). The temperature adjustment mechanism (40) is configured so as to be capable of adjusting the temperature of the liner (30) further to the inside than the inner surface (21) of the collision plates (20).

Owner:日本阿尔斯泰克

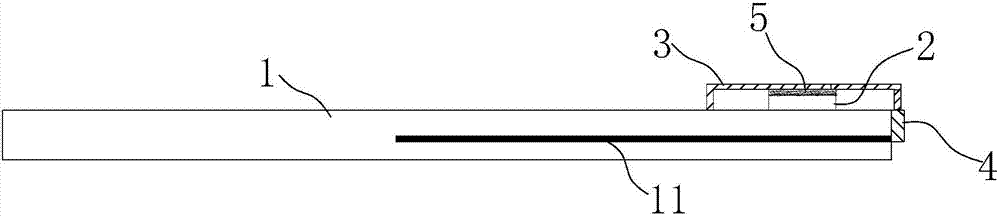

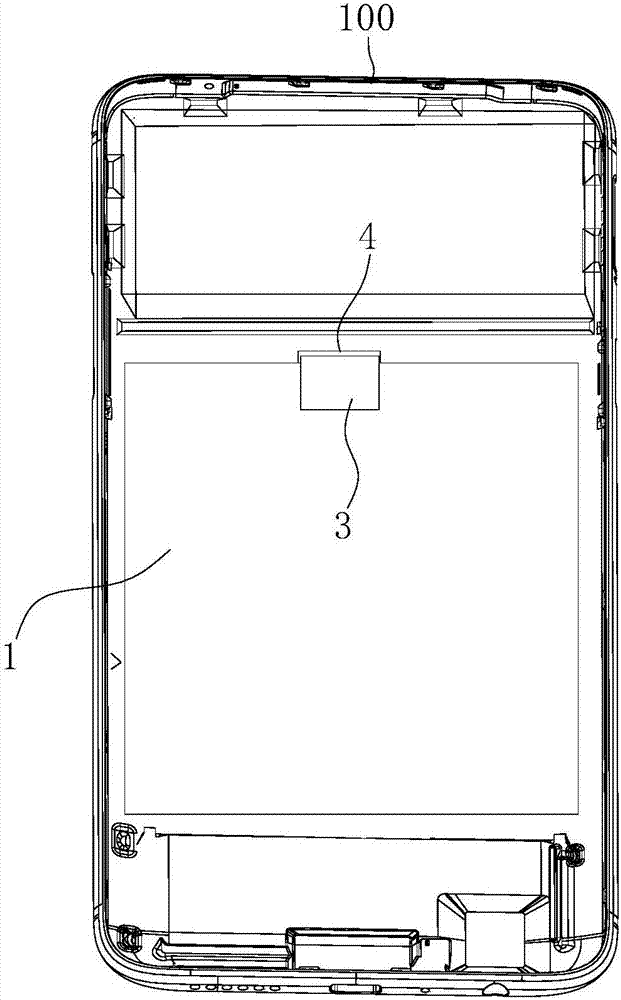

Electronic device and circuit board assembly thereof

ActiveCN107454737ASolve the problem of limited cooling areaImprove cooling effectCircuit thermal detailsMagnetic/electric field screeningHeat conductingEngineering

The present invention is suitable for the electronic equipment technology field, and provides an electronic device and a circuit board assembly thereof, wherein the circuit board assembly comprises a substrate, a shielding cover, a heating element and a heat conducting member. The heating element is arranged on the surface of the substrate, the shielding cover is fixed on the surface of the substrate, and the heating element is covered by the cover. A heat conducting glue is connected between the heating element and the shielding cover, at least one metal layer is arranged in the substrate, and the shielding cover realizes the heat conduction with the metal layer via the heat conducting member. The heat conducting member of the embodiment is attached to the shielding cover and the metal layer in the substrate simultaneously, thereby realizing the heat conduction. When the heat is accumulated on the shielding cover, the temperature of the shielding cover is higher than the temperature of the metal layer in the substrate, so that the heat can be transferred to the metal layer via the heat conducting member. Compared with the situation of only adopting the shielding cover to radiate the heat, according to the embodiment, the shielding cover and the metal layer are adopted to radiate the heat jointly, so that the heat radiation area is increased more, the heat radiation speed is improved, and the heat radiation performance of the electronic device is optimized.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

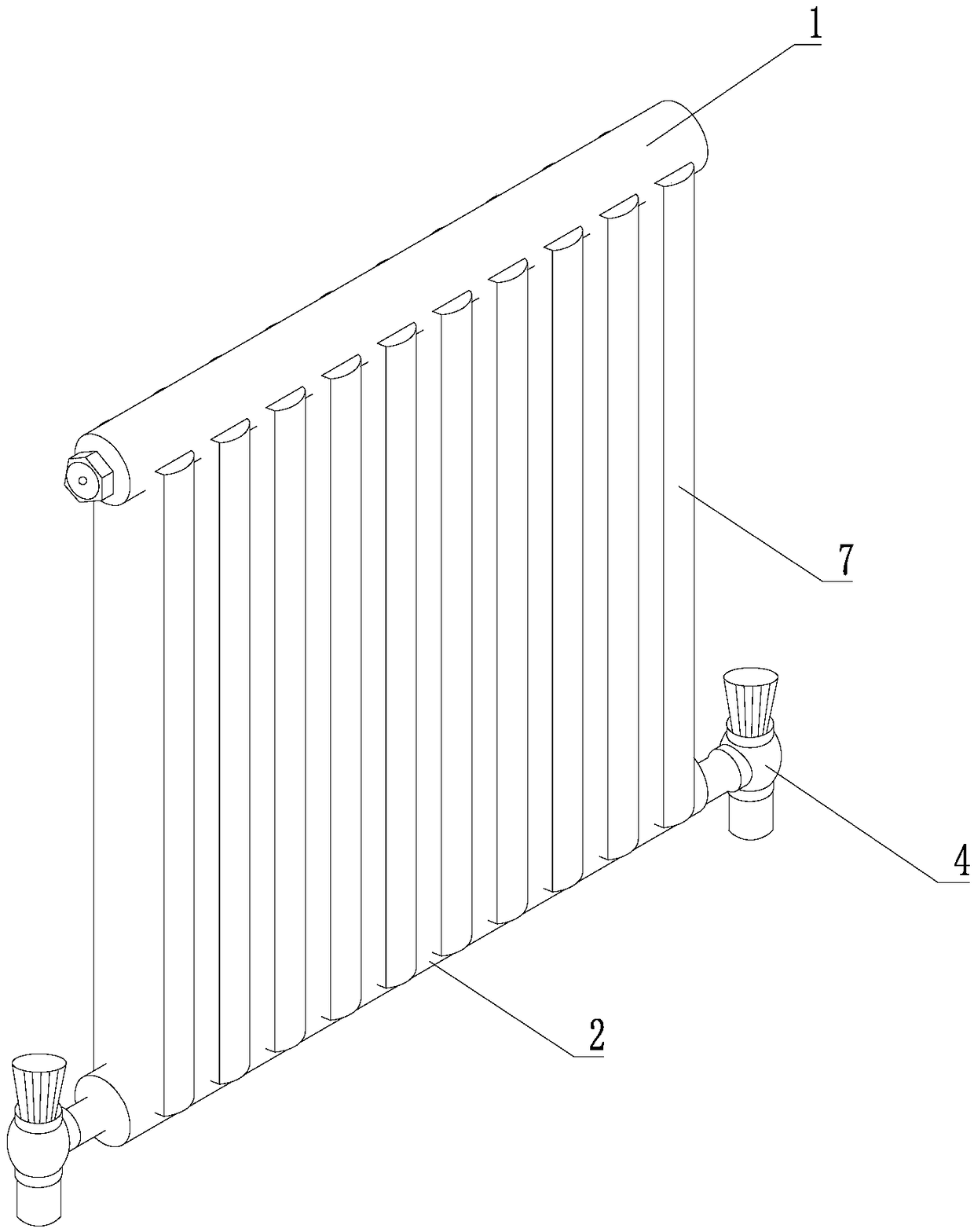

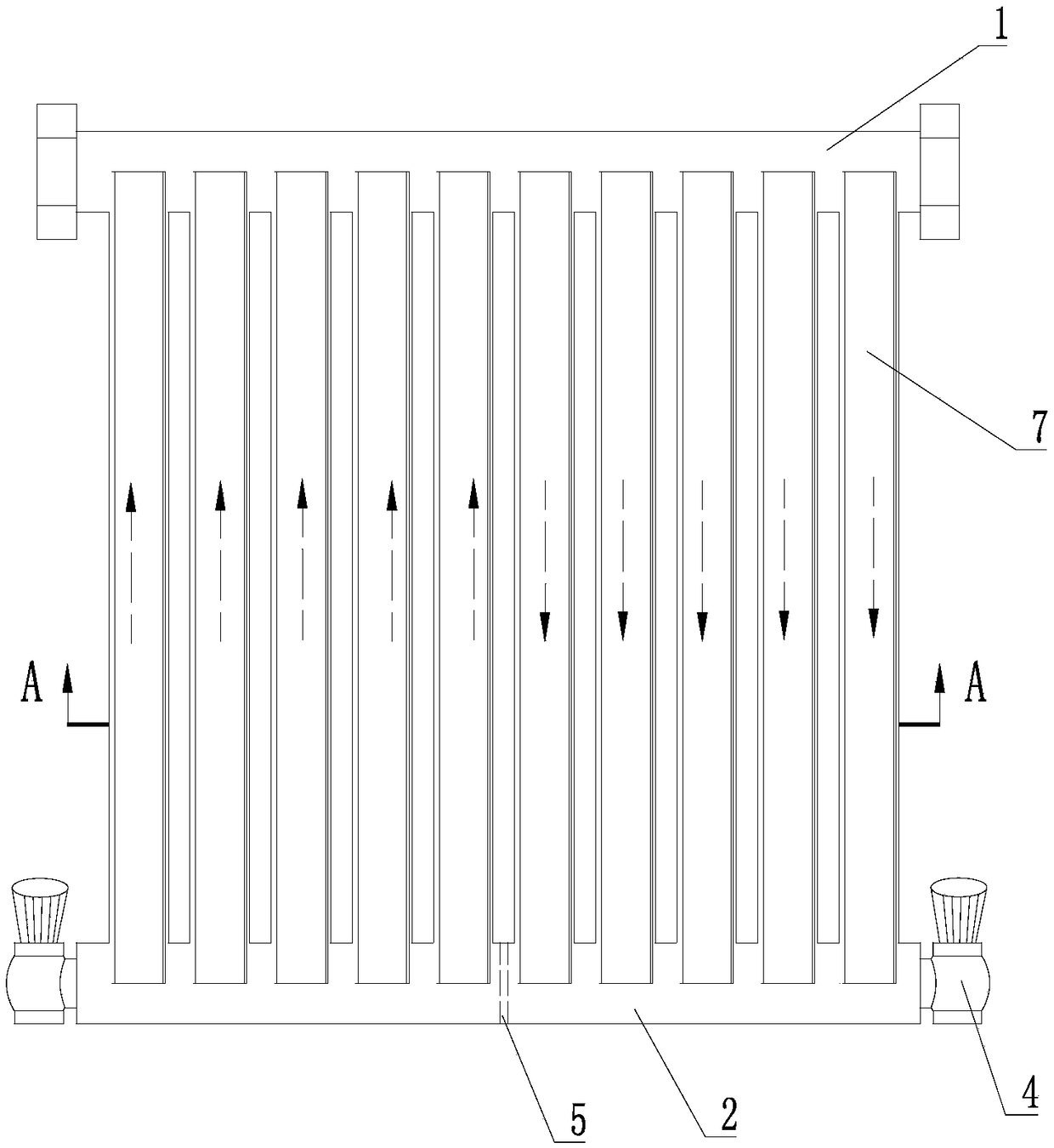

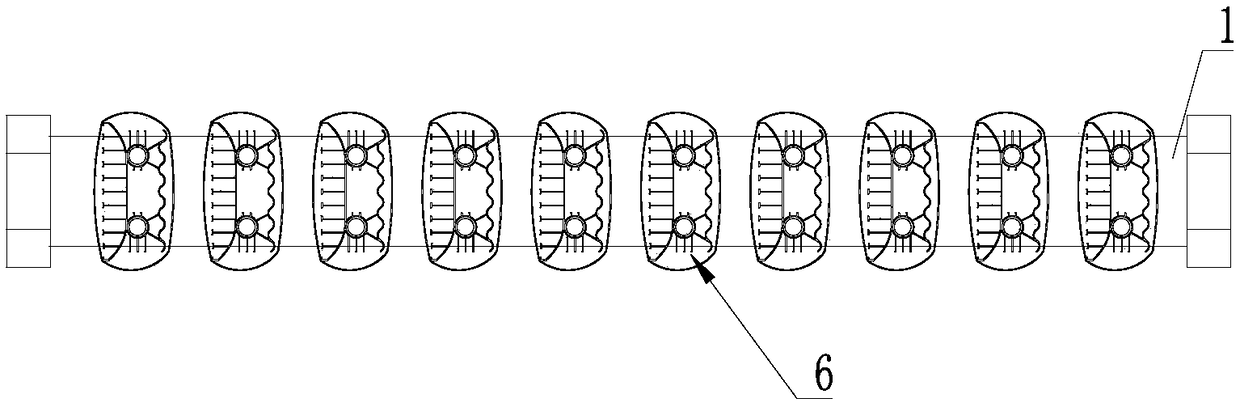

Double-water-way copper-aluminum composite radiator

InactiveCN109506291AIncrease the lengthIncrease cooling areaStationary conduit assembliesSpace heating and ventilation detailsEngineeringCopper

The invention discloses a double-water-way copper-aluminum composite radiator. The double-water-way copper-aluminum composite radiator comprises an upper water pipe and a lower water pipe which are arranged in an up-down spaced manner. A plurality of branch pipes are in communication between the upper water pipe and the lower water pipe. One end of the lower water pipe communicates with the waterinlet end of a water supply system through an adjusting valve, and the other end of the lower water pipe communicates with the water return end of the water supply system through an adjusting valve. An isolation sheet is fixedly arranged at the middle portion of the lower water pipe. A plurality of pairs of front-back symmetrically-arranged branch pipes are included. The outer sides of each pair of branch pipes are in expansion connection with one heat dissipation sectional material. The outer sides of the heat dissipation sectional materials are wrapped by a heat dissipation shell. Each heatdissipation sectional material comprises a pair of circular pipes which are in expansion connection with the corresponding pair of branch pipes. The periphery of each circular pipe outwards radiates to form a plurality of cooling fins. Each cooling fin is fixedly provided with a plurality of auxiliary fins. By adoption of a double-water-way circulation system, the heat dissipation efficiency is improved, and the heat dissipation area is increased; and under the situation that the heat dissipation efficiency is the same, only about half length of a single-water-way radiator is occupied.

Owner:CHANGYI YIRUN HVAC EQUIP

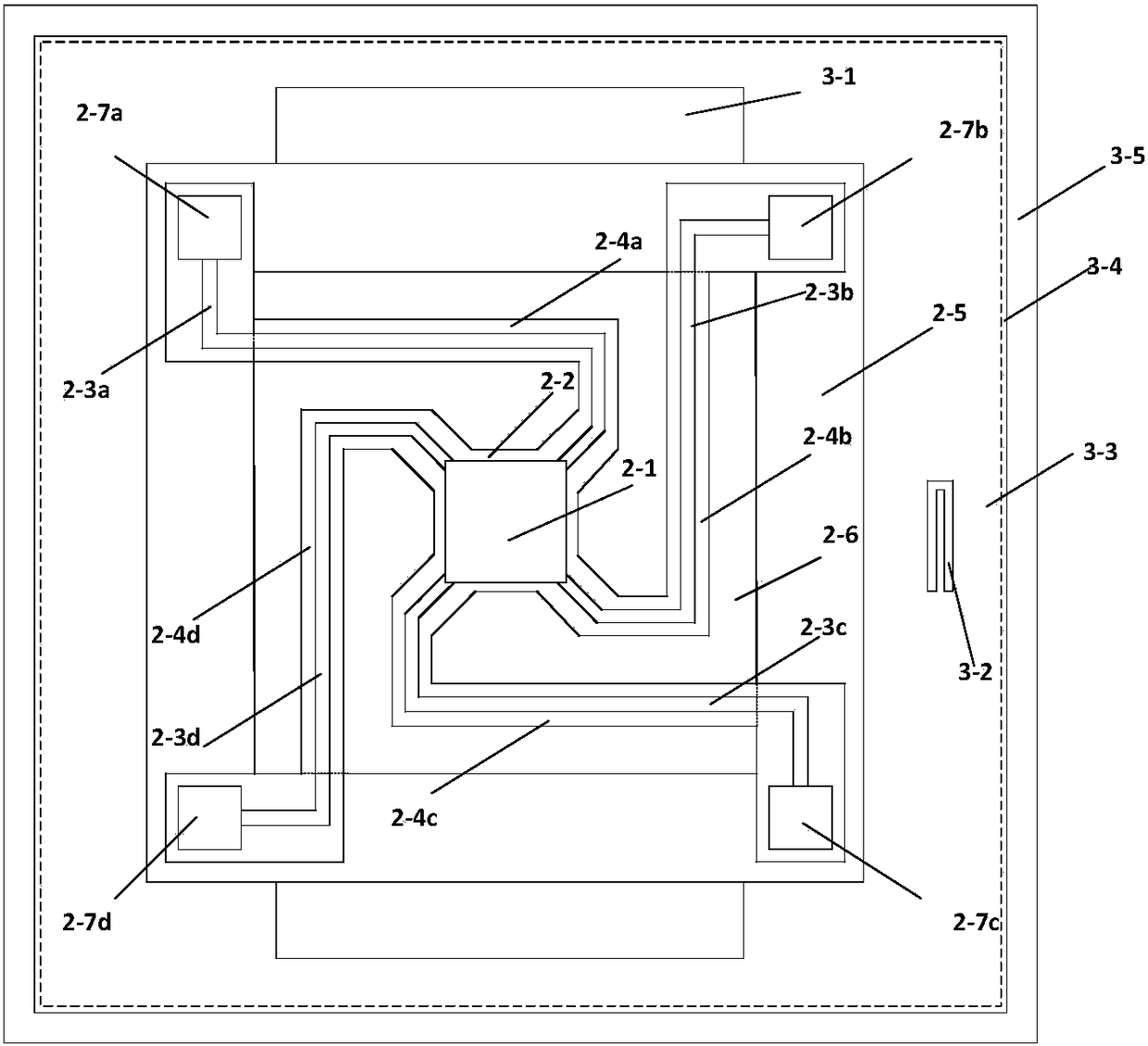

Chip-level ultra-miniature refrigerator for uncooled infrared detector

ActiveCN108493271ASimple structureHighly integratedThermoelectric device with peltier/seeback effectSolid-state devicesEngineeringCantilever

The present invention provides a chip-level ultra-miniature refrigerator for an uncooled infrared detector. The chip-level ultra-miniature refrigerator comprises an outer-layer package layer structureand an inner-layer refrigerator structure; the outer-layer package layer structure comprises a vacuum package housing, an anti-radiation layer and a radiation layer, and the top portion of the vacuumpackage housing is provided with an infrared sensitive window; the inner-layer refrigerator structure comprises an upper-layer structure, a middle-layer structure and a lower-layer structure. The chip-level ultra-miniature refrigerator performs heating and cooling of a nano-film thermoelectric layer to maintain a constant temperature so as to effectively block the heat exchange between a supportstructure and an external environment through a substrate, and a heat insulation layer is laid at the bottom portion of the substrate to further inhibit the heat conduction of the external environment. An annular cantilever beam and the support structure further avoid heat conduction, the heat insulation layer is arranged to further inhibit the internal heat conduction and exchange so as to achieve heat insulation between the infrared detector and the external environment. The anti-radiation layer is deposited and grown to inhibit heat radiation, and a vacuum package method is employed to avoid heat convection and exchange of the internal portion and the external portion.

Owner:SOUTHEAST UNIV

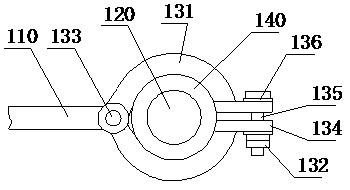

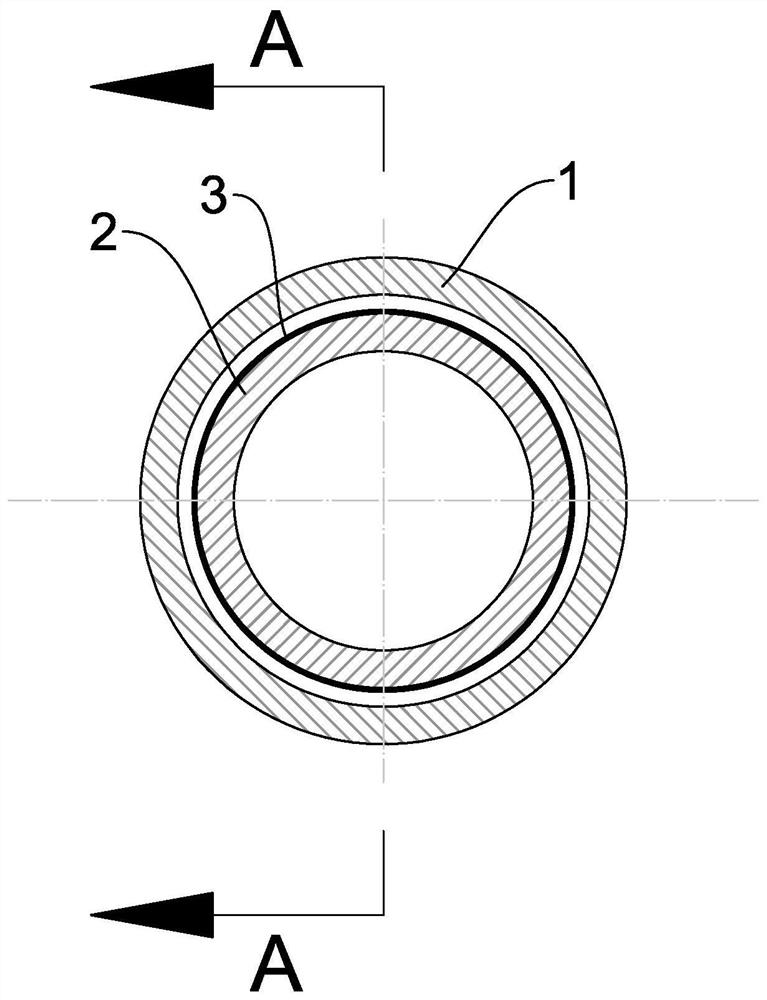

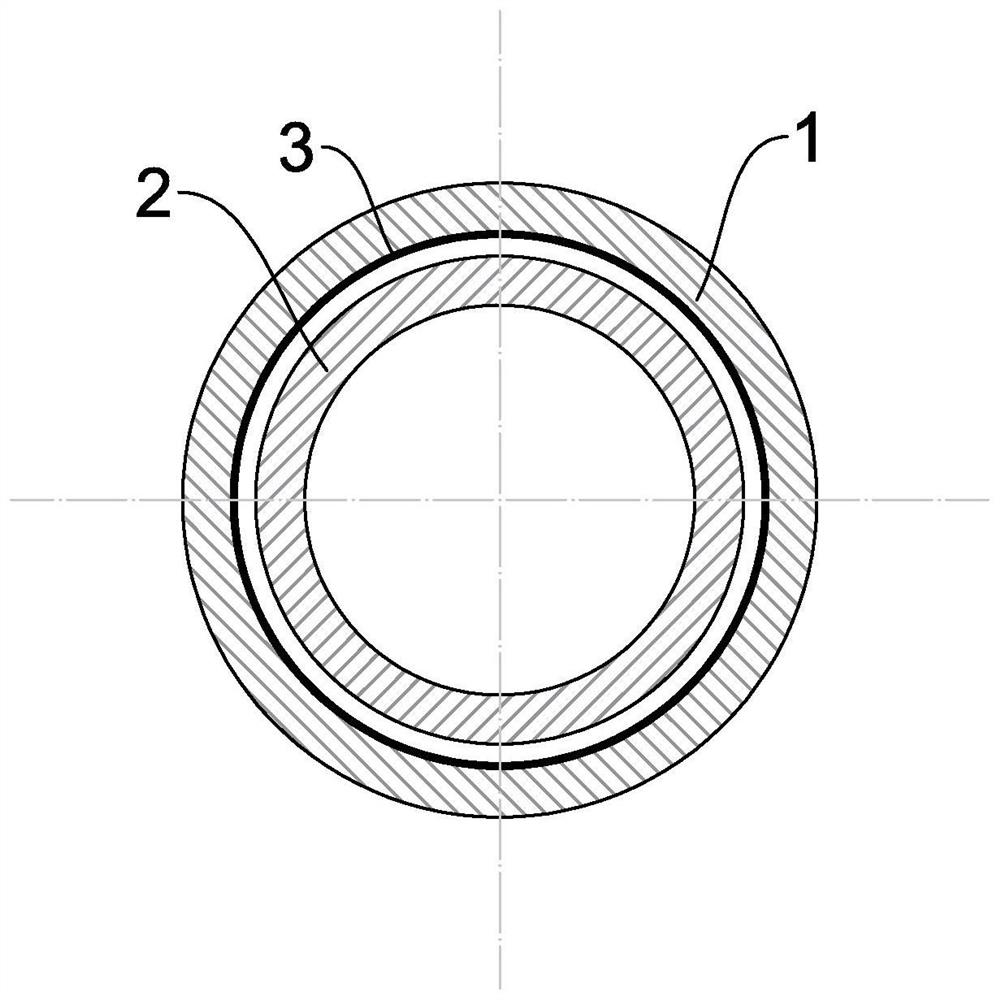

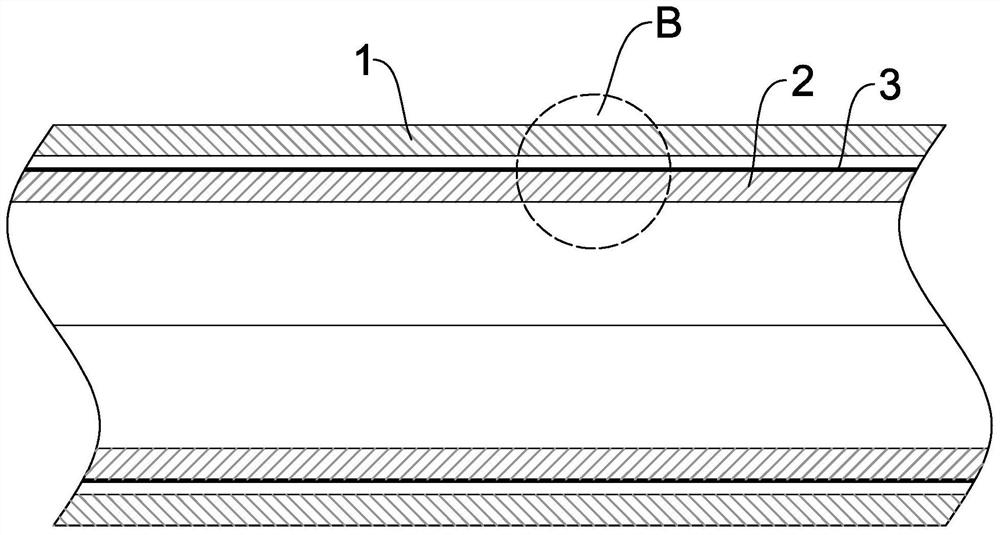

One-way heat conduction special copper tube and preparation method thereof

ActiveCN110793363BRealize heat conductionAvoid problems such as heat loss caused by reverse heat conductionIndirect heat exchangersThermodynamicsEngineering

The invention relates to the field of heat conduction pieces, in particular to a one-way heat-conduction special copper pipe and a preparing method thereof. The one-way heat-conduction special copperpipe comprises an outer copper pipe body and an inner copper pipe body which are sleeved with each other. The inner wall of the outer copper pipe body communicates with the outer wall of the inner copper pipe body. The inner wall surface of the outer copper pipe body or the outer wall surface of the inner copper pipe body is covered with high-molecular vesicle layer. The high-molecular vesicle layer is composed of a plurality of high-molecular vesicles which contain liquid. One-way heat conduction can be realized, the problem of the overheat of a to-be-cooled piece caused by the inverse heat conduction in the cooling process or the heat loss caused by the inverse heat conduction during heating by means of the one-way heat conduction function can be avoided, and the problem of the damage tothe to-be-cooled piece caused by the excessive cooling or the damage to a to-be-heated piece caused by the too rapid temperature raising during heating by means of the one-way heat conduction function can be avoided.

Owner:安徽德诠新材料科技有限公司

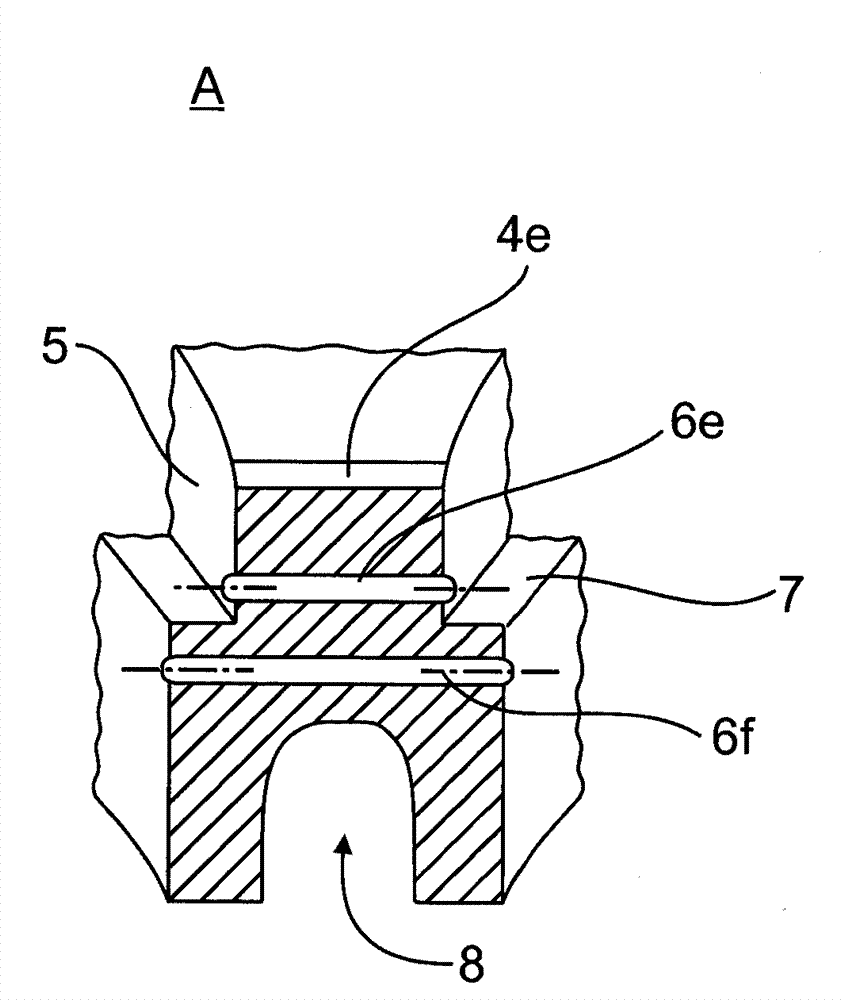

Thermally and/or mechanically actuated component wall of a fluid and/or gas-conveying component, in particular a cylinder head of a combustion engine

The invention relates to thermally and / or mechanically actuated component wall of a fluid and / or gas-conveying component, in particular a cylinder head of a combustion engine. The component wall is provided with at least one area which is threated from cracking due to load, wherein the crack is formed in the component wall (5) from the outer side of the wall under the operating condition; and at least one crack prevention part (6), which is arranged in a crack extending part and prevents the crack from expanding, and especially traverses through the component wall (5) to expand to important component area (8). According to the invention, in the areas (5, 10) threathened by cracks, the outer side of the wall is provided with a crack starting part (4), which prevents the forming and expanding of cracks which are not under control.

Owner:MAN NUTZFAHRZEUGE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com